Patents

Literature

454 results about "Diamond cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diamond cutting is the practice of changing a diamond from a rough stone into a faceted gem. Cutting diamond requires specialized knowledge, tools, equipment, and techniques because of its extreme difficulty.

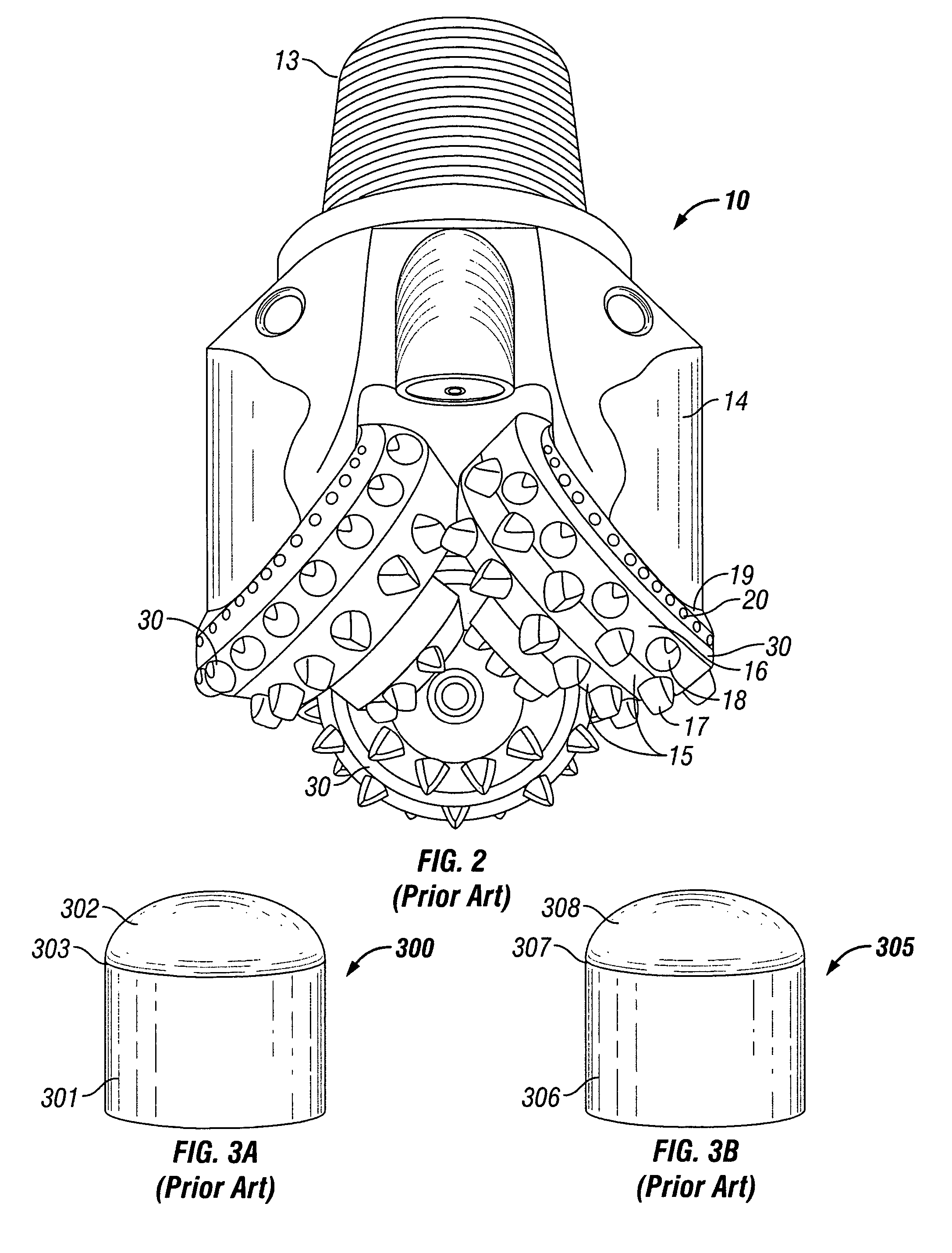

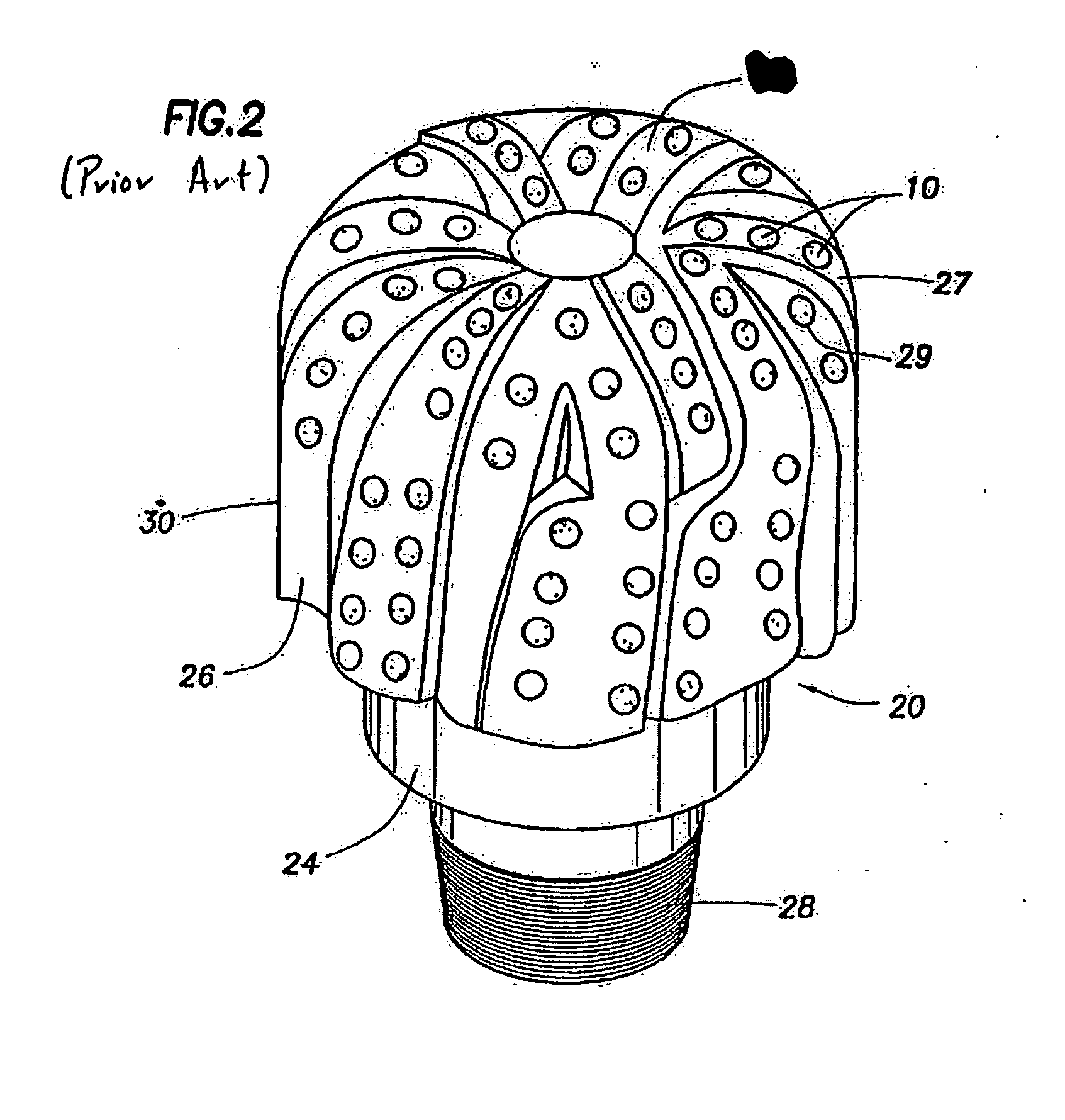

Rolling cutter

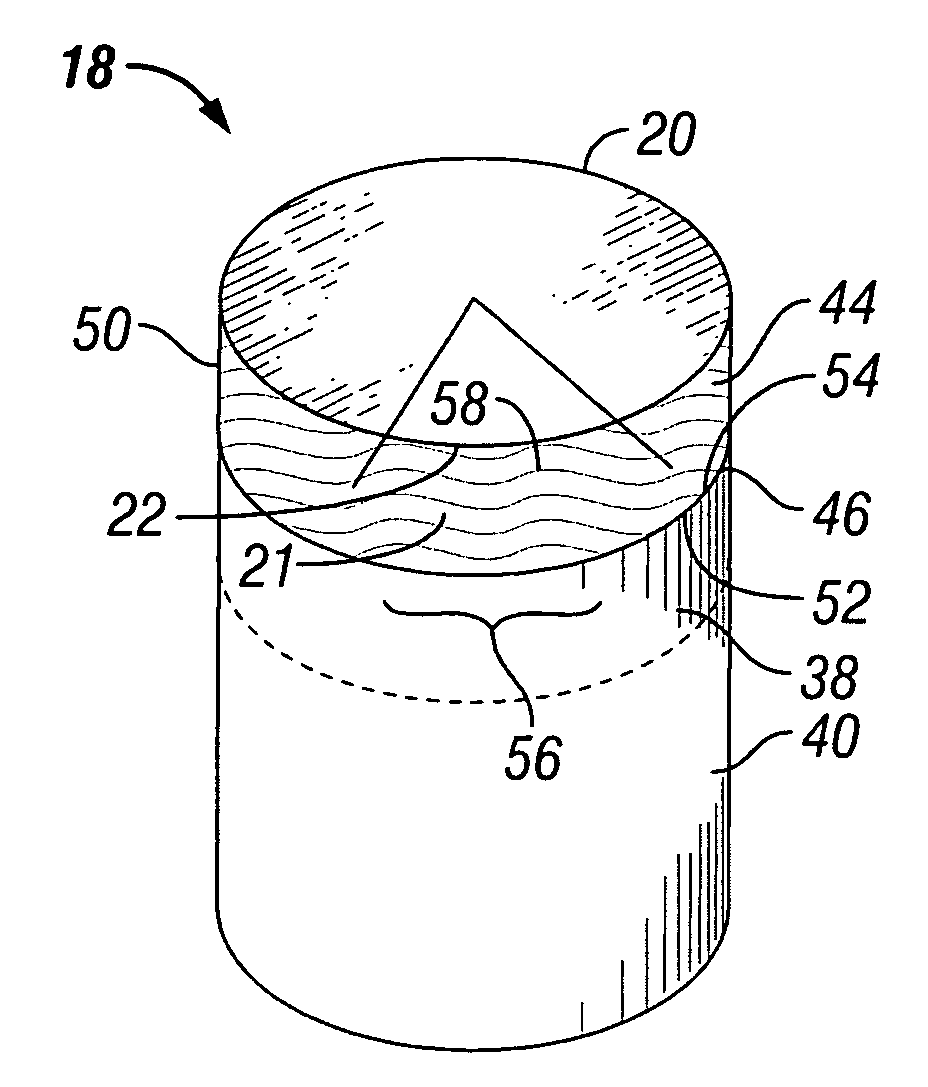

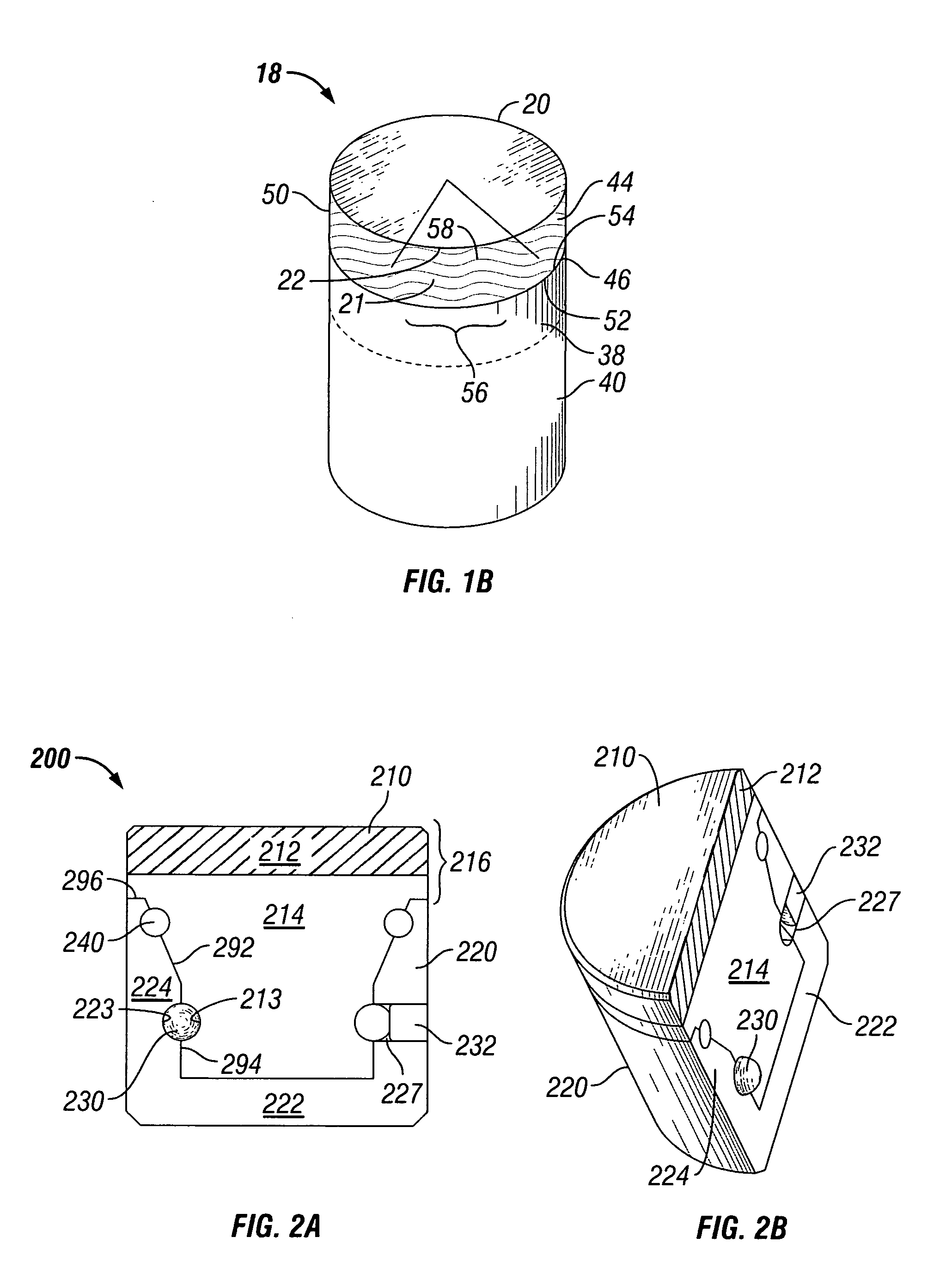

A cutting element for a drill bit that includes an outer support element having at least a bottom portion and a side portion; and an inner rotatable cutting element, a portion of which is disposed in the outer support element, wherin the inner rotatable cutting element includes a substrate and a diamond cutting face having a thickness of at least 0.050 inches disposed on an upper surface of the substrate; and wherein a distance from an upper surface of the diamond cutting face to a bearing surface between the inner rotatable cutting element and the outer support element ranges from 0 to about 0.300 inches is disclosed.

Owner:SMITH INT INC

Rolling cutter

Owner:SMITH INT INC

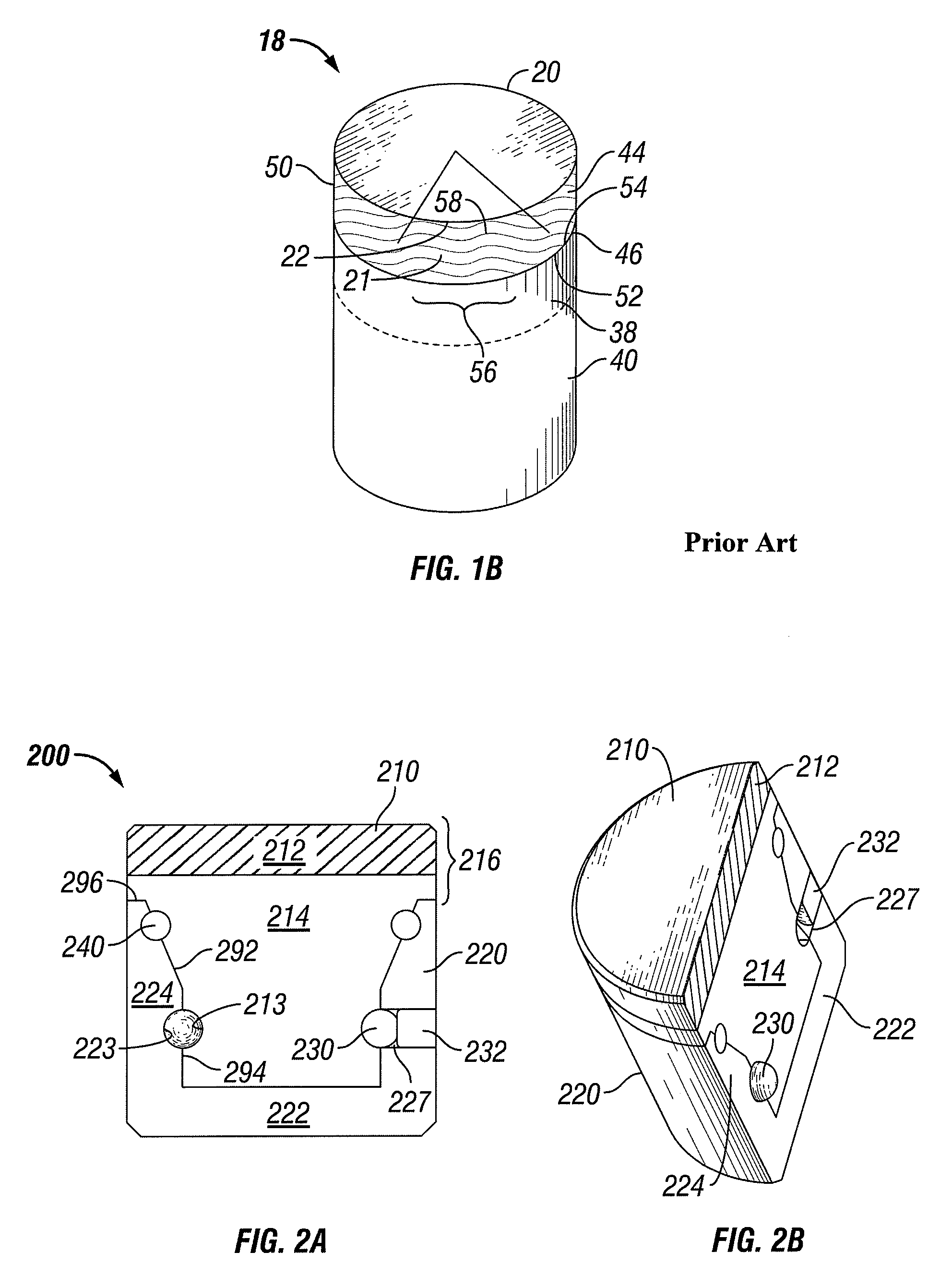

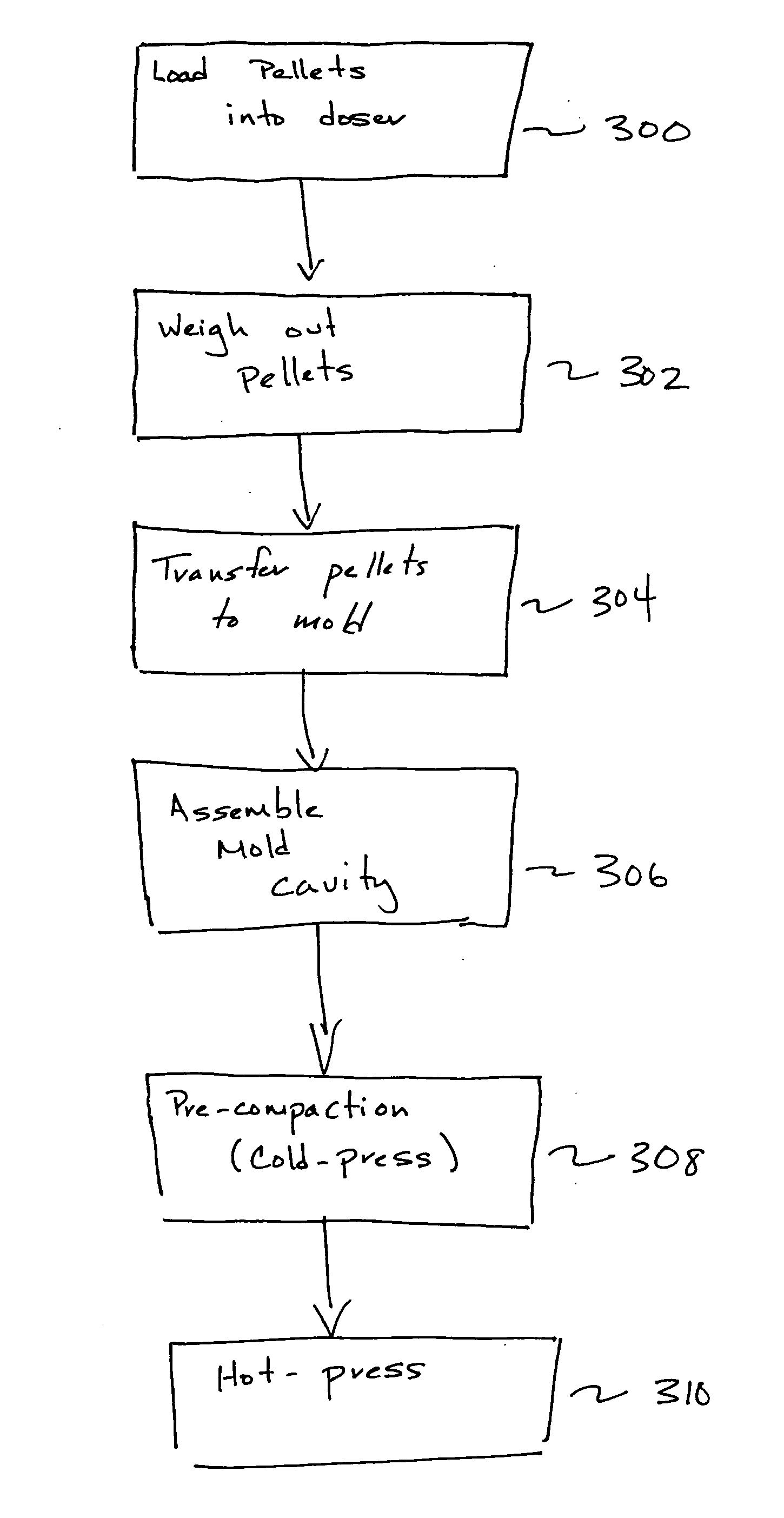

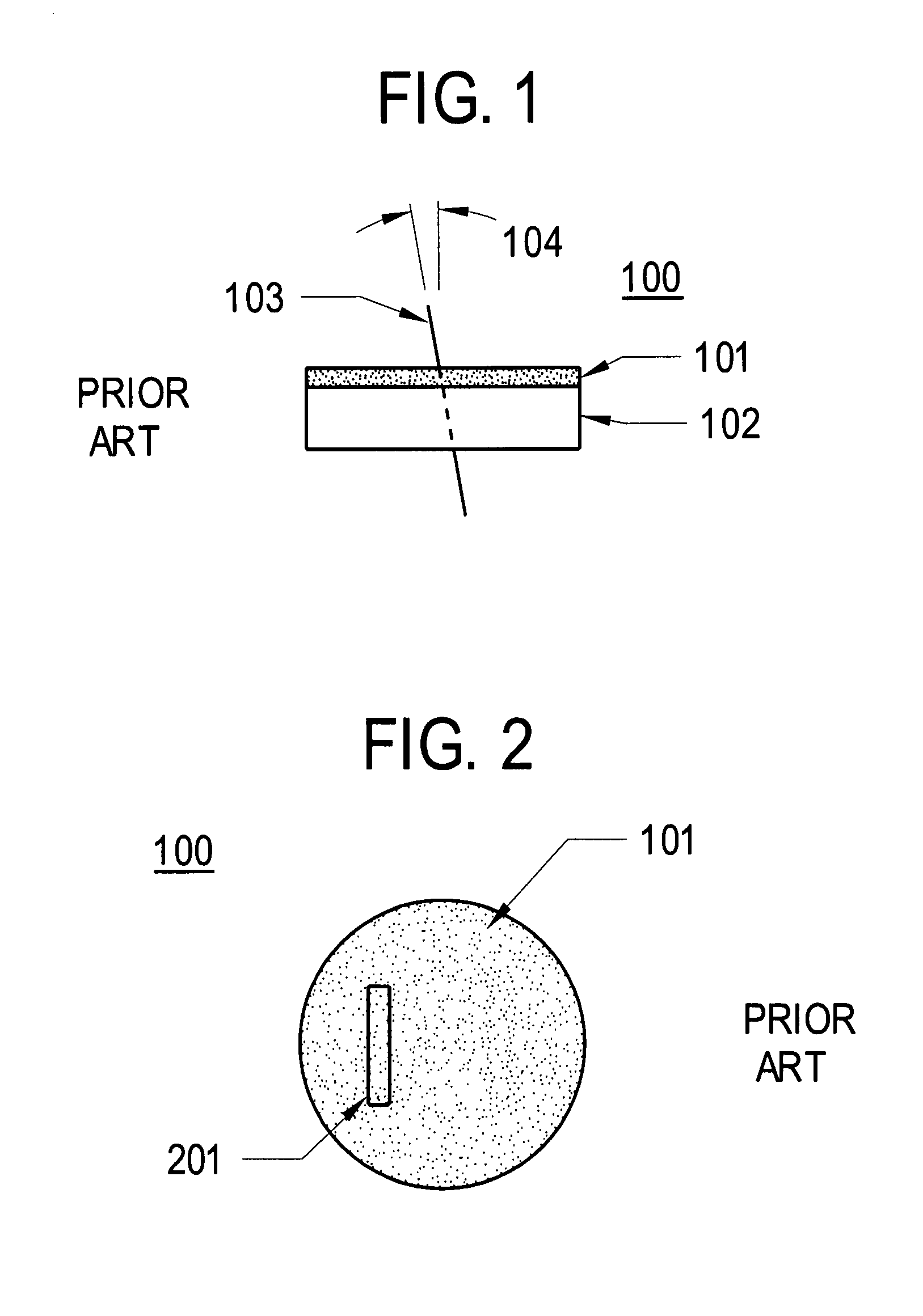

Impregnated diamond cutting structures

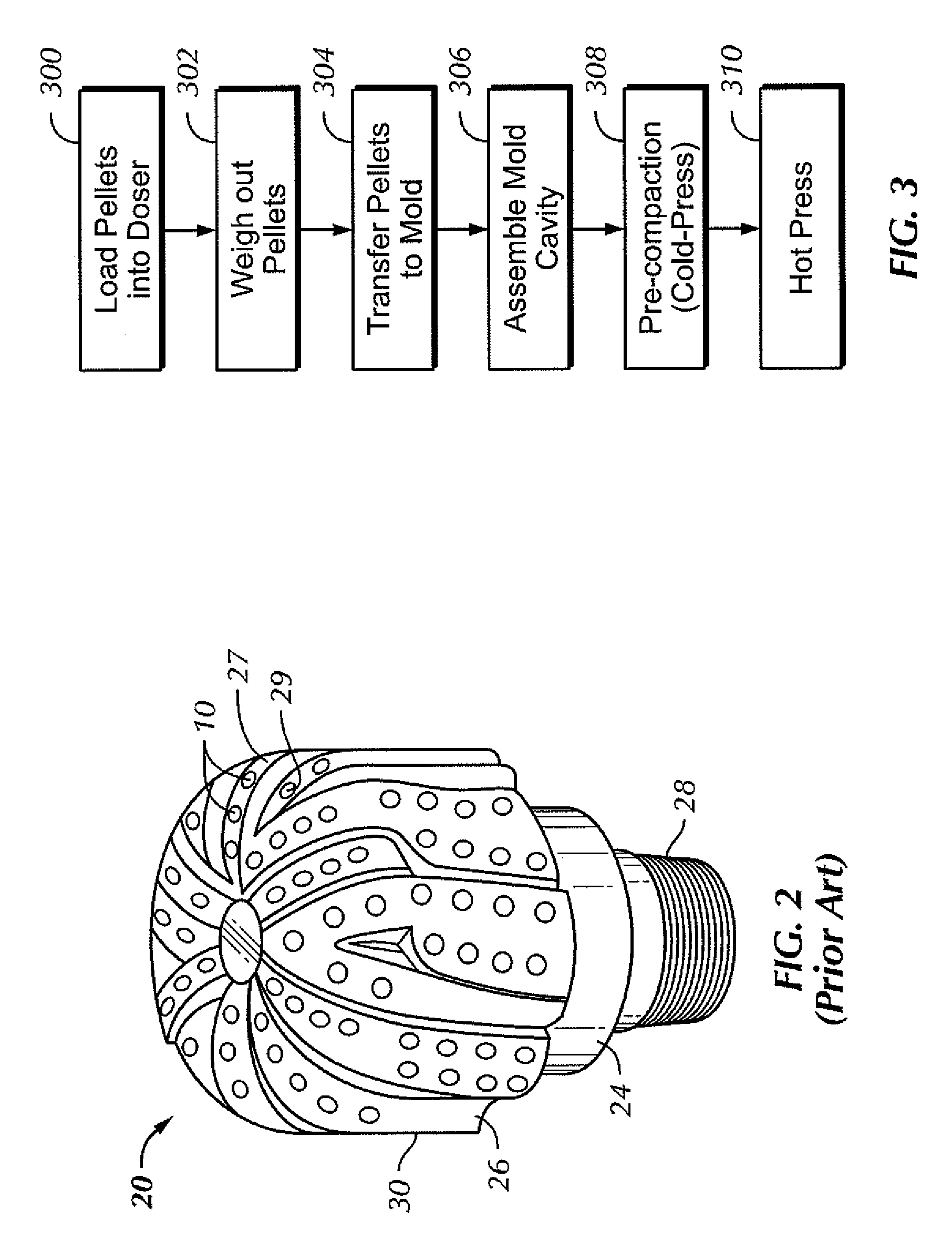

An insert for a drill bit that includes diamond particles disposed in a matrix material, wherein the diamond particles have a contiguity of 15% or less is disclosed. A method of forming a diamond-impregnated cutting structure, that includes loading a plurality of substantially uniformly coated diamond particles into a mold cavity, pre-compacting the substantially uniformly coated diamond particles using a cold-press cycle, and heating the compacted, substantially uniformly coated diamond particles with a matrix material to form the diamond impregnated cutting structure is also disclosed.

