Patents

Literature

730 results about "Casing string" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In drilling technology, casing string is a long section of connected oilfield pipe that is lowered into a wellbore and cemented.

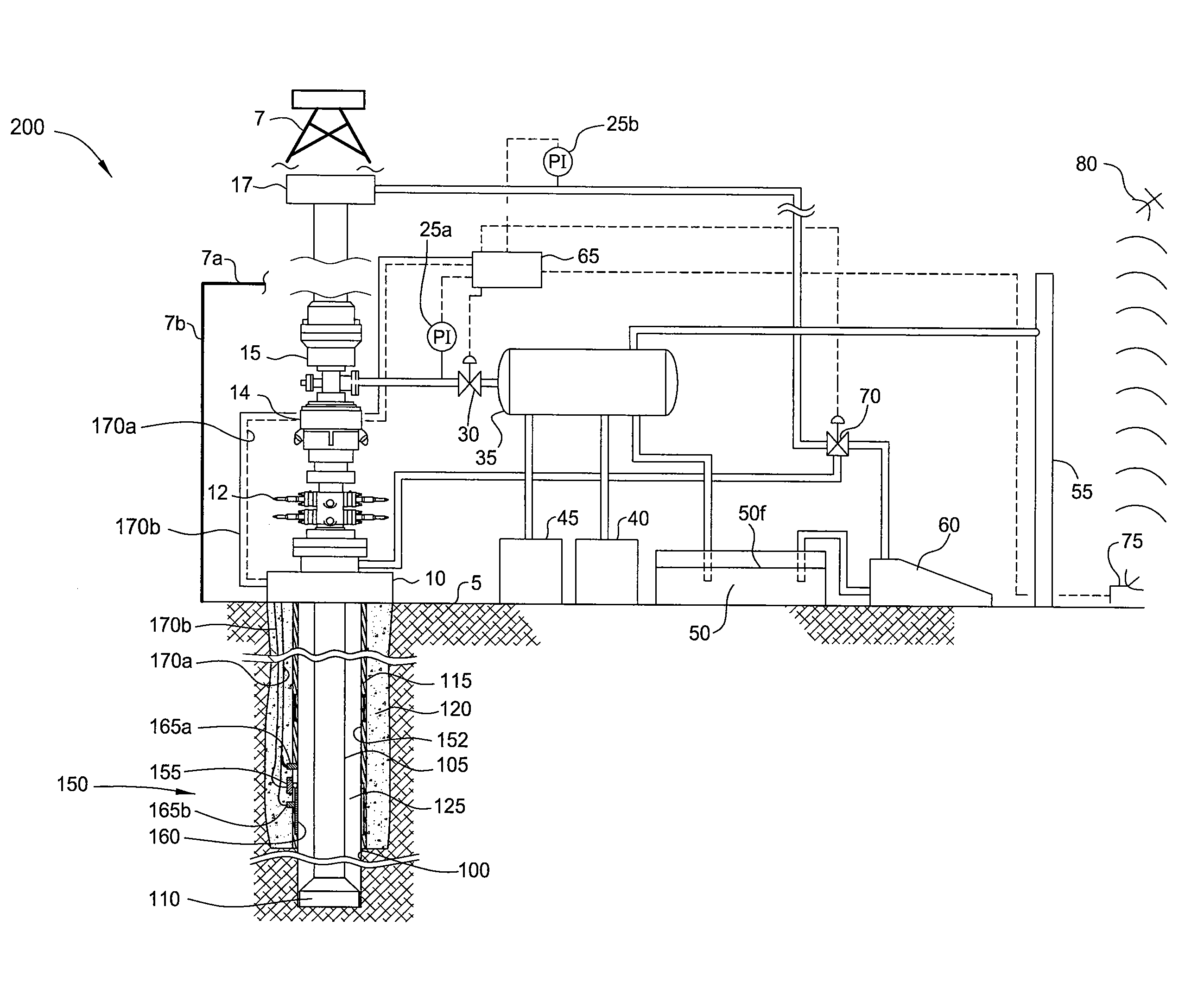

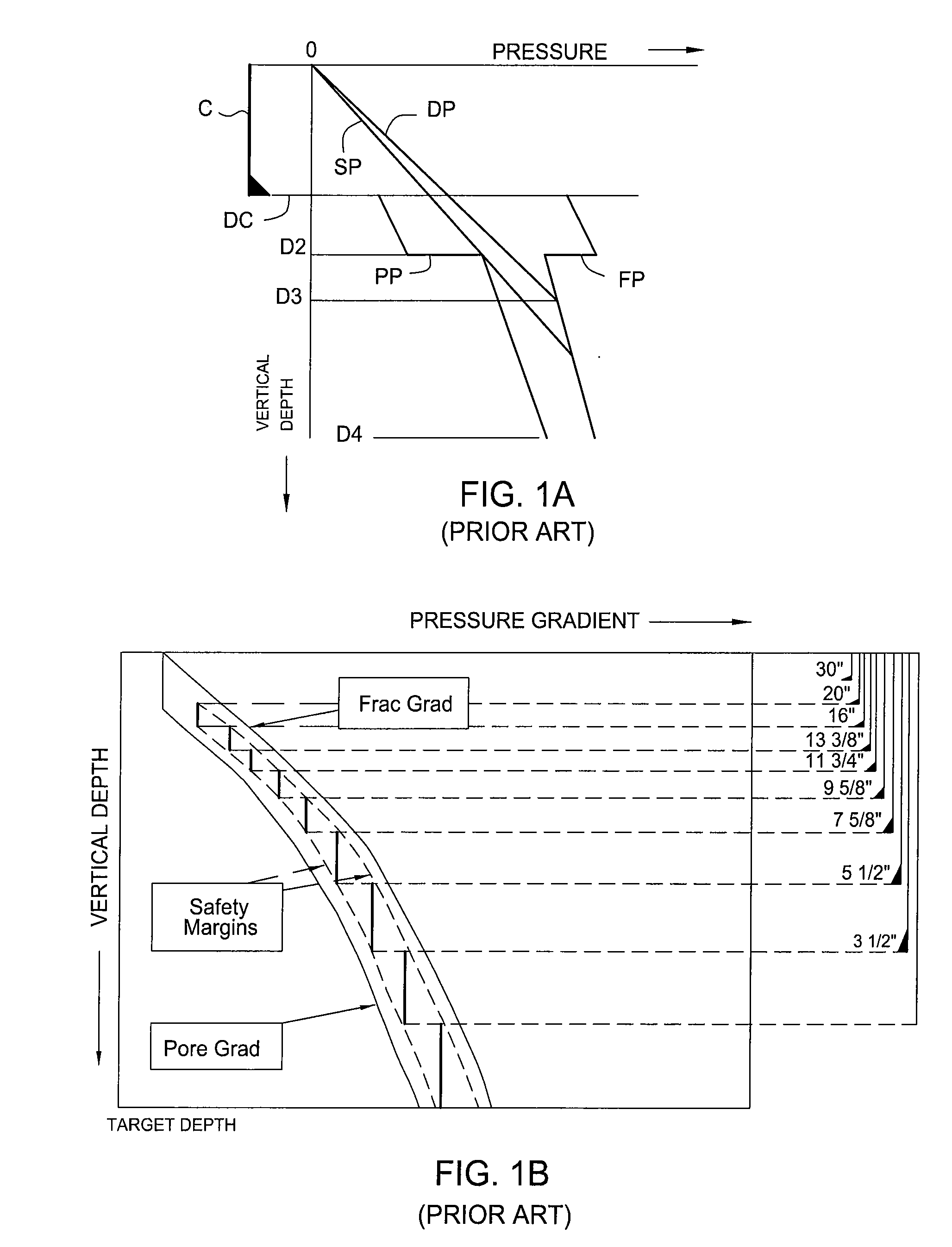

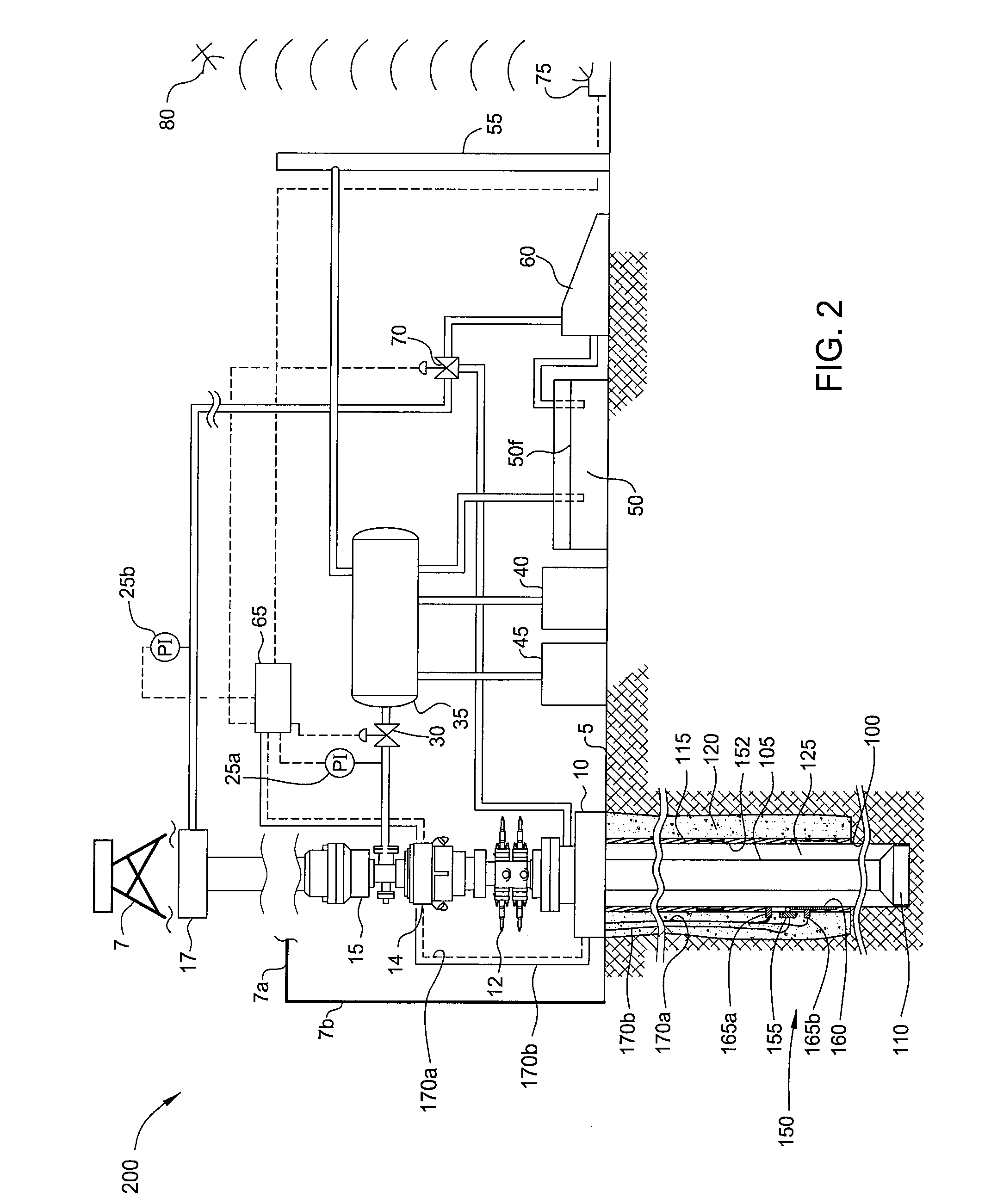

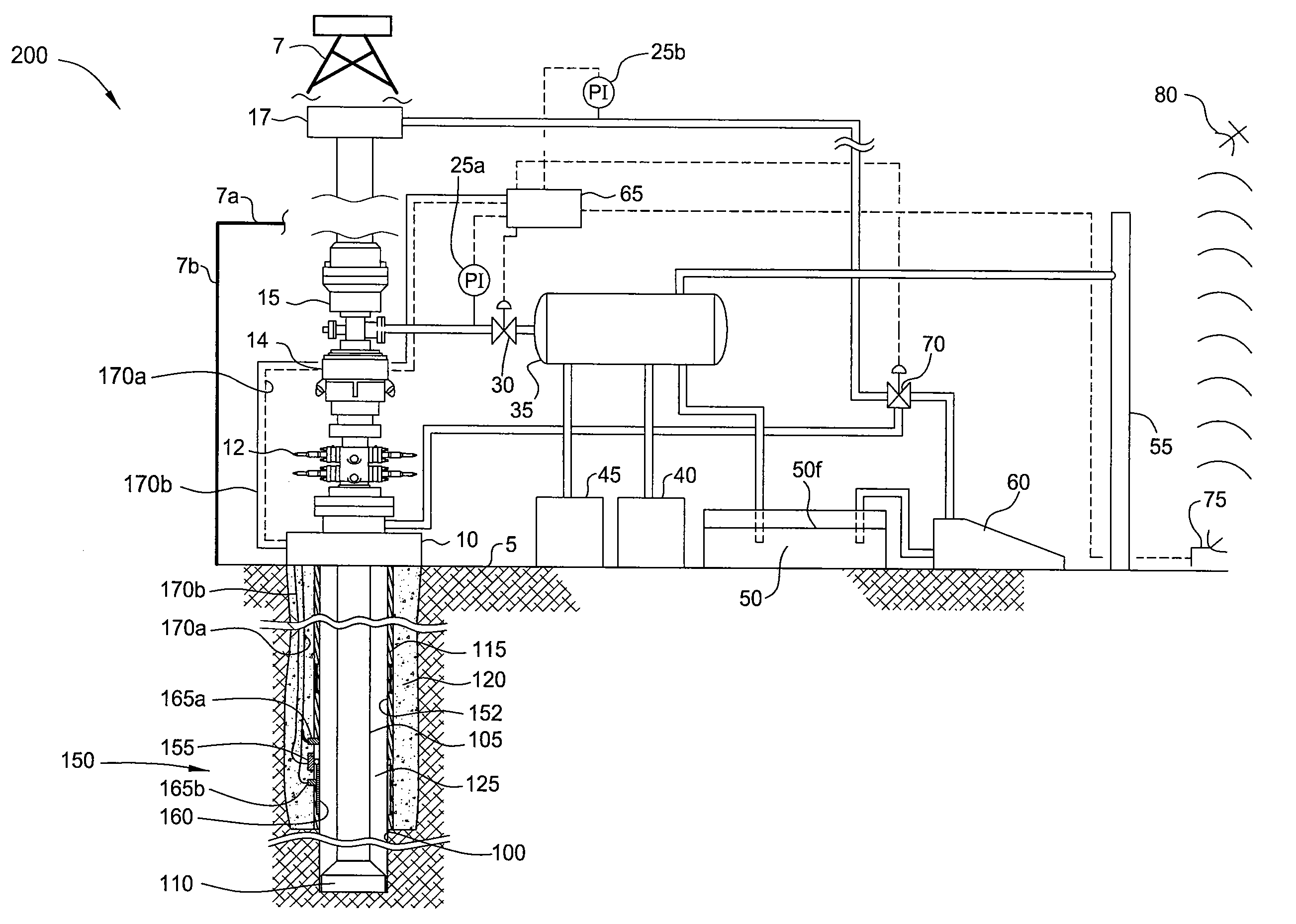

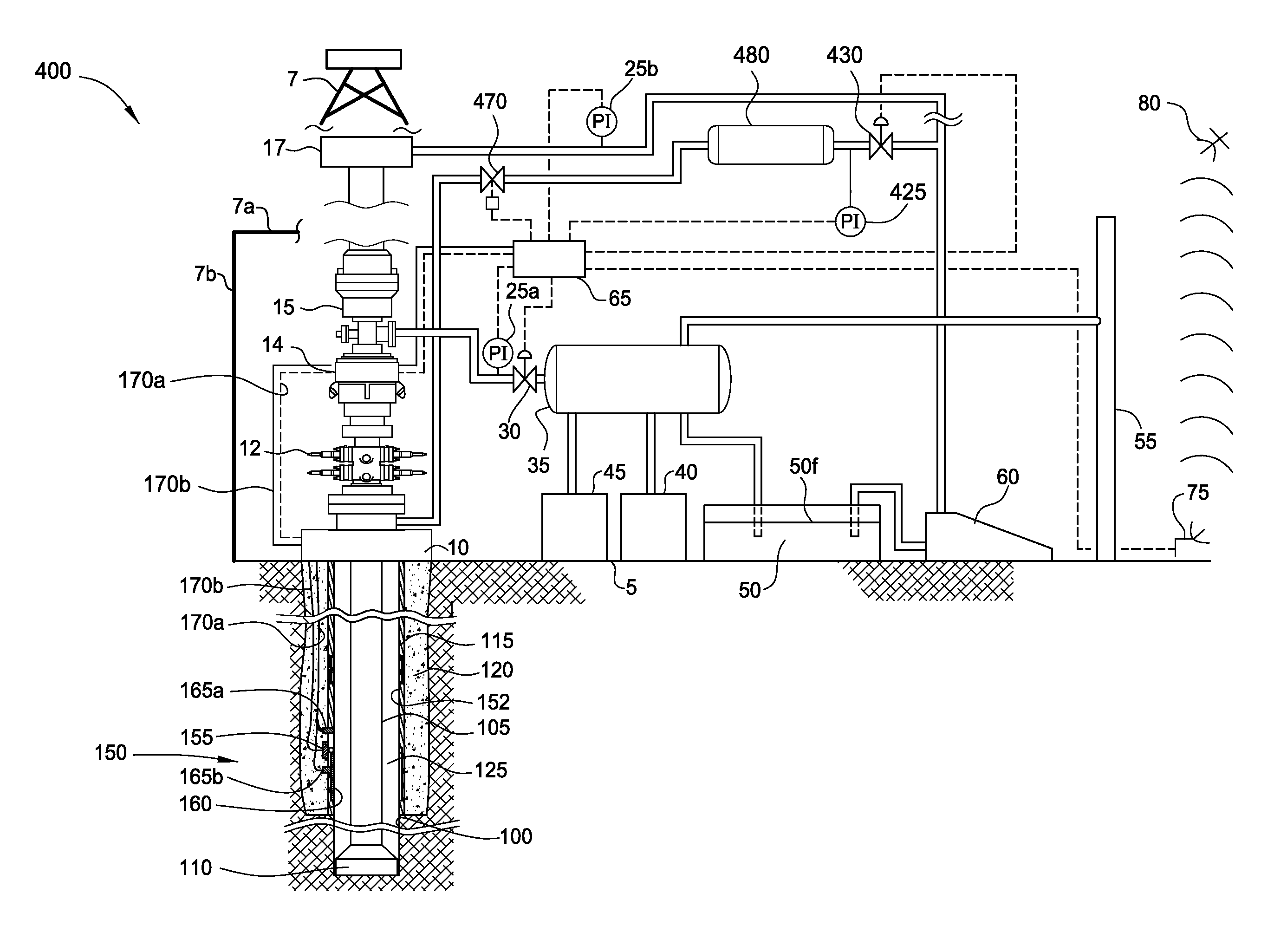

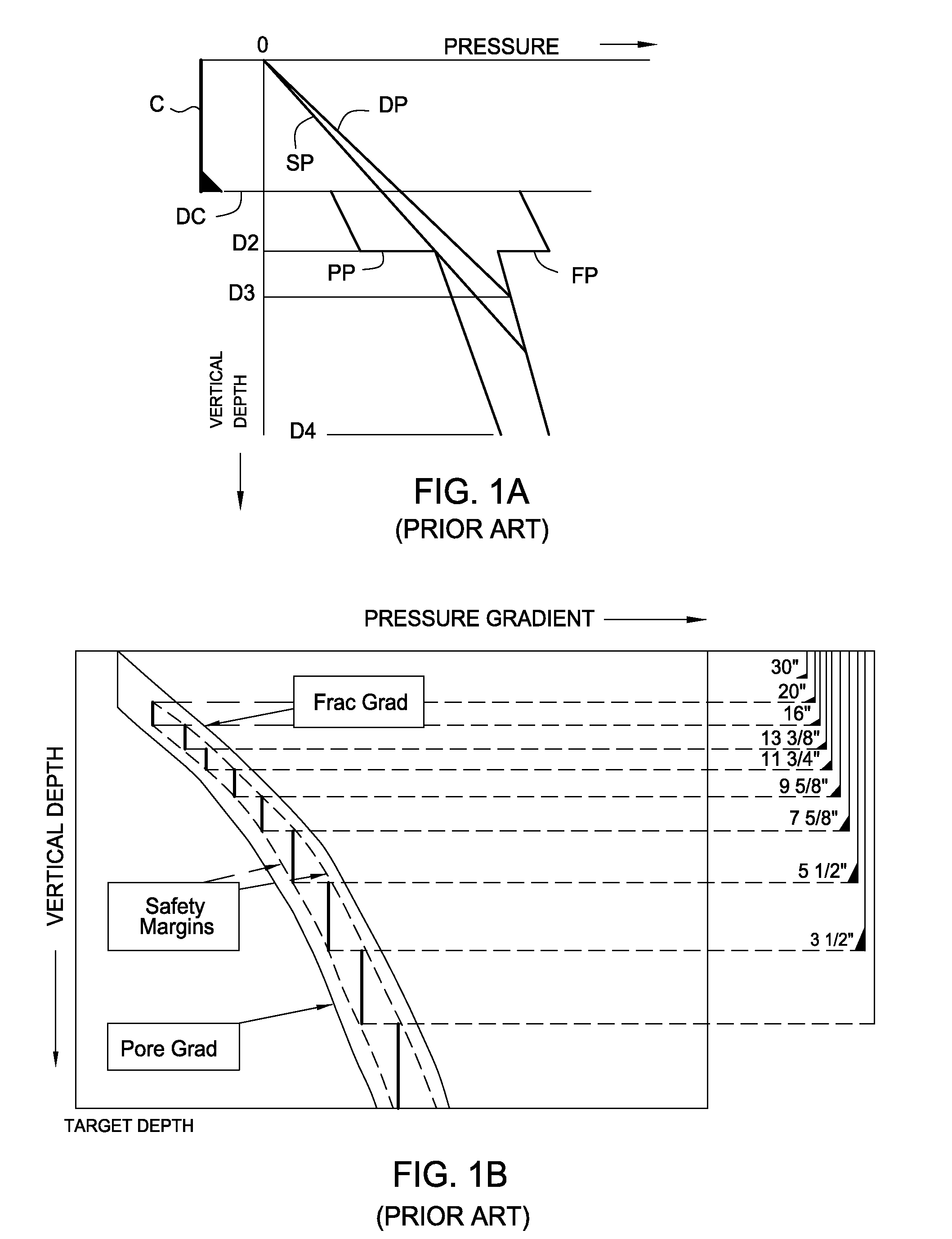

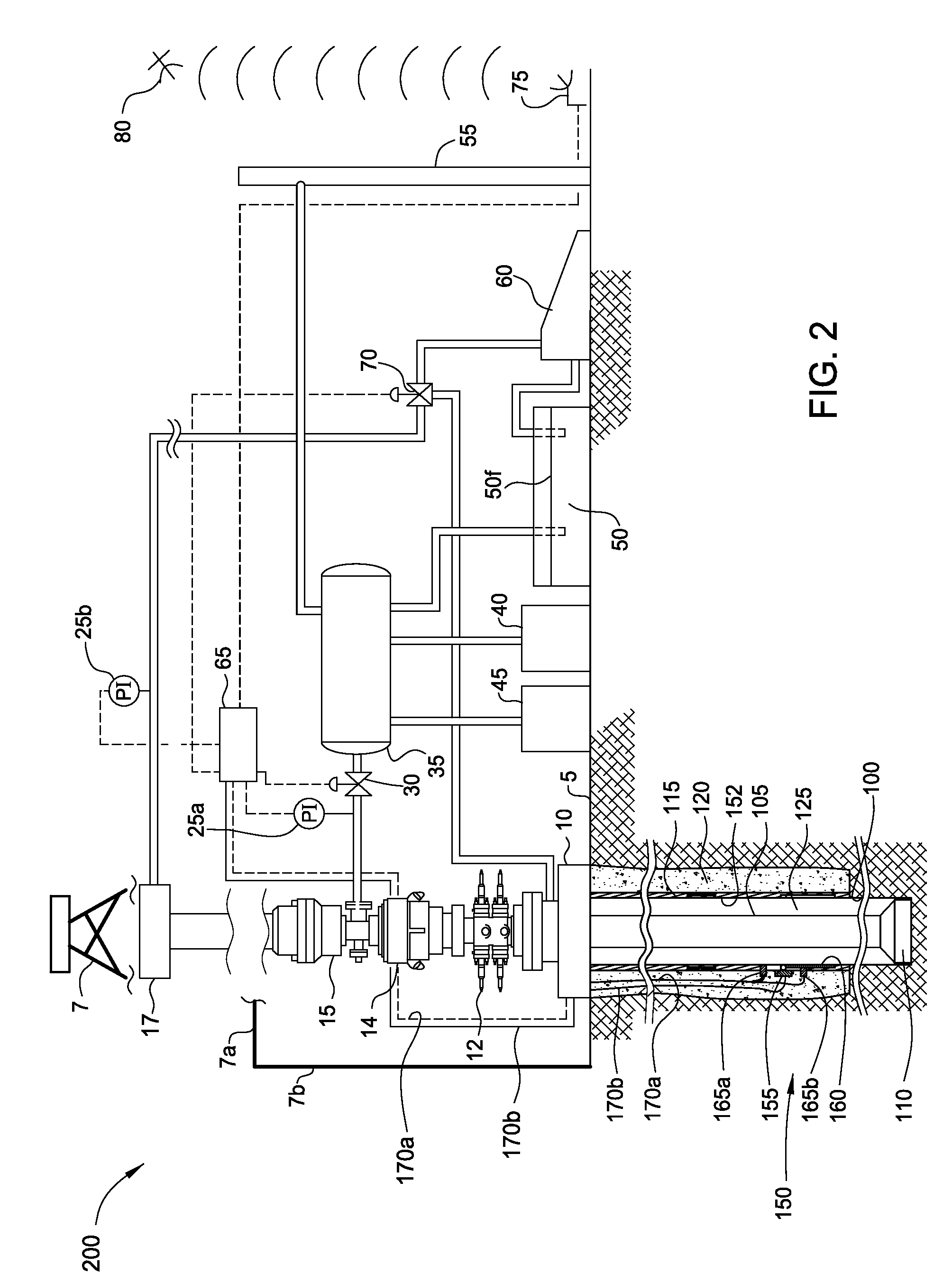

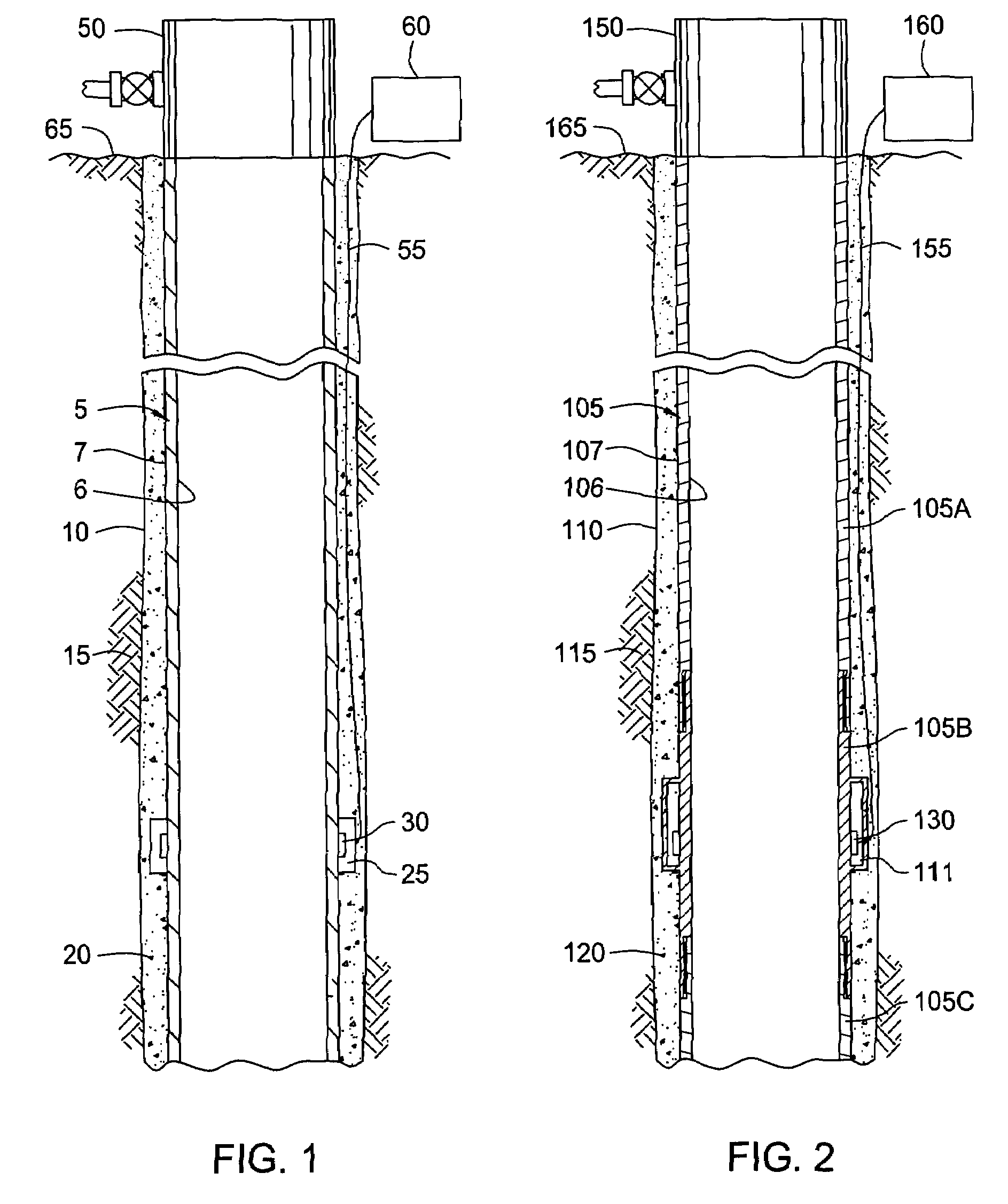

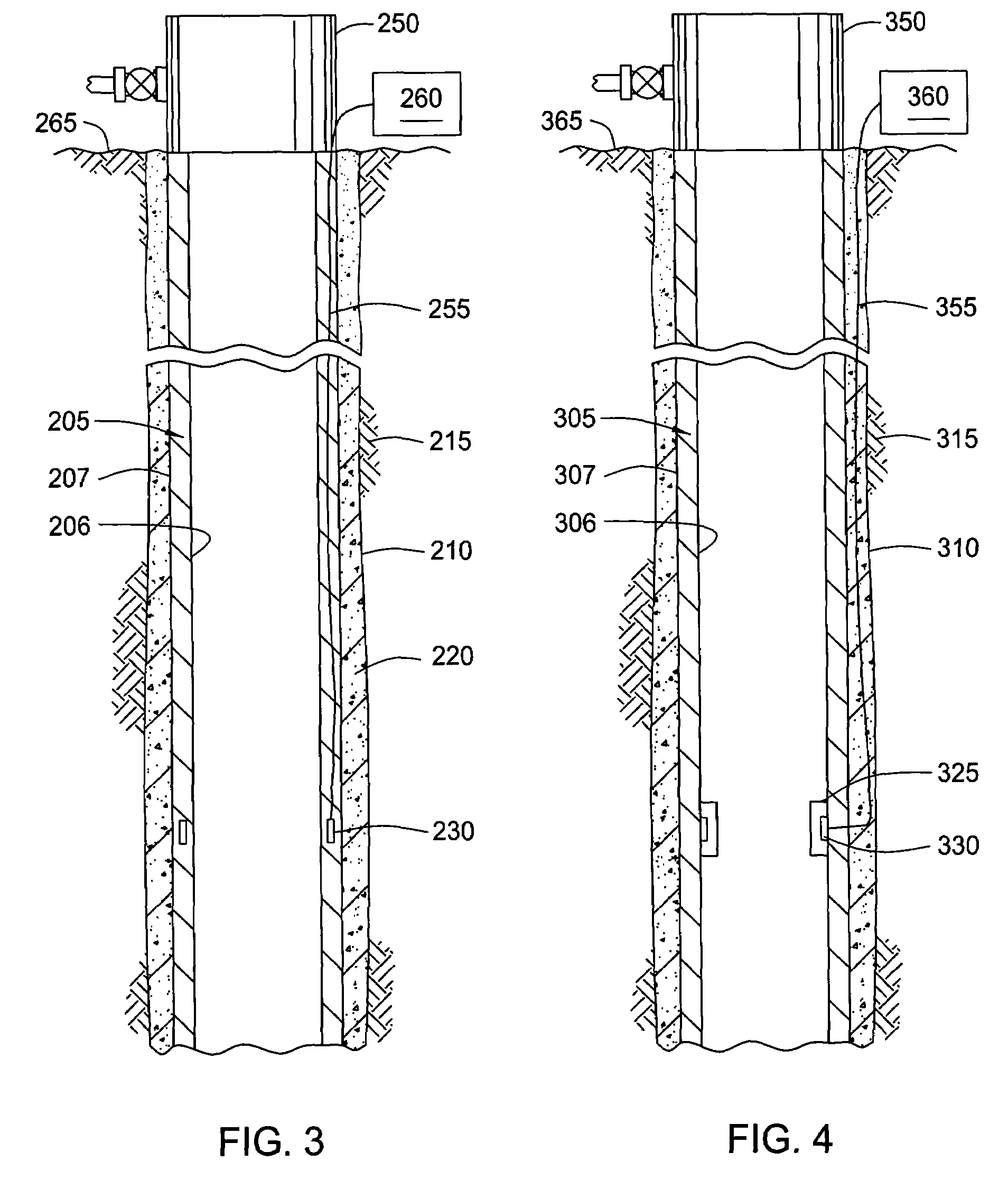

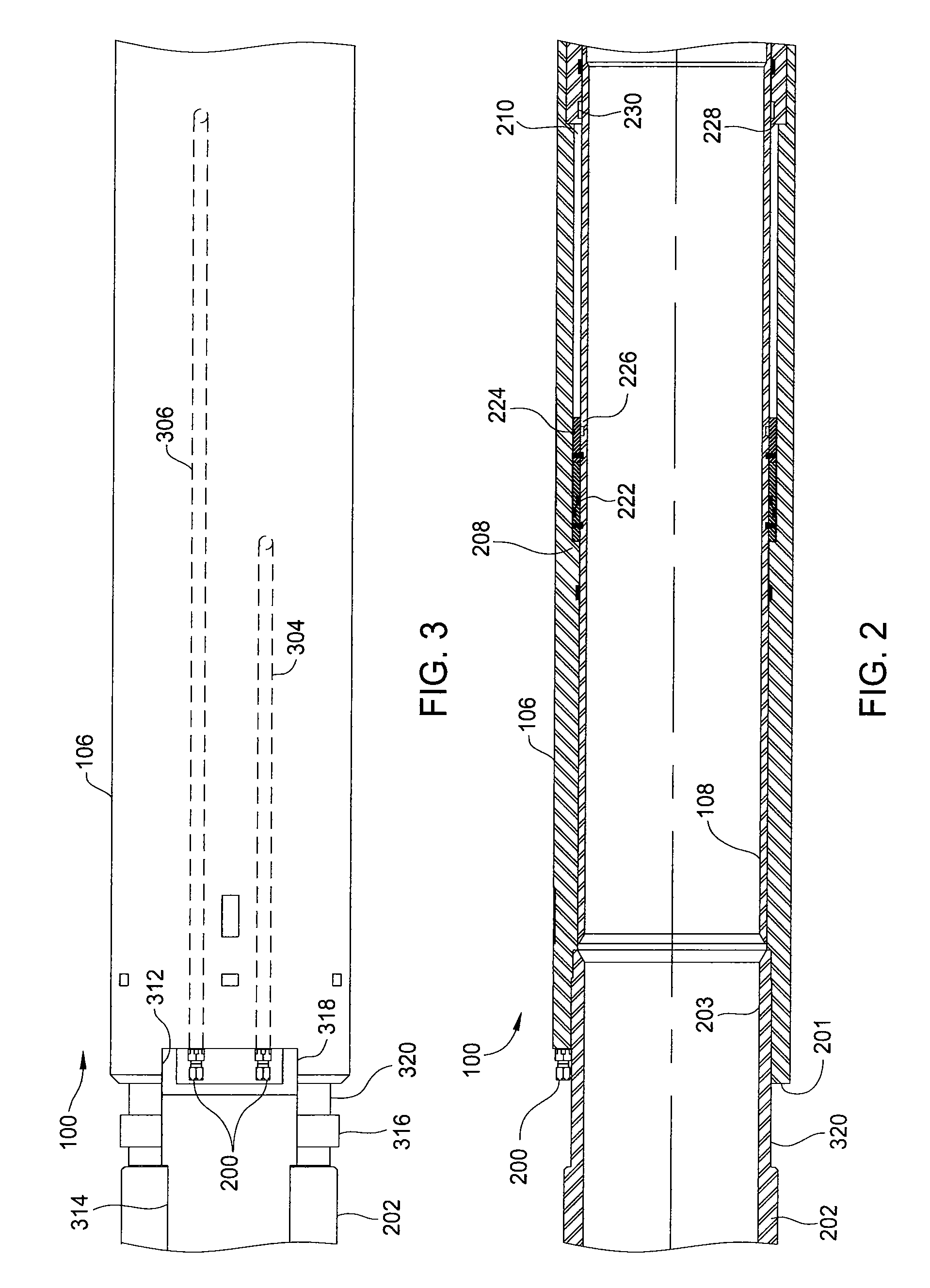

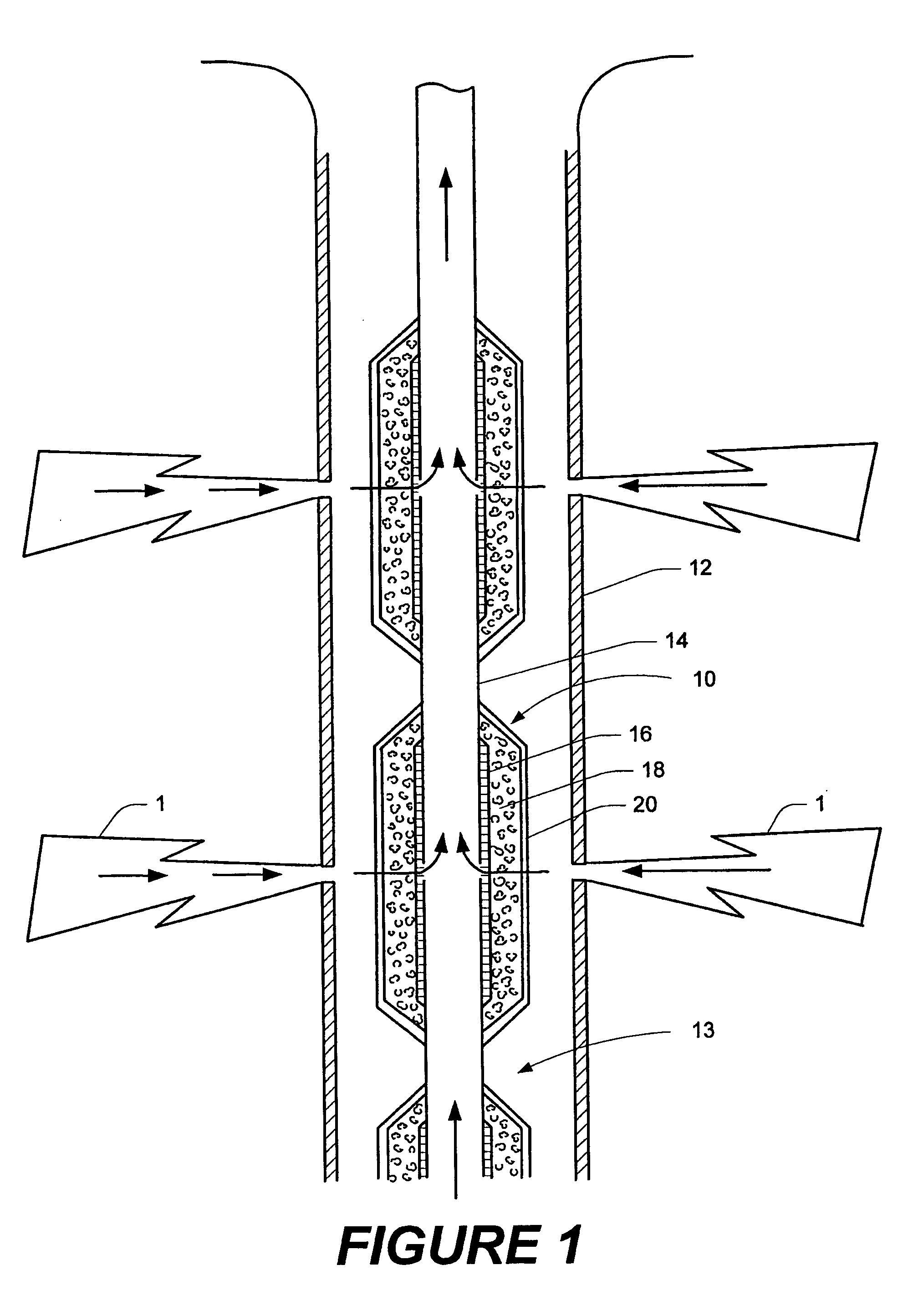

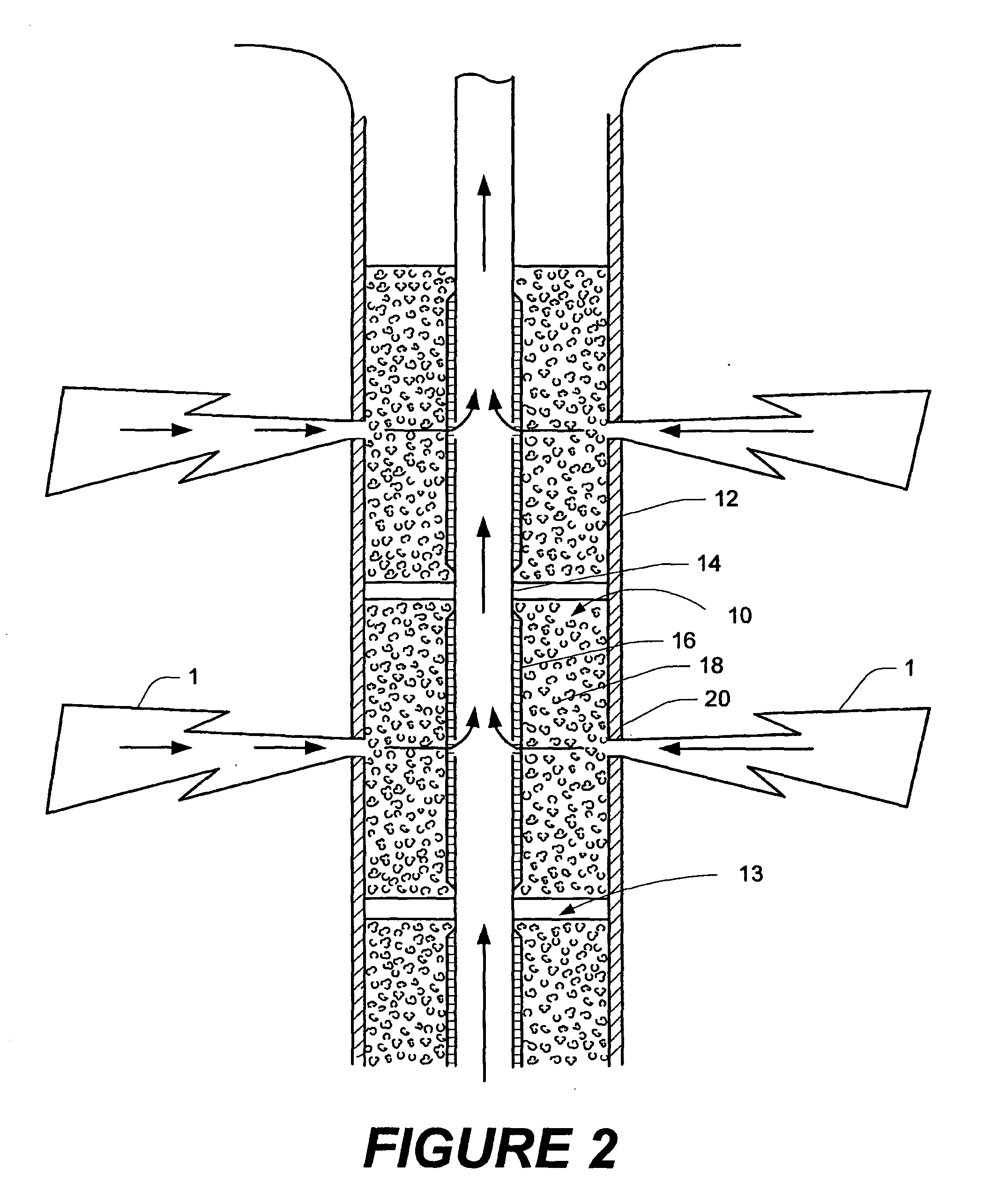

Annulus pressure control drilling systems and methods

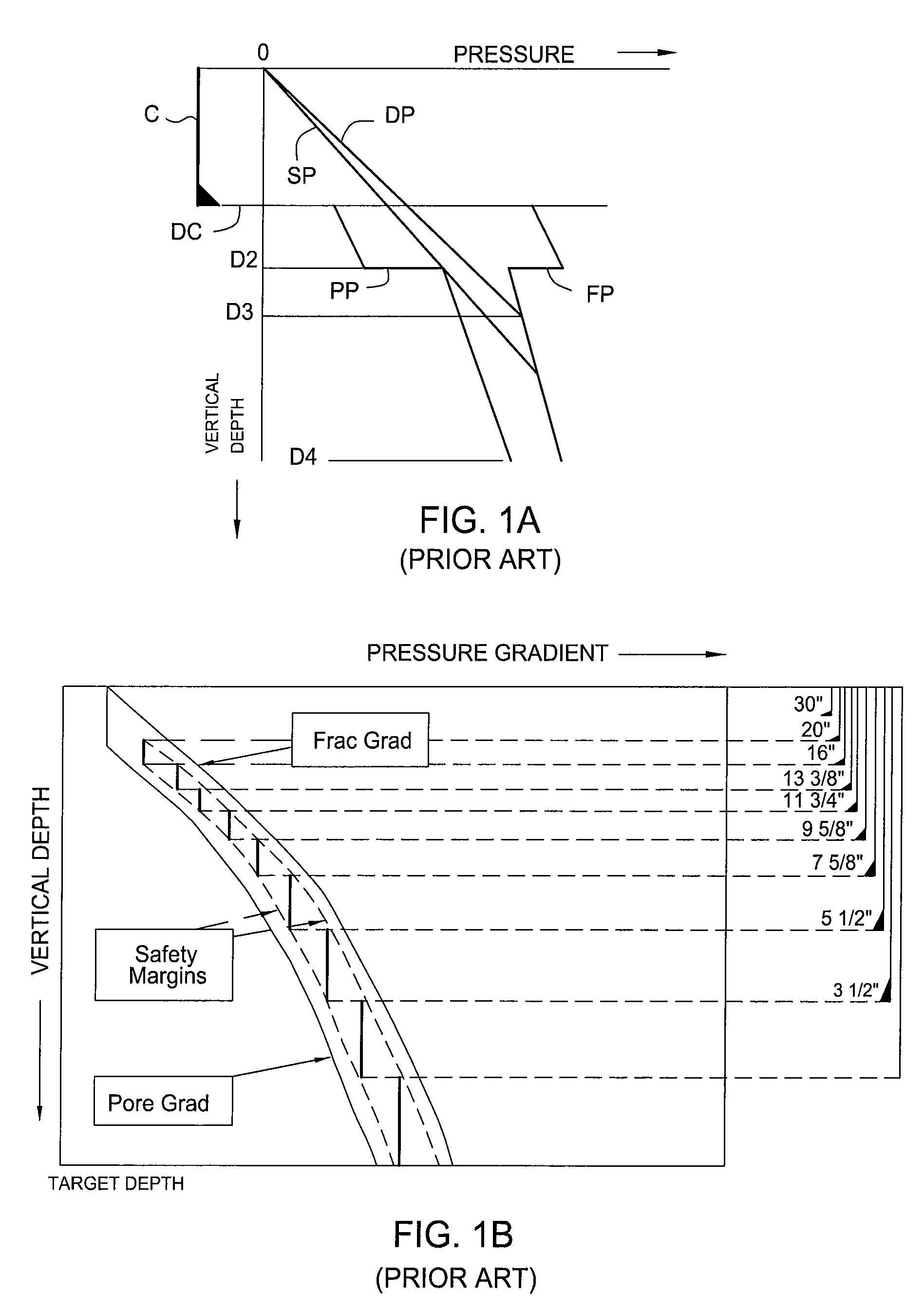

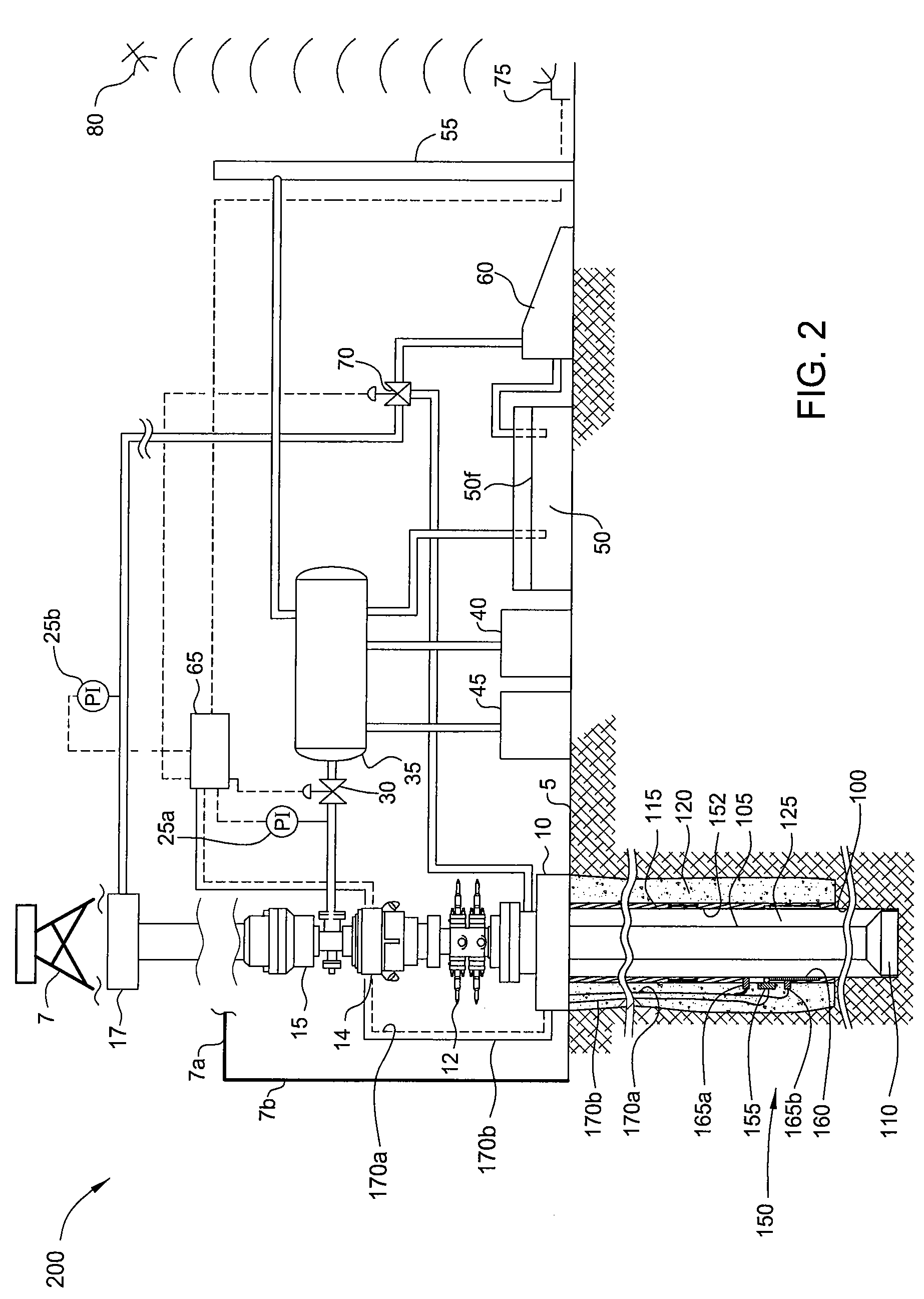

In one embodiment, a method for drilling a wellbore includes an act of drilling the wellbore by injecting drilling fluid through a tubular string disposed in the wellbore, the tubular string comprising a drill bit disposed on a bottom thereof. The drilling fluid exits the drill bit and carries cuttings from the drill bit. The drilling fluid and cuttings (returns) flow to a surface of the wellbore via an annulus defined by an outer surface of the tubular string and an inner surface of the wellbore. The method further includes an act performed while drilling the wellbore of measuring a first annulus pressure (FAP) using a pressure sensor attached to a casing string hung from a wellhead of the wellbore. The method further includes an act performed while drilling the wellbore of controlling a second annulus pressure (SAP) exerted on a formation exposed to the annulus.

Owner:WEATHERFORD TECH HLDG LLC

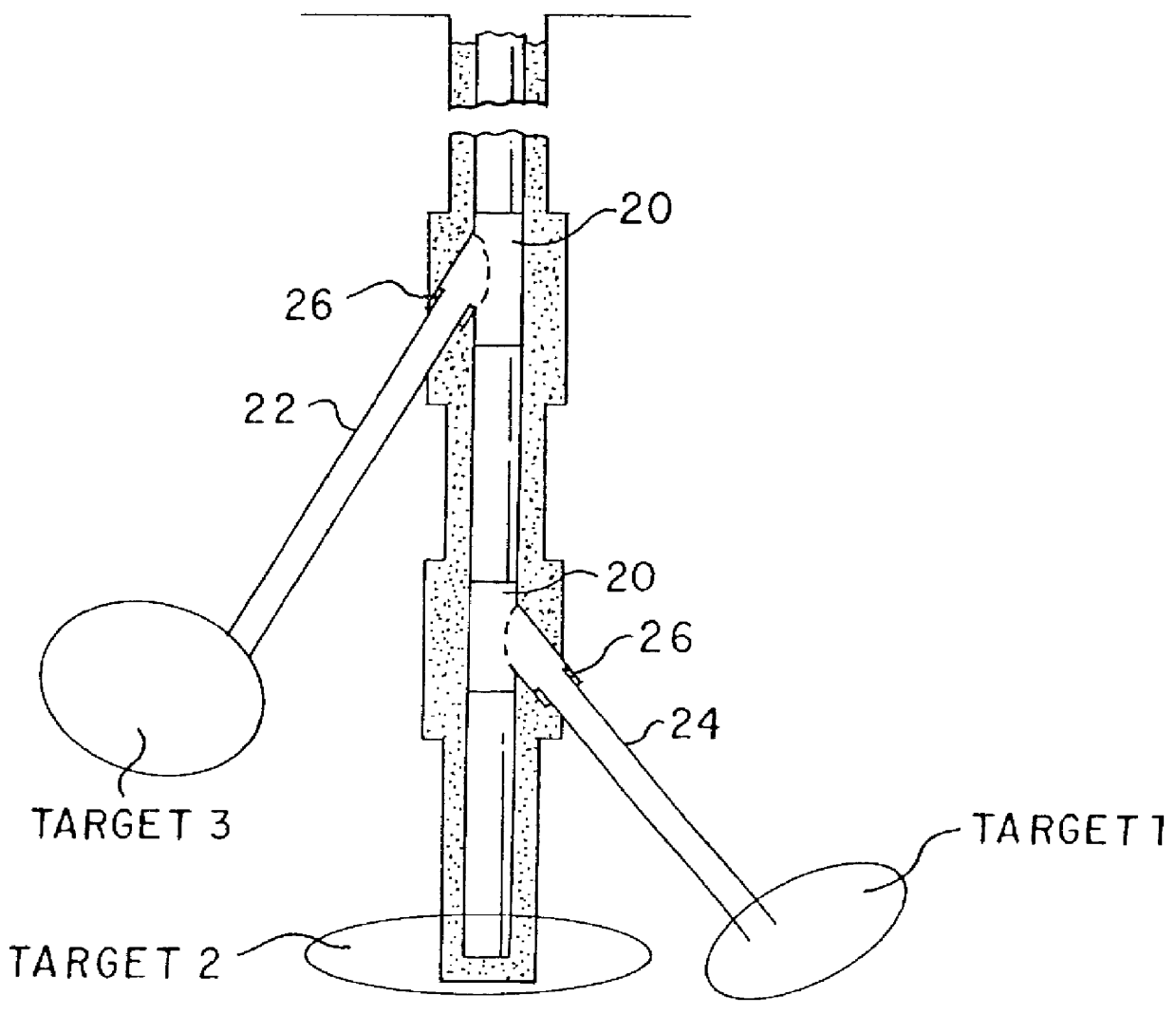

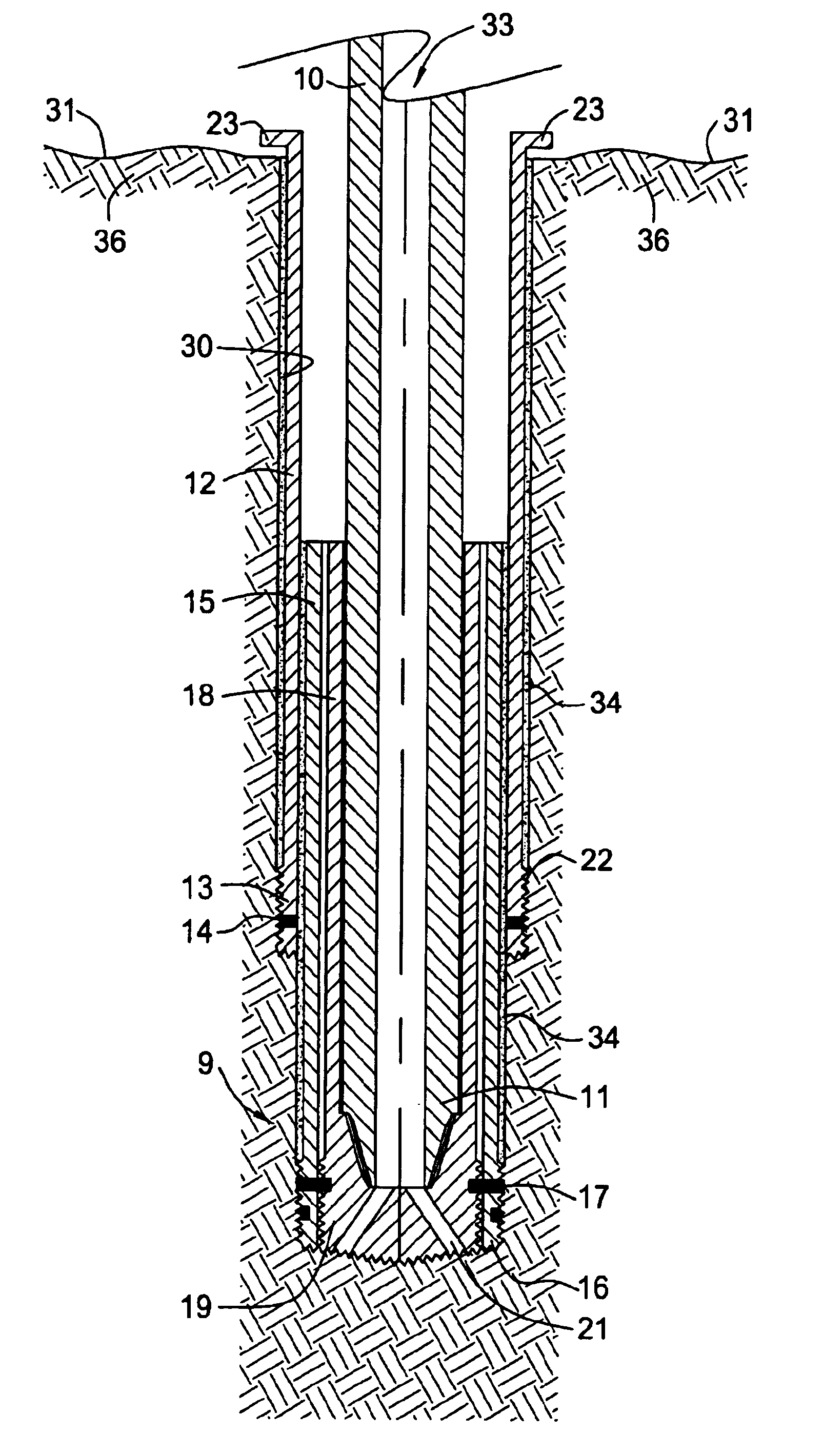

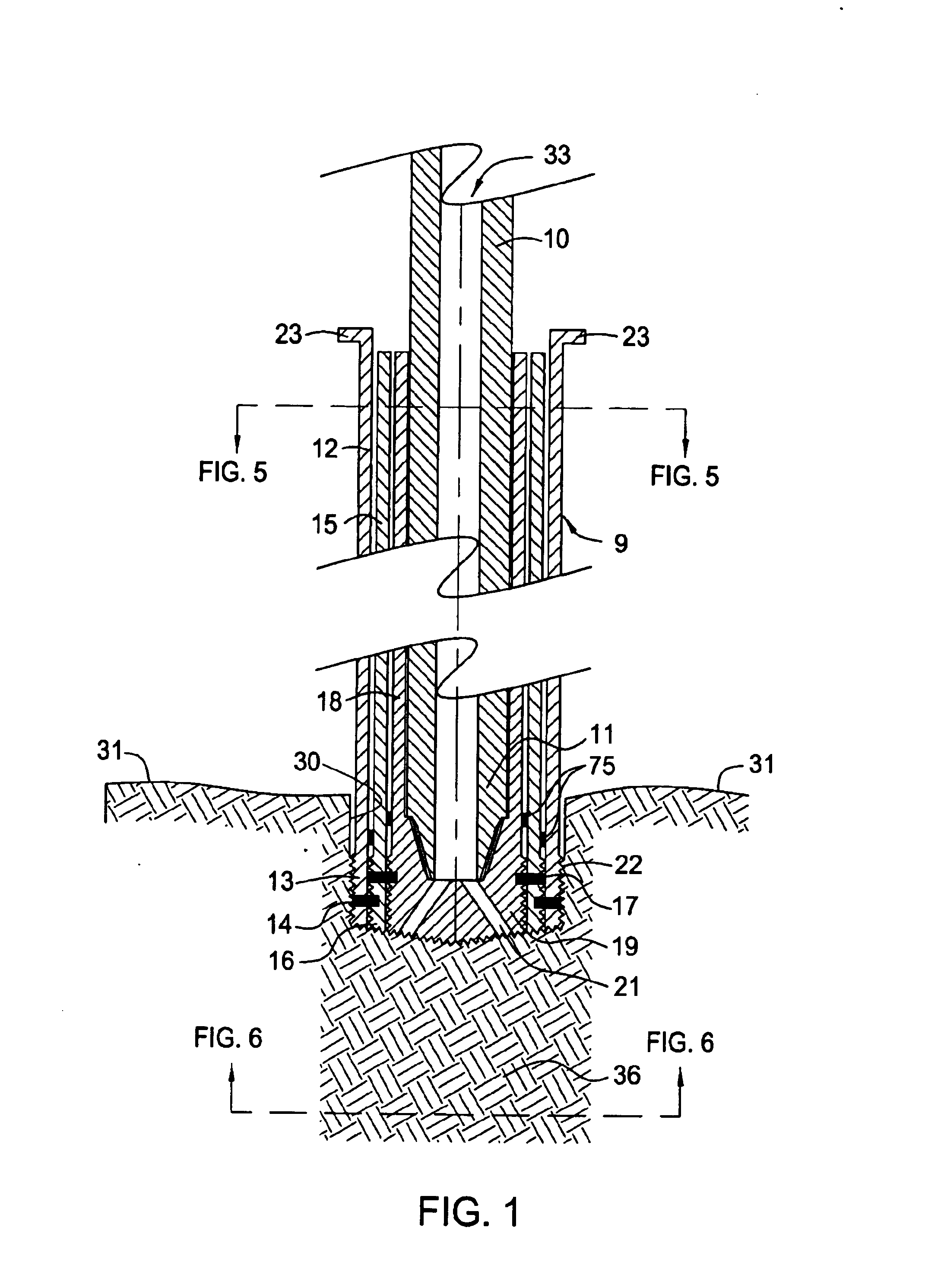

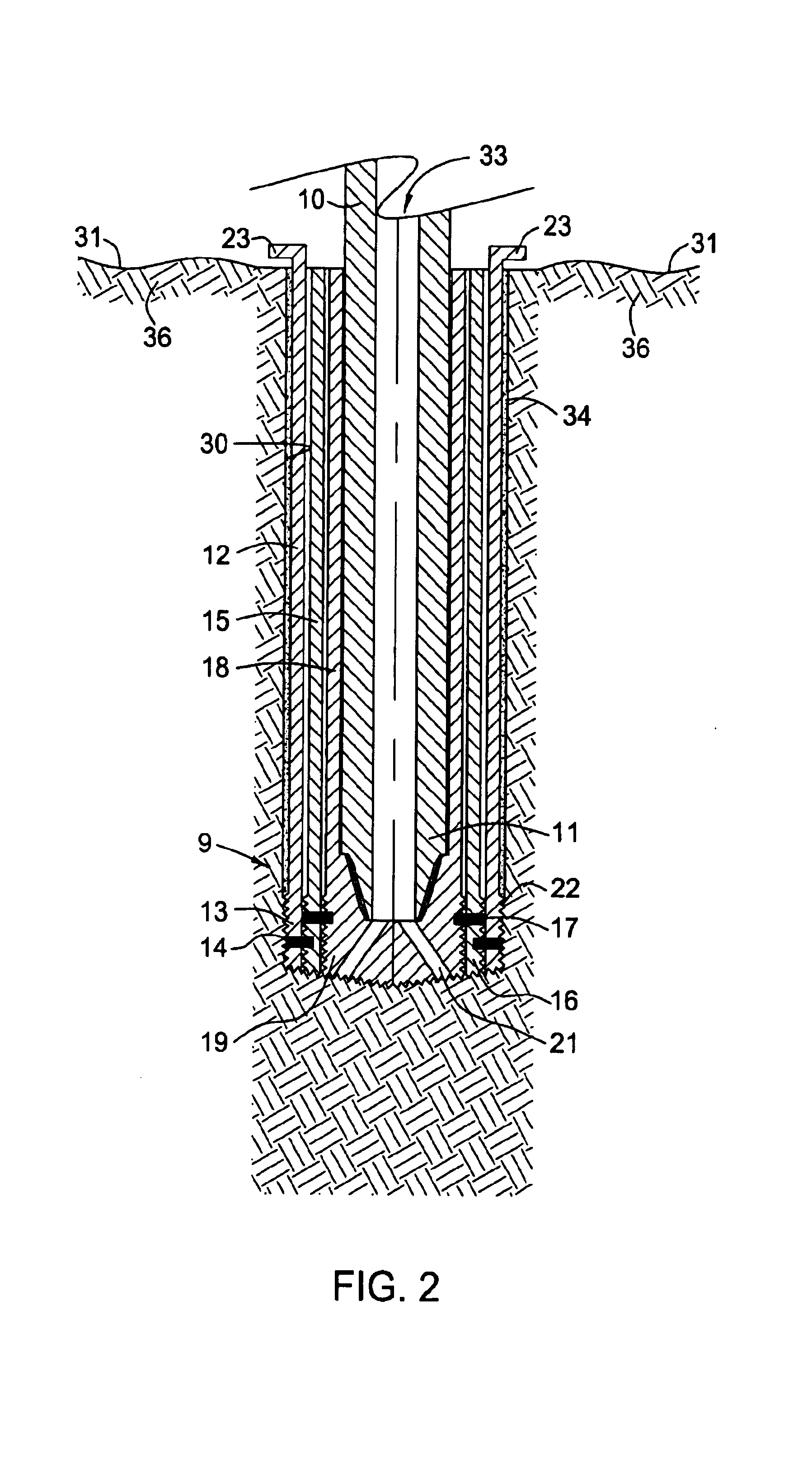

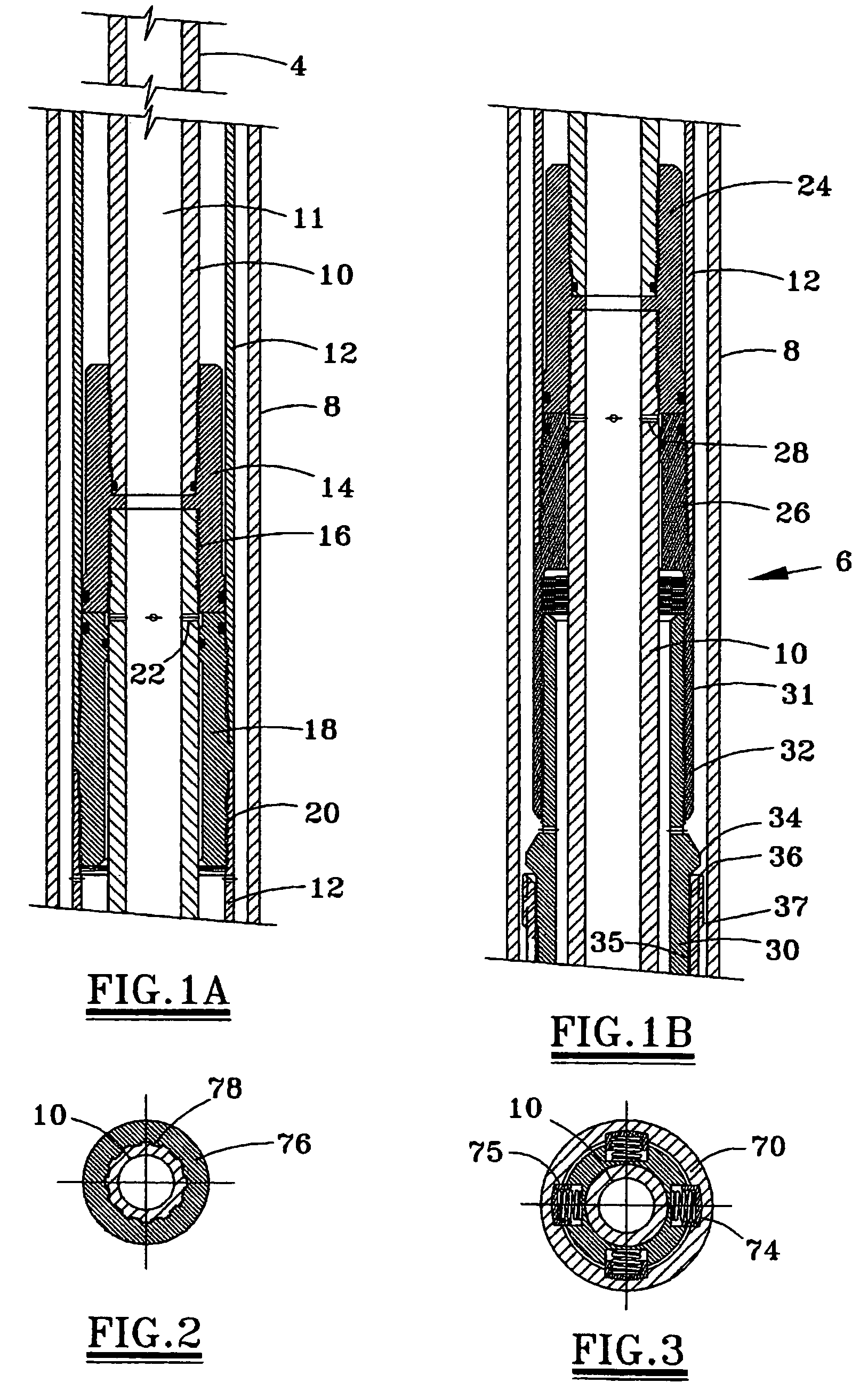

