Patents

Literature

101results about How to "Small curvature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

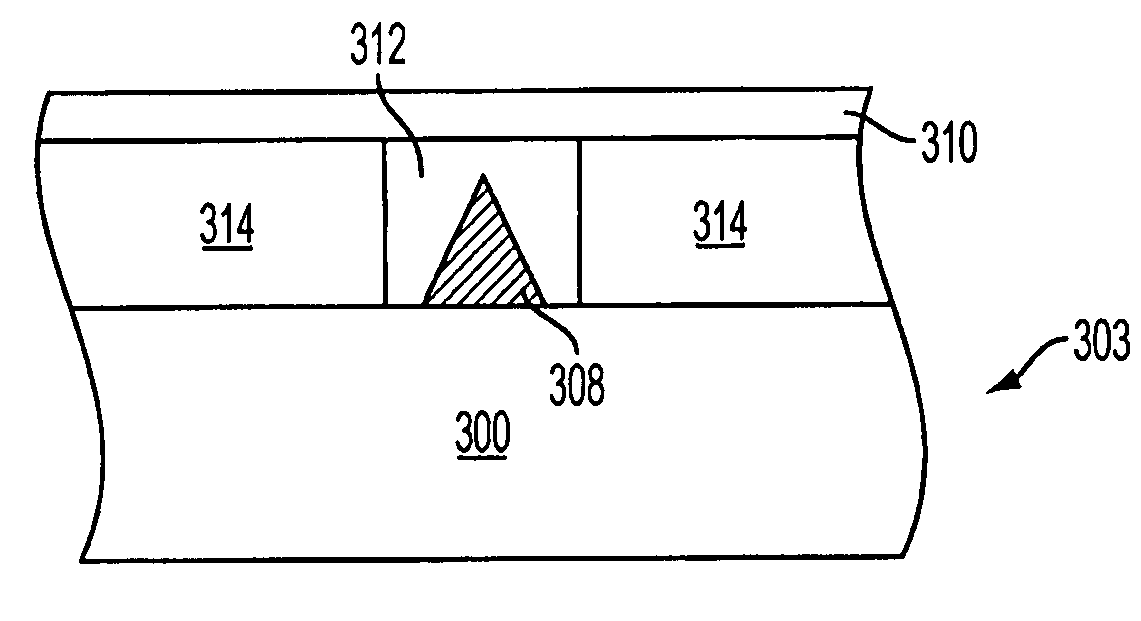

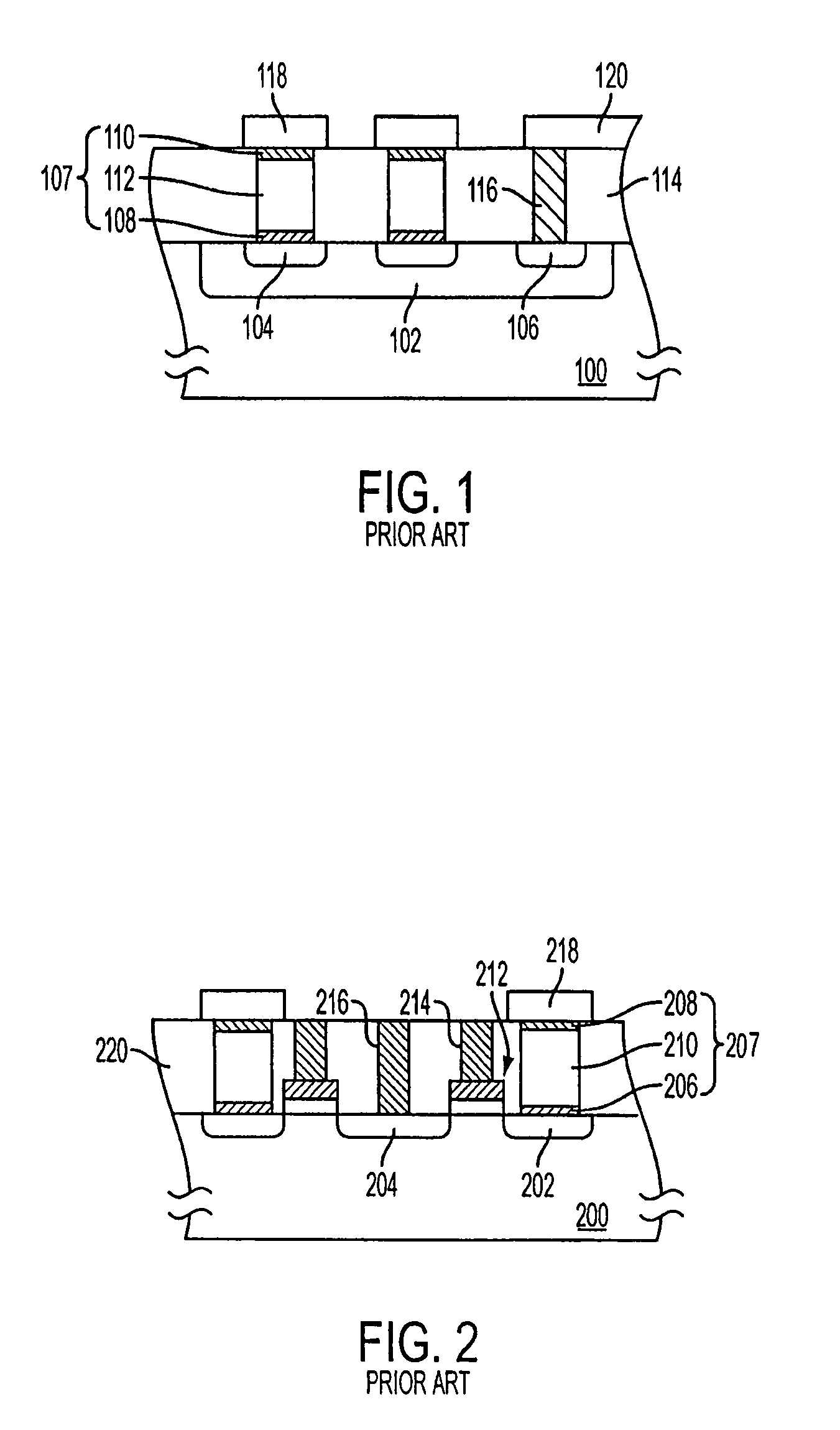

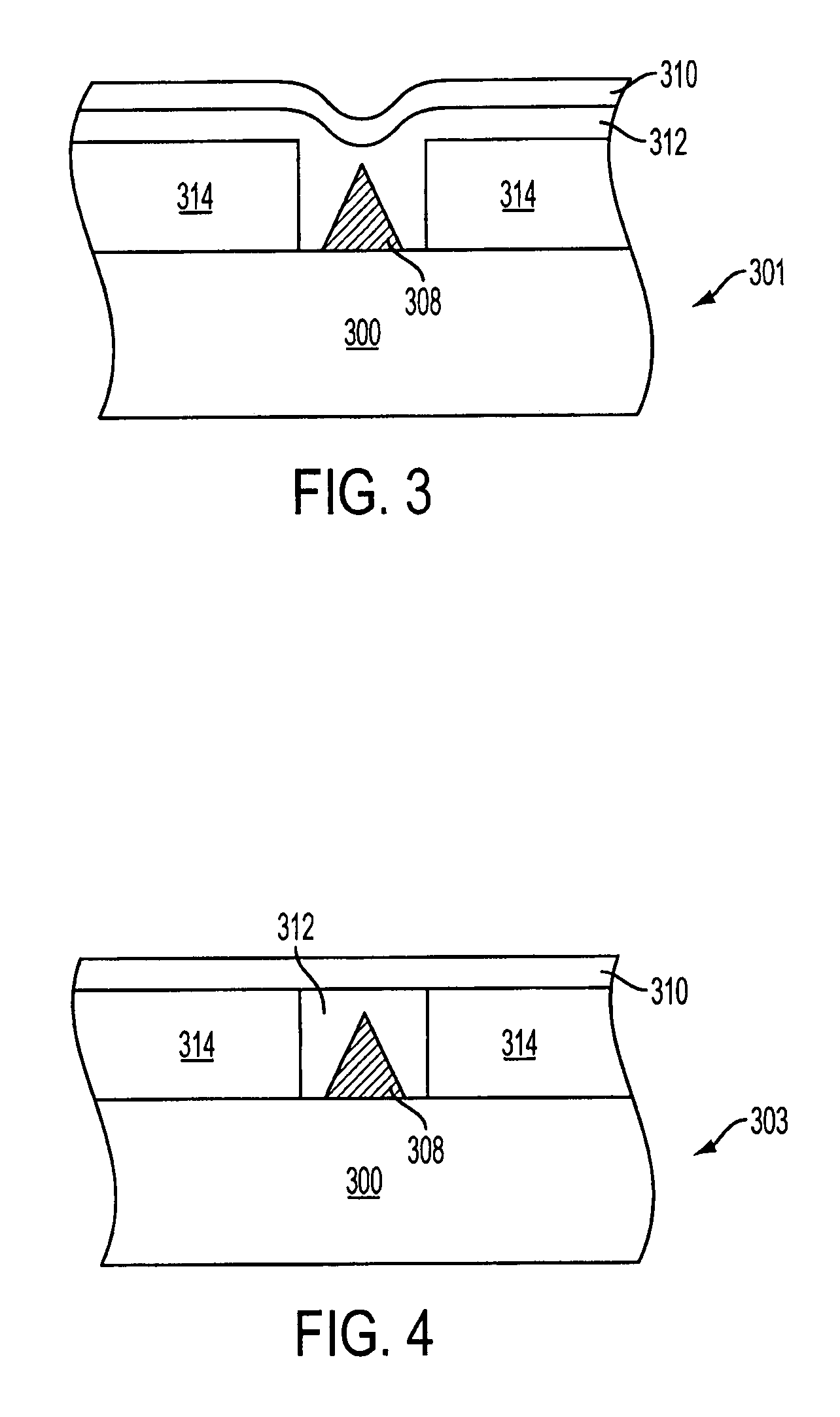

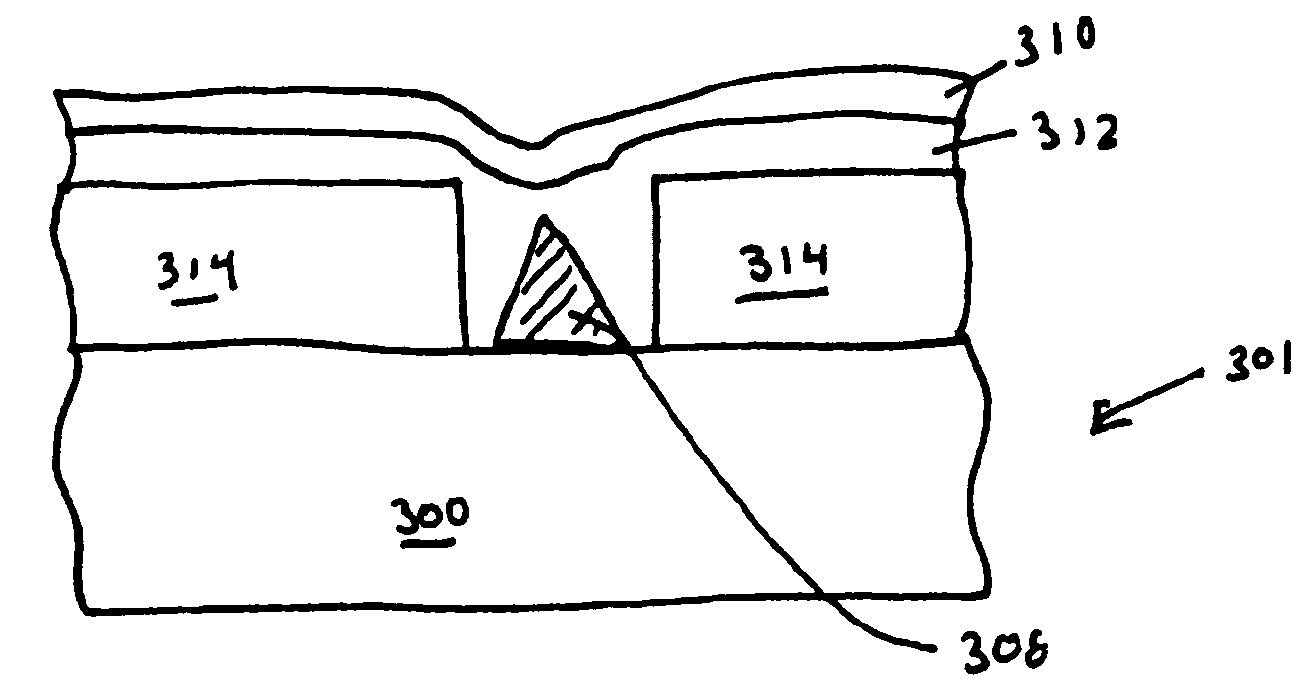

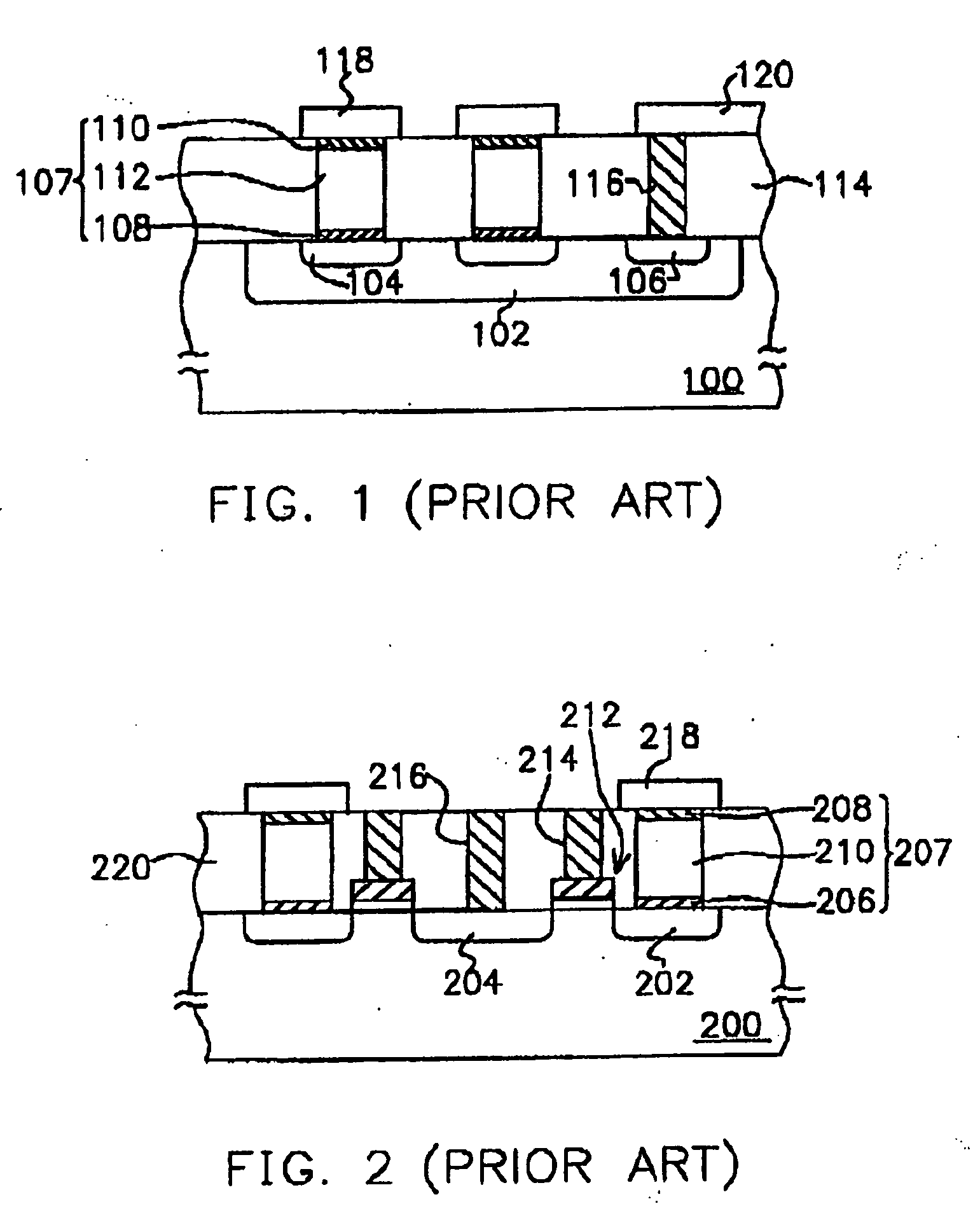

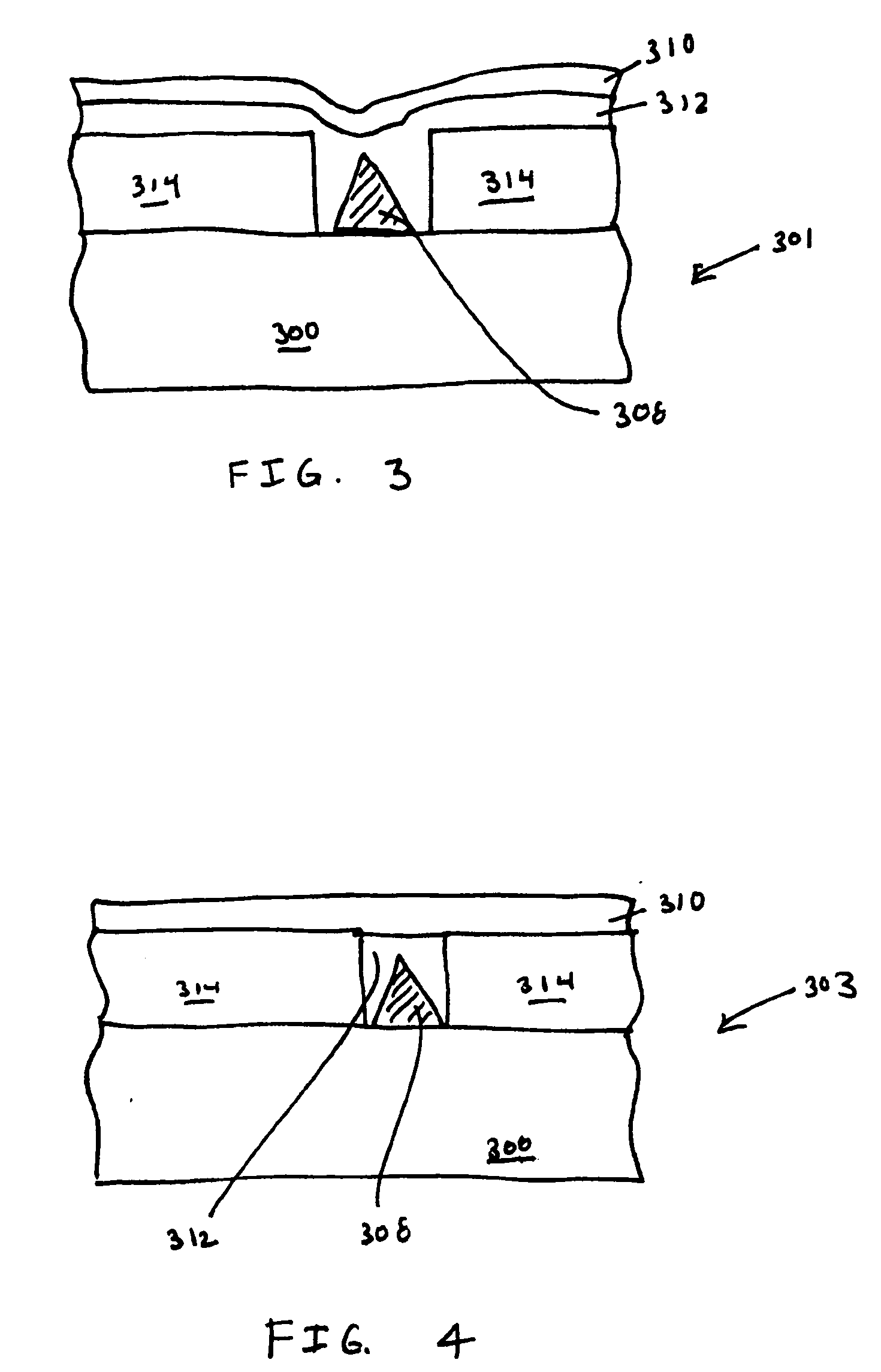

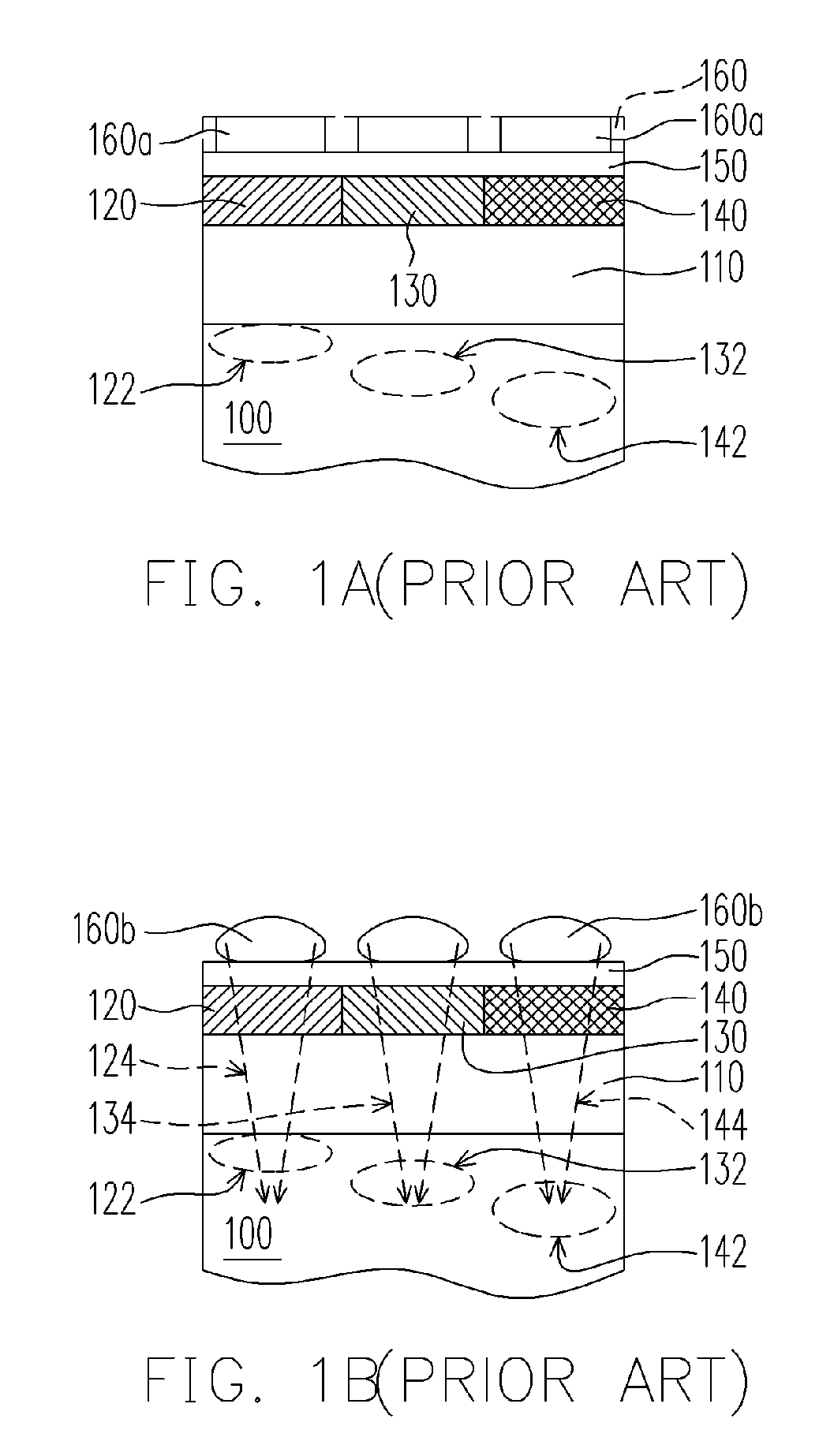

Reproducible resistance variable insulating memory devices having a shaped bottom electrode

ActiveUS7521705B2Small curvatureEnhances the local electric fieldSemiconductor/solid-state device manufacturingBulk negative resistance effect devicesElectrical resistance and conductanceEngineering

The present invention relates to the use of a shaped bottom electrode in a resistance variable memory device. The shaped bottom electrode ensures that the thickness of the insulating material at the tip of the bottom electrode is thinnest, creating the largest electric field at the tip of the bottom electrode. The arrangement of electrodes and the structure of the memory element makes it possible to create conduction paths with stable, consistent and reproducible switching and memory properties in the memory device.

Owner:MICRON TECH INC

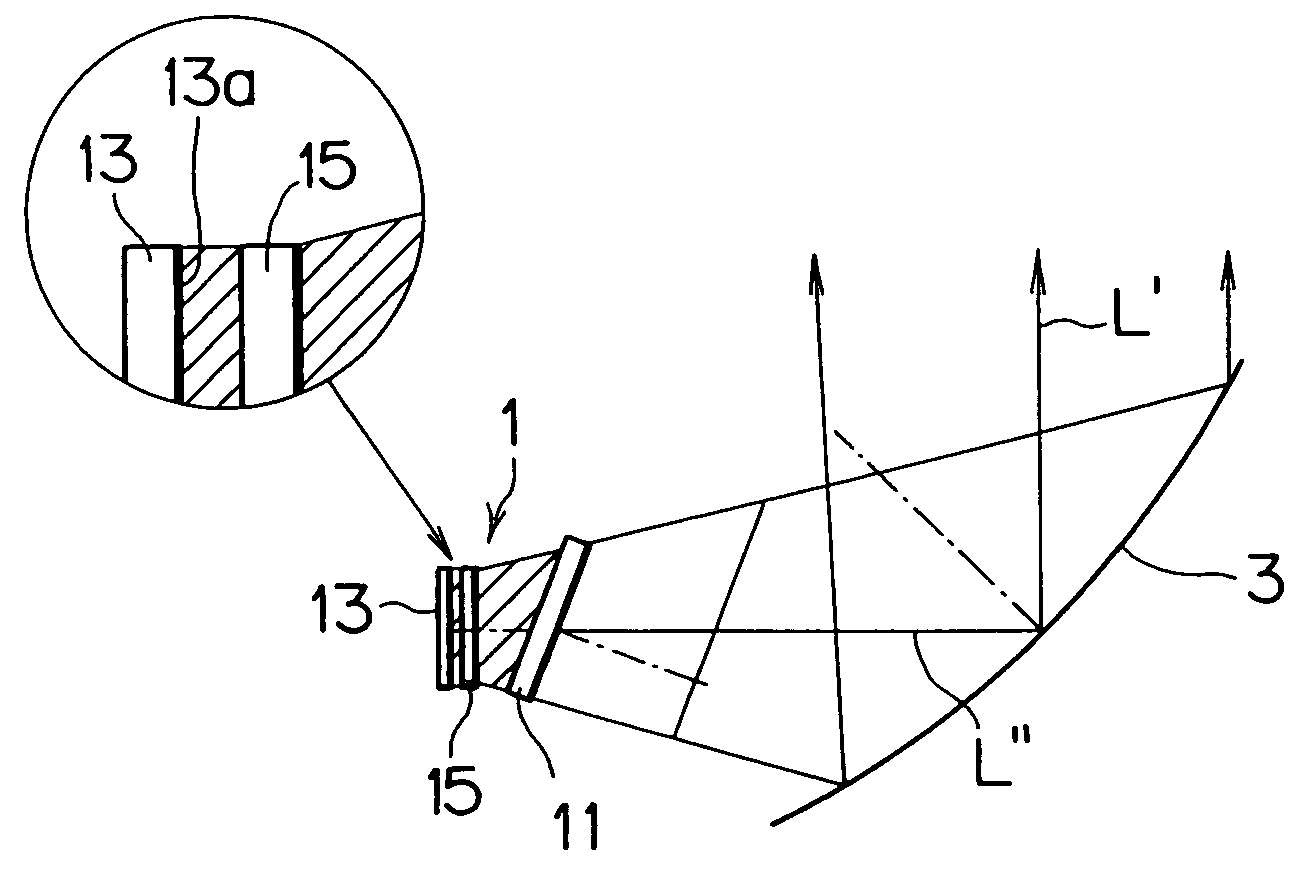

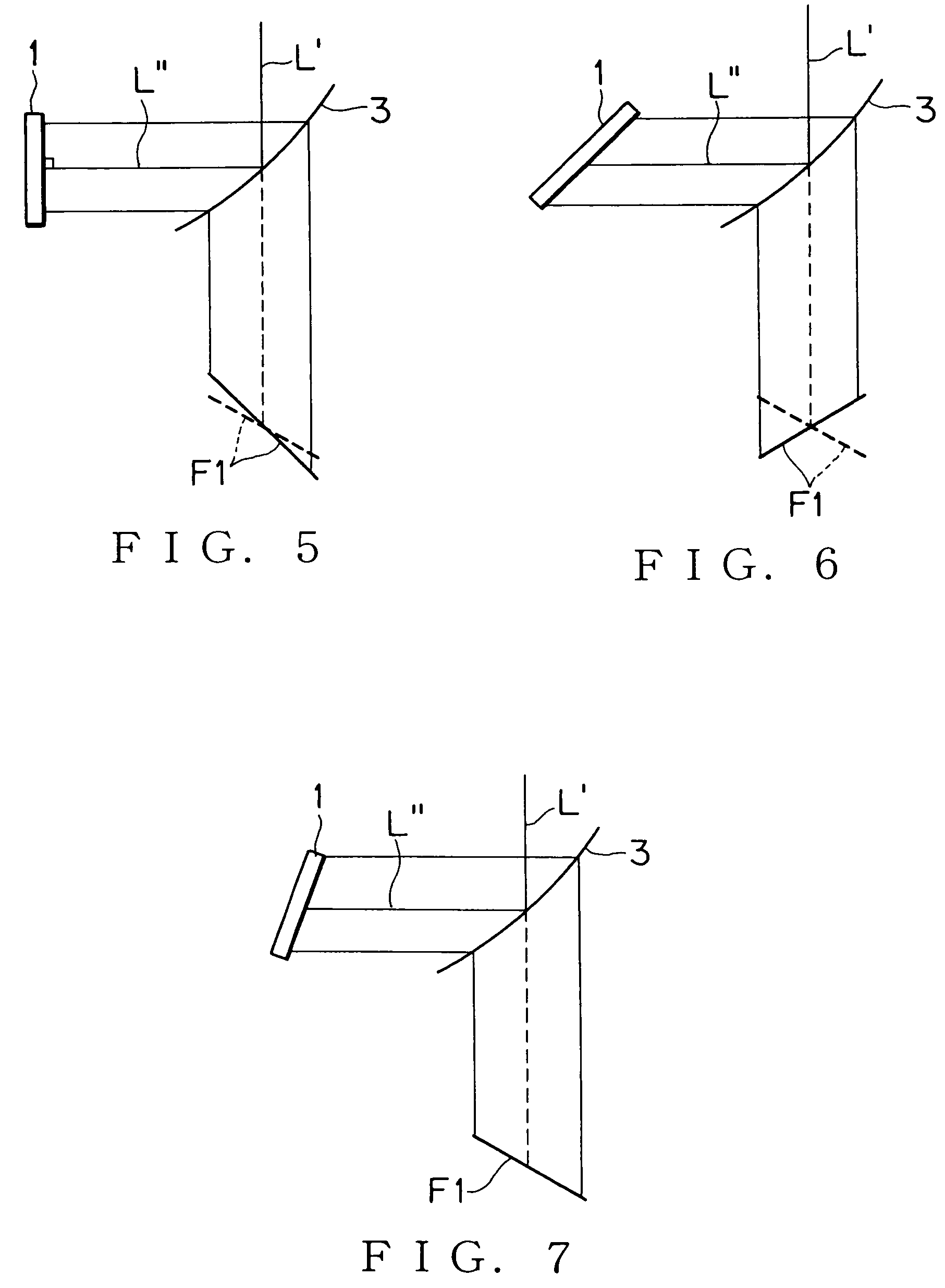

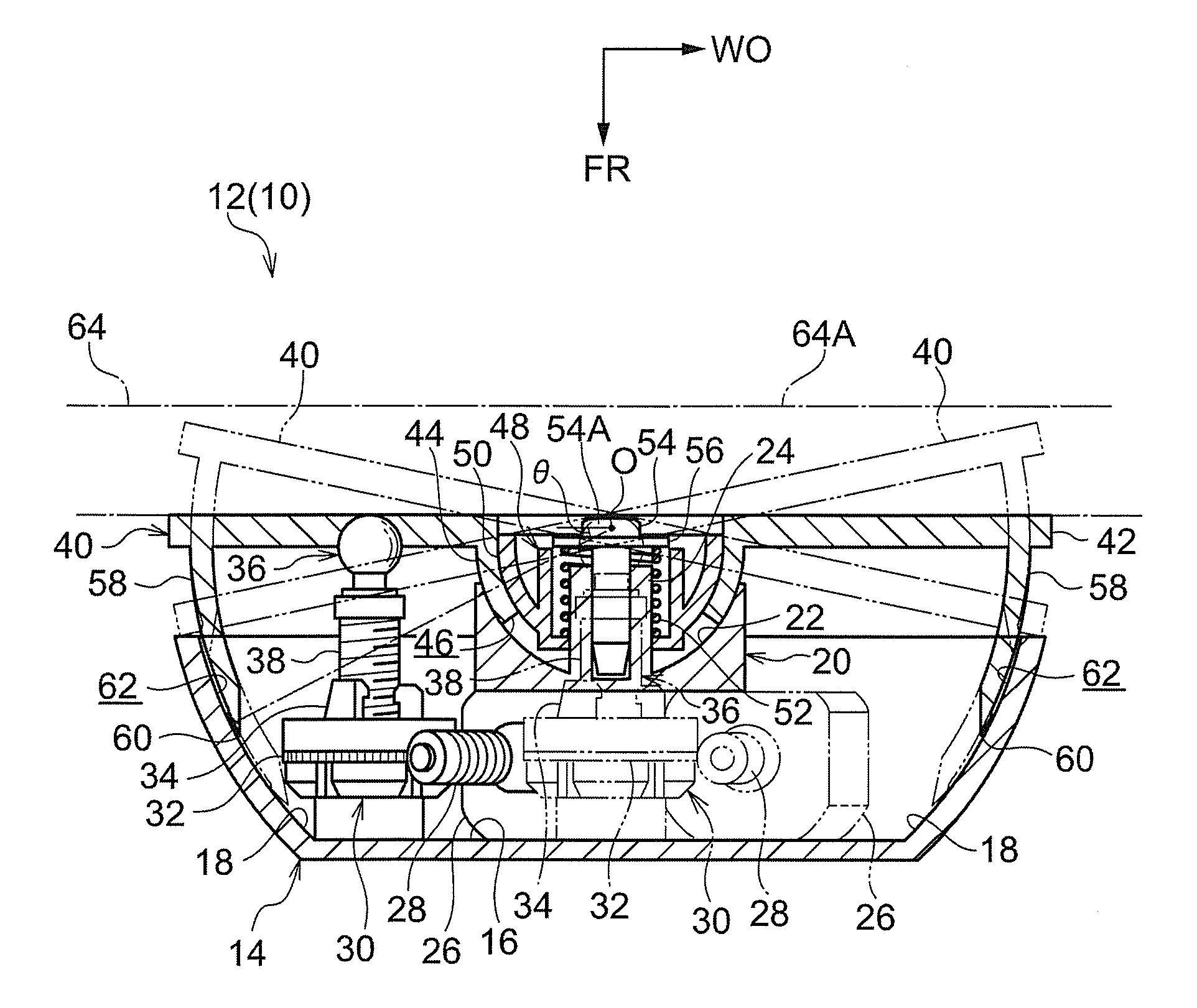

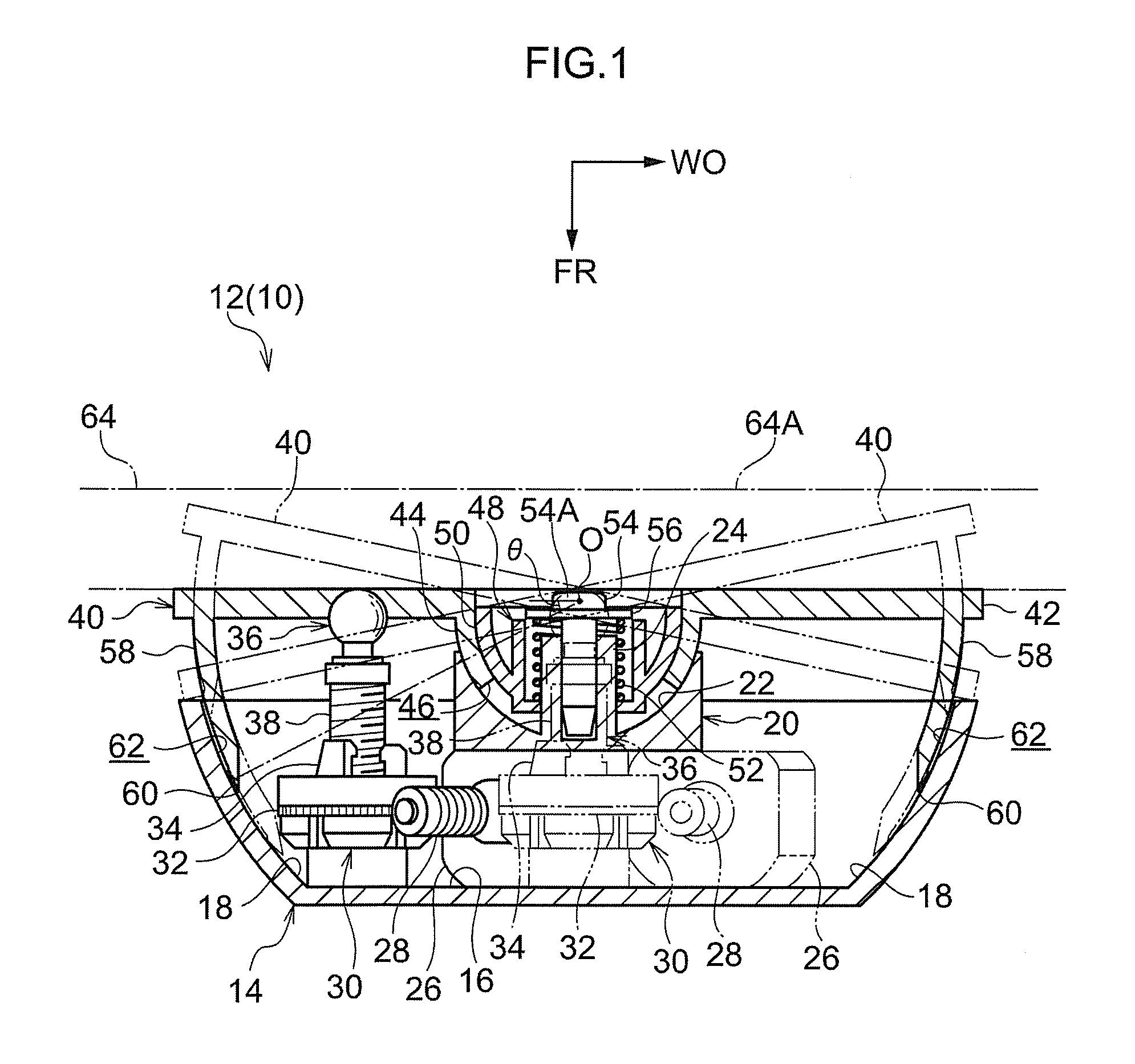

Luminous display device

ActiveUS7599012B2Easy to useAvoid uneven brightnessShow cabinetsMeasurement apparatus componentsLiquid-crystal displayLight beam

In the rear of a liquid crystal display arranged with an inclination to a line of sight reflected by a concave mirror, a backlight and a focusing lens member are arranged in such a manner that the backlight and the focusing lens member are positioned on a plane perpendicular to the line of sight reflected by the concave mirror, and the focusing lens member focuses beams of illumination light from the backlight in such a manner that the beams of illumination light stays within a range of the liquid crystal display.

