Patents

Literature

7144 results about "Thin layer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thin-layer chromatography (TLC) is a chromatography technique used to separate non-volatile mixtures. Thin-layer chromatography is performed on a sheet of glass, plastic, or aluminium foil, which is coated with a thin layer of adsorbent material, usually silica gel, aluminium oxide (alumina), or cellulose.

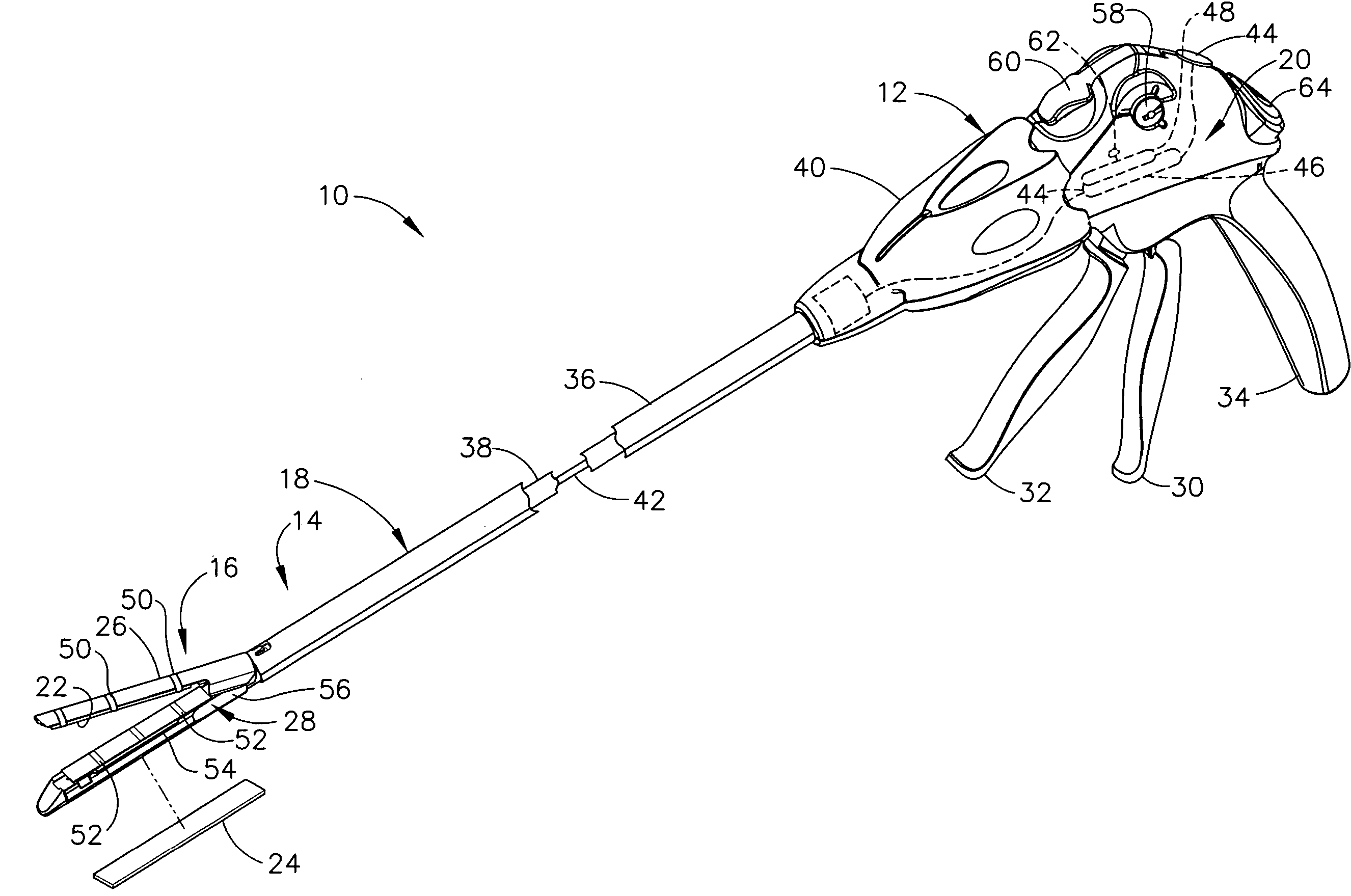

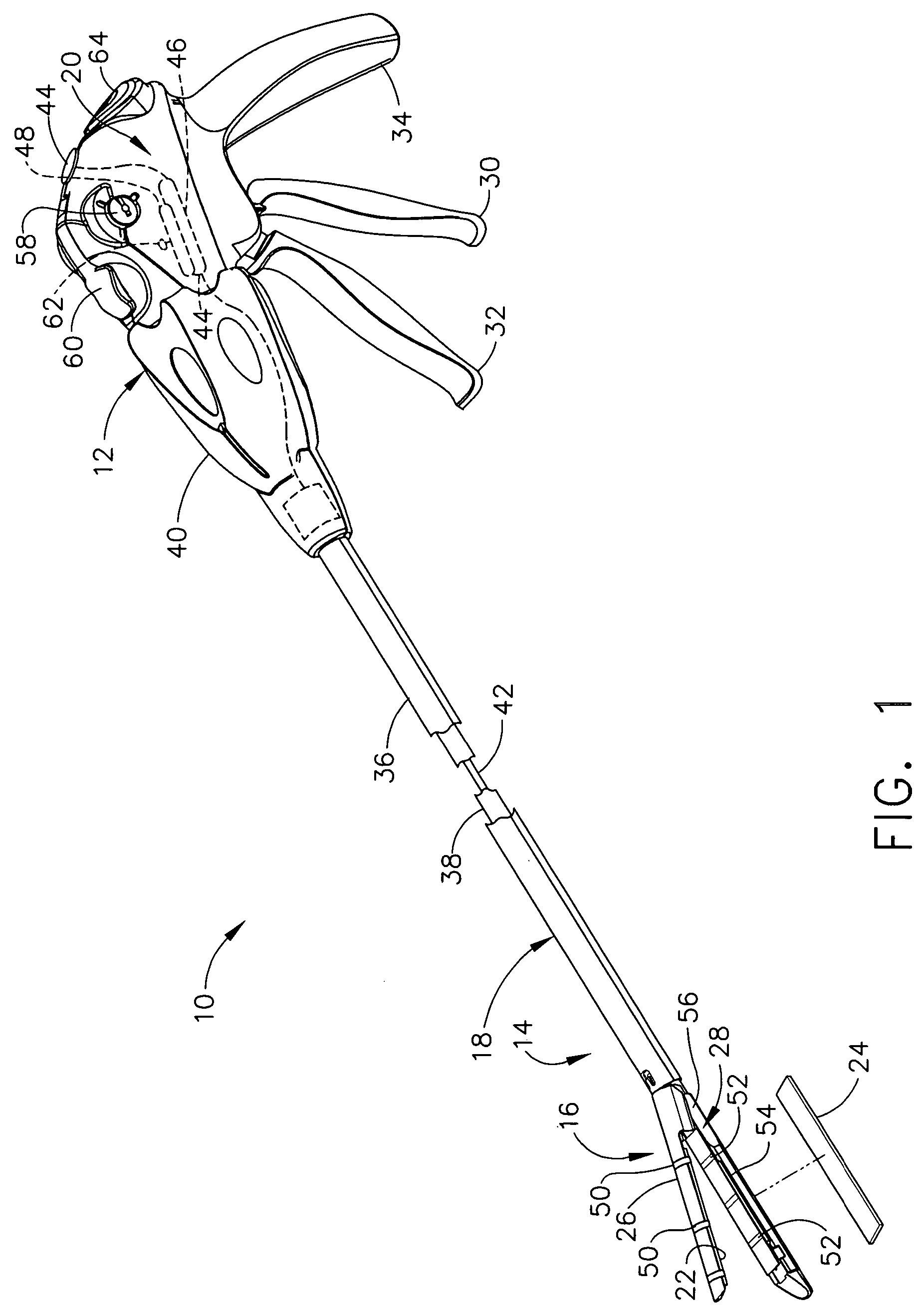

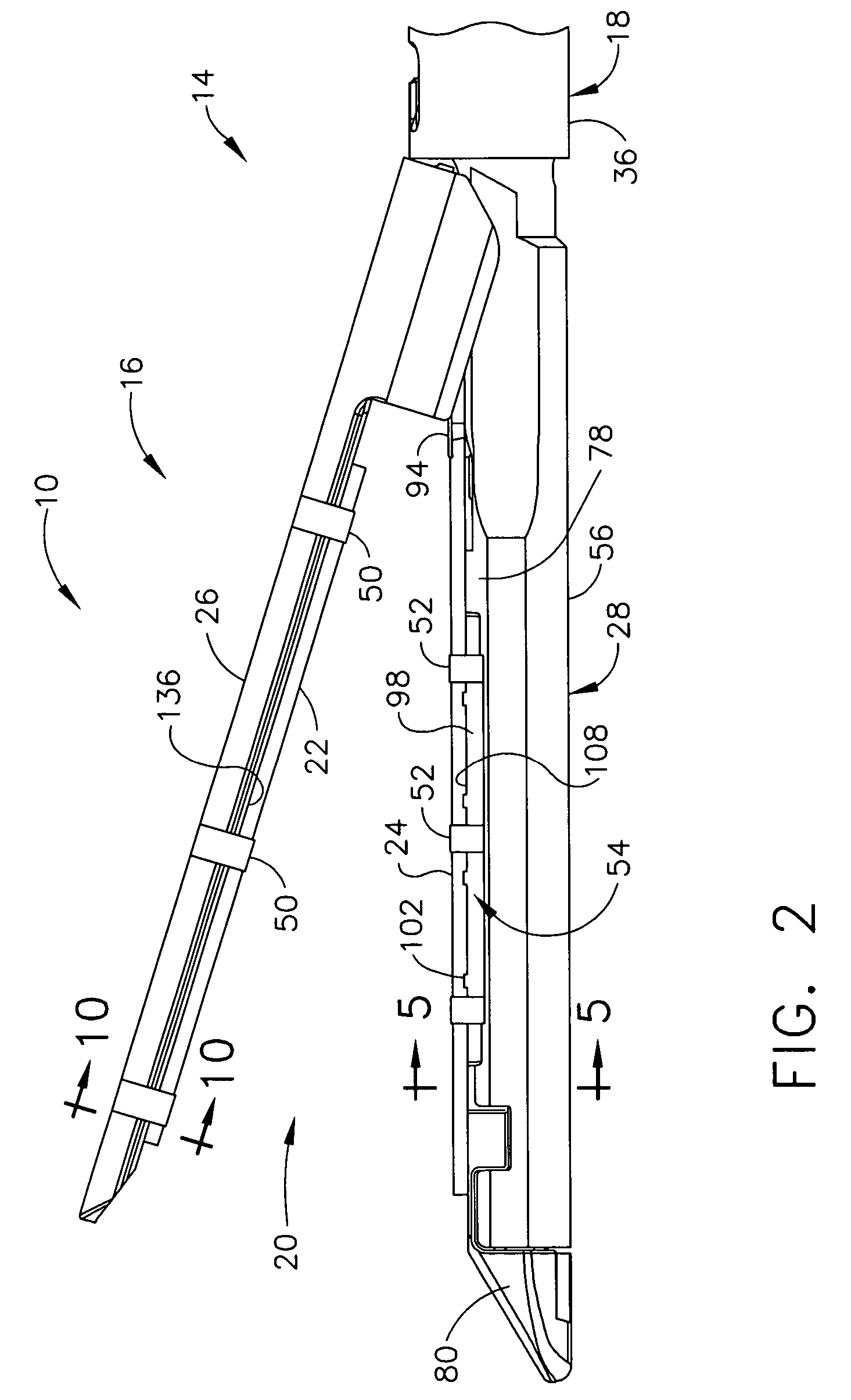

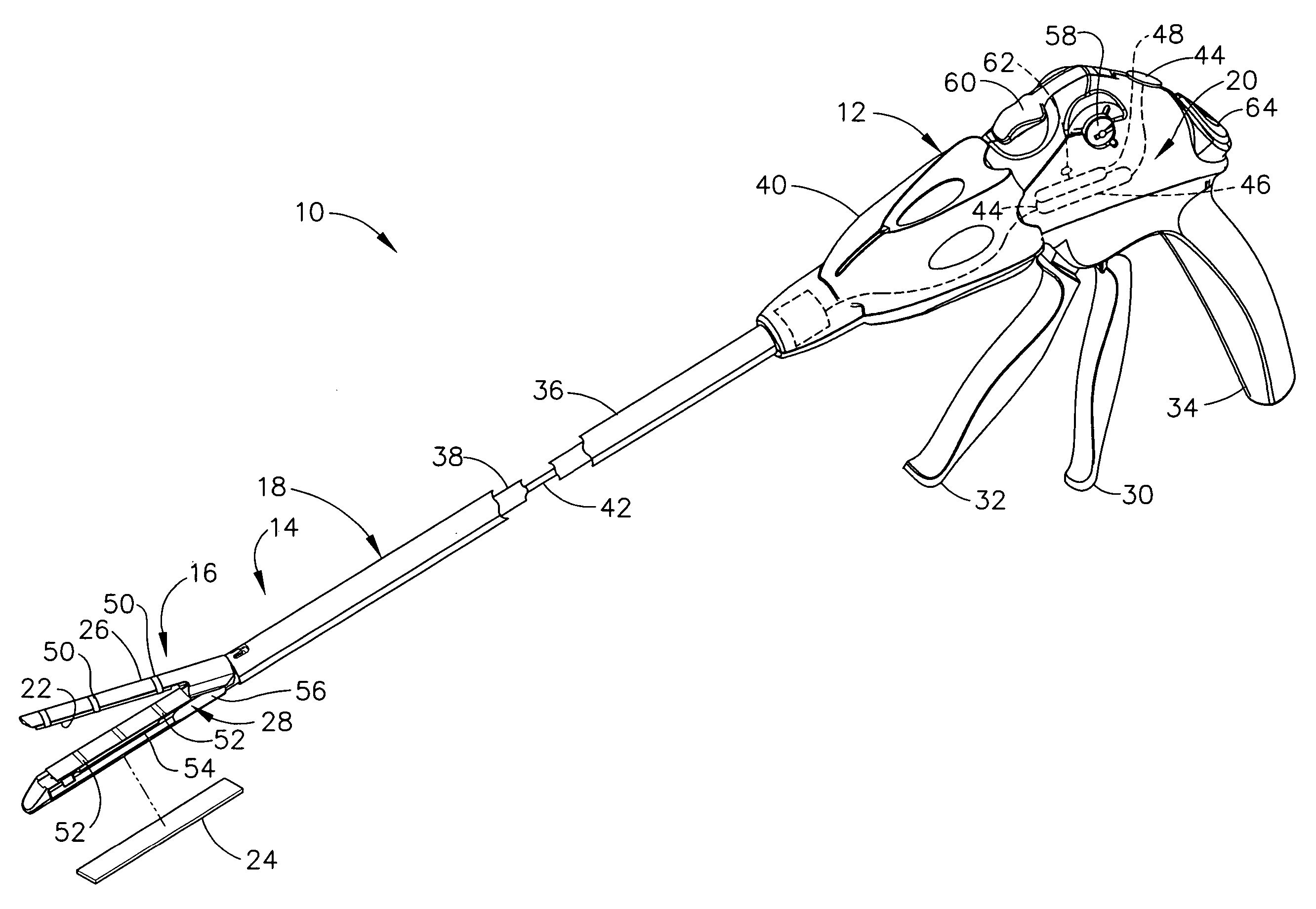

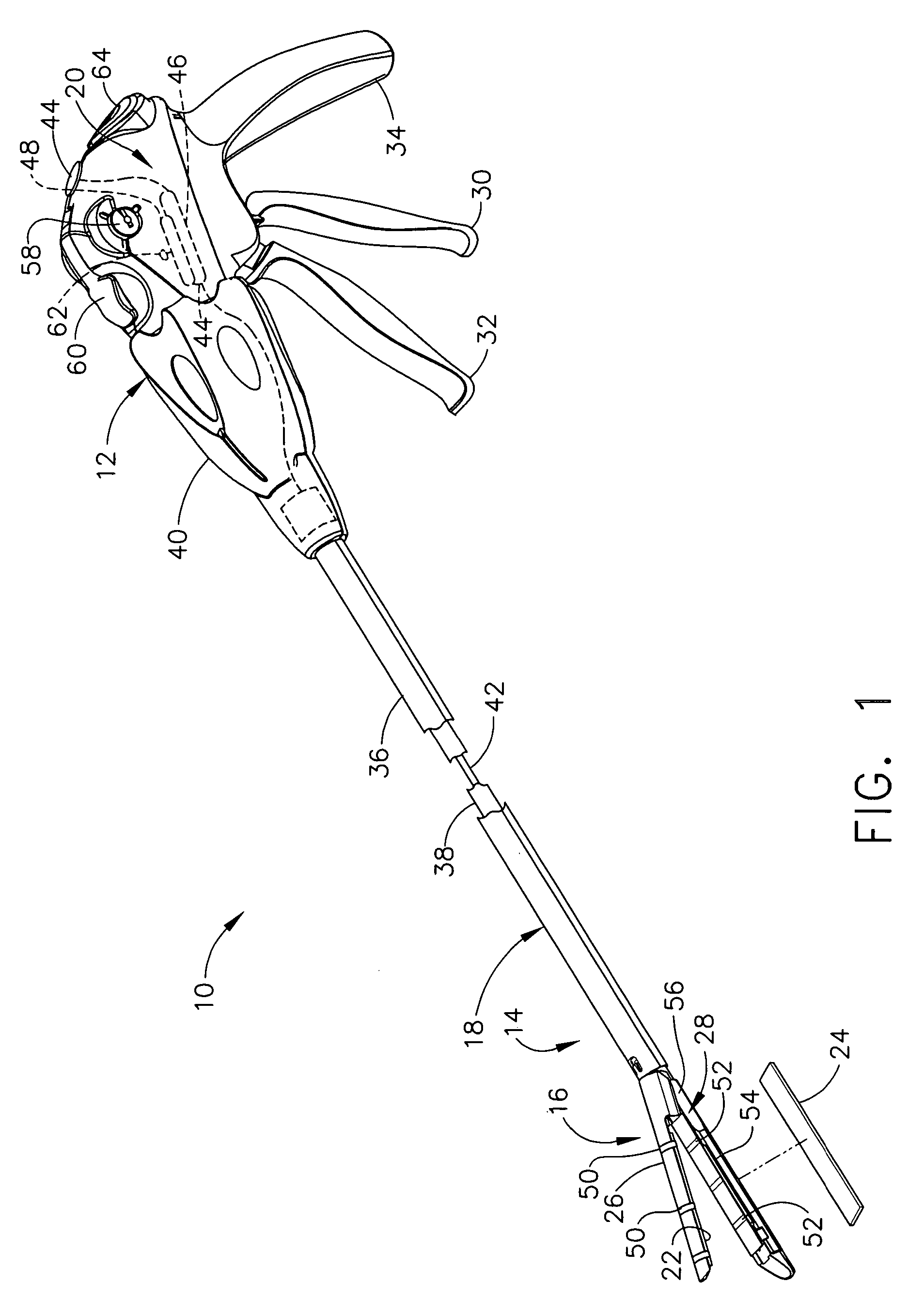

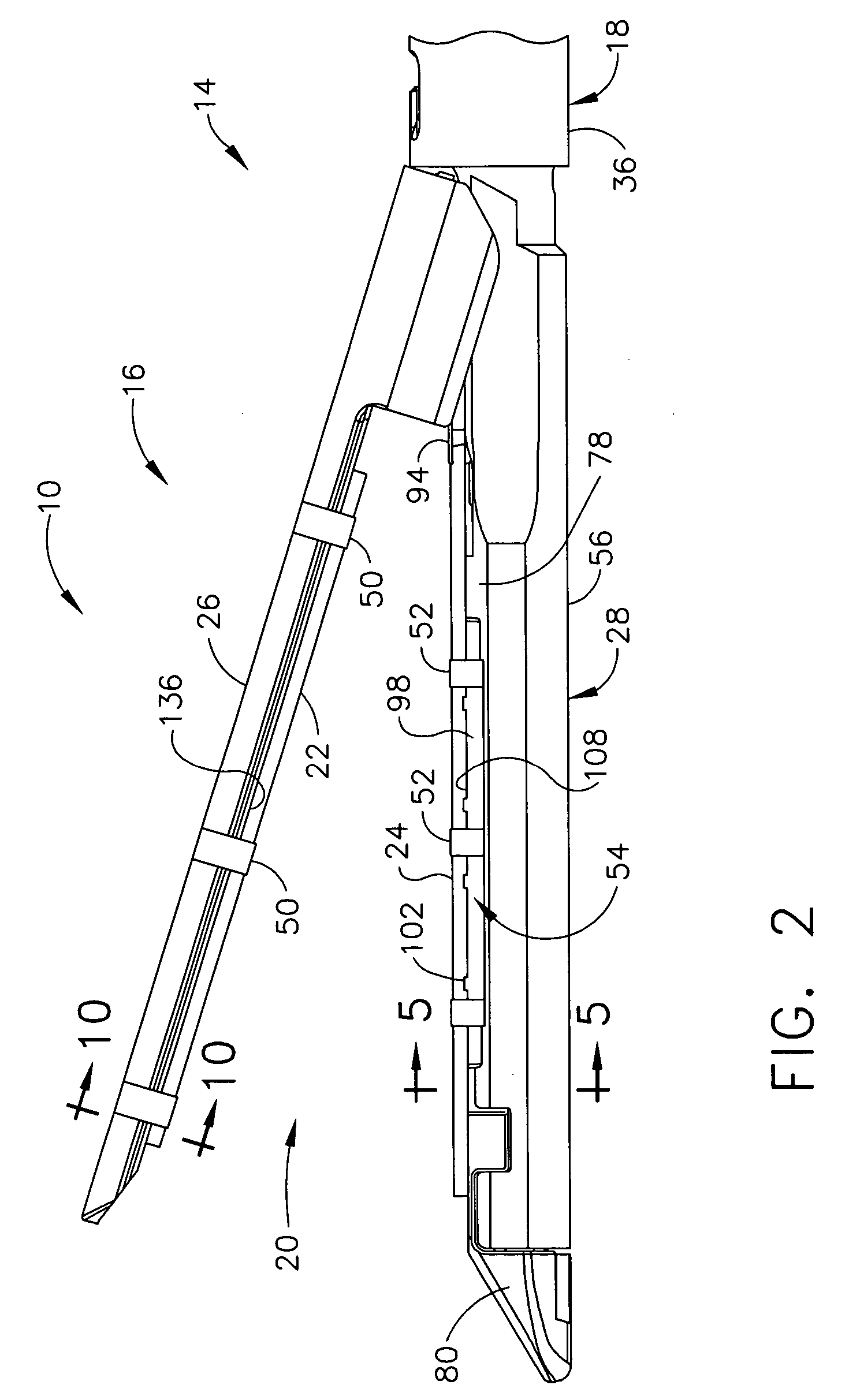

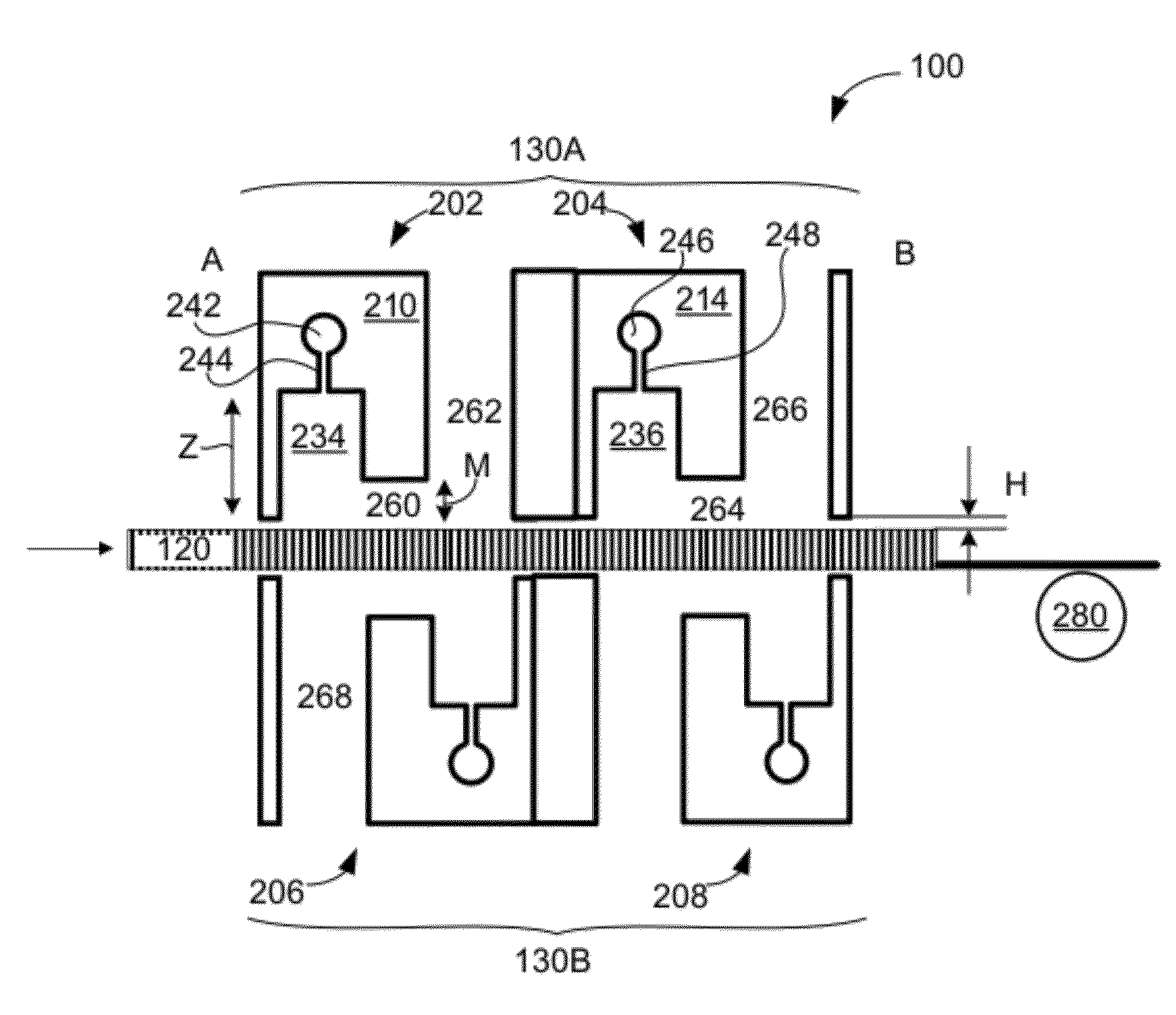

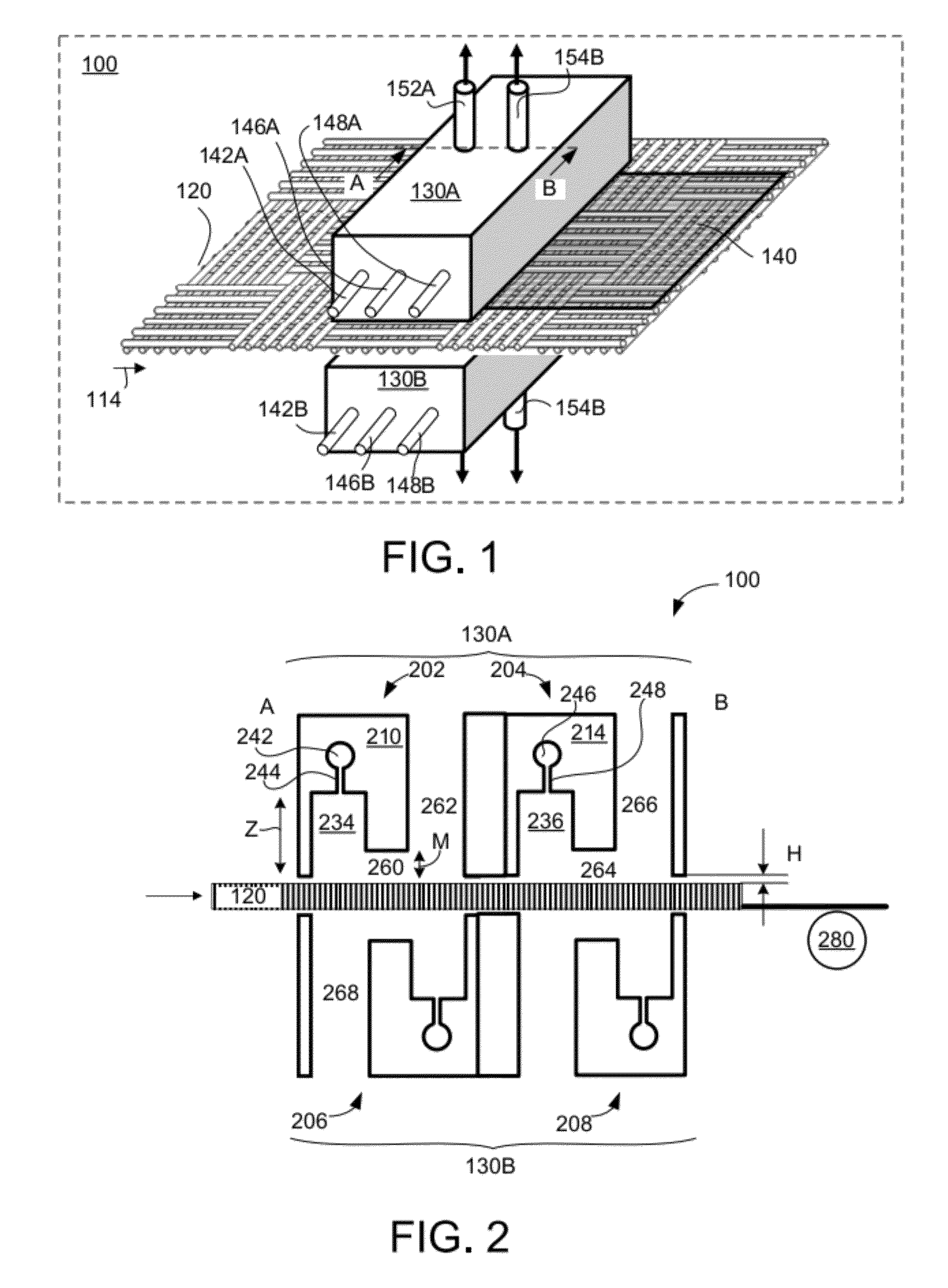

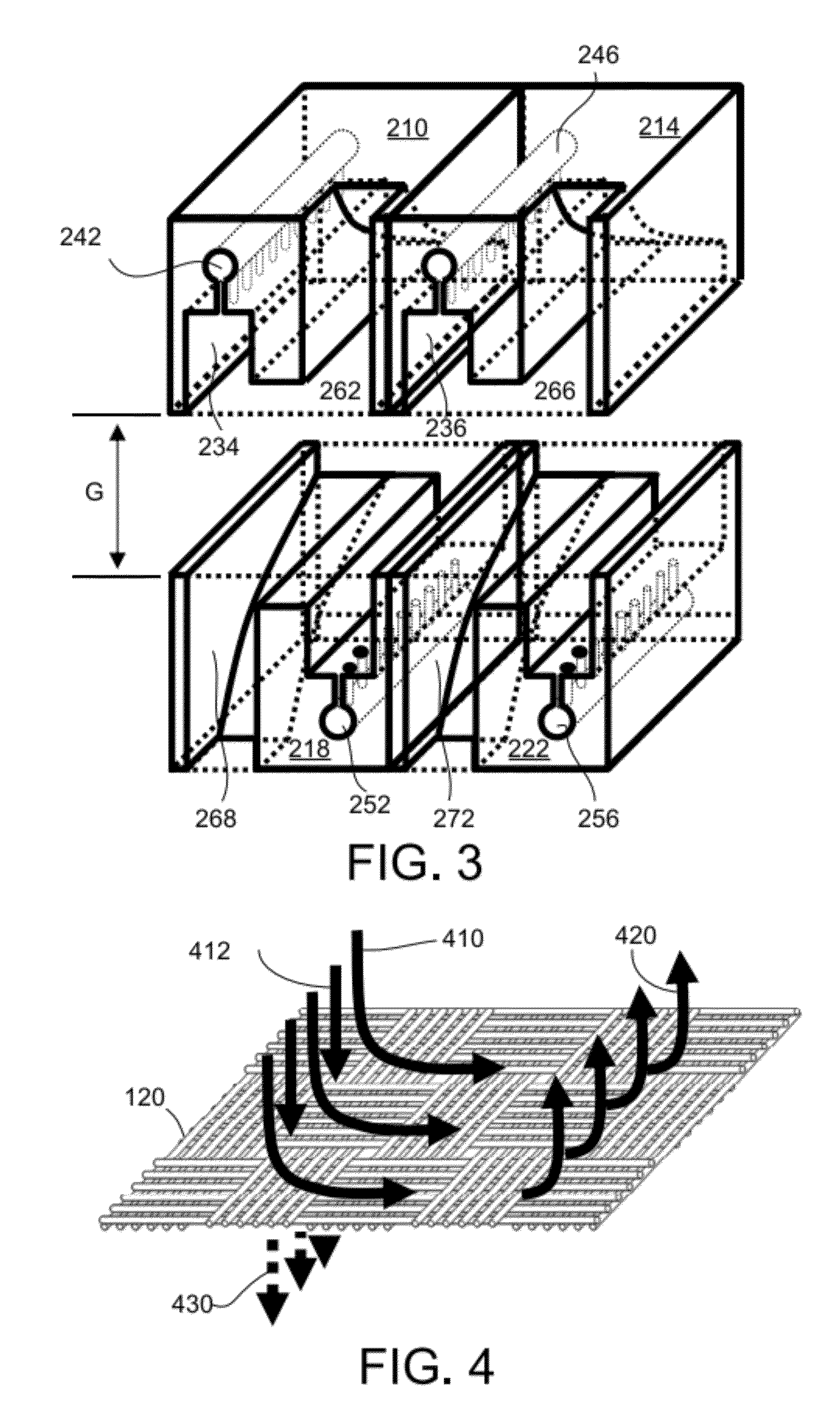

Surgical stapling instrument having an electroactive polymer actuated buttress deployment mechanism

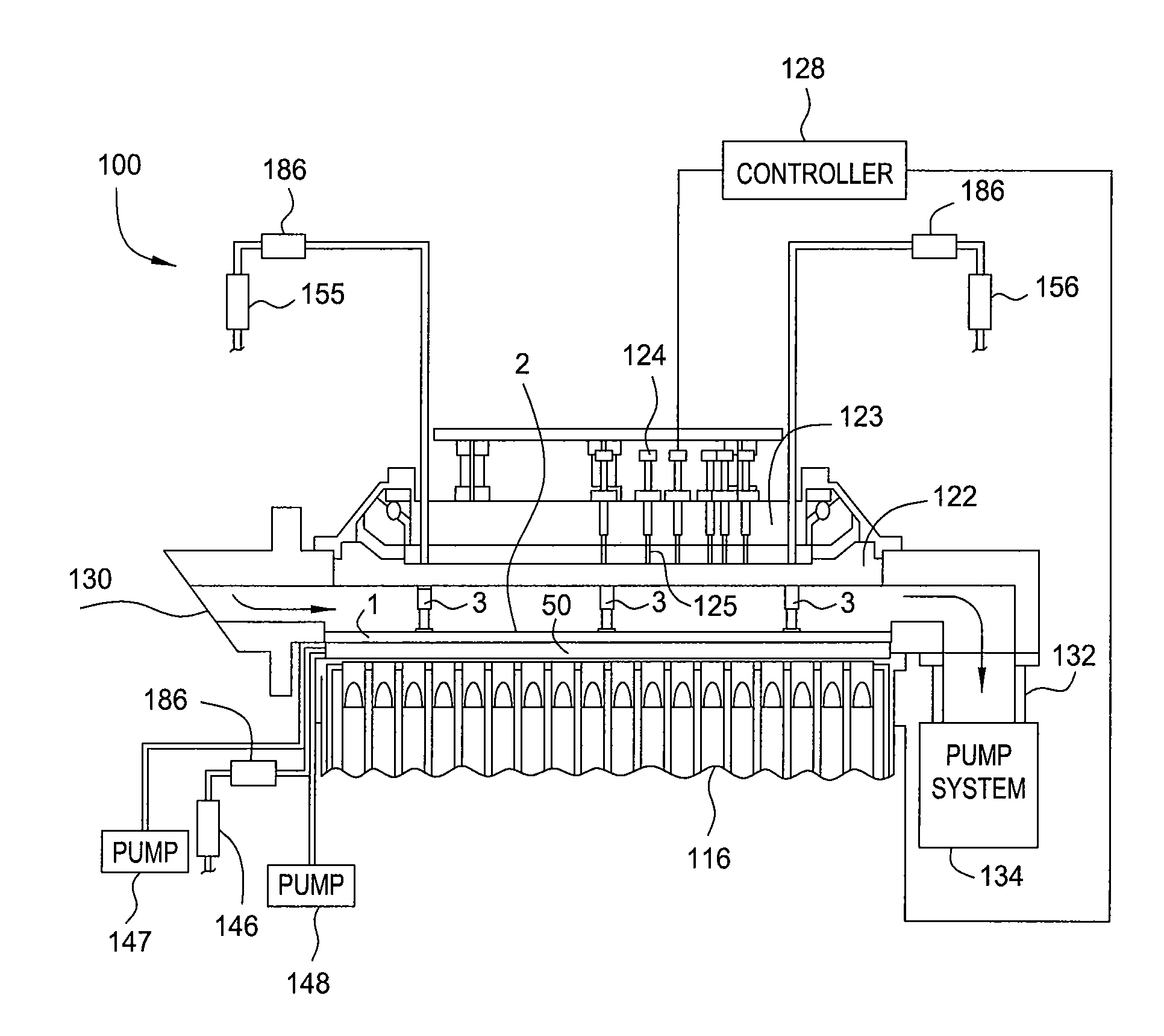

A surgical instrument for being endoscopically or laparoscopically inserted to a surgical site for simultaneous stapling and severing of tissue includes electrically actuated deployment of buttress pads held on inner surfaces of upper and lower jaws of a staple applying assembly. Thereby, thick or thin layers may be stapled and severed without improper staple formation nor with nonoptimal deployment of the buttress pads. Electroactive polymer (EAP) actuated latches, an EAP channel, or a rigid channel with an EAP pinch lock reliably hold the buttress pad until deployment is desired with a low force to separate the stapled and severed buttress pad / tissue combination with the respective EAP mechanism activated for deployment.

Owner:CILAG GMBH INT

Surgical stapling instrument having an electroactive polymer actuated buttress deployment mechanism

ActiveUS20060025816A1Reliable materialAvoid deploymentSuture equipmentsStapling toolsButtressSurgical staple

A surgical instrument for being endoscopically or laparoscopically inserted to a surgical site for simultaneous stapling and severing of tissue includes electrically actuated deployment of buttress pads held on inner surfaces of upper and lower jaws of a staple applying assembly. Thereby, thick or thin layers may be stapled and severed without improper staple formation nor with nonoptimal deployment of the buttress pads. Electroactive polymer (EAP) actuated latches, an EAP channel, or a rigid channel with an EAP pinch lock reliably hold the buttress pad until deployment is desired with a low force to separate the stapled and severed buttress pad / tissue combination with the respective EAP mechanism activated for deployment.

