Patents

Literature

1411 results about "Silylene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silylenes are chemical compounds containing a divalent silicon atom without any electrical charge. Both dicoordinate and tricoordinate silylenes are reported in the literature. They are considered to be heavier analogues of carbene. In earlier times, they were called silene, but this is a mistake, as that term means compounds of π-bonded silicon: Si=C. The generic term analogous to carbene is "silicene."

Precursor source mixtures

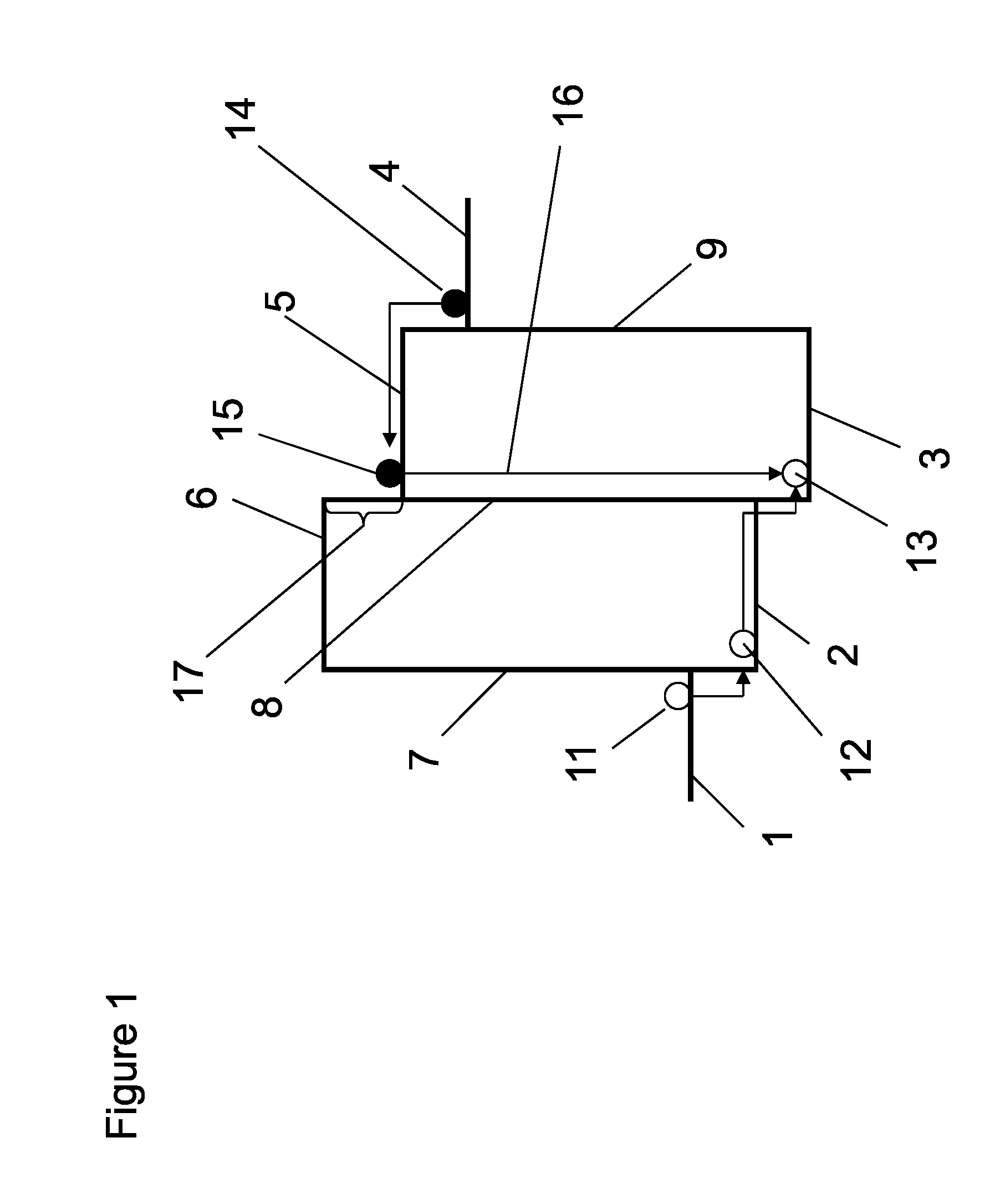

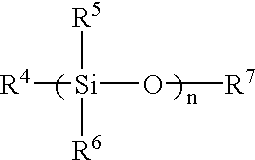

A precursor source mixture useful for CVD or ALD of a film comprising: at least one precursor composed of an element selected from the group consisting of Li, Na, K, Rb, Cs, Fr, Be, Mg, Ti, Zr, Hf, Sc, Y, La, V, Nb, Ta, Cr, Mo, W, Mn, Re, Fe, Ru, Os, Co, Rh, Ir, Ni, Pd, Pt, Cu, Ag, Au, Zn, Cd, Hg, B, Al, Ga, In, Tl, Si, Ge, Sn, Pb, As, P, Sb and Bi, to which is bound at least one ligand selected from the group consisting of hydride, alkyl, alkenyl, cycloalkenyl, aryl, alkyne, carbonyl, amido, imido, hydrazido, phosphido, nitrosyl, nitryl, nitrate, nitrile, halide, azide, alkoxy, siloxy, silyl, and halogenated, sulfonated or silyated derivatives thereof, which is dissolved, emulsified or suspended in an inert liquid selected from the group consisting of aliphatic hydrocarbons, aromatic hydrocarbons, alcohols, ethers, aldehydes, ketones, acids, phenols, esters, amines, alkylnitrile, halogenated hydrocarbons, silyated hydrocarbons, thioethers, amines, cyanates, isocyanates, thiocyanates, silicone oils, nitroalkyl, alkylnitrate, and mixtures thereof. The precursor source mixture may be a solution, emulsion or suspension and may consist of a mixture of solid, liquid and gas phases which are distributed throughout the mixture.