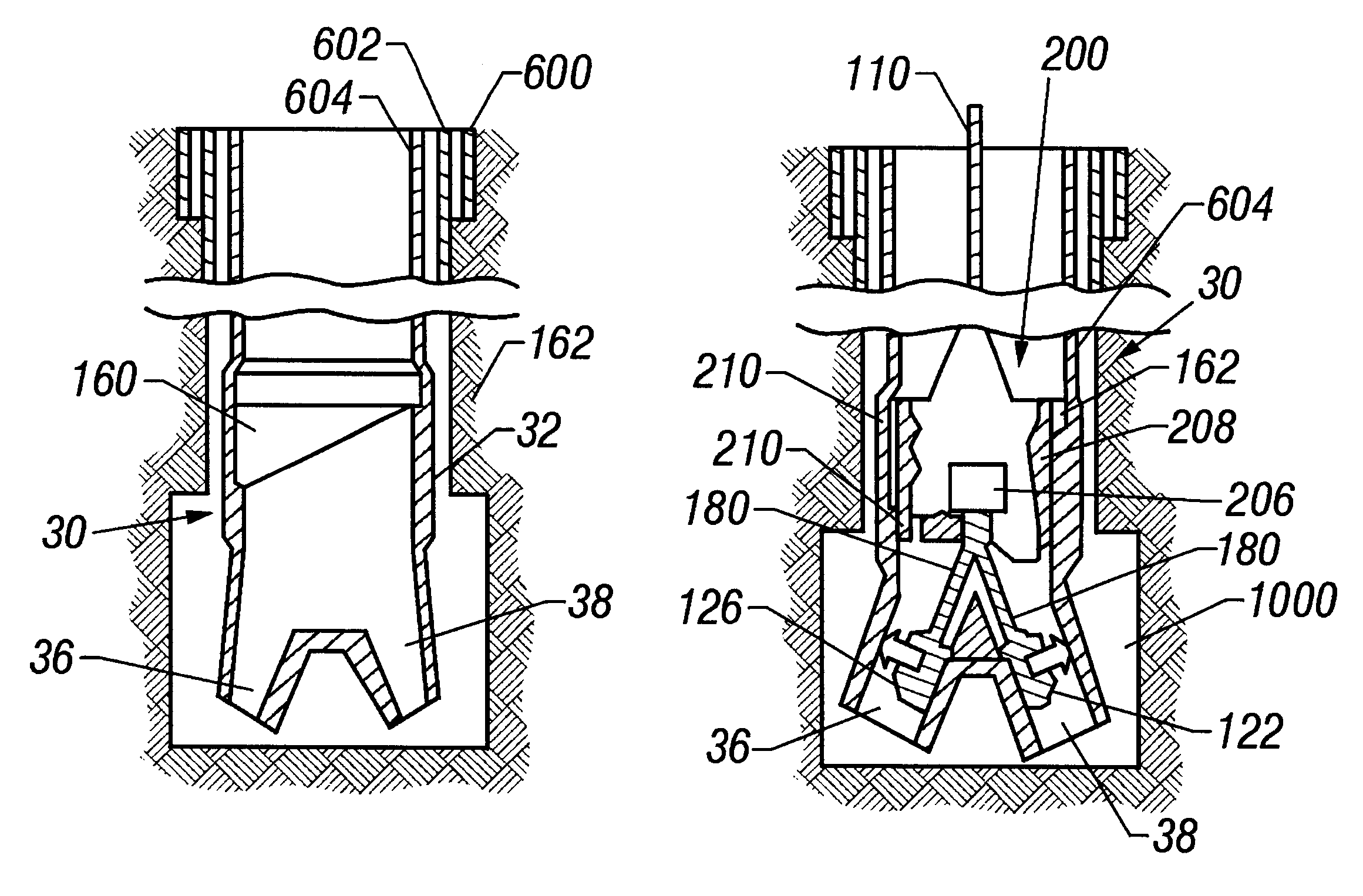

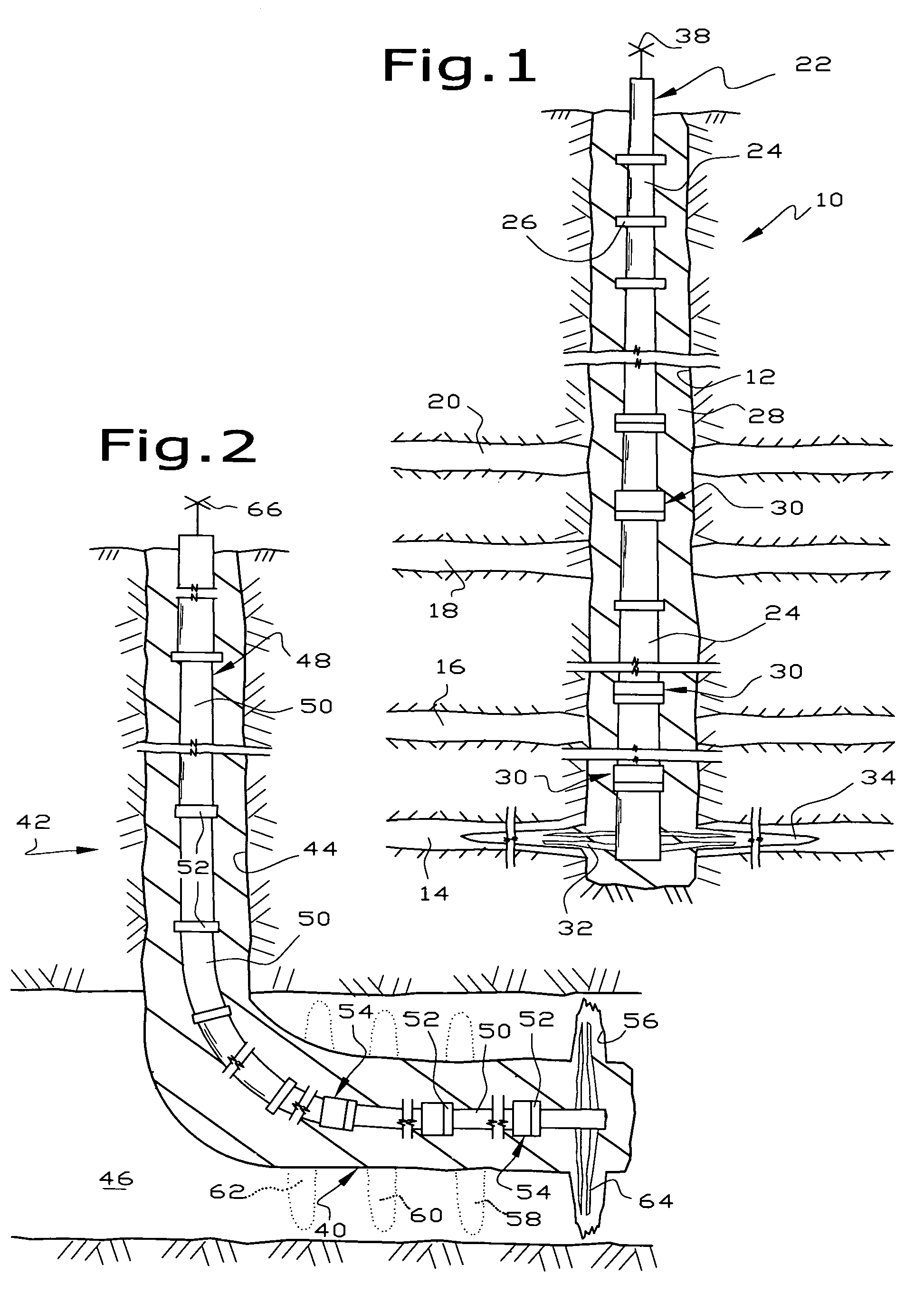

Apparatus and method for establishing branch wells from a parent well

InactiveUS6056059AOptimized areaFluid communicationDrilling rodsFluid removalCasing hangerCasing string

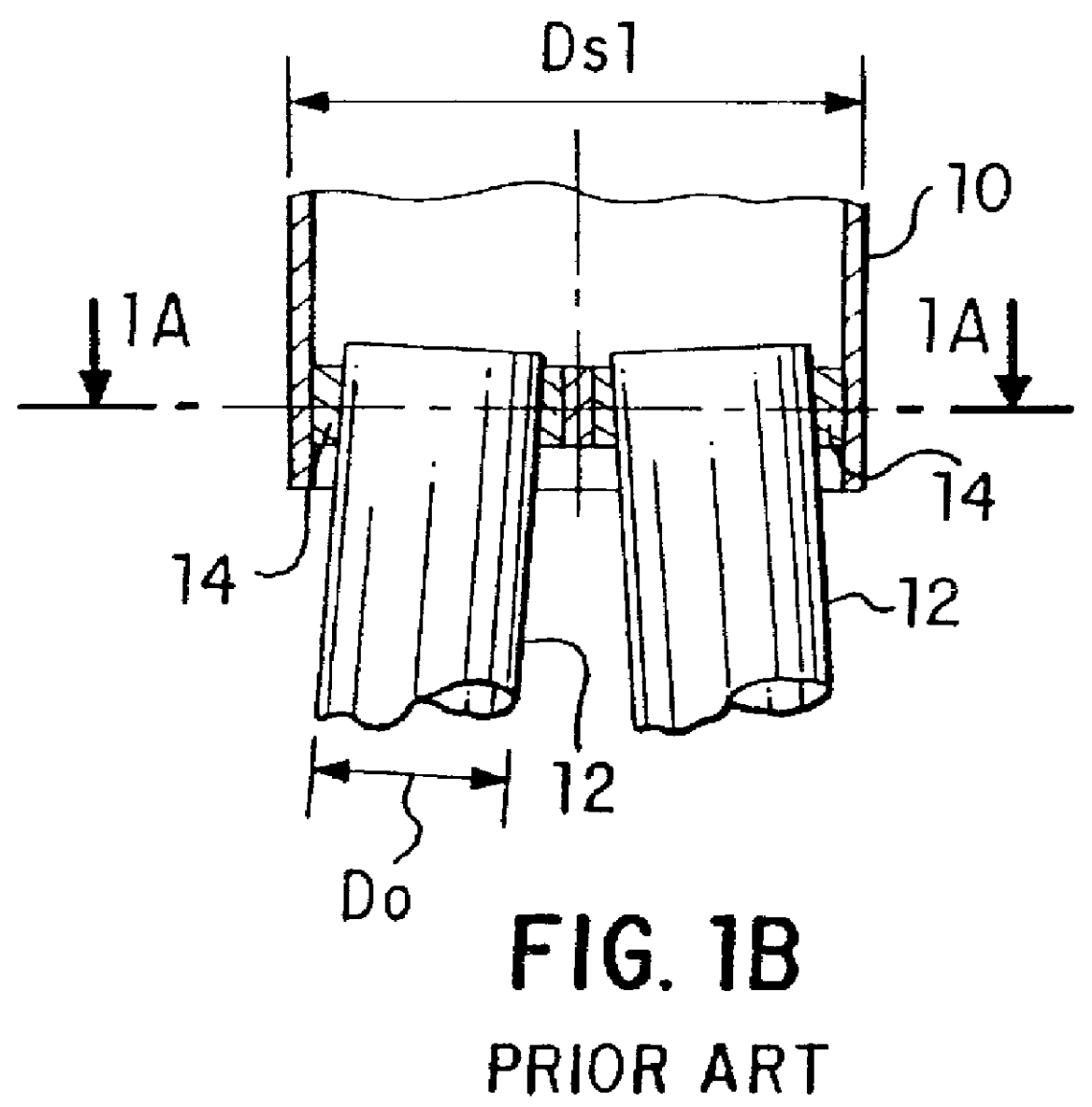

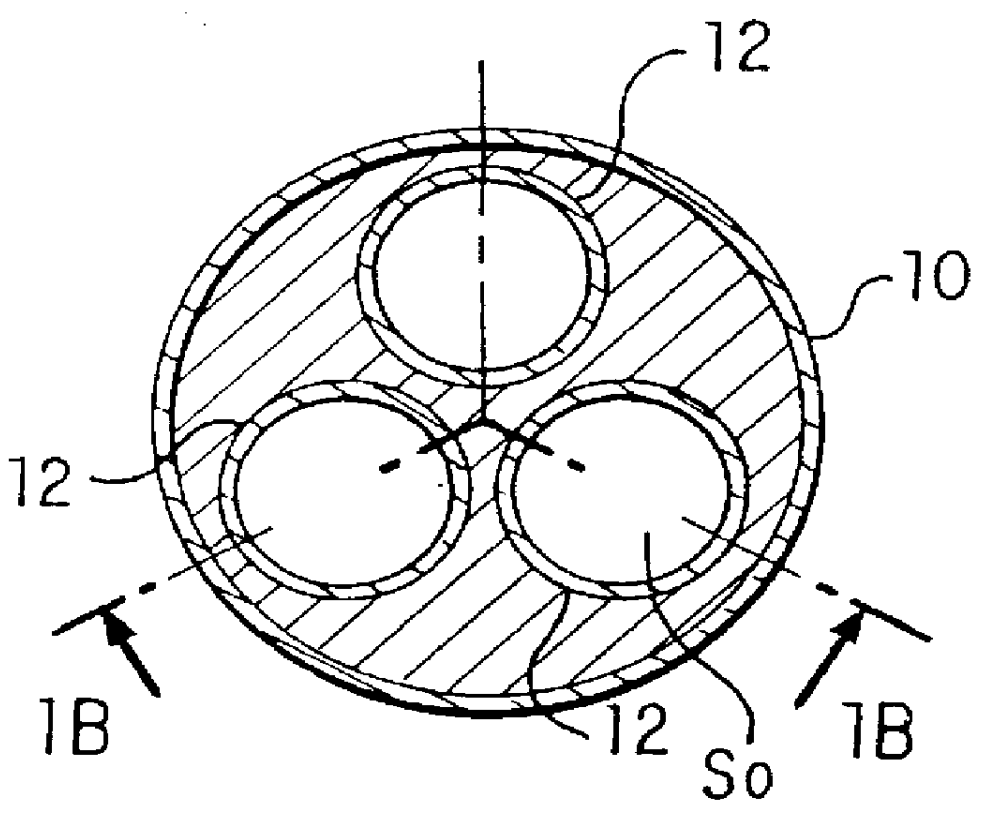

A method and apparatus for creating multiple branch wells from a parent well is disclosed. According to a first embodiment of the invention a multiple branching sub is provided for placement at a branching node of a well. Such sub includes a branching chamber and a plurality of branching outlet members. The outlet members, during construction of the branching sub, have previously been distorted into oblong shapes so that all of the branching outlet members fit within an imaginary cylinder which is coaxial with and substantially the same radius as the branching chamber. According to one embodiment, the distorted outlet members are characterized by an outer convex shape. In another embodiment, the distorted outlet members are characterized by an outer concave shape when in a retracted state. After deployment of the branching sub via a parent casing in the well, a forming tool is lowered to the interior of the sub. The outlet members are extended outwardly by the forming tool and simultaneously formed into substantially round tubes. Next, each outlet member is plugged with cement, after which each branch well is drilled through a respective outlet member. If desired, each branch may be lined with casing and sealed to a branching outlet by means of a casing hanger. A manifold placed in the branching chamber controls the production of each branch well to the parent well. According to a second embodiment of the invention, a pressure resistant branching sub is provided which may be installed in series with a casing string, and the associated equipment used for the installation operation and intervention of a well. The branching sub includes a main pipe and a lateral outlet.

