Patents

Literature

62results about How to "Avoid excessive height" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

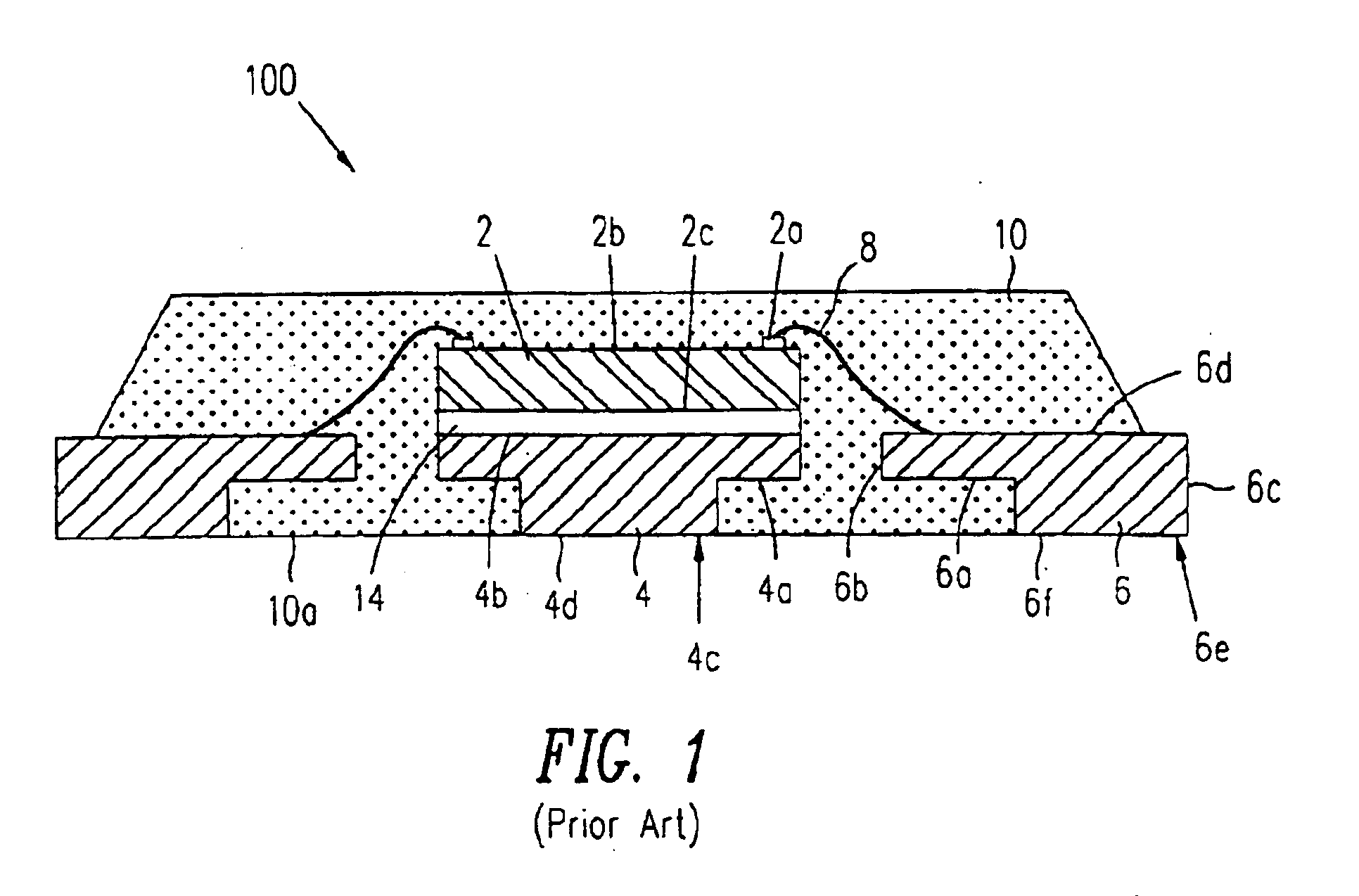

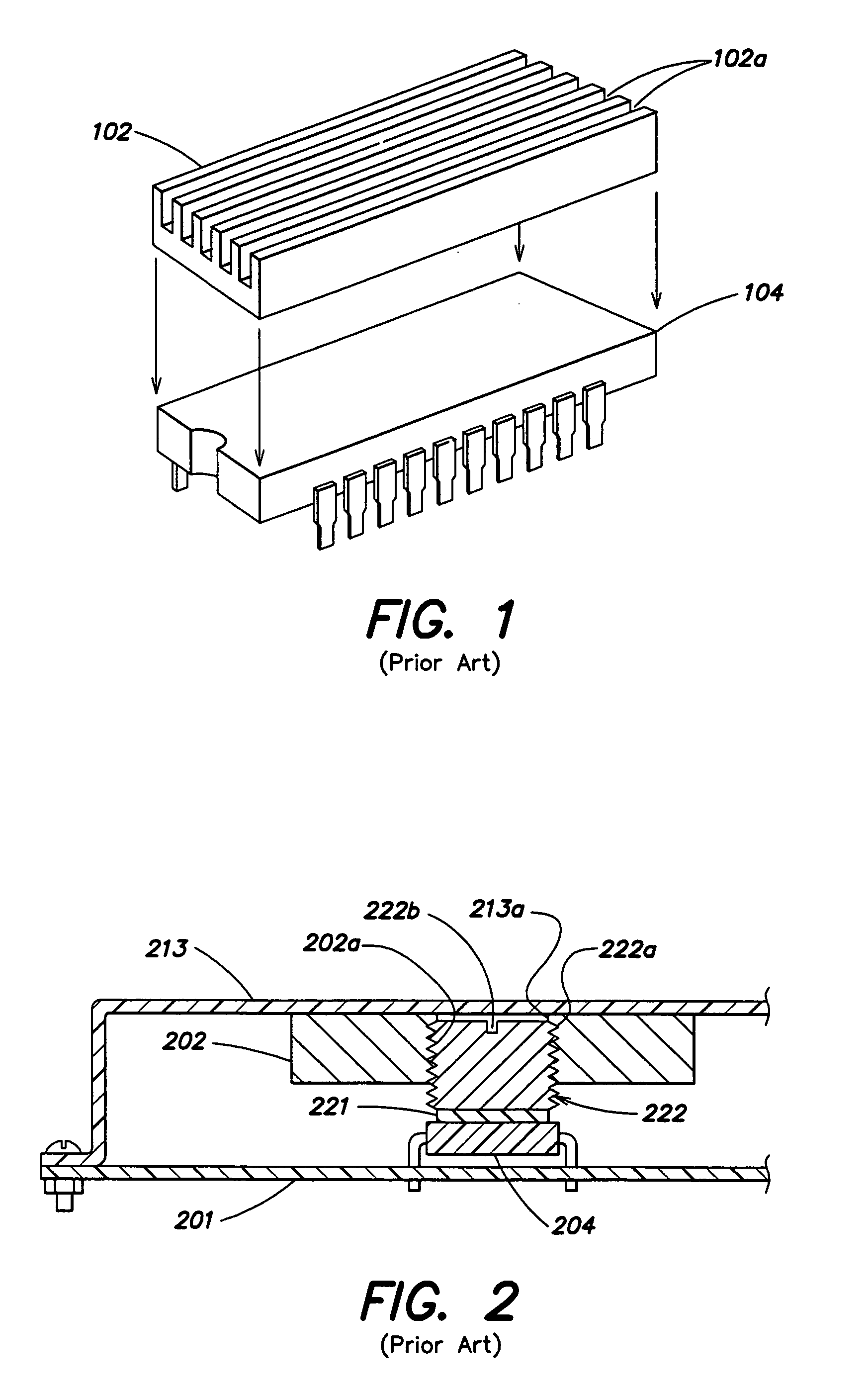

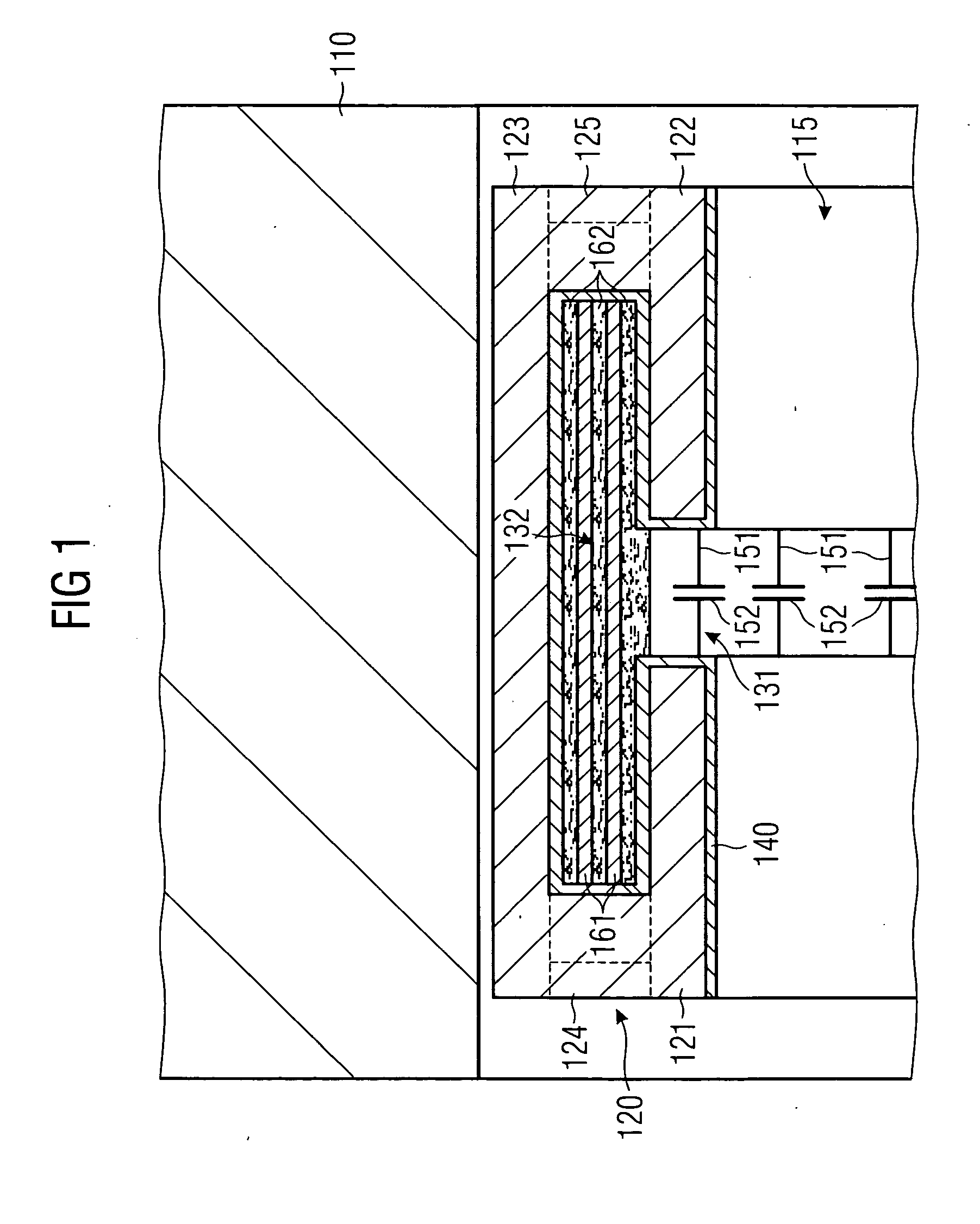

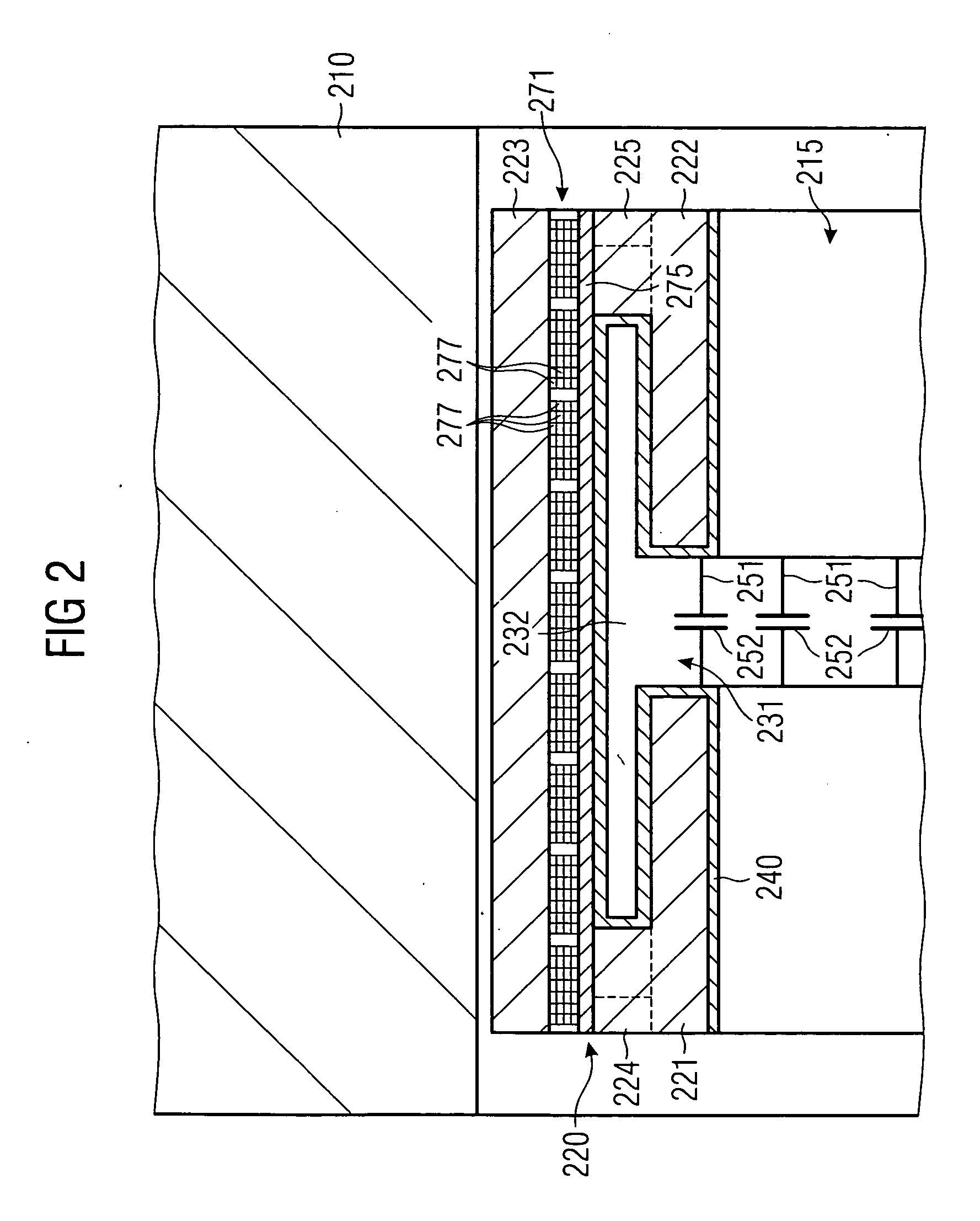

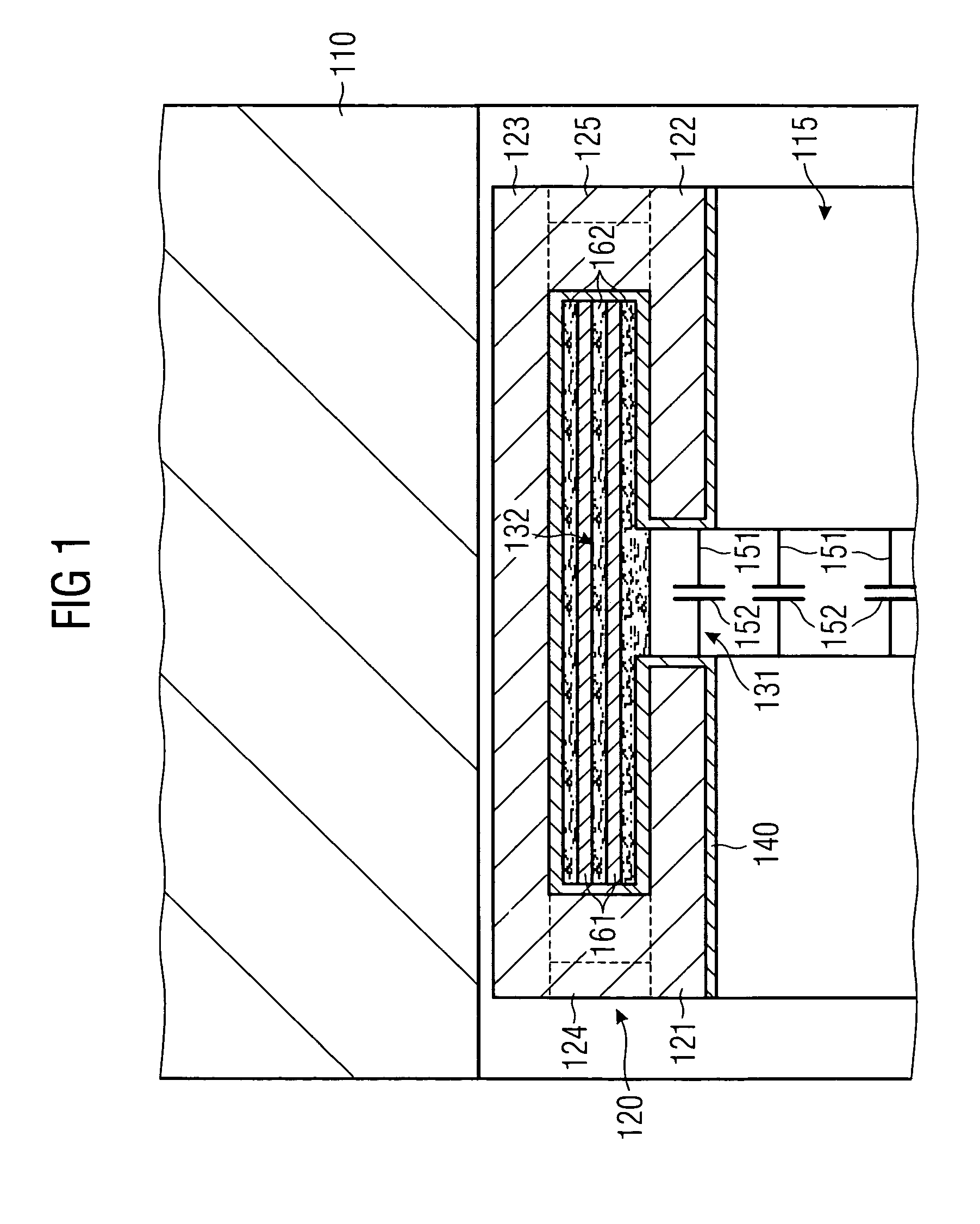

Semiconductor package

