Patents

Literature

2461 results about "Polymer coatings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

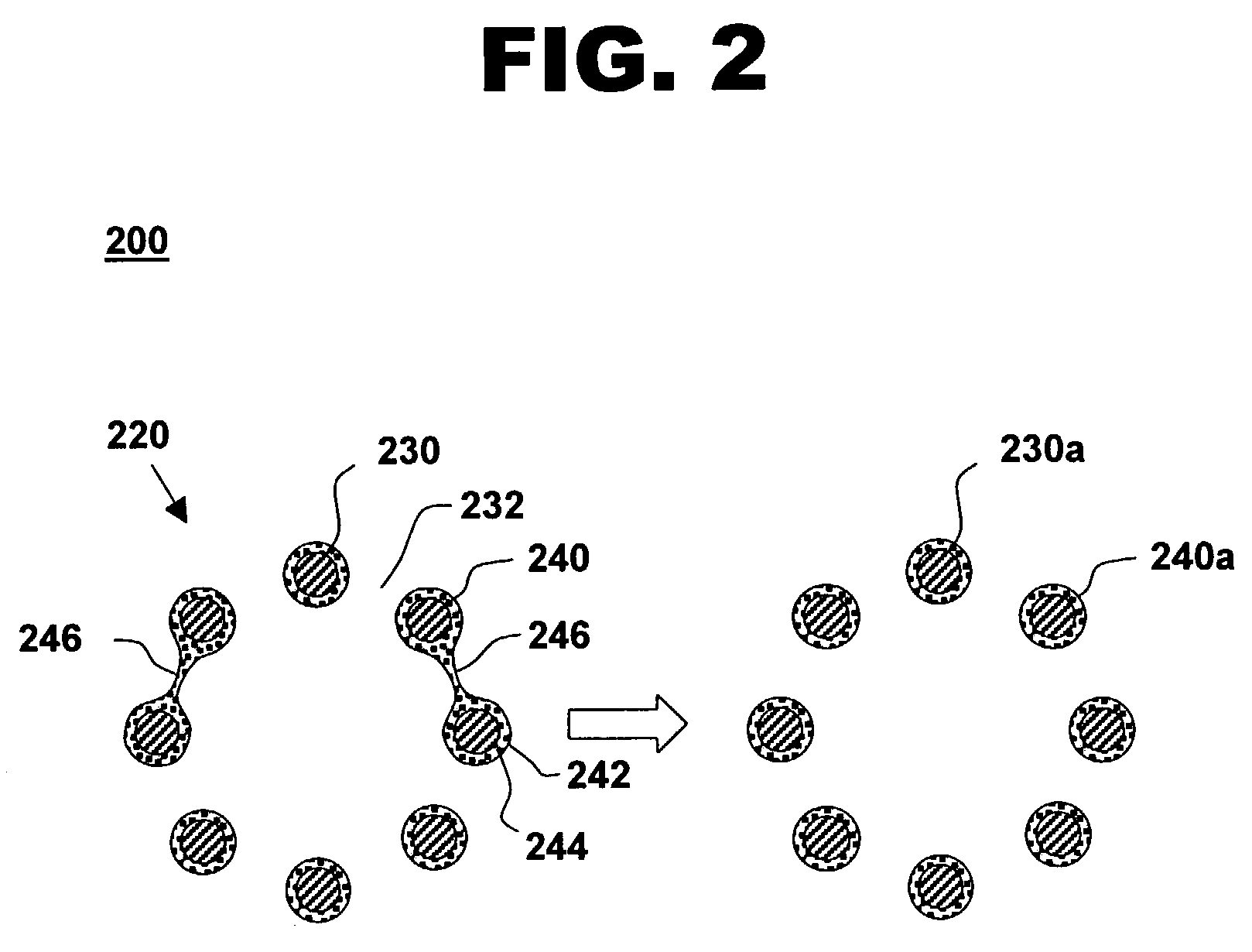

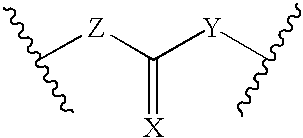

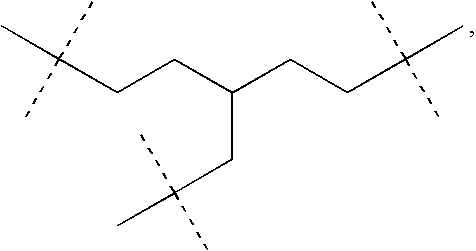

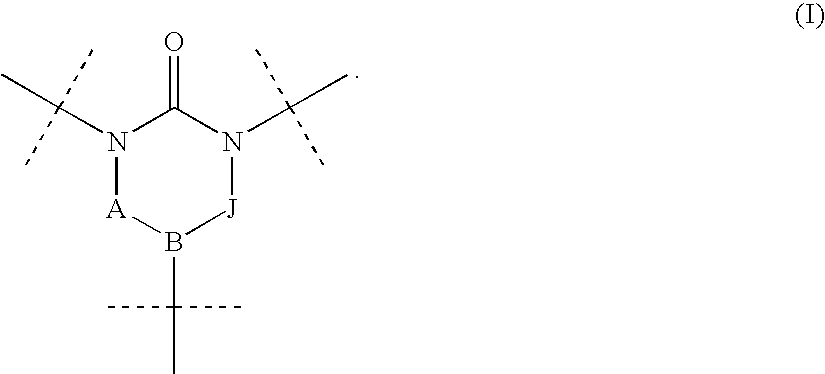

Poly(beta-amino alcohols), their preparation, and uses thereof

ActiveUS20130302401A1Organic active ingredientsPeptide/protein ingredientsChemical structureFibrosis

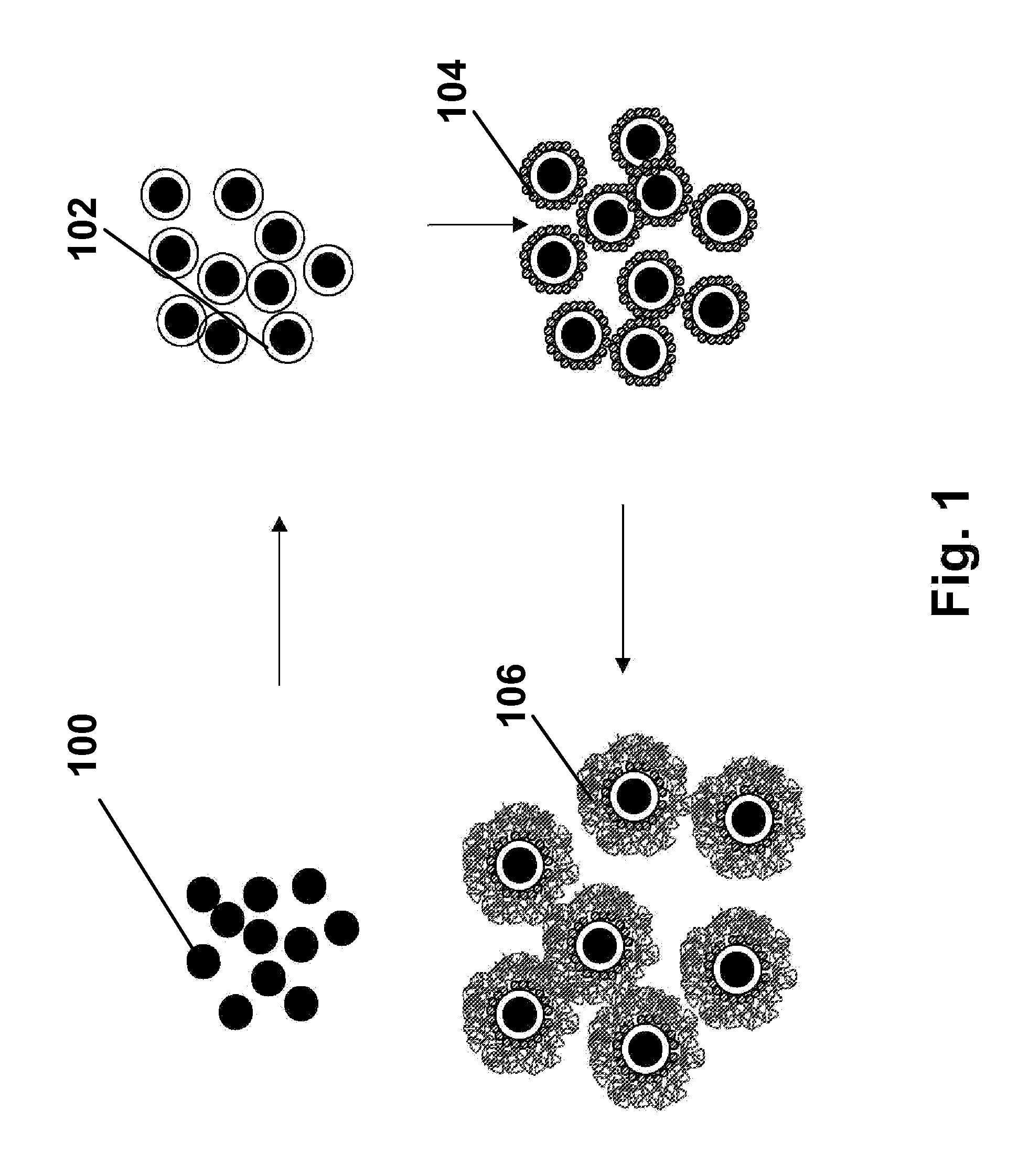

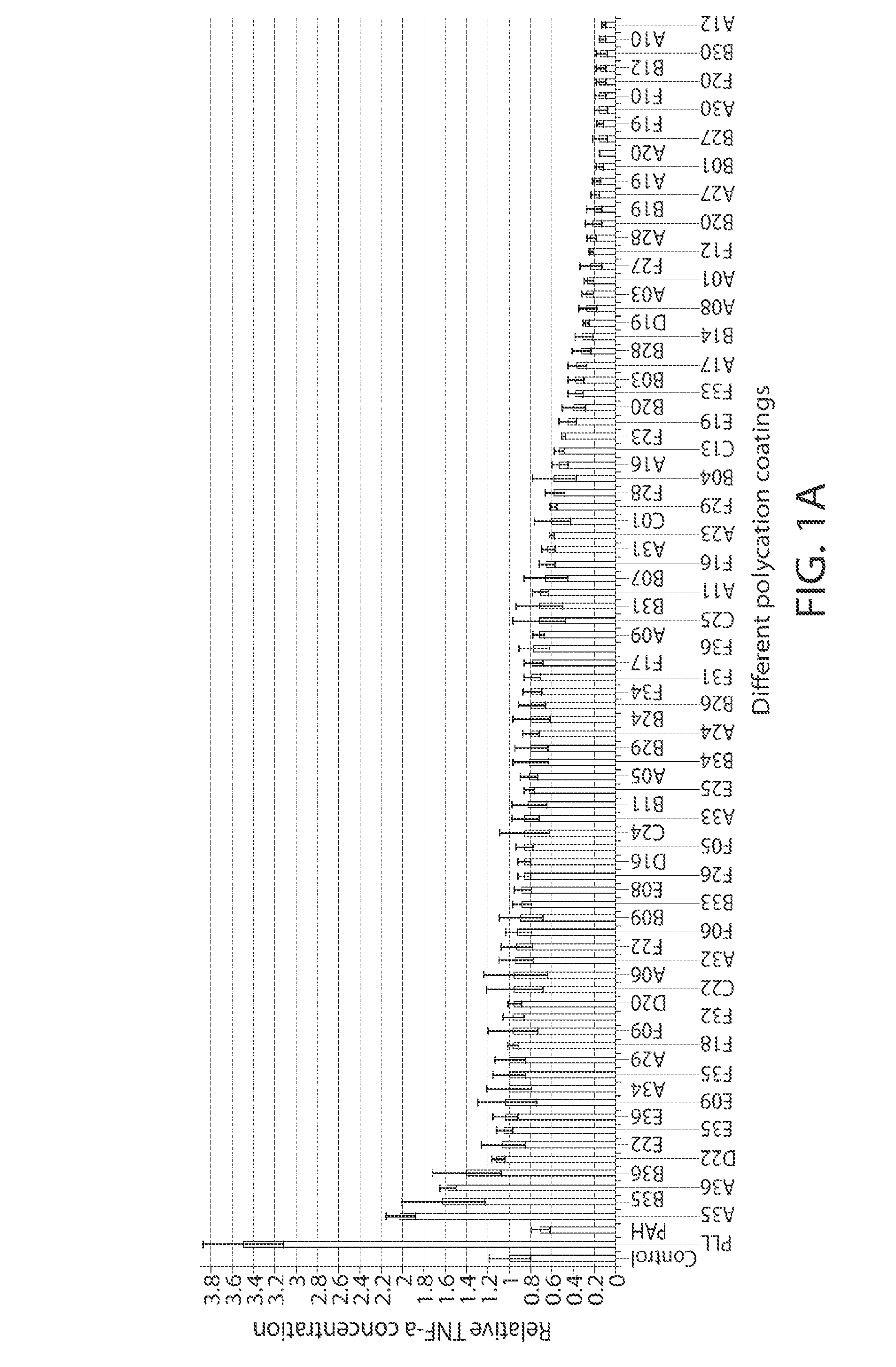

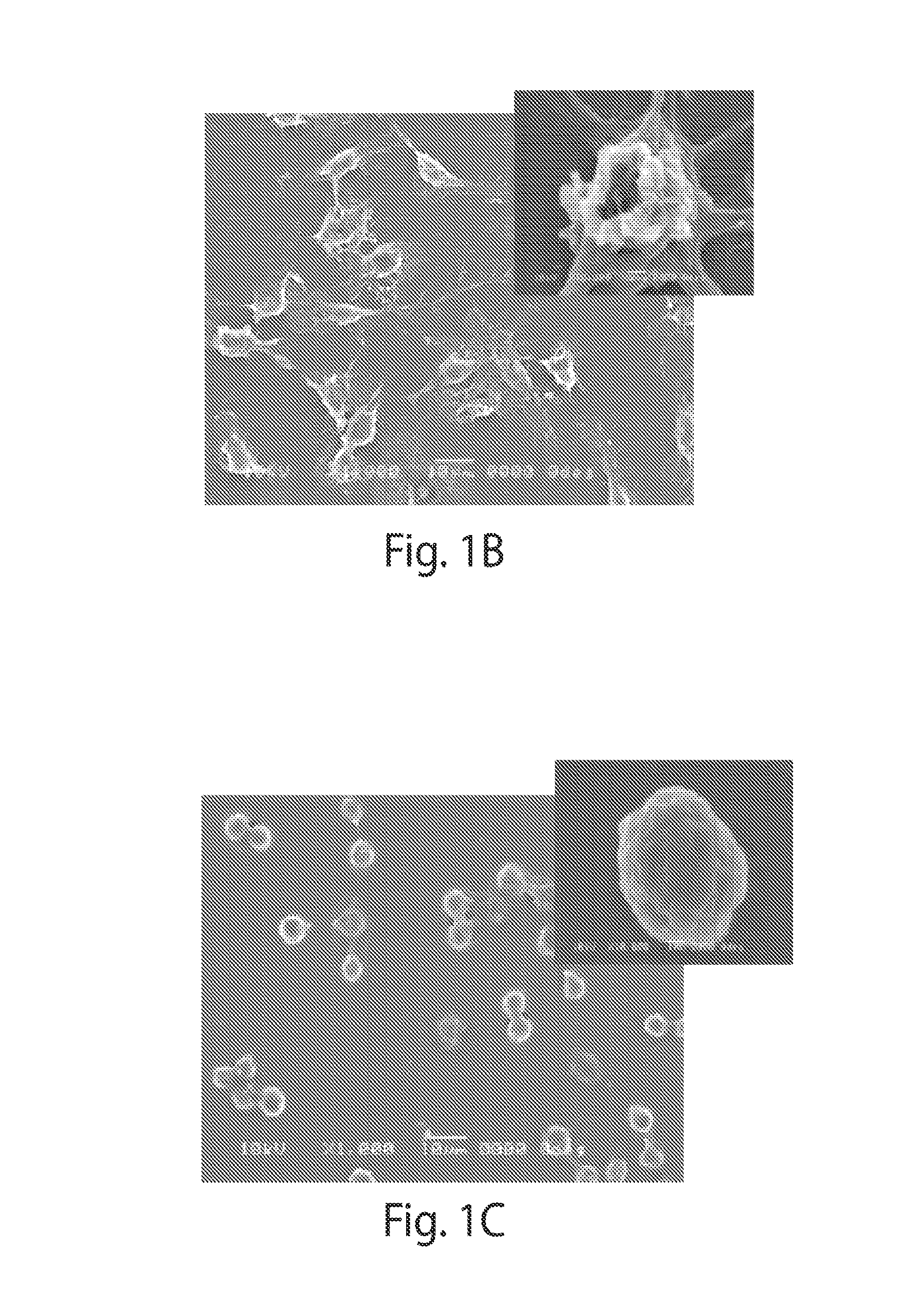

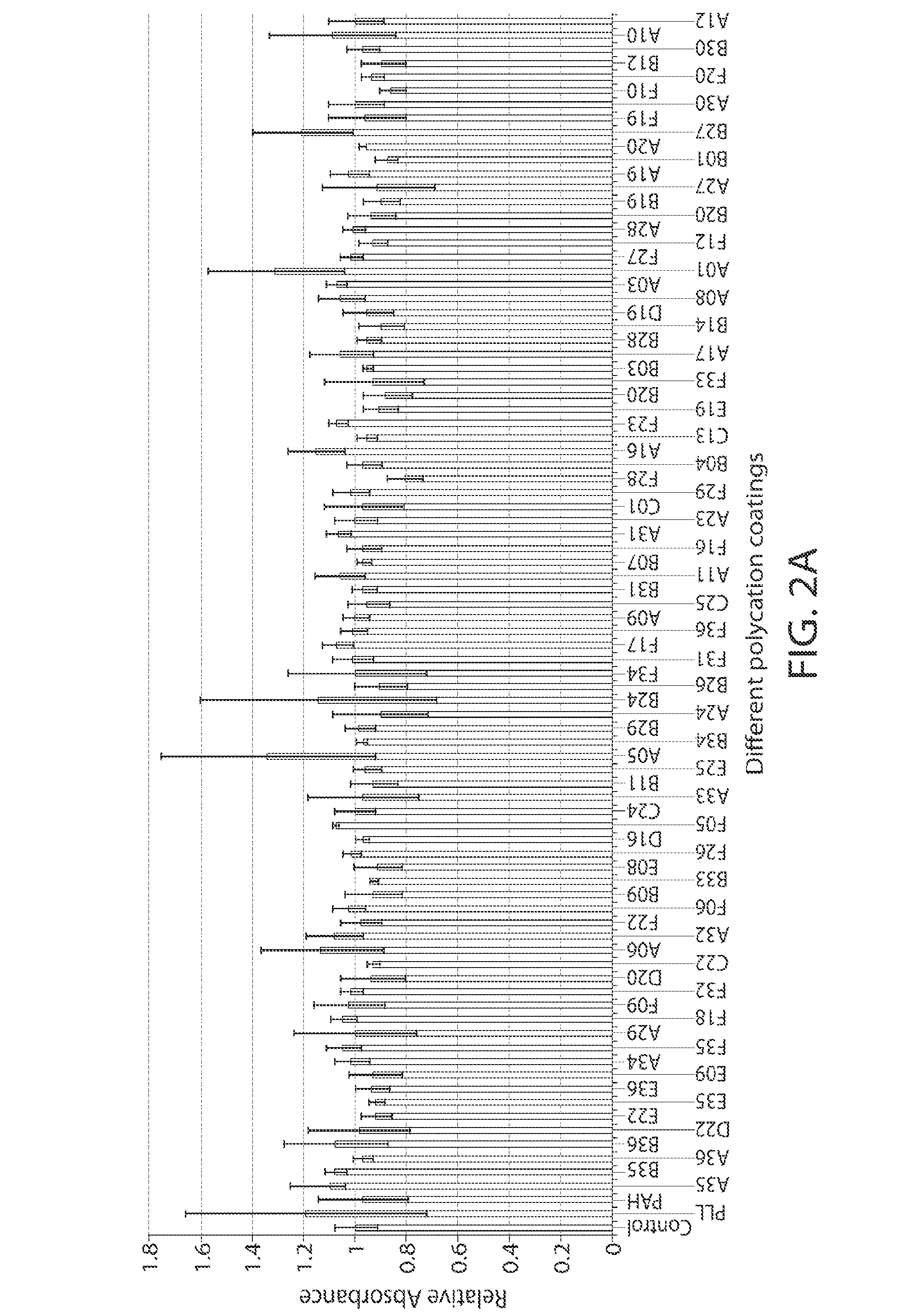

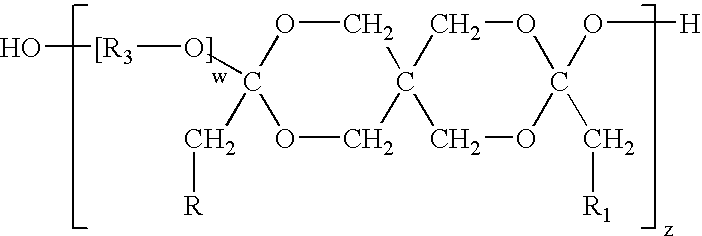

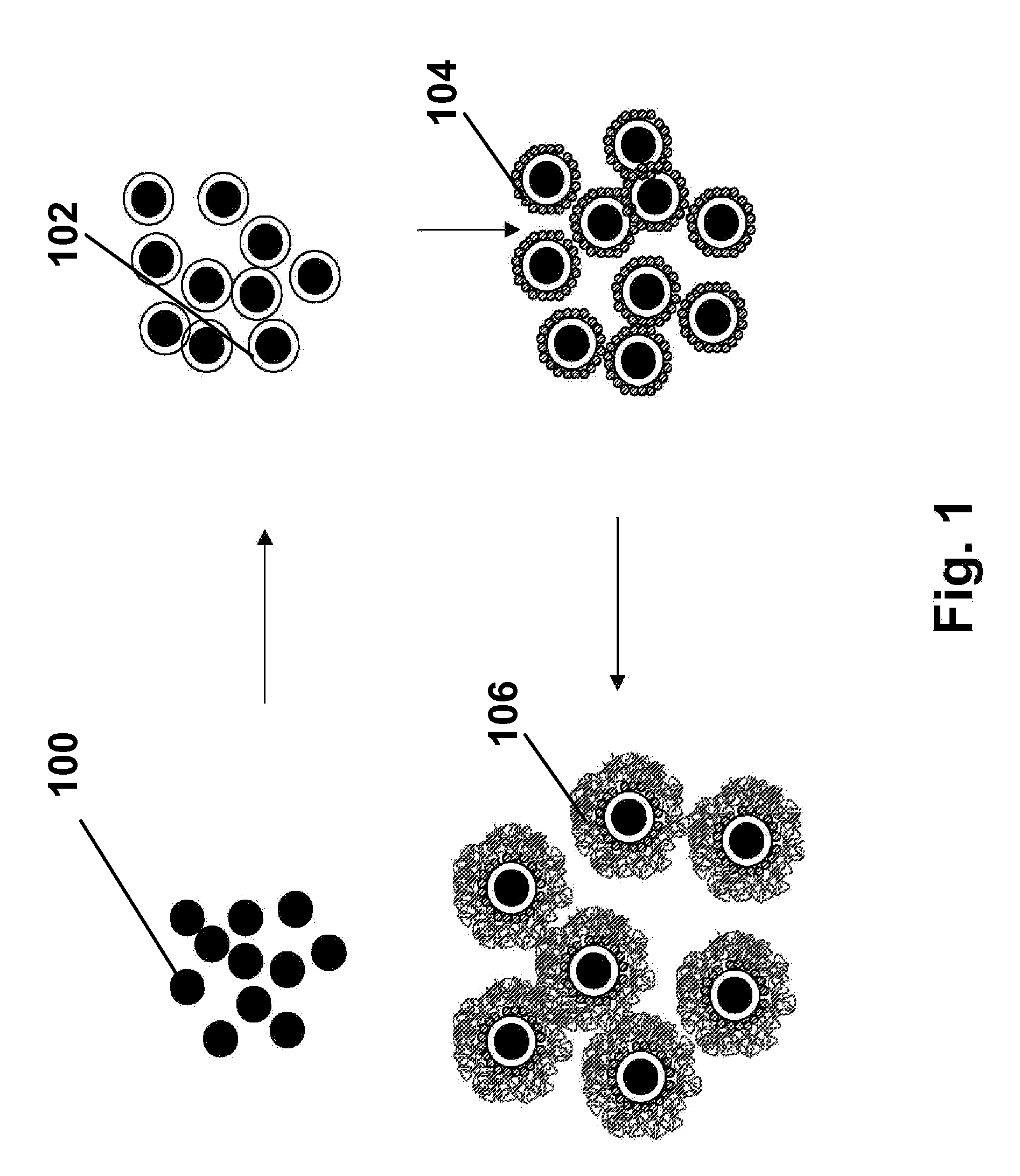

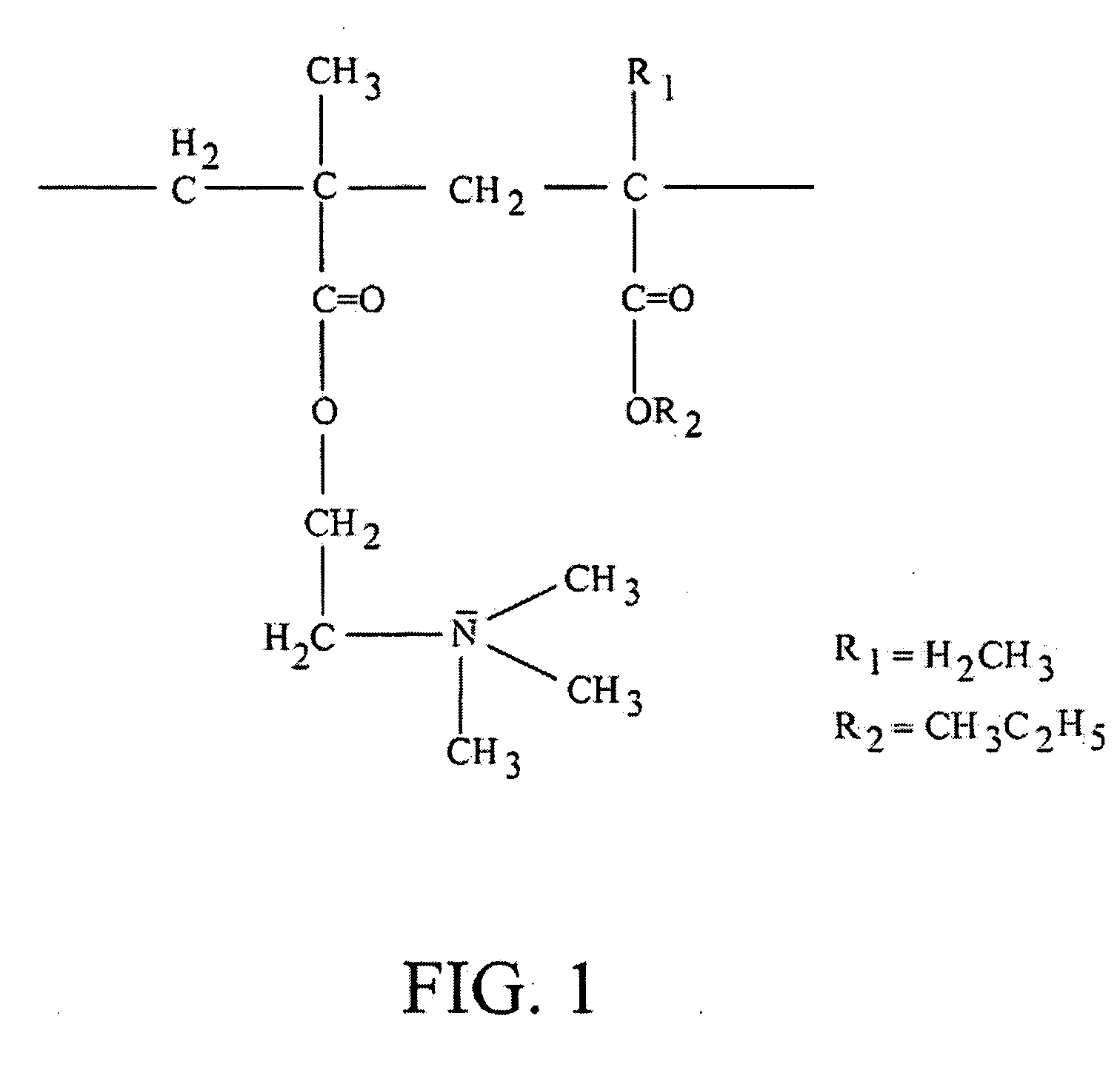

A new class of poly(beta-amino alcohols) (PBAAs) has been prepared using combinatorial polymerization. The inventive PBAAs may be used in biotechnology and biomedical applications as coatings (such as coatings of films or multilayer films for medical devices or implants), additives, materials, excipients, non-biofouling agents, micropatterning agents, and cellular encapsulation agents. When used as surface coatings, these PBAAs elicited different levels of inflammation, both in vitro and in vivo, depending on their chemical structures. The large chemical diversity of this class of materials allowed us to identify polymer coatings that inhibit macrophage activation in vitro. Furthermore, these coatings reduce the recruitment of inflammatory cells, and reduce fibrosis, following the subcutaneous implantation of carboxylated polystyrene microparticles. These polymers may be used to form polyelectrolyte complex capsules for cell encapsulation. The invention may also have many other biological applications such as antimicrobial coatings, DNA or siRNA delivery, and stem cell tissue engineering.