Owner:SCHLUMBERGER TECH CORP

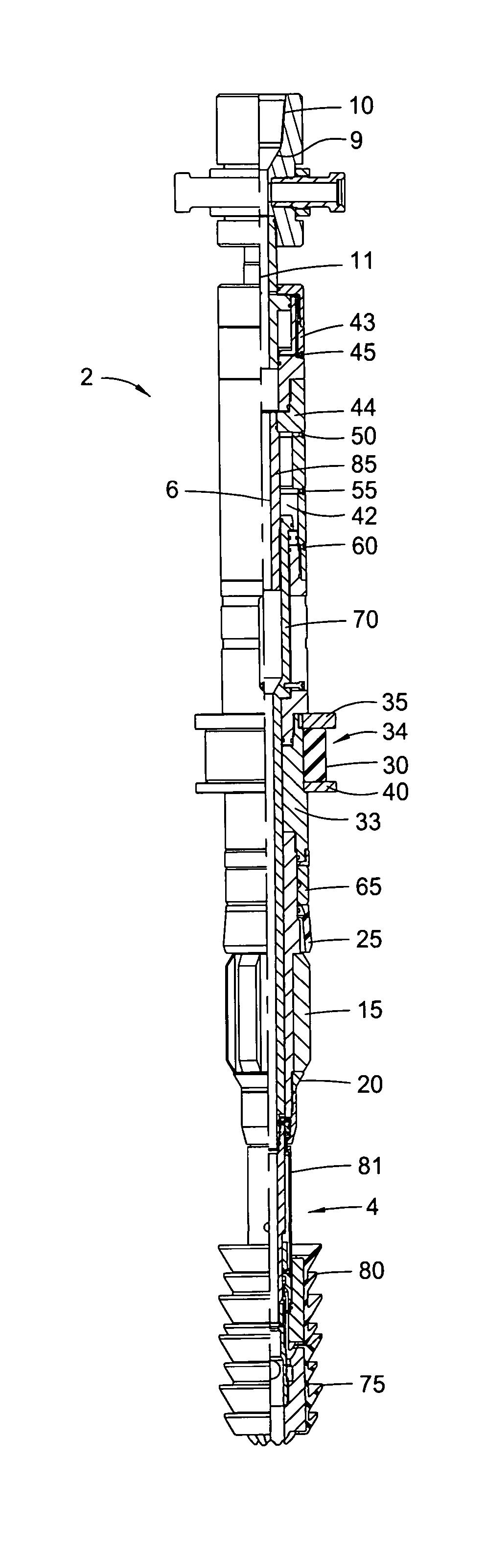

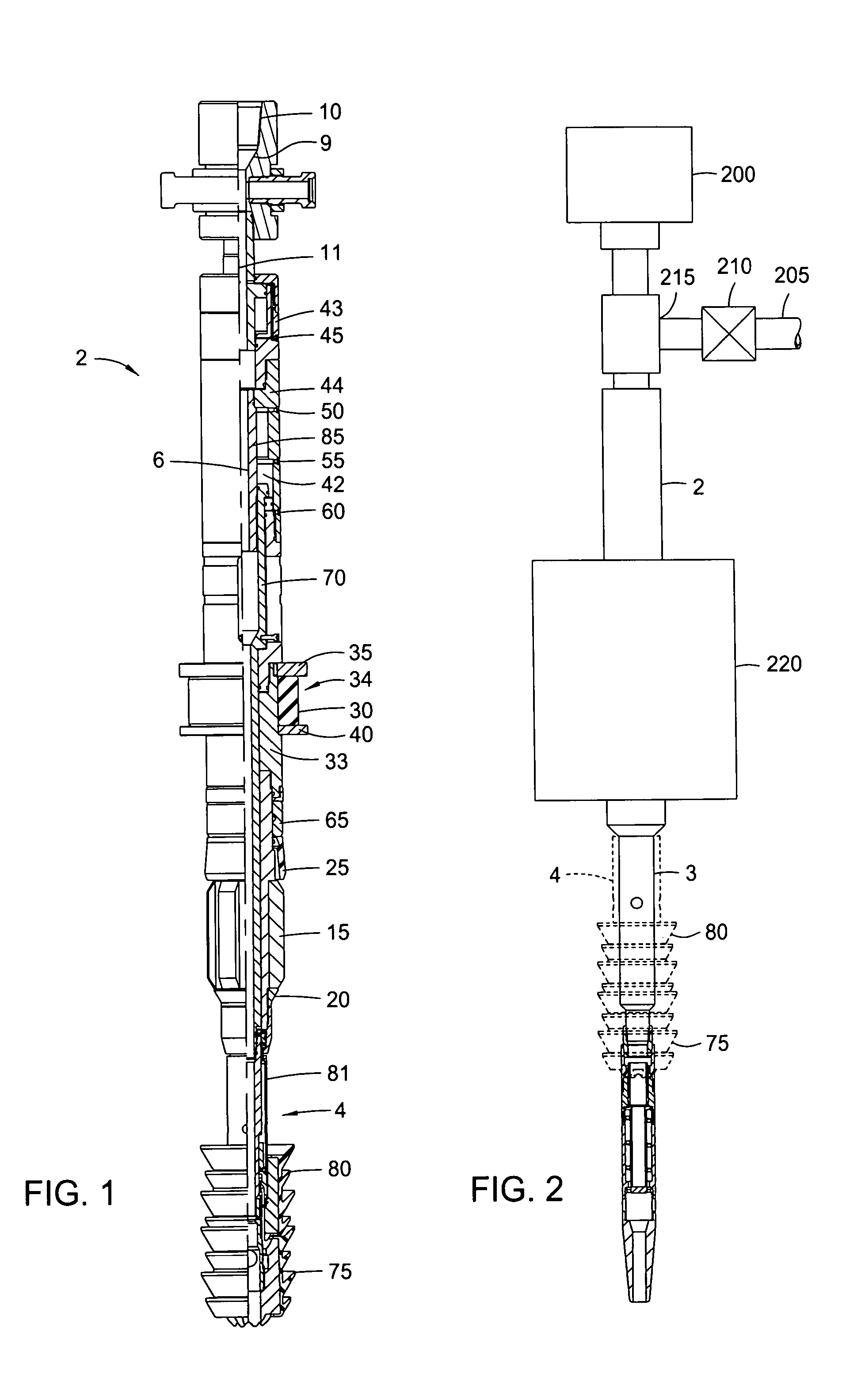

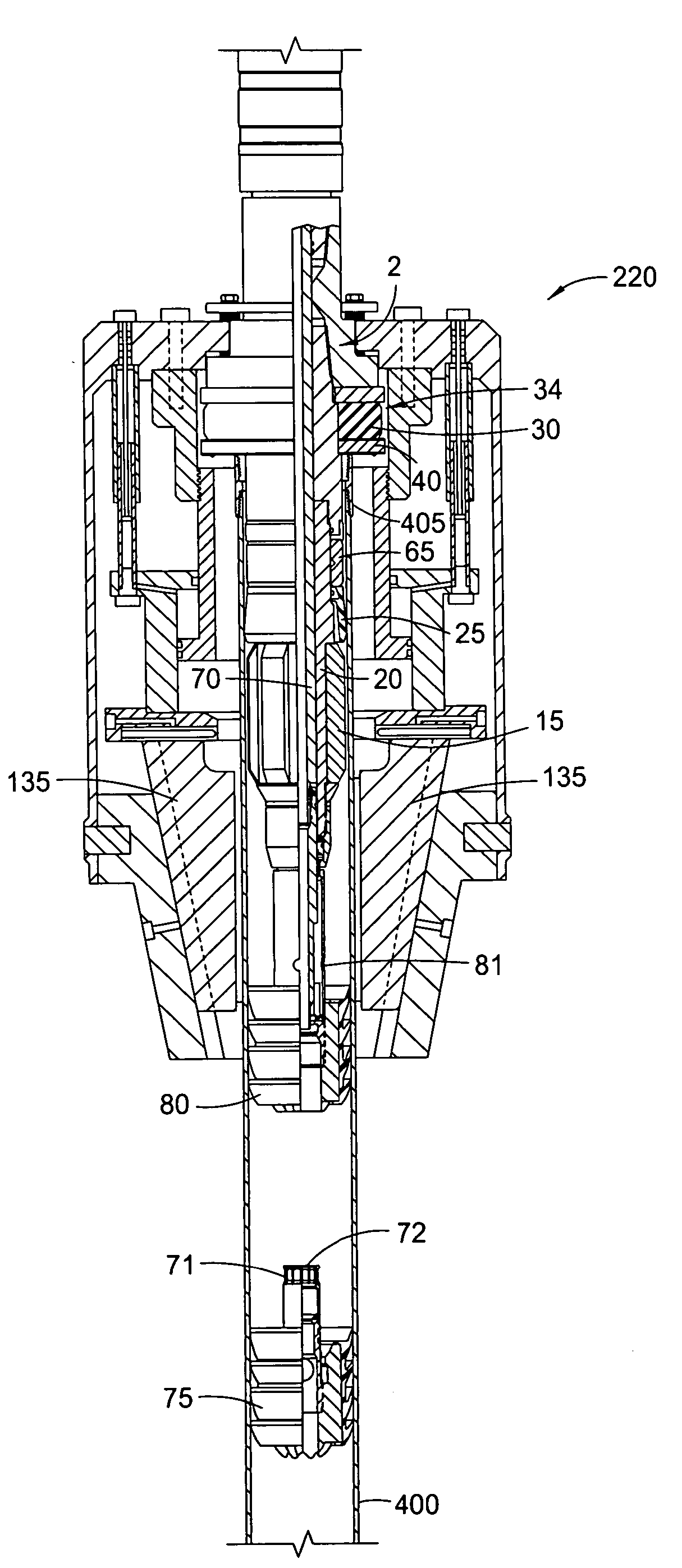

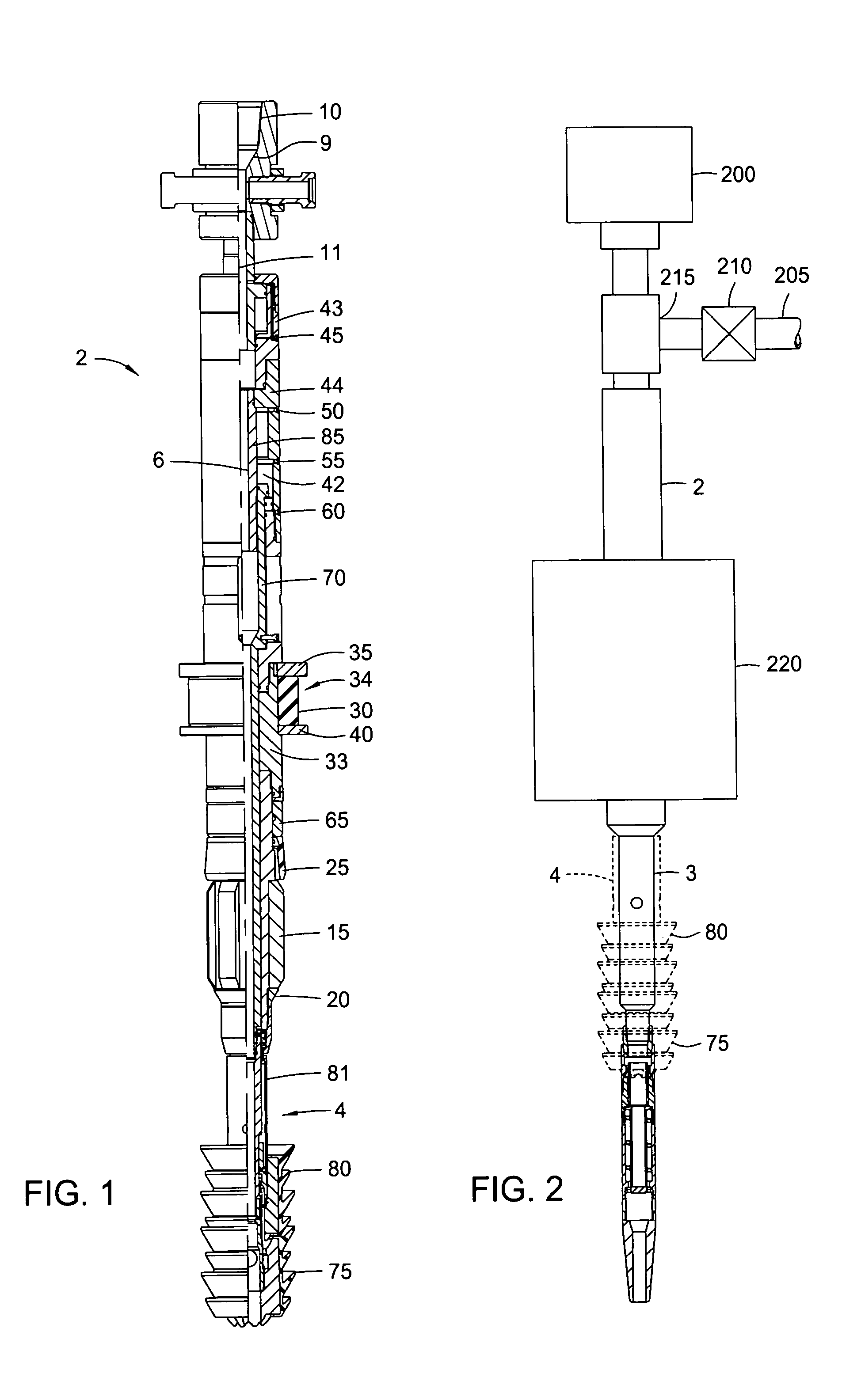

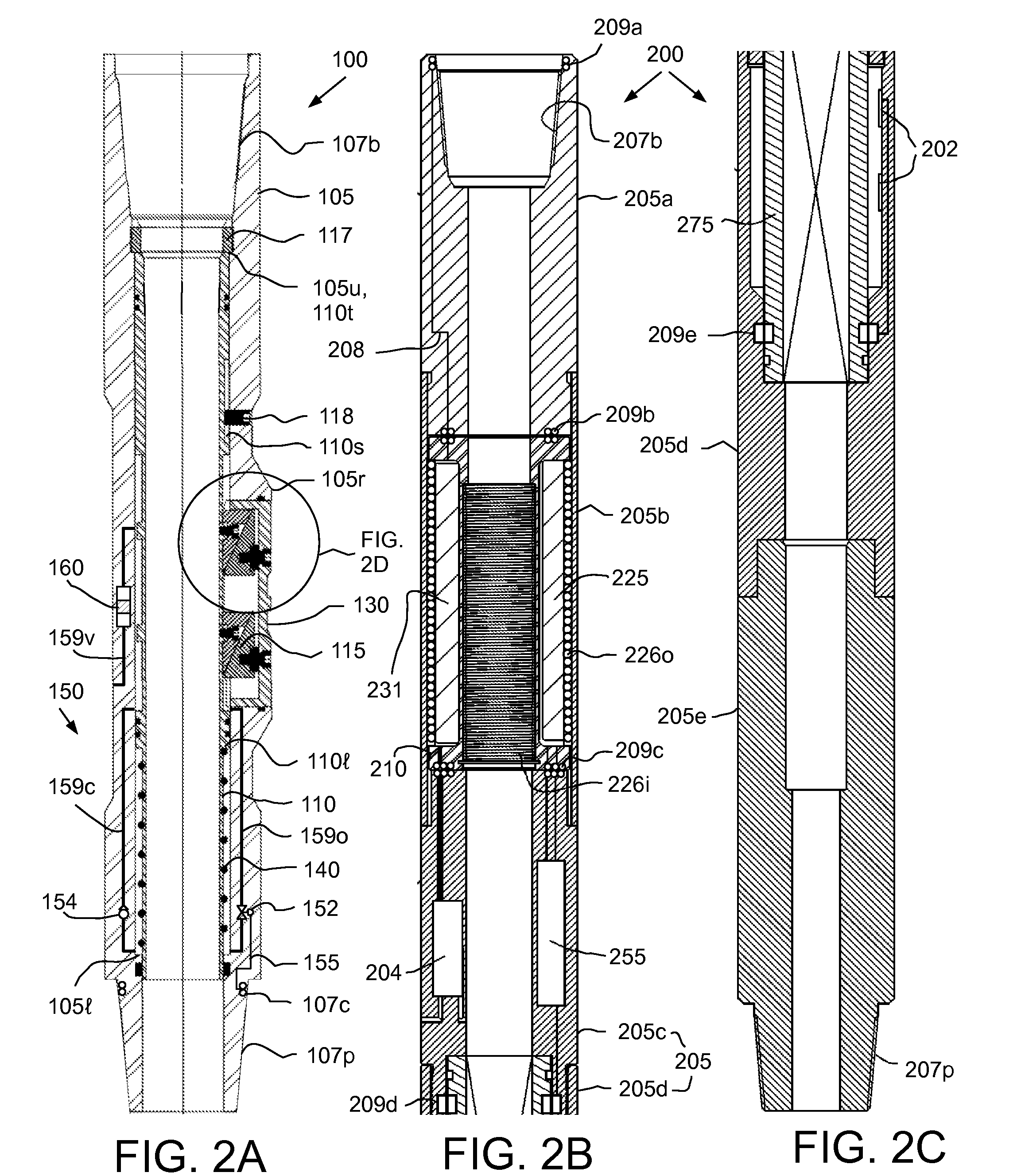

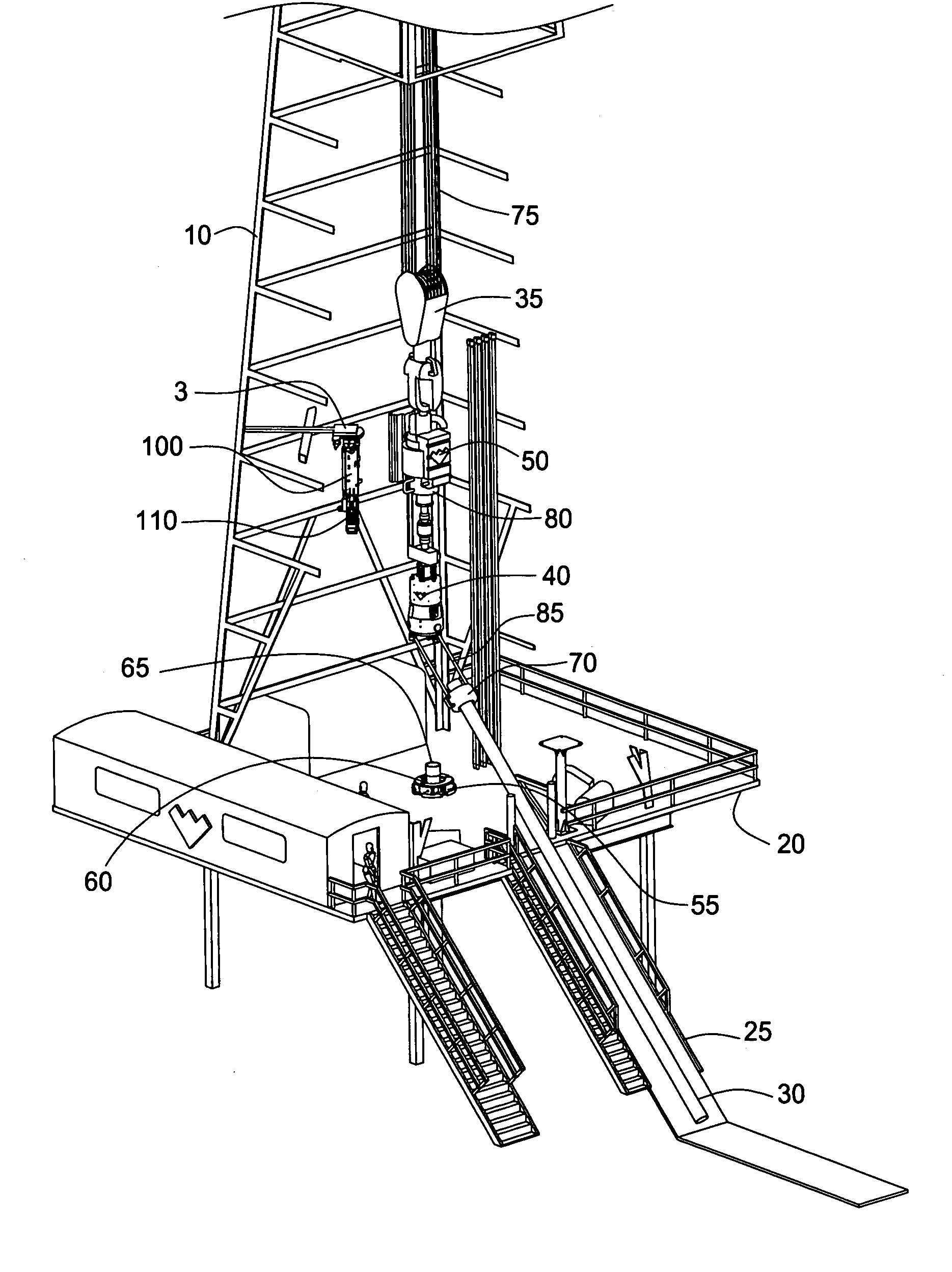

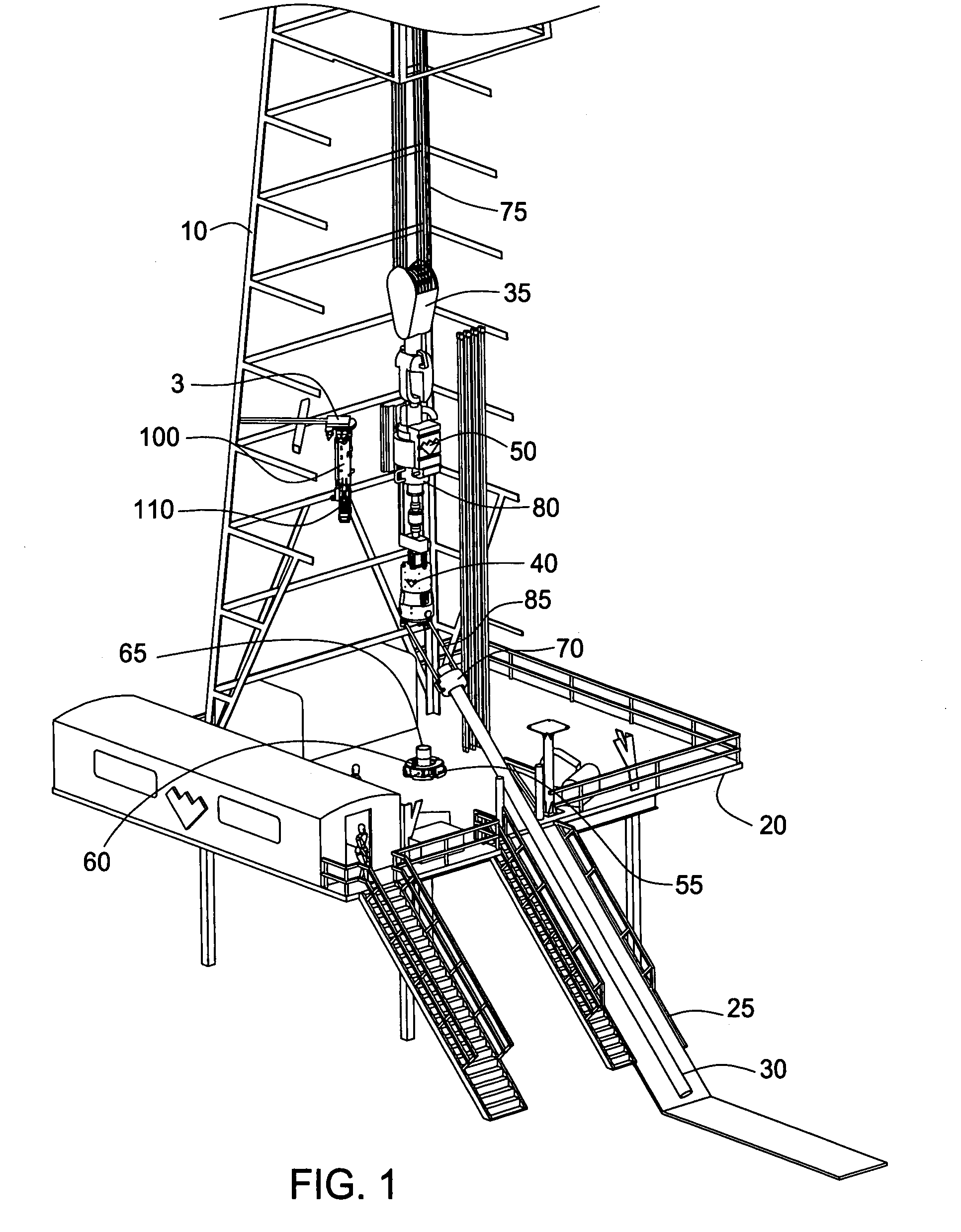

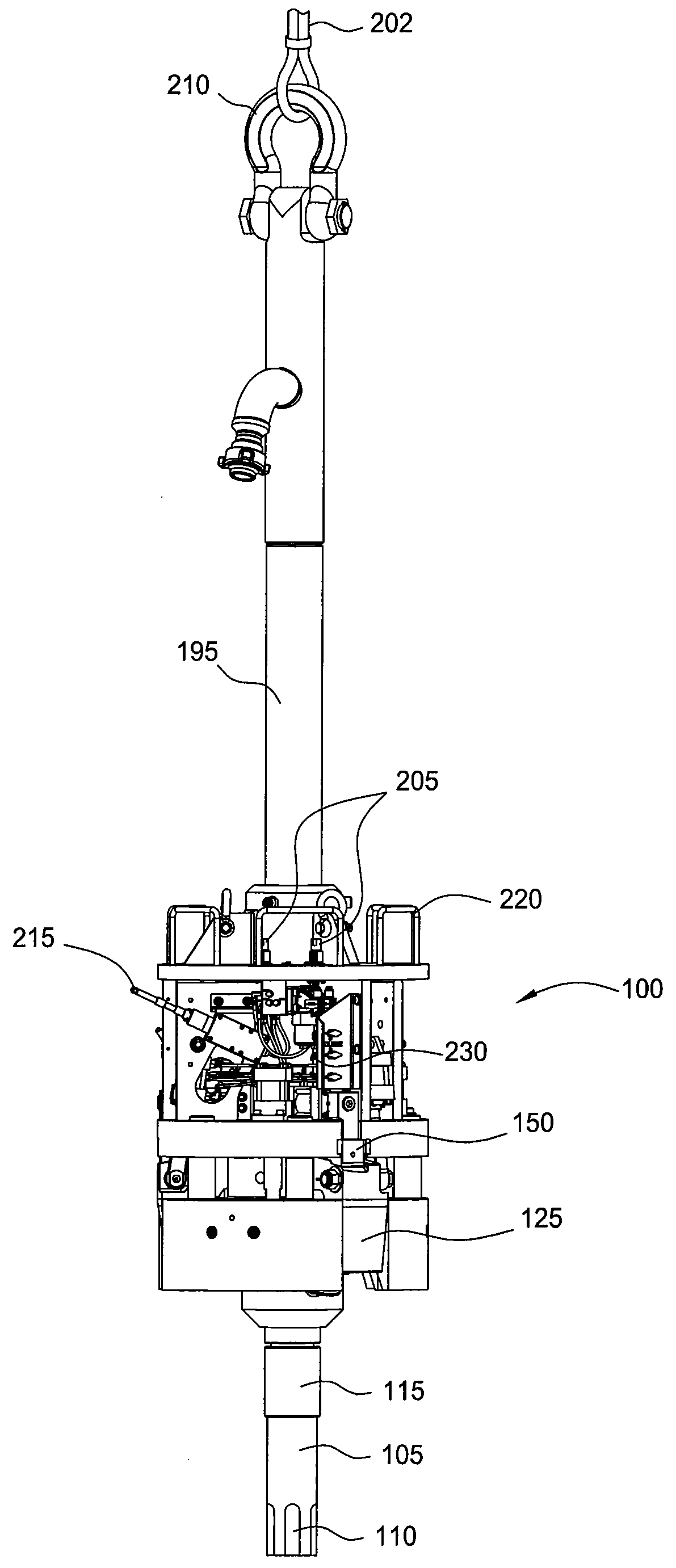

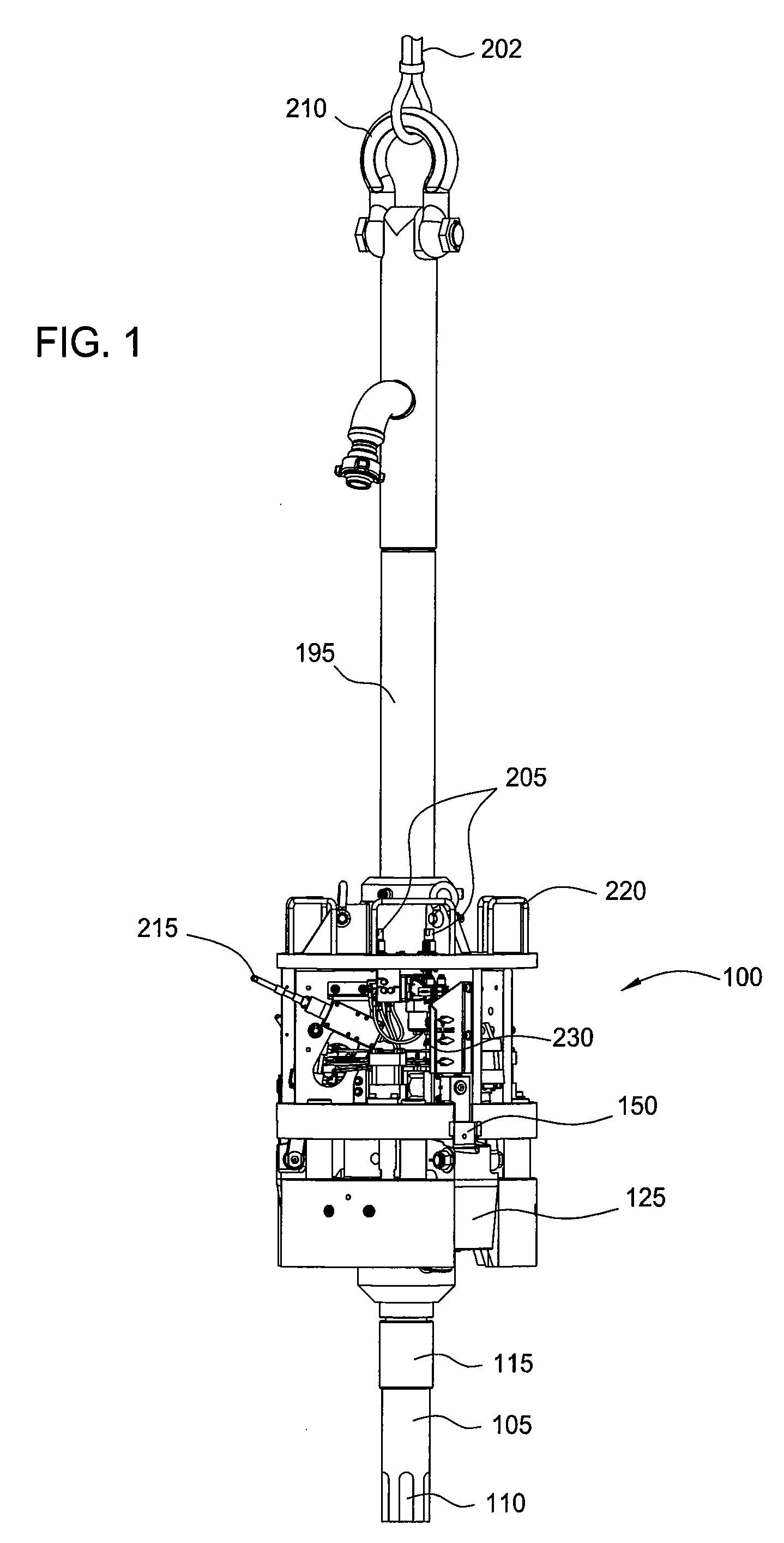

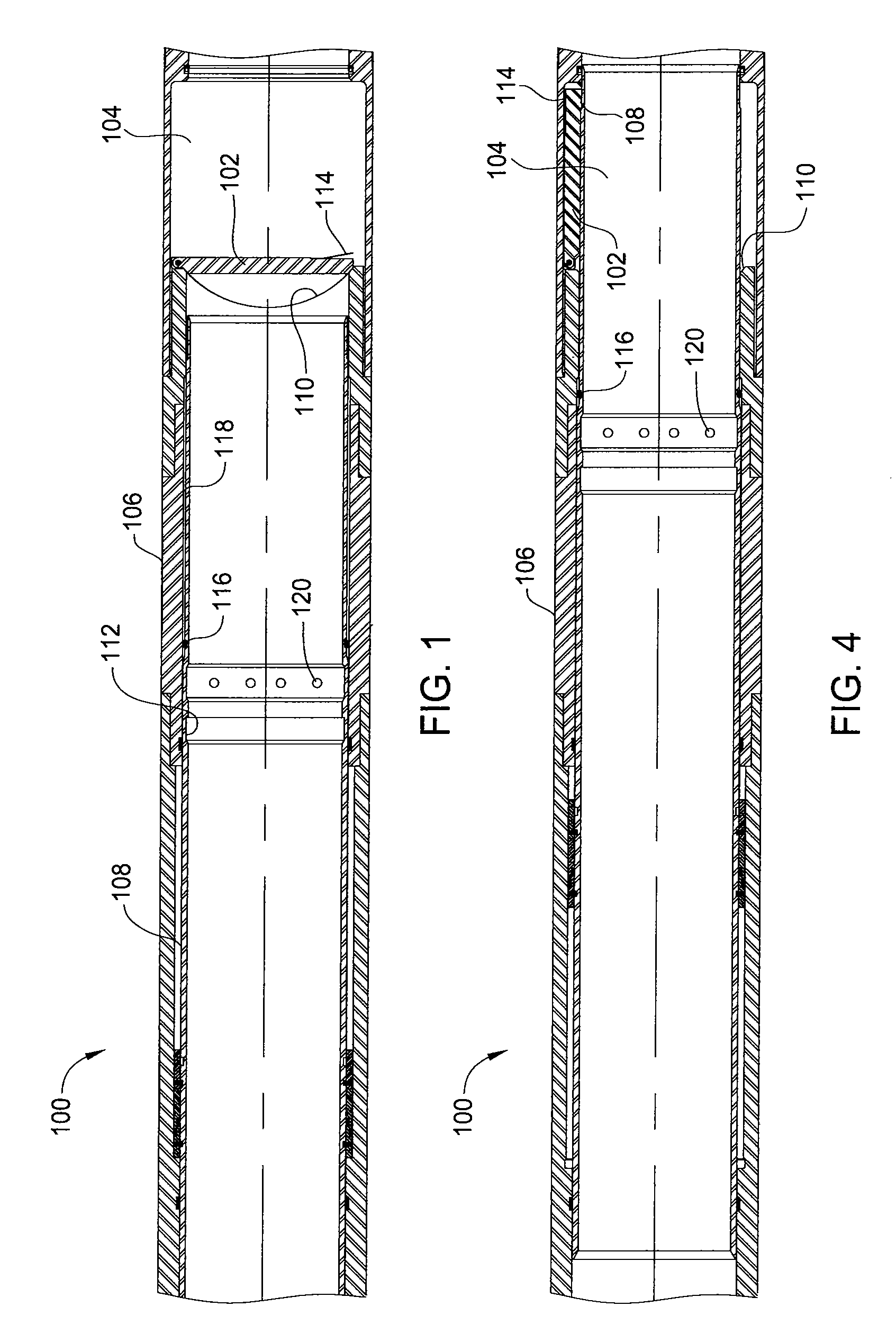

Methods and apparatus for handling and drilling with tubulars or casing

InactiveUS20050000691A1Shorten the timeReduce laborMechanical apparatusDrilling rodsTop driveWell drilling

The present invention provides a method and apparatus for handling tubulars and drilling with tubulars such as casing into a formation. In one aspect of the invention, the apparatus comprises a circulating head and a cementing head operatively connectible to a gripping member. The circulating head is used to circulate drilling fluid while drilling with casing, and the cementing head is used to cement the casing string within the formation at a desired depth. The present invention also relates to methods and apparatus for isolating a tensile load from a drilling apparatus rotated by a top drive. In one aspect, the present invention provides a load isolator apparatus having an isolator body operatively connected to the top drive and a torque body at least partially disposed in the isolator body. In operation, the bearing assembly transfers the tensile load from the torque body to the isolator body.