Owner:GLOBALFOUNDRIES INC

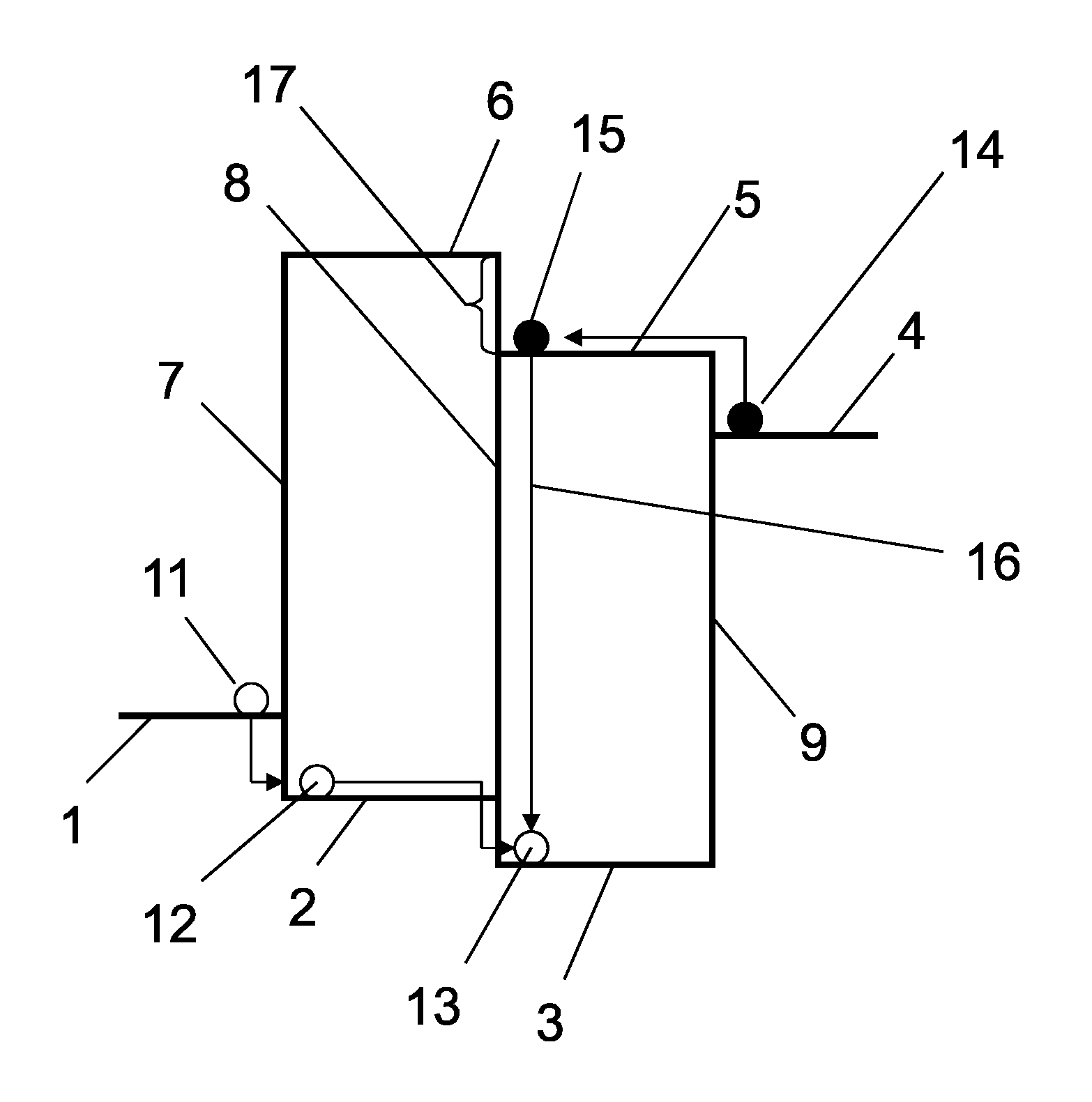

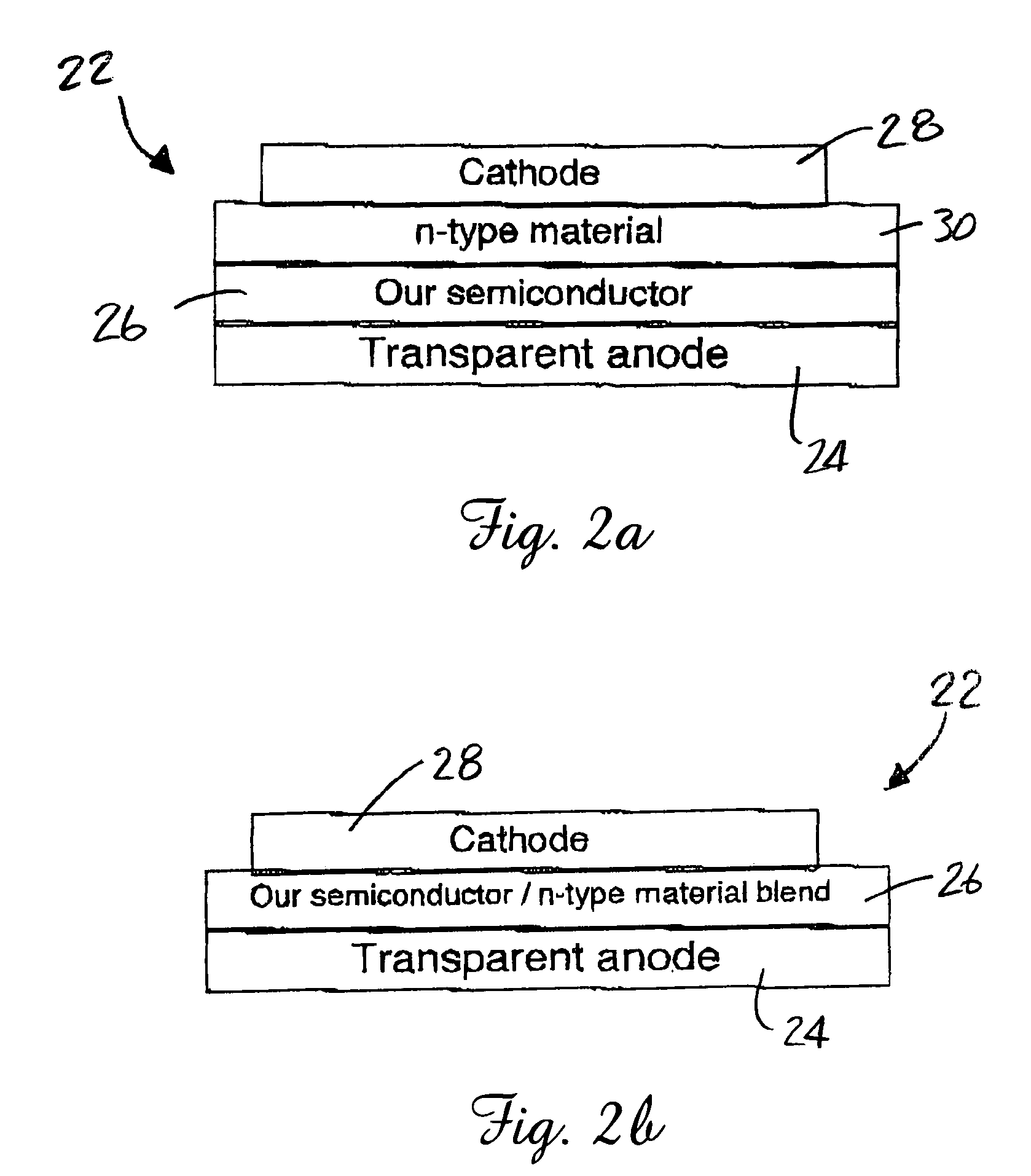

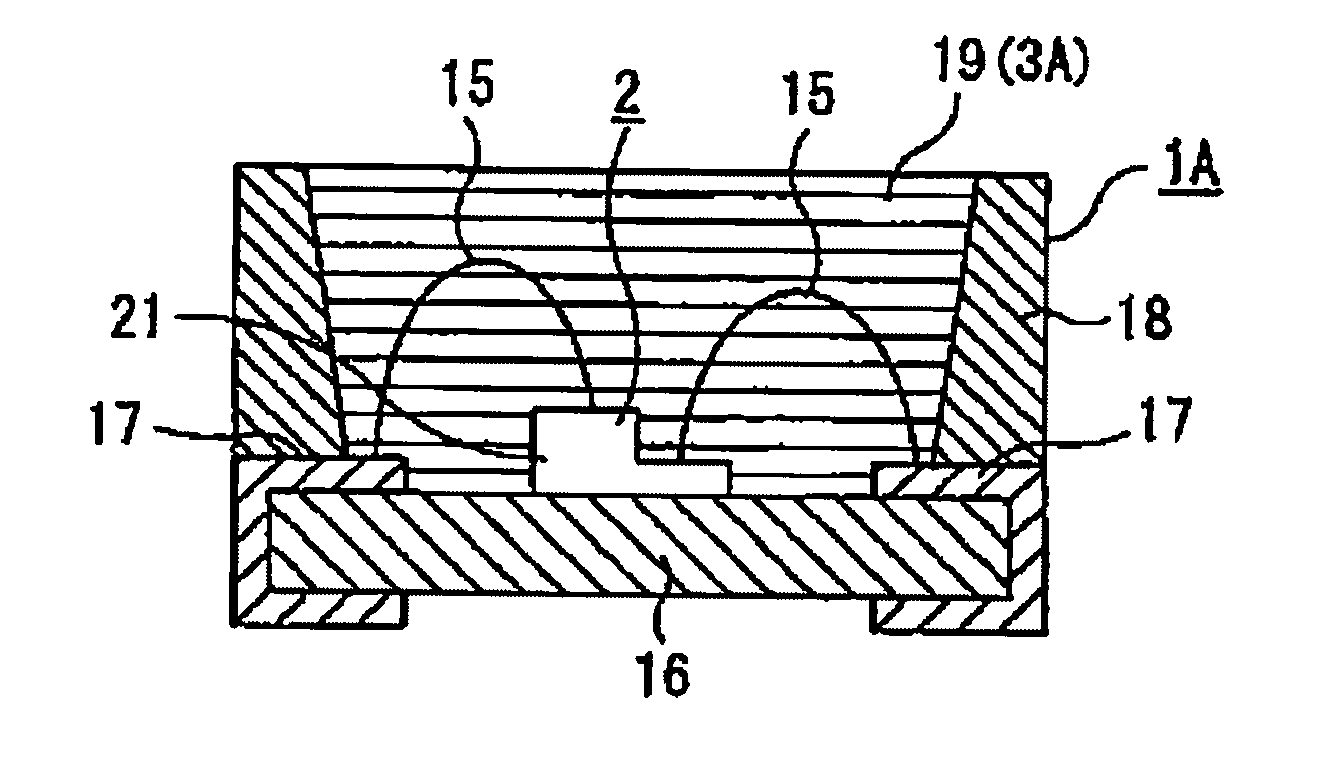

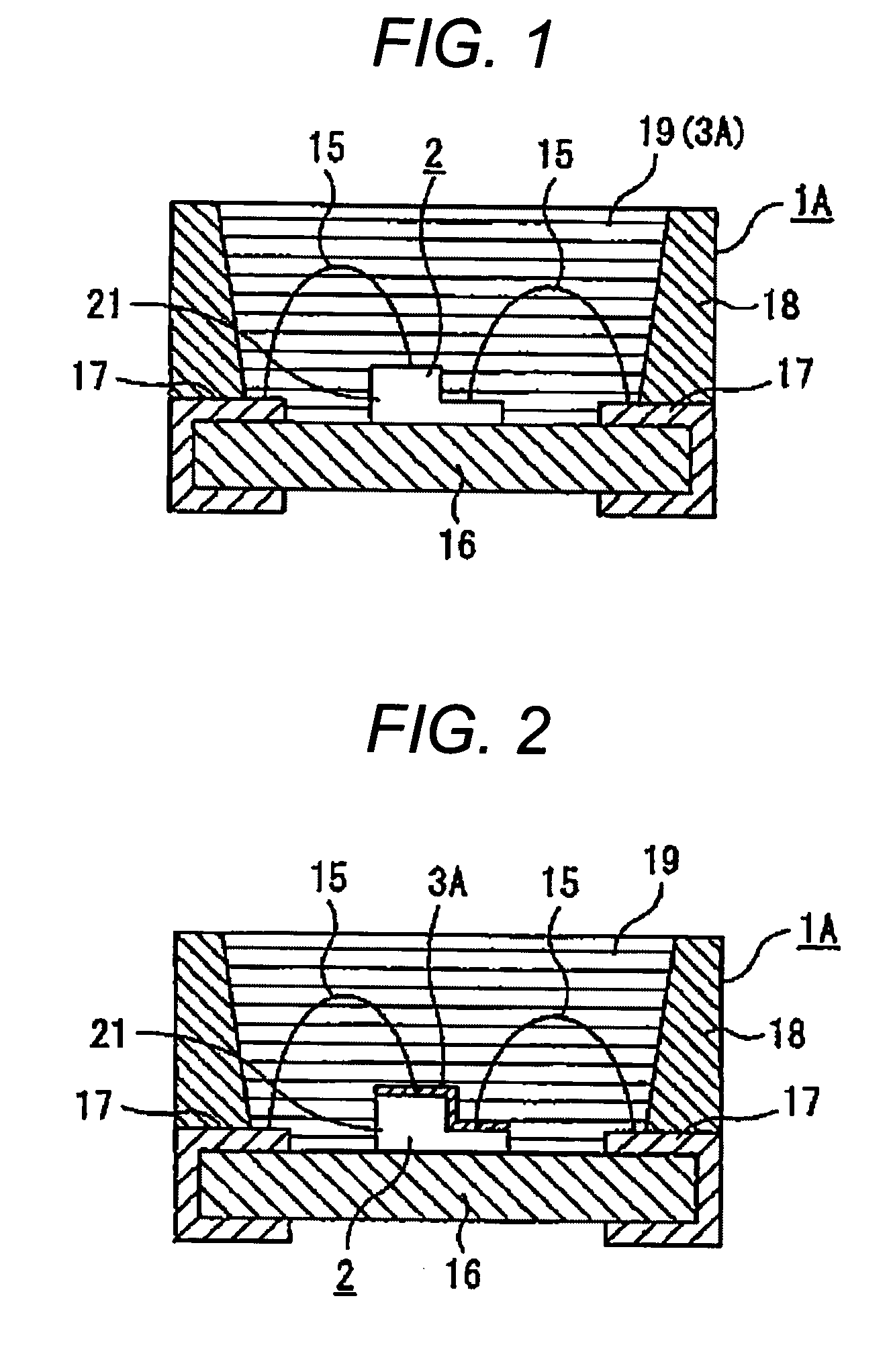

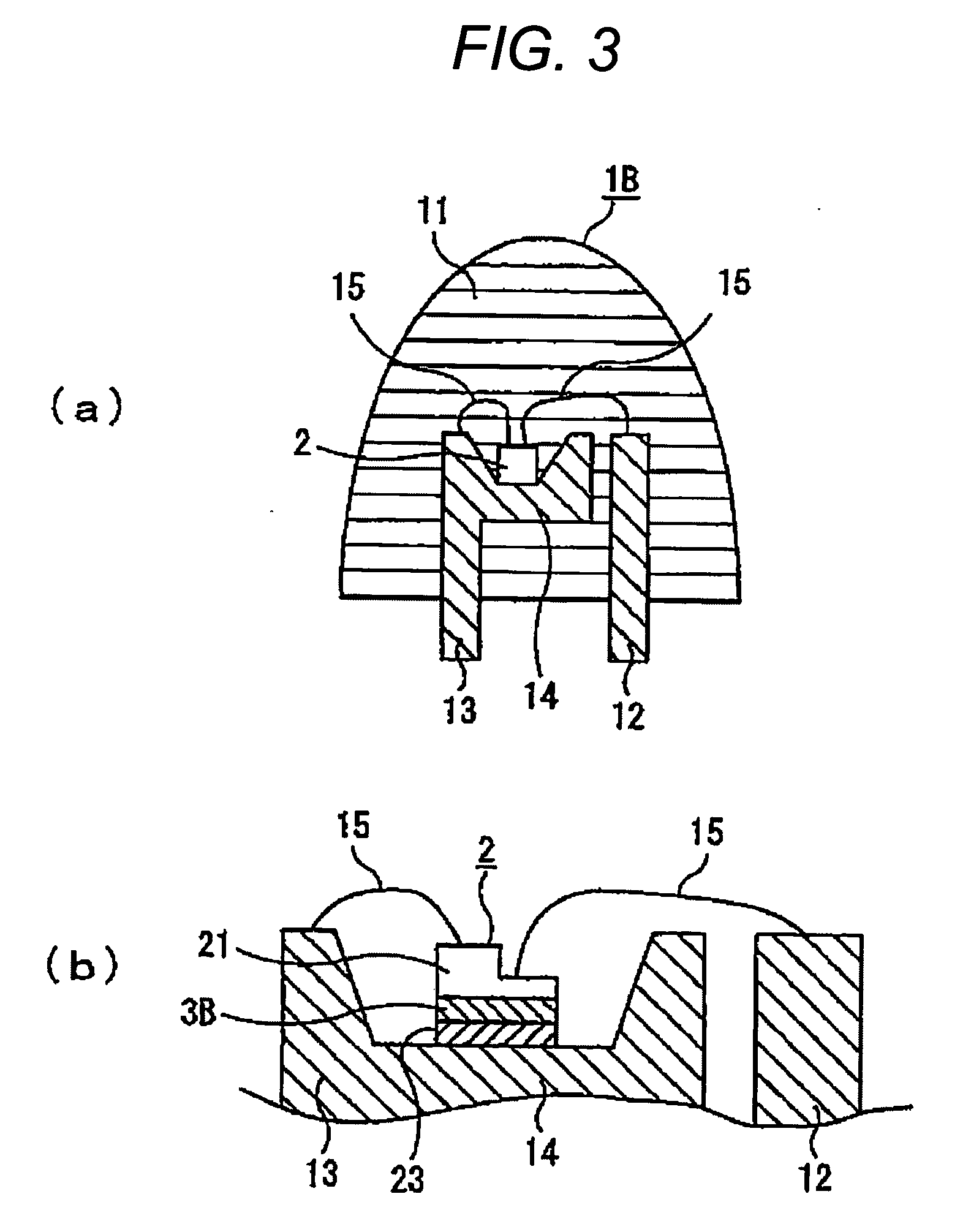

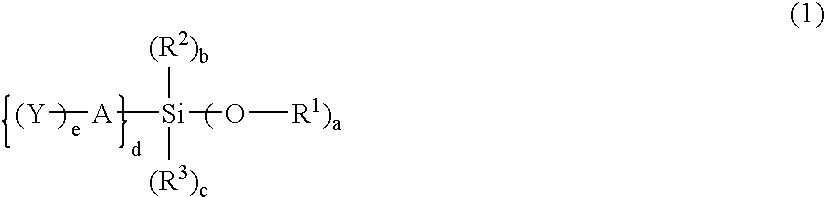

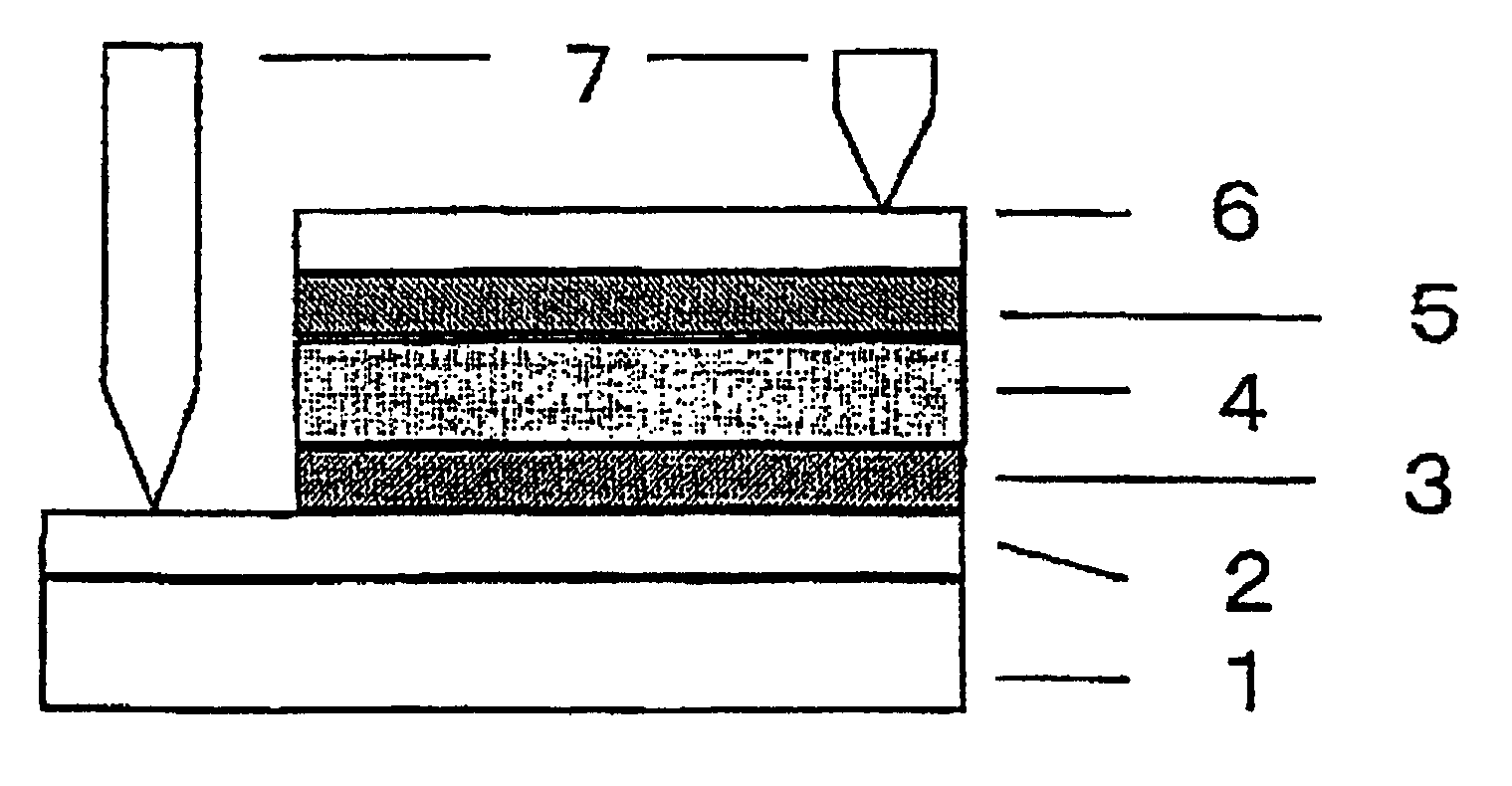

Light emitting element

InactiveUS20130105787A1Improve light emission efficiencySufficient durability lifeOrganic chemistrySolid-state devicesSilyleneAlkaline earth metal

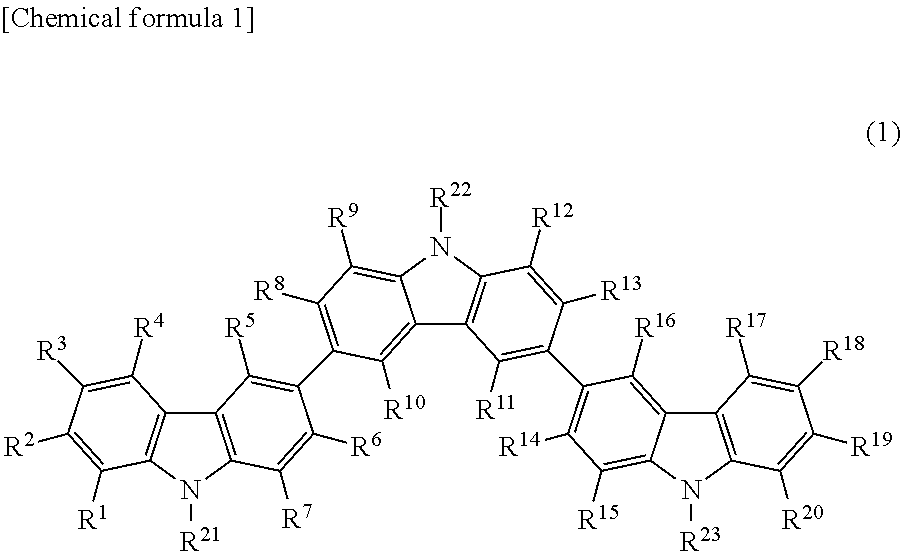

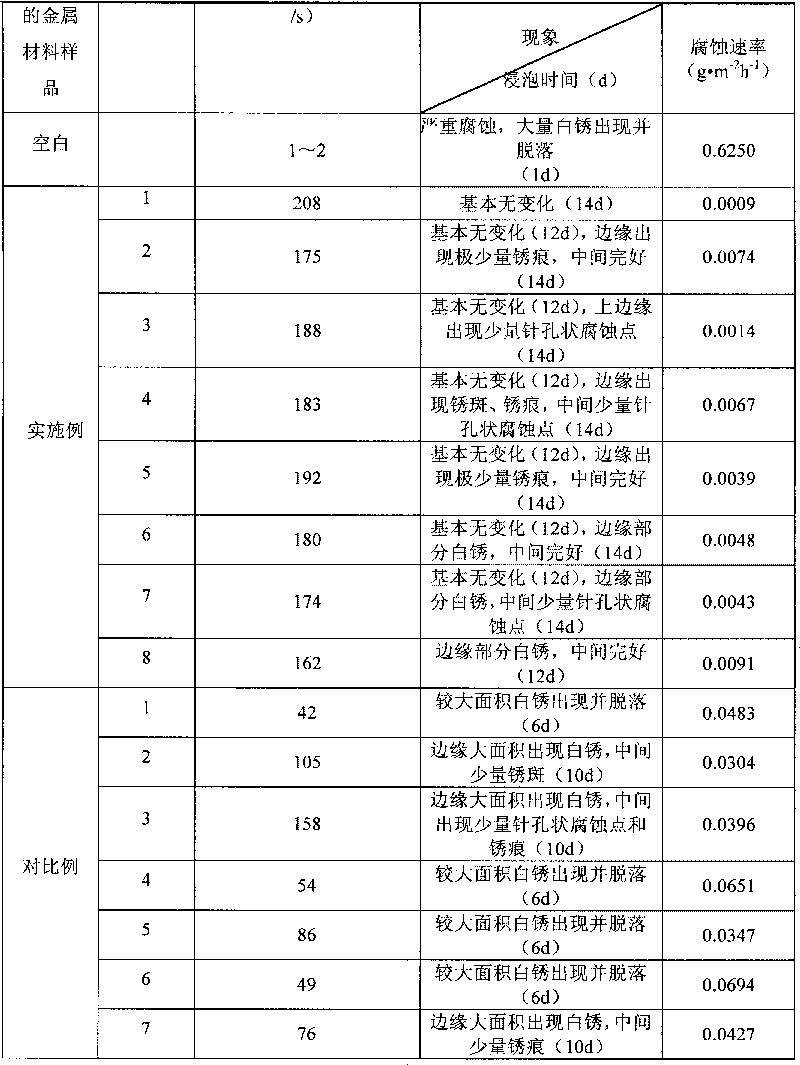

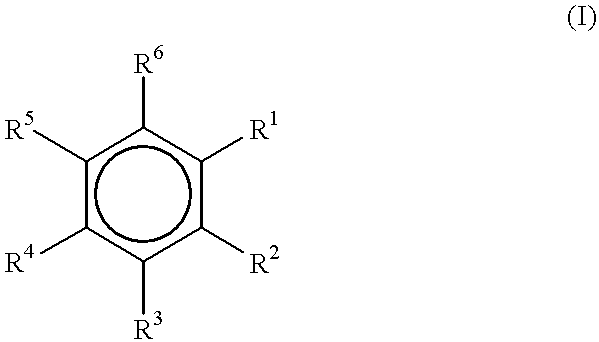

Provided is an organic thin film light emitting element which has achieved all of improved luminous efficiency, improved driving voltage and improved durability life. Specifically provided is a light emitting element which comprises a hole transport layer and an electron transport layer between a positive electrode and a negative electrode and emits light by means of electrical energy. The light emitting element is characterized in that: the hole transport layer of the light emitting element contains a compound represented by general formula (1); the electron transport layer contains a donor compound; and the donor compound is an alkali metal, an inorganic salt containing an alkali metal, a complex of an alkali metal and an organic substance, an alkaline earth metal, an inorganic salt containing an alkaline earth metal, or a complex of an alkaline earth metal and an organic substance. (In the formula, R1-R20 each represents one group selected from the group consisting of hydrogen, deuterium, an alkyl group, a cycloalkyl group, an amino group, an aryl group, a heterocyclic group, a heteroaryl group, an alkenyl group, a cycloalkenyl group, an alkynyl group, analkoxy group, an alkylthio group, an arylether group, an arylthioether group, a halogen, a cyano group, a —P(═O)R24R25 group and a silyl group; R24 and R25 each represents an aryl group or a heteroaryl group; and these substituents may be further substituted, or adjacent two substituents may combine together to form a ring. Meanwhile, R21-R23 may be the same or different and each represents one group selected from the group consisting of an alkyl group, a cycloalkyl group, an aryl group and a heteroaryl group; and these substituents maybe further substituted.)

