Patents

Literature

9306results about "Drill bits" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

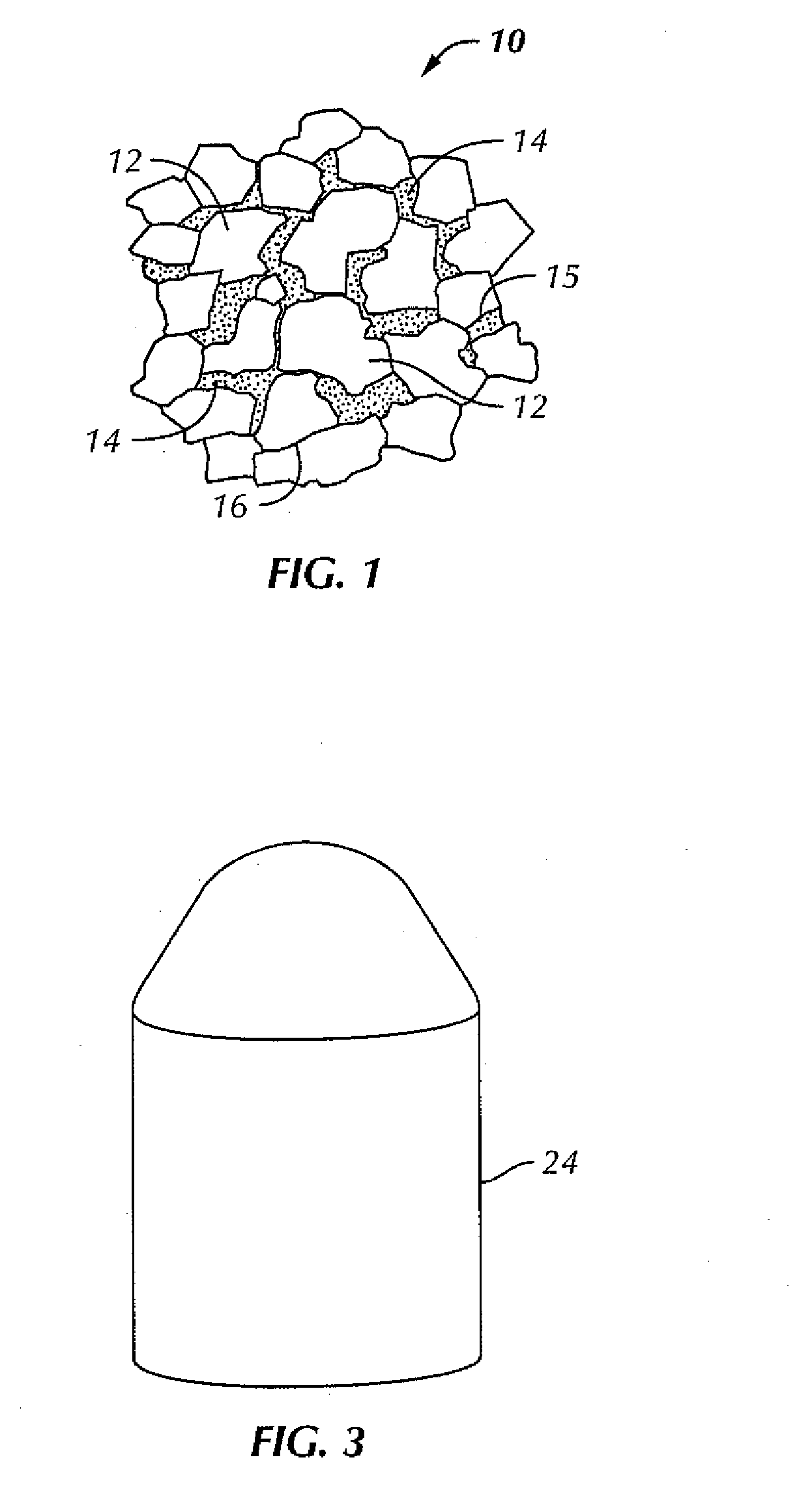

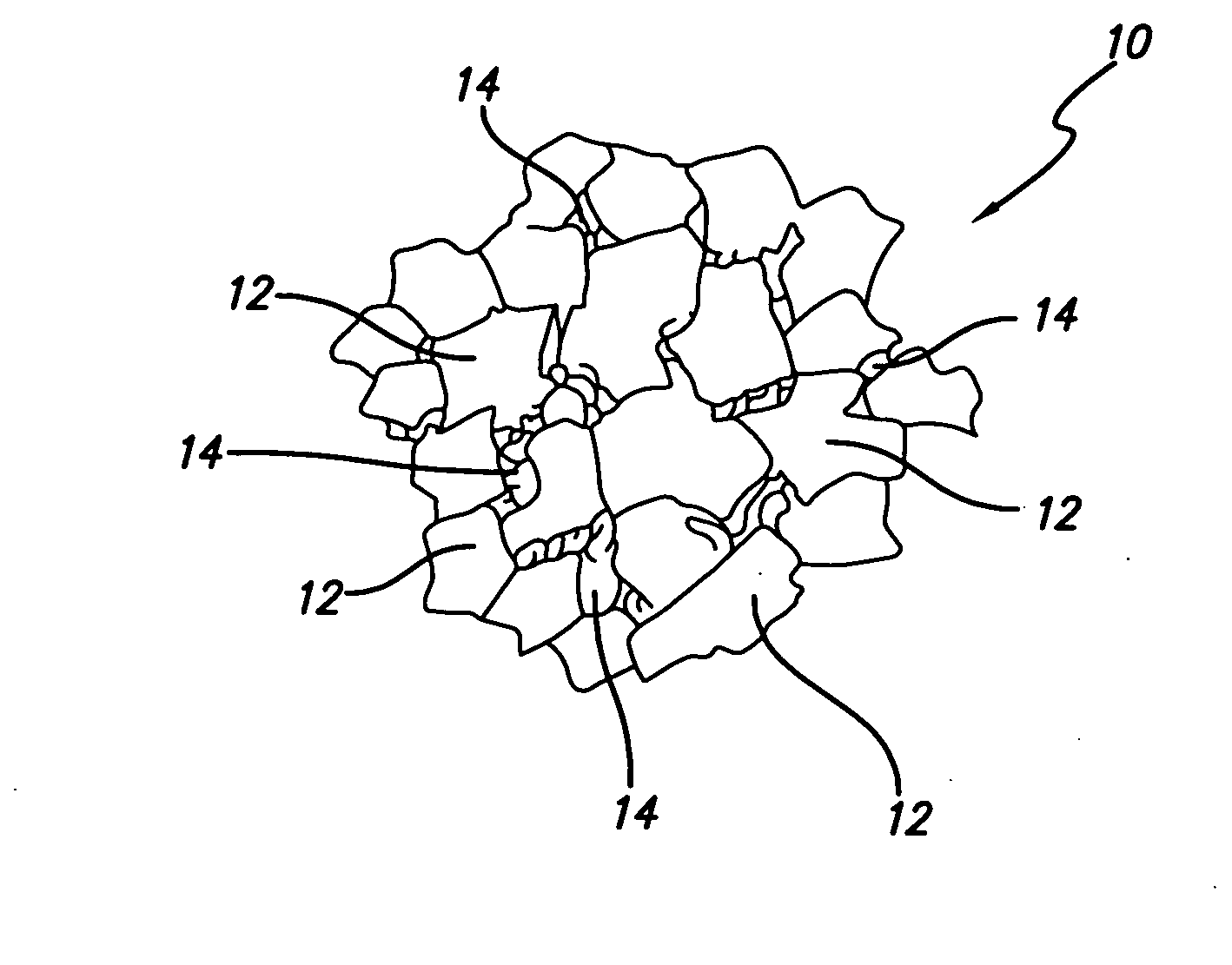

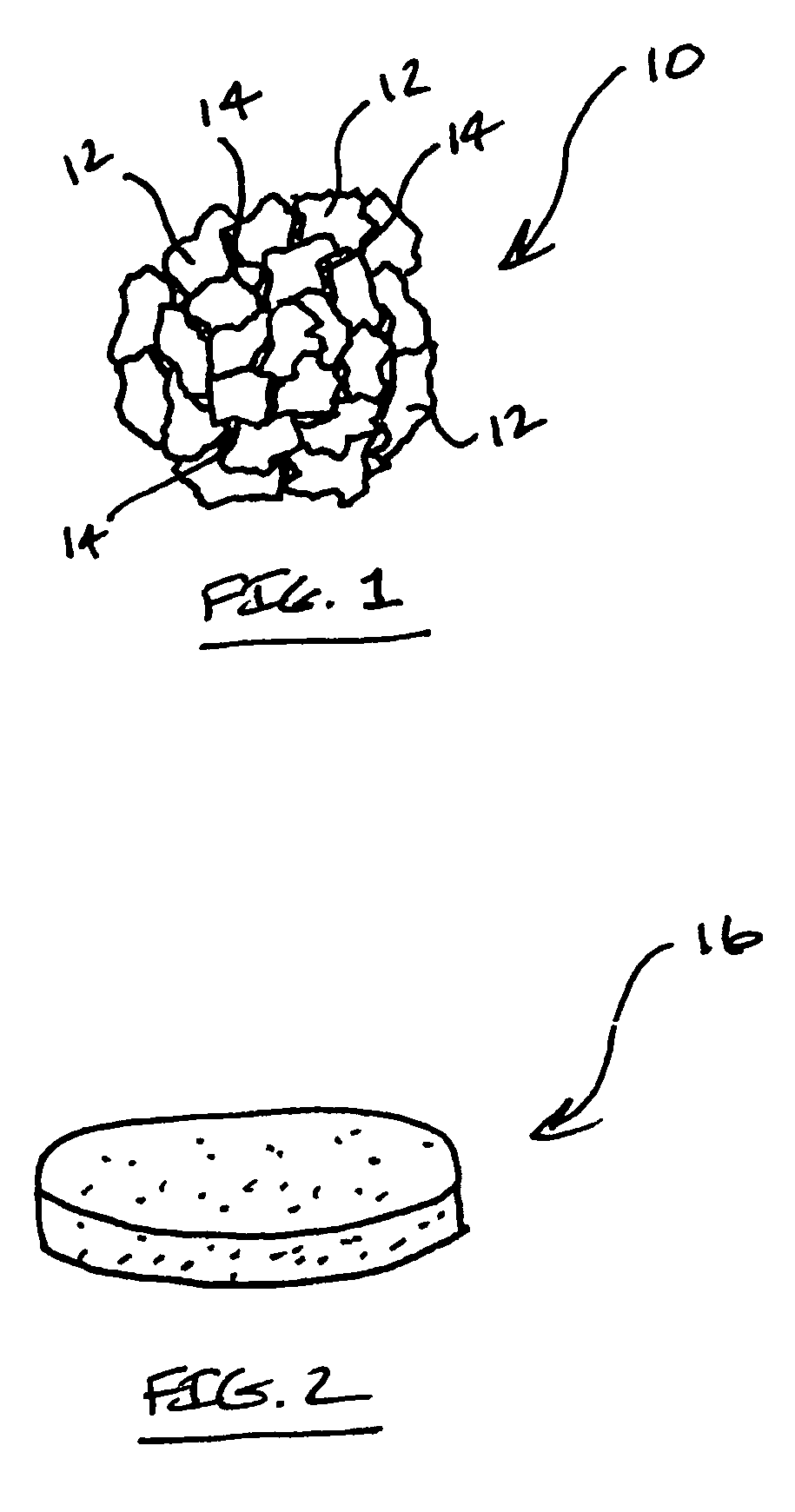

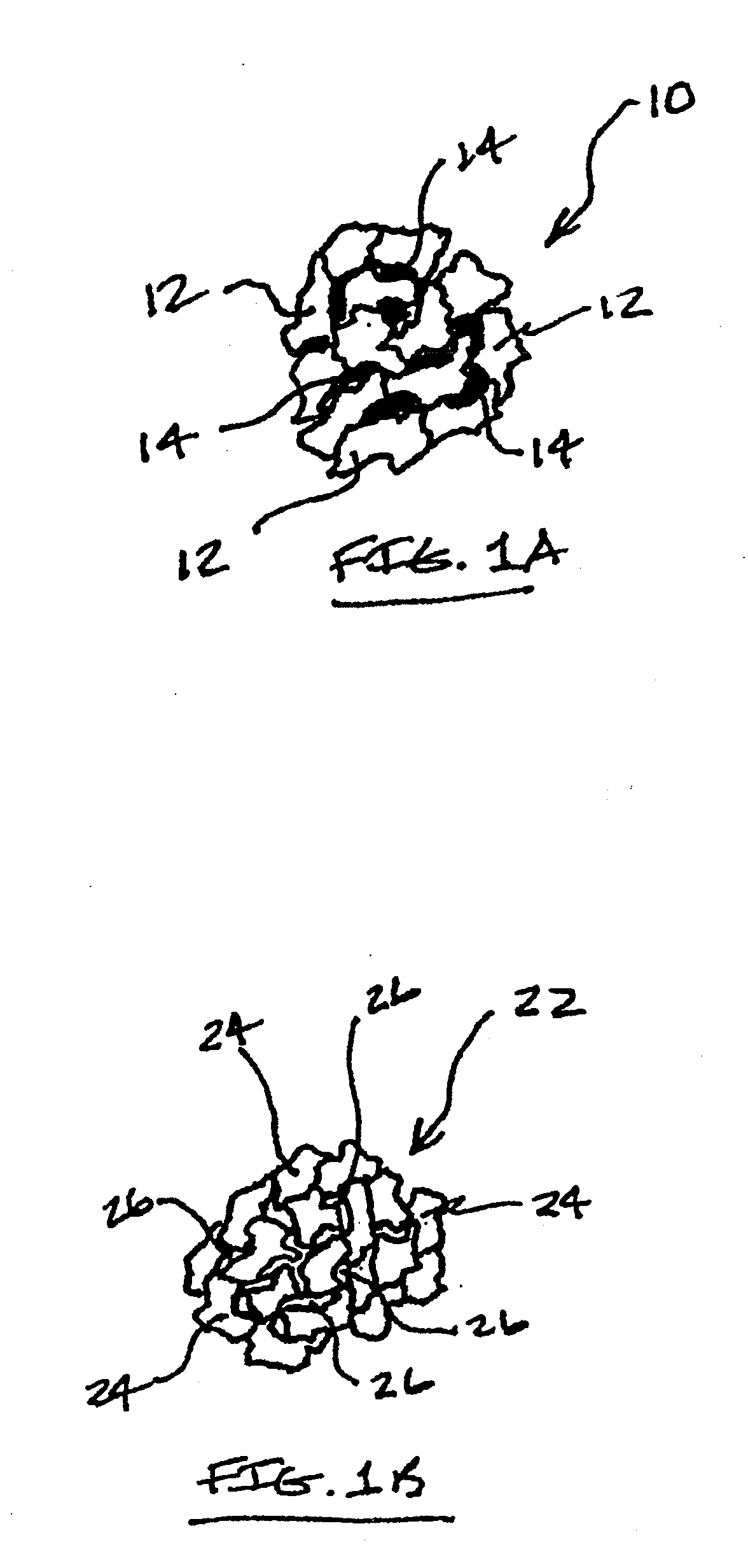

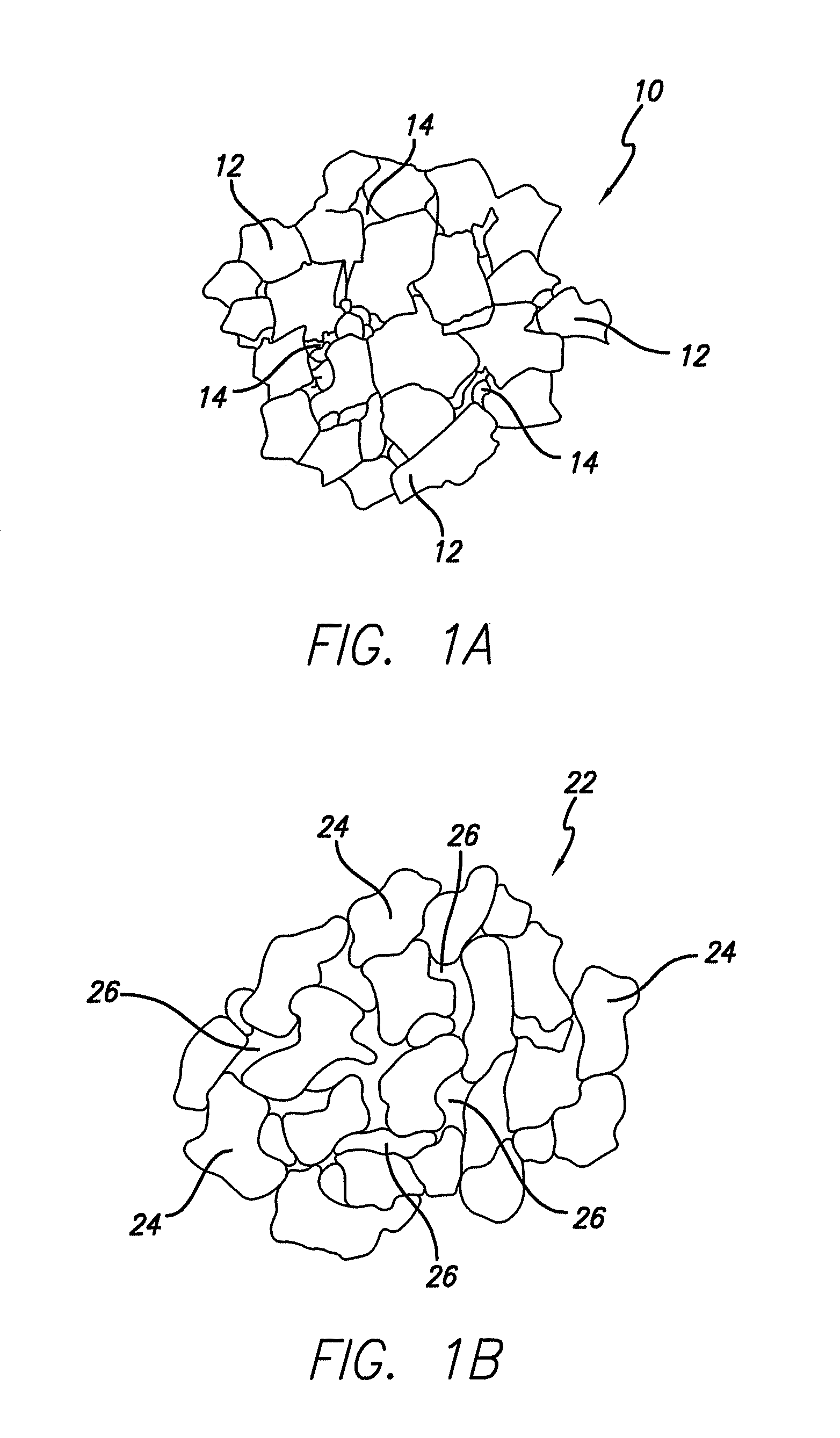

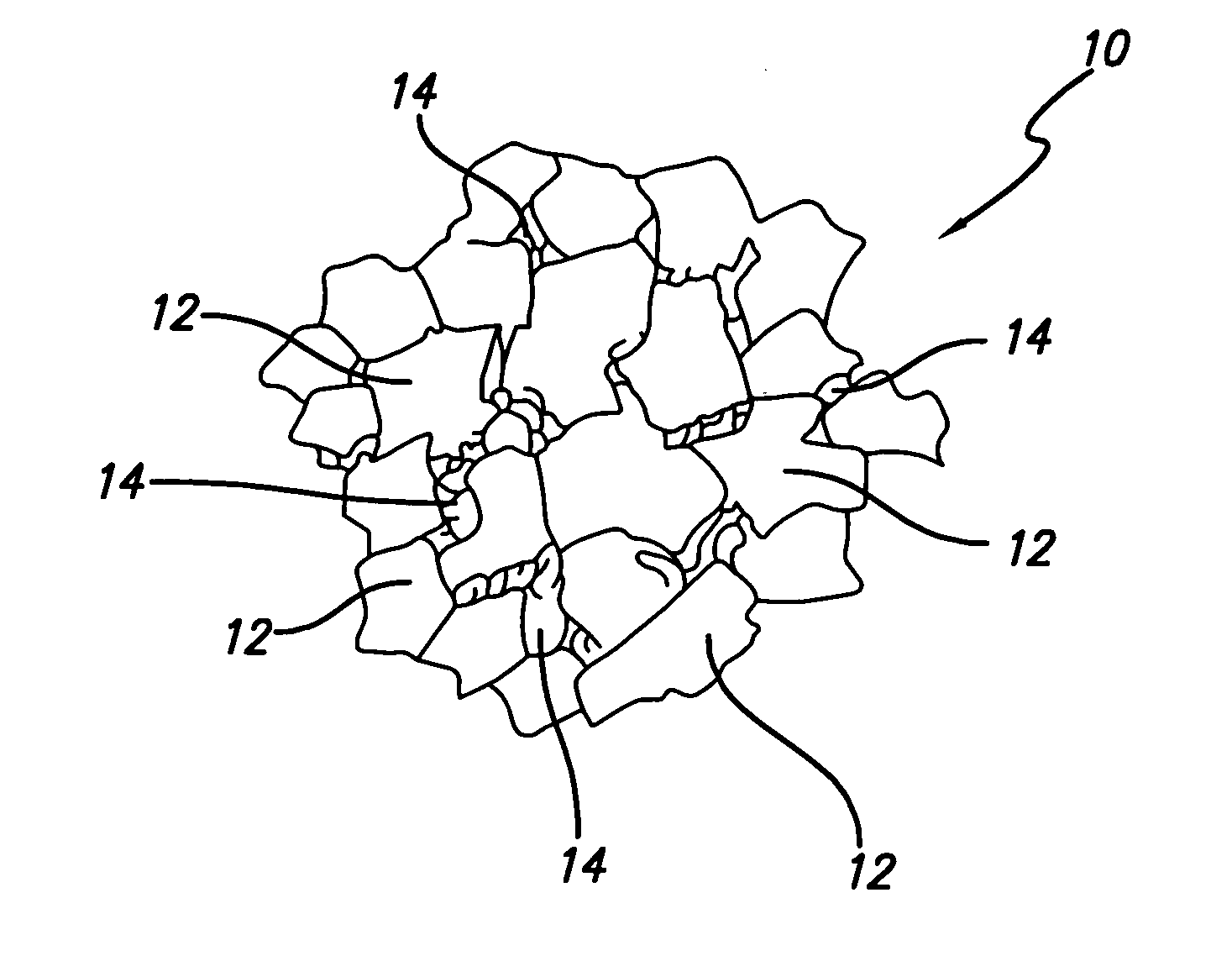

Nano-reinforced wc-co for improved properties

InactiveUS20080179104A1Increase resistanceImprove toughnessMaterial nanotechnologyDrill bitsCarbideNanometre

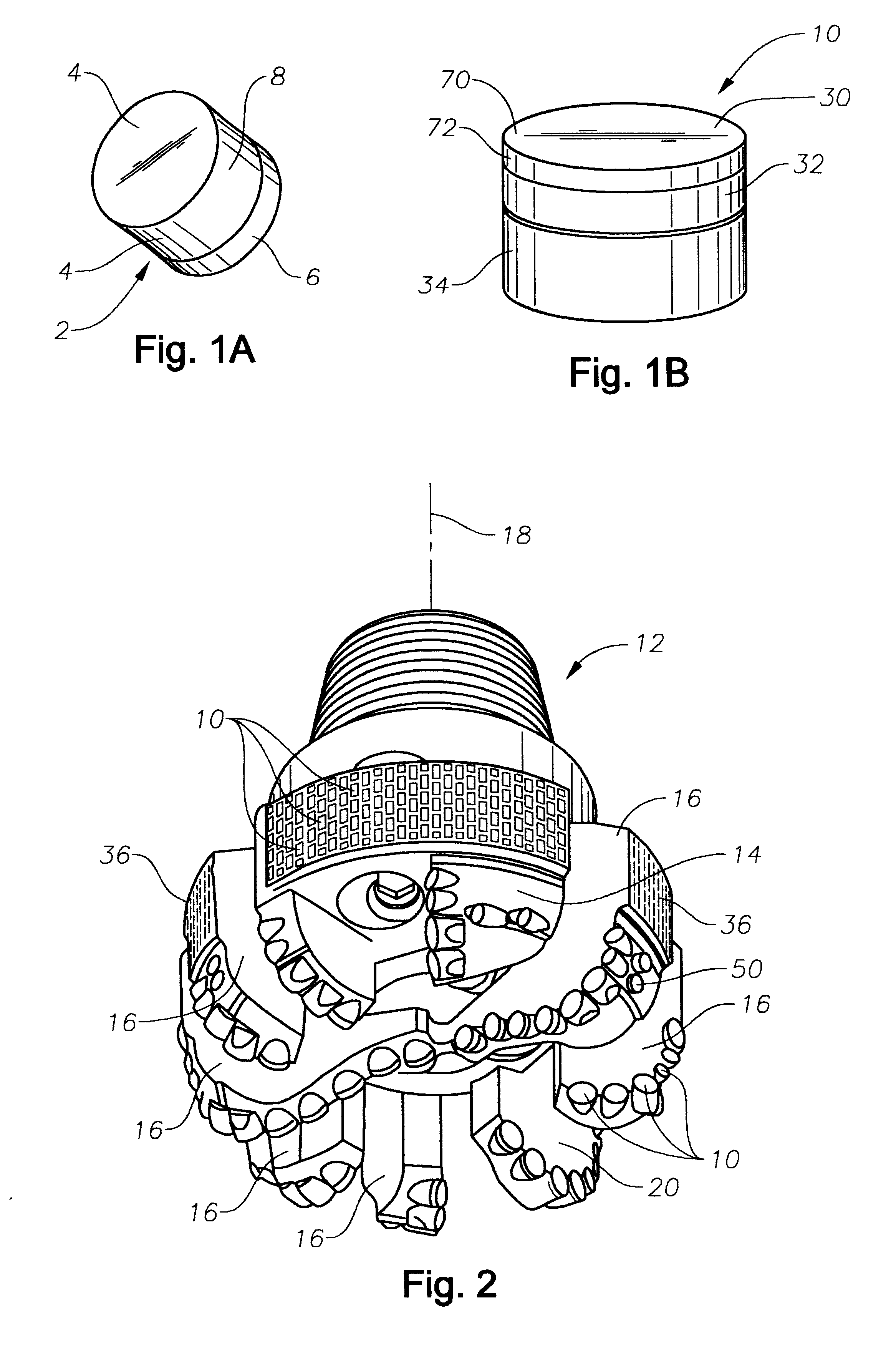

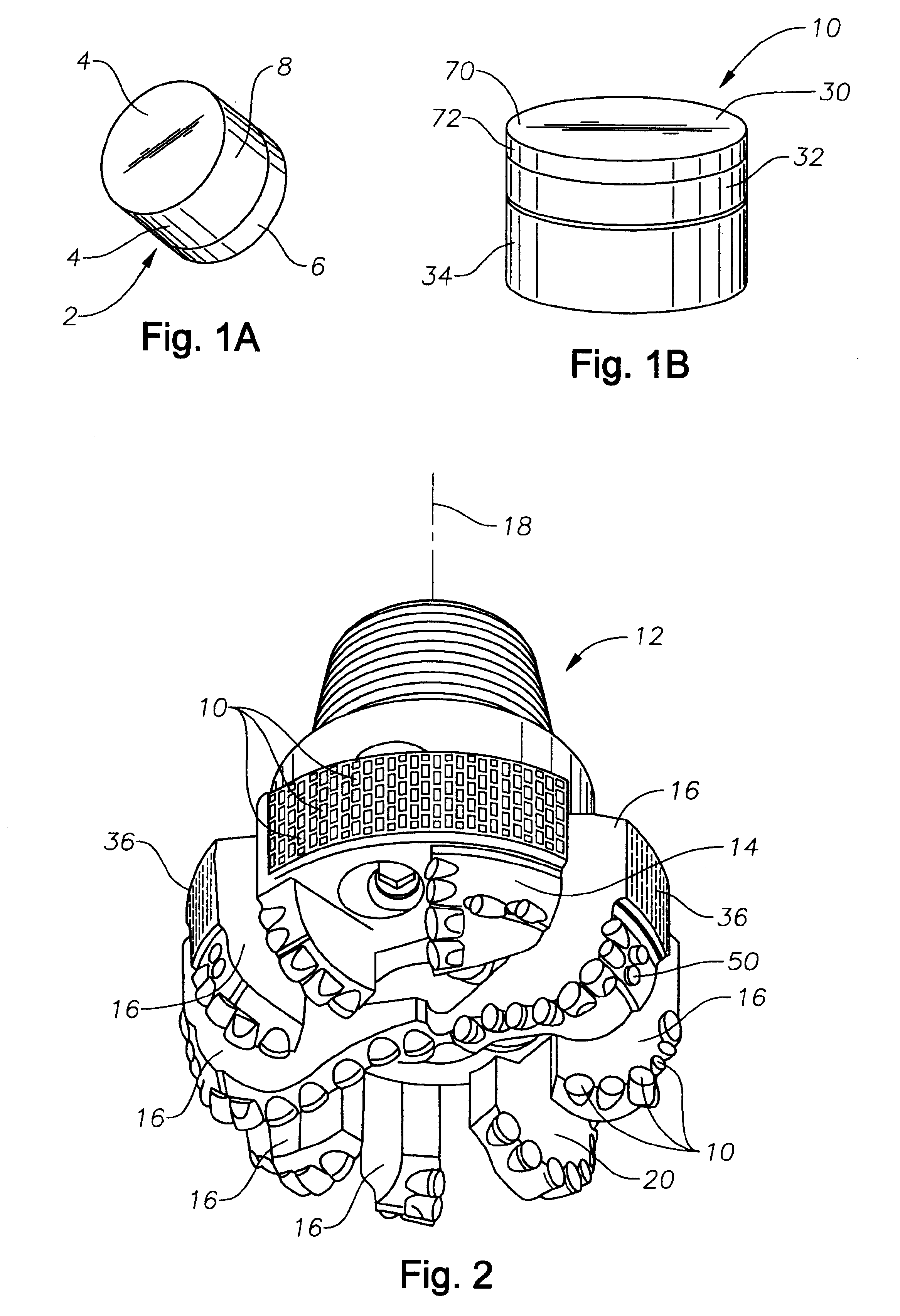

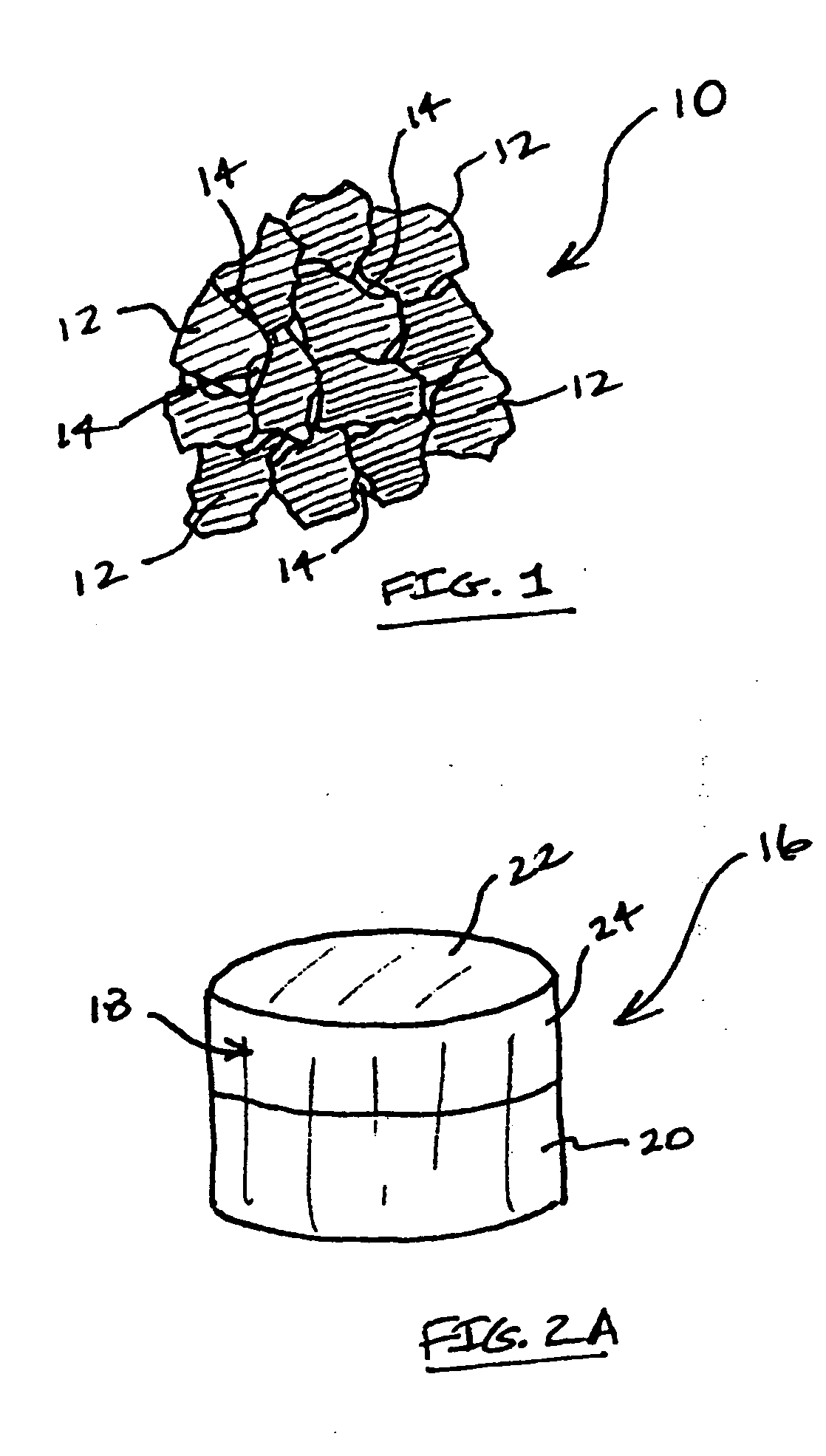

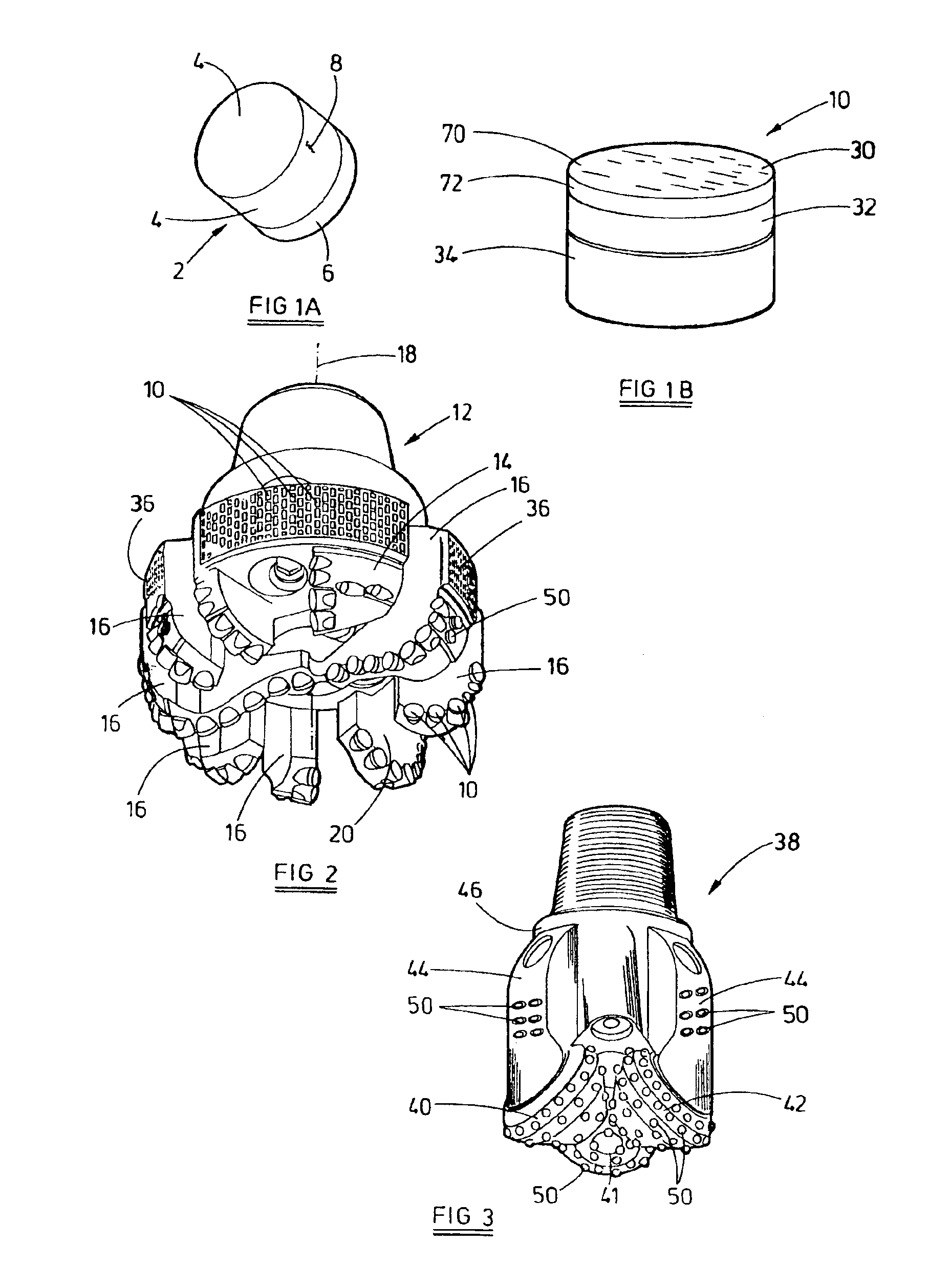

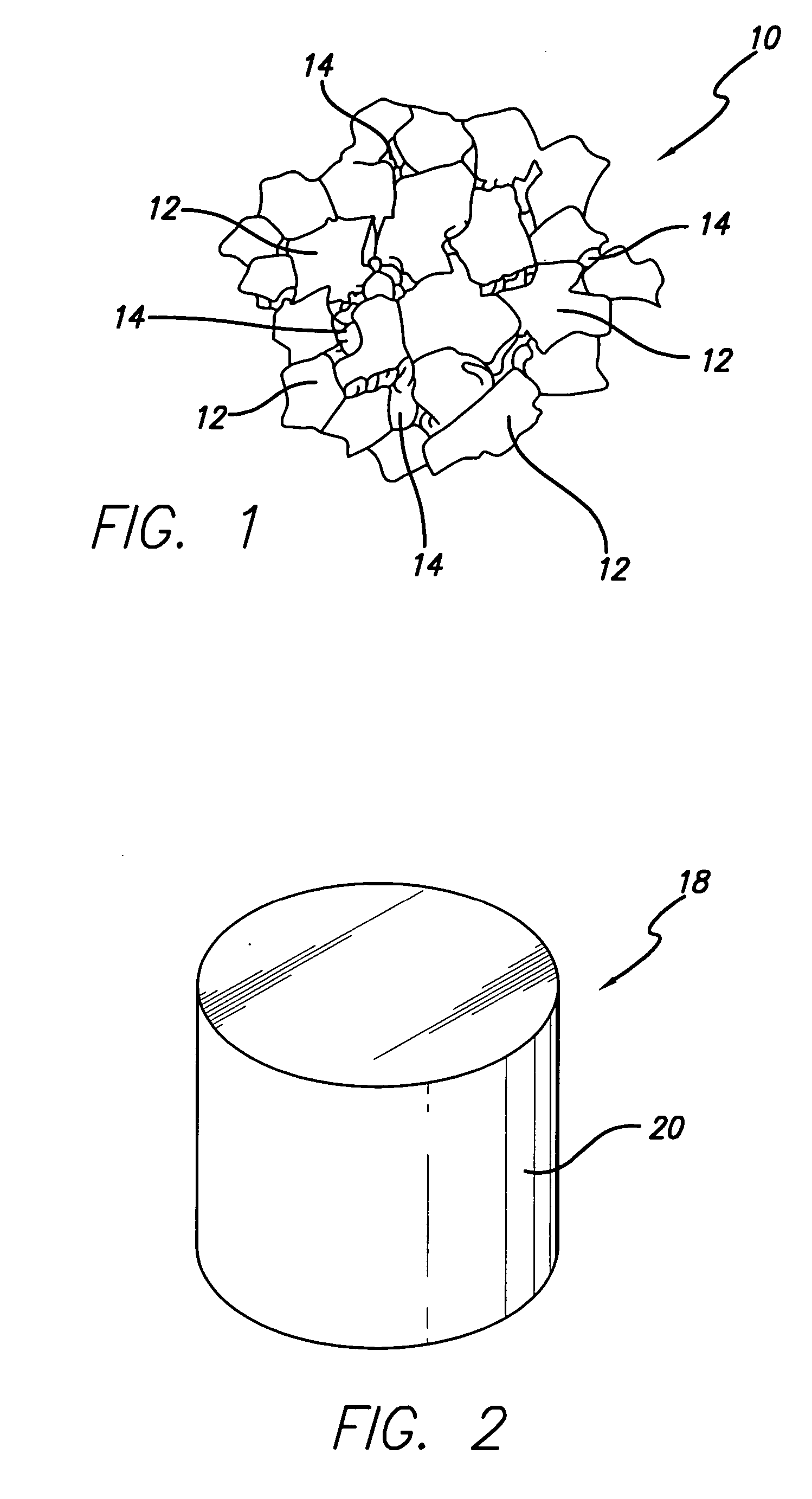

A drill bit that includes a bit body; and at least one cutting element for engaging the formation disposed on the bit body, the at least one cutting element comprising: a ductile phase; a plurality of carbide particles dispersed in the ductile phase; and a plurality of nanotubes integrated into the cutting element is disclosed.