Owner:CILAG GMBH INT

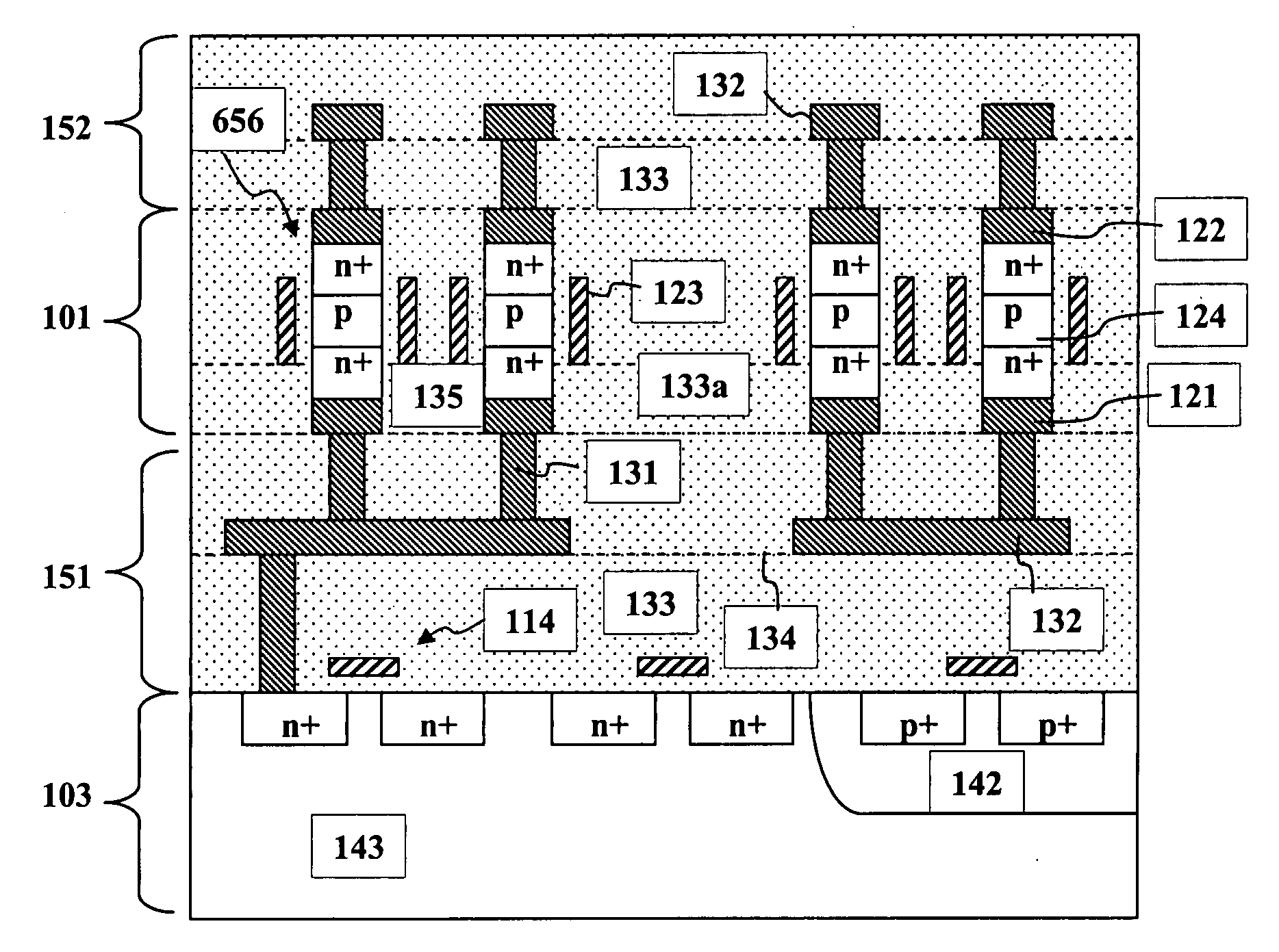

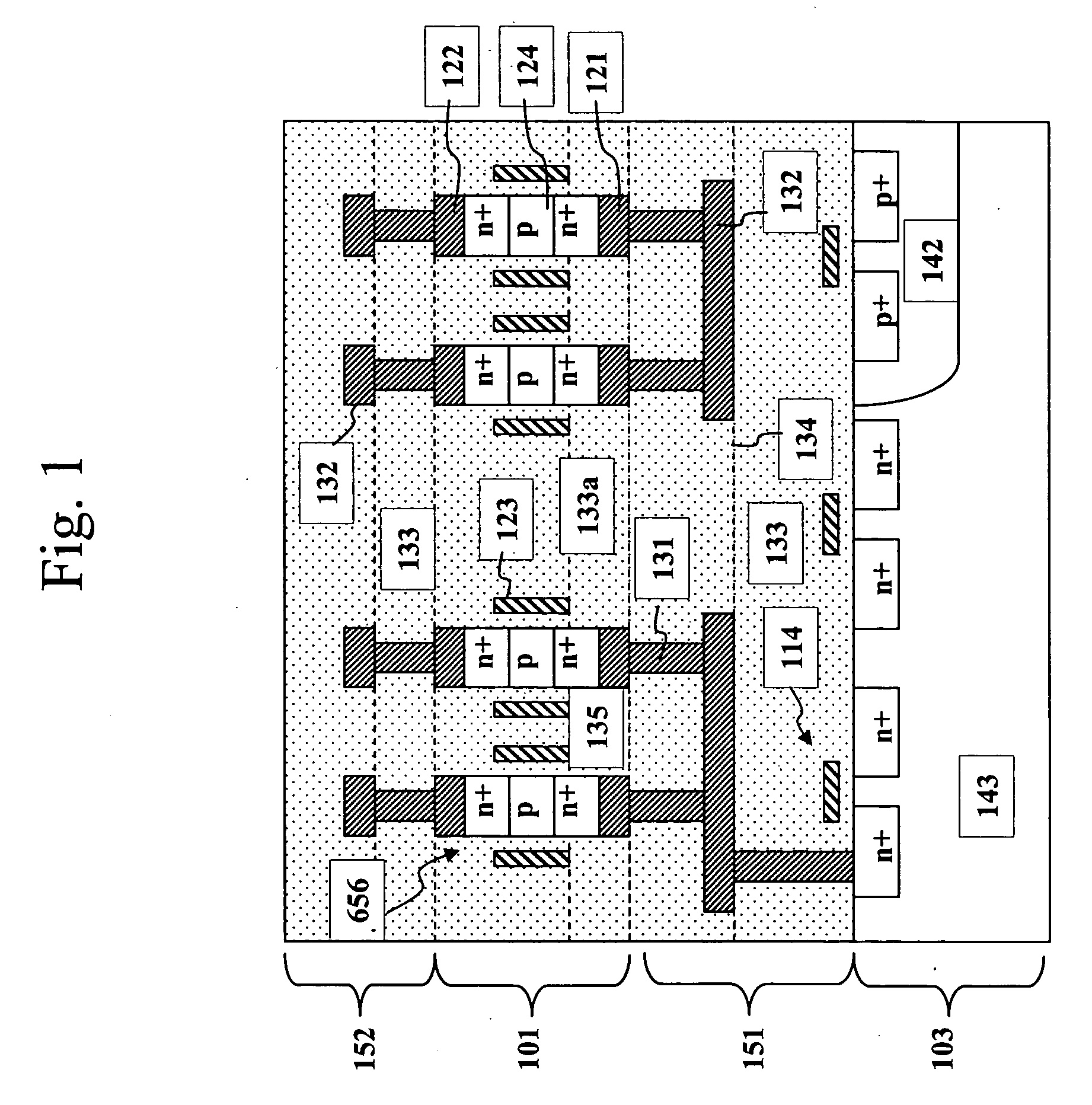

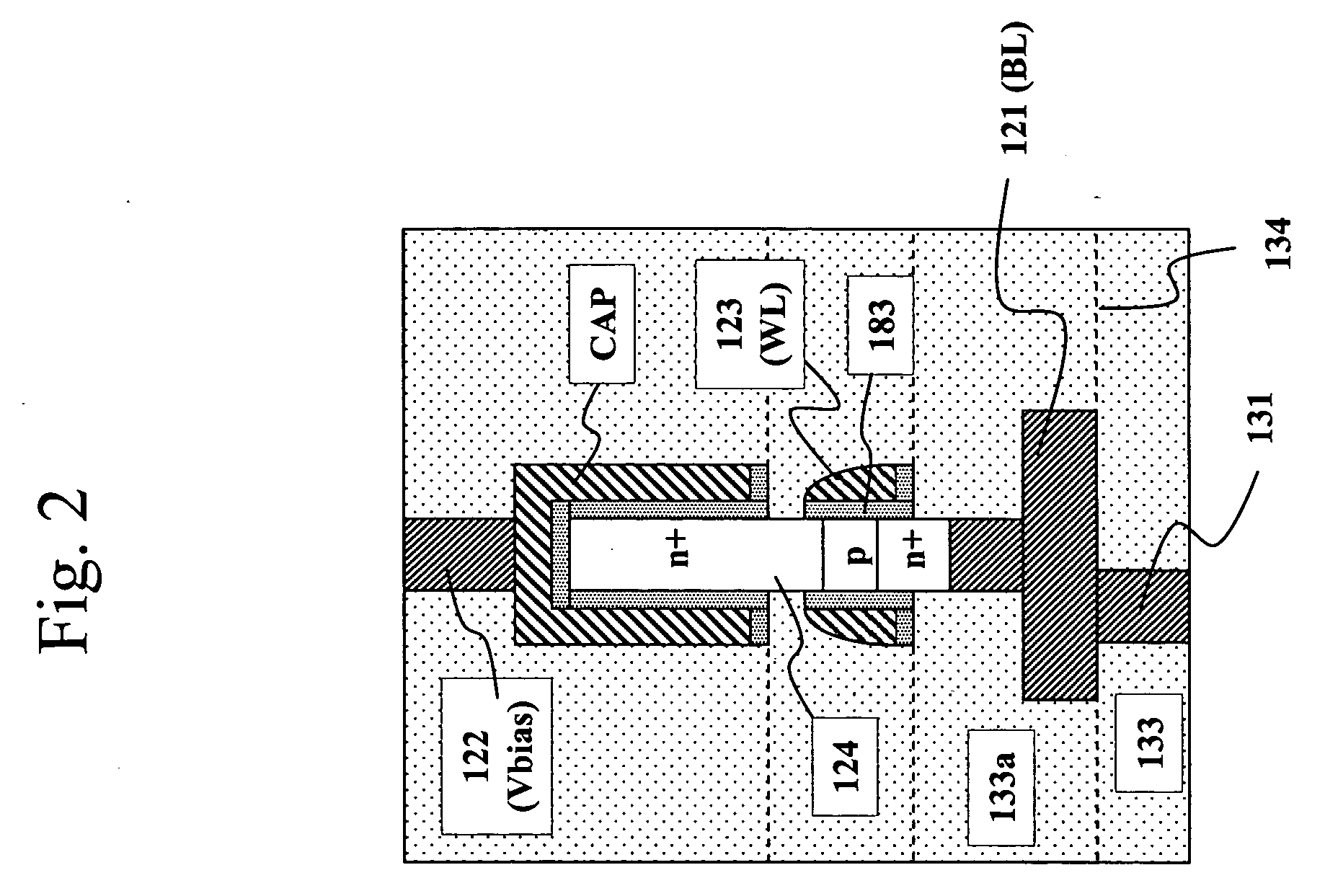

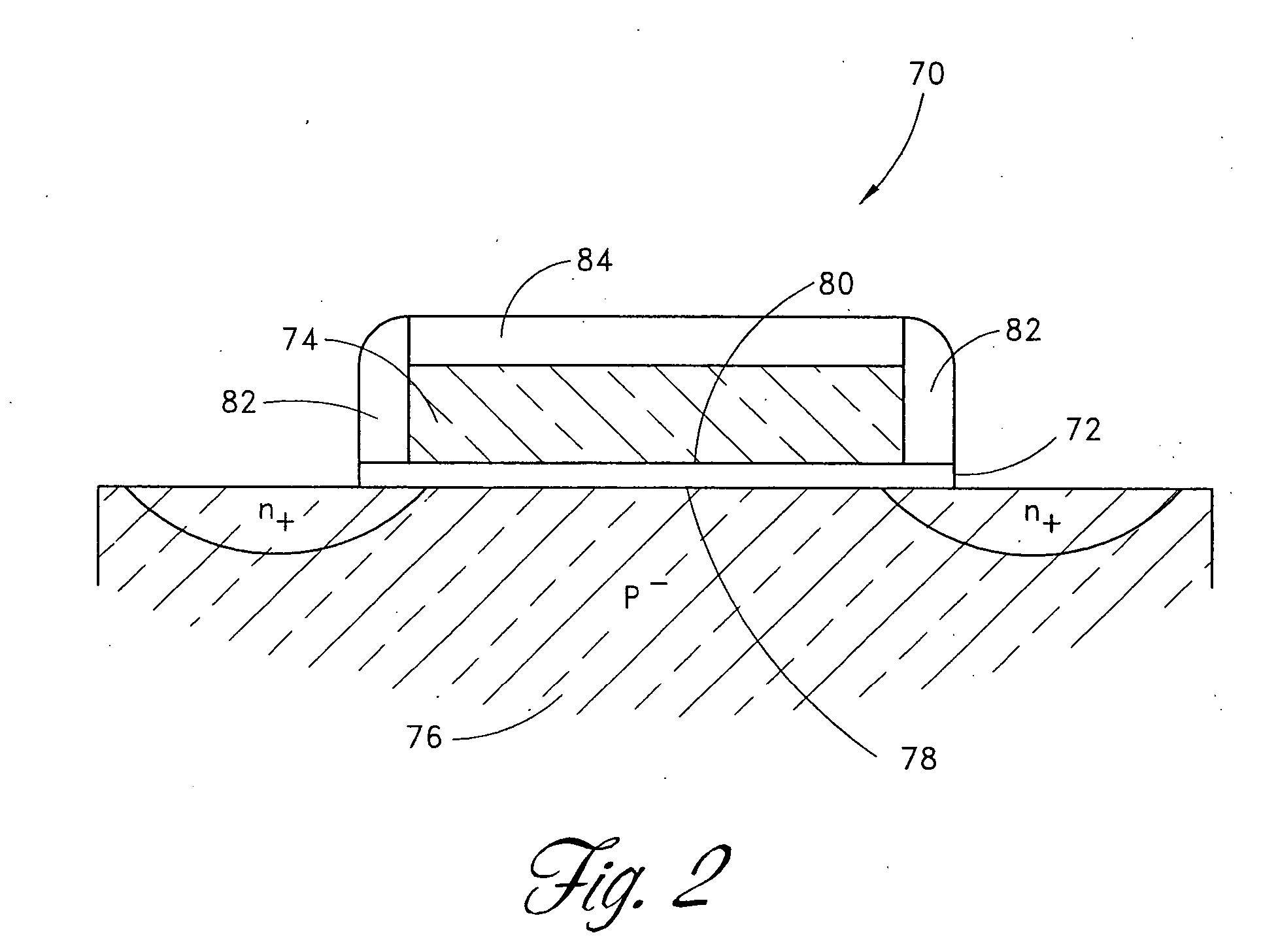

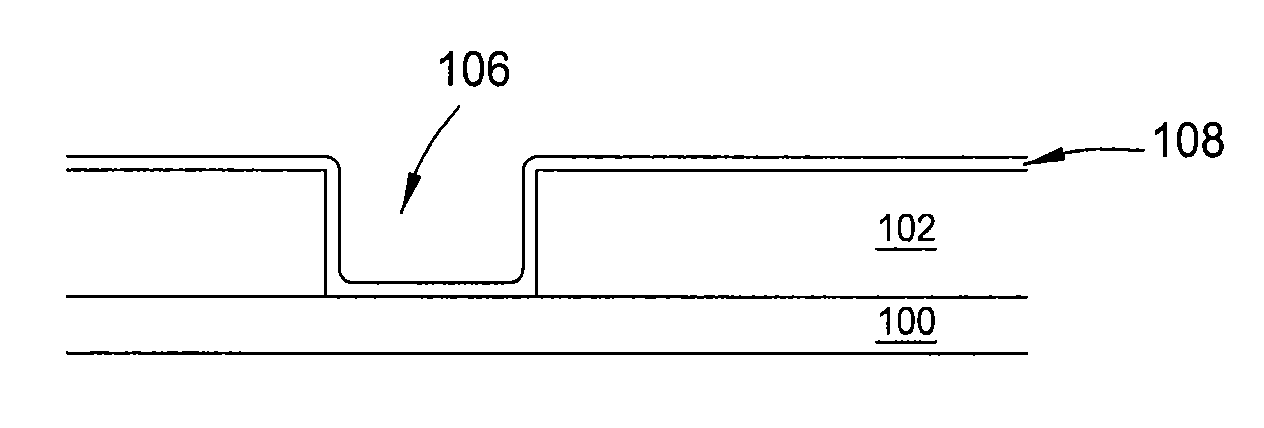

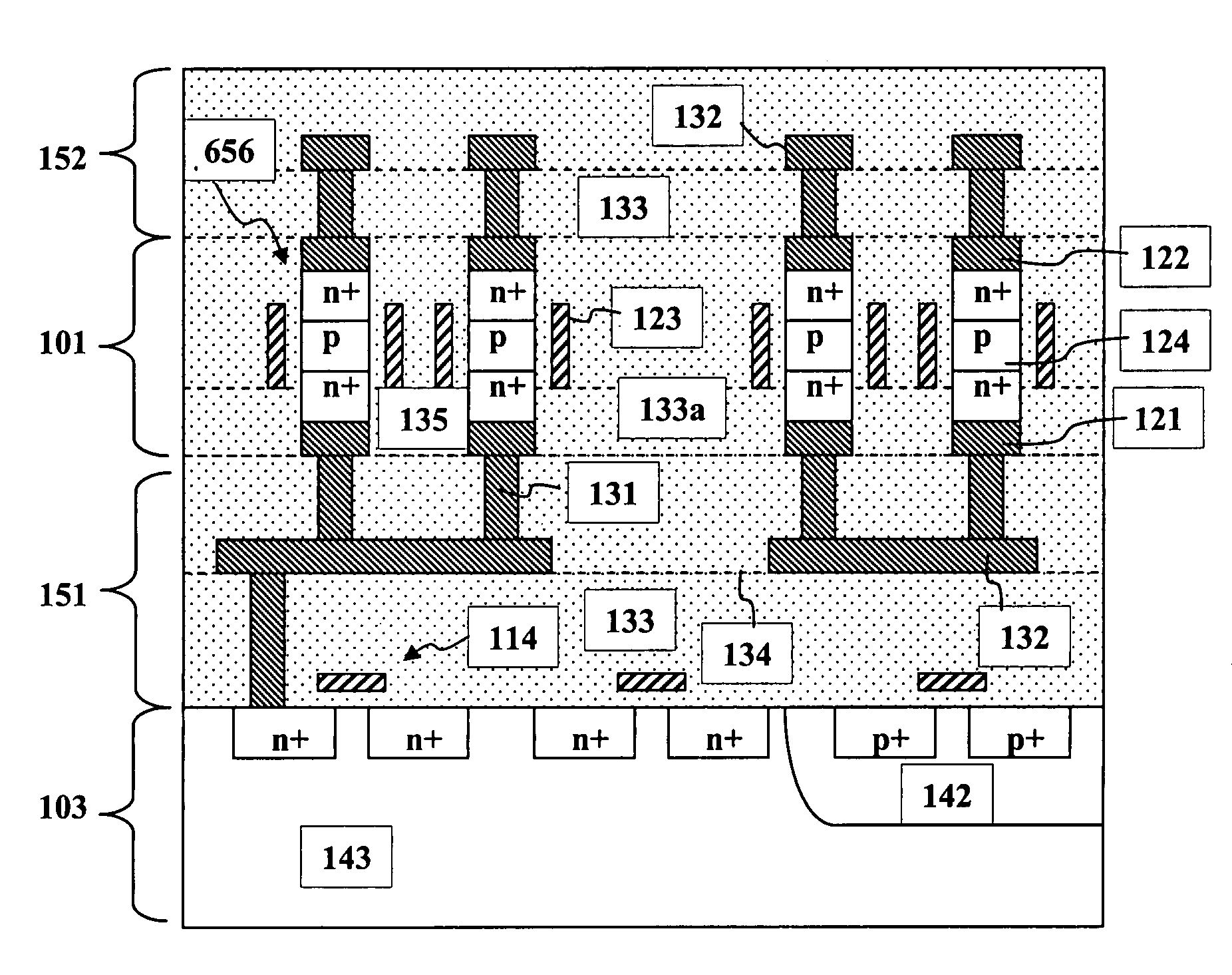

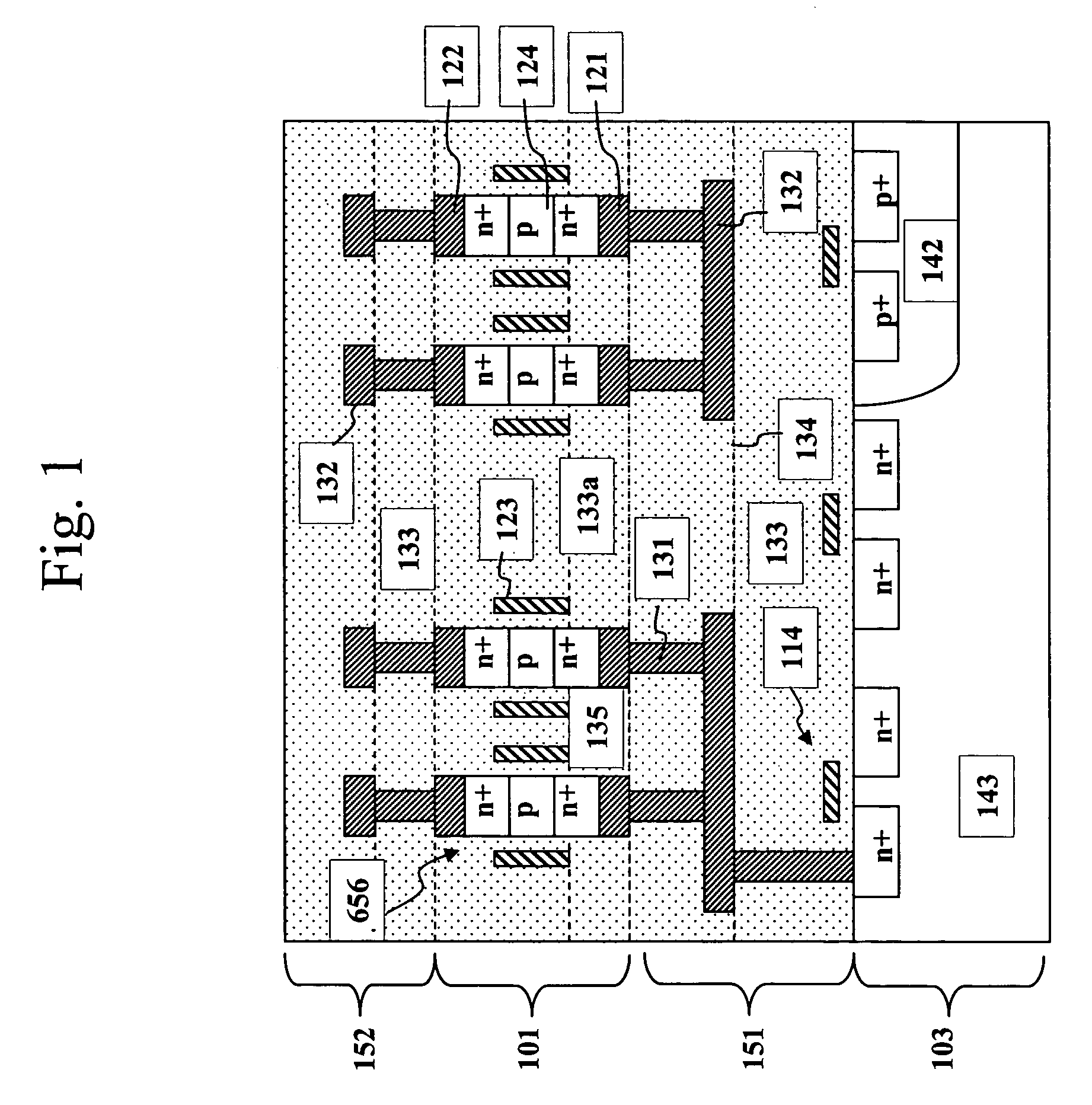

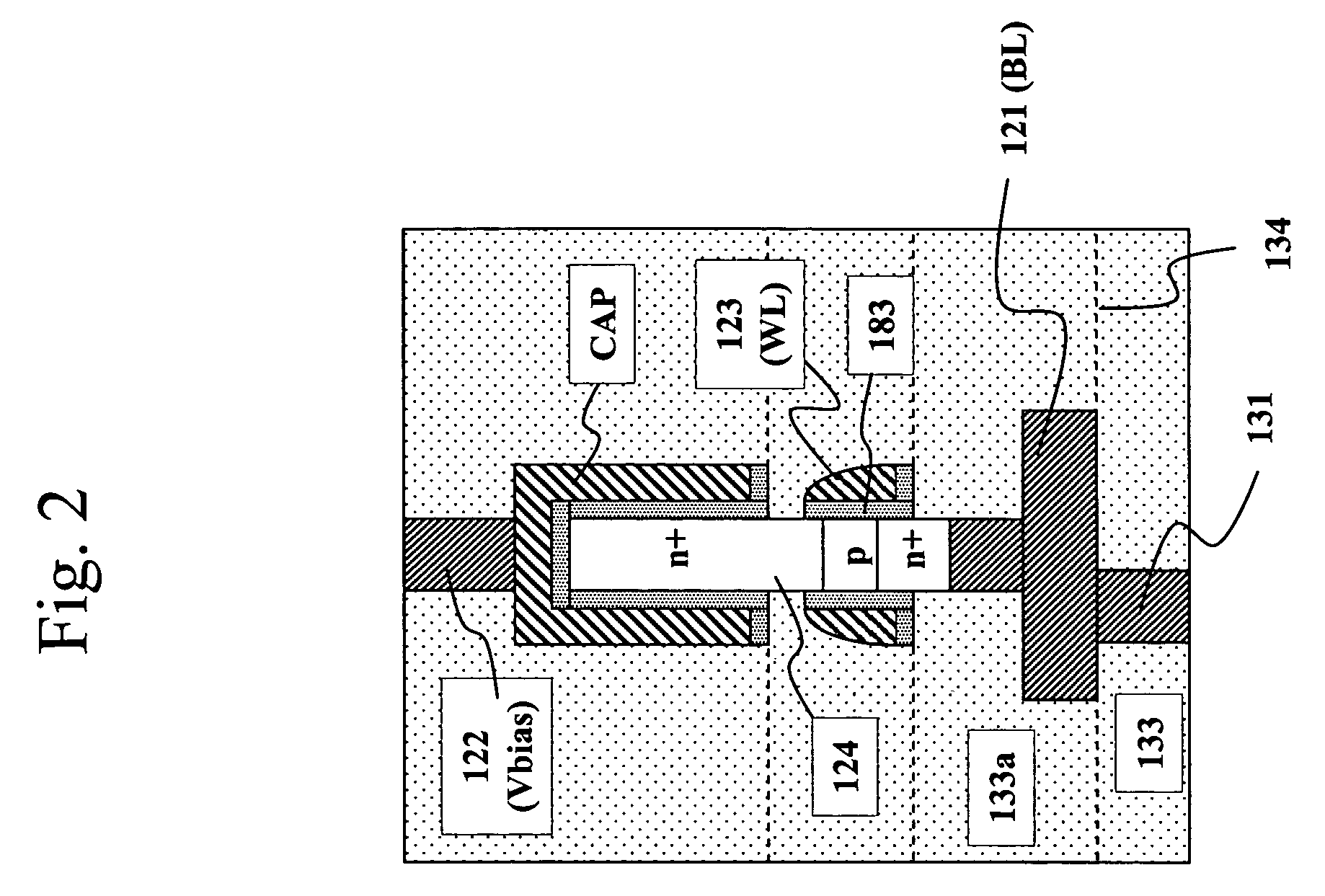

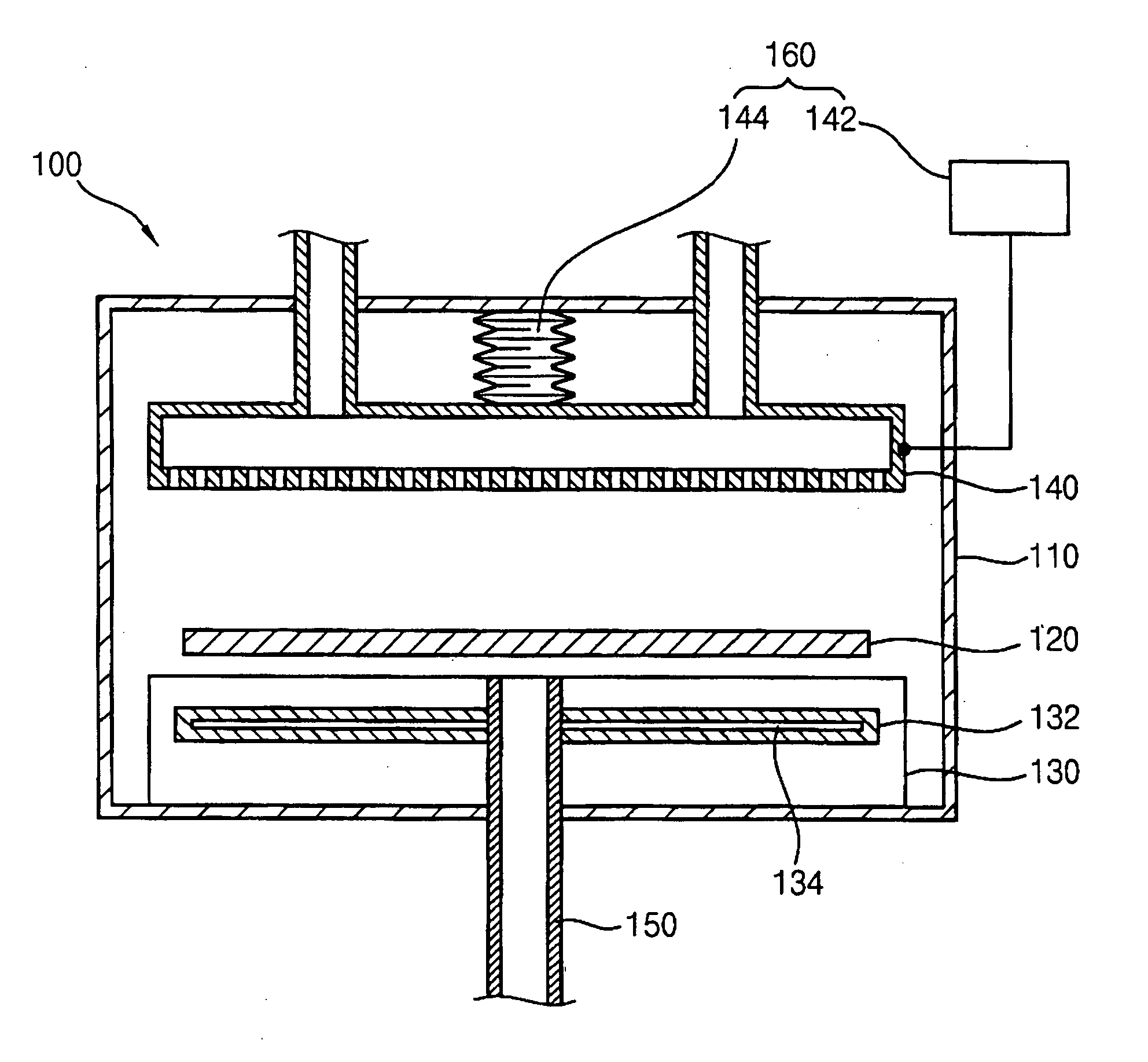

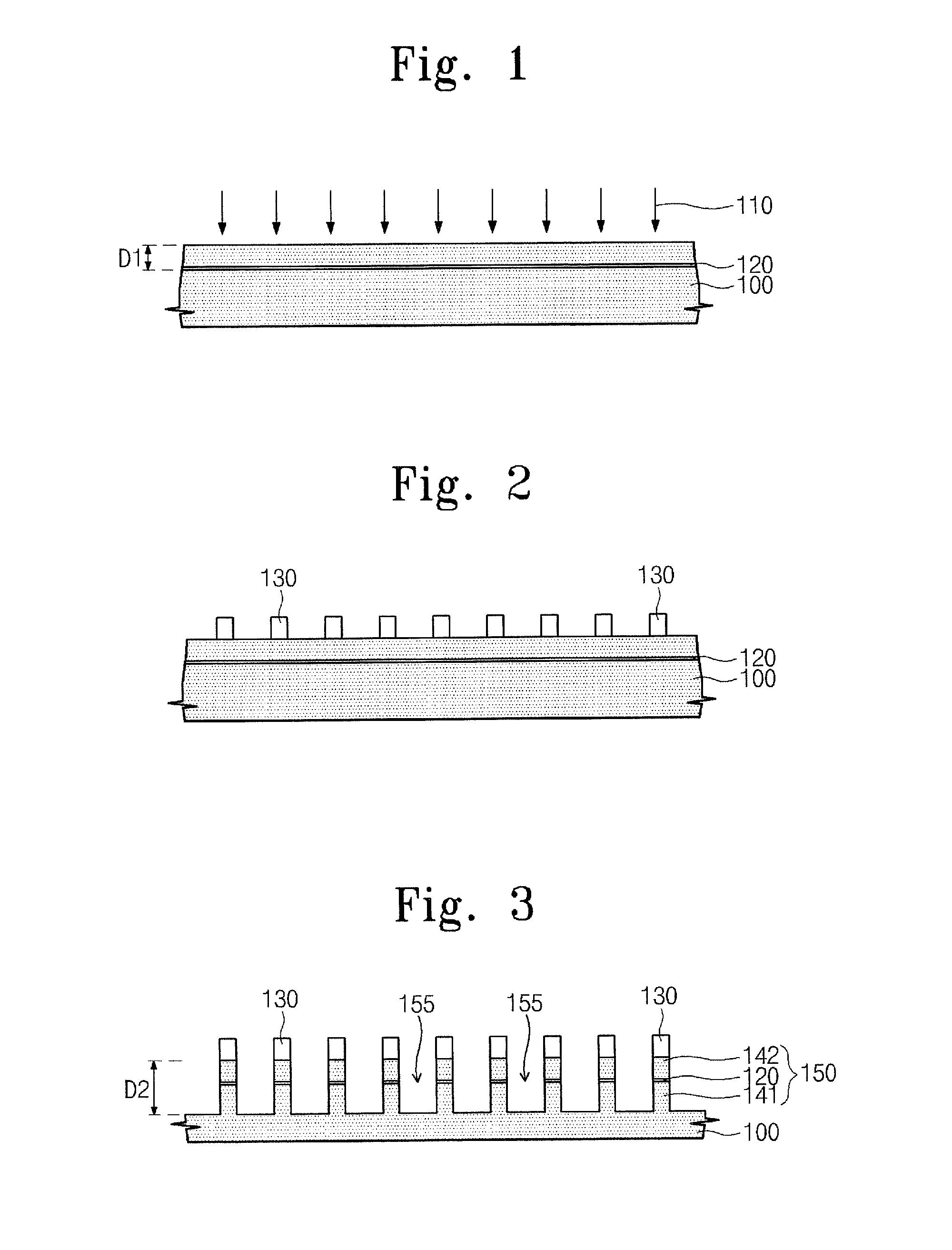

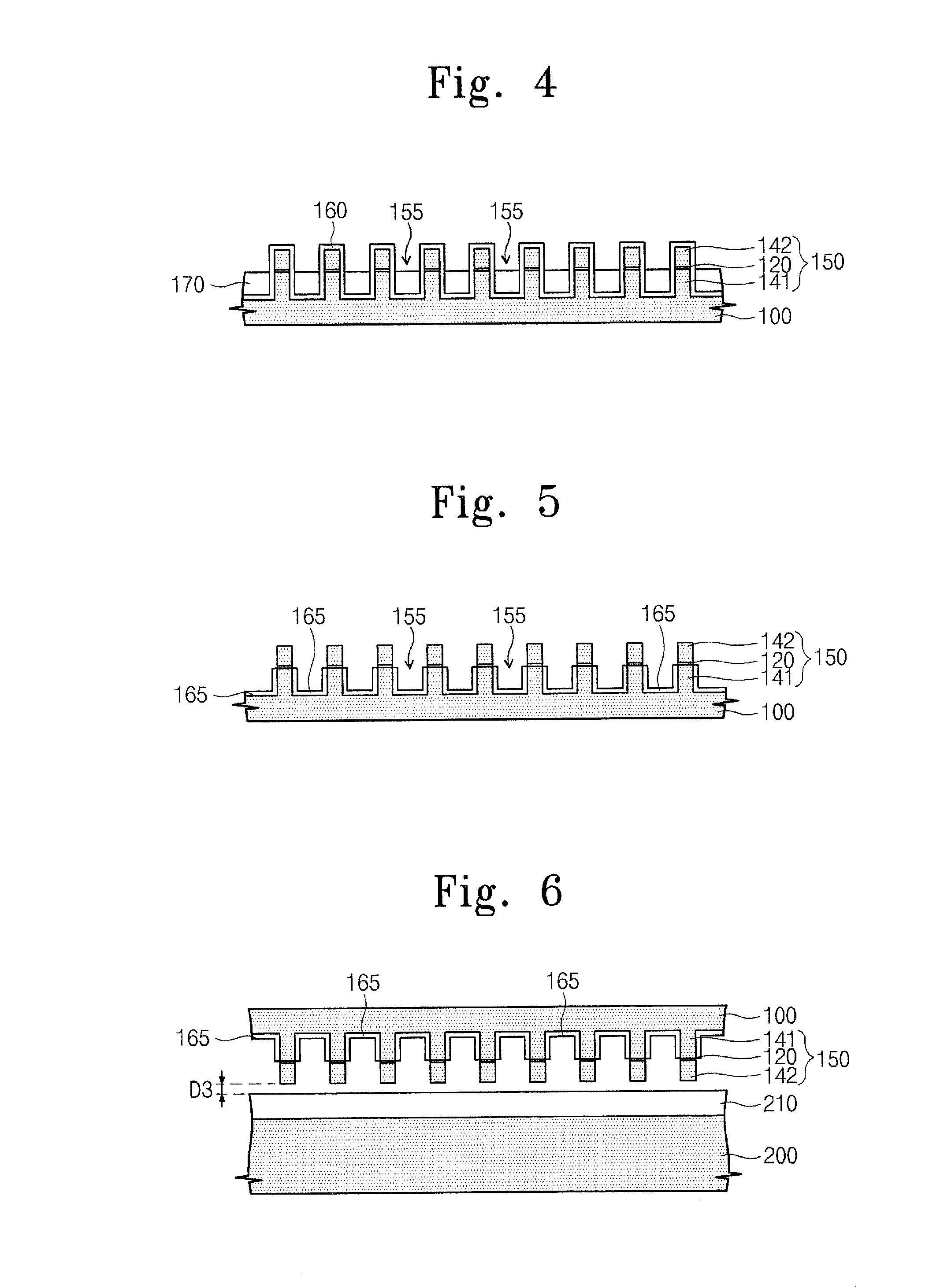

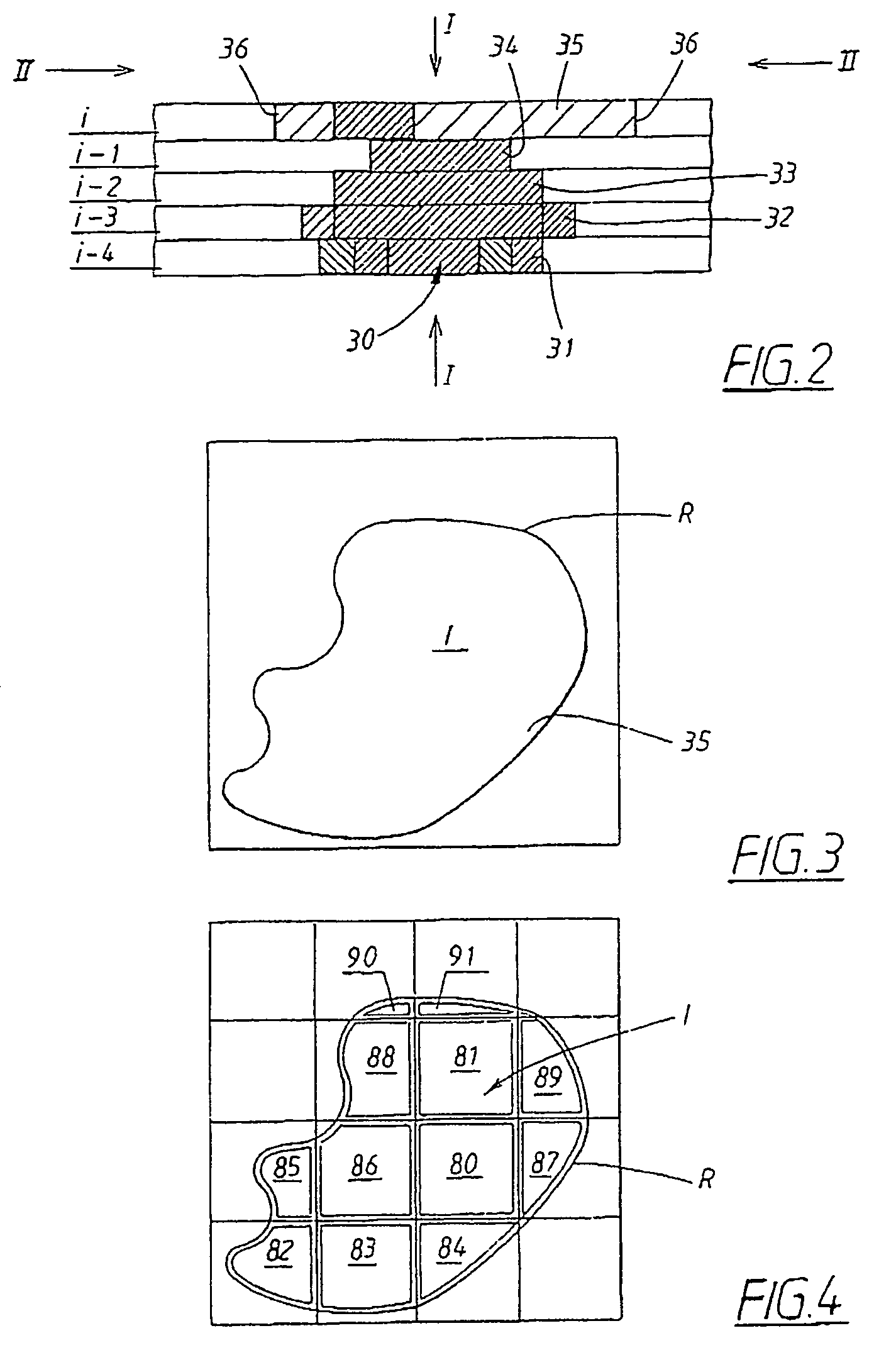

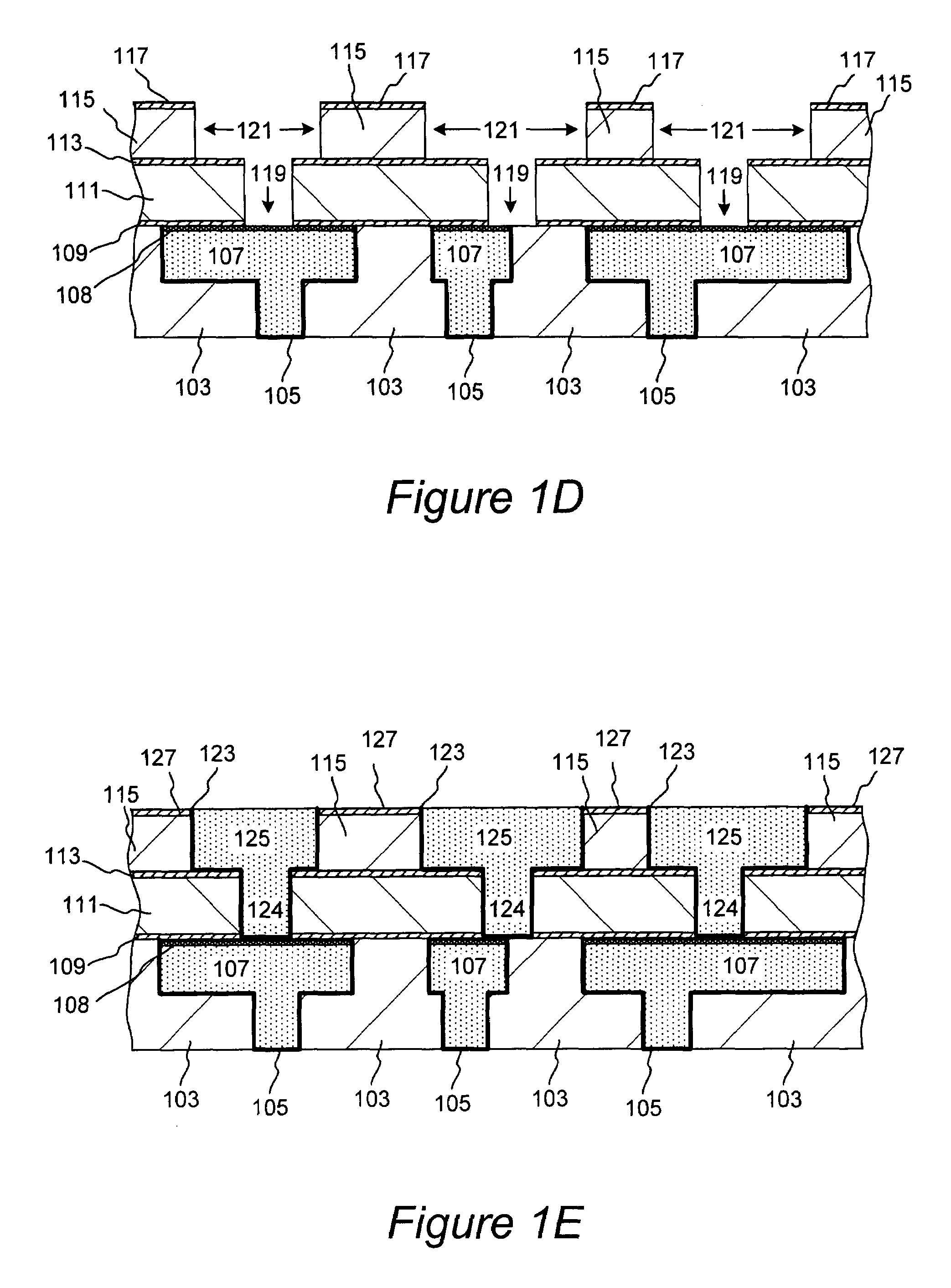

Vertical memory device structures

Vertically oriented semiconductor memory cells are added to a separately fabricated substrate that includes electrical devices and / or interconnect. The plurality of vertically oriented semiconductor memory cells are physically separated from each other, and are not disposed within the same semiconductor body. The plurality of vertically oriented semiconductor memory cells can be added to the separately fabricated substrate as a thin layer including several doped semiconductor regions which, subsequent to attachment, are etched to produce individual doped stack structures, which are then supplied with various dielectric coatings, gate electrodes, and contacts by means of further processing operations. Alternatively, the plurality of vertically oriented semiconductor memory cells may be completely fabricated prior to attachment. DRAMs, SRAMs, non-volatile memories, and combinations of memory types can be provided.