Owner:TORAY IND INC

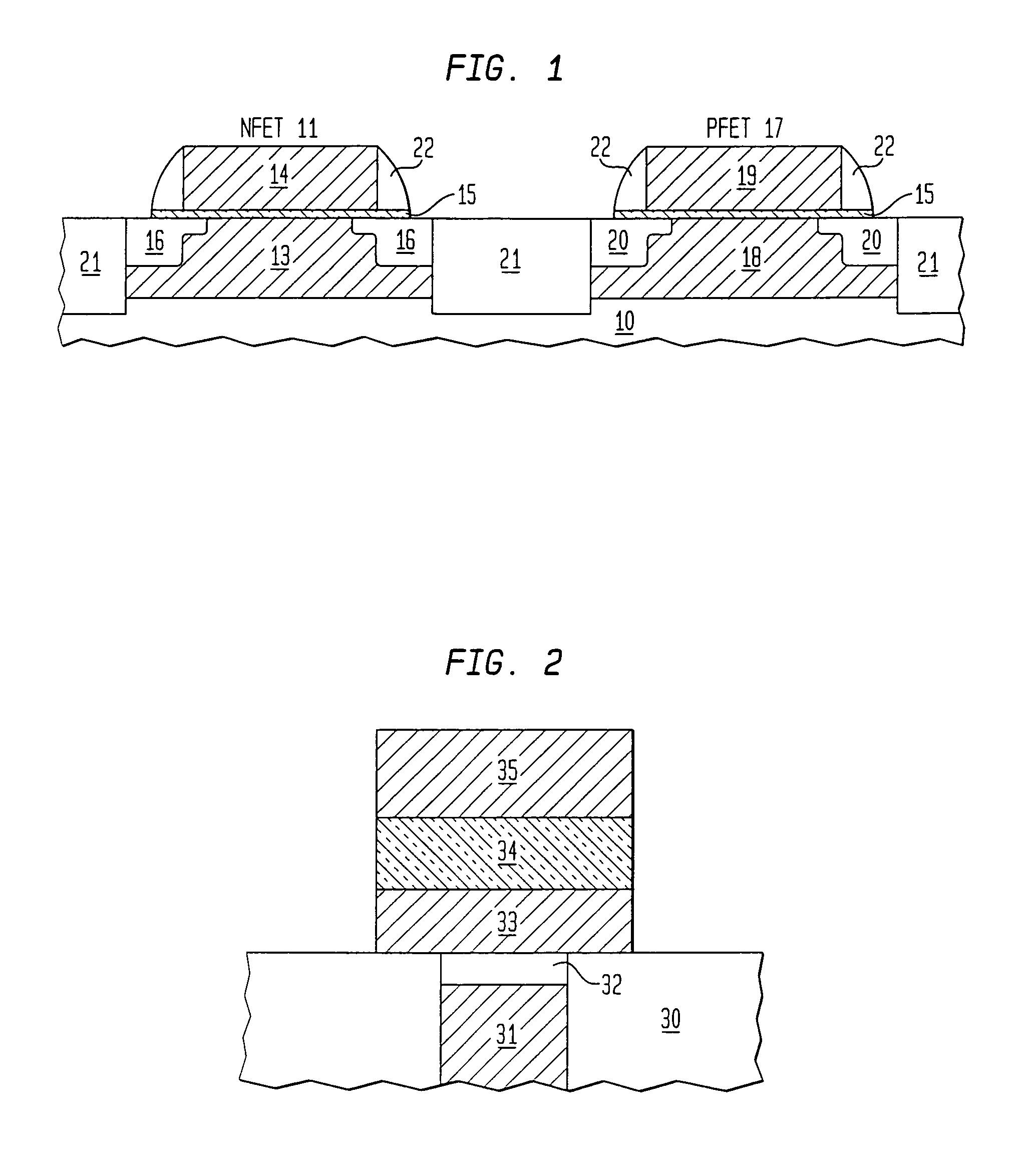

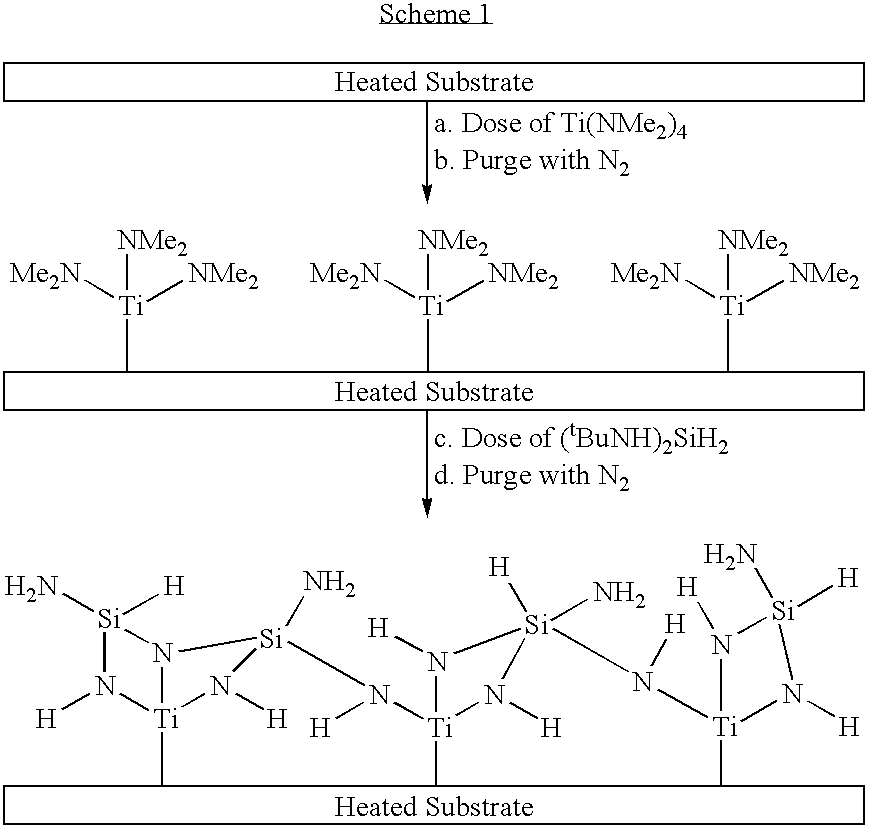

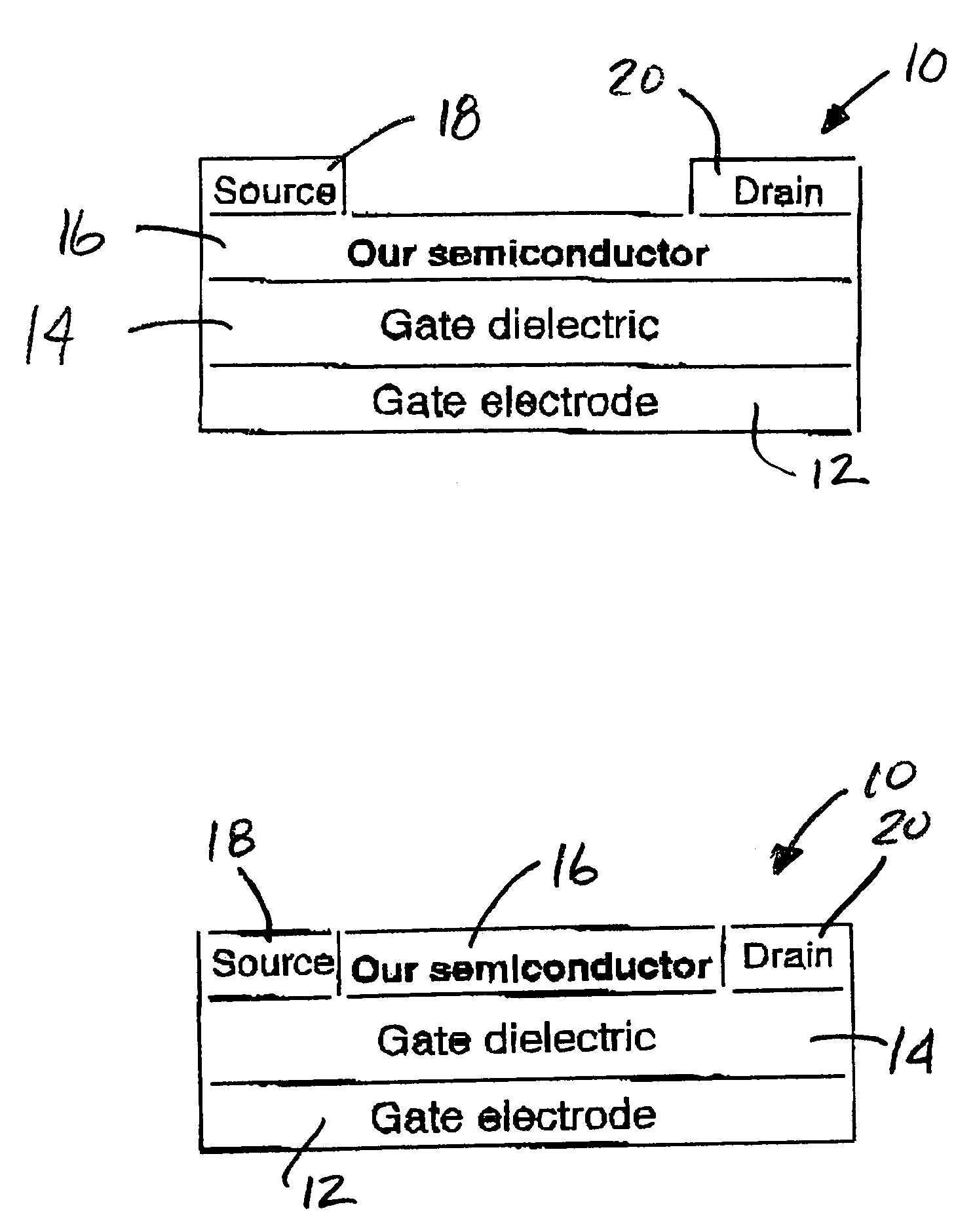

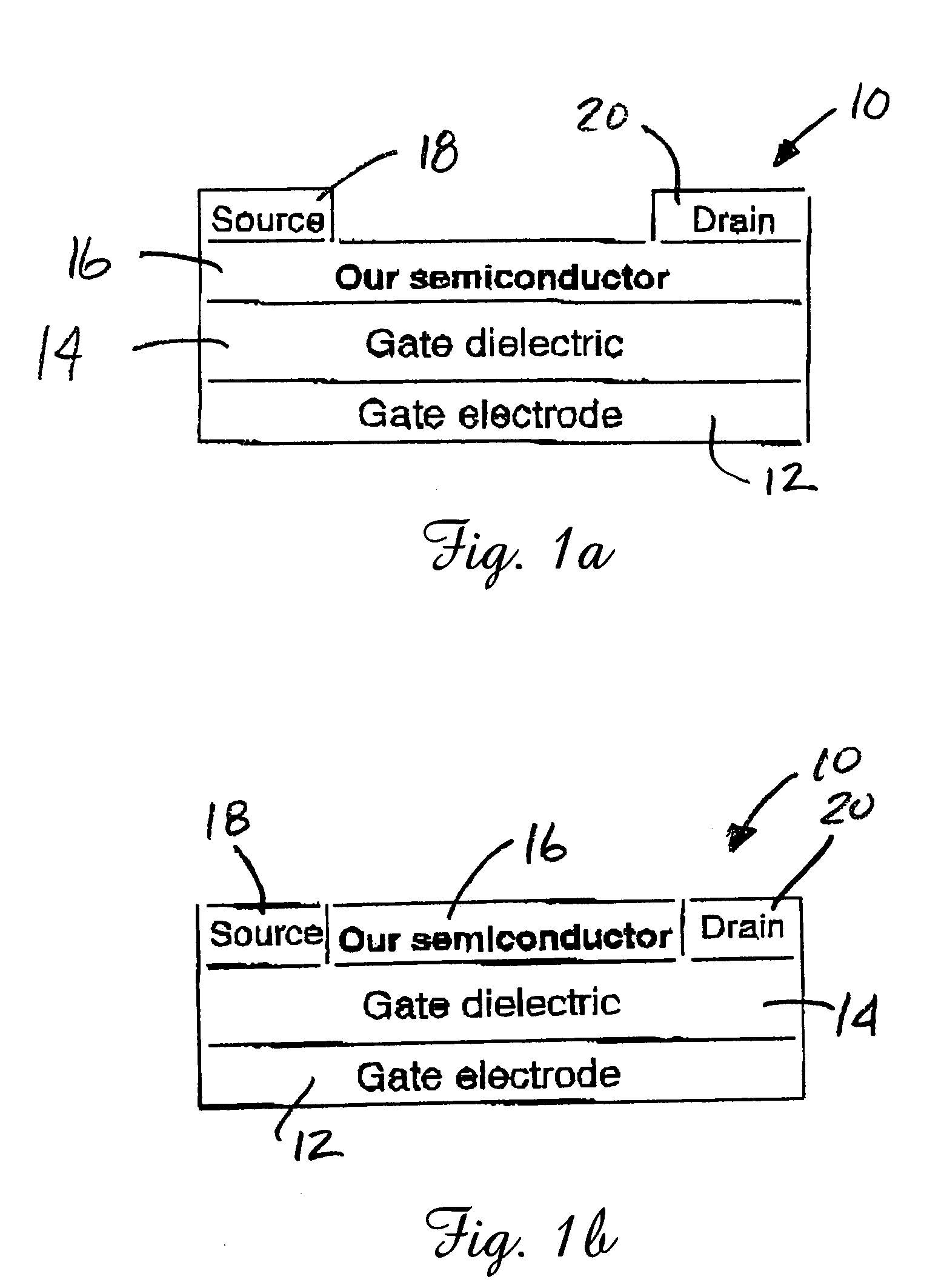

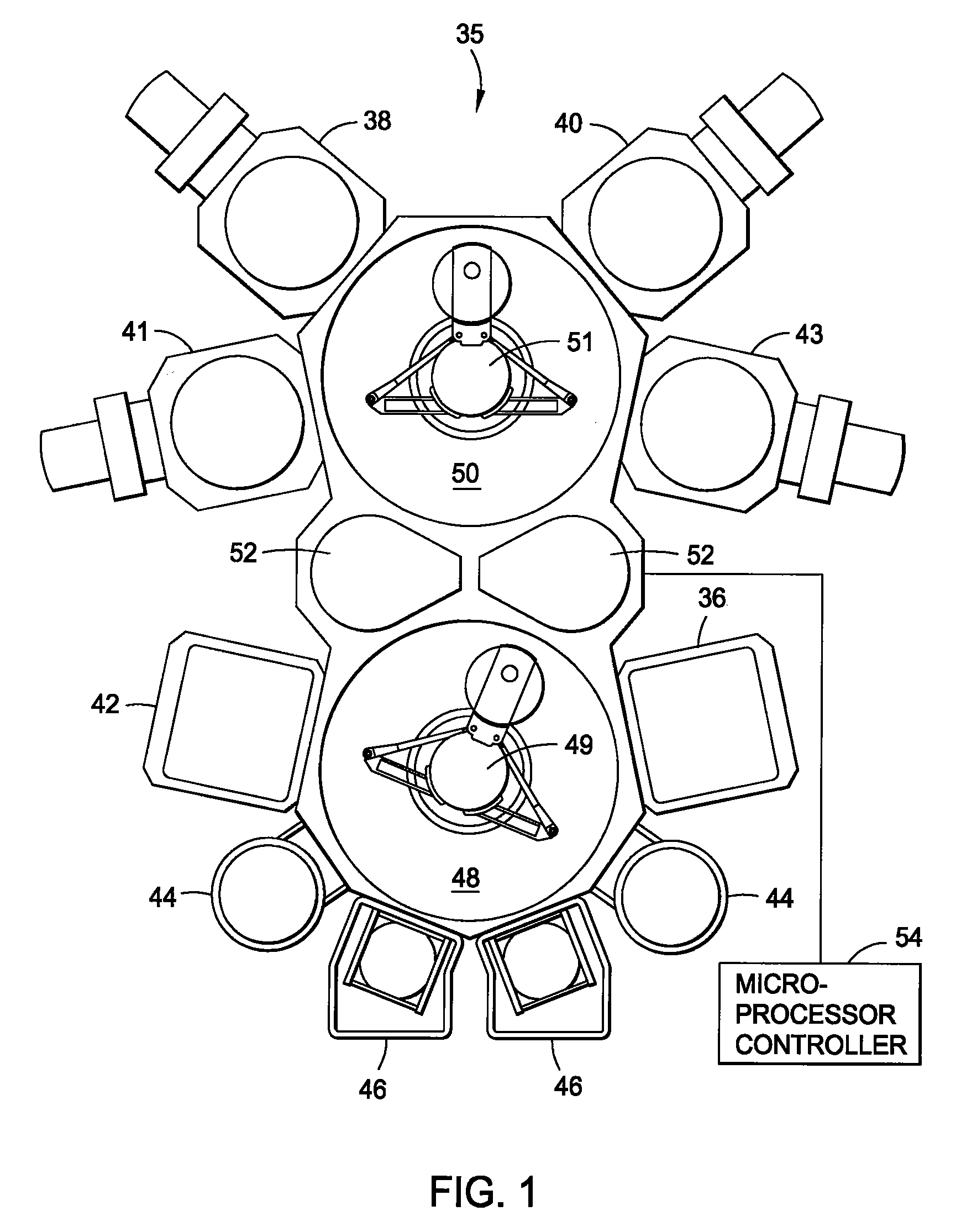

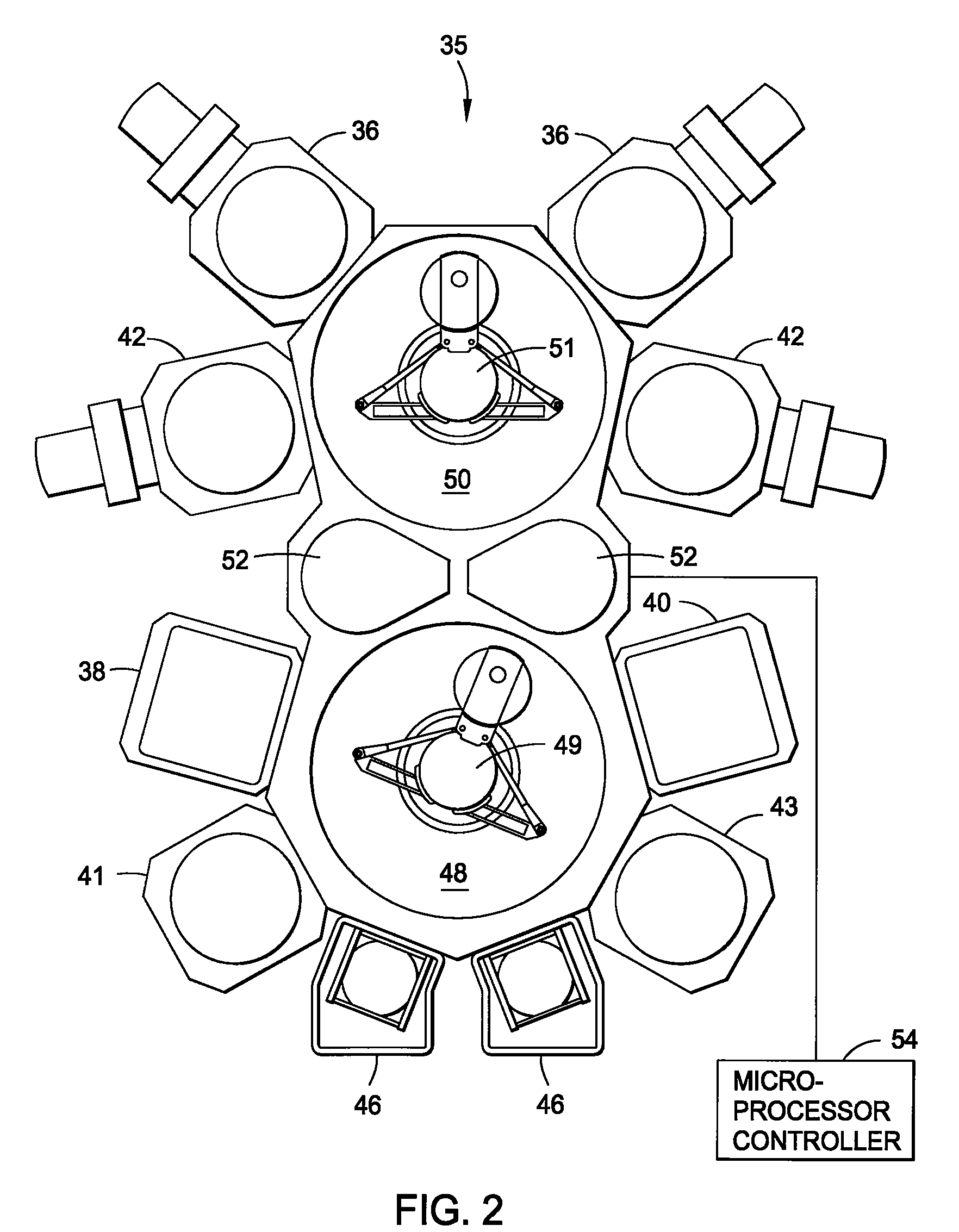

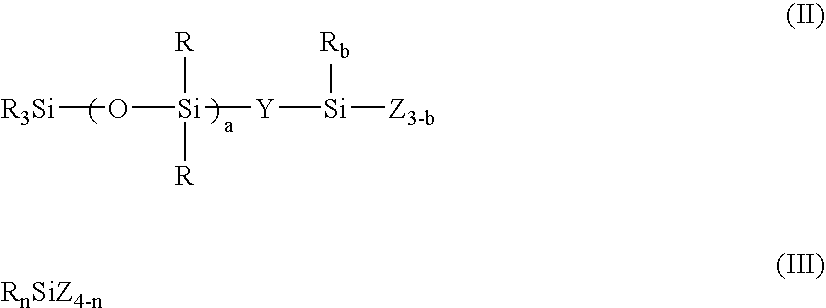

Preparation of metal silicon nitride films via cyclic deposition

InactiveUS20060182885A1Quality improvementProcess safetyLighting support devicesSemiconductor/solid-state device manufacturingSilyleneSilanes

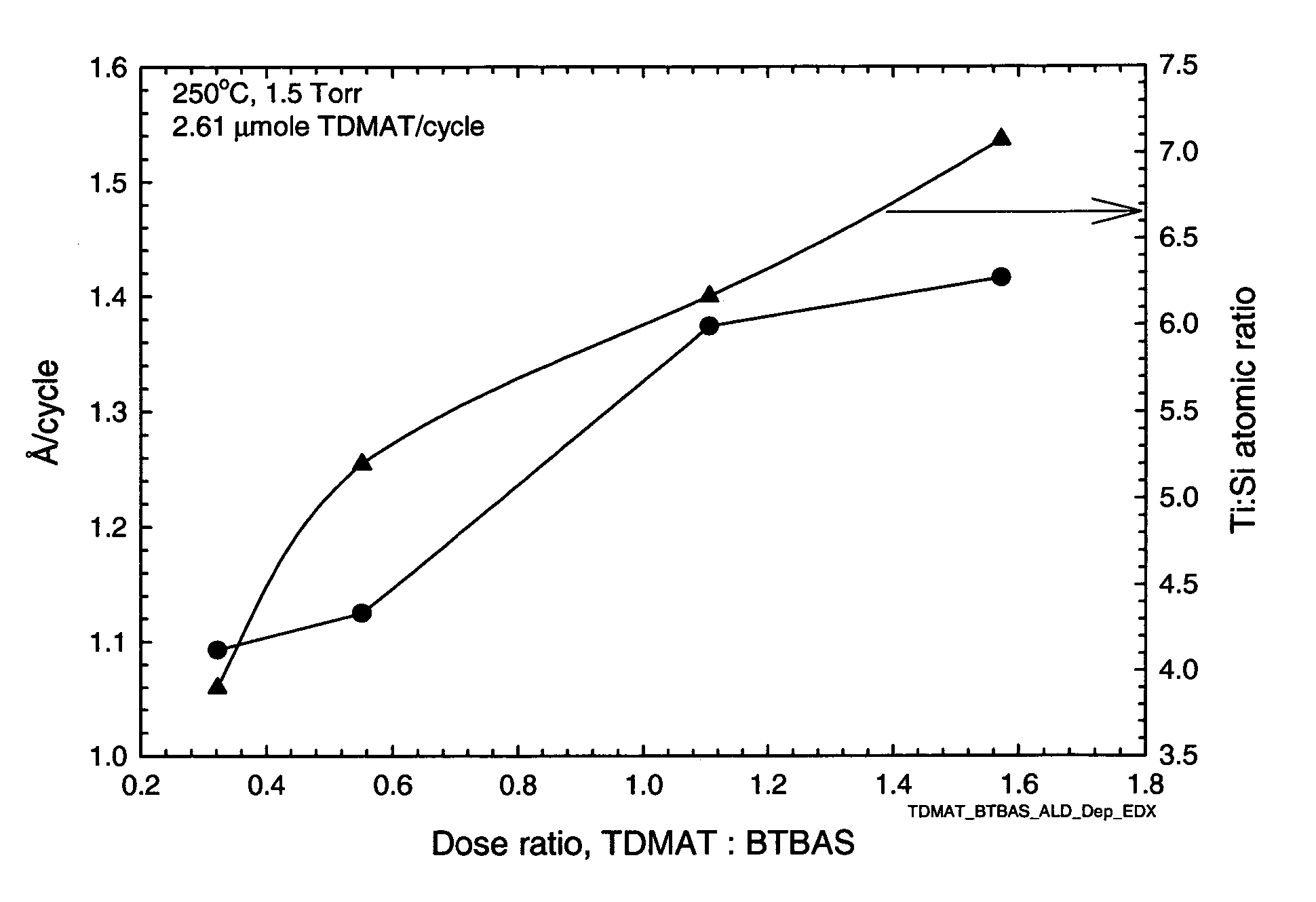

This invention relates to an improved process for producing ternary metal silicon nitride films by the cyclic deposition of the precursors. The improvement resides in the use of a metal amide and a silicon source having both NH and SiH functionality as the precursors leading to the formation of such metal-SiN films. The precursors are applied sequentially via cyclic deposition onto the surface of a substrate. Exemplary silicon sources are monoalkylamino silanes and hydrazinosilanes represented by the formulas: (R1NH)nSiR2mH4-n-m (n=1,2; m=0,1,2; n+m=<3); and (R32N—NH)xSiR4yH4-x-y (x=1,2; y=0,1,2; x+y=<3) wherein in the above formula R1-4 are same or different and independently selected from the group consisting of alkyl, vinyl, allyl, phenyl, cyclic alkyl, fluoroalkyl, silylalkyls.

Owner:VERSUM MATERIALS US LLC

Silylethynylated heteroacenes and electronic devices made therewith

Owner:UNIV OF KENTUCKY RES FOUND

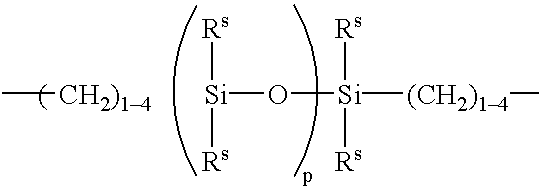

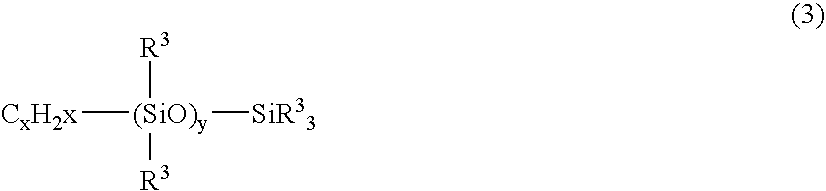

Hydrogel from polysiloxane-containing urethane prepolymer, tris (trimethylsiloxy) silylpropyl methacrylate, and a hydrophilic comonomer

