Patents

Literature

6492 results about "Ratchet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A ratchet is a mechanical device that allows continuous linear or rotary motion in only one direction while preventing motion in the opposite direction. Ratchets are widely used in machinery and tools. The word ratchet is also used informally to refer to a ratcheting socket wrench.

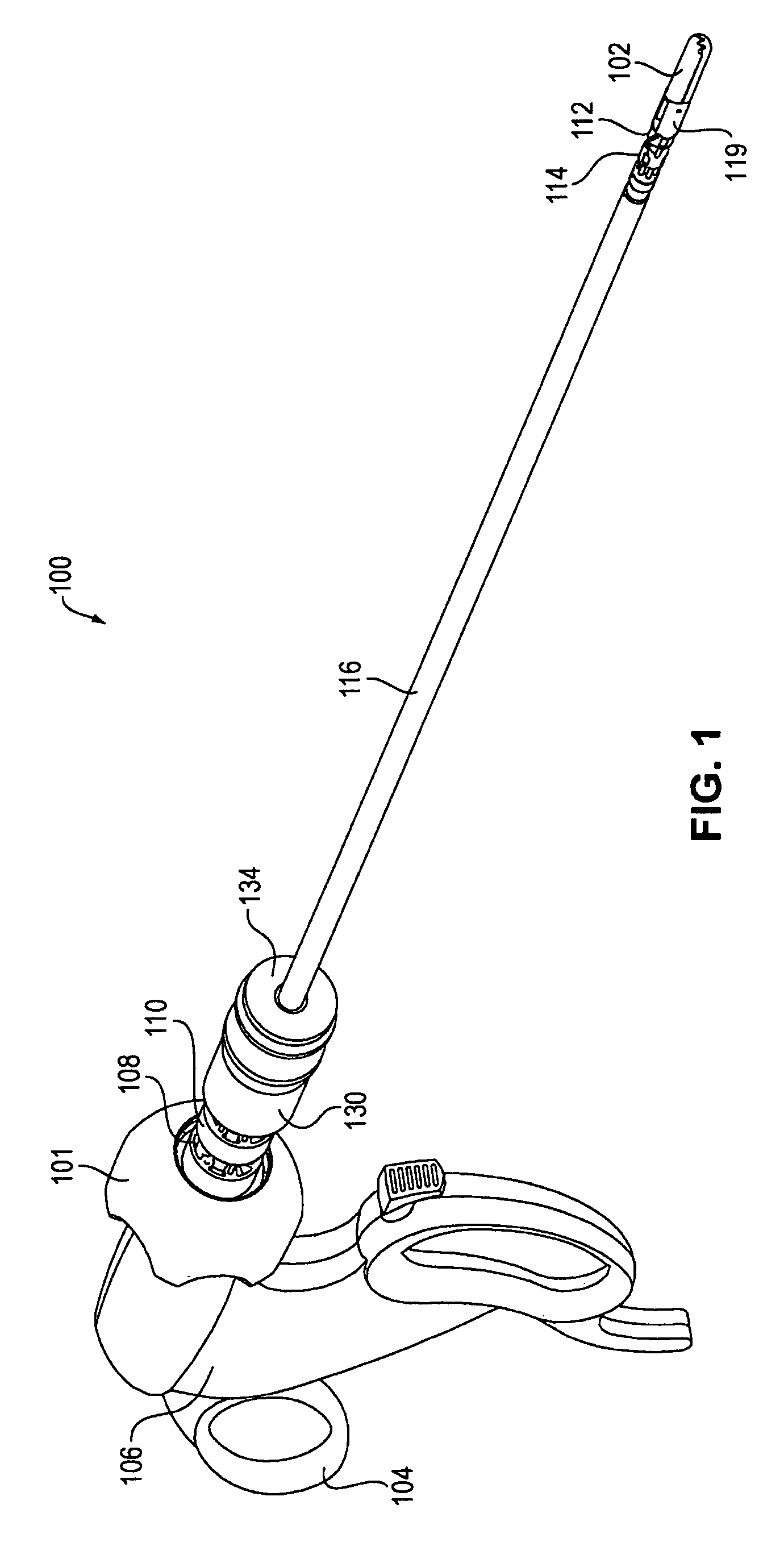

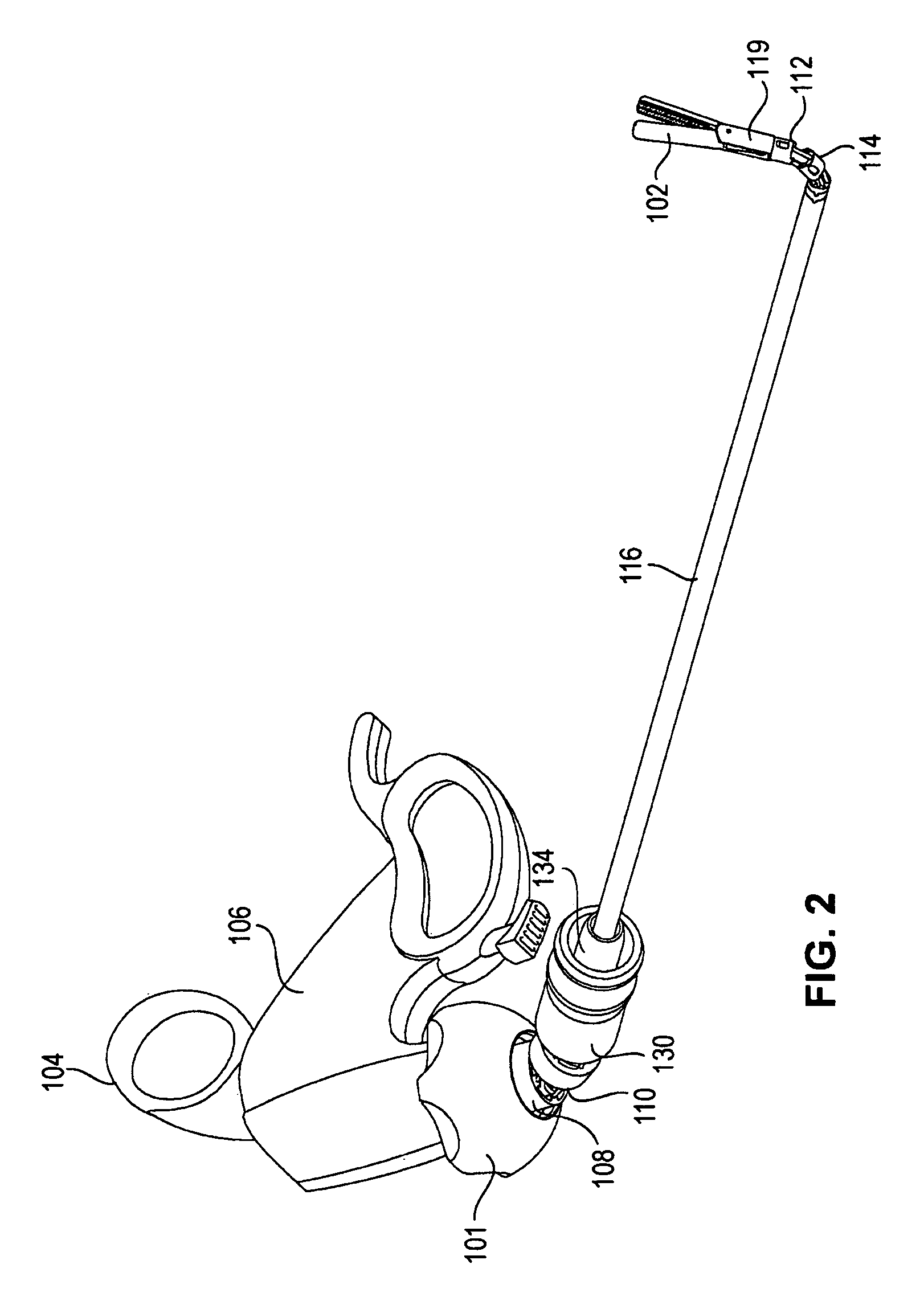

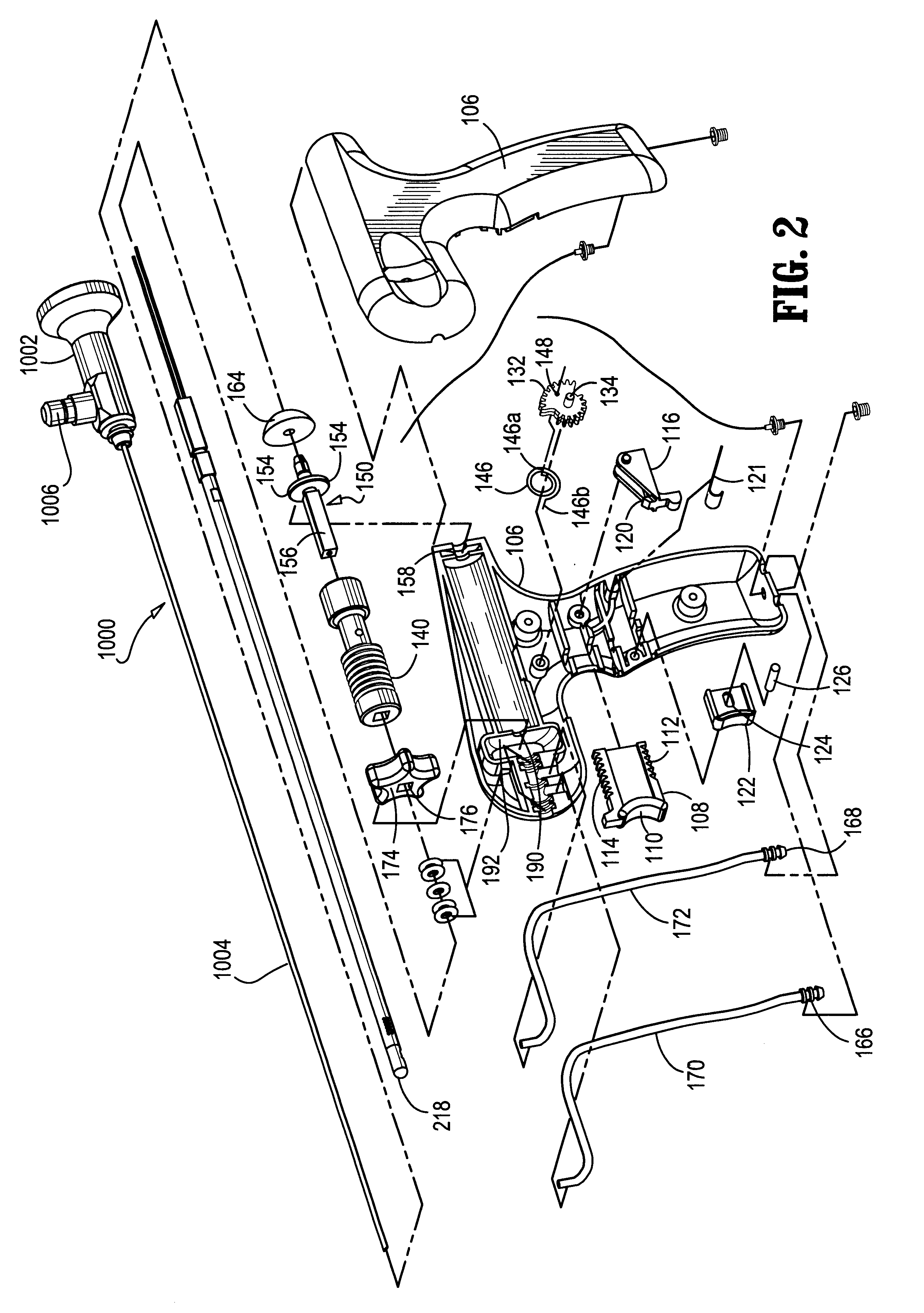

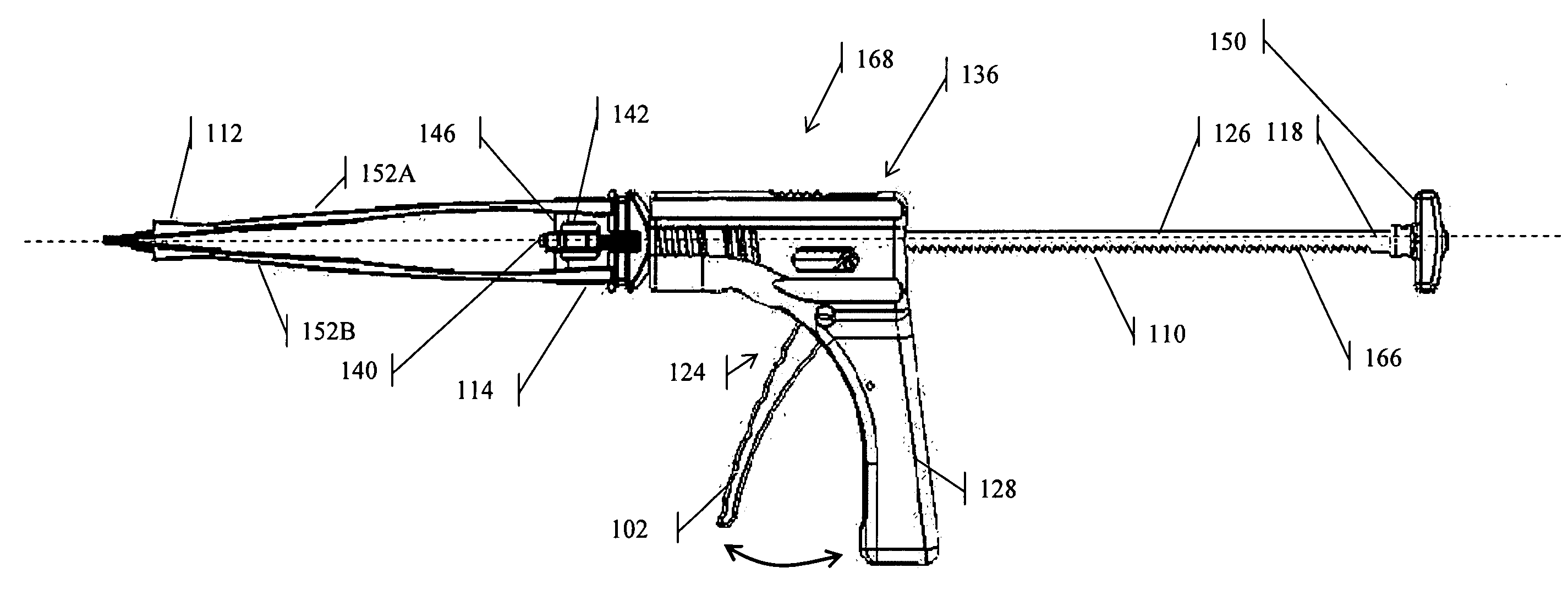

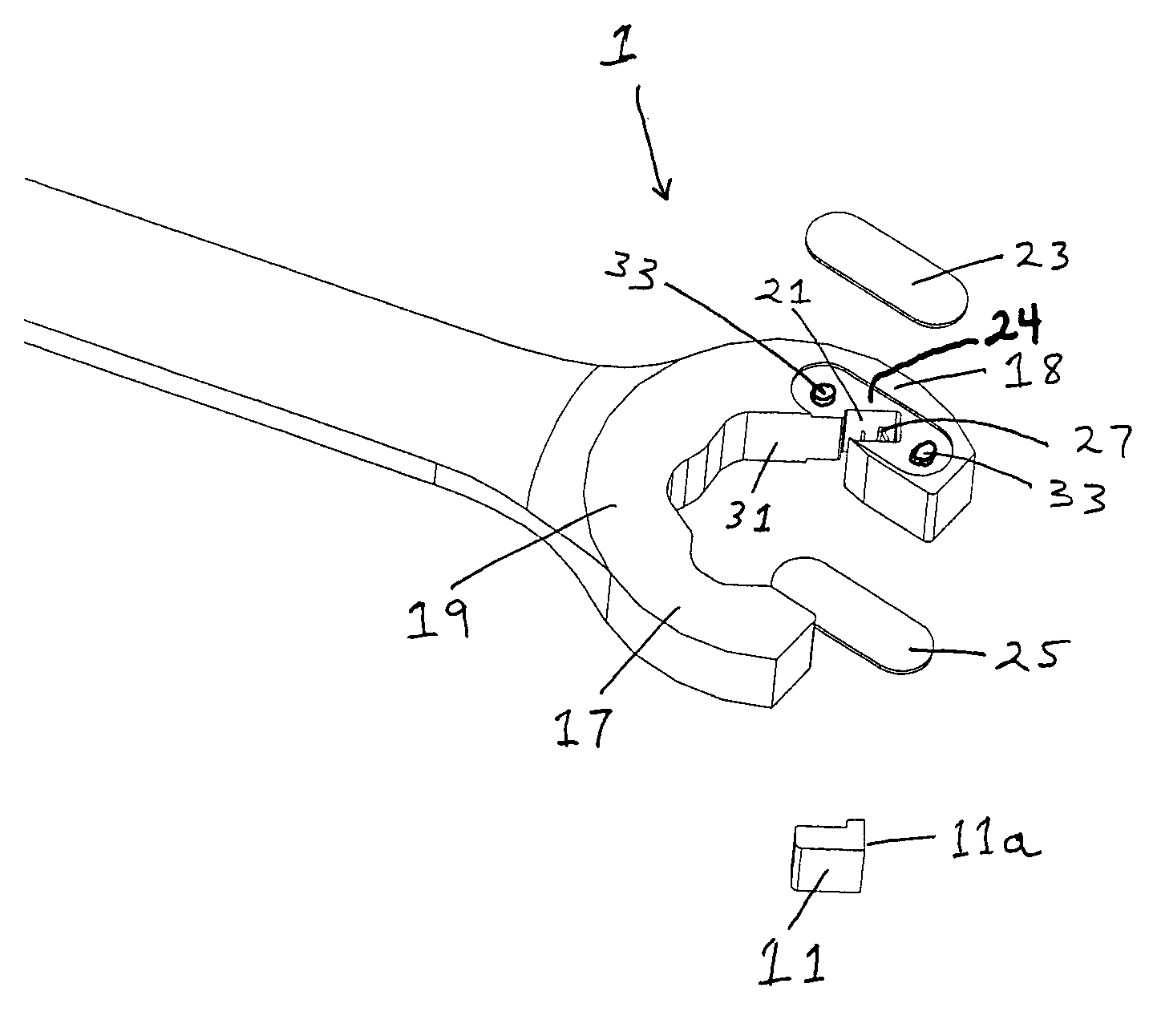

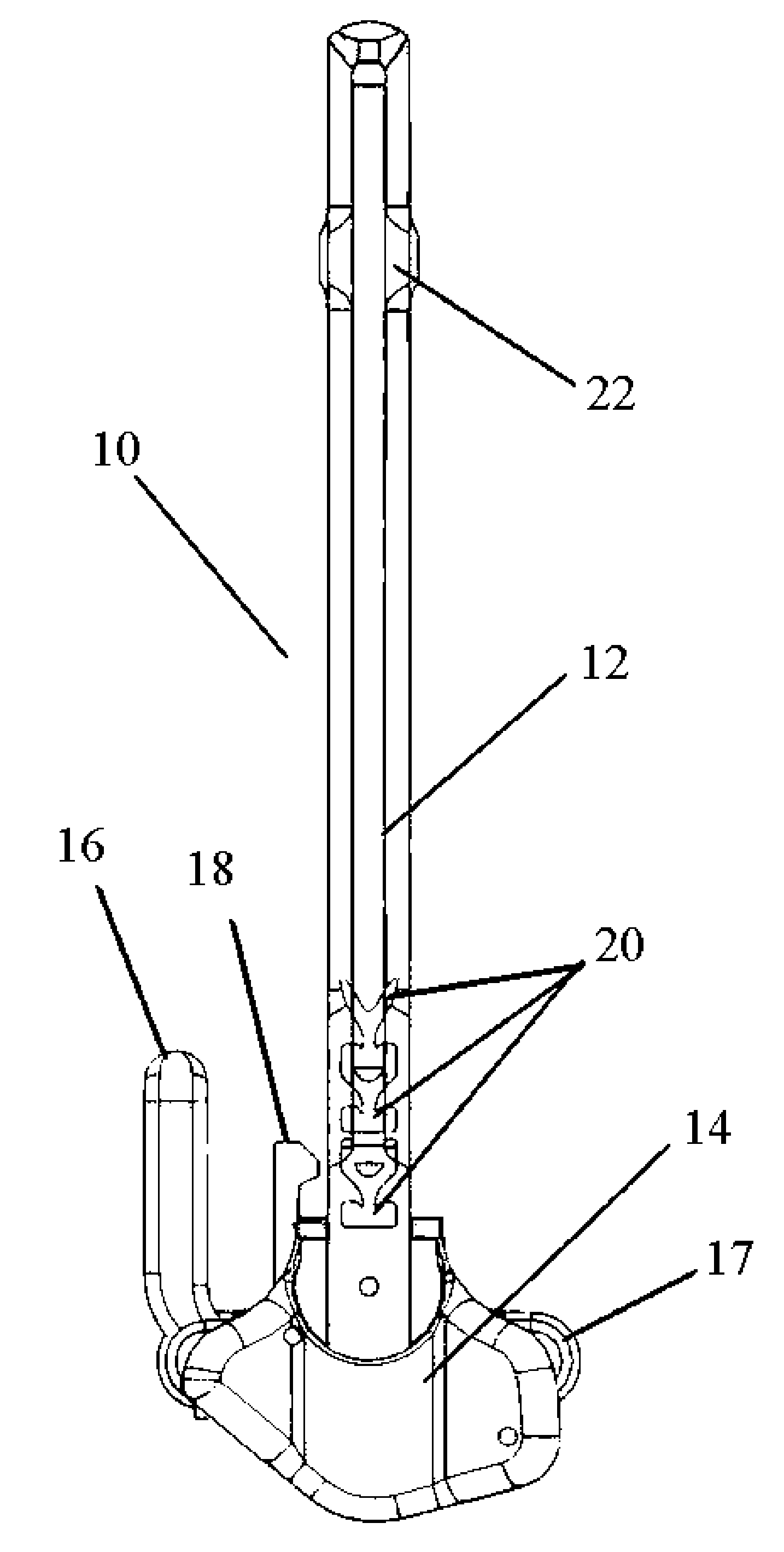

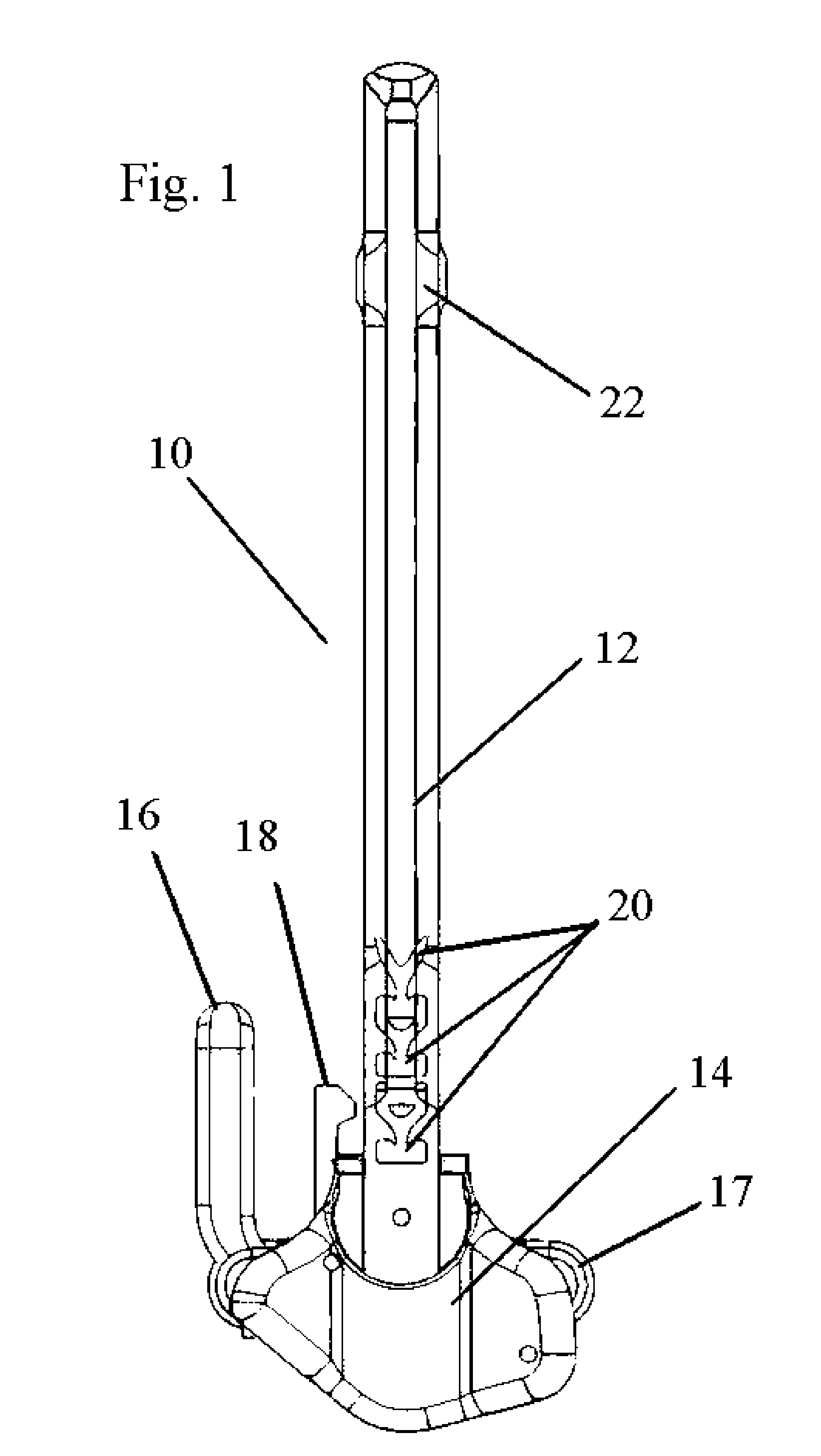

Surgical instrument having a directional switching mechanism

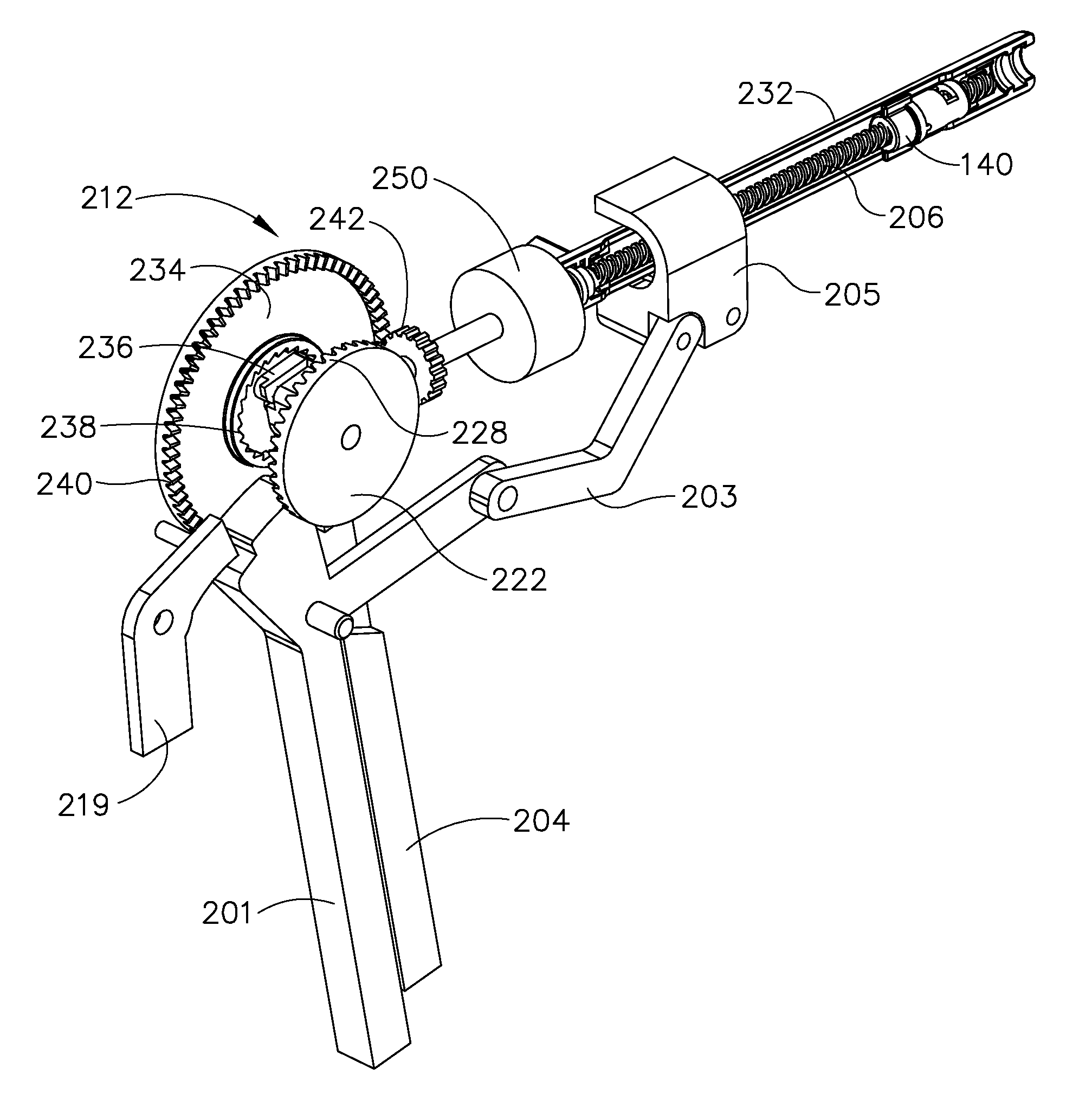

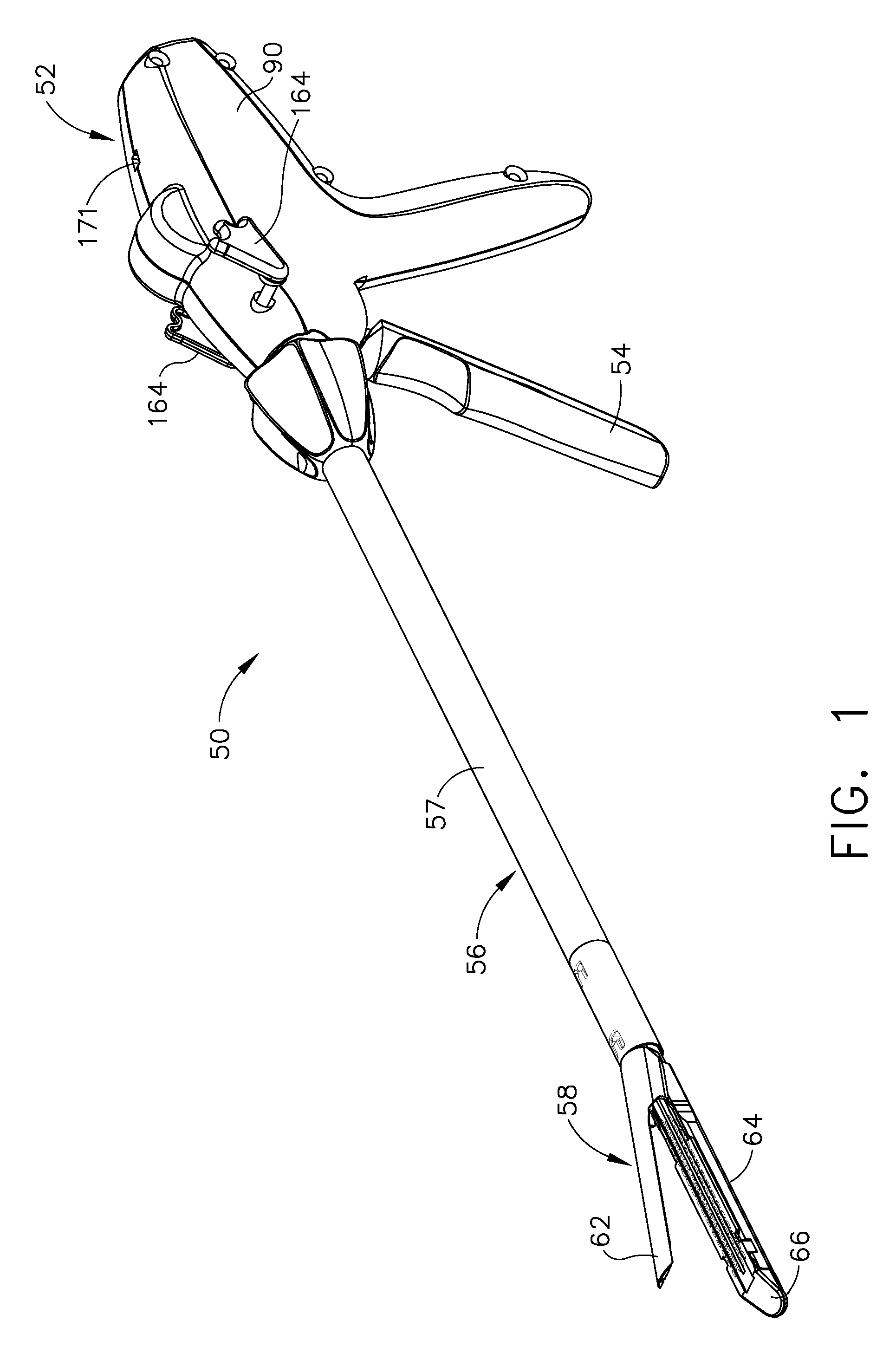

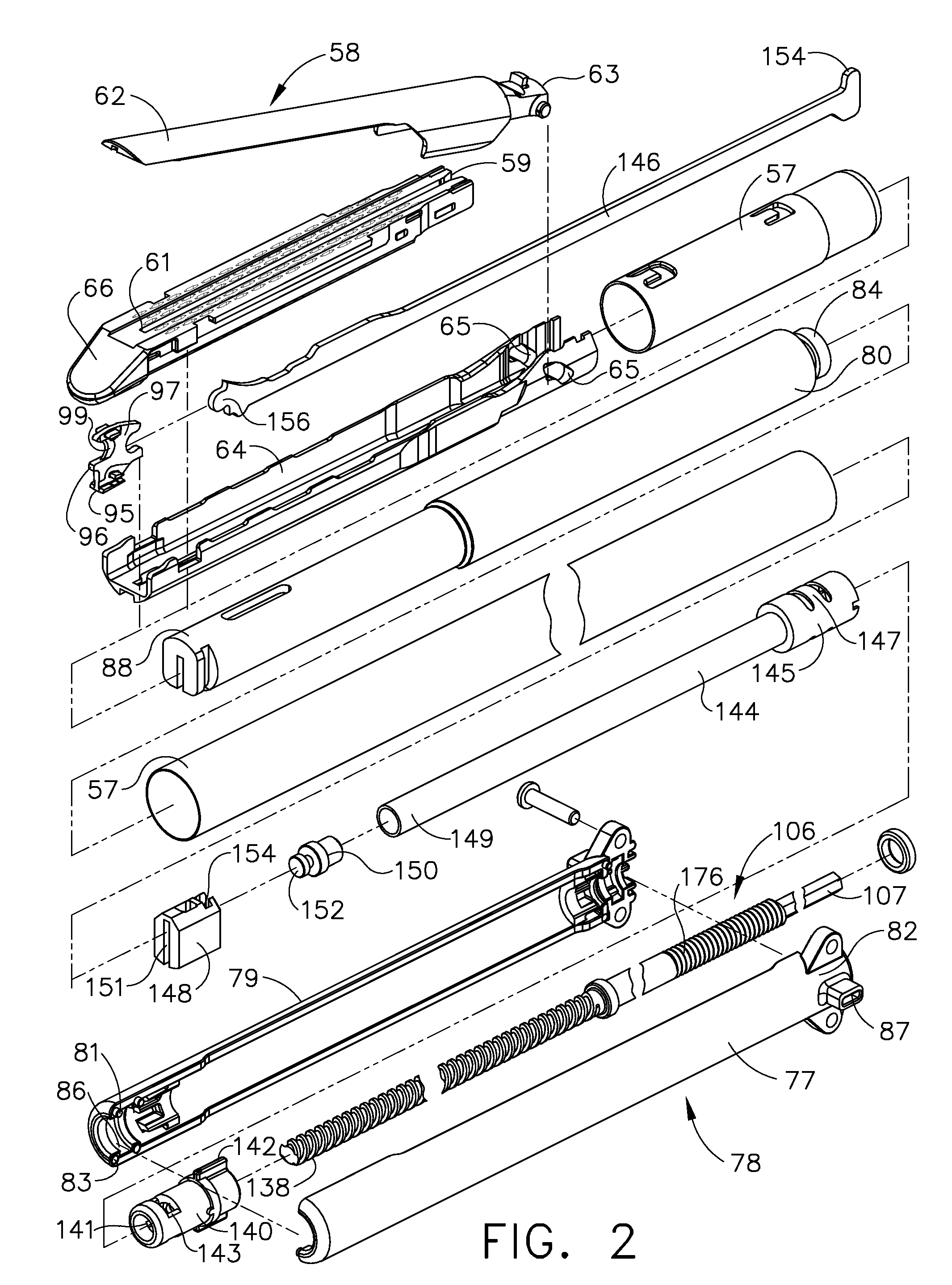

A surgical instrument including a switching mechanism which allows a surgeon to selectively advance or retract a staple driver and / or cutting member within a staple cartridge. In various embodiments, the surgical instrument can include a handle, a trigger operatively coupled to the handle, a firing drive, and an end effector. The firing drive can include a first ratchet assembly configured to advance a cutting member in the end effector and a second ratchet assembly configured to retract the cutting member. The trigger can include first and second pawls pivotably mounted thereon which are configured to be selectively engaged with the first and second ratchet assemblies, respectively. In at least one embodiment, the trigger can be configured to slide between a first position in which the first pawl is engaged with the first ratchet assembly and a second position in which the second pawl is engaged with the second ratchet assembly.