Owner:MASSACHUSETTS INST OF TECH

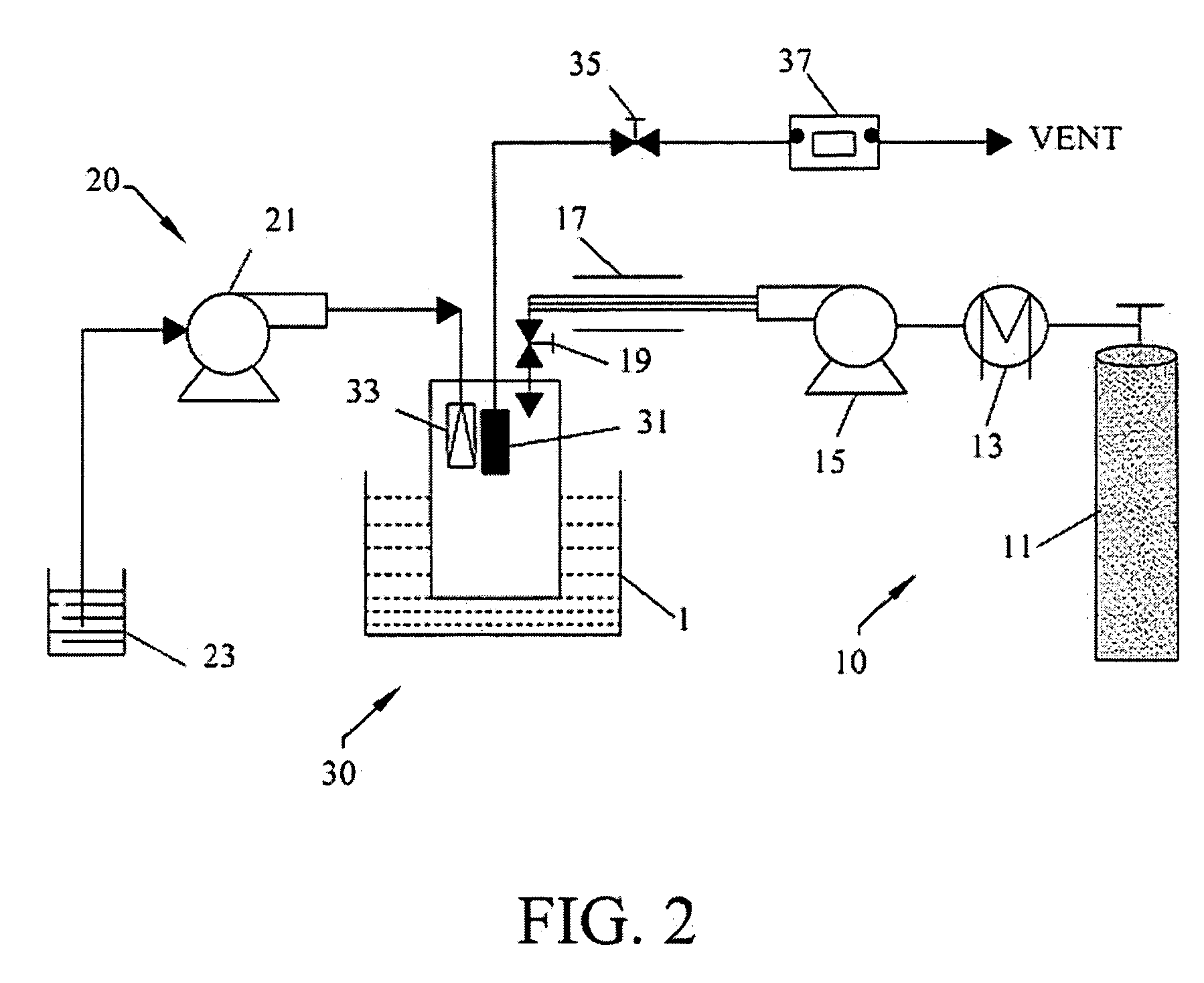

Apparatus and methods for plasma enhanced chemical vapor deposition of polymer coatings

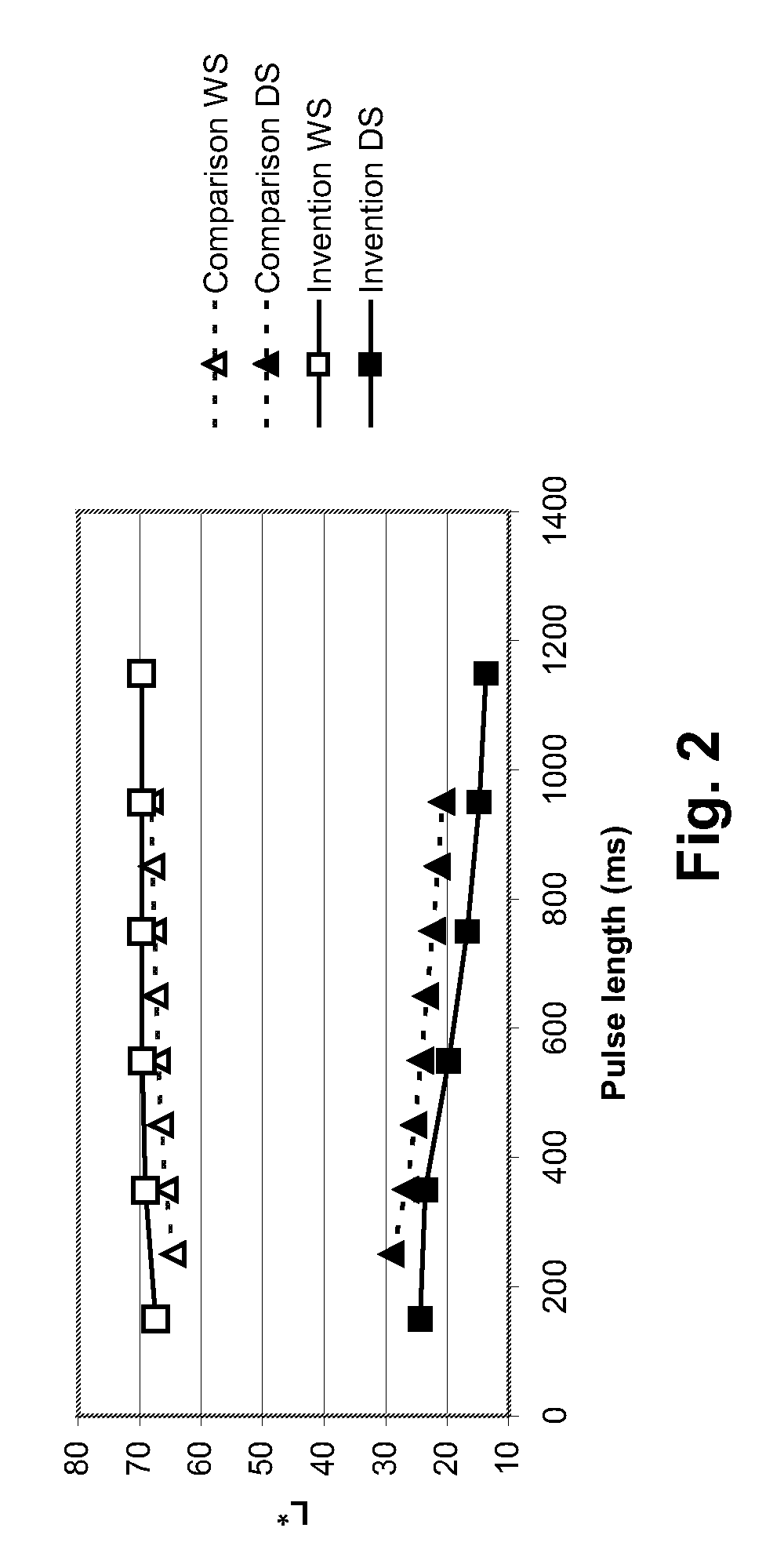

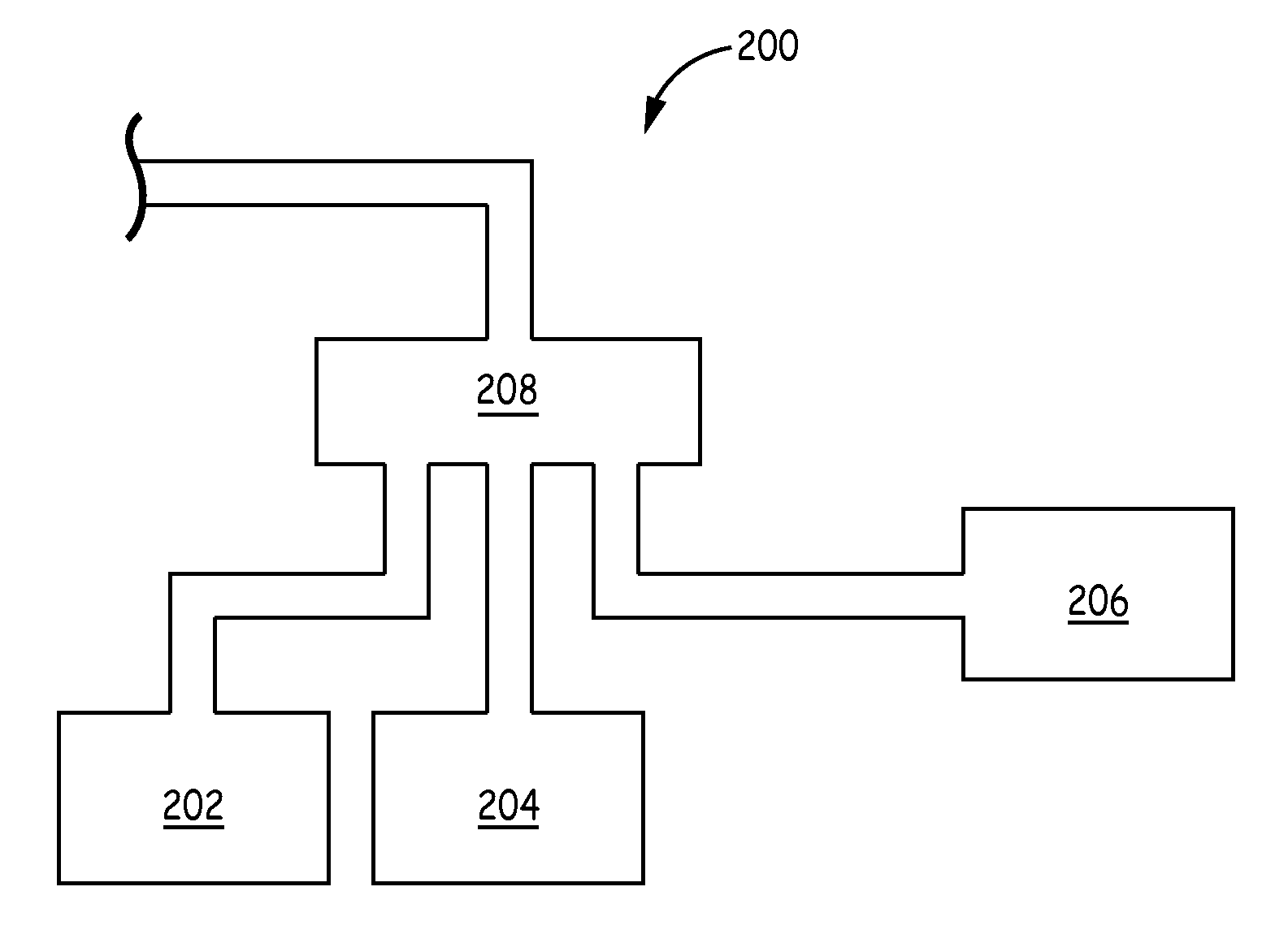

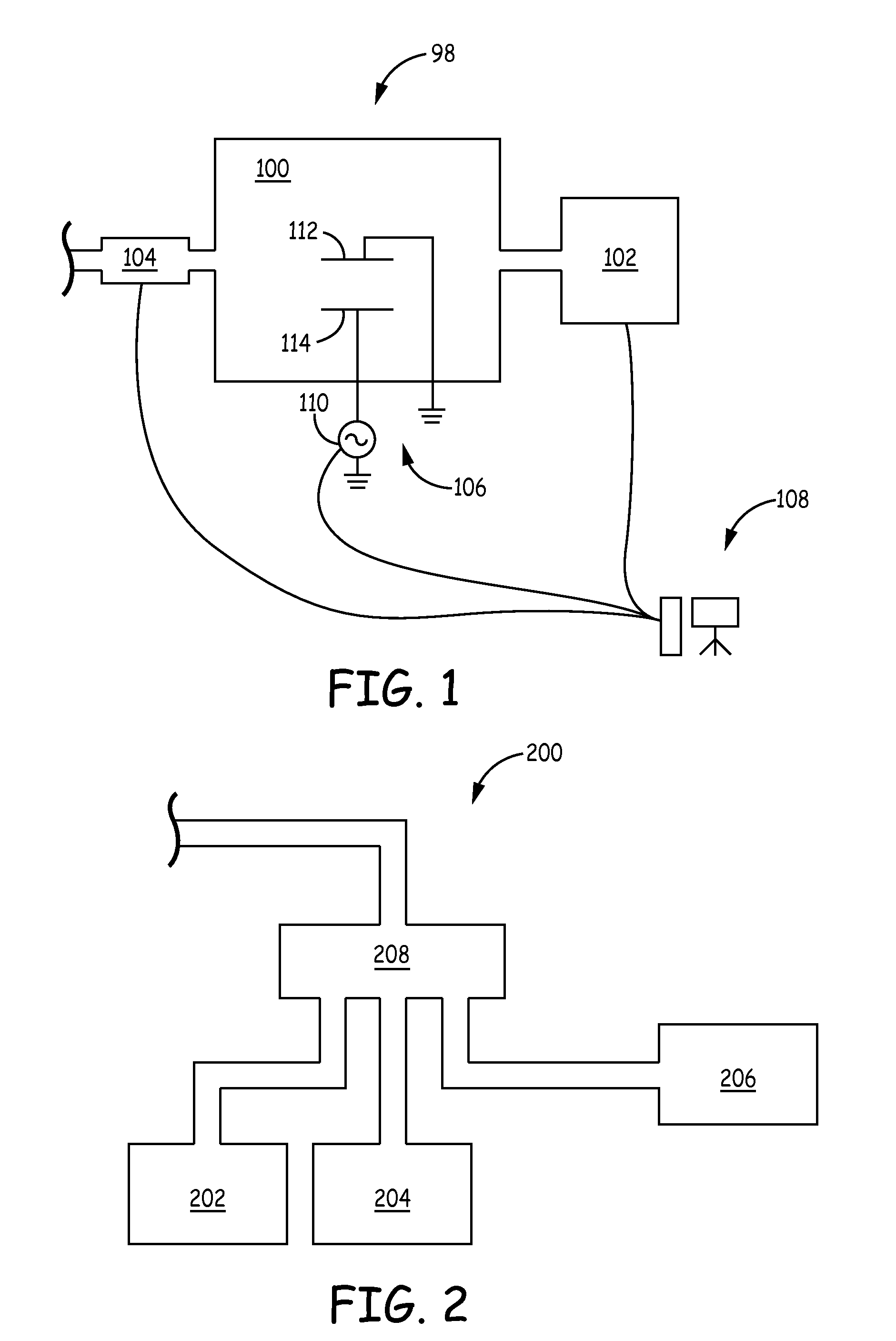

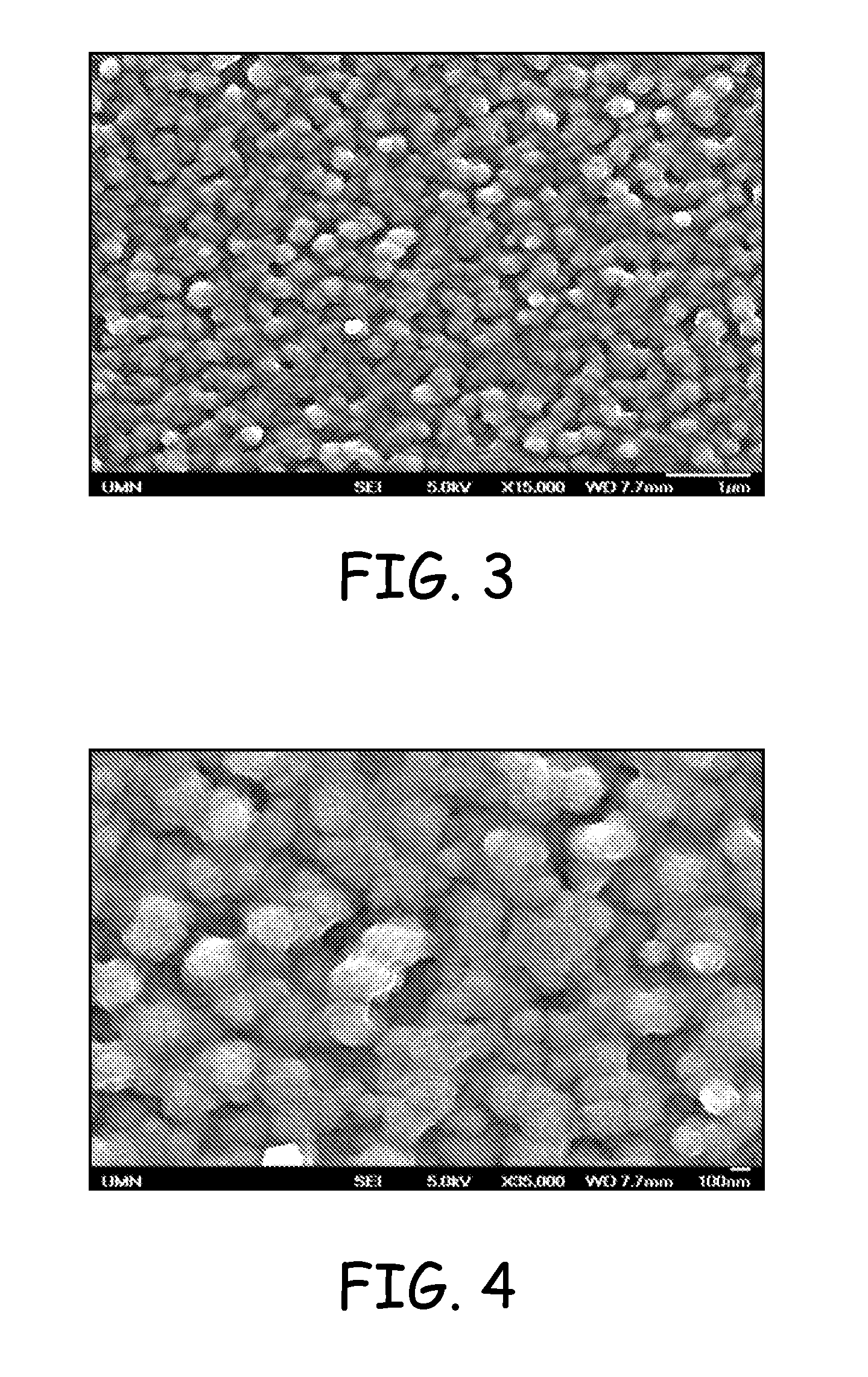

Apparatuses and methods are described that involve the deposition of polymer coatings on substrates. The polymer coatings generally comprise an electrically insulating layer and / or a hydrophobic layer. The hydrophobic layer can comprise fused polymer particles have an average primary particle diameter on the nanometer to micrometer scale. The polymer coatings are deposited on substrates using specifically adapted plasma enhanced chemical vapor deposition approaches. The substrates can include computing devices and fabrics.