Owner:SMITH INT INC

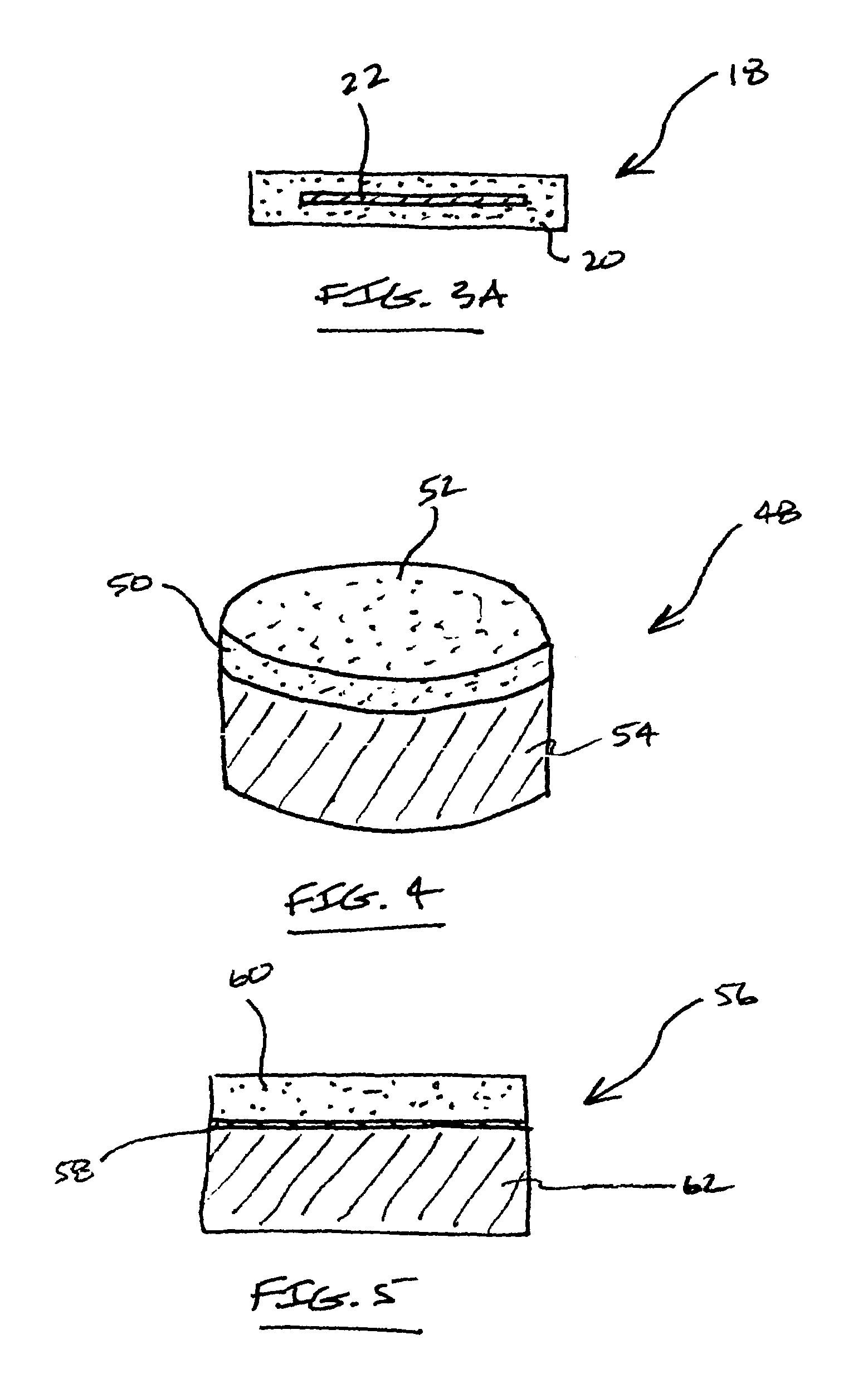

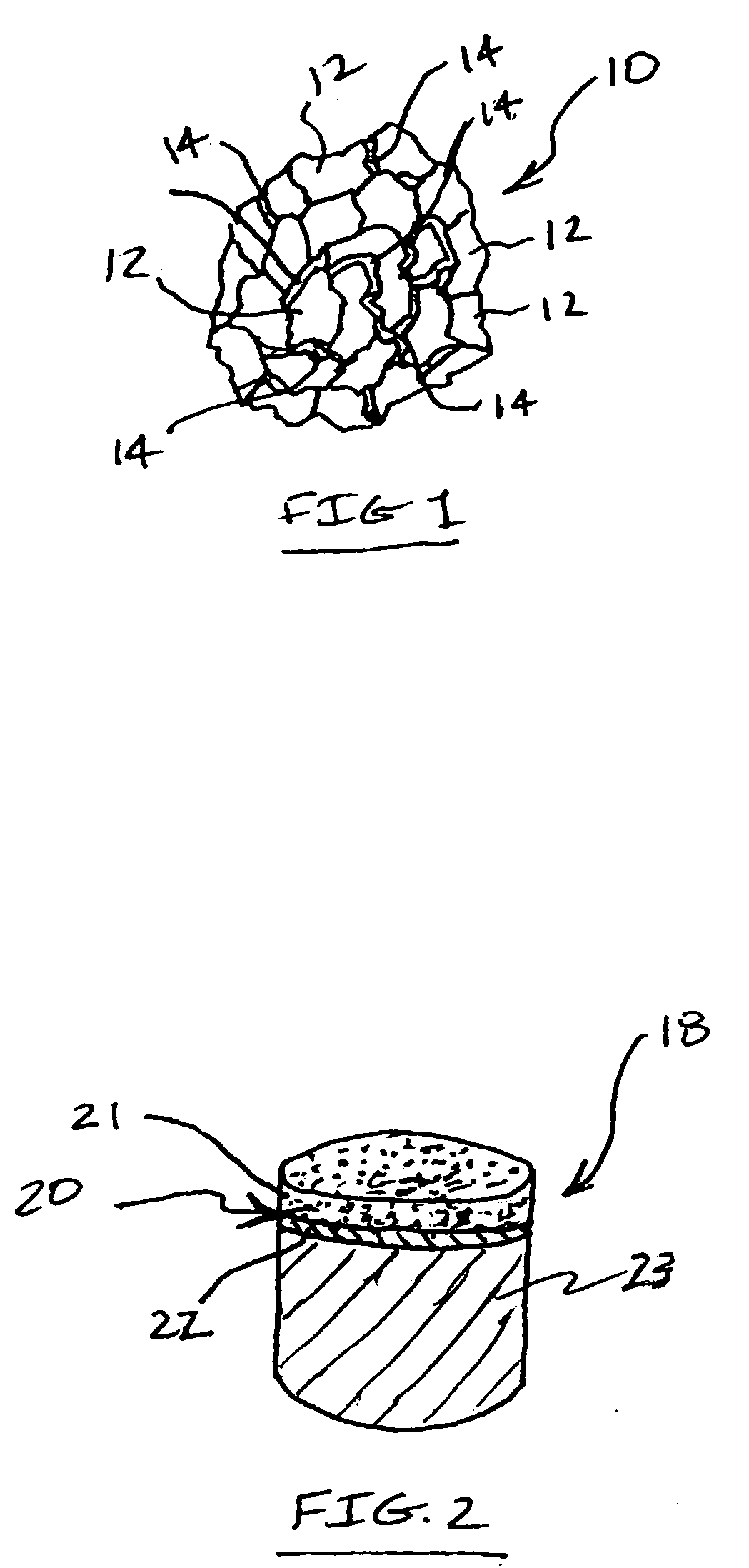

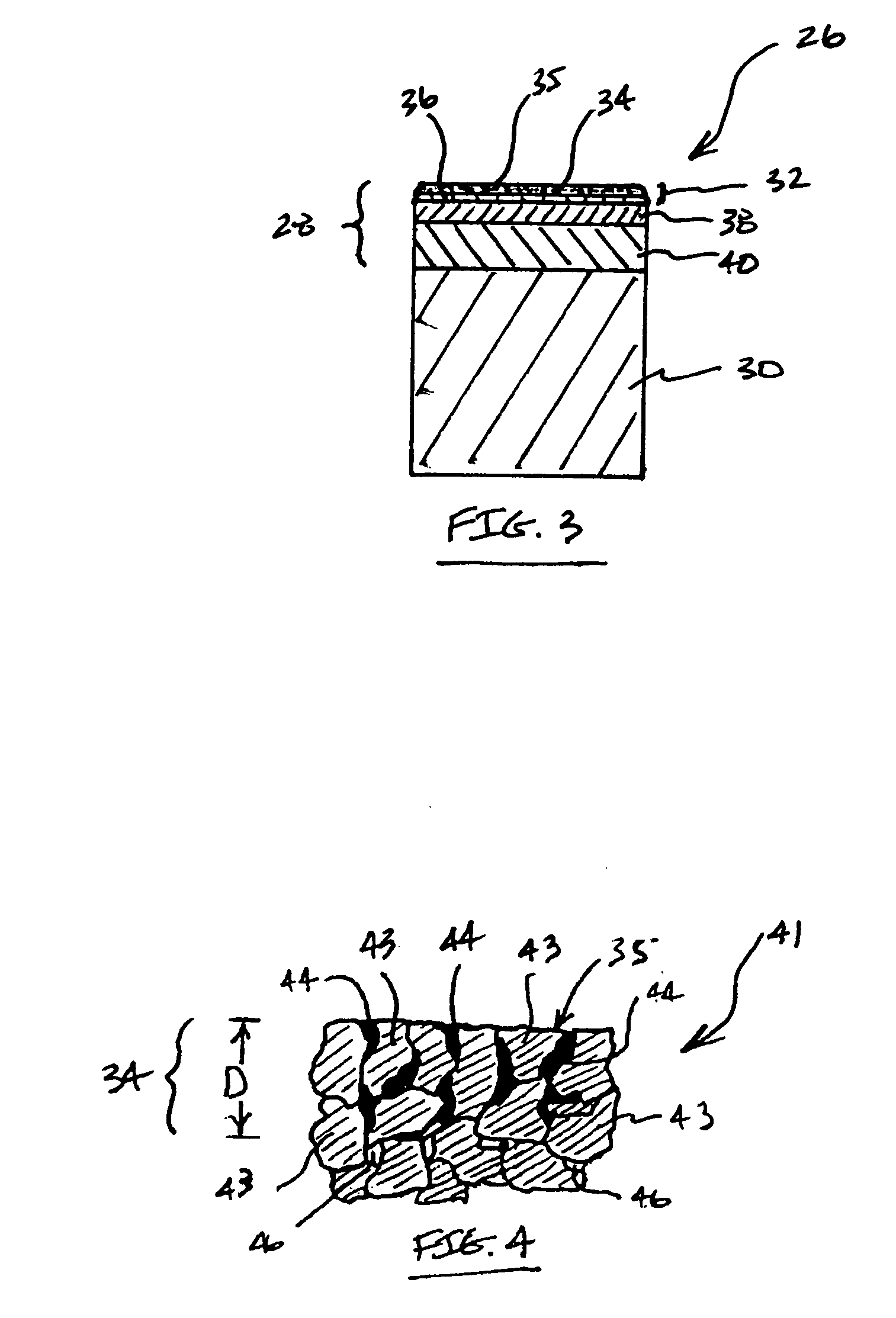

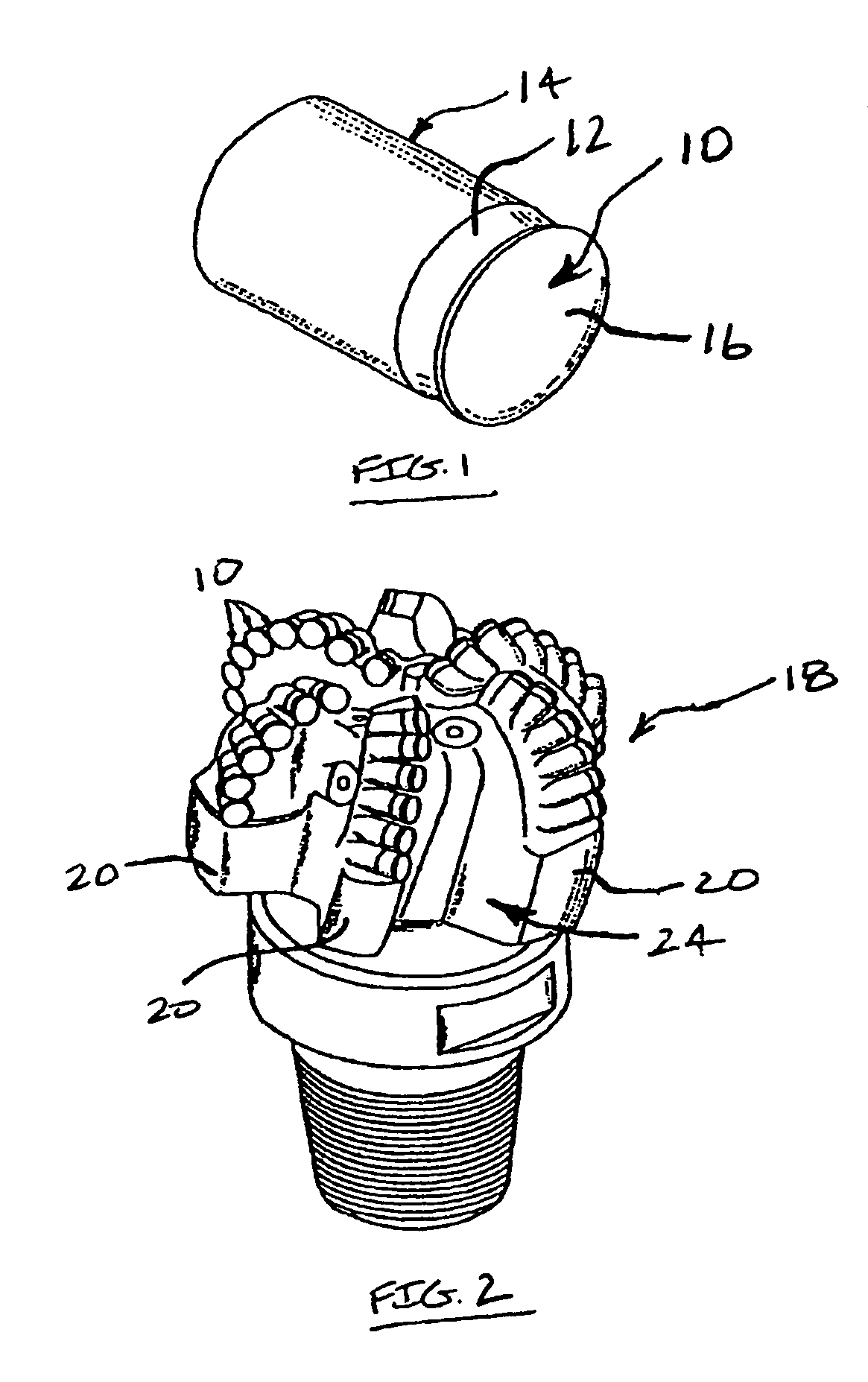

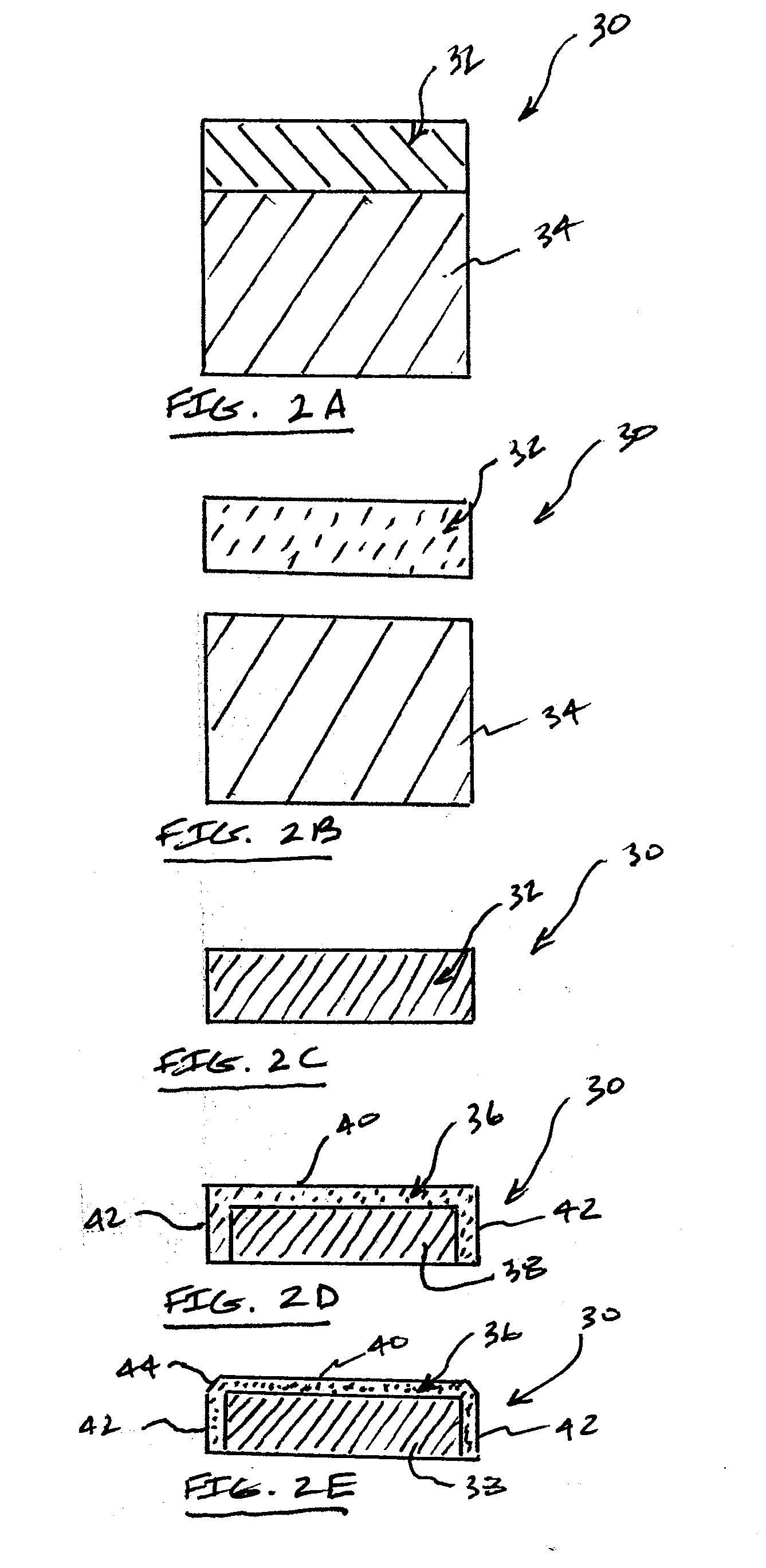

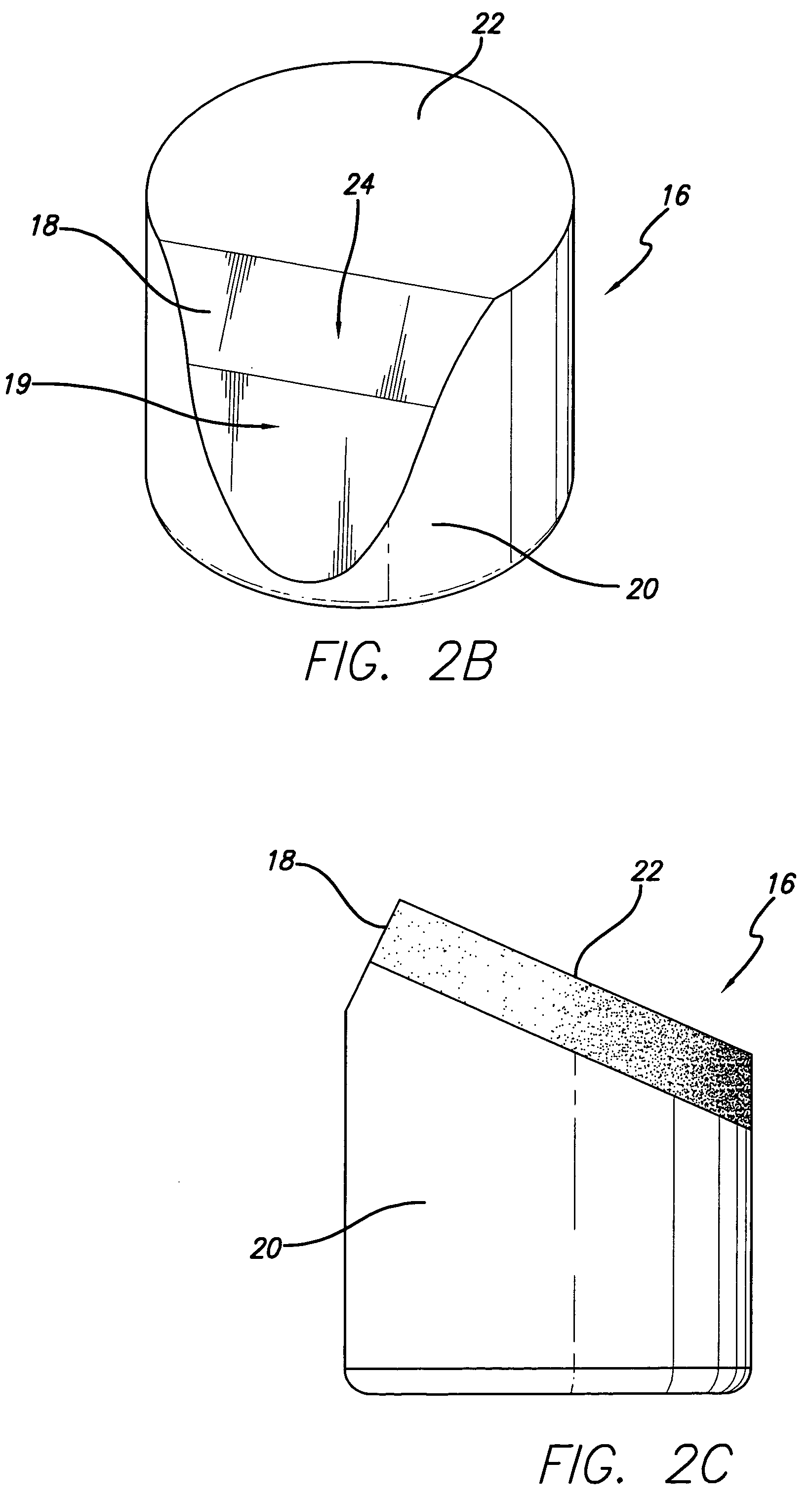

Polycrystalline diamond cutters with working surfaces having varied wear resistance while maintaining impact strength

InactiveUS6601662B2Improve wear resistanceMaintain strengthDrill bitsConstructionsDiamond crystalPolycrystalline diamond