Owner:BESANG

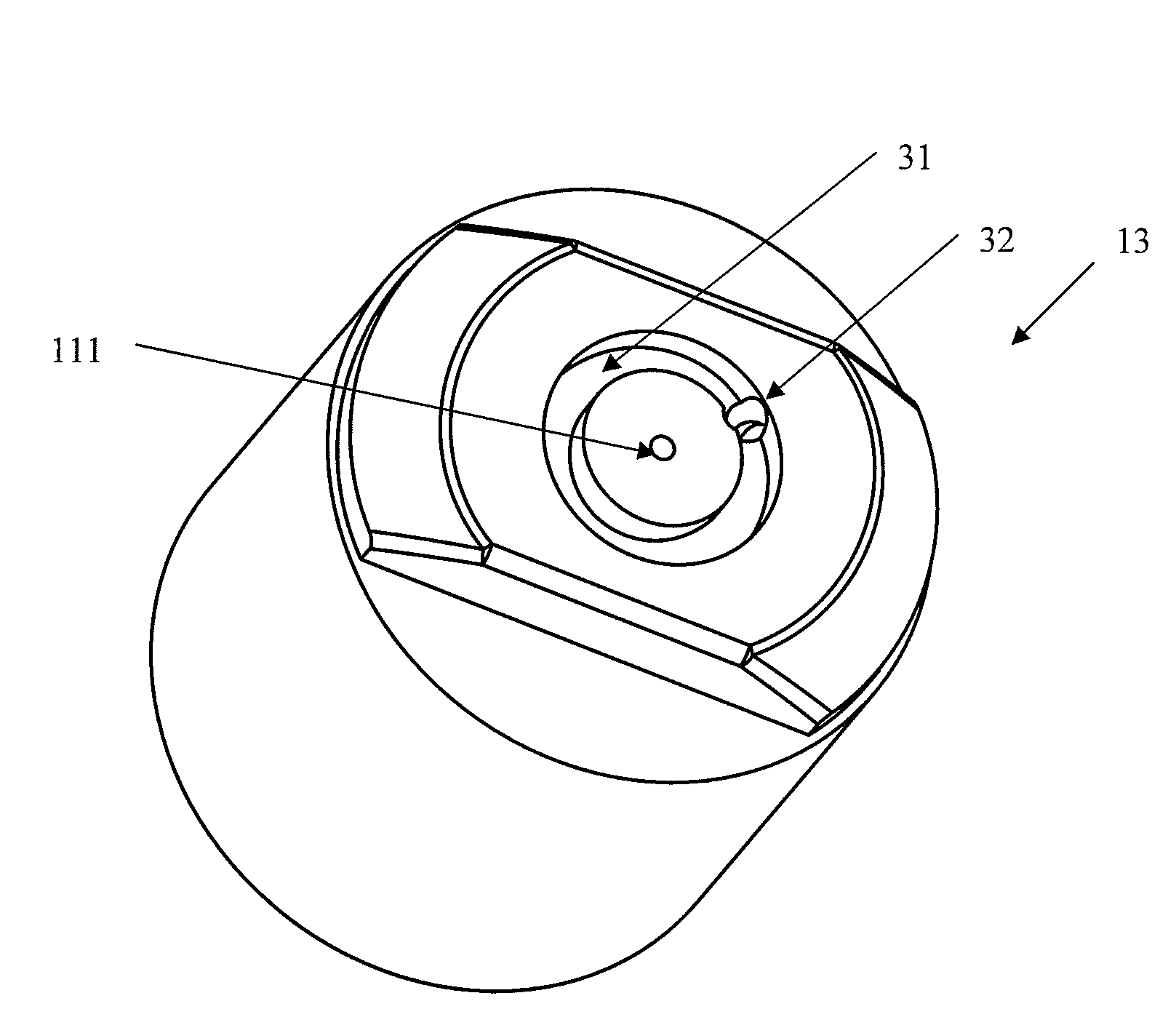

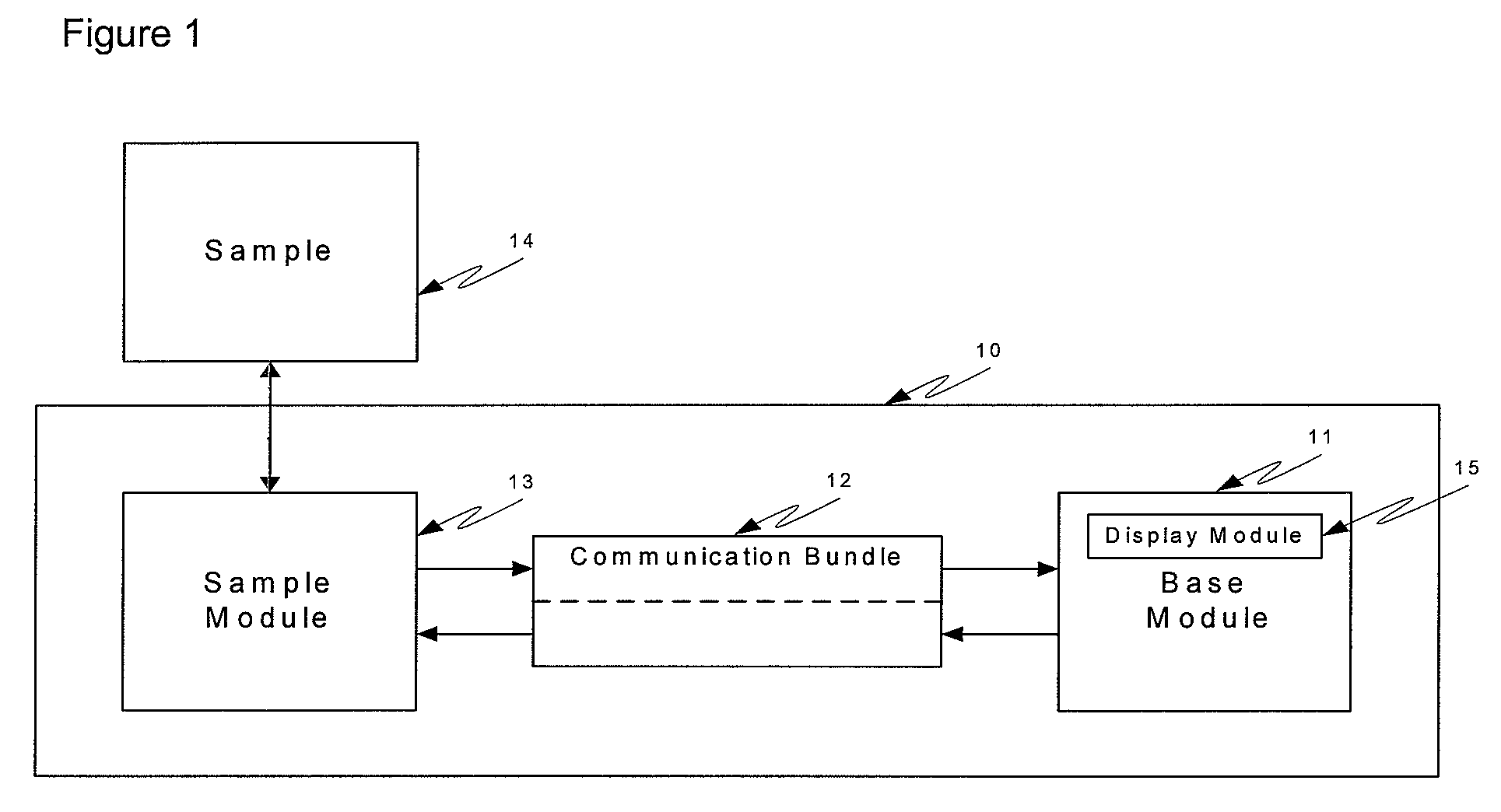

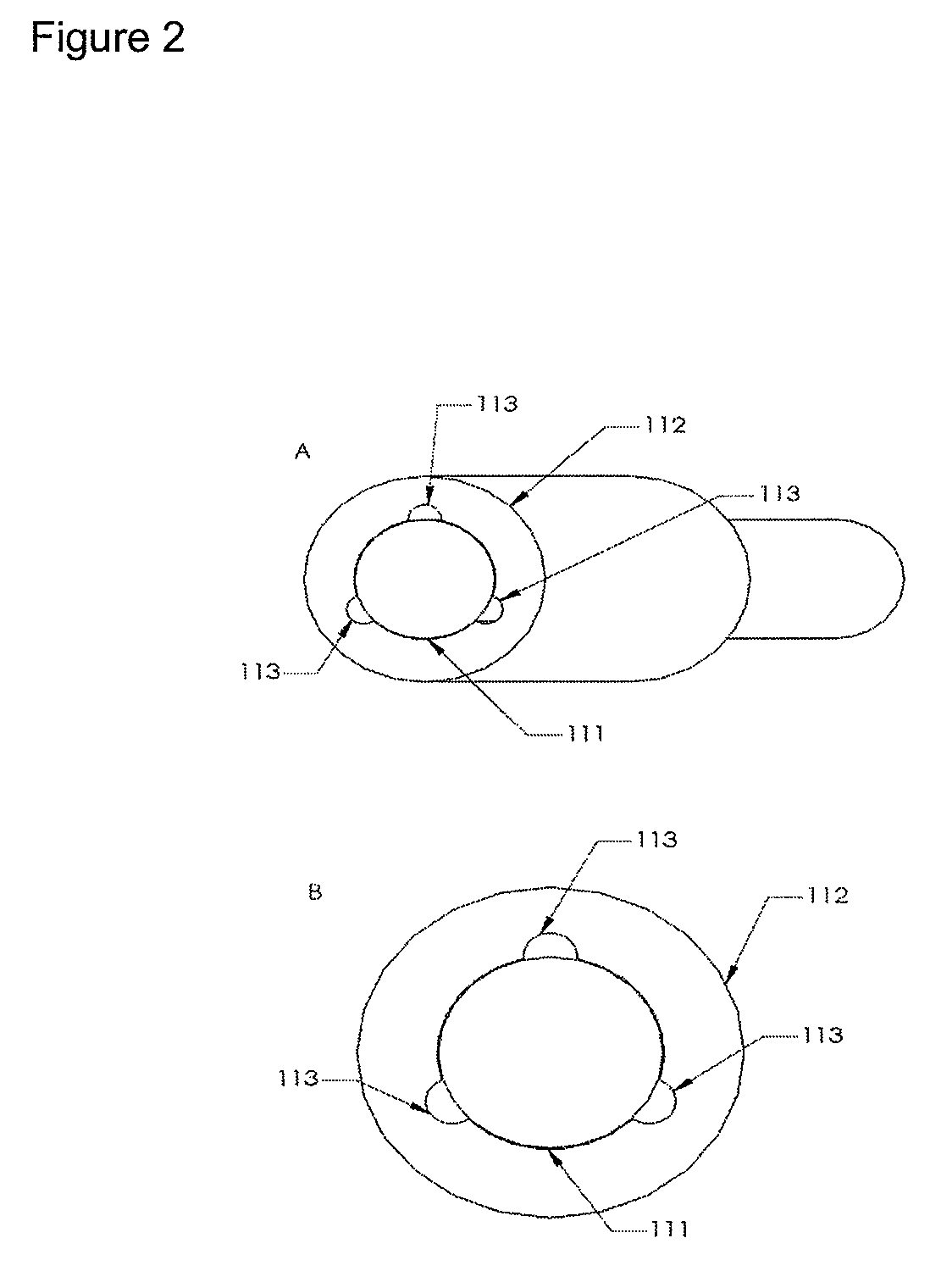

Method and apparatus for coupling a channeled sample probe to tissue

ActiveUS8504128B2Good optical performanceError minimizationMedical devicesMaterial analysis by optical meansAnalyteThin layer

Sampling is controlled in order to enhance analyte concentration estimation derived from noninvasive sampling. More particularly, sampling is controlled using controlled fluid delivery to a region between a tip of a sample probe and a tissue measurement site. The controlled fluid delivery enhances coverage of a skin sample site with the thin layer of fluid. Delivery of contact fluid is controlled in terms of spatial delivery, volume, thickness, distribution, temperature, and / or pressure.

Owner:GLT ACQUISITION

Thin films

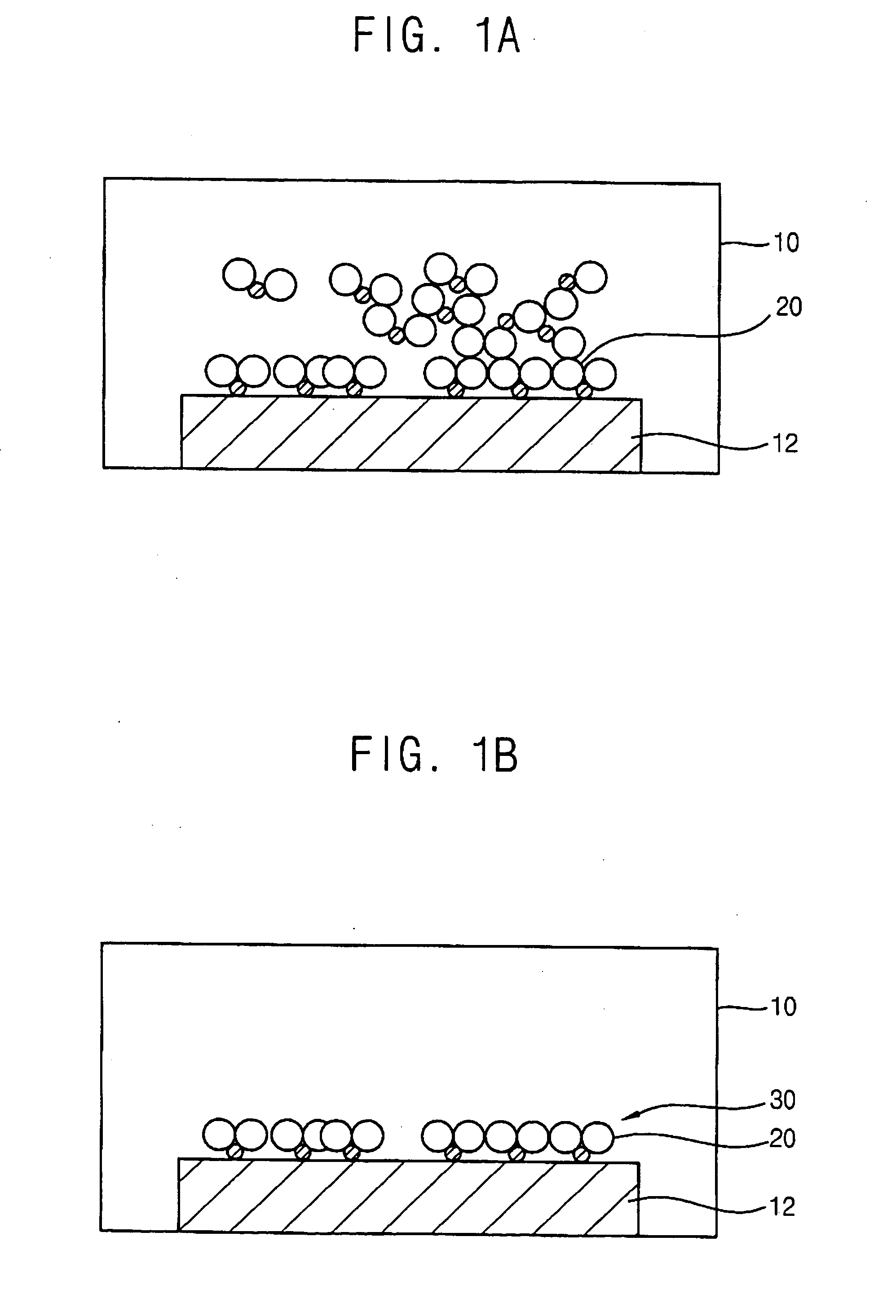

InactiveUS20050181555A1Quality improvementHigh dielectric constantSolid-state devicesSemiconductor/solid-state device manufacturingGate dielectricSilicon oxide

Thin films are formed by formed by atomic layer deposition, whereby the composition of the film can be varied from monolayer to monolayer during cycles including alternating pulses of self-limiting chemistries. In the illustrated embodiments, varying amounts of impurity sources are introduced during the cyclical process. A graded gate dielectric is thereby provided, even for extremely thin layers. The gate dielectric as thin as 2 nm can be varied from pure silicon oxide to oxynitride to silicon nitride. Similarly, the gate dielectric can be varied from aluminum oxide to mixtures of aluminum oxide and a higher dielectric material (e.g., ZrO2) to pure high k material and back to aluminum oxide. In another embodiment, metal nitride (e.g., WN) is first formed as a barrier for lining dual damascene trenches and vias. During the alternating deposition process, copper can be introduced, e.g., in separate pulses, and the copper source pulses can gradually increase in frequency, forming a transition region, until pure copper is formed at the upper surface. Advantageously, graded compositions in these and a variety of other contexts help to avoid such problems as etch rate control, electromigration and non-ohmic electrical contact that can occur at sharp material interfaces. In some embodiments additional seed layers or additional transition layers are provided.

Owner:ASM INTERNATIONAL

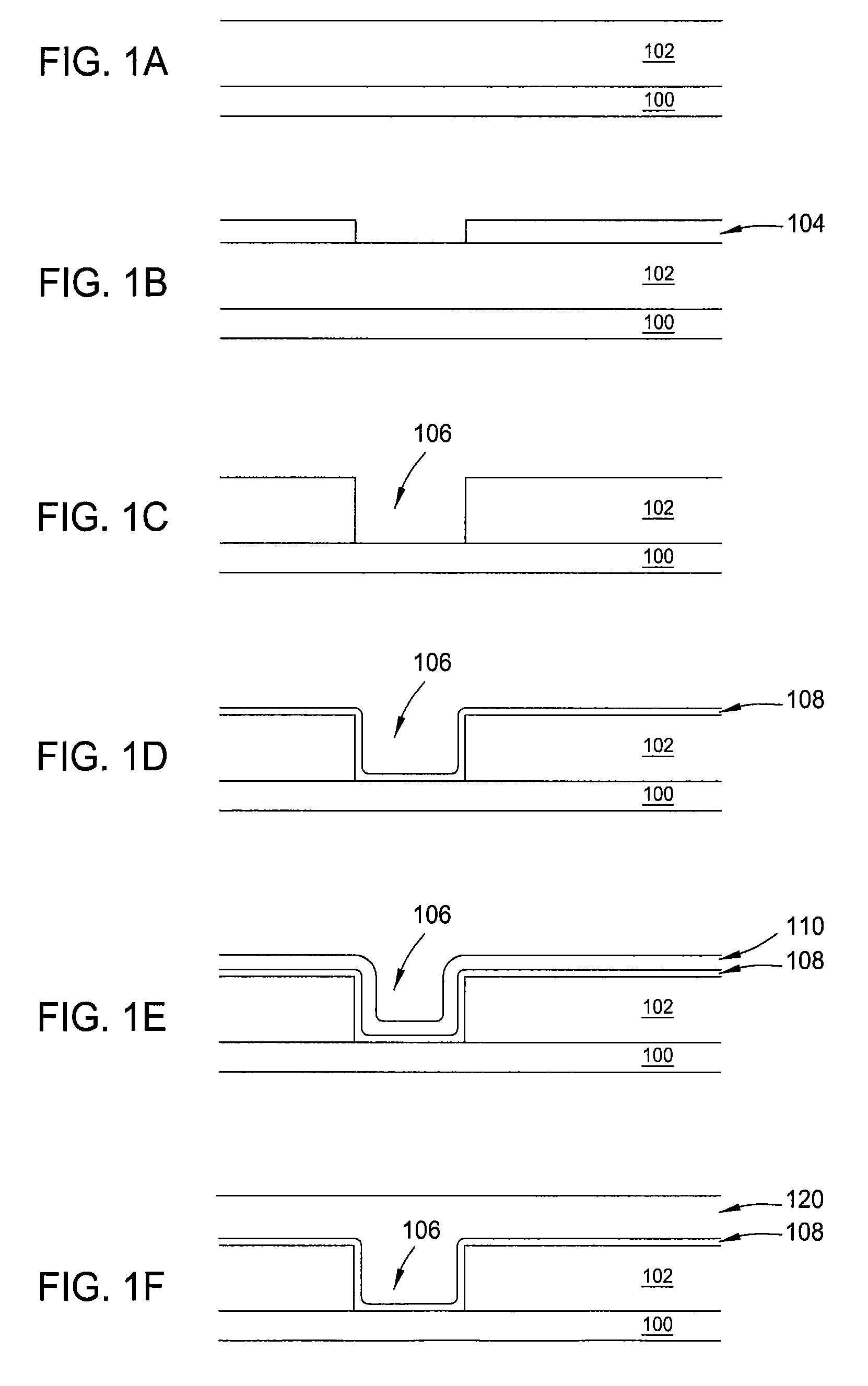

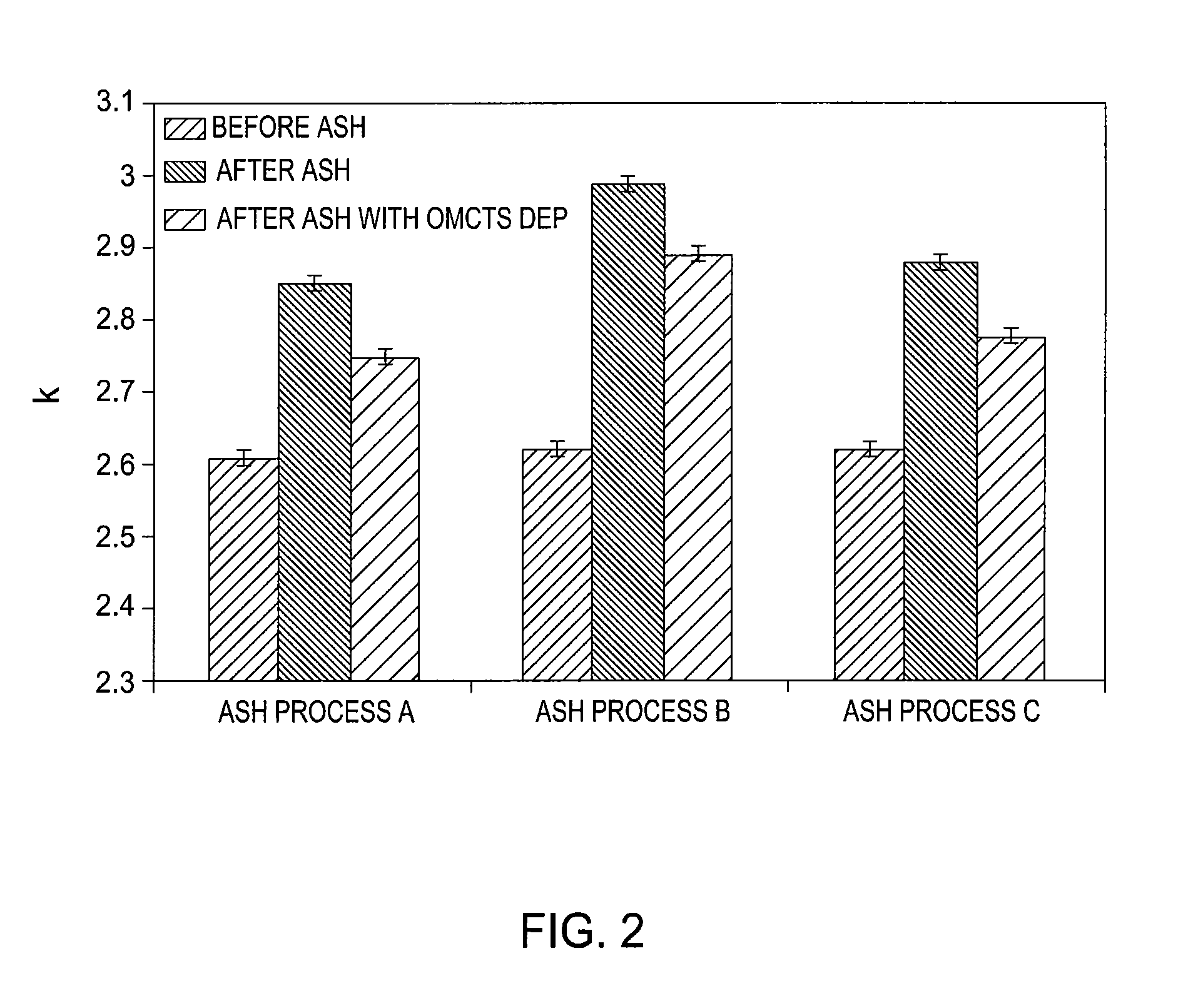

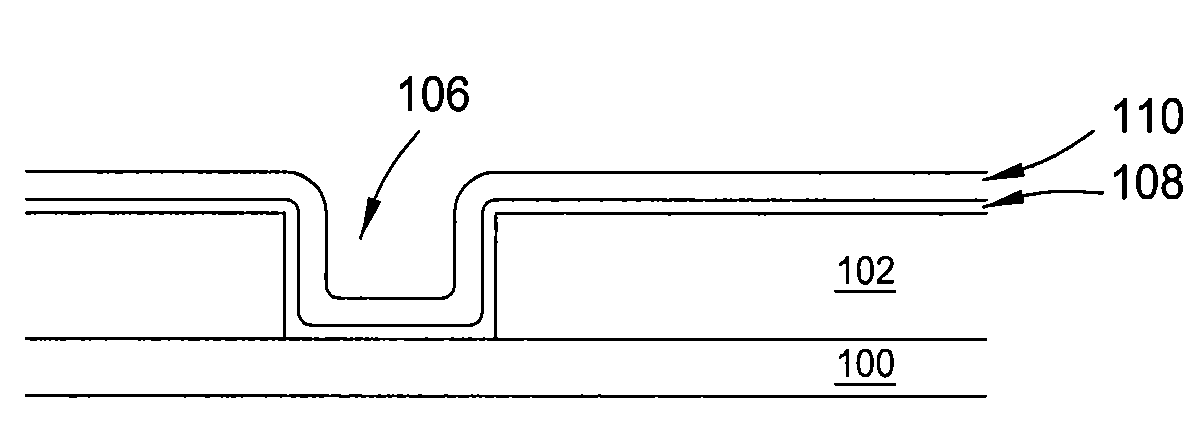

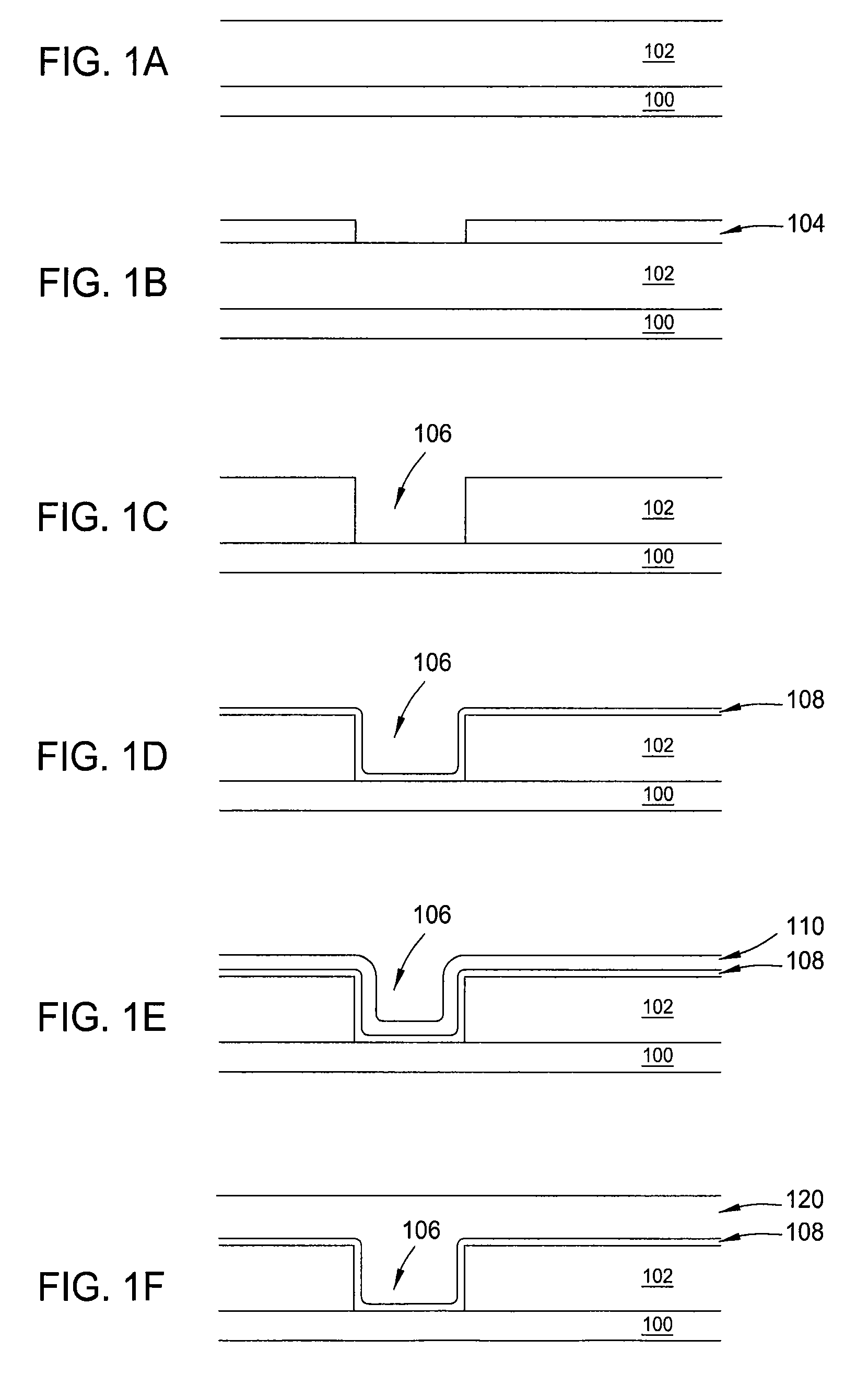

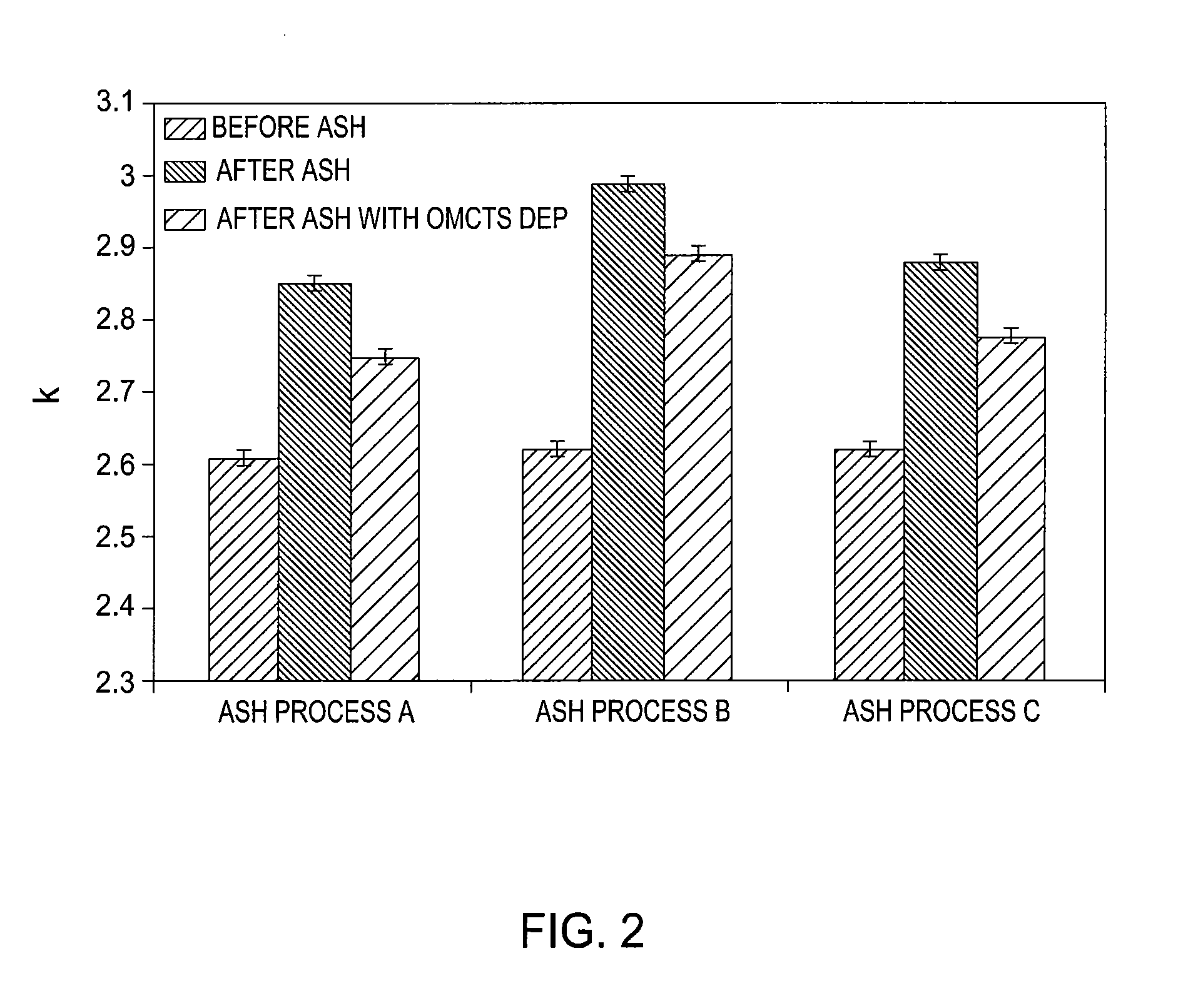

Method to minimize wet etch undercuts and provide pore sealing of extreme low k (k<2.5) dielectrics

ActiveUS8445075B2Constant ratePrevents undercuts and CD lossVacuum evaporation coatingPretreated surfacesNitrogenThin layer

Methods of processing films on substrates are provided. In one aspect, the methods comprise treating a patterned low dielectric constant film after a photoresist is removed from the film by depositing a thin layer comprising silicon, carbon, and optionally oxygen and / or nitrogen on the film. The thin layer provides a carbon-rich, hydrophobic surface for the patterned low dielectric constant film. The thin layer also protects the low dielectric constant film from subsequent wet cleaning processes and penetration by precursors for layers that are subsequently deposited on the low dielectric constant film.