Owner:LIQUIPEL IP

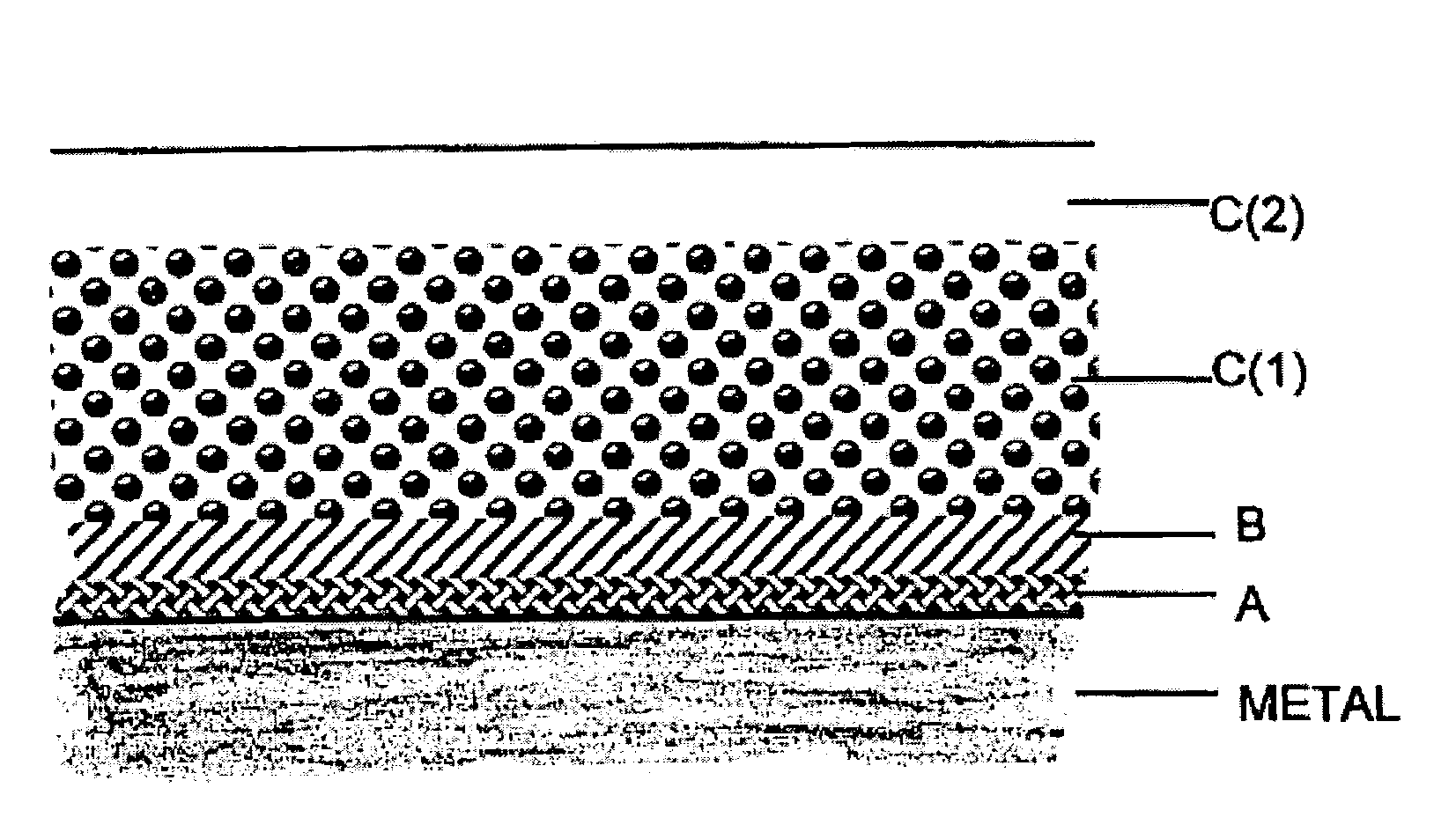

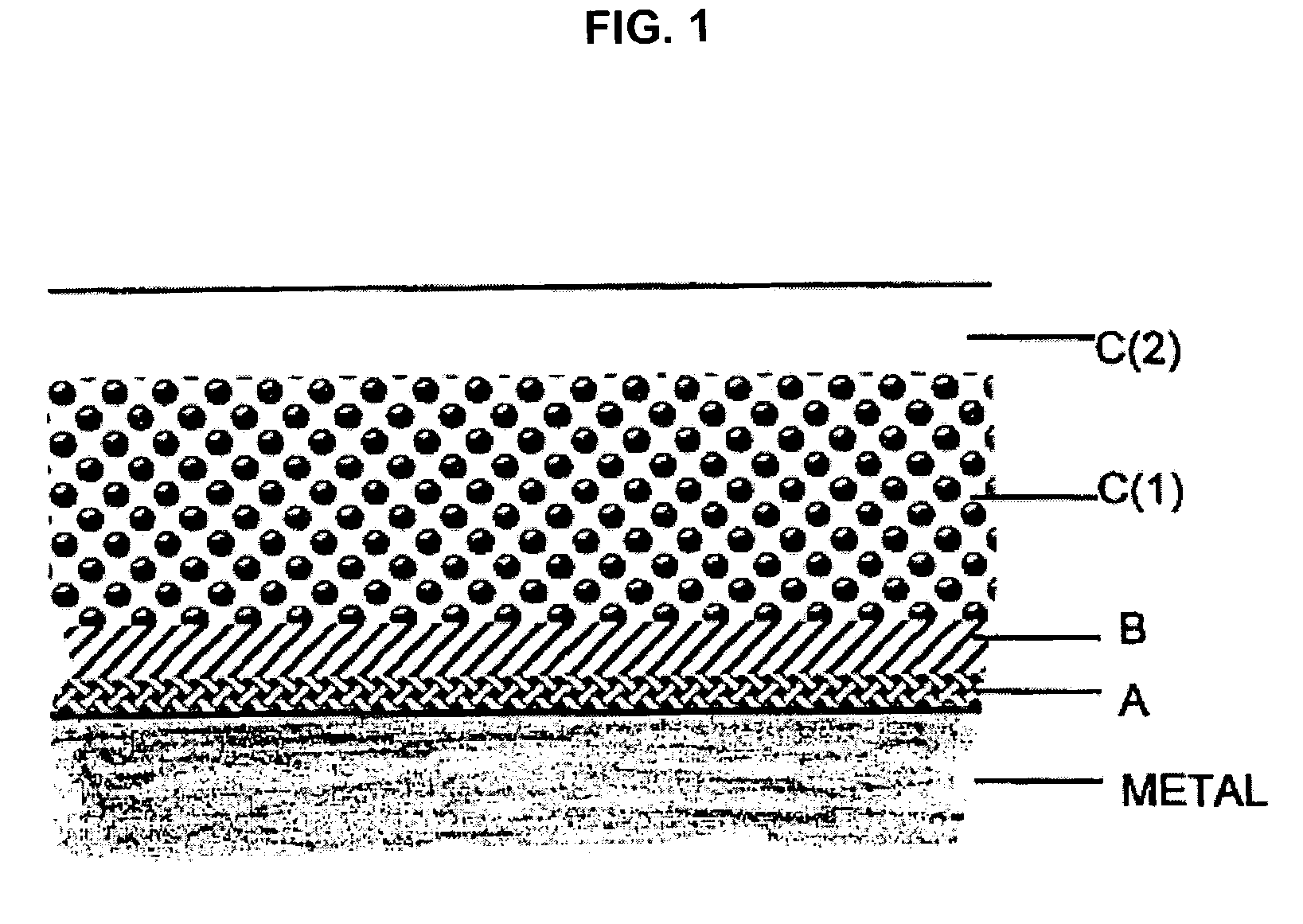

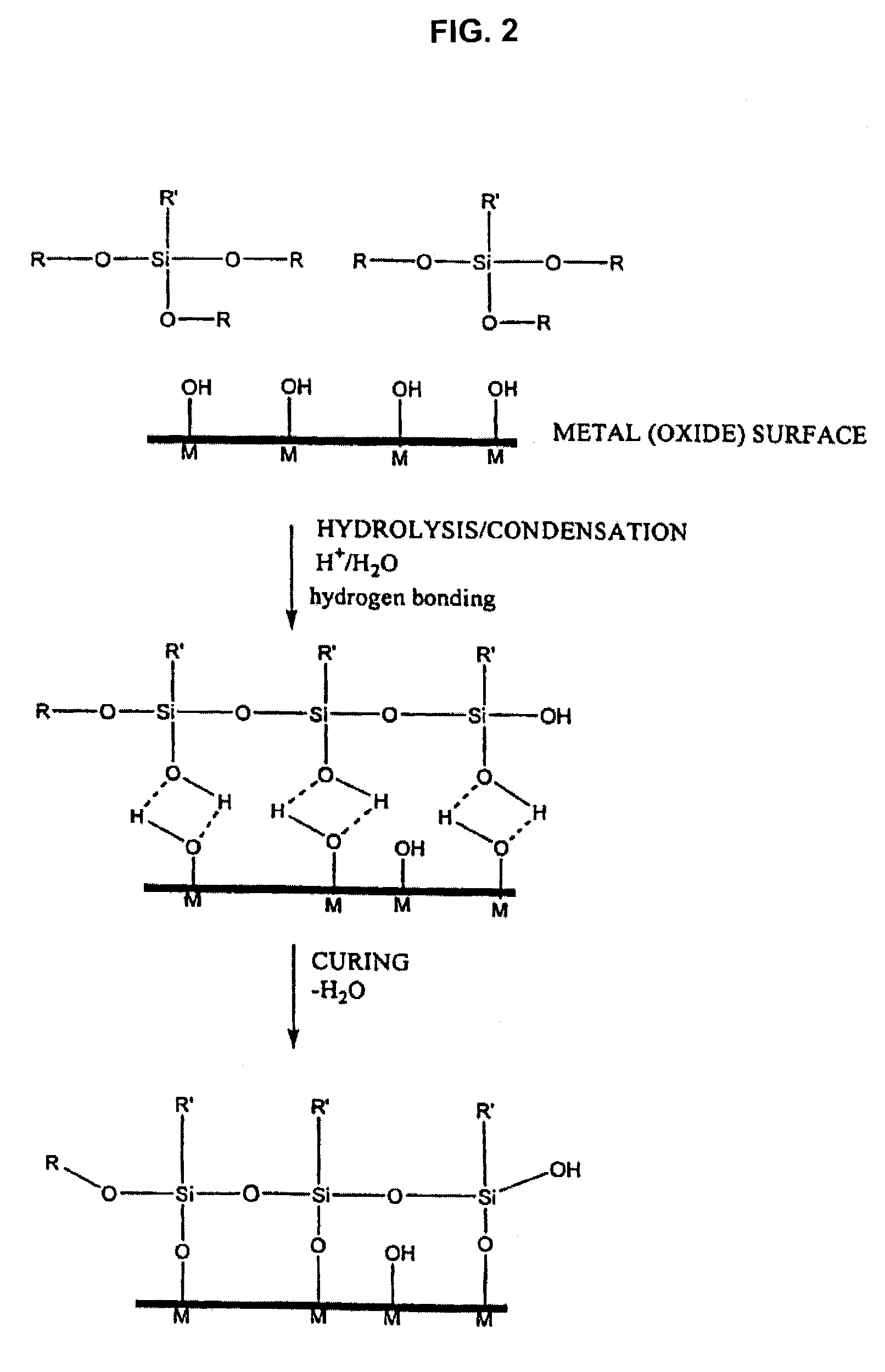

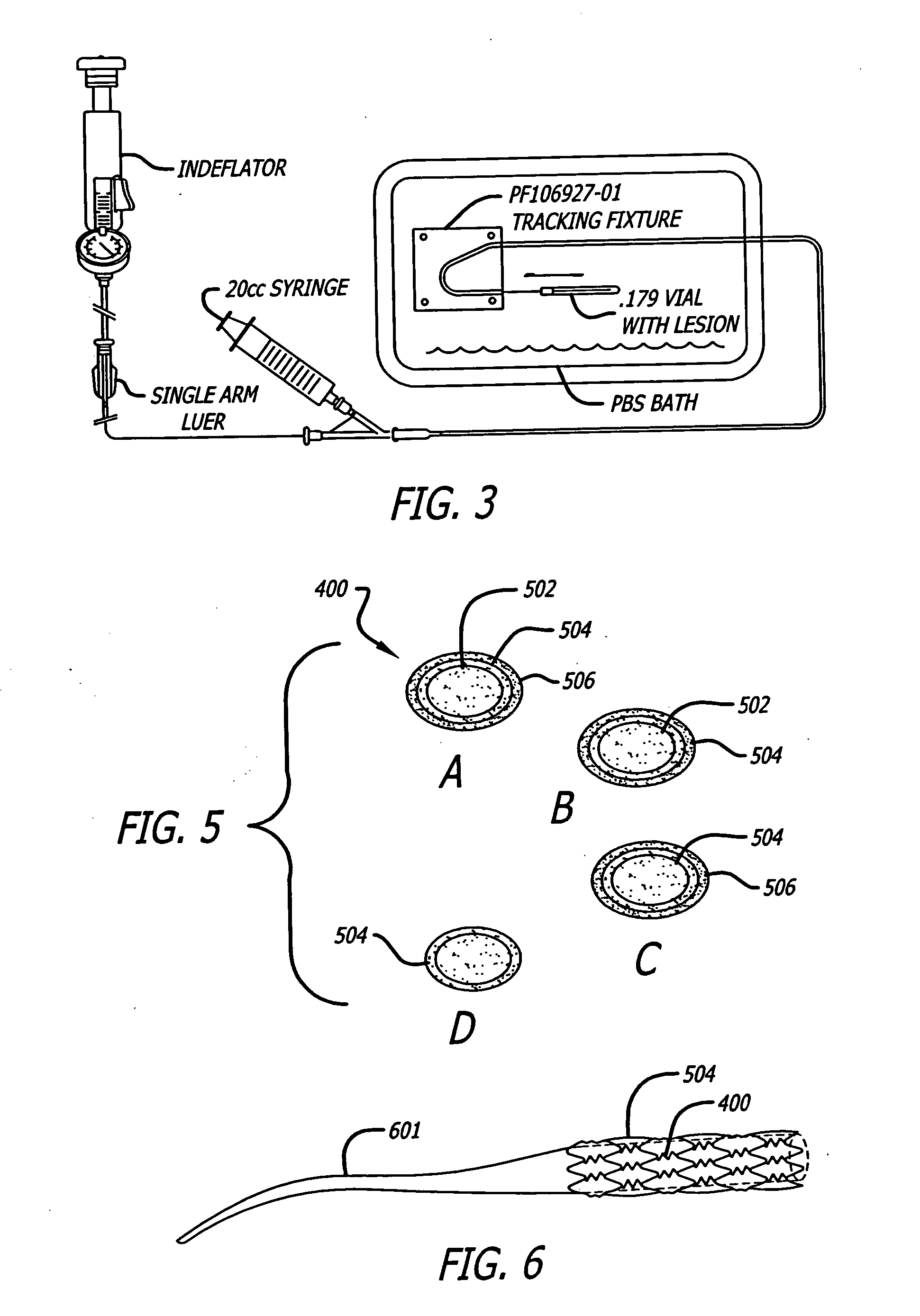

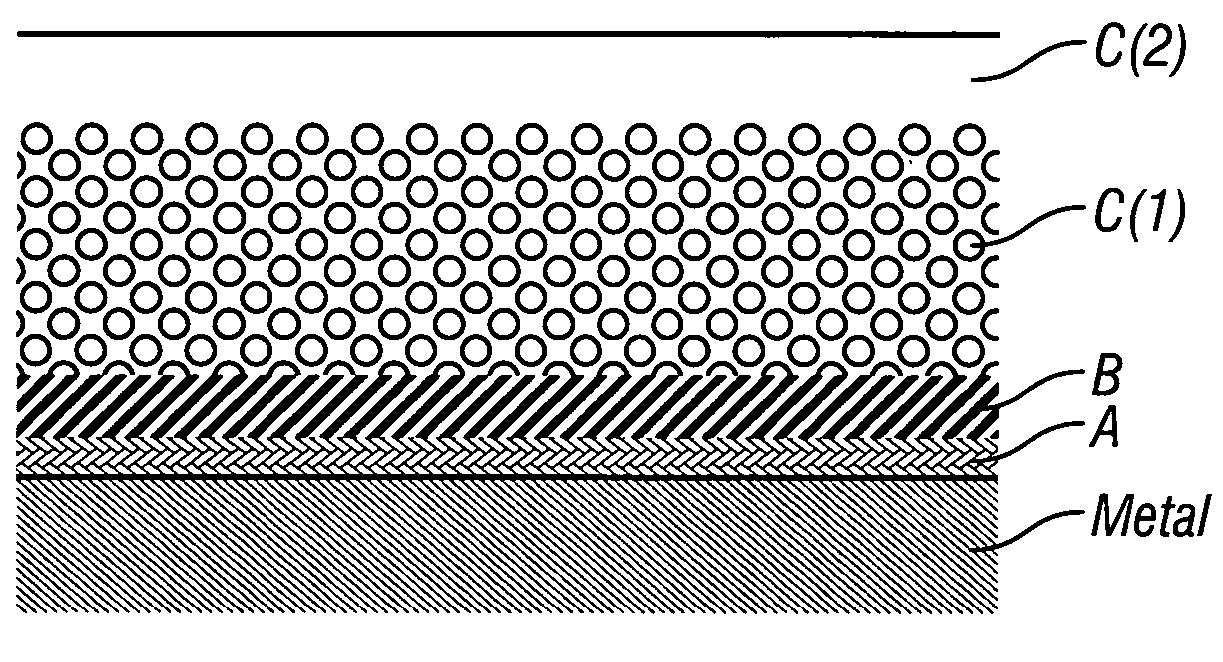

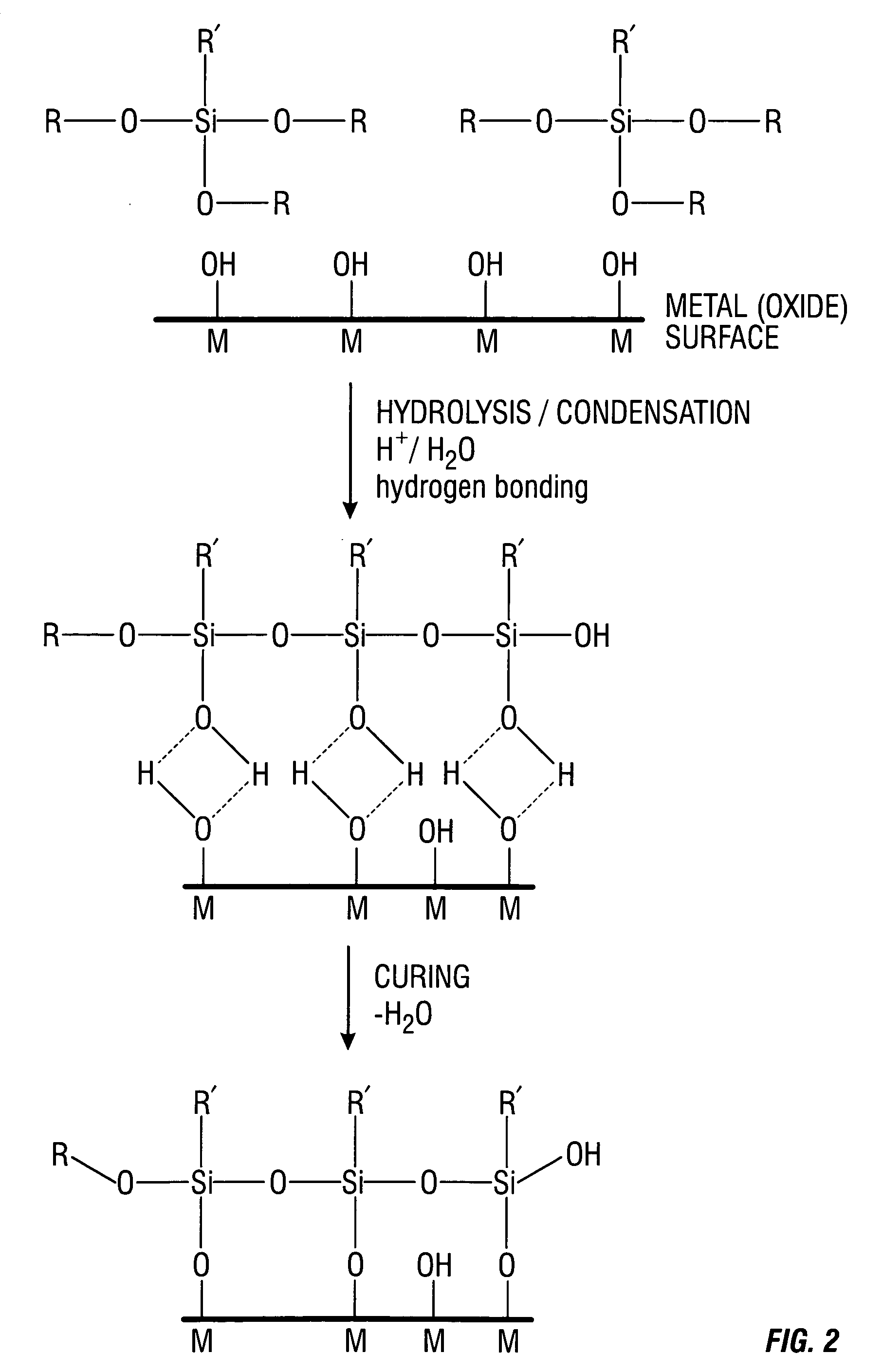

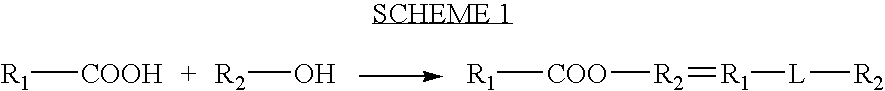

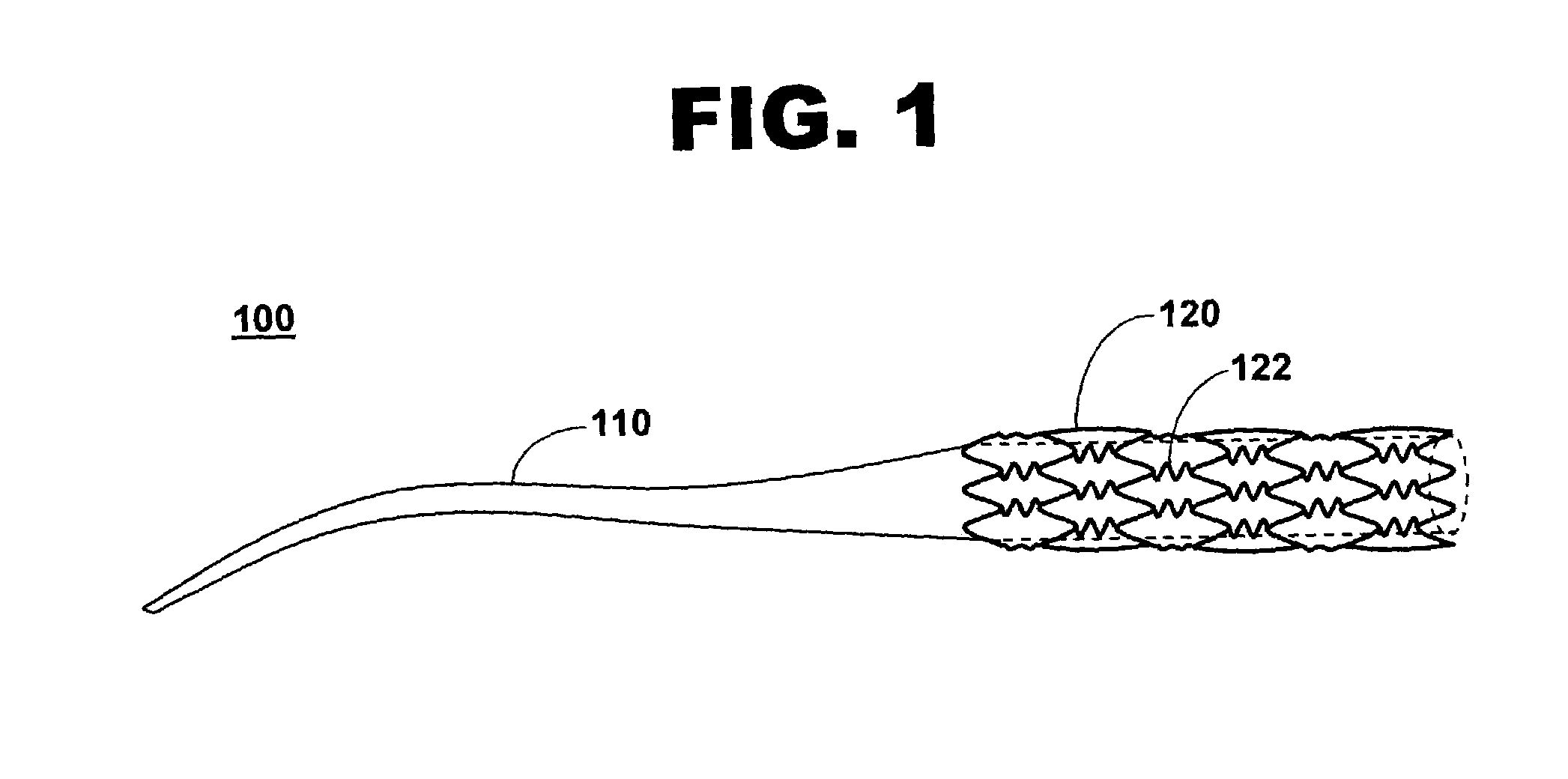

Polymer coating for medical devices

Coatings are provided in which surfaces may be activated by covalently bonding a silane derivative to the metal surface, covalently bonding a lactone polymer to the silane derivative by in situ ring opening polymerization, and depositing at least one layer of a polyester on the bonded lactone. Biologically active agents may be deposited with the polyester layers. Such coated surfaces may be useful in medical devices, in particular stents.

Owner:CV THERAPEUTICS INC

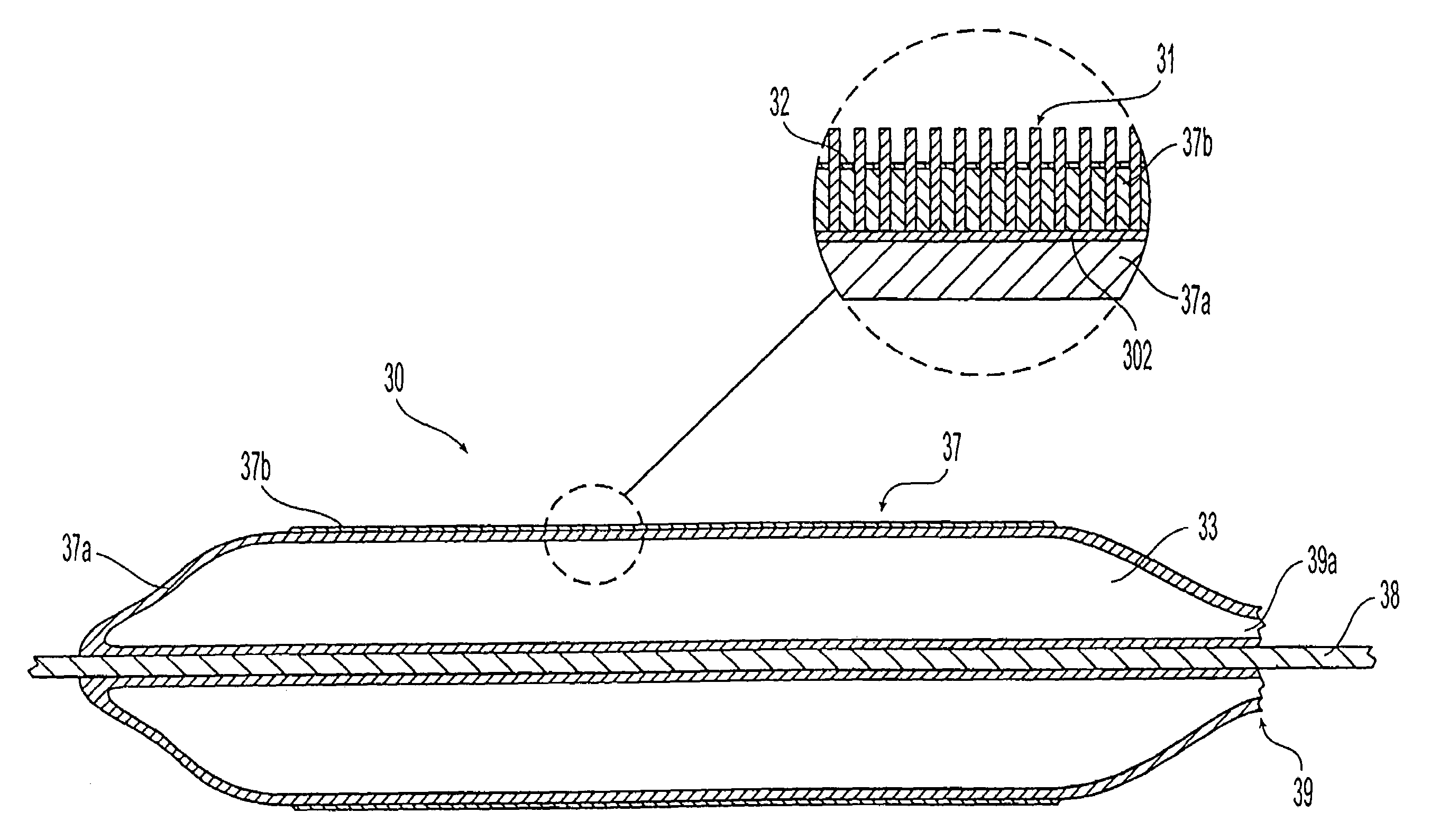

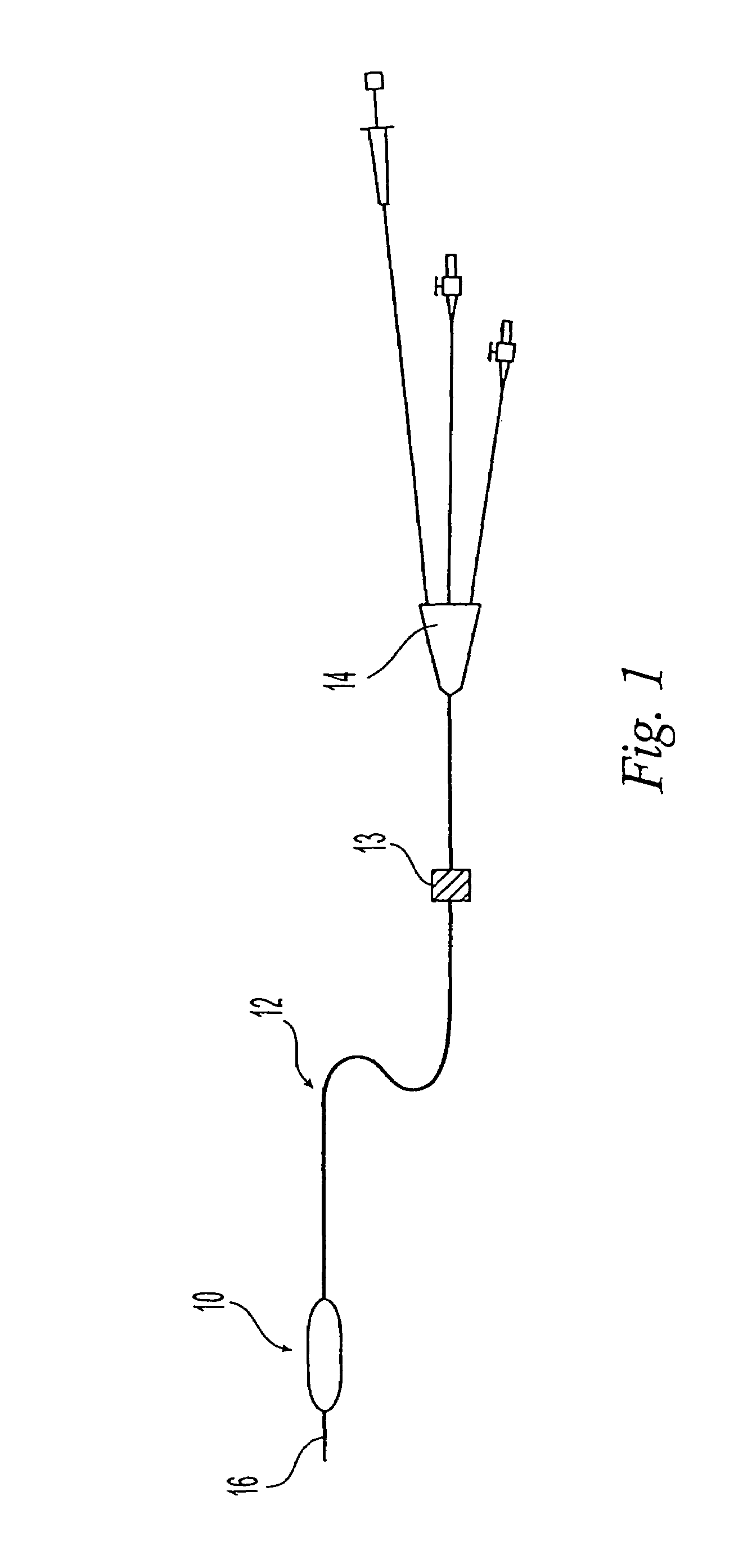

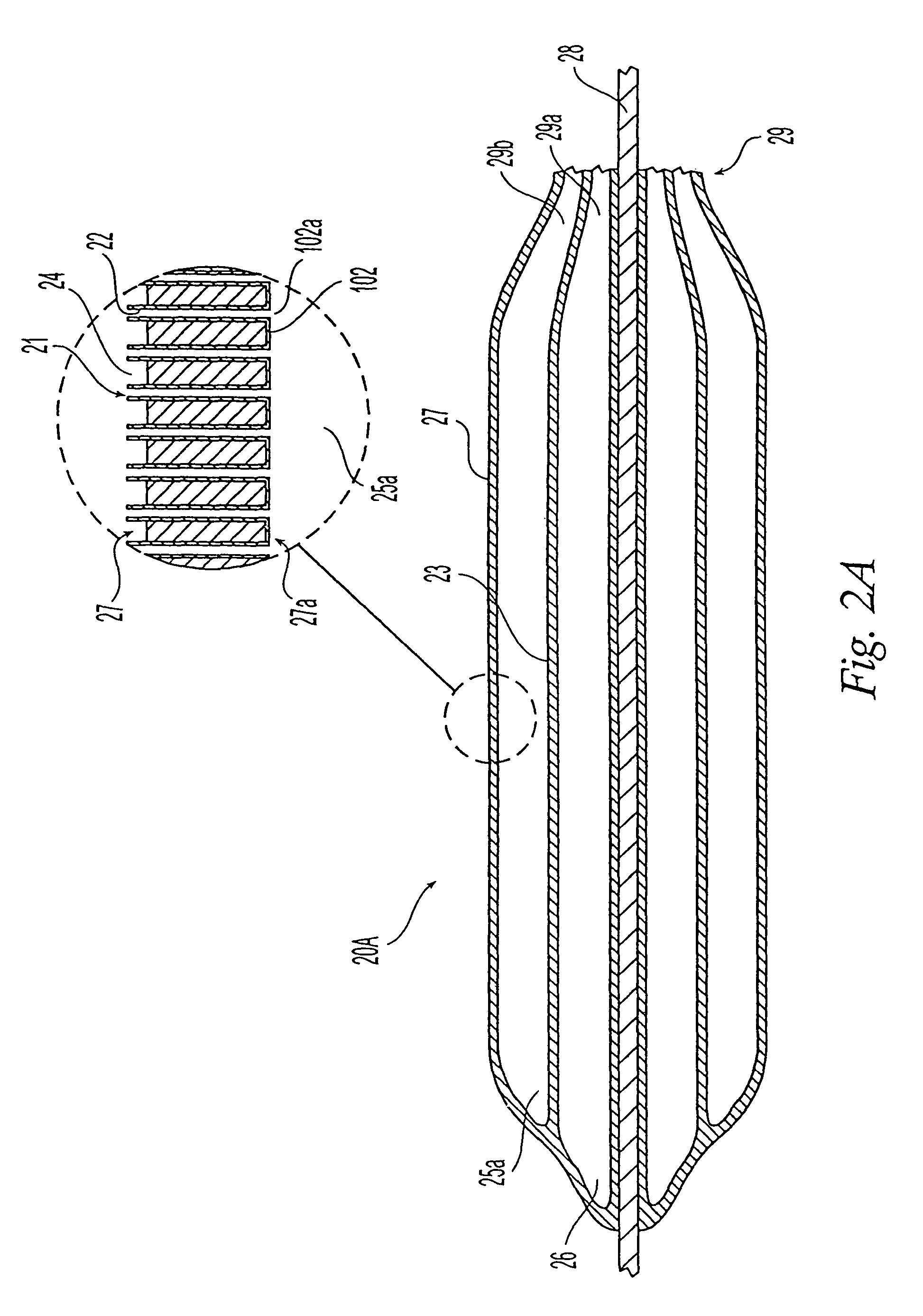

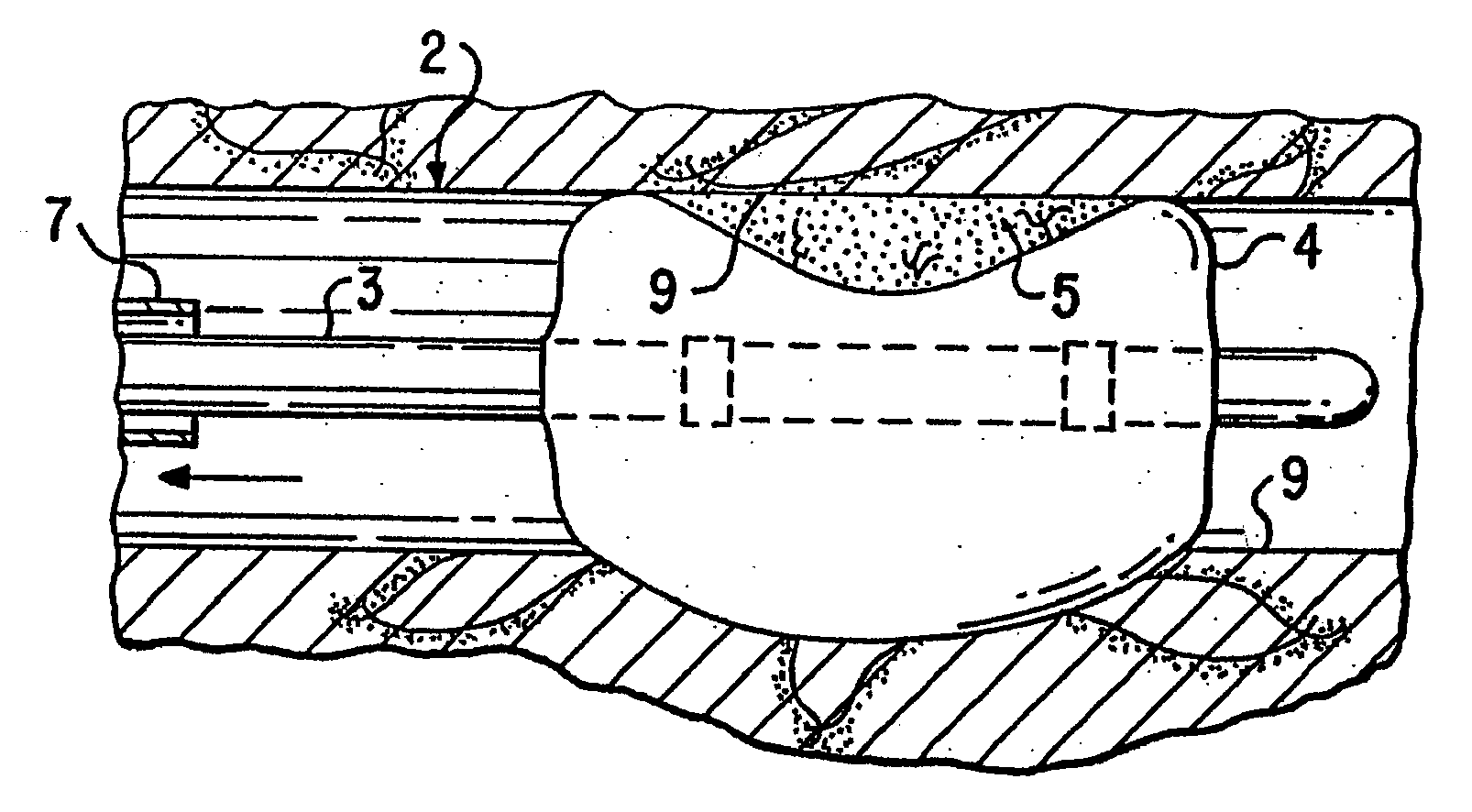

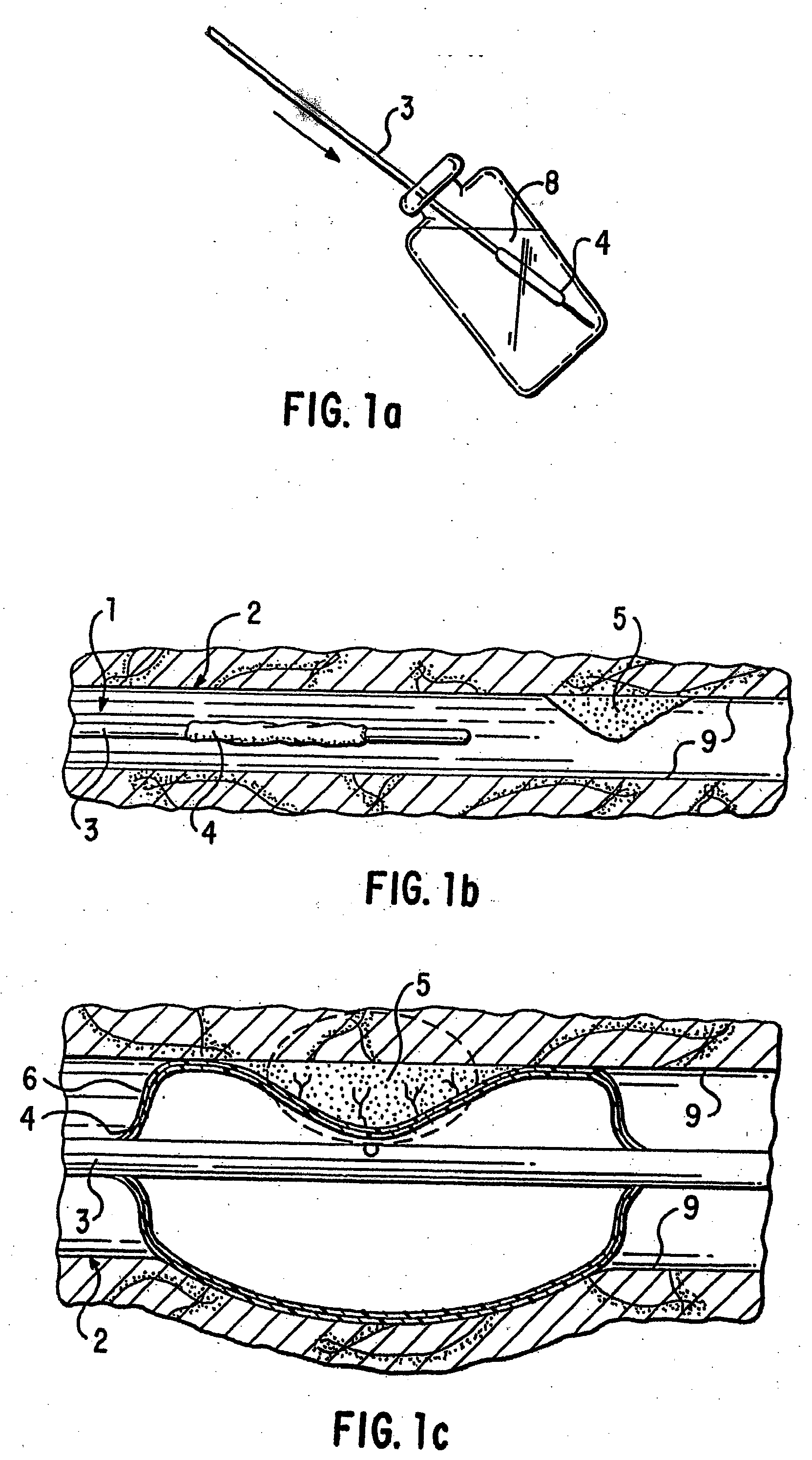

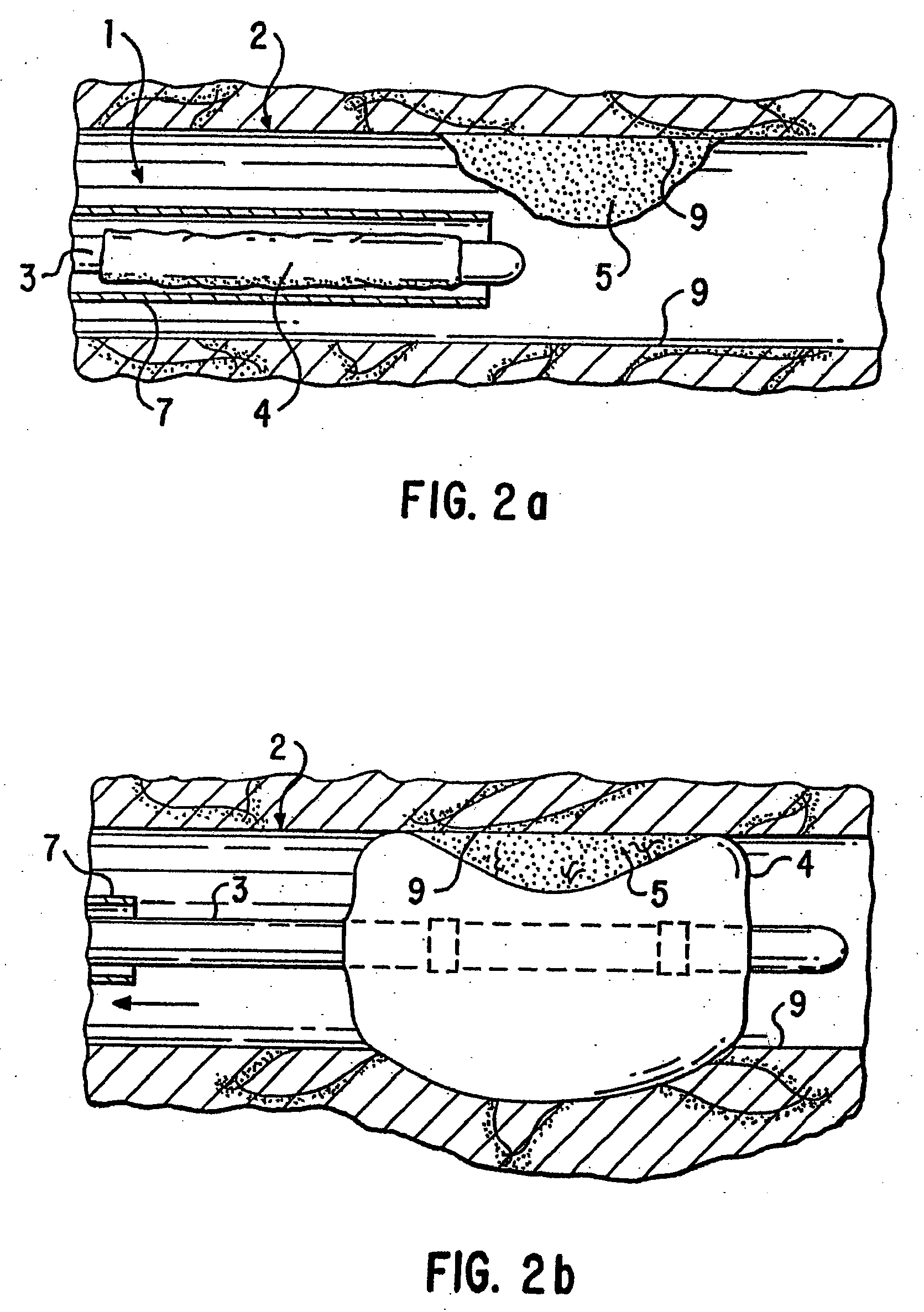

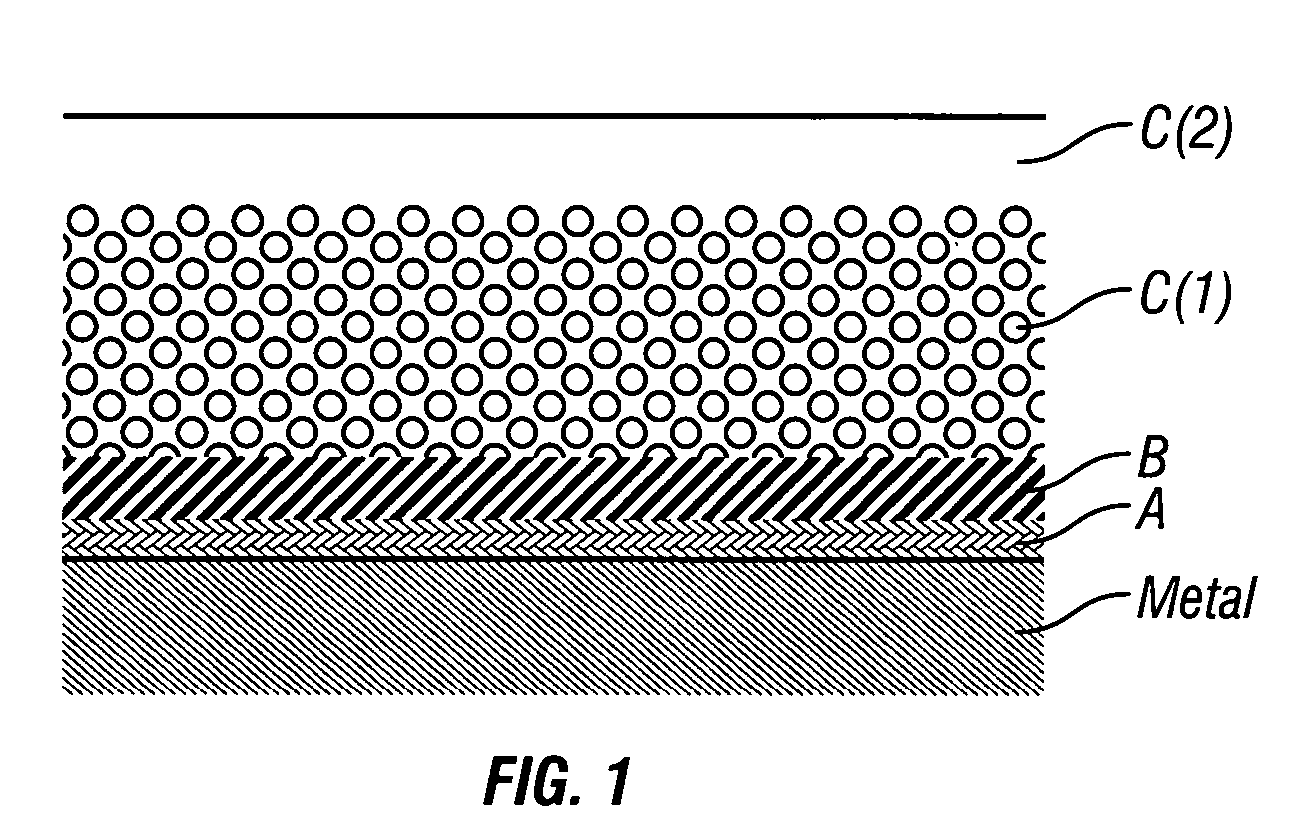

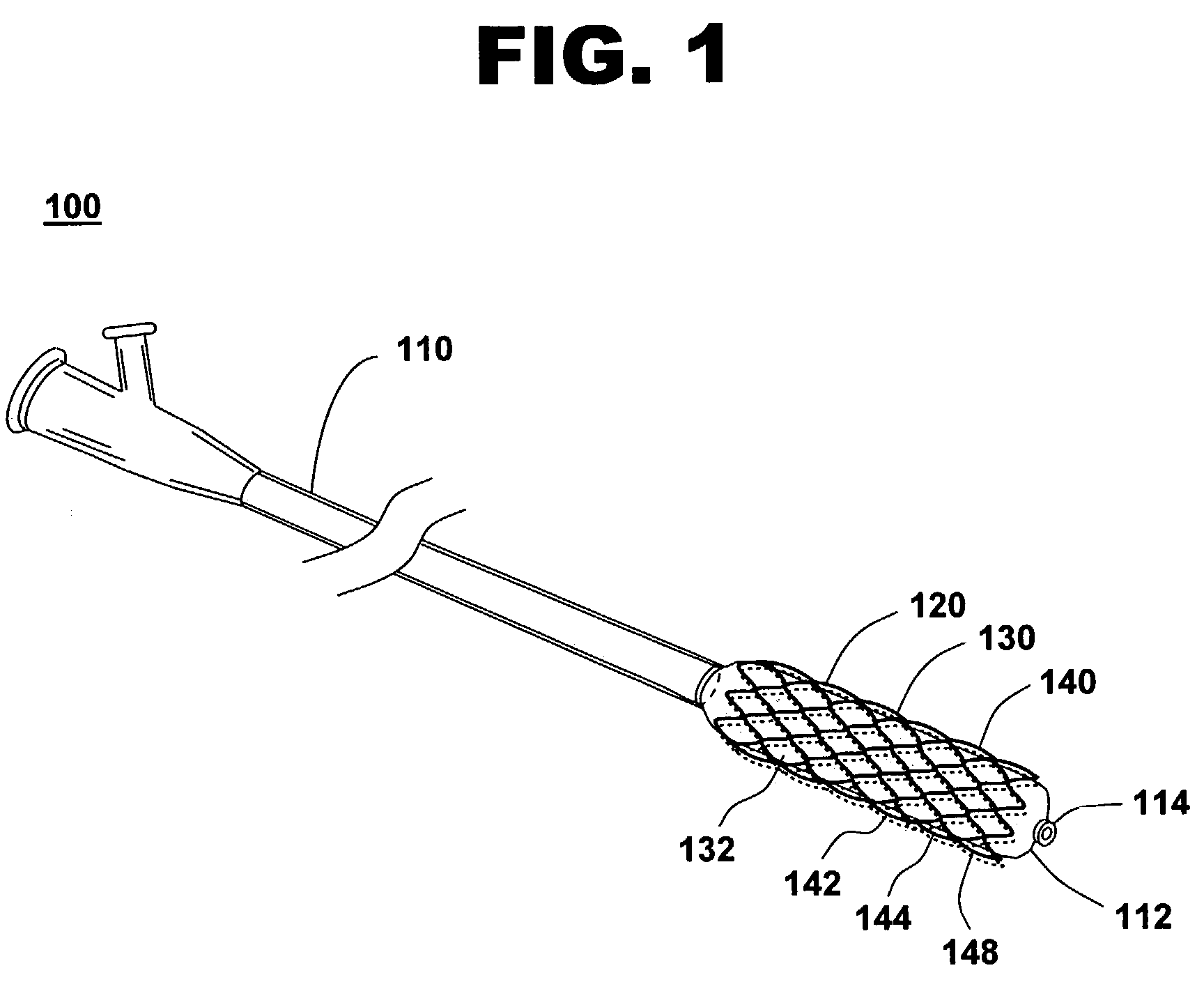

Medical device for delivery of a biologically active material to a lumen

An apparatus for delivery of biologically active materials comprises a catheter and balloon having micro-needles or pores. In the apparatus, the balloon can have a polymer coating containing the biologically active material, and the apparatus can include a sheath surrounding the balloon. In one embodiment the biologically active material is delivered through lumens in the micro-needles. Another embodiment of the invention is an apparatus for delivery of biologically active materials comprising a catheter with a balloon disposed thereon and a shockwave generator for producing a shockwave for delivering the biologically active material to a body lumen. Methods for delivery of biologically active materials are also disclosed.

