Patents

Literature

33228results about "Engine seals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

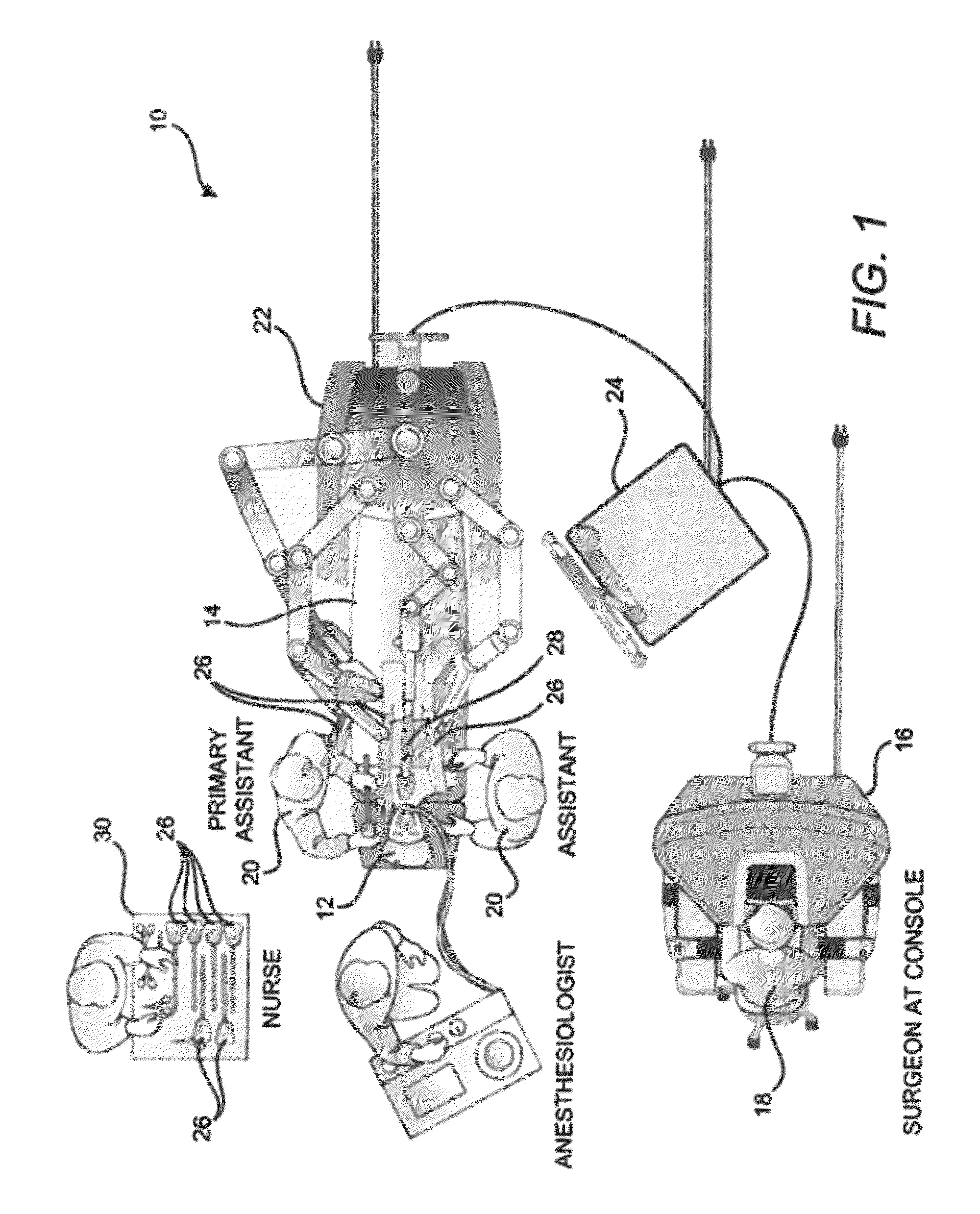

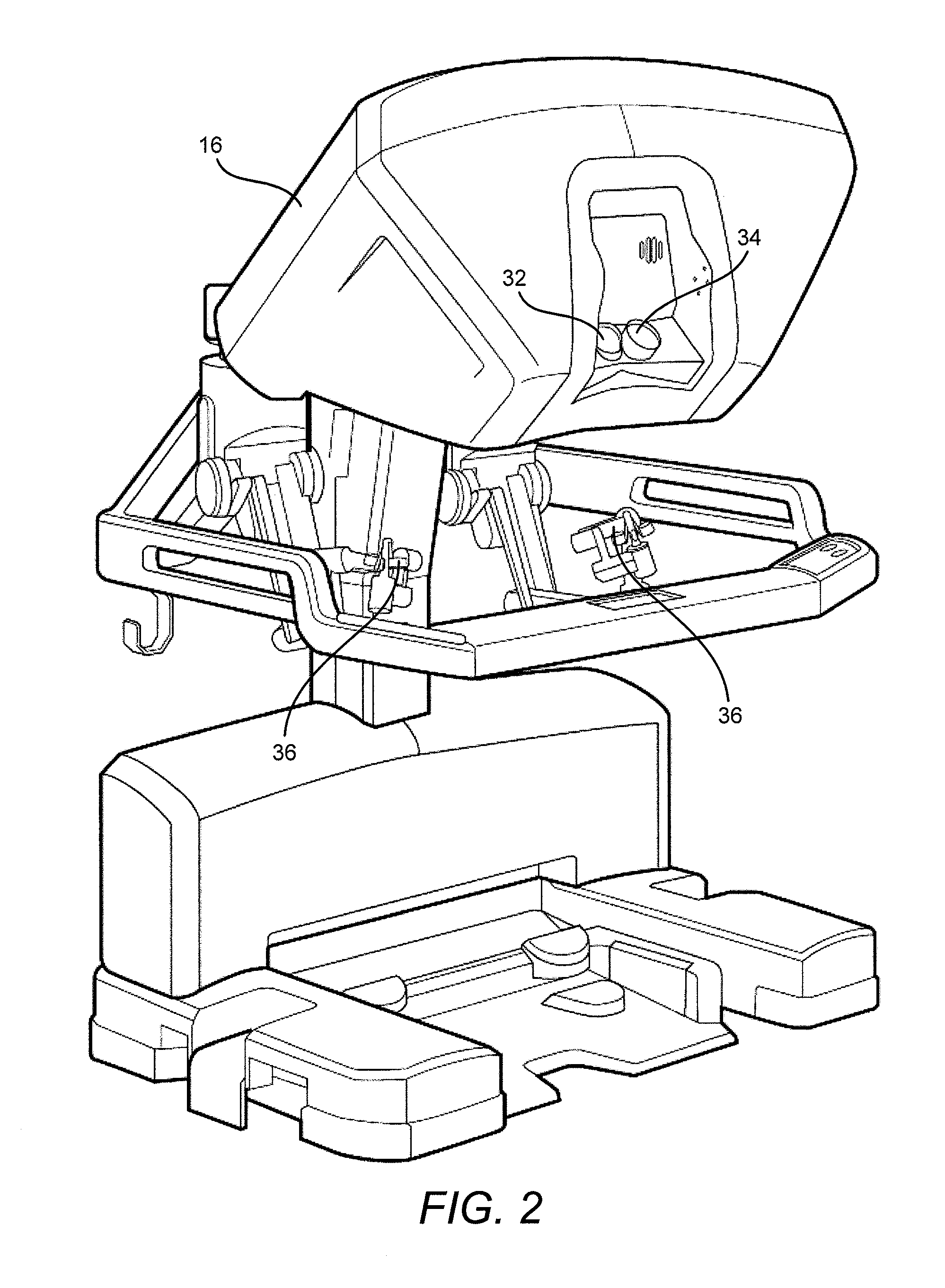

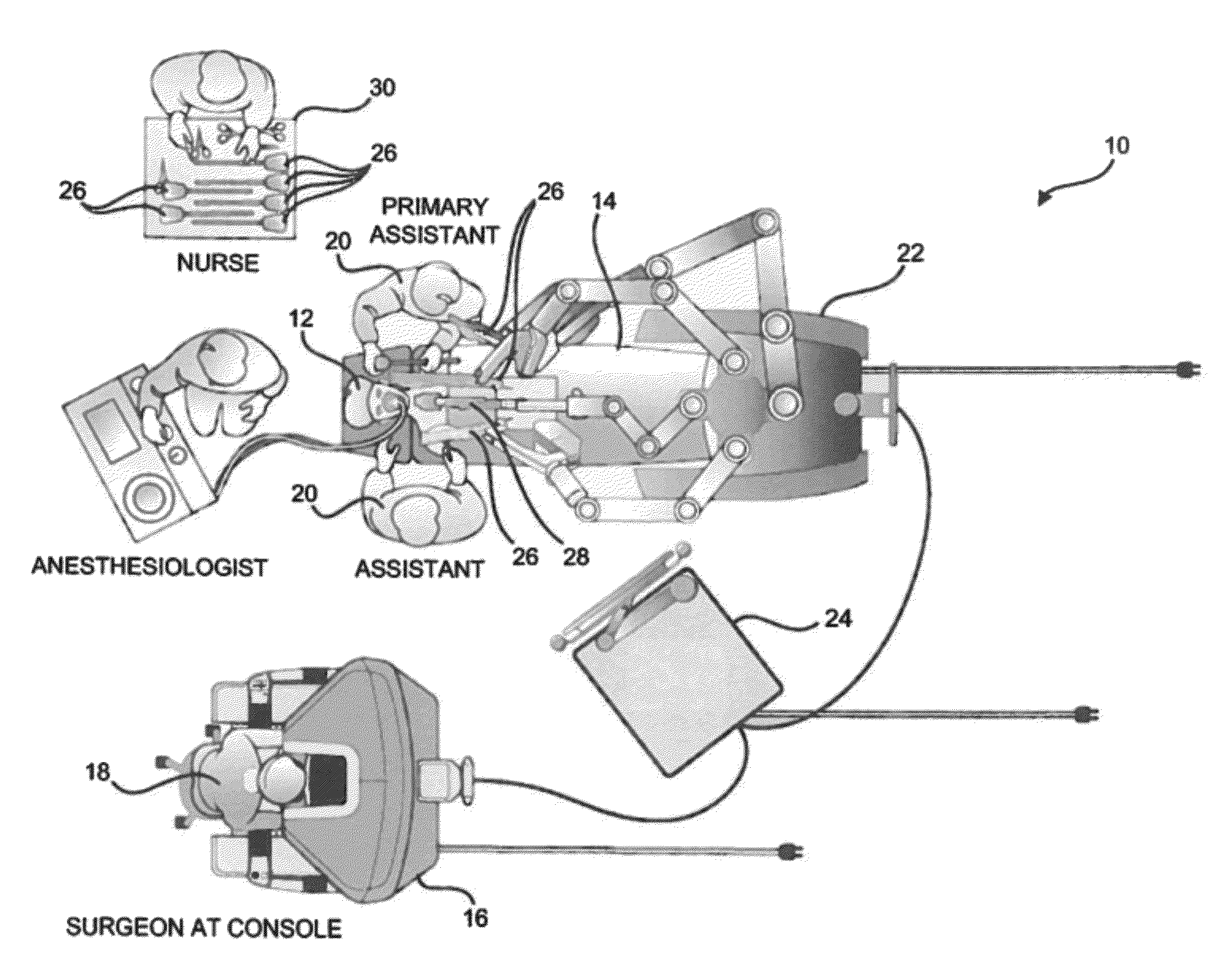

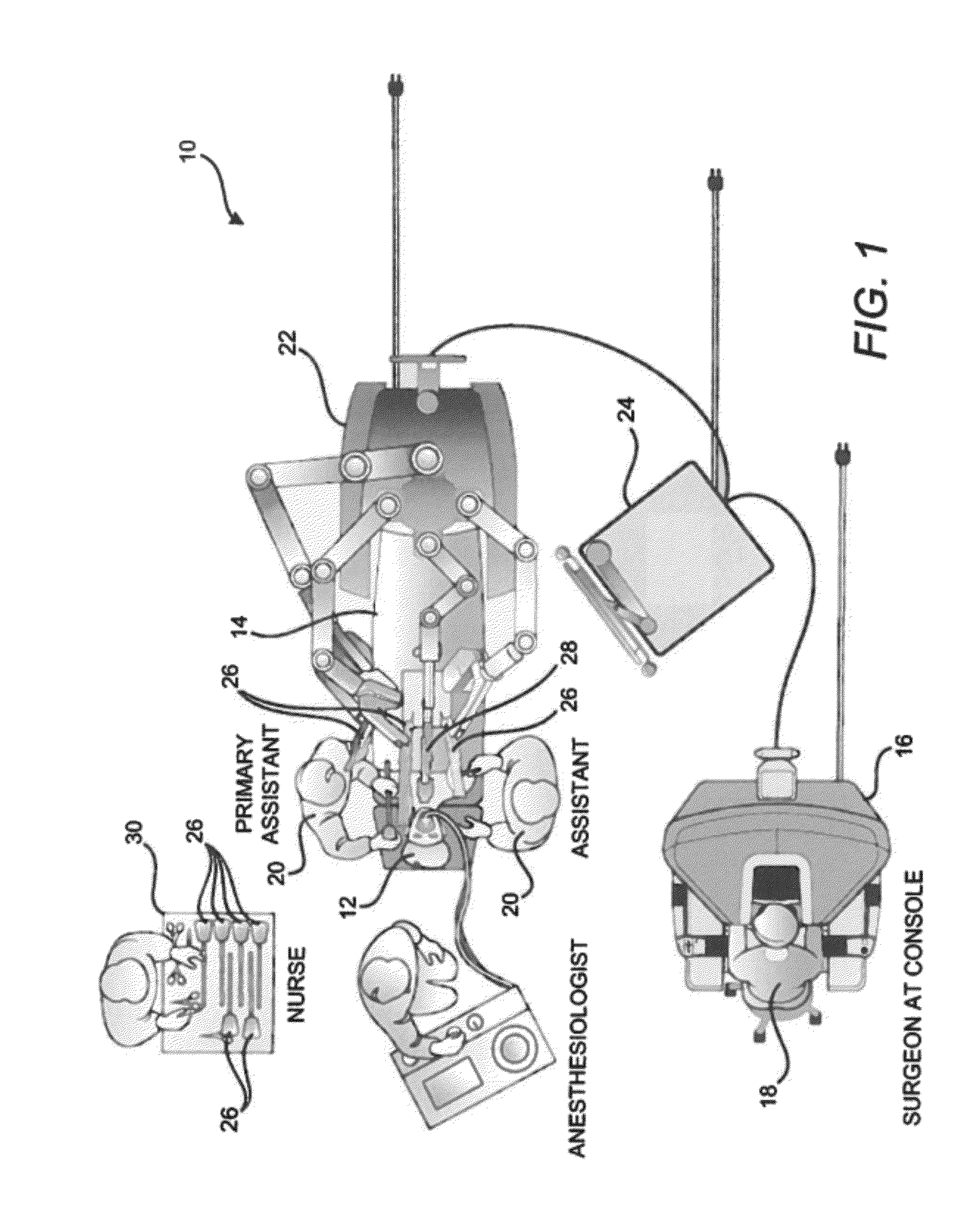

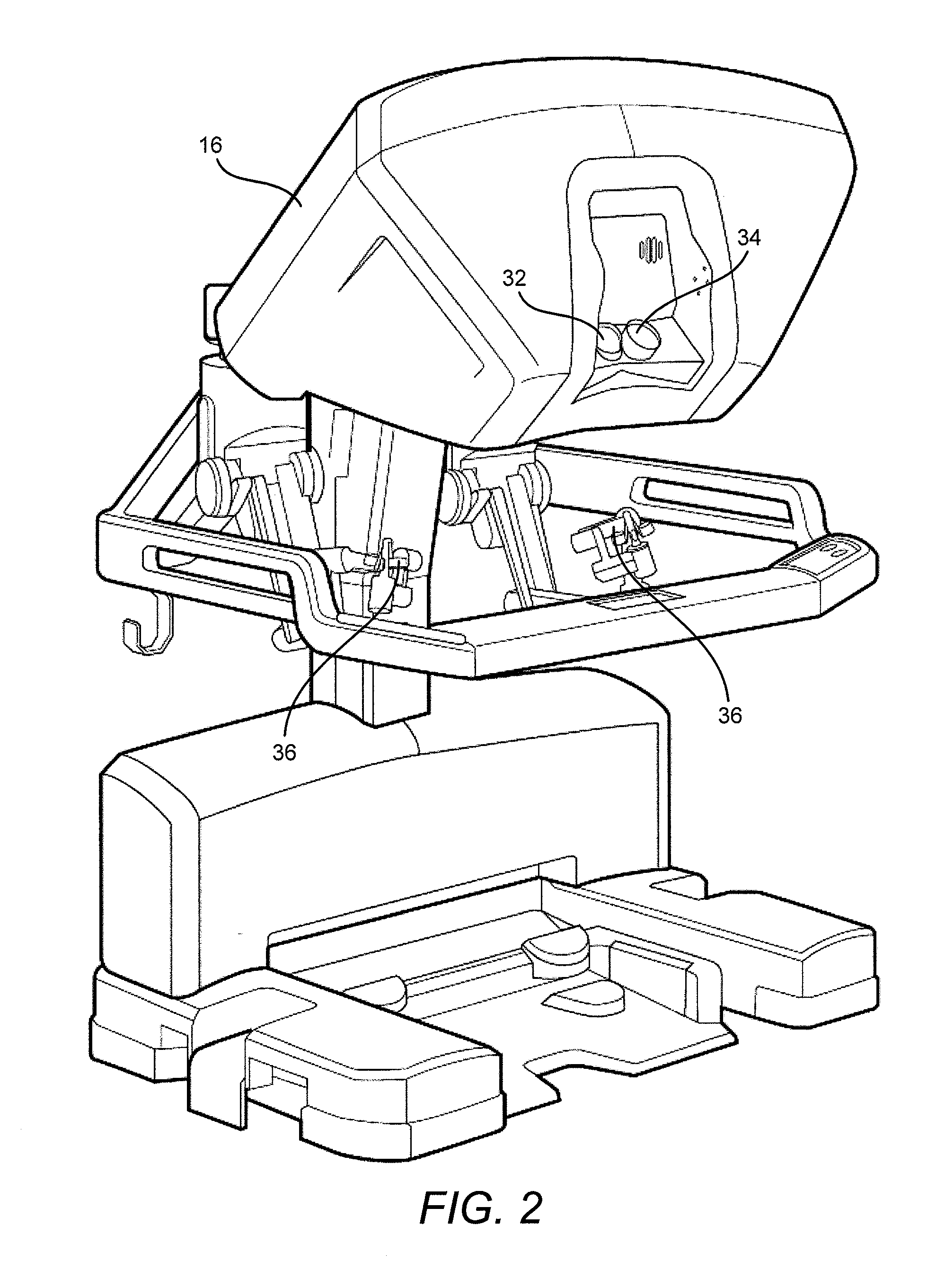

Seals and sealing methods for a surgical instrument having an articulated end effector actuated by a drive shaft

Owner:INTUITIVE SURGICAL OPERATIONS INC

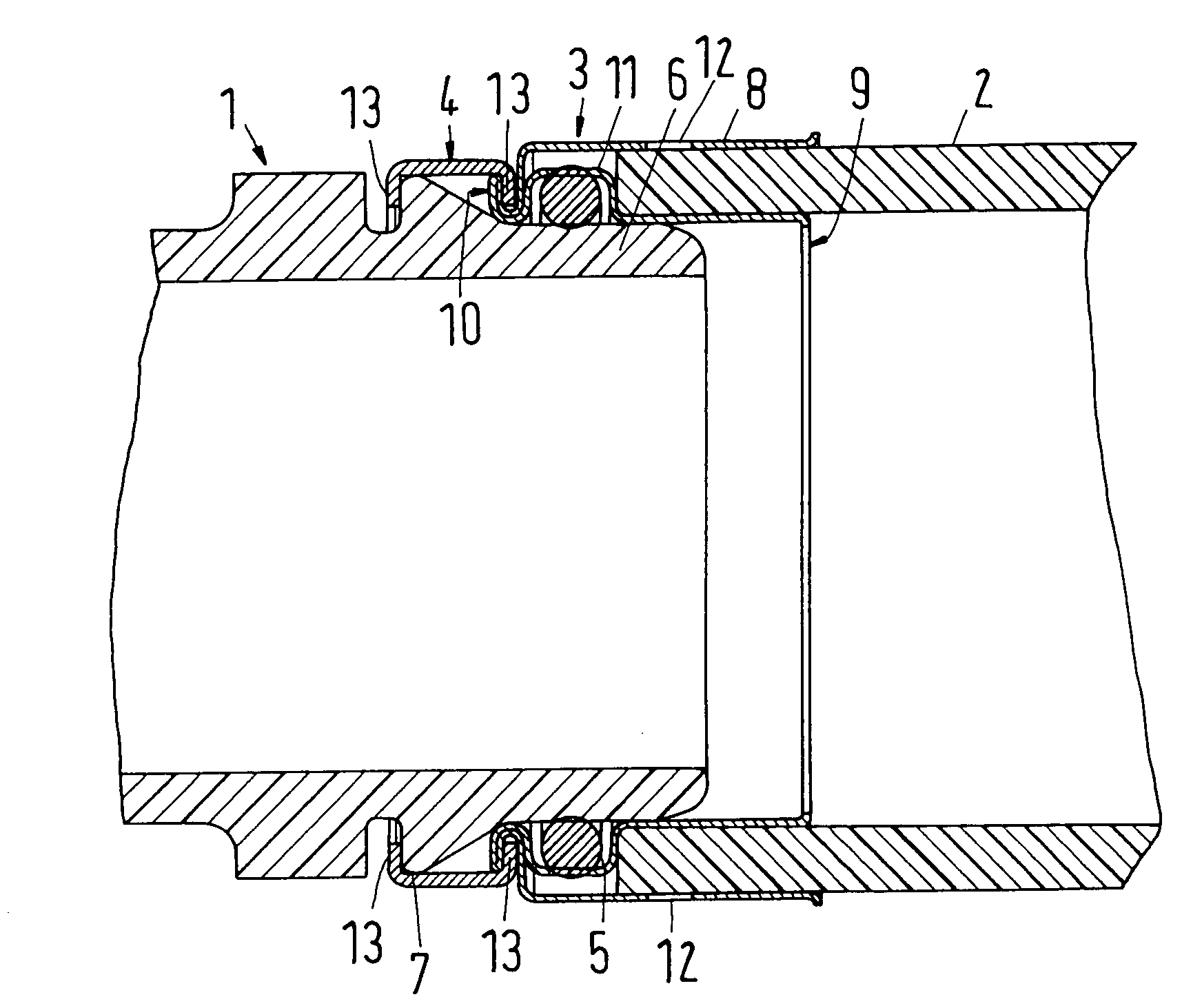

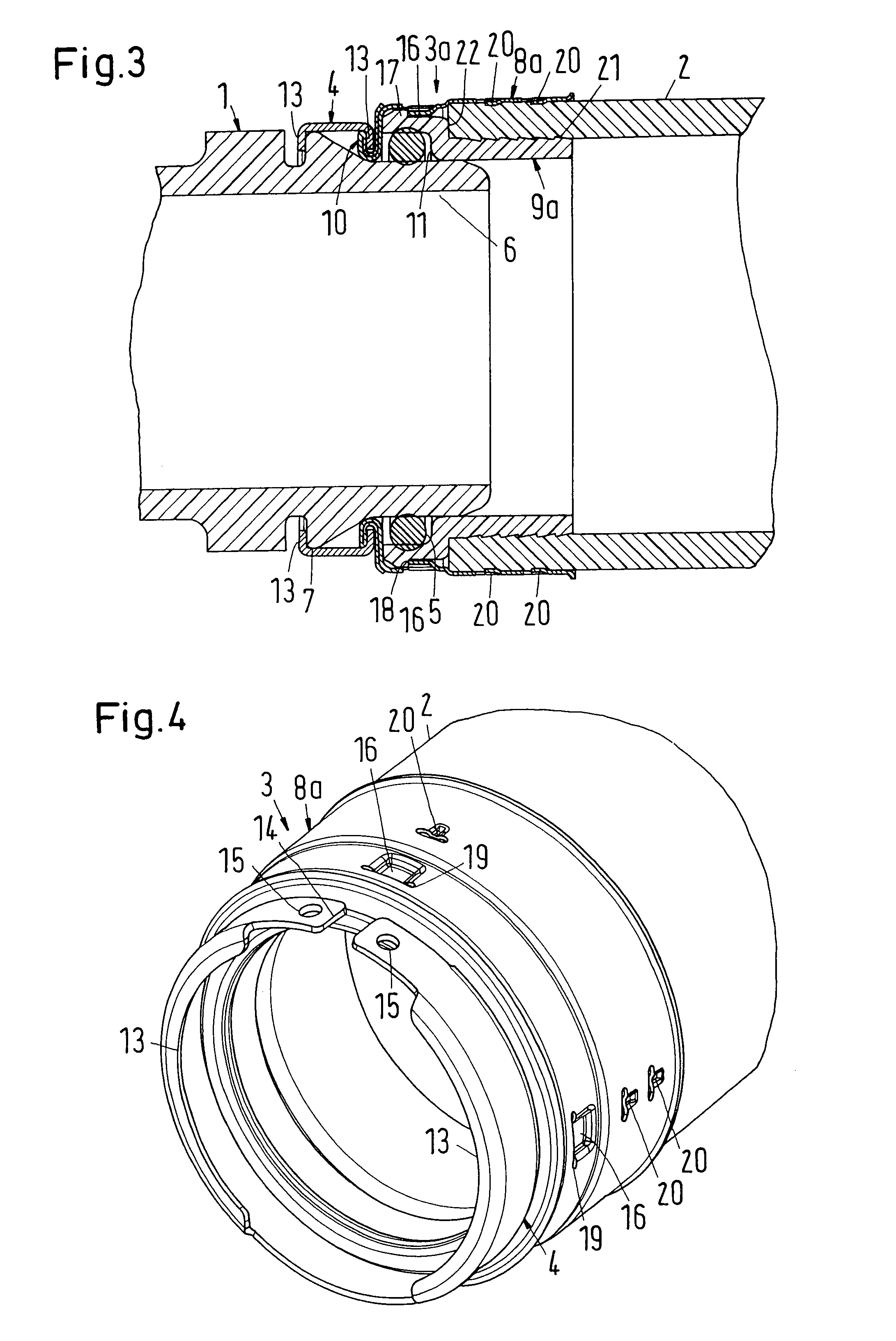

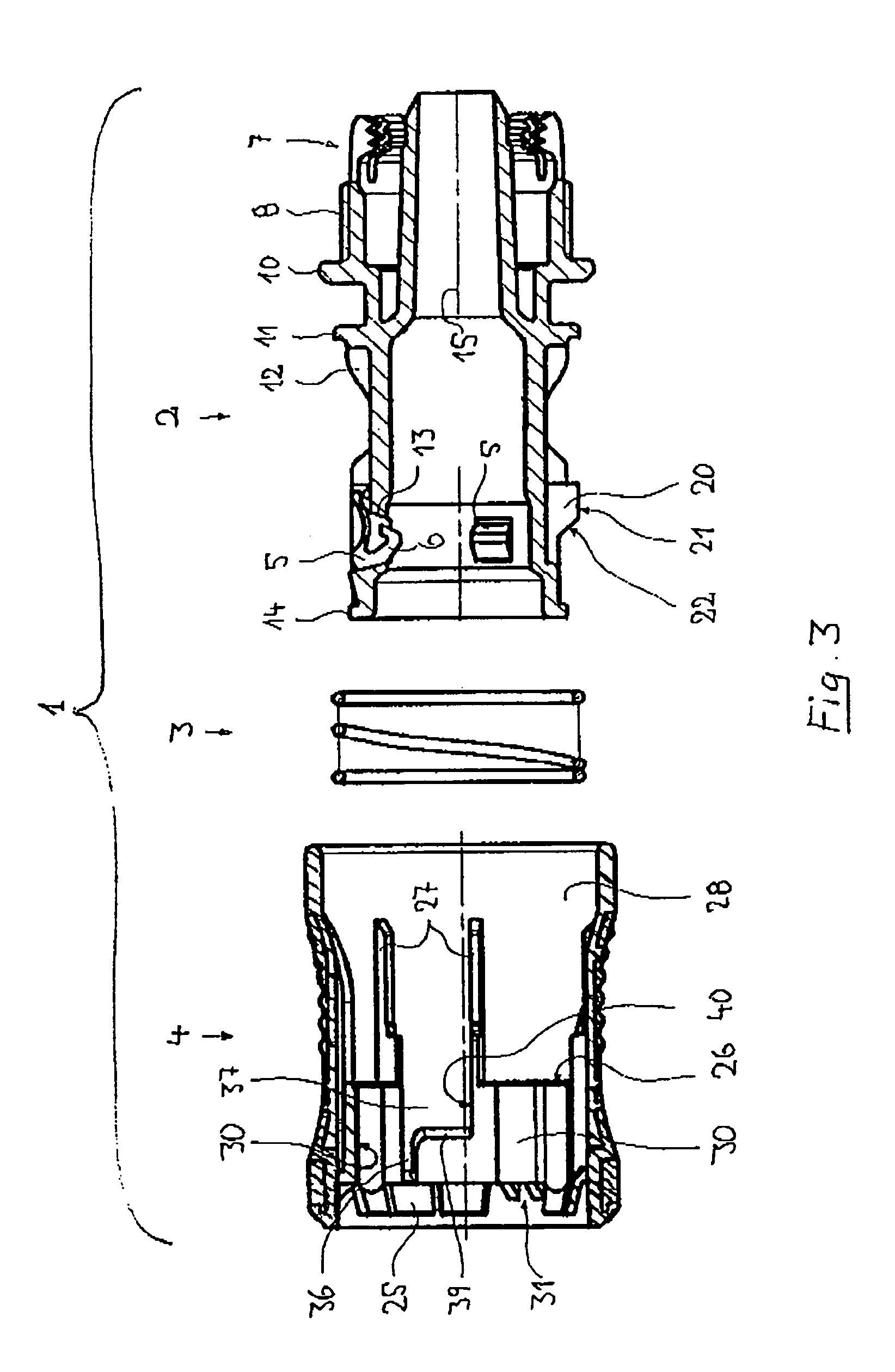

Plug-type connection arrangement for a hose and a pipe

InactiveUS7562910B2More compact constructionIncrease axial loadEngine sealsPipe elementsEngineeringFlange

A plug-type connection arrangement for a hose and a pipe, the connection arrangement comprising a sleeve having an outer wall and an inner wall, wherein the hose is insertable from an end of the sleeve and is clampable in the sleeve, wherein the sleeve has at another end thereof a first annular groove with an open resilient connecting ring which extends over more than 180° and is lockable to the sleeve and the pipe, and a sealing ring for sealing the sleeve relative to the pipe in a connected state of the pipe and the hose, the connecting ring being comprised of a plate spring ring with inwardly directed flanges at both circumferential edges thereof, wherein the flanges of one circumferential edge are engageble in the first annular groove and the flanges of the other circumferential edge are engageable behind a holding rib on the pipe, wherein the sealing ring is mounted in a second annular groove formed by the inner wall of the sleeve and the axially inner wall of the first annular groove, and wherein an end portion of the pipe is insertable into the sleeve.

Owner:NORMA GERMANY GMBH

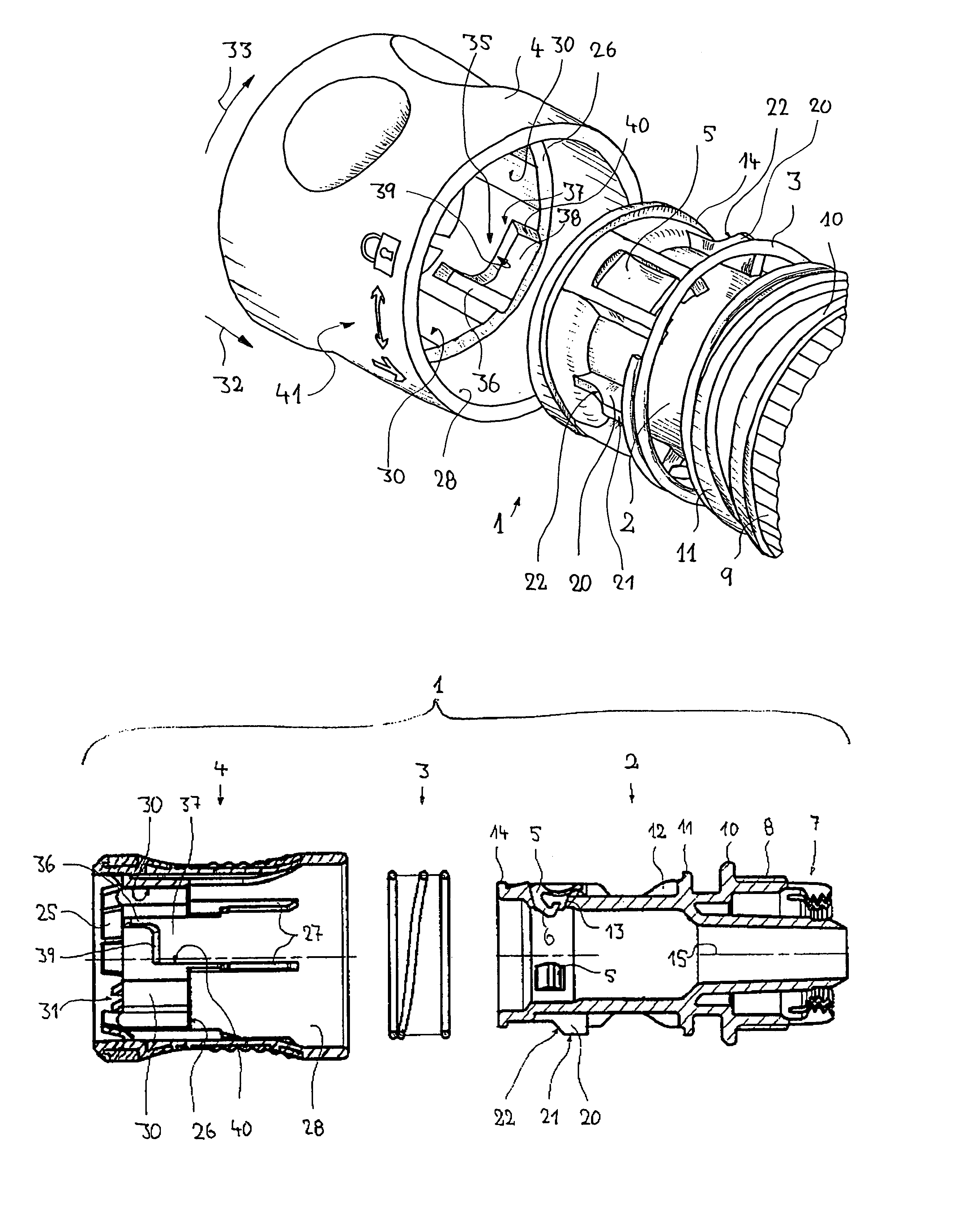

Coupling part for a fluid coupling device

InactiveUS7021669B1Avoid disconnectionGuaranteed uptimeSleeve/socket jointsEngine sealsFluid couplingEngineering

A coupling part for a fluid coupling device, especially a hose coupling, which has a looking device switchable between two positions. The locking device has locking elements mounted on a base body, and a socket-shaped actuating element that interacts with the locking elements. The coupling part is switchable between a retaining and releasing positions by an axial releasing movement of the actuating element. In the retaining position, the locking elements hold the counterpart of the coupling, e.g. a hose stem, to prevents it from being pulled out and, in the releasing position, the locking elements release the same in order to disengage the coupling. The actuating element can be moved from the retaining position into a locking position, prohibiting a releasing movement, by rotating the actuating element in a limited manner around the longitudinal axis of the coupling. As a result, the coupling is prevented from being unintentionally disengaged.