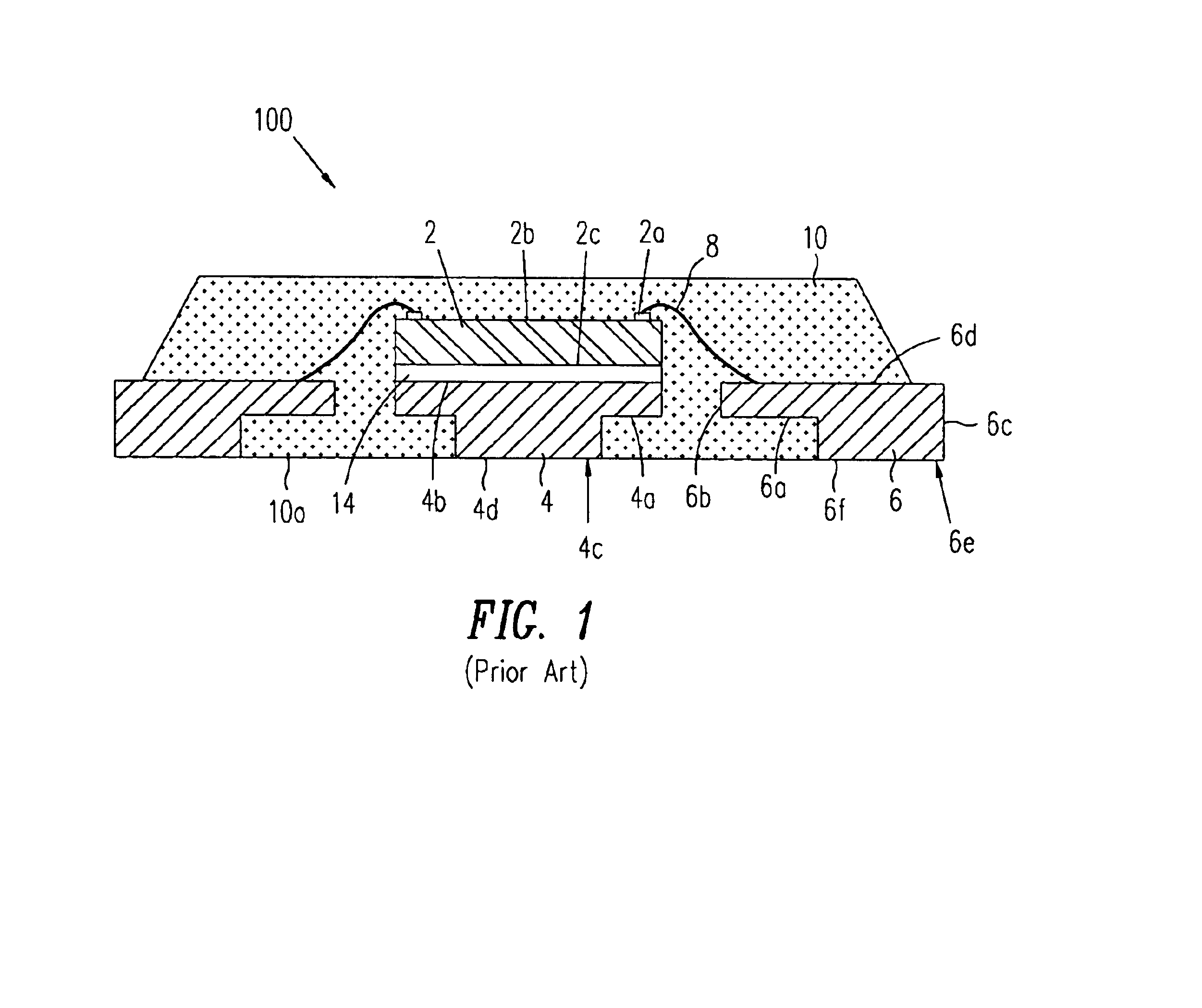

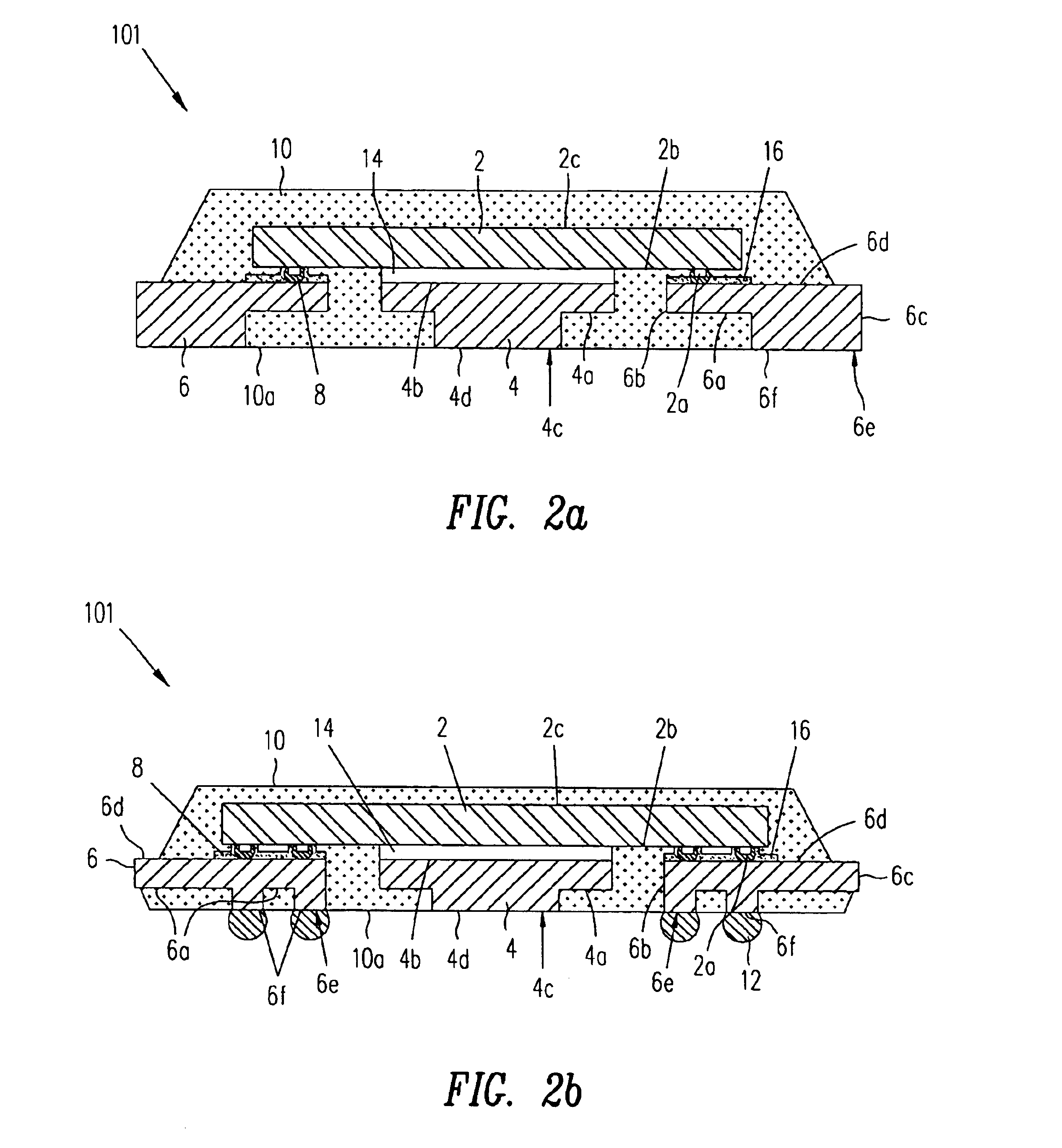

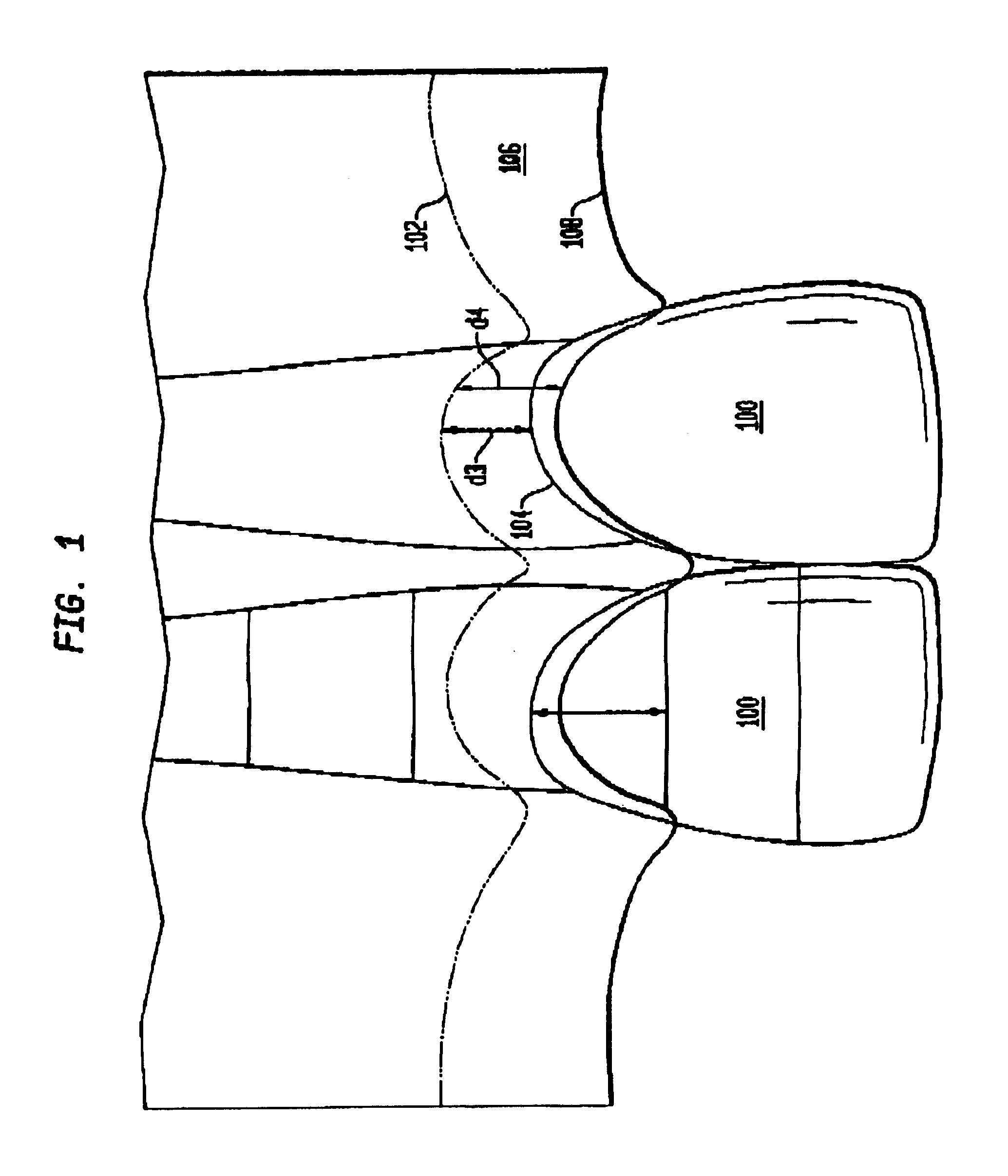

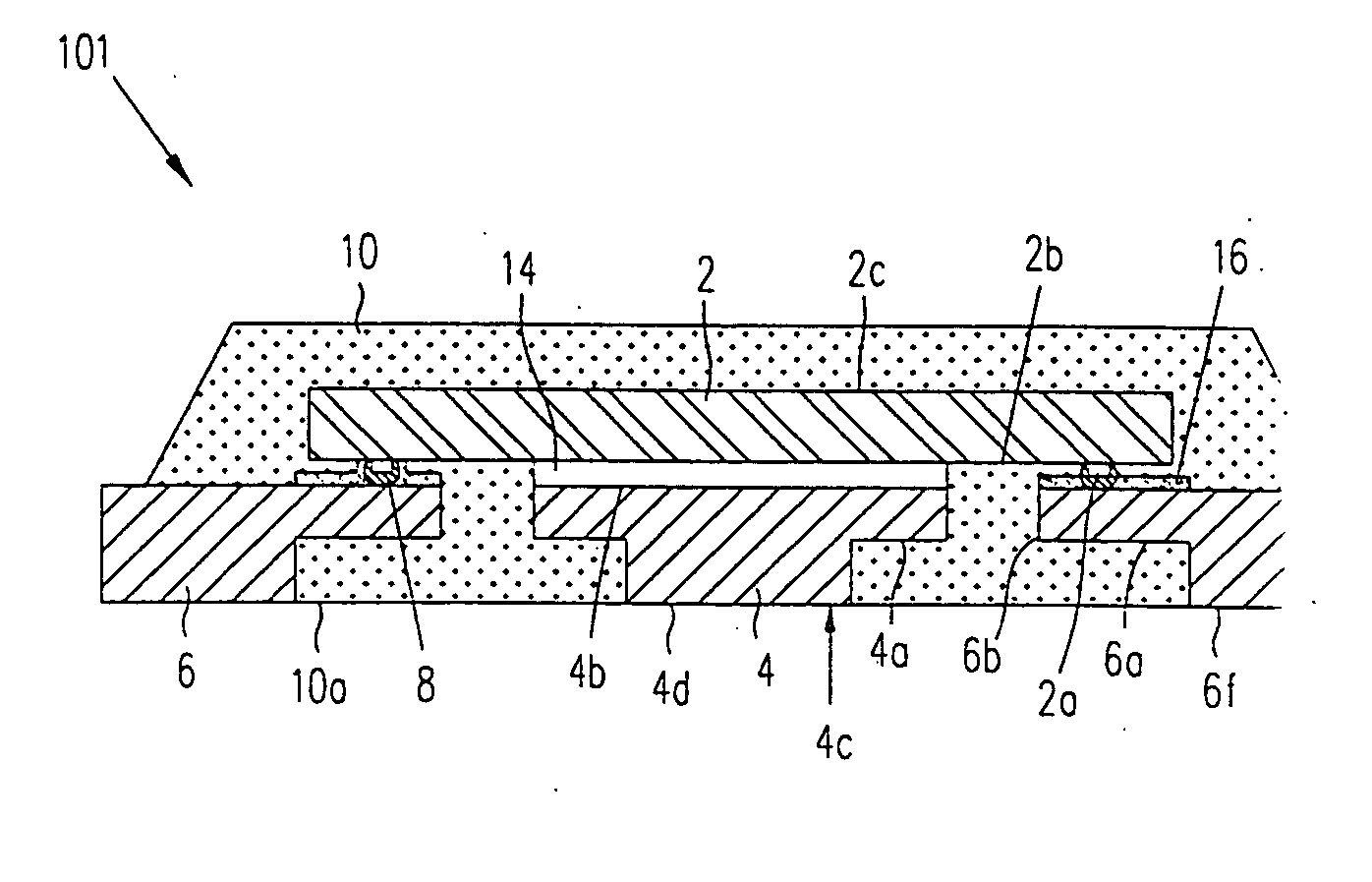

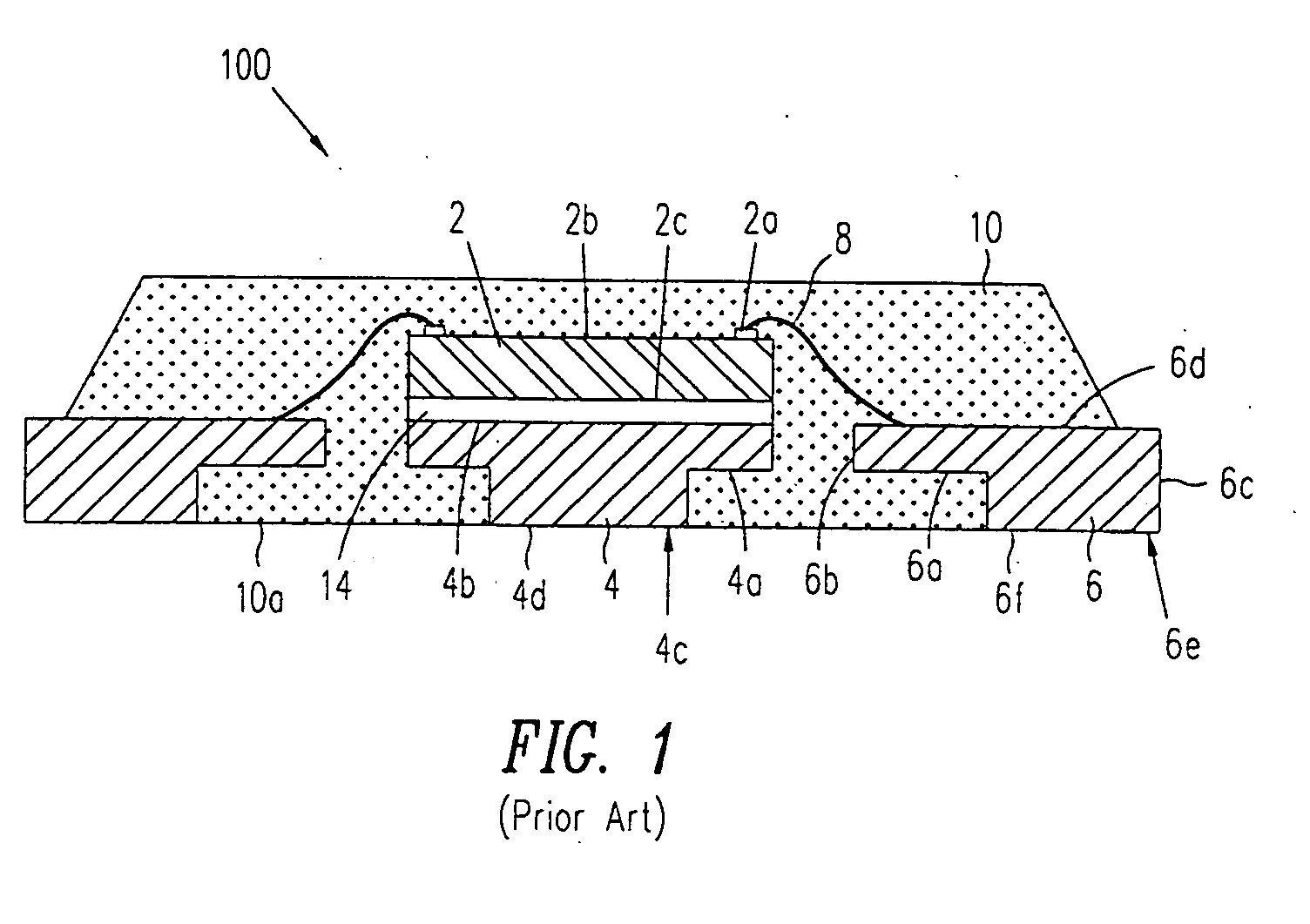

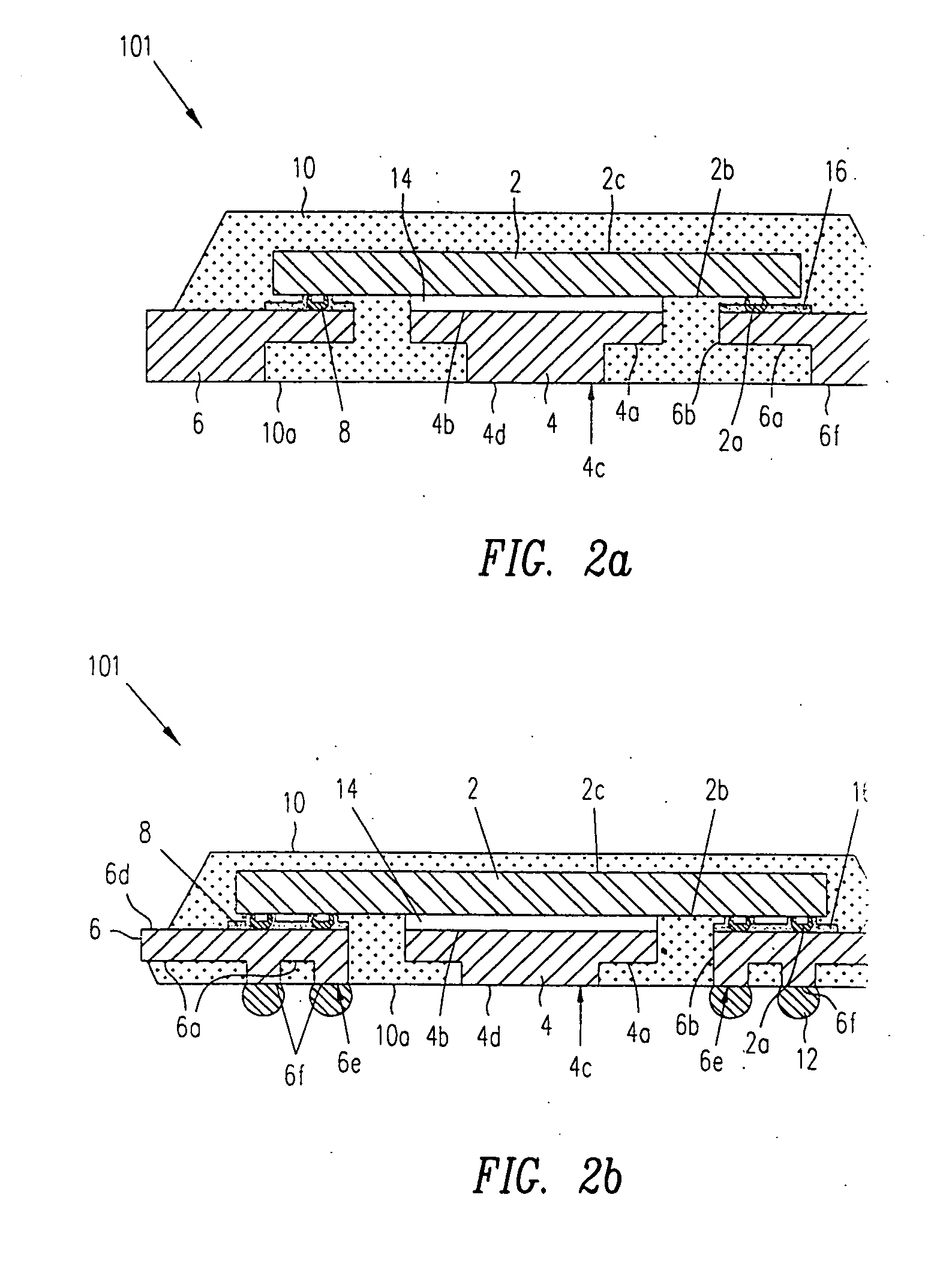

InactiveUS6858919B2Lesser mounting heightLesser footprintSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipSemiconductor package