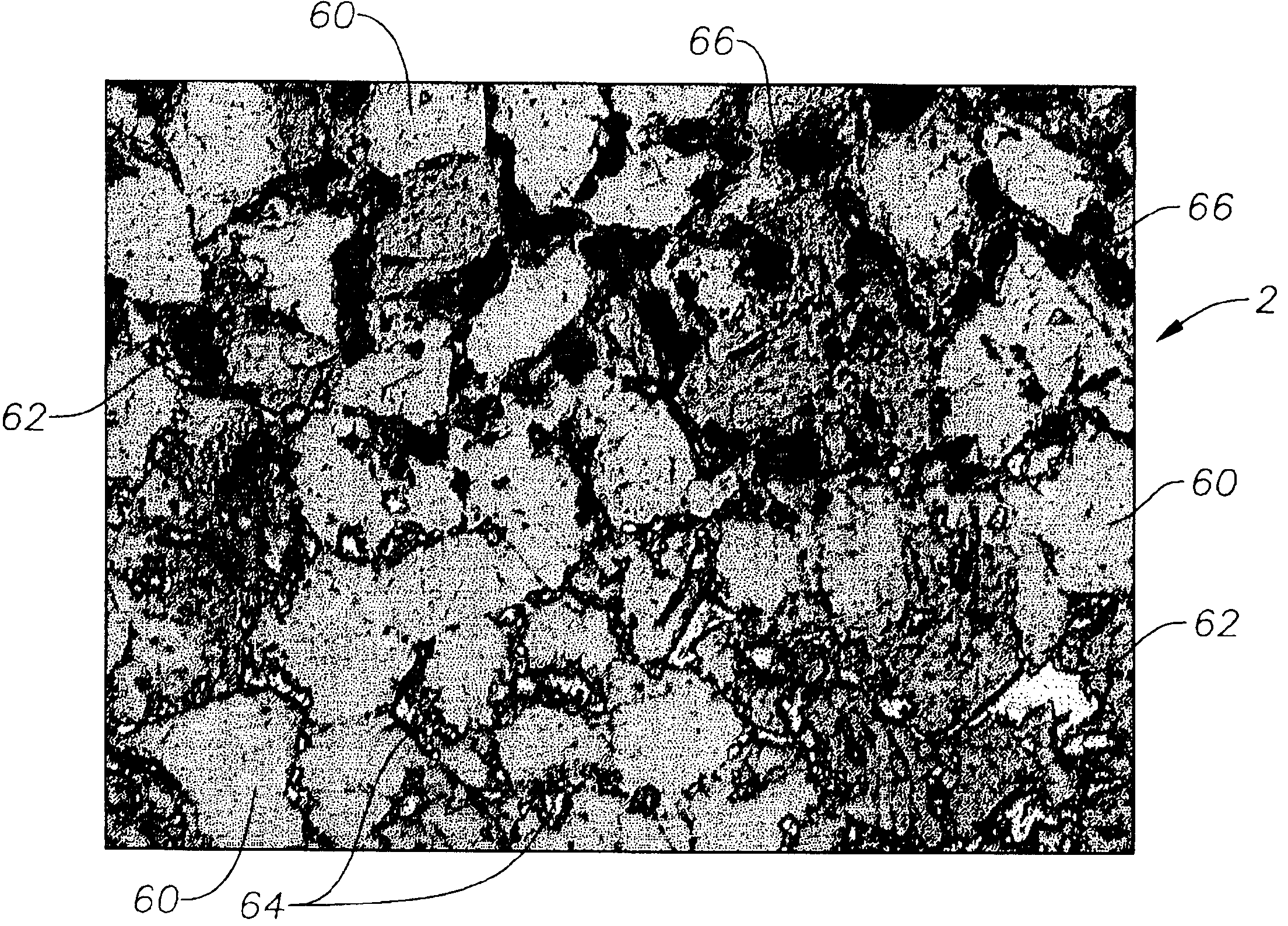

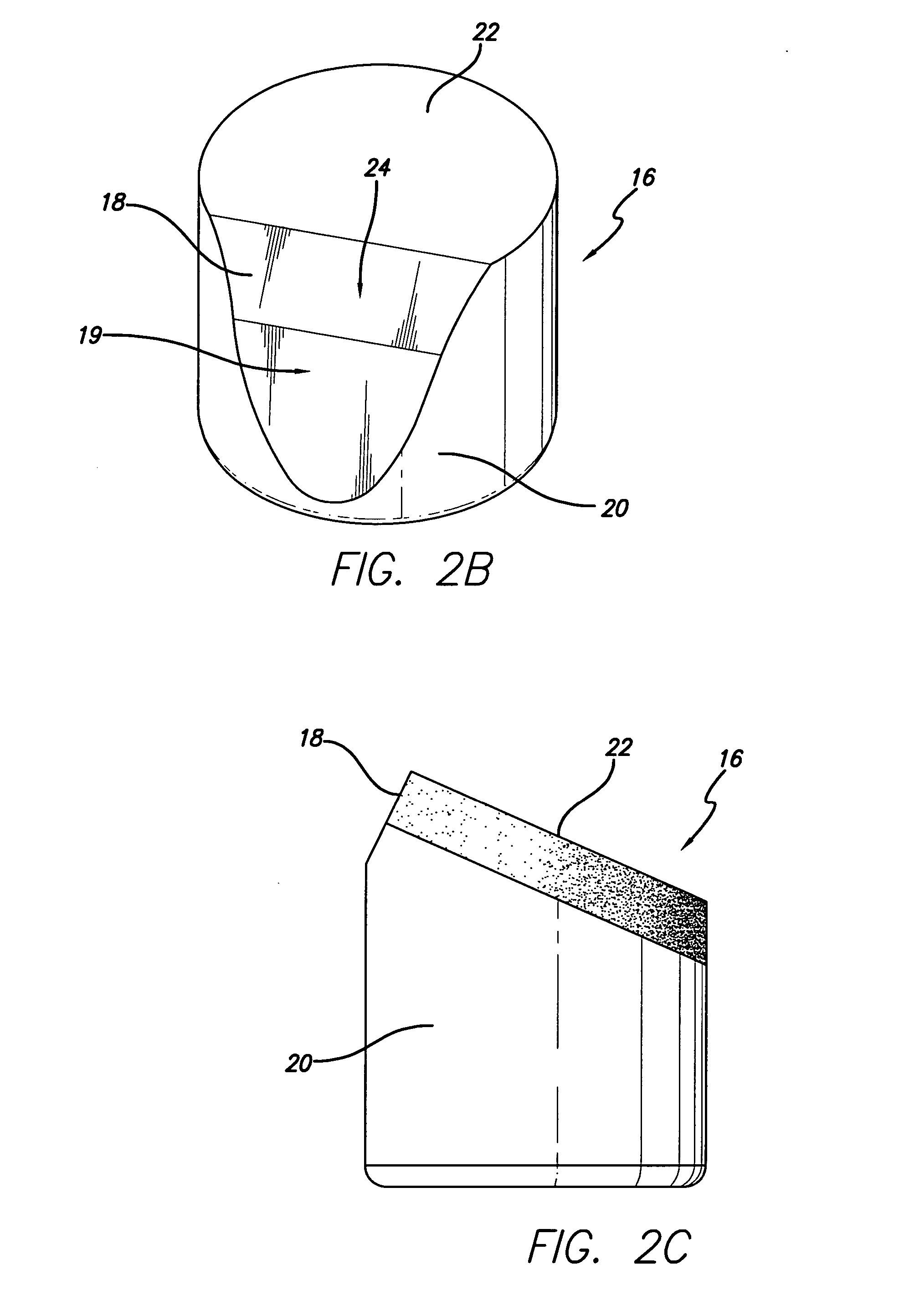

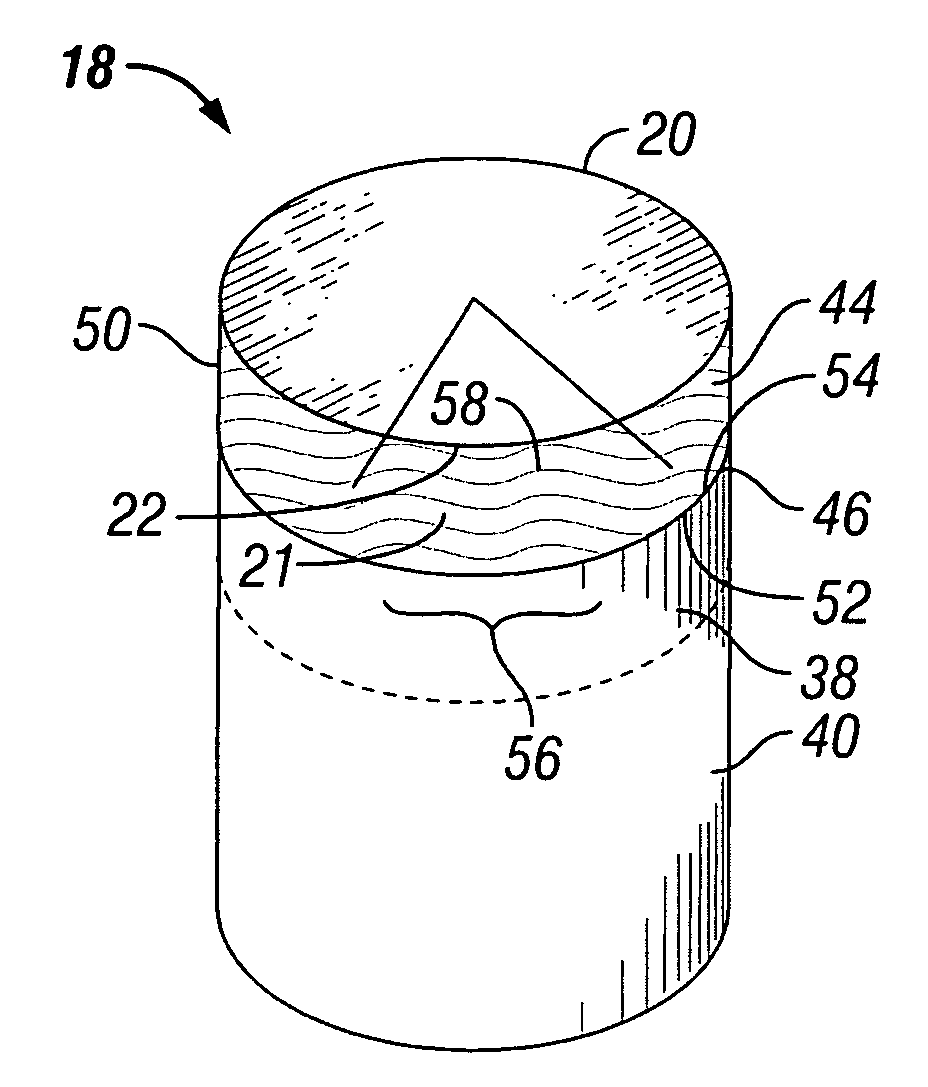

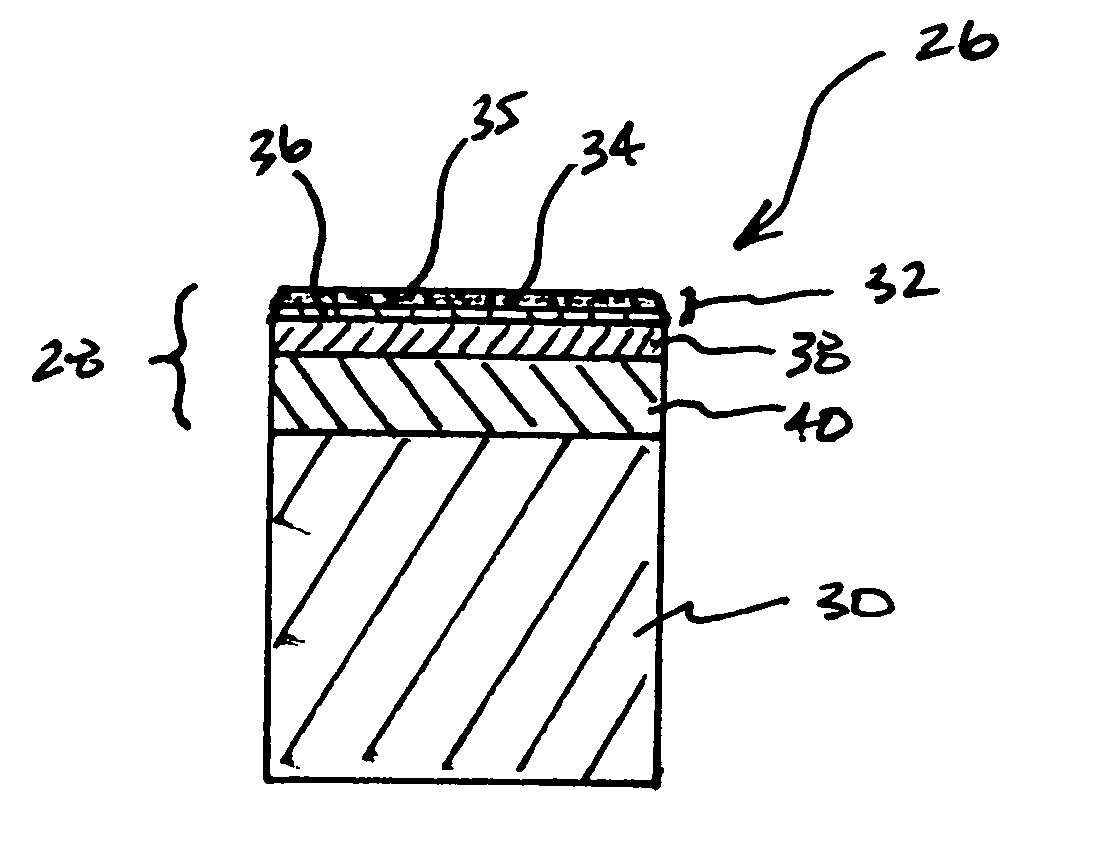

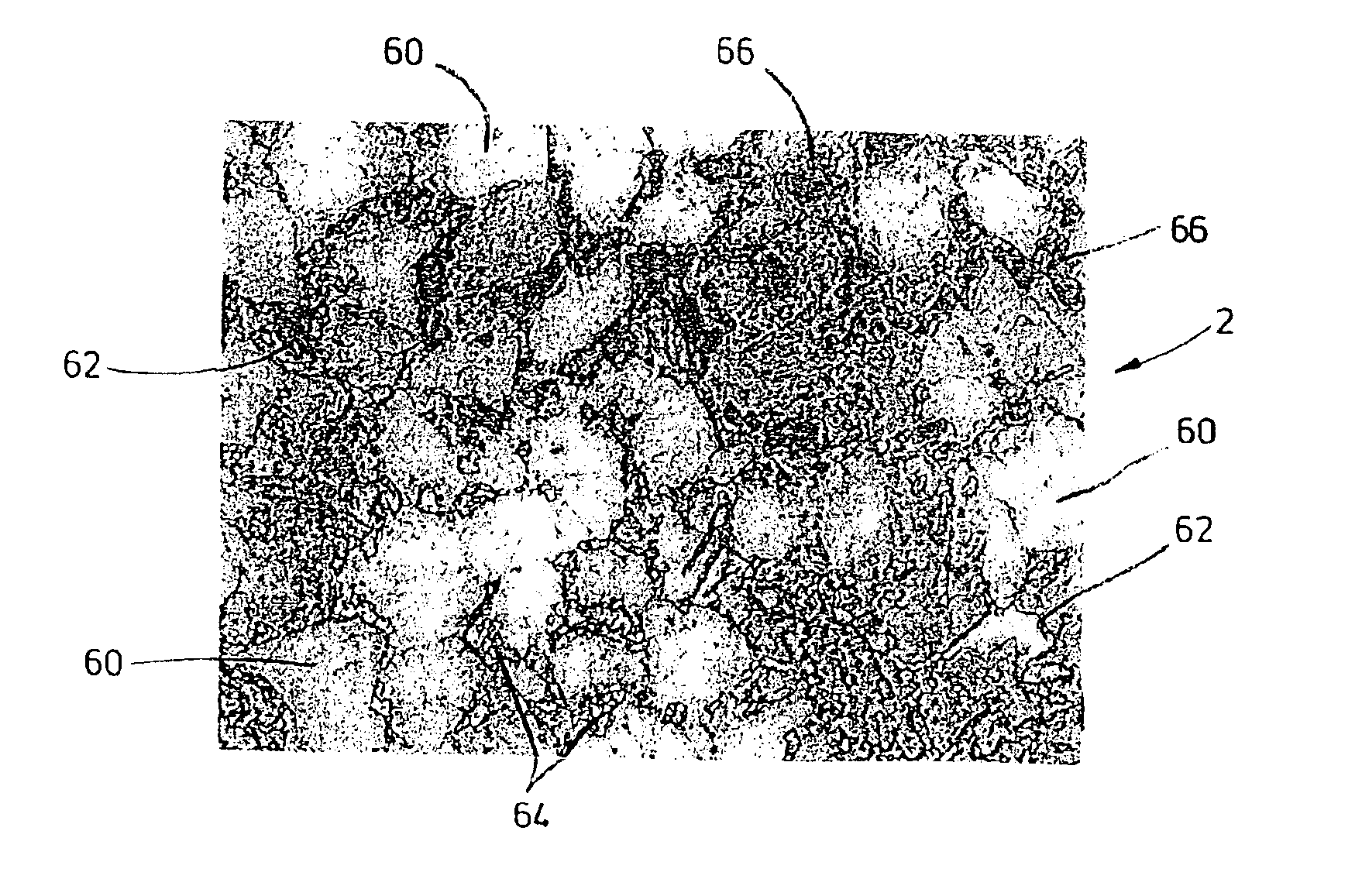

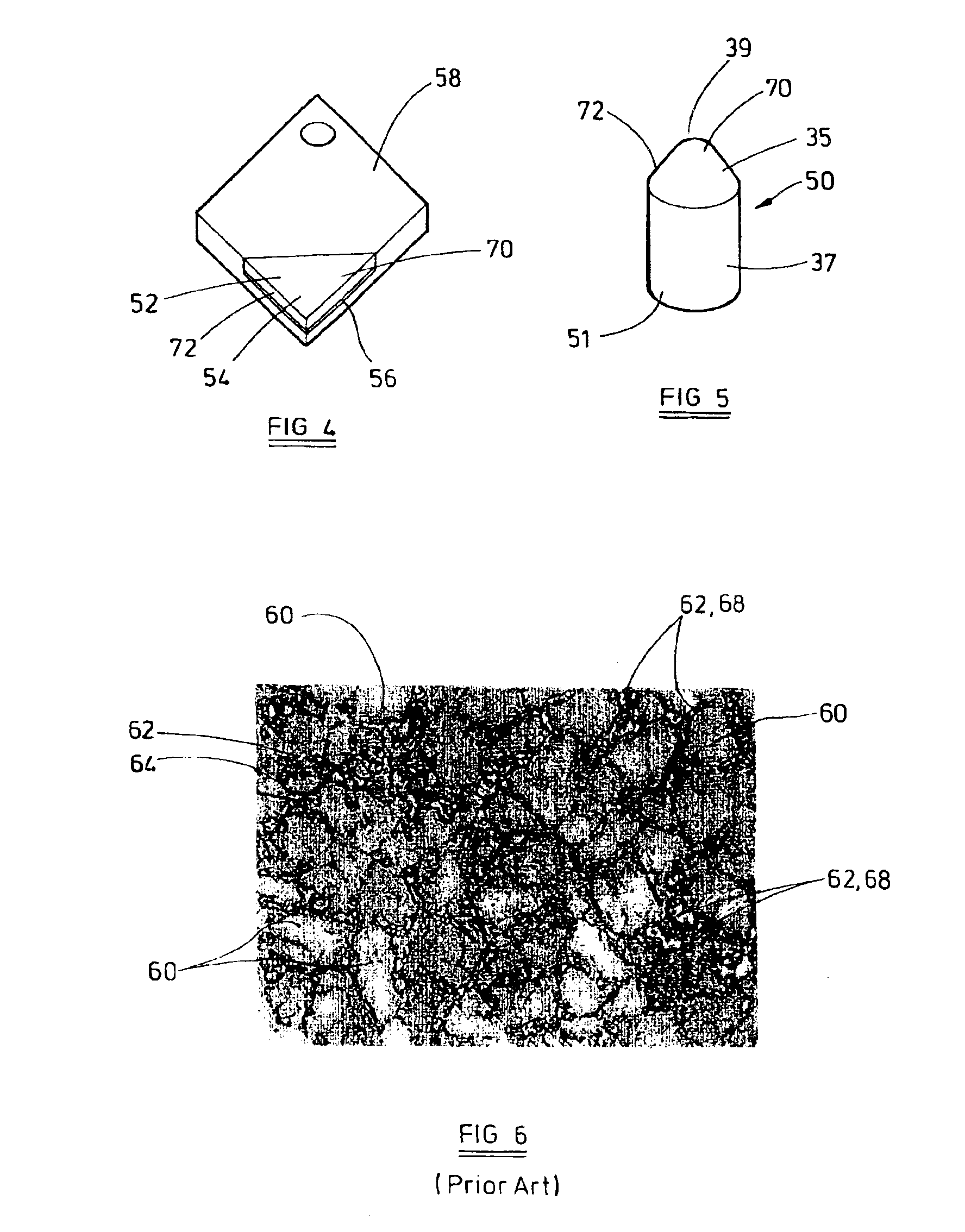

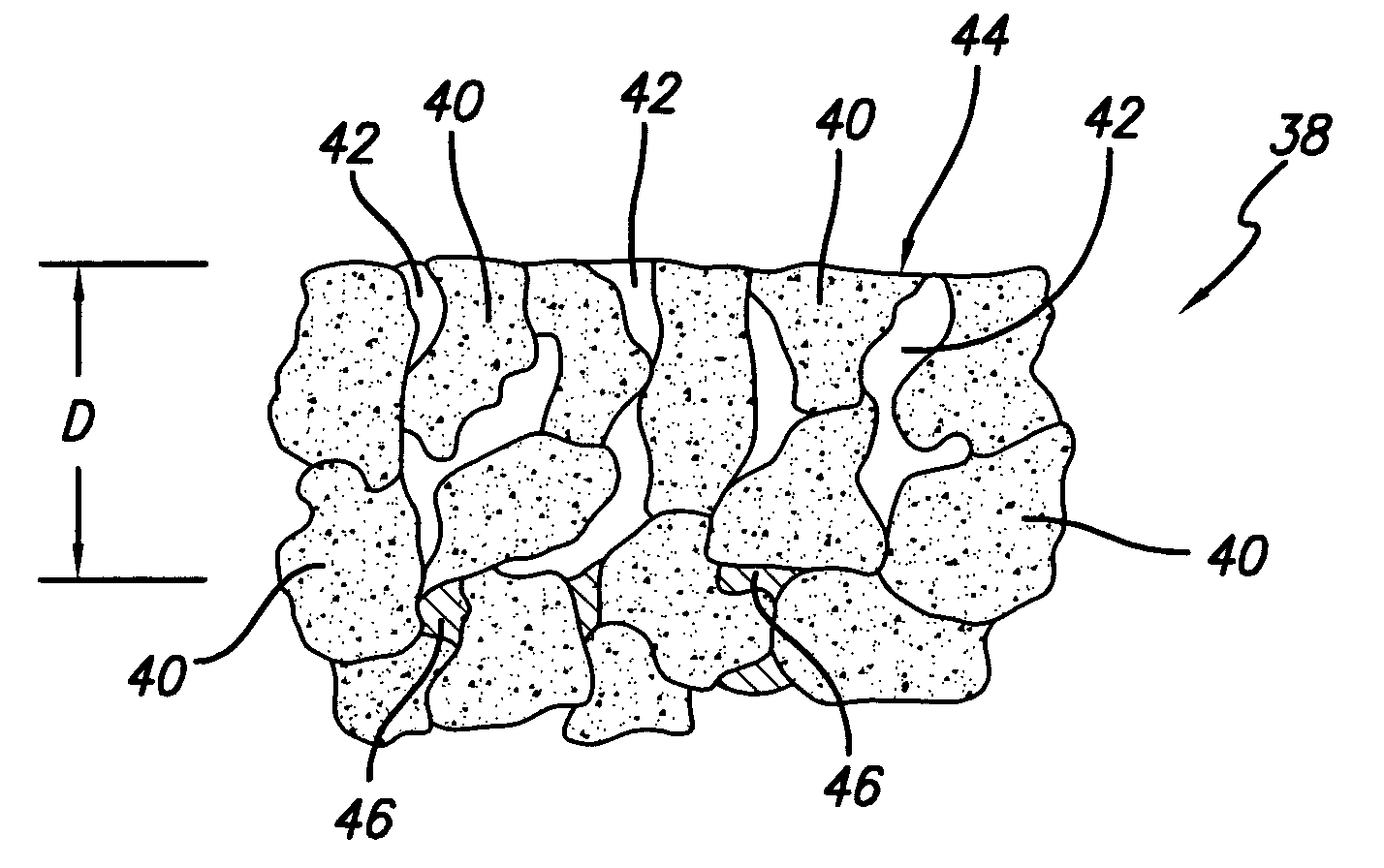

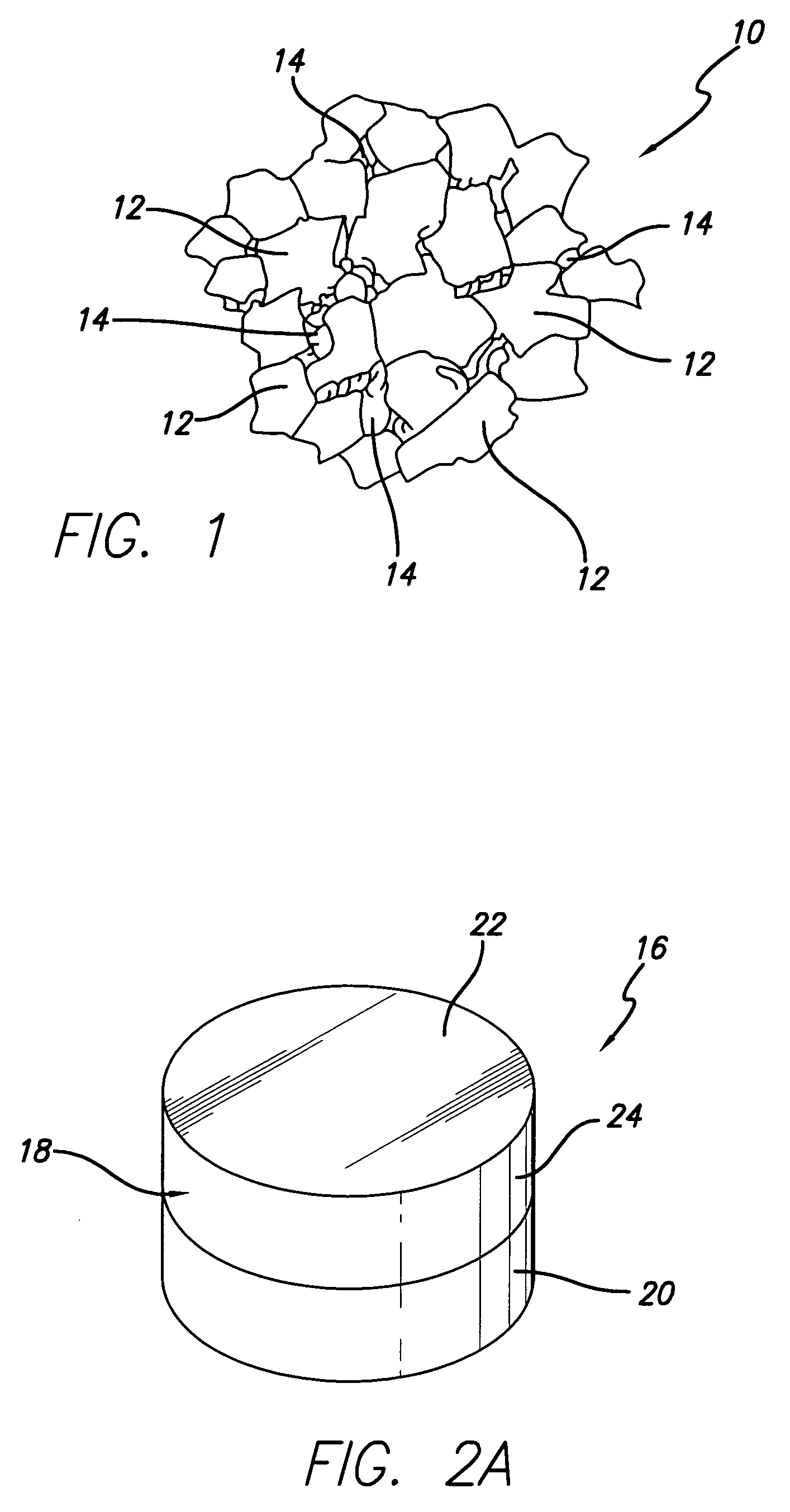

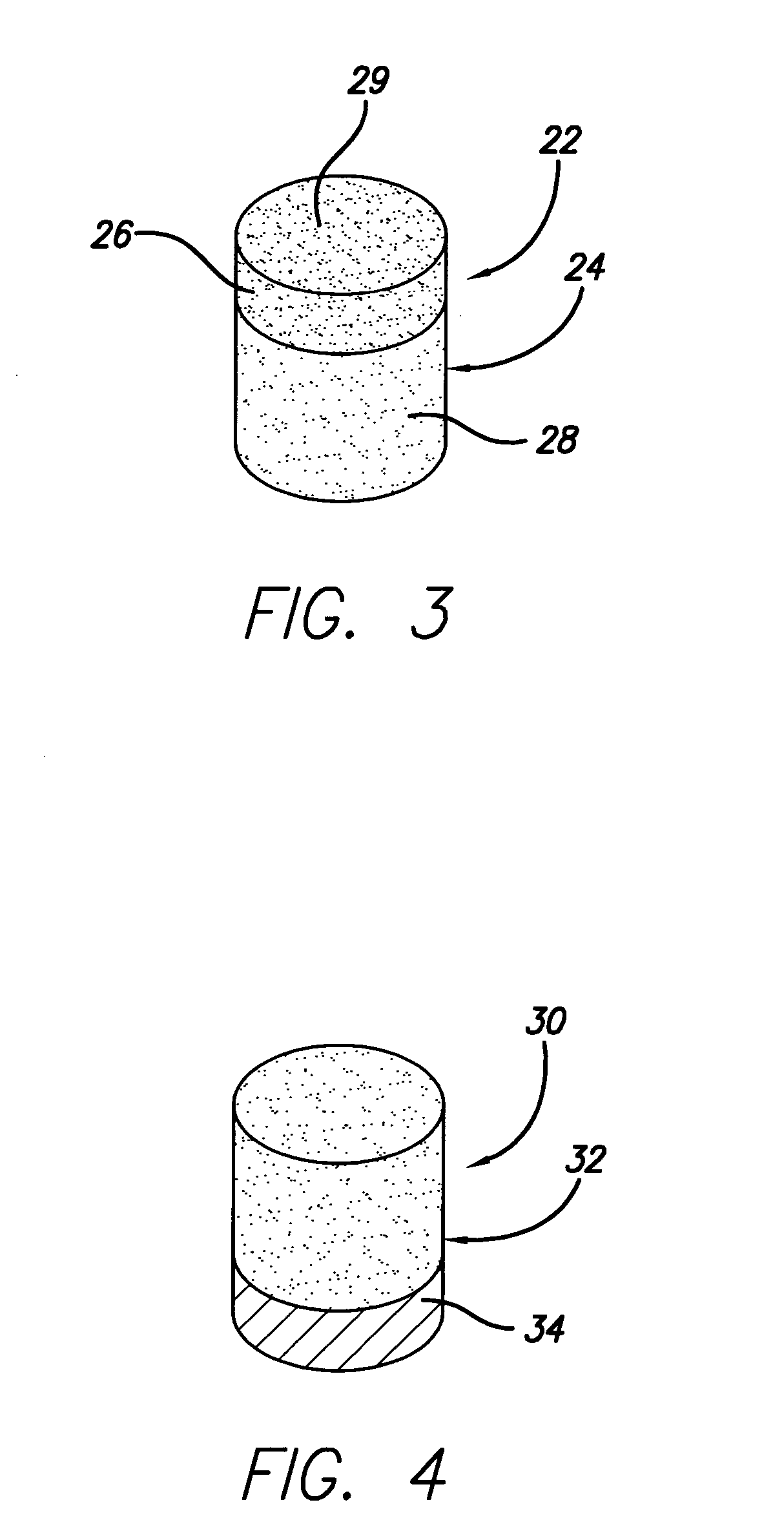

Disclosed is a polycrystalline diamond or diamond-like element with greatly improved wear resistance without loss of impact strength. These elements are formed with a binder-catalyzing material in a high-temperature, high-pressure (HTHP) process. The PCD element has a body with a plurality of bonded diamond or diamond-like crystals forming a continuous diamond matrix that has a diamond volume density greater than 85%. Interstices among the diamond crystals form a continuous interstitial matrix containing a catalyzing material. The diamond matrix table is formed and integrally bonded with a metallic substrate containing the catalyzing material during the HTHP process. The diamond matrix body has a working surface, where a first portion of the interstitial matrix in the body adjacent to the working surface is substantially free of the catalyzing material, and a second portion of the interstitial matrix in the body adjacent to the working surface contains the catalyzing material. The first portion of the interstitial matrix and the second portion of the interstitial matrix have substantially the same impact strength.

