Patents

Literature

5755 results about "Gate valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A gate valve, also known as a sluice valve, is a valve that opens by lifting a barrier (gate) out of the path of the fluid. Gate valves require very little space along the pipe axis and hardly restrict the flow of fluid when the gate is fully opened. The gate faces can be parallel but are most commonly wedge-shaped (in order to be able to apply pressure on the sealing surface).

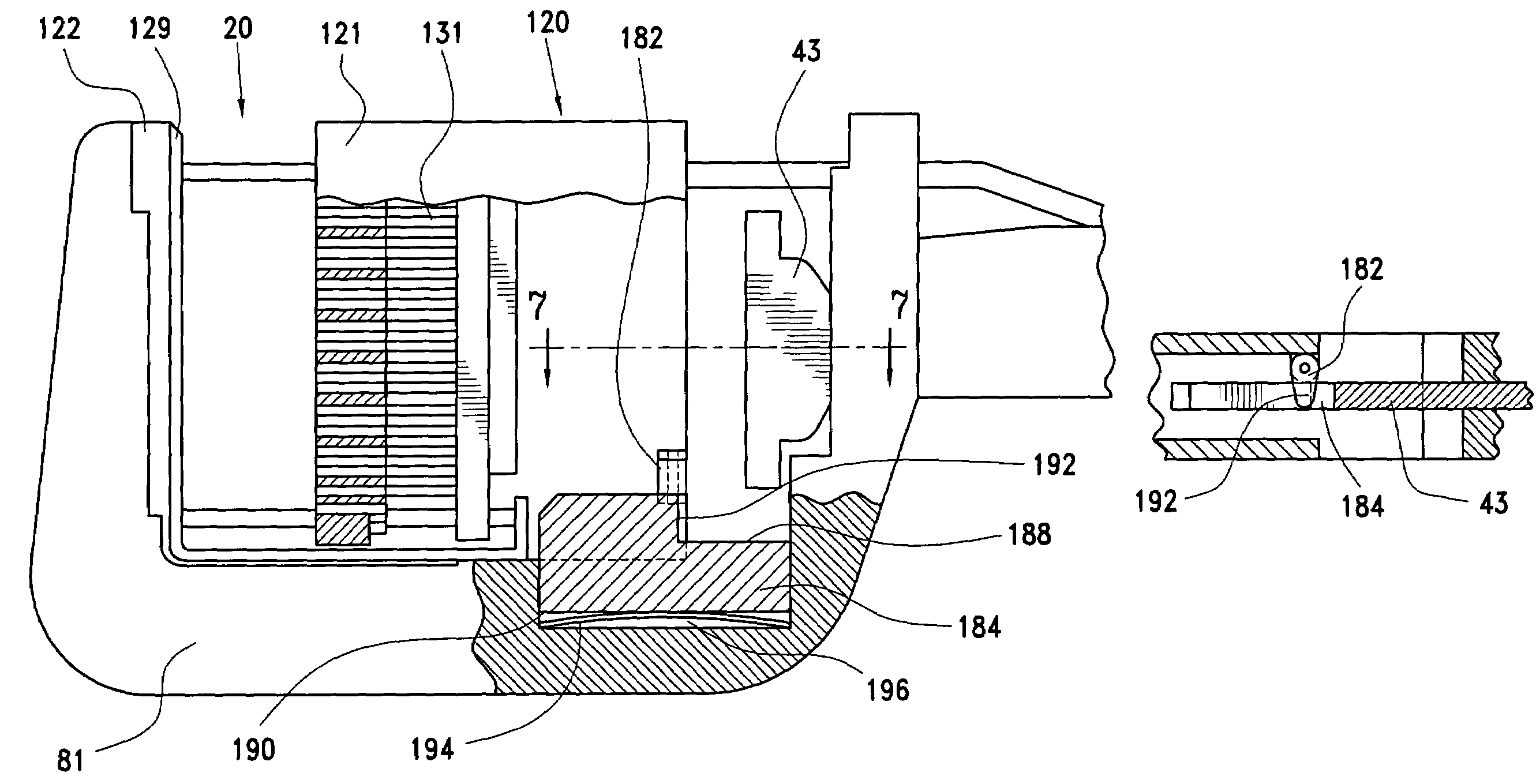

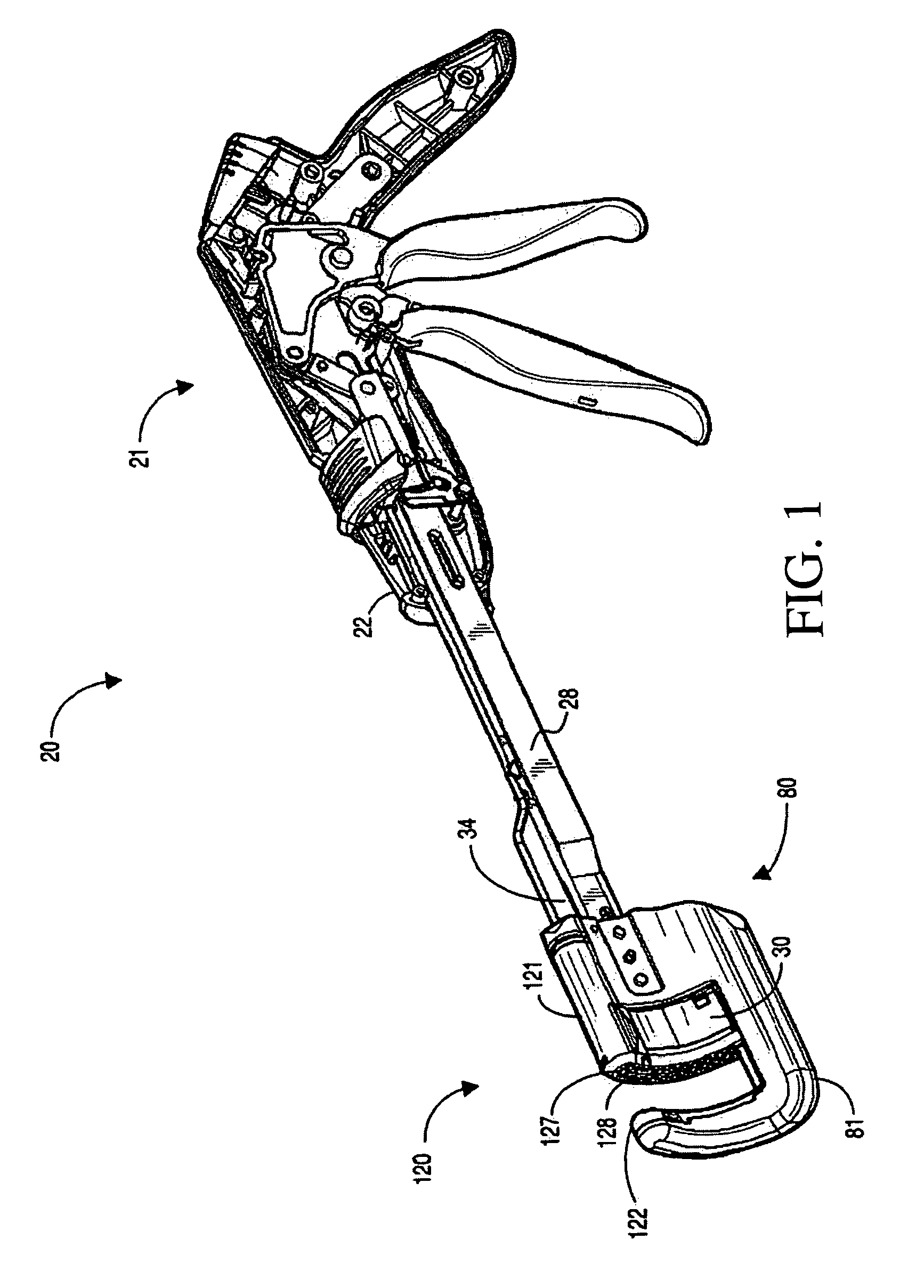

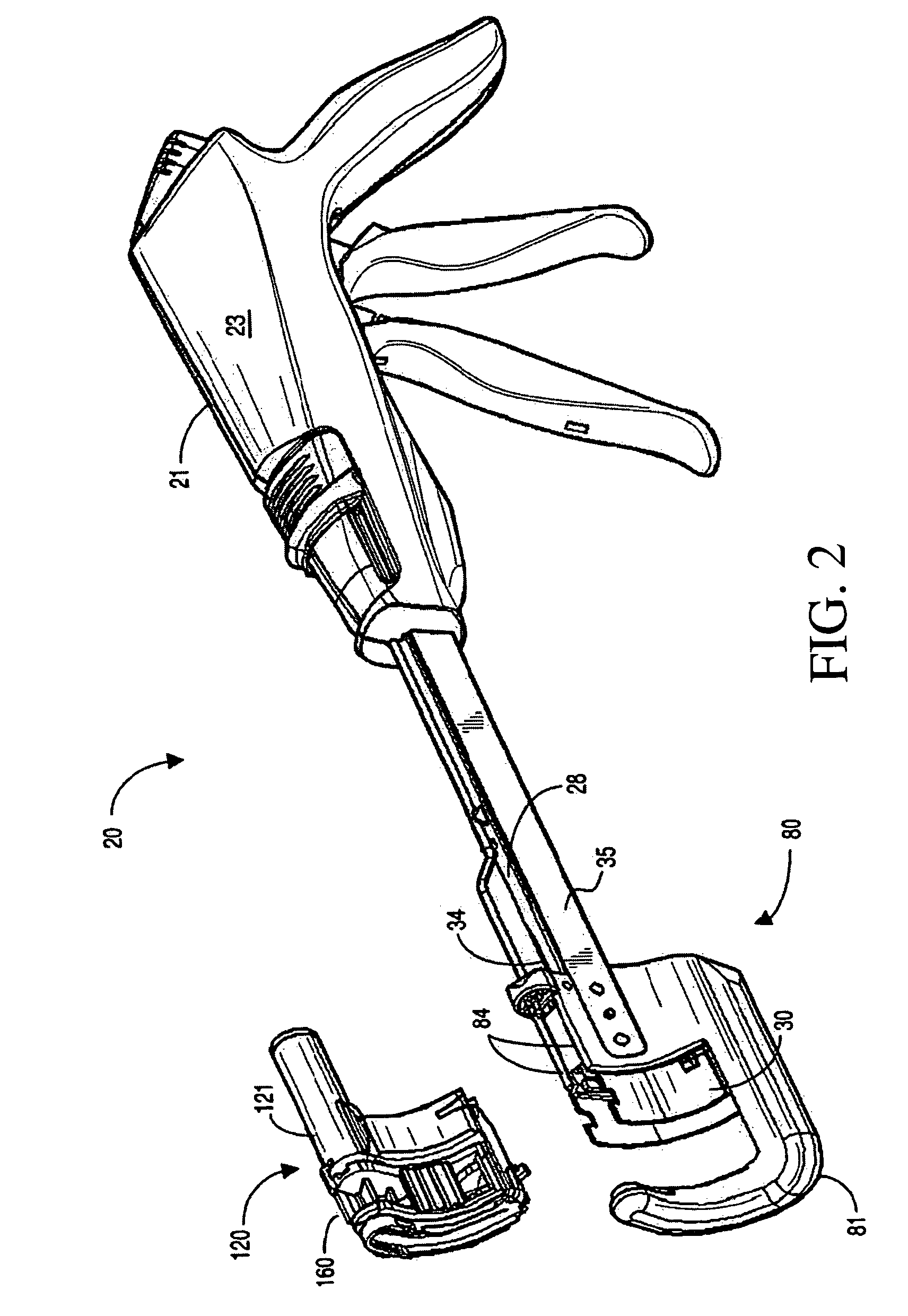

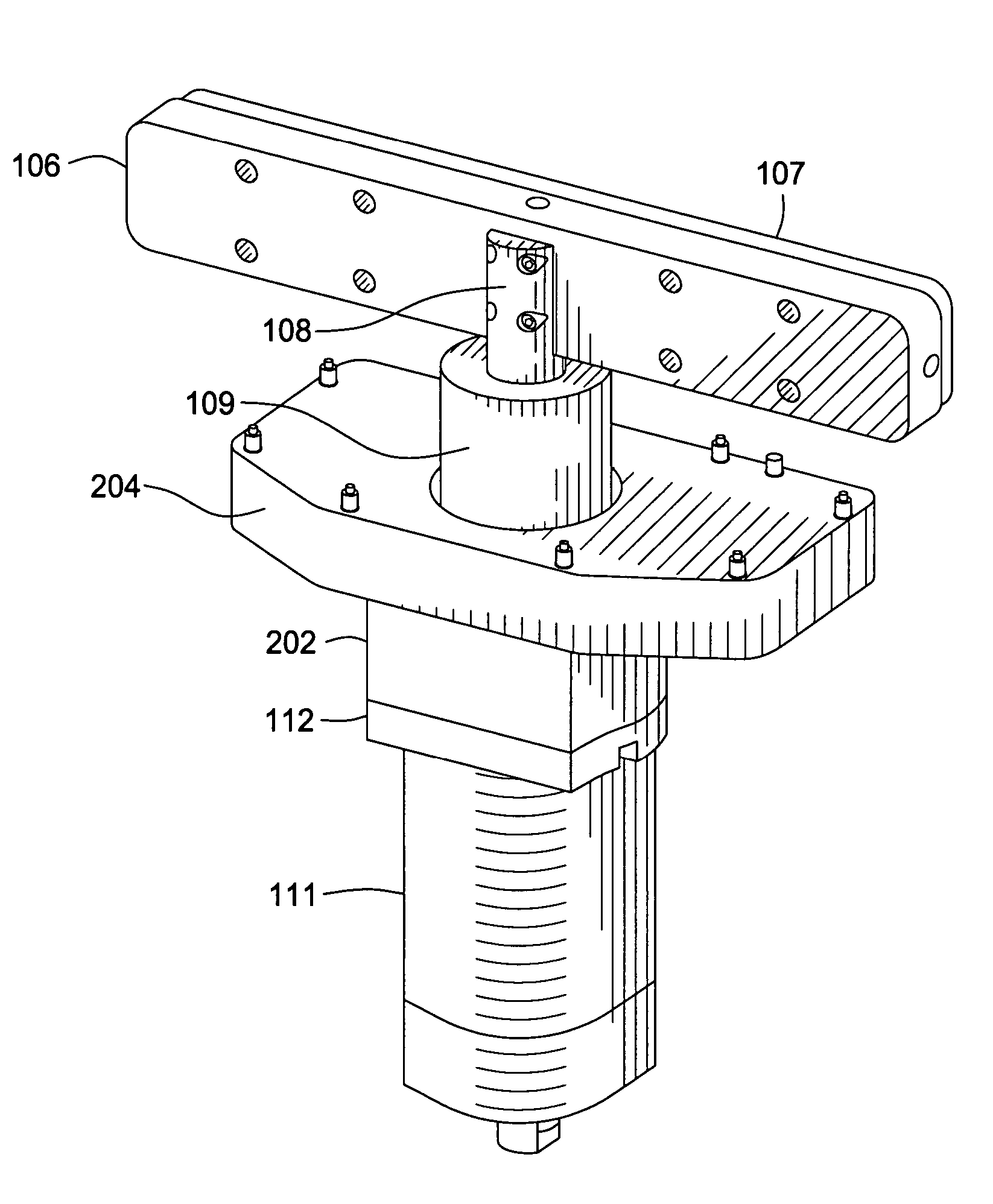

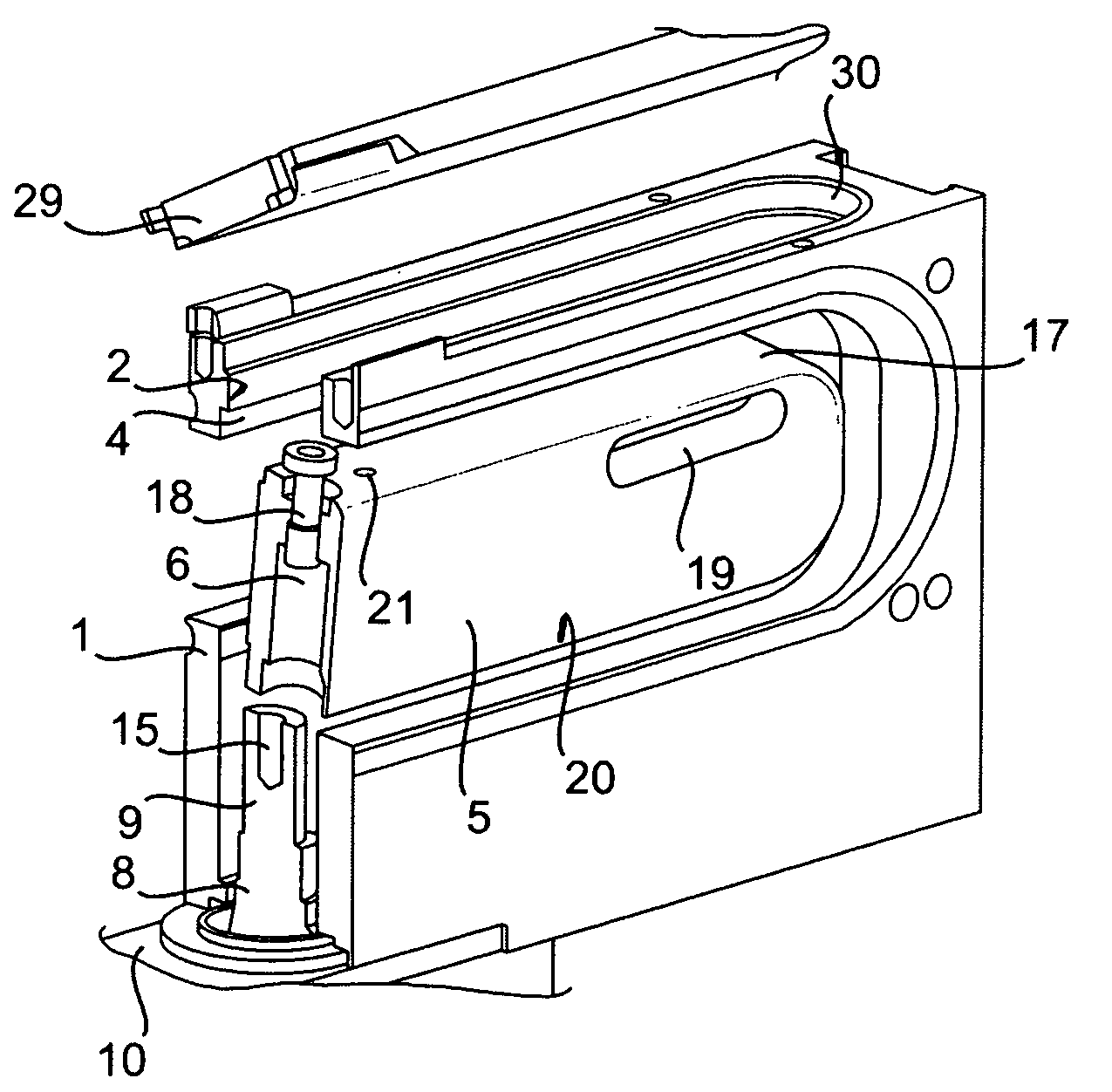

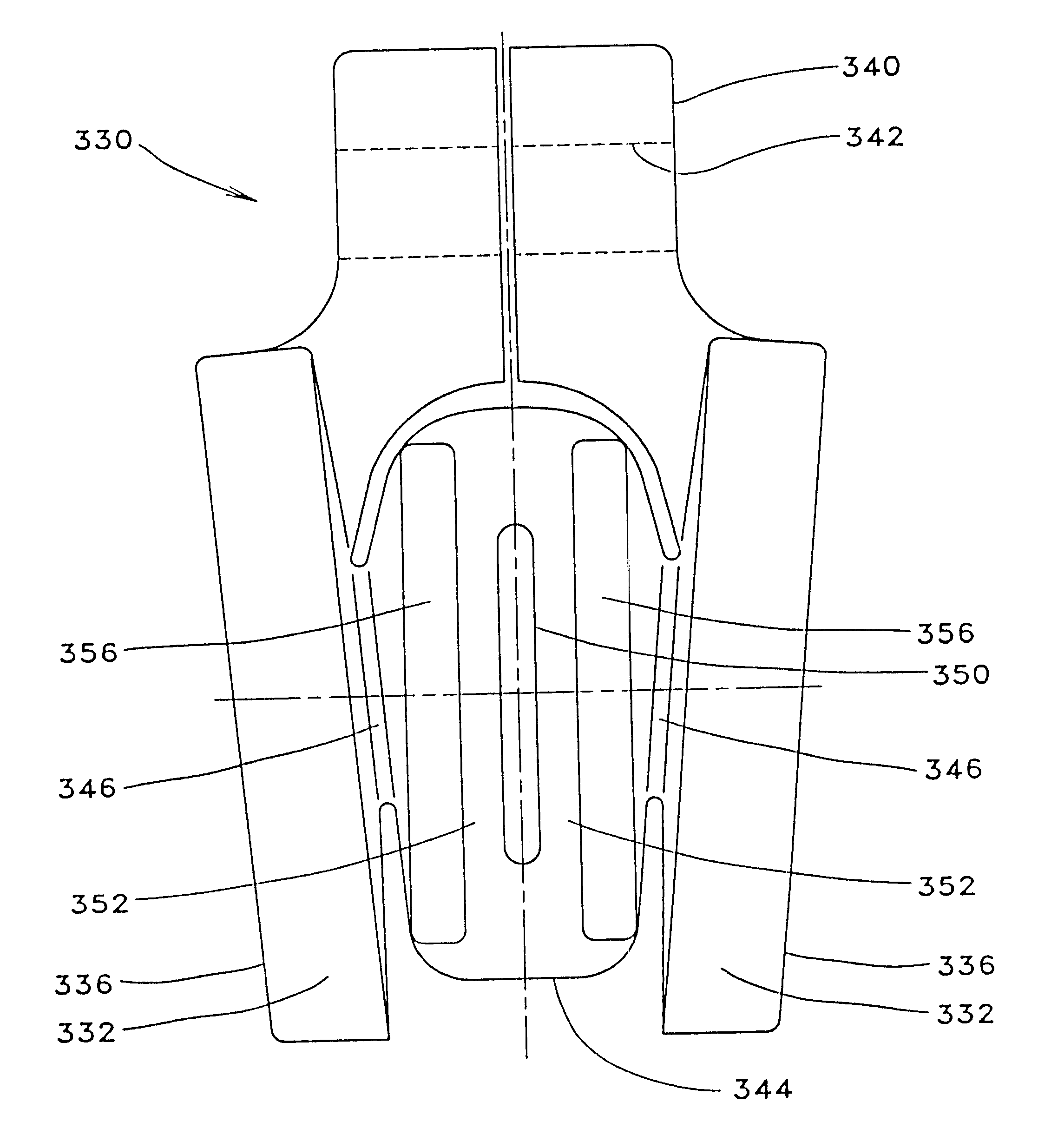

Swing gate for device lockout in a curved cutter stapler

ActiveUS7641092B2Avoid fireSufficient forceSuture equipmentsStapling toolsBiological activationLockout Mechanism

A linear surgical stapler adapted for applying a plurality of surgical fasteners to body tissue includes an anvil structure and a cartridge housing containing a plurality of surgical fasteners. The cartridge housing and anvil structure are relatively movable between a first spaced apart position and a second position in close approximation with one another. A firing mechanism is associated with the cartridge housing for ejecting the surgical fasteners from the cartridge housing to be driven against the anvil structure. A lockout mechanism interacts with the cartridge housing for selective activation and deactivation. The lockout mechanism includes a swing gate tab secured to the cartridge housing at a position adjacent a lockout lever, such that firing of the linear surgical stapler rotates the swing gate tab releasing the lockout lever for preventing further firing of the used cartridge housing.

Owner:ETHICON ENDO SURGERY INC

Single-sided inflatable vertical slit valve

Owner:APPLIED MATERIALS INC

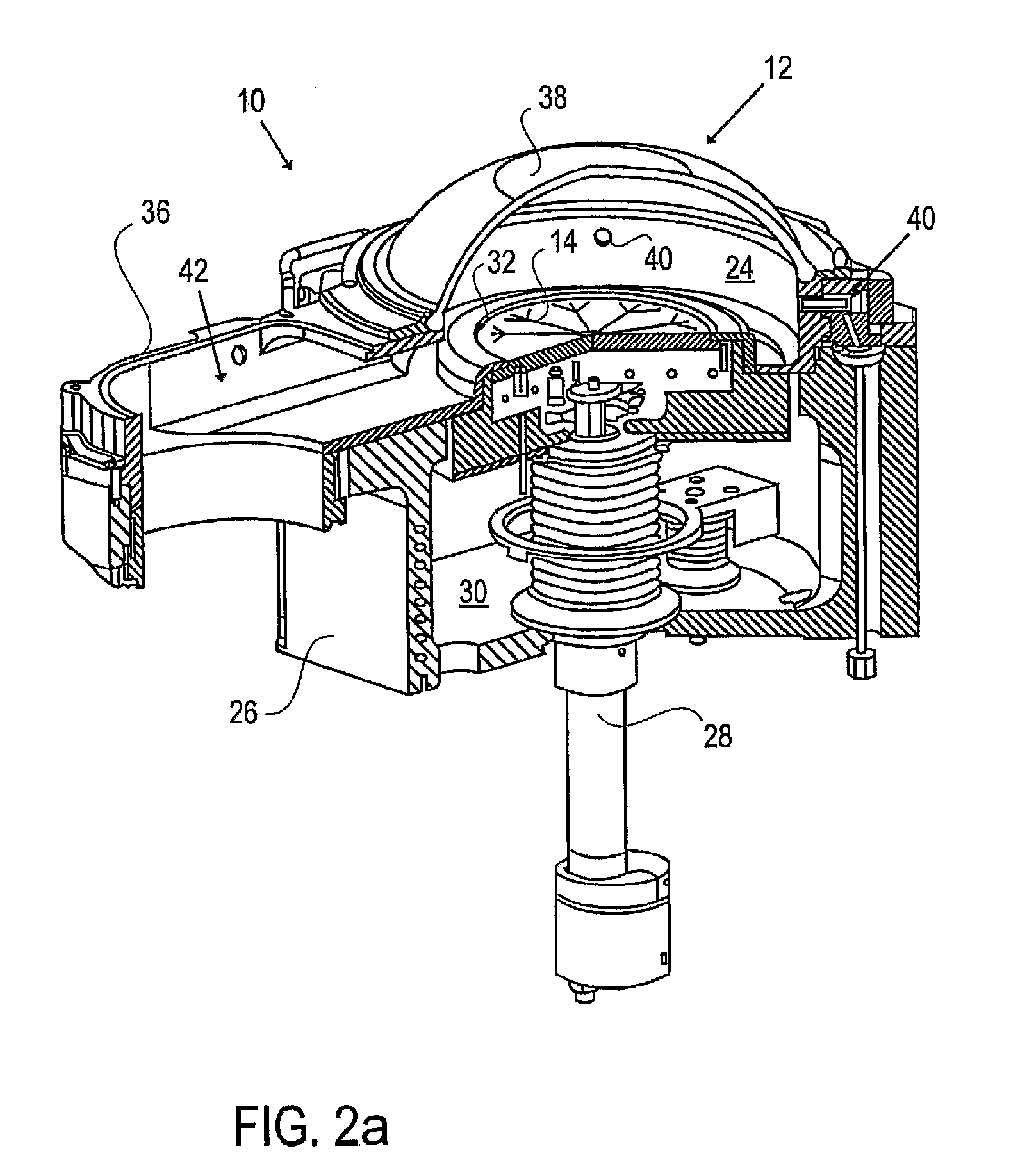

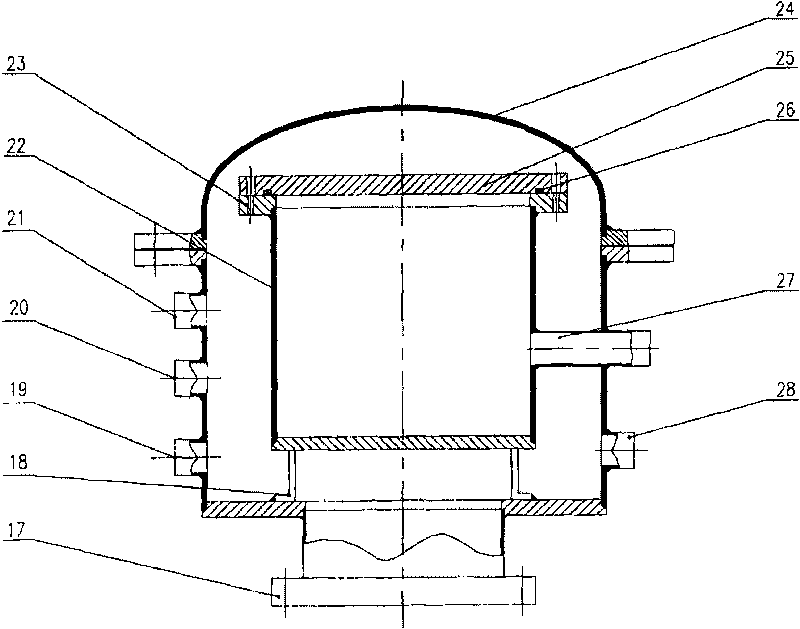

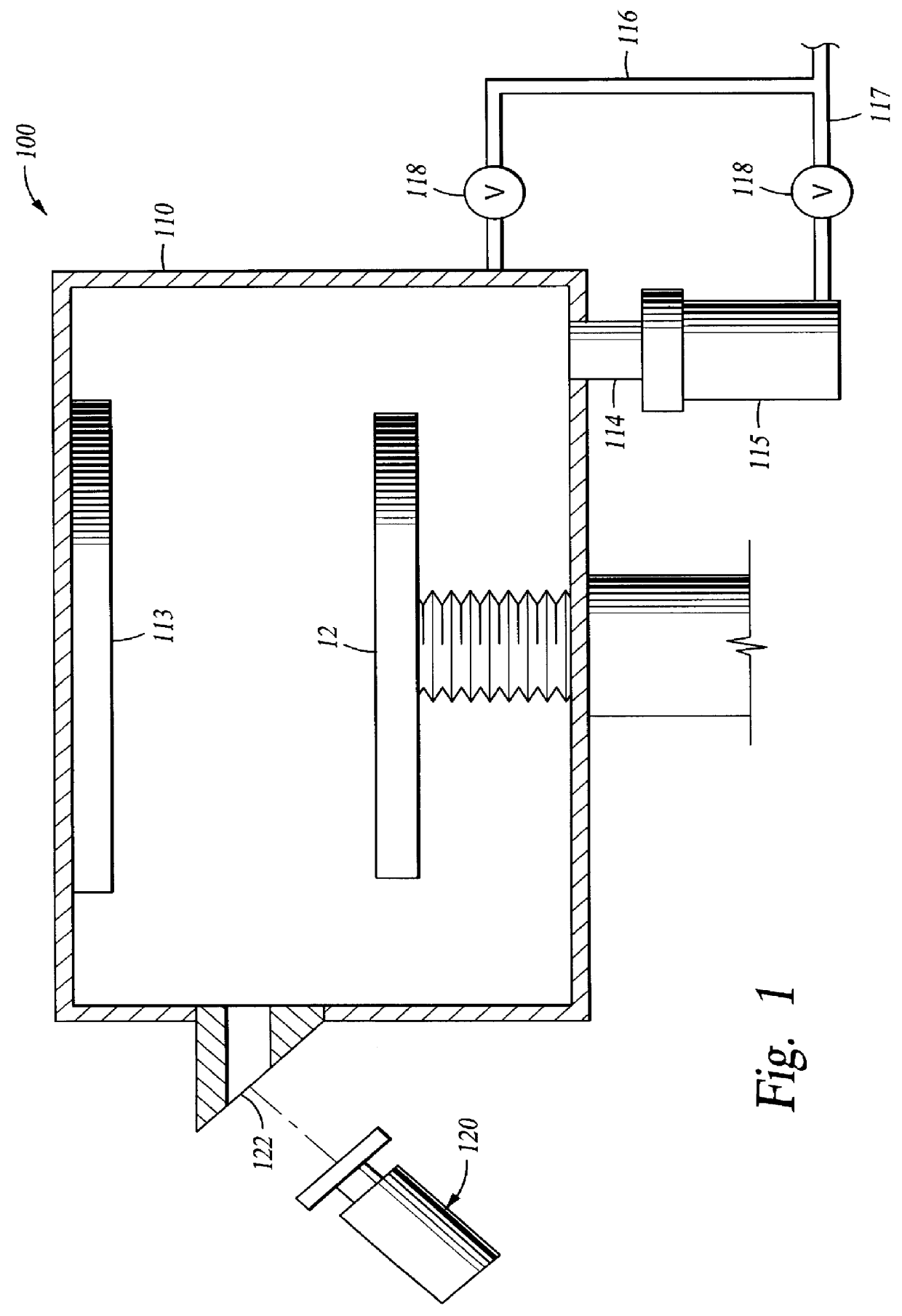

Vacuum processing apparatus

ActiveUS20050051093A1Easy to disconnectOperation efficiency can be improvedSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDouble wallEngineering

A vacuum processing apparatus includes a vacuum processing chamber having a processing table for supporting an object to be processed and carrying out processing using a gas. The vacuum processing chamber has an axisymmetric structure, including a double wall structure, and a gate valve for sealing an opening through which the object enters the processing chamber.

Owner:HITACHI HIGH-TECH CORP

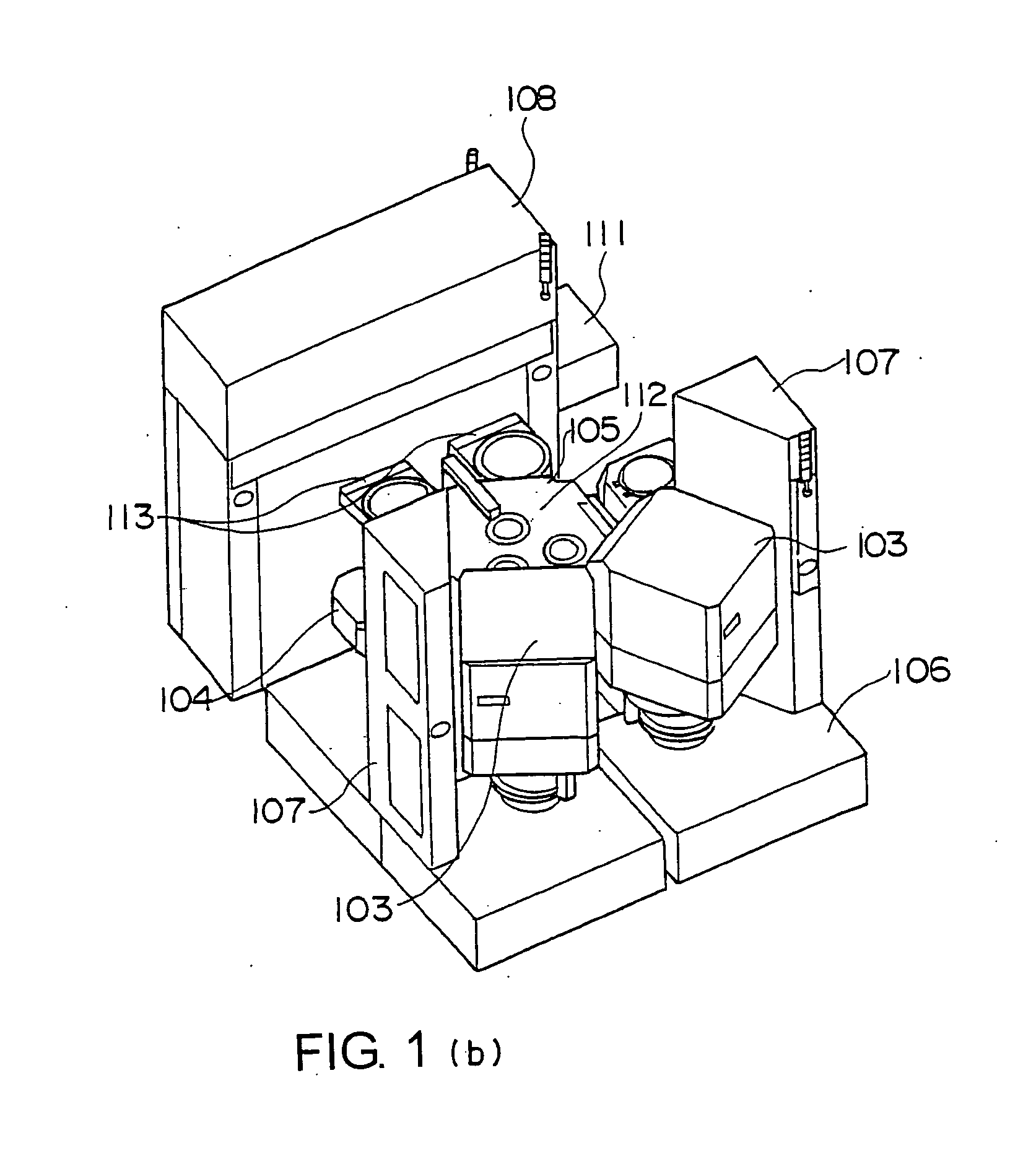

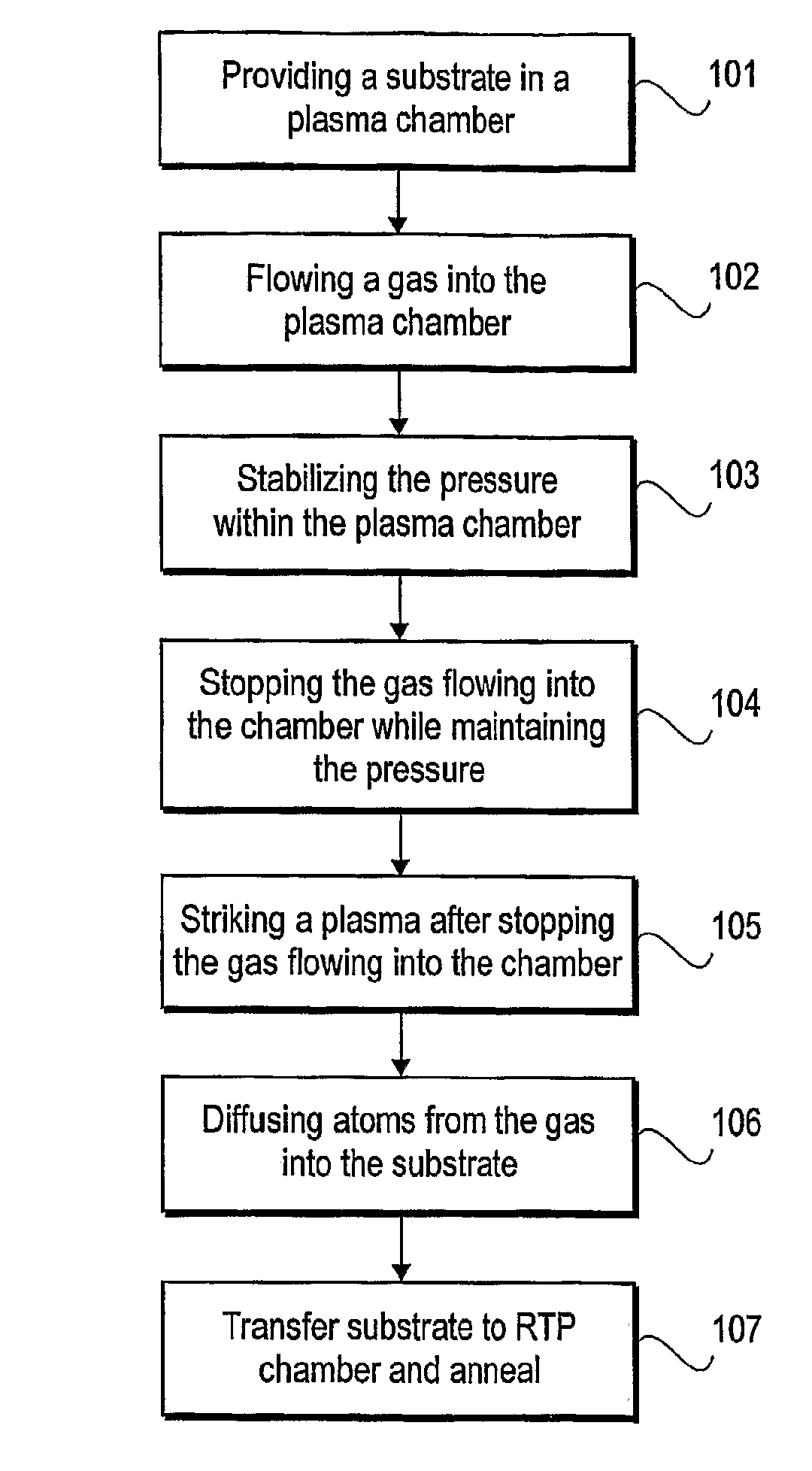

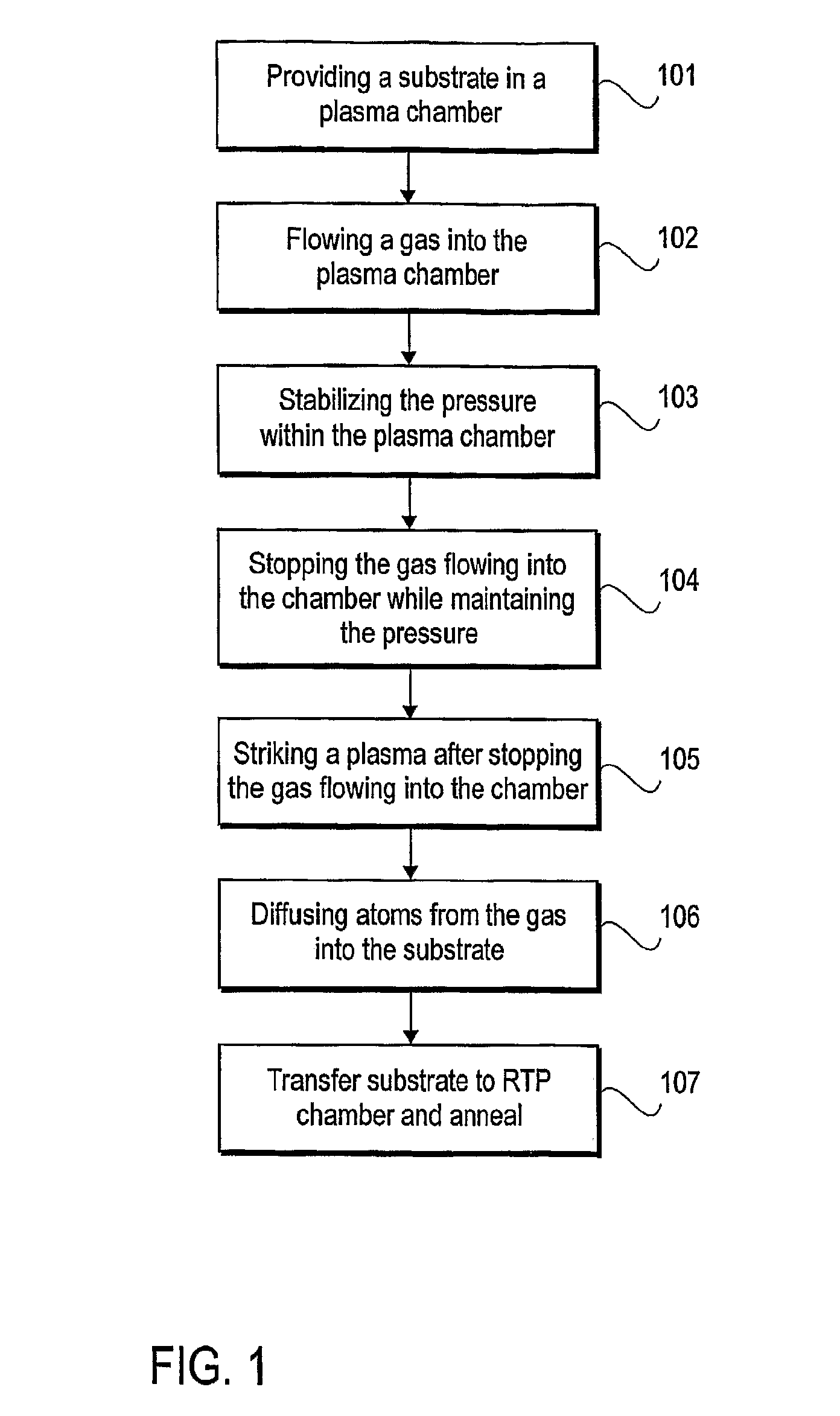

Elimination of flow and pressure gradients in low utilization processes

InactiveUS7955646B2Polycrystalline material growthSemiconductor/solid-state device manufacturingGate dielectricChemical vapor deposition

The amount of atoms diffused into a substrate may be made uniform or the thickness of a thin film may be made uniform in a low species utilization process by stopping the flow of gas into a reaction chamber during the low species utilization process. Stopping the flow of gas into a reaction chamber may entail closing the gate valve (the valve to the vacuum pump), stabilizing the pressure within the reaction chamber, and maintaining the stabilized pressure while stopping the gas flowing into the chamber. Low species utilization processes include the diffusion of nitrogen into silicon dioxide gate dielectric layers by decoupled plasma nitridation (DPN), the deposition of a silicon dioxide film by rapid thermal processing (RTP) or chemical vapor deposition (CVD), and the deposition of silicon epitaxial layers by CVD.

