Patents

Literature

19581 results about "Silanes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Binary silicon-hydrogen compounds are saturated chemical compounds with the empirical formula SiHₙ. All contain tetrahedral silicon and terminal hydrides. They only have Si–H and Si–Si single bonds. The bond lengths are 146.0 pm for a Si–H bond and 233 pm for a Si–Si bond. The structures of the silanes are analogues of the alkanes, starting with silane, SiH₄, the analogue of methane, continuing with disilane Si₂H₆, the analogue of ethane, etc.

Method of depositing a low k dielectric with organo silane

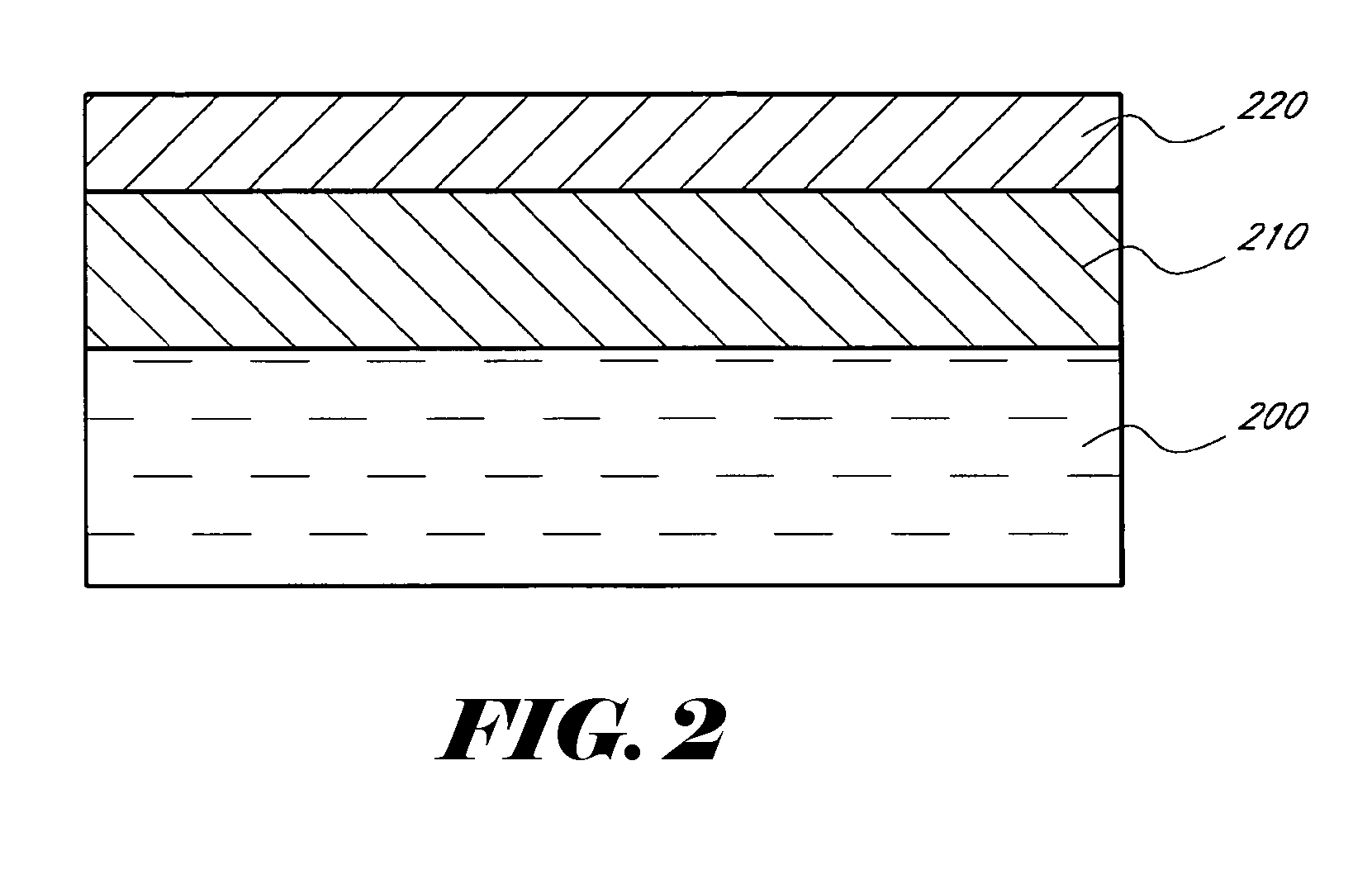

InactiveUS6054379ASemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilane compoundsSilanes

A method and apparatus for depositing a low dielectric constant film by reaction of an organo silane compound and an oxidizing gas. The oxidized organo silane film has excellent barrier properties for use as a liner or cap layer adjacent other dielectric layers. The oxidized organo silane film can also be used as an etch stop or an intermetal dielectric layer for fabricating dual damascene structures. The oxidized organo silane films also provide excellent adhesion between different dielectric layers. A preferred oxidized organo silane film is produced by reaction of methyl silane, CH3SiH3, and N2O.

Owner:APPLIED MATERIALS INC

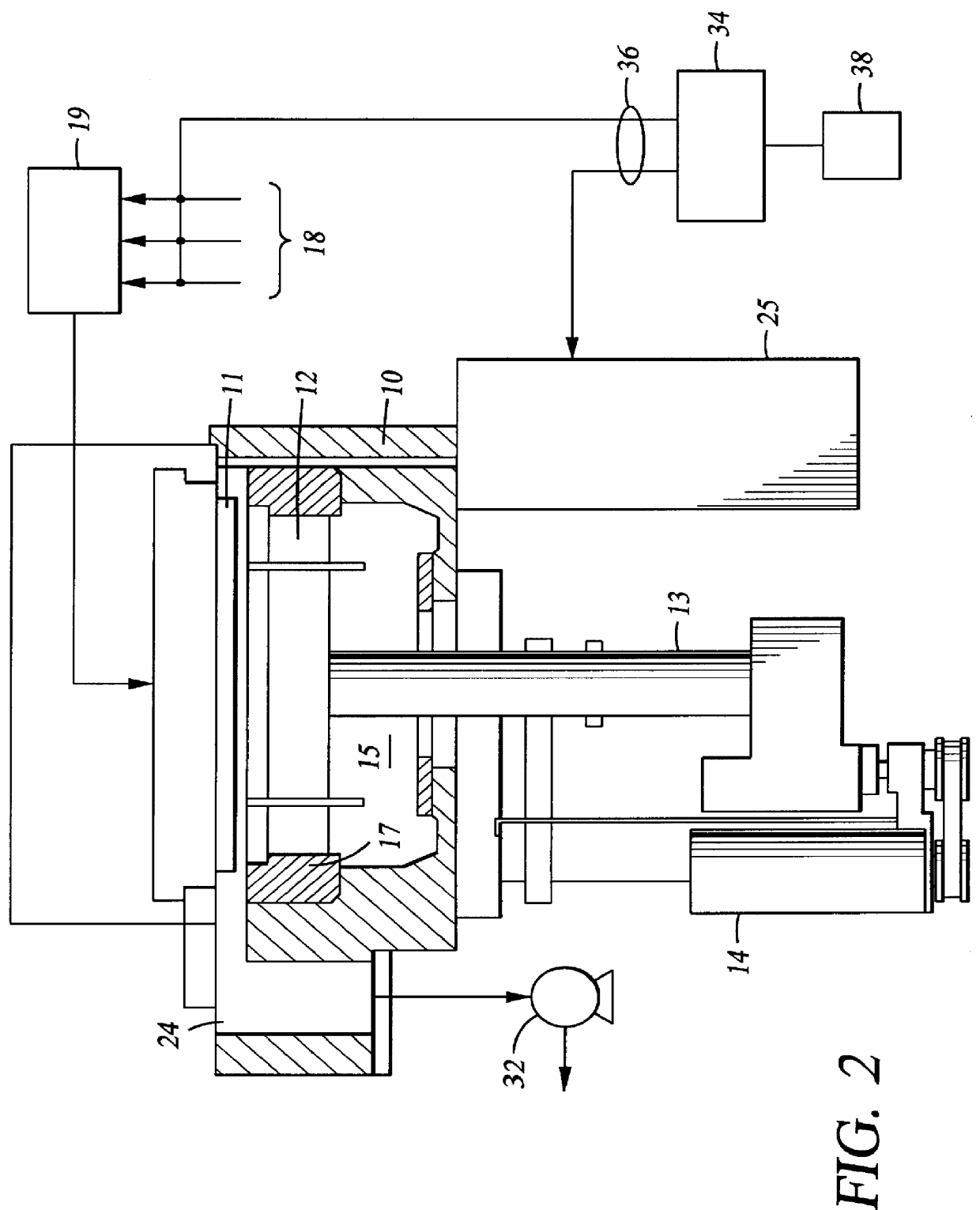

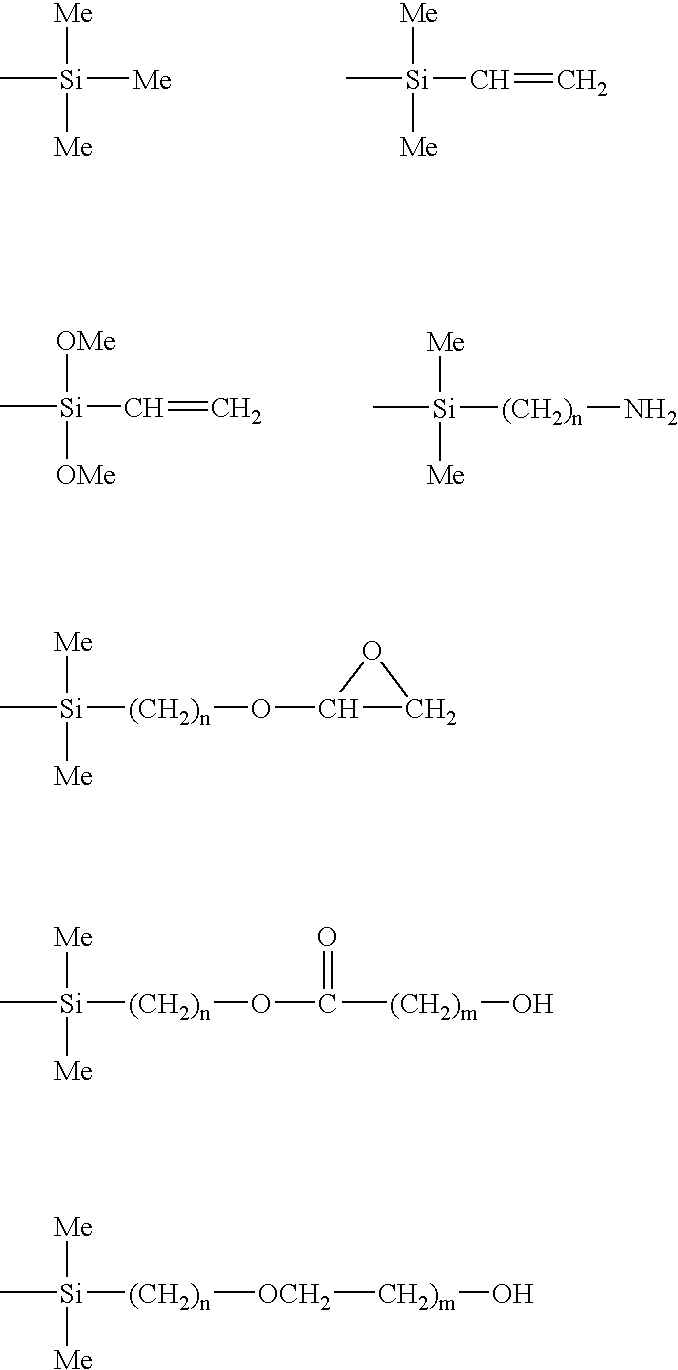

Organosilicon compounds

InactiveUS6849754B2Improve bindingAvoid large quantitiesSilicon organic compoundsOrganic chemistry methodsAlcoholSilanes

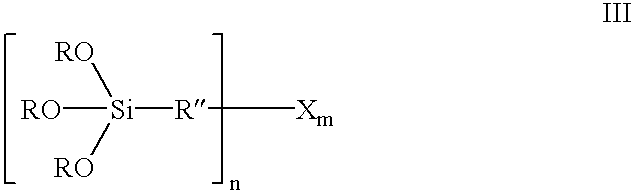

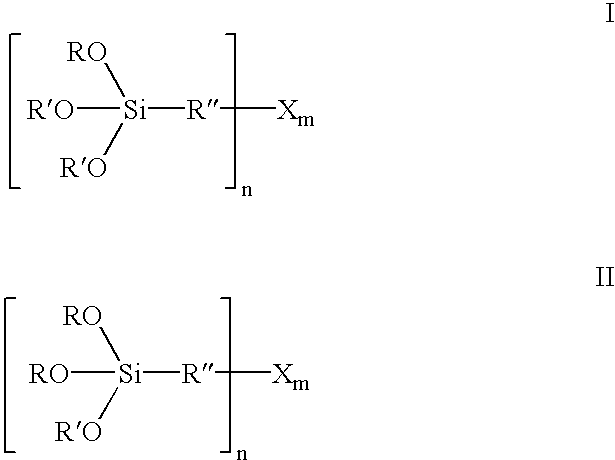

Organosilicon compounds of the general formula I and / or II are produced by reacting silanes of the general formula III with alcohols of the general formula R′—OH, with elimination of R—OH, wherein R—OH may be continuously separated from the reaction mixture by distillation. The organosilicon compounds may be used in rubber mixtures. Compounds, such as rubbers, produced using such organosilicon compounds.

Owner:EVONIK DEGUSSA GMBH

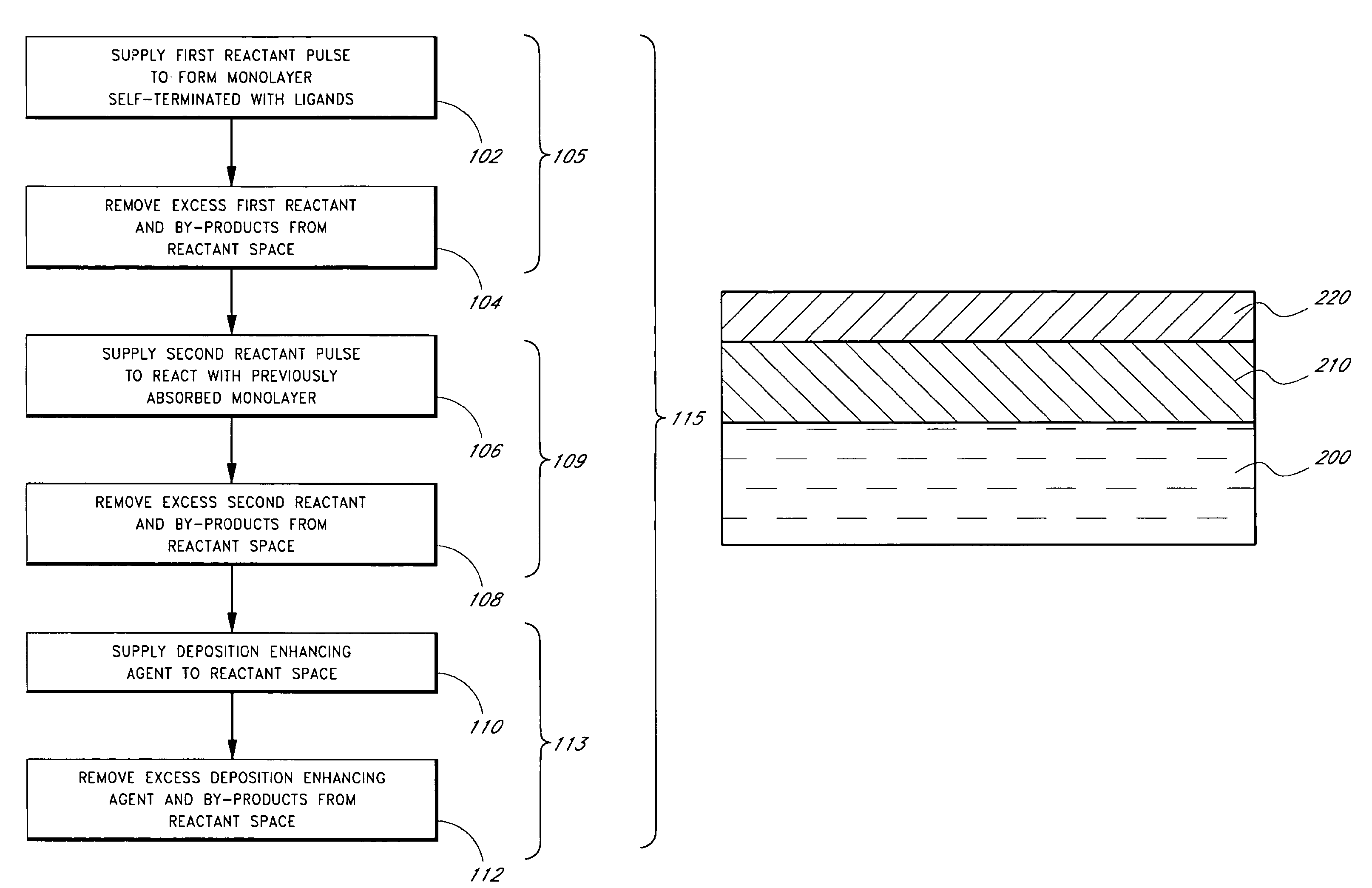

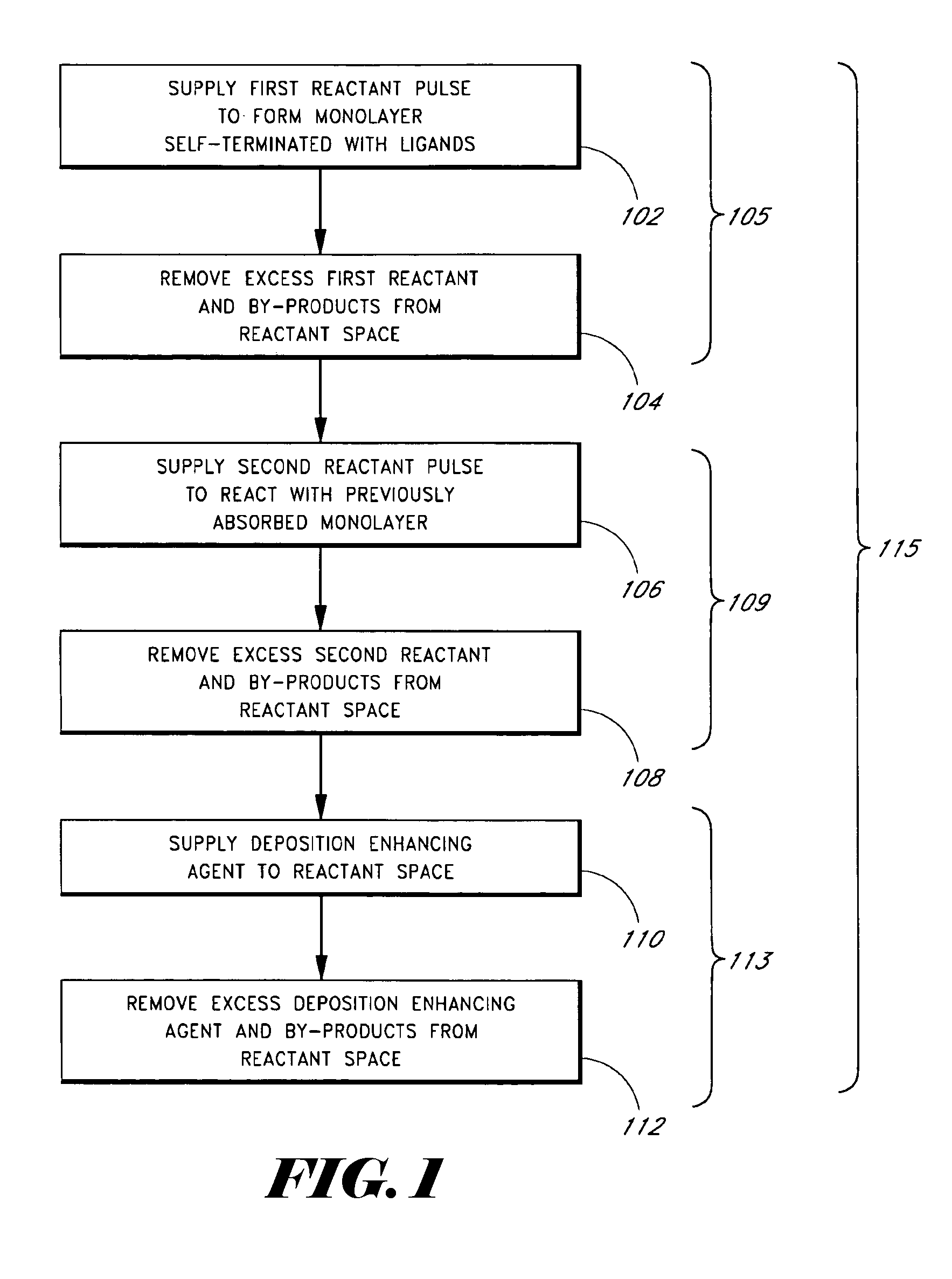

Enhanced thin film deposition

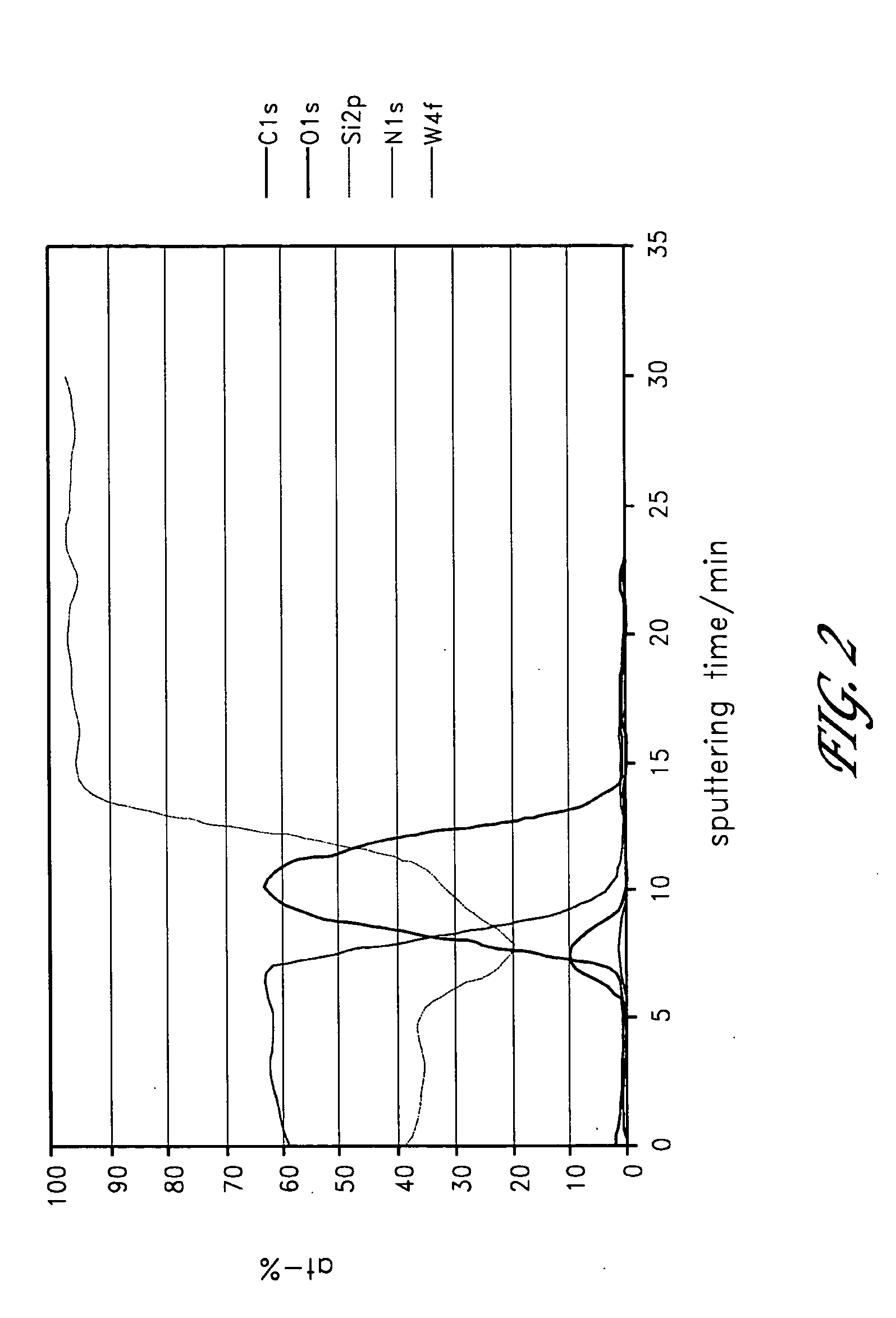

ActiveUS20070148350A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSilanesNitrogen

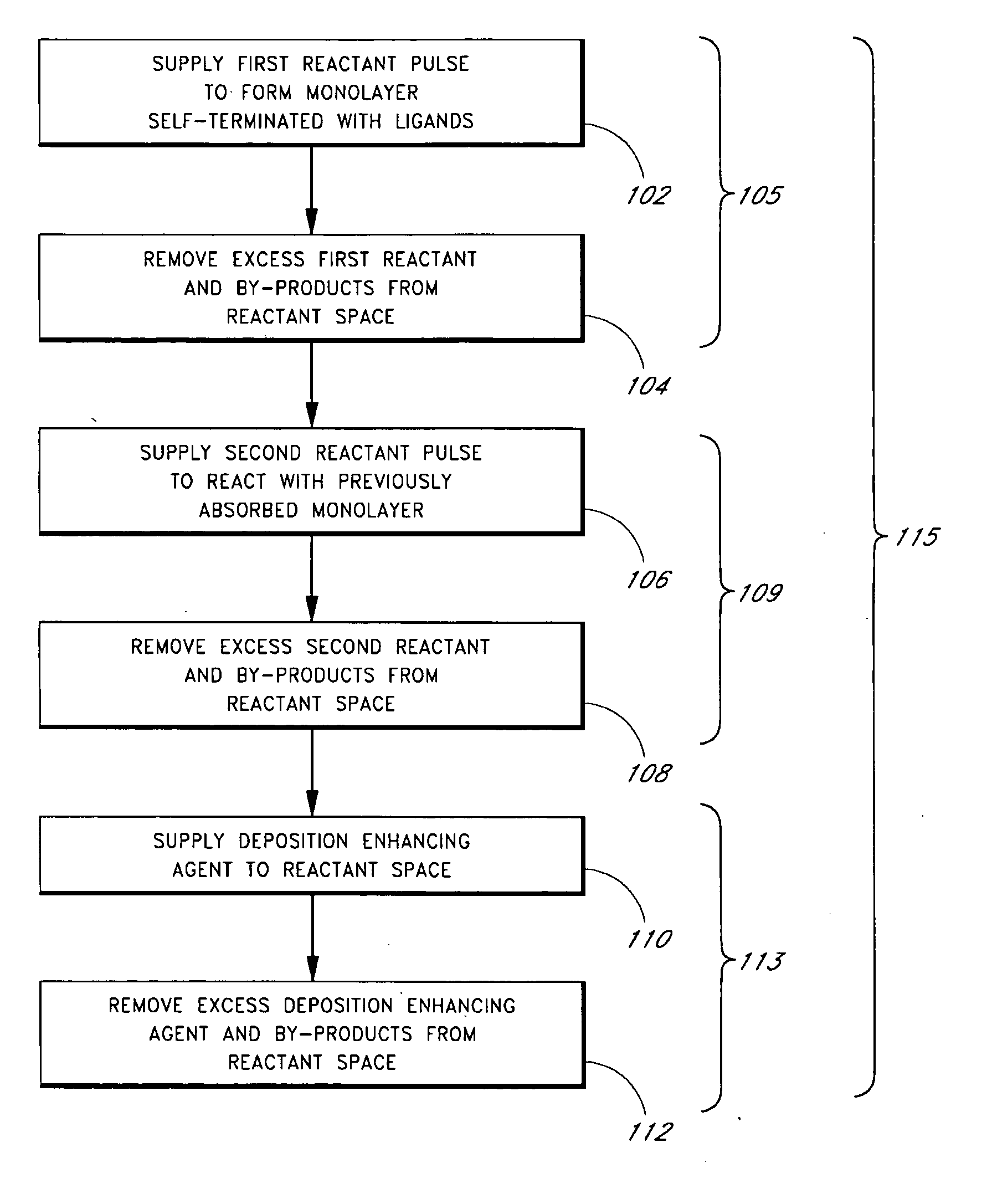

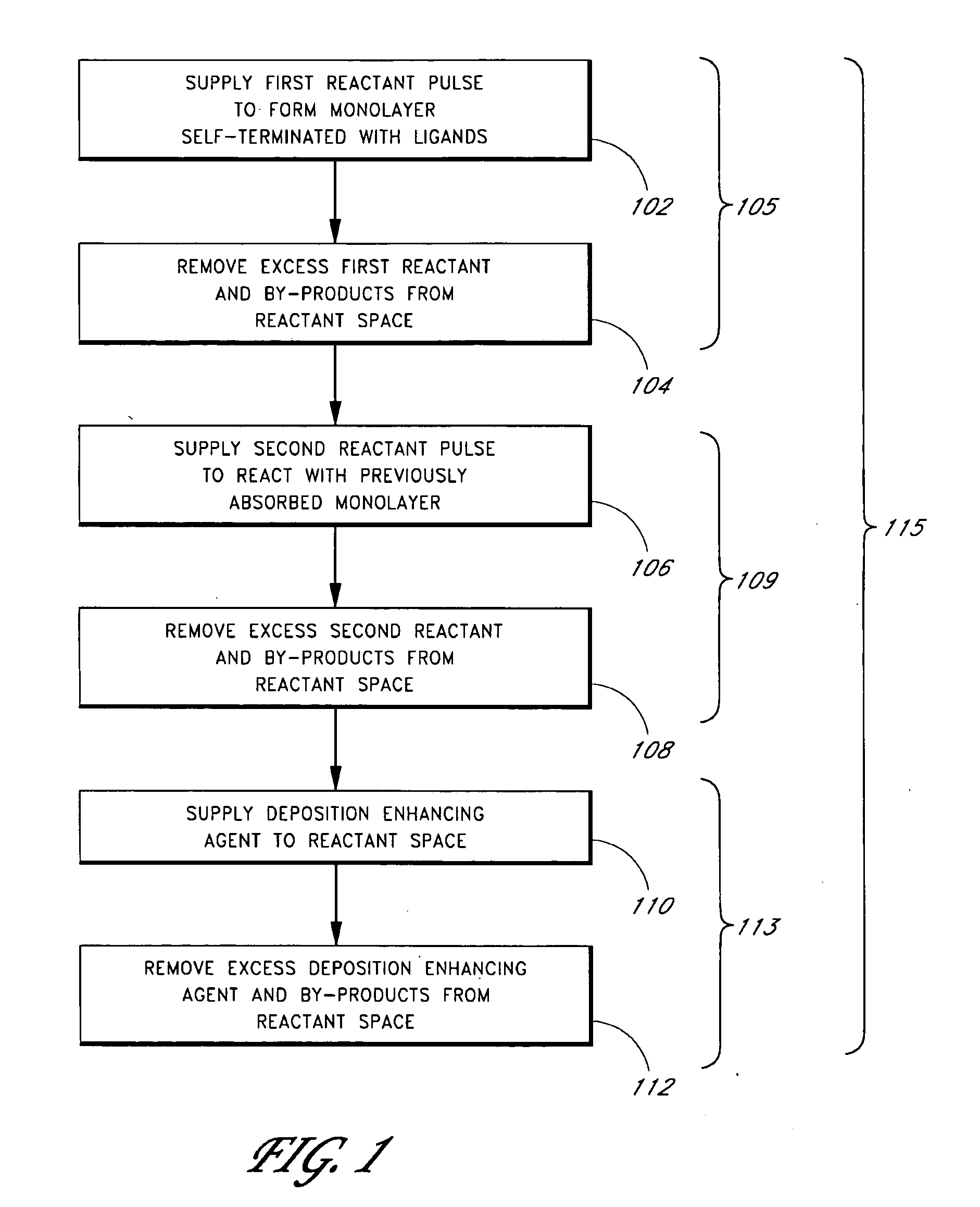

Methods of producing metal-containing thin films with low impurity contents on a substrate by atomic layer deposition (ALD) are provided. The methods preferably comprise contacting a substrate with alternating and sequential pulses of a metal source chemical, a second source chemical and a deposition enhancing agent. The deposition enhancing agent is preferably selected from the group consisting of hydrocarbons, hydrogen, hydrogen plasma, hydrogen radicals, silanes, germanium compounds, nitrogen compounds, and boron compounds. In some embodiments, the deposition-enhancing agent reacts with halide contaminants in the growing thin film, improving film properties.

Owner:ASM INTERNATIONAL

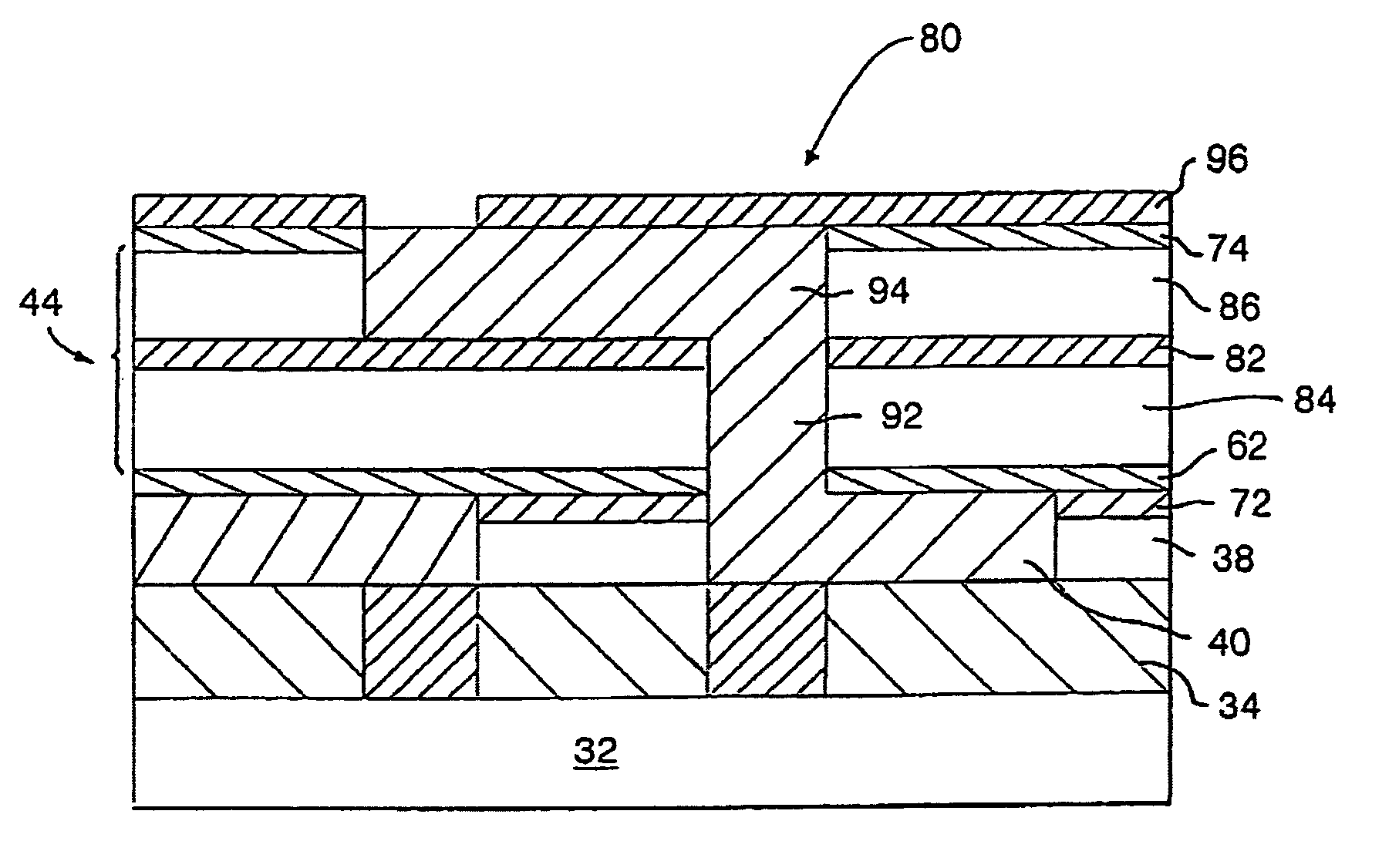

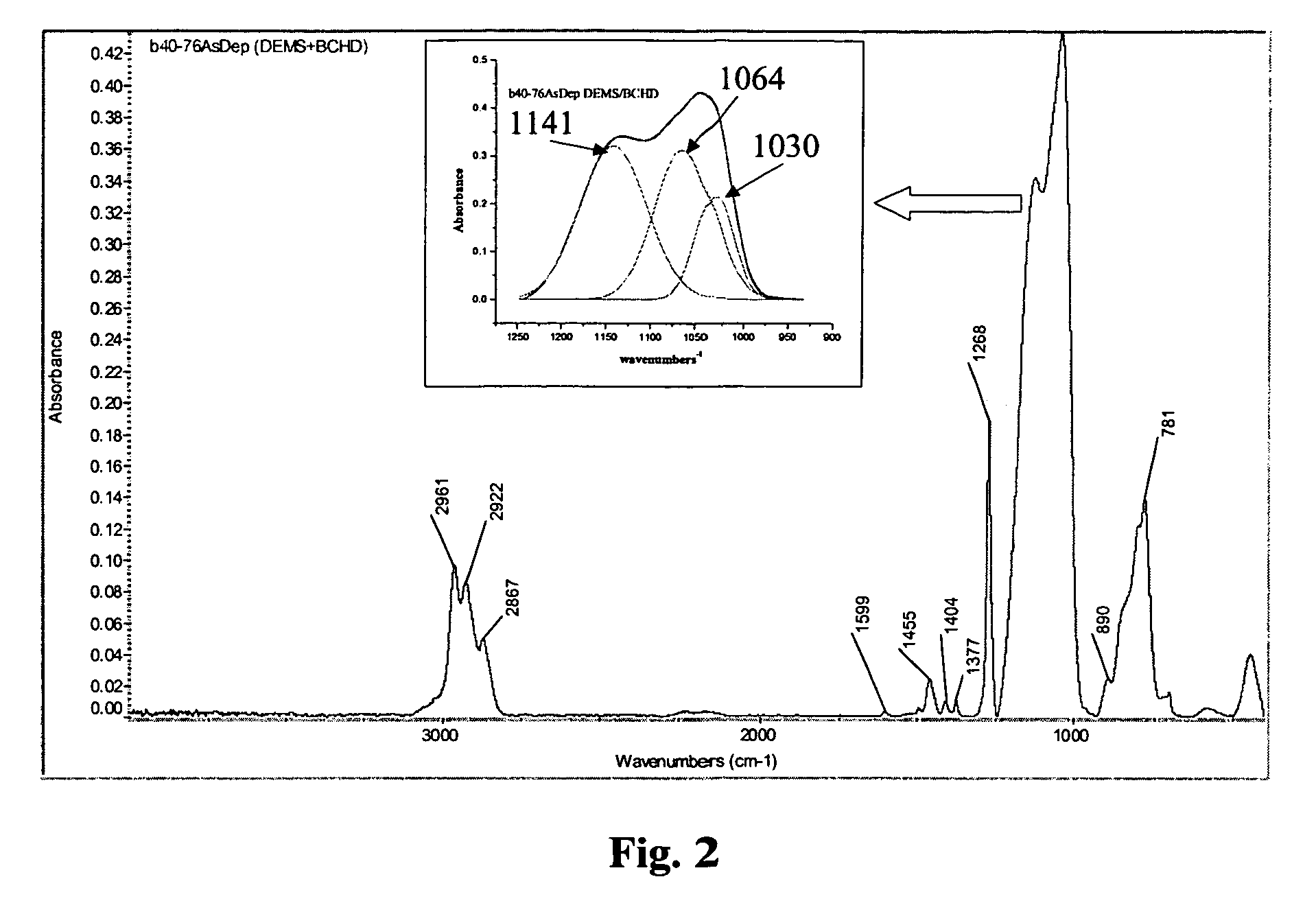

Method for fabricating an ultralow dielectric constant material as an intralevel or interlevel dielectric in a semiconductor device and electronic device made

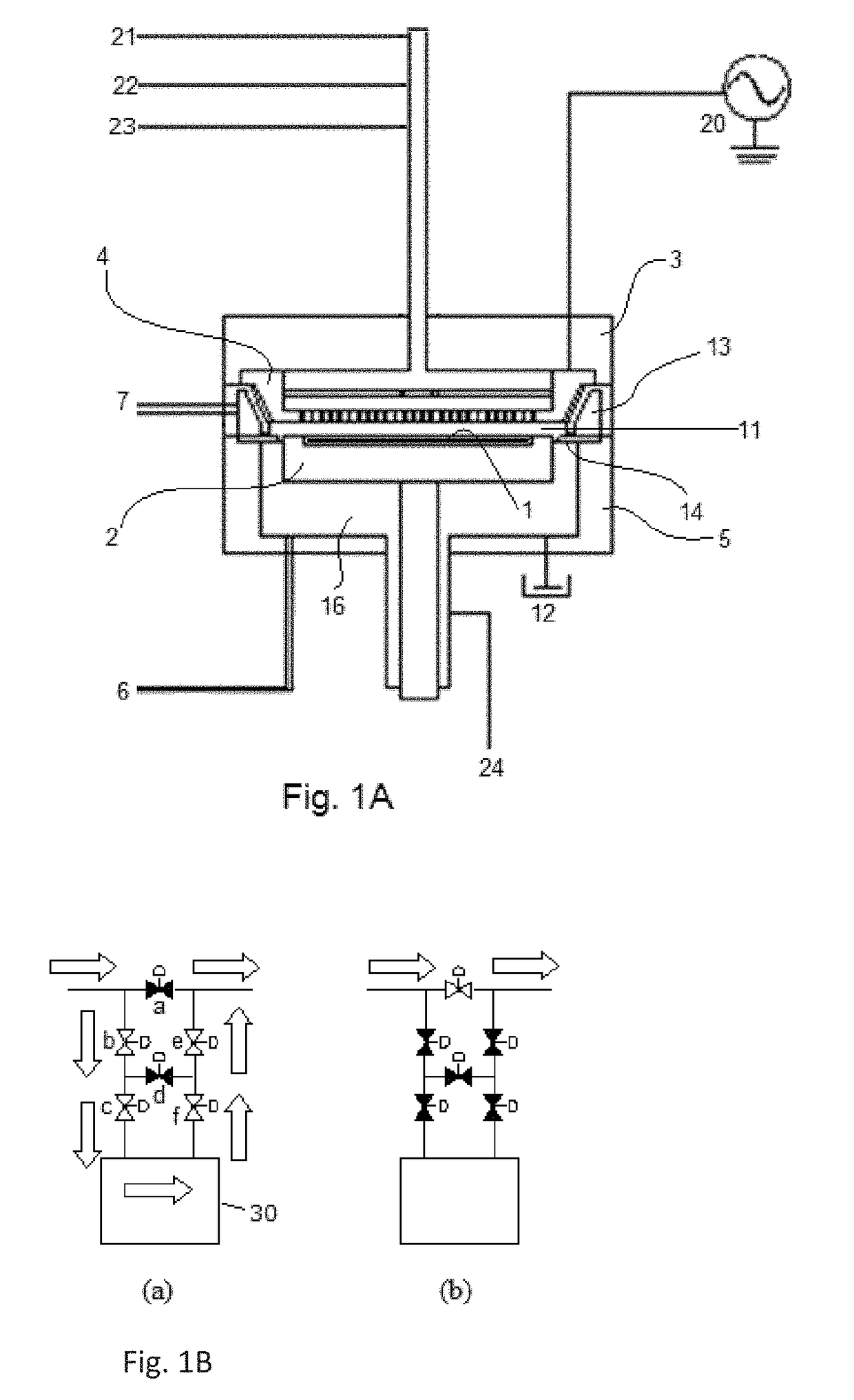

InactiveUS7049247B2Low costReduce tensile stressSemiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseParallel plate

A method for fabricating a thermally stable ultralow dielectric constant film comprising Si, C, O and H atoms in a parallel plate chemical vapor deposition process utilizing a plasma enhanced chemical vapor deposition (“PECVD”) process is disclosed. Electronic devices containing insulating layers of thermally stable ultralow dielectric constant materials that are prepared by the method are further disclosed. To enable the fabrication of a thermally stable ultralow dielectric constant film, specific precursor materials are used, such as, silane derivatives, for instance, diethoxymethylsilane (DEMS) and organic molecules, for instance, bicycloheptadiene and cyclopentene oxide.