Owner:REEDHYCALOG UK

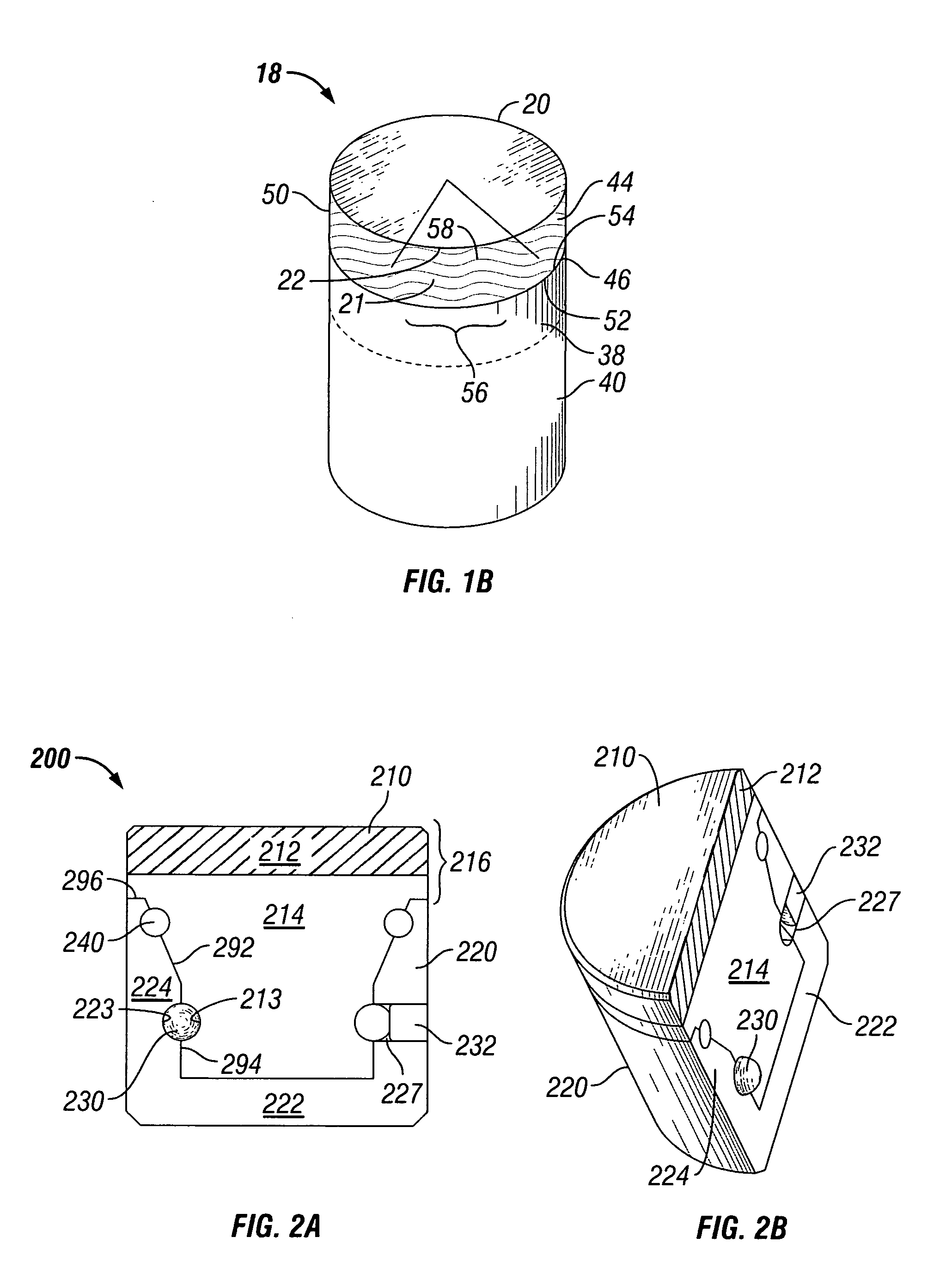

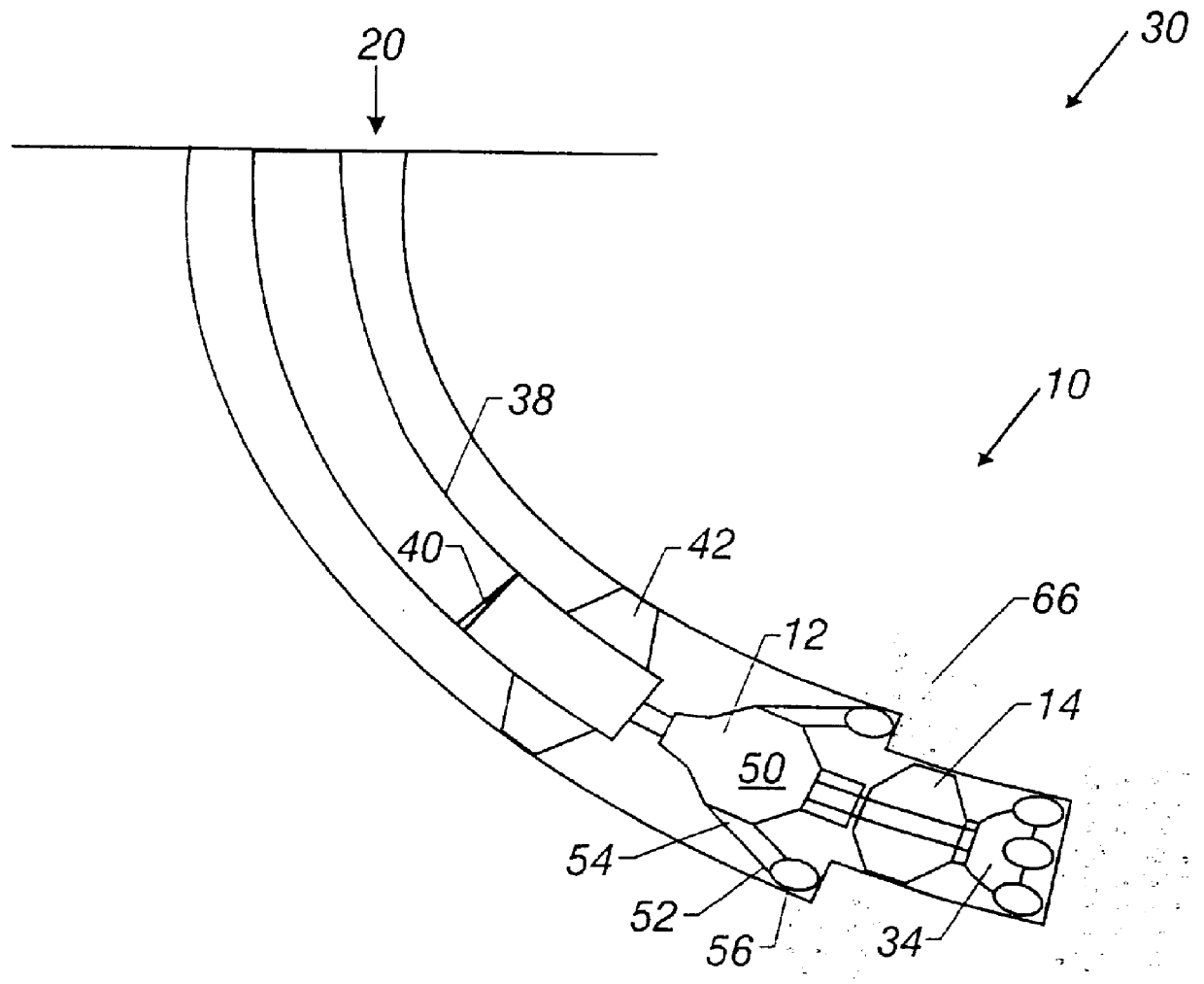

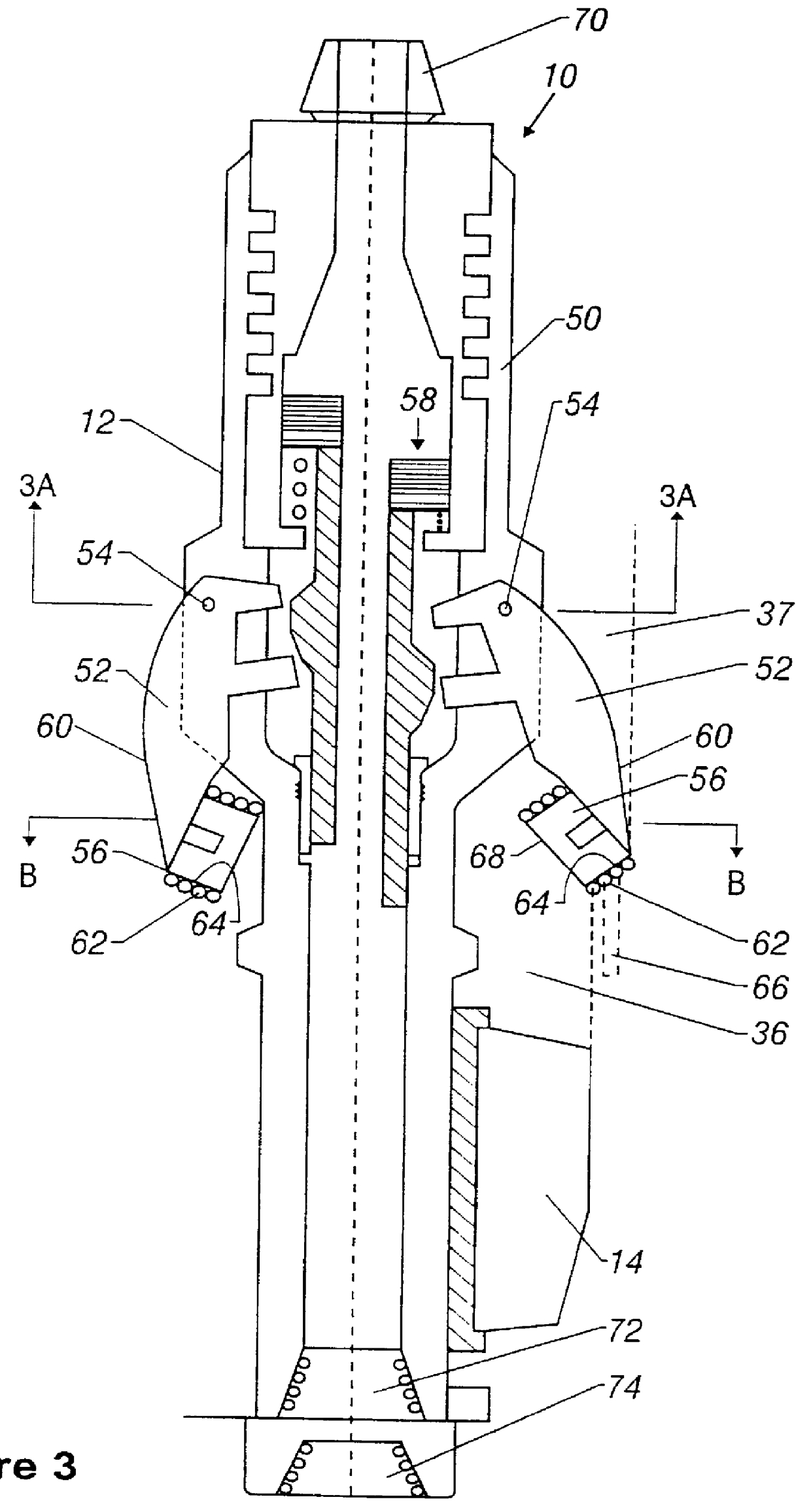

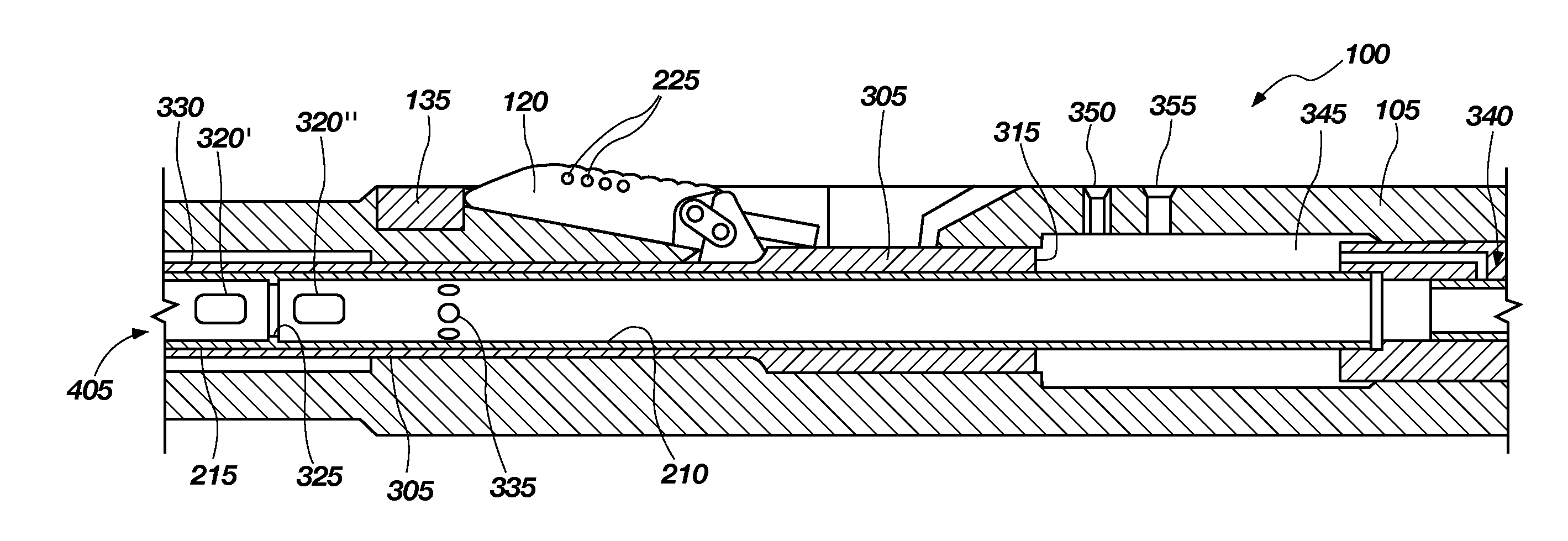

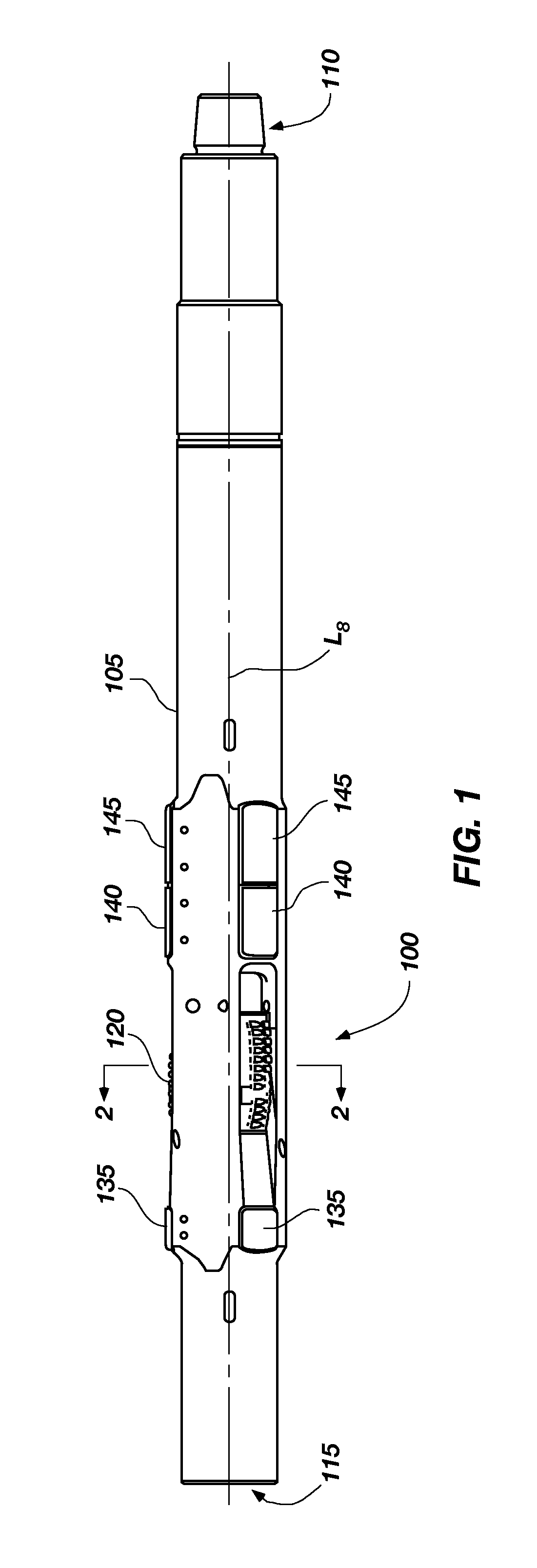

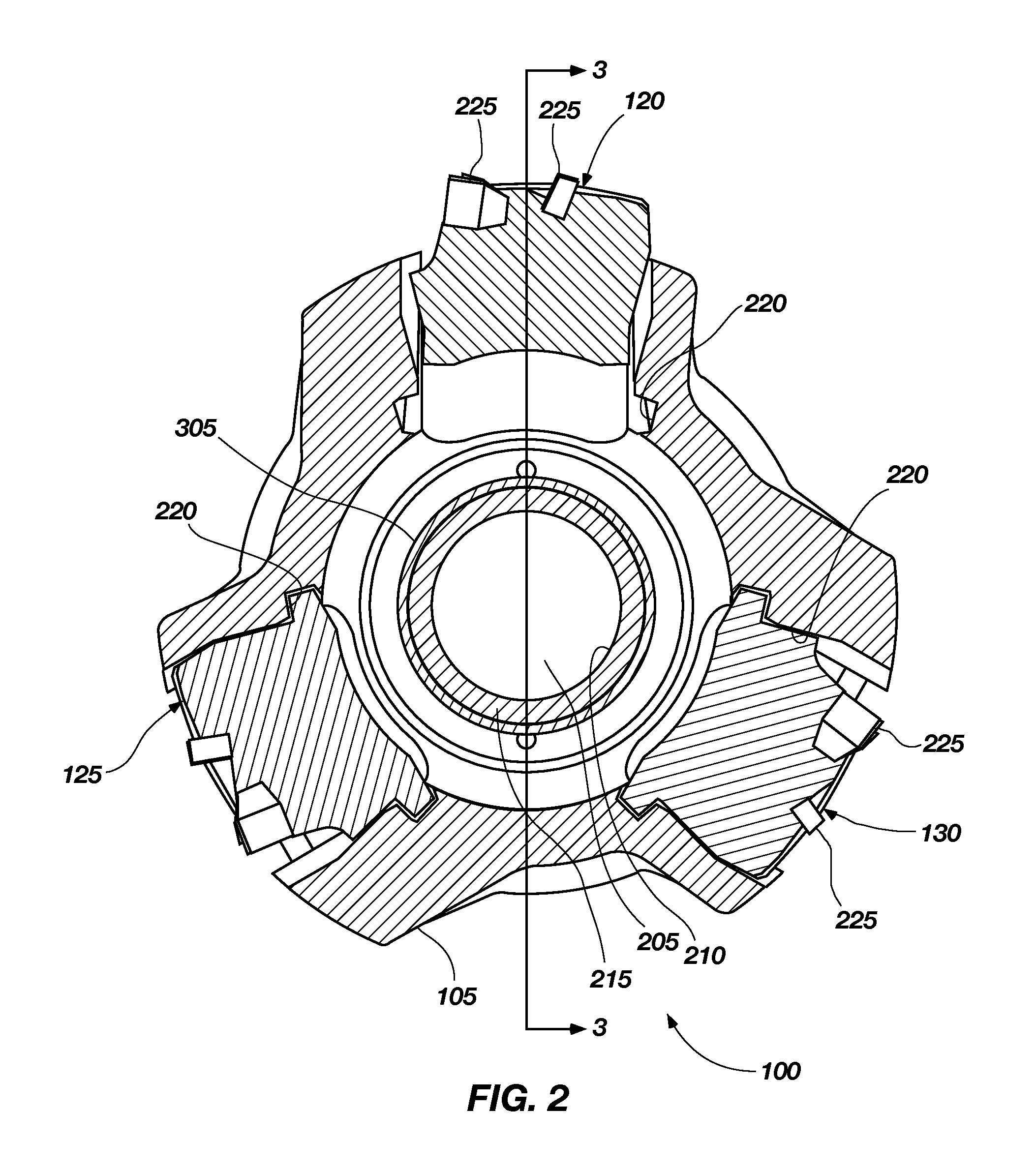

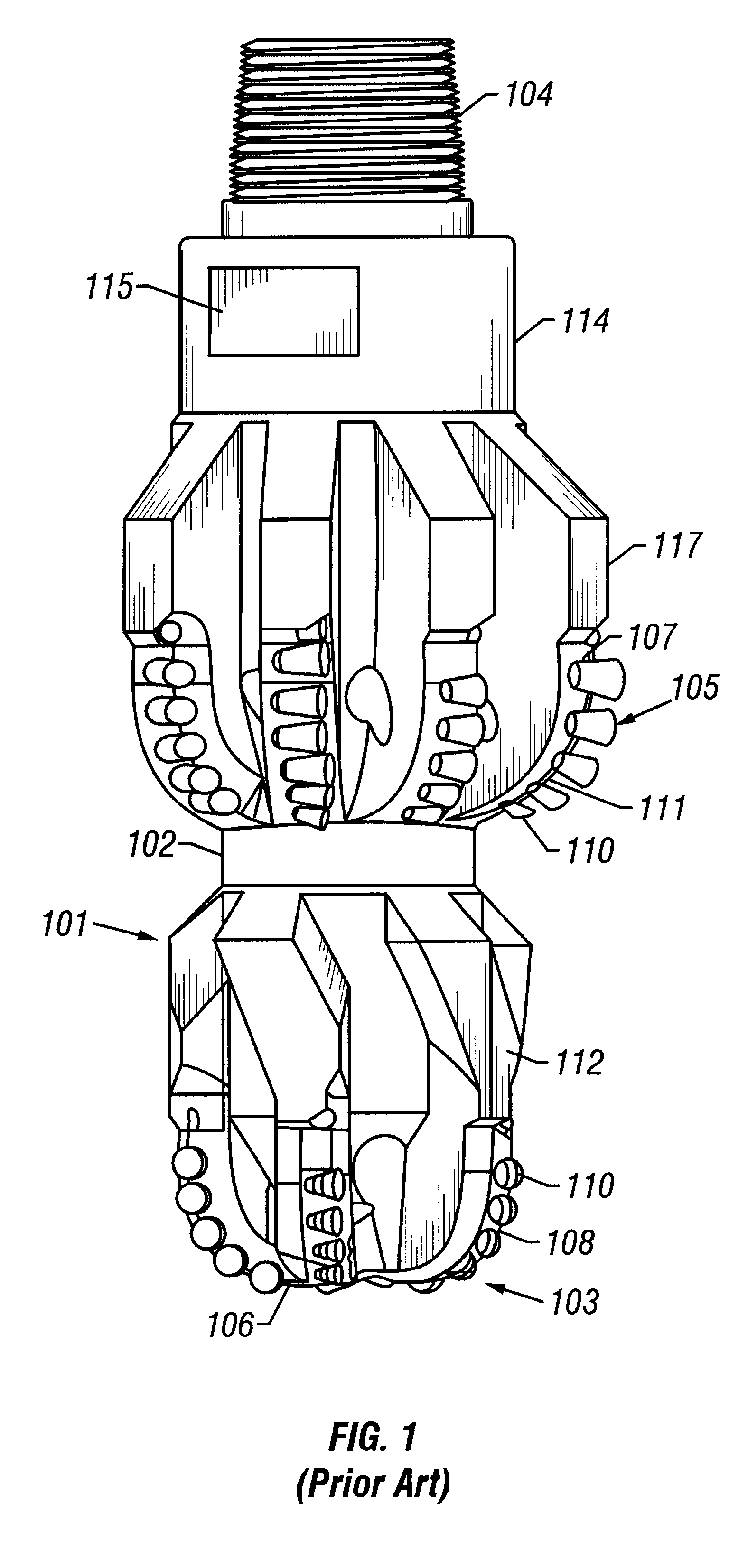

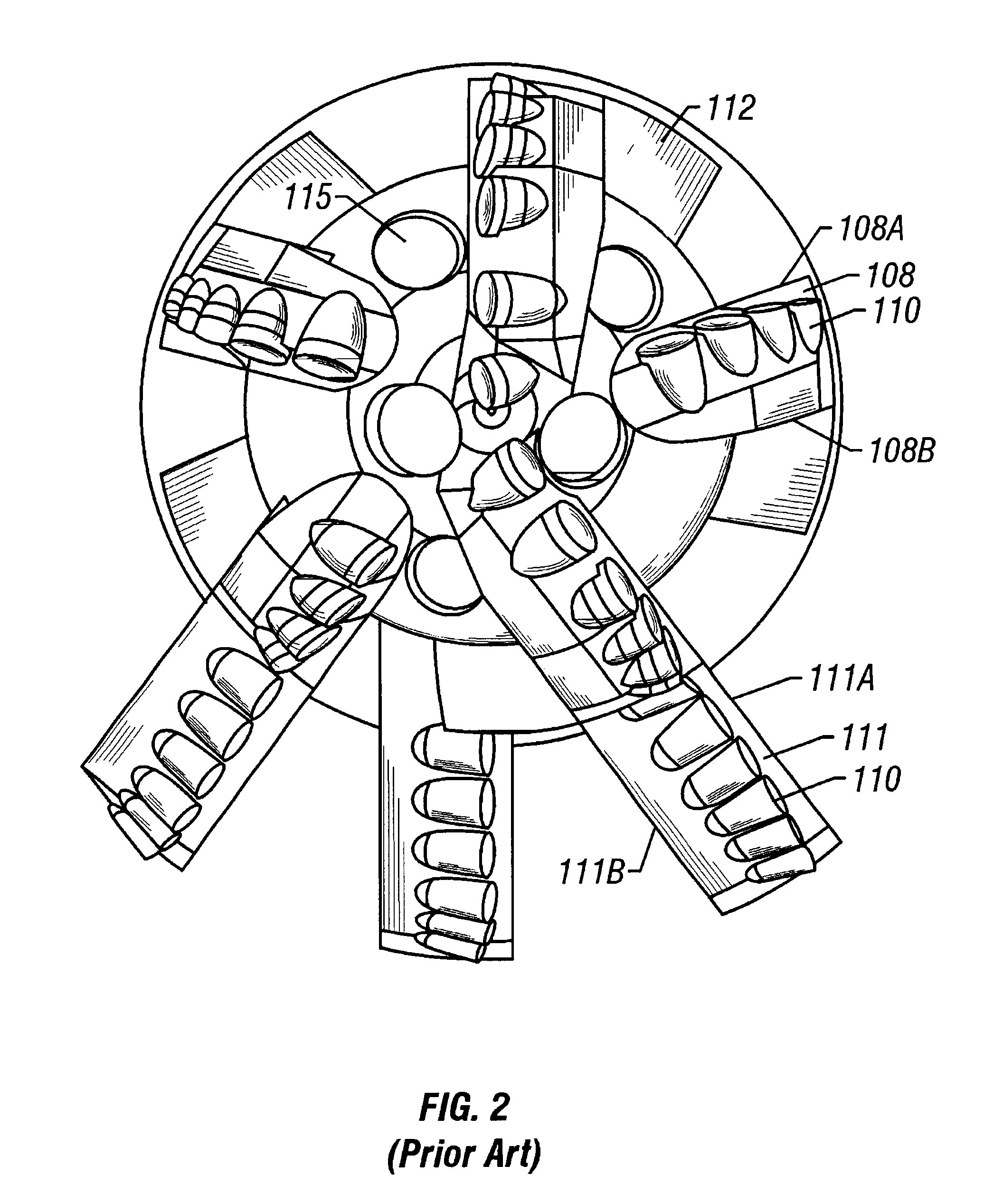

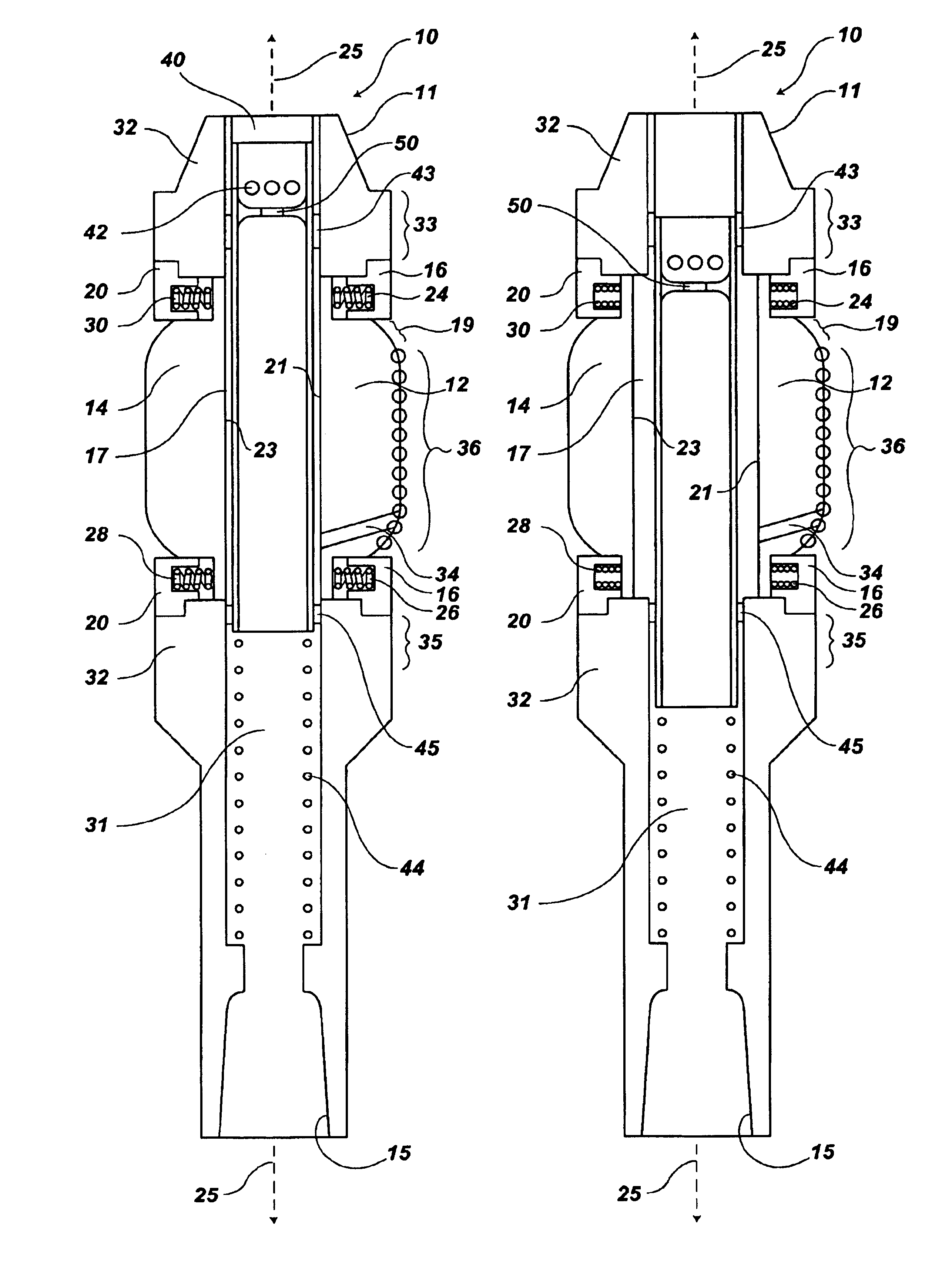

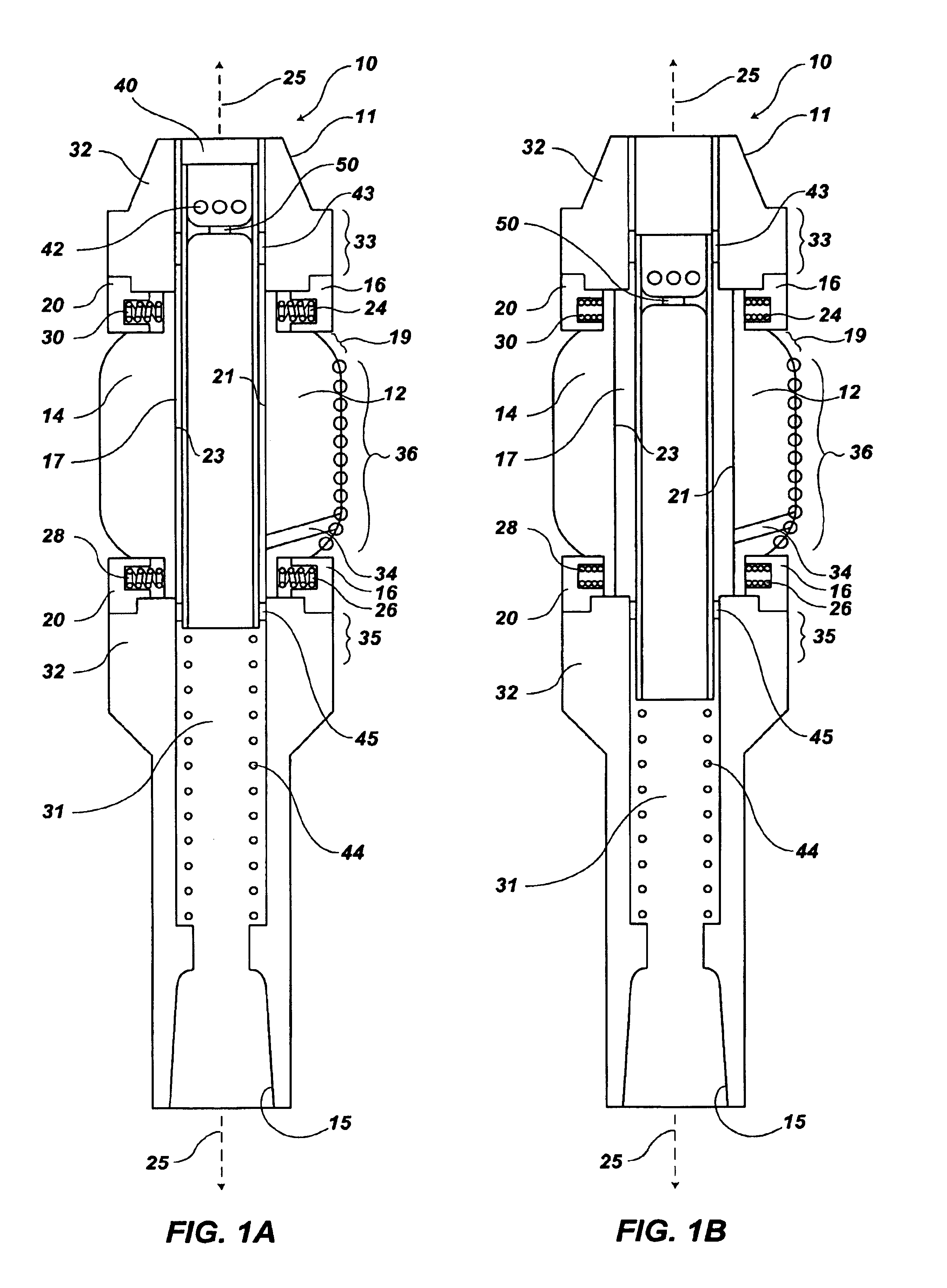

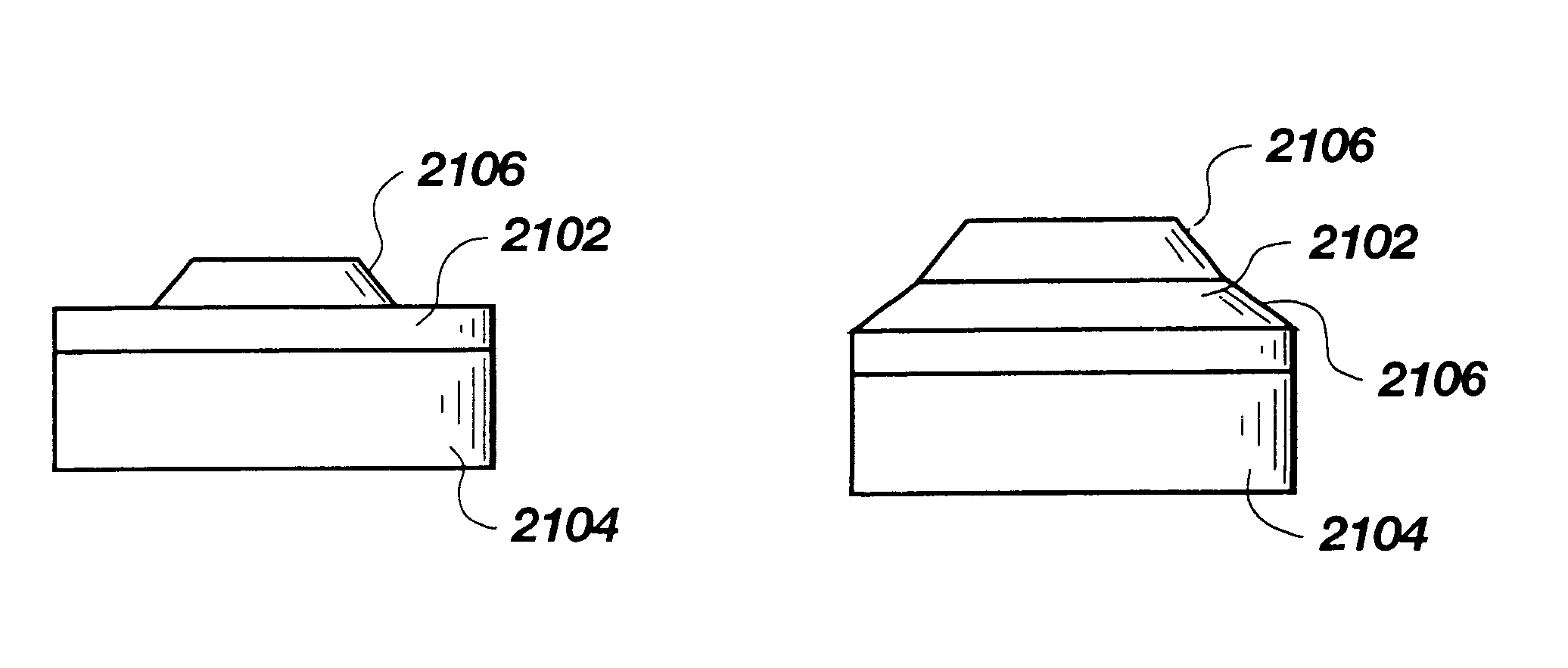

Expandable underreamer/stabilizer

A downhole tool that functions as an underreamer, or alternatively, as a stabilizer in an underreamed borehole. The tool includes one or more moveable arms disposed within a body having a flowbore therethrough in fluid communication with the wellbore annulus. The tool alternates between collapsed and expanded positions in response to differential fluid pressure between the flowbore and the wellbore annulus. In one embodiment, the tool moves automatically in response to differential pressure. In a second embodiment, the tool must be selectively actuated before it is moveable. When the tool expands, the arms are preferably translated axially upwardly, while simultaneously being extended radially outwardly from the body. The expanded tool diameter is adjustable at the surface without changing components. The arms may include borehole engaging pads that comprise cutting structures or wear structures or both, depending upon the function of the tool.