Owner:CILAG GMBH INT

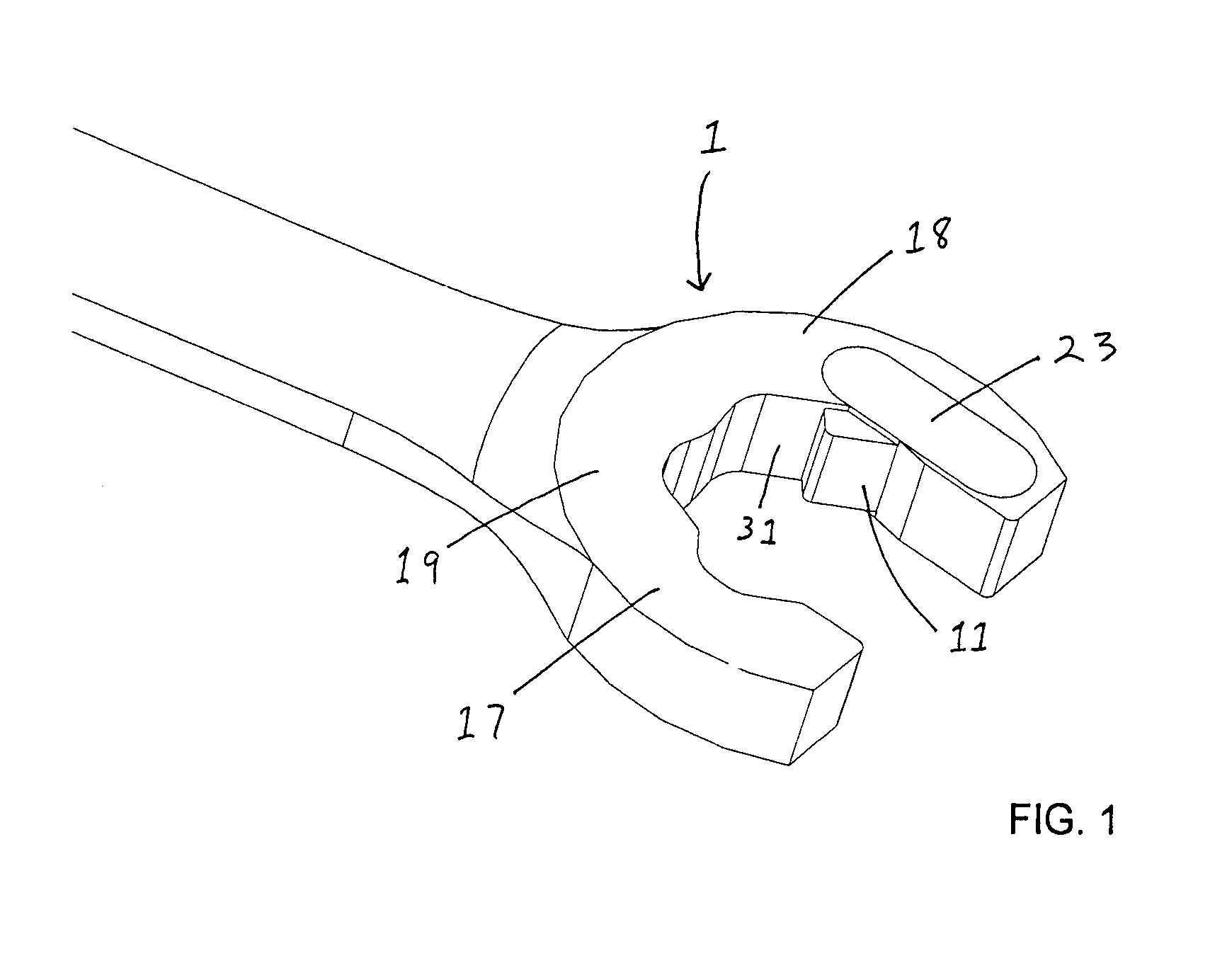

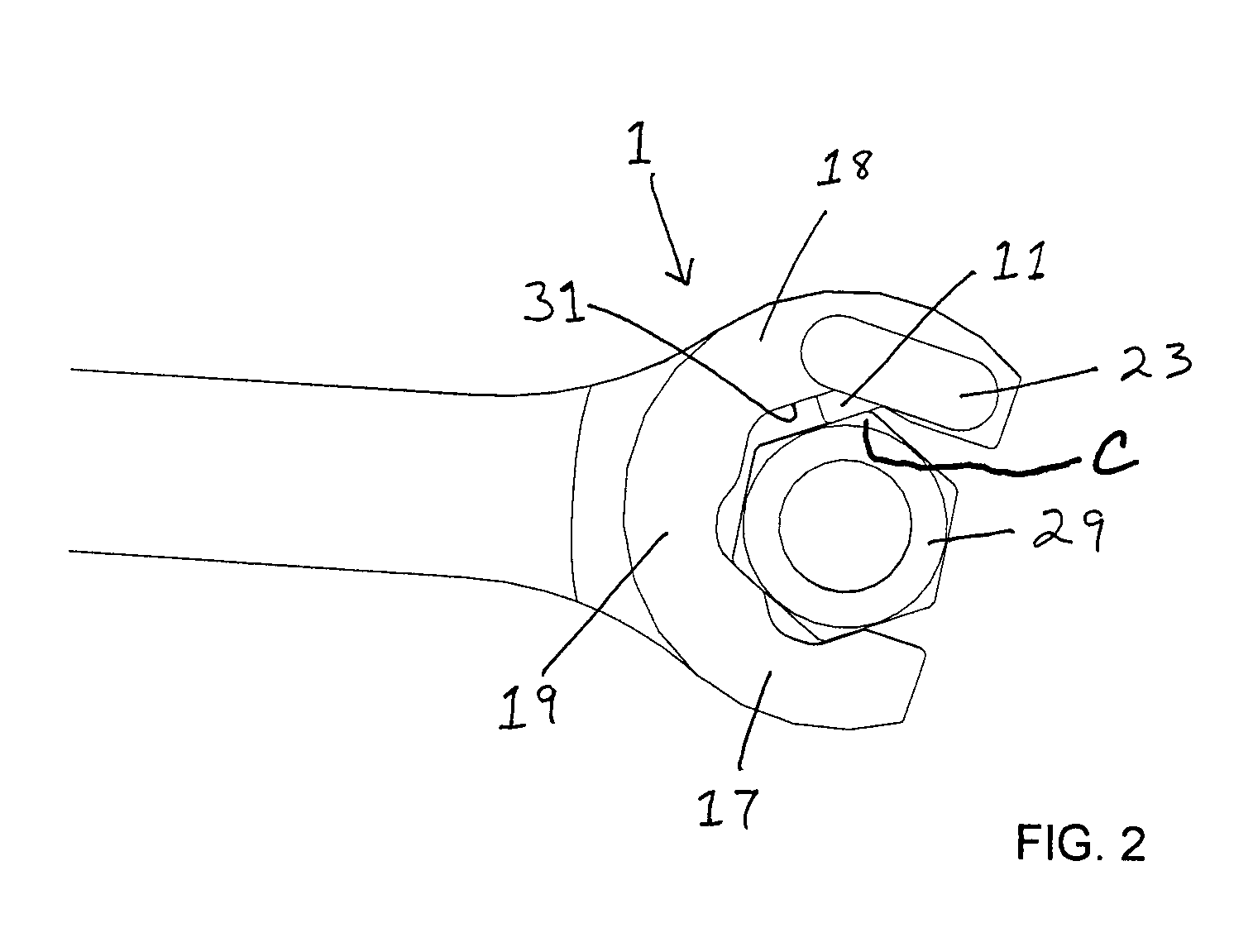

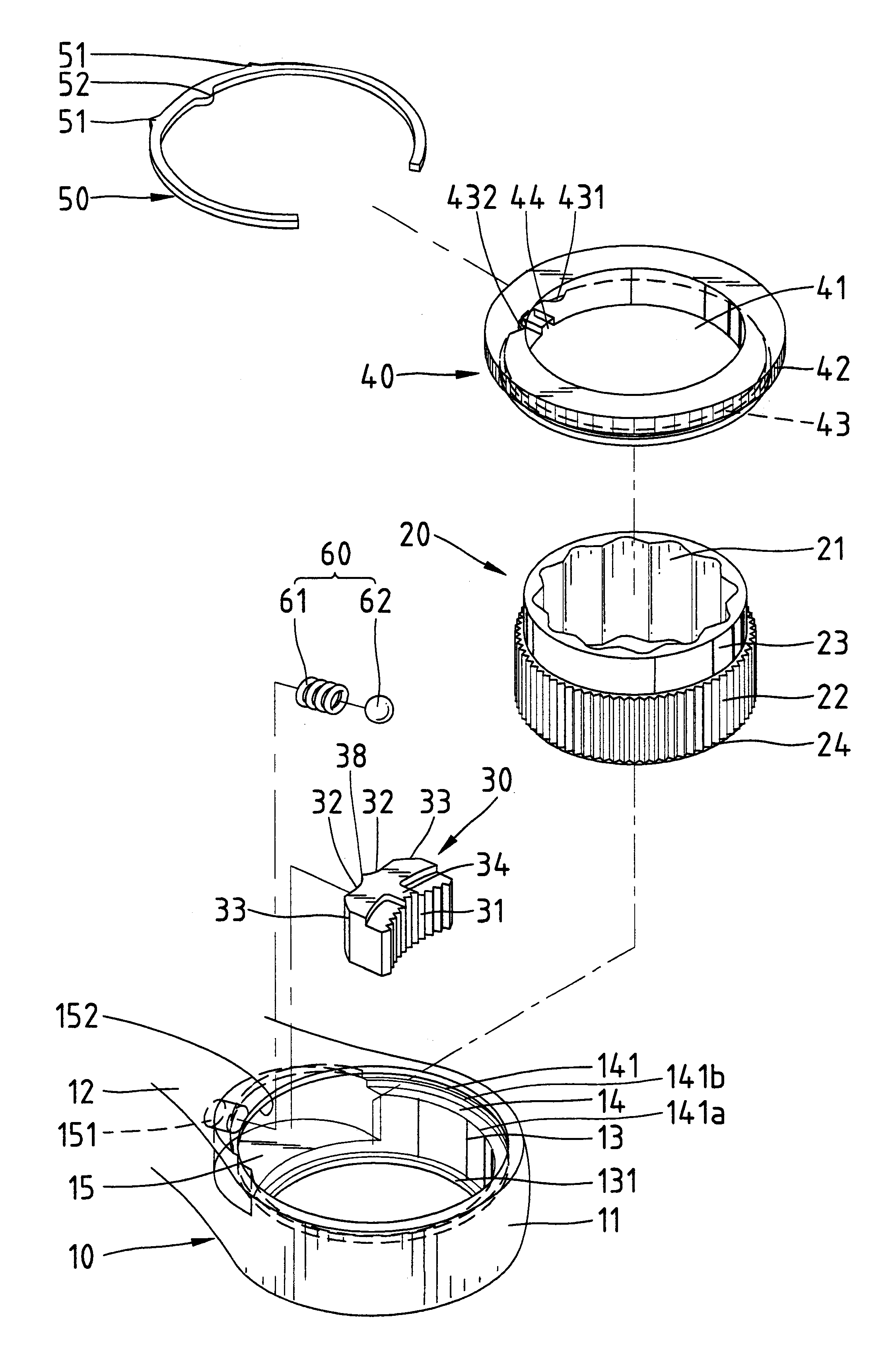

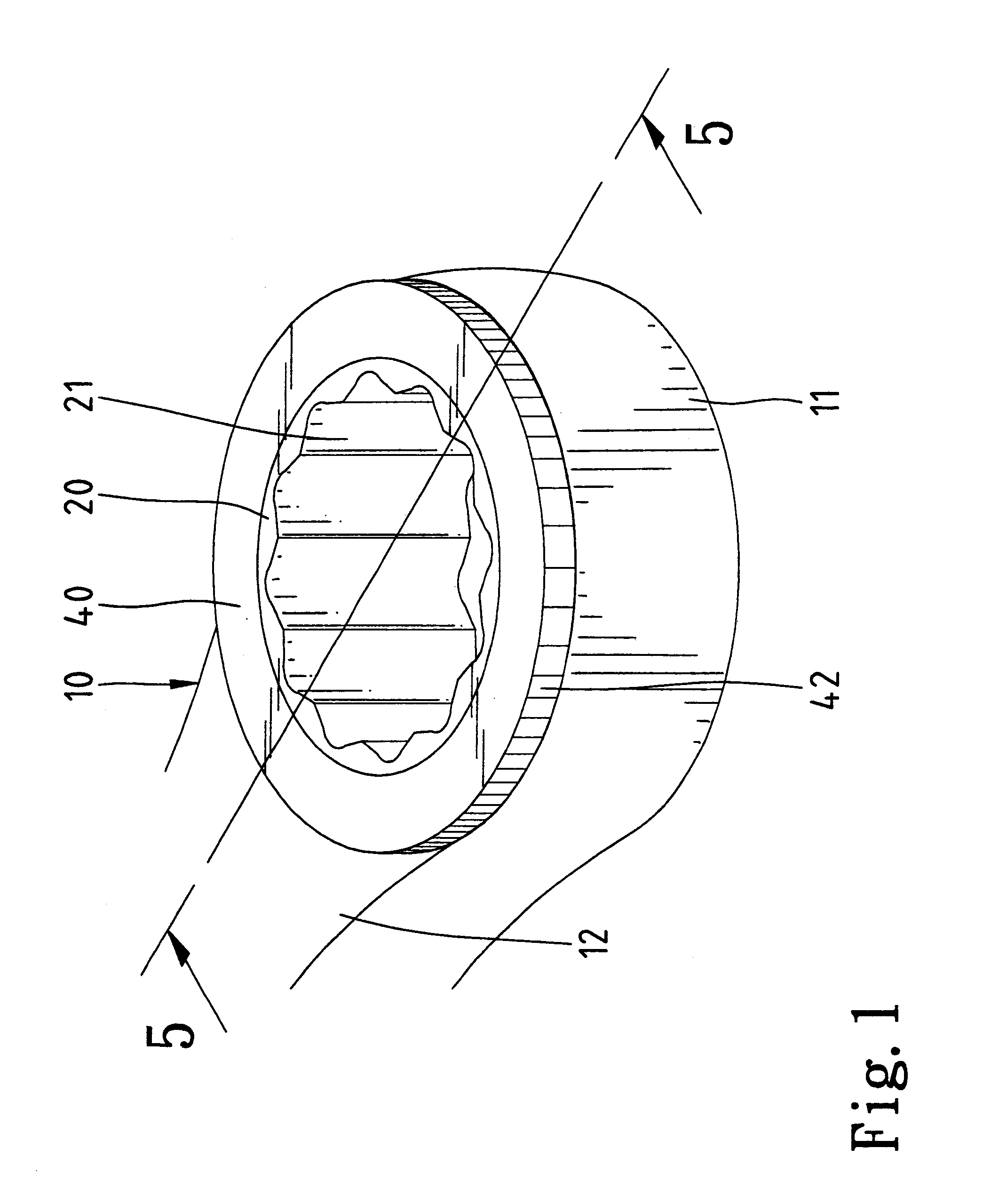

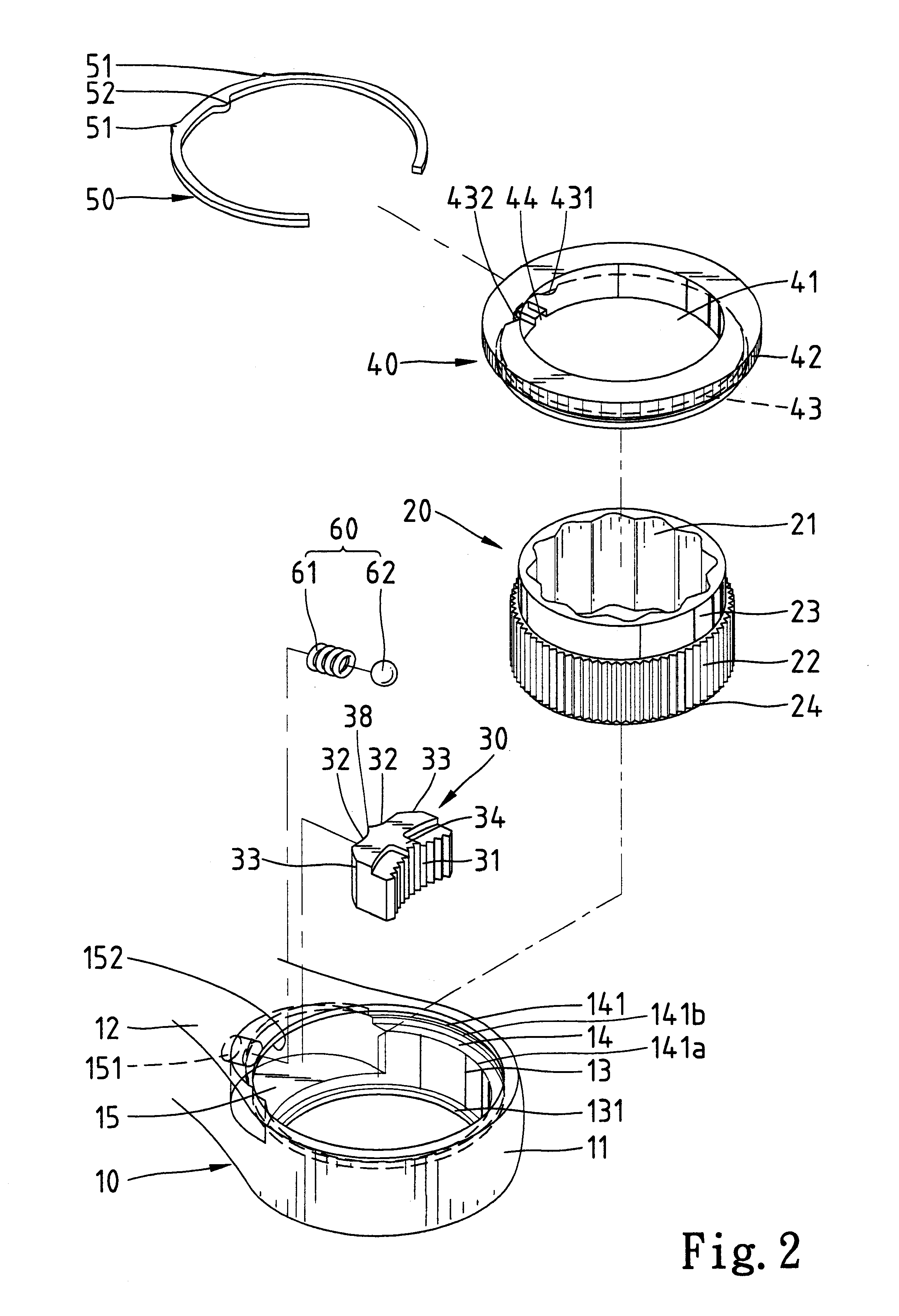

Tool with rotation lock

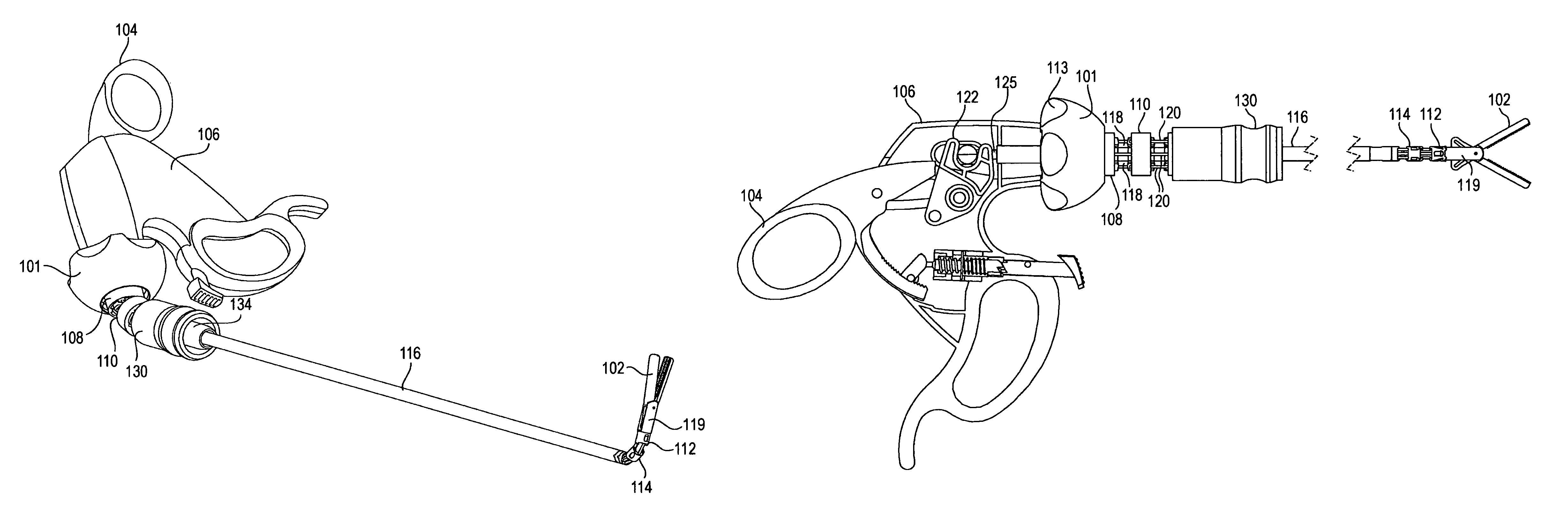

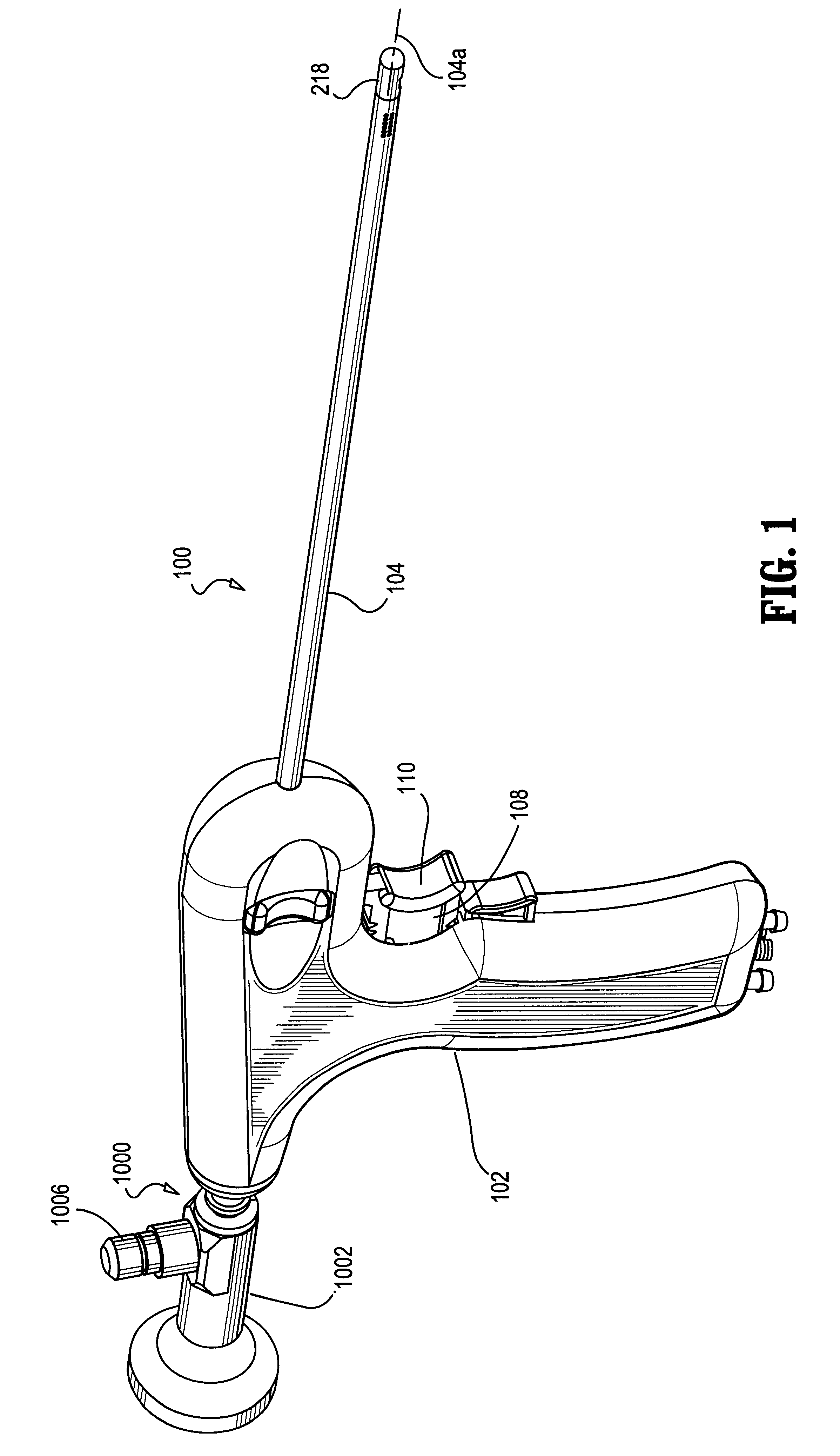

The invention provides surgical or diagnostic tools and associated methods that offer improved user control for operating remotely within regions of the body. These tools include a proximally-located actuator for the operation of a distal end effector, as well as proximally-located actuators for articulational and rotational movements of the end effector. Control mechanisms and methods refine operator control of end effector actuation and of these articulational and rotational movements. A rotation lock provides for enablement and disablement of rotatability of the end effector. The tool may also include other features. A multi-state ratchet for end effector actuation provides enablement-disablement options with tactile feedback. A force limiter mechanism protects the end effector and manipulated objects from the harm of potentially excessive force applied by the operator. An articulation lock allows the fixing and releasing of both neutral and articulated configurations of the tool and of consequent placement of the end effector.

Owner:INTUITIVE SURGICAL OPERATIONS INC

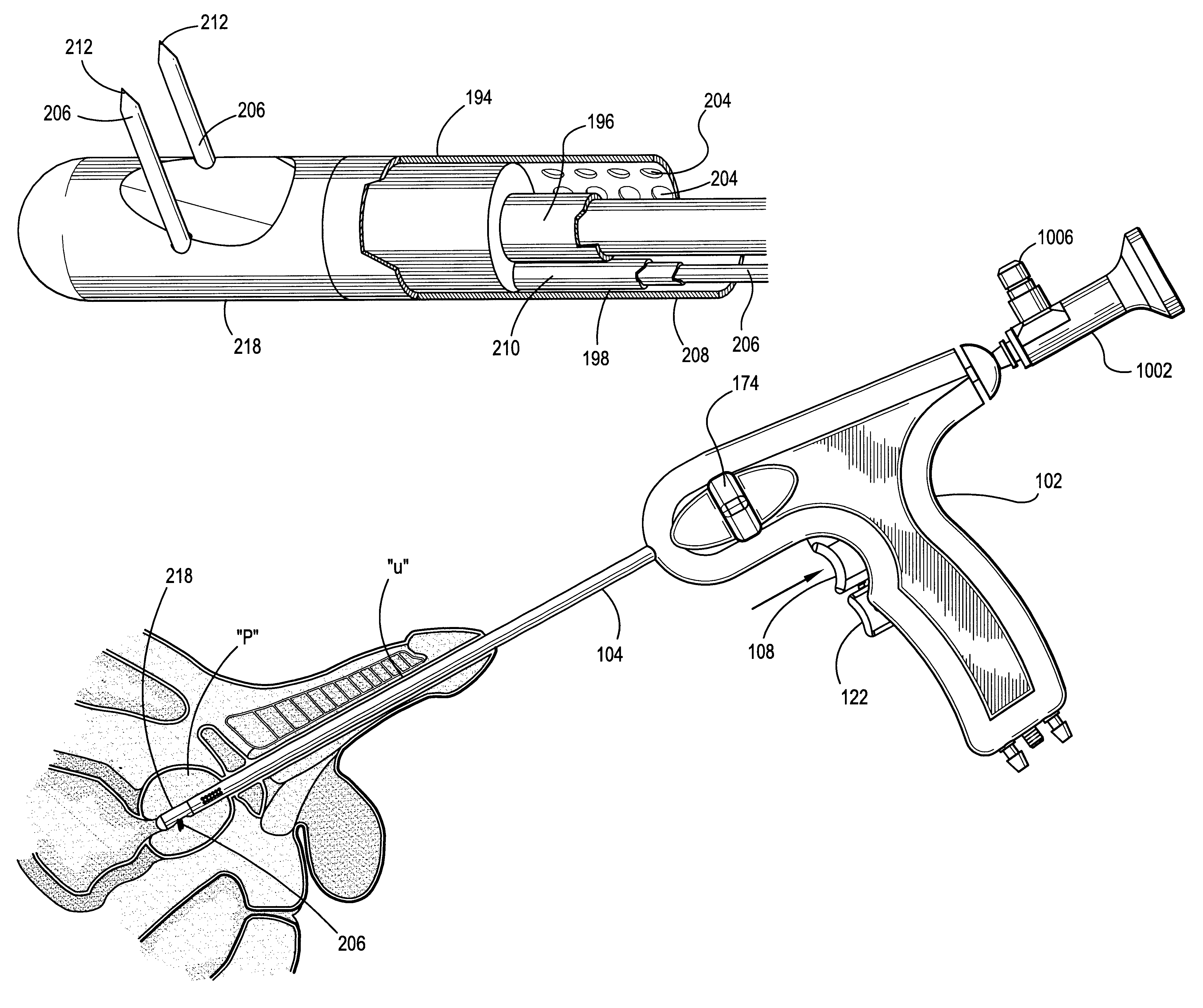

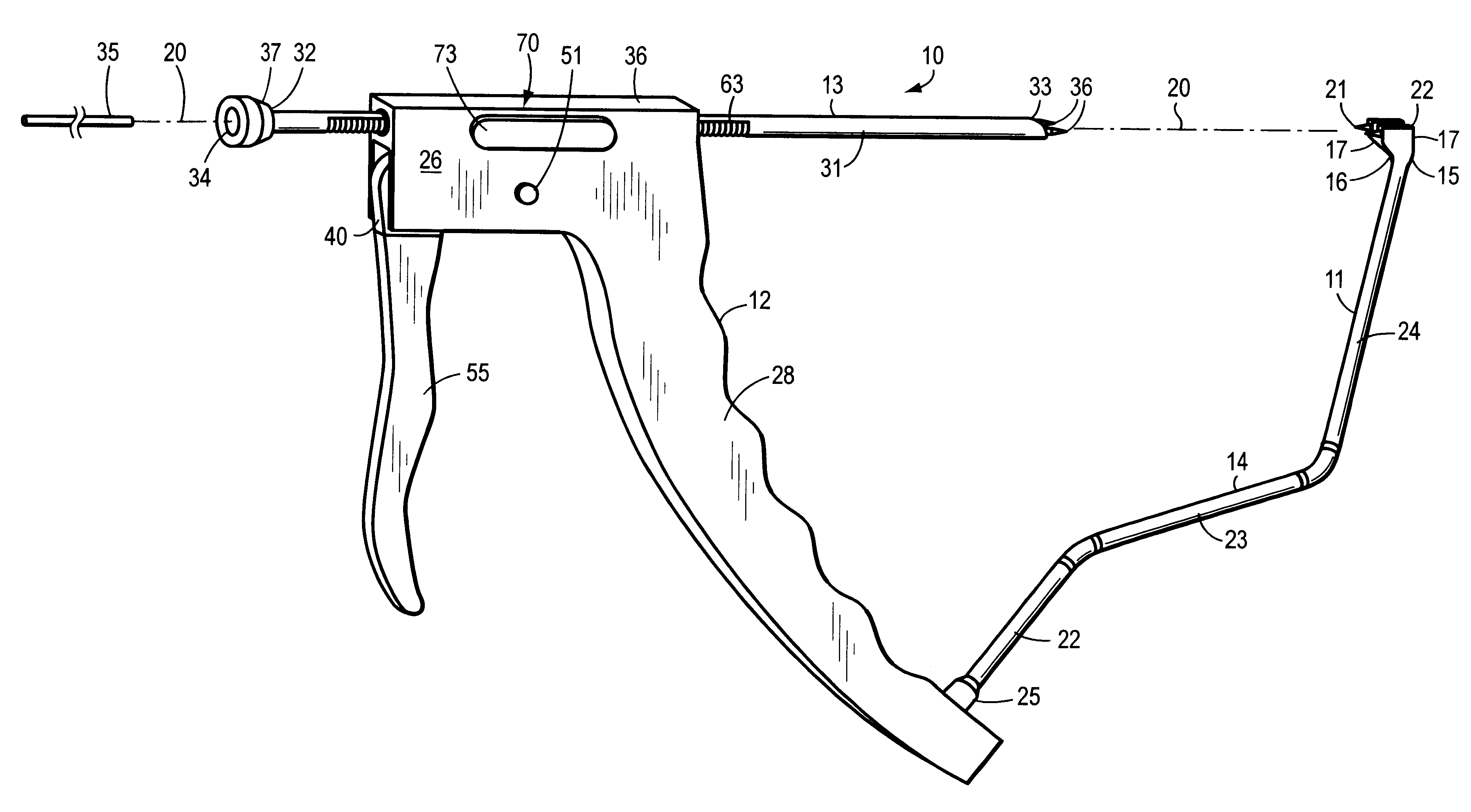

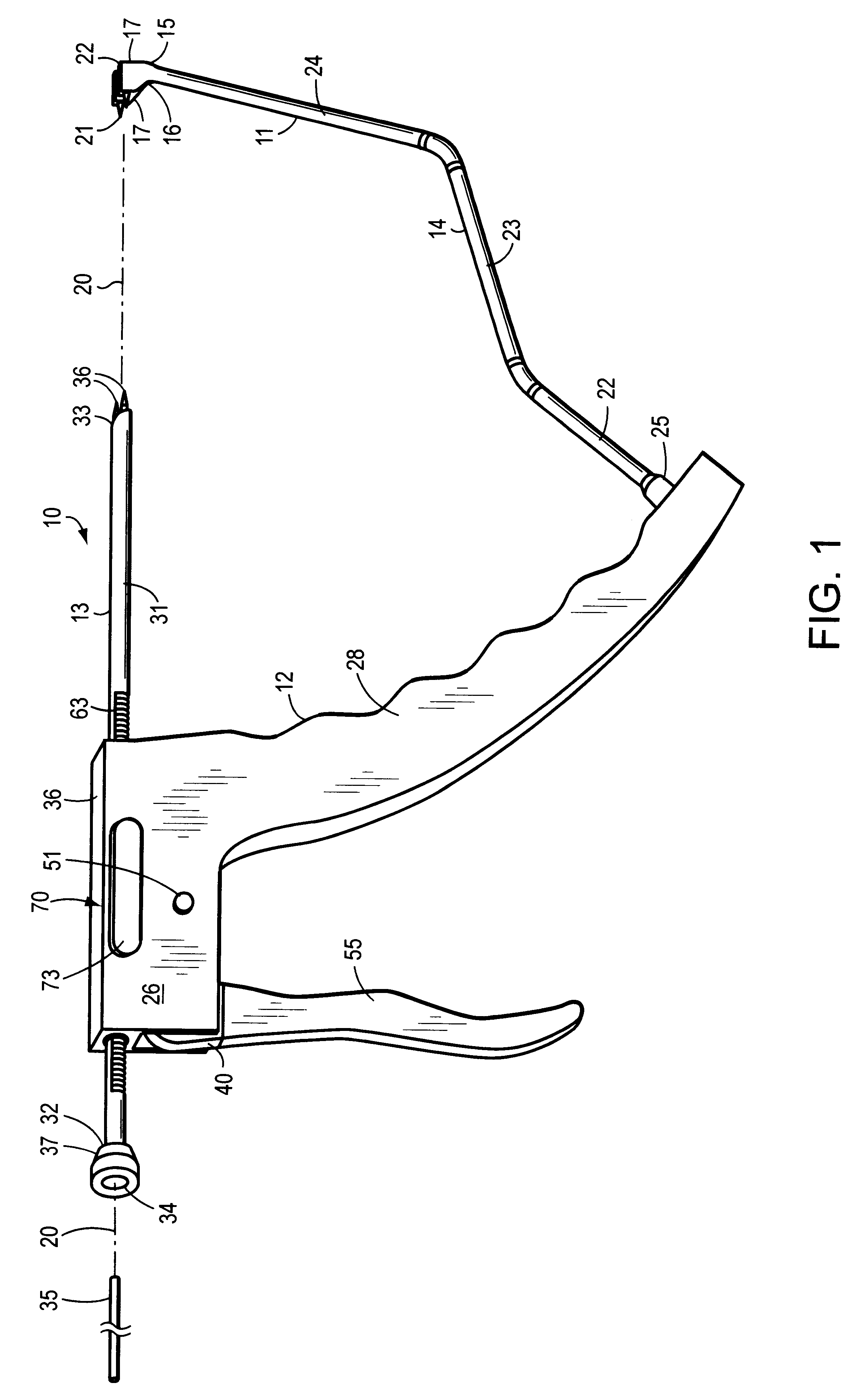

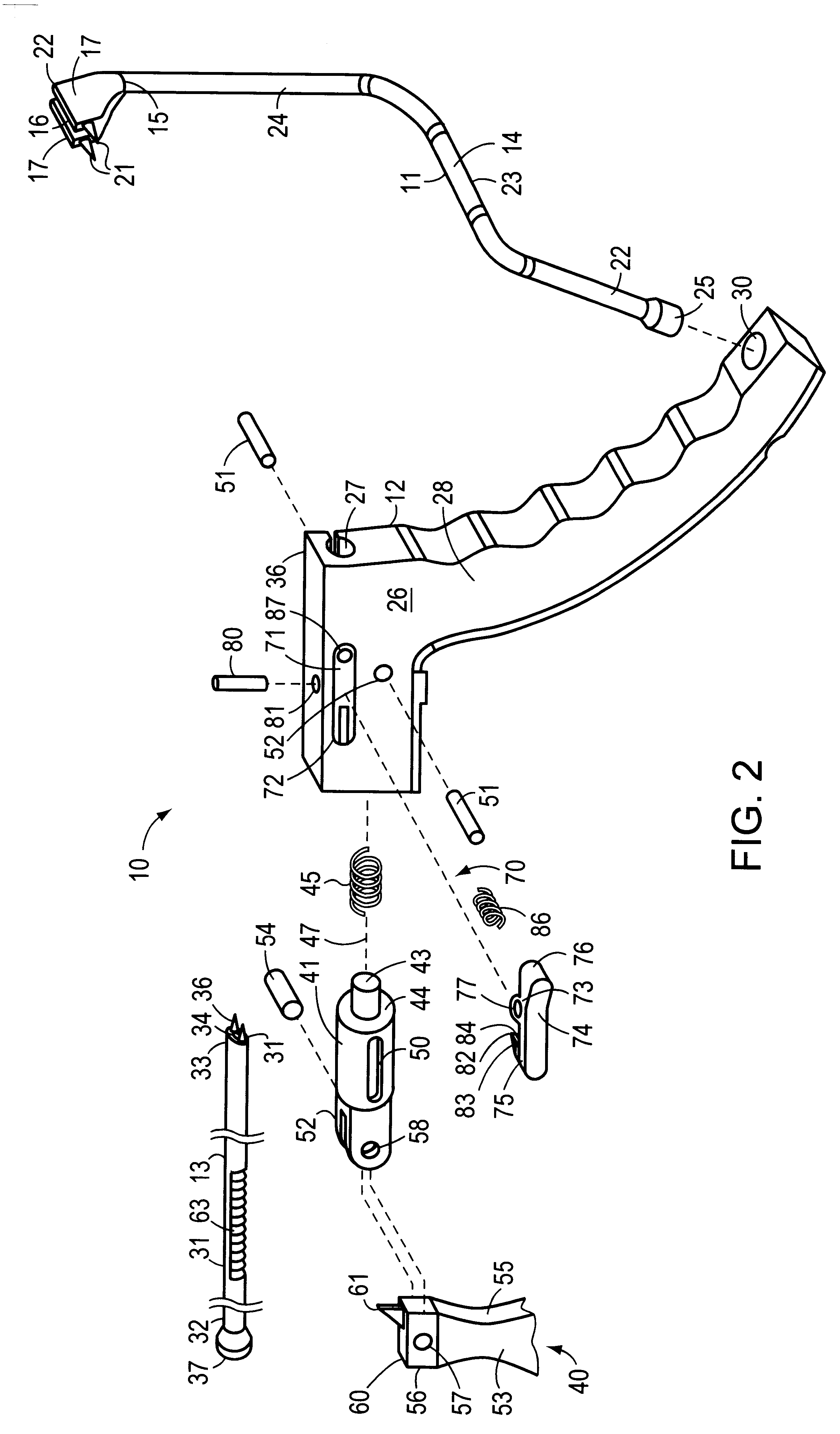

Apparatus and method for thermal treatment of body tissue

An apparatus and method for the thermal treatment of tissue, e.g., prostatic tissue, with RF energy is disclosed. The apparatus includes a handle dimensioned to be grasped with a single hand of a surgeon, an elongated portion extending distally from the handle and defining a longitudinal axis, at least one electrode extending within the elongated portion and movable between a non-deployed position and a fully deployed position, and a trigger mechanism associated with the handle and having a trigger operatively connected to the one electrode. The trigger is movable to selectively and incrementally move the one electrode between the non-deployed position and the fully deployed position. A ratchet mechanism permits movement of the trigger in one direction corresponding to movement of the one electrode toward the fully deployed position while preventing movement of the trigger in a second direction. The elongated portion of the apparatus may be rotatable about the longitudinal axis to reposition the one electrode.