Owner:YAZAKI CORP

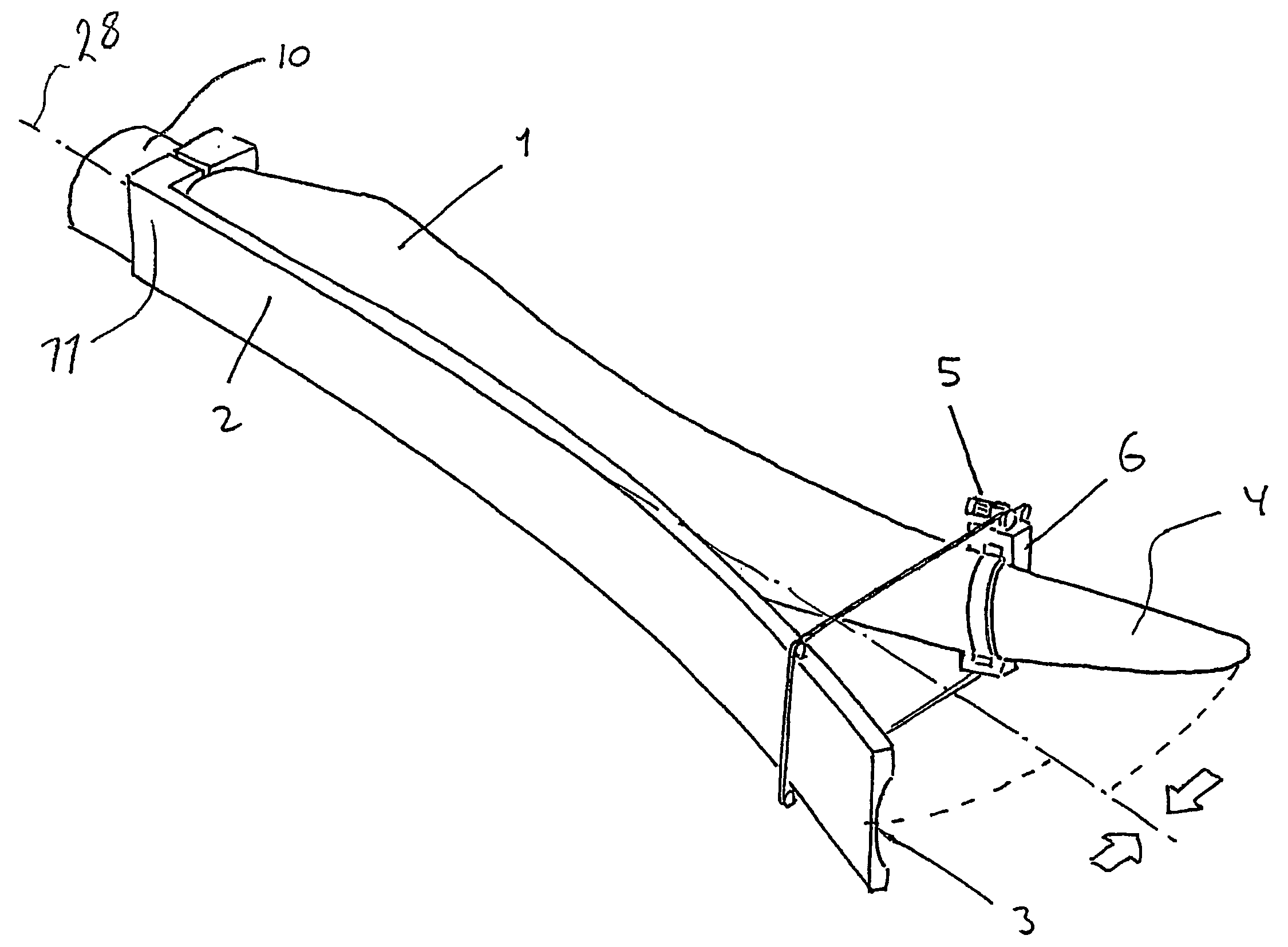

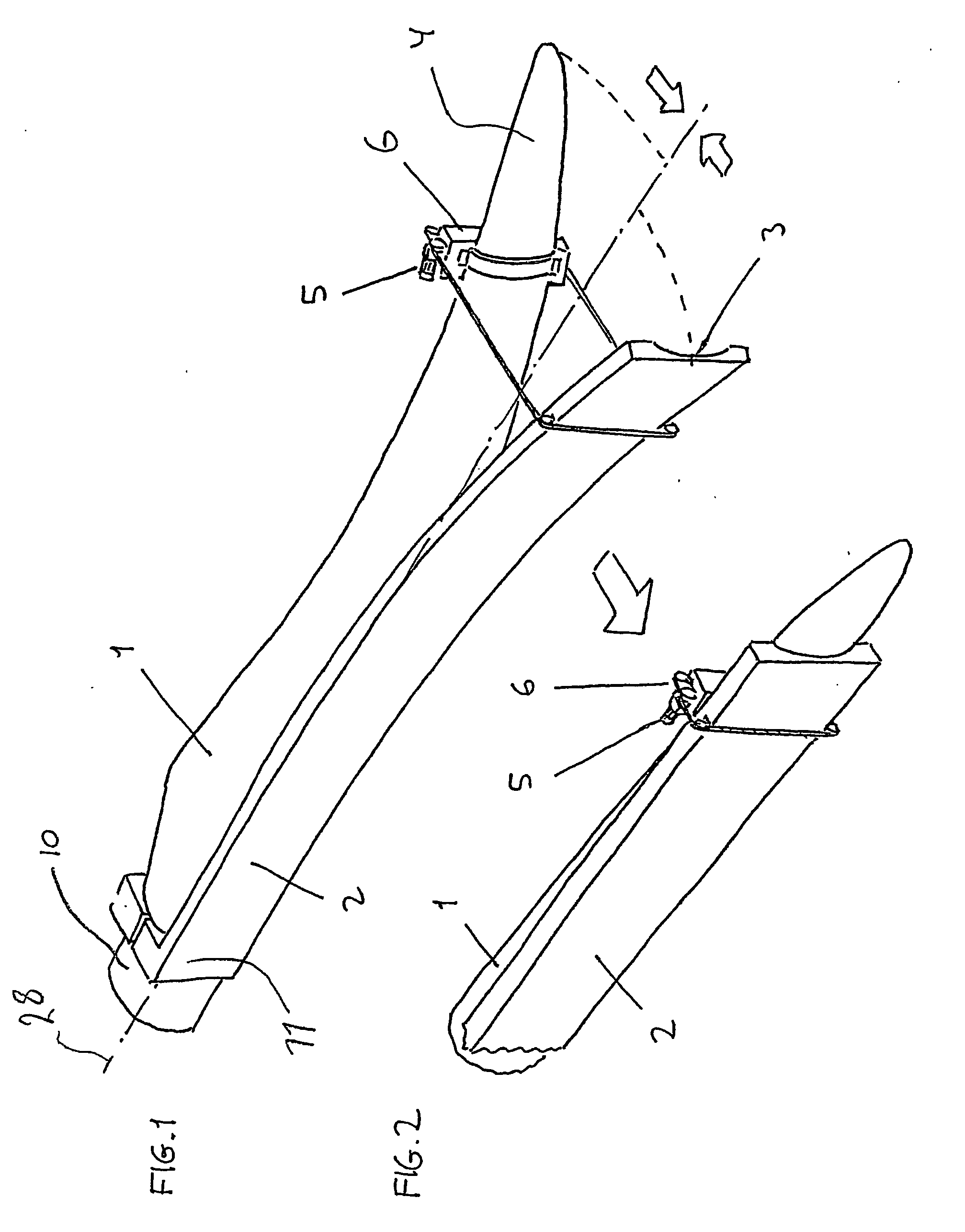

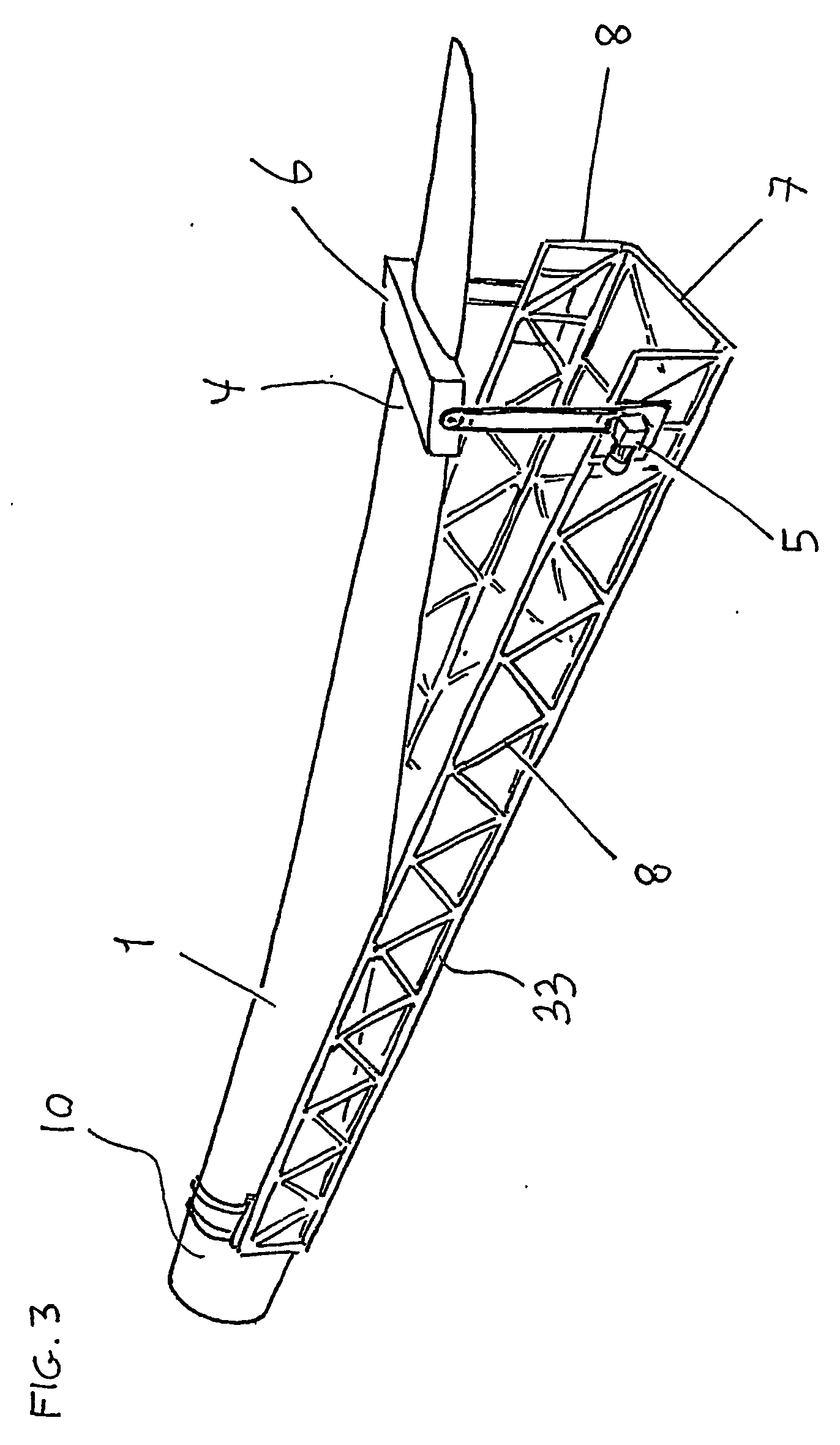

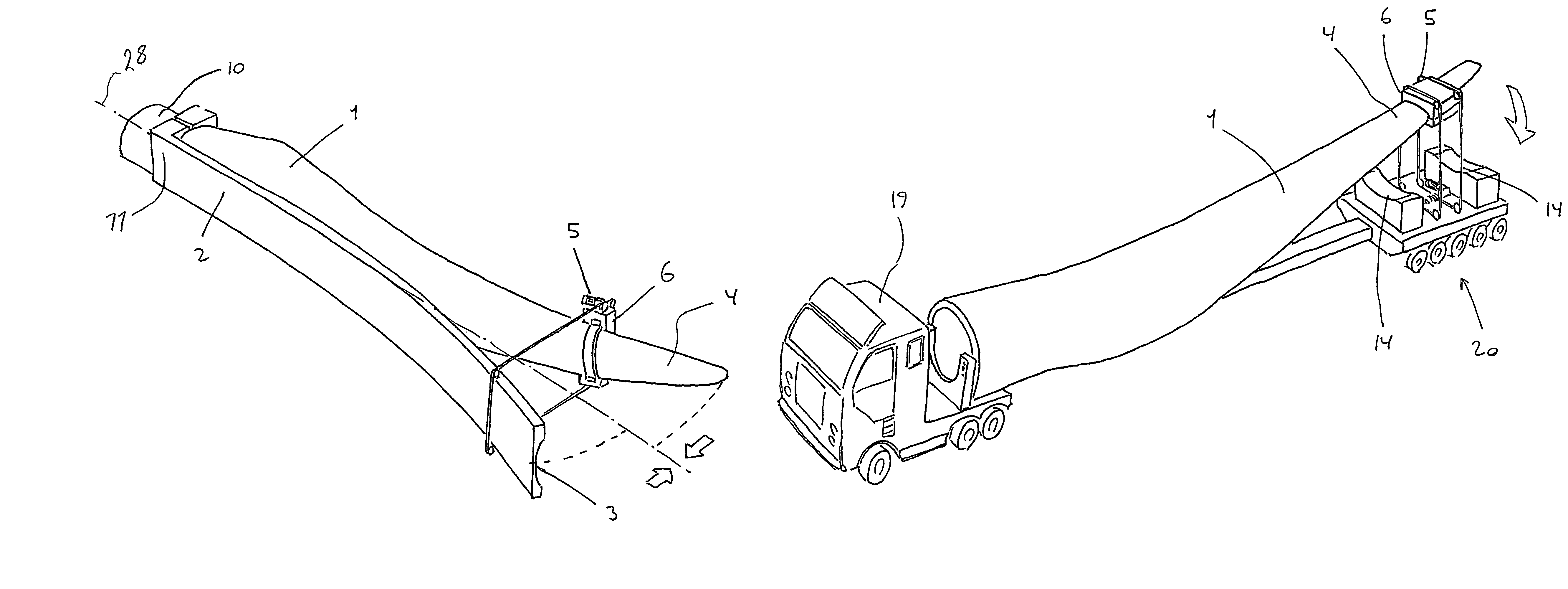

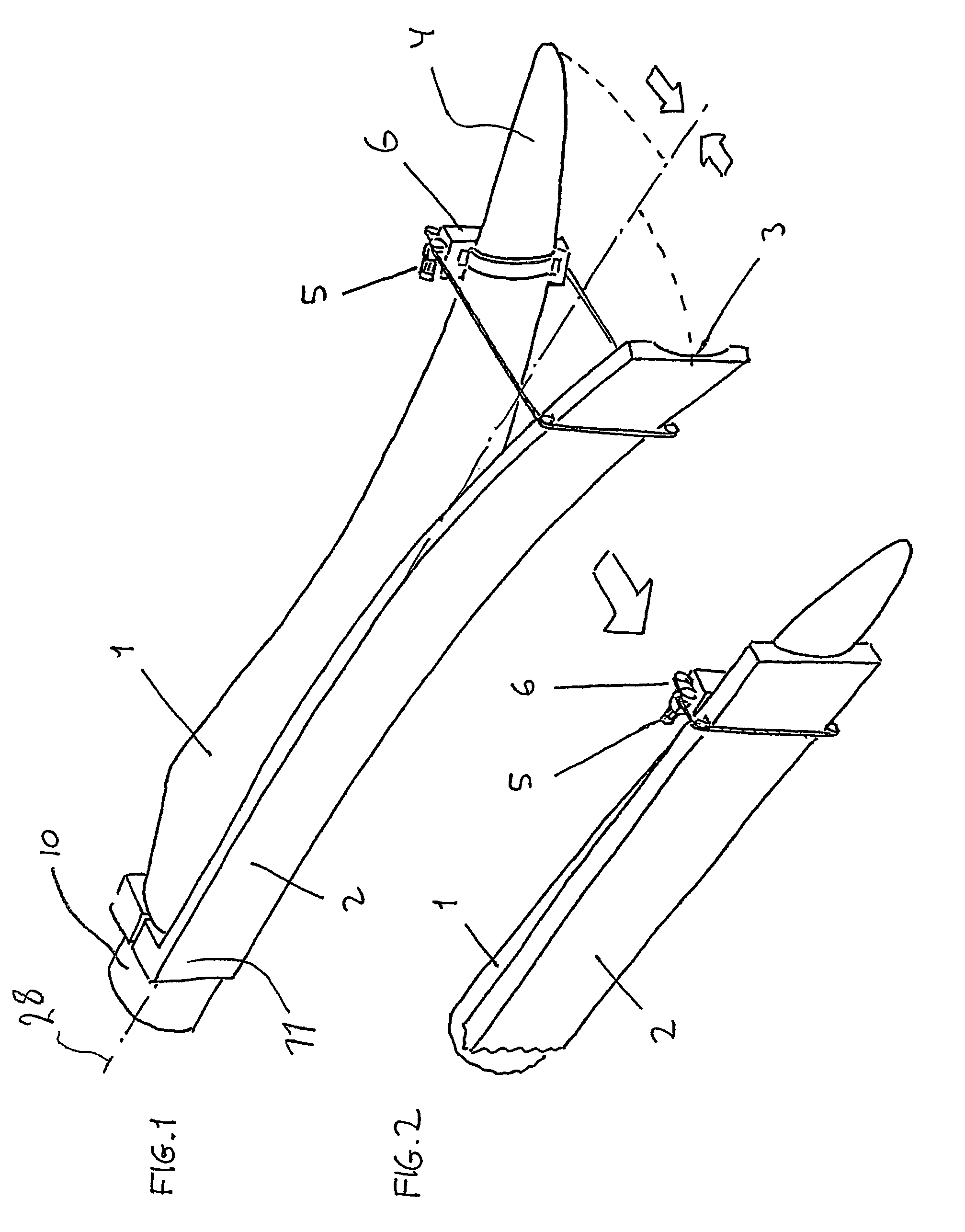

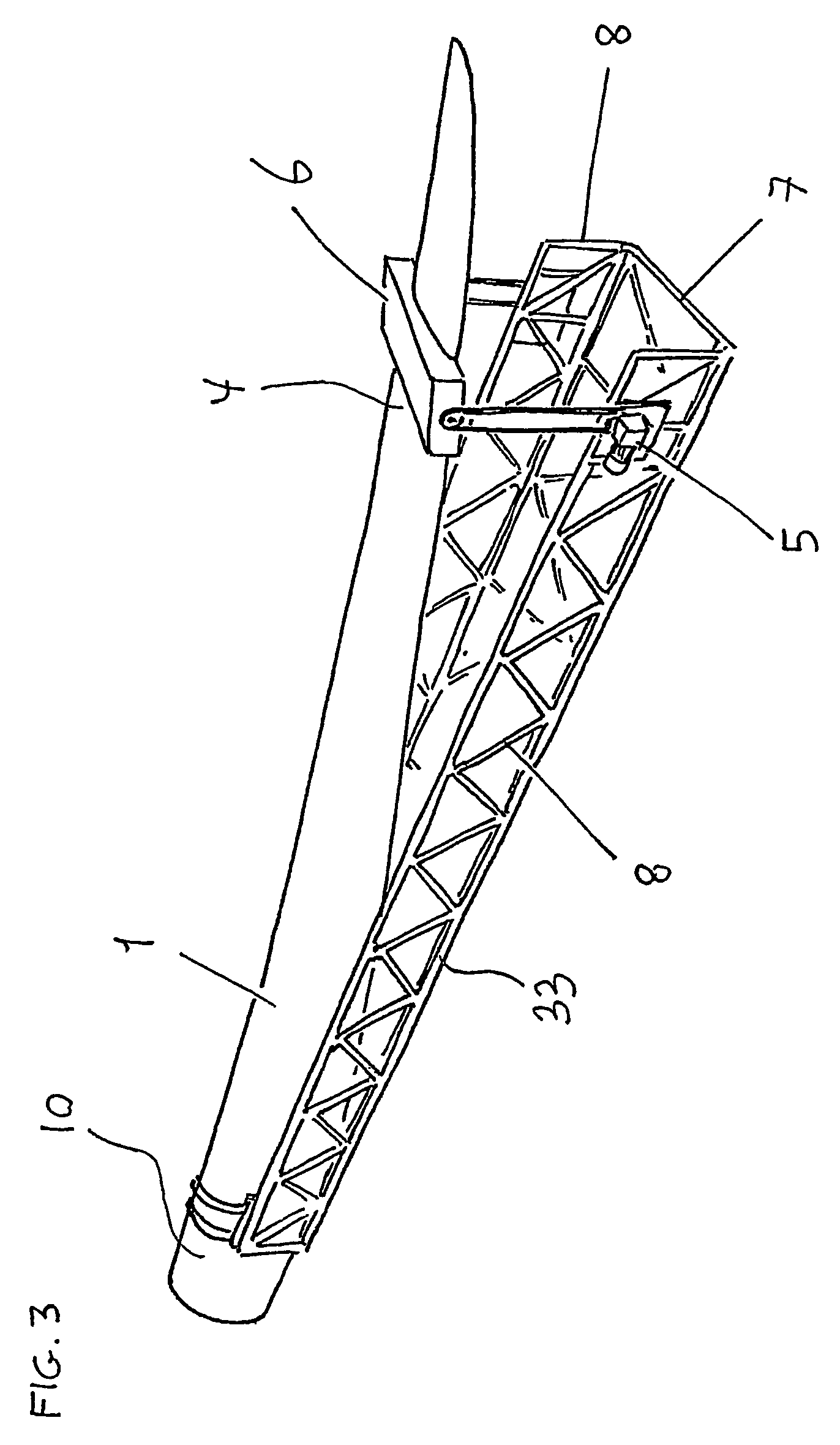

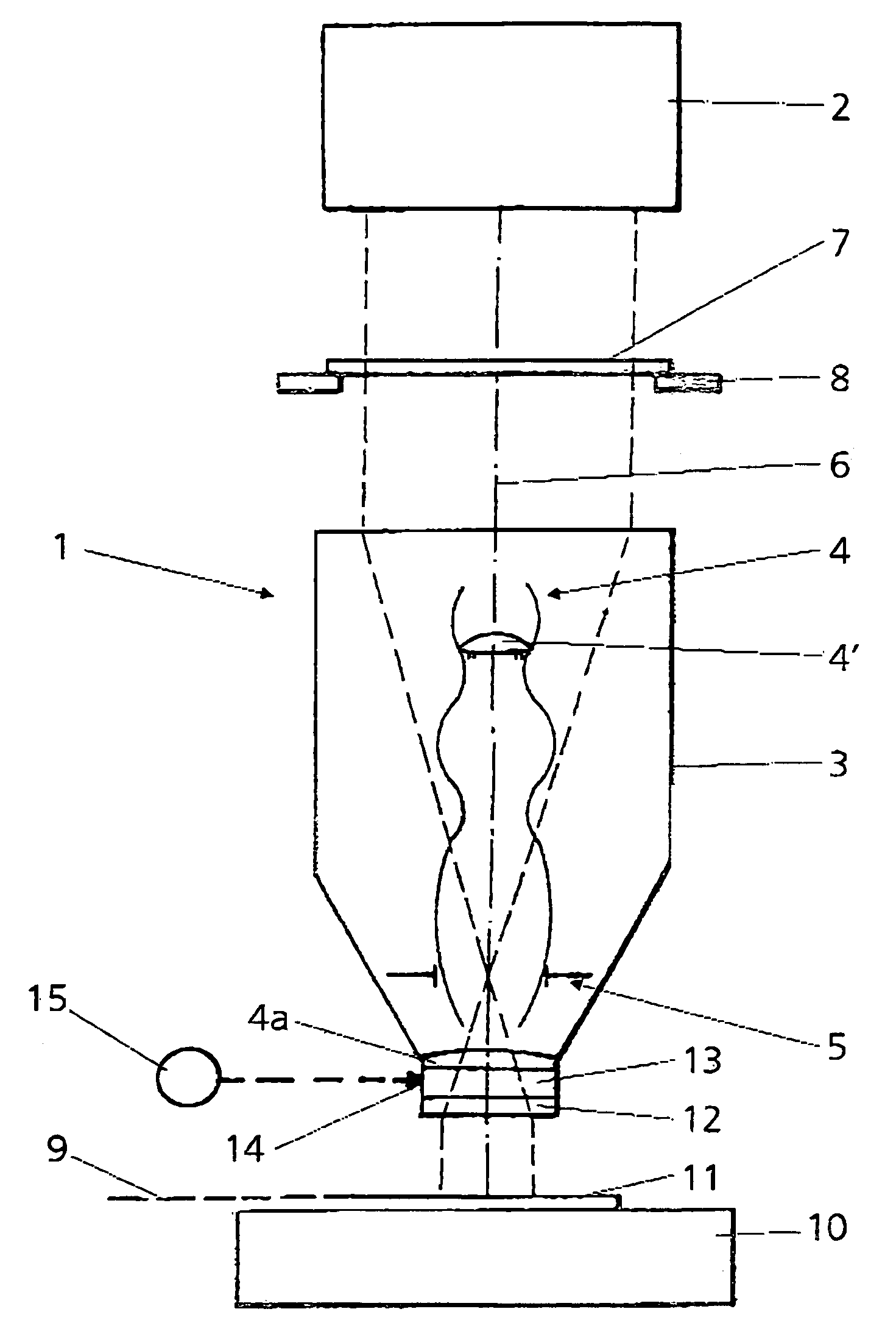

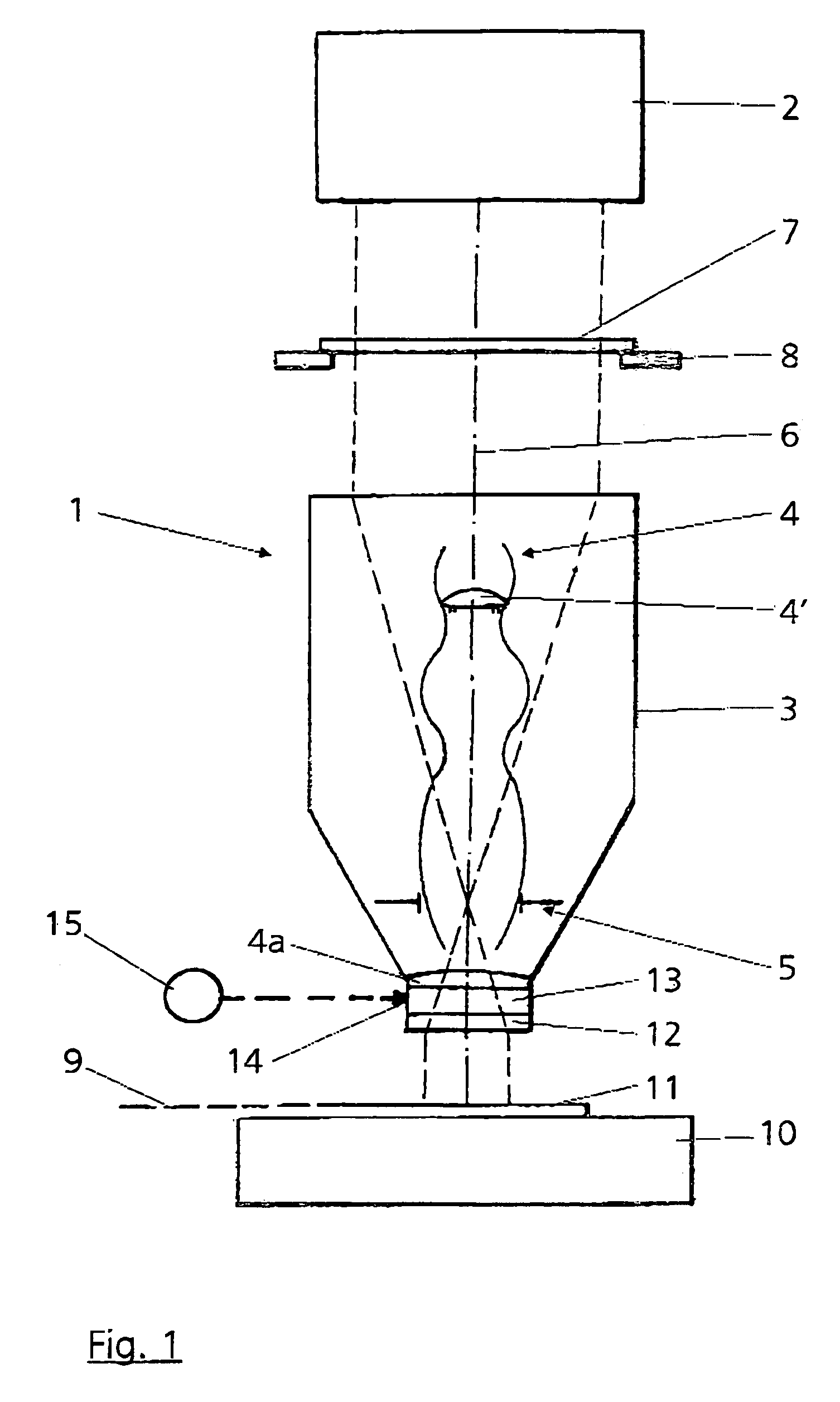

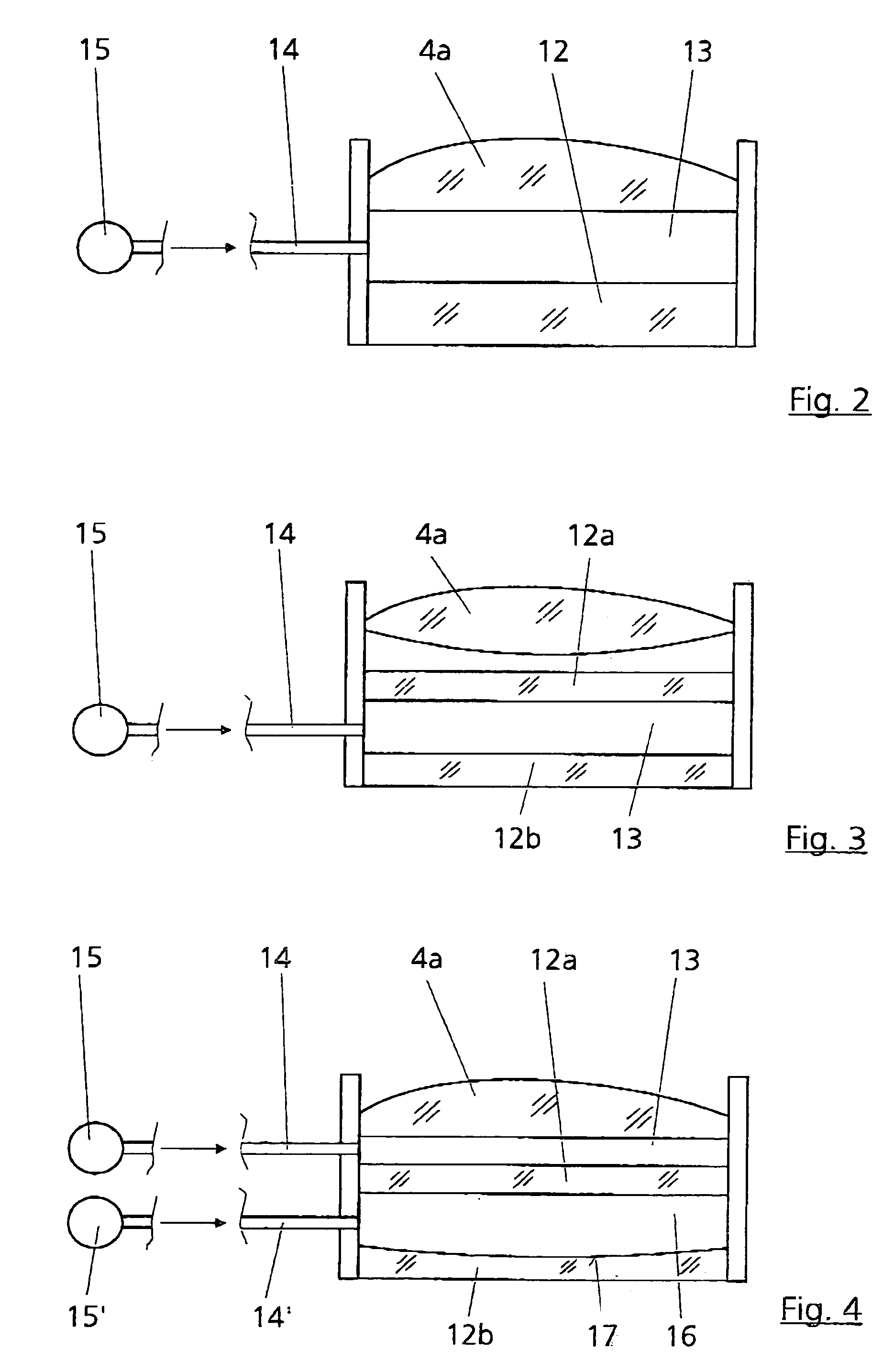

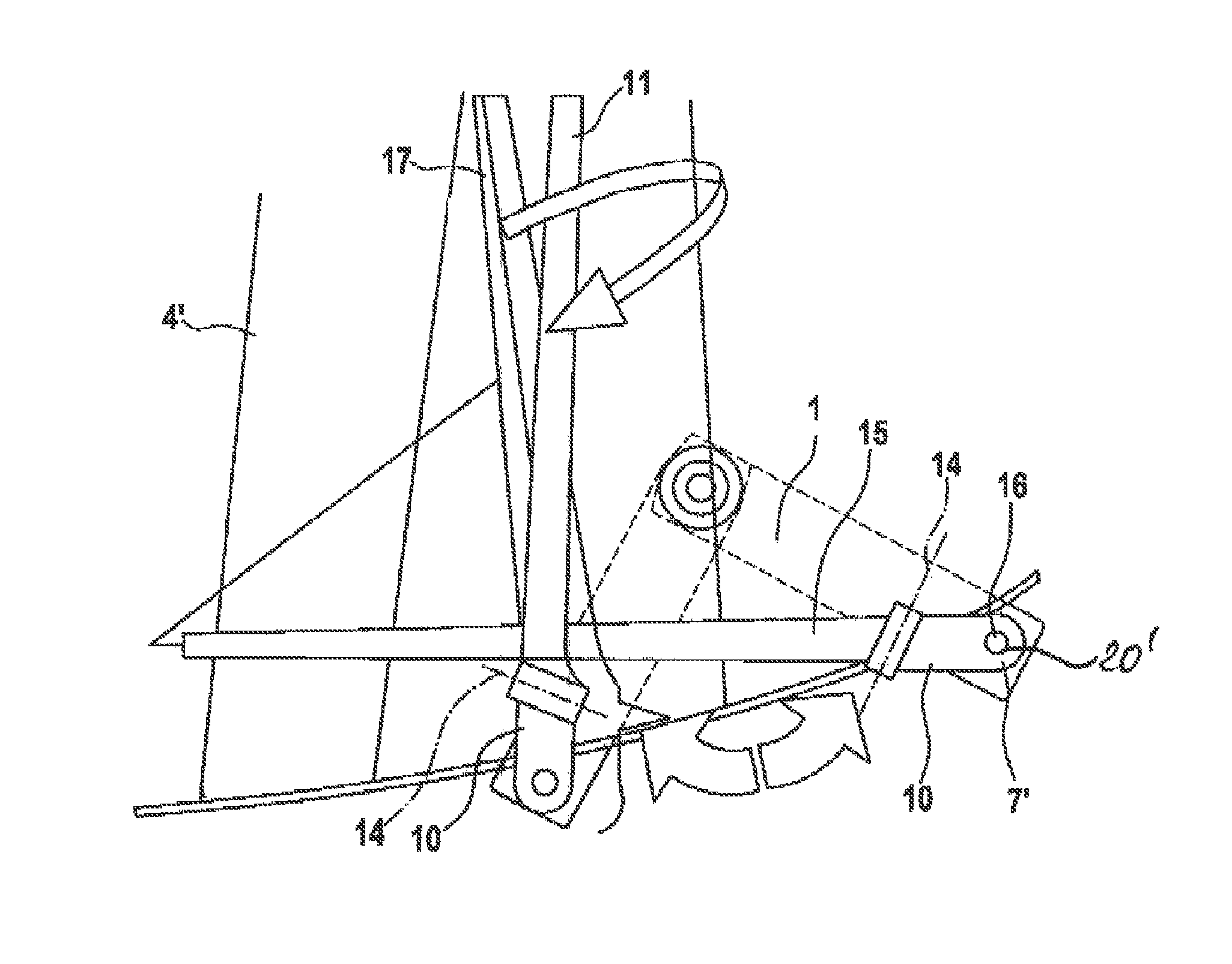

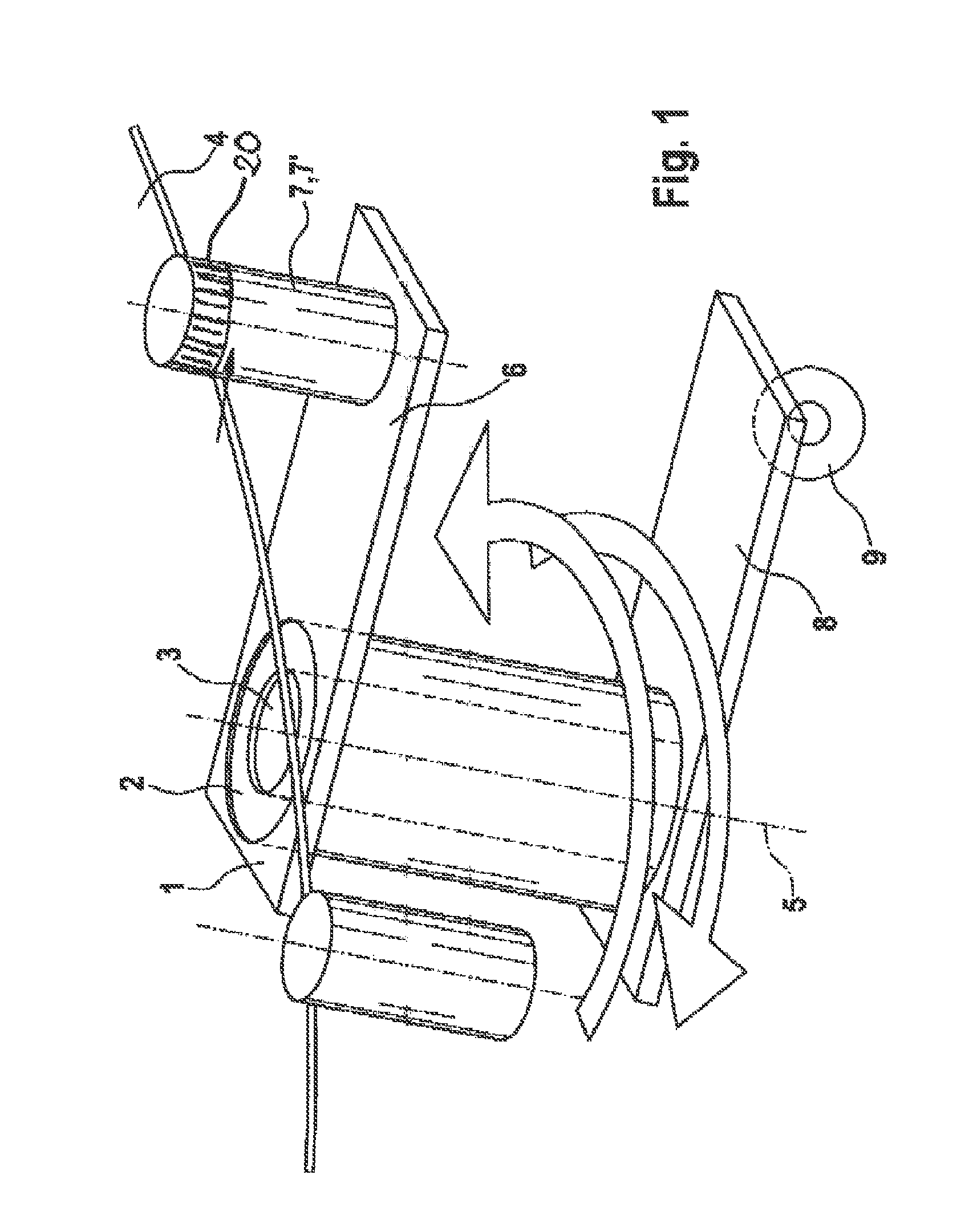

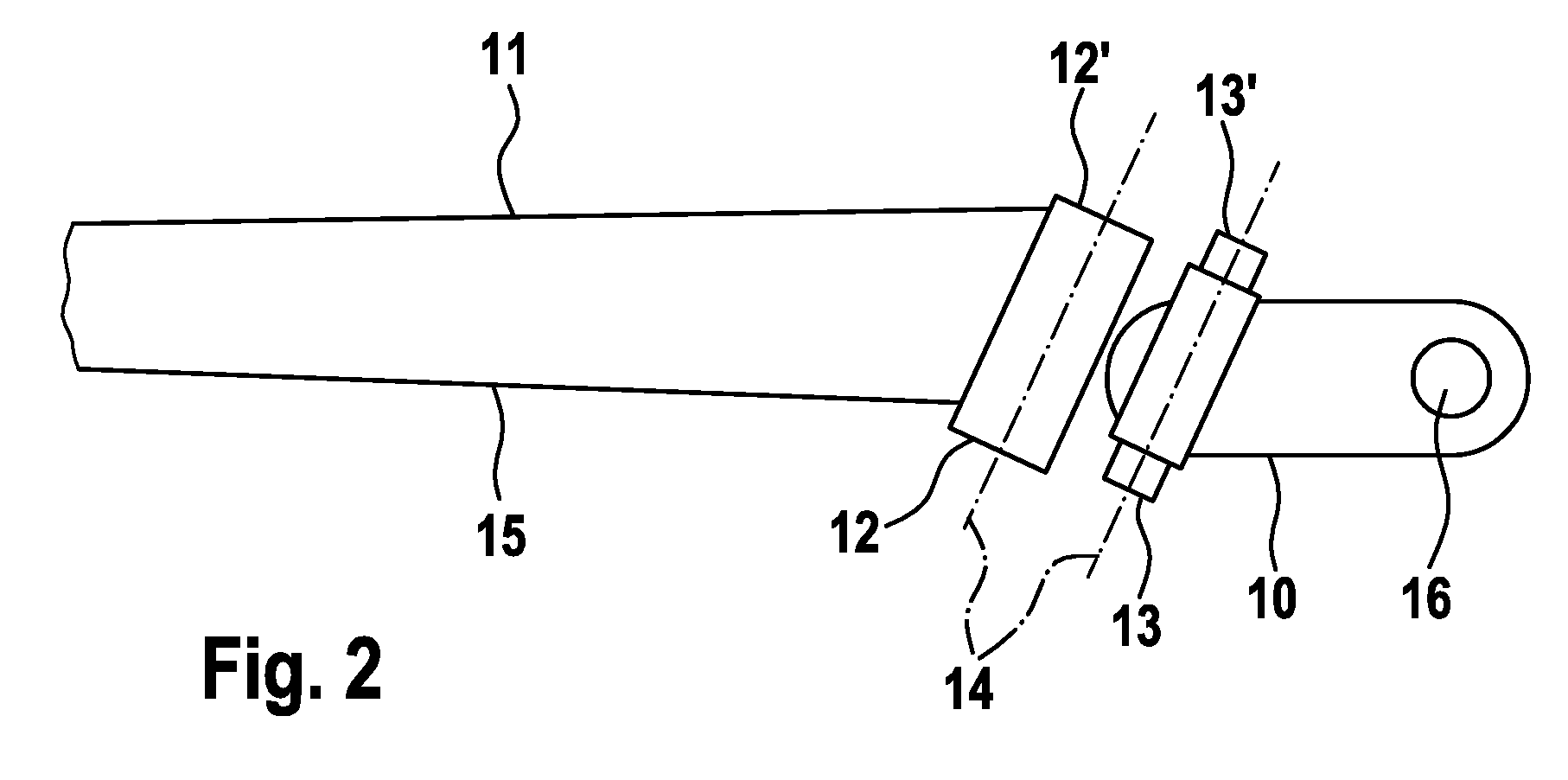

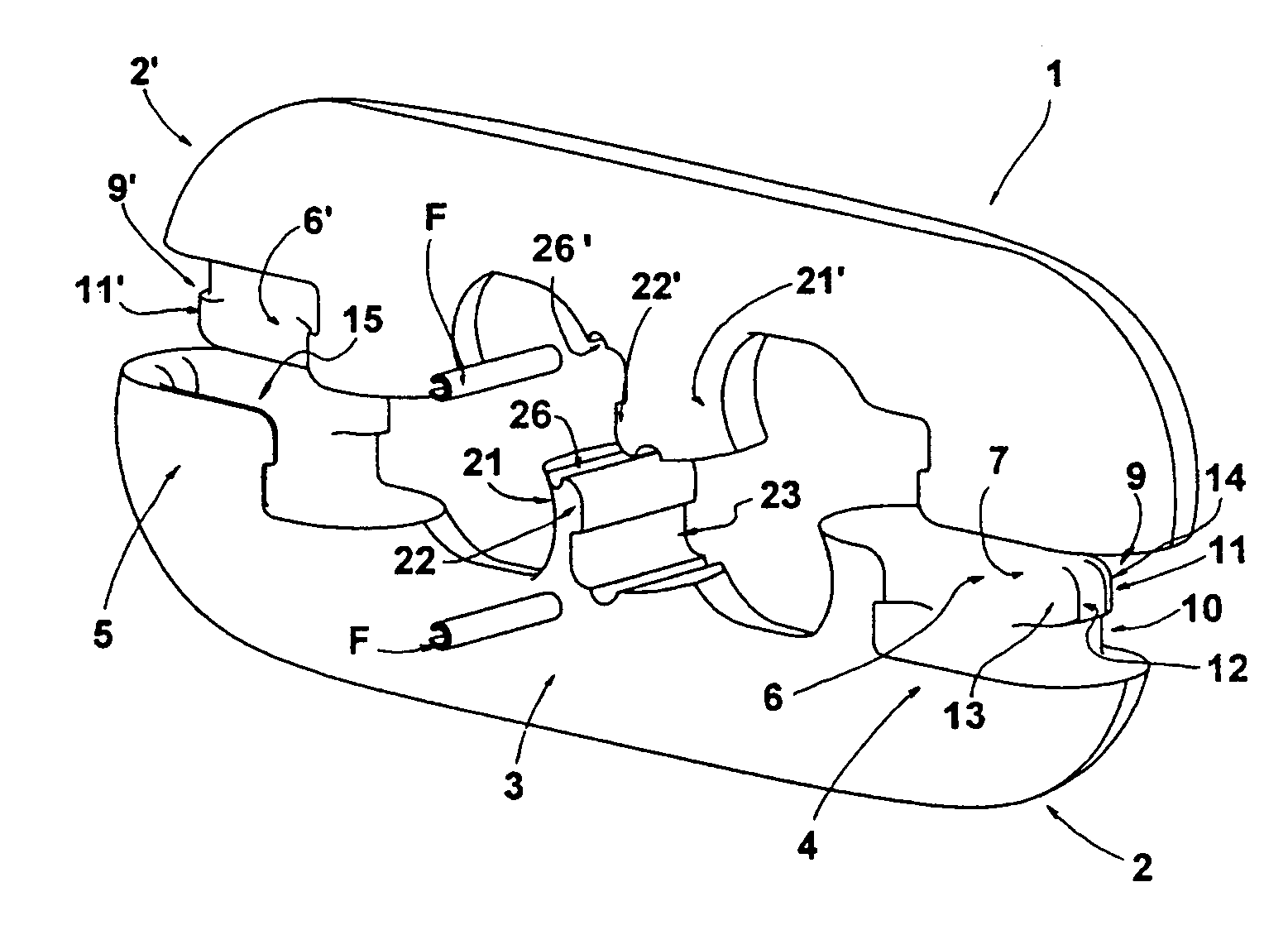

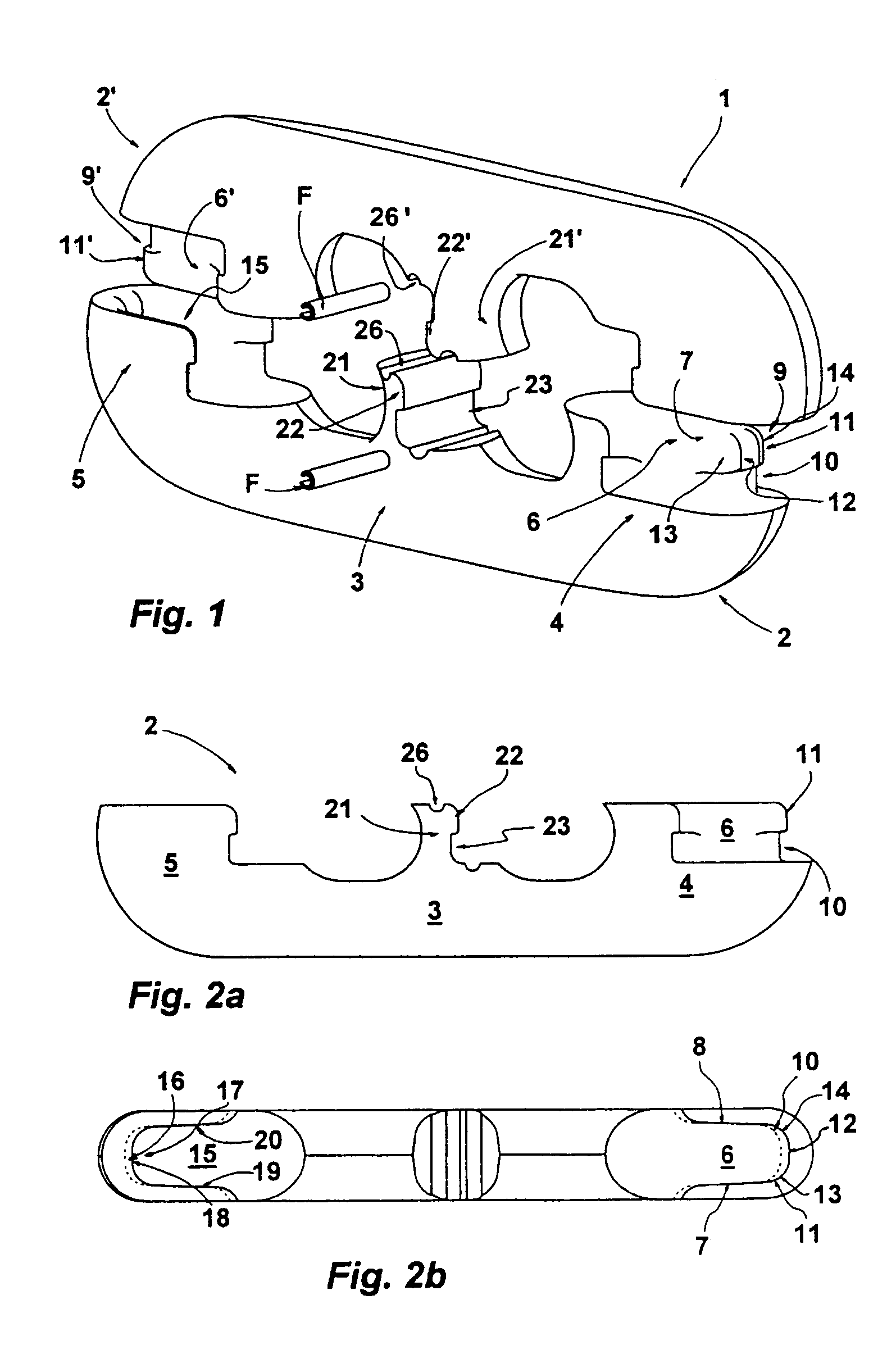

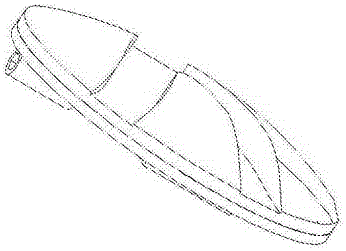

Transporting and storing curved wind turbine blades

A method of transporting and storing a wind turbine blade (1) including a blade root (10) and a blade tip (4), where the wind turbine blade curves in the unloaded state in such a manner that the blade (1) presents a substantially concave face (30) and a substantially convex face (12), and such that said blade tip (4) is spaced apart from the longitudinal central axis (28) of said blade root (10). By the method, the wind turbine blade (1) is prestressed by means of prestressing means (2, 5, 6, 9, 13, 16, 17, 21, 22, 23, 24, 25, 26, 33) at a distance from the blade root (10) in such a manner that the blade tip (4) is brought closer to the longitudinal central axis (28) of the blade root (10). The invention also relates to a curved wind turbine blade (1) being provided with inner ballast tanks (21) at a distance from the blade root (10), whereby the blade is prestressed by filling said ballast tanks in such a manner that the blade tip (4) may be brought closer to the longitudinal central axis (28) of the blade root (10). The invention further relates to an apparatus including prestressing means for loading a curved blade at a distance from the blade root (10) in such a manner that the blade tip (4) is brought closer to the longitudinal central axis (28) of the blade root (10).

Owner:LM GLASSFIBER

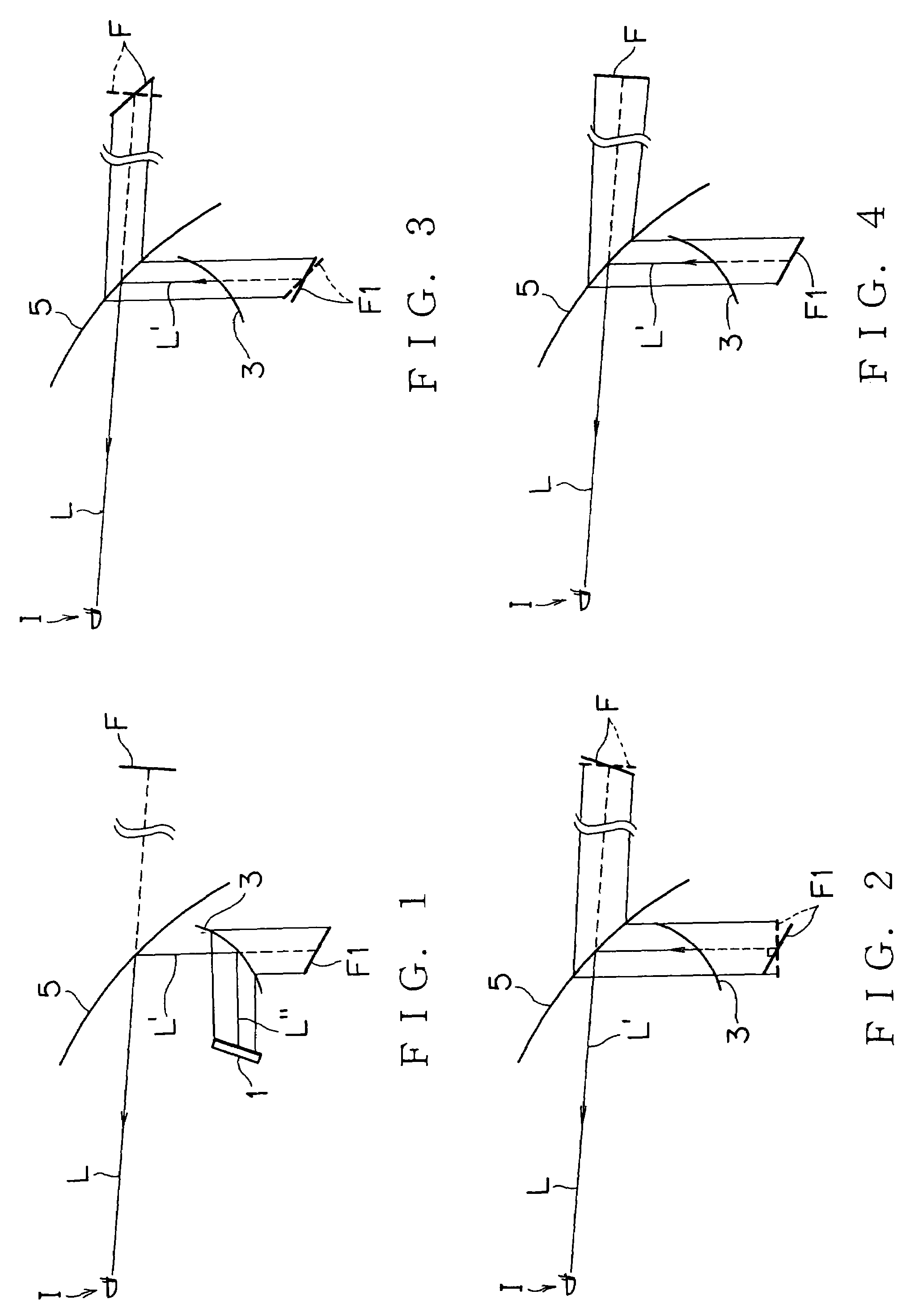

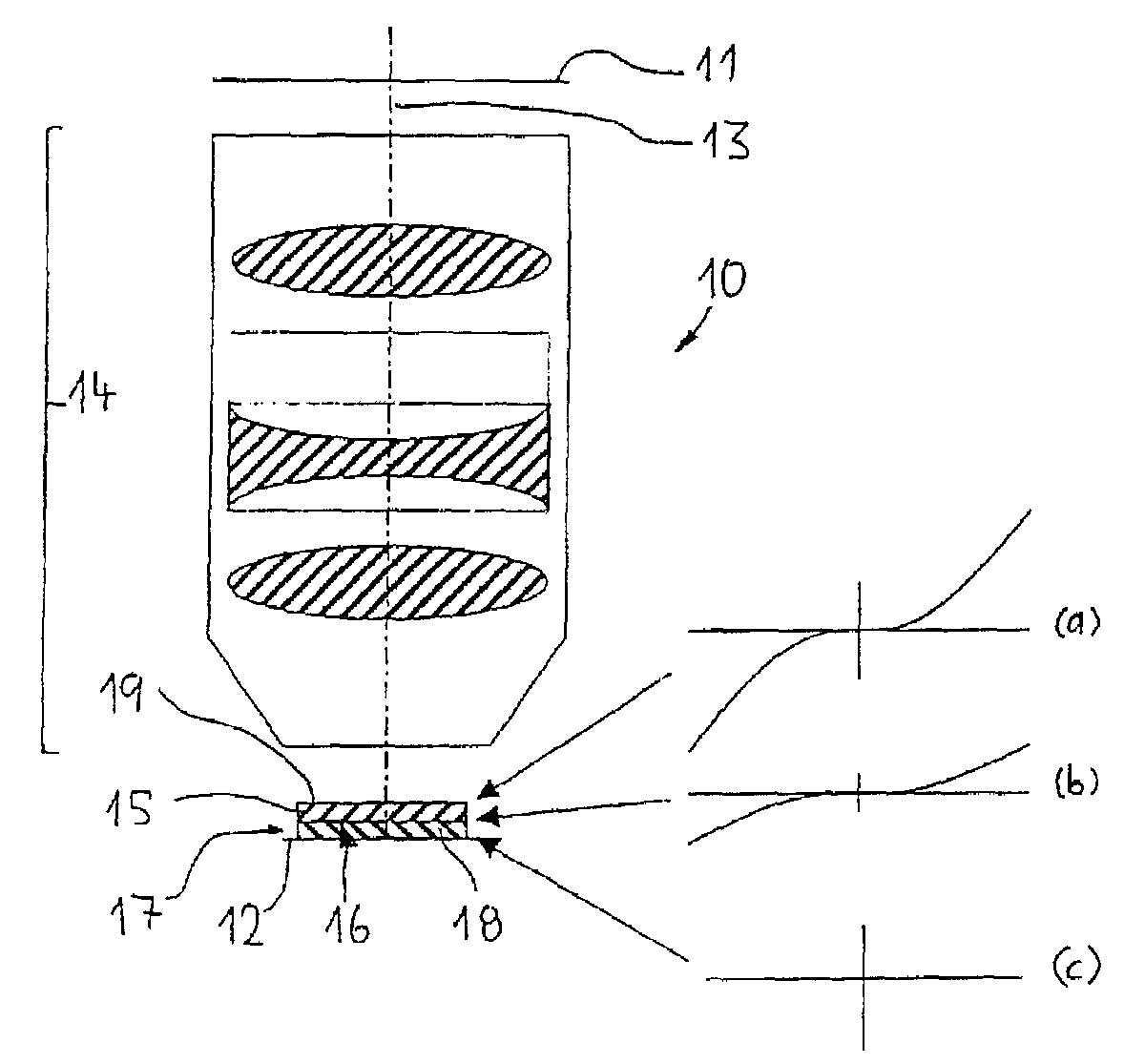

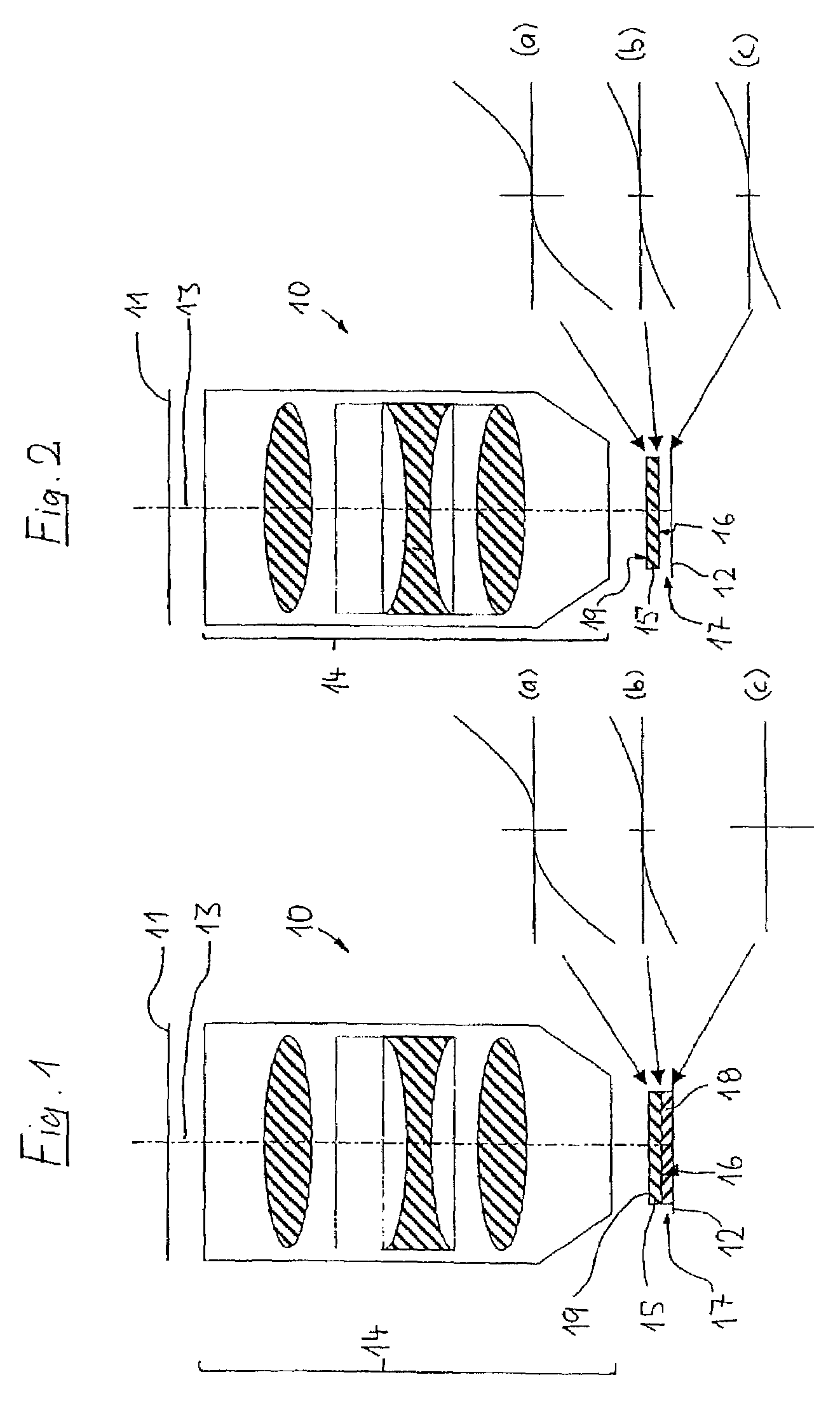

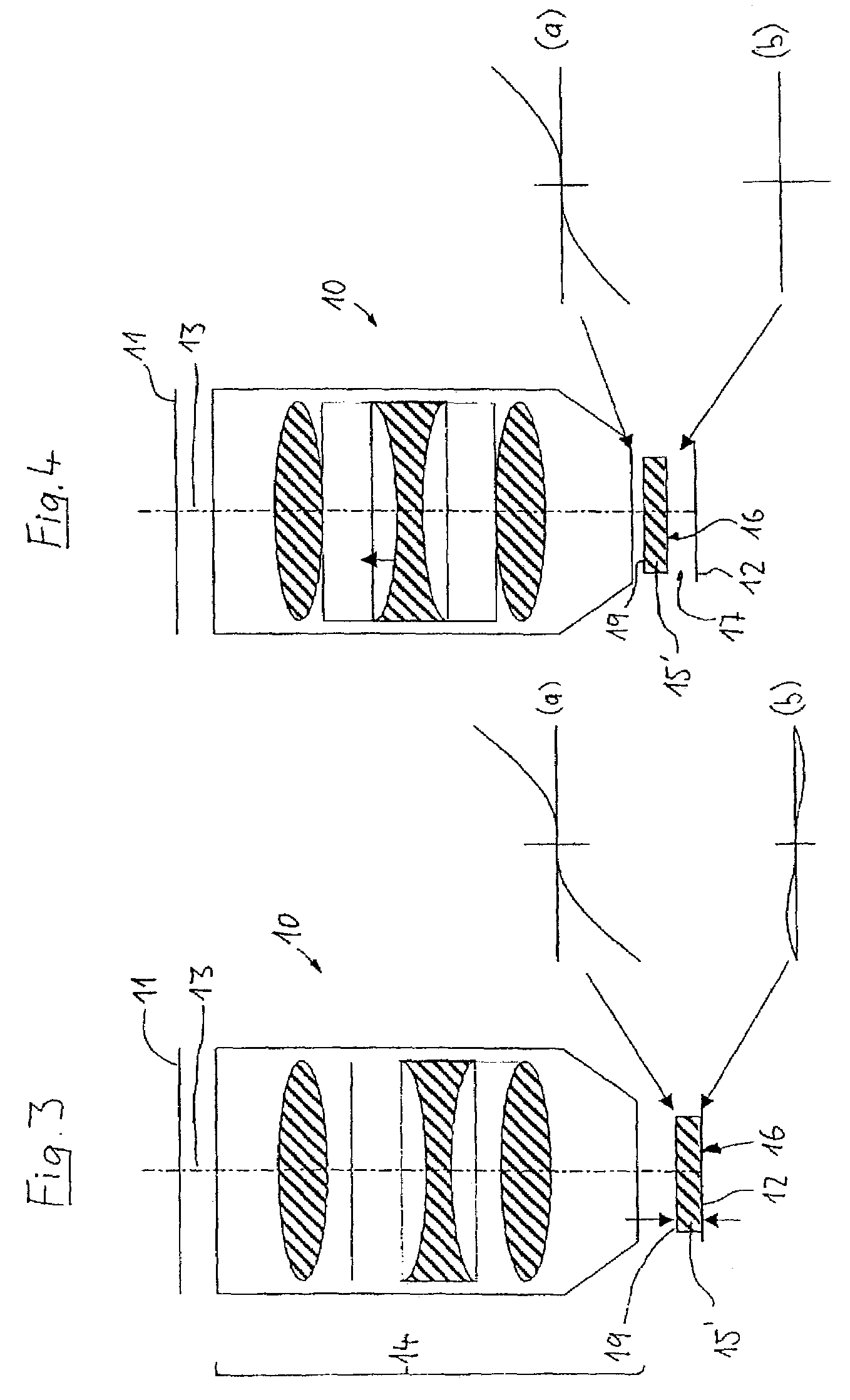

Projection objective, especially for microlithography, and method for adjusting a projection objective

InactiveUS7209292B2Favorably carry-outSmall curvatureSemiconductor/solid-state device manufacturingMicroscopesOptical axisRefractive index

A method of adjusting a projection objective permits the projection objective to be adjusted between an immersion configuration and a dry configuration. The projection objective includes optical elements arranged along an optical axis thereof, which include a first group of elements following the object plane and a last optical element following the first group, which is arranged near the image plane. The last optical element defines an exit surface of the projection objective, which is arranged at a working distance from the image plane. The last optical element is substantially without refracting power and has no or only slight curvature. The method includes varying the thickness of the last optical element, changing the refractive index of the space between the exit surface and the image plane by introducing or removing an immersion medium, and axially displacing the last optical element to set a working distance.