Owner:APPLIED MATERIALS INC

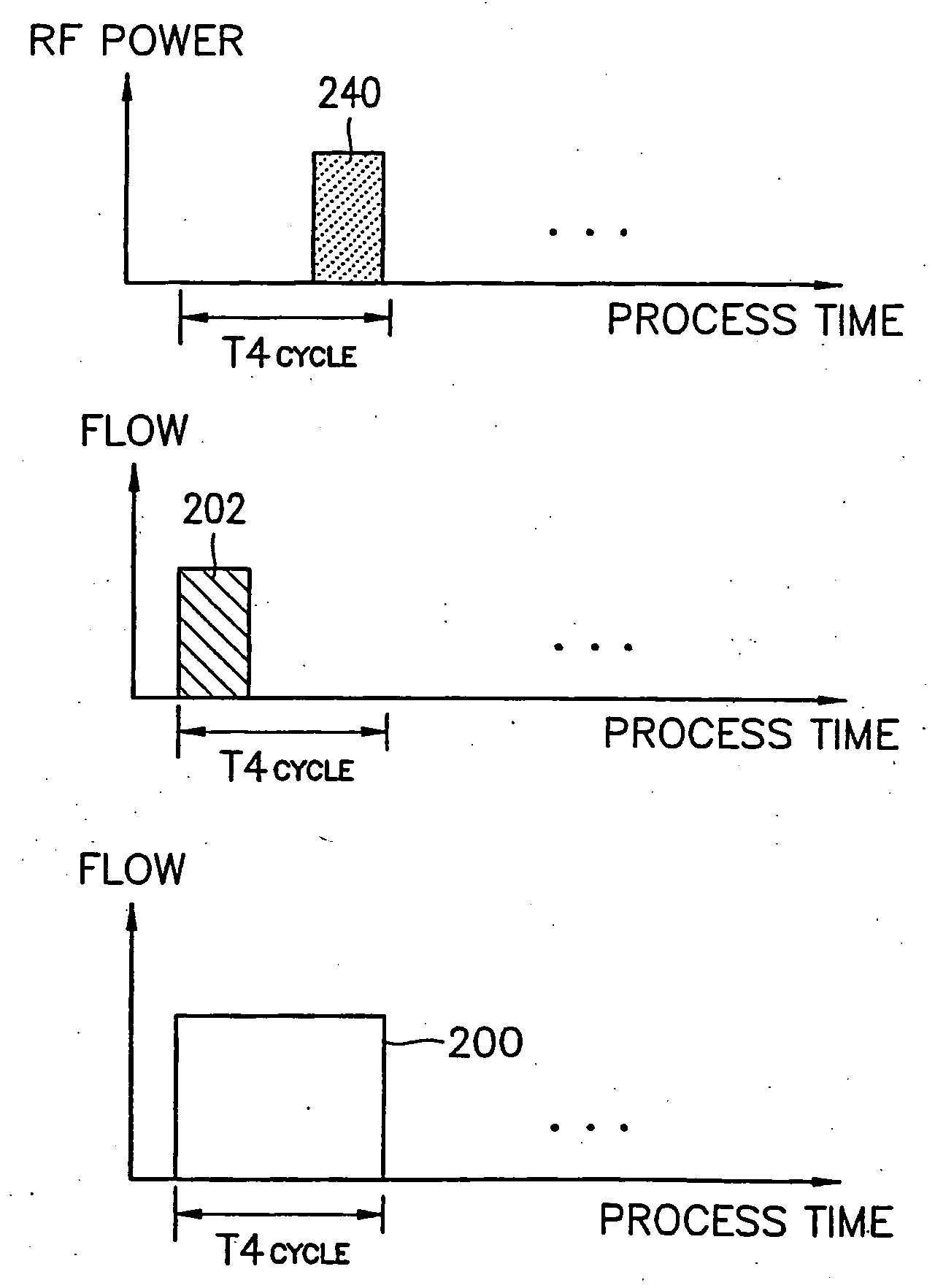

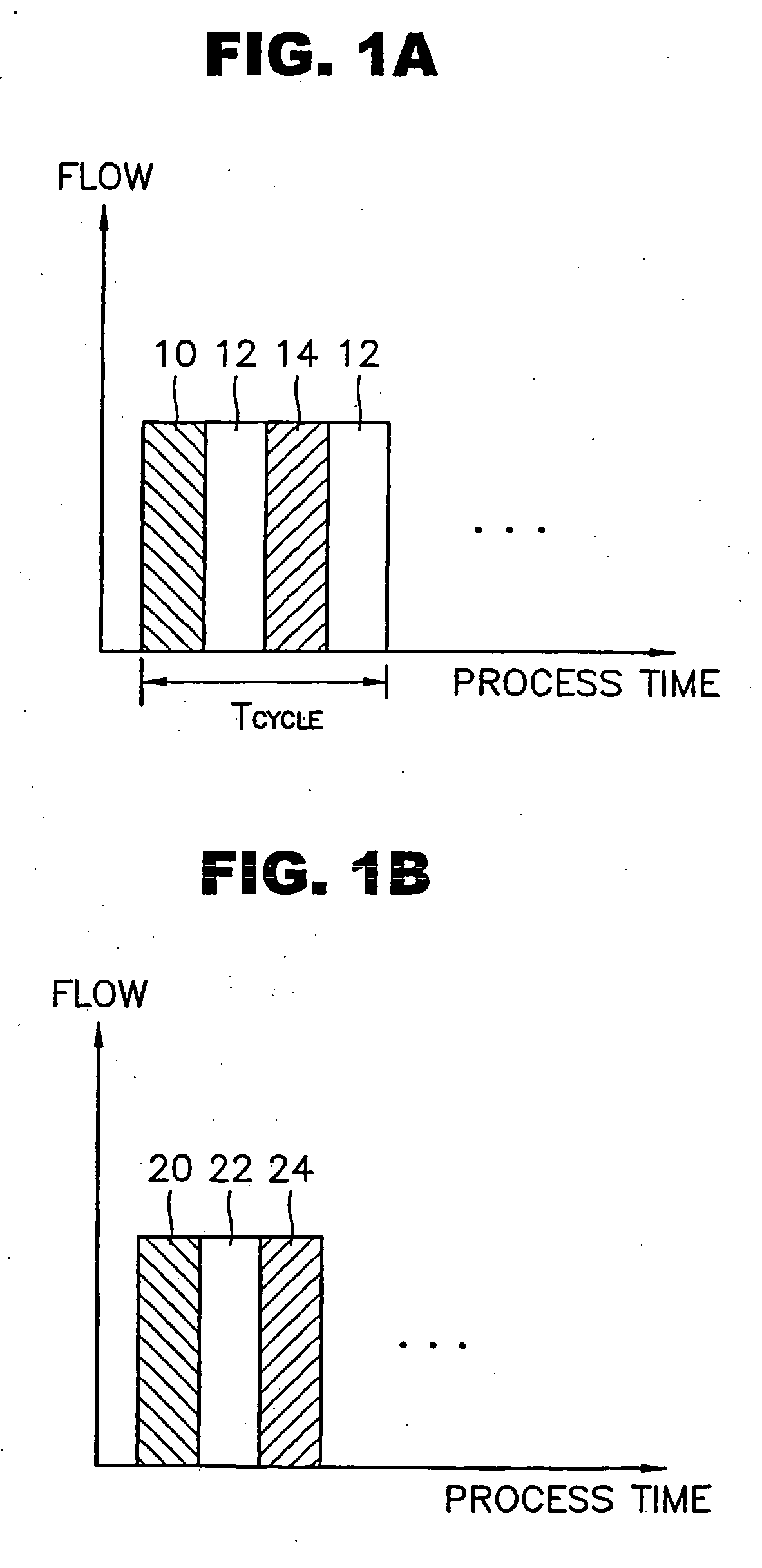

Method for forming thin film

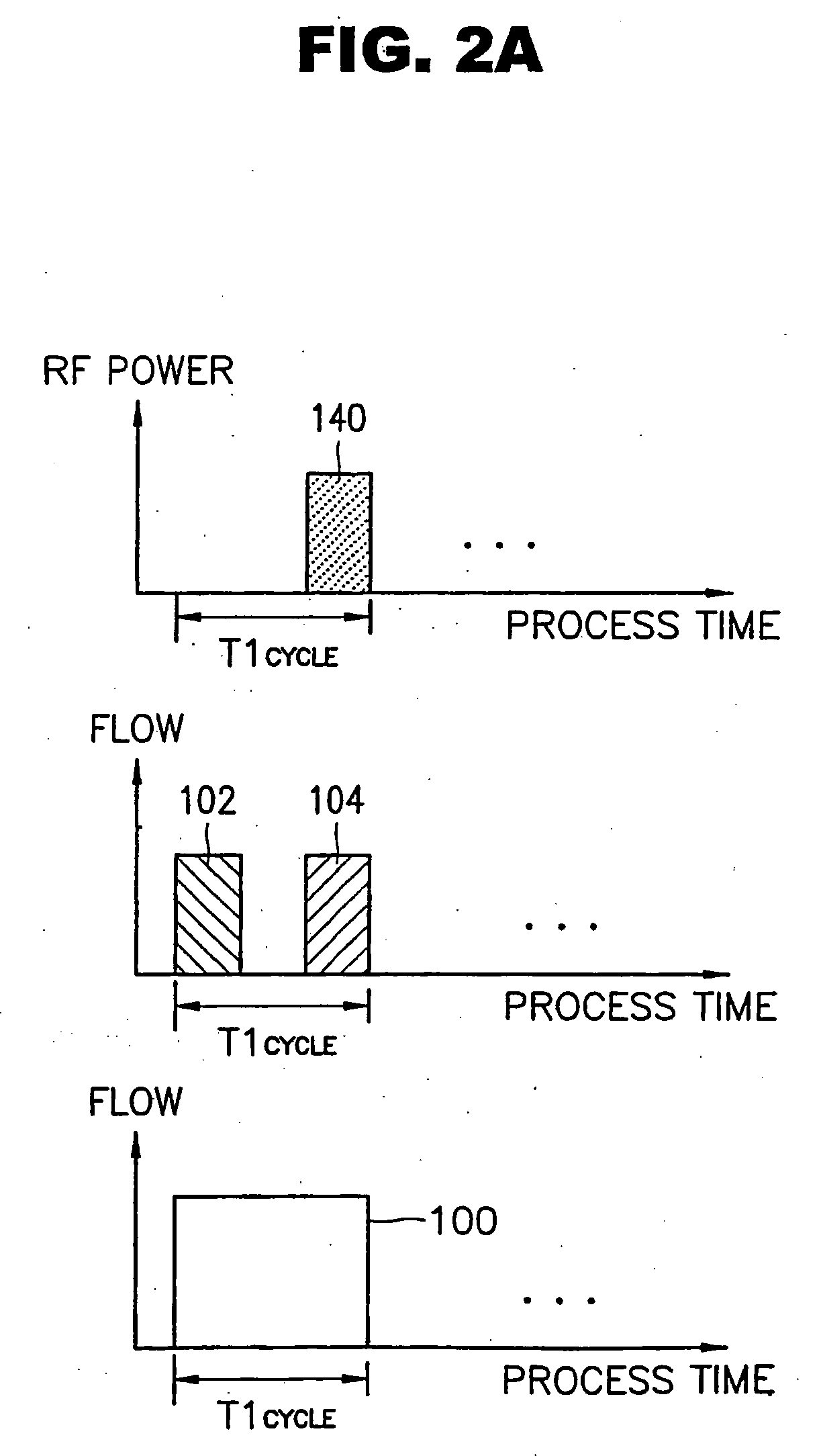

InactiveUS20050037154A1Prolonged durationIncrease ratingsSemiconductor/solid-state device manufacturingChemical vapor deposition coatingThin layerProduct gas

Method for forming a thin film at low temperature by using plasma pulses is disclosed. While a purge gas or a reactant purge gas activated by plasma is continuously supplied into a reactor, a source gas is supplied intermittently into the reactor during which period plasma is generated in the reactor so that the source gas and the purge gas activated by plasma reacts, so that a thin film is formed according to the method. Also, a method for forming a thin layer of film containing a plural of metallic elements, a method for forming a thin metallic film containing varied contents by amount of the metallic elements by using a supercycle Tsupercycle comprising a combination of simple gas supply cycles Tcycle, . . . , and a method for forming a thin film containing continuously varying compositions of the constituent elements by using a supercycle Tsupercycle comprising a combination of simple gas supply cycles Tcycle, . . . , are disclosed. The methods for forming thin films disclosed here allows to shorten the purge cycle duration even if the reactivity between the source gases is high, to reduce the contaminants caused by the gas remaining in the reactor, to form a thin film at low temperature even if the reactivity between the source gases is low, and also to increase the rate of thin film formation.

Owner:ASM GENITECH KOREA

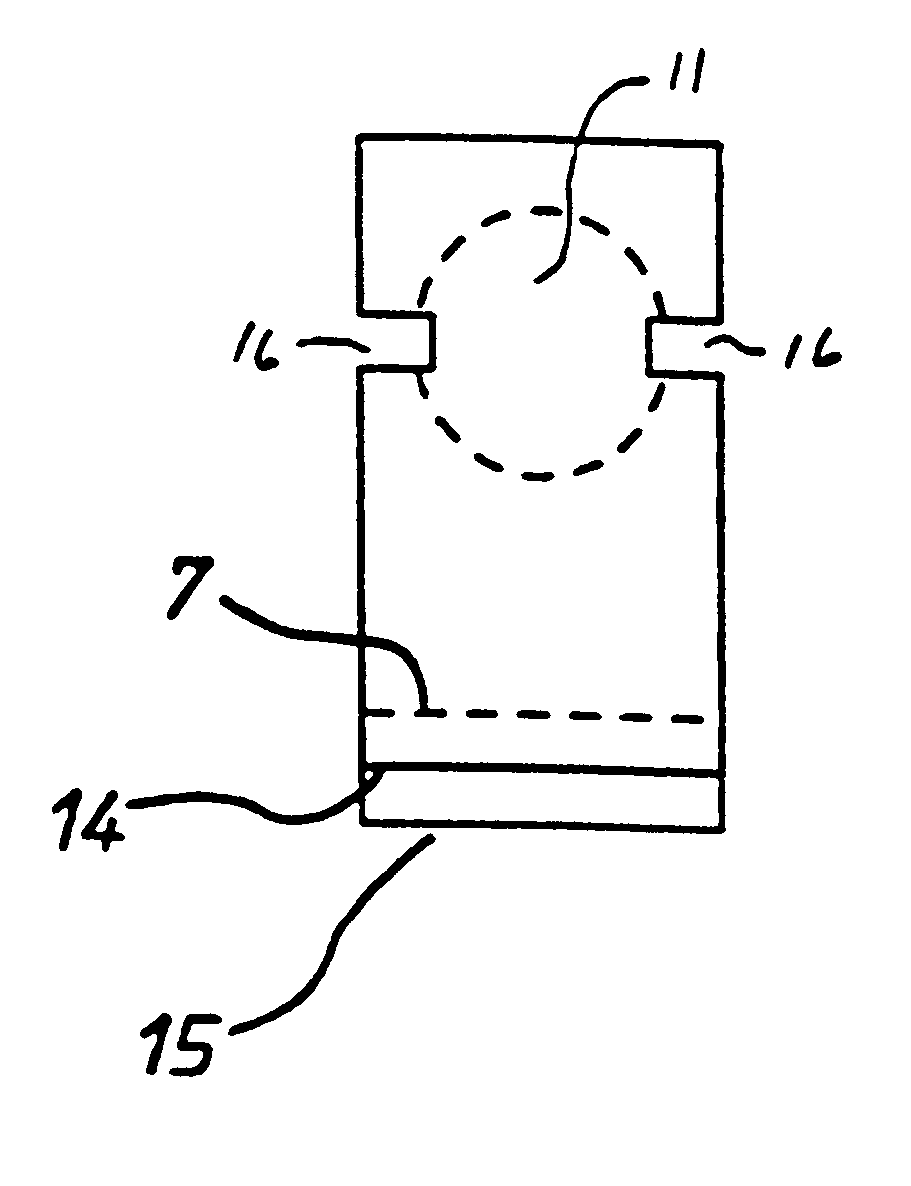

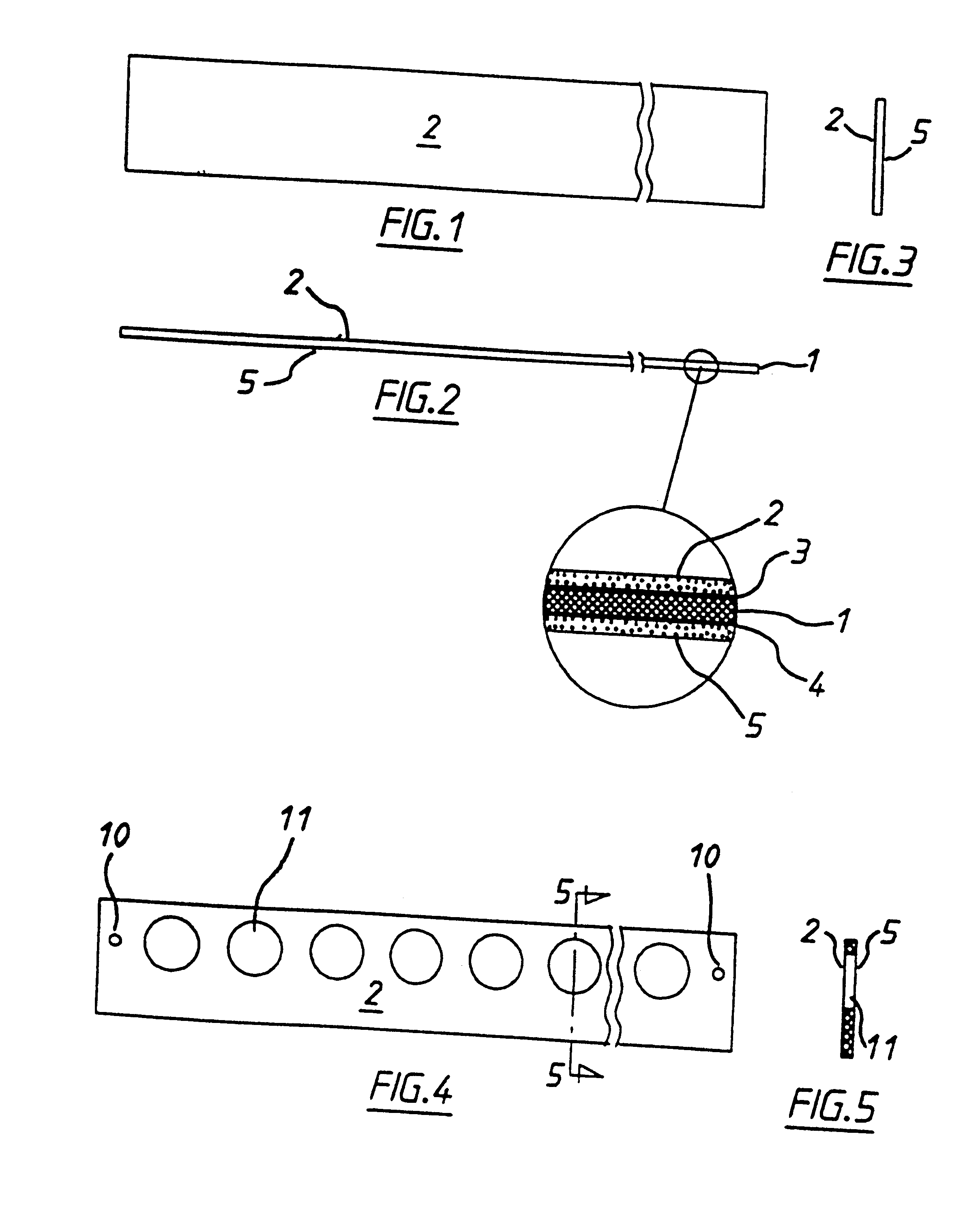

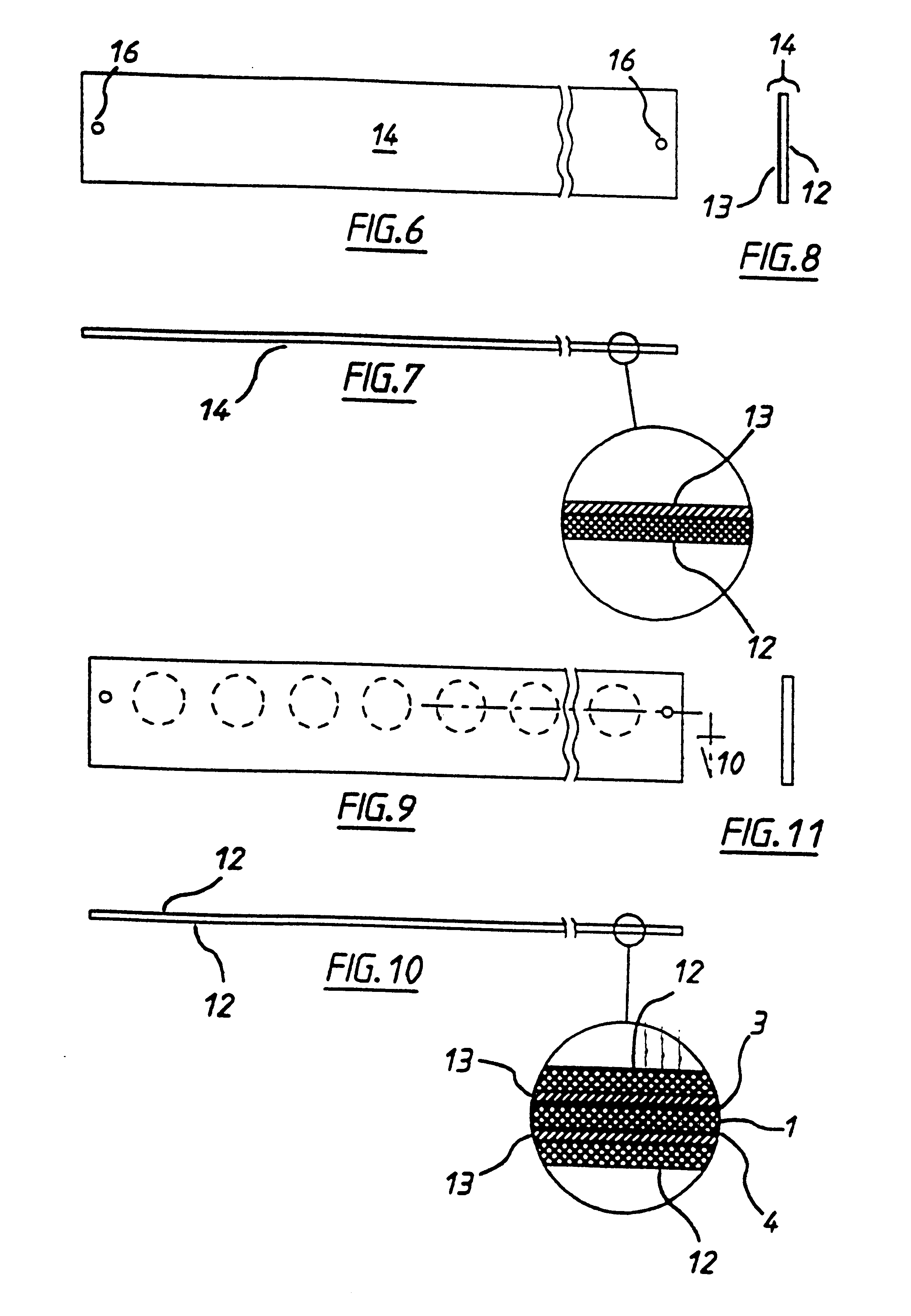

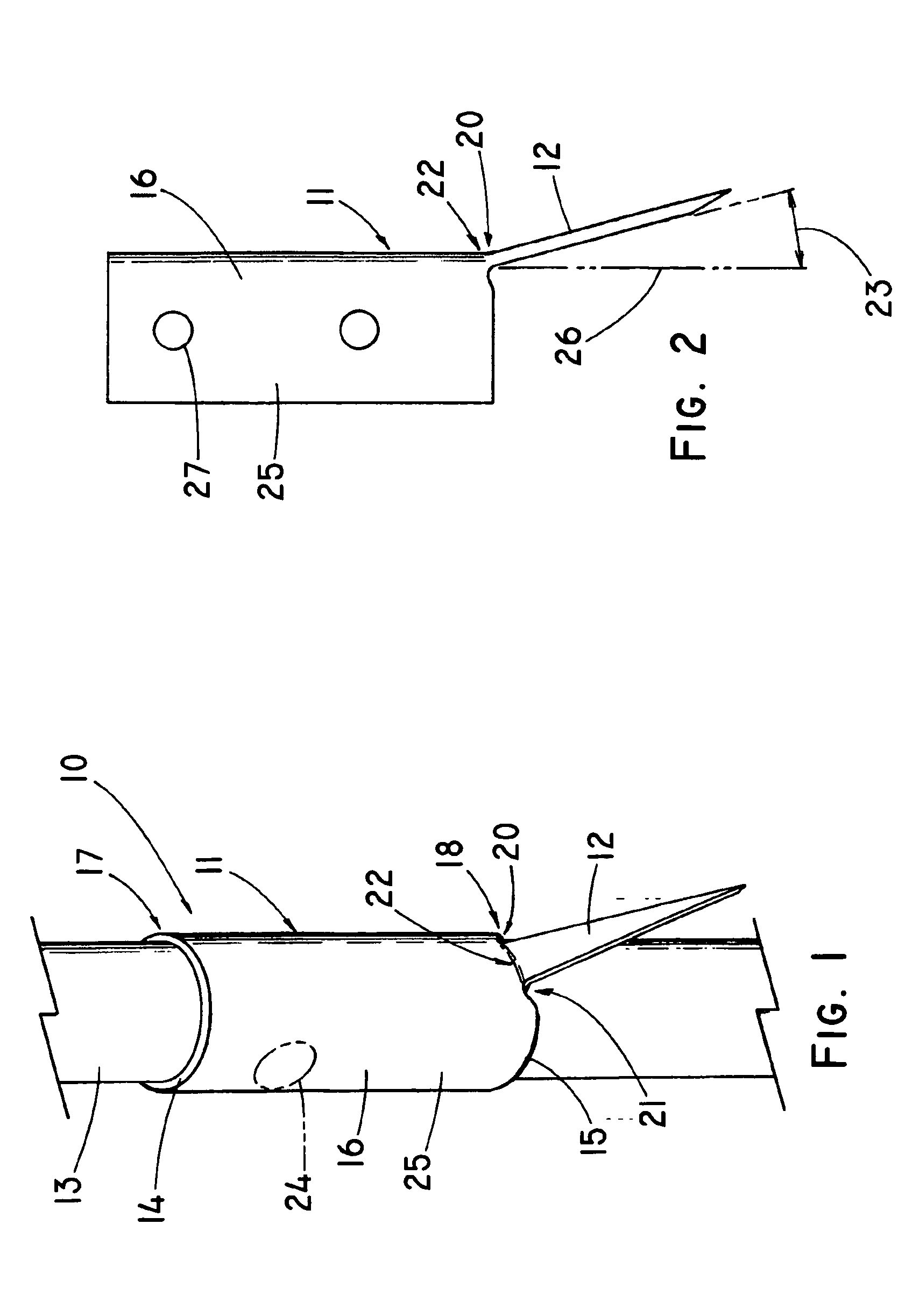

Electrochemical cell

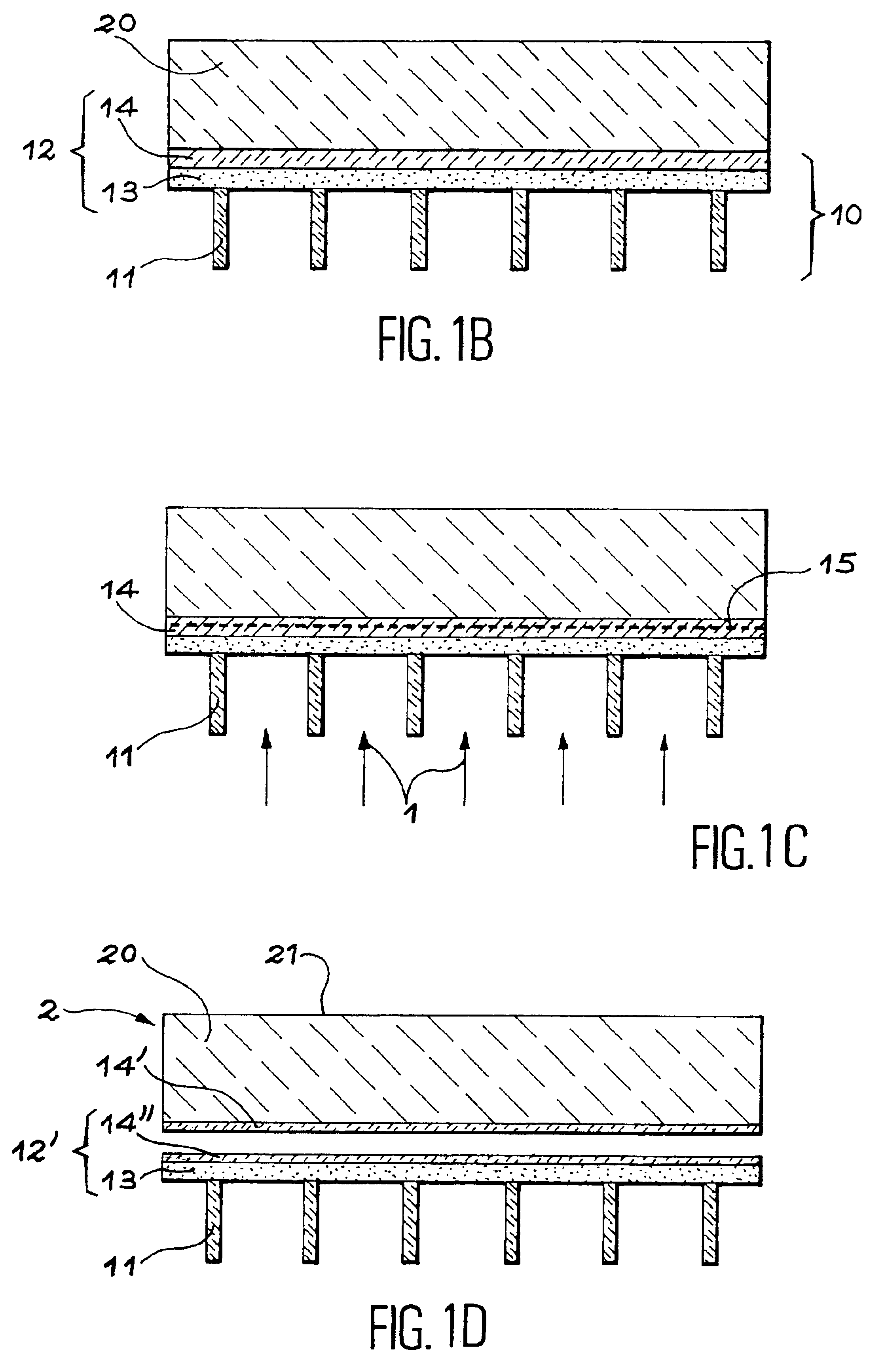

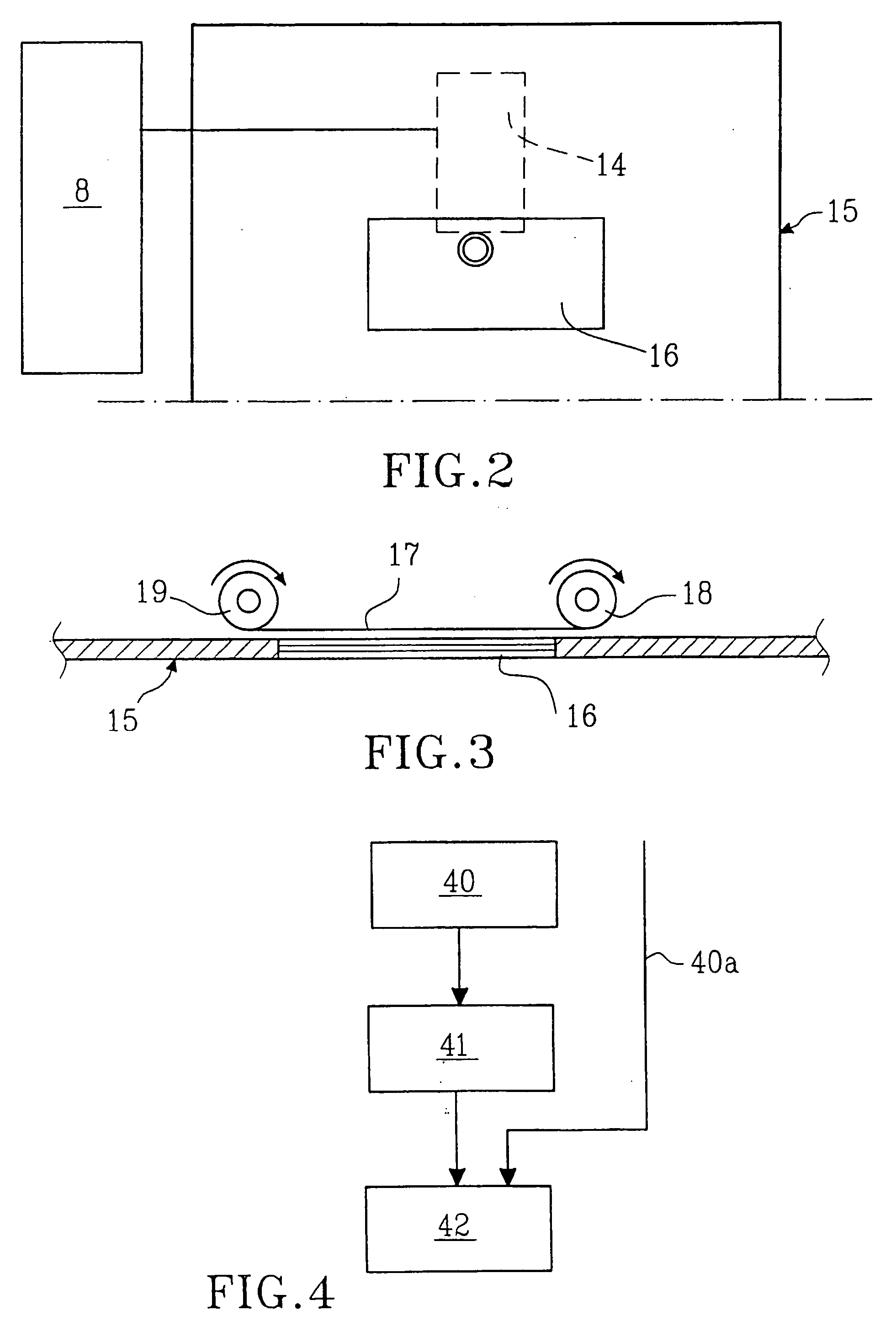

A method of manufacture of a thin layer electrochemical cell (FIGS. 12, 14) comprising the steps of:forming an aperture (11) extending through a sheet (1) of electrically resistive material, said aperture defining a side wall of the cell,mounting a first thin electrode layer (13) to one side of the sheet and extending over aperture (11) whereby to define a cell first end wall,mounting a second thin electrode layer (13) to the other side of the sheet and extending over aperture (11) whereby to define a second cell end wall in substantial overlying registration with the first electrode, andproviding means (16) for admission of a liquid into the cell.

Owner:LIFESCAN INC

Vertical memory device structures

Vertically oriented semiconductor memory cells are added to a separately fabricated substrate that includes electrical devices and / or interconnect. The plurality of vertically oriented semiconductor memory cells are physically separated from each other, and are not disposed within the same semiconductor body. The plurality of vertically oriented semiconductor memory cells can be added to the separately fabricated substrate as a thin layer including several doped semiconductor regions which, subsequent to attachment, are etched to produce individual doped stack structures, which are then supplied with various dielectric coatings, gate electrodes, and contacts by means of further processing operations. Alternatively, the plurality of vertically oriented semiconductor memory cells may be completely fabricated prior to attachment. DRAMs, SRAMs, non-volatile memories, and combinations of memory types can be provided.

Owner:BESANG

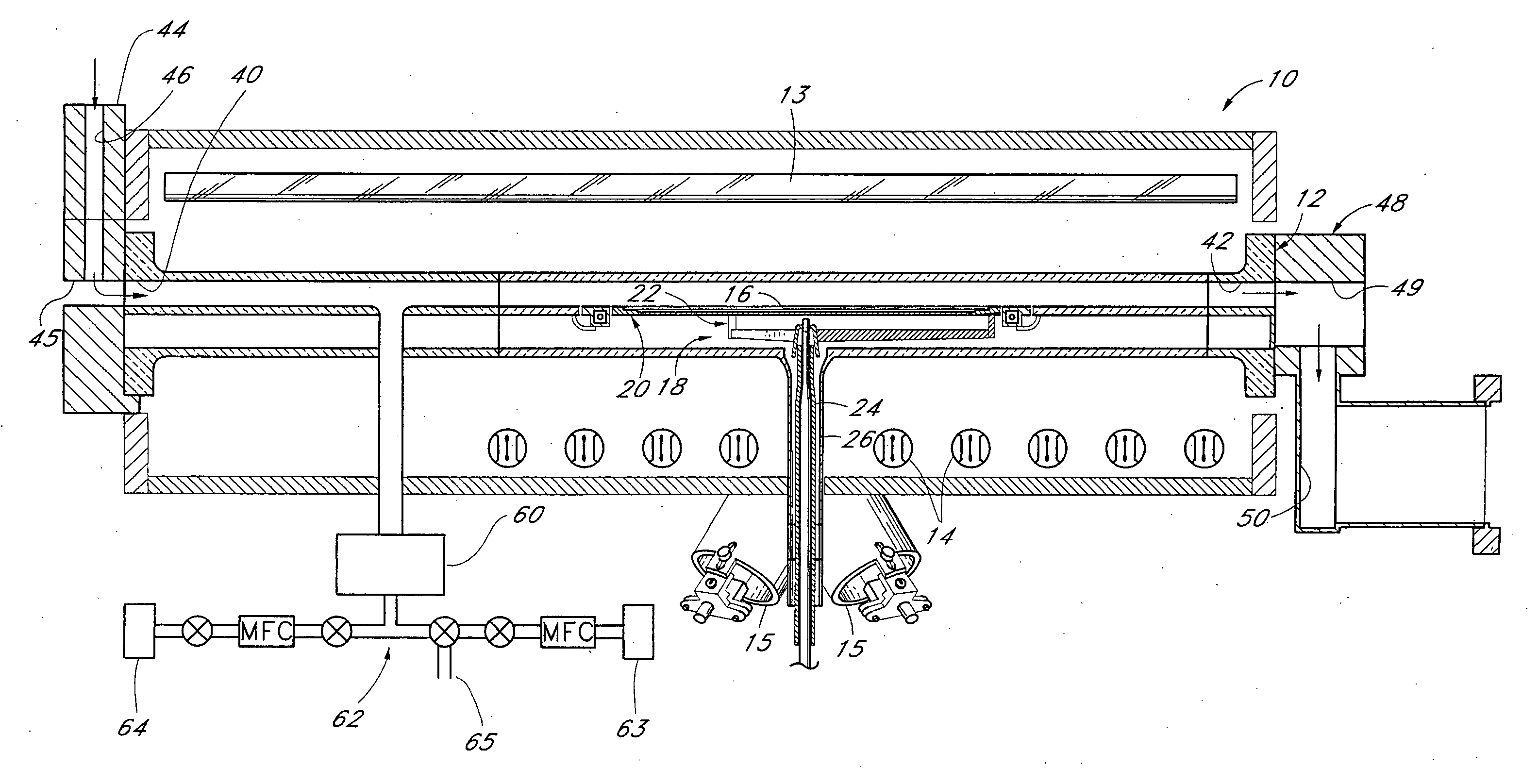

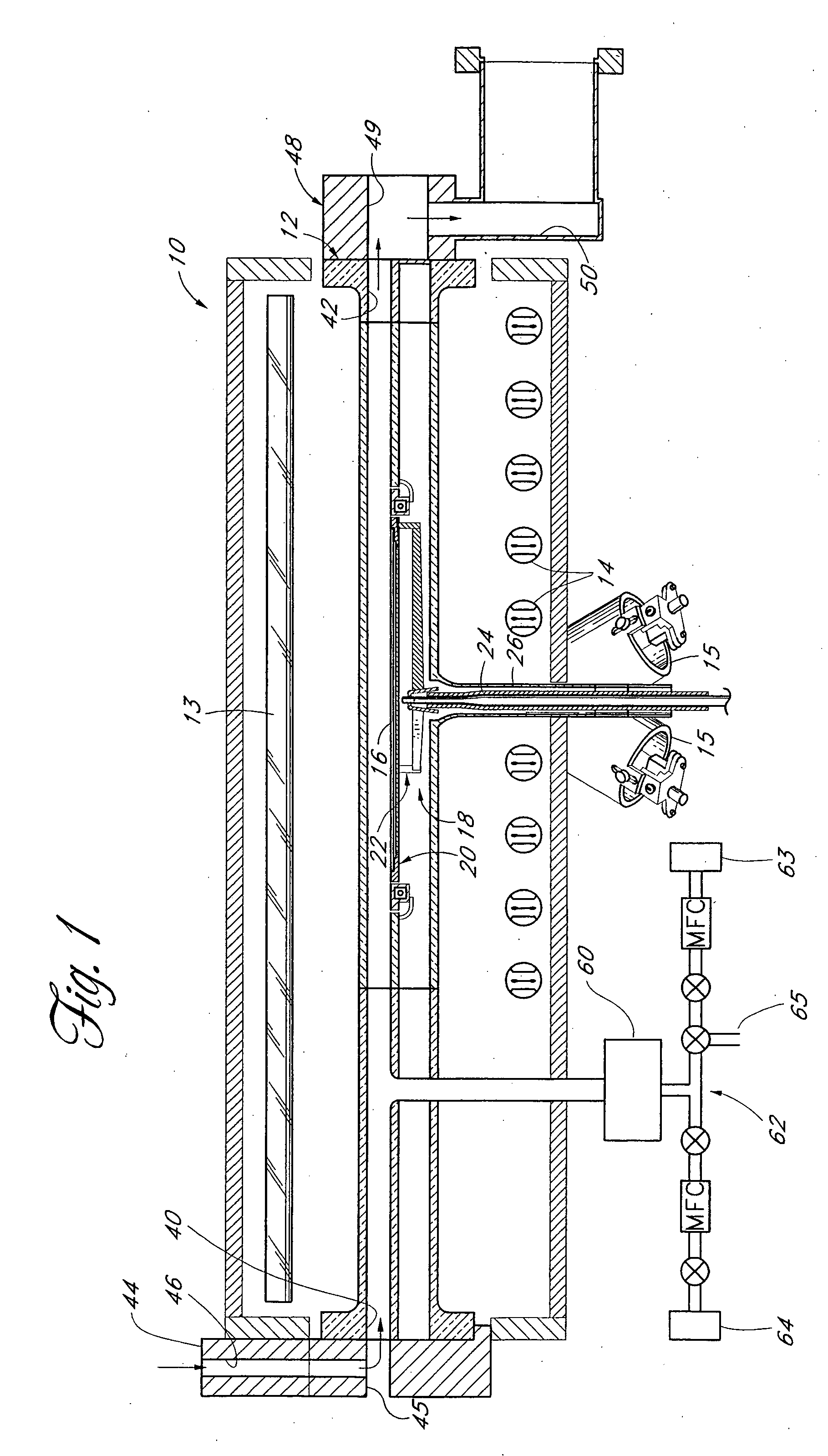

Method of forming a layer on a semiconductor substrate and apparatus for performing the same

InactiveUS20060000411A1Preventing deterioration of layerIncrease total manufacturing throughputSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDevice materialThin layer

In a method of forming a thin layer for a semiconductor device through an ALD process and a CVD process in the same chamber, a semiconductor substrate is introduced into a processing chamber, and an interval between a showerhead and the substrate is adjusted to a first gap distance. A first layer is formed on the substrate at a first temperature through an ALD process. The interval between the showerhead and the substrate is additionally adjusted to a second gap distance, and a second layer is formed on the first layer at a second temperature through a CVD process. Accordingly, the thin layer has good current characteristics, and the manufacturing throughput of a semiconductor device is improved.