Owner:INTEL CORP

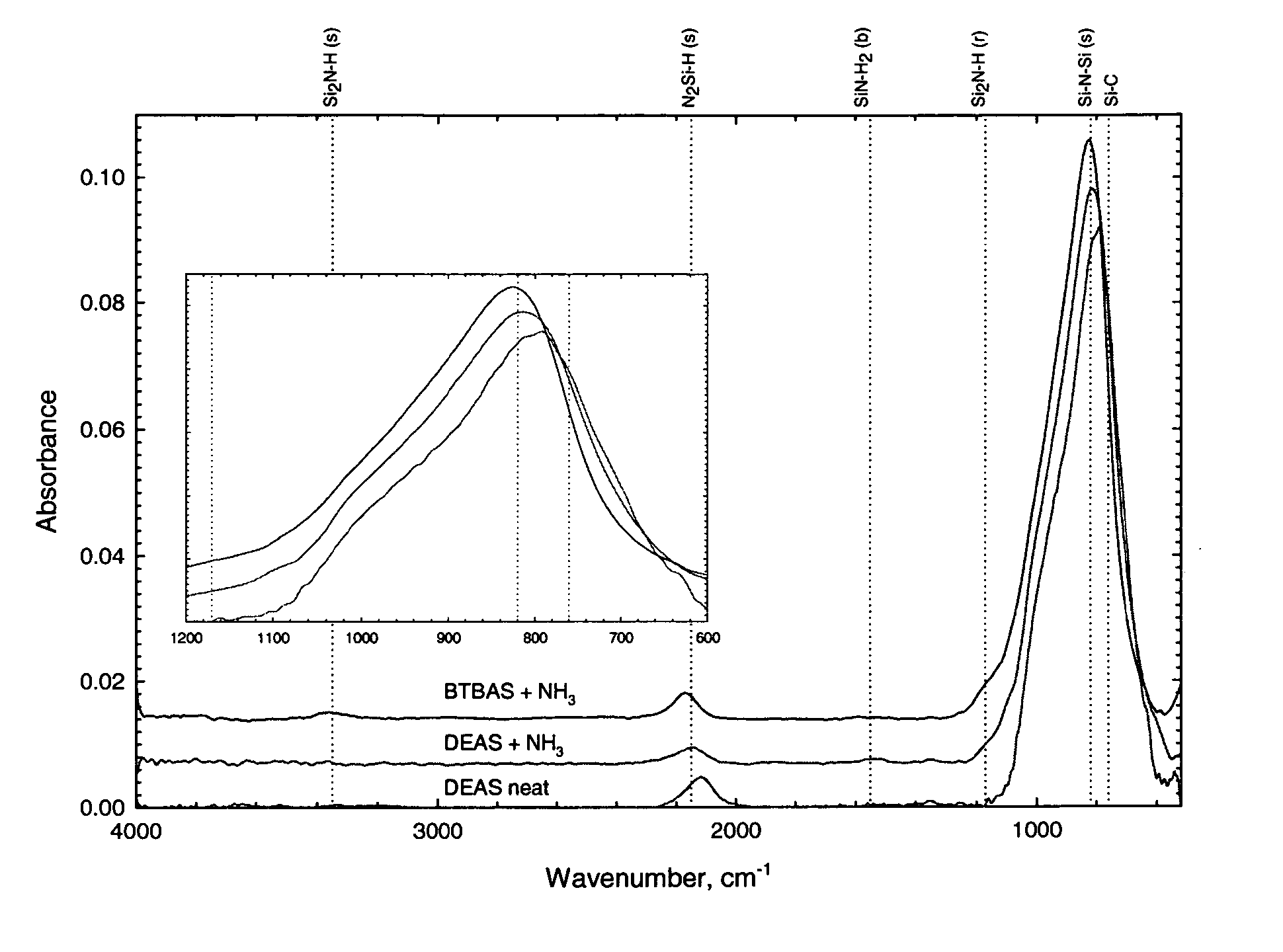

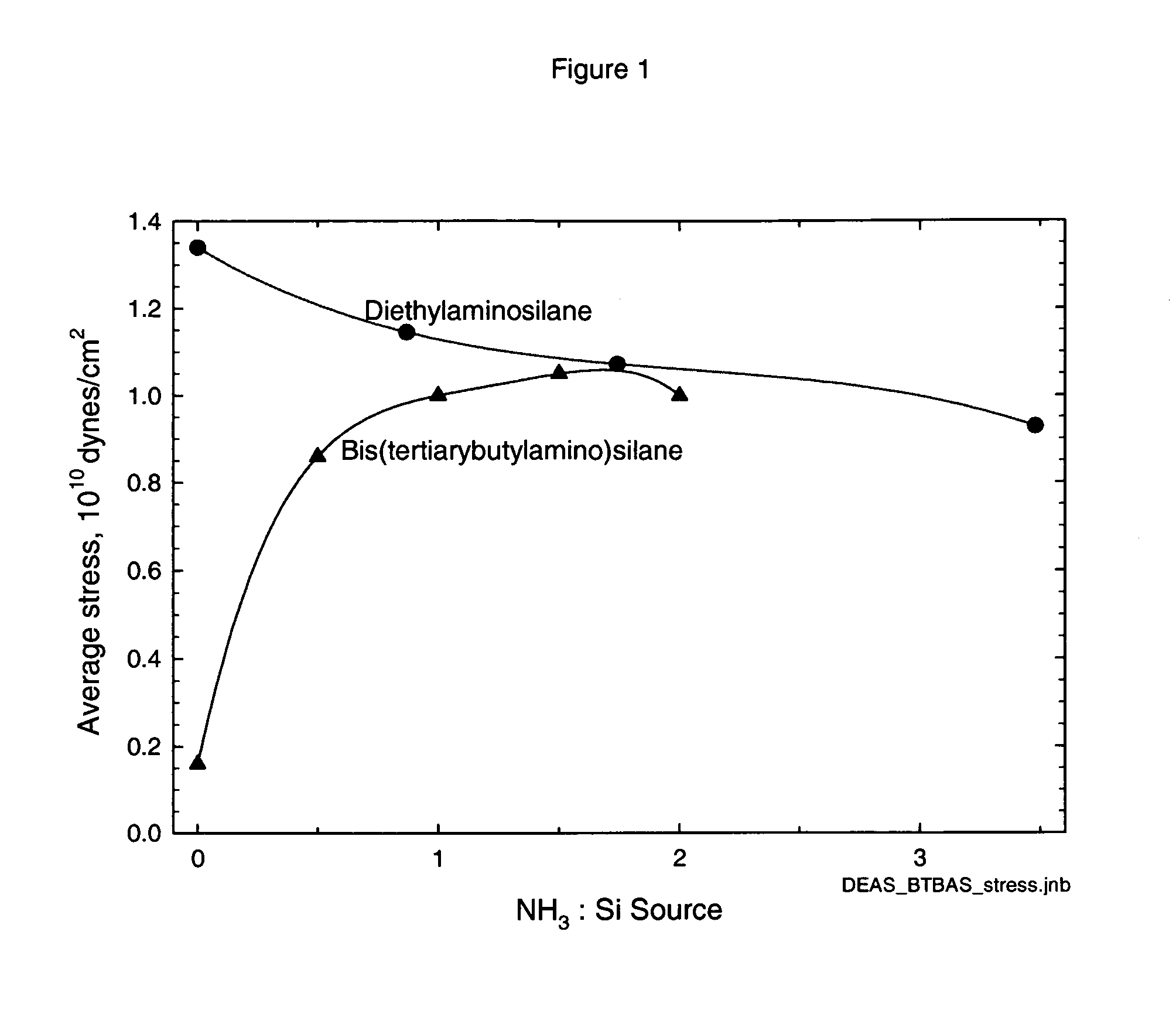

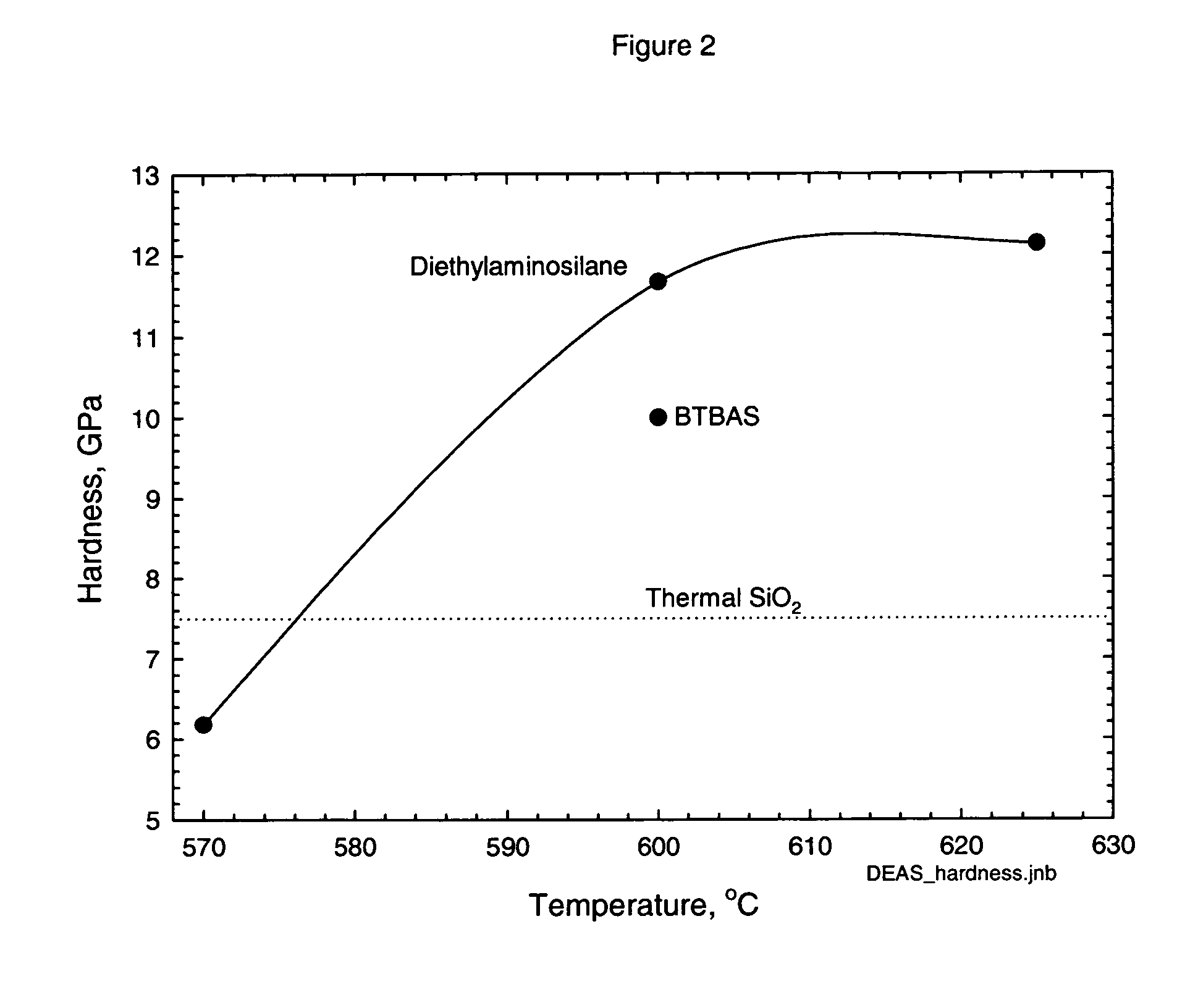

Precursors for CVD silicon carbo-nitride films

ActiveUS20060258173A1Easy to movePromote formationGroup 4/14 element organic compoundsSemiconductor/solid-state device manufacturingSilanesRoom temperature

Classes of liquid aminosilanes have been found which allow for the production of silicon carbo-nitride films of the general formula SixCyNz. These aminosilanes, in contrast, to some of the precursors employed heretofore, are liquid at room temperature and pressure allowing for convenient handling. In addition, the invention relates to a process for producing such films. The classes of compounds are generally represented by the formulas: and mixtures thereof, wherein R and R1 in the formulas represent aliphatic groups typically having from 2 to about 10 carbon atoms, e.g., alkyl, cycloalkyl with R and R1 in formula A also being combinable into a cyclic group, and R2 representing a single bond, (CH2)n, a ring, or SiH2.

Owner:VERSUM MATERIALS US LLC

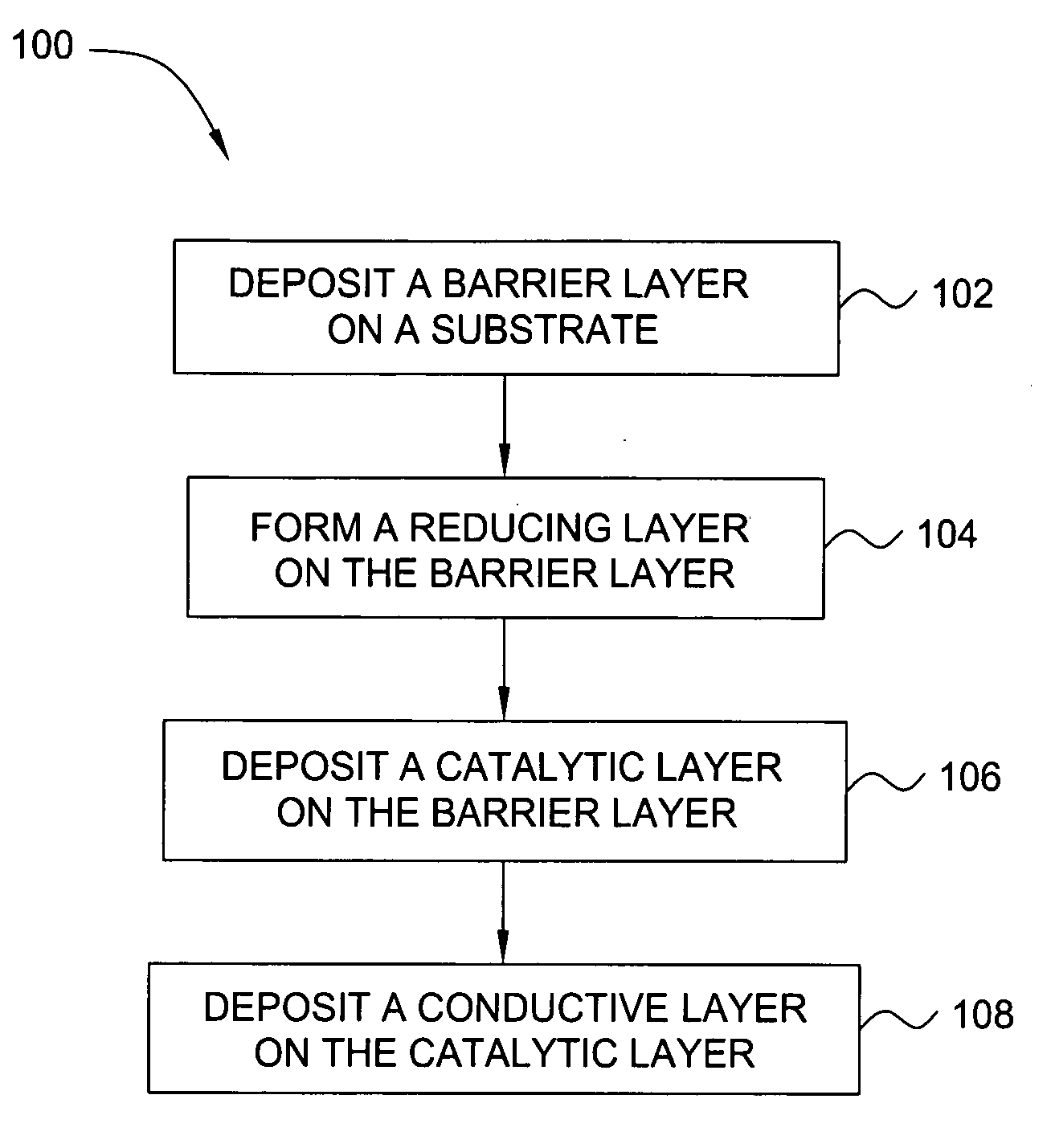

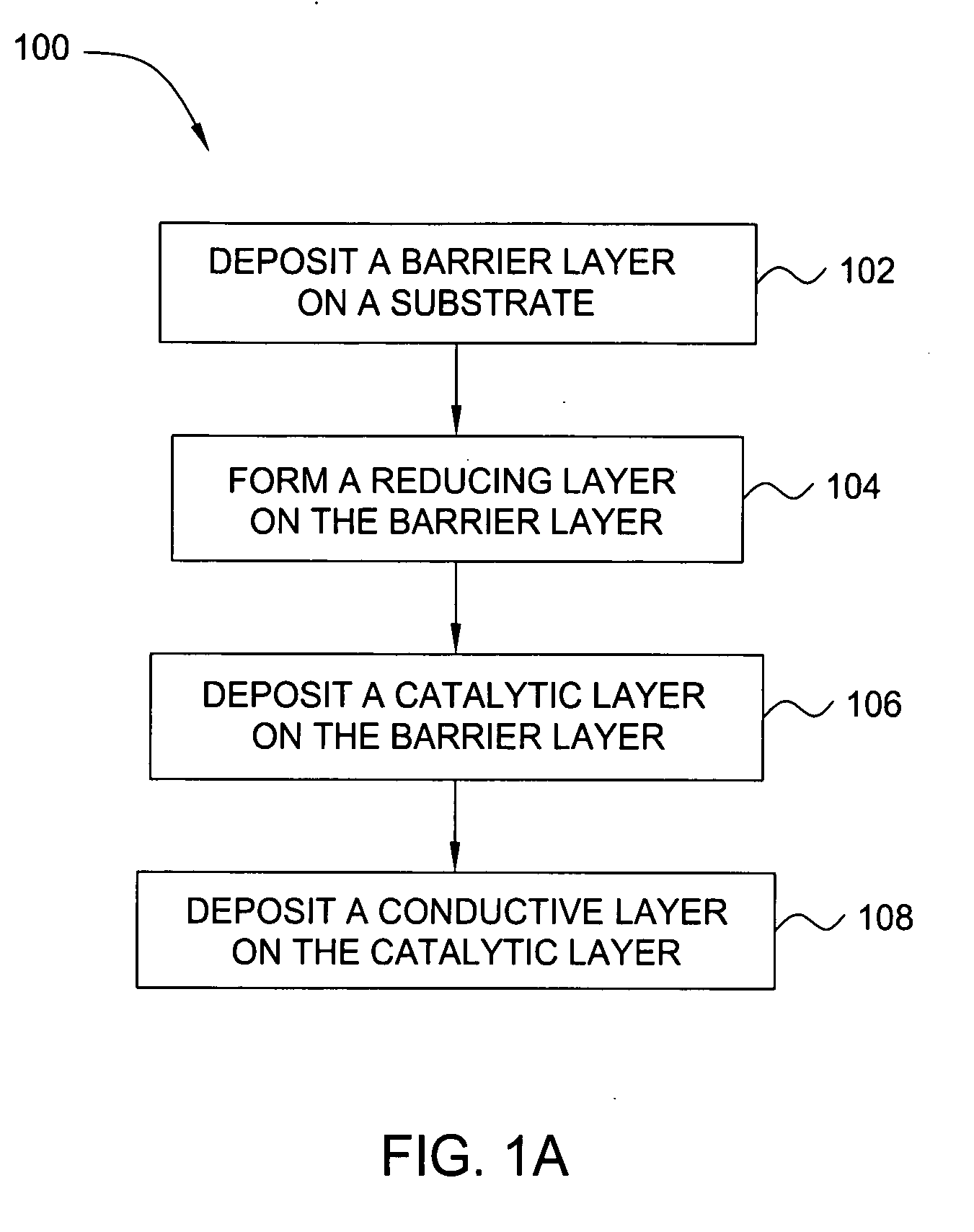

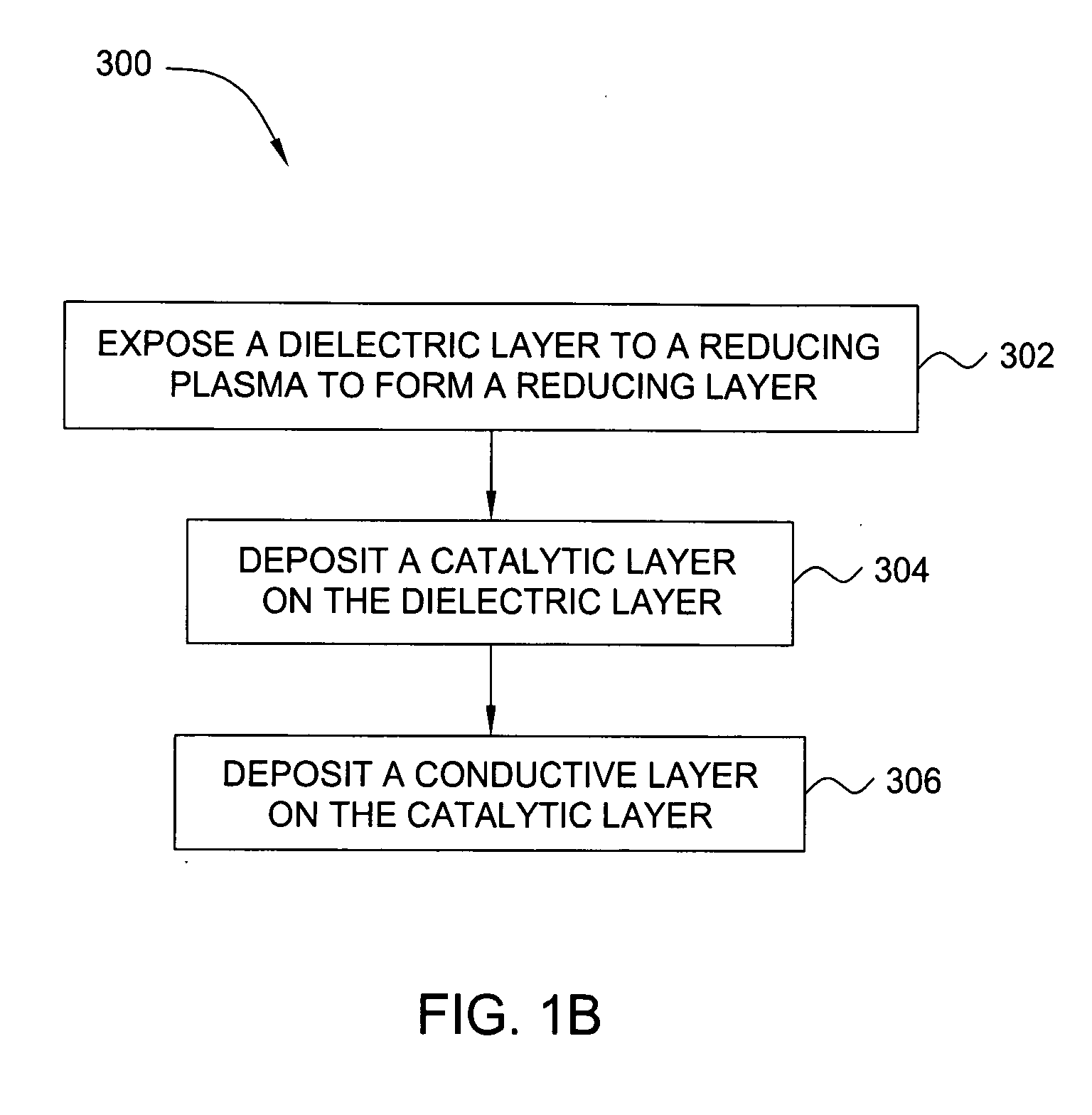

Deposition of an intermediate catalytic layer on a barrier layer for copper metallization

InactiveUS20060240187A1Solid-state devicesSemiconductor/solid-state device manufacturingIridiumSilanes

In one embodiment, a method for depositing a conductive material on a substrate is provided which includes exposing a substrate containing a barrier layer to a volatile reducing precursor to form a reducing layer during a soak process, exposing the reducing layer to a catalytic-metal precursor to deposit a catalytic metal-containing layer on the barrier layer, and depositing a conductive layer (e.g., copper) on the catalytic metal-containing layer. The volatile reducing precursor may include phosphine, diborane, silane, a plasma thereof, or a combination thereof and be exposed to the substrate for a time period within a range from about 1 second to about 30 seconds during the soak process. The catalytic metal-containing layer may contain ruthenium, cobalt, rhodium, iridium, nickel, palladium, platinum, silver, or copper. In one example, the catalytic metal-containing layer is deposited by a vapor deposition process utilizing ruthenium tetroxide formed by an in situ process.

Owner:APPLIED MATERIALS INC

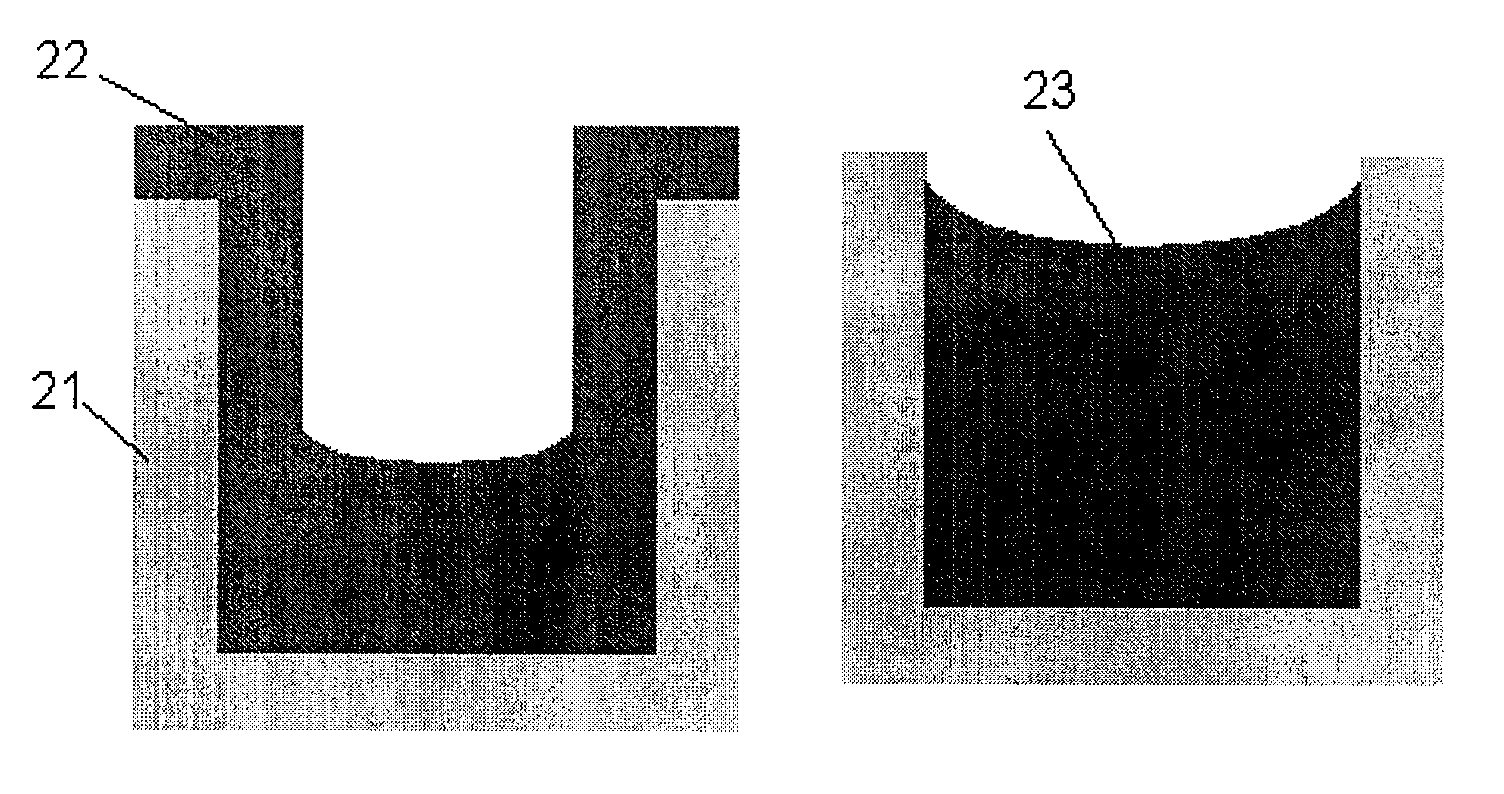

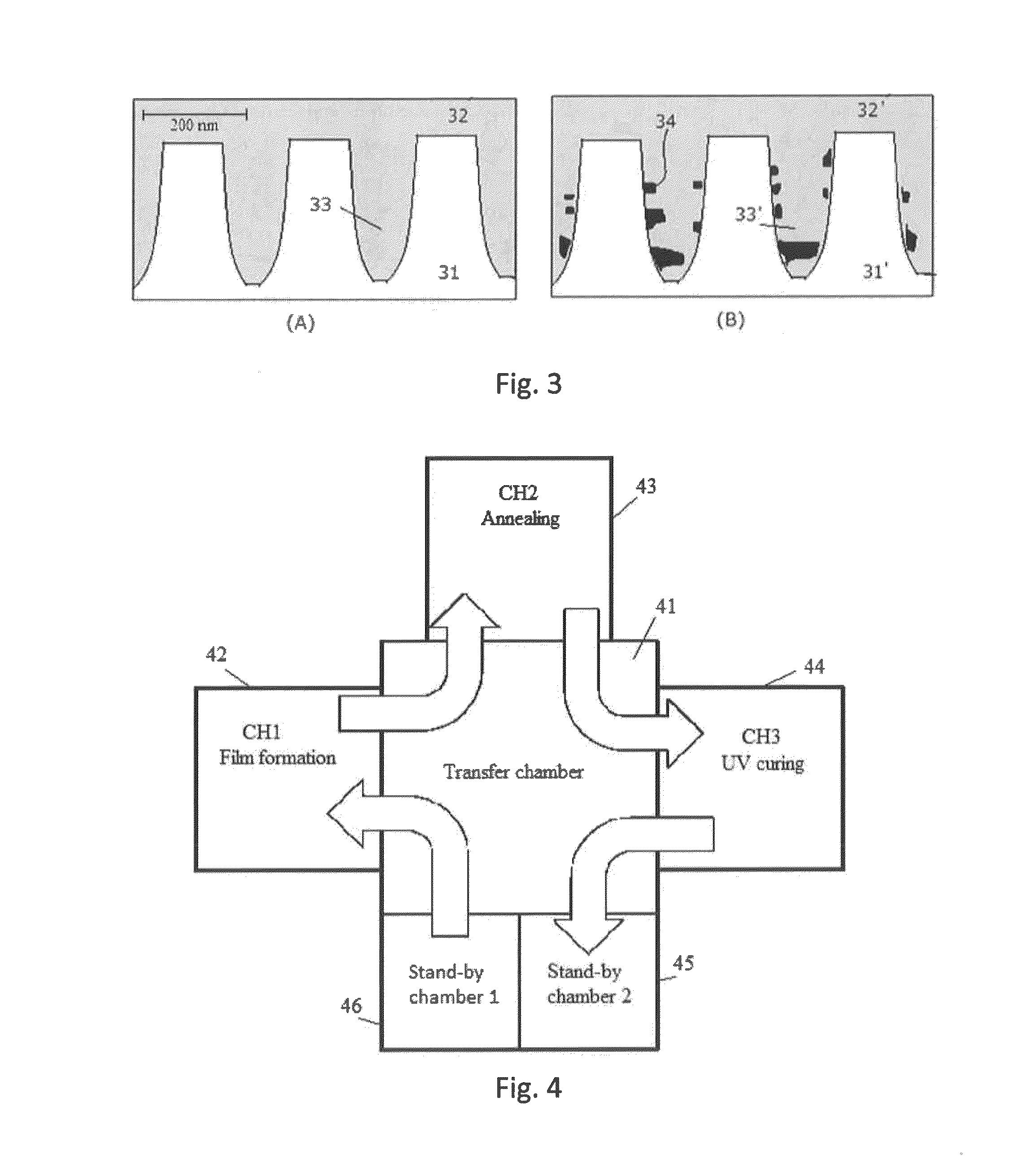

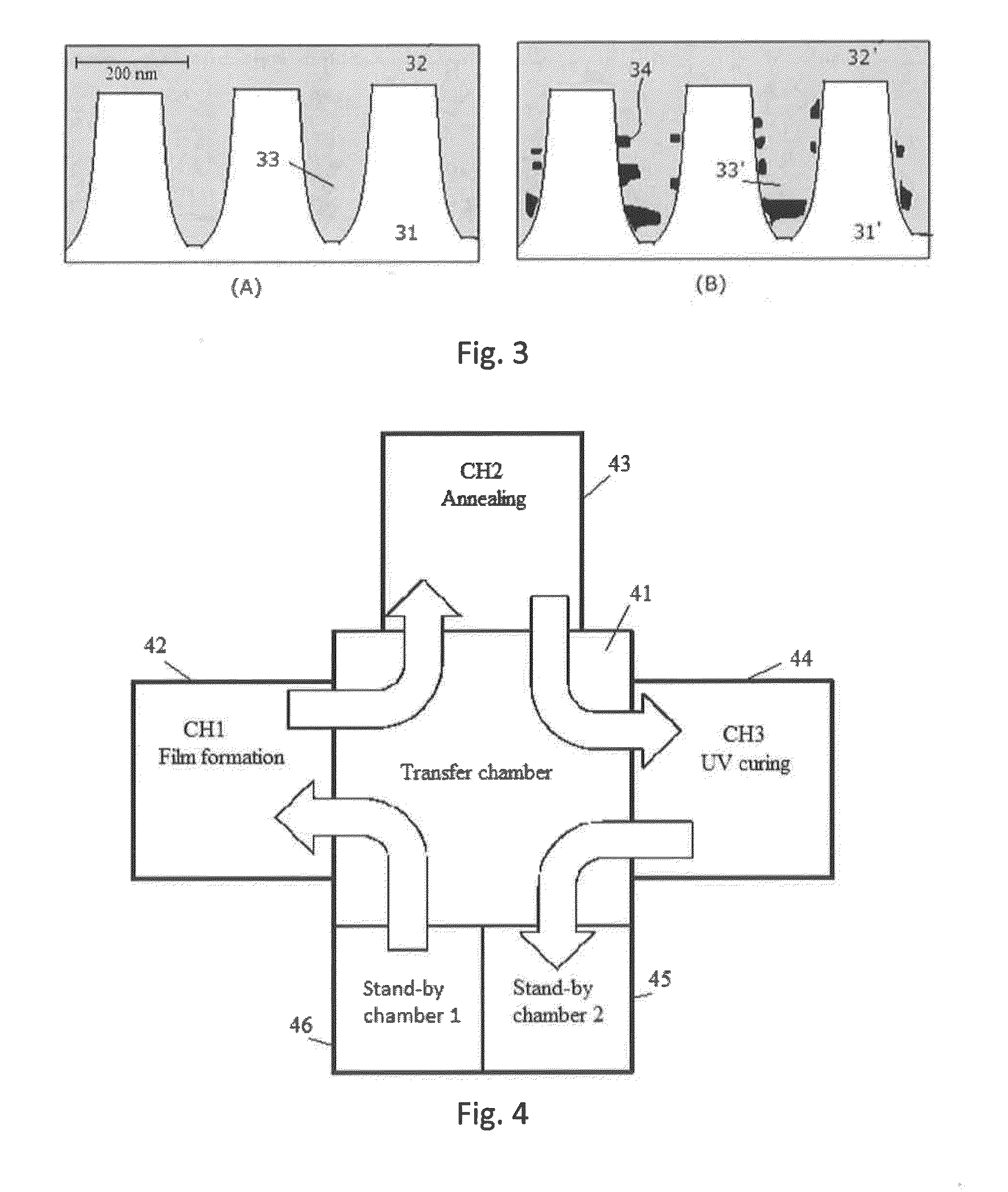

Method for depositing flowable material using alkoxysilane or aminosilane precursor

ActiveUS7825040B1Reducing film shrinkageReduce carbon contentSolid-state devicesSemiconductor/solid-state device manufacturingSilanesPlasma reaction

A method of filling a recess with an insulation film includes: introducing an alkoxysilane or aminosilane precursor containing neither a Si—C bond nor a C—C bond into a reaction chamber where a substrate having an irregular surface including a recess is placed; and depositing a flowable Si-containing insulation film on the irregular surface of the substrate to fill the recess therewith by plasma reaction at −50° C. to 100° C.