Owner:SMITH INT INC

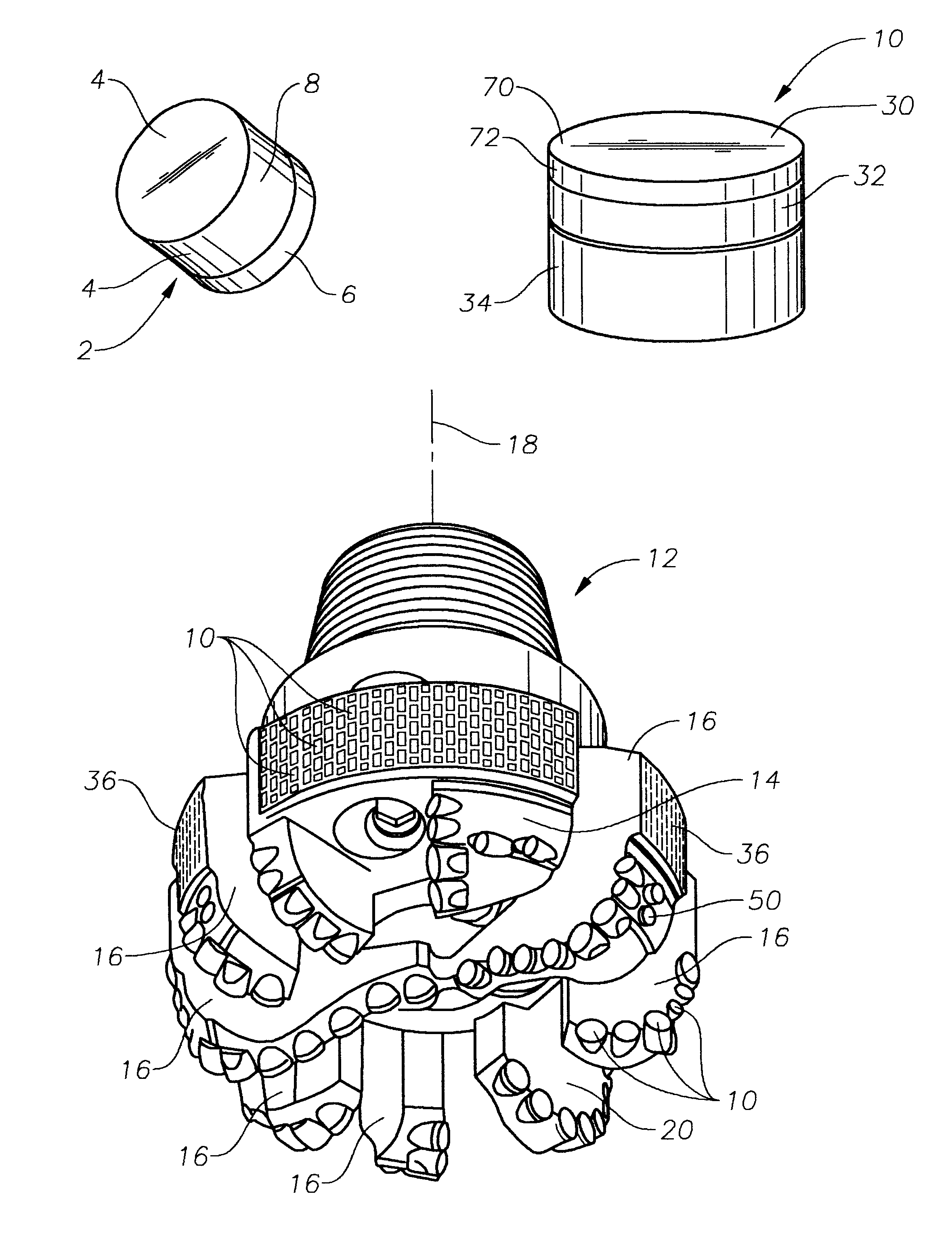

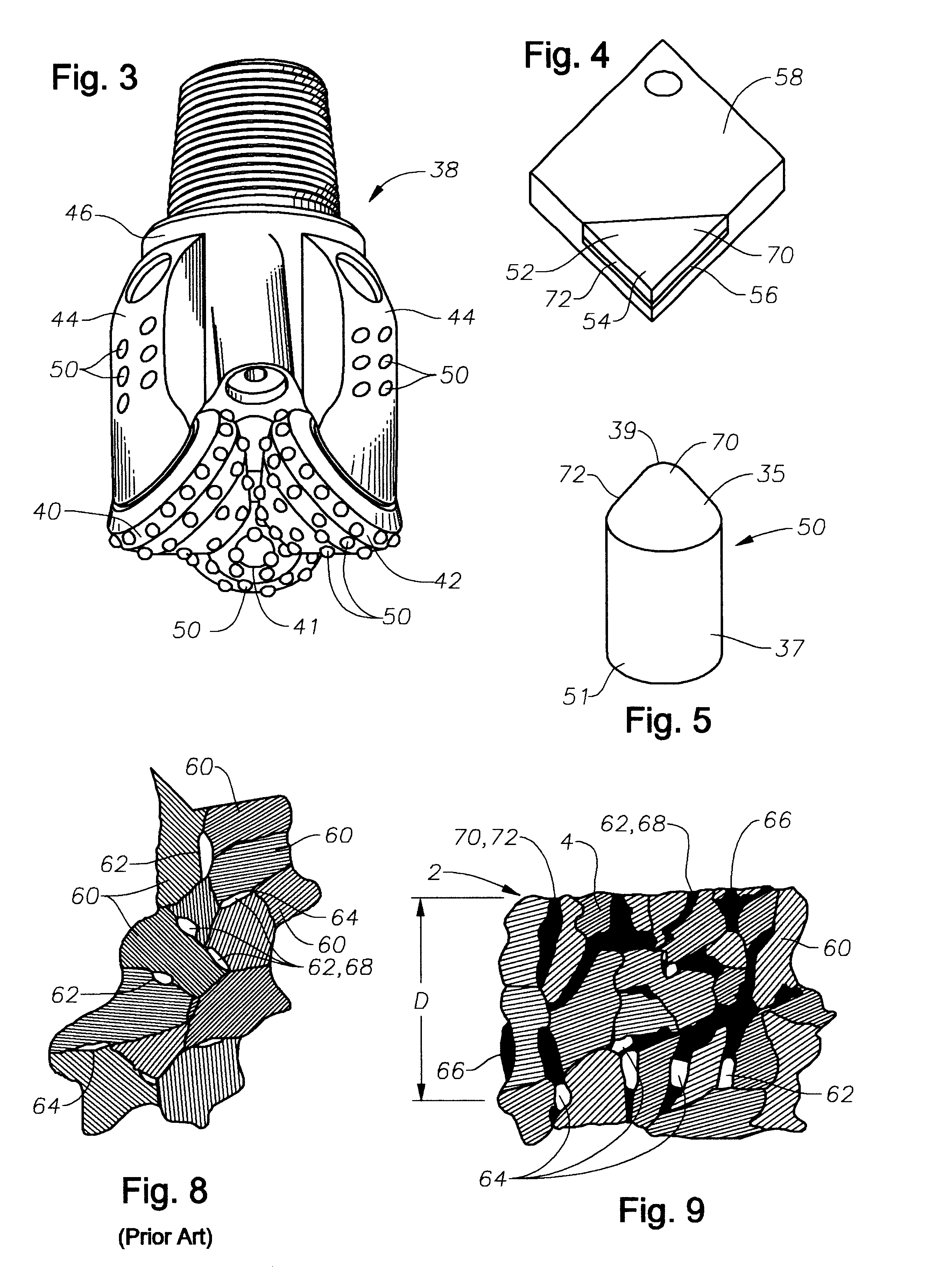

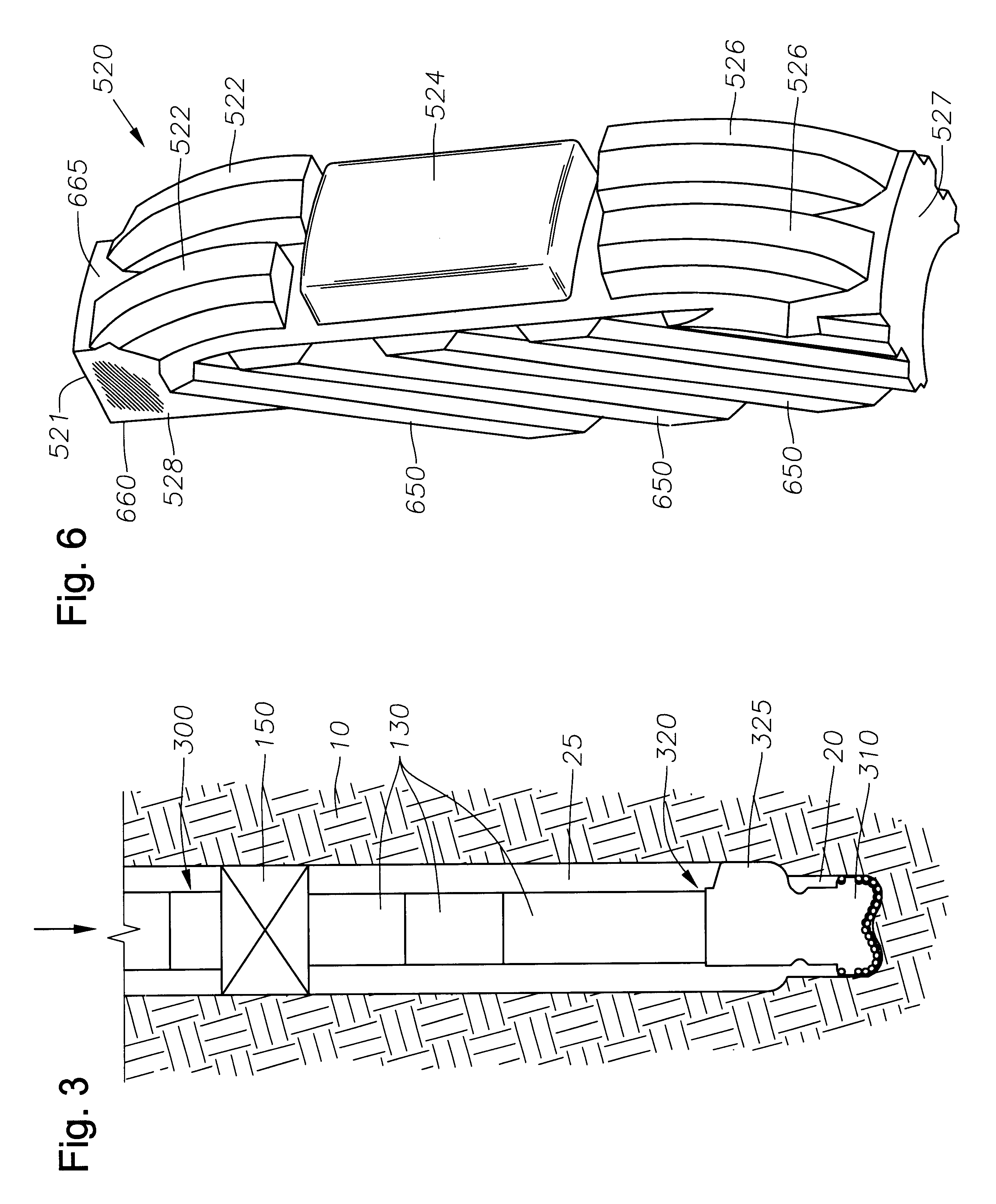

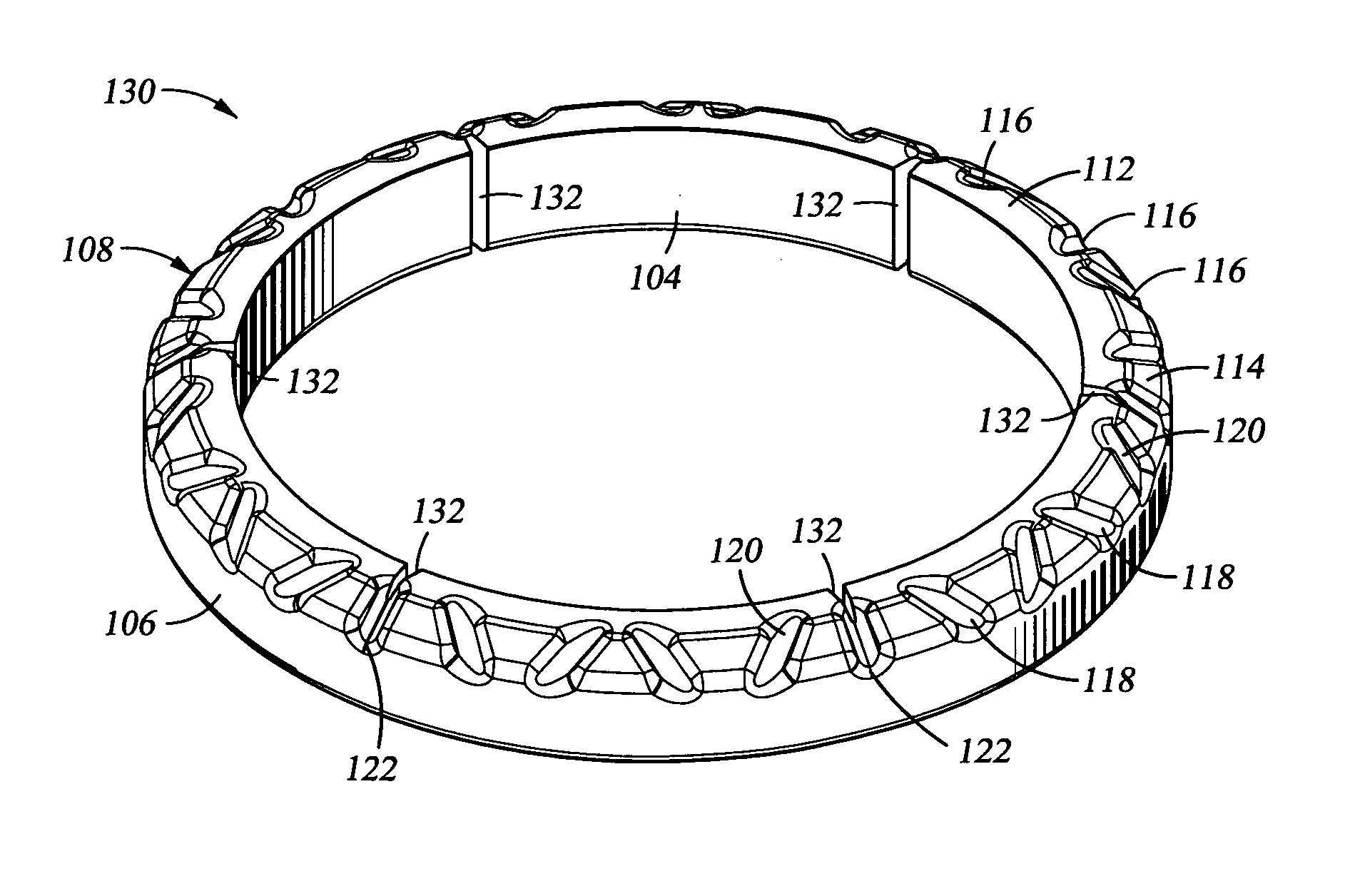

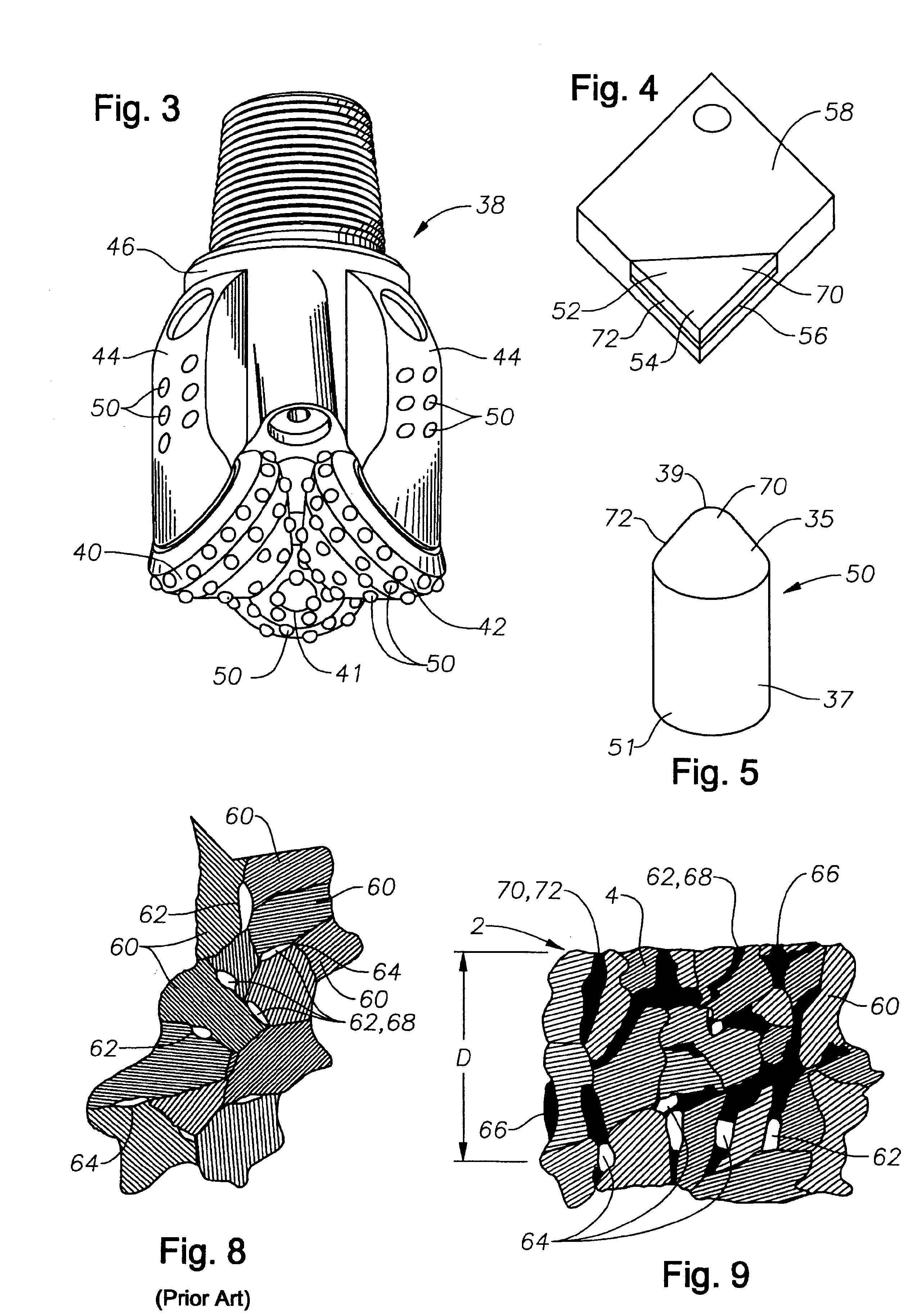

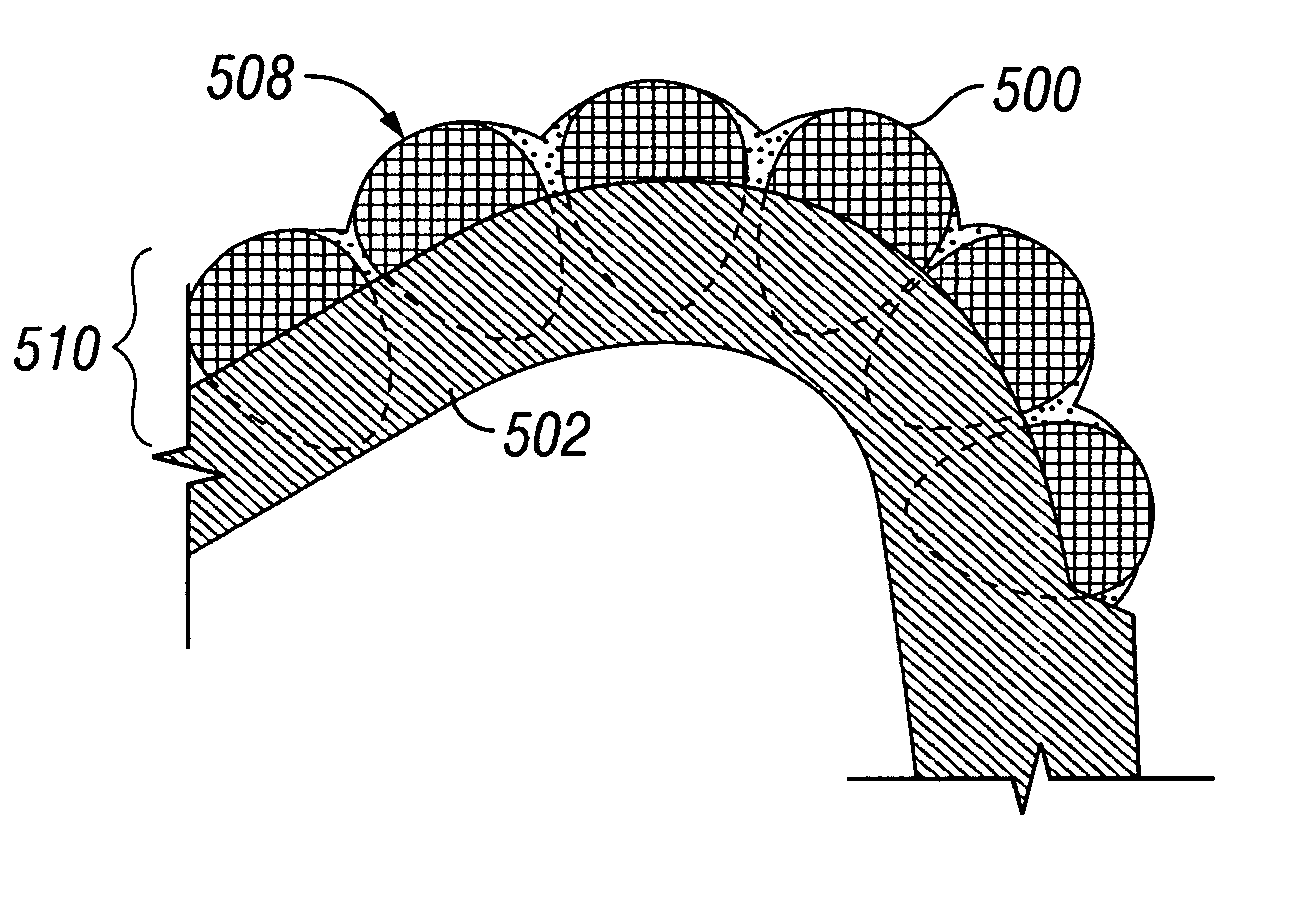

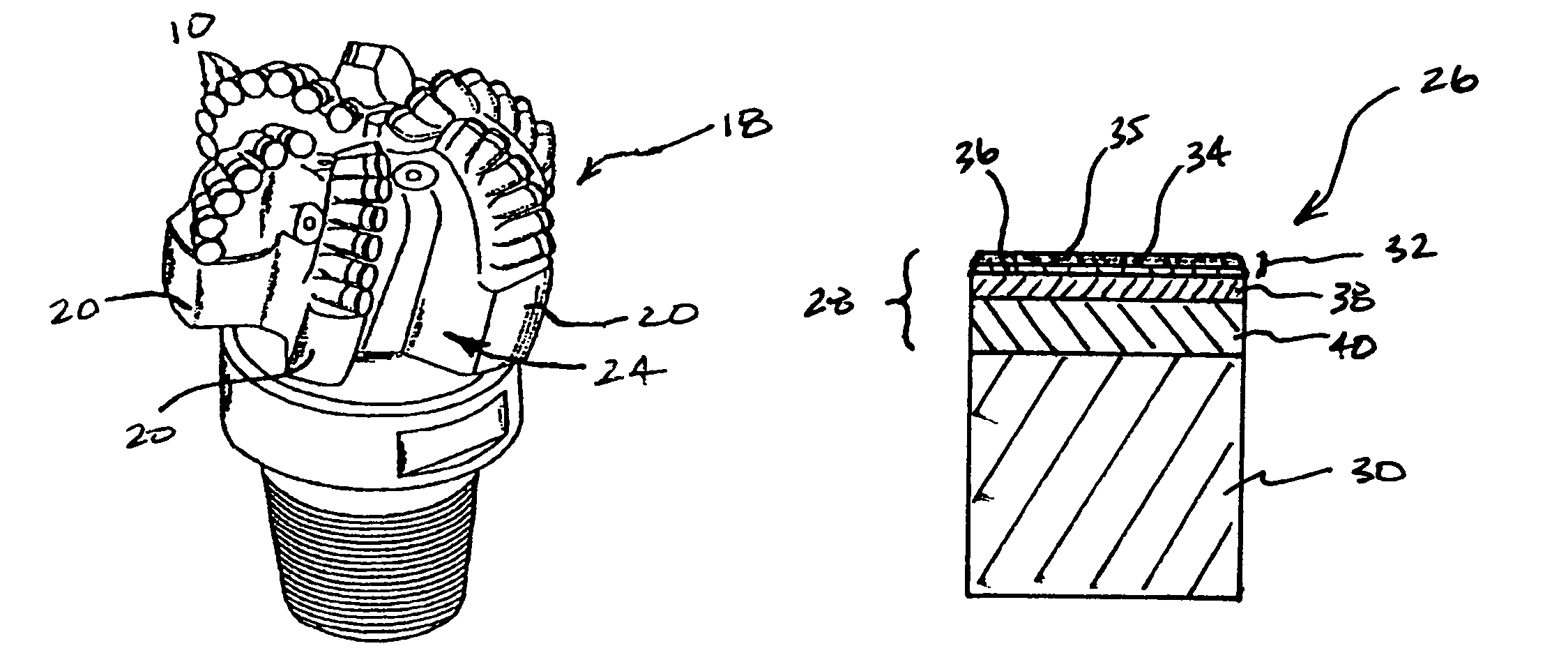

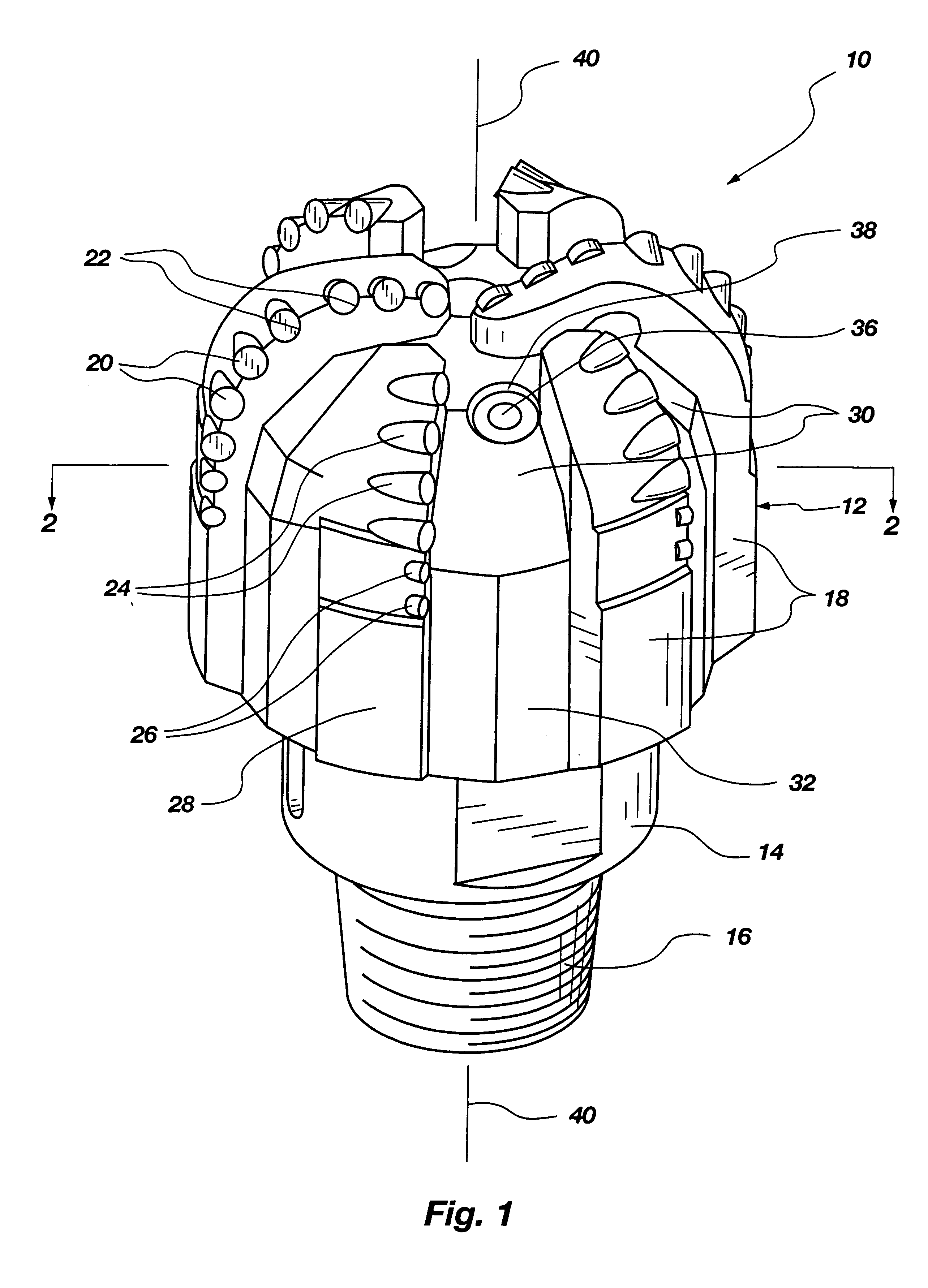

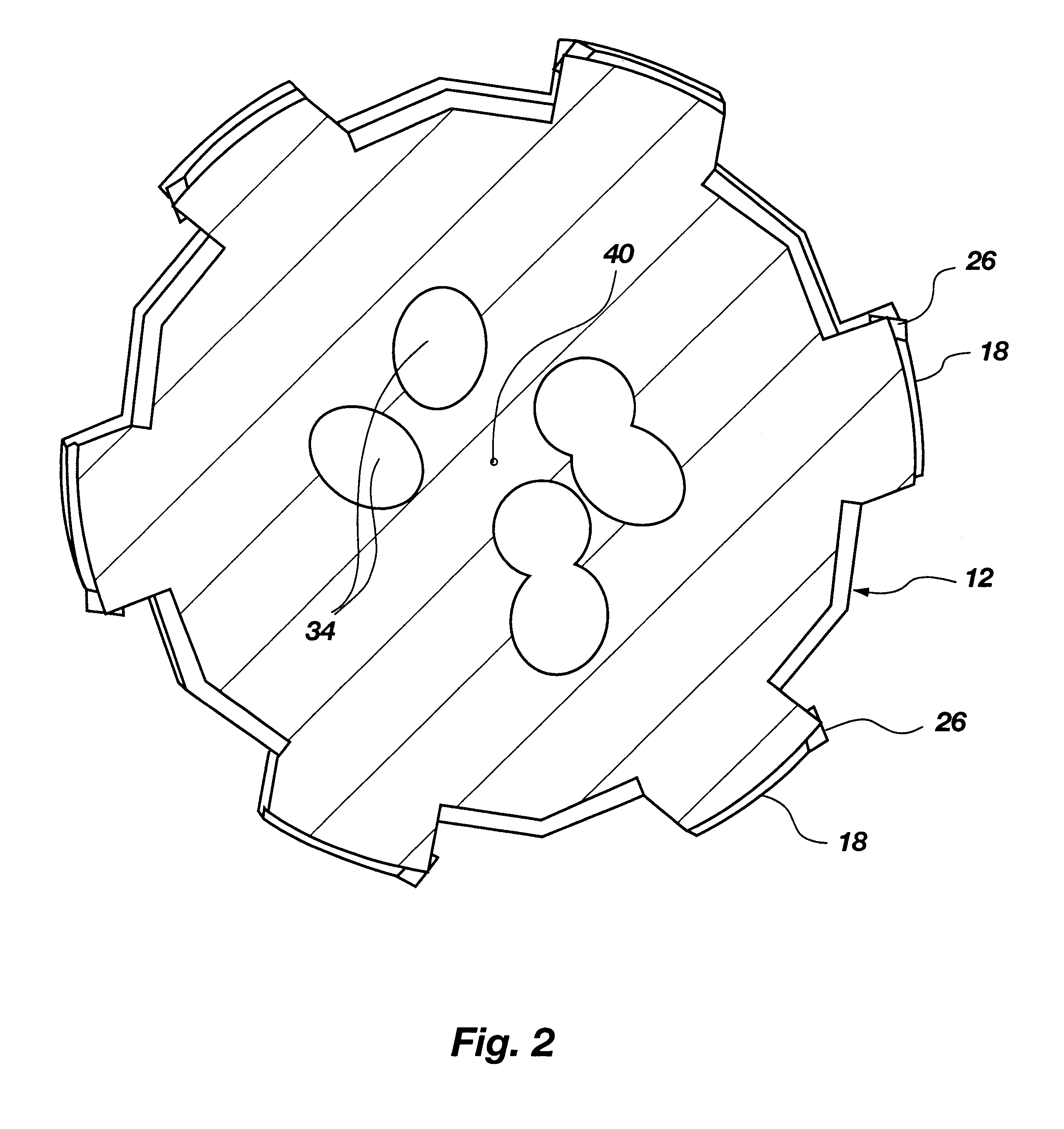

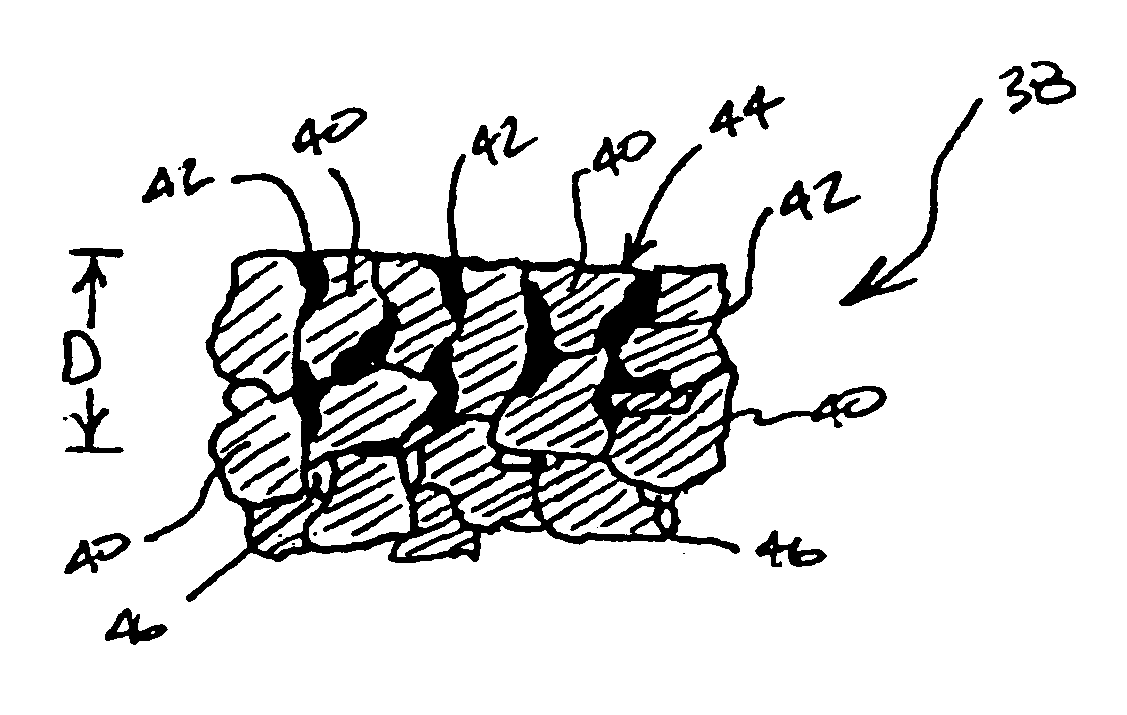

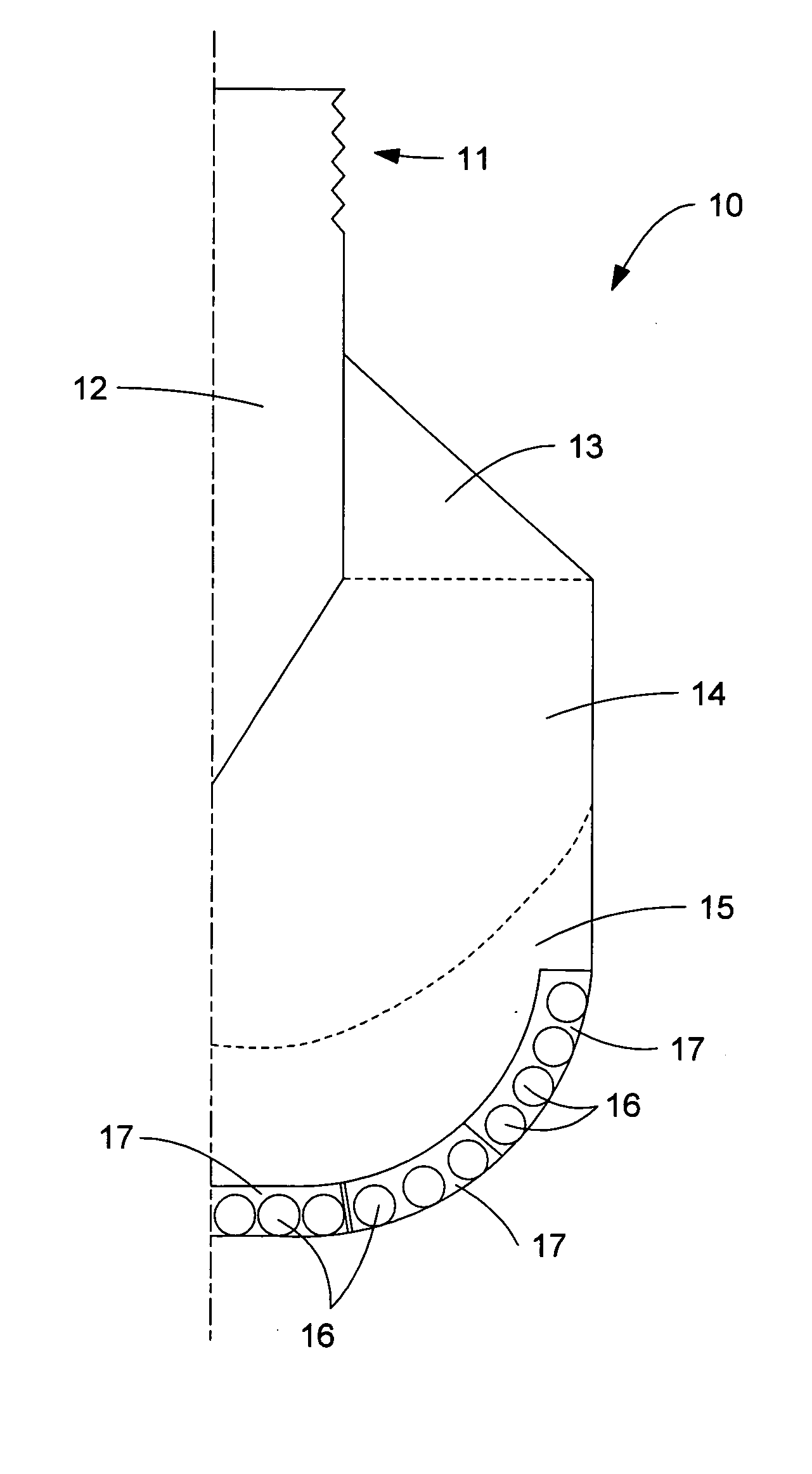

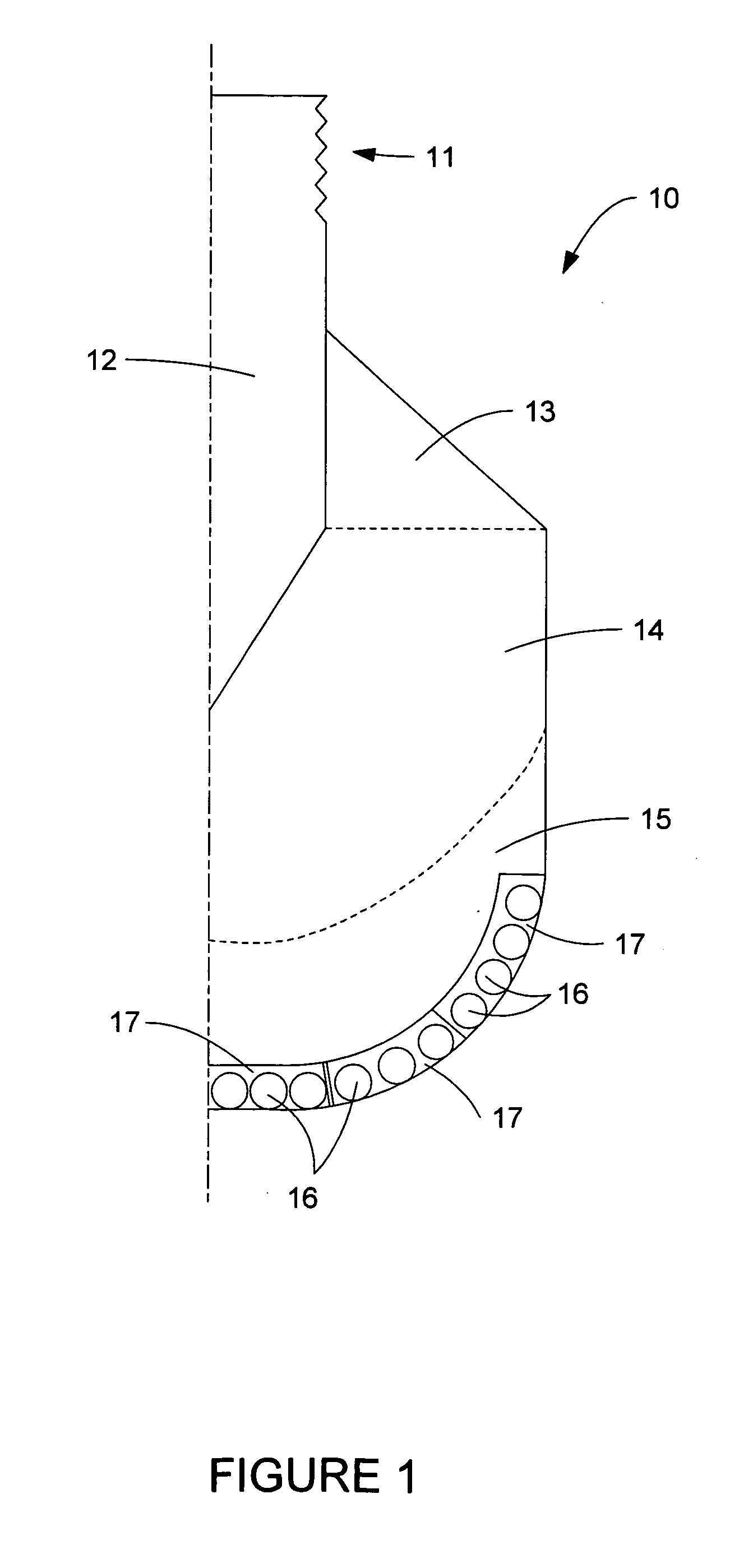

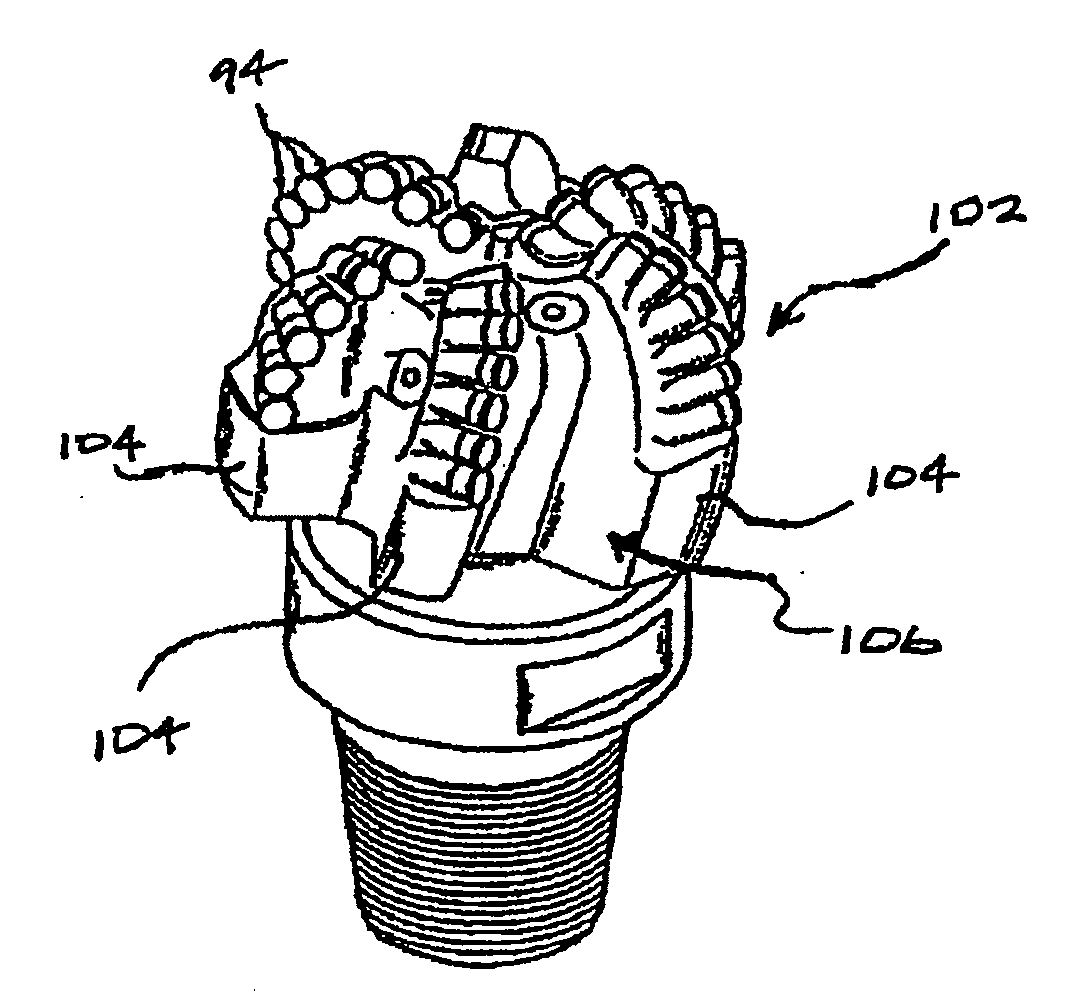

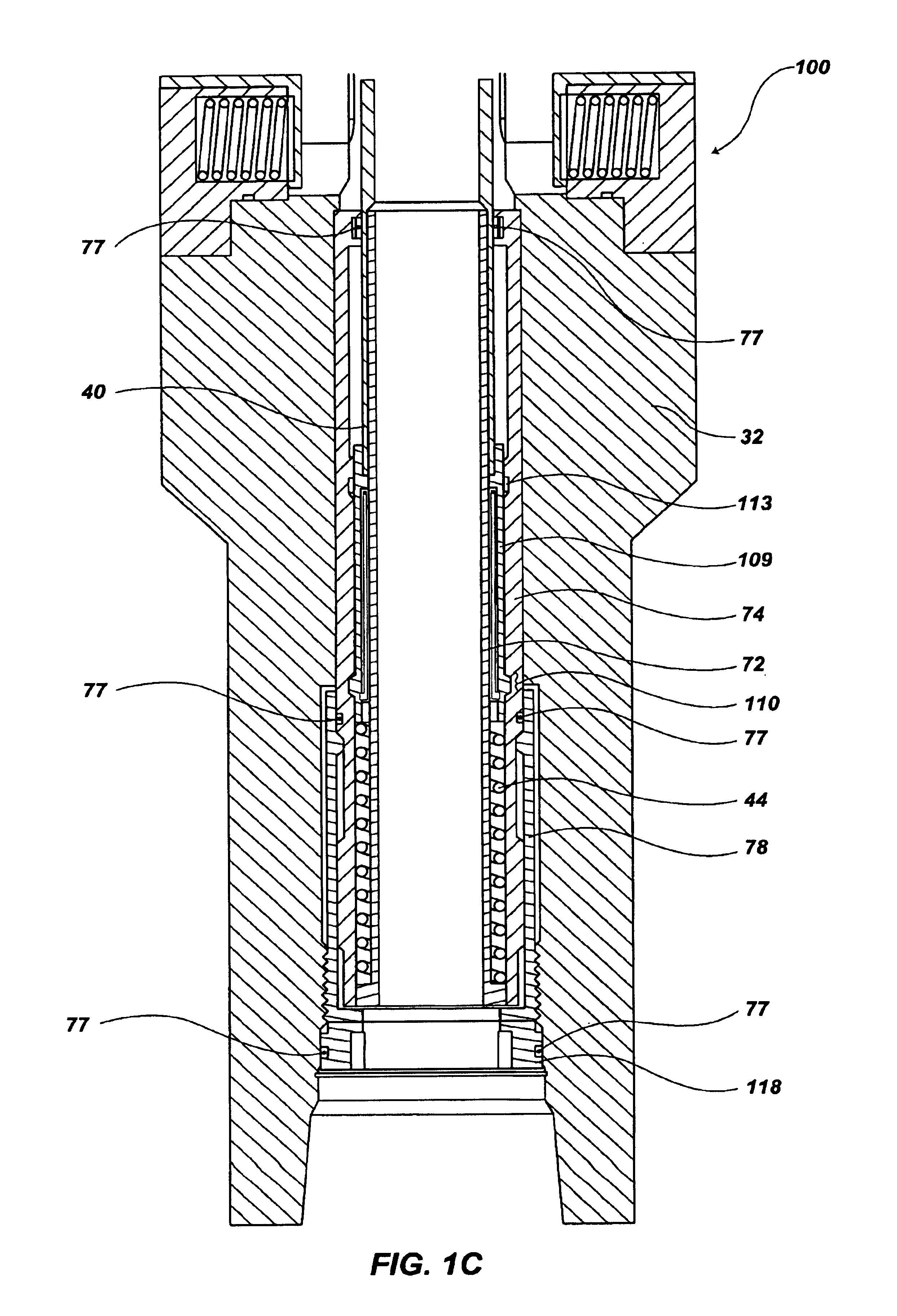

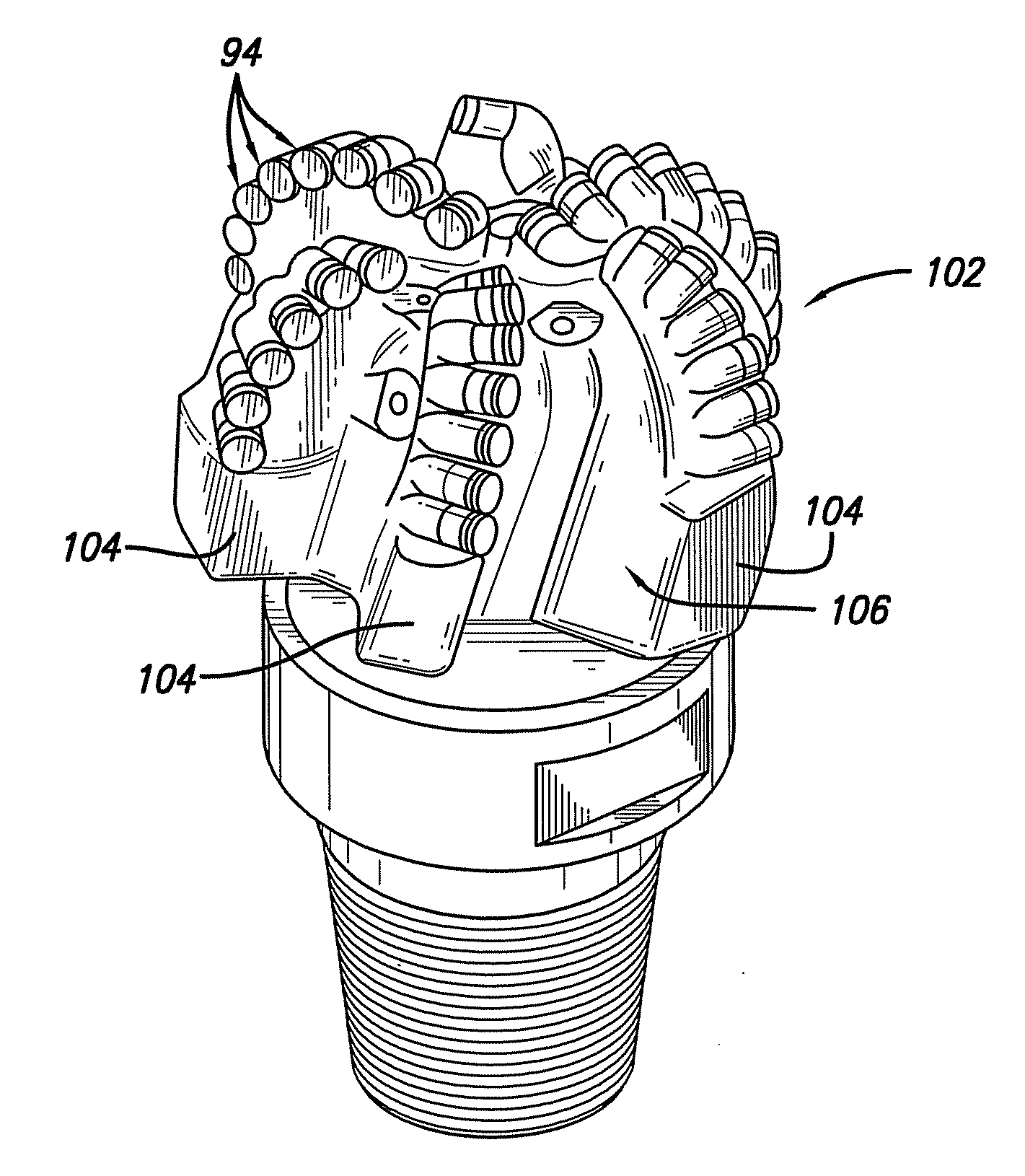

Drill bit arcuate-shaped inserts with cutting edges and method of manufacture

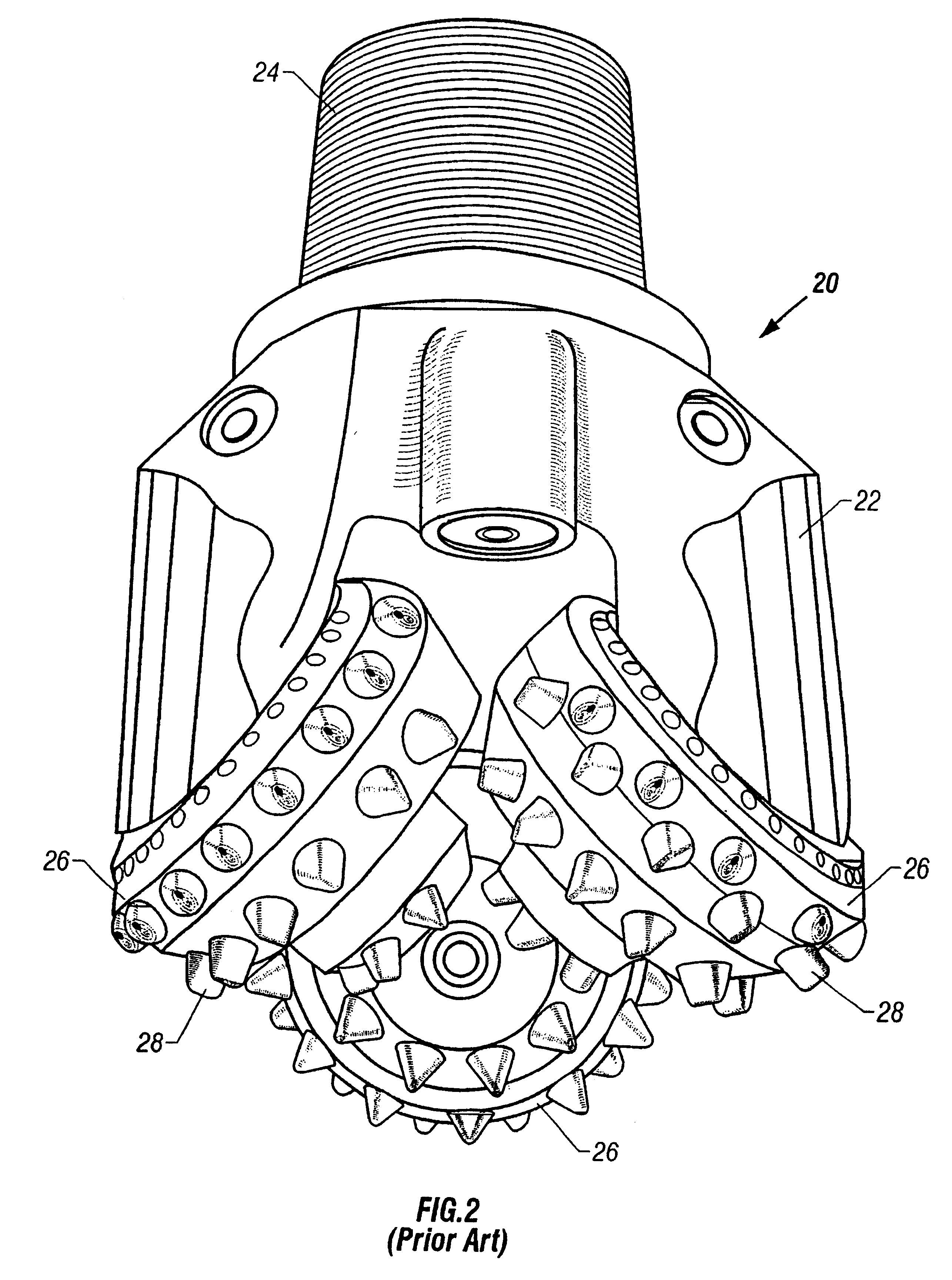

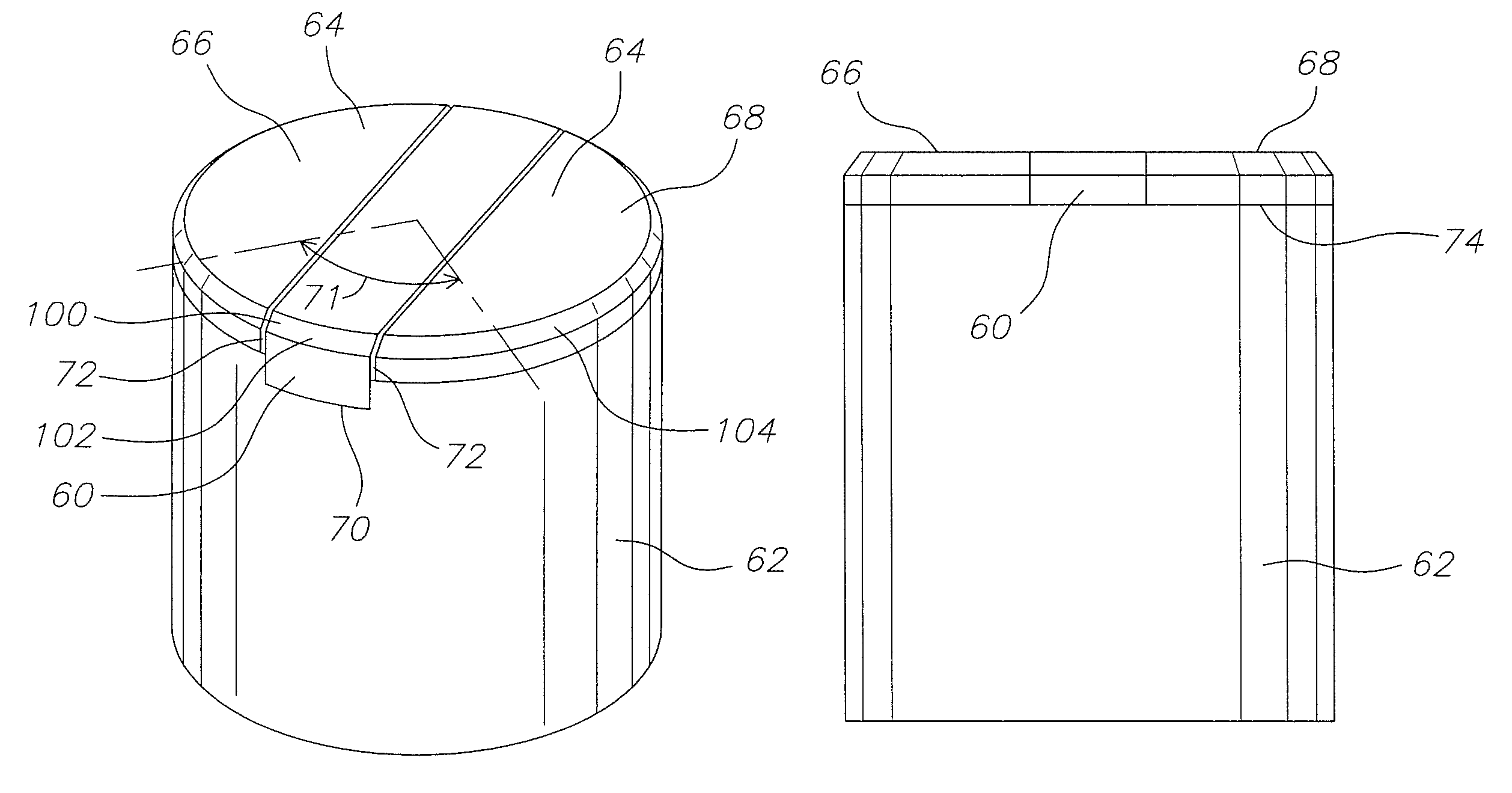

InactiveUS7331410B2Extended bit lifeImprove abilitiesDrill bitsMetal-working drilling toolsStress relievingEngineering