Owner:SAMSUNG ELECTRONICS CO LTD

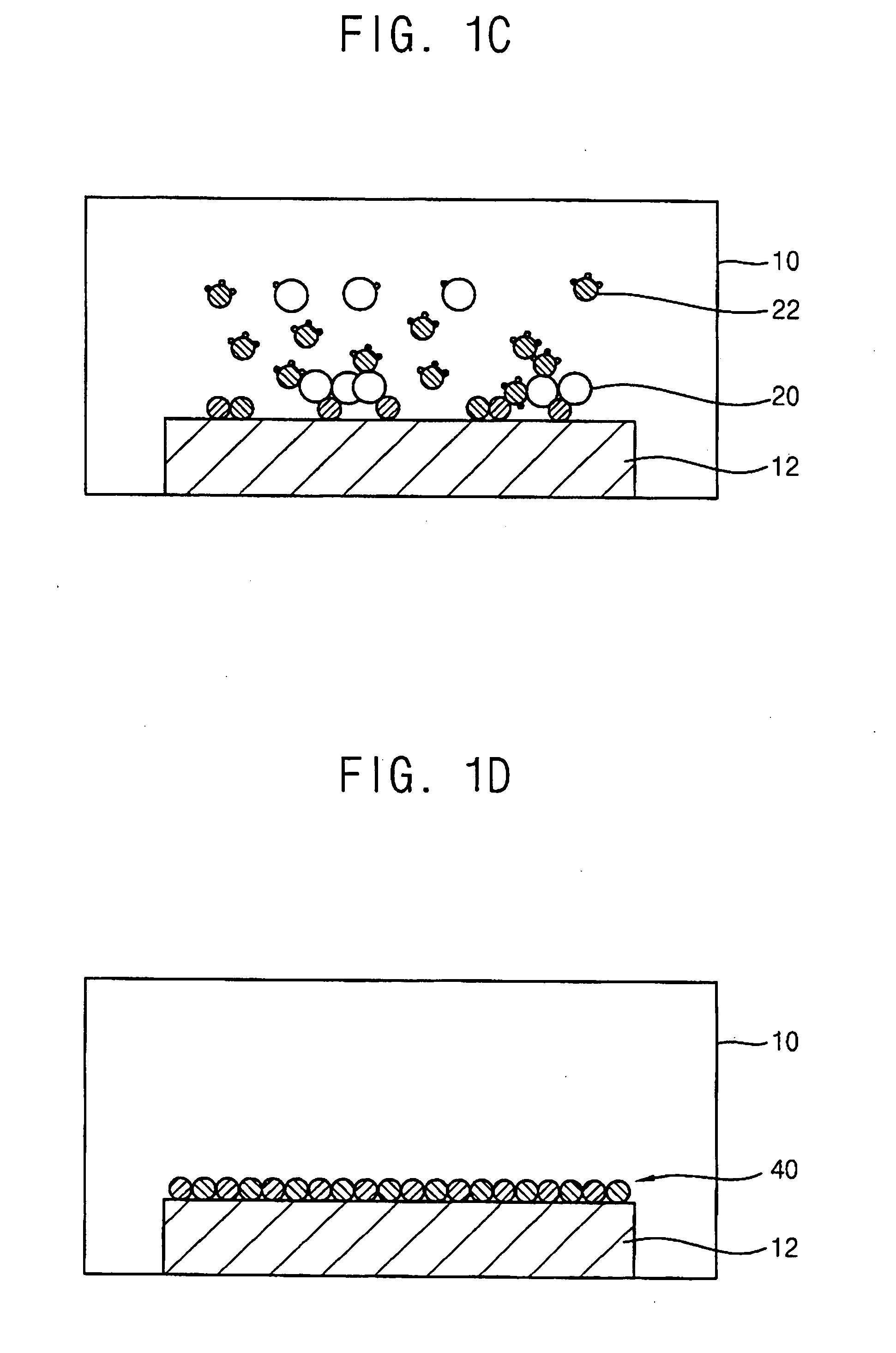

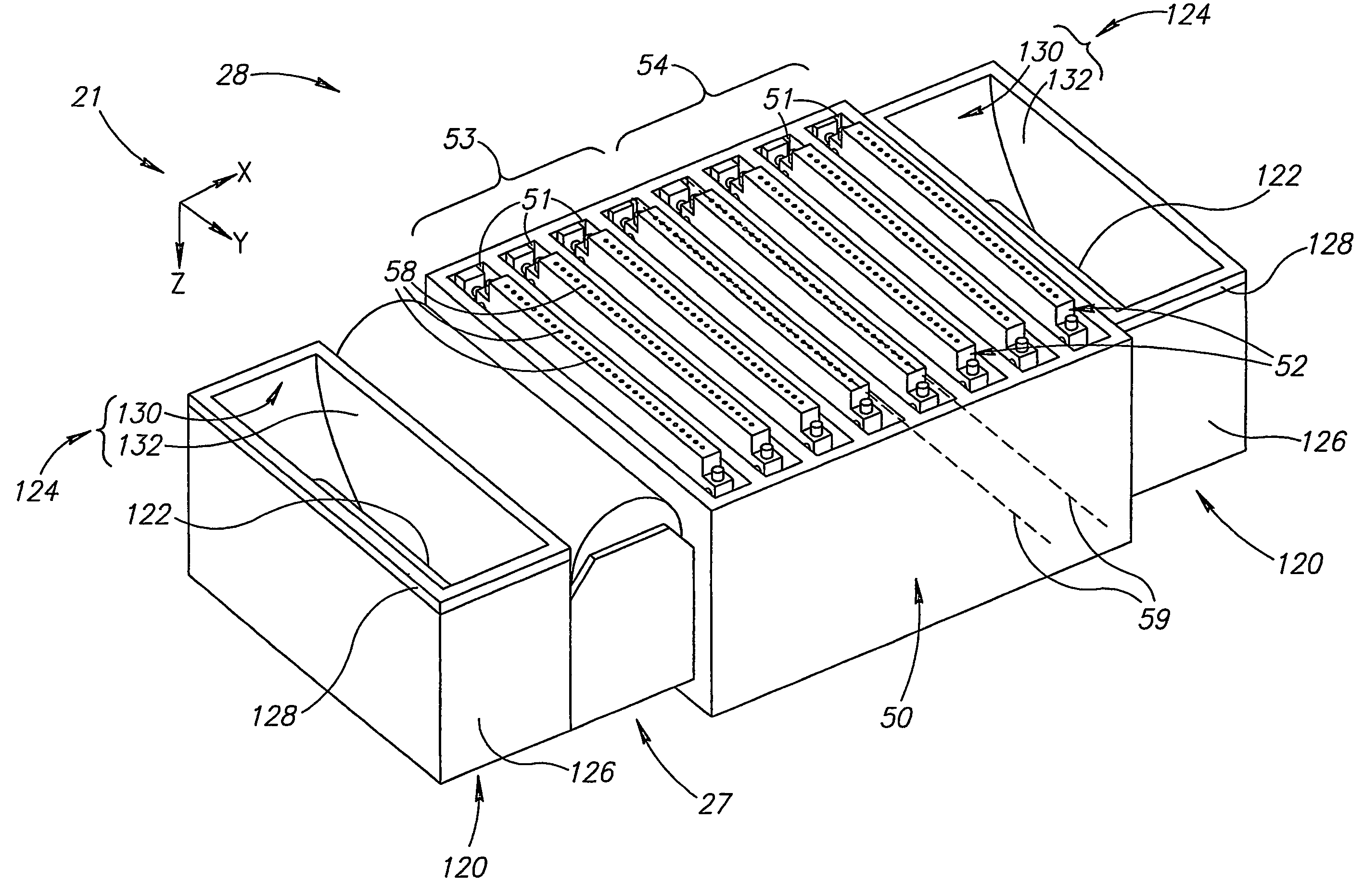

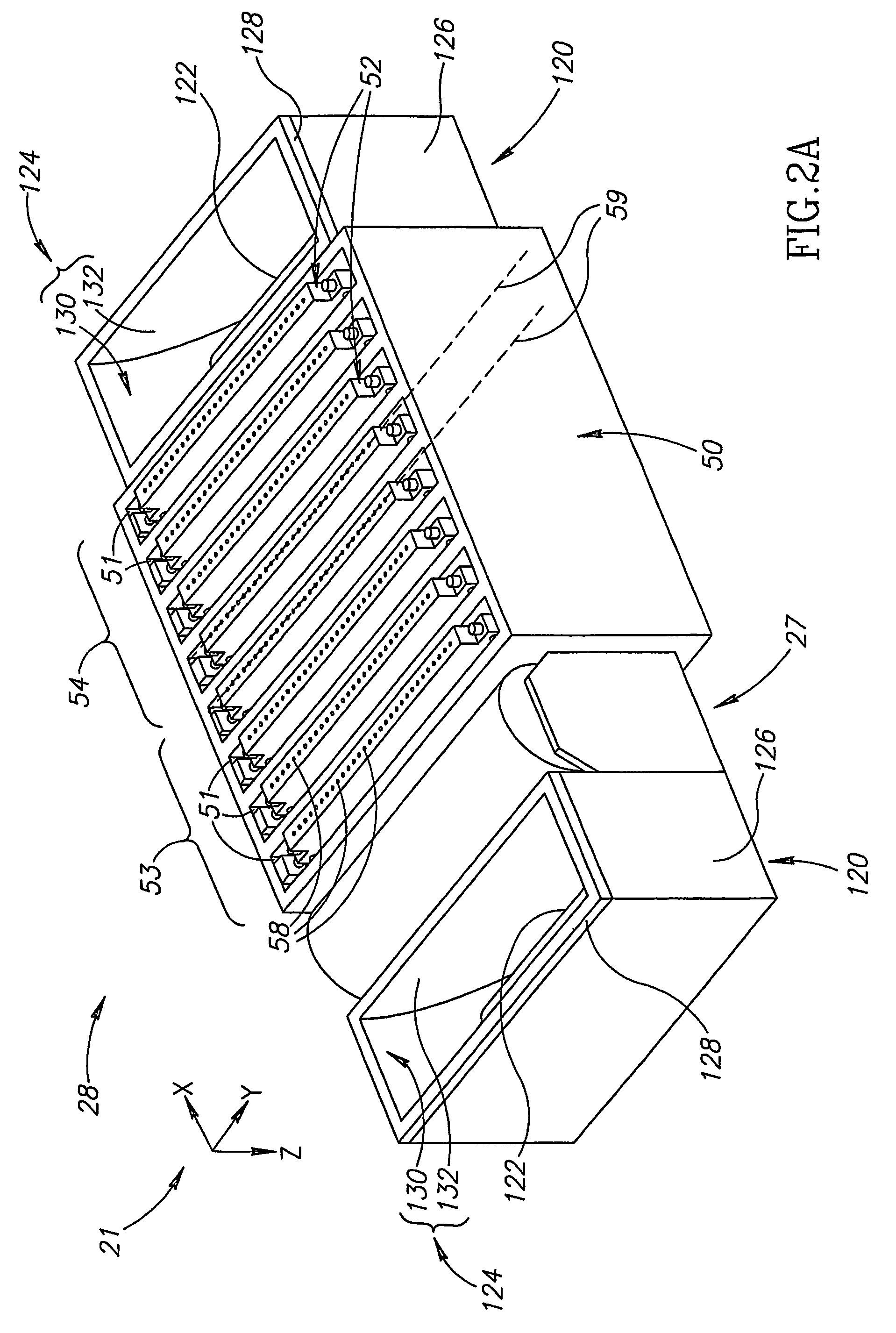

Rapid prototyping apparatus

ActiveUS7500846B2Improve operating characteristicsRapid productionConfectionerySweetmeatsThin layerEngineering

Apparatus for producing an object by sequentially forming thin layers of a construction material one on top of the other responsive to data defining the object, the apparatus comprising: a plurality of printing heads each having a surface formed with a plurality of output orifices and controllable to dispense the construction material through each orifice independently of the other orifices; a shuttle to which the printing heads are mounted; a support surface; and a controller adapted to control the shuttle to move back and forth over the support surface and as the shuttle moves to control the printing heads to dispense the construction material through each of their respective orifices responsive to the data to form a first layer on the support surface and thereafter, sequentially the other layers; wherein each printing head is dismountable from the shuttle and replaceable independently of the other printing heads.

Owner:OBJET GEOMETRIES

Method to minimize wet etch undercuts and provide pore sealing of extreme low k (k<2.5) dielectrics

ActiveUS20110092077A1Constant ratePrevents undercuts and CD lossVacuum evaporation coatingSemiconductor/solid-state device manufacturingThin layerNitrogen

Methods of processing films on substrates are provided. In one aspect, the methods comprise treating a patterned low dielectric constant film after a photoresist is removed form the film by depositing a thin layer comprising silicon, carbon, and optionally oxygen and / or nitrogen on the film. The thin layer provides a carbon-rich, hydrophobic surface for the patterned low dielectric constant film. The thin layer also protects the low dielectric constant film from subsequent wet cleaning processes and penetration by precursors for layers that are subsequently deposited on the low dielectric constant film.

Owner:APPLIED MATERIALS INC

Antireflective coatings comprising poly(oxyalkylene) colorants

InactiveUS6048662AReduce the amplitudeImprove anti-reflectionPhotosensitive materialsRadiation applicationsCounterionThin layer

This invention relates to antireflective coatings comprising polymeric polyoxyalkylenated colorants. More particularly, the present invention relates to antireflective coatings for utilization in forming thin layers between reflective substrates and photoresist coatings. Such antireflective coatings are very useful and beneficial within the production and fabrication of semiconductors through photolithographic procedures due to the liquid, non-crystallizing nature of polyoxyalkylenated colorants, and the lack of potentially damaging counterions, metals, and / or electrolytes within the inventive antireflective colored coatings. The inventive coatings may also be applied on lenses, mirrors, and other optical components. Methods of forming such antireflective coatings are also contemplated within this invention.

Owner:MILLIKEN & CO

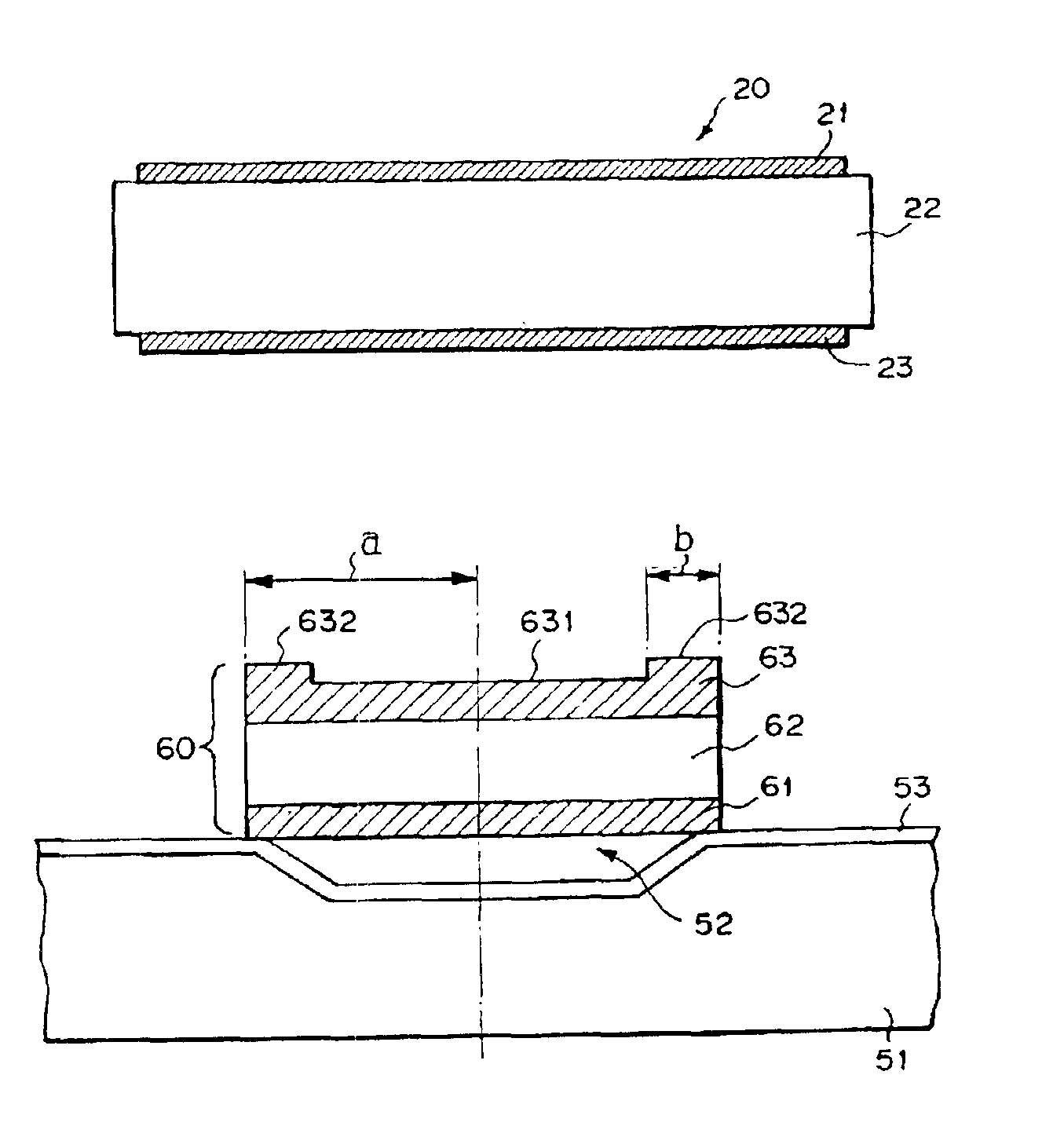

Organic vertical-cavity surface-emitting laser

InactiveUS6160828ALaser active region structureExcitation process/apparatusVertical-cavity surface-emitting laserThin layer

Organic vertical-cavity surface-emitting lasers ("OVCSELs"), in which a thin layer of organic material is disposed between highly reflective mirrors to thereby form a vertical cavity within a stacked arrangement. The lasers of the present invention each comprise a first mirror layer; a layer of active organic material over the first mirror layer; and a second mirror layer over the layer of first active organic material. The active organic material lases when pumped to thereby produce laser light. The present invention provides for optical semiconductor lasers with desired properties such as narrow bandwidth emission, the minimal use of active organic materials, and the facilitation of wavelength tuning and electrical pumping.

Owner:PRINCETON UNIV THE TRUSTEES OF

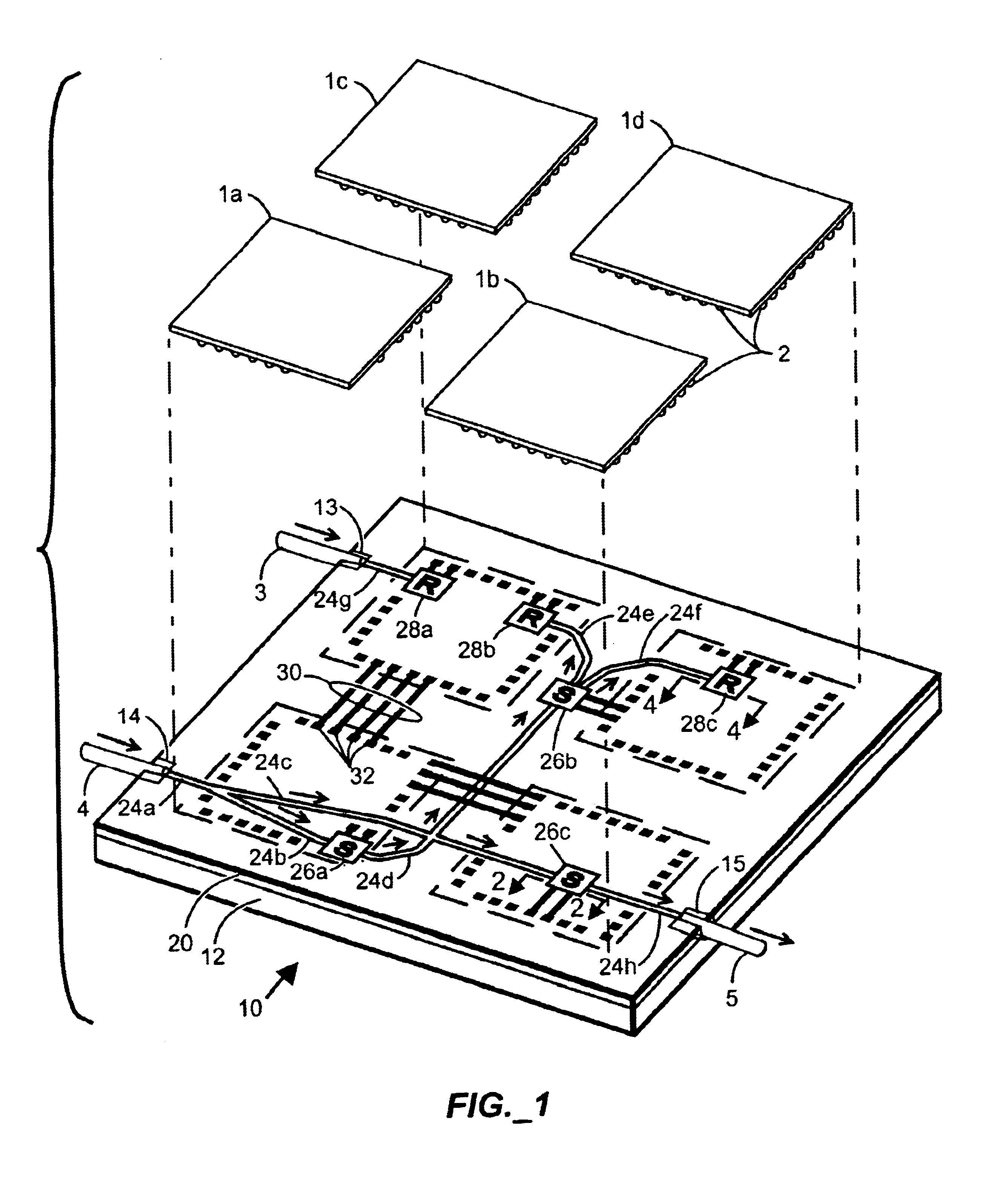

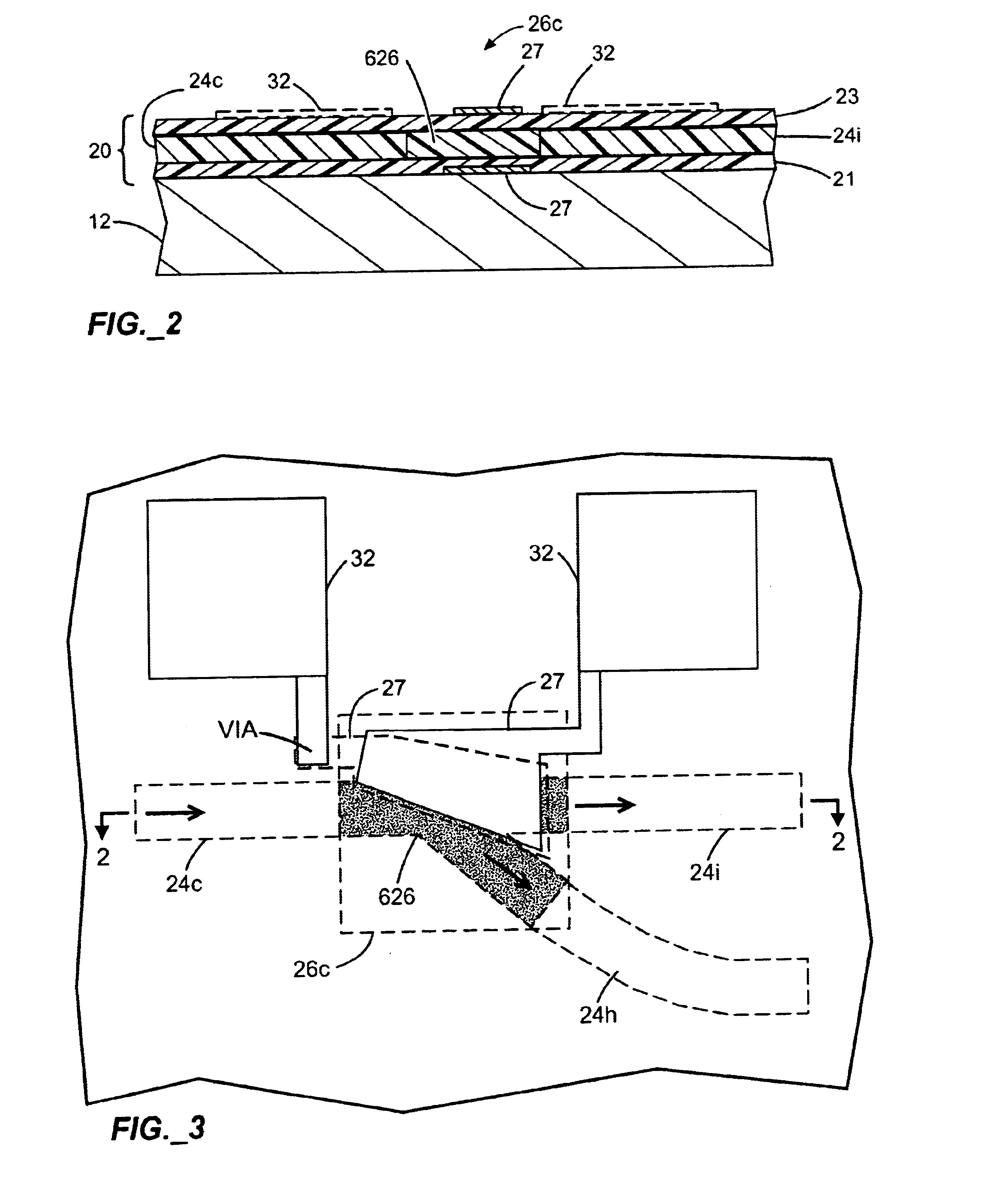

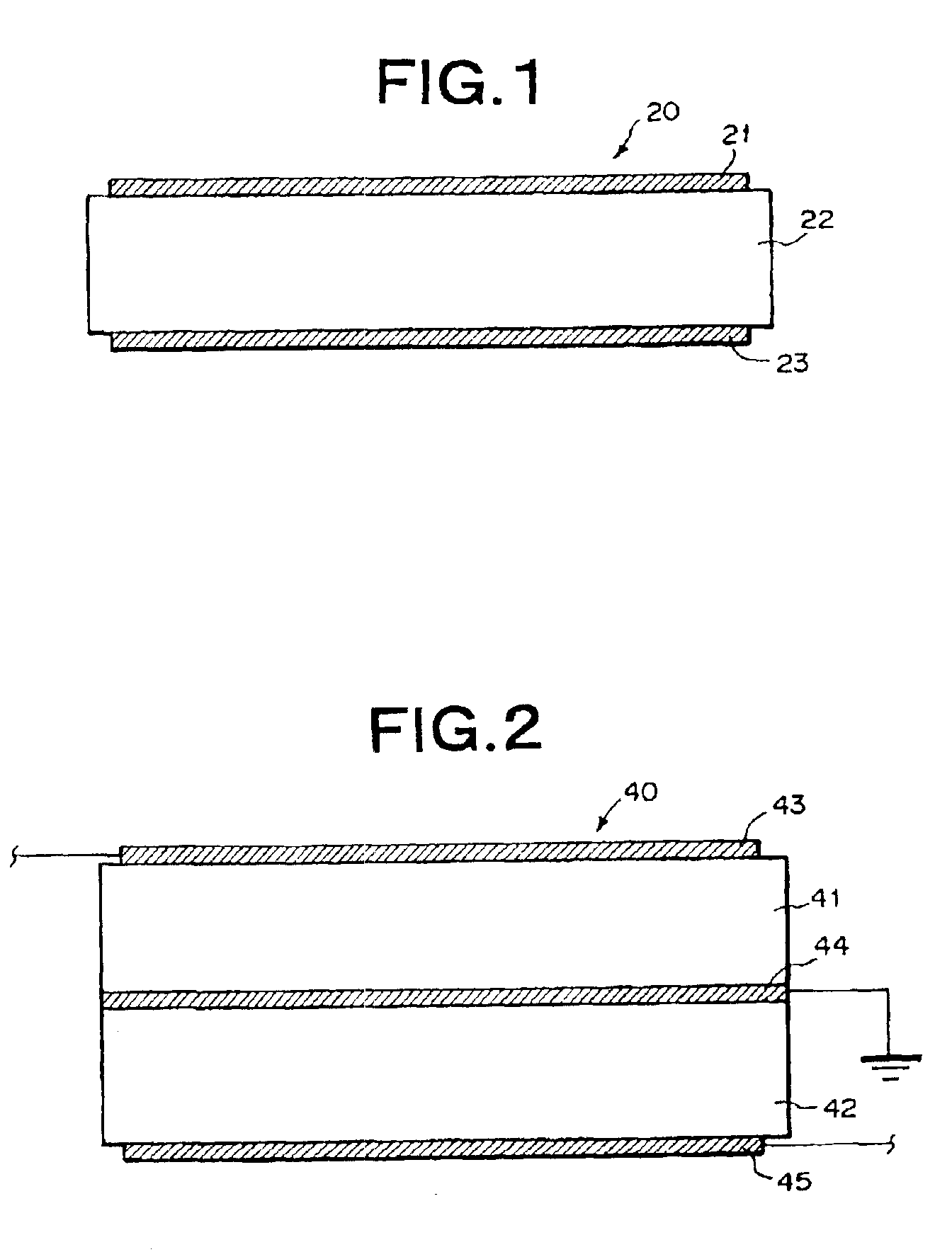

Multi-layer opto-electronic substrates with electrical and optical interconnections and methods for making

InactiveUS6845184B1Reduce area requirementsOptical coupling efficiency improvementSemiconductor/solid-state device detailsSolid-state devicesElectricityThin layer

Opto-electrical systems having electrical and optical interconnections formed in thin layers are disclosed. In one set of preferred embodiments, optical signals are conveyed between layers by respective vertical optical couplers disposed on the layers. In other preferred embodiments, optical signals are conveyed by stack optical waveguide coupling means. Yet other preferred embodiments have electrical via means formed in one or more layers to covey electrical signals between two or more layers.

Owner:FUJITSU LTD

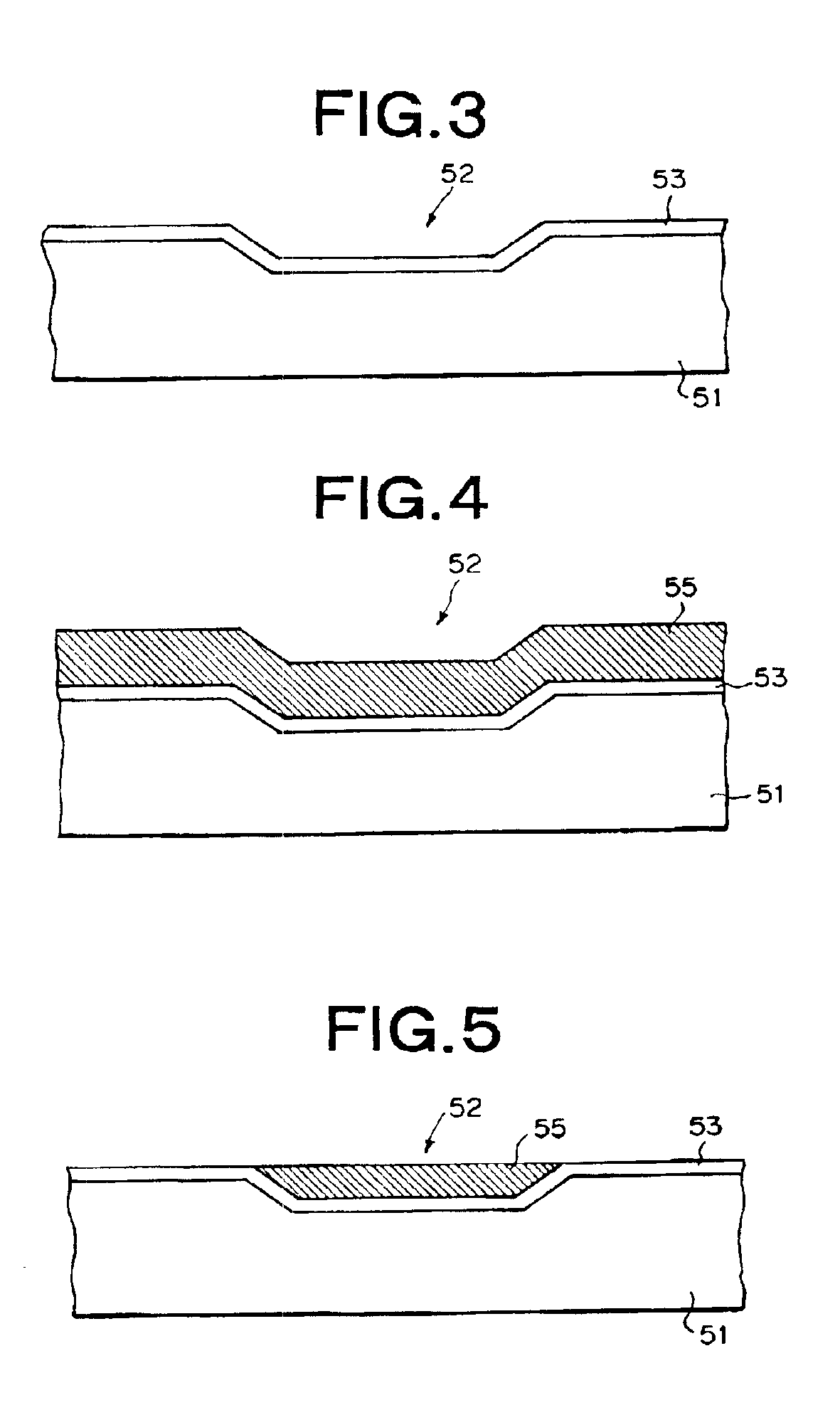

Method for producing a thin film comprising introduction of gaseous species

InactiveUS6946365B2Solid-state devicesSemiconductor/solid-state device manufacturingThin layerMaterials science

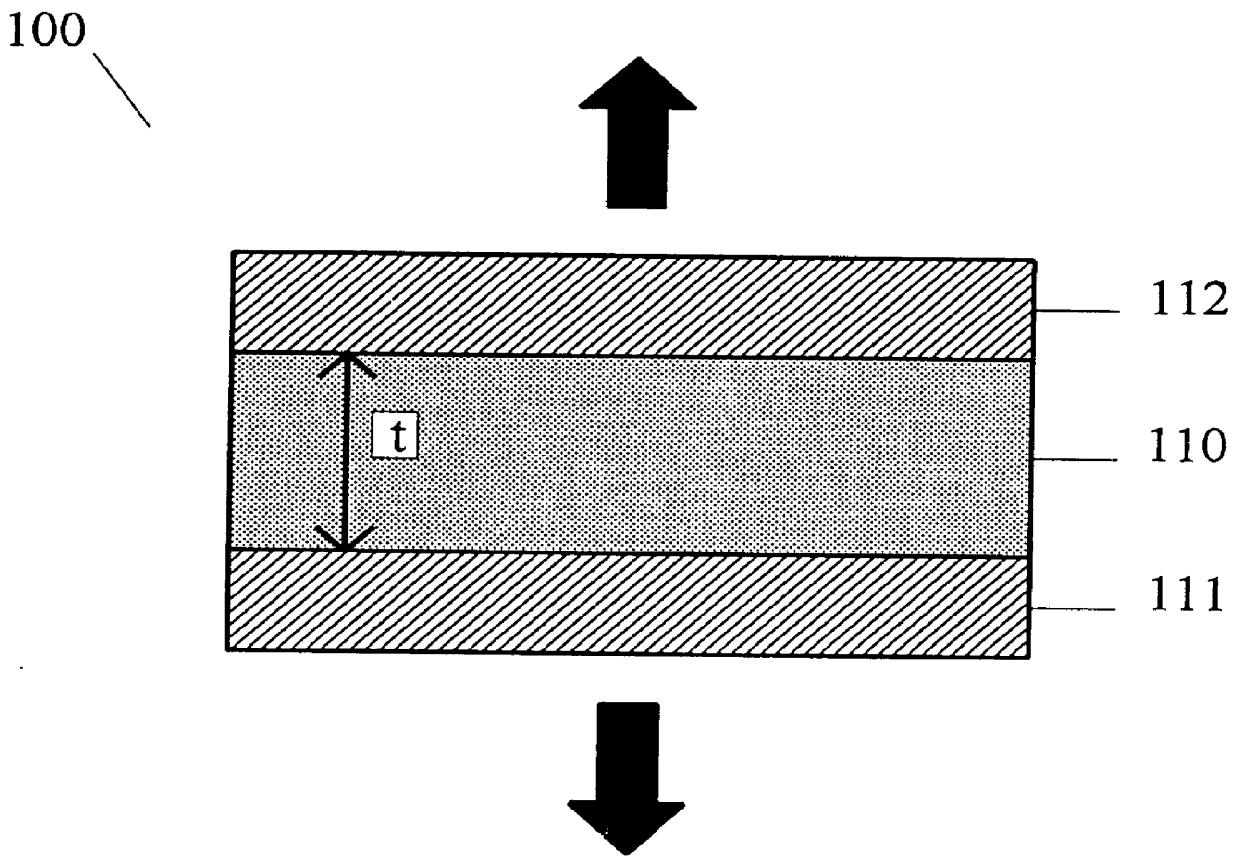

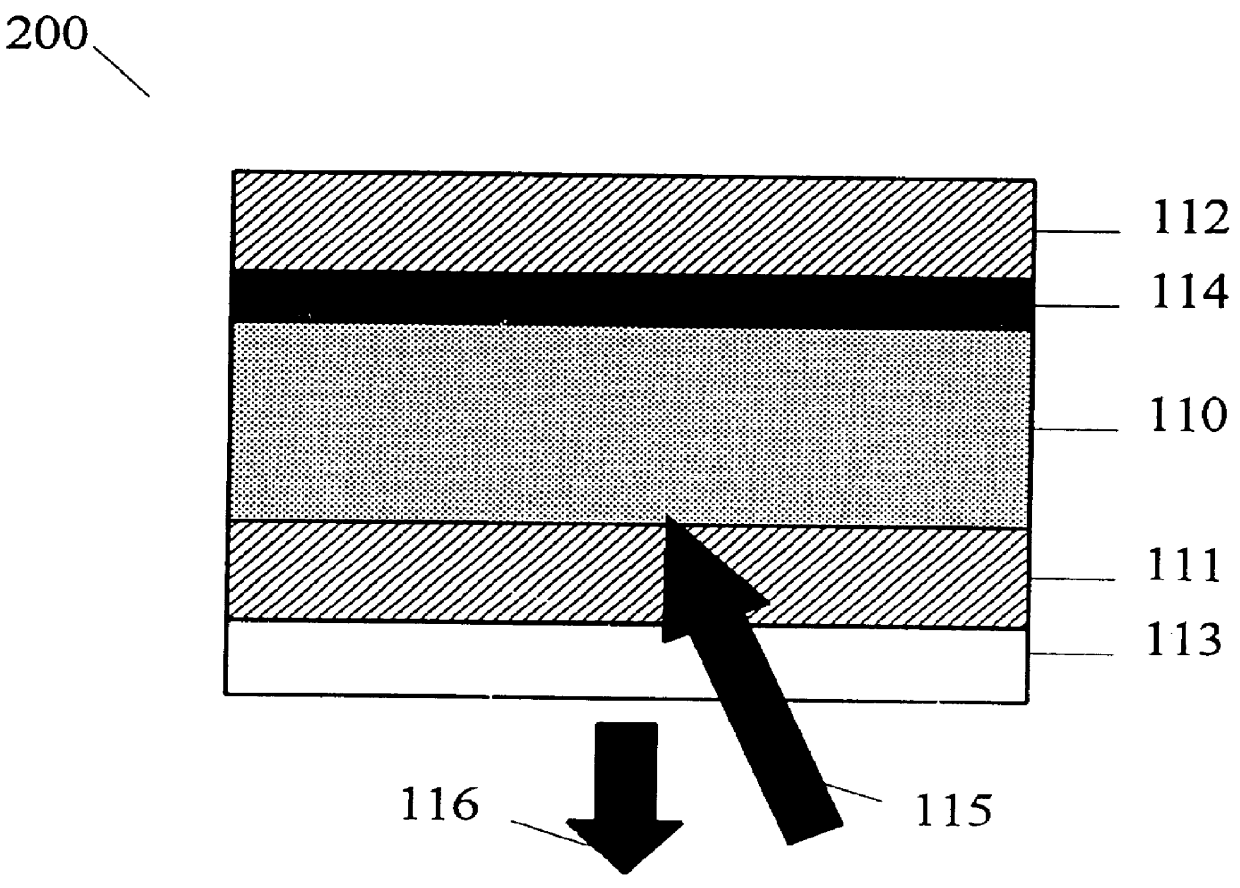

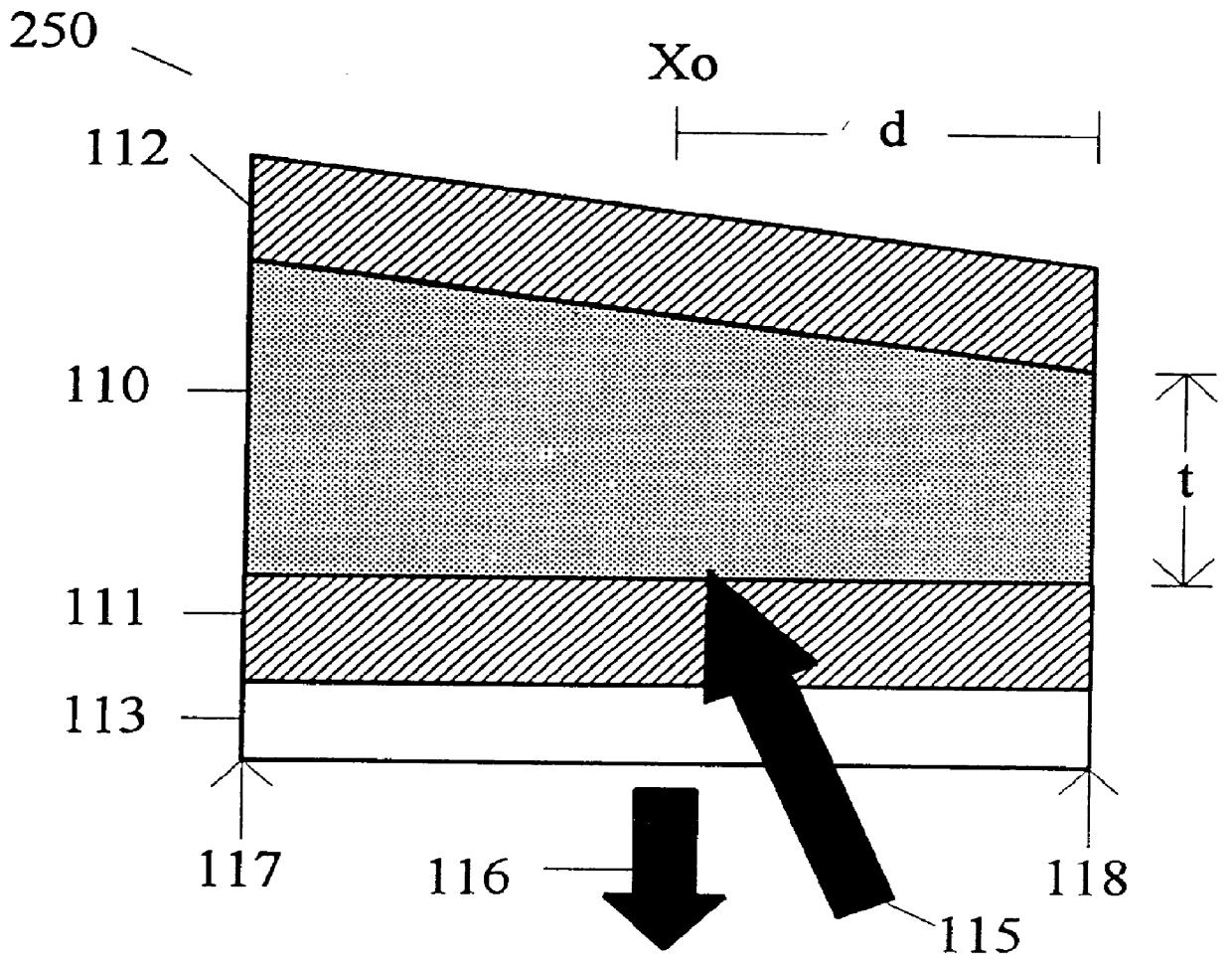

A method for making a thin layer from a structure. A stacked structure is made of a first part designed to facilitate the introduction of gaseous species and of a second part, the second part having a first free face and a second face integral with the first part. A gaseous species is introduced into the structure, from the first part, to create an embrittled zone, a thin layer being thus delimited between the first face of the second part and the embrittled zone. The thin layer is separated from the remaining of the structure at the level of the embrittled zone.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Thin film acoustic resonator and method of producing the same