Owner:APPLIED MATERIALS INC

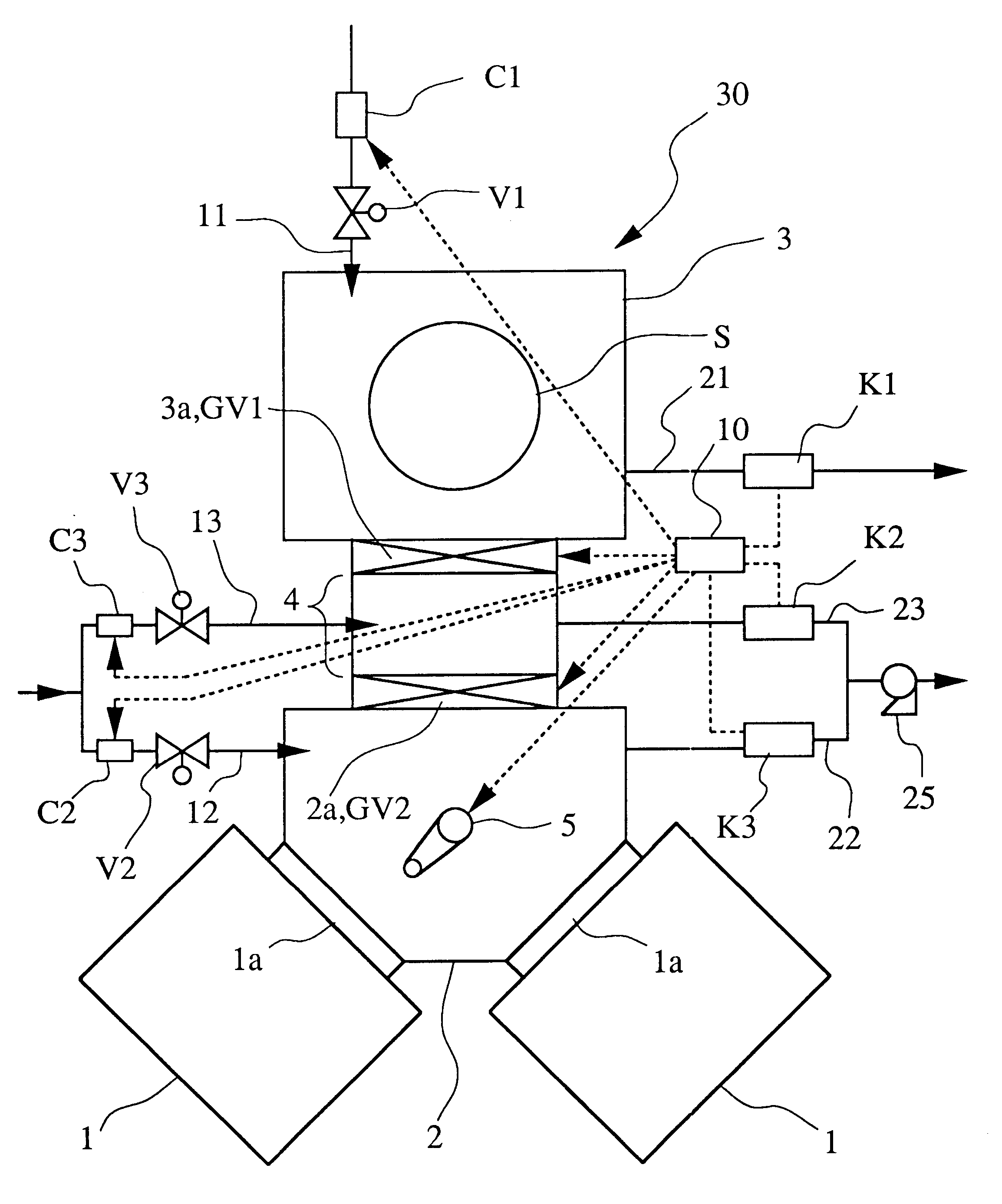

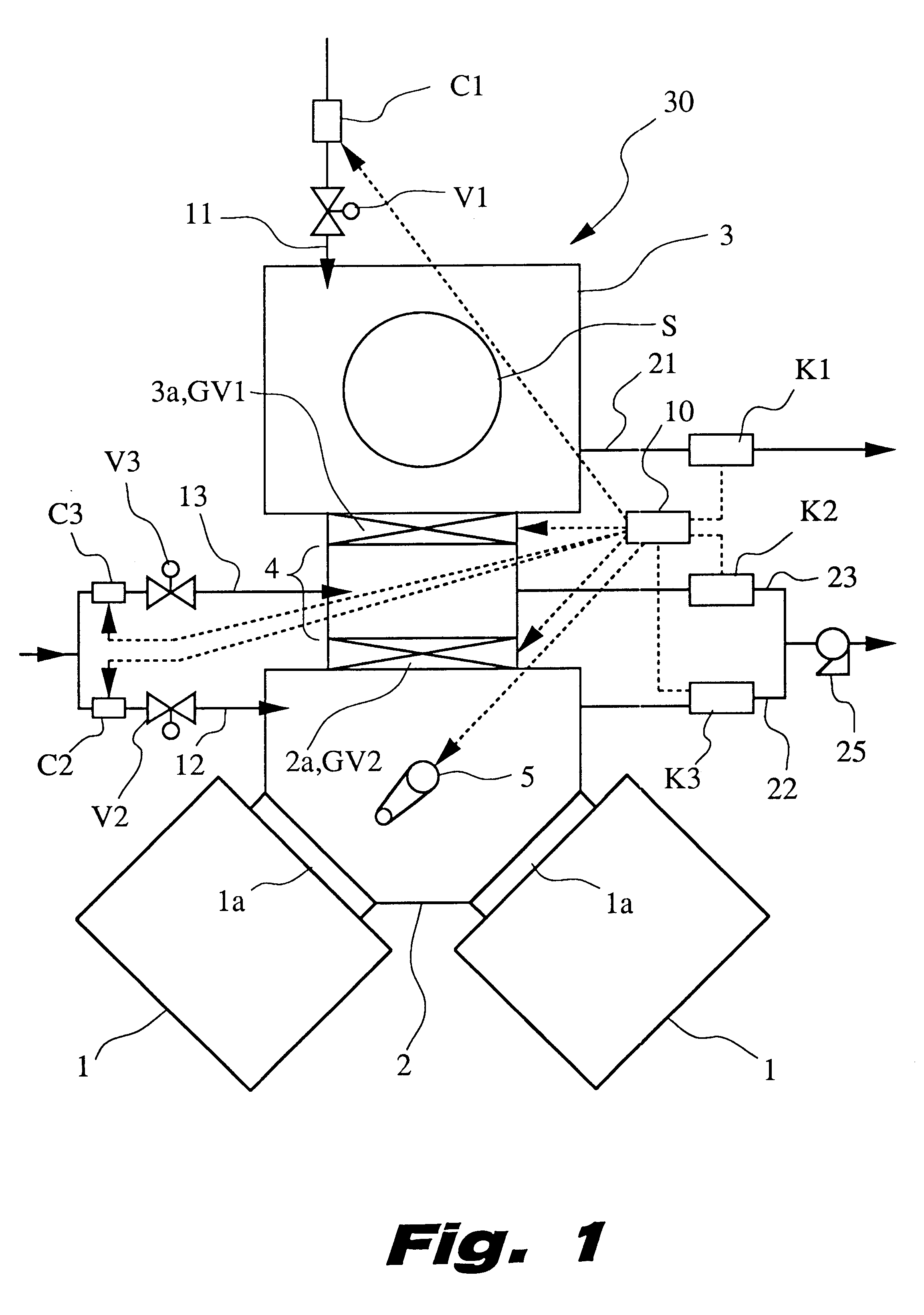

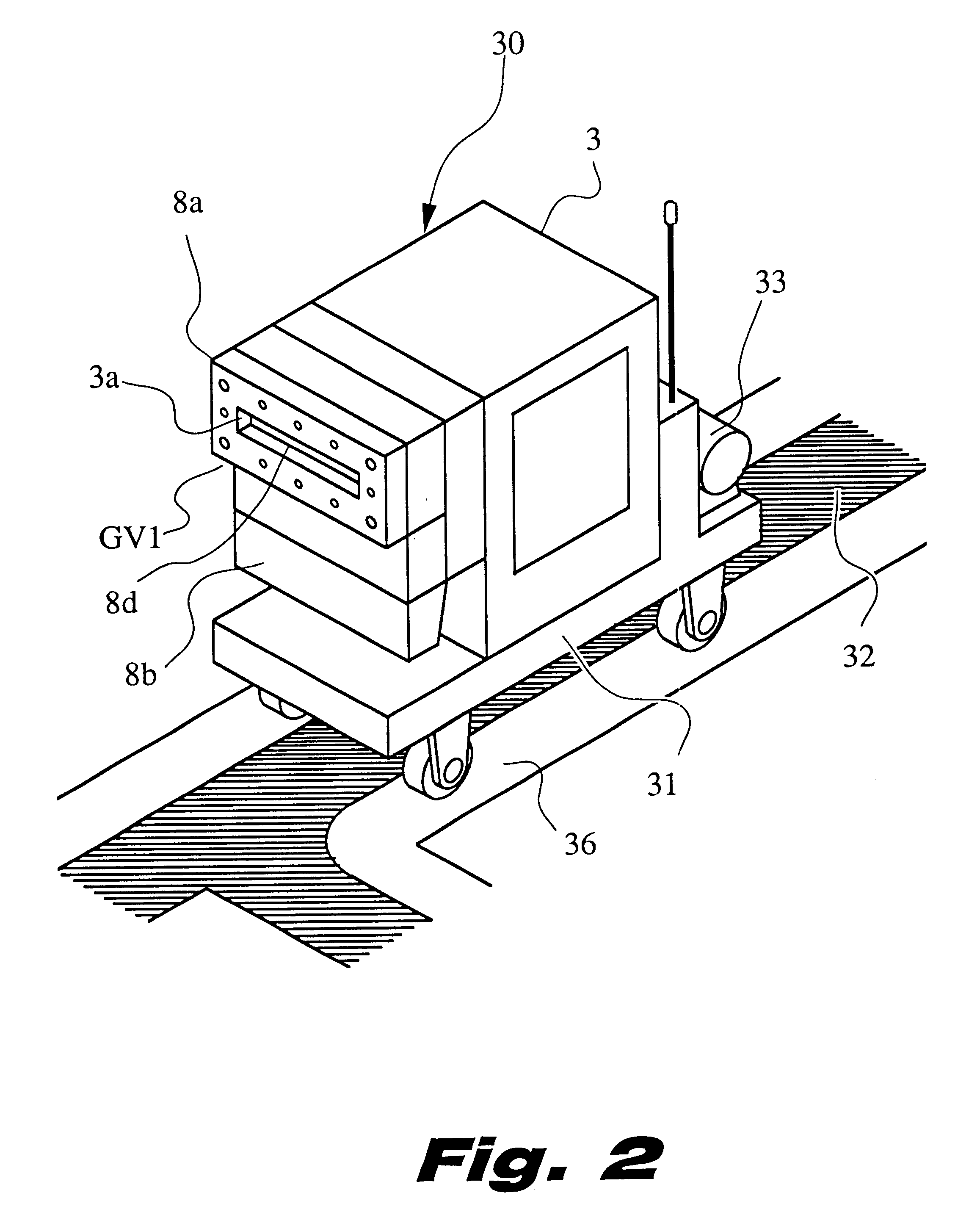

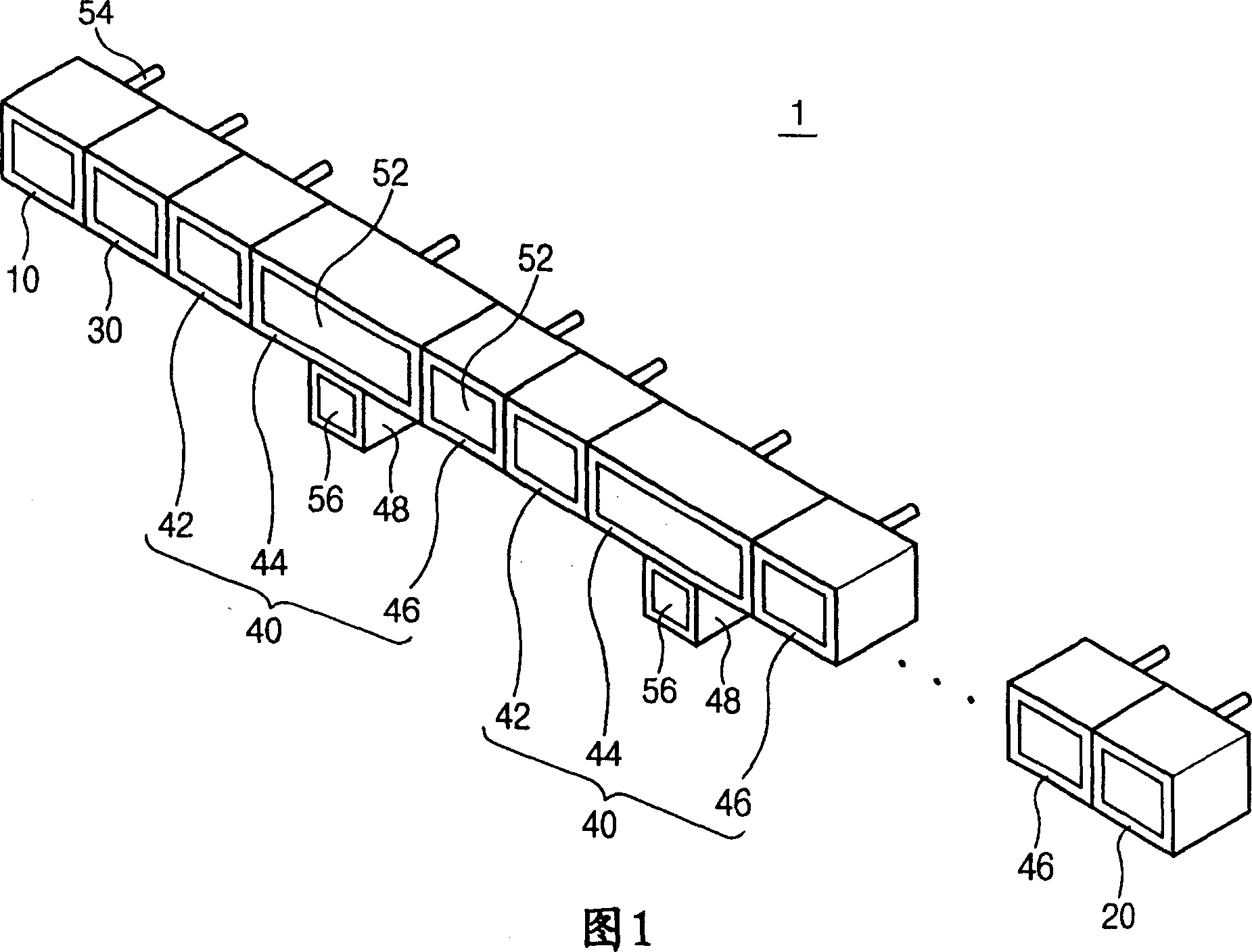

Transportation method for substrate wafers and transportation apparatus

The present invention uses a transportation robot furnished with a storage chamber 3 that can store substrate wafers S under an inert gas atmosphere, and when transporting substrate wafers S between transportation chambers 2 installed on processing apparatus 1 and holding an inert gas atmosphere, connection chamber 4 is disposed between storage chamber 3 and transportation chamber 2 when placing and removing substrate wafers S between storage chamber 3 of transportation robot 30 and the transportation chamber 2 of processing apparatus 1, and after introducing inert gas into the connection chamber 4 at low pressure, opening the gate valves GV1 and GV2 between storage chamber 3 and transportation chamber 2.

Owner:NIPPON SANSO CORP

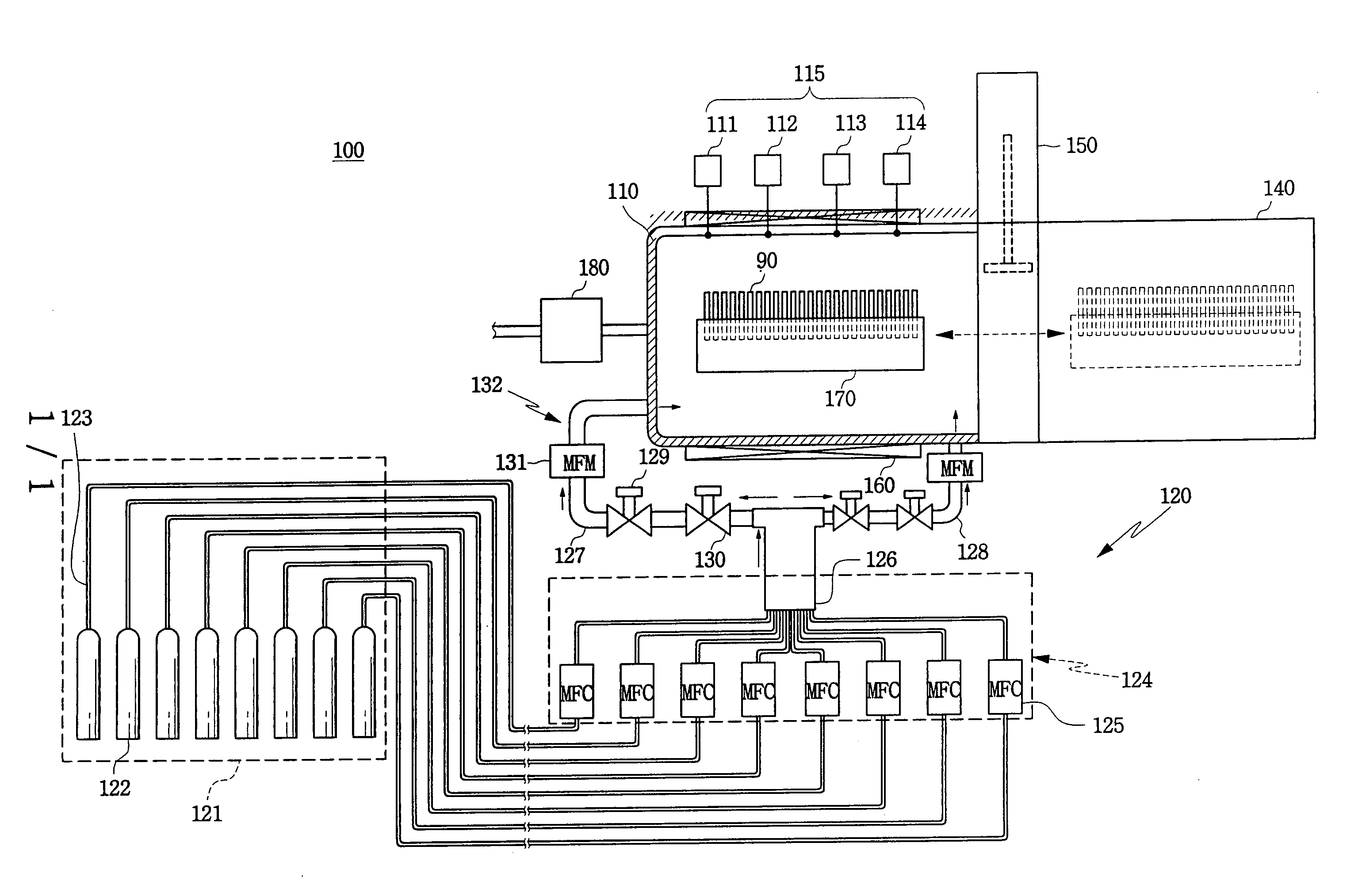

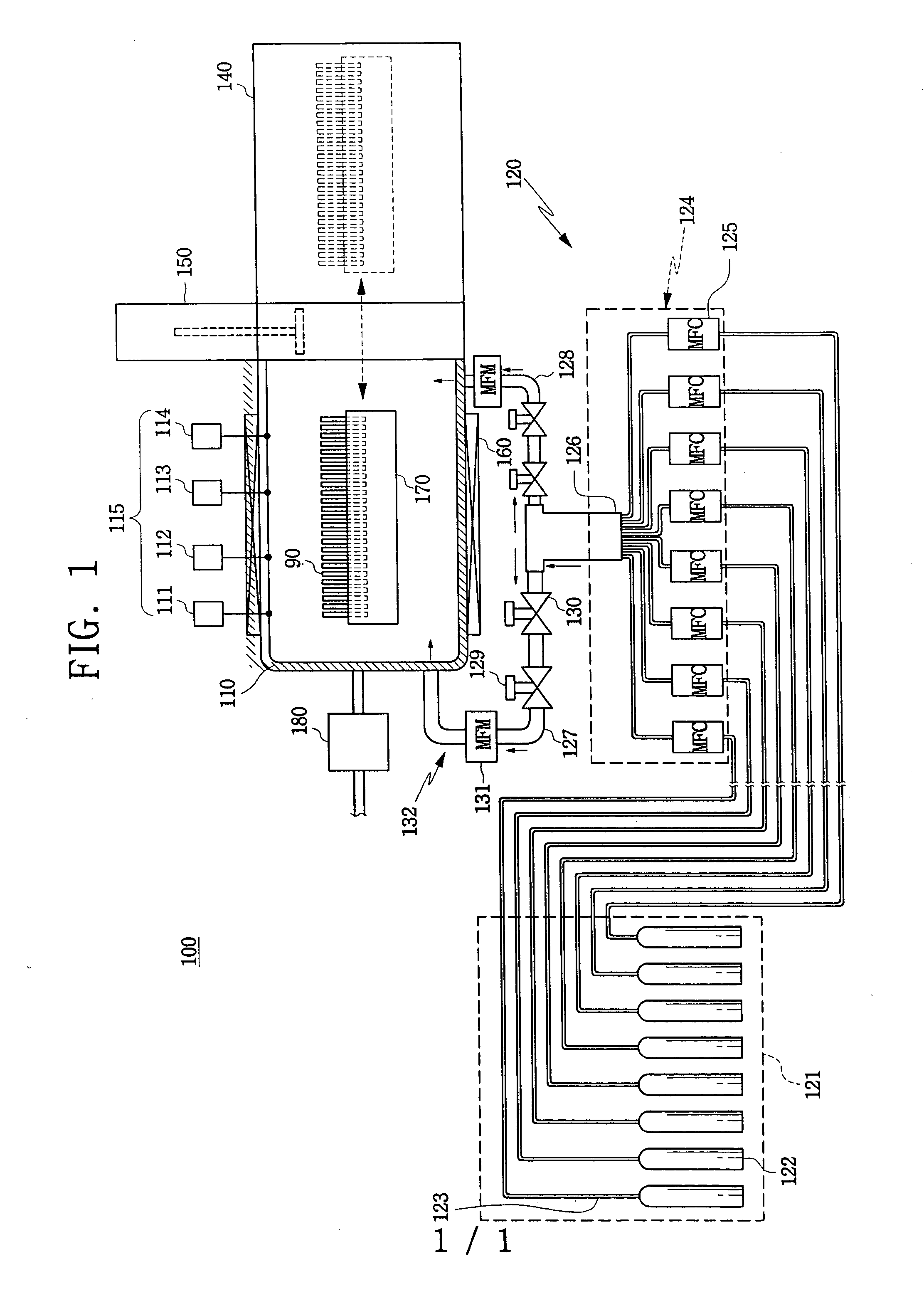

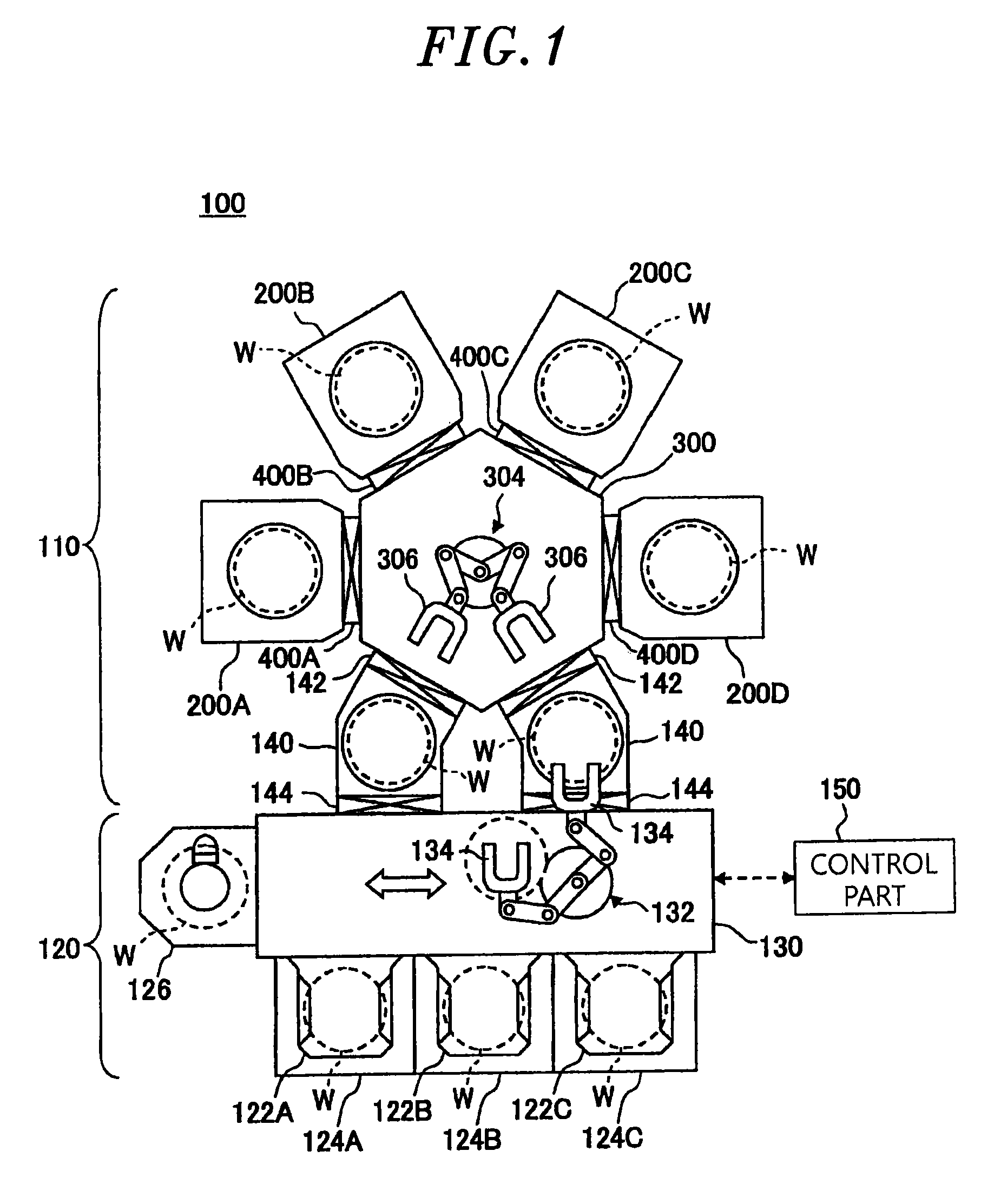

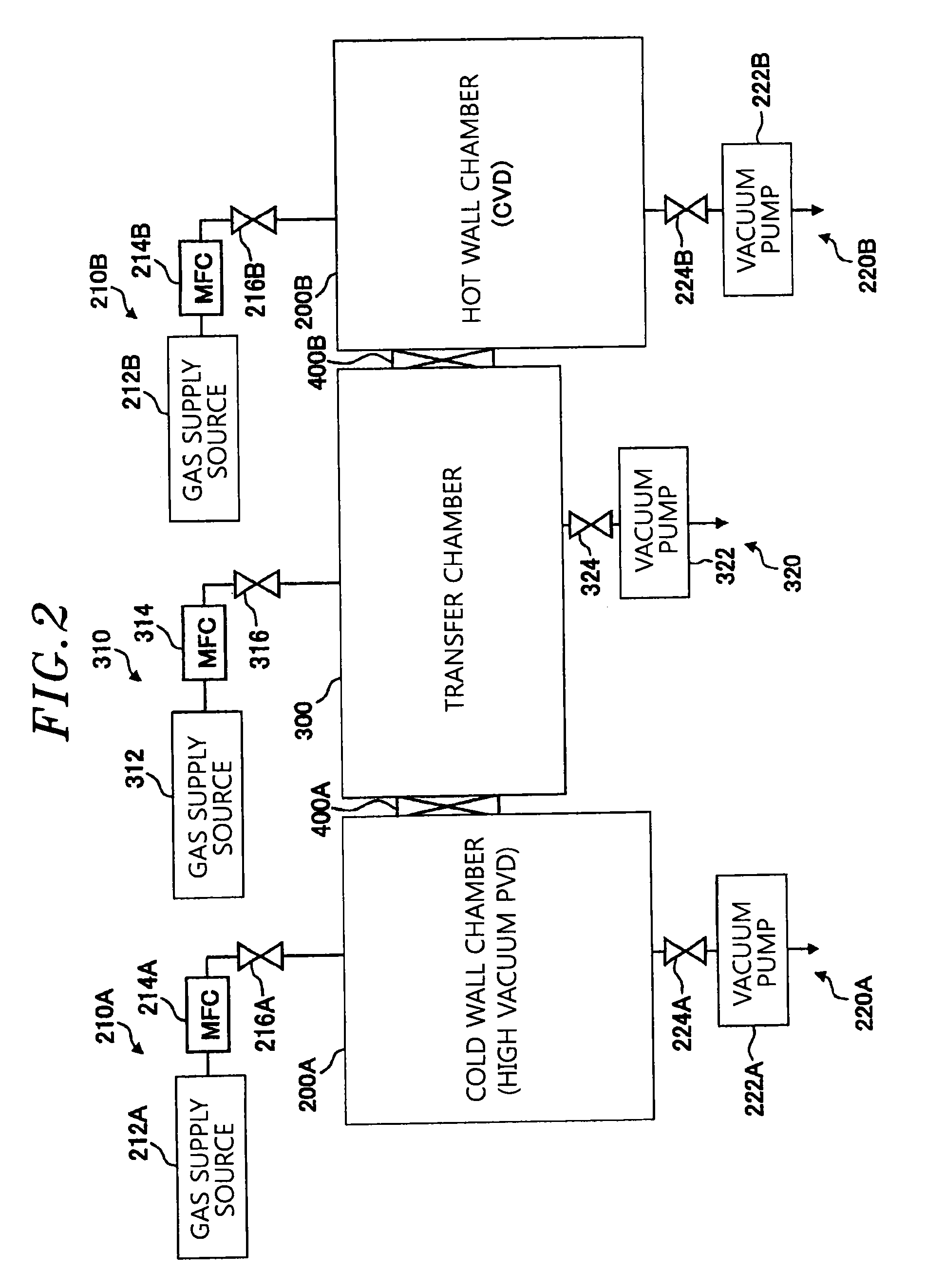

Substrate processing apparatus

ActiveUS20170253968A1Quality improvementSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringGas supply

Described herein is a technique that can improve a quality of substrate processing. A substrate processing apparatus may include: a plurality of processing chambers; a vacuum transfer chamber; a plurality of transfer chambers; a plurality of gate valves; a plurality of first gas supply units configured to supply an inert gas to a substrate; a transfer robot; and a control unit configured to control the plurality of first gas supply units and the transfer robot to: supply the inert gas to the substrate at a first flow rate when a distance between a gas supply port and the substrate passing through the plurality of gate valves is a first distance; and supply the inert gas to the substrate at a second flow rate greater than the first flow rate when the distance between the gas supply port and the substrate is a second distance greater than the first distance when the substrate passes through the plurality of gate valves.

Owner:KOKUSA ELECTRIC CO LTD

Apparatus for processing substrate

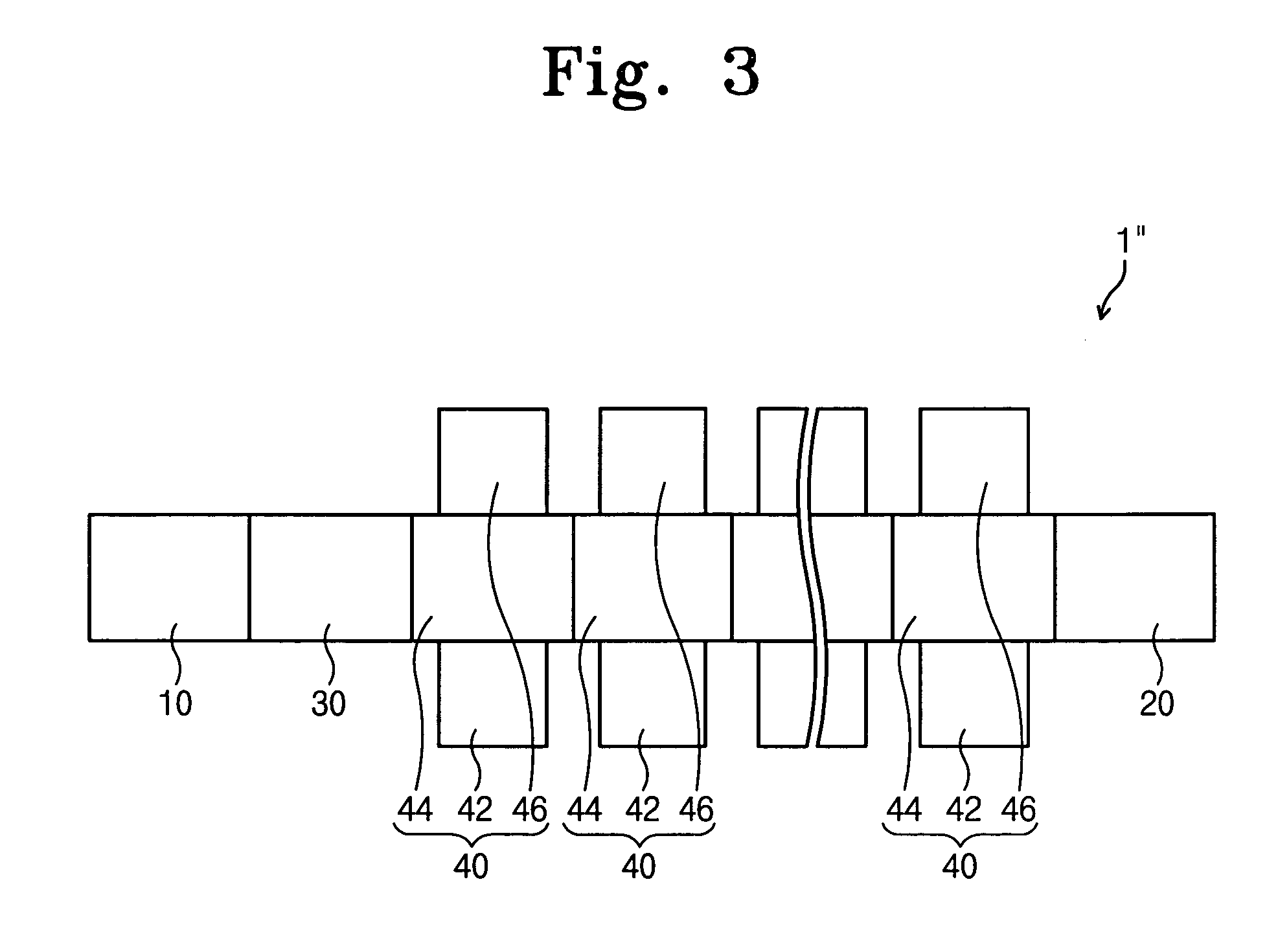

ActiveUS20060174829A1Reduce areaShorten the timeLiquid surface applicatorsSemiconductor/solid-state device manufacturingThin layerLight-emitting diode

In a substrate processing apparatus for forming thin layers on a substrate used for an organic light emitting diode, the apparatus includes a mask attaching chamber, a deposition chamber and a mask detaching chamber. The mask attaching chamber, the deposition chamber and the mask detaching chamber are provided with a transferring guide installed thereinside, and a substrate supporter for supporting the substrate moves along the transferring guide in or between the chambers. Thus, a time for processing the substrate and an area for the apparatus may be reduced. Also, the chambers are grouped in one or more, and a gate valve is installed between the grouped chambers for opening and closing a path between the grouped chambers. Accordingly, the chambers may be continuously maintained in a vacuum state when any one of the chambers is repaired.