Owner:CARL ZEISS SMT GMBH

Reproducible resistance variable insulating memory devices and methods for forming same

ActiveUS20070034848A1Enhances local electric fieldSmall curvatureSemiconductor/solid-state device manufacturingBulk negative resistance effect devicesElectrical resistance and conductanceElectric field

The present invention relates to the use of a shaped bottom electrode in a resistance variable memory device. The shaped bottom electrode ensures that the thickness of the insulating material at the tip of the bottom electrode is thinnest, creating the largest electric field at the tip of the bottom electrode. The arrangement of electrodes and the structure of the memory element makes it possible to create conduction paths with stable, consistent and reproducible switching and memory properties in the memory device.

Owner:MICRON TECH INC

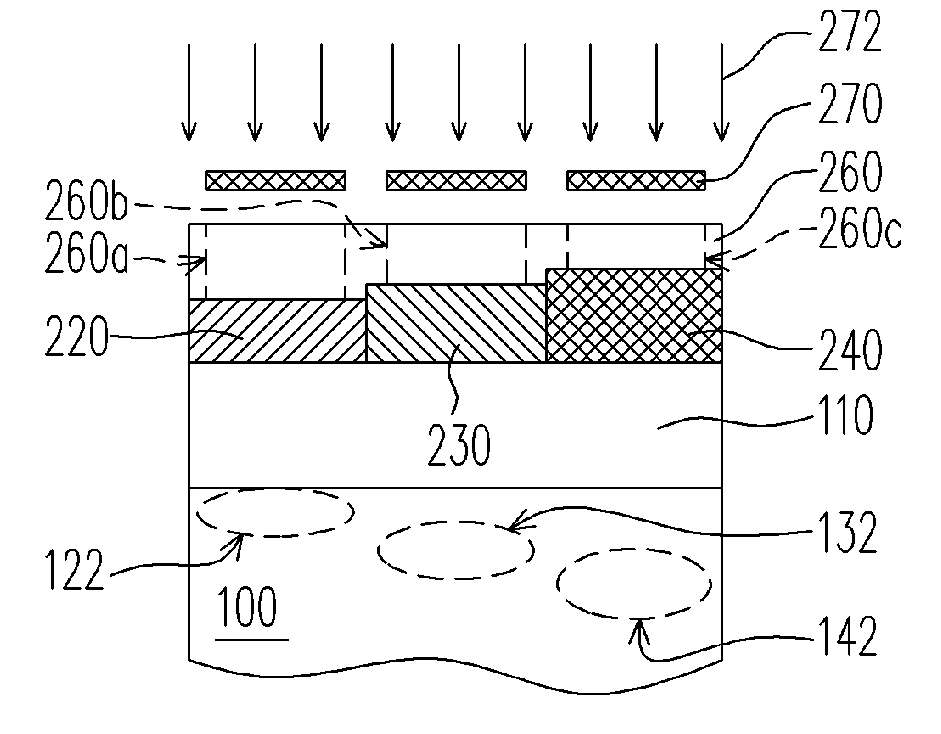

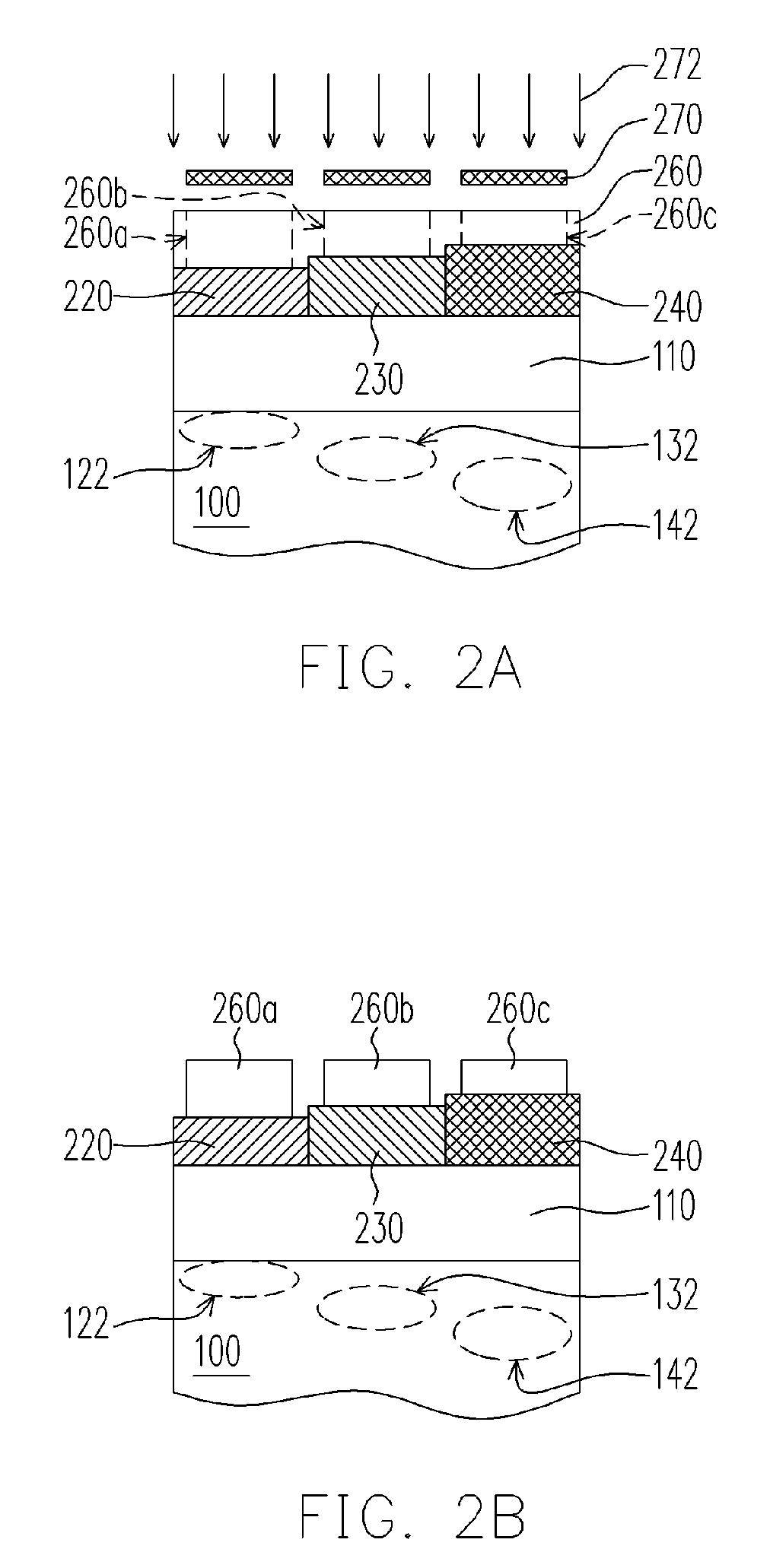

Method for forming microlenses of different curvatures and fabricating process of solid-state image sensor

ActiveUS20070008421A1Small curvatureMany timesTelevision system detailsSolid-state devicesMicrolensSolid-state

A method for forming microlenses of different curvatures is described, wherein a substrate having at least a first and a second areas different in height is provided. A transparent photosensitive layer having a planar surface is formed on the substrate and then patterned into at least two islands of different thicknesses respectively over the first area and the second area. The at least two islands are heated and softened to form at least two microlenses of different curvatures respectively over the first area and the second area, wherein the higher an area is, the smaller the curvature of the corresponding microlens is.

Owner:UNITED MICROELECTRONICS CORP

Transporting and storing curved wind turbine blades

ActiveUS7690875B2Convenient storage and transportationEasy to transportVehicle to carry long loadsMachines/enginesTurbine blade

A method of transporting and storing a wind turbine blade includes providing a wind turbine blade including a blade root having a longitudinal central axis and a blade tip. The wind turbine blade curves in an unloaded state in such a manner that the blade presents a substantially concave face and a substantially convex face, and such that the blade tip is spaced apart from the longitudinal central axis of the blade root. The wind turbine blade is prestressed at a distance from the blade root in such a manner that the blade tip is brought closer to the longitudinal central axis of the blade root.