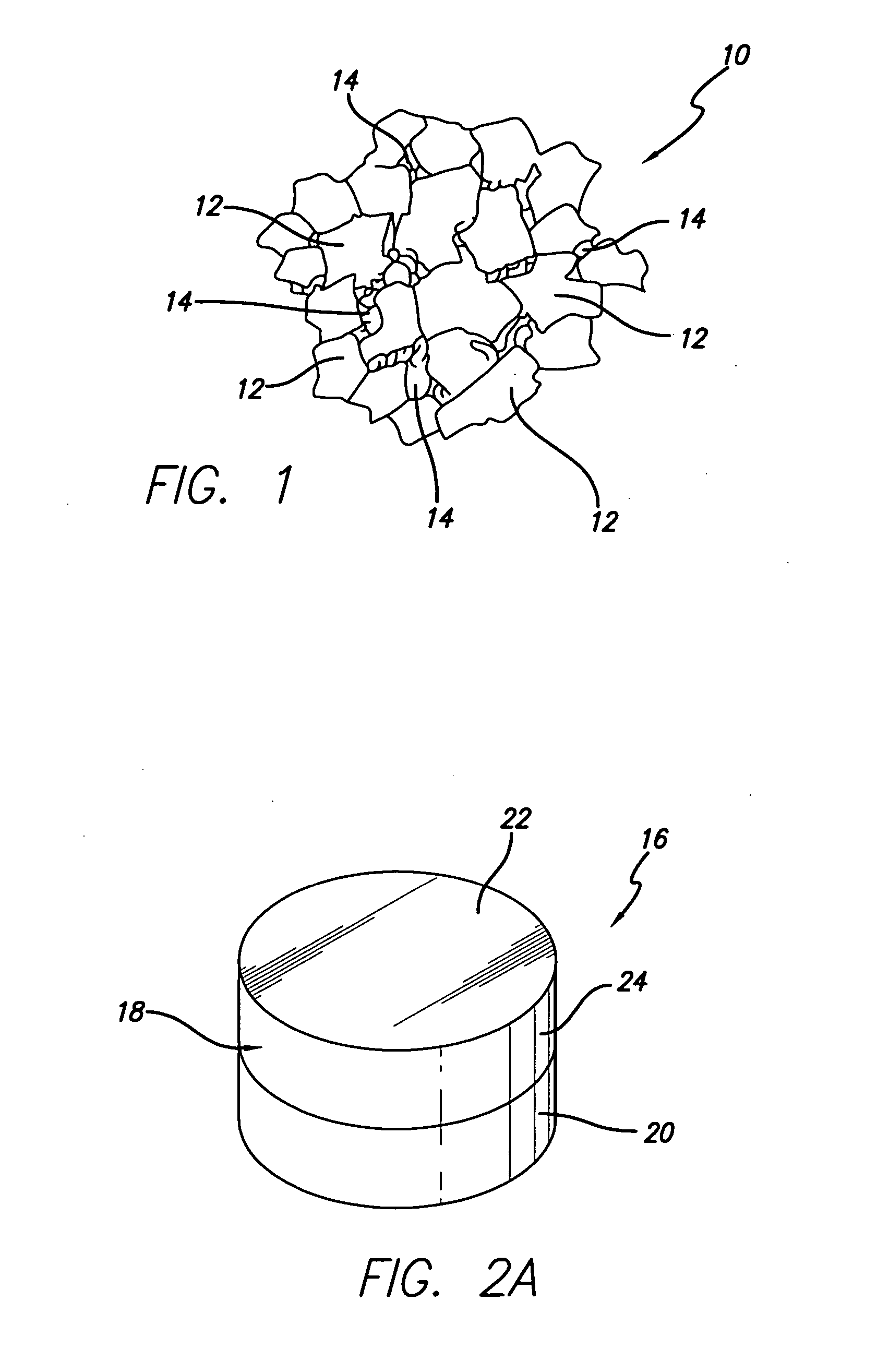

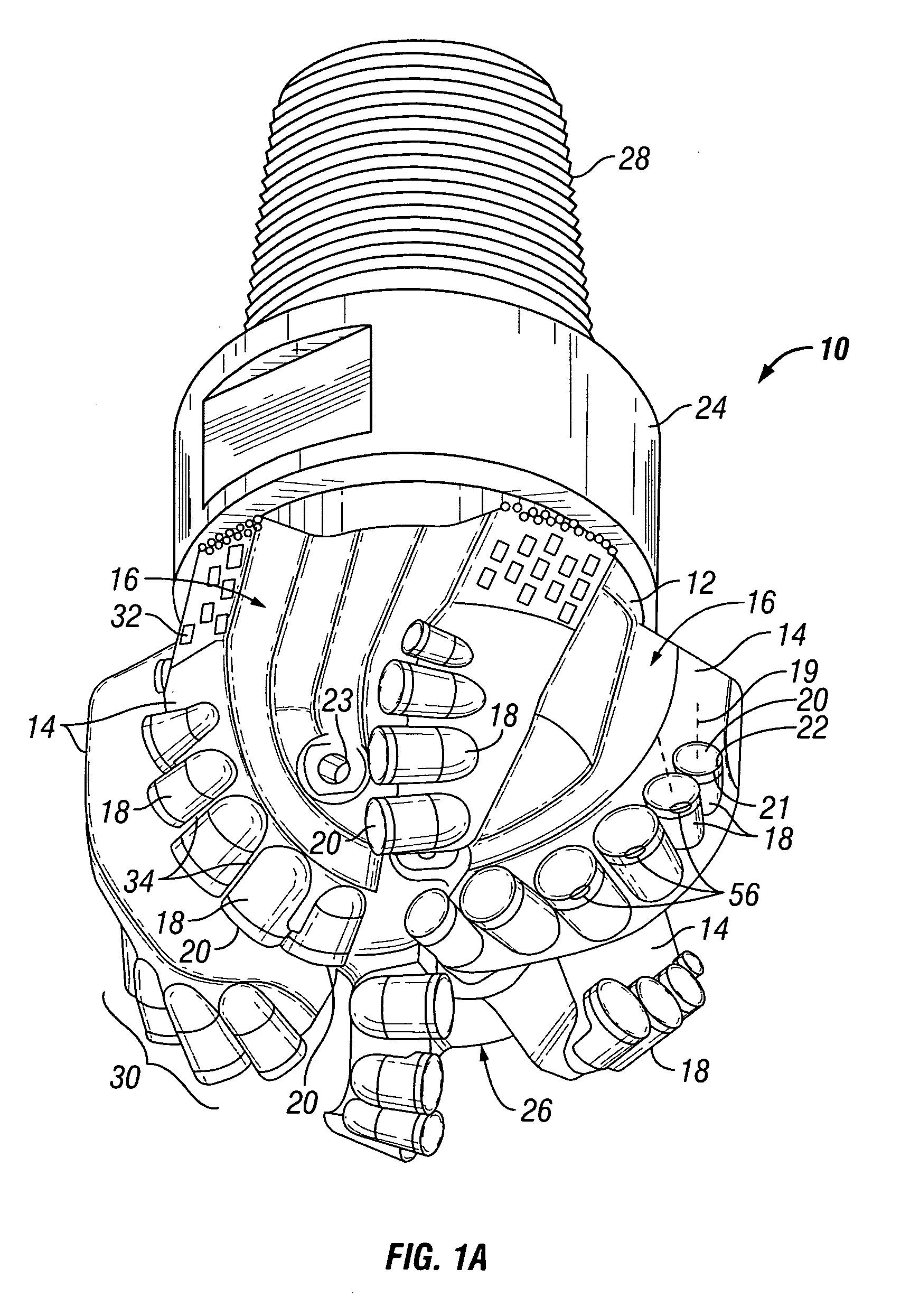

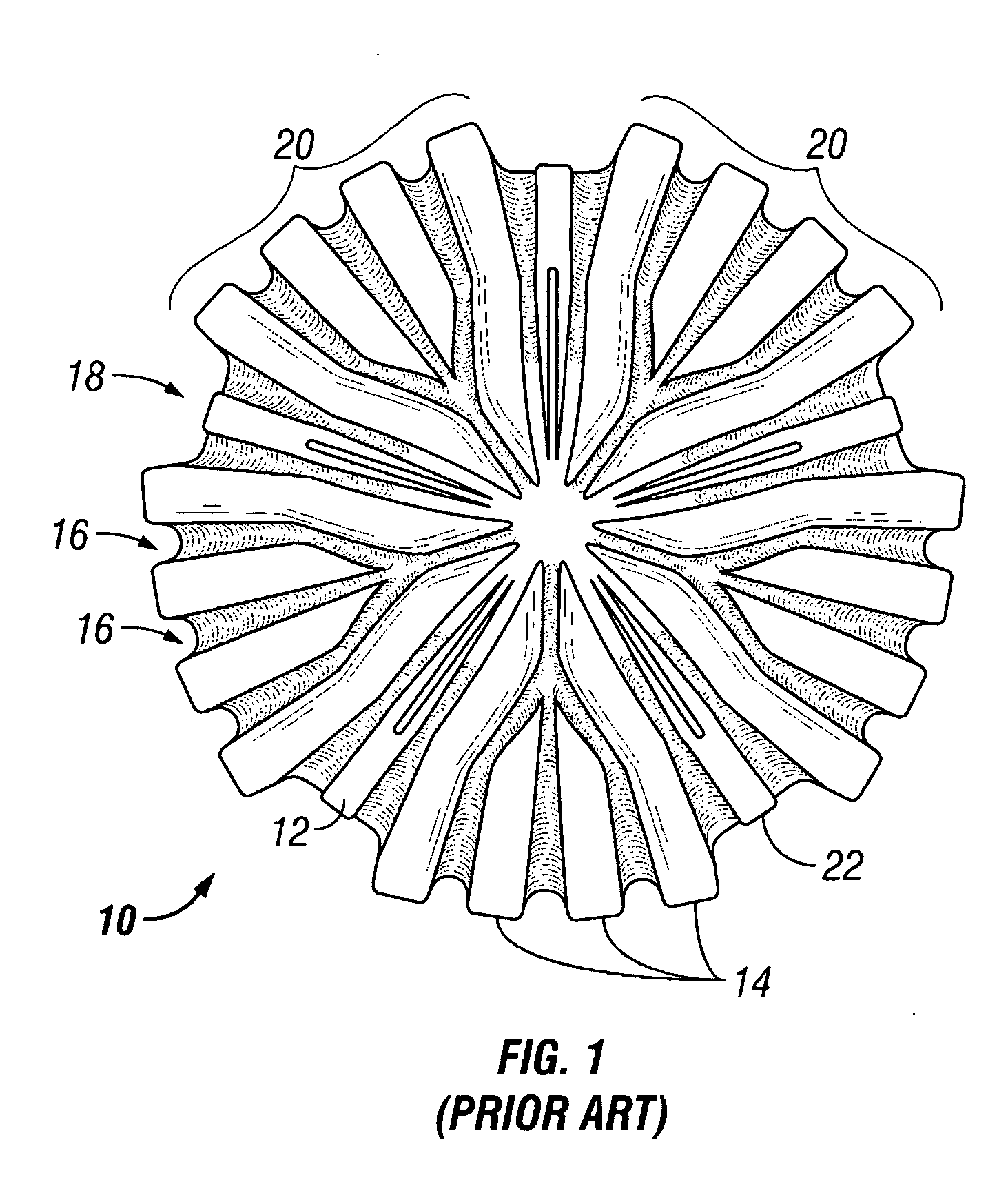

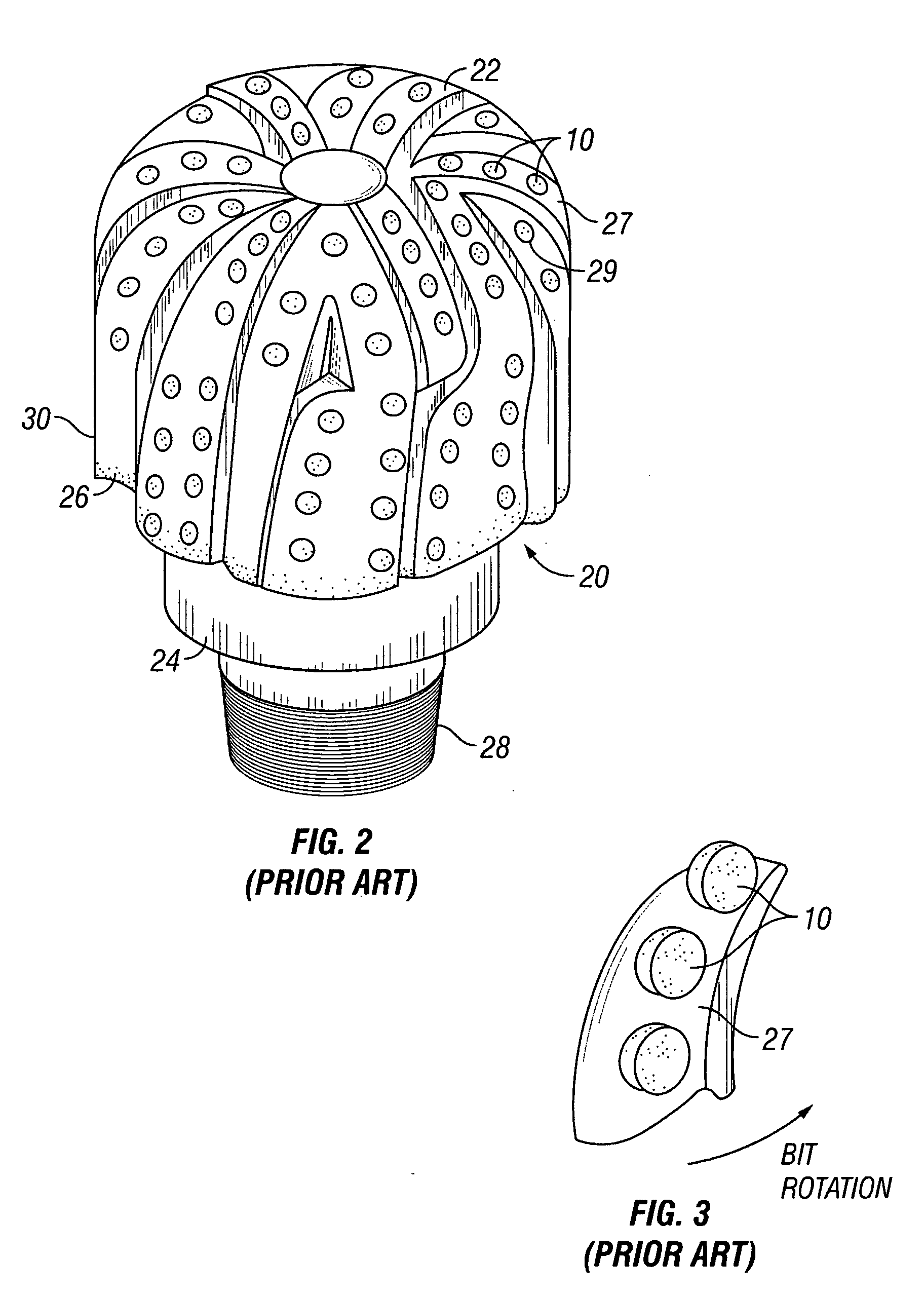

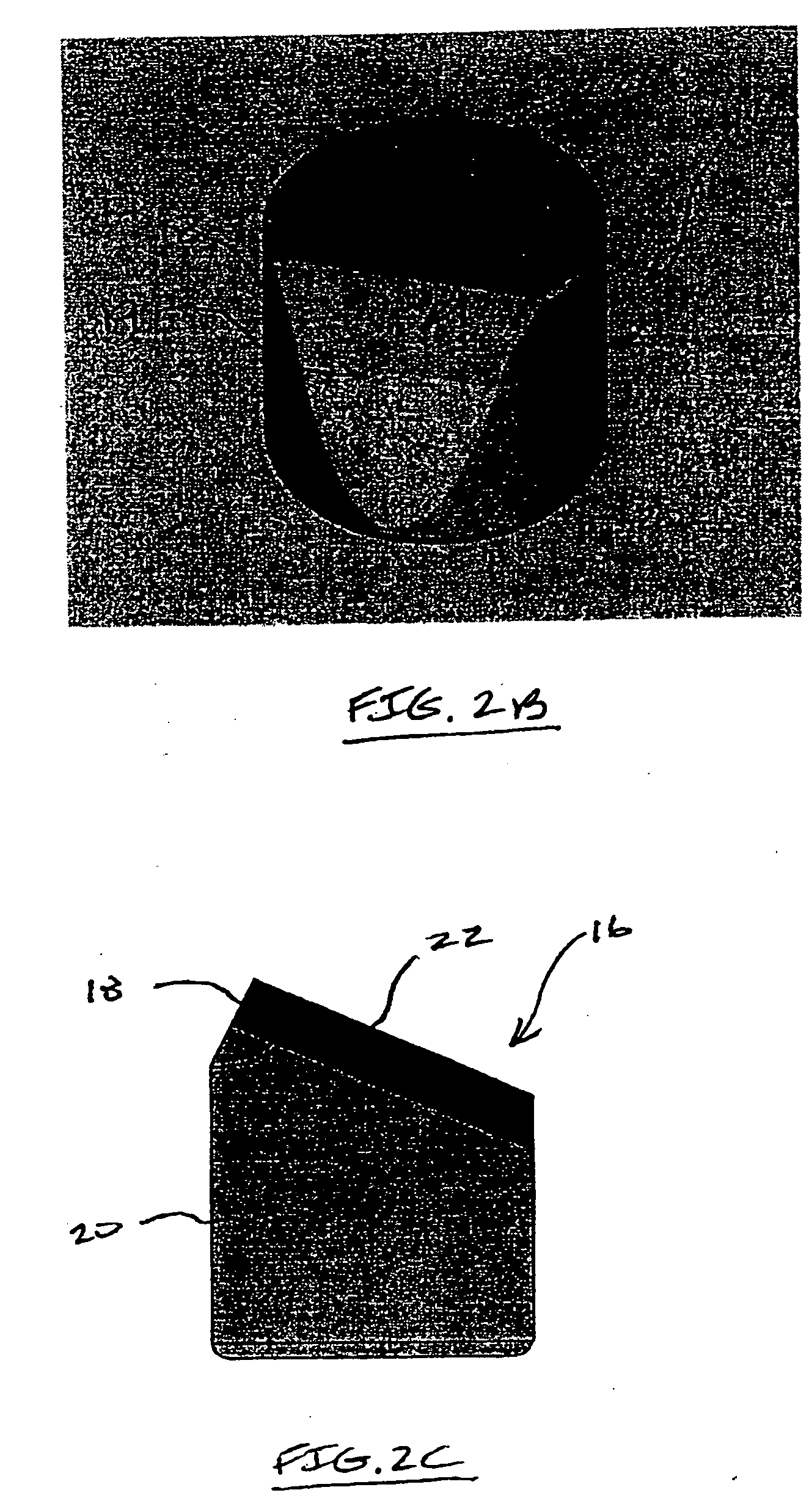

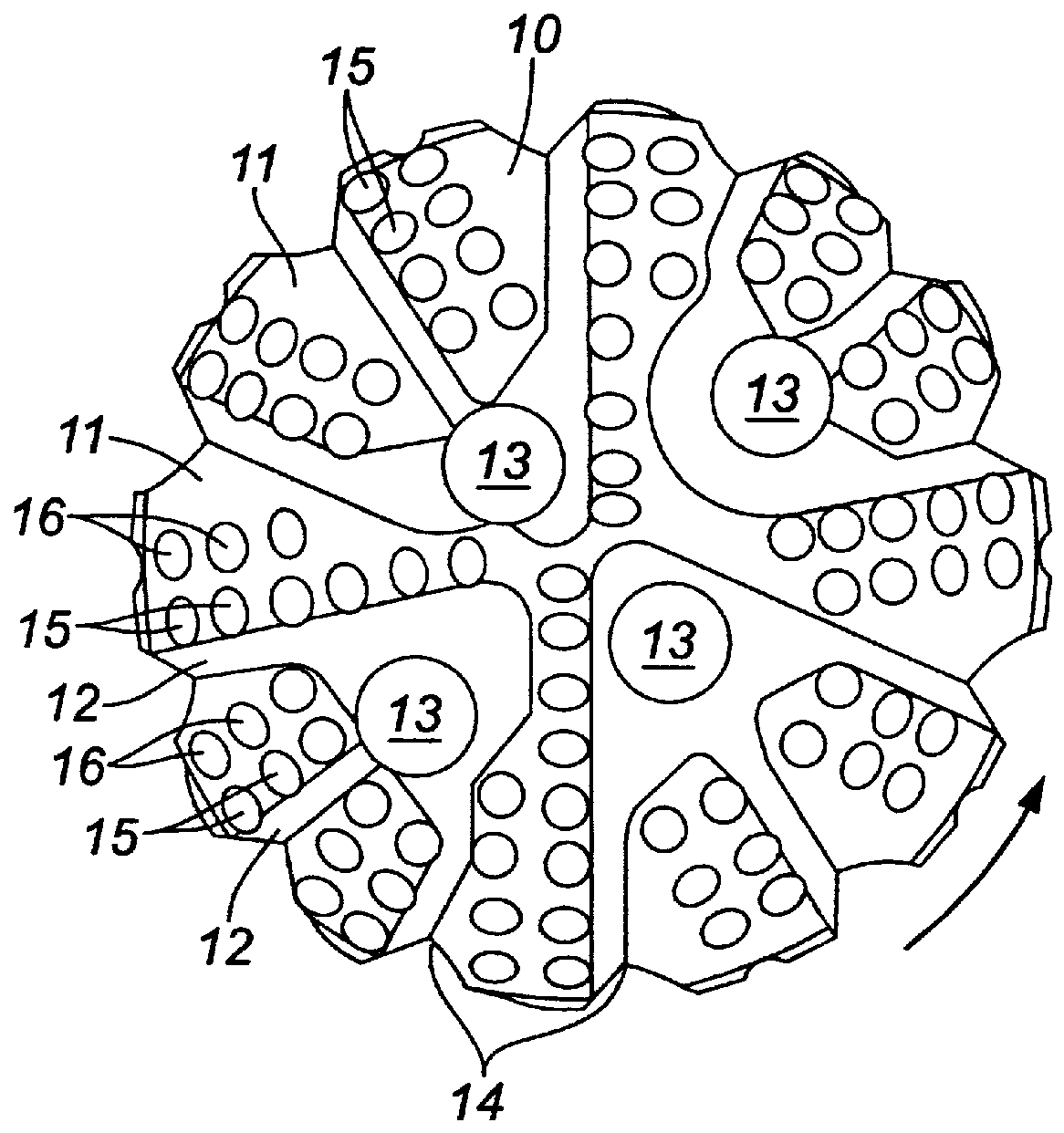

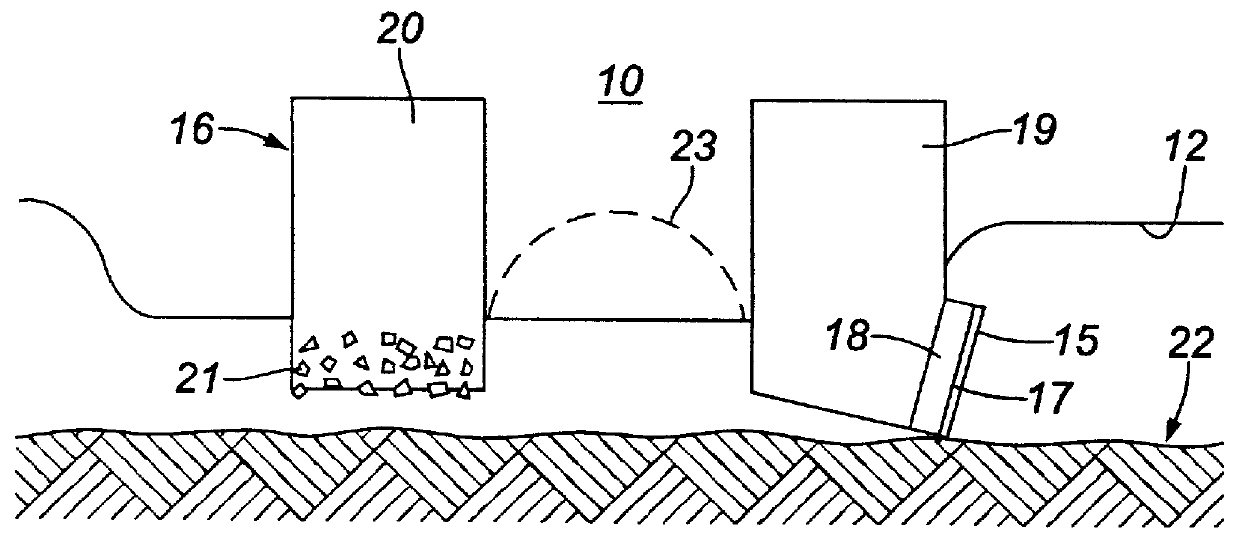

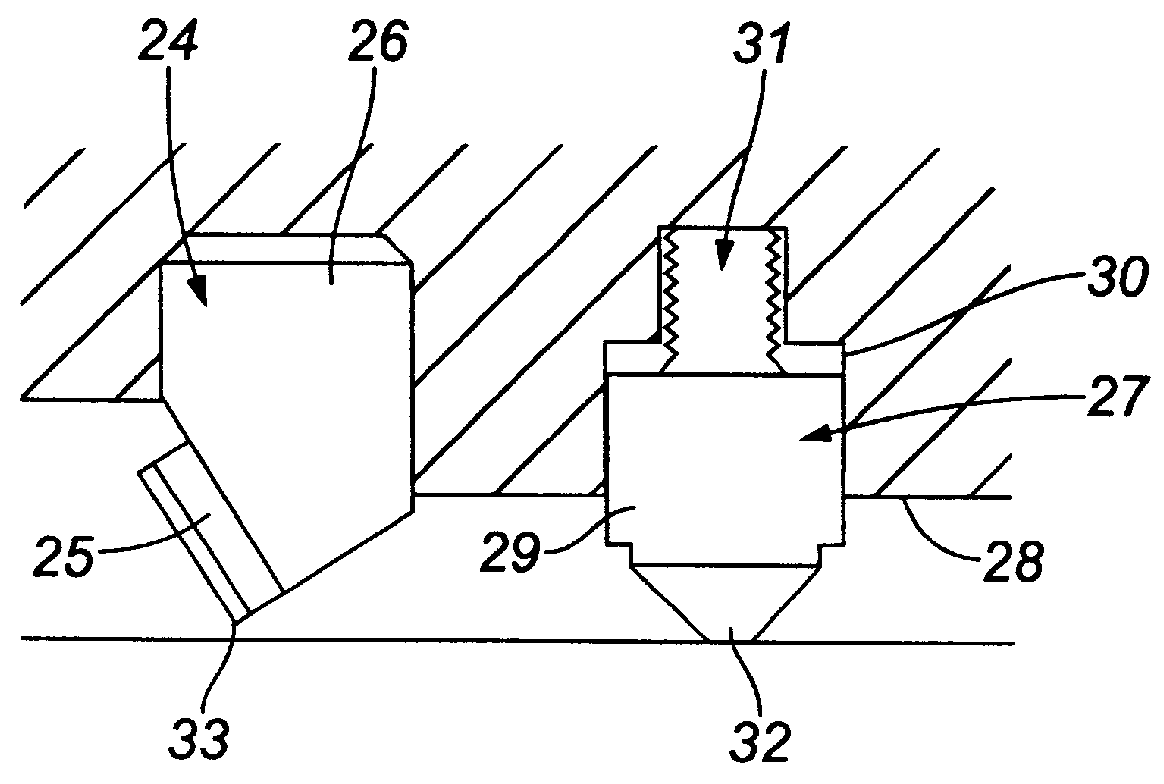

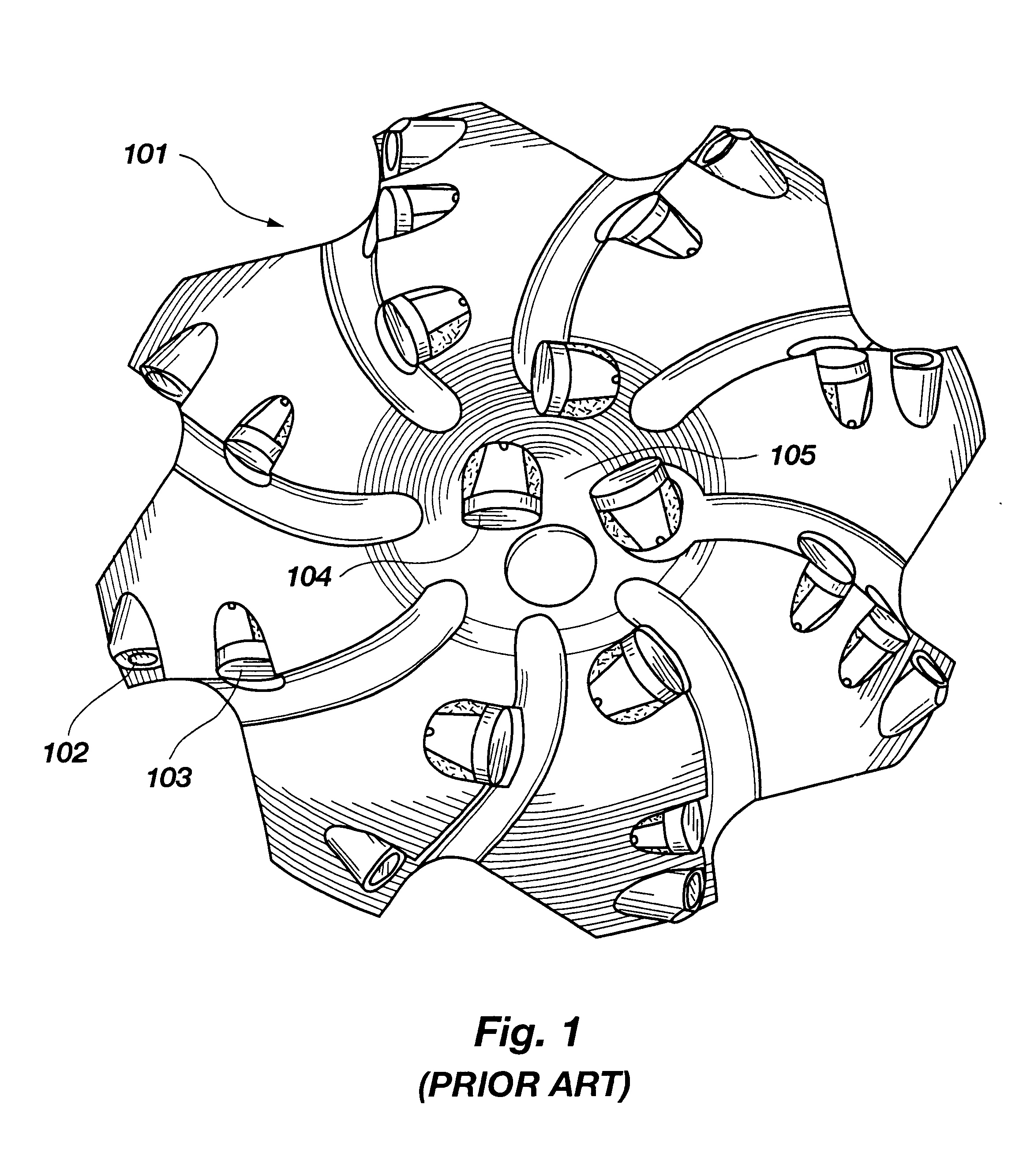

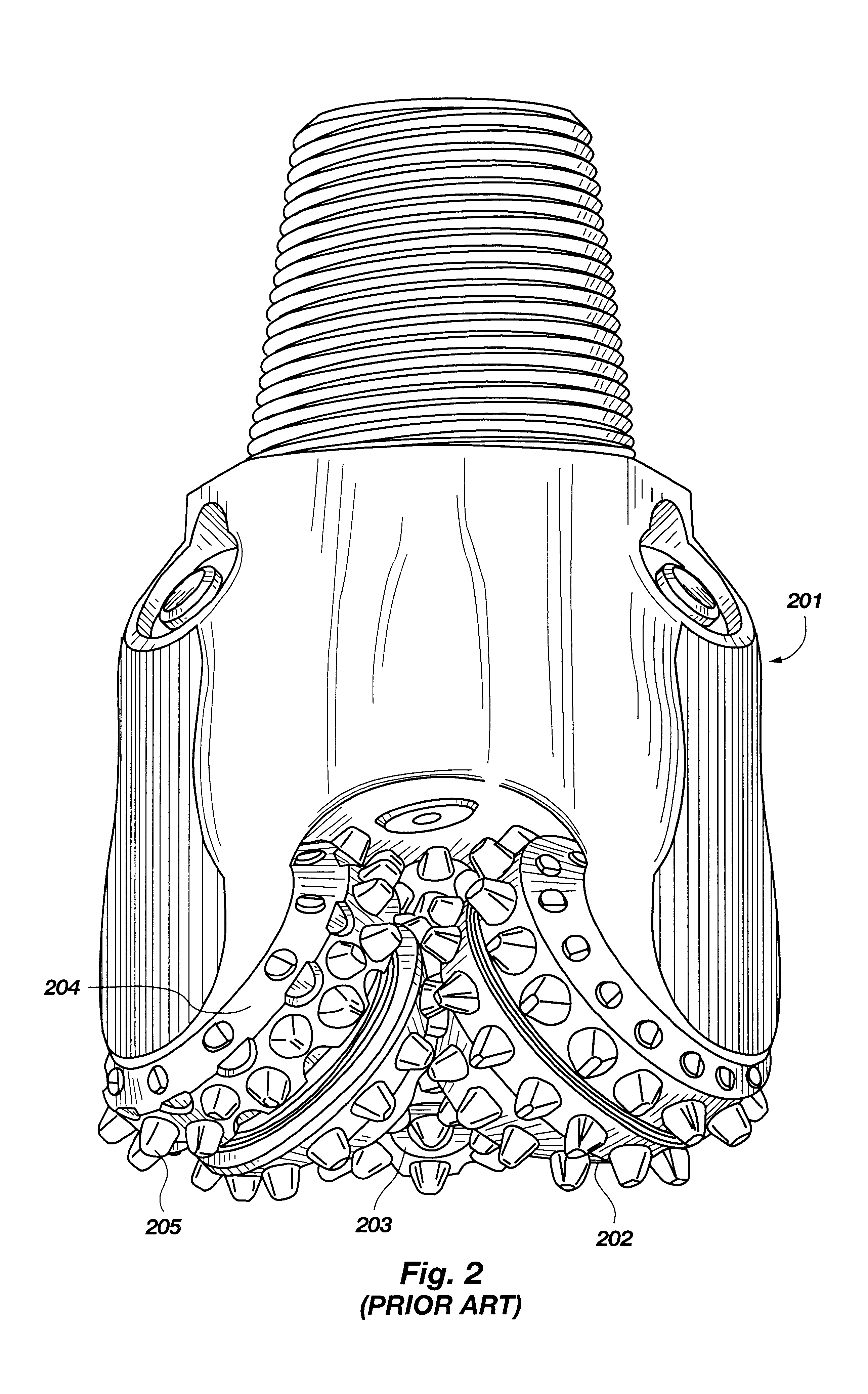

Disclosed are a variety of arcuate-shaped inserts for drill bits, and in particular, for placement in rolling cone cutters of drill bits. The arcuate inserts include 360° or ring-shaped inserts, as well as inserts of smaller arcuate length. The arcuate inserts are suitable for use in all surfaces of the rolling cone cutter, and in other locations in drill bits, and may have specialized cutting surfaces and material enhancements to enhance their cutting duty performance. Certain arcuate inserts may include stress relieving discontinuities such that, upon assembly into the cone or during drilling, the arcuate inserts may fragment in a controlled and predicted manner into shorter arcuate lengths.

Owner:SMITH INT INC

High volume density polycrystalline diamond with working surfaces depleted of catalyzing material

InactiveUS6861137B2Improve wear resistancePigmenting treatmentDrill bitsDiamond crystalPolycrystalline diamond

Disclosed is a method for manufacturing a polycrystalline diamond or diamond-like element with greatly improved wear resistance without loss of impact strength. These elements are formed with a binder-catalyzing material in a high-temperature, high-pressure (HTHP) process. The PCD element has a body with a plurality of bonded diamond or diamond-like crystals forming a continuous diamond matrix that has a diamond volume density greater than 85%. Interstices among the diamond crystals form a continuous interstitial matrix containing a catalyzing material. The diamond matrix table is formed and integrally bonded with a metallic substrate containing the catalyzing material during the HTHP process. The diamond matrix body has a working surface, where a portion of the interstitial matrix in the body adjacent to the working surface is substantially free of the catalyzing material, and the remaining interstitial matrix contains the catalyzing material. Typically, less than about 70% of the body of the diamond matrix table is free of the catalyzing material.

Owner:REEDHYCALOG UK

Diamond-bonded bodies and compacts with improved thermal stability and mechanical strength

Thermally stable diamond-bonded compacts include a diamond-bonded body having a thermally stable region extending a distance below a diamond-bonded body surface. The thermally stable region comprises a matrix first phase of bonded together diamond crystals, and a second phase interposed within the matrix phase. At least some population of the second phase comprises a reaction product formed between an infiltrant material and the diamond crystals at high pressure / high temperature conditions. The diamond bonded body further includes a polycrystalline diamond region that extends a depth from the thermally stable region and has a microstructure comprising a polycrystalline diamond matrix phase and a catalyst material disposed within interstitial regions of the matrix phase. The compact includes a substrate attached to the diamond-bonded body.

Owner:SMITH INT INC

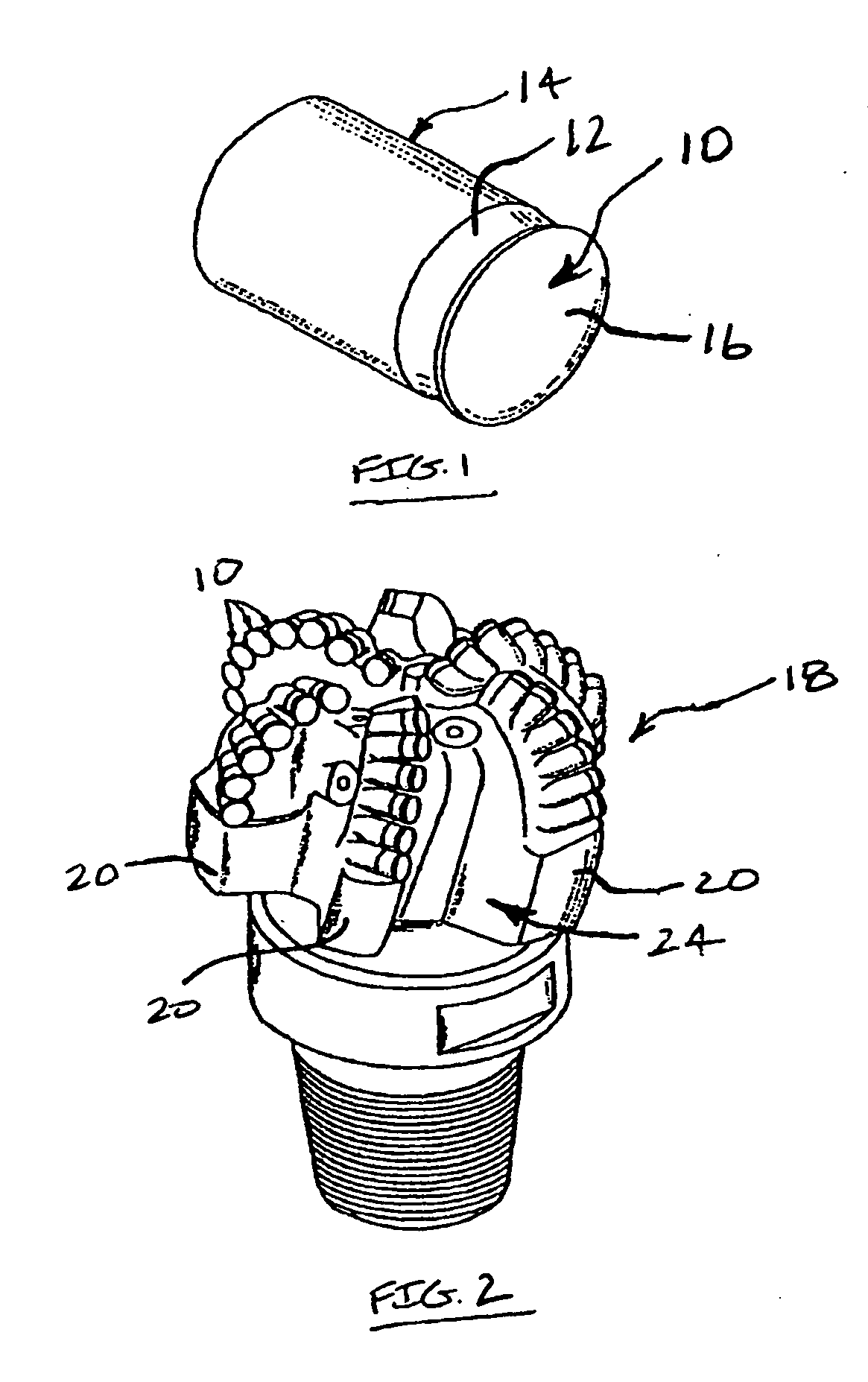

Rolling cutter

A cutting element for a drill bit that includes an outer support element having at least a bottom portion and a side portion; and an inner rotatable cutting element, a portion of which is disposed in the outer support element, wherin the inner rotatable cutting element includes a substrate and a diamond cutting face having a thickness of at least 0.050 inches disposed on an upper surface of the substrate; and wherein a distance from an upper surface of the diamond cutting face to a bearing surface between the inner rotatable cutting element and the outer support element ranges from 0 to about 0.300 inches is disclosed.

Owner:SMITH INT INC

Thermally stable ultra-hard material compact construction

InactiveUS7377341B2Improve adhesionMatch thermal expansion characteristicDrill bitsConstructionsSuperhard materialHigh pressure

Thermally stable ultra-hard compact constructions of this invention comprise an ultra-hard material body that includes a thermally stable region positioned adjacent a surface of the body. The thermally stable region is formed from consolidated materials that are thermally stable at temperatures greater than about 750° C. The thermally stable region can occupy a partial portion of or the entire ultra-hard material body. The ultra-hard material body can comprise a composite of separate ultra-hard material elements that each form different regions of the body, at least one of the regions being thermally stable. The ultra-hard material body is attached to a desired substrate, an intermediate material is interposed between the body and the substrate, and the intermediate material joins the substrate and body together by high pressure / high temperature process.

Owner:SMITH INT INC

Thermally stable diamond bonded materials and compacts

InactiveUS20050263328A1Improve thermal stabilityGood adhesionDrill bitsConstructionsMaterials scienceTemperature and pressure

Thermally stable diamond bonded materials and compacts include a diamond body having a thermally stable region and a PCD region, and a substrate integrally joined to the body. The thermally stable region has a microstructure comprising a plurality of diamond grains bonded together by a reaction with a reactant material. The PCD region extends from the thermally stable region and has a microstructure of bonded together diamond grains and a metal solvent catalyst disposed interstitially between the bonded diamond grains. The compact is formed by subjecting the diamond grains, reactant material, and metal solvent catalyst to a first temperature and pressure condition to form the thermally stable region, and then to a second higher temperature condition to both form the PCD region and bond the body to a desired substrate.

Owner:SMITH INT INC

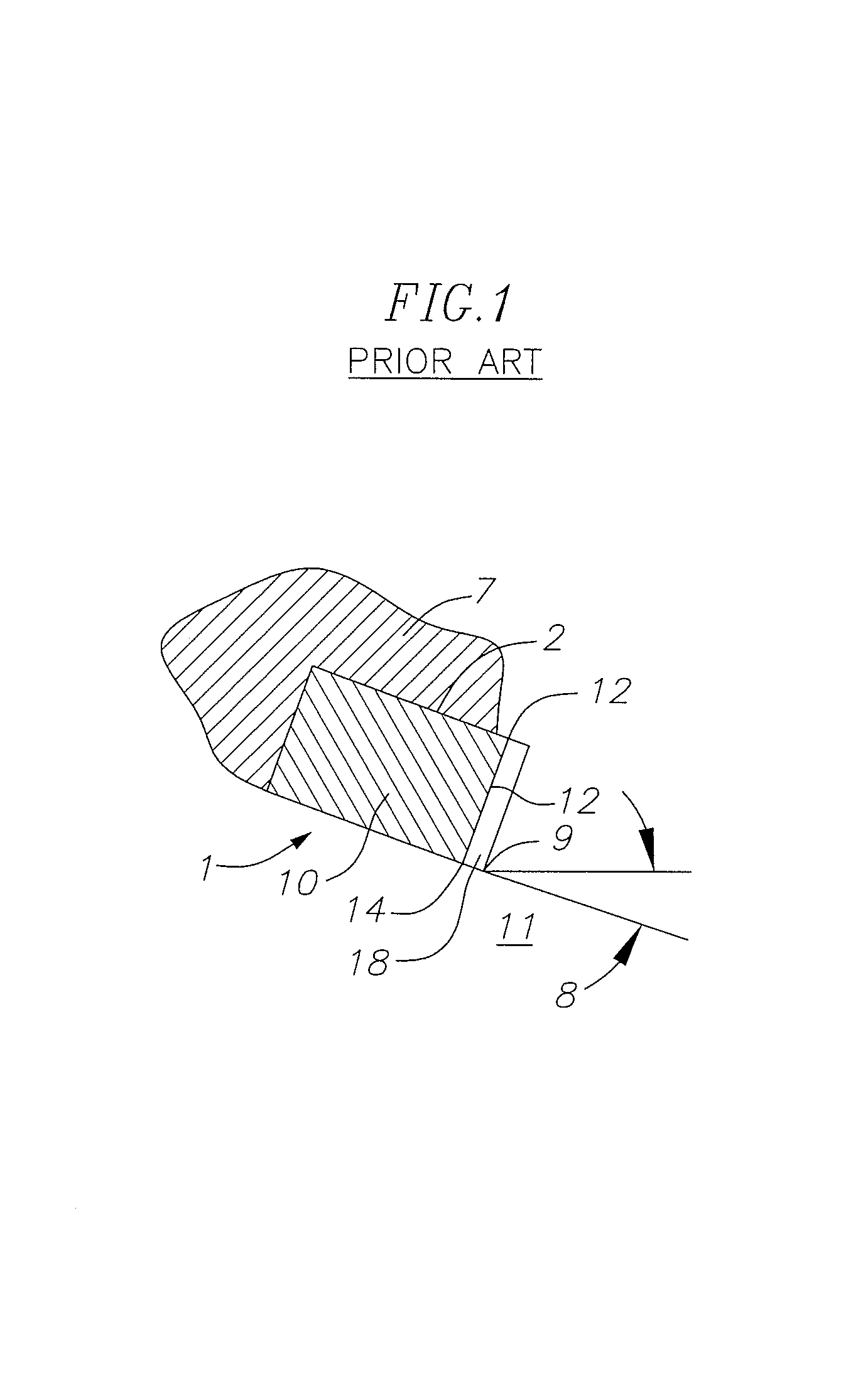

Novel bits and cutting structures

This invention provides an improved cutting element for downhole cutting tools including a support element and a beveled shearing element disposed on the support element and a drill bit including the cutting element; a cutting element including a support element and a shearing element disposed on the support element, wherein the shearing element includes TSP, a sharpened cutting edge, and at least one blended edge that forms part of an interface with the support element and a drill bit including the cutting element. Cutting inserts including an insert body and the shearing elements disclosed above are provided. Also provided are methods for forming the cutting elements and drill bit inserts and a method for drilling mixed earth formations using the improved downhole cutting tools of the present invention.