Owner:SEMES CO LTD

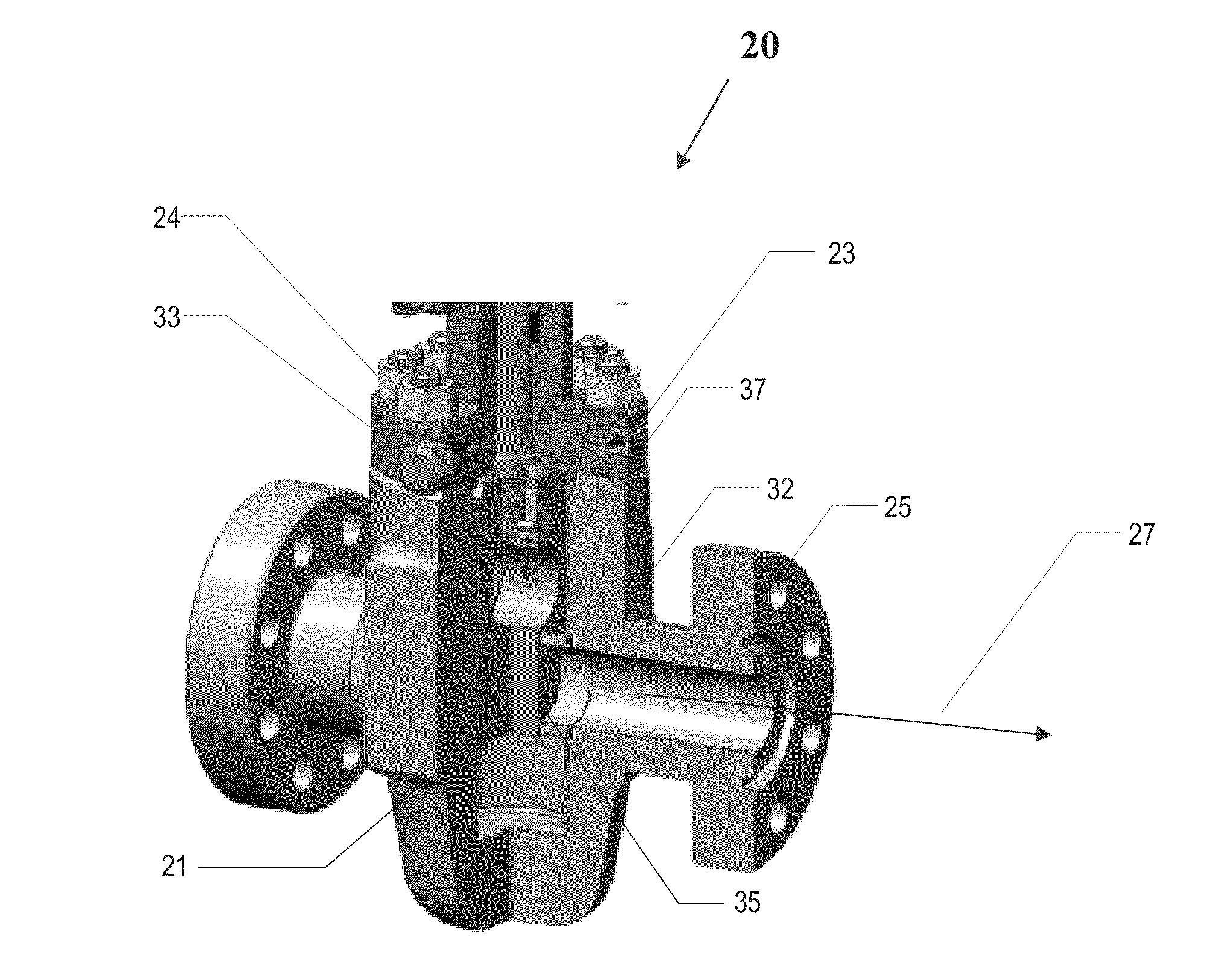

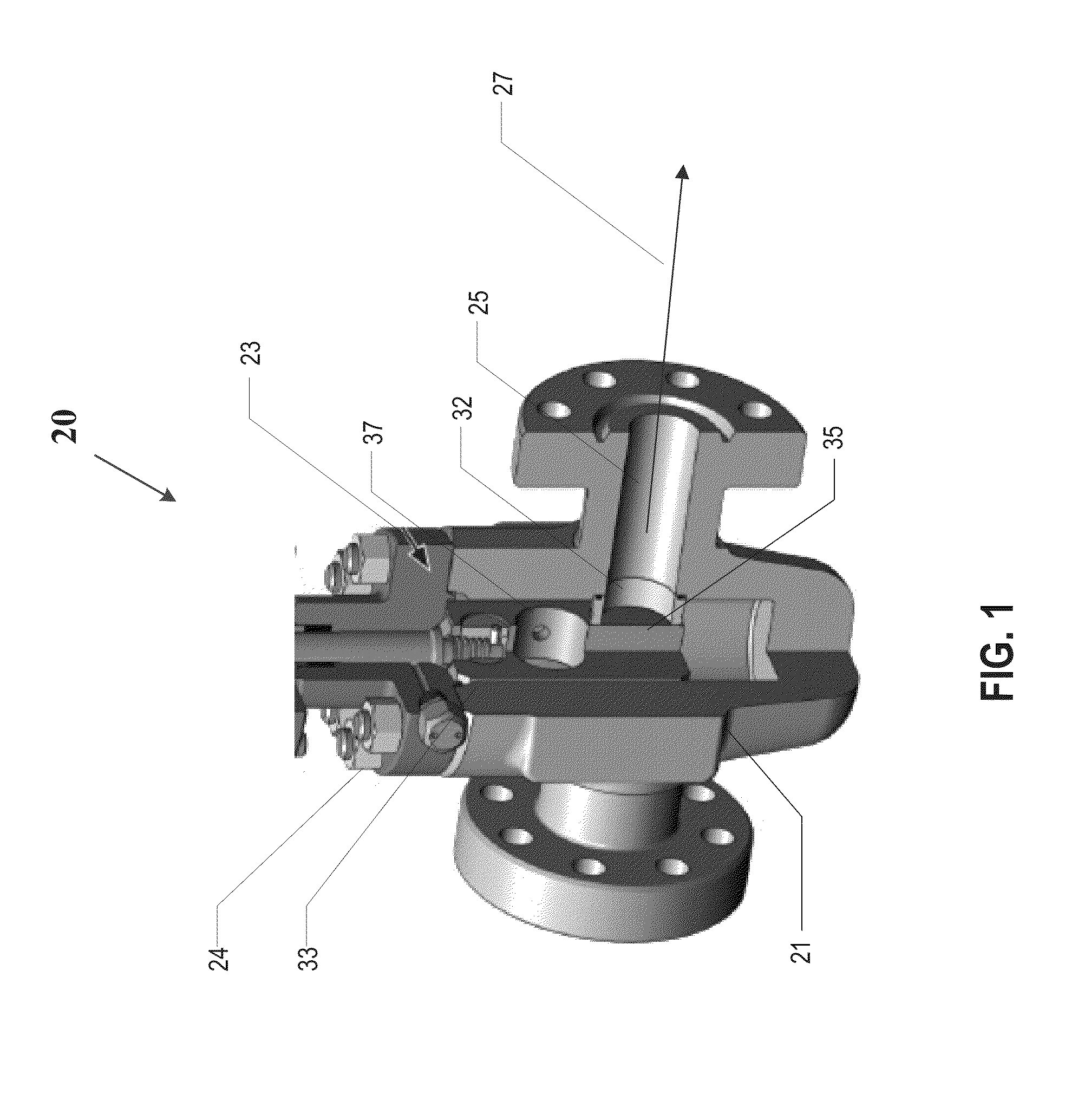

Method and apparatus for replacing BOP with gate valve

Owner:WORLDWIDE OILFIELD MACHINE INC

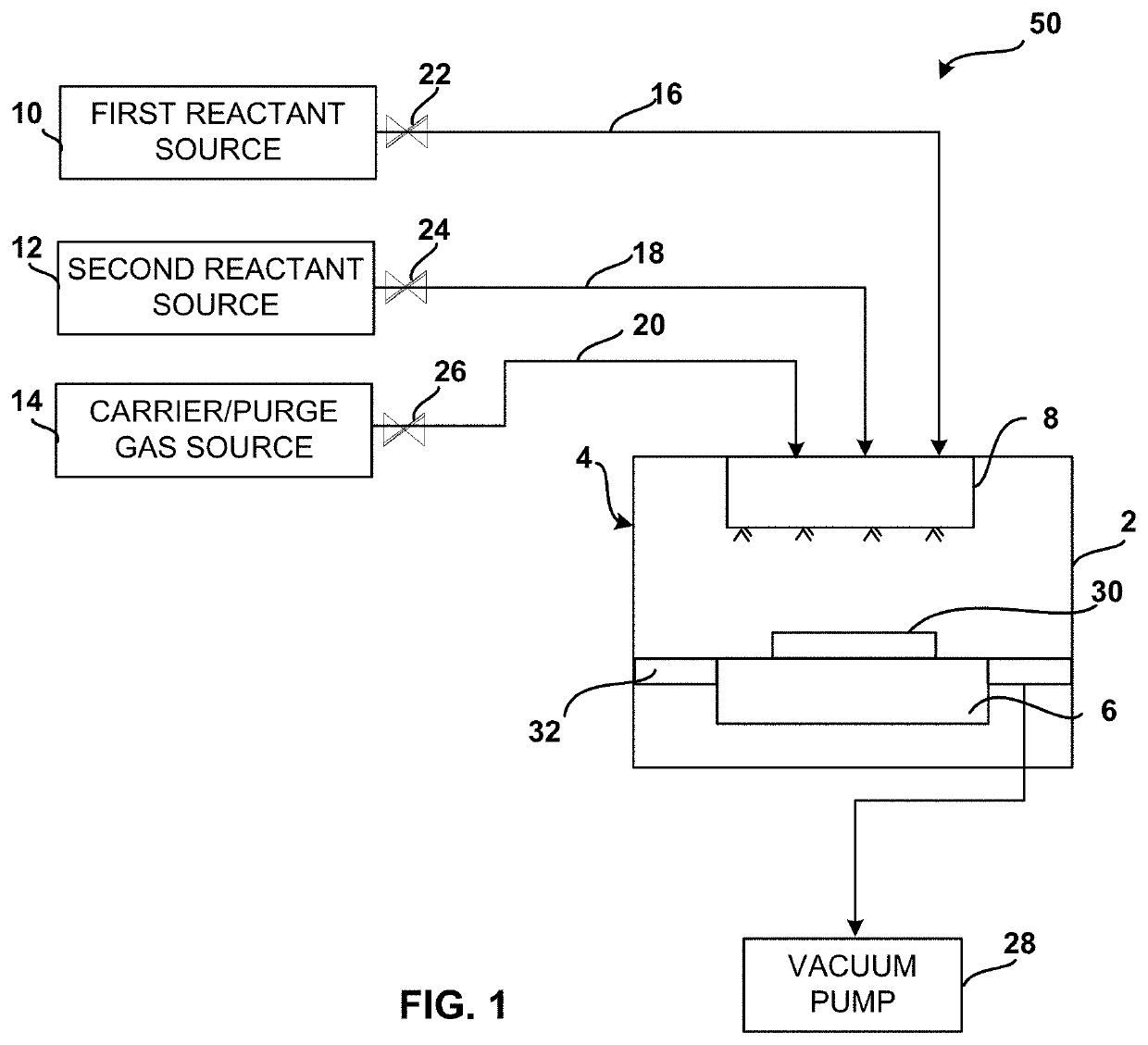

Gas supply unit and semiconductor device manufacturing apparatus using the same

InactiveUS20050016452A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingDevice materialManufactured apparatus

A semiconductor device manufacturing apparatus is provided. The semiconductor device manufacturing apparatus comprises a furnace having a closed predetermined space for seating a wafer, a loading device located at one side of the furnace to load the wafer on which a prior process may have been performed, a gate valve interposed between the furnace and the loading device to selectively open / close a pathway between the furnace and the loading device, a heater for heating an interior of the furnace, a vacuum pump for maintaining the interior of the furnace with a suitable pressure necessary to the process, a gas reservoir for storing individually various kinds of reaction gases supplied from an exterior of the space, a gas mixing device connected to the gas reservoir to mix the various kinds of reaction gases supplied from the gas reservoir with an even mixing ratio, at least two mixed gases supply pipes connected to the gas mixing device to supply the reaction gases mixed in the gas mixing device to each direction of the furnace, and a mixed gases flow control unit installed at the mixed gases supply pipe to control the flow of the reaction gases supplied through the mixed gases supply pipe.

Owner:SAMSUNG ELECTRONICS CO LTD

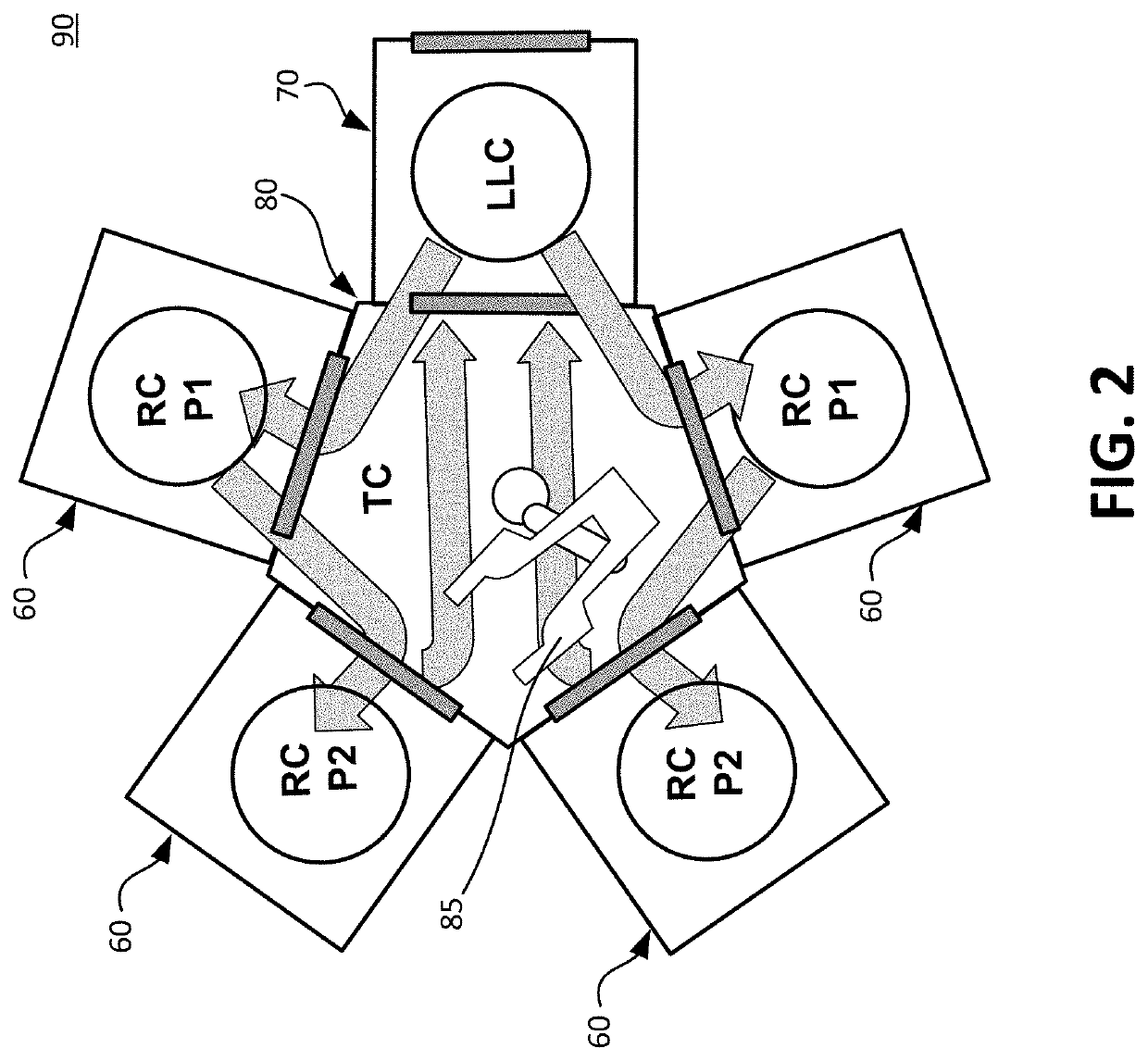

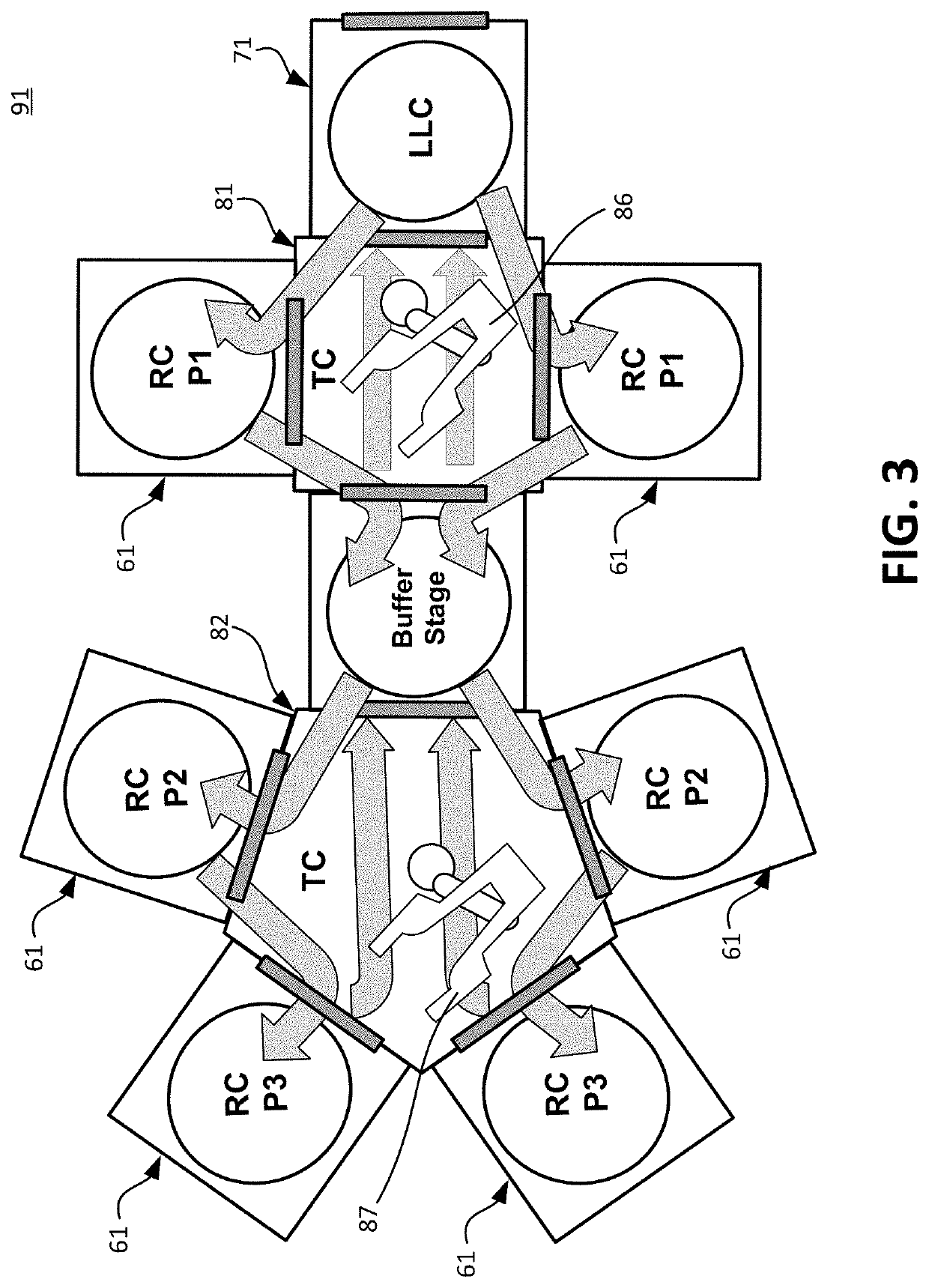

Reactor system with multi-directional reaction chamber

A reactor system may comprise a plurality of reaction chambers; a plurality of transfer chambers; and / or at least two gate valves coupled to each reaction chamber of the plurality of reaction chambers. A first gate valve of the at least two gate valves may fluidly couple a first respective reaction chamber of the plurality of reaction chambers to a first transfer chamber of the plurality of transfer chambers, and a second gate valve of the at least two gate valves may fluidly couple the first respective reaction chamber to a second transfer chamber of the plurality of transfer chambers. In various embodiments, each of the plurality of transfer chambers may comprise a transfer tool, wherein each transfer tool may be configured to transfer a substrate into and / or out of multiple reaction chambers.

Owner:ASM IP HLDG BV

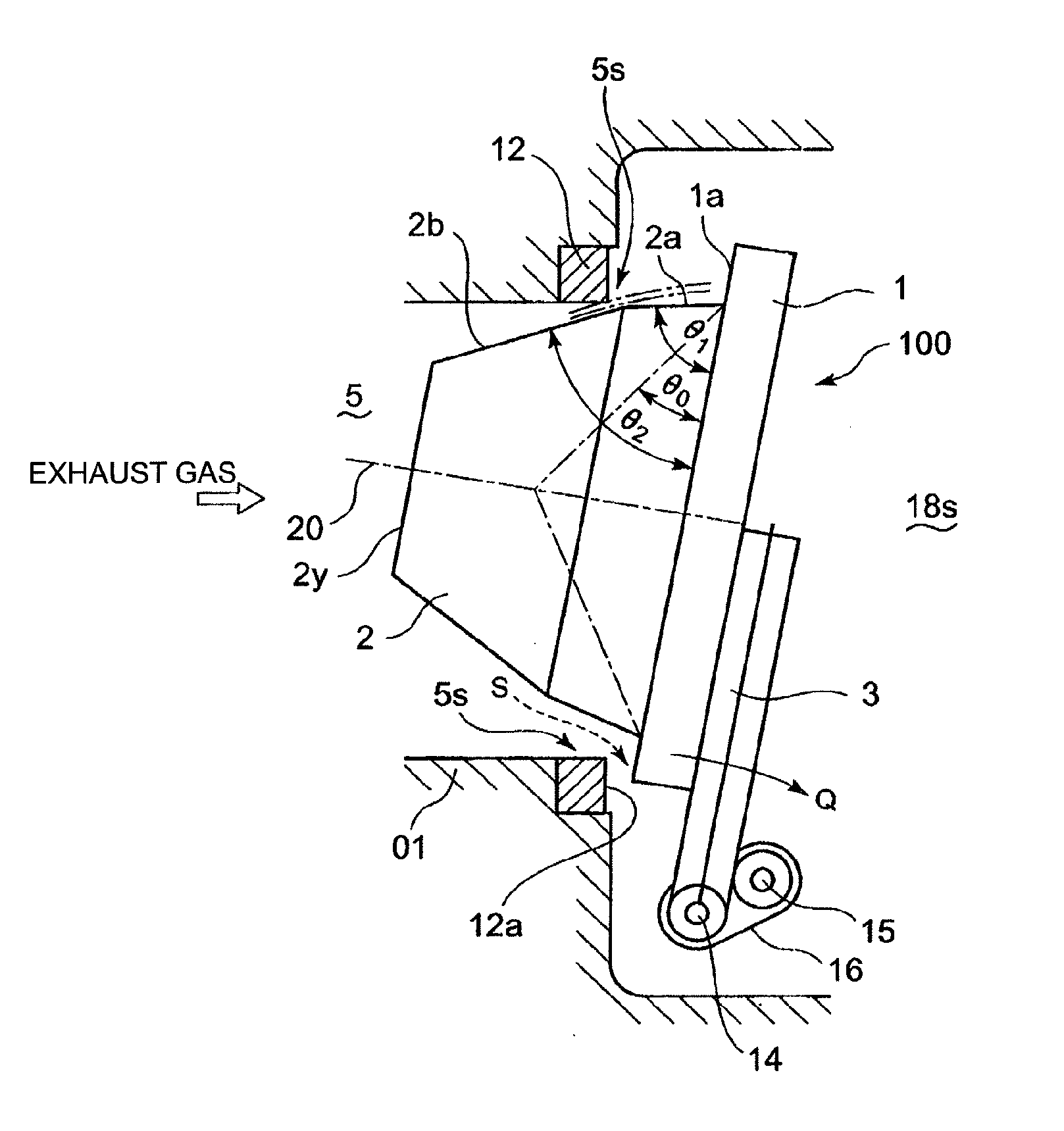

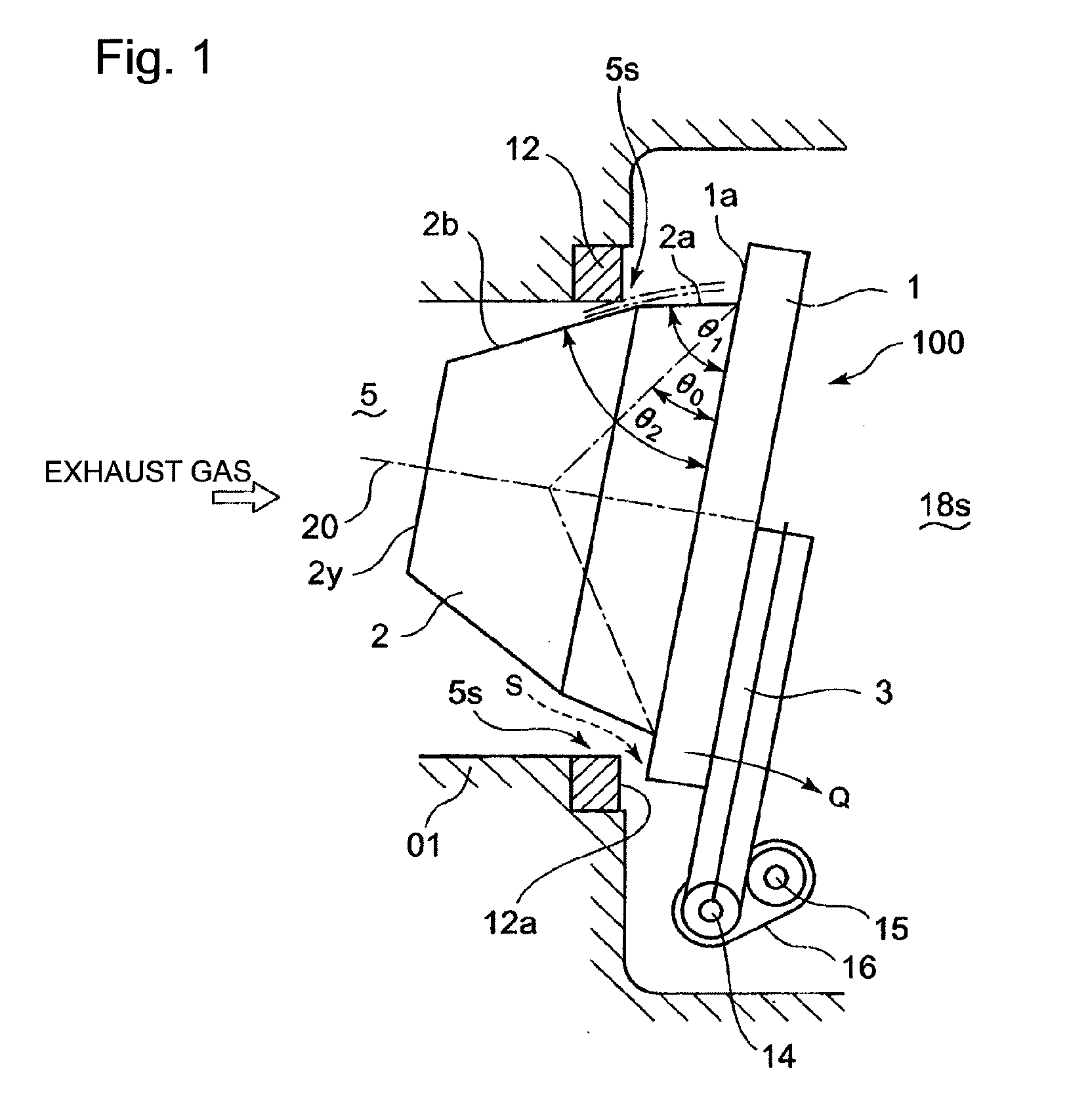

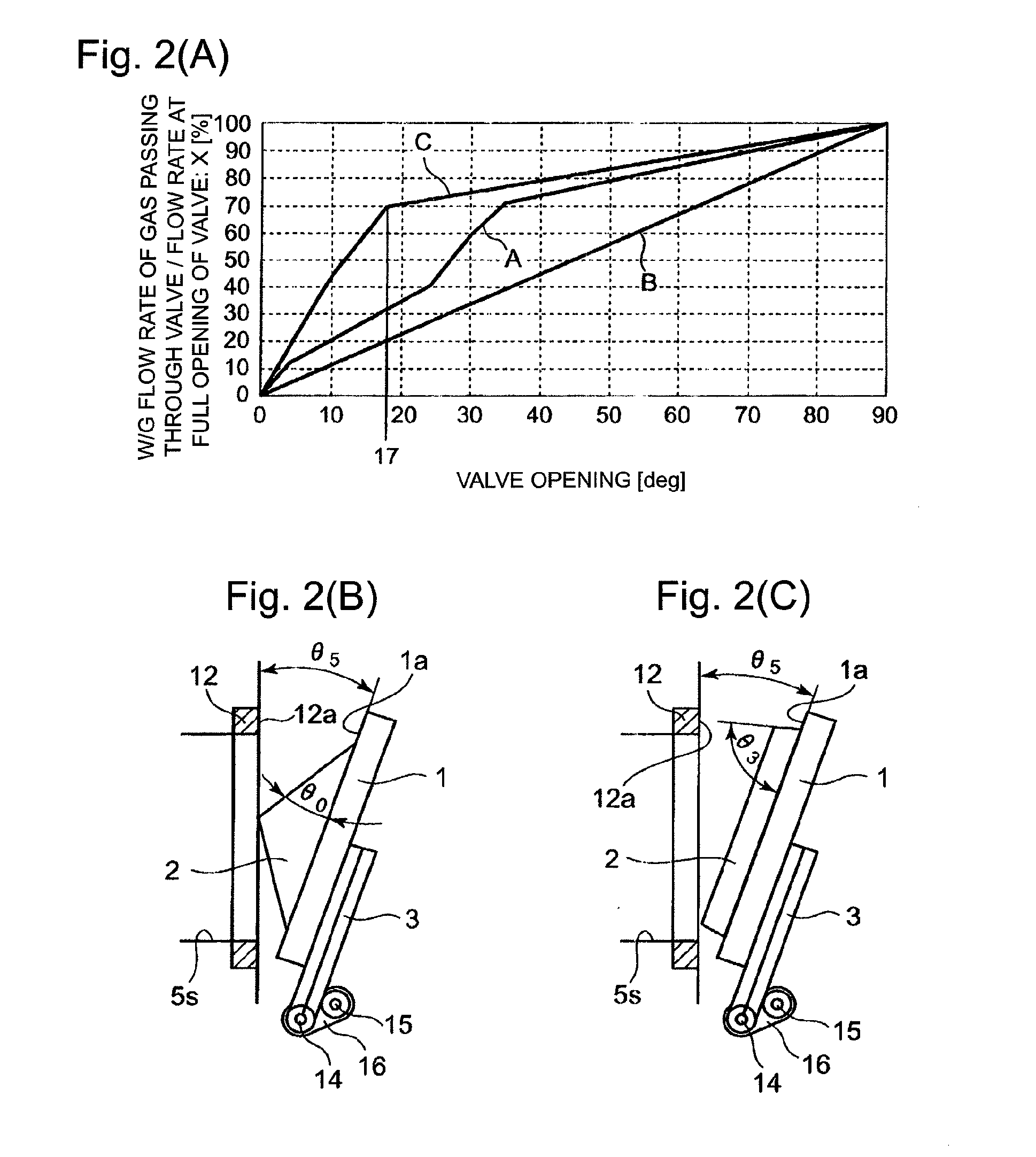

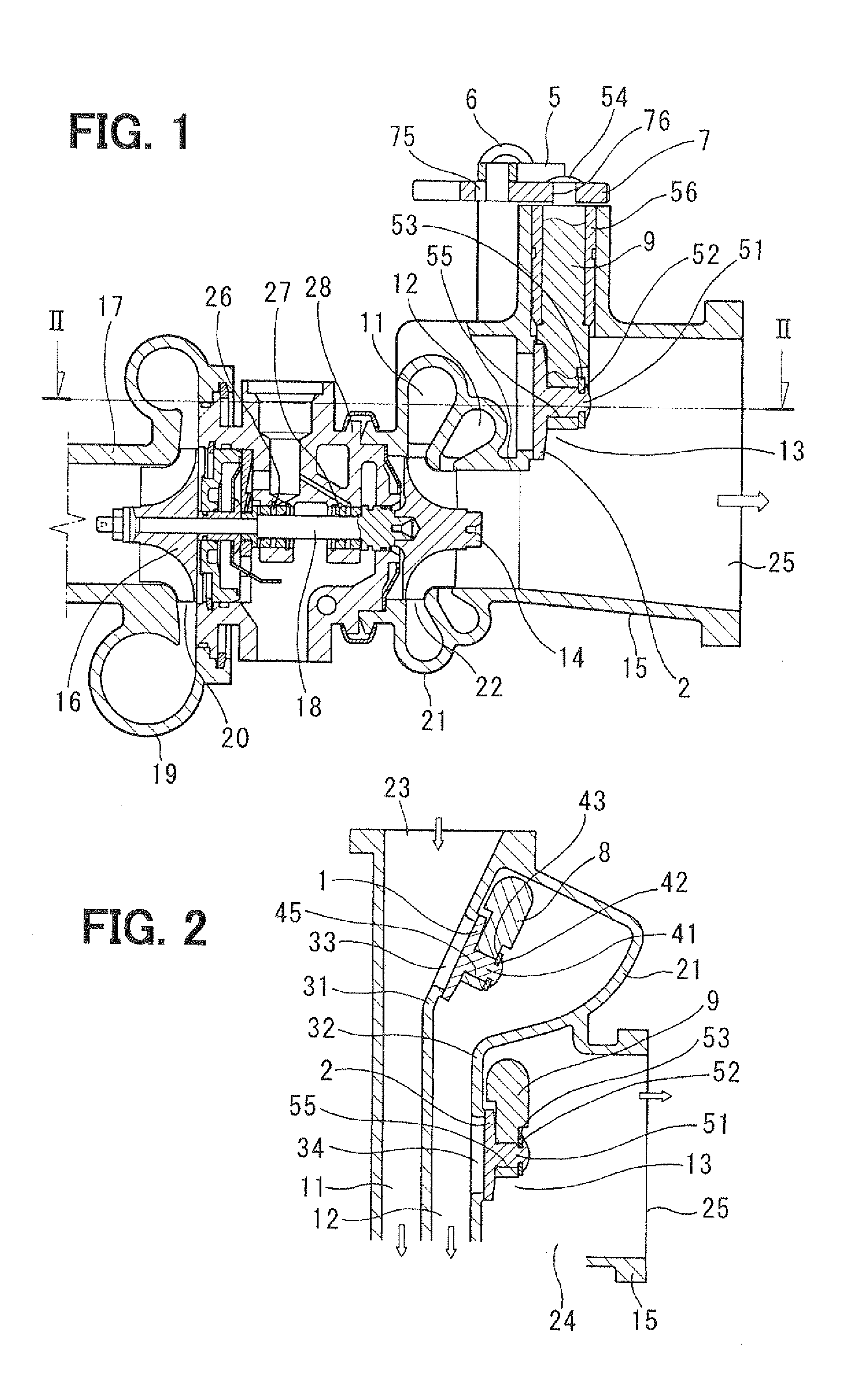

Waste gate valve device

InactiveUS20120312010A1Reduce exhaust gas passage areaRaise the ratioInternal combustion piston enginesEngine controllersEngineeringGate valve

A waste gate valve device in which a waste gate valve 100 is fully closed when a valve body of the waste gate valve 100 moves from an exhaust outlet passage 18s side toward an exhaust bypass passage 5 side and touches a seat face 12a of a valve seat part 12, wherein the valve body of the waste gate valve is provided with a protrusion 2 of a prescribed height on a touching side where the valve body of the waste gate valve touches the seat face 12a, the protrusion being configured so as to reduce an exhaust gas passage area of the exhaust gas.