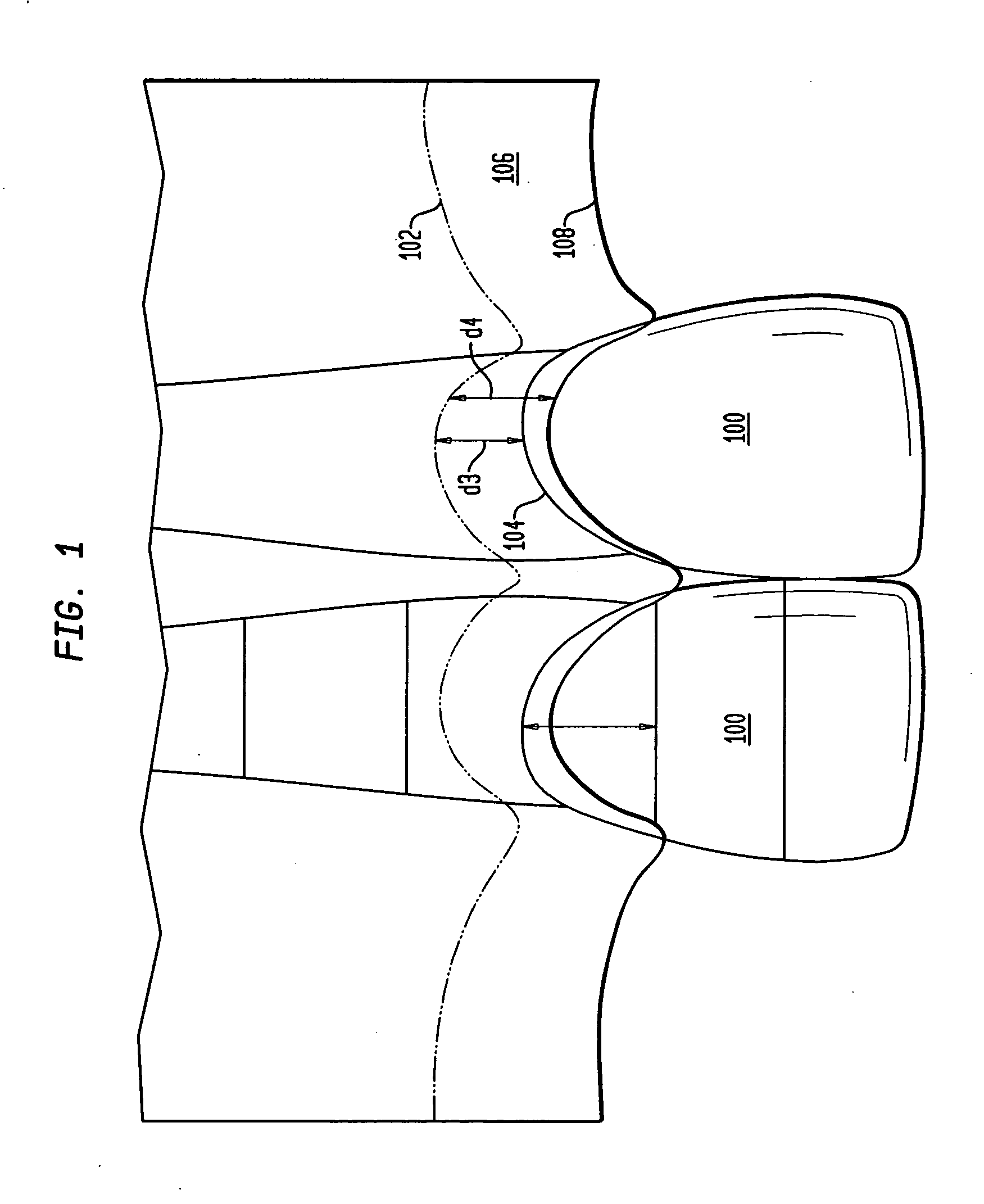

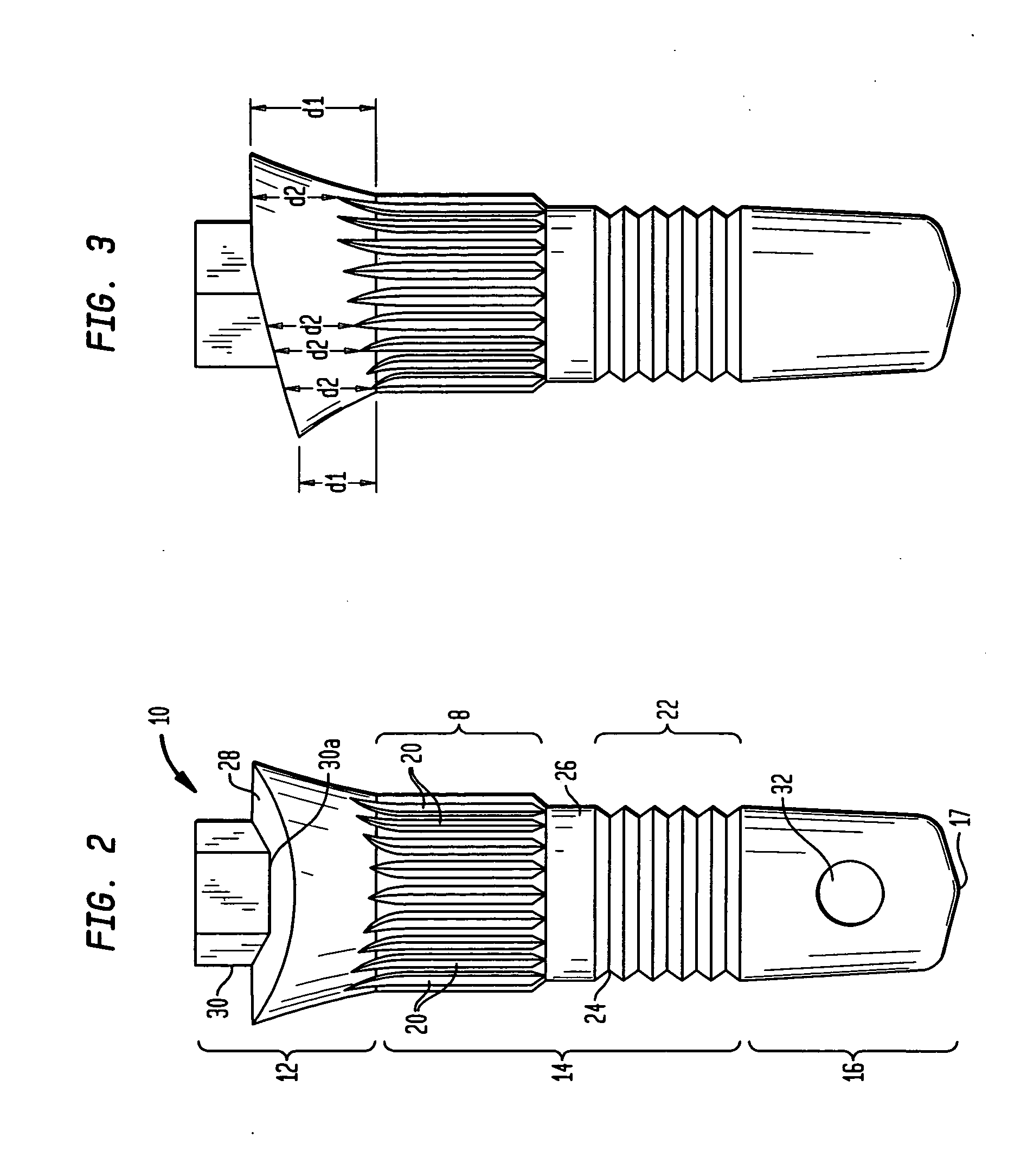

A semiconductor package is disclosed that bonds a semiconductor chip to a leadframe using a flip chip technology. An exemplary semiconductor package includes a semiconductor chip having a plurality of input-output pads at an active surface thereof. A plurality of leads are superimposed by the bond pads and active surface of the semiconductor chip. The leads have at least one exposed surface at a bottom surface of the package body. A plurality of conductive connecting means electrically connect the input-output pads of the chip to the leads. A package body is formed over the semiconductor chip and the conductive connecting means. The bottom surface portions of the leads are exposed to the outside.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