Owner:SMITH INT INC

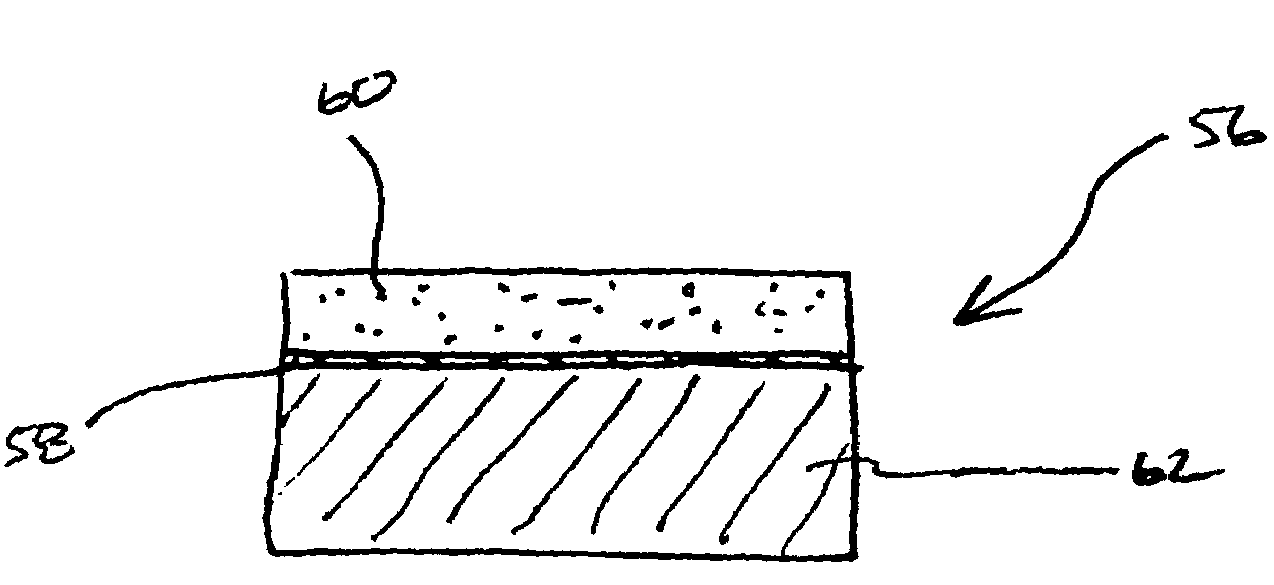

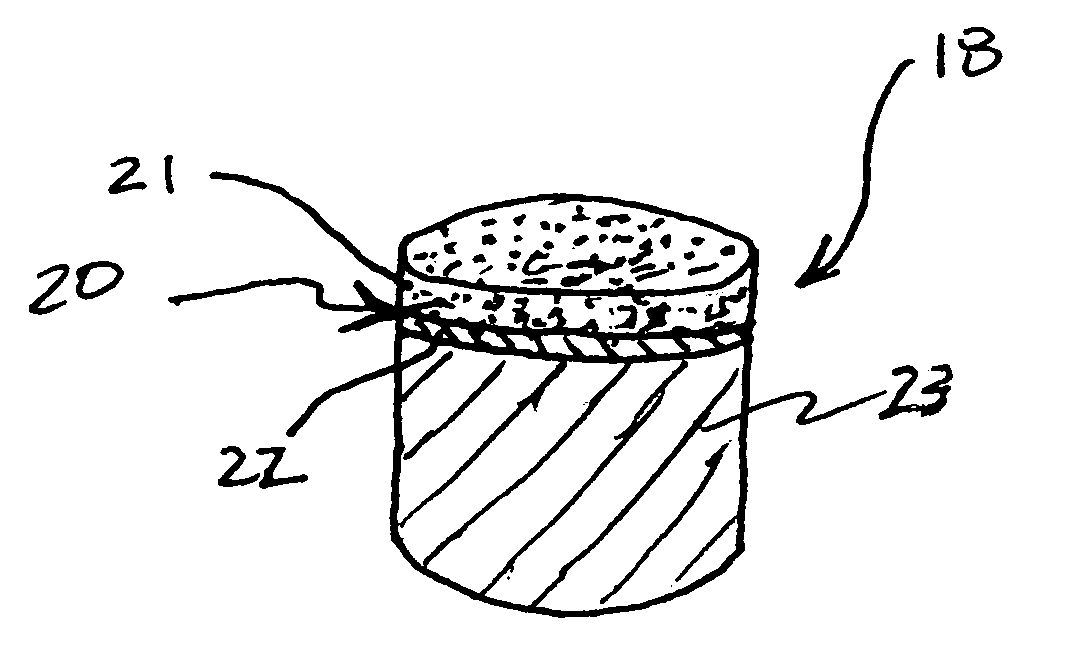

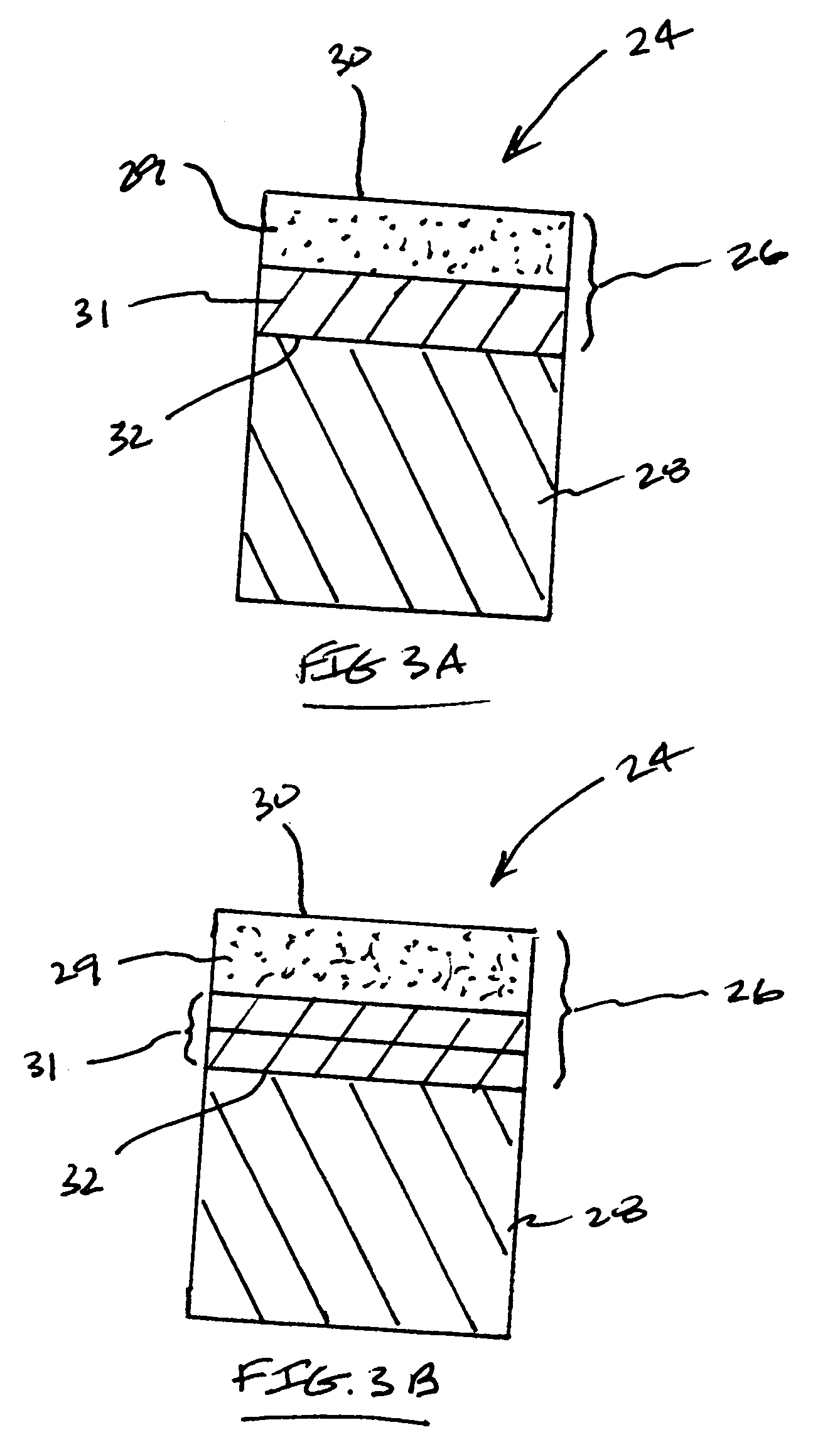

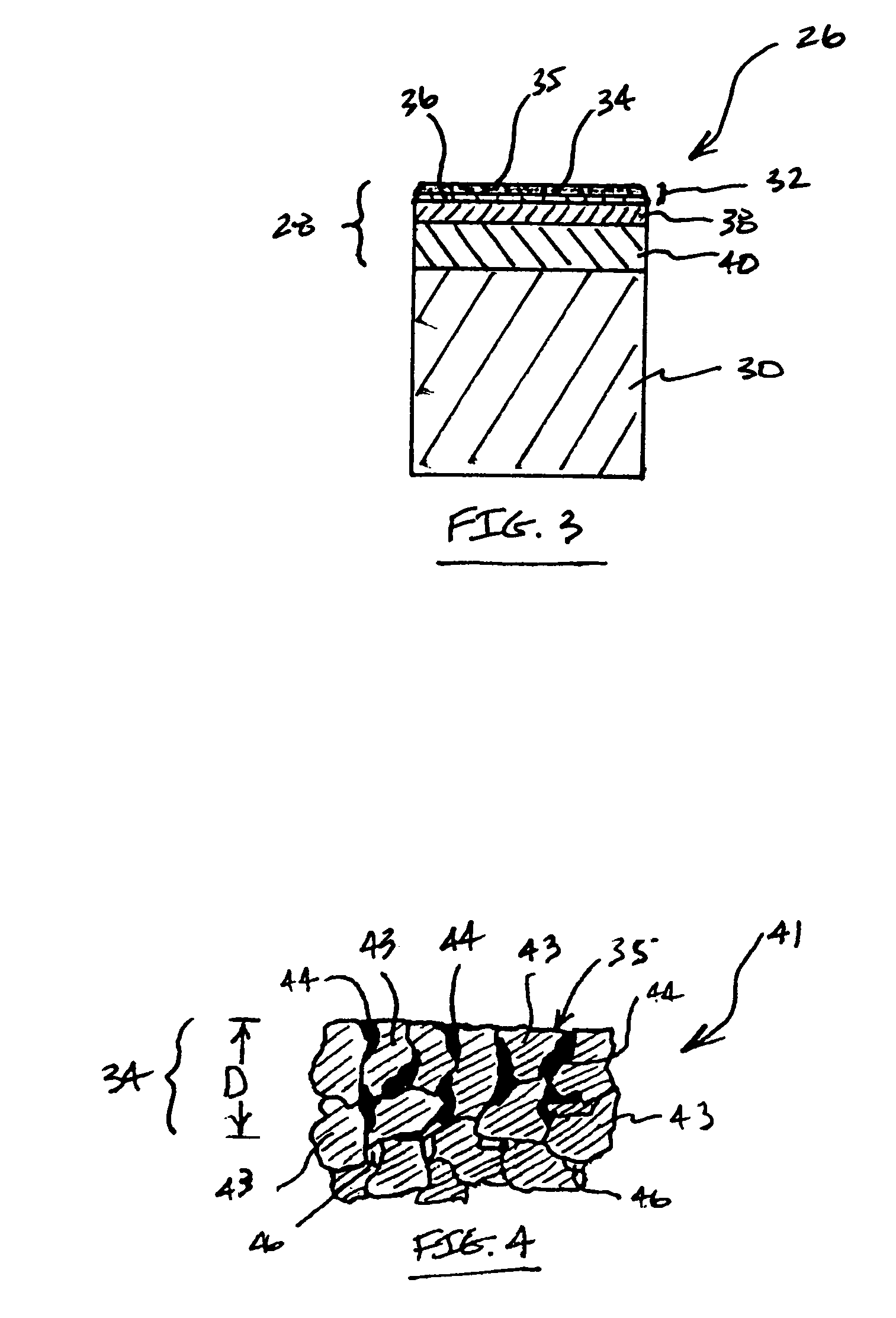

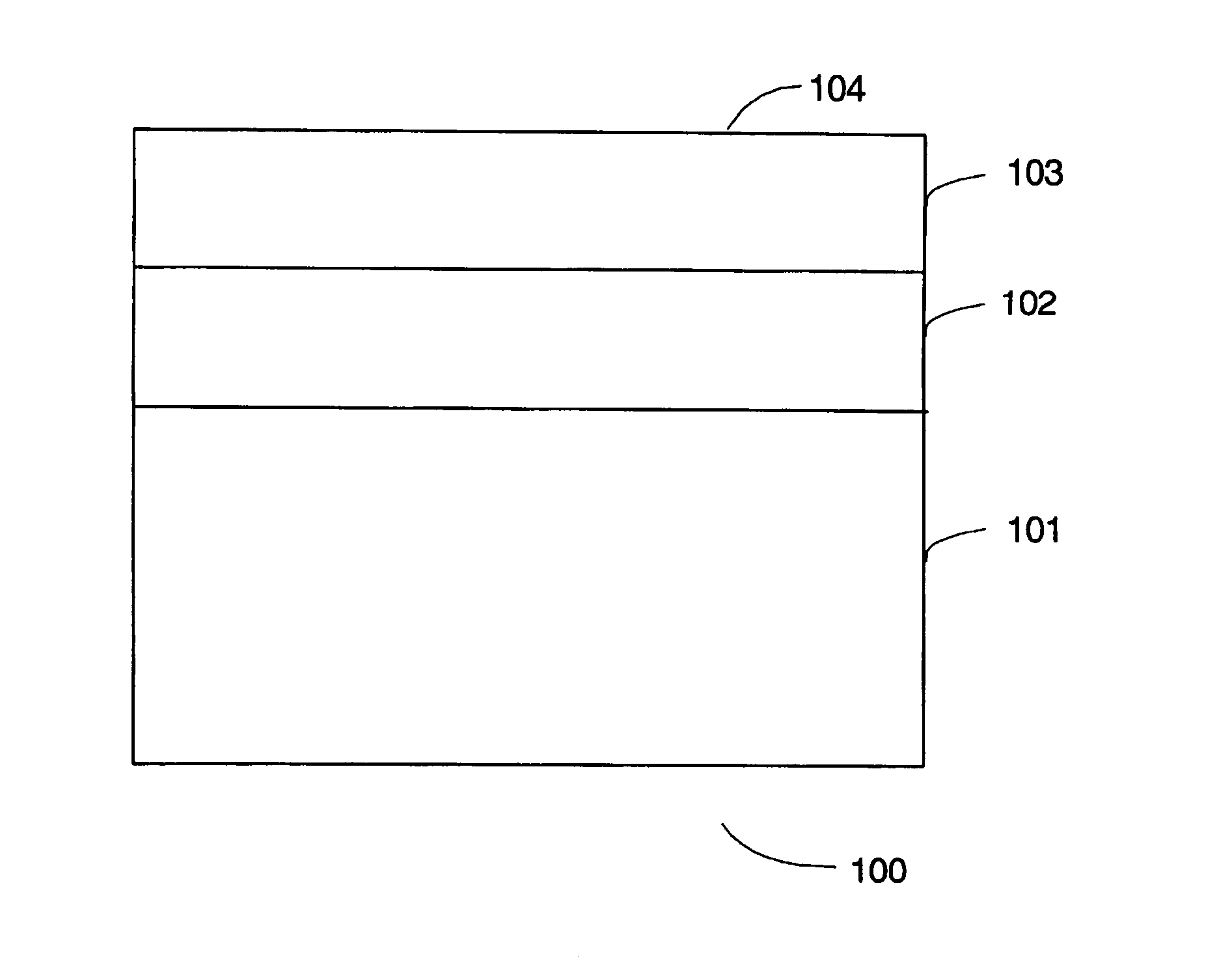

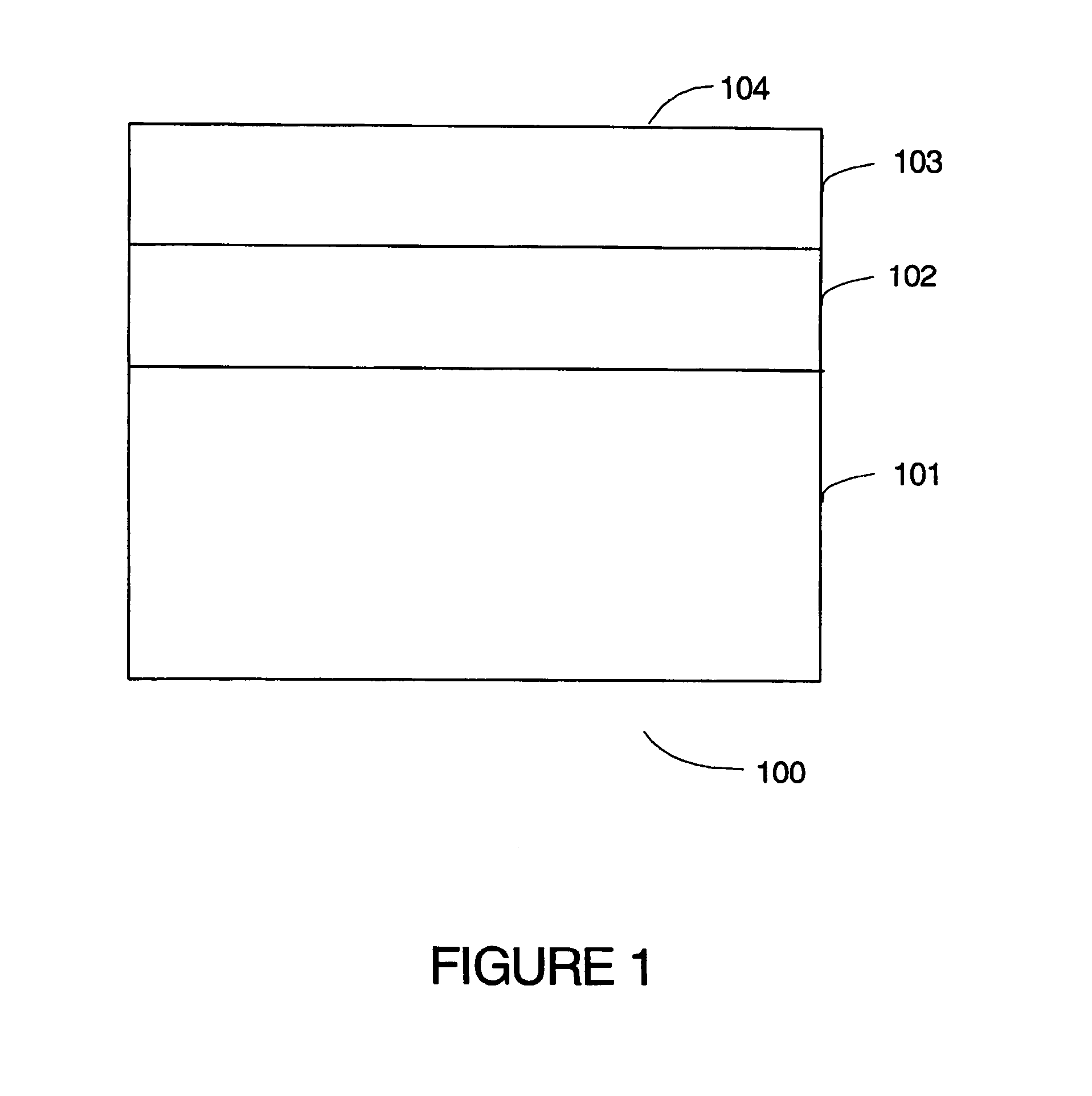

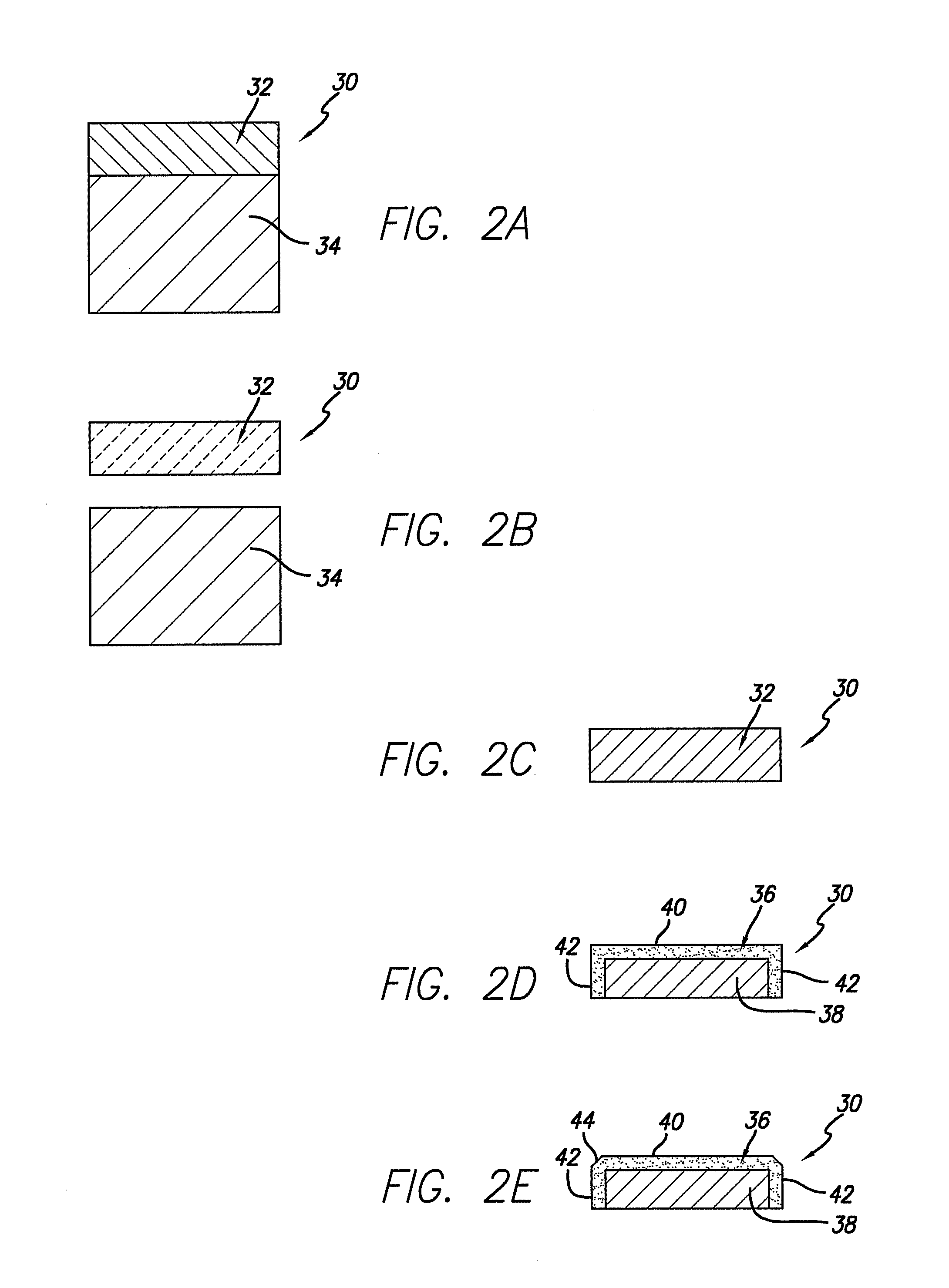

Cutting elements formed from ultra hard materials having an enhanced construction

InactiveUS20060162969A1Eliminate or resist any cracking during useDifferential wear resistanceDrill bitsConstructionsSuperhard materialInter layer

Cutting elements of this invention include an ultra hard body joined with a metallic substrate. The body includes an uppermost layer comprising a plurality of bonded ultra hard crystals and interstitial regions, and that defines a body working surface. The uppermost layer includes an outer region that is relatively more thermally stable than a remaining portion of the uppermost layer. The body further includes an intermediate layer joined to the uppermost layer, comprising a plurality of bonded ultra hard crystals, and having a wear resistance less than that of the uppermost layer remaining region. The body may additionally include a lowermost PCD layer that is interposed between and attached to the intermediate layer and the substrate.

Owner:SMITH INT INC

Cutting elements formed from ultra hard materials having an enhanced construction

InactiveUS7350601B2Eliminate or resist any cracking during useDifferential wear resistanceDrill bitsConstructionsSuperhard materialWear resistance

Cutting elements of this invention include an ultra hard body joined with a metallic substrate. The body includes an uppermost layer comprising a plurality of bonded ultra hard crystals and interstitial regions, and that defines a body working surface. The uppermost layer includes an outer region that is relatively more thermally stable than a remaining portion of the uppermost layer. The body further includes an intermediate layer joined to the uppermost layer, comprising a plurality of bonded ultra hard crystals, and having a wear resistance less than that of the uppermost layer remaining region. The body may additionally include a lowermost PCD layer that is interposed between and attached to the intermediate layer and the substrate.

Owner:SMITH INT INC

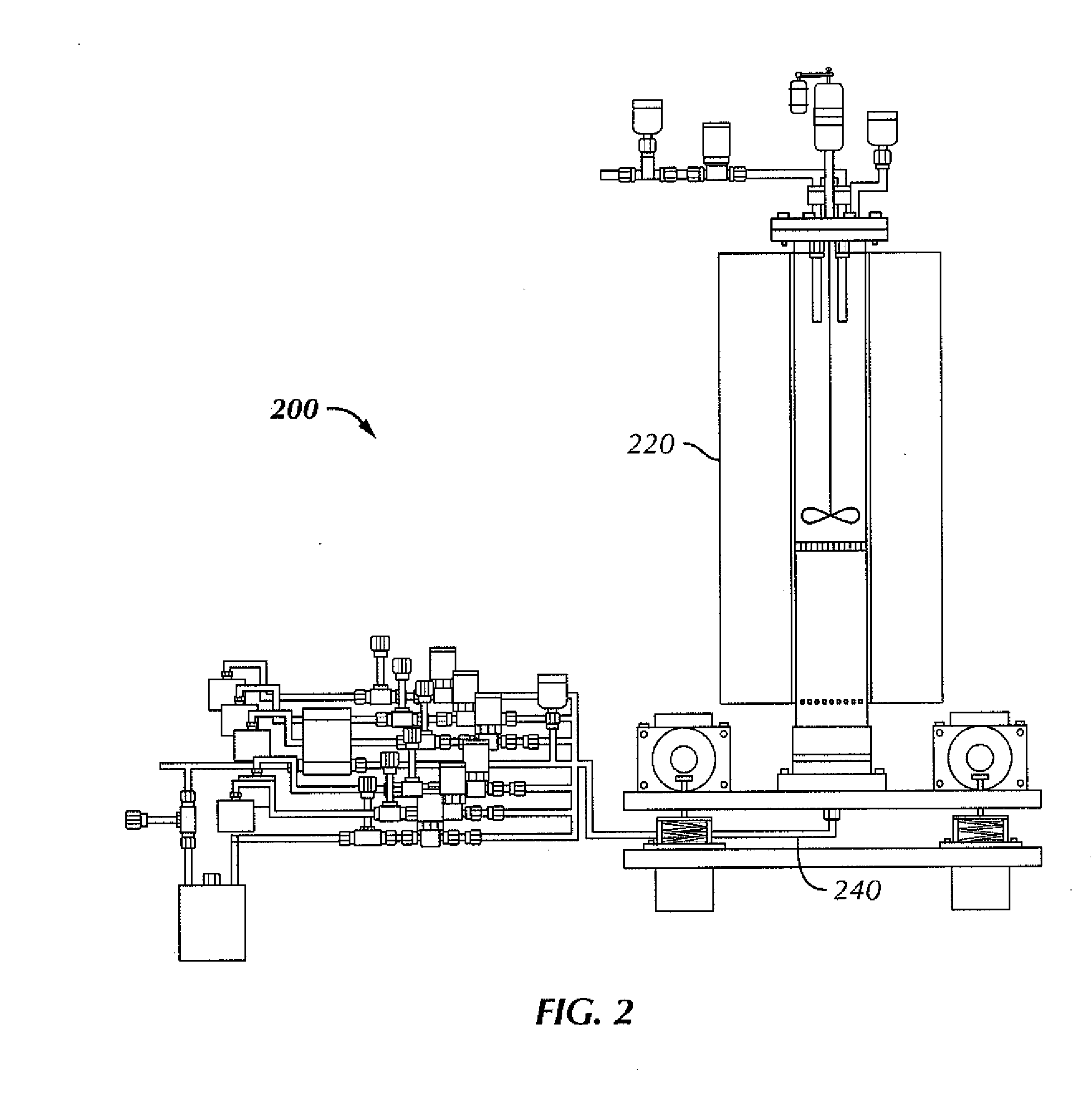

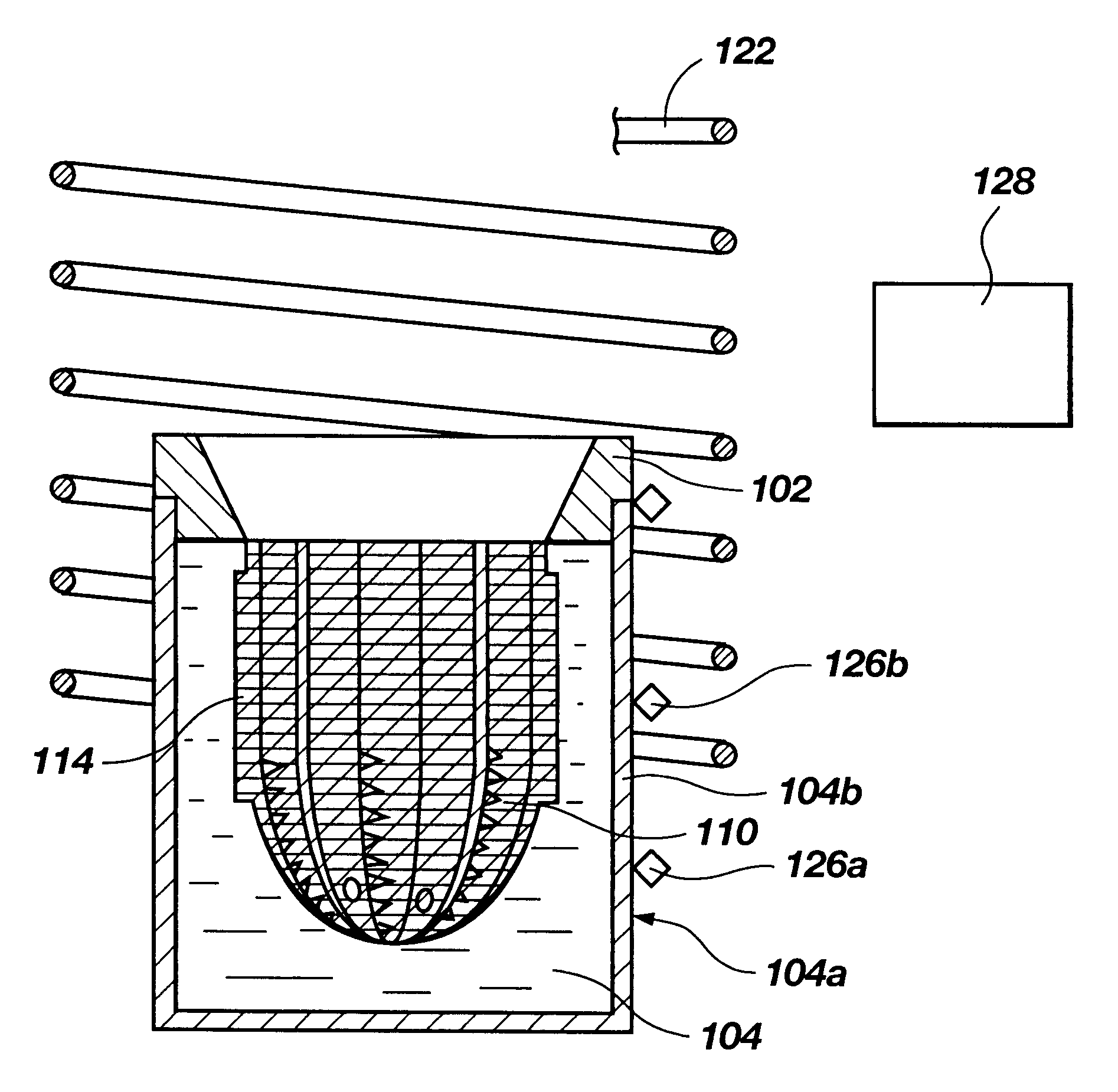

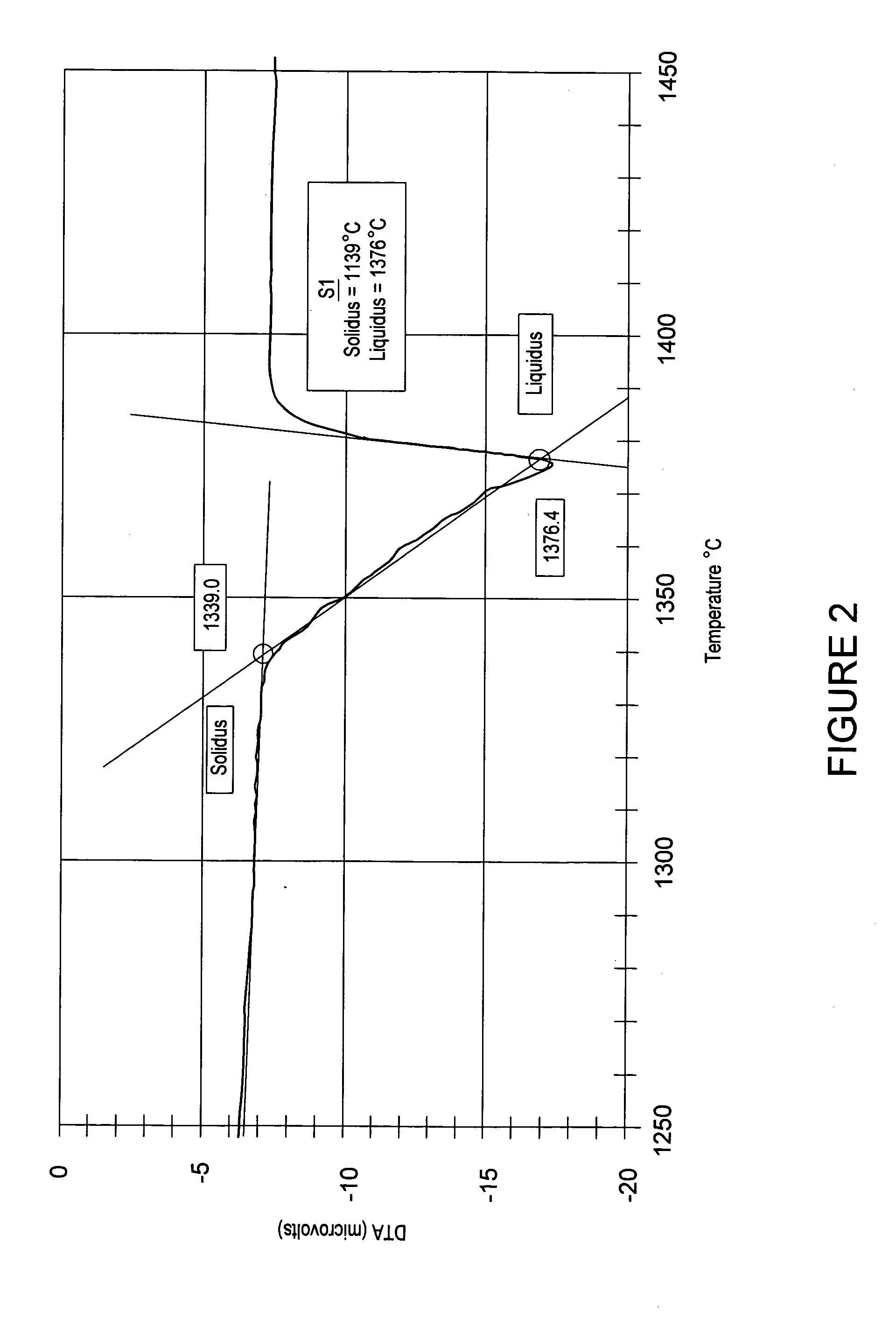

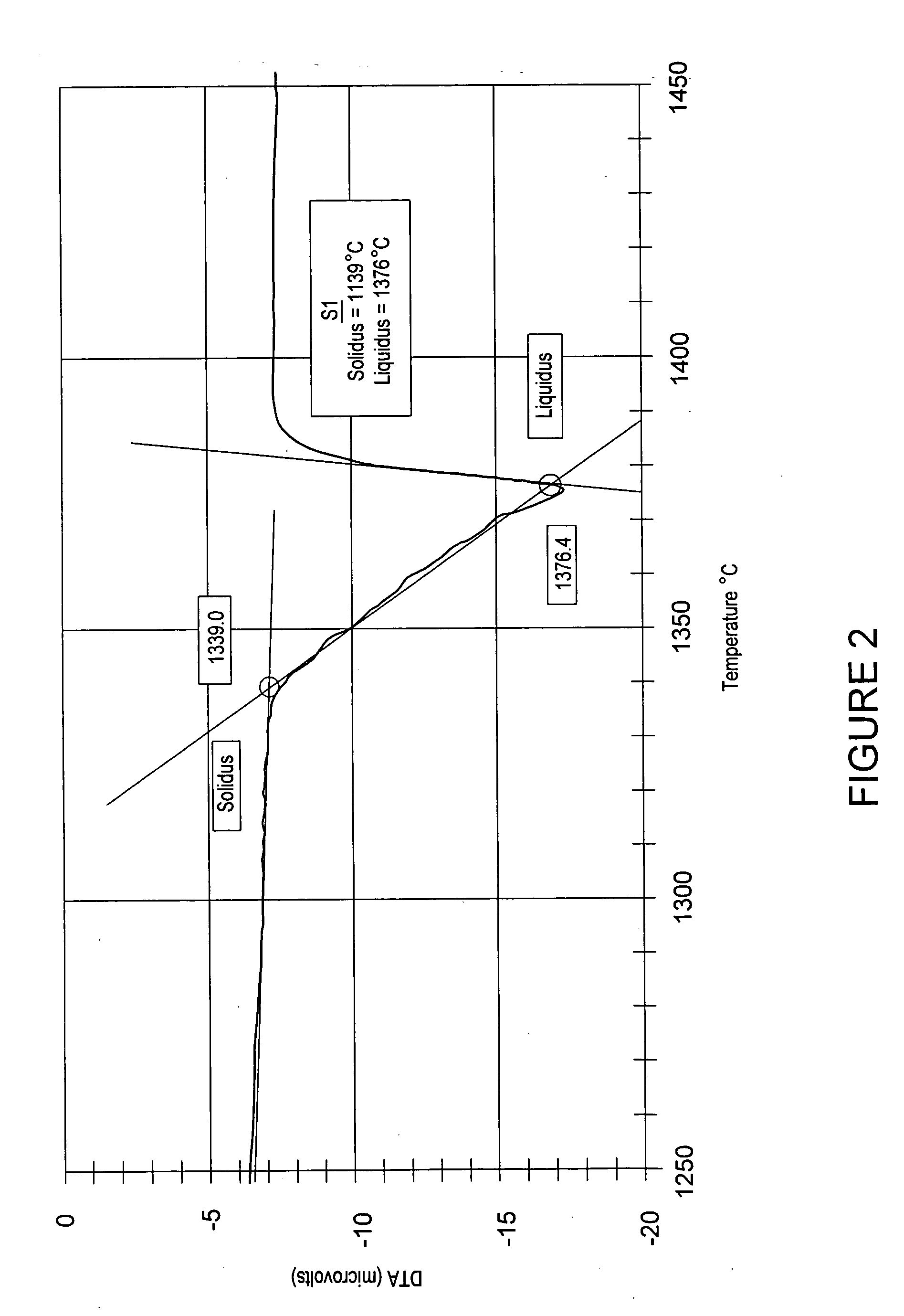

Methods of high temperature infiltration of drill bits and infiltrating binder

A method of manufacturing a bit body, other drilling-related component, or other article of manufacture, including fabricating a particulate-based matrix and infiltrating the particulate-based matrix with a binder that includes cobalt or iron. The binder may be a cobalt alloy or an iron alloy. The particulate-based matrix may be disposed within a non-graphite mold. The particulate-based matrix and binder are placed within an induction coil and an alternating current is applied to the induction coil in order to directly heat the binder, permitting the binder to infiltrate or otherwise bind the particles of the matrix together. The molten binder may then be directionally cooled by forming a cooling zone around an end portion of the bit body and increasing the size of the cooling zone relative to the bit body. The invention also includes a bit body, other drilling-related component, or other article of manufacture which includes a particulate-based matrix that is bound together with a binder that includes iron or cobalt.

Owner:BAKER HUGHES INC

Thermally stable diamond polycrystalline diamond constructions

ActiveUS20060060392A1Improve thermal stabilityGood adhesionDrill bitsConstructionsDiamond crystalPolycrystalline diamond

Thermally stable diamond constructions comprise a diamond body having a plurality of bonded diamond crystals and interstitial regions disposed among the crystals. A metallic substrate is attached to the body. The body includes a first region substantially free of a catalyst material that extends a partial depth from a surface into the body, and a second region that includes the catalyst material. The body can include natural diamond grains and / or a blend of natural and synthetic diamond grains, and is treated to form the first region. Before treatment, a portion of the body to be treated is finished to an approximate final dimension so that the depth of the first region of the finished product is substantially the same as when treated. During treatment, catalyst materials as well as non-catalyst metallic materials are removed from the diamond body to provide a further enhanced degree of thermal stability.

Owner:SMITH INT INC

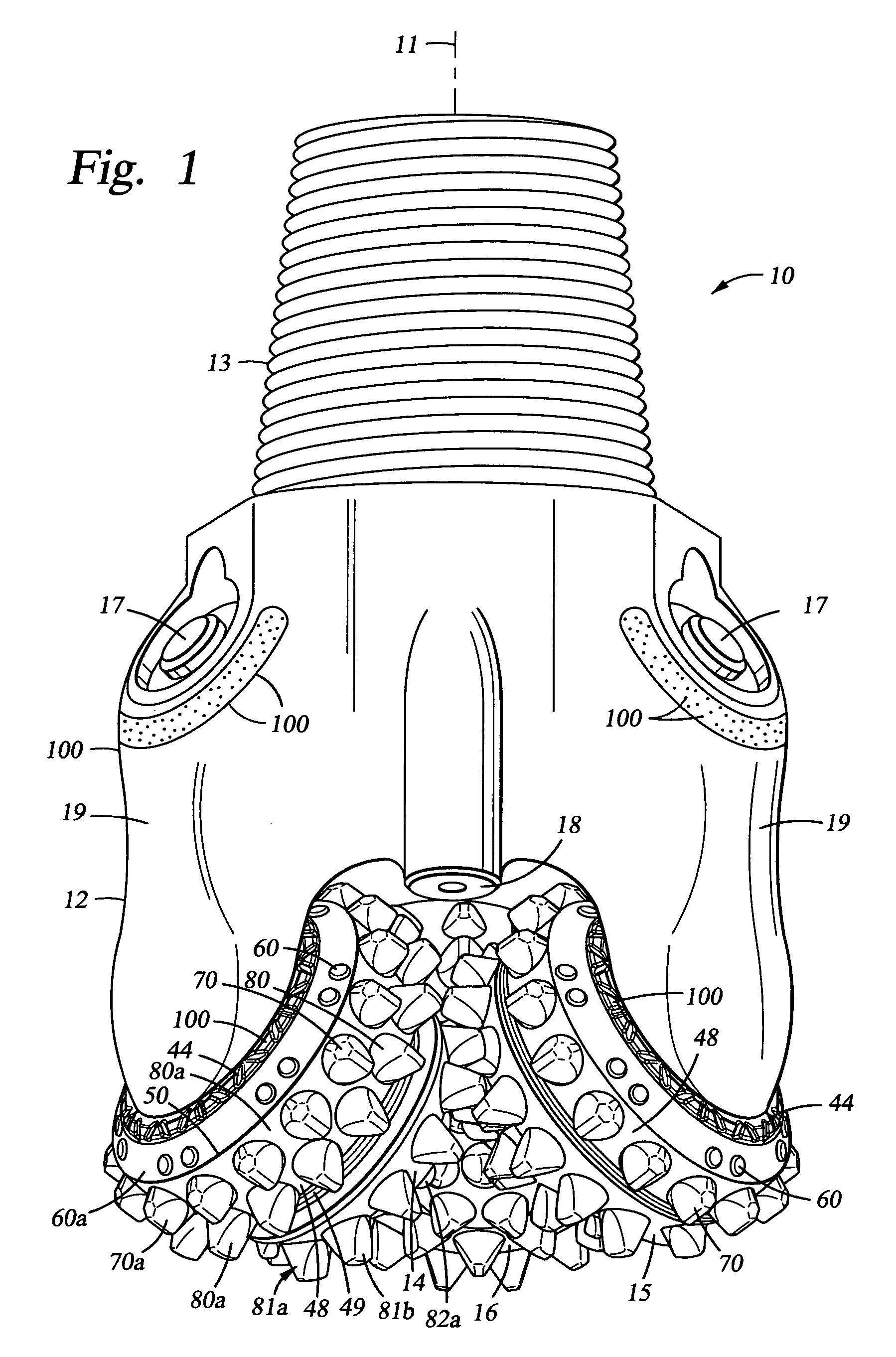

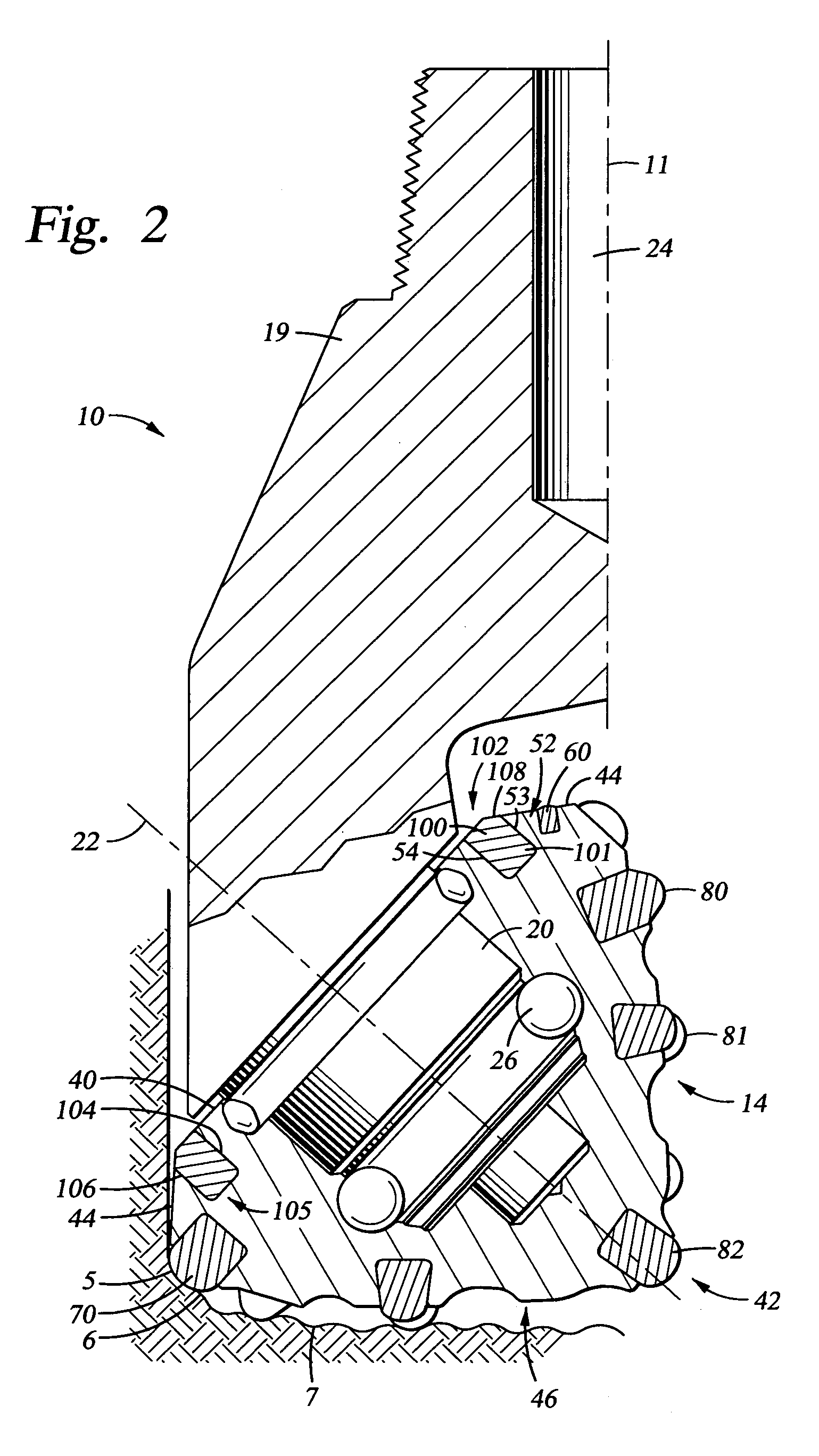

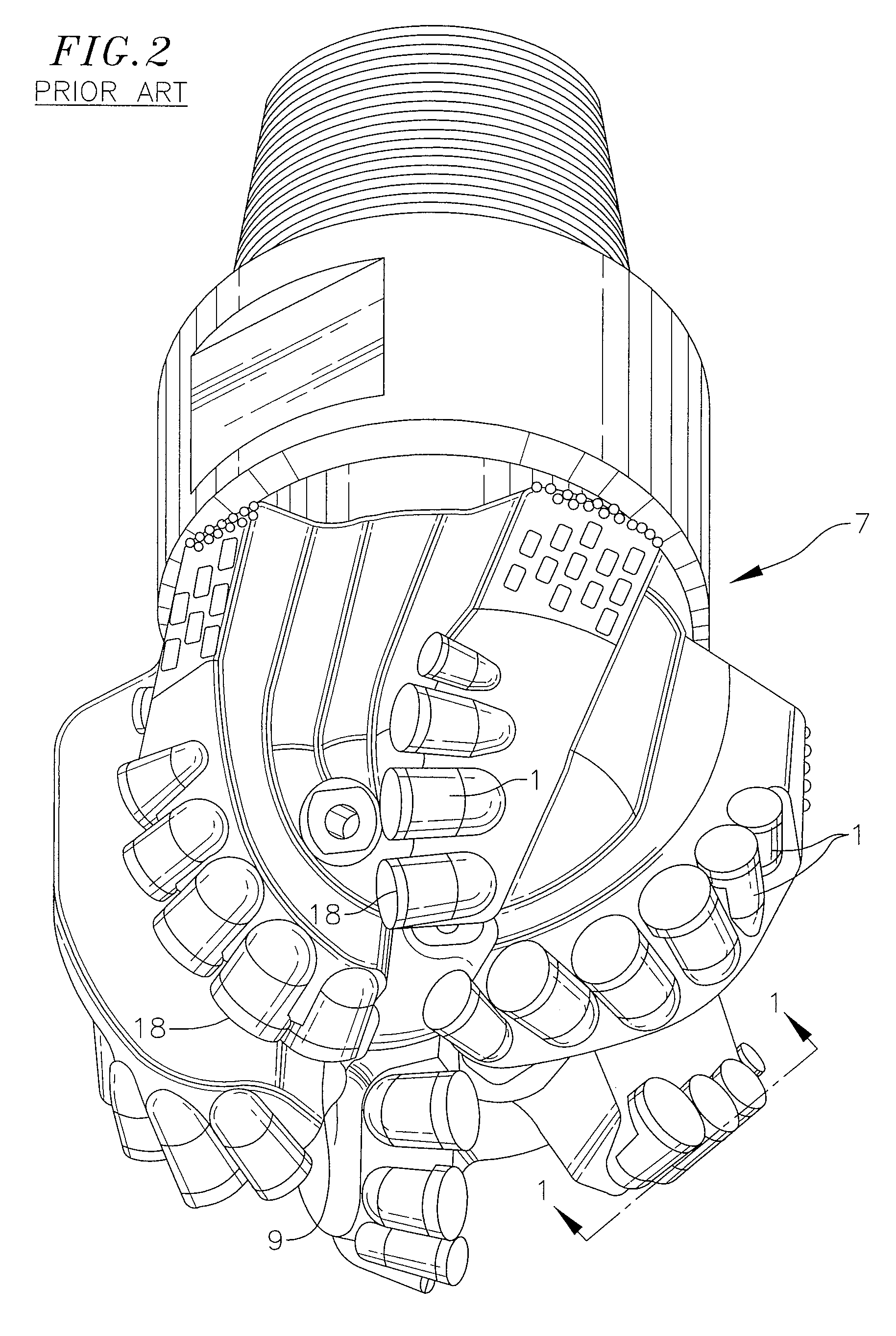

Method for simulating drilling of roller cone bits and its application to roller cone bit design and performance

InactiveUS6516293B1Electric/magnetic detection for well-loggingDrill bitsEngineeringVisual perception

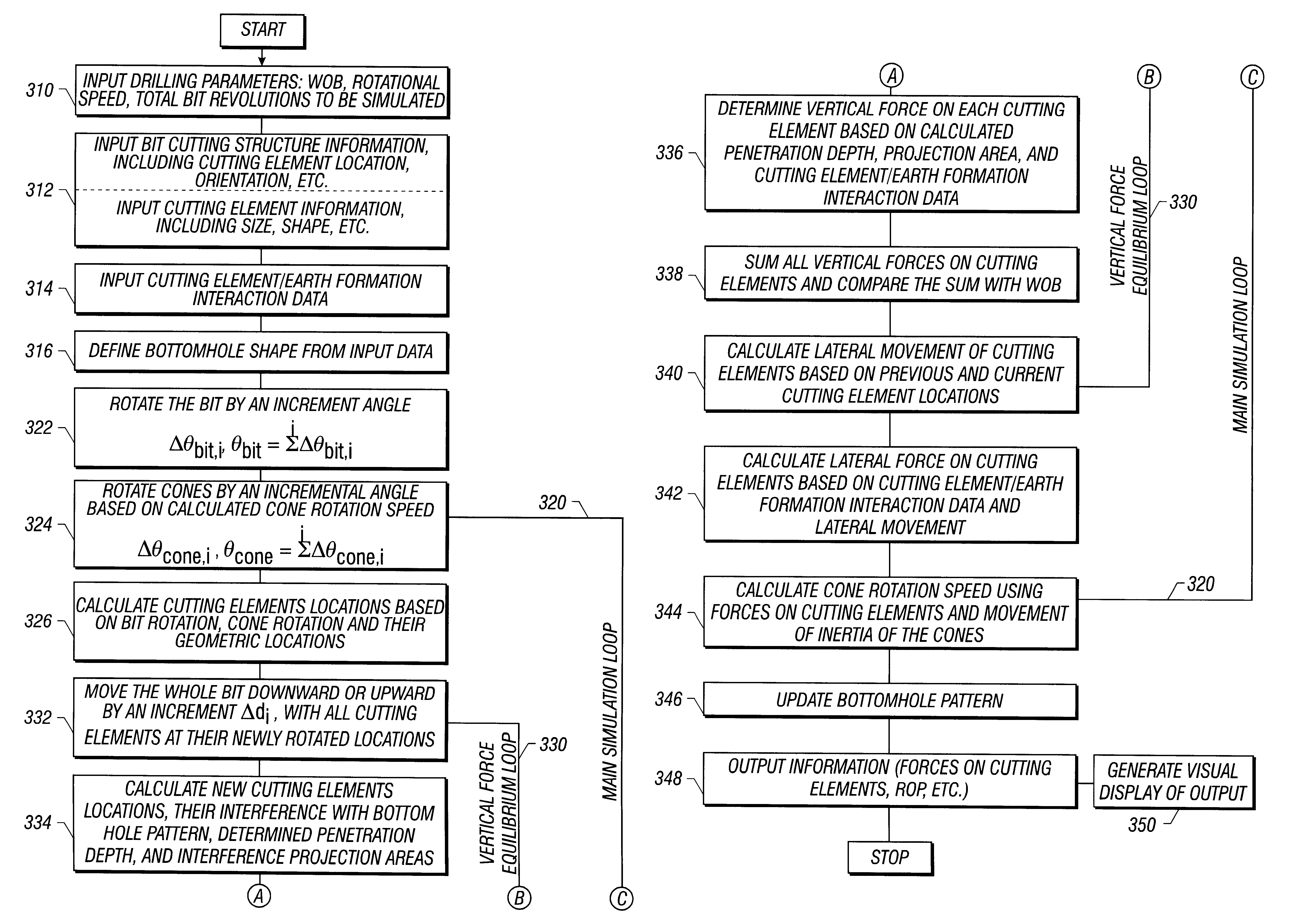

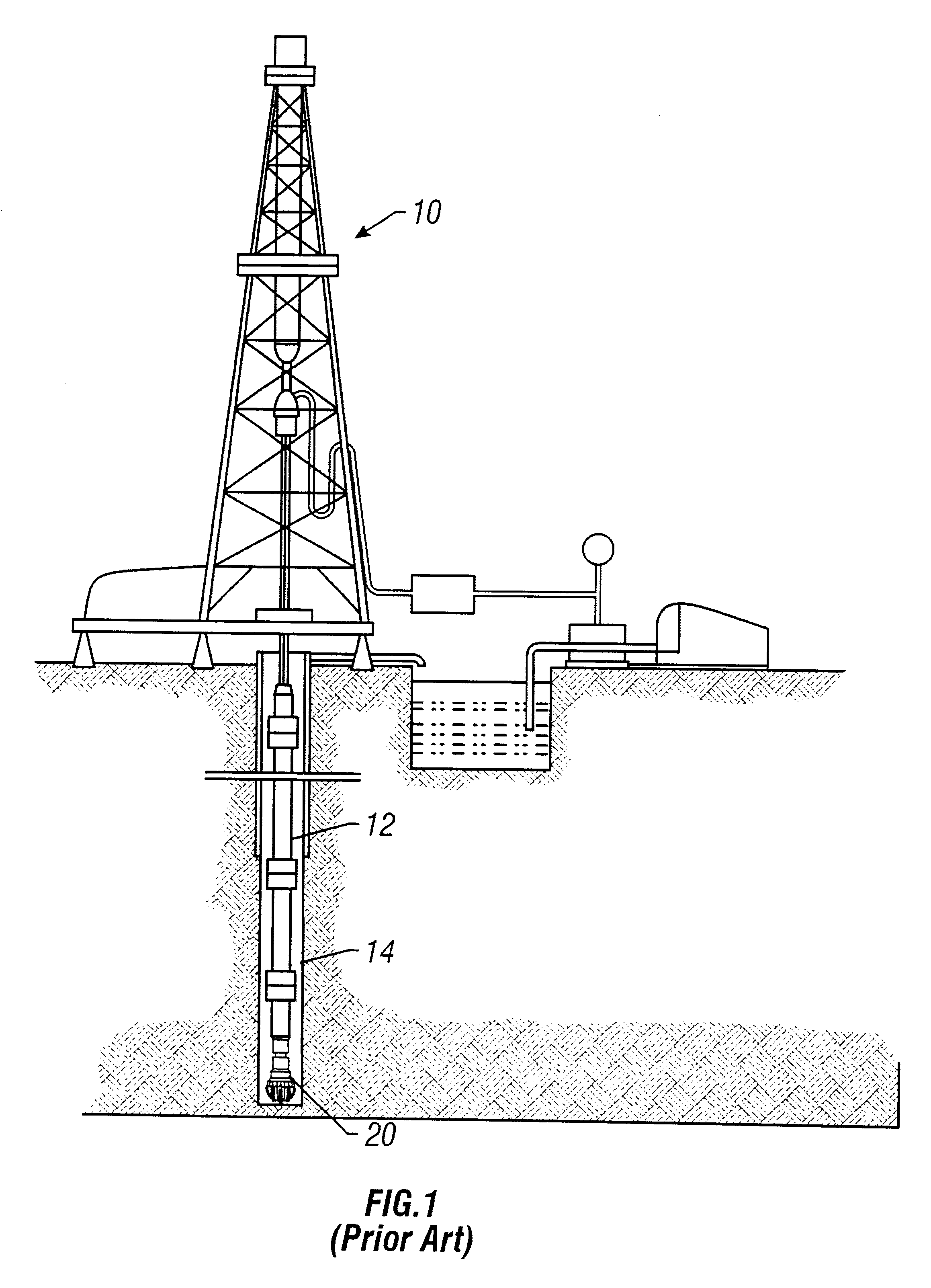

A method for simulating the drilling performance of a roller cone bit drilling an earth formation may be used to generate a visual representation of drilling, to design roller cone drill bits, and to optimize the drilling performance of a roller cone bit. The method for generating a visual representation of a roller cone bit drilling earth formations includes selecting bit design parameters, selecting drilling parameters, and selecting an earth formation to be drilled. The method further includes calculating, from the bit design parameters, drilling parameters and earth formation, parameters of a crater formed when one of a plurality of cutting elements contacts the earth formation. The method further includes calculating a bottomhole geometry, wherein the crater is removed from a bottomhole surface. The method also includes incrementally rotating the bit and repeating the calculating of crater parameters and bottomhole geometry based on calculated roller cone rotation speed and geometrical location with respect to rotation of said roller cone drill bit about its axis. The method also includes converting the crater and bottomhole geometry parameters into a visual representation.