Owner:GARDENA KRESS KASTNER GMBH

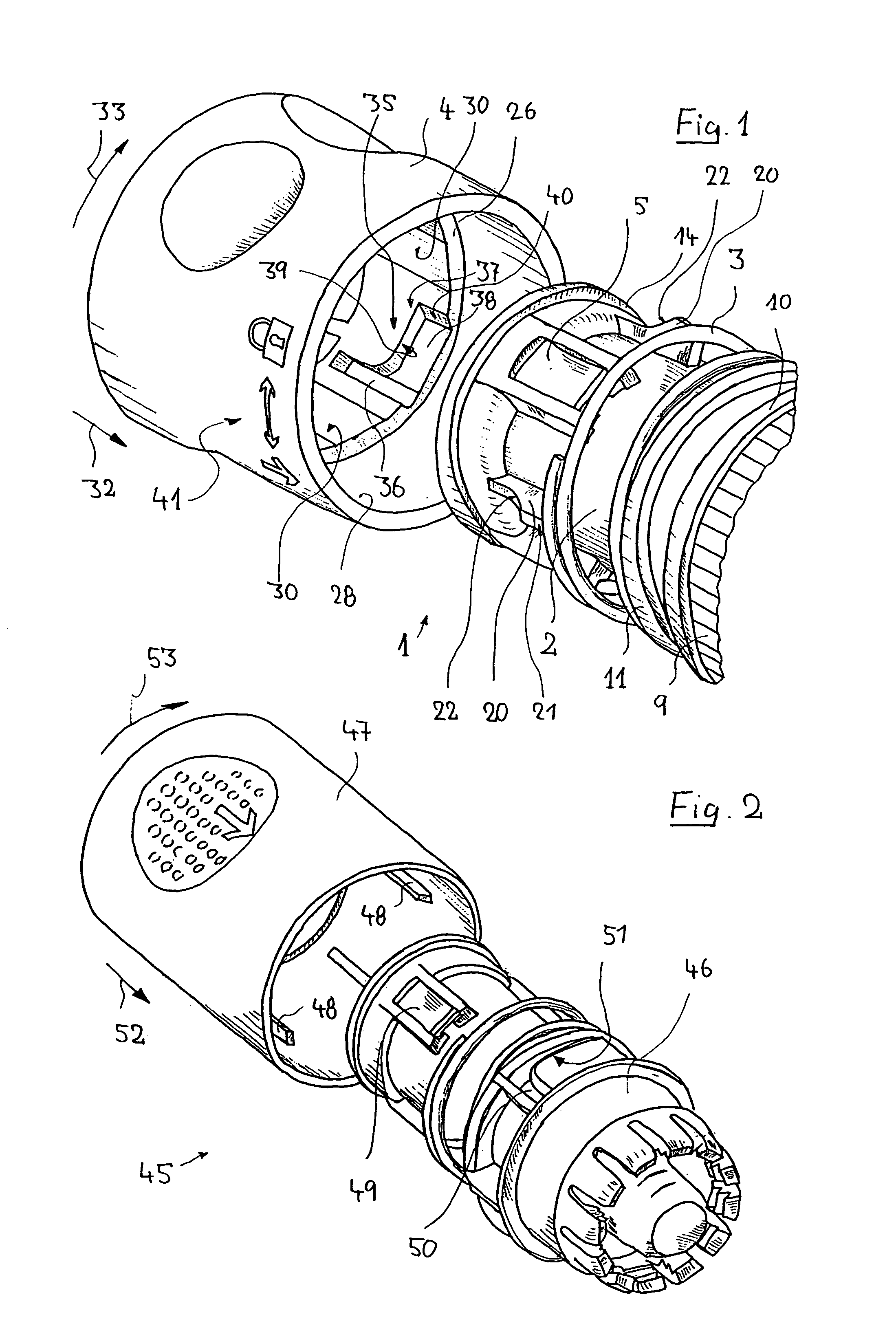

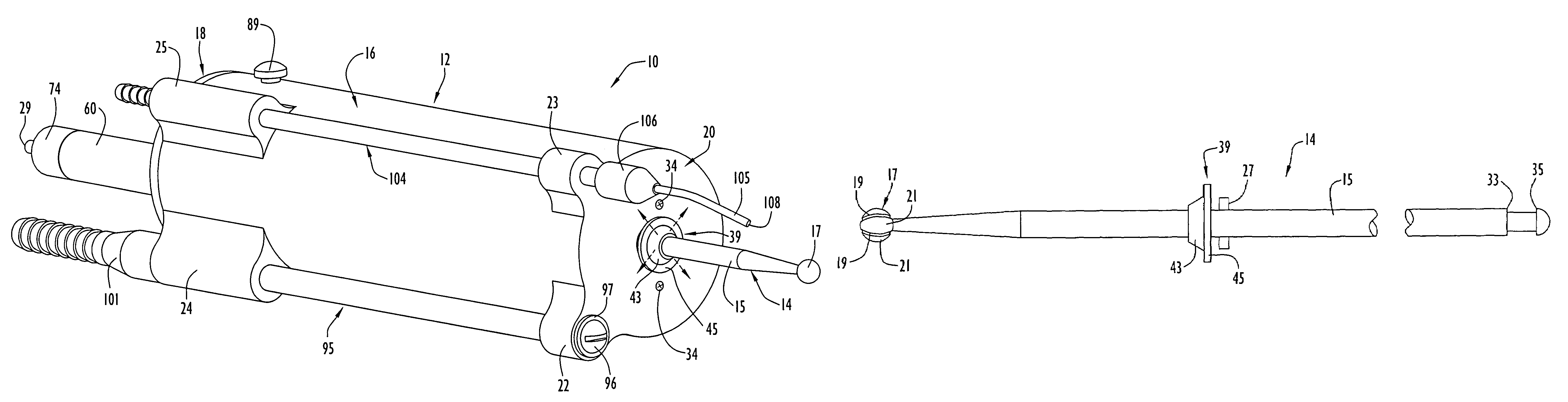

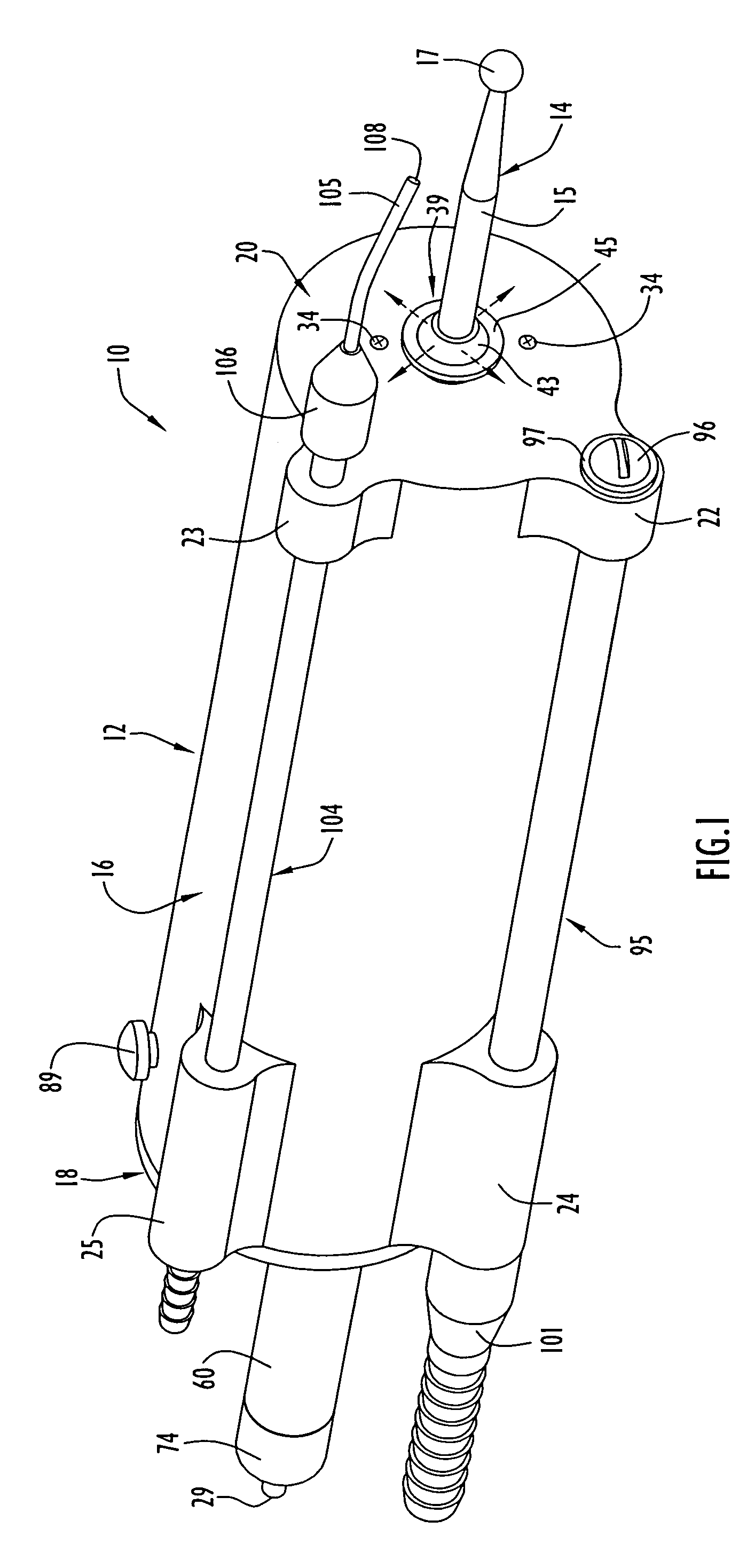

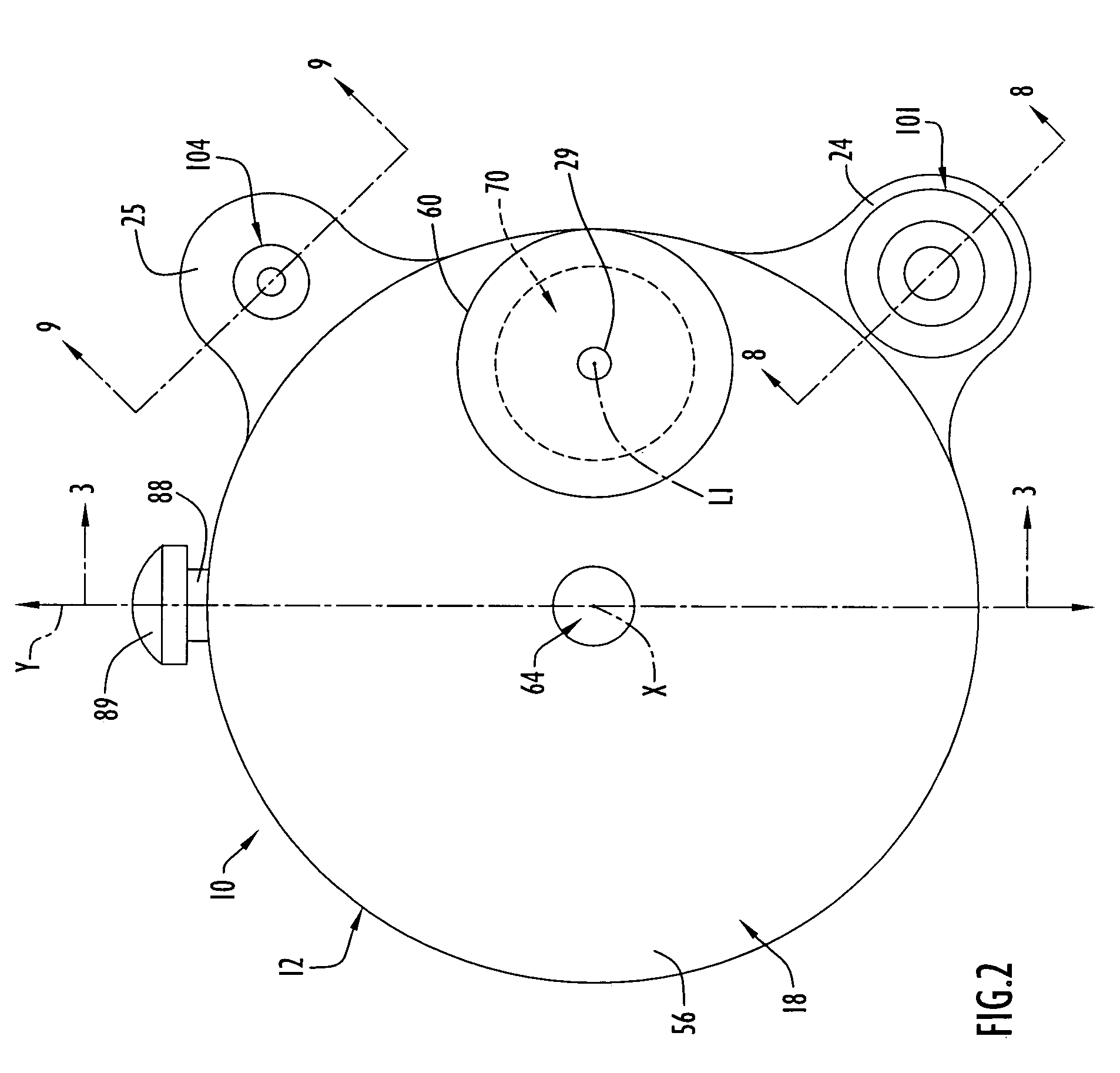

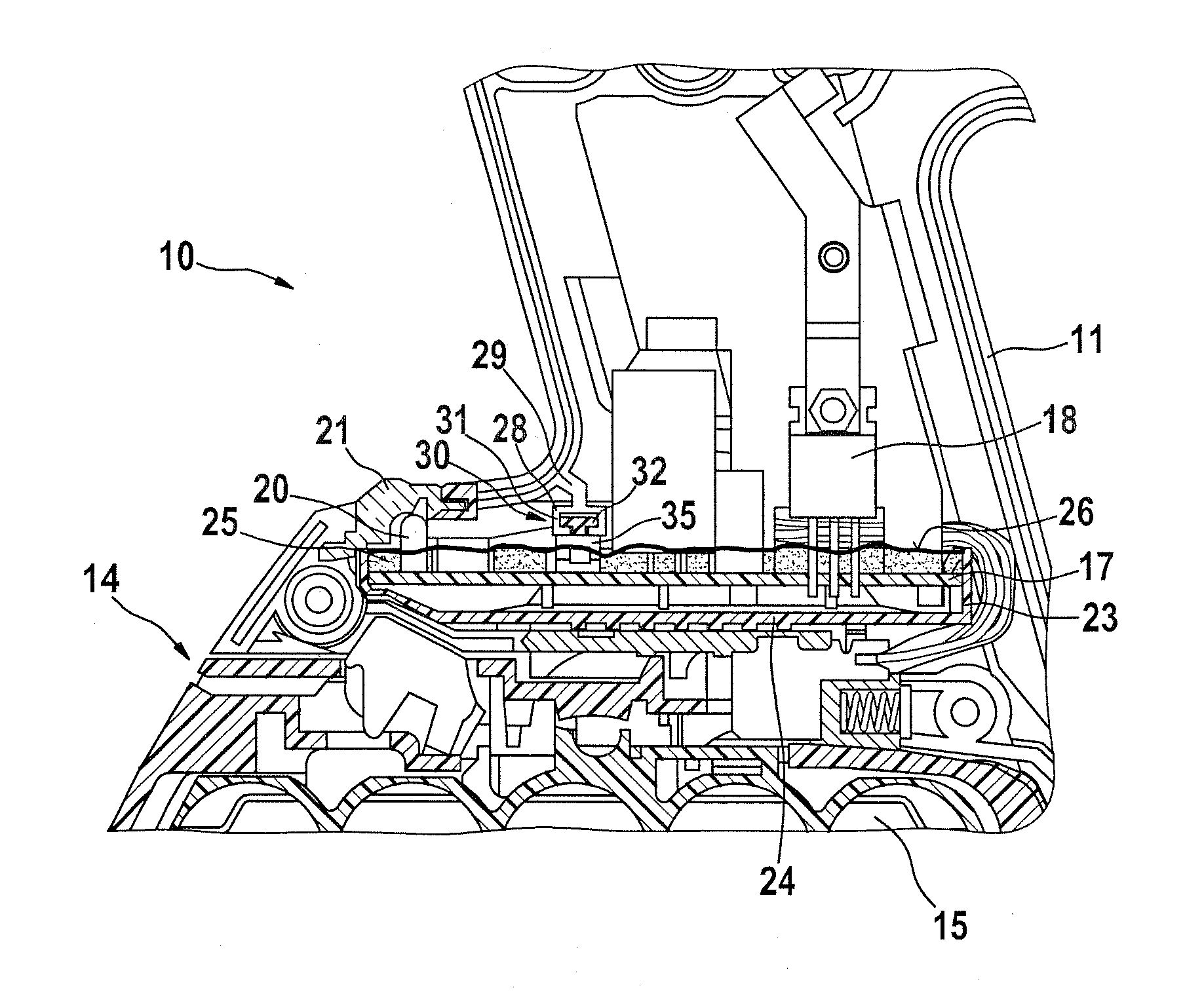

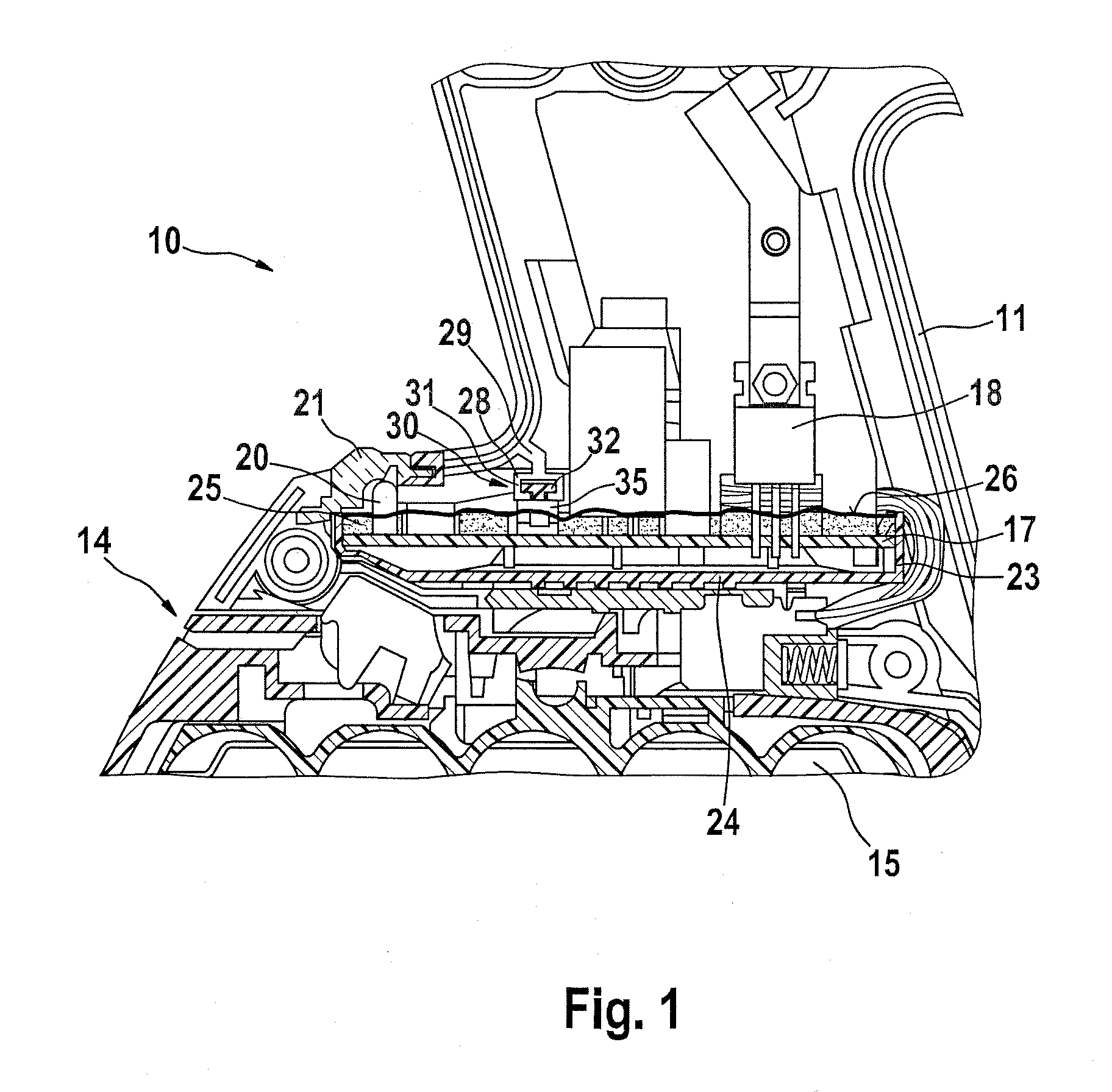

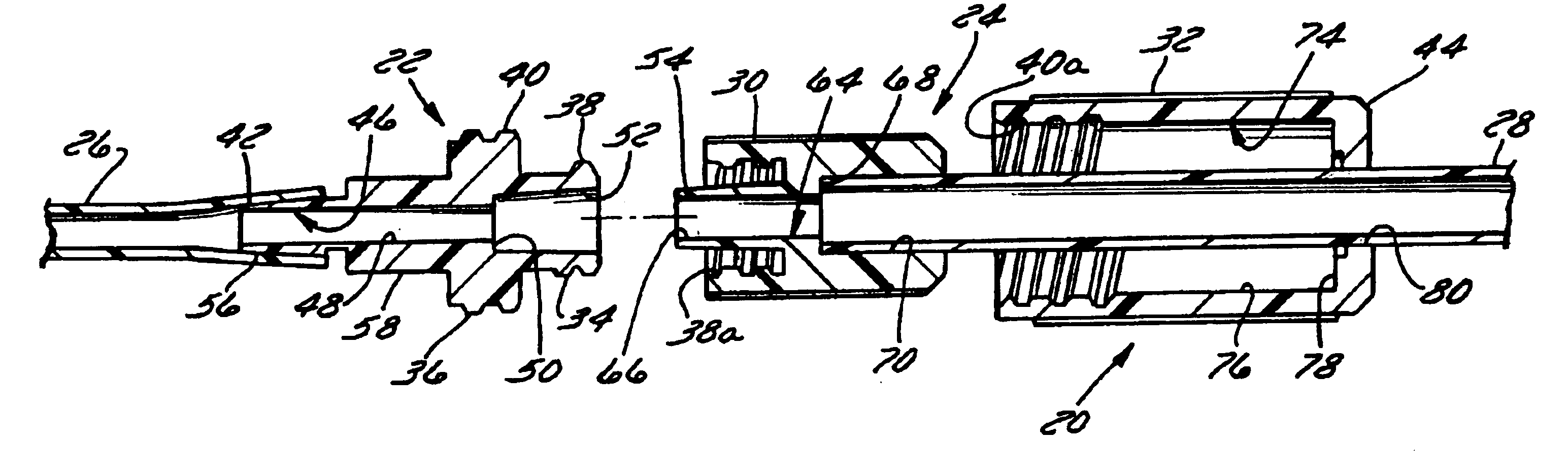

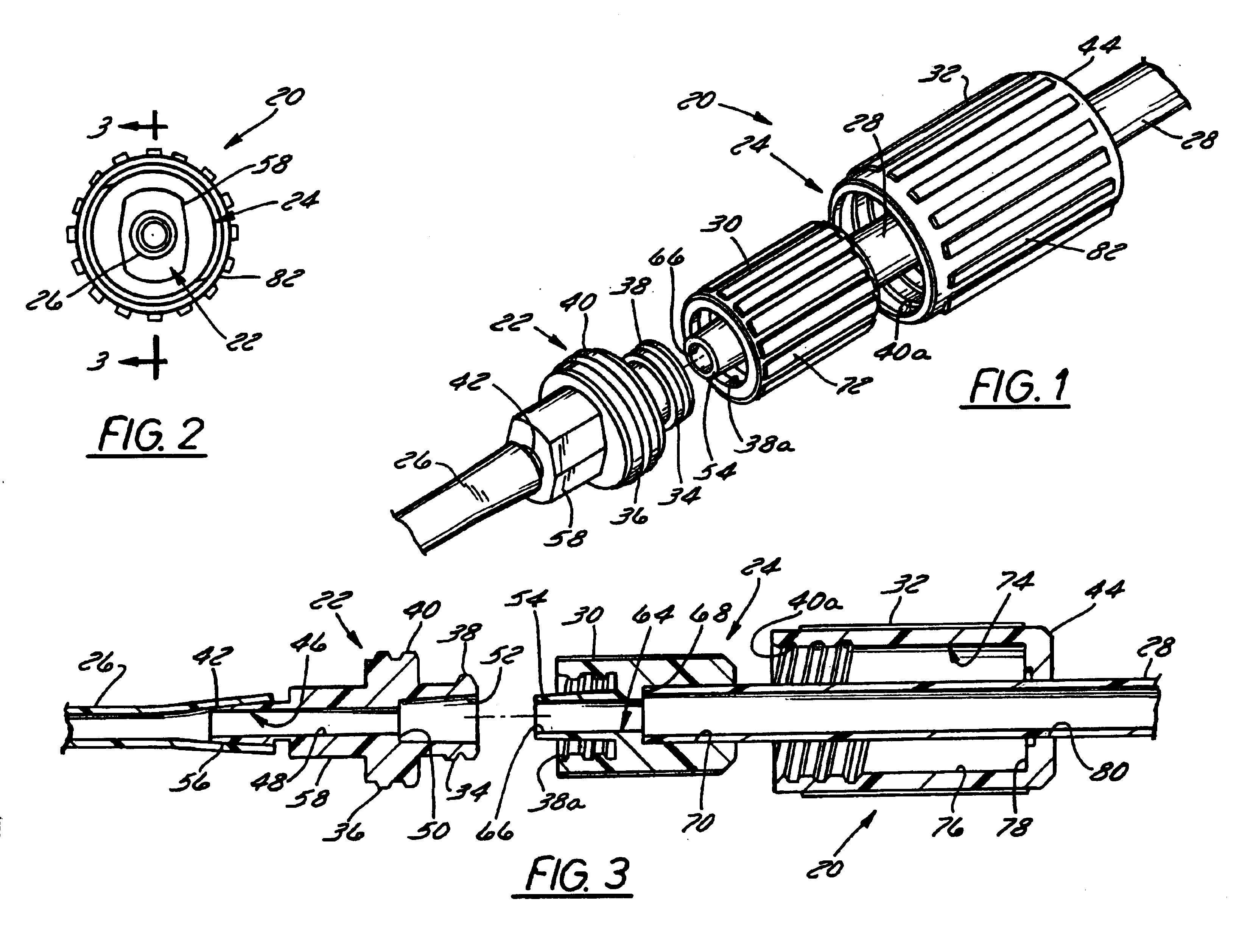

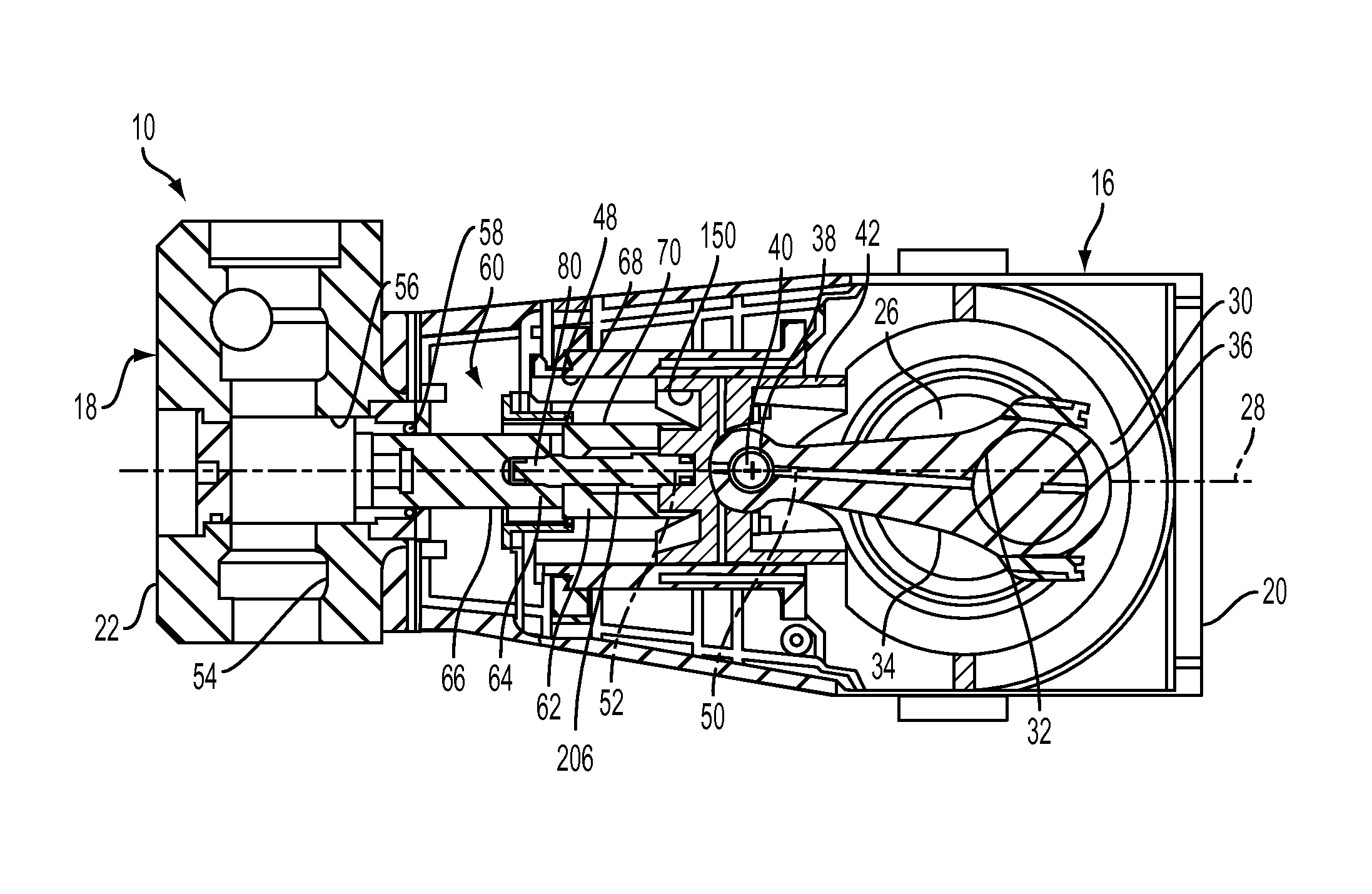

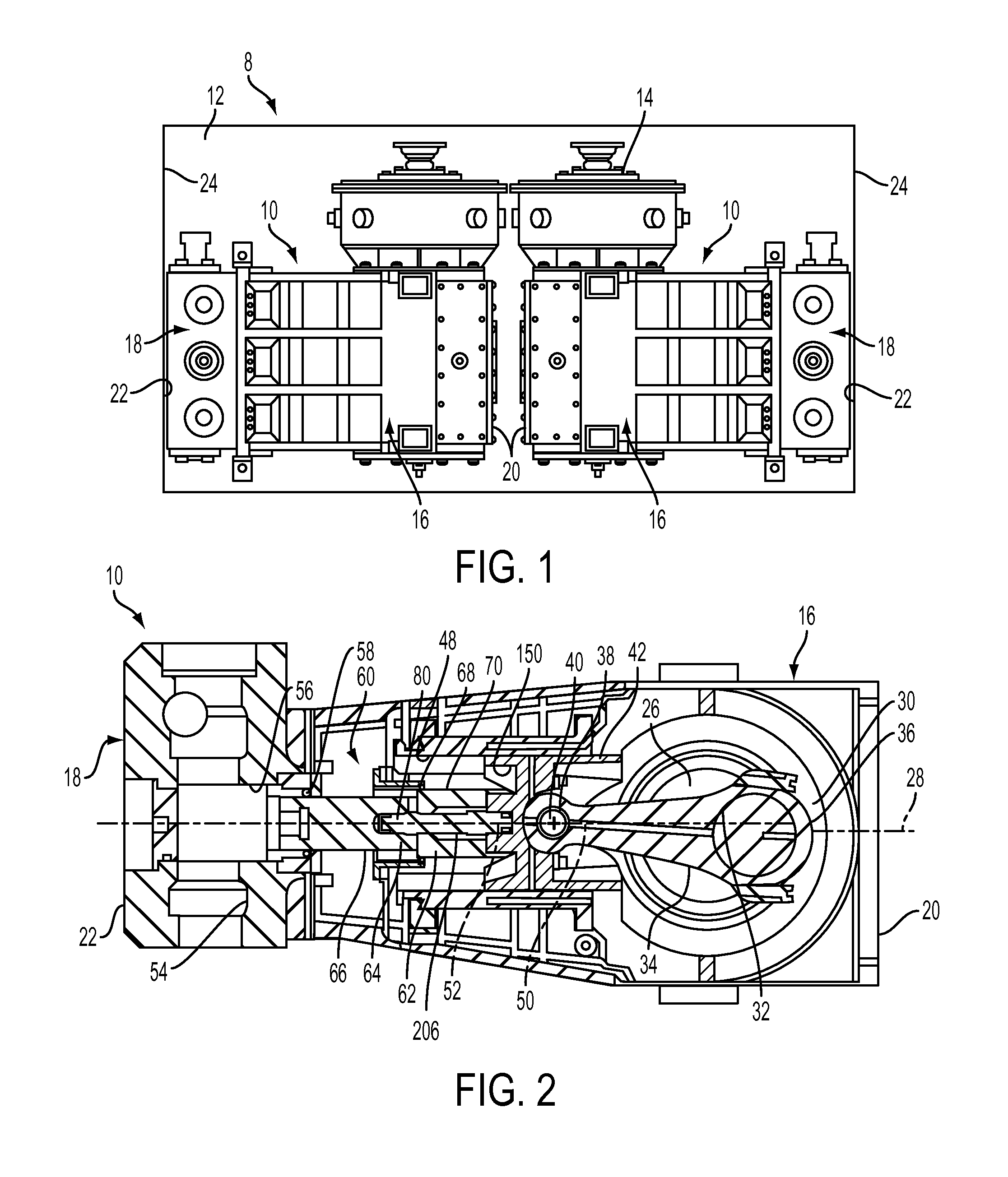

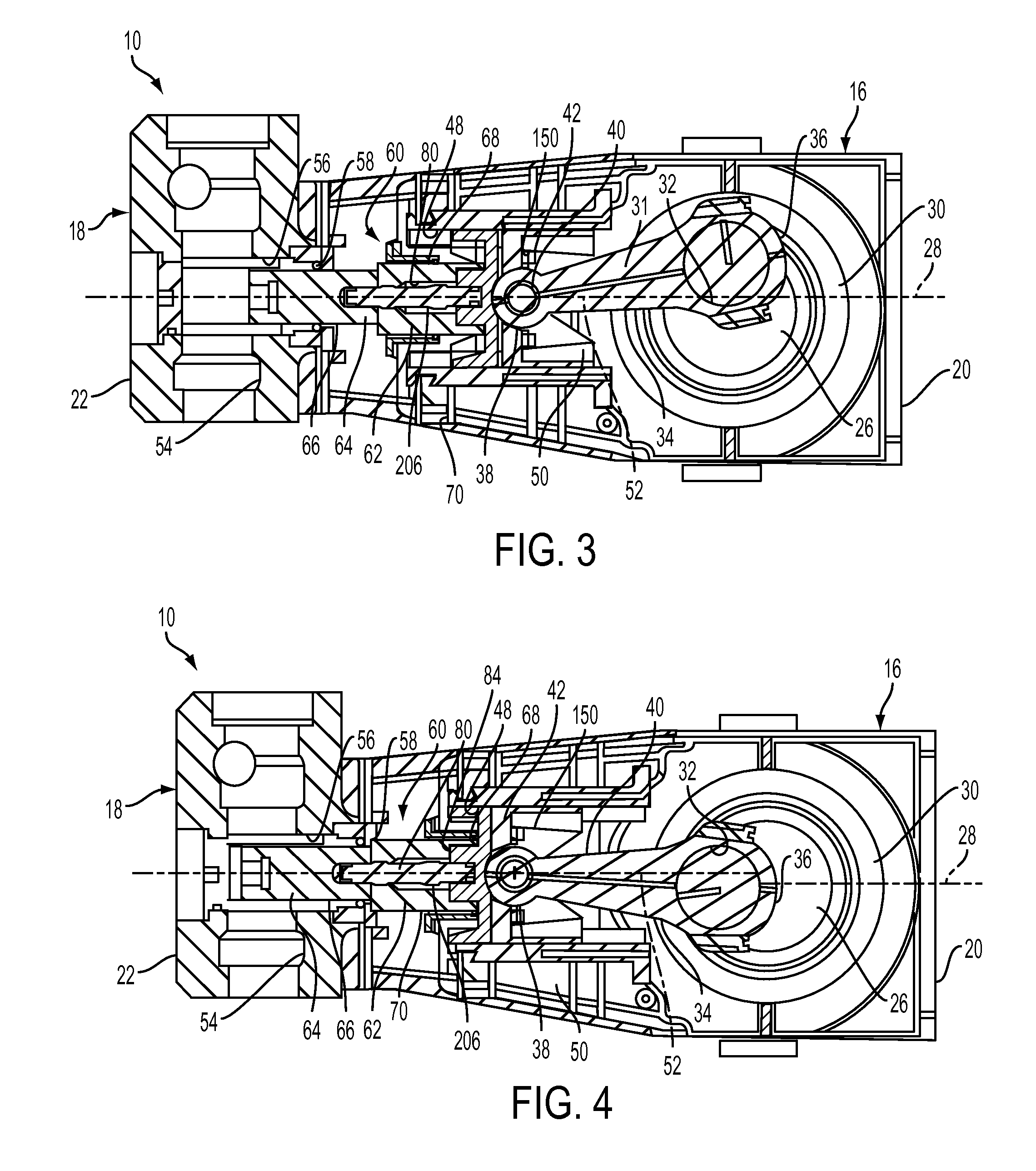

Motorized surgical handpiece

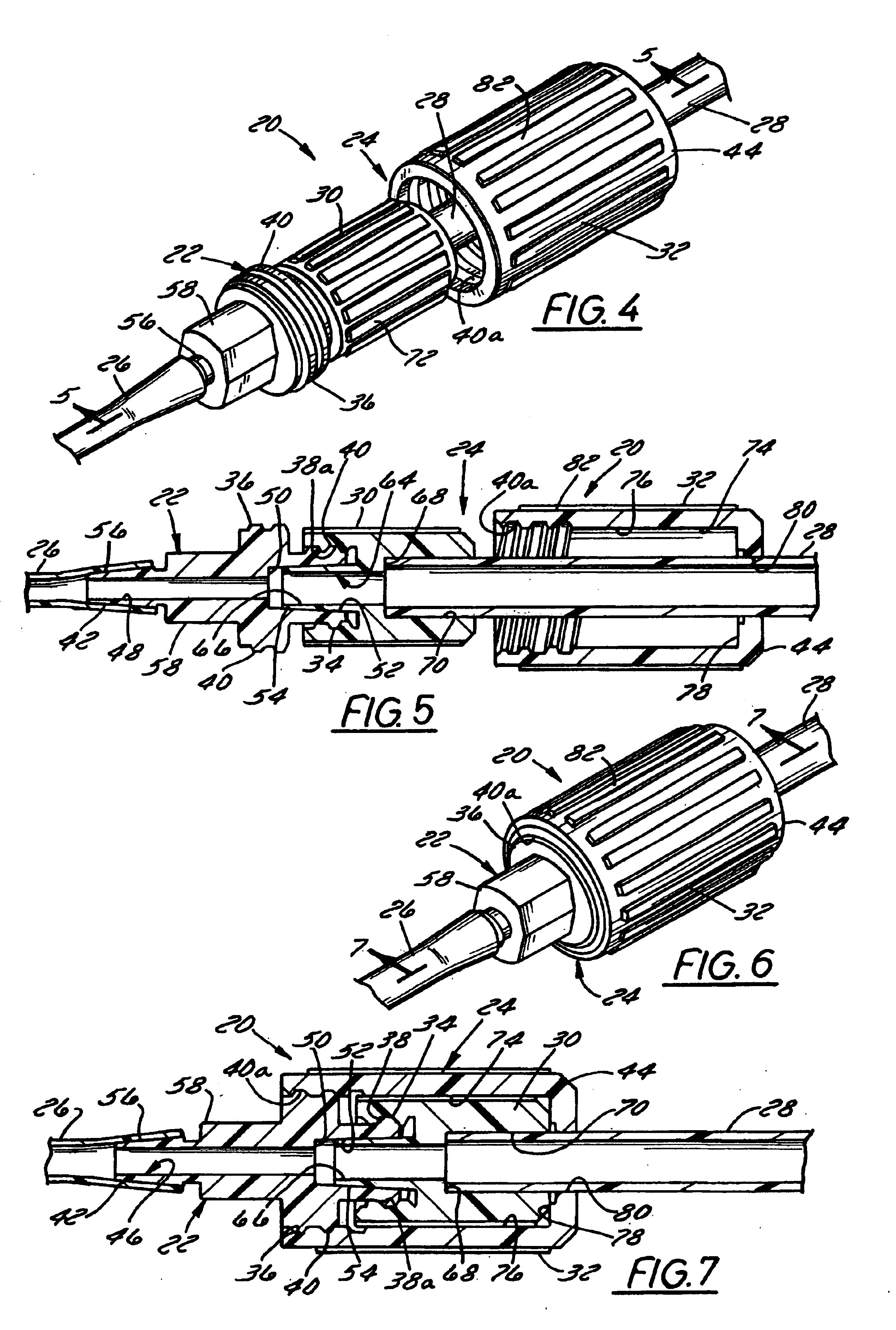

A motorized surgical handpiece comprises a housing enclosing an interior containing a motor and an output shaft for being driven in rotation by the motor. The output shaft has a central longitudinal axis, a bore extending therethrough for receiving a shank of a surgical tool to be rotatably driven by the output shaft, a forward end portion extending forwardly beyond the motor and a rearward end portion extending rearwardly beyond the motor. The housing has a continuous lumen extending entirely therethrough formed in part by the output shaft bore for insertion of a bore brush through the lumen for cleaning when the surgical tool is removed from the handpiece. The handpiece has forward and rearward labyrinth seals comprising rotor components respectively attached to the forward and rearward end portions of the output shaft for rotation in corresponding stator components with there being a labyrinthine clearance between each rotor component and its stator component to receive pressurized air during use and during cleaning of the handpiece to avoid the entry of contaminants.