Owner:SMITH INT INC

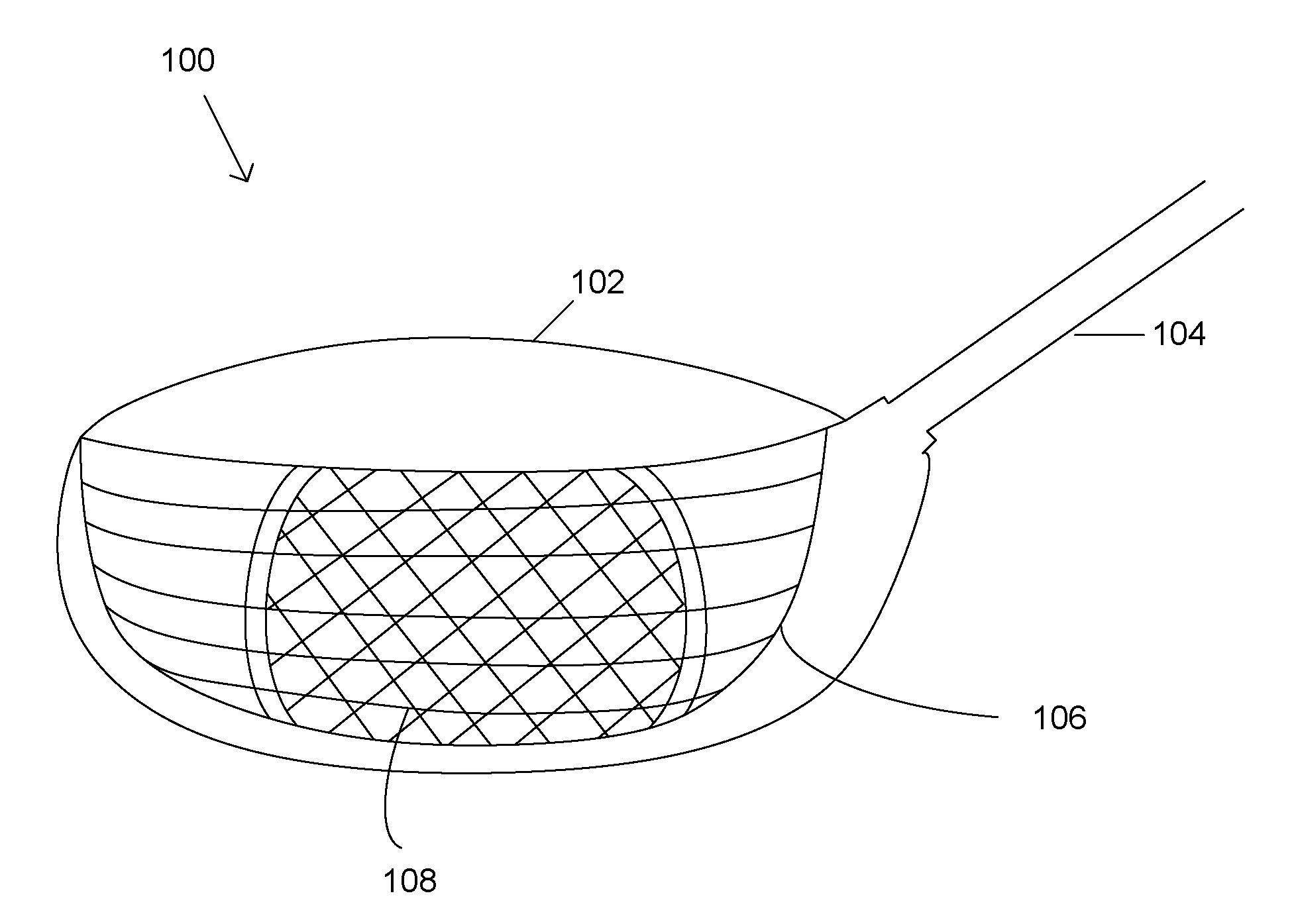

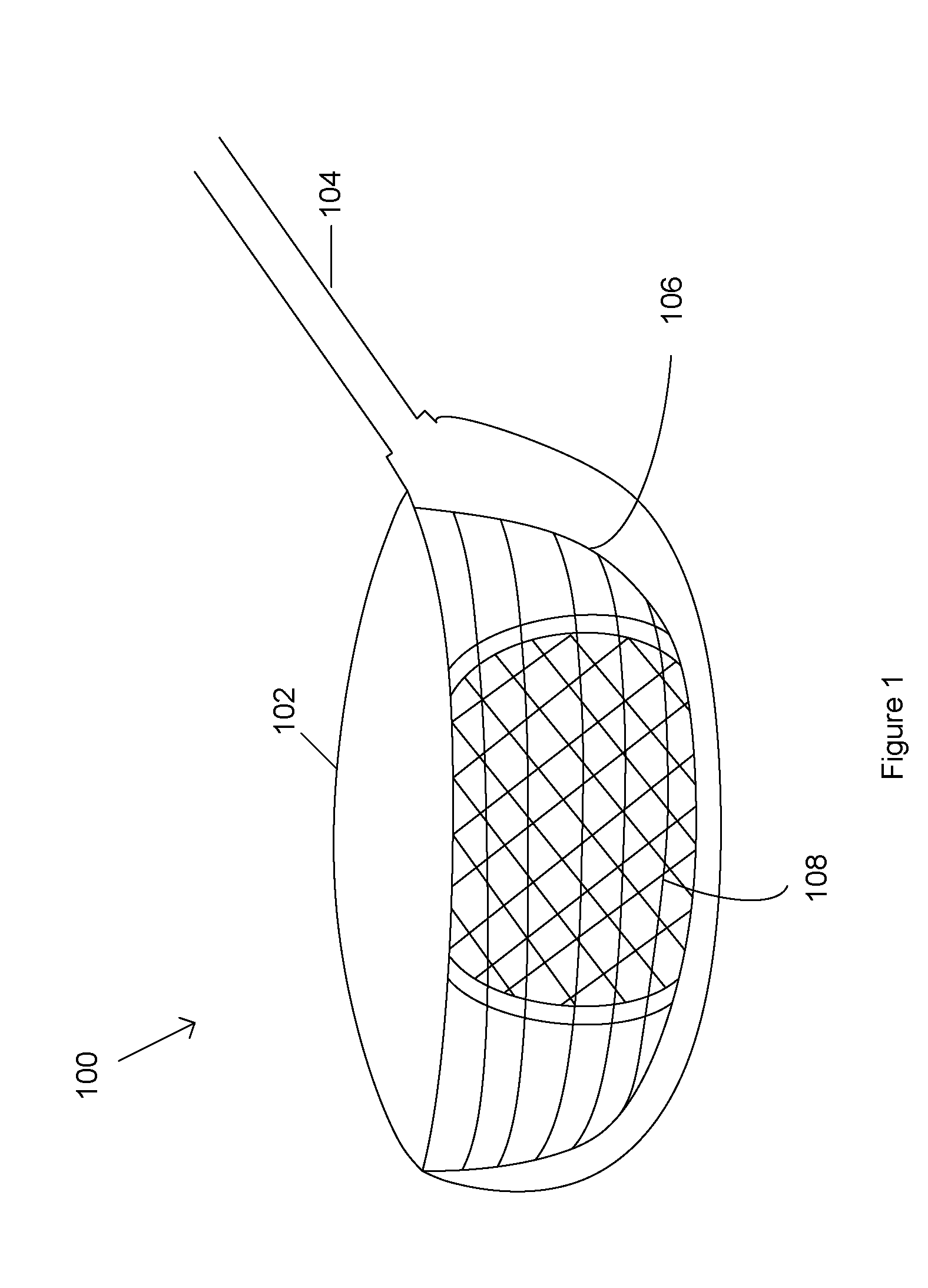

Treatment for the hitting surface of a golf club and a method for applying the same

InactiveUS20080051212A1Prevent slidingGood lookingGolf clubsRacket sportsLaser etchingDiamond cutting

A treatment that can be applied to the face of a golf club head complies with USGA regulations but imparts certain advantageous characteristics. The treatment can comprise a certain pattern and can be imparted to the club head via laser etching, diamond cutting, chemical etching or any other process that will achieve the desired result. In accordance with USGA rules, the treatment must cover the intended area of impact on the golf club face.