Owner:LM GLASSFIBER

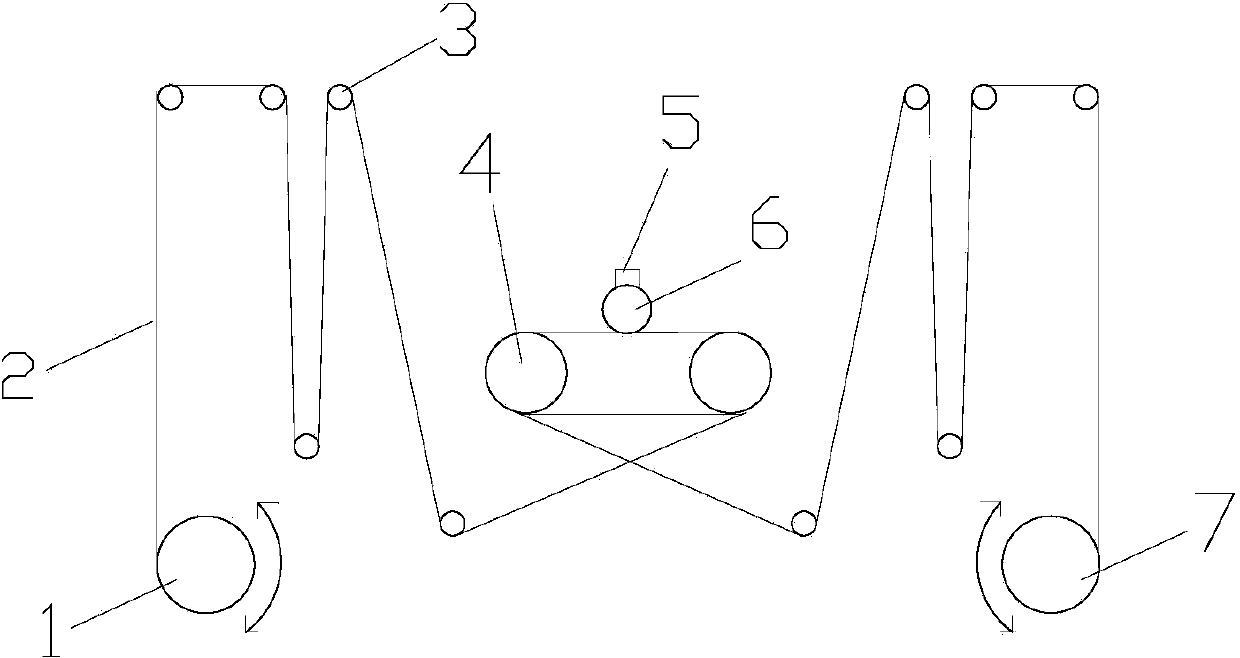

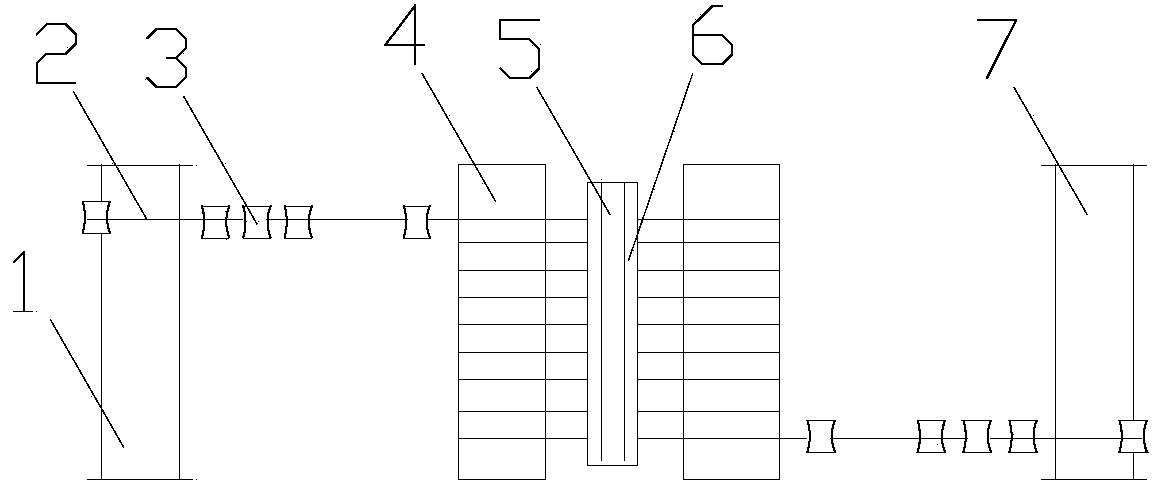

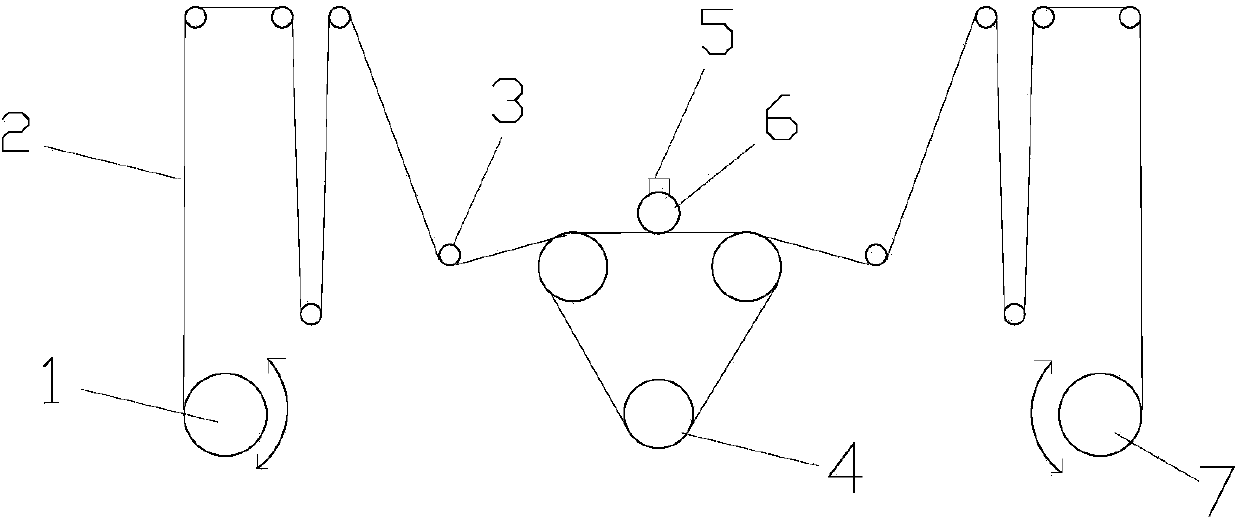

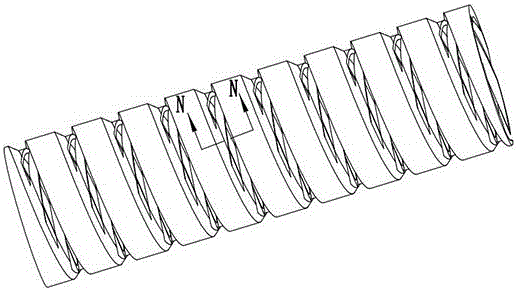

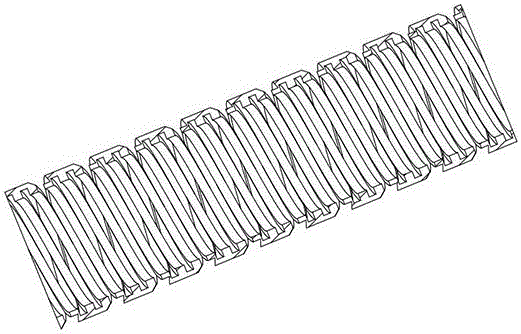

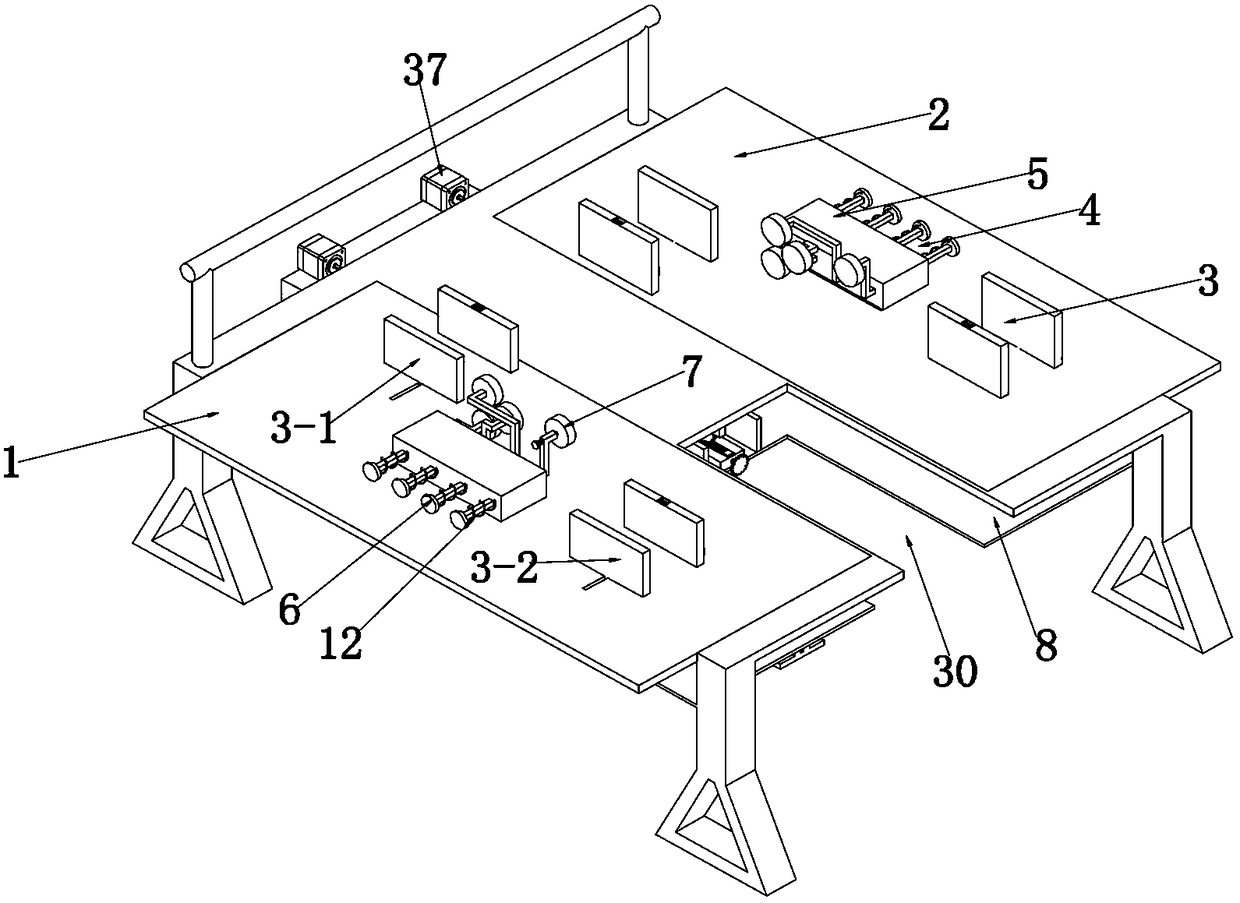

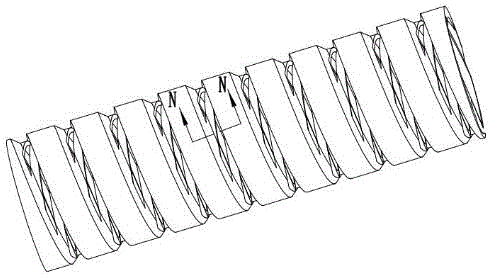

Method and equipment for cutting large-diameter silicon carbide single crystals by aid of diamond wires

The invention belongs to the field of technologies for processing advanced materials, and particularly provides a method and equipment for efficiently cutting large-diameter single crystals by the aid of diamond wires. The method and the equipment have the advantages that the equipment is convenient to operate and is provided with a multi-wire cutting machine and the diamond cutting wires, the diameters of the diamond cutting wires range from 120 micrometers to 400 micrometers, diamond particles are plated on outer layers of the diamond cutting wires, multiple pieces of large-diameter SiC crystal bars can be cut by the aid of reciprocating high-speed cutting movement of the diamond cutting wires, the surface roughness, the bending and the total thicknesses of cut SiC wafers hardly vary, and a plurality of target crystals can be cut in each procedure; the crystal can be cut at high speeds, crystal cutting elapsed time is short, and accordingly the silicon carbide wafers can be efficiently cut by the aid of the method and the equipment.

Owner:SICC CO LTD

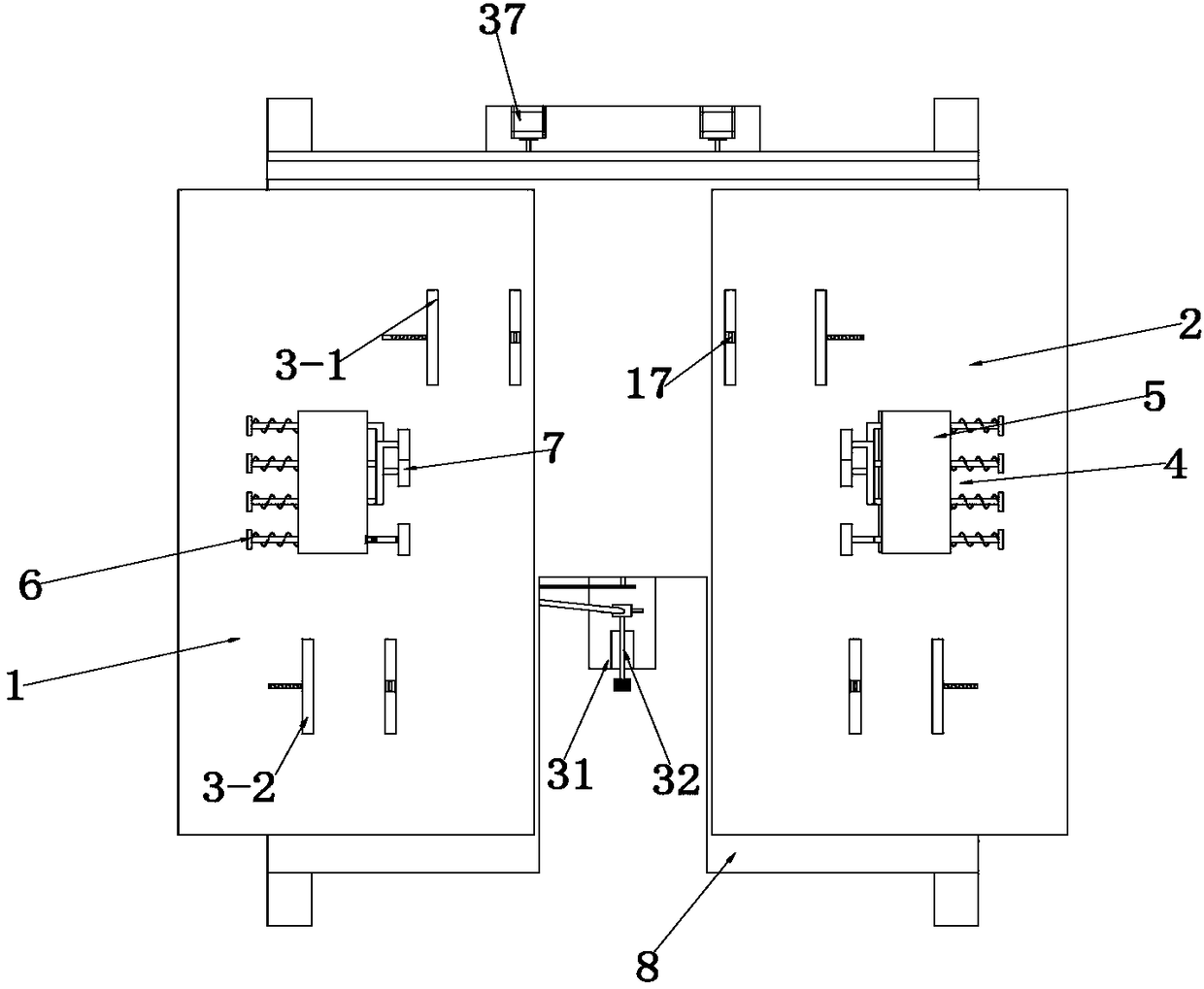

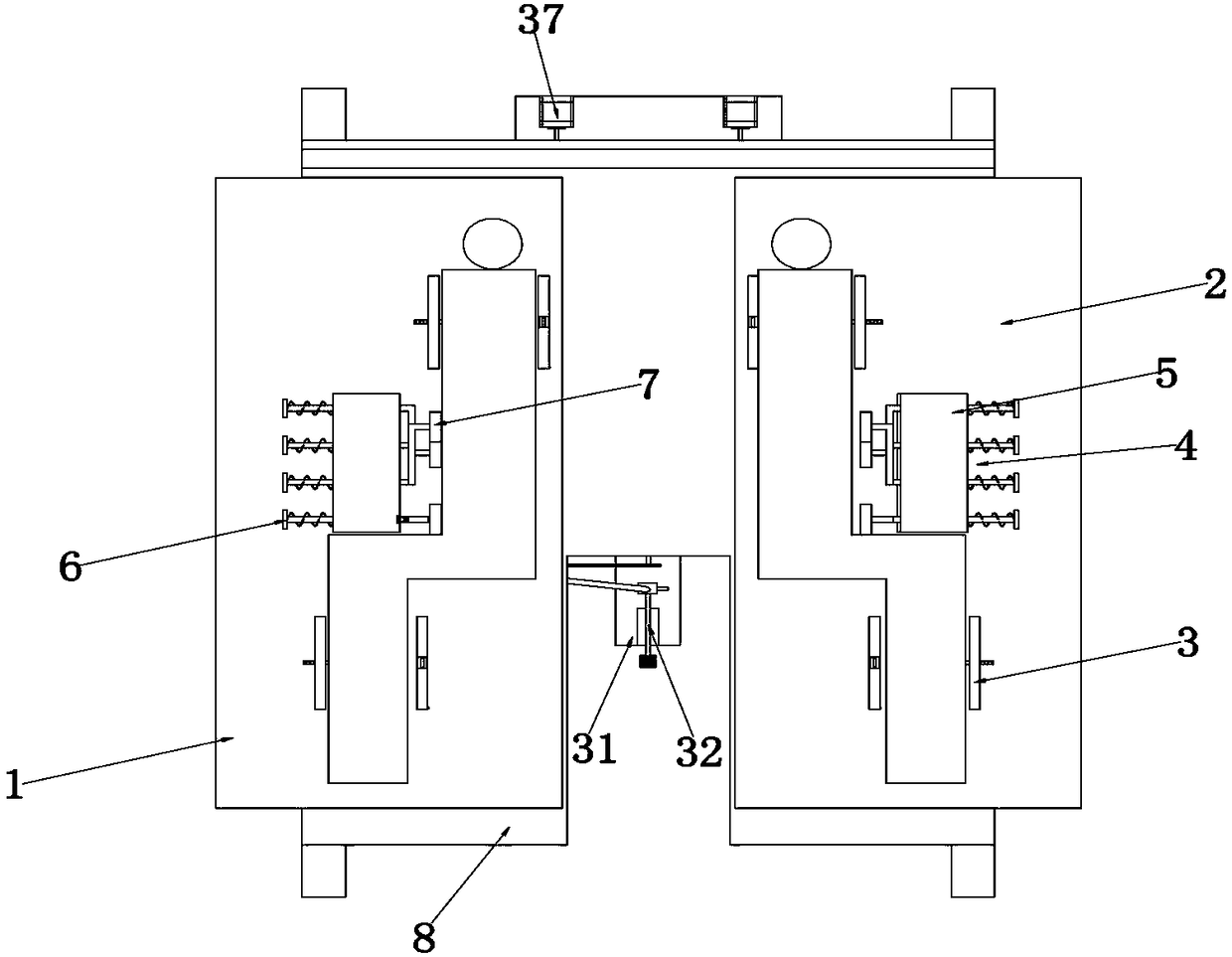

Synchronous spraying device for large machine

InactiveCN105772293ARealize simultaneous sprayingEnsure consistencySpraying apparatusArthrobotrysMechanical engineering

The invention provides a synchronous spraying device for a large machine. The synchronous spraying device comprises a plurality of movable bases (1), wherein a six-axis joint robot is installed on each movable base (1), and a spray gun is installed at the tail end of each six-axis joint robot; a steel plate (2) is arranged at the front end of each movable base (1), a piston cylinder (3) is further horizontally arranged at the front end of each movable base (1), the outer end of a piston rod of each piston cylinder (3) is level with the outer side of the corresponding steel plate (2) while retracting, and an electrically-controlled magnetic attraction device (4) is arranged at the rear end of each movable base (1); and the movable bases (1) attract the electrically-controlled magnetic attraction devices (4) through the steel plates (2) and are sequentially connected in series to form an integrated movable platform. According to the synchronous spraying device provided by the invention, the integrated movable platform formed by sequentially connecting the plurality of movable bases (1) in series is provided, and synchronous spraying of all the six-axis joint robots can be realized; and moreover, the problem of interference is avoided, and the consistency of the spraying quality of parts of the large machine can be ensured.

Owner:李富平

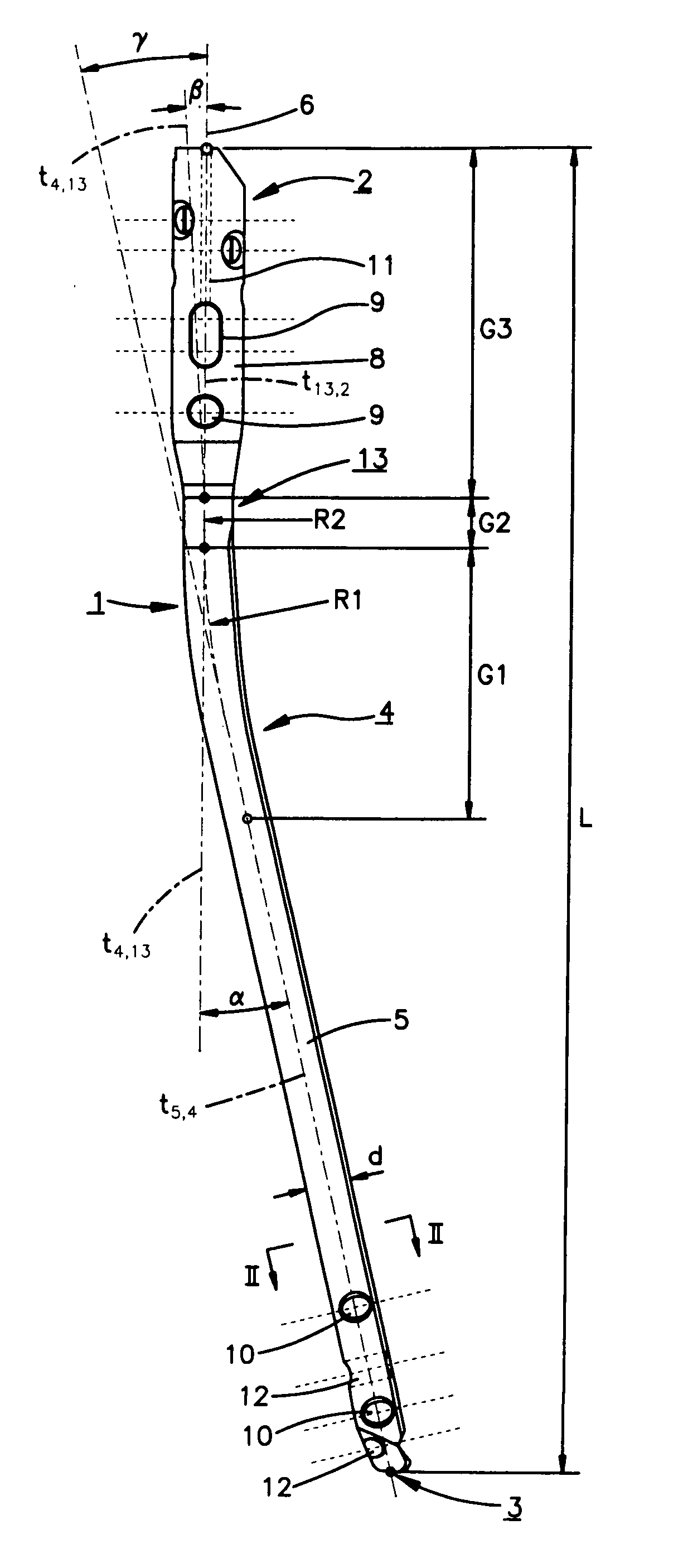

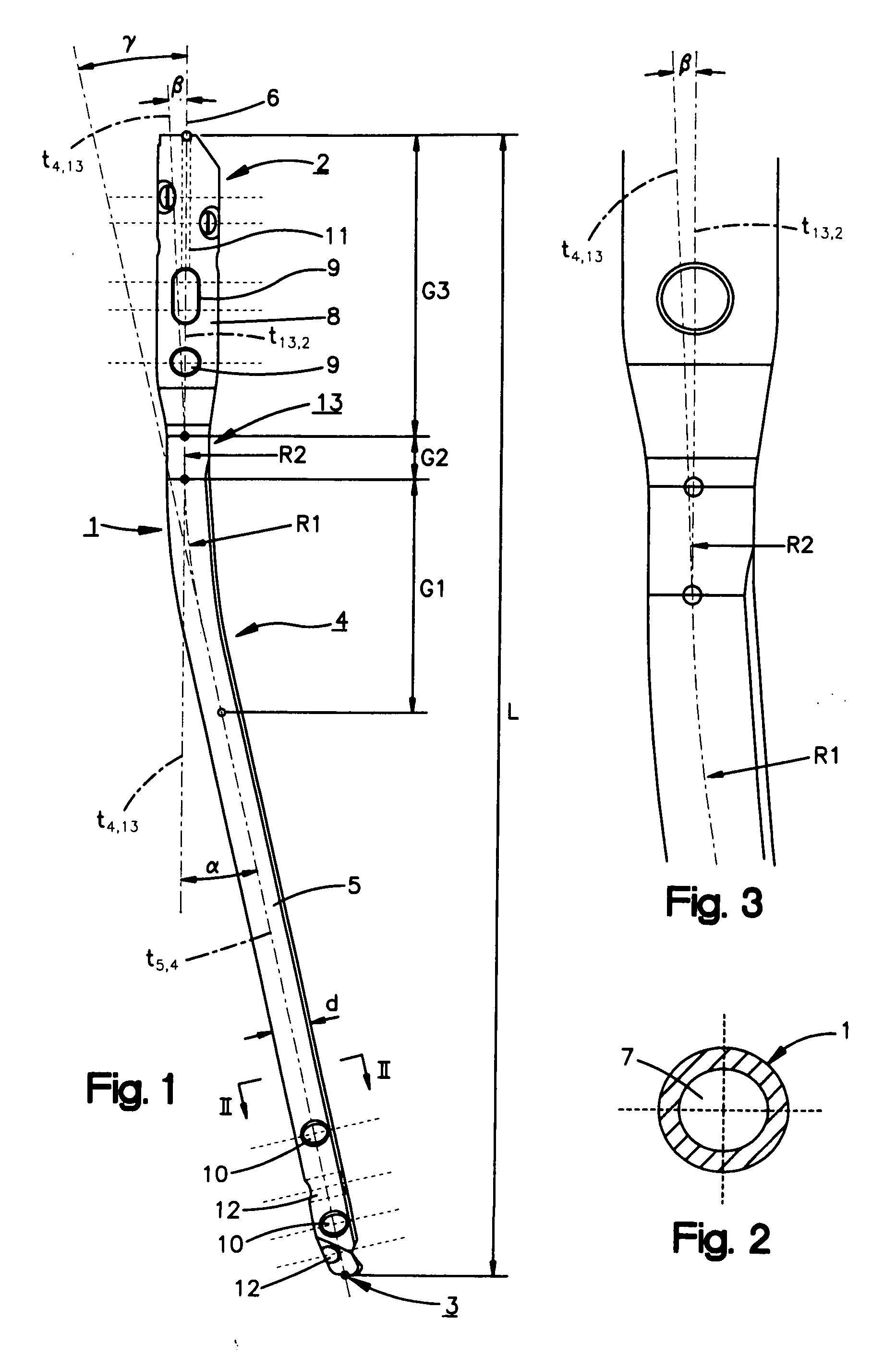

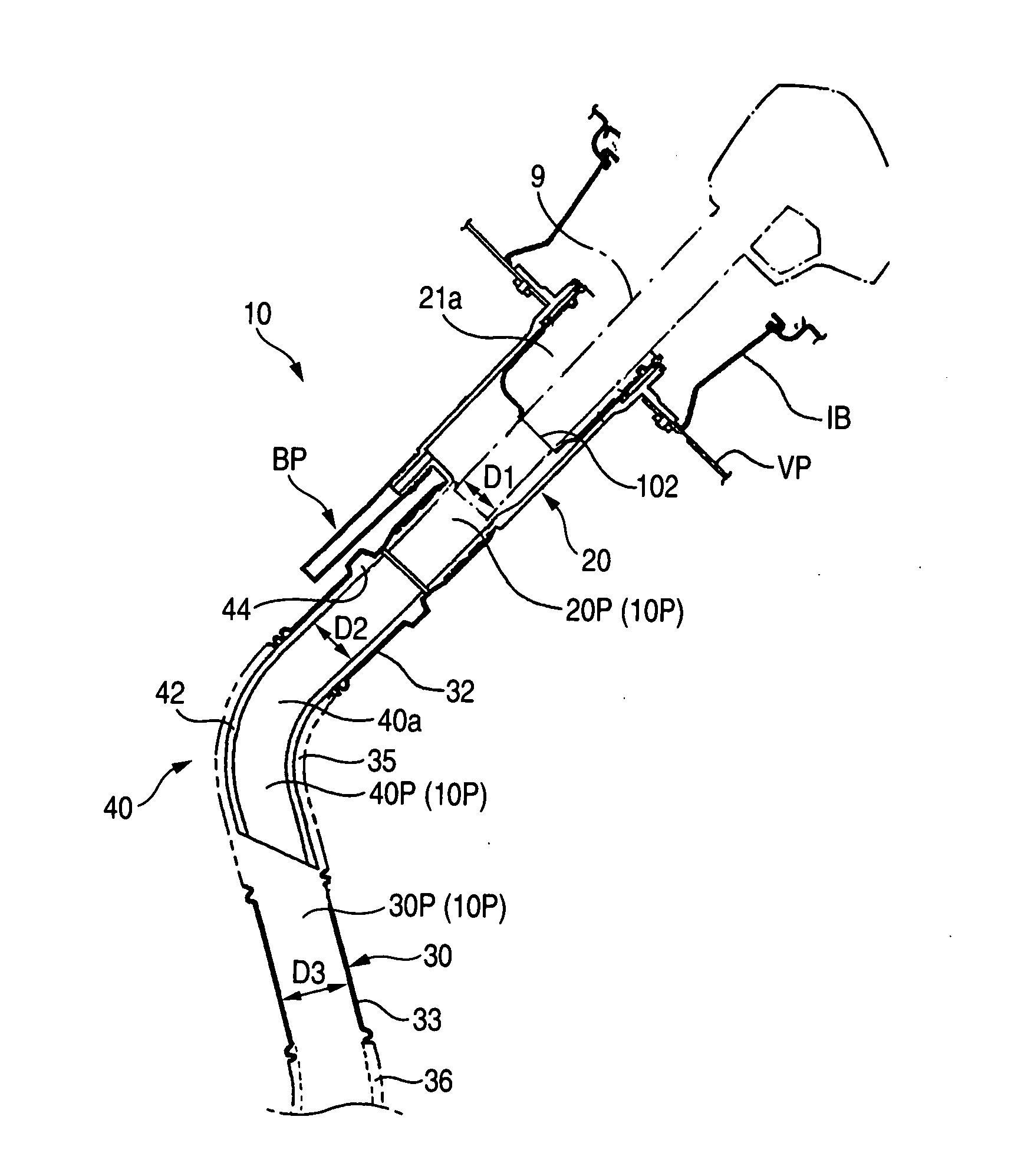

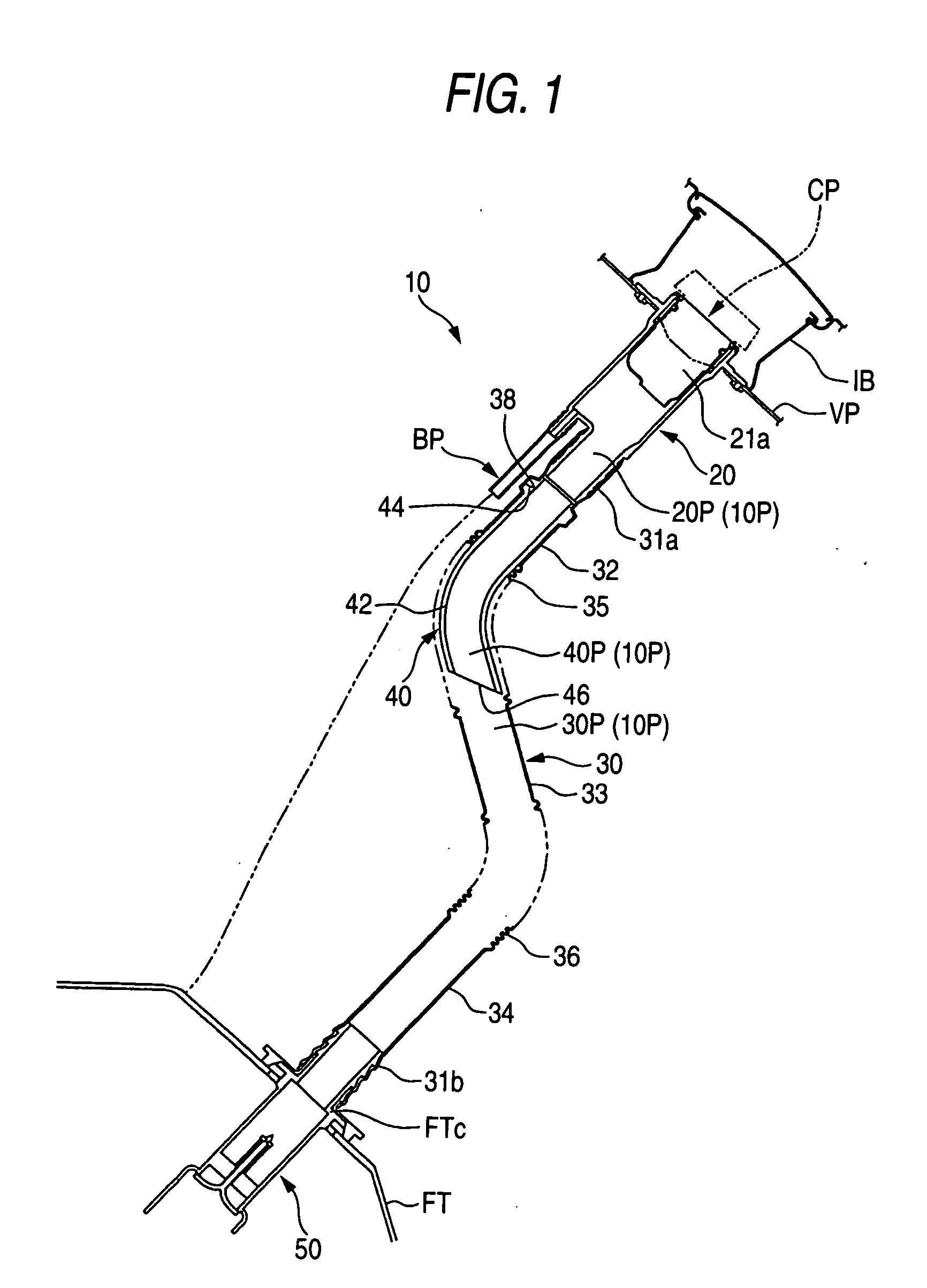

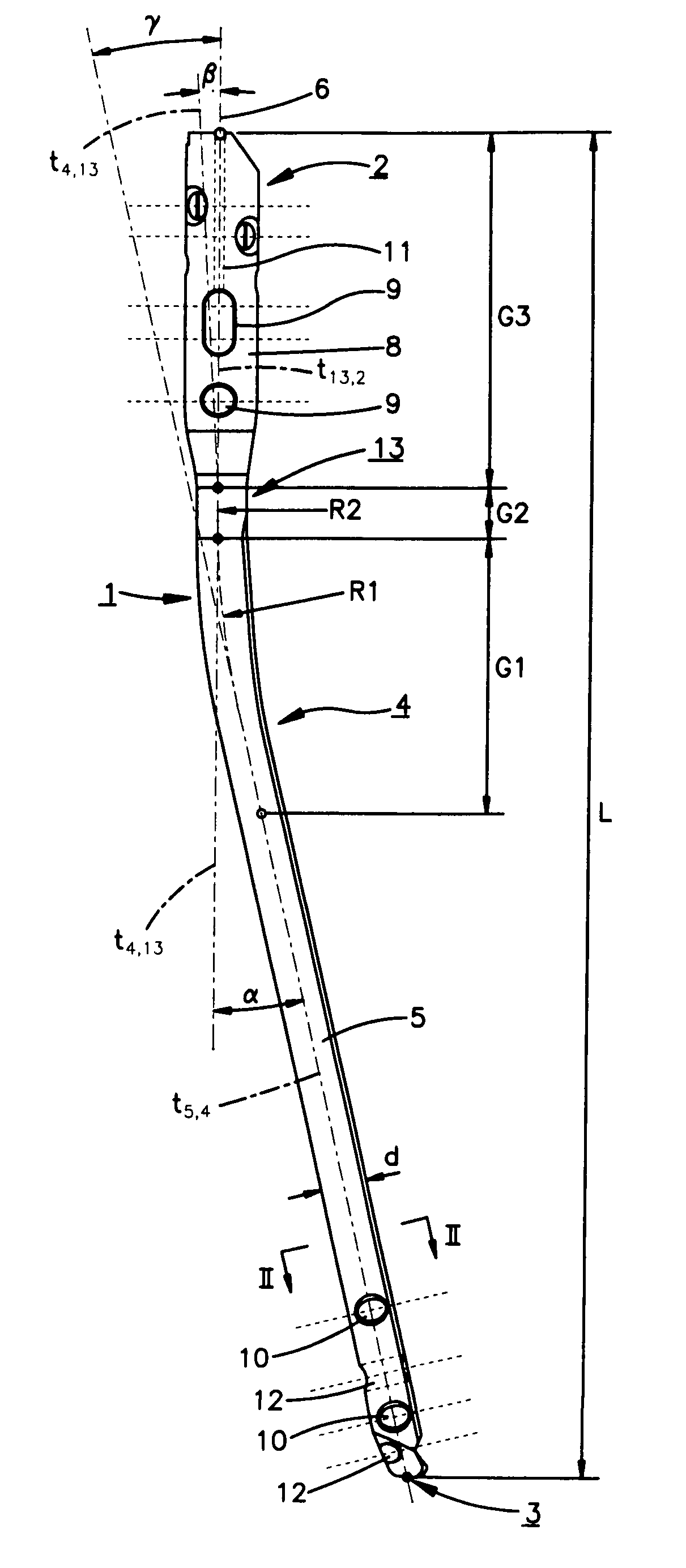

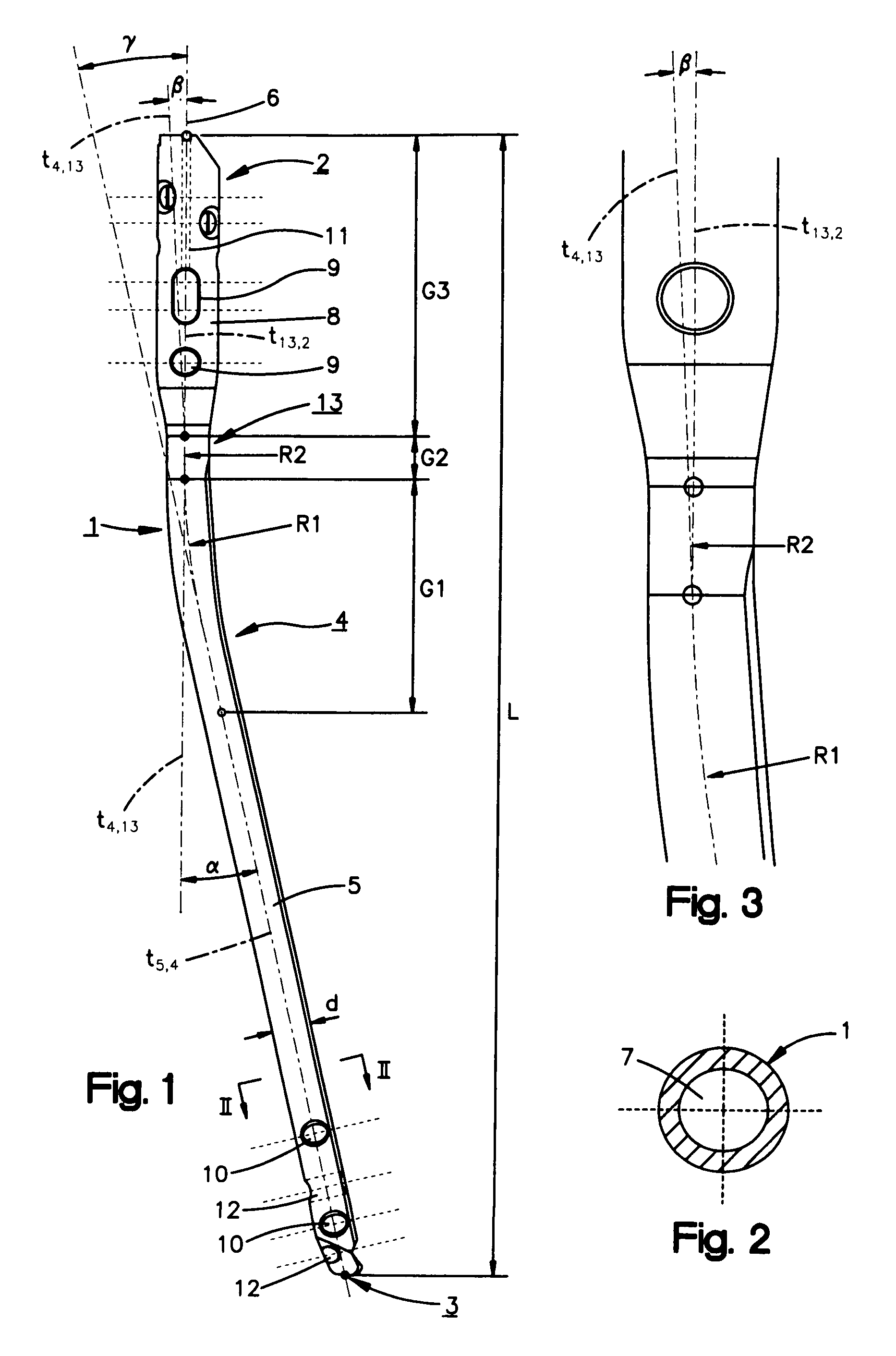

Intramedullary nail

ActiveUS20080009869A1Small curvatureCurvature of the intramedullary nail is slightInternal osteosythesisJoint implantsTibiaMedullary cavity

An intramedullary nail, particular for use with a tibia, may have a proximal end part, a distal end part adapted to be introduced into a medullary space, and a central section. The central section includes a first curved section having a first length with a first radius of curvature, and a second curved section having a second length shorter than the first length and a second radius of curvature smaller than the first radius of curvature. The second radius of curvature may be less than the first radius of curvature. The intramedullary nail also includes a central axis. Tangents at two end points of the central section, including the first and second curved sections, enclose an angle gamma between about 9° and about 12°. The intramedullary nail may have a total length ranging from 200 to 500 mm.