A polyurethane based prepolymer is provided and useful in biomedical devices which provides high oxygen permeability and superior physical properties. A hydrogel is produced from a comonomer mixture containing a polysiloxane-containing urethane prepolymer, tris(trimethylsiloxy)-silylpropyl methacrylate and a hydrophilic comonomer. The hydrogel is especially useful for biomedical materials such as contact lenses and implants.

Owner:BAUSCH & LOMB INC

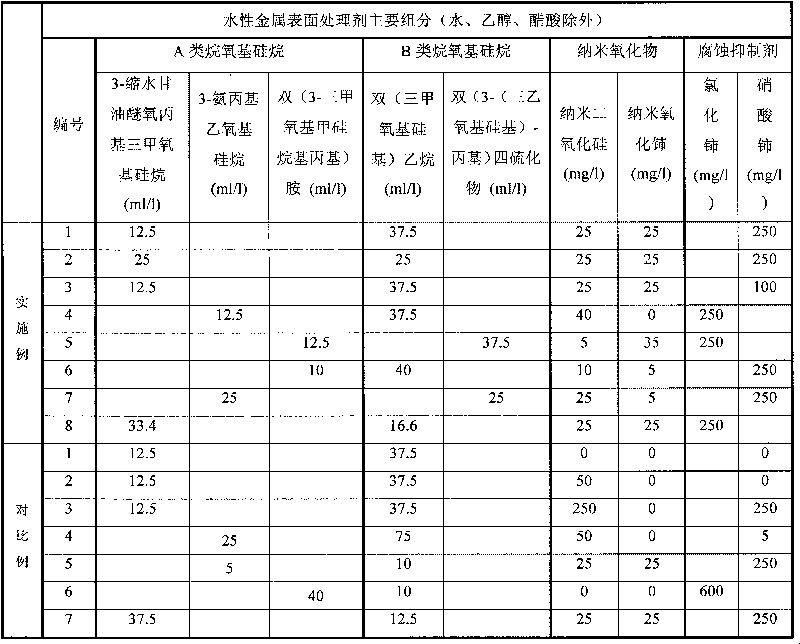

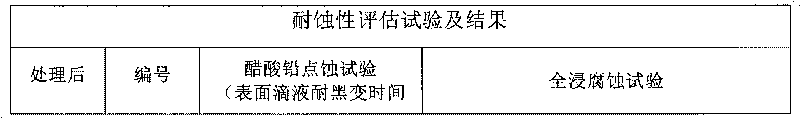

Environment-friendly nano water-based silane treatment agent capable of improving anti-corrosion performance of metal surface

ActiveCN101717930ASimple processApplicable industrial scaleMetallic material coating processesWater basedEpoxy

The invention discloses an environment-friendly nano water-based silane treatment agent capable of improving anti-corrosion performance of metal surface. The treatment agent is water-based silane solution which consists of at least one alkoxy silane containing epoxy or at least one alkoxy silane containing amino, at least one disilyl silane, nano-silicon dioxide, rare earth salt type corrosion inhibitor or rare earth salt type and rare earth nano oxide, water, or acetic acid and a small amount of ethanol. The metal material is coated by using the silane solution for impregnation, brushing, spraying or spin-coating, a siloxane layer is formed on the metal surface, then the long-acting corrosion resistance is formed by curing for 3 hours at the temperature of 100 DEG C, and a nano organic silane film which has close bonding force with a coating is formed. Nanoparticles can not only improve the corrosion resistance and enhance the mechanical strength of the silane film in a coating layer, but also realize the synergistic corrosion resistance with the corrosion inhibitor. The technology has the advantages of simple process, greenness, environmental protection and strong practicality.