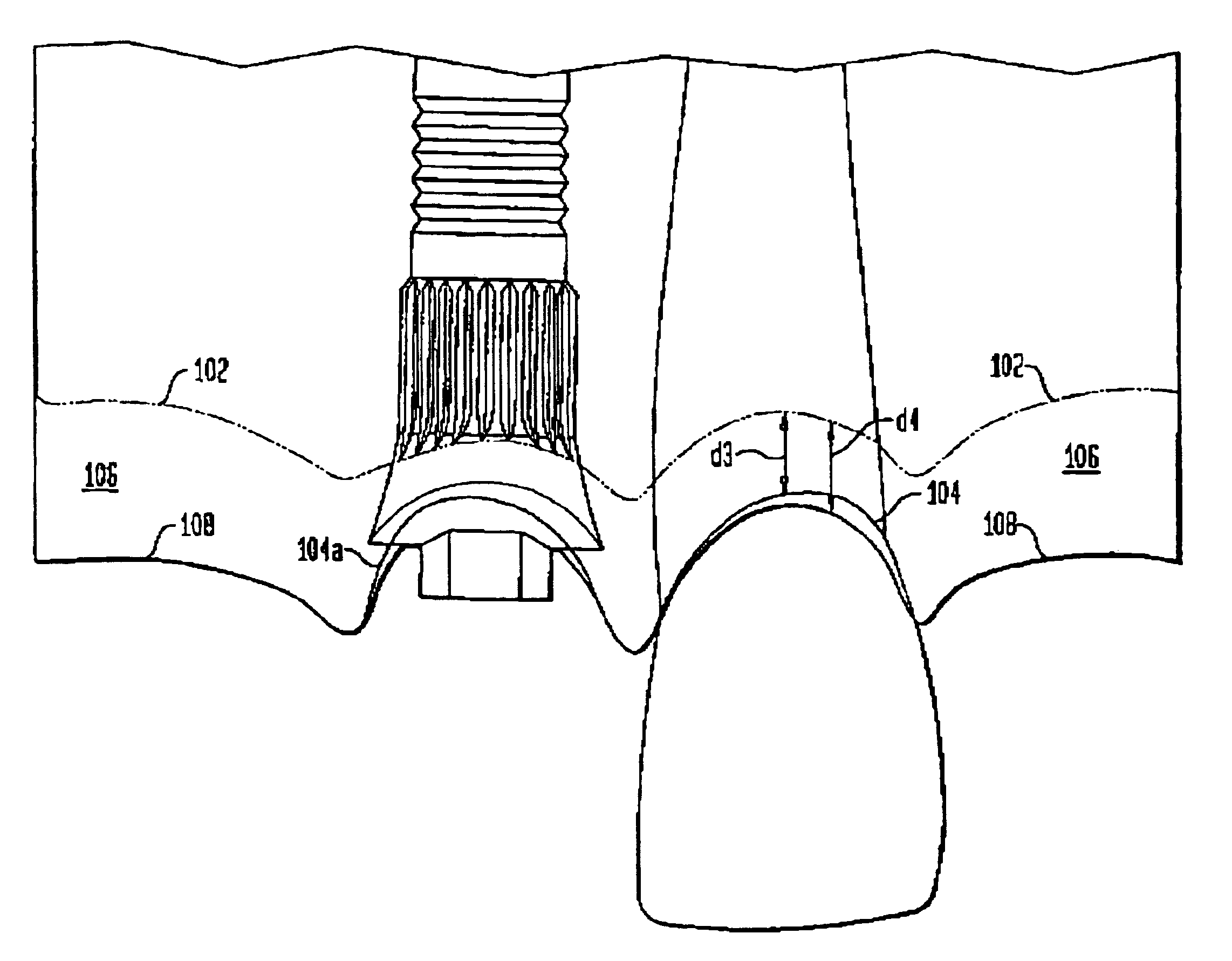

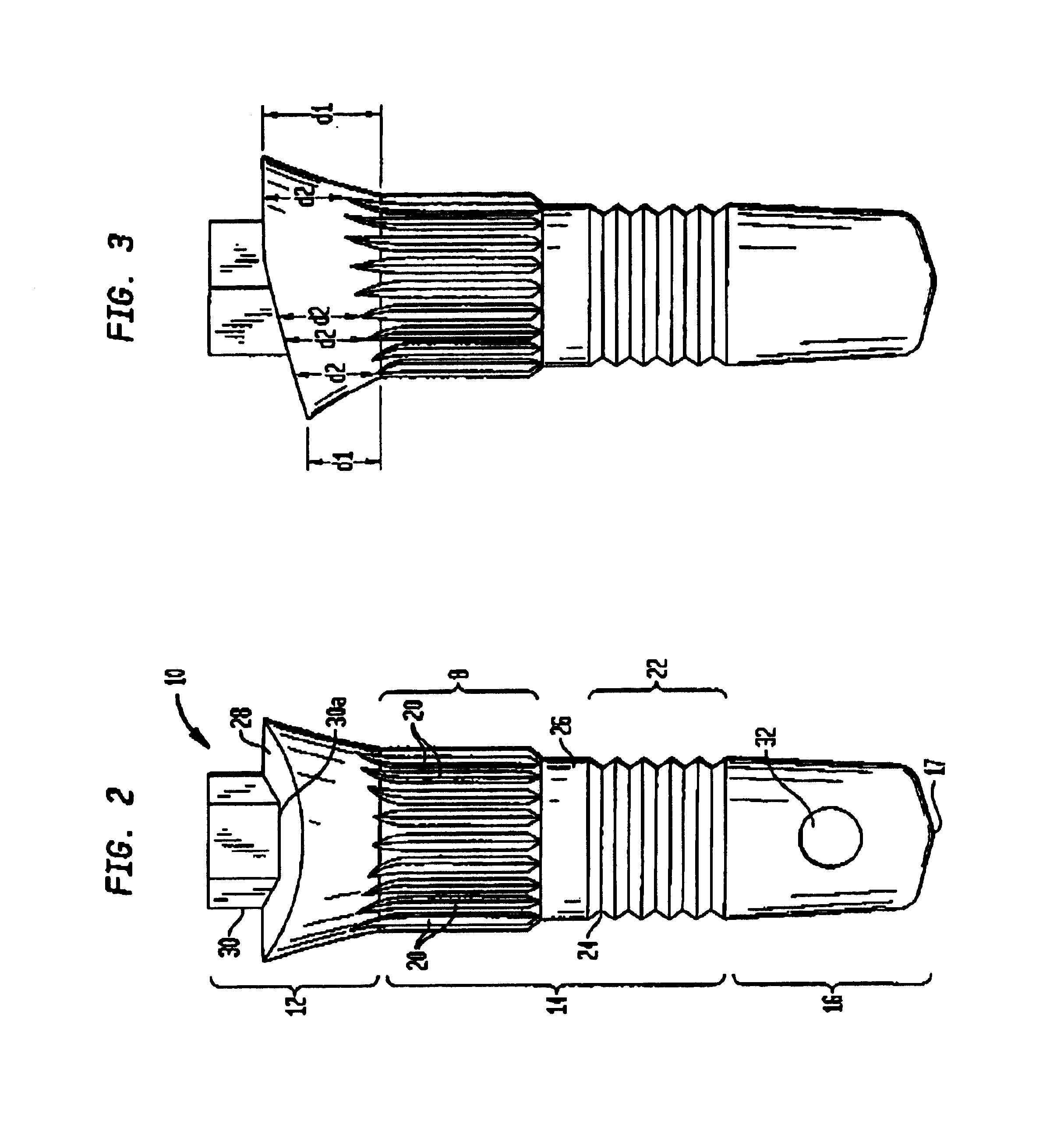

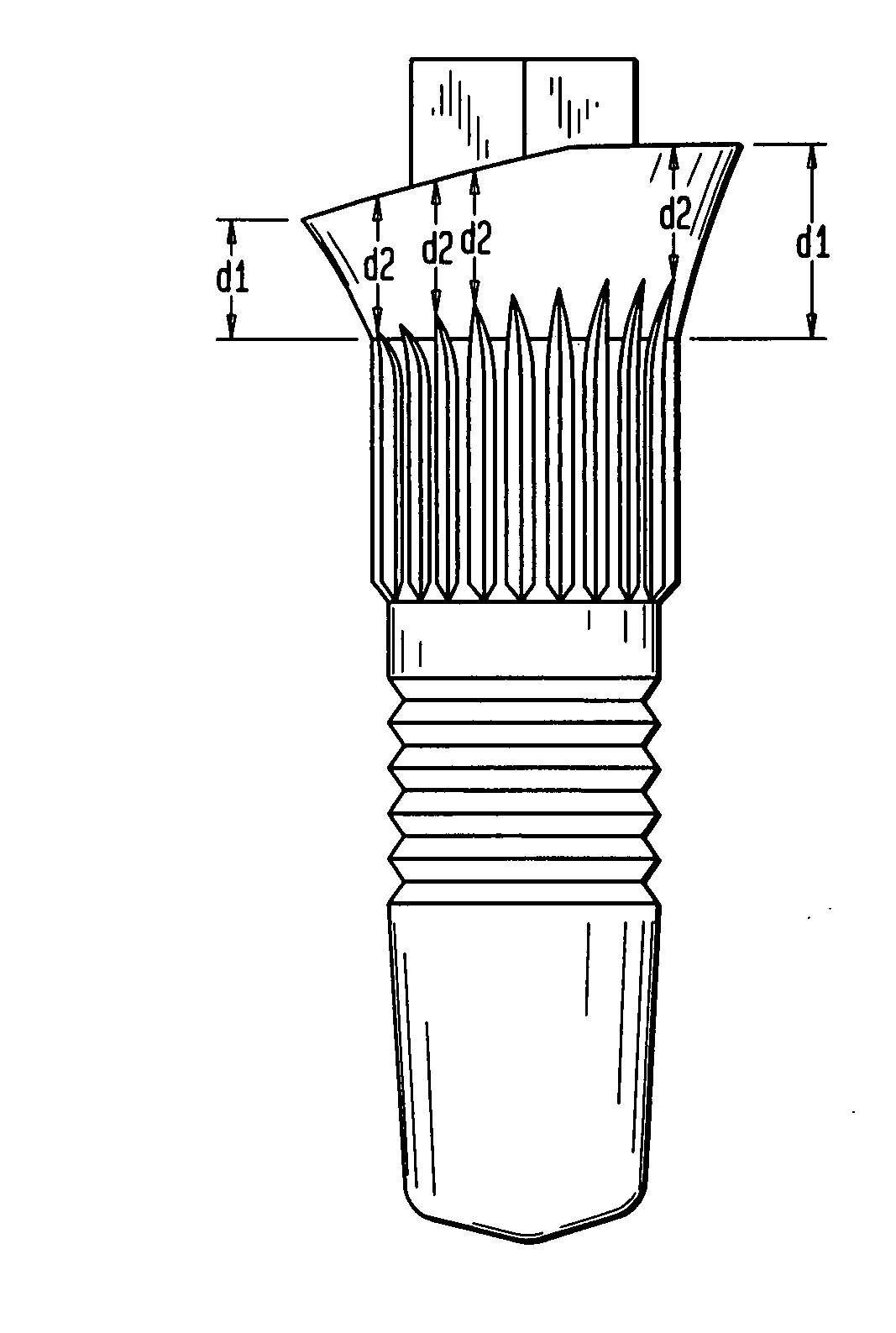

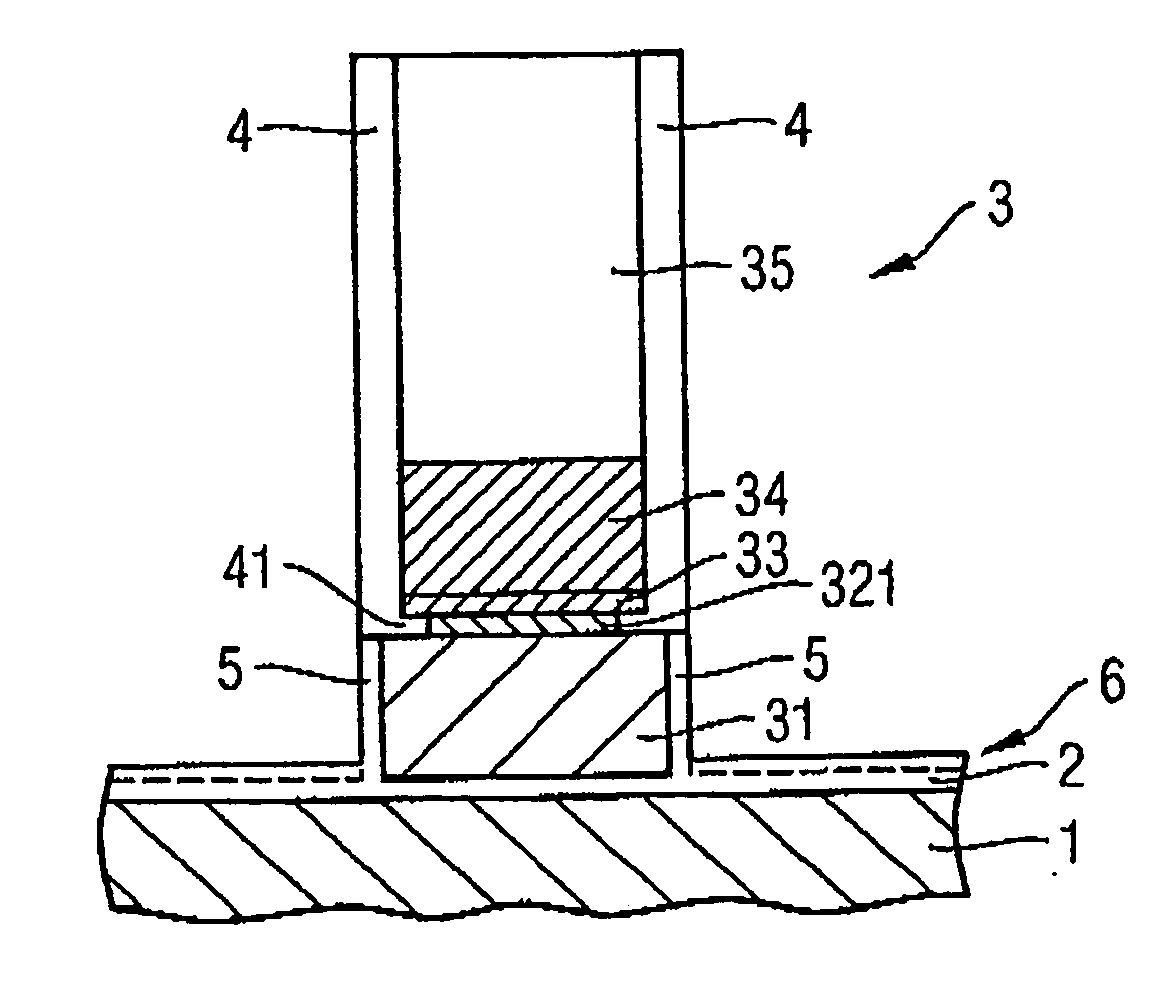

Dental implants and dental implant/prosthetic tooth systems

InactiveUS6854972B1Decrease heightIncrease heightDental implantsCemento-enamel junctionDental implant

A one-piece dental implant having a longitudinal axis comprises a head portion at a first end of the implant, a tip portion at a second end of the implant and a body portion between the head portion and the tip portion. The body portion has a first portion proximate the head portion with a plurality of longitudinal grooves substantially parallel to the longitudinal axis and a second portion proximate the tip portion having a substantially circumferential groove, wherein the outer diameter of the first portion is greater than the outer diameter of the second portion. The first and second portions are for being embedded in the jaw bone. The dental implant is preferably dimensioned to conform to the natural shape of the cervical ⅓ of the root of the tooth being replaced, and to the natural relationship between the cemento-enamel junction of the tooth being replaced and to minimize adverse immunological responses by the jaw bone during healing, thereby improving the aesthetic appearance of the implant and prosthetic tooth attached thereto. A dental implant and prosthetic tooth system is also disclosed, wherein the prosthetic tooth conforms to the shape of the cervical ⅓ of the crown of the tooth being replaced. A method for implanting a dental implant through use of a reference, is also disclosed.

Owner:ELIAN NICHOLAS

Athletic shoe

An athletic shoe has a sole composed of an inner layer and an outer layer that comes into contact with the ground surface. In the athletic shoe, a plurality of downward projecting projections are formed on the lower surface of the outer layer as parts of the outer layer, and a ring-shaped flange portion is formed as a part of the outer layer to surround the corresponding projection. The ring-shaped flange portion slants upward from its outer edge toward the inner edge. When a downward pressure greater than a predetermined value acts onto a portion where the projection and the corresponding flange portion are formed, the flange deforms in order to move the projection downward. In another athletic shoe, a plurality of projections is formed on the outer surface of a sole, and a depression is formed in the outer surface of the sole in the vicinity of each of the projections. The athletic shoe is excellent in terms of performance in gripping a soft ground surface such as a lawn surface and the easiness of walking on hard surfaces such as a paved path or a floor.