Owner:MAX OUT GOLF

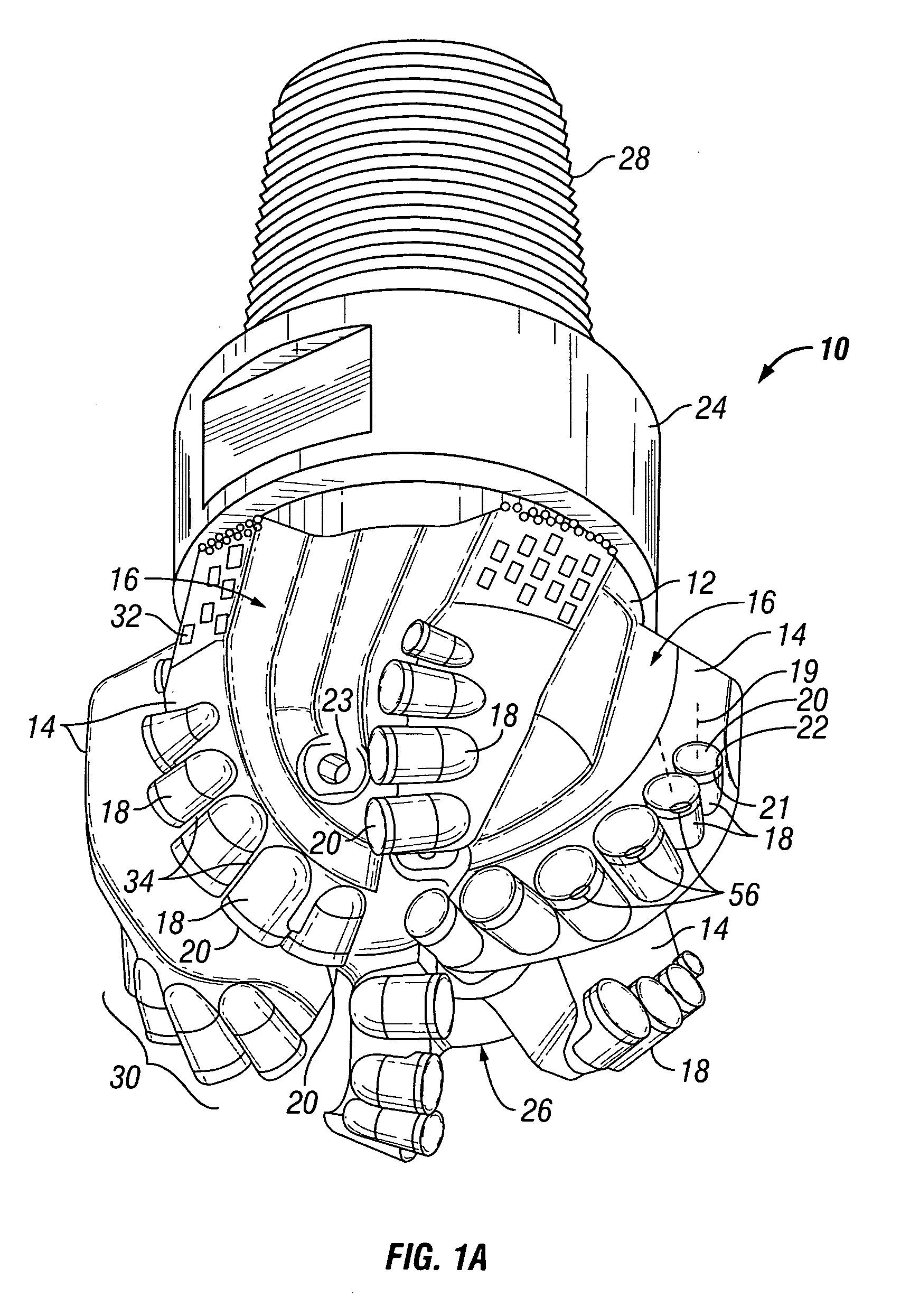

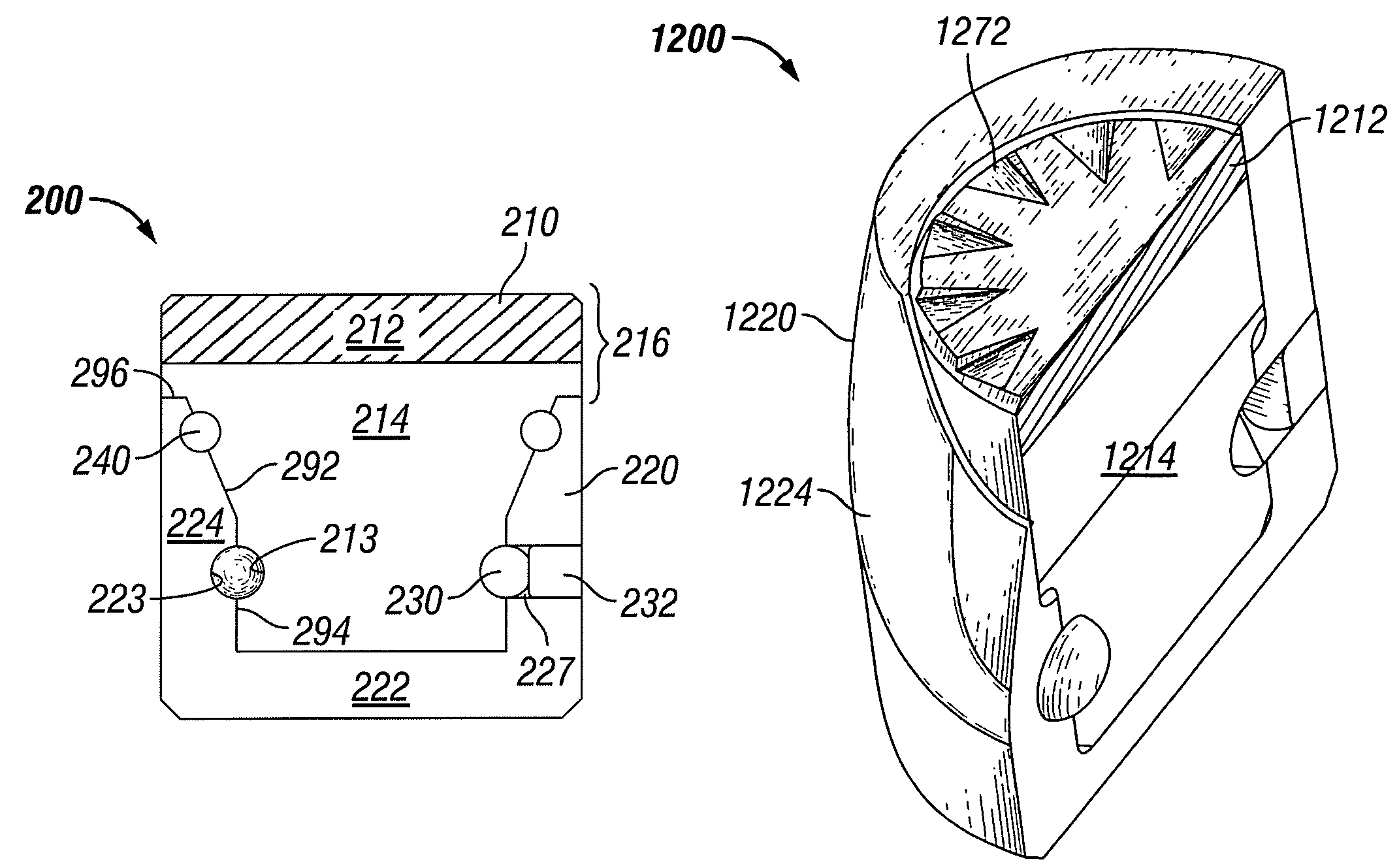

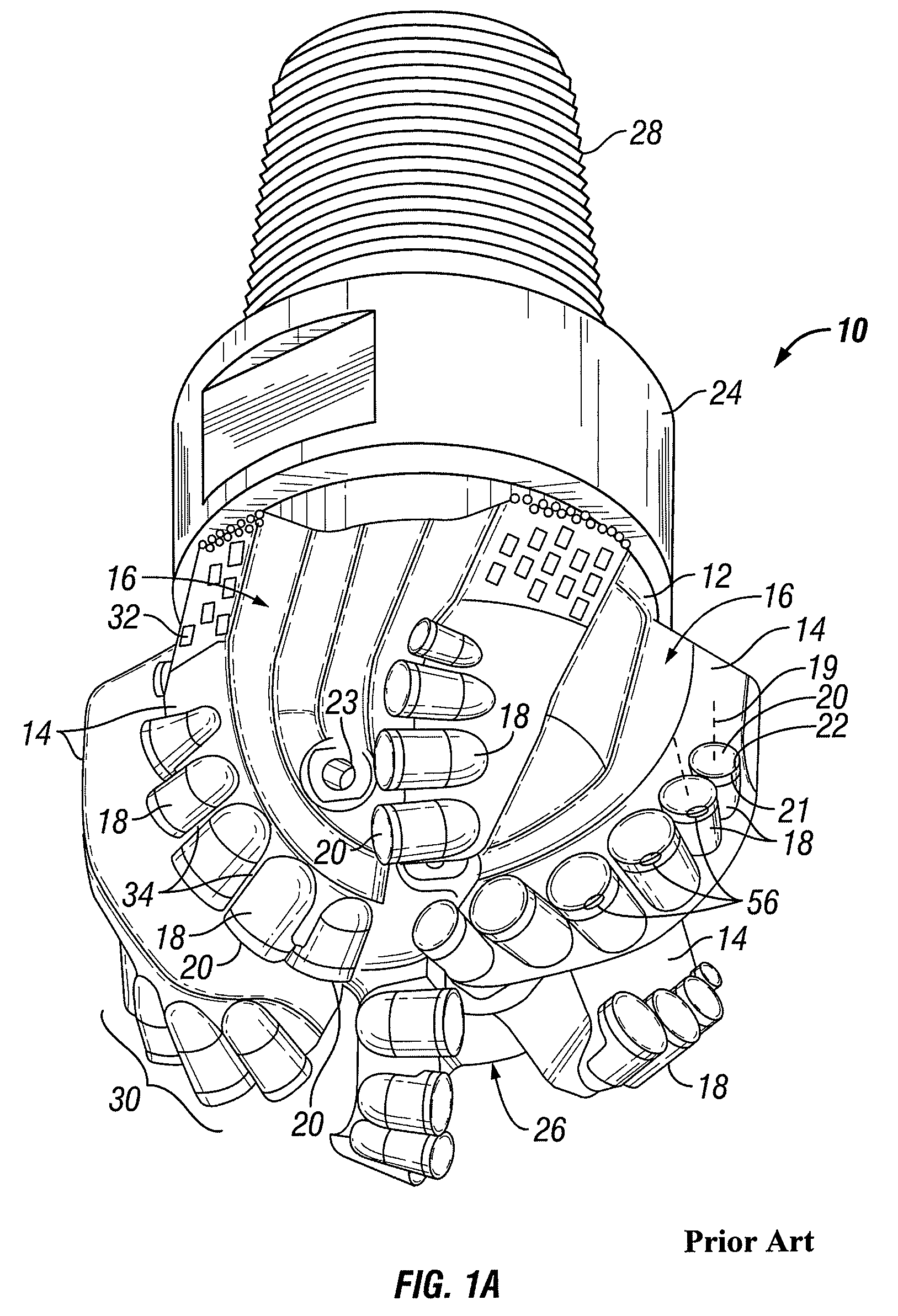

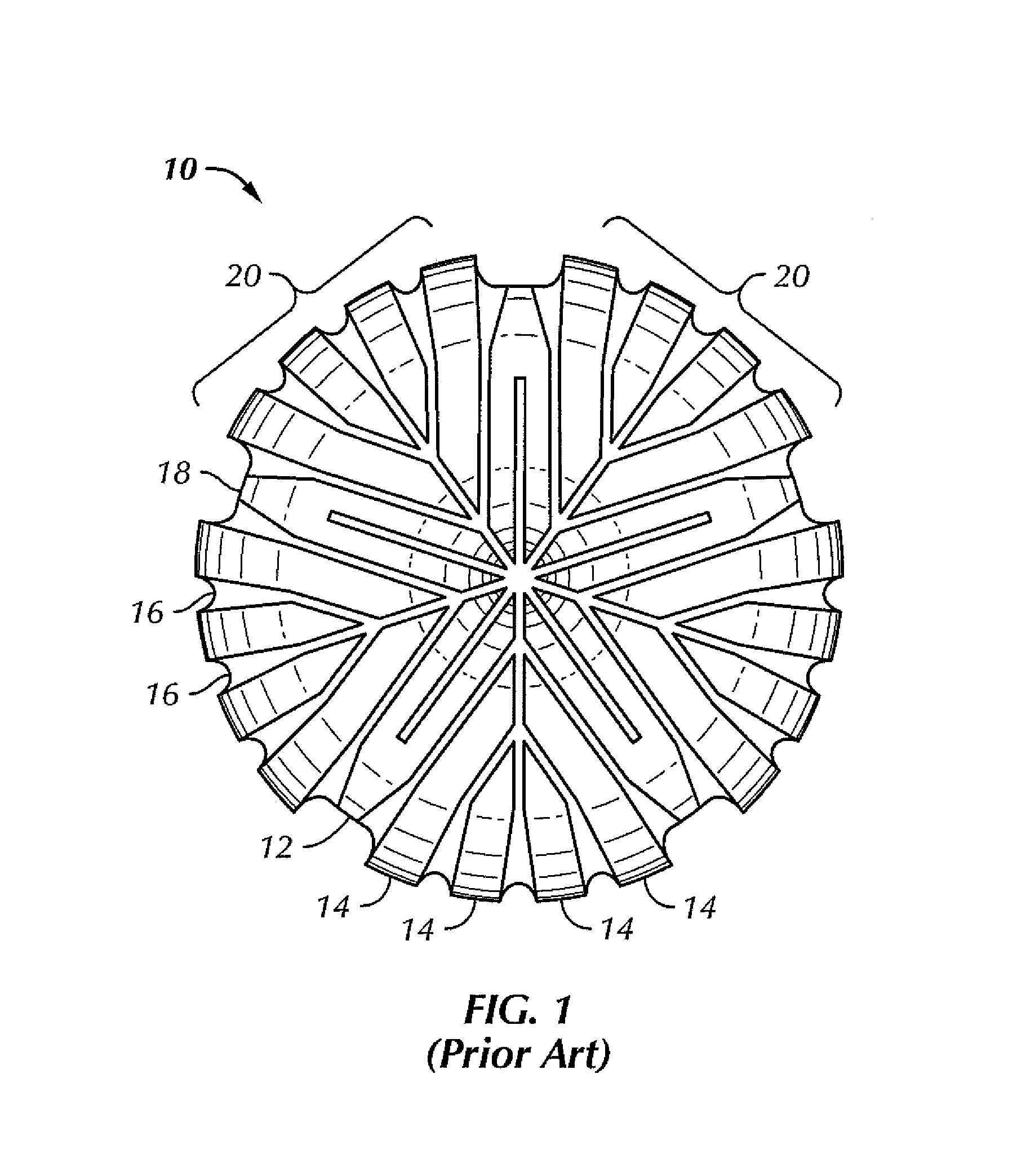

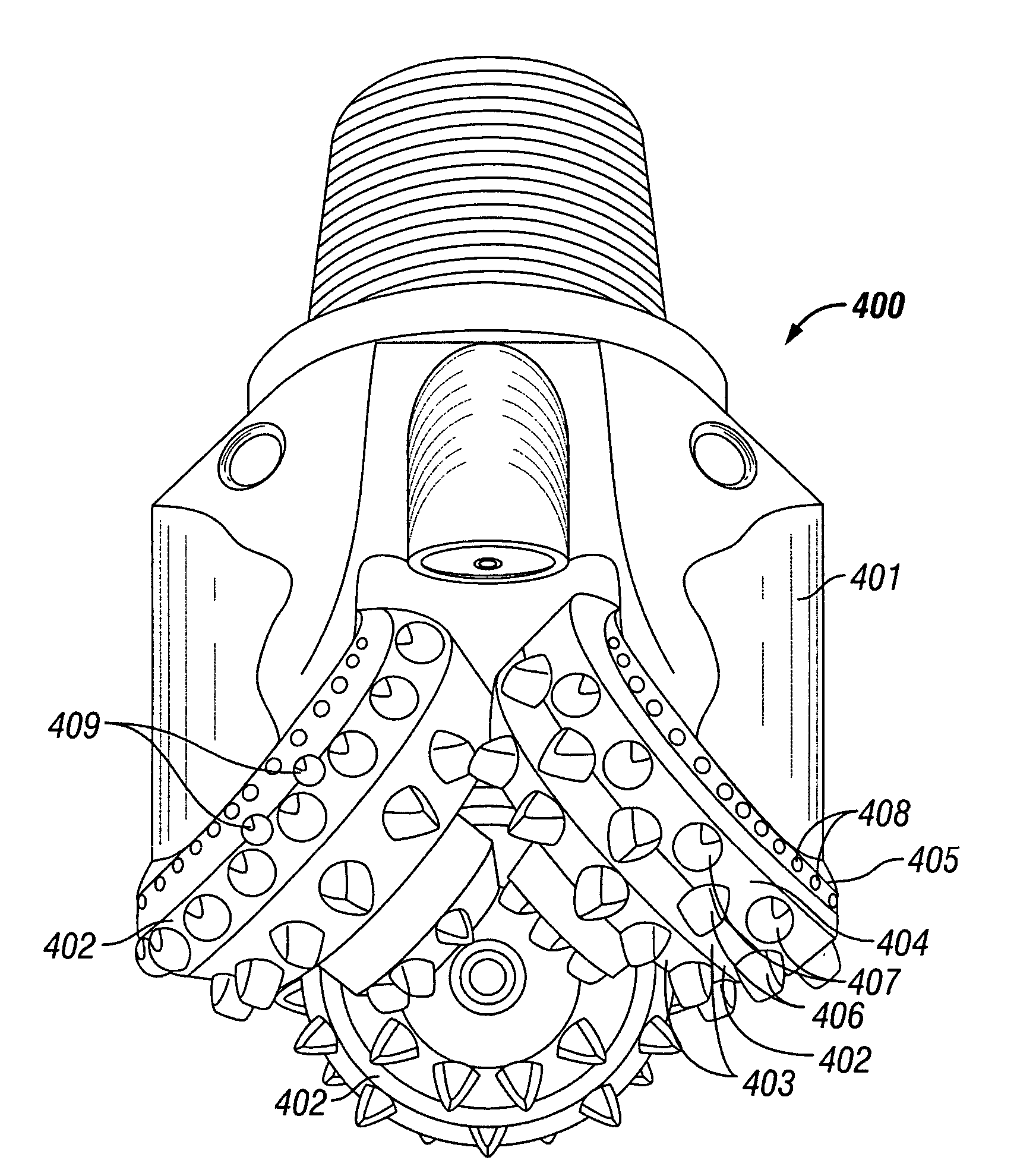

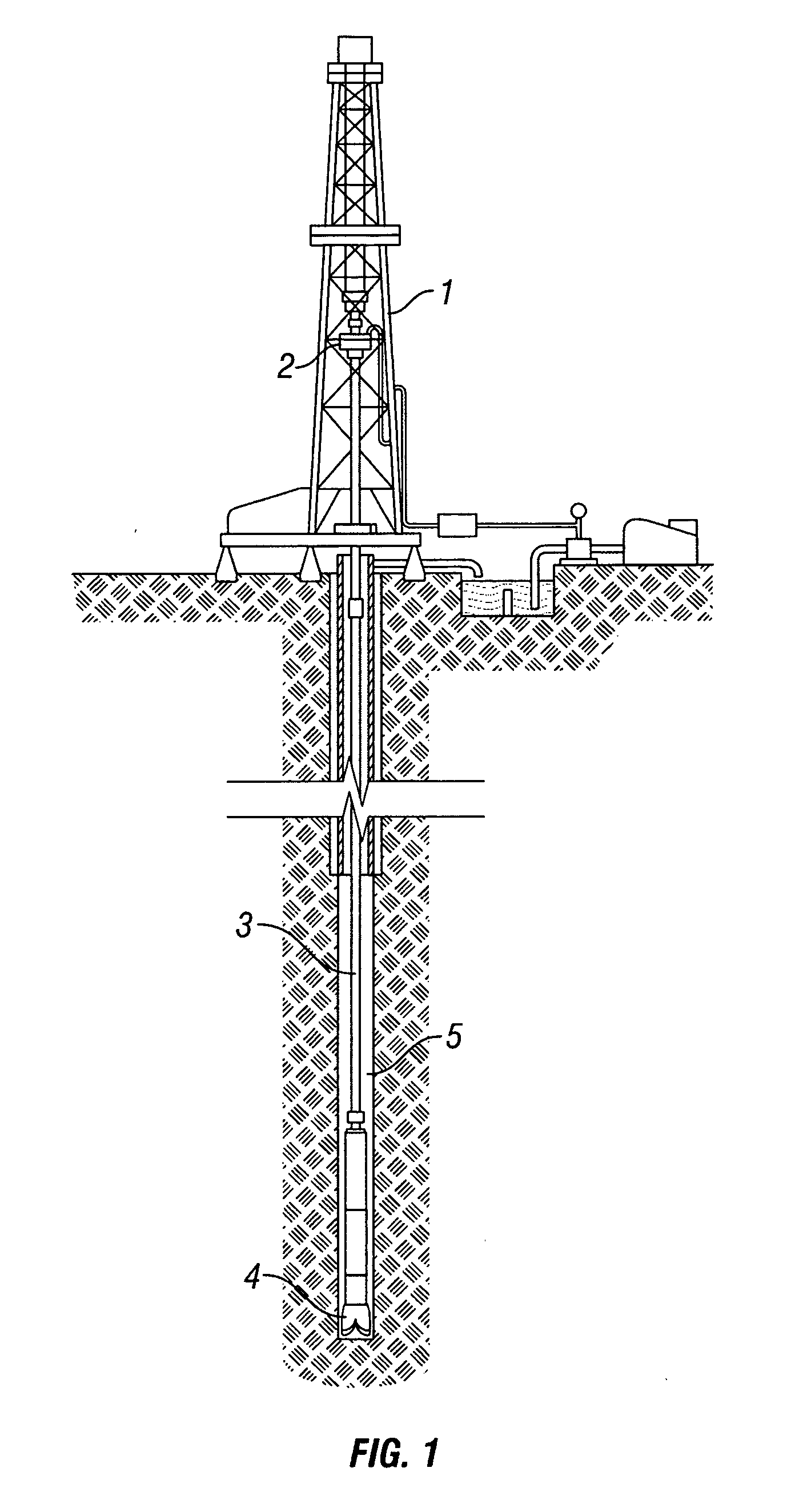

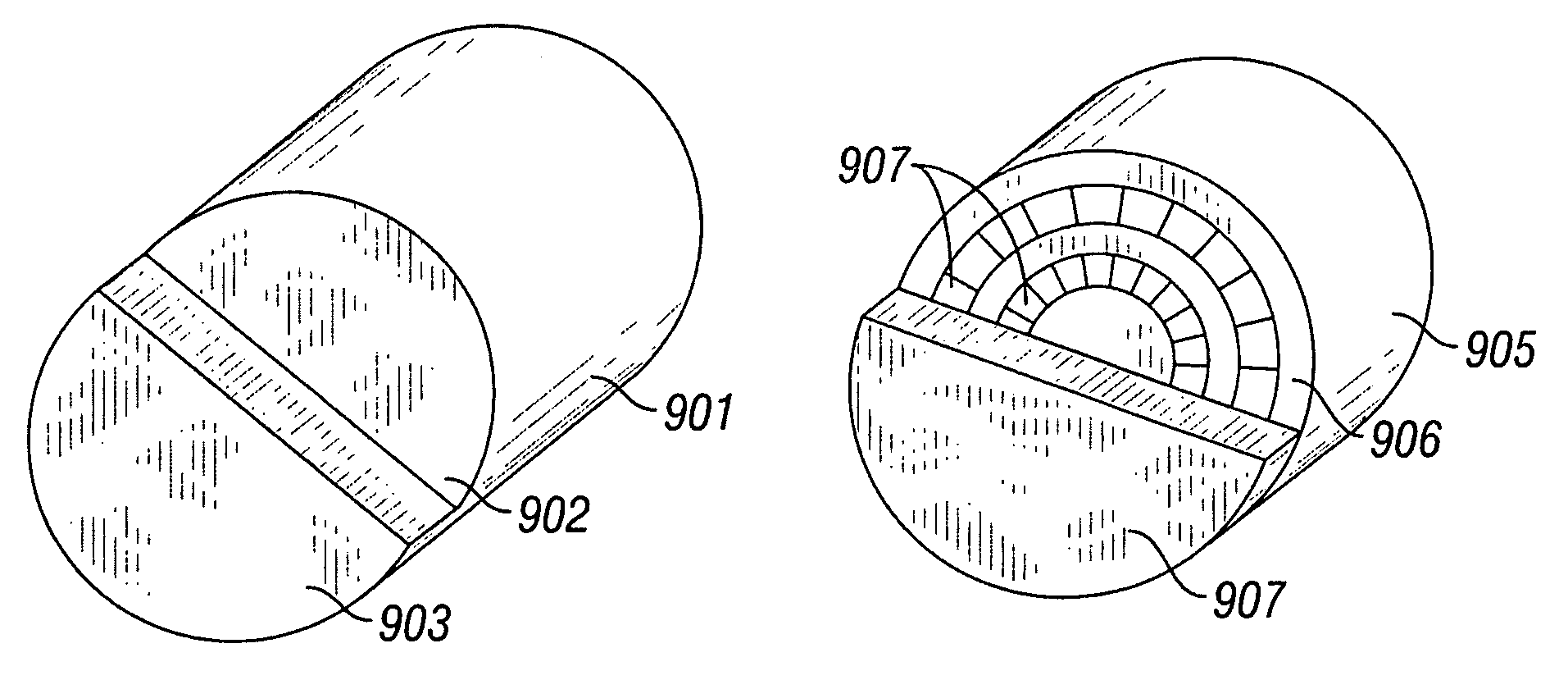

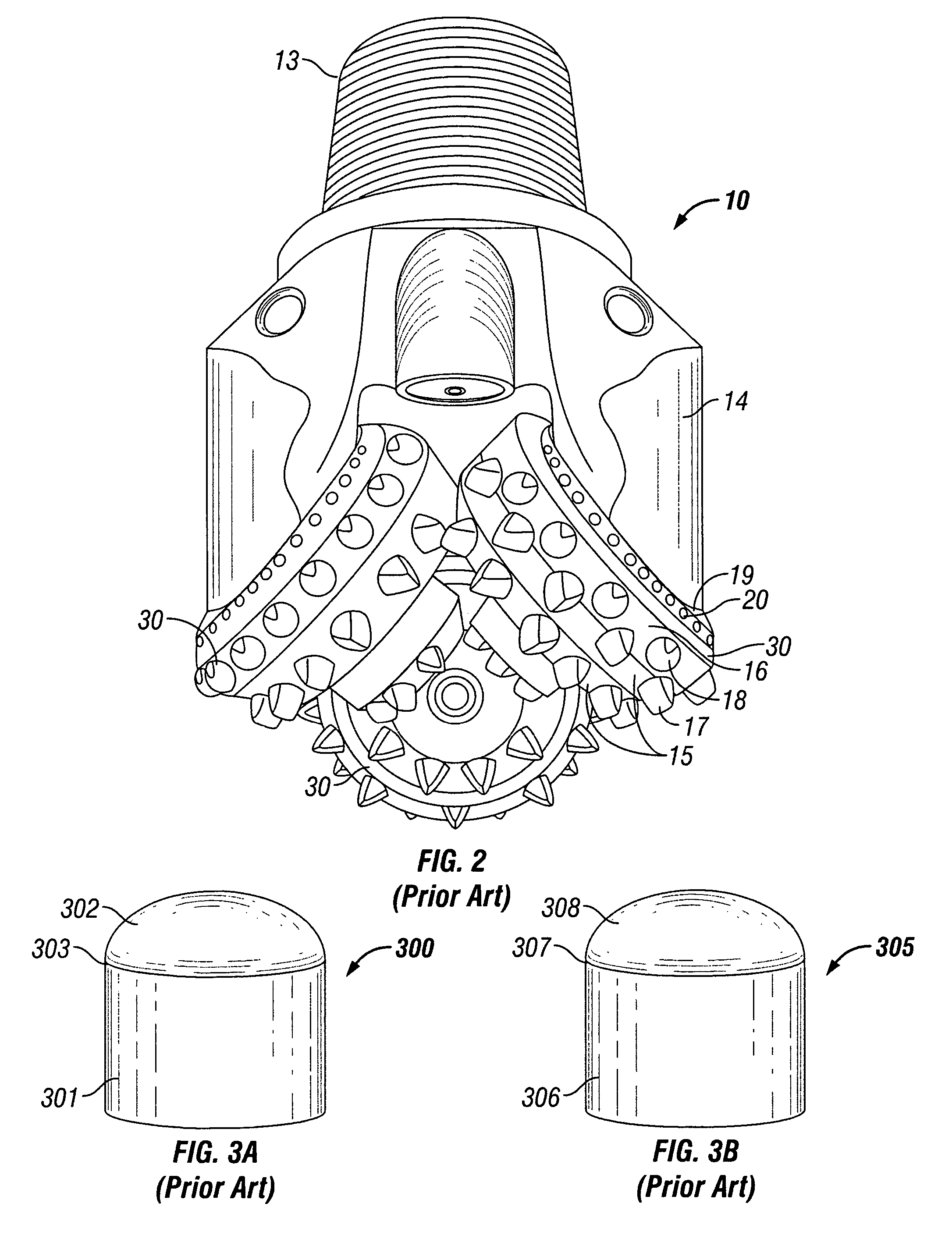

Thermally stable diamond cutting elements in roller cone drill bits

A roller cone drill bit for drilling earth formations includes a bit body having at least one roller cone rotably attached to the bit body and a plurality of cutting elements disposed on the at least one roller cone in a plurality of rows arranged circumferentially around the at least one roller cone, wherein at least one cutting element in the gage row, the heel row, or a surface of the at least one roller cone bounded by the gage and heel rows comprises thermally stable polycrystalline diamond or a thermally stable polycrystalline diamond composite. The at least one cutting element may be a TSD insert or a TSD composite insert and may be formed by brazing, sintering, or bonding by other technologies known in the art a thermally stable polycrystalline diamond table to a substrate. The interface between the diamond table and the substrate may be non-planar. A roller cone drill bit includes a bit body, at least one roller cone rotably attached to the bit body, and a plurality of cutting elements disposed on the at least one roller cone, where at least one of the plurality of cutting elements comprises thermally stable polycrystalline diamond or a thermally stable polycrystalline diamond composite and a cutting surface, wherein at least a portion of the cutting surface is contoured.

Owner:SMITH INT INC

Impregnated diamond cutting structures

An insert for a drill bit that includes diamond particles disposed in a matrix material, wherein the diamond particles have a contiguity of 15% or less is disclosed. A method of forming a diamond-impregnated cutting structure, that includes loading a plurality of substantially uniformly coated diamond particles into a mold cavity, pre-compacting the substantially uniformly coated diamond particles using a cold-press cycle, and heating the compacted, substantially uniformly coated diamond particles with a matrix material to form the diamond impregnated cutting structure is also disclosed.

Owner:SMITH INT INC

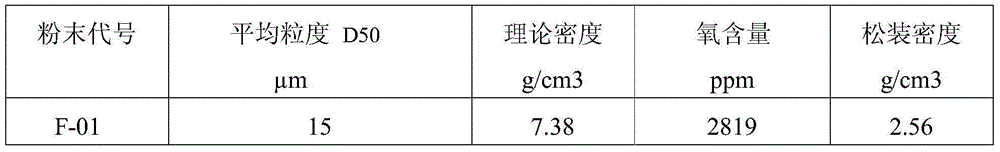

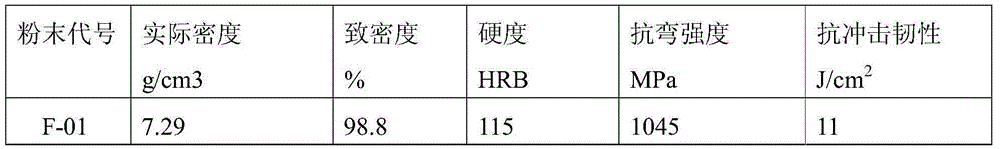

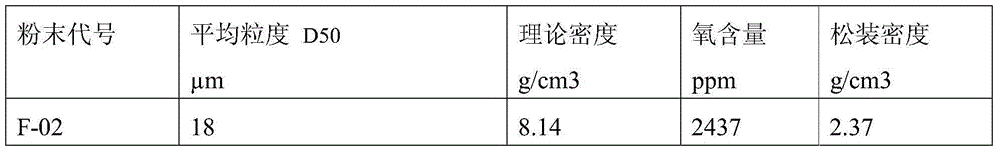

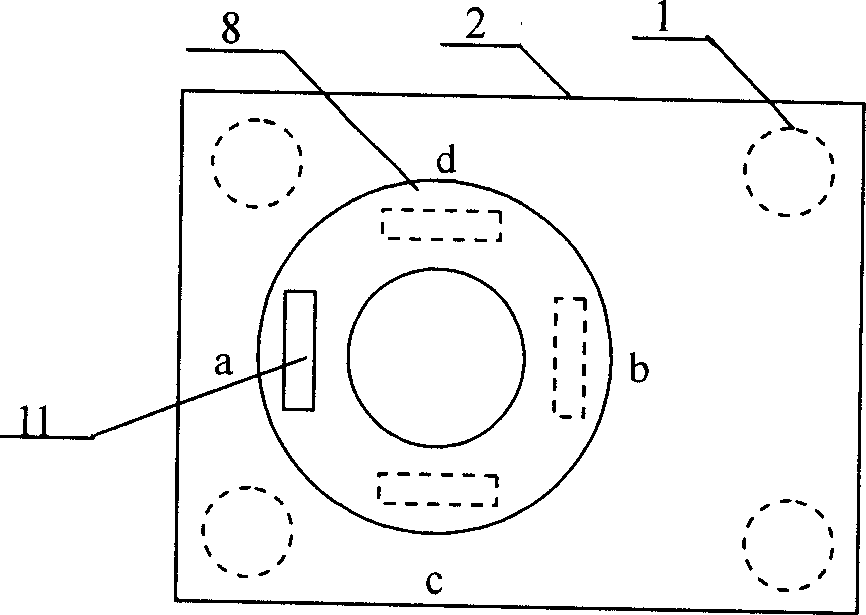

Circular diamond saw blade bit and manufacturing method thereof

The invention discloses a circular diamond saw blade bit and a manufacturing method thereof. The circular diamond saw blade bit is made of diamond particles and matrix powder used for consolidation of the diamond particles. The matrix powder comprises, by mass percent, 40%-80% of Fe, 15%-30% of Cu, 0%-10% of Ni, 2%-8% of Sn, 0%-10% of Co, 0%-5% of Me and the balance inevitable impurities. Me is at least one of Mn, Ti, Si, Cr, P and Al. The manufacturing method comprises the steps of mixing raw materials, conducting cold-press molding and free sintering. The manufacturing method is simple and can effectively avoid the loss of a graphite mould and reduce manufacturing cost. Meanwhile, a volume production requirement can be met, and blade bits in complicated shapes can be produced; production efficiency is prolonged, and the service life of the tool is similar to that of a tool manufactured through a hot-press sintering method; the purpose that high-quality diamond cutting tools are produced under the condition of low cost can be achieved; and the circular diamond saw blade bit and a manufacturing method thereof are easy to popularize in an industrialized manner.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

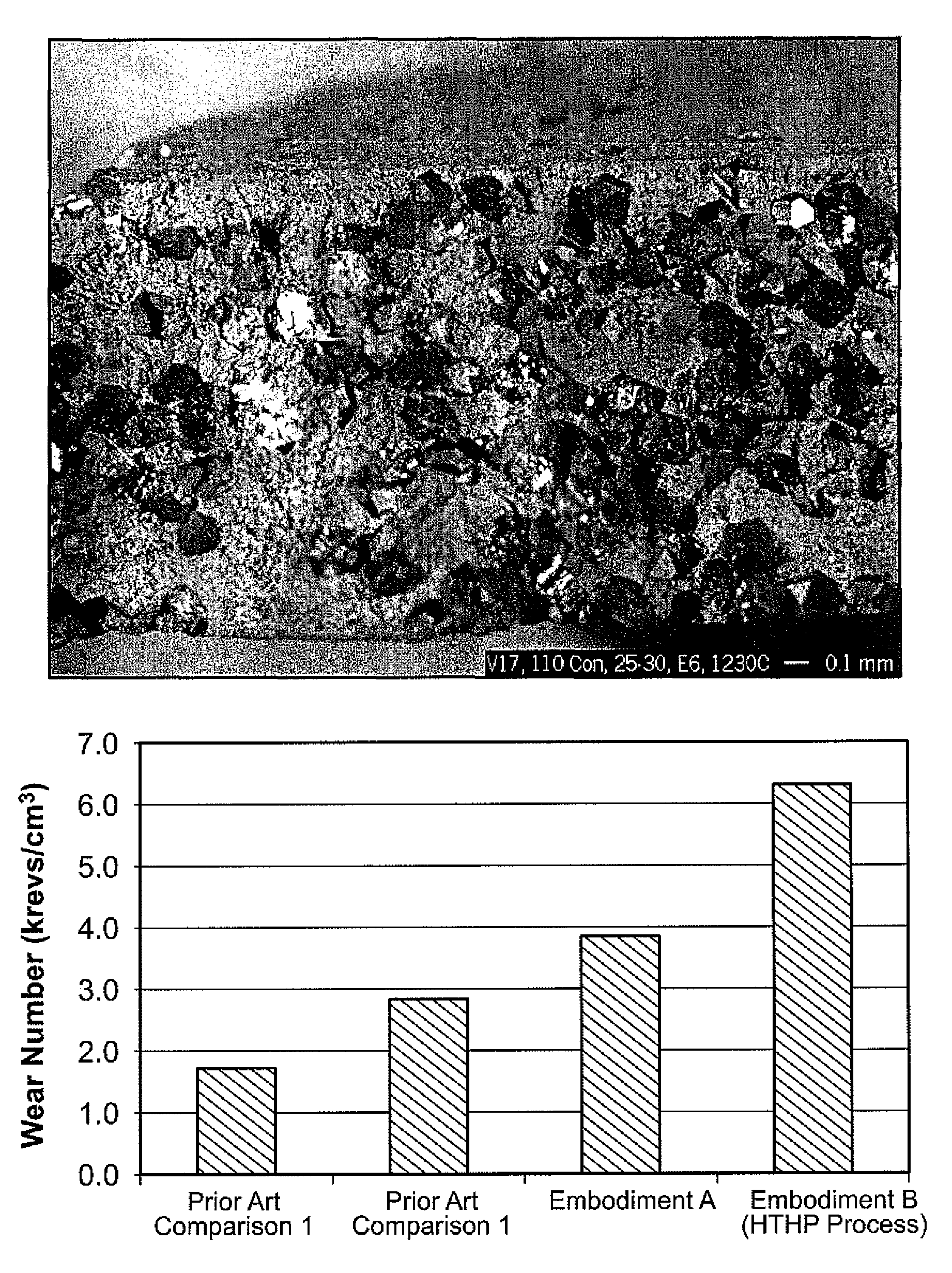

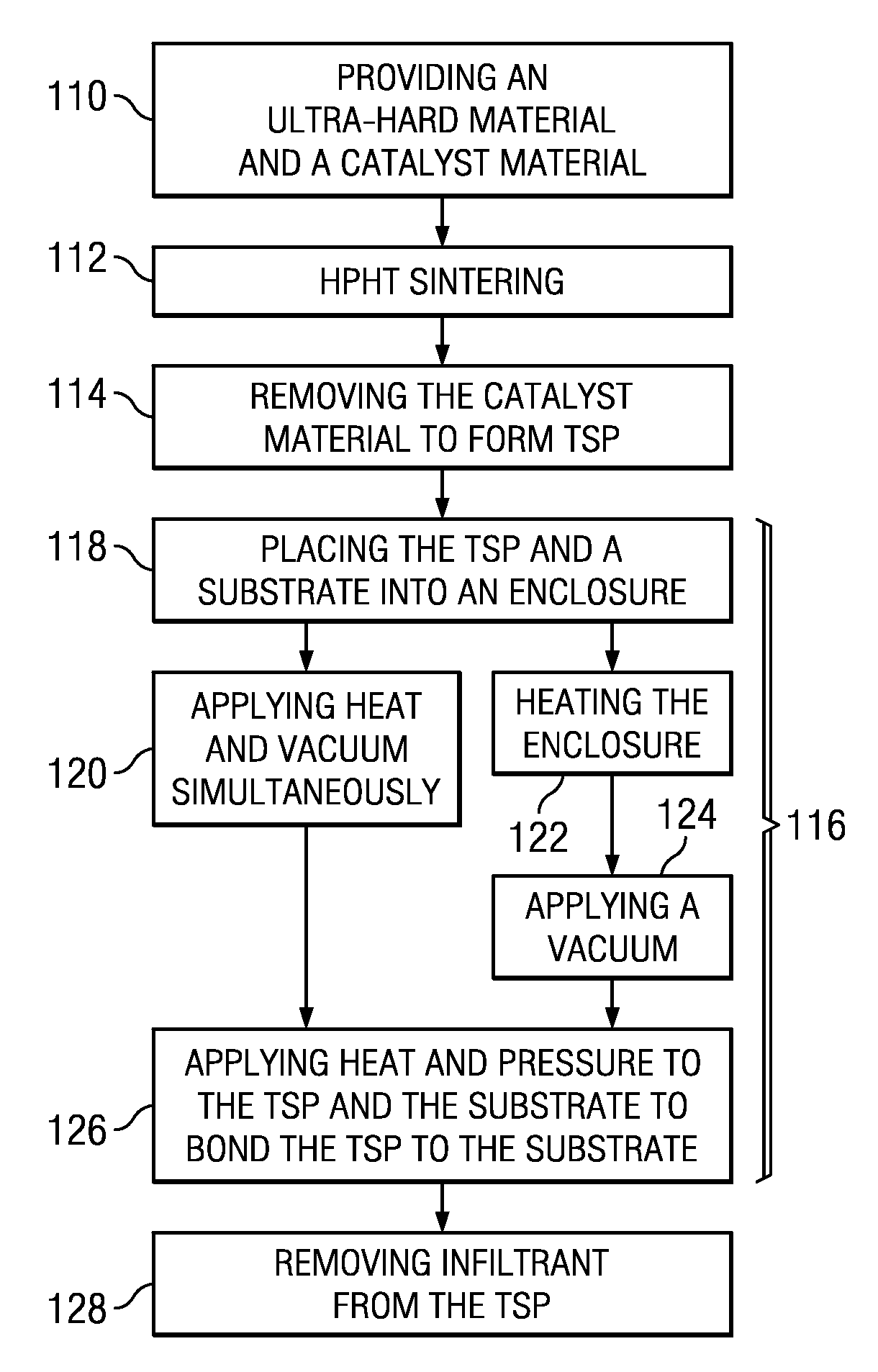

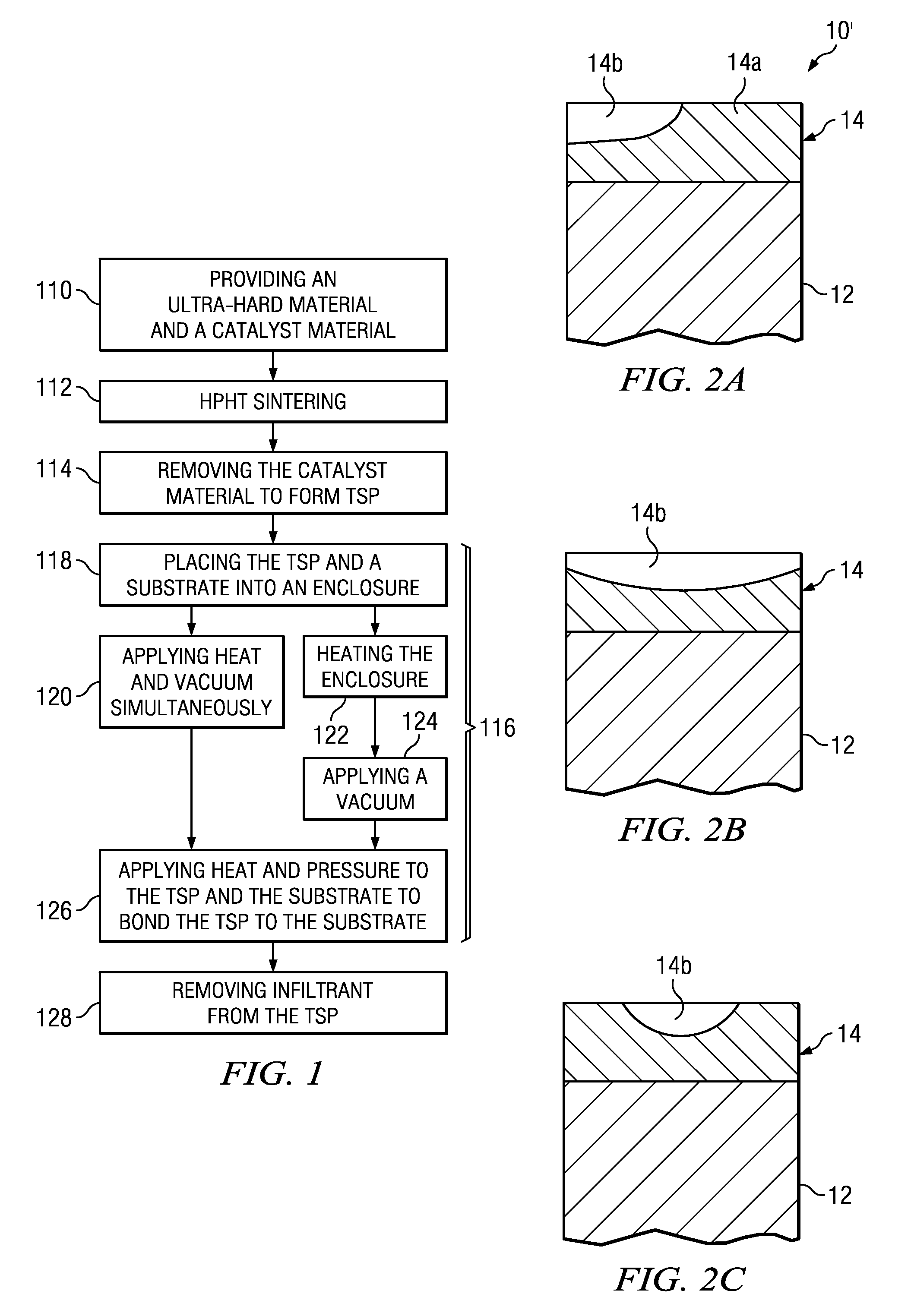

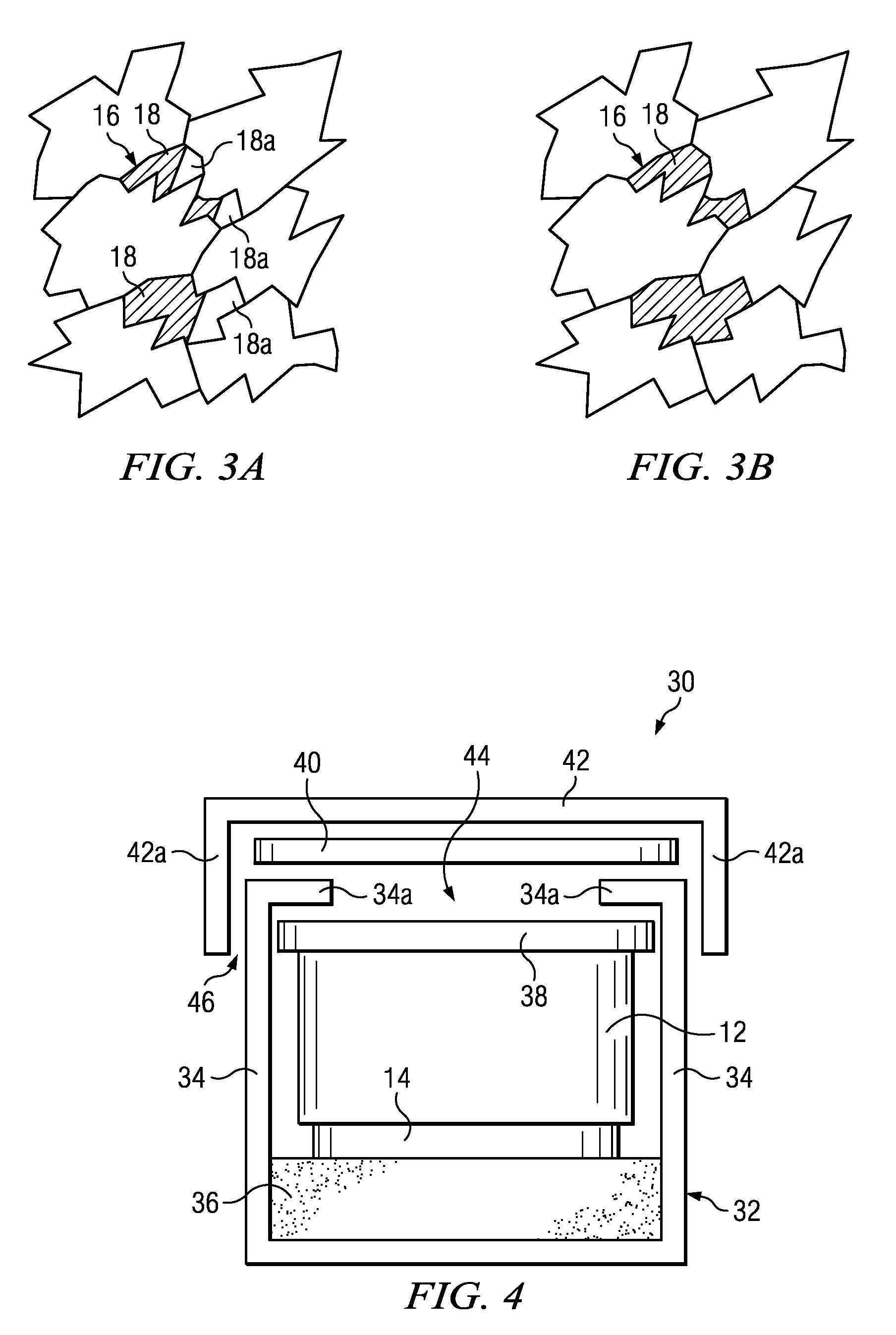

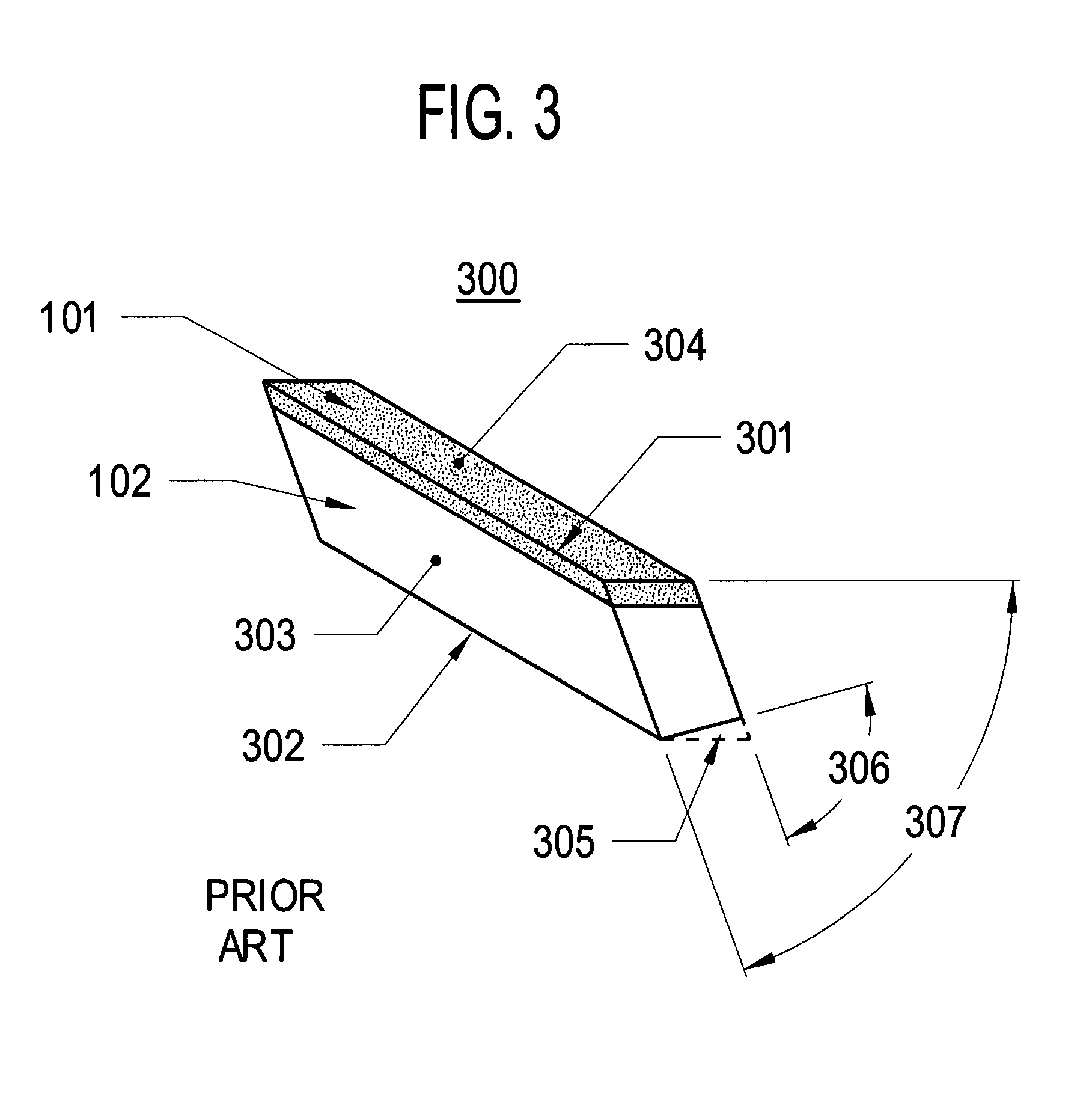

Method of forming a thermally stable diamond cutting element

InactiveUS20110030283A1Improve thermal characteristicsReduce thermal stressPressurized chemical processOther chemical processesDiamond cuttingDiamond crystal

In one aspect, a vacuum-sealed can is used during the bonding process to improve the properties of an infiltrated TSP cutting element. In one embodiment, ultra hard diamond crystals and a catalyst material are sintered to form a polycrystalline diamond material (PCD). This PCD material is leached to remove the catalyst, forming a thermally stable product (TSP). The TSP material and a substrate are placed into an enclosure such as a can assembly, heated, and subjected to a vacuum in order to remove gas, moisture and other residuals that can inhibit infiltration of the infiltrant into the TSP layer. The can assembly is then subjected to high temperature, high pressure bonding to bond the TSP material to the substrate. During bonding, material from the substrate infiltrates the TSP layer.