Owner:UNITED STATES SURGICAL CORP

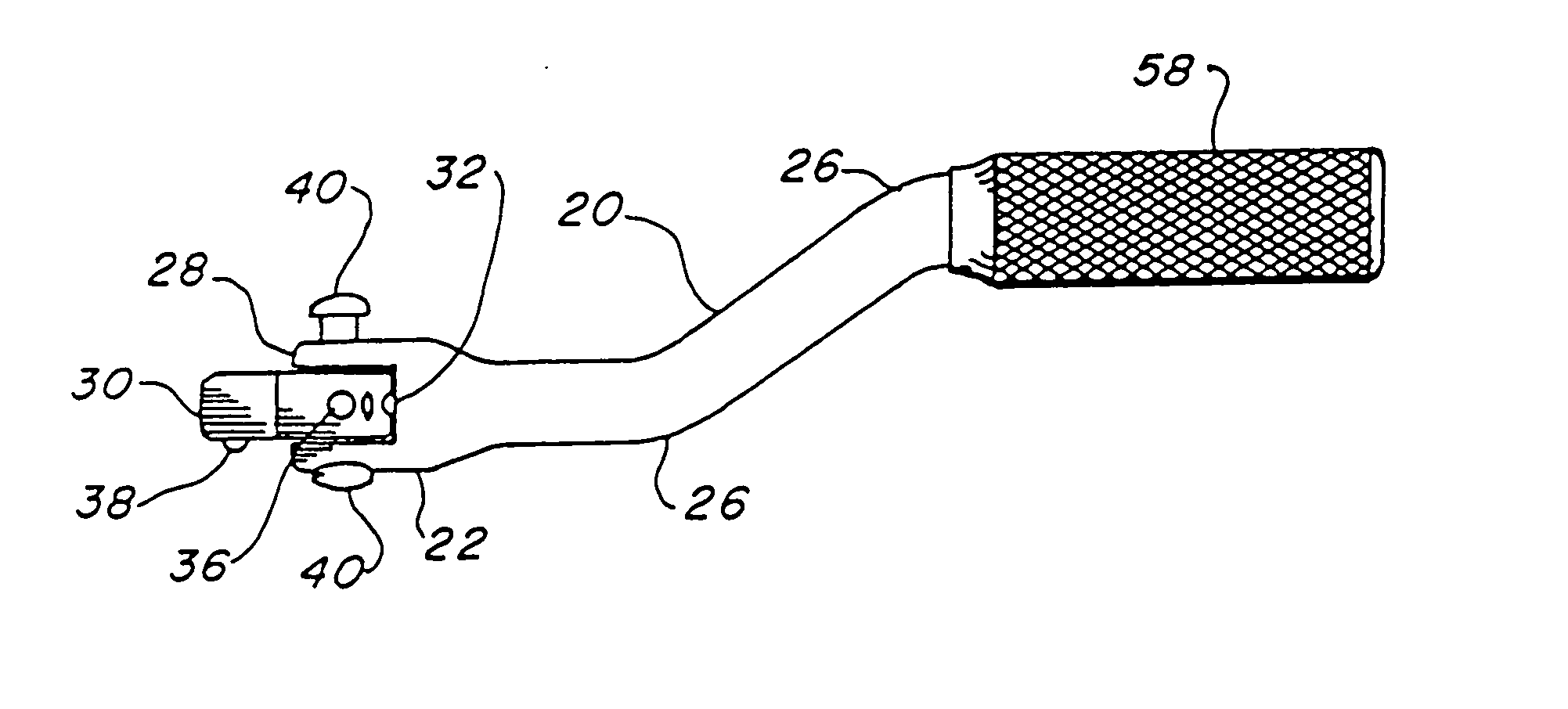

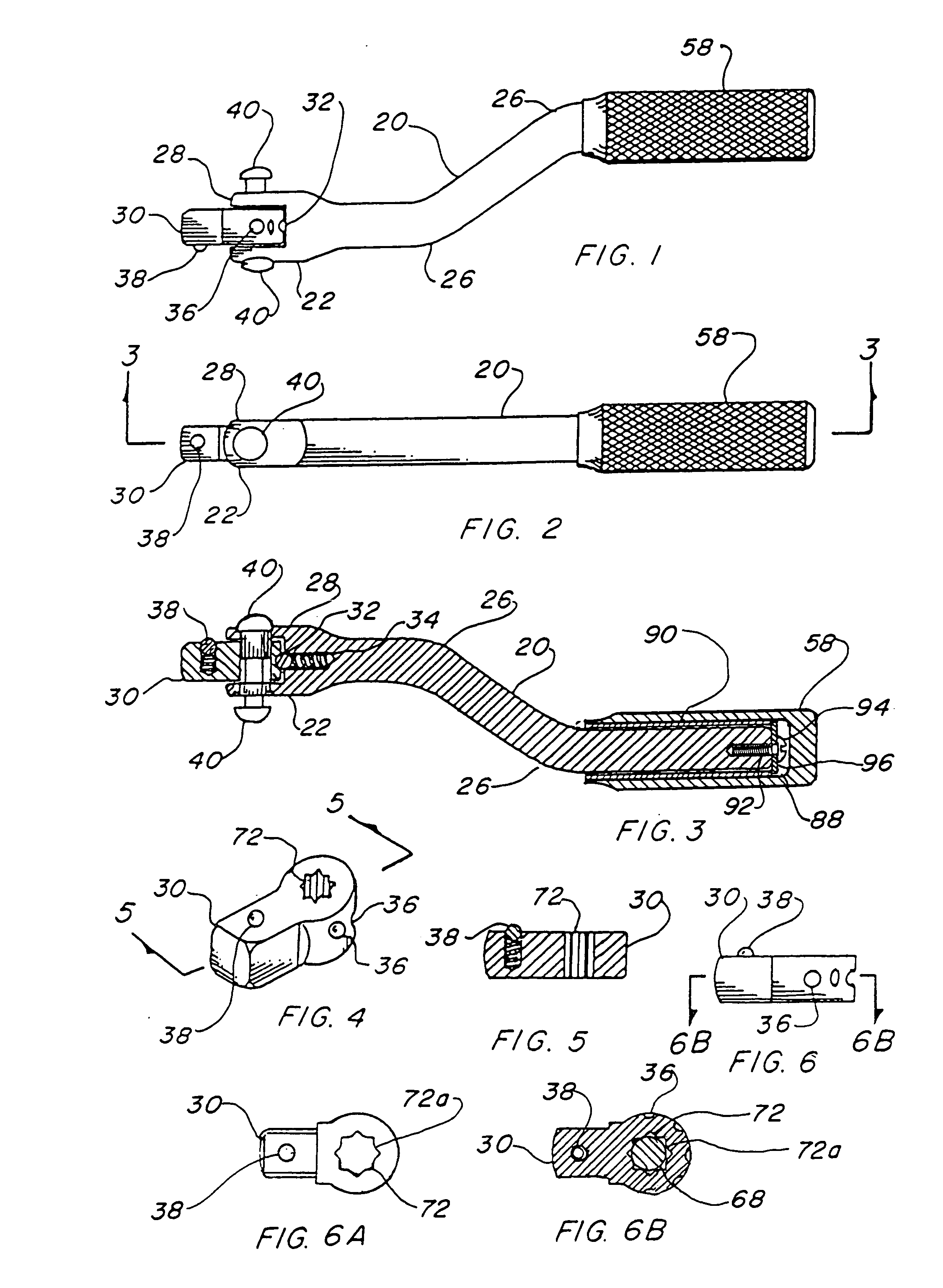

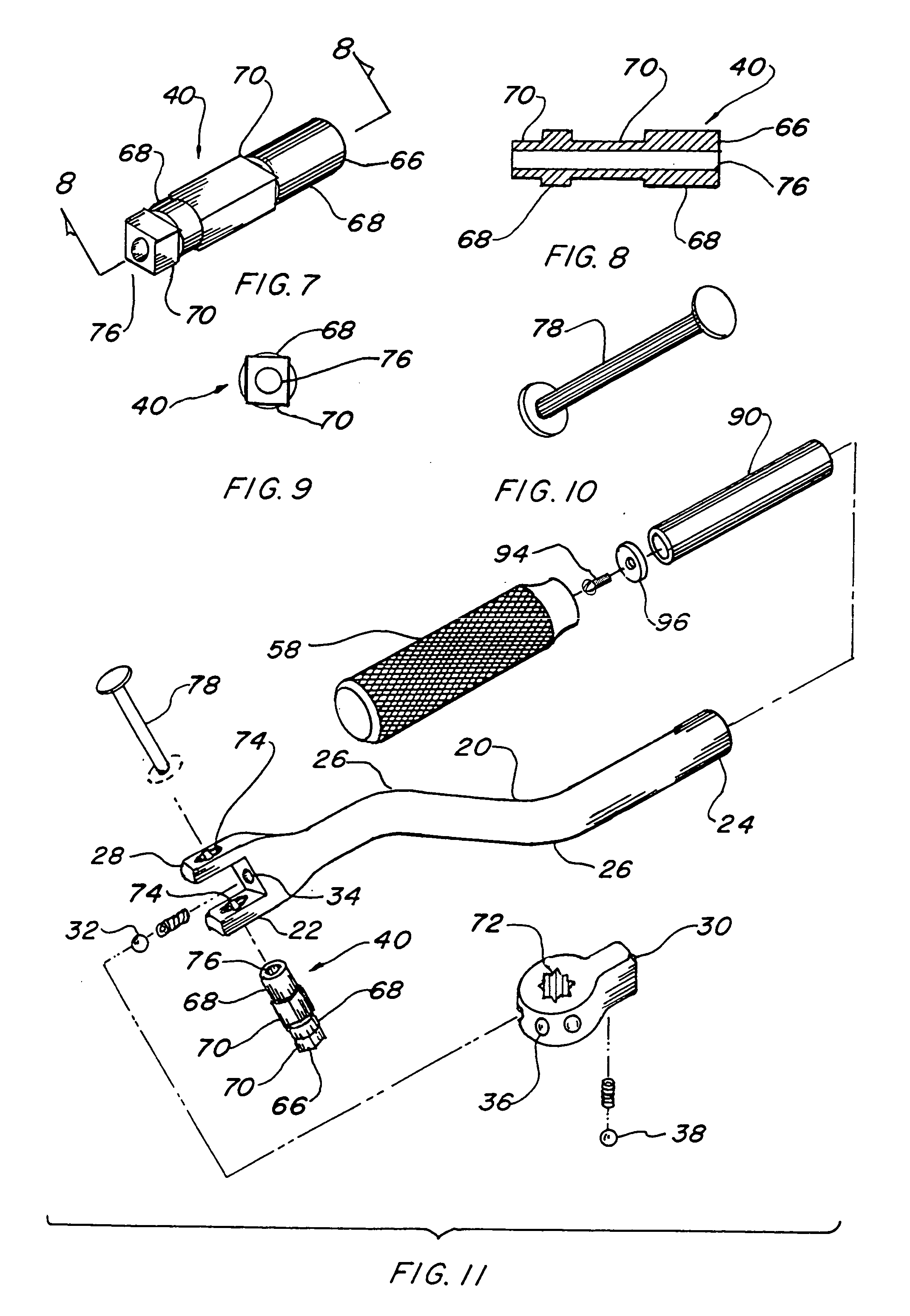

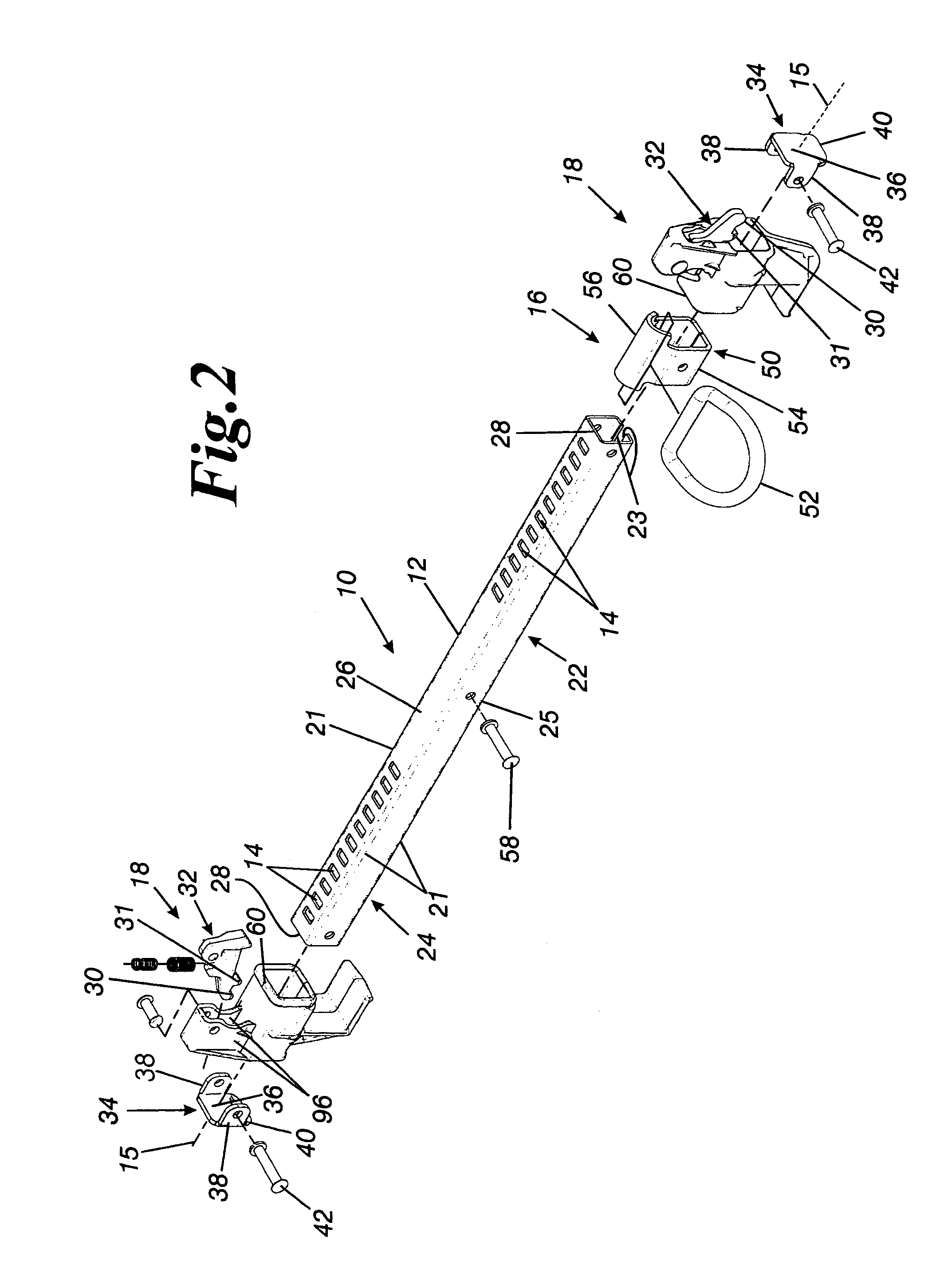

Hinged socket wrench speed handle

InactiveUS20050120836A1Improve tool lifeShorten the timeSpannersWrenchesEngineeringAngular displacement

A hinged socket wrench having an offset shank (20) with a first end (22) and a second end (24). Attached to the first end (22) is a clevis (28) which receives a 180-degree drive head held by a hinge pin (40). The drive head consists of either a square drive head (30) or a ratchet drive head (31). To the second end is attached a rotatable handle (58), which rotates the wrench upon reciprocation of the handle (58). A second embodiment of the hinged socket wrench includes a second clevis (28) that is added to the second end (24) of the offset shank. The second clevis (28) adds further combinations of angular displacement of the handle (58). Thus, increasing the value of the wrench as a tool and also its productivenss in difficult work areas. Five configurations of the hinge pin (40) provide additional surface interface with both the hinge pin and the handle yoke improving the structural integrity and prolonging tool life.

Owner:ANDERSON STEVEN P

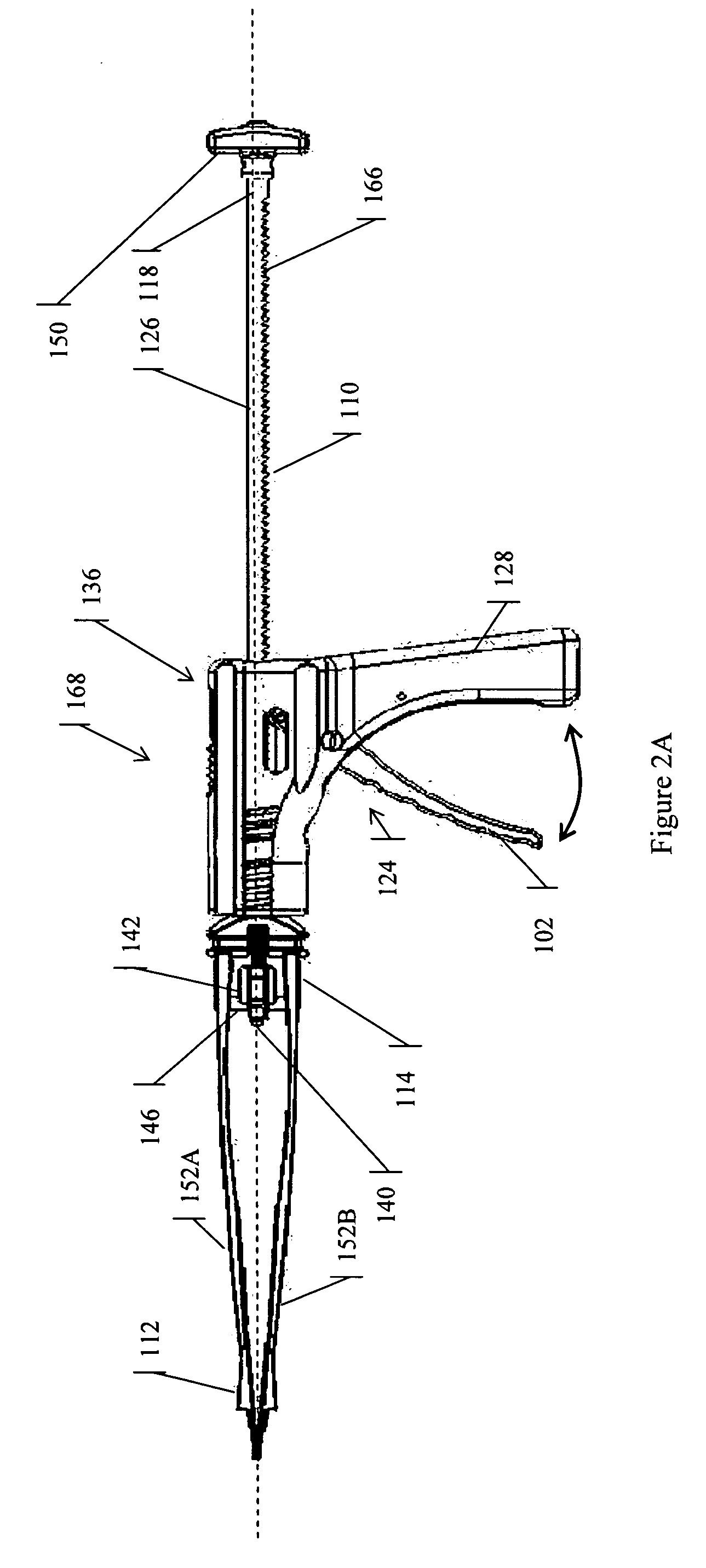

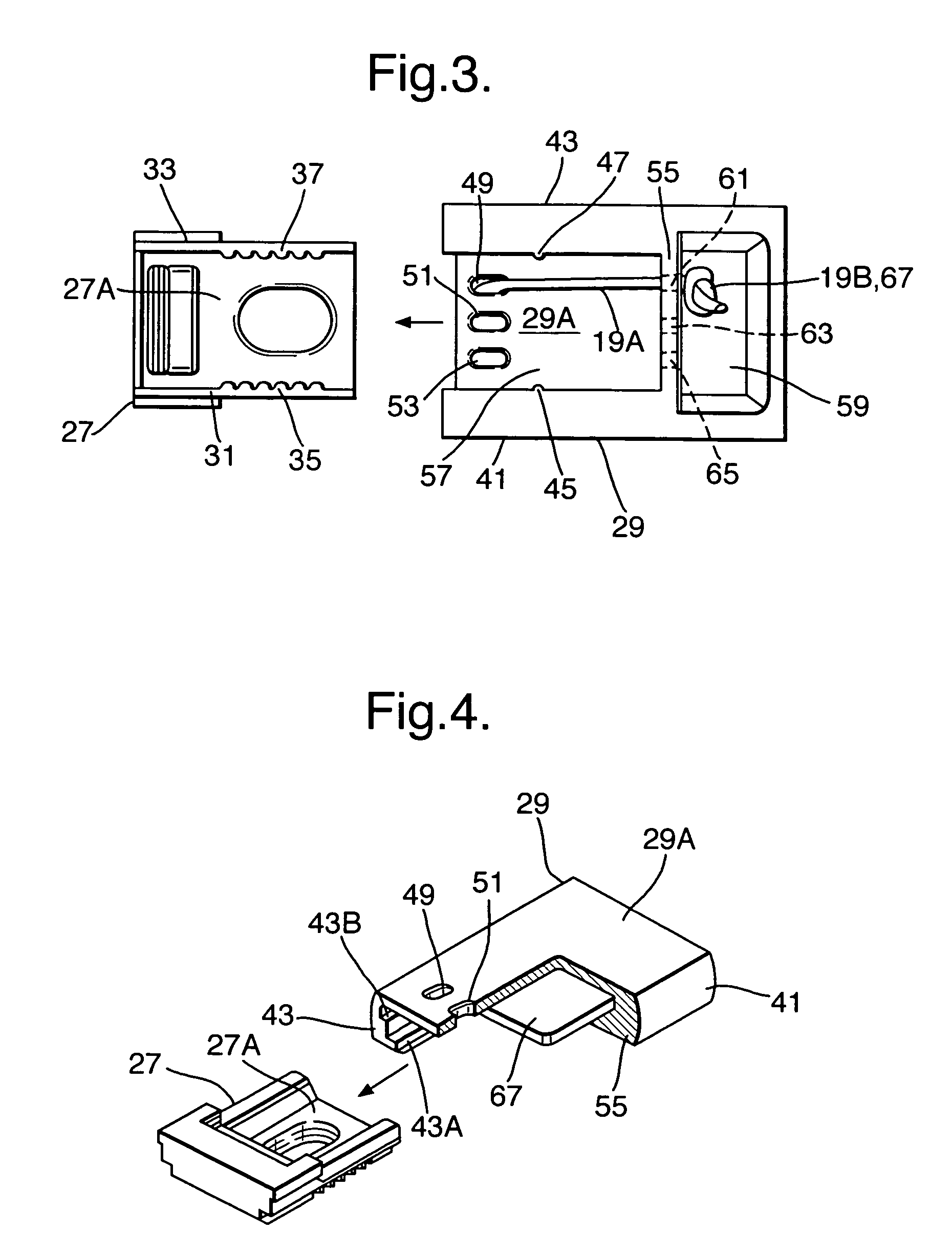

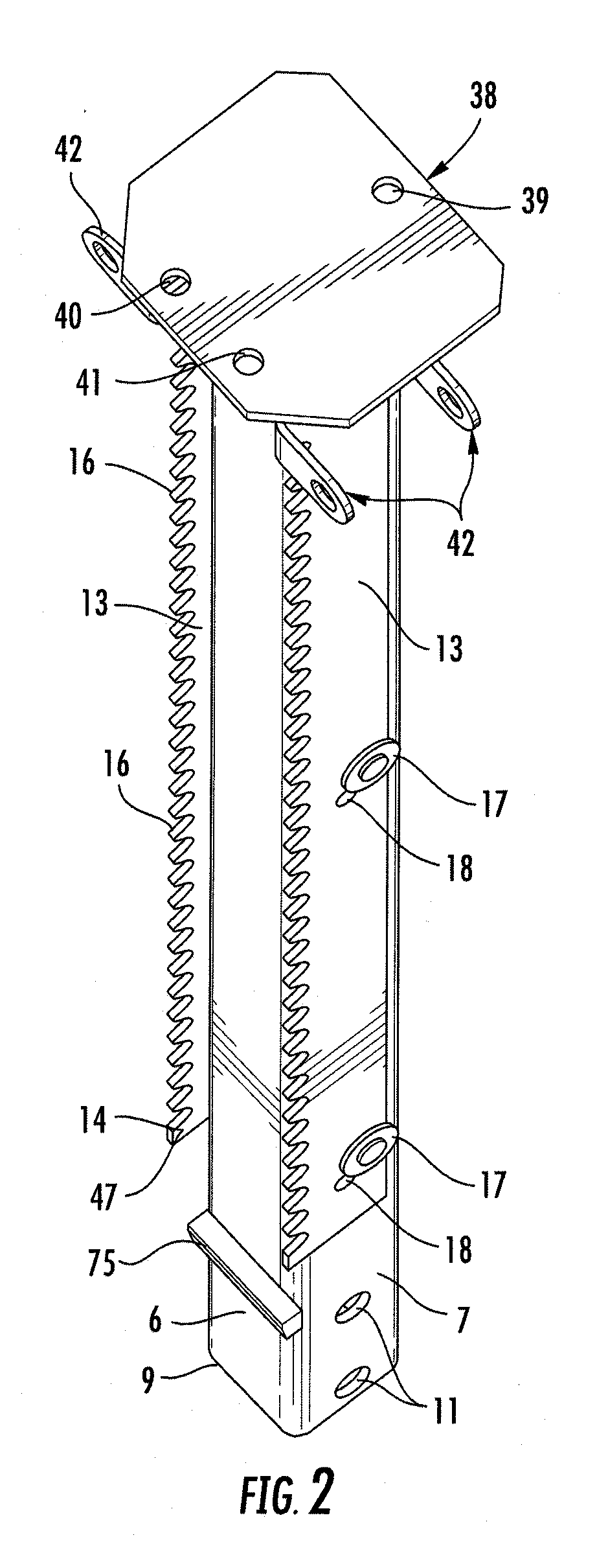

Surgical drill guide

InactiveUS6210415B1Easy to useEasy to manufactureProsthesisOsteosynthesis devicesSurgical drillDrill hole

A surgical drill guide for directing a guide tube toward a target. The guide tube has first and second sets of teeth extending along an exterior surface thereof. A through passage in an operating mechanism housing receives the guide tube. A first actuator or guide tube advancing mechanism uses a ratchet and pawl mechanism to advance the guide tube distally. A guide tube locking mechanism, that includes another ratchet and pawl mechanism prevents any unwanted proximal motion by providing a releasable lock against any unwanted proximal motion of the guide tube during use.

Owner:LAB ENG & MFG

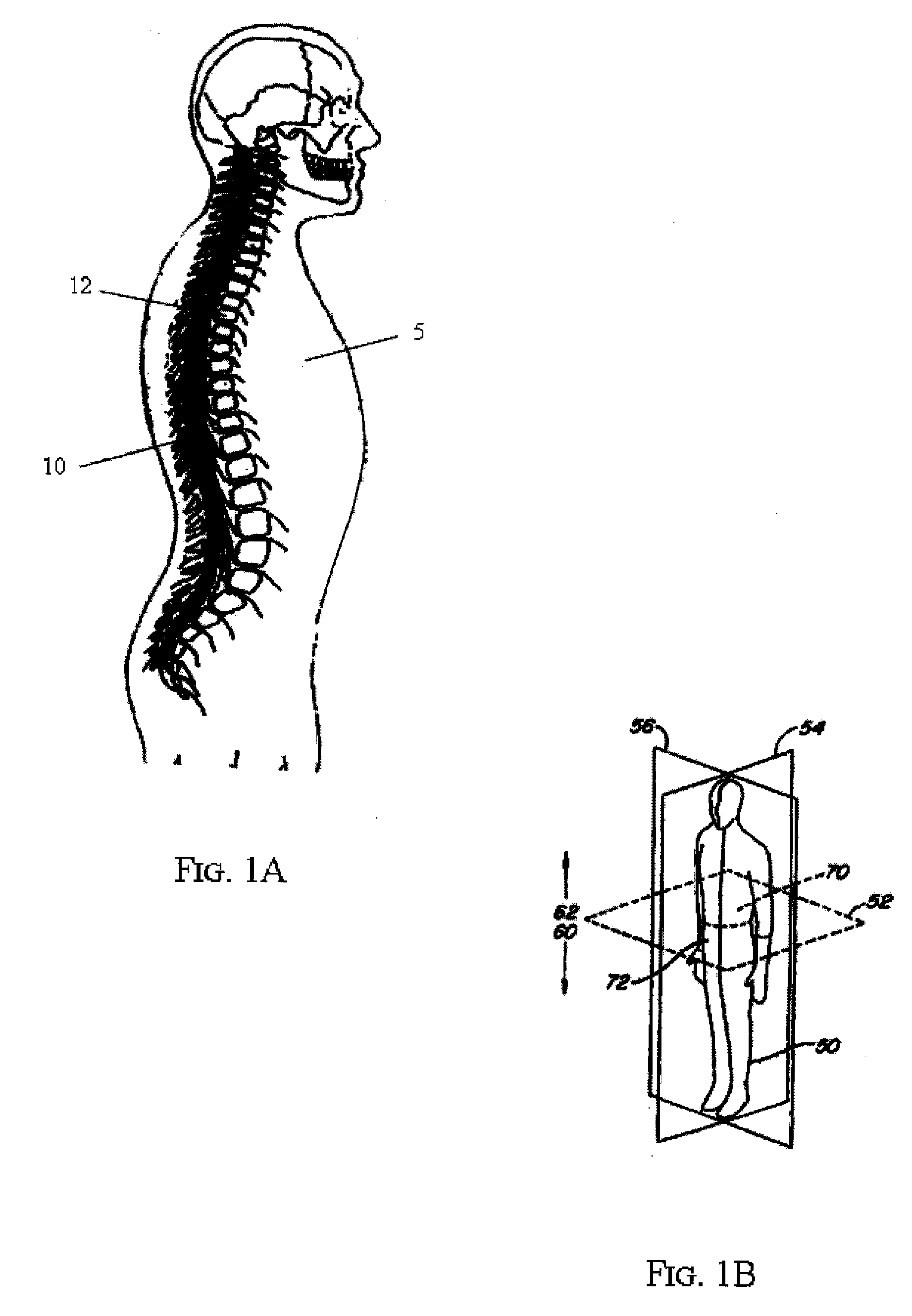

Spinal implant distractor/inserter

ActiveUS20090005784A1Distracting vertebraInternal osteosythesisDiagnosticsIntervertebral spaceEngineering

A method for distracting a pair of adjacent vertebrae and inserting an implant within the intervertebral space between the adjacent vertebrae using a posterior angle is described. The method employs a vertebral distractor-inserter comprising a housing, a pair of opposing arms in mechanical communication with the housing, a driving rod extending through at least a portion of the housing and between the arms, wherein the driving rod comprises an axis and a surface with a plurality of angled ratchet teeth on at least a portion of the surface, and a ratchet drive mechanism in mechanical communication with the driving rod.

