Method and equipment for cutting large-diameter silicon carbide single crystals by aid of diamond wires

A silicon carbide single crystal and diamond cutting wire technology, applied in stone processing equipment, fine working devices, manufacturing tools, etc., can solve the problems of large damage layer on the surface of the wafer, low production efficiency, and inability to meet high-efficiency production. Efficient cutting and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The multi-wire cutting machine adopts an electroplated diamond cutting wire with a diameter of 400 μm, and utilizes the reciprocating high-speed cutting motion of the electroplated diamond wire to efficiently cut 2-inch SiC crystal rods;

[0053] The diamond cutting wire has an electroplated diamond particle size of 40-50 μm;

[0054] The substrate of the diamond cutting wire is high carbon steel wire with a diameter of 300 μm;

[0055] The swing angle is 0°;

[0056] The angle of the large-diameter SiC crystal is 0°

[0057] The specific cutting steps are as follows:

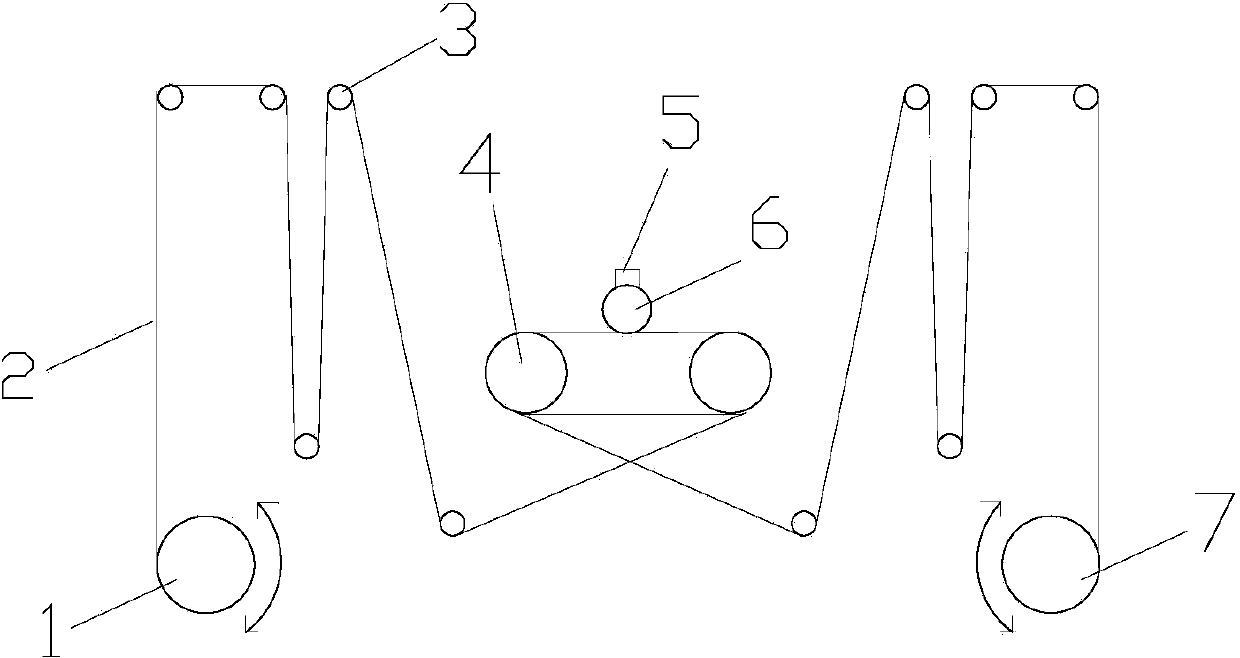

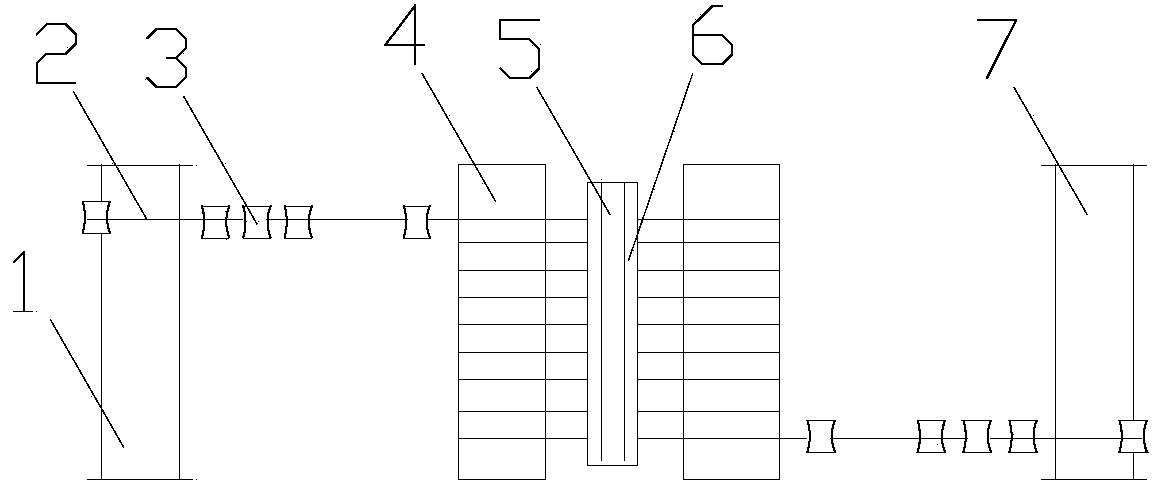

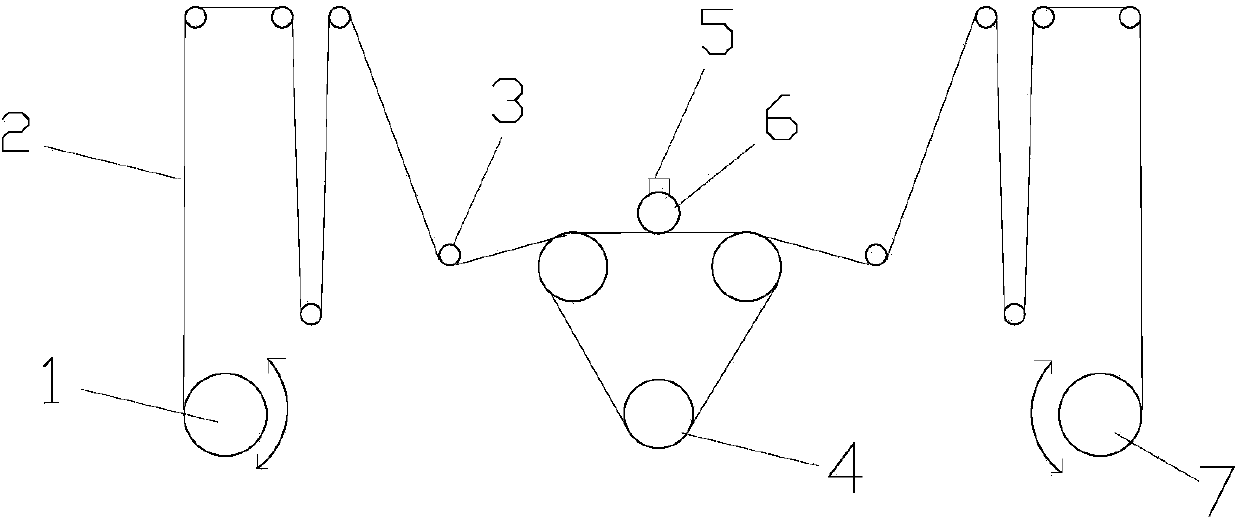

[0058] (1) Winding: the diamond cutting wire is equidistantly wound on the sheave, and a parallel wire network with uniform tension distribution is formed on the upper and lower sides of the sheave;

[0059] (2) Install the SiC crystal to be cut: fix the 2-inch SiC crystal rod to be cut on the workbench;

[0060] (3) Set the process parameters: set the running speed of the cutting line to 1100m / min a...

Embodiment 2

[0065] The multi-wire cutting machine uses an electroplated diamond cutting wire with a diameter of 150 μm, and utilizes the reciprocating high-speed cutting motion of the electroplated diamond wire to efficiently cut 2-inch SiC crystal rods.