Owner:SYNTHES USA

Projection exposure machine comprising a projection lens

InactiveUS7203007B2Corrected more efficientlyAccurate imagingPhotomechanical exposure apparatusMicrolithography exposure apparatusProjection lensImage plane

A projection exposure machine comprises a projection lens with a lens arrangement and at least one stop. The lens arrangement comprises a group of optical elements which is arranged between the stop and the image plane. An optical element of the group situated close to the image plane has a thickness of at least 6.5% of the entire stop diameter.

Owner:CARL ZEISS SMT GMBH

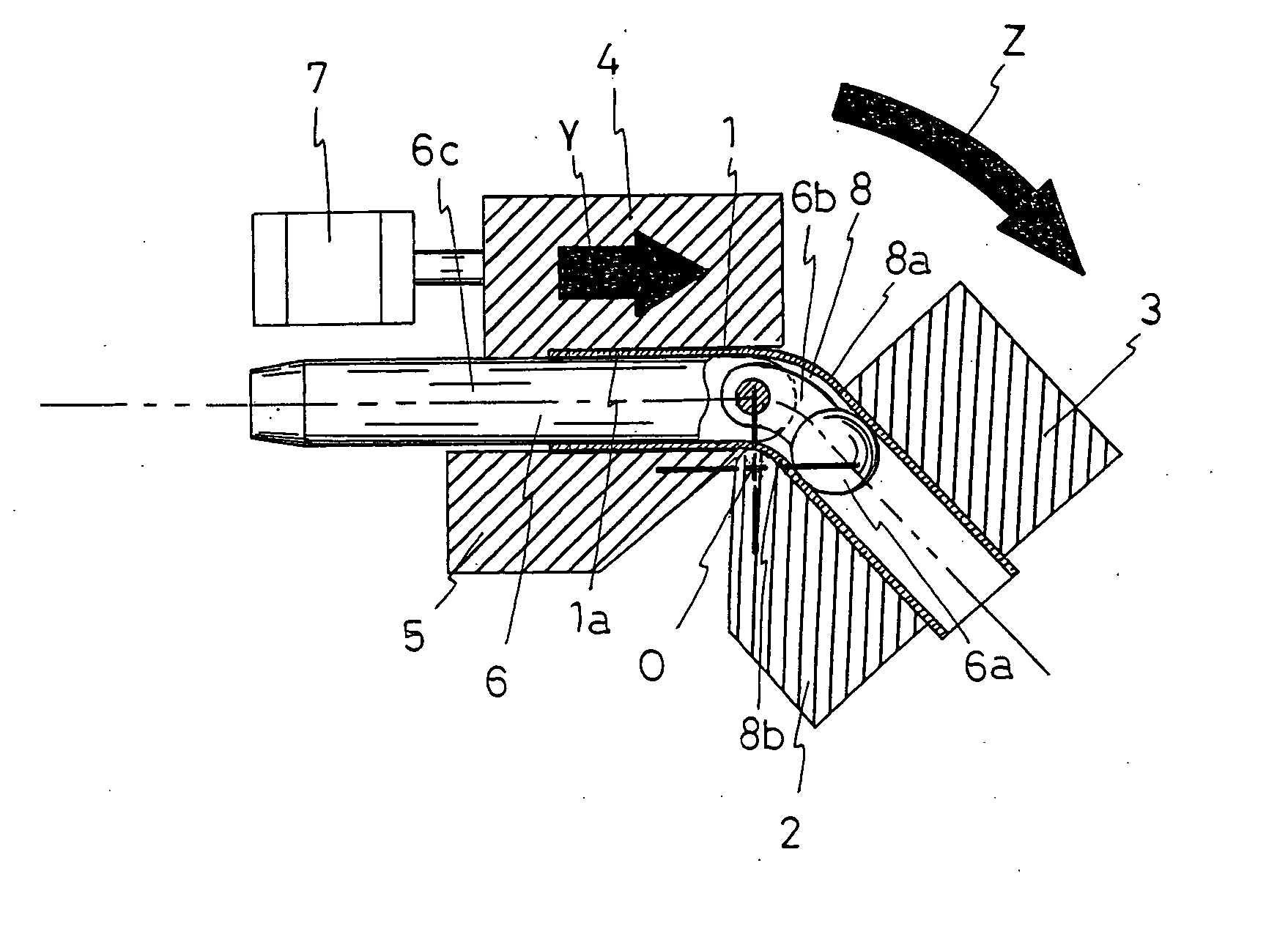

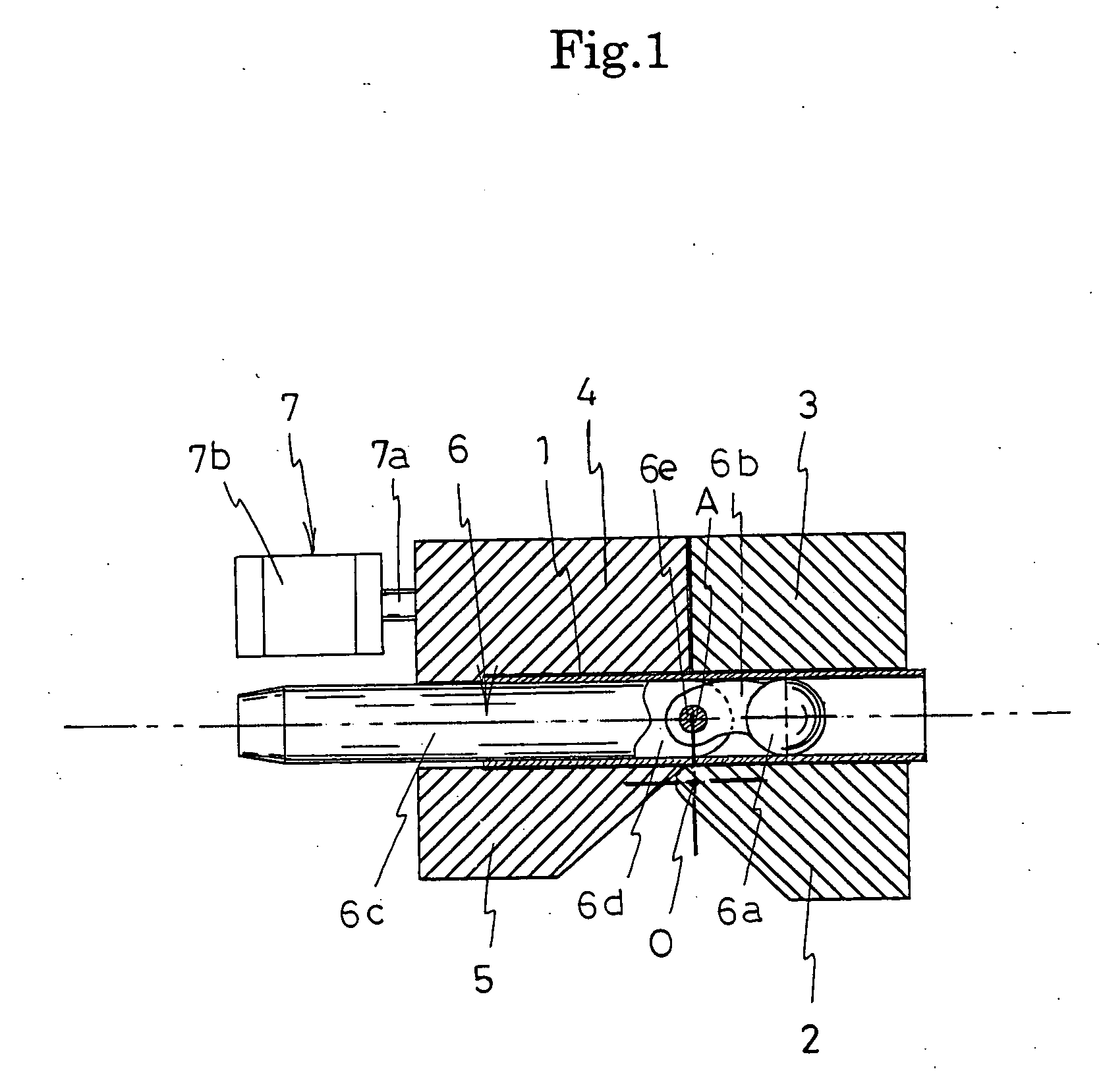

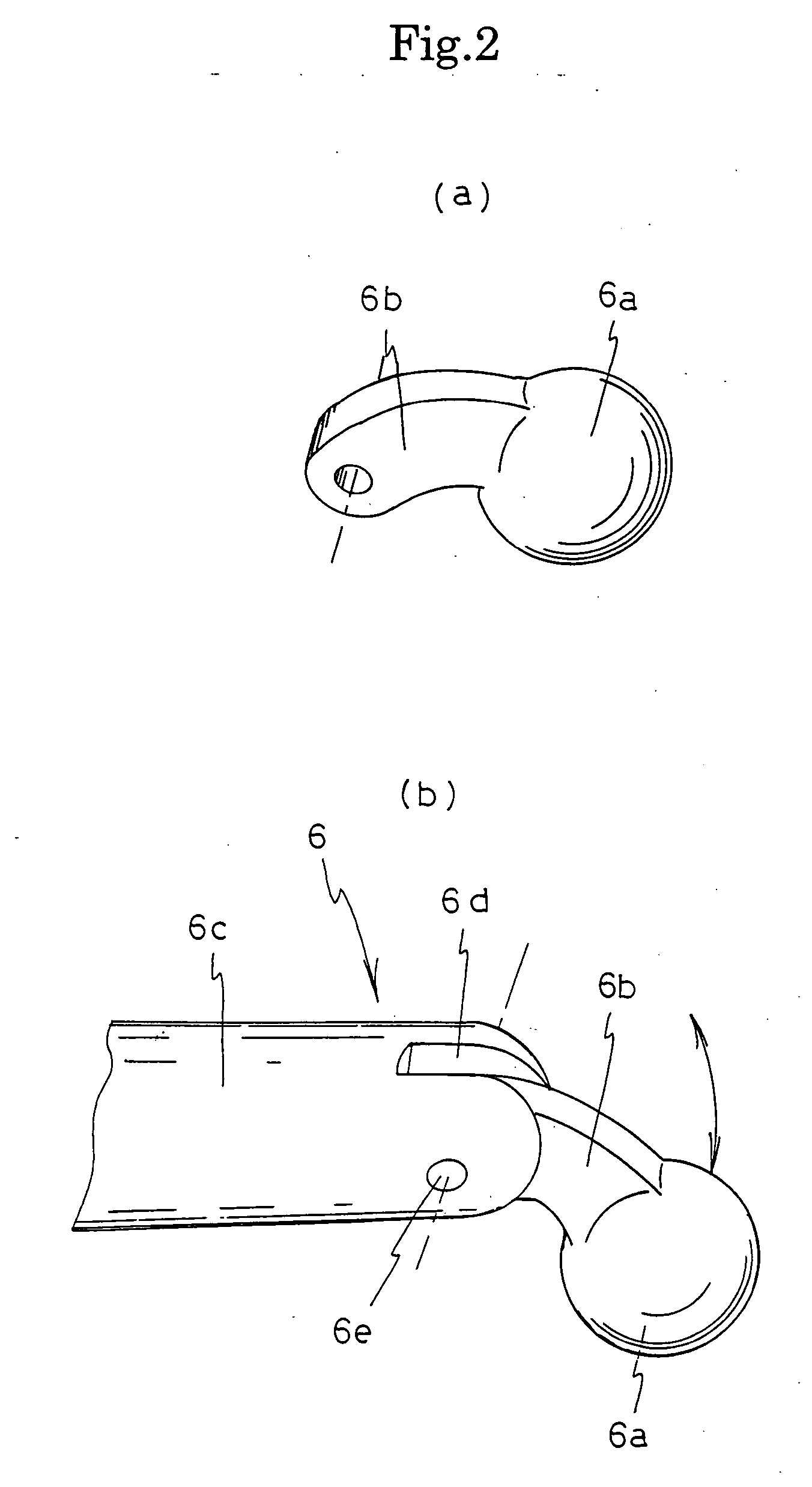

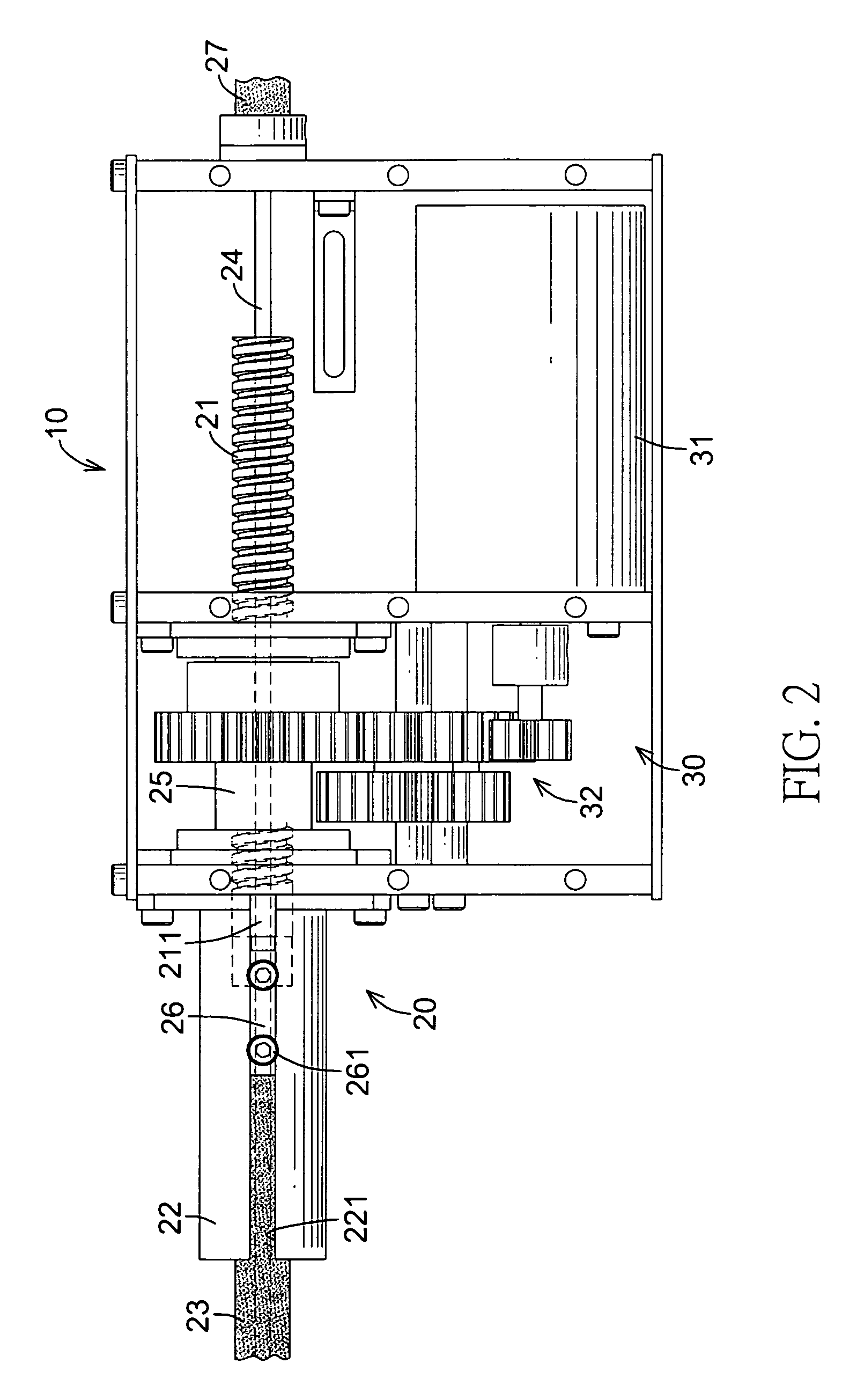

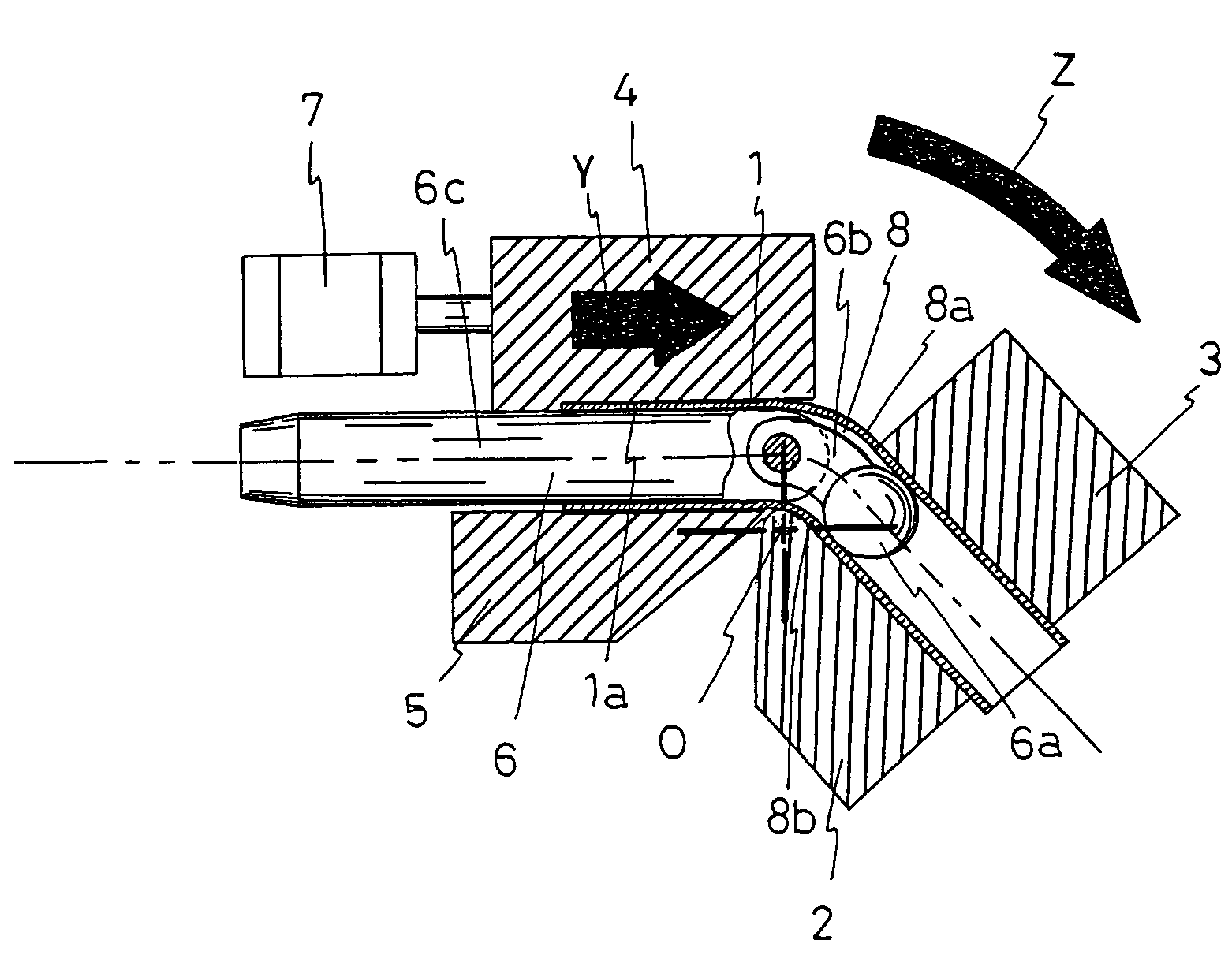

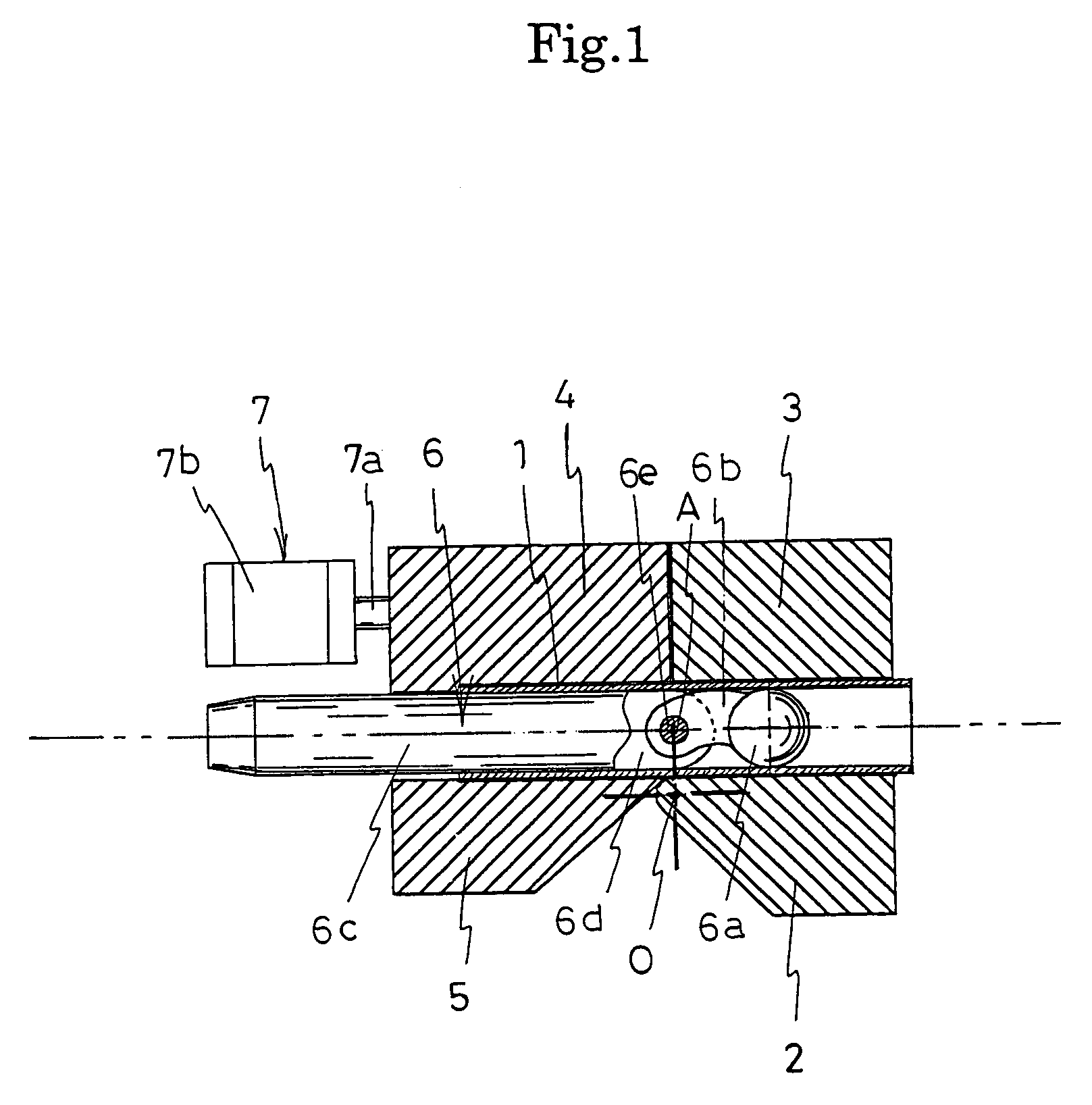

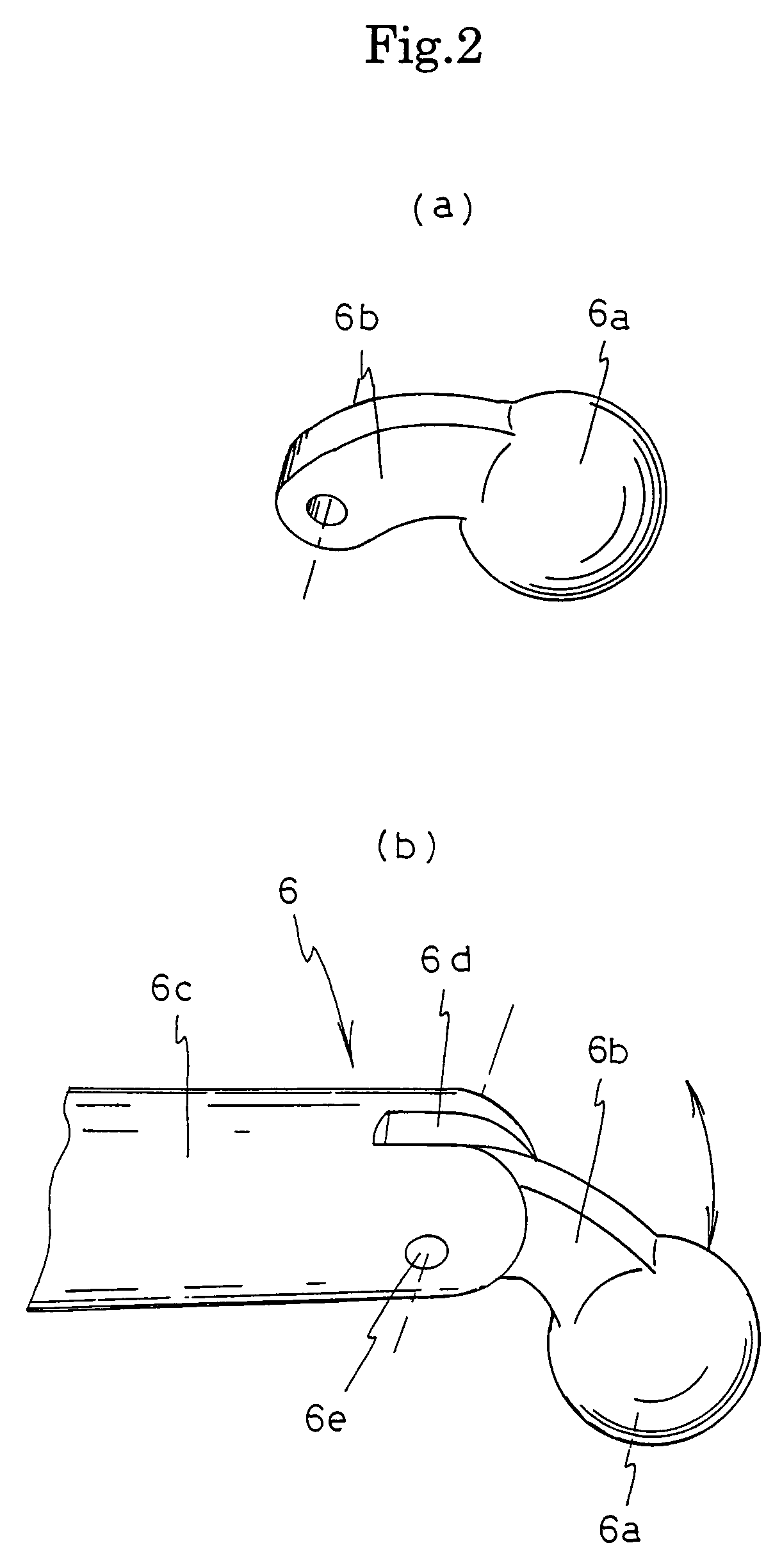

Bending apparatus

A bending apparatus which can bend pipes and obtain as small curvature as possible without flattening or buckling easily occurring in the bending region. The bending apparatus comprises a bending die for a pipe, a clamping die which rotates together with the bending die while clamping the pipe, a pressure die which hold down the pipe, and a metal core which is inserted into the pipe and maintains the shape of the bending region, wherein the metal core is a spherical metal core rotatably supported by an arch shaped arm on the leading end of a core holder.

Owner:SANOH IND CO LTD

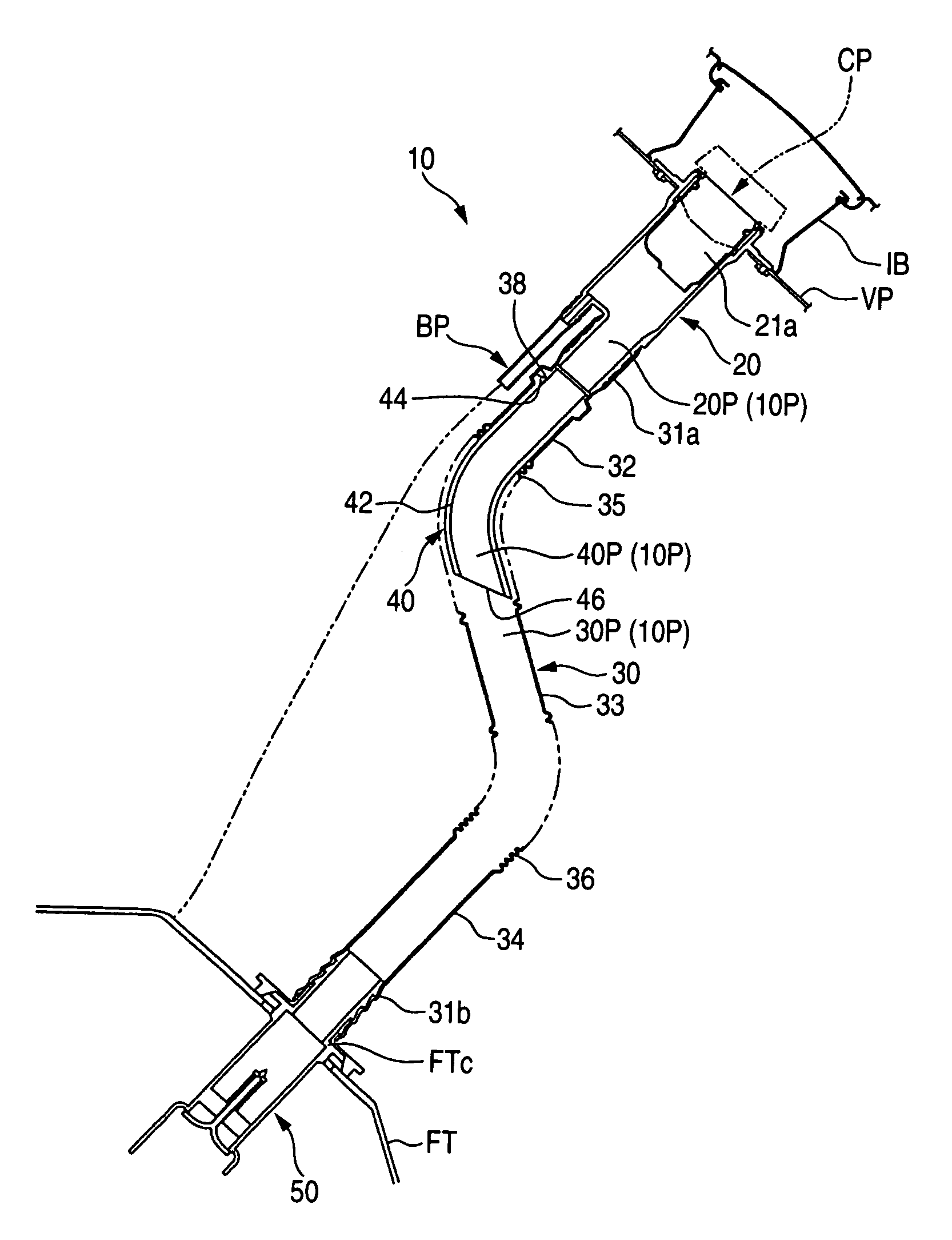

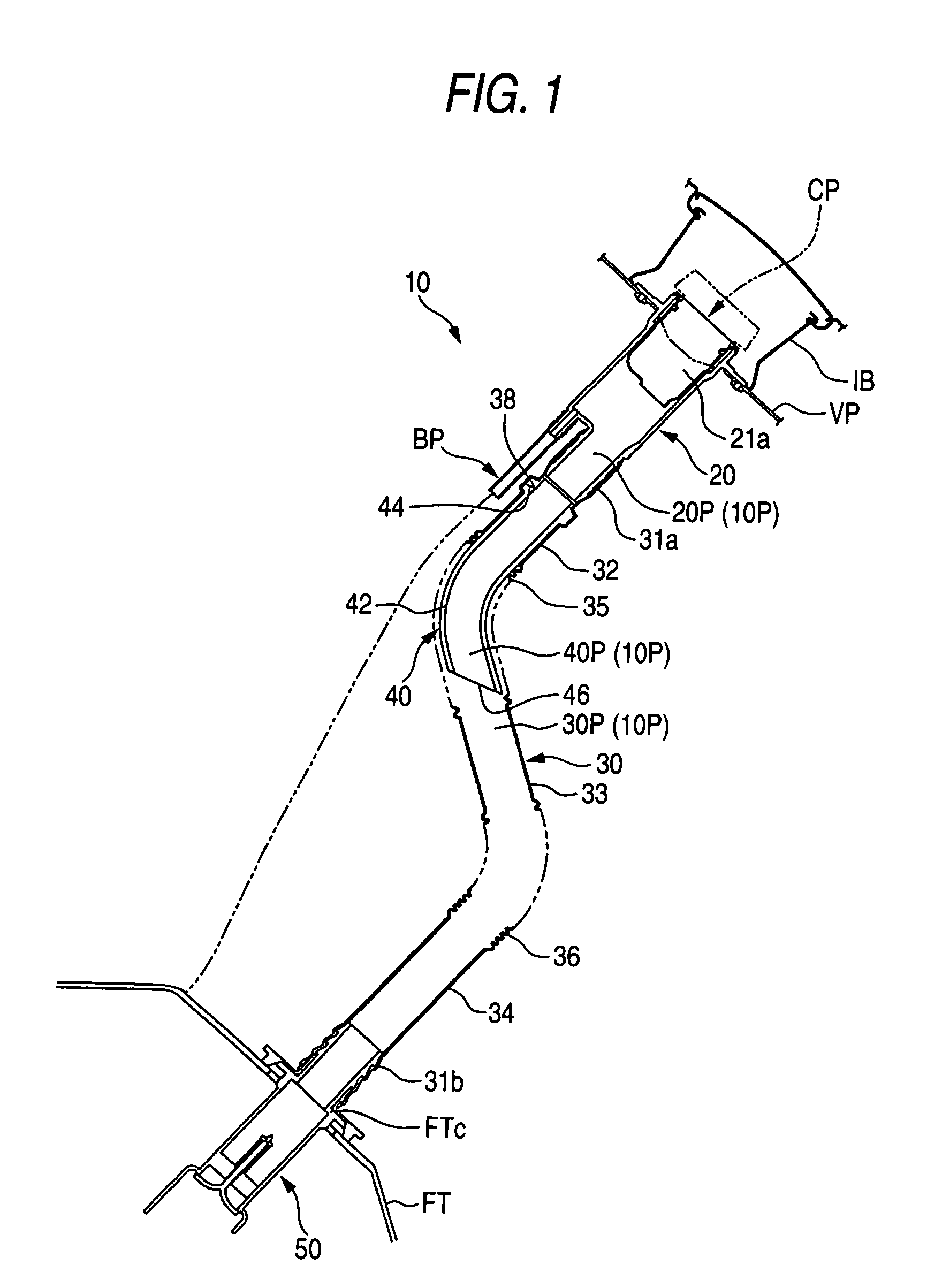

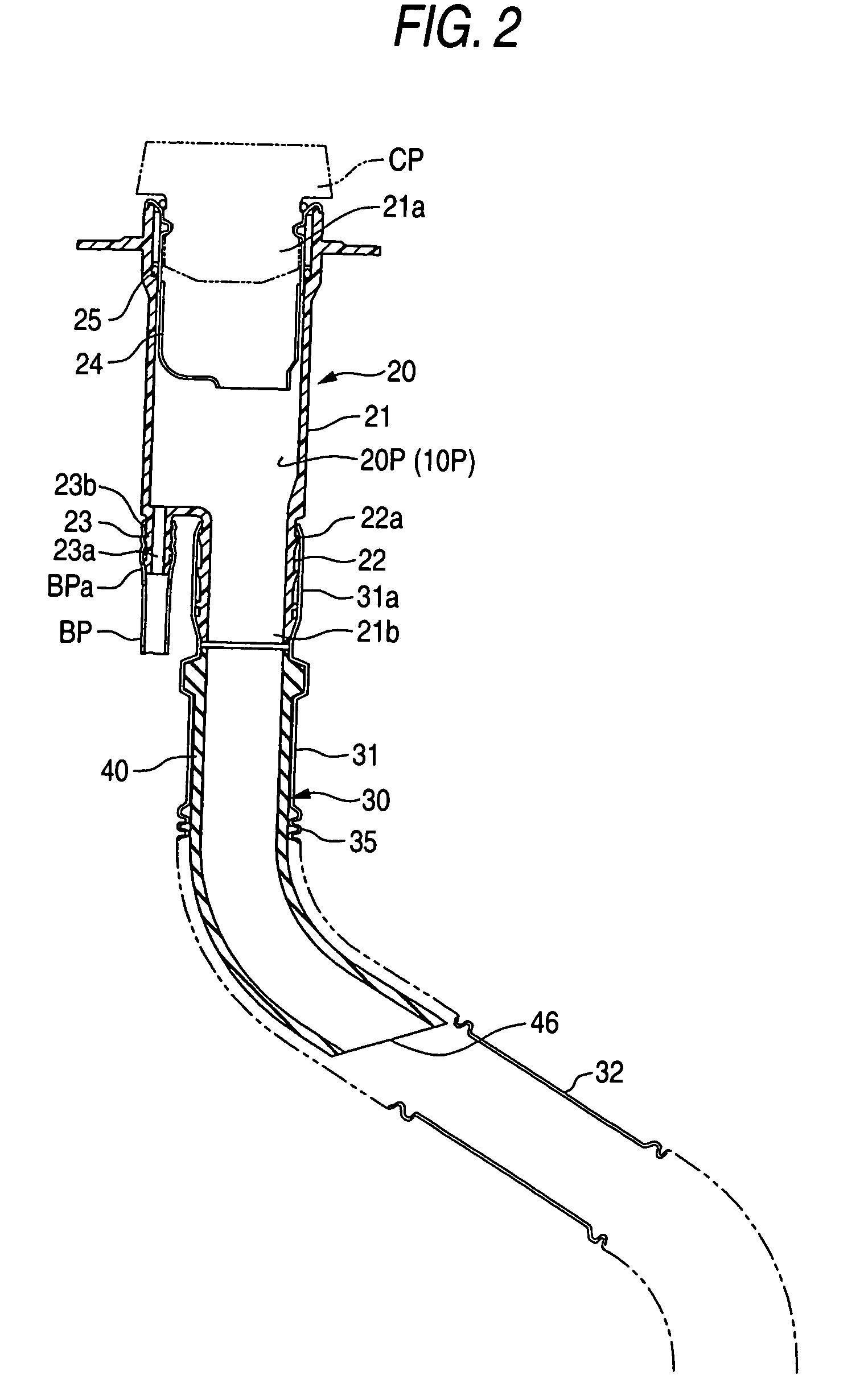

Wiper system for front windscreens of motor vehicles

InactiveUS8205291B2Effective uniform keepingSmall curvatureWindow cleanersVehicle cleaningEngineeringMotorized vehicle