Owner:SPINAL ELEMENTS INC

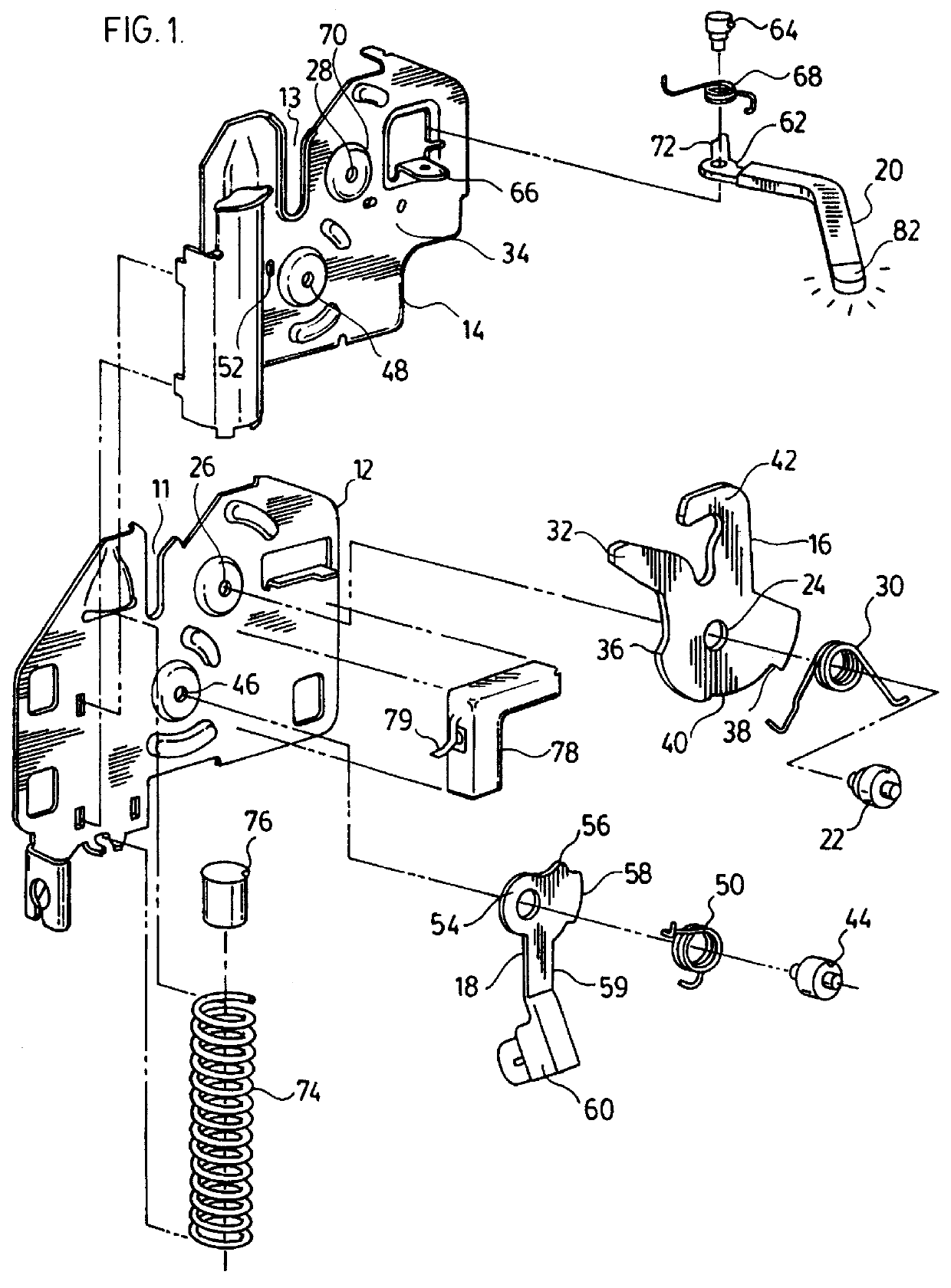

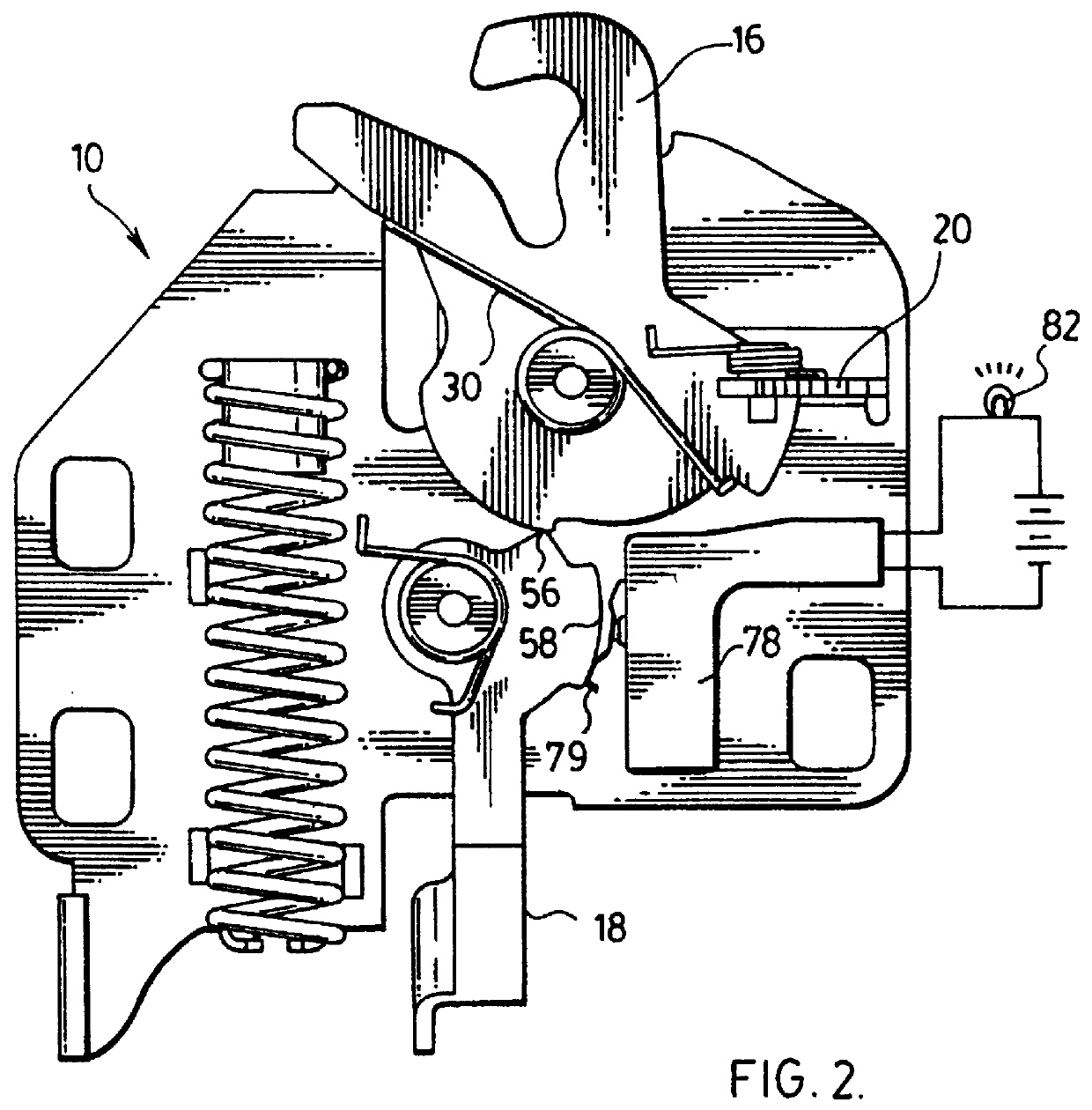

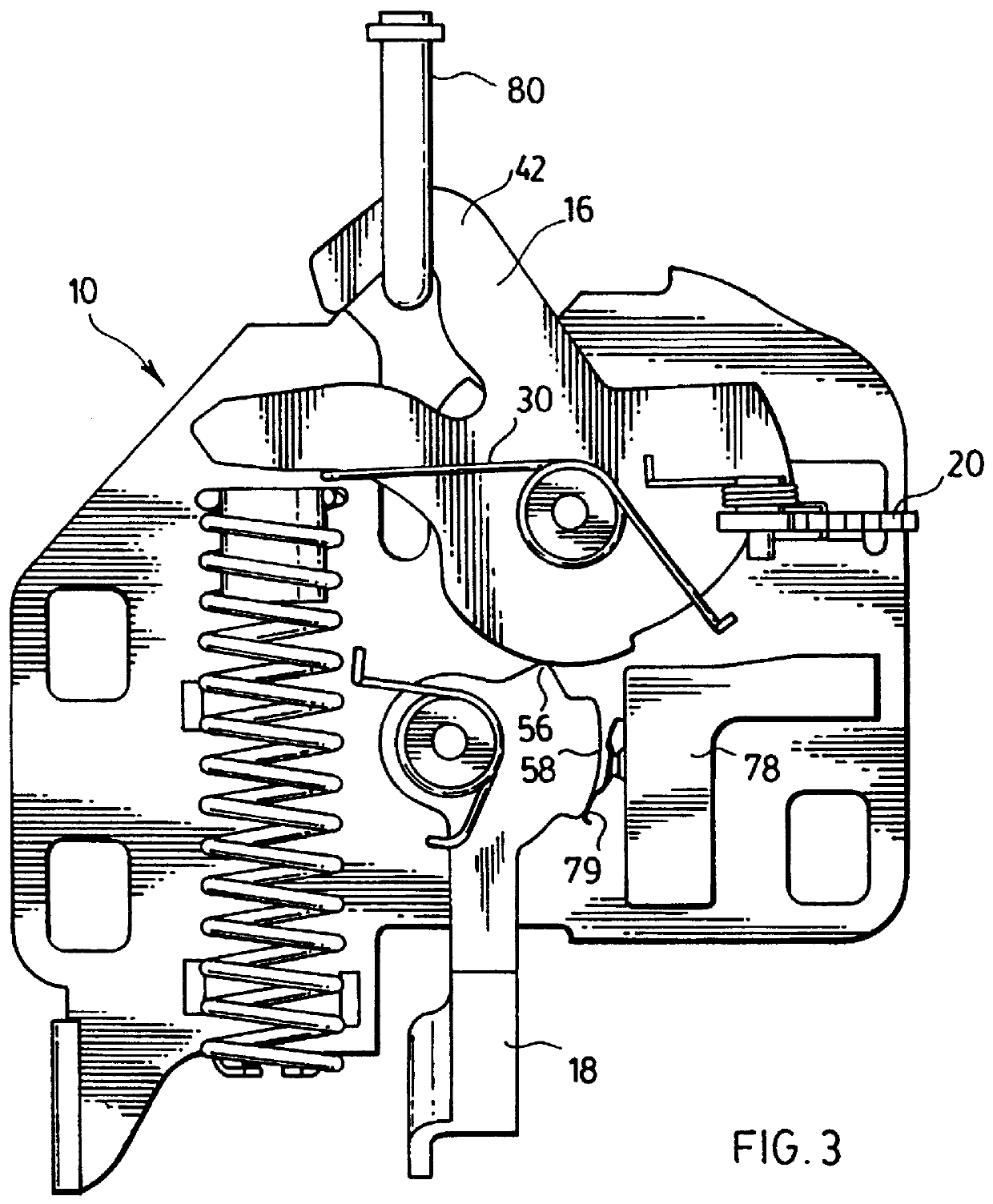

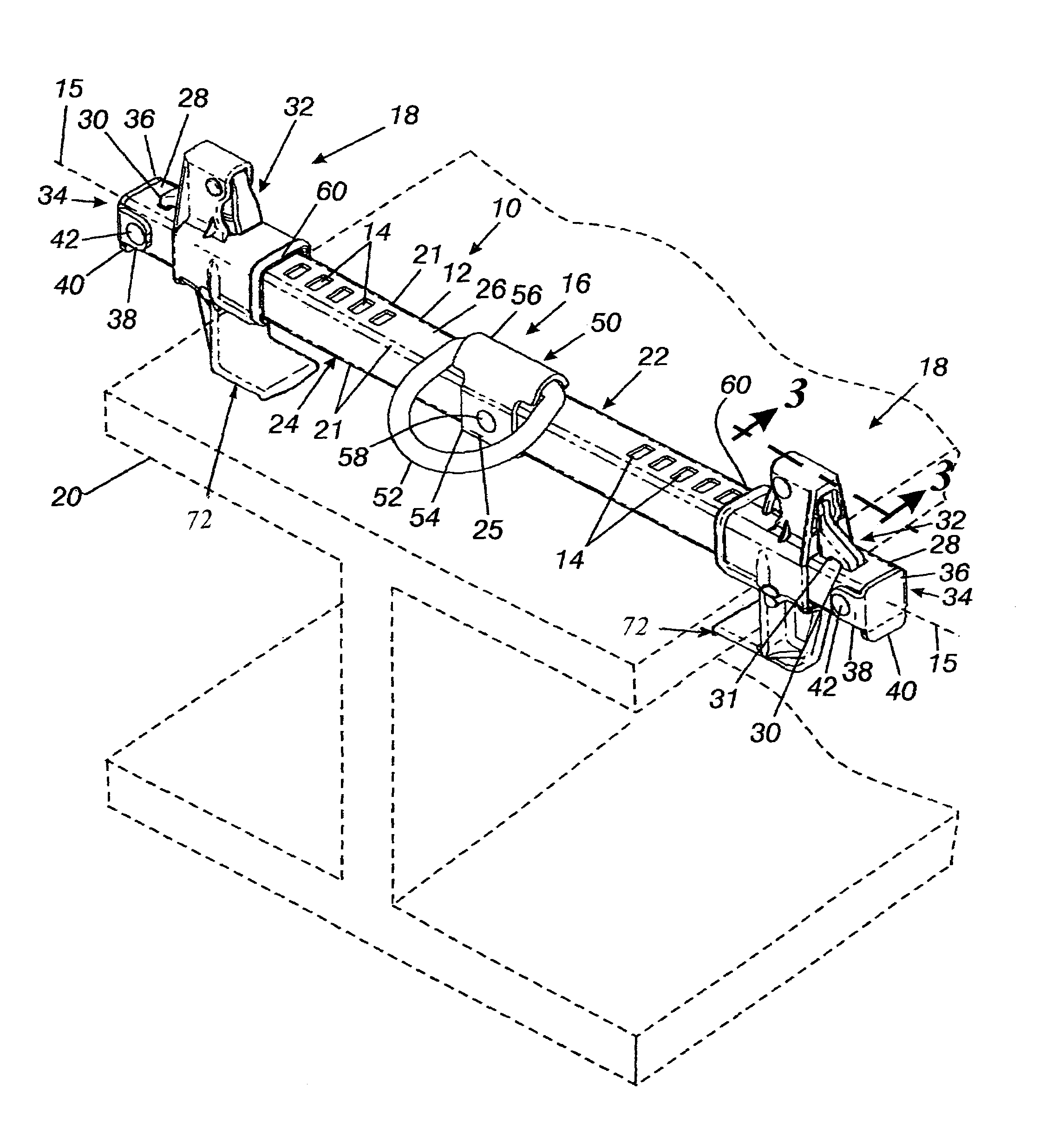

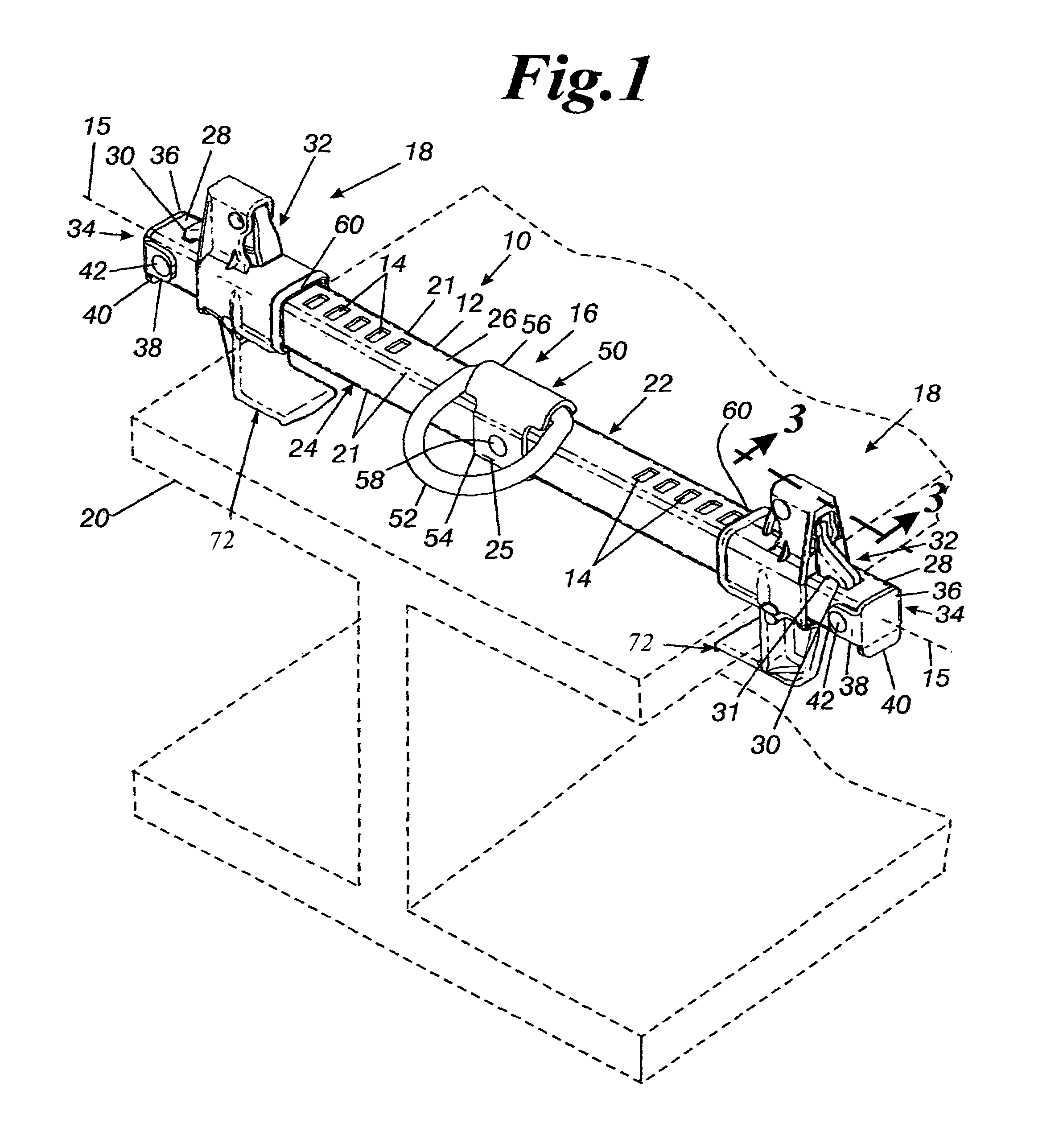

Hood latch for an engine compartment

PCT No. PCT / CA97 / 00941 Sec. 371 Date Aug. 16, 1999 Sec. 102(e) Date Aug. 16, 1999 PCT Filed Dec. 10, 1997 PCT Pub. No. WO98 / 26144 PCT Pub. Date Jun. 18, 1998A hood latch assembly (10) has a housing (14) having a mouth (13). A ratchet (16) is pivotally mounted within the housing (14) to cooperate with the mouth (13) to pivot between an open, a secondary closed and a primary closed condition for receiving, engaging and cinching a keeper of a striker (80). The ratchet (16) is biased to the open condition. A pivotally mounted primary pawl (18) is biased for engagement with the ratchet (16) to releasably retain the ratchet (16) in the primary closed condition. A pivotally mounted secondary pawl (62) is biased for engagement with the ratchet (16) to releasably retain the ratchet (16) in the secondary closed condition. The secondary pawl (62) has a release lever (20) which rotates between a deployed position and a retracted position. As the ratchet (16) engages the striker (80), the ratchet (16) will rotate in a latching sense from the open condition to the secondary closed condition. As the ratchet (16) further rotates from the secondary closed to the primary closed condition, fully engaging the striker (80), the secondary pawl (62) follows the ratchet (16), allowing the release lever (20) to rotate from a deployed position to a retracted position. Upon release of the primary engagement by disengaging the primary pawl (18), the ratchet (16) will rotate from the primary closed to the secondary closed condition. The secondary pawl (62) will follow the ratchet (16) rotating the release lever (20) from the retracted position to the deployed position. The operator then manipulates the release lever (20) to release the ratchet (16), allowing the ratchet (16) to rotate from the secondary closed to the open condition.

Owner:ATOMA INT CORP

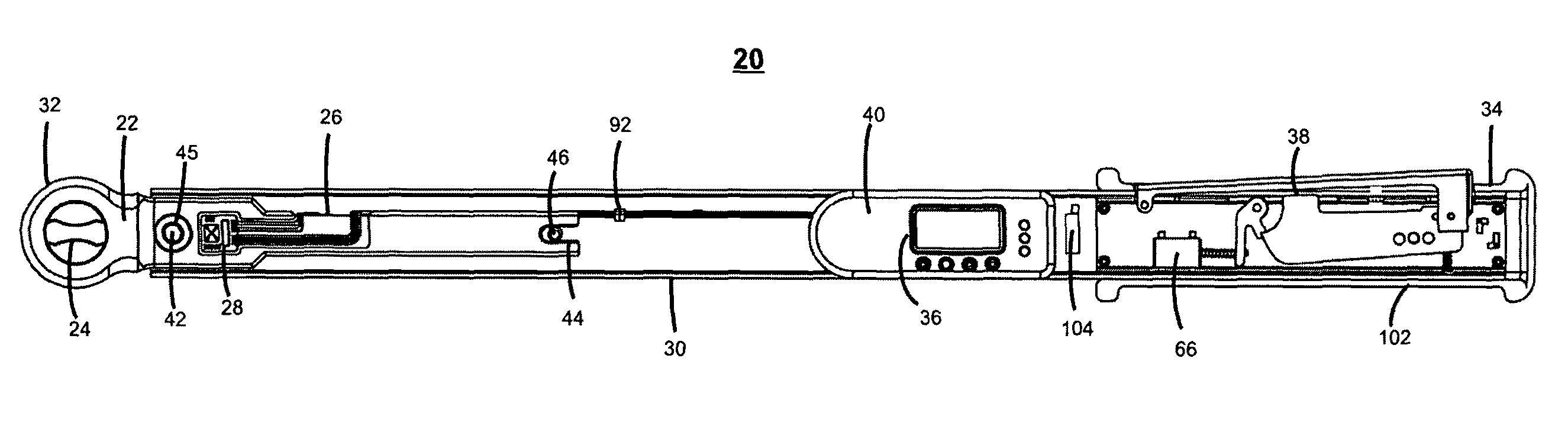

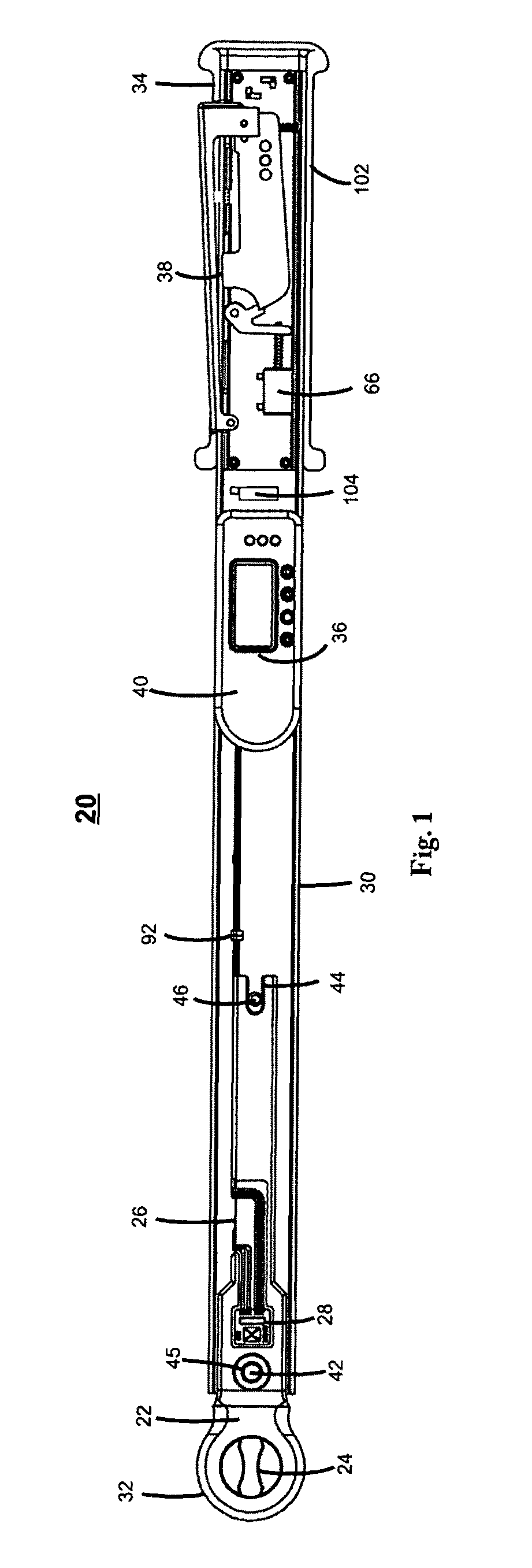

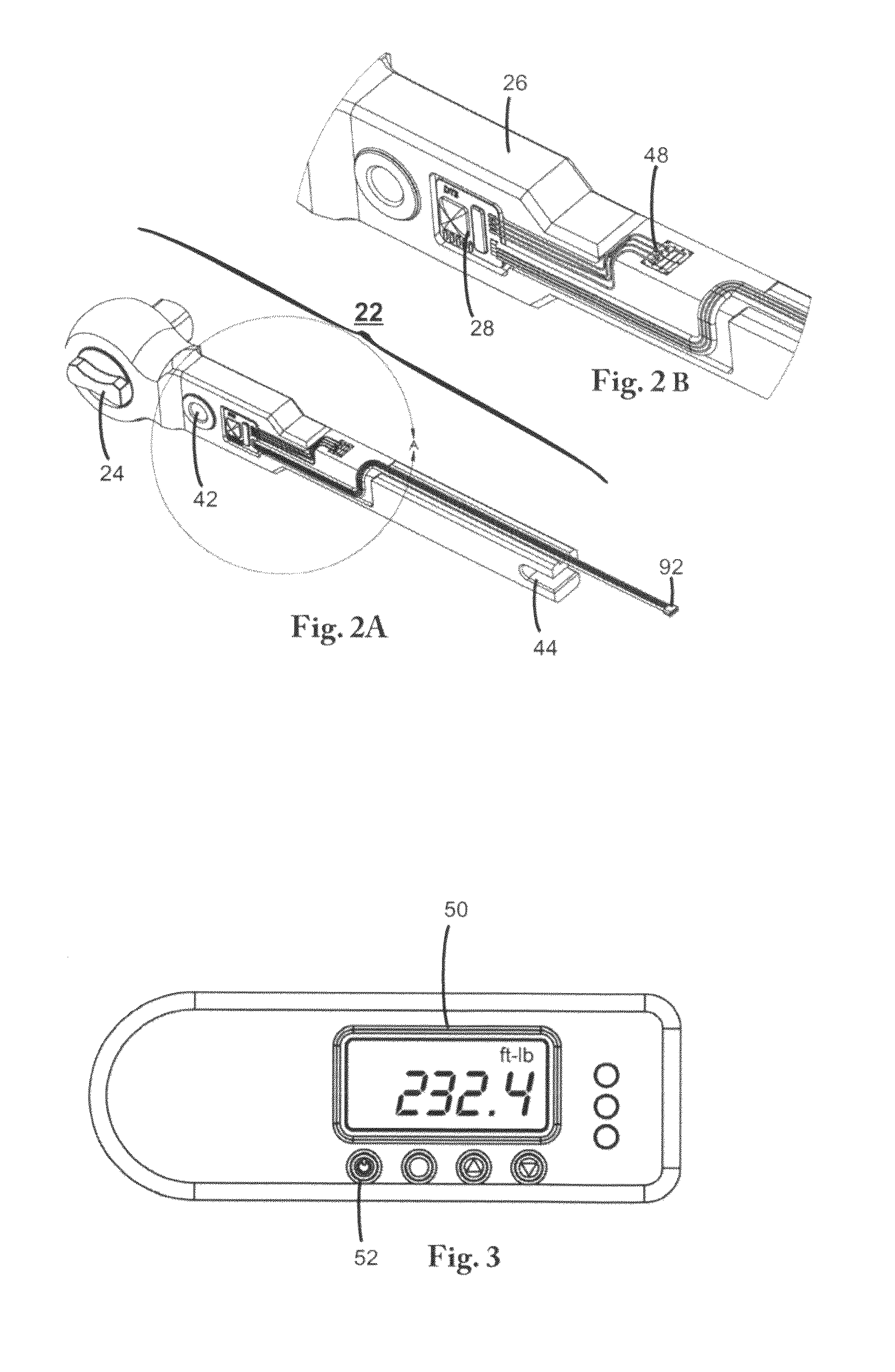

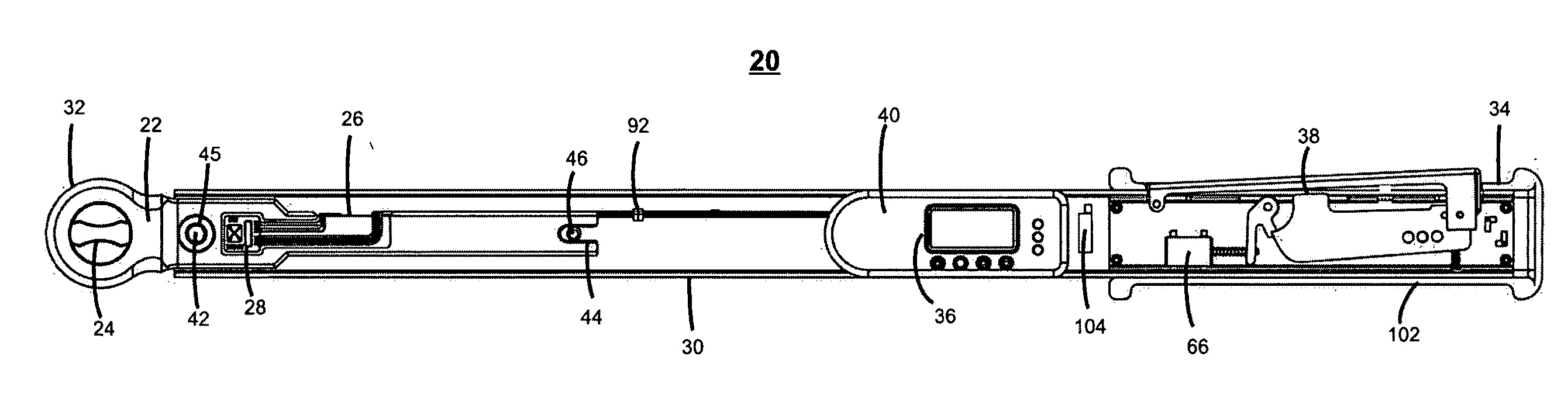

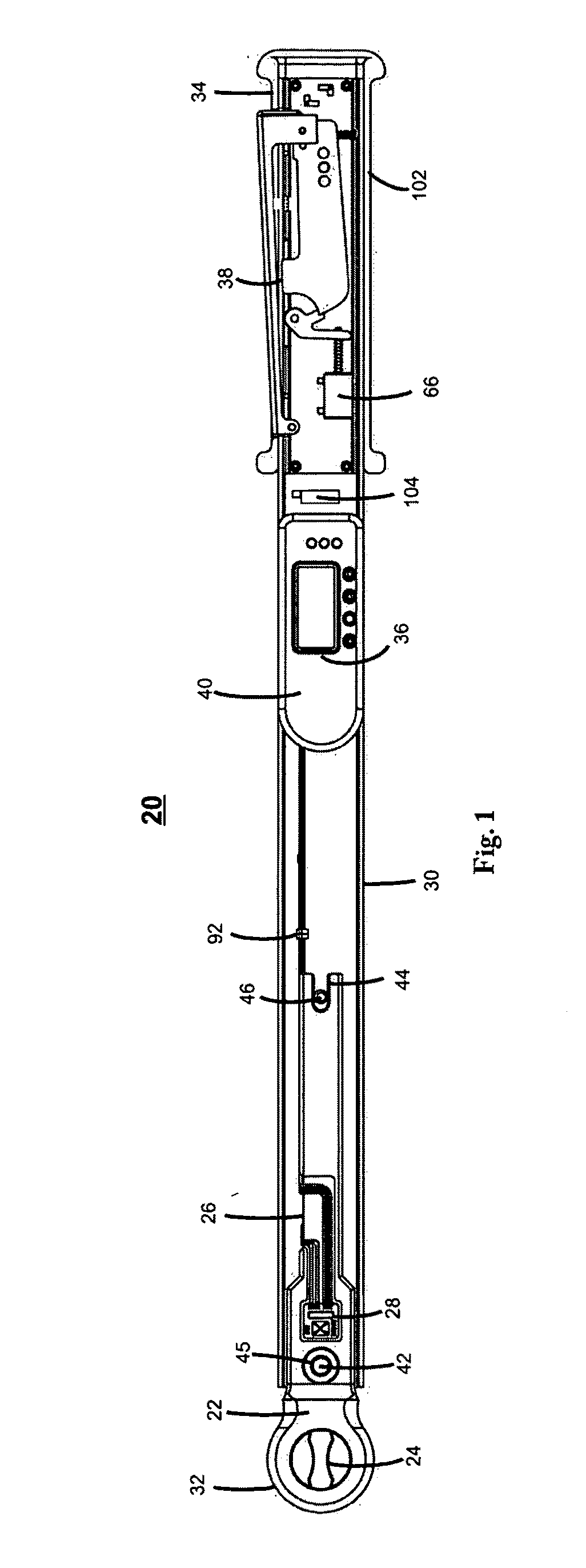

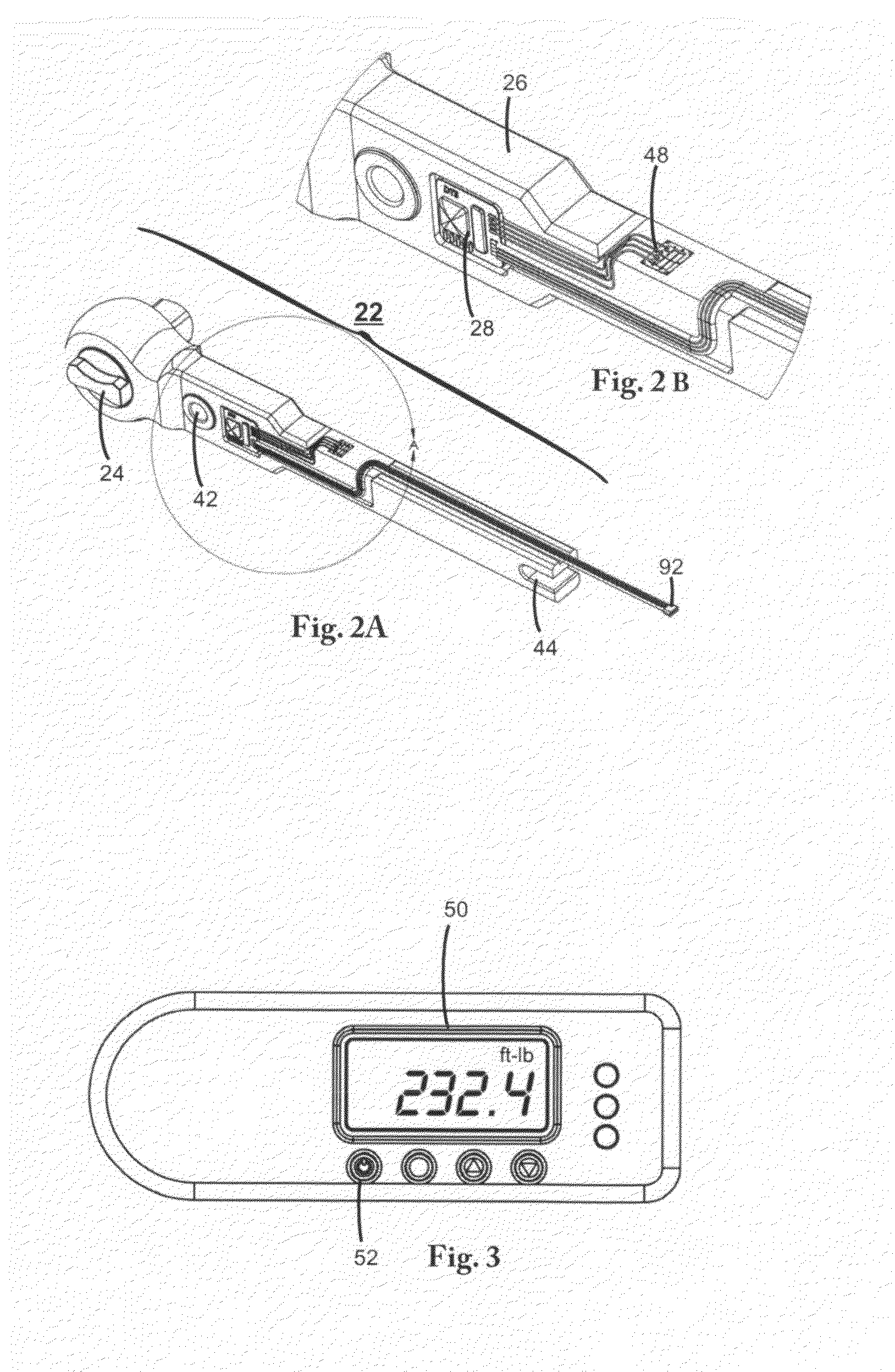

Electromechanical wrench

ActiveUS8171828B2Measurement of torque/twisting force while tighteningWork measurementRatchetEngineering

An electromechanical wrench has a housing that has a working end and a gripping end, with a driver positioned at the working end, and a handle positioned at the gripping end. The wrench further includes a click wrench emulator mechanism provided at the handle. A method of using an electromechanical wrench to secure a fastener using angular measurement without the need for establishing a zero reference point, and allowing for ratcheting, is also provided. A method of counting the number of fasteners secured by an electromechanical wrench during a wrenching job is further provided.

Owner:DIGITOOL SOLUTIONS

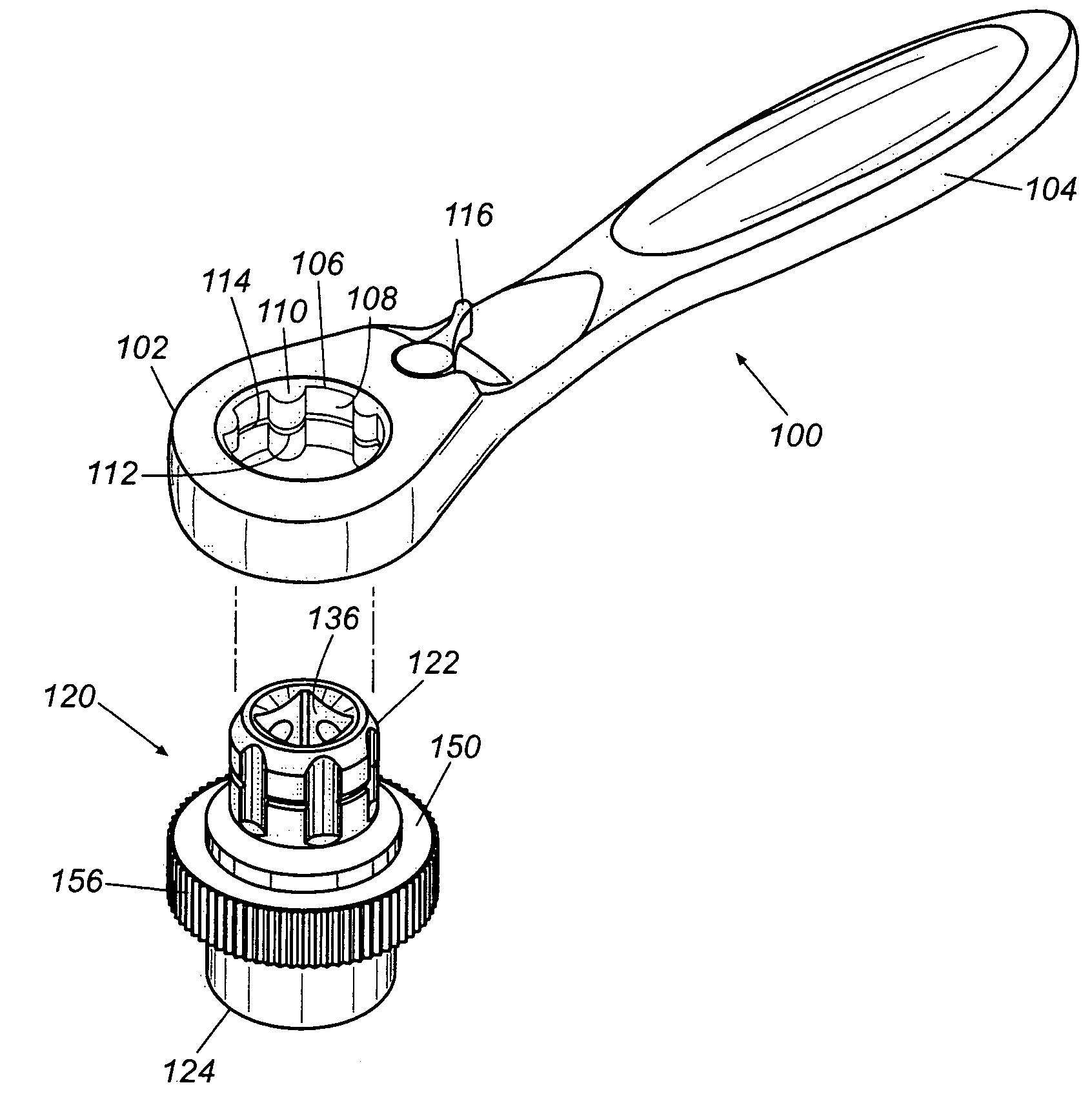

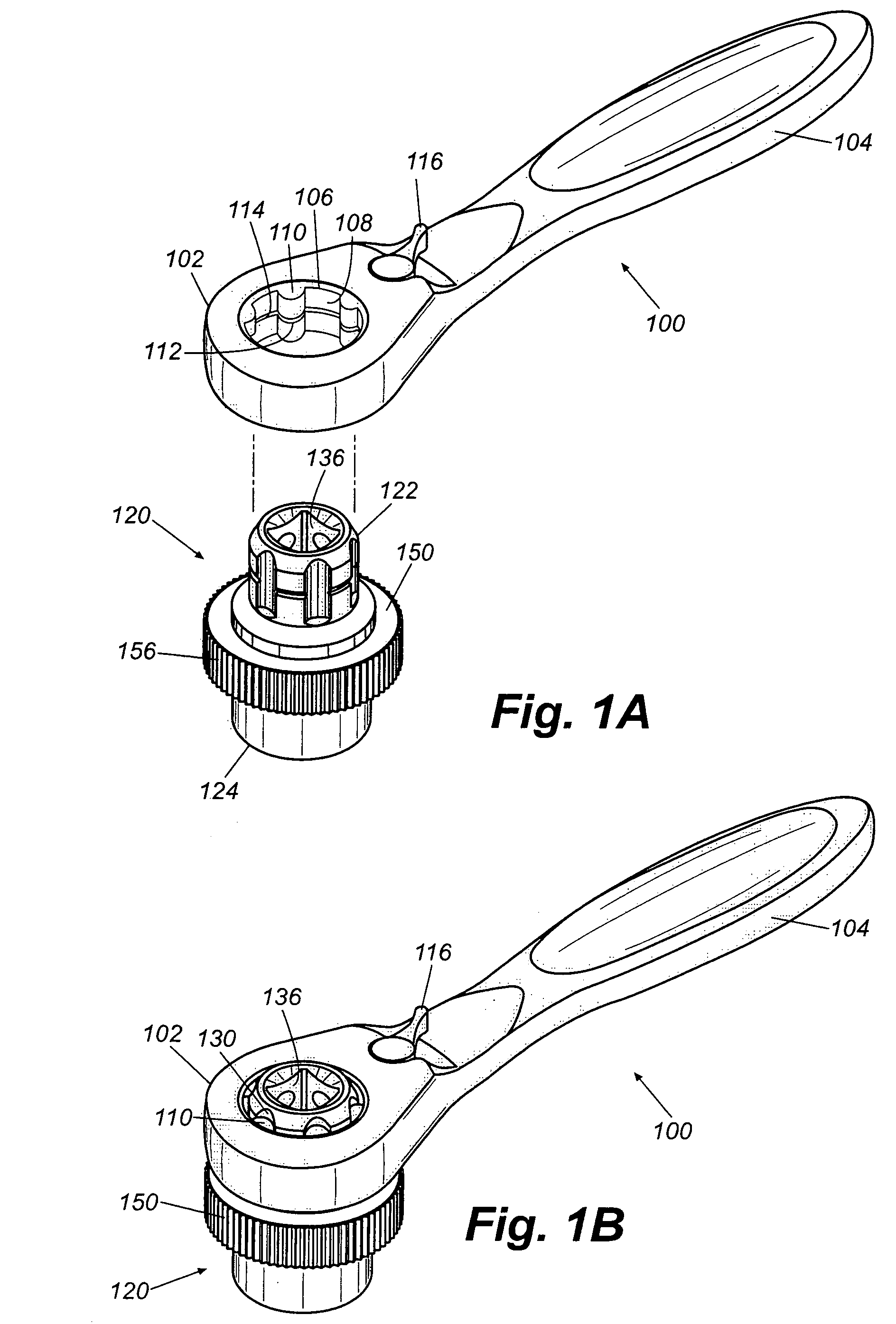

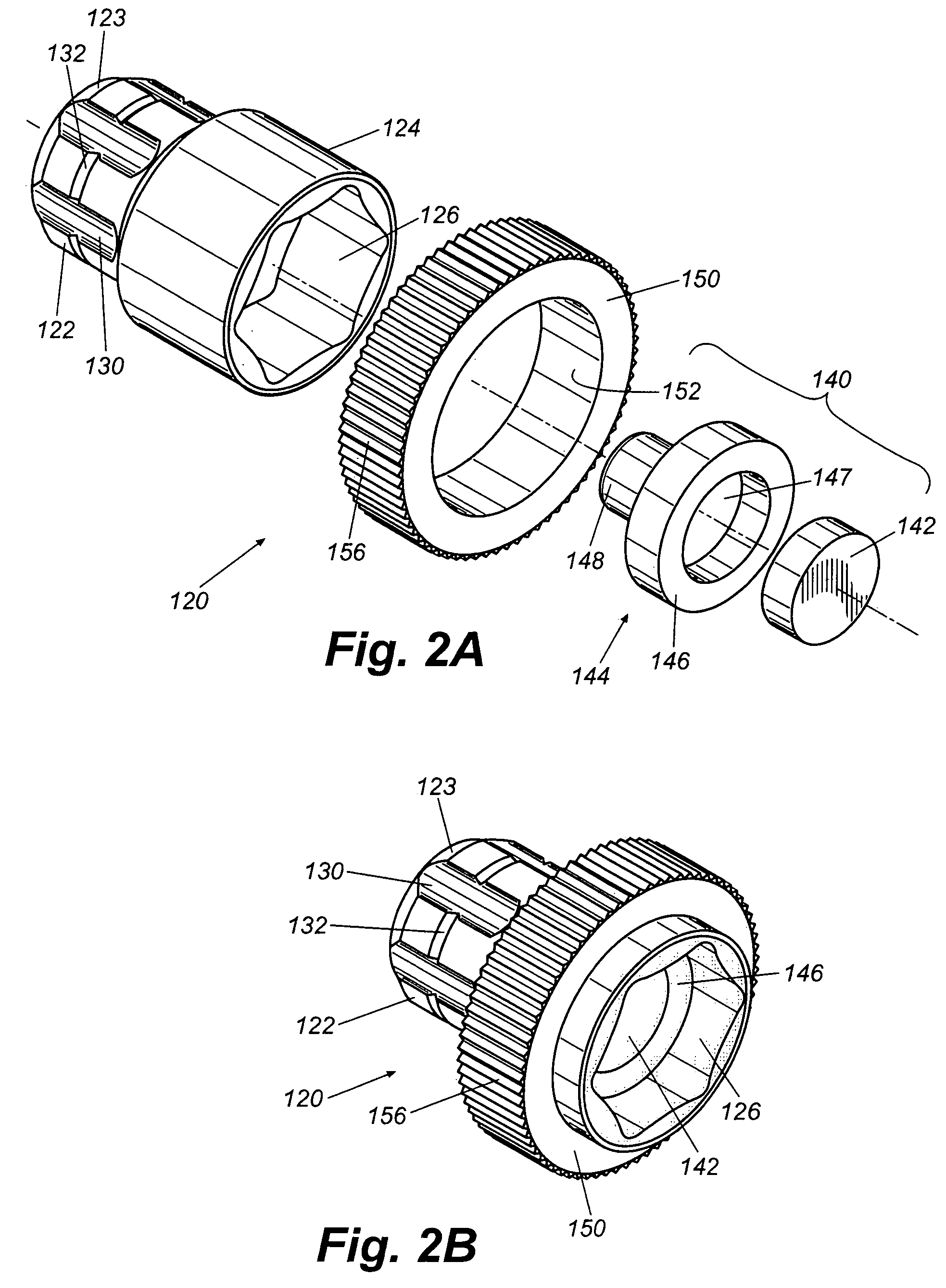

Oil drain plug socket for a wrench assembly

A ratchet wrench, the ratchet wrench having a head portion defining a substantially cylindrical inner engaging surface and a plurality of ribs extending radially inward therefrom. The socket includes a first portion defining a plurality of depressions axially aligned with the longitudinal axis in an outer surface thereof, the first portion being releasably received by the substantially cylindrical inner engaging surface, and a second portion including a cylindrical outer surface and defining a hexagonal recess therein. A grip ring includes a knurled outer surface and is disposed on the second portion outer surface. A magnetic insert is received in the hexagonal recess.

Owner:EASCO HAND TOOLS

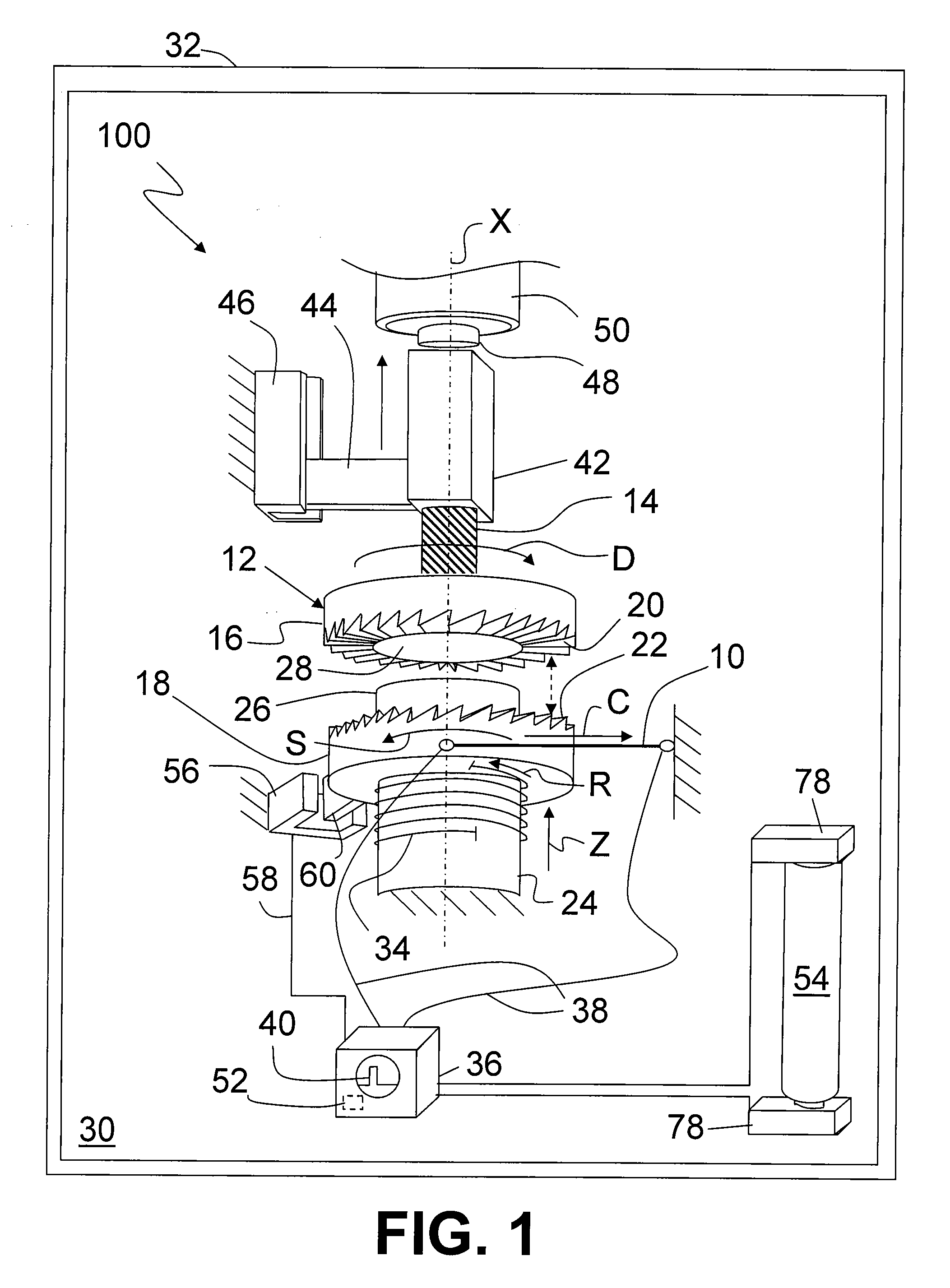

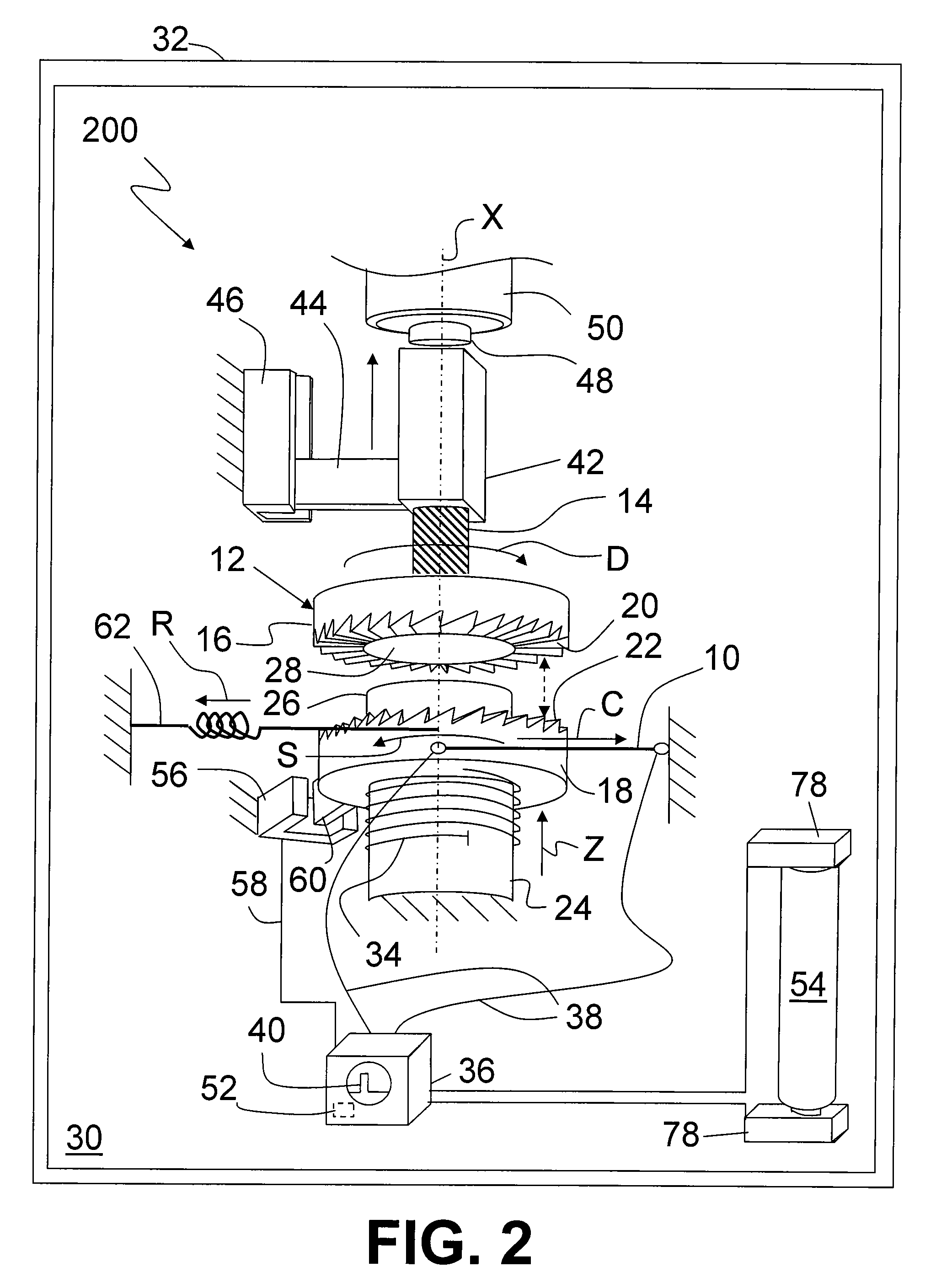

Lead screw delivery device using reusable shape memory actuator device

ActiveUS20090143730A1More compact and less complicated designInfusion devicesMedical devicesRatchetRotational axis

A drug delivery device drive that includes a single shape memory alloy wire actuator to advance a lead screw via a ratcheting mechanism and method thereof are disclosed. In one embodiment, a shape memory alloy wire is operably connected to one of a pair of ratchet wheels and configured to drive incrementally the rotation of the connected ratchet wheel via a contraction, which in turn drives the rotation of the other ratchet wheel about a rotational axis which moves a lead screw and advances a plunger to dispense a liquid drug from a drug container. A drug delivery device using the shape memory alloy wire actuator in combination with the ratcheting mechanism to incrementally rotate a shaft, a lead screw or a sleeve provides for a more compact an less complicated design.