Owner:WEATHERFORD TECH HLDG LLC

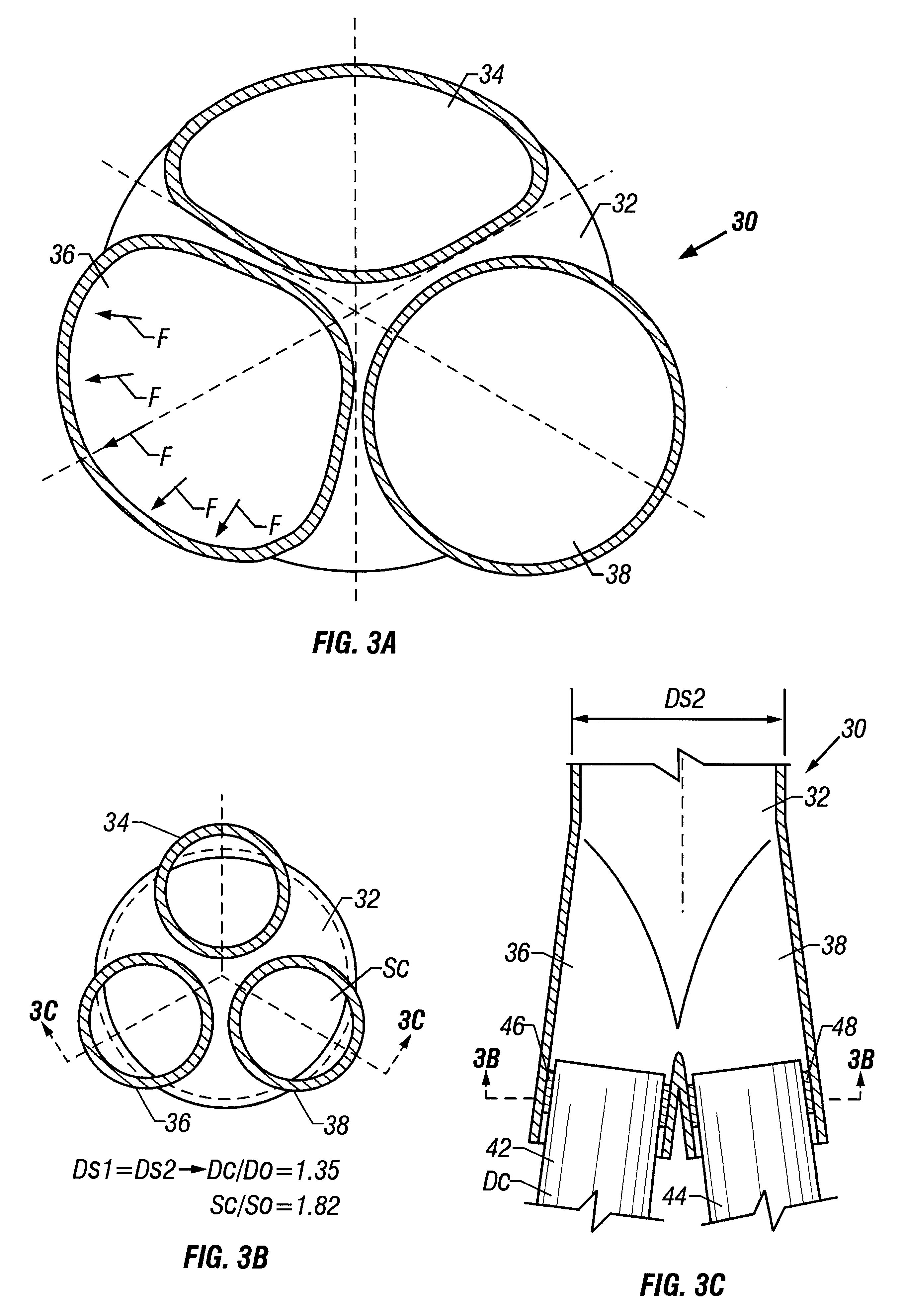

Drilling with concentric strings of casing

InactiveUS6857487B2Cost for assemblyReduce equipment costsEarth drilling toolsDrilling rodsWell drillingEngineering

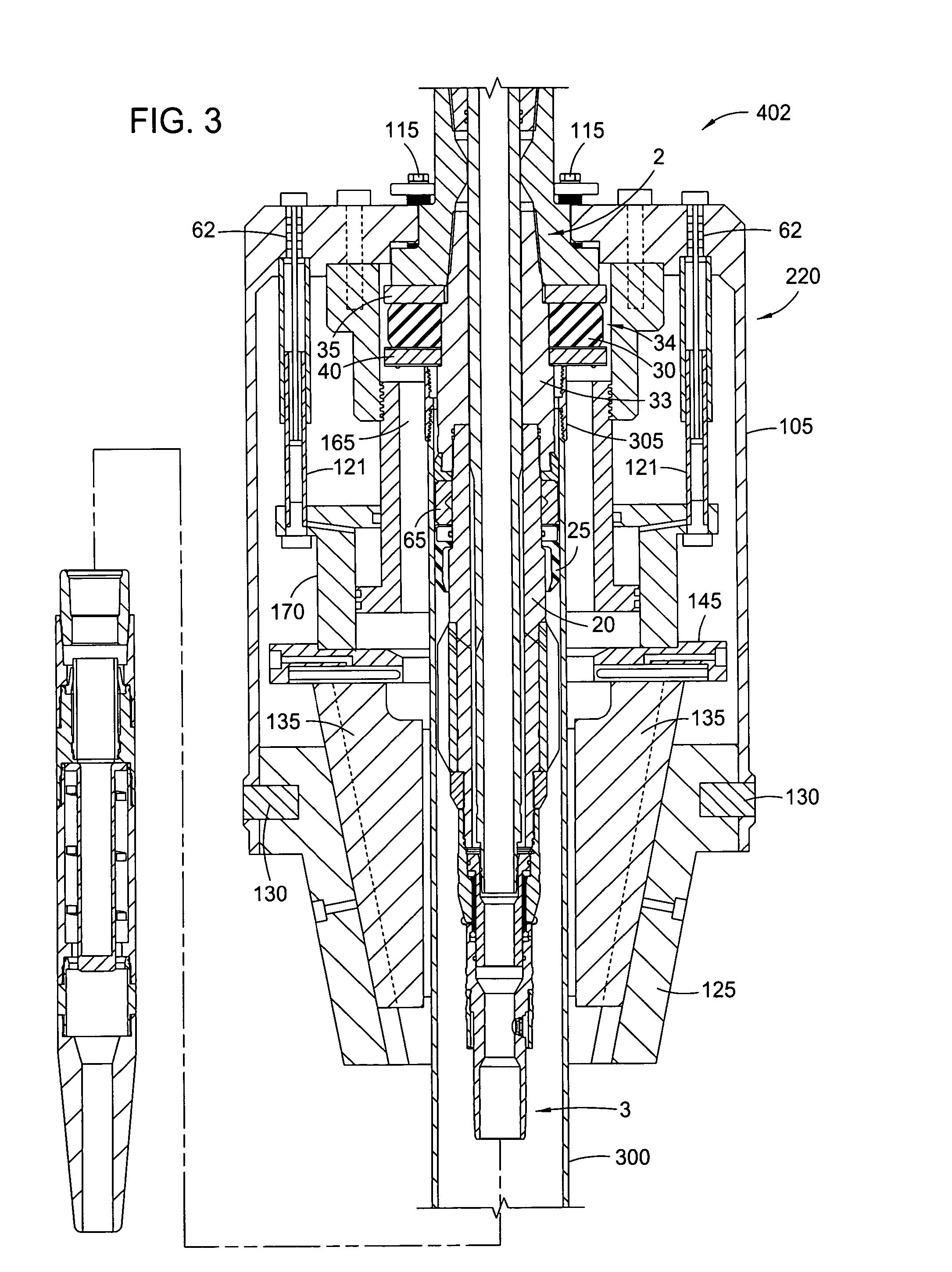

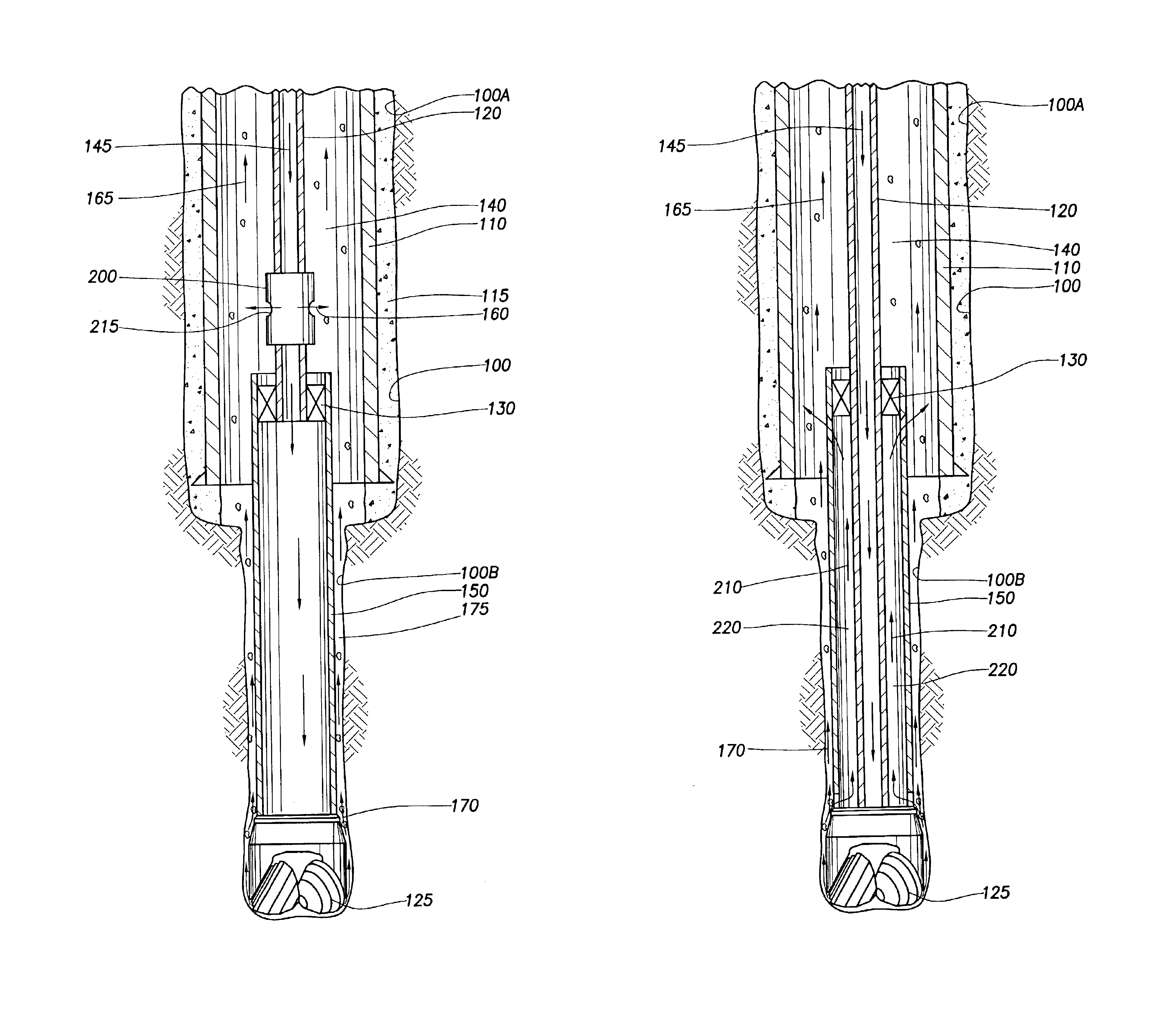

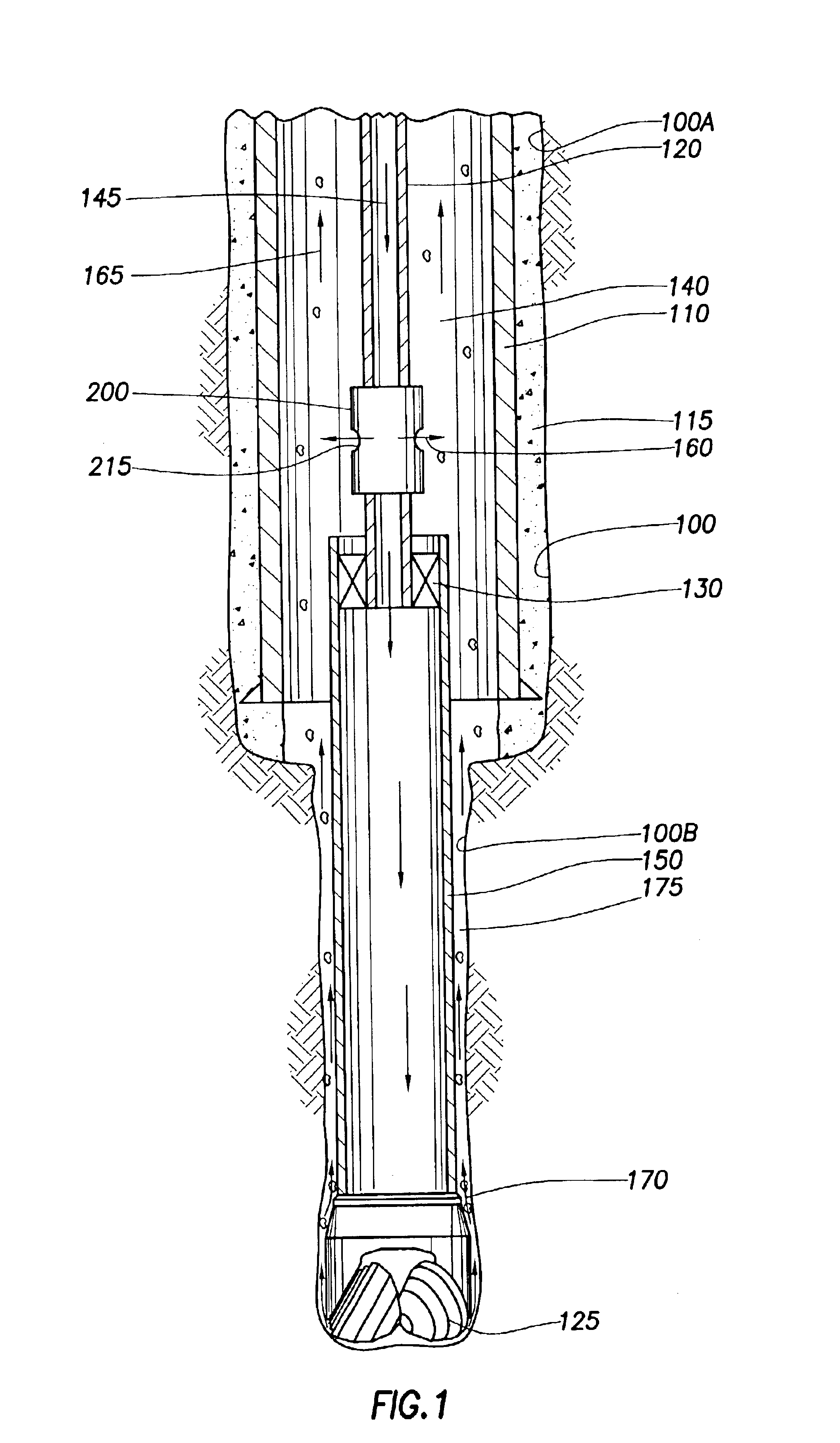

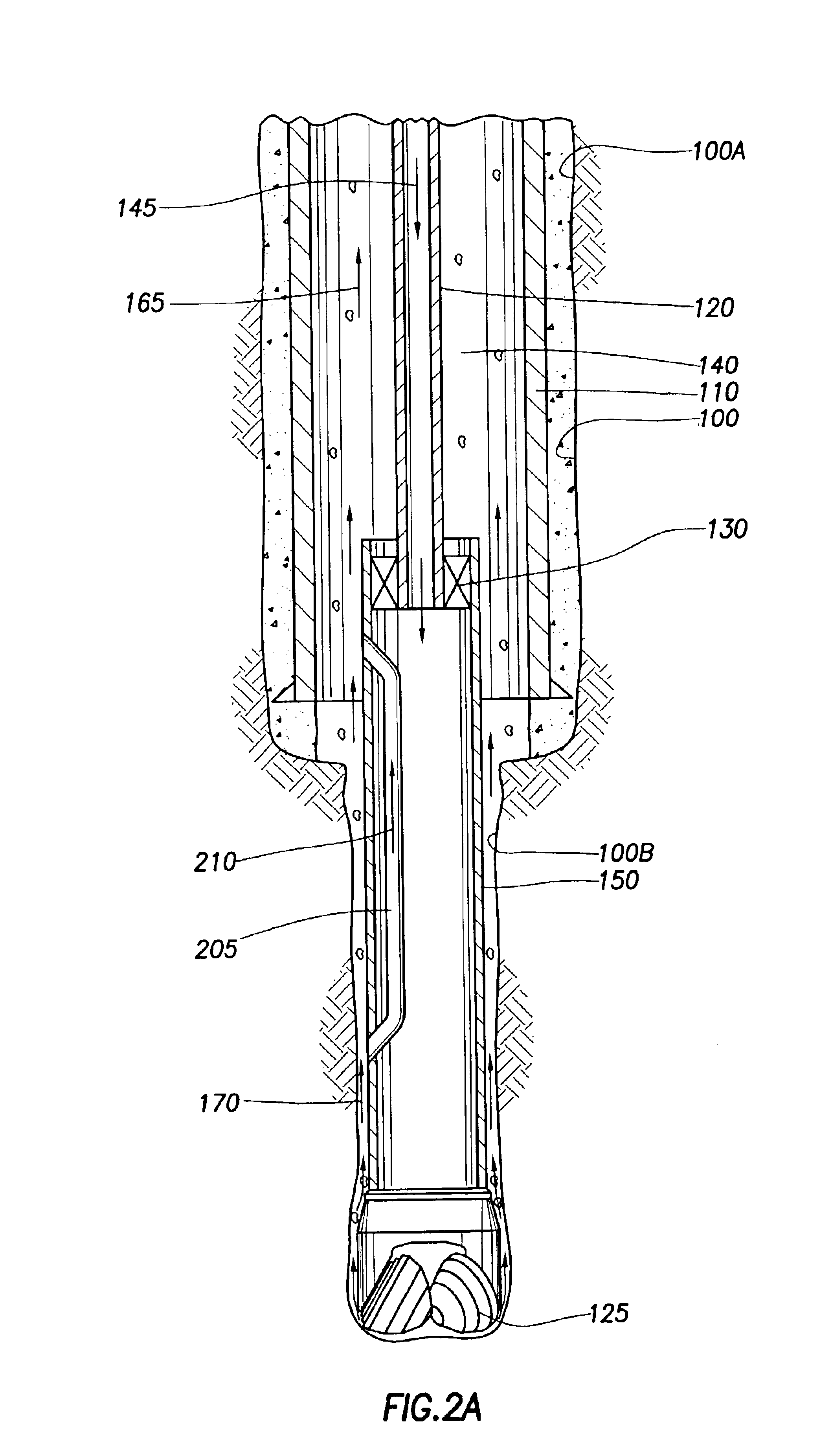

The present invention provides a method and apparatus for setting concentric casing strings within a wellbore in one run-in of a casing working string. In one aspect of the invention, the apparatus comprises a drilling system comprising concentric casing strings, with each casing string having a drill bit piece disposed at the lower end thereof. The drill bit pieces of adjacent casing strings are releasably connected to one another. In another aspect of the invention, a method is provided for setting concentric casing strings within a wellbore with the drilling system. In another aspect of the invention, the releasably connected drill bit pieces comprise a drill bit assembly.

Owner:WEATHERFORD TECH HLDG LLC

Casing strings and methods of using such strings in subterranean cementing operations

ActiveUS20060086503A1Extension of timeSolid waste managementFluid removalCasing stringWell cementing

Improved casing strings, and methods of using improved casing strings in subterranean cementing operations, are provided. An example of an apparatus is a pipe string comprising at least one pipe section and a delivery system of an activator. Another example of an apparatus is a pipe string comprising at least one pipe section and a delivery system of a set retarder. An example of a method is a method of cementing in a subterranean formation. Other examples of methods are methods of cementing in a subterranean formation comprising a well bore.

Owner:HALLIBURTON ENERGY SERVICES INC

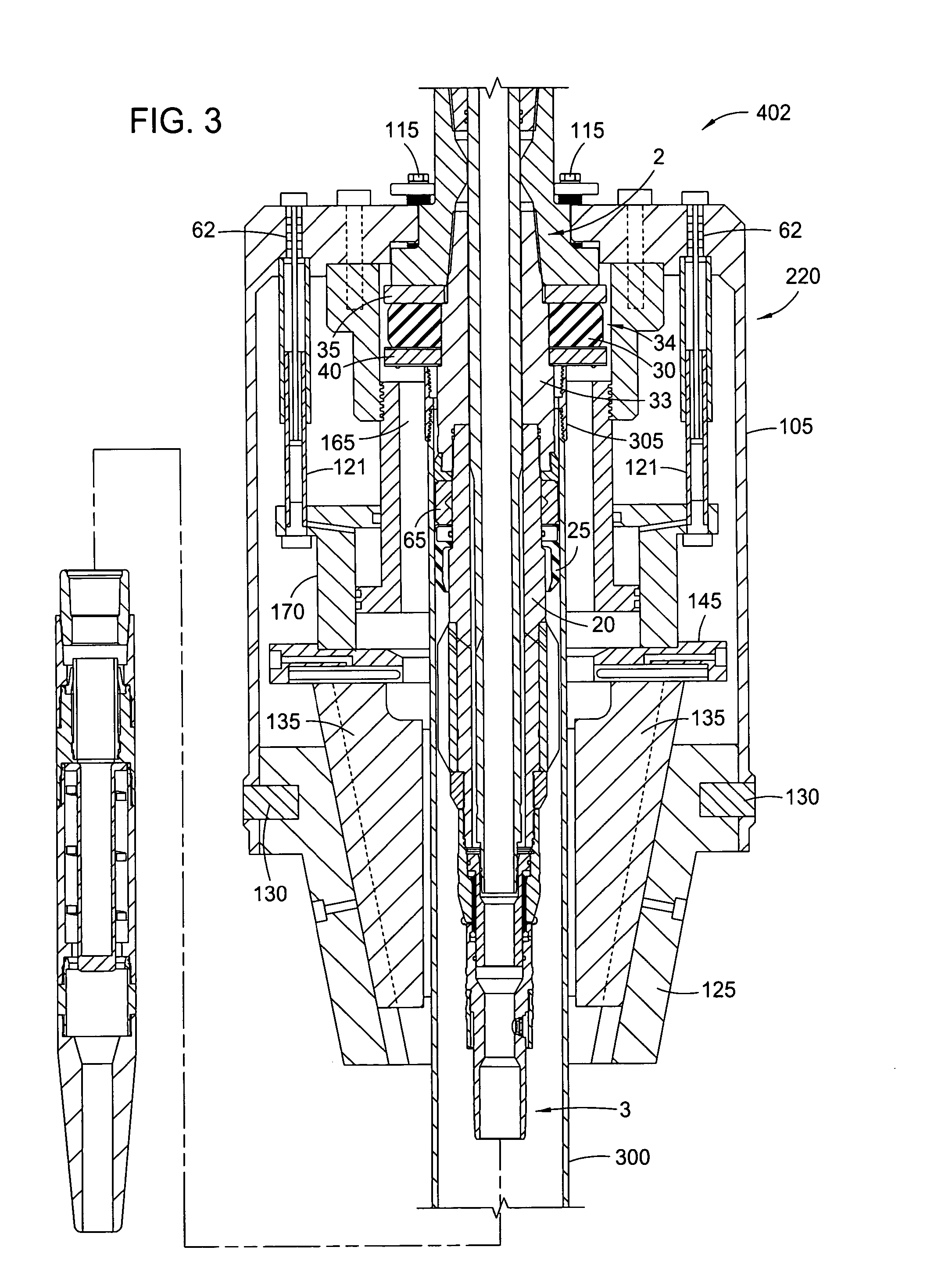

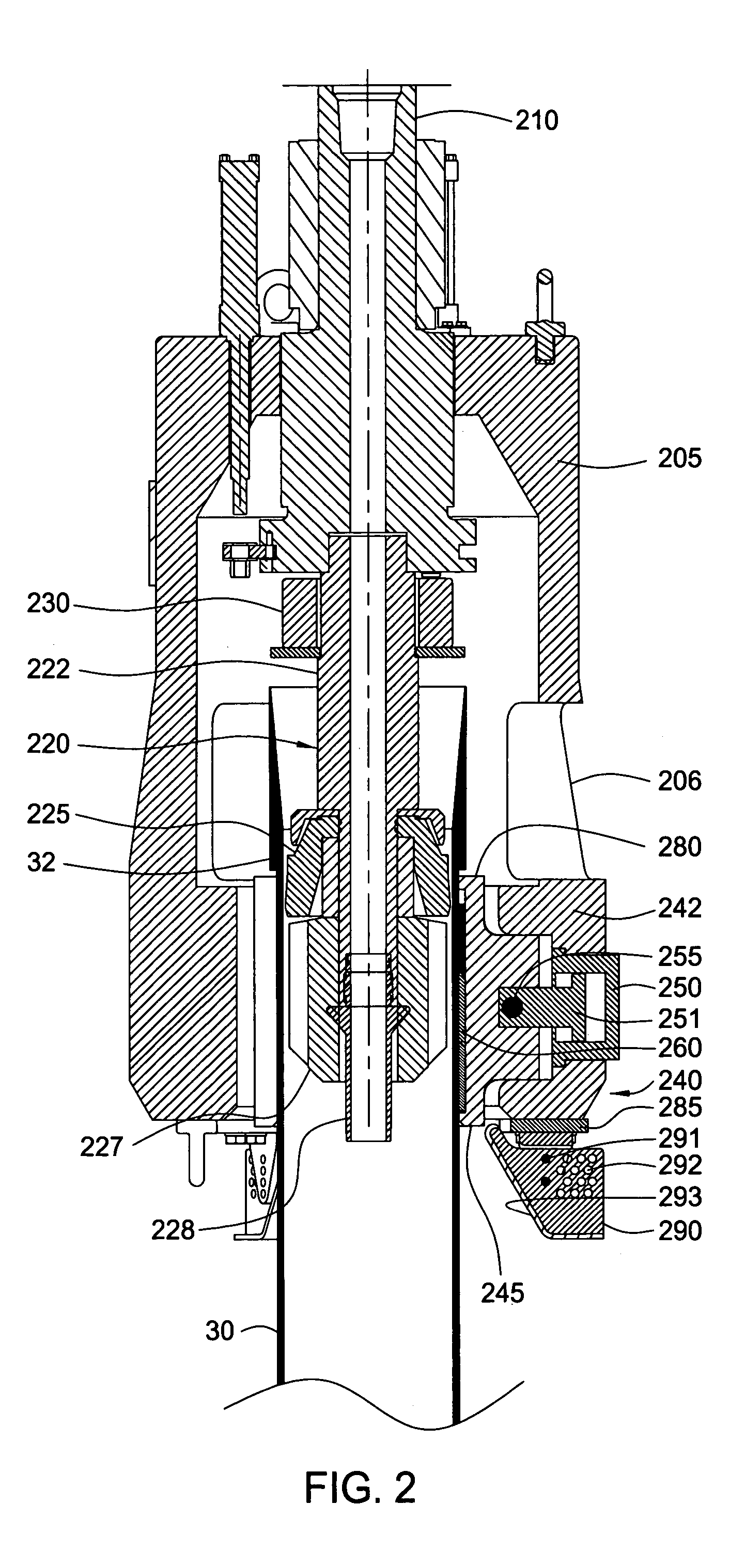

Casing pushdown and rotating tool

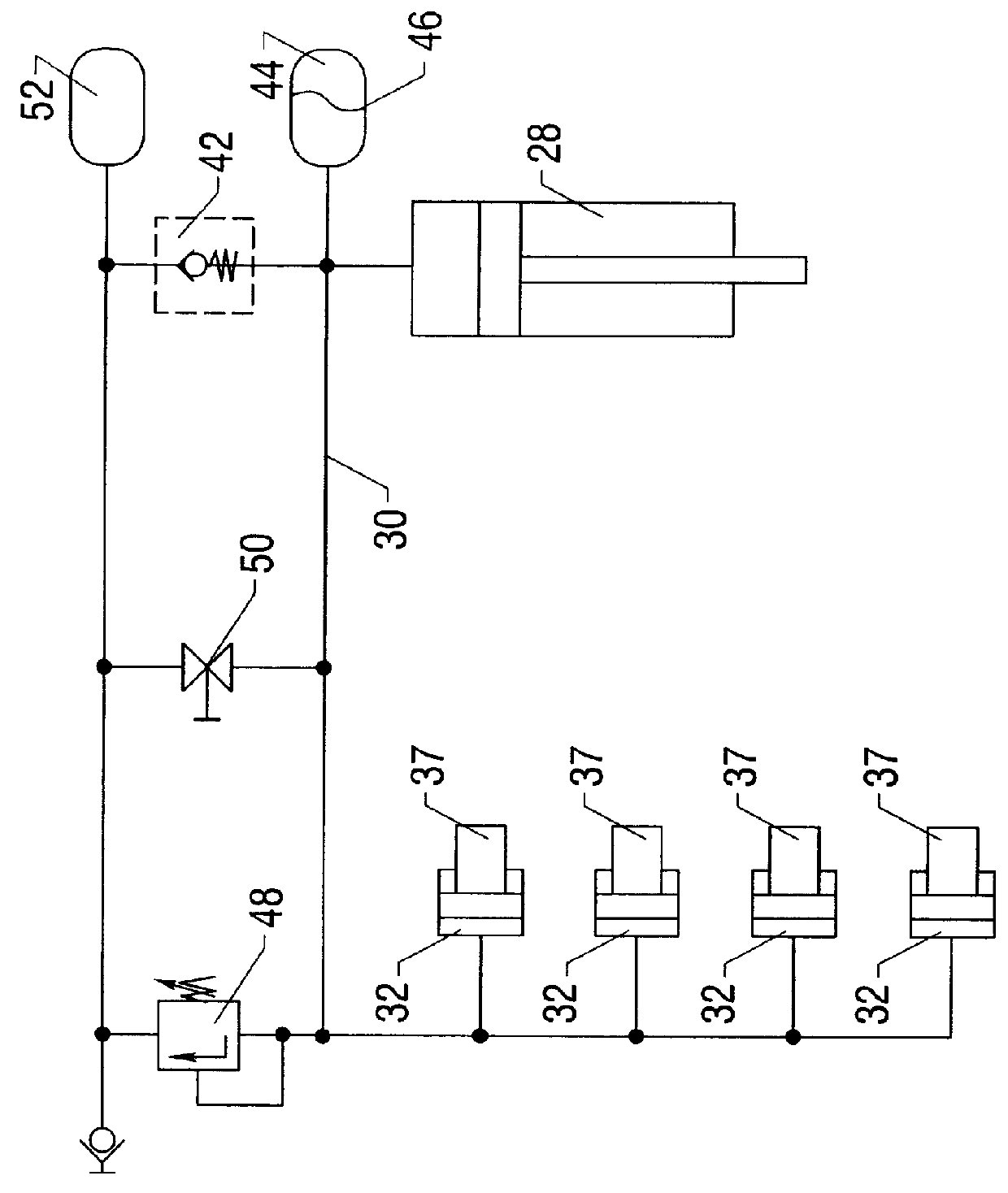

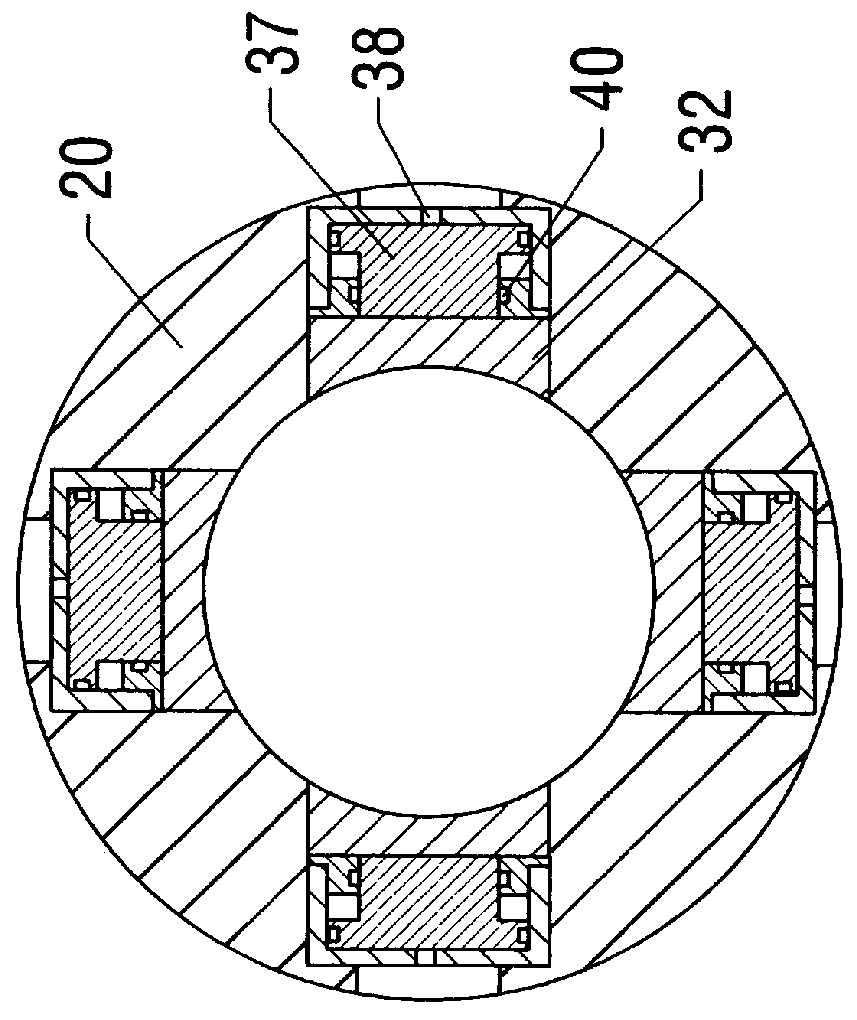

A pushdown and rotating tool for holding, pushing, and rotating a floated casing string into a wellbore is provided. The tool includes a mandrel, a housing attached about the external diameter of the mandrel and shaped to receive a collared casing, a jaws assembly within the housing, and an automatic hydraulics system for actuating the jaws. The mandrel and housing are connected such that they can move telescopically relative to one another, and such motion actuates the jaws. The tool has a threaded coupling for a top drive connection, the top drive providing the pushdown and rotational forces which are transmitted to the casing by way of the tool. The mandrel also has an internal passage-way through its length and a male connection at the bottom. The tool facilitates floating a casing into a substantially horizontal wellbore when the casing becomes buoyant and tries to "kick back" out of the well, or when the floated casing becomes stuck and requires rotation to extend beyond the obstacle.

Owner:BJ SERVICES CO

Methods and apparatus for handling and drilling with tubulars or casing

InactiveUS7325610B2Reduce laborShorten the timeMechanical apparatusDrilling rodsTop driveWell drilling

The present invention provides a method and apparatus for handling tubulars and drilling with tubulars such as casing into a formation. In one aspect of the invention, the apparatus comprises a circulating head and a cementing head operatively connectible to a gripping member. The circulating head is used to circulate drilling fluid while drilling with casing, and the cementing head is used to cement the casing string within the formation at a desired depth. The present invention also relates to methods and apparatus for isolating a tensile load from a drilling apparatus rotated by a top drive. In one aspect, the present invention provides a load isolator apparatus having an isolator body operatively connected to the top drive and a torque body at least partially disposed in the isolator body. In operation, the bearing assembly transfers the tensile load from the torque body to the isolator body.

Owner:WEATHERFORD TECH HLDG LLC

Apparatus and method for drilling with casing

The present invention generally relates to a method and an apparatus for drilling with casing. In one aspect, a method of drilling a wellbore with casing is provided, including placing a string of casing with a drill bit at the lower end thereof into a previously formed wellbore and urging the string of casing axially downward to form a new section of wellbore. The method further includes pumping fluid through the string of casing into an annulus formed between the casing string and the new section of wellbore. The method also includes diverting a portion of the fluid into an upper annulus in the previously formed wellbore. In another aspect, a method of drilling with casing to form a wellbore is provided. In yet another aspect, an apparatus for forming a wellbore is provided. In still another aspect, a method of casing a wellbore while drilling the wellbore is provided.

Owner:WEATHERFORD TECH HLDG LLC

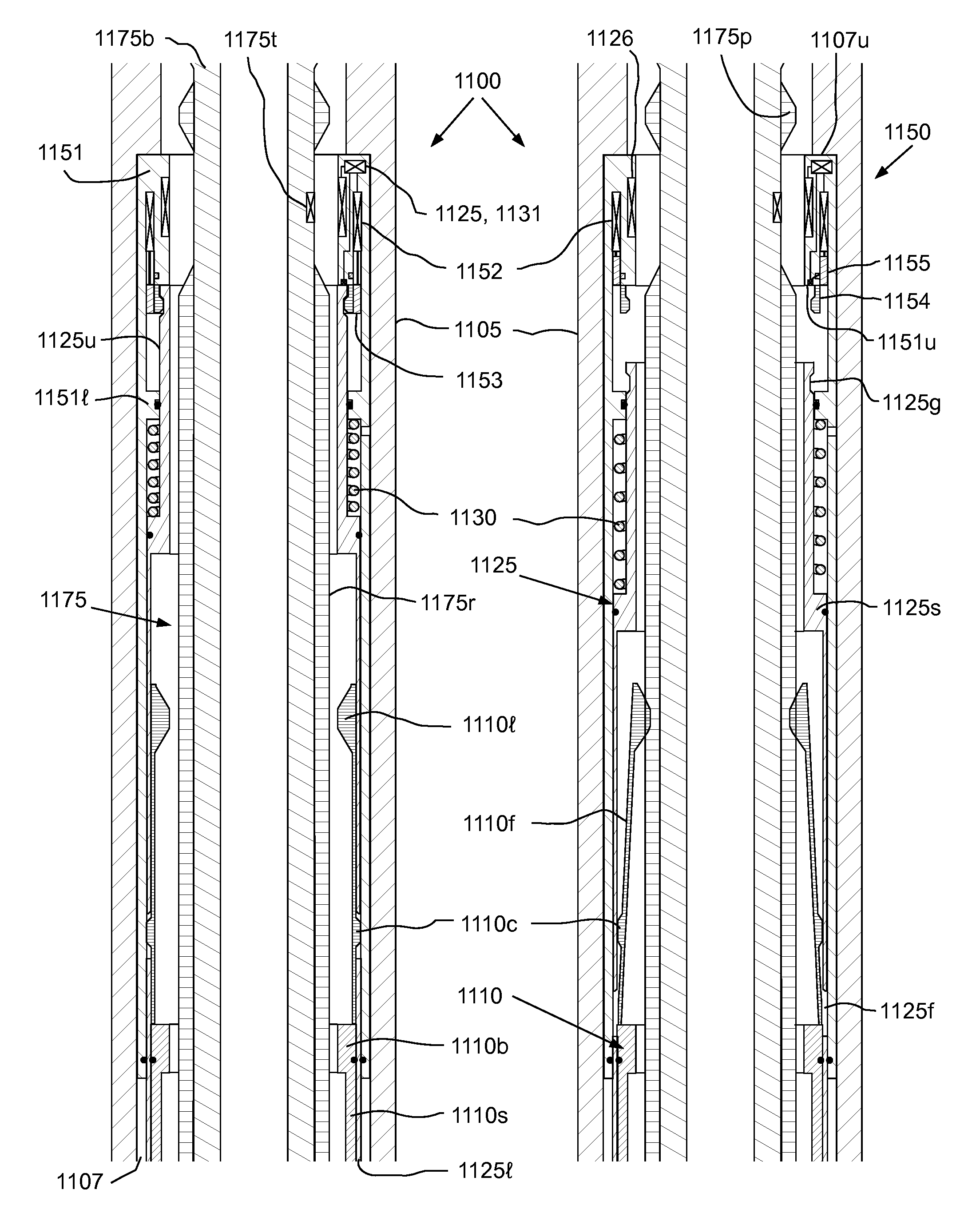

Signal operated isolation valve

A method of drilling a wellbore includes drilling the wellbore through a formation by injecting drilling fluid through a drill string and rotating a drill bit. The drill string includes a shifting tool, a receiver in communication with the shifting tool, and the drill bit. The method further includes retrieving the drill string from the wellbore through a casing string until the shifting tool reaches an actuator. The casing string includes an isolation valve in an open position and the actuator. The method further includes sending a wireless instruction signal to the receiver. The shifting tool engages the actuator in response to the receiver receiving the instruction signal. The method further includes operating the actuator using the engaged shifting tool, thereby closing the isolation valve and isolating the formation from an upper portion of the wellbore.

Owner:WEATHERFORD TECH HLDG LLC

Annulus pressure control drilling systems and methods

In one embodiment, a method for drilling a wellbore includes an act of drilling the wellbore by injecting drilling fluid through a tubular string disposed in the wellbore, the tubular string comprising a drill bit disposed on a bottom thereof. The drilling fluid exits the drill bit and carries cuttings from the drill bit. The drilling fluid and cuttings (returns) flow to a surface of the wellbore via an annulus defined by an outer surface of the tubular string and an inner surface of the wellbore. The method further includes an act performed while drilling the wellbore of measuring a first annulus pressure (FAP) using a pressure sensor attached to a casing string hung from a wellhead of the wellbore. The method further includes an act performed while drilling the wellbore of controlling a second annulus pressure (SAP) exerted on a formation exposed to the annulus.

Owner:WEATHERFORD TECH HLDG LLC

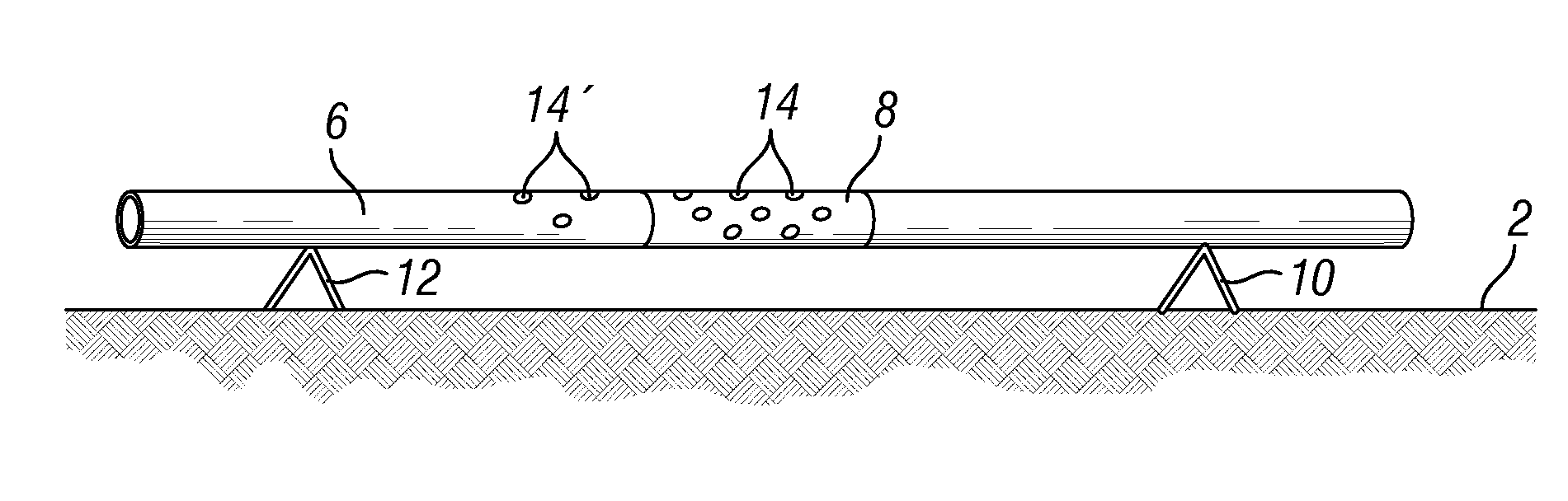

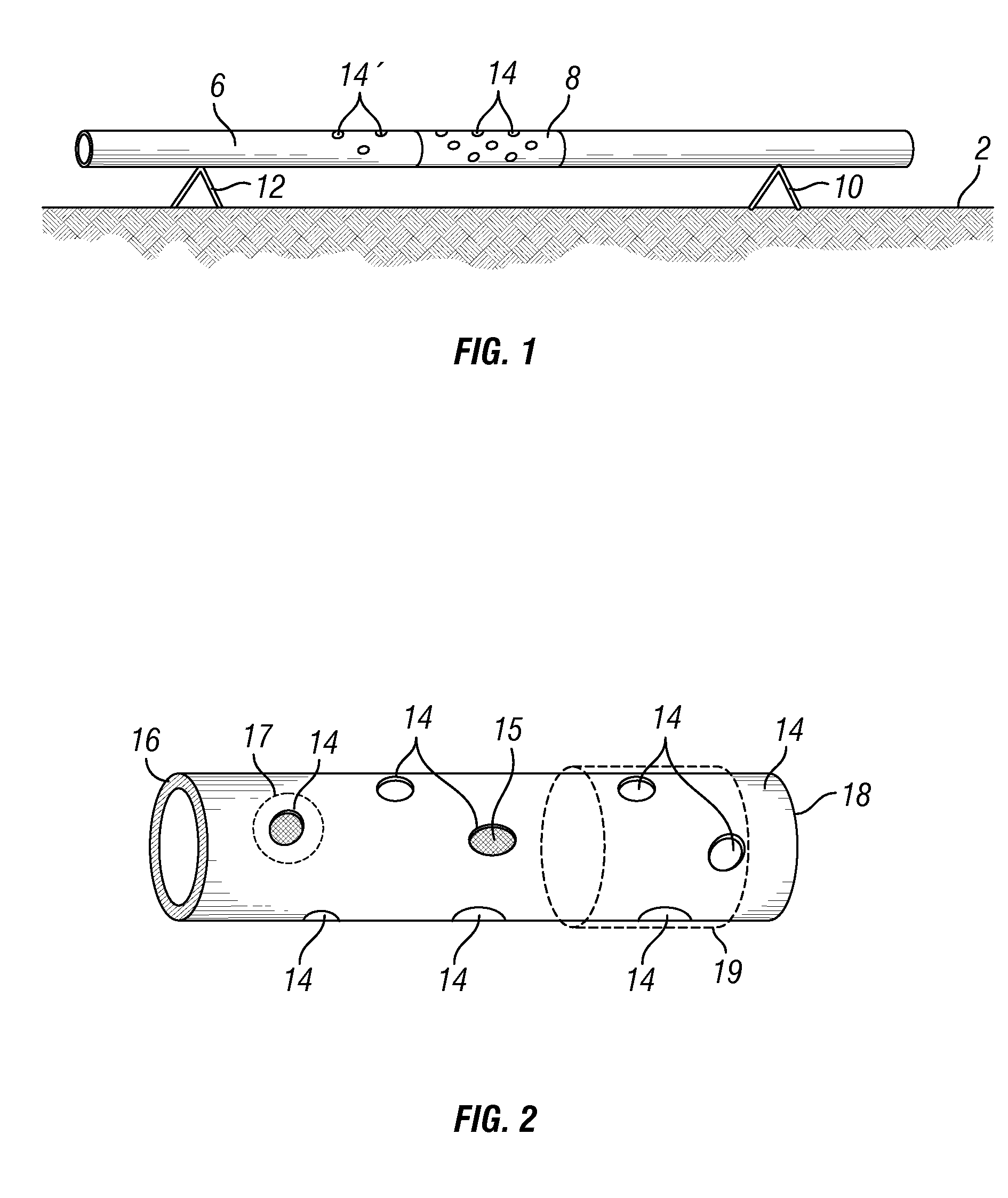

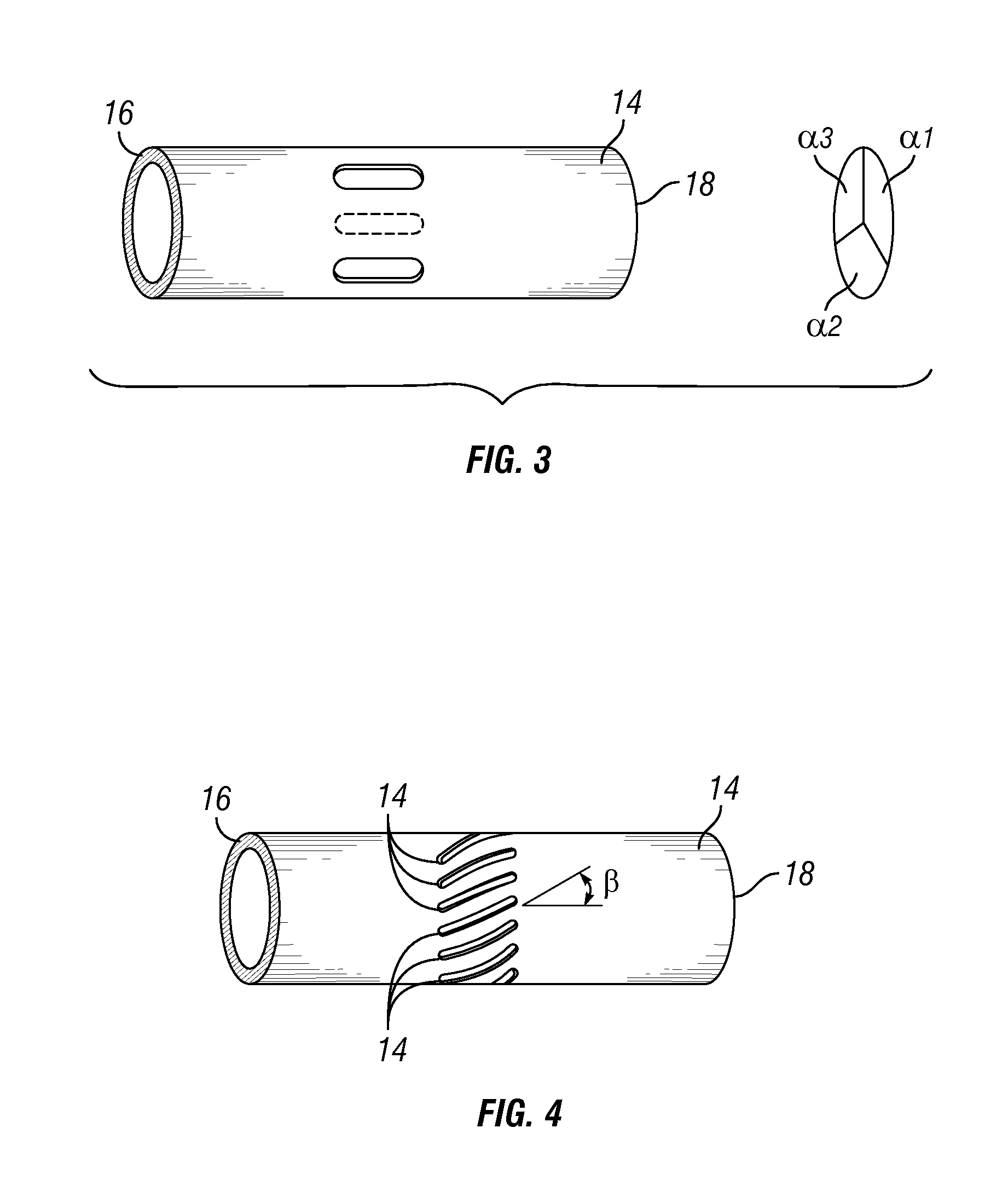

Methods of producing flow-through passages in casing, and methods of using such casing

Methods of making and using wellbore casing are described, one method comprising providing a plurality of flow-through passages in a portion of a casing while the casing is out of hole; temporarily plugging the flow-through passages with a composition while out of hole; running the casing in hole in a wellbore intersecting a hydrocarbon-bearing formation; and exposing the composition to conditions sufficient to displace the composition from the flow-through passages while in hole. Methods of using the casing may include pumping a stimulation treatment fluid through the casing string and into a formation through the flow-through passages in the first casing joint; plugging the flow-through passages in the first casing section; and exposing a second casing joint of the casing string to conditions sufficient to displace the composition from the flow-through passages in the second casing joint.