Owner:SMITH INT INC

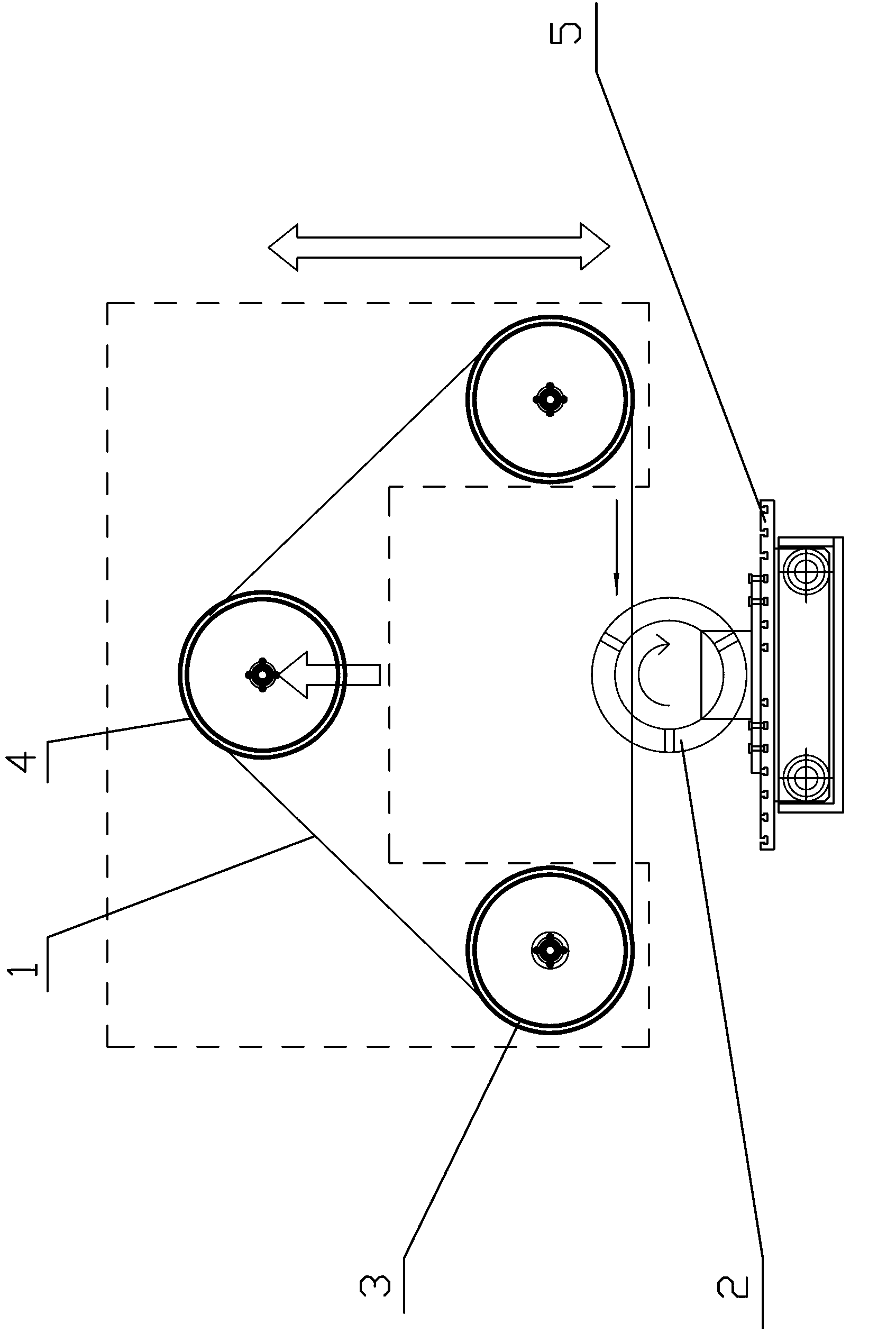

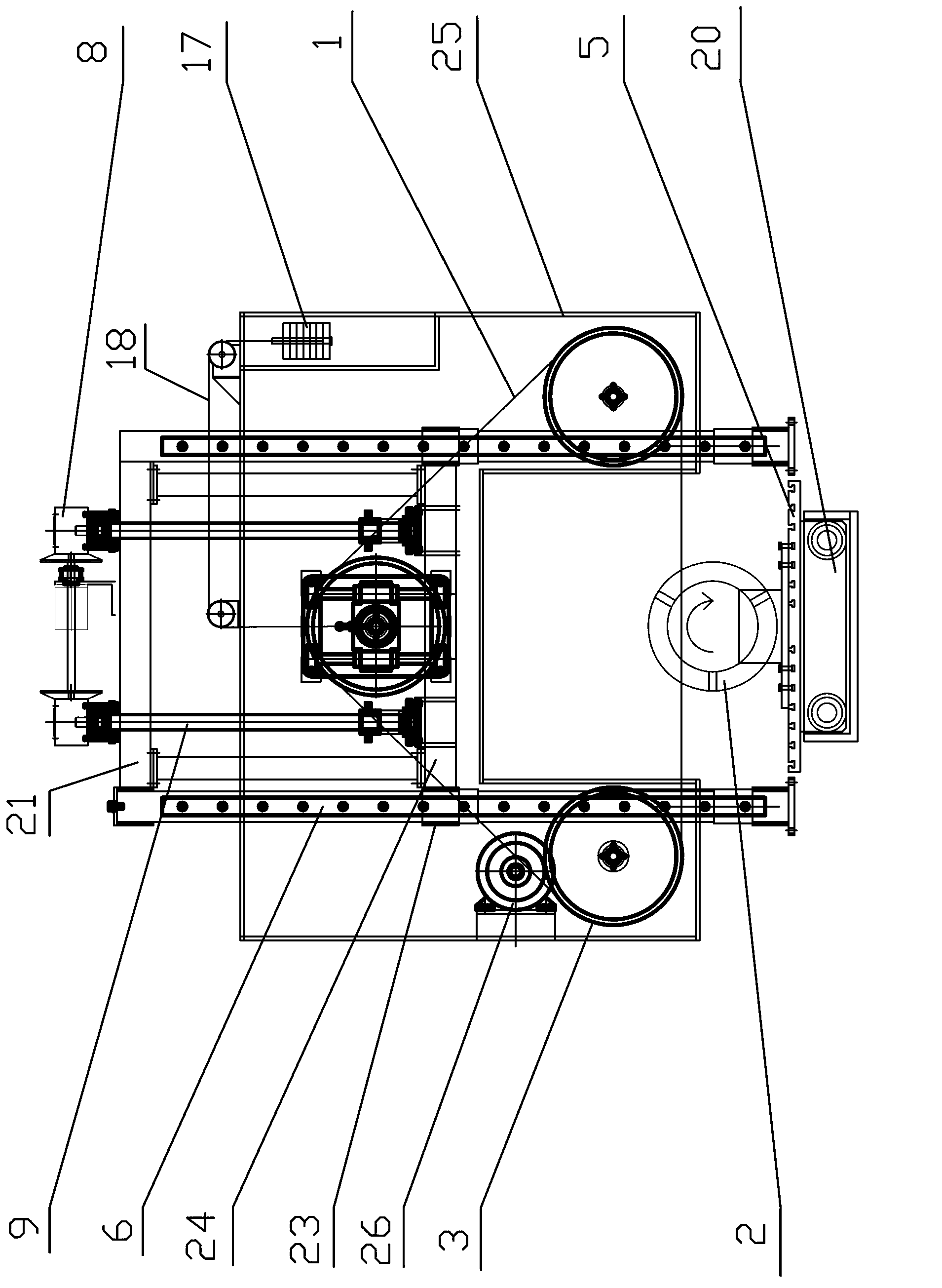

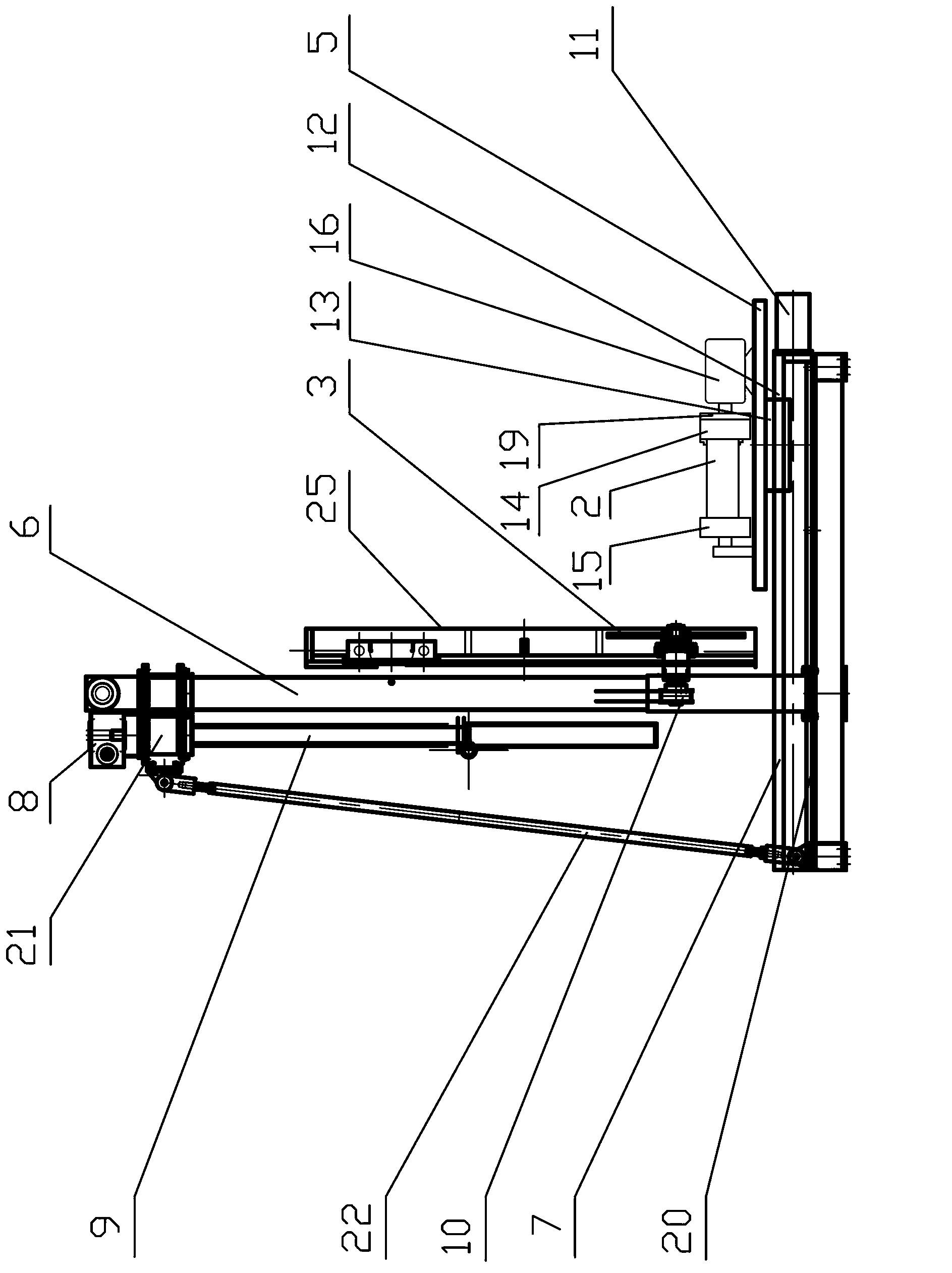

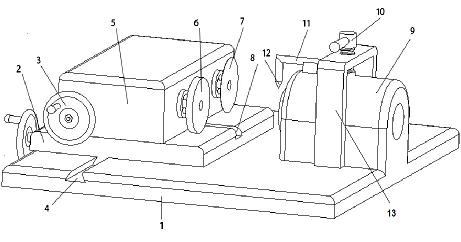

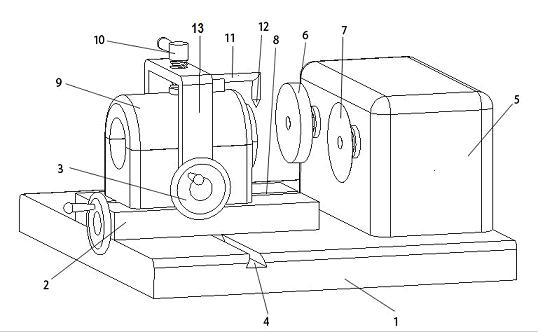

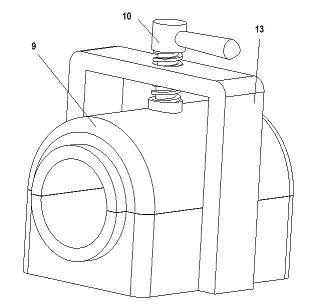

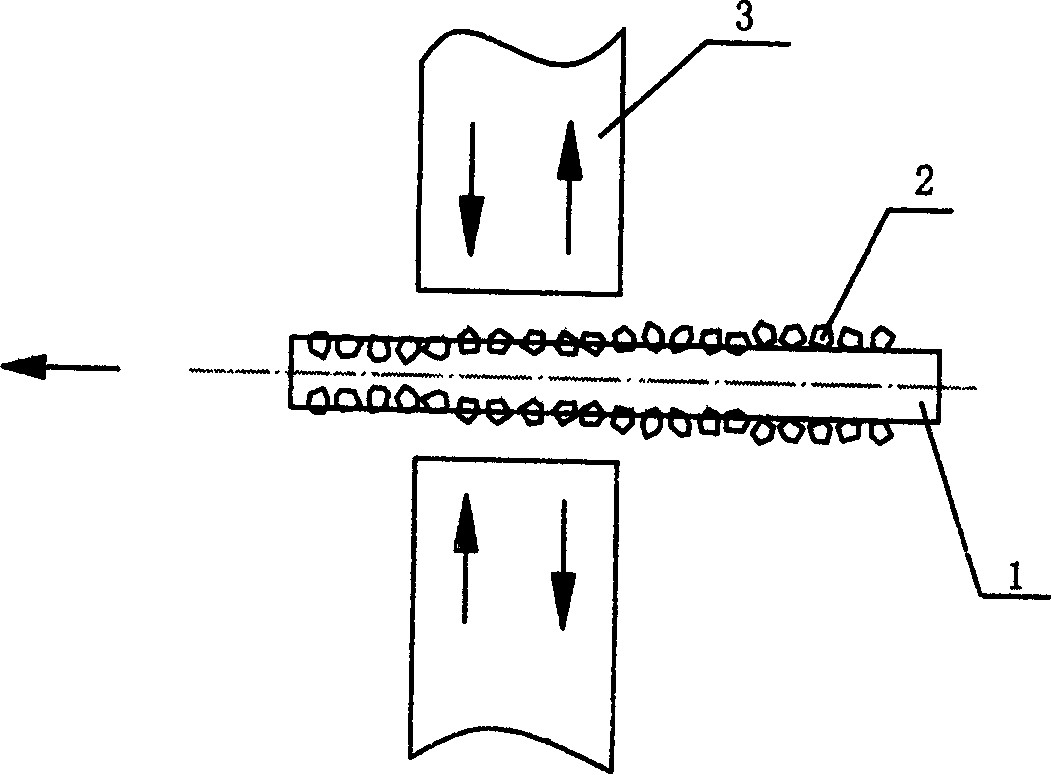

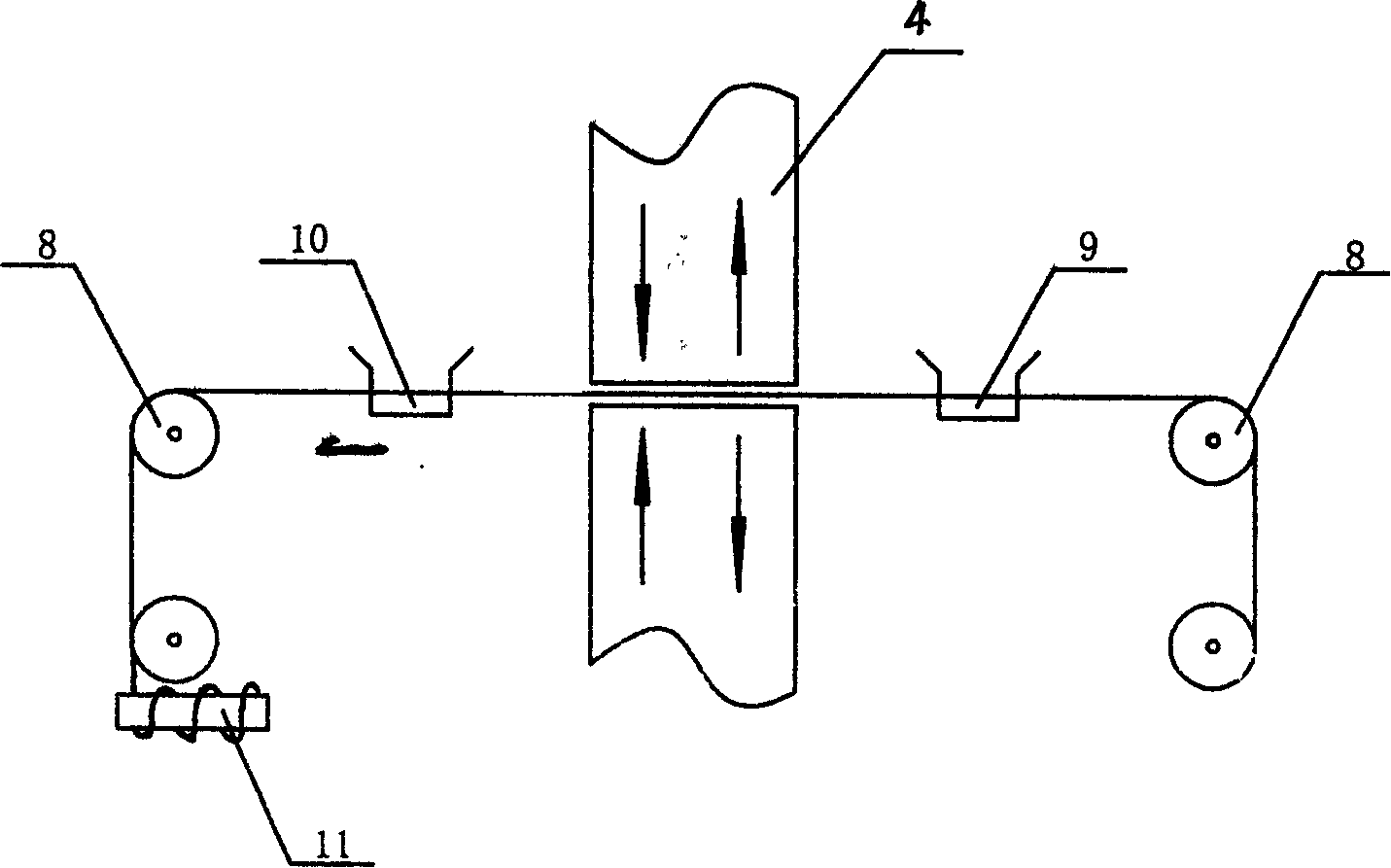

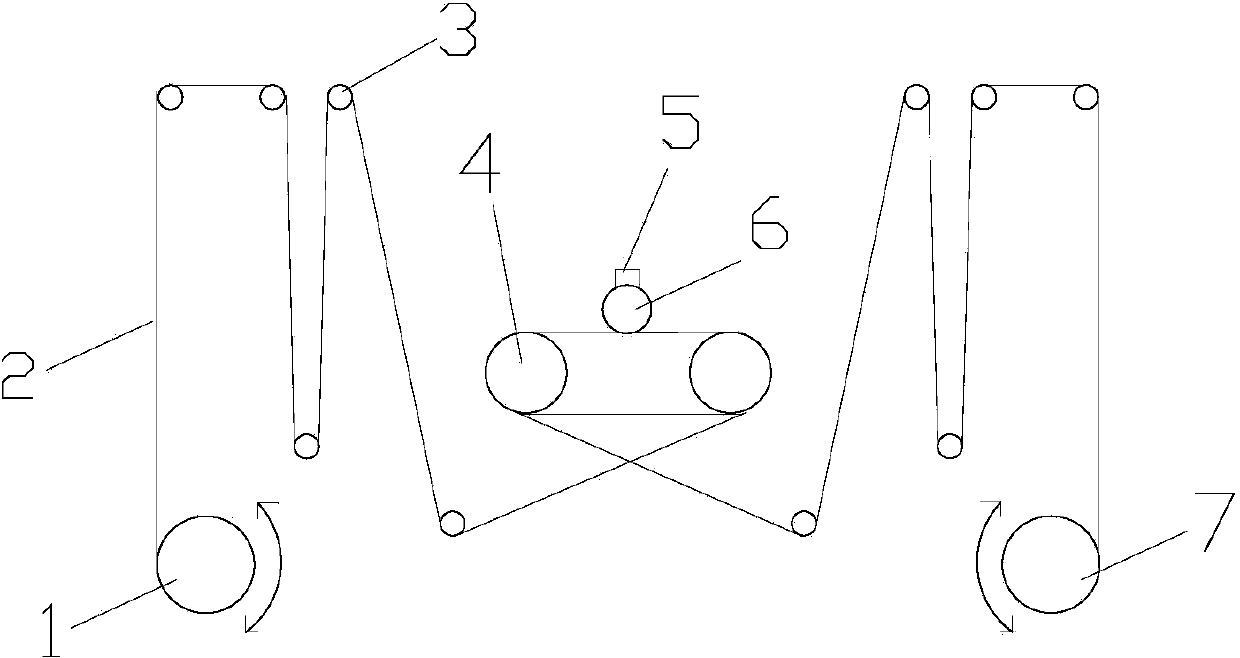

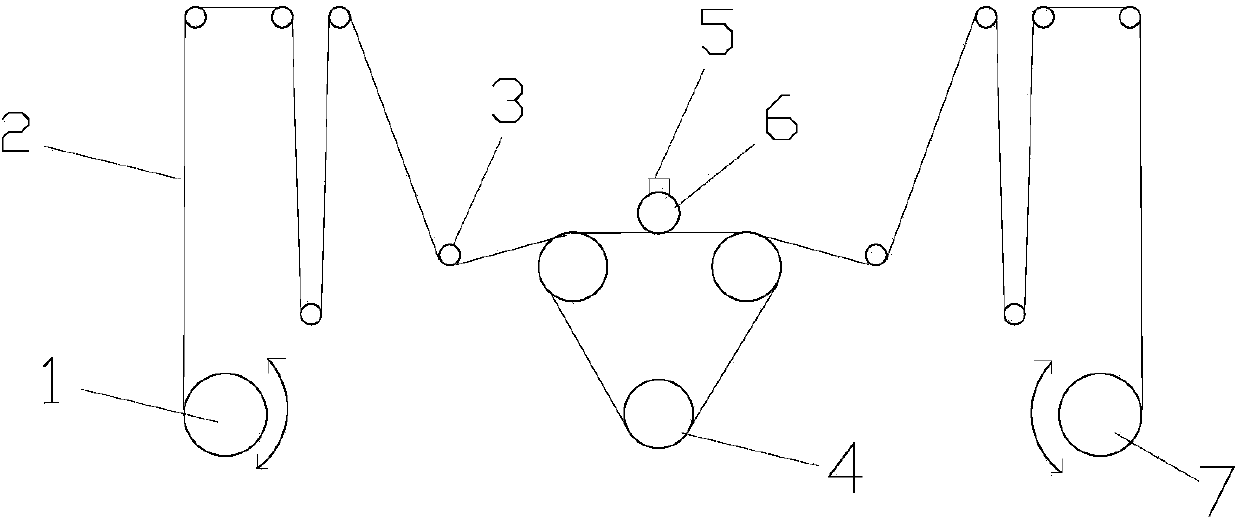

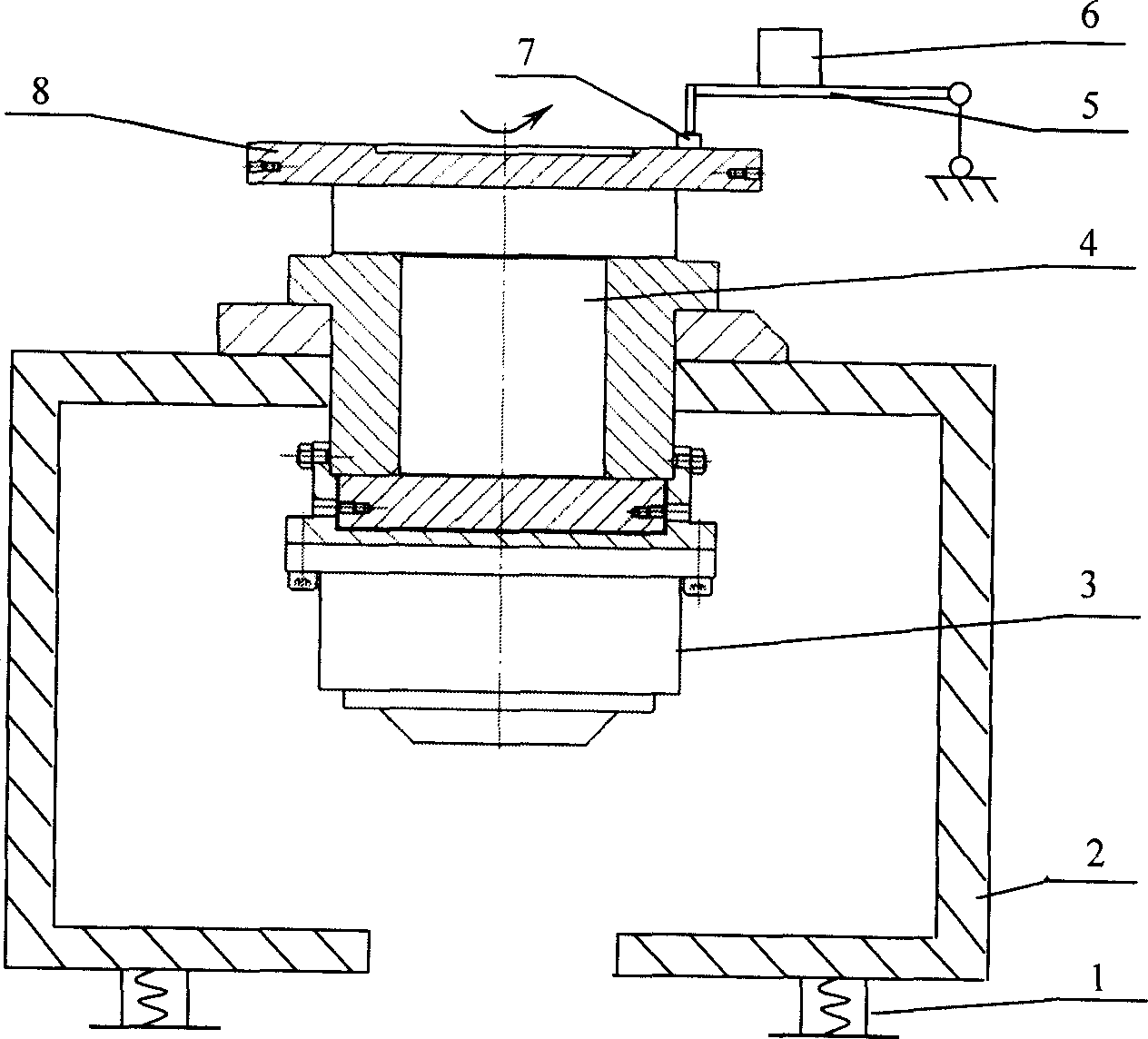

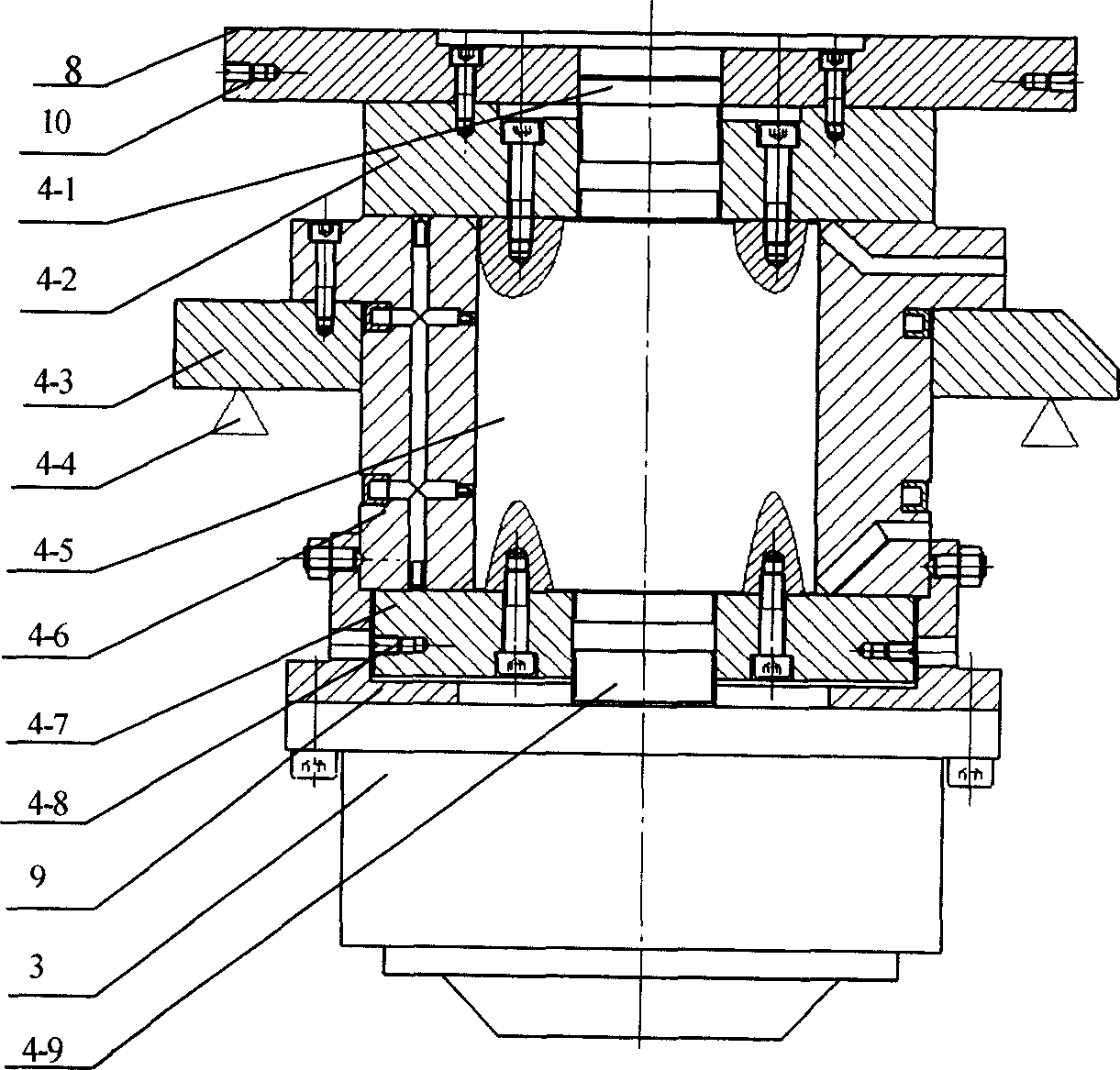

Diamond fretsaw cutting method and device

ActiveCN103302754AImprove cutting efficiencyFast cutting accuracyFine working devicesDiamond cuttingDrive wheel

The invention discloses a diamond fretsaw cutting method and device. An annular diamond fretsaw is used for cutting a crystal ingot workpiece; the annular diamond fretsaw surrounds a plurality of horizontal guide wheels and is tensioned by a tension mechanism; under the driving of one of the guide wheels, namely, a driving wheel, the annular diamond fretsaw operates at a high speed; under the driving of a lifting mechanism, the annular diamond fretsaw is fed to a crystal ingot cutting workpiece and retracts upward; and in a cutting process of the annular diamond fretsaw, the crystal ingot workpiece is driven by a rotary mechanism to rotate uni-directionally around a shaft of the workpiece. According to the method and the device, the annular diamond fretsaw has a higher linear speed; when a workpiece rotates uni-directionally and continuously, point contacting type cutting between the diamond fretsaw and the crystal ingot workpiece is realized; and diamond particles can be pressed into a cut material more easily, so that the device has a cutting efficiency about ten times of that of the ordinary fretsaw diamond cutting.