Owner:ASM JAPAN

Organoaminodisilane precursors and methods for depositing films comprising same

Described herein are precursors and methods for forming silicon-containing films. In one aspect, there is provided a precursor of Formula I:wherein R1 is selected from linear or branched C3 to C10 alkyl group, linear or branched C3 to C10 alkenyl group, linear or branched C3 to C10 alkynyl group, C1 to C6 dialkylamino group, electron withdrawing group, and C6 to C10 aryl group; R2 is selected from hydrogen, linear or branched C1 to C10 alkyl group, linear or branched C3 to C6 alkenyl group, linear or branched C3 to C6 alkynyl group, C1 to C6 dialkylamino group, C6 to C10 aryl group, linear or branched C1 to C6 fluorinated alkyl group, electron withdrawing group, and C4 to C10 aryl group; optionally wherein R1 and R2 are linked together to form ring selected from substituted or unsubstituted aromatic ring or substituted or unsubstituted aliphatic ring; and n=1 or 2.

Owner:VERSUM MATERIALS US LLC

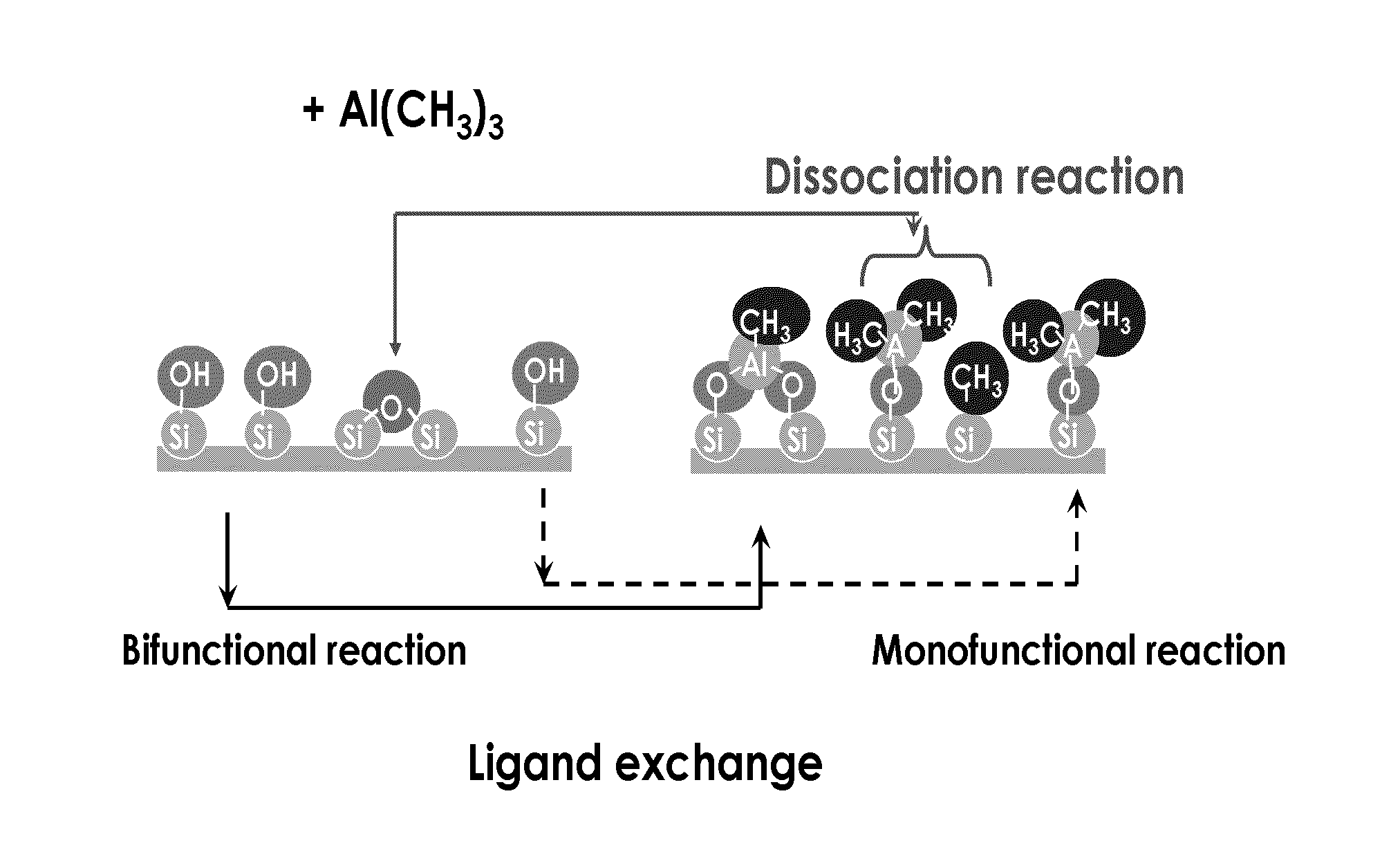

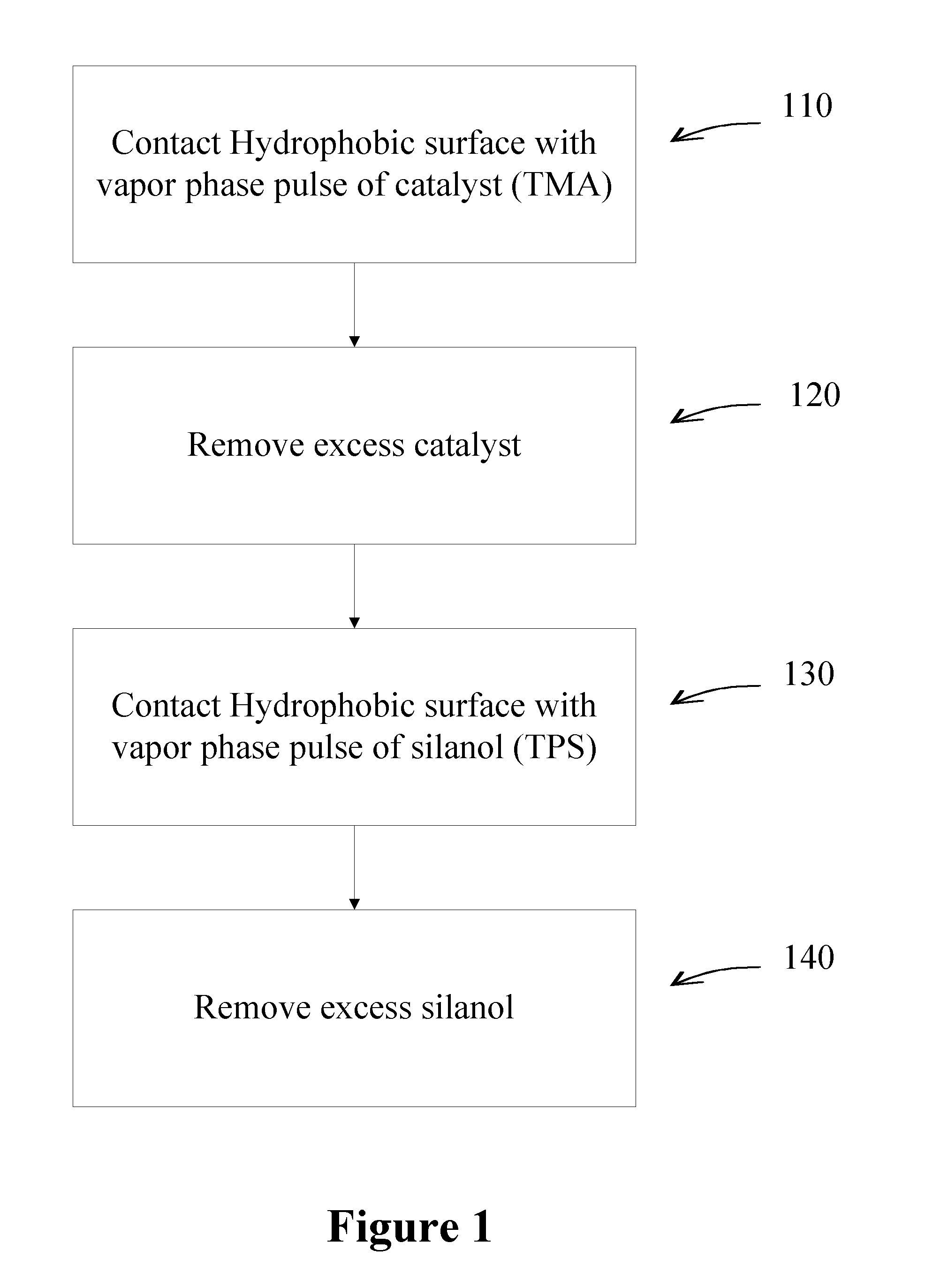

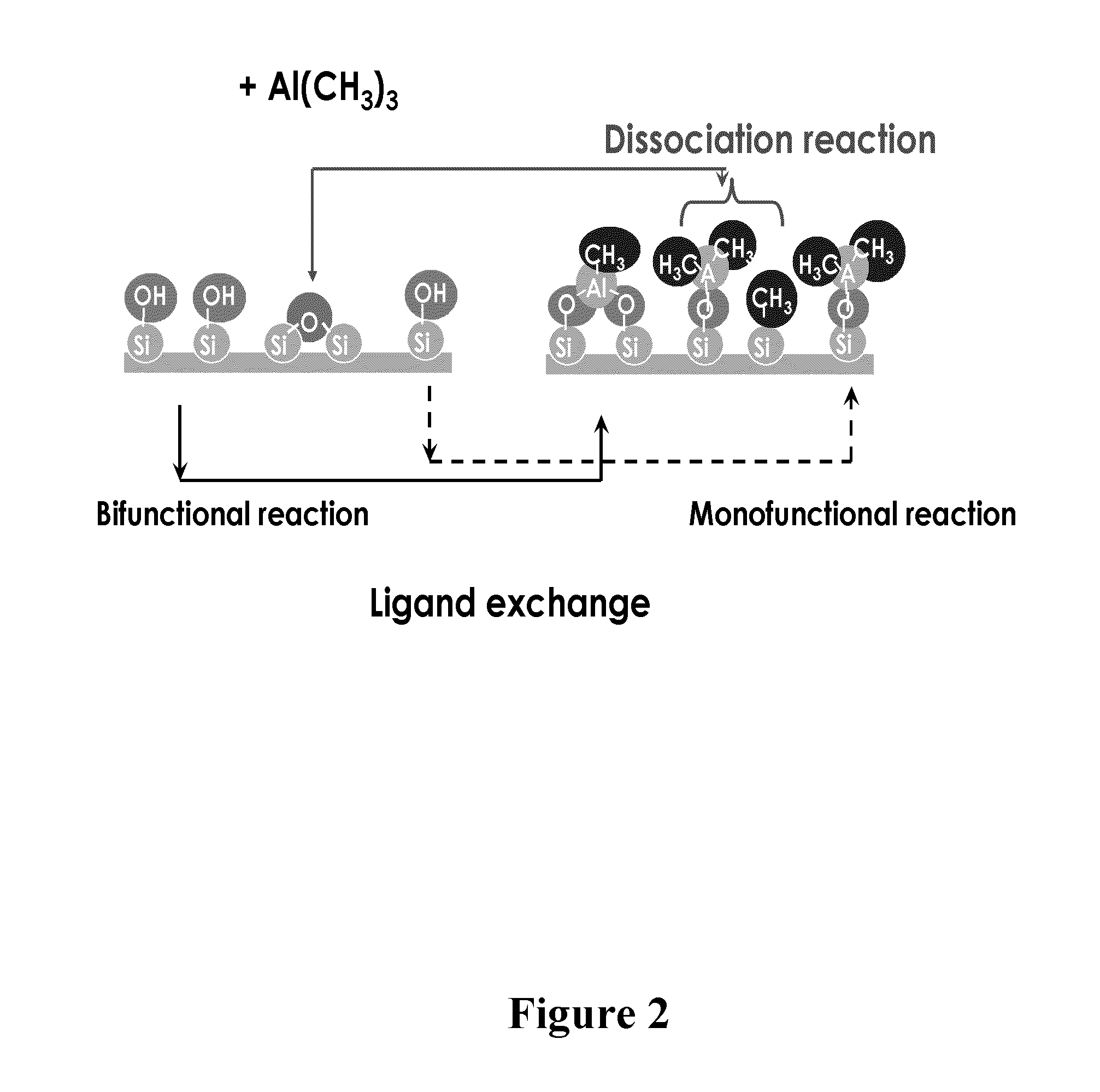

Deposition of silicon dioxide on hydrophobic surfaces

InactiveUS20120263876A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSilanolSilicon dioxide

Methods for forming silicon dioxide thin films on hydrophobic surfaces are provided. For example, in some embodiments, silicon dioxide films are deposited on porous, low-k materials. The silicon dioxide films can be deposited using a catalyst and a silanol. In some embodiments, an undersaturated dose of one or more of the reactants can be used in forming a pore-sealing layer over a porous material.