Owner:SCHLUMBERGER TECH CORP

Casing strings and methods of using such strings in subterranean cementing operations

Improved casing strings, and methods of using improved casing strings in subterranean cementing operations, are provided. An example of an apparatus is a pipe string comprising at least one pipe section and a delivery system of an activator. Another example of an apparatus is a pipe string comprising at least one pipe section and a delivery system of a set retarder. An example of a method is a method of cementing in a subterranean formation. Other examples of methods are methods of cementing in a subterranean formation comprising a well bore.

Owner:HALLIBURTON ENERGY SERVICES INC

Annulus pressure control drilling systems and methods

In one embodiment, a method for drilling a wellbore includes an act of drilling the wellbore by injecting drilling fluid through a tubular string disposed in the wellbore, the tubular string comprising a drill bit disposed on a bottom thereof. The drilling fluid exits the drill bit and carries cuttings from the drill bit. The drilling fluid and cuttings (returns) flow to a surface of the wellbore via an annulus defined by an outer surface of the tubular string and an inner surface of the wellbore. The method further includes an act performed while drilling the wellbore of measuring a first annulus pressure (FAP) using a pressure sensor attached to a casing string hung from a wellhead of the wellbore. The method further includes an act performed while drilling the wellbore of controlling a second annulus pressure (SAP) exerted on a formation exposed to the annulus.

Owner:WEATHERFORD TECH HLDG LLC

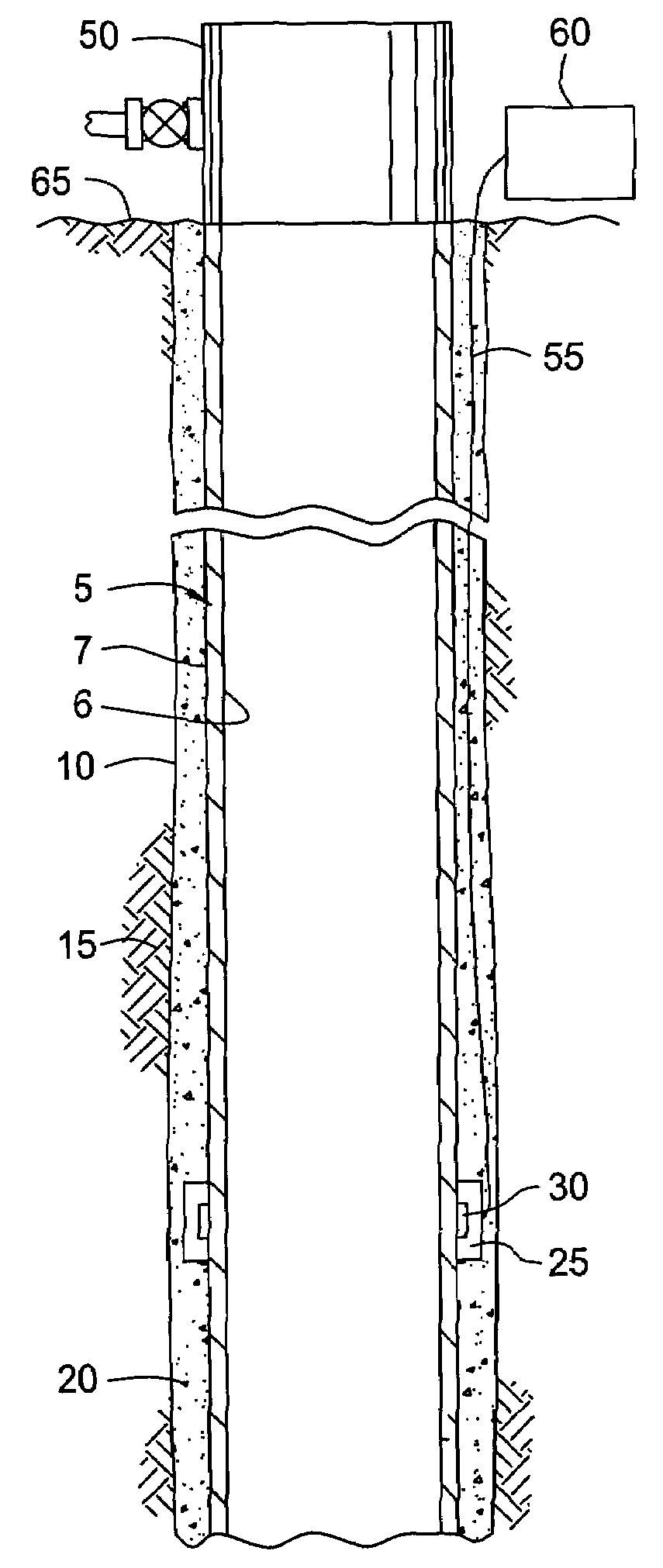

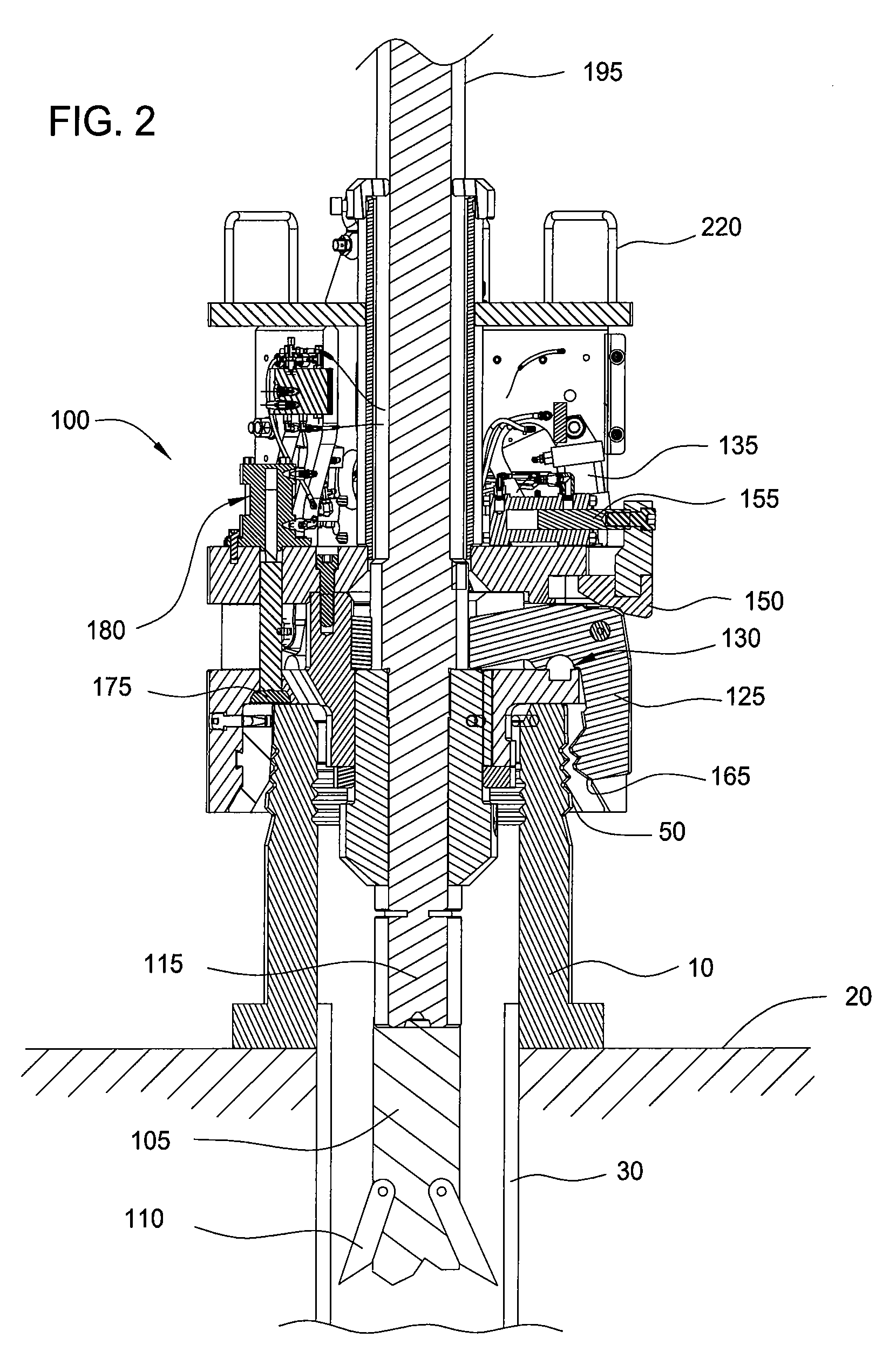

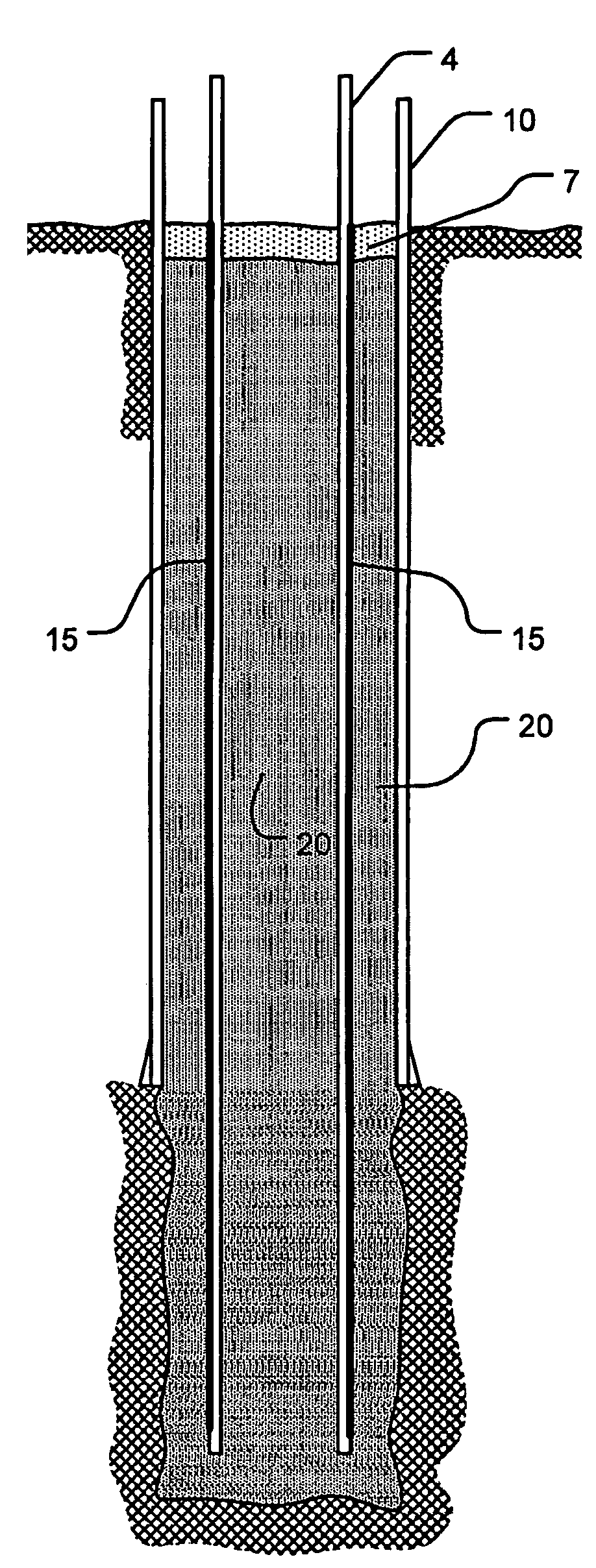

Permanent downhole deployment of optical sensors

The present invention involves methods and apparatus for permanent downhole deployment of optical sensors. Specifically, optical sensors may be permanently deployed within a wellbore using a casing string. In one aspect, one or more optical sensors are disposed on, in, or within the casing string. The optical sensors may be attached to an outer surface of the casing string or to an inner surface of the casing string, as well as embedded within a wall of the casing string. The optical sensors are capable of measuring wellbore parameters during wellbore operations, including completion, production, and intervention operations.

Owner:WEATHERFORD TECH HLDG LLC

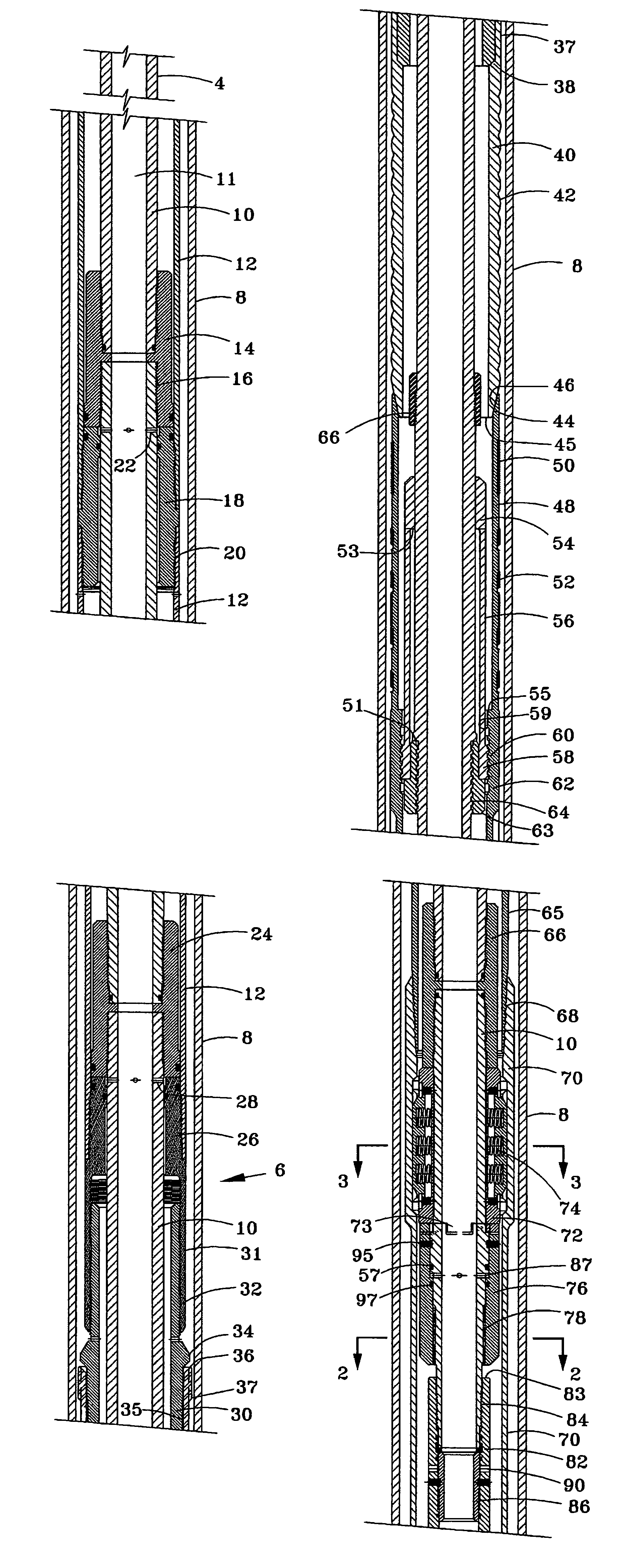

Method and apparatus for drilling with casing

InactiveUS7140445B2Operational securityEliminate needDrilling rodsConstructionsTop driveCasing string

Methods and apparatus for drilling with a top drive system are provided. In one aspect, a top drive system includes a top drive, top drive adapter, and a tubular positioning apparatus. In another aspect, the top drive adapter is pivotably connected to the top drive for pivoting the top drive adapter toward the casing string with respect to the top drive. In another aspect, the system includes a telescopic link system connected to a lower portion of the top drive adapter to move the casing string into engagement with the top drive adapter. In another aspect, the top drive adapter includes a housing operatively connected to the top drive and a plurality of retaining members disposed in the housing for gripping the tubular. In another aspect, the tubular positioning apparatus includes a gripping member for engaging a tubular and a conveying member for positioning the gripping member. A spinner may be provided to rotate the tubular.

Owner:WEATHERFORD TECH HLDG LLC

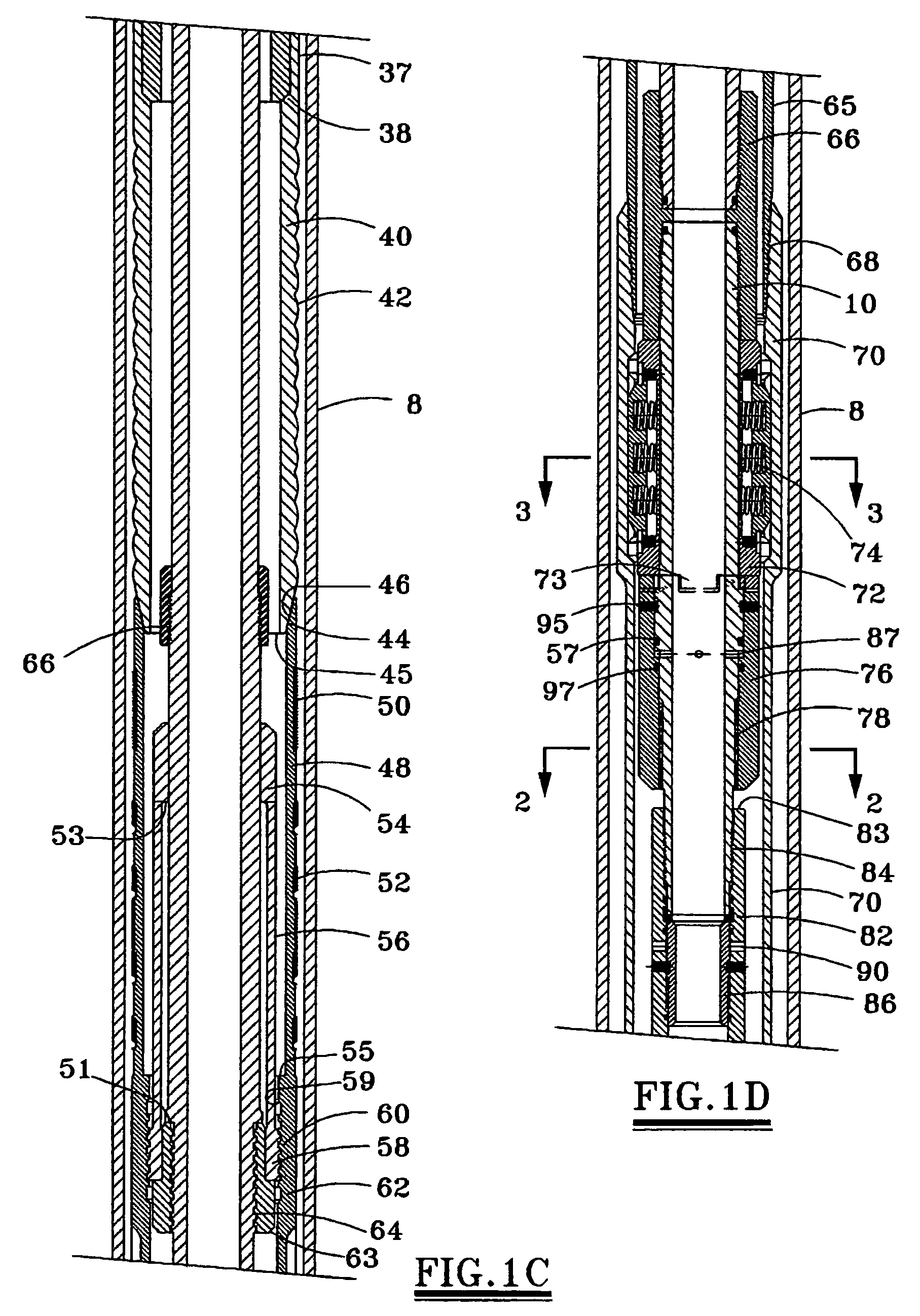

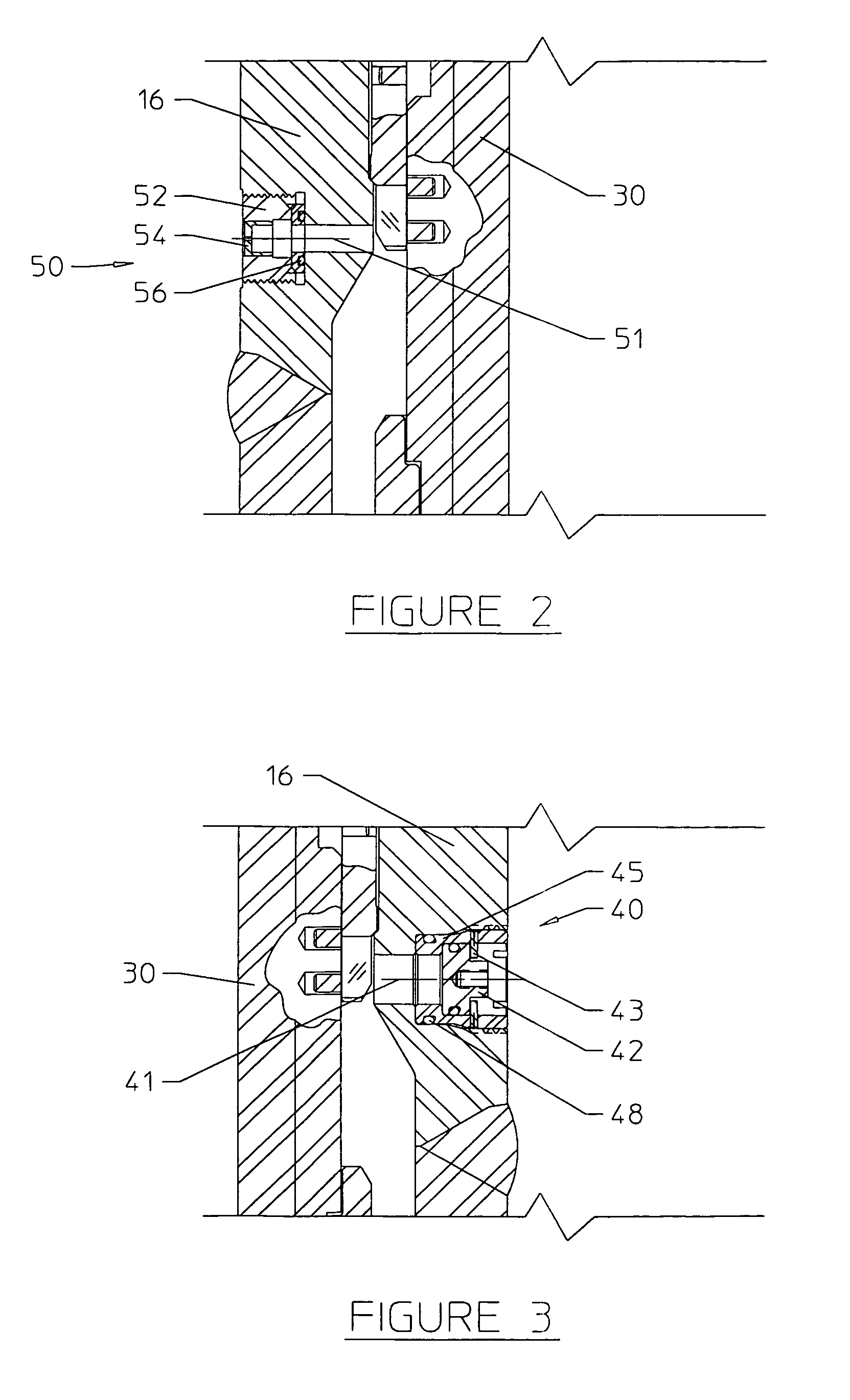

Expandable liner hanger system and method

The liner hanger assembly seals with casing 8 and supports a liner 98 within a well. The tubular liner hanger 48 and a tubular expander 40 may be position downhole on a running tool at a desired depth along the casing string 8. An actuator assembly 6 may forcably move the tubular expander 40 into the tubular hanger, expanding the liner hanger to seal and secure the hanger against the casing string 8. After the running tool has been removed, a seal nipple may be sealed to the sealing sleeve of the tubular expander. A selectively releasable clutch 73 is provided for allowing rotation of the liner to rotate the liner with the running tool, and thereafter to disengage and release the running tool from the set liner hanger.