Owner:HAISO TECH

Polysiloxane composition

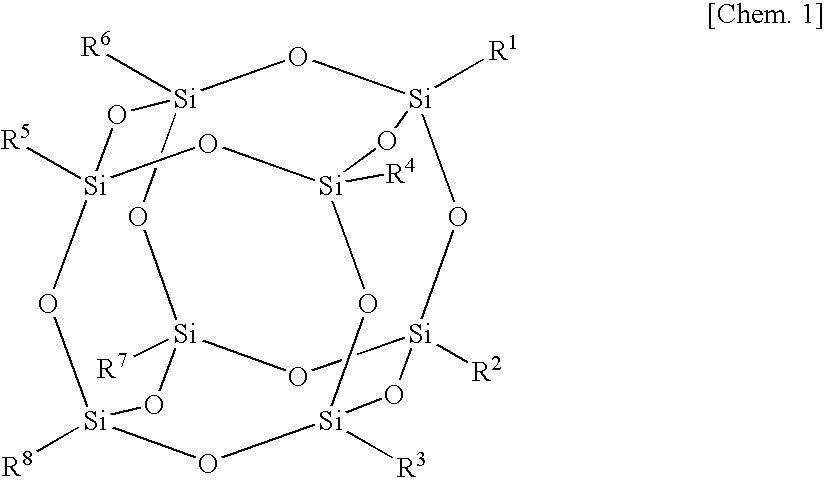

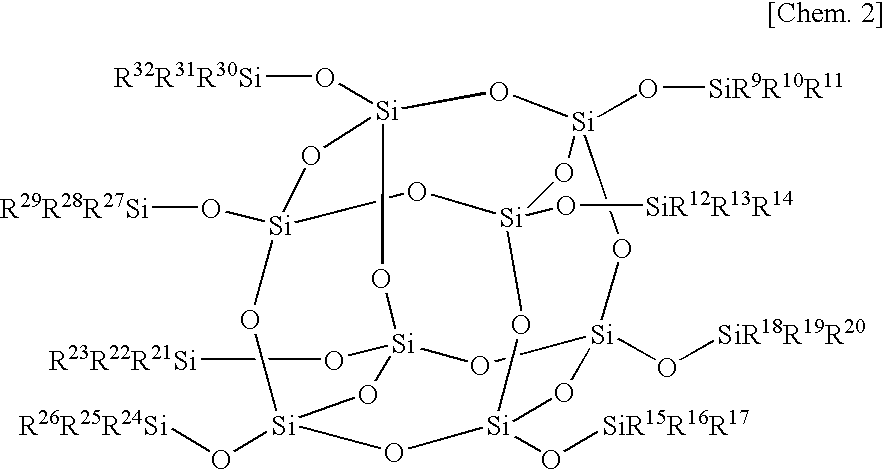

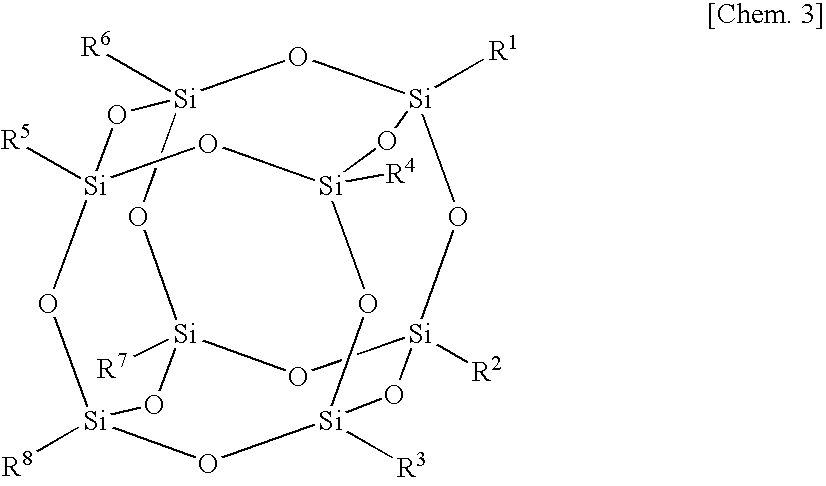

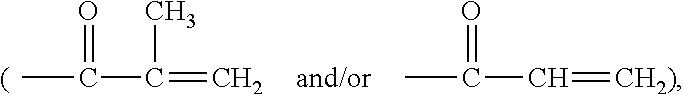

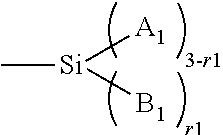

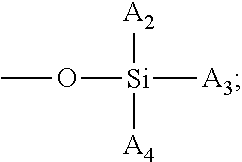

ActiveUS20100063221A1High transparencyImprove heat resistanceCoatingsOptical elementsSilyleneHeat resistance

A polysiloxane composition having high transparency, while being excellent in heat resistance and light resistance is provided.A polysiloxane composition is composed of (A) a polysiloxane which is a polysiloxane compound having a polyhedral skeleton having 6 to 24 silicon atoms in its molecule and which has at least one group containing a hydrolyzable silyl group bonded to a Si atom constituting the polyhedral skeleton, and (B) a photoacid generator. The hydrolyzable silyl group is preferably an alkoxysilyl group.

Owner:KANEKA CORP

Amphiphilic siloxane-containing (meth)acrylamides and uses thereof

The invention provides an amphiphilic siloxane-containing (meth)acrylamide which comprises one sole (meth)acrylamido group, one sole tris(trimethylsiloxy)silyl group, and one polyethylene glycol segment which is either dangling polymer chain or a hydrophilic linker between the (meth)acrylamido group and the tris(trimethylsiloxy)silyl group. The present invention is also related to a polymer, an actinically-crosslinkable silicone-containing prepolymer, a silicone hydrogel polymeric material, or a silicone hydrogel contact lens, which comprises monomeric units derived from an amphiphilic siloxane-containing (meth)acrylamido group, one tris(trimethylsiloxy)silyl group of the invention. In addition, the invention provides a method for making silicone hydrogel contact lenses using a water-based lens-forming formulation comprising an amphiphilic siloxane-containing (meth)acrylamido group, one tris(trimethylsiloxy)silyl group of the invention and / or an actinically-crosslinkable silicone-containing prepolymer of the invention.

Owner:ALCON INC

Curable resin composition

The object of the present invention is to provide a novel acrylic-modified silyl-terminated polyether resin composition which is advantageous not only in terms of the availability of raw materials and the ease of synthetic reaction, but also in fast-curing, good storage stability, good weatherability, high adhesiveness, thus promising high potentials of industrial utilization. Further, the object of the present invention is also to develop an environment-friendly curable composition which is a major social consideration. The composition is a curable composition comprising an oxyalkylene polymer (A) containing silyl functional group capable of crosslinking by forming a siloxane bond and a copolymer (B) having a molecular chain comprising alkyl acrylate and / or alkyl methacrylate monomer units and containing silyl functional group capable of crosslinking by forming a siloxane bond, said copolymer (B) having both dialkoxysilyl and trialkoxysilyl groups as said silyl functional group.

Owner:KANEKA CORP

2′-silyl containing thiocarbonate protecting groups for RNA synthesis

ActiveUS7999087B2Avoid lostEfficient couplingSugar derivativesBulk chemical productionSilyleneProtecting group

Nucleoside monomers, nucleic acids, e.g., oligonucleotides and polynucleotides, methods of making each, methods of deprotecting each, and the like are disclosed herein. Aspects of the invention include 2′ silyl containing thiocarbonate protecting groups. Corresponding compositions and methods are provided.

Owner:UNIV OF COLORADO THE REGENTS OF +1

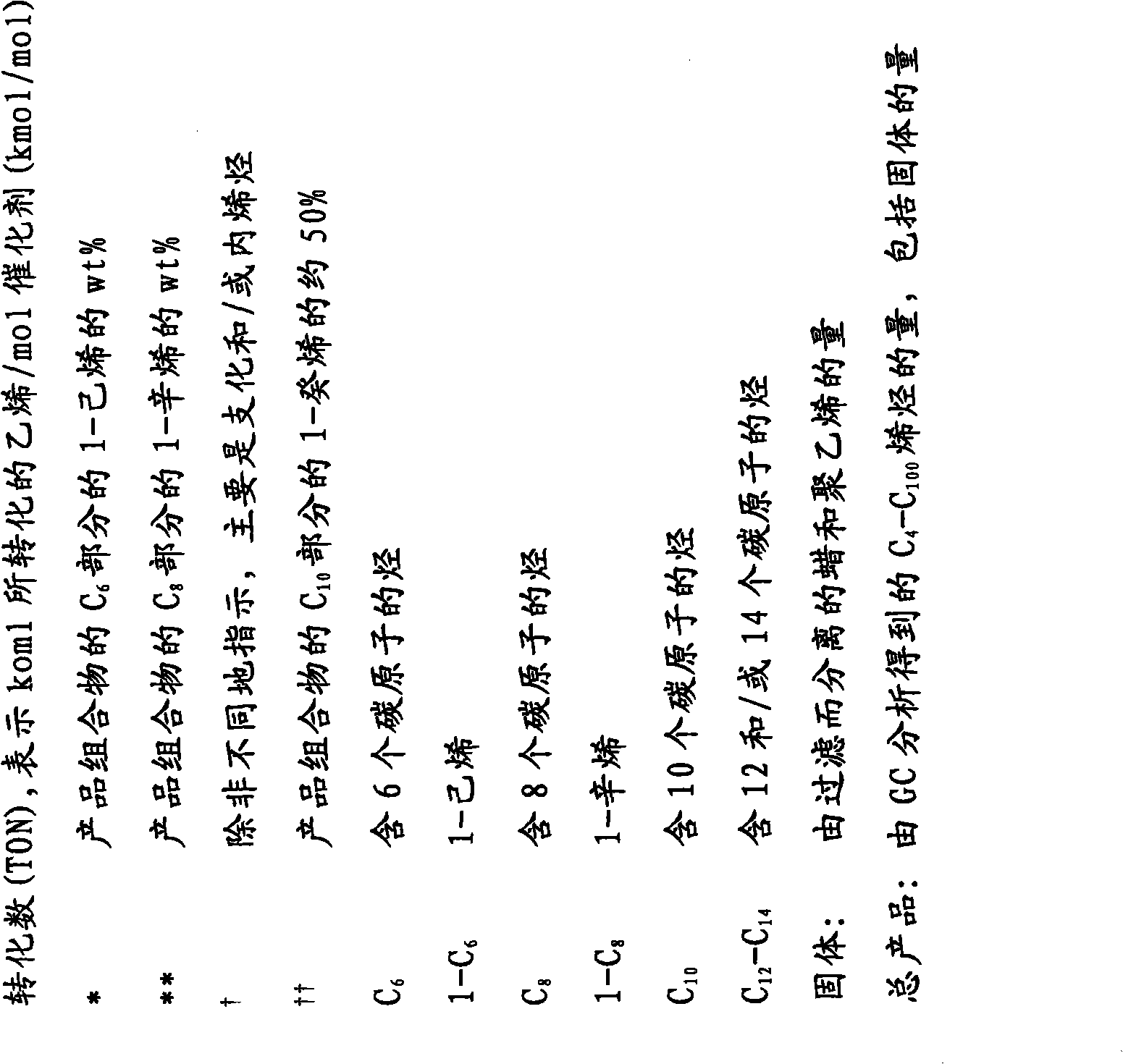

Catalytic process for the oligomerization of olefinic monomers

InactiveCN101351424AGroup 5/15 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsSilylene1-Octene

A process for the simultaneous trimerization and tetramerization of olefinic monomers , wherein the process comprises contacting at least one olefinic monomer with catalyst system comprising : a) a source of chromium, molybdenum or tungsten; b) a ligand having the general formula (I) ; (R<1>)2P-X-P (R<1>)m(R<2>)n wherein : X is a bridging group of the formula -N(R<3>)-, wherein R<3> is selected from hydrogen, a hydrocarbyl group, a substituted hydrocarbyl group, a heterohydrocarbyl group, a substituted heterohydrocarbyl group, a silyl group or derivative thereof; the R<1> groups are independently selected from an optionally substituted aromatic group bearing a polar substituent on at least one of the ortho-positions; and the R<2> groups are independently selected from hydrocarbyl, substituted hydrocarbyl, heterohydrocarbyl and substituted heterohydrocarbyl groups and c) a cocatalyst. The present invention further relates to a process for the simultaneous trimerization and tetramerization of ethylene to 1-hexene and 1-octene.

Owner:SHELL INT RES MAATSCHAPPIJ BV

Olefin block copolymers, processes for producing the same and uses thereof

Olefin block copolymers (A-1) are disclosed represented by the formula (I) PO1-g1-B1 . . . (I) wherein PO1 is a segment comprised of repeating units derived from an olefin having 2 to 20 carbon atoms, g1 is an ester, ether, amide, imide, urethane, urea, silylether or carbonyl linkage, and B1 is a segment containing an unsaturated hydrocarbon or a hetero atom. The olefin block copolymers are suitable for uses in adhesives, various molded articles such as construction and civil engineering materials, automobile interior and exterior materials, gasoline tanks, electric and electronic parts, medical care and sanitation materials, materials of miscellaneous goods, resin materials having environmental degradation properties, films and sheets, modifiers and dispersions.

Owner:MITSUI CHEM INC

Curable composition

InactiveUS20090182091A1Less discolorationGood adhesivenessOther chemical processesEster polymer adhesivesSilylenePlasticizer

The present invention has its object to provide a curable composition which comprises a guanidine compound as a non-organotin type catalyst, is less discolored, has good surface curability, depth curability, strength rise and adhesiveness, and can retain the curability even after storage; the above object can be achieved by a curable composition which comprises: (A) an organic polymer containing a silyl group capable of crosslinking under siloxane bond formation, the silyl group being a group represented by the general formula (1): —SiX3 (1) (wherein X represents a hydroxyl group or a hydrolyzable group and the three X groups may be mutually the same or different), (B) a guanidine compound (B-1) as a silanol condensation catalyst, and (C) a plasticizer, wherein the content of the component (B-1) is not lower than 0.1 part by weight but lower than 8 parts by weight per 100 parts by weight of the component (A), and a non-phthalate ester plasticizer accounts for 80 to 100% by weight of the (C) component plasticizer.

Owner:KANEKA CORP

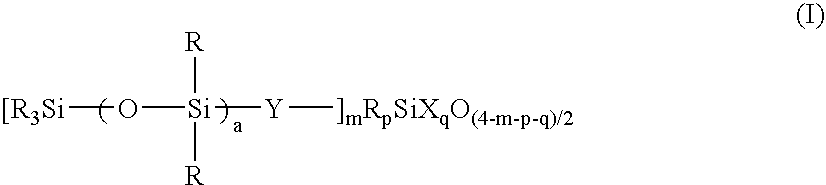

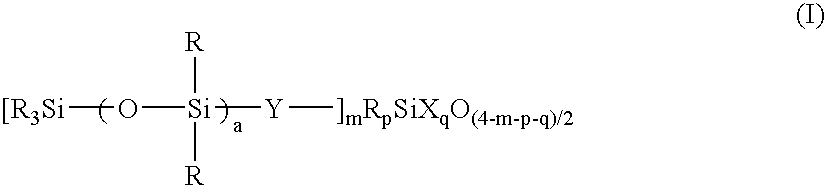

Carbon and/or silicon bridged binuclear metallocene catalyst for styrene polymerization

InactiveUS6010974AHigh catalytic activityHigh Molecular Weight DistributionOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationArylSilylene

An alkylene and / or silylene bridged binuclear metallocene catalyst for styrene polymerization is represented by the following formula (I): where M1 and M2 are the same or different transition metal of Group IVb of the Periodic Table; Cp1 and Cp2 are the same or different cyclopentadienyl; alkyl, alkoxy, silyl or halogen substituted cyclopentadienyl; indenyl; alkyl, alkoxy, silyl or halogen substituted indenyl; fluorenyl; or alkyl, alkoxy, silyl or halogen substituted fluorenyl, which is capable of pi -electron, eta 5-bonding with M1 or M2; each of E1, E2 and E3, independently of one another, is a carbon atom or a silicon atom; m, p and q are integers of 0 to 15 and m+p+q> / =1; each of R1, R2, R3, R4, R5 and R6, independently of one another, is a hydrogen, an alkyl, an aryl, an alkoxy or a halogen; X is a hydrogen, an alkyl, an alkoxy or a halogen; and n is 3. M1 and M2 may also be in cardin form by mixture of (I) with a compound which abstructs an X gray from each metal atom and substitution then with non-coordinating anions.

Owner:CHEIL IND INC

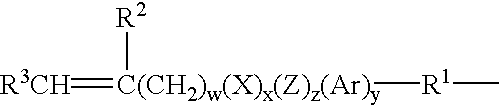

Silyl (METH) acrylate copolymers, processes for preparing the same, antifouling paint compositions containing the silyl (METH) acrylate copolymers, antifouling coating films formed from the antifouling paint compositions, antifouling methods using the antifouling paint compositions, and hulls or underwater structures coated with the antifouling coating films

InactiveUS6458878B1Improve antifouling performanceSuppressed hydrolysis rateAntifouling/underwater paintsPaints with biocidesMeth-Unsaturated monomer

Disclosed is a silyl (meth)acrylate copolymer which comprises 20 to 80% by weight of (a) silyl (meth)acrylate constituent units (I), 0.01 to 40% by weight of (b) acrylic unsaturated monomer constituent units (II) and 5 to 79.9% by weight of Ĉ unsaturated monomer constituent units other than the constituent units (a) and (b). Also disclosed is a process for preparing the silyl (meth)acrylate copolymer, an antifouling paint composition comprising the copolymer, a coating film formed from the paint composition, a hull with the coating film and an antifouling method using the paint composition.

Owner:CHUGOKU MARINE PAINTS

Conjugated diene polymer, conjugated diene polymer composition, and method for producing conjugated diene polymer

A conjugated diene polymer is provided that comprises a conjugated diene-based constituent unit and a constituent unit of formula (I) below, at least one terminus of the polymer being modified by a compound of formula (II):wherein X1, X2, and X3 independently denote a group of formula (Ia) below, a hydroxy group, a hydrocarbyl group, or a substituted hydrocarbyl group, and at least one of X1, X2, and X3 is a group of formula (Ia) below or a hydroxy group,wherein R1 and R2 independently denote a hydrocarbyl group having 1 to 6 carbon atoms, a substituted hydrocarbyl group having 1 to 6 carbon atoms, a silyl group, or a substituted silyl group, and R1 and R2 may be bonded so as to form, together with the nitrogen atom, a ring structure,wherein n denotes an integer of 1 to 10, R3, R4, and R5 independently denote a hydrocarbyl group having 1 to 4 carbon atoms or a hydrocarbyloxy group having 1 to 4 carbon atoms, at least one of R3, R4, and R5 is a hydrocarbyloxy group, and A denotes a nitrogen atom-containing functional group.