Owner:ASM IP HLDG BV

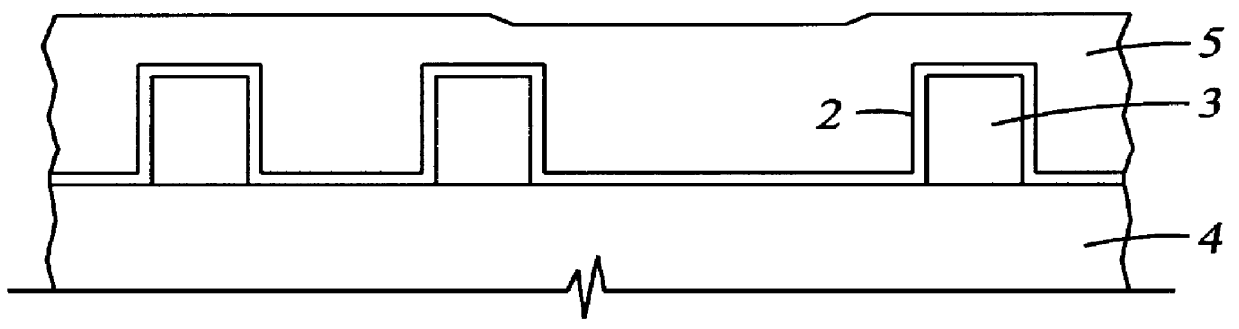

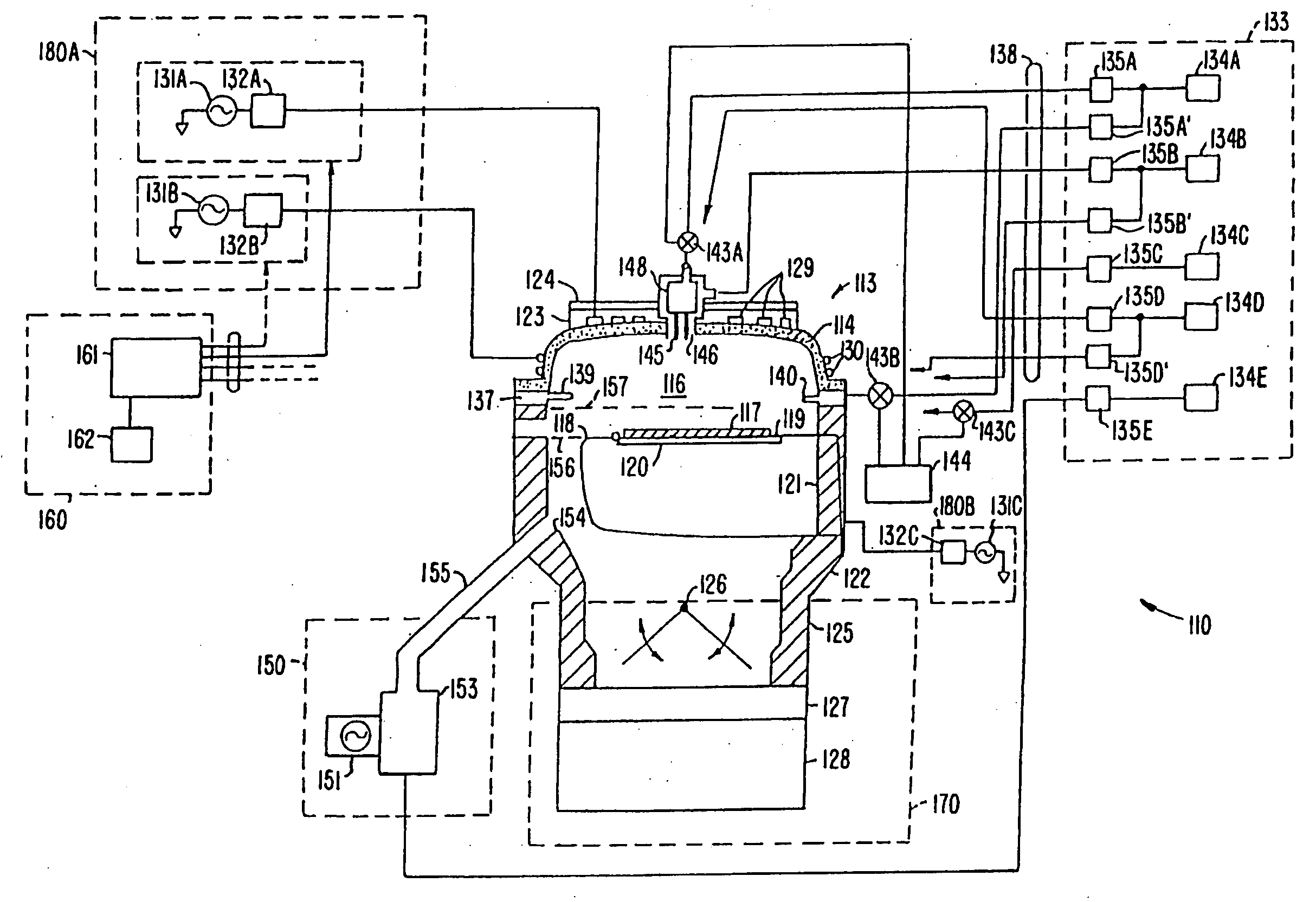

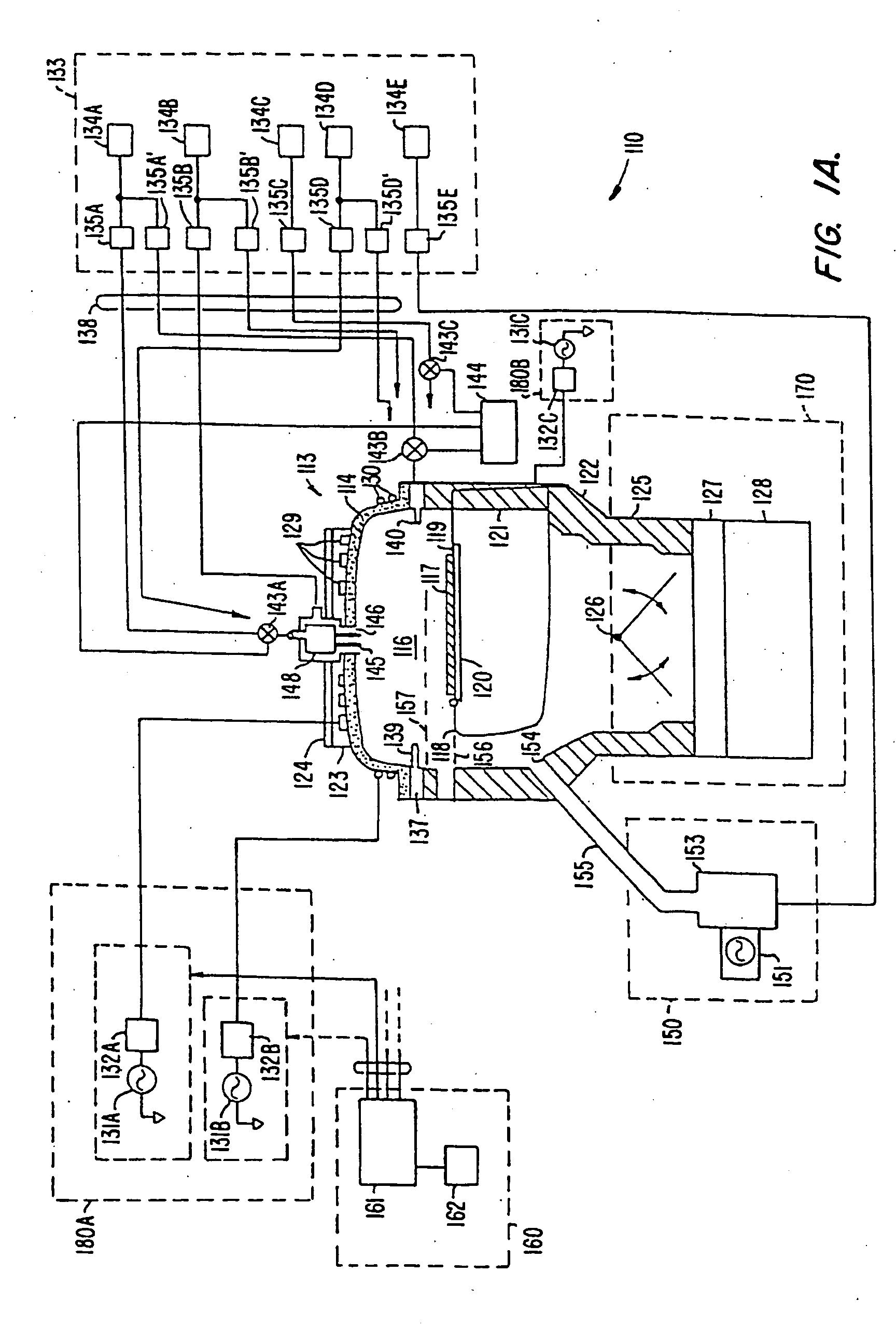

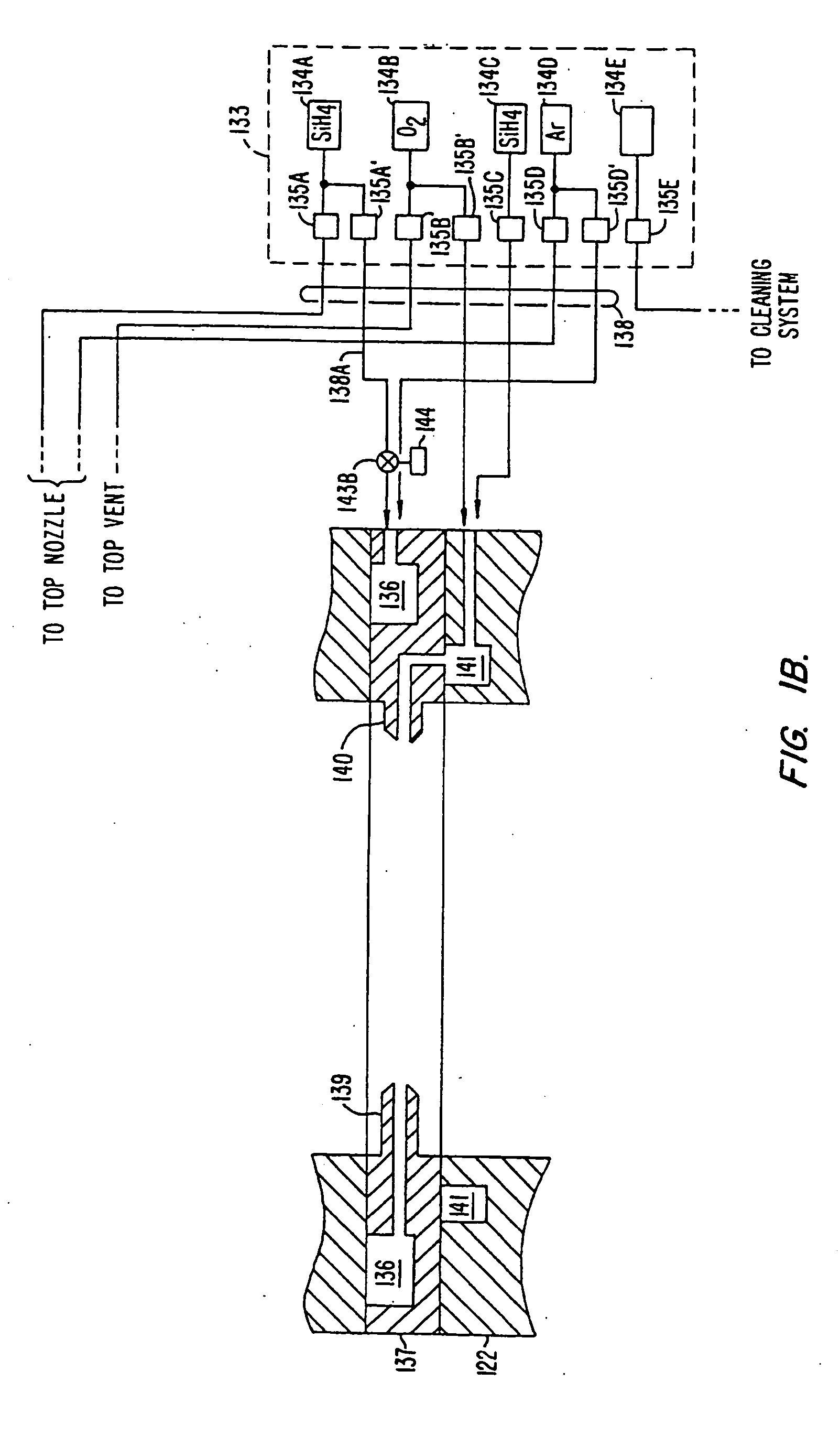

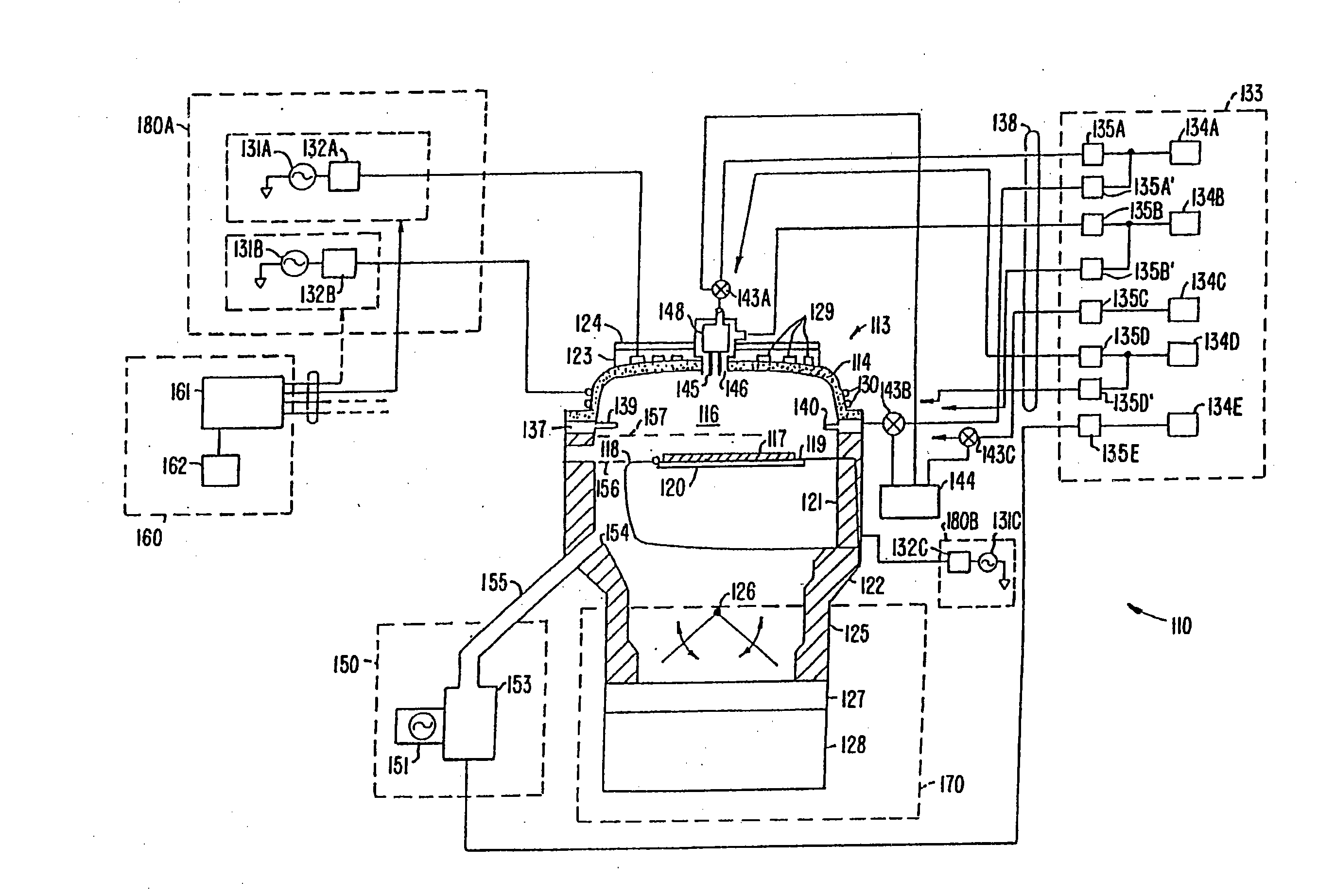

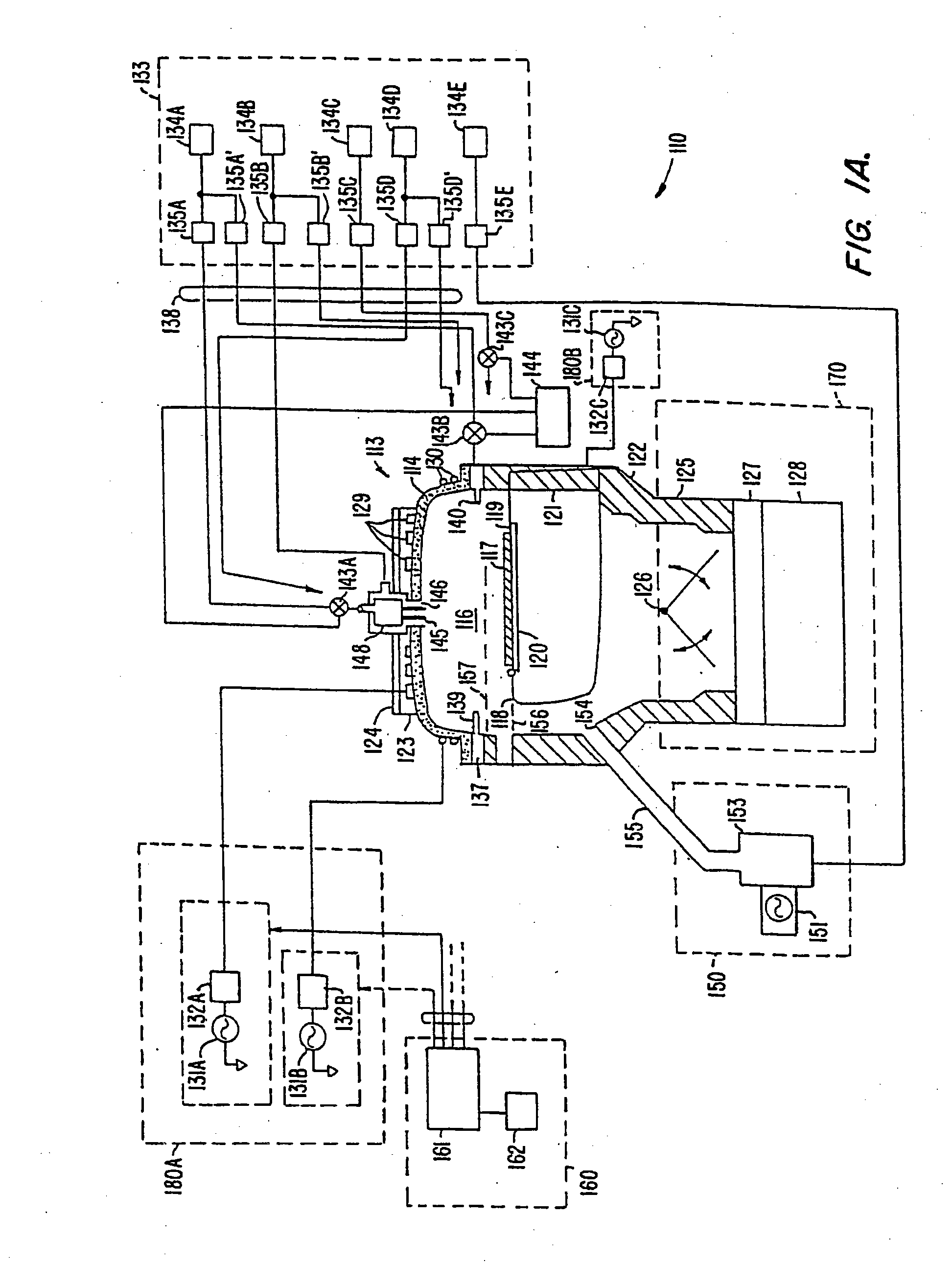

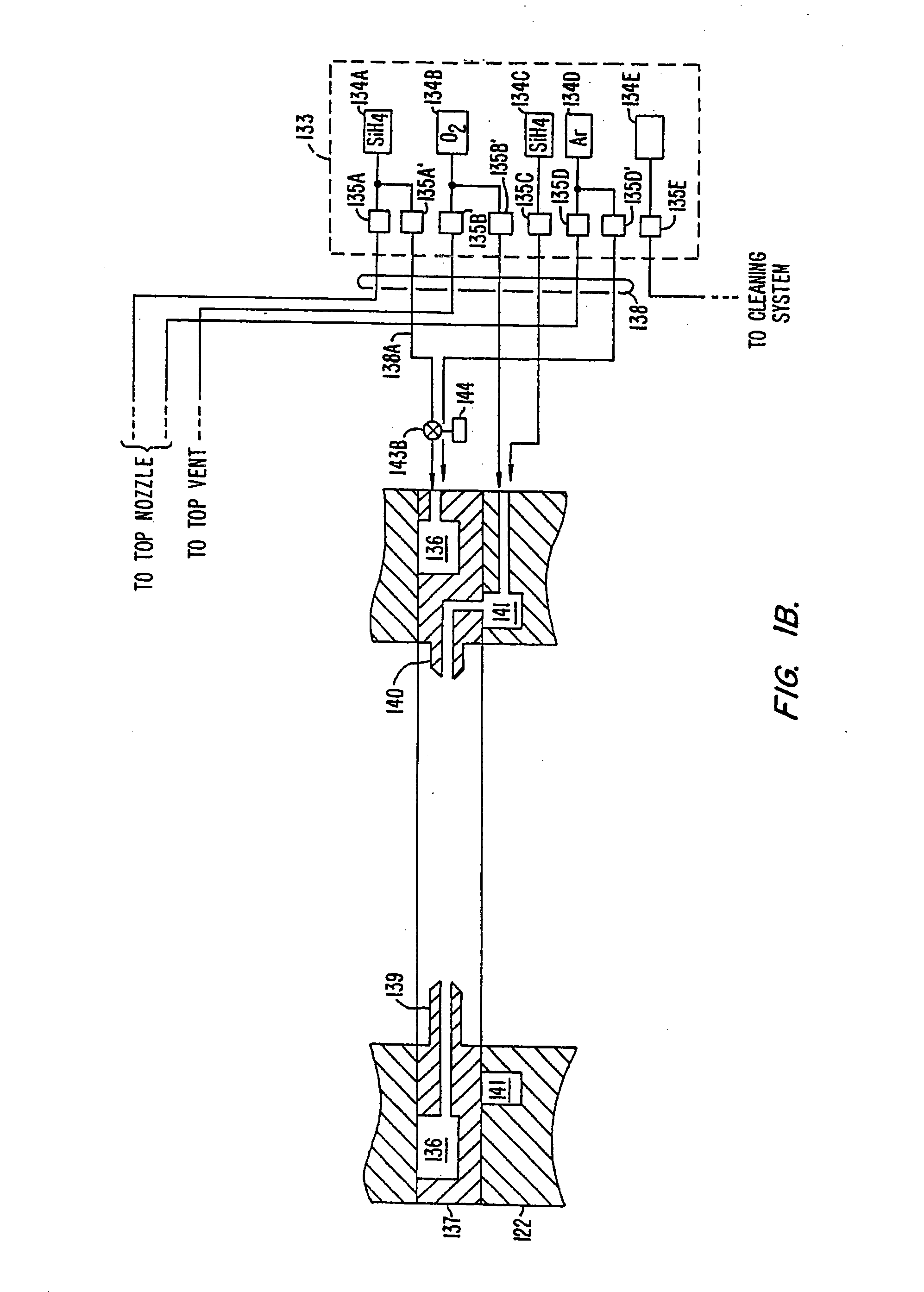

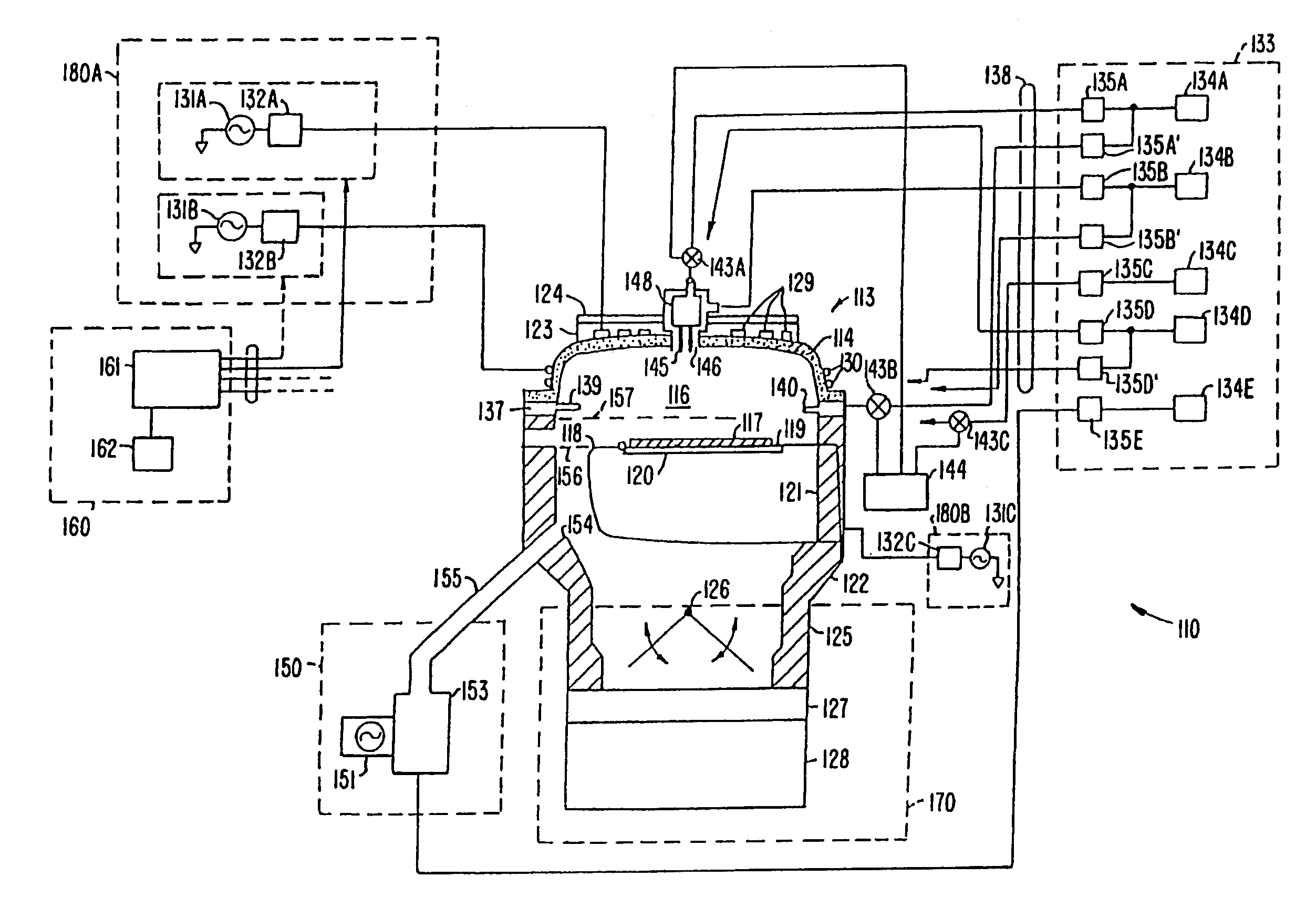

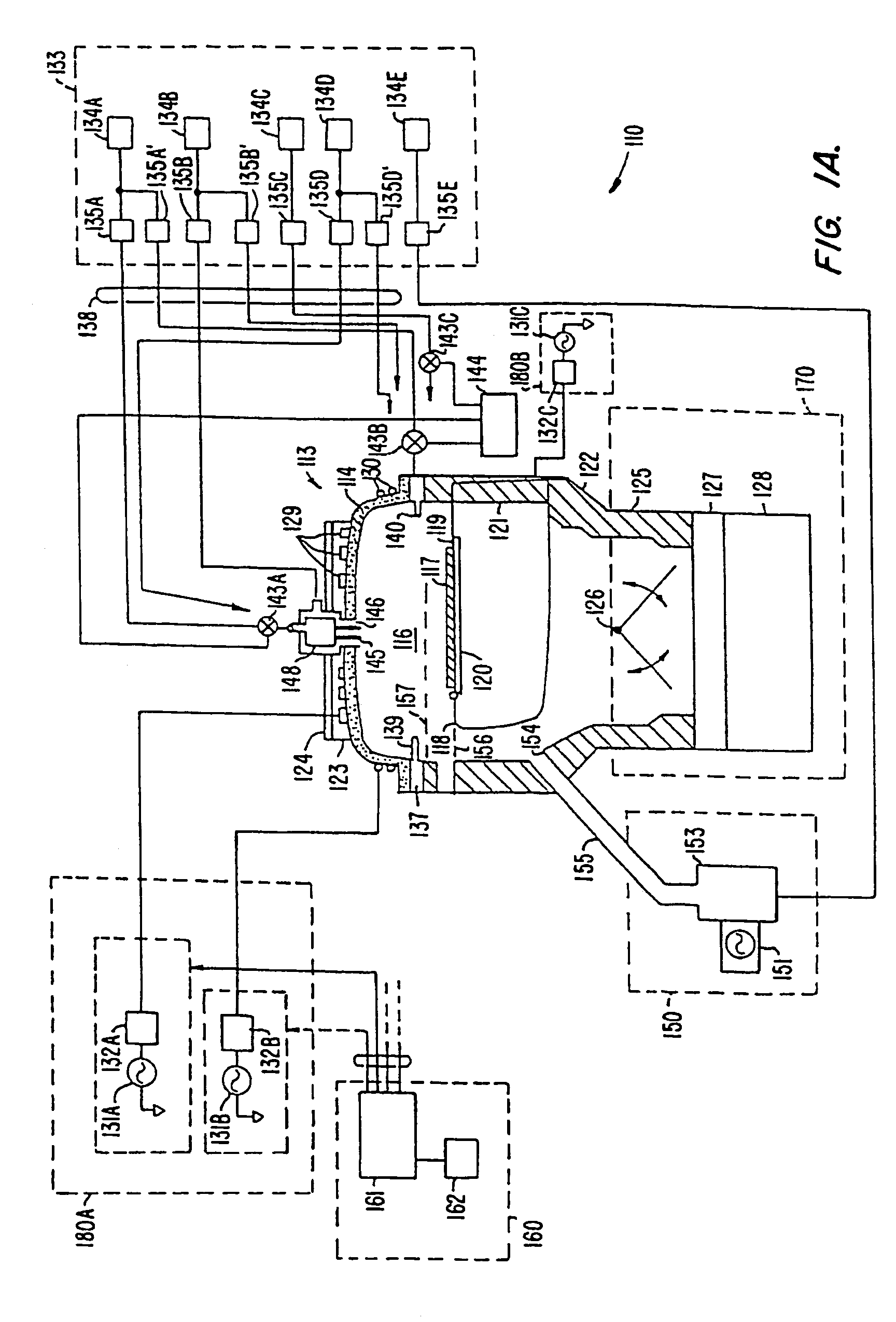

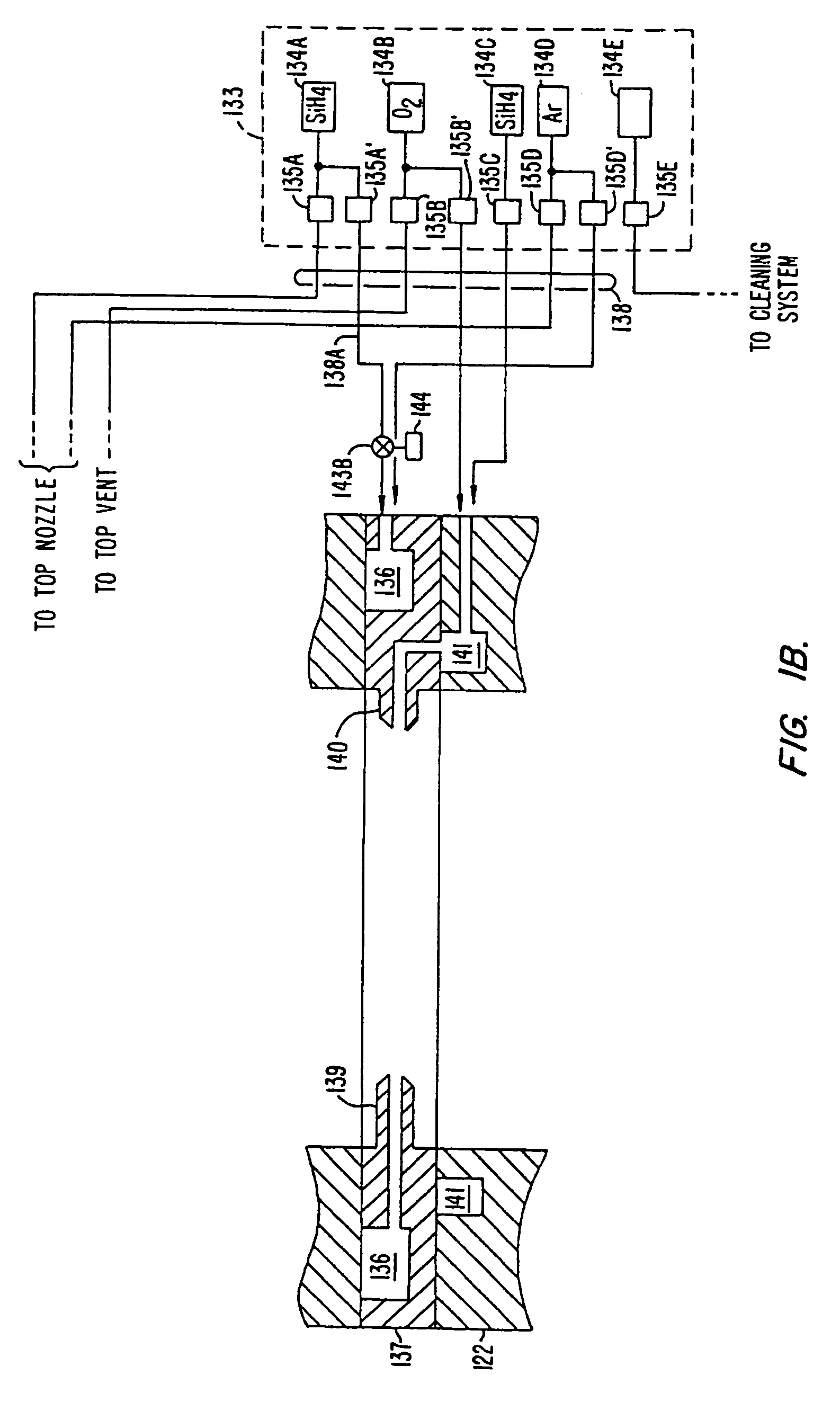

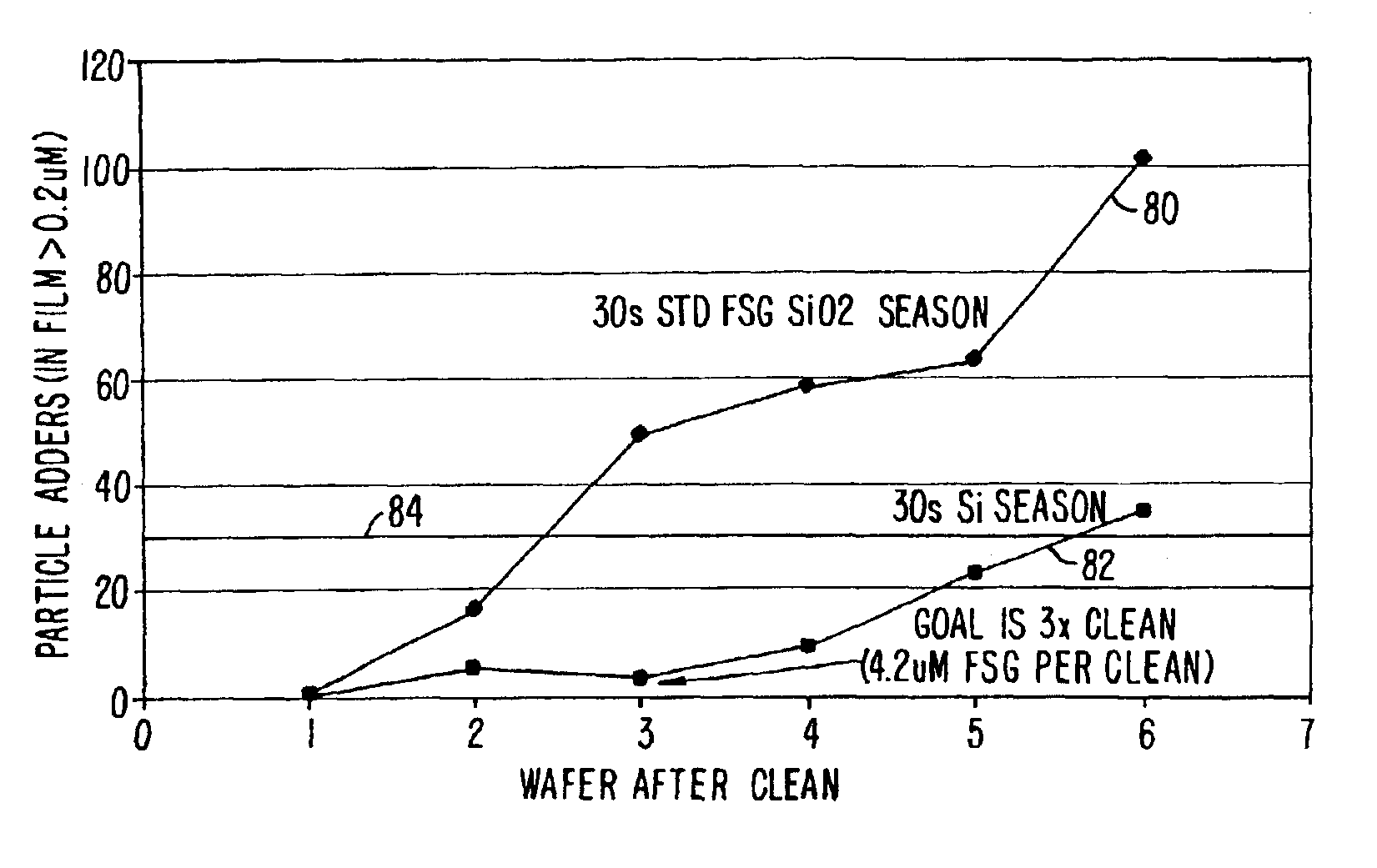

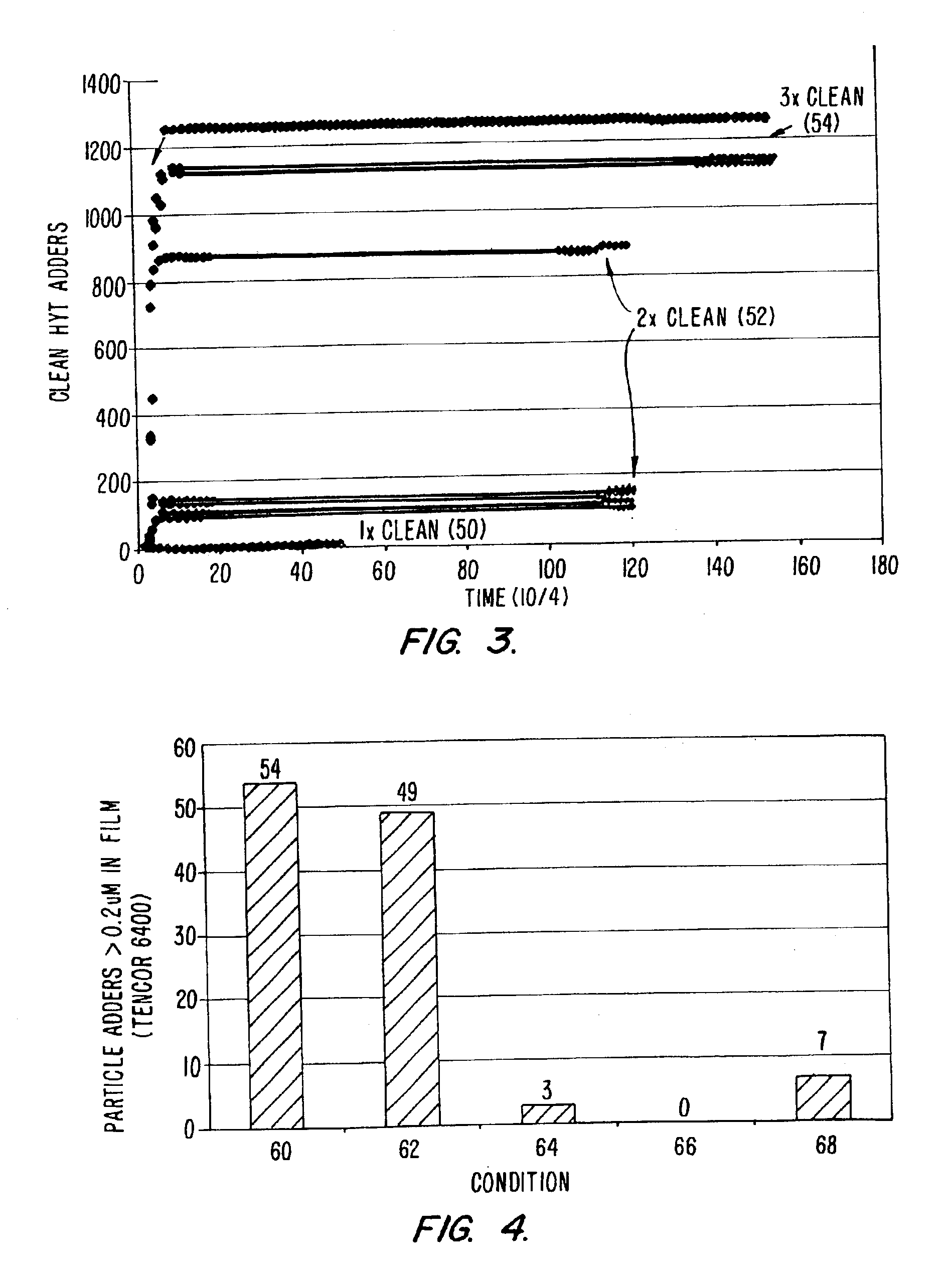

HDP-CVD seasoning process for high power HDP-CVD gapfil to improve particle performance

InactiveUS20050250340A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSilanesSilicon oxide

A method of operating a substrate processing chamber that includes, prior to a substrate processing operation, flowing a seasoning gas comprising silane and oxygen into said chamber at a flow ratio of greater than or equal to about 1.6:1 oxygen to silane to deposit a silicon oxide film over at least one aluminum nitride nozzle exposed to an interior portion of the chamber. Also, a substrate processing system that includes a housing, a gas delivery system for introducing a seasoning gas into a vacuum chamber, where the gas delivery system comprises one or more aluminum nitride nozzles exposed to the vacuum chamber, a controller and a memory having a program having instructions for controlling the gas delivery system to flow a seasoning gas that has an oxygen to silane ratio greater than or equal to about 1.6:1 to deposit a silicon oxide film on the aluminum nitride nozzles.

Owner:APPLIED MATERIALS INC

Silane and borane treatments for titanium carbide films

ActiveUS8841182B1Reduce oxidized portionPrevent oxidationSemiconductor/solid-state device manufacturingSilanesCompound (substance)

Methods of treating metal-containing thin films, such as films comprising titanium carbide, with a silane / borane agent are provided. In some embodiments a film including titanium carbide is deposited on a substrate by an atomic layer deposition (ALD) process. The process may include a plurality of deposition cycles involving alternating and sequential pulses of a first source chemical that includes titanium and at least one halide ligand, a second source chemical that includes metal and carbon, where the metal and the carbon from the second source chemical are incorporated into the thin film, and a third source chemical, where the third source chemical is a silane or borane that at least partially reduces oxidized portions of the titanium carbide layer formed by the first and second source chemicals. The treatment can form a capping layer on the metal carbide film.

Owner:ASM IP HLDG BV

Hdp-cvd seasoning process for high power hdp-cvd gapfil to improve particle performance

InactiveUS20060219169A1Liquid surface applicatorsSemiconductor/solid-state device manufacturingSilanesSilicon oxide

A method of operating a substrate processing chamber that includes, prior to a substrate processing operation, flowing a seasoning gas comprising silane and oxygen into said chamber at a flow ratio of greater than or equal to about 1.6:1 oxygen to silane to deposit a silicon oxide film over at least one aluminum nitride nozzle exposed to an interior portion of the chamber. Also, a substrate processing system that includes a housing, a gas delivery system for introducing a seasoning gas into a vacuum chamber, where the gas delivery system comprises one or more aluminum nitride nozzles exposed to the vacuum chamber, a controller and a memory having a program having instructions for controlling the gas delivery system to flow a seasoning gas that has an oxygen to silane ratio greater than or equal to about 1.6:1 to deposit a silicon oxide film on the aluminum nitride nozzles.