Owner:TIW

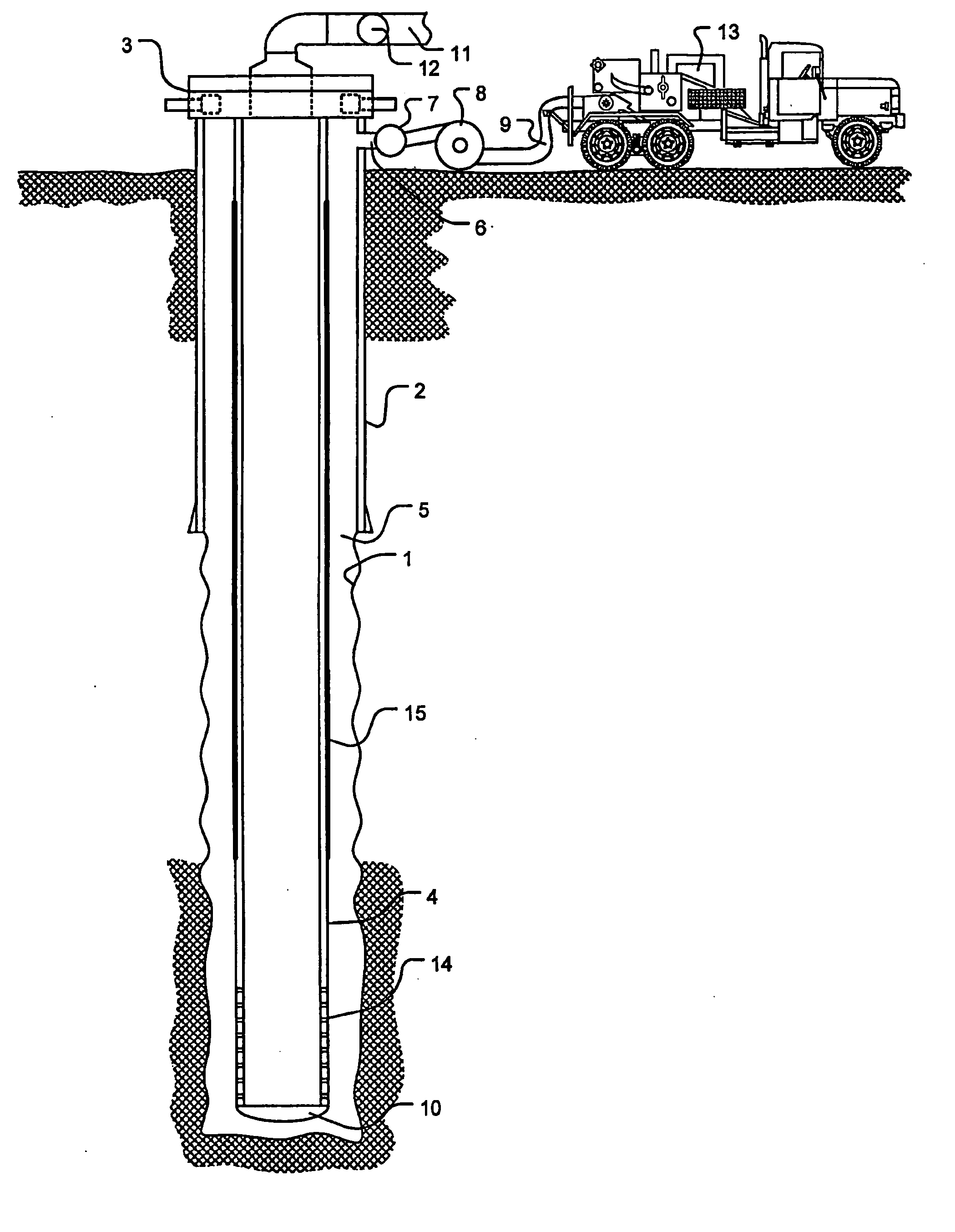

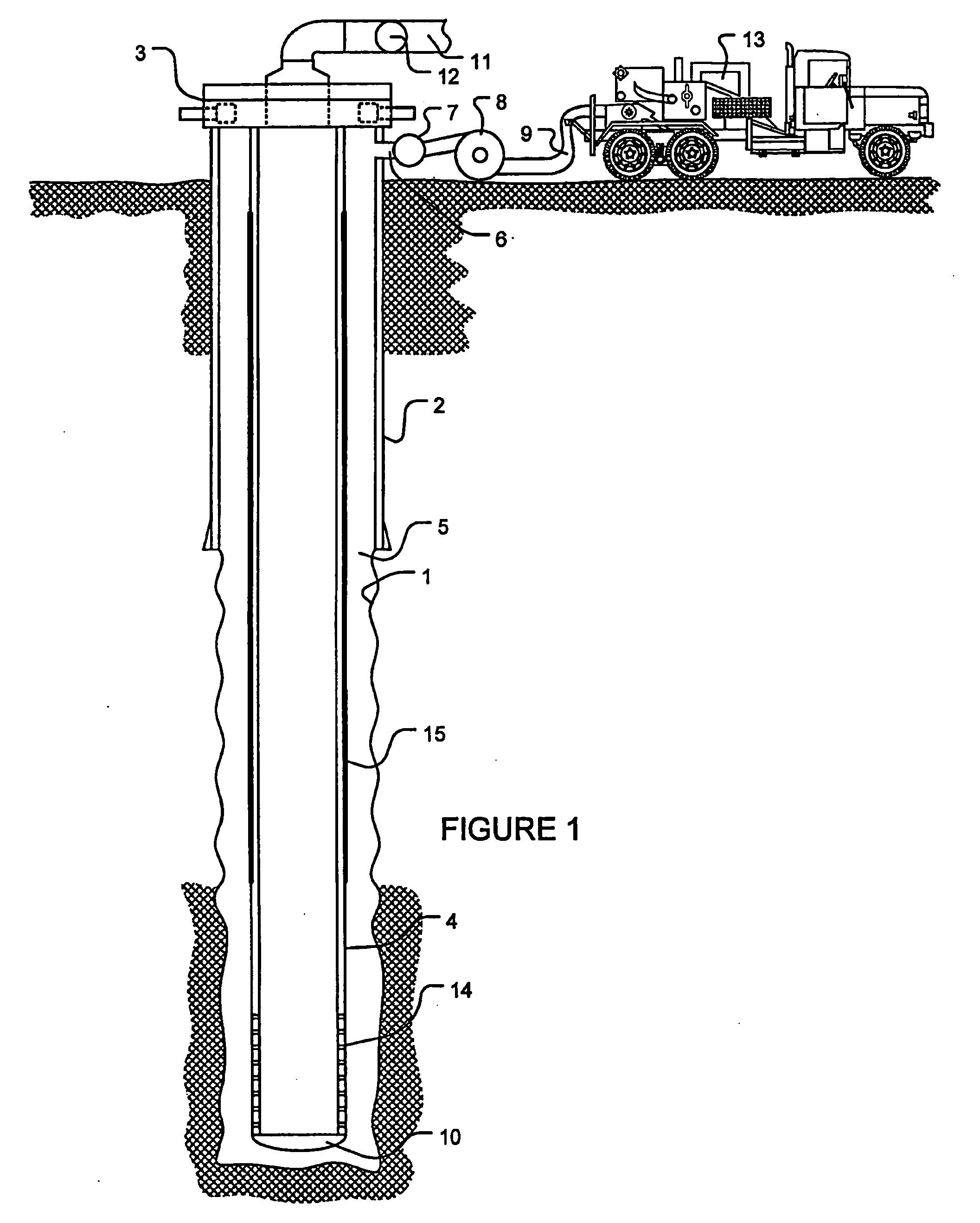

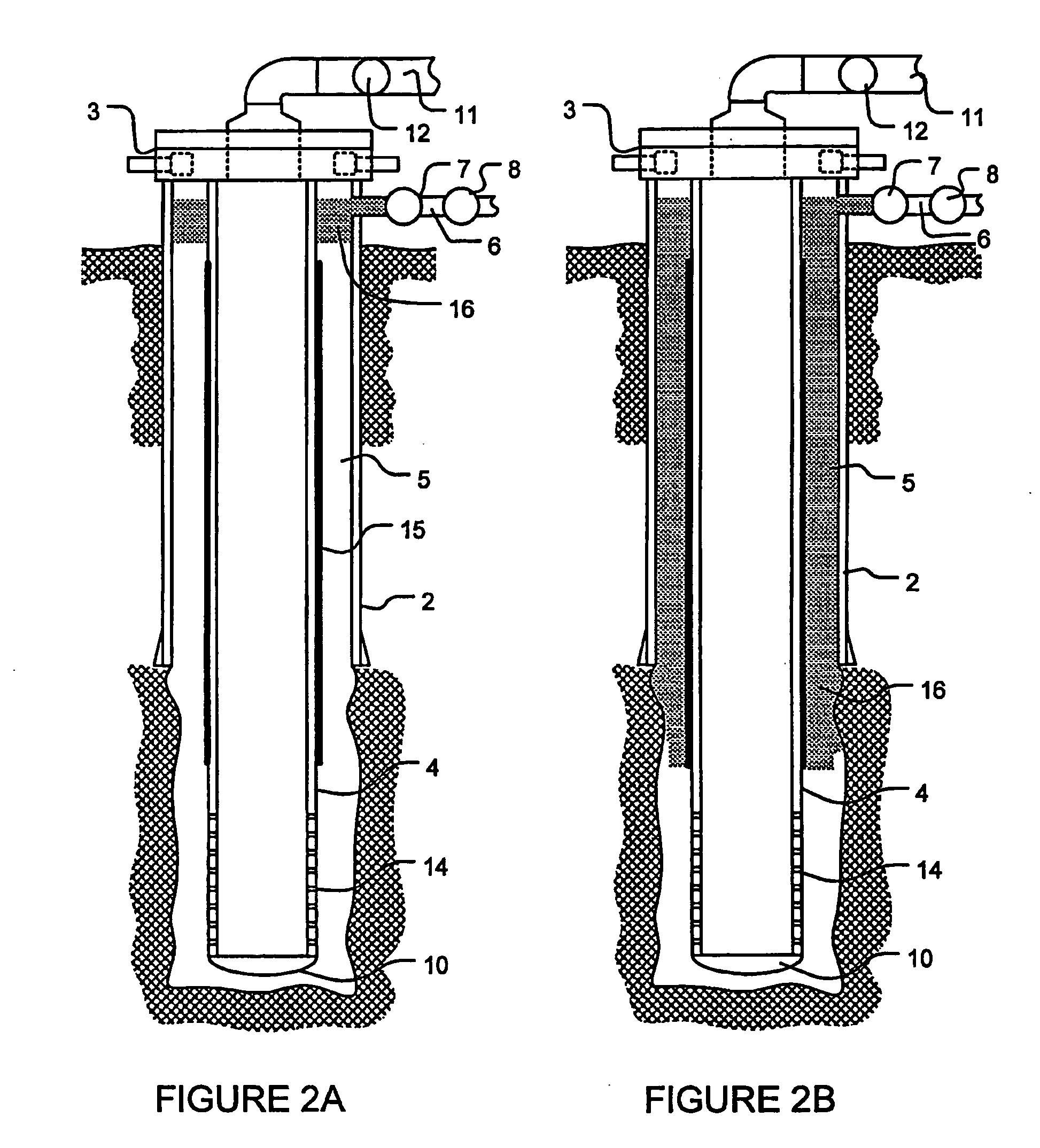

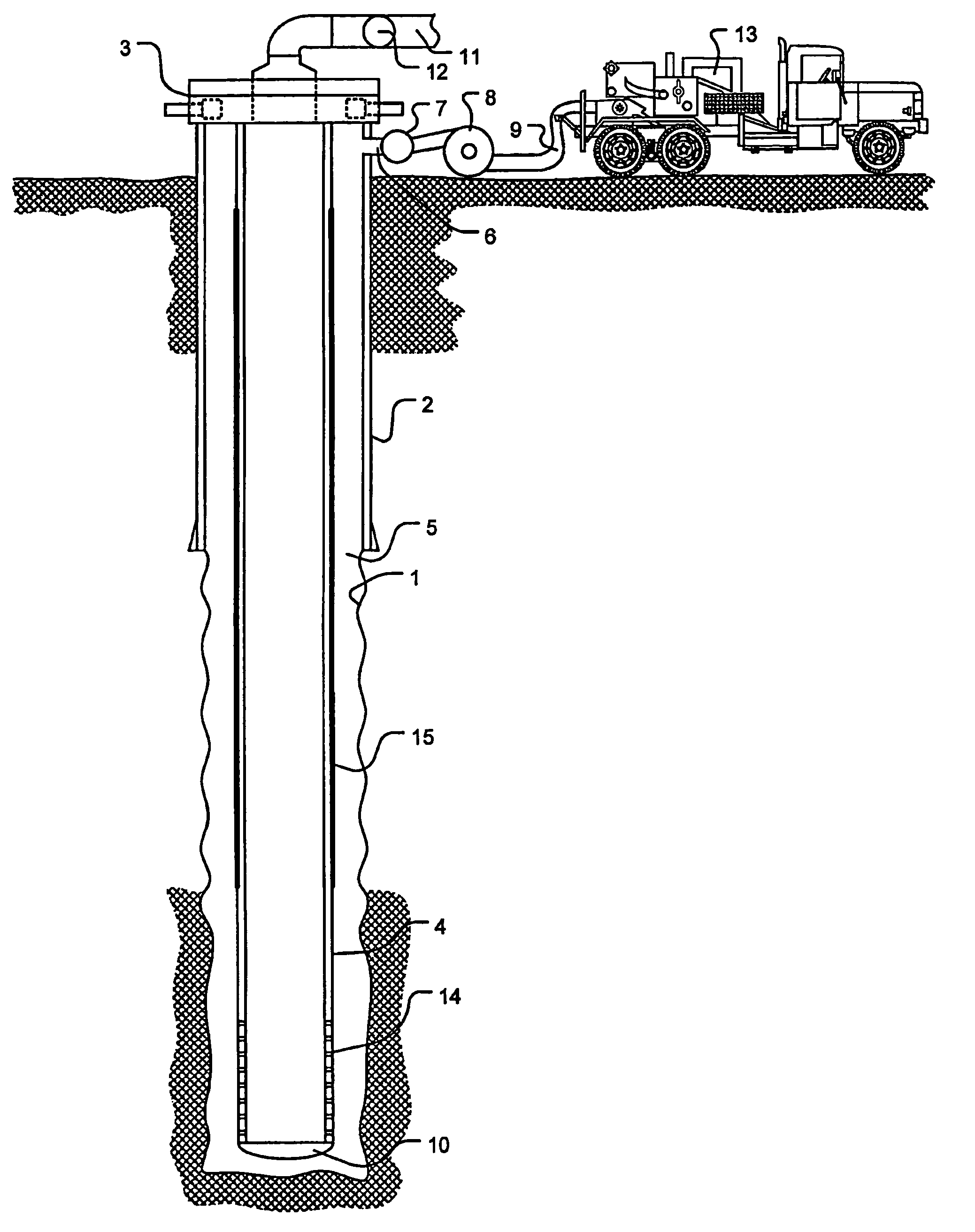

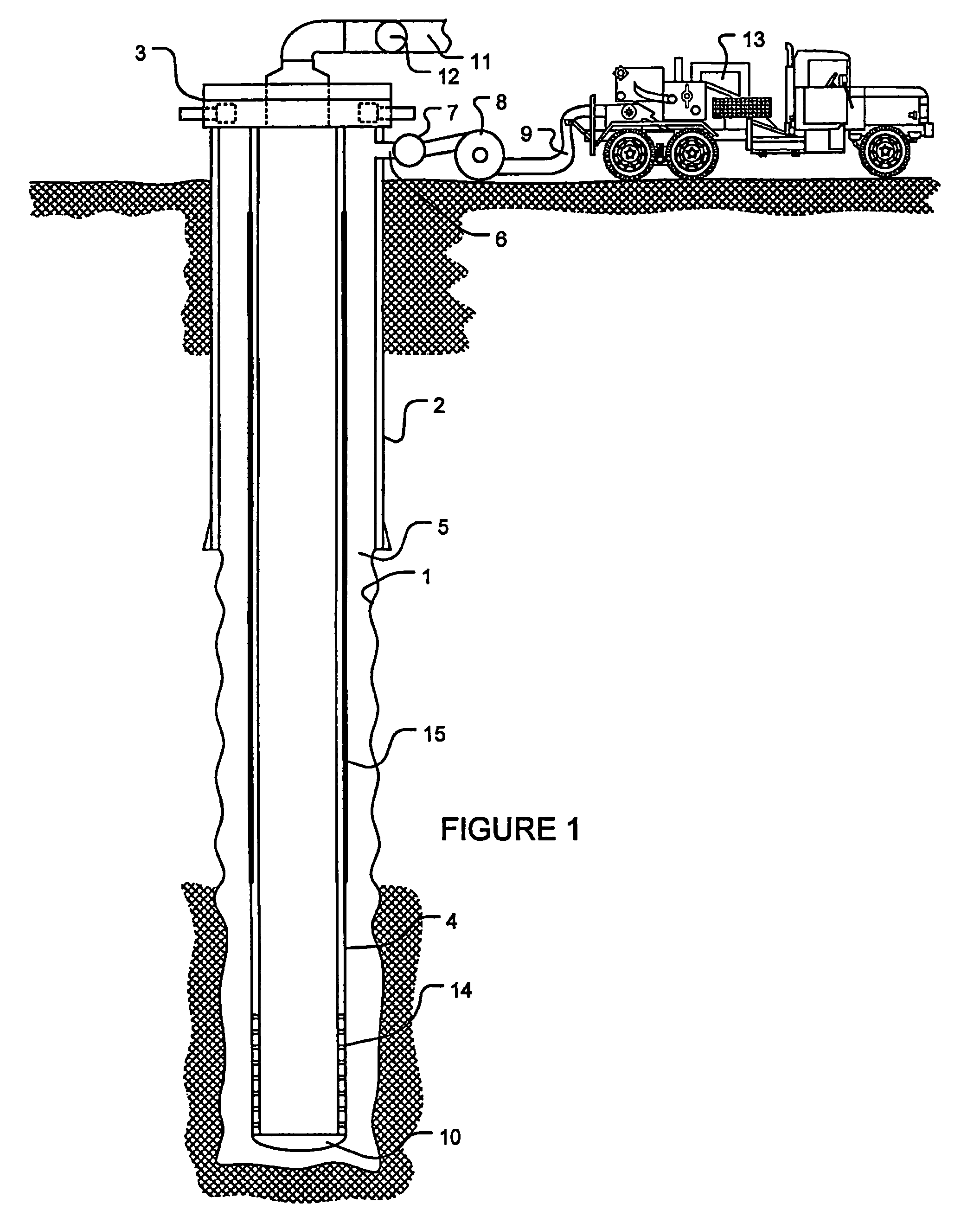

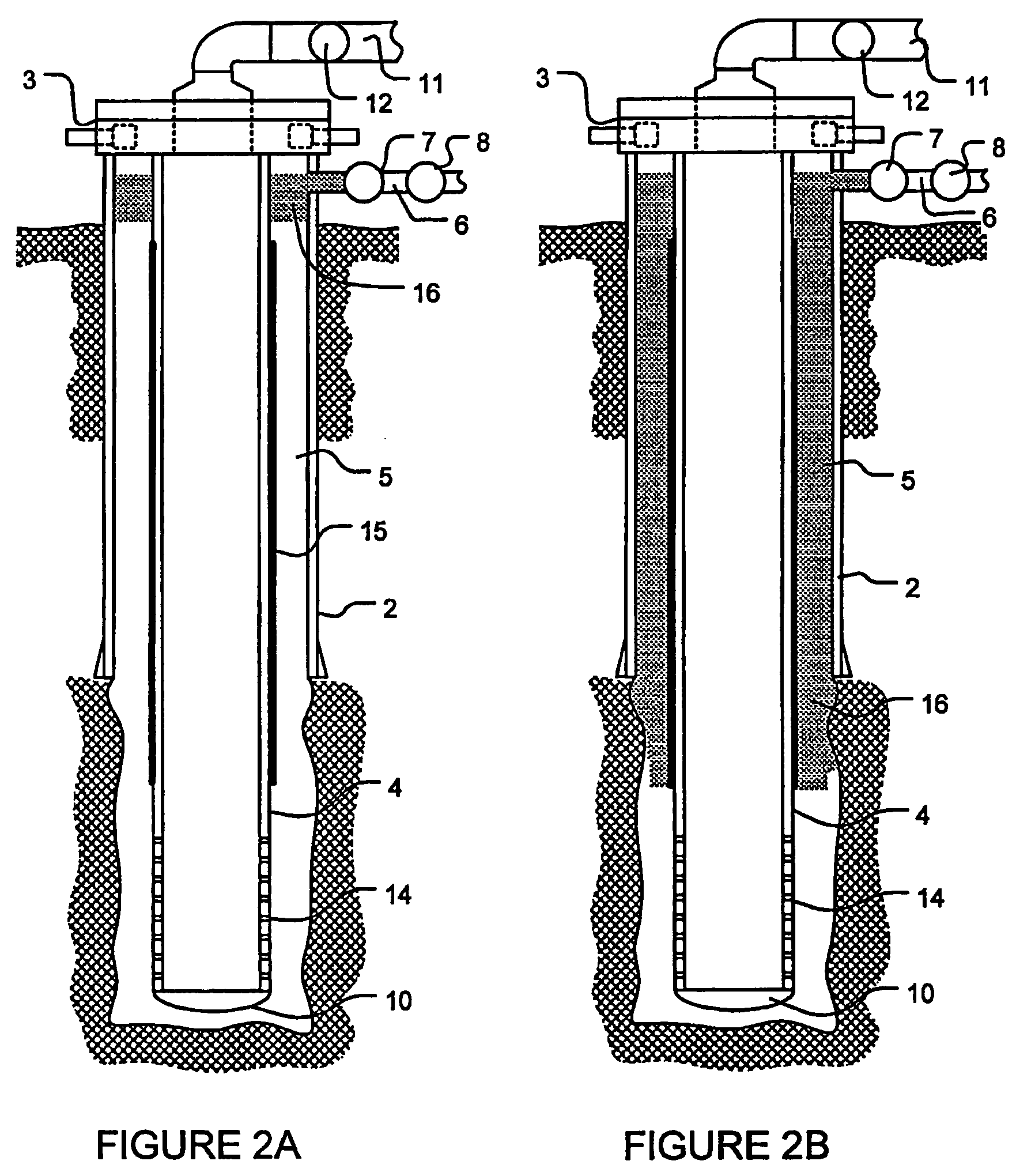

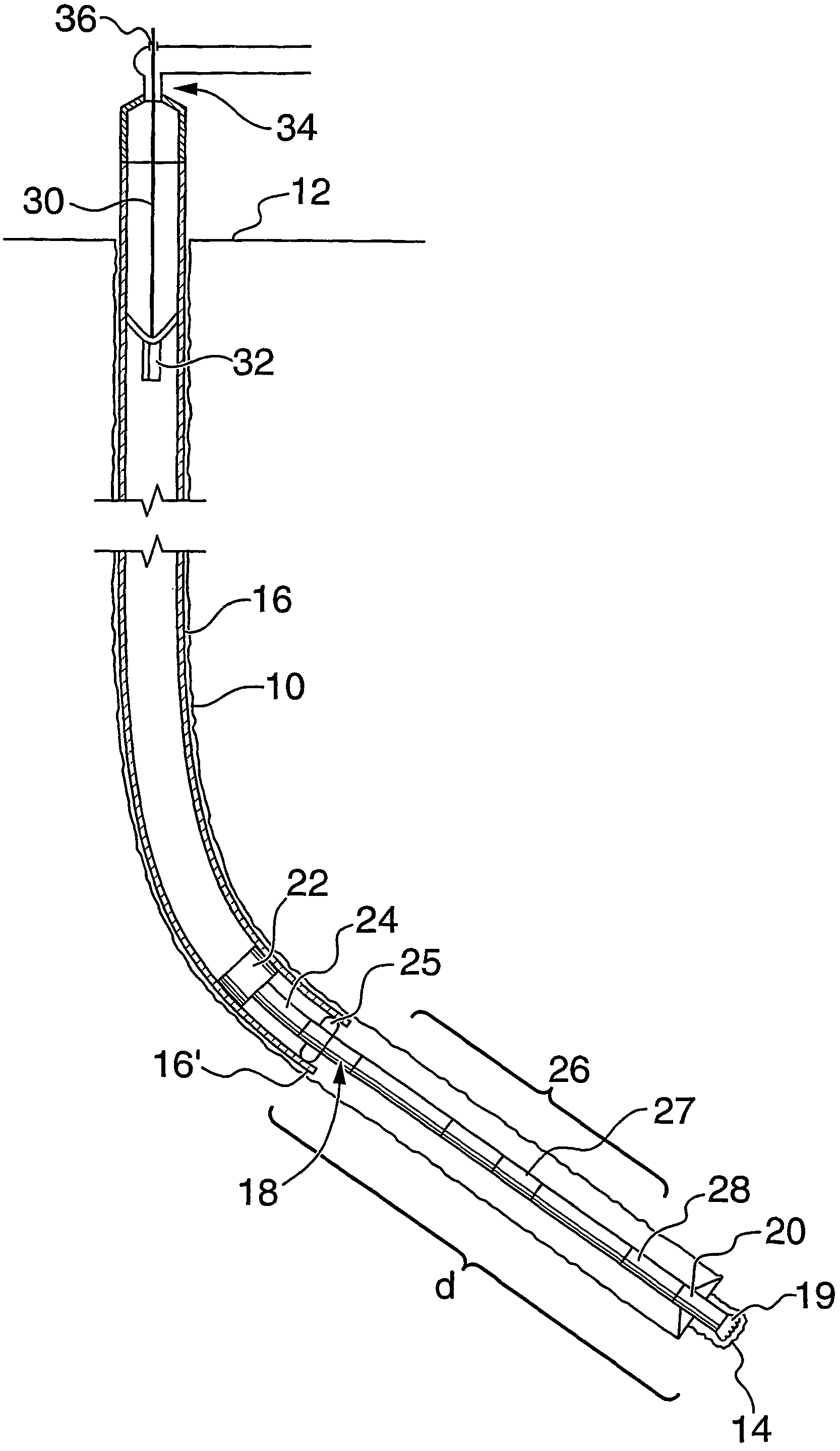

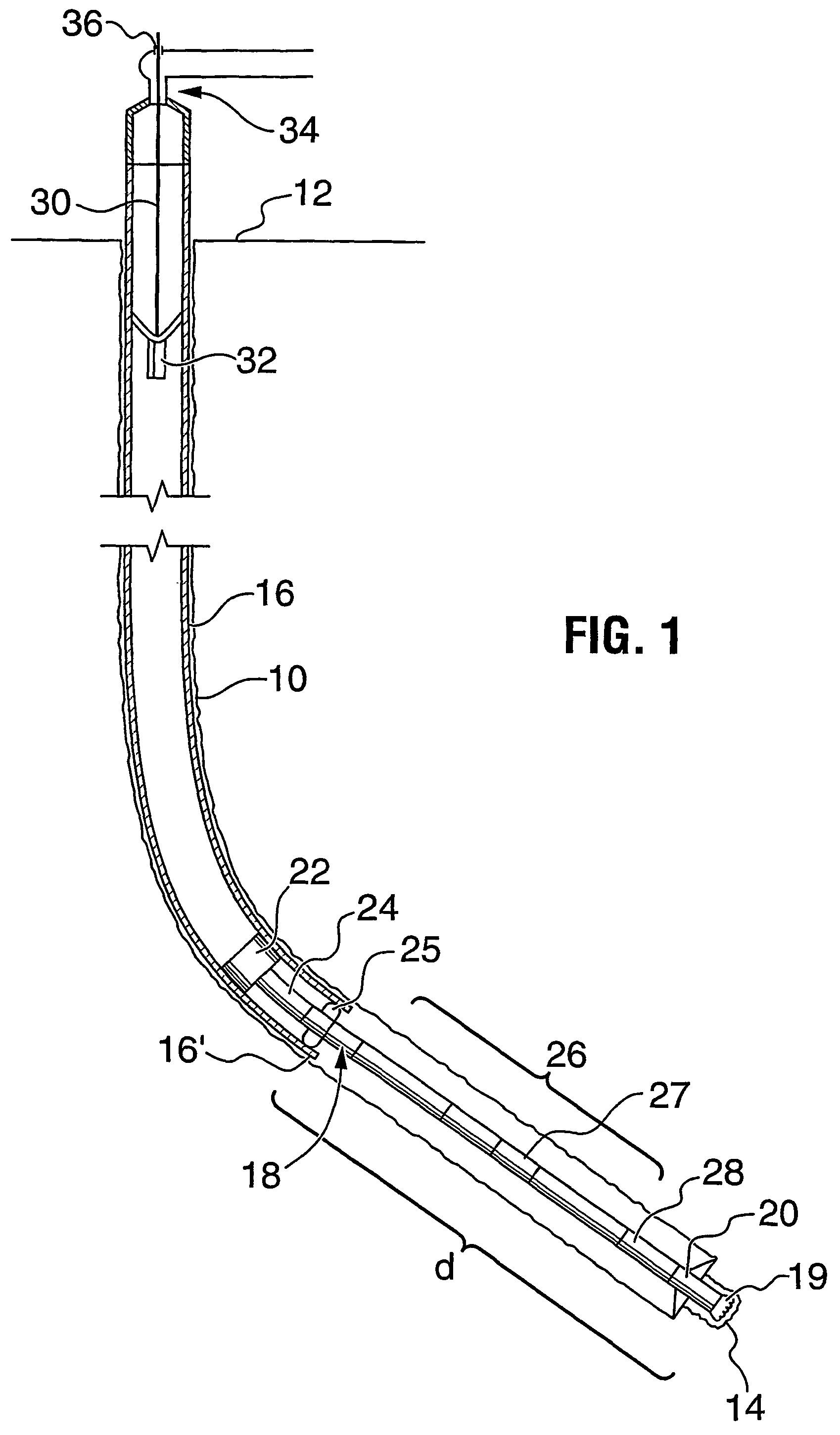

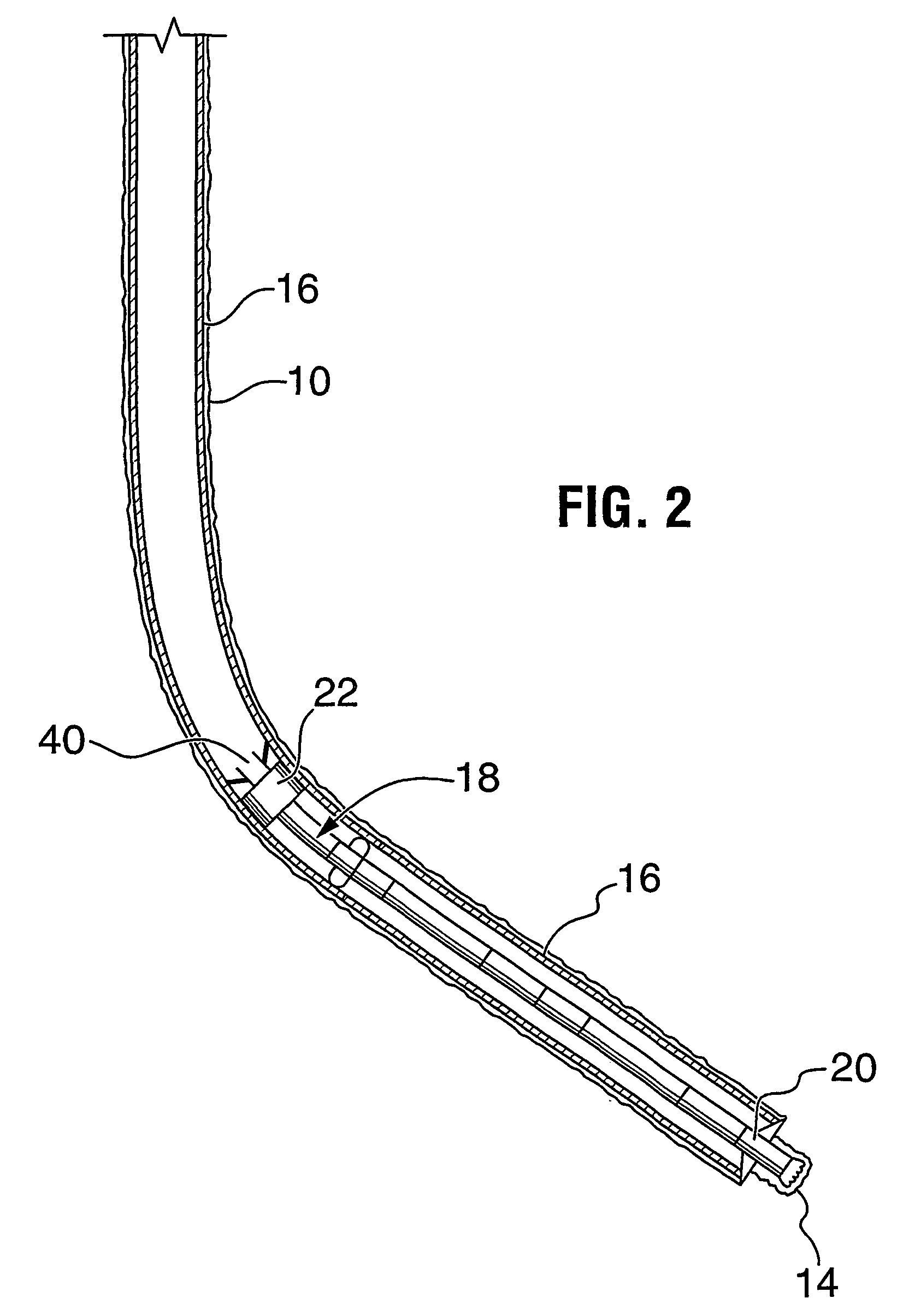

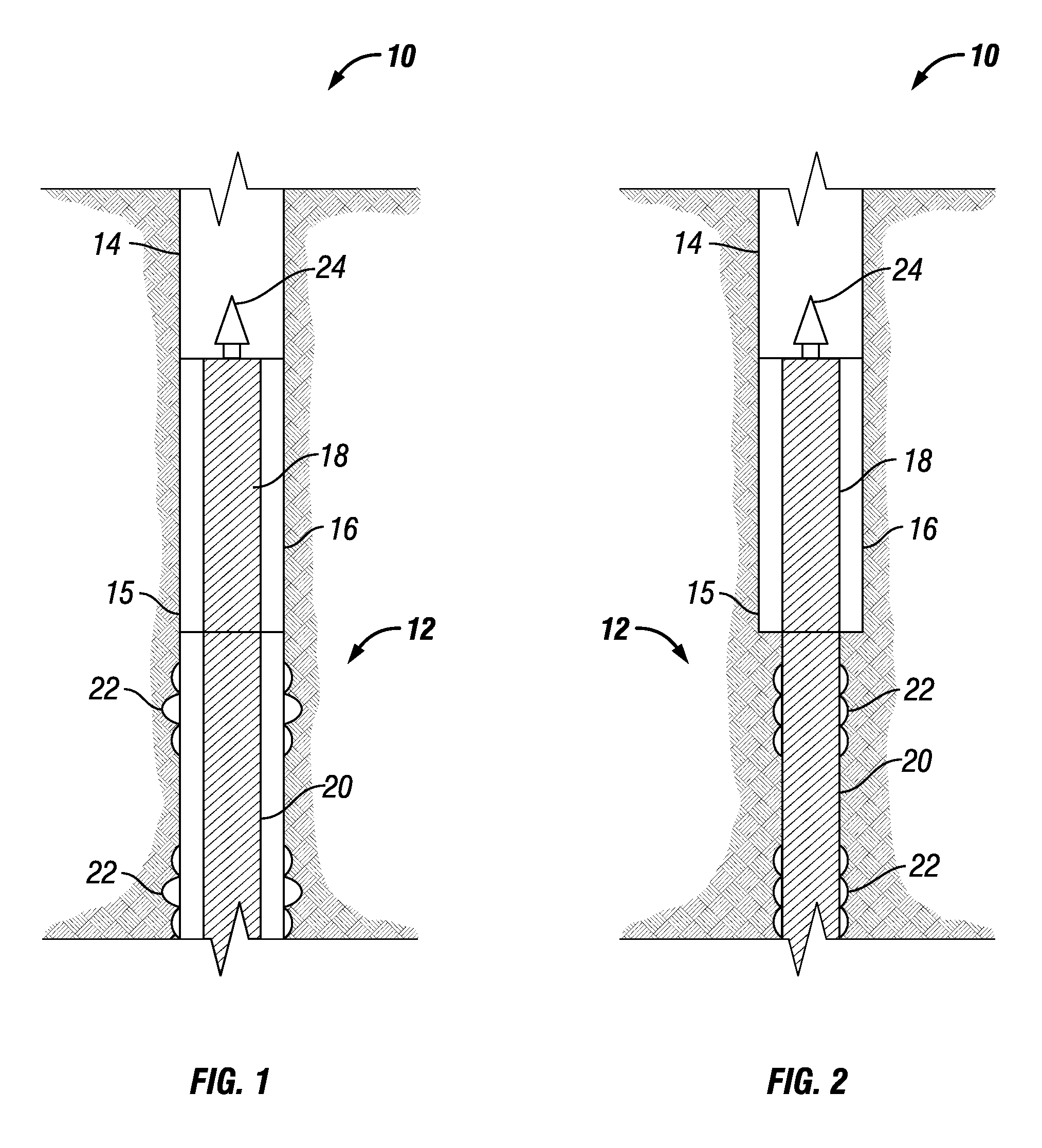

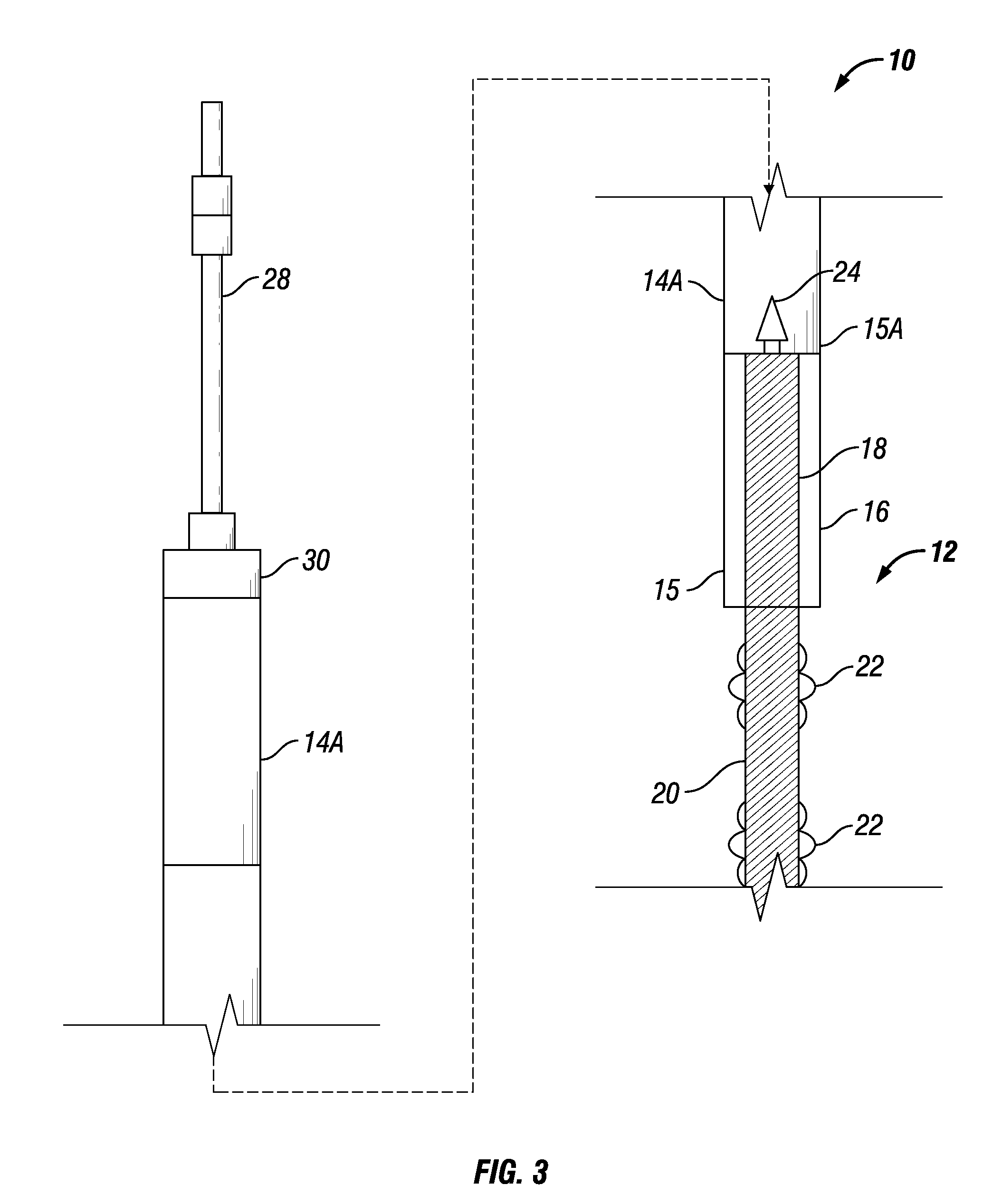

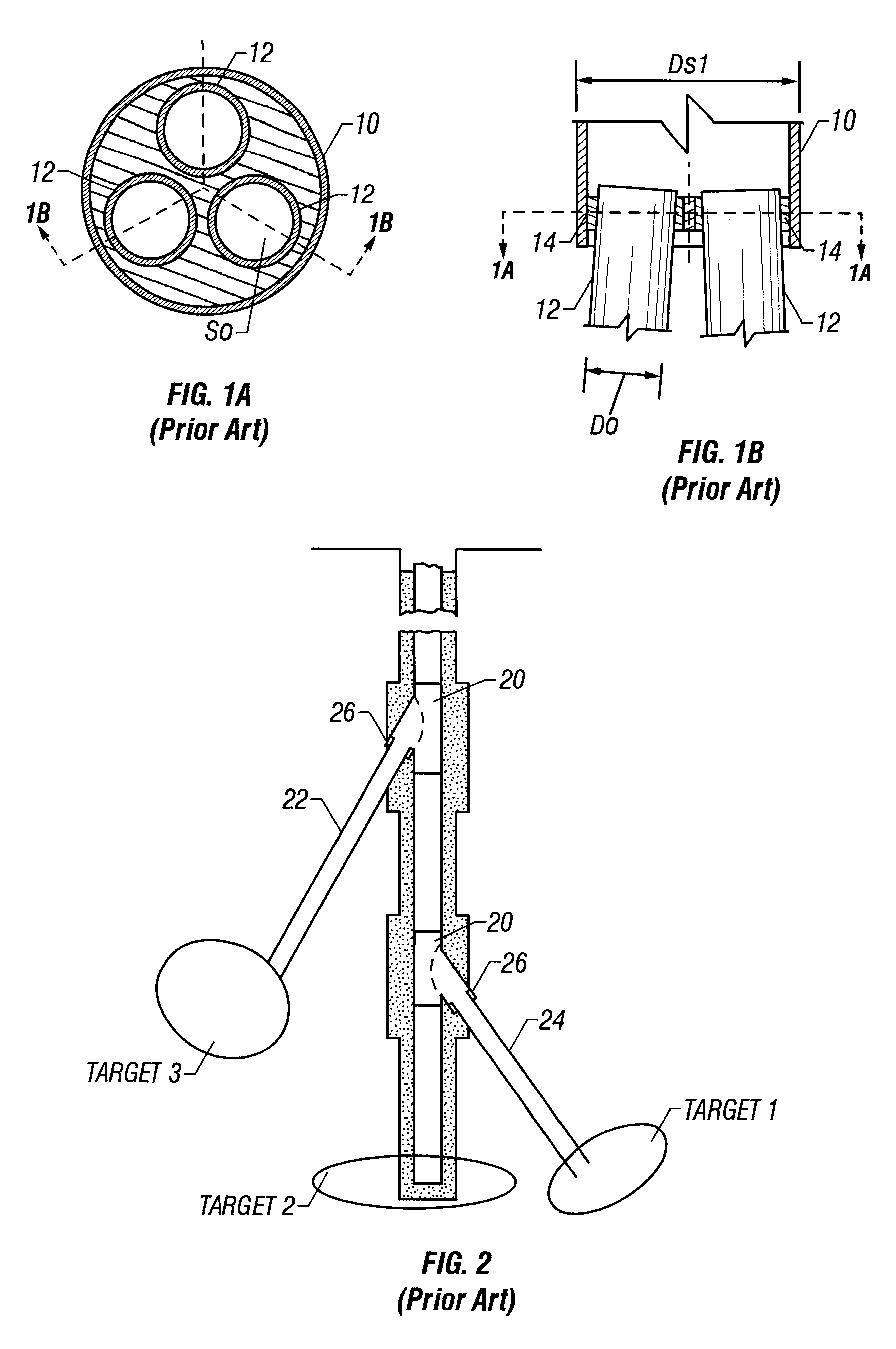

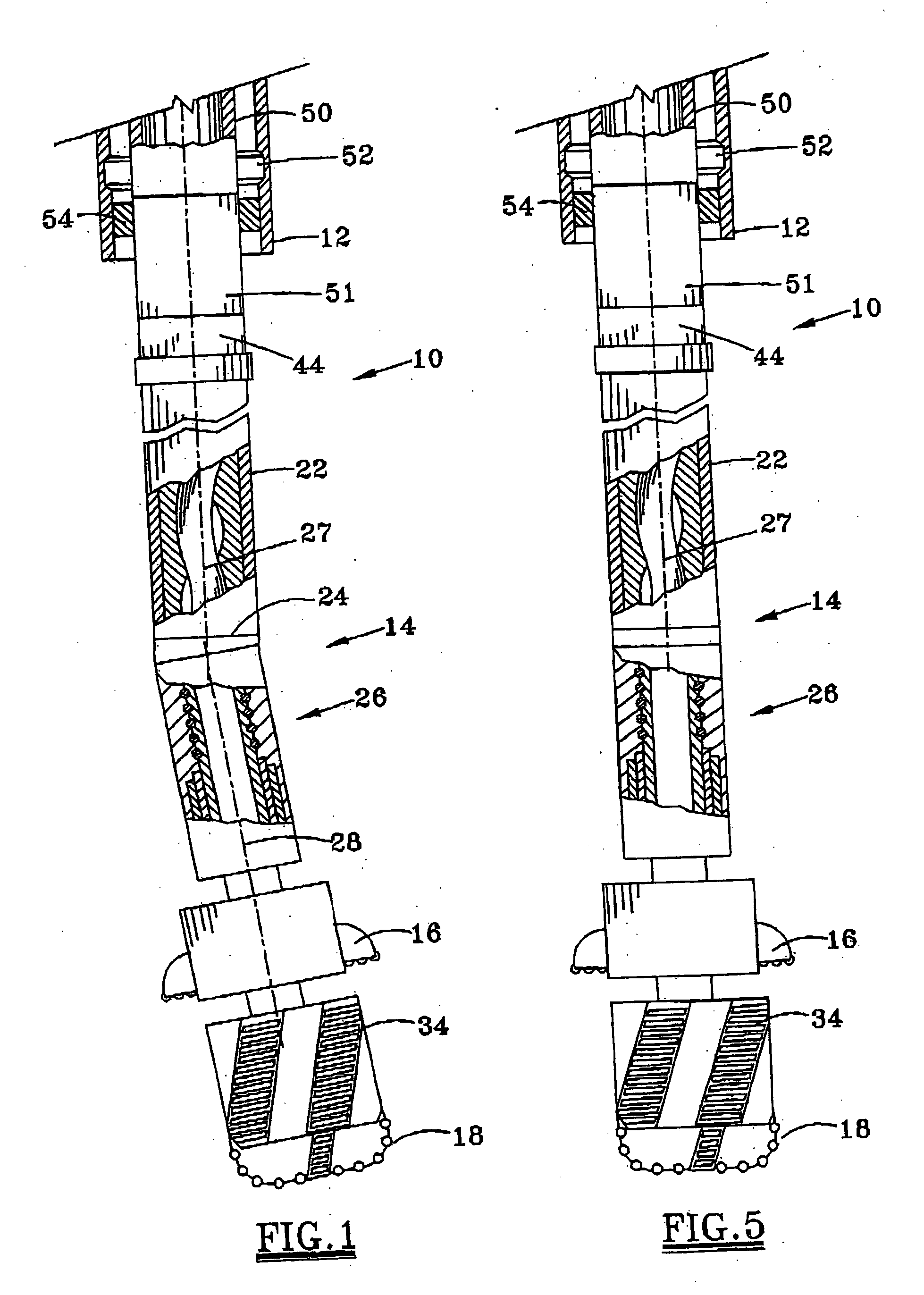

Method for drilling with casing

A method for drilling boreholes using casing (16) as the drill string and for advancing a casing string toward the bottom of the borehole is described. In the method, the drilling assembly (26) is used as a guide over which the drill string (16) is advanced toward the bottom of the borehole prior to removing the drilling assembly from the wellbore.

Owner:SCHLUMBERGER TECH CORP

Method and apparatus of reservoir stimulation while running casing

A method for stimulating a reservoir formation while running a casing string into the wellbore includes the steps of: connecting a stimulation assembly to a casing string, the stimulation assembly including a packer actuator in operational connection with a packer and a logging sensor; running the casing string into the wellbore and positioning the logging assembly proximate to a selected reservoir formation; logging the reservoir formation; positioning the stimulation assembly proximate to the reservoir formation; actuating the packer to substantially isolate the reservoir formation from the wellbore; performing the stimulation operation; releasing the packers from sealing engagement with the wellbore; positioning the logging assembly proximate to the reservoir formation; logging the reservoir formation; and disconnecting the stimulation assembly from the casing string.

Owner:SCHLUMBERGER TECH CORP

Casing hanger assembly with rupture disk in support housing and method

A casing hanger support assembly supports an inner casing string within a well containing an outer casing string and a production tubing string. The casing hanger support housing supports the casing hanger in the well, with a casing hanger being secured to an upper end of the inner casing string. One or more of a rupture disk and a blowout plug are provided in a wall of the casing hanger support housing for maintaining the desired pressure differential between an annulus within the outer casing string and an annulus exterior of the outer casing string, thereby preventing casing collapse or burst.