Owner:MITSUBISHI HEAVY IND LTD

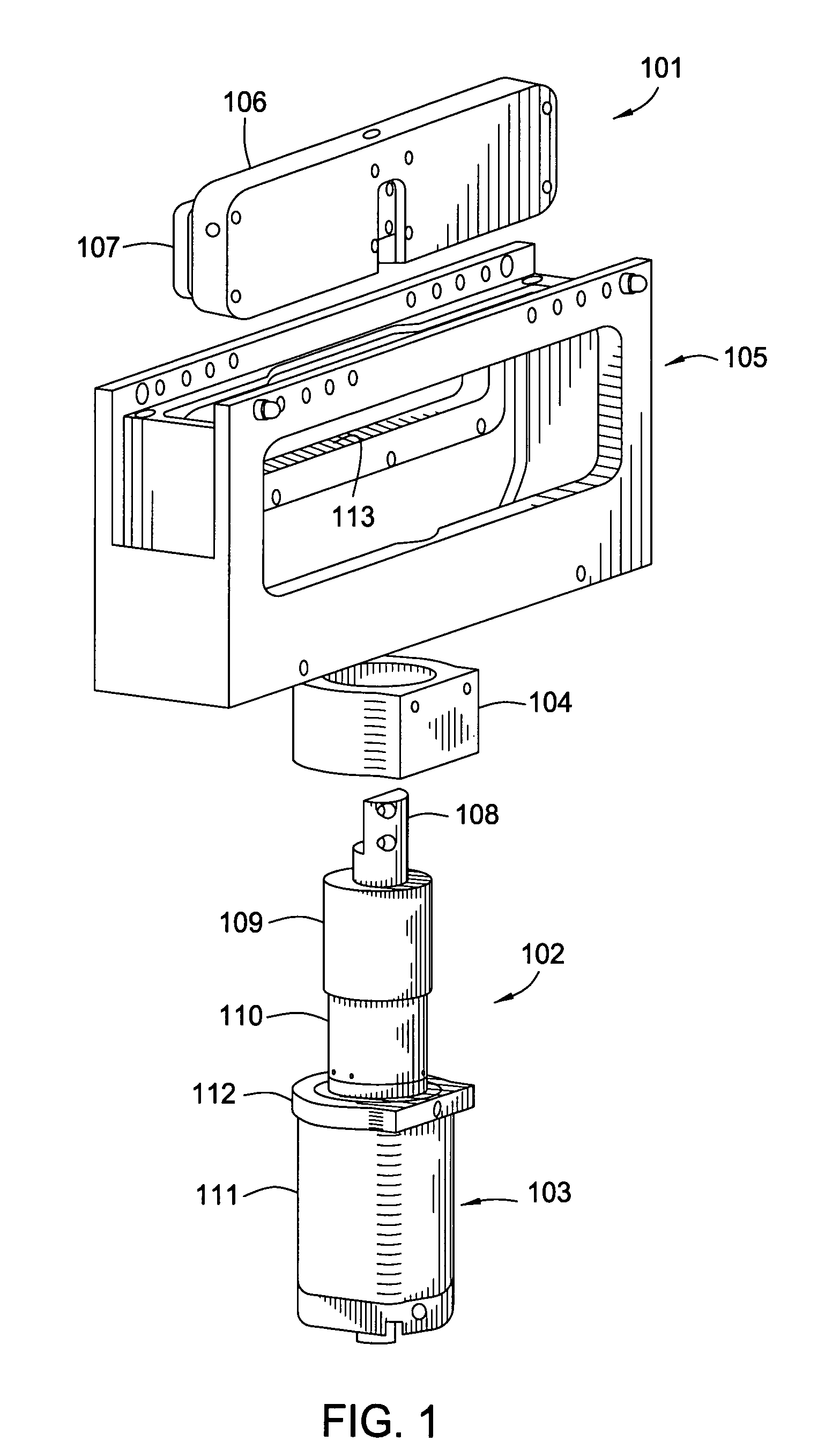

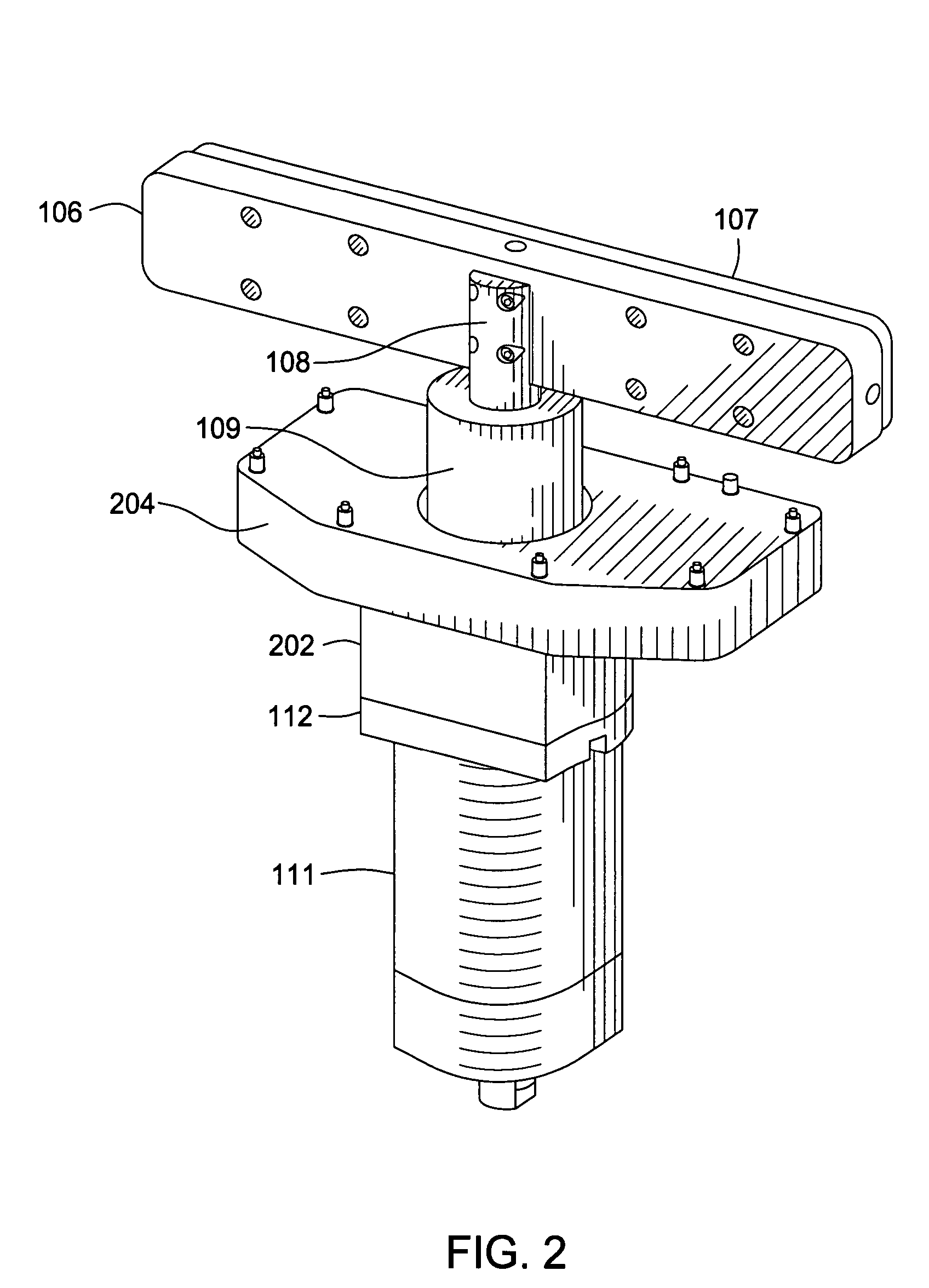

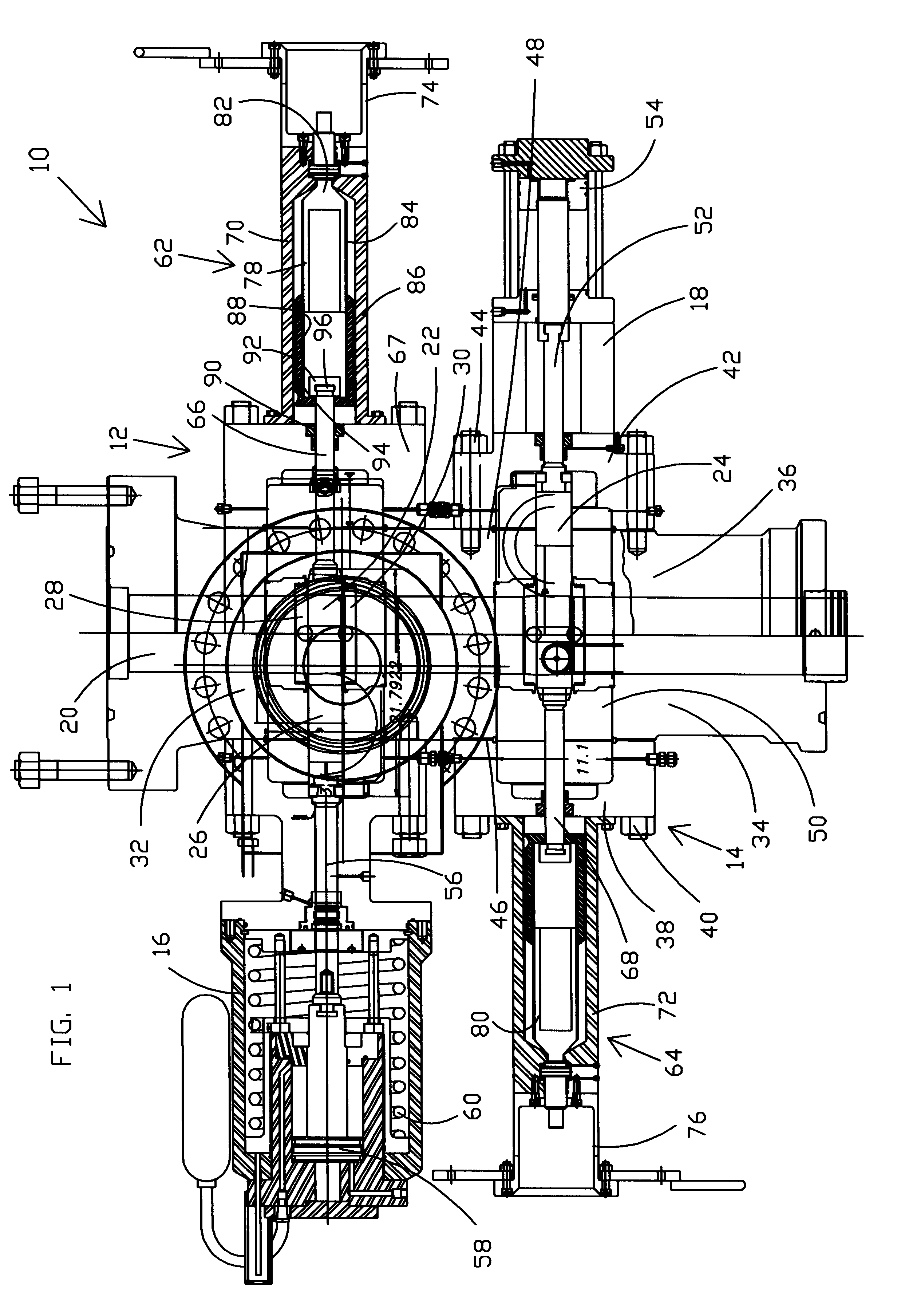

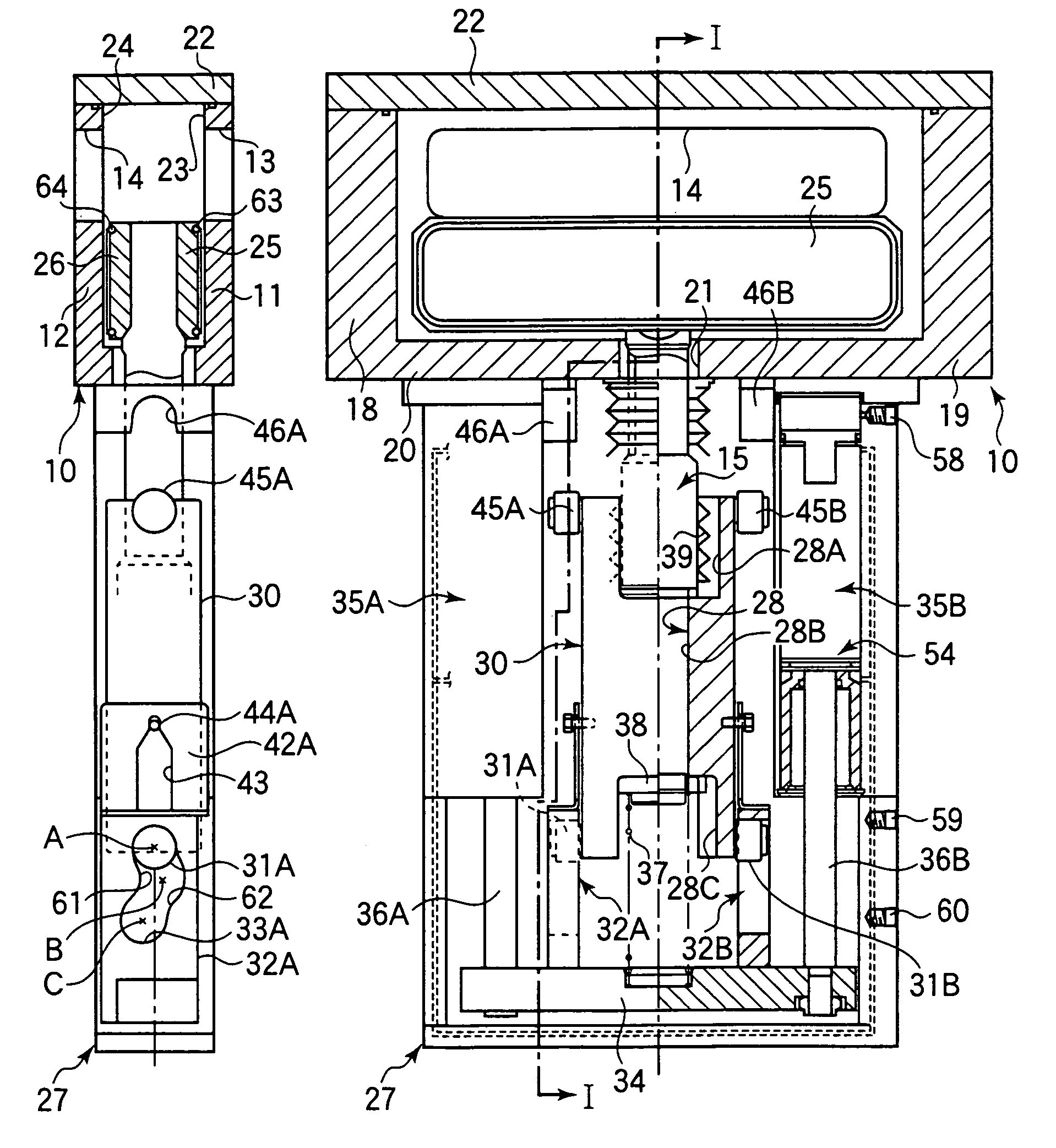

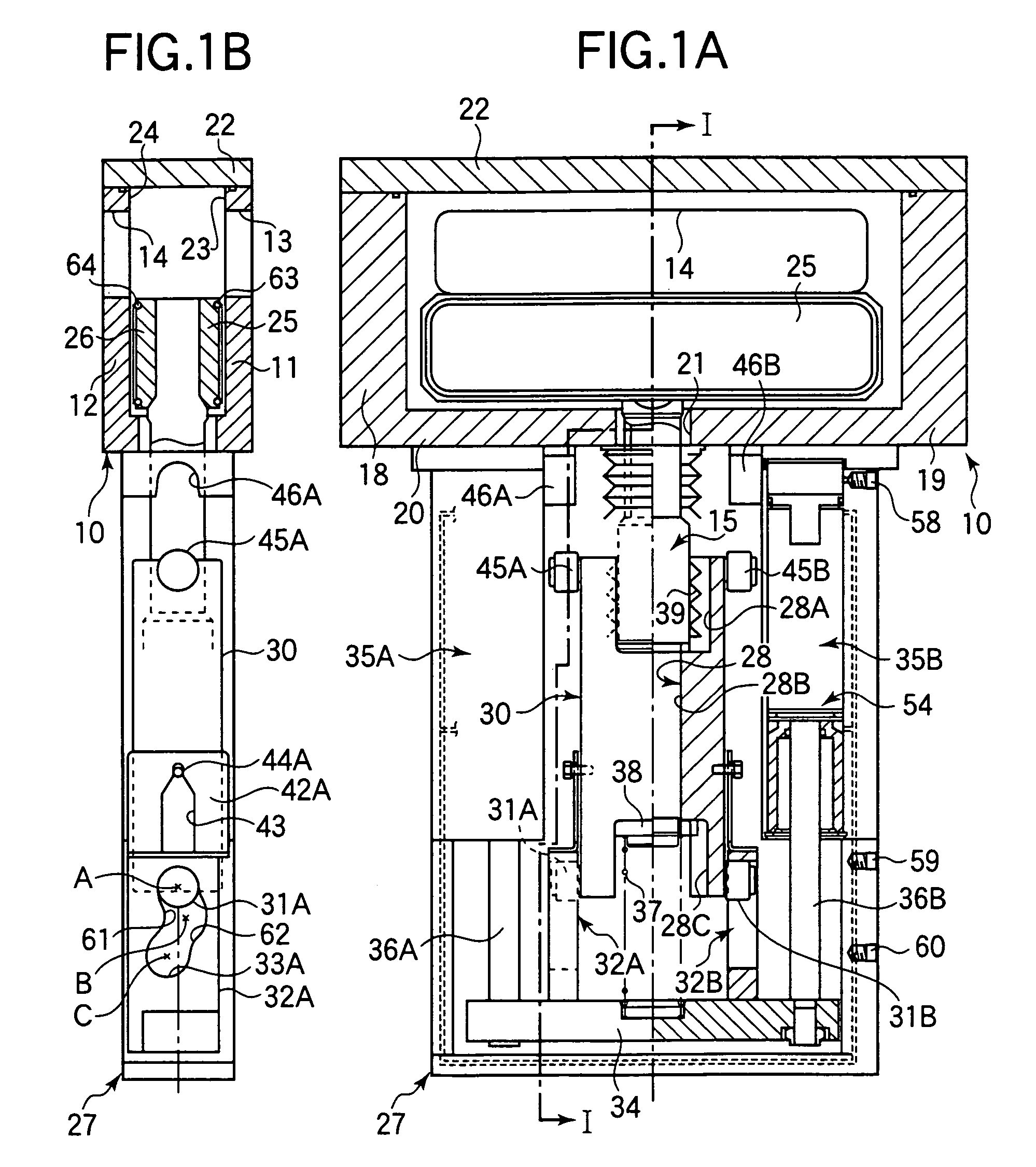

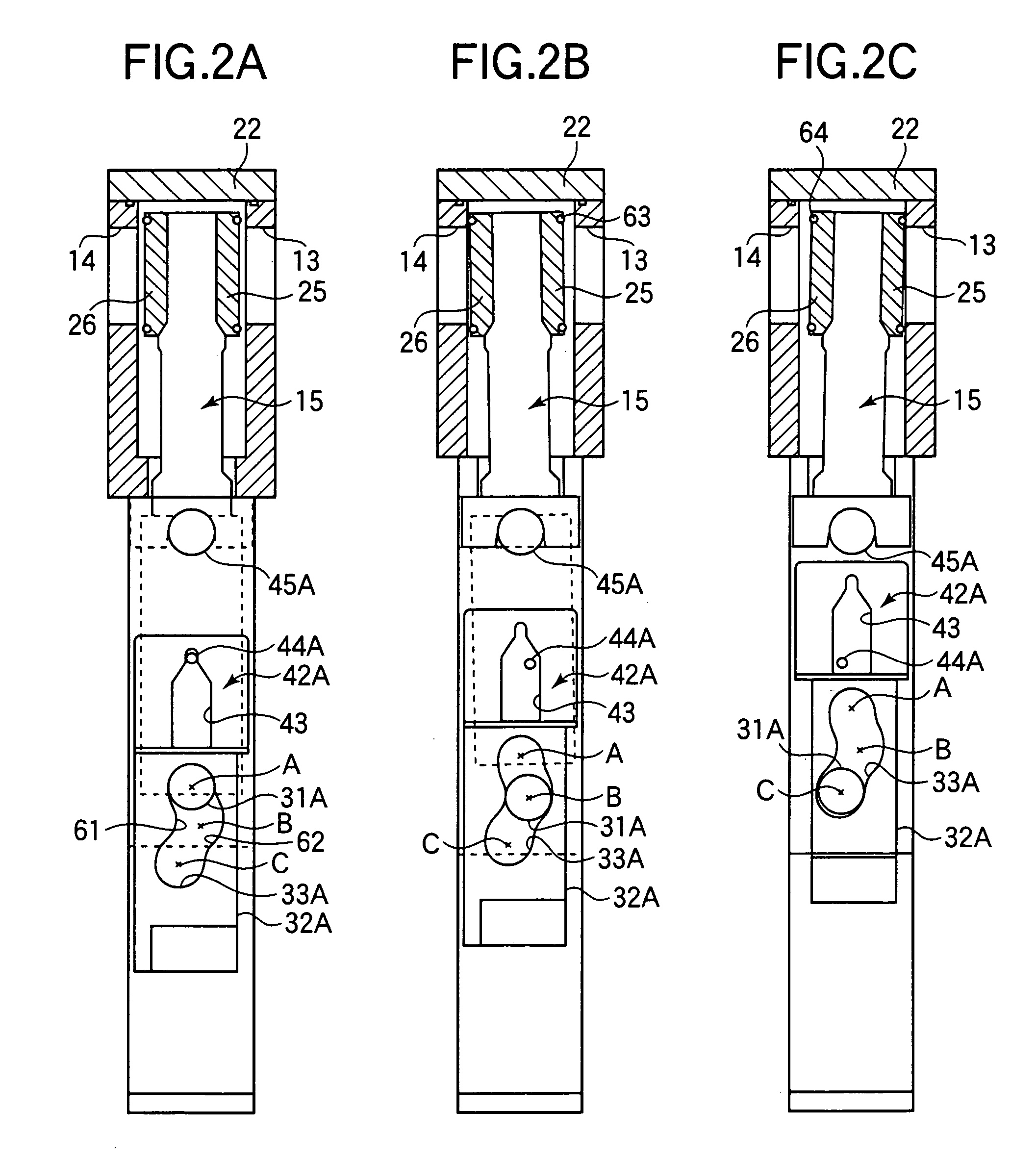

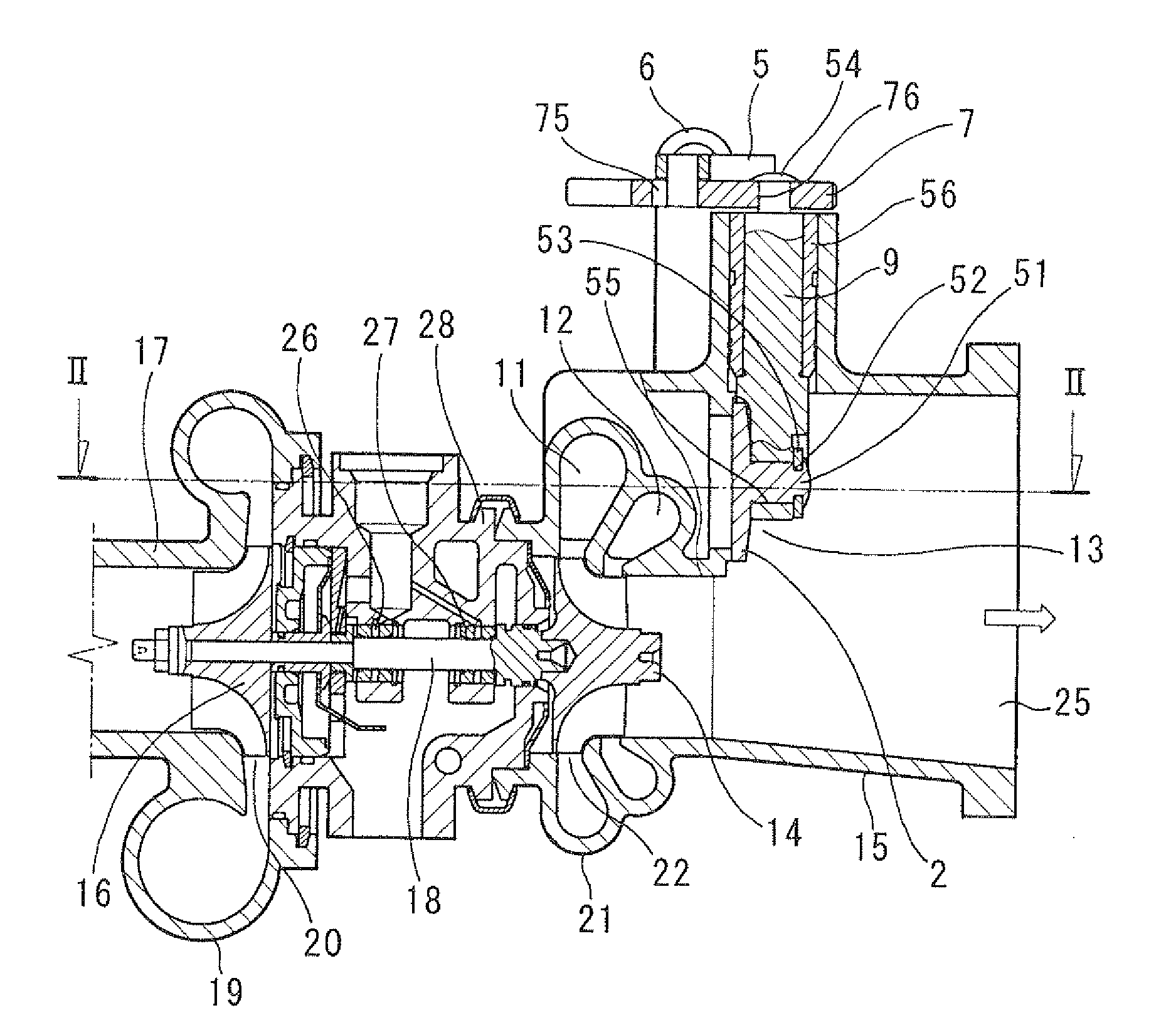

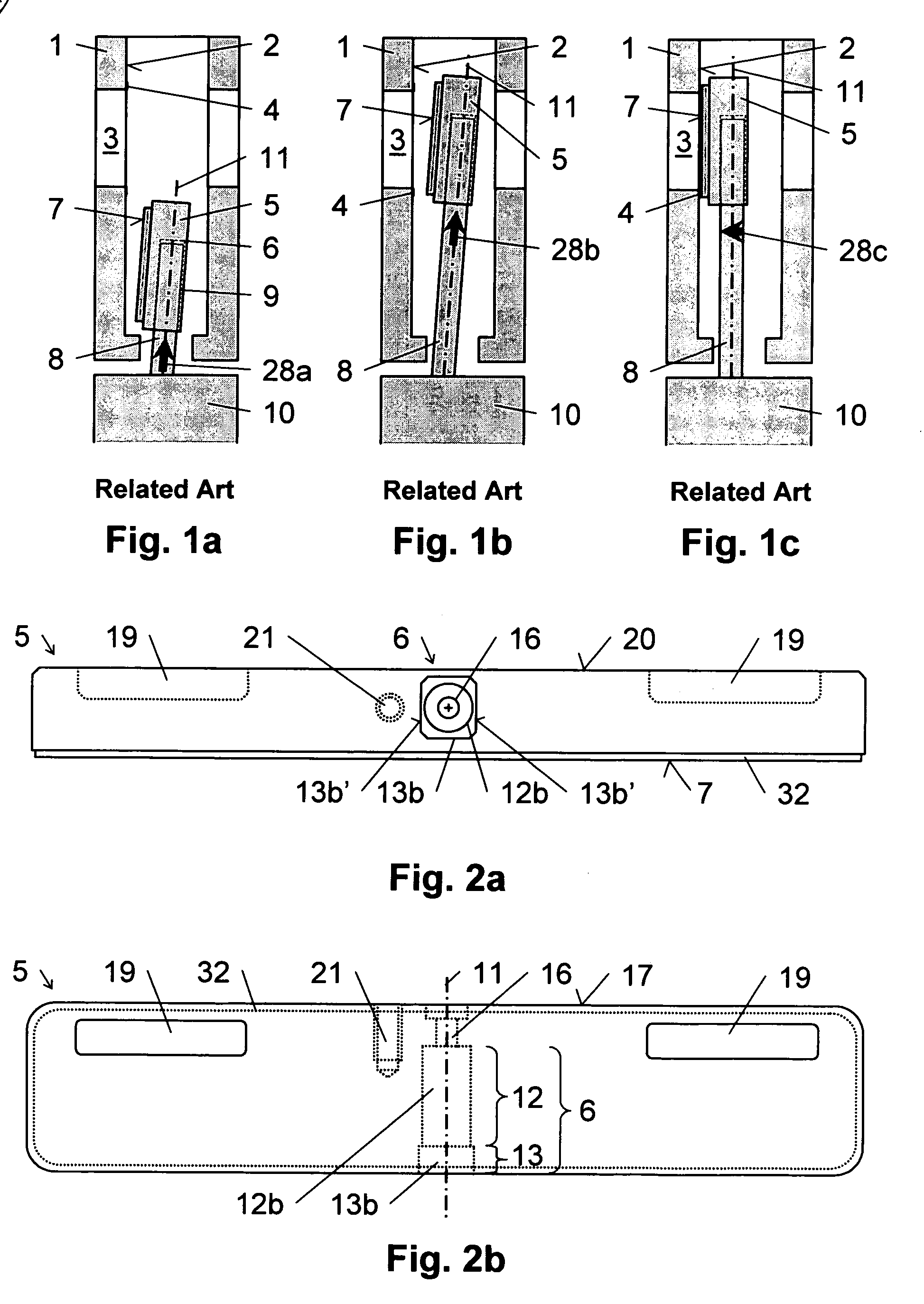

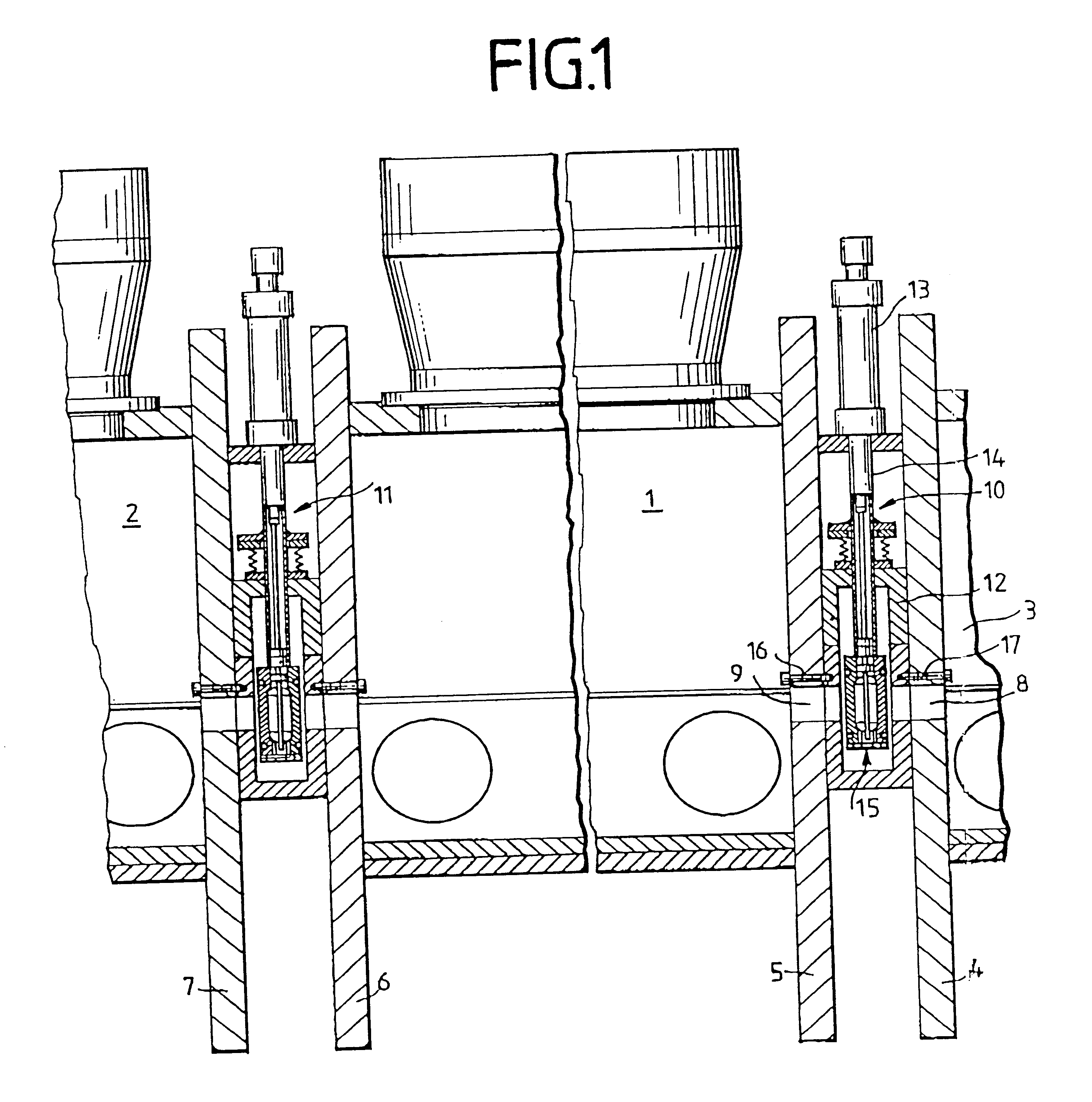

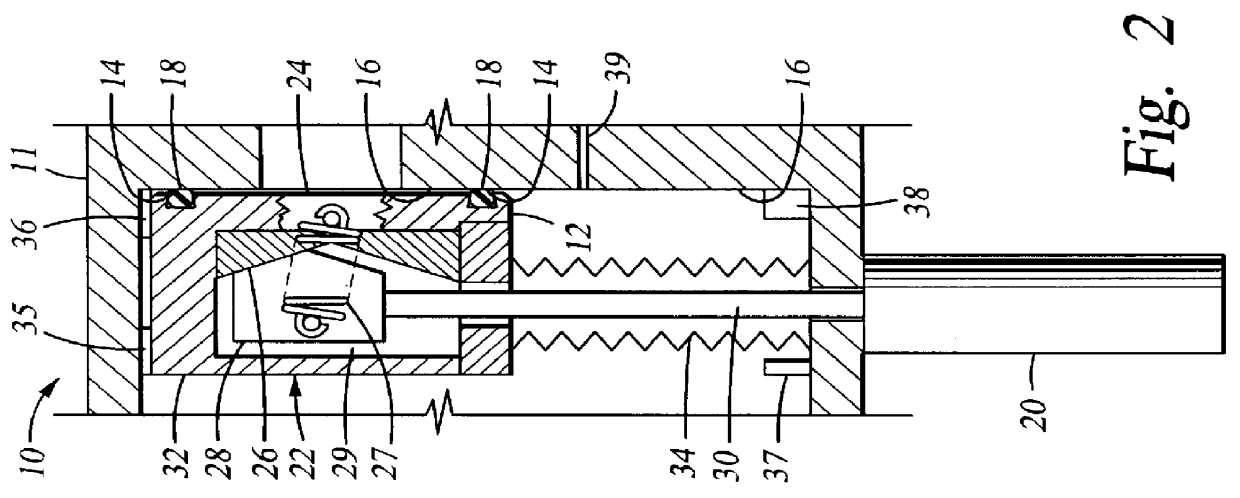

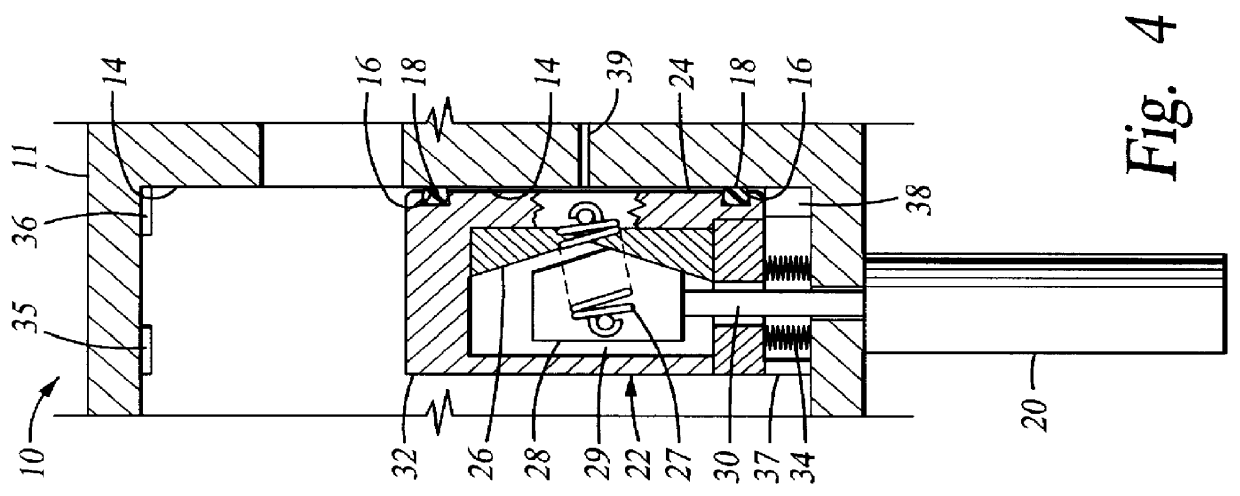

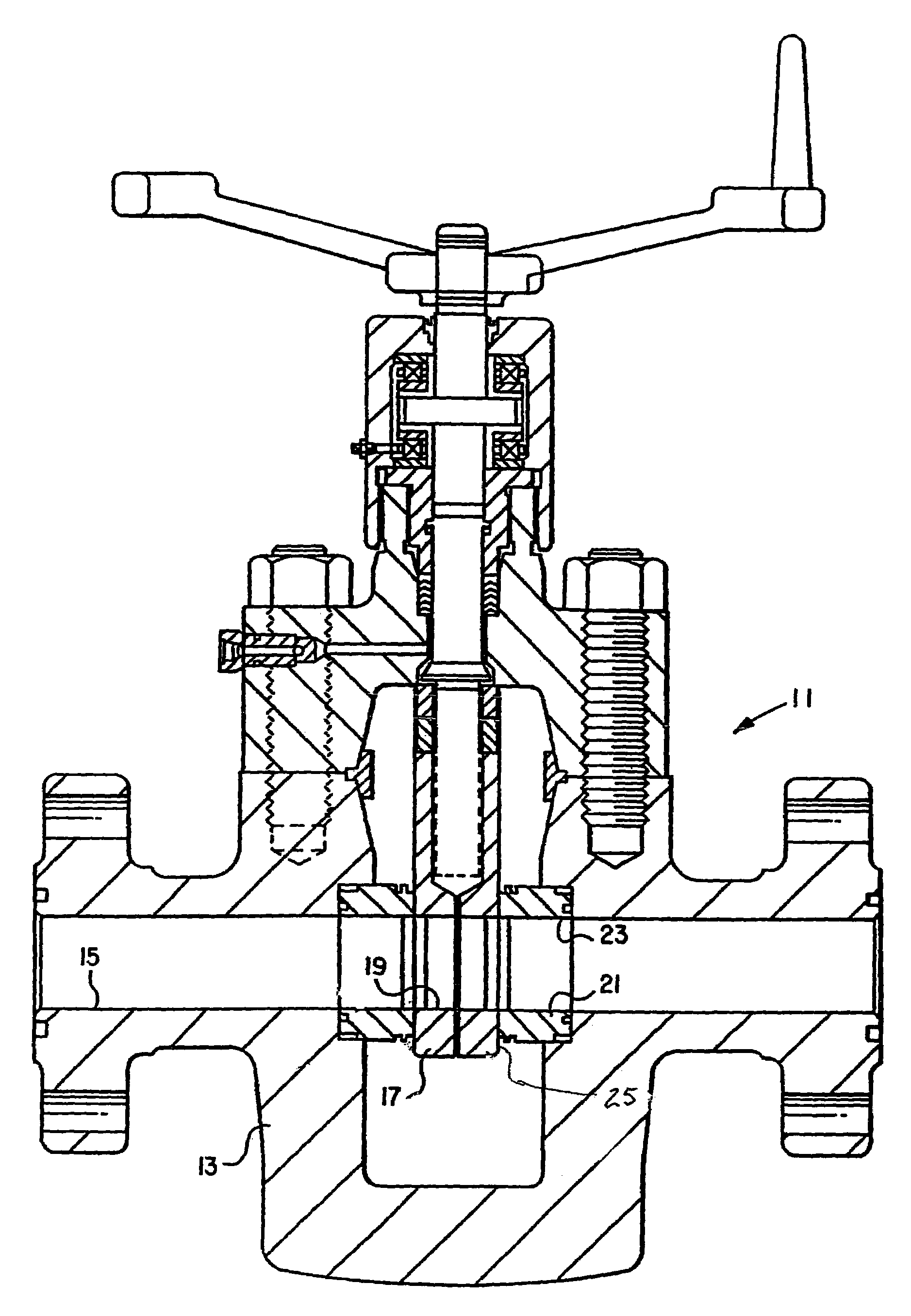

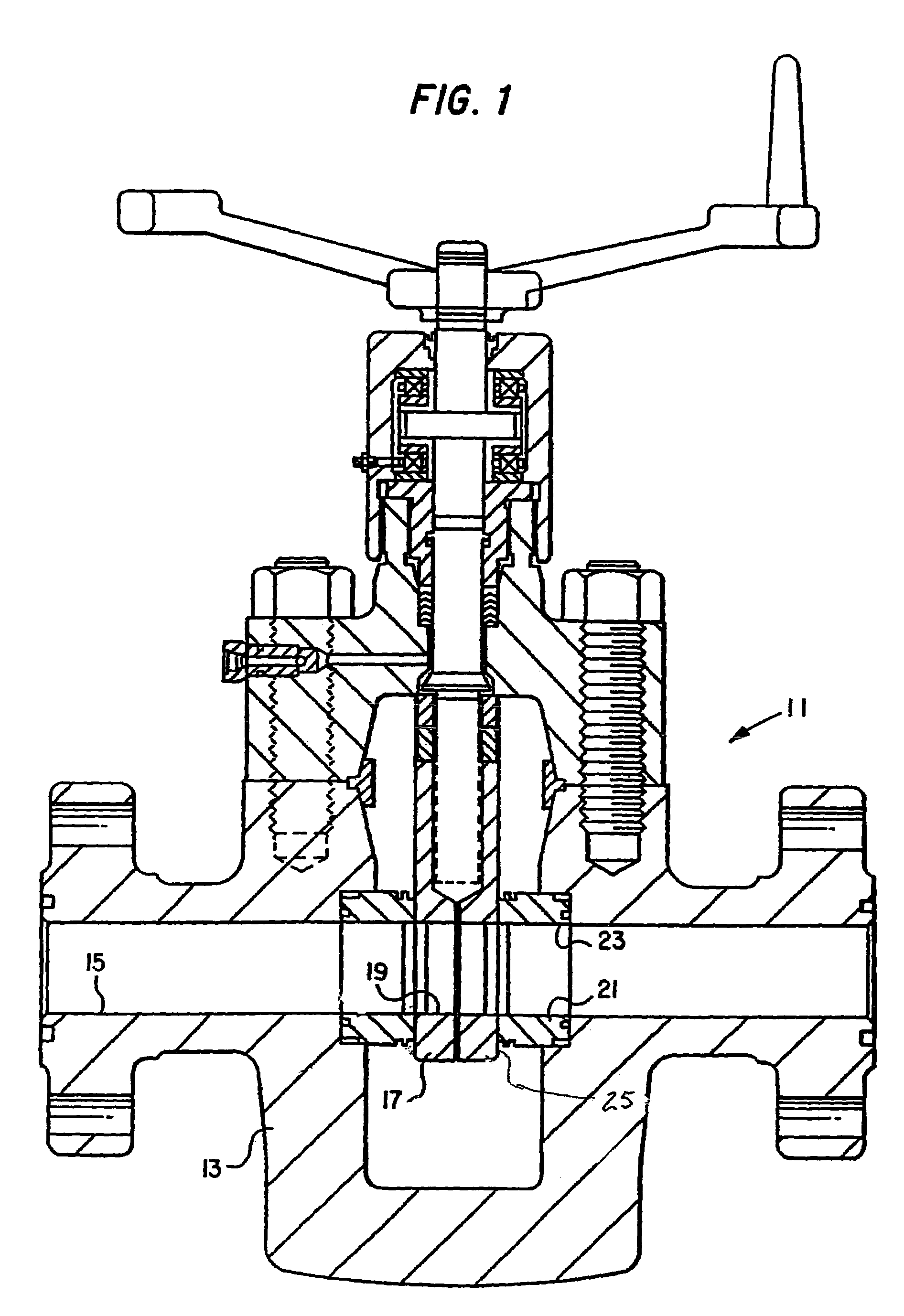

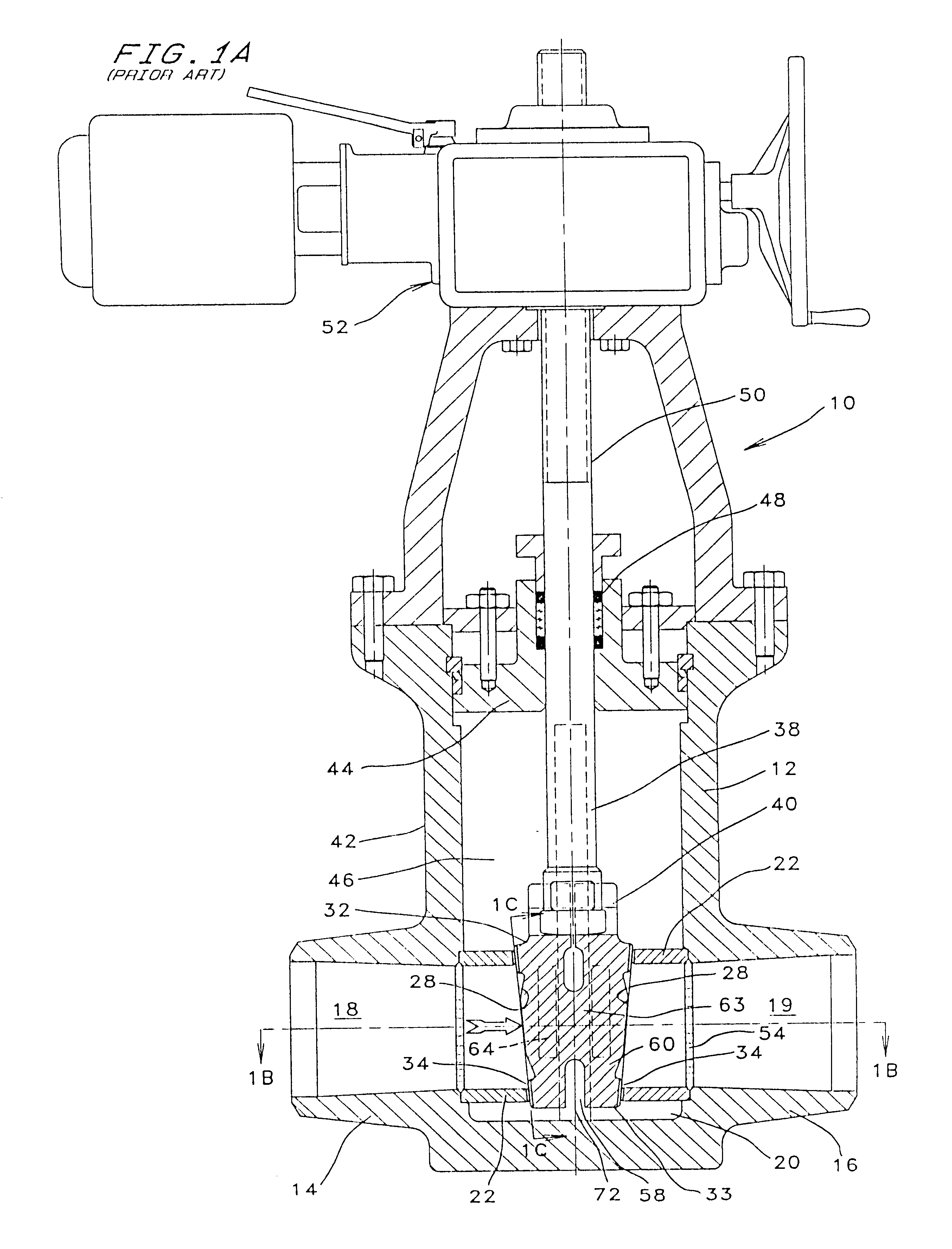

Gate valve

ActiveUS7066443B2Improve reliabilityReduce the number of partsOperating means/releasing devices for valvesSlide valveEngineeringCam

A gate valve has a transfer chamber-side valve element and a process chamber-side valve element connected to a single shaft actuated with a single three-position air cylinder to selectively close a process chamber opening and a transfer chamber opening or fully open both the openings to allow an object to pass therethrough. A lever member is secured to the single shaft. A roller supported by the lever member is kept in engagement with a cam groove of a cam member. A cam support member for supporting the cam member is connected to the piston rod of the three-position air cylinder. A spring is interposed between the lever member and the cam support member. When the piston rod is in the first (lower extremity) position, both the transfer chamber-side valve element and the process chamber-side valve element fully open the transfer chamber opening and the process chamber opening, respectively. As the piston rod shifts from the first position to the second position, the roller shifts from engagement with an upper position of the cam groove to engagement with an intermediate position, causing the process chamber-side valve element to close the process chamber opening. As the piston rod shifts from the second position to the third (upper extremity) position, the roller shifts from the engagement with the intermediate position to engagement with a lower position of the cam groove, causing the transfer chamber-side valve element to close the transfer chamber opening.