Owner:APPLIED MATERIALS INC

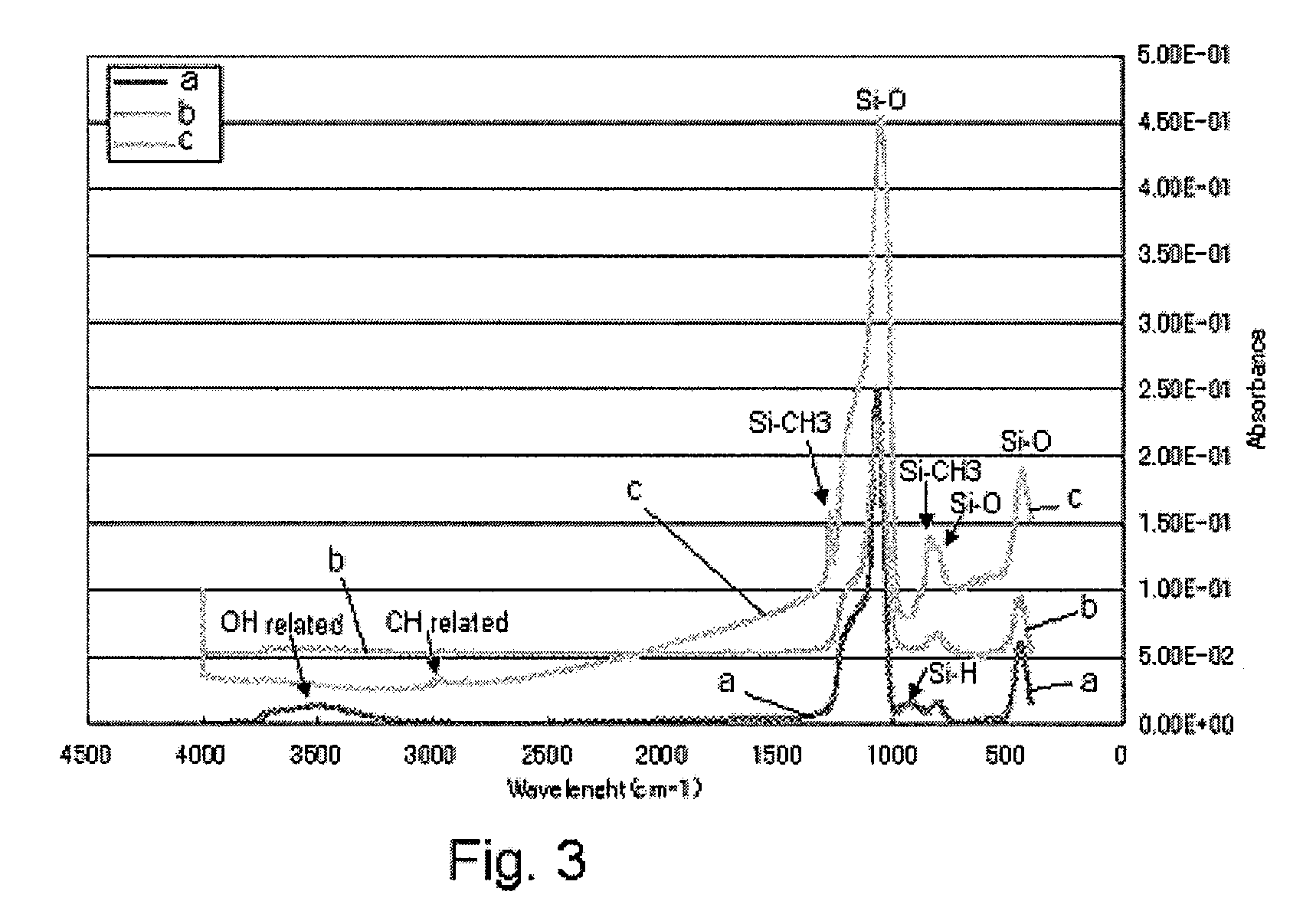

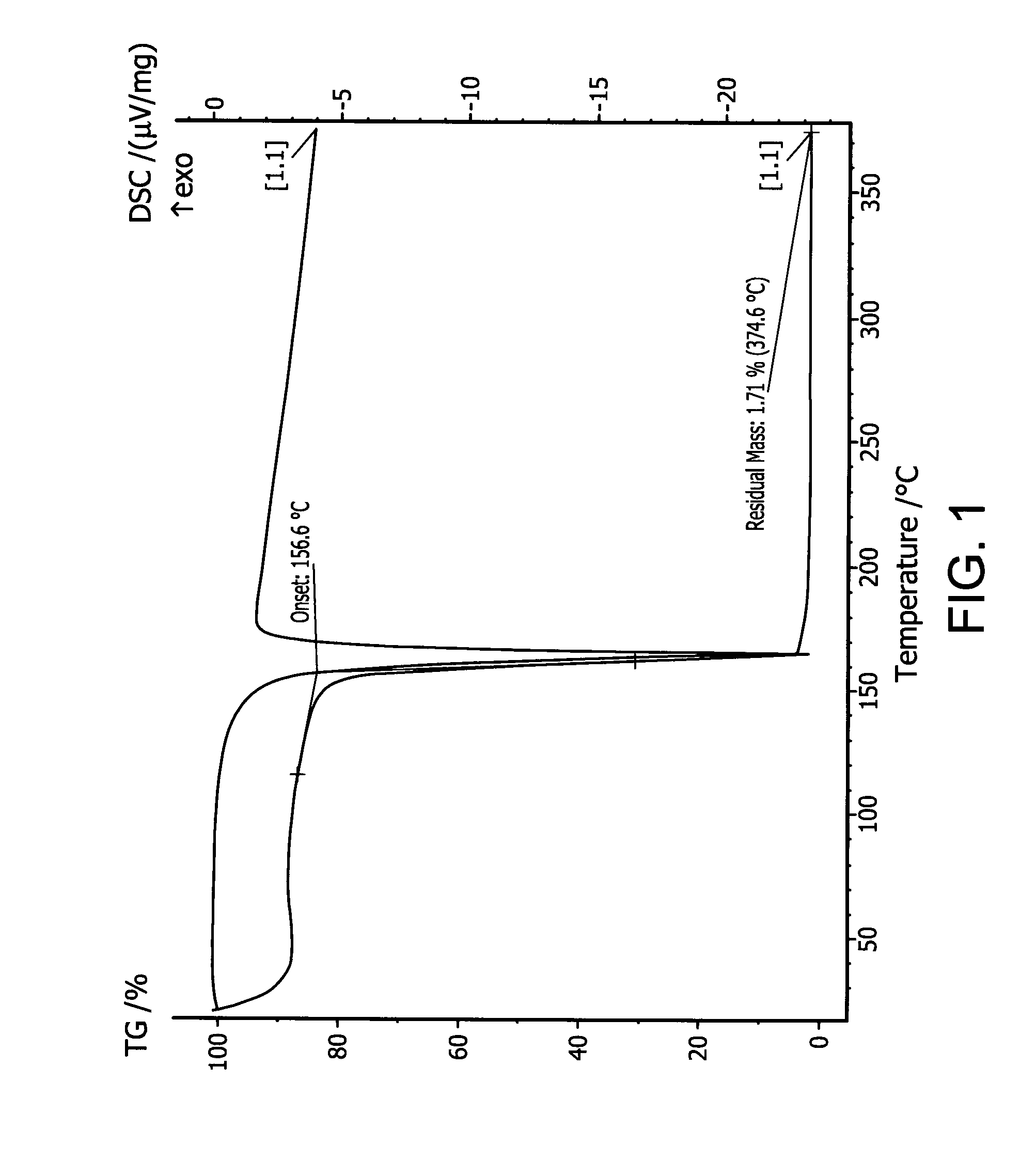

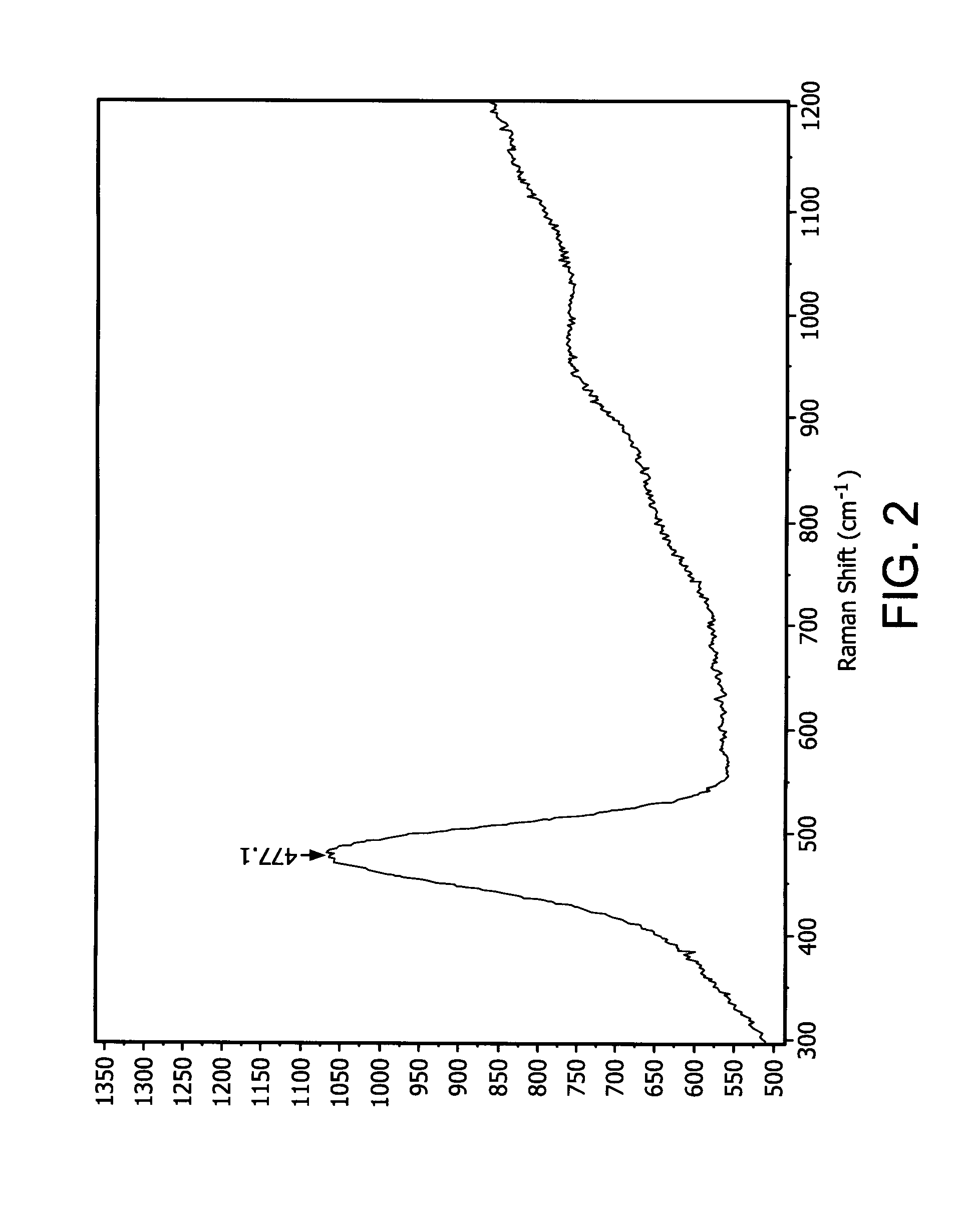

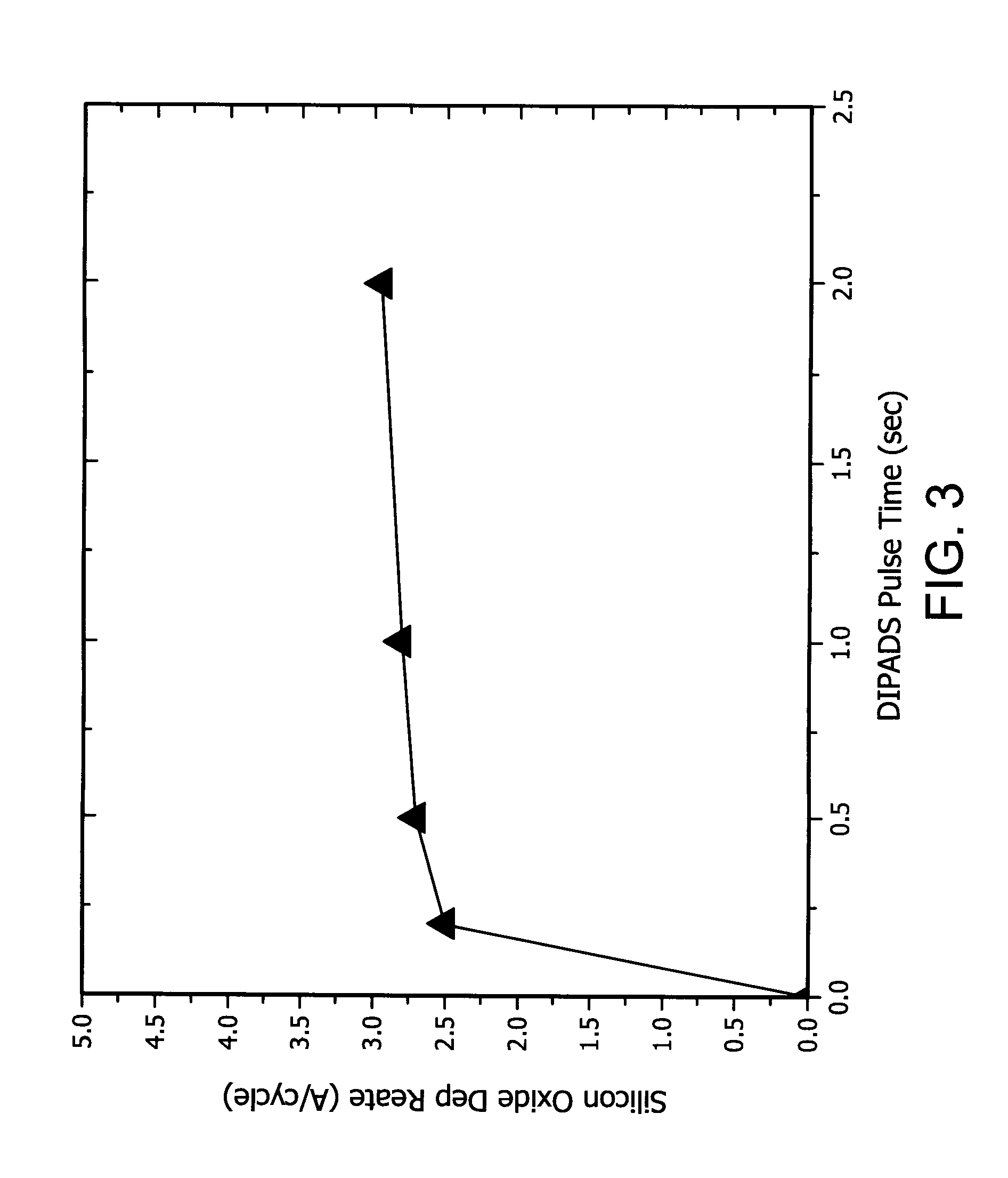

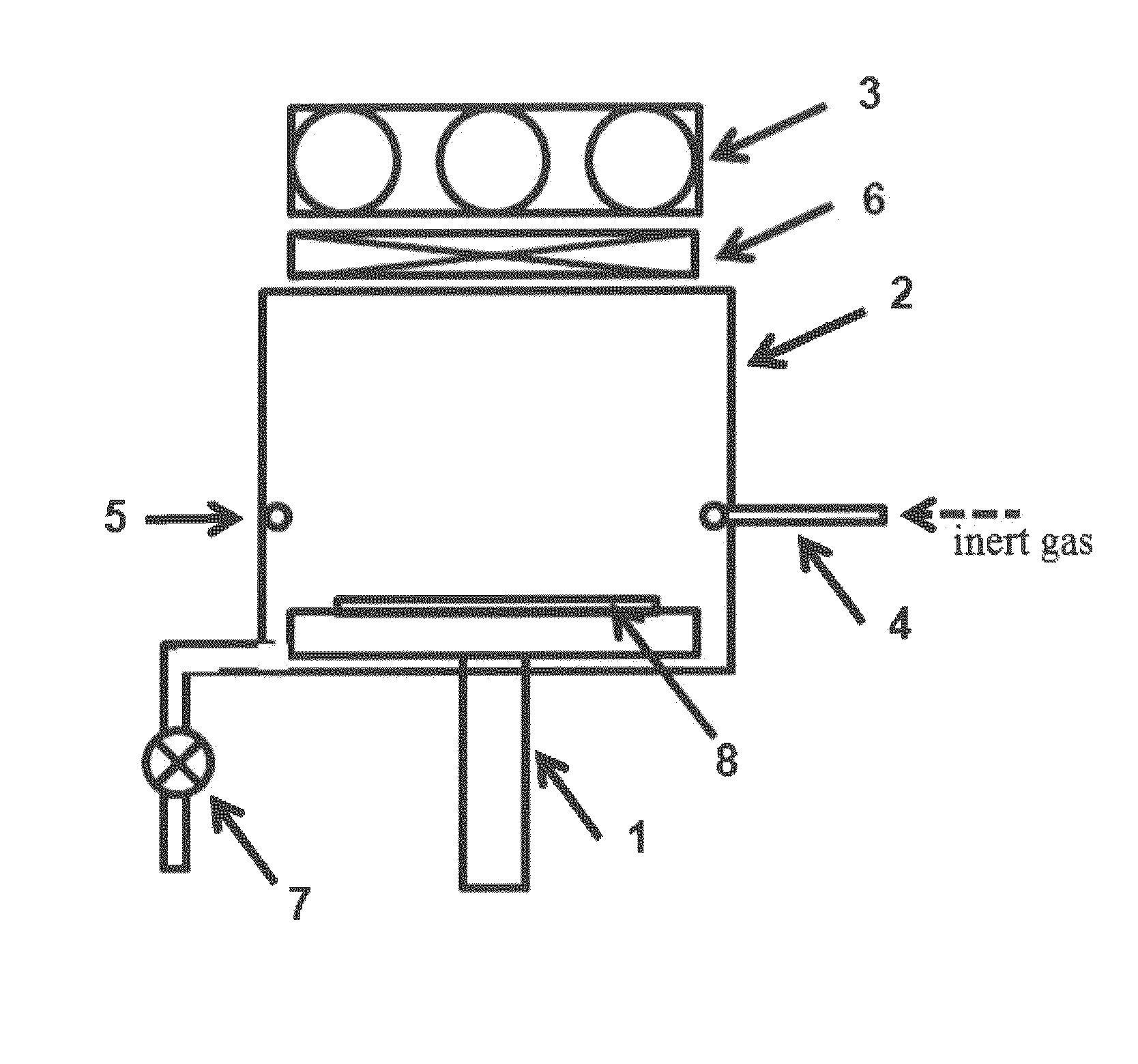

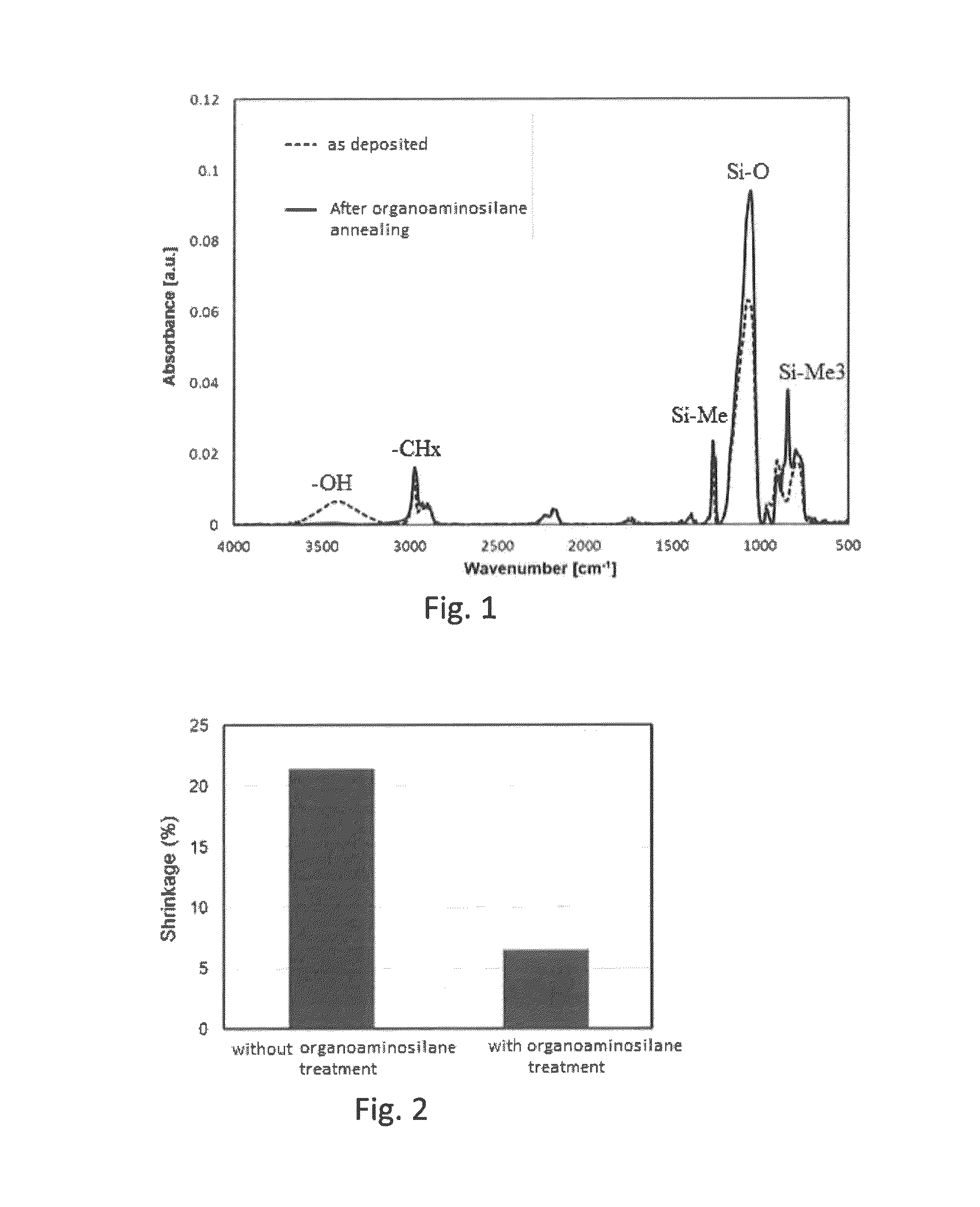

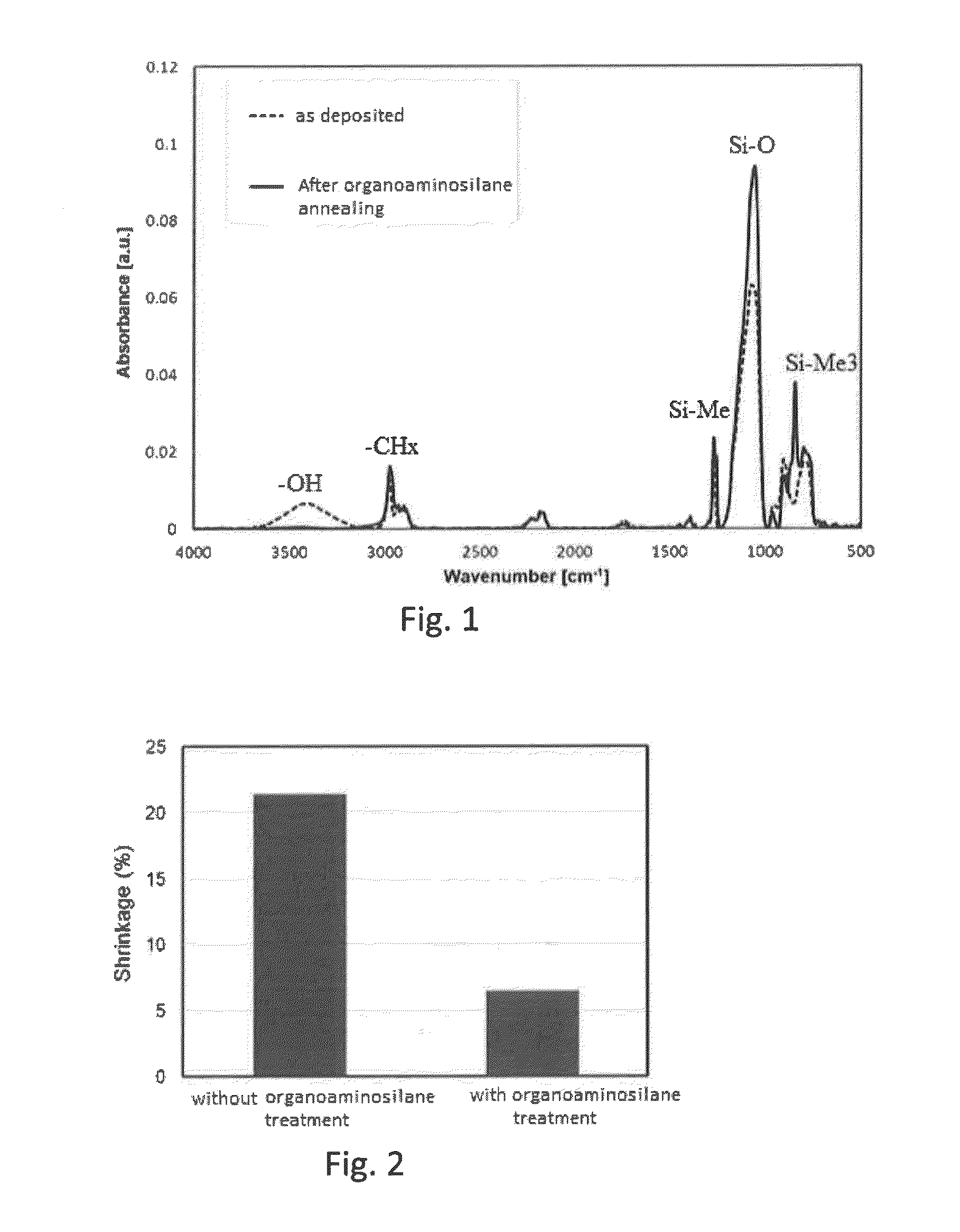

Method for forming SiOCH film using organoaminosilane annealing

ActiveUS9190263B2Improve liquidityReduce the amount requiredSemiconductor/solid-state device manufacturingPolymer scienceSilanes

Owner:ASM IP HLDG BV

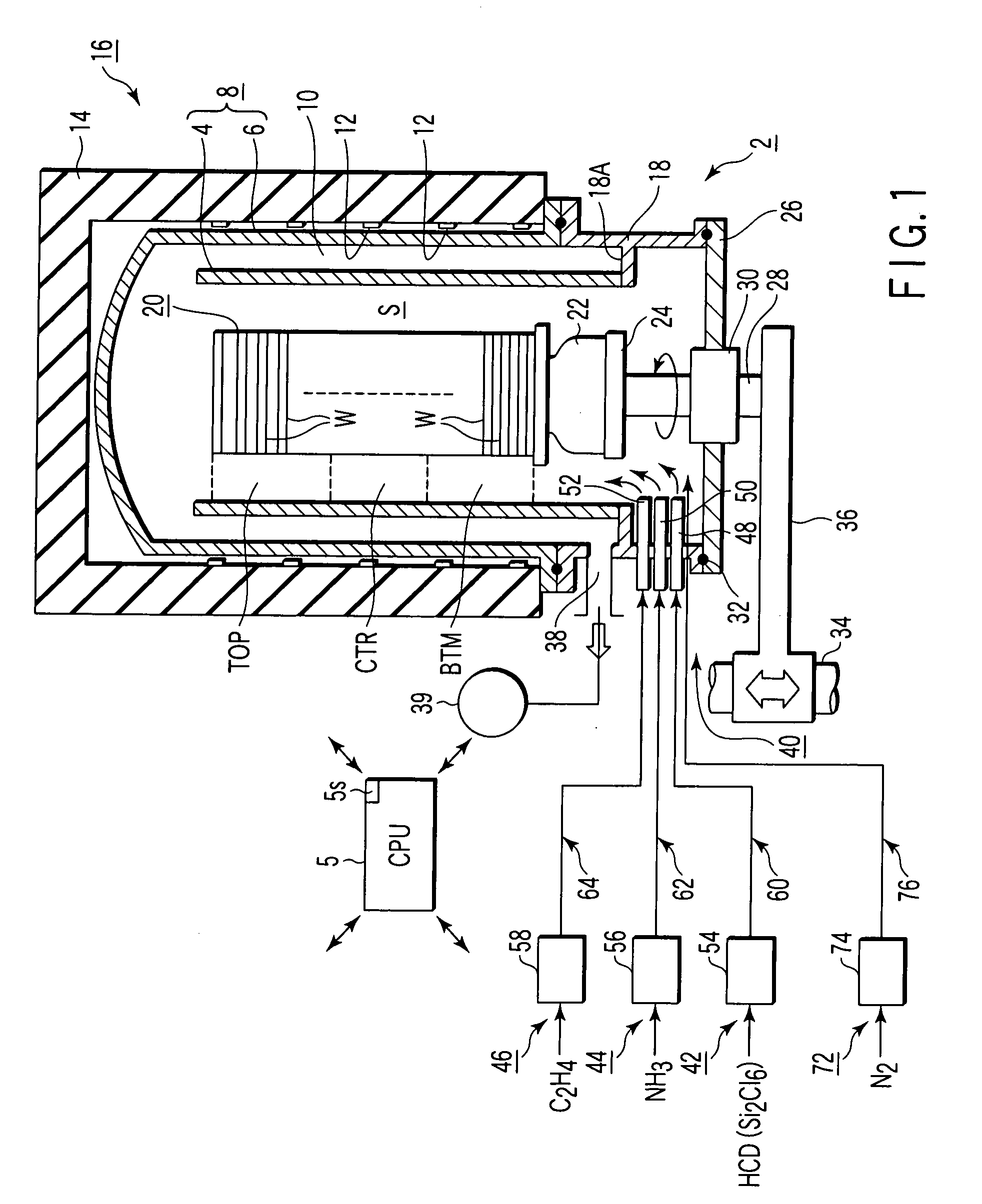

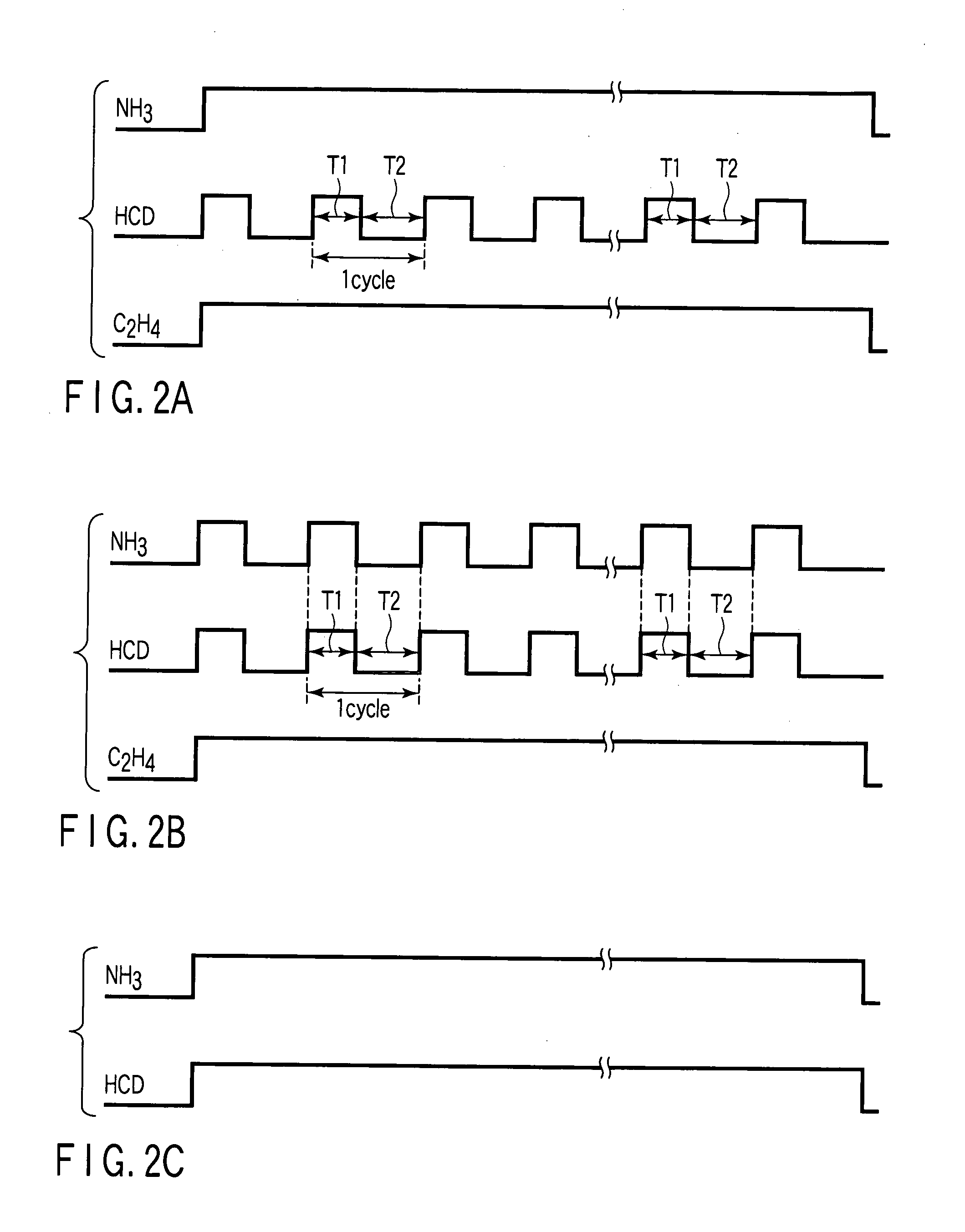

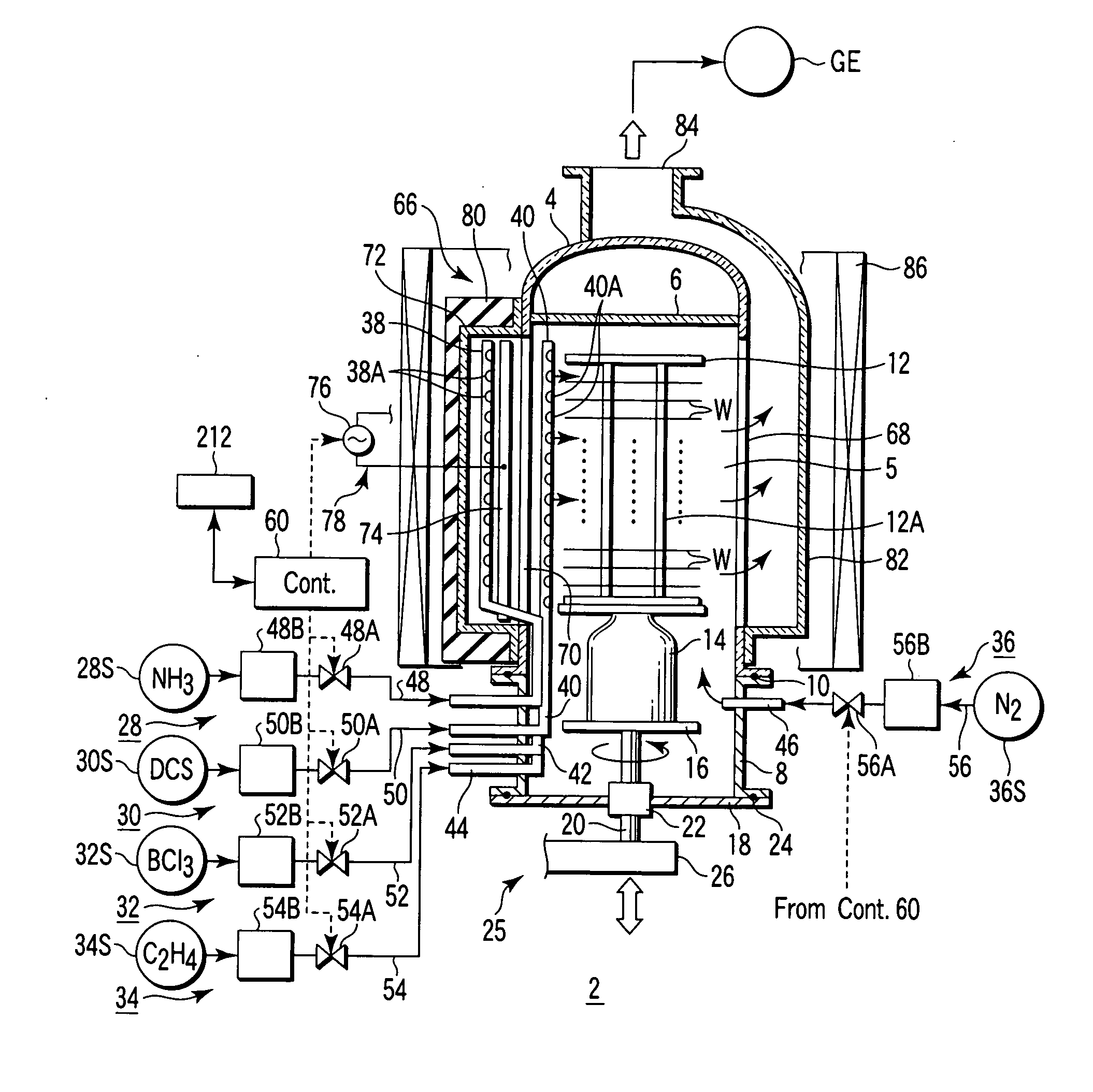

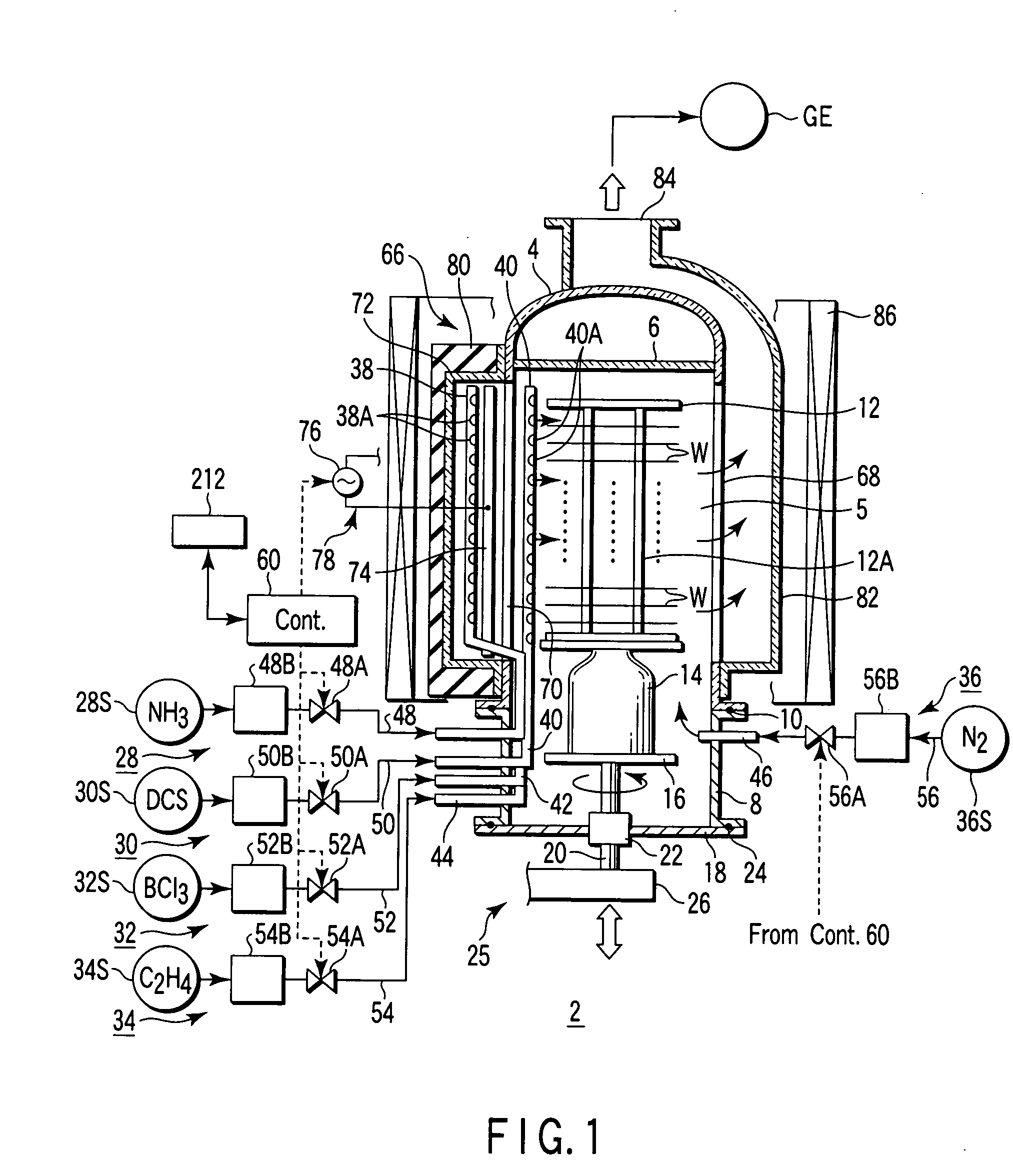

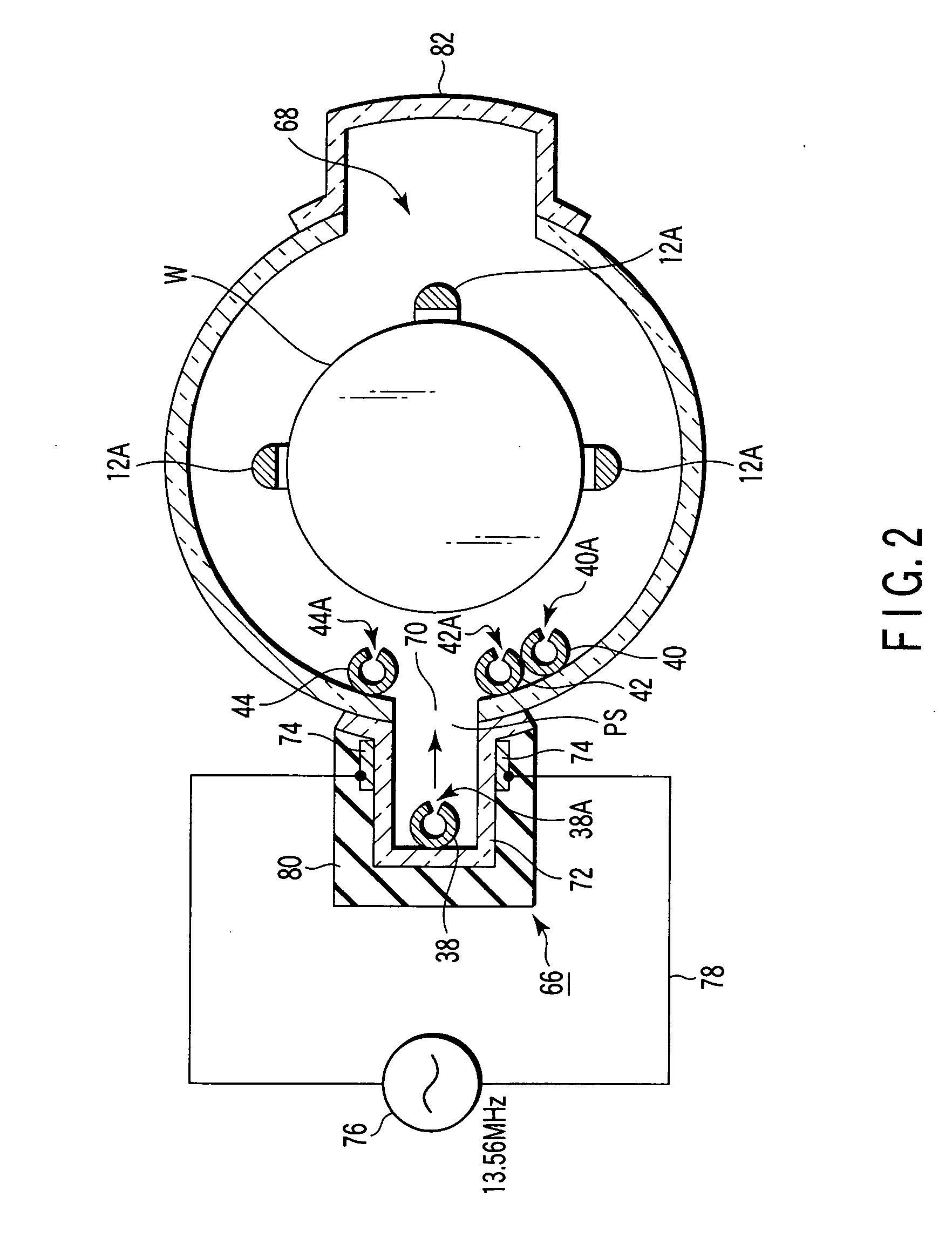

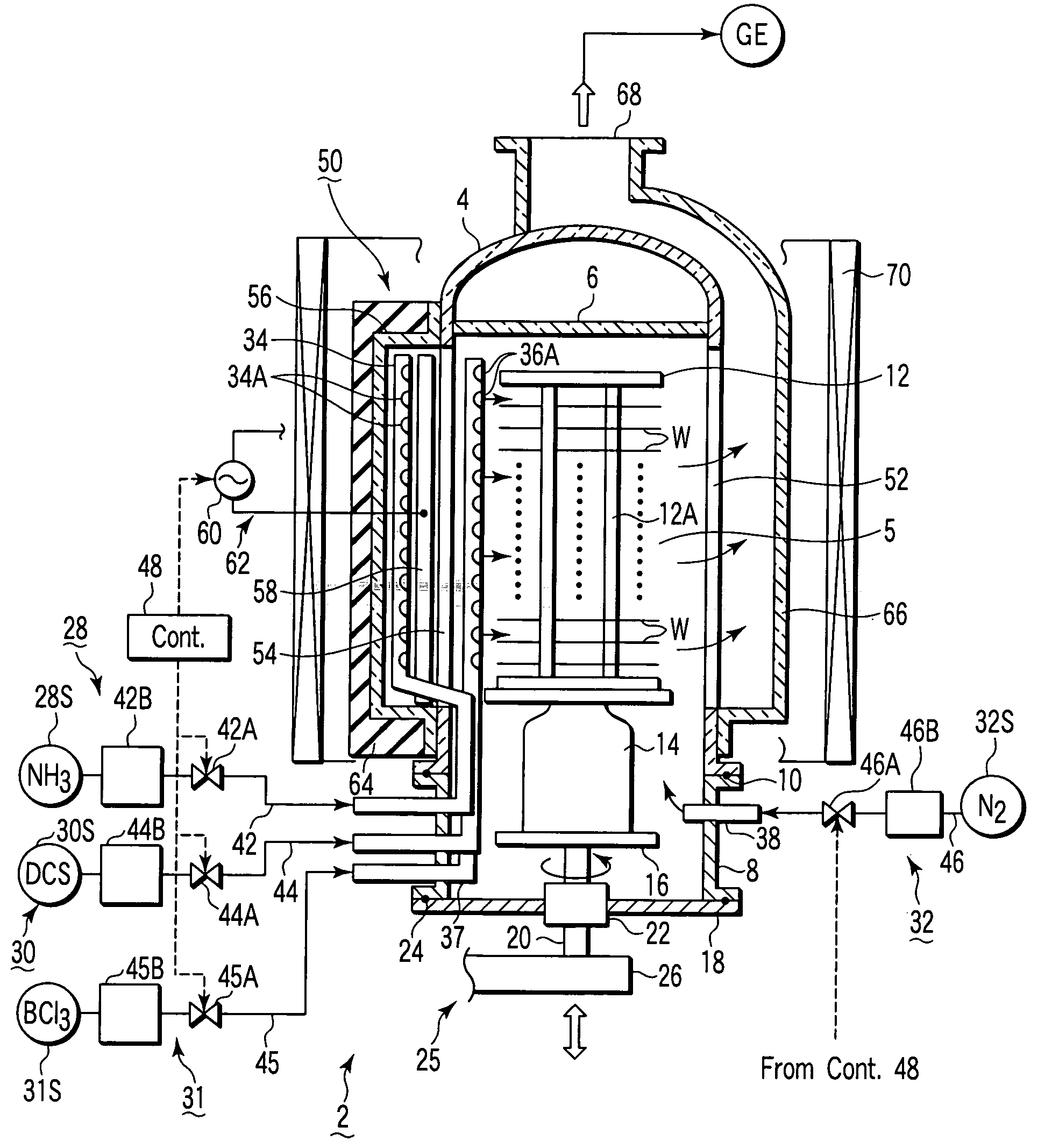

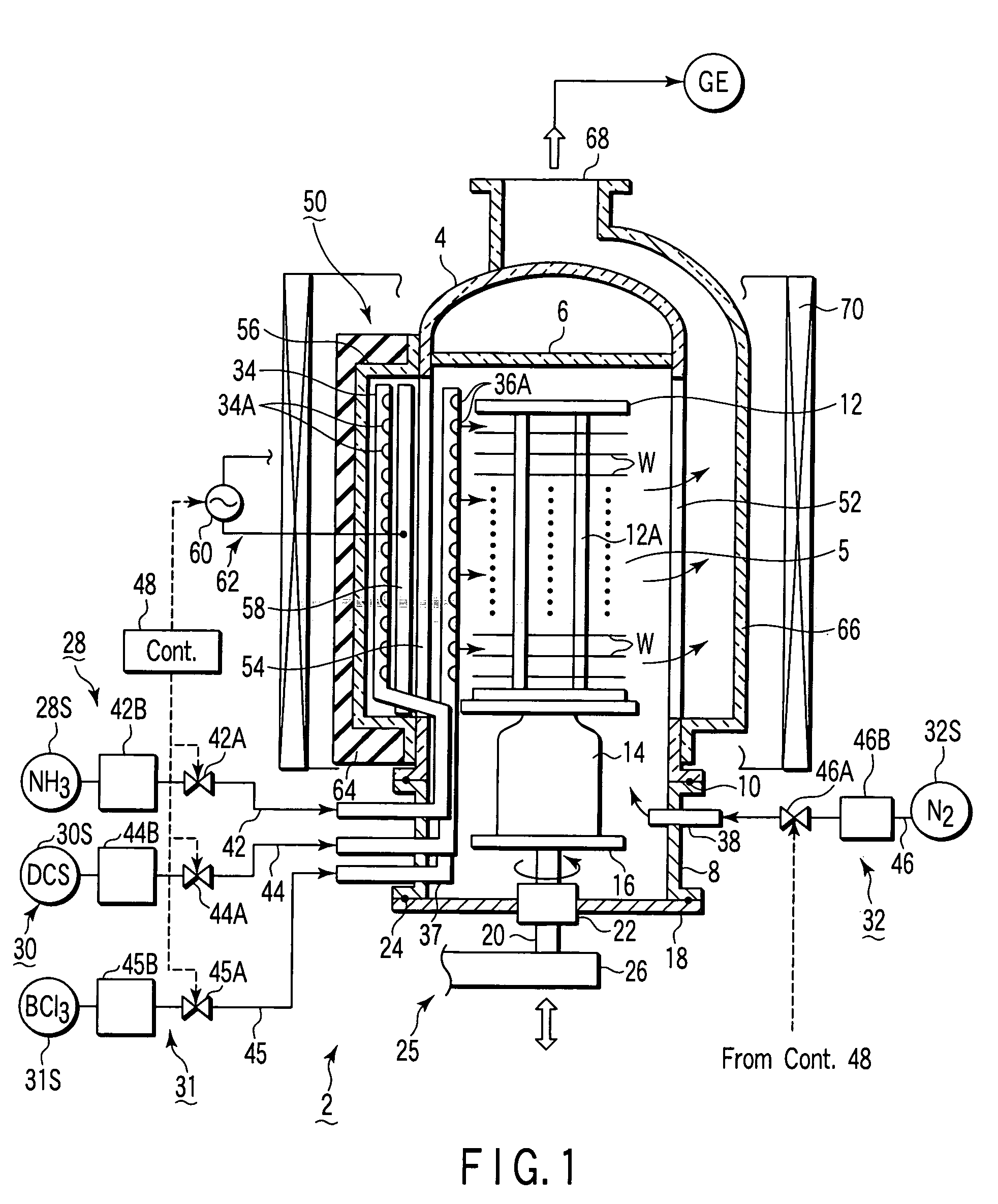

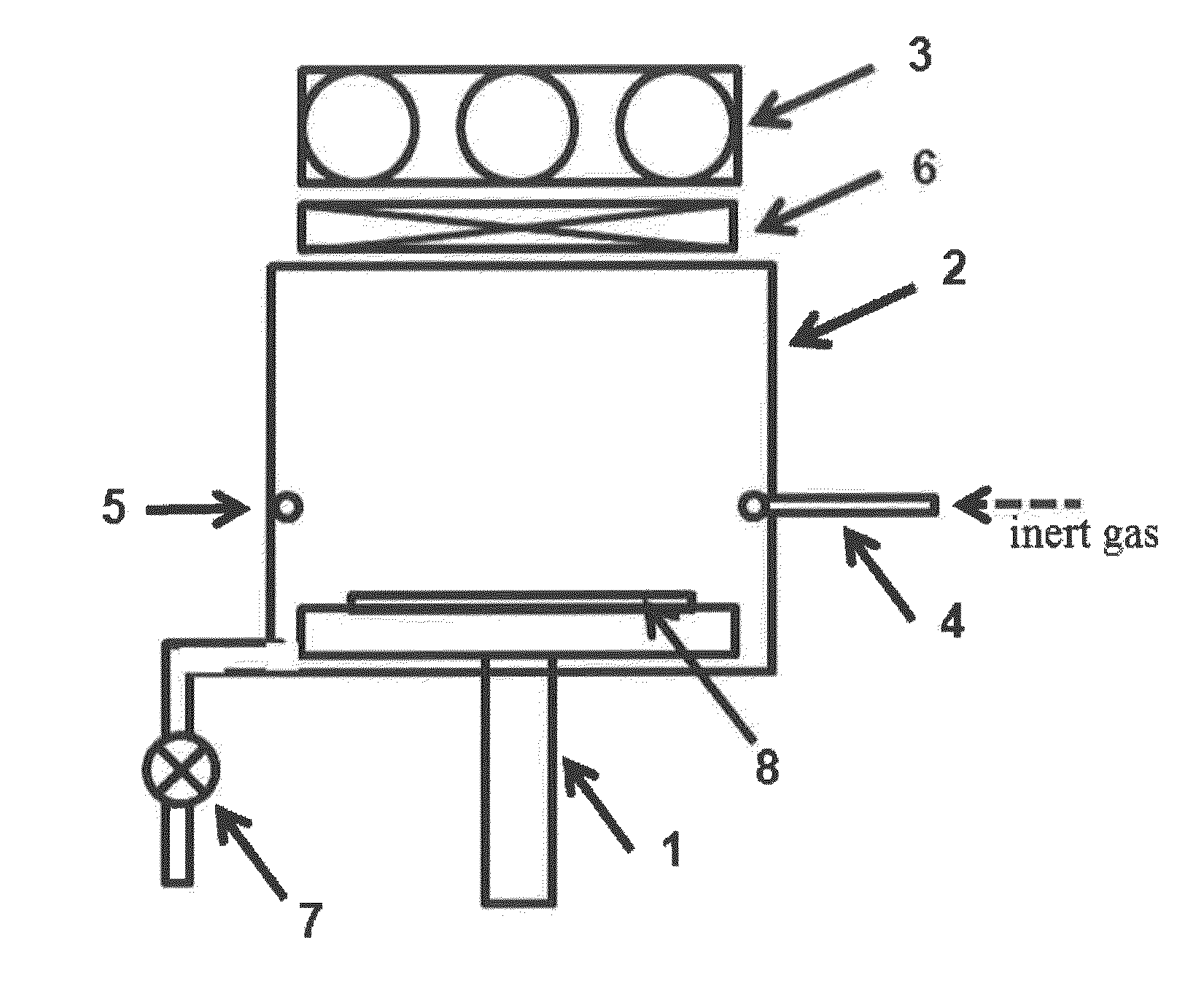

Cvd method for forming silicon nitride film

ActiveUS20060286817A1Low process temperatureImprove controllabilitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilanesAmmonia gas

A CVD method for forming a silicon nitride film includes exhausting a process chamber (8) that accommodates a target substrate (W), and supplying a silane family gas (HCD) and ammonia gas (NH3) into the process chamber, thereby forming a silicon nitride film on the target substrate by CVD. Said forming a silicon nitride film on the target substrate alternately includes a first period of performing supply of the silane family gas (HCD) into the process chamber (8), and a second period of stopping supply of the silane family gas.