Owner:DRIL QUIP

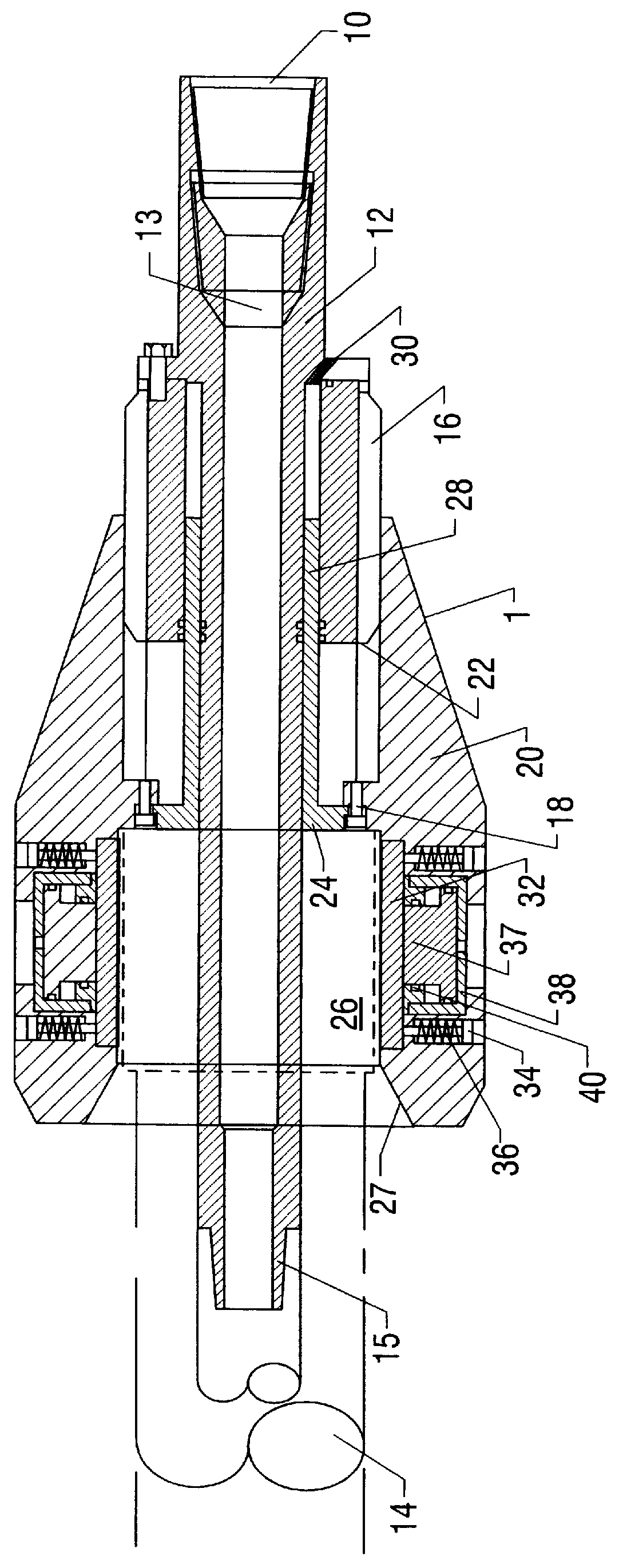

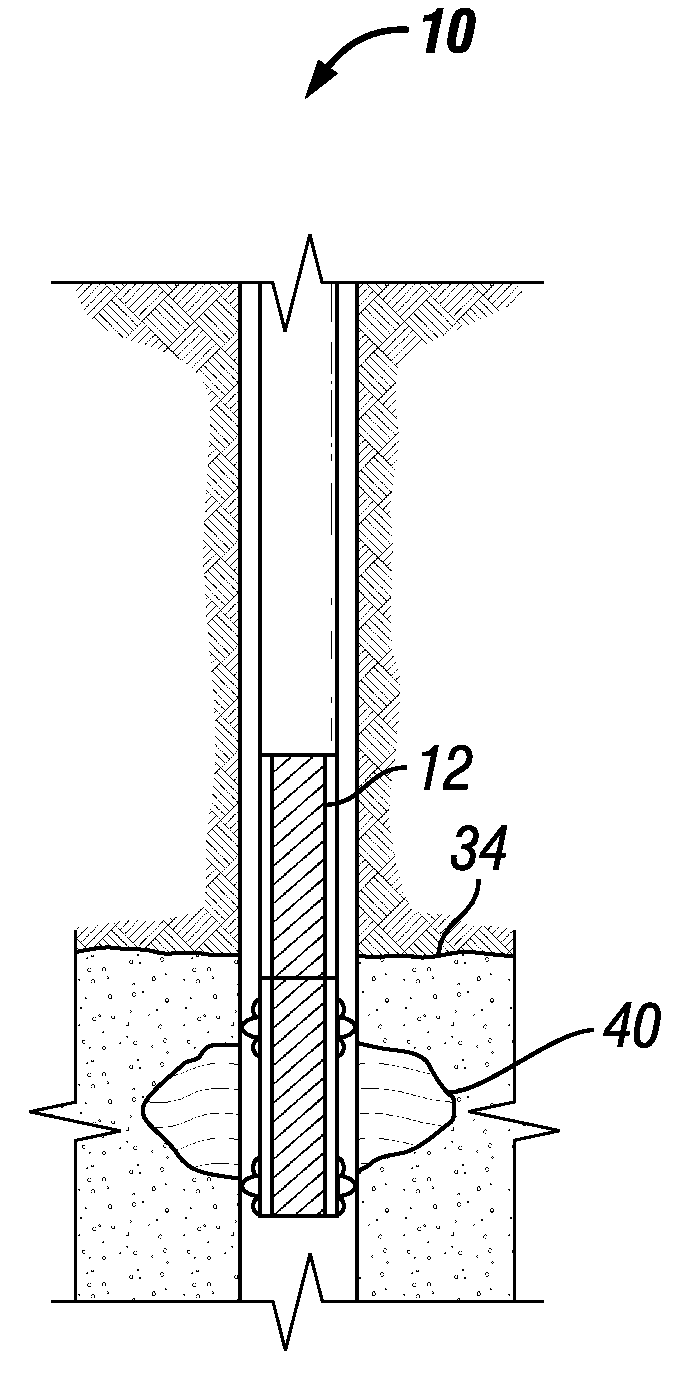

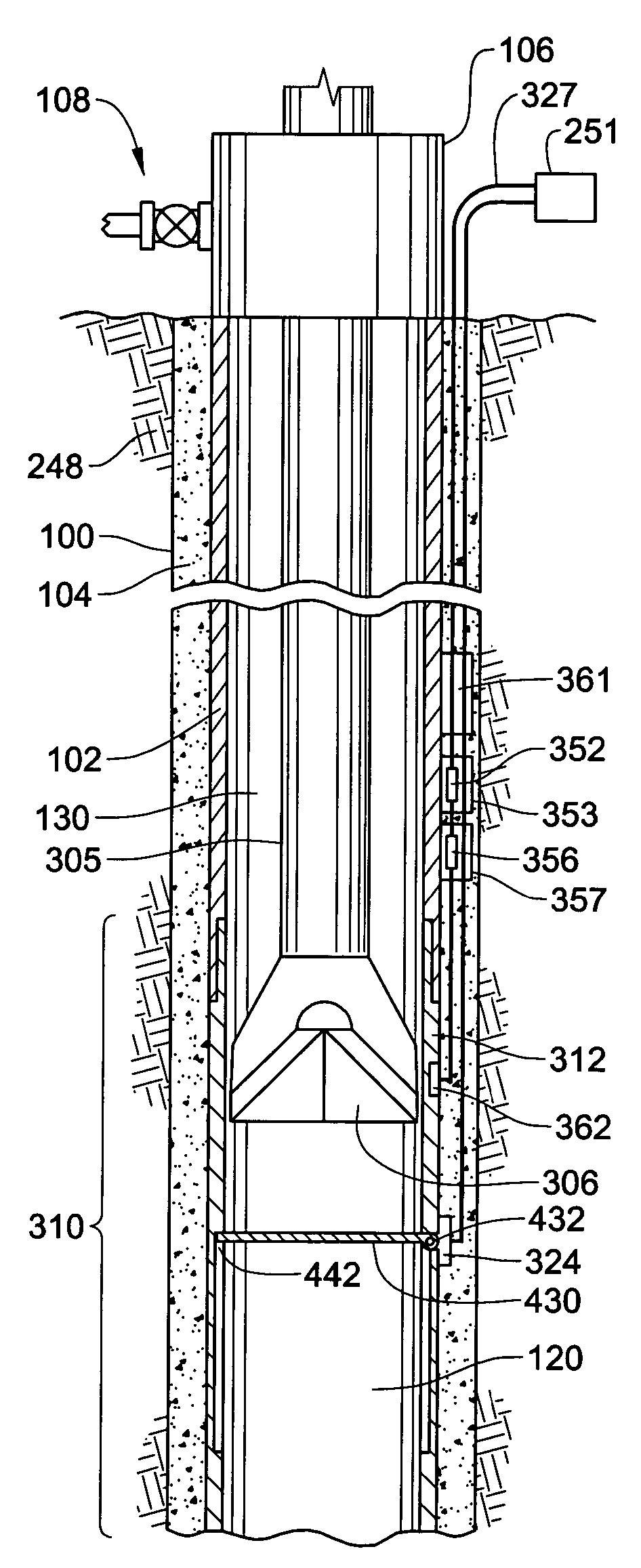

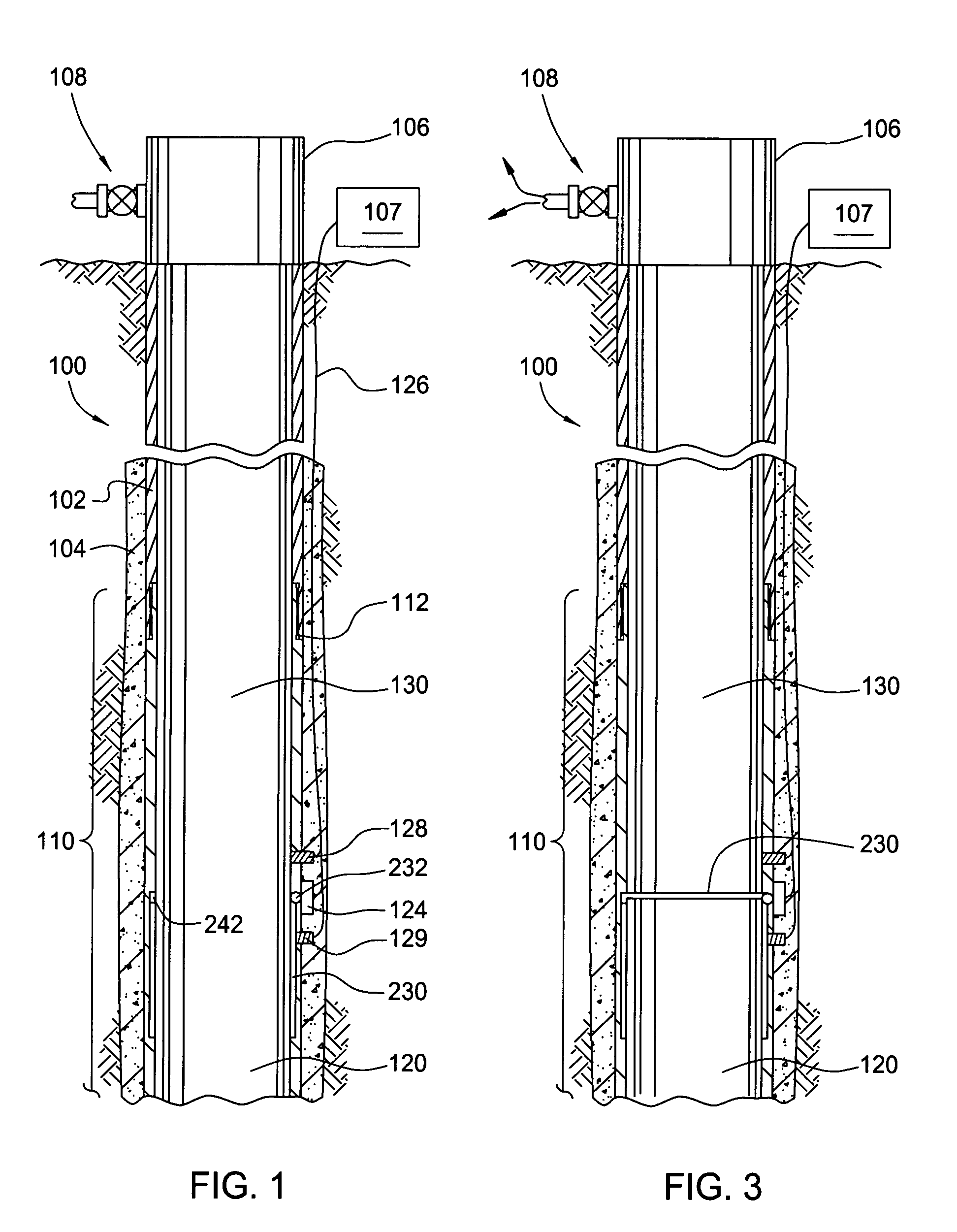

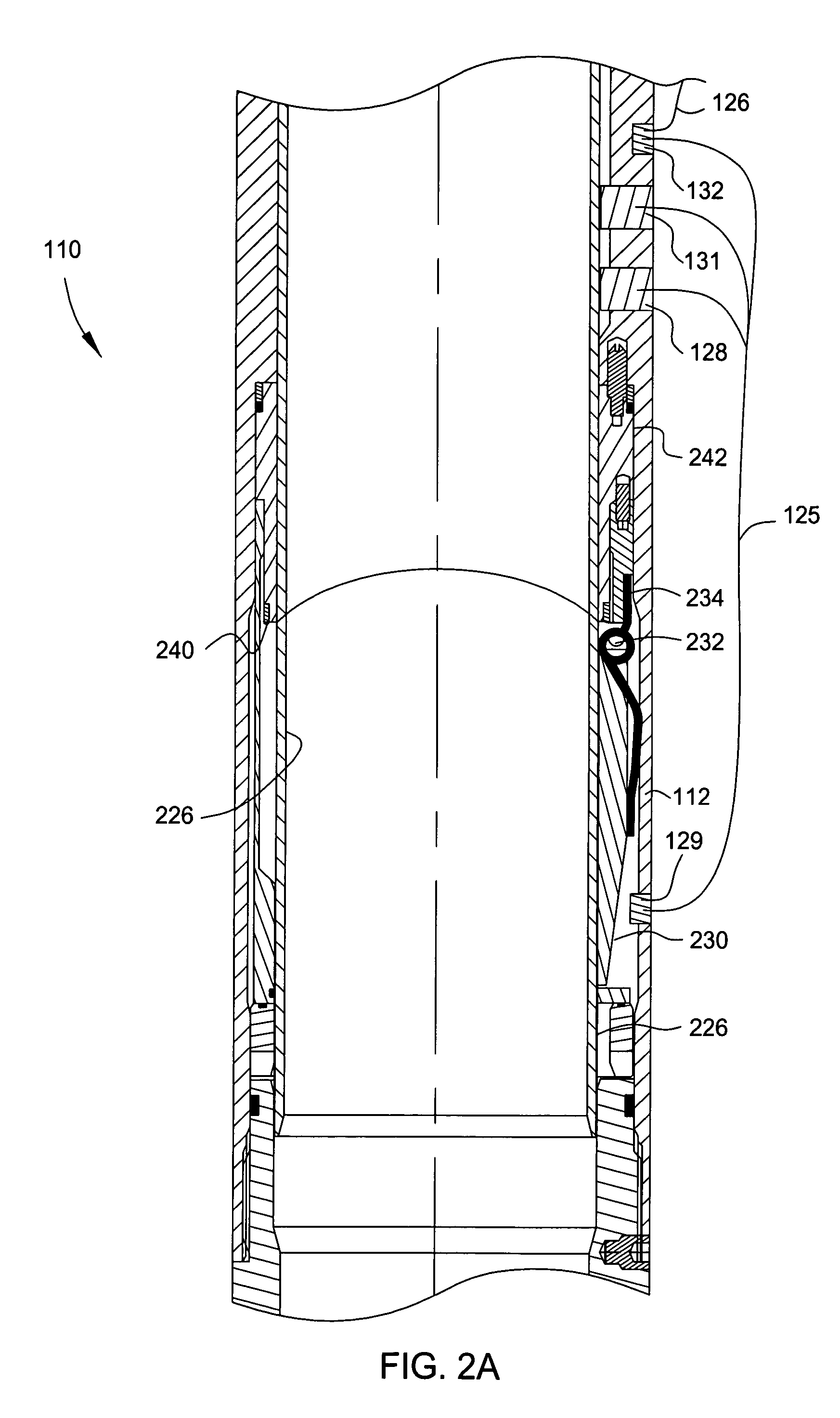

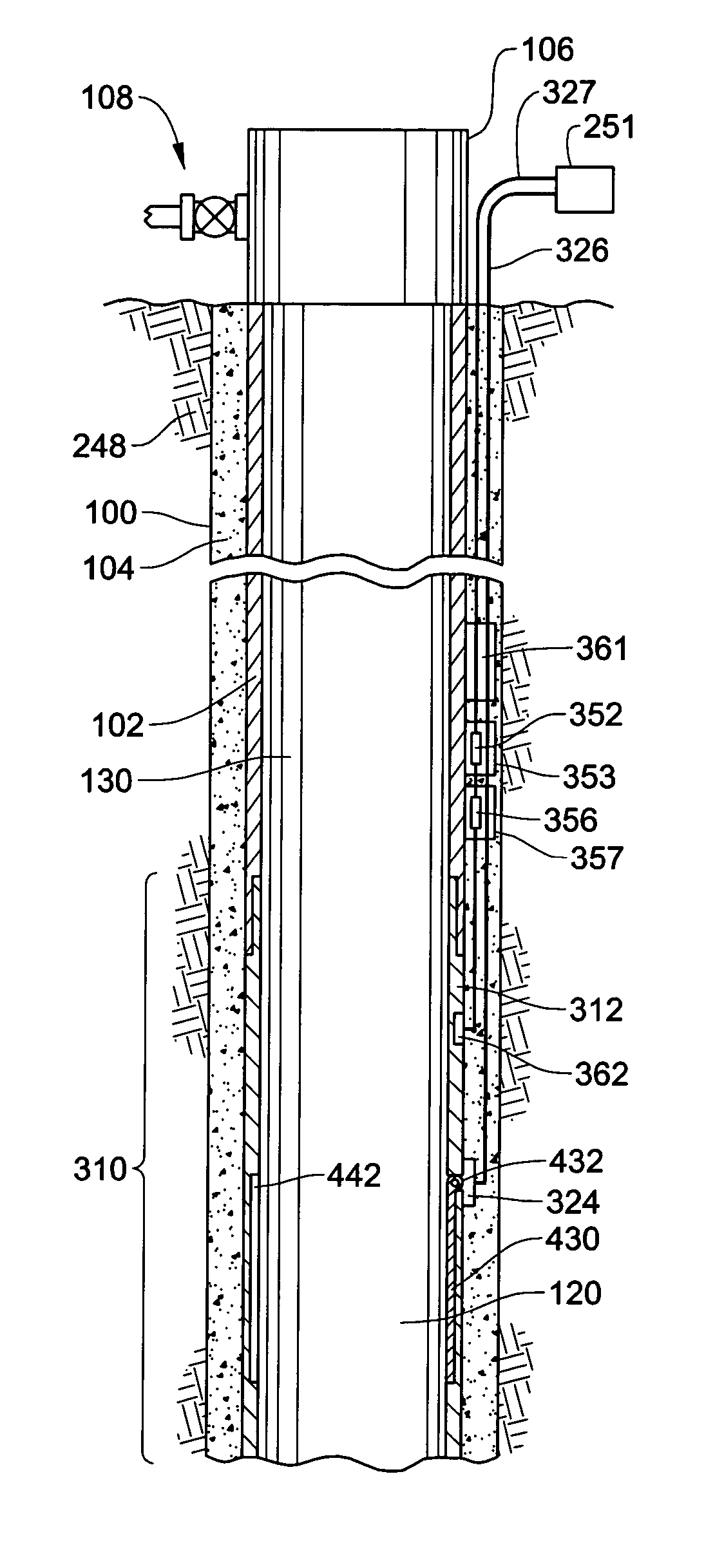

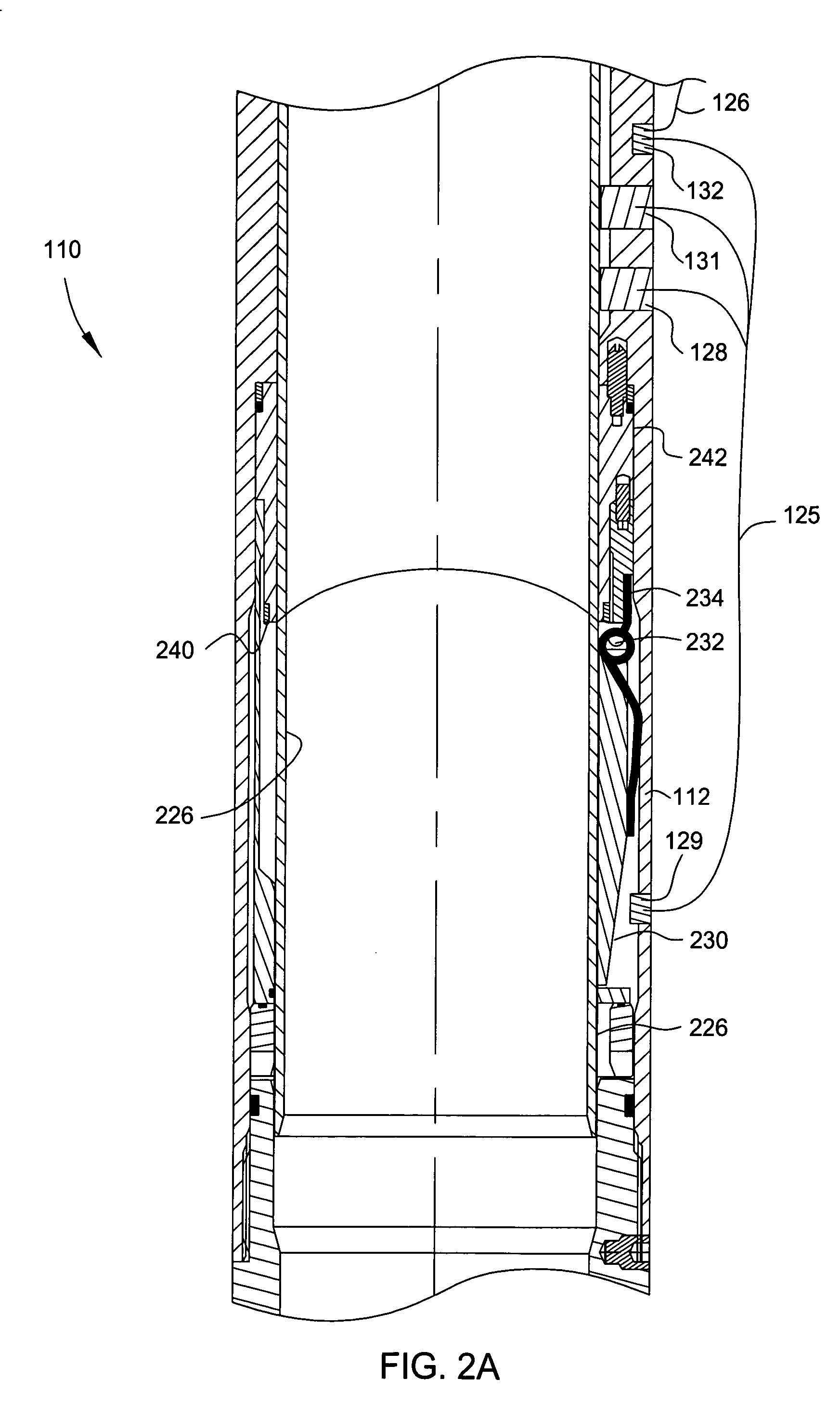

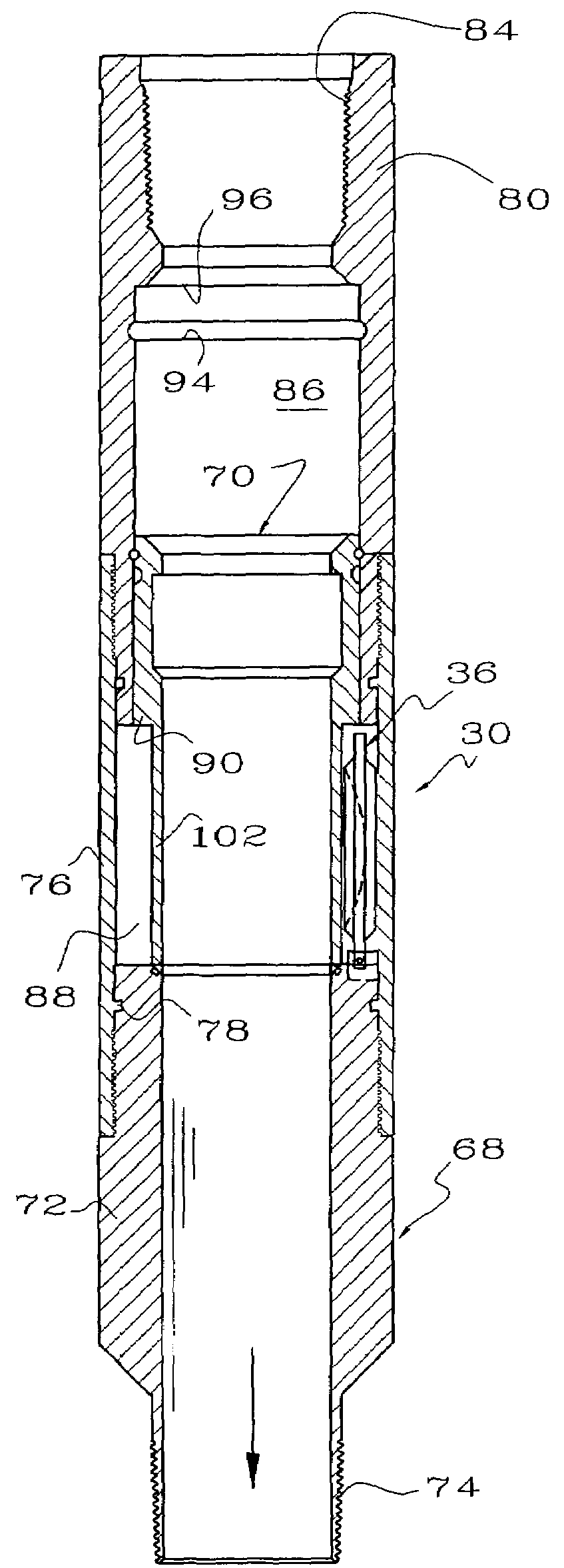

Instrumentation for a downhole deployment valve

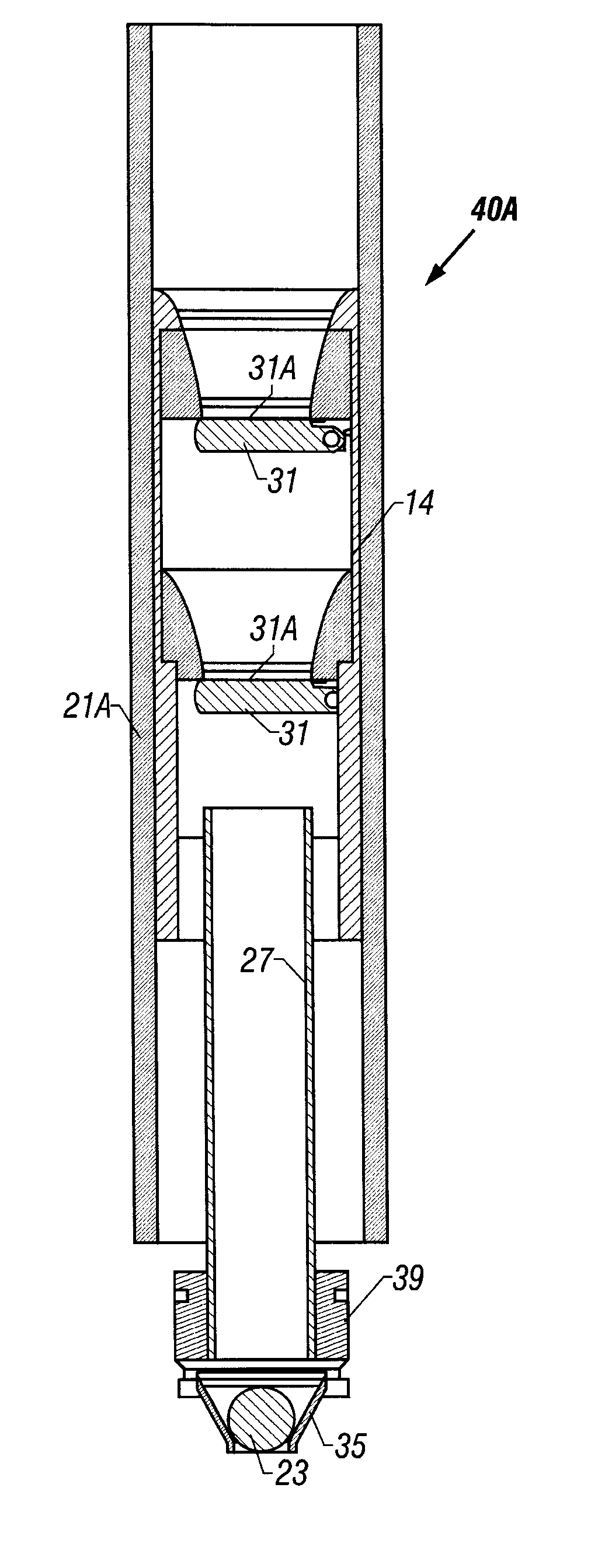

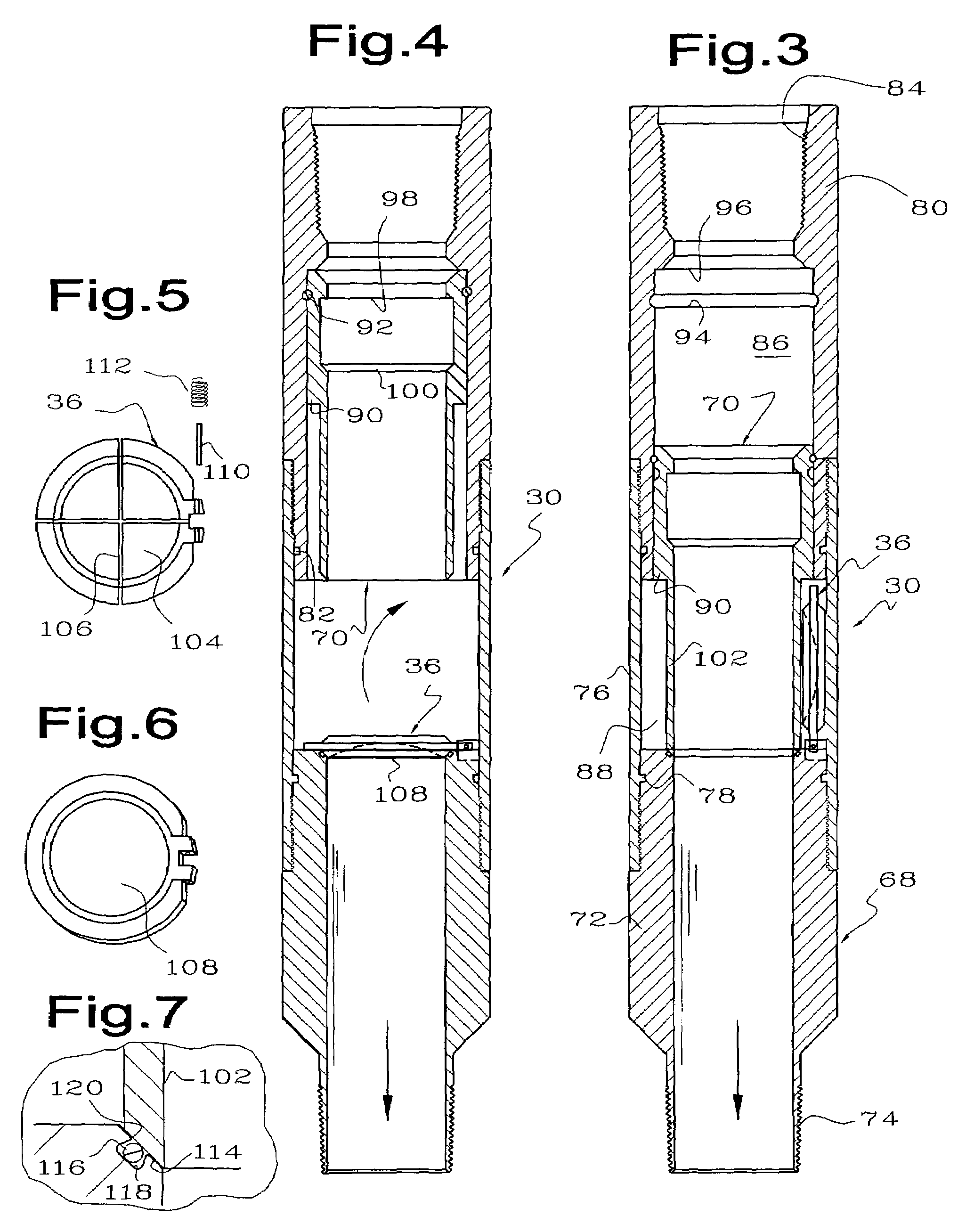

The present generally relates to apparatus and methods for instrumentation associated with a downhole deployment valve or a separate instrumentation sub. In one aspect, a DDV in a casing string is closed in order to isolate an upper section of a wellbore from a lower section. Thereafter, a pressure differential above and below the closed valve is measured by downhole instrumentation to facilitate the opening of the valve. In another aspect, the instrumentation in the DDV includes sensors placed above and below a flapper portion of the valve. The pressure differential is communicated to the surface of the well for use in determining what amount of pressurization is needed in the upper portion to safely and effectively open the valve. Additionally, instrumentation associated with the DDV can include pressure, temperature, seismic, acoustic, and proximity sensors to facilitate the use of not only the DDV but also telemetry tools.