Owner:BRIDGESTONE SPORTS

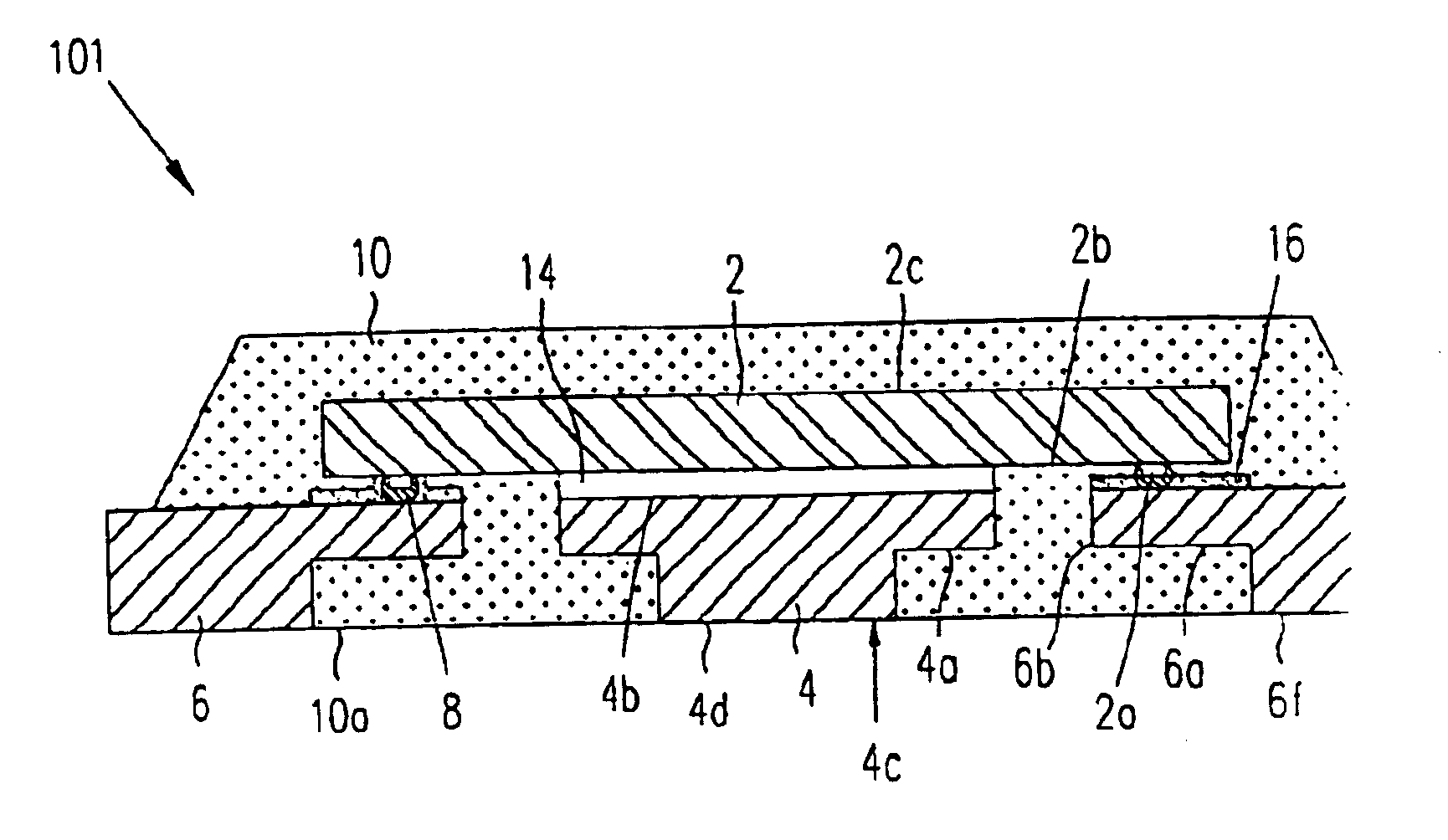

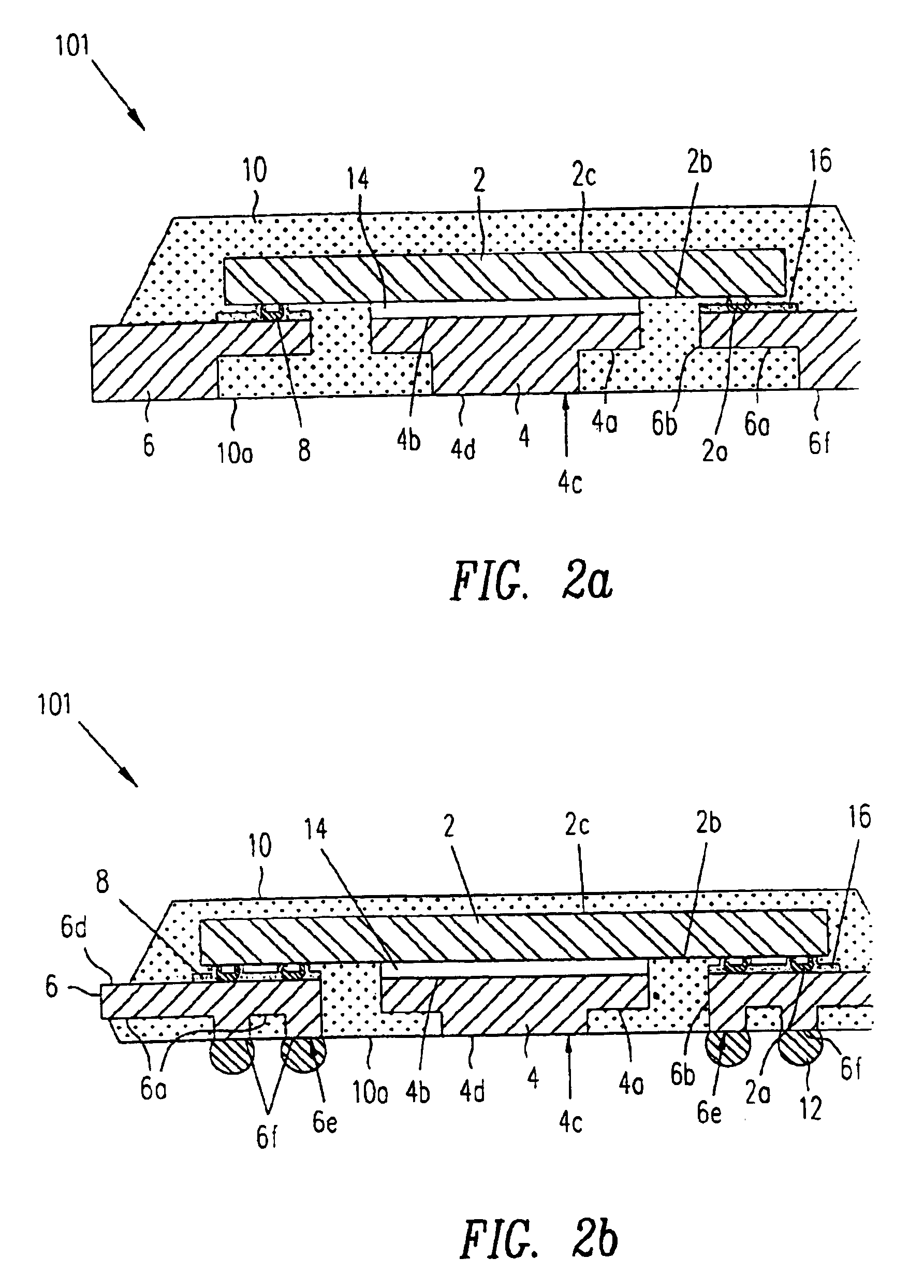

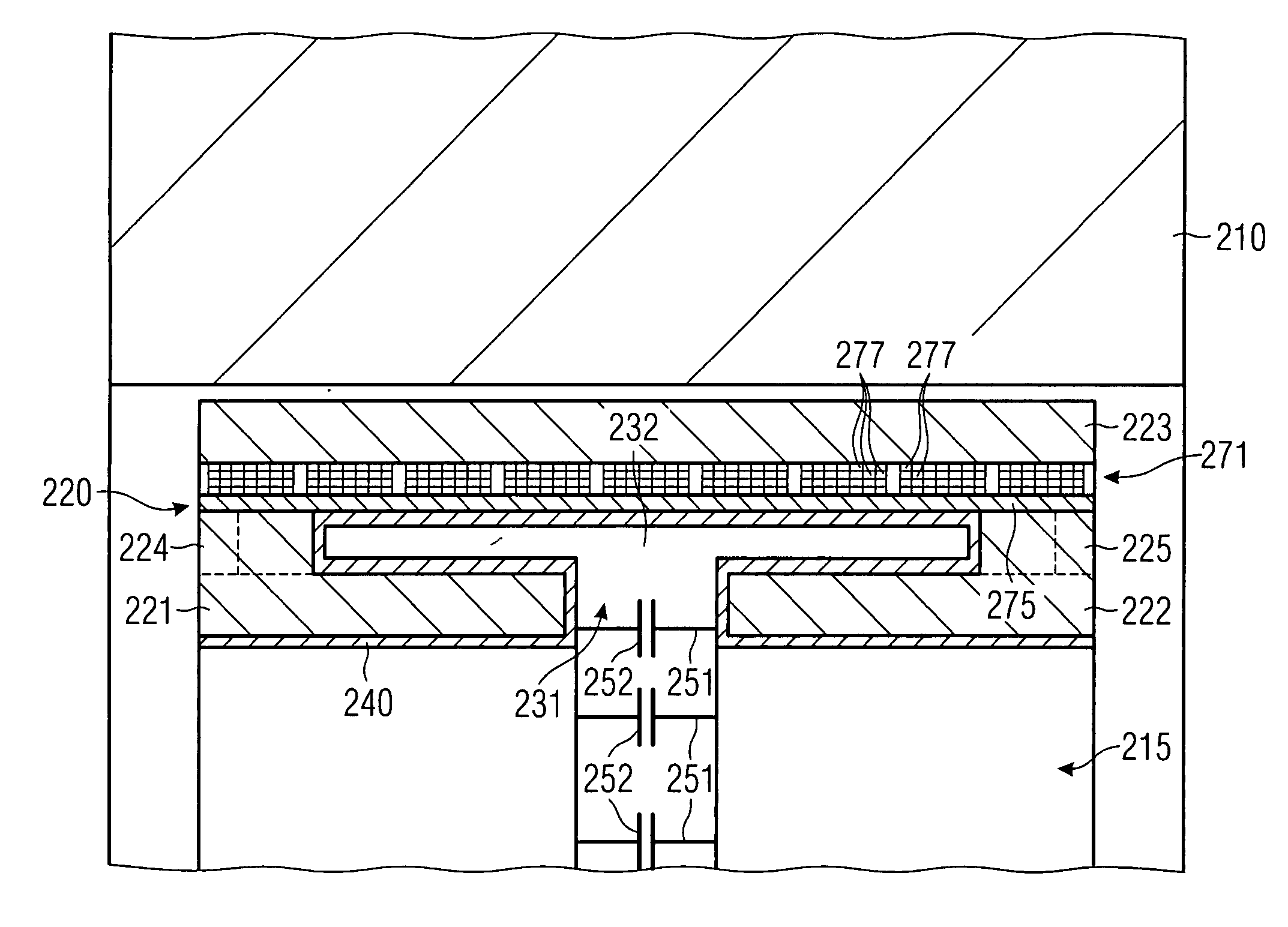

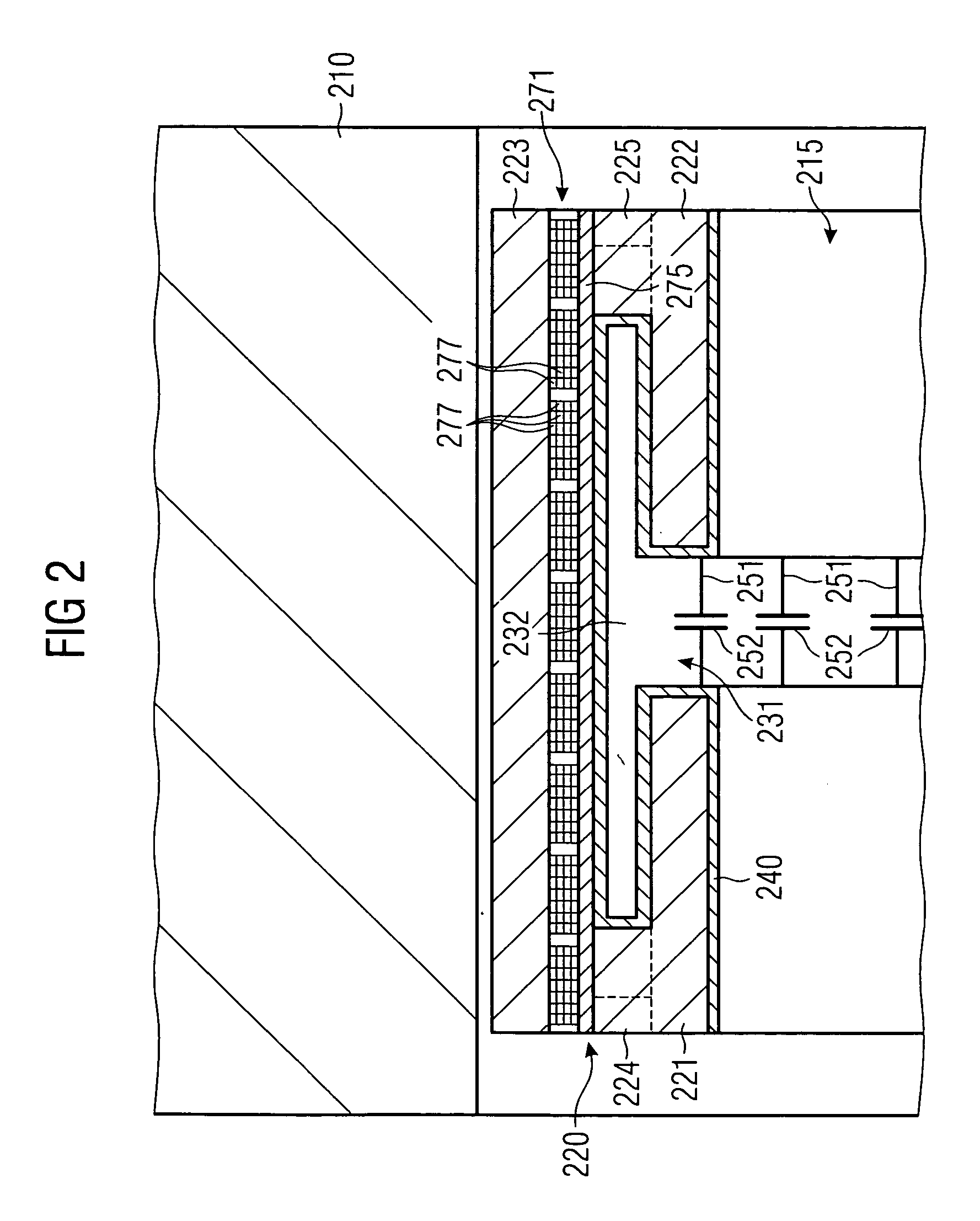

Semiconductor package

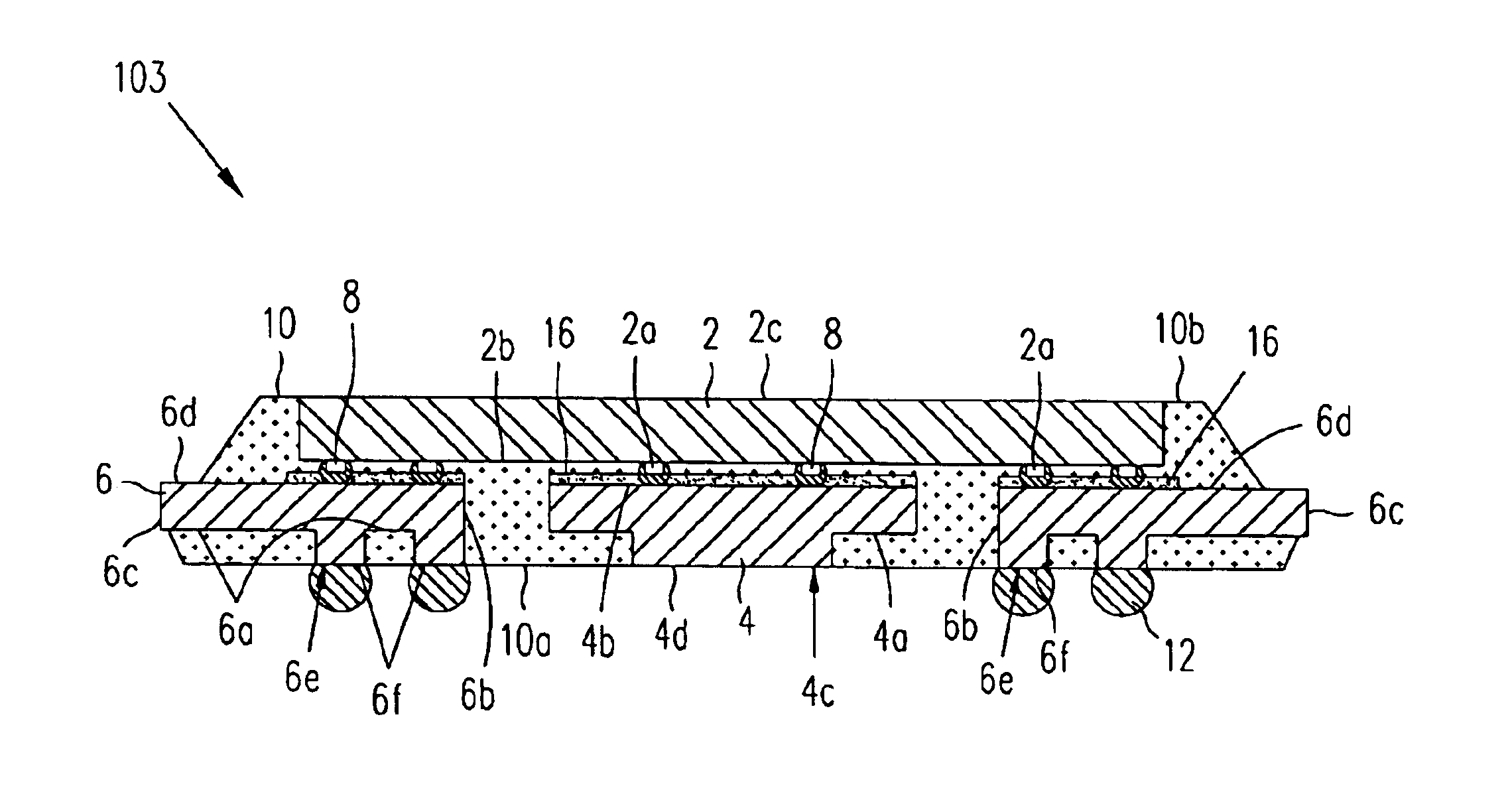

InactiveUS6953988B2Lesser footprintAvoid excessive heightSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipSemiconductor package

A semiconductor package is disclosed that bonds a semiconductor chip to a leadframe using a flip chip technology. An exemplary semiconductor package includes a semiconductor chip having a plurality of input-output pads at an active surface thereof. A plurality of leads are superimposed by the bond pads and active surface of the semiconductor chip. The leads have at least one exposed surface at a bottom surface of the package body. A plurality of conductive connecting means electrically connect the input-output pads of the chip to the leads. A package body is formed over the semiconductor chip and the conductive connecting means. The bottom surface portions of the leads are exposed to the outside.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