Owner:SUMITOMO CHEM CO LTD

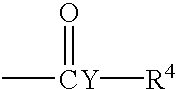

Reactive silica particles, process for manufacturing the same, use of the same

InactiveUS6160067AGroup 4/14 element organic compoundsPigmenting treatmentWeather resistanceOrganic compound

Reactive silica particles capable of producing coatings exhibiting excellent scratch resistance, weather resistance, adhesiveness, and curability, while satisfying a wide spectrum of performances from transparency to semi-transparency and providing a glossy surface as well as a frosty surface. Reactive silica particles comprises silica particles and an organic compound chemically bonded to the silica particles via a silyloxy group, wherein the organic compound has a polymerizable unsaturated group, a group represented by the following formula (1), (wherein X is a group selected from -NH-, -O-, and -S- and Y is a group selected from oxygen and sulfur, provided that when X is -O-, Y is a sulfur atom), and a group represented by the following formula (2), (wherein Z is a group selected from oxygen and sulfur)

Owner:JSR CORPORATIOON

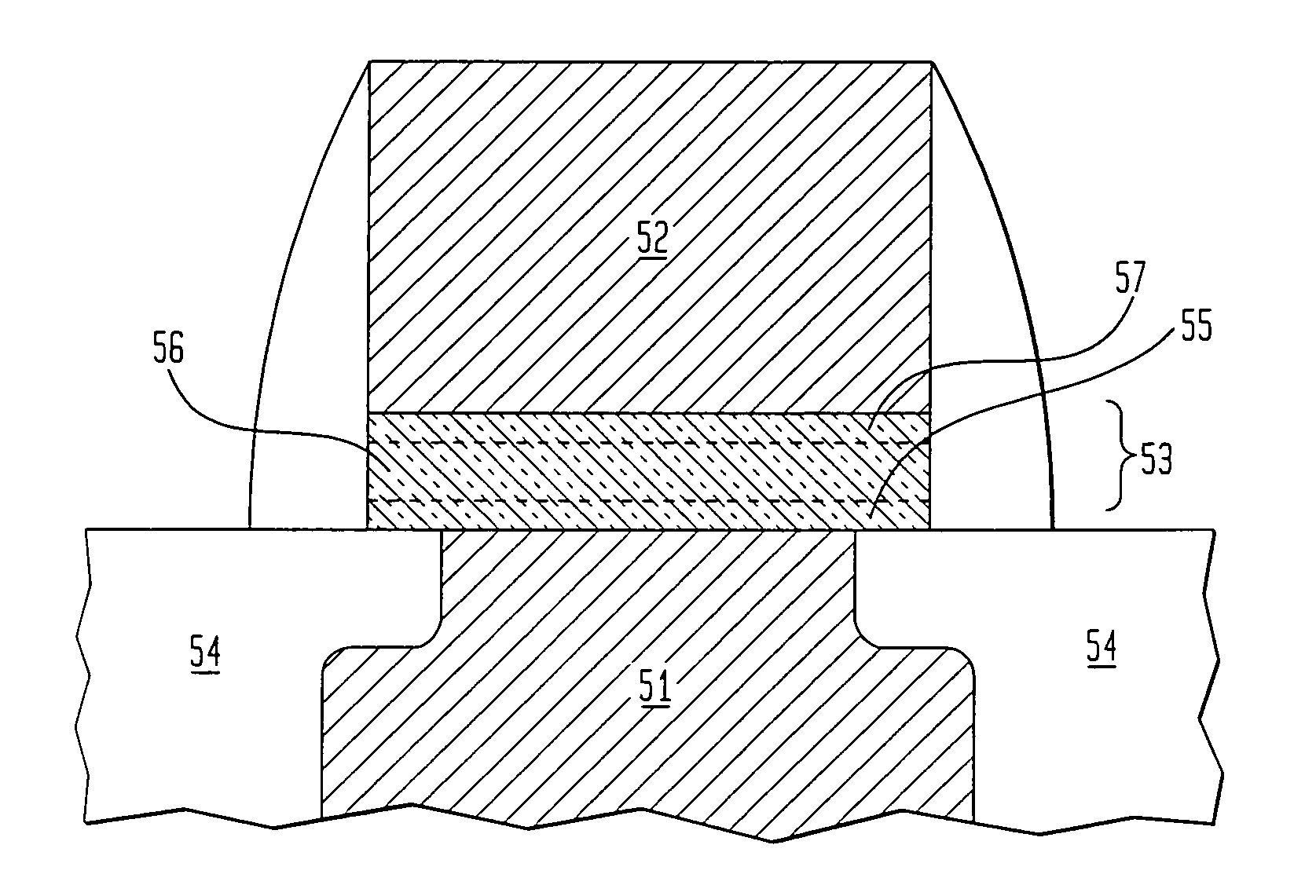

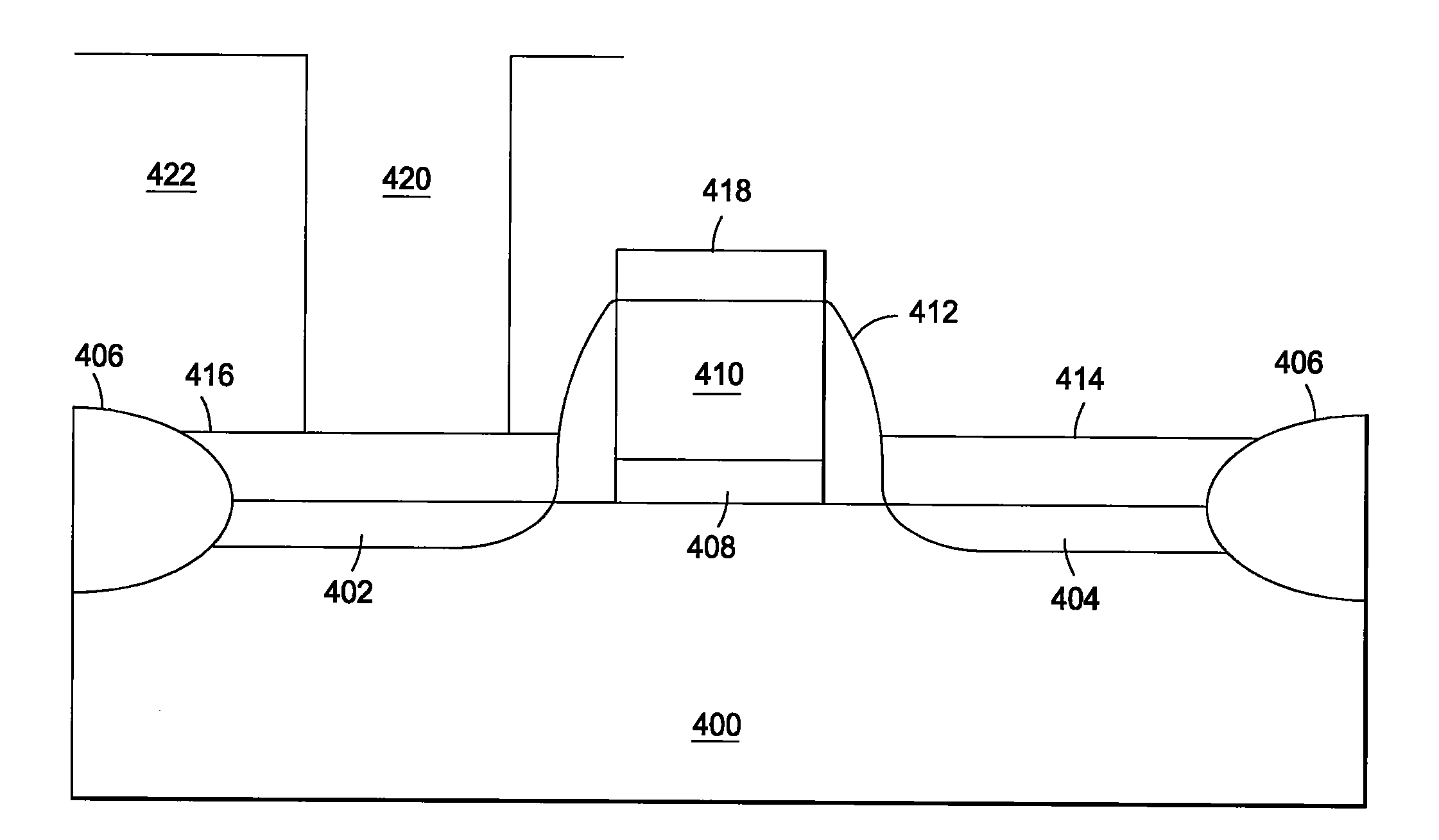

Process for forming cobalt and cobalt silicide materials in tungsten contact applications

InactiveUS20090004850A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSalicideSilylene

Embodiments of the invention described herein generally provide methods for forming cobalt silicide layers and metallic cobalt layers by using various deposition processes and annealing processes. In one embodiment, a method for forming a metallic silicide containing material on a substrate is provided which includes forming a metallic silicide material over a silicon-containing surface during a vapor deposition process by sequentially depositing a plurality of metallic silicide layers and silyl layers on the substrate, depositing a metallic capping layer over the metallic silicide material, heating the substrate during an annealing process, and depositing a metallic contact material over the barrier material. In one example, the metallic silicide layers and the metallic capping layer both contain cobalt. The cobalt silicide material may contain a silicon / cobalt atomic ratio of about 1.9 or greater, such as greater than about 2.0, or about 2.2 or greater.

Owner:APPLIED MATERIALS INC

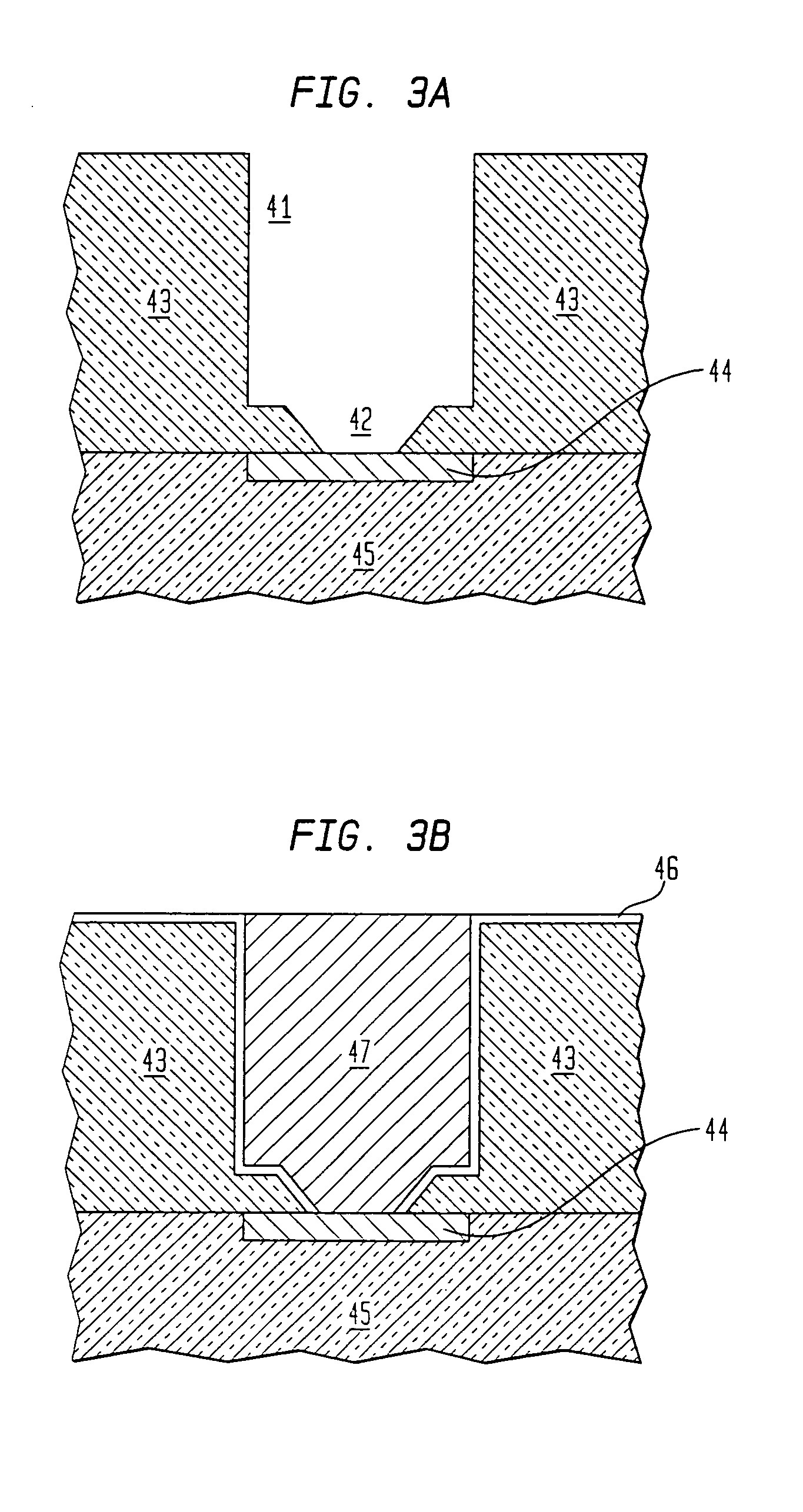

Low cost flowable dielectric films

ActiveUS20140073144A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSilyleneSilanes

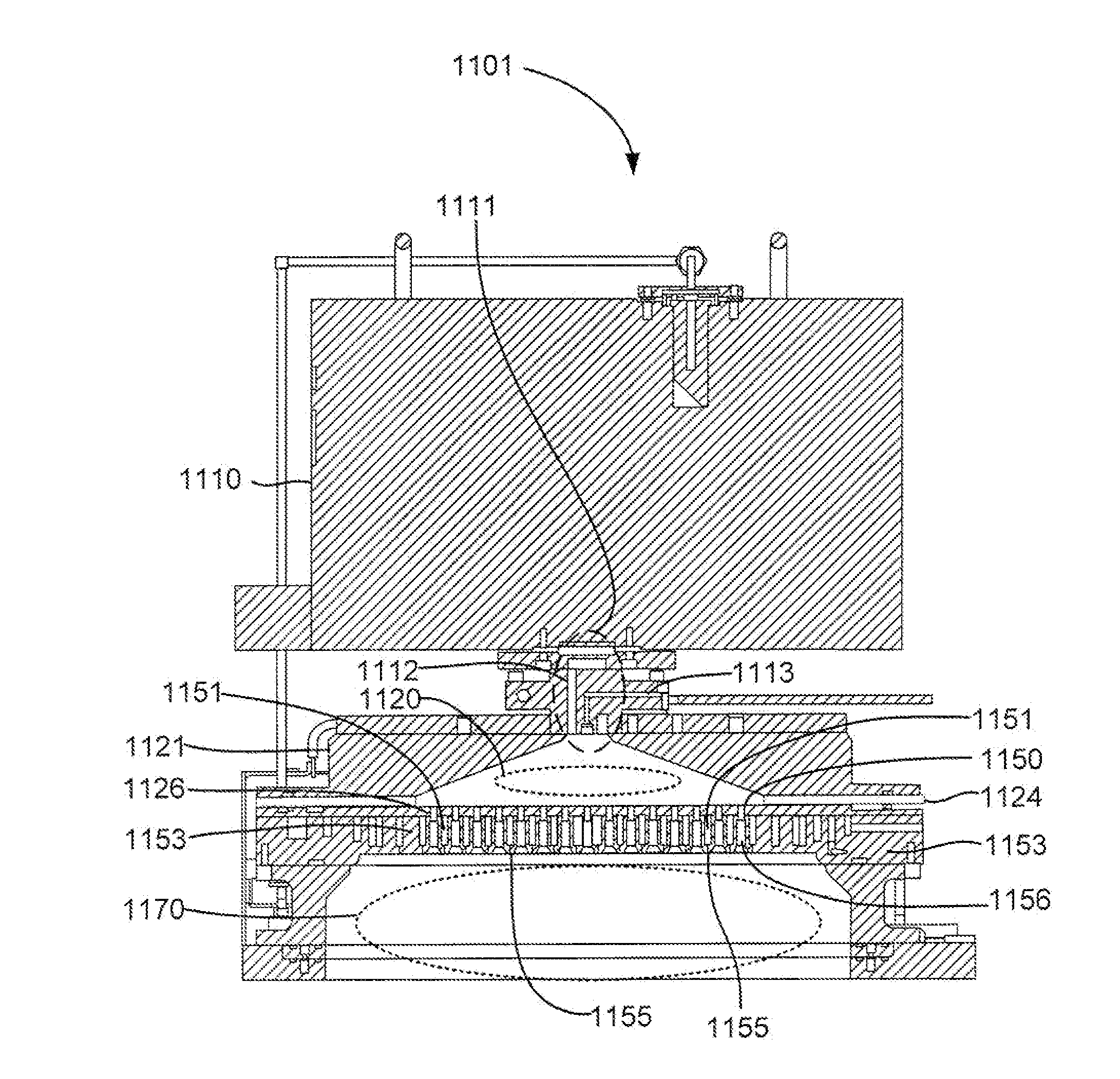

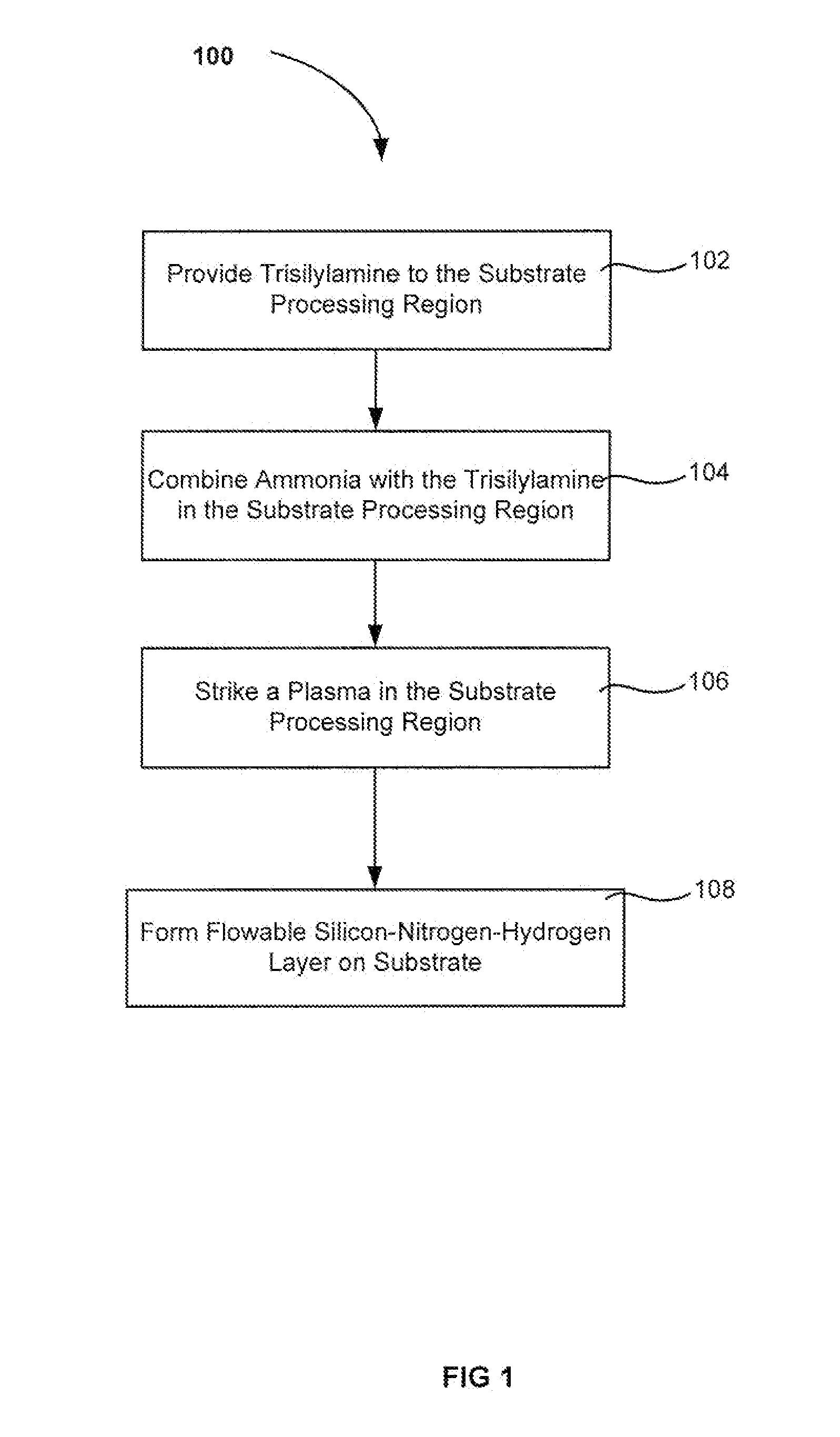

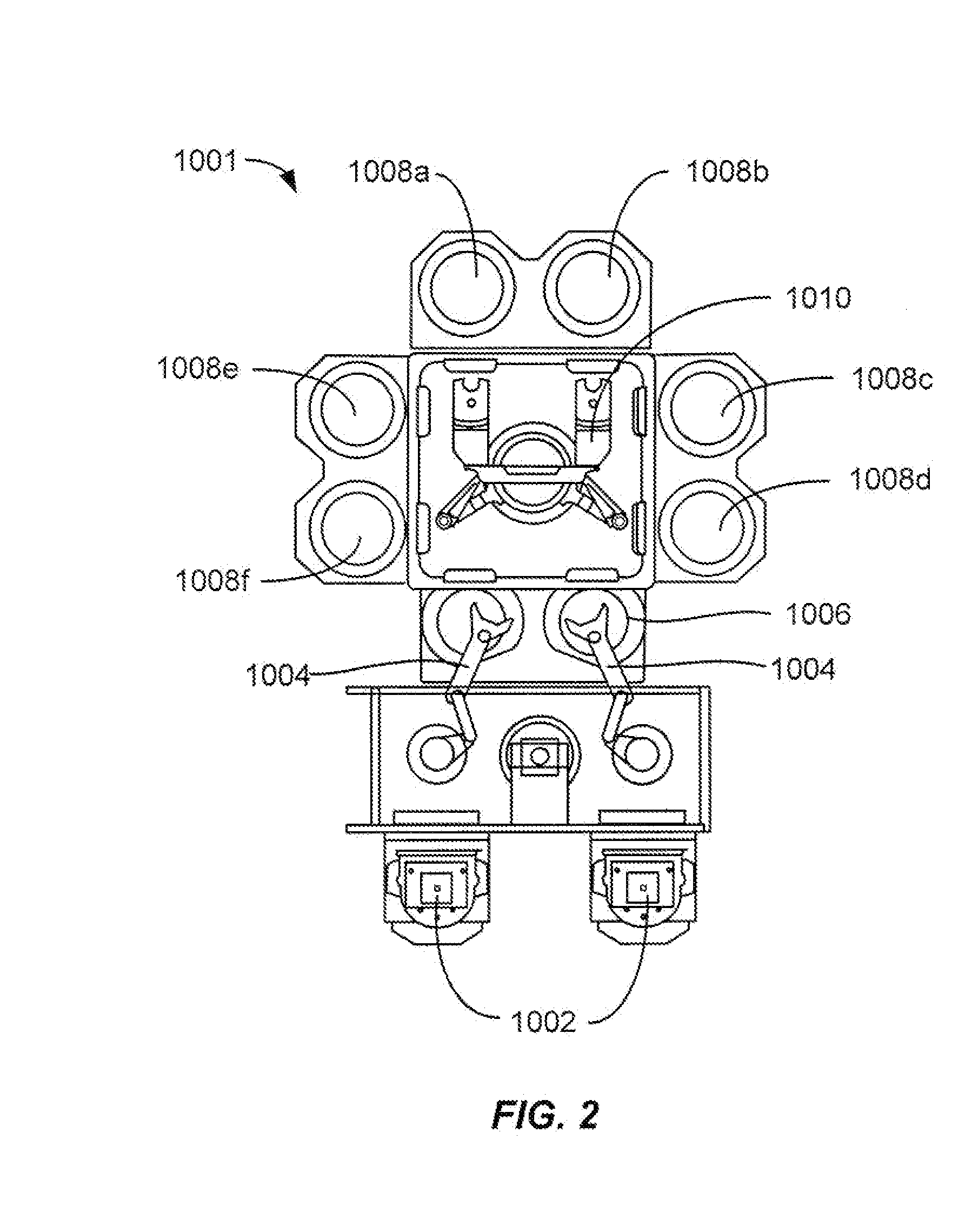

A method of forming a dielectric layer is described. The method deposits a silicon-containing film by chemical vapor deposition using a local plasma. The silicon-containing film is flowable during deposition at low substrate temperature. A silicon precursor (e.g. a silylamine, higher order silane or halogenated silane) is delivered to the substrate processing region and excited in a local plasma. A second plasma vapor or gas is combined with the silicon precursor in the substrate processing region and may include ammonia, nitrogen (N2), argon, hydrogen (H2) and / or oxygen (O2). The equipment configurations disclosed herein in combination with these vapor / gas combinations have been found to result in flowable deposition at substrate temperatures below or about 200° C. when a local plasma is excited using relatively low power.

Owner:APPLIED MATERIALS INC

Electron donors

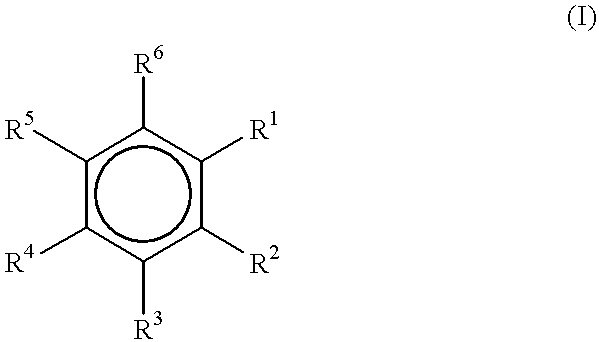

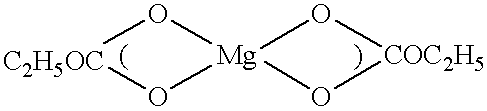

A method of polymerizing at least one olefin comprising contacting the olefin with a catalyst composition comprising:1) a procatalyst composition comprising a magnesium and titanium-containing component and an electron donor compound of the structure:wherein R1 is ethoxy, and R2 is an alkoxy group having from one to ten carbon atoms, and R3-R6 are each individually, hydrogen, hydrocarbyl, hydrocarboxy, nitro, a silyl group or a halogen,2) a cocatalyst and optionally3) a selectivity control agent.

Owner:UNION CARBIDE CHEM & PLASTICS TECH CORP

Curable polysiloxane composition, and polysiloxane cured product, optical member, member for aerospace industry, semiconductor light-emitting device, illuminating device and image display device using the same

ActiveUS20110098420A1Improve heat resistanceImprove light resistanceSemiconductor/solid-state device detailsSolid-state devicesHeat resistanceLight emitting device

The present invention provides a curable polysiloxane composition which is excellent in light resistance (particularly ultraviolet resistance) and adhesion and has a sufficient heat resistance / hydrothermal resistance and film-forming property and which generates little foaming at curing and does not generate cracks, peeling, coloring, and foaming even when used for a long period of time. A curable polysiloxane composition which comprises a specific hydrosilyl group-containing polysiloxane compound, a specific polysiloxane compound comprising two or more silanol groups in one molecule, and a dehydrogenative condensation reaction catalyst.