Owner:WEATHERFORD TECH HLDG LLC

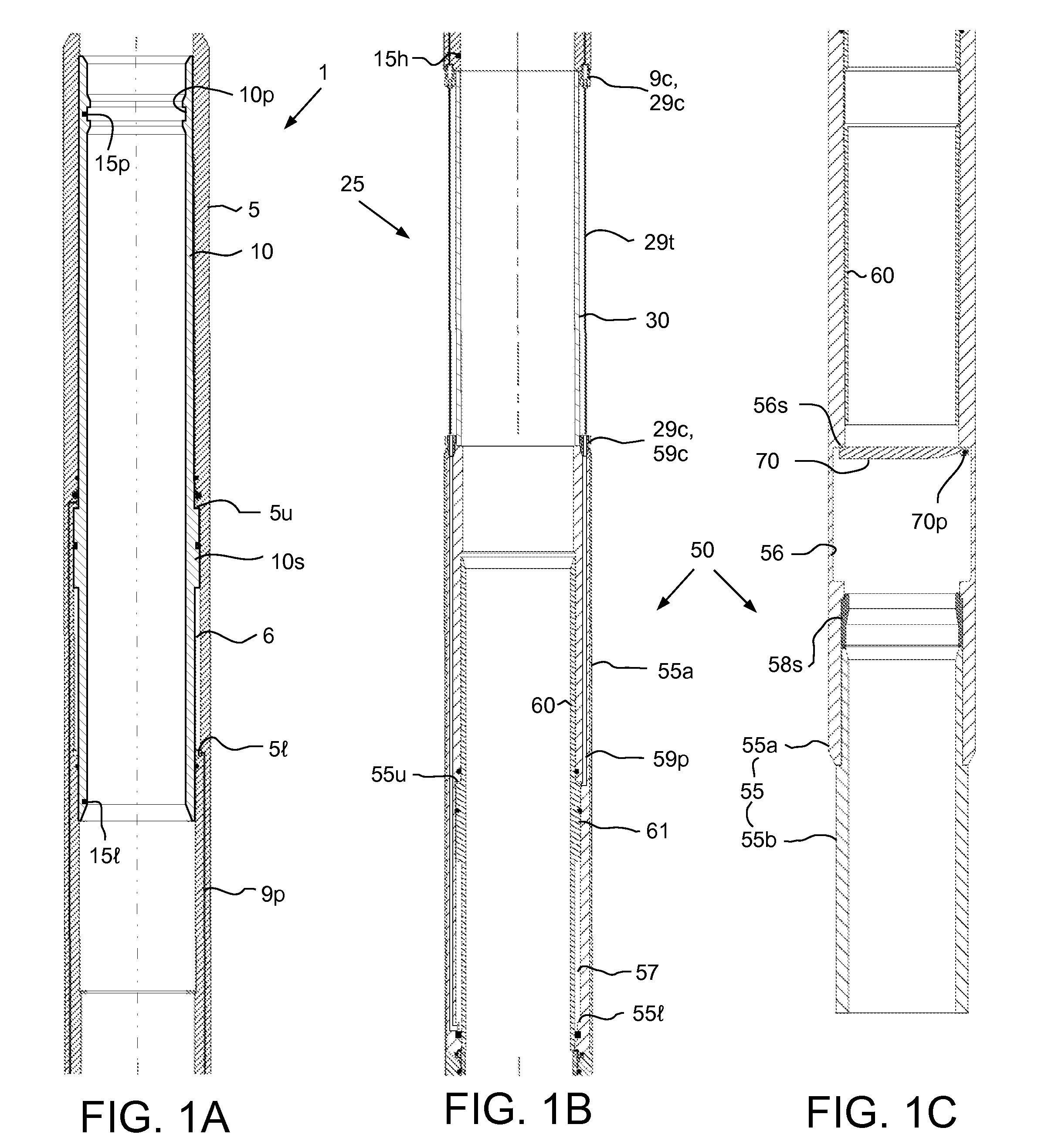

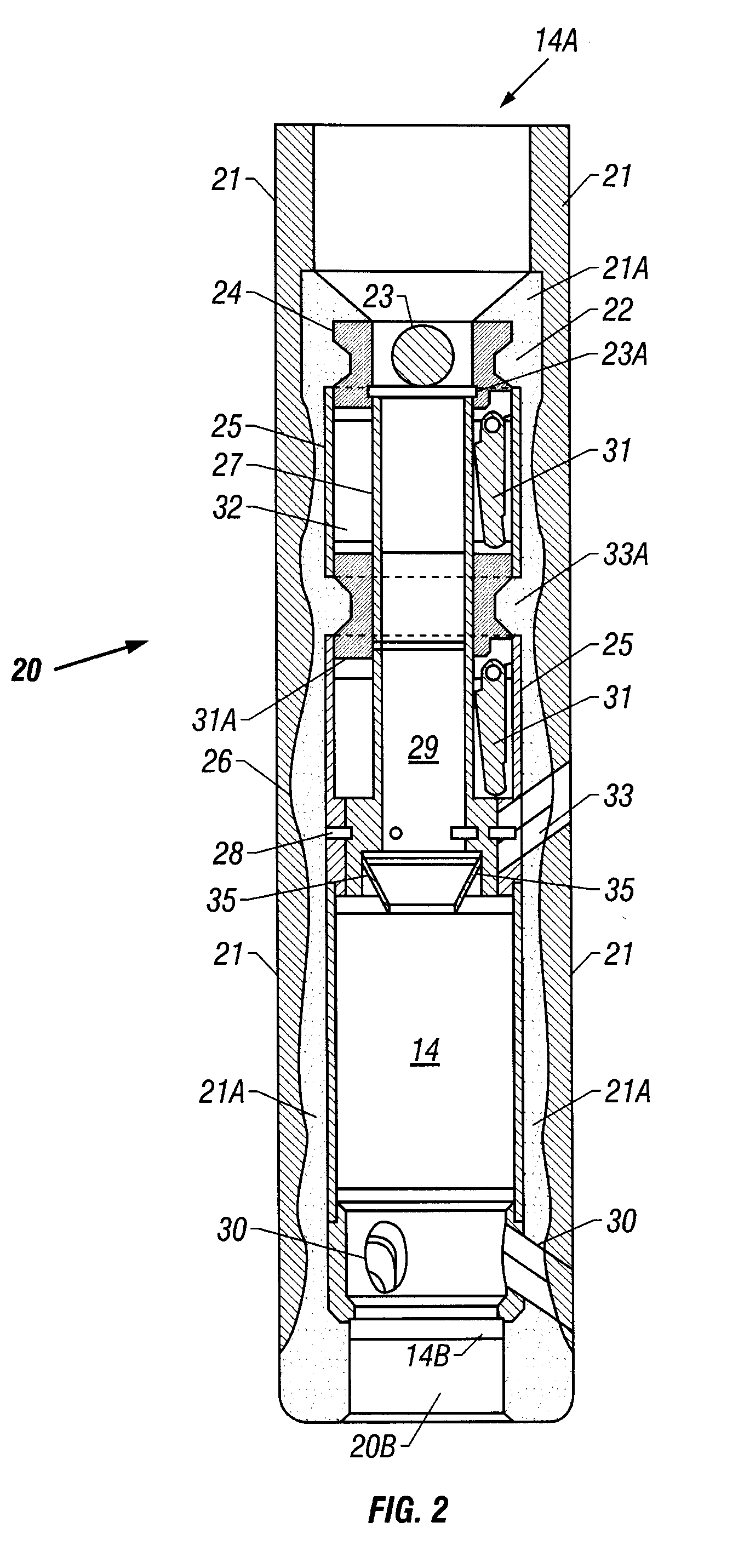

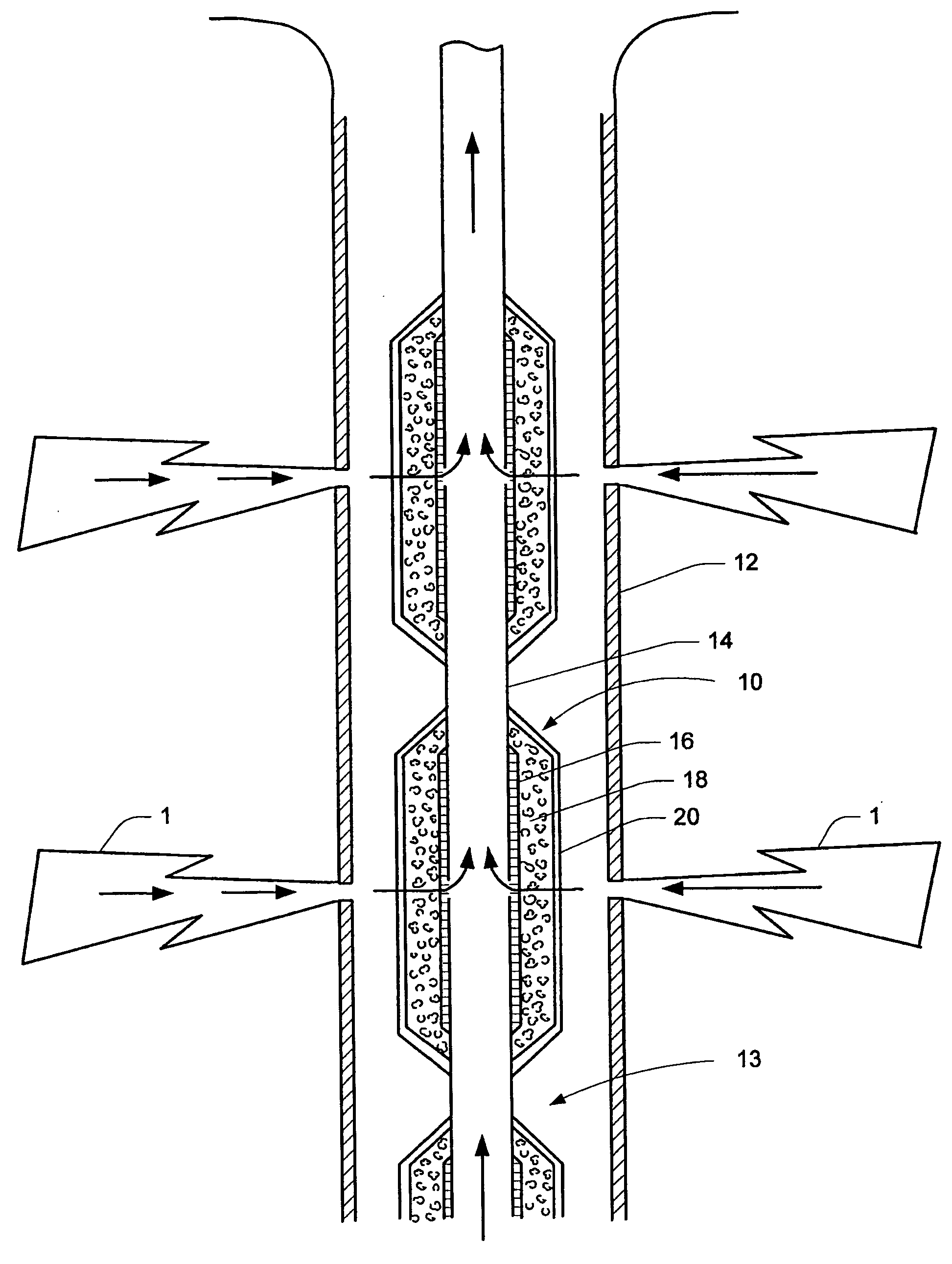

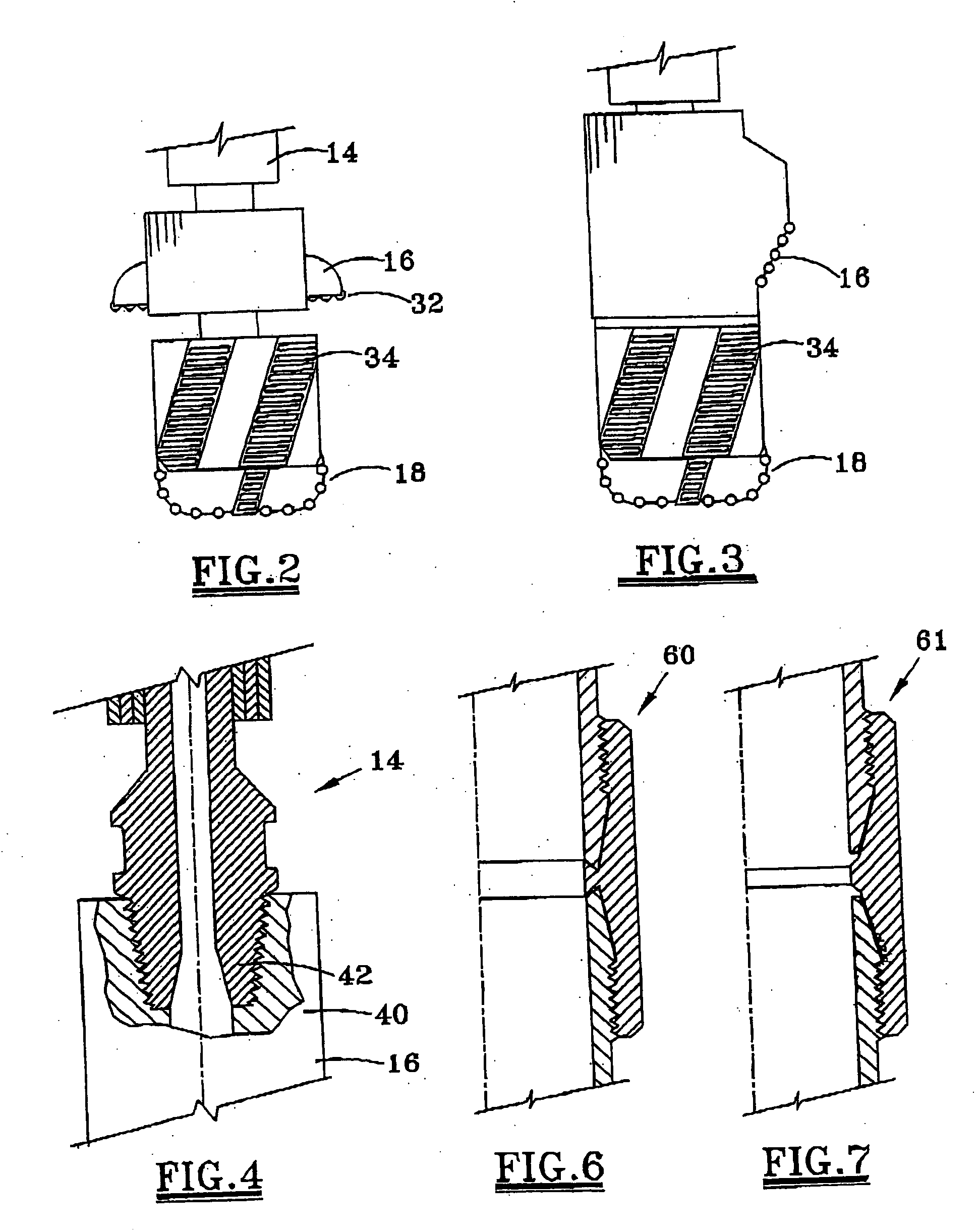

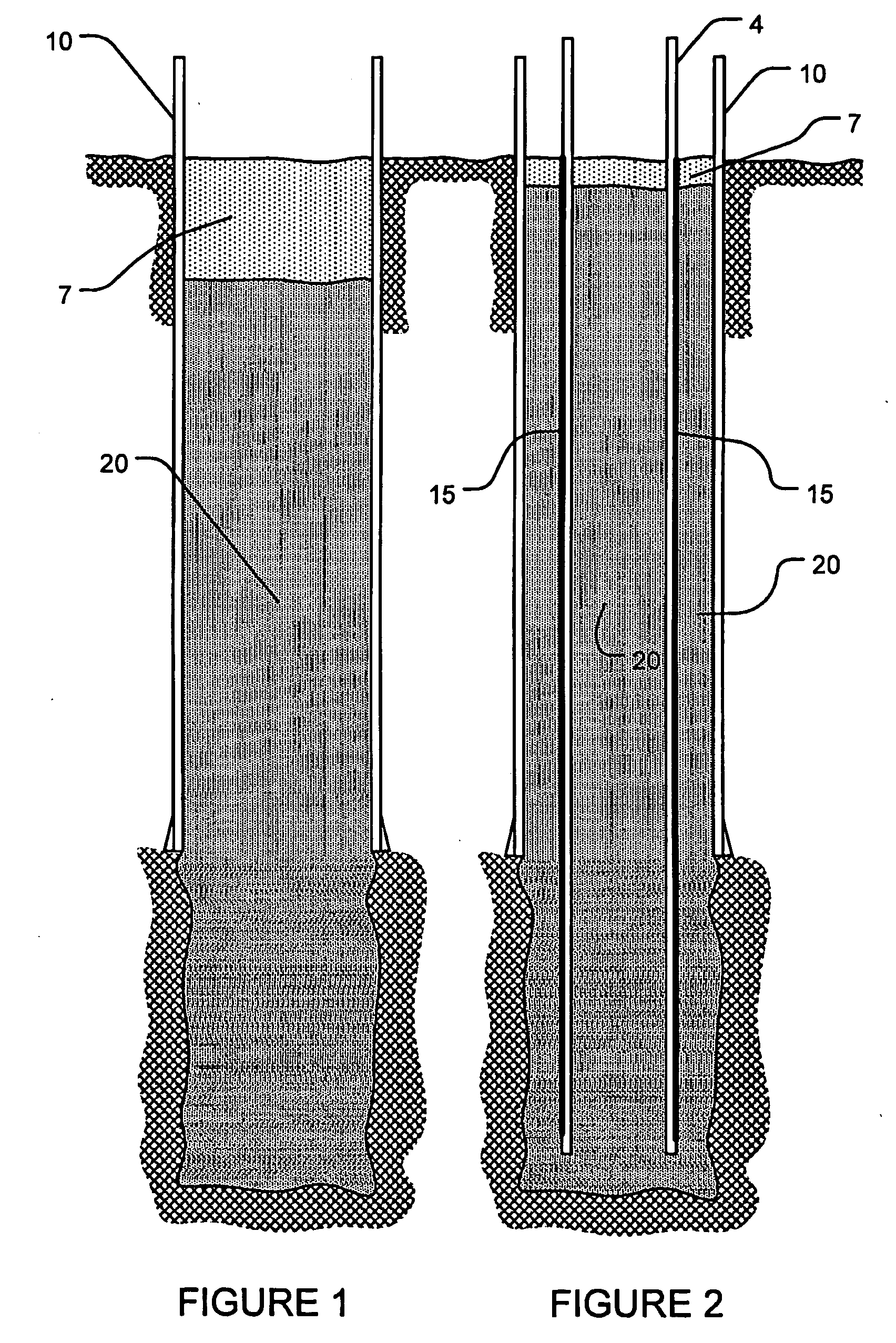

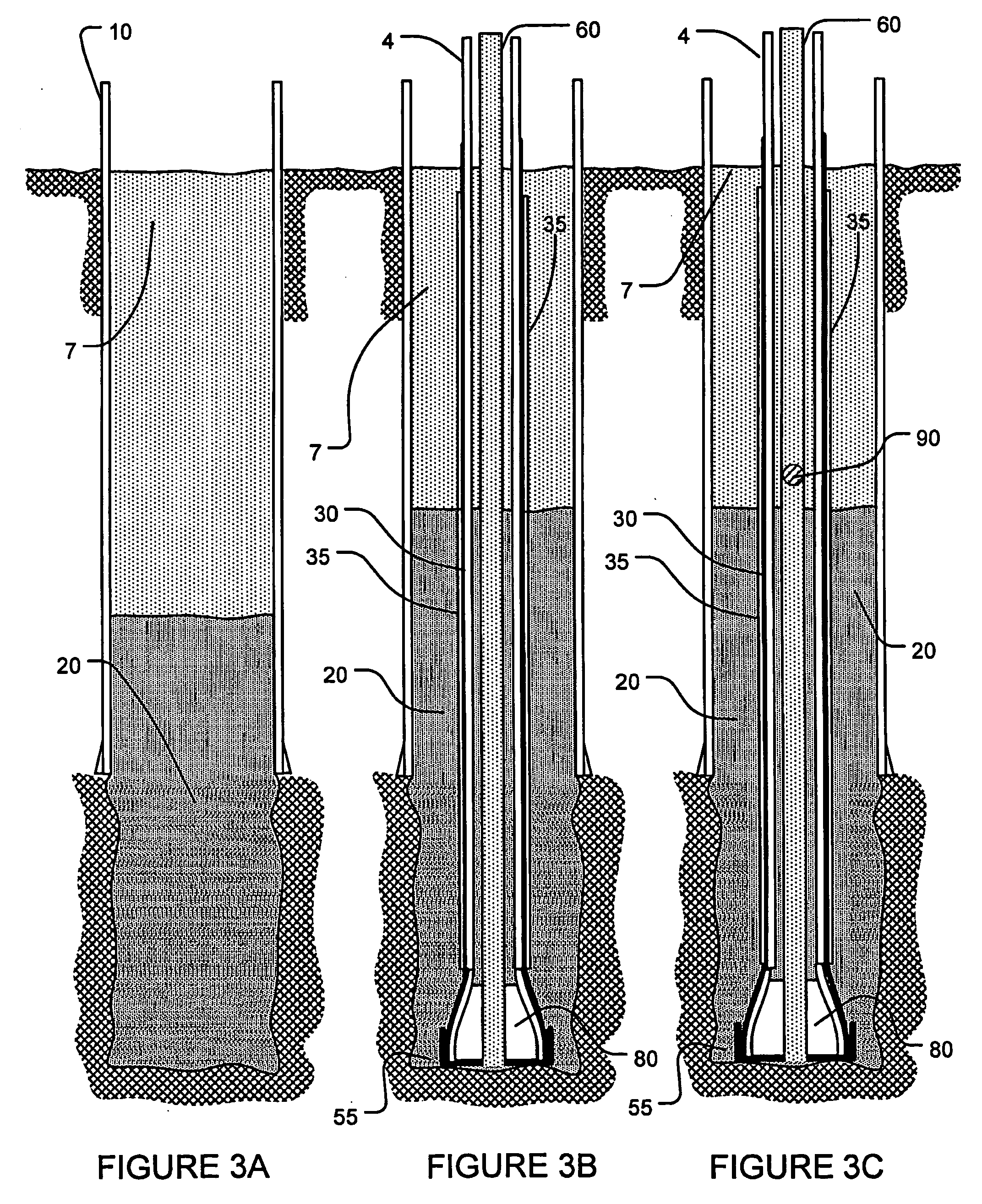

Multi-purpose float equipment and method

A float shoe / collar apparatus and method for multi-purpose use in running a tubular string such as a casing string or liner into a wellbore and for optimizing cementing operations. In one presently preferred embodiment, the apparatus permits auto filling of the tubular string as the string is lowered into the wellbore. Circulation can be effected through down jets for washing the wellbore as necessary. After the tubular string is positioned, the down jets can be blocked off and up jets opened to thereby direct cement upwardly to optimize cement placement. Check valves can also be activated to prevent flow from the wellbore into the tubular string. In one embodiment, the apparatus comprises an inner member and tubular member. The inner member is movable upon release of shear pins to cause longitudinal movement relative to the outer member. The movement of the inner member may close a plurality of downward jets and may also open a plurality of upward jets, if desired. The apparatus may also be equipped with a set of check valves which can be held open on run in, and subsequently activated to thereby automatically close upon cementing to prevent "u-tubing" of fluid back into the casing. In another embodiment a float collar comprises the same valve / valves as the float shoe, without jets. This float collar may be run in conjunction with a guide shoe, with or without jets.

Owner:FORUM US

Methods and apparatus for subsea well intervention and subsea wellhead retrieval

The present invention generally relates to methods and apparatus for subsea well intervention operations, including retrieval of a wellhead from a subsea well. In one aspect, a method of performing an operation in a subsea well is provided. The method comprising the step of positioning a tool proximate a subsea wellhead. The tool has at least one grip member and the tool is attached to a downhole assembly. The method also comprising the step of clamping the tool to the subsea wellhead by moving the at least one grip member into engagement with a profile on the subsea wellhead. The method further comprising the step of applying an upward force to the tool thereby enhancing the grip between the grip member and the profile on the subsea wellhead. Additionally, the method comprising the step of performing the operation in the subsea well by utilizing the downhole assembly. In another aspect, an apparatus for use in a subsea well is provided. In a further aspect, a method of cutting a casing string in a subsea well is provided.

Owner:WEATHERFORD TECH HLDG LLC

Instrumentation for a downhole deployment valve

The present generally relates to apparatus and methods for instrumentation associated with a downhole deployment valve or a separate instrumentation sub. In one aspect, a DDV in a casing string is closed in order to isolate an upper section of a wellbore from a lower section. Thereafter, a pressure differential above and below the closed valve is measured by downhole instrumentation to facilitate the opening of the valve. In another aspect, the instrumentation in the DDV includes sensors placed above and below a flapper portion of the valve. The pressure differential is communicated to the surface of the well for use in determining what amount of pressurization is needed in the upper portion to safely and effectively open the valve. Additionally, instrumentation associated with the DDV can include pressure, temperature, seismic, acoustic, and proximity sensors to facilitate the use of not only the DDV but also telemetry tools.

Owner:WEATHERFORD TECH HLDG LLC

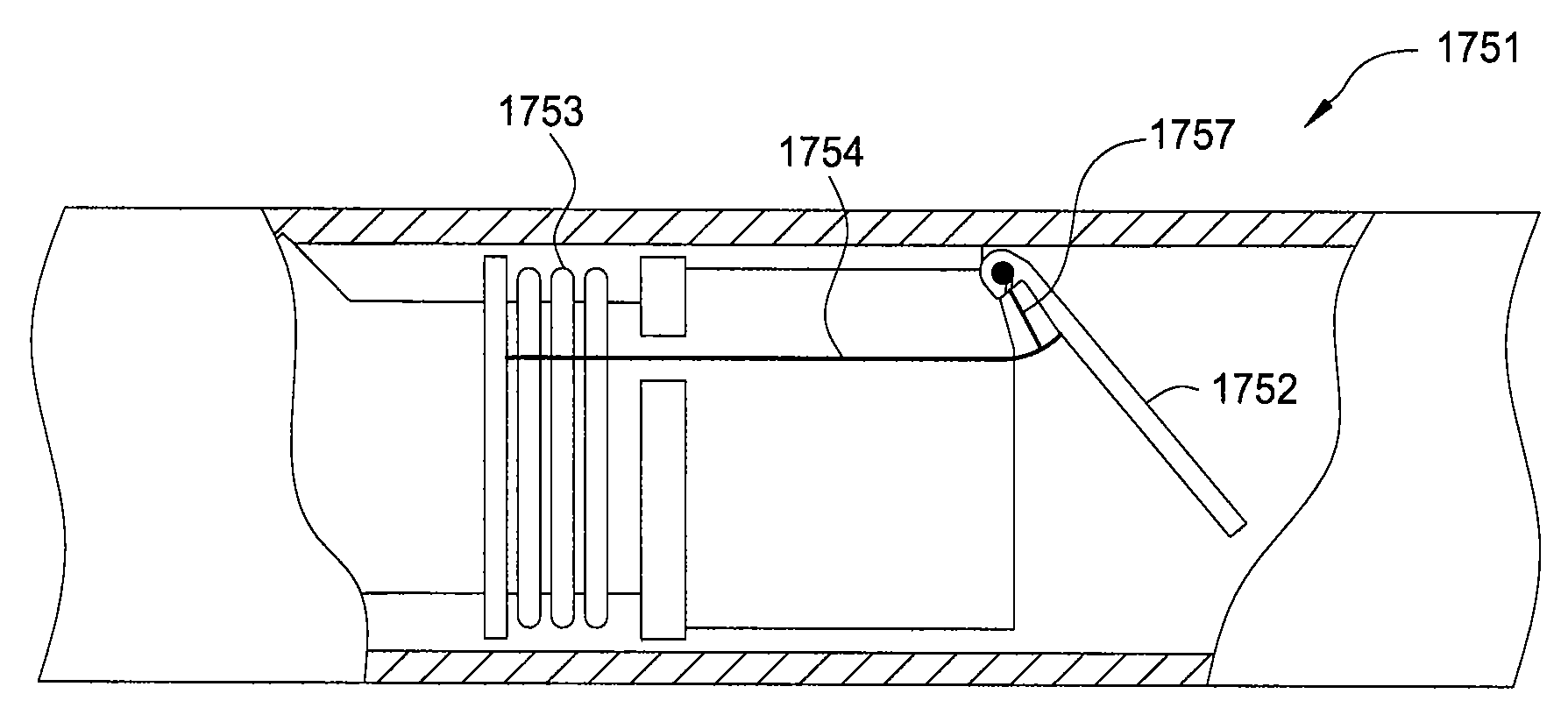

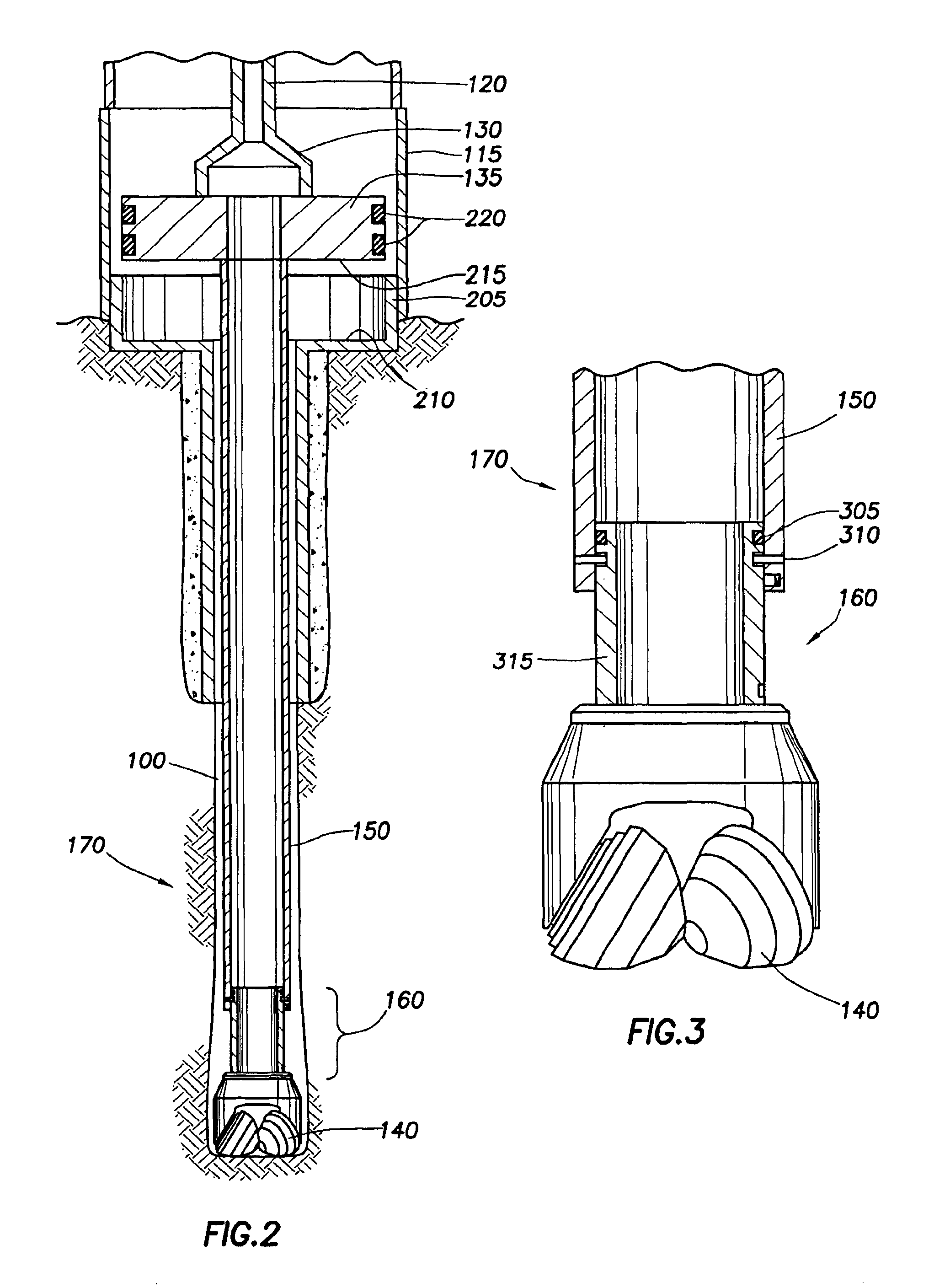

Downhole deployment valves

Methods and apparatus enable reliable and improved isolation between two portions of a bore extending through a casing string disposed in a borehole. A downhole deployment valve (DDV) may provide the isolation utilizing a valve member such as a flapper that is disposed in a housing of the DDV and is designed to close against a seat within the housing. The DDV includes an operating mechanism for opening / closing the DDV. In use, pressure in one portion of a well that is in fluid communication with a well surface may be bled off and open at well surface while maintaining pressure in another portion of the casing string beyond the DDV.

Owner:WEATHERFORD TECH HLDG LLC

Apparatus and method for establishing branch wells from a parent well

InactiveUS6283216B1Optimized areaFluid communicationFluid removalDirectional drillingRadial positionCasing string

A method and apparatus for multilateral completion comprises providing a casing string having a casing, a branching sub connected to the casing, and a locating profile. An expanding tool positionable in the branching sub is adapted to mate with the locating profile to fix a position of the expanding tool, such as to rotationally orient the expanding tool, fix a radial position of the expanding tool, and / or fix an axial position of the expanding tool. The branching sub has a non-expanded state, and the expanding tool is adapted to expand the branching sub.

Owner:SCHLUMBERGER TECH CORP

Method and apparatus for temporarily maintaining a downhole foam element in a compressed state

The present invention is directed to a degradable wrap and method for temporarily maintaining a downhole foam element in a compressed state. The degradable wrap is fitted around the foam element and temporarily maintains the foam element in a compressed state against an outer surface of a downhole sand control device. It is provided to keep the foam element in the compressed state while a production assembly comprising the downhole sand control device and foam element mounted thereon is placed downhole in a well bore adjacent to a production zone. The degradable wrap is permeable to the production fluid and degrades over time. Once the degradable wrap has degraded the foam element fills the annulus between the production screen and casing string or well bore wall. The foam element acts to inhibit the flow of water along the annulus and is useful in zone isolation.

Owner:HALLIBURTON ENERGY SERVICES INC

Method and apparatus for stimulating hydrocarbon wells

InactiveUS7287596B2Prevent downward flowMinimal hindranceConstructionsFluid removalCasing stringMechanical engineering

Owner:NINE DOWNHOLE TECHNOLOLGIES LLC

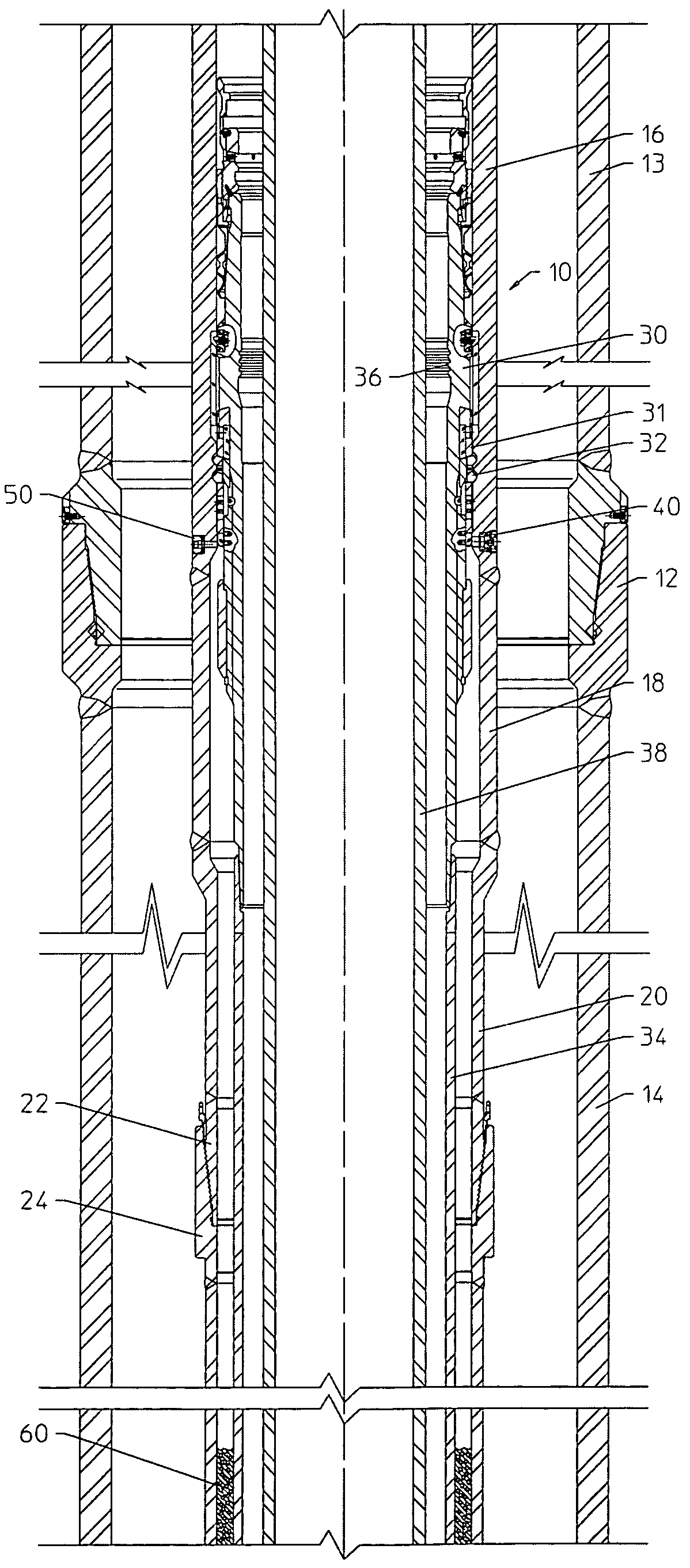

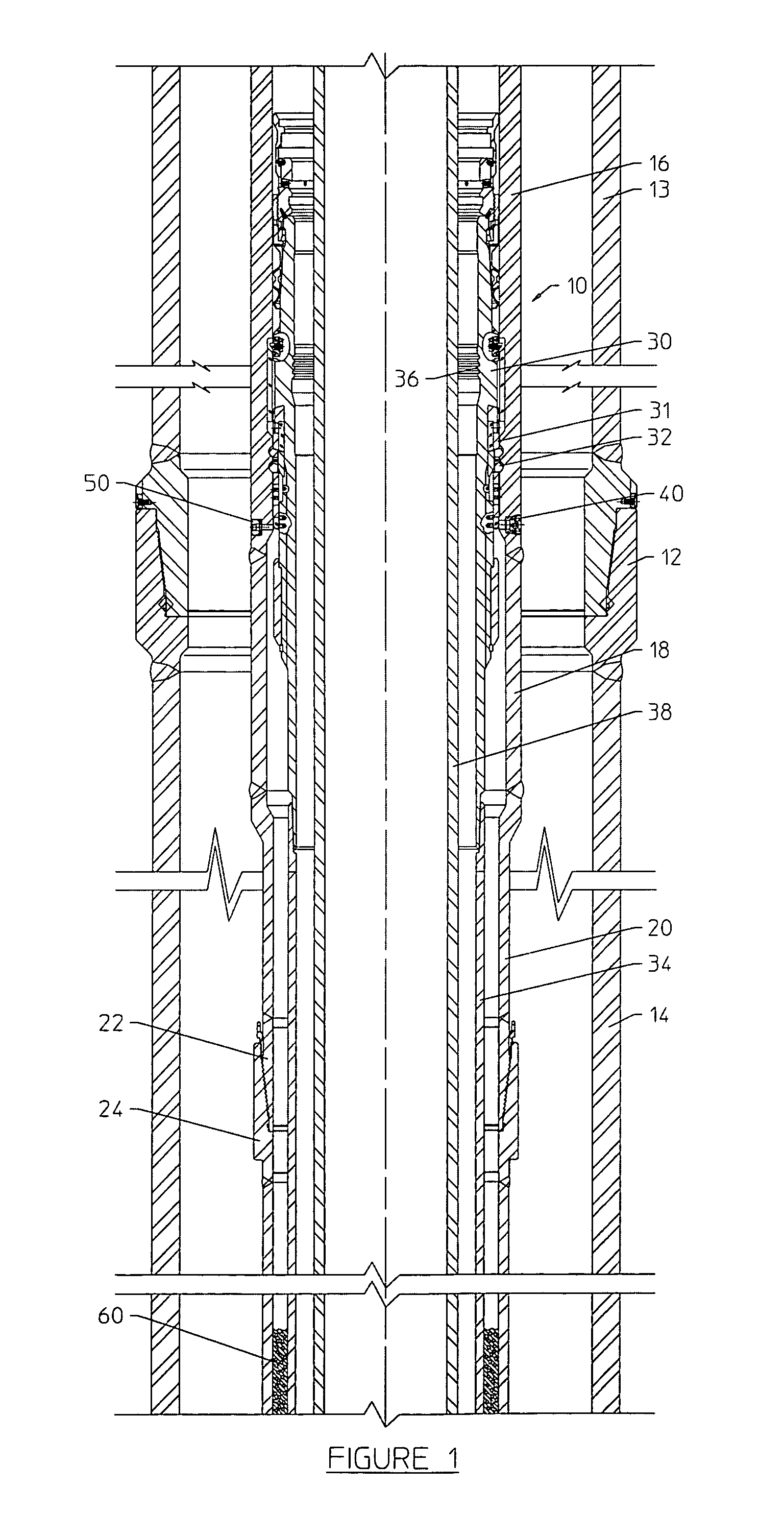

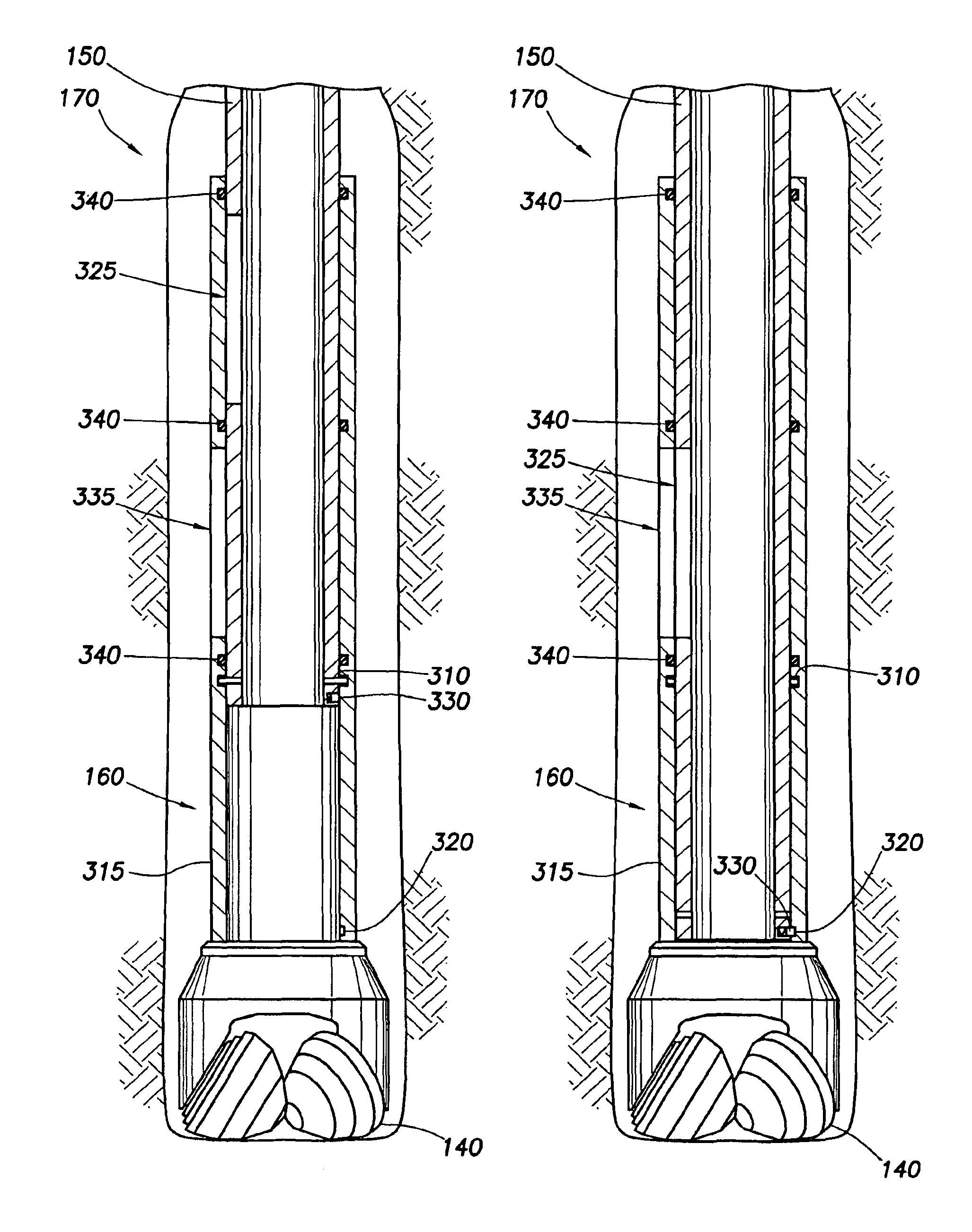

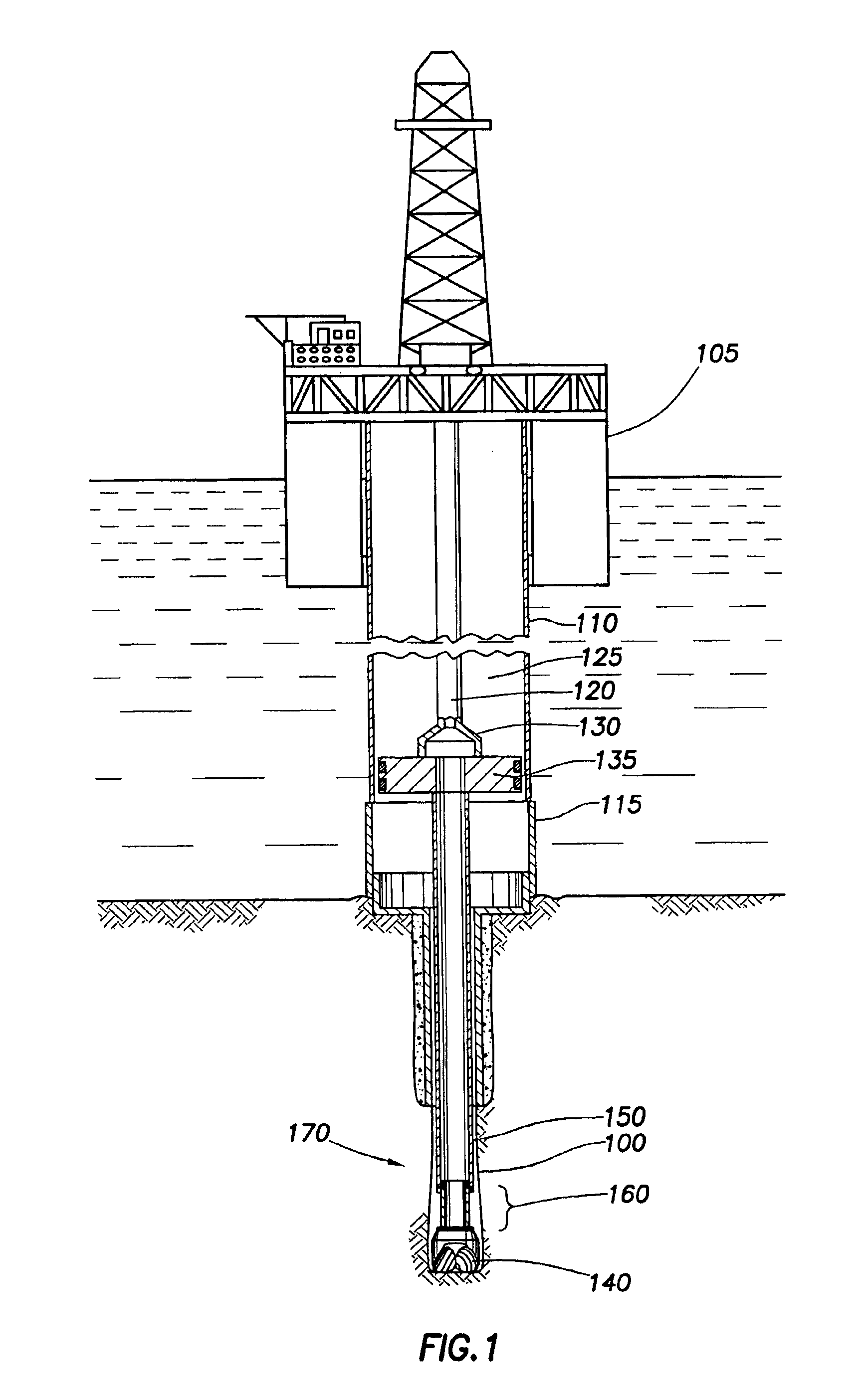

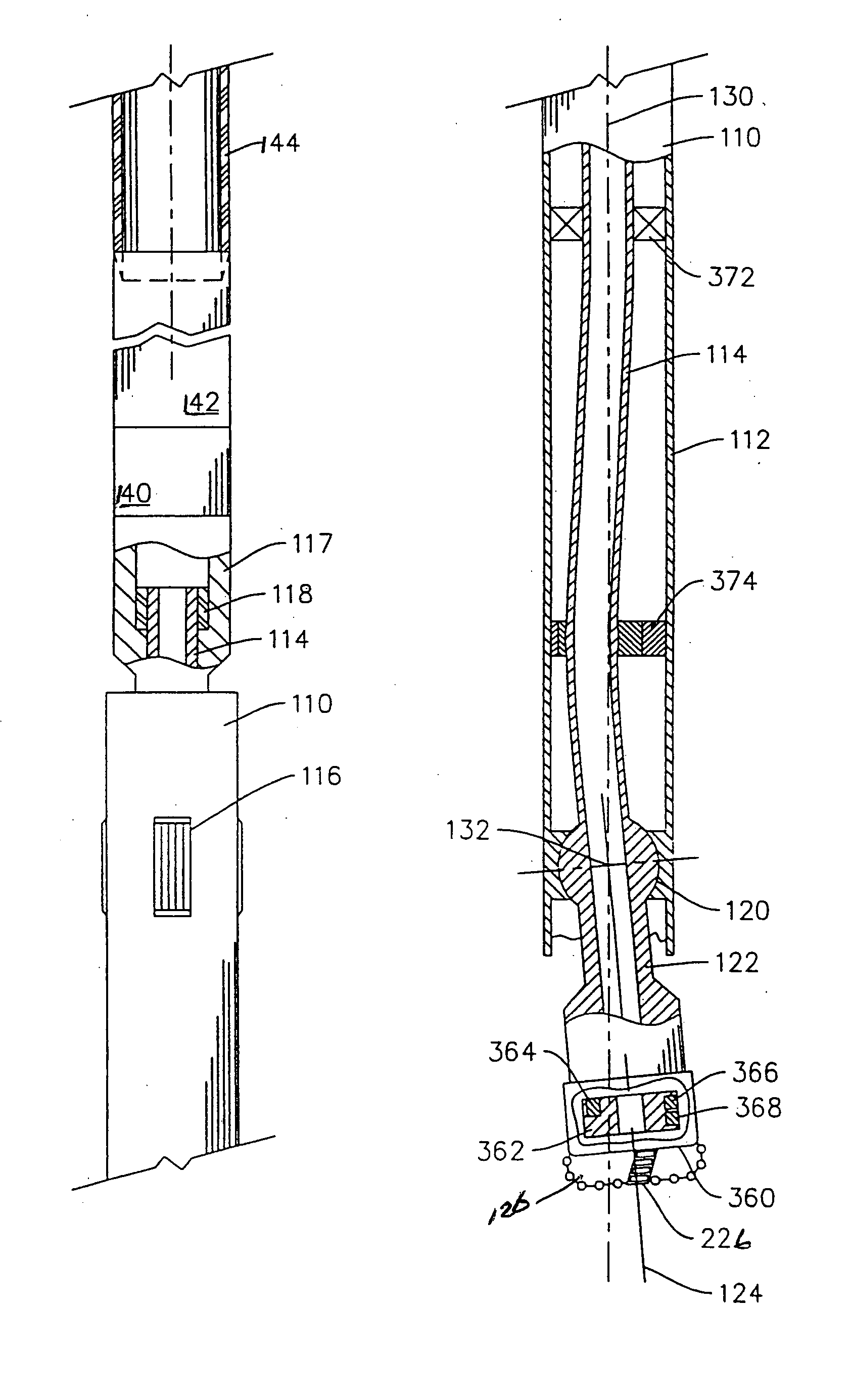

Apparatus and method of drilling with casing

InactiveUS6899186B2Shorten the lengthShorten the axial lengthDrilling rodsConstructionsCasing hangerCasing string

The present invention generally relates to methods for drilling a subsea wellbore and landing a casing mandrel in a subsea wellhead. In one aspect, a method of drilling a subsea wellbore with casing is provided. The method includes placing a string of casing with a drill bit at the lower end thereof in a riser system and urging the string of casing axially downward. The method further includes reducing the axial length of the string of casing to land a wellbore component in a subsea wellhead. In this manner, the wellbore is formed and lined with the string of casing in a single run. In another aspect, a method of forming and lining a subsea wellbore is provided. In yet another aspect, a method of landing a casing mandrel in a casing hanger disposed in a subsea wellhead is provided.

Owner:WEATHERFORD TECH HLDG LLC

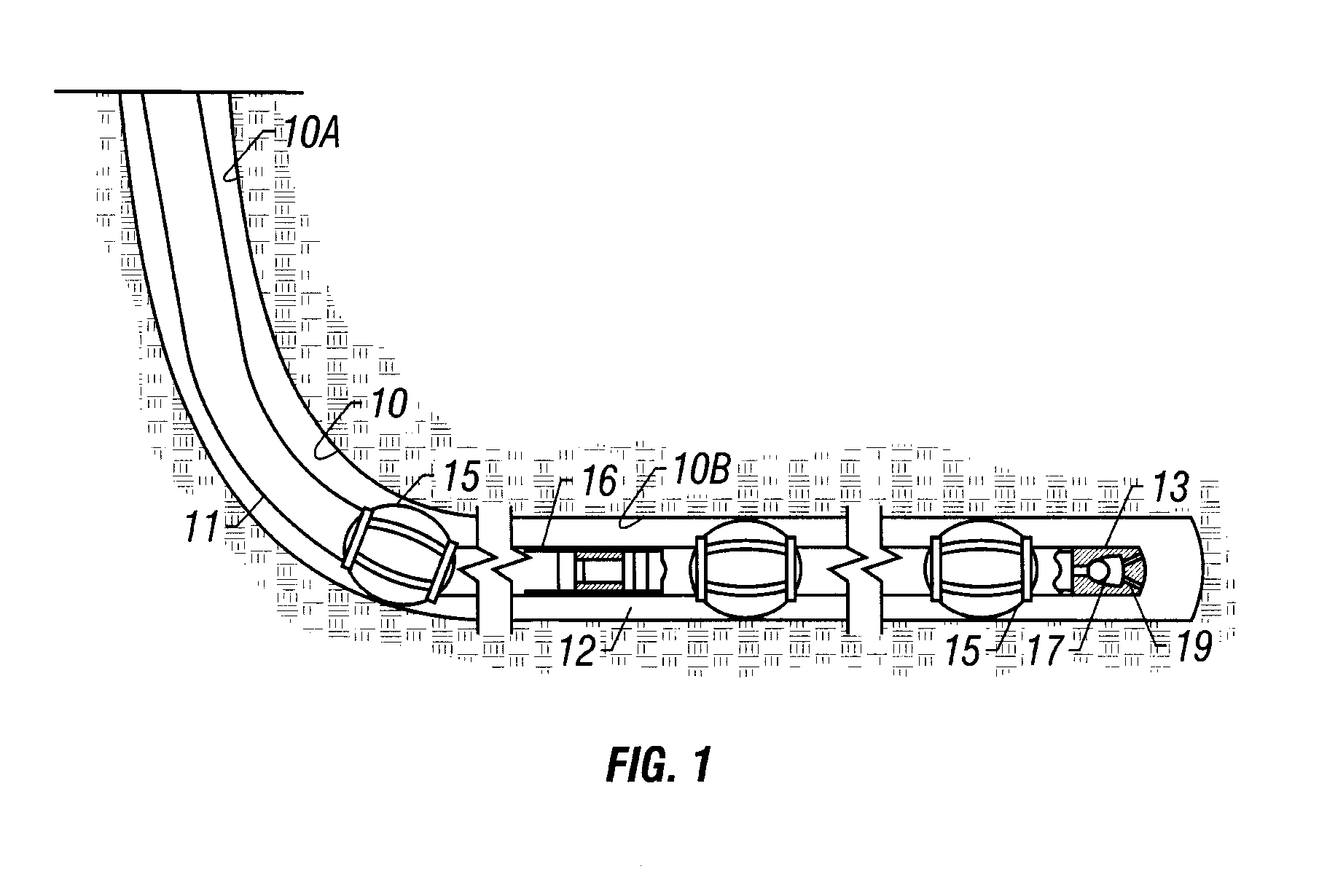

Drilling with casing

A borehole may be drilled utilizing the bottom hole assembly 10, 50 with a downhole motor 14, 110, which may offset at a selected bend angle. A bend for directional drilling may be provided by a PDM, or by a RSD. A gauge section 36 secured to the pilot bit 18 has a uniform diameter bearing surface along an axial length of at least 60% of the pilot bit diameter. The bit or reamer 16 has a bit face defining the cutting diameter of the drilled hole. The axial spacing between the bend and the bit face is controlled to less than fifteen times the bit diameter. The downhole motor, pilot bit and bit may be retrieved from the well while leaving the casing string in the well.

Owner:HALLIBURTON ENERGY SERVICES INC

Casing strings and methods of using such strings in subterranean cementing operations

ActiveUS20060086502A1Improved casing stringDrilling rodsSolid waste managementWell cementingCasing string

Improved casing strings, and methods of using improved casing strings in subterranean operations, are provided. An example of a method is a method of cementing a pipe string in a subterranean formation. Another example of a method is a method of cementing a pipe string in a well bore. An example of an apparatus is an improved pipe string comprising at least one pipe section; and a delivery system of an activator; wherein the delivery system of an activator is disposed adjacent an outer surface of the at least one pipe section.

Owner:HALLIBURTON ENERGY SERVICES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com