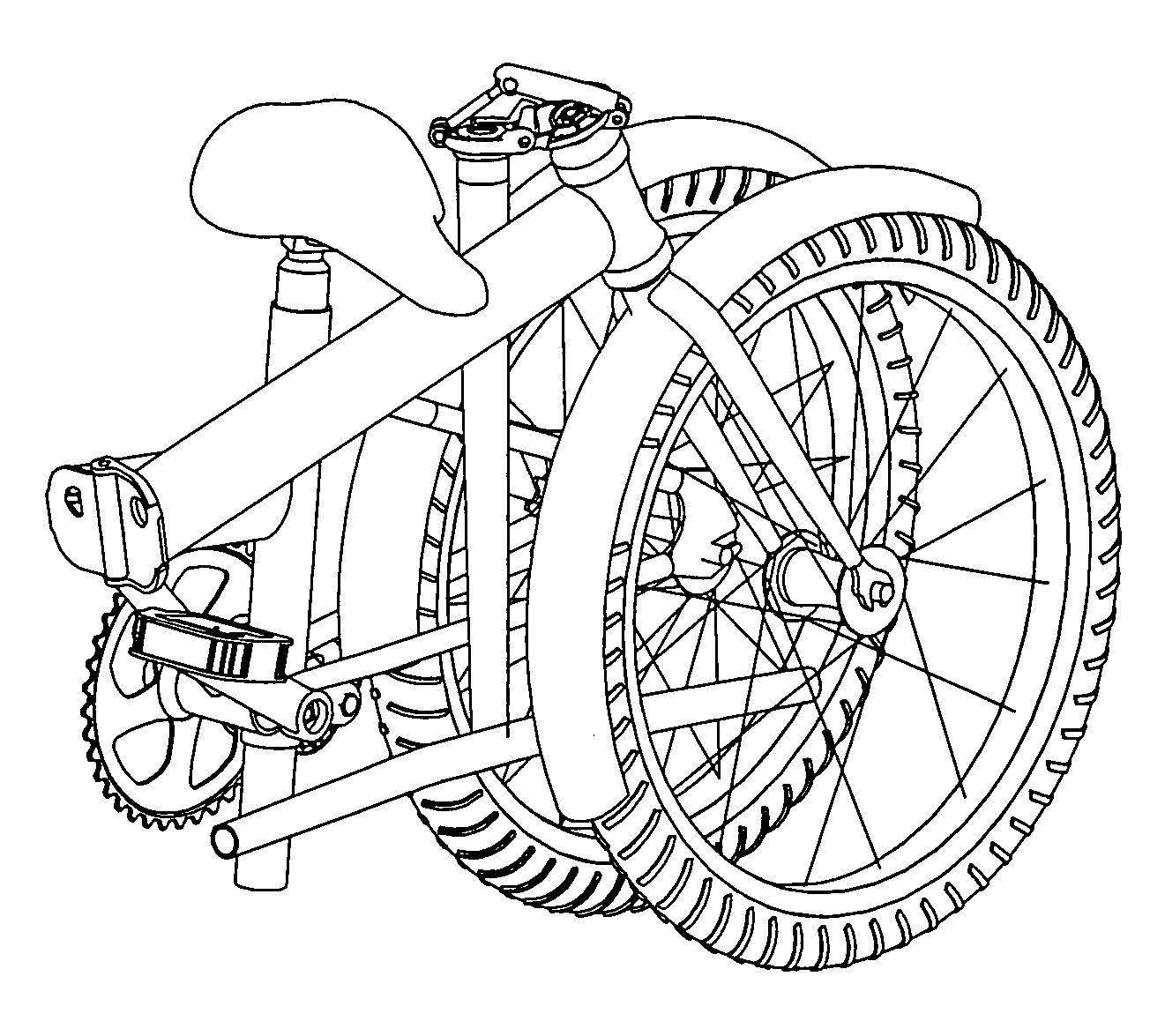

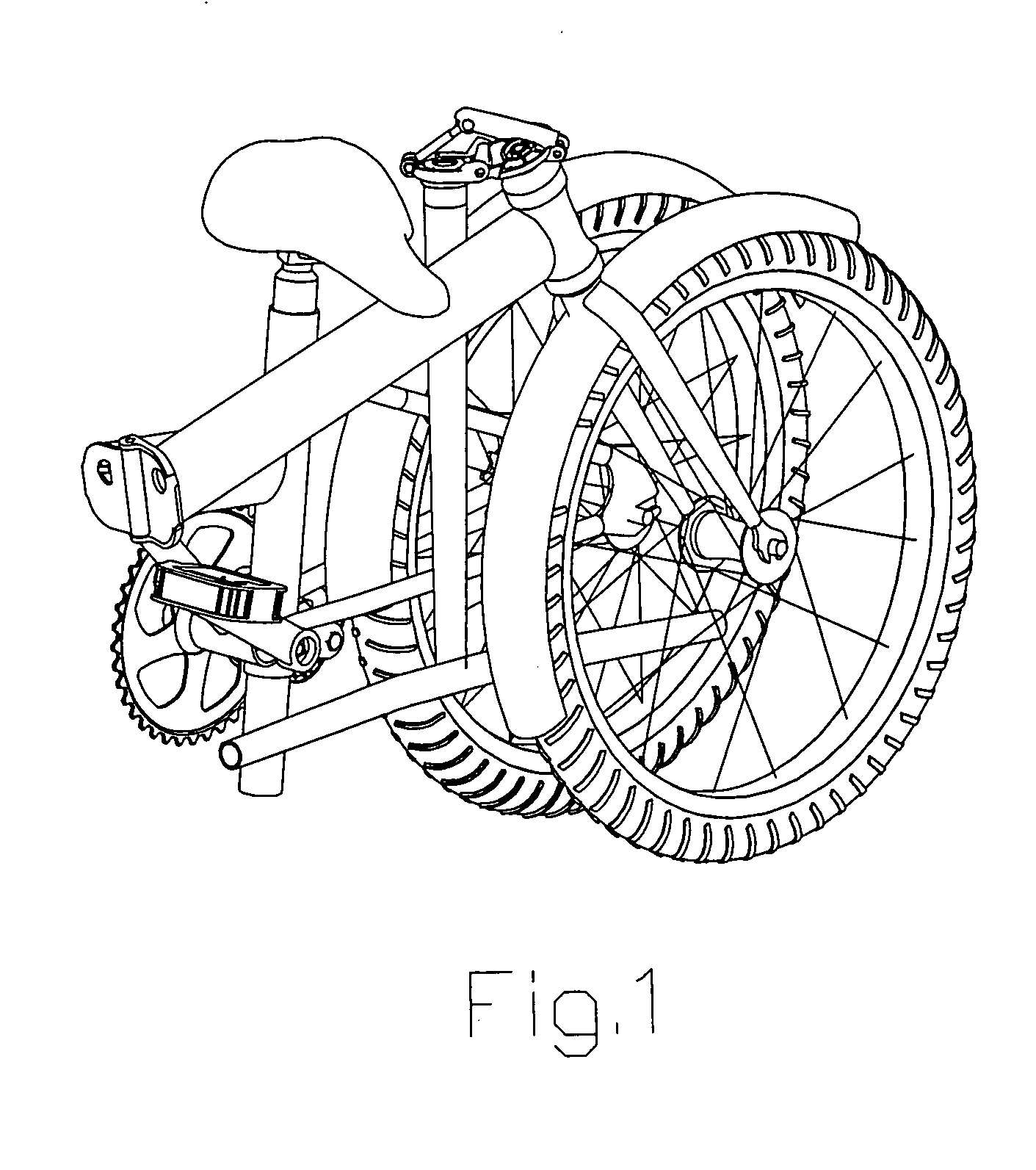

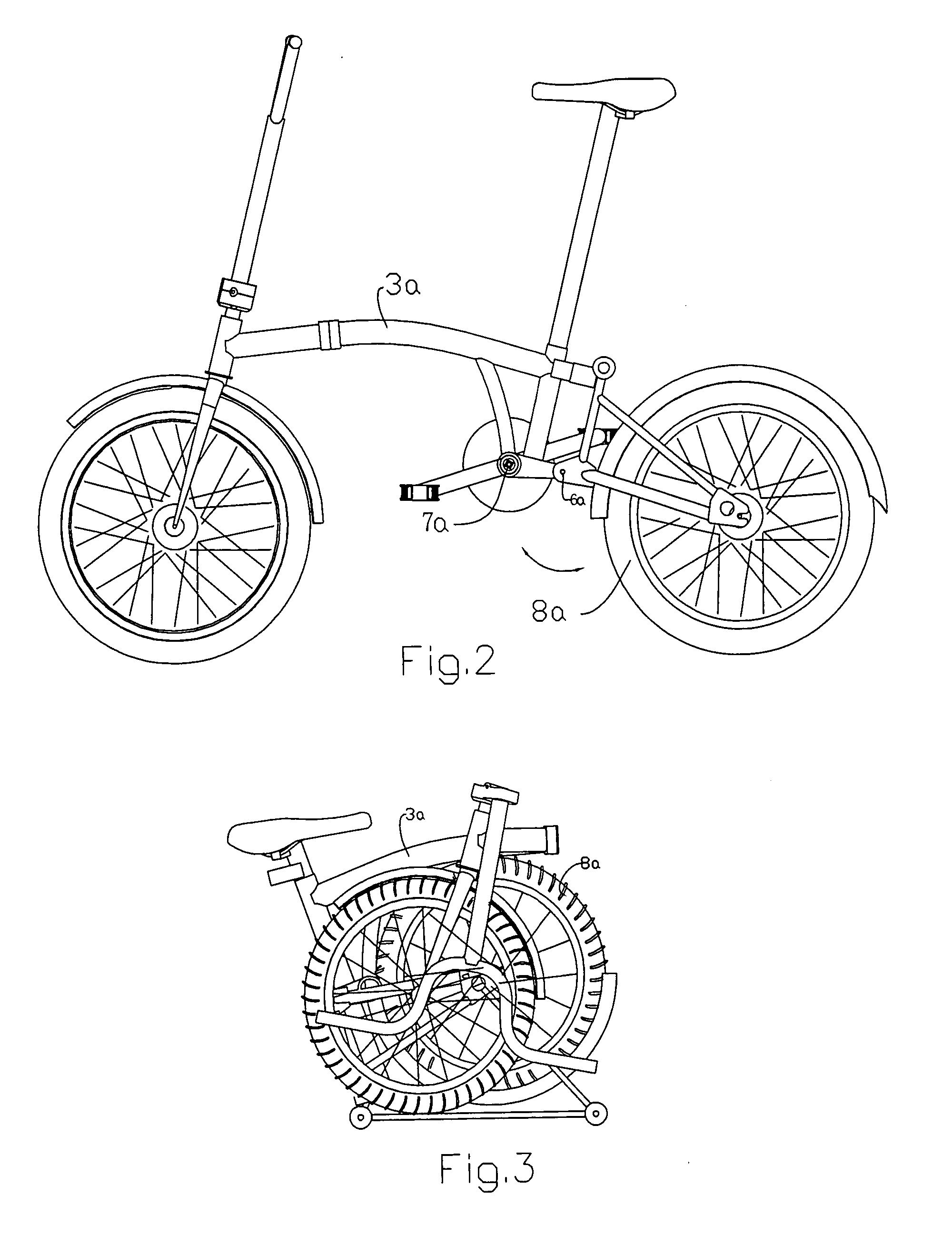

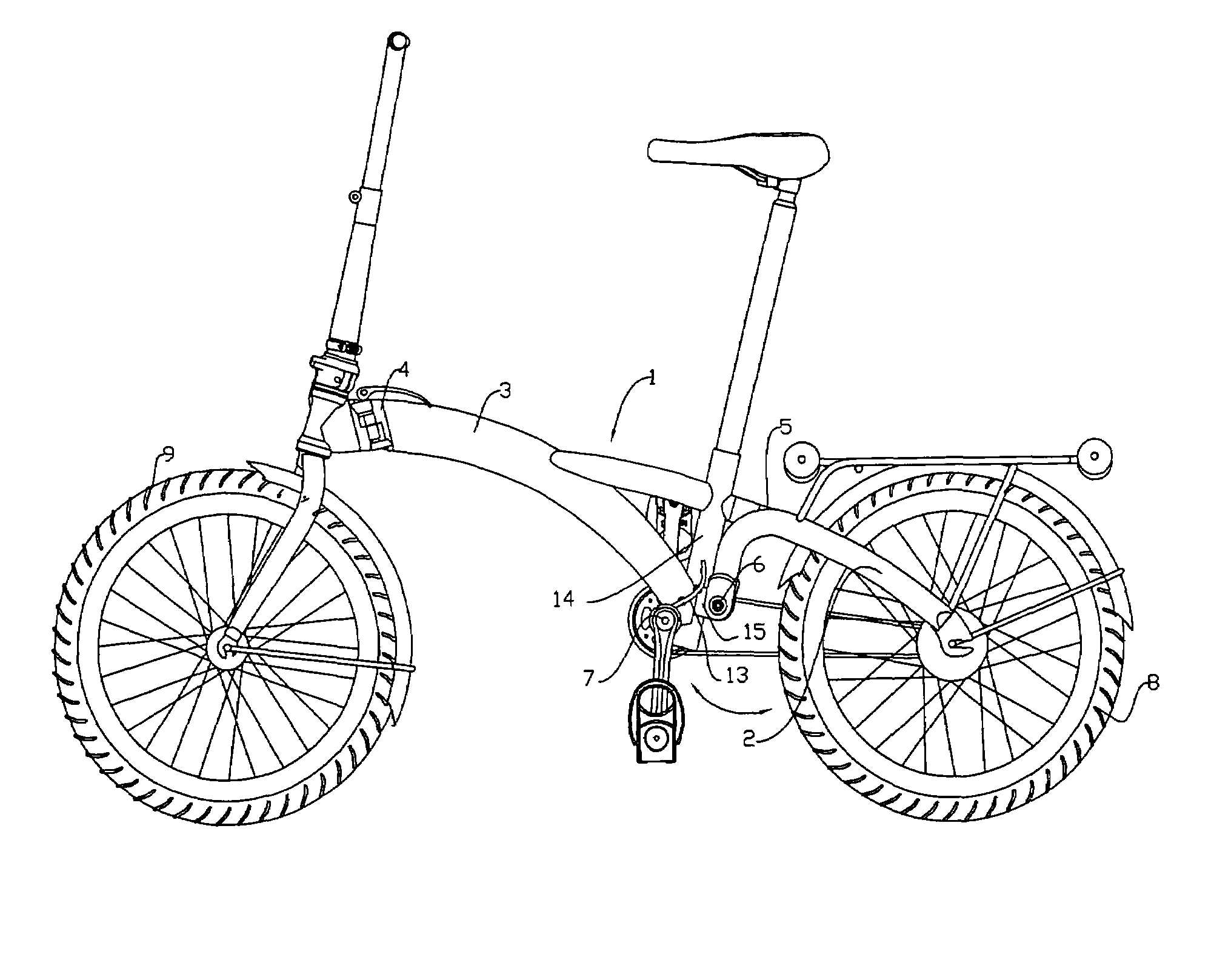

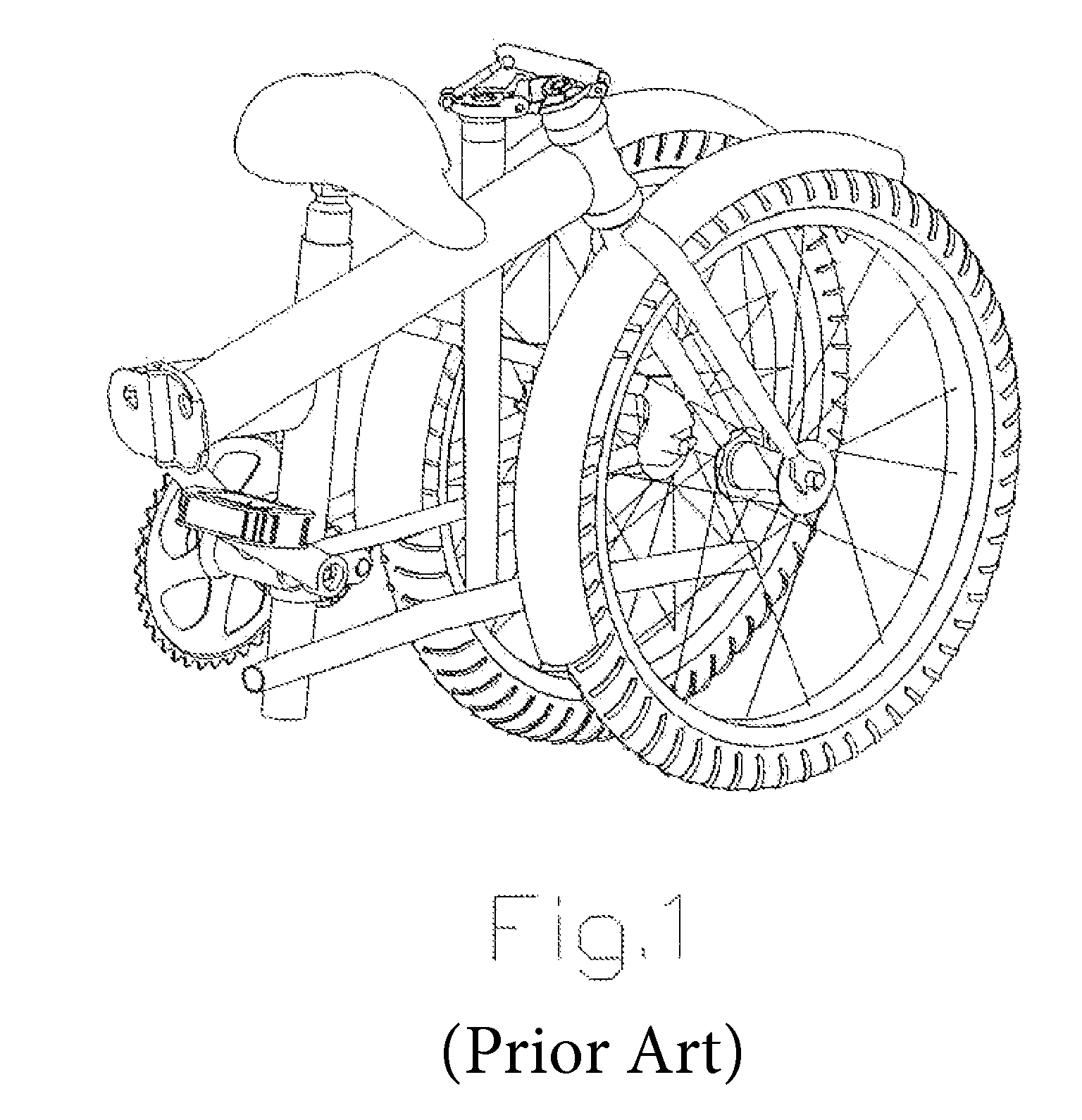

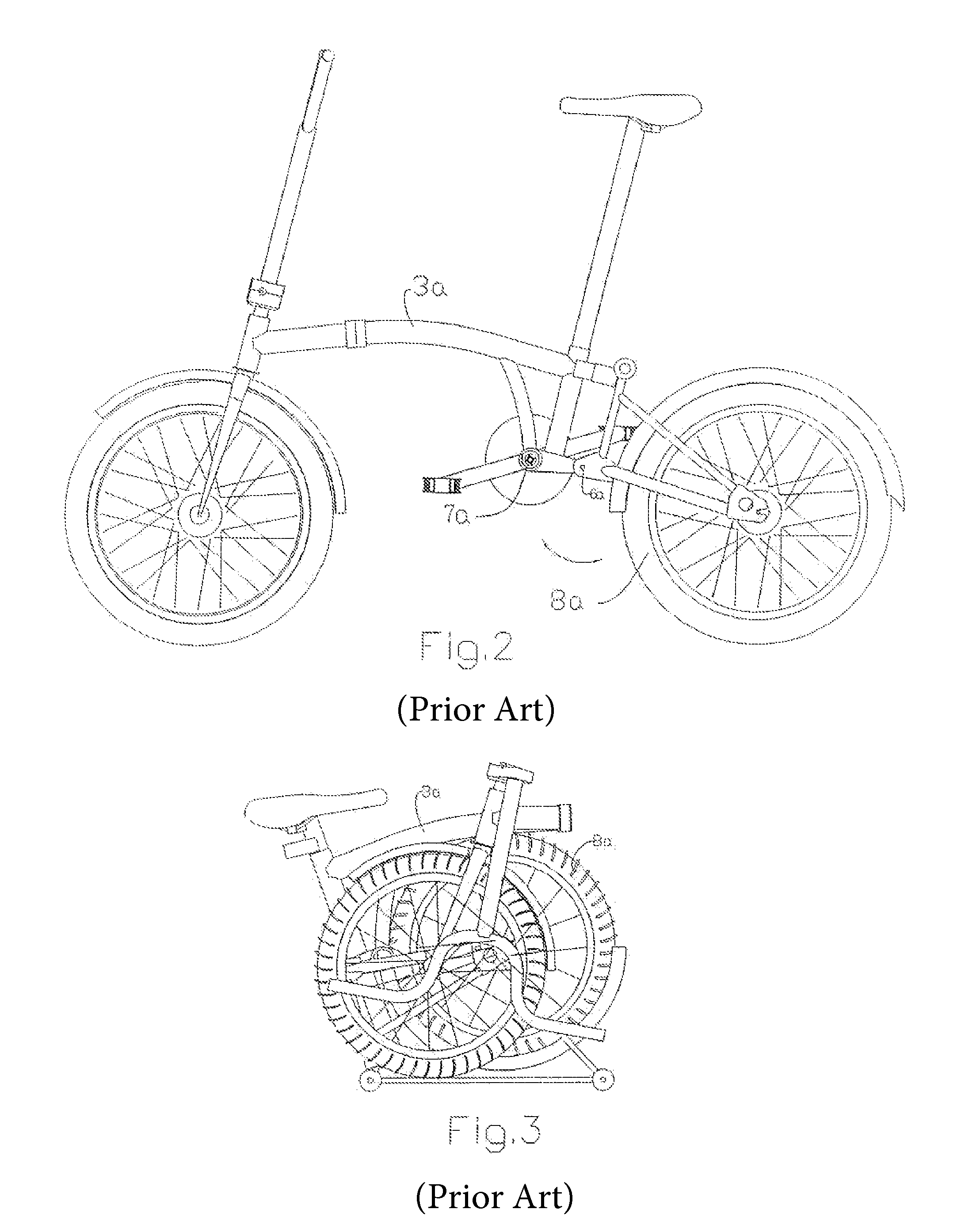

Folding bicycle

InactiveUS20070210556A1Avoid excessive widthAvoid excessive heightPassenger cyclesWheel based transmissionShaped beamAcute angle

The present invention discloses a folding bicycle, wherein a folding joint is installed on the beam, and the rear fork is hinged with the frame via a hinge axle, on the rear fork is installed a support bar which rests against the frame; and wherein the beam is S-shaped, and the hinge axle is tilted by an acute angle with respect to the central axle of the frame. When the bicycle is folded, the front and rear wheels are located separately, each at one side of the beam and within the concave section of the S-shaped beam, so that the bicycle is more compact and has a less width after being folded.

