Shock-absorbing and resistance-reducing energy conservation device for mechanical sliding of automobile

An energy-saving device and mechanical technology, applied in control devices, vehicle parts, transportation and packaging, etc., can solve the problems of uncomfortable driving and riding, broken pawl arms, etc., and achieve cost reduction, rapid installation, and extended service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] specific implementation

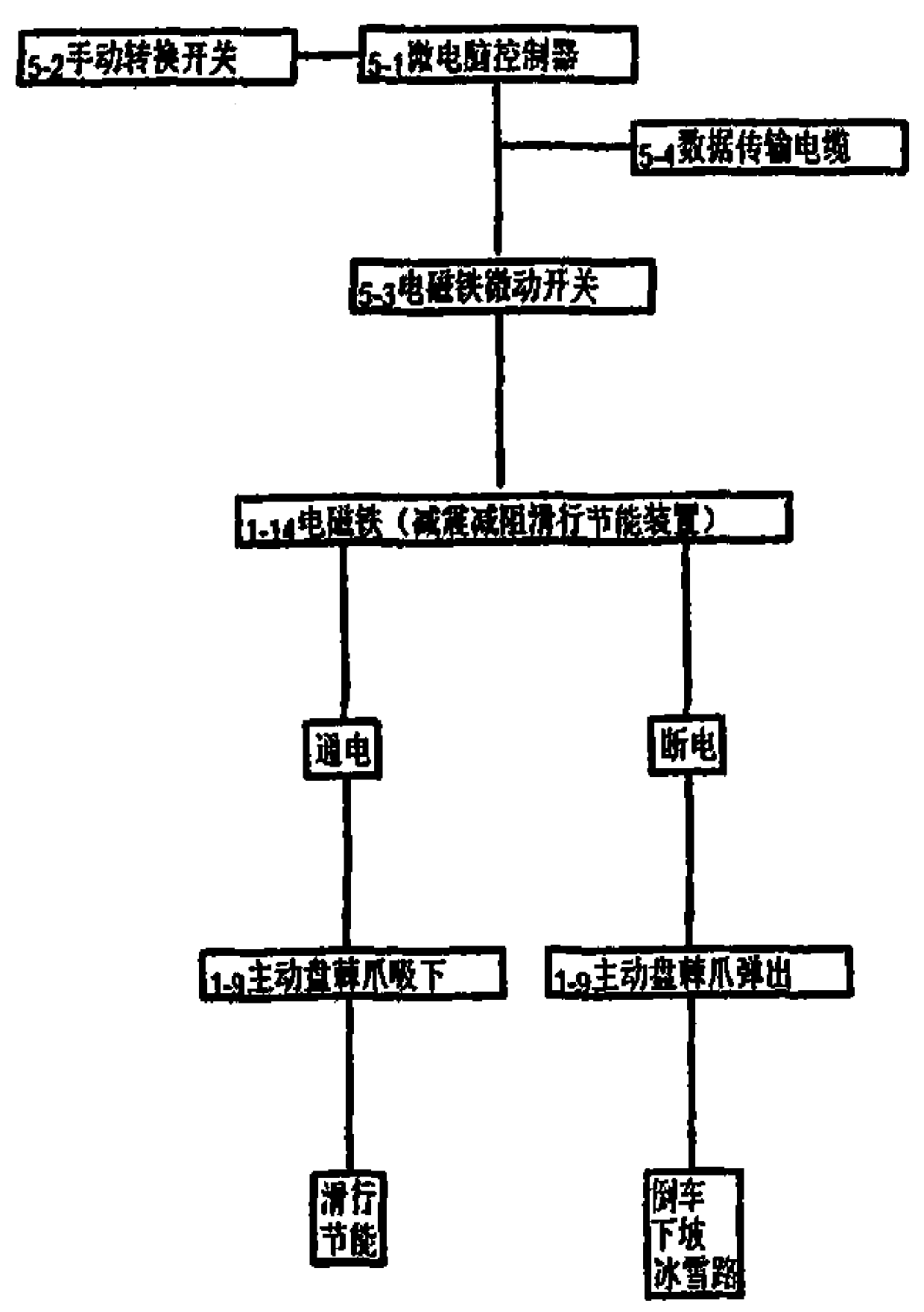

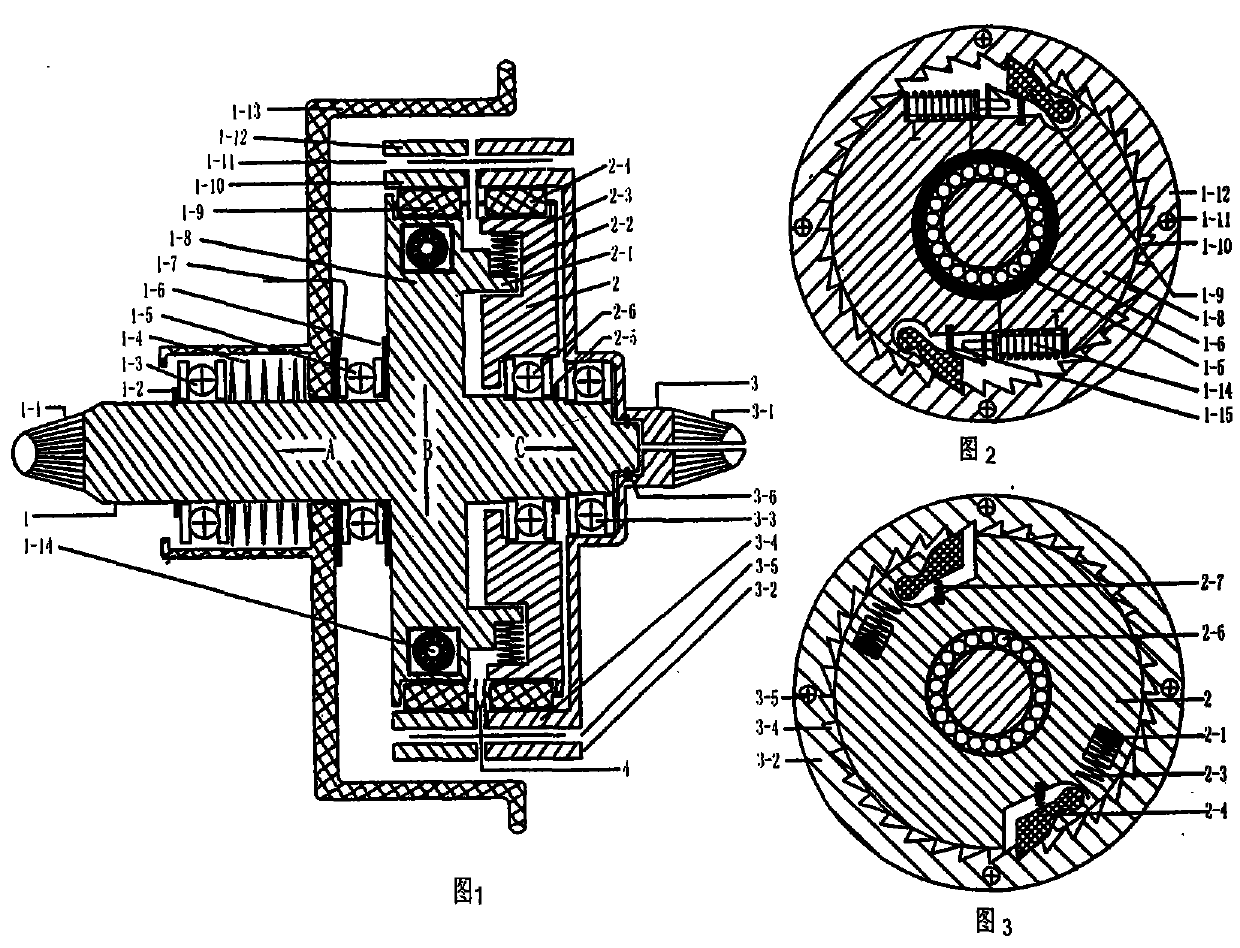

[0025] Specific embodiments of the present invention are as figure 1 , figure 2 , image 3 , Figure 4 As shown, the following design and processing are carried out: Drive shaft 1: Drive shaft 1 is also called input shaft, and the drive shaft 1 is processed into a "+"-like overall structure, which is divided into three sections according to the different application functions of the "+" structure. (See figure 1 ), the first segment A is the dust-proof function and the power supply system segment, the second segment B is the drive disc 1-8 segment, the third segment C is the shock-absorbing acceleration disc 2 and the driven shaft sliding bearing 3-3 force Arm support section. Drive shaft 1A section is designed and processed with drive shaft spline 1-1, dustproof function and power supply system. If the drive shaft spline 1-1 position is a flange due to different models, it should be designed and processed accordingly. The dustproof funct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com