Owner:ROGERS WILLIAM G

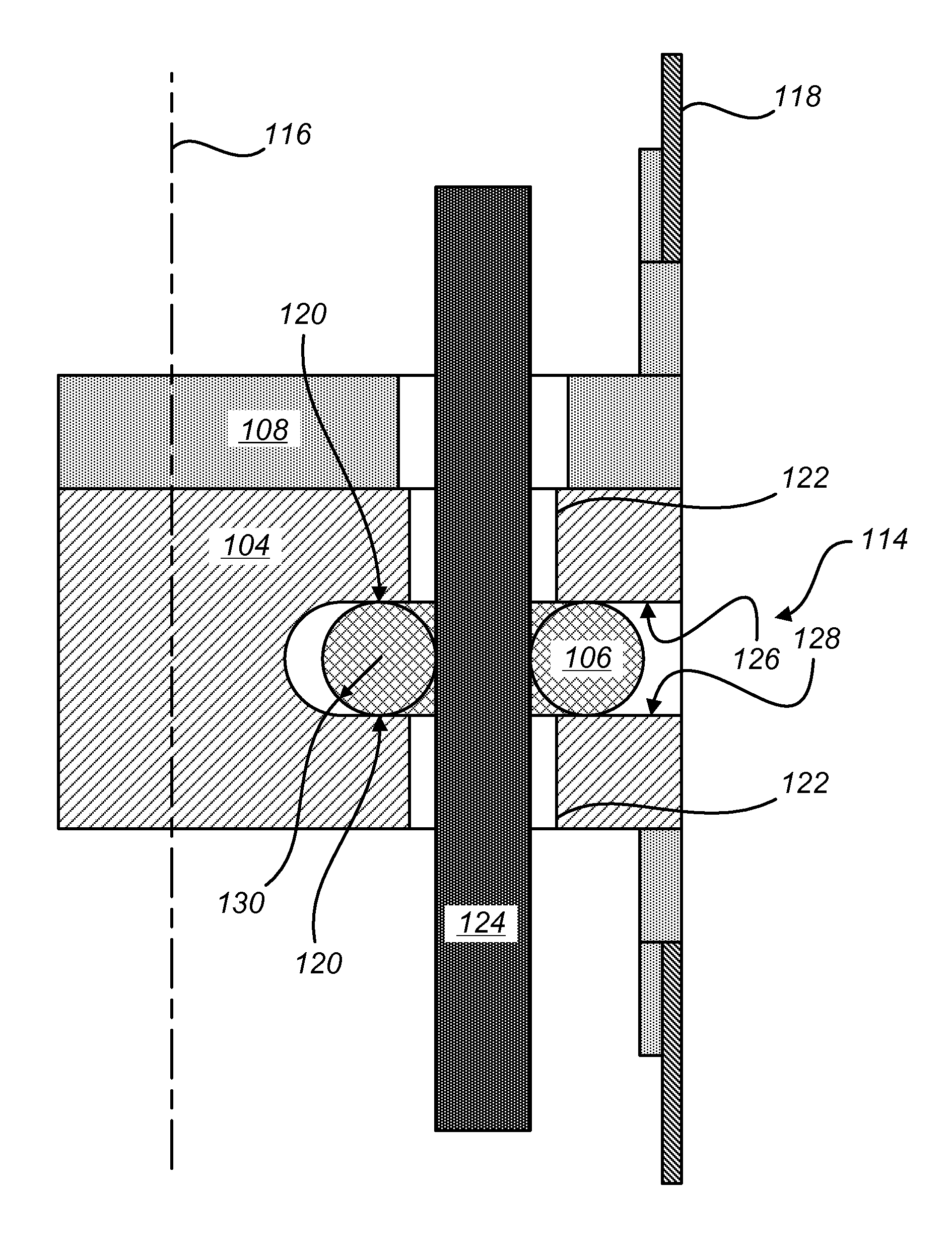

Seals and sealing methods for a surgical instrument having an articulated end effector actuated by a drive shaft

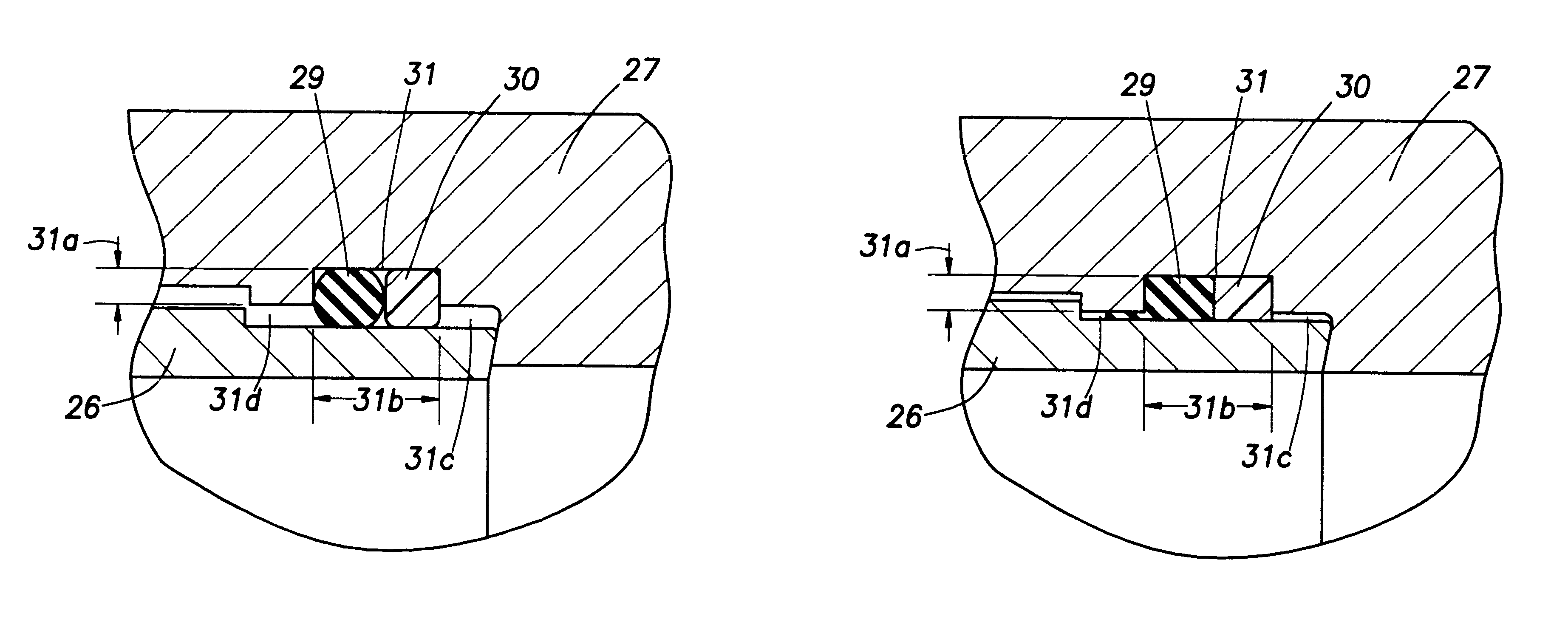

Sealing assemblies and methods are disclosed for sealing a surgical instrument having an internal drive shaft subject to lateral displacement. A sealing assembly includes a rigid portion shaped to interface with an instrument shaft of the surgical instrument. A laterally oriented slot is open at a radially perimeter location and configured to receive an o-ring seal via the perimeter location. Apertures are disposed on opposing sides of the slot and open to the slot. The apertures are configured to receive the drive shaft there through and are larger than the drive shaft to accommodate lateral displacement of the drive shaft. The slot includes opposing internal sides spaced to interface with opposed axial surfaces of the o-ring seal. The seal inhibits axial transmission of an insufflated gas and / or bodily fluids while accommodating lateral displacement of the drive shaft.

Owner:INTUITIVE SURGICAL OPERATIONS INC

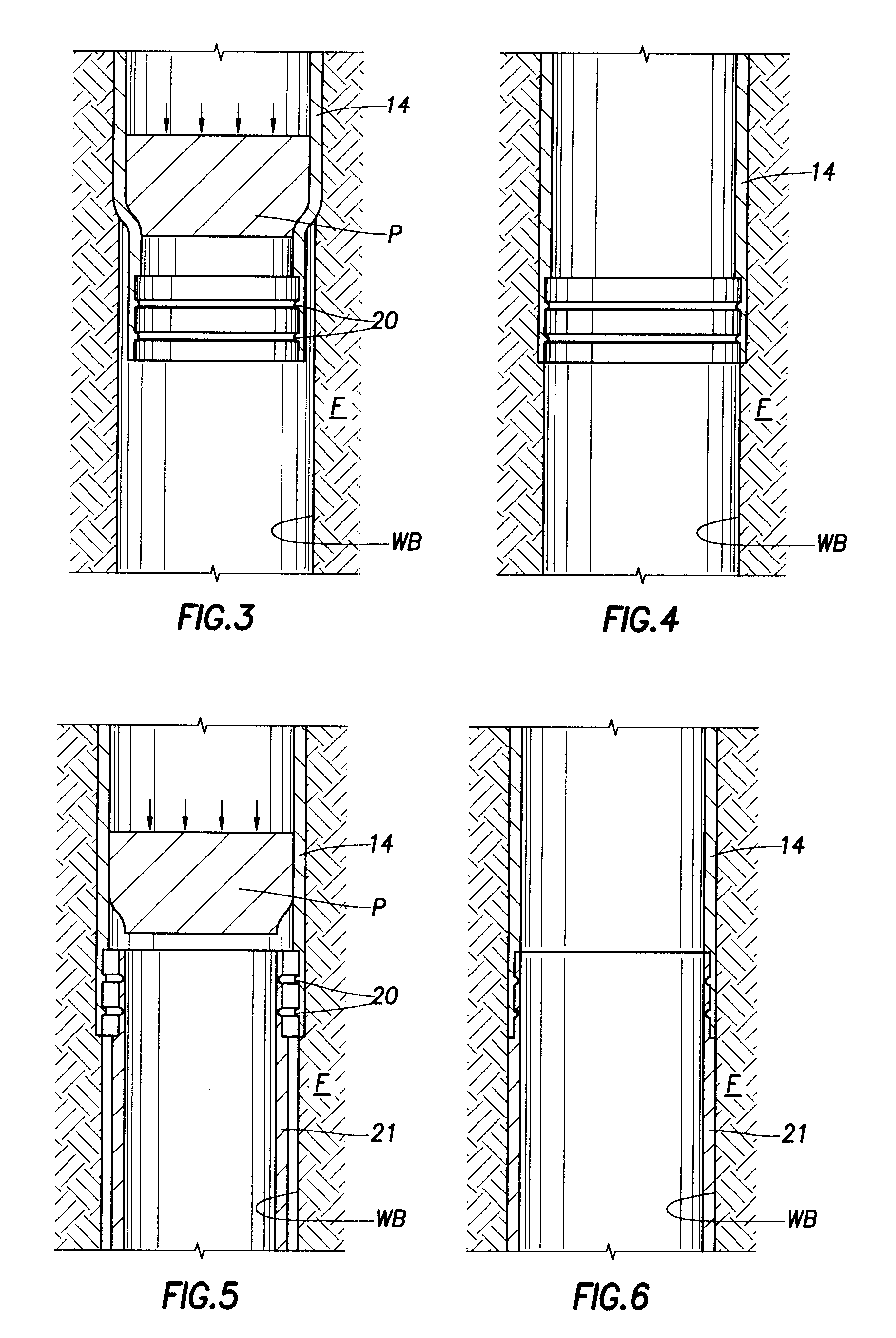

Expandable joint connector

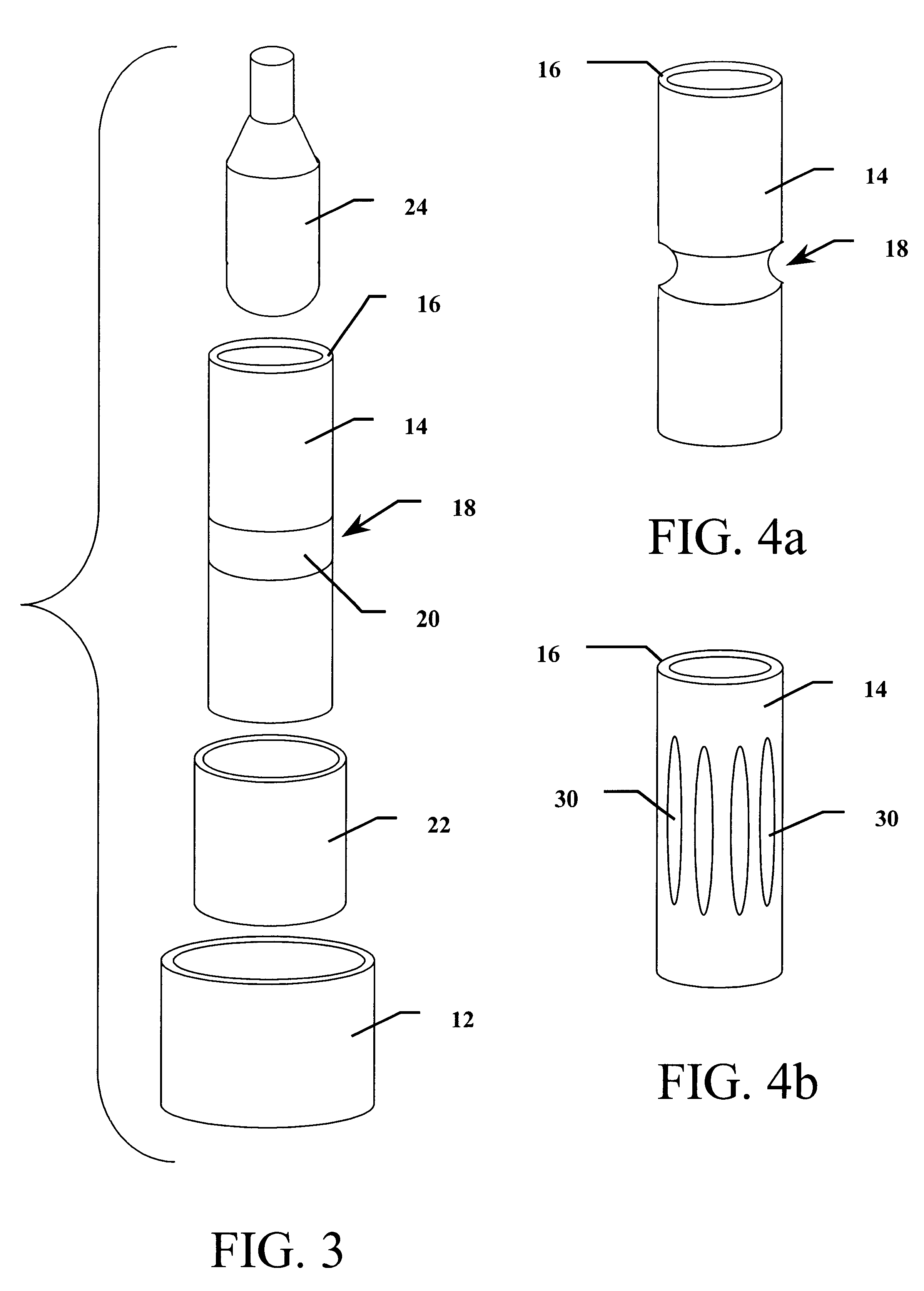

InactiveUS6409175B1Lessen and eliminate radial engagementRadial expansionDrilling rodsCable inlet sealing meansEngineeringScrew thread

Methods and apparatus are provided for obtaining a secure mechanical connection and a pressure-tight seal in the overlapping area of two telescoping tubular bodies. The two bodies, including the overlapping area, are radially expanded to increase the inside diameter of the bodies. The expansion forces an annular seal in the overlapping area into a pressure-sealing engagement between the bodies. A string of pipe assembled from joints secured to each other by telescoping, threadedly engaged expanded pin and box connections may be radially expanded into a surrounding well bore to provide a cased well having an internal diameter greater than the original internal diameter of the pipe string. The seal in the connection comprises an annular elastomeric seal ring and an annular Teflon spacer ring carried in a specially dimensioned groove formed in either the box or the pin, or both members of the connection. Radial expansion of the connection causes axial contraction of the groove, which acts with the spacer ring to expand the seal ring radially to seal the annular space created between the expanded pin and box.

Owner:ENVENTURE GLOBAL TECH LLC

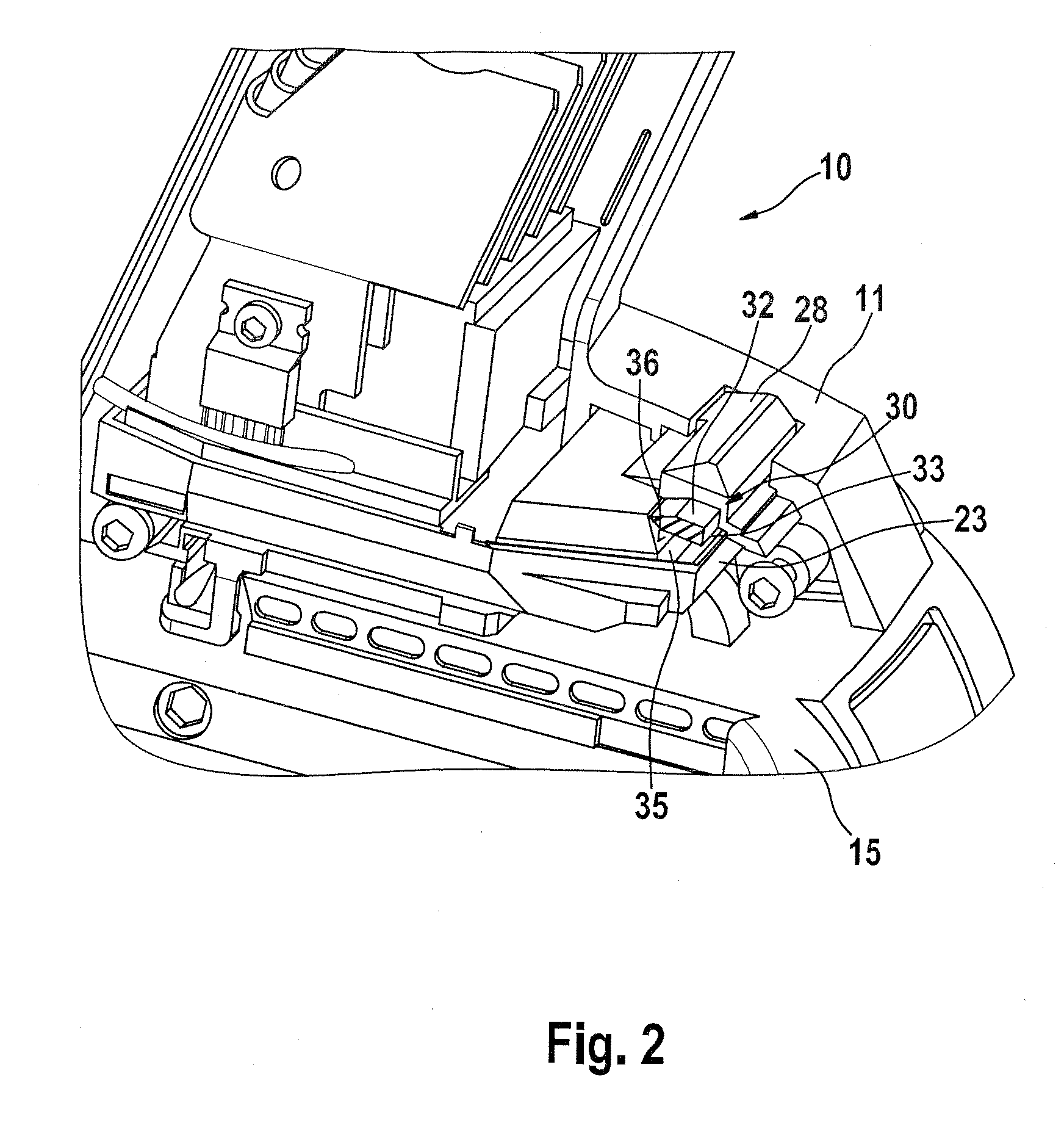

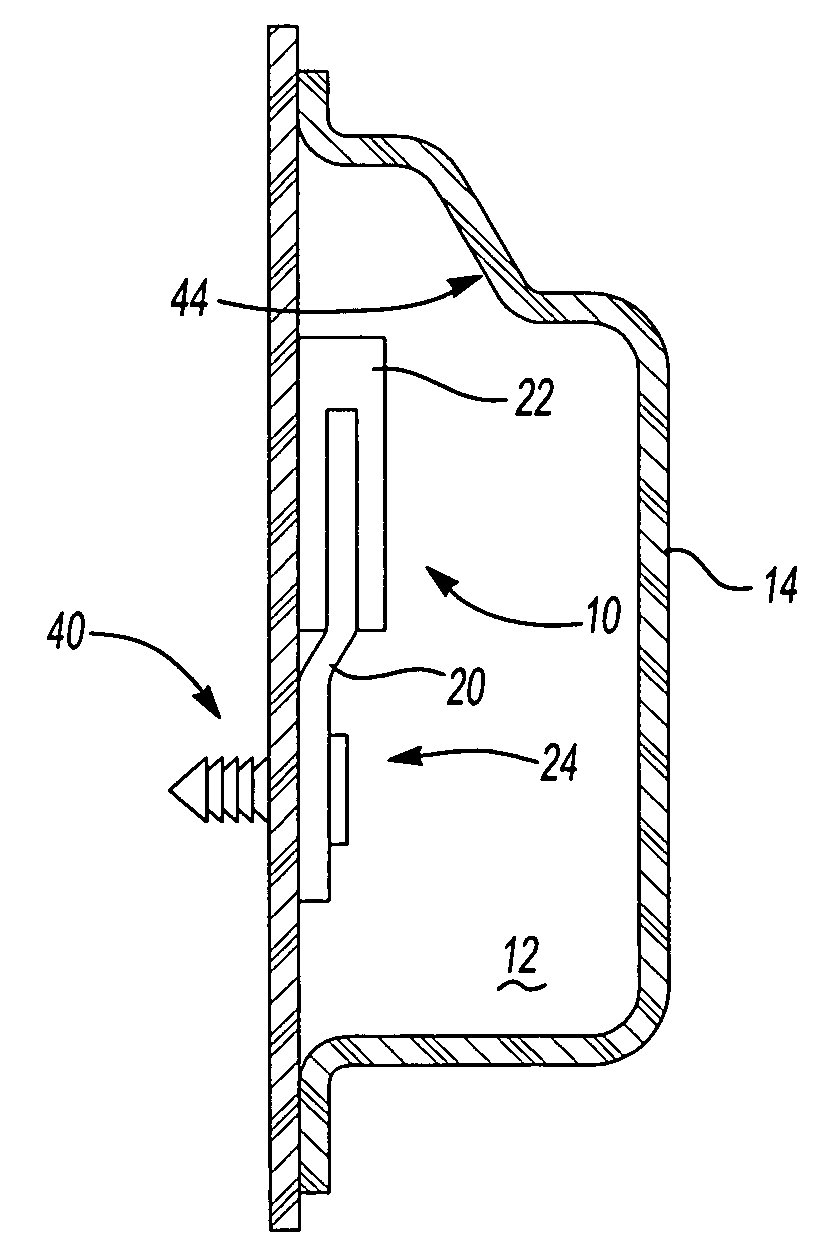

Electrical appliance, in particular hand-held power tool

The invention relates to an electrical appliance, in particular a hand-held power tool, having an appliance housing, a circuitry substrate that is situated in the appliance housing and equipped with components, and sealing elements for preventing the influx of dirt into the region of the circuitry substrate. According to the invention, the sealing elements seal a subregion of the circuitry substrate off from other regions inside the appliance housing.

Owner:ROBERT BOSCH GMBH

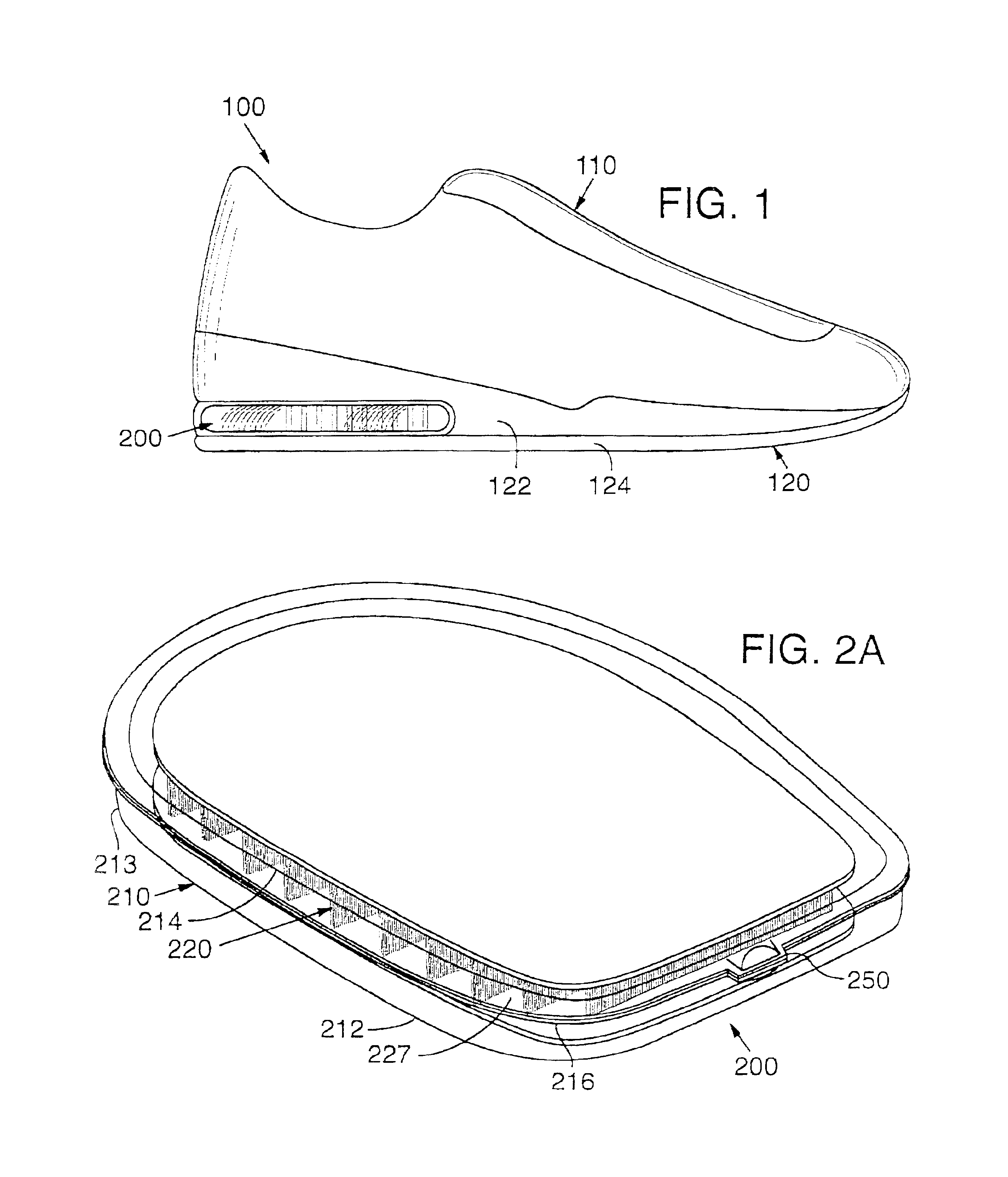

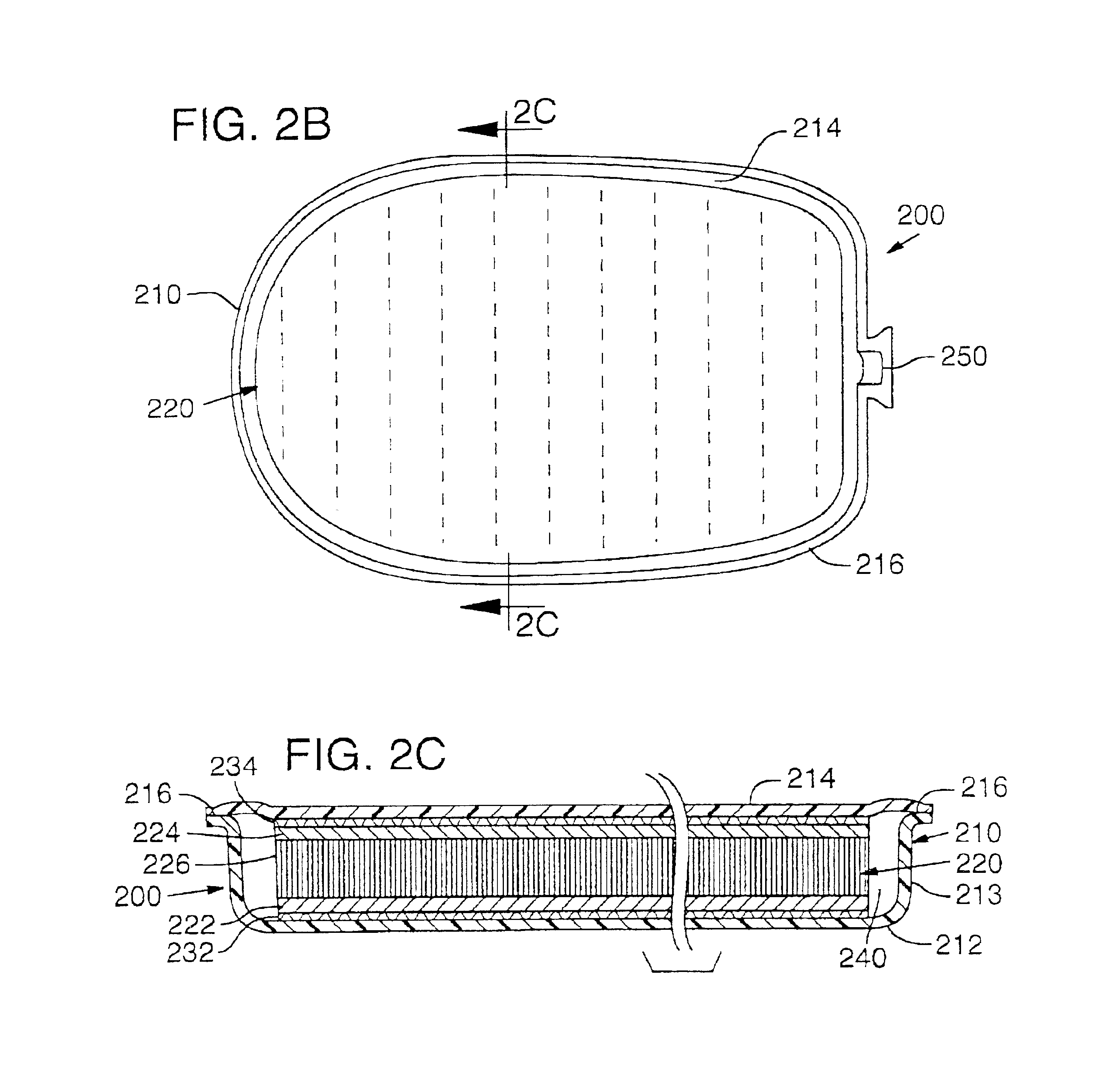

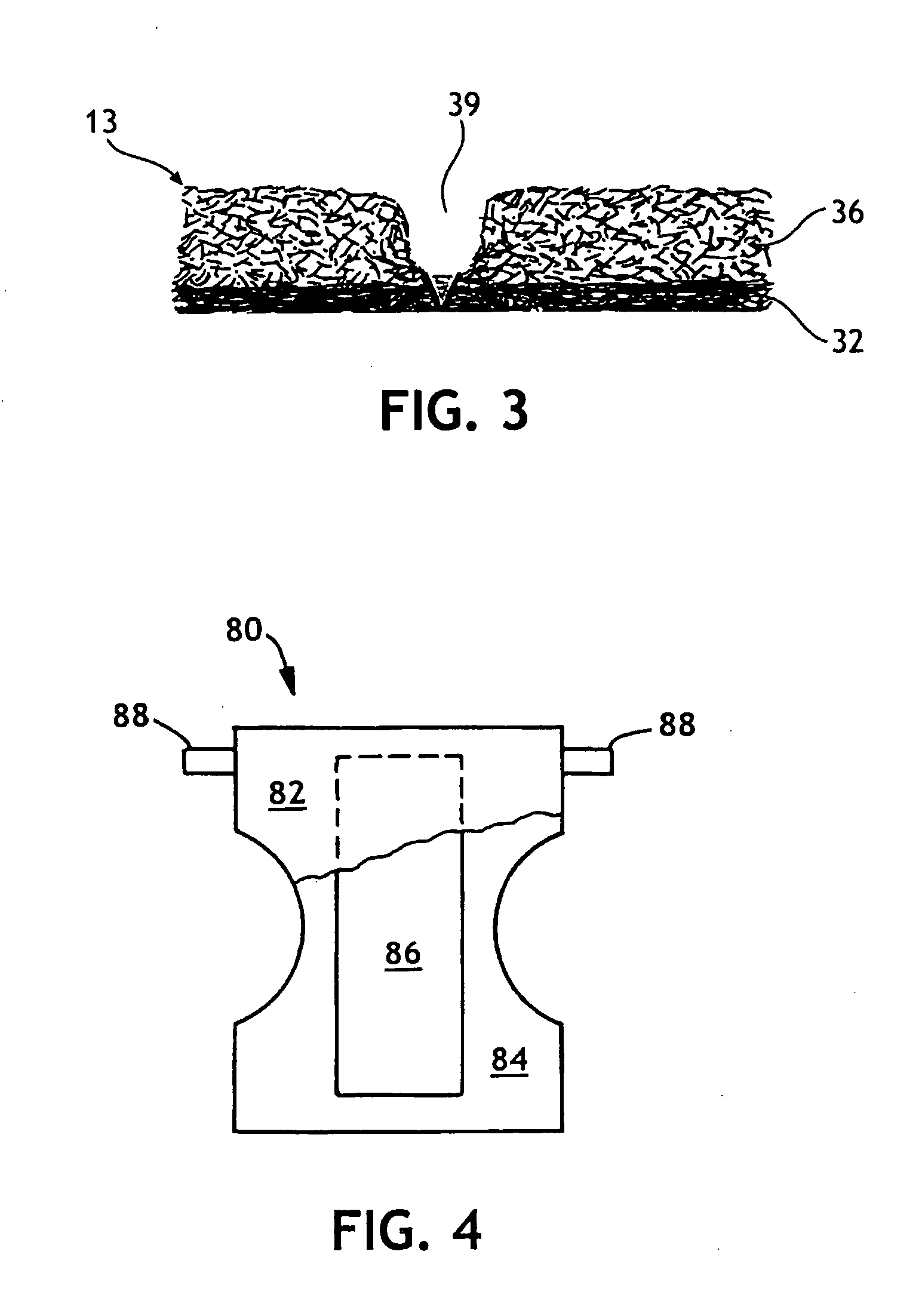

Method of thermoforming a bladder structure

InactiveUS6837951B2Increase awarenessImprove efficiencySolesOrnamental textile articlesBladder structureThermal contact

A method for thermoforming a resilient, fluid-filled bladder structure with thermal contact molding is disclosed. The bladder includes two sheets of thermoplastic material that are separated by at least one core formed of two spaced outer layers connected together by a plurality of connecting members. The bladder is formed by bonding the sheets to the core, bonding the sheets to each other around the periphery of the core and forming a sidewall between the sheets in a single mold. A fluid is then inserted into the space bounded by the peripheral bond and the two sheets such that the connecting members are extended.

Owner:NIKE INC

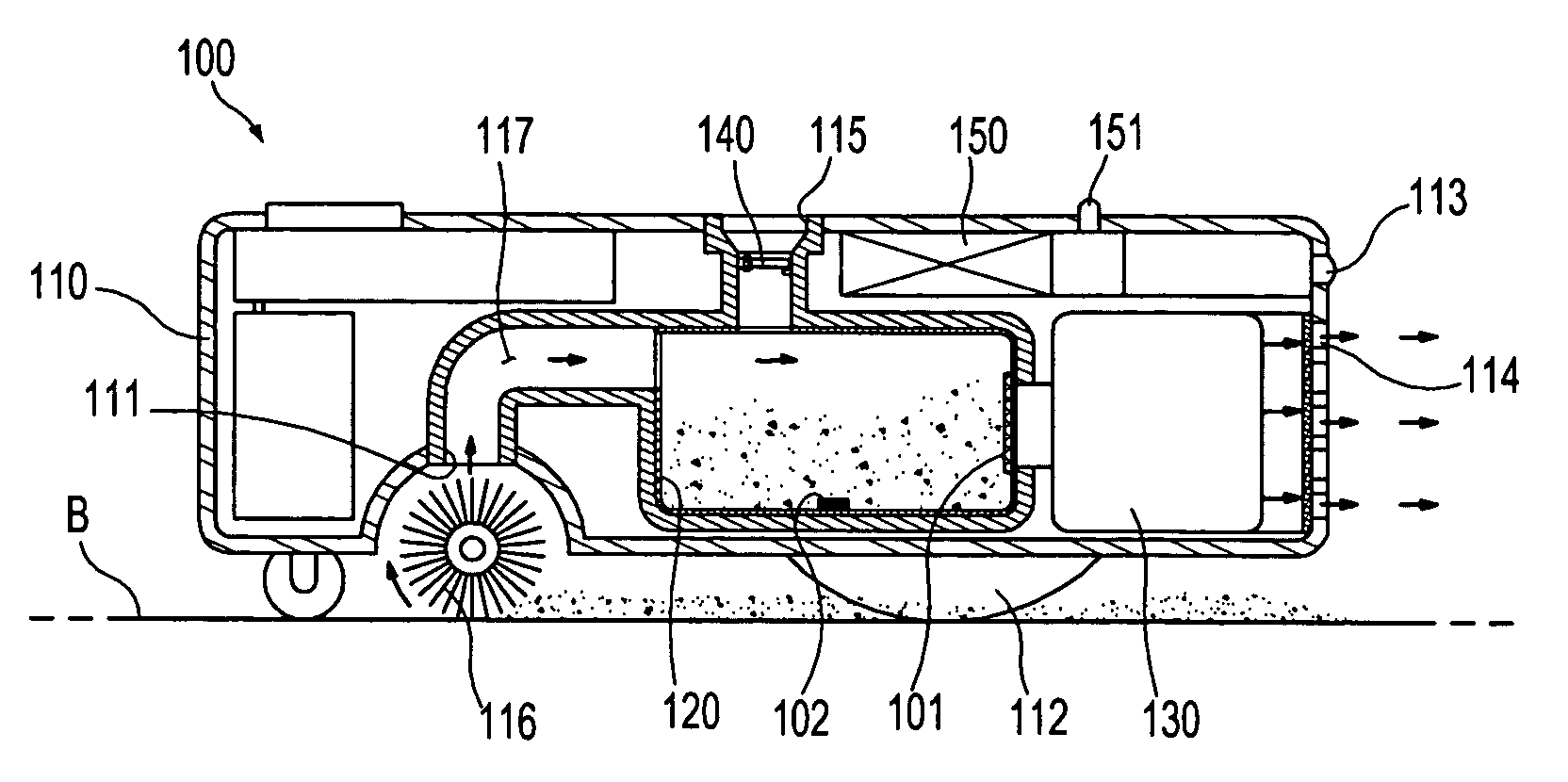

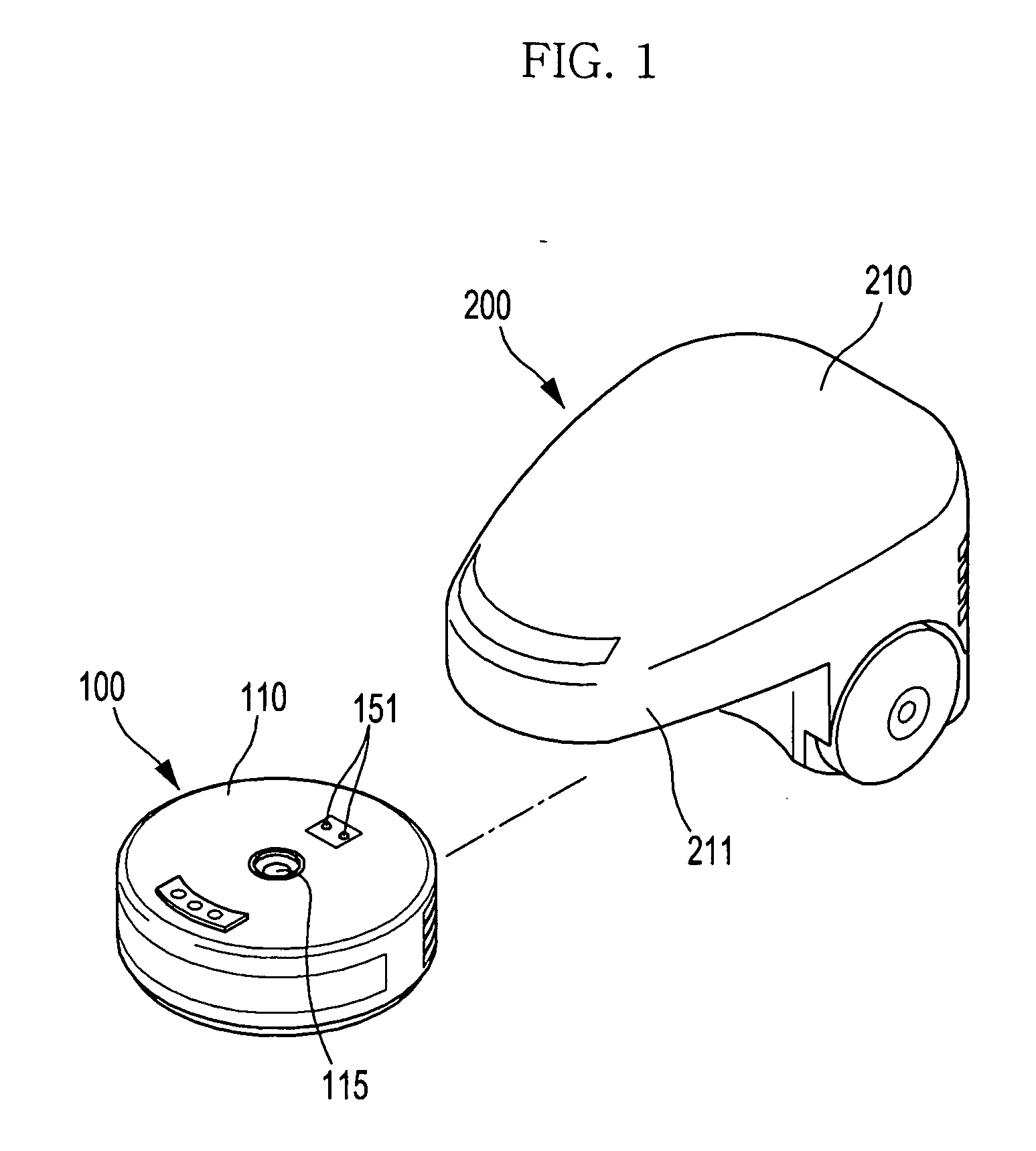

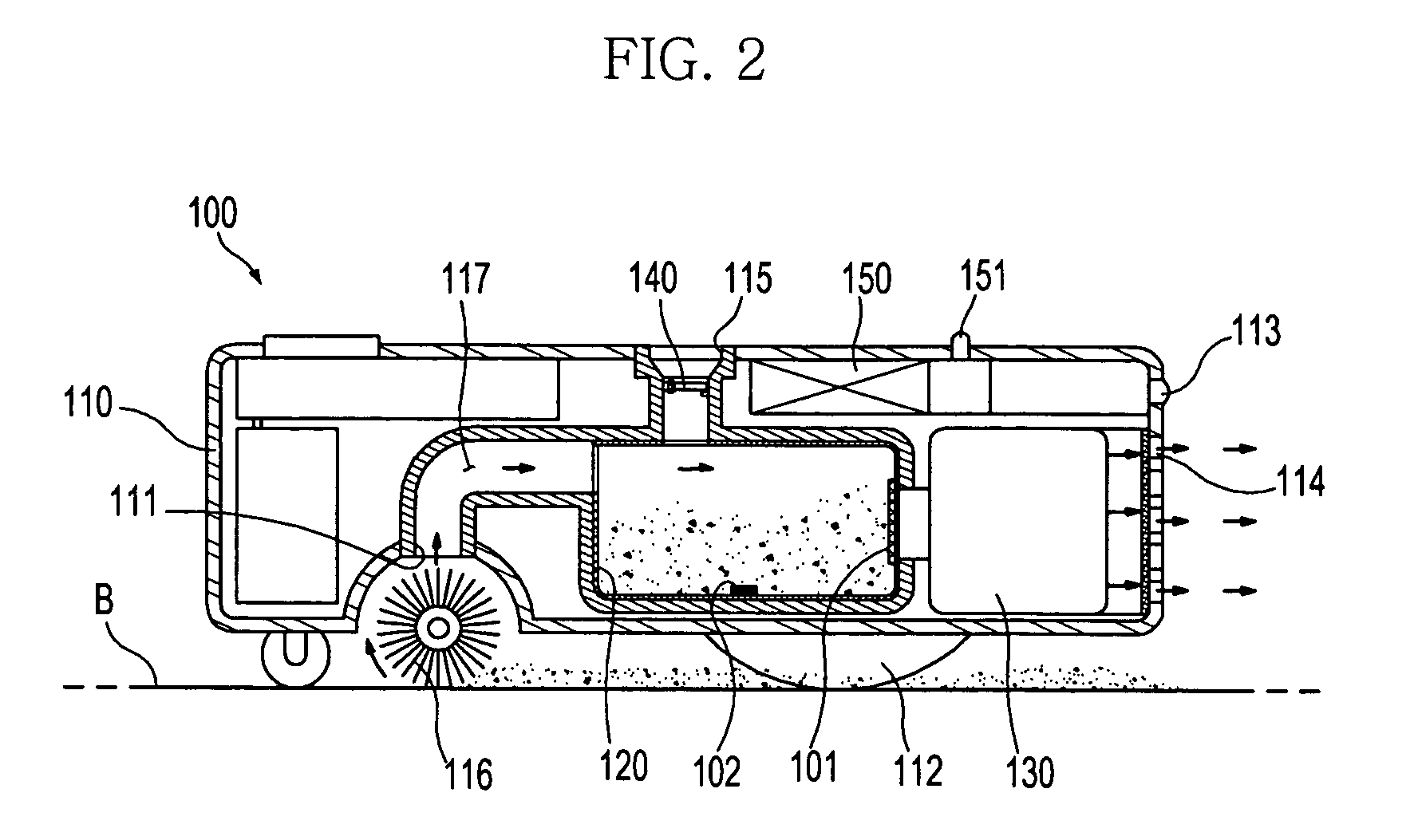

Cleaner system

InactiveUS20070157415A1Improved connecting position and structureImprove dust removal effectEngine sealsSuction cleanersDocking stationEngineering

A cleaner system having an improved connecting position and structure between a robot cleaner and a docking station for achieving an improvement in dust removal performance of the docking station. The docking station performs manual cleaning. The robot cleaner has a dust outlet at a top wall of the robot body to discharge the dust collected in the first dust collector into the docking station, and the docking station has a connection port at a position thereof corresponding to the dust outlet to receive the dust discharged from the dust outlet. The robot cleaner or docking station includes a connector to connect the dust outlet to the connection port. The docking station includes a suction part, suction pipe, and suction hole for manual operation. A channel switching member is mounted in the docking station to selectively apply power required to suck dust to the connection port or suction hole.