Owner:TAK WEI HON DAVID

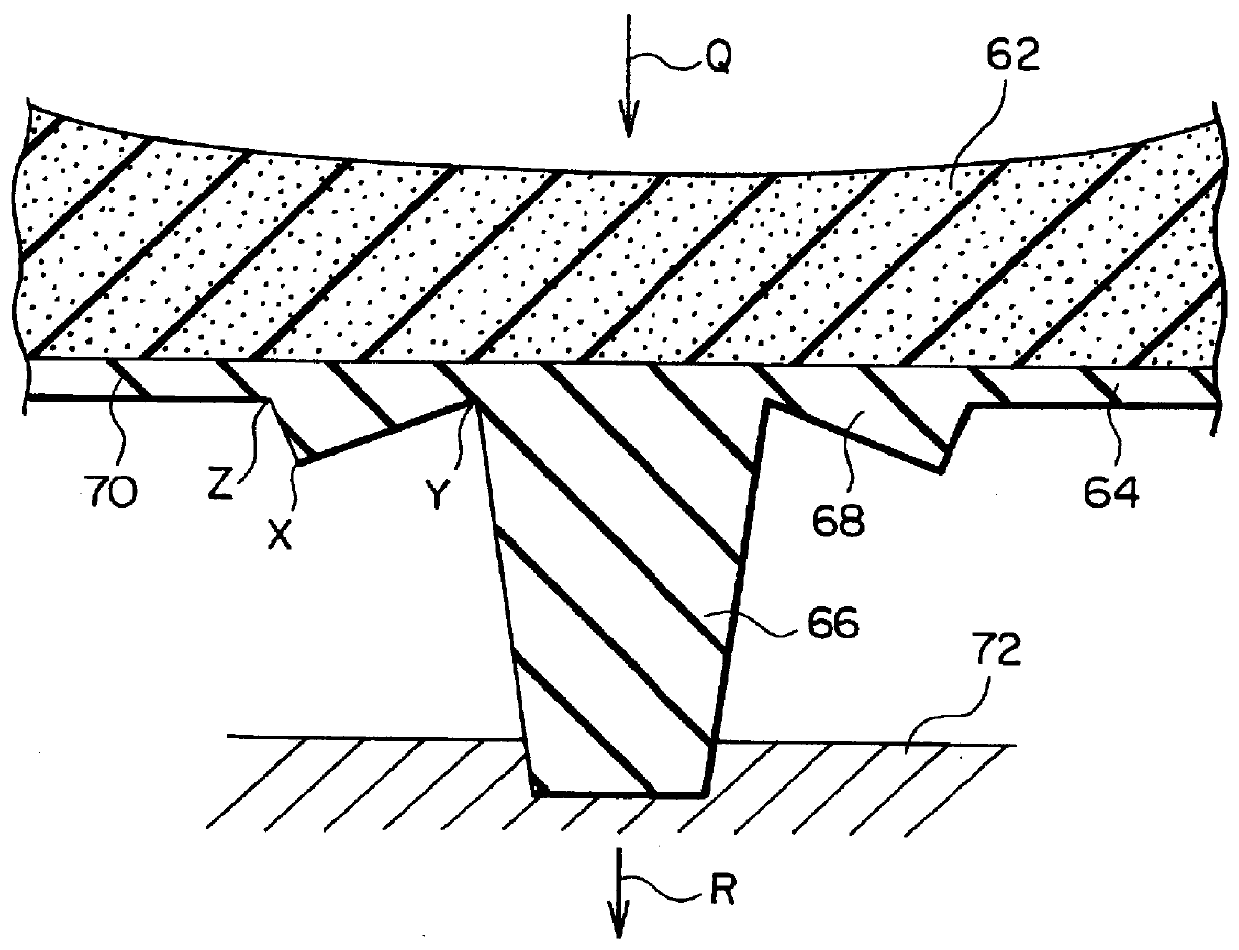

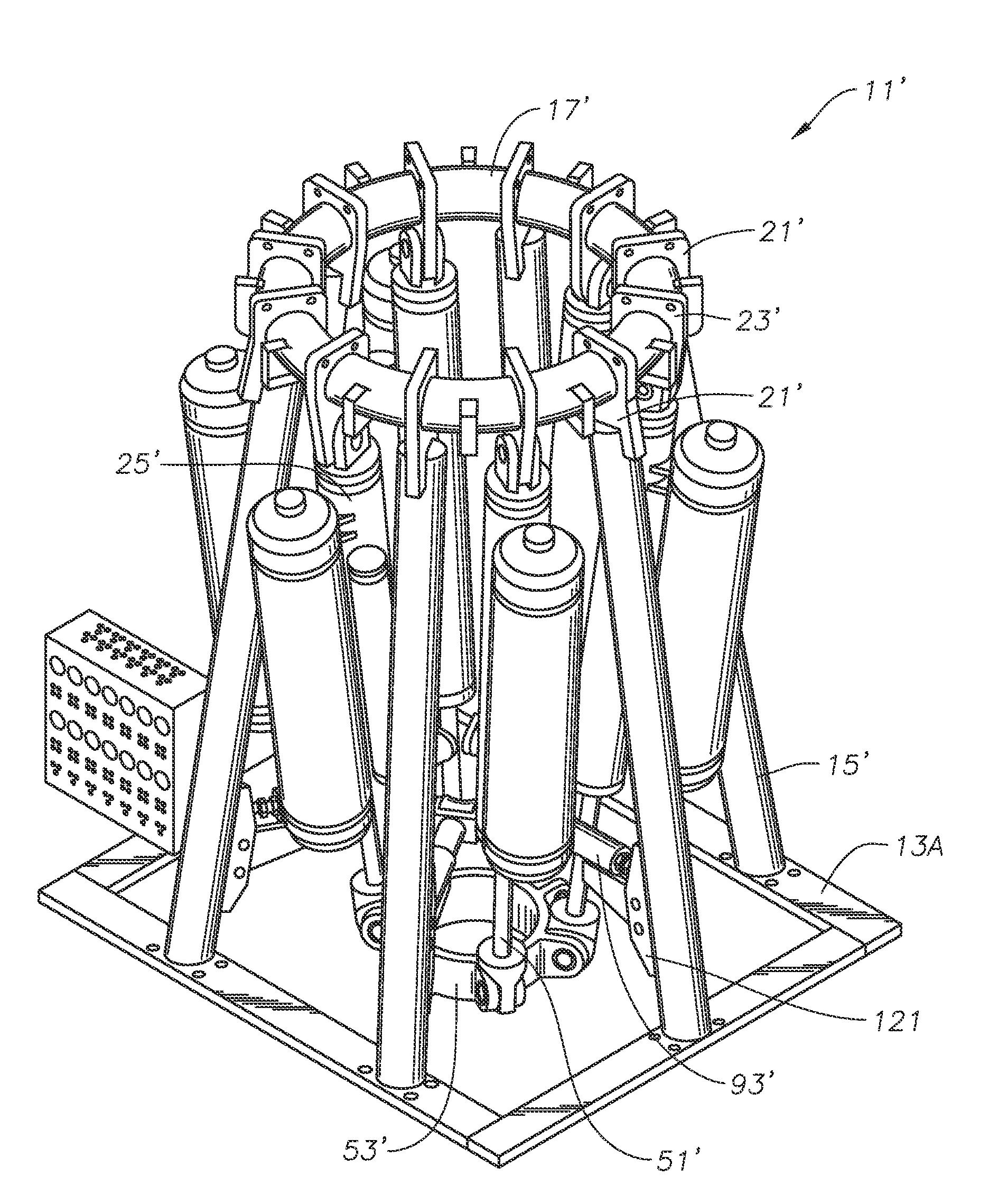

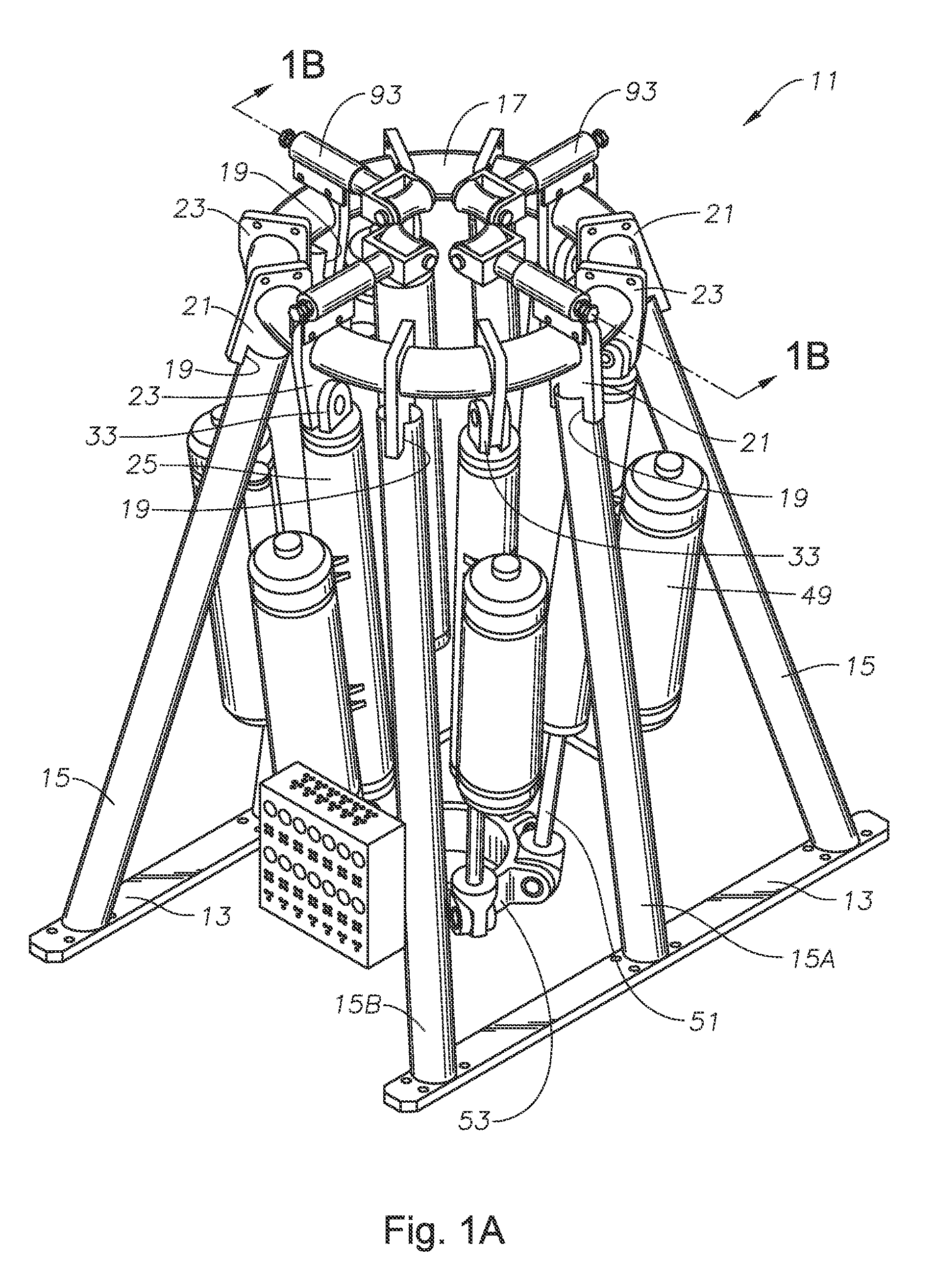

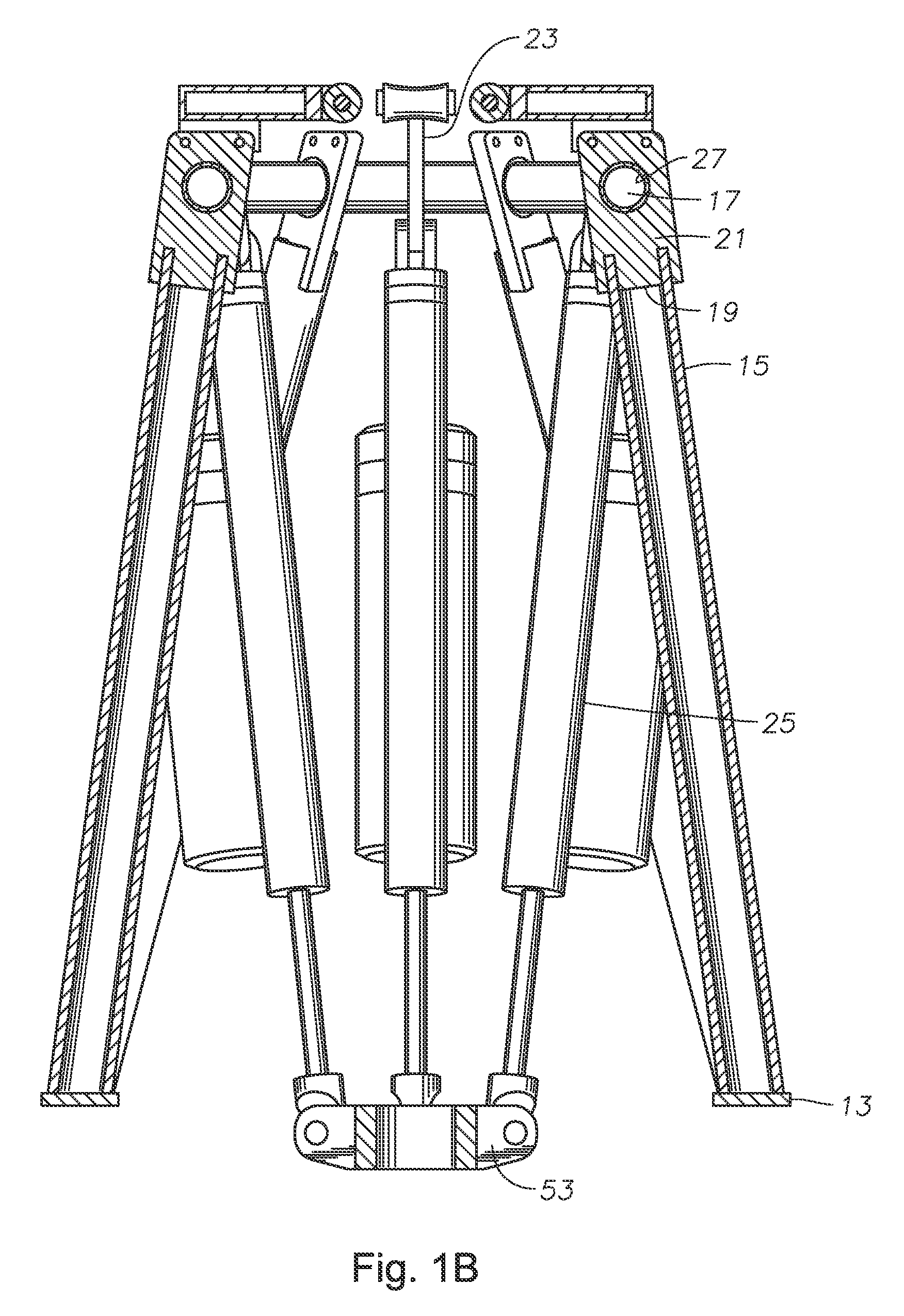

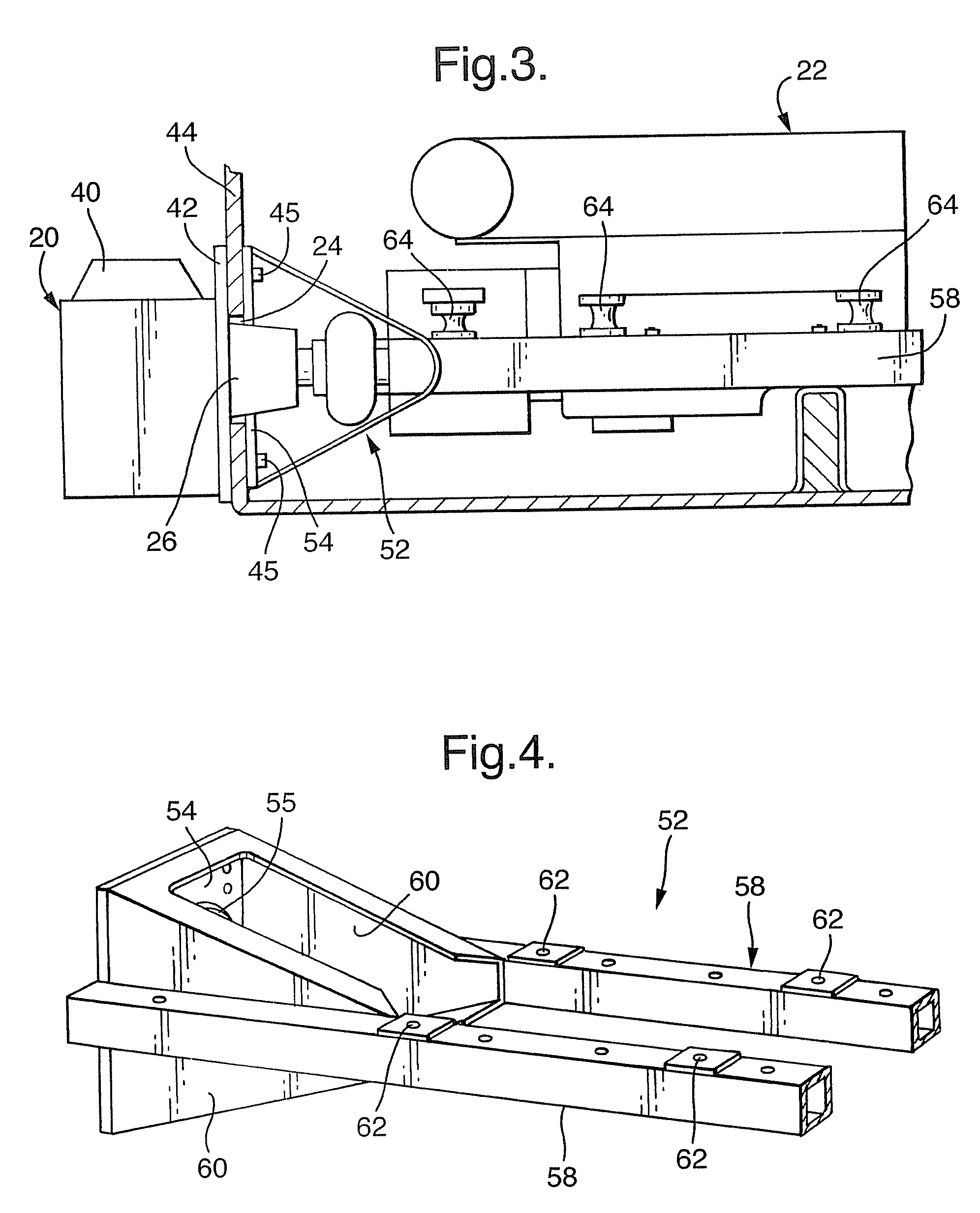

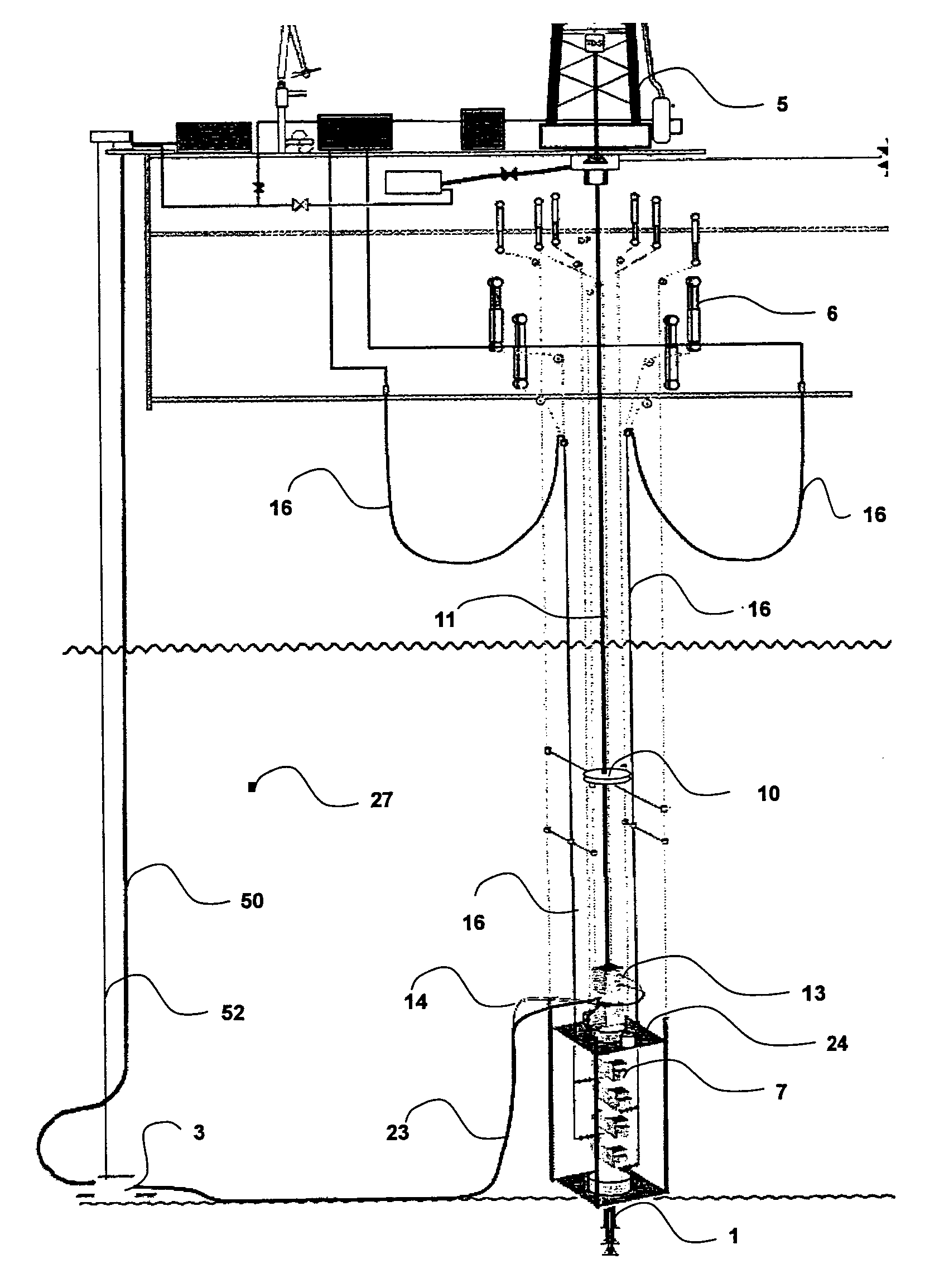

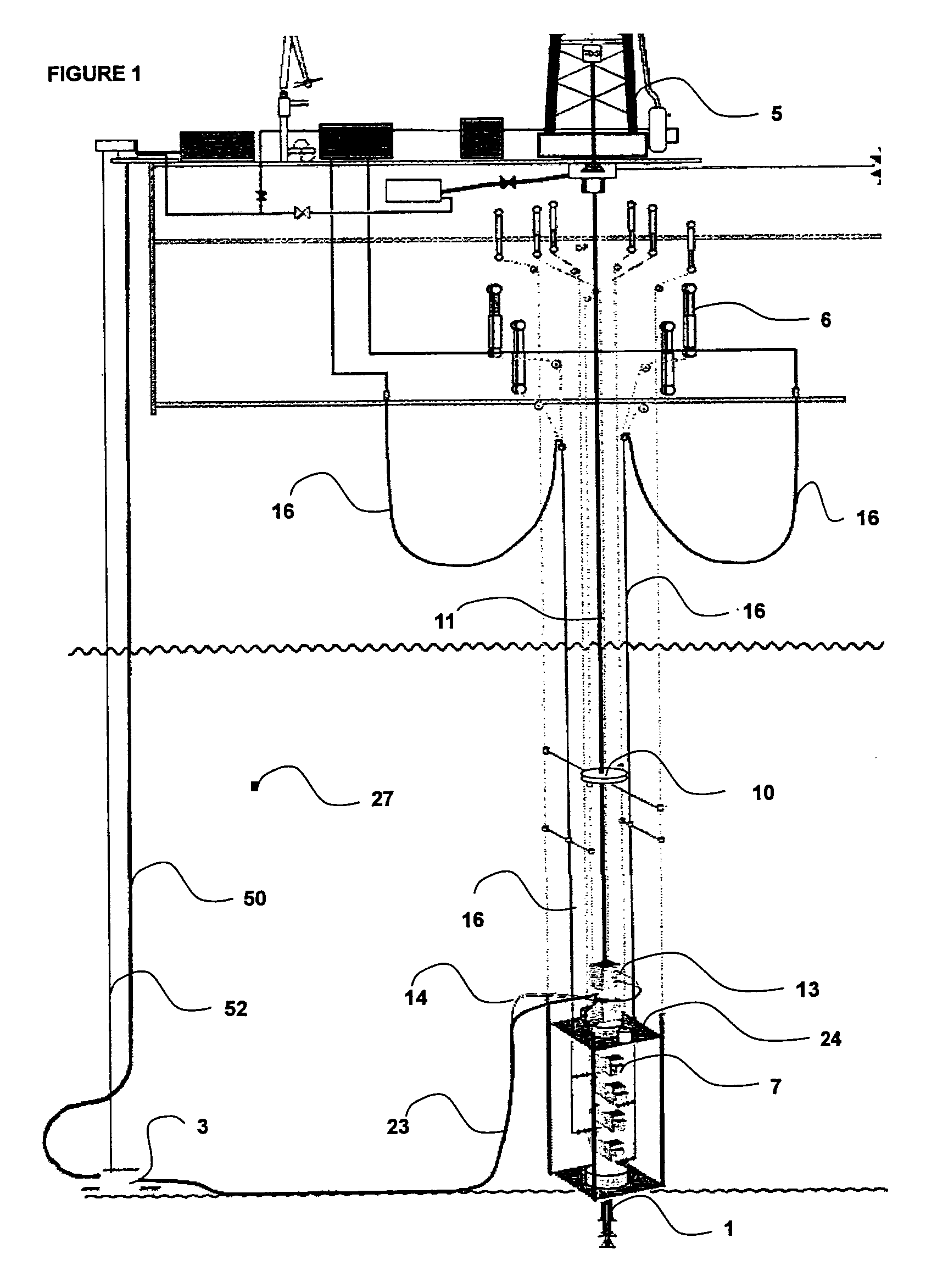

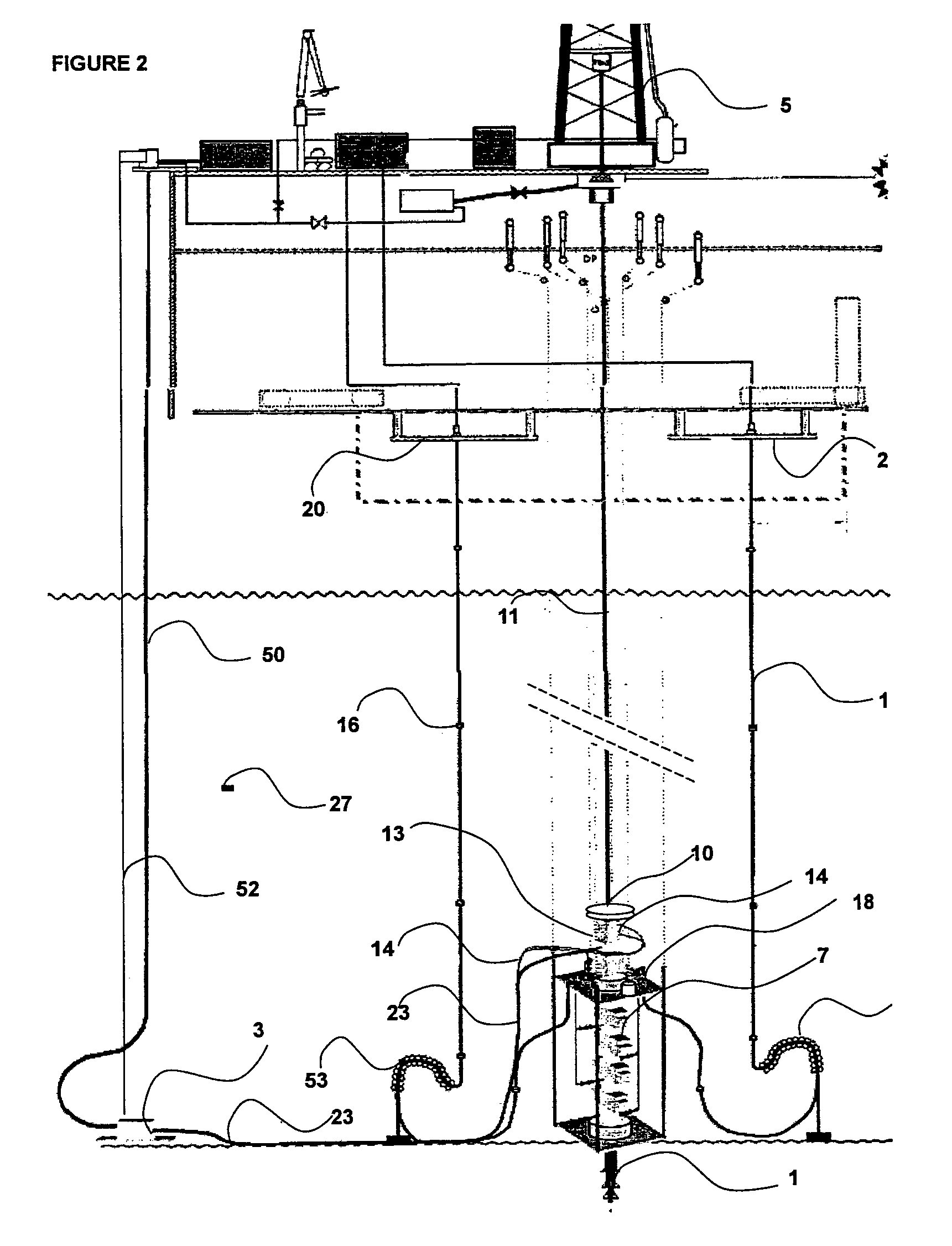

Riser tensioner system

ActiveUS20120247783A1Decreases required vertical spacingMinimal vertical spacing of deckDrilling rodsFluid removalEngineeringFloating platform

A riser tensioner system maintains a tensile force in a riser having an axis and extending from a subsea wellhead assembly through an opening in a floating platform deck. The tensioner includes a plurality of tensioner legs having lower ends mounted to the deck, and upper ends having slots formed therein to receive leg attachment plates having an opening therein through which a tubular support ring passes. A plurality of cylinders extend between the tubular support ring and a tensioner ring and couple to the support ring with cylinder attachment plates through which the tubular support ring passes. An upper end of each cylinder pivots about the mounting point, and a lower end of each cylinder adjustably mounts to the tensioner ring.