Owner:SMC CORP

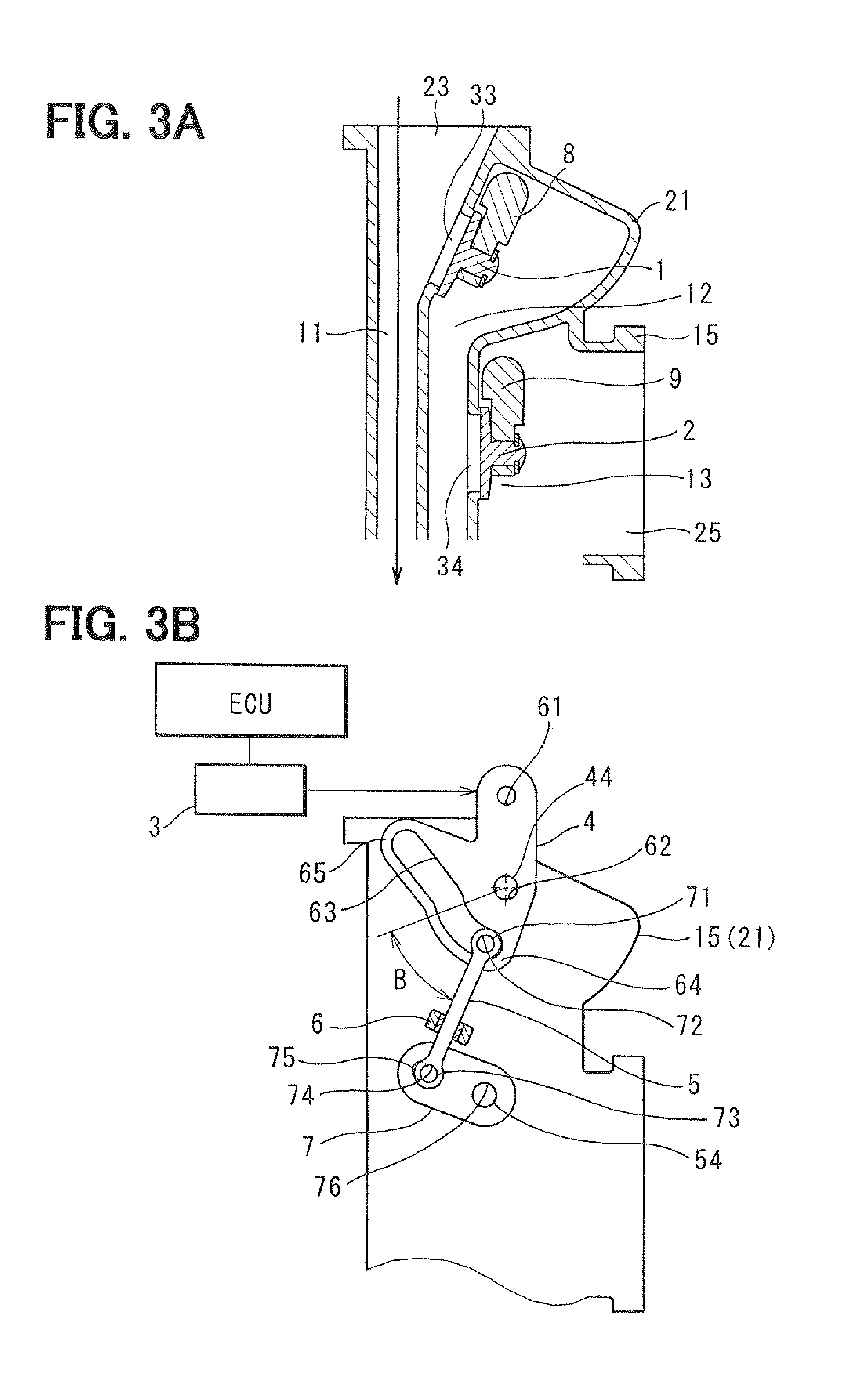

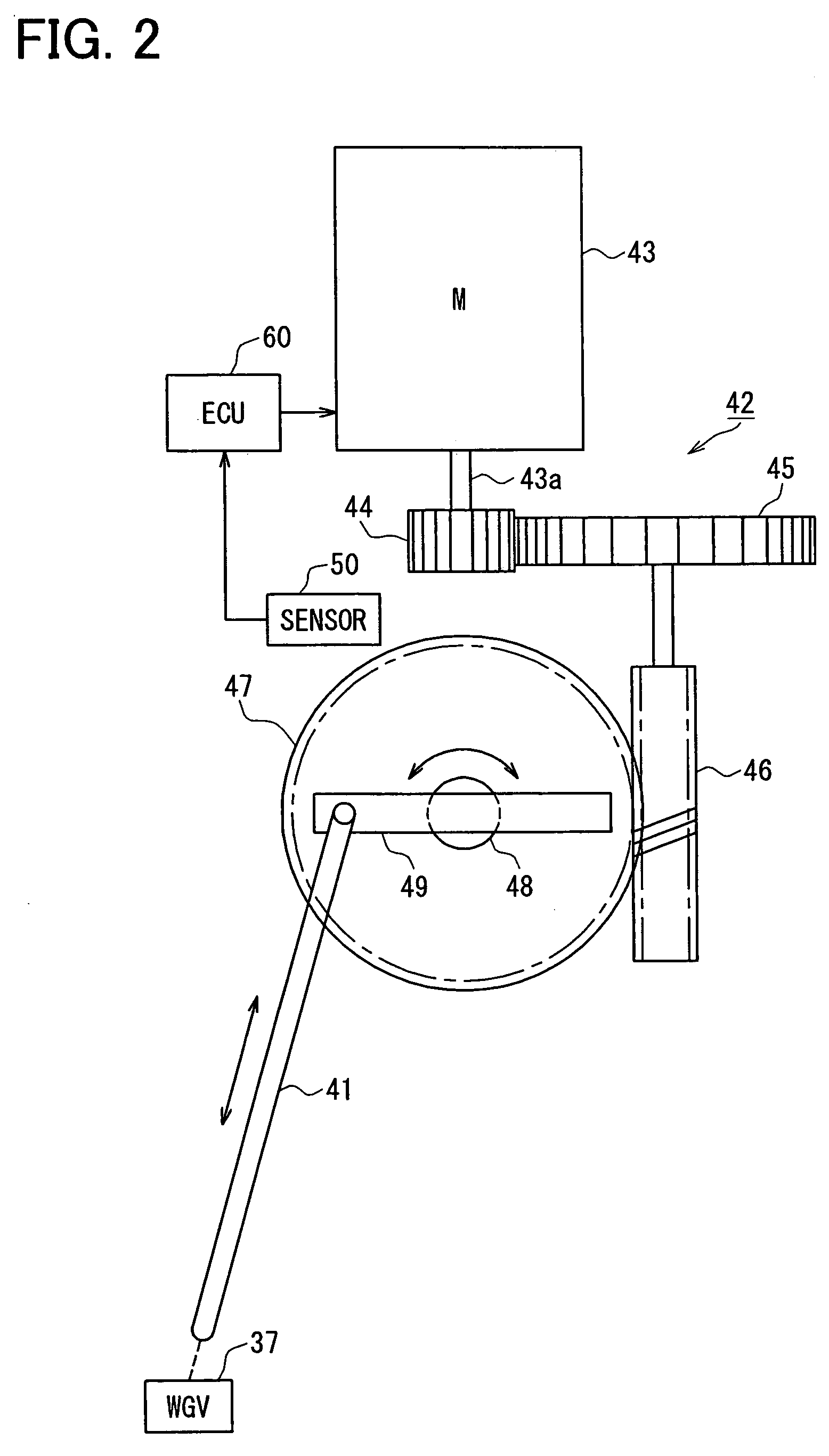

Exhaust gas control apparatus for engine

InactiveUS20120060494A1Easy to installReduce weightInternal combustion piston enginesEngine controllersEngineeringOperation mode

A flow rate control valve and a waste-gate valve are operatively linked to a common cam plate, which is driven by an actuator. The cam plate has a first driving portion for rotating the flow rate control valve in a synchronized manner with rotation of the cam plate. The cam plate has a second driving portion for rotating the waste-gate valve in accordance with the rotation of the cam plate, wherein an operational pattern for the waste-gate valve is different from that for the flow rate control valve. As above, two valves are operated by one actuator so as to move independently from each other.

Owner:DENSO CORP

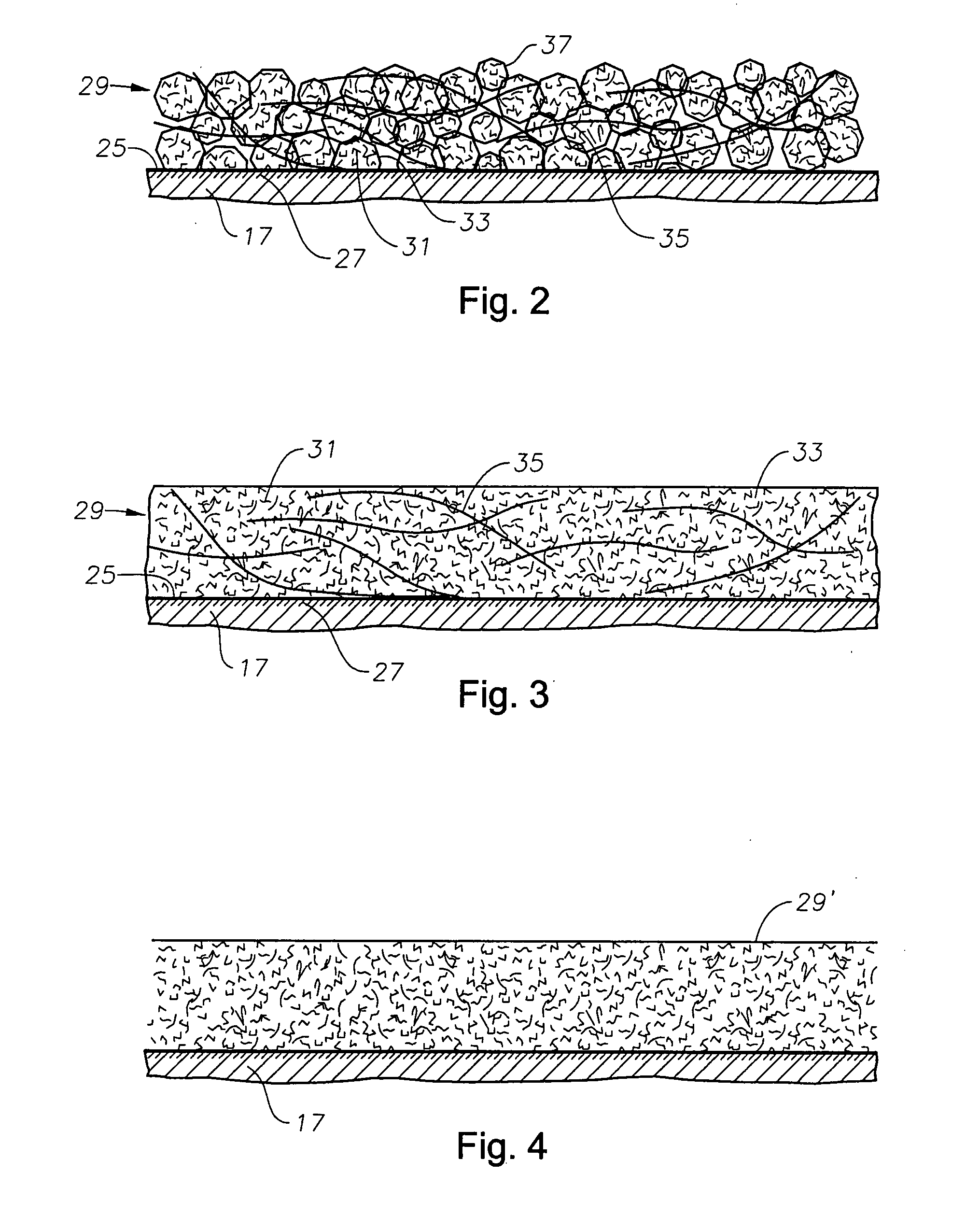

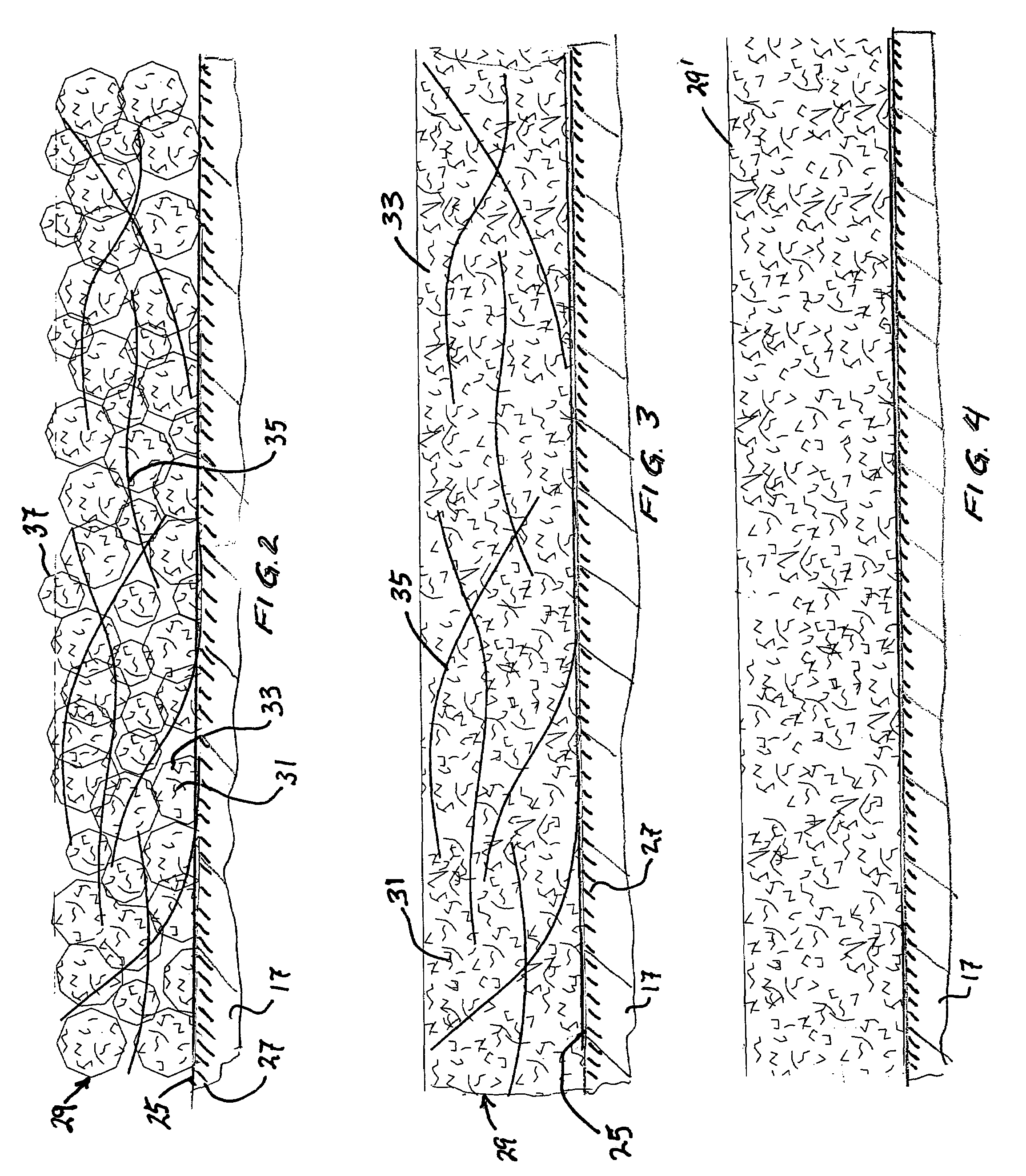

Low friction coatings for dynamically engaging load bearing surfaces

A gate valve has a body, the body having a cavity and a flow passage intersecting the cavity. A seat ring is mounted to the body at the intersection of the flow passage and the cavity, the seat ring having an engaging face. A gate in the cavity has an engaging face that slidingly engages the face of the seat ring while being moved between open and closed positions. A friction-resistant coating is on at least one of the faces.

Owner:VETCO GRAY LLC

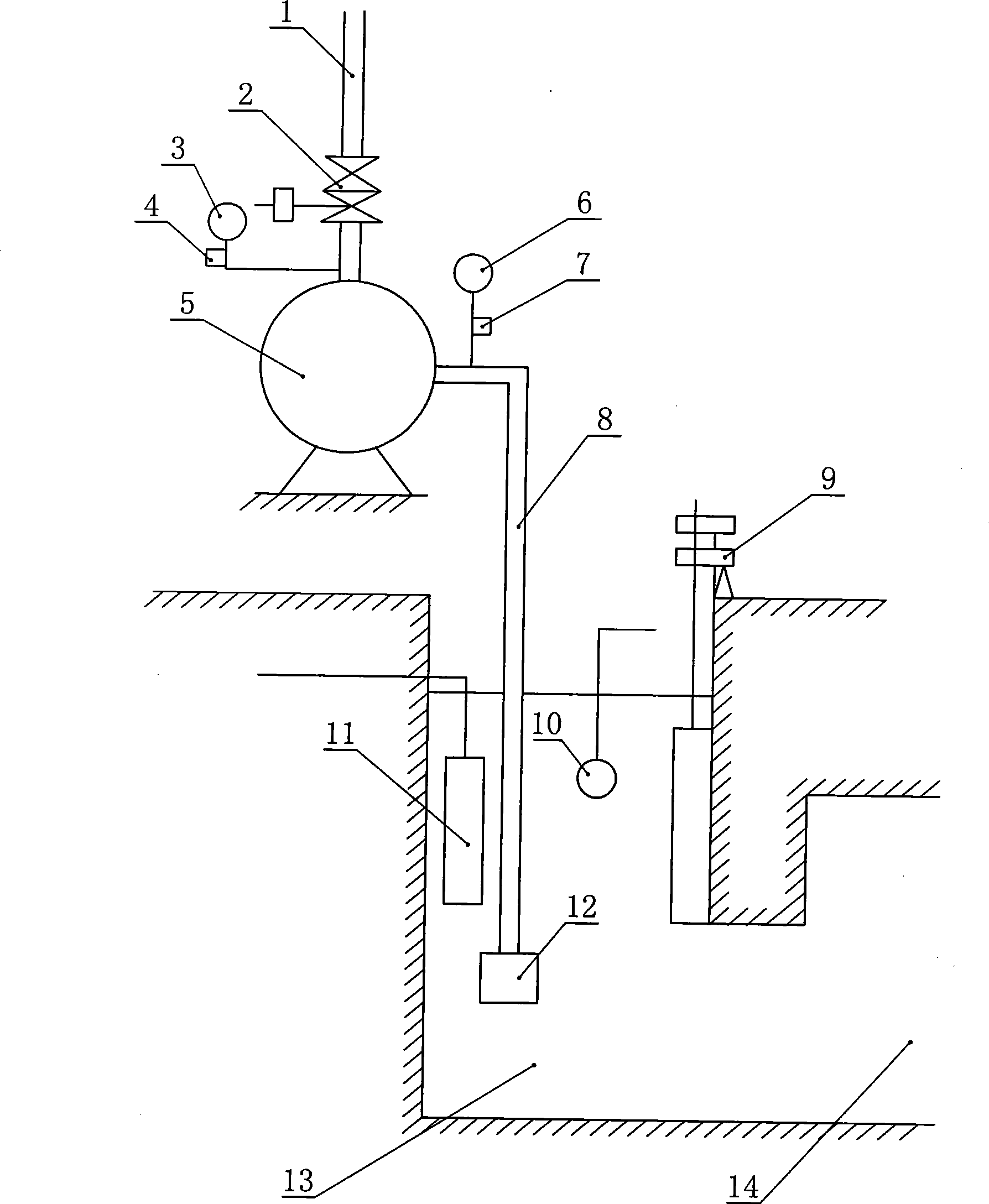

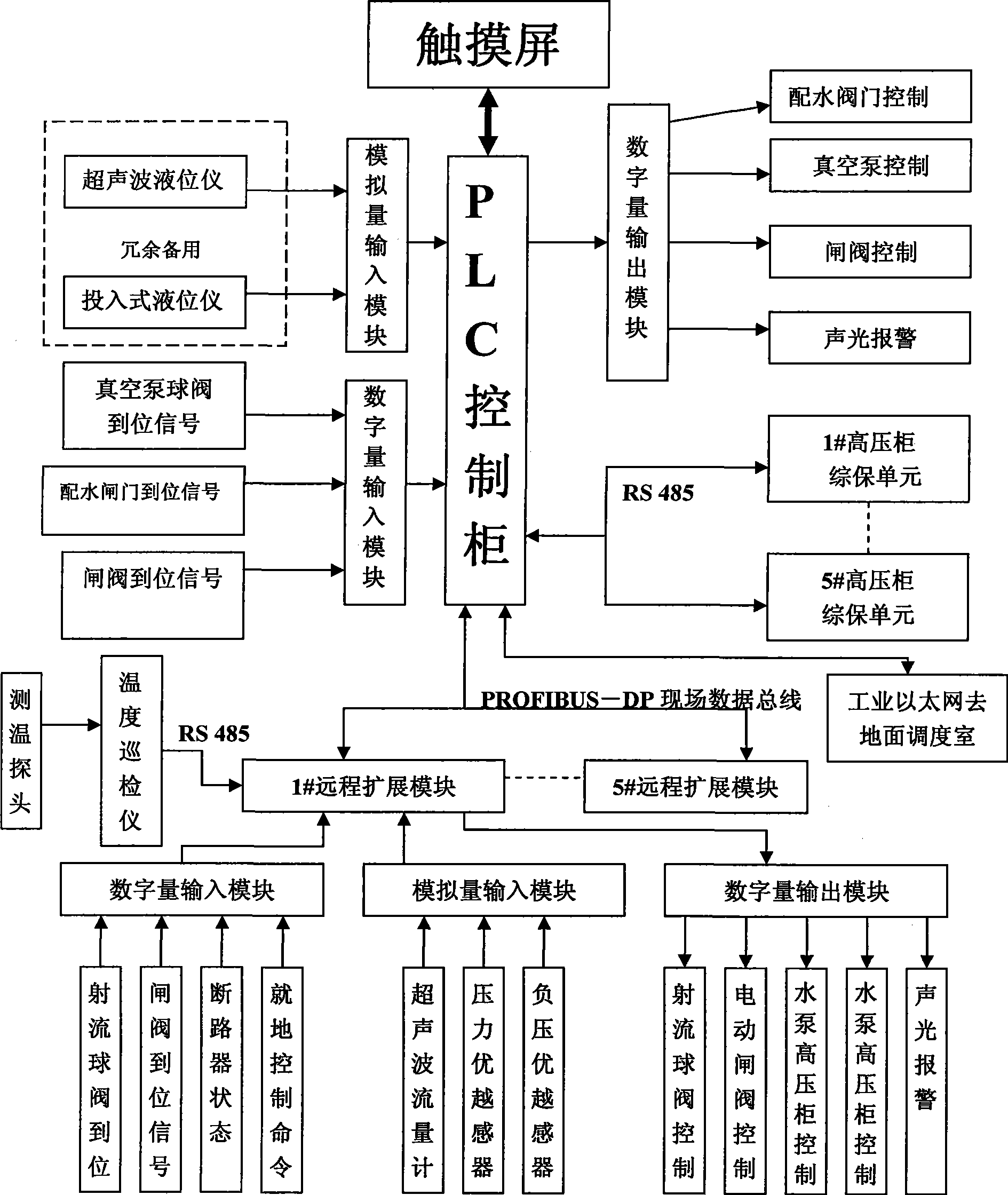

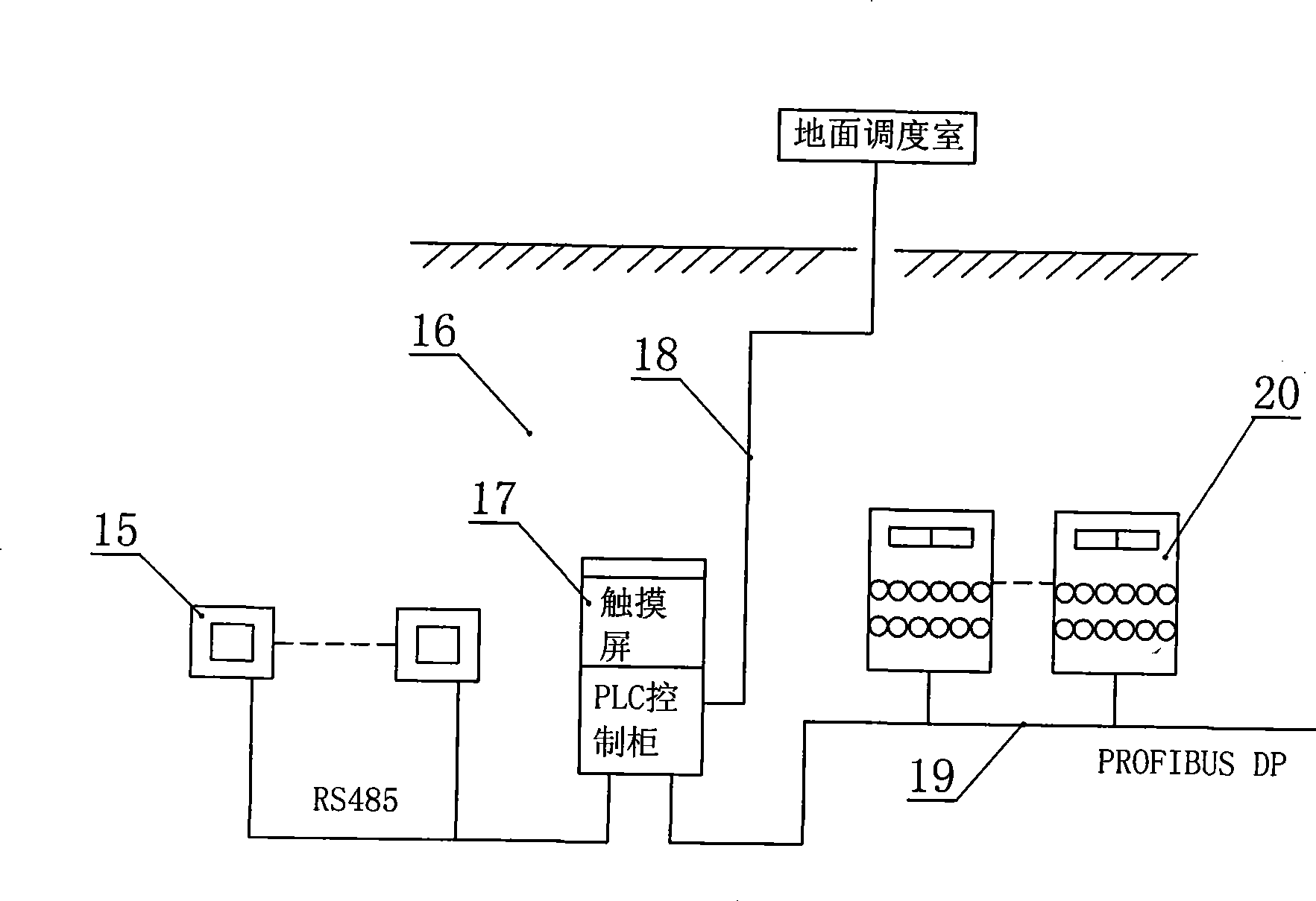

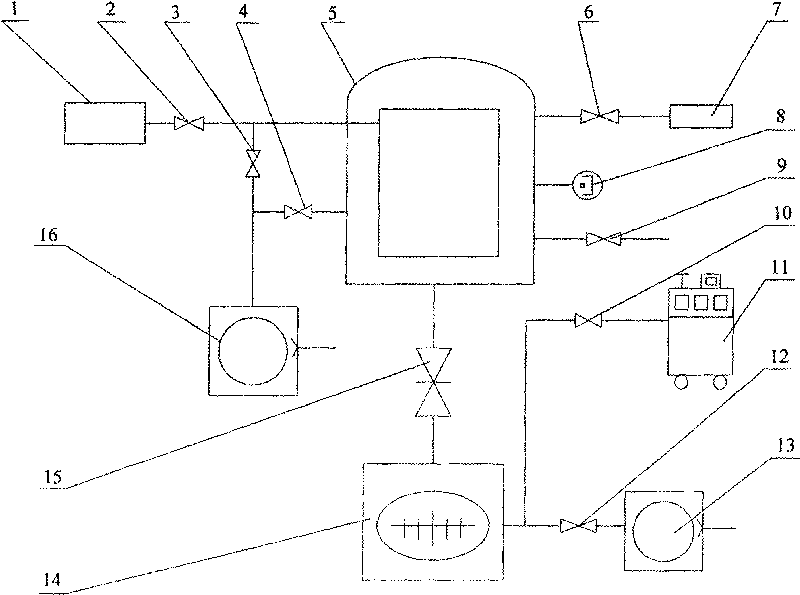

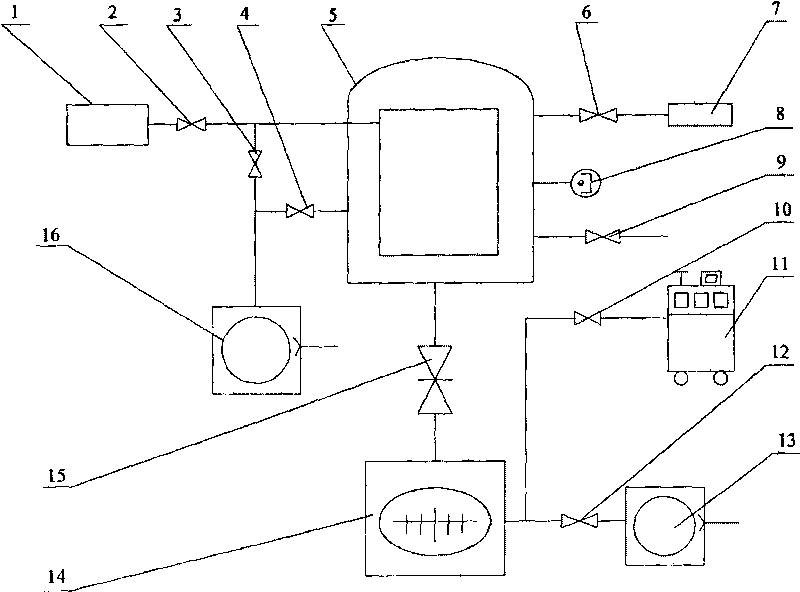

Automatic monitoring system for down-hole central pumping room drainage

The invention relates to an underground central pump room draining automatic monitoring system, which comprises a PLC control cabinet, a remote expanding module, a site data bus, a contact screen, an analog quantity and switching value input module, various monitoring probes, a travel switch, a level instrument and an executable section. A monitoring net adopts a form of combining a PROFIBUS DP site data bus and an industrial ethernet. A monitoring method for the system comprises: (1) monitoring the absorbing well water level; (2) monitoring the state for starting a high pressure switching cabinet by a water pump; (3) judging the valve levels of a gate valve, a ball valve of a water jet pumping device and a water distribution gate; (4) judging the valve levels of a vacuum pump ball valve; (5) measuring each equipment temperature measuring point; (6) measuring signals of a pressure sensor and a negative pressure sensor; (7) judging system faults; (8) automatically controlling the start-stop and operation numbers of the water pumps according to the absorbing well water level conditions; and (9) setting power supply peak avoiding time periods, and automatically selecting starting time and numbers of a pump. The system improves the system working reliability, reduces the equipment fault rate, and adopts a three-stage monitoring structure for a draining system.

Owner:BINHU COAL MINE ZAOZHUANG MINING GRP

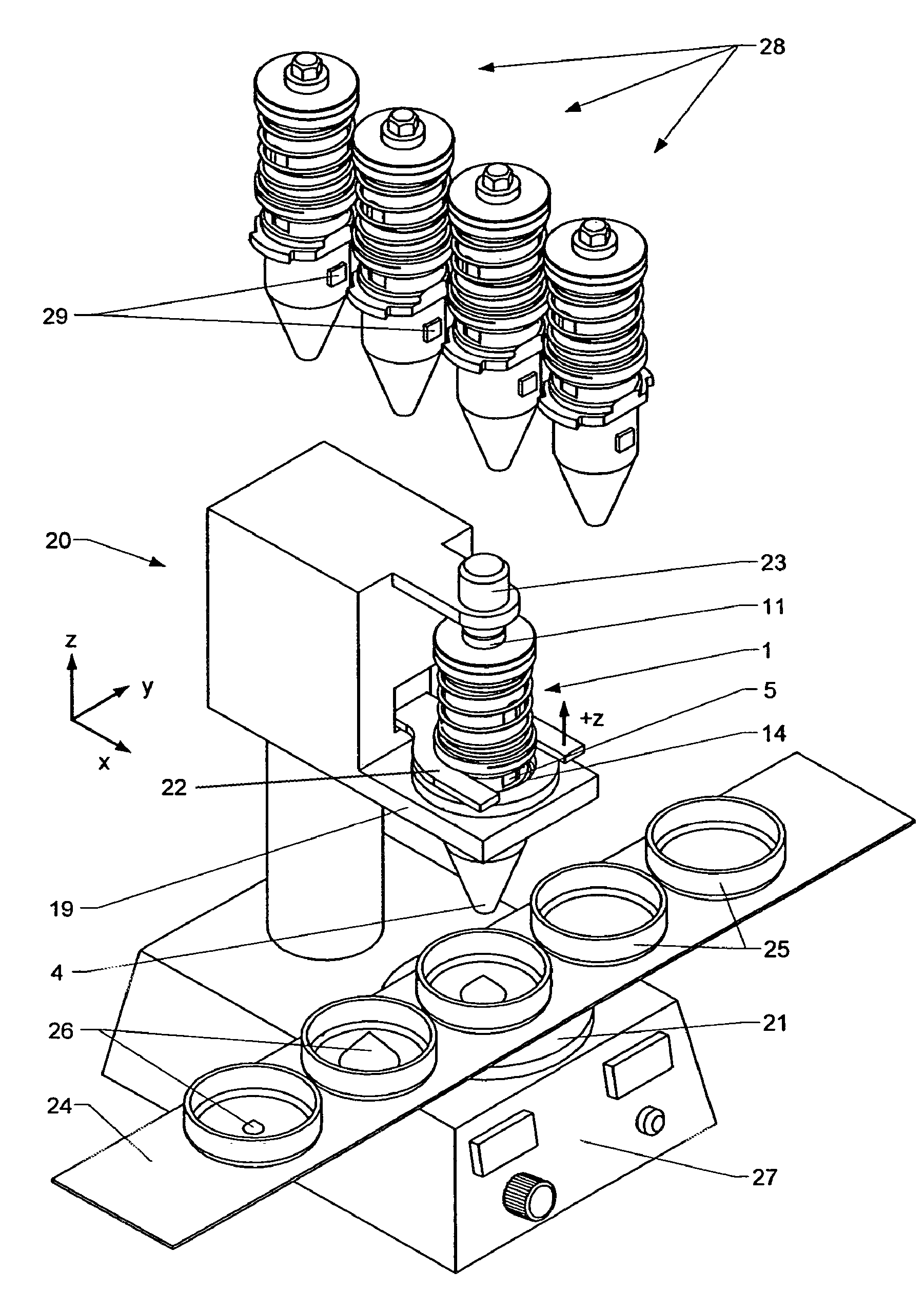

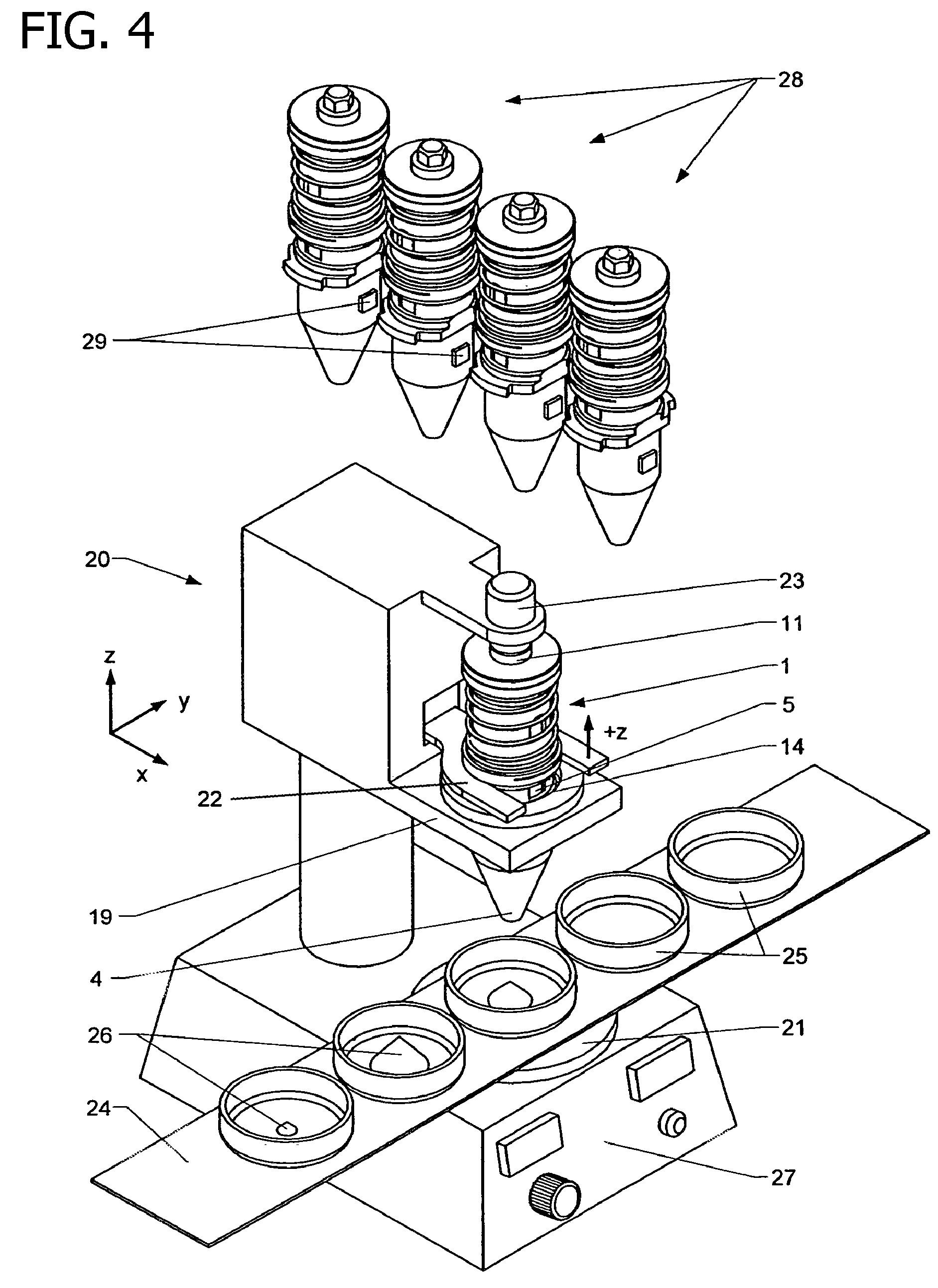

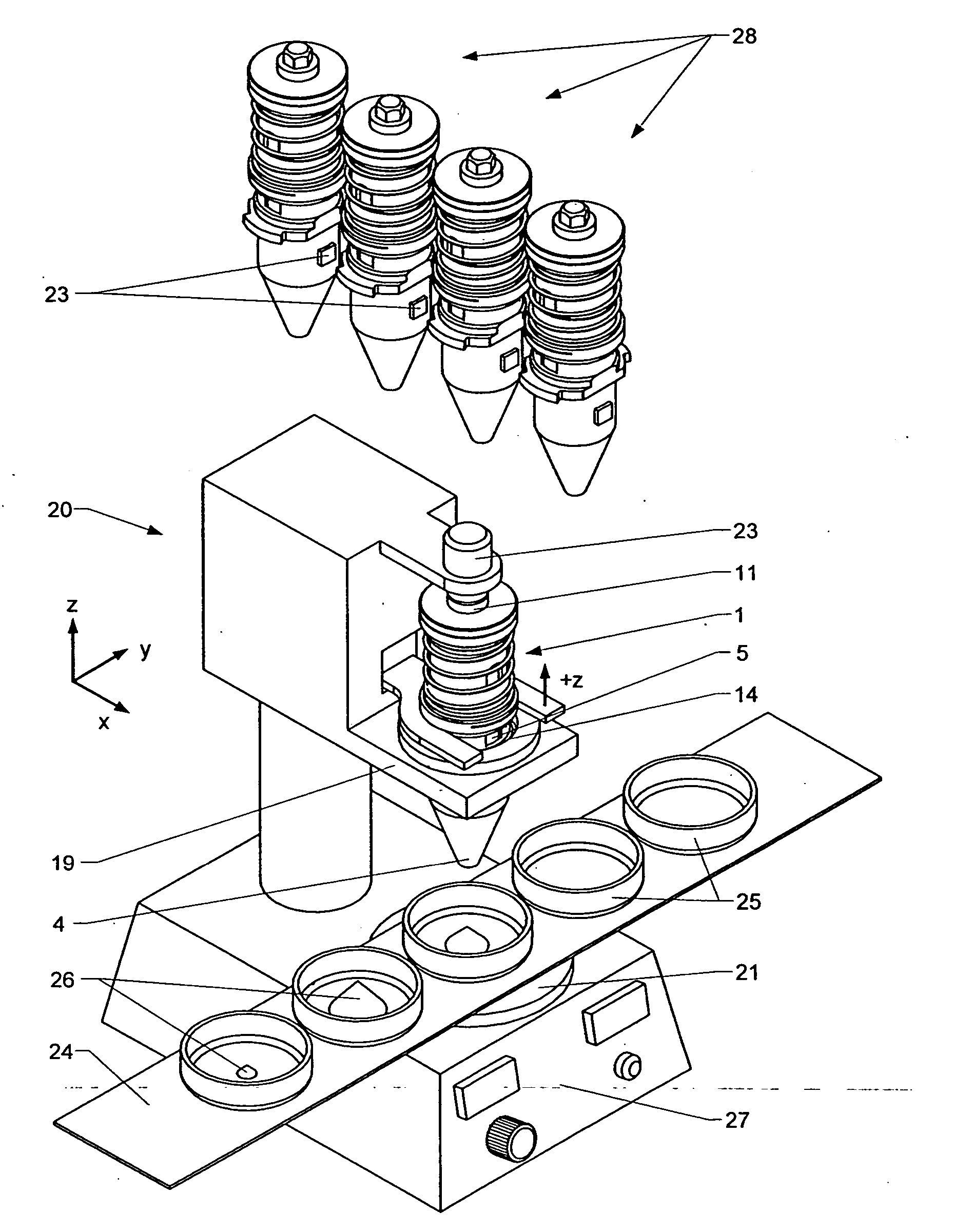

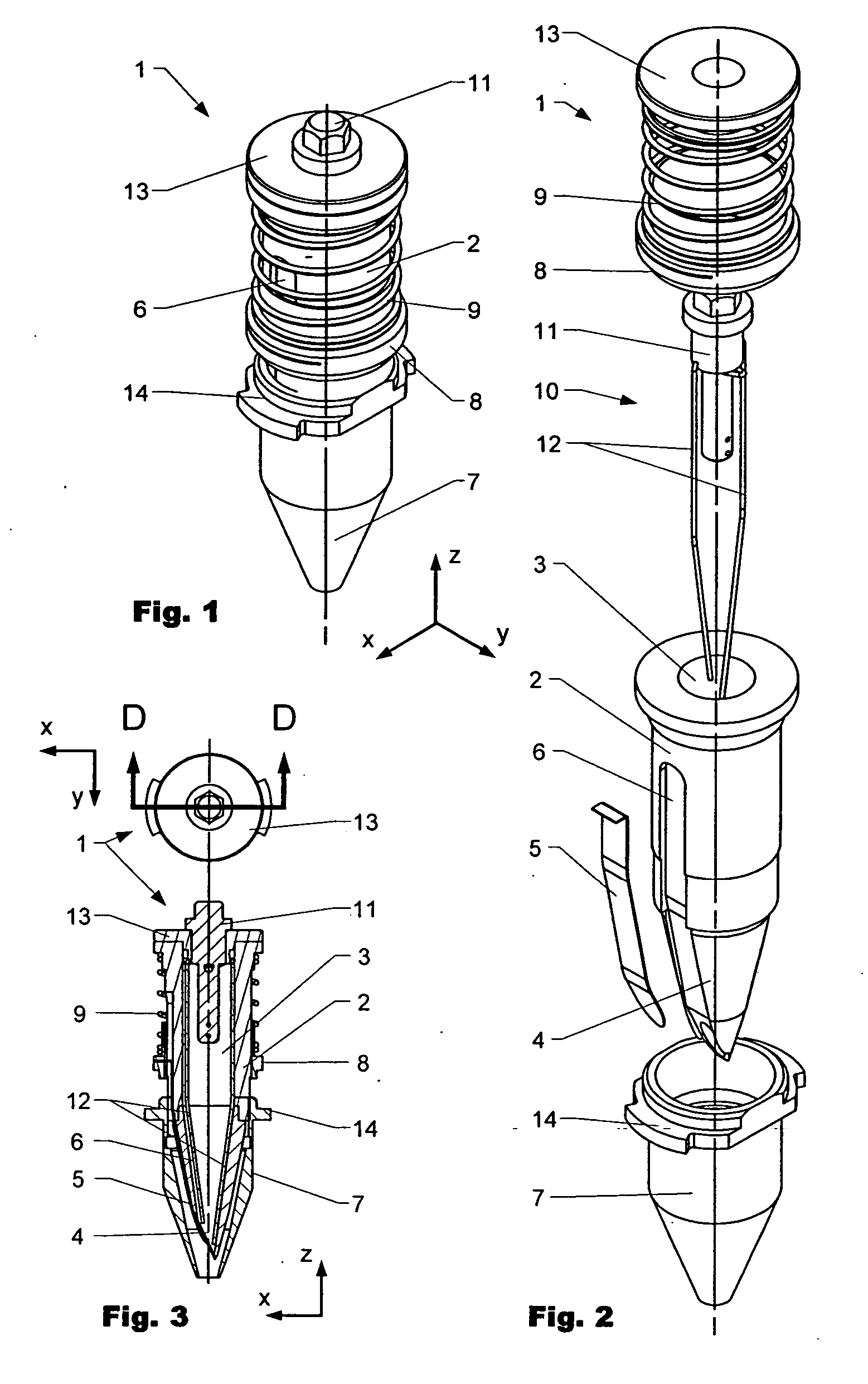

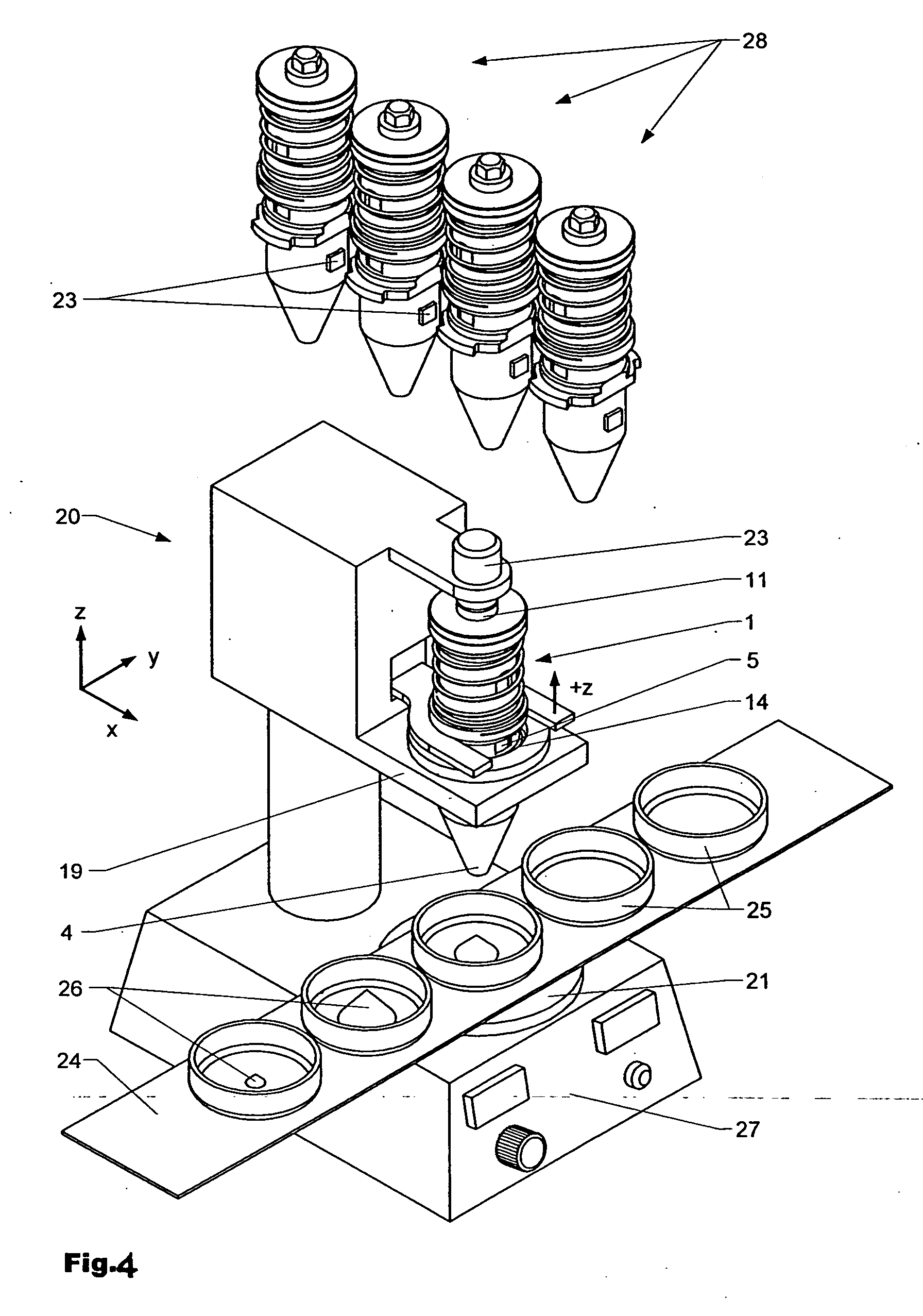

Apparatus and methods for storing and dispensing solid material

InactiveUS7614429B2Easy to fillEasy to emptyLarge containersLaboratory glasswaresGate valveControl unit

The invention is directed to a dispensing unit suitable to precisely dispense material in powdery and / or granular form. The dispensing device comprises an gate valve opening sealingly closed by a blend. A control unit, which is interconnected to a scaling device, controls the opening of the gate valve opening by the position of the blend. The precise amount of the material is adjusted in relation to the signal of the scaling device.