Owner:BOSTON SCI SCIMED INC

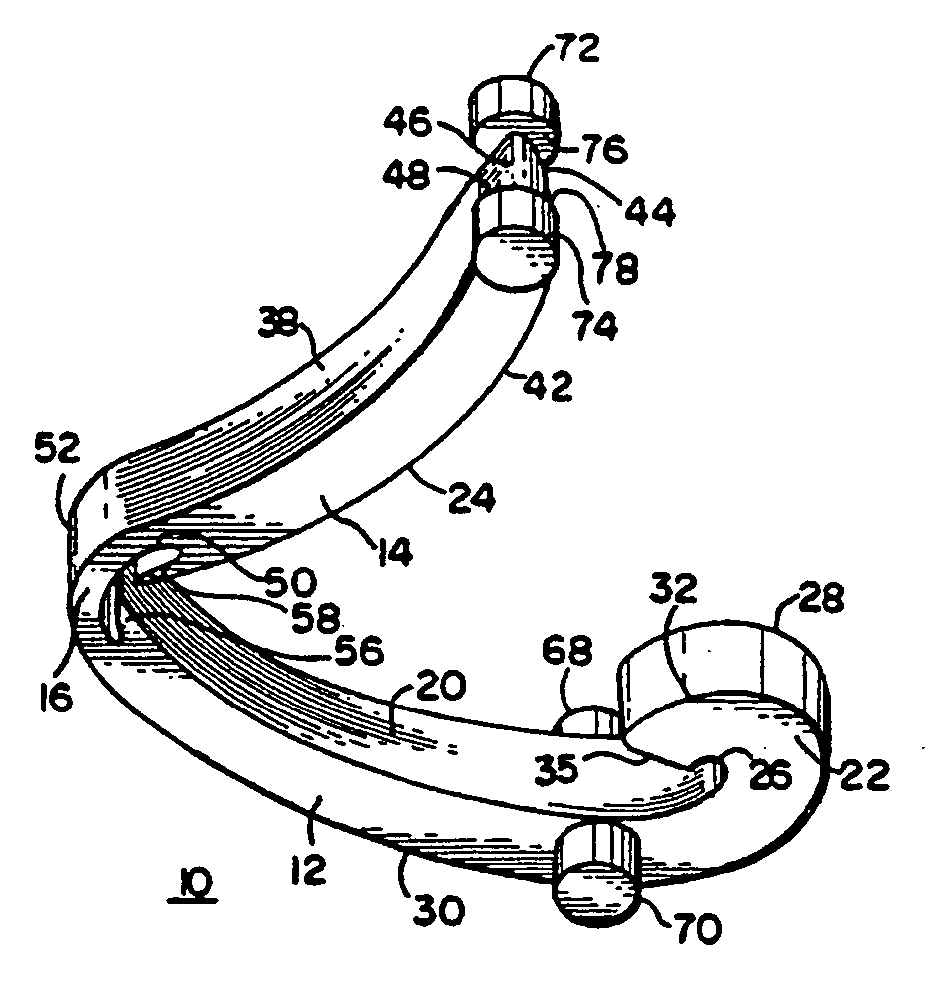

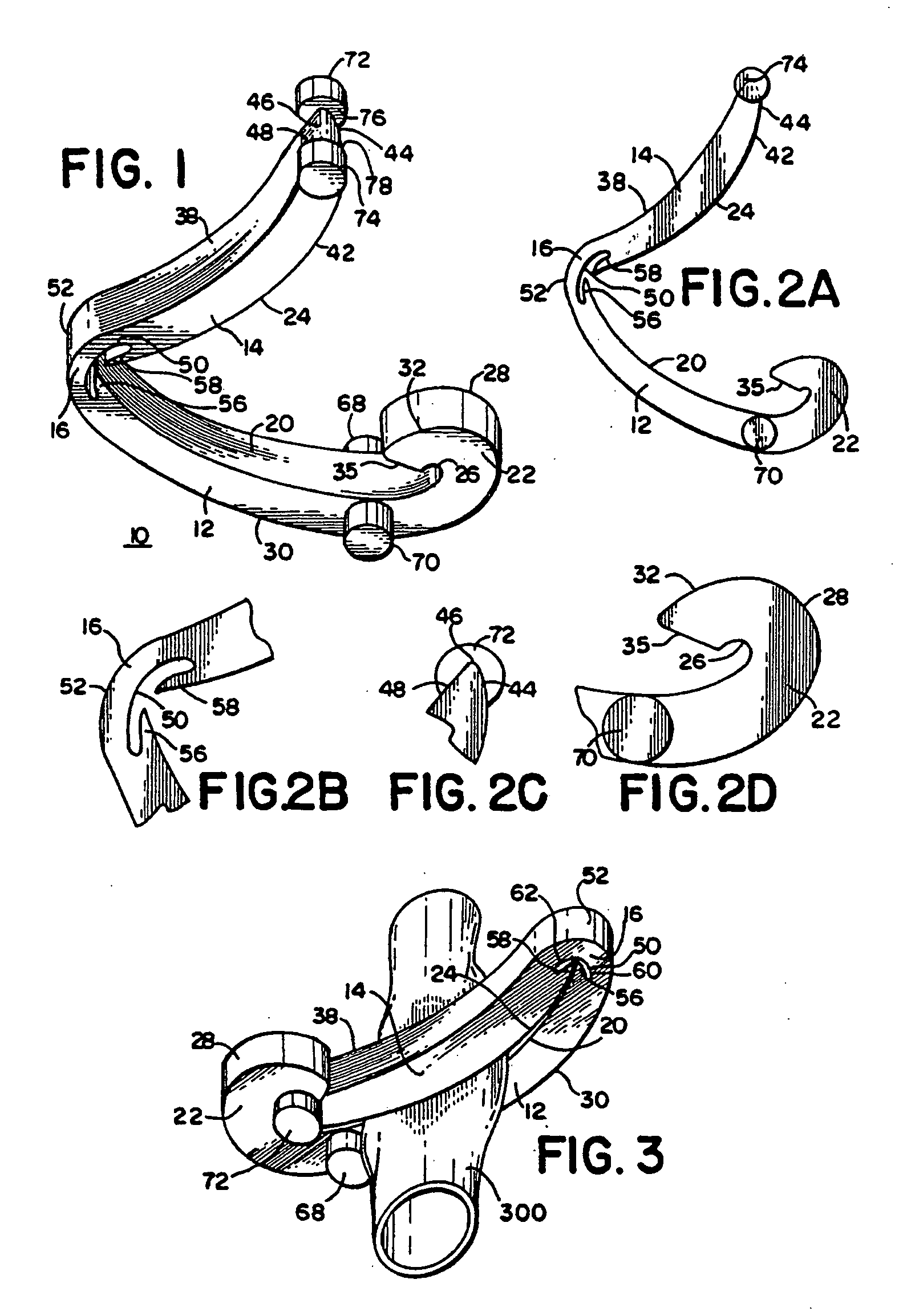

Coated ligating clip

A polymeric, surgical clip having first and second curved leg members joined at their proximal end by a hinge portion and movable from an open position to a closed position for clamping a vessel between curved opposing inner surfaces. The clip includes a coating on its exterior which reduces the friction between the leg members and complementary locking mechanisms disposed at the distal end portions of the leg members, and stabilizes closing of the clip. The coating can be any coating, including a polymer coating such as one which includes polytetrafluoroethylene. The coating may be applied using a solvent such as HFC43-10.

Owner:PILLING WECK INC

Nanoparticle-based controlled release polymer coatings for medical implants

InactiveUS20050095267A1Improve solubilityFacilitated releaseStentsSurgeryControlled releaseSolubility

Implantable medical devices having a nanoparticle coating applied thereon. The nanoparticle coating comprises nanopulverized antiproliferative compounds. More specifically, the nanoparticulate antiproliferative compounds comprise particles less than 500 nm in size. The nanoparticle size of the compounds improves compounds' solubility. In addition to improving the solubility of otherwise insoluable antiproliferative compounds, the nanoparticle size minimizes the preparation and formulation required to prepare a dose of the antiproliferative compounds.

Owner:MEDTRONIC VASCULAR INC

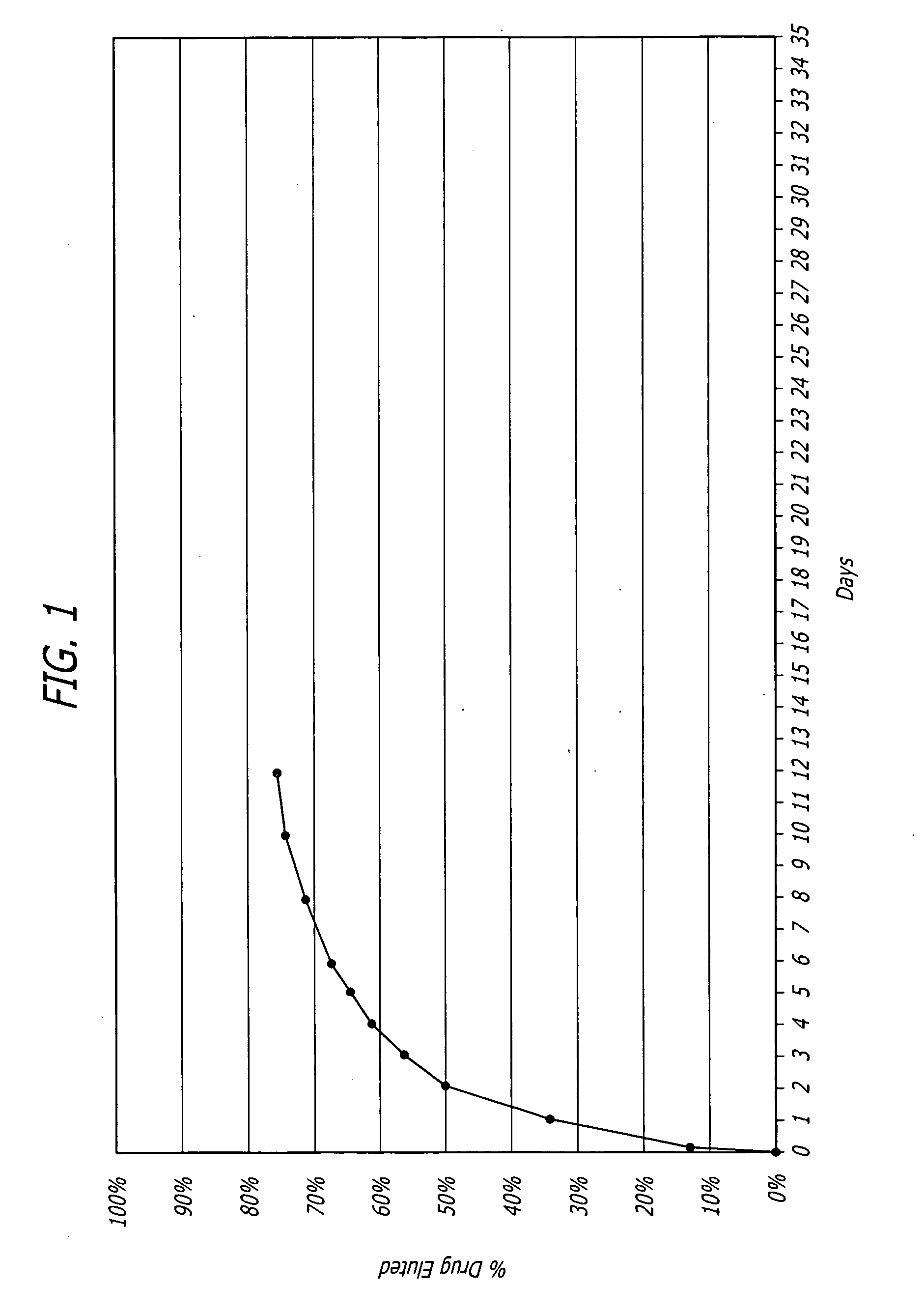

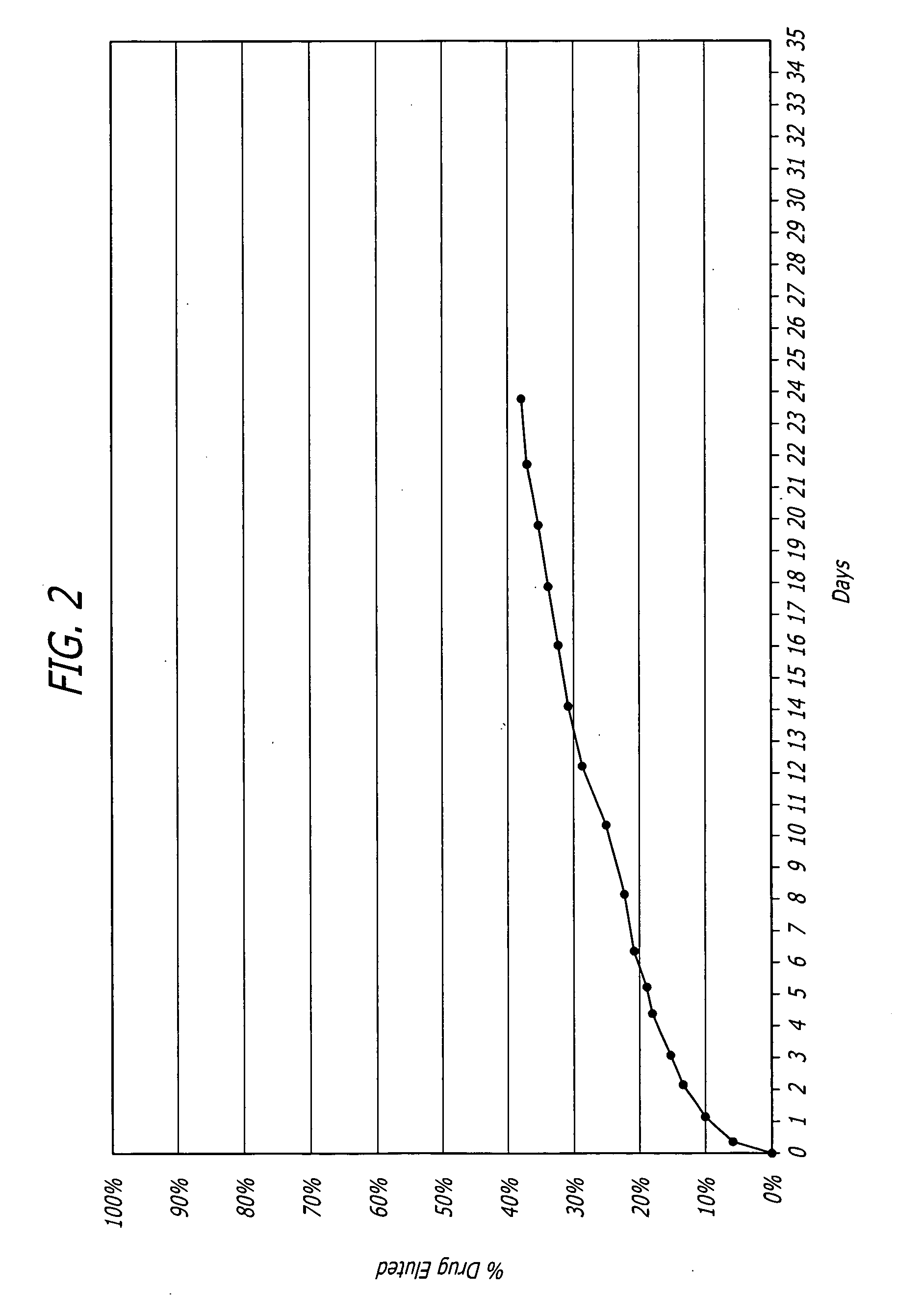

Hydrophobic biologically absorbable coatings for drug delivery devices and methods for fabricating the same

