Cold metal plate strip cold continuous rolling production line and production method

A metal strip and cold continuous rolling technology, which is applied in the direction of metal rolling, metal rolling, metal processing equipment, etc., can solve the problems that affect the production line production capacity, disc shear chipping, difficult to realize, etc., to achieve improved rolling Control flexibility and production capacity, improve energy saving and emission reduction capabilities, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

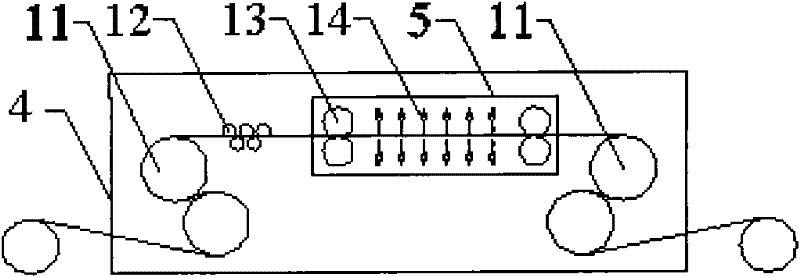

[0048] According to one embodiment of the present invention, the high-pressure jet descaling device and the stretching straightening device such as figure 2 The settings shown are for cold rolling production of continuous cold metal strips and for descaling and descaling.

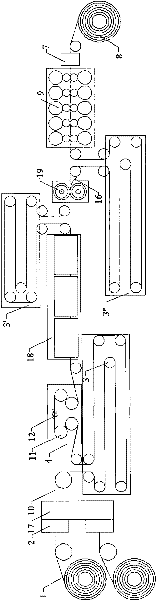

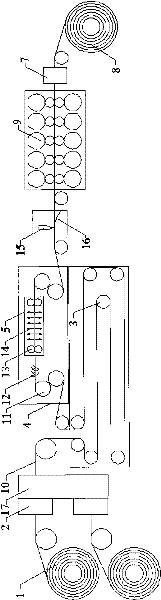

[0049] According to one embodiment of the present invention, the continuous cold metal sheet and strip cold tandem rolling production line with above-mentioned setting is such as image 3 As shown, it includes setting one or two sets of uncoilers 1, and supporting head and tail shearing machines 2 and welding equipment 17, a set of loopers 3 for storing strips and buffering, a set of stretching and straightening devices 4 and a Set of high-pressure jet descaling unit 5. The stretch straightening device 4 includes two tension roller sets 11 and one bending roller set 12, the tension rollers are respectively arranged before and after the high-pressure jet descaling unit 5, and the bending rollers are arrang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com