Owner:TOKYO ELECTRON LTD

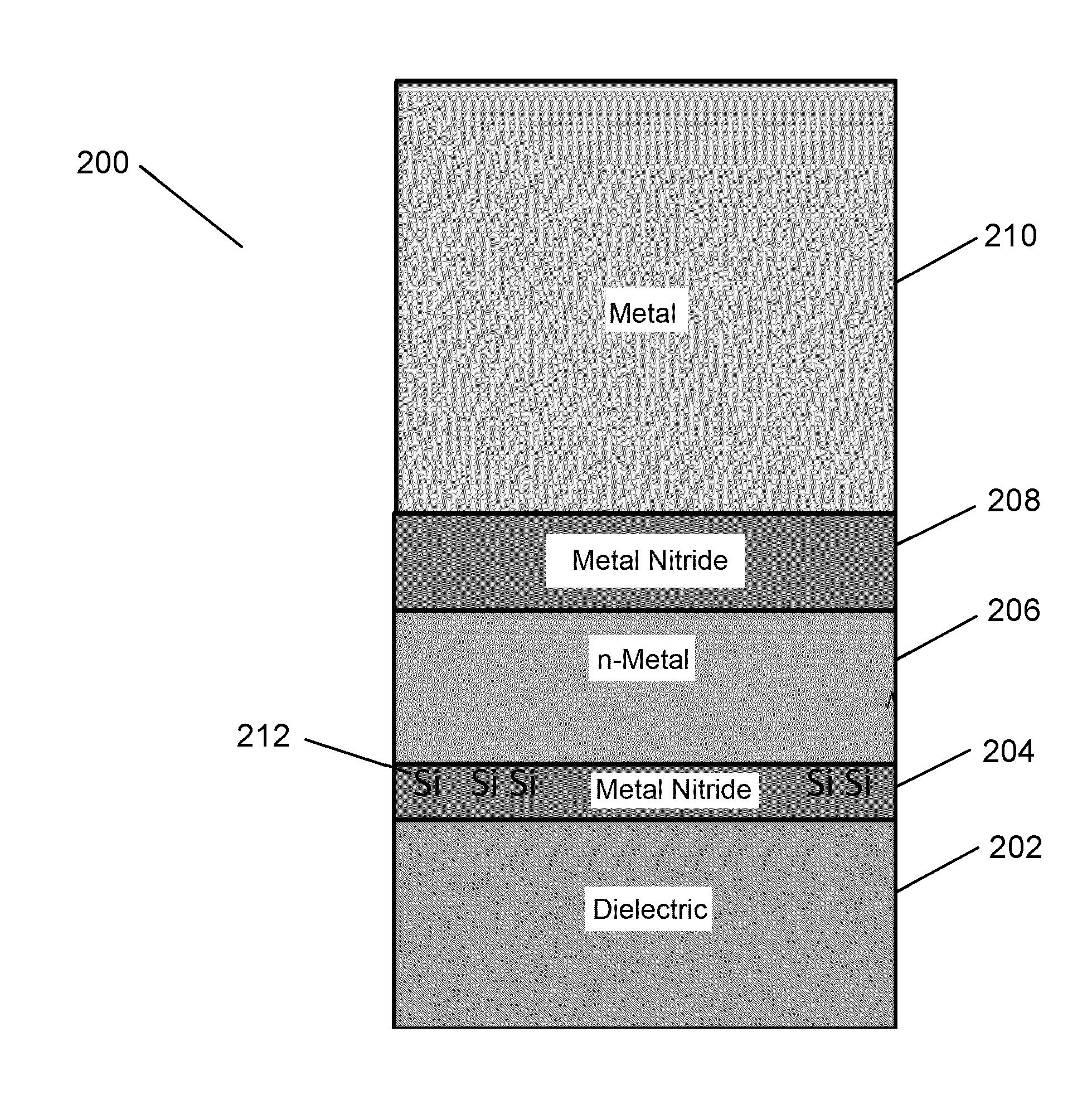

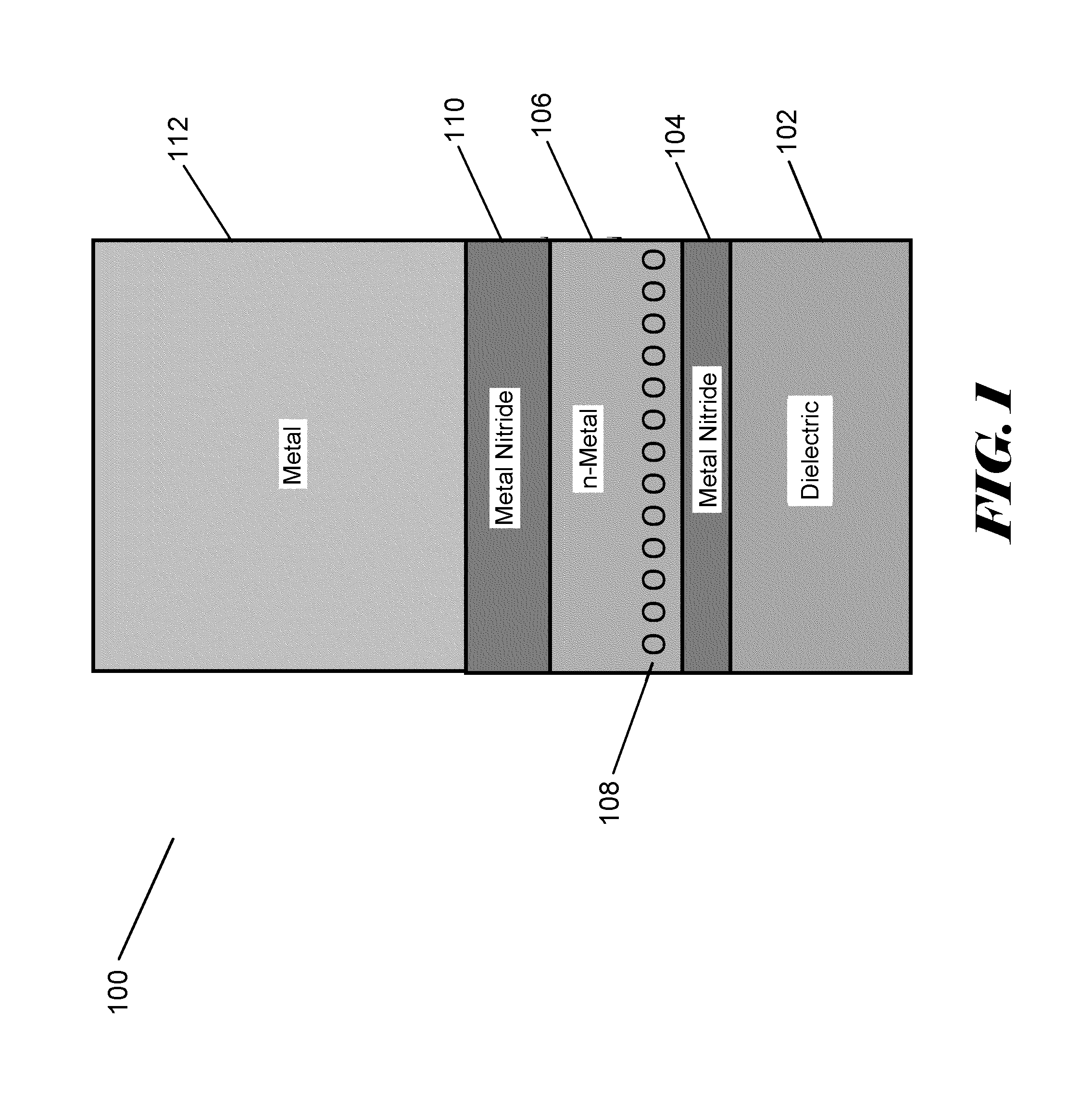

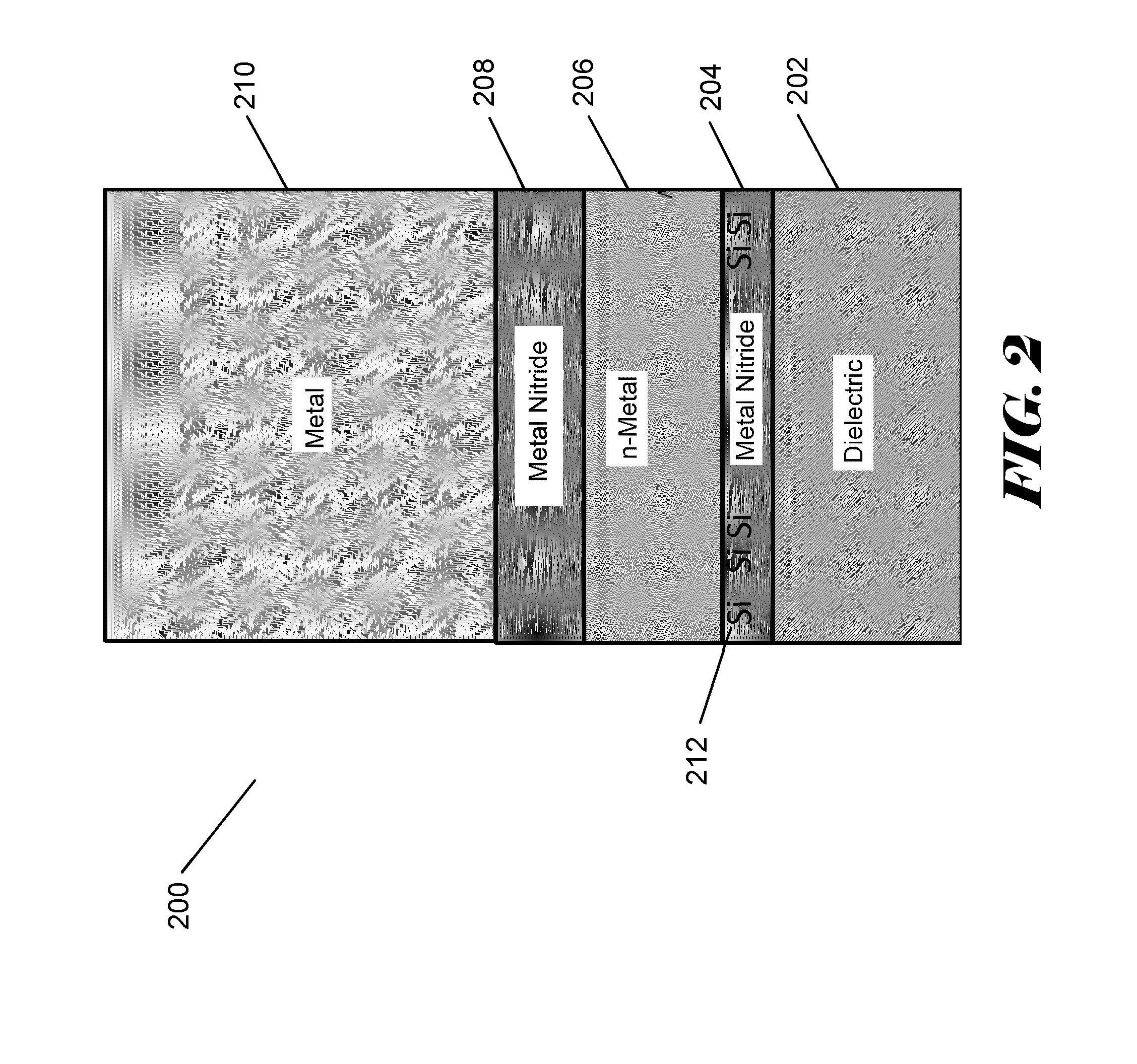

Silane or borane treatment of metal thin films

ActiveUS20140273428A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSilanesGate stack

The negative effect of oxygen on some metal films can be reduced or prevented by contacting the films with a treatment agent comprising silane or borane. In some embodiments, one or more films in an NMOS gate stack are contacted with a treatment agent comprising silane or borane during or after deposition.

Owner:ASM IP HLDG BV

HDP-CVD seasoning process for high power HDP-CVD gapfil to improve particle performance

InactiveUS7109114B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSilanesSilicon oxide

A method of operating a substrate processing chamber that includes, prior to a substrate processing operation, flowing a seasoning gas comprising silane and oxygen into said chamber at a flow ratio of greater than or equal to about 1.6:1 oxygen to silane to deposit a silicon oxide film over at least one aluminum nitride nozzle exposed to an interior portion of the chamber. Also, a substrate processing system that includes a housing, a gas delivery system for introducing a seasoning gas into a vacuum chamber, where the gas delivery system comprises one or more aluminum nitride nozzles exposed to the vacuum chamber, a controller and a memory having a program having instructions for controlling the gas delivery system to flow a seasoning gas that has an oxygen to silane ratio greater than or equal to about 1.6:1 to deposit a silicon oxide film on the aluminum nitride nozzles.

Owner:APPLIED MATERIALS INC

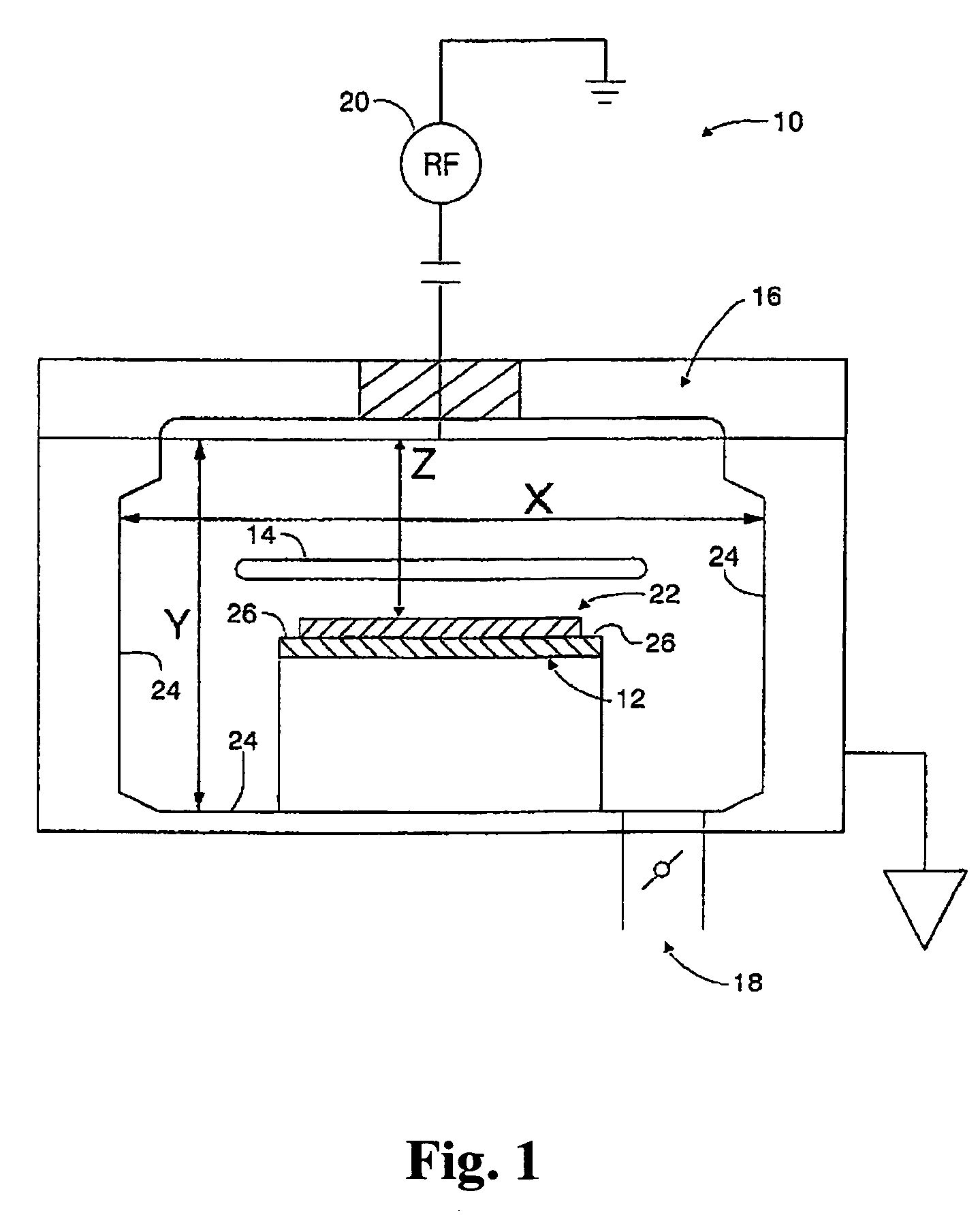

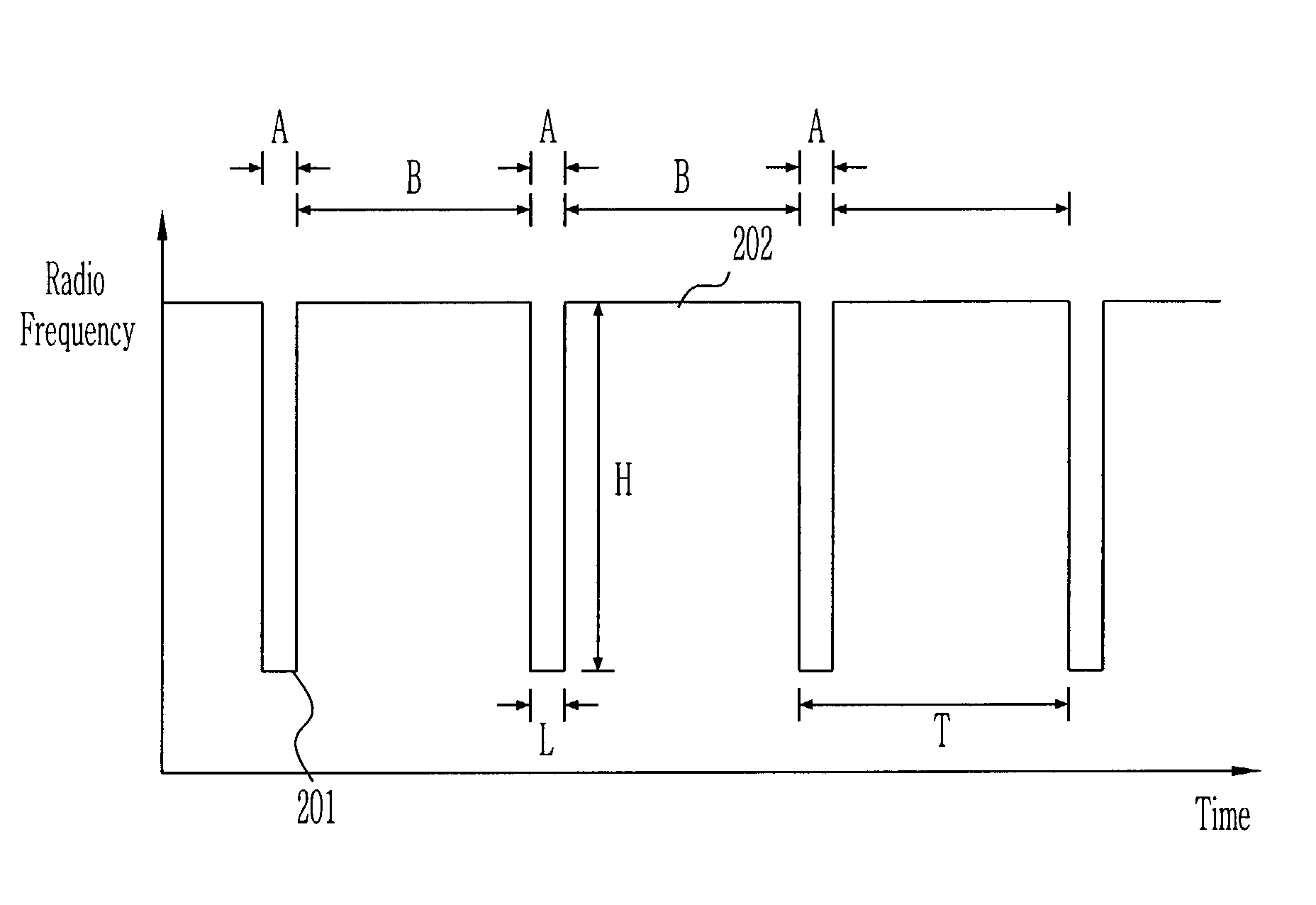

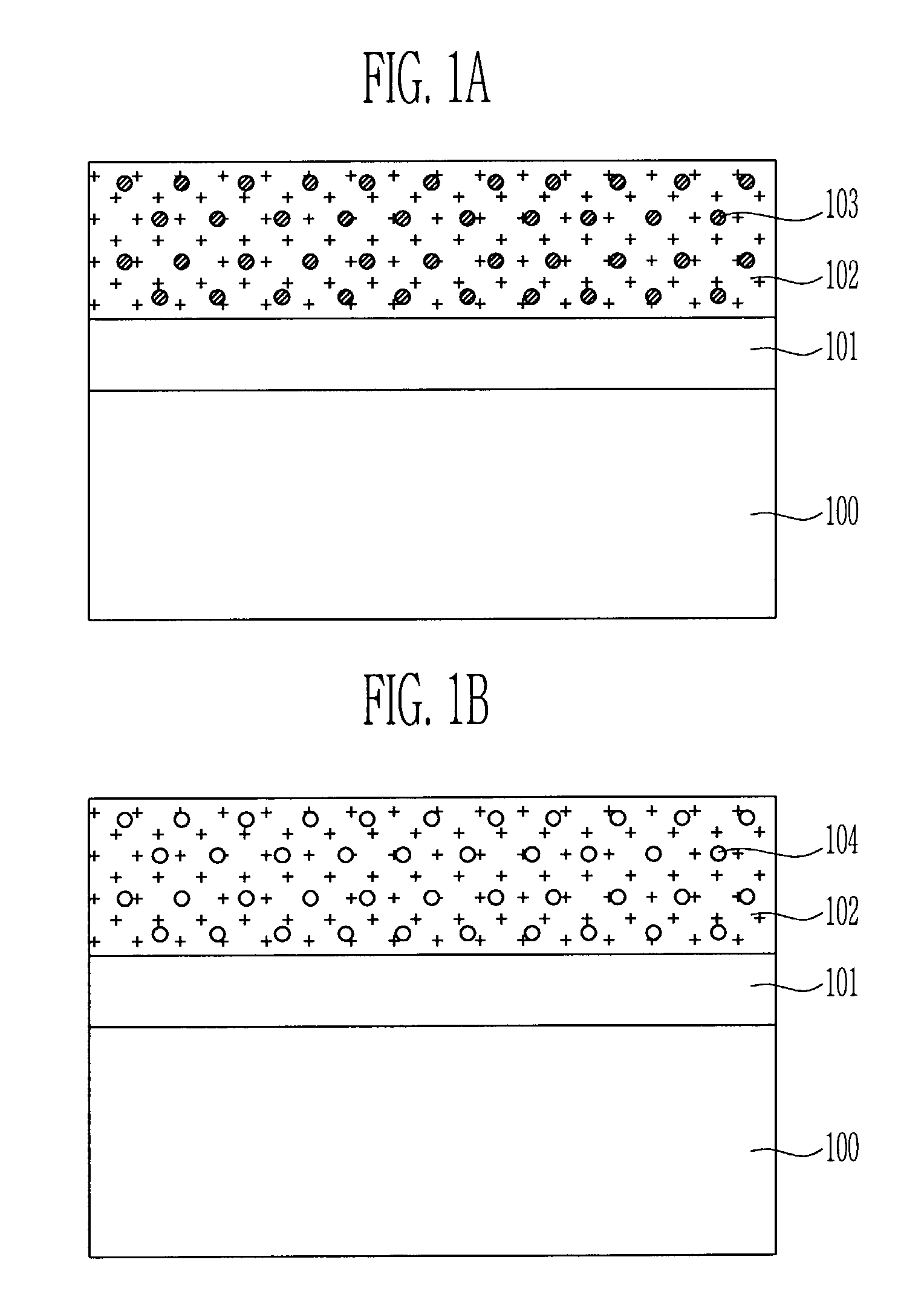

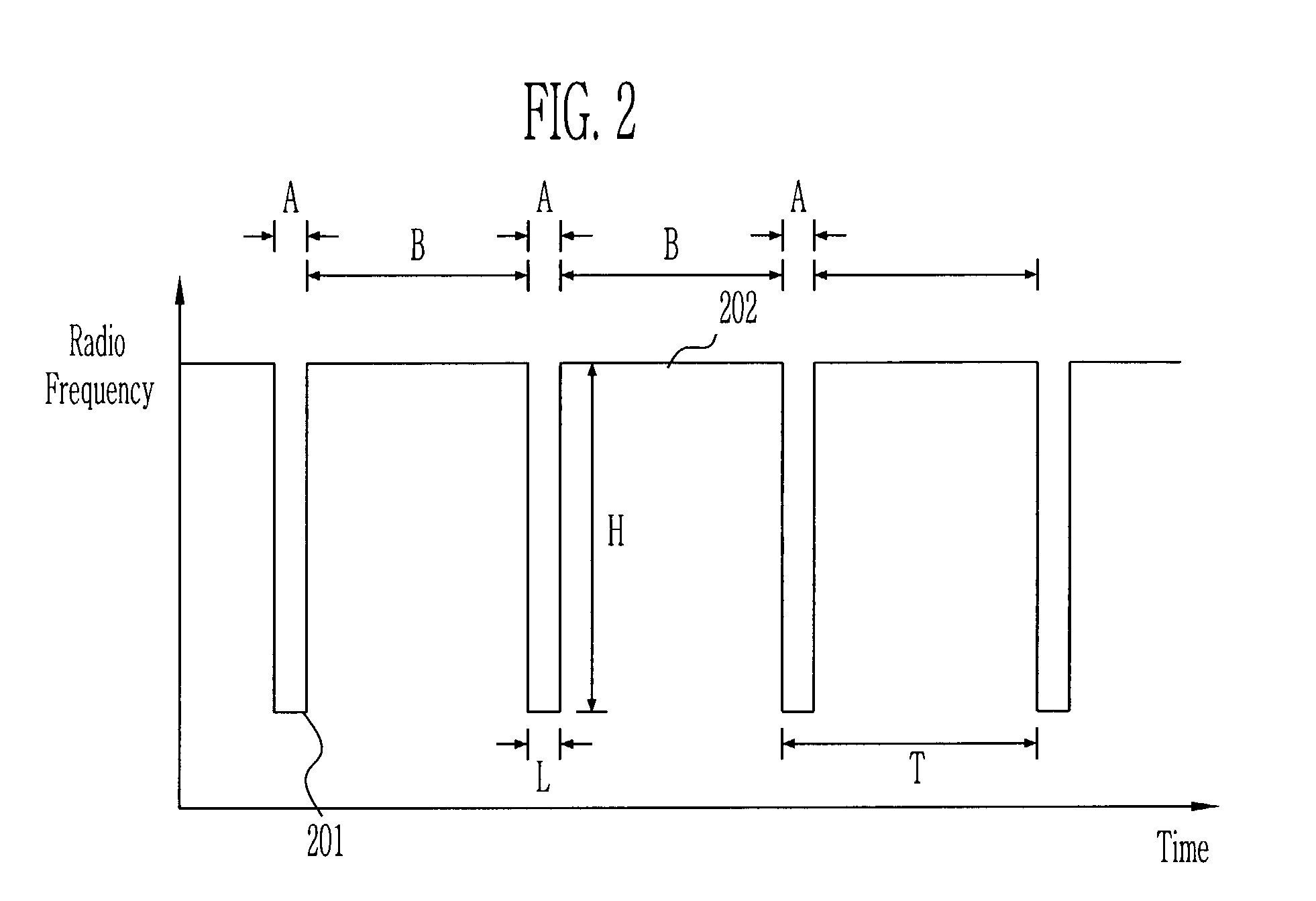

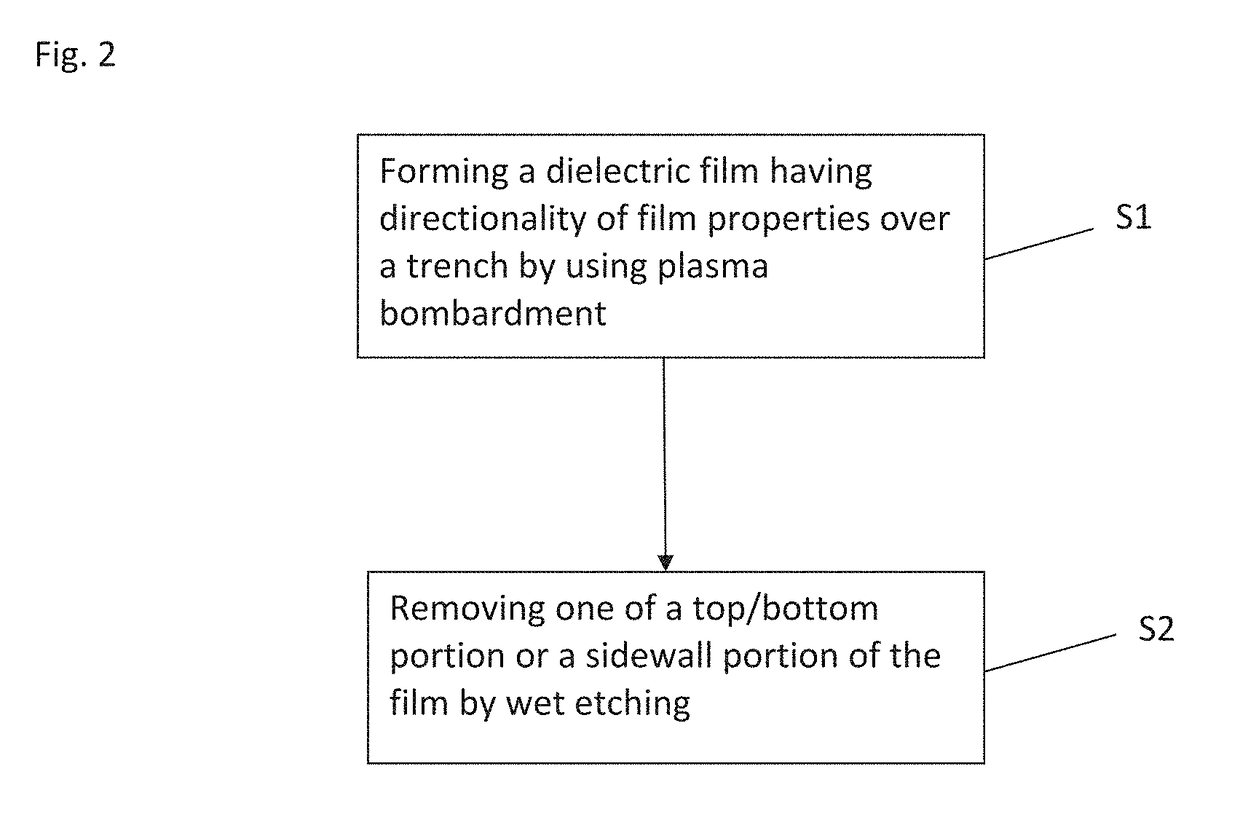

Method of forming insulating layer in semiconductor device

The present invention relates to a method of forming an insulating film in a semiconductor device. After a mixed gas of alkyl silane gas and N2O gas is supplied into the deposition equipment, a radio frequency power including a short pulse wave for causing incomplete reaction upon a gas phase reaction is applied to generate nano particle. The nano particle is then reacted to oxygen radical to form the insulating film including a plurality of nano voids. A low-dielectric insulating film that can be applied to the nano technology even in the existing LECVD equipment is formed.

Owner:SK HYNIX INC

Home and personal care compositions comprising silicon-based lubricants

InactiveUS7465439B2Cosmetic preparationsOrganic detergent compounding agentsPersonal carePolymer science

A composition for personal, home, or laundry treatment comprising a polymer made up of one or more crosslinked rake or comb silicone copolymer segments. A process for making copolymers for use in such compositions involves hydrosilylation in the presence of a catalyst.

Owner:CONOPCO INC D B A UNILEVER

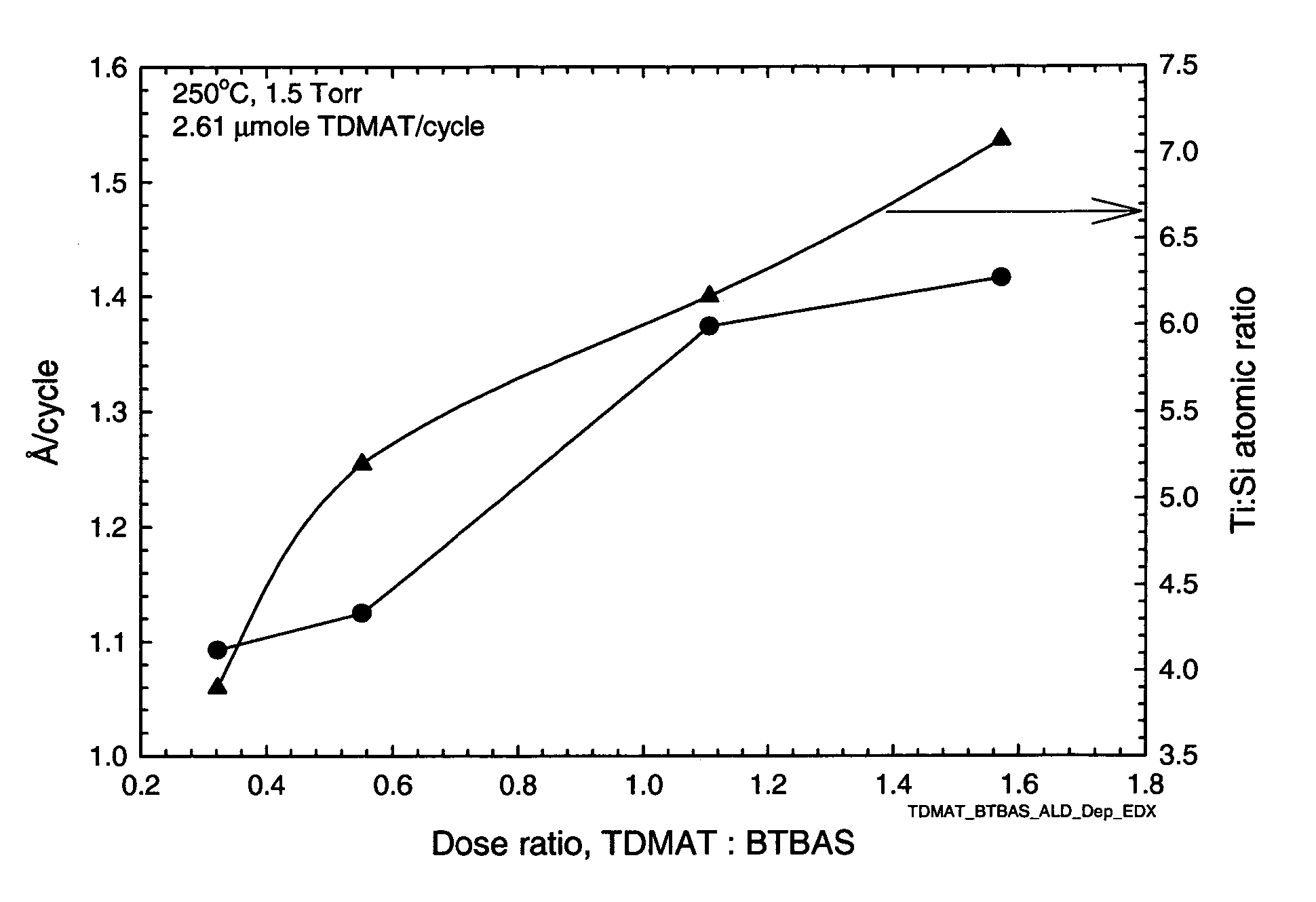

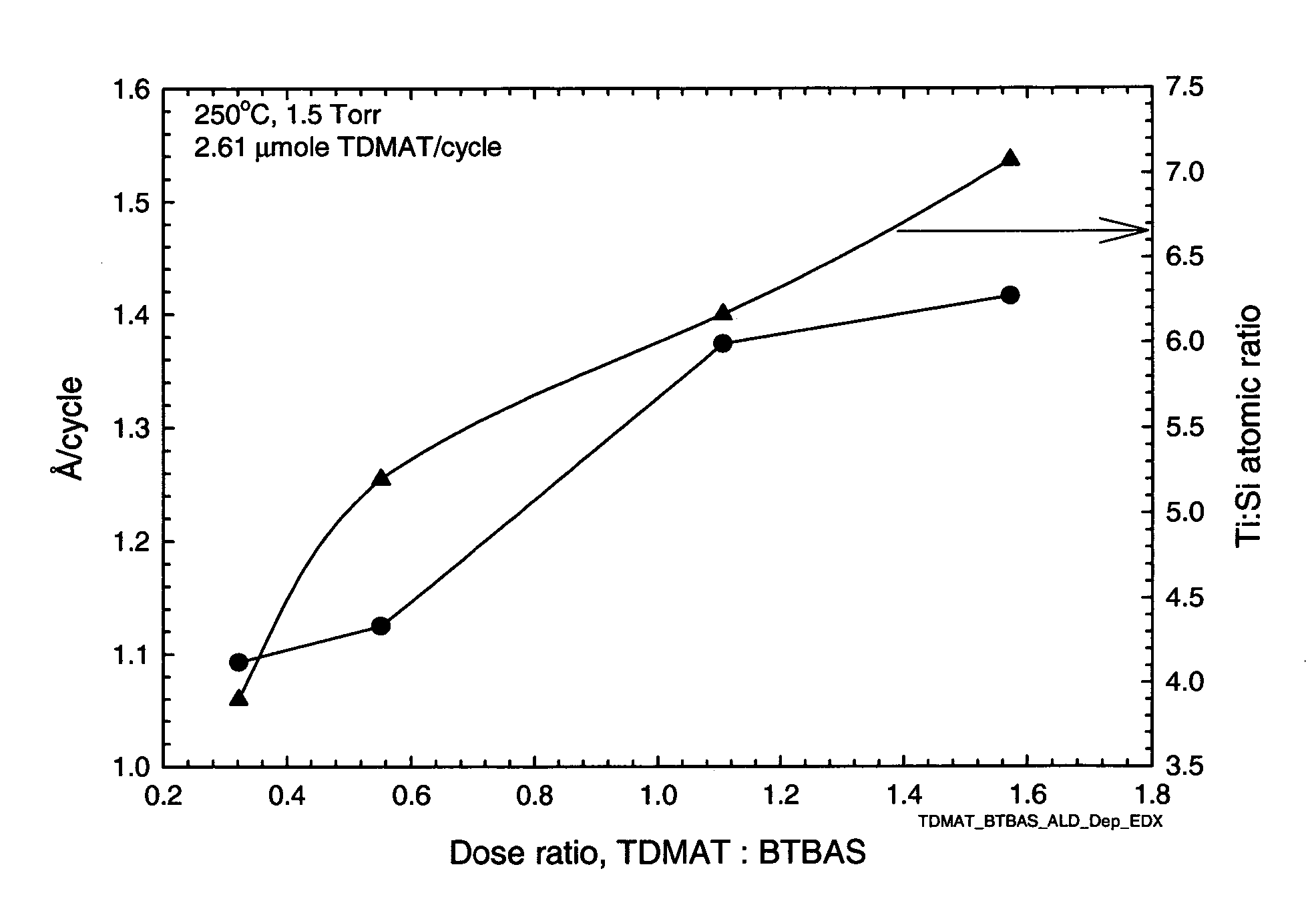

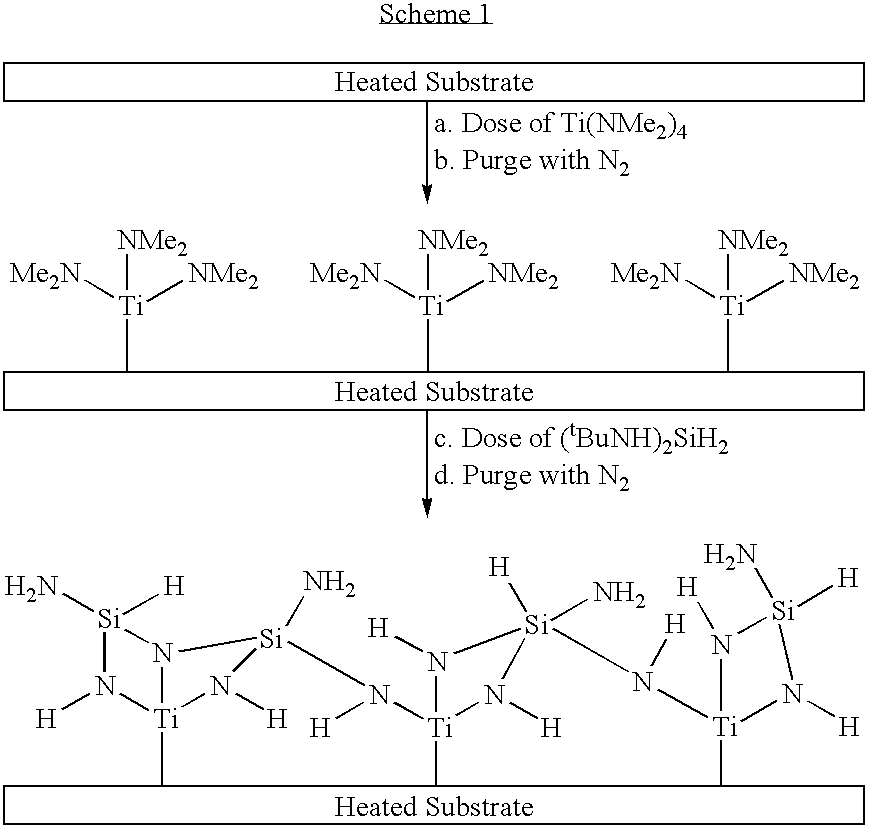

Preparation of metal silicon nitride films via cyclic deposition

InactiveUS20060182885A1Quality improvementProcess safetyLighting support devicesSemiconductor/solid-state device manufacturingSilyleneSilanes

This invention relates to an improved process for producing ternary metal silicon nitride films by the cyclic deposition of the precursors. The improvement resides in the use of a metal amide and a silicon source having both NH and SiH functionality as the precursors leading to the formation of such metal-SiN films. The precursors are applied sequentially via cyclic deposition onto the surface of a substrate. Exemplary silicon sources are monoalkylamino silanes and hydrazinosilanes represented by the formulas: (R1NH)nSiR2mH4-n-m (n=1,2; m=0,1,2; n+m=<3); and (R32N—NH)xSiR4yH4-x-y (x=1,2; y=0,1,2; x+y=<3) wherein in the above formula R1-4 are same or different and independently selected from the group consisting of alkyl, vinyl, allyl, phenyl, cyclic alkyl, fluoroalkyl, silylalkyls.