Owner:ABBOTT CARDIOVASCULAR

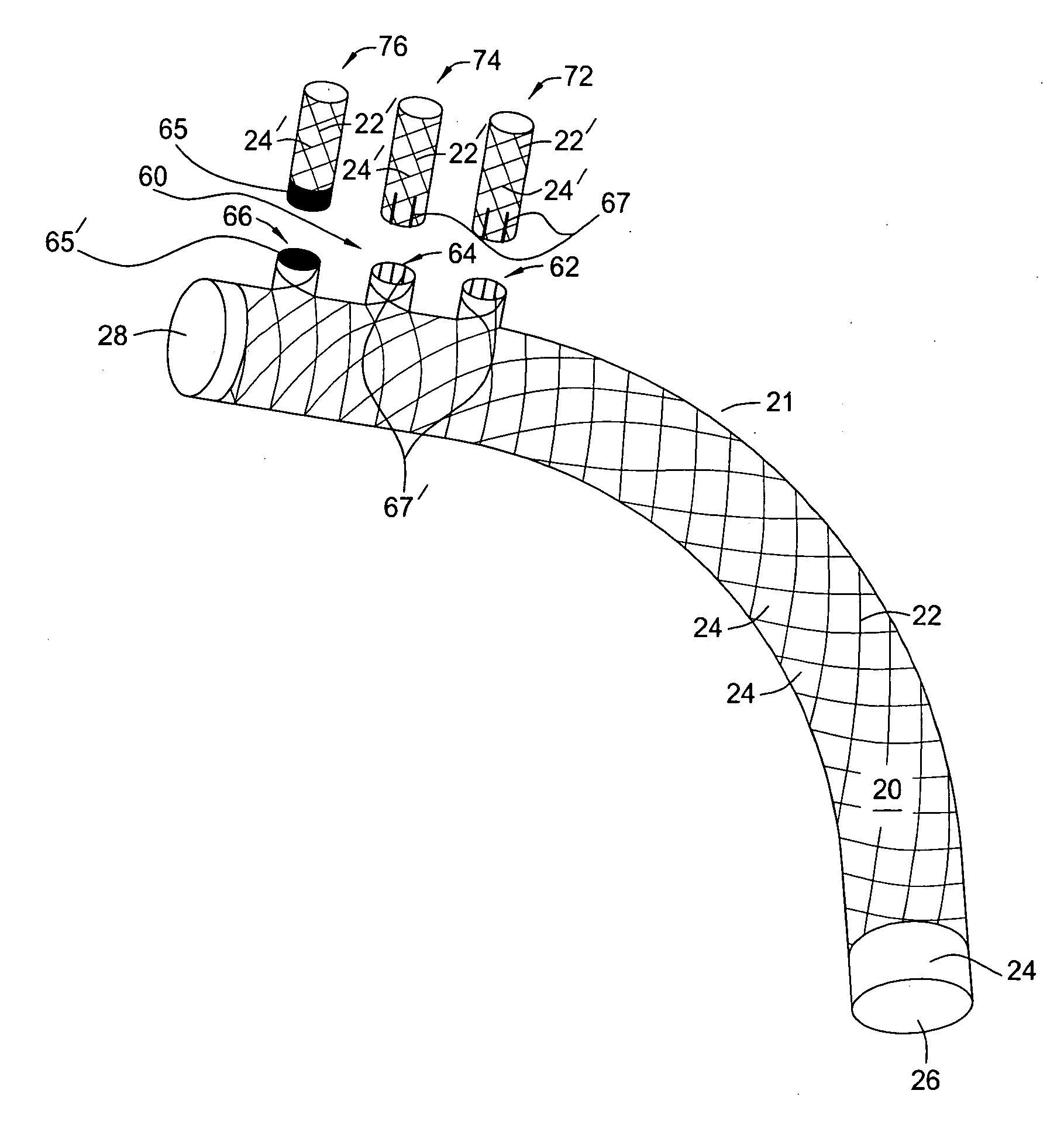

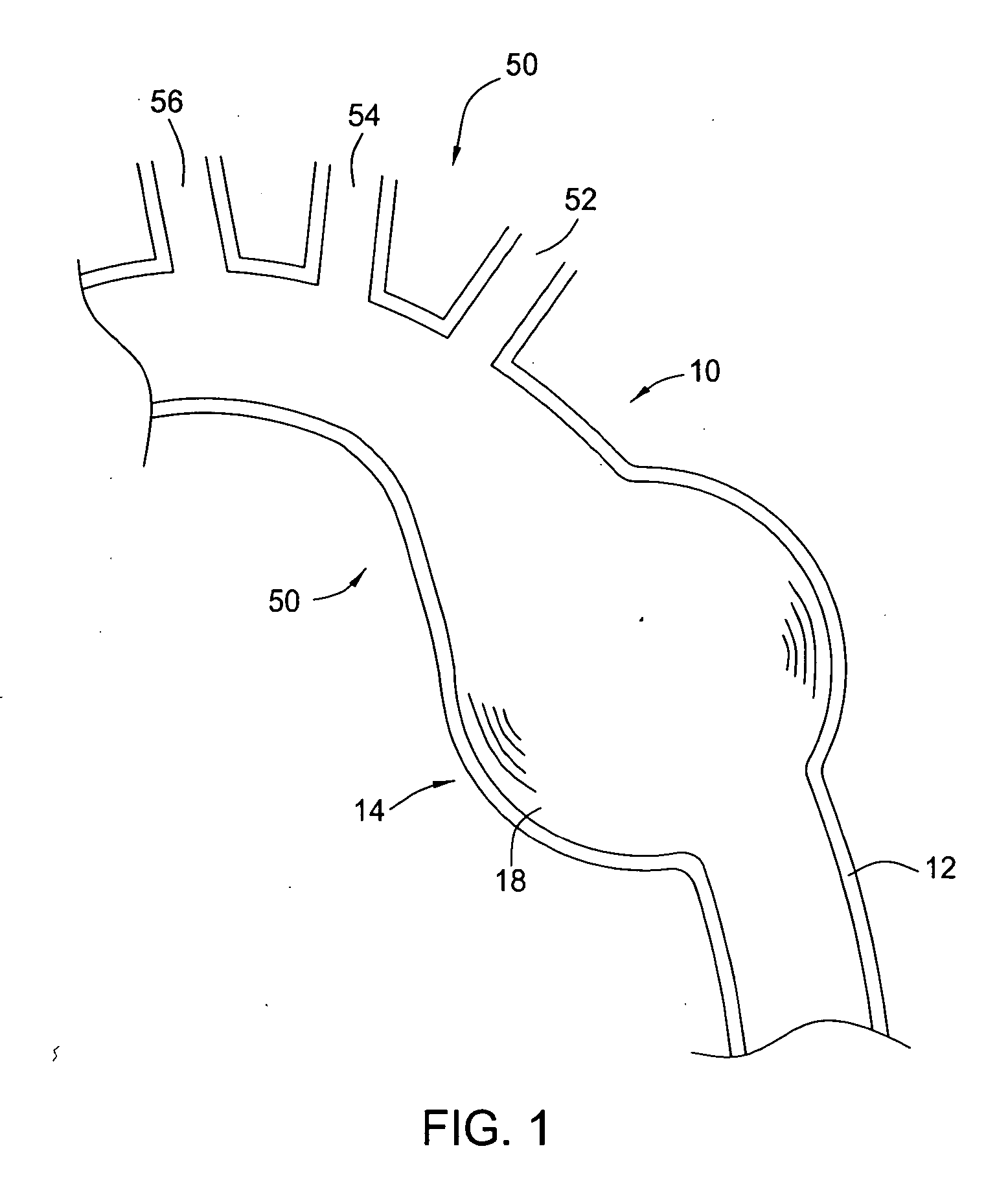

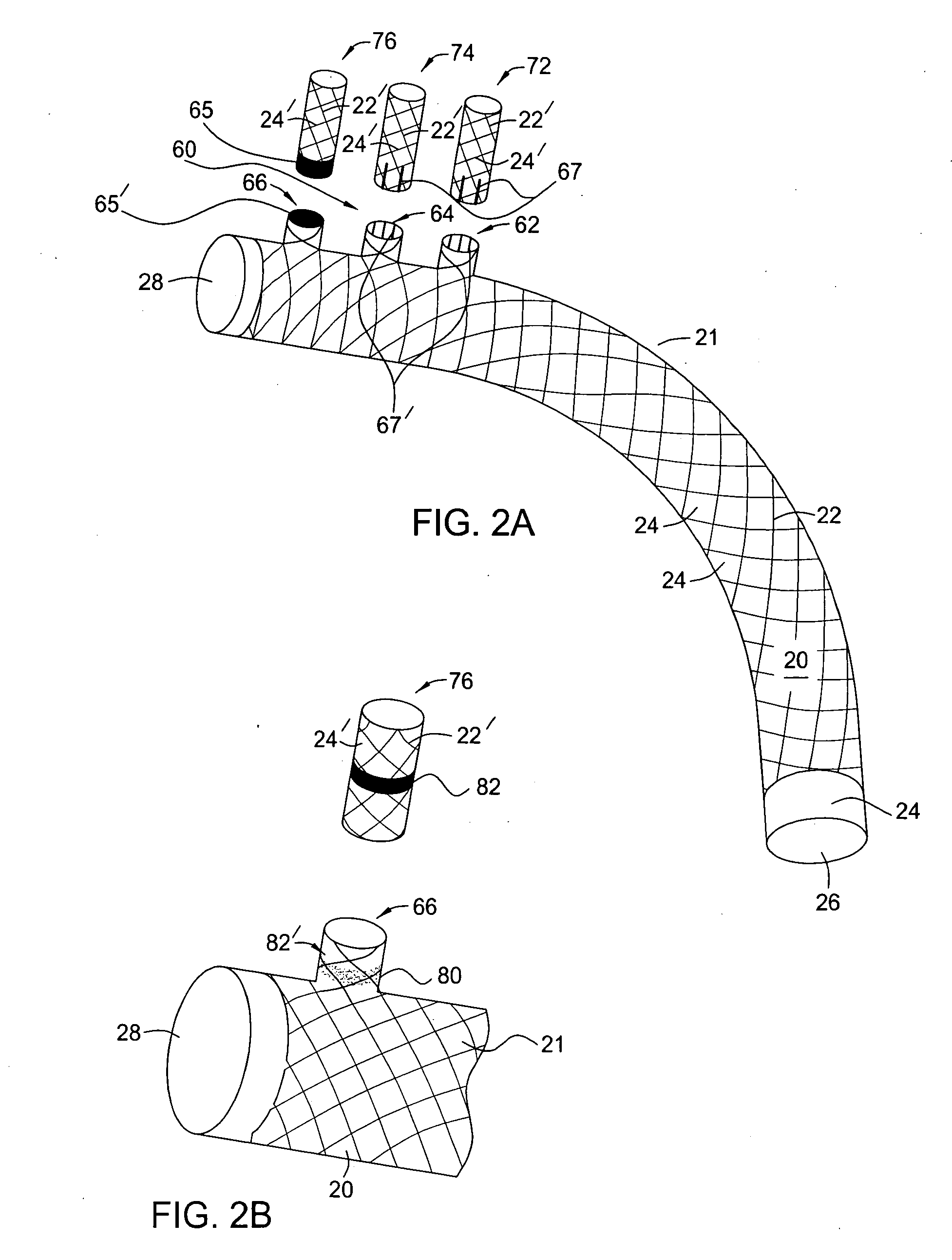

Methods and apparatus for treatment of aneurysms adjacent branch arteries

Owner:MEDTRONIC VASCULAR INC

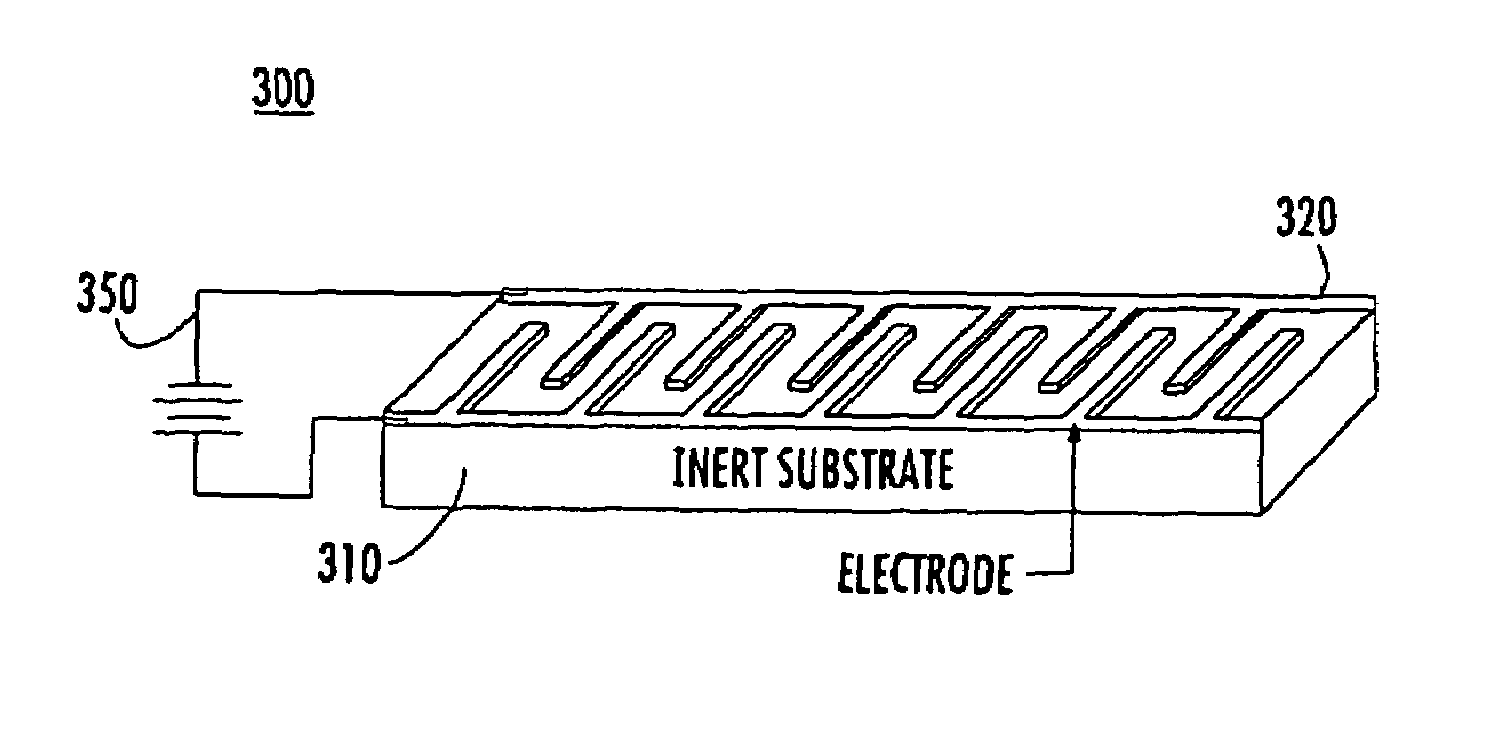

Electrophoretic particles, and processes for the production thereof

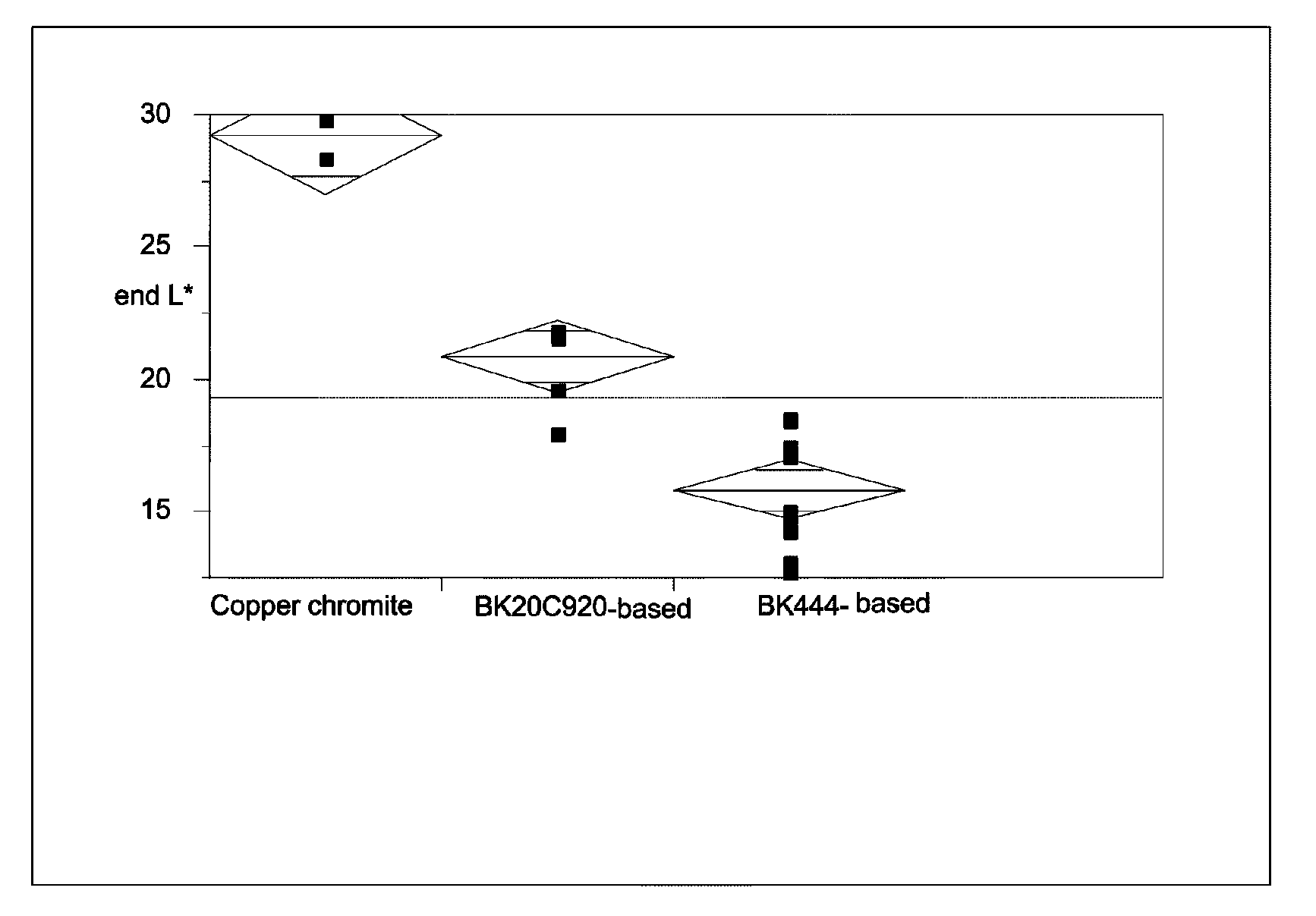

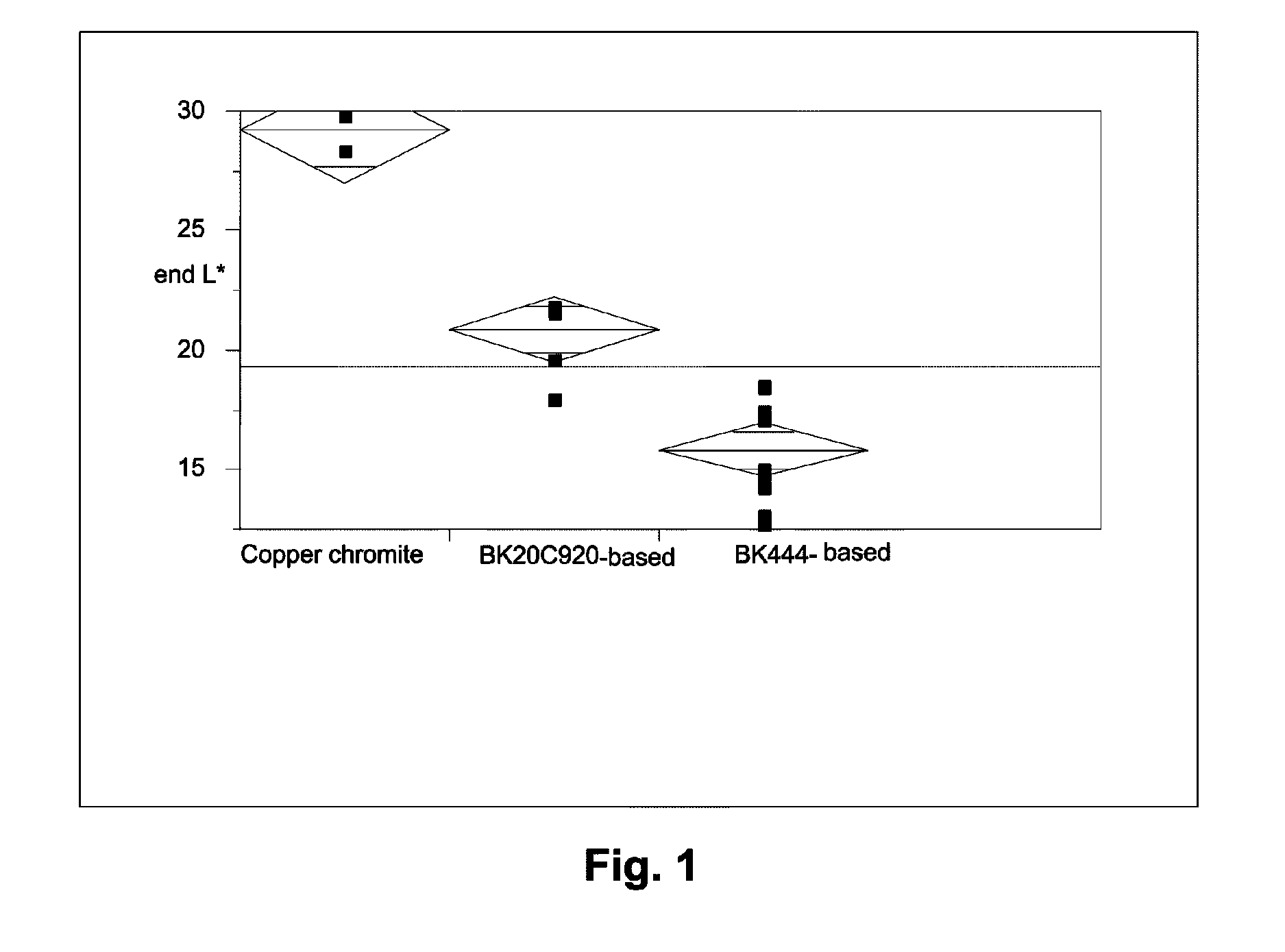

InactiveUS20050000813A1Volume/mass flow measurementFluid pressure measurement by electric/magnetic elementsElectrophoresisCopper chromite

Owner:E INK CORPORATION

Loading and release of water-insoluble drugs

Owner:BOSTON SCI SCIMED INC

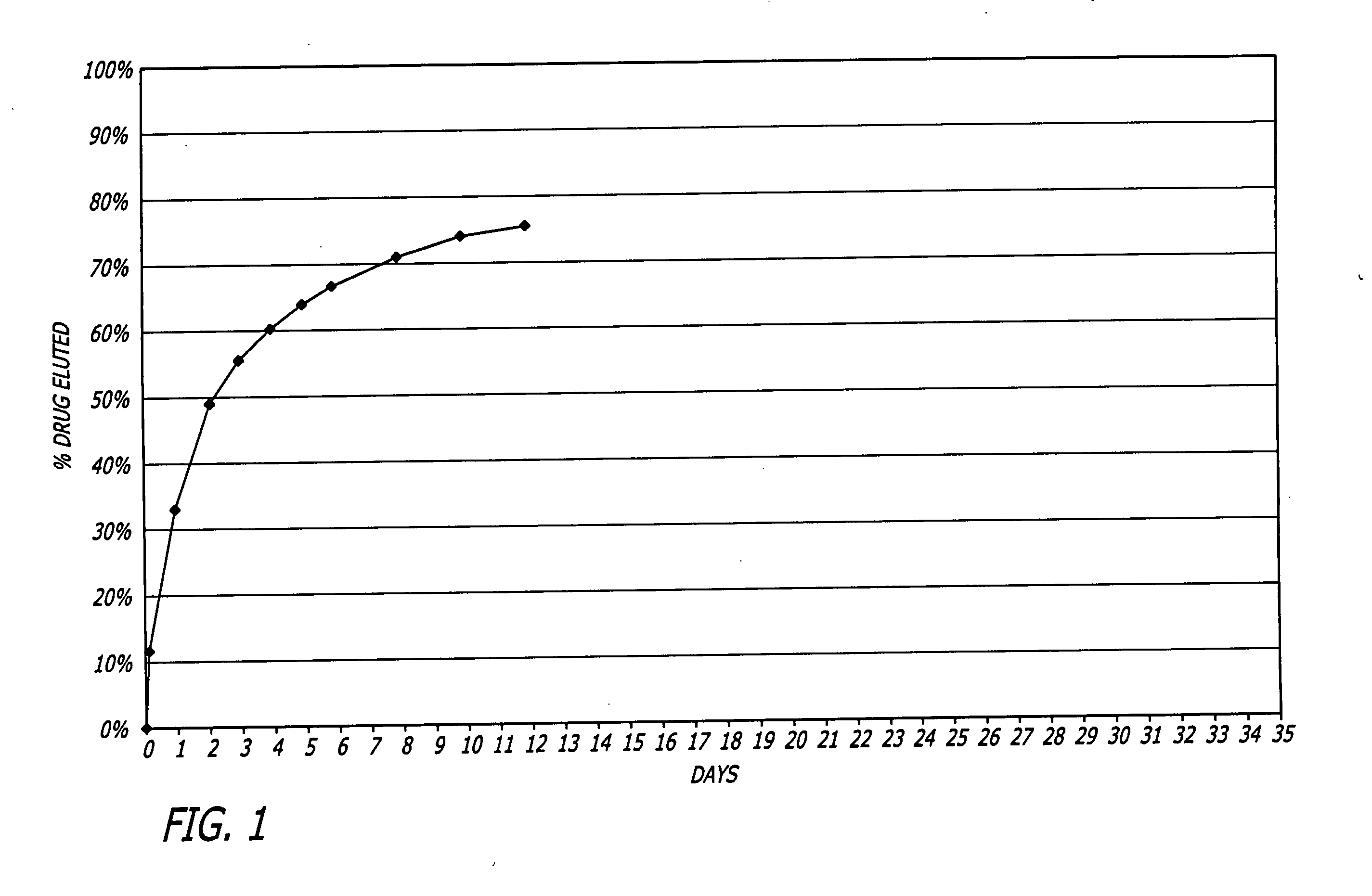

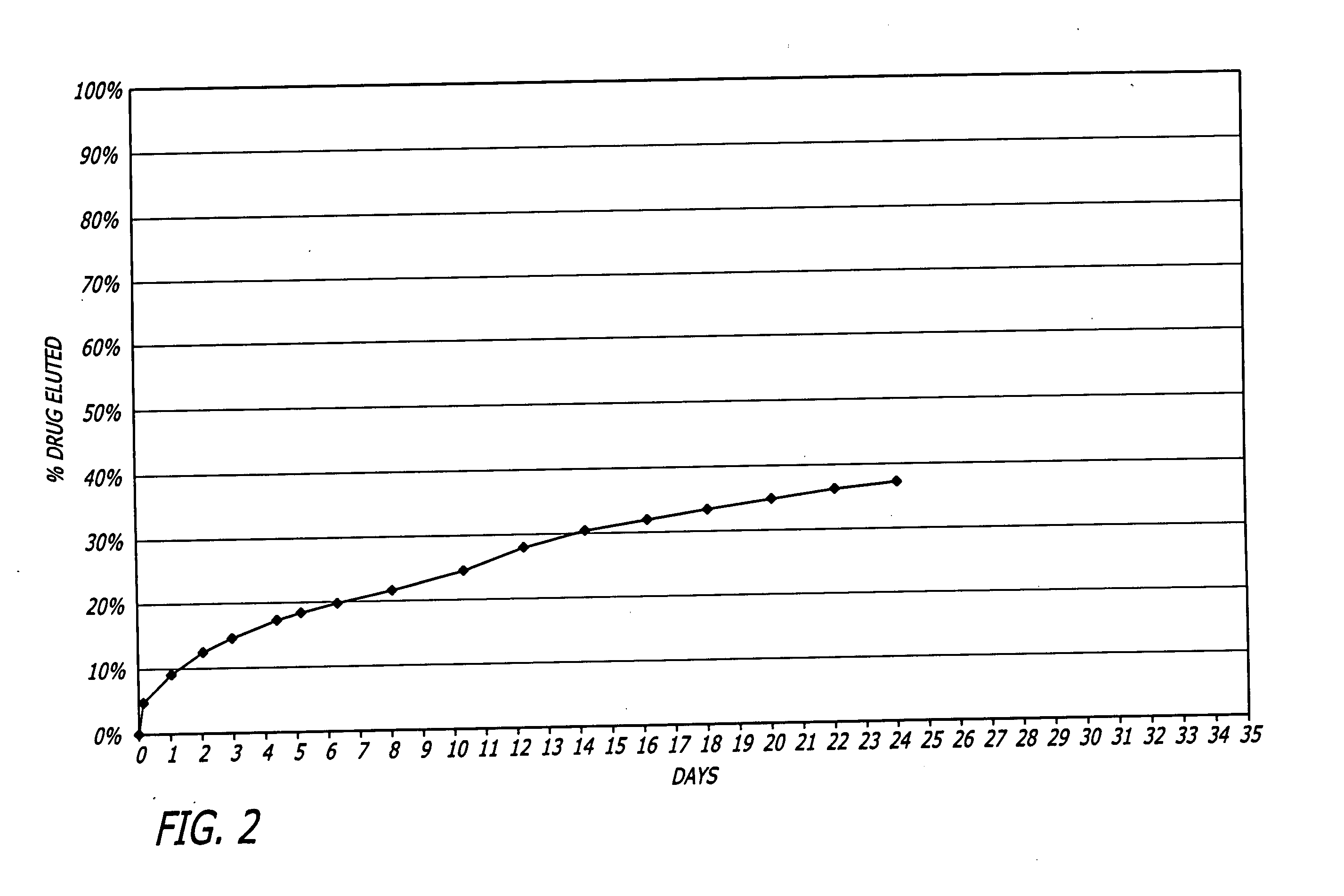

Biocompatible controlled release coatings for medical devices and related methods

ActiveUS20050084515A1High elasticity/ductilityResist erosionSurgeryMedical preparationsSolubilityBiocompatible coating

Biocompatible coatings for medical devices are disclosed. Specifically, polymer coatings designed to control the release of bioactive agents from medical devices in vivo are disclosed wherein the solubility parameters of polymers and drugs are closely matched to control elute rate profiles. The present application also discloses providing vascular stents with controlled release coatings and related methods for making these coatings.

Owner:MEDTRONIC VASCULAR INC

Polymer coating for medical devices

Coatings are provided in which surfaces may be activated by covalently bonding a silane derivative to the metal surface, covalently bonding a lactone polymer to the silane derivative by in situ ring opening polymerization, and depositing at least one layer of poly(lactide-co-caprolactone) copolymer on the bonded lactone. Biologically active agents may be disposed with the poly(lactide-co-caprolactone) copolymer layers. Such coated surfaces may be useful in medical devices, in particular stents.

Owner:CV THERAPEUTICS INC

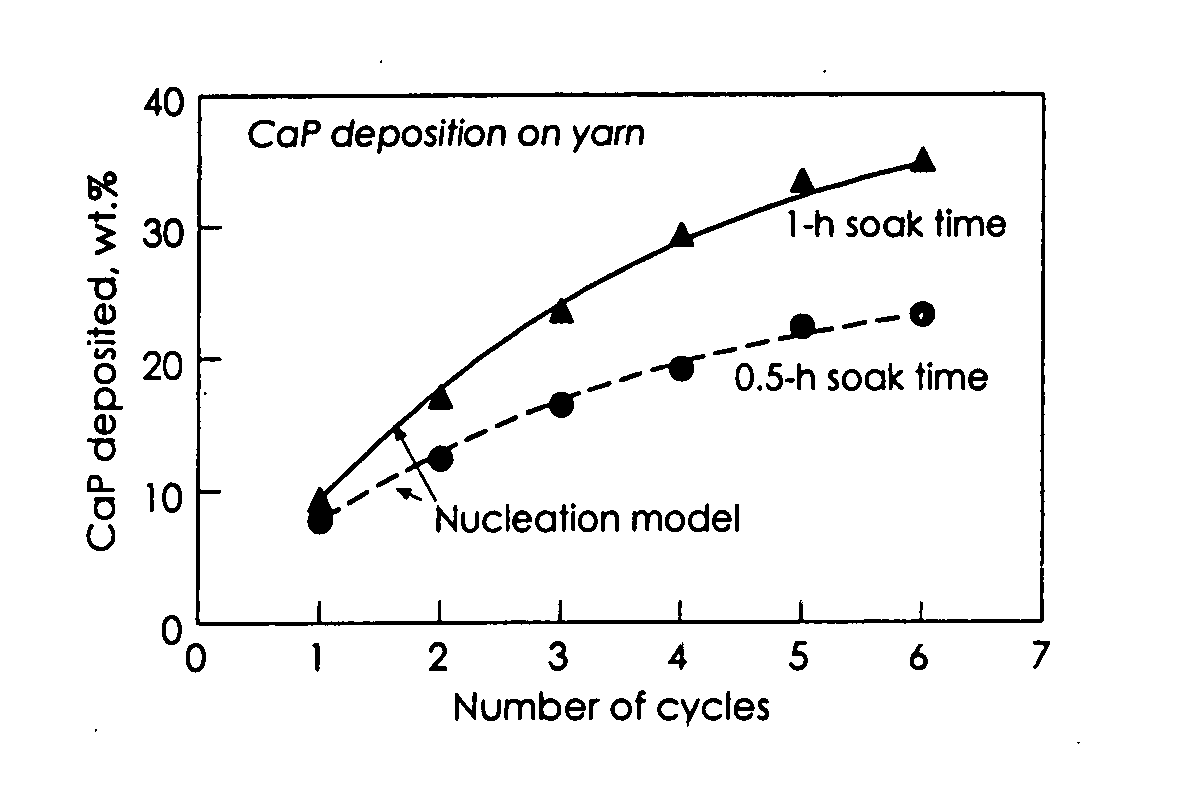

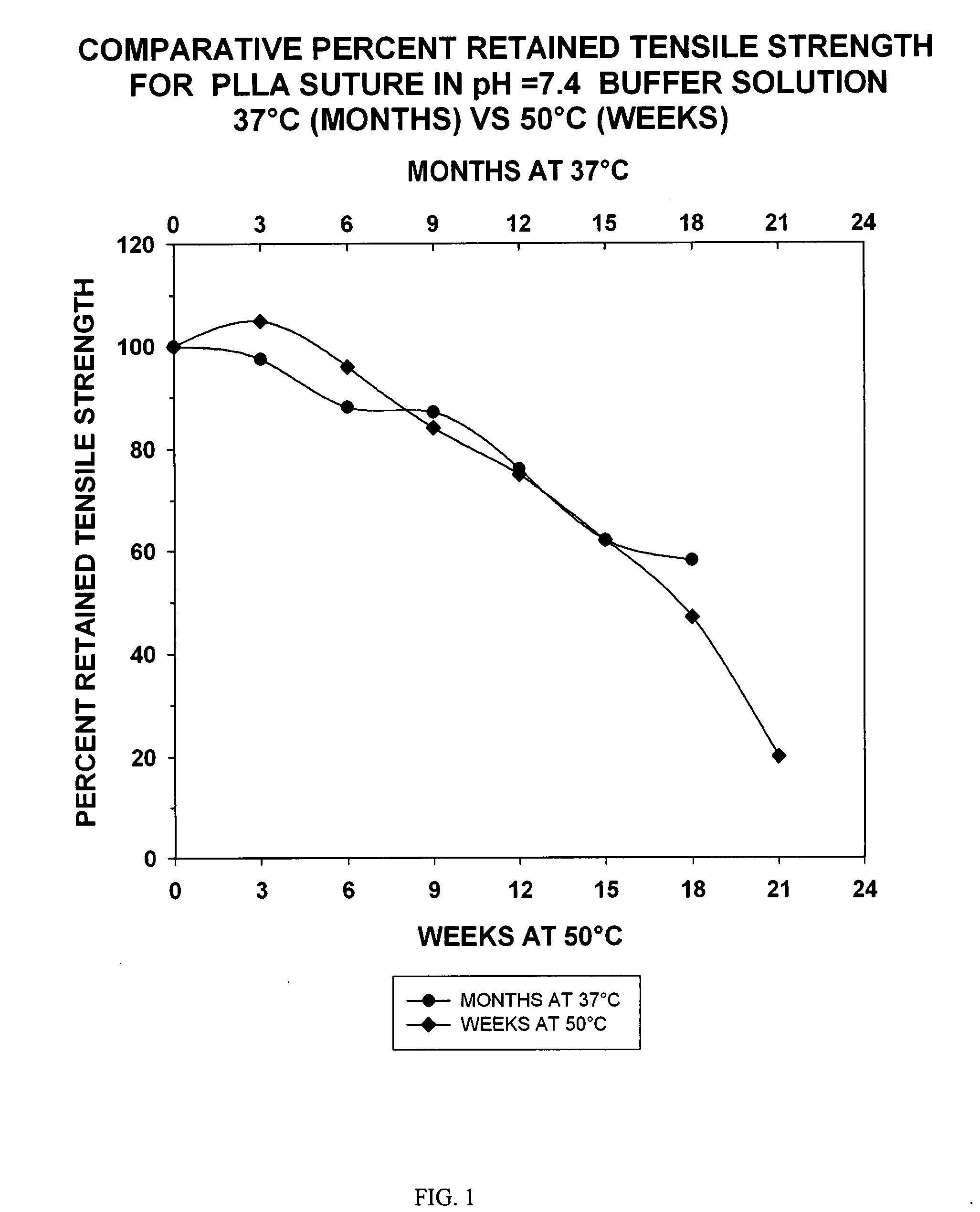

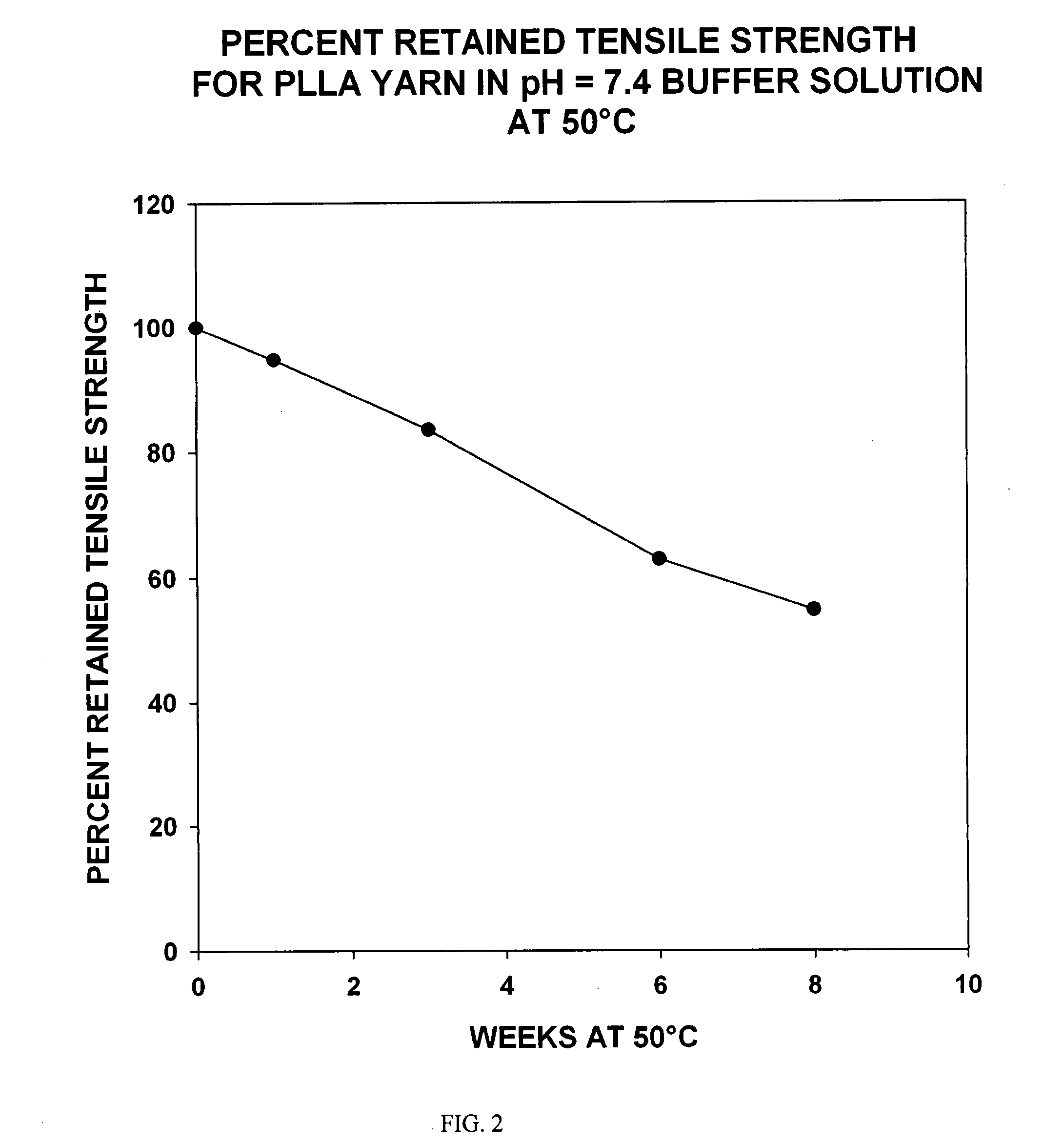

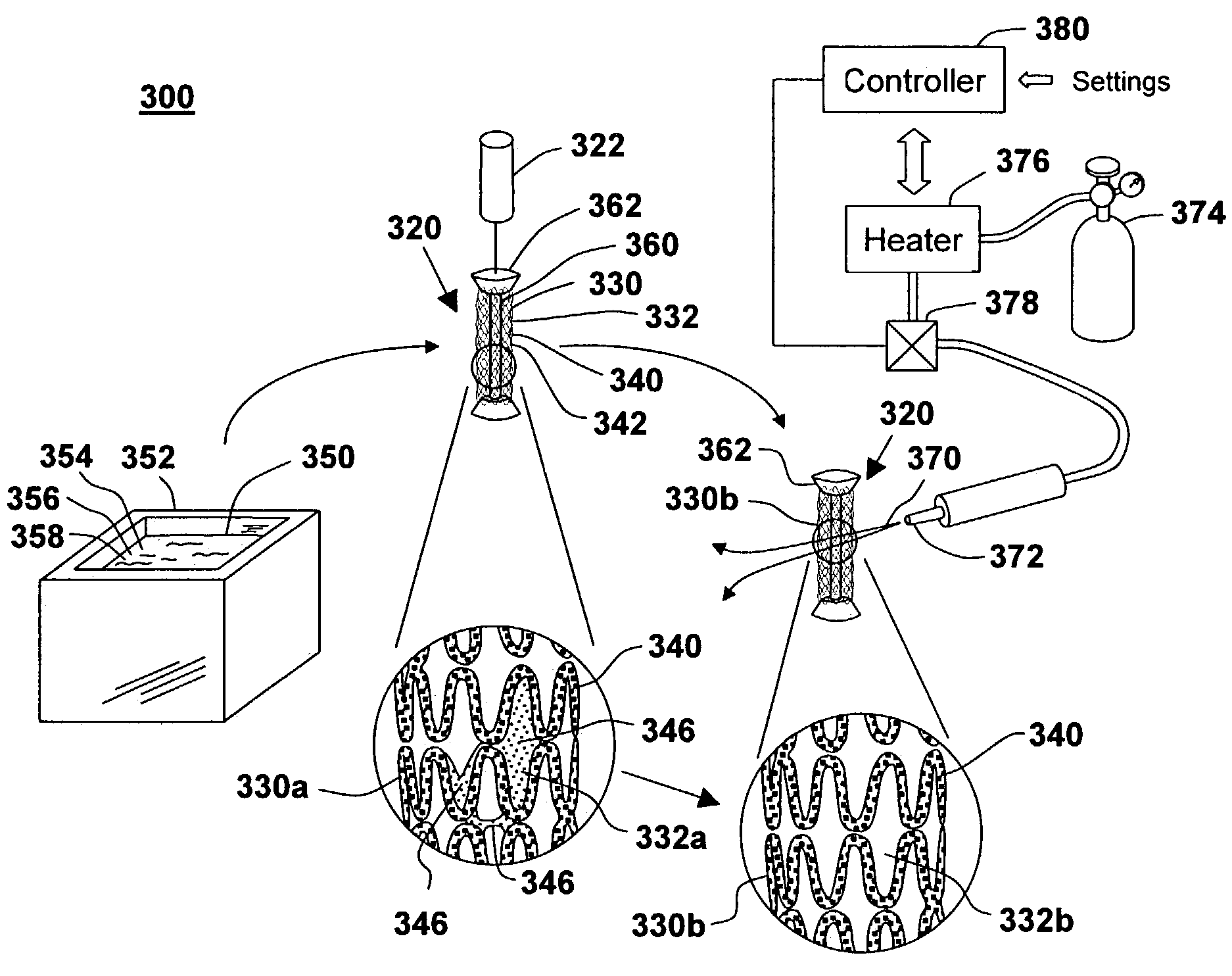

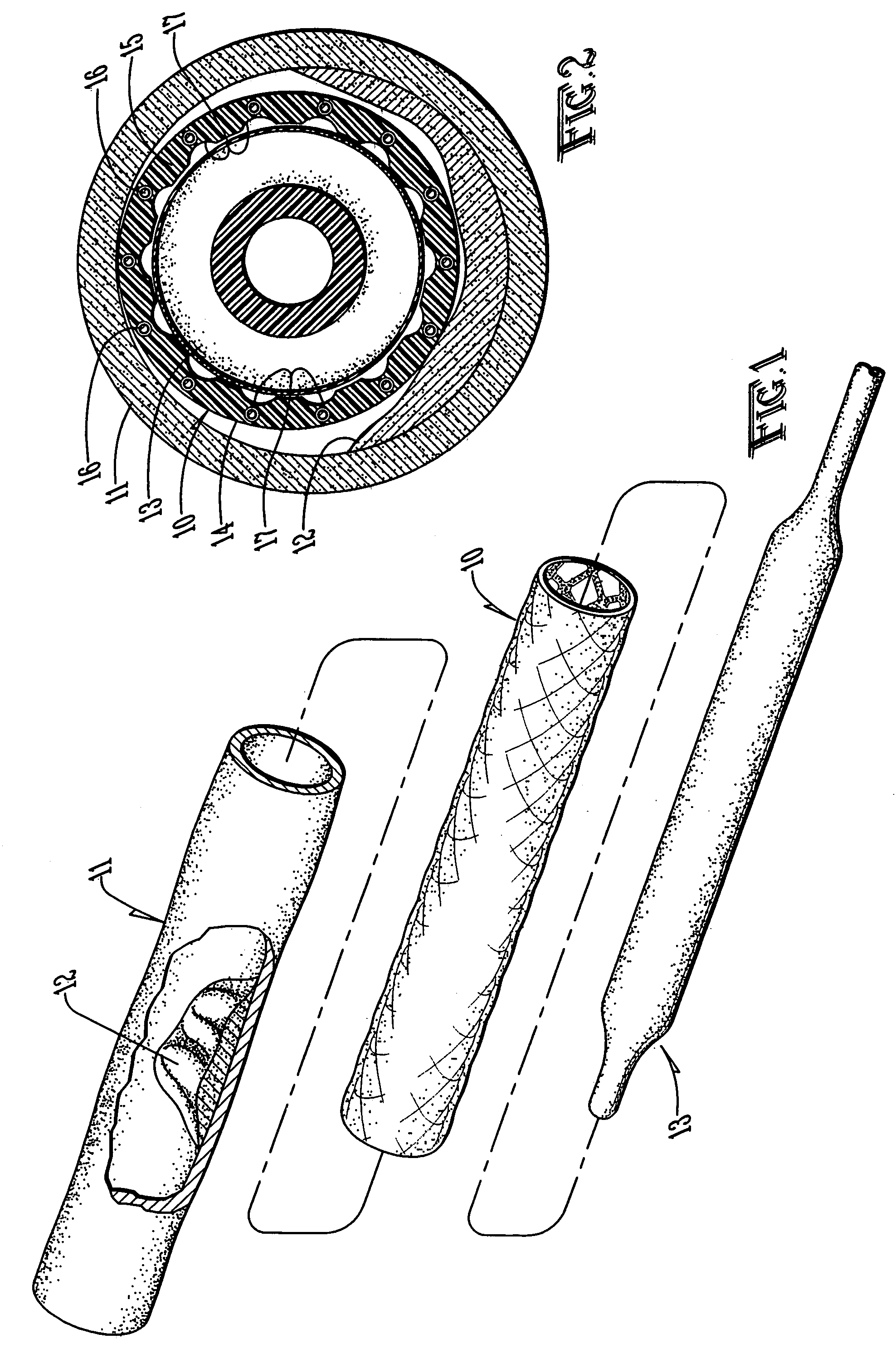

Calcium phosphate polymer composite and method

A bone-repair composite includes a core and a sheath. The core is a first primary unit including a combination of a first set of yarns coated with a calcium phosphate mineral layer. The first set of yarns being made from a first group of one ore more polymers. The sheath is a second primary unit a combination of a second set of yarns or one or more polymer coatings. The second set of yarns being made from a second group of one or more polymers, wherein the composite is made by covering the core with the sheath, and the composite is compression molded to allow the sheath to bond to the core. The bone-repair composite has a bending modulus comparable to that of a mammalian bone, such that the ratio of the core to the sheath is provided to maximize the mechanical strength of the bone-repair composite to mimic the mammalian bone.