InactiveUS6842088B2Improve temperature stabilityImprovement factorNanotechPiezoelectric/electrostrictive device manufacture/assemblyThin-film bulk acoustic resonatorElectromechanical coupling coefficient

Owner:MEMS SOLUTIONS INC

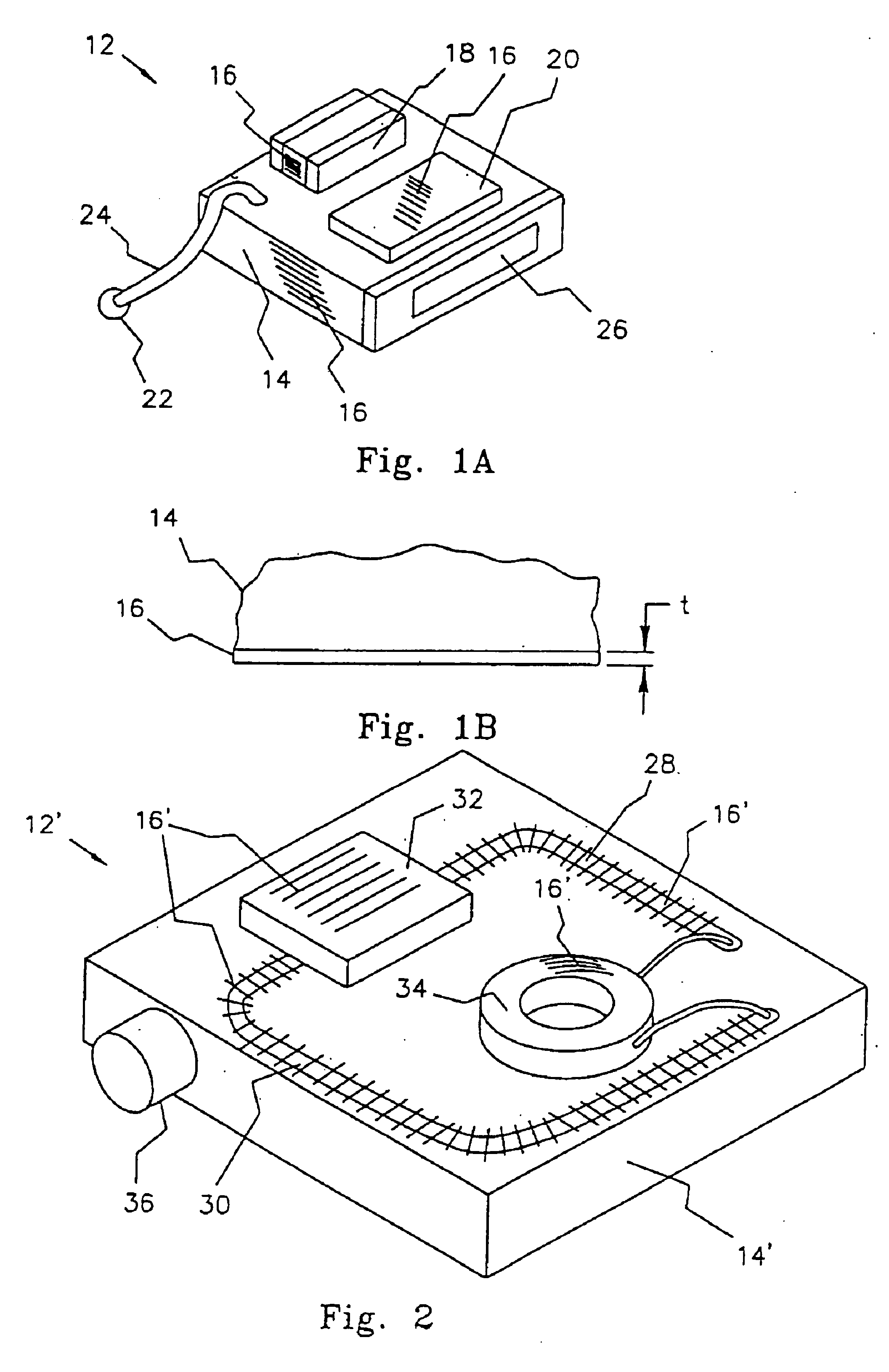

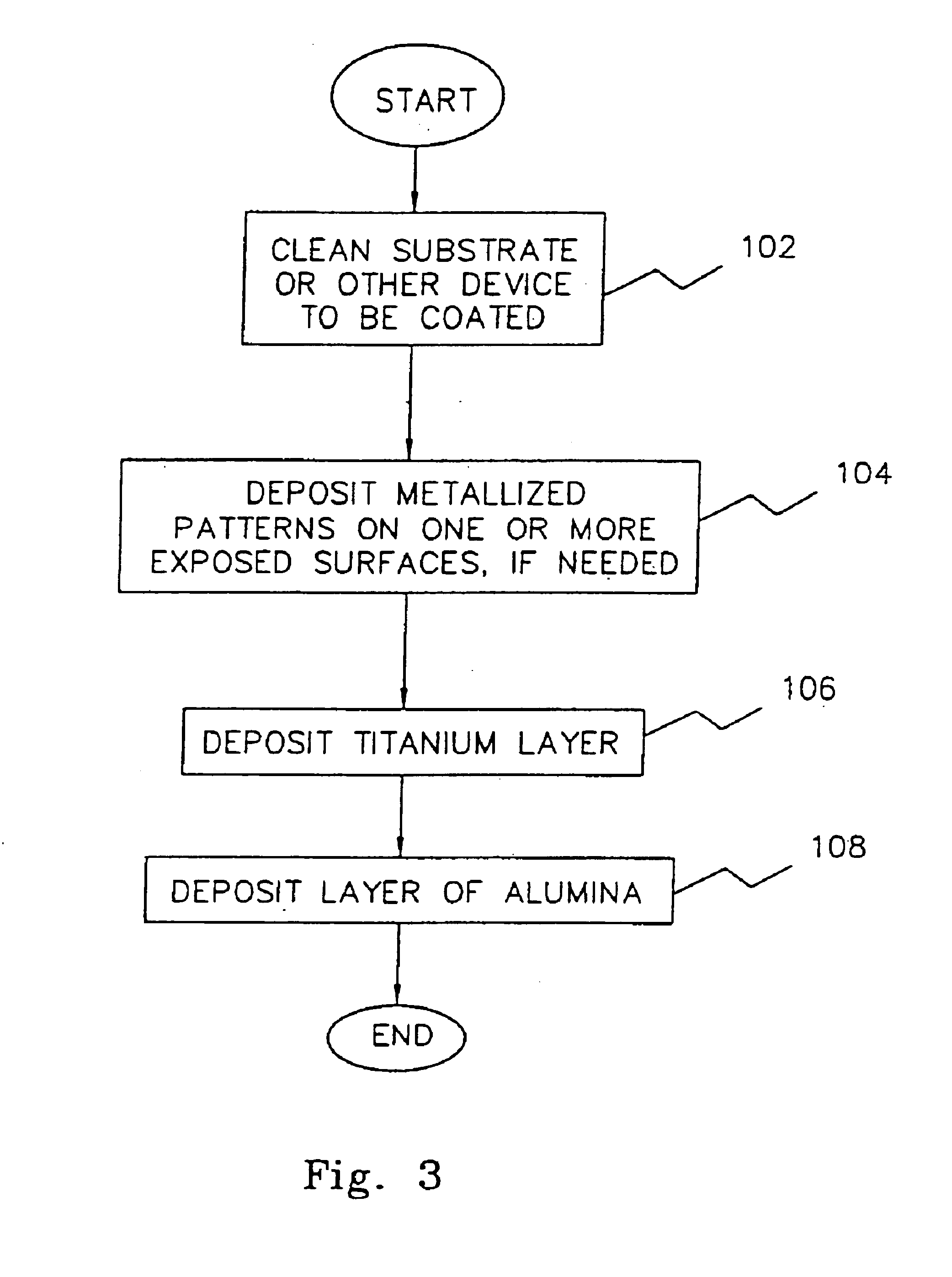

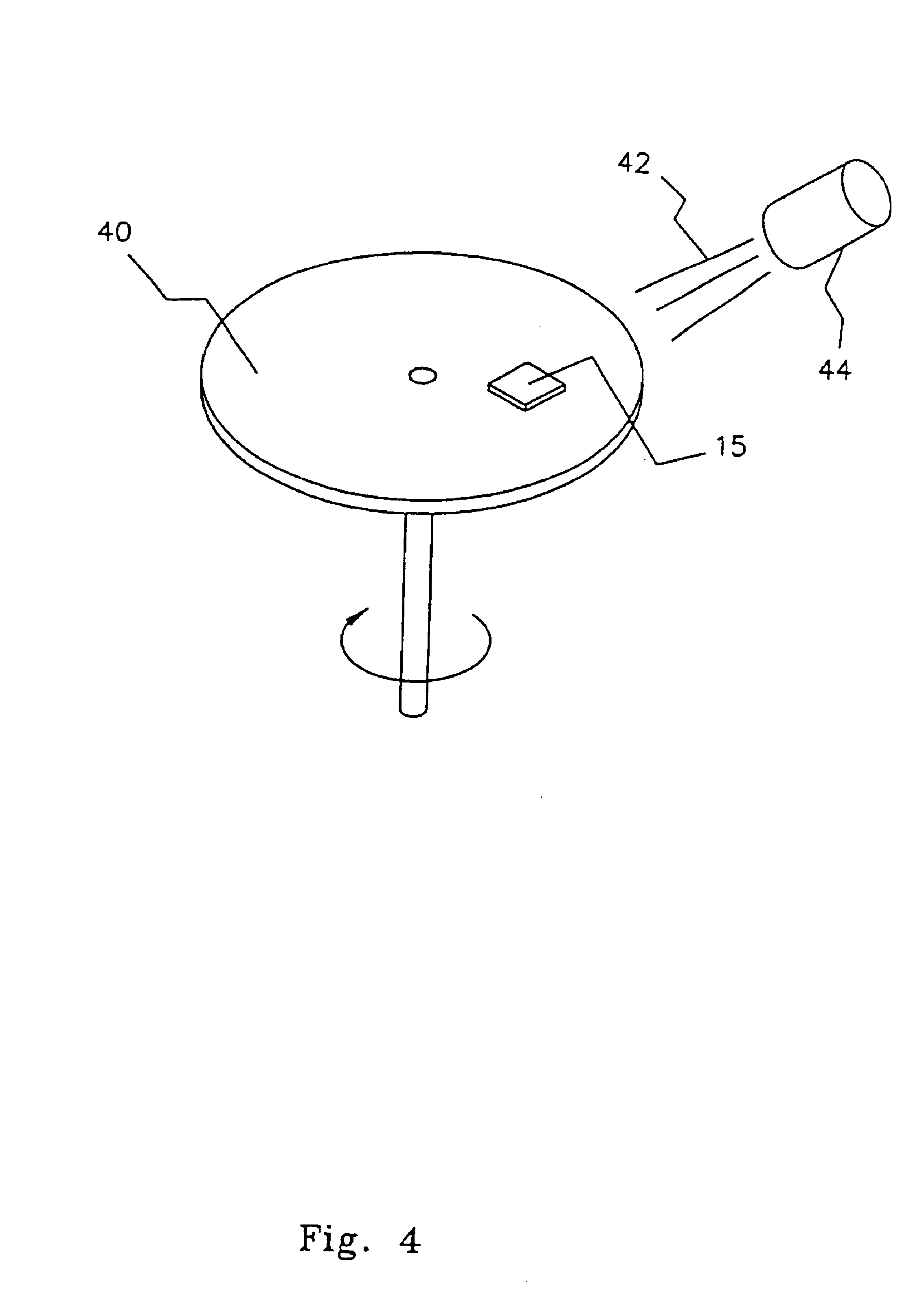

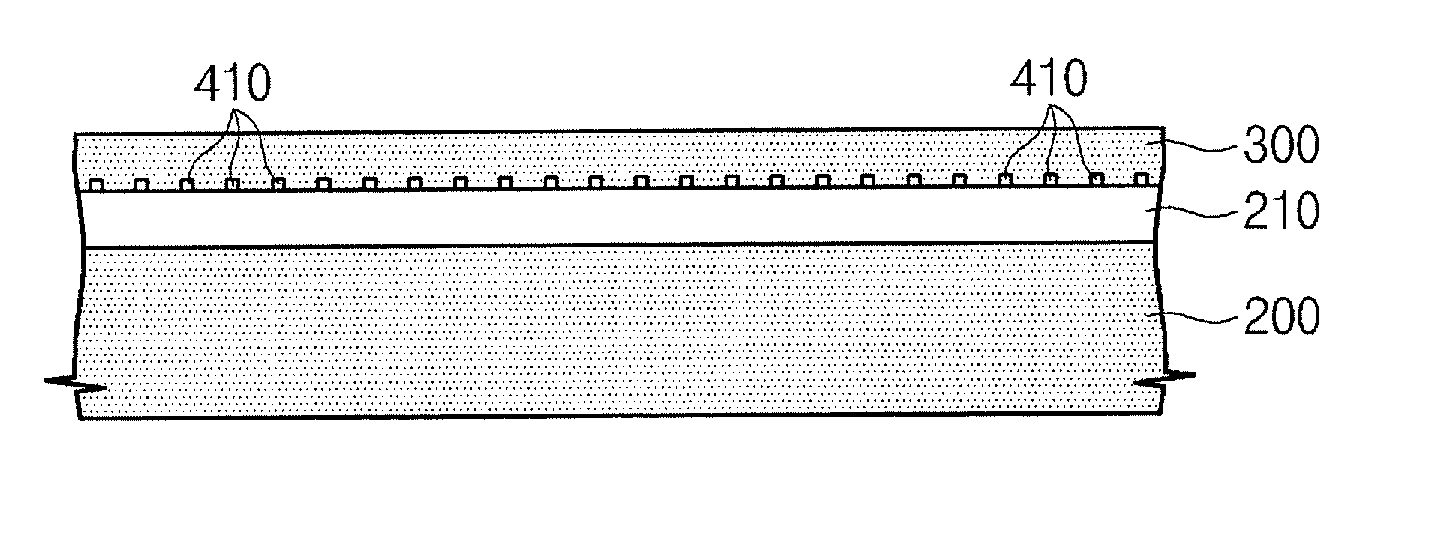

Alumina insulation for coating implantable components and other microminiature devices

InactiveUS6844023B2Efficient use ofImprove insulation performanceElectrotherapyVacuum evaporation coatingBiocompatible coatingThin layer

A protective, biocompatible coating or encapsulation material protects and insulates a component or device intended to be implanted in living tissue. The coating or encapsulation material comprises a thin layer or layers of alumina, zirconia or other ceramic, less than 25 microns thick, e.g., 5-10 microns thick. The alumina layer(s) may be applied at relatively low temperature. Once applied, the layer provides excellent hermeticity, and prevents electrical leakage. Even though very thin, the alumina layer retains excellent insulating characteristics. In one embodiment, an alumina layer less than about 6 microns thick provides an insulative coating that exhibits less than 10 pA of leakage current over an area 75 mils by 25 mils area while soaking in a saline solution at temperatures up to 80° C. over a three month period.

Owner:MEDTRONIC MIMIMED INC

Method of fabricating semiconductor wafer

InactiveUS20080213982A1Solid-state devicesSemiconductor/solid-state device manufacturingThin layerSingle crystal

Provided is a method of fabricating a semiconductor wafer. The method includes preparing a substrate wafer having a non-single-crystalline thin layer; disposing at least one single crystalline pattern adjacent to the non-single-crystalline thin layer on the substrate wafer; and forming a material layer contacting the single crystalline pattern on the non-single-crystalline thin layer.

Owner:SAMSUNG ELECTRONICS CO LTD

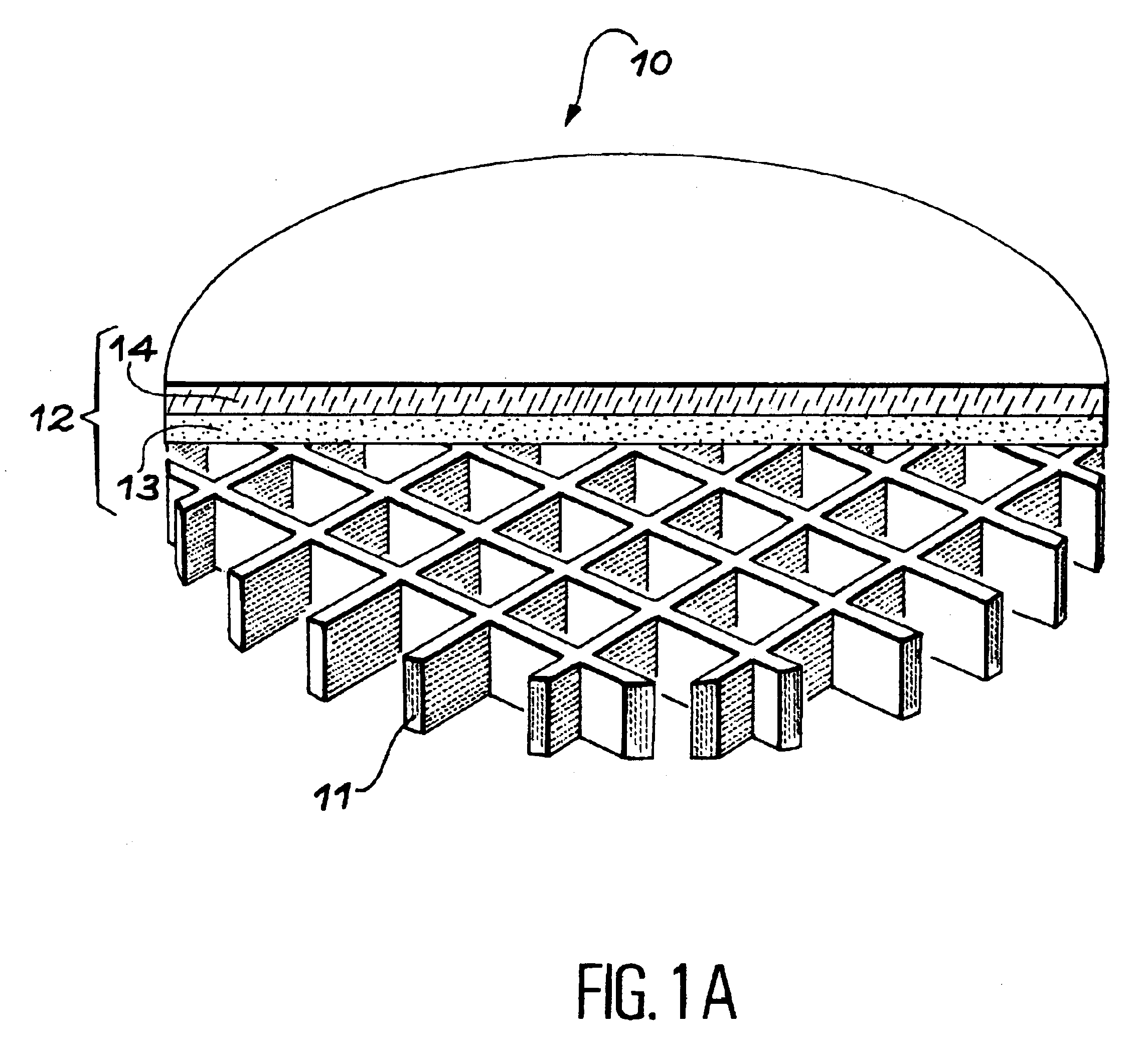

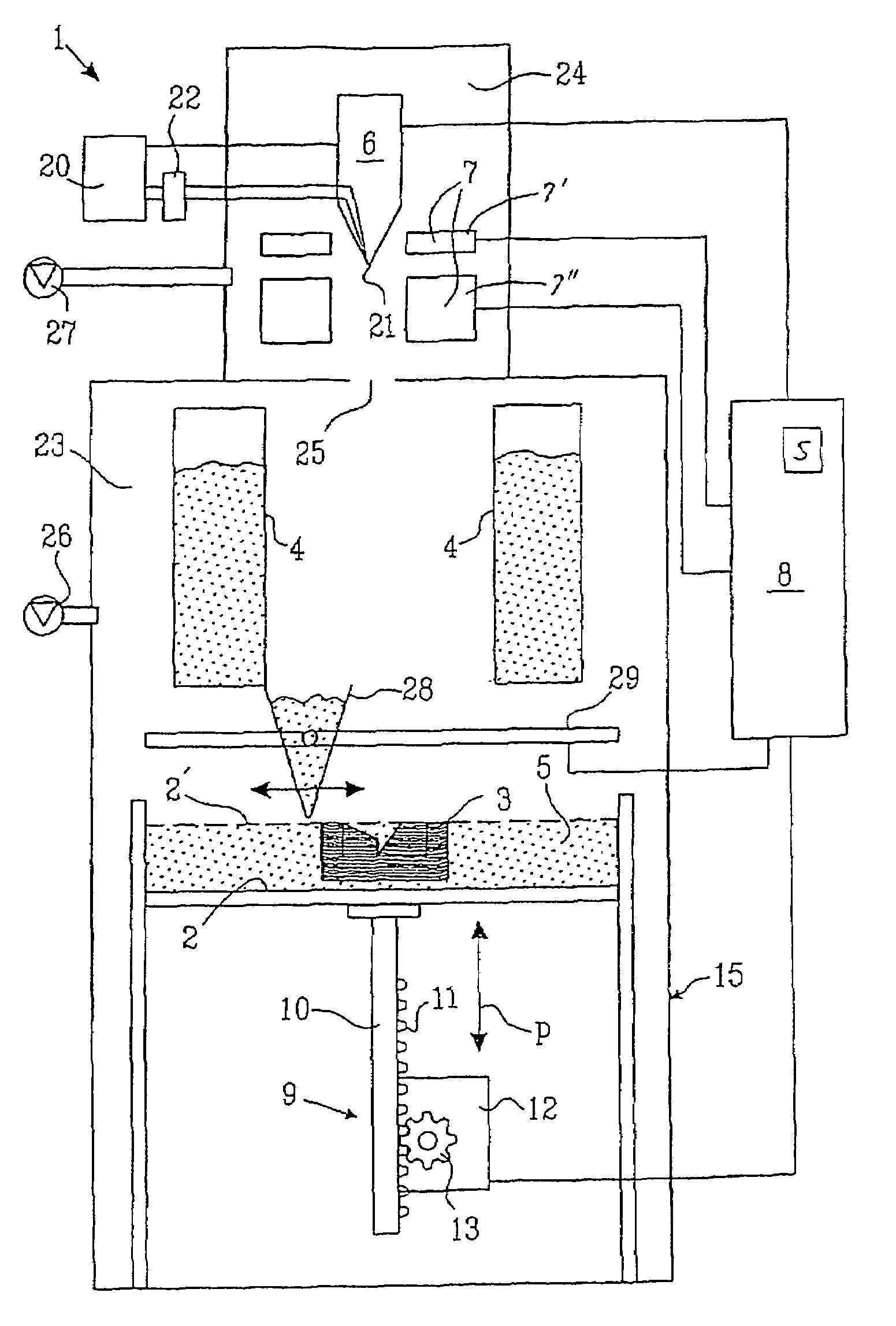

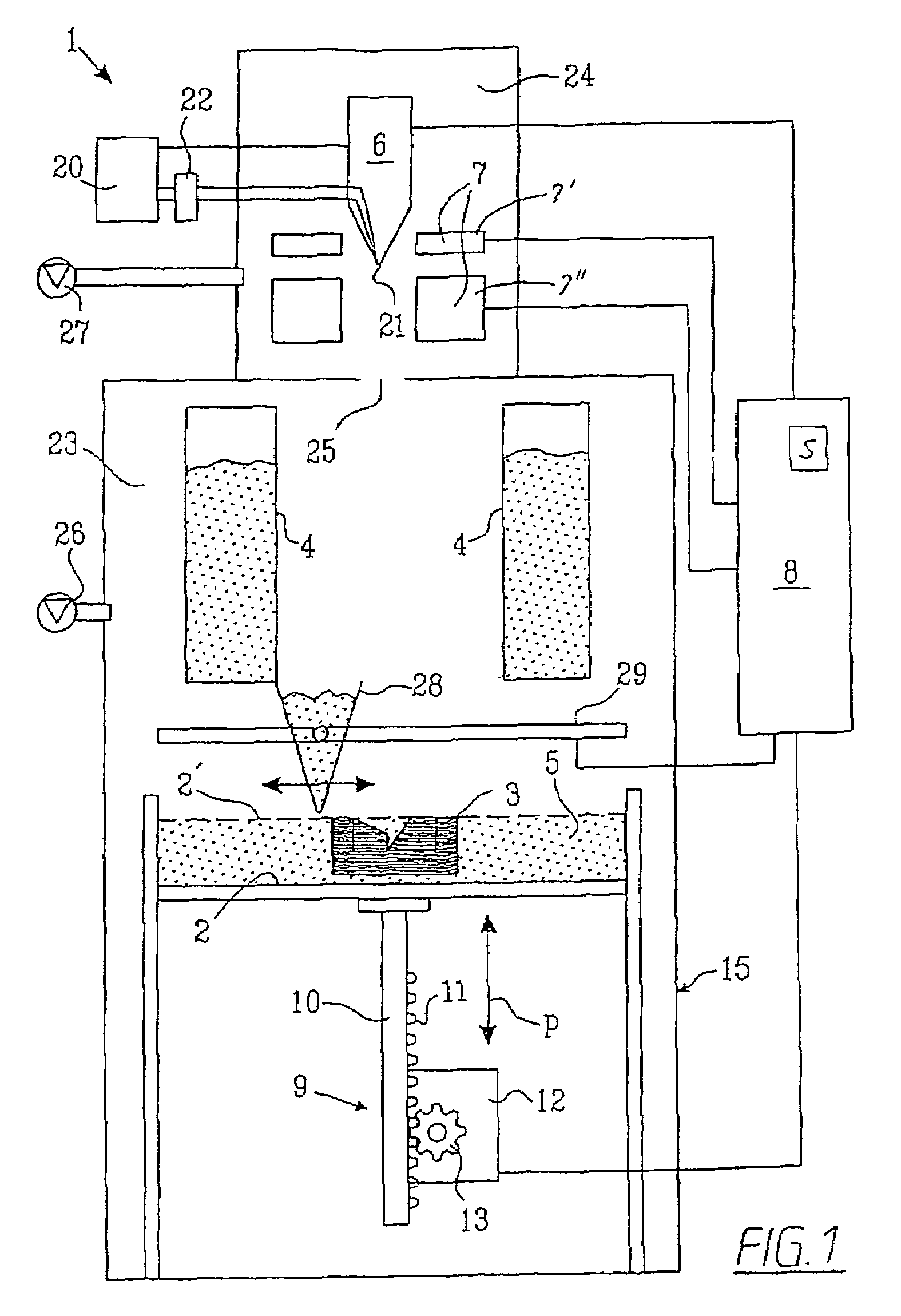

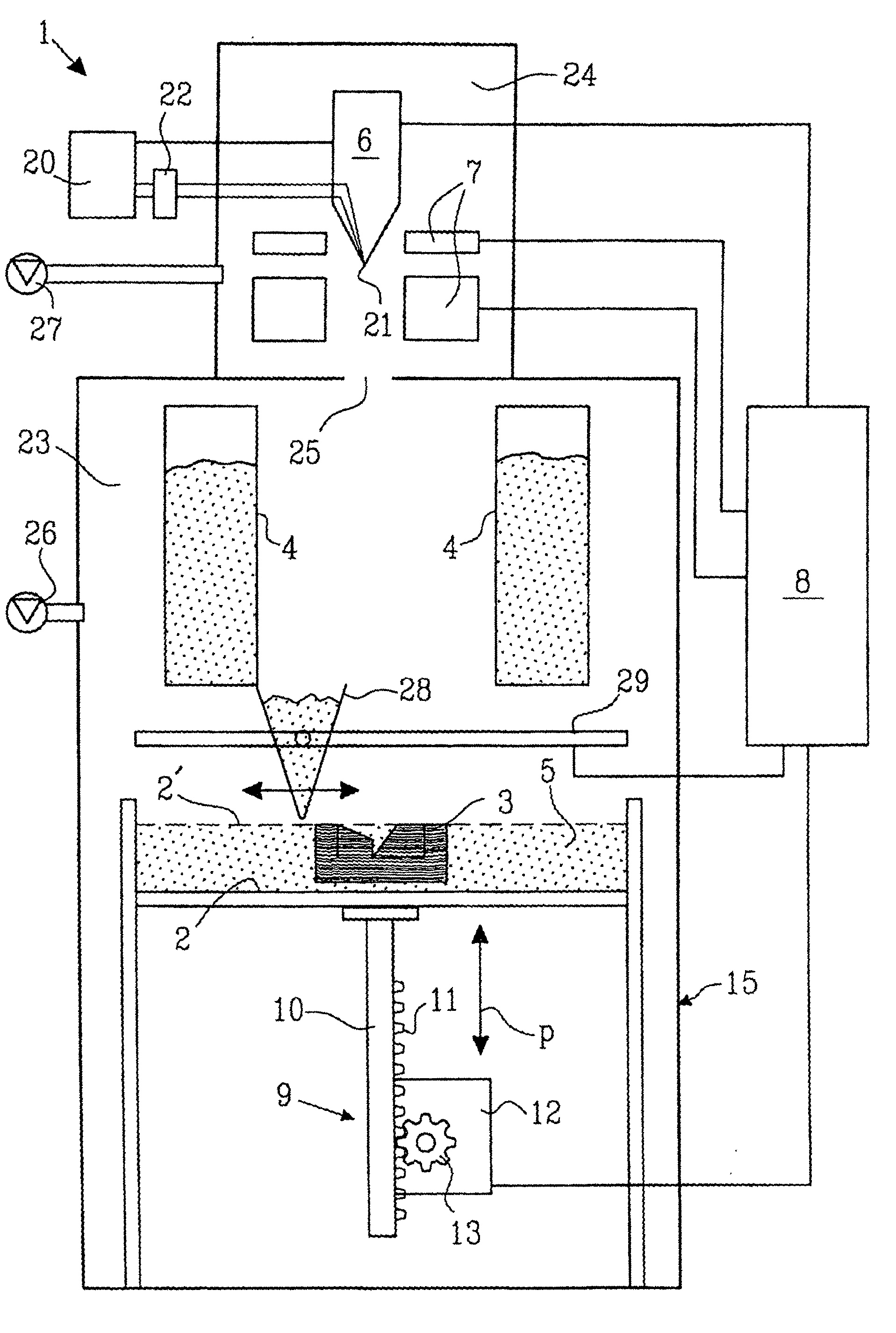

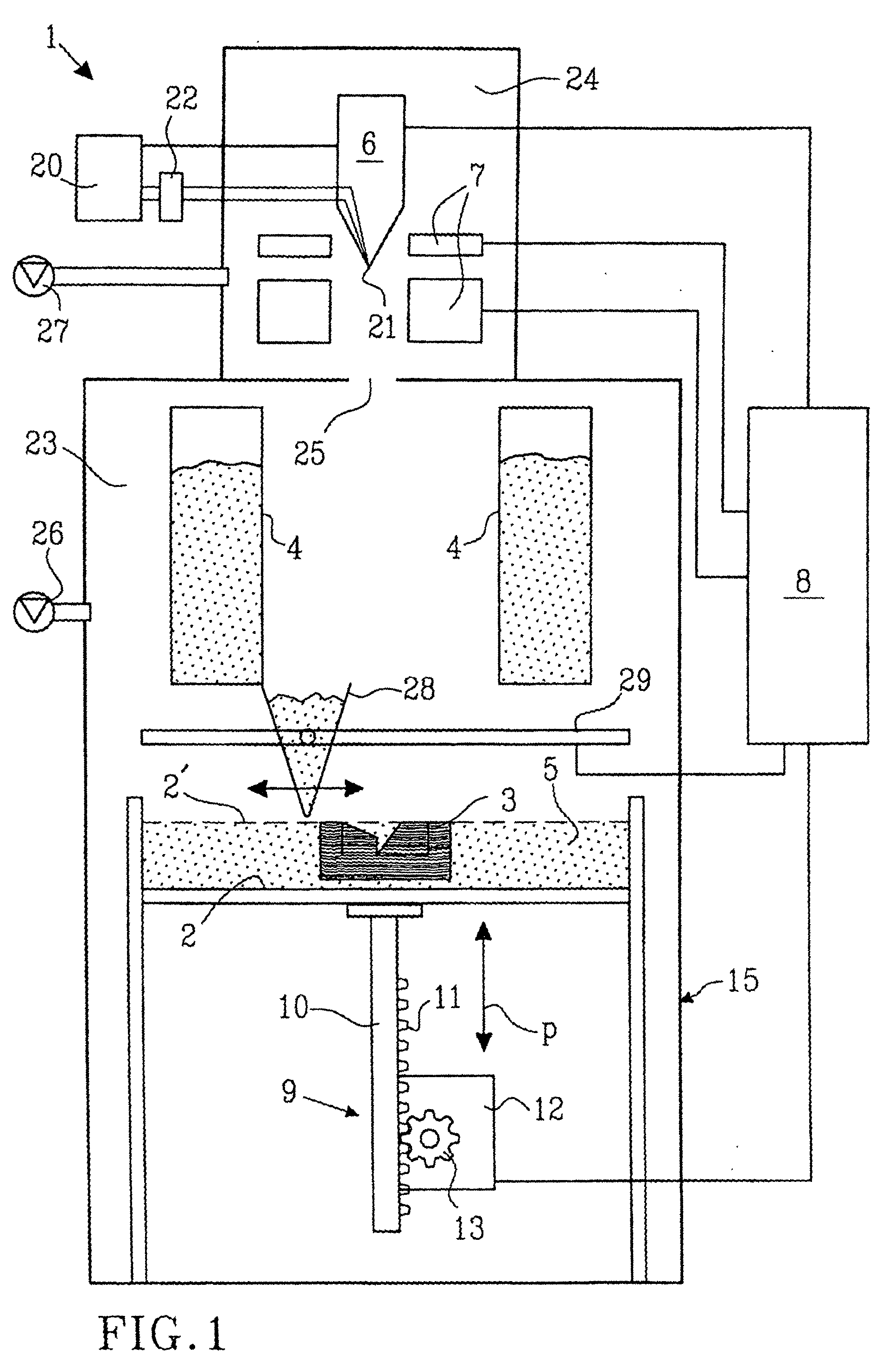

Arrangement and method for producing a three-dimensional product

Arrangement for producing a three-dimensional product, which arrangement comprises a work table on which said three-dimensional product is to be built up, a powder dispenser which is arranged so as to distribute a thin layer of powder on the work table for forming a powder bed, a radiation gun for delivering energy to the powder, fusing together of the powder then taking place, means for guiding the beam emitted by the radiation gun over said powder bed for forming a cross section of said three-dimensional product by fusing together parts of said powder bed, and a control computer in which information about successive cross sections of the three-dimensional product is stored, which cross sections build up the three-dimensional product, where the control computer is intended to control said means for guiding the radiation gun over the powder bed according to an operating scheme forming a cross section of said three-dimensional body, said three-dimensional product being formed by successive fusing together of successively formed cross sections from by the powder dispenser, and method for producing three-dimensional product using such an arrangement.