Owner:SAMSUNG ELECTRONICS CO LTD

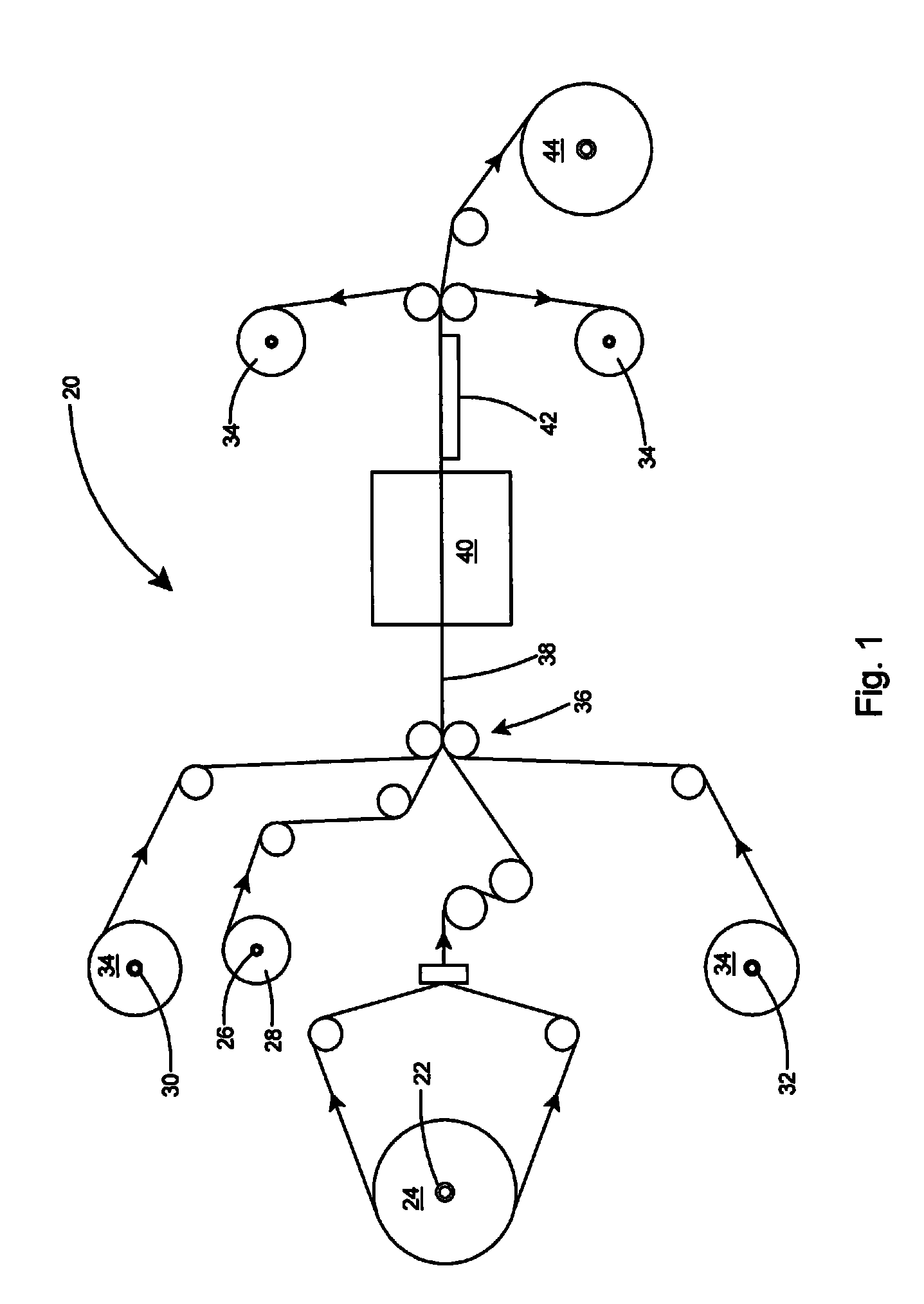

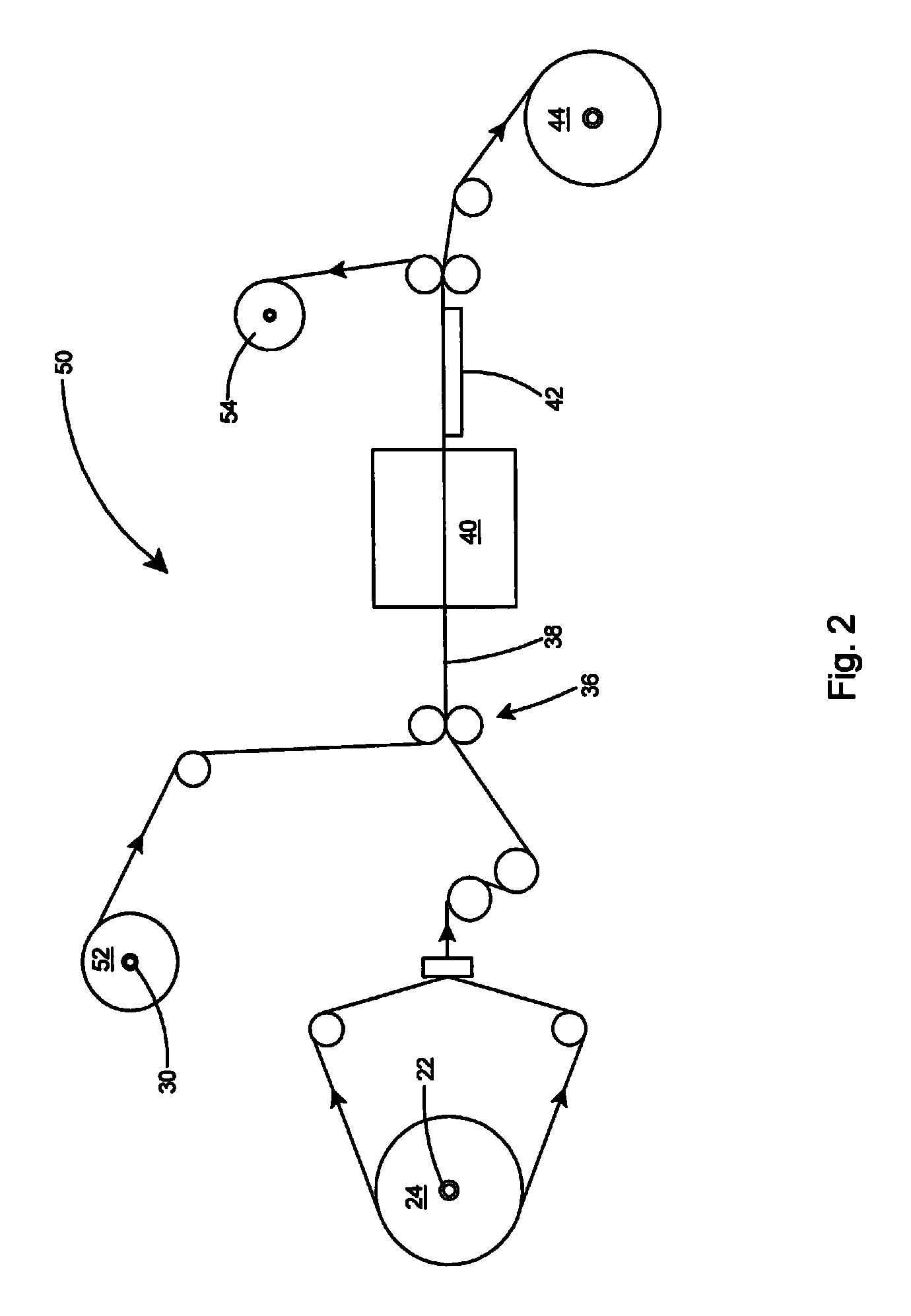

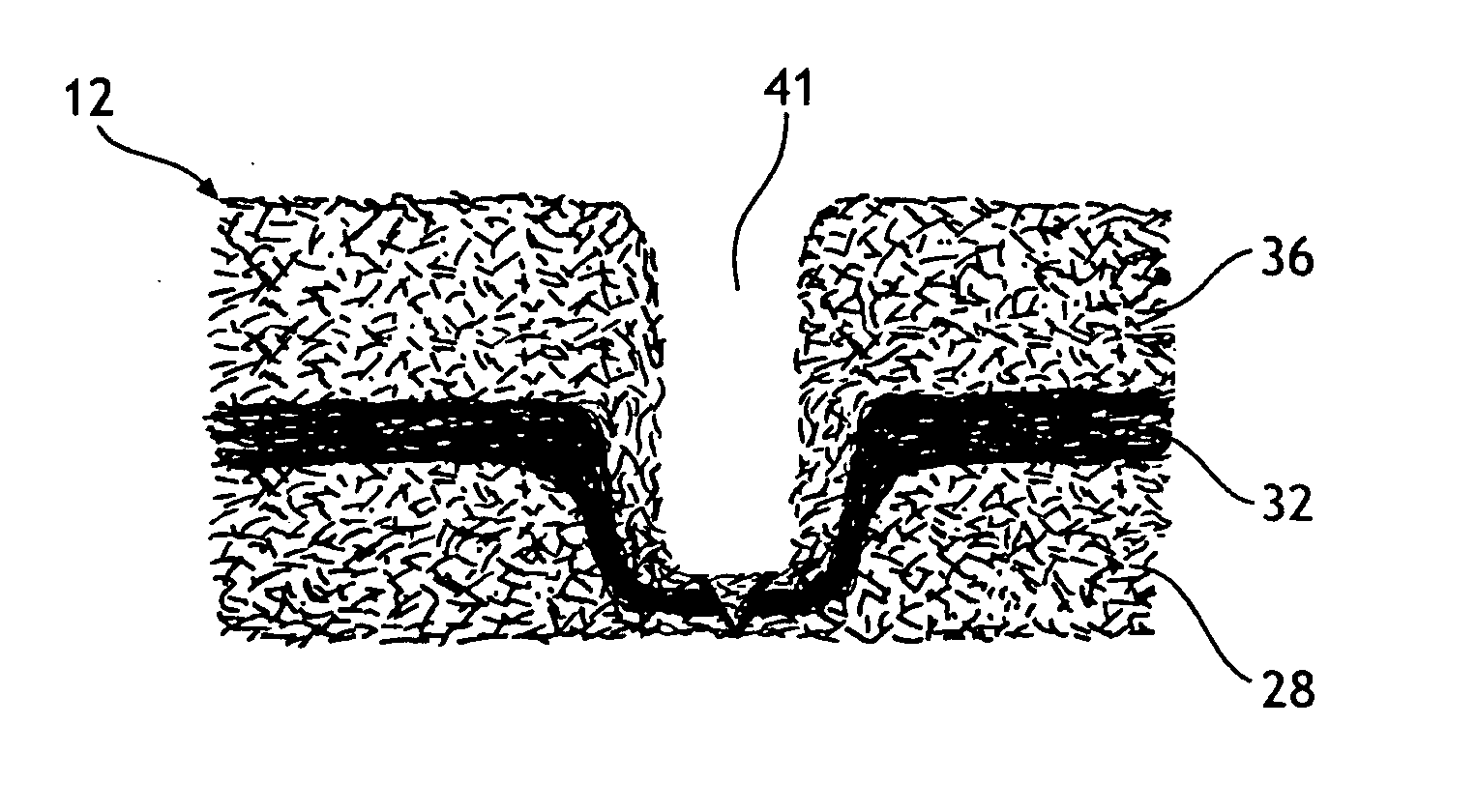

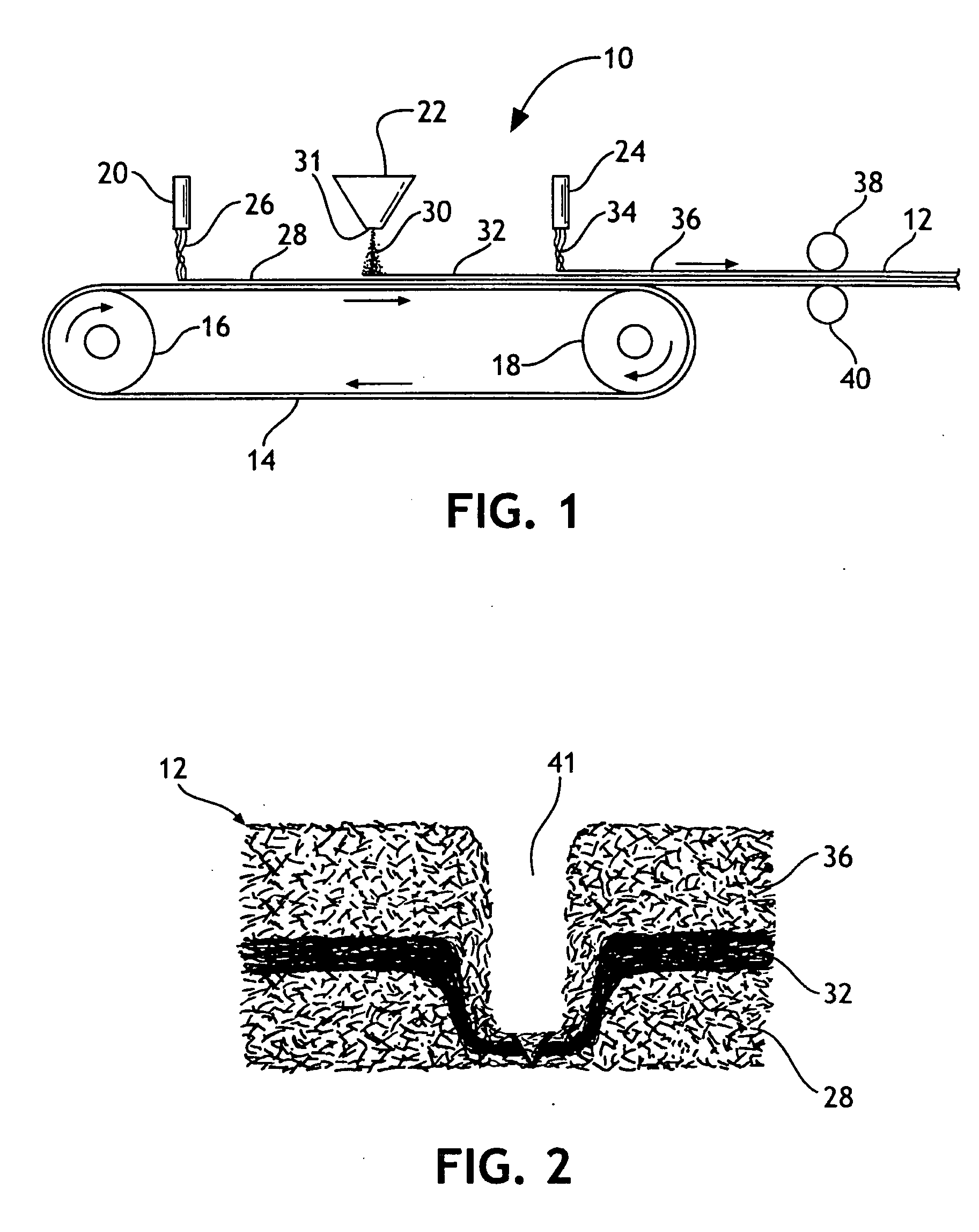

Nonwovens produced from multicomponent fibers

InactiveUS20080311815A1Reduce blockingReduce fusionNon-fibrous pulp additionNatural cellulose pulp/paperPolymer scienceSlurry

A water non-dispersible polymer microfiber is provided comprising at least one water non-dispersible polymer wherein the water non-dispersible polymer microfiber has an equivalent diameter of less than 5 microns and length of less than 25 millimeters. A process for producing water non-dispersible polymer microfibers is also provided, the process comprising: a) cutting a multicomponent fiber into cut multicomponent fibers; b) contacting a fiber-containing feedstock with water to produce a fiber mix slurry; wherein the fiber-containing feedstock comprises cut multicomponent fibers; c) heating the fiber mix slurry to produce a heated fiber mix slurry; d) optionally, mixing the fiber mix slurry in a shearing zone; e) removing at least a portion of the sulfopolyester from the multicomponent fiber to produce a slurry mixture comprising a sulfopolyester dispersion and water non-dispersible polymer microfibers; and f) separating the water non-dispersible polymer microfibers from the slurry mixture. A process for producing a nonwoven article is also provided.

Owner:EASTMAN CHEM CO

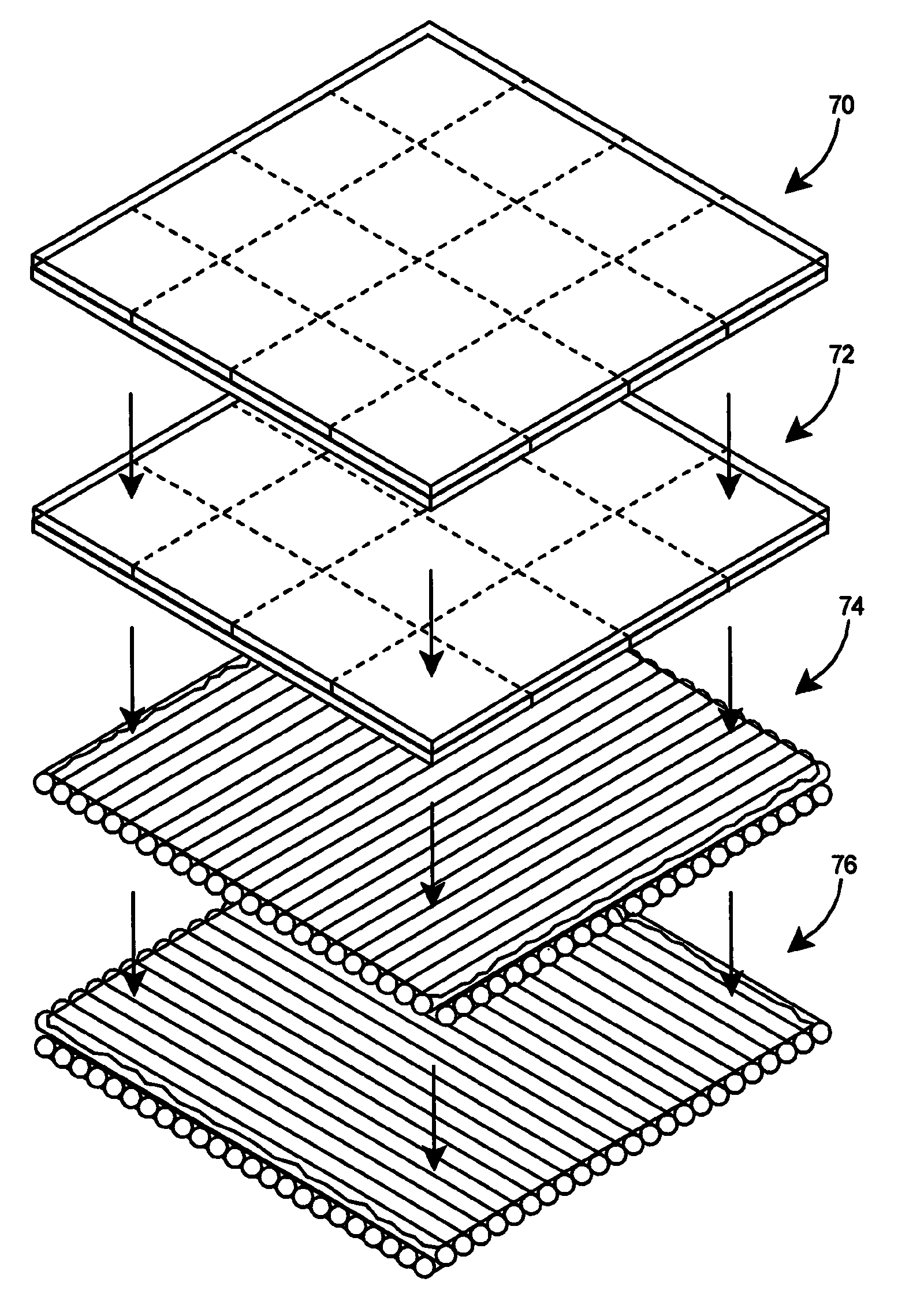

Ballistic-resistant panel including high modulus ultra high molecular weight polyethylene tape

A ballistic-resistant panel in which the entire panel or a strike-face portion thereof is formed of a plurality of sheets of high modulus high molecular weight polyethylene tape. The sheets of high modulus polyethylene tape can be in the form of cross-plied laminated layers of tape strips or a woven fabric of tape strips. The strips of UHMWPE tape include a width of at least one inch and a modulus of greater than 1400 grams per denier. The ballistic-resistant panel may include a backing layer of conventional high modulus fibers embedded in resin. A wide variety of adhesives were found acceptable for bonding the cross-plied layers of high modulus polyethylene tape together for forming the ballistic-resistant panels of the present invention.

Owner:DUPONT SAFETY & CONSTR INC

Nonwoven fabric liner and diaper including a nonwoven laminate liner

The present invention provides a bodyside liner for a disposable absorbent article that is a nonwoven fabric laminate that includes a thin layer of fine fibers that has a basis weight of less than 2.5 grams per square meter. The present invention also provides disposable absorbent garments, such as diapers, that in such a nonwoven fabric laminate to reduce the migration of particles in absorbent garments.

Owner:KIMBERLY-CLARK WORLDWIDE INC

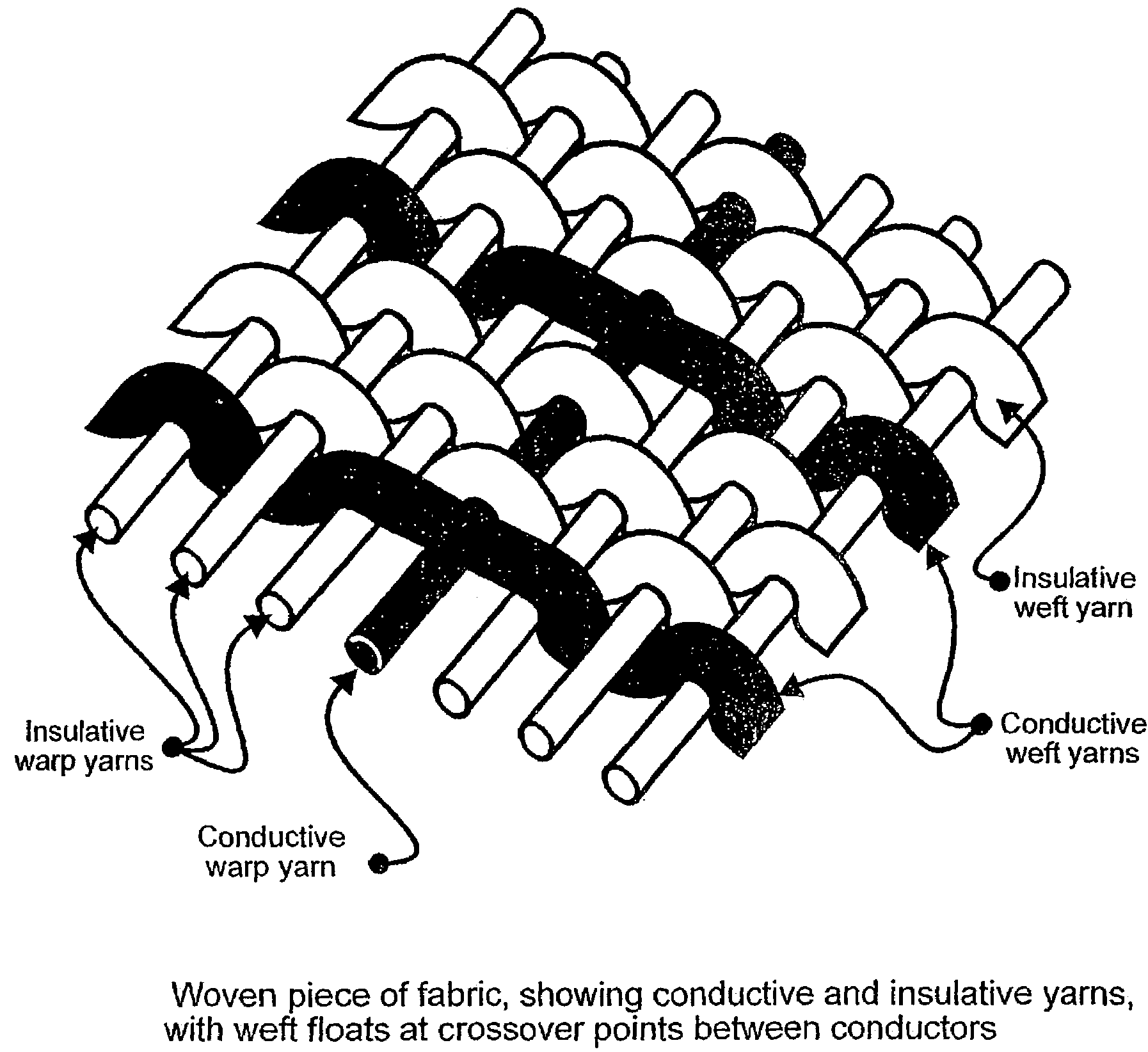

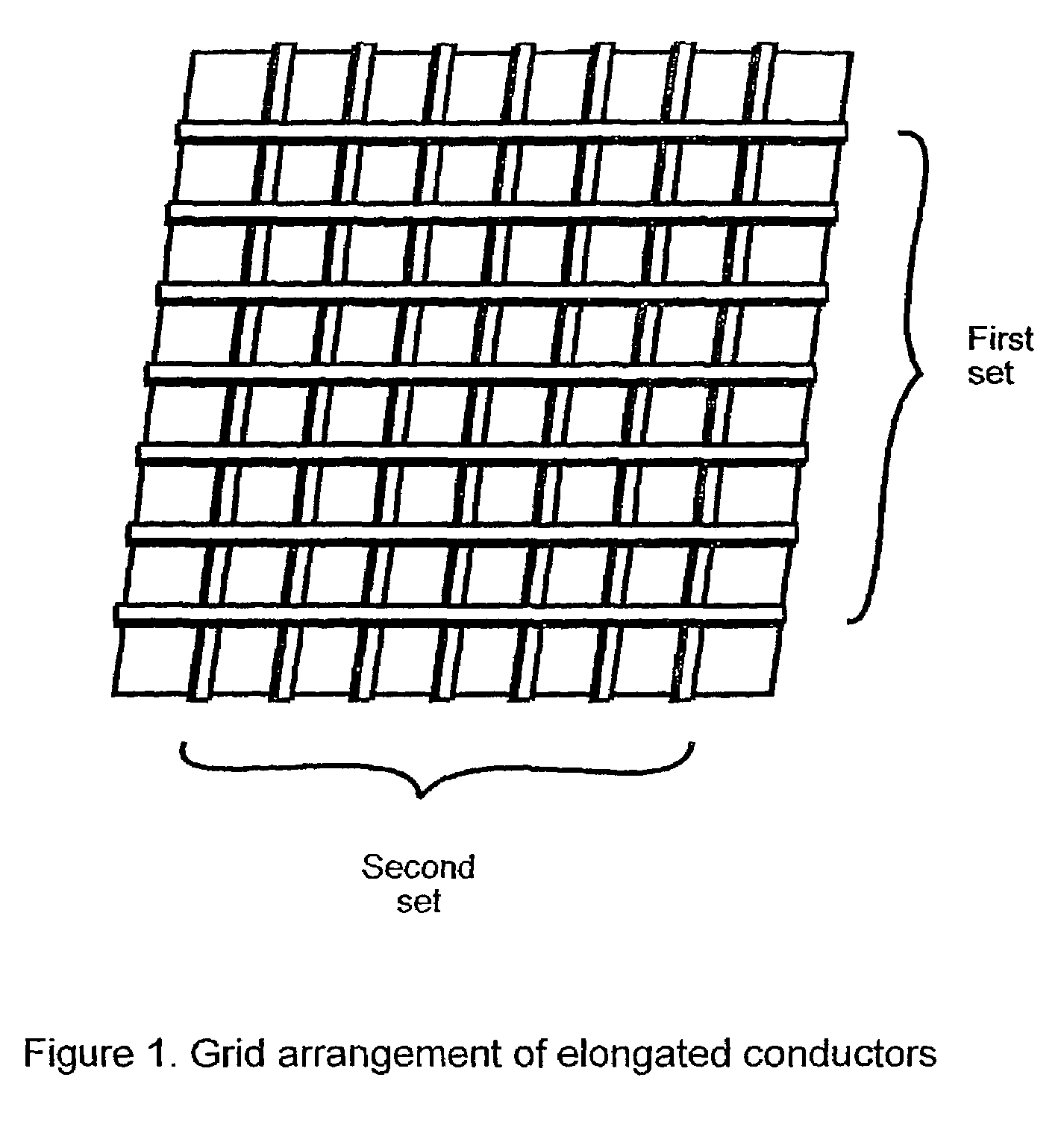

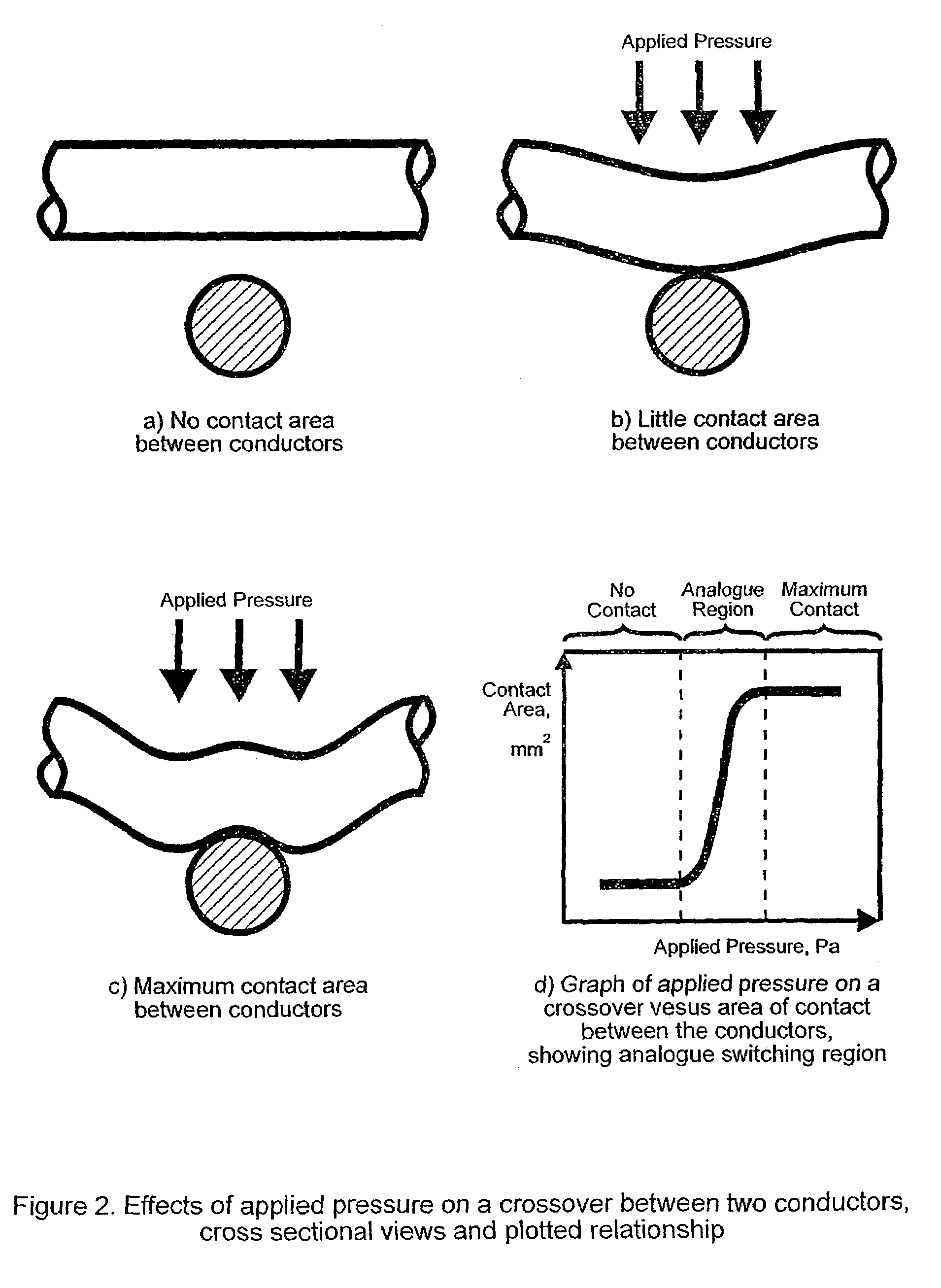

Conductive pressure sensitive textile

InactiveUS7365031B2Low production costReduce edge effectsForce measurementInsulated cablesElectrical conductorEngineering

A fabric including within its construction a first elongated electrical conductor crossed by a second elongated electrical conductor, the conductors being normally biased apart at a crossover point of said fibres with an air gap between them, whereby application of pressure in a direction substantially normal to a plane of the fabric causes the conductors to make contact. The fabric may be woven, knitted, non-woven or plaited. The fabric can be used as a pressure sensor, switch or other sensor.