Owner:TELEFLEX MEDICAL INC +1

Reflowed drug-polymer coated stent and method thereof

The present invention provides a method of forming a drug-polymer coated stent. A polymeric coating is applied onto at least a portion of a stent framework and dried. A jet of heated gas is directed towards excess coating portions of the dried polymeric coating. The excess coating portions, which extend into apertures of the stent framework, are removed from the apertures of the stent framework by reflowing the polymeric coating with the directed jet of heated gas. A drug-polymer coated stent with a reflowed drug-polymer coating and a system for treating a vascular condition are also disclosed.

Owner:MEDTRONIC VASCULAR INC

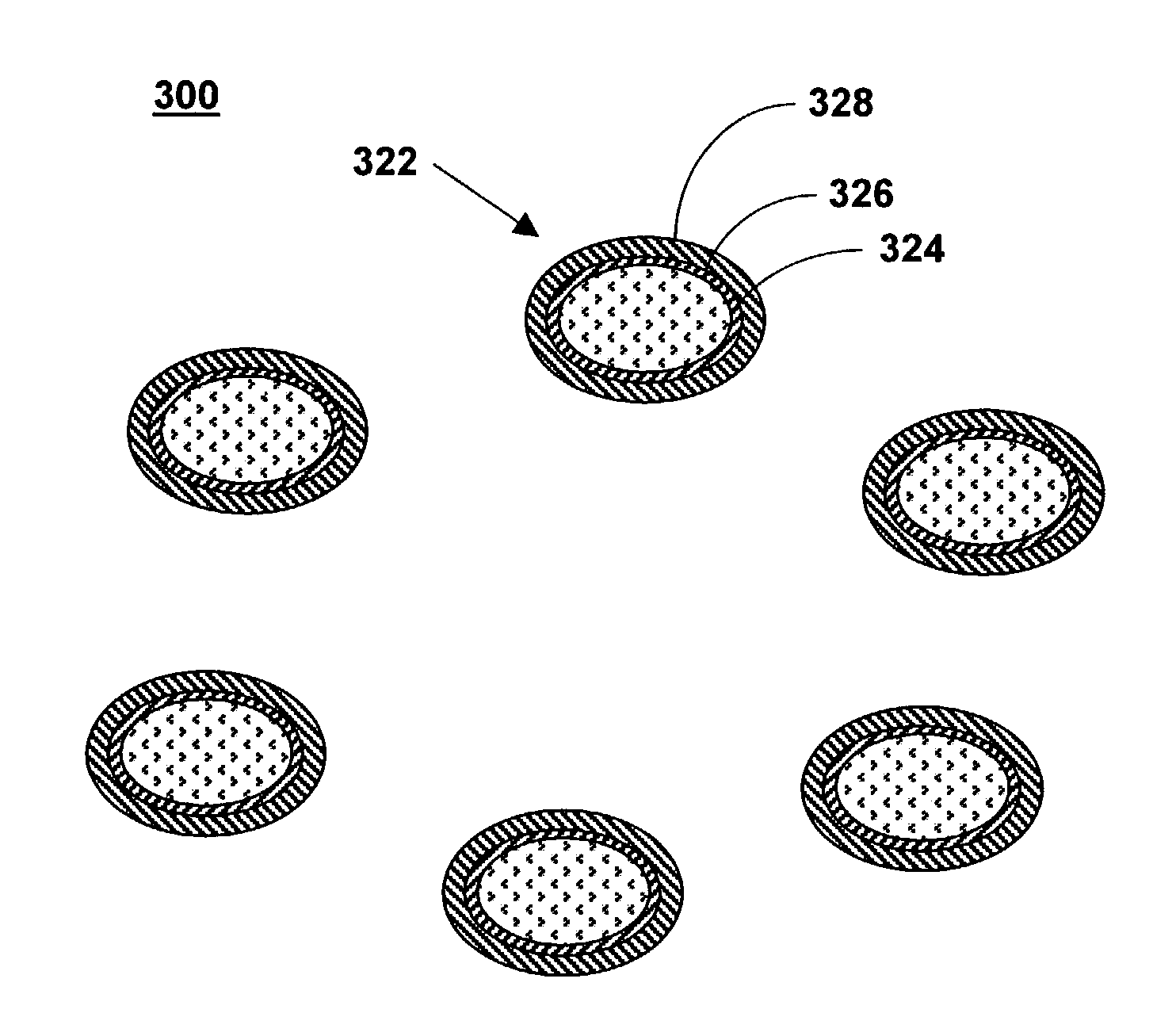

Injectable sustained release delivery devices

ActiveUS20040176341A1Organic active ingredientsCosmetic preparationsControlled releasePolymer coatings

An injectable drug delivery device includes a core containing one or more drugs and one or more polymers. The core may be surrounded by one or more polymer outer layers (referred to herein as "coatings," "skins," or "outer layers"). In certain embodiments, the device is formed by extruding or otherwise preforming a polymeric skin for a drug core. The drug core may be co-extruded with the skin, or inserted into the skin after the skin has been extruded, and possibly cured. In other embodiments, the drug core may be coated with one or more polymer coatings. These techniques may be usefully applied to fabricate devices having a wide array of drug formulations and skins that can be selected to control the release rate profile and various other properties of the drugs in the drug core in a form suitable for injection using standard or non-standard gauge needles. The device may be formed by combining at least one polymer, at least one drug, and at least one liquid solvent to form a liquid suspension or solution wherein, upon injection, such suspension or solution under goes a phase change and forms a gel. The configuration may provide for controlled release of the drug(s) for an extended period.

Owner:EYEPOINT PHARMA INC

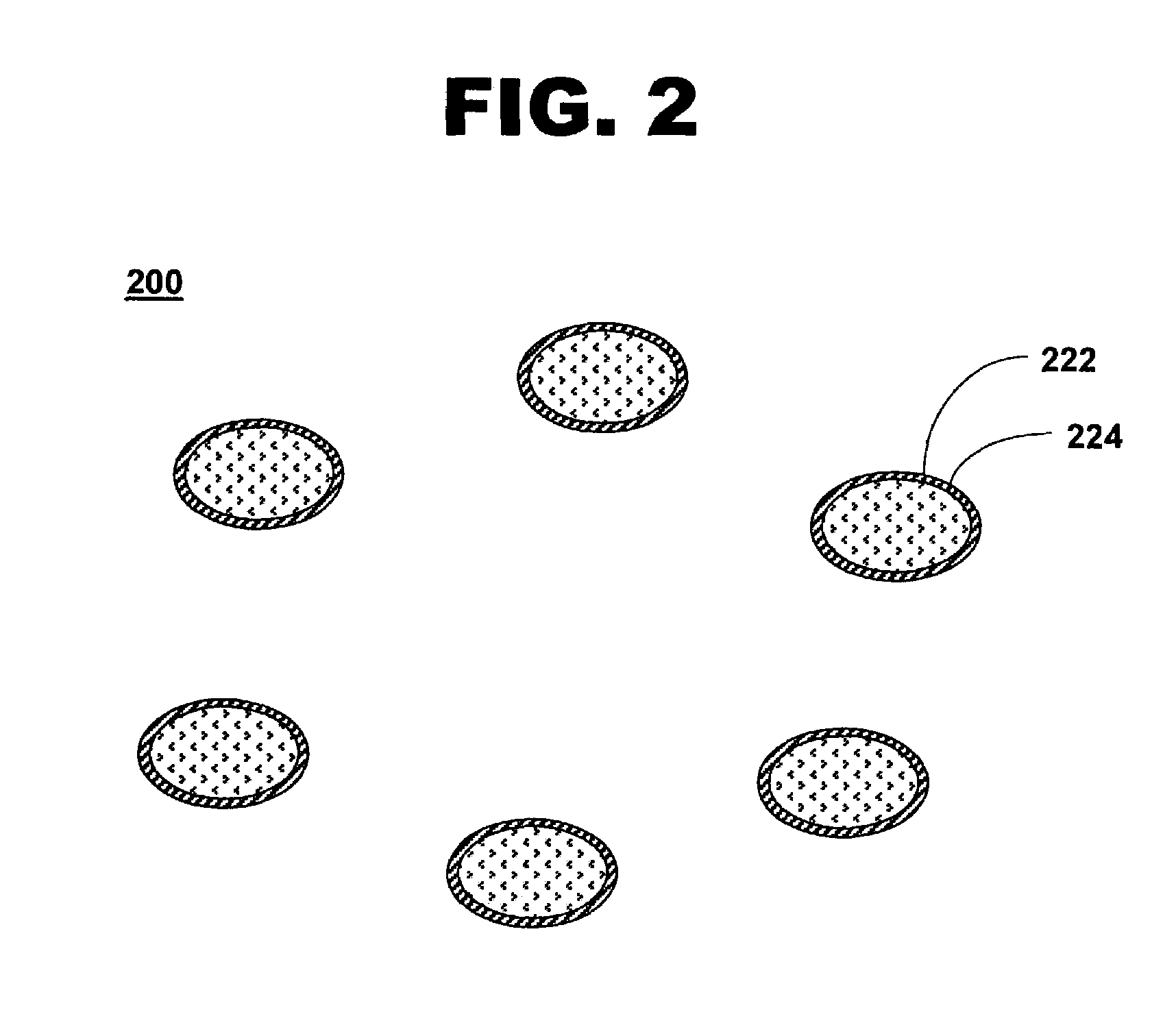

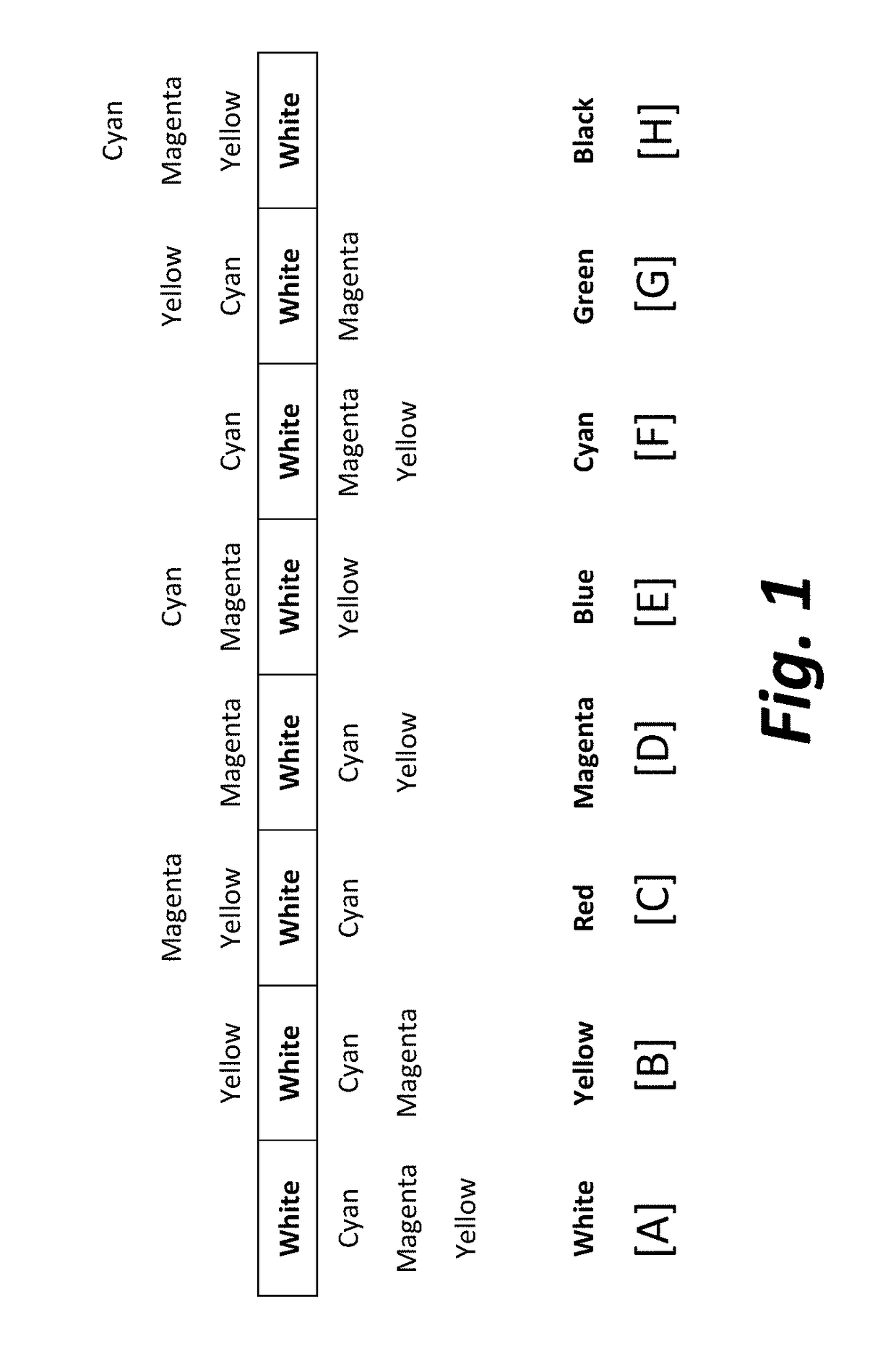

Particles for use in electrophoretic displays

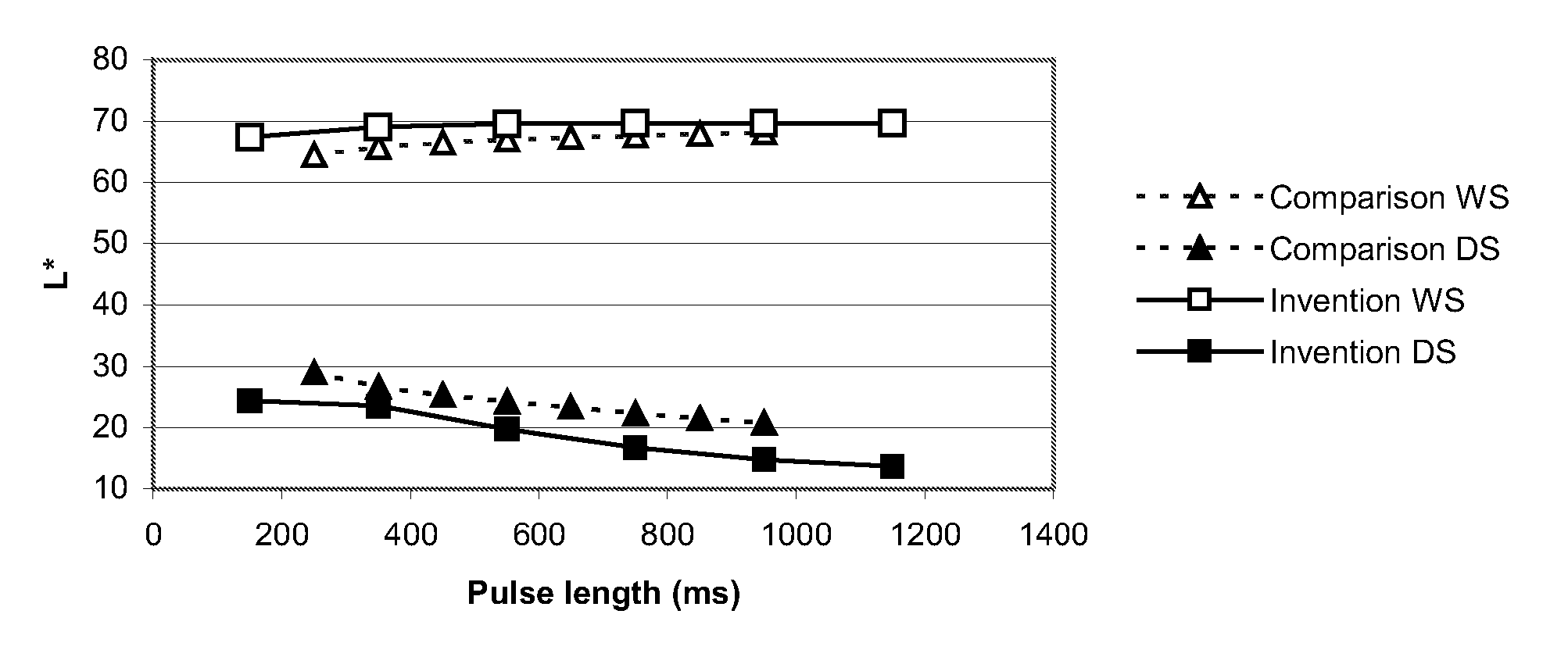

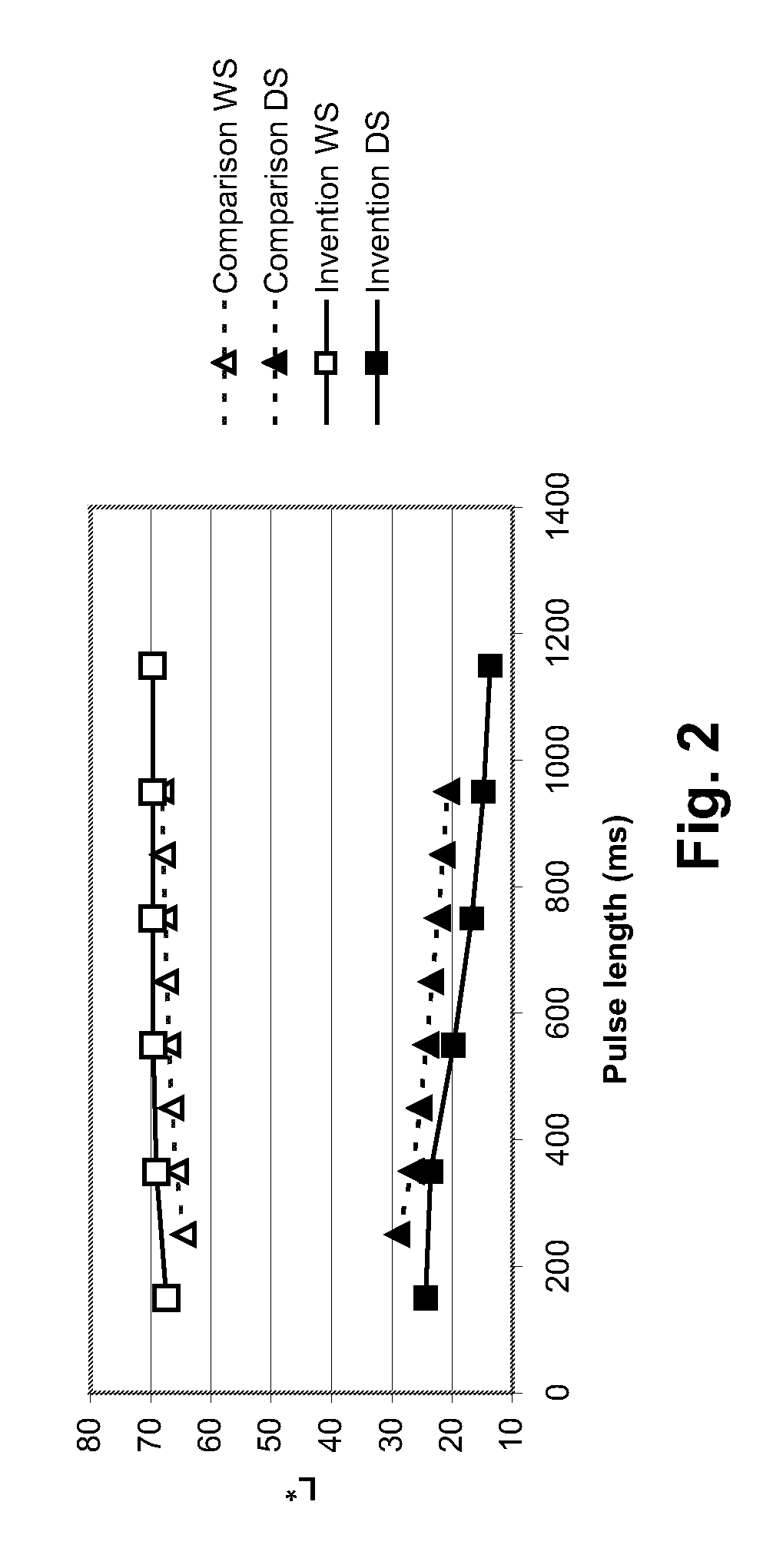

ActiveUS20080013156A1Liquid surface applicatorsSynthetic resin layered productsPolymer coatingsInorganic pigments

A particle for use in an electrophoretic display comprises a light-scattering inorganic core and a light-transmissive colored shell of an organic pigment. The core may be titania and the shell may be formed of particles having an average particle size less than 700 nm. The particles are produced by treating a light-scattering inorganic pigment with a polymer which adsorbs on both the inorganic pigment and an organic pigment; and adding the organic pigment and allowing the organic pigment to mix with the polymer-coated inorganic pigment. The particles may have a polymer coating.

Owner:E INK CORPORATION

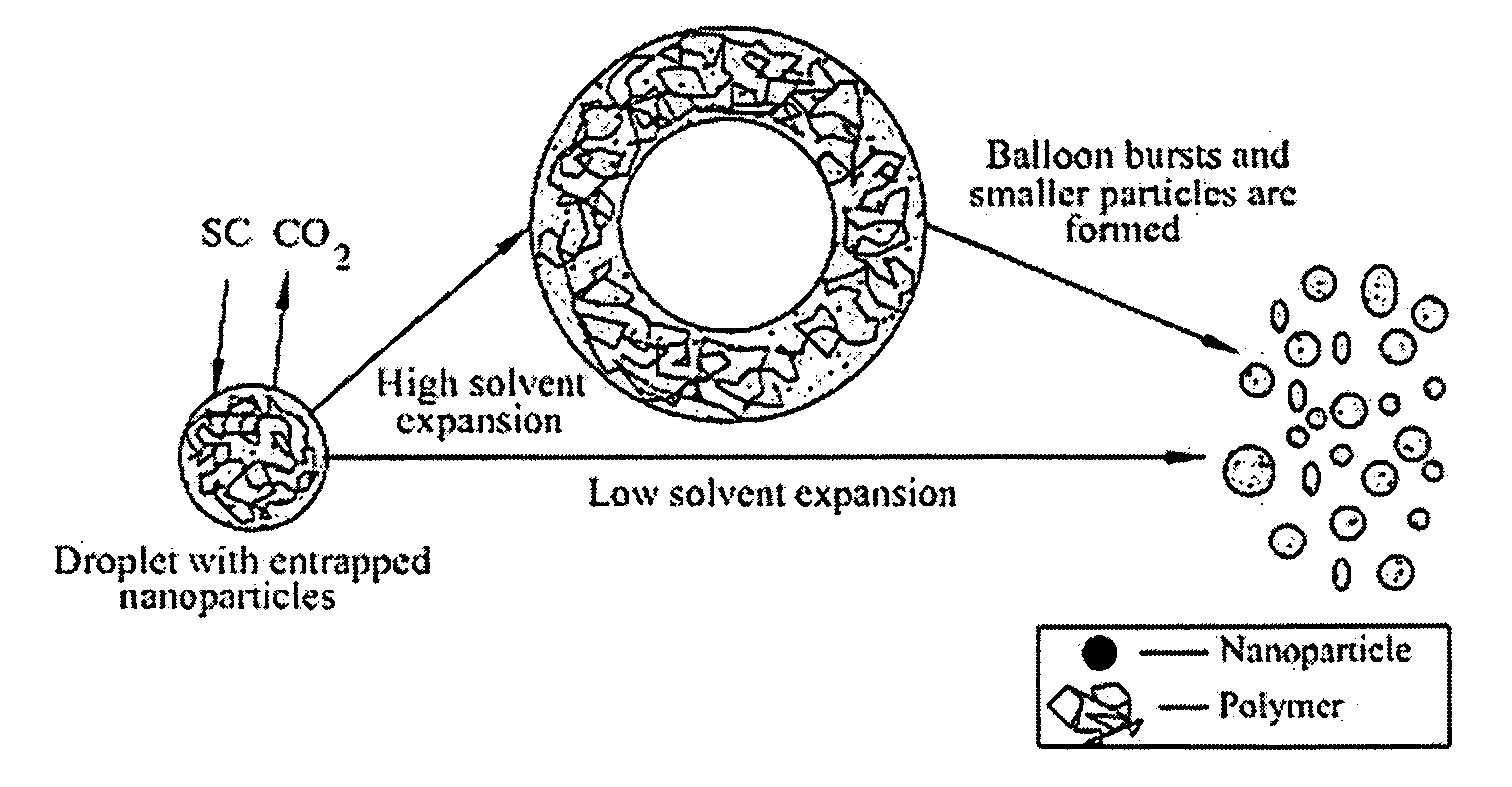

Polymer coating/encapsulation of nanoparticles using a supercritical antisolvent process

InactiveUS20050191491A1Speed up the processGranule coatingPretreated surfacesSolventSupercritical carbon dioxide

A process, method and / or system for preparing polymer-coated nanoparticles and / or other ultrafine particles utilizing a supercritical fluid, e.g., supercritical carbon dioxide (SC CO2), as an antisolvent that may be added to a solution of a polymer and an organic solvent in which insoluble nanoparticles or the like are suspended. The coating process occurs when the supercritical fluid (e.g., SC CO2) and the nanoparticle-containing suspension are combined to cause the suspended nanoparticles to precipitate as coated nanoparticles. Processing parameters for optimizing and / or enhancing the efficacy and / or efficiency of the coating process, method and / or system and for controlling the coating and / or agglomeration of coated particles are also described. The process, method and / or system has wide ranging applicability, e.g., for coating and / or encapsulation of pharmaceuticals, cosmetics, food products, chemicals, agrochemicals, pesticides, polymers, coatings, catalysts and the like.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

Electrophoretic particles, and processes for the production thereof

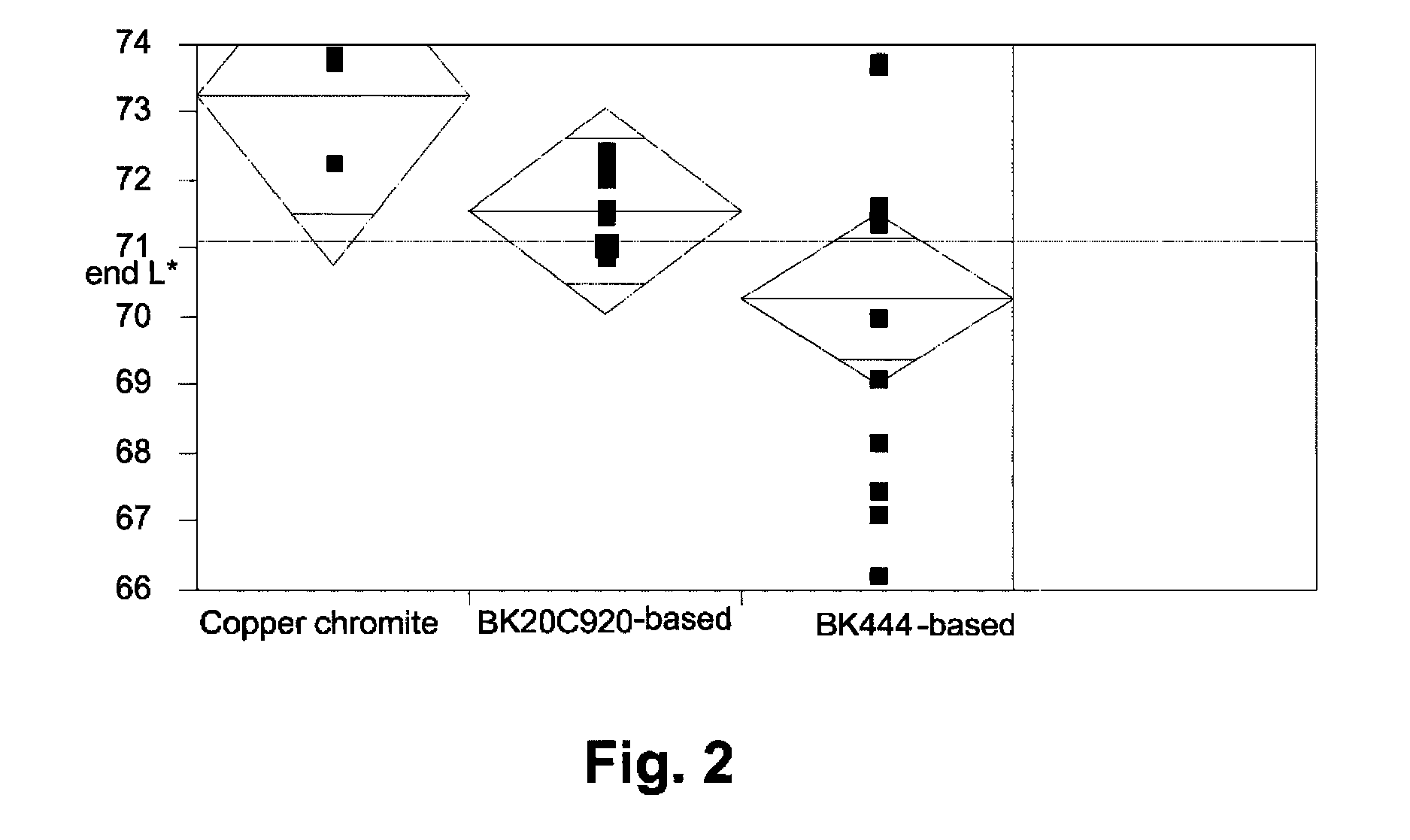

ActiveUS8270064B2Easy to useGood color saturationPigmenting treatmentStatic indicating devicesMagnetiteManganese oxide

An electrophoretic medium comprises at least one electrically charged particle dispersed posed in a fluid. The electrically charged particle comprises an inorganic black pigment having a surface area of at least about 7 m2 / g. Preferred pigments are magnetite and mixed metal oxides containing two or more of iron, chromium, nickel, manganese, copper and cobalt, for example copper iron manganese oxide spinel and copper chromium manganese oxide spinel. The inorganic black pigment may bear a polymer coating.

Owner:E INK CORPORATION +1

Electrophoretic medium and display with improved image stability

ActiveUS7903319B2Static indicating devicesElectrographic processes using charge patternPolymer scienceElectrophoresis

An electrophoretic medium comprises a fluid and a plurality of electrically charged particles disposed in the fluid and capable of moving therethrough on application of an electrical field to the medium. Each of the charged particles has a polymer coating comprising a first group. A polymer is dispersed in the fluid, this polymer having a plurality of second groups capable of attracting the first groups on the particles so that the polymer in the fluid forms a complex with the electrophoretic particles.

