Method and device for controlling failure of input shaft speed sensor in automotive AMT (automated mechanical transmission)

A technology of input shaft speed and control method, which is applied in the field of sensor failure control, can solve problems such as inaccurate clutch pressure, impact on vehicle safety, vehicle vibration, etc., to ensure comfort and safety, improve market competitiveness, Accurate effect of clutch slip and clutch engagement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0022] The invention proposes a control method that can still ensure the normal operation of the vehicle and ensure the comfort and safety of the vehicle after the speed sensor of the input shaft of the transmission of the AMT vehicle fails.

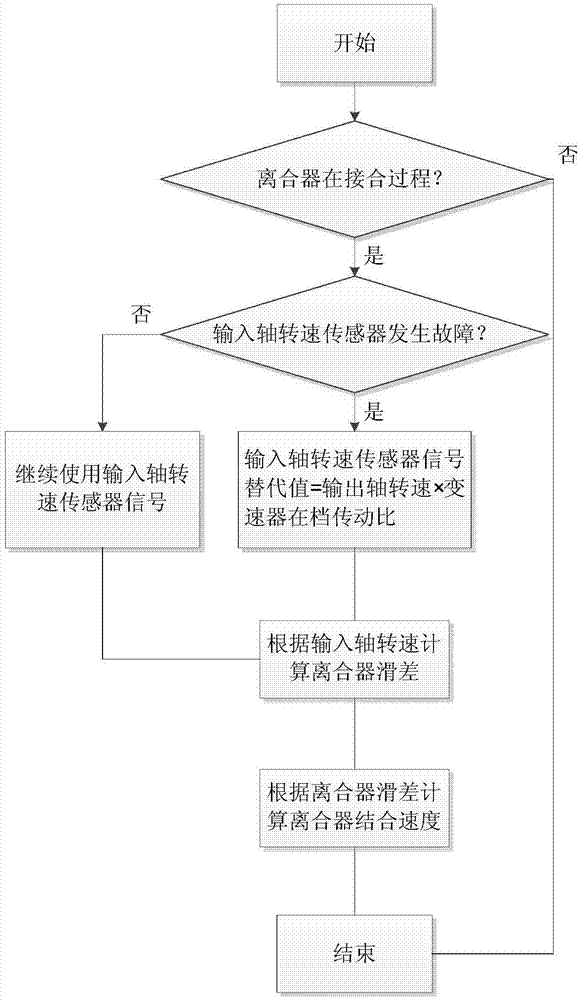

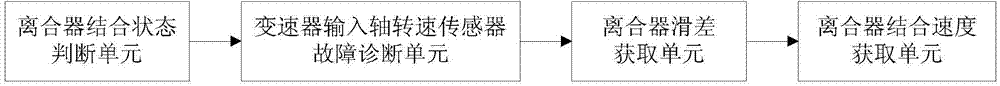

[0023] Control method of the present invention comprises the following steps:

[0024] (1) Determine whether the clutch is in the process of engaging, if yes, go to step (2); if not, go to step (6);

[0025] (2) Detect whether the transmission input shaft speed sensor is faulty, if yes, go to step (3); otherwise go to step (4);

[0026] (3) Calculate the value of the transmission input speed according to the following formula to replace the detection value of the transmission input shaft speed sensor, and calculate the clutch slip according to this value, and proceed to step (5):

[0027] Transmission i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com