Owner:CHINA NONFERROUS METAL (GUILIN) GEOLOGY & MINING CO LTD

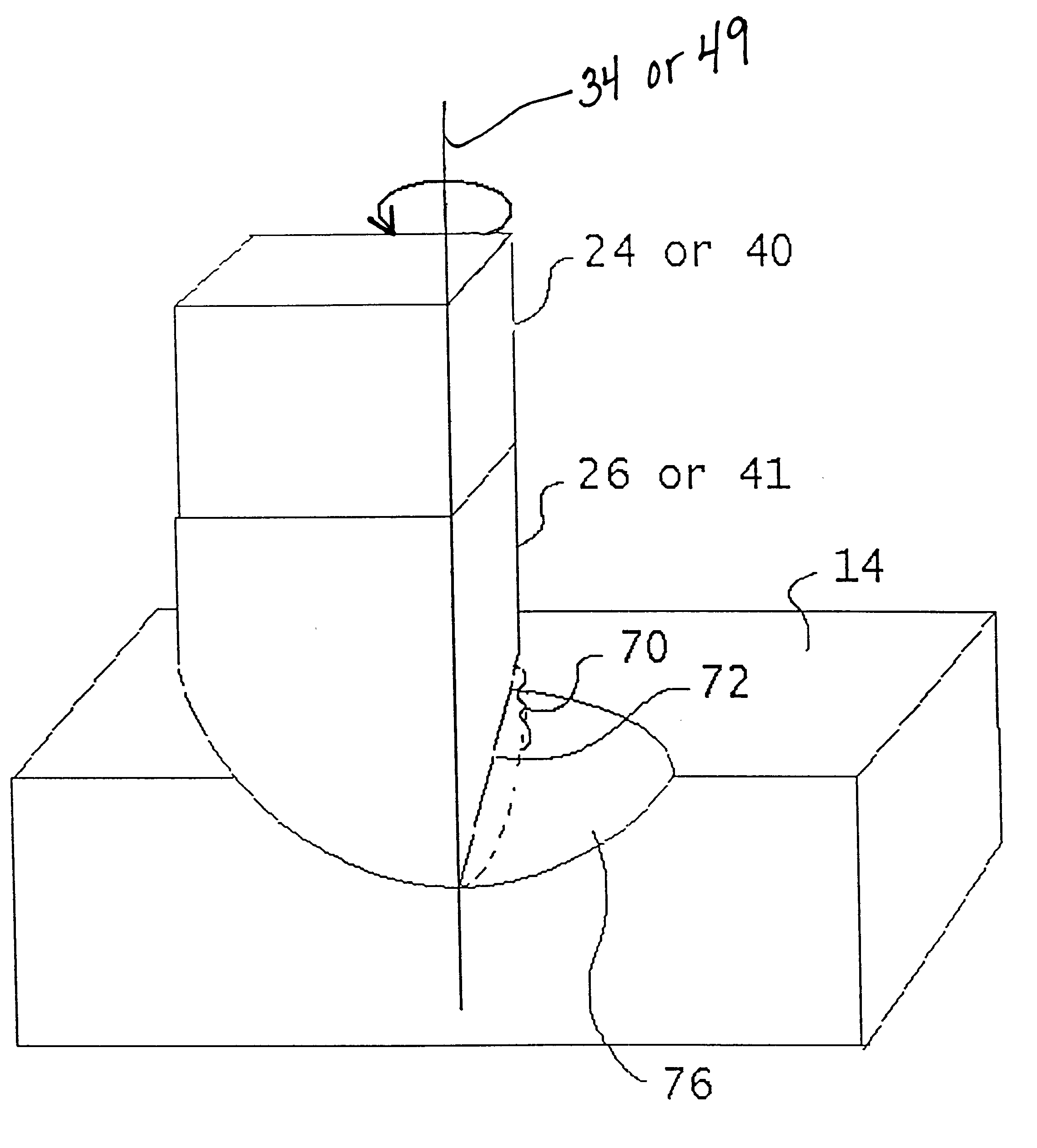

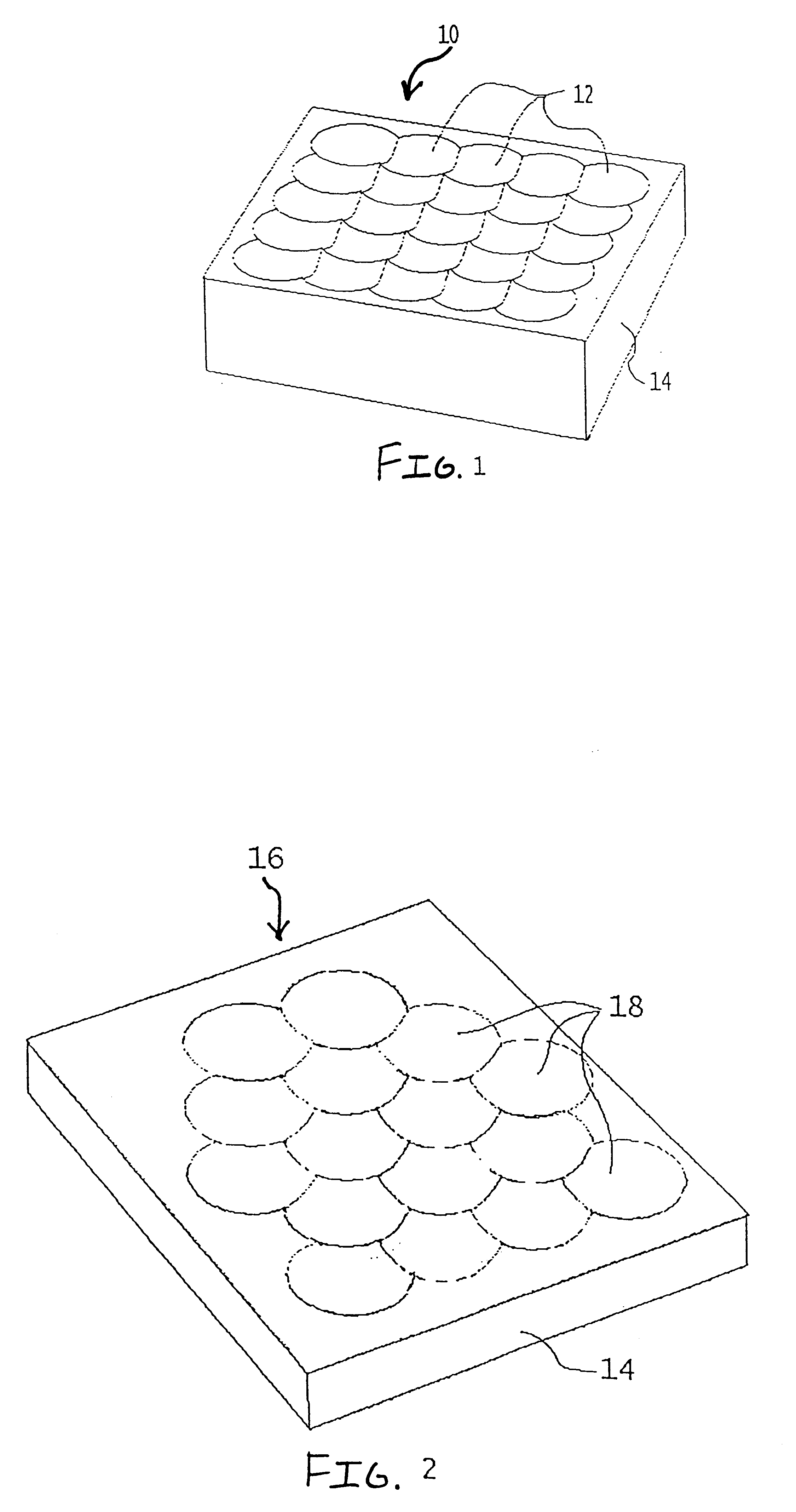

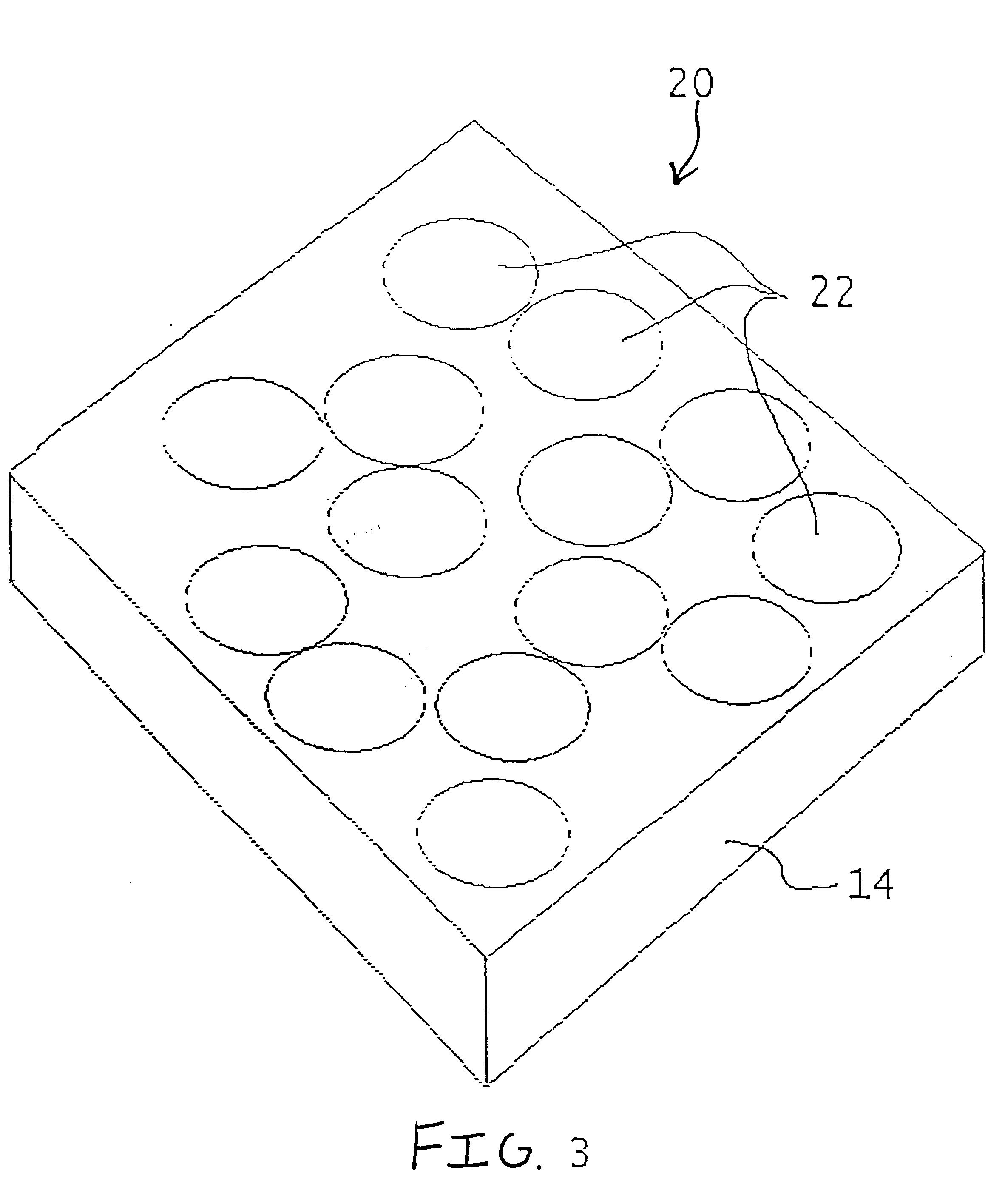

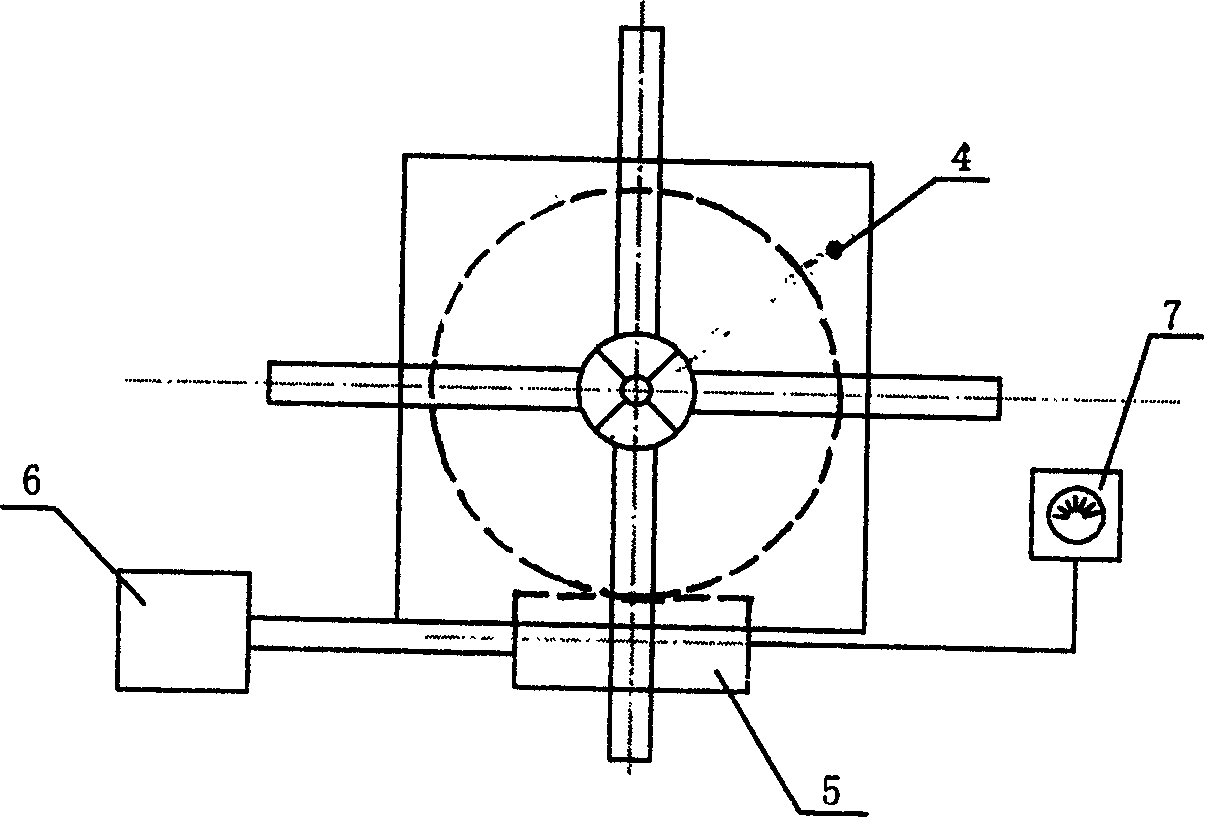

Apparatus for forming a microlens mold

InactiveUS6846137B1Precise processQuality improvementMilling cuttersOptical articlesDiamond cuttingFill factor

An apparatus for making microlens molds and microlens array molds is described which utilizes a forming element having a rotating half radius diamond cutting member. A substrate is alignably arranged with the diamond cutting member so that the cutting member can mill a mold cavity in the substrate. The apparatus can be used to make high sag lens molds with high accuracy and a nearly 100% fill factor.

Owner:EASTMAN KODAK CO

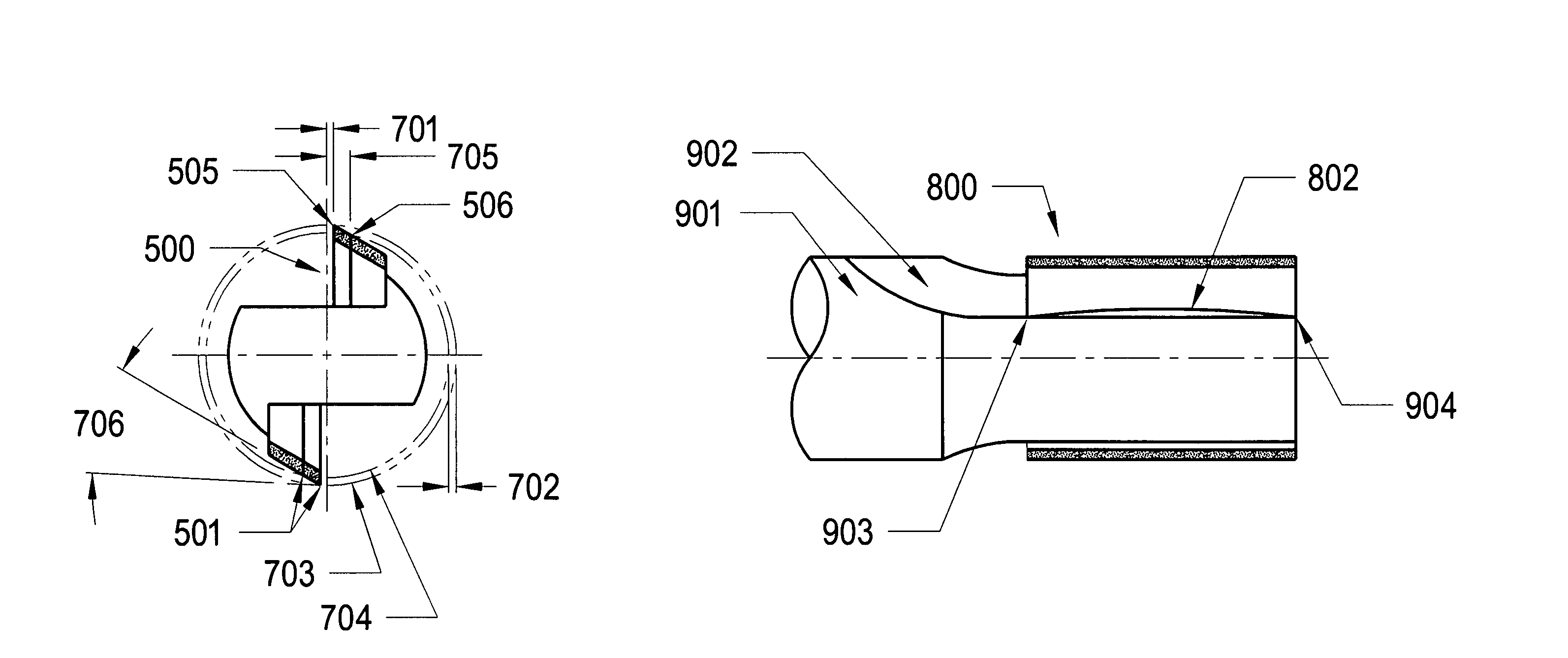

Thermally stable diamond cutting elements in roller cone drill bits

A roller cone drill bit for drilling earth formations includes a bit body having at least one roller cone rotably attached to the bit body and a plurality of cutting elements disposed on the at least one roller cone in a plurality of rows arranged circumferentially around the at least one roller cone, wherein at least one cutting element in the gage row, the heel row, or a surface of the at least one roller cone bounded by the gage and heel rows comprises thermally stable polycrystalline diamond or a thermally stable polycrystalline diamond composite. The at least one cutting element may be a TSD insert or a TSD composite insert and may be formed by brazing, sintering, or bonding by other technologies known in the art a thermally stable polycrystalline diamond table to a substrate. The interface between the diamond table and the substrate may be non-planar. A roller cone drill bit includes a bit body, at least one roller cone rotably attached to the bit body, and a plurality of cutting elements disposed on the at least one roller cone, where at least one of the plurality of cutting elements comprises thermally stable polycrystalline diamond or a thermally stable polycrystalline diamond composite and a cutting surface, wherein at least a portion of the cutting surface is contoured.

Owner:SMITH INT INC

Crashing-preventing type rock sample cutting and grinding device and cutting and grinding process thereof

InactiveCN102172876AAvoid chippingAvoid stress concentrationGrinding machinesStone-like material working toolsDiamond cuttingDrive shaft

The invention relates to a crashing-preventing type rock sample cutting and grinding device and a cutting and grinding process thereof, wherein a motor of the crashing-preventing type rock sample cutting and grinding device drives two parallel transmission shafts, one is provided with a diamond cutting piece, the other one is provided with a grinding wheel, and a clamping device is opposite to the diamond cutting piece and the grinding wheel; a feeding device can run along a base so as to adjust the positions between the clamping device and the diamond cutting piece, and between the clamping device and the grinding wheel; the clamping device is provided with a holder that penetrates from a bracket, the holder is split, an upper holding body and a lower holding body are buckled to form a cylindrical holding cavity, the upper holding body is provided with a clamping rocking handle which is in threaded connection with the upper holding body by penetrating through the bracket, a cooling pipe is arranged on the holder, and a nozzle of the cooling pipe is arranged in front of the holding cavity. The crashing-preventive type rock sample cutting and grinding device integrates cutting and grinding, and the problem that a rock sample is easy to be clamped to be crashed is solved, the operation is simple and convenient and successful rate is high.

Owner:NORTHEAST GASOLINEEUM UNIV

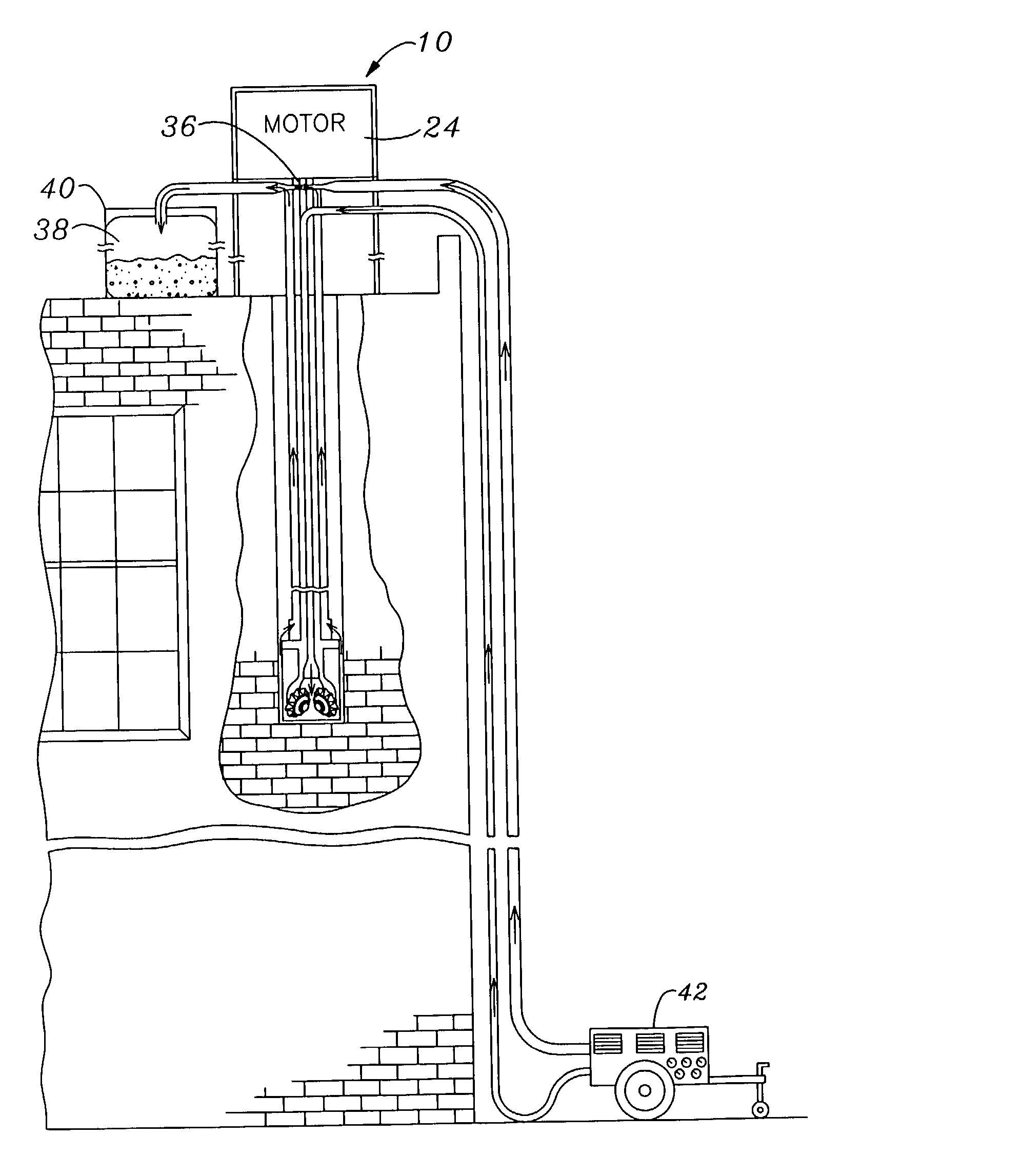

Advanced processes for coring and grouting masonry

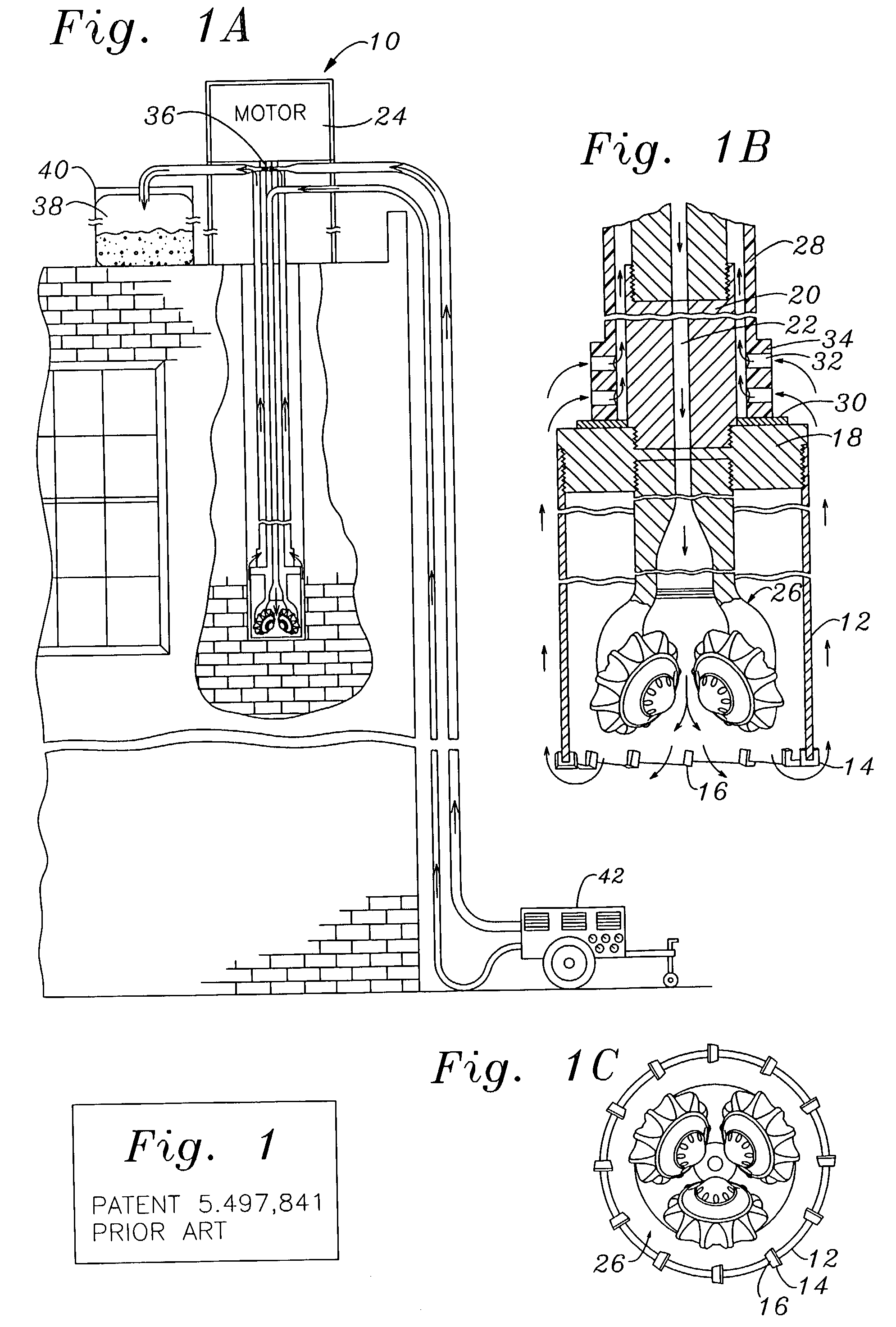

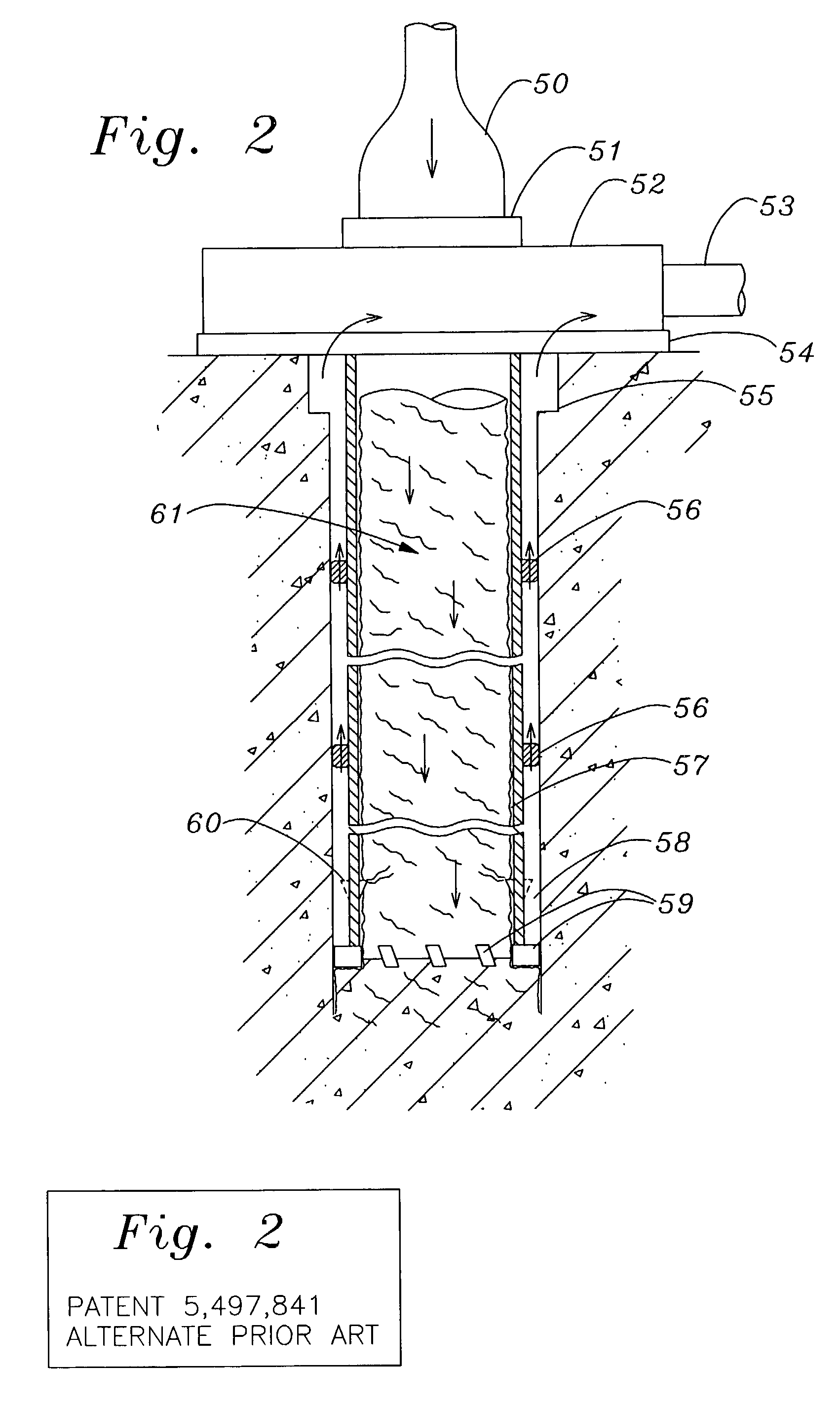

Advanced masonry coring systems for coring and grouting masonry walls are disclosed in this patent. The systems include rotating machinery and a drill column in the form of a cylindrical double-piped string of pipe sections, rotating a cylindrical drill body. The drill body mounts cutting end faces having alternative means of employing carbide or diamond cutting and / or pulverizing elements. The double drill pipe weight is made workable through new aerospace composite fabrication. The double pipe permits more efficient routing of air and removal of drill cuttings. Advancement in various system components and means of placing reinforcement into walls is disclosed. Further disclosure is included of advanced means of optimizing resin grouting materials and procedures to fill the wall cavities created by the core drill, integrating the reinforcement into the walls.

Owner:MOHLENHOFF WILLIAM

Cvd diamond cutting insert

A blade, particularly a razor blade, comprises a layer of CVD diamond having a monolithic elongate cutting edge.

Owner:WORT CHRISTOPHER JOHN HOWARD +4

Process and apparatus for producing highly wear resistant diamond cutting wires

InactiveCN1456410AUniform diameterImprove wear resistanceHot-dipping/immersion processesMetal sawing toolsDiamond cuttingPunching

A technology and apparatus for manufacturing the antiwear combined cutting diamond wire features that the diamond microparticles are inlaid in the subsurface of steel wire by squeezing or punching. Its advantages are long length up to 60 km, uniform diameter, and high antiwear performance and tension strength.