Owner:VERSUM MATERIALS US LLC

Film formation method and apparatus for semiconductor process

ActiveUS20060205231A1Improve controllabilityReduce the amount requiredSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilanesProcess engineering

An insulating film is formed on a target substrate by CVD, in a process field to be selectively supplied with a first process gas containing a silane family gas, a second process gas containing a nitriding or oxynitriding gas, and a third process gas containing a carbon hydride gas. This method alternately includes first to fourth steps. The first step performs supply of the first and third process gases to the field while stopping supply of the second process gas to the process field. The second step stops supply of the first to third process gases to the field. The third step performs supply of the second process gas to the field while stopping supply of the first and third process gases to the field. The fourth step stops supply of the first to third process gases to the field.

Owner:TOKYO ELECTRON LTD

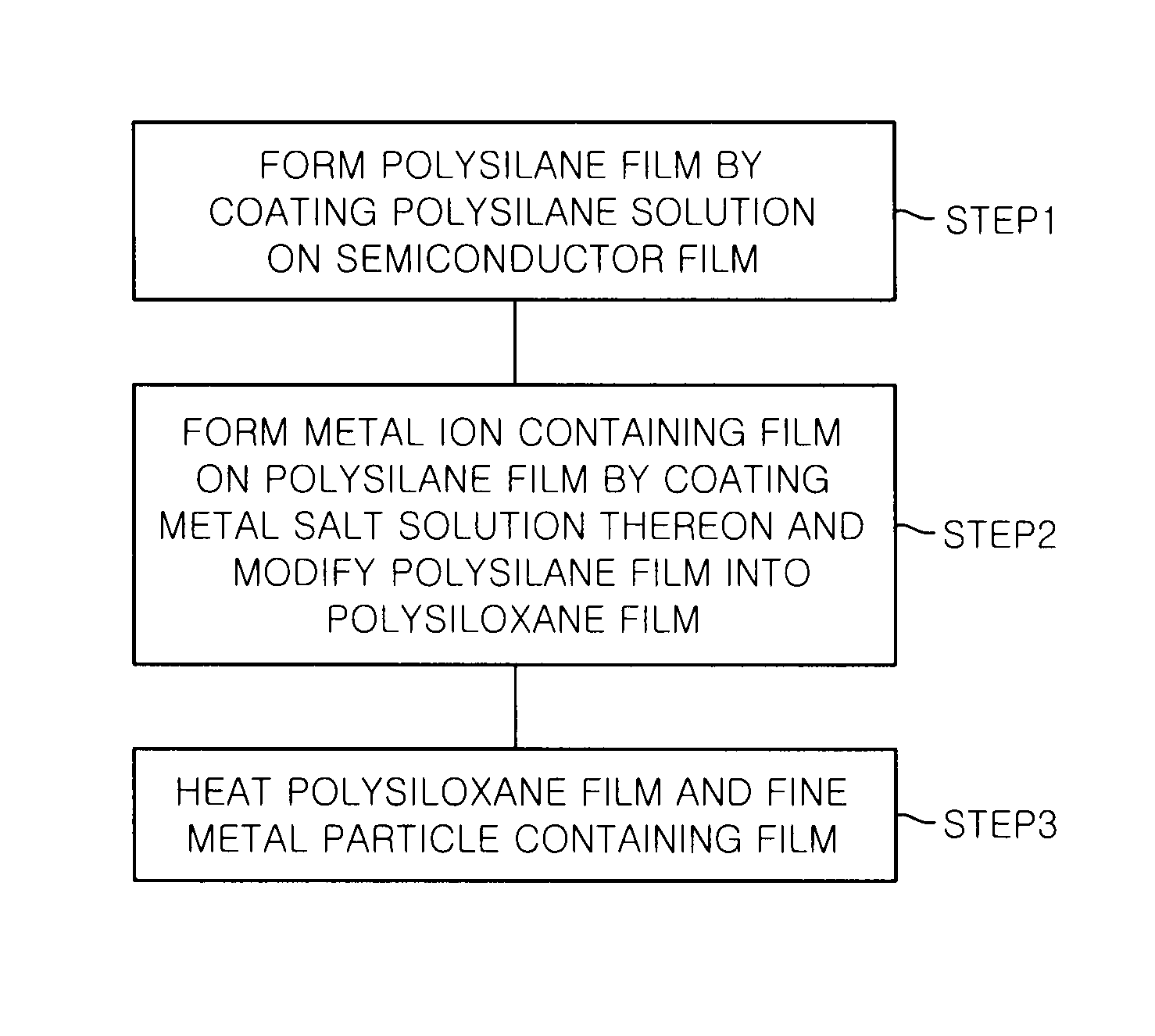

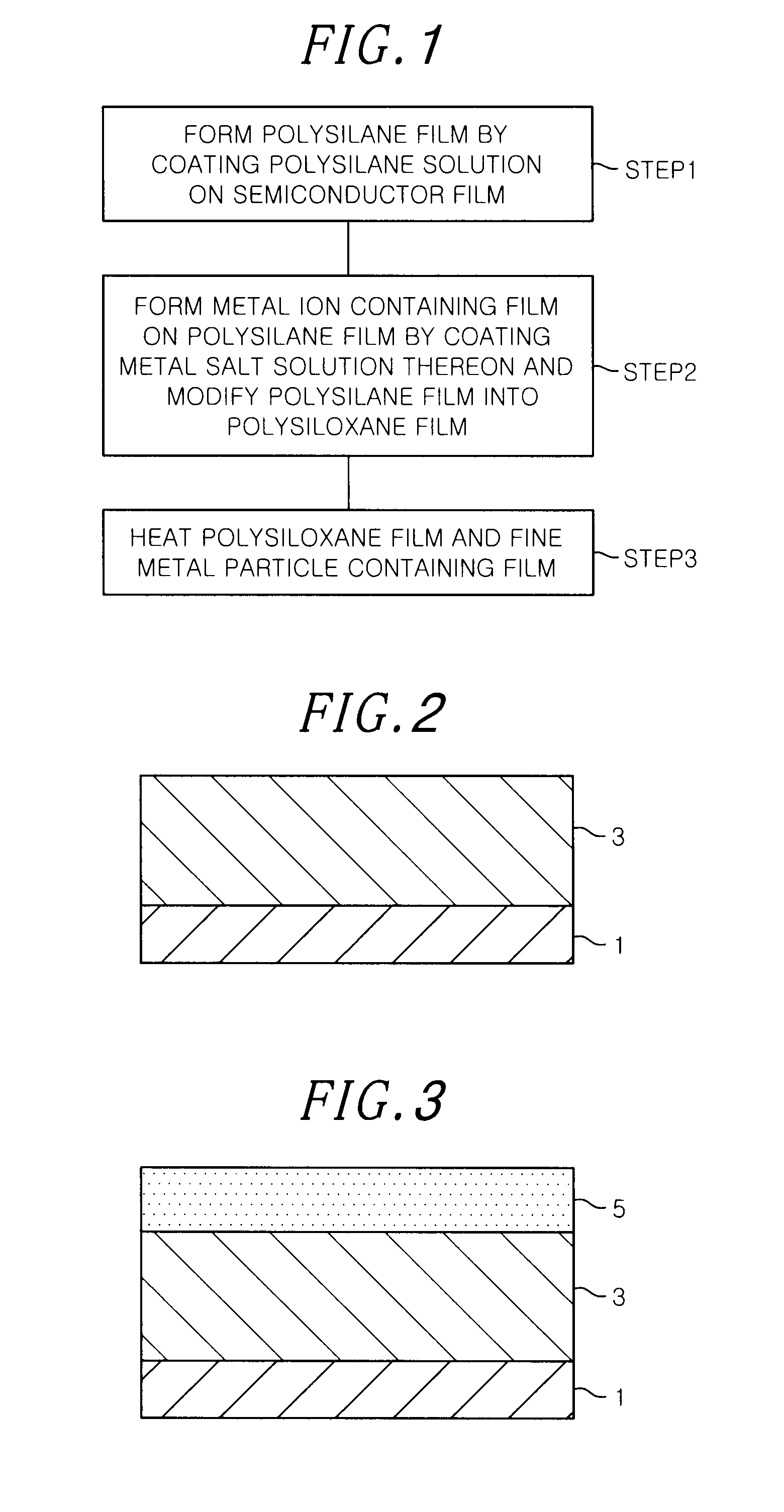

Film forming method, semiconductor device, manufacturing method thereof and substrate processing apparatus therefor

InactiveUS8785311B2Solid-state devicesSemiconductor/solid-state device manufacturingSemiconductor materialsSilanes

In a method for forming a stacked substrate of a MOS (Metal Oxide Semiconductor) structure including an oxide film serving as a gate insulating film formed on a semiconductor material layer having a film or substrate shape; and a conductive film serving as a gate electrode formed on the oxide film, a polysilane film on the semiconductor material layer is formed by coating a polysilane solution on a surface of a substrate to which the semiconductor material layer is exposed. A film containing metal ions is formed on the polysilane film by coating a metal salt solution thereon, and the polysilane film and the film containing metal ions are respectively modified into a polysiloxane film and a film containing fine metal particles to form the stacked substrate.

Owner:TOKYO ELECTRON LTD

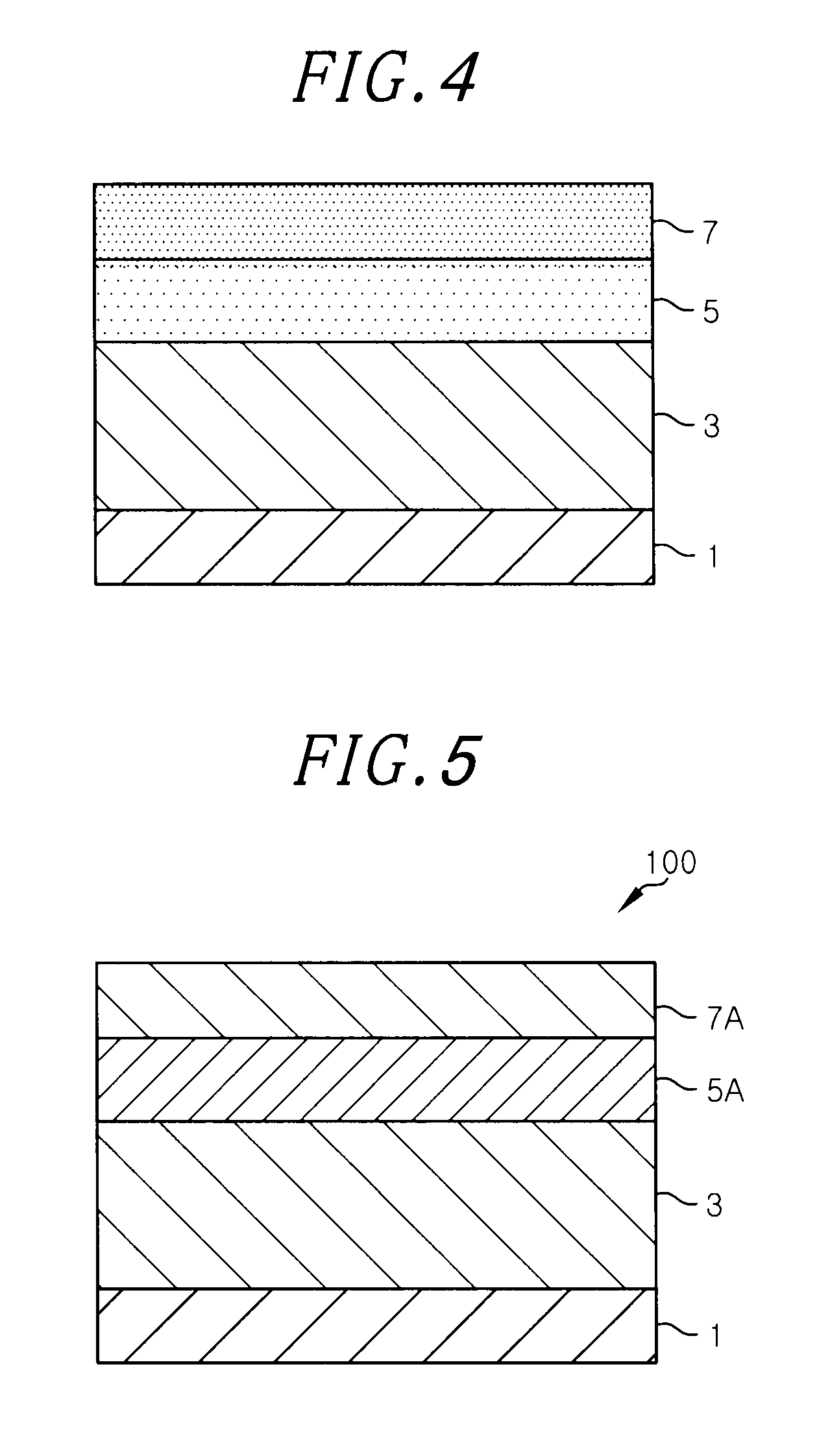

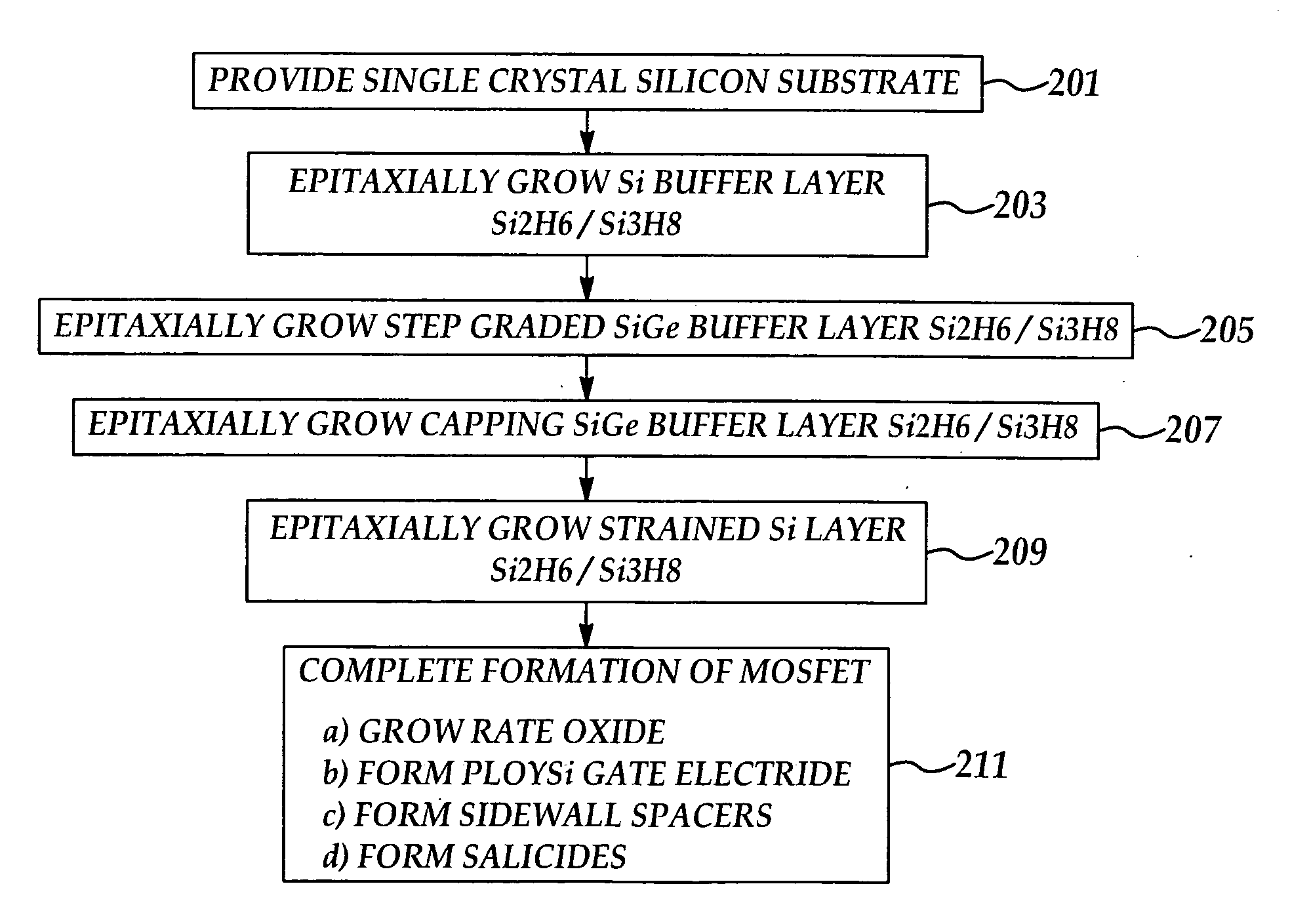

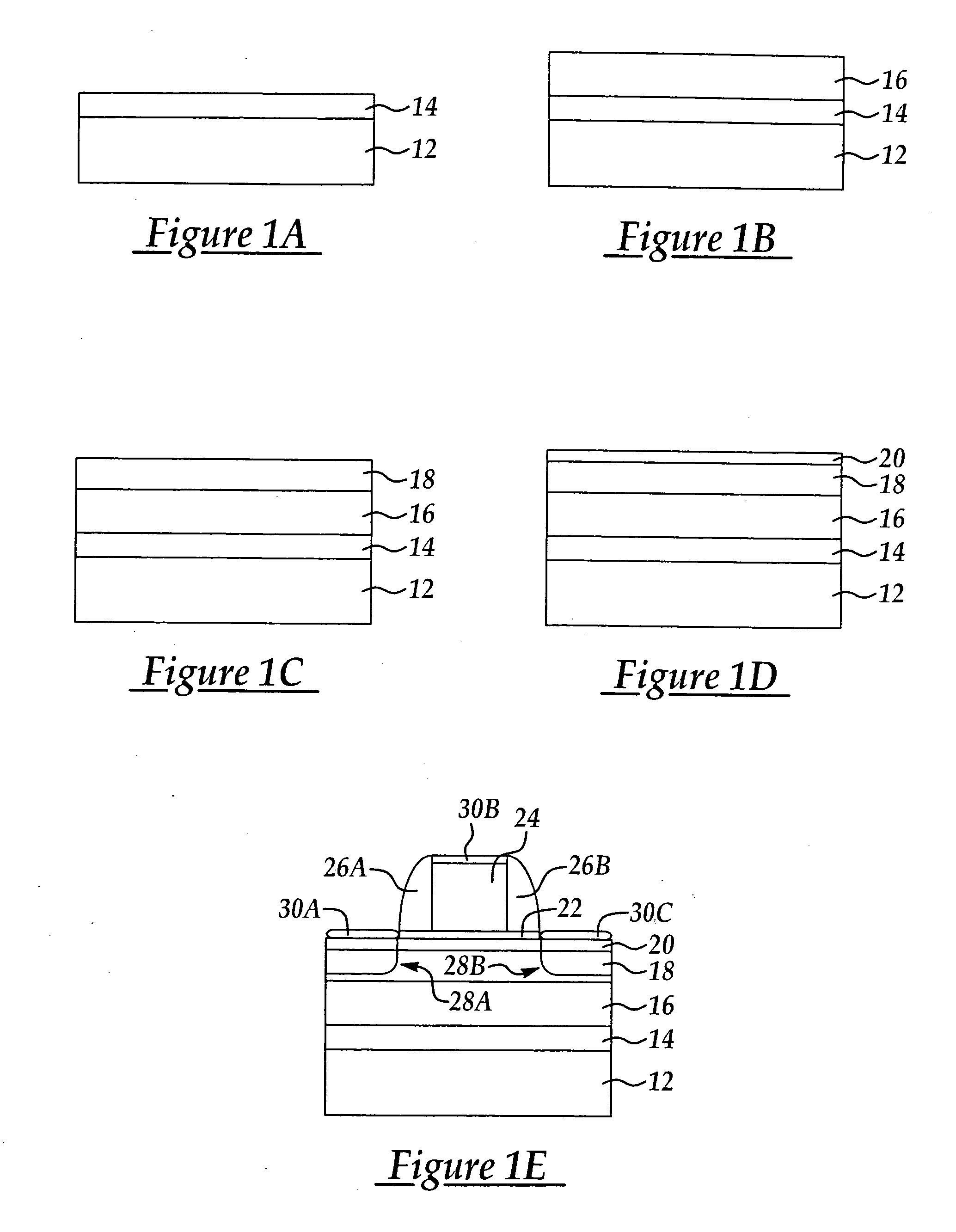

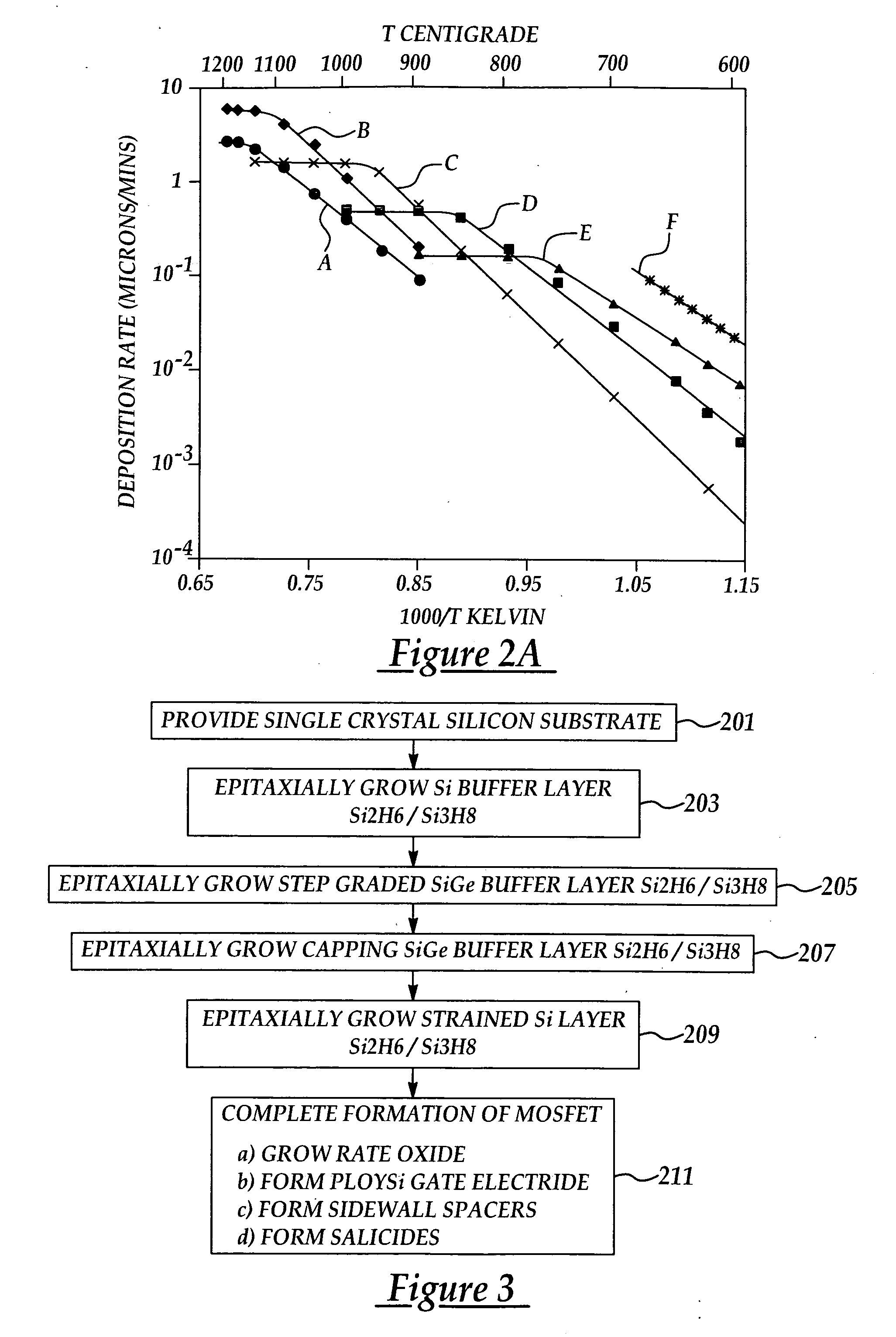

Method for producing high throughput strained-si channel mosfets

InactiveUS20050245058A1Improve throughputReduce defect densityPolycrystalline material growthFrom solid stateSilanesMaterials science

A method for forming a strained silicon layer device with improved wafer throughput and low defect density including providing a silicon substrate; epitaxially growing a first silicon layer using at least one deposition precursor selected from the group consisting of disilane and trisilane; epitaxially growing a step-grade SiGe buffer layer over and contacting the first silicon layer using at least one deposition precursor selected from the group consisting of disilane and trisilane; epitaxially growing a SiGe capping layer over and contacting the step-grade SiGe buffer layer using at least one deposition precursor selected from the group consisting of disilane and trisilane; and, epitaxially growing a second silicon layer using at least one deposition precursor selected from the group consisting of disilane and silane.

Owner:TAIWAN SEMICON MFG CO LTD

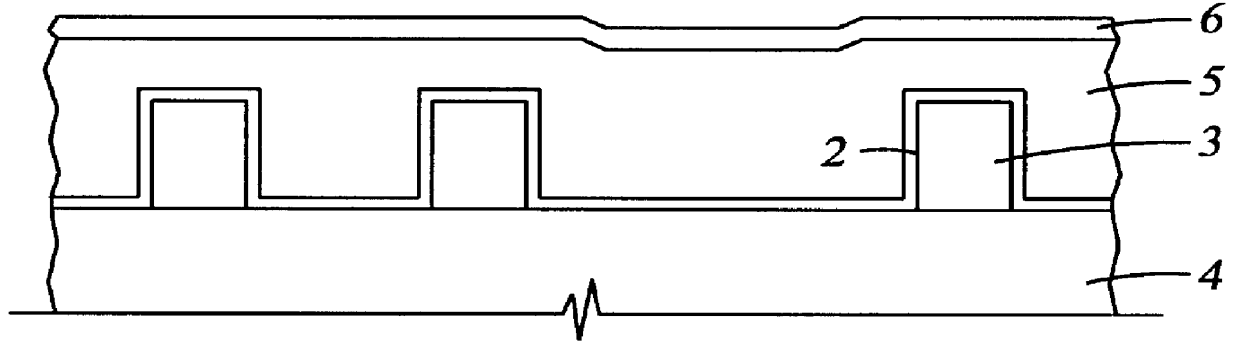

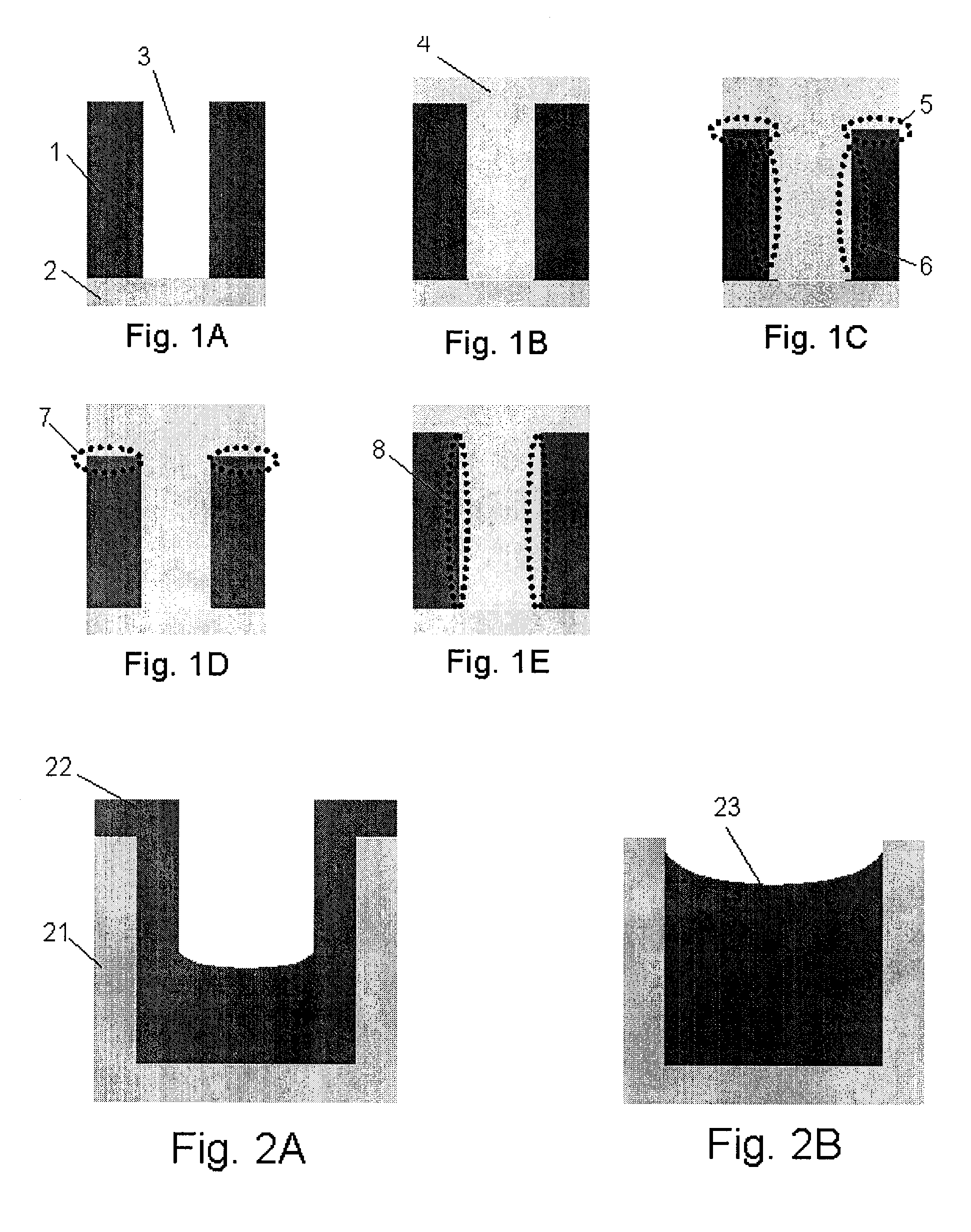

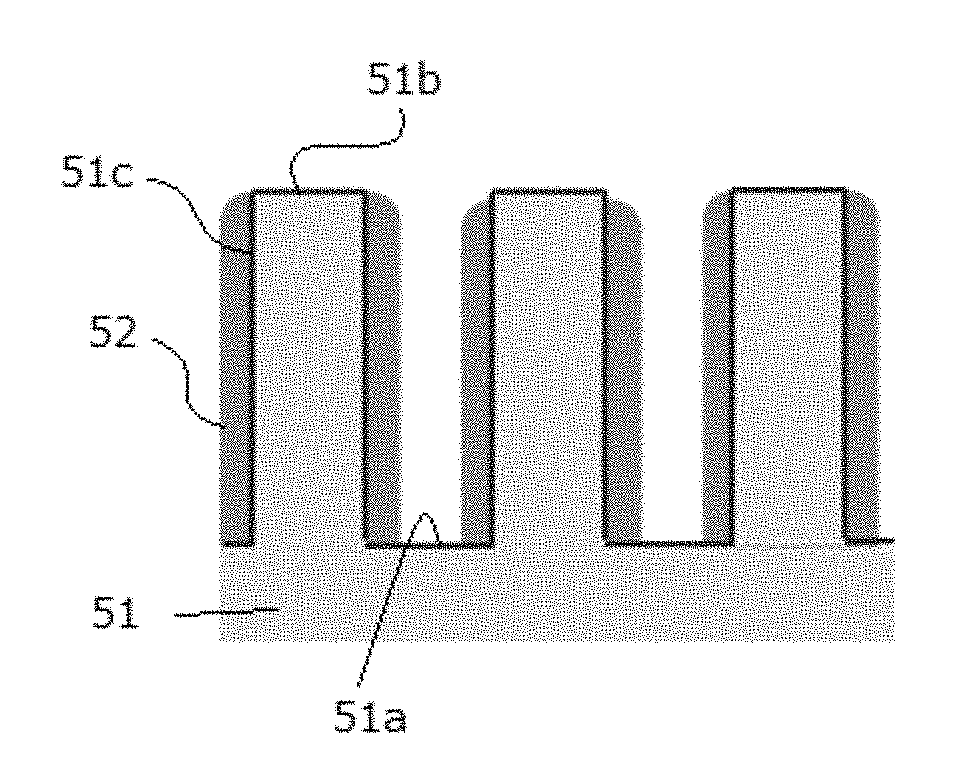

Method for forming spacers using silicon nitride film for spacer-defined multiple patterning

ActiveUS20170316940A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSurface patternSilanes

A method of forming spacers for spacer-defined multiple pattering (SDMP), includes: depositing a pattern transfer film by PEALD on the entire patterned surface of a template using halogenated silane as a precursor and nitrogen as a reactant at a temperature of 200° C. or less, which pattern transfer film is a silicon nitride film; dry-etching the template using a fluorocarbon as an etchant, and thereby selectively removing a portion of the pattern transfer film formed on a top of a core material and a horizontal portion of the pattern transfer film while leaving the core material and a vertical portion of the pattern transfer film as a vertical spacer, wherein a top of the vertical spacer is substantially flat; and dry-etching the core material, whereby the template has a surface patterned by the vertical spacer on a underlying layer.

Owner:ASM IP HLDG BV

Si seasoning to reduce particles, extend clean frequency, block mobile ions and increase chamber throughput

Owner:APPLIED MATERIALS INC

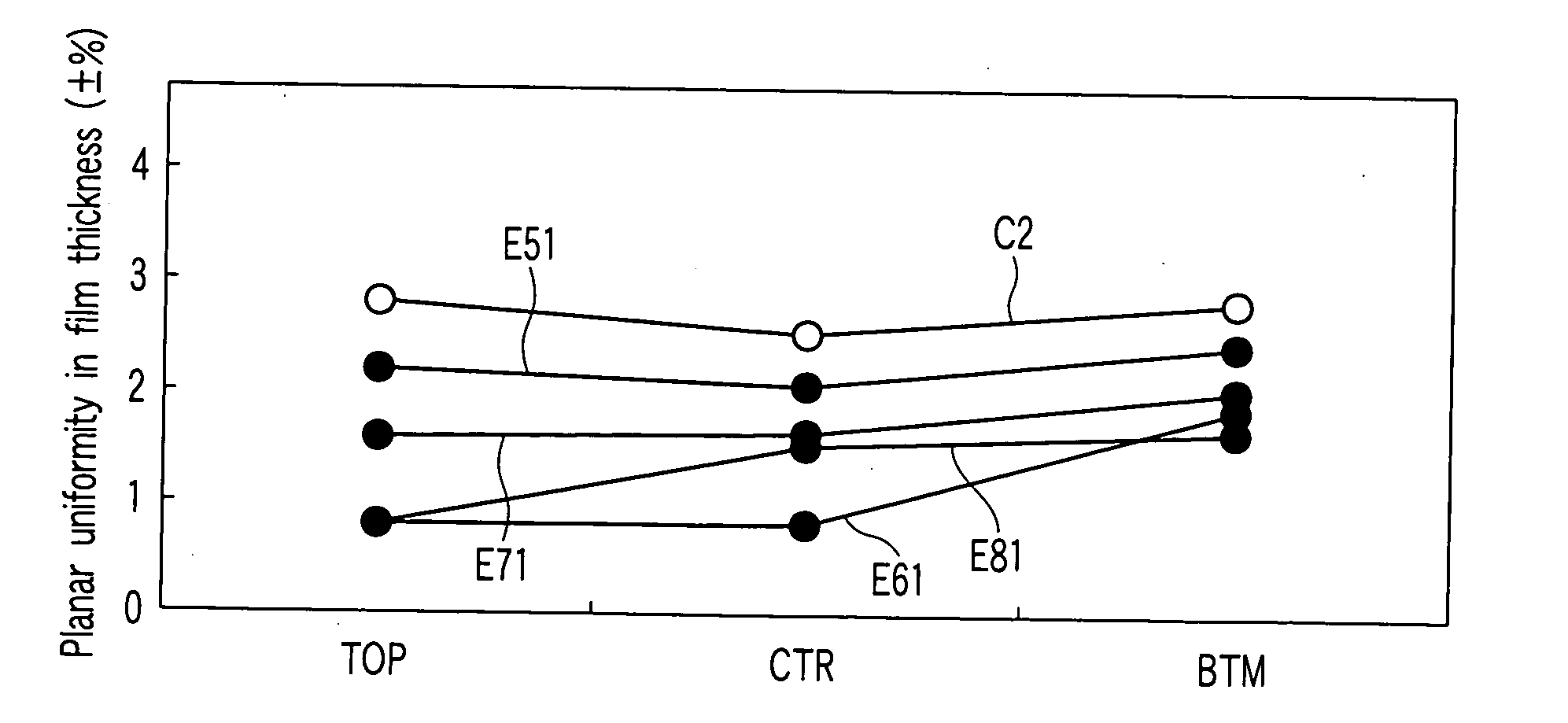

Film formation method and apparatus for semiconductor process

ActiveUS20060032443A1Low dielectric constantImprove corrosion resistanceSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilanesProcess engineering

An impurity-doped silicon nitride or oxynitride film is formed on a target substrate by CVD, in a process field to be selectively supplied with a first process gas containing a silane family gas, a second process gas containing a nitriding or oxynitriding gas, and a third process gas containing a doping gas. This method alternately includes first to fourth steps. The first step performs supply of the first and third process gases to the field. The second step stops supply of the first to third process gases to the field. The third step performs supply of the second process gas to the field while stopping supply of the first and third process gases to the field, and includes an excitation period of exciting the second process gas by an exciting mechanism. The fourth step stops supply of the first to third process gases to the field.

Owner:TOKYO ELECTRON LTD

Method for Forming SiOCH Film Using Organoaminosilane Annealing

ActiveUS20150056821A1Improve liquidityReduce the amount requiredSemiconductor/solid-state device manufacturingPolymer scienceSilanes

Owner:ASM IP HLDG BV

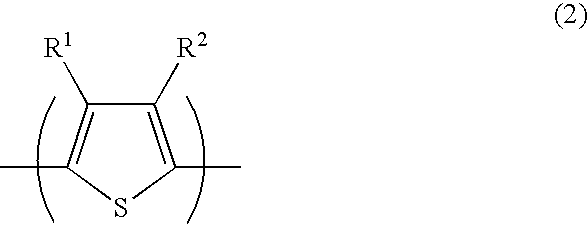

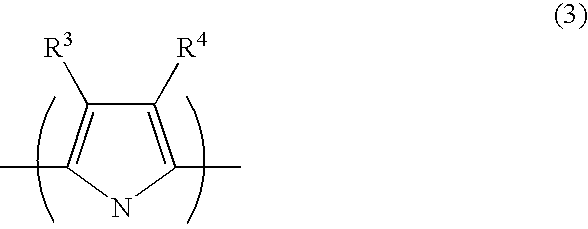

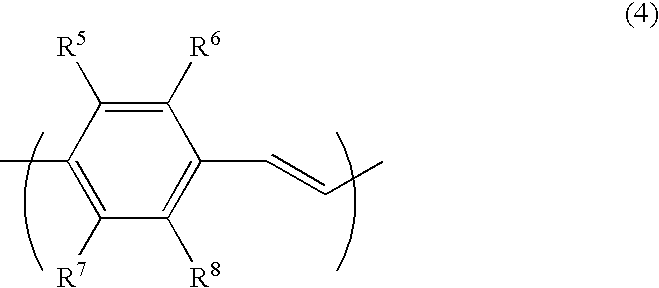

Composition containing carbon nanotubes having coating thereof and process for producing them

ActiveUS20060052509A1Not impair characteristicImprove conductivityMaterial nanotechnologySynthetic resin layered productsColloidal silicaConductive polymer

The object of the present invention is to provide a carbon nanotube composition that does not impair the characteristics of the carbon nanotubes itself, allows the carbon nanotubes to be dispersed or solubilized in a solvent, does not cause separation or aggregation of the carbon nanotubes even during long-term storage, has superior electrical conductivity, film formability and moldability, can be easily coated or covered onto a base material, and the resulting coated film has superior moisture resistance, weather resistance and hardness; a composite having a coated film composed thereof; and, their production methods. In order to achieve this object, the present invention provides a carbon nanotube composition that contains a conducting polymer (a) or heterocyclic compound trimer (i), a solvent (b) and carbon nanotubes (c), and may additionally contain a high molecular weight compound (d), a basic compound (e), a surfactant (f), a silane coupling agent (g) and colloidal silica (h) as necessary; a composite having a coated film composed of the composition; and, their production methods.