Owner:SMITH INT INC

Polycrystalline diamond partially depleted of catalyzing material

Owner:REEDHYCALOG UK

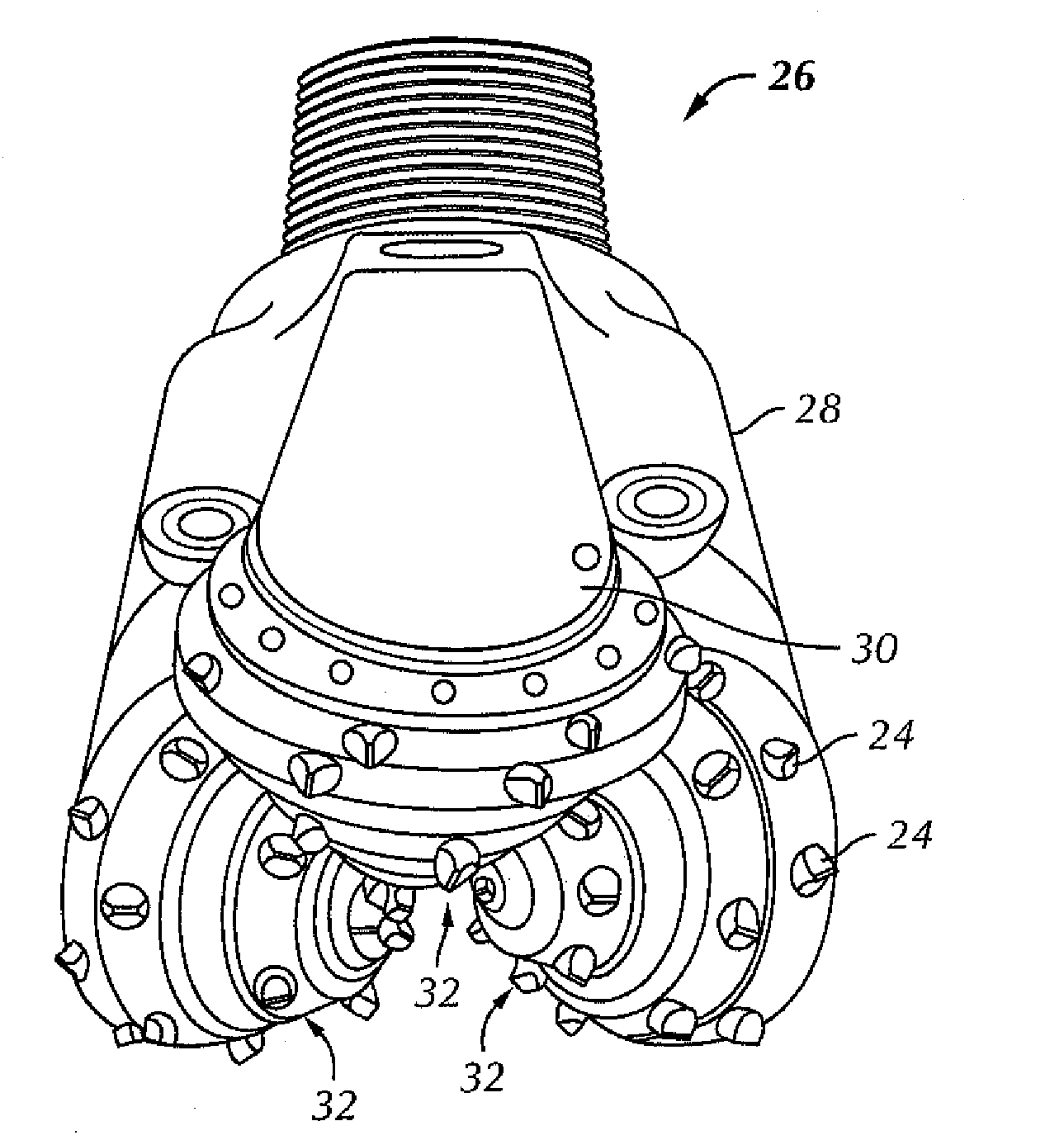

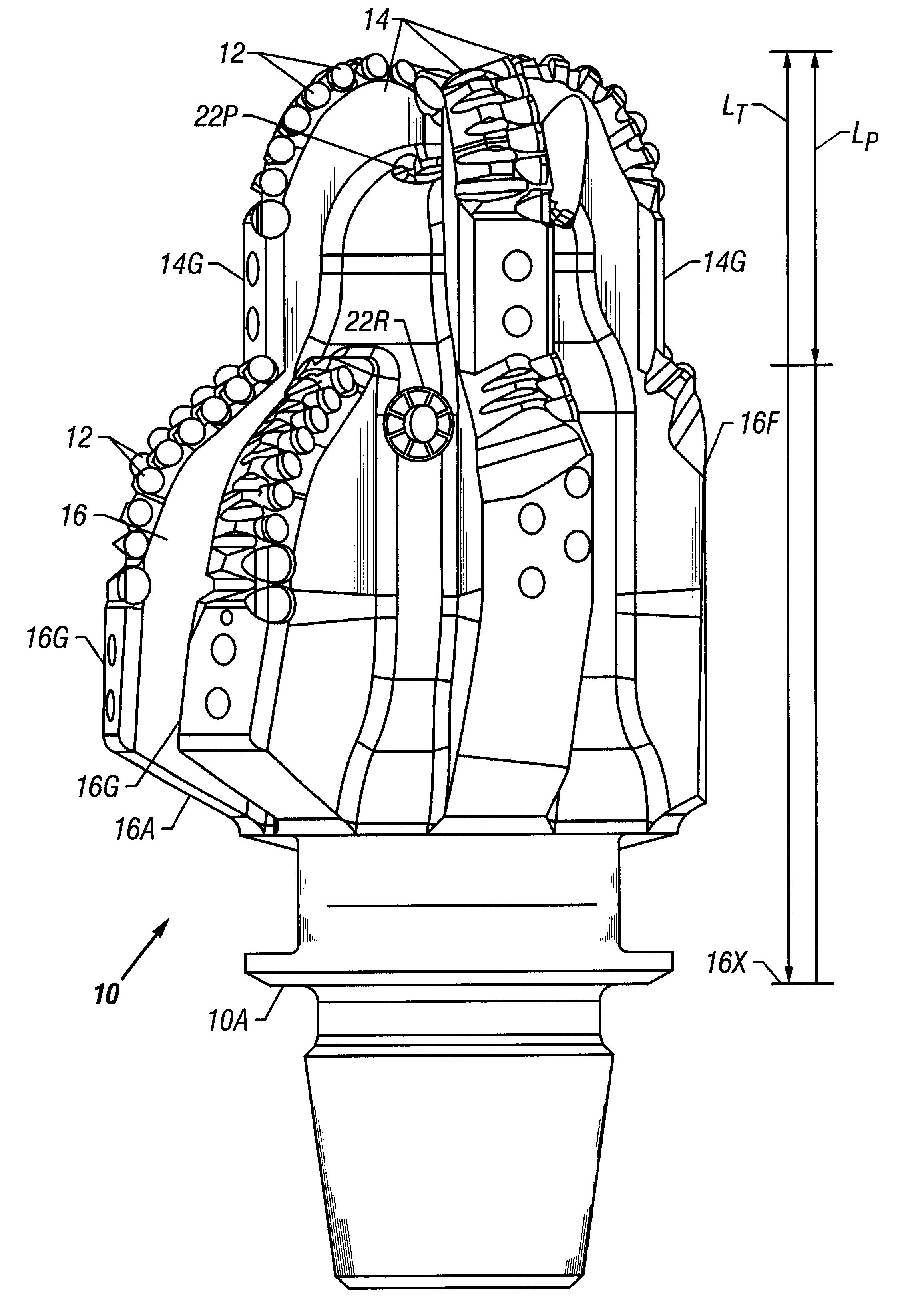

Rotary drill bit having moveable formation-engaging members

Formation engaging elements are moveably mounted onto a drill bit. Such elements may be used to protect other rigidly mounted formation engaging elements from impacts that occur during use of the drill bit, or they may be used to alter the aggressiveness of the drill bit when used in directional drilling operations.

Owner:REEDHYCALOG UK

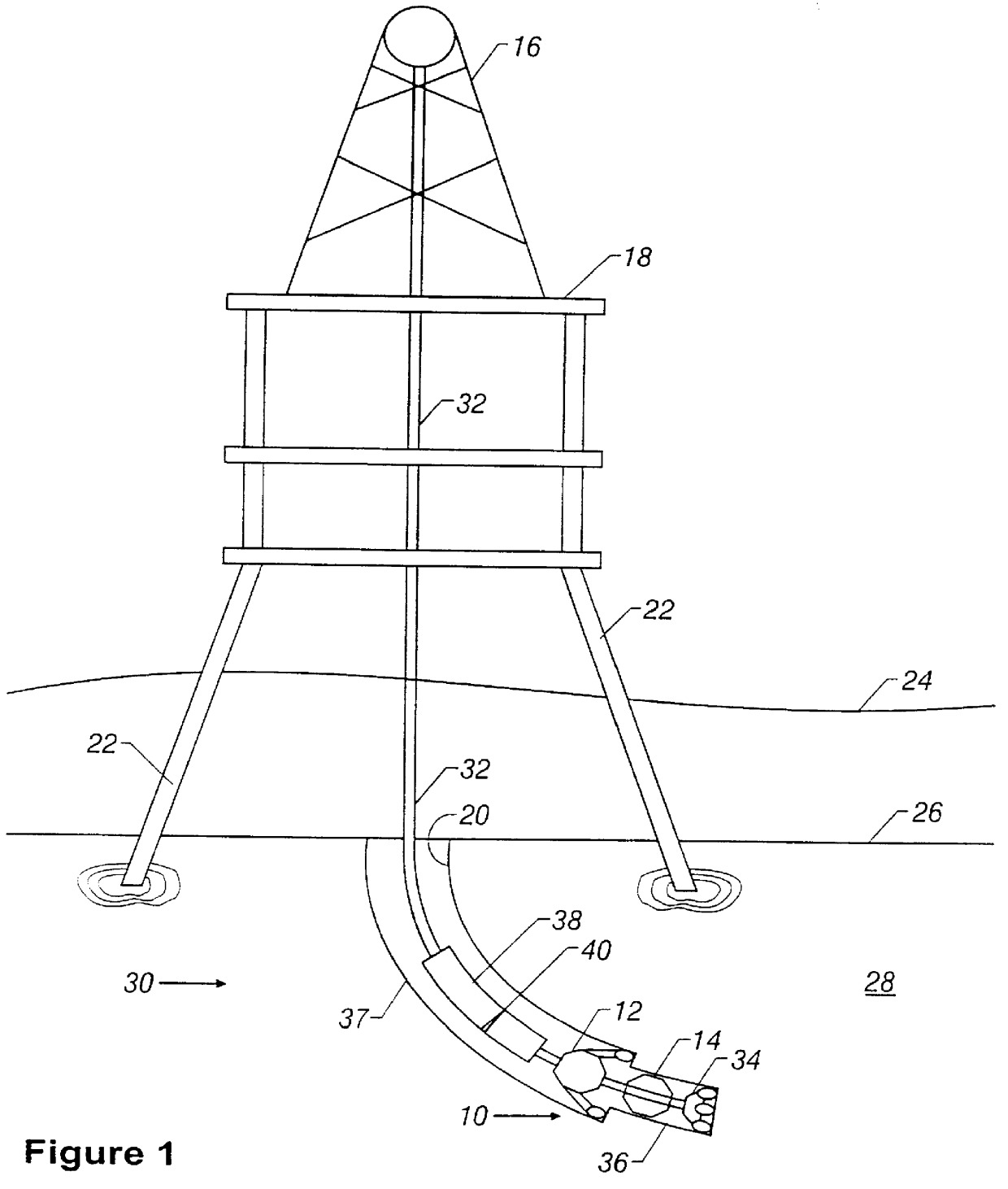

Integrated directional under-reamer and stabilizer

The present invention is an apparatus for use in drilling operations. It uses an under-reamer having a plurality of elongated arms with cutting elements at the ends of the arms for enlarging a previously drilled borehole drilled by a drill bit. One or more stabilizers in close proximity to the under-reamer provide stability to the under-reamer and the drill bit. The stabilizer could be rotating or non-rotating; and could be positioned between the under-reamer and the drill bit, or above the under reamer or above a directional device on the drillstring. The cutting arms are selectively operable to perform the enlargement. The stabilizer may be provided with members that closely fit the size of the borehole.

Owner:BAKER HUGHES INC

Earth-boring bits

ActiveUS20050247491A1Low melting pointLowered melting point of the binder facilitates proper infiltration of the massDrill bitsCutting machinesBorideNiobium

The present invention relates to compositions and methods for forming a bit body for an earth-boring bit. The bit body may comprise hard particles, wherein the hard particles comprise at least one carbide, nitride, boride, and oxide and solid solutions thereof, and a binder binding together the hard particles. The binder may comprise at least one metal selected from cobalt, nickel, and iron, and, optionally, at least one melting point reducing constituent selected from a transition metal carbide in the range of 30 to 60 weight percent, boron up to 10 weight percent, silicon up to 20 weight percent, chromium up to 20 weight percent, and manganese up to 25 weight percent, wherein the weight percentages are based on the total weight of the binder. In addition, the hard particles may comprise at least one of (i) cast carbide (WC+W2C) particles, (ii) transition metal carbide particles selected from the carbides of titanium, chromium, vanadium, zirconium, hafnium, tantalum, molybdenum, niobium, and tungsten, and (iii) sintered cemented carbide particles.

Owner:BAKER HUGHES INC +1

Polycrystalline diamond having improved thermal stability

InactiveUS20080230280A1Improved thermal characteristic and mechanical propertyAvoiding unwanted deteriorationDrill bitsConstructionsPolycrystalline diamondThermal stability

PCD constructions include a PCD body comprising a polycrystalline matrix region, a first region that includes a replacement material positioned remote from a body surface, and a second region that is substantially free of the replacement material and that extends a depth from the body surface. The PCD construction can further include a substrate that is attached to the body. The PCD body is formed by removing a solvent catalyst material used to form the body, replacing the removed solvent catalyst material with a replacement material, and then removing the replacement material from a region of the body to thereby form the second region. The replacement material can be introduced into the PCD body during a HPHT process, and the substrate may or may not be the source of the noncatalyzing material.

Owner:SMITH INT INC

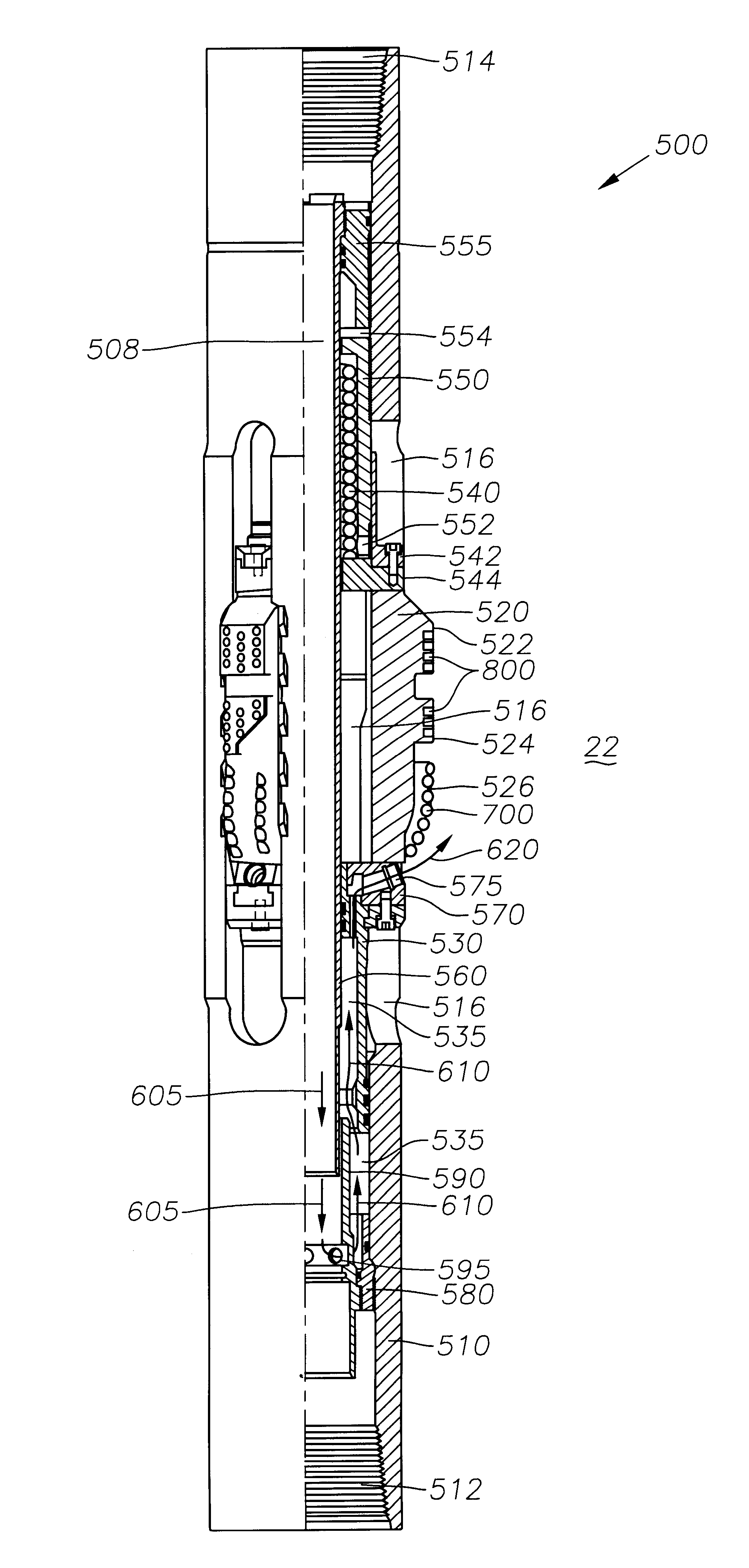

Remotely controlled apparatus for downhole applications and methods of operation

An apparatus for use downhole is disclosed that, in one configuration includes a downhole tool configured to operate in an active position and an inactive position and an actuation device, which may include a control unit. The apparatus includes a telemetry unit that sends a first pattern recognition signal to the control unit to move the tool into the active position and a second pattern recognition signal to move the tool into the inactive position. The apparatus may be used for drilling a subterranean formation and include a tubular body and one or more extendable features, each positionally coupled to a track of the tubular body, and a drilling fluid flow path extending through a bore of the tubular body for conducting drilling fluid therethrough. A push sleeve is disposed within the tubular body and coupled to the one or more features. A valve assembly is disposed within the tubular body and configured to control the flow of the drilling fluid into an annular chamber in communication with the push sleeve; the valve assembly comprising a mechanically operated valve and / or an electronically operated valve. Other embodiments, including methods of operation, are provided.

Owner:BAKER HUGHES OILFIELD OPERATIONS LLC

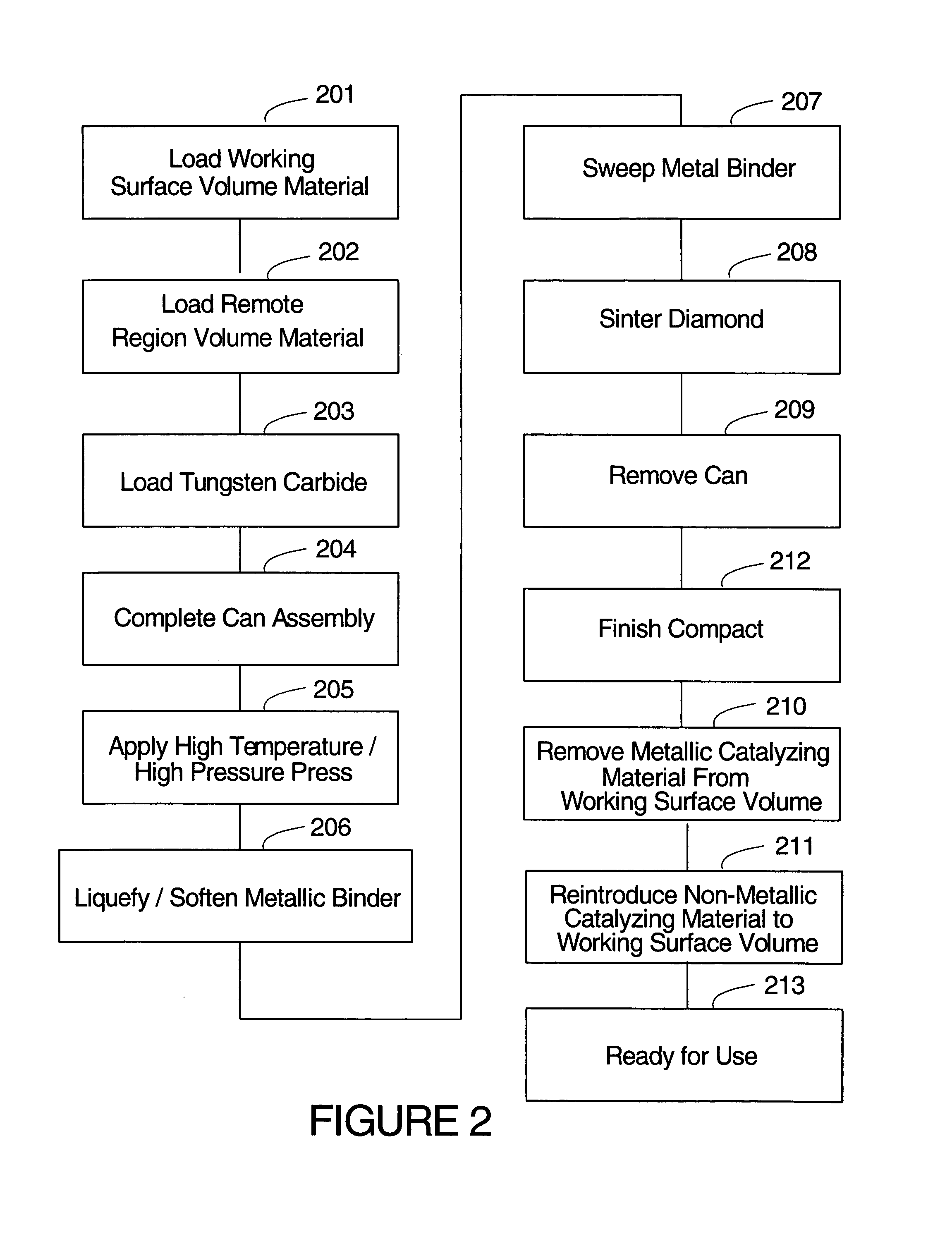

Polycrystalline diamond compact (PDC) cutting element having multiple catalytic elements

InactiveUS7635035B1Improve thermal stabilityPigmenting treatmentDrill bitsPolycrystalline diamondThermal stability

A polycrystalline diamond compact useful for wear, cutting, drilling, drawing and like applications is provided with a first diamond region remote from the working surface which has a metallic catalyzing material and a second diamond region adjacent to or including the working surface containing a non-metallic catalyst and the method of making such a compact is provided. This compact is particularly useful in high temperature operations, such as hard rock drilling because of the improved thermal stability at the working surface.

Owner:US SYNTHETIC CORP

Earth-boring bits

InactiveUS20050211475A1Low melting pointLowered melting point of the binder facilitates proper infiltration of the massDrill bitsMetal-working drilling toolsBorideNiobium

The present invention relates to compositions and methods for forming a bit body for an earth-boring bit. The bit body may comprise hard particles, wherein the hard particles comprise at least one carbide, nitride, boride, and oxide and solid solutions thereof, and a binder binding together the hard particles. The binder may comprise at least one metal selected from cobalt, nickel, and iron, and at least one melting point reducing constituent selected from a transition metal carbide in the range of 30 to 60 weight percent, boron up to 10 weight percent, silicon up to 20 weight percent, chromium up to 20 weight percent, and manganese up to 25 weight percent, wherein the weight percentages are based on the total weight of the binder. In addition, the hard particles may comprise at least one of (i) cast carbide (WC+W2C) particles, (ii) transition metal carbide particles selected from the carbides of titanium, chromium, vanadium, zirconium, hafnium, tantalum, molybdenum, niobium, and tungsten, and (iii) sintered cemented carbide particles.

Owner:ATI PROPERTIES +1

Bi-centered drill bit having improved drilling stability mud hydraulics and resistance to cutter damage

A bi-center drill bit includes pilot and reaming blades affixed to a body at azimuthally spaced locations. The blades have PDC cutters attached at selected positions. In one aspect, the pilot blades form a section having length along the bit axis less than about 80 percent of a diameter of the section. In another aspect, selected pilot blades and corresponding reaming blades are formed into single spiral structures. In another aspect, shapes and positions of the blades and inserts are selected so that lateral forces exerted by the reaming and the pilot sections are balanced as a single structure. Lateral forces are preferably balanced to within 10 percent of the total axial force on the bit. In another aspect, the center of mass of the bit is located less than about 2.5 percent of the diameter of the bit from the axis of rotation. In another aspect, jets are disposed in the reaming section oriented so that their axes are within about 30 degrees of normal to the axis of the bit. In another aspect, the reaming blades are shaped to conform to the radially least extensive, from the longitudinal axis, of a pass-through circle or a drill circle, so the cutters on the reaming blades drill at the drill diameter, without contact to the cutters on the reaming blades when the bit passes through an opening having about the pass-through diameter.

Owner:SMITH INT INC

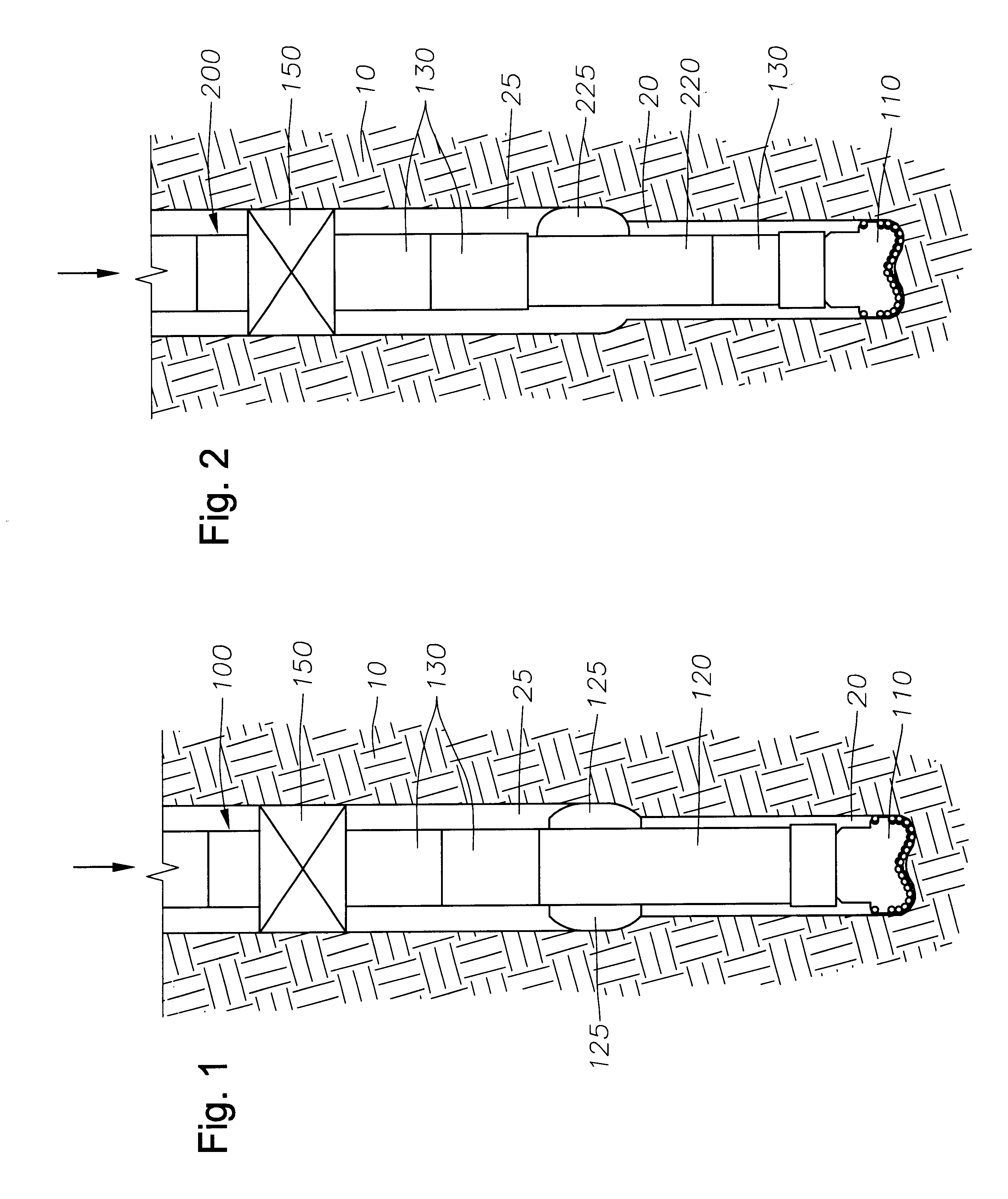

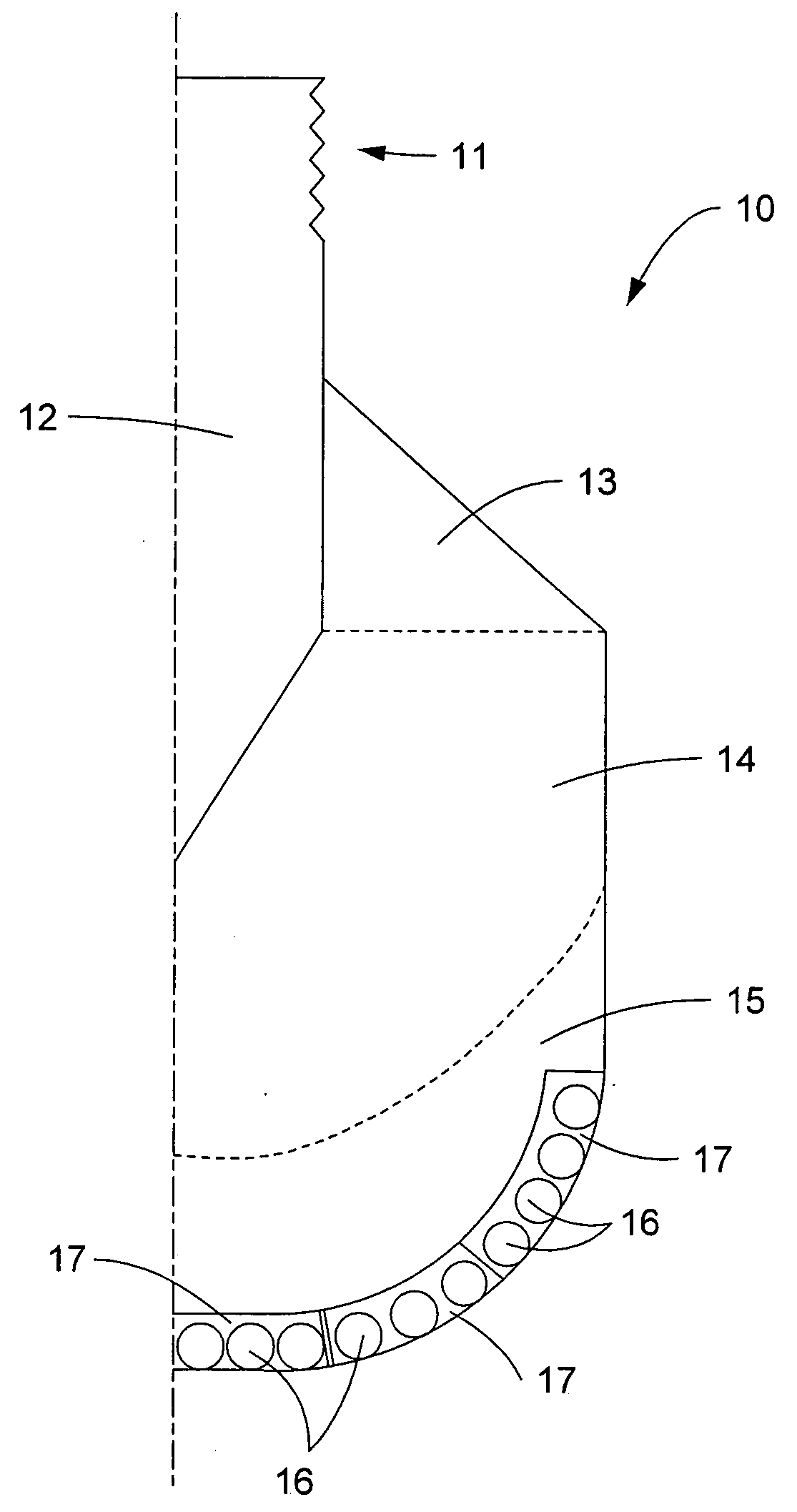

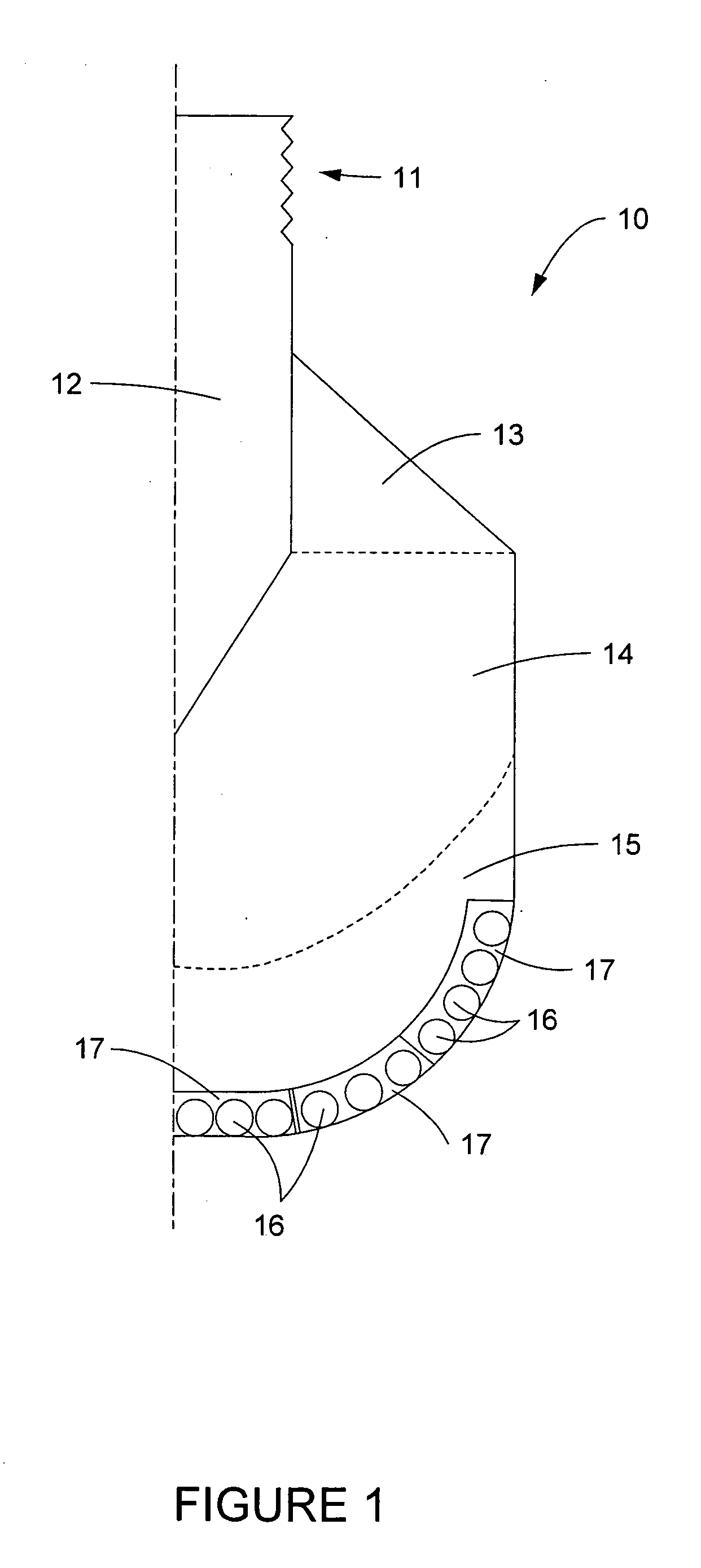

Expandable reamer apparatus for enlarging boreholes while drilling and methods of use

ActiveUS7036611B2Reduce capacityReduce the cross-sectional areaSurveyDrill bitsFixed bearingWell drilling

An expandable reamer apparatus and methods for reaming a borehole, wherein a laterally movable blade carried by a tubular body may be selectively positioned at an inward position and an expanded position. The laterally movable blade, held inwardly by blade-biasing elements, may be forced outwardly by drilling fluid selectively allowed to communicate therewith by way of an actuation sleeve disposed within the tubular body. Alternatively, a separation element may transmit force or pressure from the drilling fluid to the movable blade. Further, a chamber in communication with the movable blade may be pressurized by way of a downhole turbine or pump. A ridged seal wiper, compensator, movable bearing pad, fixed bearing pad preceding the movable blade, or an adjustable spacer element to alter expanded blade position may be included within the expandable reamer. In addition, a drilling fluid pressure response indicating an operational characteristic of the expandable reamer may be generated.

Owner:BAKER HUGHES OILFIELD OPERATIONS LLC

Superabrasive cutting element with enhanced durability and increased wear life and apparatus so equipped

InactiveUS6202770B1Extended service lifeReduced tendency to catastrophically spallDrill bitsConstructionsEngineeringMechanical engineering

A cutting element for use in drilling subterranean formations. The cutting element includes a superabrasive table mounted to a supporting substrate. The superabrasive table includes a two-dimensional cutting face having a cutting edge along at least a portion of its periphery, and a first surface extending forwardly and inwardly from a location radially interior of the cutting edge at a first angle of orientation with respect to the longitudinal axis of the cutting element. The cutting face also includes at least a second surface located between the first surface and the cutting edge and oriented at a different, greater angle to the longitudinal axis than the angle of orientation of the first surface.

Owner:BAKER HUGHES INC

Thermally stable diamond polycrystalline diamond constructions

ActiveUS20060060390A1Improve thermal stabilityGood adhesionPigmenting treatmentDrill bitsDiamond crystalPolycrystalline diamond

Thermally stable diamond constructions comprise a diamond body having a plurality of bonded diamond crystals, a plurality of interstitial regions disposed among the crystals, and a substrate attached to the body. The body includes a working surface and a side surface extending away from the working surface to the substrate. The body comprises a first region adjacent the side surface that is substantially free of a catalyst material and that extends a partial depth into the diamond body. The first region can further extend to at least a portion of the working surface and a partial depth therefrom into the diamond body. The diamond body can be formed from natural diamond grains and / or a mixture of natural and synthetic diamond grains. A surface of the diamond body is treated to provide the first region, and before treatment is finished to an approximate final dimension.

Owner:SMITH INT INC

Polycrystalline diamond constructions having improved thermal stability

ActiveUS20080223623A1Good adhesionImprove thermal stabilityDrill bitsConstructionsDiamond crystalPolycrystalline diamond

Owner:SMITH INT INC

Thermally stable polycrystalline diamond cutting elements and bits incorporating the same

Owner:SMITH INT INC

Thermally-stable polycrystalline diamond materials and compacts

InactiveUS20050230156A1Improve thermal stabilityImprove bindingDrill bitsConstructionsDiamond crystalPolycrystalline diamond

Thermally-stable polycrystalline diamond materials of this invention comprise a first phase including a plurality of bonded together diamond crystals, and a second phase including a reaction product formed between a binder / catalyst material and a material reactive with the binder / catalyst material. The reaction product is disposed within interstitial regions of the polycrystalline diamond material that exists between the bonded diamond crystals. The first and second phases are formed during a single high pressure / high temperature process condition. The reaction product has a coefficient of thermal expansion that is relatively closer to that of the bonded together diamond crystals than that of the binder / catalyst material, thereby providing an improved degree of thermal stability to the polycrystalline diamond material.

Owner:SMITH INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com