[0066] The diamond cutting wire has an electroplated diamond particle size of 20-25 μm;

[0067] The substrate of the diamond cutting wire is high carbon steel wire with a diameter of 100 μm;

[0068] The swing angle is 5°;

[0069] The angle of the large-diameter SiC crystal is 0°

[0070] The specific cutting steps are as follows:

[0071] (1) Winding: the diamond cutting wire is equidistantly wound on the sheave, and a parallel wire network with uniform tension distribution is formed on the upper and lower sides of the sheave;

[0072] (2) Install the SiC crystal to be cut: fix the 2-inch SiC crystal rod to be cut on the workbench;

[0073] (3) Set the process parameters: set the running speed of the cutting line to 800m / min and ...

Embodiment 3

[0078] The multi-wire cutting machine adopts an electroplated diamond cutting wire with a diameter of 200 μm, and utilizes the reciprocating high-speed cutting motion of the electroplated diamond wire to efficiently cut 3-inch SiC crystal rods;

[0079] The diamond cutting wire has an electroplated diamond particle size of 25-30 μm;

[0080] The substrate of the diamond cutting wire is high carbon steel wire with a diameter of 150 μm;

[0081] The swing angle is 10°;

[0082] The angle of the large-diameter SiC crystal is 0°

[0083] The specific cutting steps are as follows:

[0084] (1) Winding: the diamond cutting wire is equidistantly wound on the sheave, and a parallel wire network with uniform tension distribution is formed on the upper and lower sides of the sheave;

[0085] (2) Install the SiC crystal to be cut: fix the 3-inch SiC crystal rod to be cut on the workbench;

[0086] (3) Set the process parameters: set the running speed of the cutting line to 900m / min a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com