Owner:ROCHE DIABETES CARE INC +1

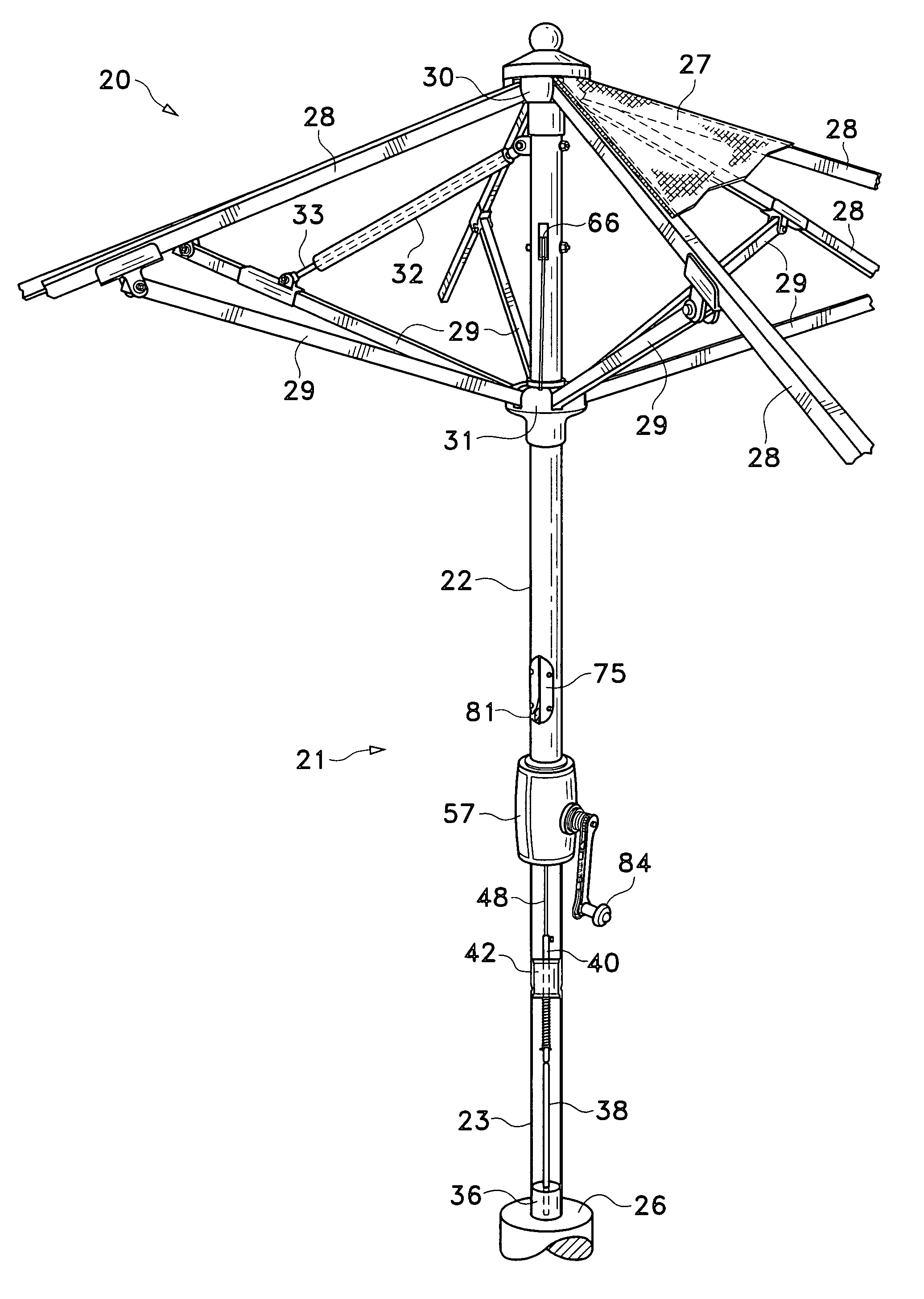

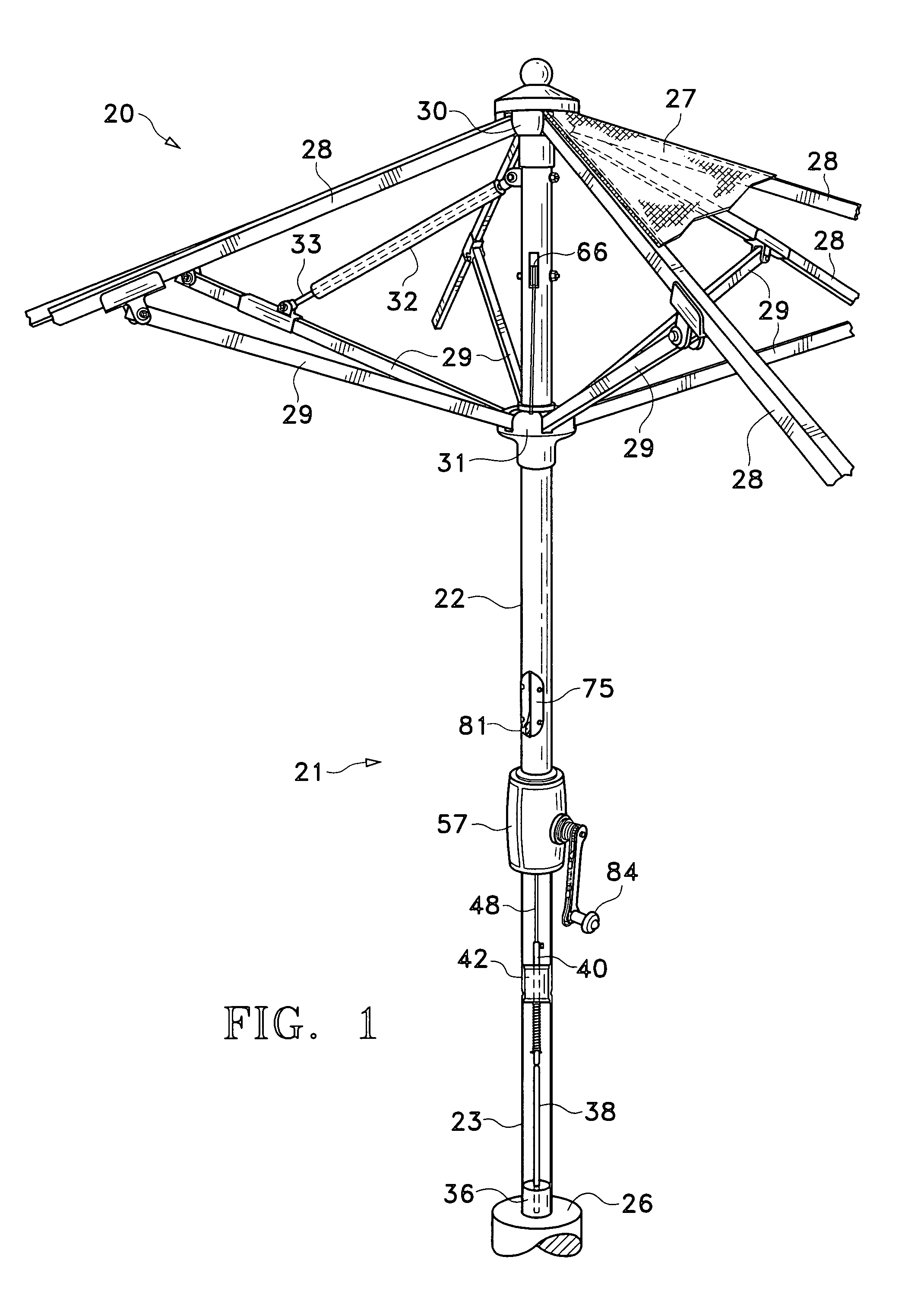

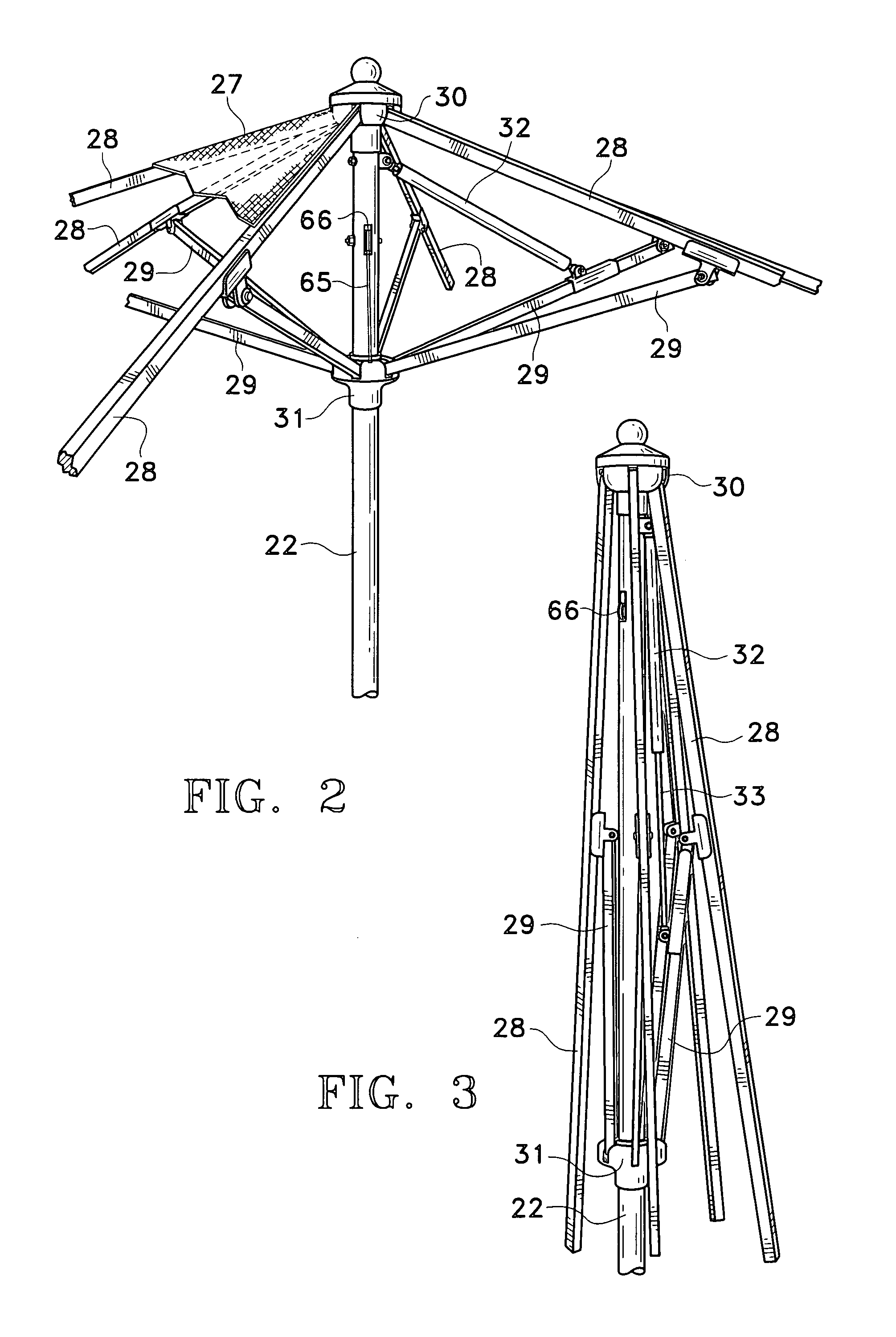

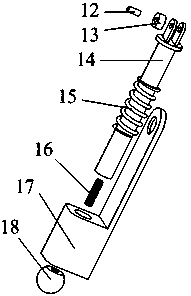

Self closing stationary umbrella

InactiveUS7665477B1Easy to manufacturePerforms betterWalking sticksUmbrellasHydraulic cylinderEngineering

An outdoor umbrella that closes automatically in high wind is disclosed. The wind causes the main support post of the umbrella to flex from the vertical dislodging a plunger from its weight bearing mounting on a rigid rod. The plunger is attached to an actuator rod extending upward within the support post. When the plunger is displaced the actuator rod is caused to move downward thereby activating a releasing ratchet which frees a shaft to rotate and the cable which holds the canopy to unwind. A hydraulic cylinder attached to one of the canopy ribs presses on the rib to close the canopy and maintain the canopy in closed orientation. As the canopy closes a reset mechanism is activated which resets the plunger onto the rigid rod. Once closed the canopy will remain closed until raised by manually rewinding the cable onto the shaft using a hand crank attached to the end of the shaft. A second ratchet assembly incorporated into the hand crank prevents the hand crank from spinning when the umbrella closes.

Owner:HATHAWAY MARTIN

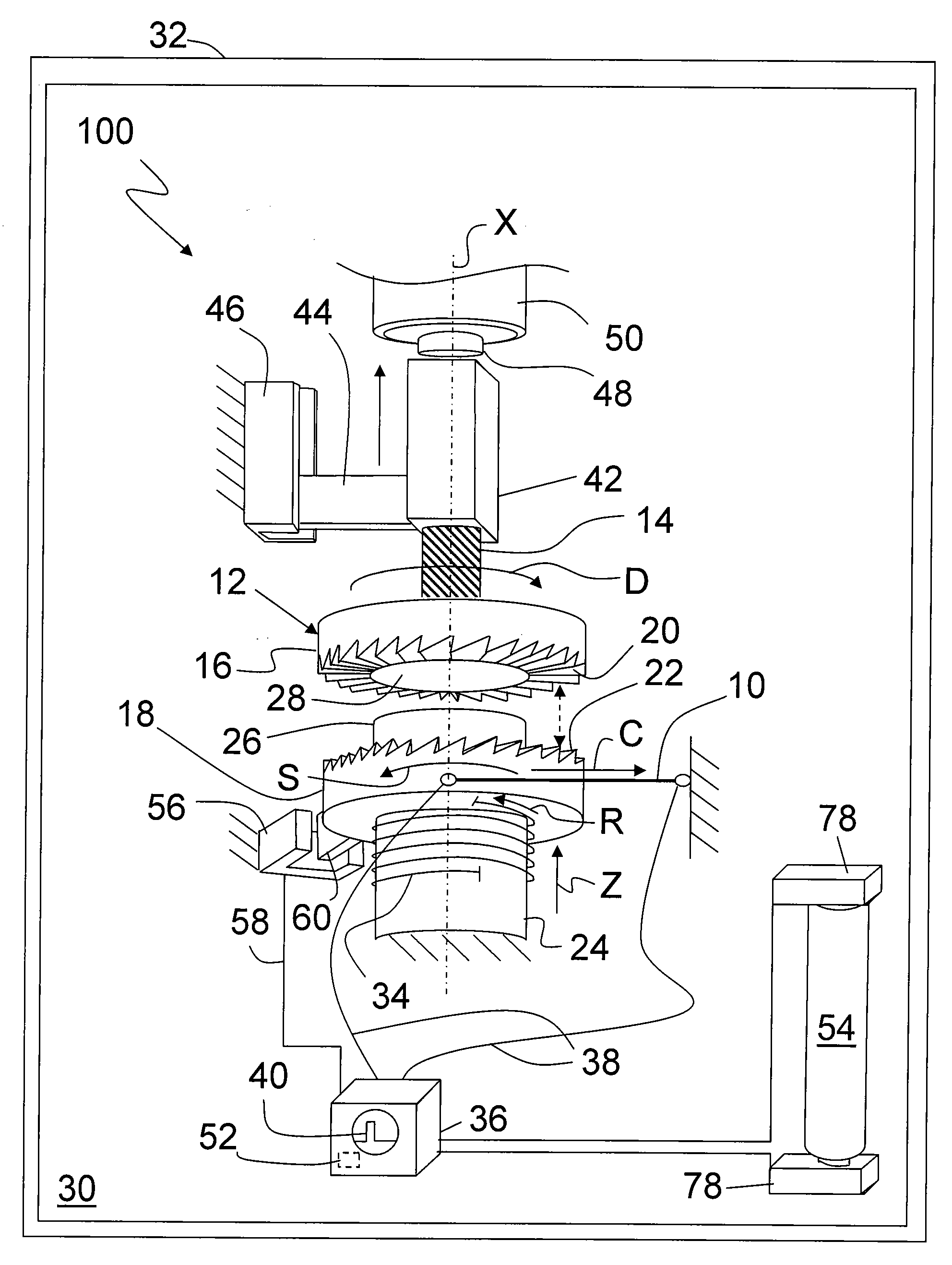

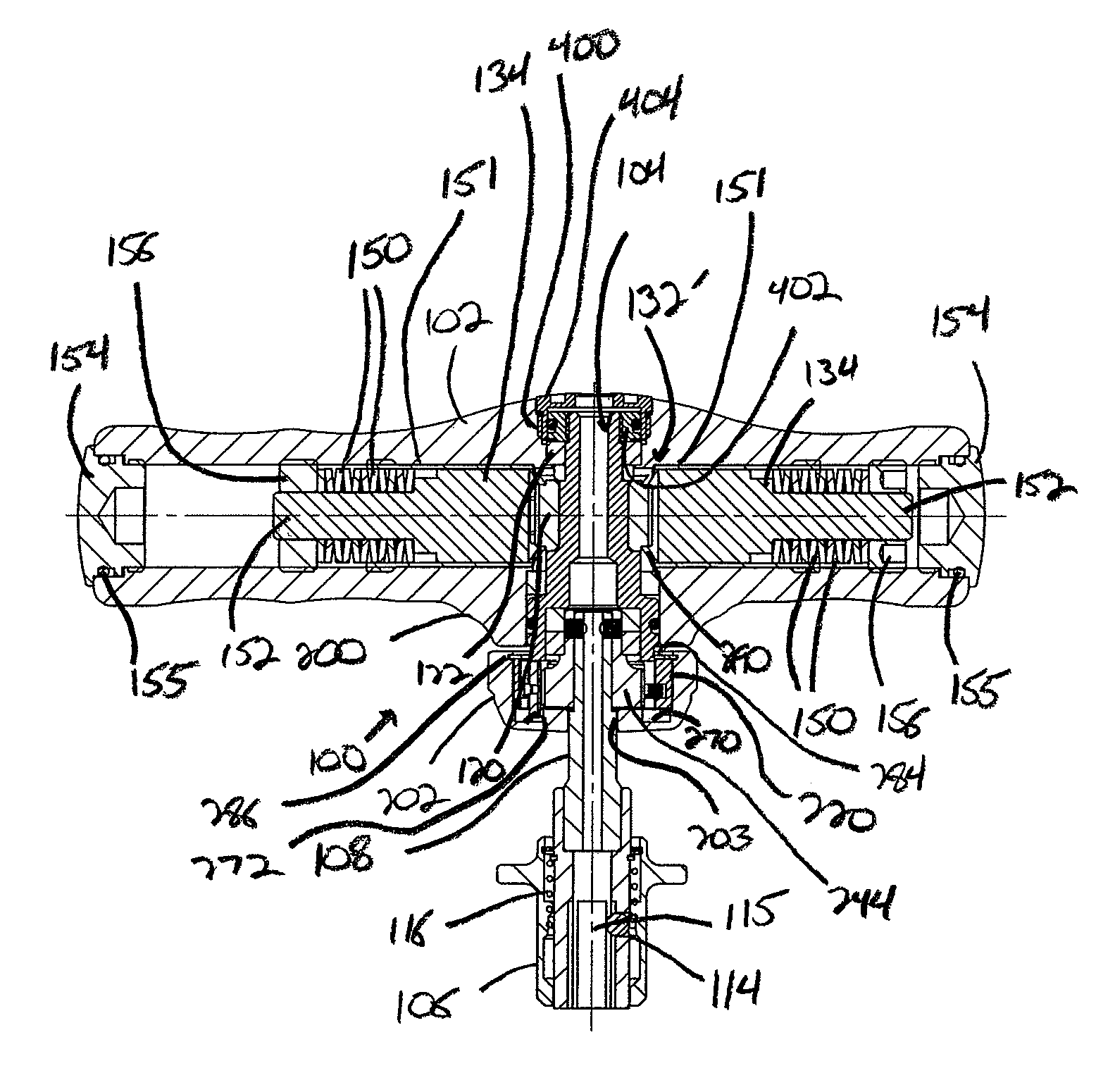

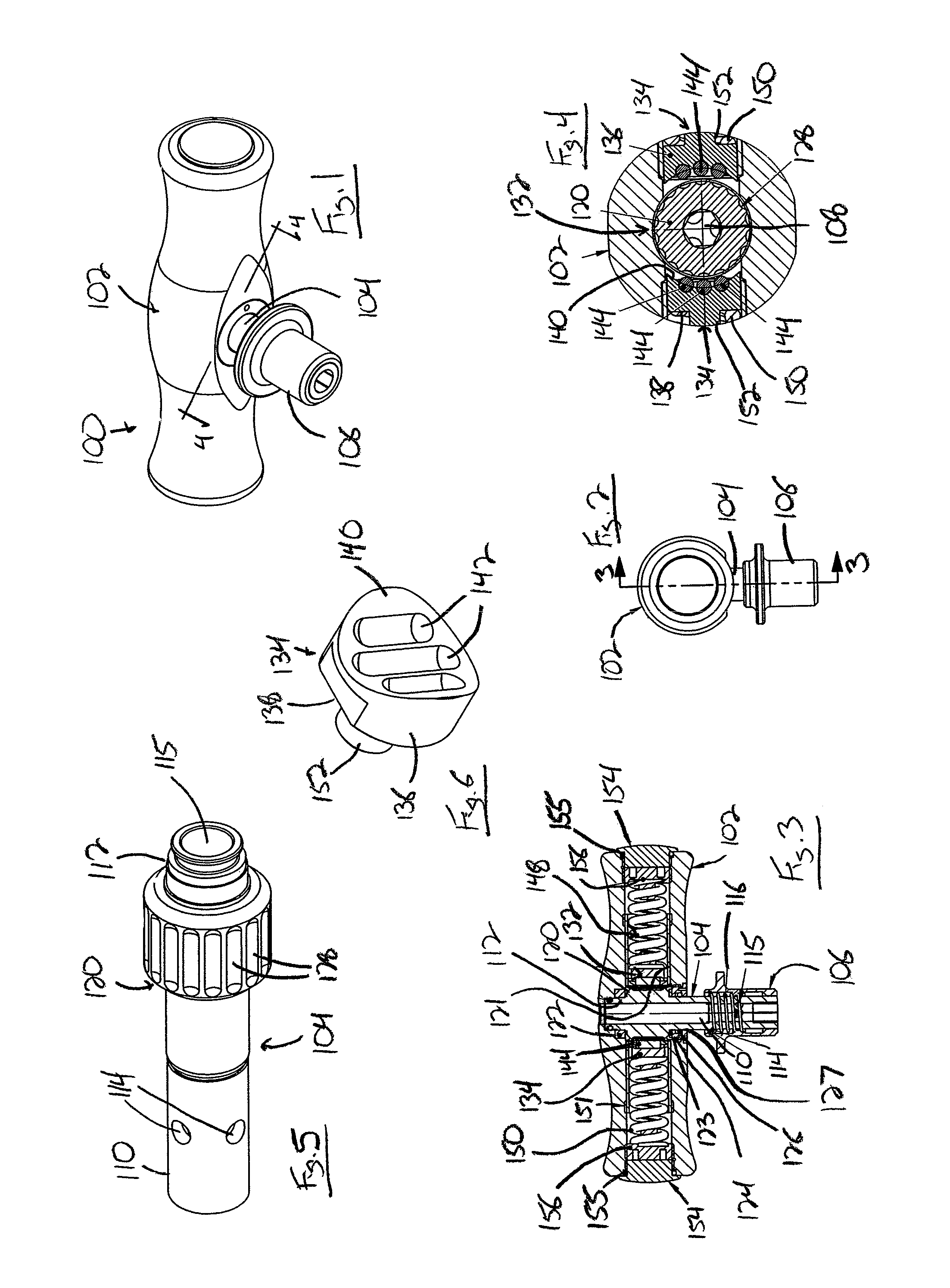

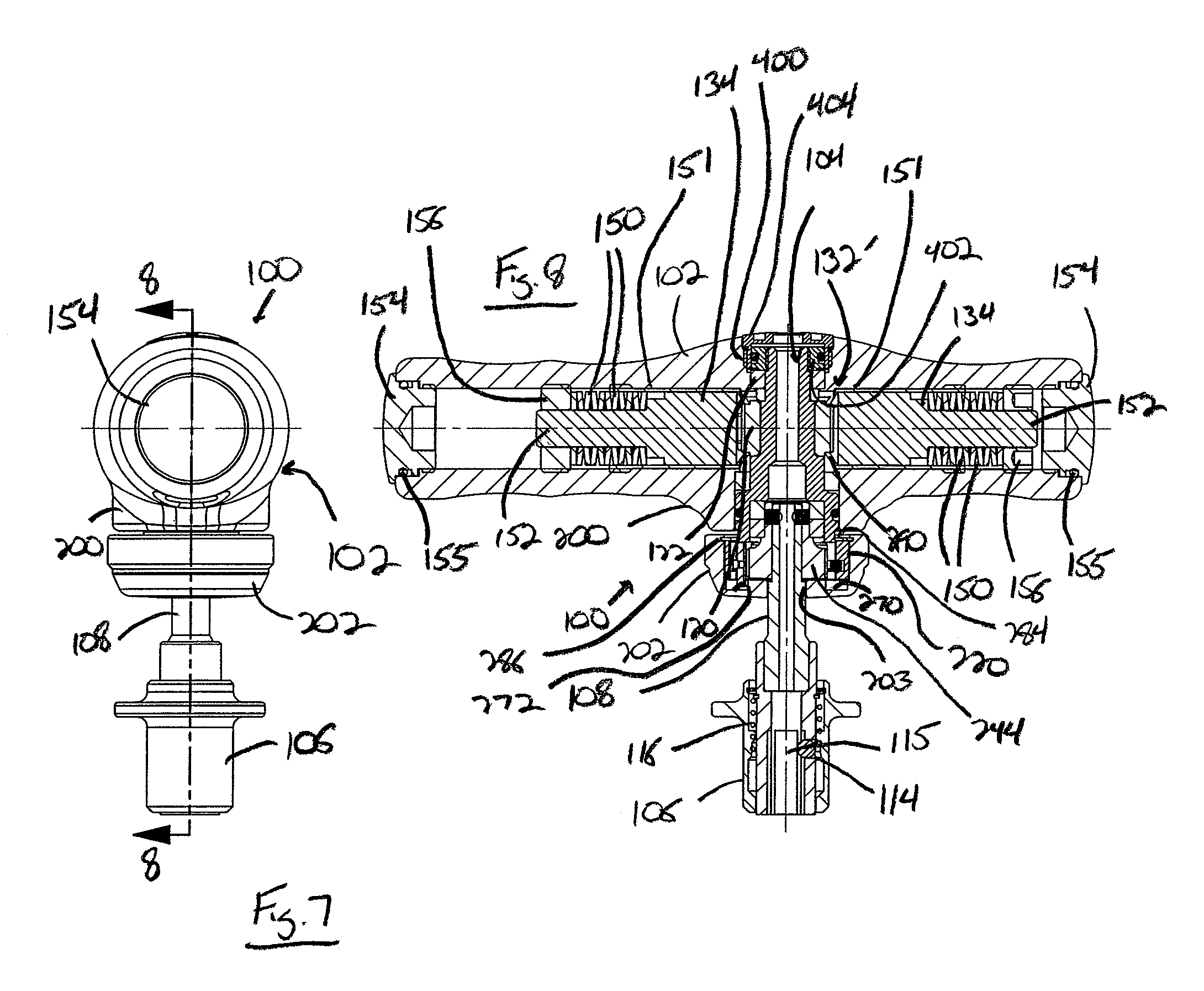

Ratcheting torque wrench

InactiveUS7430945B2Low profileReduces friction and resulting wearSpannersWrenchesDrive shaftControl theory

A tool is provided for driving fasteners that includes a torque limiting mechanism therein. The torque limiting mechanism includes a first frictional engagement member disposed on the drive shaft for the tool that is engaged by one or more second frictional engagement members disposed on one or more sides of the first frictional member. The second frictional engagement members are biased into engagement with the first member by biasing members disposed within the handle that can be adjusted in order to provide more or less of a biasing force to control the frictional engagement of the second member with the first member and thereby control the torque limiting function of the torque limiting mechanism. In addition, a drive shaft is also engaged with a ratcheting mechanism that enables the tool to drive a fastener into a suitable substrate in only a single direction.

Owner:GAUTHIER BIOMEDICAL

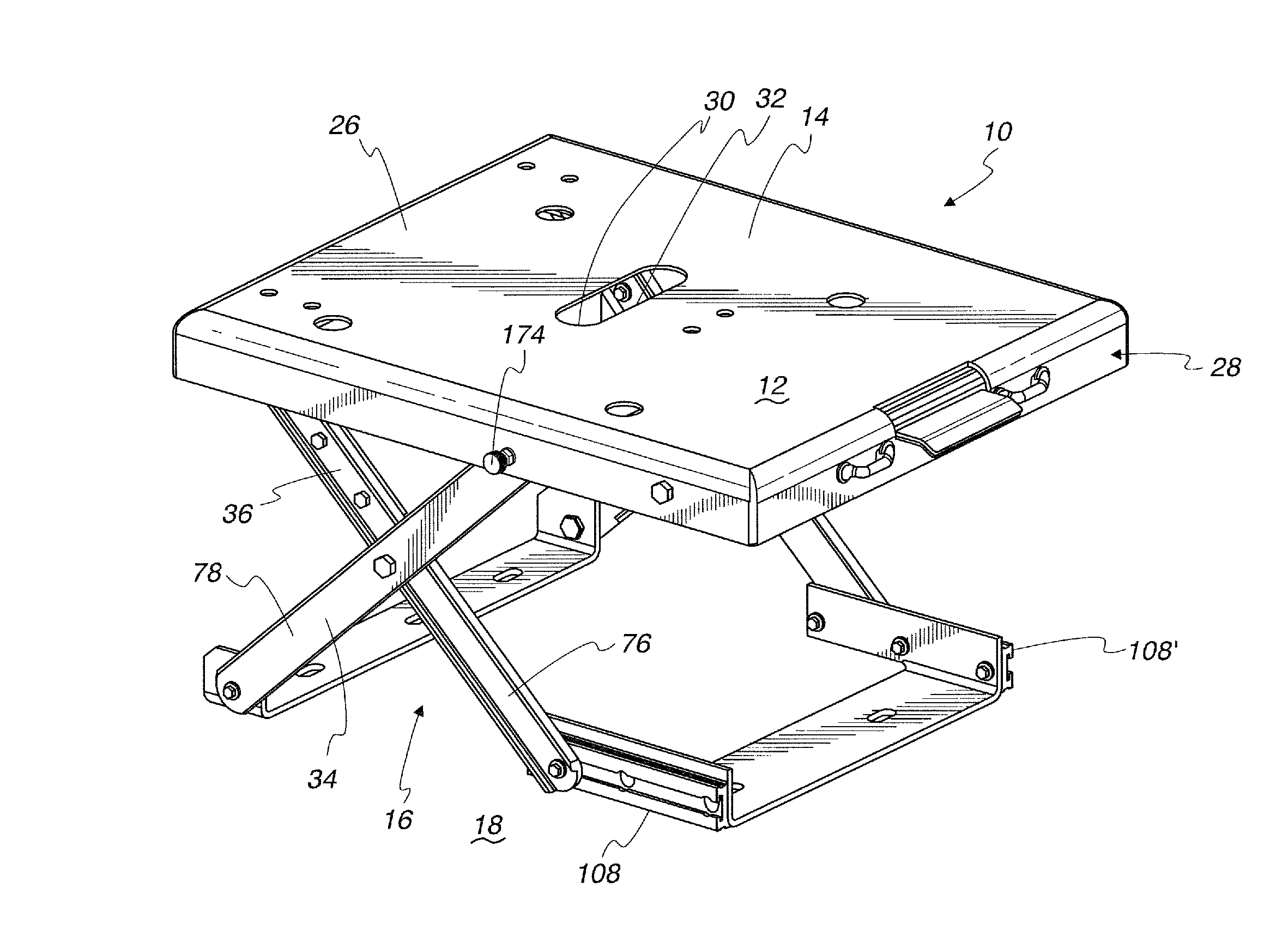

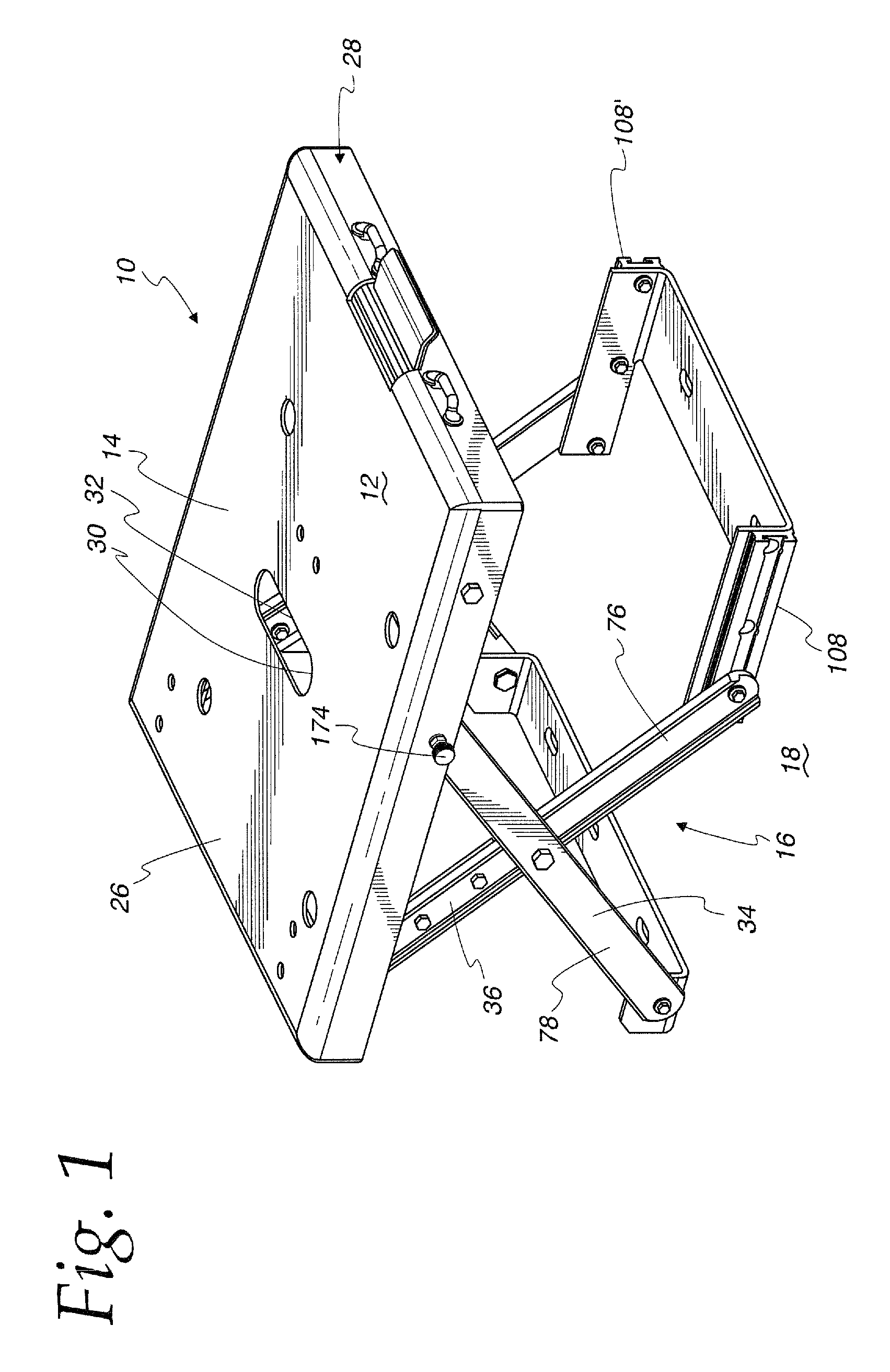

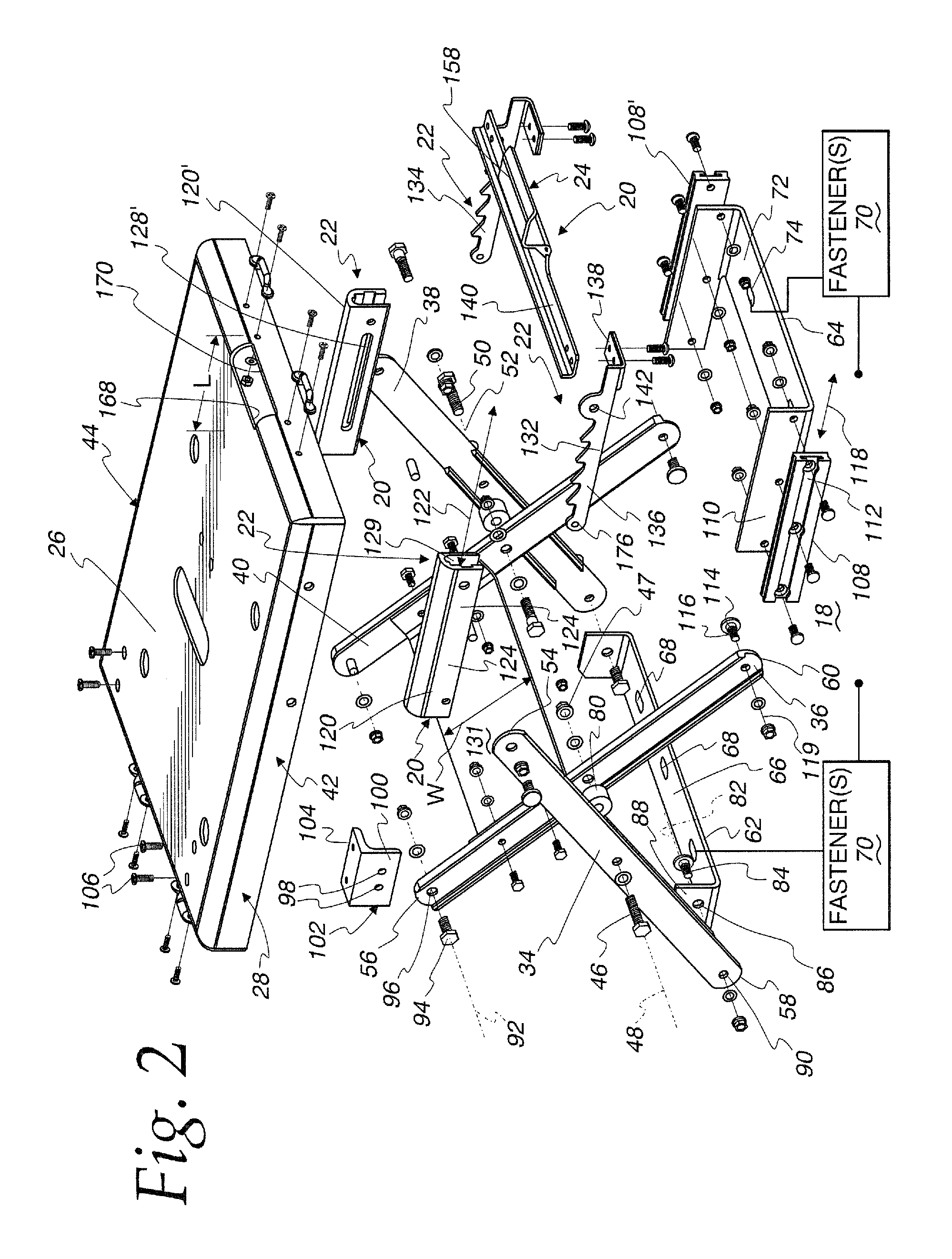

Variable height support

A variable height support with a platform and a base supporting the platform and reconfigurable to selectively change a height of a support surface on the platform relative to a subjacent surface. A control assembly is operable to selectively: a) maintain the support surface at a selected height; and b) release the platform to allow the base to be reconfigured to change the height of the support surface. The control assembly has a ratchet subassembly that, with the control assembly in a first state, allows the base to be reconfigured by exerting a continuous upward force upon the platform that causes the platform to elevate and be blocked within a range at a plurality of different vertical locations against downward movement. The control assembly further has an actuator that is repositionable to change the control assembly into a second state wherein the platform can be lowered over the range.