Owner:MITSUBISHI CHEM CORP

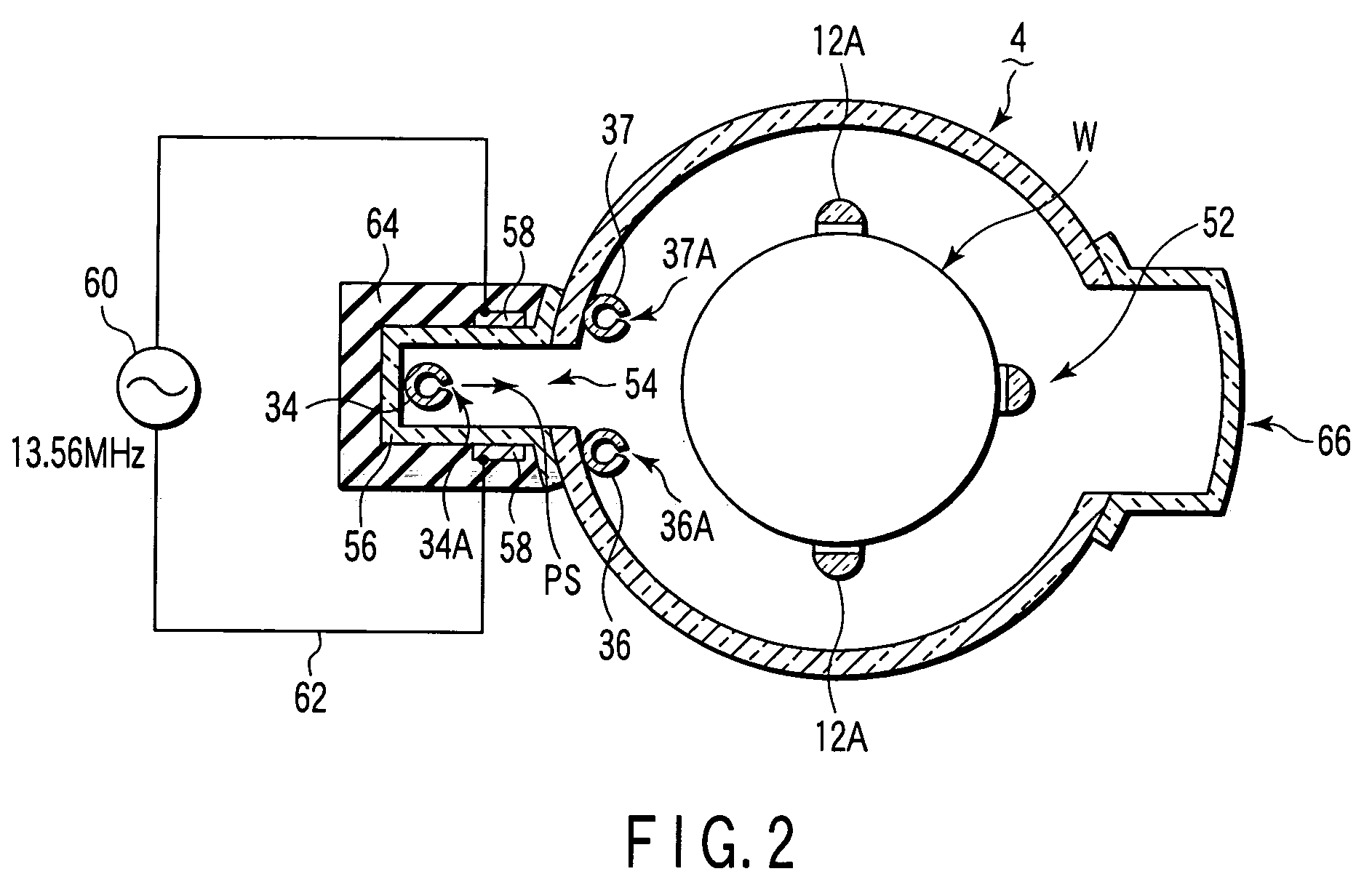

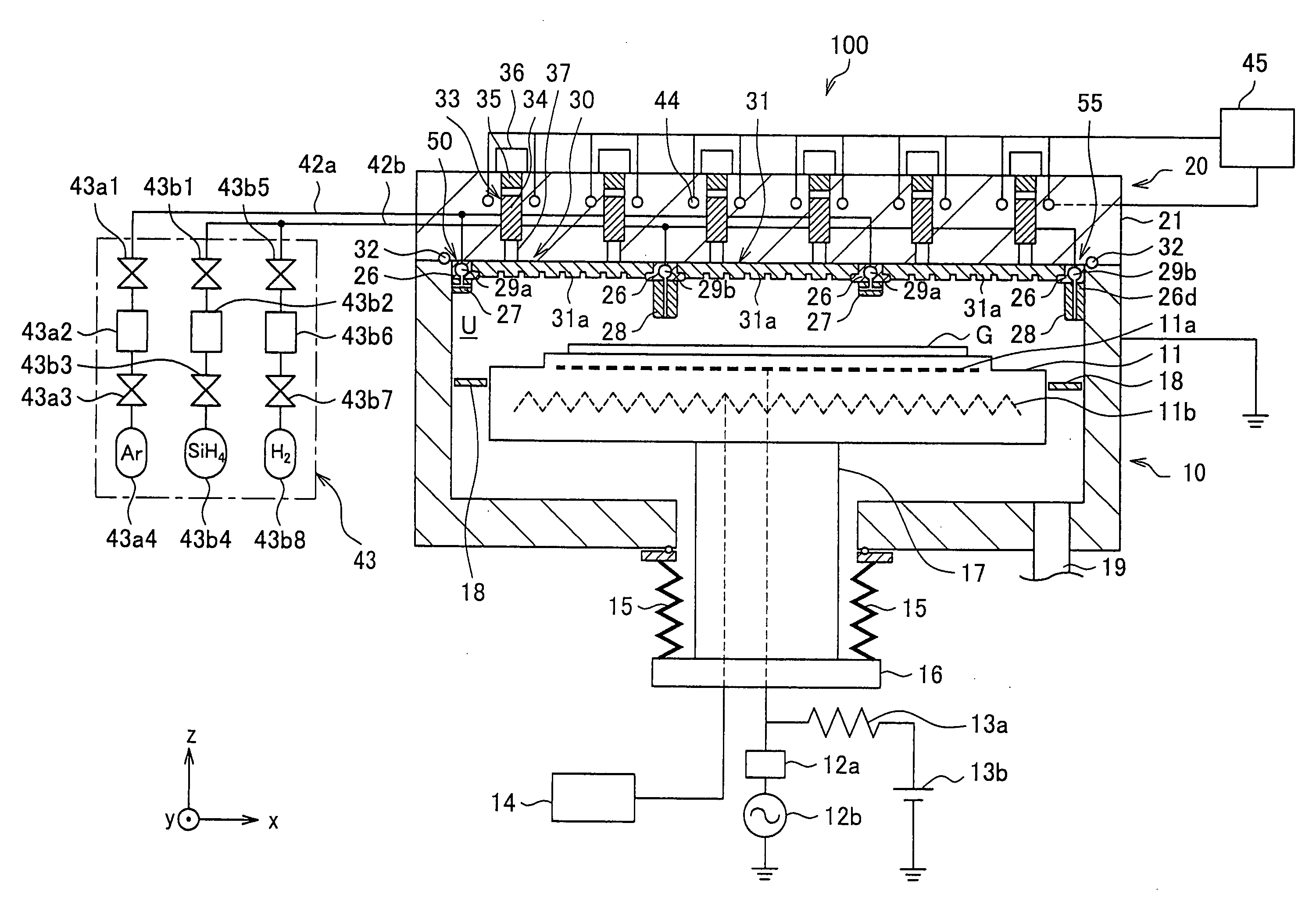

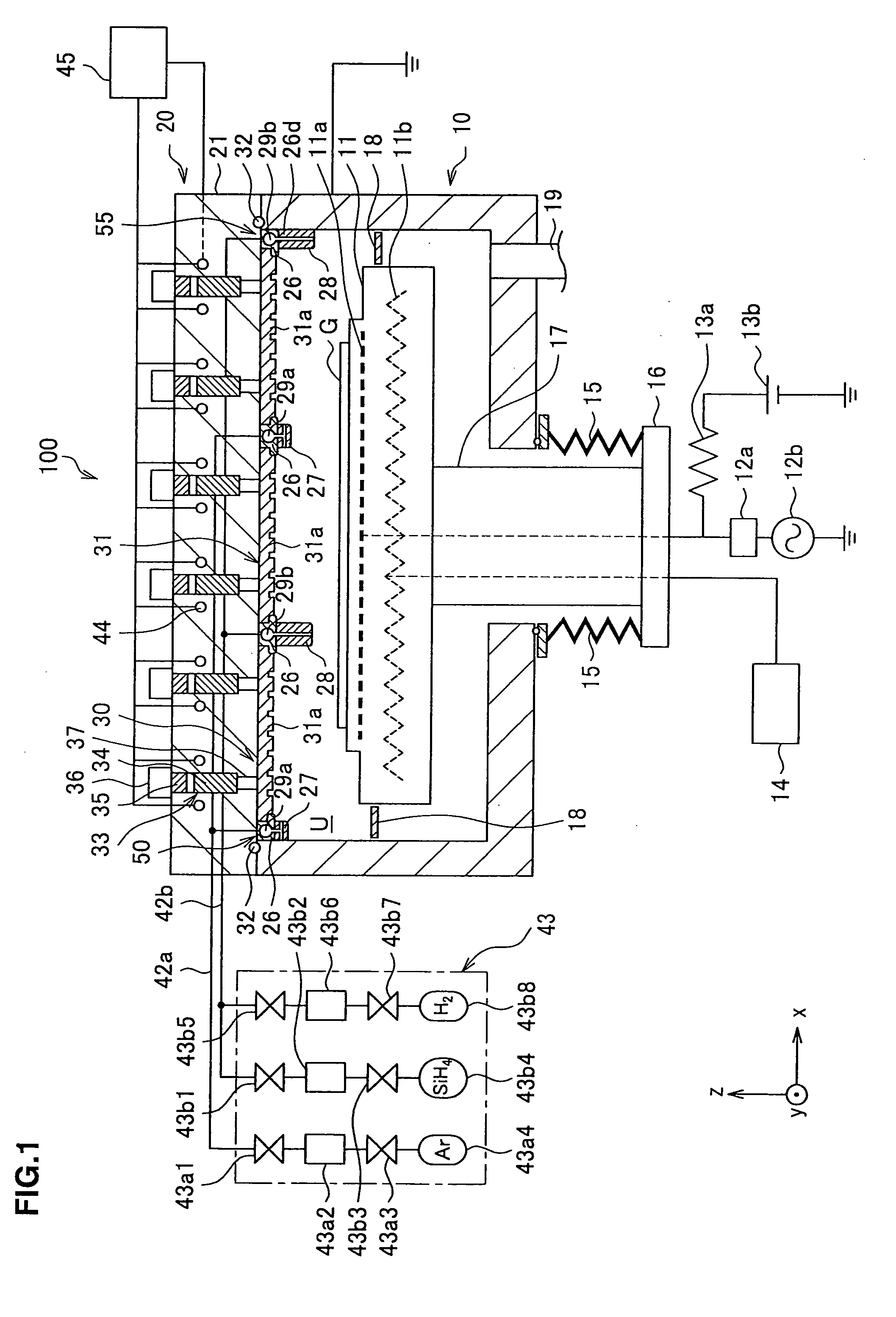

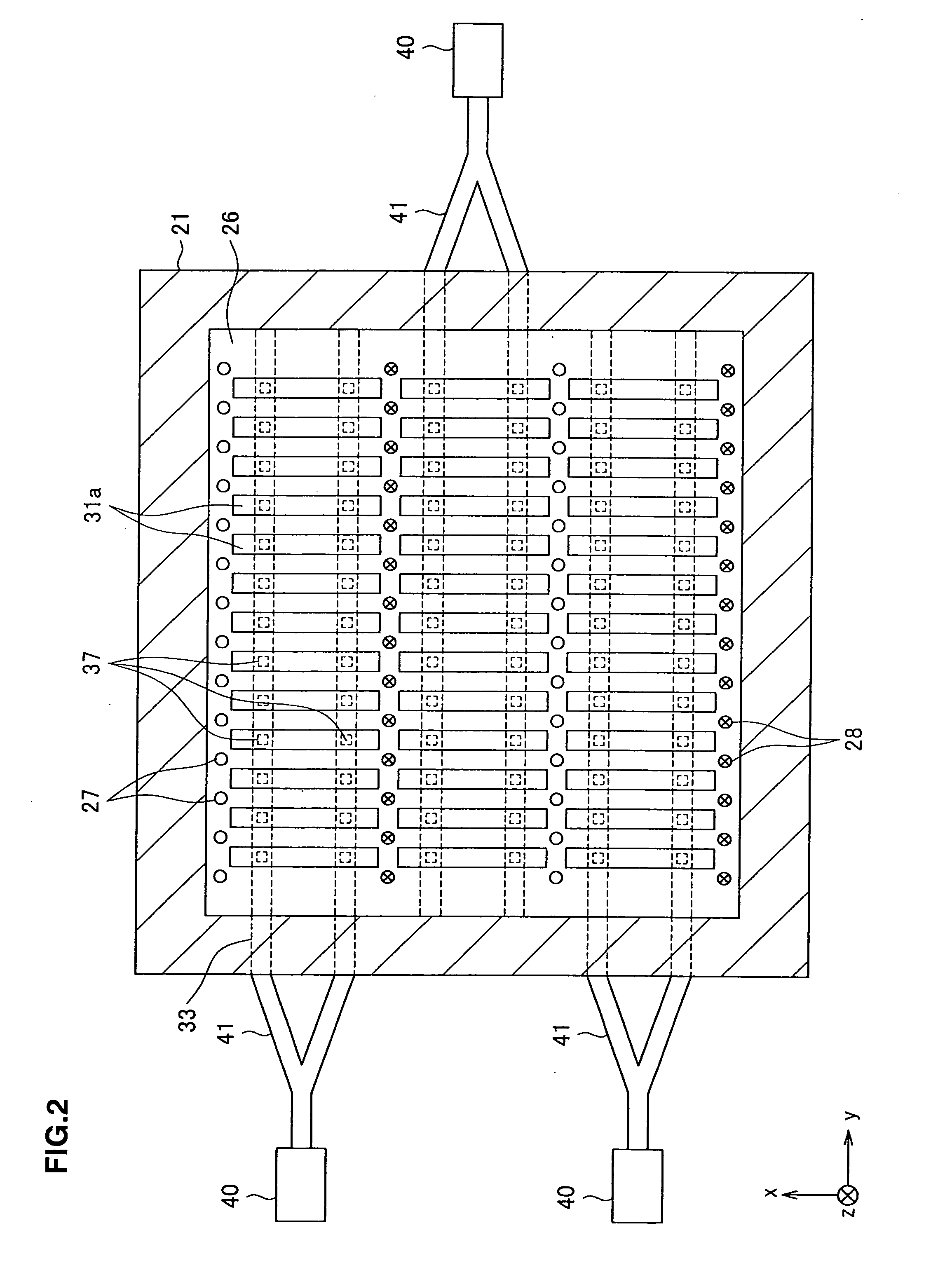

Plasma processing apparatus and plasma processing method

At a frame 26 in a microwave plasma processing apparatus 100, numerous horizontal spray gas nozzles 27 formed therein injection holes A and numerous vertical gas nozzles 28 formed therein injection holes B are fixed. A first gas supply means 50 injects argon gas through the injection holes A into an area near each dielectric parts 31a. A second gas supply means 55 injects silane gas and hydrogen gas through the injection holes B into a position at which the gases do not become over-dissociated. The gases injected as described above are raised to plasma with a microwave transmitted through each dielectric parts 31a. Since the vertical gas nozzles 28 are mounted at positions at which they do not block the flow of plasma traveling toward a substrate G, ions and electrons do not collide with the vertical gas nozzles 28 readily.

Owner:TOKYO ELECTRON LTD

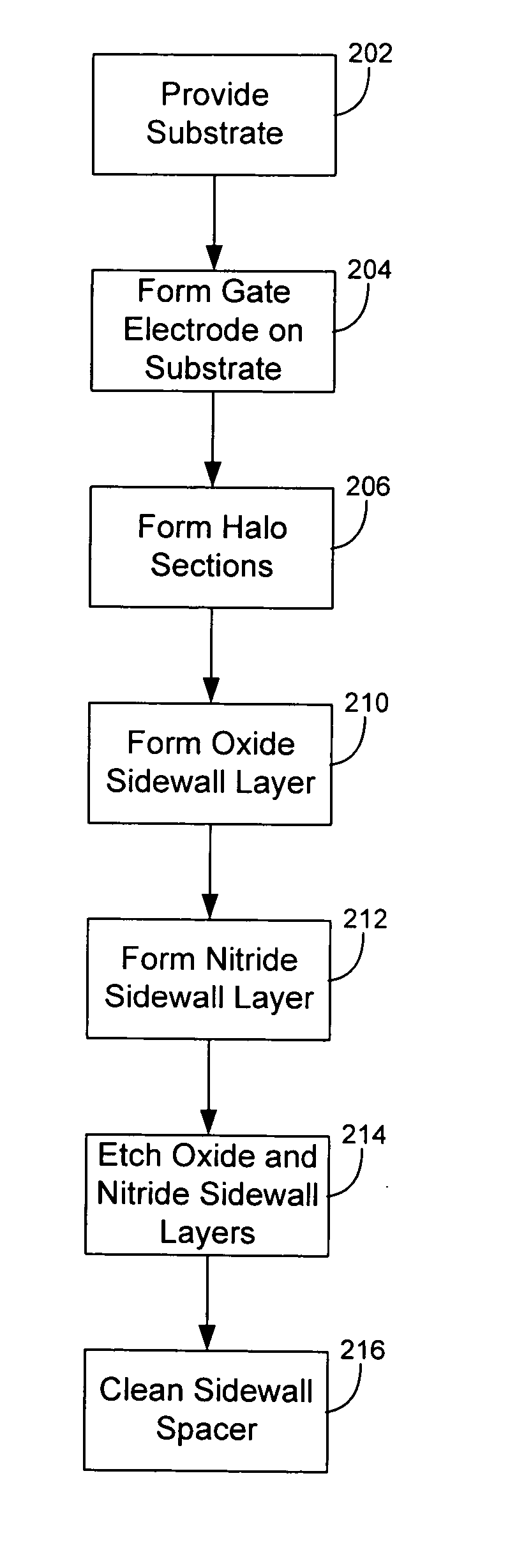

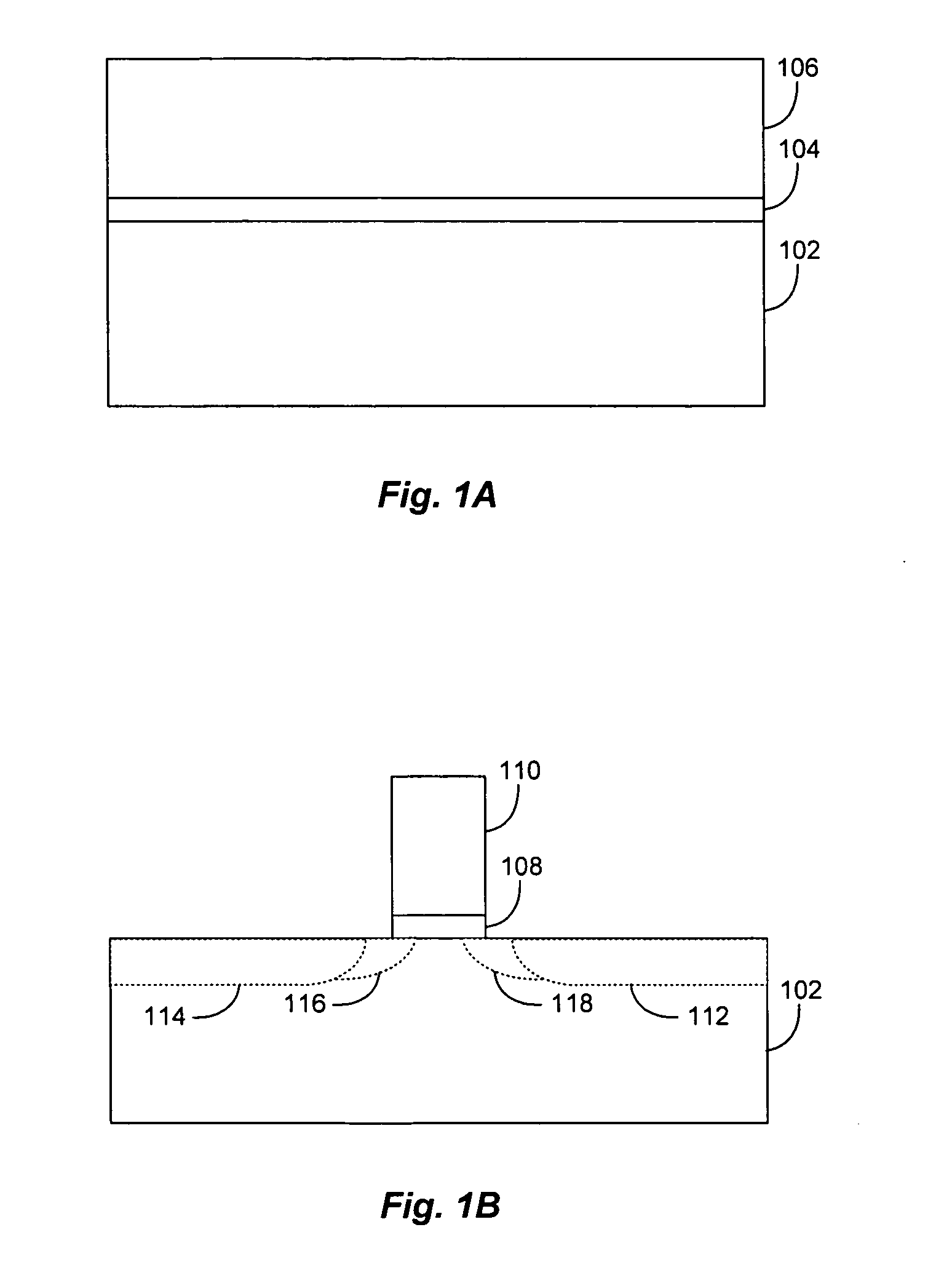

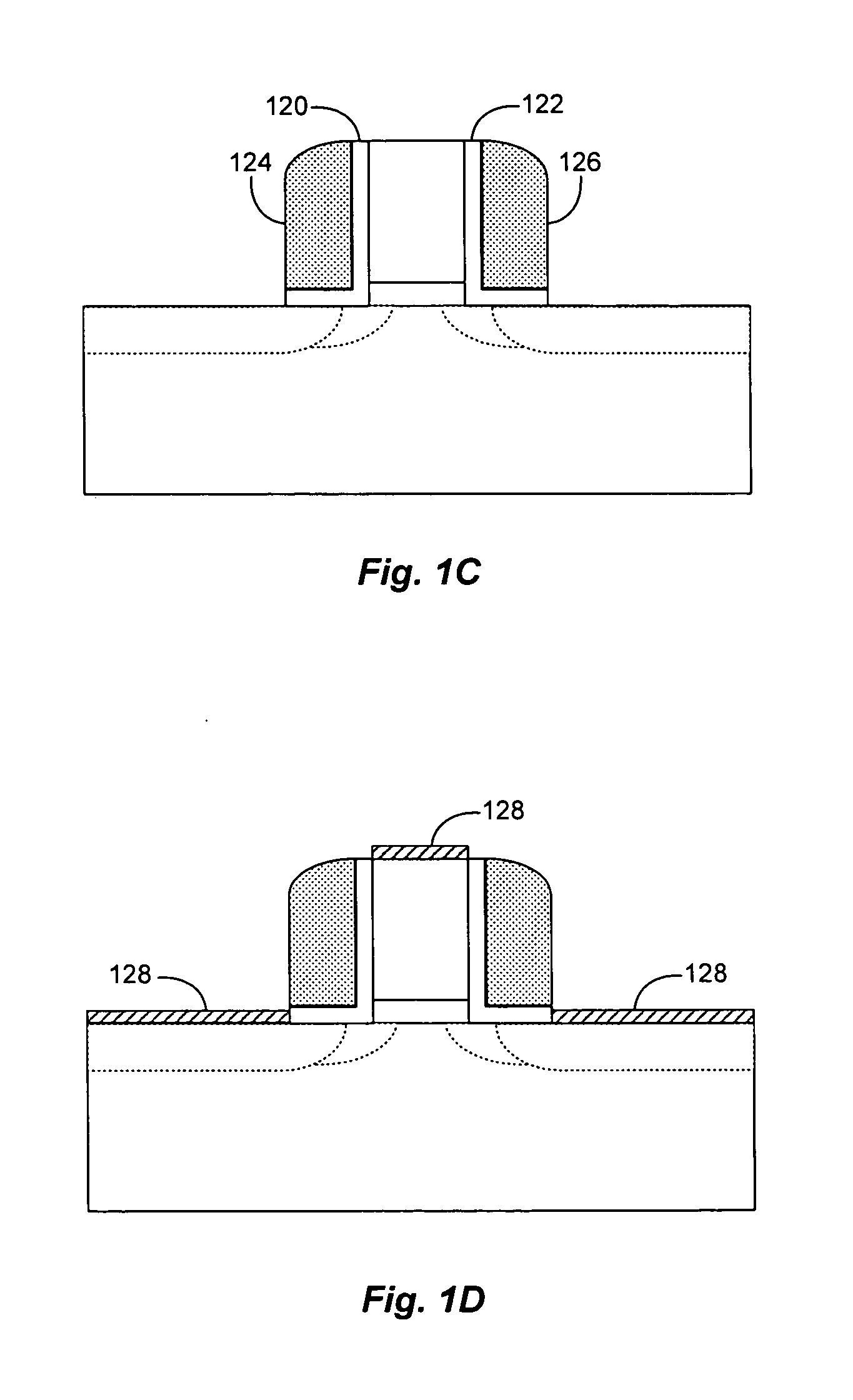

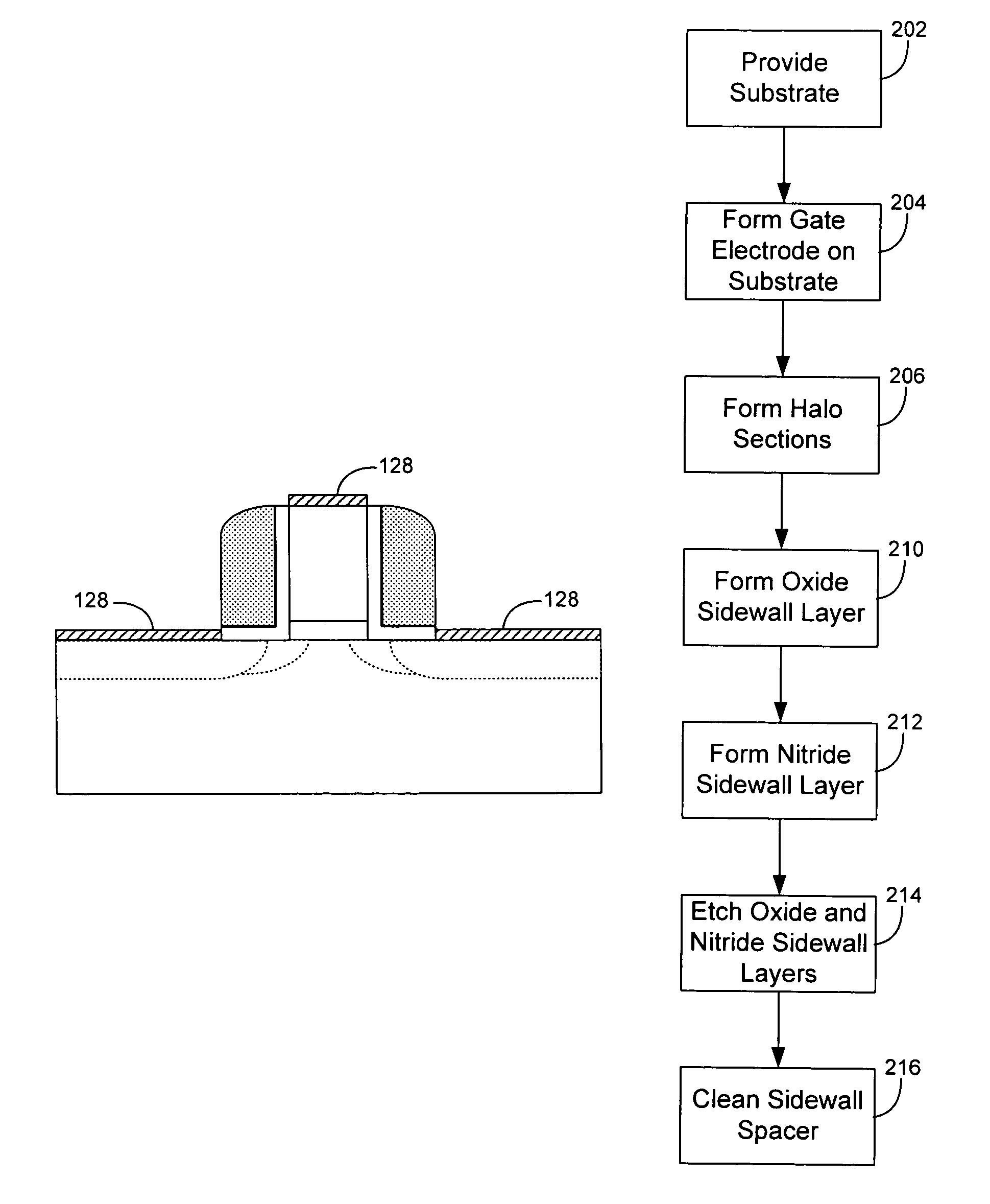

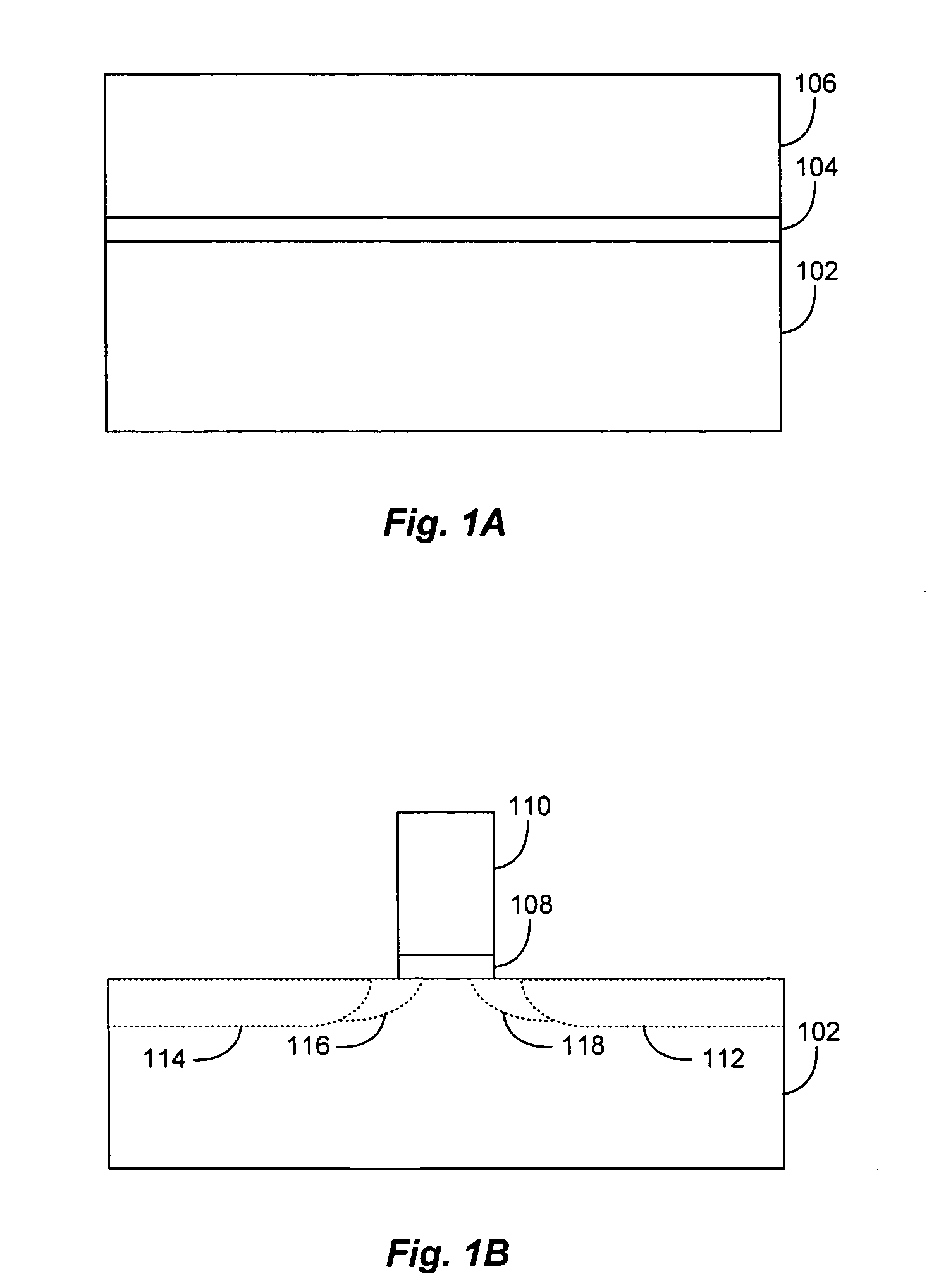

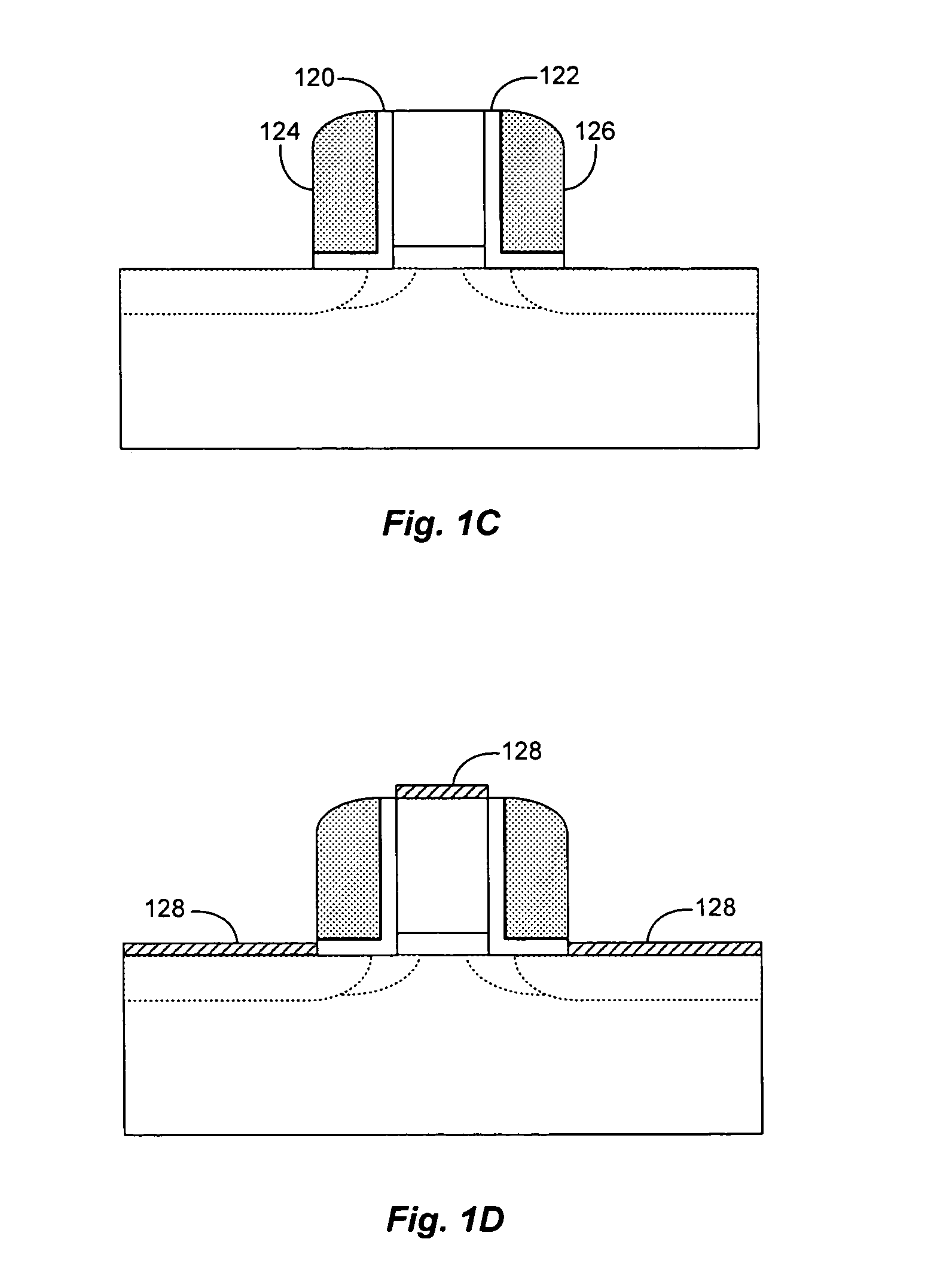

Method for forming a low thermal budget spacer

InactiveUS20050266622A1Semiconductor/solid-state device manufacturingSemiconductor devicesSilanesNitride

A method of forming a sidewall spacer on a gate electrode of a metal oxide semiconductor device that includes striking a first plasma to form an oxide layer on a side of the gate electrode, where the first plasma is generated from a oxide gas that includes O3 and bis-(tertiarybutylamine)silane, and striking a second plasma to form a carbon-doped nitride layer on the oxide layer, where the second plasma may be generated from a nitride gas that includes NH3 and the bis-(tertiarybutylamine)silane. The first and second plasmas may be formed using plasma CVD and the bis-(tertiarybutylamine)silane flows uninterrupted between the striking of the first plasma and the striking of the second plasma.

Owner:APPLIED MATERIALS INC

Method for forming a low thermal budget spacer

InactiveUS7049200B2Semiconductor/solid-state device manufacturingSemiconductor devicesSilanesNitride

A method of forming a sidewall spacer on a gate electrode of a metal oxide semiconductor device that includes striking a first plasma to form an oxide layer on a side of the gate electrode, where the first plasma is generated from a oxide gas that includes O3 and bis-(tertiarybutylamine)silane, and striking a second plasma to form a carbon-doped nitride layer on the oxide layer, where the second plasma may be generated from a nitride gas that includes NH3 and the bis-(tertiarybutylamine)silane. The first and second plasmas may be formed using plasma CVD and the bis-(tertiarybutylamine)silane flows uninterrupted between the striking of the first plasma and the striking of the second plasma.

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com