Owner:ROBERT BOSCH GMBH

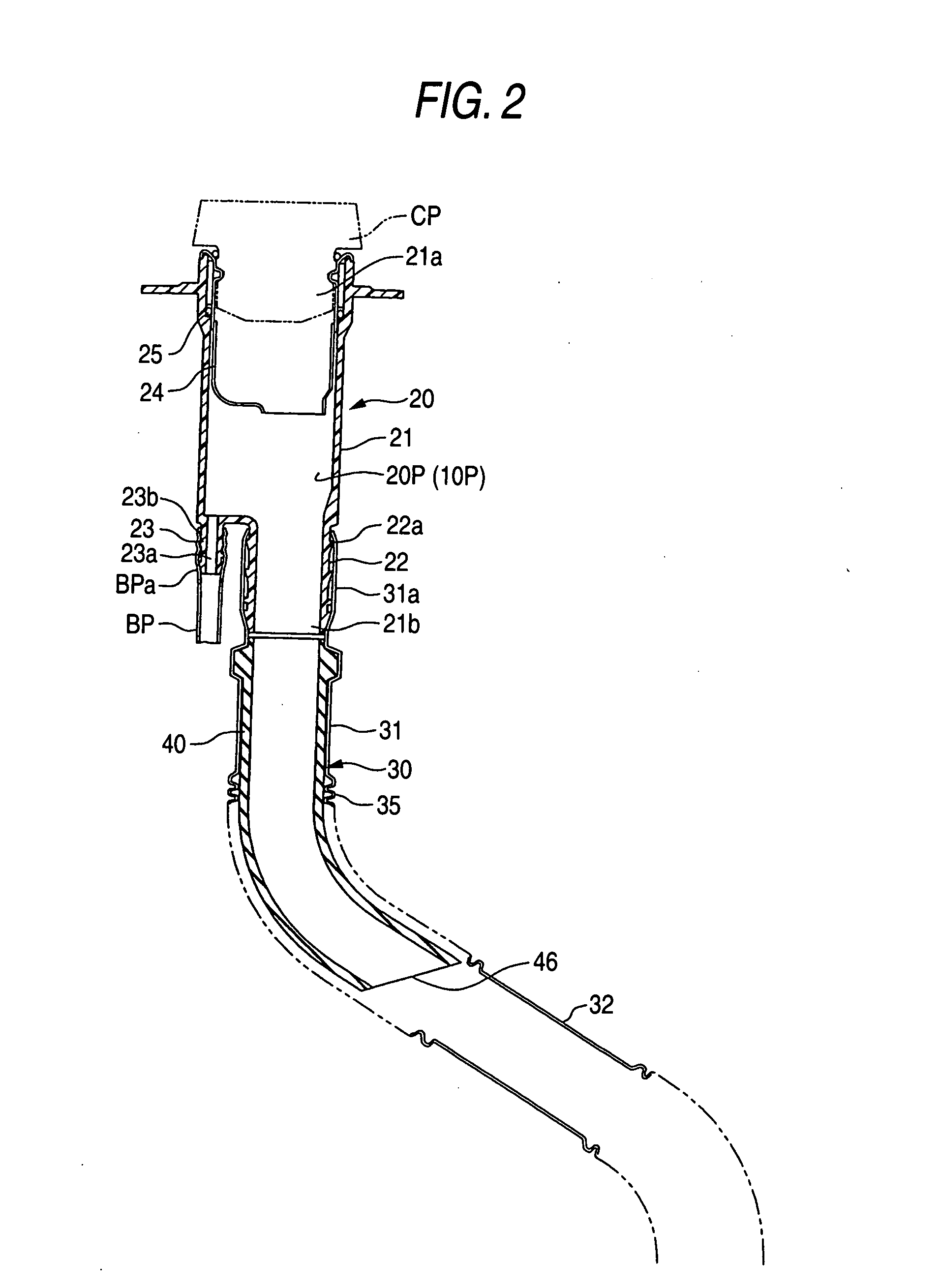

Filler device

InactiveUS20050005998A1Flow resistance of can not be highSmall curvatureLiquid fillingSolid materialElastomerFuel tank

A filler device comprising: a filler neck including a pouring inlet through which a fuel is injected and a neck connection portion; a connection pipe including a pipe connection end to which the neck connection portion is connected and a bellows part which is curved along a filling passage to a fuel tank; wherein the fuel injected through the pouring inlet is fed into the fuel tank through a filling passage, the connection pipe is provided with a pipe-side engaging portion on a back side of the pipe connection portion, the filler device further includes an inner tube including a tube body formed of a flexible elastomer material and inserted into the connection pipe, and a tube-side engaging portion projecting from an outer circumference at an end of the tube body, the inner tube is configured so that the tube body covers an inner wall of the bellows part and that the tube-side engaging portion is engaged with the pipe-side engaging portion, when the inner tube is inserted into the connection pipe, reaching to the back side of the pipe connection end.

Owner:TOYODA GOSEI CO LTD

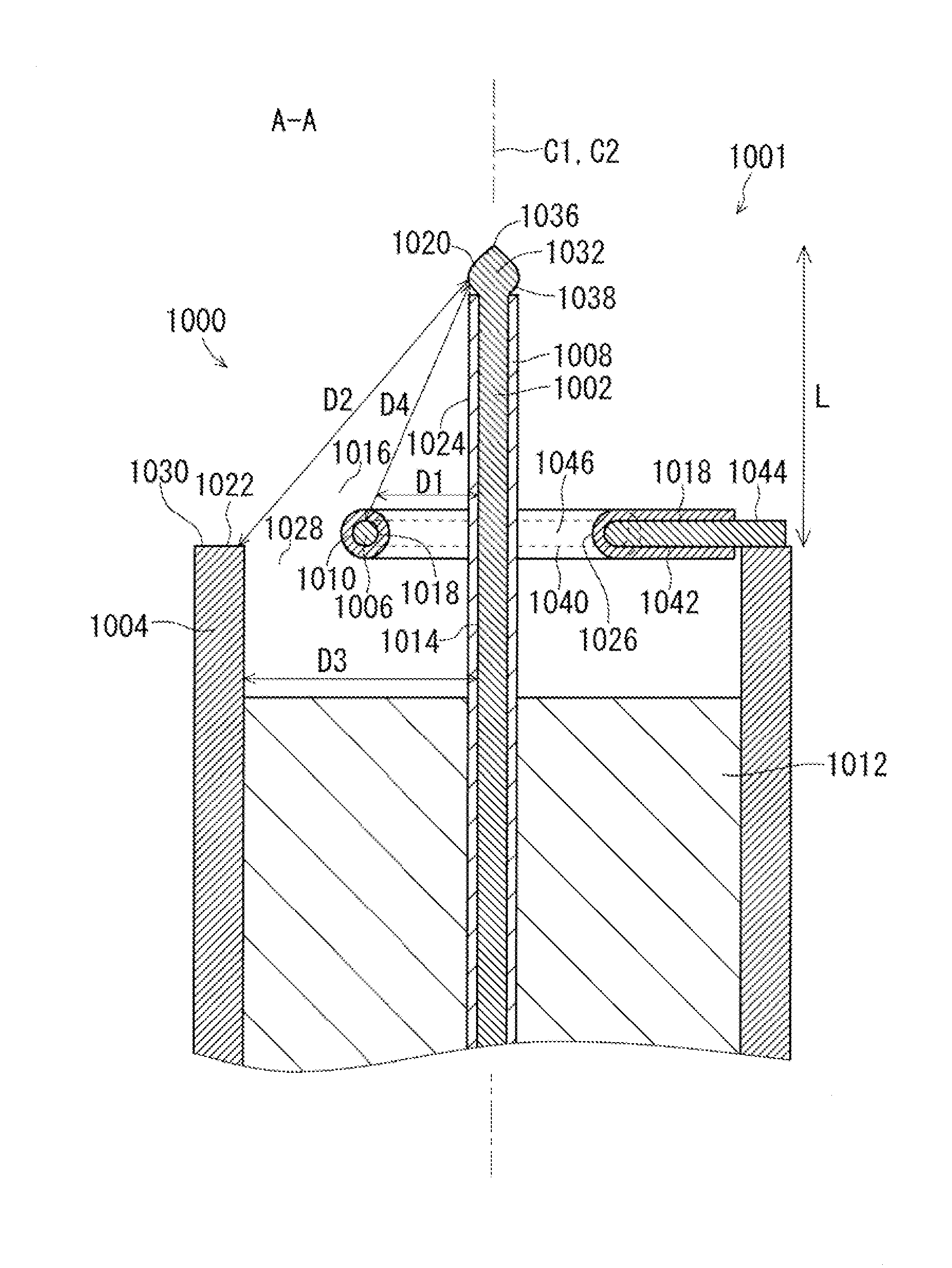

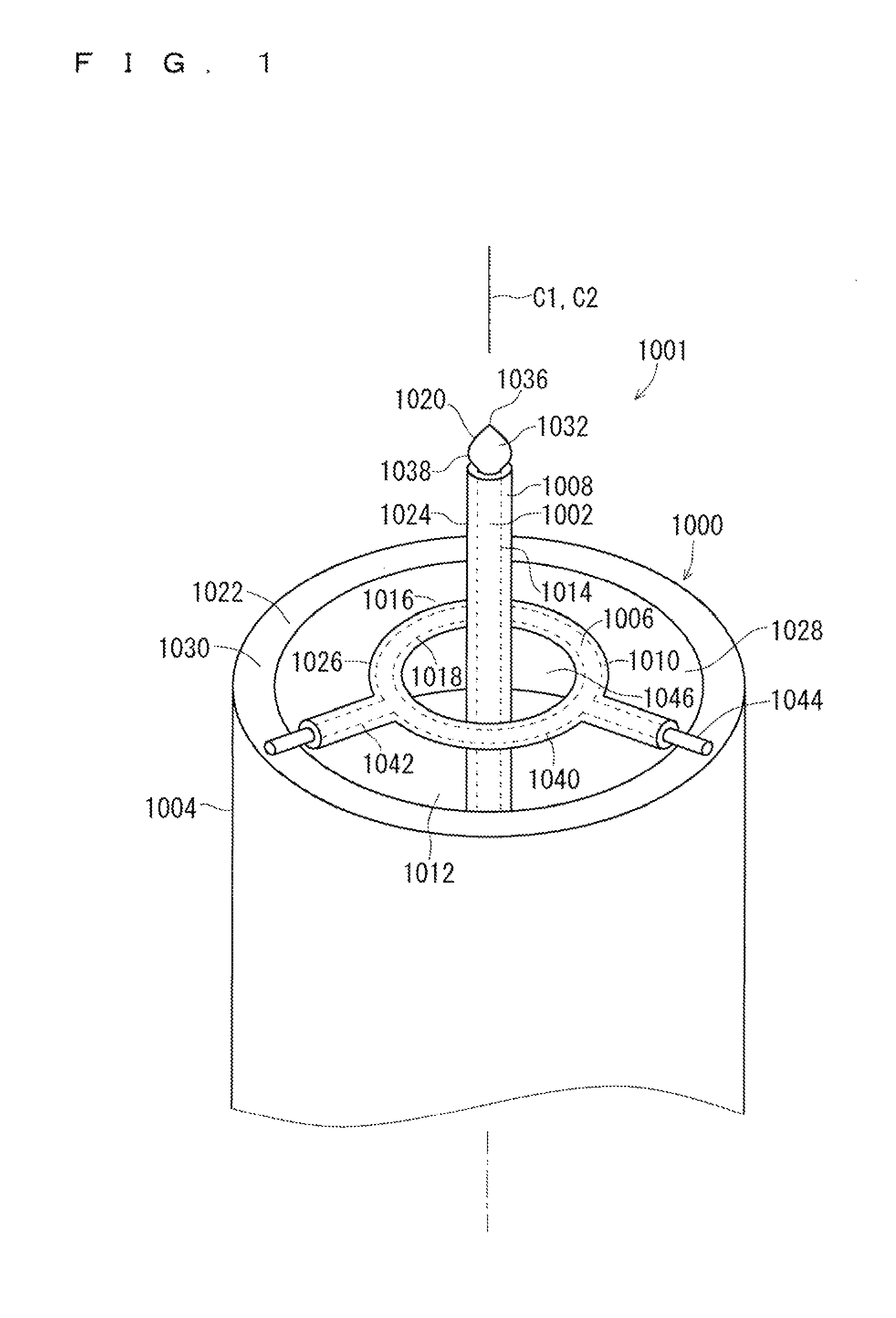

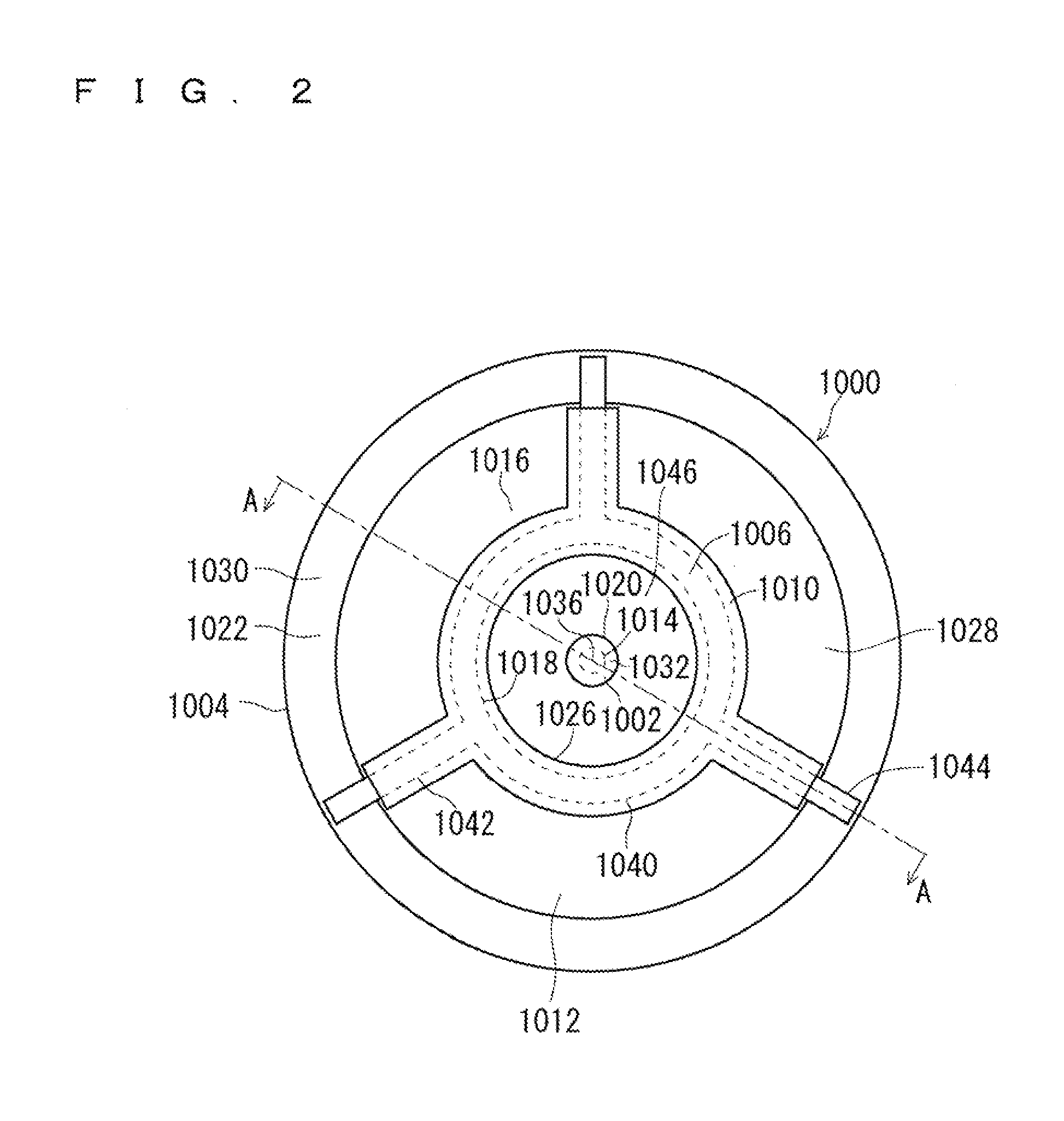

Ignition device of internal combustion engine and electrode structure of the ignition device

An ignition device having an electrode structure including an anode, a cathode, an auxiliary electrode, an anode coating, an auxiliary electrode coating, and an anode supporting body. A coated surface of the anode is opposed to a coated surface of the auxiliary electrode with the anode coating, a combustion space, and the auxiliary electrode coating therebetween. An exposed surface of the anode is opposed to an exposed surface of the cathode with the combustion space therebetween. A distance D1 from the coated surface of the anode to the coated surface of the auxiliary electrode via the anode coating, the combustion space, and the auxiliary electrode coating is shorter than a distance D2 from the exposed surface of the anode to the exposed surface of the cathode via the combustion space (D1<D2). A combustion bomb may be used as the cathode.

Owner:NGK INSULATORS LTD

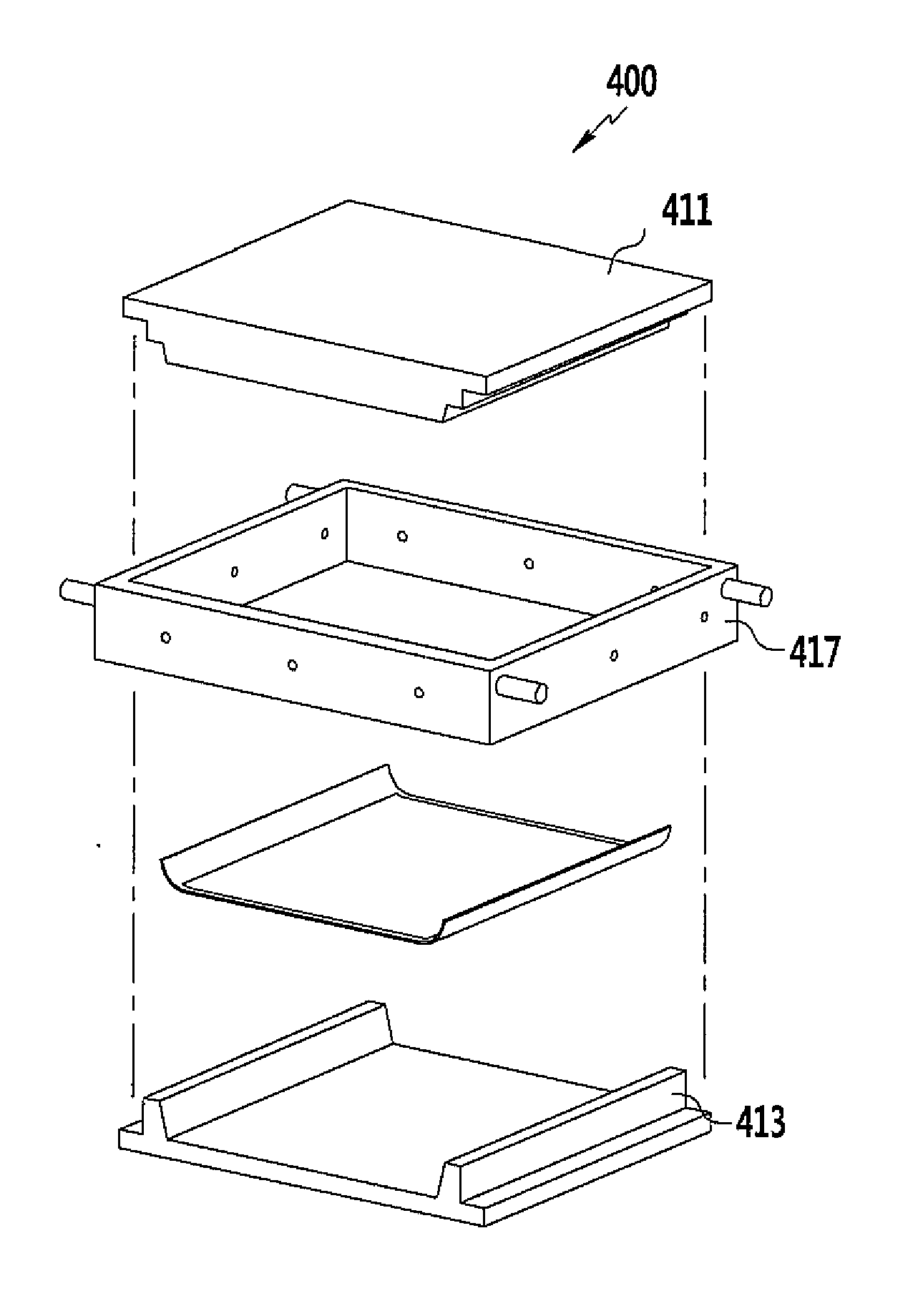

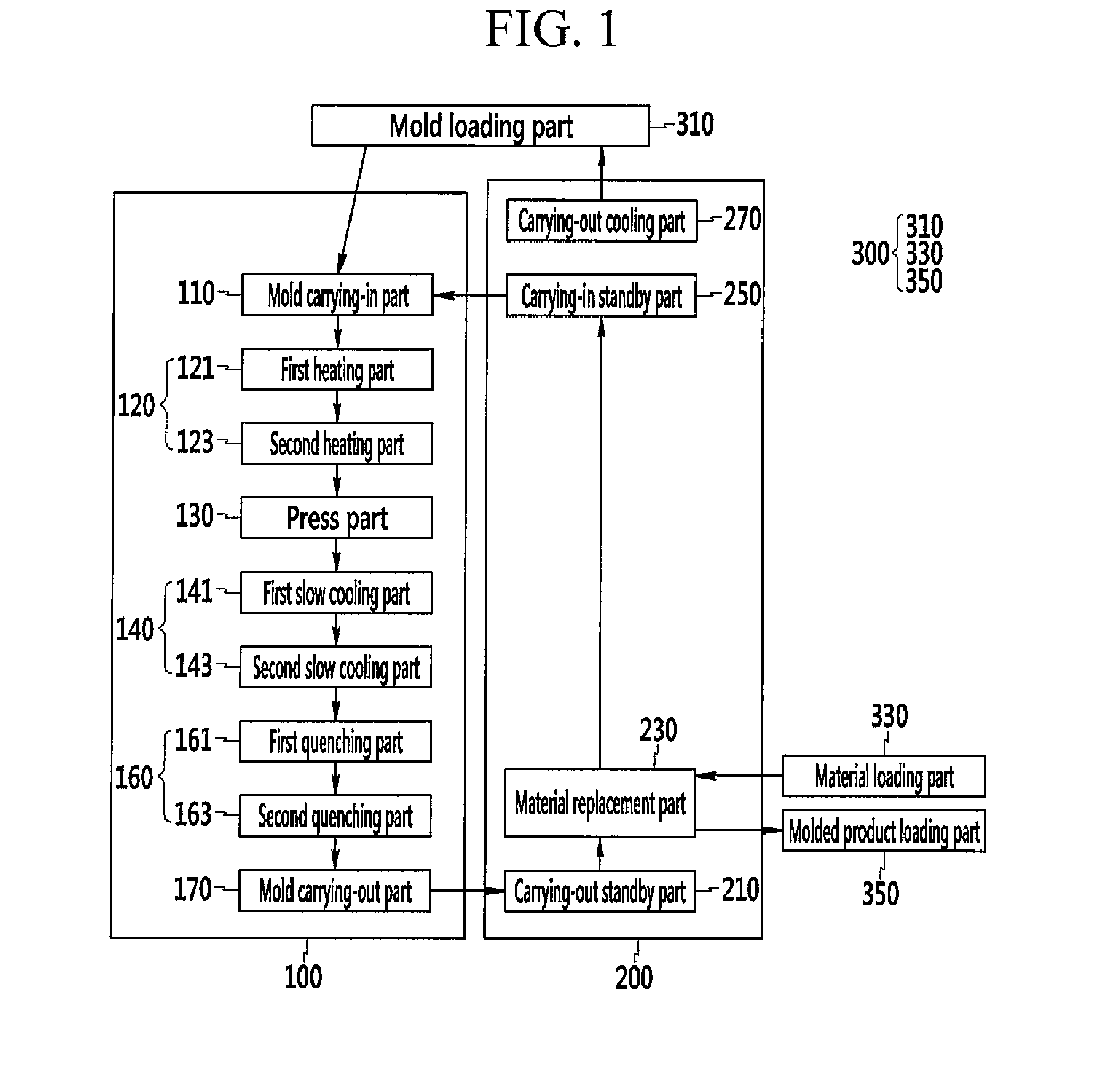

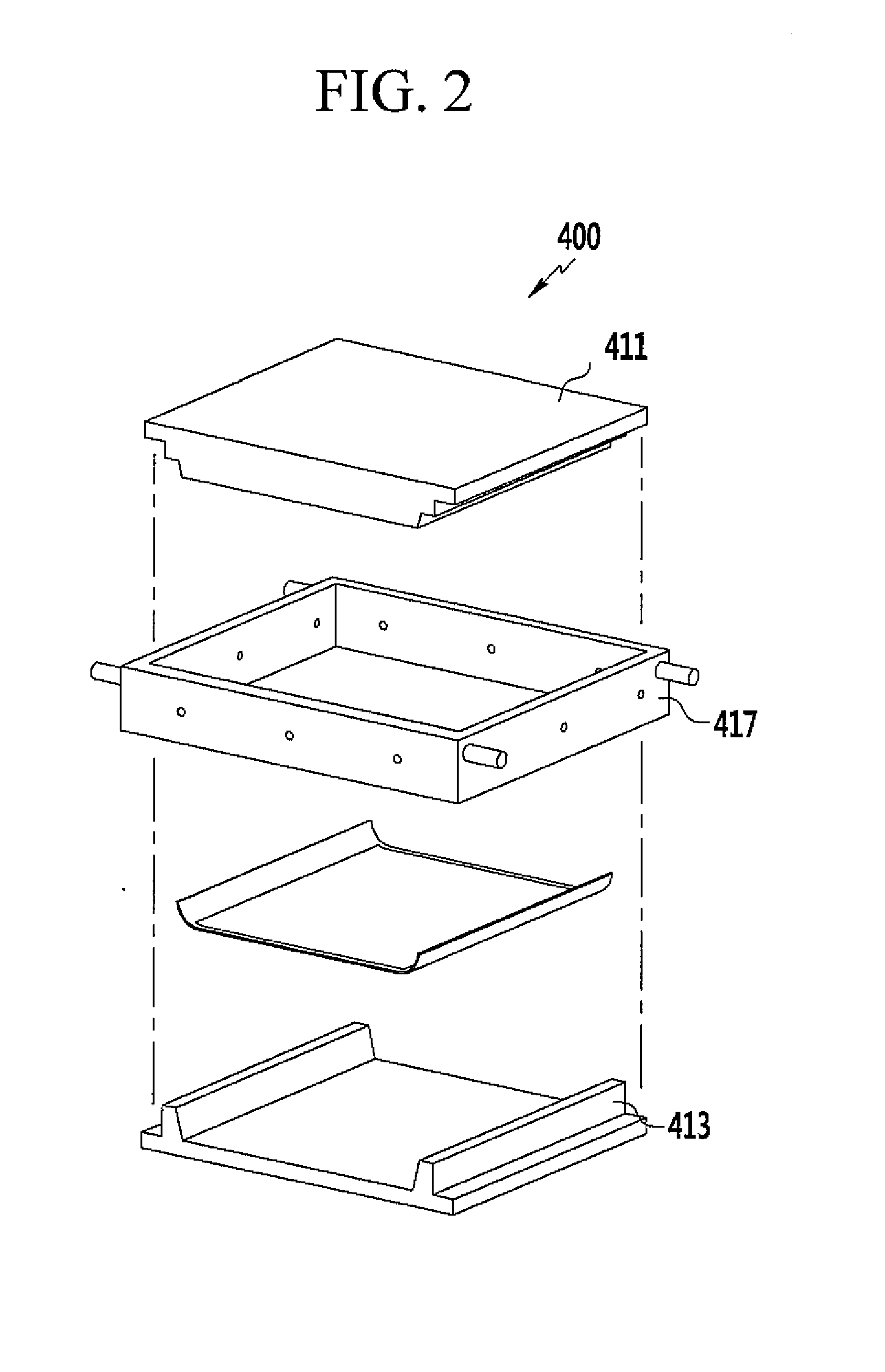

Apparatus and method for manufacturing 3D glass

InactiveUS20140373573A1Easy to manufactureShorten production timeGlass transportation apparatusGlass reforming apparatusMetallurgyShell molding

Owner:SAMSUNG DISPLAY CO LTD

Filler pipe

InactiveUS7198078B2Flow resistance of can not be highSmall curvatureLiquid fillingSolid materialElastomerFuel tank

A filler device or pipe comprising: a filler neck including a pouring inlet, a neck connection portion, and a connection pipe which includes a bellows part and which is connected to the neck connection portion. Fuel is injected through the pouring inlet and fed into the fuel tank through a filling passage of the filler device. The filler device further includes an inner tube including a tube body formed of a flexible elastomer material, which is inserted into the connection pipe. The tube body and the connection pipe having cooperating engaging members for holding the tube body within the connection pipe. The tube body covers an inner wall of the bellows part.