Owner:E INK CORPORATION

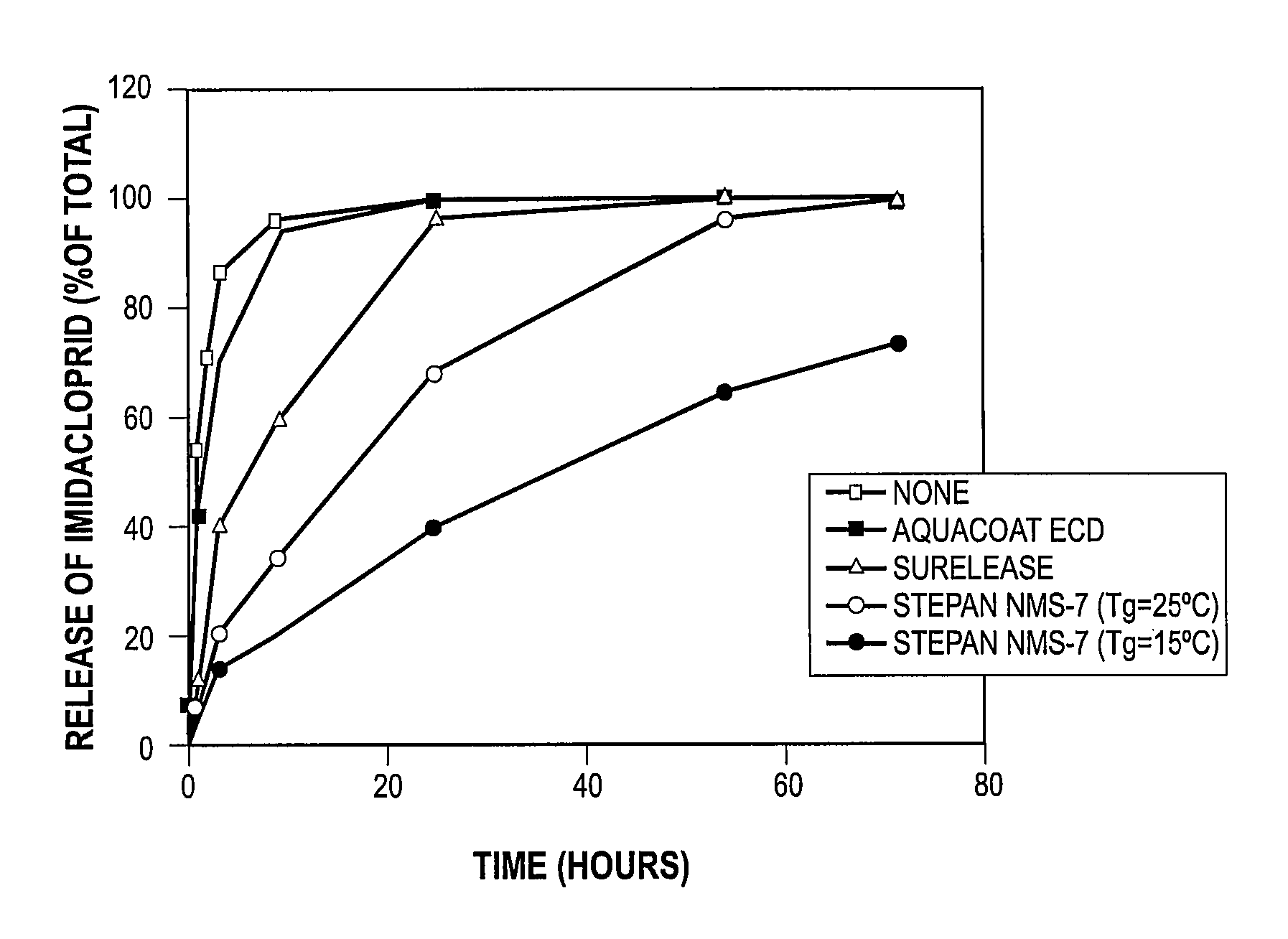

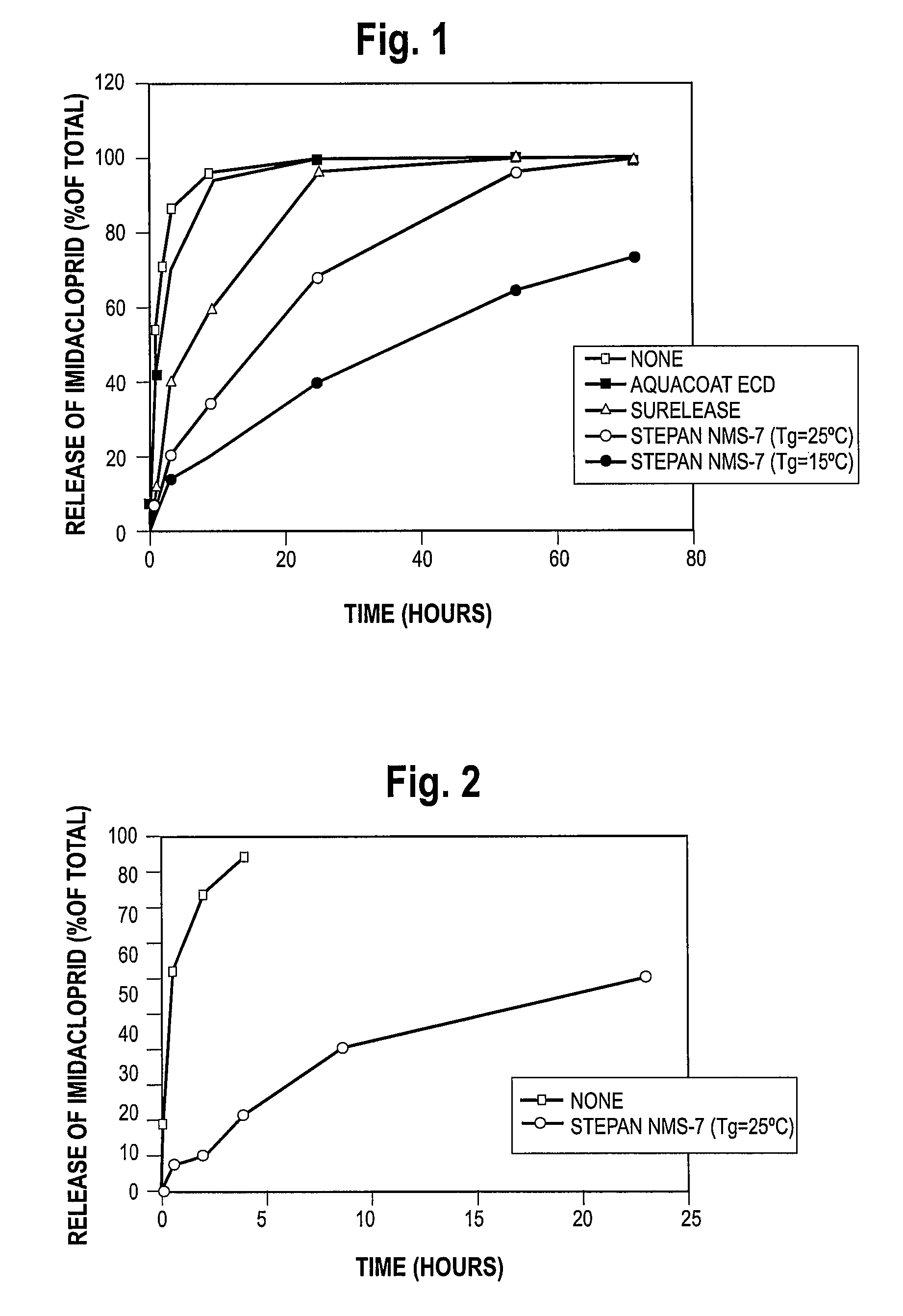

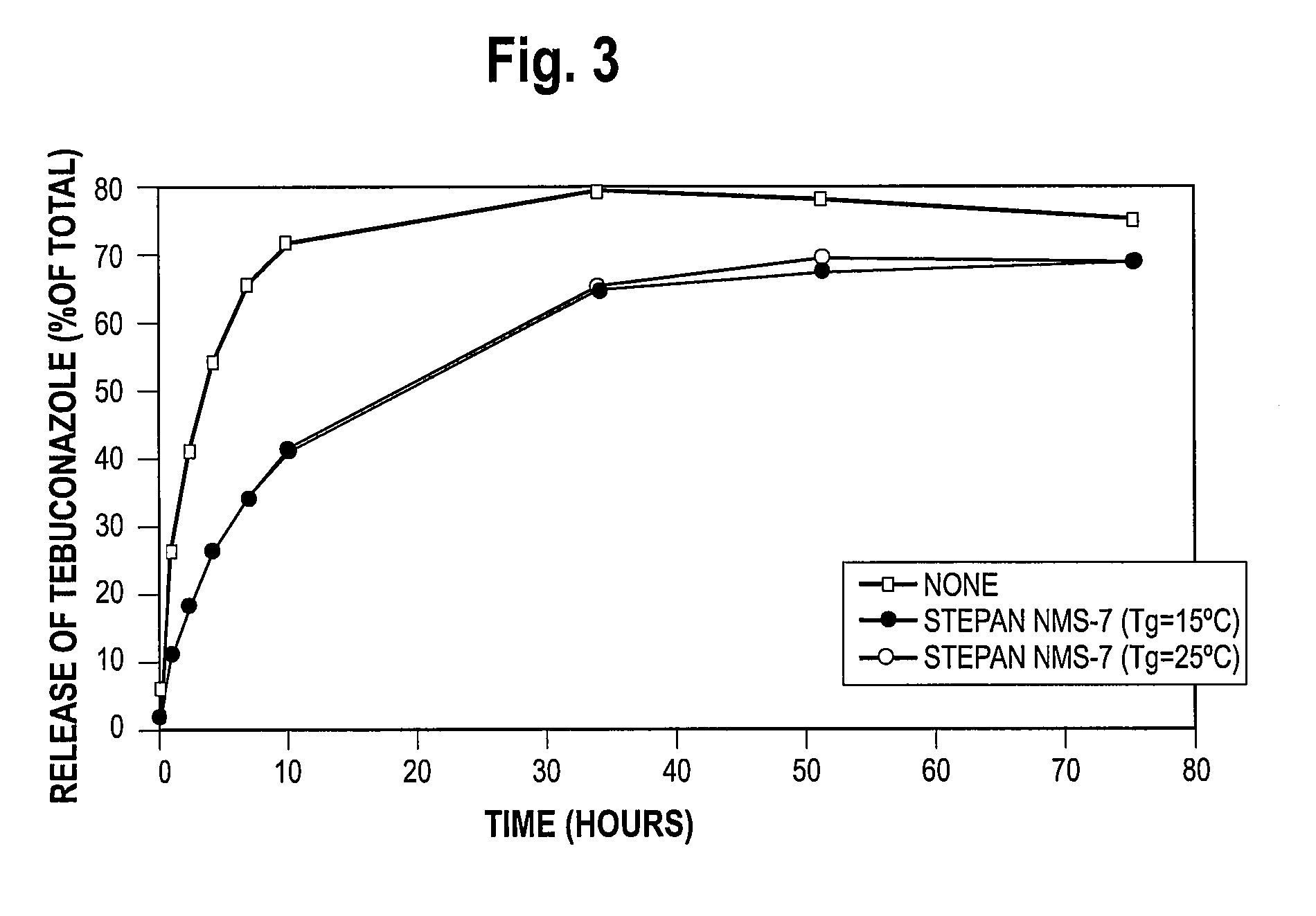

Method of controlling the release of agricultural active ingredients from treated plant seeds

InactiveUS7774978B2Easy and fast and economical to administerEffective controlBiocideDead plant preservationSolubilityEmulsion

A method of controlling the release rate of an agricultural active ingredient from a seed that has been treated with that active includes providing a seed that has been treated with the active ingredient, applying to the treated seed a film that includes an emulsion of a polymer in a liquid in which both the agricultural active ingredient and the polymer have low levels of solubility, and then curing the film to form a water insoluble polymer coating on the surface of the treated seed. Seeds that have been treated by this method are also provided.

Owner:STEPAN COMPANY

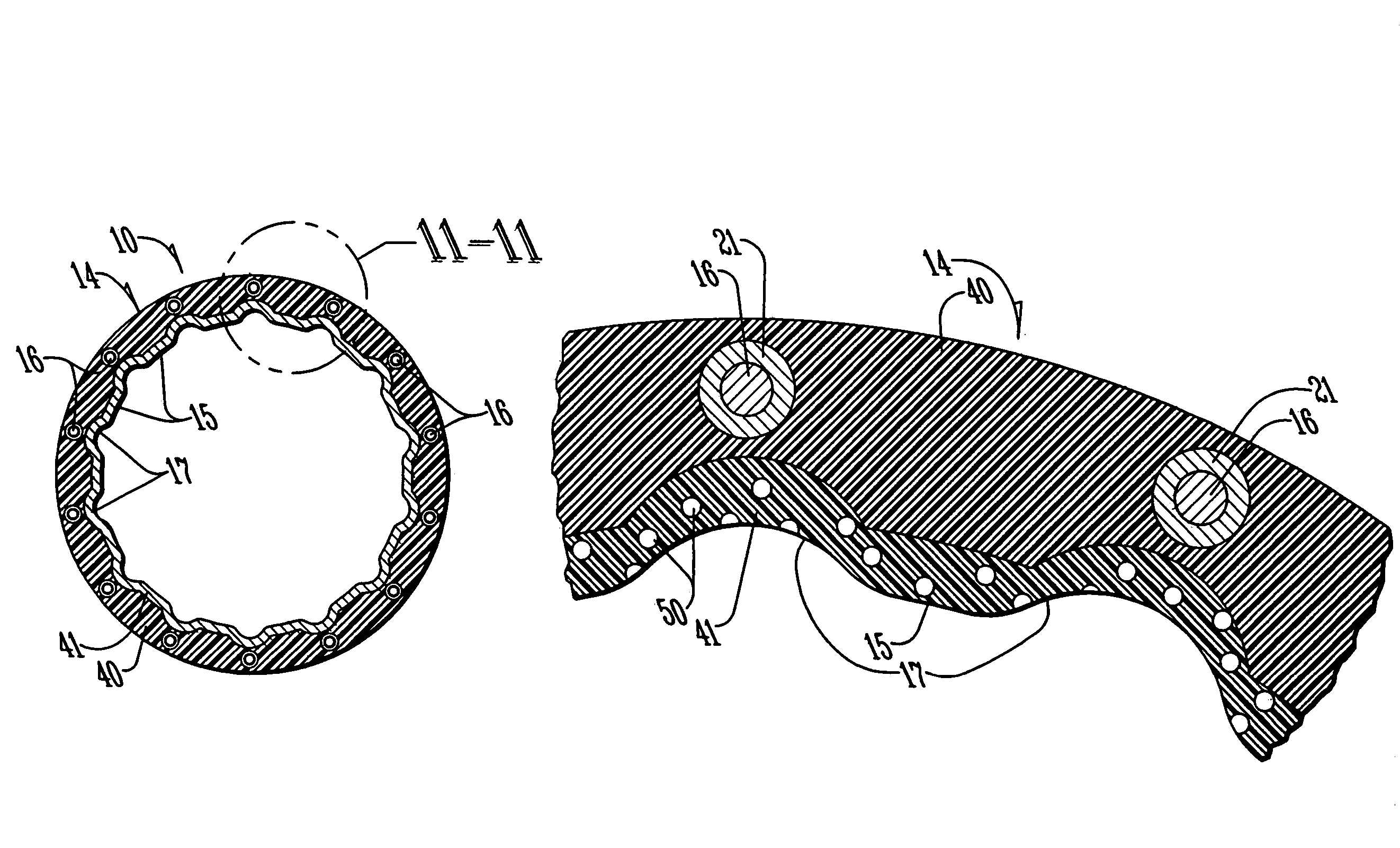

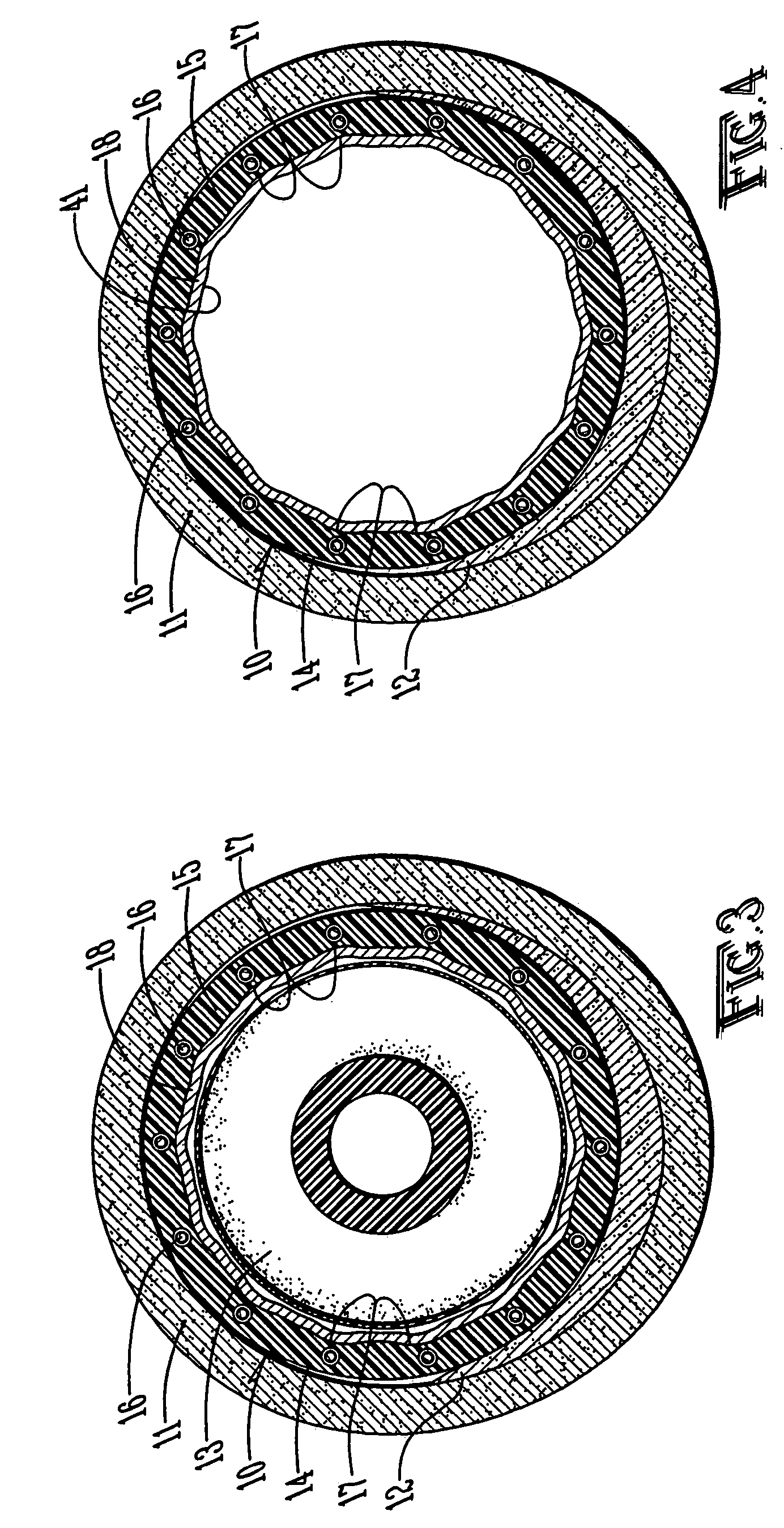

Encased stent

InactiveUS7311727B2Prevent restenosisImprove scalabilityStentsSurgeryCell Cycle InhibitionPolyethylene glycol

An encased stent that discourages restenosis by having a homogenous endothelial cell lining along the inner wall of the stent. The endothelial cell lining may be coated on the stent before the stent is placed in the artery, or the endothelial cell lining may be grown after placement by several factors that encourage such growth and discourage restenosis. The endothelial cells to coat the stent may be genetically modified to enhance the growth of the endothelial cells into a homogeneous lining. The stent has a continuous lining in the form of a multi-layer polymer coating, including a conducting biocorrosion inhibiting layer and a continuous film of polyurethane coupled by a coupling agent to polyethylene glycol. Various drugs and cell factors may be incorporated into the lining, such as anti-thrombin, anti-inflammatory and anti-coagulant drugs, cell cycle inhibitors, and vascular endothelial growth factors.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

Photochemical crosslinkers for polymer coatings and substrate tie-layer

Owner:INNOVATIVE SURFACE TECHNOLOGIES LLC

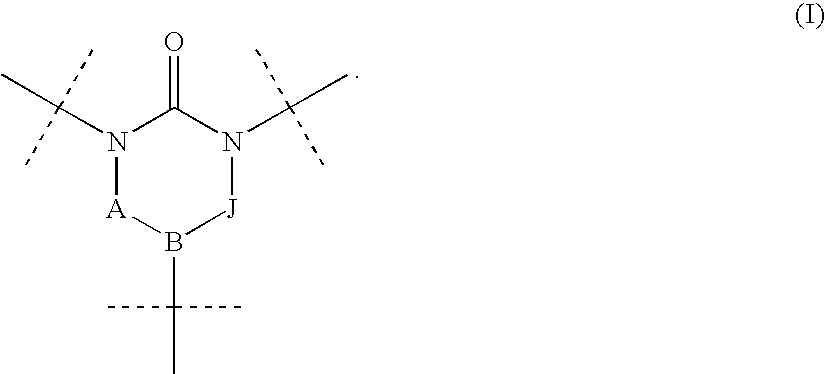

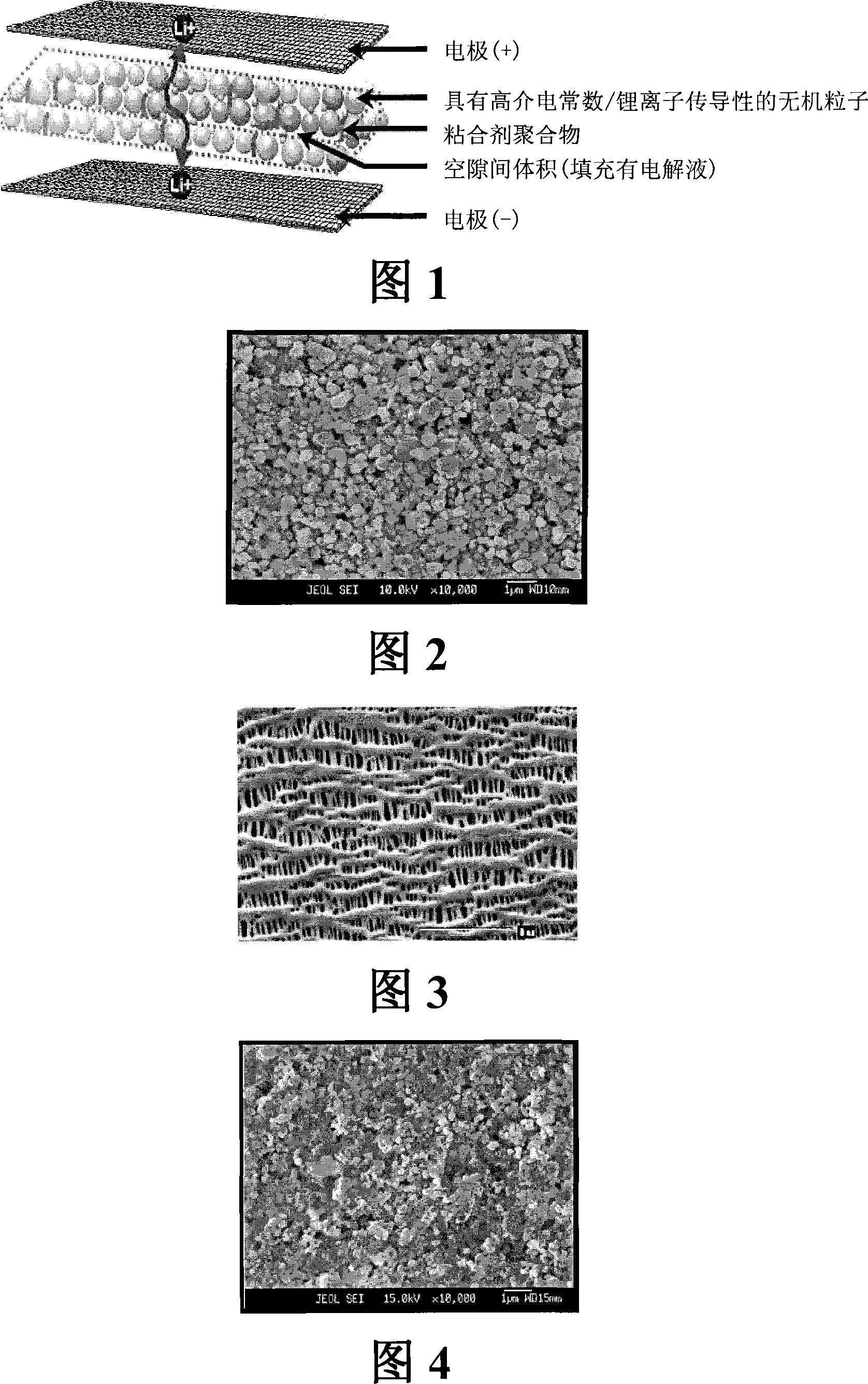

Organic/inorganic composite porous film and electrochemical device prepared thereby

ActiveCN101002347AImprove thermal safetyImprove performanceLi-accumulatorsCell component detailsInorganic particleInorganic particles

Disclosed is an organic / inorganic composite porous film comprising: (a) inorganic particles; and (b) a binder polymer coating layer formed partially or totally on surfaces of the inorganic particles, wherein the inorganic particles are interconnected among themselves and are fixed by the binder polymer, and interstitial volumes among the inorganic particles form a micropore structure. A method for manufacturing the same film and an electrochemical device including the same film are also disclosed. An electrochemical device comprising the organic / inorganic composite porous film shows improved safety and quality.

Owner:LG ENERGY SOLUTION LTD +1

Stent with phenoxy primer coating

The present invention provides a system for treating a vascular condition, which includes a catheter; a stent coupled to the catheter, the stent including a stent framework; a phenoxy primer coating operably disposed on the stent framework; and a drug-polymer coating disposed on the phenoxy primer coating. The present invention also provides a drug-coated stent and a method of manufacturing a drug-coated stent.

Owner:MEDTRONIC VASCULAR INC

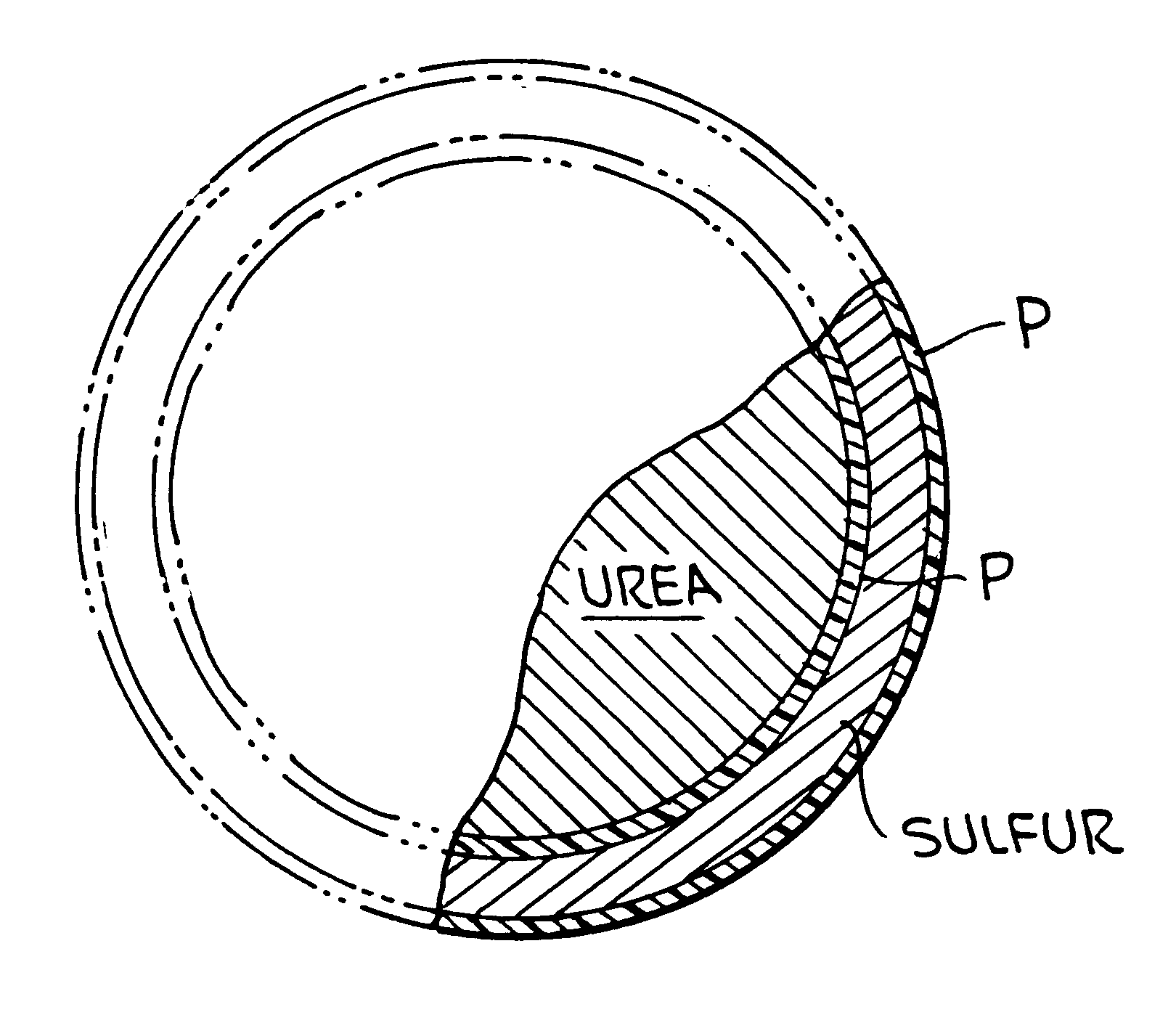

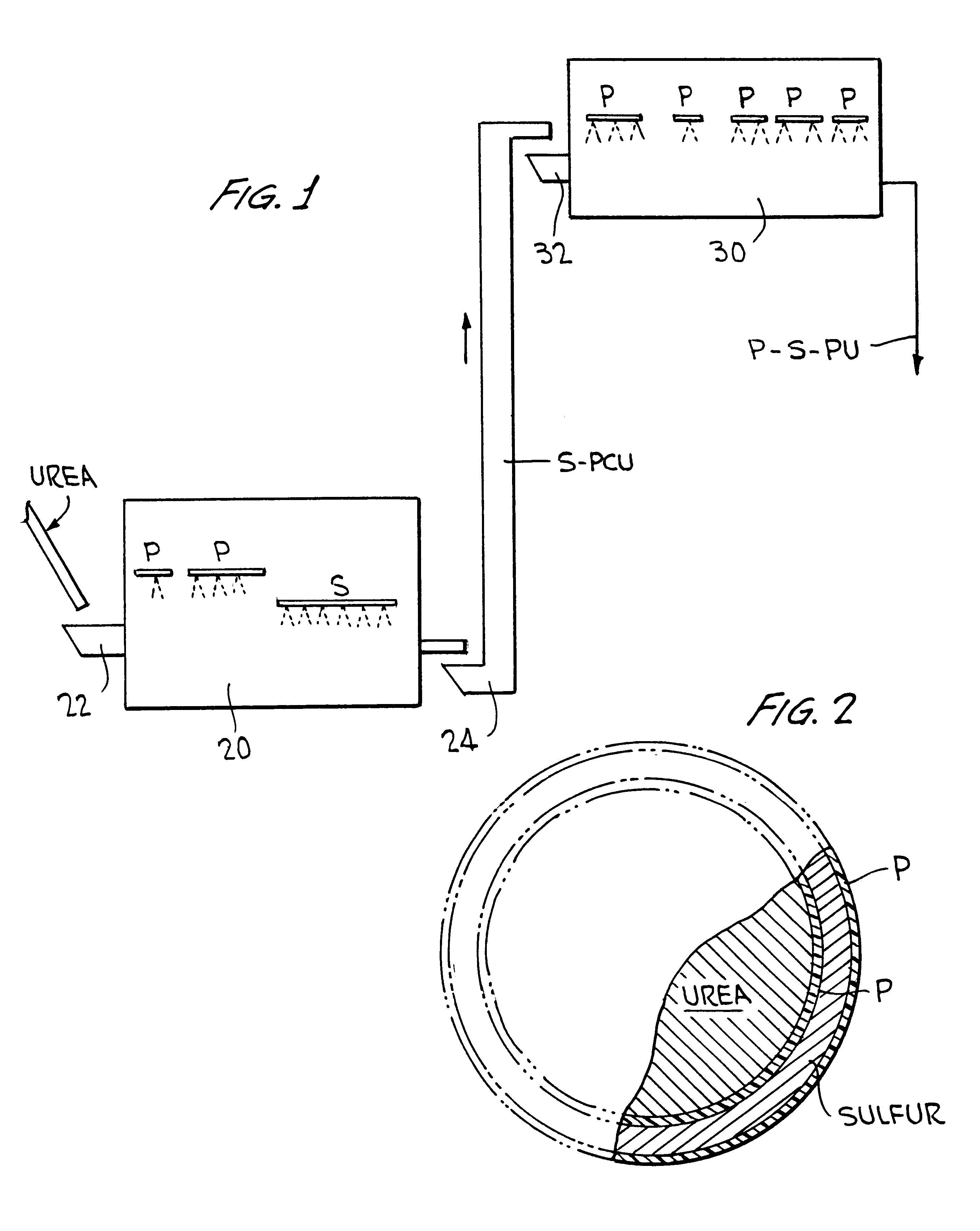

Polymer-sulfur-polymer coated fertilizers

InactiveUS6338746B1Good resistance to abrasionAvoid serious impactBiocideMaterial granulationControlled releasePositive control

The present invention described a polymer coated fertilizer, such as urea, subsequently coated with a layer of sulfur and thereafter a further coating of polymer. Preferably, the polymer coatings are formed by the direct in situ co-polymerization of the components of the polymer on the fertilizer and on the sulfur coating. The compositions provide positive controlled release characteristics, are abrasion and impact resistant and are substantially more economical to produce than polymer coated fertilizers.