Owner:INTELLIGENT TEXTILES

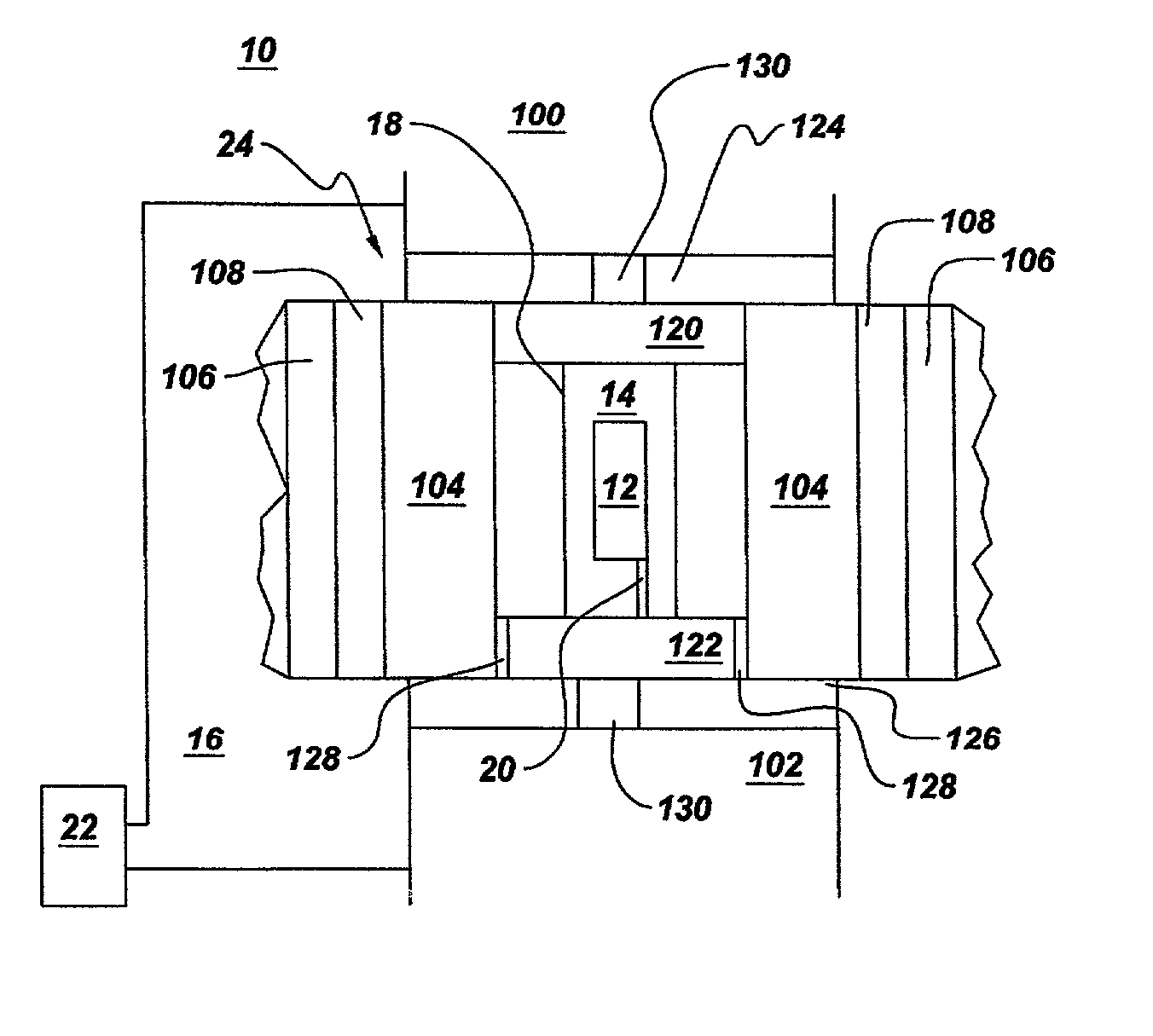

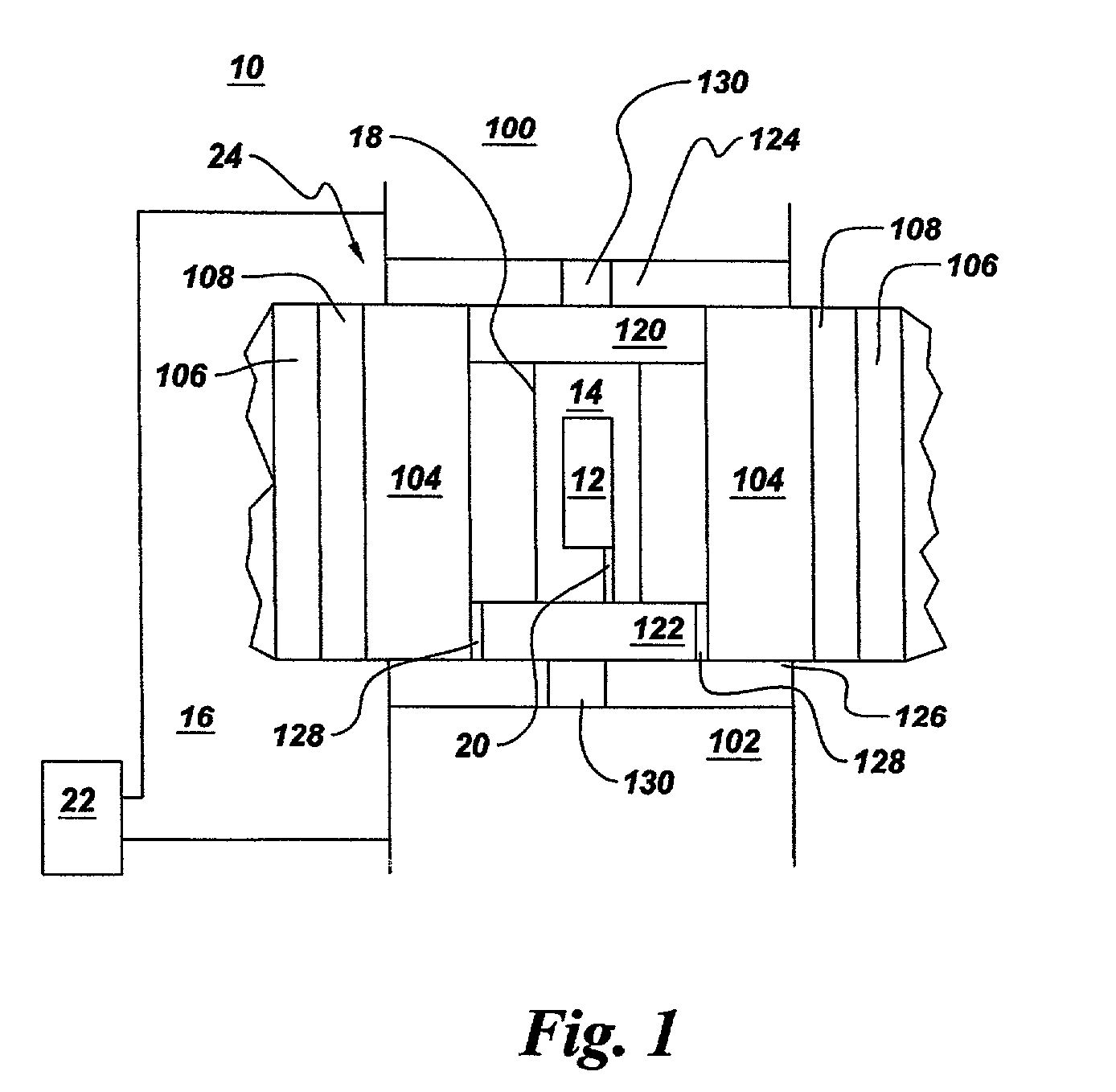

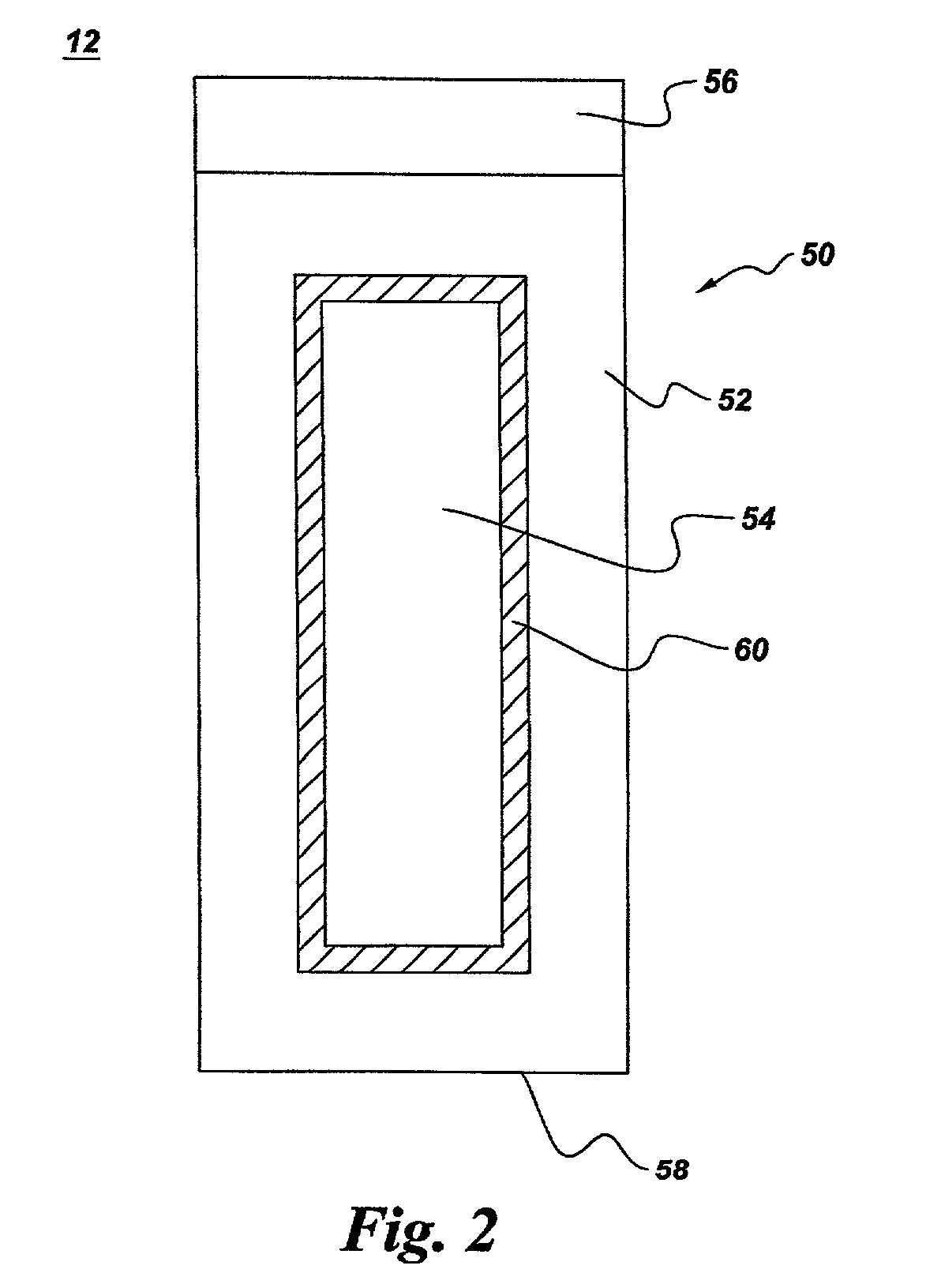

High temperature fluid sample aging cell

ActiveUS9784667B2Engine sealsWeather/light/corrosion resistanceAge methodPressure controlled ventilation

Owner:OFI TESTING EQUIP

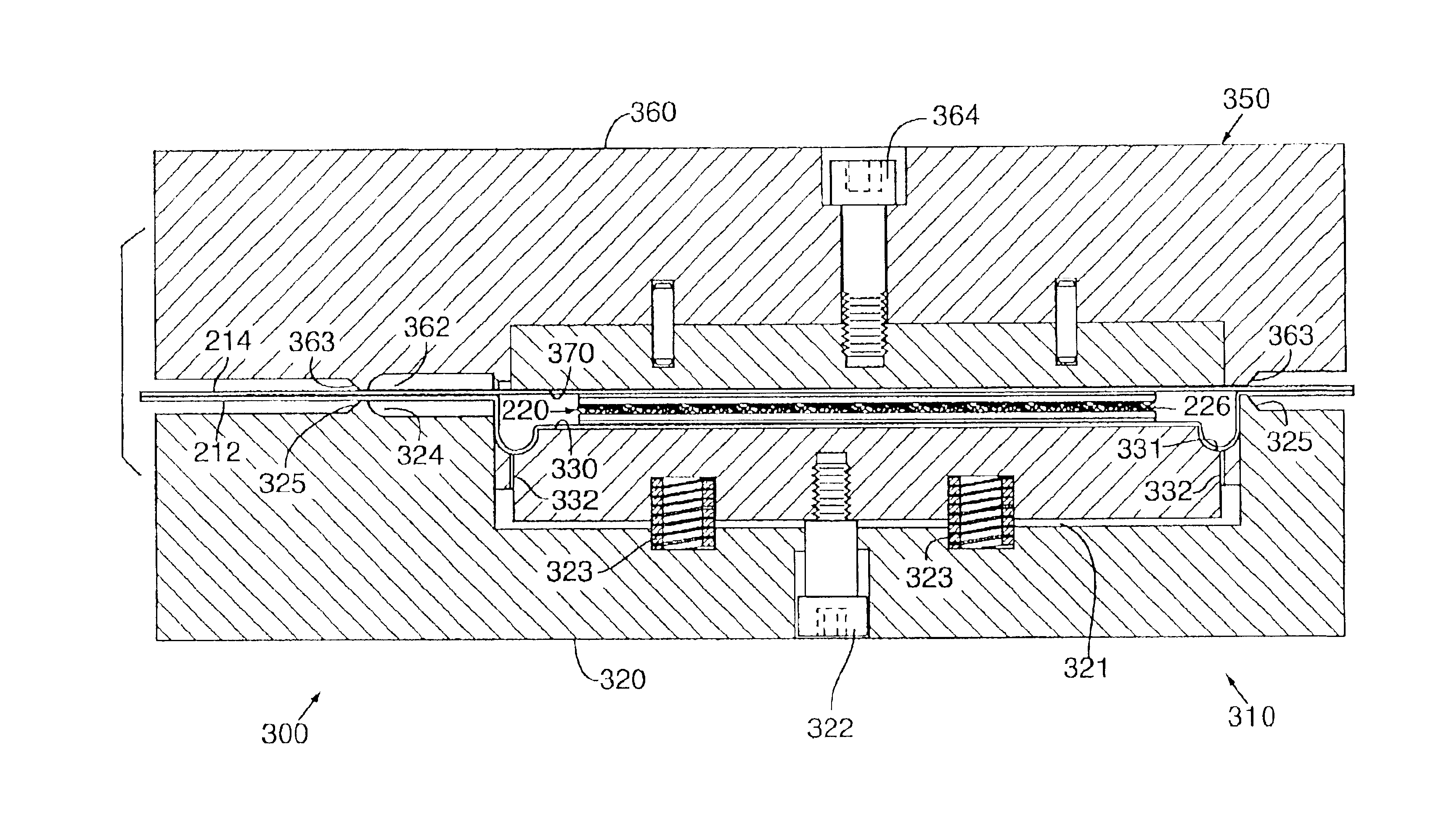

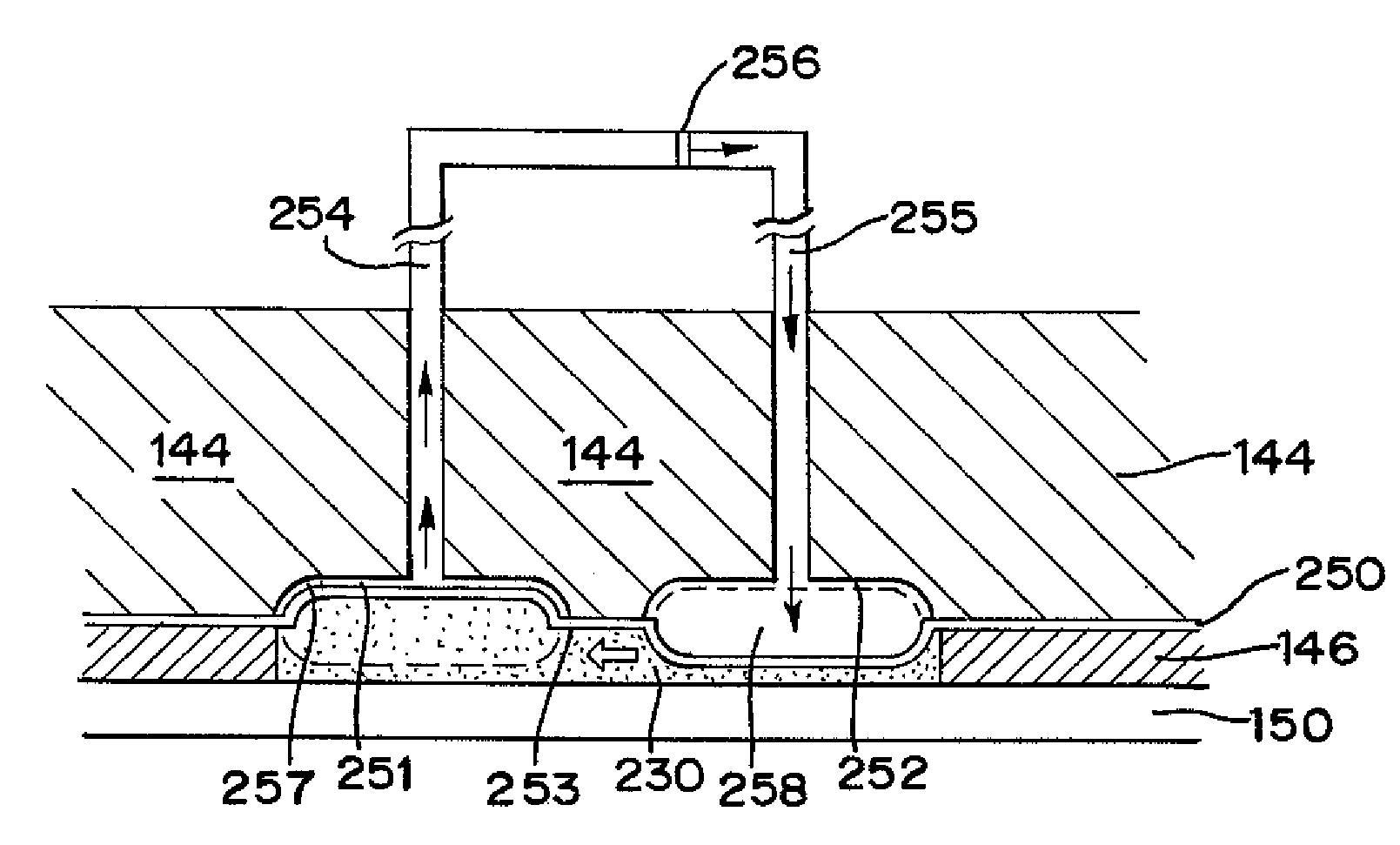

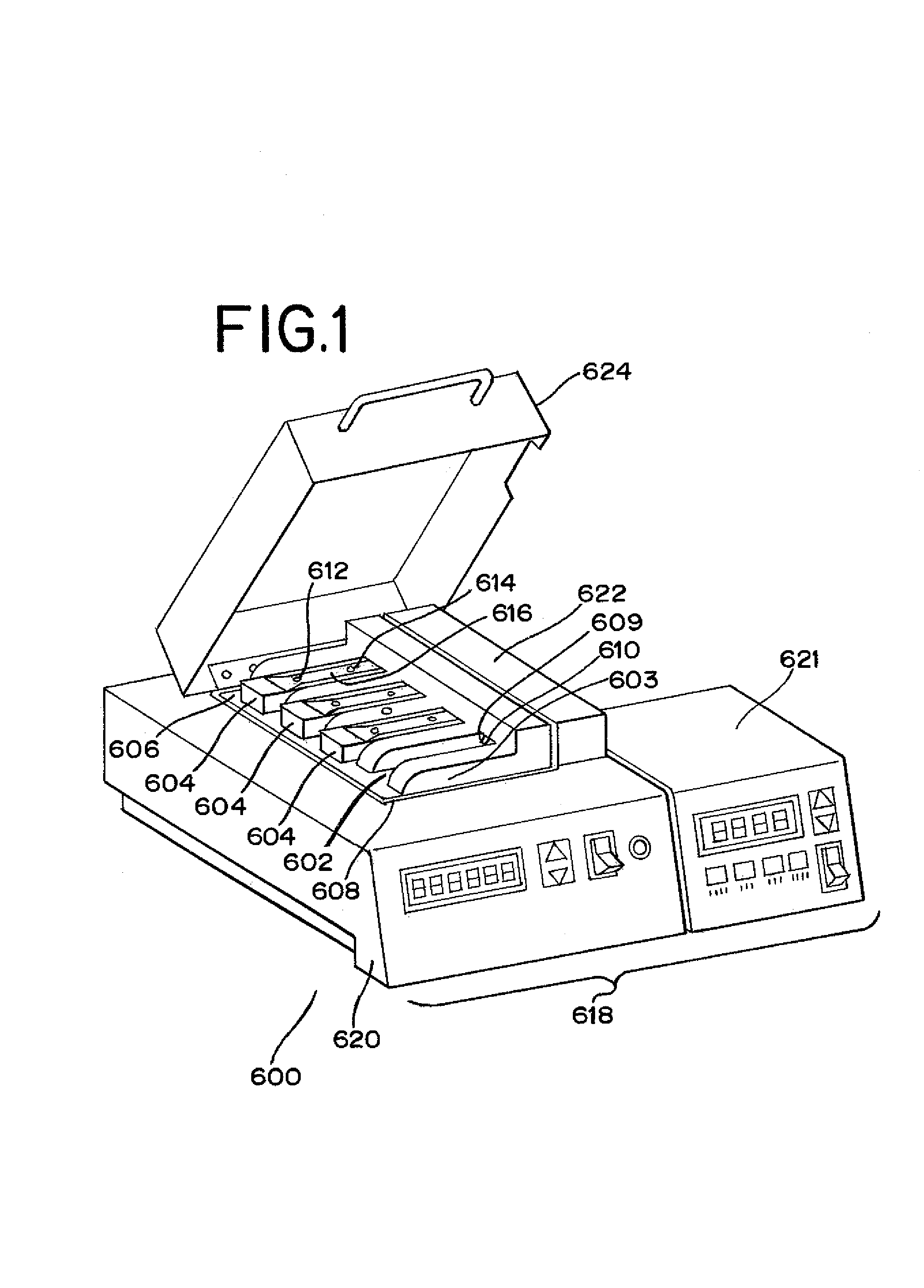

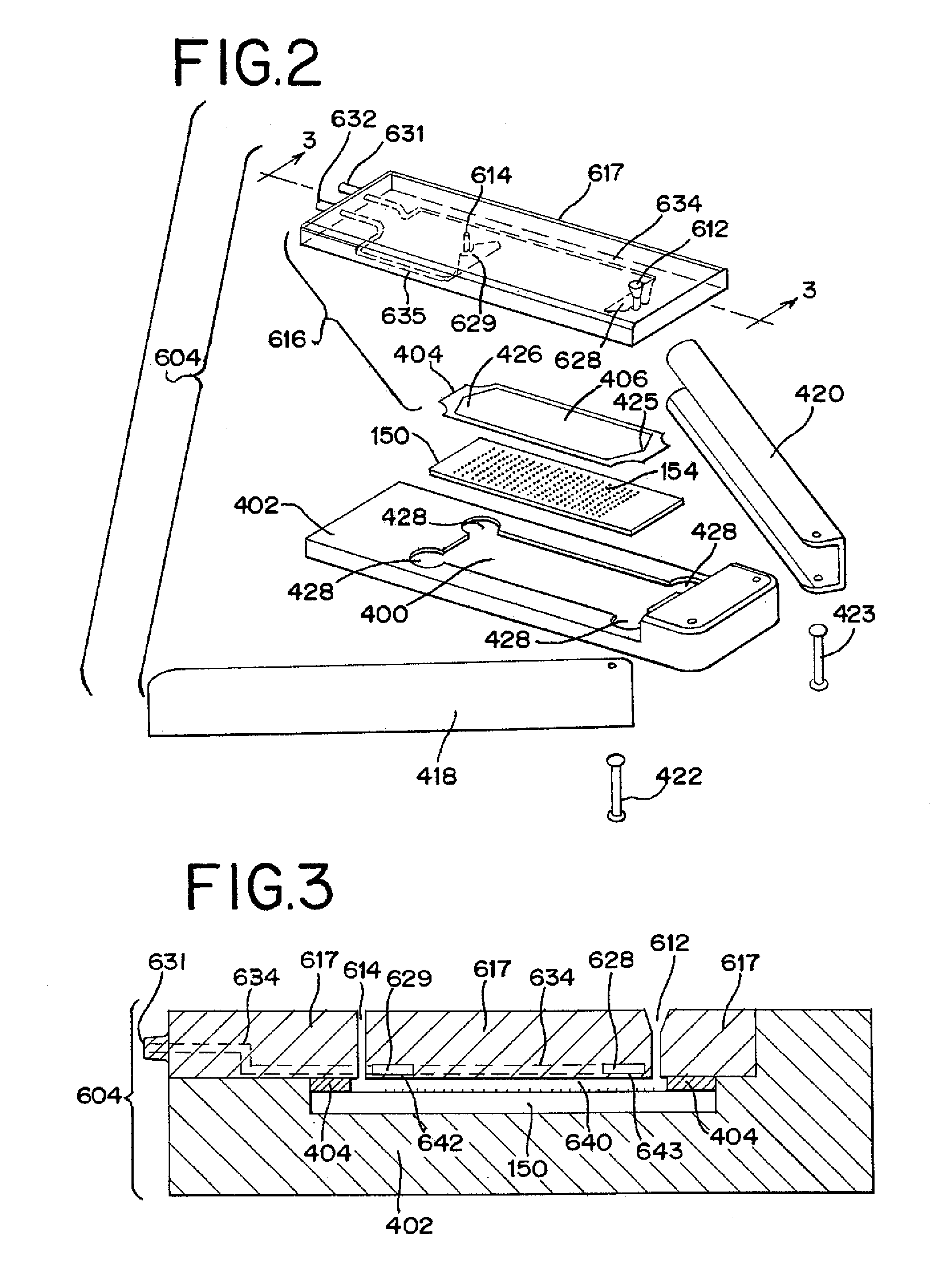

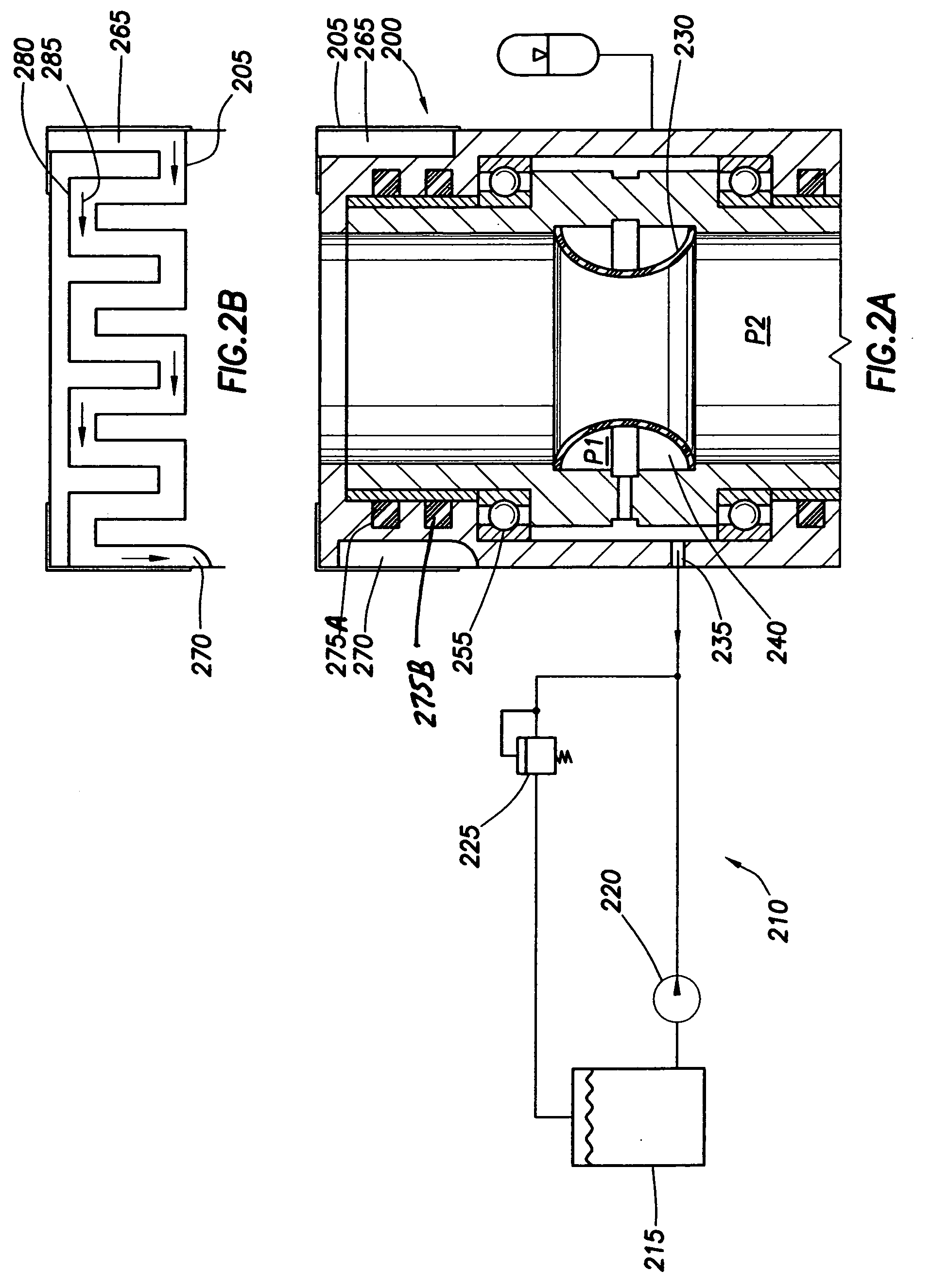

Method and system for microfluidic interfacing to arrays

InactiveUS7223363B2Reduce amountLower the volumeShaking/oscillating/vibrating mixersFlow mixersChemical reactionComputer module

A method and system for providing a fluidic interface to slides bearing microarrays of biomolecules or other samples immobilized thereon to perform a variety of chemical reactions or processing steps on the slide. An interface device seals against the slide to form a chamber or chambers containing all or a portion of the microarray, providing selective access to portions of the slide. The interface device includes inlet and outlet ports permitting liquid sample and reagents to be introduced to and removed from the chamber accessing the slide surface. Pre- and post-array microfluidic circuitry may be included in the interface device or in attachable modules. The system may include one or more compartments for collecting and storing waste fluids.

Owner:ROCHE NIMBLEGEN

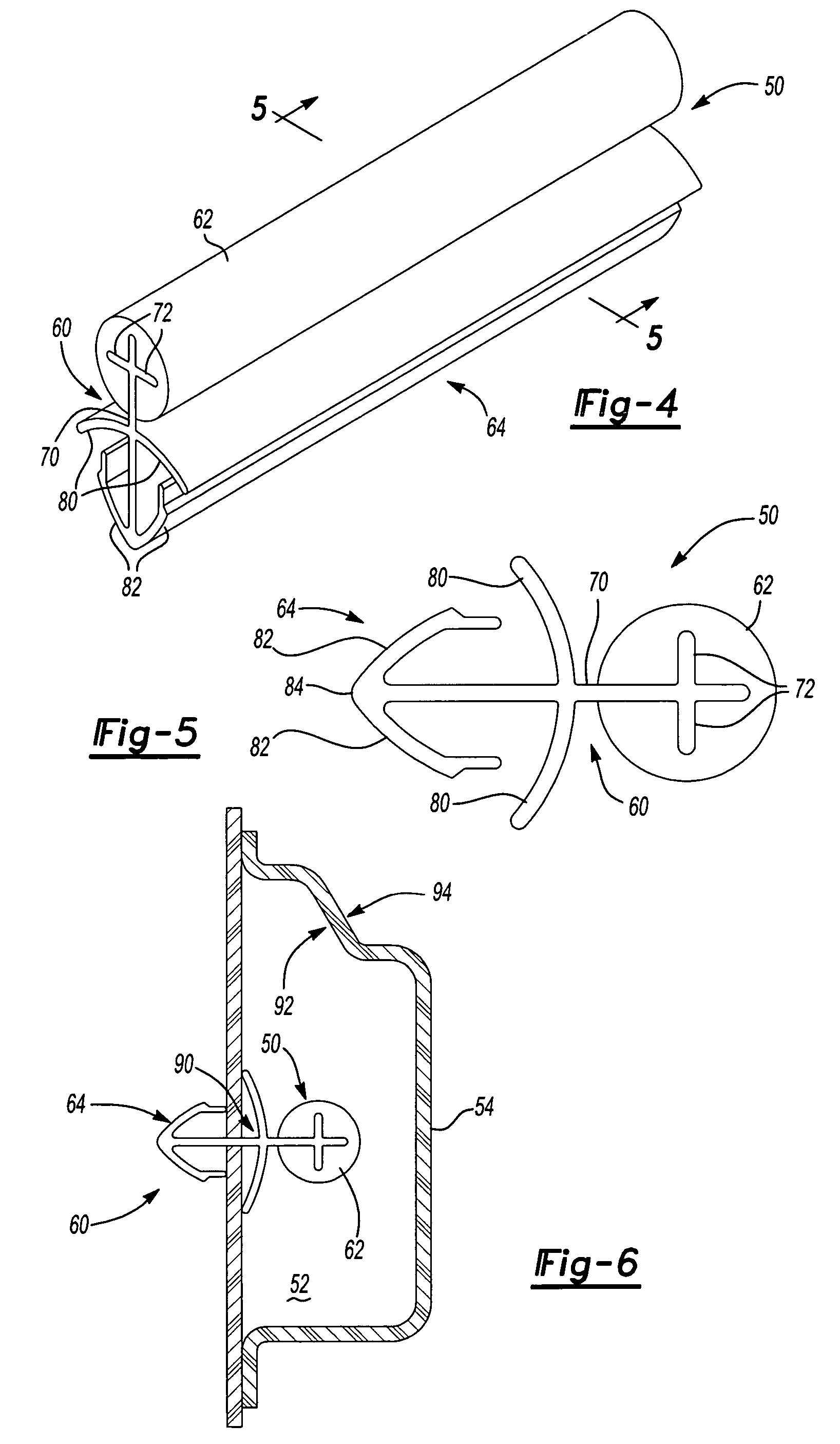

Medical tubing connector

A medical connector, usable to securely couple a first tubular medical device to a second tubular medical device, includes first and second fittings cooperating with the first and second medical devices, respectively. The first and second fittings may each include a nipple, a ferrule, or some other structure that is connected to the associated medical device and that is connectable to the other fitting. The second fitting may additionally include a tubular sleeve that slides over the second medical device and the ferrule or other component of the second fitting. The two components of the second fitting are sequentially connectable to the first fitting through distinctly different motions to provide a redundant, secure connection. For example, the first fitting may include a first set of left-handed threads and a second set of right-handed threads, and the components of the second fitting may have corresponding left-handed and right-handed threads.