Owner:江晓平 +2

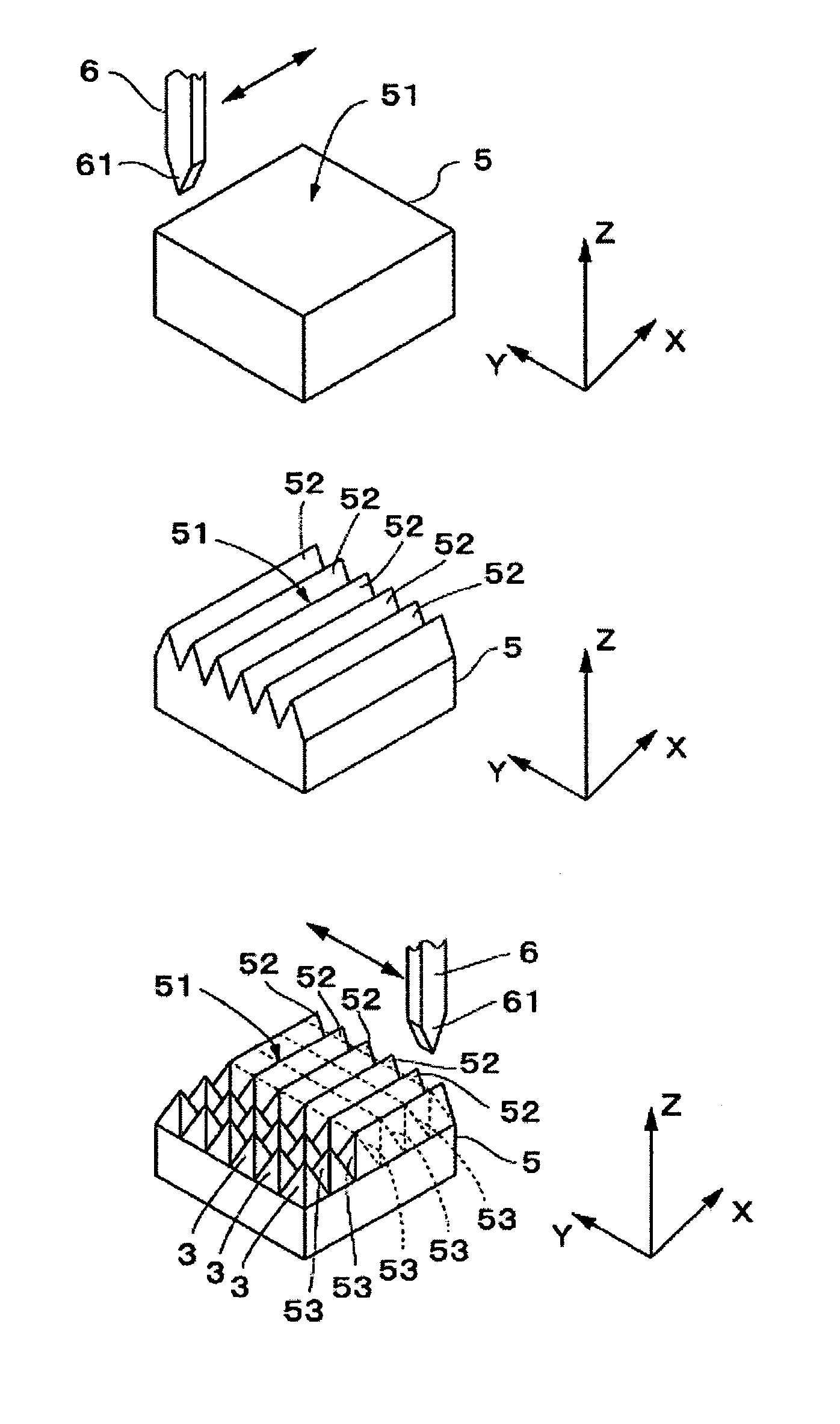

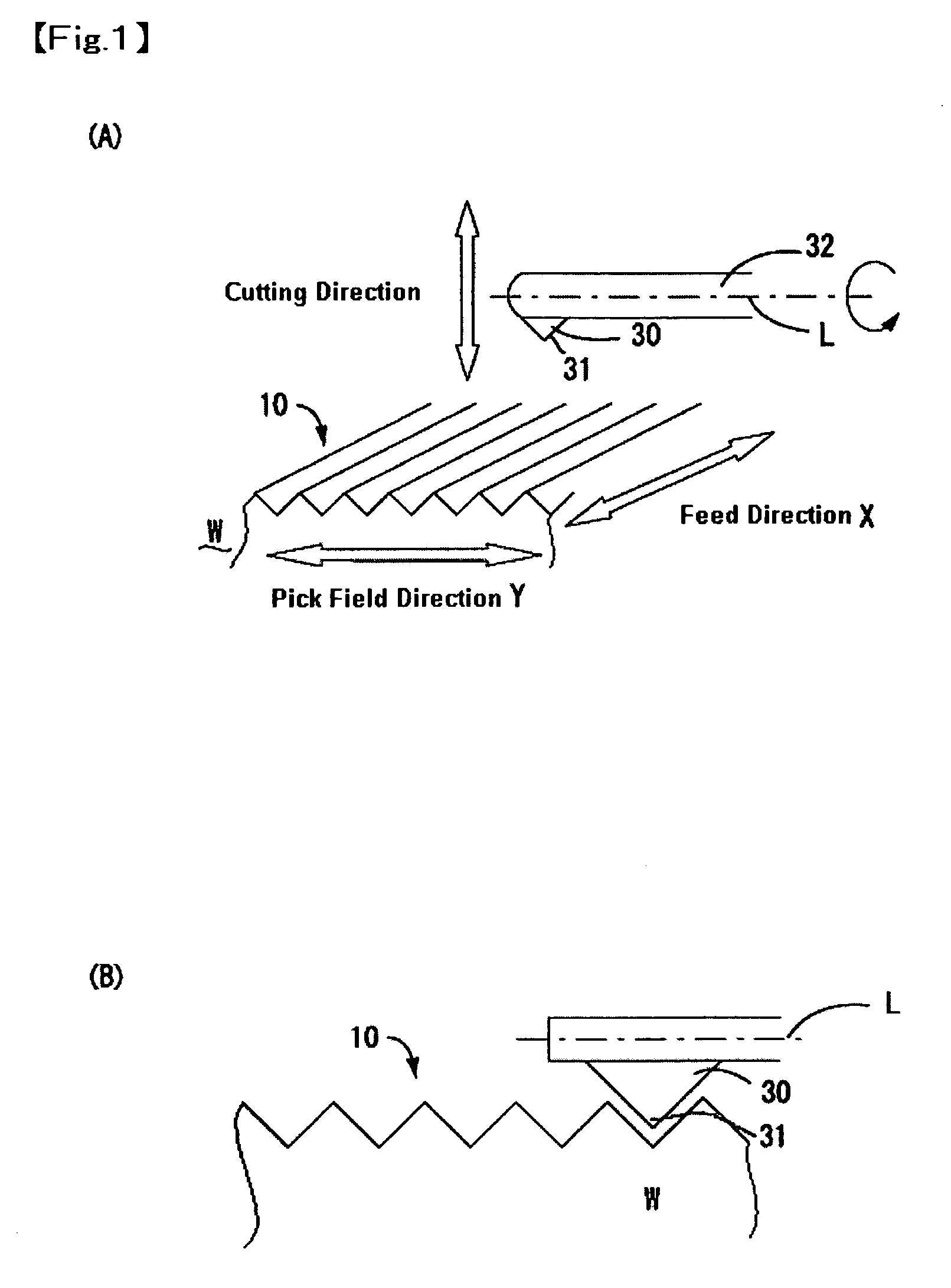

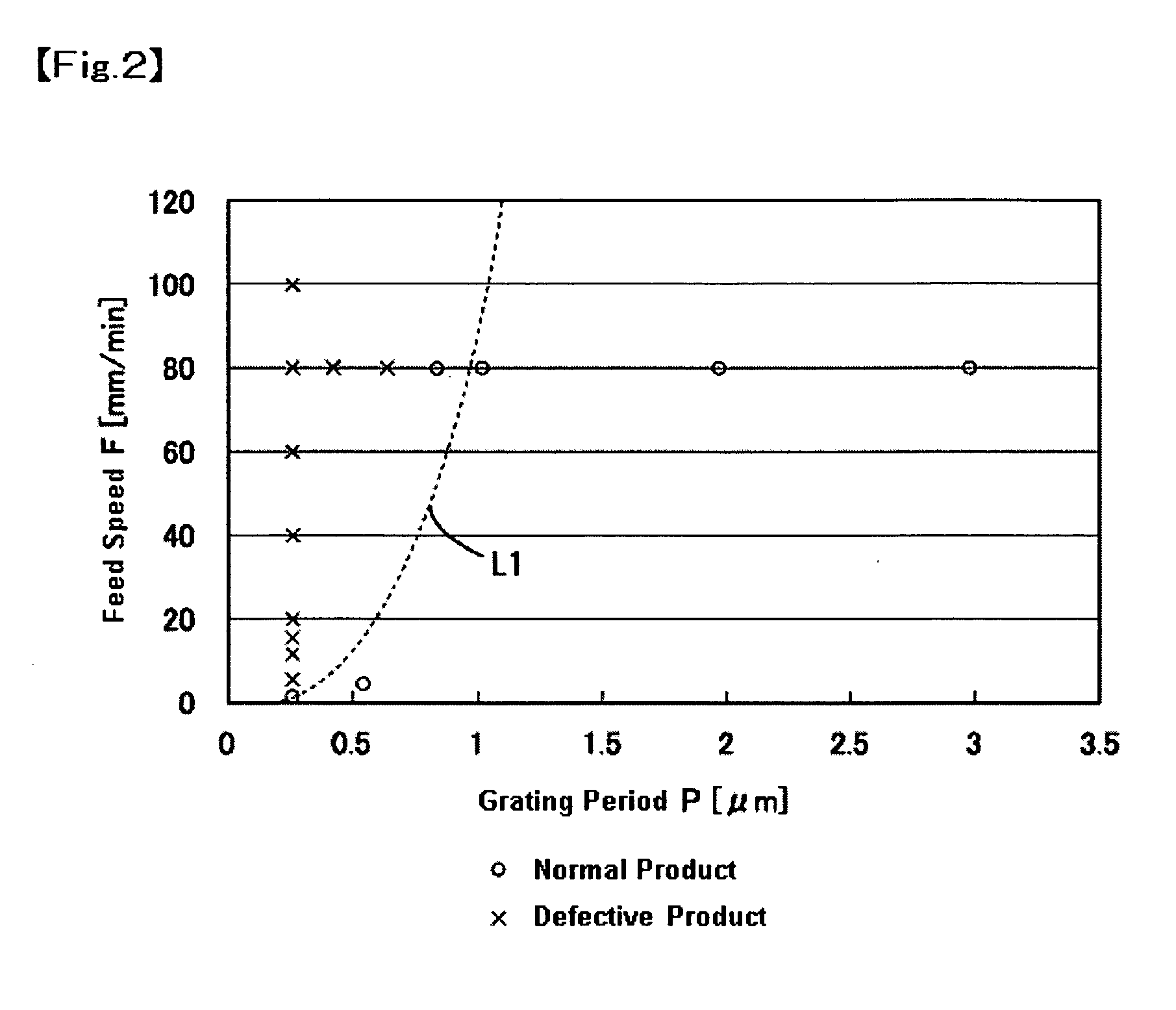

Grating forming method, molding die, molded product and manufacturing method for master member for manufacturing molding die

InactiveUS20050025423A1Reducing roughness and swellingRestrict formDiffraction gratingsCoupling light guidesDiamond cuttingVibration amplitude

A grating forming method for forming a fine grating with a grating period of 1 μm or less on a surface of a blank material including cutting the surface of the blank material with a blade tip part of a diamond cutting tool. When the fine grating with the grating period of “P”μm is formed and the feed speed of the diamond cutting tool is set to be “F” mm / min, the feed speed “F” is set to satisfy the conditional expression: F<1 0 0 P3. The vibration amplitude of the diamond cutting tool in a perpendicular direction to the surface of the blank material is set to be “A”μm, the vibration amplitude “A” is set to satisfy the following conditional expression: A<0. 0 1 8 P2. The feed amount per revolution of the diamond cutting tool is set to be “S”μm, the feed amount per revolution “S” is set to satisfy the following conditional expression: S<2. 9 P3. These conditional expressions are applied to a blank material, a molding die, a molded product, and a master member for manufacturing a molding die.

Owner:SANKYO SEIKI MFG CO LTD

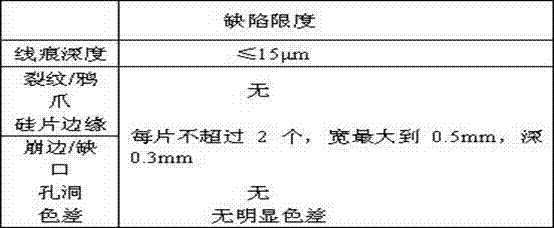

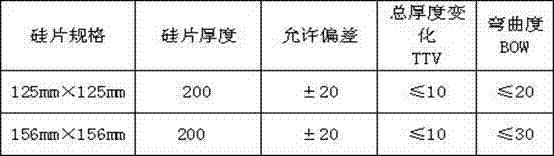

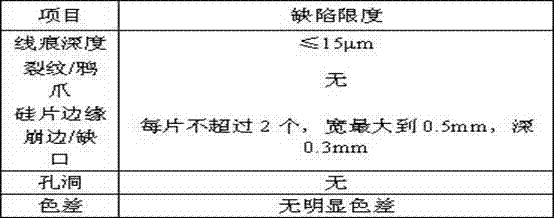

Solar-grade silicon wafer being cut by diamond wire and cutting method thereof

InactiveCN102390094AFast cutting speedSave silicon resourcesFine working devicesDiamond cuttingMicrometer

The invention discloses a solar-grade silicon wafer being cut by a diamond wire and a cutting method thereof. A mono-crystalline silicon square rod is cut by a diamond wire. The cutting method comprises the following steps that: the mono-crystalline silicon square rod which is formed by squaring, grinding and sharpening a mono-crystalline silicon circular rod, the mono-crystalline silicon square rod is fixed on a resin strip through an adhesive bar, the resin strip is fixed on an adhesive plate, then the adhesive plate and the mono-crystalline silicon square rod are collectively placed into a working cabin to be preheated, cutting liquid is circulated in the working cabin to work, then the diamond cutting is performed, the cut mono-crystalline silicon wafer is inversely arranged on a degumming device to degum, and the mono-crystalline silicon wafer is washed by ultrasonic and then is centrifugally dehydrated. Due to the adoption of the cutting method, the photoelectric conversion efficiency and the cutting efficiency of the mono-crystalline silicon wafer can be improved, a silicon wafer with the thickness of 140 to 200 micrometers can be produced, the qualification rate of the product can reach more than 98 percent; and silicon powder is recyclable, so valuable silicon resource can be saved, and the environment-friendly production can be really realized during the production process.

Owner:江西金葵能源科技有限公司

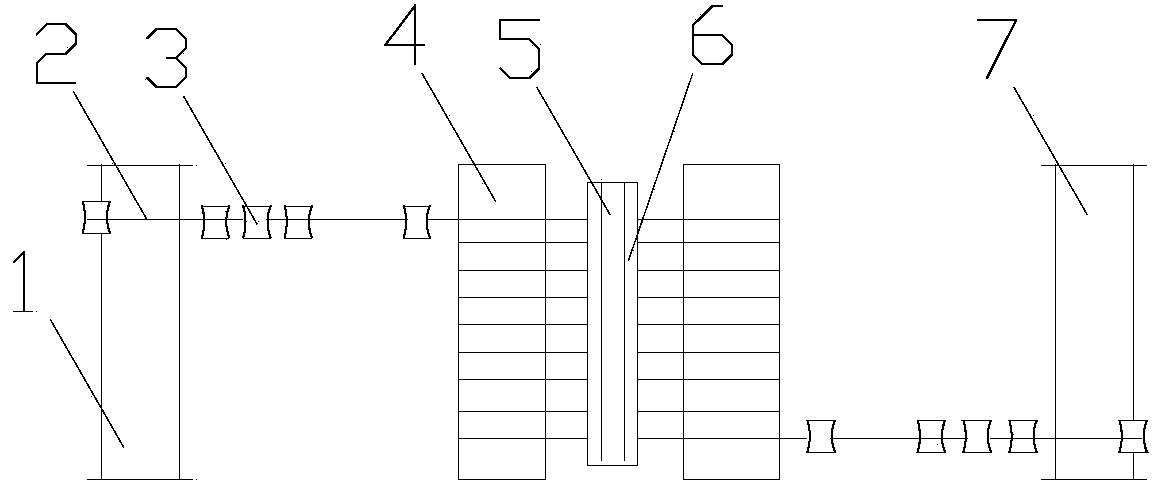

Method and equipment for cutting large-diameter silicon carbide single crystals by aid of diamond wires

The invention belongs to the field of technologies for processing advanced materials, and particularly provides a method and equipment for efficiently cutting large-diameter single crystals by the aid of diamond wires. The method and the equipment have the advantages that the equipment is convenient to operate and is provided with a multi-wire cutting machine and the diamond cutting wires, the diameters of the diamond cutting wires range from 120 micrometers to 400 micrometers, diamond particles are plated on outer layers of the diamond cutting wires, multiple pieces of large-diameter SiC crystal bars can be cut by the aid of reciprocating high-speed cutting movement of the diamond cutting wires, the surface roughness, the bending and the total thicknesses of cut SiC wafers hardly vary, and a plurality of target crystals can be cut in each procedure; the crystal can be cut at high speeds, crystal cutting elapsed time is short, and accordingly the silicon carbide wafers can be efficiently cut by the aid of the method and the equipment.

Owner:SICC CO LTD

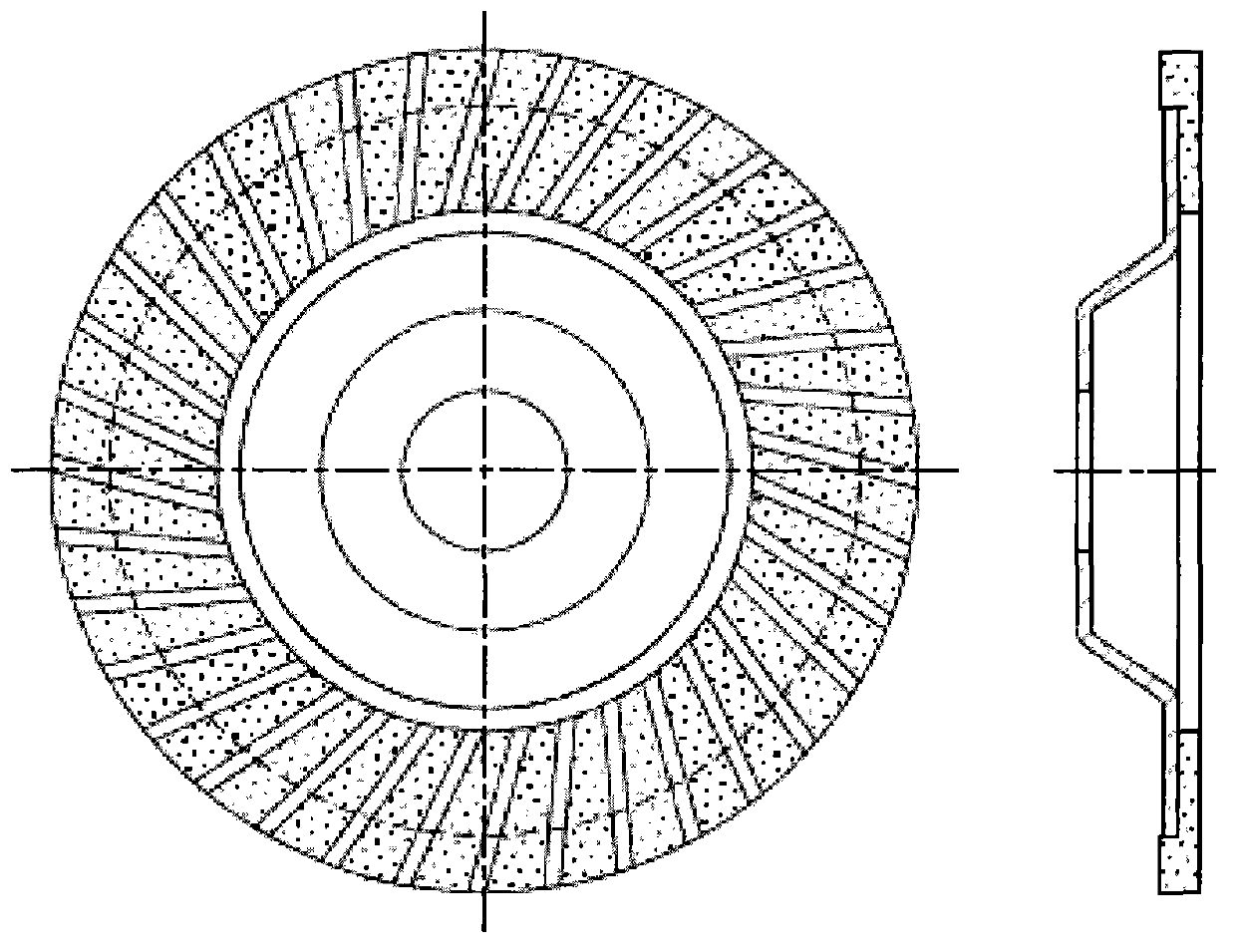

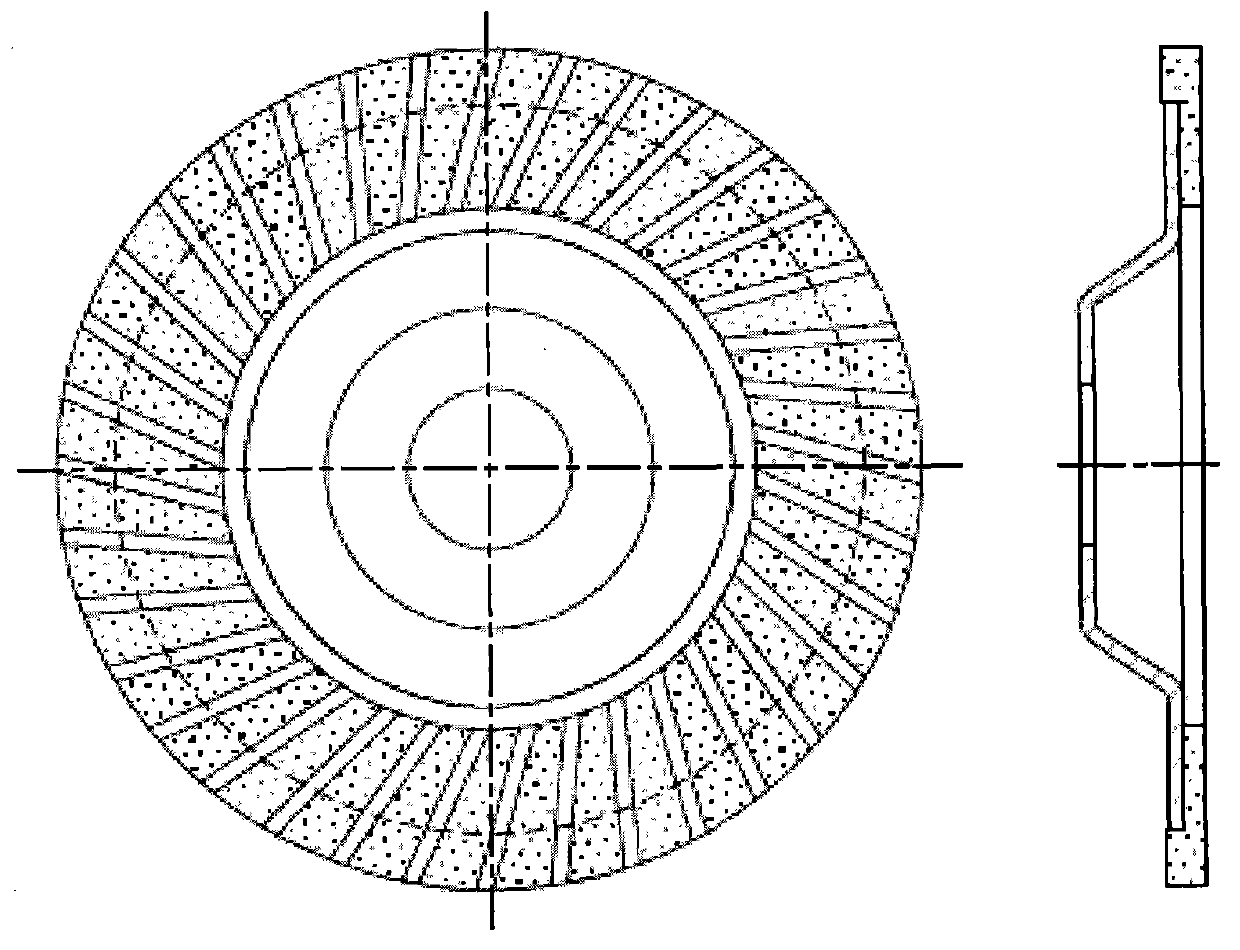

Diamond cutting grinding piece

ActiveCN103273433AGuaranteed connection strengthSafe and reliable performanceFlexible-parts wheelsStone-like material working toolsDiamond cuttingBrick

The invention relates to a diamond cutting grinding piece. The diamond cutting grinding piece comprises a diamond cutting grinding piece body arranged on a substrate, wherein the diamond cutting grinding piece body is evenly distributed in the circumferential direction, and corrugated water channels which are beneficial to heat dissipation and chip removal in the process of grinding are formed in the surface of the diamond cutting grinding piece body. The diamond cutting grinding piece organically combines the cutting performance and grinding performance through the unique design, is simple and reliable in structure, convenient to operate, low in manufacturing cost and long in service life, solves the problem that the cutting performance and the grinding performance of a diamond tool are independent from each other in an existing market, and is particularly applicable to cutting and grinding of building materials such as stones, concrete, ceramics, bricks and tiles.

Owner:JIANGSU FENGTAI TOOLS

Brazed rotary cutting tool, an insert for a brazed rotary cutting tool, and methods for manufacturing the same

InactiveUS8176825B1Easy to maintain alignmentEasy alignmentMetal sawing devicesDrill bitsDiamond cuttingCarbide

A method for producing carbide and diamond cutting tool inserts adapted to compensate for braze-induced warp is provided. In this method, the anticipated warpage of the insert from brazing is considered prior to cutting the insert from a PCD and carbide disk and the cutting path for the insert is adjusted to compensate. The adjusted cutting path creates an insert shape that, after warping as a result of the brazing process, will conform substantially to the originally intended insert or cutting tool shape. Also, a method of providing relief on the bottom surface of a brazeable insert is provided. Further, tools produceable by these methods are disclosed, such as a diamond edged rotary cutting tool with a substantially sinusoidal rake face and cutting edge.