Owner:ANCRA INTERNATIONAL CORPORATON

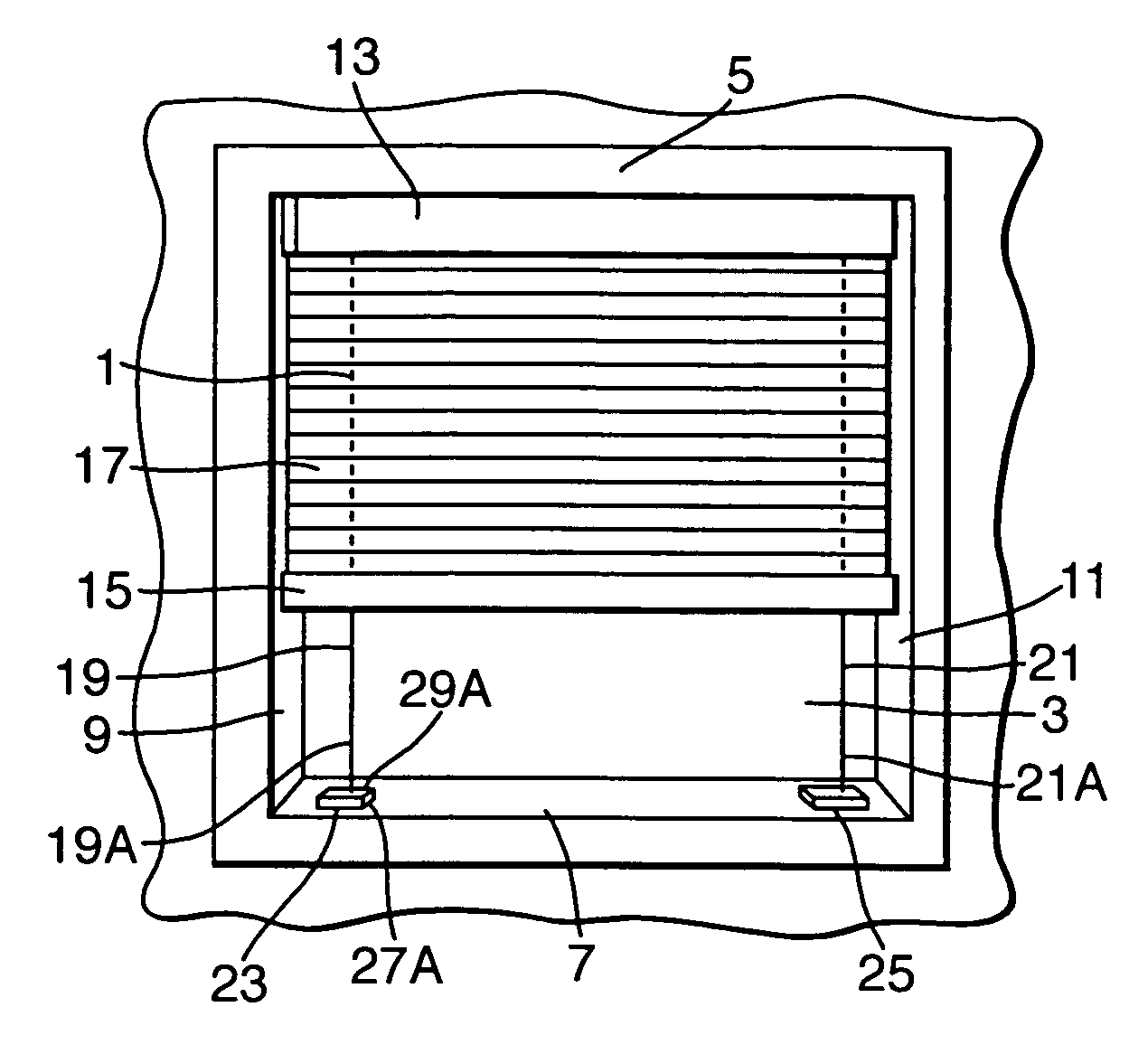

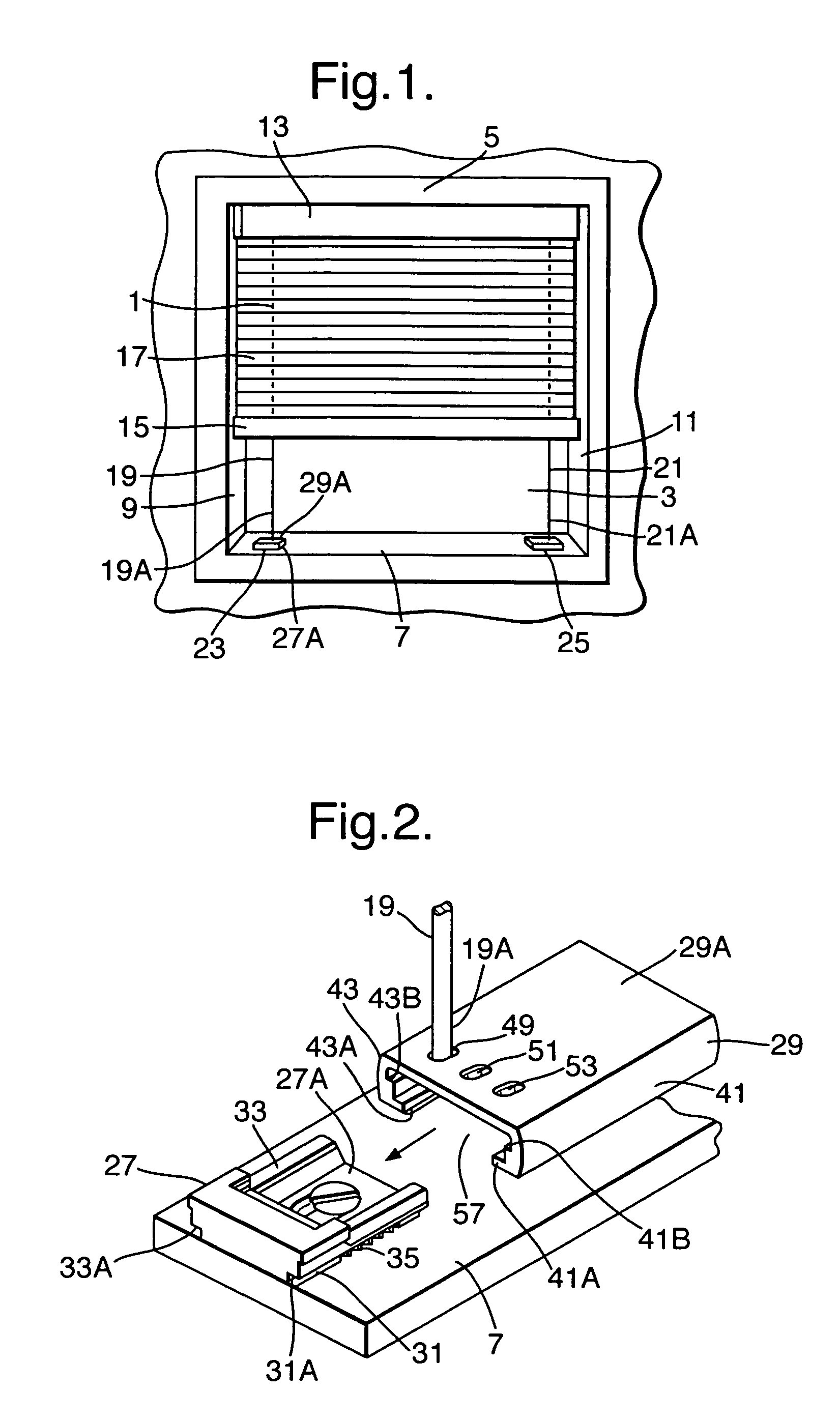

Mounting device for a guide cord

A two-part mounting device for attaching a free end of a guide cord of a window covering to a window frame. The device includes a base that can be secured to the frame and a holder which can be attached to the free end of the cord. The holder and the free end of the guide cord can be moved, relative to the base, in opposite directions, by sliding the holder in either one of the opposite directions while the holder and base remain engaged. The holder and base can also be disengaged by sliding the holder in one of the opposite directions. The device also includes a ratchet and pawl mechanism.

Owner:HUNTER DOUGLAS IND BV

Ratchetable open-ended wrench

A ratchetable open-ended wrench having a slidable retractable jaw member in a slot in one of its jaws and having a cover plate, preferably two cover plates, welded to the jaw in a manner such that the cover plate forms a load-bearing structural member within the jaw.

Owner:DIMON HUGBUNADARHUS EHF

Expandable liner hanger system and method

ActiveUS7278492B2Improve abilitiesShorten the lengthDrilling rodsFluid removalRatchetClassical mechanics

Owner:TIW

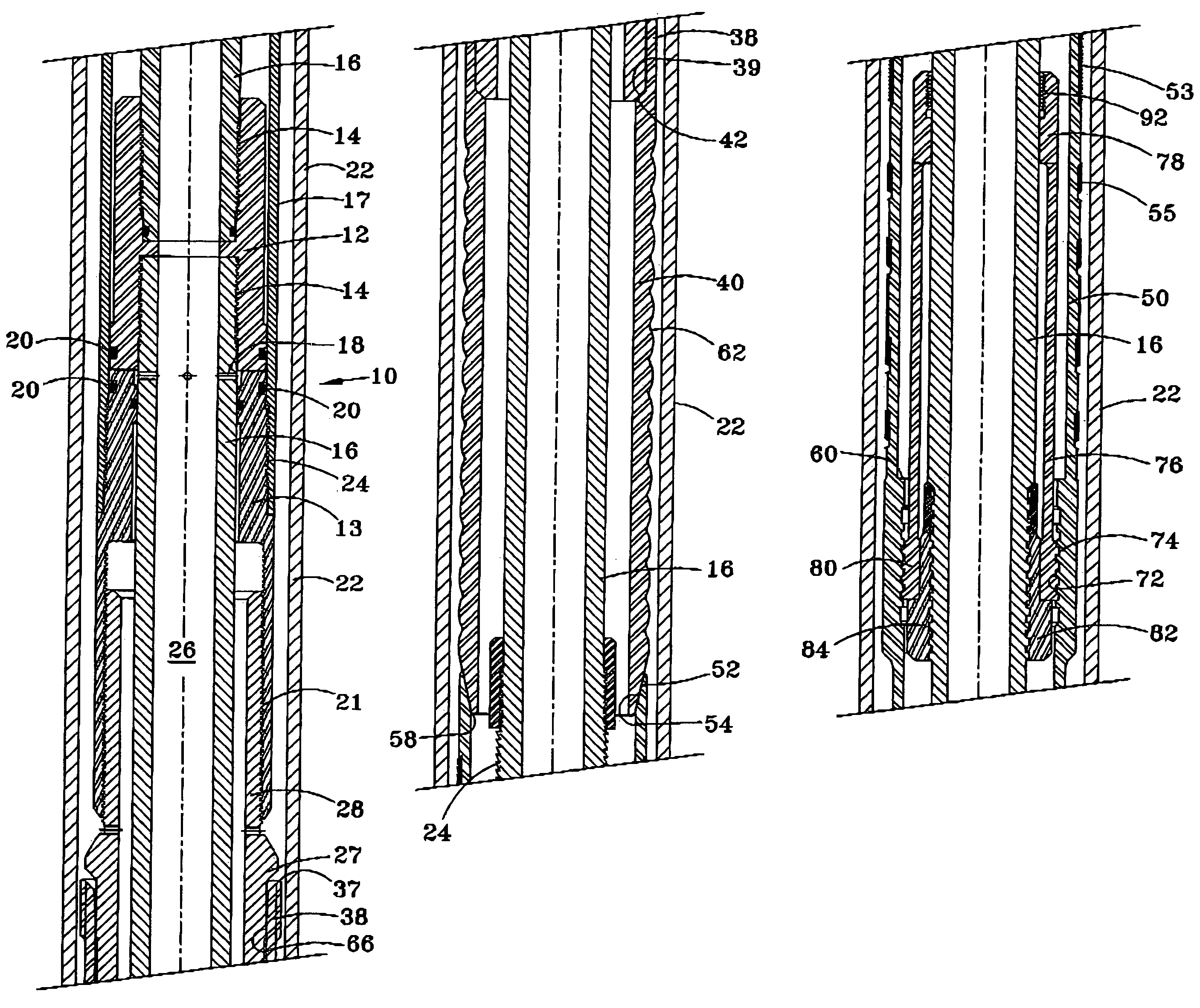

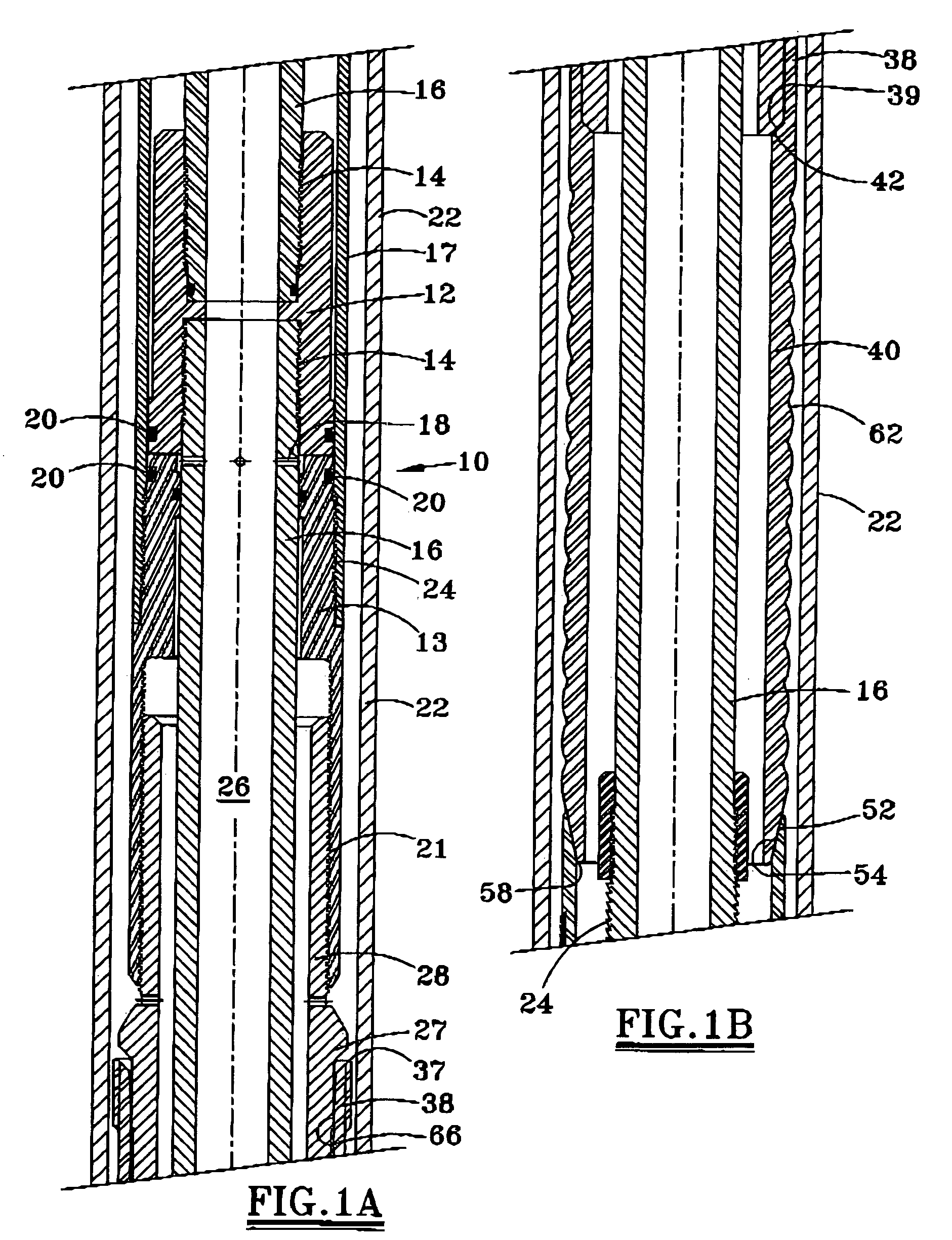

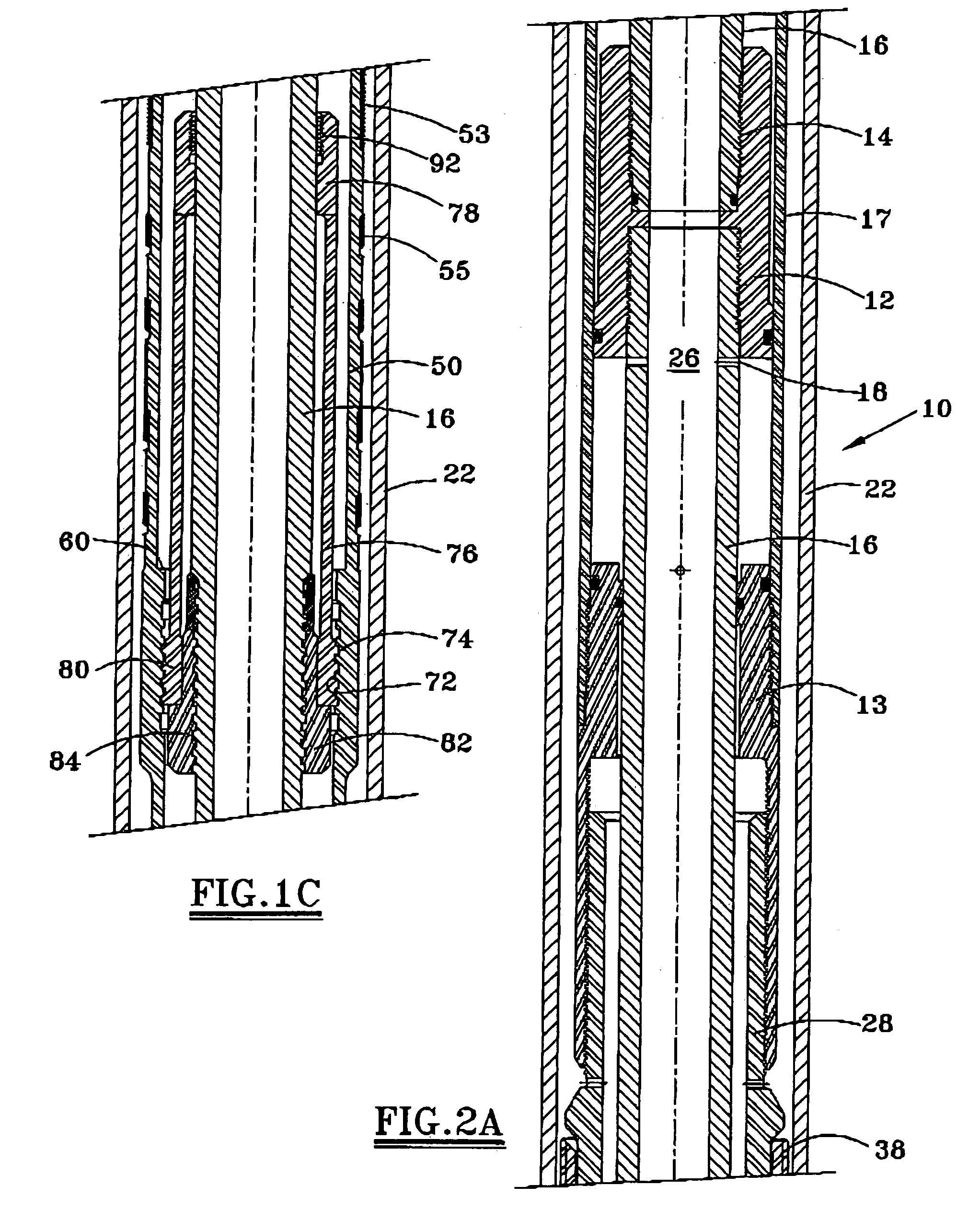

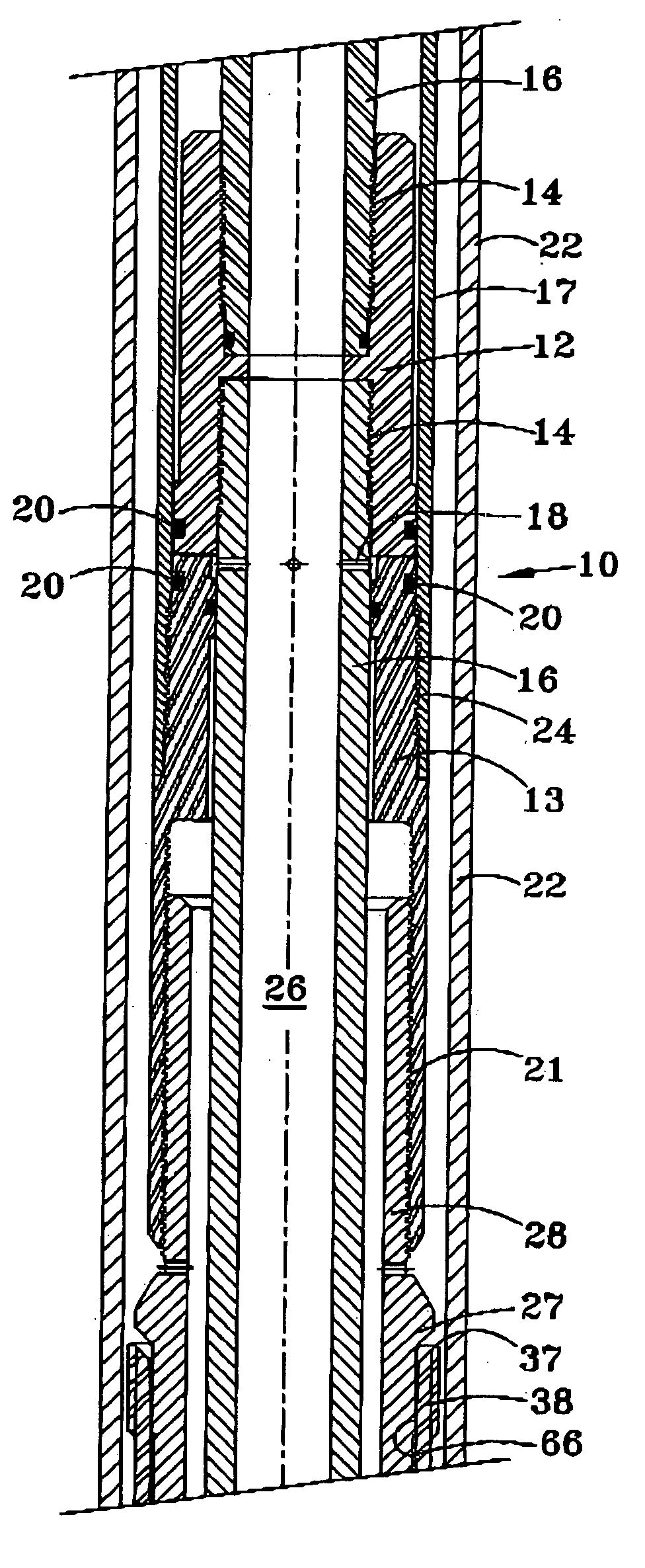

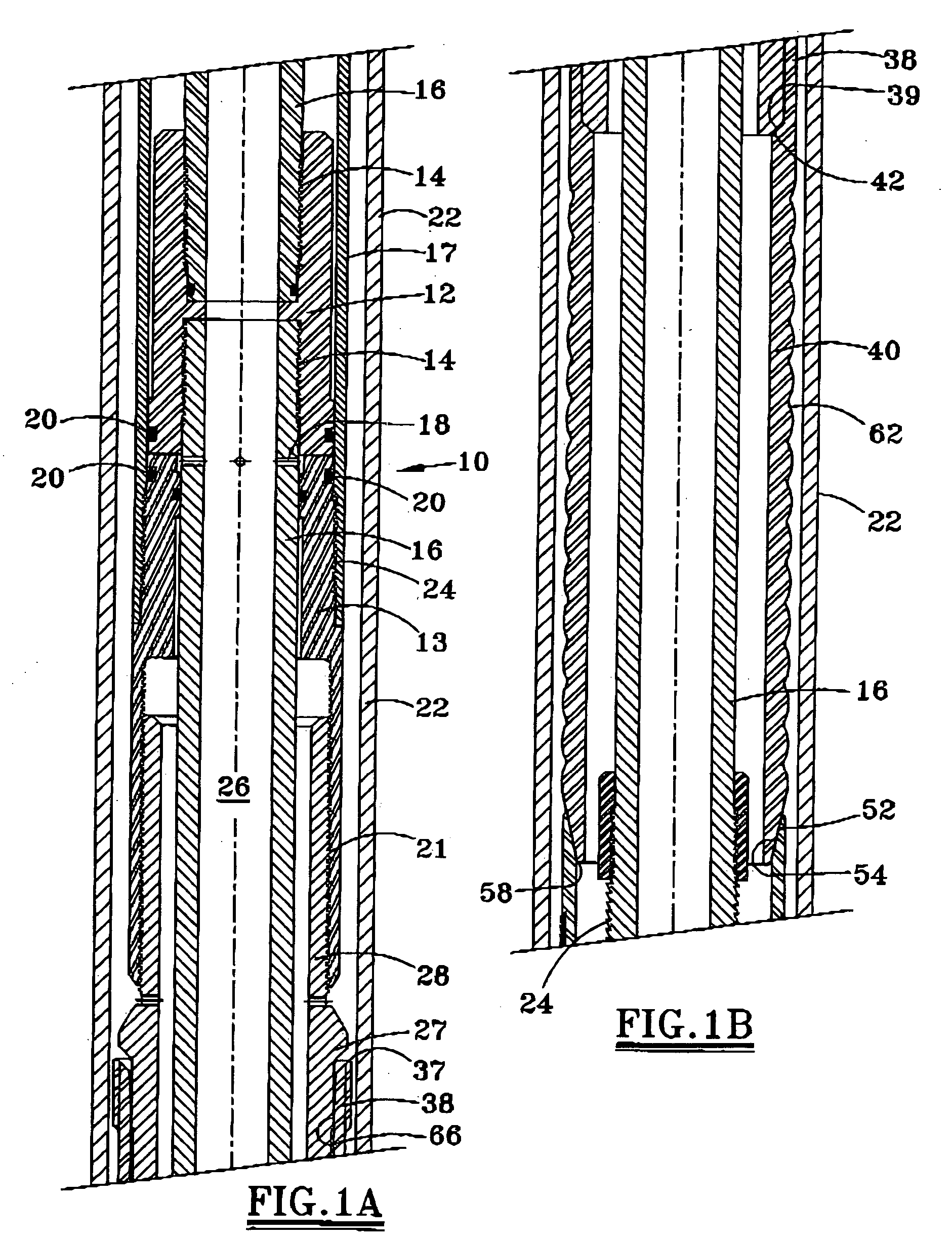

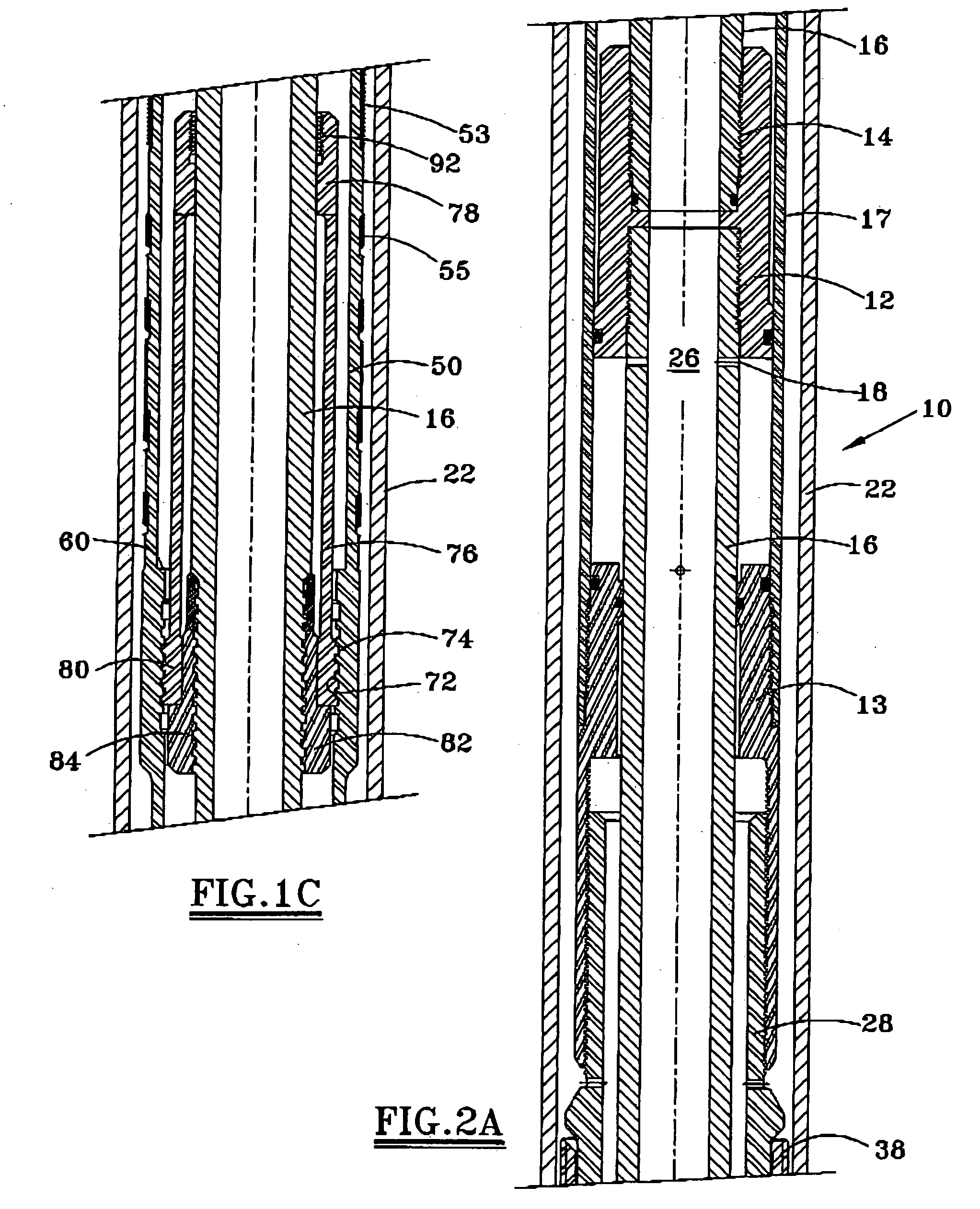

Expandable liner hanger system and method

ActiveUS20050263294A1Reliable releaseConstructed moreDrilling rodsFluid removalEngineeringCasing string

A liner hanger assembly seals with casing 22 and supports a liner 90 within a well. The tubular liner hanger body 50 and a tubular expander 40 may be positioned downhole at a desired depth on a running tool. An actuator assembly 12, 24 may forcibly move the tubular expander 40 into the liner hanger body 50, expanding the liner hanger body to seal and secure the hanger body to the casing string 22. The running tool may be released from the set liner hanger by an axially movable collet mechanism, such as ratchet ring 92 and a catch mechanism, such as threads 94. The running string thus need not be rotated to release from the set liner hanger.

Owner:TIW

Electromechanical wrench

ActiveUS20110132157A1Measurement of torque/twisting force while tighteningWork measurementFastenerWrench

An electromechanical wrench has a housing that has a working end and a gripping end, with a driver positioned at the working end, and a handle positioned at the gripping end. The wrench further includes a click wrench emulator mechanism provided at the handle. A method of using an electromechanical wrench to secure a fastener using angular measurement without the need for establishing a zero reference point, and allowing for ratcheting, is also provided. A method of counting the number of fasteners secured by an electromechanical wrench during a wrenching job is further provided.

Owner:DIGITOOL SOLUTIONS

Sliding anchorage device

An anchorage safety device for steelworkers. The safety device is configured to be slidably coupleable to a flanged structural beam to which a lanyard may be attached to secure a workman against a fall. The anchorage device includes an elongate cross-member having a plurality of apertures formed there-through to allow adjustment of the anchorage device to accommodate various beams; a lanyard attachment apparatus, affixed to the mid-point of the cross-member, for receiving a clip of a workman's lanyard; and opposed first and second clamps for coupling the device to the flange of a beam. The clamps include a ratchet pawl having first and second teeth for selectively engaging the cross-member apertures. The worker needs only one hand to release the ratchet pawl from the apertures by simultaneously applying pressure on an enlarged engagement surface of the ratchet pawl and a clamp housing surface that is opposed to the enlarged engagement surface. Since both forces must be simultaneously applied in opposite directions, inadvertent disengagement of the clamp from the cross-member is obviated.

Owner:REEVES ERIC W

Reversible ratchet wrench

A reversible ratchet wrench includes a handle from which a head extends. The head includes a compartment and a receiving hole in communication with the compartment. A drive member is rotatably mounted in the compartment and a pawl is slidably mounted in the compartment. A ring is mounted in the compartment and around an end of the drive member. A reversing plate is pivotably mounted to the end of the drive member and operatively connected to the ring to turn therewith. A switching member is pivotably mounted in the receiving hole of the head. The switching member is operatively connected to a tip piece of the ring to turn therewith. The switching member is operatively connected to the pawl to move the pawl for changing a driving rotating direction of the reversible ratchet wrench when the reversing plate is moved between two positions corresponding to two opposite driving rotating directions.

Owner:HU BOBBY

Charging Handle for Automatic Rife

ActiveUS20110226120A1Easy to startGreat leverageFiring/trigger mechanismsRifleElectrical and Electronics engineering

Owner:MAGPUL INDUSTRIES

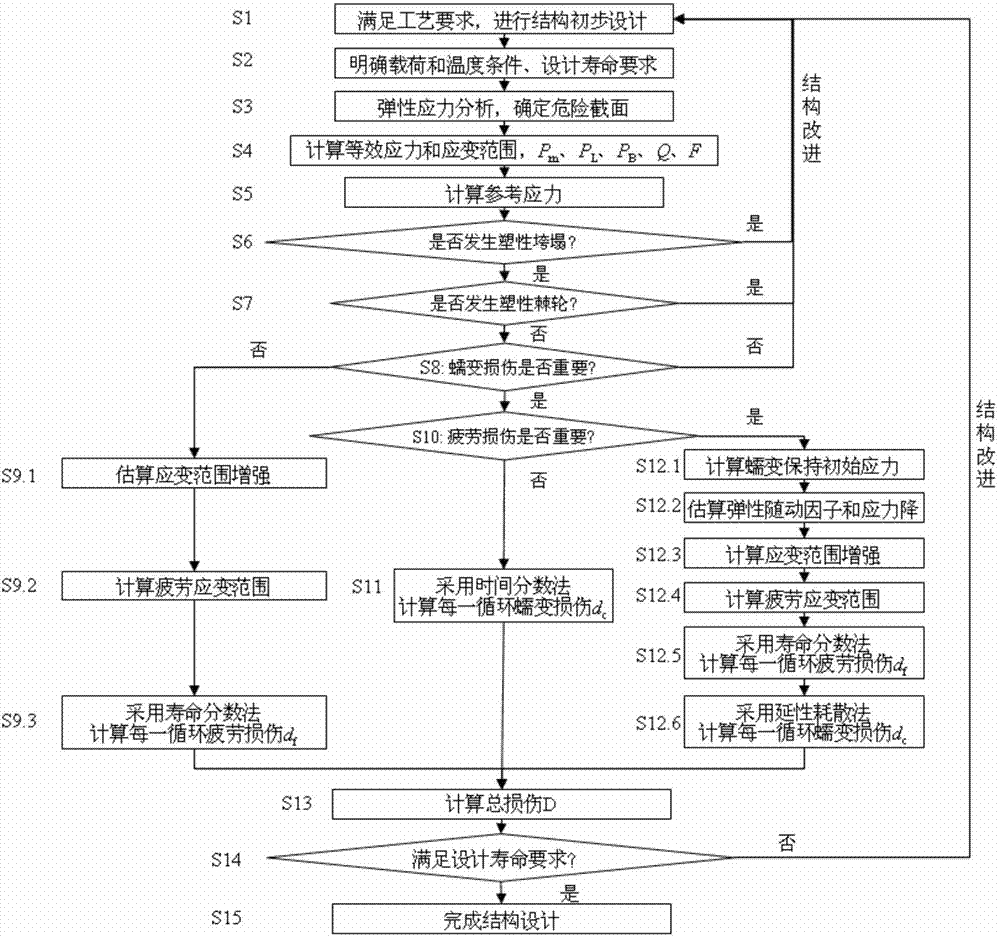

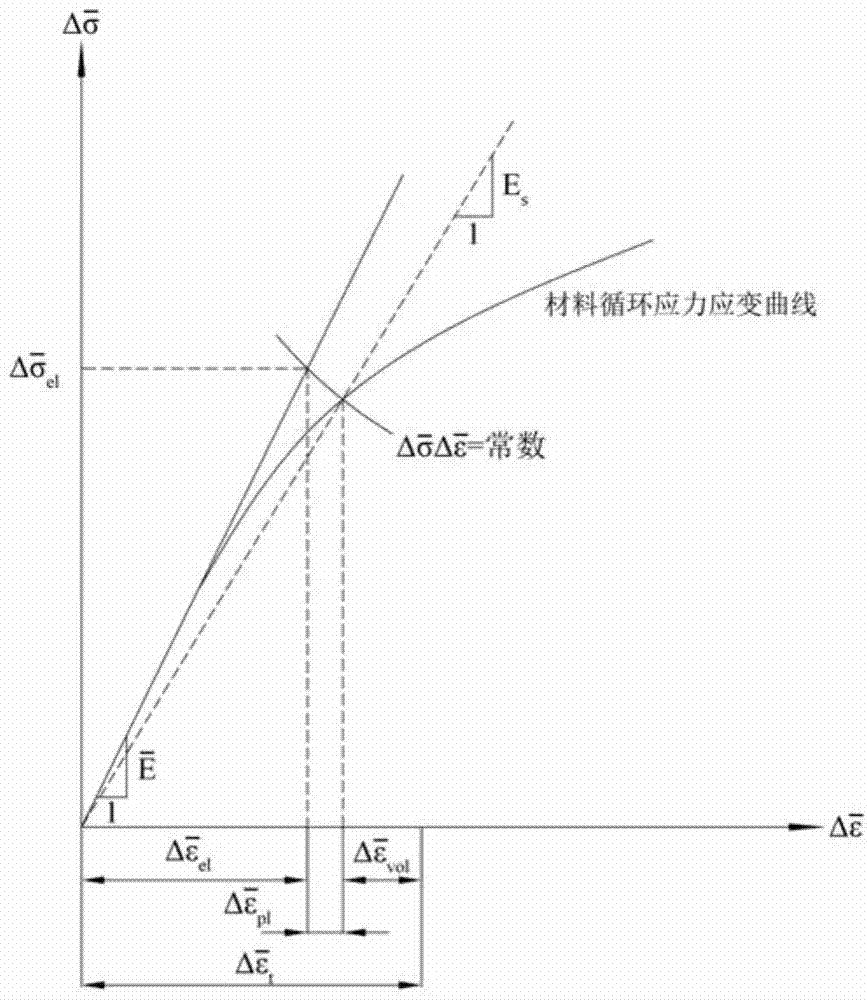

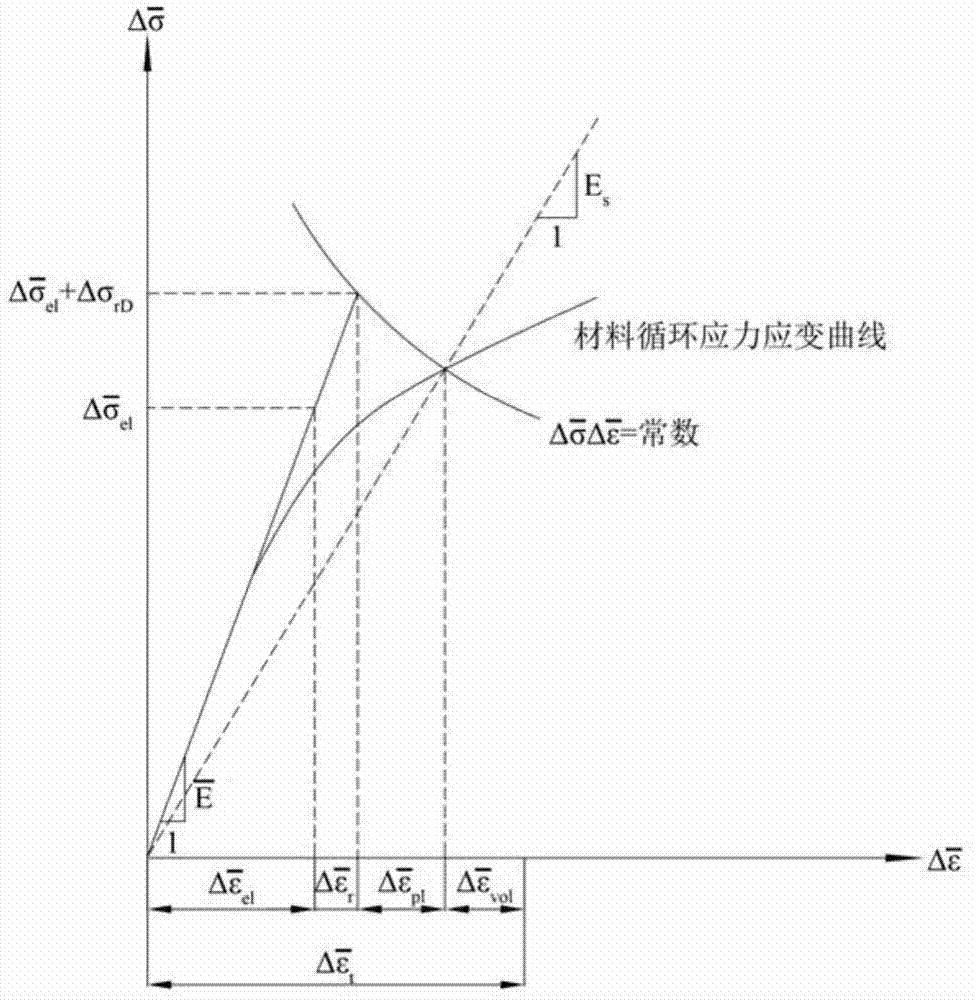

Service life based high-temperature container creep fatigue strength design method

The invention discloses a service life based high-temperature container creep fatigue strength design method. The method comprises the steps of 1, performing structure preliminary design; 2 determining load and temperature conditions and the design service life requirement; 3, determining dangerous sections; 4, calculating the equivalent stress and strain range; 5, calculating reference stress; 6, determining whether plastic collapse occurs; 7 determining whether the plastic ratchet occur; 8, determining whether creep damage is important; 9, estimating fatigue damage of each cycle when the creep damage is not important; 10, determining whether the fatigue damage is important; 11, estimating the creep damage when the fatigue damage is not important; 12, estimating damage of each cycle when the creep damage and the fatigue damage are non-ignorable; 13, estimating creep-fatigue total damage; 14, performing result analysis and structural design improvement; 15, completing structural design. According to the method, the foundation is laid for national establishing of creep and fatigue failure mode based high-temperature pressure container design standards and achieving design and manufacture of high-temperature pressure containers according to the service life.

