Draining and blow-drying equipment

A technology of water filtration and equipment, which is applied in the field of water filtration and drying equipment, can solve the problems of slow drying and impurity attachment, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the embodiment shown in accompanying drawing:

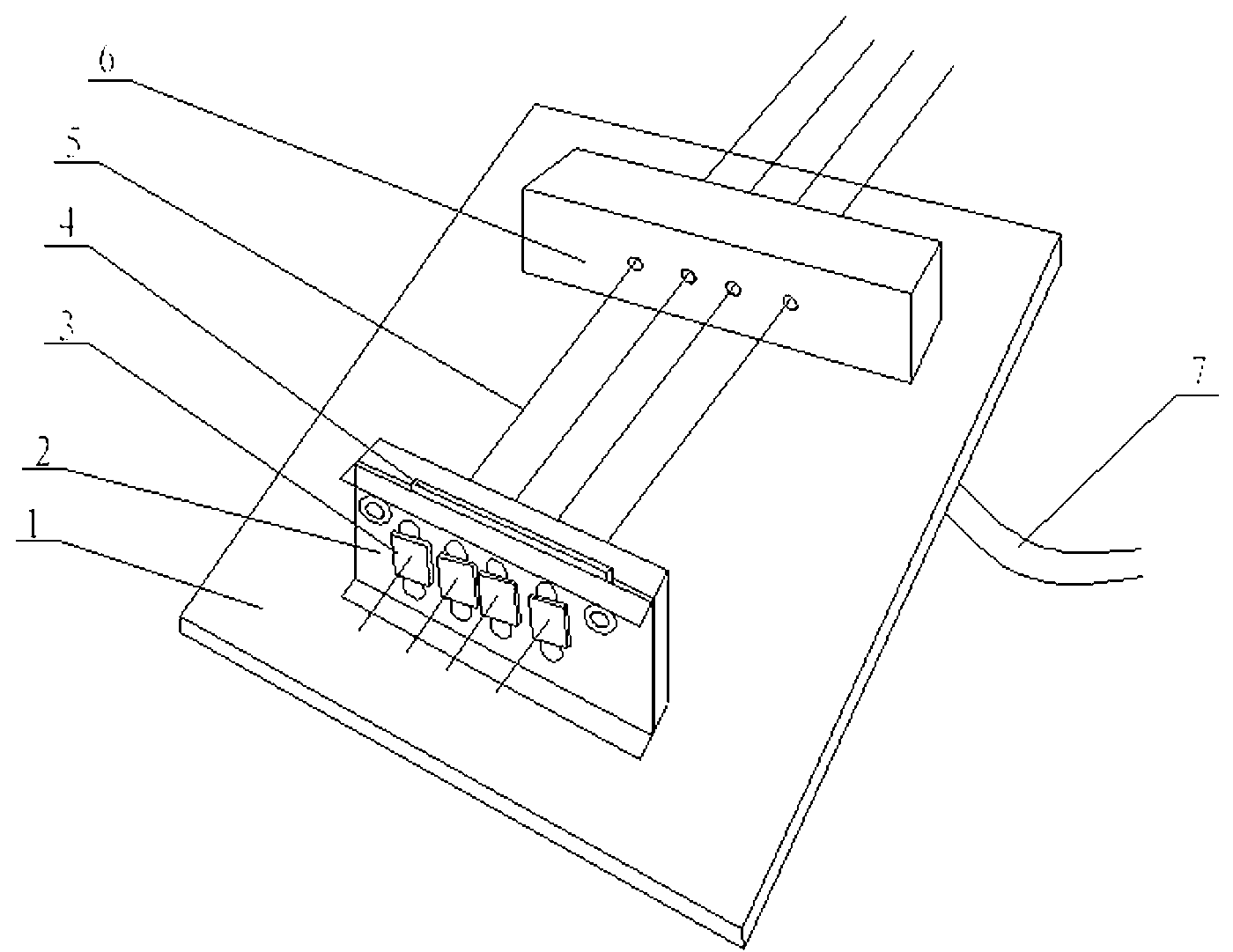

[0011] Such as figure 1 The shown water filtering and drying equipment includes: a base 1, a splint 2 arranged on the base 1, a drying box 6 arranged on the base 1, a water filter 4 is sandwiched between the splint 2, and a drying box 6 The inner cavity is connected with the air pipe 7 of the blower, and the splint 2 is provided with through holes, and the two sides of the drying box 6 are provided with through holes. The through hole of case 6 passes through drying case 6 .

[0012] The silk thread 5 also passes through an independent water filter 3 before passing through the through hole of the splint 2, and the independent water filter 3 is close to the splint by the friction of the silk thread.

[0013] In this embodiment, four wires 5 are arranged in parallel.

[0014] The above-mentioned embodiments are only to illustrate the tech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com