Owner:A B KORKOR MEDICAL

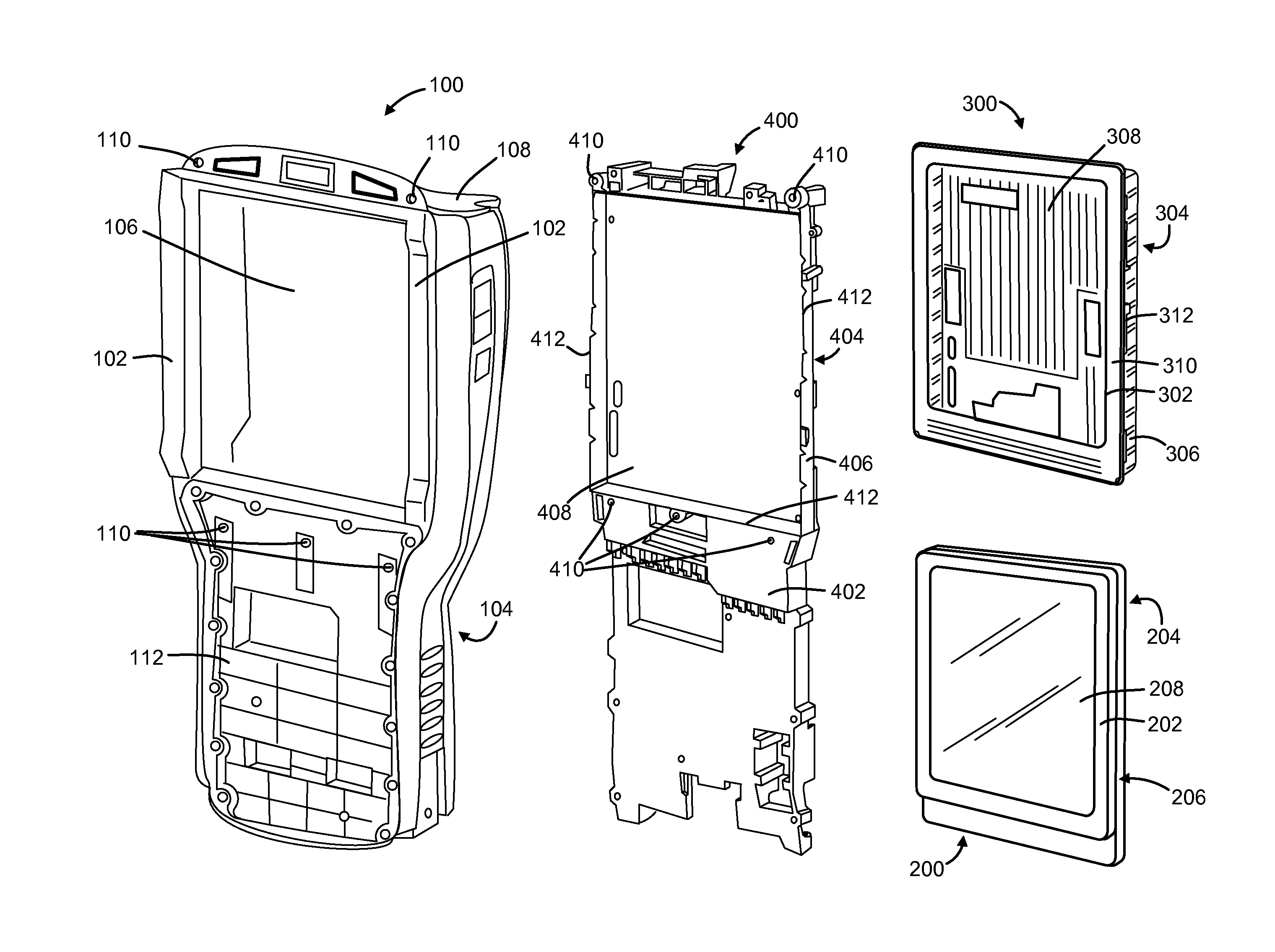

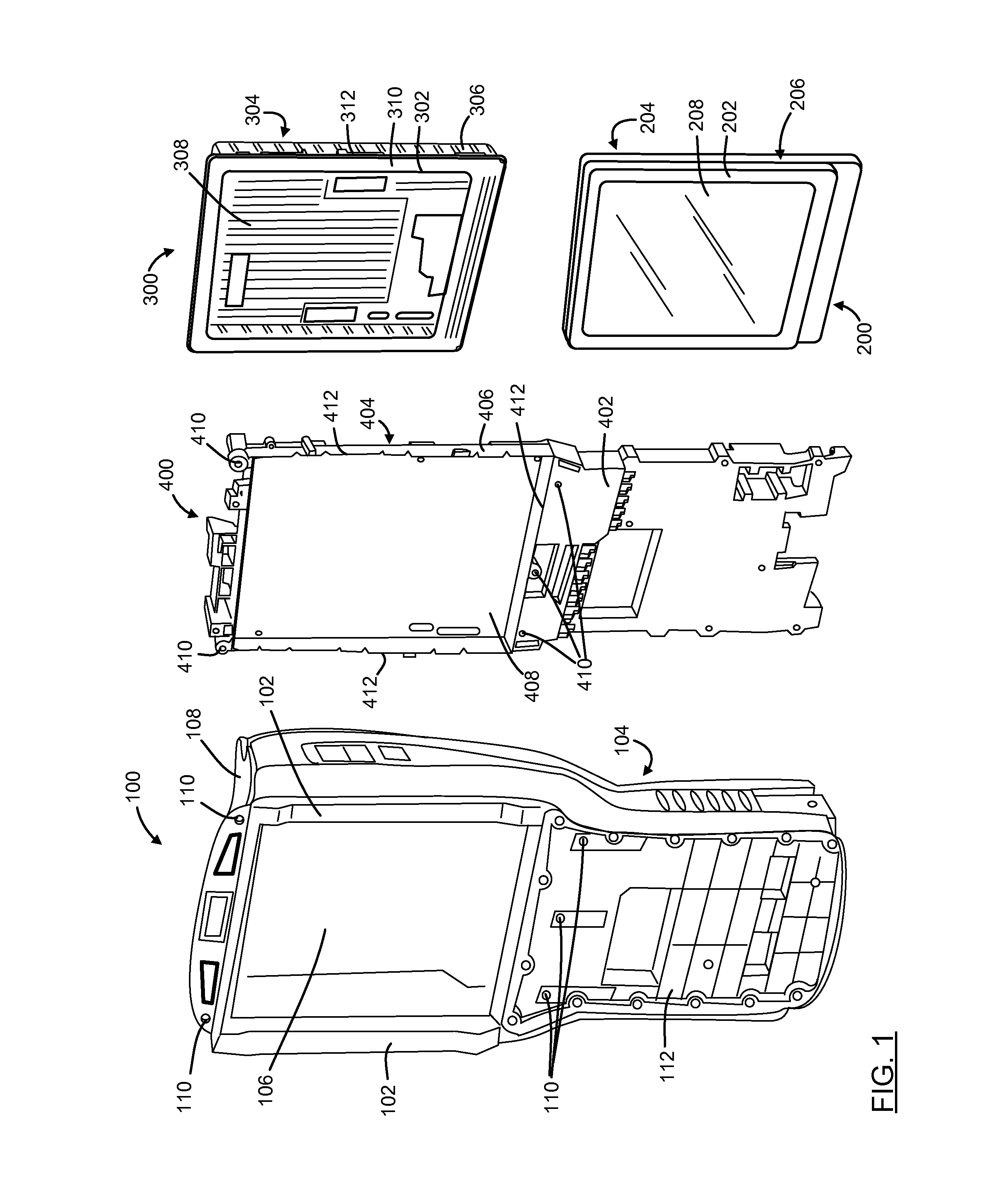

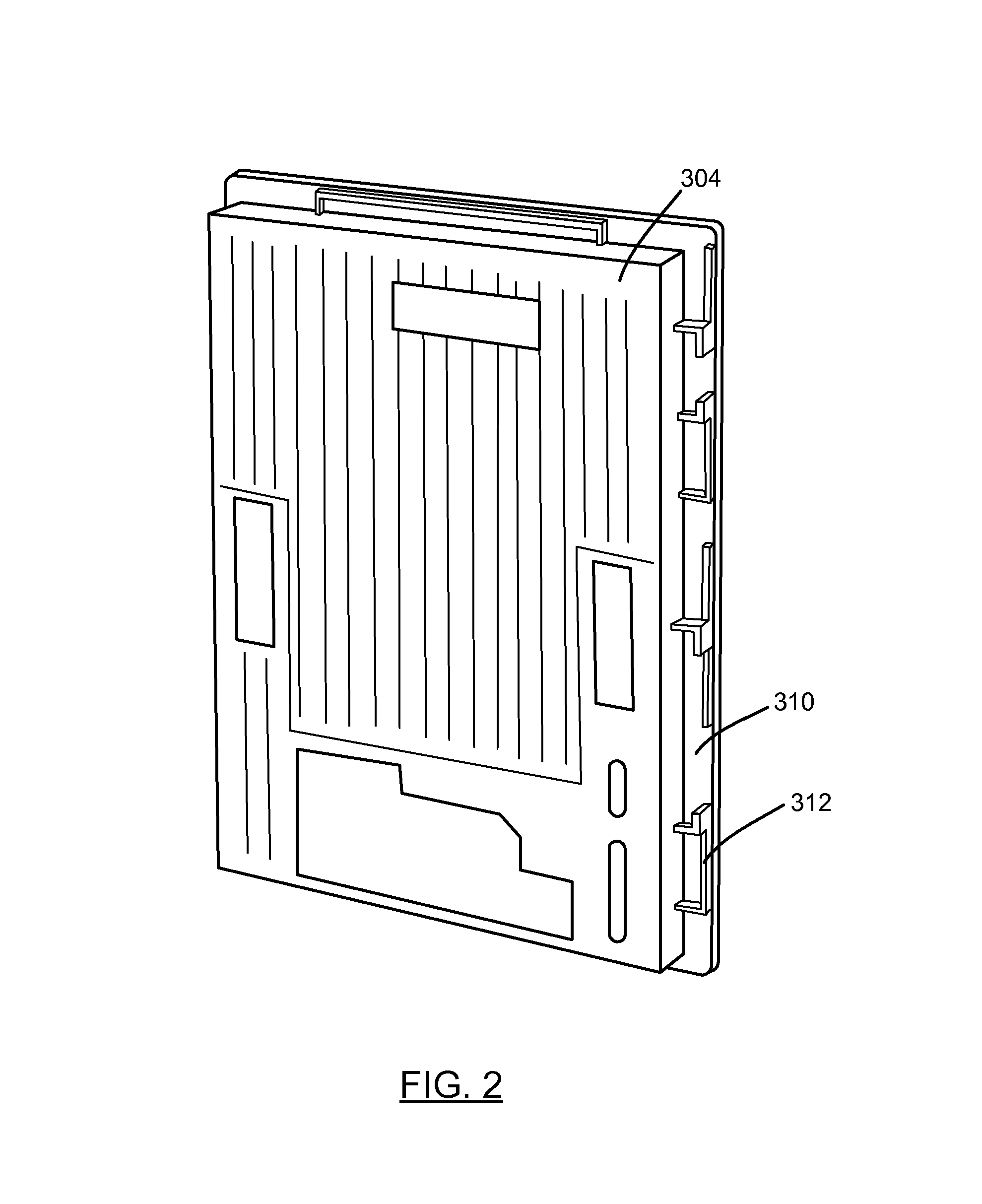

Apparatus and method for assembling display of indicia reading terminal

Owner:HAND HELD PRODS

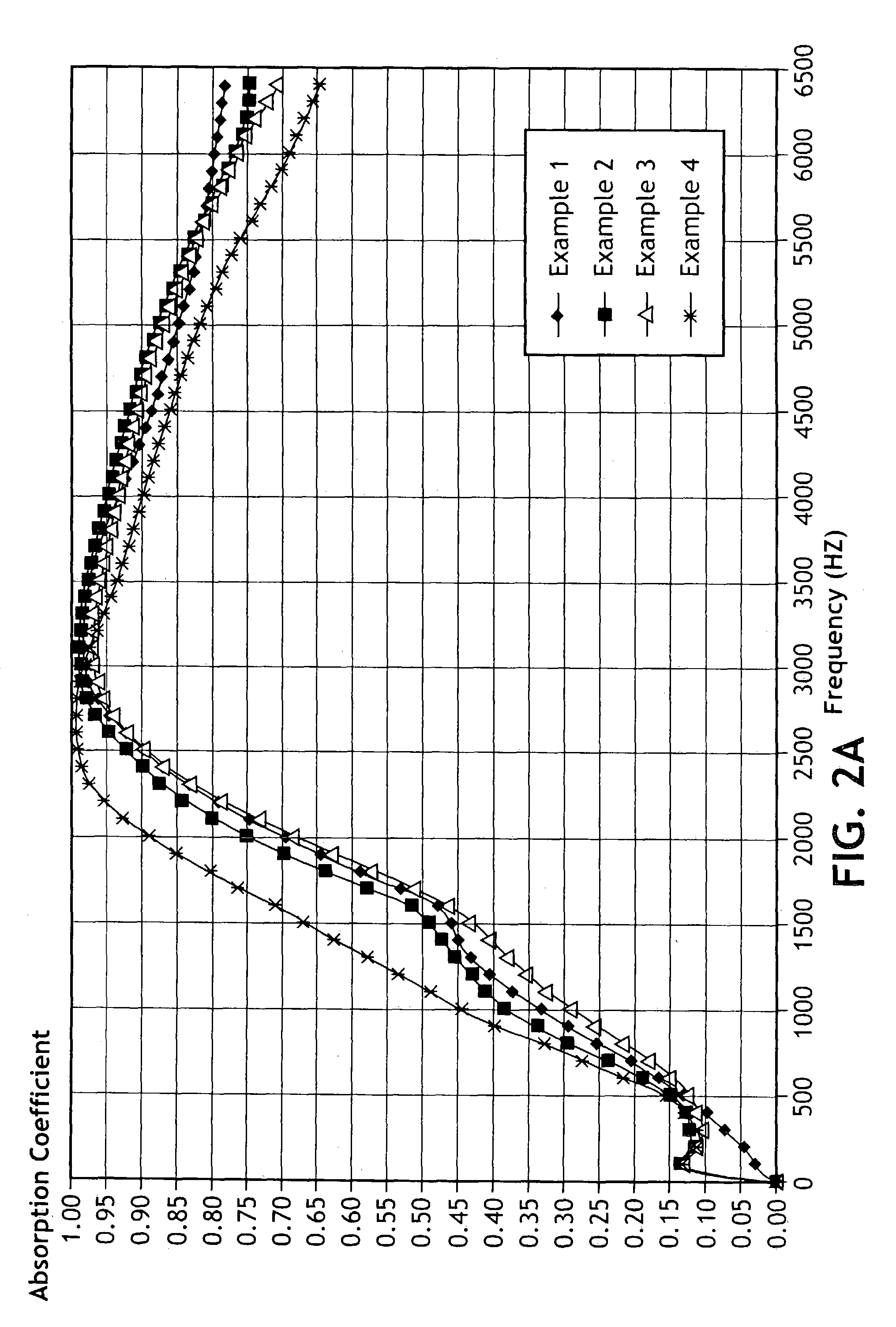

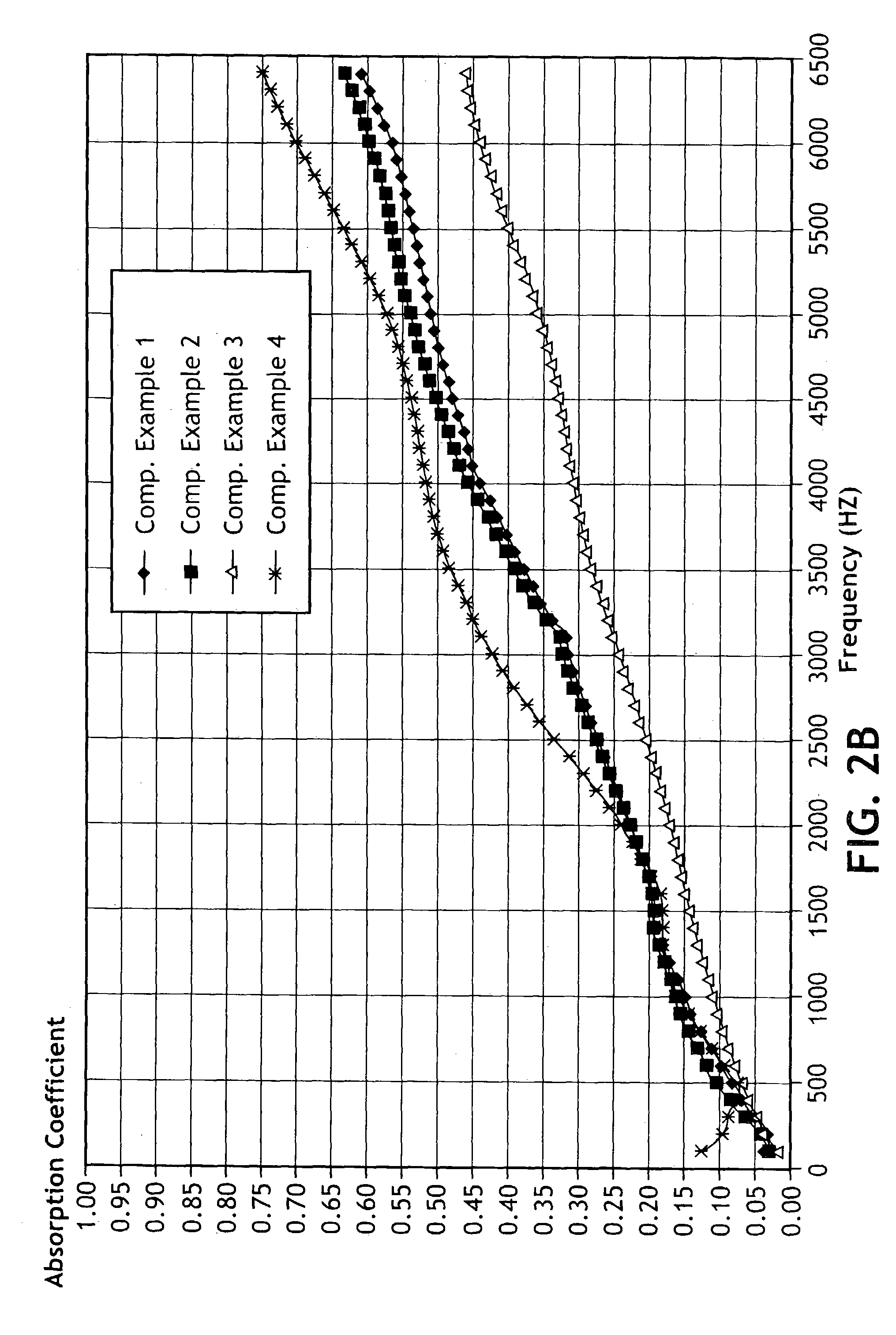

Nonwoven containing acoustical insulation laminate

The present invention relates to an acoustical insulation material containing a first layer formed from a nonwoven web having a density of at least 50 kg / m3 wherein the nonwoven web is formed from thermoplastic [meltblown] fibers having an average fiber diameter of less than about 7 microns; and a second layer of a high loft material. The high loft material of the present invention provides bulk to the first layer and may or may not have sound attenuating properties. Examples of the high loft material include, for example, fiberglass and high loft nonwoven webs. Also disclosed in a method of attenuating sound waves passing from a sound source area to a second area. The method includes positioning an acoustical insulation material containing a first layer formed from a nonwoven web having a density of at least 50 kg / m3 wherein the nonwoven web is formed from thermoplastic [meltblown] fibers having an average fiber diameter of less than about 7 microns; and a second layer of a high loft material, between the sound source area and the second area.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Rotating control head radial seal protection and leak detection systems

Owner:WEATHERFORD TECH HLDG LLC

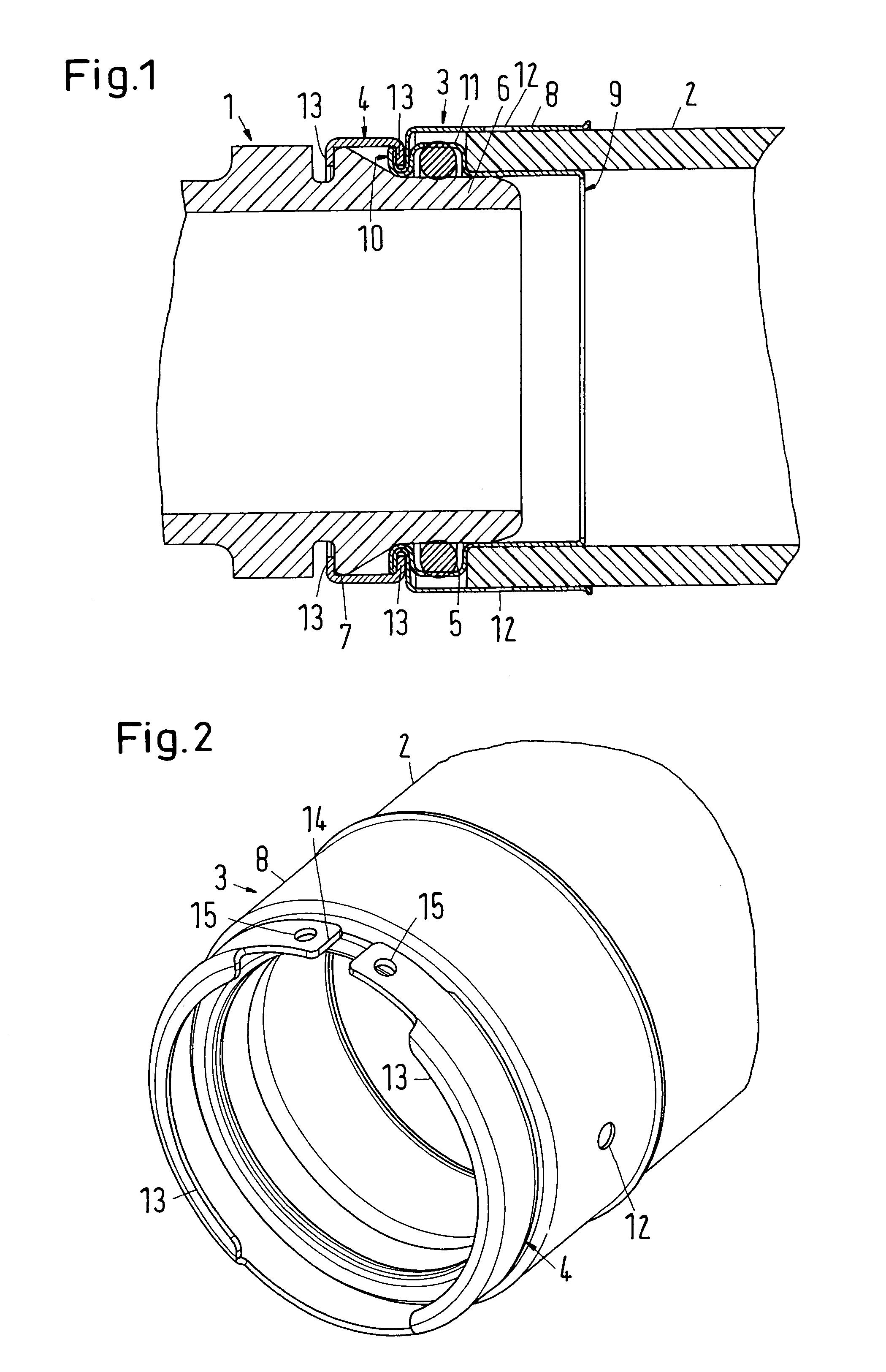

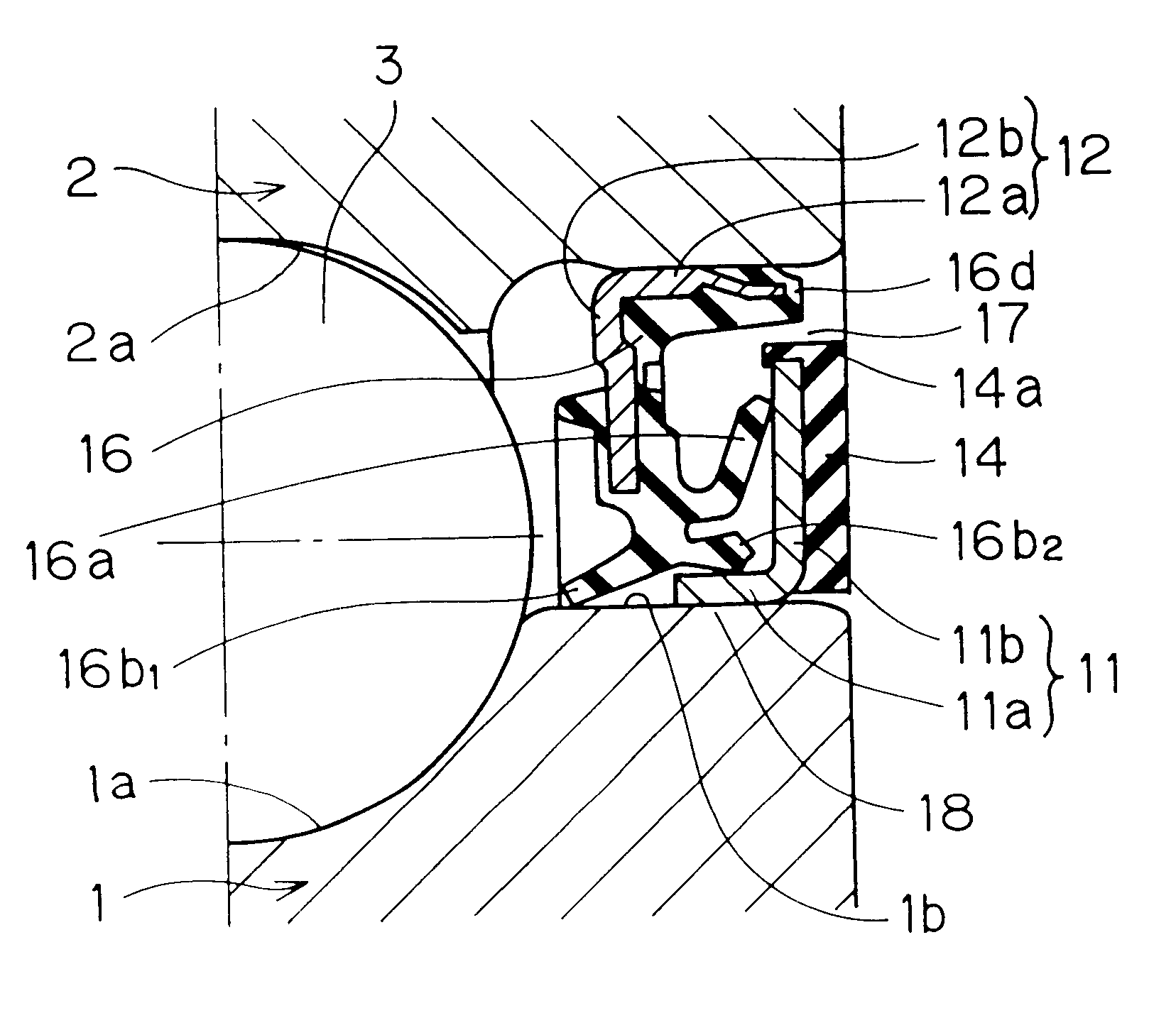

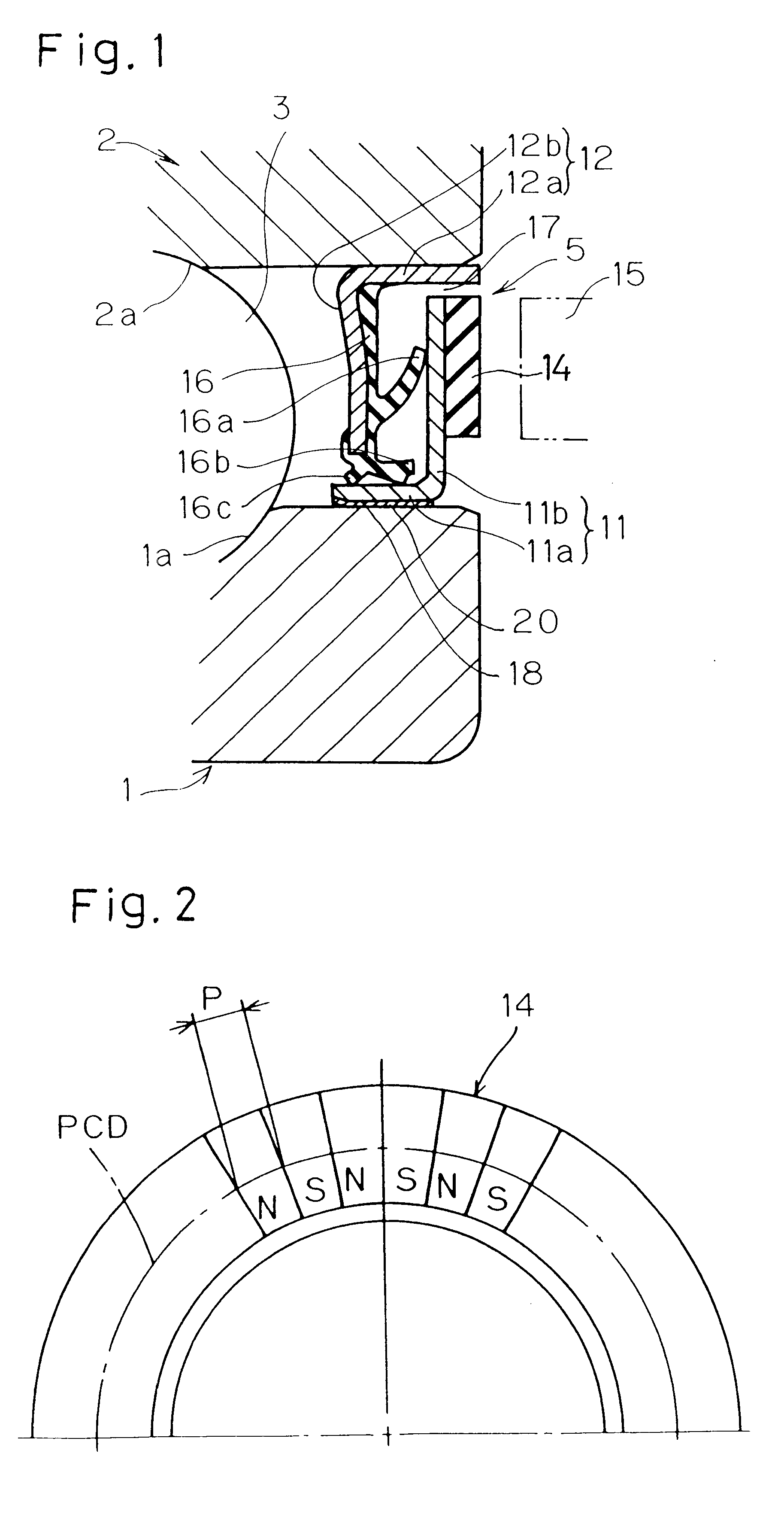

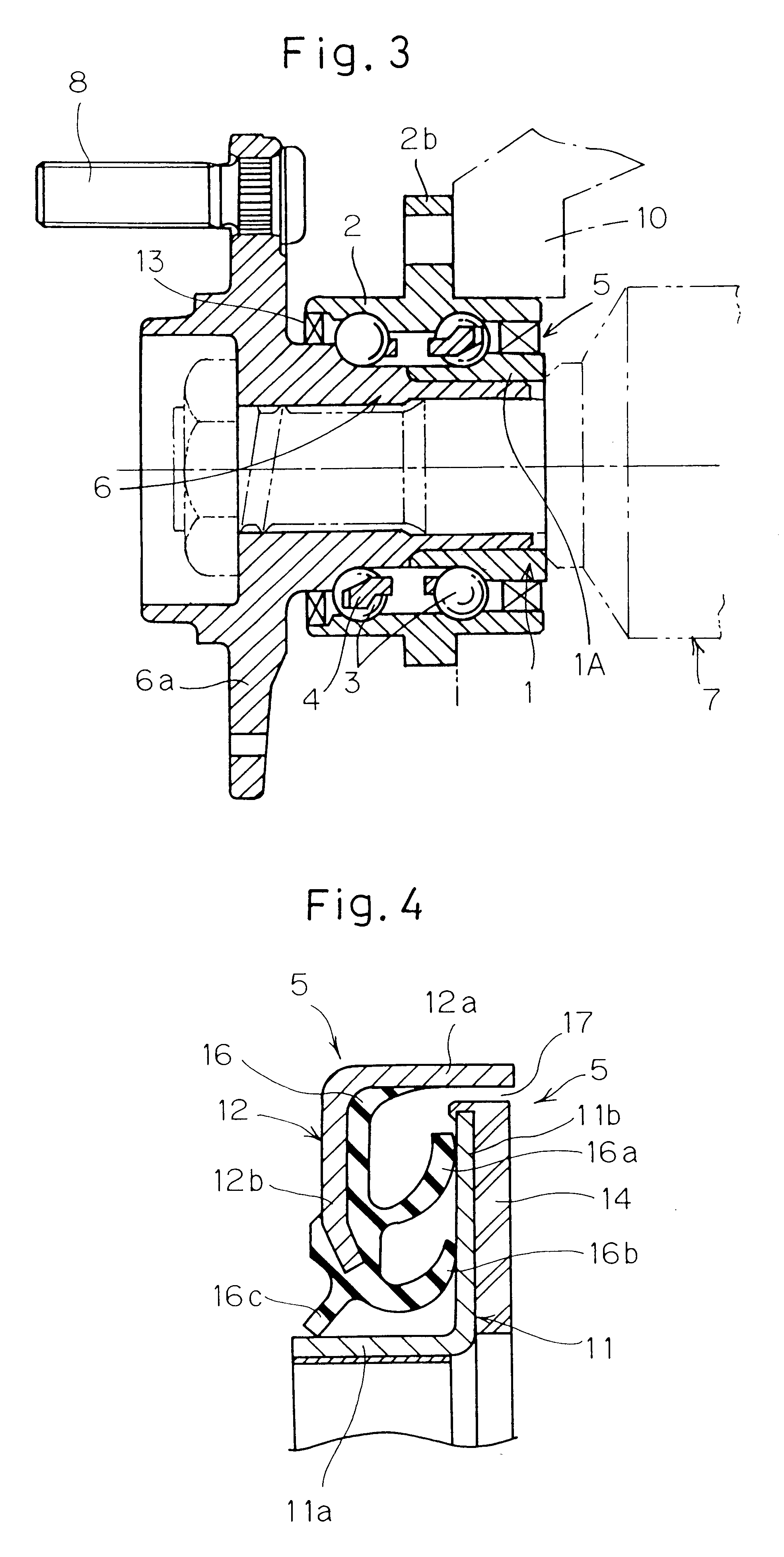

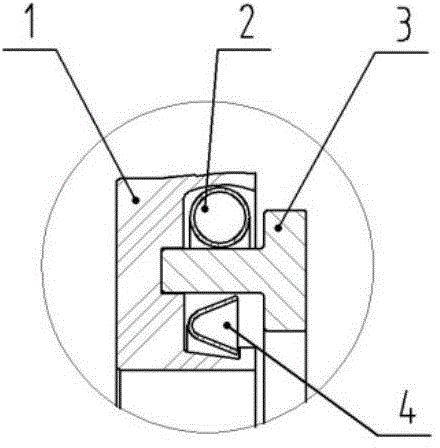

Wheel bearing and sealing device therefor

A wheel bearing includes a sealing device 5 positioned between inner and outer members 1 and 2. This sealing device 5 includes an elastic member 14, which eventually forms an encoder grid and is provided on a first annular sealing plate 11. A second annular sealing plate 12 is provided with sealing lips 16a to 16c. An engagement 18 between a cylindrical wall 11a of the first annular sealing plate 11 and the inner member 1 is provided with an elastic member 20 made of a material dissimilar to that for the elastic material 14. This elastic member 20 may be a rubber coated layer, resin paint layer, a thin film of adhesive material or a ring-shaped rubber member. Thereby, any possible ingress of water across an engagement surface of the annular sealing plate is prevented, accompanied by increase of the lifetime of the bearing, with no problem associated with separation and displacement of the annular sealing plates. The magnetic flux density can also be easily secured.

Owner:NTN CORP

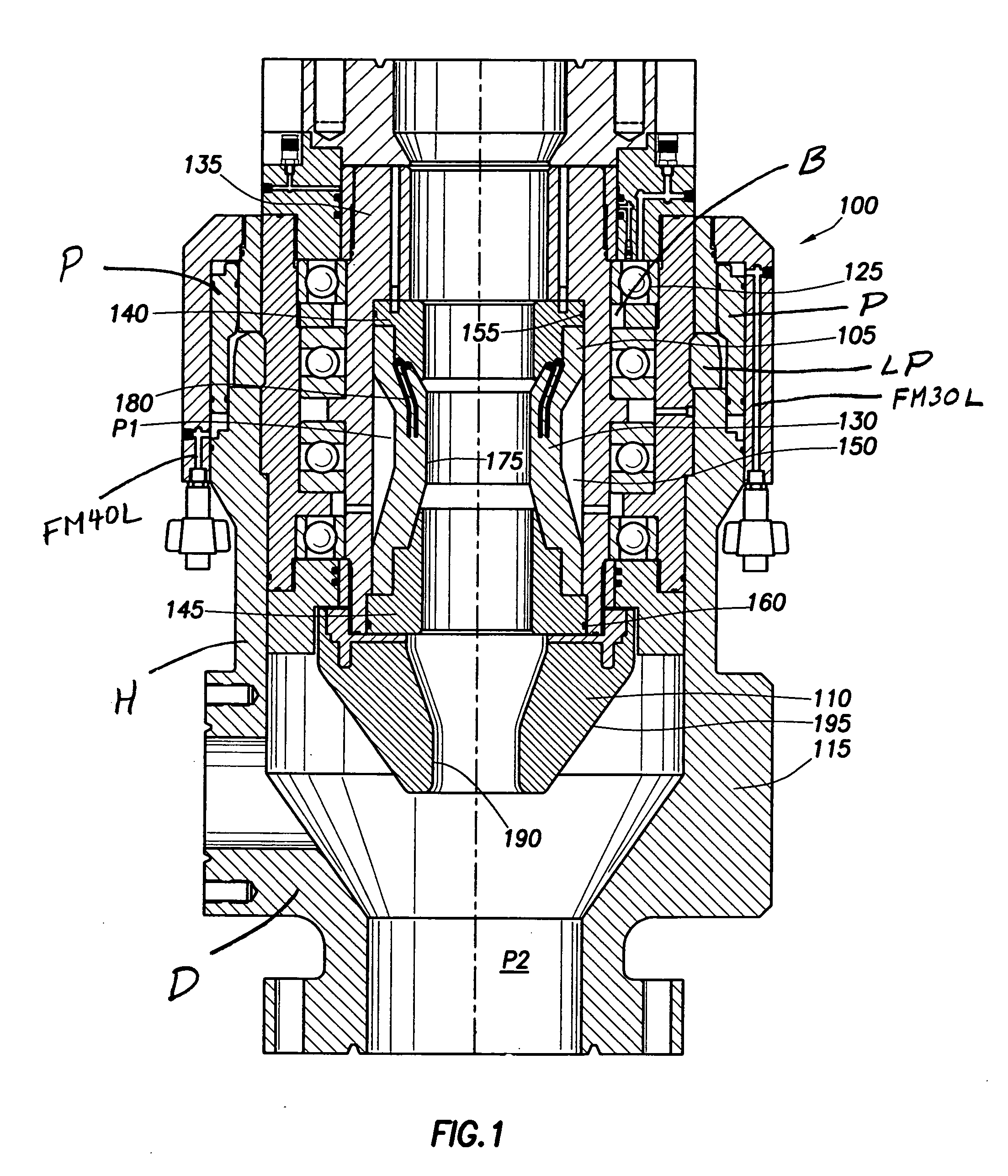

Reciprocating pump assembly

ActiveUS8707853B1Easy to fixEngine sealsPositive displacement pump componentsReciprocating motionPlunger

A reciprocating pump assembly having a power end housing and a fluid end housing and a cylinder having at least a portion within the power end. A plunger assembly reciprocates between the power end housing and the fluid end housing of the pump assembly, the plunger assembly having a crosshead, a first section limited to movement within the power end and a second section moveable within the fluid end housing. The pump assembly also includes a seal housing disposed within the cylinder, the seal housing having a proximal end adjacent an entrance to the cylinder, and a distal end disposed within the cylinder. A power end seal is secured to the seal housing proximate the distal end and a fluid end seal is disposed within the fluid end housing. The power end seal sealingly engages an outer surface of the first section and the fluid end seal sealingly engages an outer surface of the second section such that during the reciprocating movement of the plunger assembly, fluid end proppant is deterred from contaminating the outer surface of the first section and thus, contaminating the power end seal.