Owner:HEFEI GENERAL MACHINERY RES INST

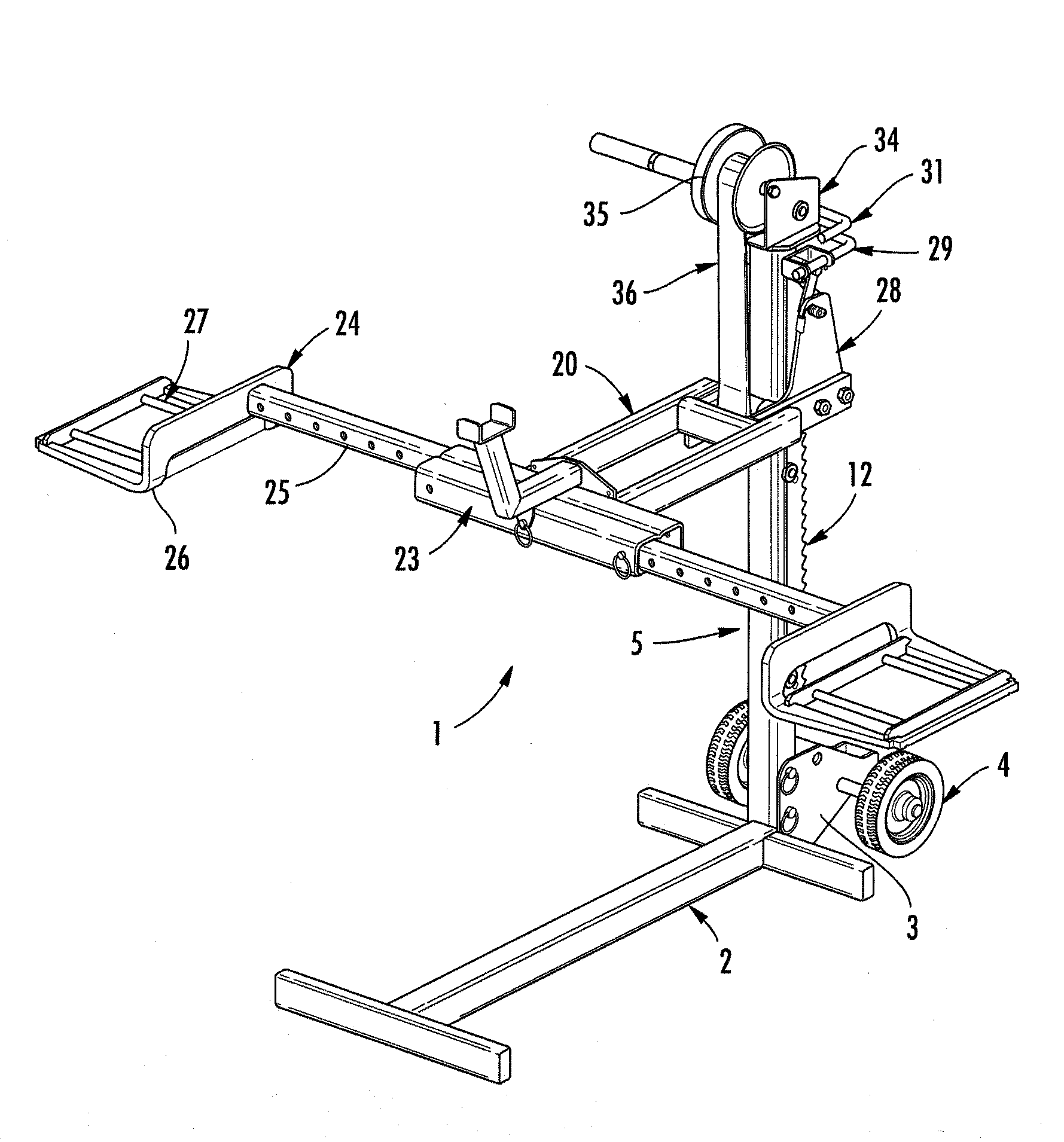

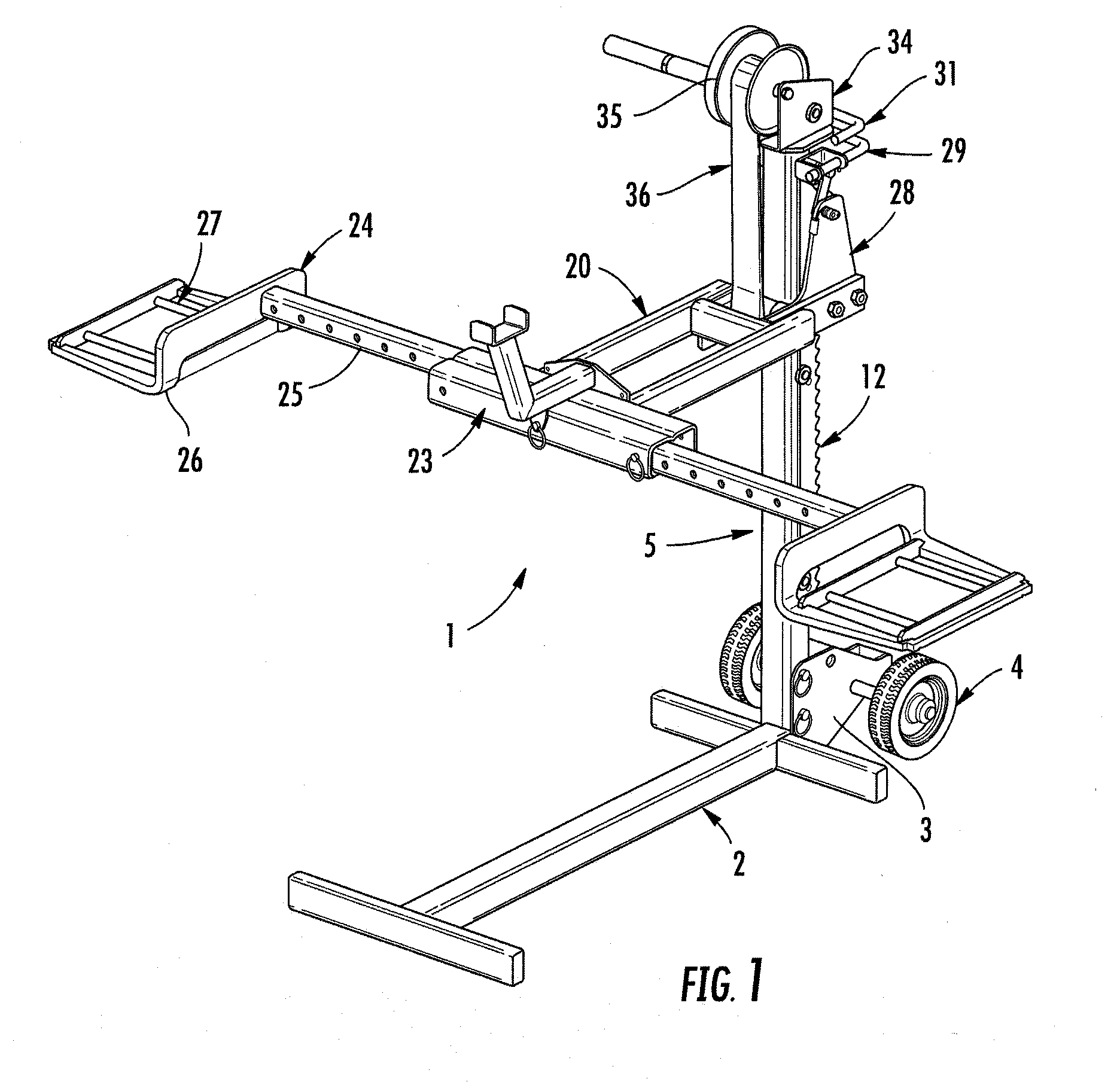

Apparatuses and methods for an improved vehicle jack

Various embodiments of a vehicle jack include a base, an upright support mounted adjacent to and extending upwardly from the base, a toothed rack, a toothed bar pin, and a release handle. The toothed rack has a first end and a second end and defines a plurality of ratchet troughs therebetween, and the toothed rack is mounted adjacent the upright support. The ratchet assembly is adapted to move along a path defined by the upright support, and the toothed bar pin, which is mounted adjacent the ratchet assembly, is adapted to selectively engage a portion of the toothed rack adjacent one of the plurality of ratchet troughs as the ratchet assembly moves along the path. The release handle is mounted adjacent the second end of the toothed rack, and the release handle is adapted to selectively disengage the toothed bar pin from one of the plurality of ratchet troughs.

Owner:MOJACK DISTRIBUTORS

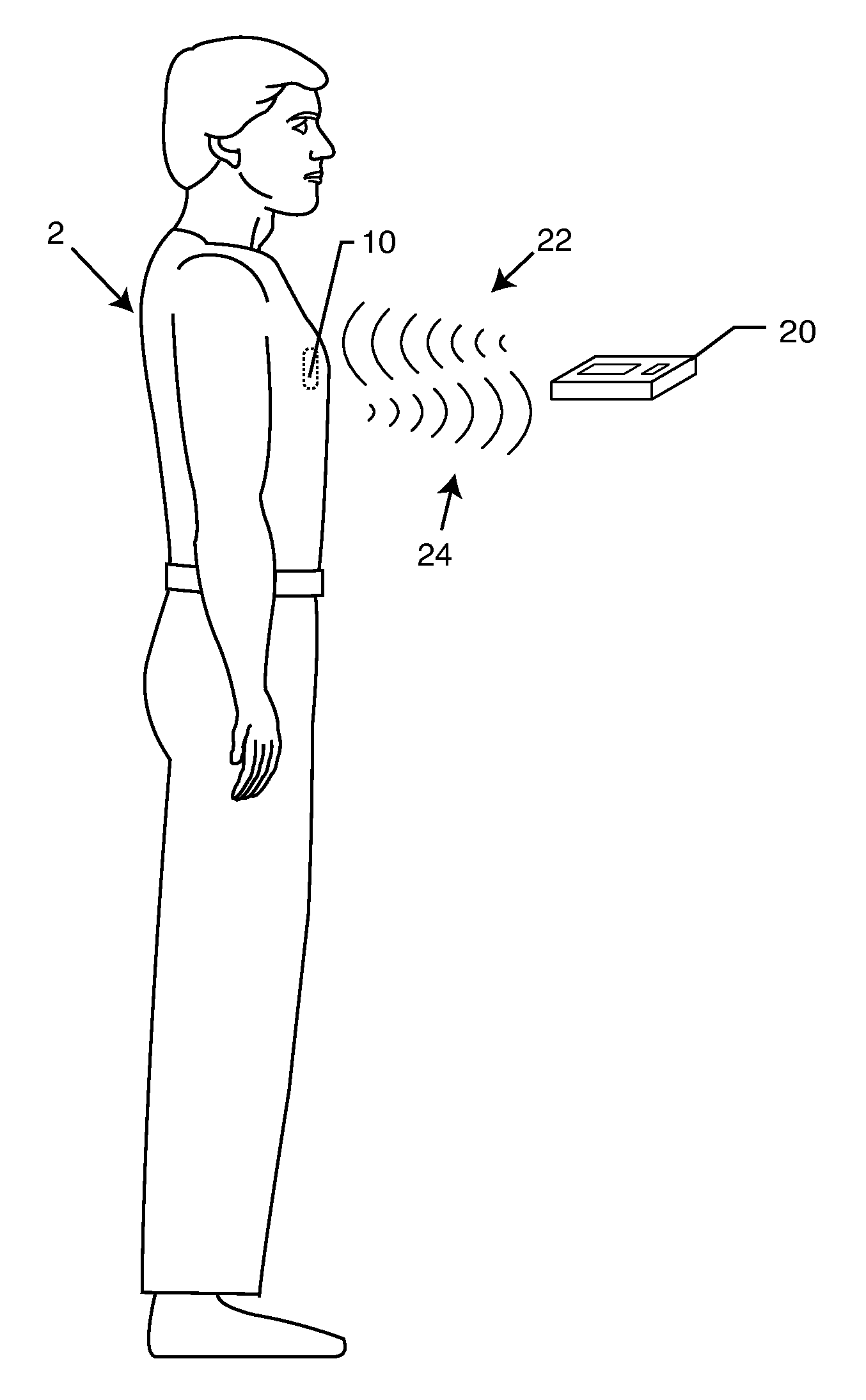

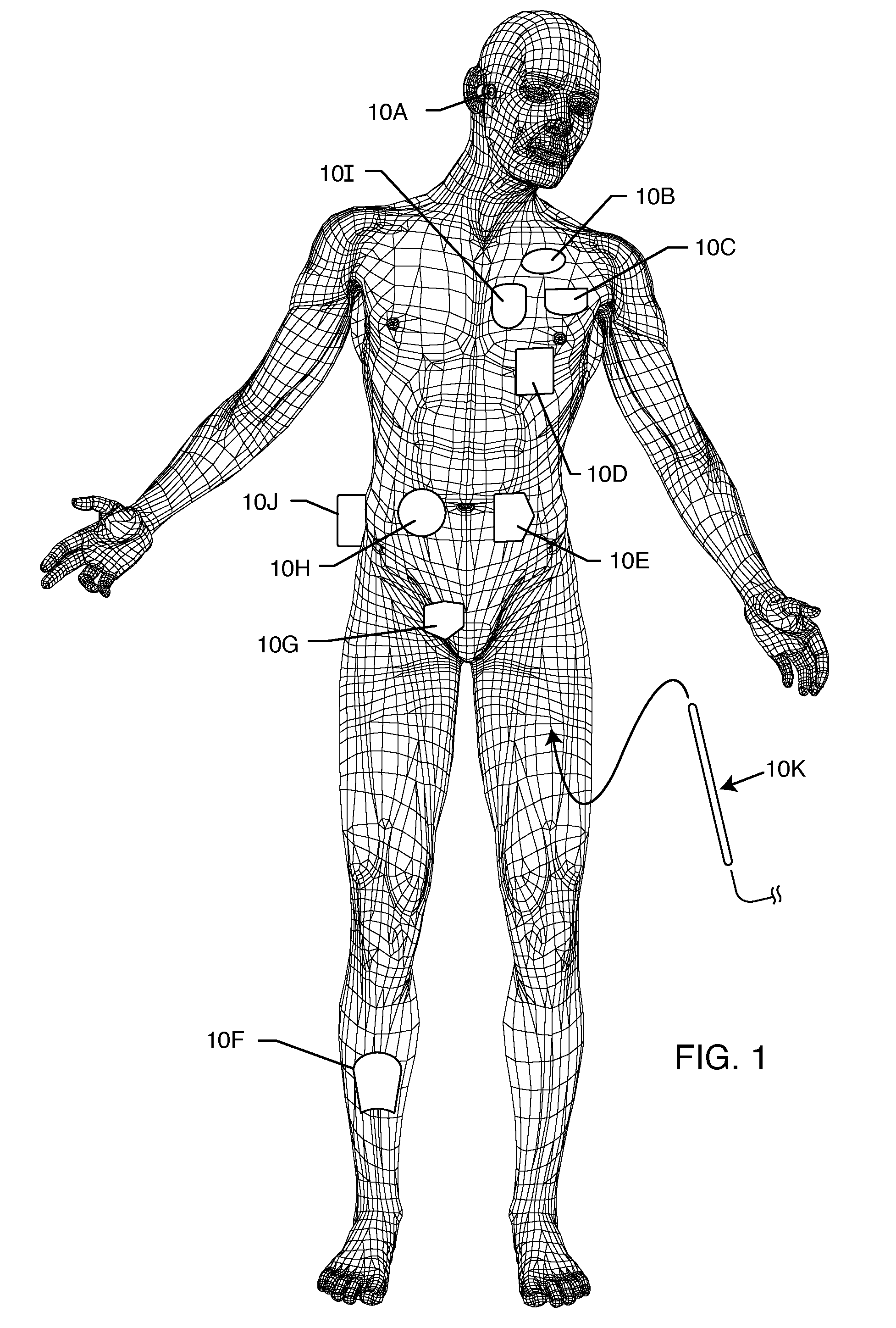

Implanted lead sleeve having RFID tag

An identification device for an implantable lead includes an associated implantable sleeve and a radio frequency identification device (RFID) tag associated with the sleeve. The RFID tag includes information relating to the implantable lead, its associated lead system, or an associated implantable medical device. The RFID tag may be hermetically sealed within the sleeve and the sleeve selectively fixed along a length of the lead. The sleeve may comprise a loop forming an aperture, a crimped clamp device, a clamp device including a ratchet, clip, or rivet mechanism, or a clamp device including two separate clamshells, all of which allow for secure attachment to the lead. Alternatively, the sleeve may integrally be formed as part of the lead between a lead conductor and an insulated lumen. An external interrogator may be used for identifying information contained within the RFID tag.

Owner:WILSON GREATBATCH LTD

Reversible ratchet-type wrench

A wrench comprises a handle and a head extending from the handle. A peripheral wall defining a hole in the head includes a compartment. An annular groove is defined in an end of the peripheral wall defining the hole. The annular groove is partially coincident with the compartment. A pawl is slidably received in the compartment and biased to engage with a gear wheel in the hole. A switching member is partially mounted in the hole for moving the pawl when switching of the ratcheting direction is required. A retainer ring is partially engaged in an annular groove in the switching member and partially engaged in the annular groove of the head. The retainer ring is retained in place by a wall defining the compartment. The switching member is not moved when the pawl moves as a result of free rotation of the wrench.

Owner:HU BOBBY

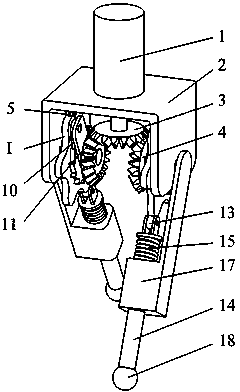

Biped robot capable of walking rapidly

ActiveCN104228993ASimplify the control problemSimplified Motion AlgorithmVehiclesRatchetControl engineering

The invention discloses a biped robot capable of walking rapidly. The biped robot is composed of a servo motor, a motor support, a driving bevel gear, driven bevel gears, check pawls, ratchet wheel cam sets, ratchet wheel connecting pins, a driving pawl, oscillating bars, roller connecting pins, rollers, shanks, compression springs, screws, thighs and feet. The servo motor drives the driving bevel gear to rotate so as to drive the symmetrically-arranged driven bevel gears to rotate oppositely and the thighs to swing forwards and backwards; the shanks always make contact with cams in the ratchet wheel cam sets through the compression springs and supporting legs are longer than swinging legs through telescopic motion of the shanks. Compared with the prior art, the biped robot has the advantages that the robot can be driven by one servo motor, so that the robot is convenient to control and high in control accuracy; except for the servo motor, other structures of the robot are all mechanical structures, so that motion cooperation is convenient; the structure is simple, machining and installation are convenient, and the robot can walk rapidly.

Owner:ZHEJIANG UNIV

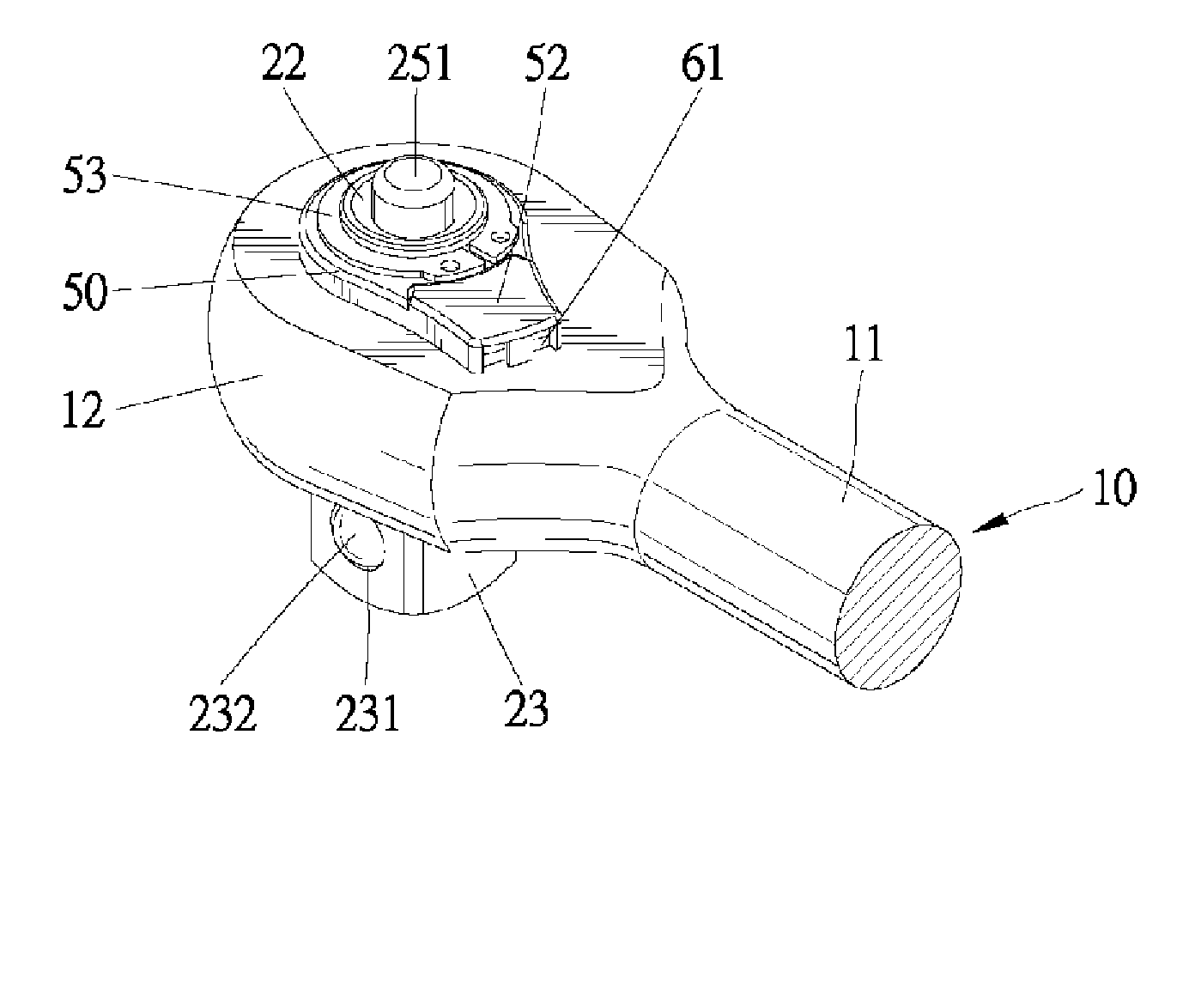

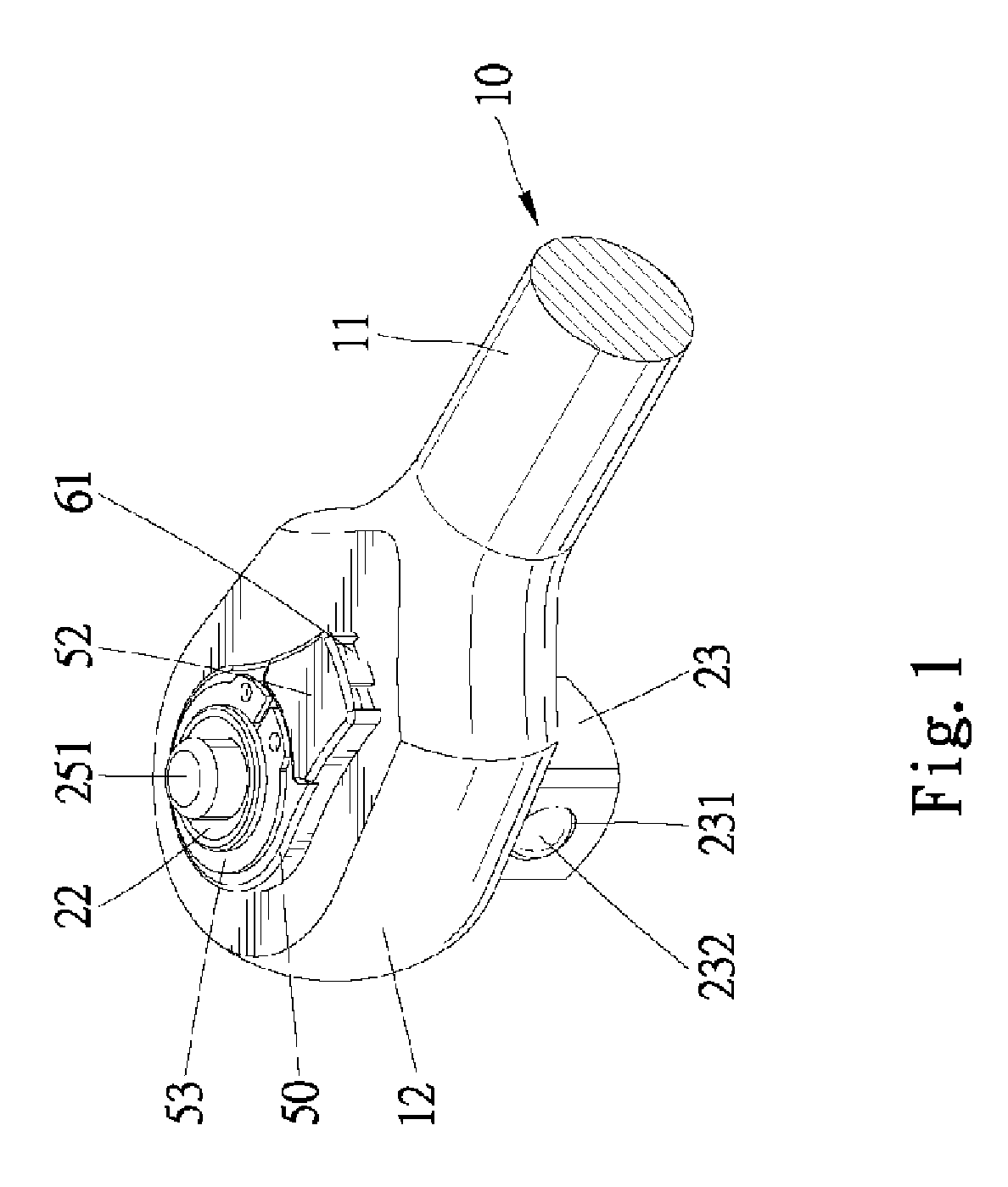

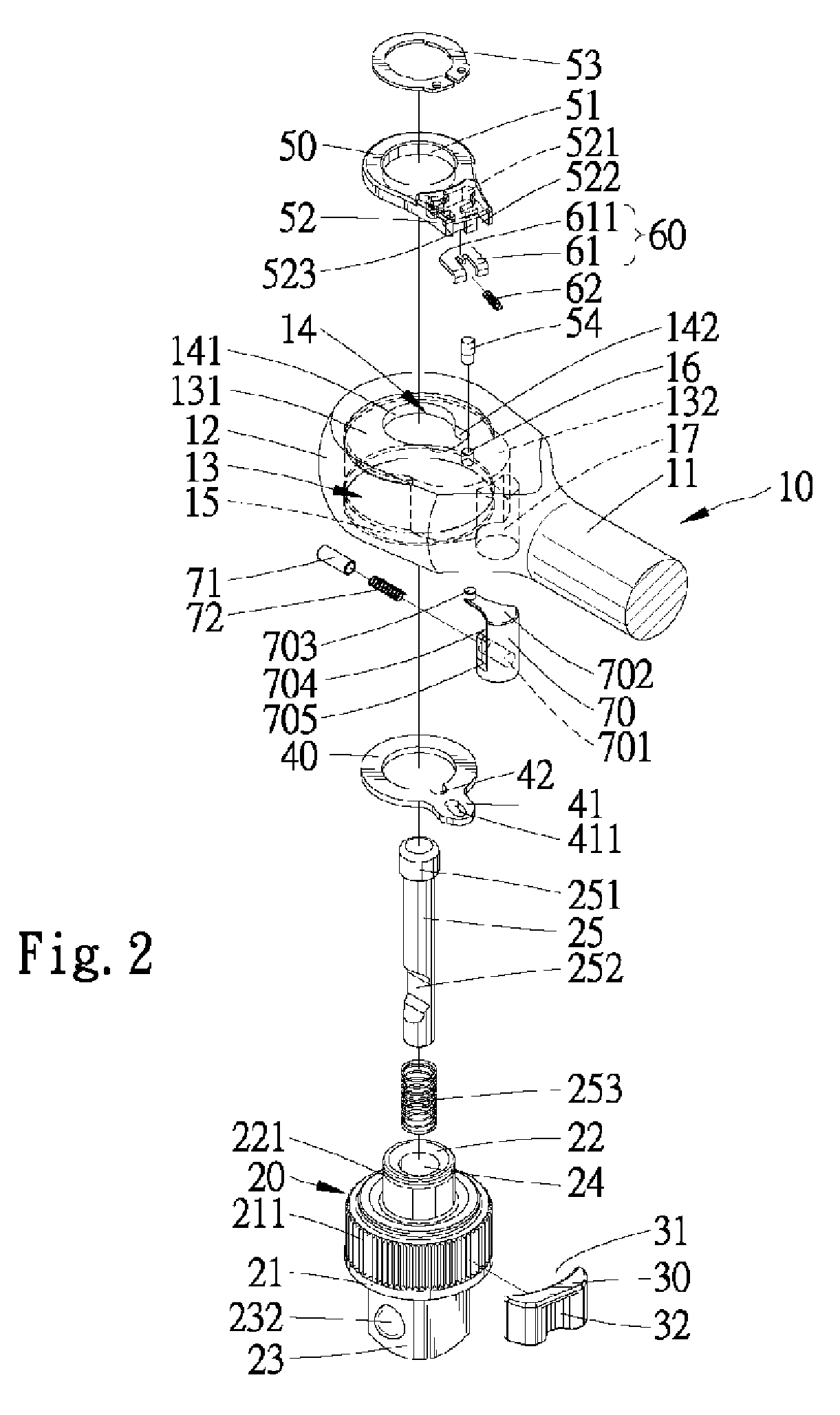

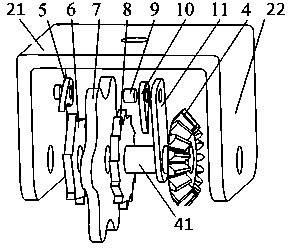

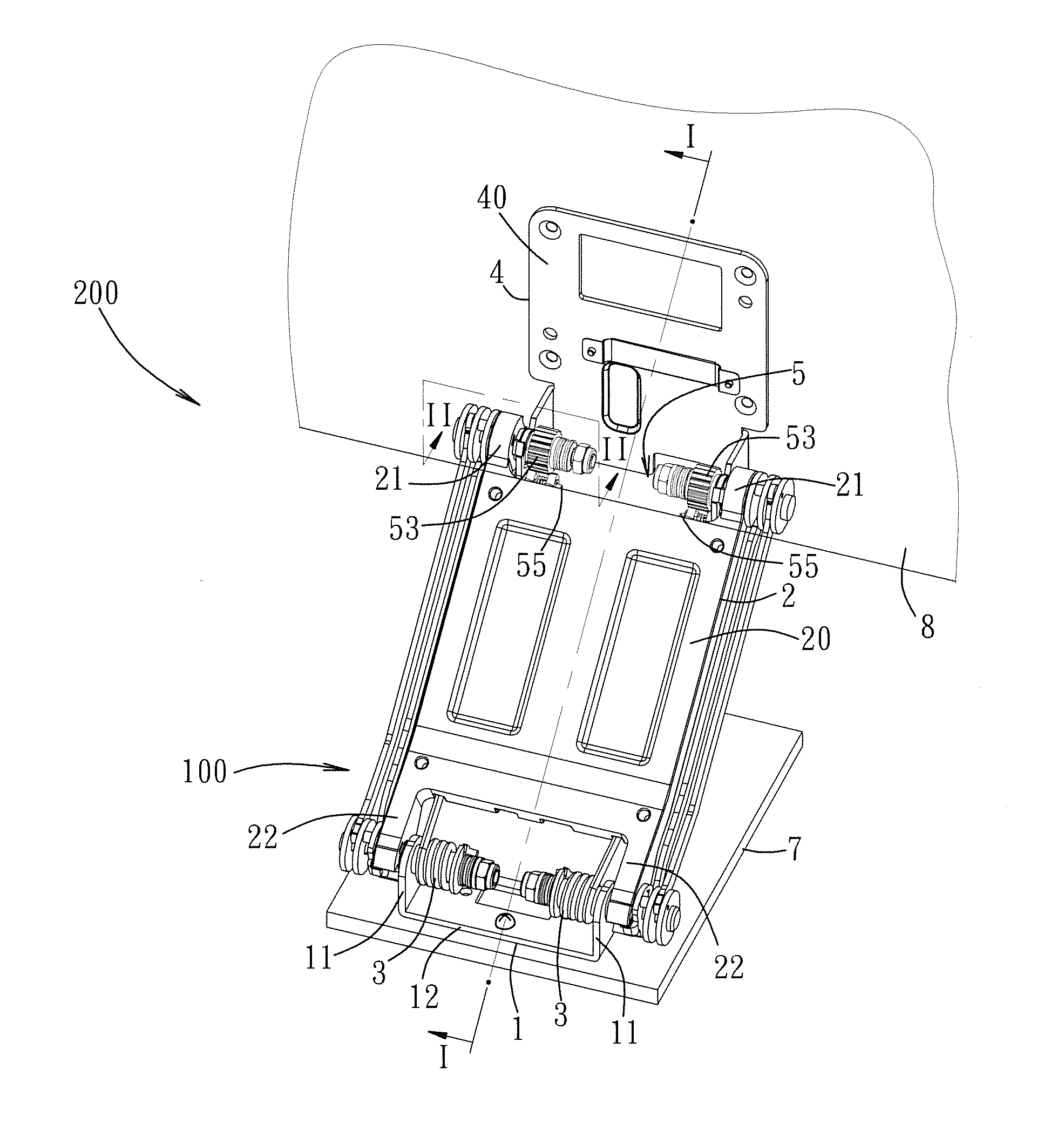

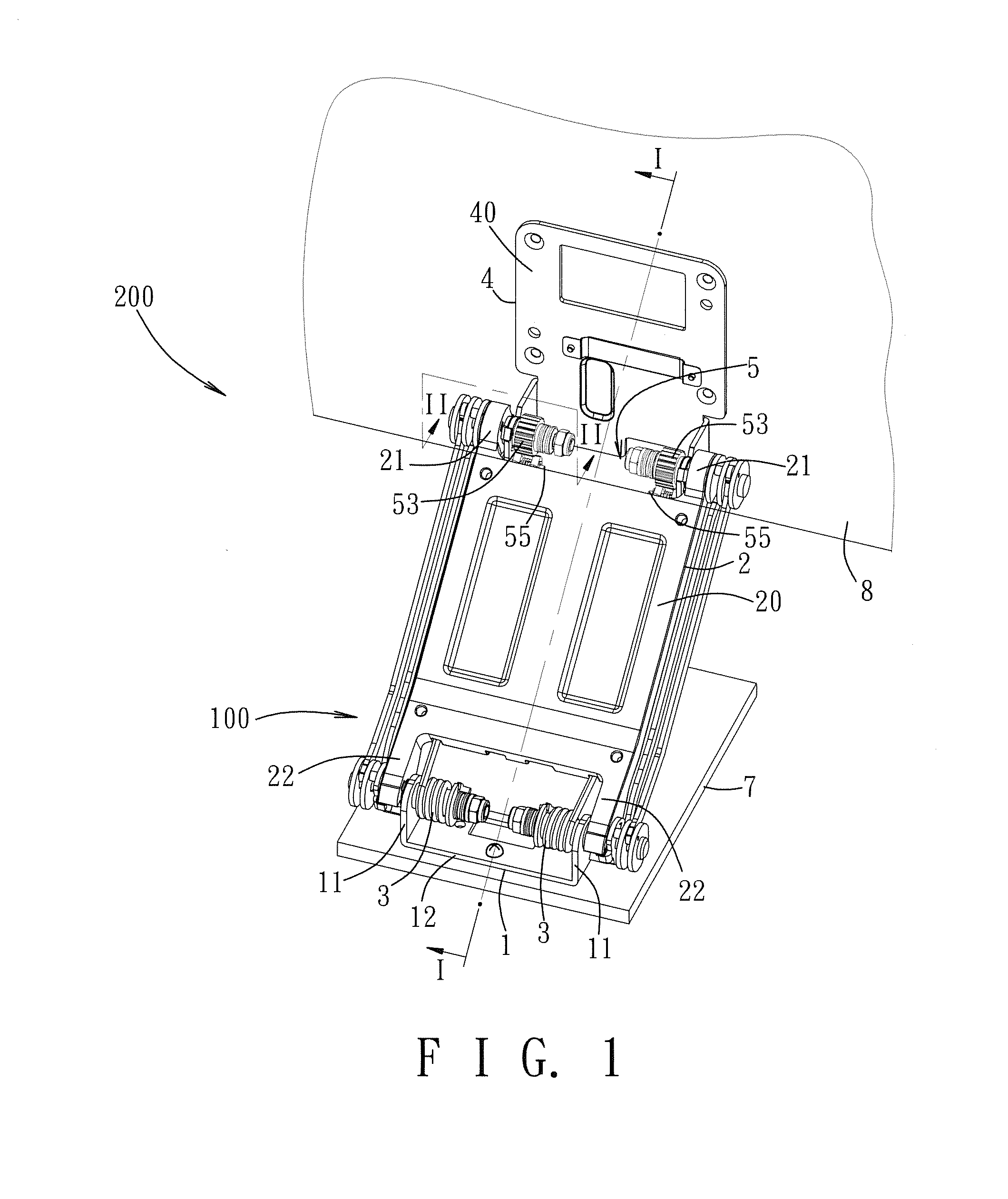

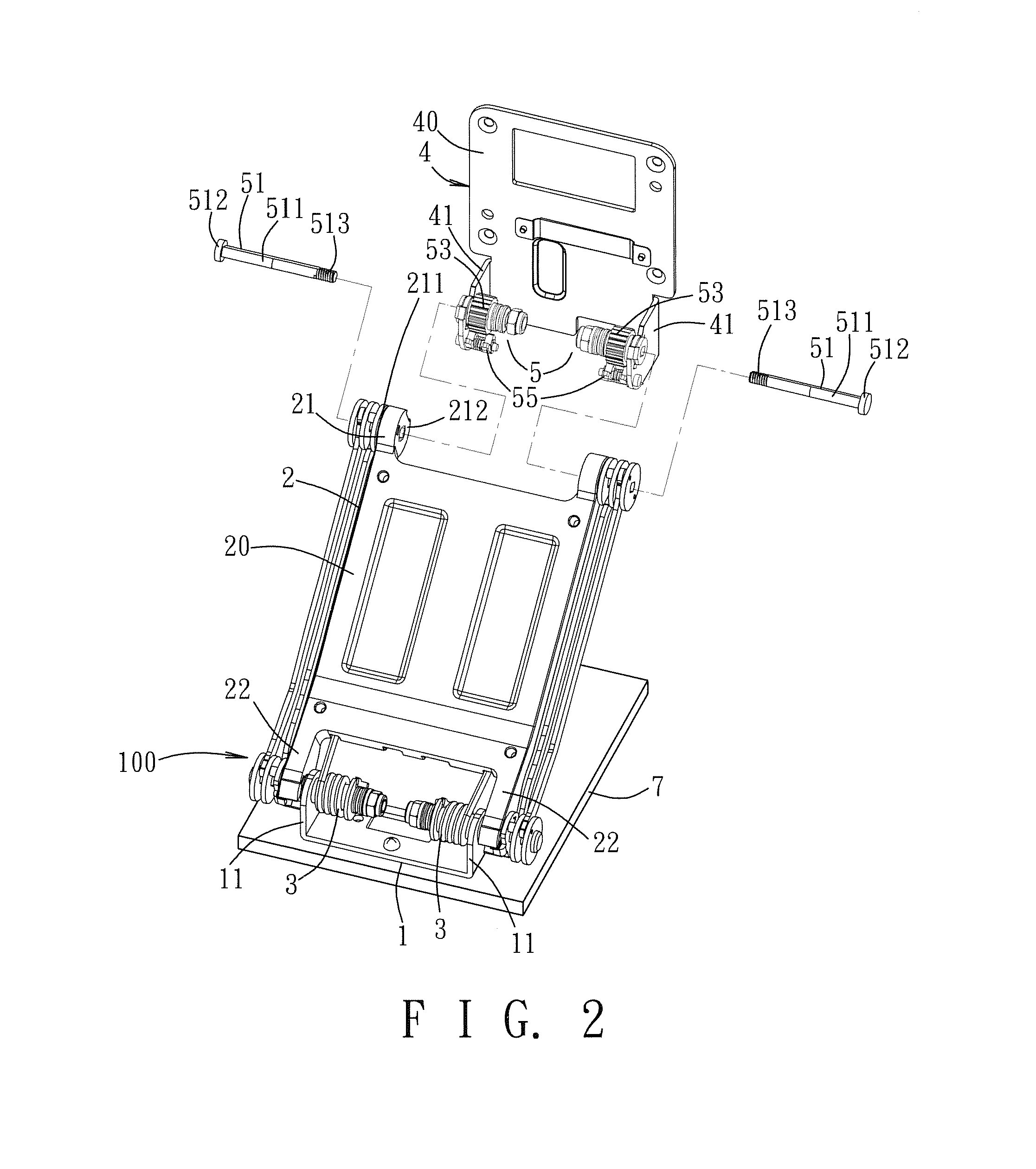

Hinge, supporting module having the hinge, and display device having the supporting module

ActiveUS20140063750A1Different frictional force and rotational torqueDifferent friction forceDigital data processing detailsWing fastenersRatchetBrake

A hinge for pivotally interconnecting first and second brackets includes a shaft having a shaft body extending through the first and second brackets and formed with an engaging end portion proximate to the second bracket, a fixing member connected to the engaging end portion, a ratchet sleeved rotatably on the shaft body between the fixing member and the second bracket, a friction mechanism having an urging unit sleeved on the shaft body between the ratchet and the fixing member and pressing the ratchet toward the second bracket, and a brake mechanism disposed on the second bracket and having a pawl member releasably engaged to the ratchet.