Owner:FREESLATE

Device and method for detecting leak rate of O type rubber sealing ring used for spaceflight

InactiveCN101726396AHigh detection sensitivityImprove detection efficiencyDetection of fluid at leakage pointEngineeringAtmospheric pressure

The invention discloses a device and a method for detecting the leak rate of an O type rubber sealing ring used for spaceflight, which belong to the technical field of the detection of spaceflight components. The device comprises gas storage equipment, an inflation valve, a first pre-pumping valve, a second pre-pumping valve, a leak detection tooling, a leak marking valve, a standard leak, a vacuum gauge, a deflation valve, a leak detection valve, a leak detector, a forestage angle valve, a prepump, a molecular pump, an ultrahigh vacuum gate valve and a vacuum booster pump. The method comprises the following steps of: firstly, pumping the pressure of a detection chamber and a dummy module below the air pressure of 10Pa, then pumping the detection chamber to a lower pressure by the molecular pump, forming a pressure difference between the detection chamber of the leak detection tooling and the dummy module and afterwards introducing high-purity gas with a standard atmosphere pressure into the dummy module. If a leak exists in a rubber sealing ring to be detected, the high-purity gas can enter the detection chamber by the sealing ring under the action of the pressure difference, and the leak rate of the sealing ring can be accurately calculated by the magnitude of the change of the output indication of the leak detector. The invention has the advantages of high detection sensitivity, high detection efficiency, reliable result and the like.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

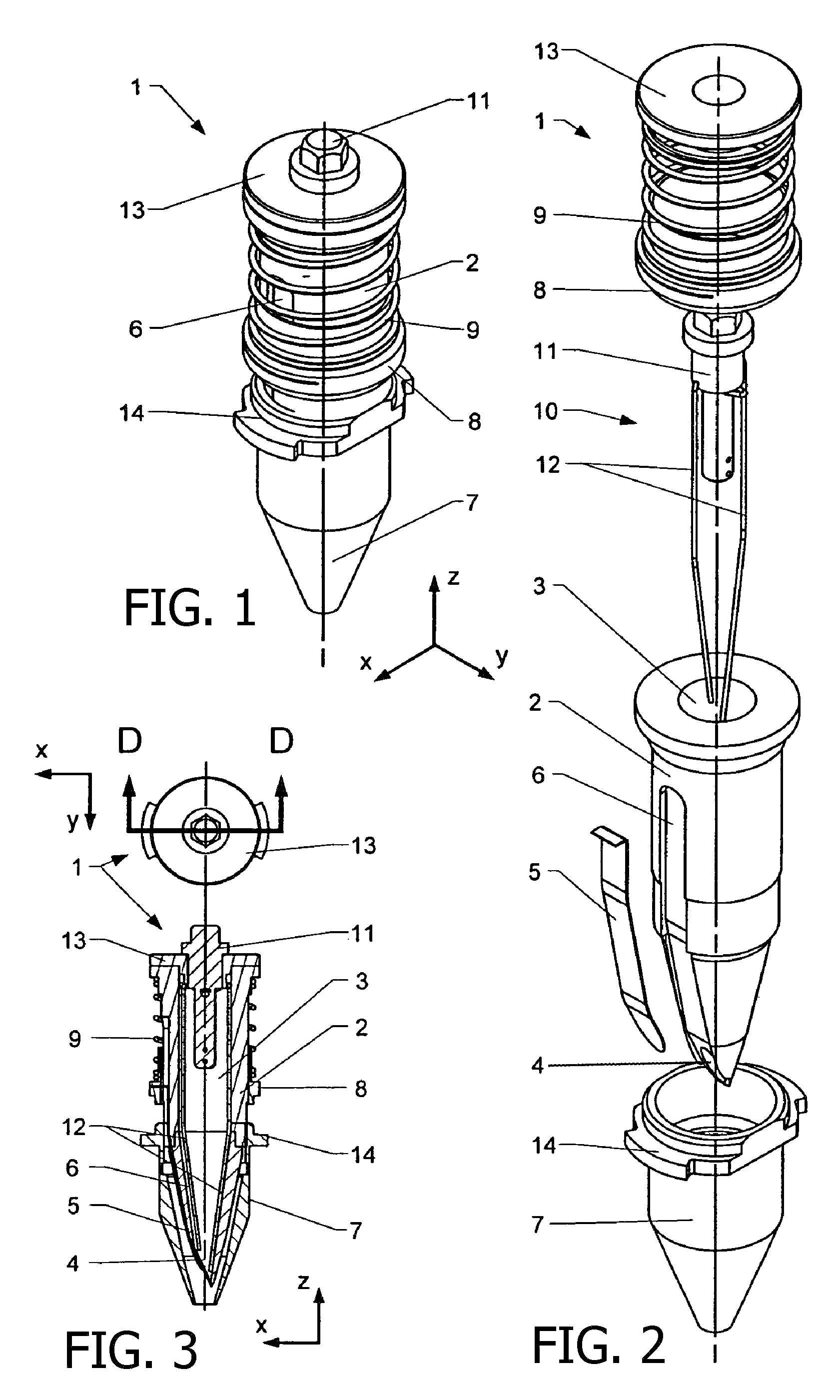

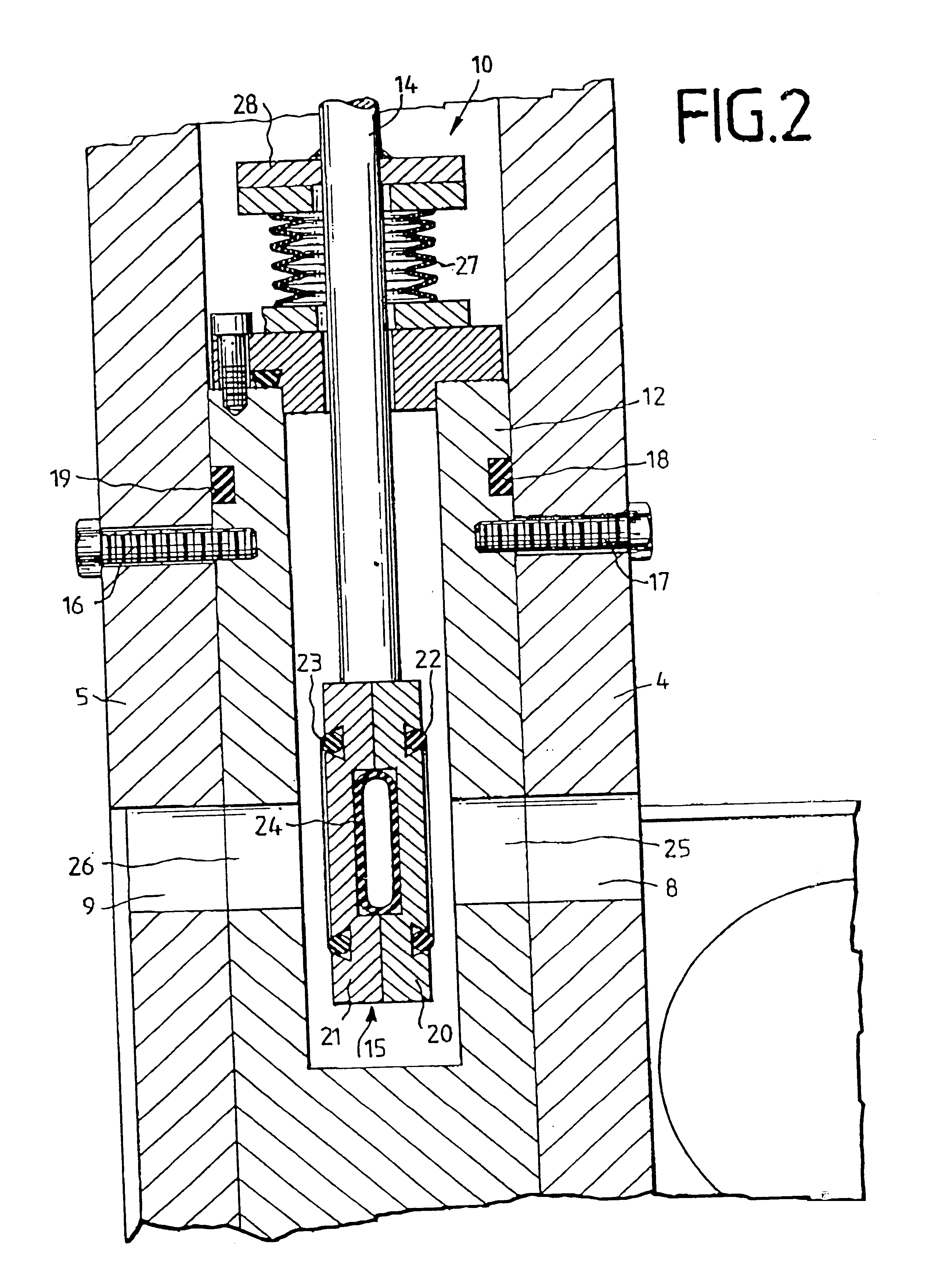

Vacuum gate valve

ActiveUS7134642B2Improve reliabilitySimple handling and maintenanceOperating means/releasing devices for valvesSlide valveGate valveValve seat

The invention provides a vacuum gate valve for closing off an opening. The vacuum gate valve can have a valve plate that can be turned so that the alignment of the valve plate will adapt to a valve seat when the valve plate is pressed against the valve seat.

Owner:VAT HLDG AG

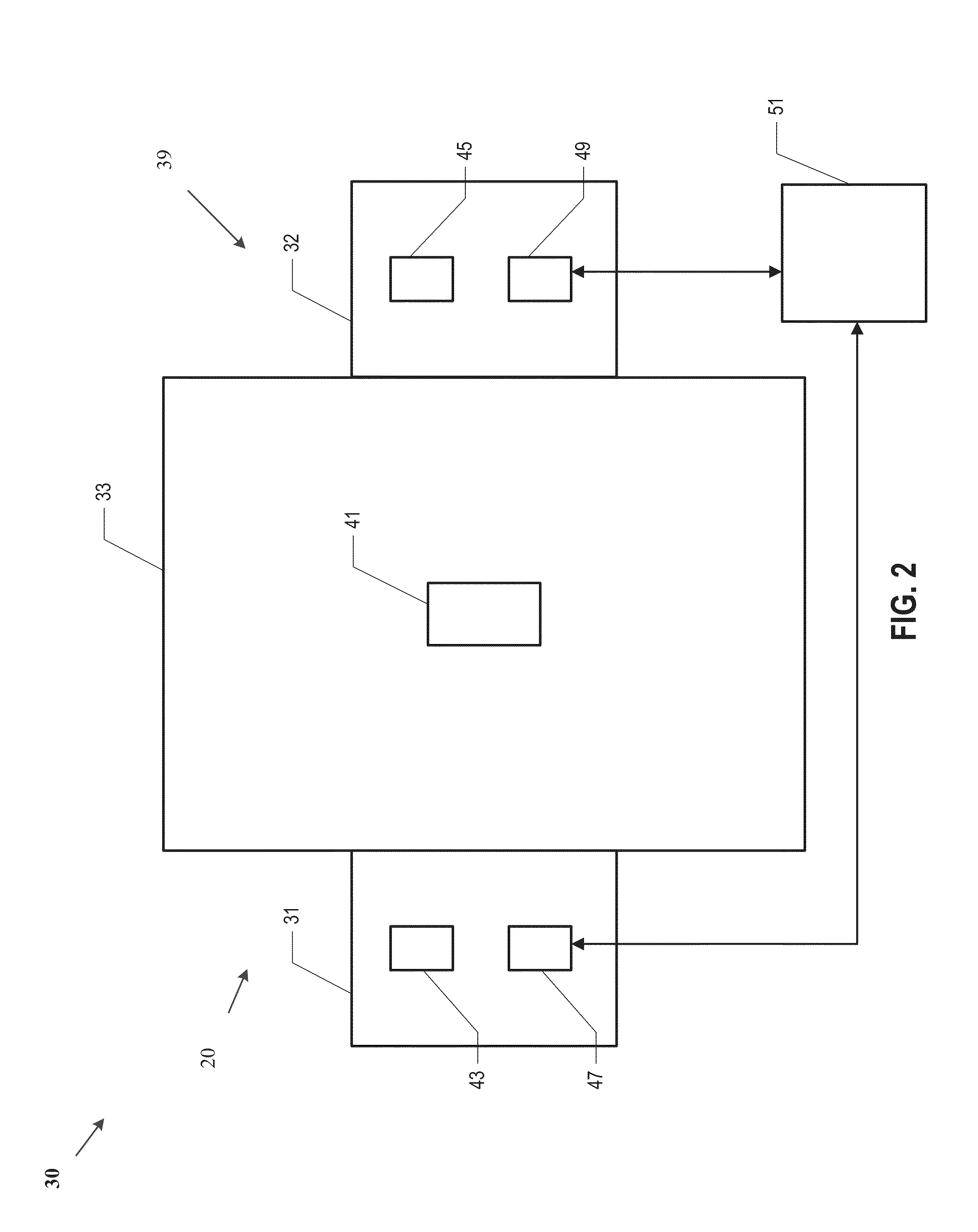

Gate Valve Real Time Health Monitoring System, Apparatus, Program Code and Related Methods

ActiveUS20140182381A1Eliminating and reducing downtimeEliminating and reducing and human interventionVibration measurement in solidsProgramme controlAcoustic emissionEngineering

Systems, apparatus, and program code, and methods for monitoring the health and other conditions of the valve, are provided. An exemplary system for monitoring the condition of the gate valve includes a logic module configured to perform the operations of receiving sensor data providing an acoustic emission, vibration, and / or stream level signature and determining the level of lubricity, level of friction, level of surface degradation, and leakage rate at a gate-valve seat interface. An exemplary method for monitoring the condition of the gate valve includes receiving sensor data providing an acoustic emission, vibration, and / or stream level signature and determining the level of lubricity, level of friction, level of surface degradation, and leakage rate at a gate-valve seat interface.

Owner:VETCO GRAY LLC

Apparatus and method for storing and dispensing material, especially in micro quantities and in combination with limited starting amounts

InactiveUS20070006942A1Improve accuracyMaximum flexibilityLarge containersLaboratory glasswaresGate valveControl unit

The invention is directed to a dispensing unit suitable to precisely dispense material in powdery and / or granular form. The dispensing device comprises an gate valve opening sealingly closed by a blend. A control unit, which is interconnected to a scaling device, controls the opening of the gate valve opening by the position of the blend. The precise amount of the material is adjusted in relation to the signal of the scaling device.

Owner:FREESLATE

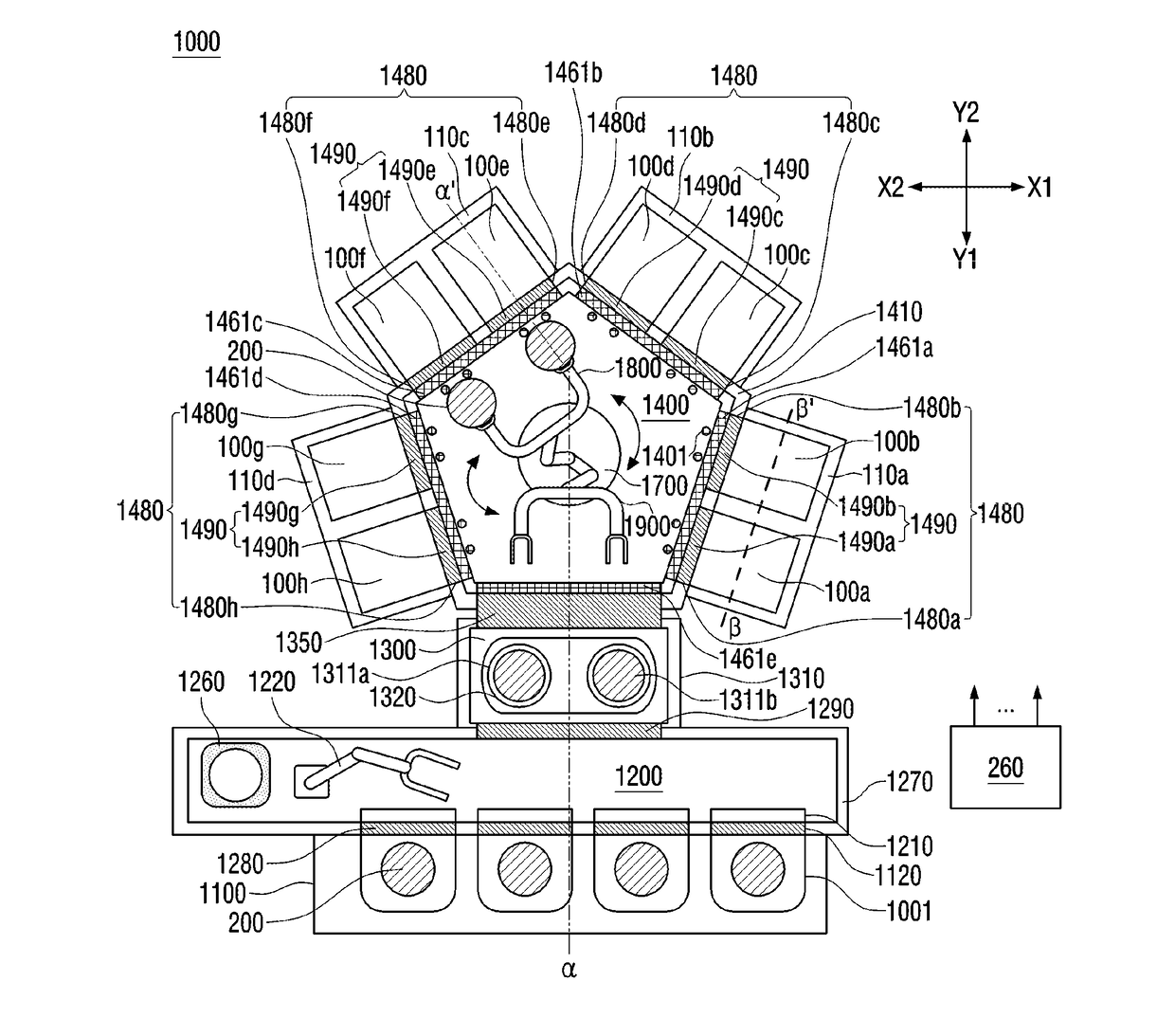

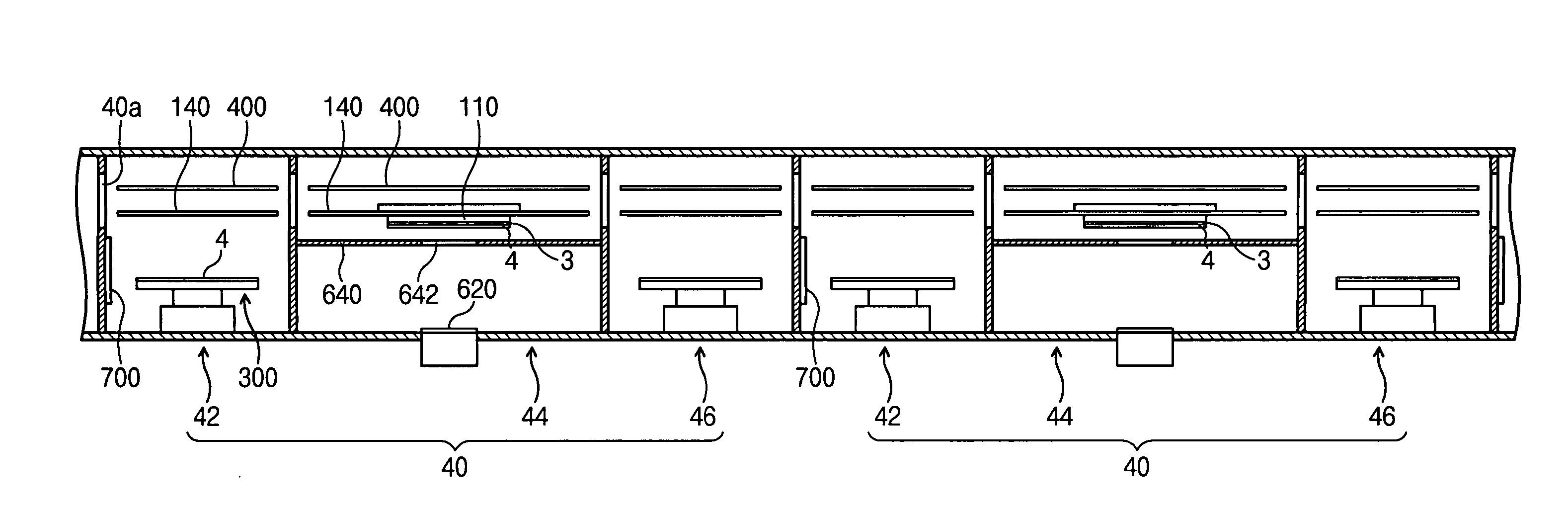

Apparatus for processing substrate

In a substrate processing apparatus for forming thin layers on a substrate used for an organic light emitting diode, the apparatus includes a mask attaching chamber, a deposition chamber and a mask detaching chamber. The mask attaching chamber, the deposition chamber and the mask detaching chamber are provided with a transferring guide installed thereinside, and a substrate supporter for supporting the substrate moves along the transferring guide in or between the chambers. Thus, a time for processing the substrate and an area for the apparatus may be reduced. Also, the chambers are grouped in one or more, and a gate valve is installed between the grouped chambers for opening and closing a path between the grouped chambers. Accordingly, the chambers may be continuously maintained in a vacuum state when any one of the chambers is repaired.