Owner:SPM OIL & GAS INC

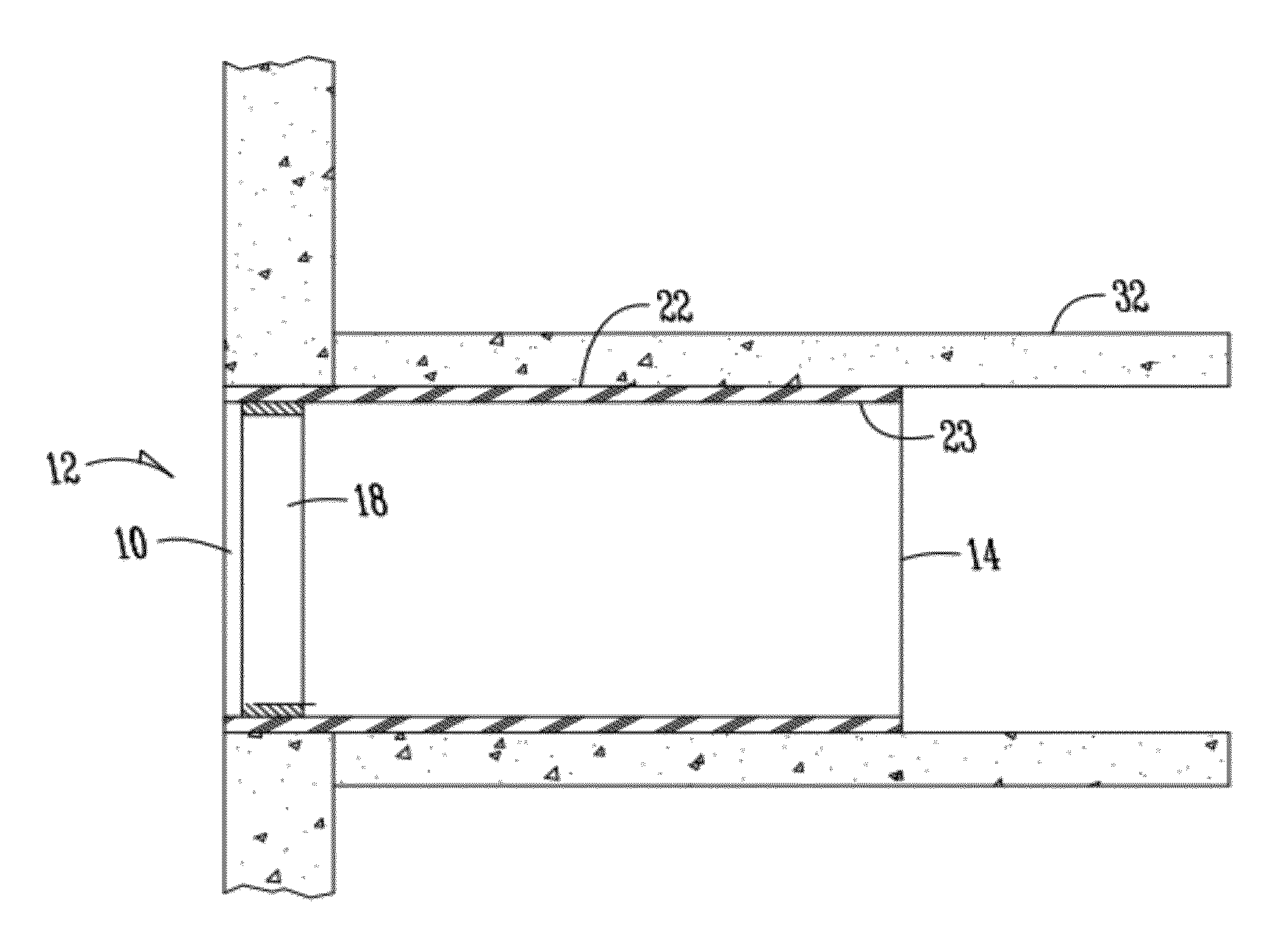

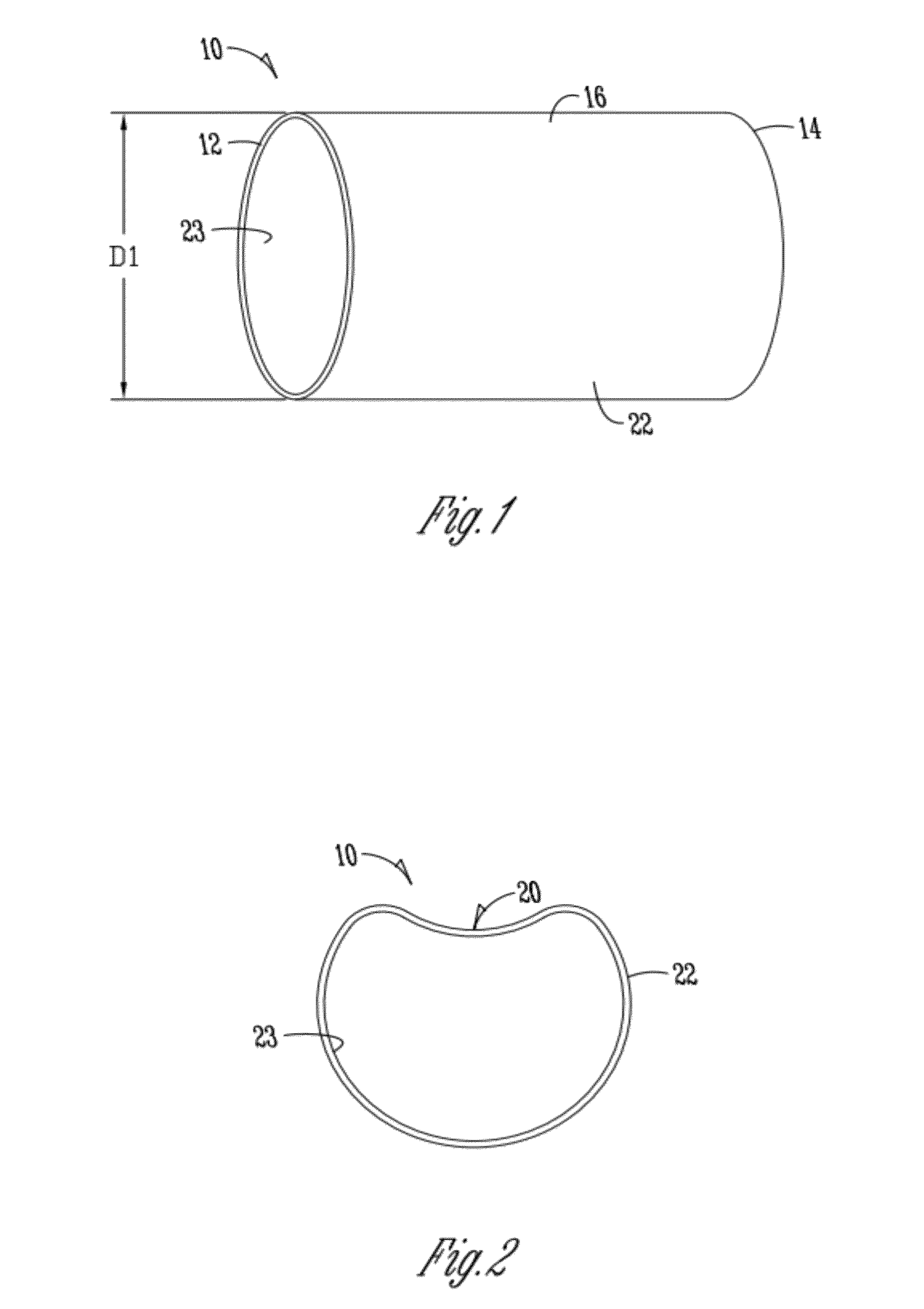

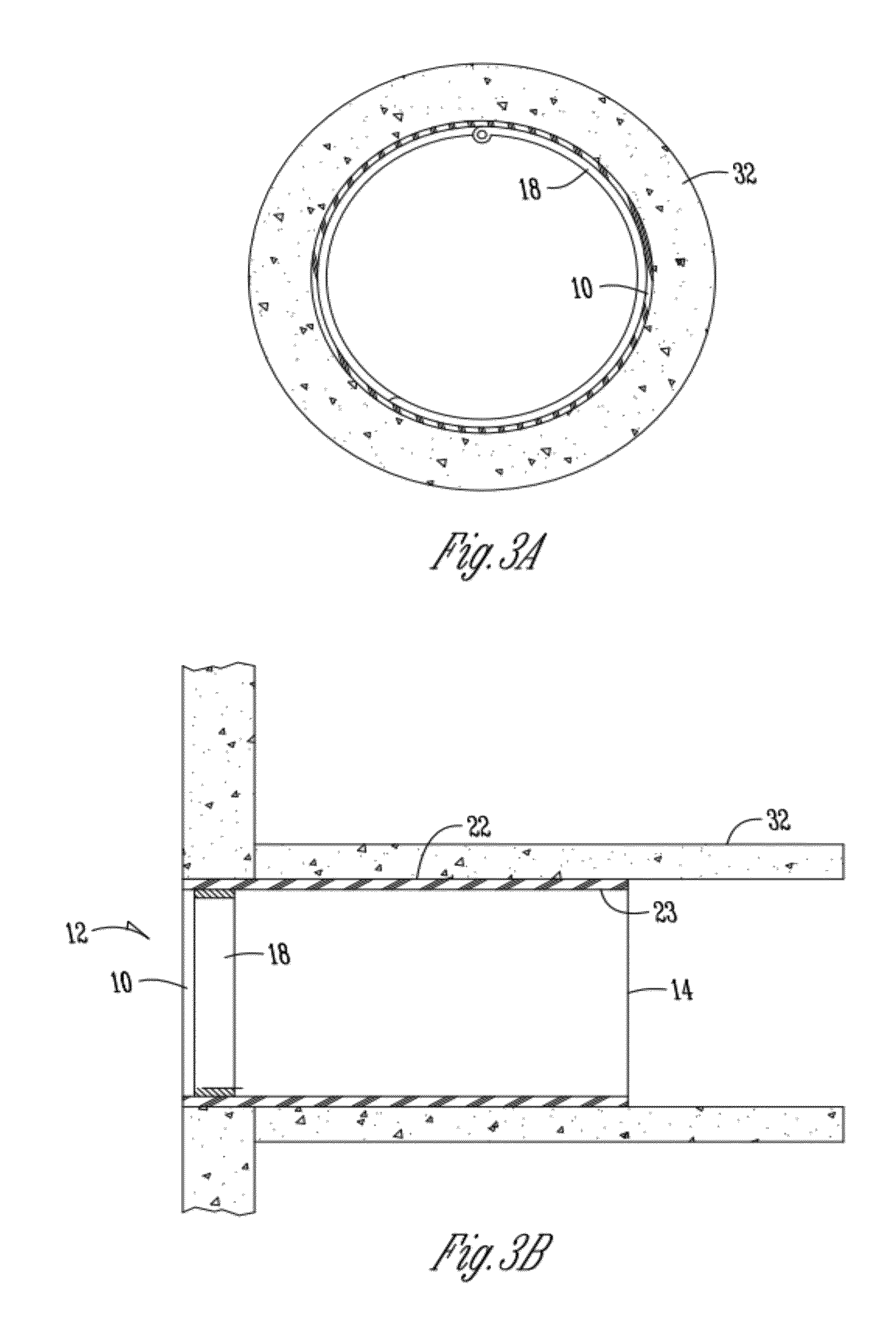

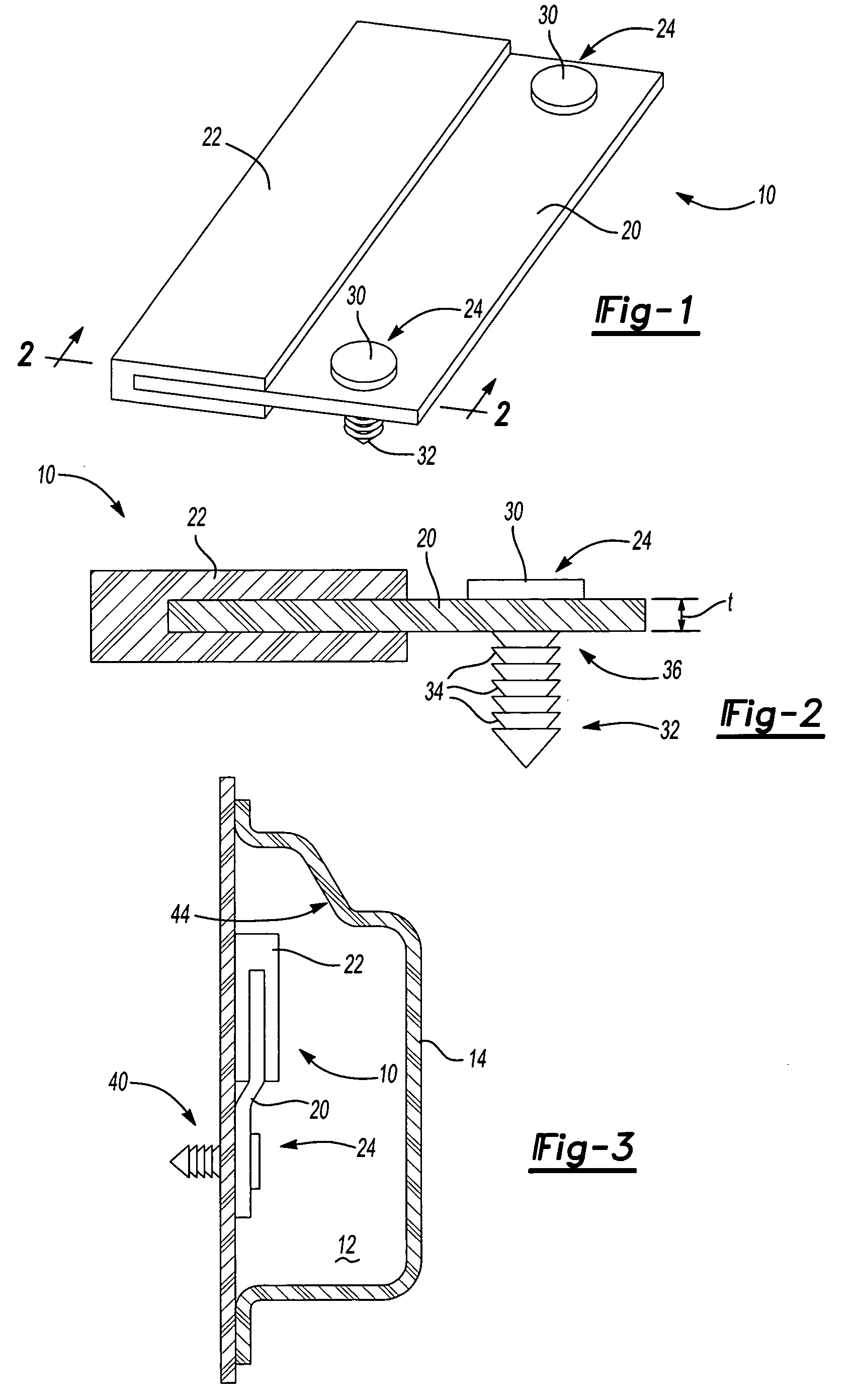

Apparatus and method for sealing pipes and underground structures

ActiveUS20120267863A1Prevent water infiltrationReduce manufacturing costSleeve/socket jointsEngine sealsCompressible materialEngineering

An apparatus and method for sealing pipes or underground structures is provided. In one embodiment, the end of a pipe is sealed by the use of a pipe liner and a sealing member. The sealing member may be a hydrophilic material, a hydrophobic material, a compressible material, or a paste. The sealing member is held in place by a mechanical fastener and a liner is installed adjacent the sealing member and against the wall of the pipe or other structure to be sealed. In another embodiment, a manhole is sealed by the use of a sealing member, a mechanical fastener, and a manhole liner.

Owner:LMK TECH LLC

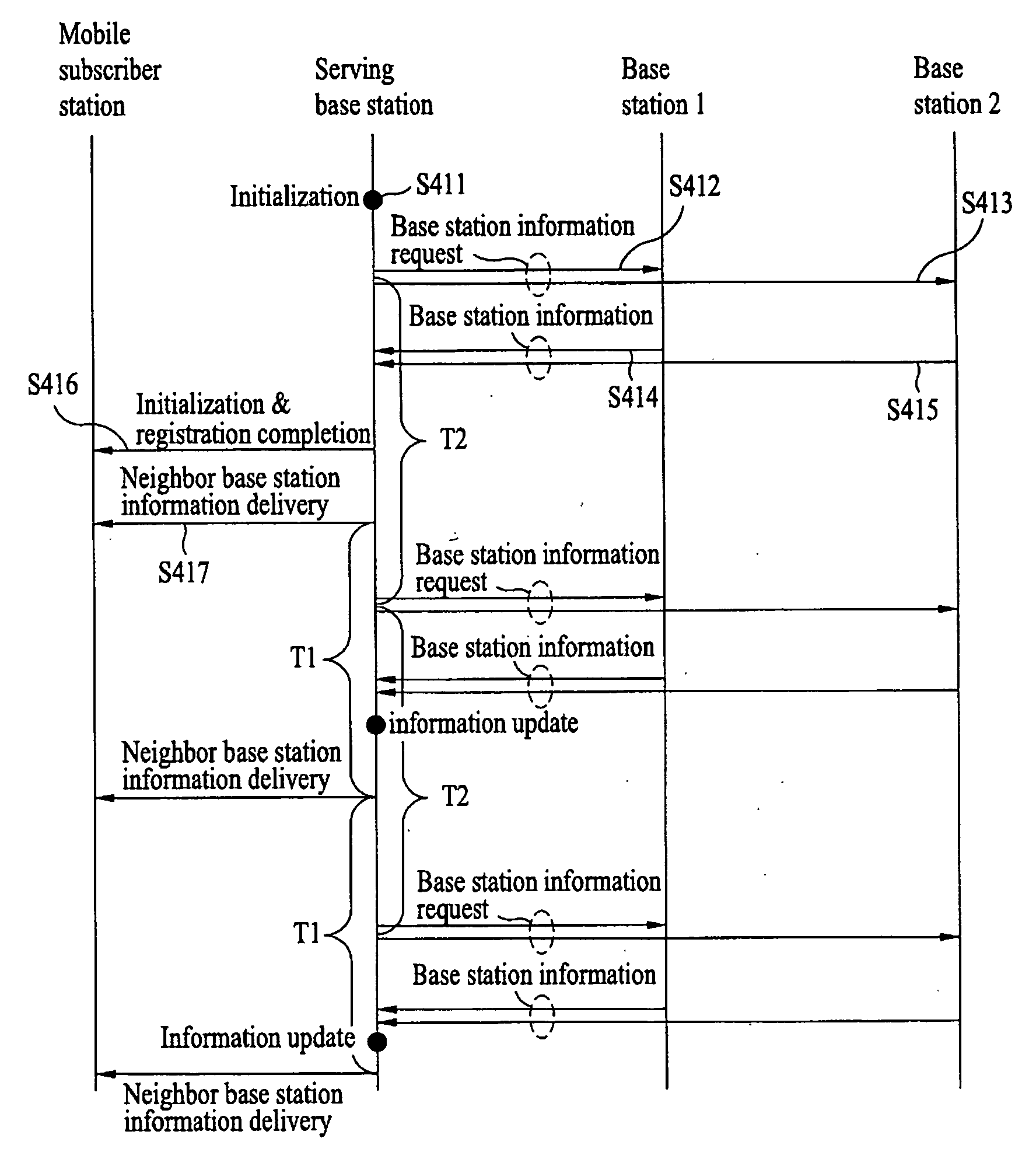

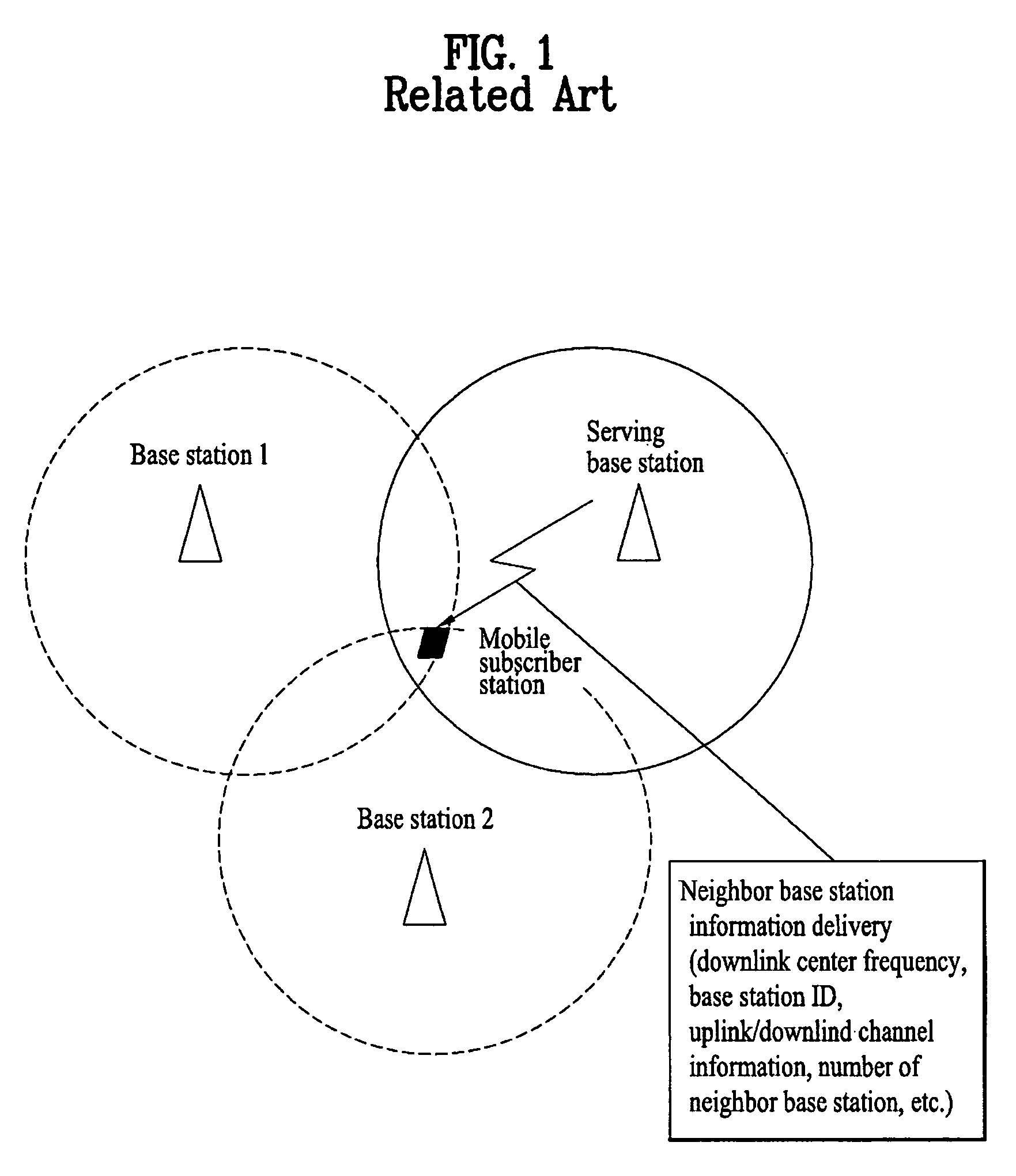

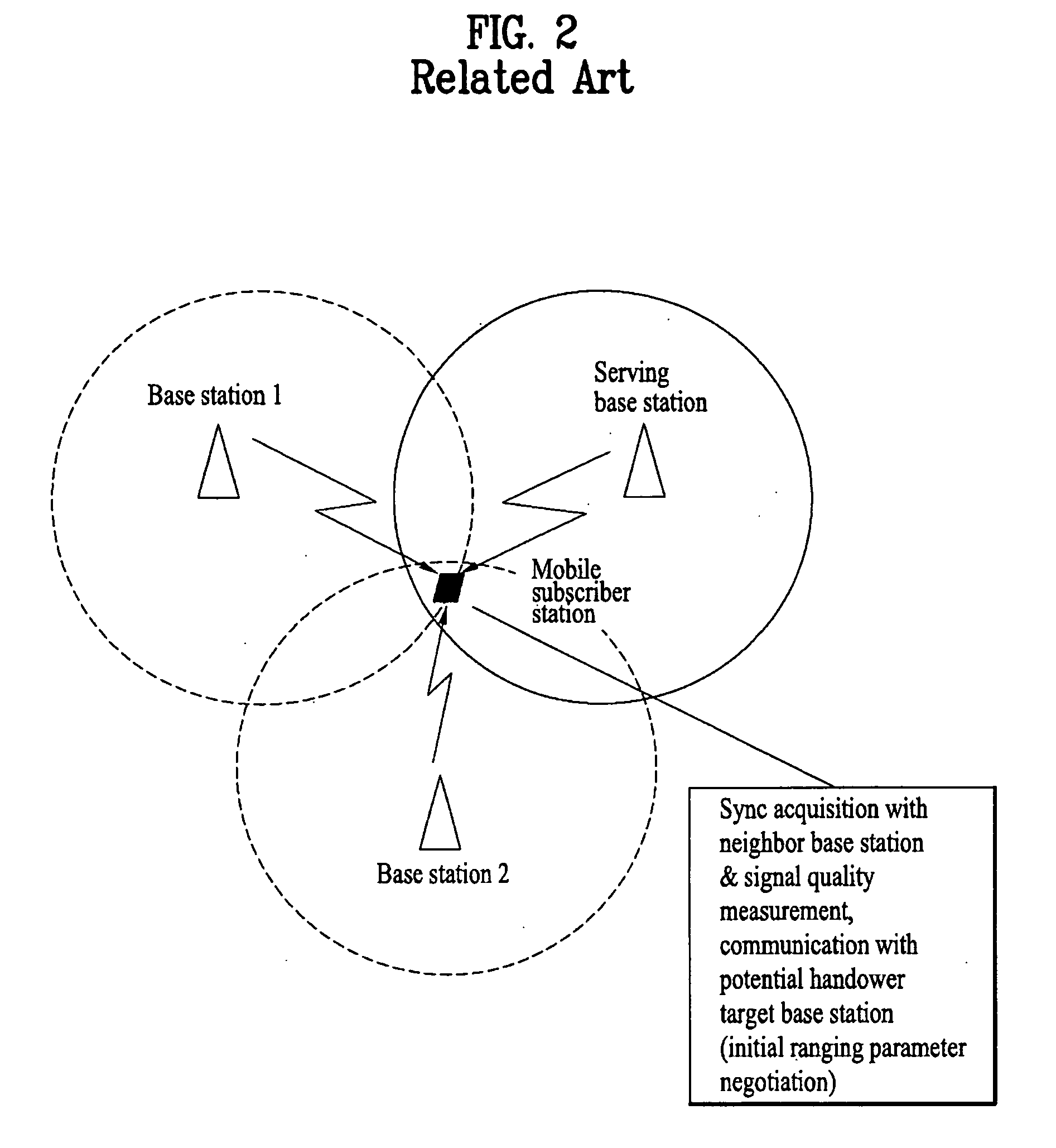

Method of communicating neighbor base station information

InactiveUS20050272403A1Engine sealsJoints with sealing surfacesSignal qualityMobile communication systems

A method uses inter-base station control messages to provide neighbor base station information to mobile subscriber stations in a mobile communication system. The method includes obtaining, at a serving base station, physical channel information of neighbor base stations over a backbone network via, either directly or via a server; periodically transmitting the obtained physical channel information from the serving base station to a mobile subscriber station connected to the serving base station; and measuring, based on the updated physical channel information, signal quality of the at least one neighbor base station at the mobile subscriber station. Thus, the serving base station receives from the neighbor base stations the inter-base station control messages containing the neighbor base station information, updates the information, and provides the updated information to the corresponding mobile subscriber station(s), to be used for a specific purpose such as handover or network entry.

Owner:LG ELECTRONICS INC

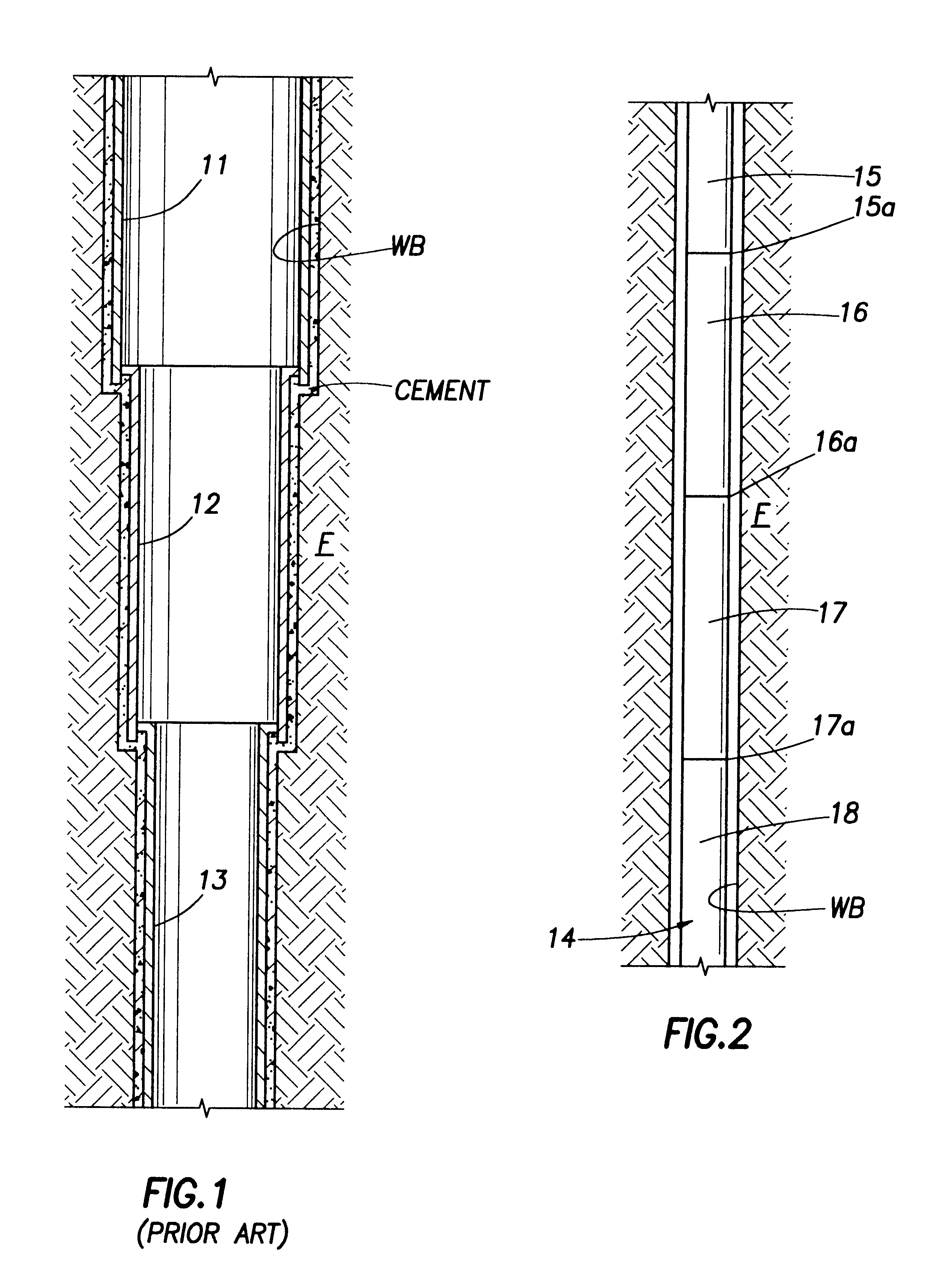

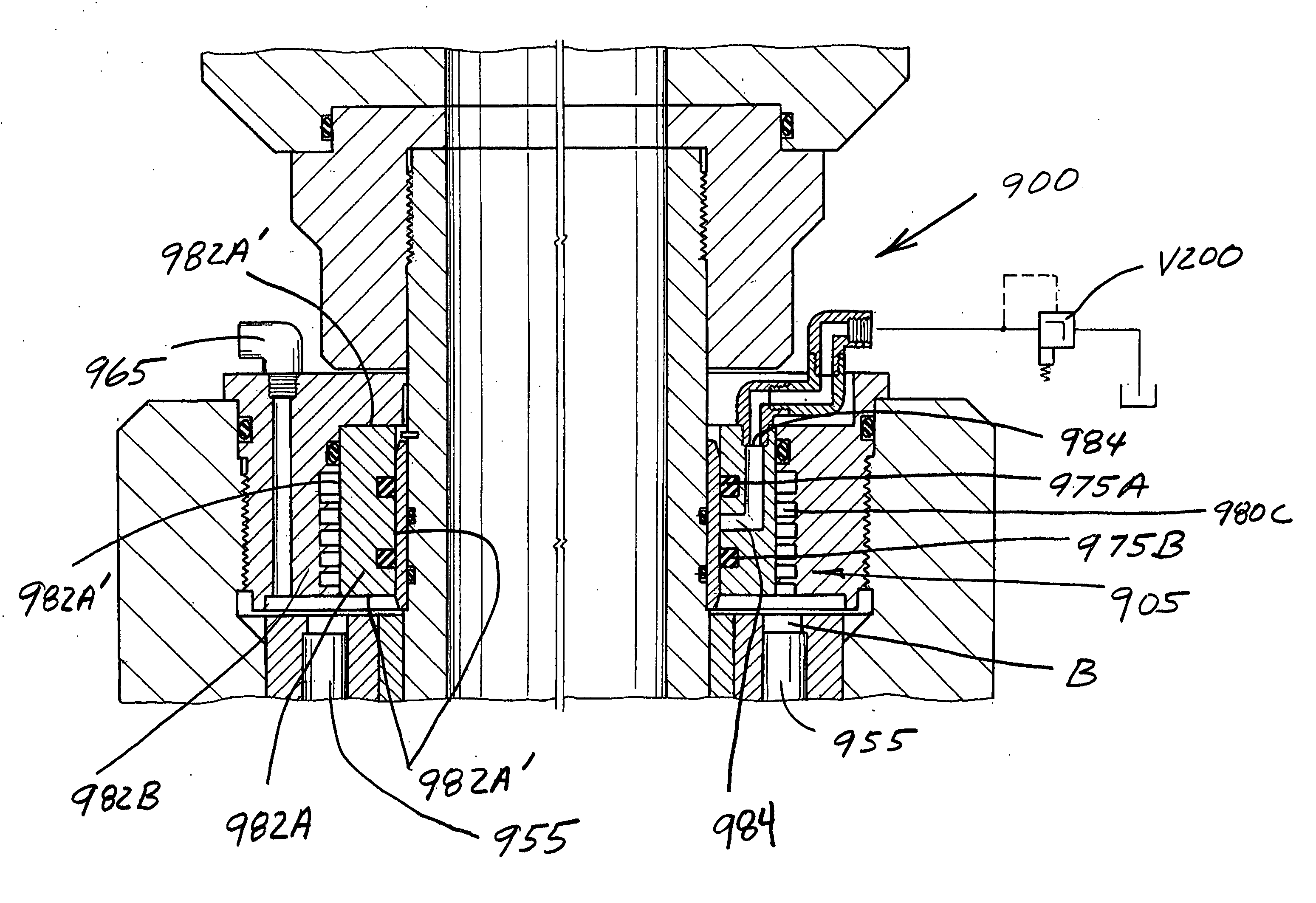

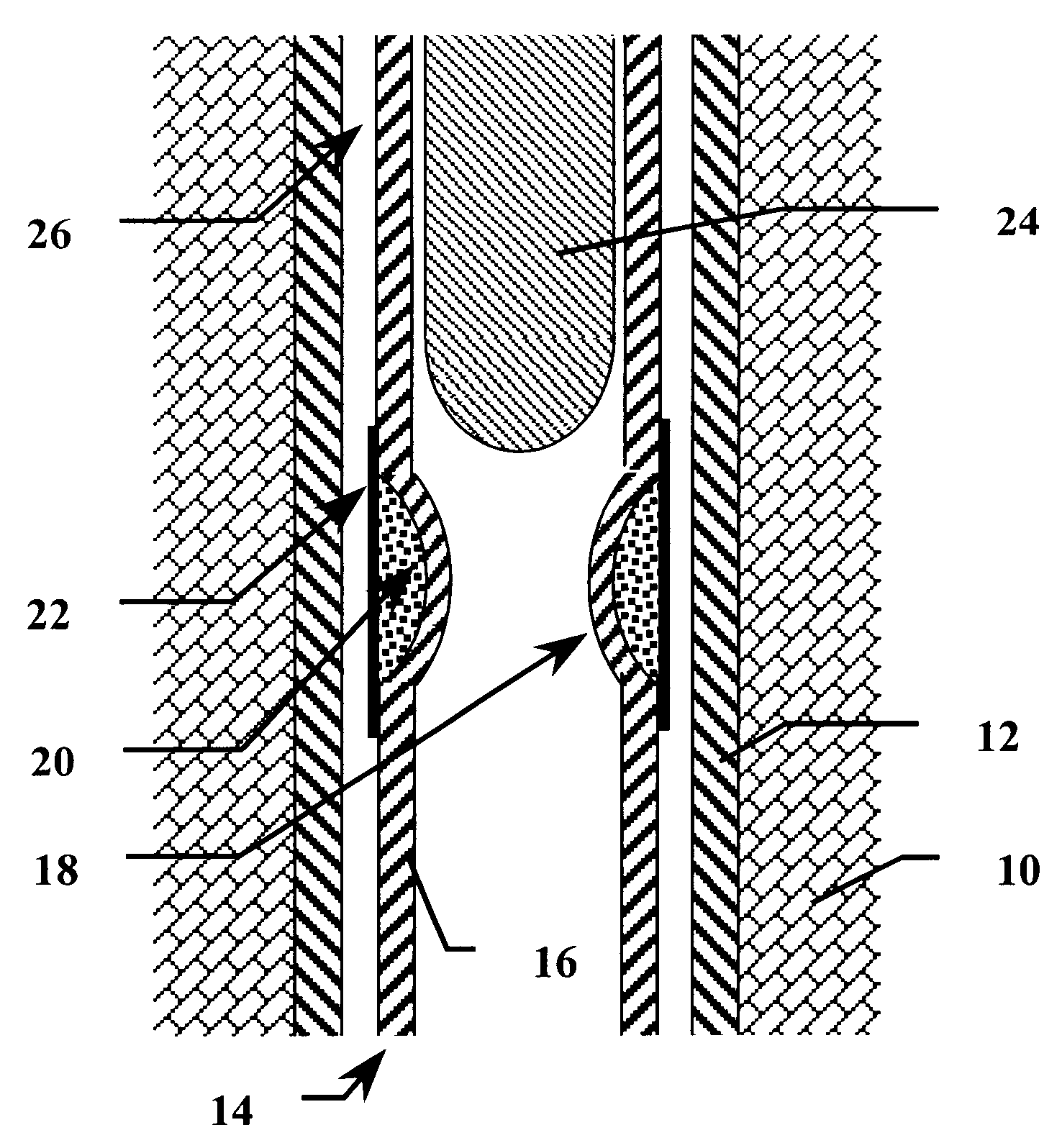

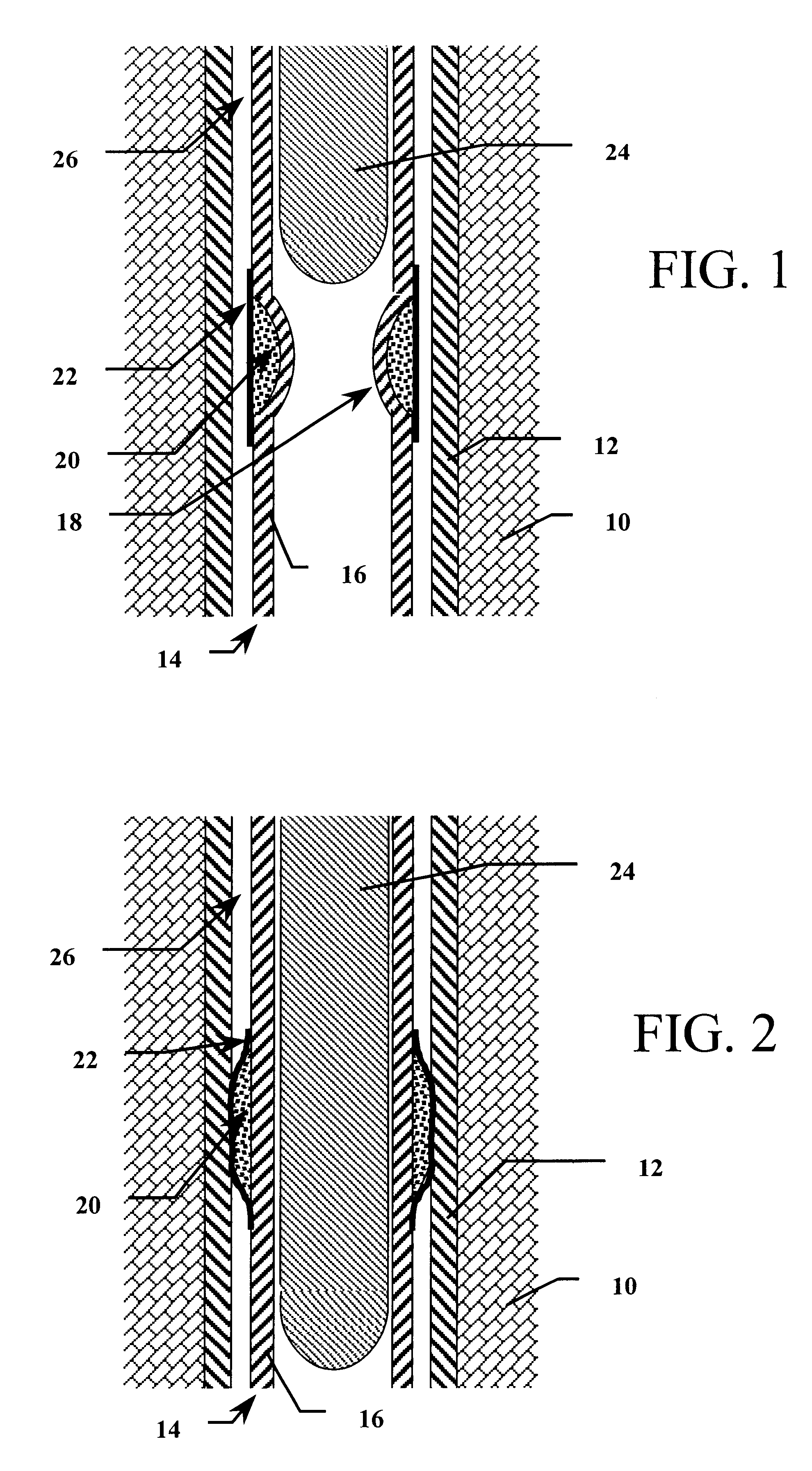

Method and apparatus for expansion sealing concentric tubular structures

InactiveUS6530574B1Resistance to degradationReduce the possibilitySleeve/socket jointsEngine sealsEngineeringSealant

A device and method for sealing a first cylinder in a fixed position inside a second concentric cylinder. The inner cylinder has an annular depression in its wall at the point of sealant placement, which causes the wall of the inner cylinder to intrude inwardly. The depression is filled with a partially compressible fluid and is covered over by a malleable / ductile sleeve. The inner cylinder is placed within the outer cylinder with the covered annular depression positioned at the desired sealing point. A cylindrical displacement device is directed through the inside of the inner cylinder where it encounters the intrusion of the annular depression. The displacement device is forced past the annular intrusion and pushes the wall outward. The partially compressible fluid is forced to expand outward under the malleable / ductile cover in a manner that intrudes into the annular space between the inner cylinder and the outer cylinder and into contact with the outer cylinder. The partially compressible fluid has a residual energy sufficient to maintain the sealing element in contact with the outer cylinder.