Owner:ARCAM AB

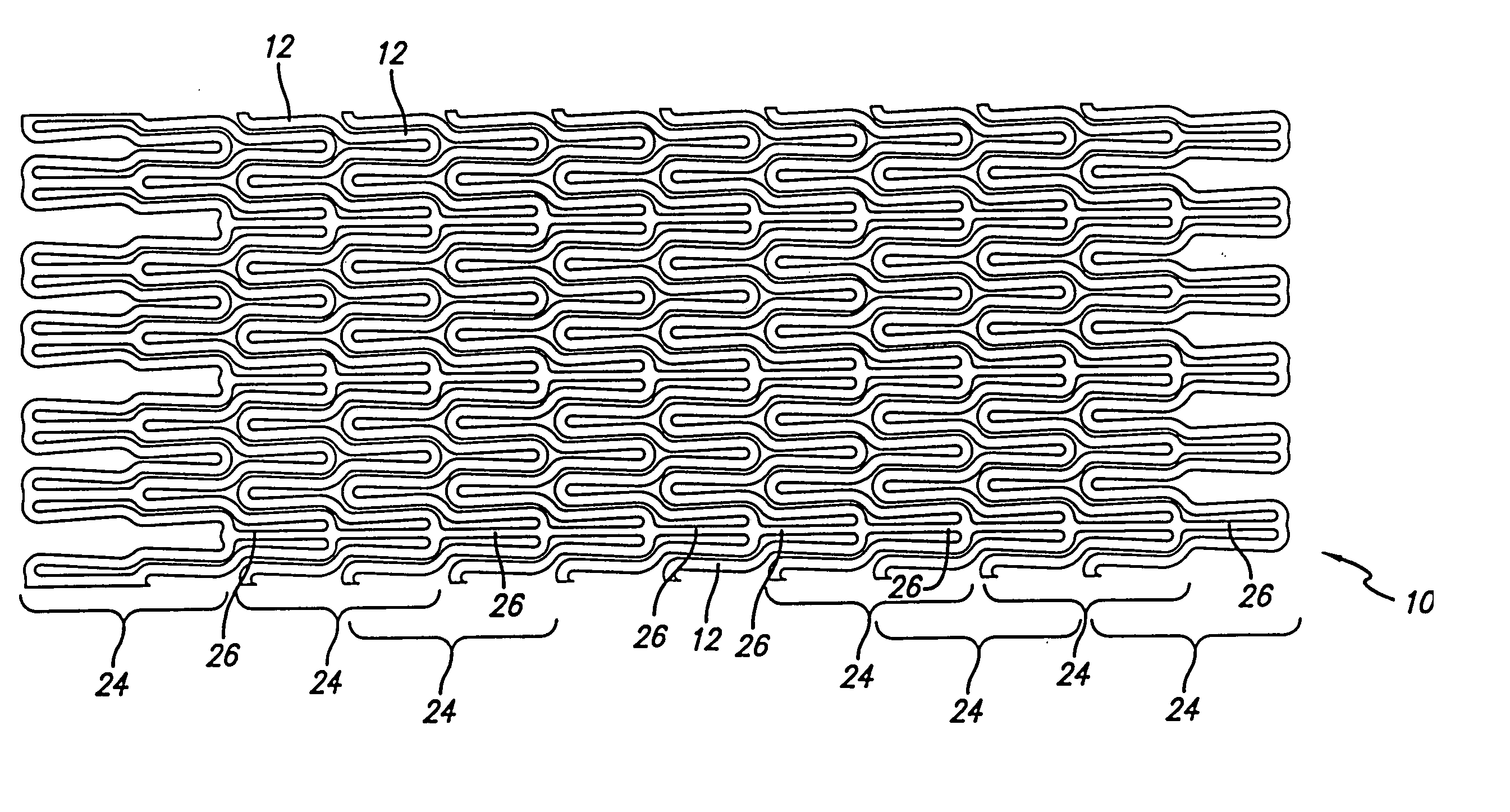

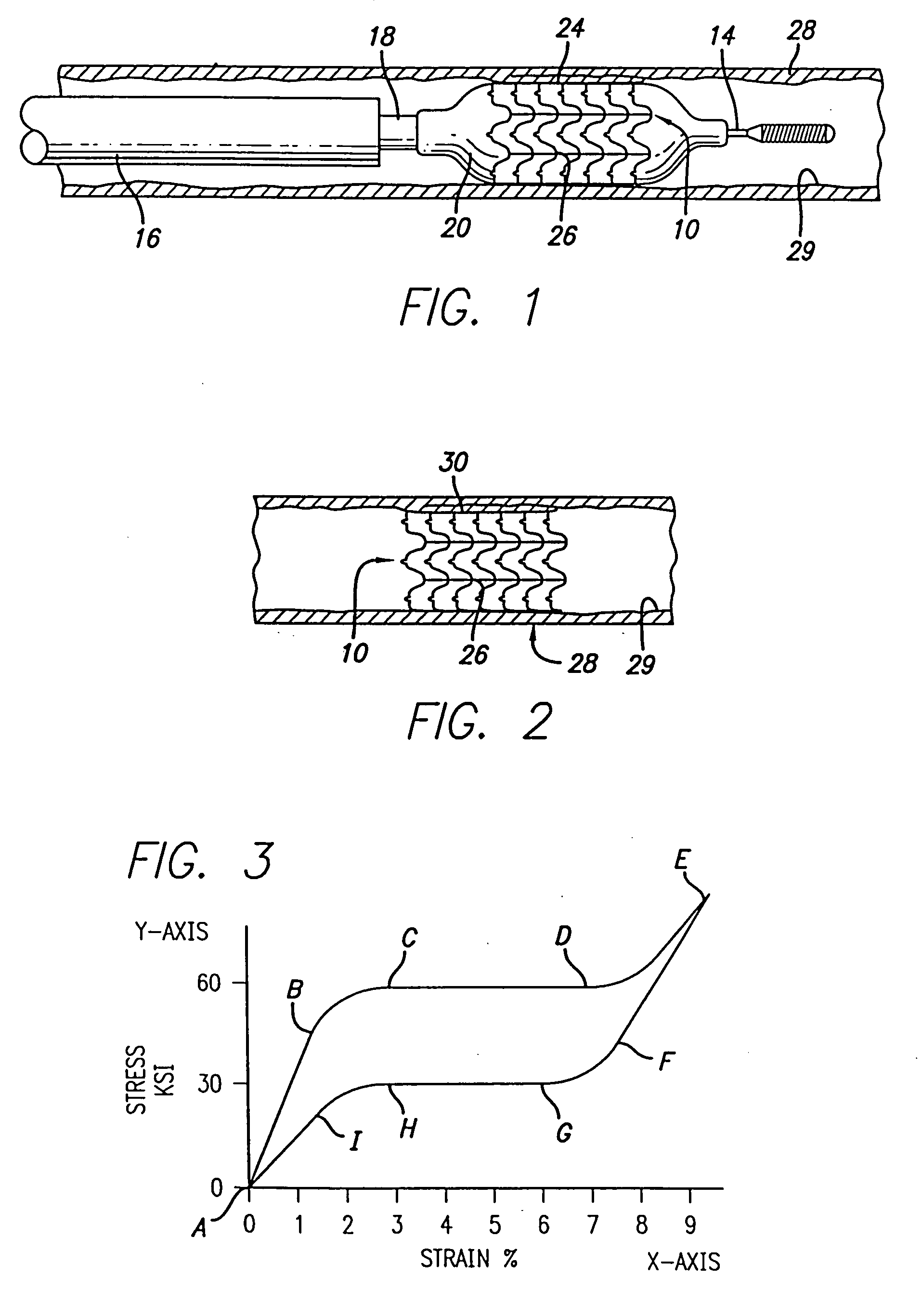

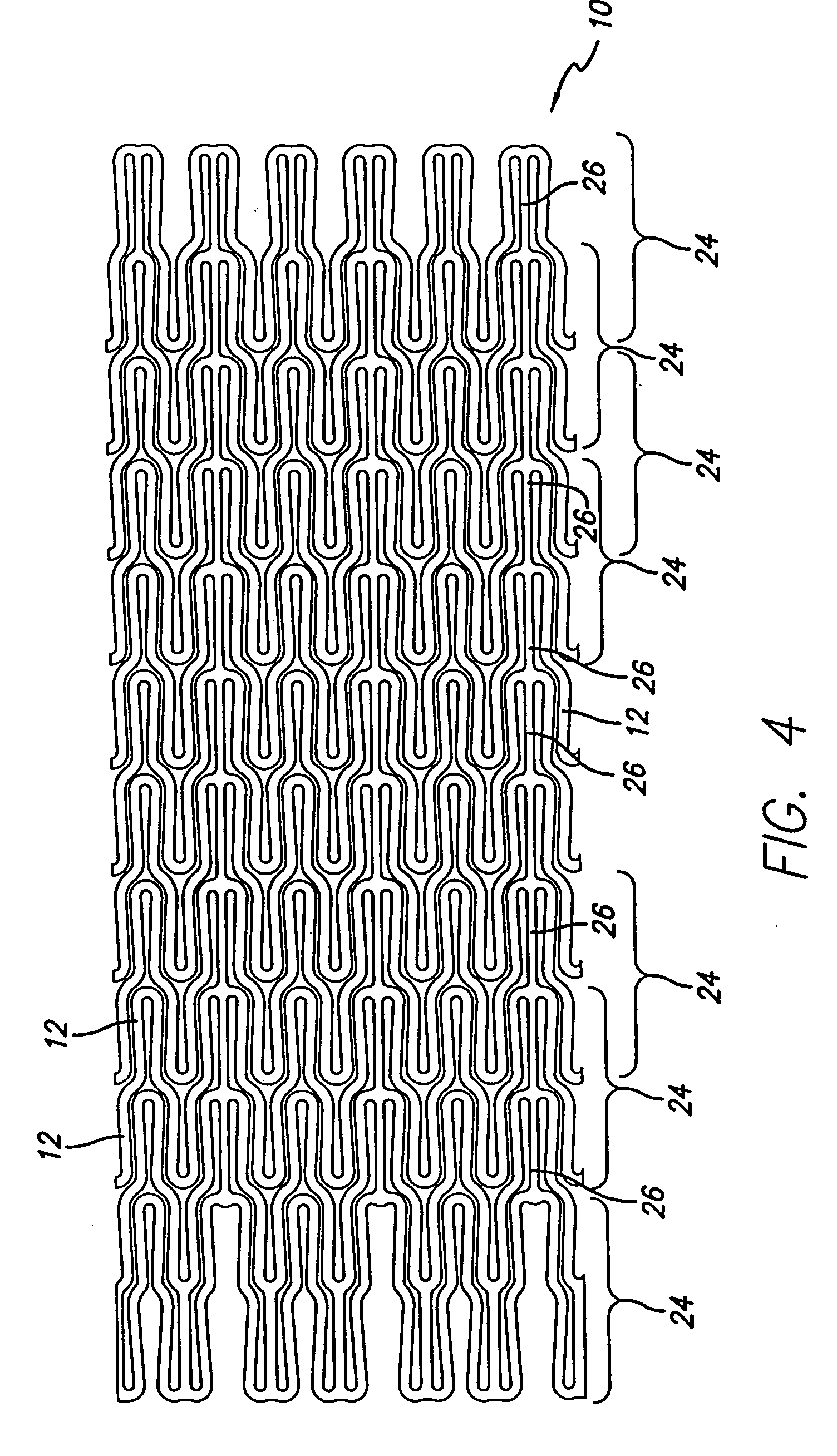

Radiopaque nitinol alloys for medical devices

Owner:ABBOTT CARDIOVASCULAR

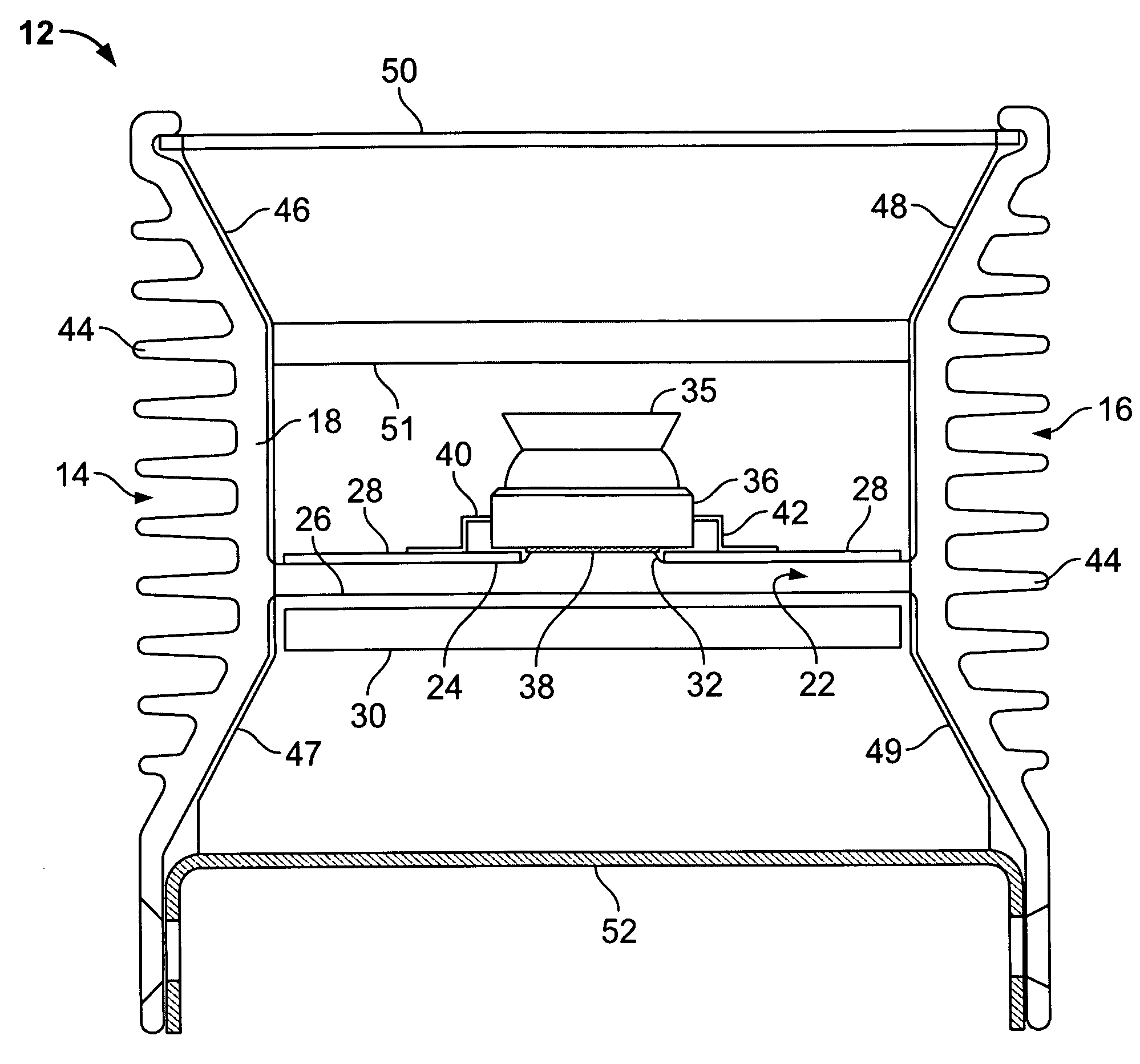

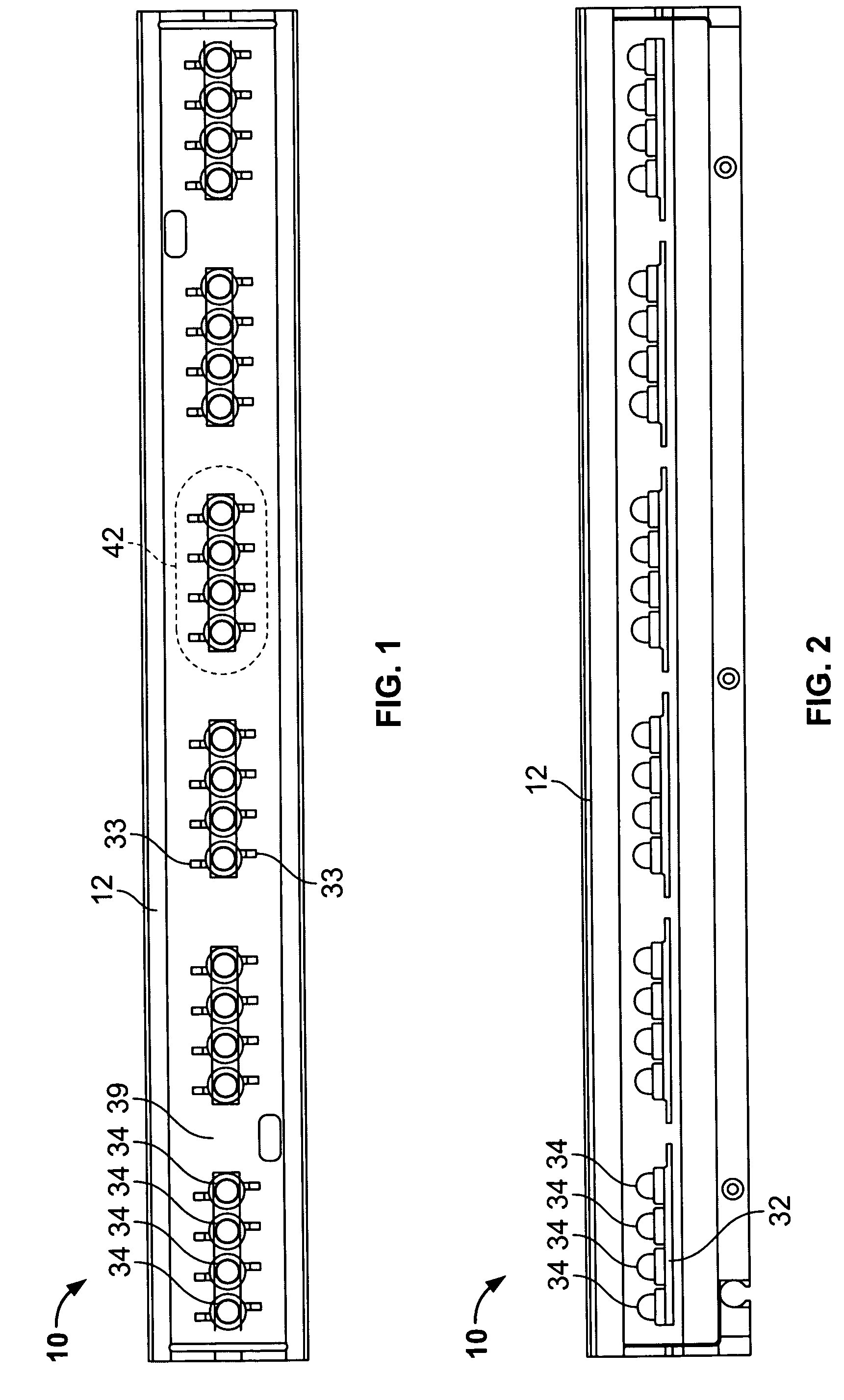

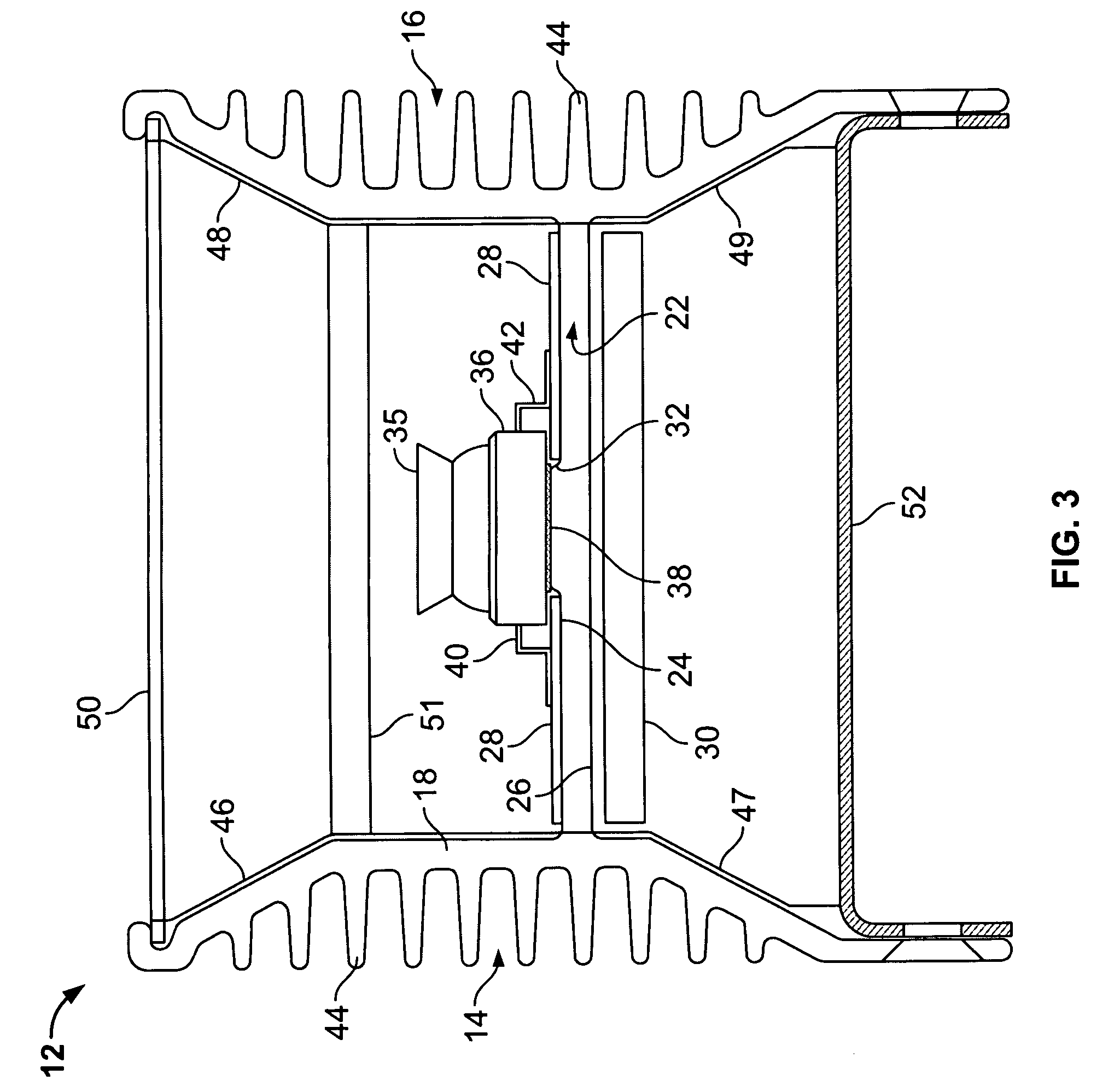

Light fixture for an LED-based aircraft lighting system

A light fixture for housing LED units is provided. The light fixture has a housing that has a substantially H-shaped cross section. The housing has a crossbar with a series of mesas defined on its upper surface. A group of LED units is attached to each of the series of mesas, each LED unit being attached with a thin layer of adhesive. The LED units are electrically insulated from the housing by either the adhesive, which may be electrically insulating, or by an electrically insulating coating on the housing.

Owner:BE AEROSPACE INCORPORATED

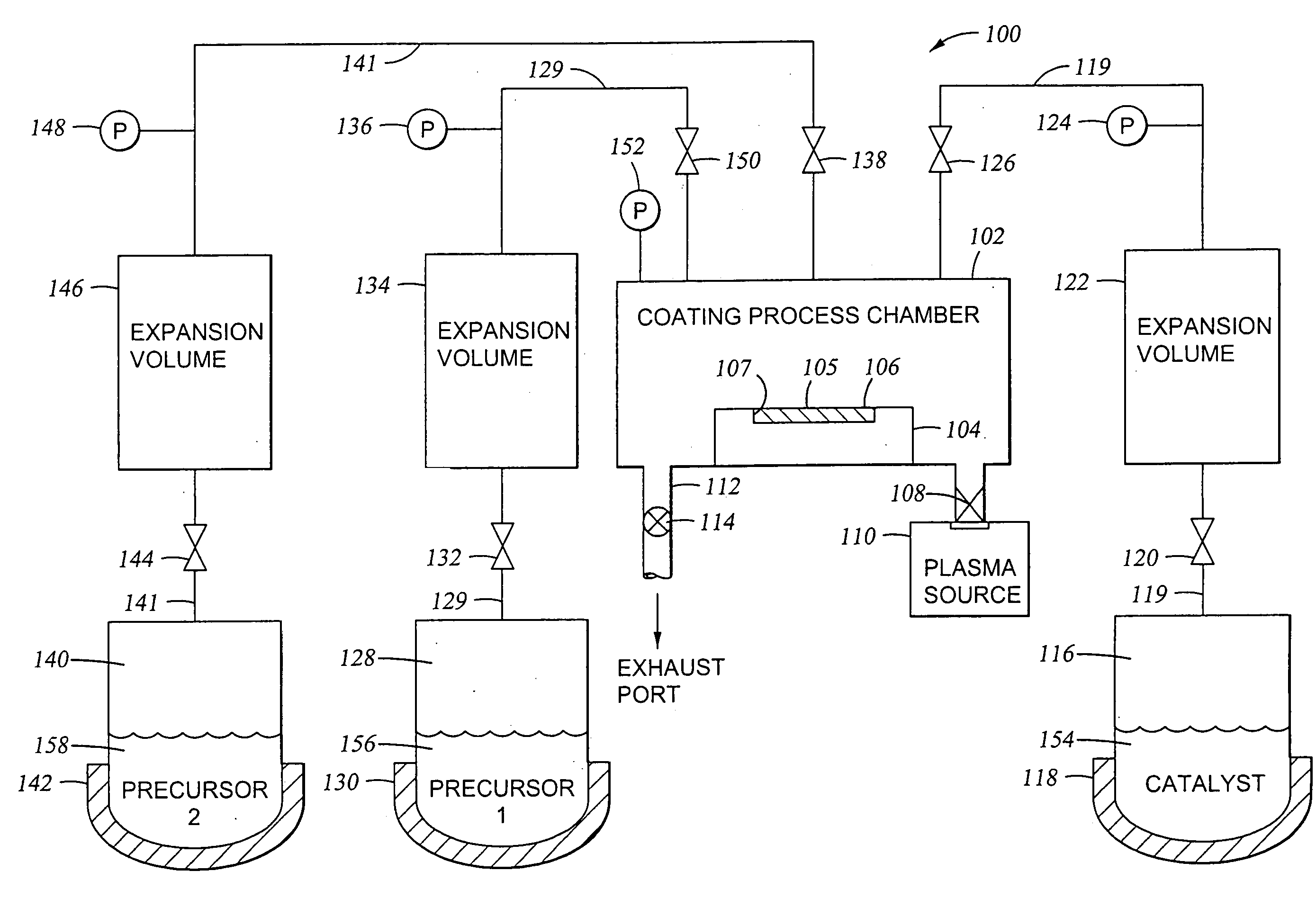

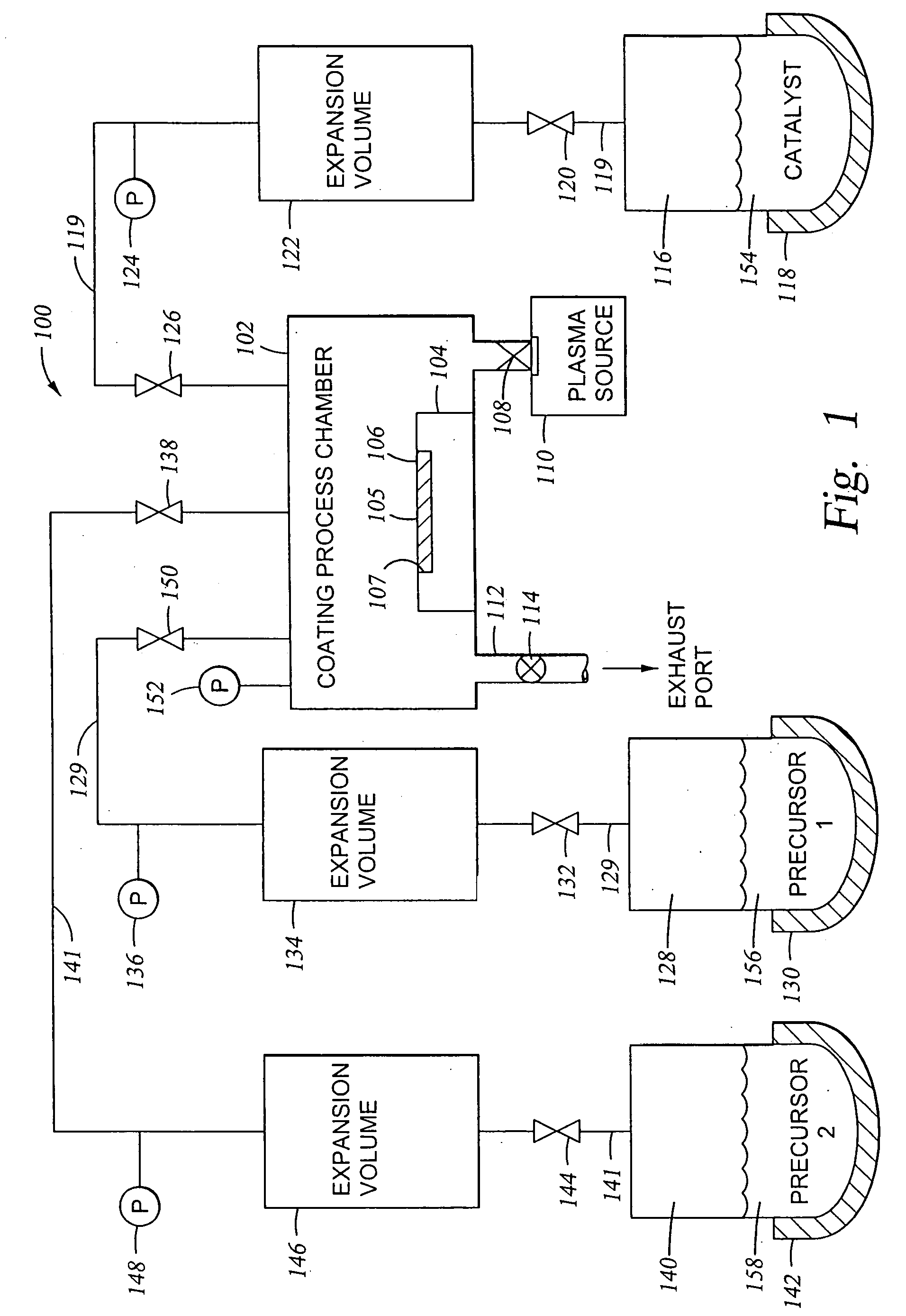

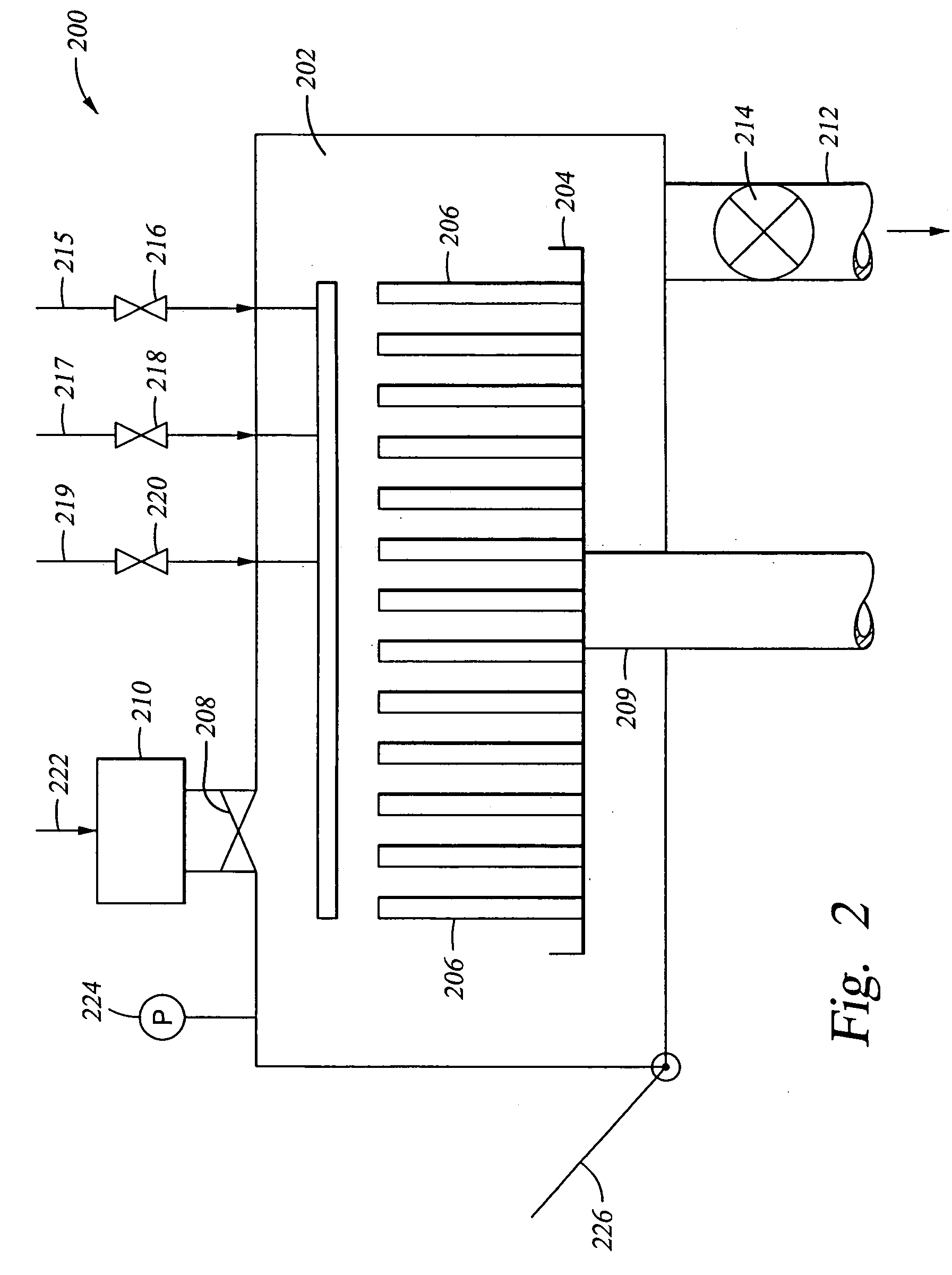

Apparatus and method for controlled application of reactive vapors to produce thin films and coatings

ActiveUS20060213441A1Highly accurate amountSimple methodMaterial nanotechnologyPretreated surfacesGas phaseThin layer

A vapor phase deposition method and apparatus for the application of thin layers and coatings on substrates. The method and apparatus are useful in the fabrication of electronic devices, micro-electromechanical systems (MEMS), Bio-MEMS devices, micro and nano imprinting lithography, and microfluidic devices. The apparatus used to carry out the method provides for the addition of a precise amount of each of the reactants to be consumed in a single reaction step of the coating formation process. The apparatus provides for precise addition of quantities of different combinations of reactants during a single step or when there are a number of different individual steps in the coating formation process. The precise addition of each of the reactants in vapor form is metered into a predetermined set volume at a specified temperature to a specified pressure, to provide a highly accurate amount of reactant.

Owner:JEFFREY D CHINN & ROMUALD NOWAK +1

Device and arrangement for producing a three-dimensional object

InactiveUS20040026807A1Reduced form requirementsSmall sizeConfectioneryWood working apparatusThin layerRunning time

A device for manufacturing a three-dimensional product, which device comprises a work table on which said three-dimensional product is to be built, a powder dispenser which is arranged to lay down a thin layer of powder on the work table for the formation of a powder bed, a ray gun for giving off energy to the powder whereby fusion of the powder takes place, members for controlling of the beam released by the ray gun across said powder bed for the formation of a cross section of said three-dimensional product through fusion of parts of said powder bed, and a controlling computer in which information about successive cross sections of the three-dimensional product is stored, which cross sections build the three-dimensional product, the controlling computer intended to control said members for guiding the ray gun across the powder bed according to a running schedule forming a cross section of said three-dimensional body, whereby said three-dimensional product is formed by successive fusion of successively formed cross sections from powder layers successively laid down by the powder dispenser.

Owner:ARCAM AB

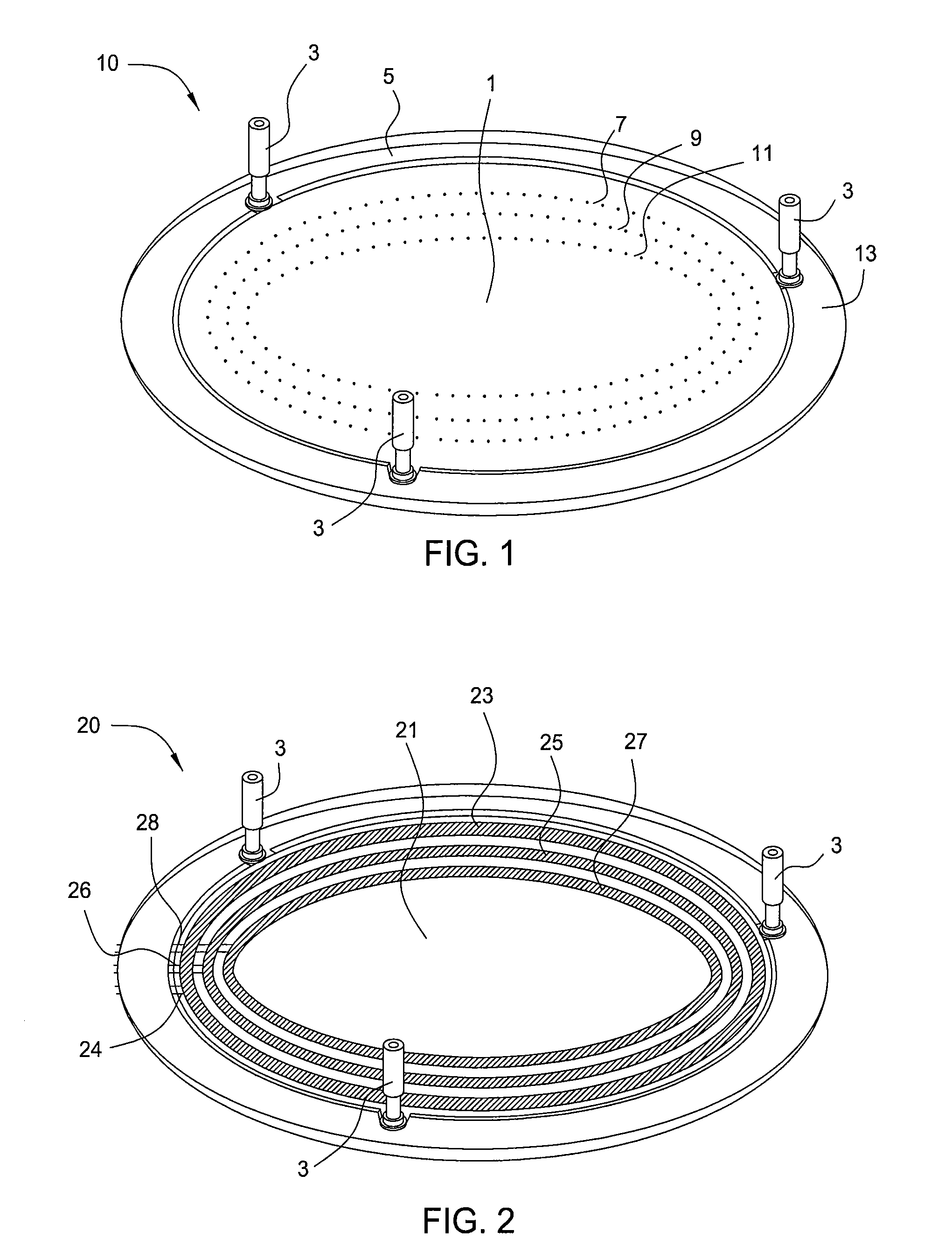

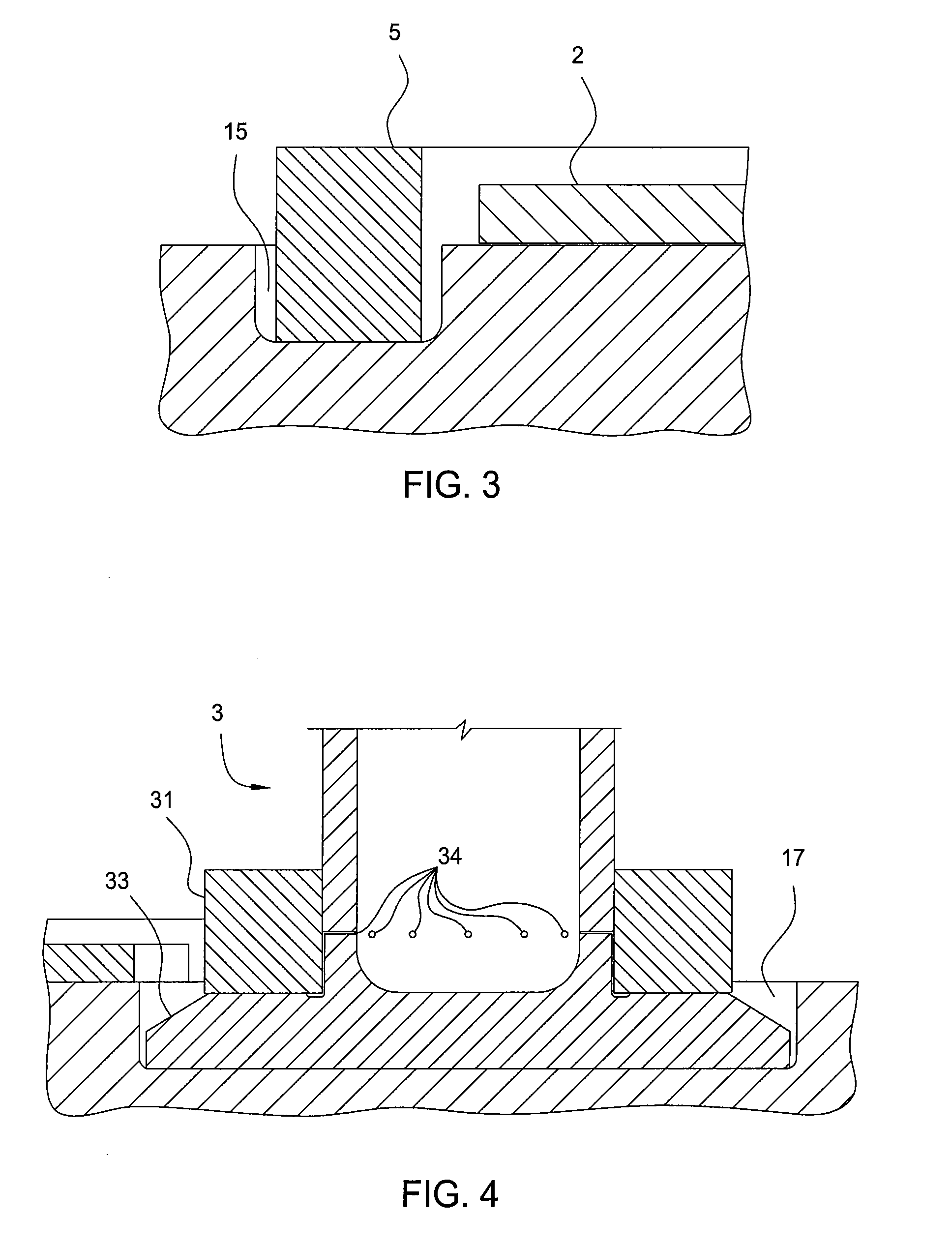

Apparatus and method for supporting, positioning and rotating a substrate in a processing chamber

ActiveUS20080276864A1Increase pressureReduce stressLiquid surface applicatorsSemiconductor/solid-state device manufacturingAir bearingThin layer

An apparatus and method for supporting, positioning and rotating a substrate are provided. In one embodiment, a support assembly for supporting a substrate includes an upper base plate and a lower base plate. The substrate is floated on a thin layer of air over the upper base plate. A positioning assembly includes a plurality of air bearing edge rollers or air flow pockets used to position the substrate in a desired orientation inside above the upper base plate. A plurality of slanted apertures or air flow pockets are configured in the upper base plate for flowing gas therethrough to rotate the substrate to ensure uniform heating during processing.