Owner:SEMES CO LTD

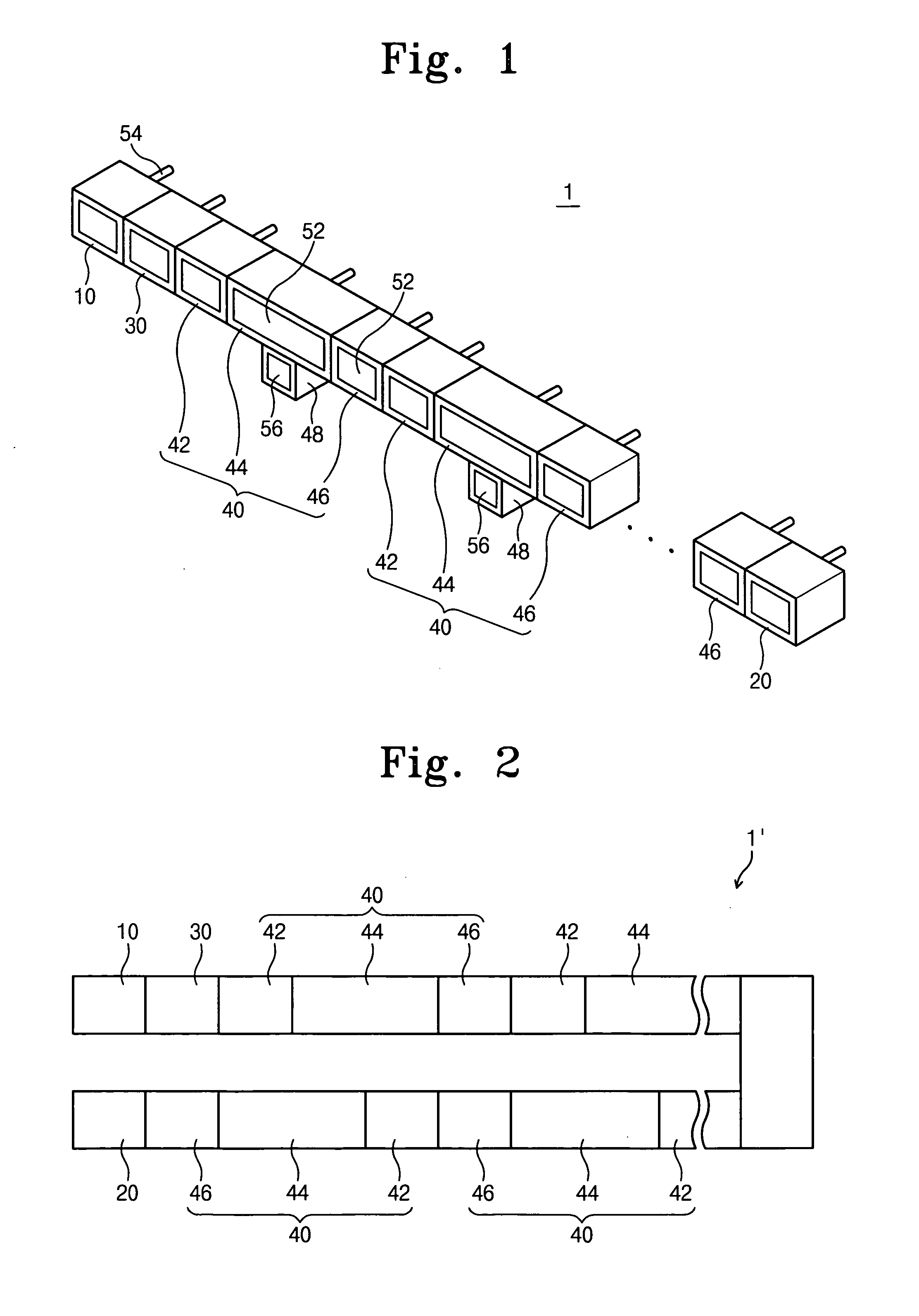

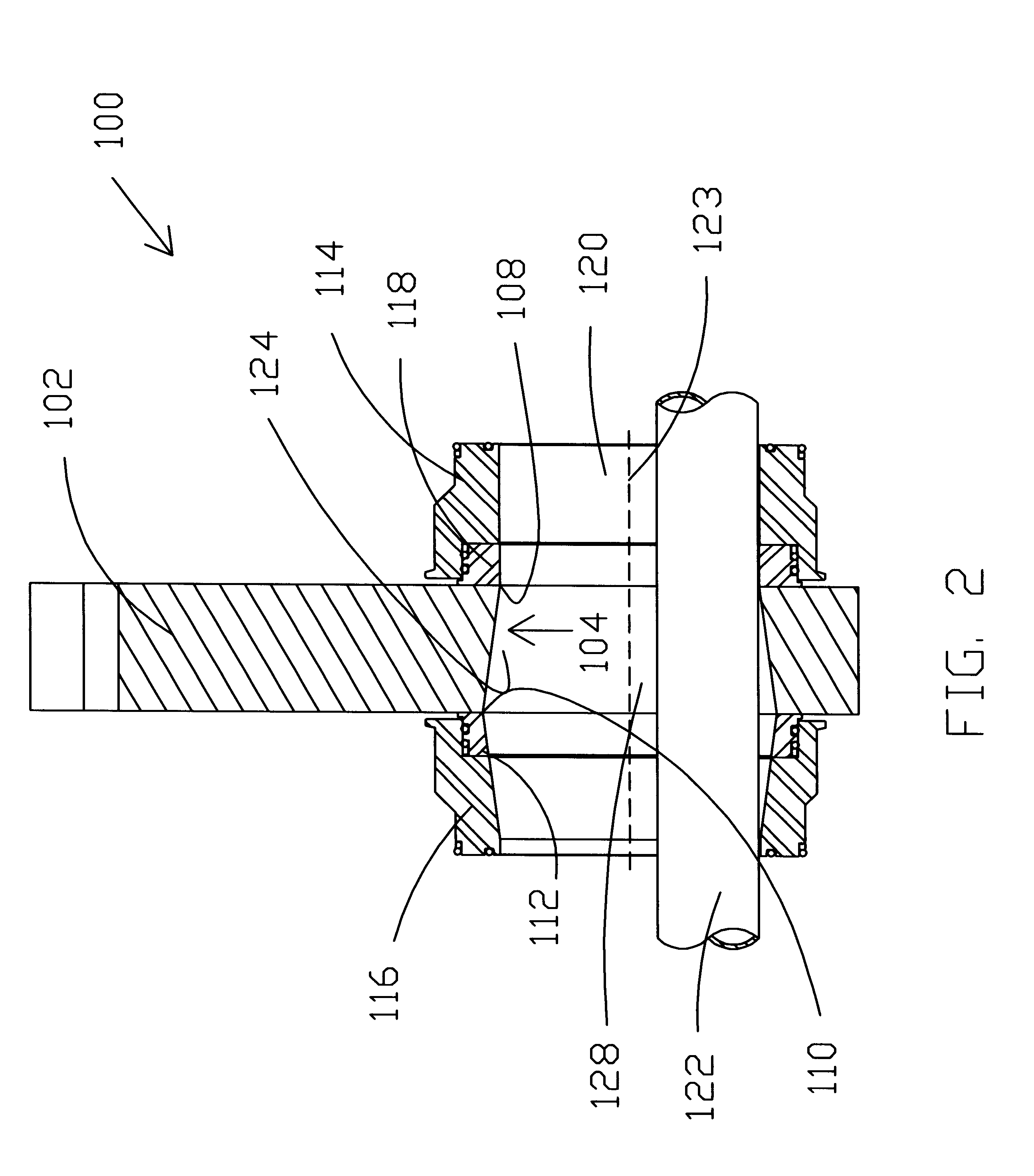

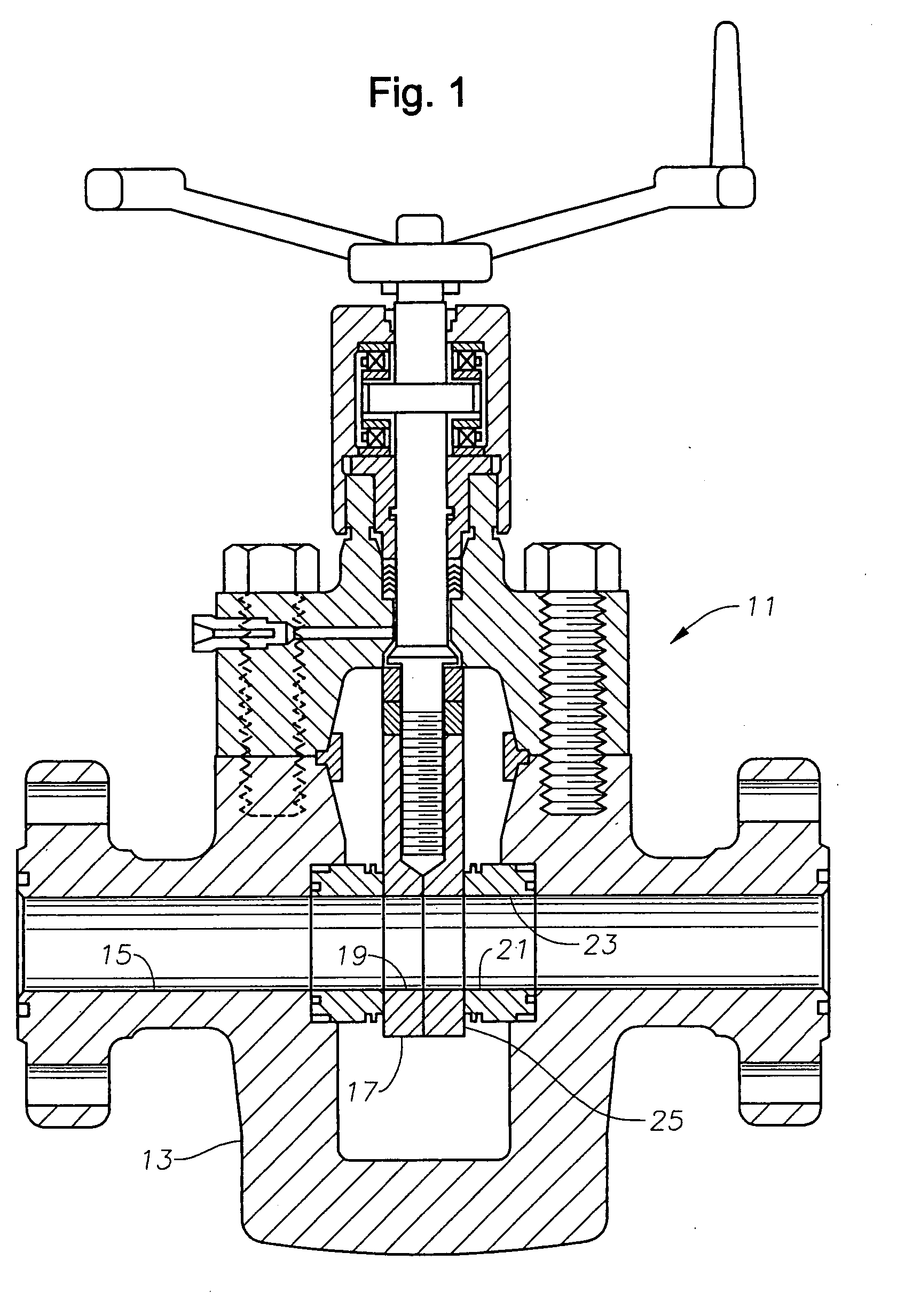

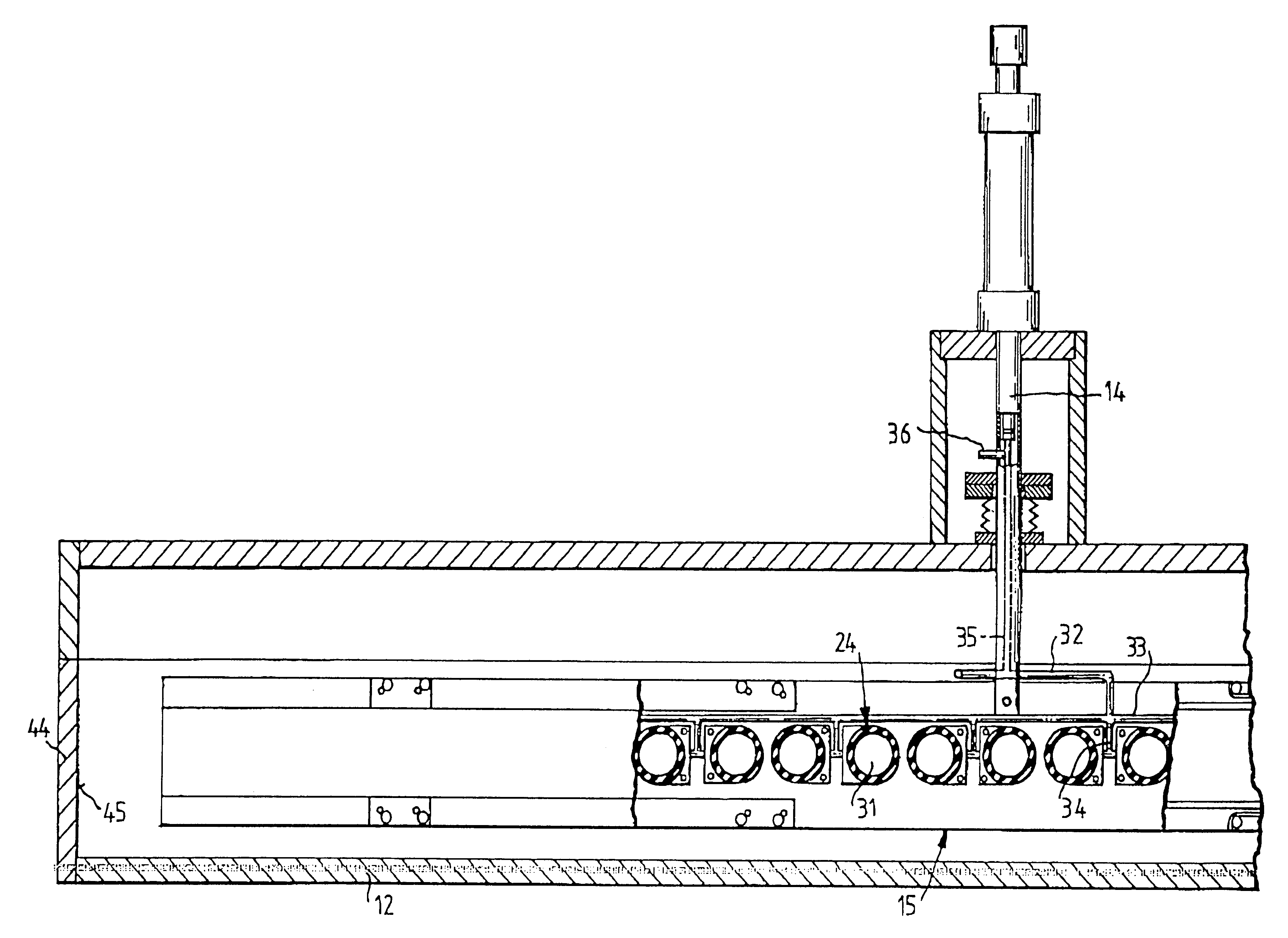

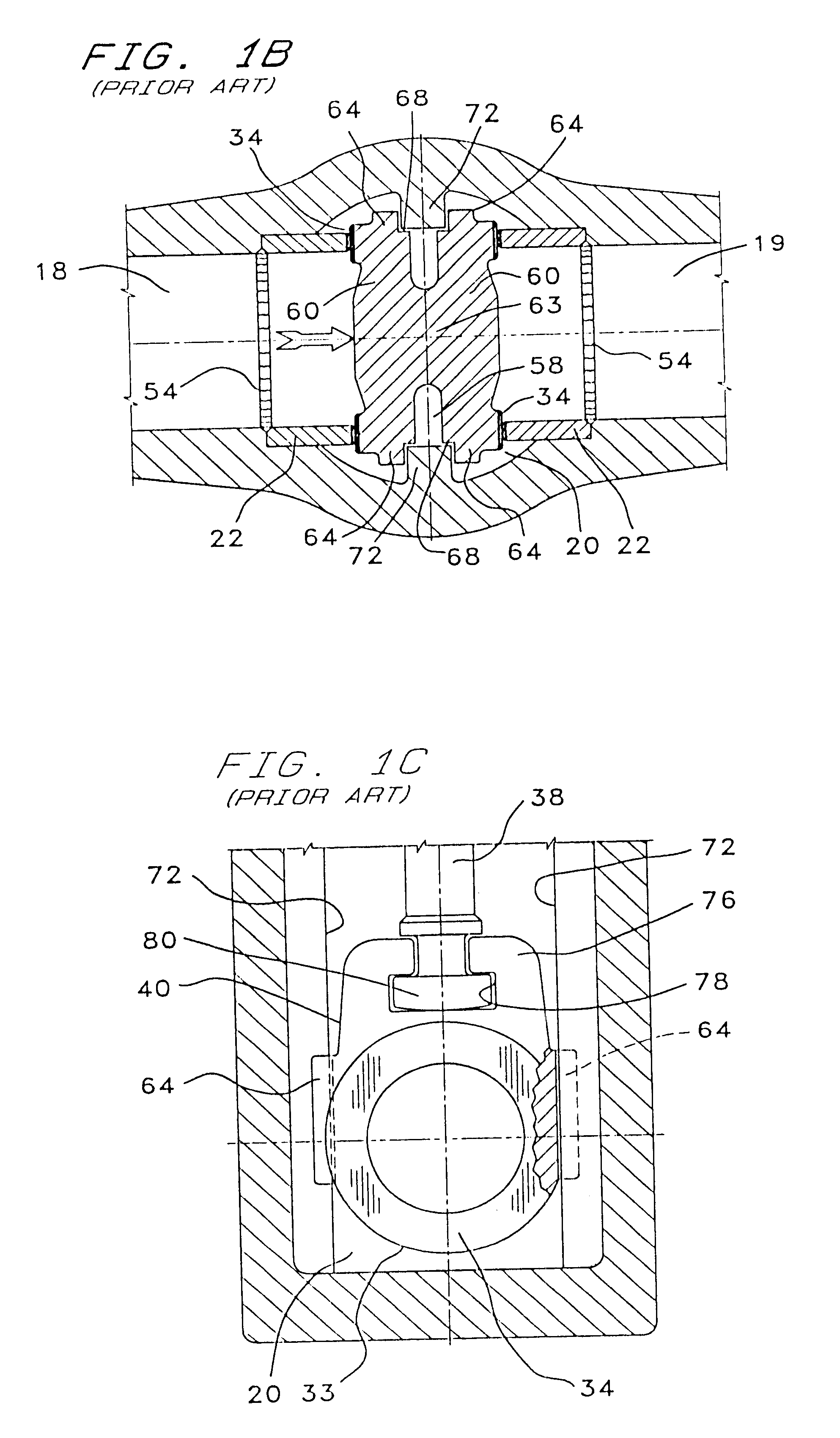

Gate valve

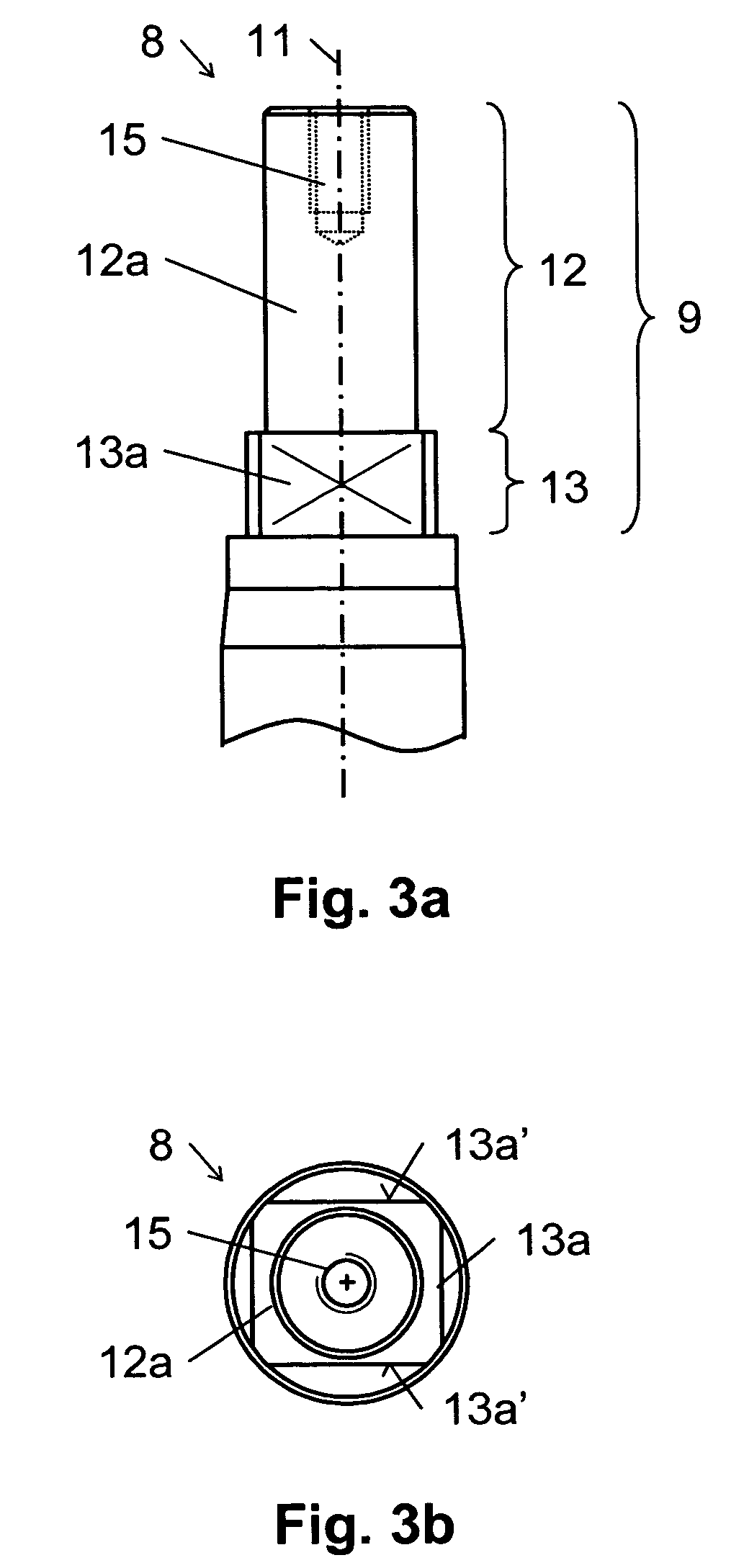

InactiveUS6302372B1Improve sealingTightnessOperating means/releasing devices for valvesVacuum evaporation coatingVacuum chamberVALVE PORT

A gate valve (1) is constructed for the simultaneous blocking or clearing of two rectangular passage openings (8,9) of two chamber walls (4,5) that are provided between two vacuum chambers (1,3) and aligned with one another. To this end, it has two valve plates (20, 21), which are a component of a slider (15), which is situated so that it can move with play from a position clearing the passage openings (8,9) to a position which closes the passage openings (8,9). To move the valve plates (20,21) to the closing setting against the passage openings (8,9) on the slider (15), at least one lifting element (24), which is acted on by pressure, is provided.

Owner:APPLIED MATERIALS GMBH & CO KG

Isolation valve with extended seal life

A gate valve assembly having a primary and secondary seating surface for preventing process fluids from contacting the seals of the valve is provided. Additionally, a purge gas inlet can be disposed in the valve body to prevent process gases from contacting the seals during operation. Still further, a primary and secondary barrier seal may be provided to prevent process gases from contacting the primary seal. Additionally, a purge gas inlet can be disposed between the primary and secondary seals to further prevent process gases from contacting the primary seal.

Owner:APPLIED MATERIALS INC

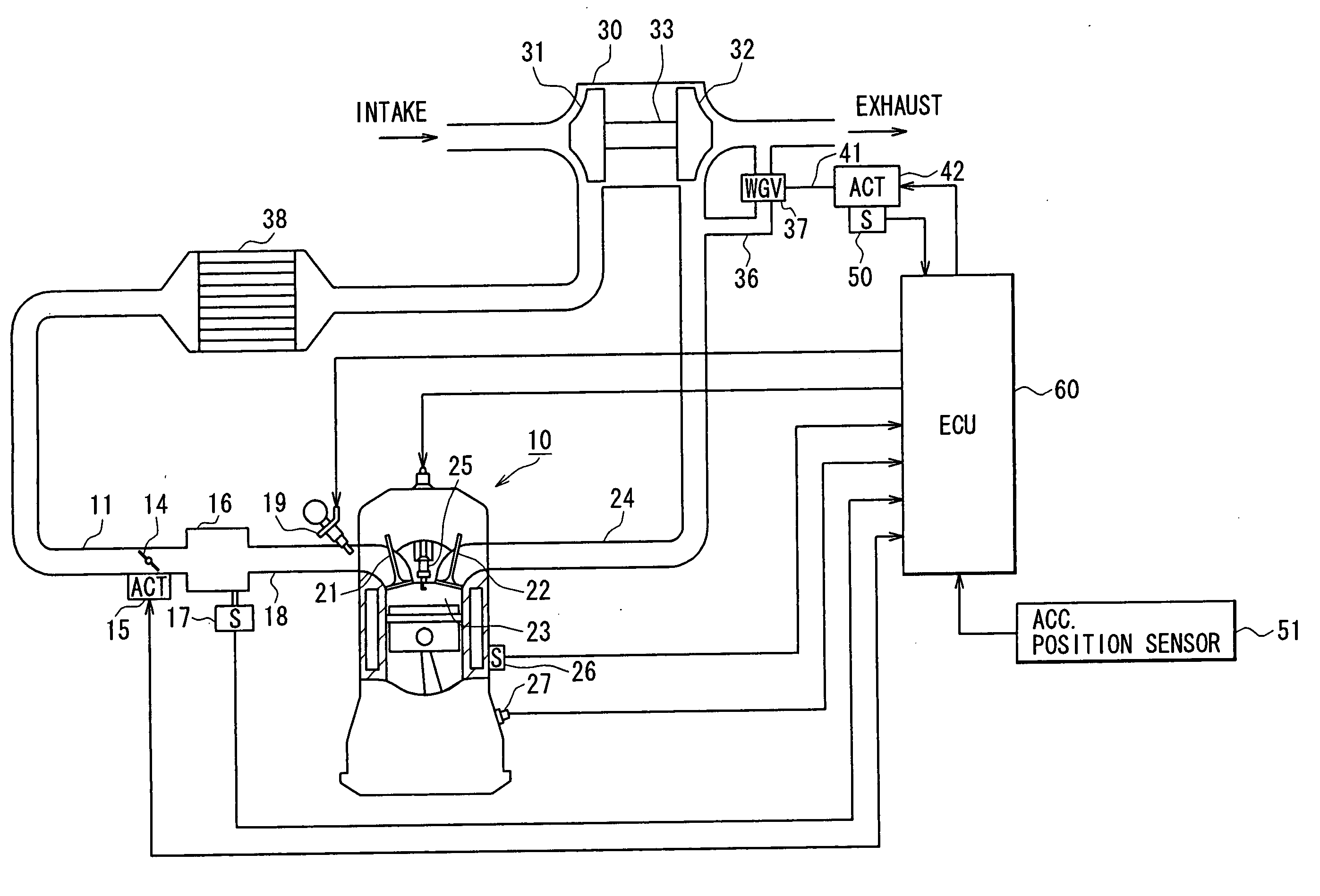

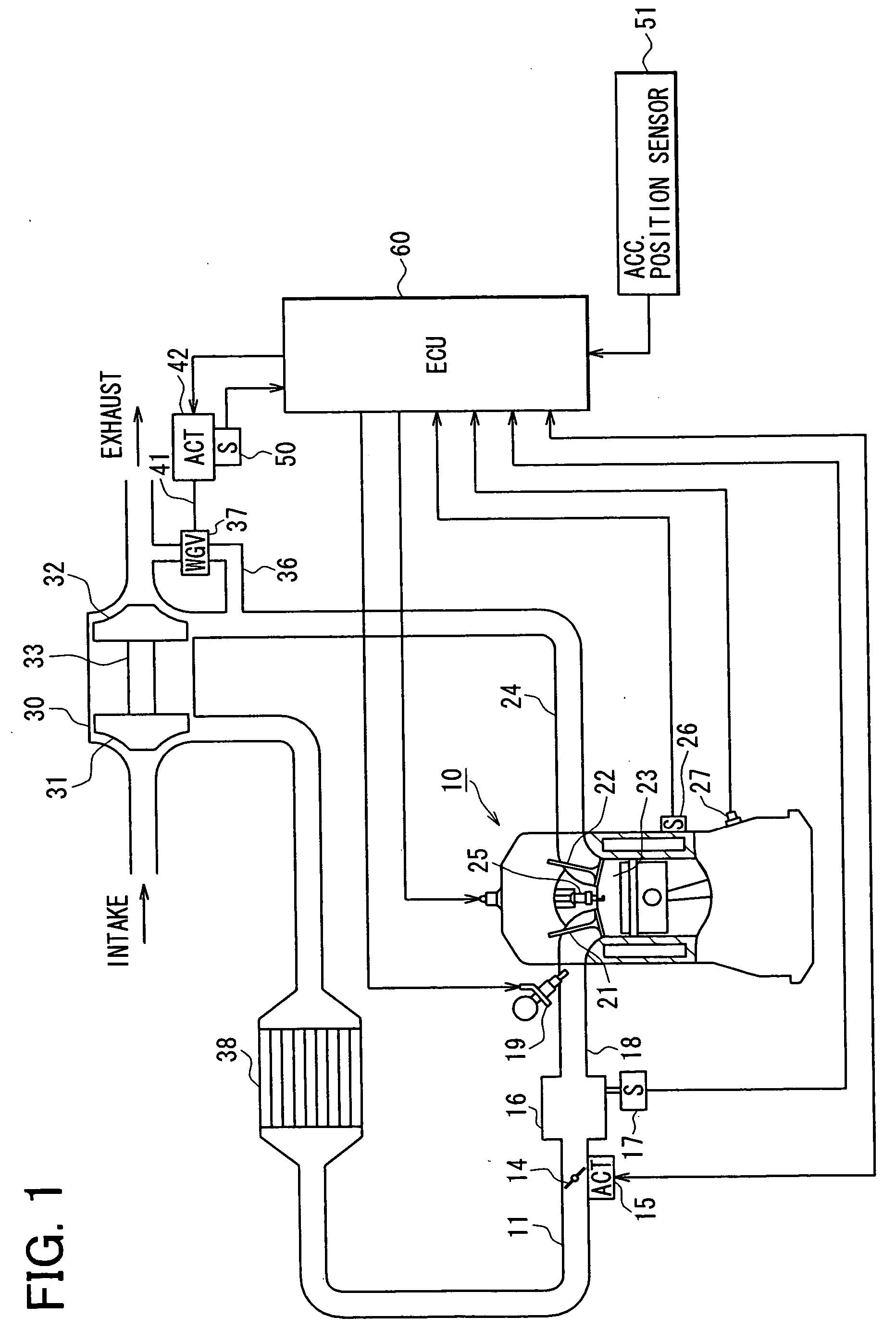

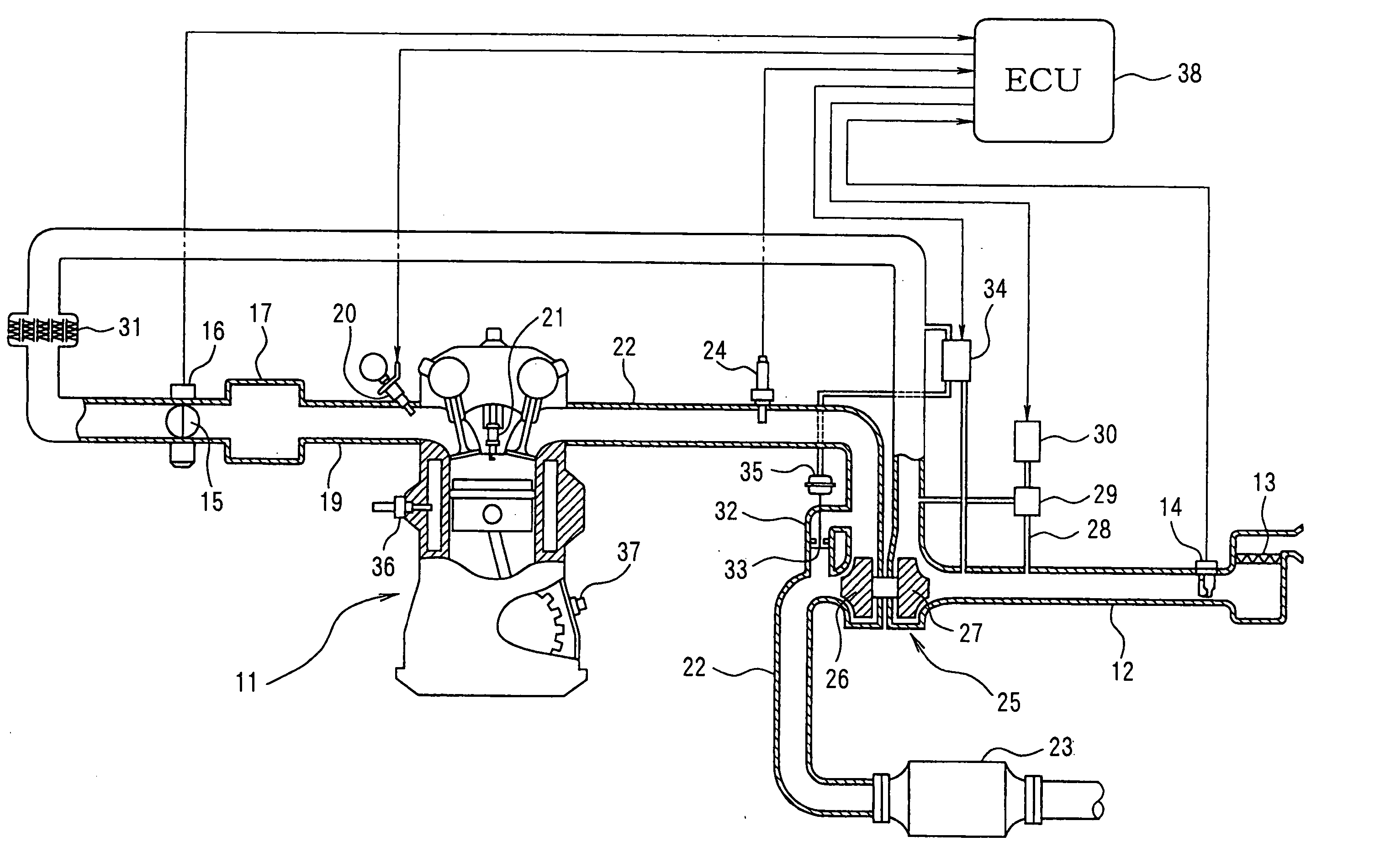

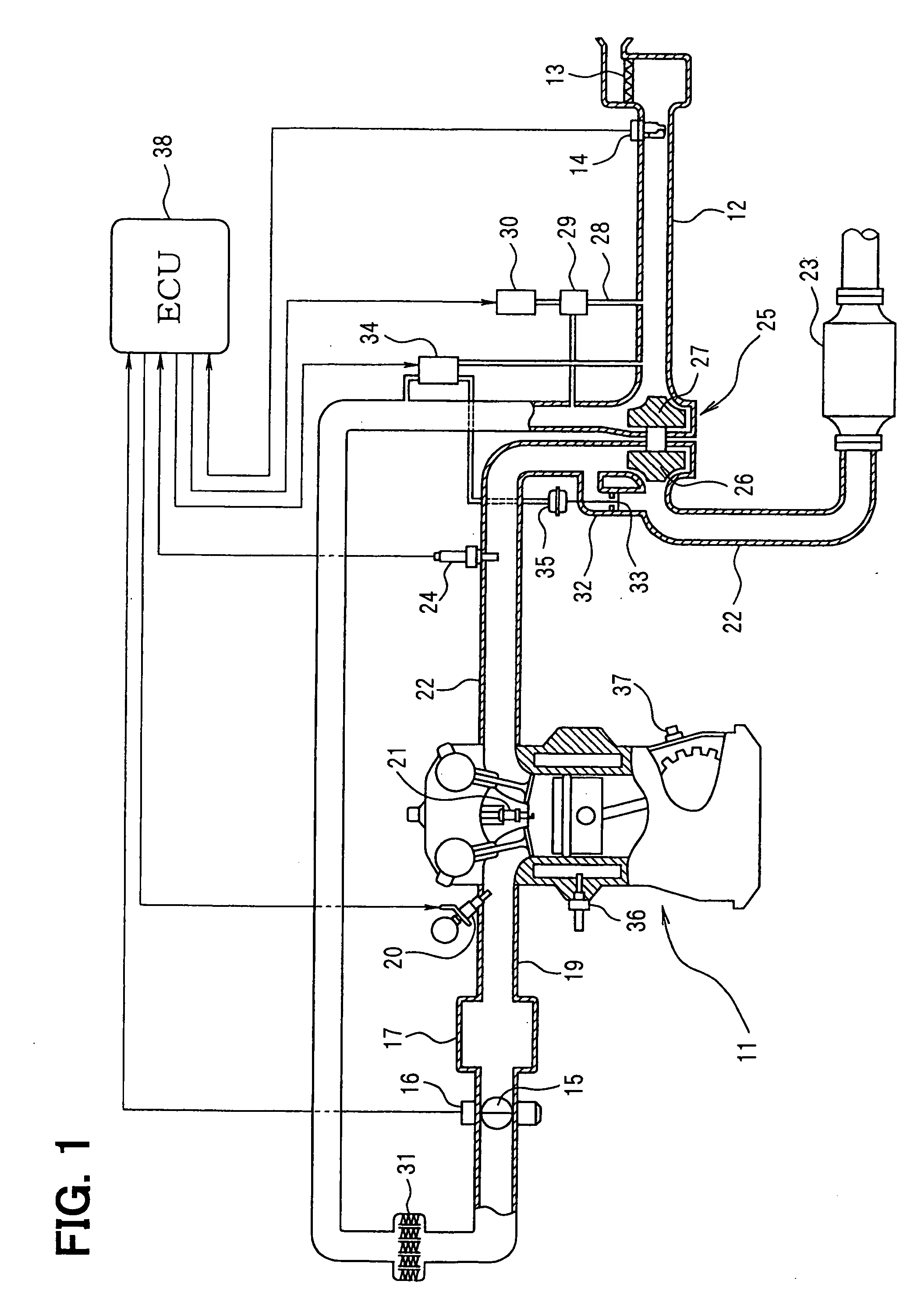

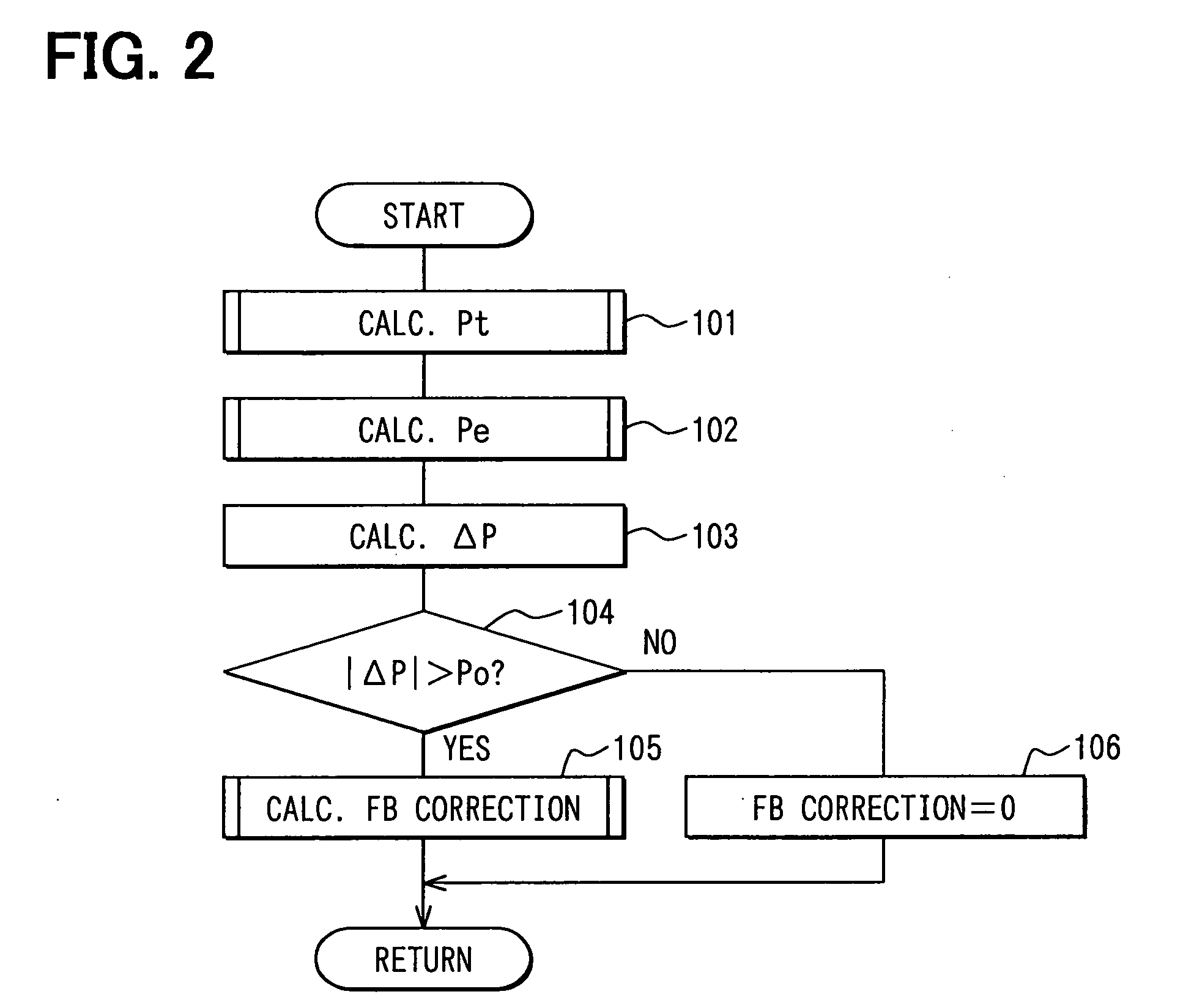

Control apparatus for internal combustion engine and control method for the same

InactiveUS20060213194A1Improve fuel efficiencyReducing a pumping lossElectrical controlInternal combustion piston enginesTurbochargerActuator

An engine includes a throttle valve provided to an intake passage and a turbocharger, which includes an exhaust turbine and an intake compressor. The intake compressor is arranged in the intake passage. A waste gate valve operated using an electric actuator is provided to a bypass passage, which bypasses the exhaust turbine. A control apparatus for the engine includes a setting unit and a control unit. The setting unit sets the position of the waste gate valve at a target position in a normal operating condition of the engine. The target position is out of a position range, in which the waste gate valve is in a substantially full close position. The control unit controls the position of the waste gate valve such that the position of the waste gate valve coincides with the target position.