Owner:ISAACSON GLENN +1

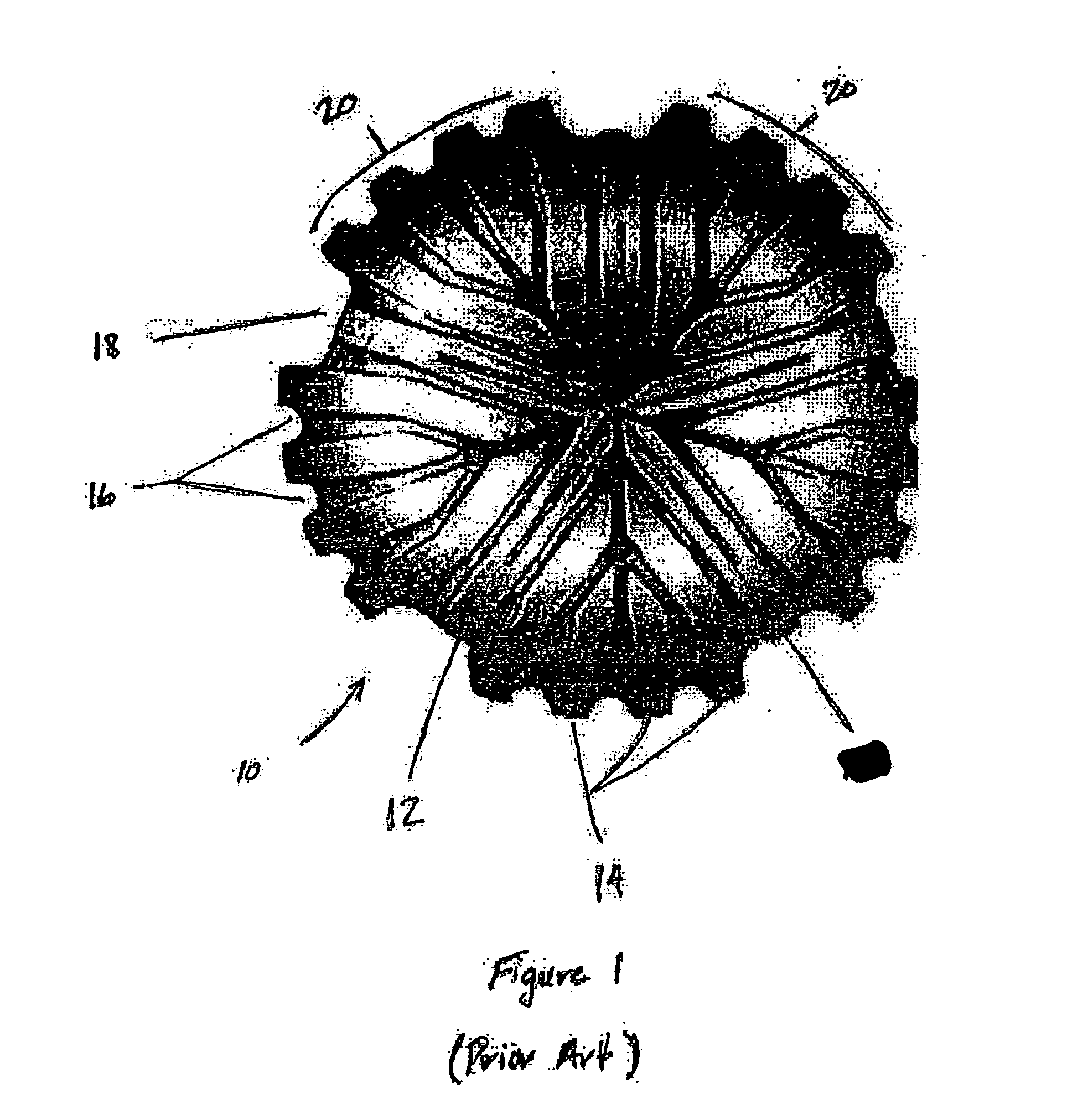

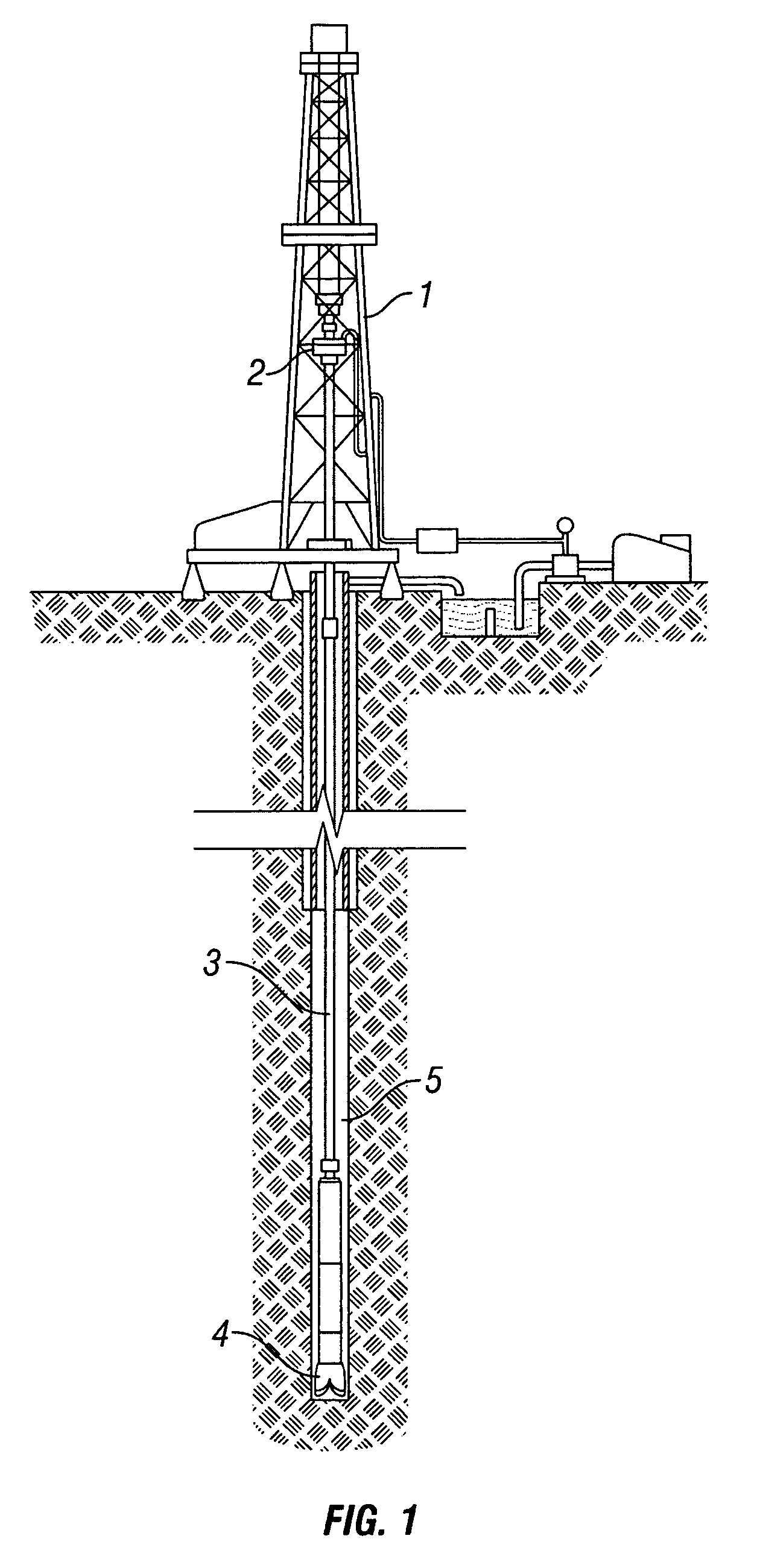

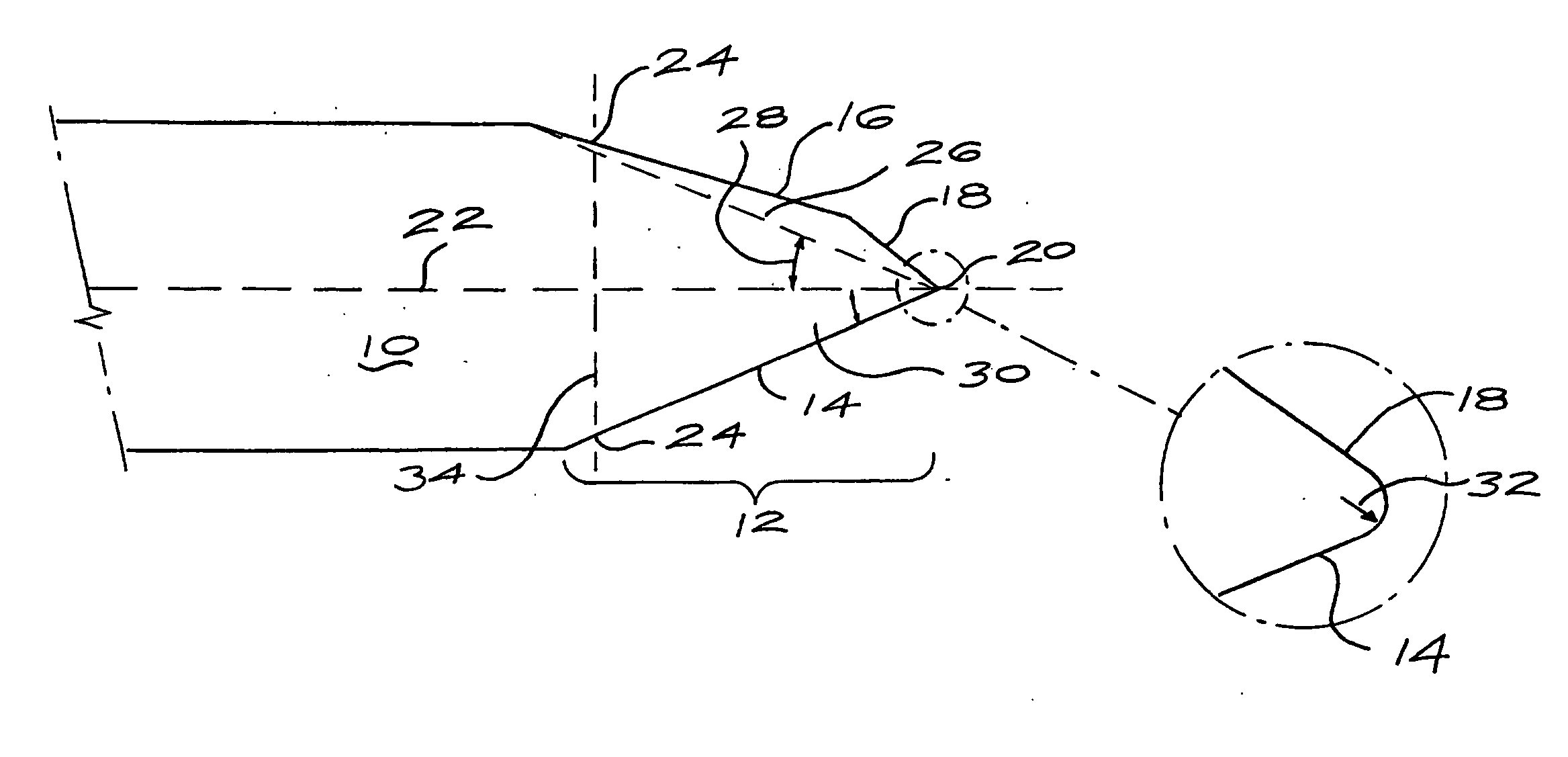

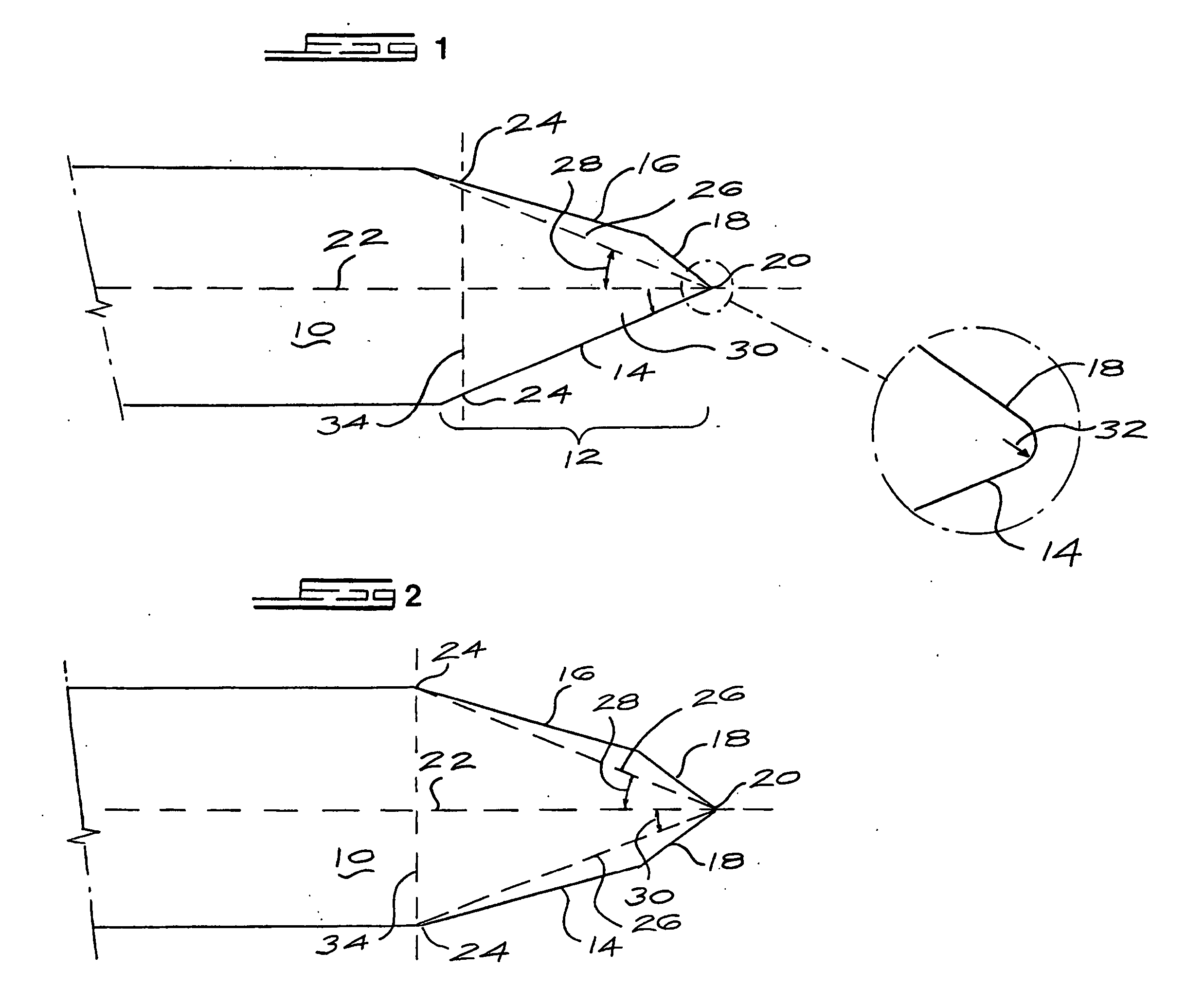

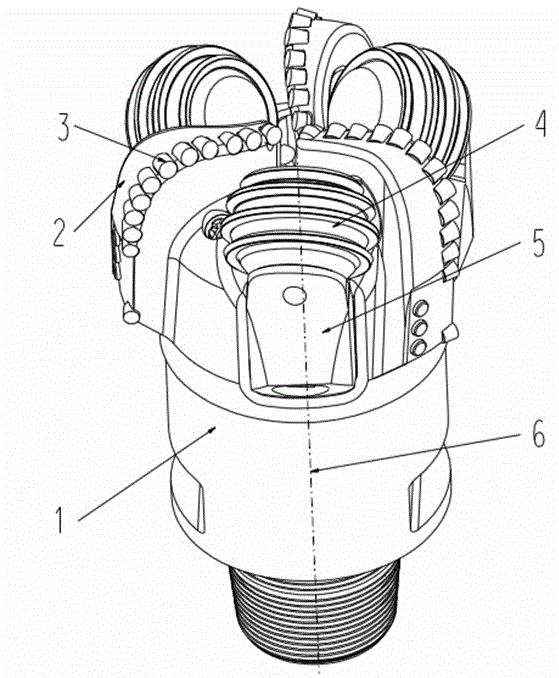

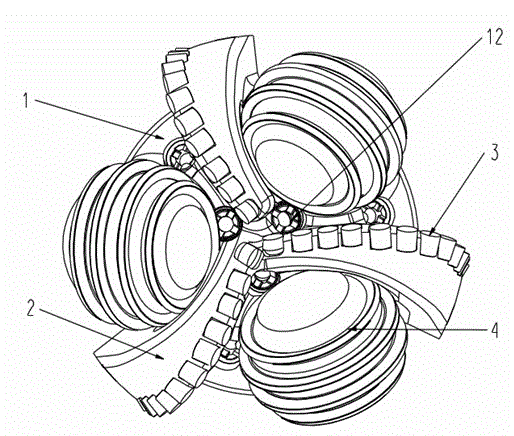

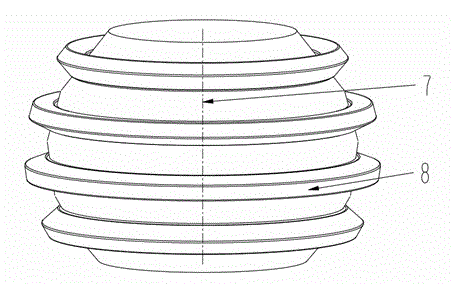

Hybrid drill bit

InactiveCN102747960AEliminate stick-slipImprove cutting efficiencyDrill bitsDiamond cuttingWell drilling

The invention relates to a hybrid drill bit for petroleum, natural gas and geological drilling. The hybrid drill bit comprises a drill bit body, wherein a cutter wing and a roller cone are arranged on the drill bit body, cutting teeth are arranged on the cutter wing, the roller cone is connected with the drill bit body through a cone leg, and the hybrid drill bit is characterized in that the roller cone is a disk type roller cone. A cutting element on the disk type roller cone is shaped like a disk cutter or an intermittent disk cutter. The patent disclosed by the invention has the beneficial effects that, 1) the scraping motion of a diamond drill bit and the rolling motion of a disk type roller cone drill bit are combined for realizing precrushing at the bottom of a well, thereby ensuring that the diamond cutting teeth can effectively bite rock, eliminating the stick-slip phenomenon of the drill bit in some special formations and the probability of impact disrepair of a polycrystalline diamond compact (PDC) and improving the cutting efficiency and the mechanical drilling speed of the drill bit; and 2) the disk type roller cone can realize the precrushing of a rock layer at the bottom of the well more steadily, reduce the impact on the PDC, enhance the stability in drilling of the drill bit and enable the drill bit to realize faster and more stable drilling.

