Method and apparatus for temporarily maintaining a downhole foam element in a compressed state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

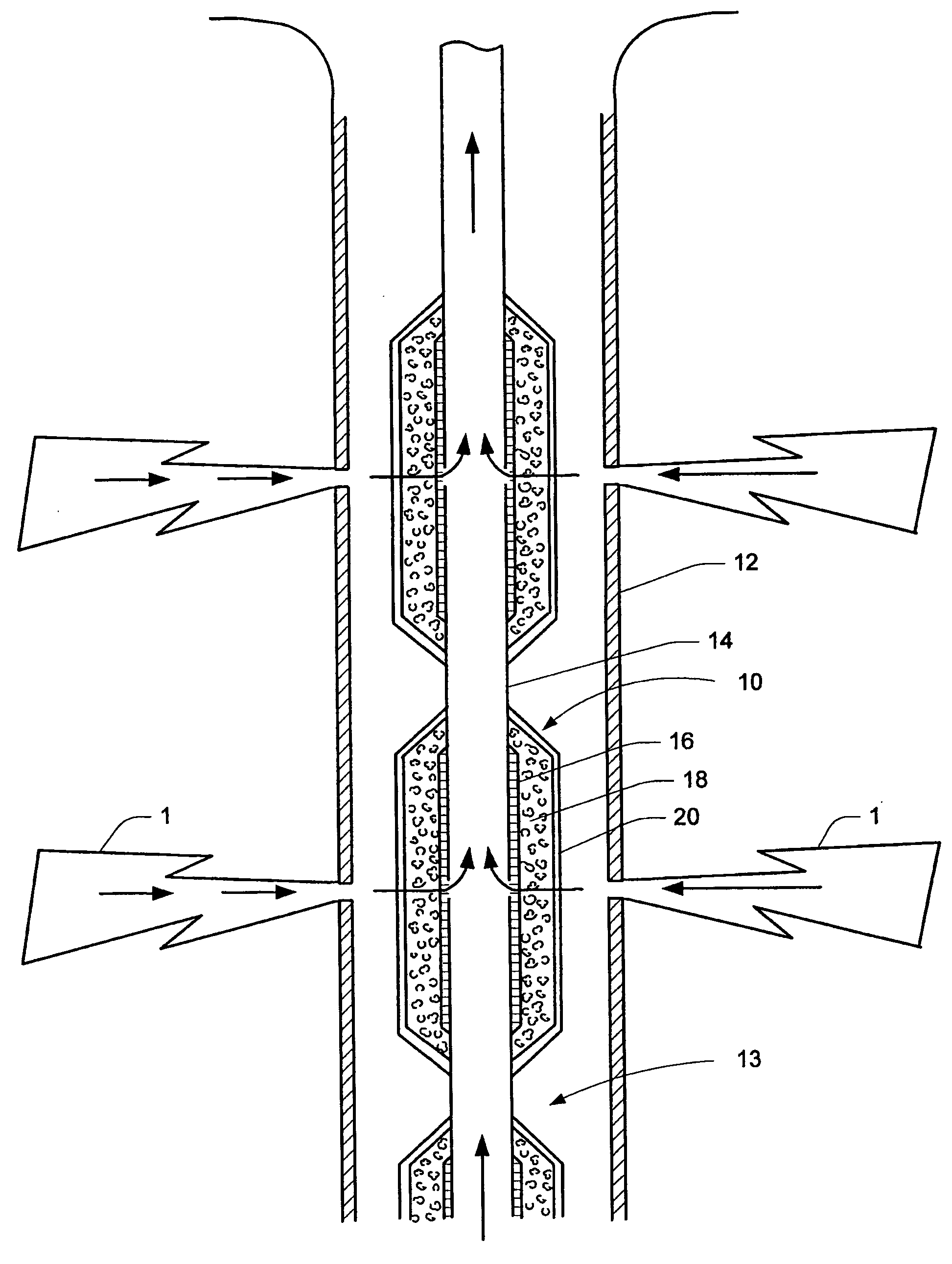

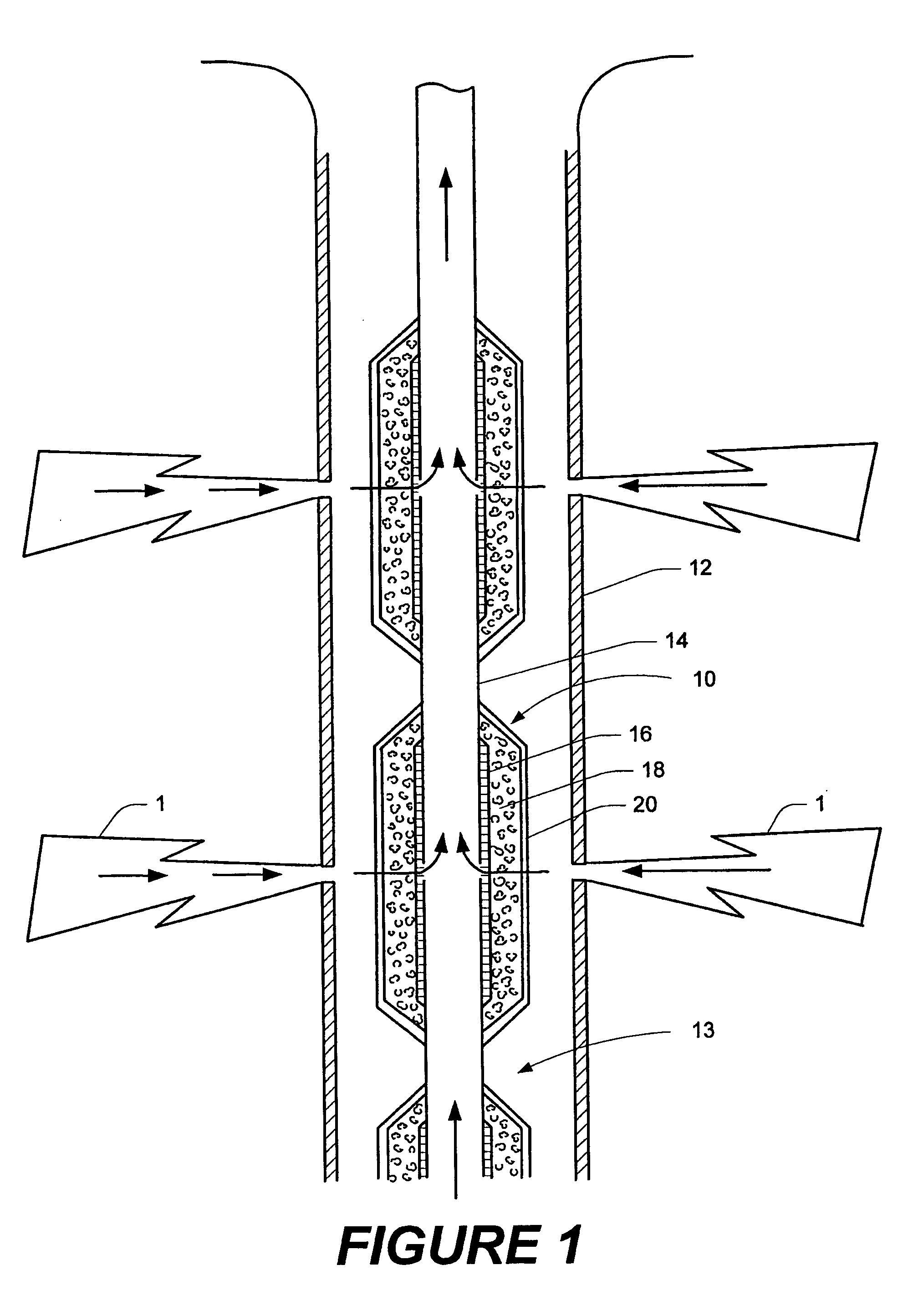

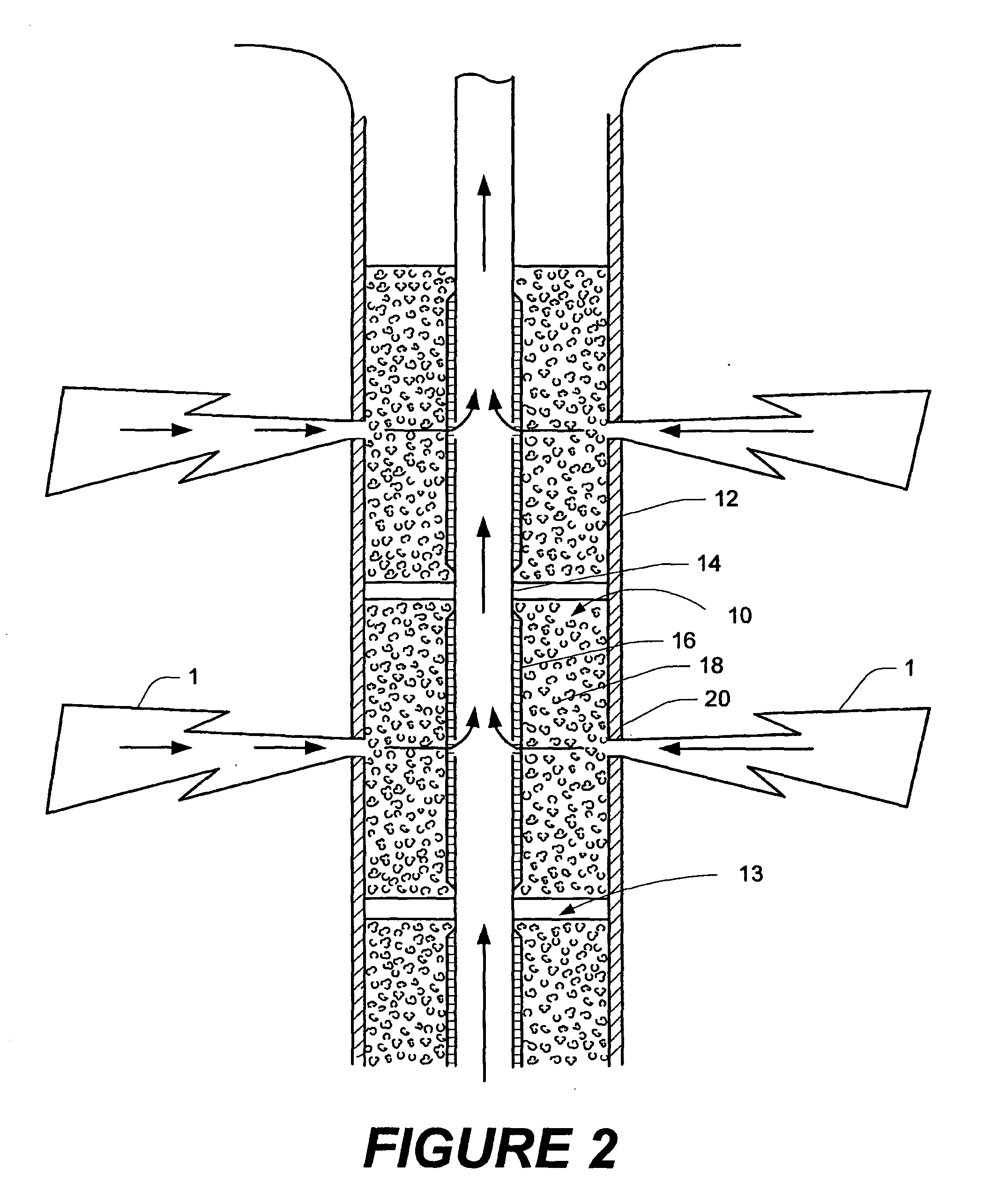

The details of the present invention will now be discussed with reference to the figures. Turning to FIG. 1, a multi-sectional production assembly in accordance with the present invention is shown generally by reference numeral 10. The production assembly 10 is shown disposed downhole inside of a casing string 12, which in turn is cemented to the wall of the well bore. The casing string 12 is perforated in the production zone, which is referred to generally by reference numeral 1. As those of ordinary skill in the art will recognize, the present invention has application in open holes as well as those lined with casing string. An annulus 13 is formed between the production assembly 10 and the casing string 12.

The production assembly 10 is formed of a base pipe 14, which is preferably a steel pipe, which has a plurality of openings to allow a production fluid to flow from the production zone 1 into the base pipe 14. The production assembly 10 comprises a sand control device 16, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com