Owner:DENSO CORP

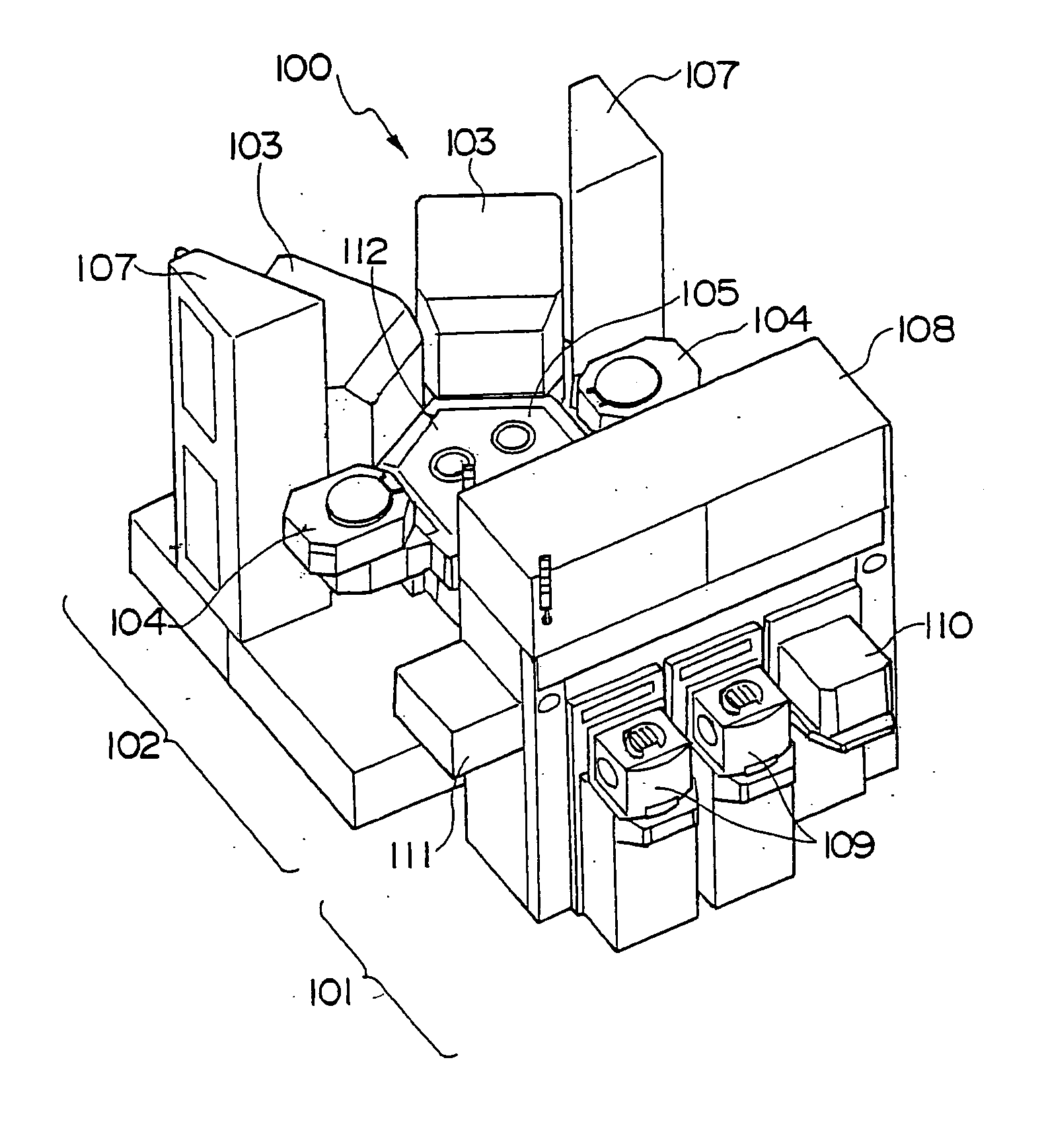

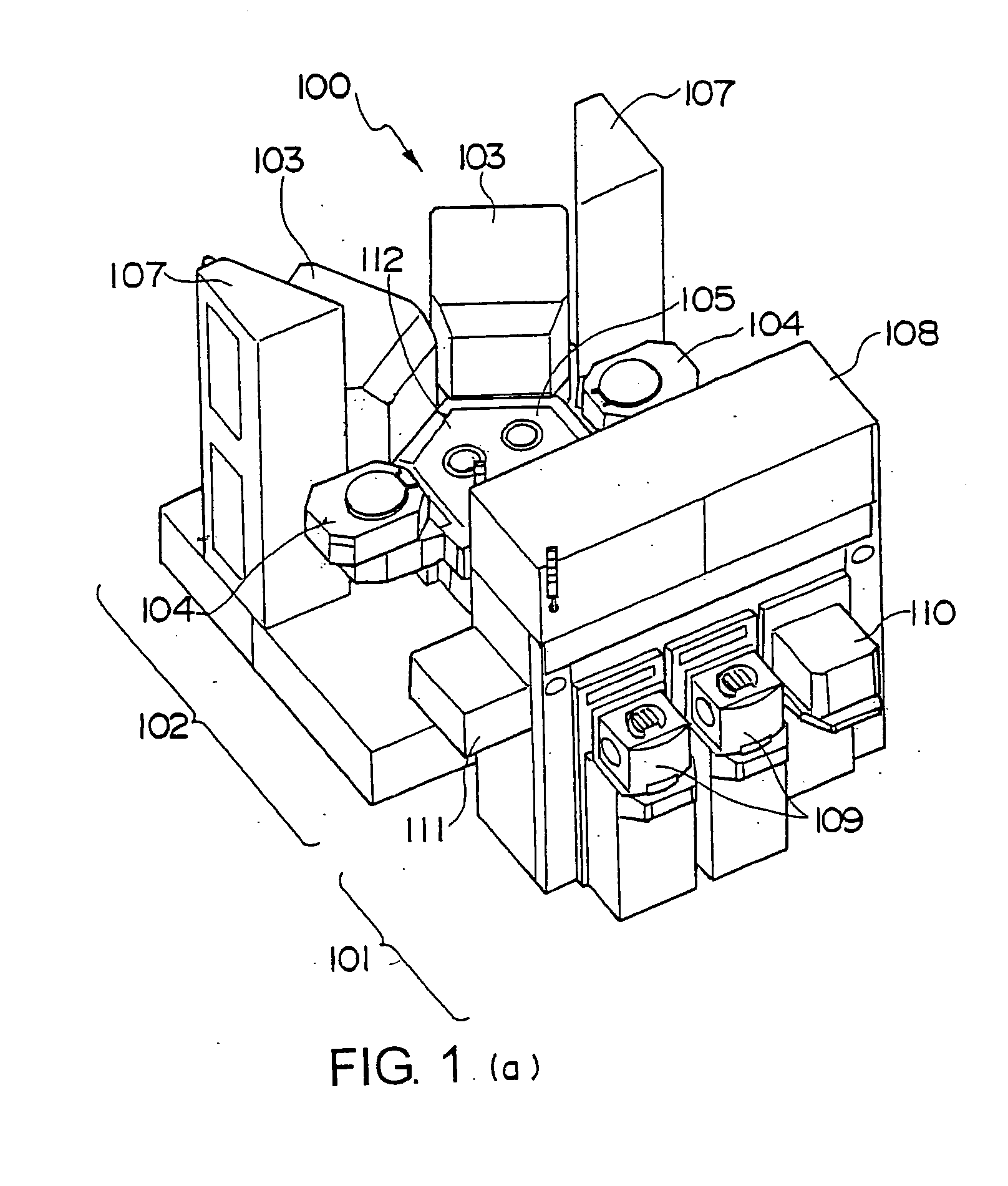

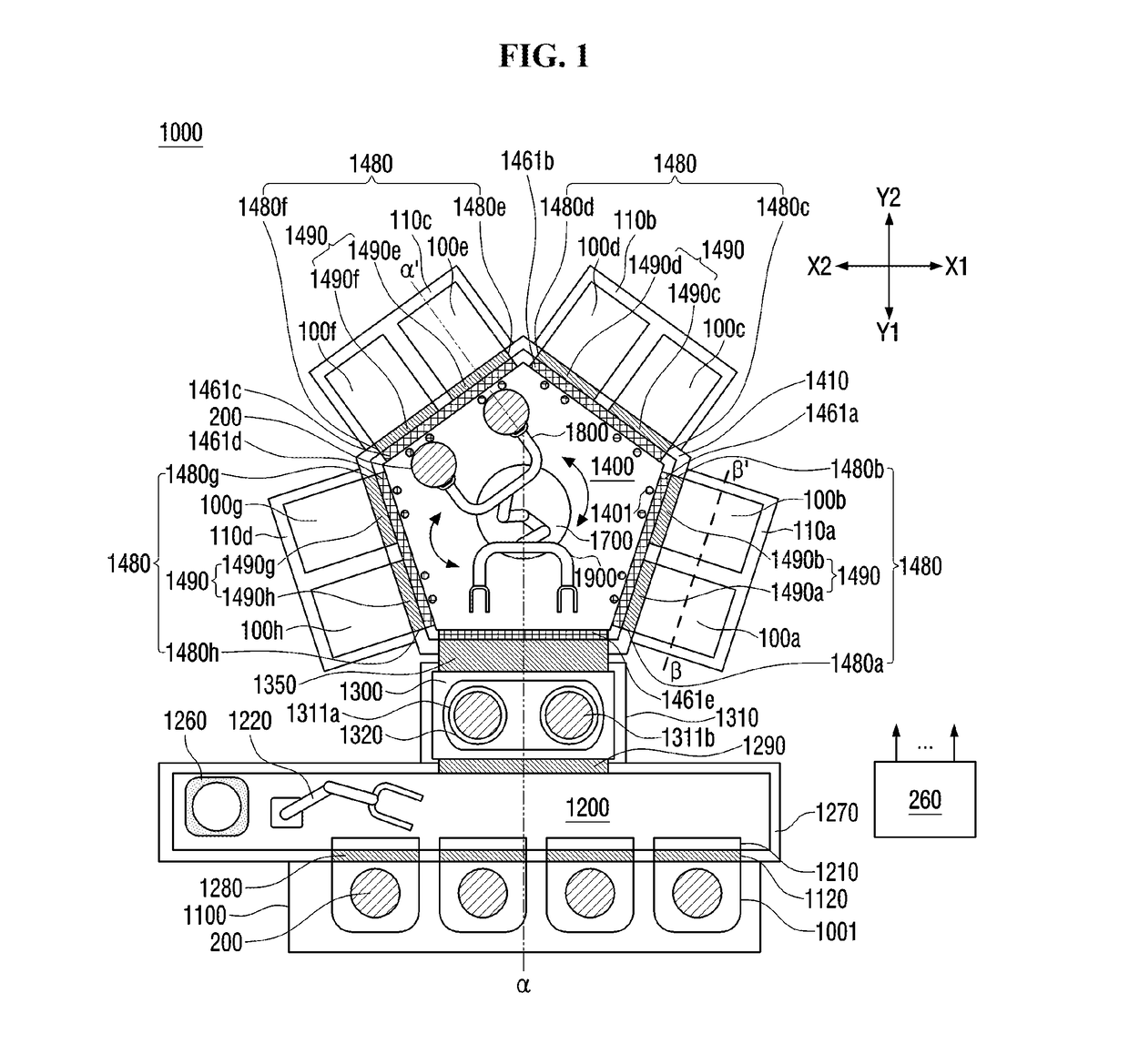

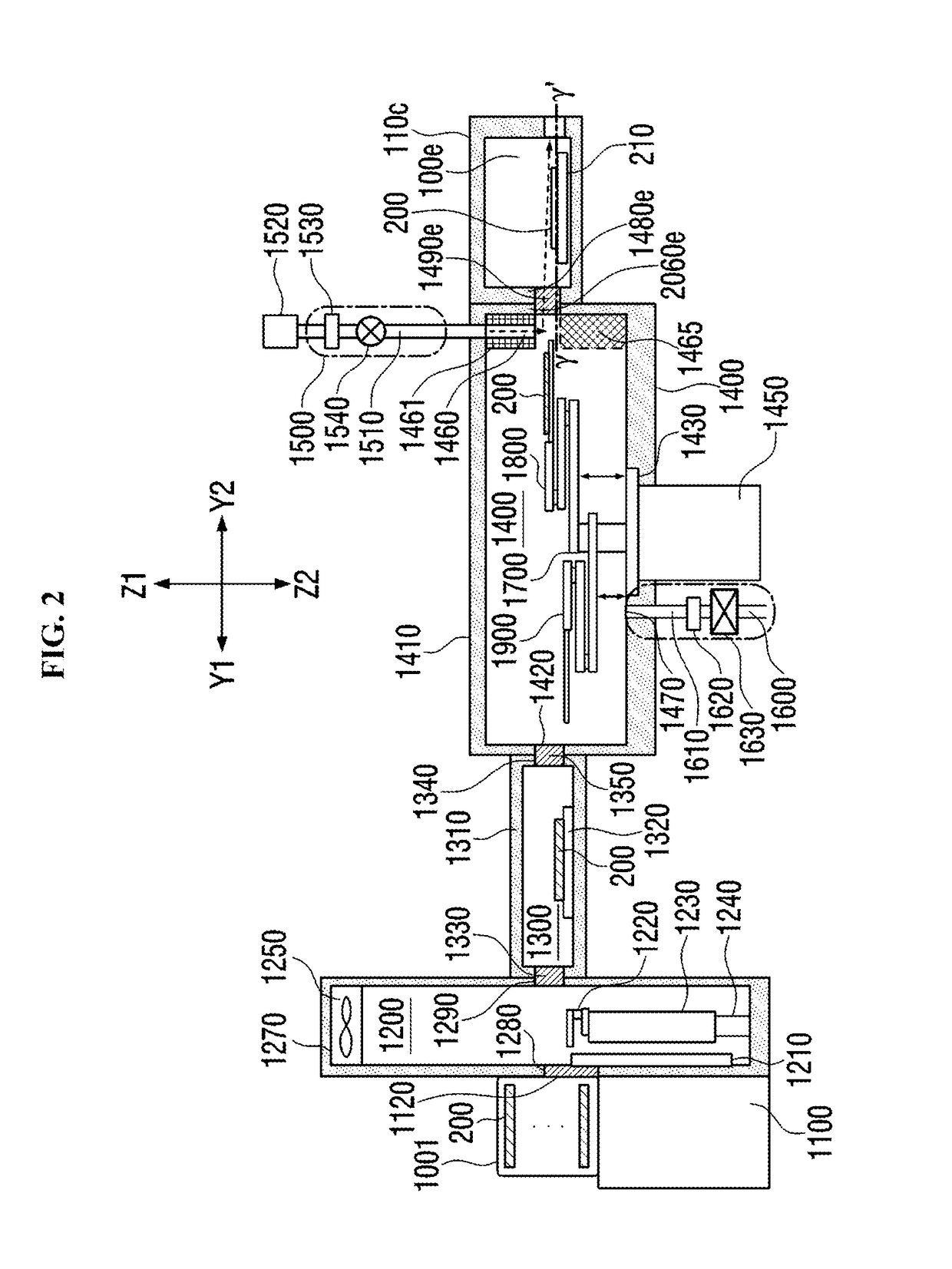

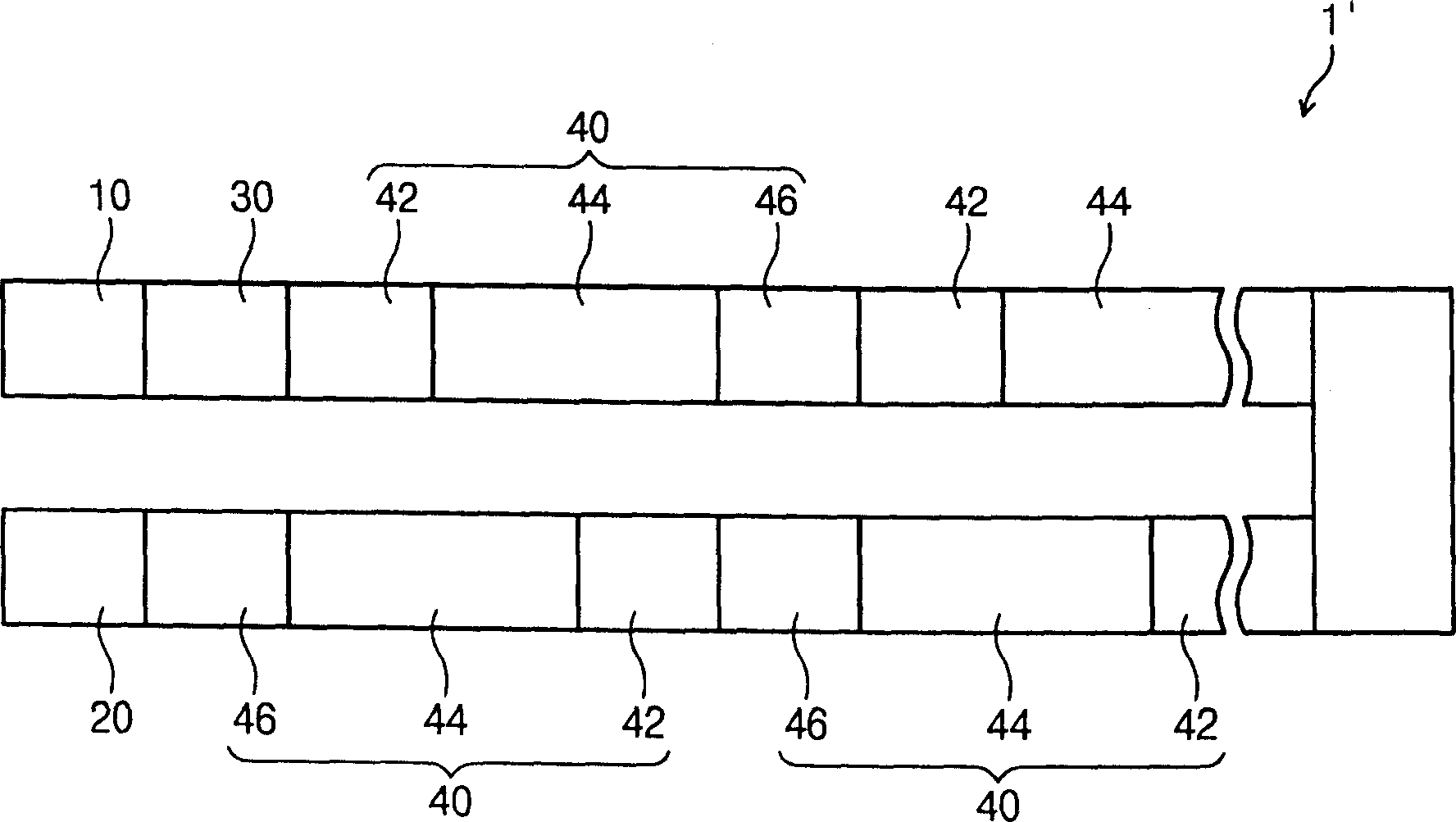

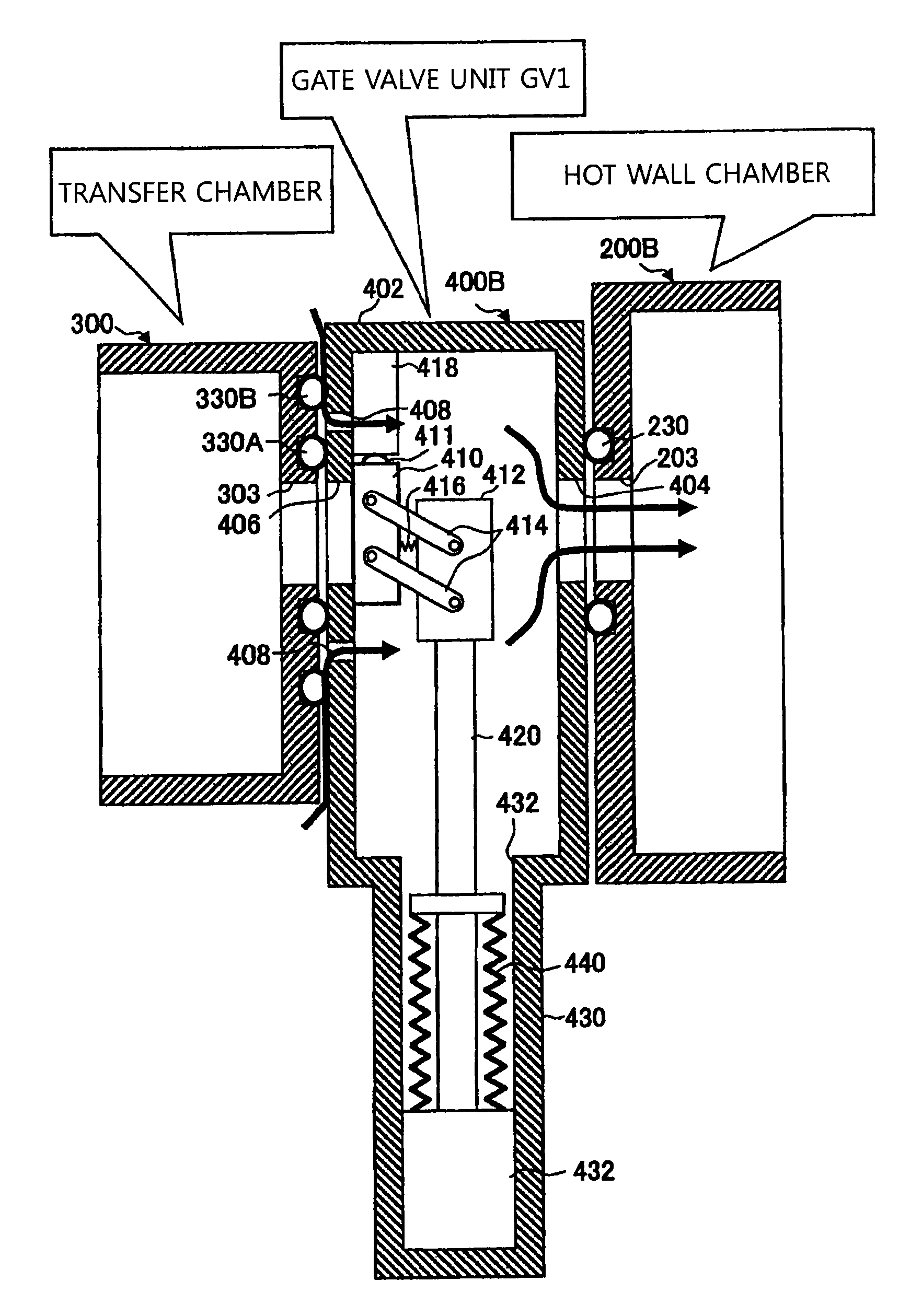

Gate valve unit, substrate processing device and substrate processing method thereof

ActiveUS9121515B2Avoid enteringVacuum evaporation coatingSputtering coatingRoom temperatureEngineering

Owner:TOKYO ELECTRON LTD

Low friction coatings for dynamically engaging load bearing surfaces

A gate valve has a body, the body having a cavity and a flow passage intersecting the cavity. A seat ring is mounted to the body at the intersection of the flow passage and the cavity, the seat ring having an engaging face. A gate in the cavity has an engaging face that slidingly engages the face of the seat ring while being moved between open and closed positions. A polymer coating is on at least one of the faces. The polymer contains a quantity of carbon nanotubes for stiffening.

Owner:VETCO GRAY LLC

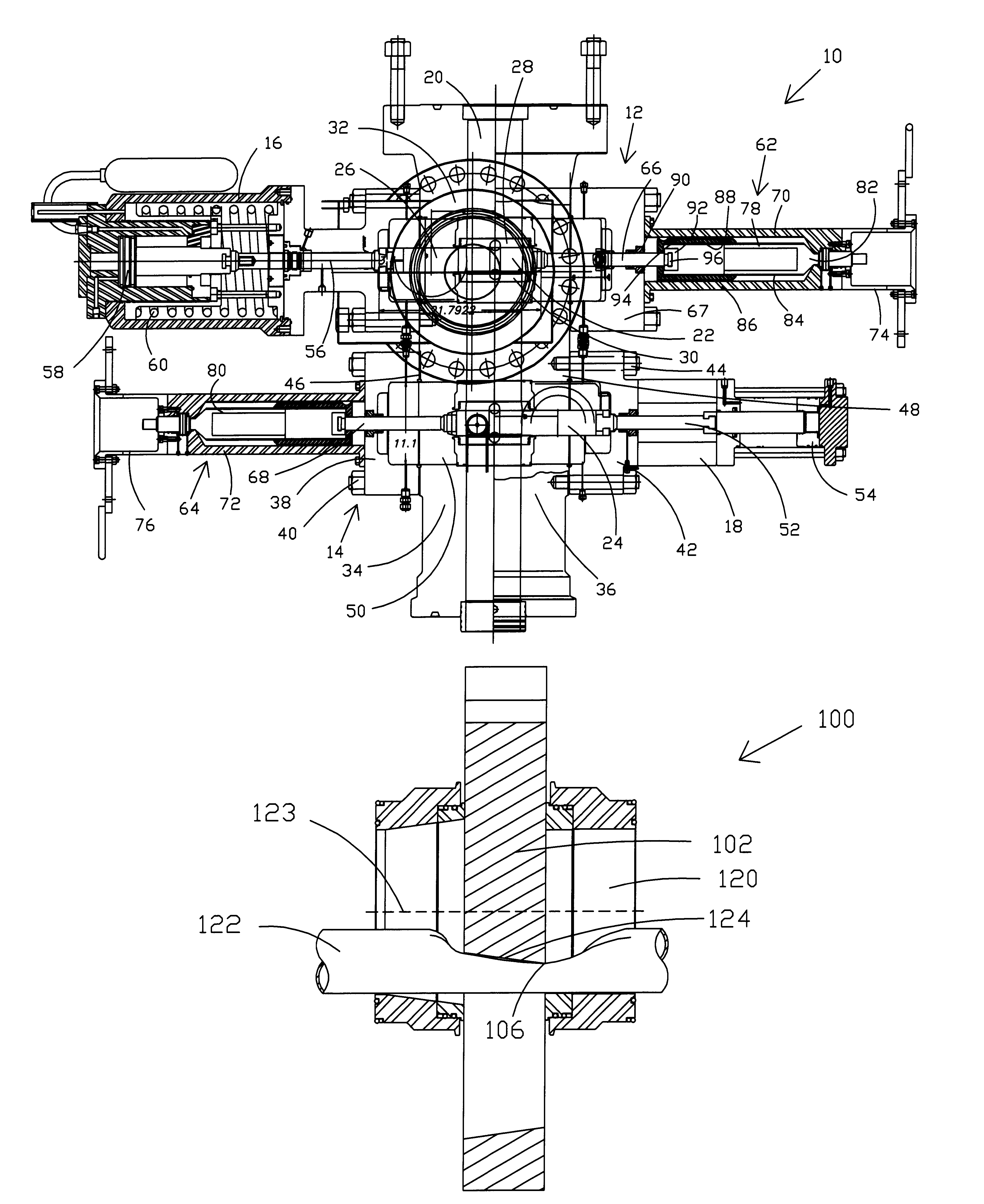

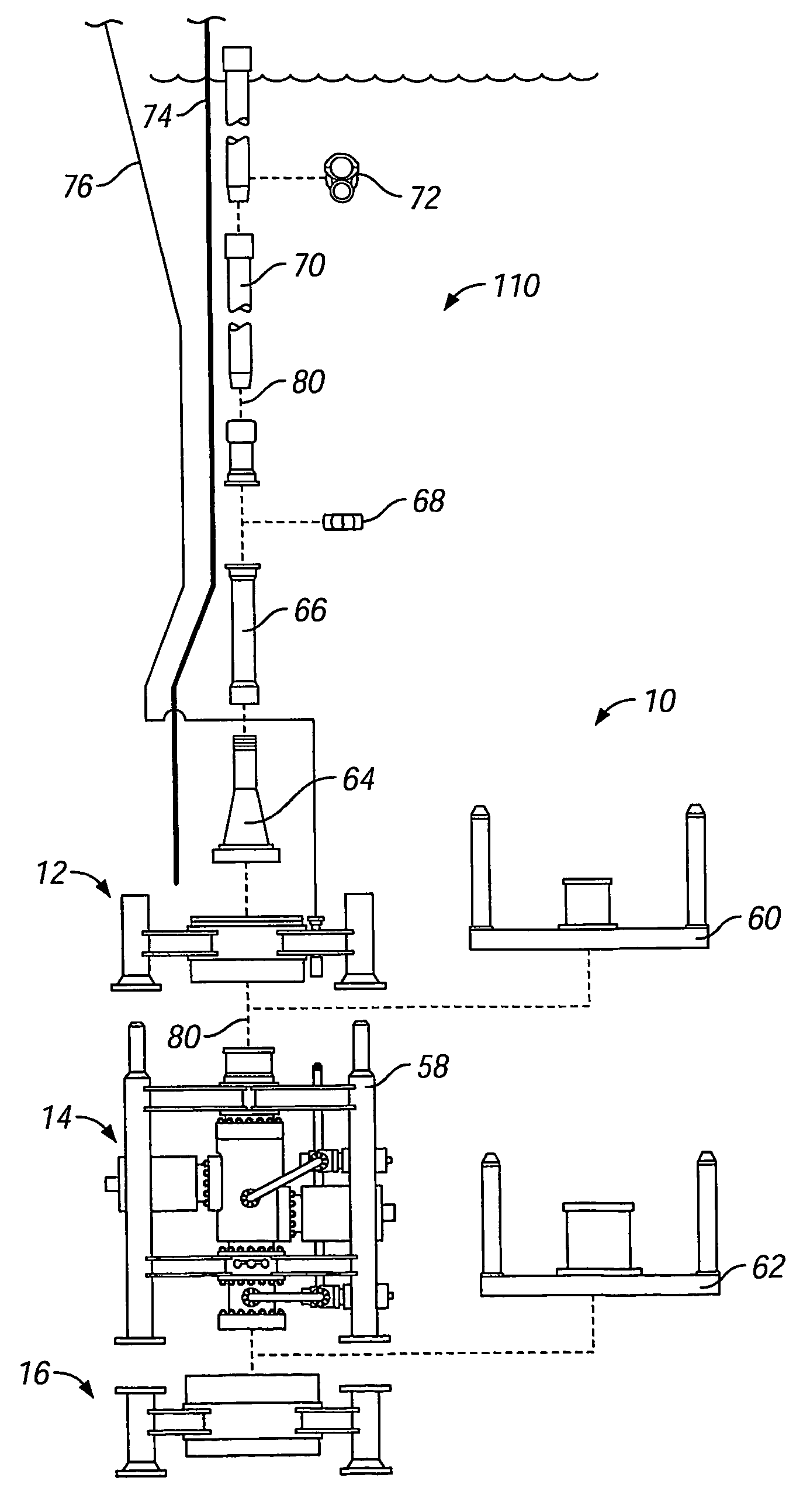

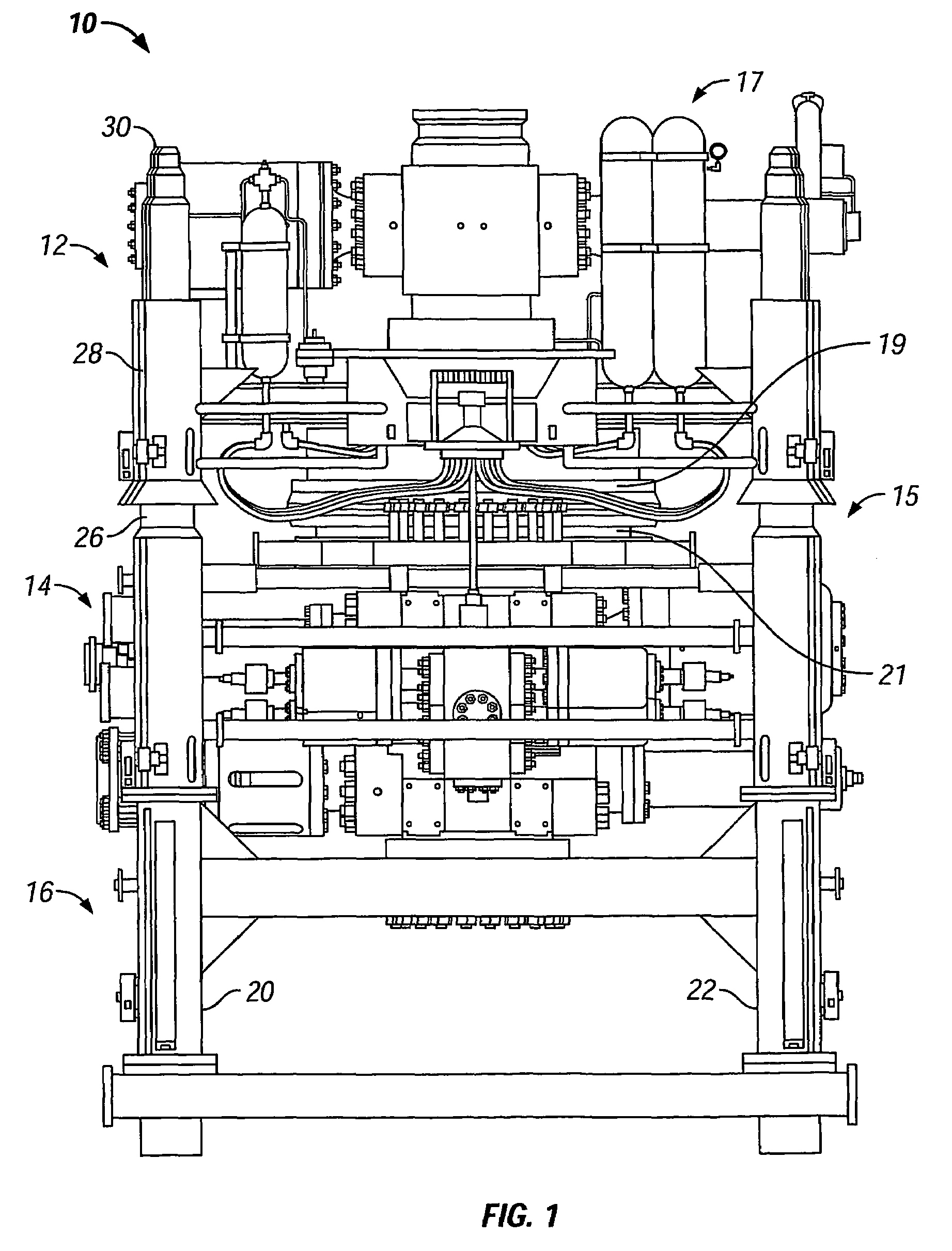

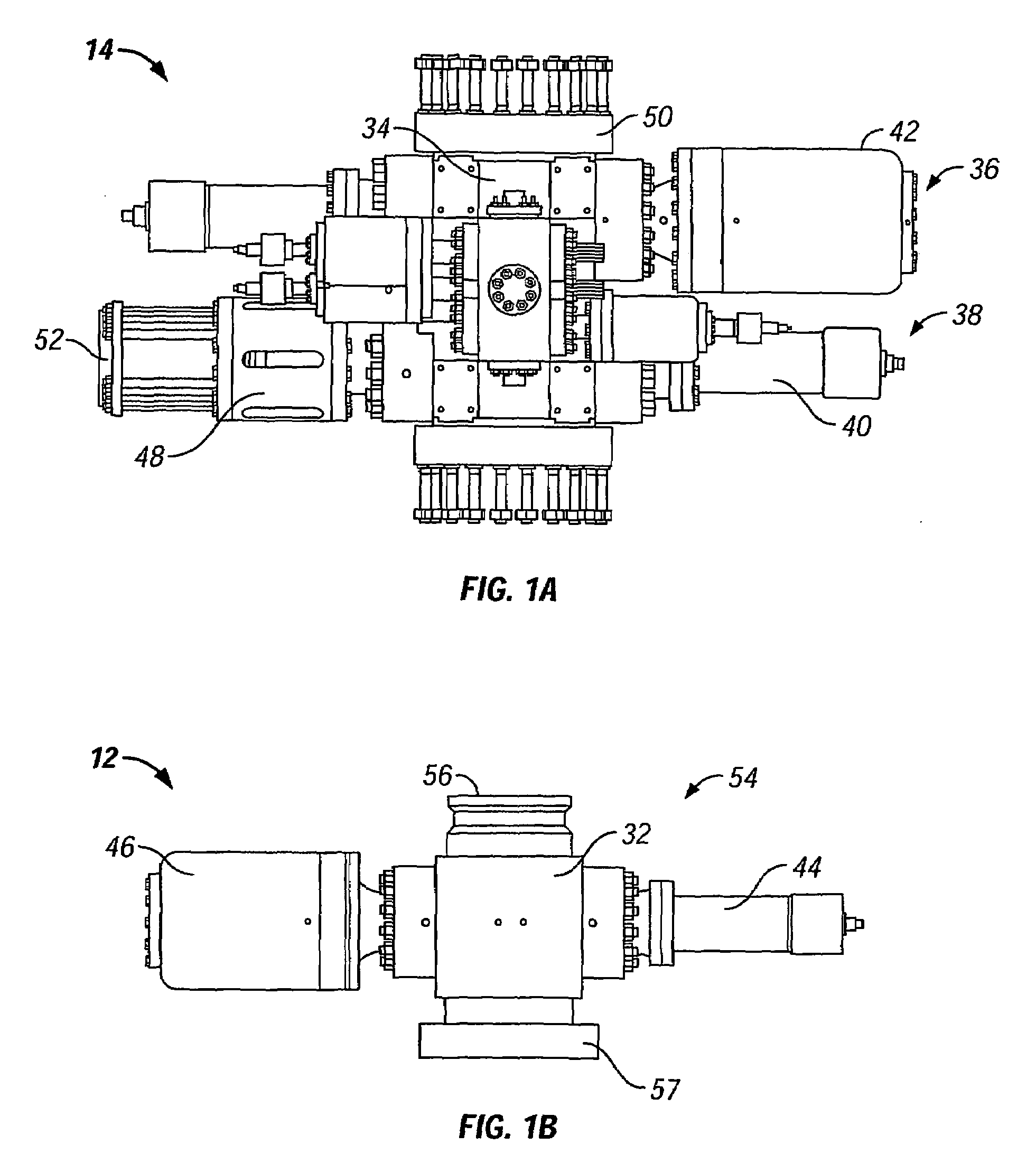

Lightweight and compact subsea intervention package and method

InactiveUS7578349B2Light weightSmall footprintFluid removalUnderwater drillingLifting capacityEngineering

The present invention discloses apparatus and methods for a lightweight subsea intervention package that may be installed using vessels with a smaller lifting capacity than semi-submersible platforms so that the subsea intervention package can be transported, installed, and removed from a subsea well in less time and with less cost. In one embodiment, the present invention comprises a lower riser package for controlling the subsea well which utilizes two hydraulically activated gate valves. An emergency disconnect package is secured to the lower riser package utilizing a disconnect mechanism. The emergency disconnect package is operable to seal the bottom of a riser if the disconnect mechanism is activated to thereby minimize environmental leakage of fluid from the riser.

Owner:WORLDWIDE OILFIELD MACHINE INC

Flexible wedge gate valve

A wedge gate valve having a valve body defining a valve chamber and flow passages and upwardly diverging circular seat surfaces of circular, flat configuration and defining seat planes. A valve disk or wedge having downwardly converging sealing surfaces is movable within said valve chamber between open and closed positions for controlling flow through the valve. Pressure boundary plates connected by hubs to the valve disk define the sealing surfaces of the disk and have bottom corners that establish line contact with the downstream seat surface and prevent any portion of said sealing surfaces of said valve disk from crossing the sealing plane of the downstream seat in the event of flow responsive downstream movement of the valve disk during its opening and closing movement. Guide ears of the disk are provided with flexible upper and lower extremities and rounded or chamfered inner end surfaces to minimize localized peak contact stress with disk guide rails of the valve body. The center section of the disk is rendered flexible by the provision of an internal transverse cavity that extends completely through the center section or is located centrally of the center section to define flexible walls between the hubs to thus provide for disk flexibility for overcoming the tendency for disk binding. A valve actuator for opening and closing the valve disk is provided with an adjustable downstop to prevent overtravel of the disk during seating.

Owner:KALSI ENG

Boost pressure estimation apparatus for internal combustion engine with supercharger

ActiveUS20050172628A1Accurate calculationLow costElectrical controlInternal combustion piston enginesTurbochargerExhaust fumes

An opening is provided for an exhaust bypass pipe that bypasses an exhaust turbine of an exhaust turbine supercharger. According to the opening, an exhaust gas amount bypassing the exhaust turbine is calculated. An exhaust gas amount supplied to the exhaust turbine is found by subtracting the waste-gate-valve-passing gas amount from an intake air amount (exhaust gas amount) detected by the air flow meter. A rotational speed of the exhaust turbine is calculated from this turbine-supplied gas amount. An estimated boost pressure is calculated from this rotational speed of the exhaust turbine. Consequently, a boost pressure can be accurately estimated without using a boost pressure sensor even under such conditions as to disable detection of boost pressures or degrade the detection accuracy in a system using a conventional boost pressure sensor.

Owner:DENSO CORP

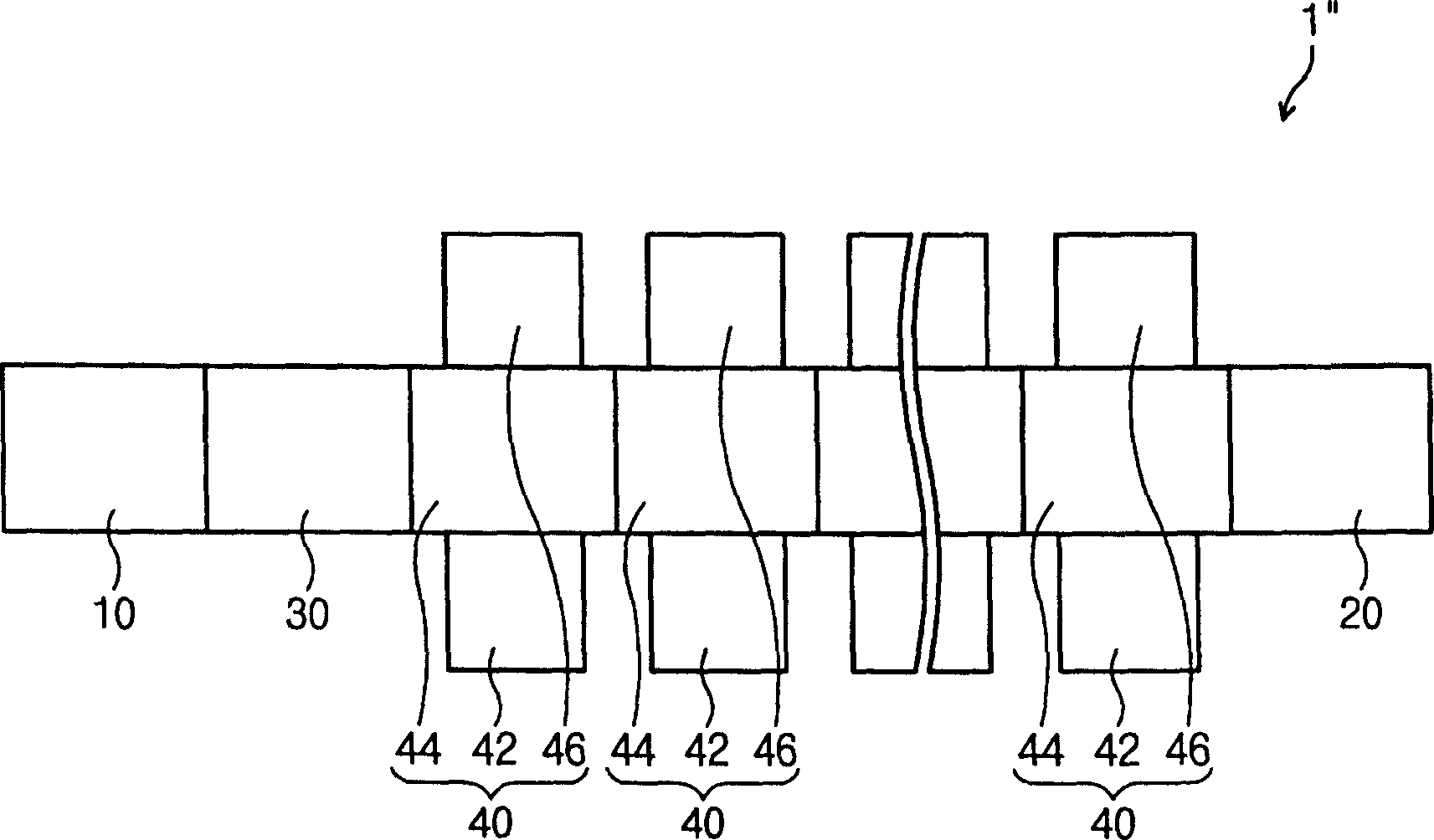

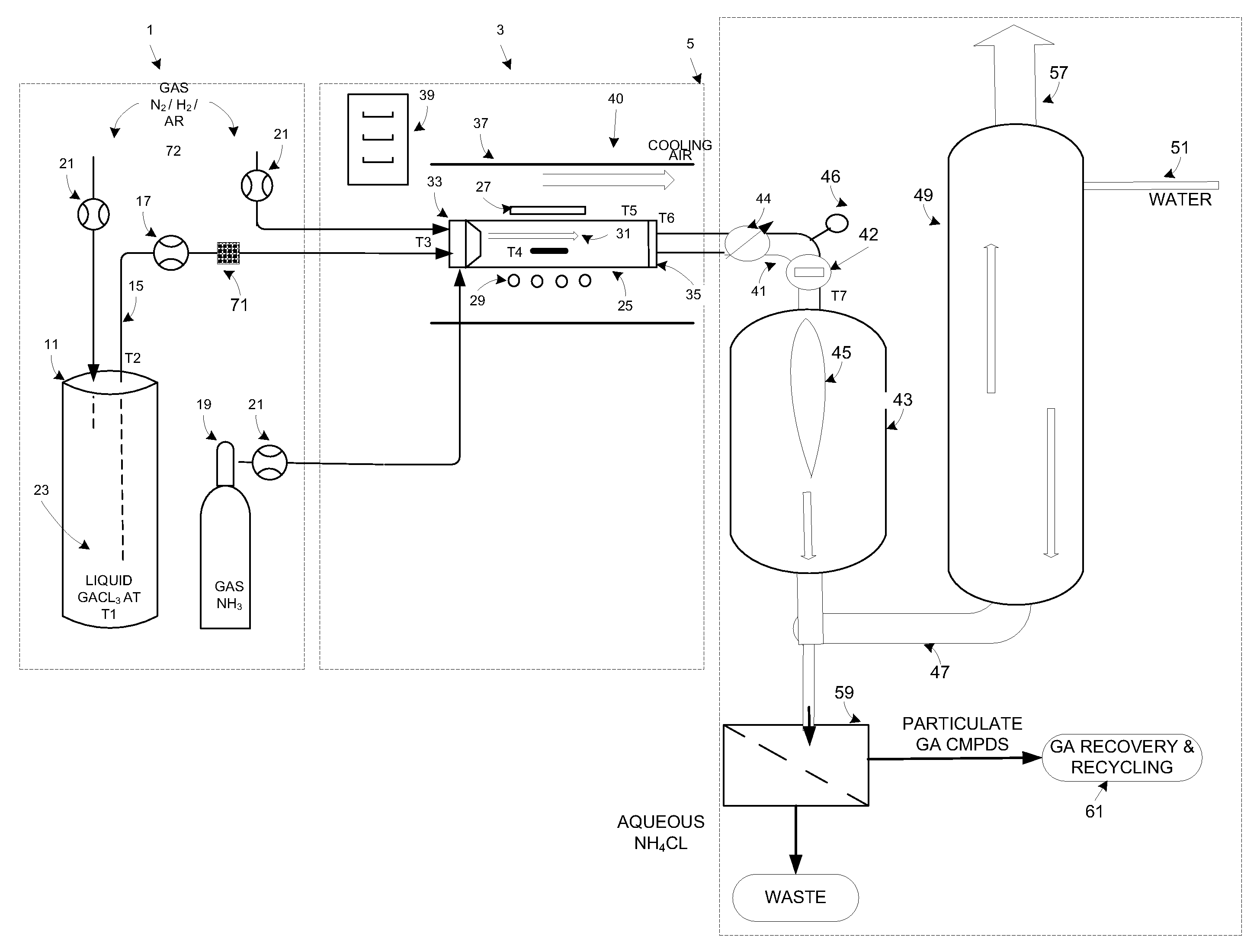

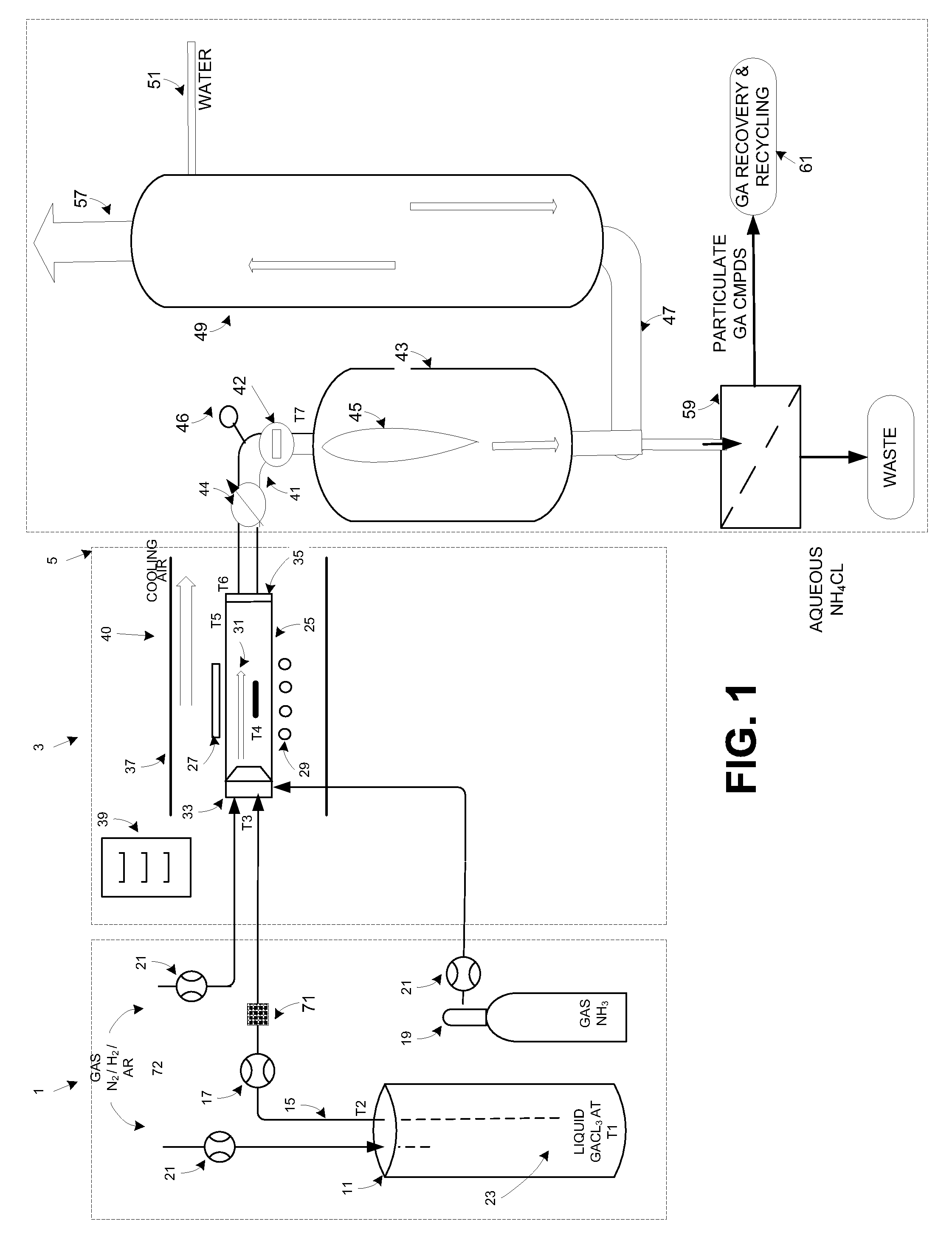

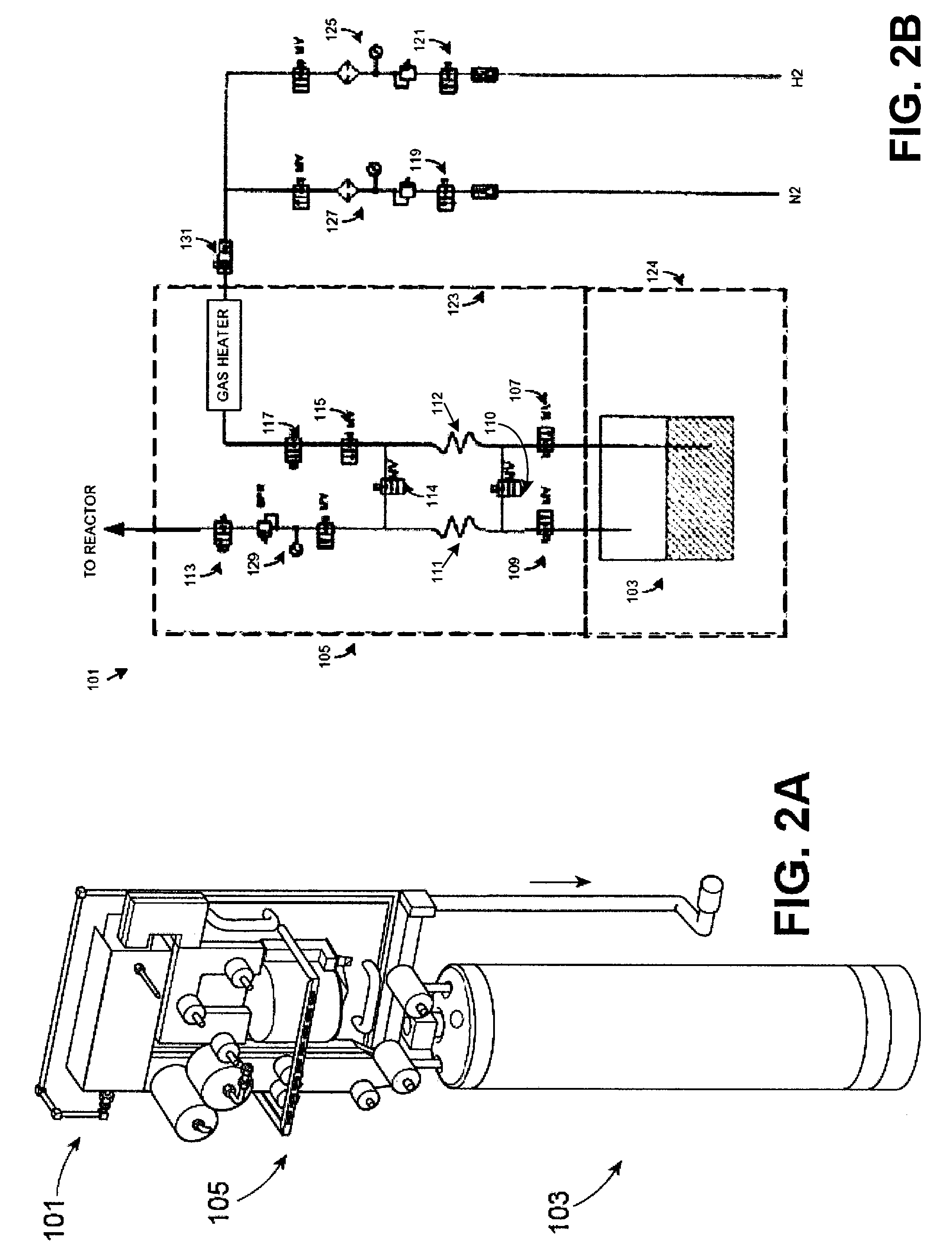

Temperature-controlled purge gate valve for chemical vapor deposition chamber

ActiveUS20090205563A1Efficiently formedEasy to depositAfter-treatment apparatusPolycrystalline material growthTemperature controlIsolation valve

The present invention relates to methods and apparatus that are optimized for producing Group III-N (nitrogen) compound semiconductor wafers and specifically for producing GaN wafers. Specifically, the methods relate to substantially preventing the formation of unwanted materials on an isolation valve fixture within a chemical vapor deposition (CVD) reactor. In particular, the invention provides apparatus and methods for limiting deposition / condensation of GaCl3 and reaction by-products on an isolation valve that is used in the system and method for forming a monocrystalline Group III-V semiconductor material by reacting an amount of a gaseous Group III precursor as one reactant with an amount of a gaseous Group V component as another reactant in a reaction chamber.

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com