Owner:SINOPEC OILFIELD EQUIP CORP

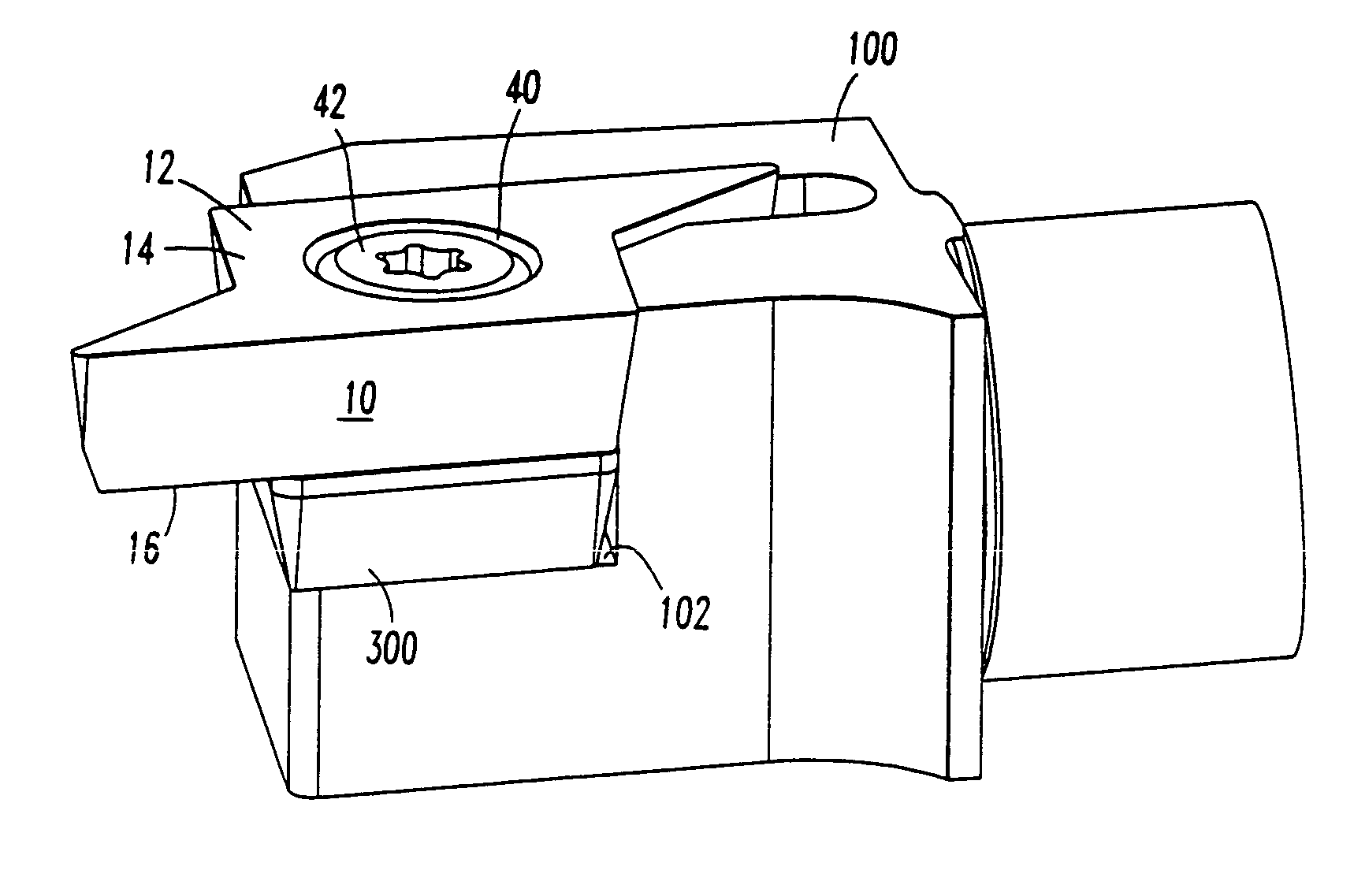

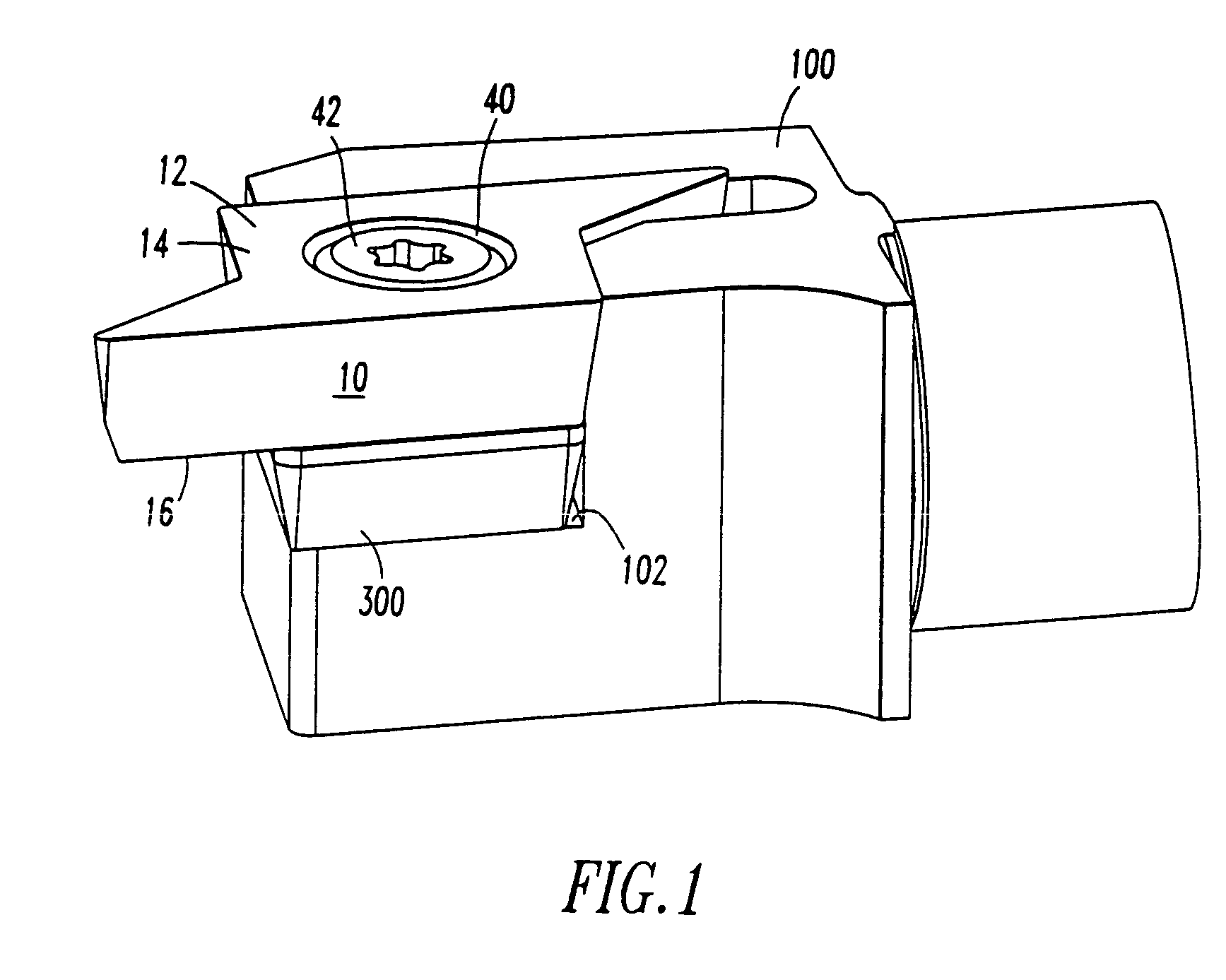

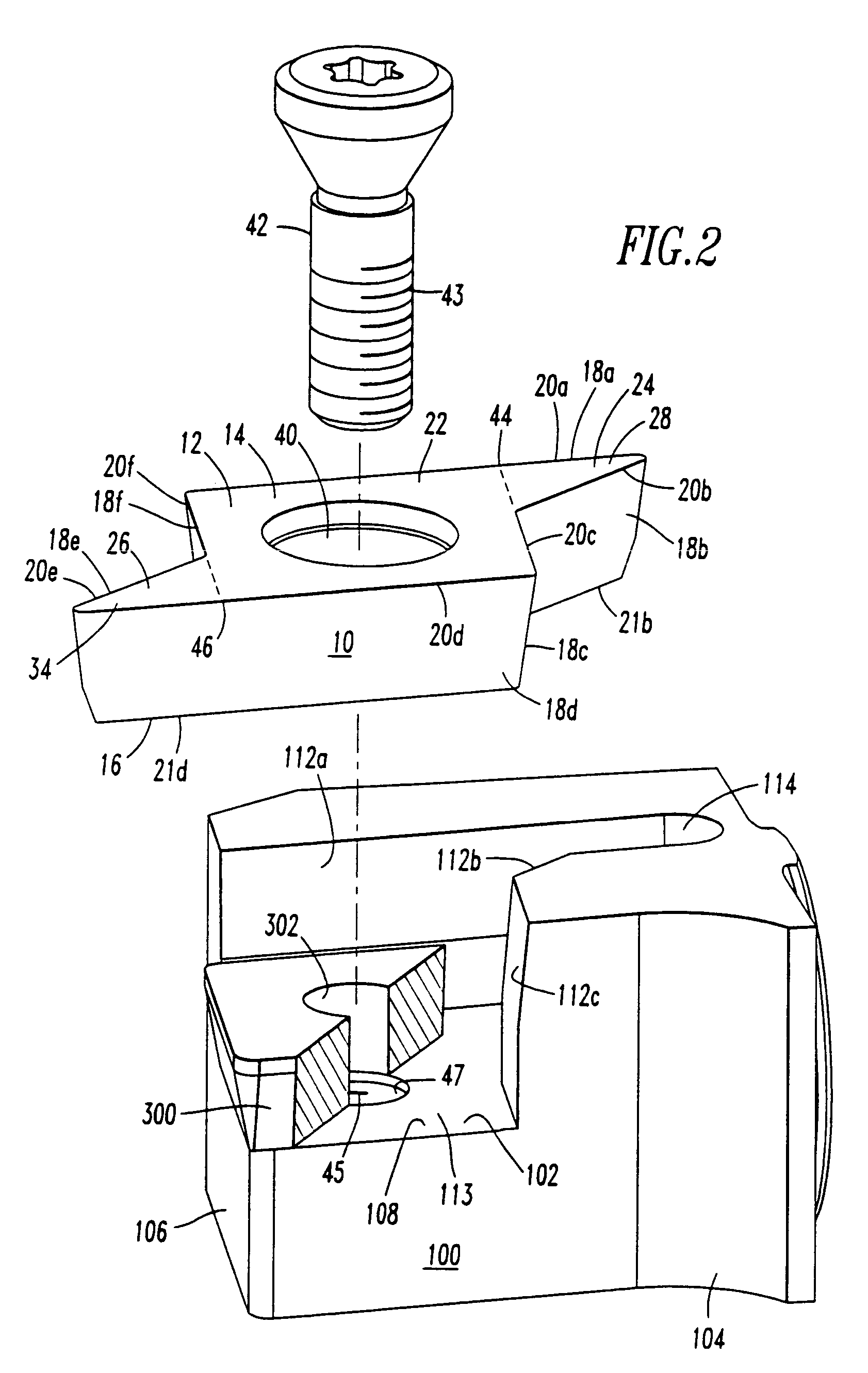

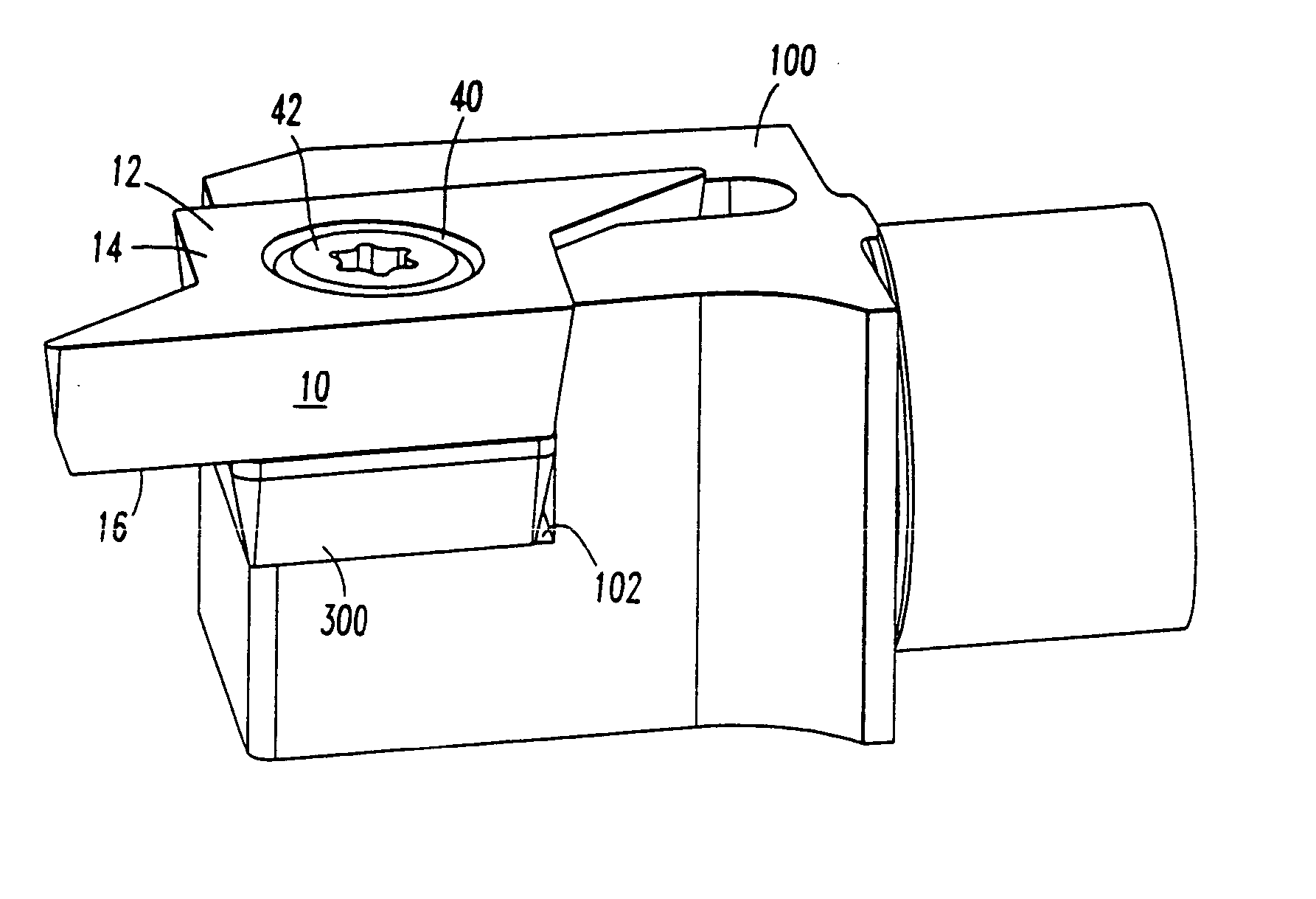

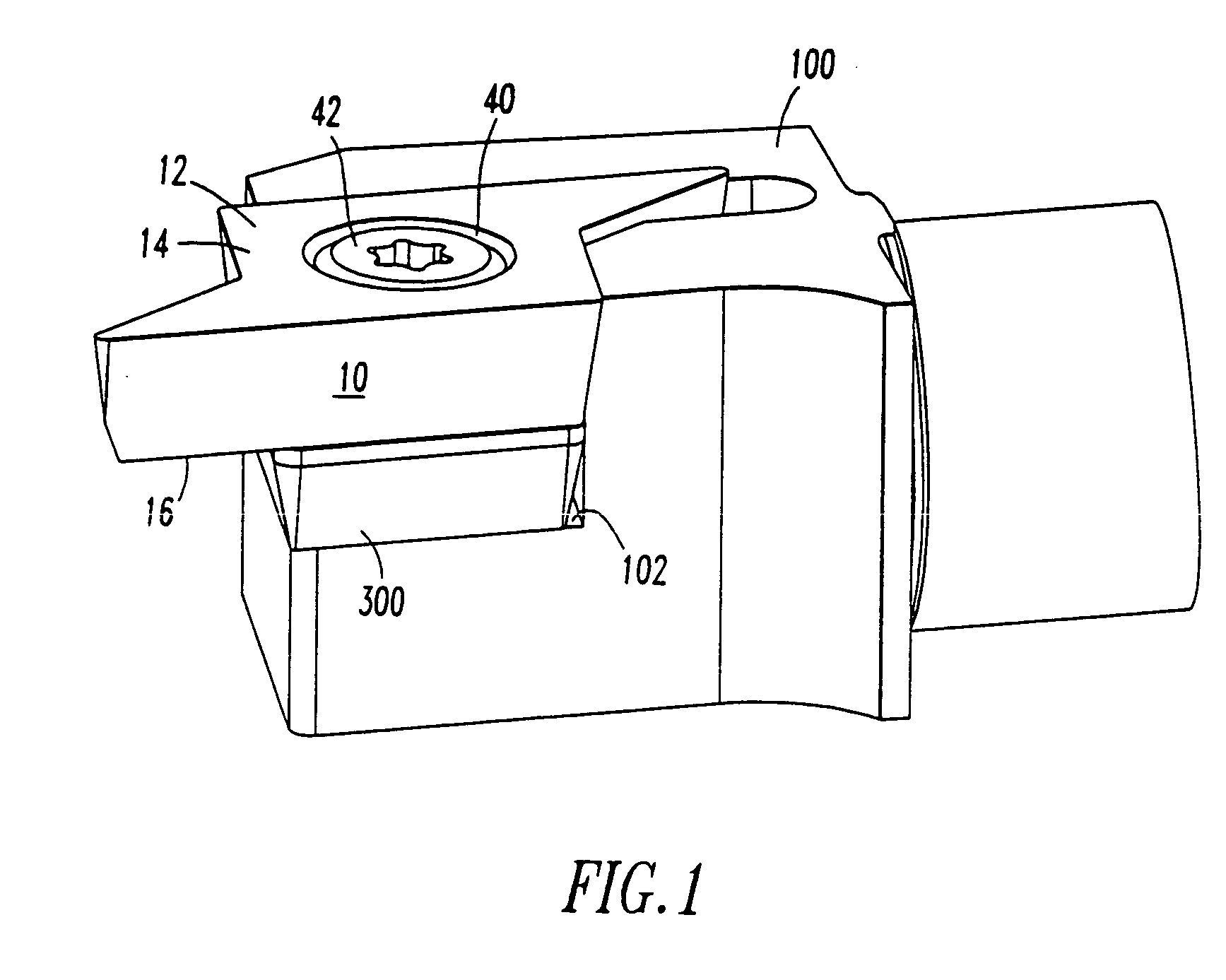

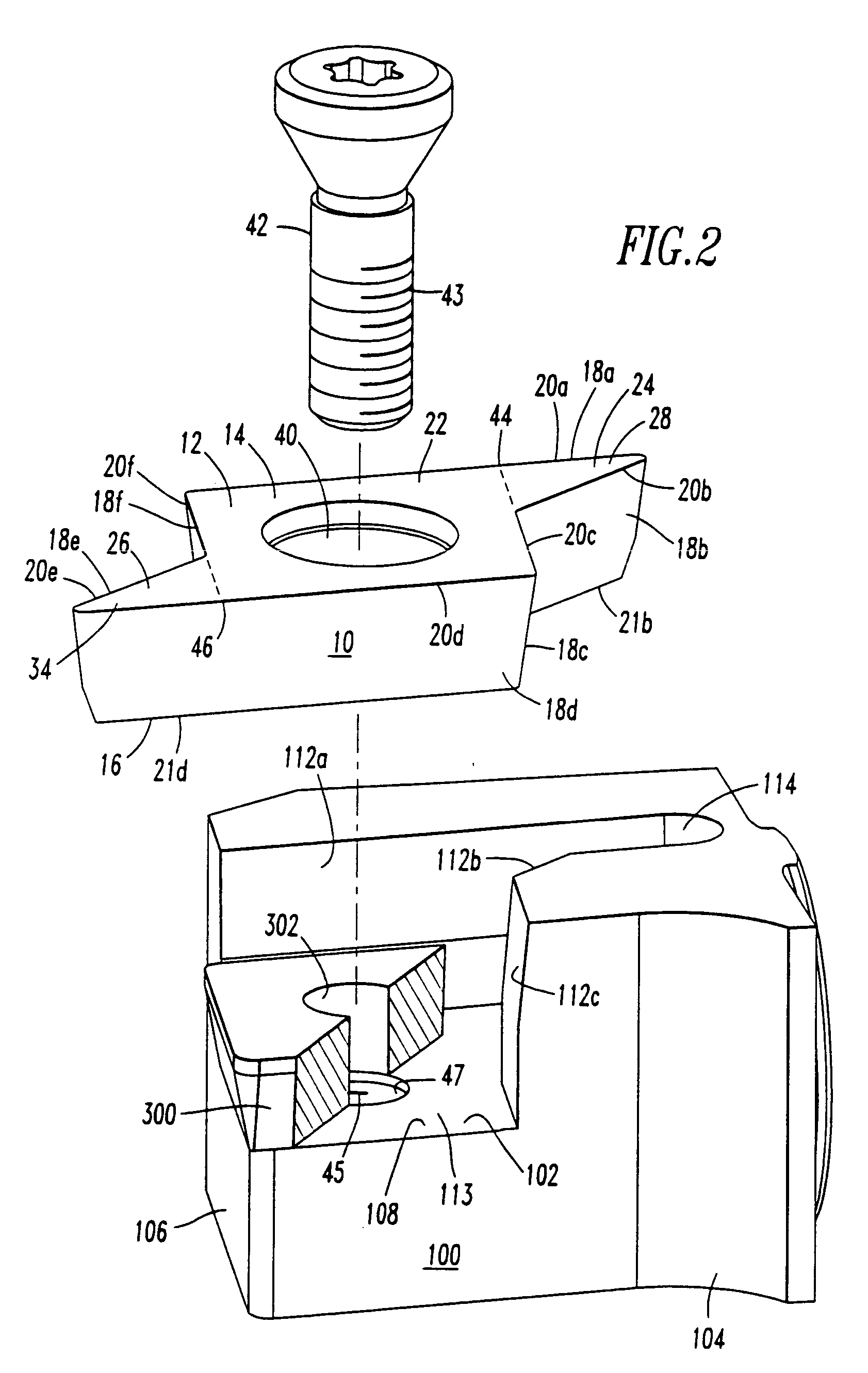

Cutting insert and toolholder for holding the same

A cutting insert for metalworking operations has an insert core with a pair of cutting portions having cutting tips extending therefrom such that a toolholder having a pocket to accept such a core is suitable to accept different cutting inserts having a common core plus different cutting portions. As a result, for example, an 80° diamond, a 55° diamond and a 35° diamond cutting insert may all be utilized within a common toolholder. The invention is also directed to a toolholder that will accept such a variety of cutting inserts.

Owner:KENNAMETAL INC

High-precision mechanical sharpening method for diamond cutter with high-efficiency and low-cost

InactiveCN1751848ASimple sharpening processLow costOther manufacturing equipments/toolsDiamond cuttingDynamic balance

A high-precision, efficient and cheap method for mechanically sharpening the diamond cutting tool includes such steps as regulating the static balance of grinding machine, turning the grinding disc, polishing it, adhering the grinding diamond particles on the surface of grinding disc, regulating the dynamic balance of the mainshaft system of grinding machine, fixing the diamond cutting tool, regulating the level degree of fixture, opening air source, turning on the grinding machine, regulating rotation speed, grinding pressure and front angle of cutting tool, and grinding.

Owner:HARBIN INST OF TECH

Cutting insert and toolholder for holding the same

InactiveUS20050019112A1Minimization requirementsCutting insertsTurning toolsDiamond cuttingMetalworking

A cutting insert for metalworking operations has an insert core with a pair of cutting portions having cutting tips extending therefrom such that a toolholder having a pocket to accept such a core is suitable to accept different cutting inserts having a common core plus different cutting portions. As a result, for example, an 80° diamond, a 55° diamond and a 35° diamond cutting insert may all be utilized within a common toolholder. The invention is also directed to a toolholder that will accept such a variety of cutting inserts.

Owner:KENNAMETAL INC

Technique for producing ultrathin diamond cutting slice of metal anchoring agent

InactiveCN101474777AImprove cutting effectHigh strengthBonded abrasive wheelsGrinding devicesDiamond cuttingHigh density

The present invention relates to the manufacturing field of hard brittle material, and especially to a technique for manufacturing an ultrathin diamond cutting slice of metal anchoring agent. The method comprises the following steps: selecting high-fundamental-grain diamond for executing surface metallization procession; precise-grinding and ball-milling the metal powder through water cooling; mixing the processed diamond and metal powder; cold pressing; hot pressing sintering to prepare thin sheet with high compactness degree; and finally clamping the thin sheet for grinding to prepare cutting slice with satisfied standard and dimension. According to the technique, the surface of diamond has stable cutting property and combination property after metallization procession. The metal powder is mechanically pre-alloyed through water cooling, precise-grinding and ball-milling and has stable performance. The high-strength and high-density cutting slice can be obtained through hot pressing sintering. The technique is easy and convenient for controlling. The cutting slice has stable cutting performance and long service lifetime.

Owner:CHANGZHOU HUAZHONG GROUP

Binder for the Fabrication of Diamond Tools

Owner:NATIONAL RESEARCH TECHNOLOGICAL UNIVERSITY +3

Preparation method for diamond cutting grinding piece

The invention relates to a preparation method for a diamond cutting grinding piece. The diamond cutting grinding piece comprises a diamond cutting grinding piece body arranged on a 65Mn steel substrate, and corrugated water channels are formed in the surface of the diamond cutting grinding piece body. The preparation method for the diamond cutting grinding piece comprises the steps of material mixture, substrate machining, compression forming, sintering and edge forming. The diamond cutting grinding piece produced through the preparation method for the diamond cutting grinding piece has the cutting effect and the grinding effect, and is safe and reliable in performance, simple and reasonable in structure, low in manufacturing cost, flexible in operation, good in sharpness of products and good in chip-removal performance.

Owner:JIANGSU FENGTAI TOOLS

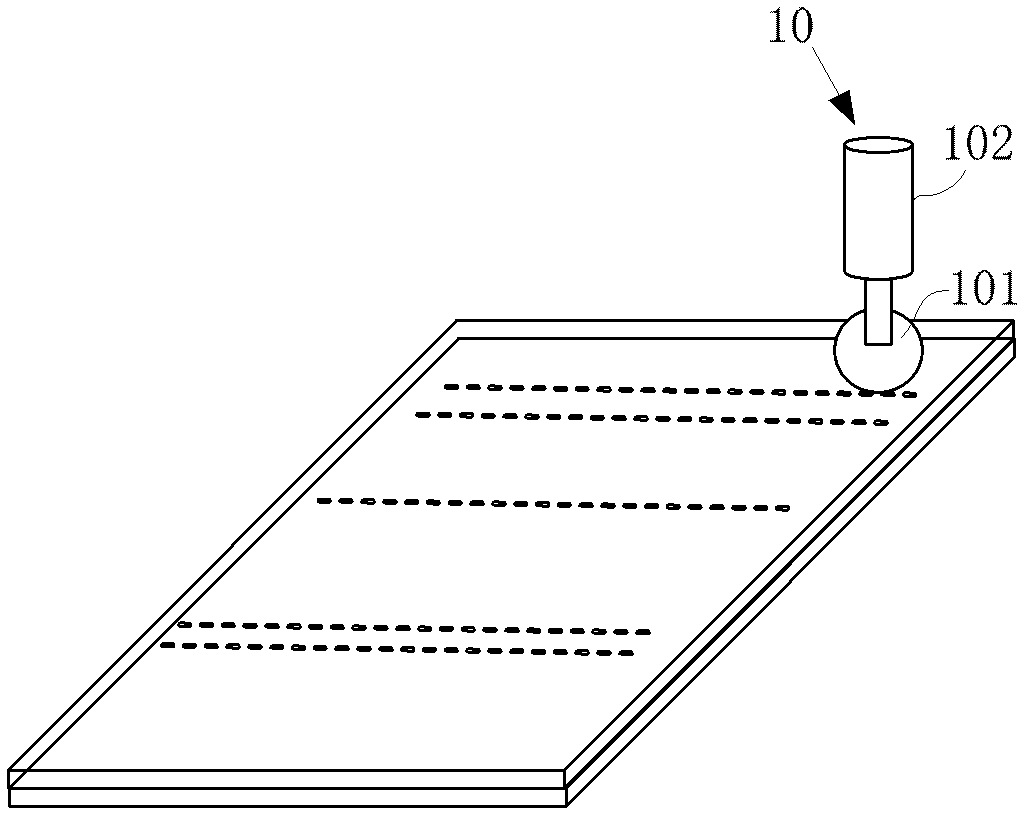

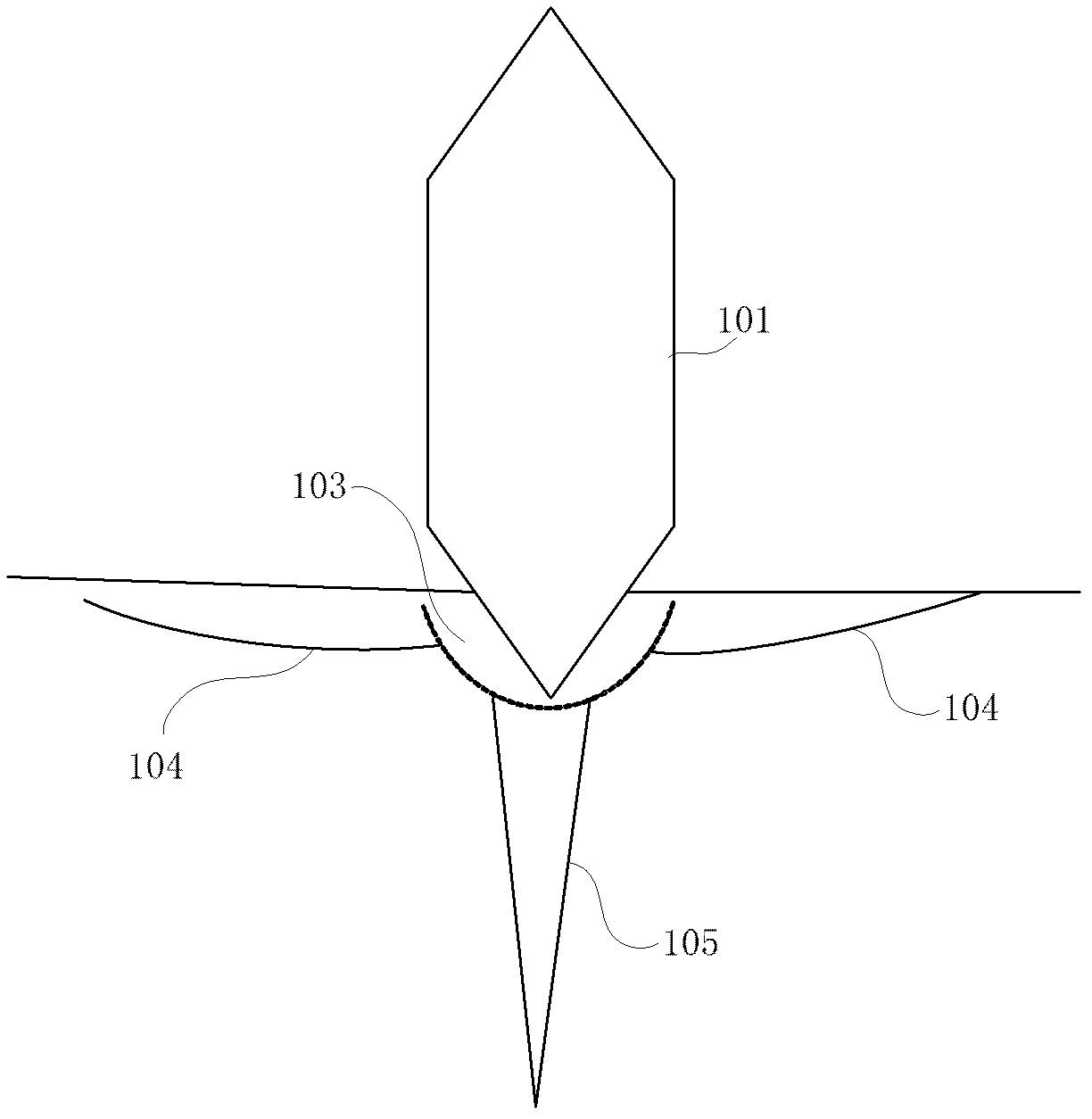

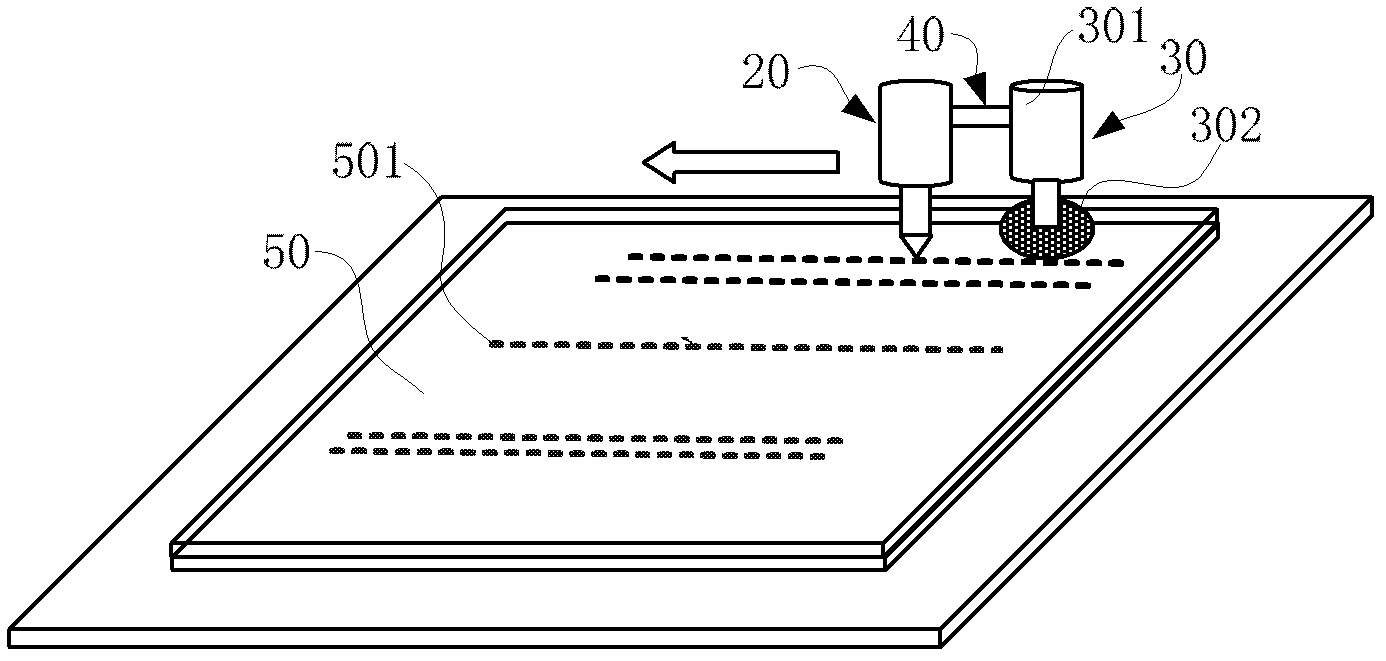

Cutting device and method of glass substrate

ActiveCN102515494AExtended service lifeIncrease frictionFine working devicesGlass severing apparatusDiamond cuttingEngineering

The present invention discloses a glass substrate cutting device, comprising a laser emission device and a cutting device, wherein the laser emission device emits a laser beam on the surface of a glass substrate to be cut to form a microgroove on the glass substrate surface, the cutting device is used for cutting the glass substrate at the position of the microgroove and comprises a cutting wheel fixing device and a diamond cutting wheel fixed on the cutting wheel fixing device. According to the invention, by using the laser emission device to emit the laser beam to form the microgroove on the glass substrate surface, the diamond cutting wheel can be embedded in the microgroove at the position of the microgroove to cut, thus the friction between the diamond cutting wheel and the glass substrate can be increased, the diamond cutting wheel is prevented from sliding when cutting, and the cutting precision is improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

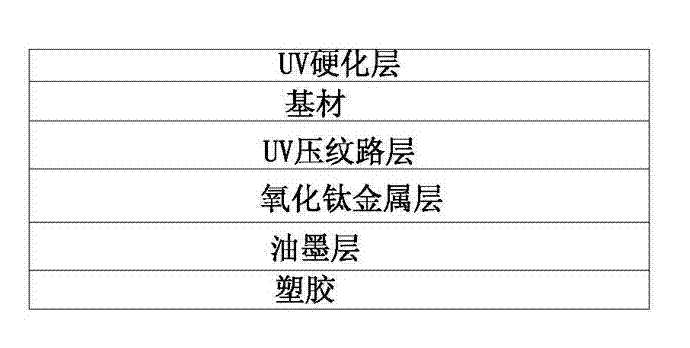

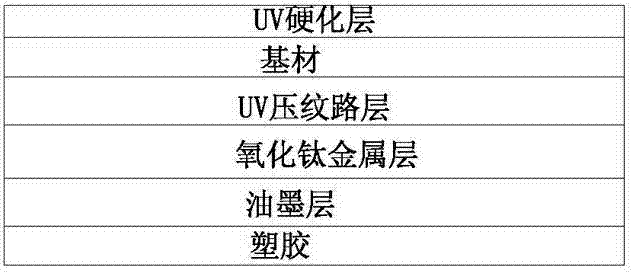

Treatment process of injecting product in mold

The invention discloses a treatment process of injecting a product in a mold, which comprises the following steps: (1) coating UV finish on one surface of a base material, curing to form a UV hardened layer; (2) coating the UV finish on the other surface of the base material, performing die casting on the UV finish to obtain lines, curing the base material in a curing furnace to form a UV line layer; (3) performing vacuum sputtering of a titanium oxide metal layer on the UV line layer, wherein the light transmittance of the titanium oxide metal layer is 75-80%; (4) printing an ink layer on the titanium oxide metal layer; (5) punching the base material with the printed ink layer to form a sheet material; (6) putting the punched sheet material in a corresponding injection mold to perform injection molding so as to obtain a finished product. The product processed by the treatment process of injecting a product in a mold of the invention has diamond cutting effect with high angularity and high stereoscopic impression, has high wear resistance, and is applicable to mobile phones, panel personal computers, and products with other structures.

Owner:GUANGDONG JANUS SMART GRP CO LTD

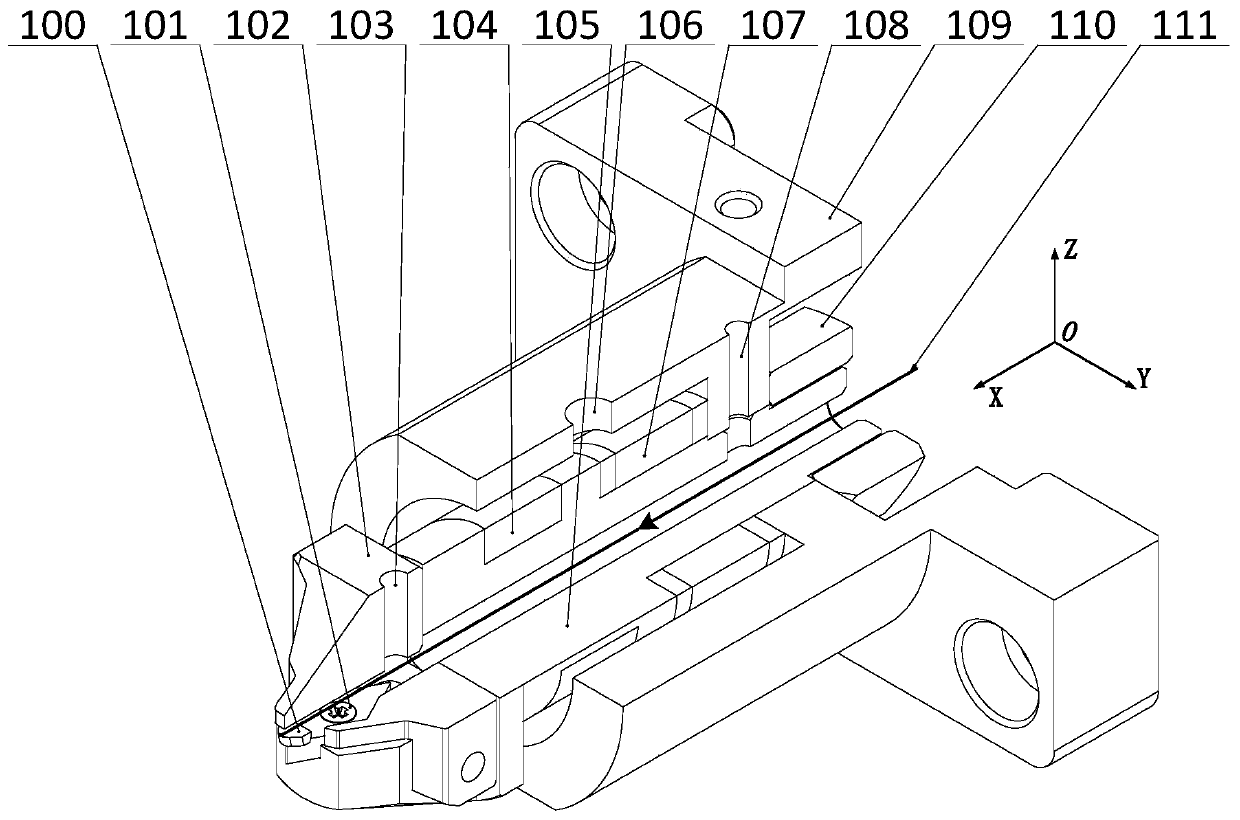

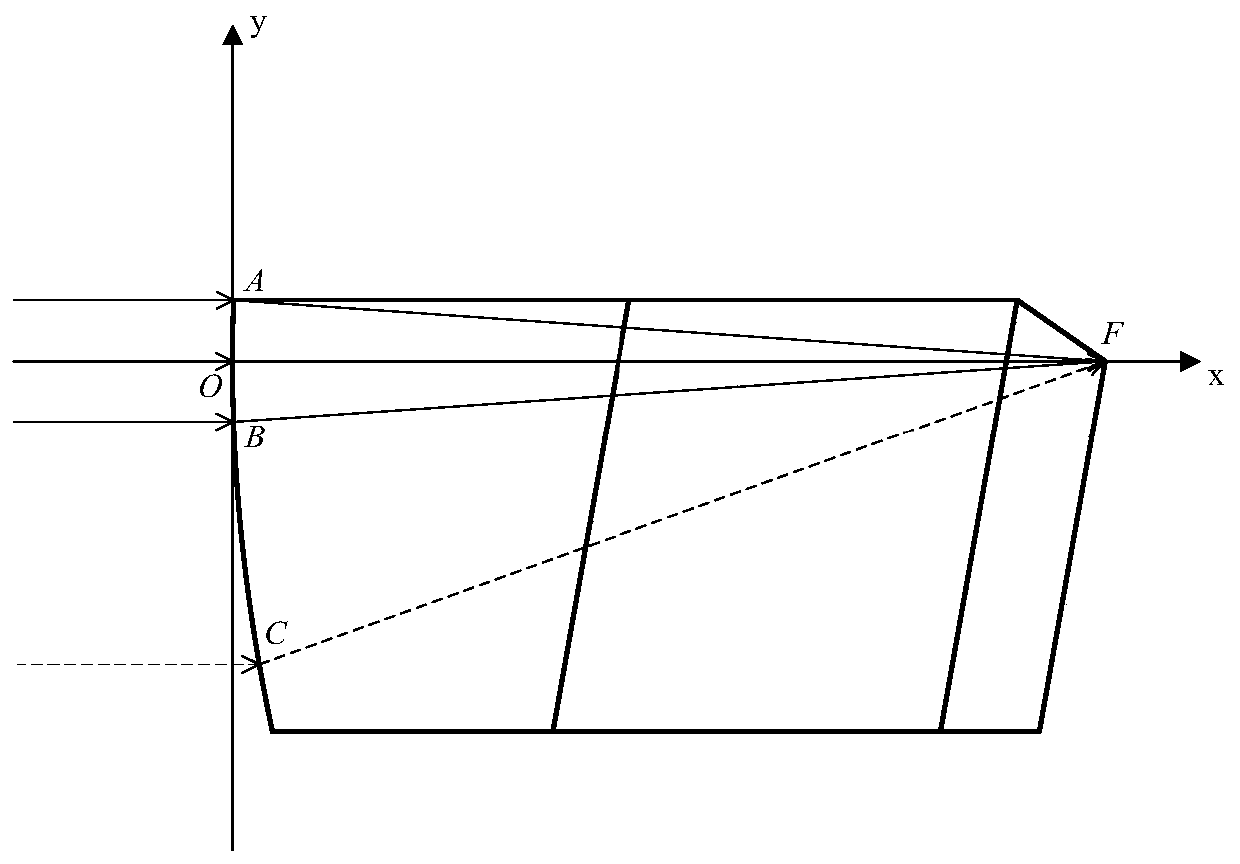

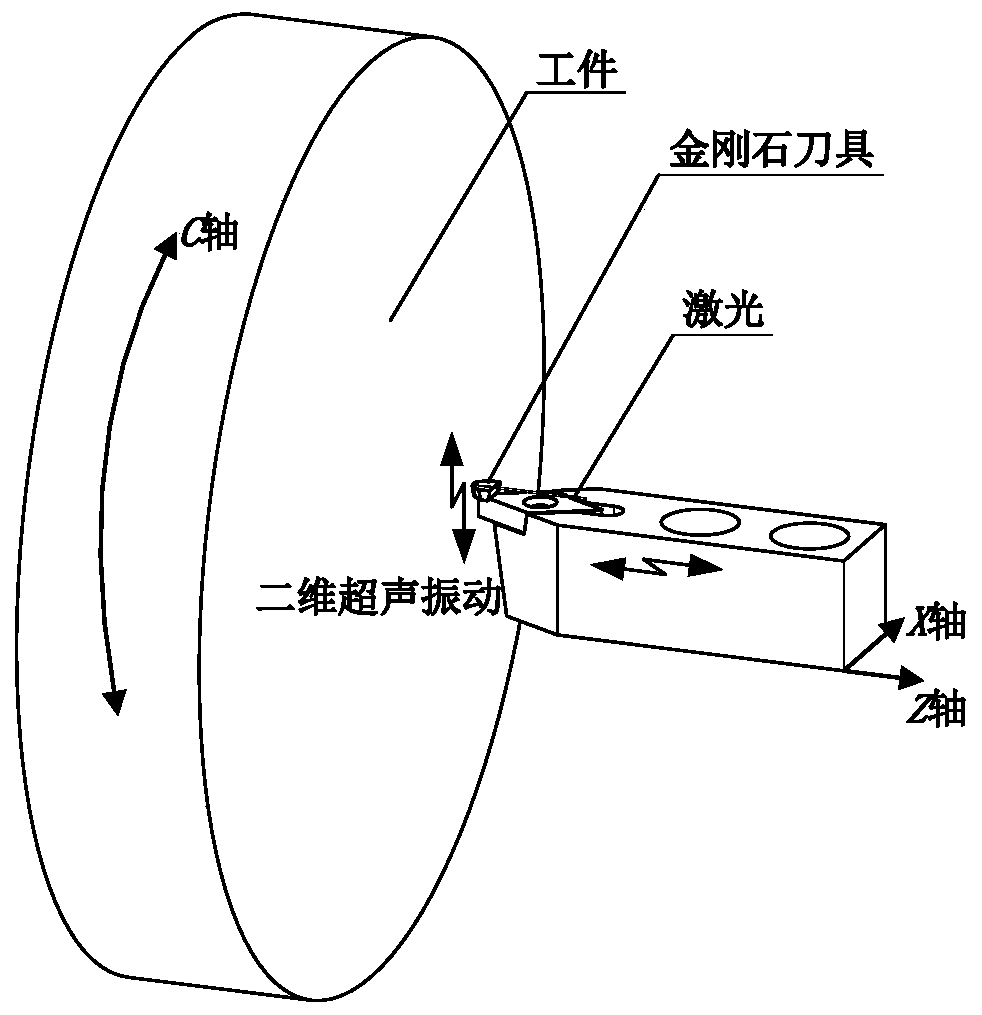

Ultrasonic vibration micro laser assisted composite single-point diamond cutting processing system

ActiveCN111069767AAvoid misalignmentGuaranteed accuracyLaser beam welding apparatusDiamond cuttingEngineering

The invention belongs to the field of ultra-precision processing, and discloses an ultrasonic vibration micro laser assisted composite single-point diamond cutting processing system. The system comprises a laser emitting module and a cutting module, wherein the laser emitting module is used to emit laser, the cutting module comprises a tool, an ultrasonic amplitude-change pole and a piezoelectricunit, a through hole is formed in the center of the ultrasonic amplitude-change pole, laser emitted by the laser emitting module is focused on the tip point of the tool through the through hole, the piezoelectric unit converts an electrical signal into a pressure signal to enable the ultrasonic amplitude-change pole to drive the tool to vibrate, thereby converting the cutting method from continuous cutting to intermittent cutting, the back end of the tool is an elliptical spherical surface, and when the tool vibrates, the laser is always focused on the tip point of the tool through the back end of the tool to avoid the misalignment of the laser and the tip point when the ultrasonic amplitude-change pole vibrates. Through the system, the organic integration of ultrasonic vibration, single point cutting technology and micro laser assisted processing technology is realized, and the processing efficiency and precision are improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com