Owner:KOCH AGRONOMIC SERVICES LLC

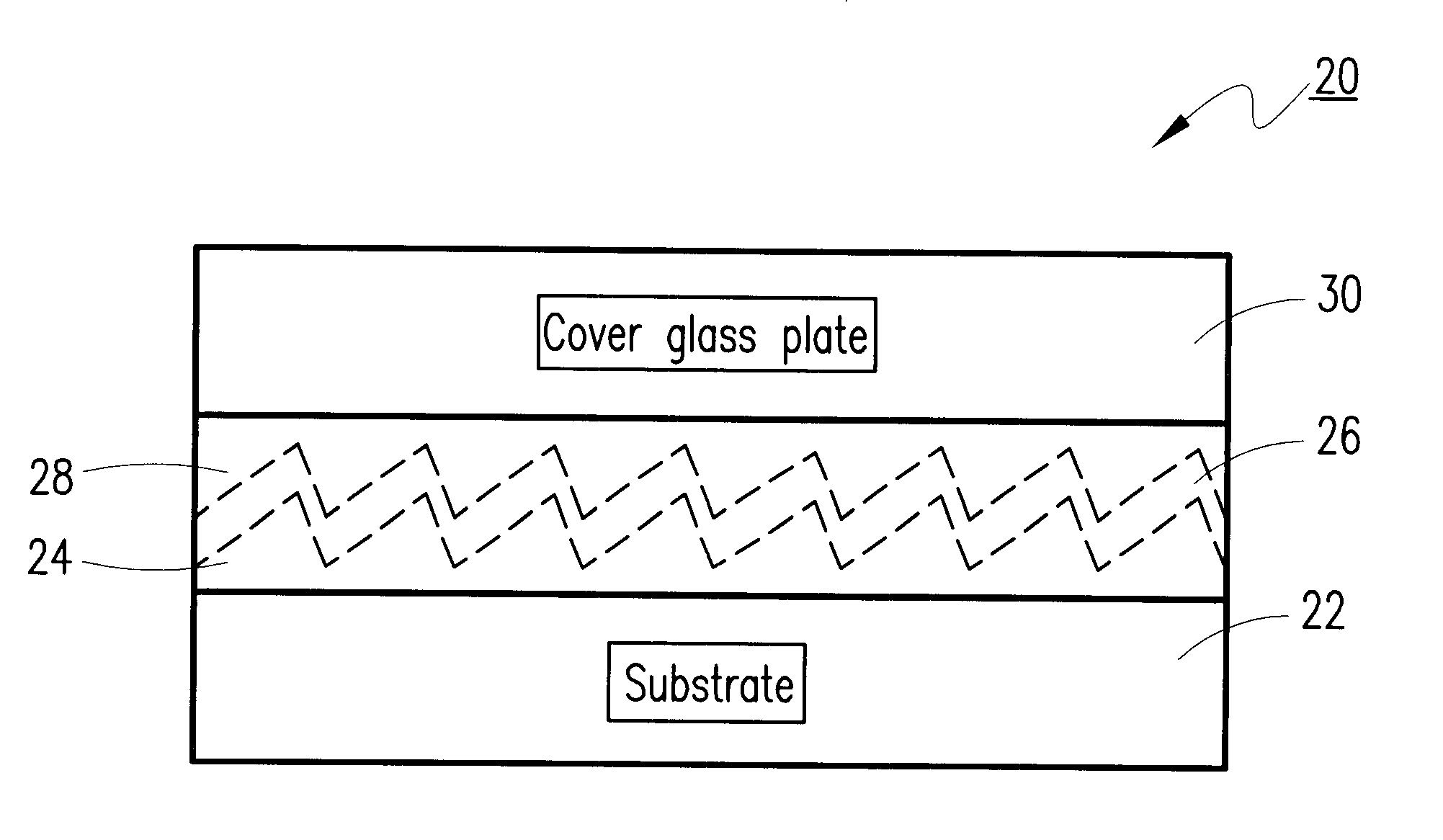

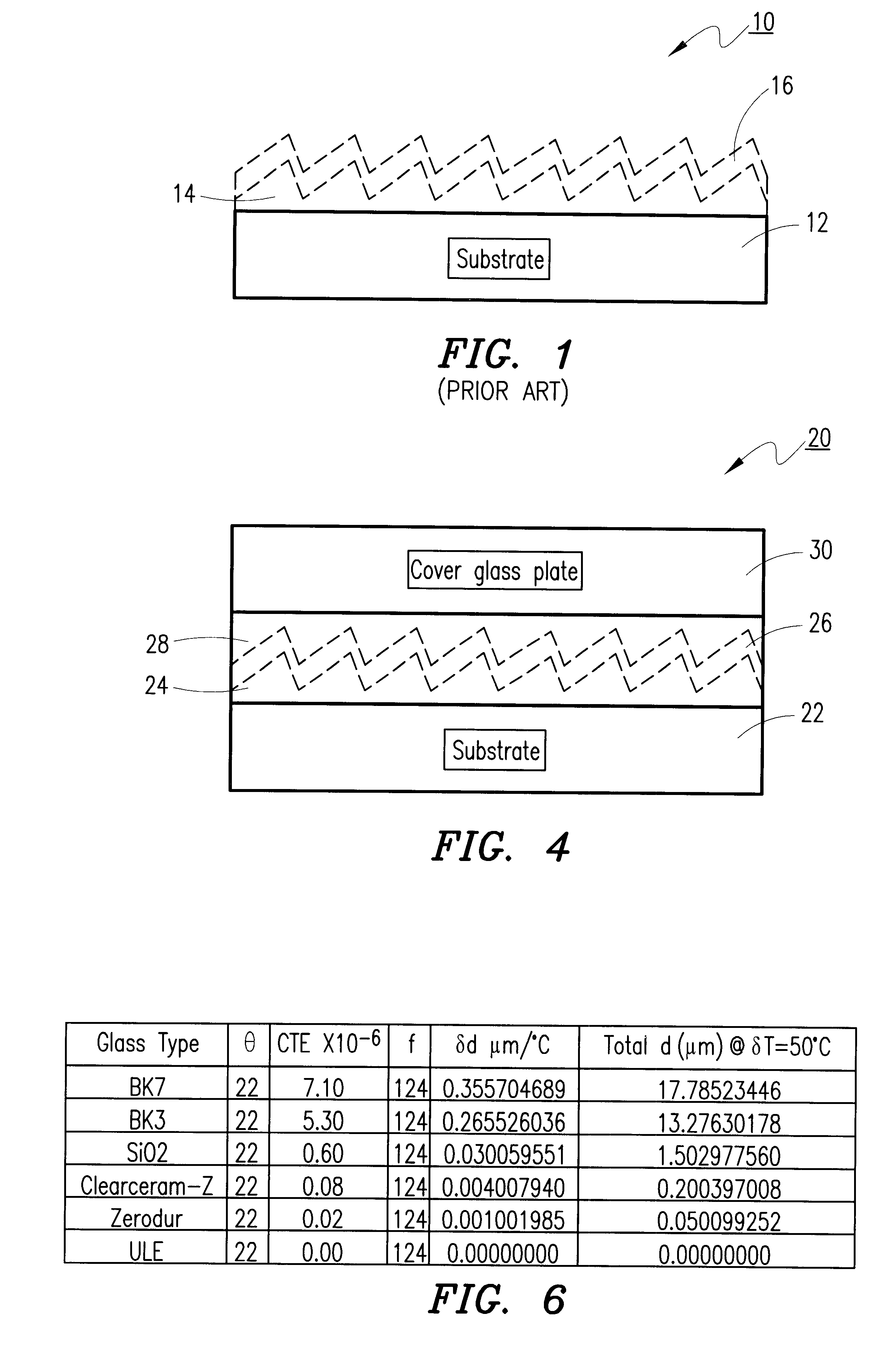

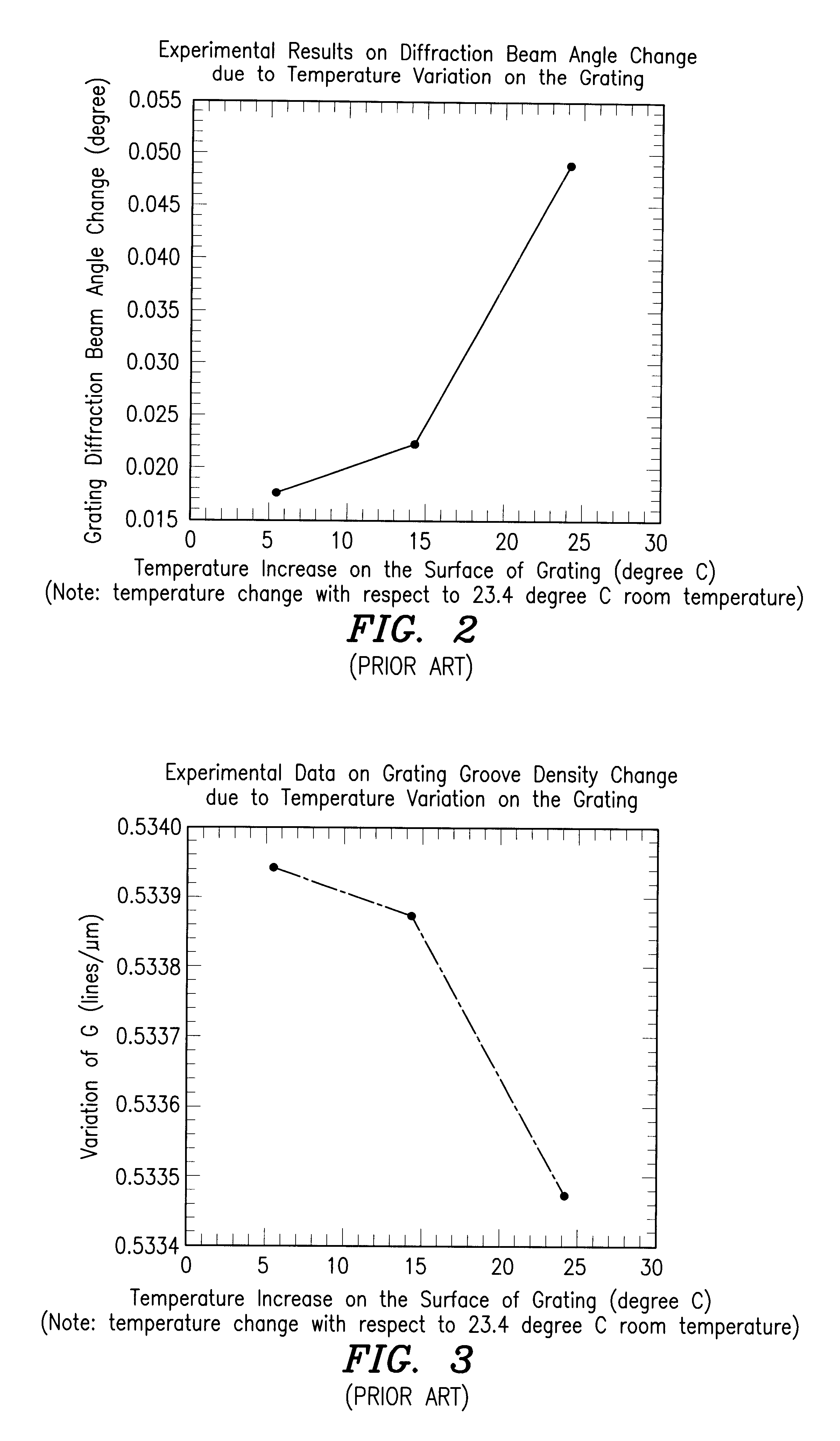

Diffraction grating for wavelength division multiplexing/demultiplexing devices

An improved diffraction grating for wavelength division multiplexing / demultiplexing devices is disclosed. The improved diffraction grating has a glass substrate, a polymer grating layer located adjacent to the glass substrate, and a metal coating layer located adjacent to the polymer grating layer. The improvement comprises a polymer coating layer located adjacent to the metal coating layer, and a glass cover located adjacent to the polymer coating layer, wherein the polymer coating layer and the glass cover compensate for thermal characteristics associated with the polymer grating layer and the glass substrate, respectively.

Owner:AUXORA

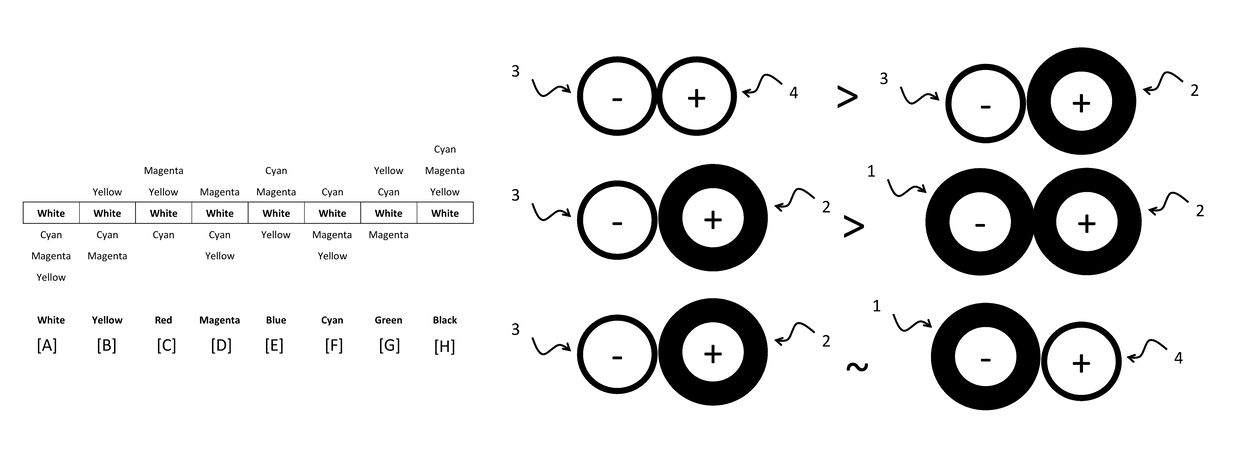

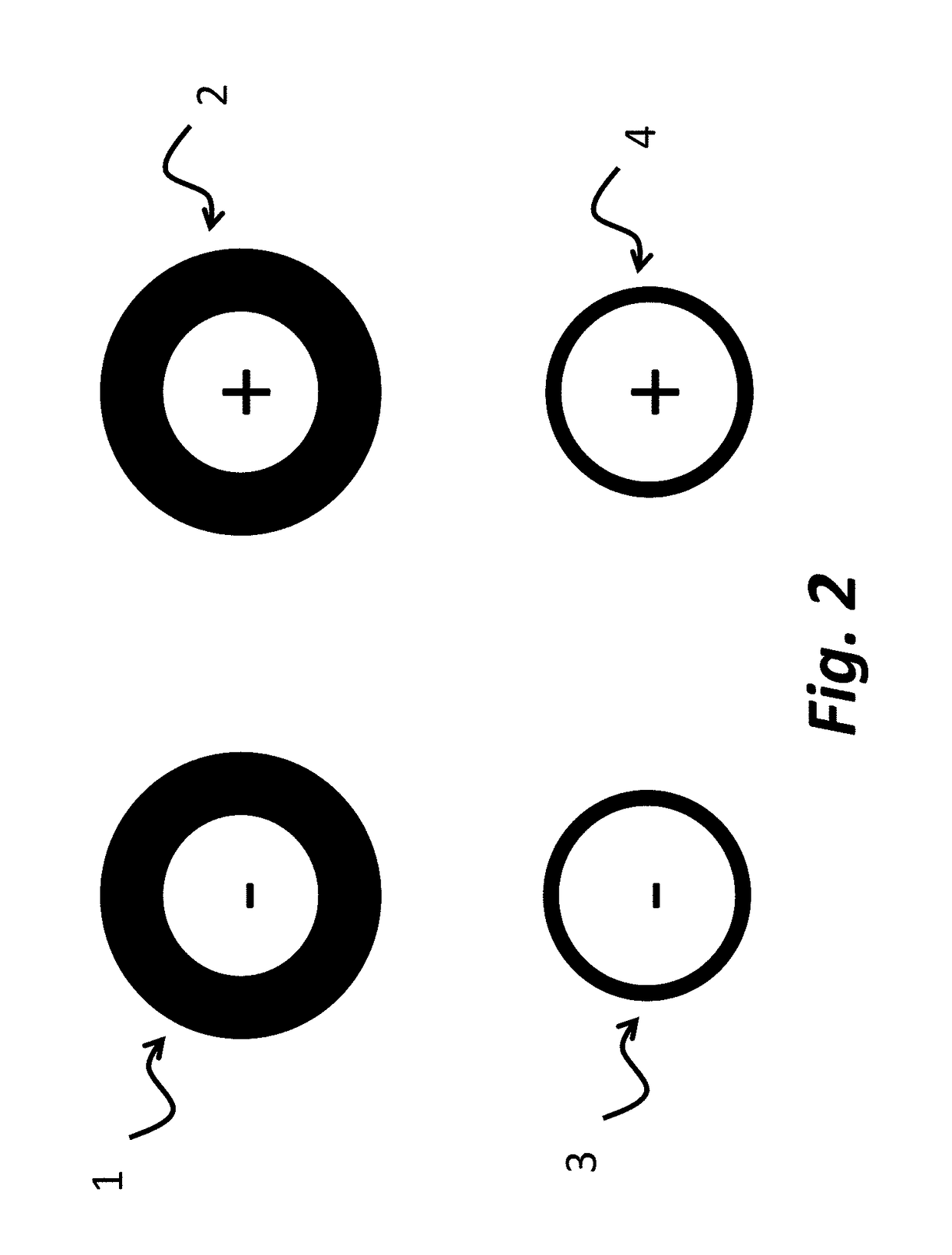

Colored electrophoretic displays

ActiveUS9921451B2Improves bistabilityStatic indicating devicesOrganic dyesElectrophoresesPolymer science

Owner:E INK CORPORATION

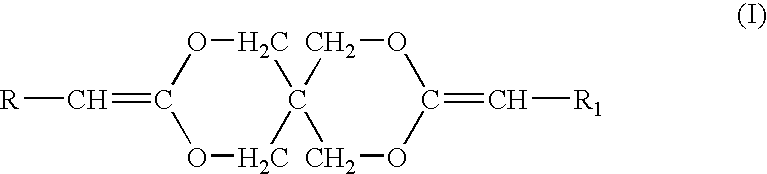

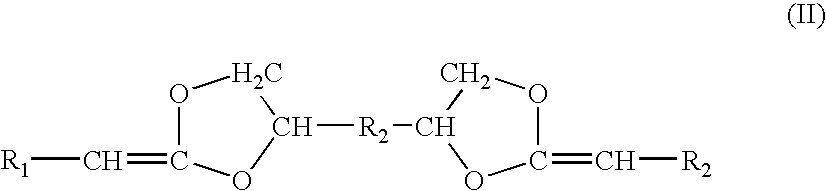

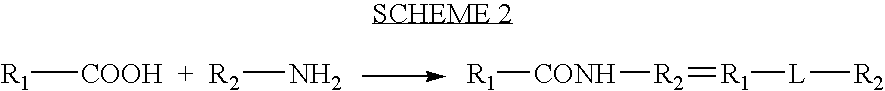

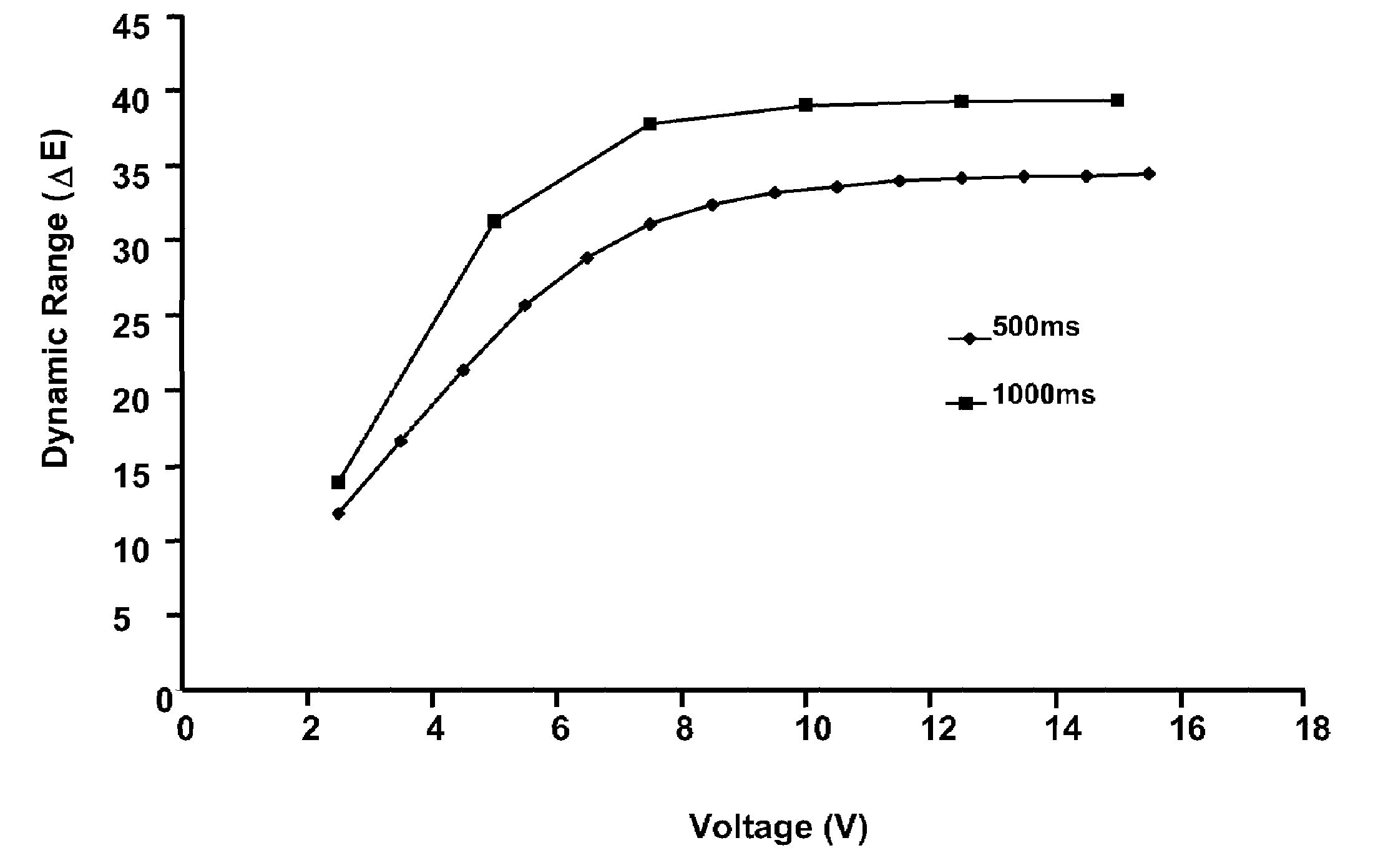

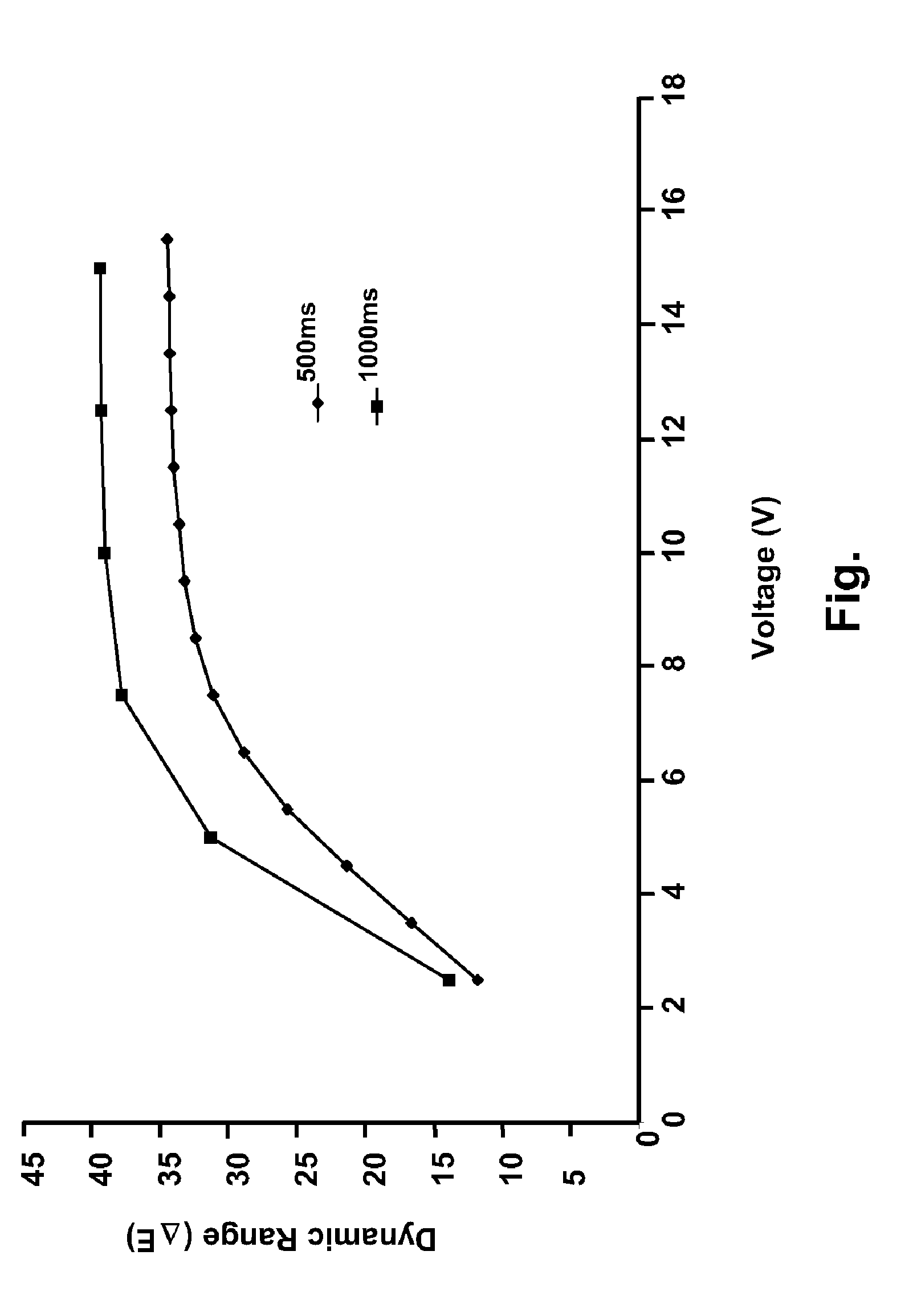

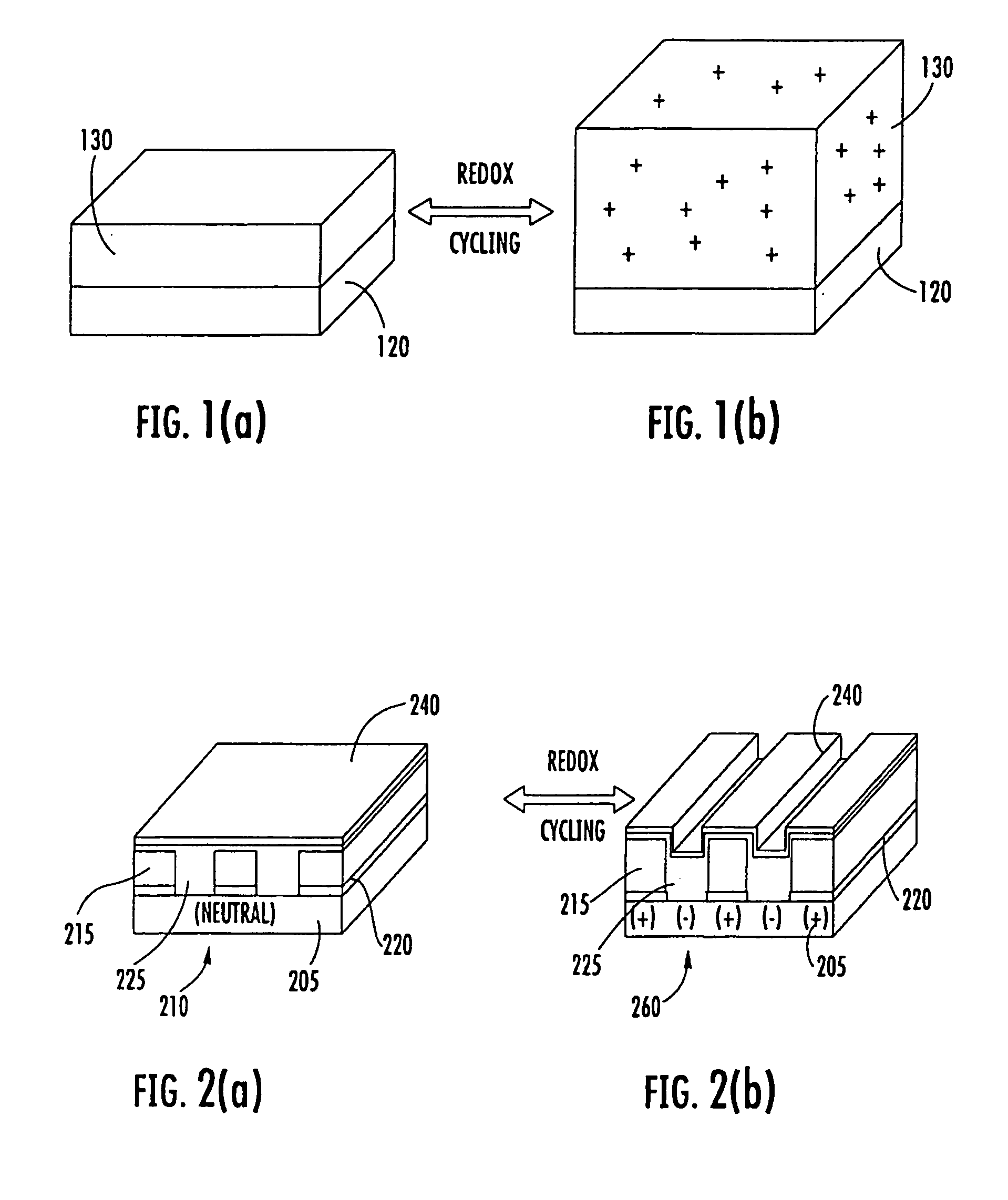

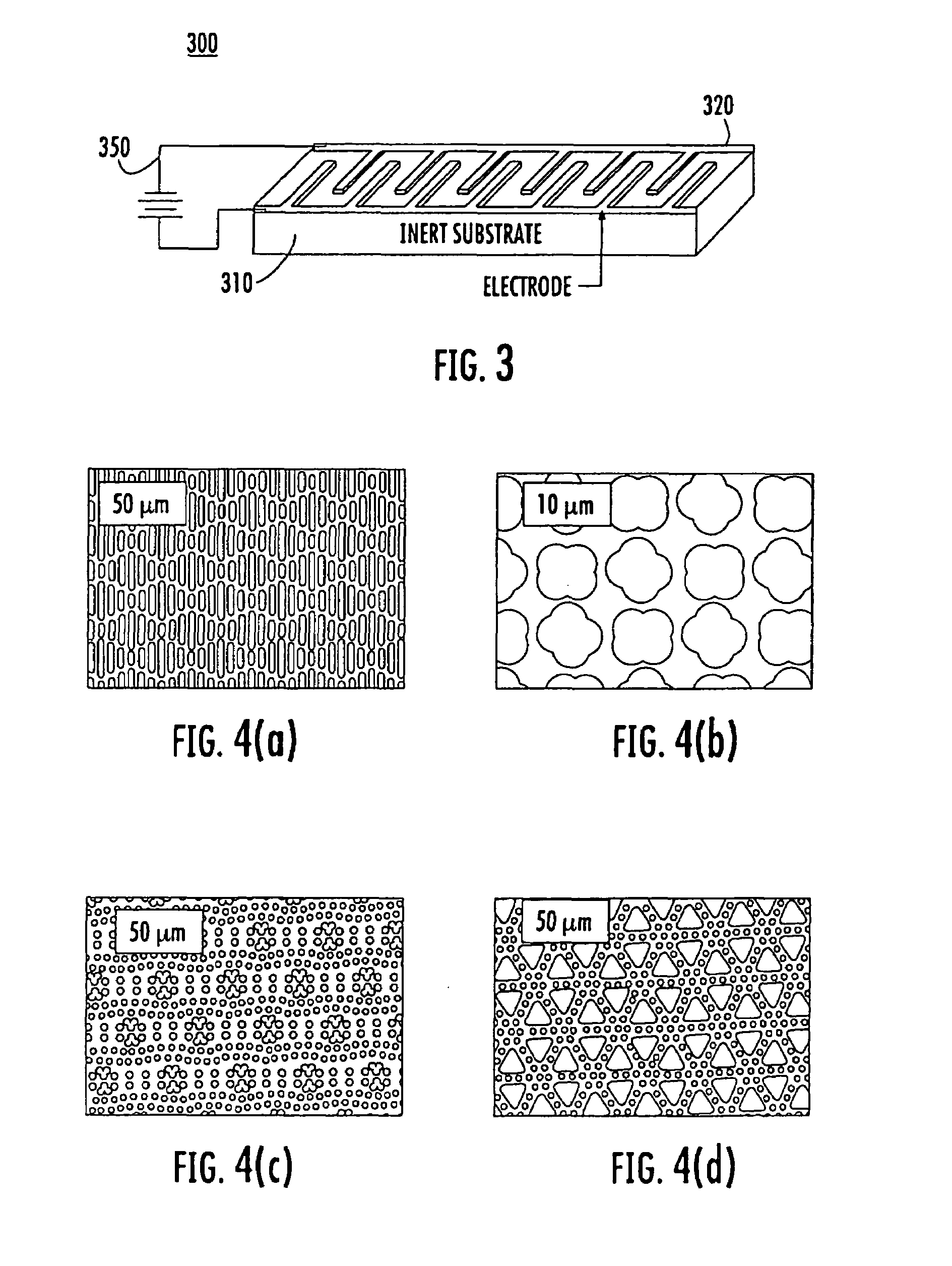

Dynamically modifiable polymer coatings and devices

A dynamic coating includes at least one polymeric layer for attachment to a surface. The polymeric layer includes at least one electrically conducting polymer including layer, wherein under influence of a dynamic signal applied to the polymeric layer, a contact angle of the polymeric layer dynamically and substantially increases or decreases upon oxidation or reduction of the polymer. The polymeric layer can also expand or contract upon oxidation or reduction. The coating can be used for a variety of applications including a non-toxic biofouling preventative system and for forming low voltage electrowetting pumps.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com