Owner:MITSUBISHI CHEM CORP

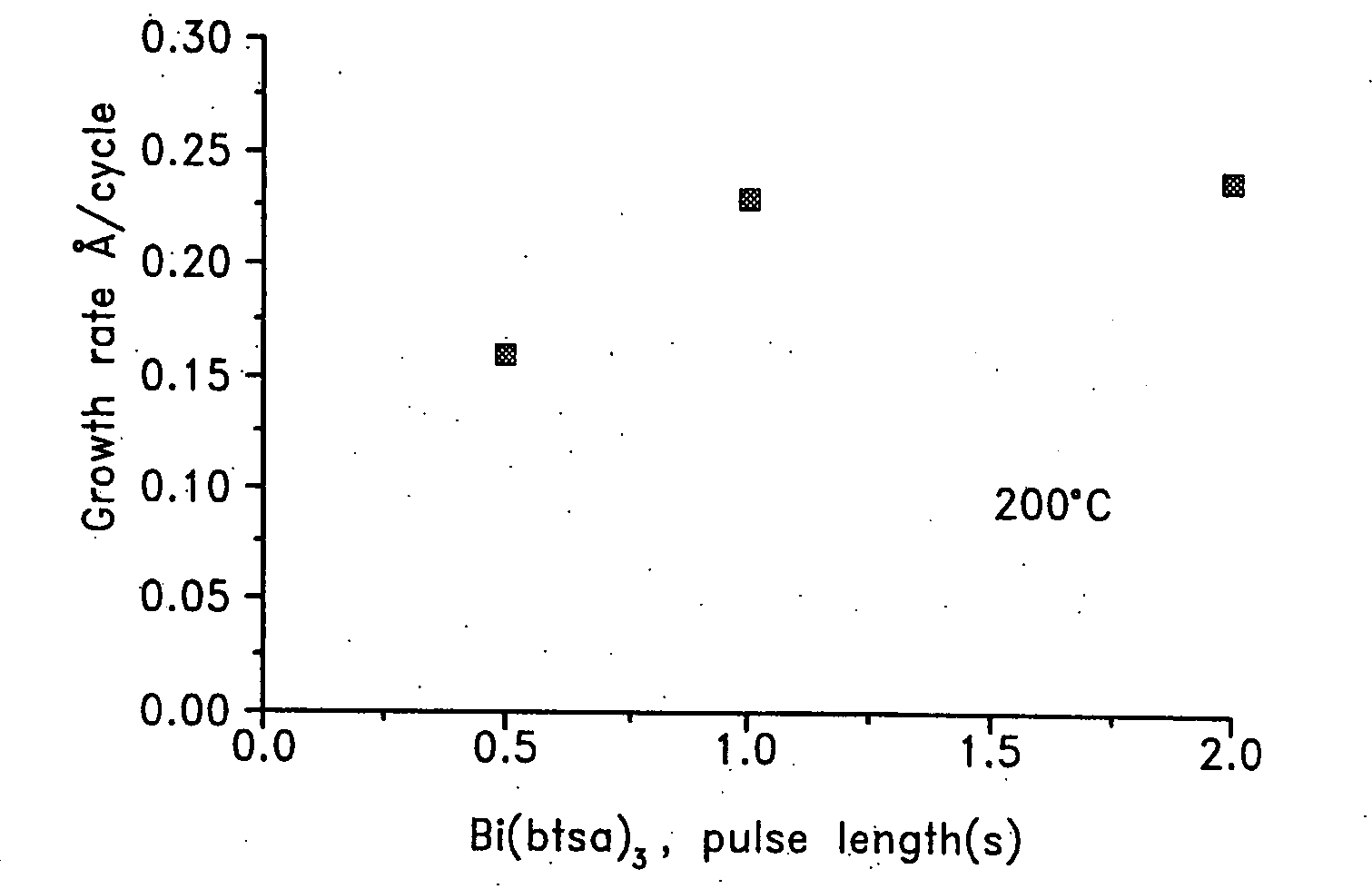

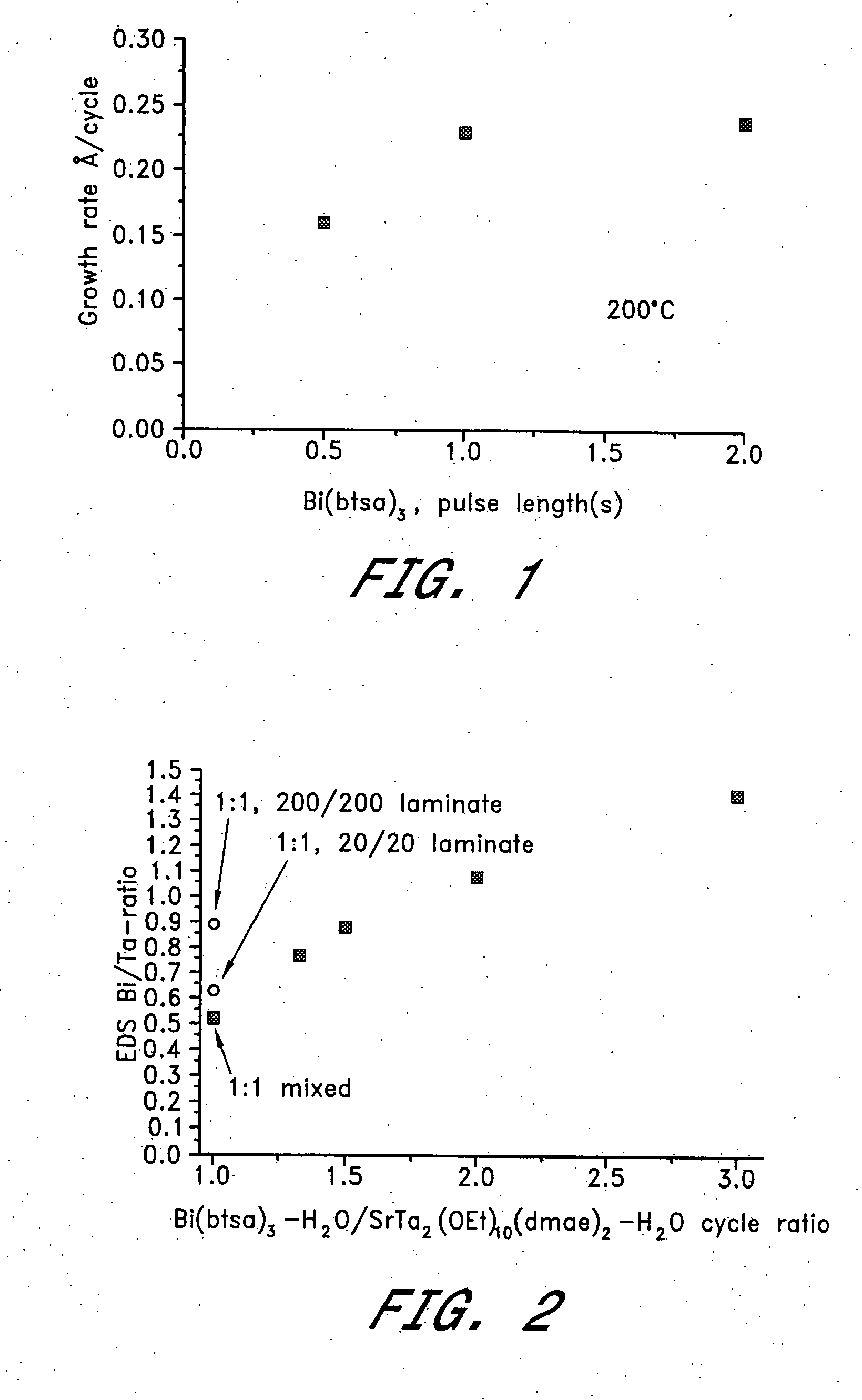

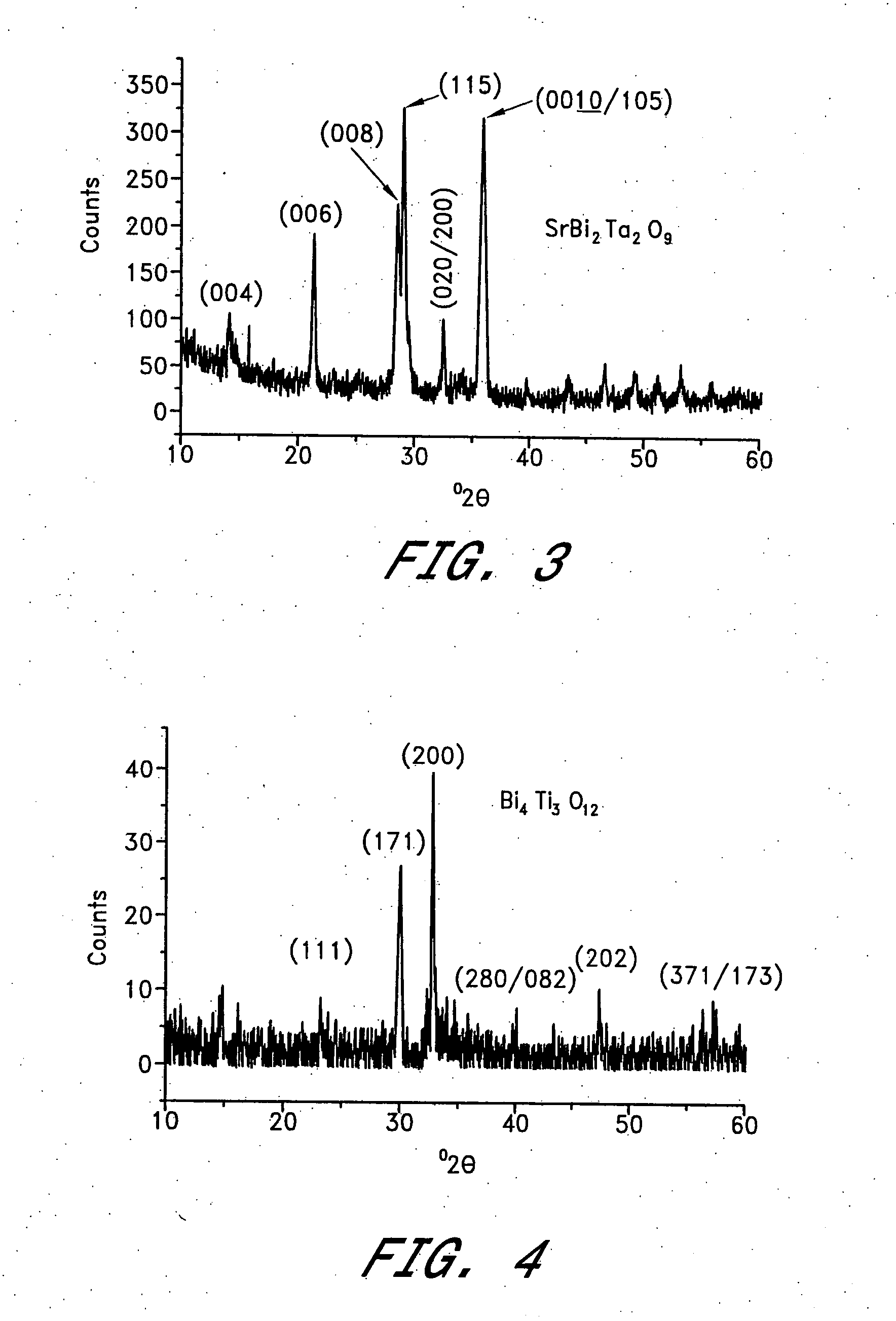

Process for producing oxide films

ActiveUS20050089632A1Reduce decreaseImprove film propertiesCeramicsSolid-state devicesSilyleneBismuth compound

A process for producing bismuth-containing oxide thin films by Atomic Layer Deposition, including using an organic bismuth compound having at least one silylamido ligand as a source material for the bismuth oxide. Bismuth-containing oxide thin films produced by the preferred embodiments can be used, for example, as ferroelectric or dielectric material in integrated circuits and / or as superconductor materials.

Owner:ASM INTERNATIONAL

Antifouling coating compositions and coated articles

InactiveUS20050227092A1Antifouling/underwater paintsLighting and heating apparatusPolymer scienceSilylene

An antifouling coating composition is provided comprising an organosilicon compound having a one end-blocked diorganopolysiloxane group and a condensation-curable silyl group in a common molecule, and optionally a heat-curable compound. The composition is applied and cured to a substrate to form a coat which has an improved surface protective function and durable water repellent and antifouling properties.

Owner:SHIN ETSU CHEM IND CO LTD

Curable composition, cured article obtained therefrom, and photochromic optical material and process for producing the same

InactiveUS20040220292A1Improve adhesionEnhance aggregation abilityCoatingsOptical elementsMethacrylateSilylene

A curable composition which provides a coating layer having high adhesion to a substrate and a hard coat layer and extremely excellent photochromic properties such as high color development intensity, high fading speed and excellent durability. This composition comprises (1) 100 parts by weight of radically polymerizable monomers including a silyl monomer such as gamma-methacryloyloxypropyl trimethoxysilane and / or an isocyanate monomer such as 2-isocyanatoethoxy methacrylate, (2) 0.01 to 20 parts by weight of an amine compound and (3) 0.01 to 20 parts by weight of a photochromic compound. A photochromic optical material having excellent adhesion between a photochromic coating layer and a resin substrate and obtained by using this composition as a coating material and a process for producing the photochromic optical material.

Owner:TOKUYAMA CORP

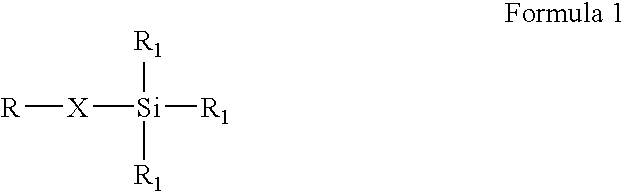

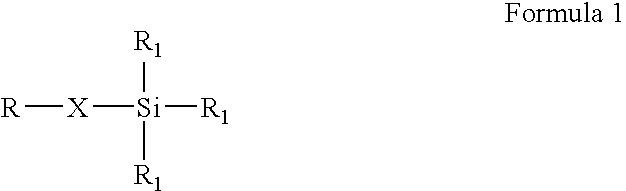

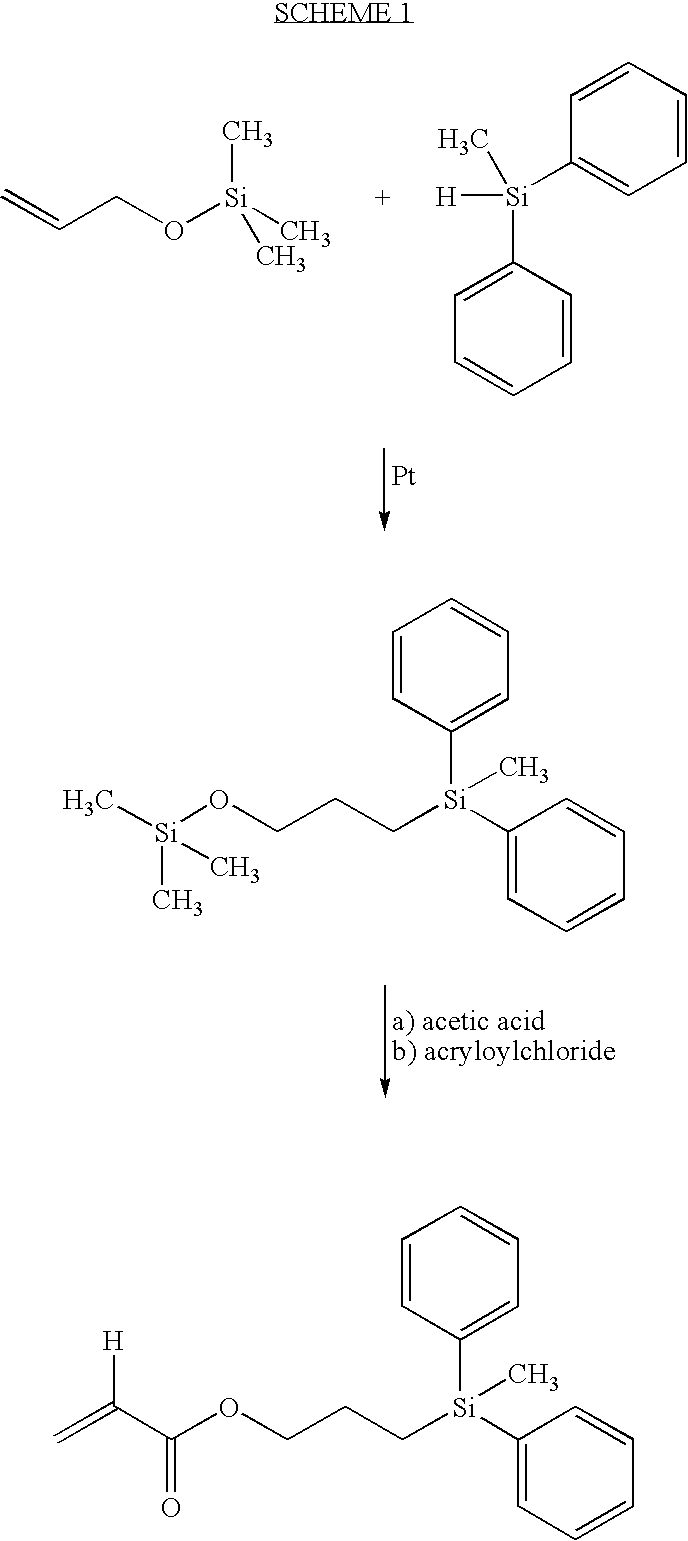

High refractive index aromatic-based silyl monomers

InactiveUS6846897B2Low production costIdeal physical propertySilicon organic compoundsOrganic chemistry methodsHydrophilic monomerSilylene

Optically transparent, relatively high refractive index polymeric compositions and ophthalmic devices such as intraocular lenses, contact lenses and corneal inlays made therefrom are described herein. The preferred polymeric compositions are produced through the polymerization of one or more aromatic-based silyl monomers or the copolymerization of one or more aromatic-based silyl monomers with one or more aromatic or non-aromatic non-siloxy-based monomers, hydrophobic monomers or hydrophilic monomers.

Owner:BAUSCH & LOMB INC

Multifunctional star-shaped prepolymers, their preparation and use

The present invention relates to coatings that possess a dynamic contact angle hysteresis in water, measured by means of a Wilhelmy balance according to DIN EN 14370, of at most 15°, and are can be manufactured from star-shaped prepolymers and / or star-shaped prepolymer-nanoparticle complexes that are cross-linkable with one another and with the surface of the substrate to be coated, the star-shaped prepolymers and / or star-shaped prepolymer-nanoparticle complexes possessing, before being cross-linked, at least three hydrophilic polymer arms that, considered of themselves, are soluble in water, and that carry on all or on some of their free ends R1 silyl terminal groups of the following general formula (I): R1 is —CRa2—Si(ORb)r(Rc)3-r, where Ra denotes hydrogen or a linear or branched alkyl group having 1 to 6 carbon atoms, ORb denotes a hydrolyzable group, Rc denotes a linear or branched alkyl group having 1 to 6 carbon atoms, and r denotes a number from 1 to 3, and that carry, on the optionally present ends not carrying silyl terminal groups, reactive groups that are reactive with respect to themselves, the substrate to be coated, entities optionally introduced into the coating, and / or with the silyl terminal groups. The present invention furthermore relates to a method for manufacturing such coatings, and to star-shaped prepolymers that are used in the coatings. The invention moreover relates to use of the star-shaped prepolymers as additives to various agents for temporary or permanent anti-soiling finishing of surfaces.

Owner:HENKEL KGAA

Curable composition

The present invention provides a curable composition which comprises: Component (A): A polyoxyalkylene polymer containing at least one reactive silyl group at a molecular chain terminus; Component (B): A polymer composed of acrylic acid alkyl ester monomer units and / or methacrylic acid alkyl ester monomer units containing, on the average, at least one reactive silyl group in each molecule; and, Component (C): An ionic surfactant, and which may be suitably used as a sealant for buildings inhibiting dust / dirt adhesion and hardly allowing traces of rain and like stains to leave thereon.

Owner:KANEKA CORP

Method of treating metals using vinyl silanes and multi-silyl-functional silanes in admixture

InactiveUS6071566AImprove adhesionImprove solubilityGroup 4/14 element organic compoundsFibre treatmentSilyleneSilanes

The present invention relates to a method of treating a metal substrate to provide permanent corrosion resistance. The method comprises applying a solution containing one or more vinyl silanes in admixture with one or more multi-silyl-functional silanes to a metal substrate in order to form a coating. The method is particularly suitable for use on zinc coated surfaces.

Owner:CHEMETALL PLC

Silane composition, silicon film forming method and solar cell production method

InactiveUS7067069B2Increase the areaFormed with easeSilicon organic compoundsSilicaSilane compoundsSilylene

A silane composition for preparing a semiconductor thin films of a solar cell is disclosed. The silane composition contains a polysilane compound represented by the formula SinRm (n is an integer of 3 or more, m is an integer of n to (2n+2) and an m number of R's are each independently a hydrogen atom, alkyl group, phenyl group or halogen atom, with the proviso that when all the m number of R's are hydrogen atoms and m=2n, n is an integer of 7 or more), and at least one silane compound selected from cyclopentasilane, cyclohexasilane and silylcyclopentasilane.

Owner:JSR CORPORATIOON

Organopolysiloxane combination for surface treatment, powder treated with the combination and cosmetic comprising the power

A combination for surface treating powder, composed of (I)organopolysiloxane or condensate thereof and (II)organopolysiloxane in a weight ratio of (I):(II) of from 95:5 to 5:95; (I)organopolysiloxane or condensate thereof and (III) acryl / silicone copolymer in a weight ratio of (I):(III) of from 95:5 to 5:95; or (I)organopolysiloxane or condensate thereof, (II)organopolysiloxane and (III) acryl / silicone copolymer in a weight ratio of (I):[(II)+(III)] of from 95:5 to 5:95, provided that each of (I), (II), and (III) may be packed together or separately, wherein (I)organopolysiloxane is represented by the following formula (1),R1a(OR2)bSiO(4-a-b) / 2 (1)wherein R1 may be the same with or different from each other and is a C1-30 alkyl, aryl, aralkyl, fluorinated alkyl or amino-substituted alkyl group, R2 is a C1-6 alkyl group, a is the number of from 0.75 to 1.5, and b is the number of from 0.2 to 3, provided that a sum of a and b is greater than 0.9 and at most 4; (II)organopolysiloxane is represented by the formula (2)R3cR4dR5eSiO(4-c-d-e) / 2 (2)wherein R3may be the same with or different from each other and is a C1-30 alkyl, aryl, aralkyl, or fluorinated alkyl group, R4 is a hydrogen atom, a hydroxyl group or a C1-6 alkoxy group and is bonded to the Si atom in the formula (2) via a group comprising carbon, oxygen, or silicon atom, and R5 is a silicone compound residue represented by the following formula wherein R3 is as defined above, c is the number of from 1.0 to 2.5, d is the number of from 0.001 to 1.5, and e is the number of from 0 to 1.5, x is an integer of from 1 to 5, and y is an integer of from 0 to 500; and (III) acryl / silicone copolymer has at least one hydrolyzable silyl group.

Owner:SHIN ETSU CHEM IND CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com