Owner:BAILEY GARY L +1

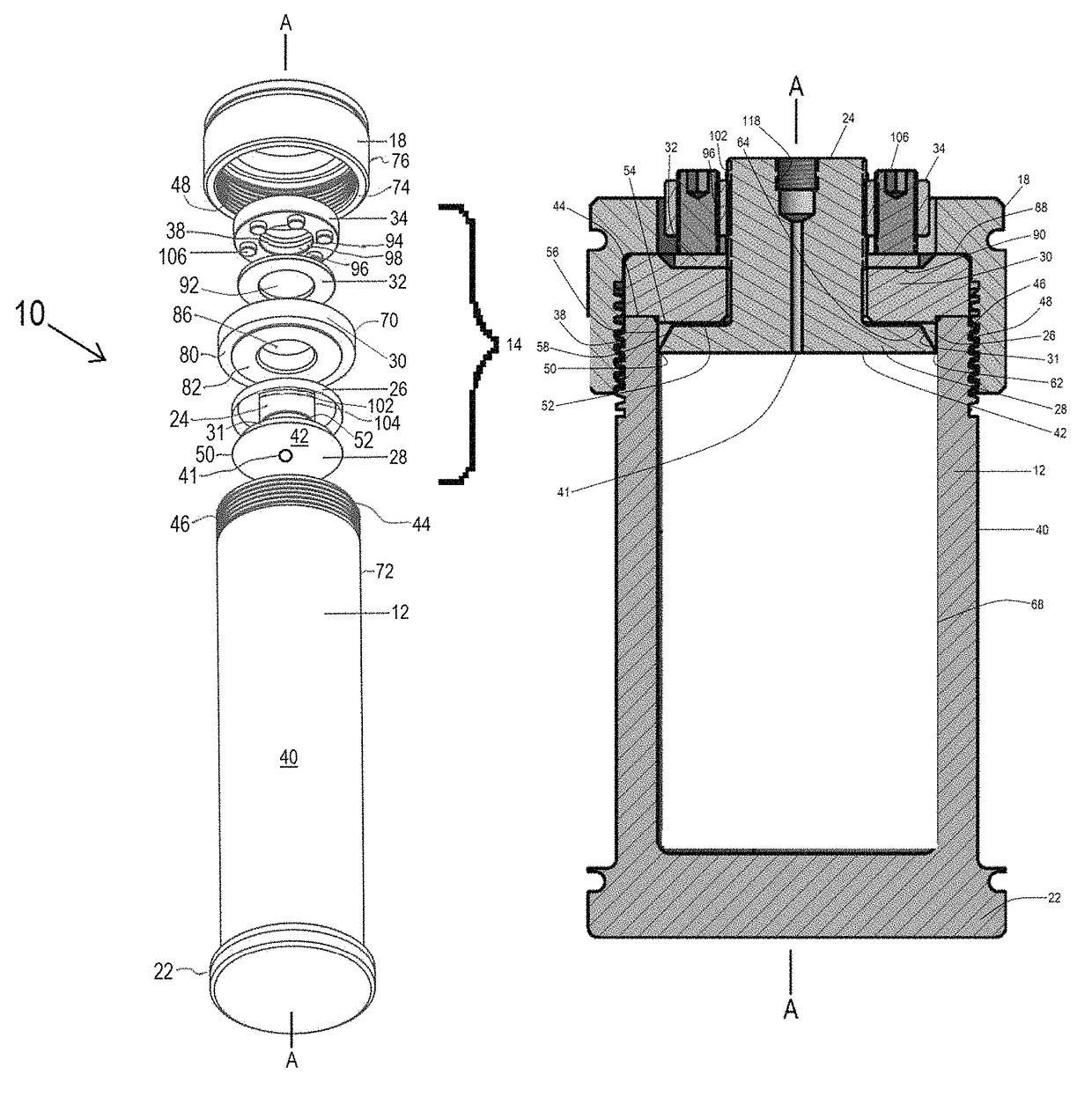

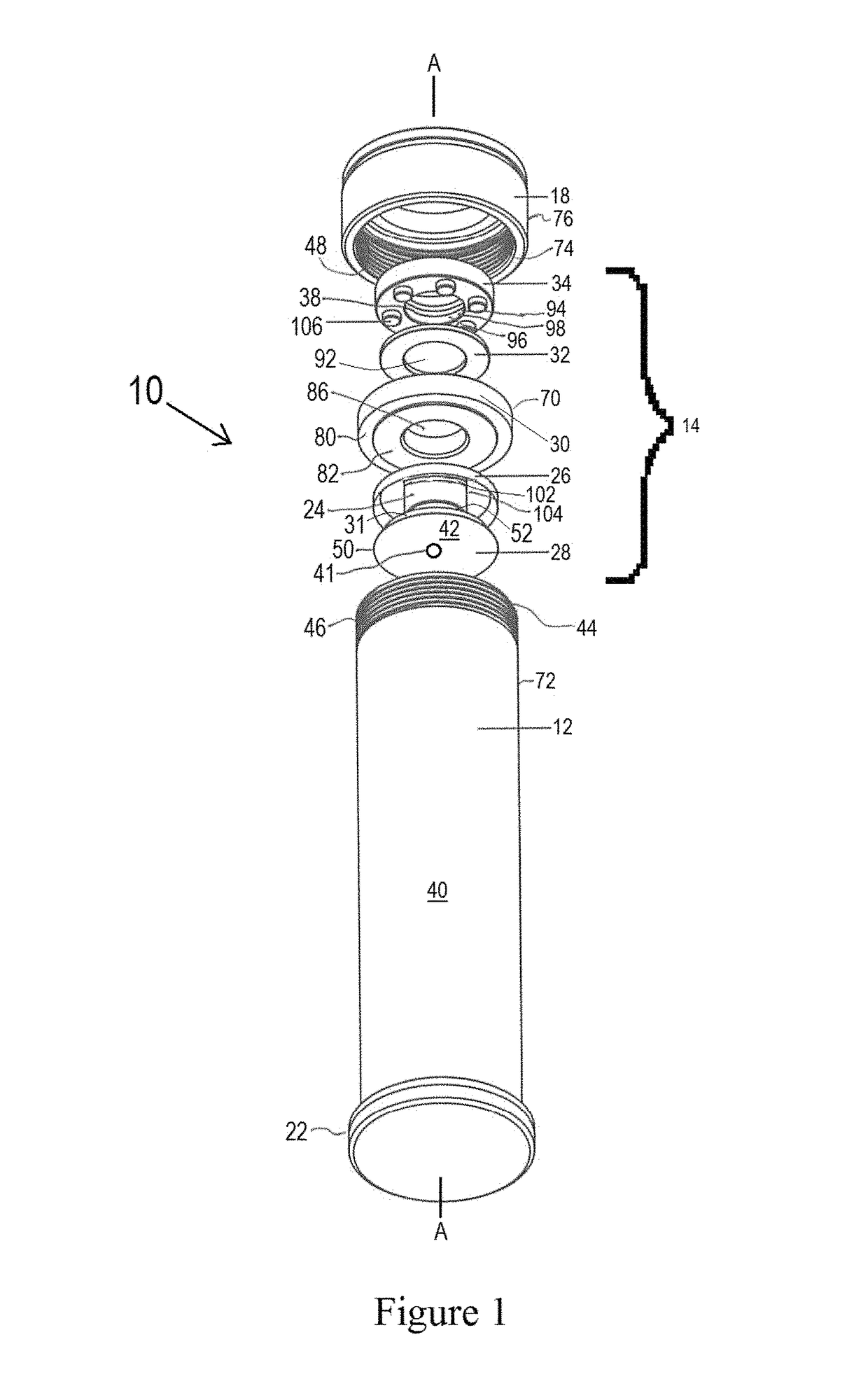

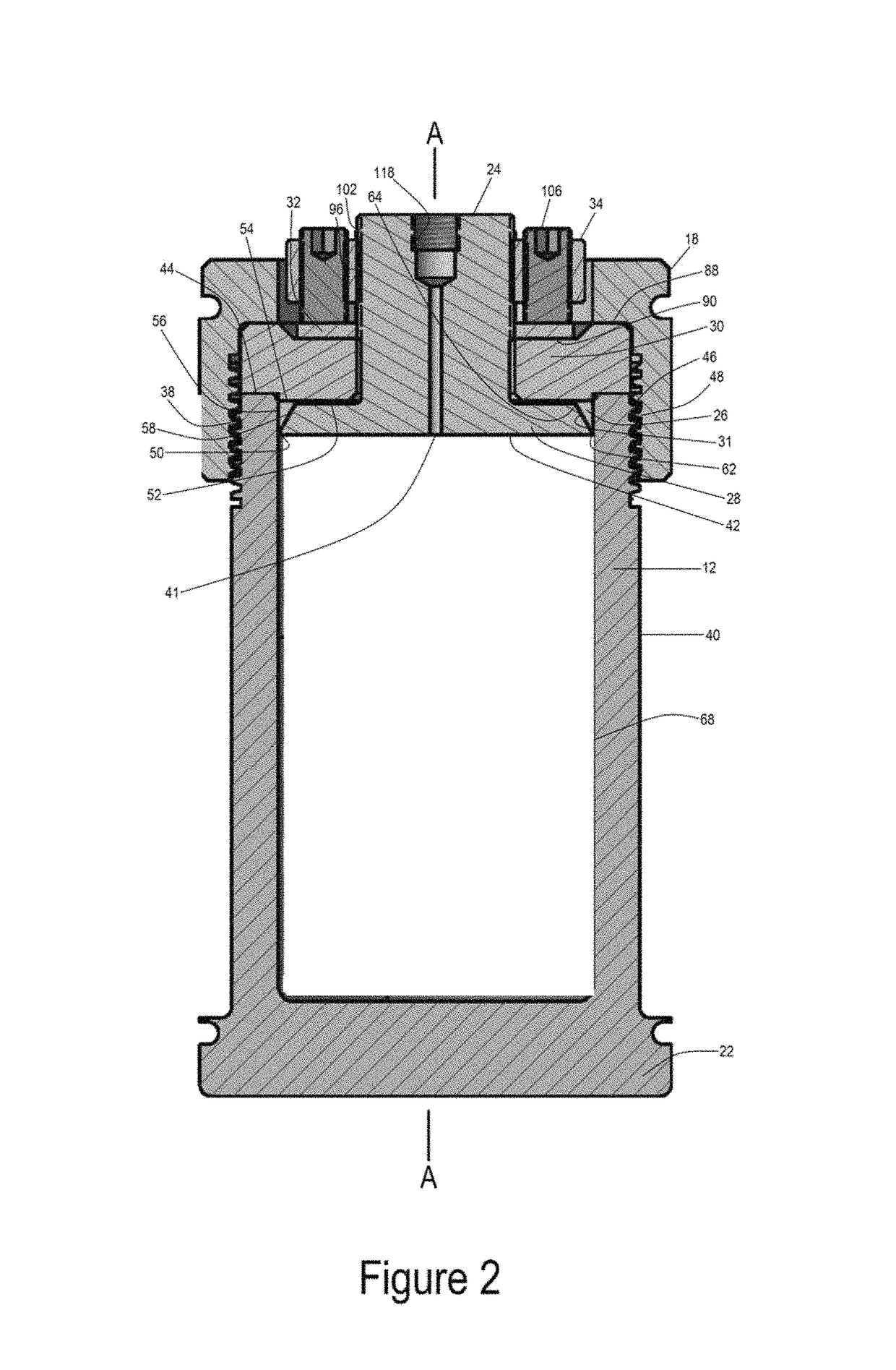

Pressure vessel

InactiveUS20030140845A1Prevent escapeAvoid creatingFrom gel statePolycrystalline material growthTemperature controlPressure transmission

A pressure vessel for processing at least one material in a supercritical fluid. The pressure vessel includes a self-pressurizing capsule for containing at least one material and the supercritical fluid in a substantially air-free environment, a pressure transmission medium surrounding the capsule for maintaining an outer pressure on the capsule, at least one heating element insertable in the pressure transmission medium such that the heating element surrounds the capsule, a temperature measurement means for measuring a temperature of the capsule, a temperature controller for controlling the temperature and providing power to the heating element, a restraint to contain and hold in place the capsule, the pressure transmission medium, and the heating element, and at least one seal between the restraint and the pressure transmission medium for preventing escape of the pressure transmission medium. Methods of using the pressure vessel, processing a material at high temperature and high pressure in the presence of a supercritical fluid within the capsule are also described.

Owner:SORAA

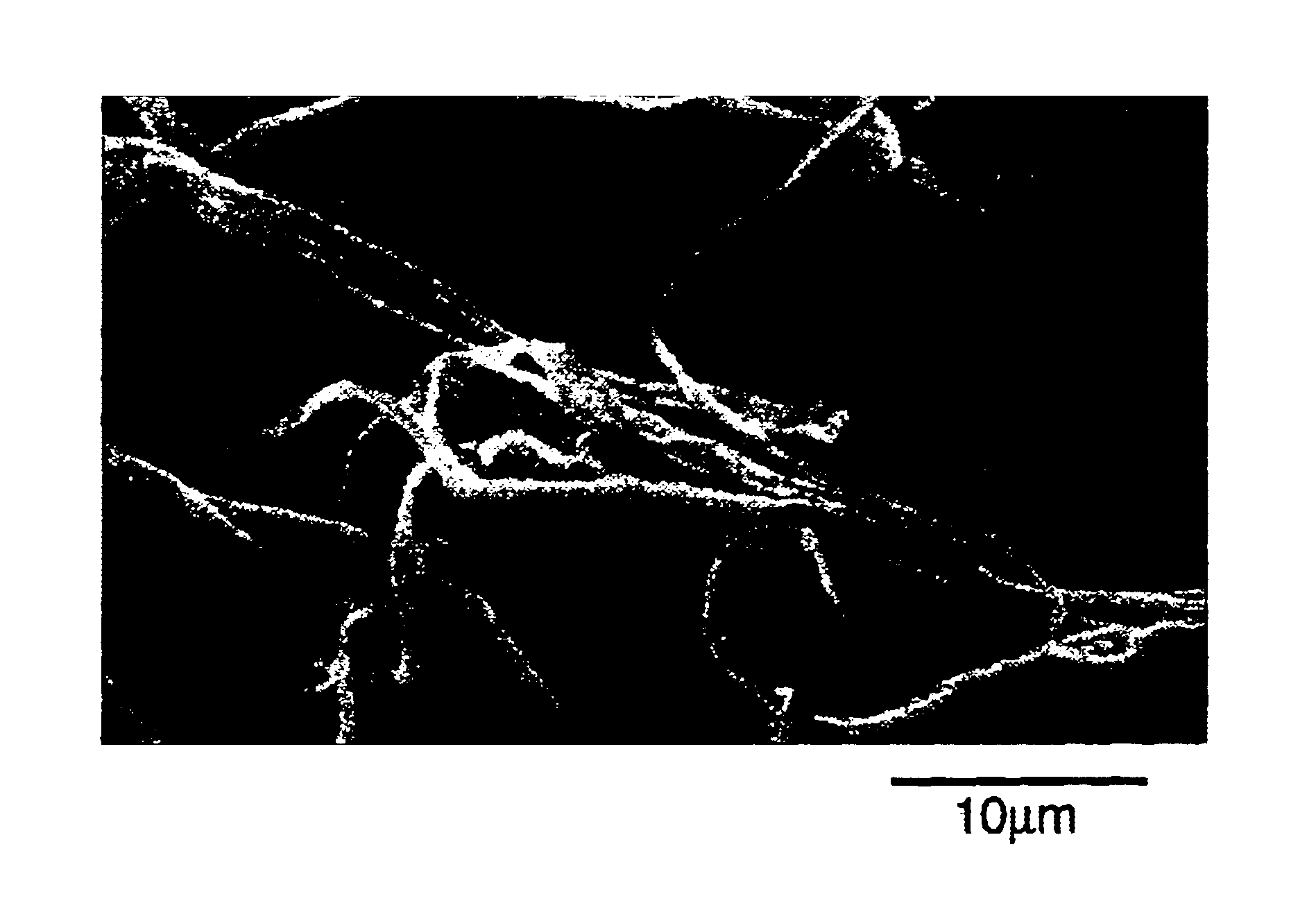

Aliphatic polyester microfibers, microfibrillated articles and use thereof

InactiveUS6890649B2Increase surface areaUseful applicationEngine sealsFilament/thread formingPolyesterParticulates

The present invention relates to aliphatic polyester microfibers, films having a microfibrillated surface, and methods of making the same. Microfibers of the invention can be prepared by imparting fluid energy, typically in the form of high-pressure water jets, to a highly oriented, highly crystalline, aliphatic polyester film to liberate microfibers therefrom. Microfibrillated films of the invention find use as tape backings, filters for particulate contaminants, such as face masks and water or air filters, fibrous mats, such as those used for removal of oil from water and those used as wipes, and thermal and acoustical insulation. Microfibers of the invention, when removed from the film matrix may be used in the preparation of woven or nonwoven articles and used as wipes for the removal of debris or dust from a surface. The microfibers and microfibrillated articles of the invention may be biodegradable, rendering them useful for geotextiles.

Owner:3M INNOVATIVE PROPERTIES CO

Sealing device and sealing ring thereof

InactiveCN104595493AClose contactAvoid deformationEngine sealsPositive displacement pump componentsEngineeringHigh pressure

The invention discloses a sealing ring, which comprises a base body, a first elastic element and a support element used for supporting, wherein the base body is provided with a groove, the support element is fixedly arranged in the groove, the first elastic element is arranged between the support element and the inner side wall of the groove in a clamping way, and in addition, the first elastic element exerts the force in the direction towards the axis center when receiving the impact by fluid. When the sealing ring provided by the invention is adopted, and when the sealing ring receives the impact by the fluid, on one hand, the base body has a certain impact resistance effect on the fluid, and on the other hand, the elastic element receives the impact effect of the fluid and exerts the force in the direction towards the axis center on the base body, so that the contact of the base body and the part passing through the shaft hole is tighter, so that a good sealing effect is achieved. Therefore the sealing ring has the excellent high-pressure fluid dynamic sealing performance, and in addition, the service life is long. The invention also discloses a sealing device comprising the sealing ring.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

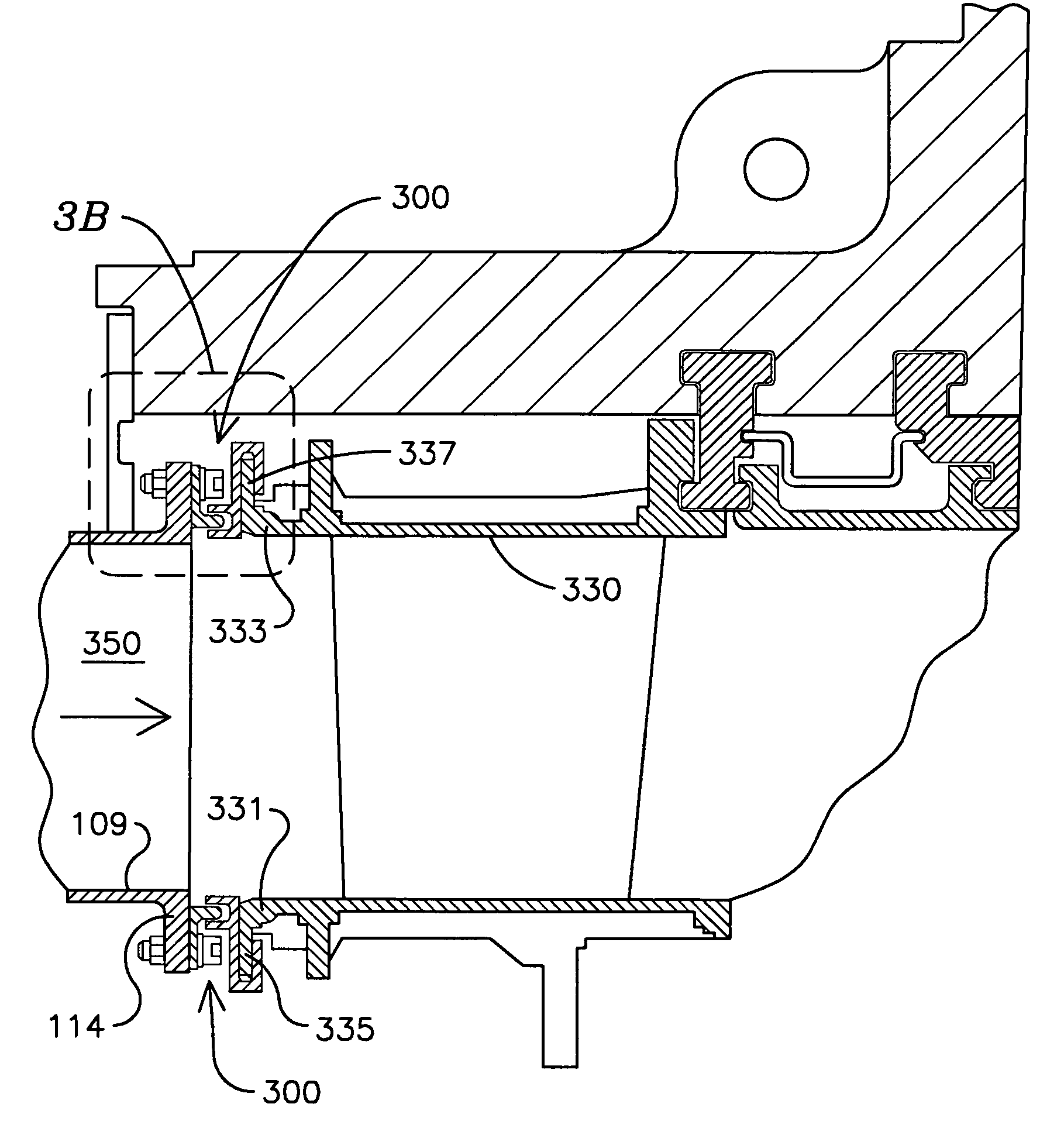

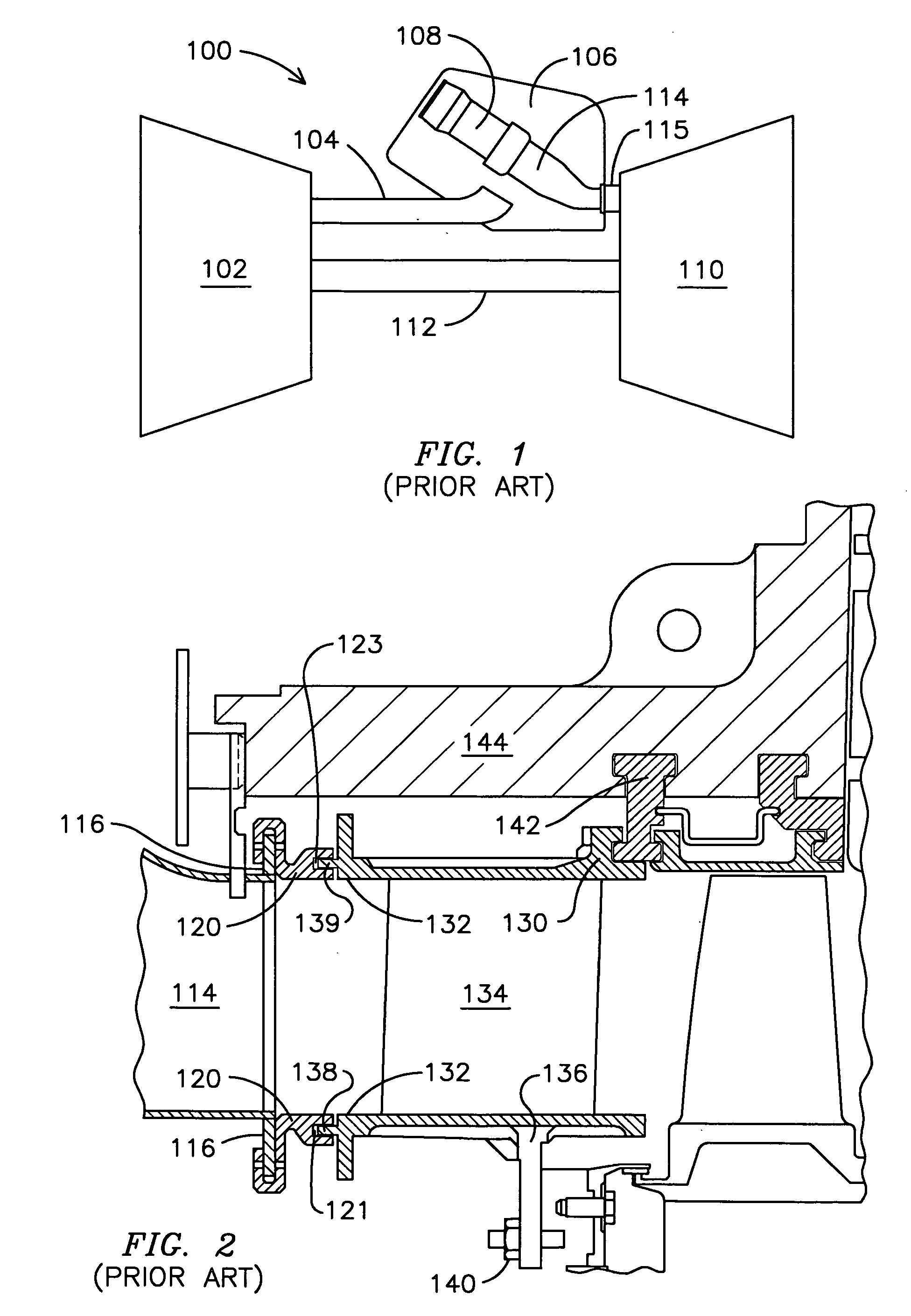

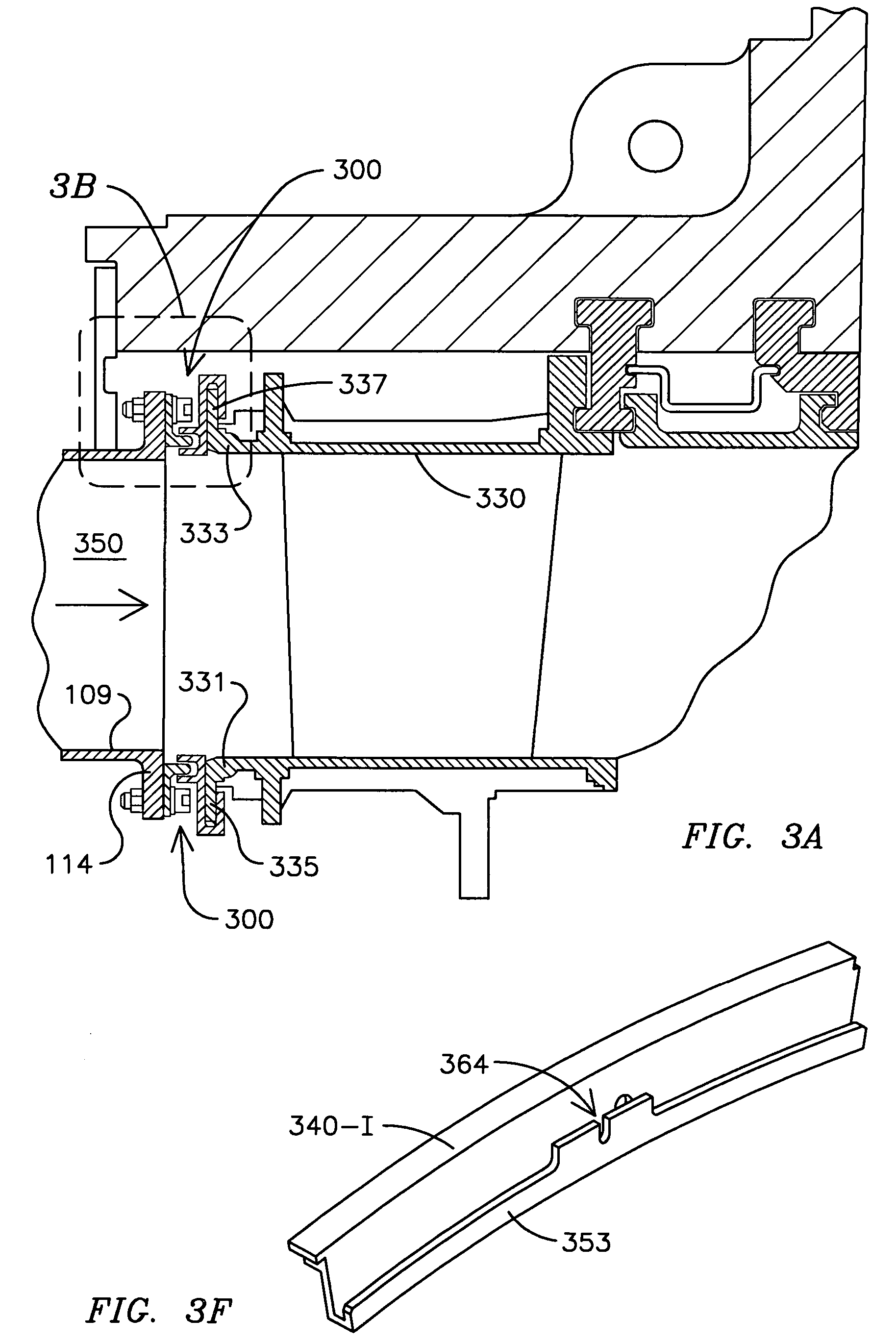

Transition-to-turbine seal apparatus and kit for transition/turbine junction of a gas turbine engine

One embodiment of a transition-to-turbine seal (300) comprises a transition exit seal (302) adapted for fixed attachment to an exit rail (116) of a transition (109), and a stage-1 seal (340). The stage-1 seal (340) comprises an axial seal slot (348) comprising parallel walls (346, 347) adapted to slidingly engage a first male member (310) of the transition exit seal (302). The stage-1 seal (340) also comprises a radial seal slot (354) comprising parallel walls (351, 353) adapted to slidingly engage a plate (338) of a row 1 vane segment (330). The transition-to-turbine seal (300) thus provides both axial and radial freedom of movement. Materials and coatings for the transition exit seal (302) and the stage-1 seal (340) are selected to promote preferential wear of these components relative to wear of the surface of the row 1 vane segment (330). Wear of the exit rail (116) is reduced or eliminated due to the noted fixed attachment.

Owner:SIEMENS ENERGY INC

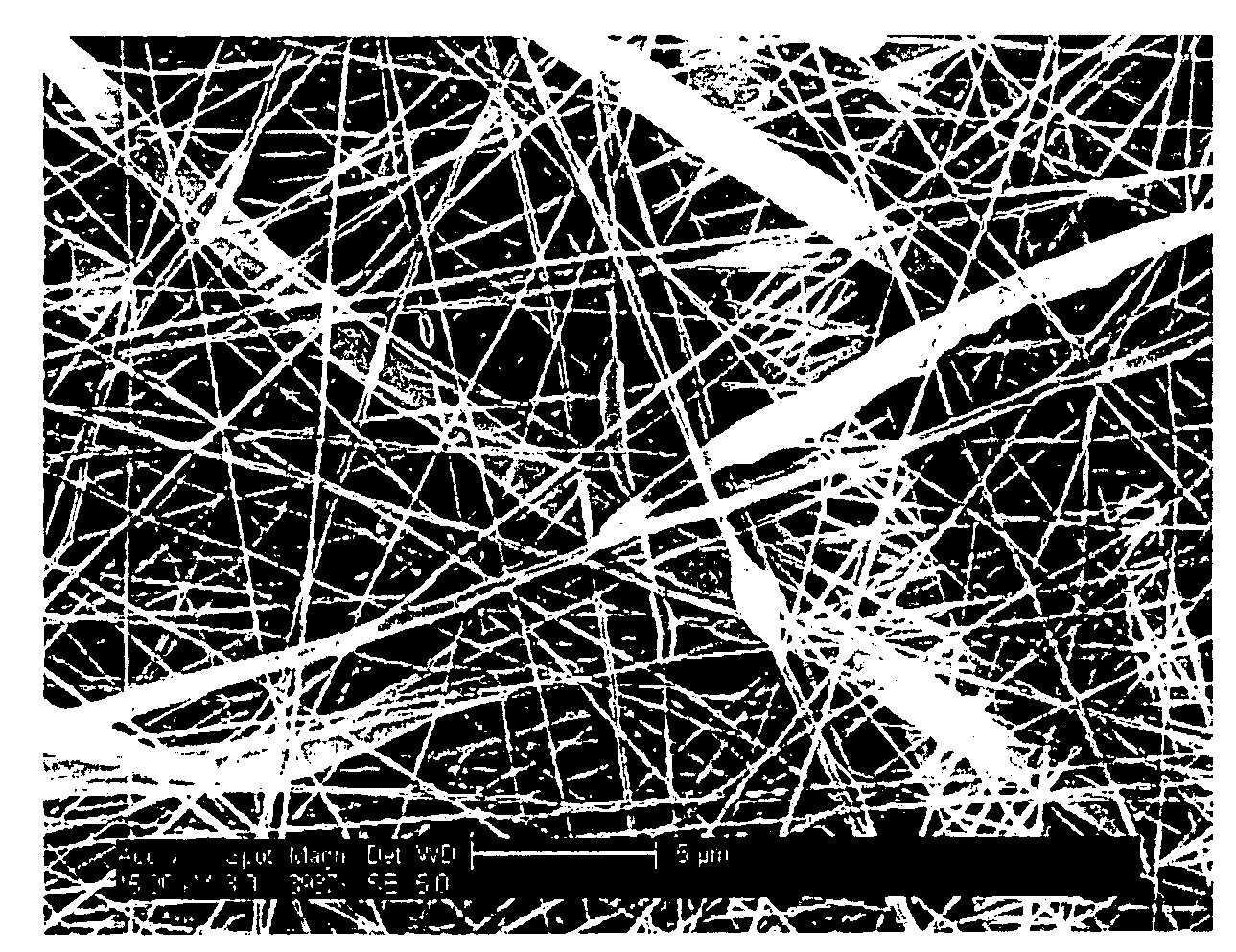

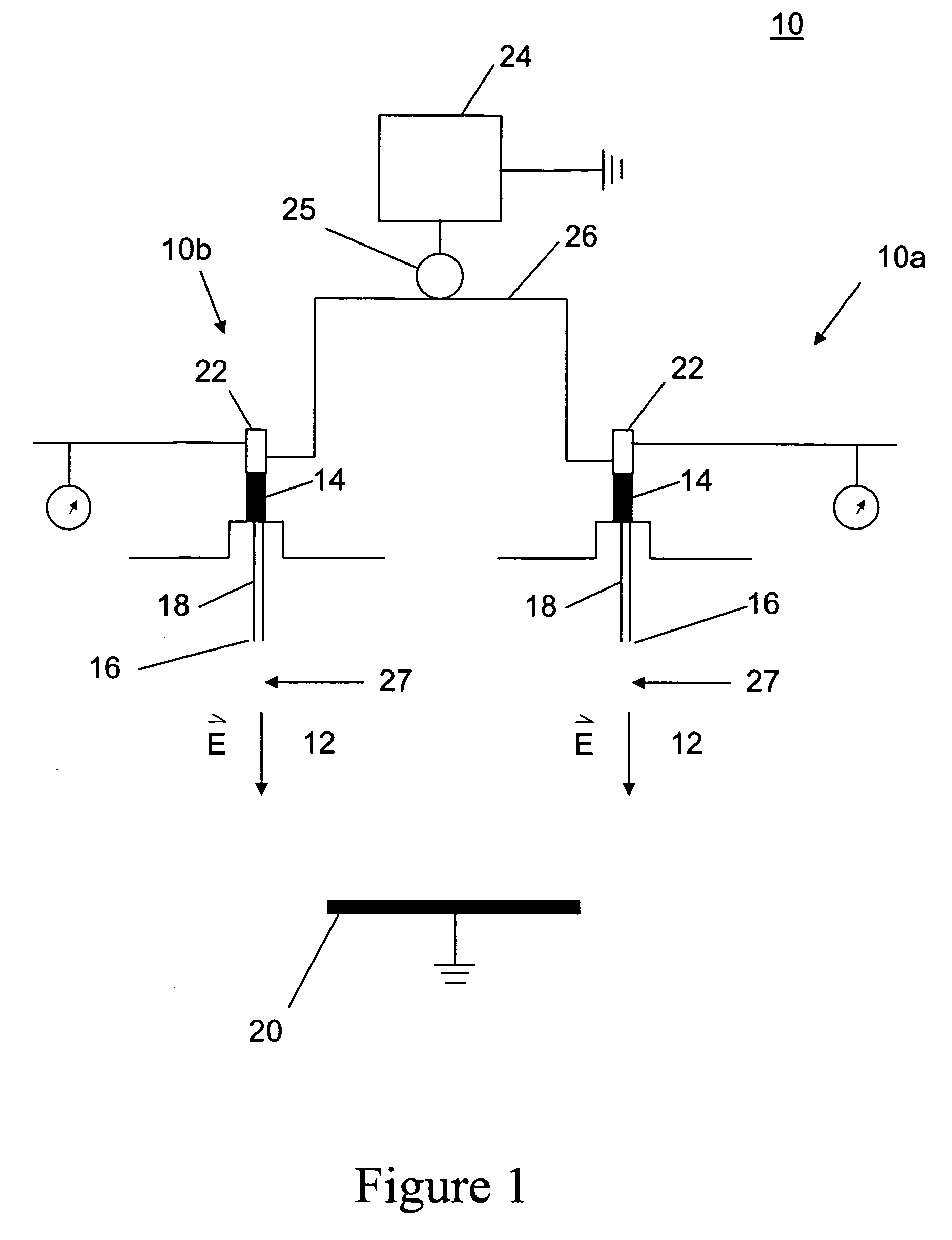

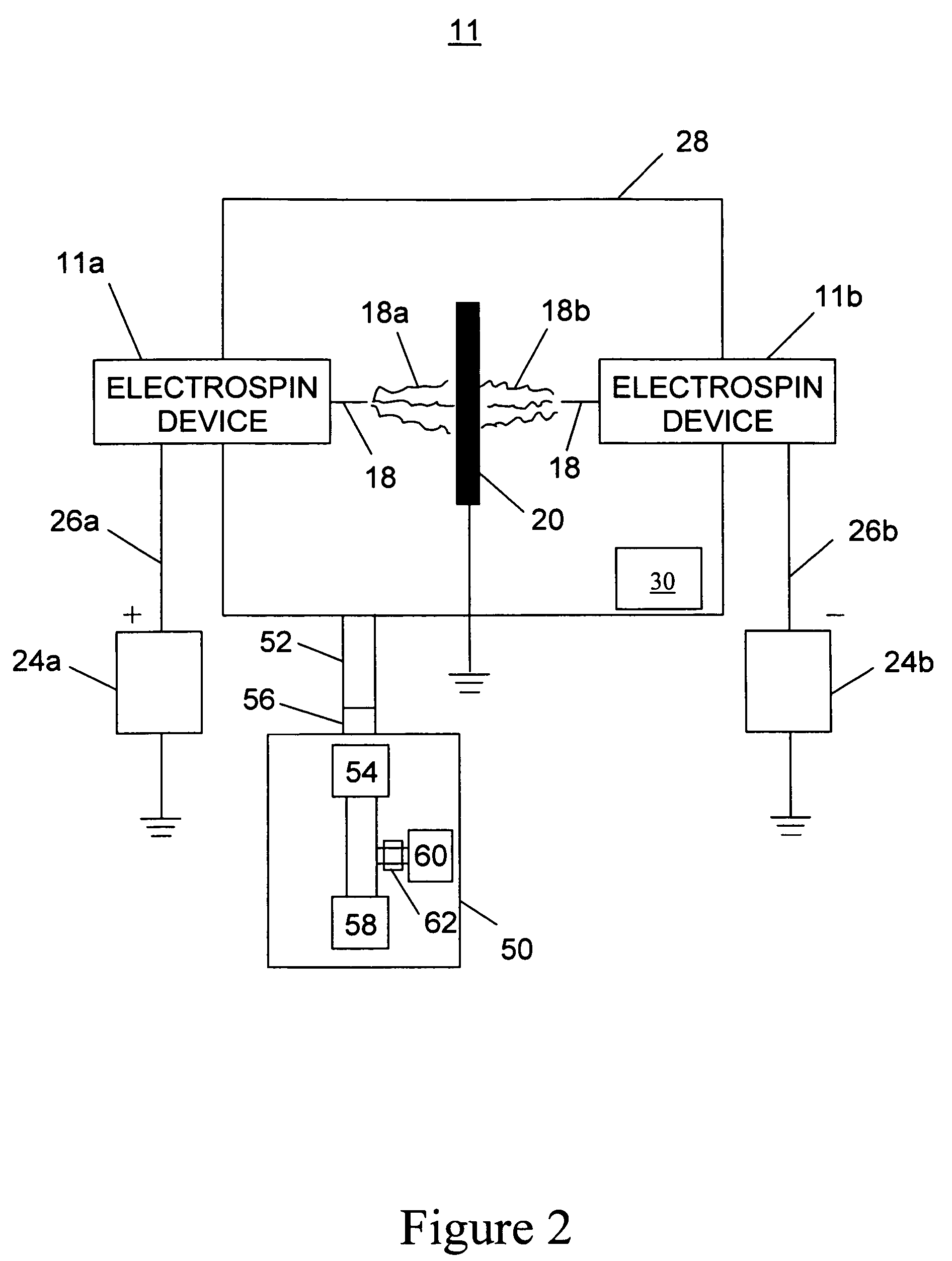

Nanofiber Mats and production methods thereof

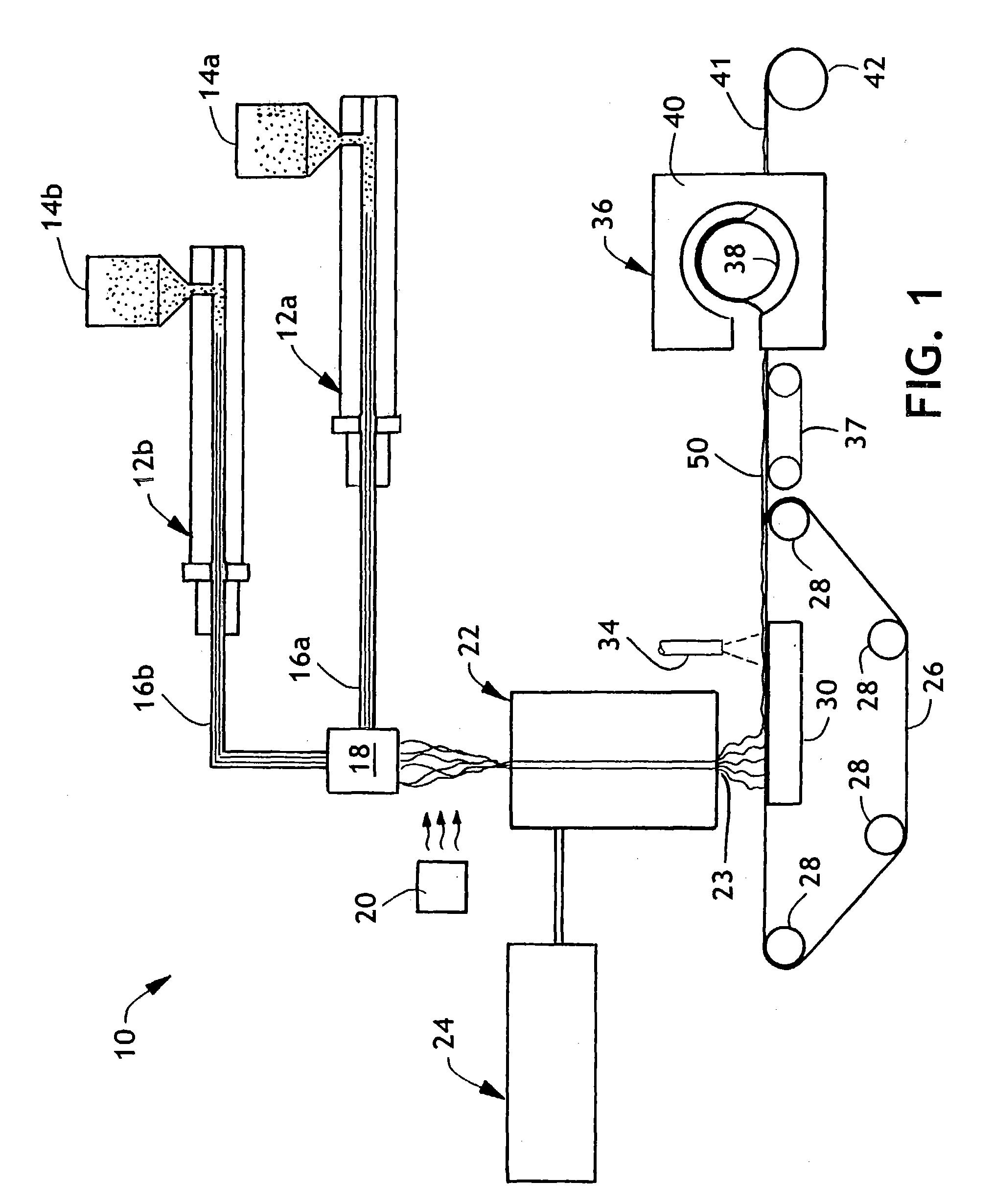

An apparatus and method in which the apparatus includes a first electrospinning device configured to electrospin first fibers of a first substance, a second electrospinning device configured to electrospin second fibers of a second substance such that first and second fibers combine in a mat formation region, and a biasing device configured to bias the first electrospinning device with a first electric polarity and to bias the second electrospinning device with a second electric polarity of opposite polarity to the first electric polarity to promote attraction and coalescence between the first and second fibers. The method electrospins under the first electric polarity first fibers from the first substance, electrospins under the second electric polarity fibers from the second substance, and coalesces the first and second fibers to form the fiber mat.

Owner:RES TRIANGLE INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com