Owner:TOYODA GOSEI CO LTD

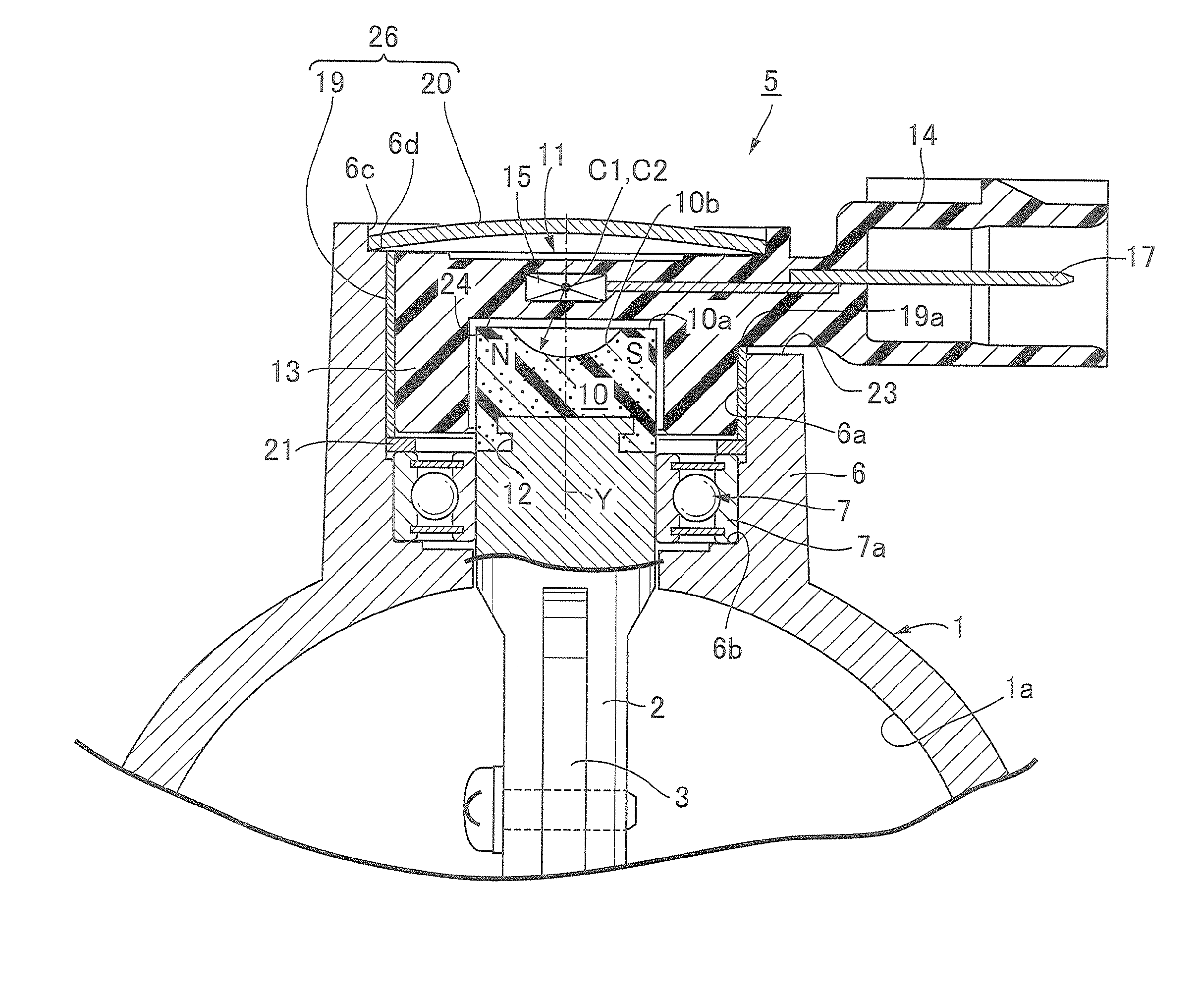

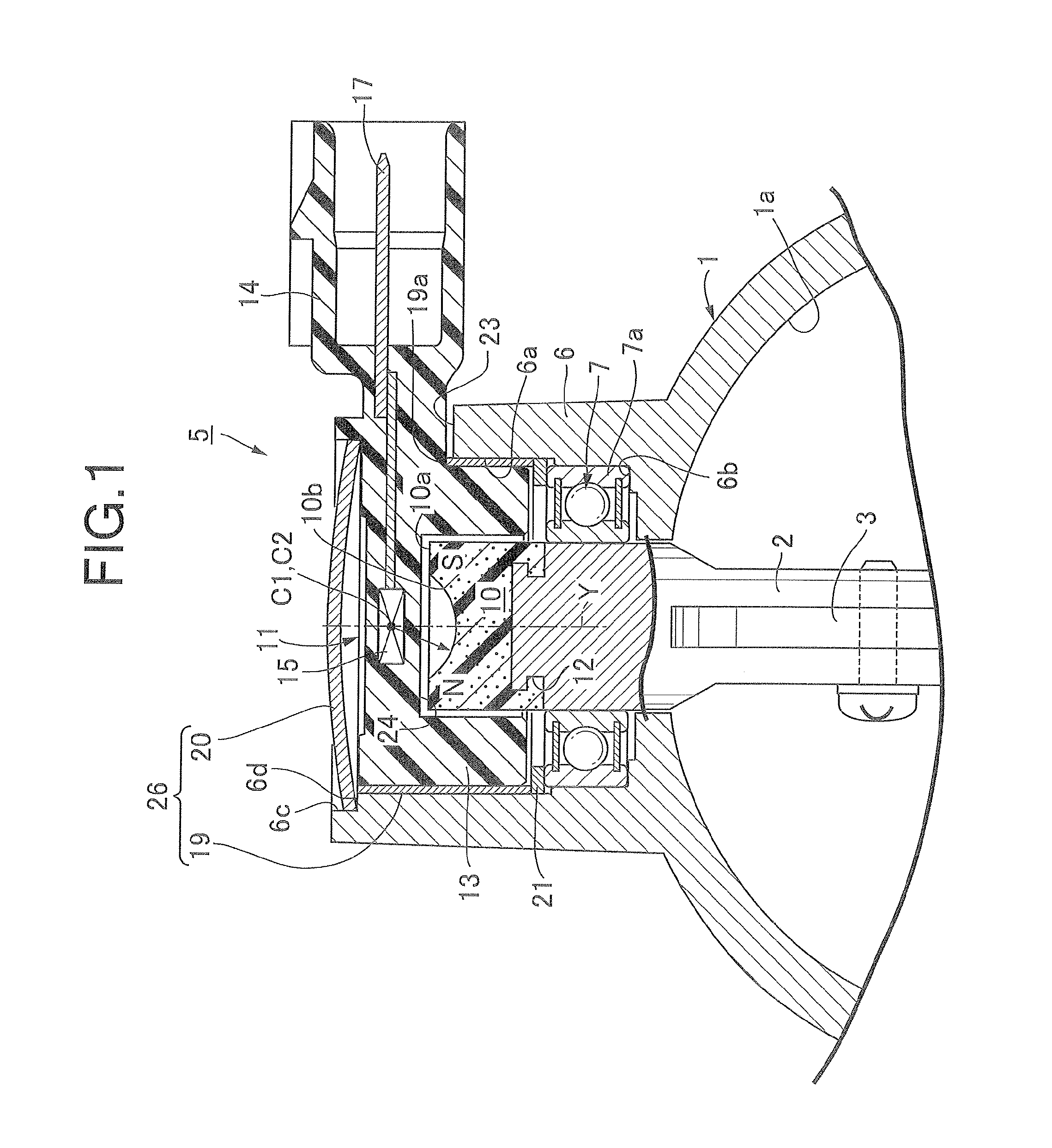

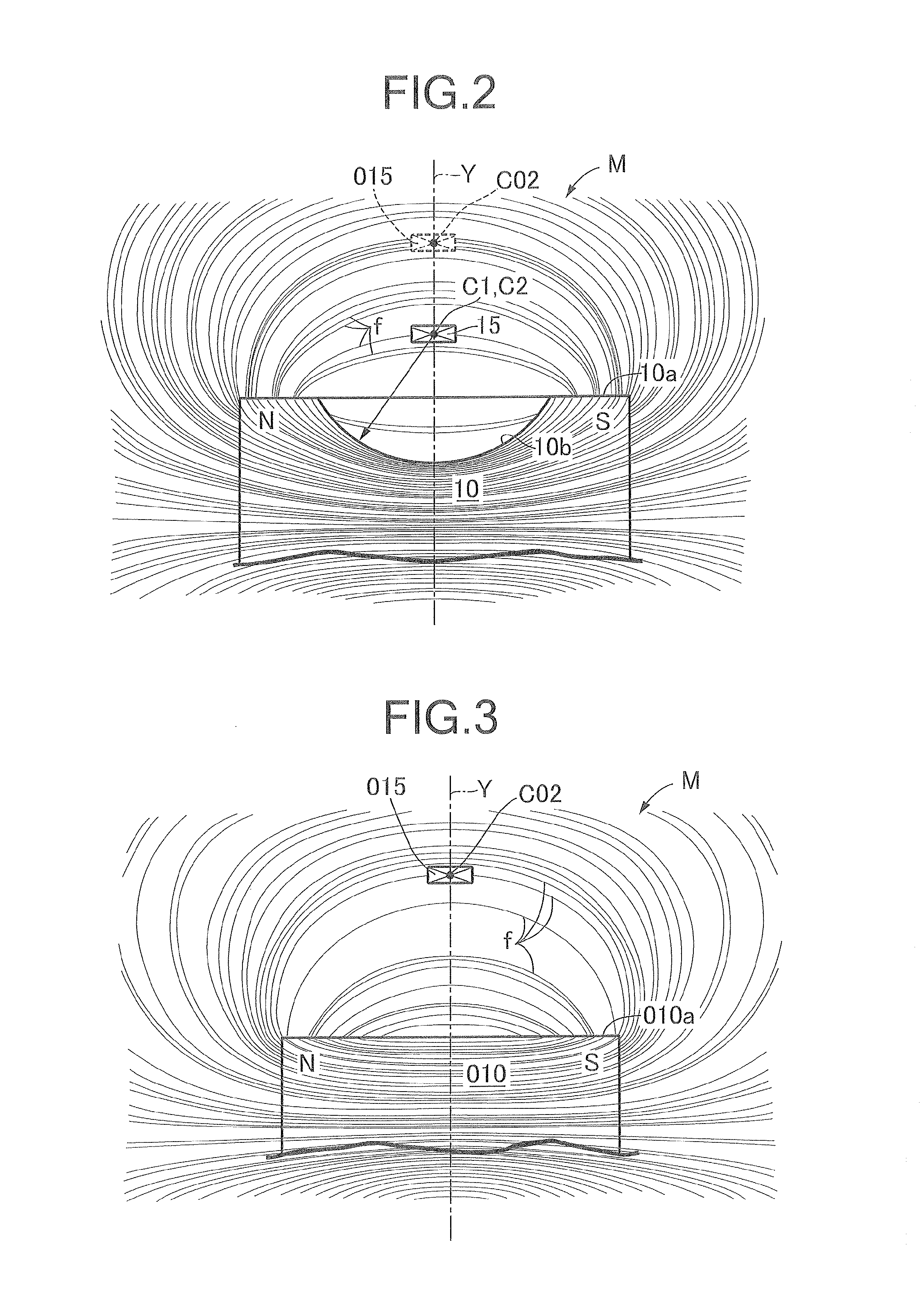

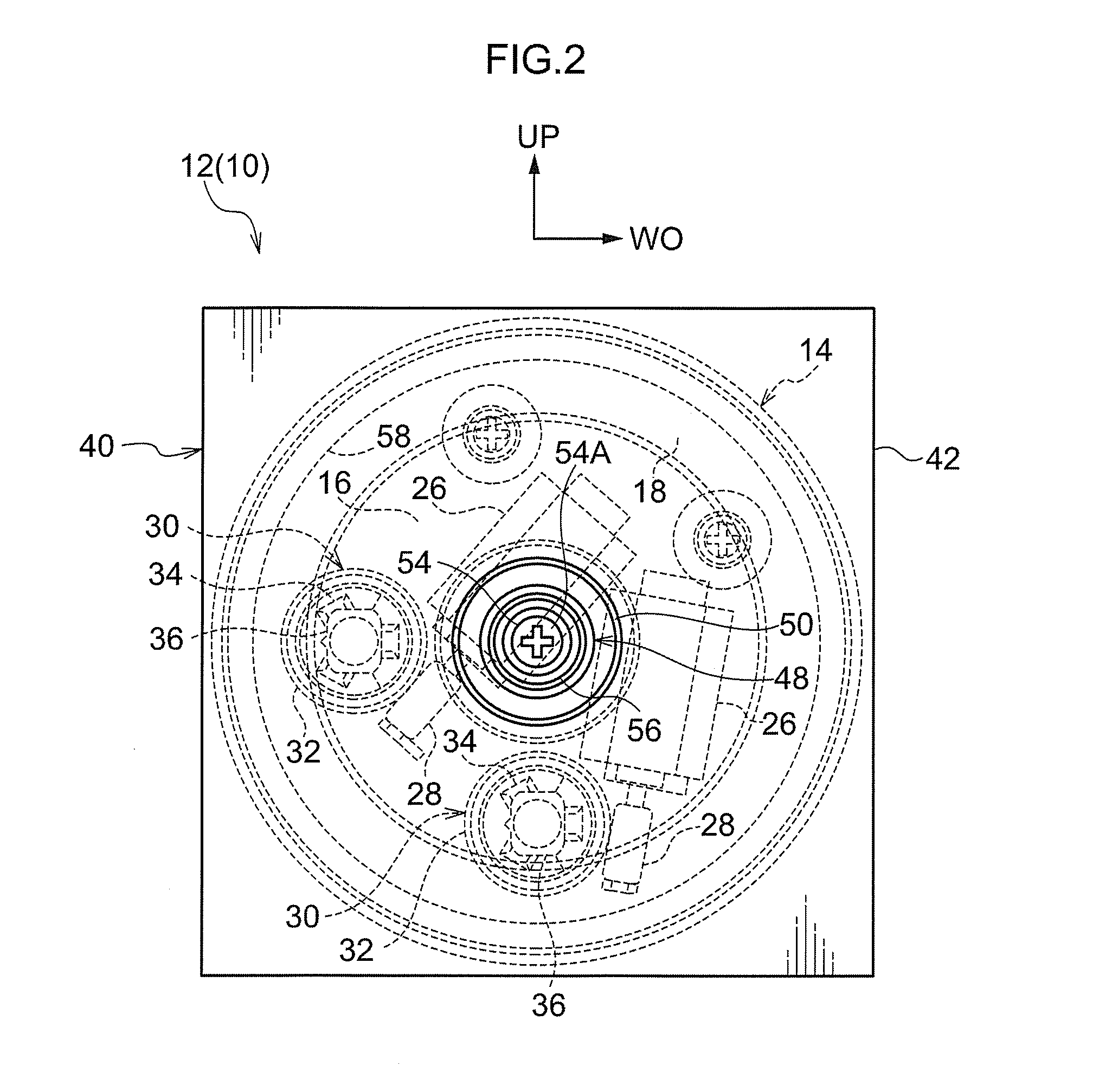

Rotation angle detector

InactiveUS20130241538A1Small sizeImprove accuracyUsing electrical meansConverting sensor outputAngular degreesTransducer

A rotation angle detector includes: a magnet attached to a rotating shaft and magnetized in a certain direction orthogonal to an axis of the rotating shaft; and a non-rotary magneto-electric transducer placed to be opposed to an end surface of the magnet, and configured to detect a rotation angle of the rotating shaft in cooperation with the magnet through magneto-electric transduction. A concave curved surface is formed in the end surface of the magnet in order to make a magnetic flux of a magnetic field facing the end surface of the magnet closer to the magnet and flattened. Accordingly, it is possible to provide a rotation angle detector which is compact in size and has a stable accuracy for detecting the rotation angle, by making the curvature of the magnetic flux near the end surface of the magnet small and placing the magneto-electric transducer in that location.

Owner:HITACHI ASTEMO LTD

Intramedullary nail

ActiveUS8262658B2Curvature of the intramedullary nail is slightSmall curvatureInternal osteosythesisJoint implantsTibiaIntramedullary rod

An intramedullary nail, particular for use with a tibia, may have a proximal end part, a distal end part adapted to be introduced into a medullary space, and a central section. The central section includes a first curved section having a first length with a first radius of curvature, and a second curved section having a second length shorter than the first length and a second radius of curvature smaller than the first radius of curvature. The second radius of curvature may be less than the first radius of curvature. The intramedullary nail also includes a central axis. Tangents at two end points of the central section, including the first and second curved sections, enclose an angle gamma between about 9° and about 12°. The intramedullary nail may have a total length ranging from 200 to 500 mm.

Owner:SYNTHES USA

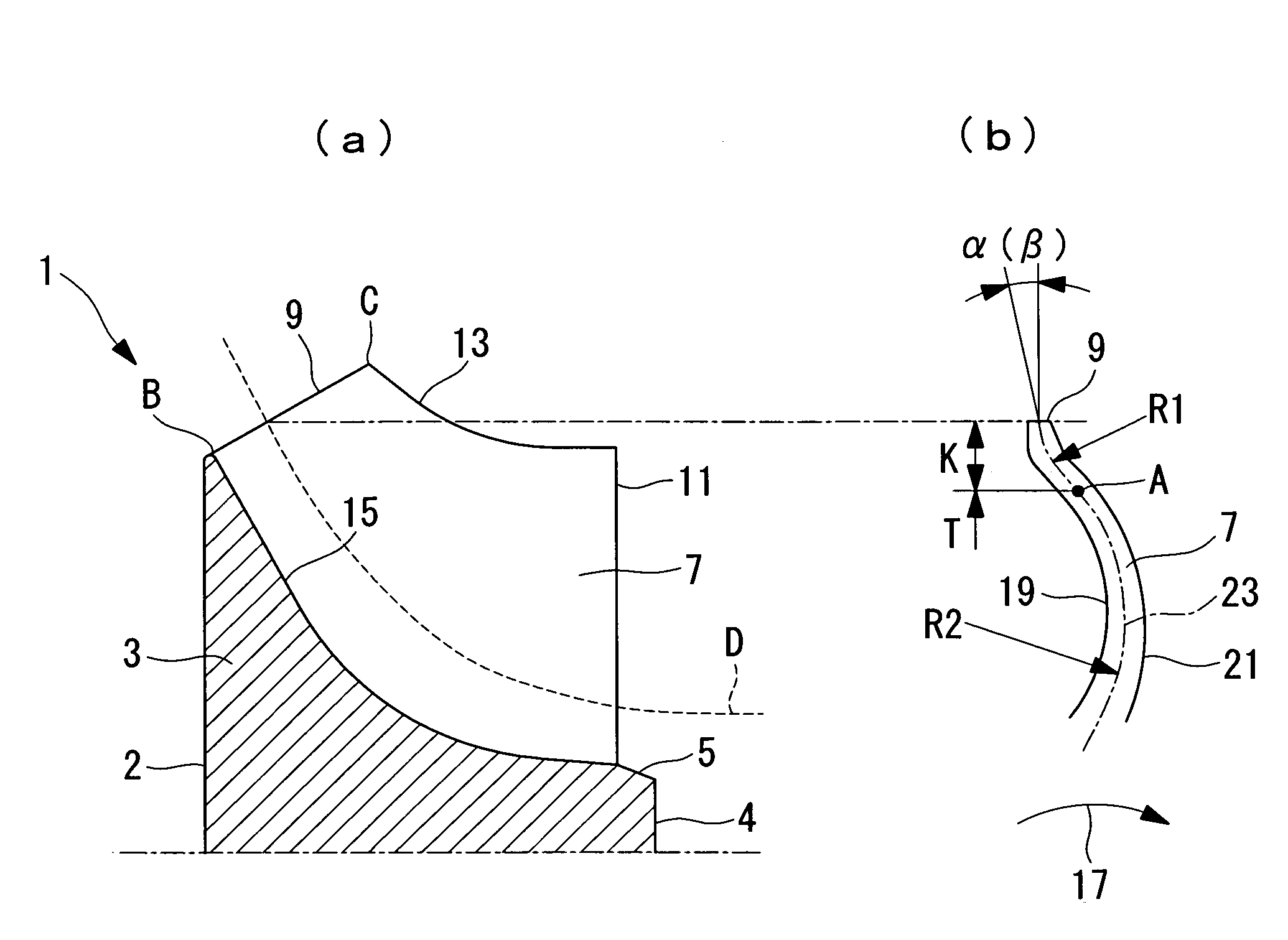

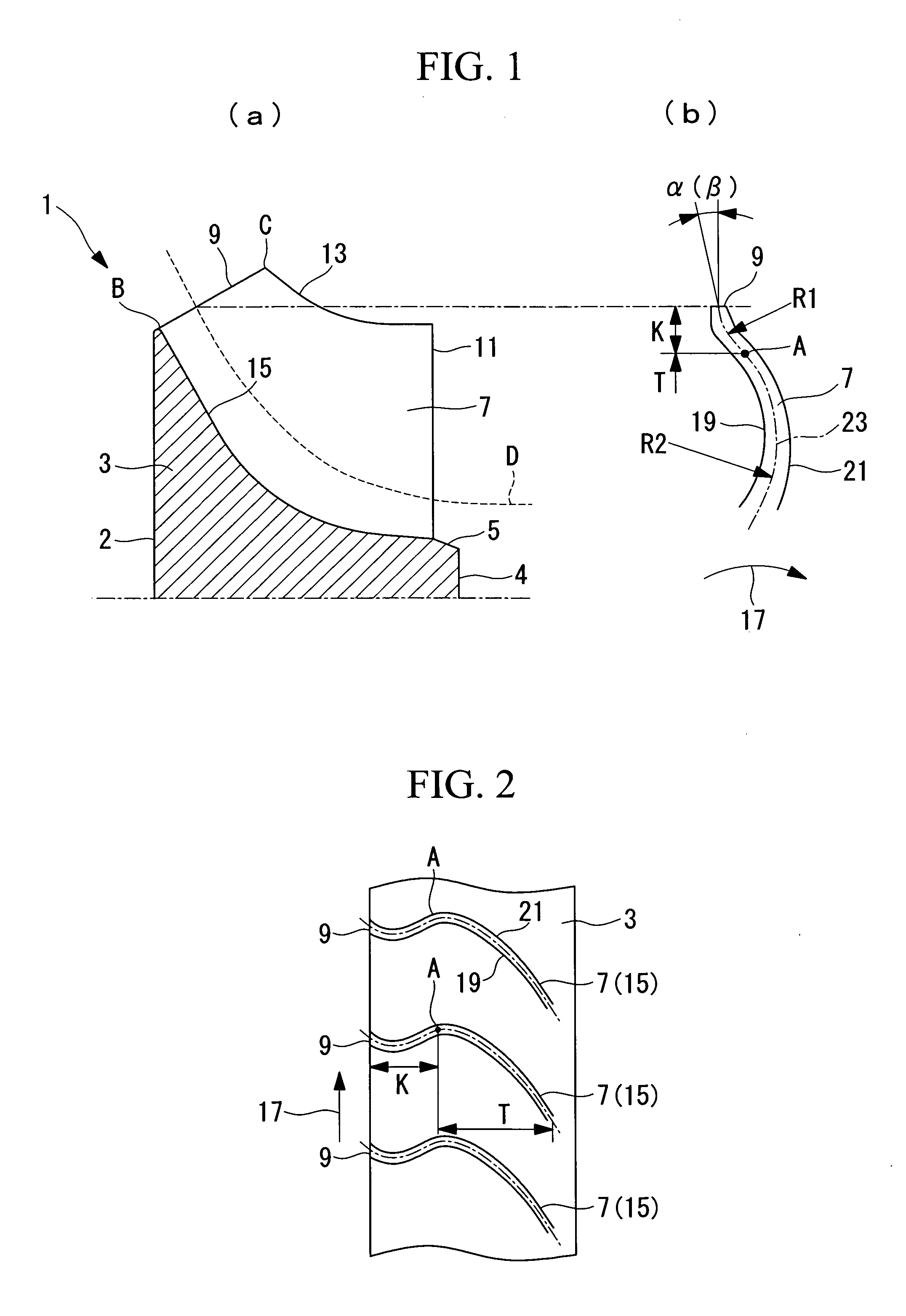

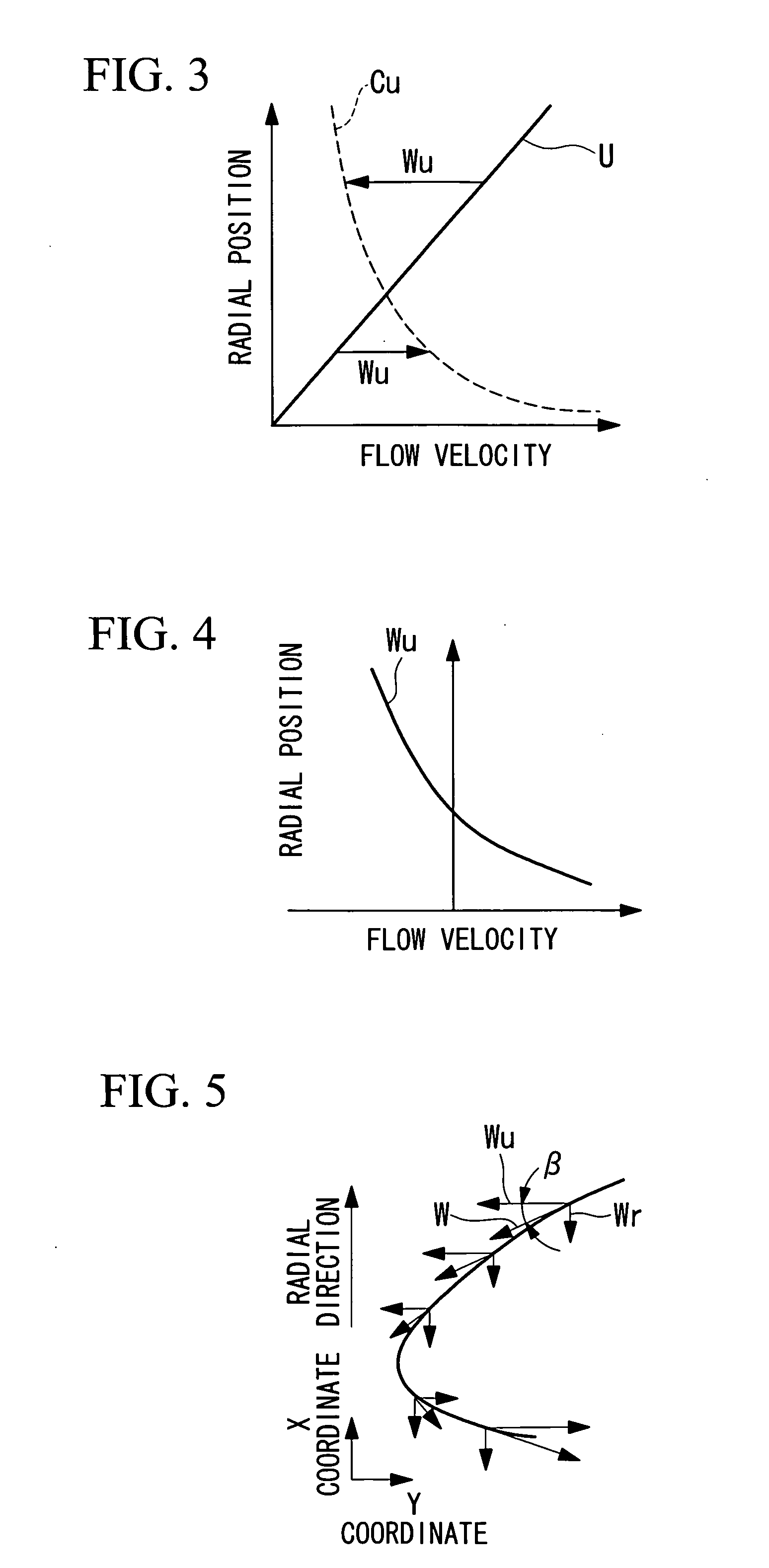

Mixed Flow Turbine or Radial Turbine

ActiveUS20100098548A1Optimal Rate of ChangeCut surfacePropellersEngine manufactureMixed flowFront edge

Intended is to provide a mixed flow turbine or a radial turbine, which can suppress an abrupt increase in a load to be applied to the front edge portion of a blade, thereby to reduce an incidence loss. The mixed flow turbine or the radial turbine comprises a hub (3), and a plurality of blades (7) arranged at substantially equal interval on the outer circumference (5) of the hub (3) and having a warpage (23) curved convexly in the rotating direction, as entirely viewed from the front edge side to the back edge side. Each blade (7) is provided, at its front edge portion, with an inflection point (K), at which the warpage (23) in the section along the outer circumference is curved concavely in the rotating direction.

Owner:MITSUBISHI HEAVY IND LTD

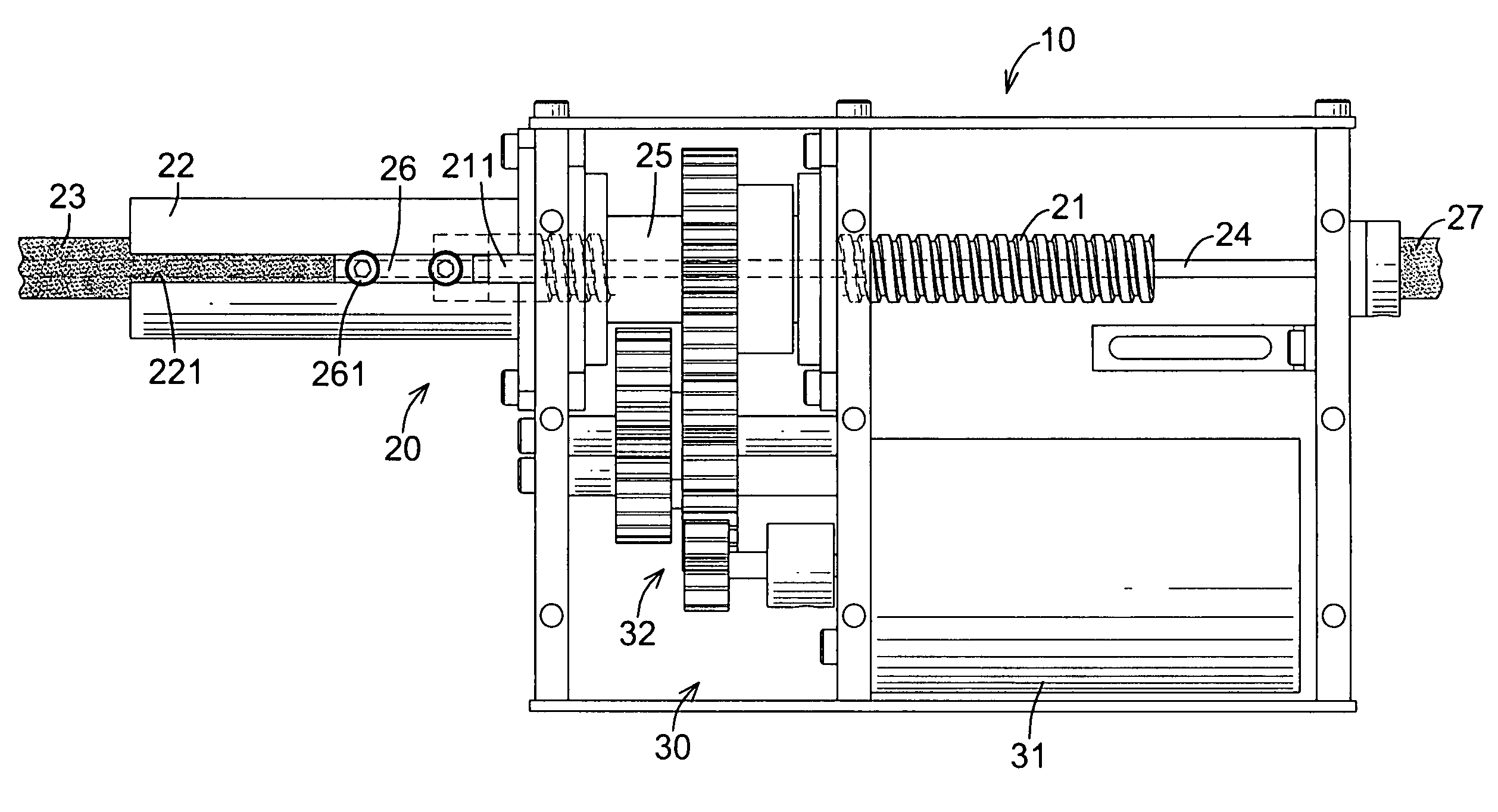

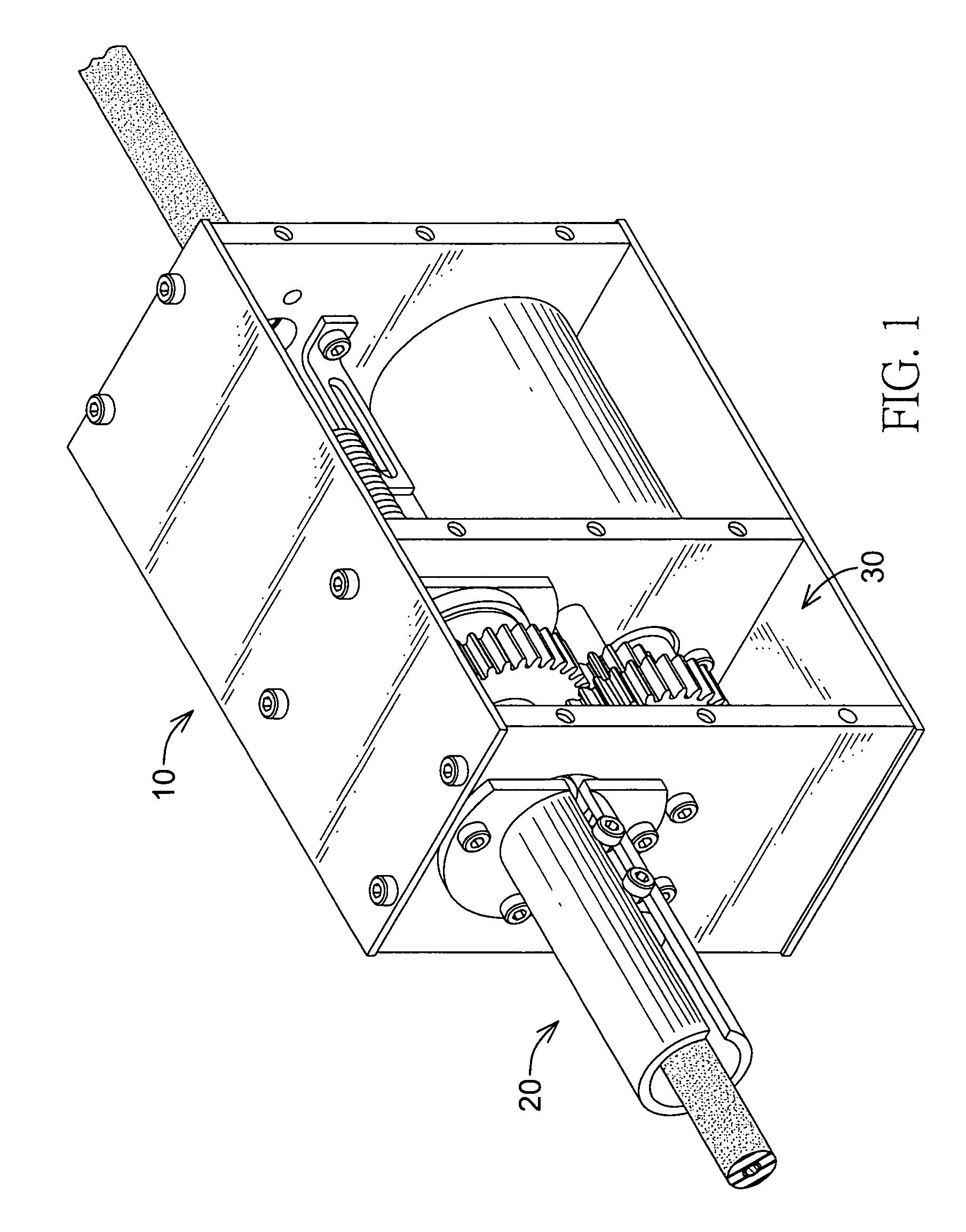

Driving device for a parking brake system

ActiveUS8051956B2Increase life-span and mechanical efficiencyExtend your lifeBraking action transmissionElectrodynamic brake systemsEngineeringParking brake

A driving device for a parking brake system includes a casing shift member, a brake cable and a driving member. The casing shift member includes a cable casing. The brake cable is mounted through the cable casing. The driving member has a driving unit connected to and driving the casing shift member to perform a longitudinal motion. Thus the cable casing applies a force on the brake cable so as to perform a brake work. Because the brake cable is tightened with the force provided by the cable casing, the brake cable is only bent slightly. Thus the curvature of the brake cable is small. That prevents the brake cable from being damaged and prolongs a life span of the brake cable. Moreover, a mechanical efficiency of the driving device is improved because the brake cable is tightened with the force provided by the cable casing.

Owner:AUTOMOTIVE RES & TESTING CENT

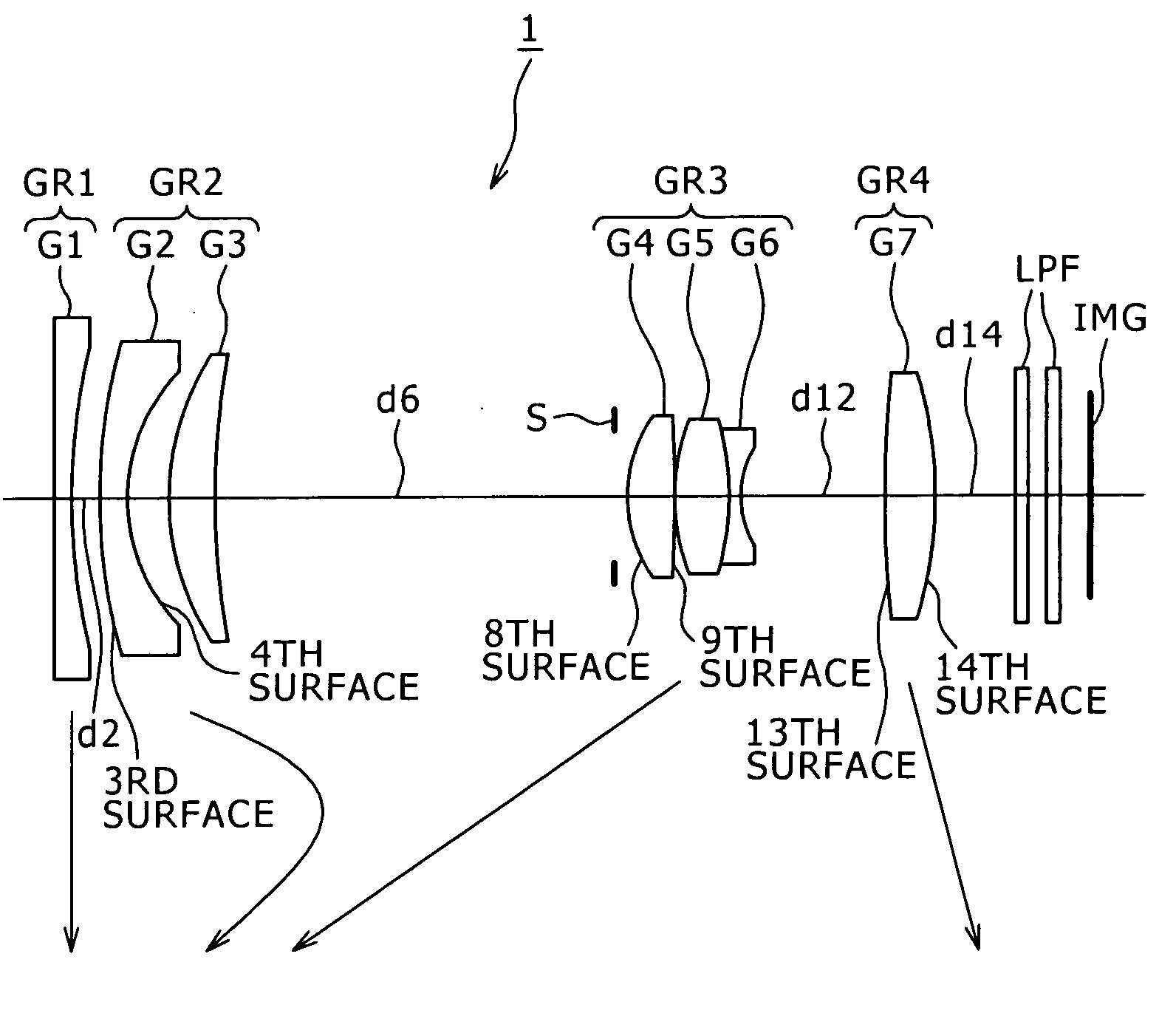

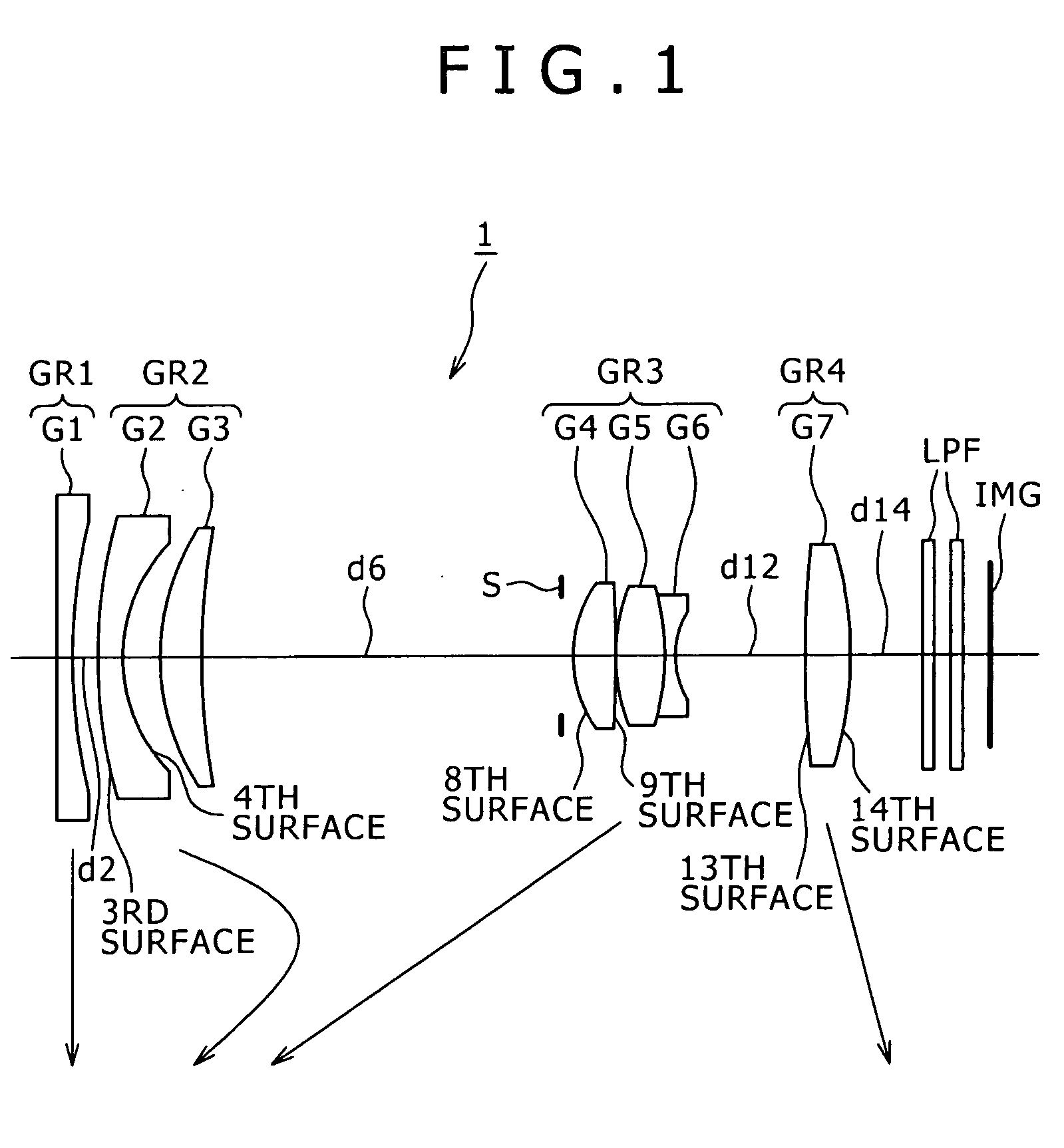

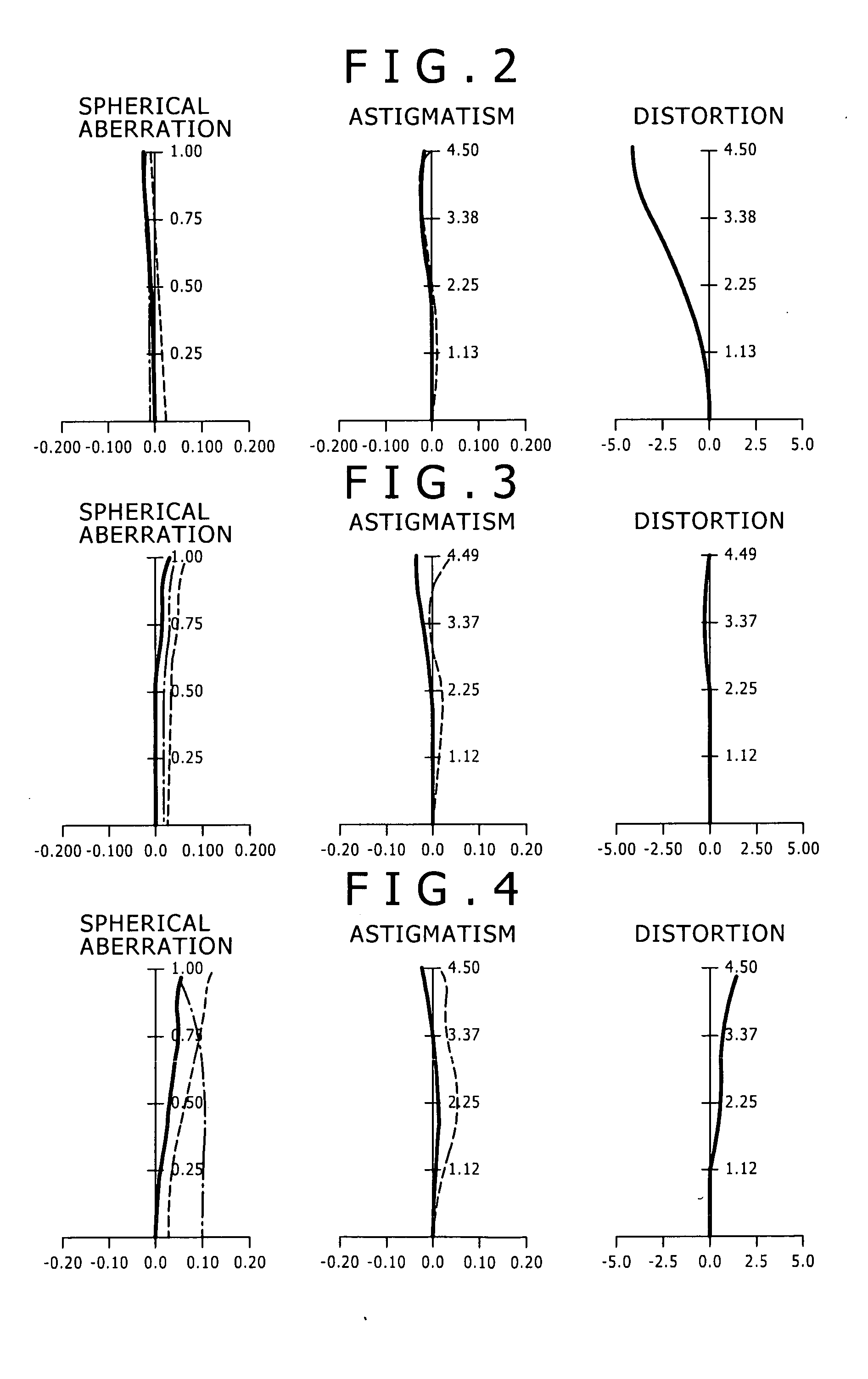

Zoom lens and image capture apparatus

A zoom lens includes, in the following order from an object side: a first lens group including negative refractive power; a second lens group including negative refractive power; and a third lens group. At least the second and third lens group are movable along an optical axis to perform a zooming action. The second lens group is movable in a direction orthogonal to the optical axis to shift an image in a direction orthogonal to the optical axis. The following (1) and (2) are satisfied: 0.5<(1−βα)×βb<1.0, and (1) 0.1<|f1 / f2|<1.25, (2) where βα is magnification of the second lens group at a telephoto end of the zoom lens; βb is magnification of a lens group on an image side relative to the second lens group; f1, f2 are focal lengths of the first, second lens group, respectively.