Owner:LITE ON ELECTRONICS (GUANGZHOU) LTD +1

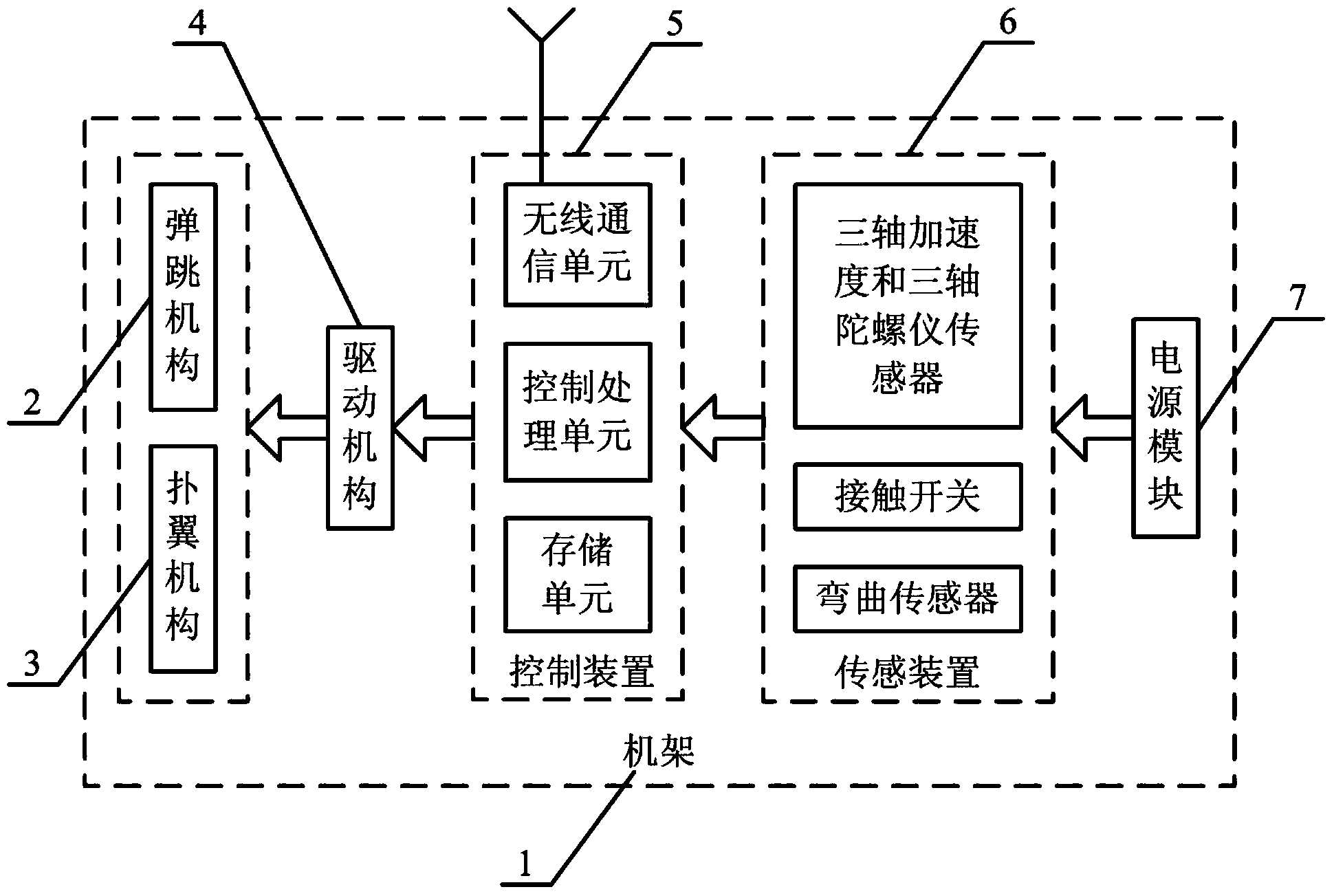

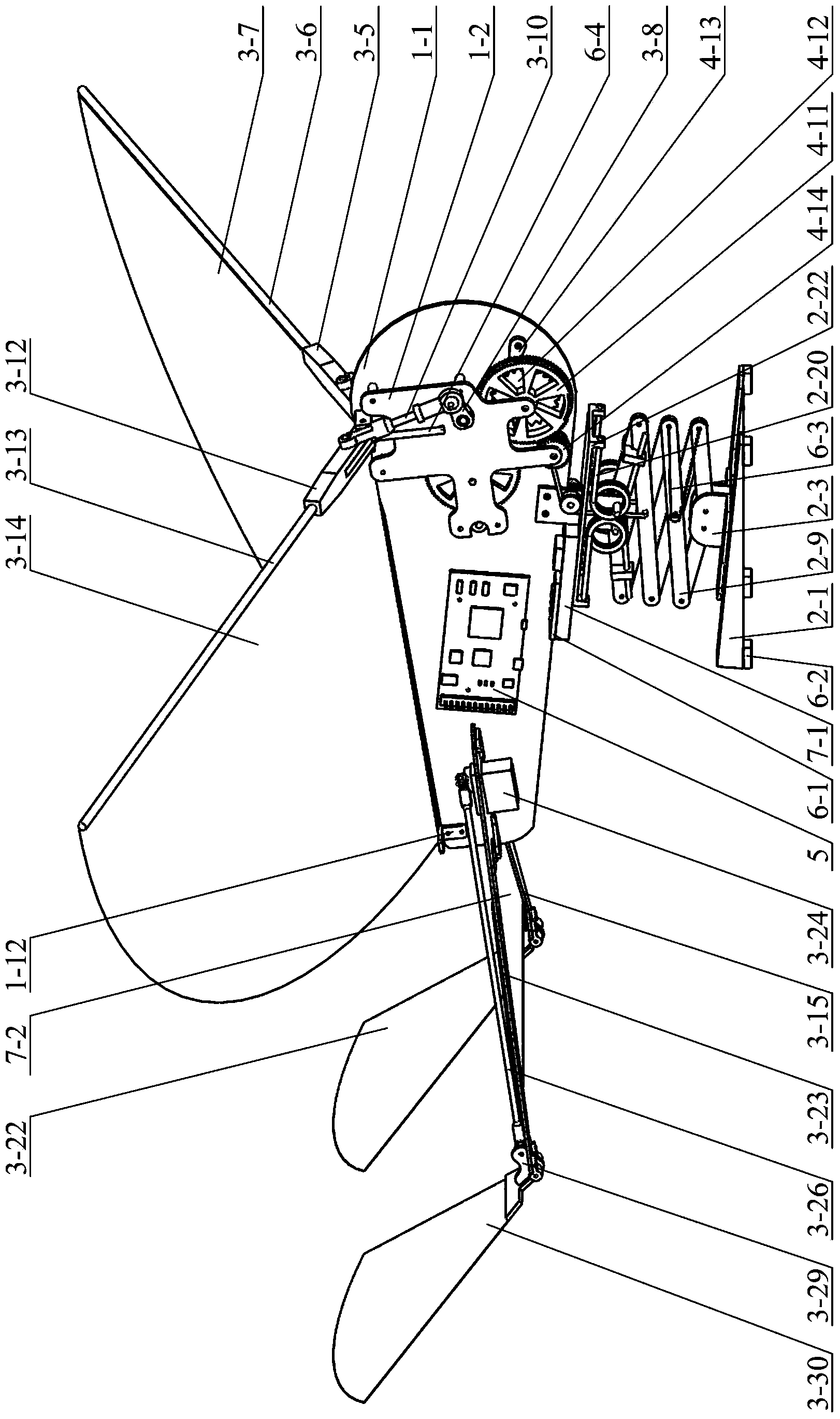

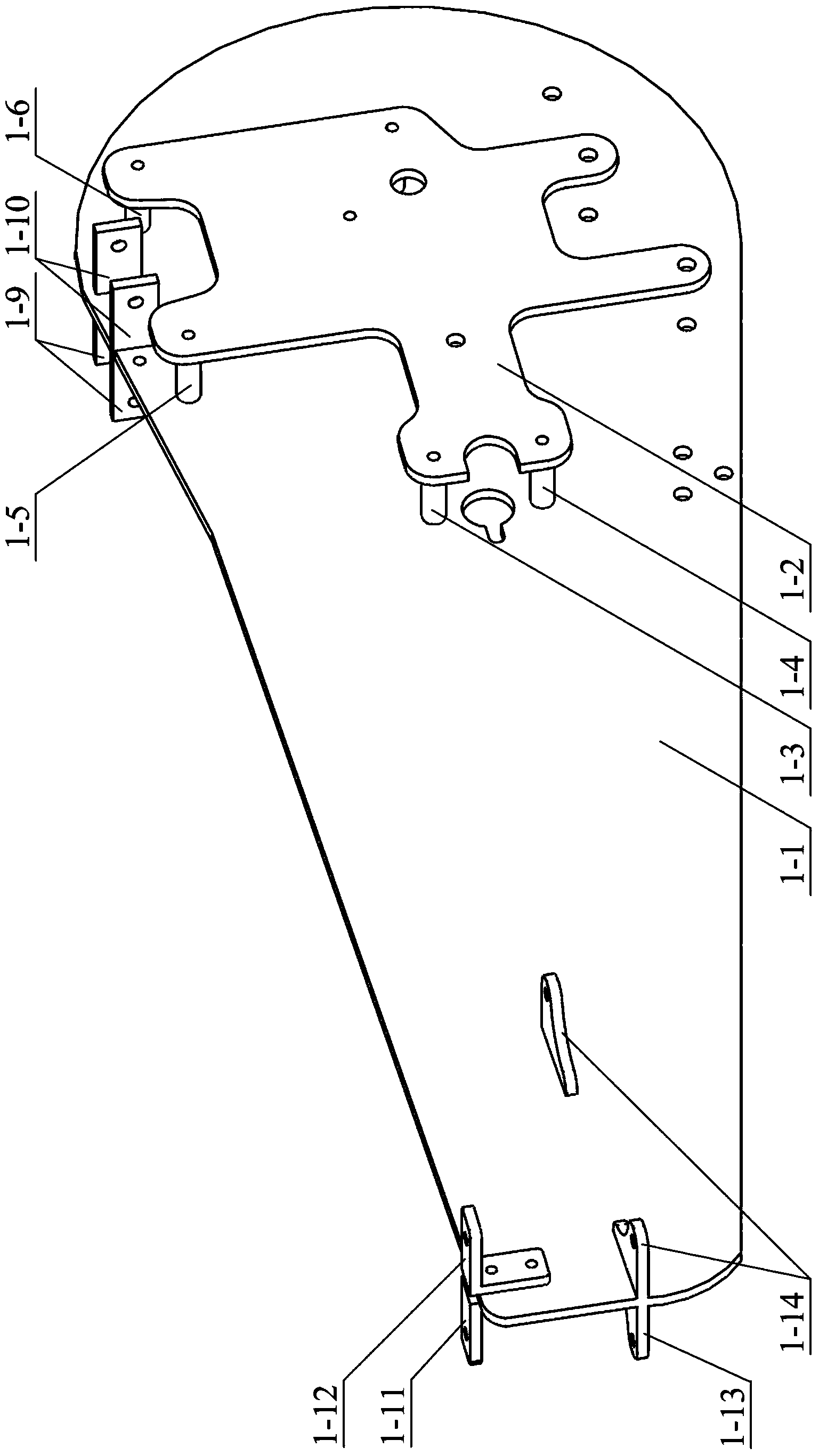

Bionic wing-flapping and bouncing multi-mode movement robot

The invention discloses a bionic wing-flapping and bouncing multi-mode movement robot which comprises a rack, a bouncing mechanism, a wing-flapping mechanism and a driving mechanism, wherein the bouncing mechanism, the wing-flapping mechanism and the driving mechanism are arranged on the rack. The bouncing mechanism comprises feet, a folding mechanism, a torsional spring frame and a winch wheel. The wing-flapping mechanism comprises two wing mechanisms and two tail wing mechanisms, wherein the two wing mechanisms and the two tail wing mechanisms are respectively symmetrical in a left-right mode. The driving mechanism comprises a driving motor, a gear transmission mechanism and a ratchet mechanism. The gear transmission mechanism comprises an input gear and an output gear meshed with the input gear. The output gear comprises a tooth-incomplete gear, a crank gear connected with a crank, and a winch wheel gear connected with the winch wheel. The crank gear is meshed with the half side, with complete teeth, of the tooth-incomplete gear, and the winch wheel gear is meshed with the half side, with incomplete teeth, of the tooth-incomplete gear. The driving mechanism with the single motor drives the wing mechanisms and the bouncing mechanism to work, the complexity and the whole mass of the robot are effectively reduced, and the feasibility of the multi-mode movement robot is improved.

Owner:SOUTHEAST UNIV

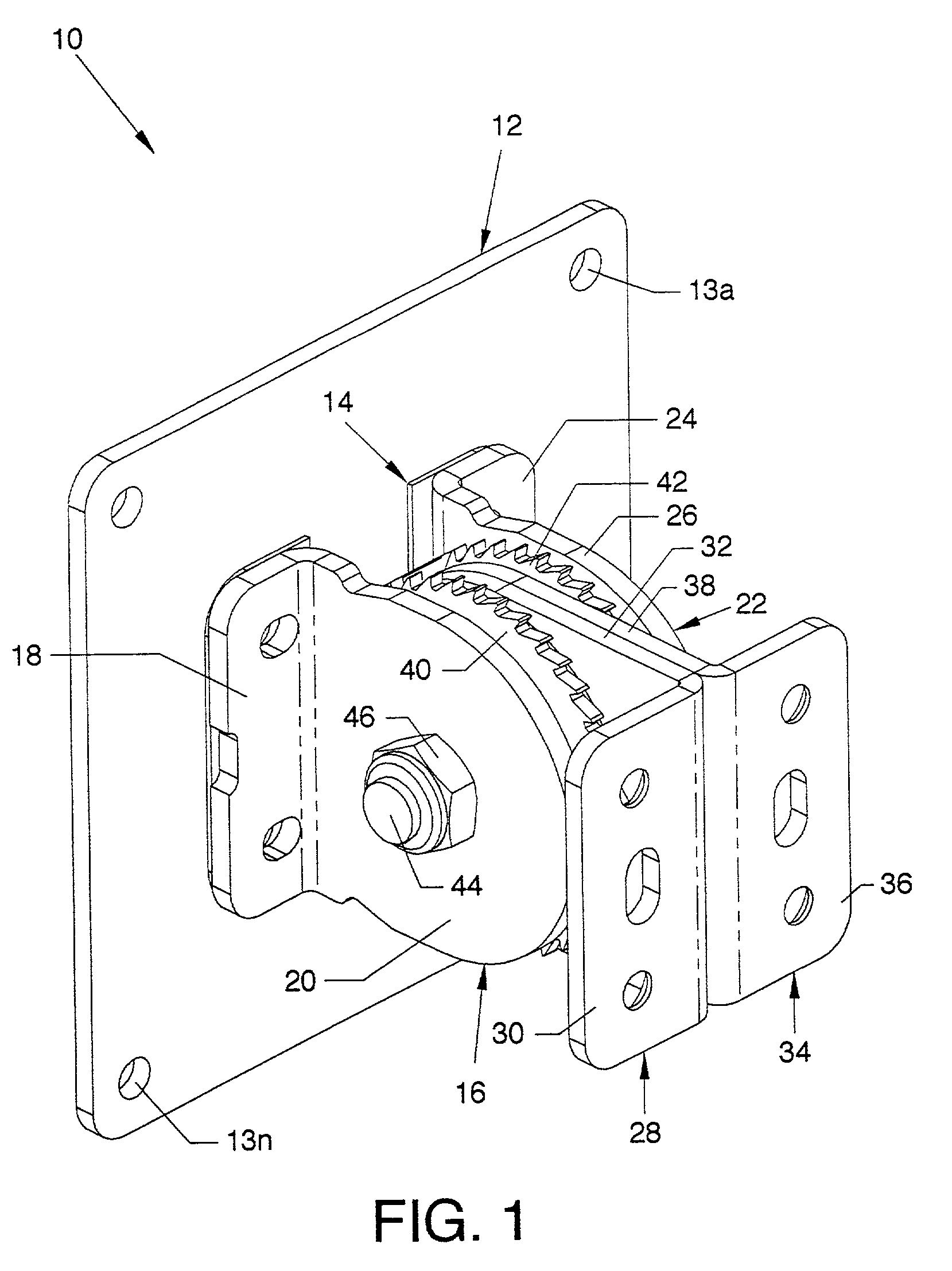

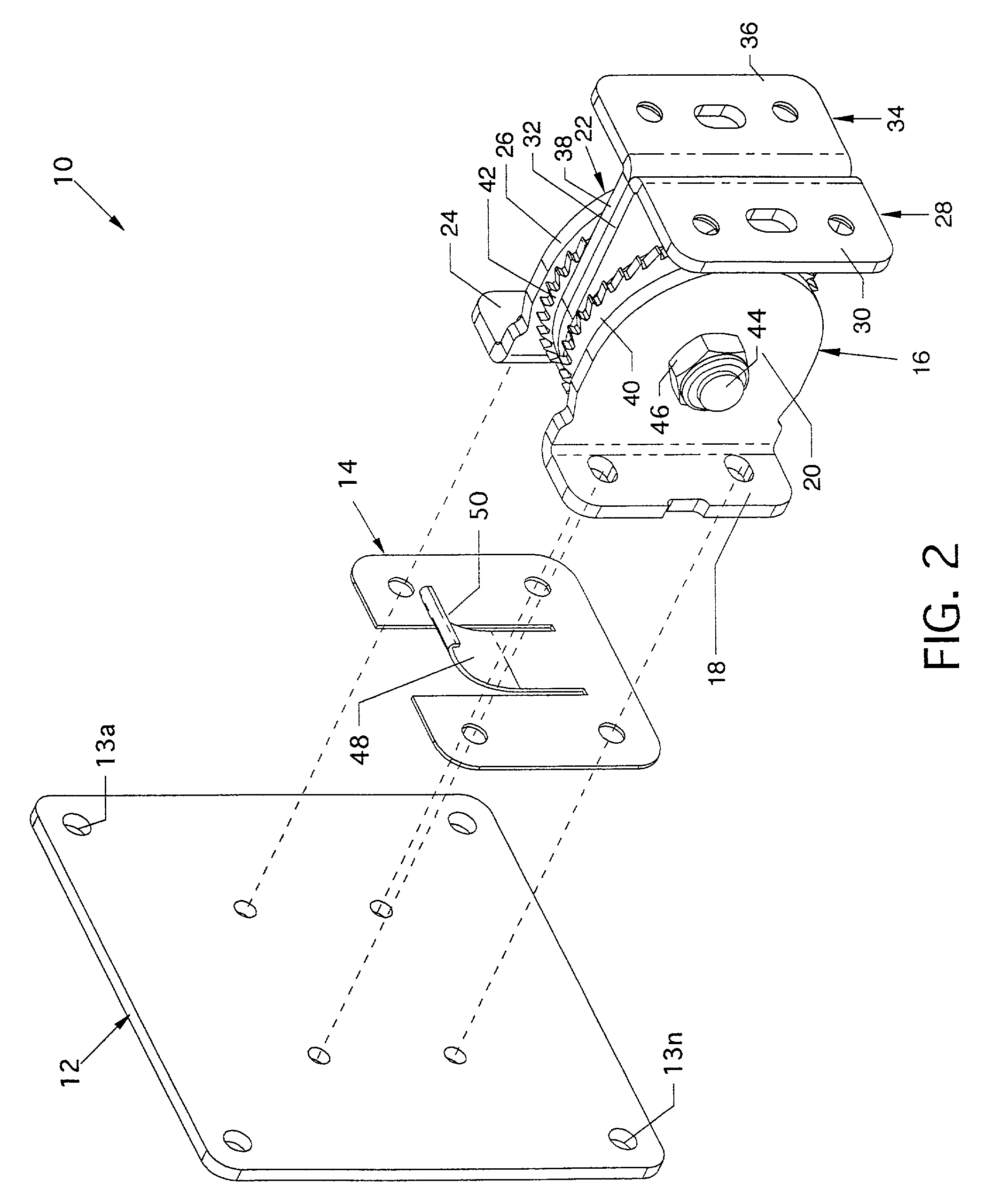

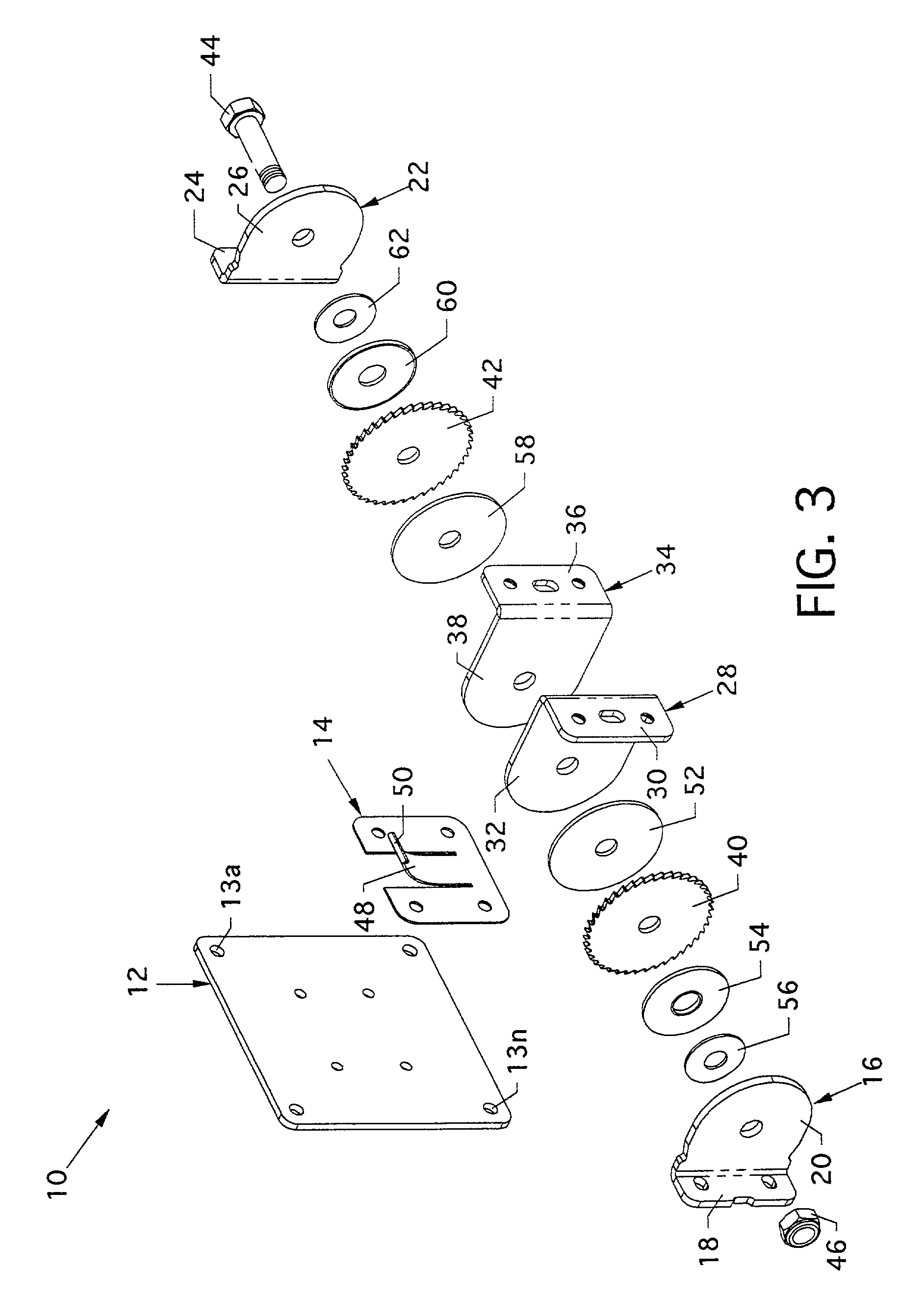

Ratcheted pivot

InactiveUS20010050327A1Reduces effort and forceEasy to operateStands/trestlesKitchen equipmentRatchetClassical mechanics

Ratcheted pivot incorporating large and small areas of frictional contact and a ratcheting mechanism to provide for rotational repositioning of a mounting plate and a load about a horizontal axis.

Owner:ERGOTRON

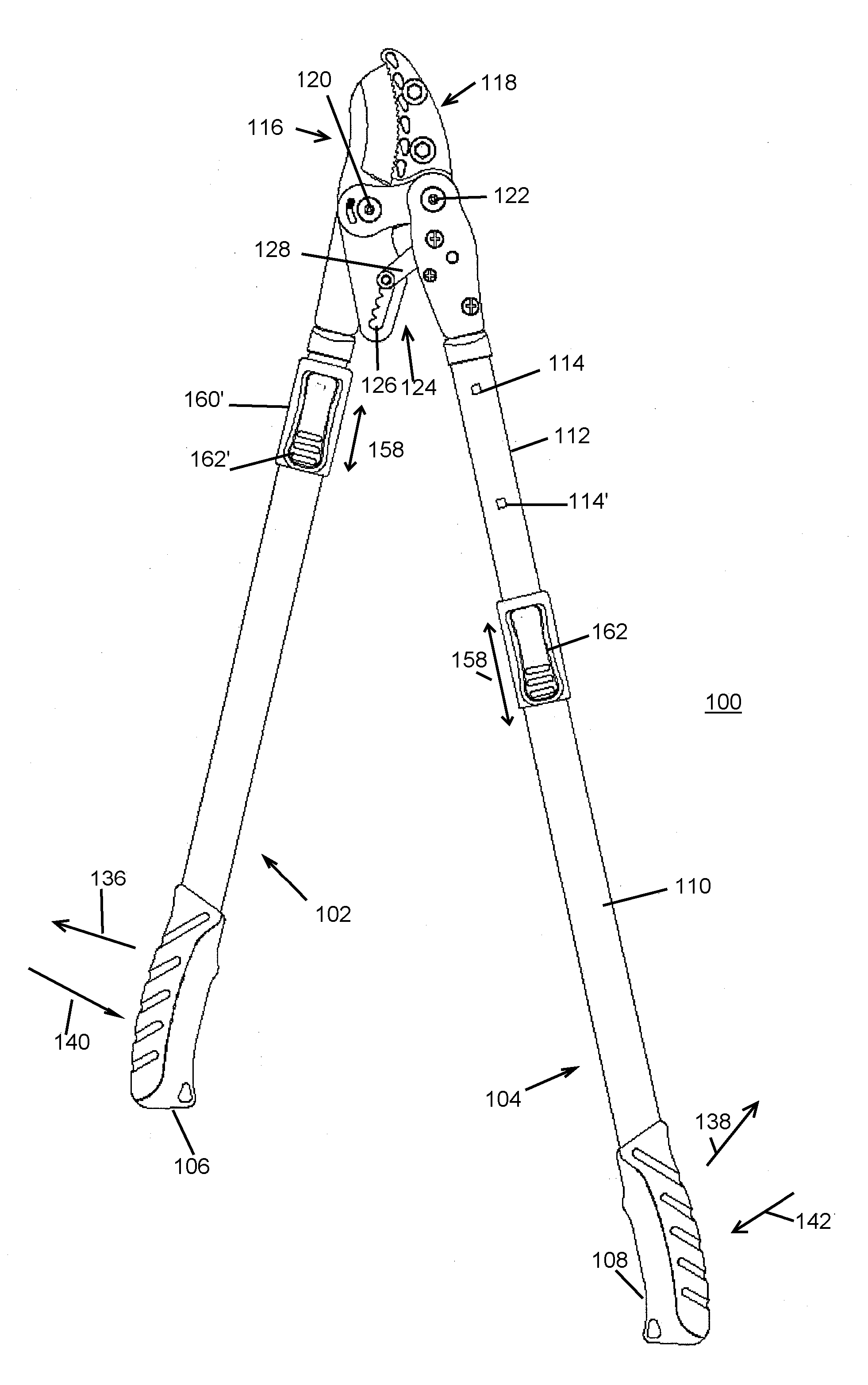

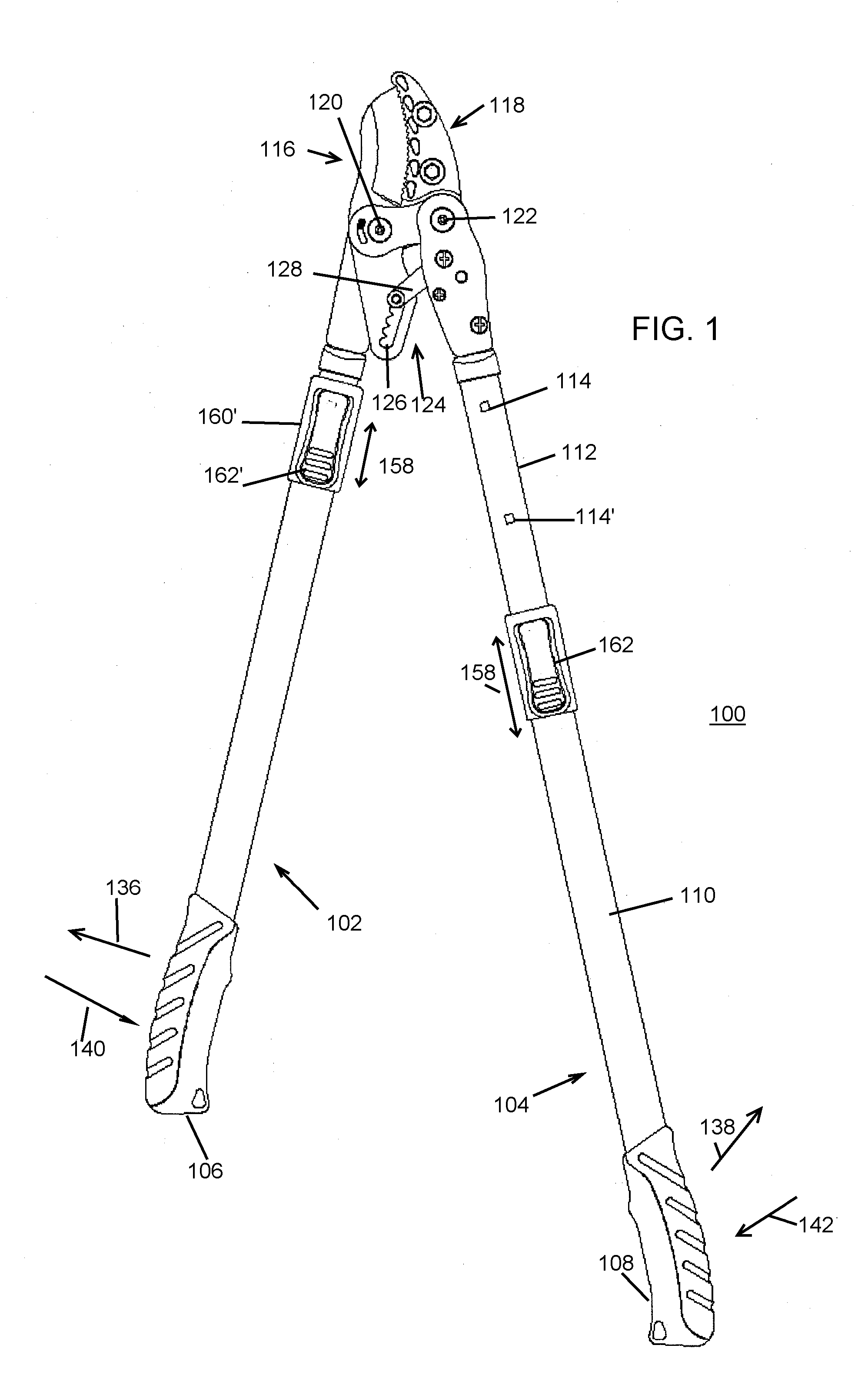

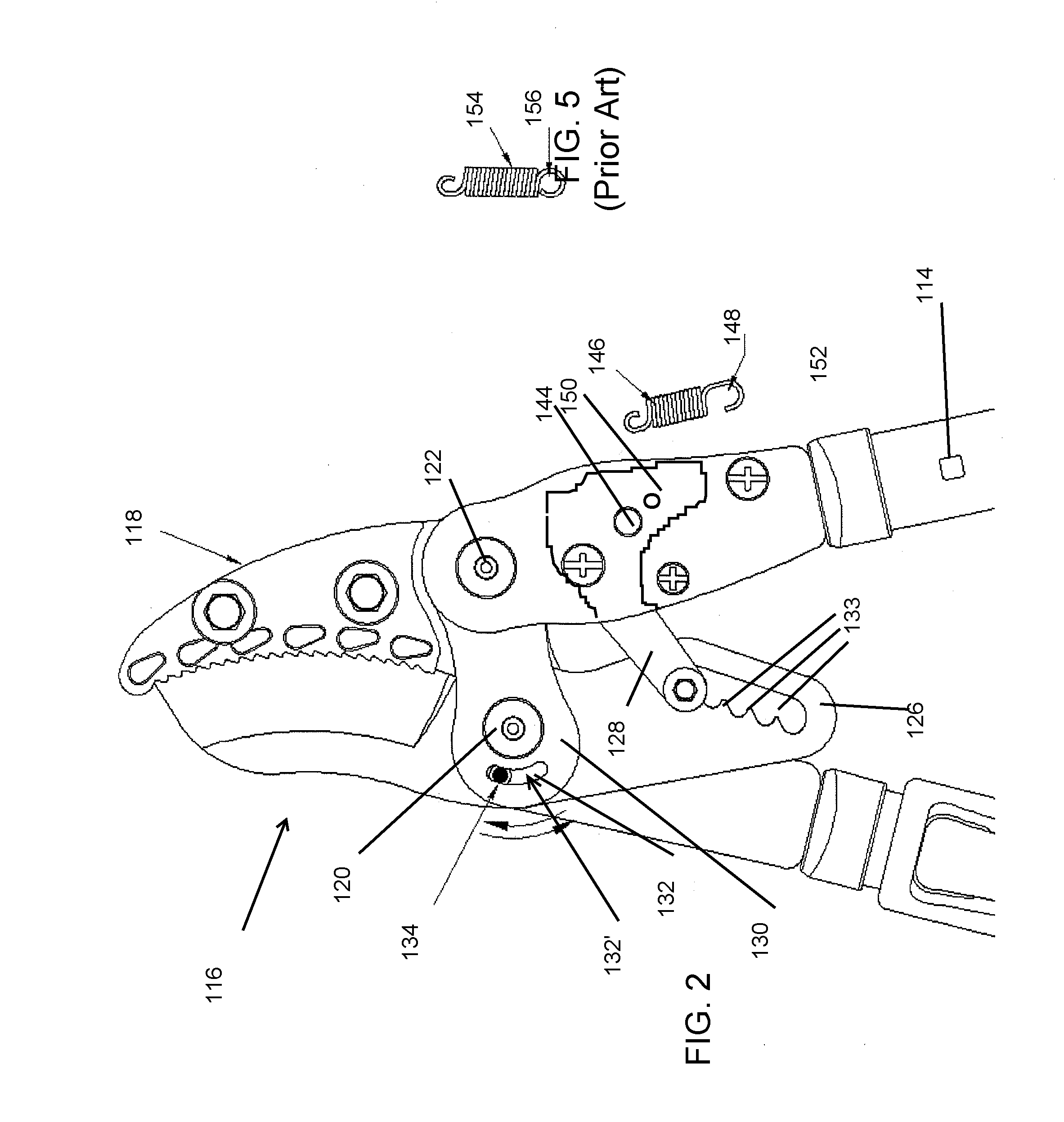

Ratchet pruner with dual pivot lubrication bolts

InactiveUS20070079512A1Reduce frictionEffectively lubricate the pivoting membersCuttersCutting implementsScrew threadKnife blades

A pruner employs dual lubricating fasteners as pivots. Each pivot has a head, and a shank which is provided with a lubricant cell and plural channels. The lubricant cell is in communication with the exterior of the shank area, the channels enabling the lubricant contained in the lubricant cell to lubricant the two blades. The lubricant cell includes a depressed oiling region for containing oil therein during re-lubrication. The shank has outer threads to mesh with inner threads of the nut. An anvil portion is provided in a material less likely to dull the blade portion. Extensible handles are providing, having lock member with square or rectangular lock iron for improved operation. A ratchet spring configuration provides ease of replacement of the spring.

Owner:BARNEL INT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com