Owner:APPLIED MATERIALS INC

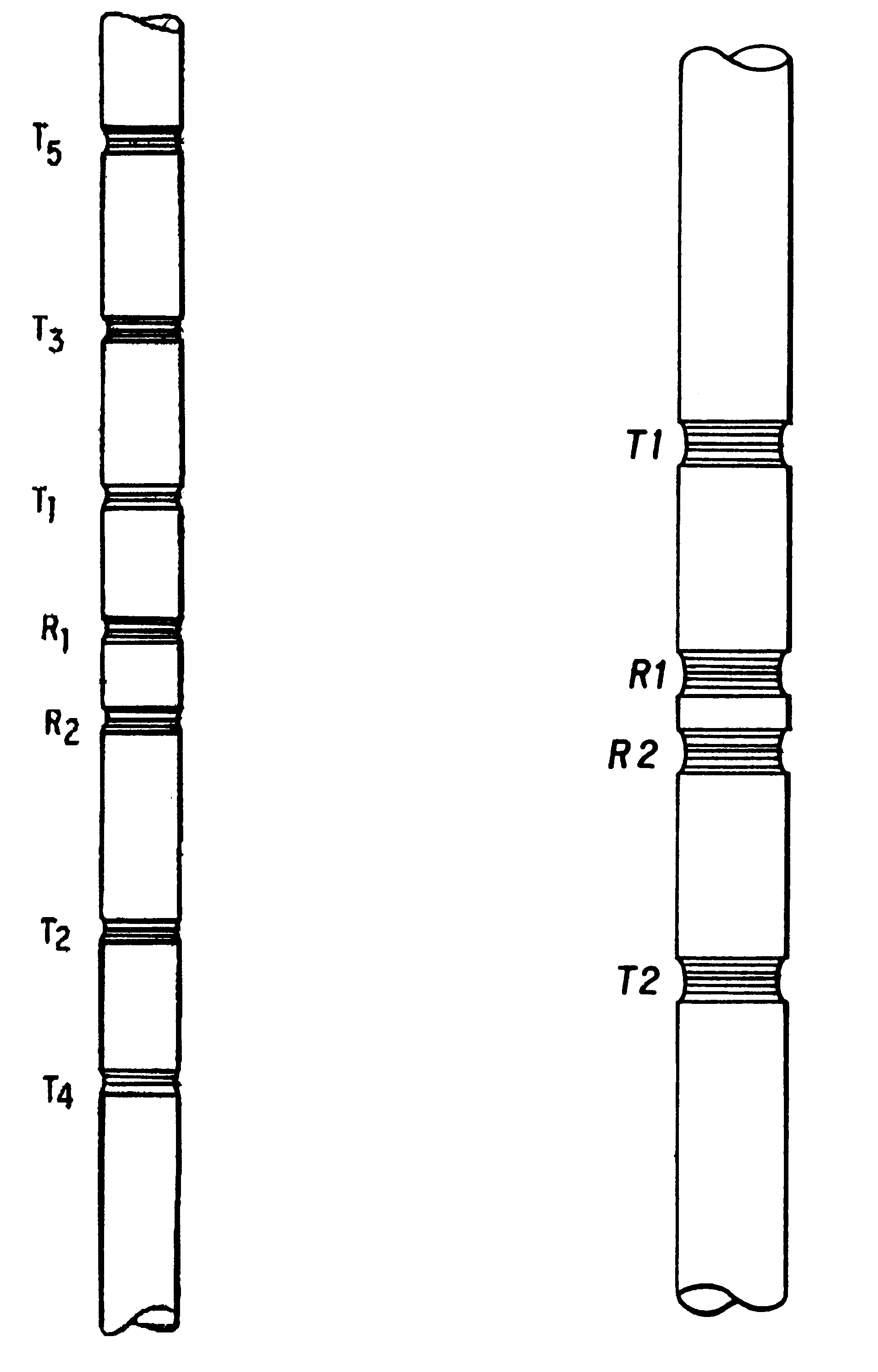

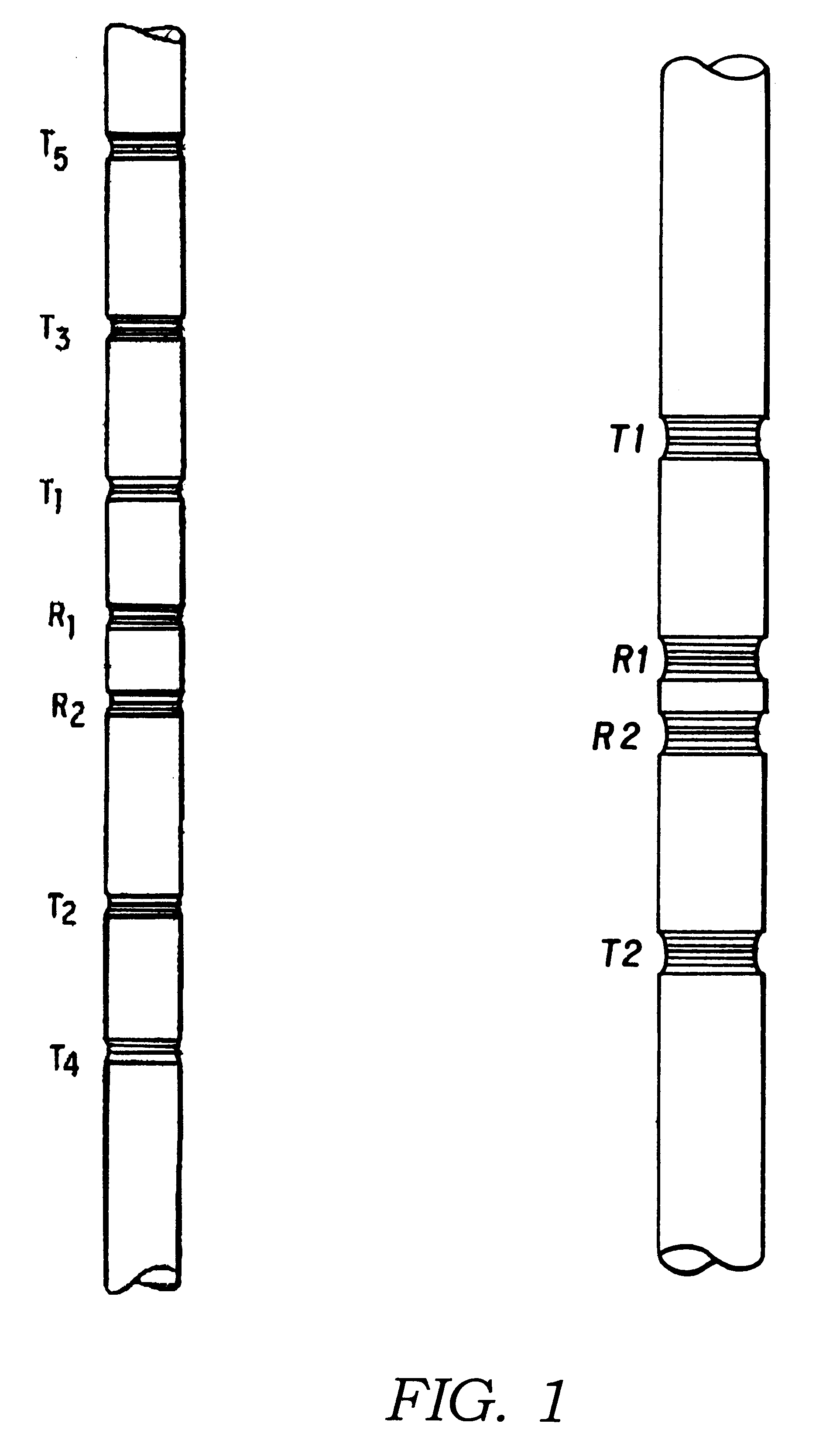

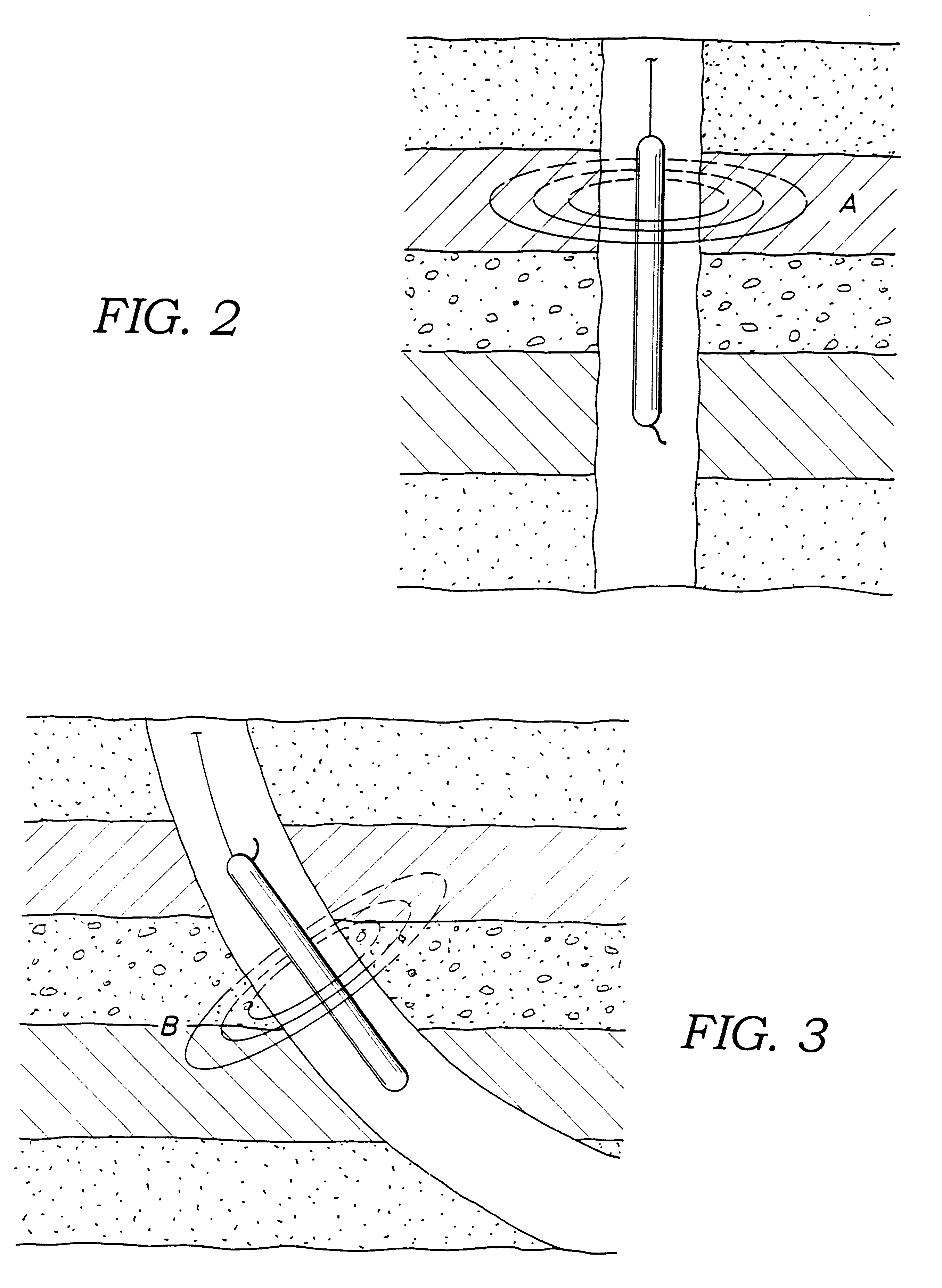

Method and apparatus for evaluating the resistivity of formations with high dip angles or high-contrast thin layers

InactiveUS6304086B1Electric/magnetic detection for well-loggingSeismology for water-loggingWell loggingThin layer

A method and apparatus for evaluating the resistivity of earth formations surrounding a borehole, particularly high-contrast thin-layer formations or at high dip angles. The method involves positioning a pair of transmitters and a pair of receivers within the borehole, the receivers or transmitters adhering to specific spacing limitations, alternately transmitting electromagnetic energy of a particular frequency and receiving voltage data associated with the transmitted energy. Multiple voltage data are acquired and a representation of a resistivity or conductivity profile is created from a formulated difference of the data from a particular depth and / or neighboring depths. The apparatus forms part of a well logging system including a well tool adapted to be moveable through a borehole. The apparatus being coupled to the well tool and adapted with means to input voltage data developed by the receivers disposed on the well tool. The apparatus further adapted with means for performing calculations to determine a conductivity profile and for recording the profile on an output record medium.

Owner:SCHLUMBERGER TECH CORP

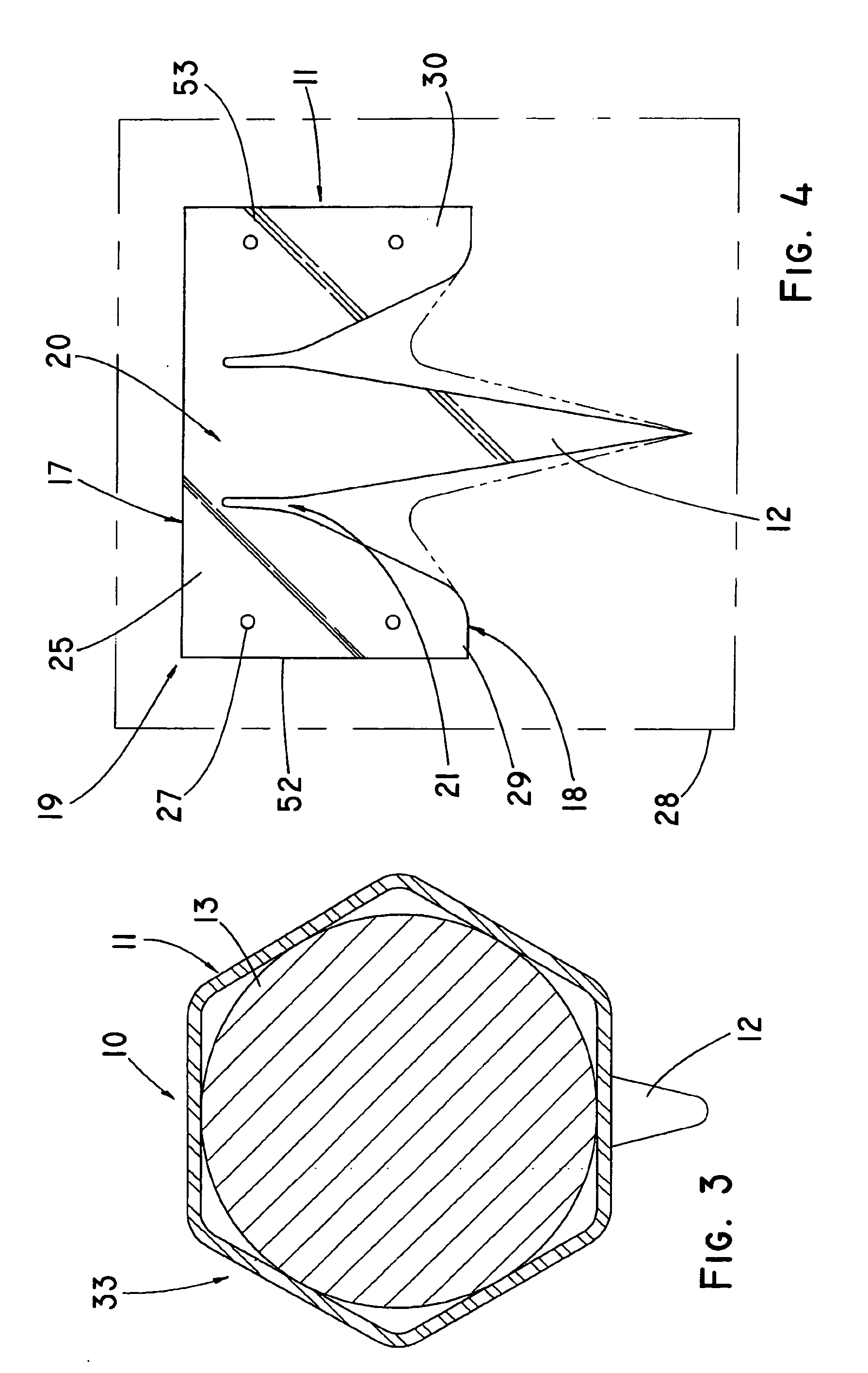

Anchoring barb for attachment to a medical prosthesis

ActiveUS20050240259A1Limited extentLimit longitudinal movementStentsBlood vesselsThin layerSpot welding

Disclosed is an anchoring element for an implantable prosthesis that includes a barb, wherein the anchoring element, which includes a basal portion, comprises a thin layer of material, such as a cannula or sheet of metal, that extends or wraps at least partially around the strut of the prosthesis to which it is attached. The barb is configured to extend outward from the basal portion to penetrate adjacent tissue. The anchoring element is either permanently affixed to the strut, such as by laser or spot welding, crimping, or some other method of bonding, or allowed to slide longitudinally over the strut between two points or stops in order to relieve any excessive loads placed upon the barb that could cause fracture. The anchoring element and strut may be configured to limit axial rotation of the barb, while still allowing longitudinal movement. In another embodiment, the slidable anchoring element may be manipulated following initial deployment to reorient the barb toward the implantation site.

Owner:COOK MEDICAL TECH LLC

Depositing thin layer of material on permeable substrate

InactiveUS20120213947A1Avoid excessive heightSpecial surfacesChemical vapor deposition coatingThin layerChemistry

Owner:VEECO ALD

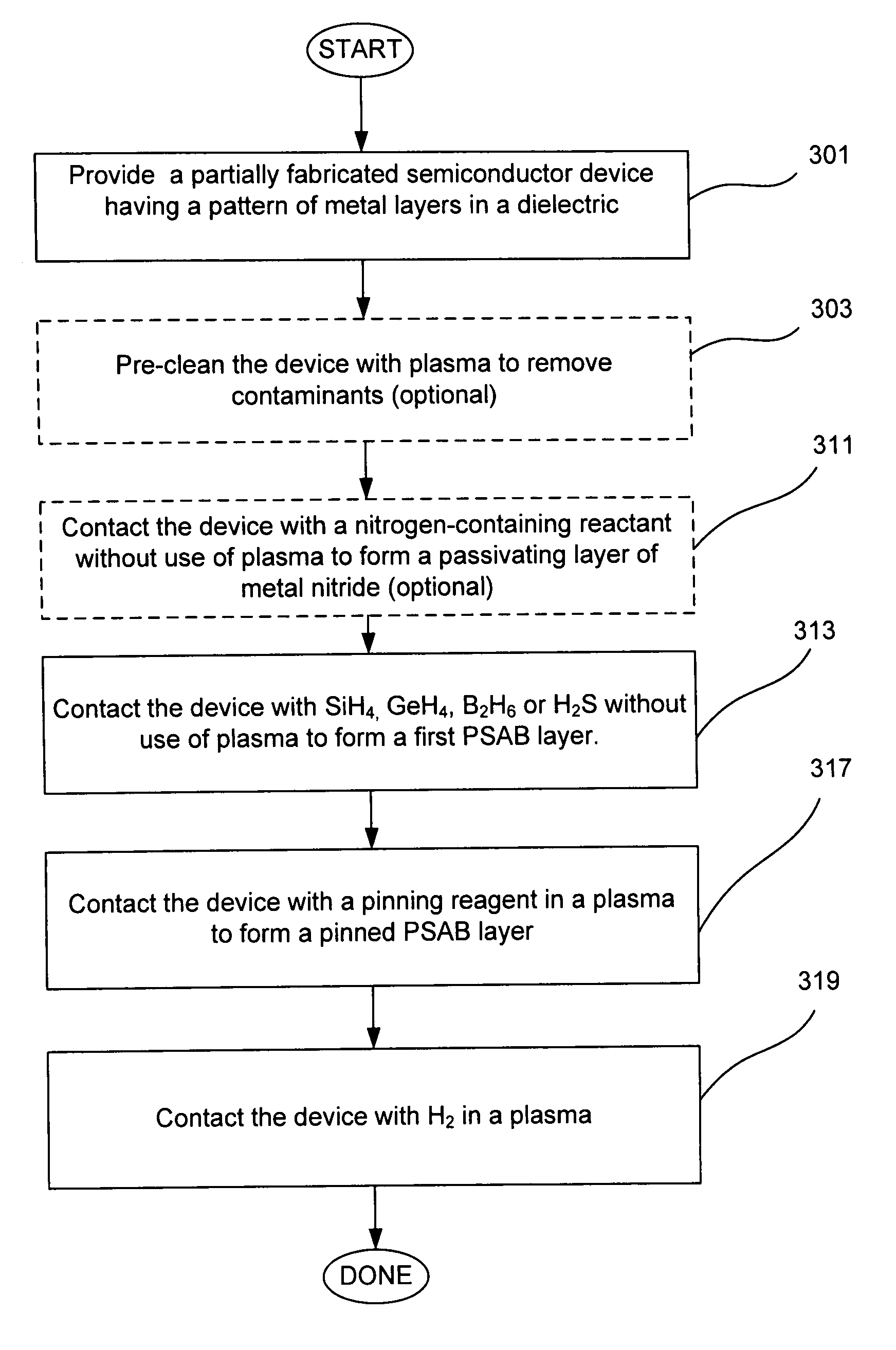

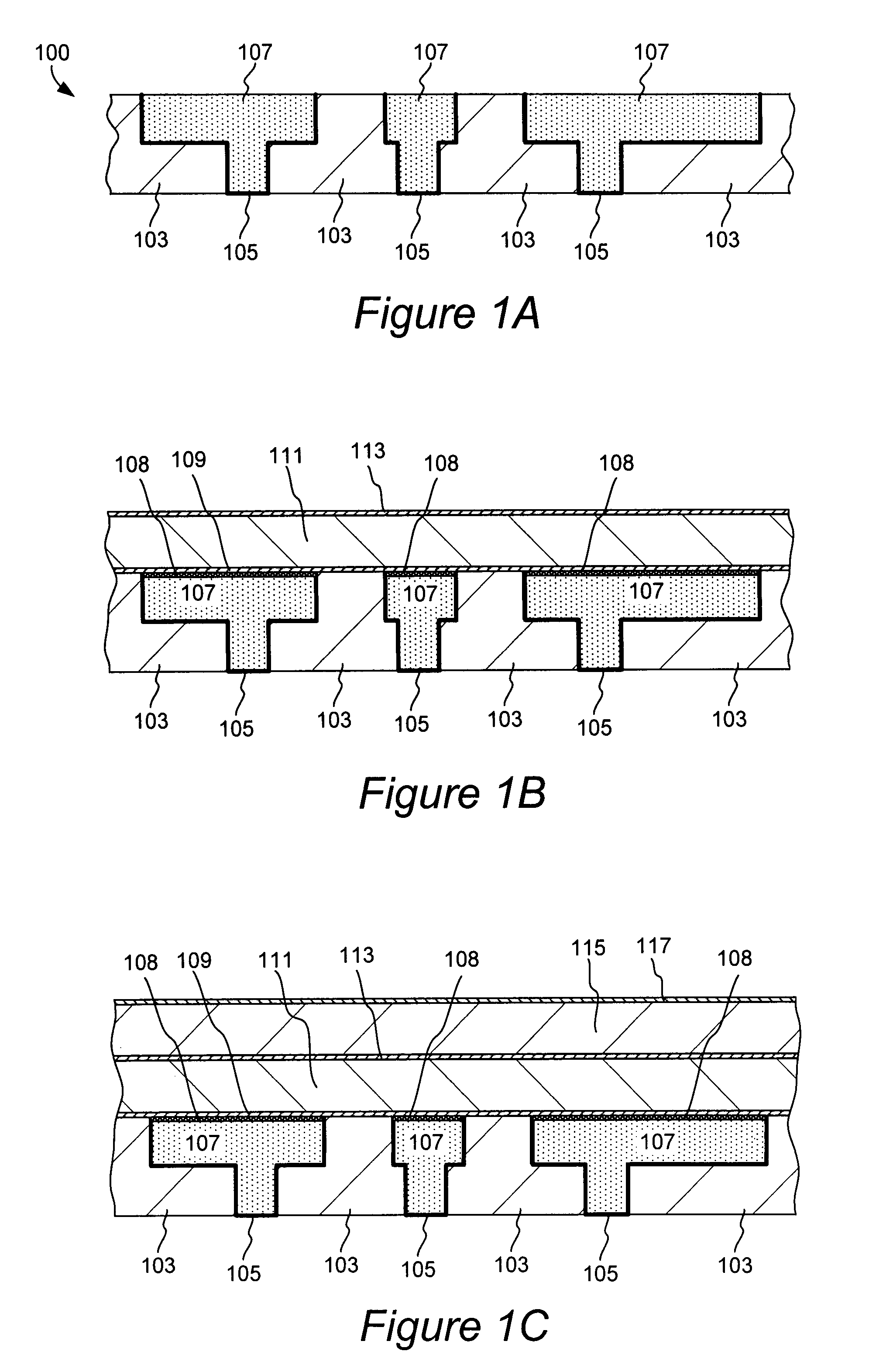

Protective self-aligned buffer layers for damascene interconnects

ActiveUS7727880B1Improving several propertyDecrease in metal electromigrationSemiconductor/solid-state device detailsSolid-state devicesSalicideMetal silicide

Protective self aligned buffer (PSAB) layers are layers of material that are selectively formed at the surface of metal layers in a partially fabricated semiconductor device. In a Damascene interconnect, PSAB layer typically resides at an interface between the metal layer and a dielectric diffusion barrier layer. PSAB layers promote improved adhesion between a metal layer and an adjacent dielectric diffusion barrier layer. Further, PSAB layers can protect metal surfaces from inadvertent oxidation during fabrication process. A PSAB layer may be formed entirely within the top portion of a metal layer, by, for example, chemically converting metal surface to a thin layer of metal silicide. Thickness of PSAB layers, and, consequently resistance of interconnects can be controlled by partially passivating metal surface prior to formation of PSAB layer. Such passivation can be accomplished by controllably treating metal surface with a nitrogen-containing compound to convert metal to metal nitride.

Owner:NOVELLUS SYSTEMS

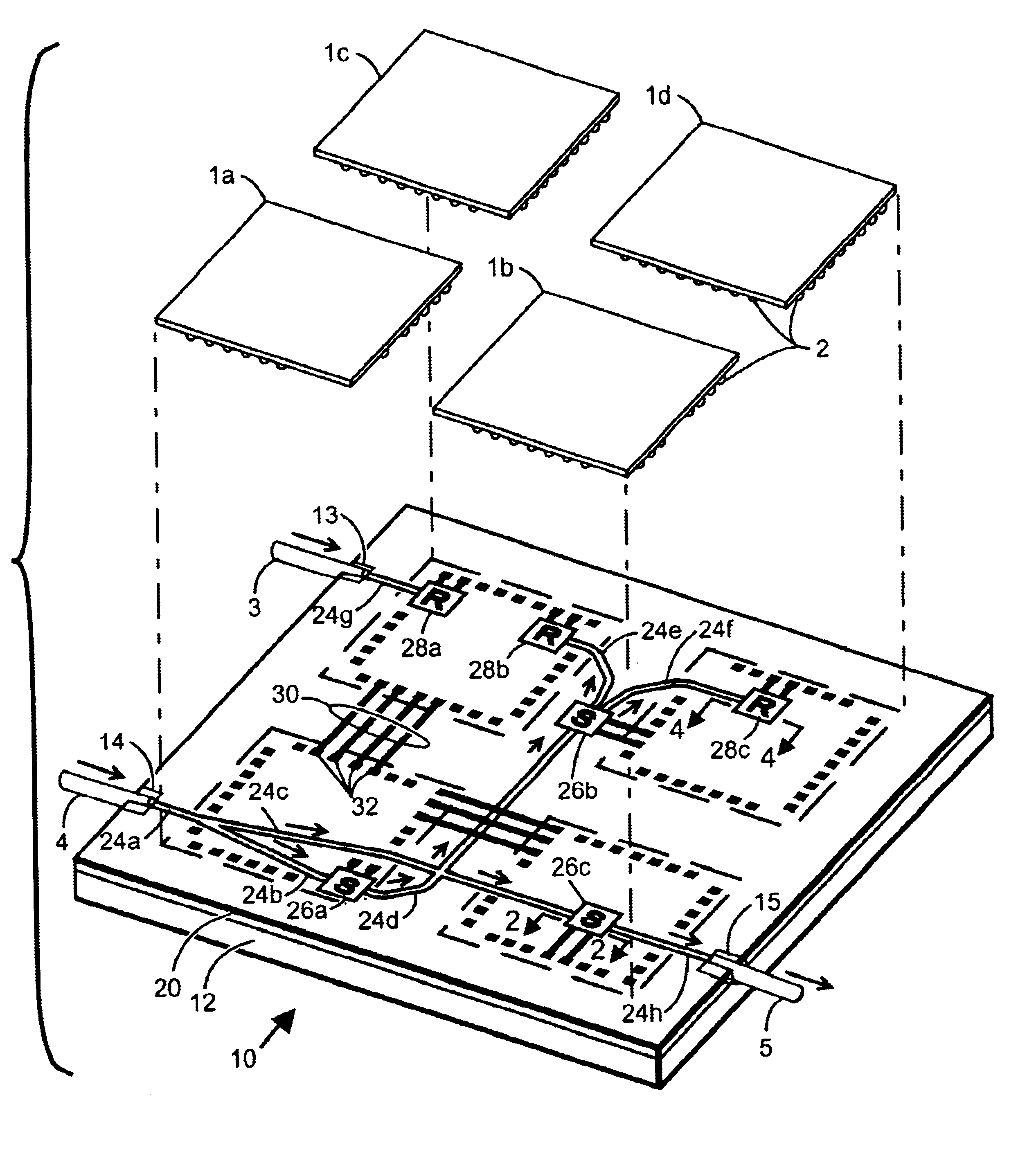

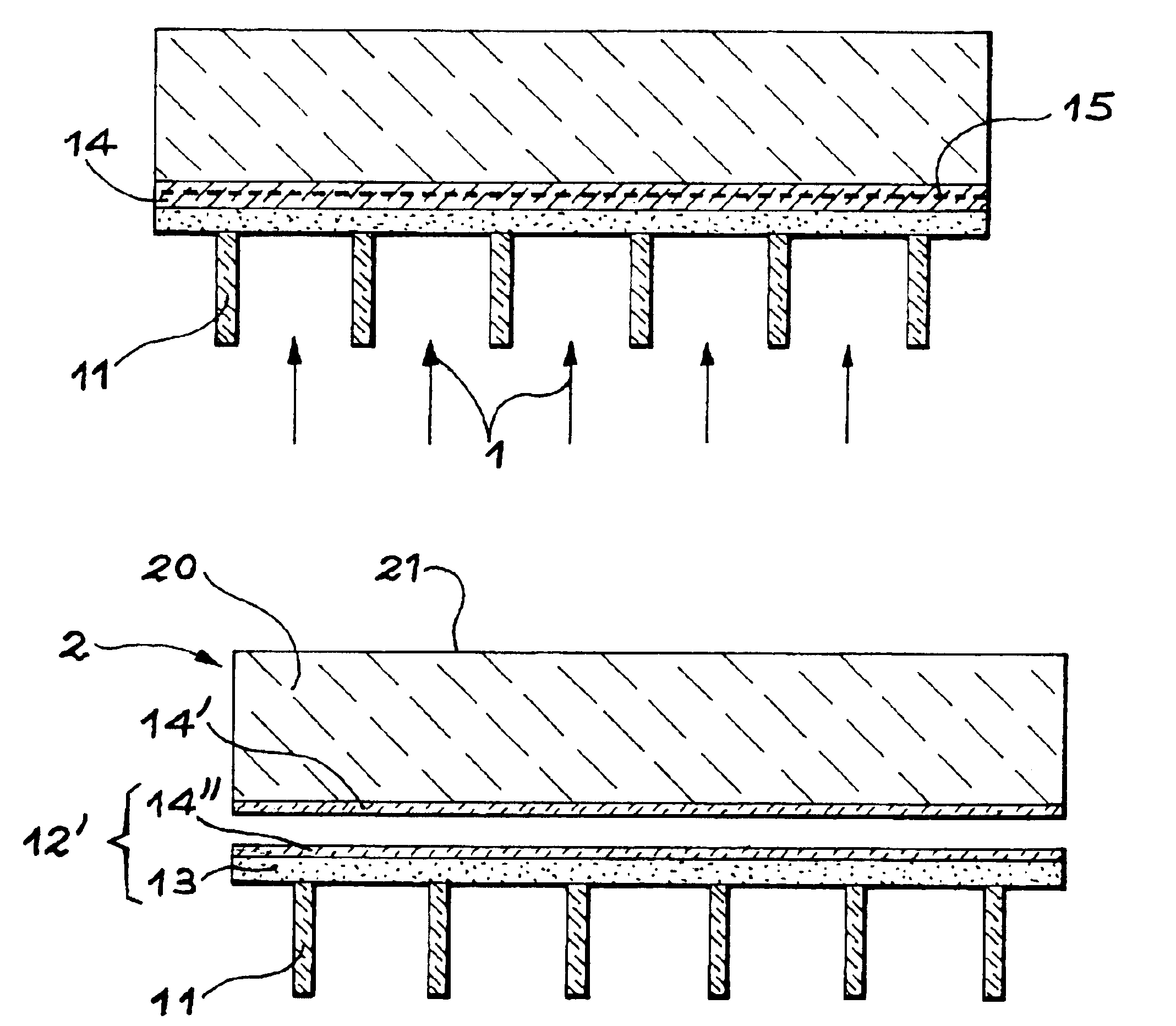

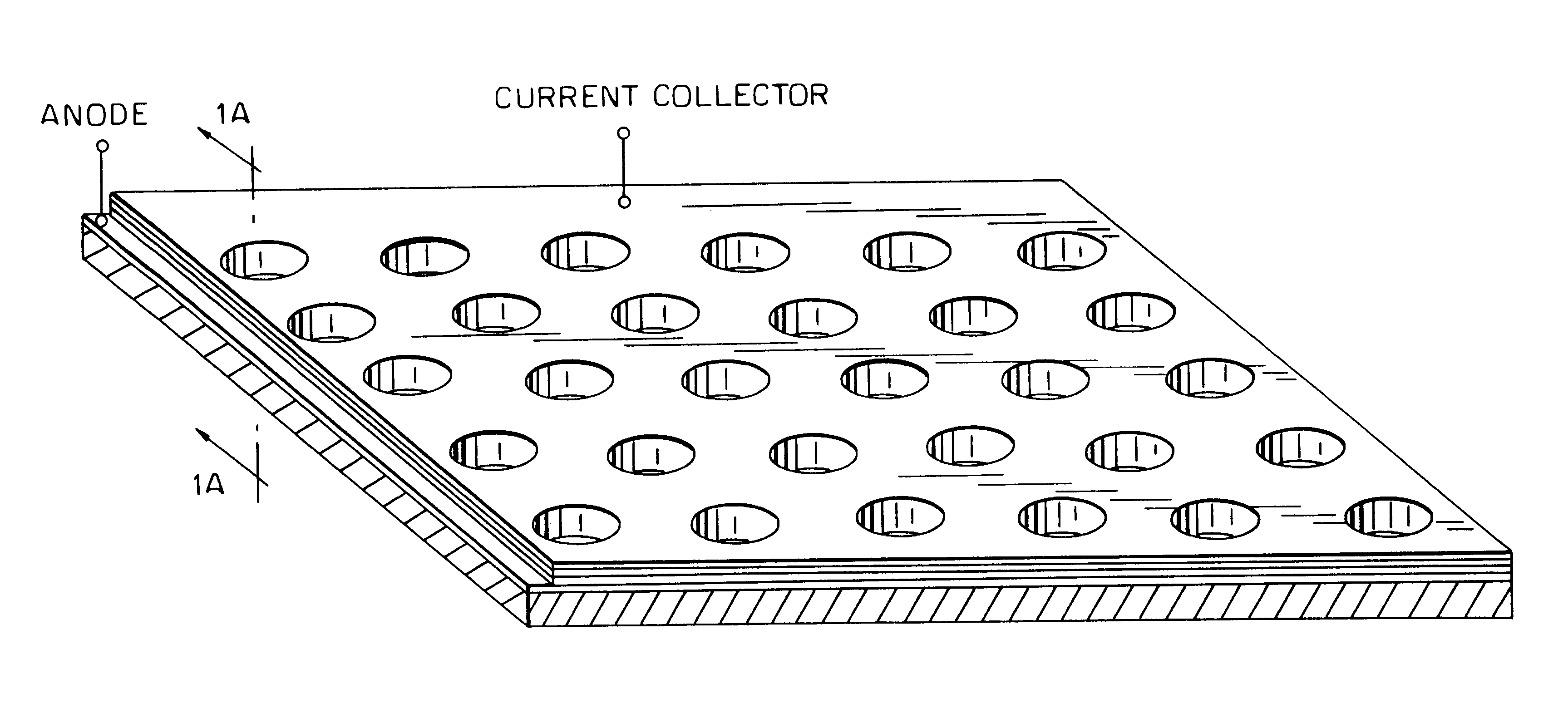

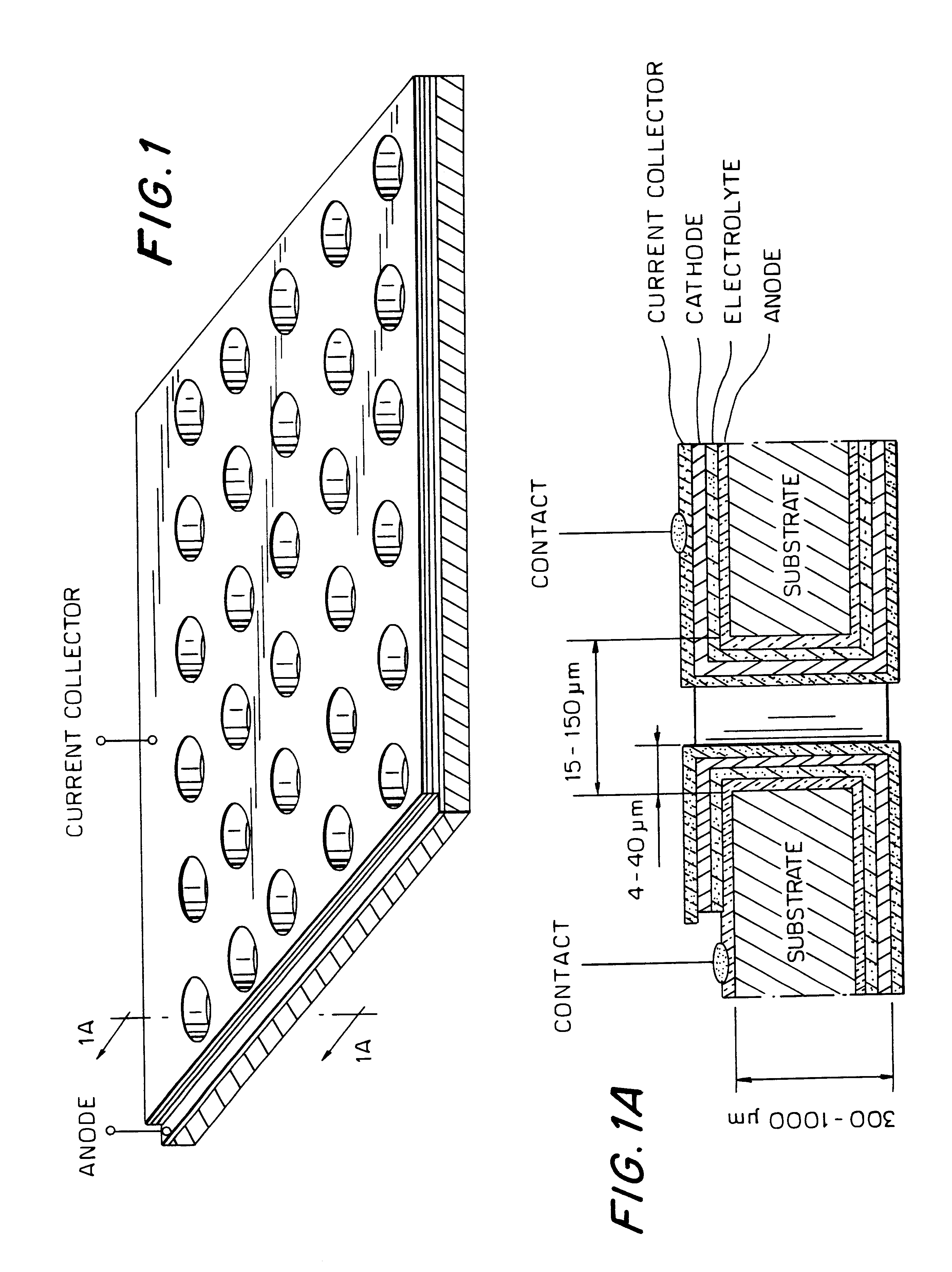

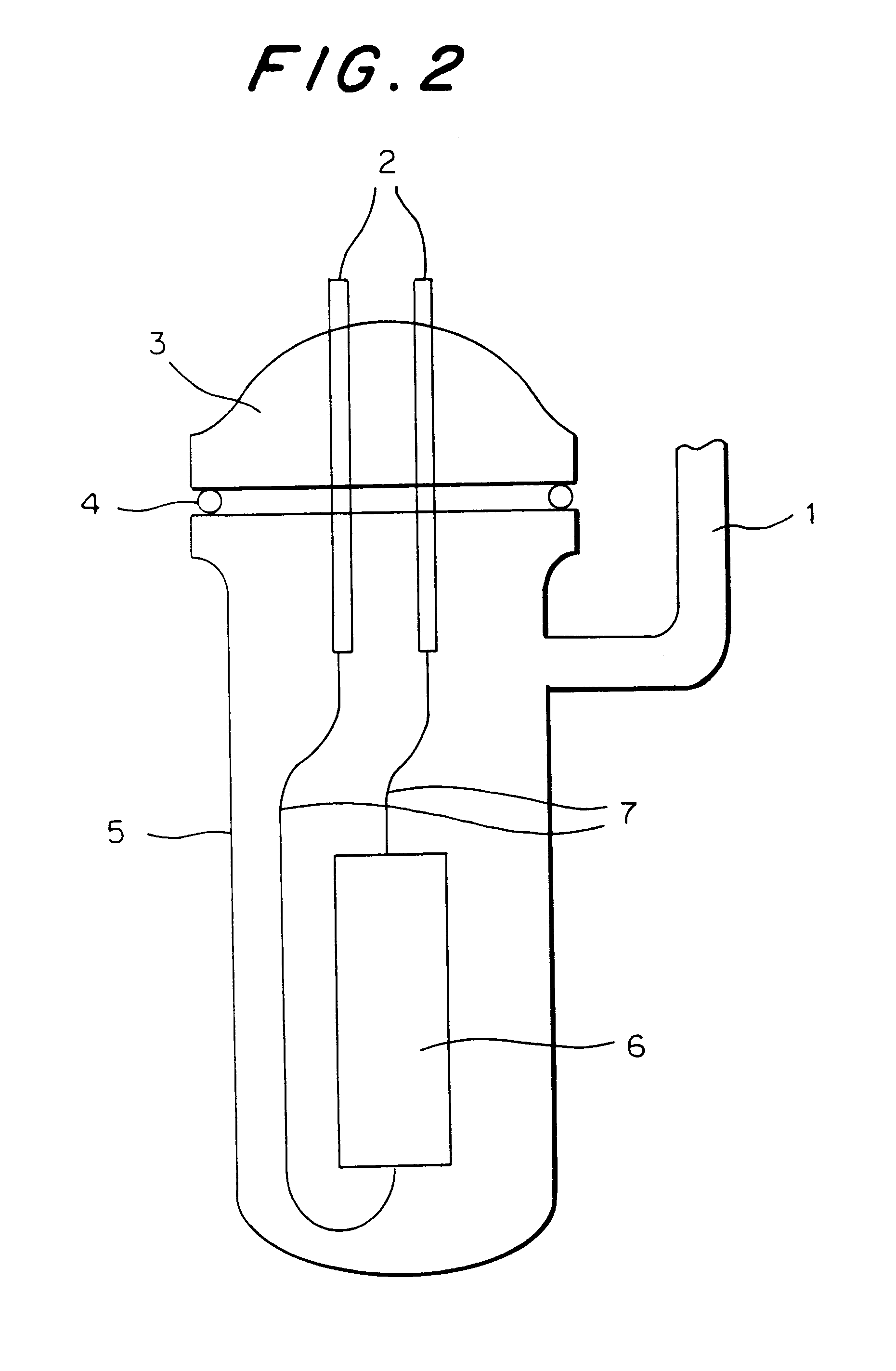

Micro electrochemical energy storage cells

InactiveUS6197450B1Improve performanceIncrease capacityPrimary cell to battery groupingFinal product manufactureThin layerOptoelectronics

Thin-film micro-electrochemical energy storage cells (MEESC) such as microbatteries and double-layer capacitors (DLC) are provided. The MEESC comprises two thin layer electrodes, an intermediate thin layer of a solid electrolyte and optionally, a fourth thin current collector layer; said layers being deposited in sequence on a surface of a substrate. The MEESC is characterized in that the substrate is provided with a plurality of through cavities of arbitrary shape, with high aspect ratio. By using the substrate volume, an increase in the total electrode area per volume is accomplished.

Owner:TEL AVIV UNIV FUTURE TECH DEVMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com