Owner:SONY CORP

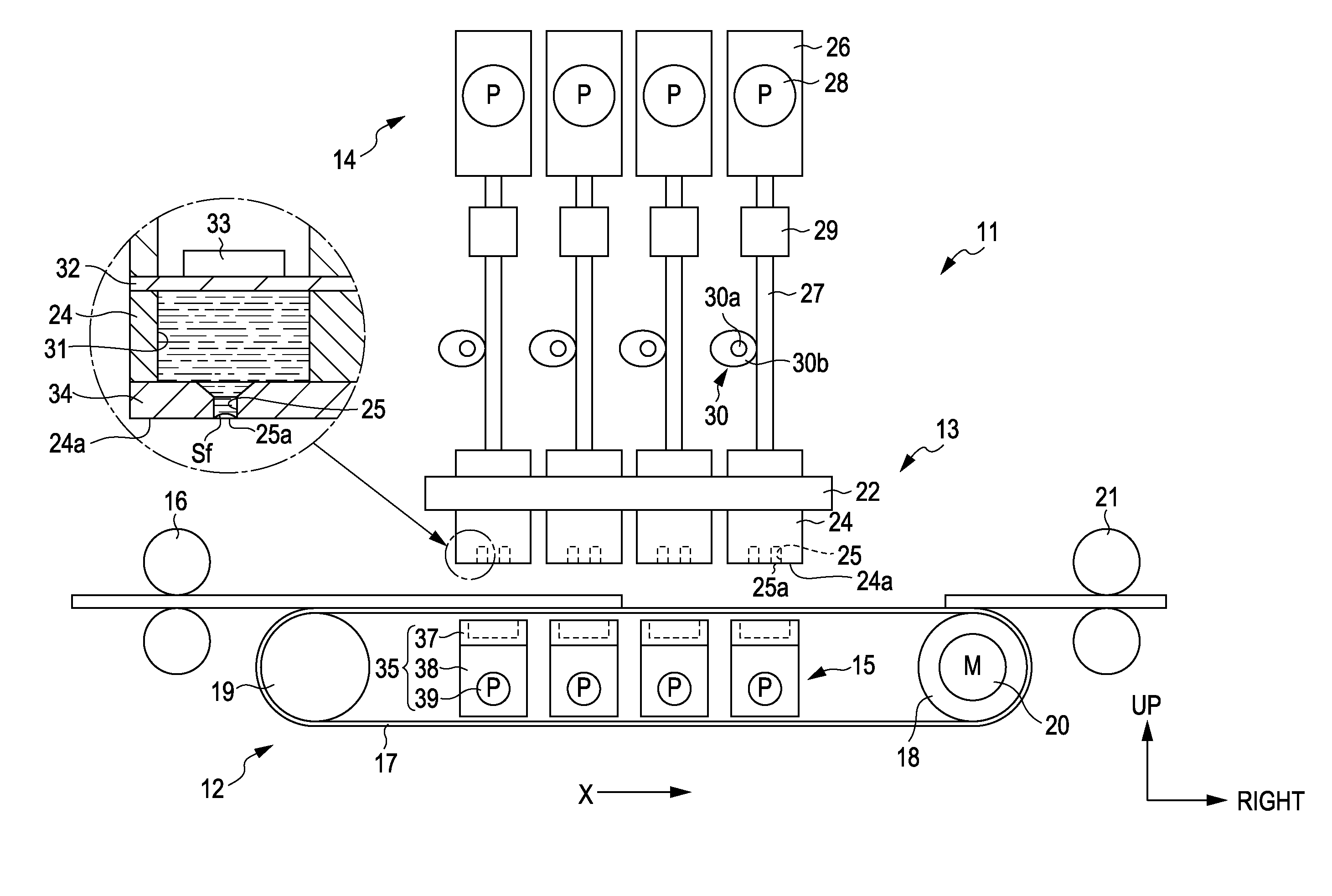

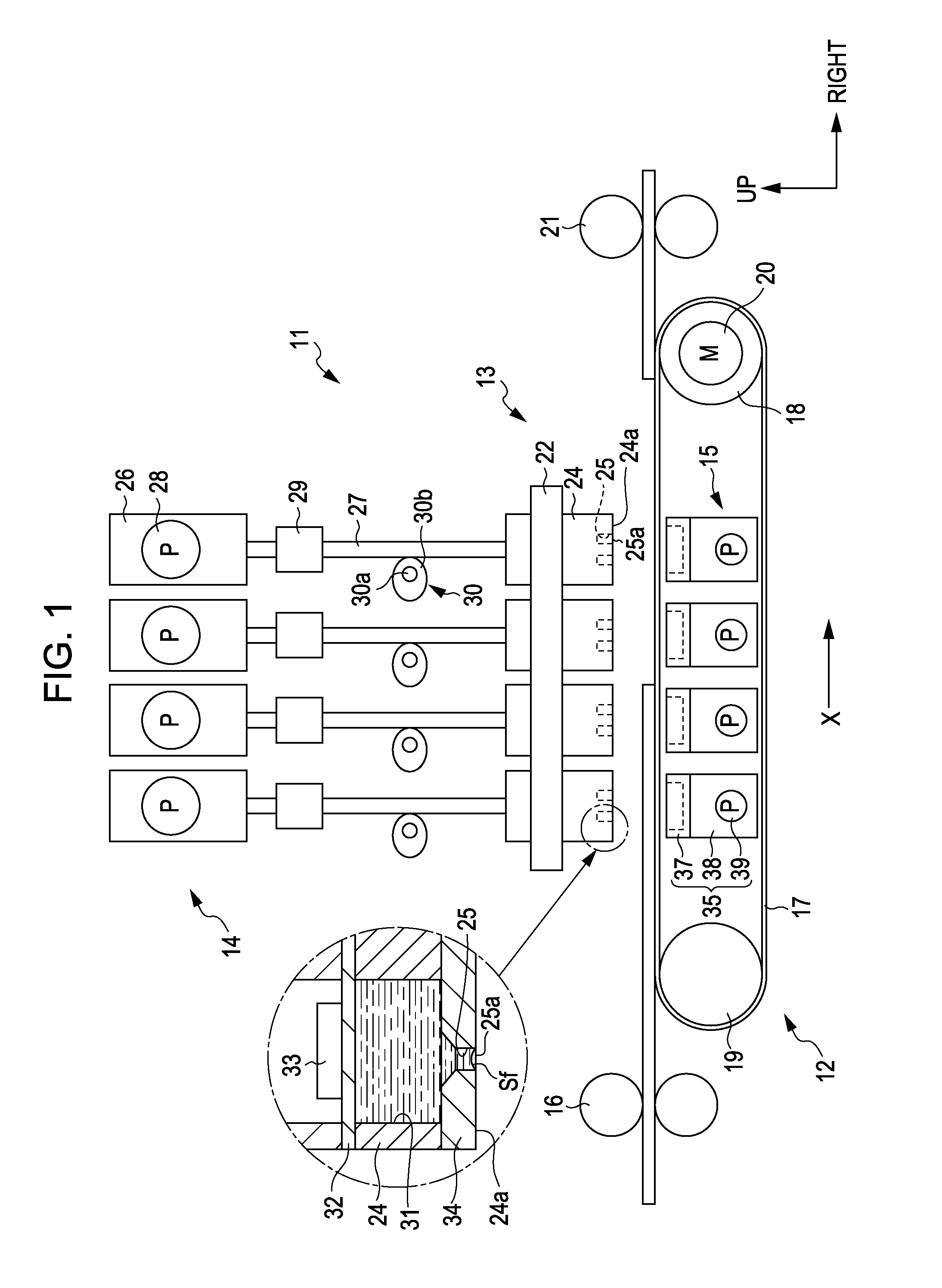

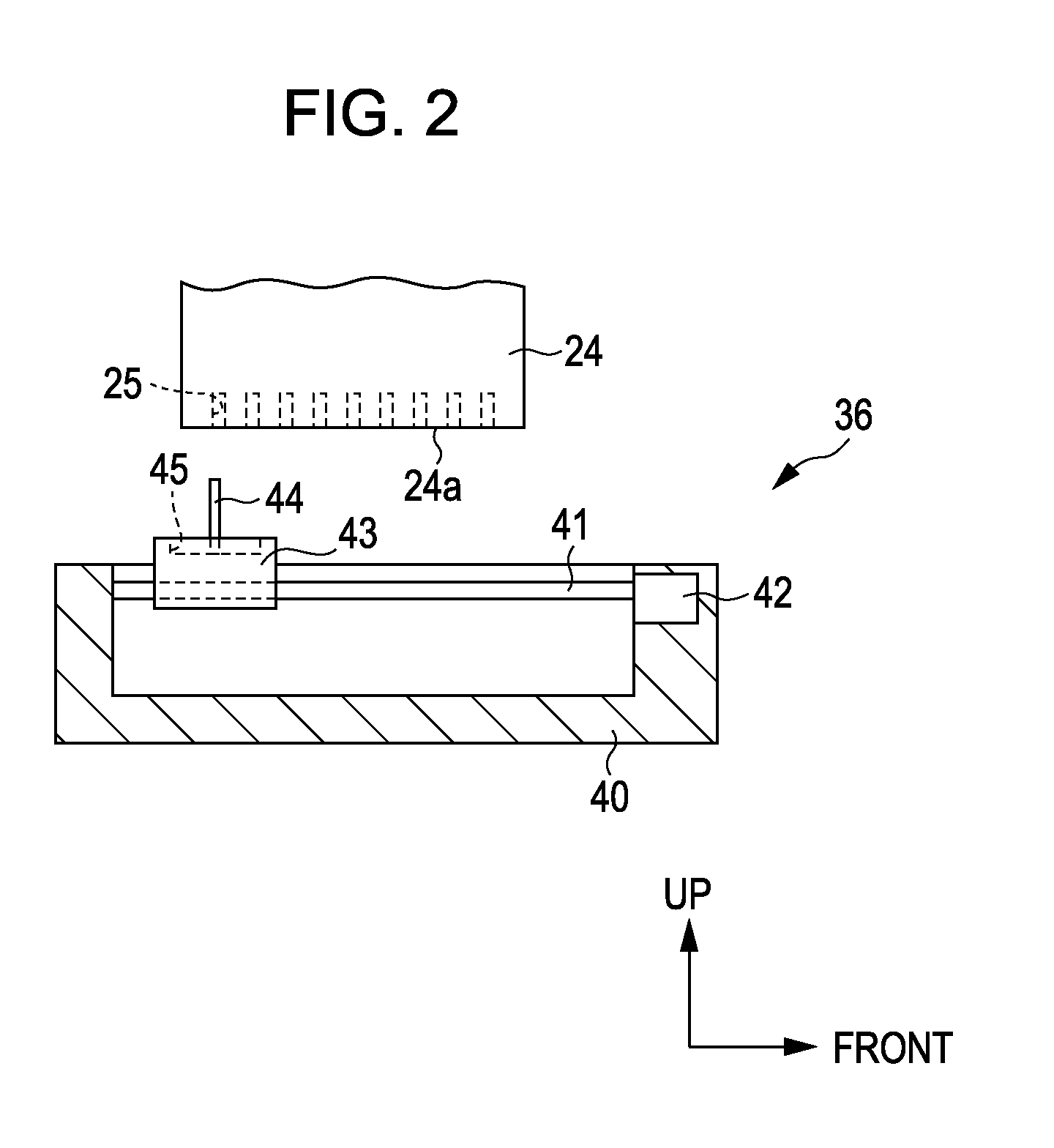

Fluid ejecting apparatus and wiping method

A fluid ejecting apparatus includes: a fluid ejecting head in which nozzles that eject fluid are provided; a wiper that wipes a nozzle formation face, in which nozzle orifices of the nozzles are formed, in the fluid ejecting head; and a pressurization mechanism which changes the curvature of a concave liquid surface formed in the nozzle, in the nozzle by performing pressurization on the fluid in the fluid ejecting head at the time of the wiping.

Owner:SEIKO EPSON CORP

Bending apparatus

A bending apparatus which can bend pipes and obtain as small curvature as possible without flattening or buckling easily occurring in the bending region. The bending apparatus comprises a bending die for a pipe, a clamping die which rotates together with the bending die while clamping the pipe, a pressure die which hold down the pipe, and a metal core which is inserted into the pipe and maintains the shape of the bending region, wherein the metal core is a spherical metal core rotatably supported by an arch shaped arm on the leading end of a core holder.

Owner:SANOH IND CO LTD

Vehicle mirror apparatus

ActiveUS20110194202A1The environment is moreAvoid dustMirrorsMountingsEngineeringMechanical engineering

Owner:KK TOKAI RIKA DENKI SEISAKUSHO

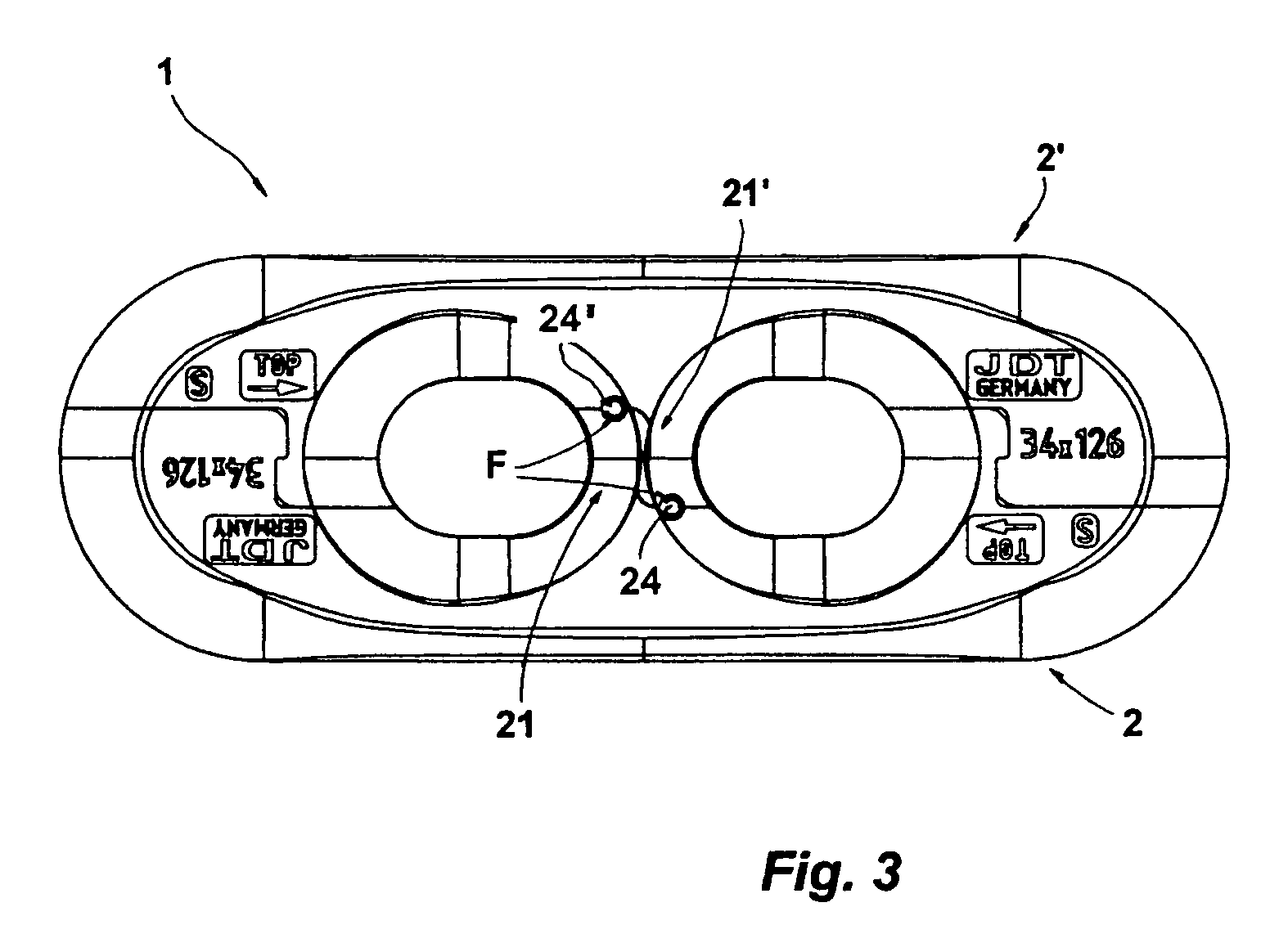

Chain lock

A chain lock for high-strength steel chains has two lock parts that are the same and can be joined together in a rotation-symmetry arrangement with one another, in the longitudinal direction. Each lock part has a longitudinal stay having arc segments that follow it at both ends. There are two coupling elements that are configured complementary to one another and are assigned to the two arc segments of each lock part. One of the elements is configured as a locking stay that follows the longitudinal extension of the lock part, and the other element is configured as a stay accommodation. The locking stay of the one lock part engages in the stay accommodation of the other lock part and rests against the complementary coupling surface of the stay accommodation with its coupling surface formed by the face end in the joining direction. The coupling surfaces comprise a coupling surface segment having a defined width, which has no curvature or only an insignificant curvature pointing in the joining direction.

Owner:J D THEILE

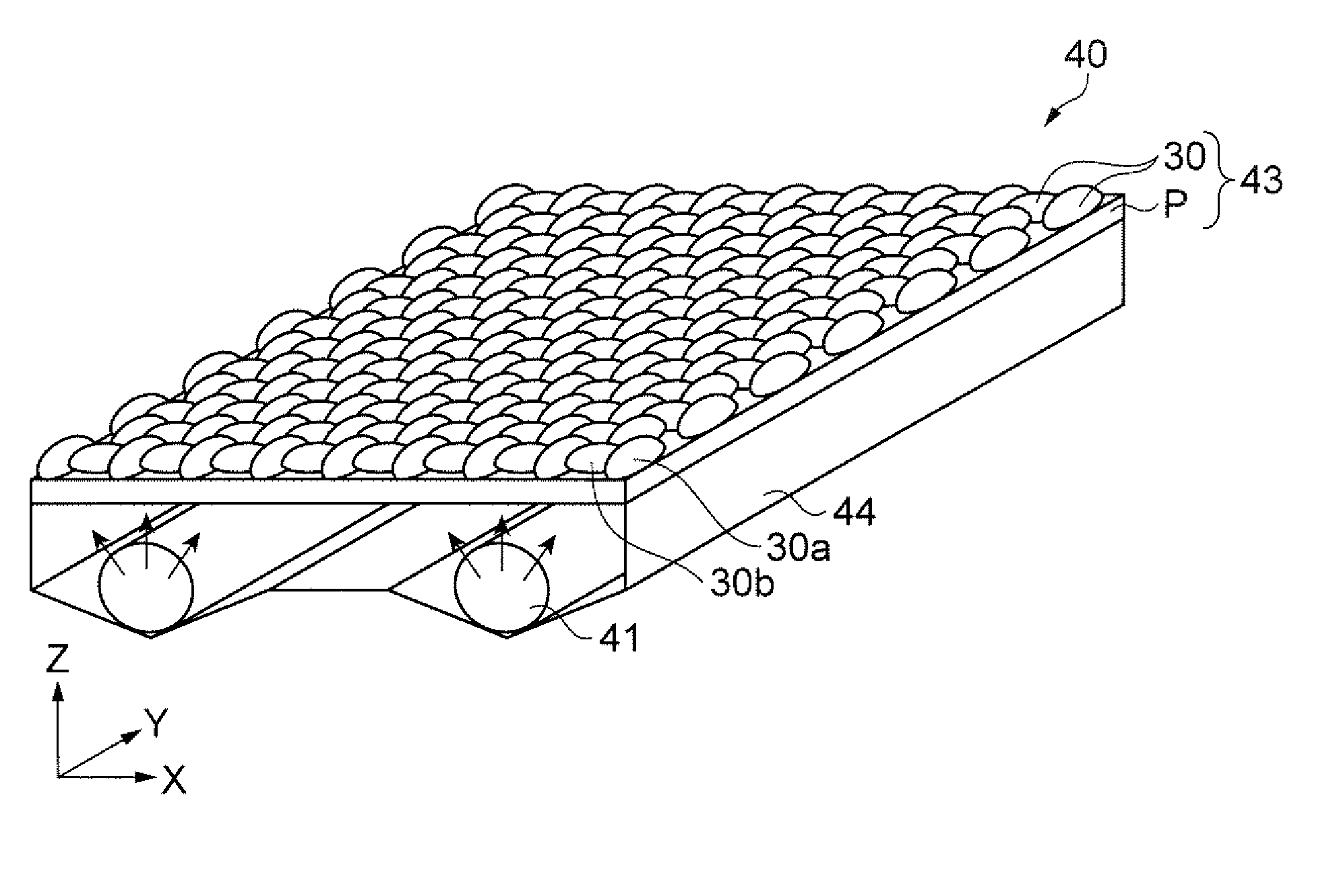

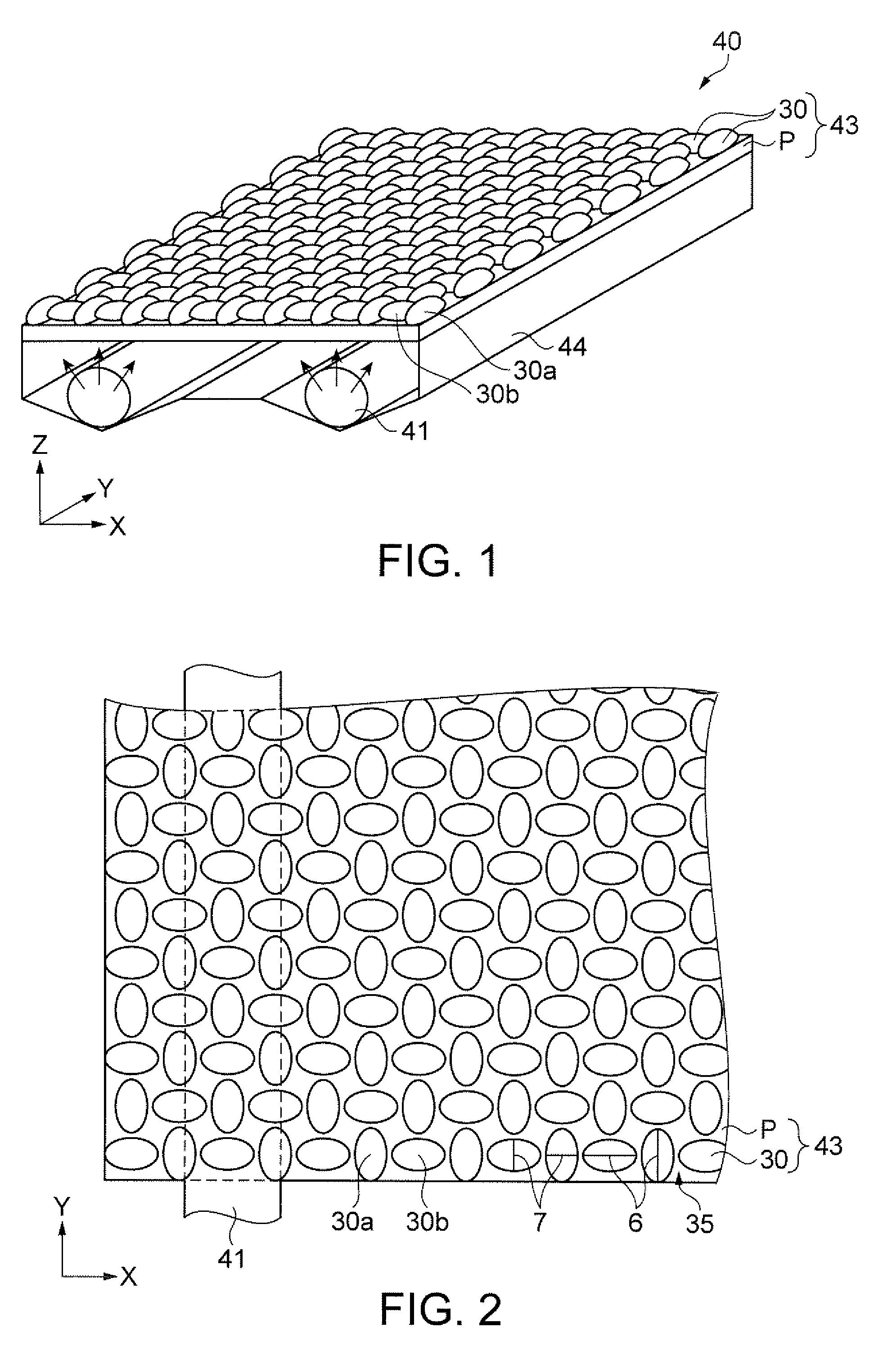

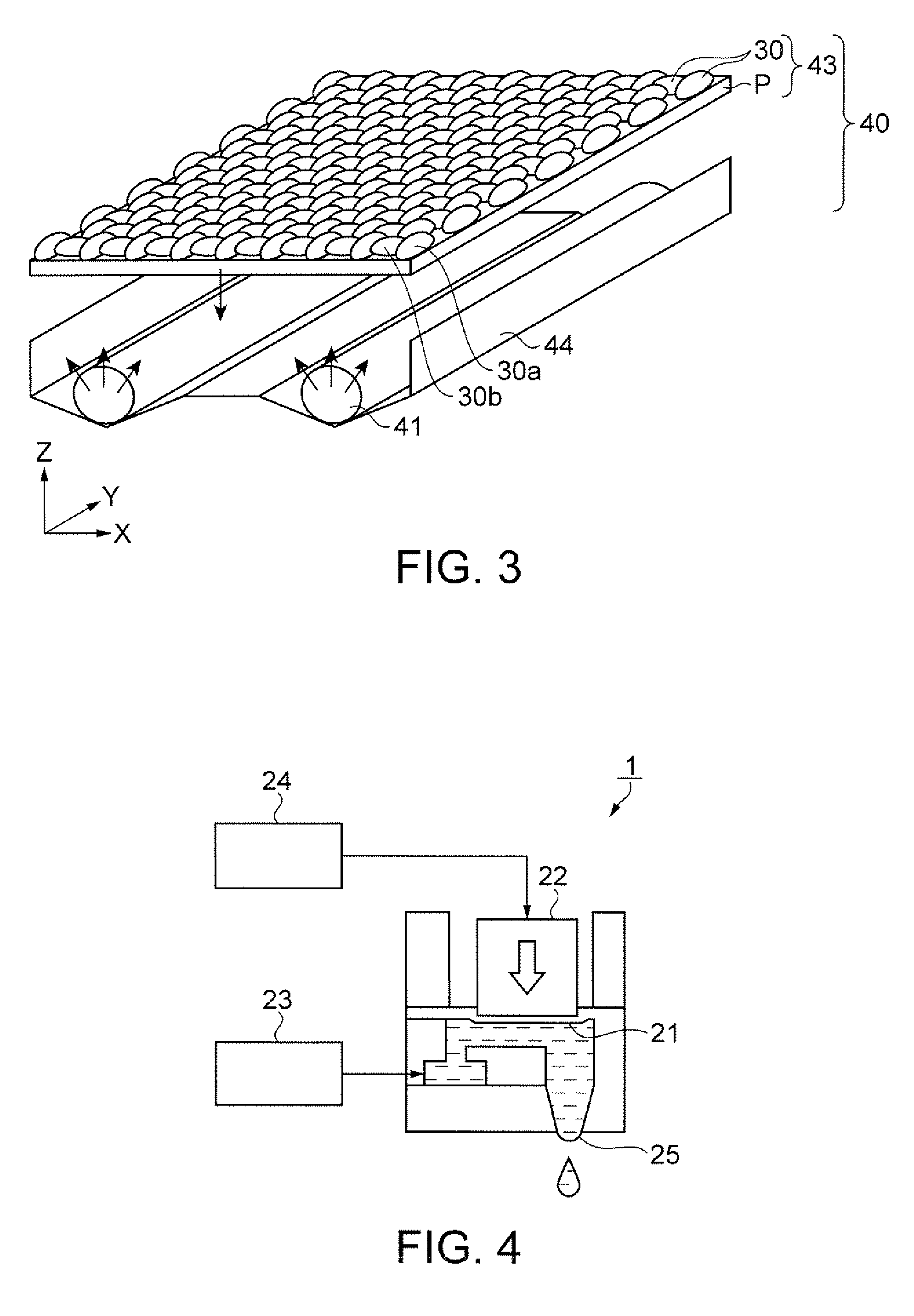

Manufacturing method of backlight unit, and backlight unit, electro-optic device, and electronic apparatus

InactiveUS20060290839A1Good opticsReduce brightnessMeasurement apparatus componentsElectric discharge tubesLong axisElectron

A backlight unit including: a light source that irradiates light; and a diffusing plate that diffuses the light irradiated from the light source, wherein the diffusing plate is provided with a first microlens of ellipsoid form, and a second microlens of ellipsoid form disposed in such a manner that long axes of the first microlens and the second microlens are approximately perpendicular to each other, and a long axis direction of the first microlens and a long axis direction of the light source are arranged approximately parallel to each other, and a long axis direction of the second microlens and the long axis direction of the light source are arranged approximately perpendicular to each other.

Owner:SEIKO EPSON CORP

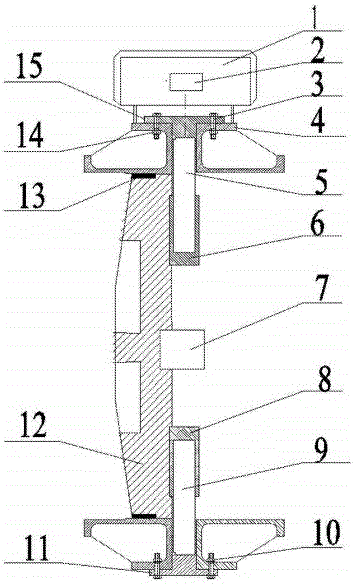

Auxiliary device for colonoscopy

ActiveCN109124963AAvoid dangerous situationsIngenious structureOperating tablesSigmoid colonBody positions

The invention relates to an auxiliary device for colonoscopy, which effectively solves the problems that the prior medical personnel are very inconvenient to press the abdomen, the patient is not fixed in body position in the examination process, the legs often slide off the bed, and the patient is pushed off the table in the process of pressing the abdomen. The technical scheme comprises a left bedplate and a right bedplate, two sets of clamping splints are arranged on the left bedplate and the right bedplate, and the two sets of clamping splints are staggered to assist the patient in realizing lateral lying posture. A left bedplate and a right bedplate are provide with an abdominal pressing device. An abdominal pressing device comprises four pressing pushrods. The four push rods are allslidably matched with the fixing box and the pressing head fixedly arranged at the front end faces the abdomen of the patient, and the positions of the pressing heads at the front end of the four pushrods are consistent with the colon curve, respectively corresponding to the positions of the sigmoid colon, the colon splenic curve, the middle section of the transverse colon, and the colon hepaticcurve of the abdomen. The invention has ingenious structure, strong practicability, and good operation effect.

Owner:HENAN PROVINCE HOSPITAL OF TCM THE SECOND AFFILIATED HOSPITAL OF HENAN UNIV OF TCM

Butterfly valve for water storage tank

InactiveCN105715808APrevent leakagePlay a diversion decompressionOperating means/releasing devices for valvesValve members for absorbing fluid energyCavitationWater storage tank

The invention discloses a butterfly valve of a water storage tank. An electromagnetic controller is mounted on a valve body, a butterfly plate with a permanent magnet is mounted in an inner cavity of the valve body; upper valve covers are respectively fixed to the upper end of the valve body, lower valve covers are respectively fixed to the lower end of the valve body, and the permanent magnet is fixed to the middle part of one end surface of the butterfly plate; an upper shaft sleeve and a lower shaft sleeve are coaxial, the upper shaft sleeve is fixed to the upper part of the end surface, on which the permanent magnet is positioned, of the butterfly plate, and the lower shaft sleeve is fixed to the lower part of the end surface, on which the permanent magnet is positioned, of the butterfly plate; the upper shaft sleeve is in matching connection with the upper valve covers through an upper valve rod, and the lower shaft sleeve is in matching connection with the lower valve covers through a lower valve rod; an inlet flow channel and two outlet flow channels are arranged on the other end surface of the butterfly plate; an inlet filter pipe is also connected to the inlet flow channel. According to the butterfly valve disclosed by the invention, the situation of leakage between the valve rods and fillings is avoided, besides, a gaseous cavitation preventing flow channel is processed on the surface of the butterfly plate, and one side of the butterfly plate is a spherical protrusion. The butterfly valve has the effects of shunting decompressing, reducing gaseous cavitation, preventing vibration and reducing noise, and the service life of the butterfly valve is prolonged. On the other hand, the inlet filter pipe has the effects of filtering water flows, and preventing valve cores from being destroyed.

Owner:陈杰

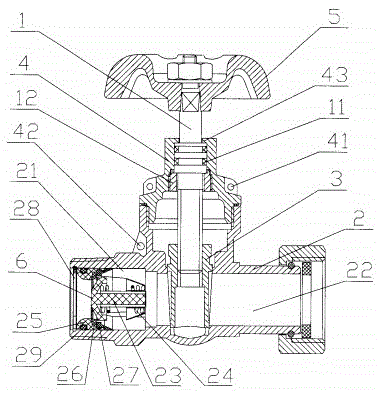

One-way valve

ActiveCN105650293ASimplify complex structuresNot easy to damageCheck valvesEqualizing valvesCheck valveEngineering

The invention discloses a one-way valve. The one-way valve comprises a valve rod, a valve body, a gate plate, a valve cover, a hand wheel and a check valve core assembly, wherein a water inlet and a water outlet are formed in the valve body, the check valve core assembly is arranged in a cavity body of the water inlet to form a check valve, at least one threading hole is formed in the valve cover, a threading hole is formed in the valve body, and a filter pipe is further connected to the outer end of the water inlet. According to the one-way valve, a gate valve and the check valve are integrated, so that the one-way valve has dual functions of two valves, and an original complex combined structure is simplified; the threading holes are formed in the valve cover and the valve body, and the valve cover and the valve body are stringed by threads, so that water is effectively prevented from being stolen by users; and furthermore, the one-way valve further has a filter function, so that the damage of the valve core is effectively prevented.

Owner:东营市东凯园区运营管理有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com