Owner:THE TECH ALLIANCE INC DBA OILPATCH TECH

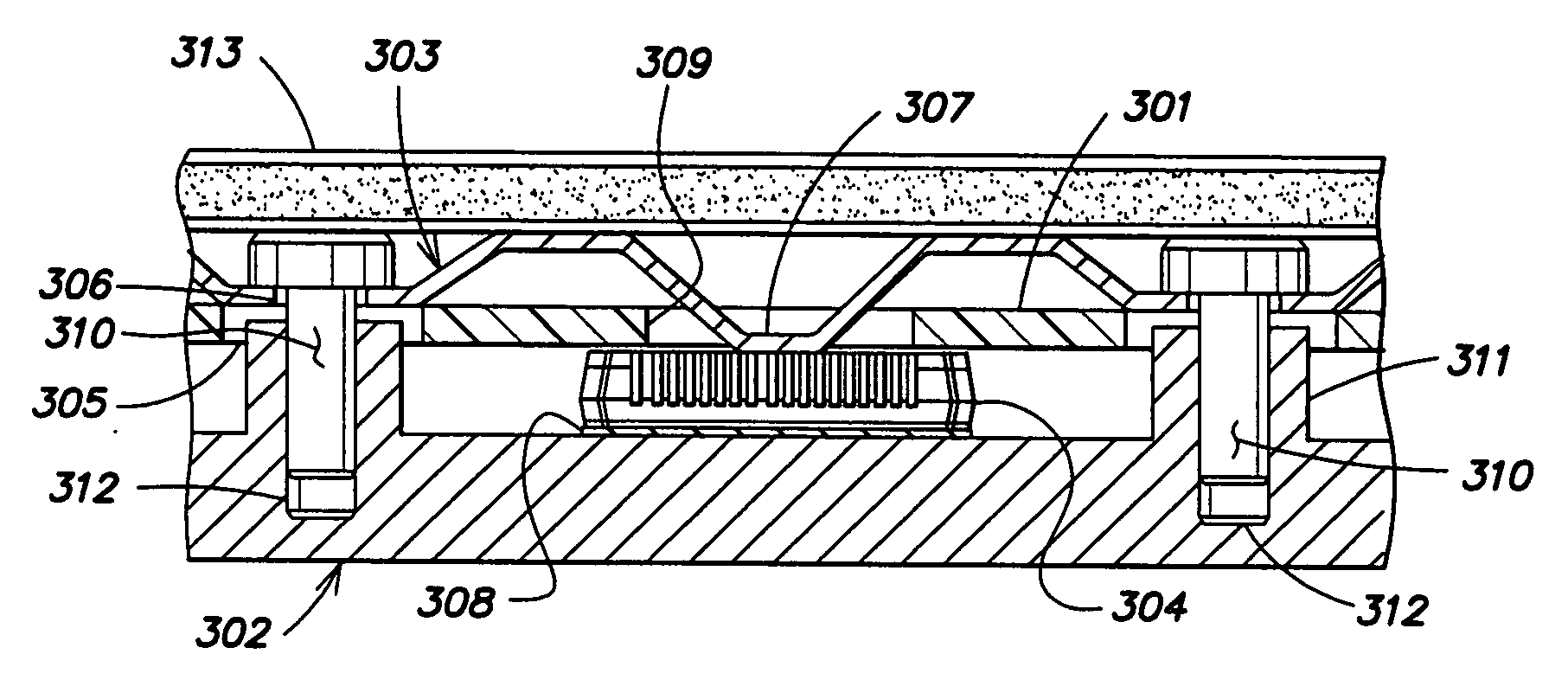

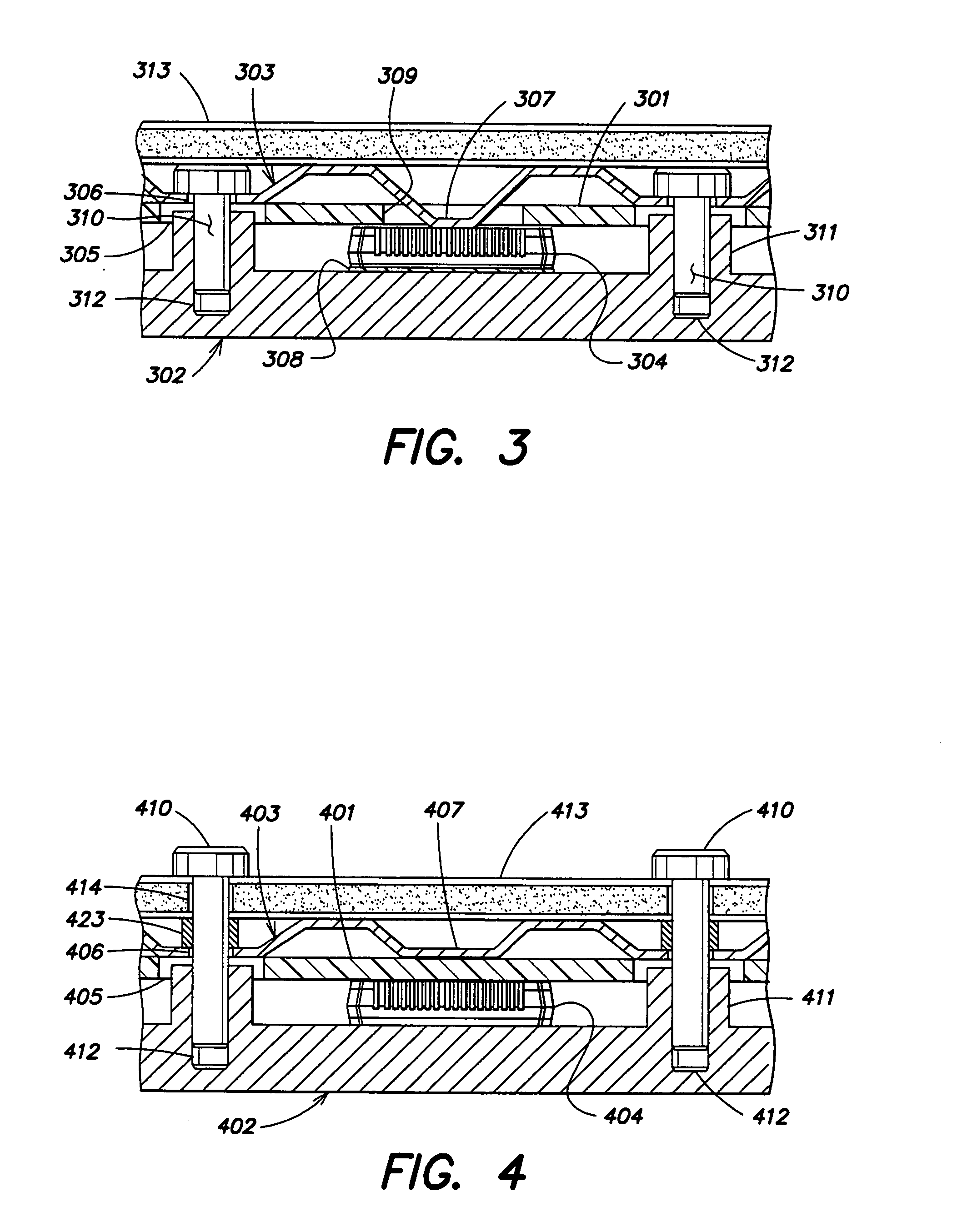

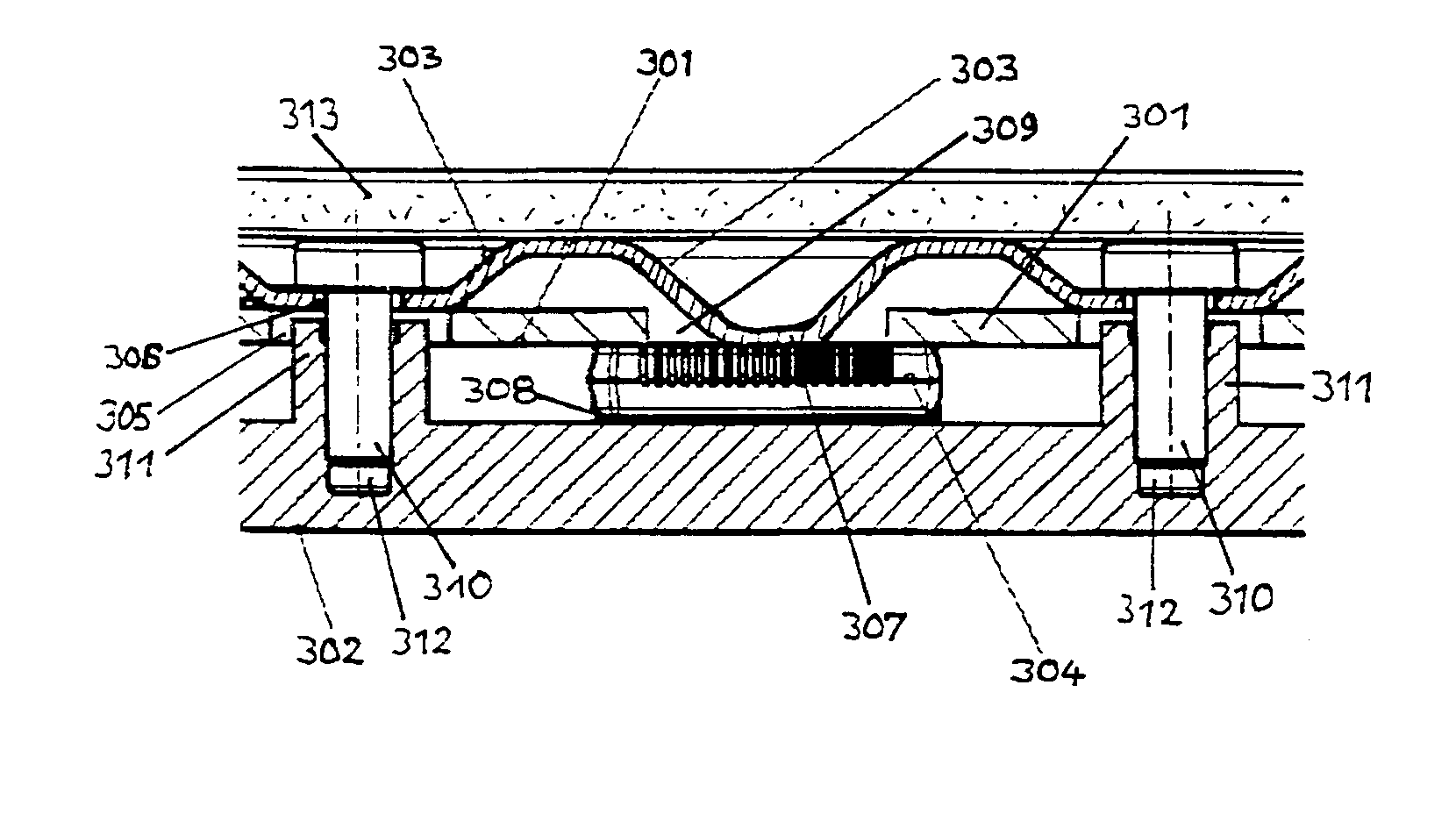

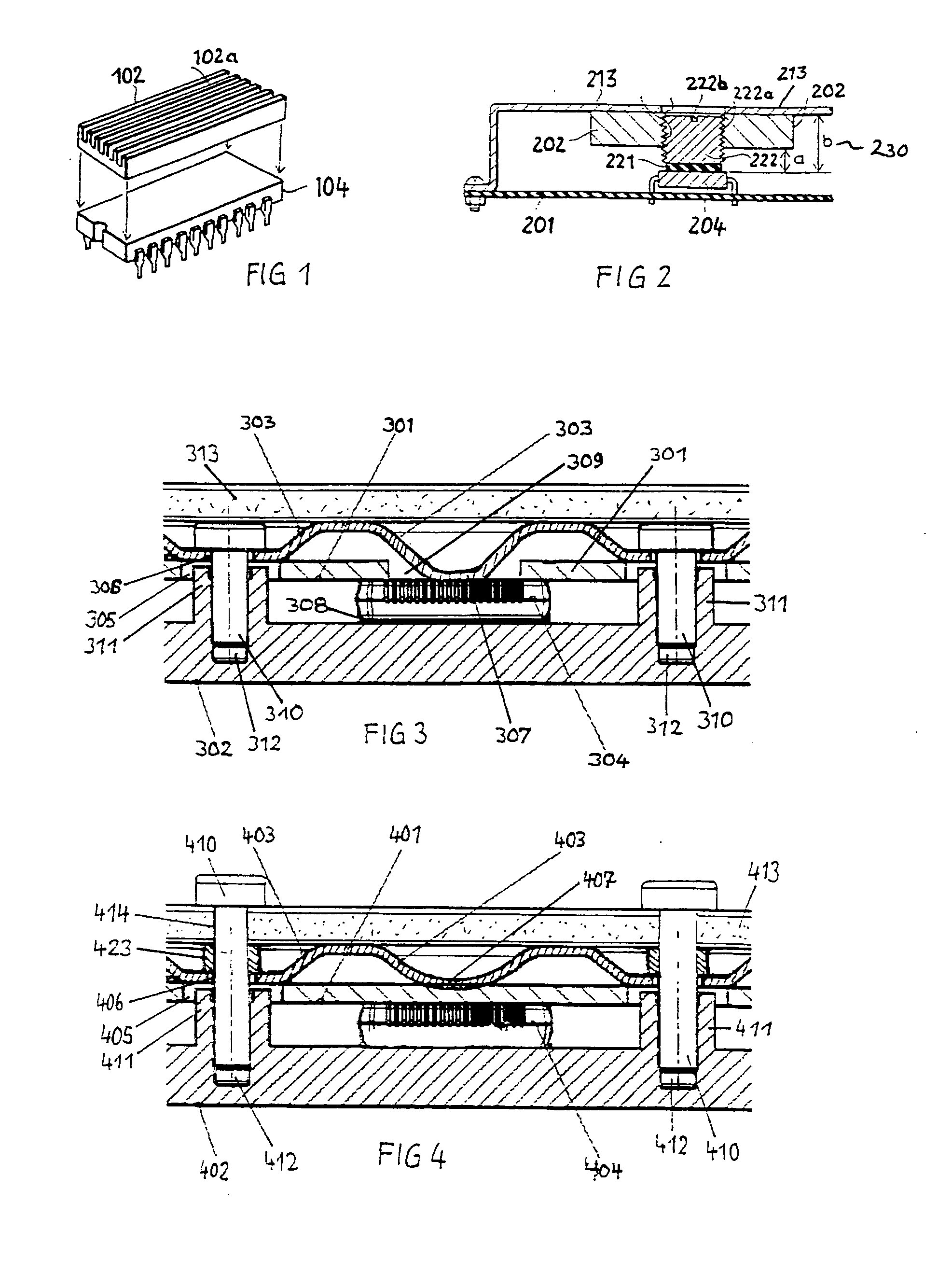

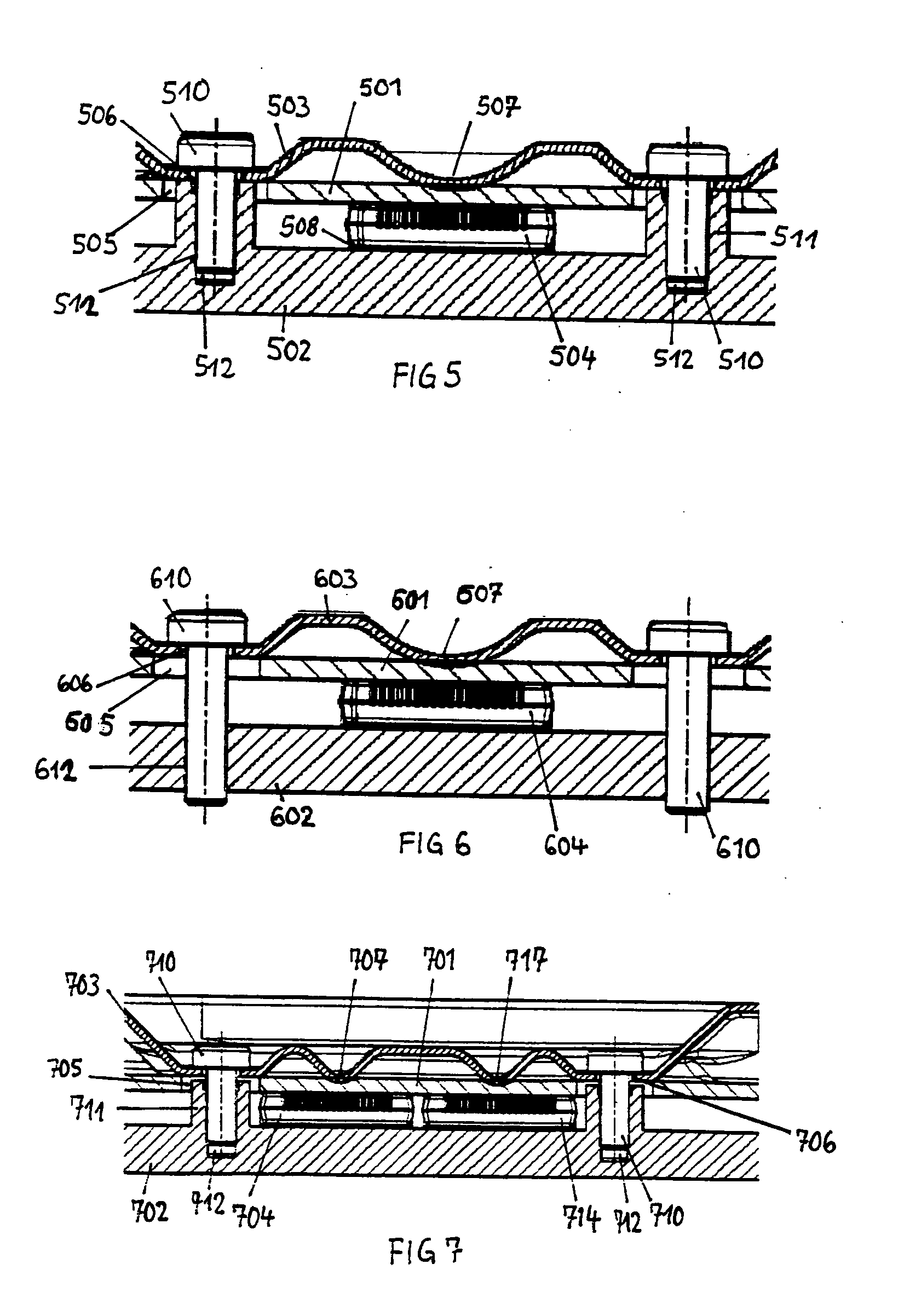

Apparatus for cooling semiconductor devices attached to a printed circuit board

ActiveUS7187553B2Significant positive effectManufacturing process is less-costlySemiconductor/solid-state device detailsSolid-state devicesCooling effectEngineering

An electronic assembly includes a semiconductor device mounted on a printed circuit board, a leaf spring and a cooling plate. A plurality of fasteners pass through co-axial apertures of the leaf spring, the printed circuit board and the cooling plate, such that a contact surface of the leaf spring imparts a force on the semiconductor device to retain the semiconductor device in a thermally conductive position with respect to the cooling plate. A positive cooling effect is achieved regardless of mounting conditions including orientation of the electronic assembly, and the position of the semiconductor device on the cooling plate.

Owner:HARMAN BECKER AUTOMOTIVE SYST

Apparatus for cooling semiconductor devices attached to a printed circuit board

ActiveUS20050128713A1Significant positive effectManufacturing process is less-costlySemiconductor/solid-state device detailsSolid-state devicesDevice materialCooling effect

An electronic assembly includes a semiconductor device mounted on a printed circuit board, a leaf spring and a cooling plate. A plurality of fasteners pass through co-axial apertures of the leaf spring, the printed circuit board and the cooling plate, such that a contact surface of the leaf spring imparts a force on the semiconductor device to retain the semiconductor device in a thermally conductive position with respect to the cooling plate. A positive cooling effect is achieved regardless of mounting conditions including orientation of the electronic assembly, and the position of the semiconductor device on the cooling plate.

Owner:HARMAN BECKER AUTOMOTIVE SYST

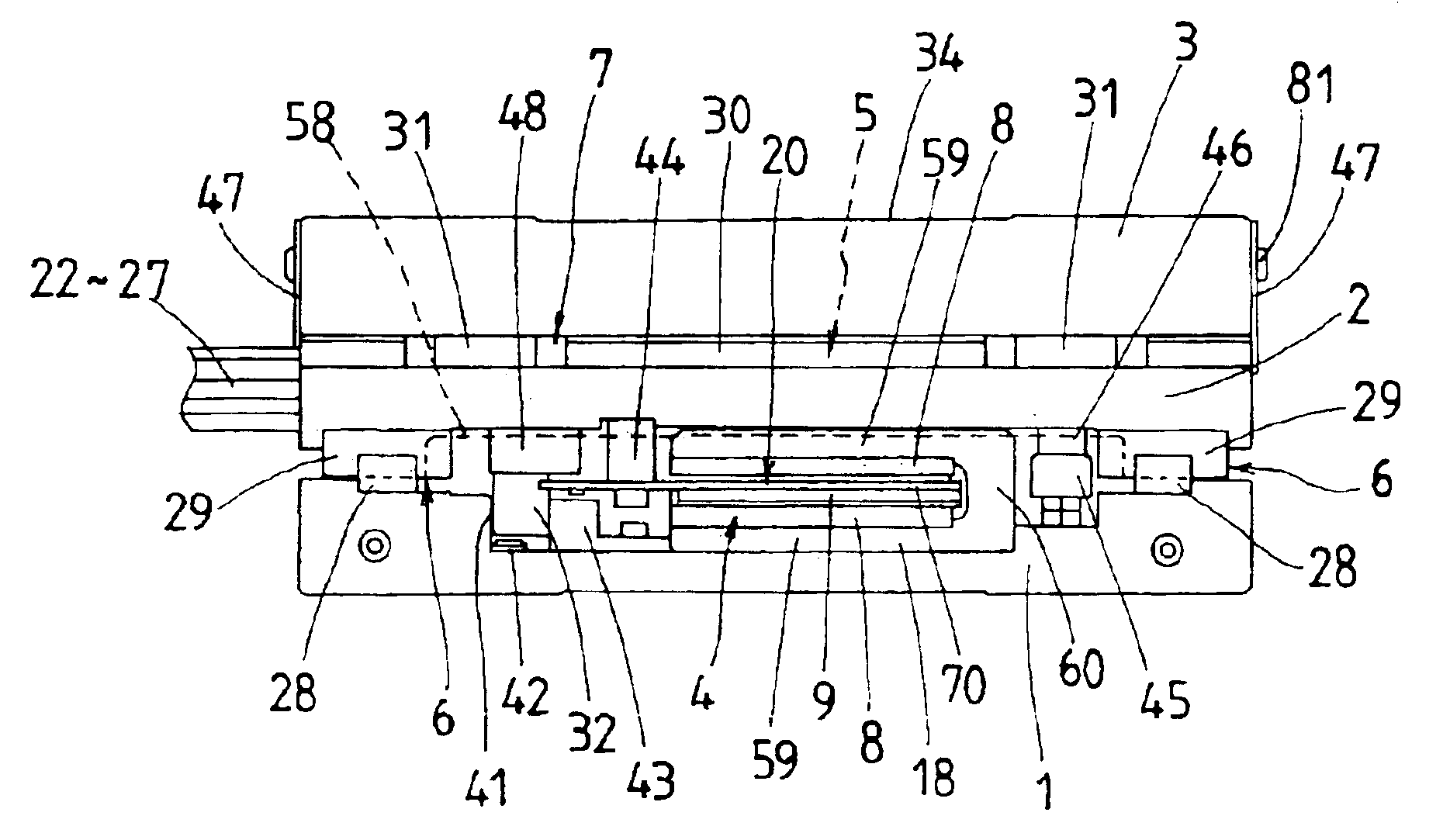

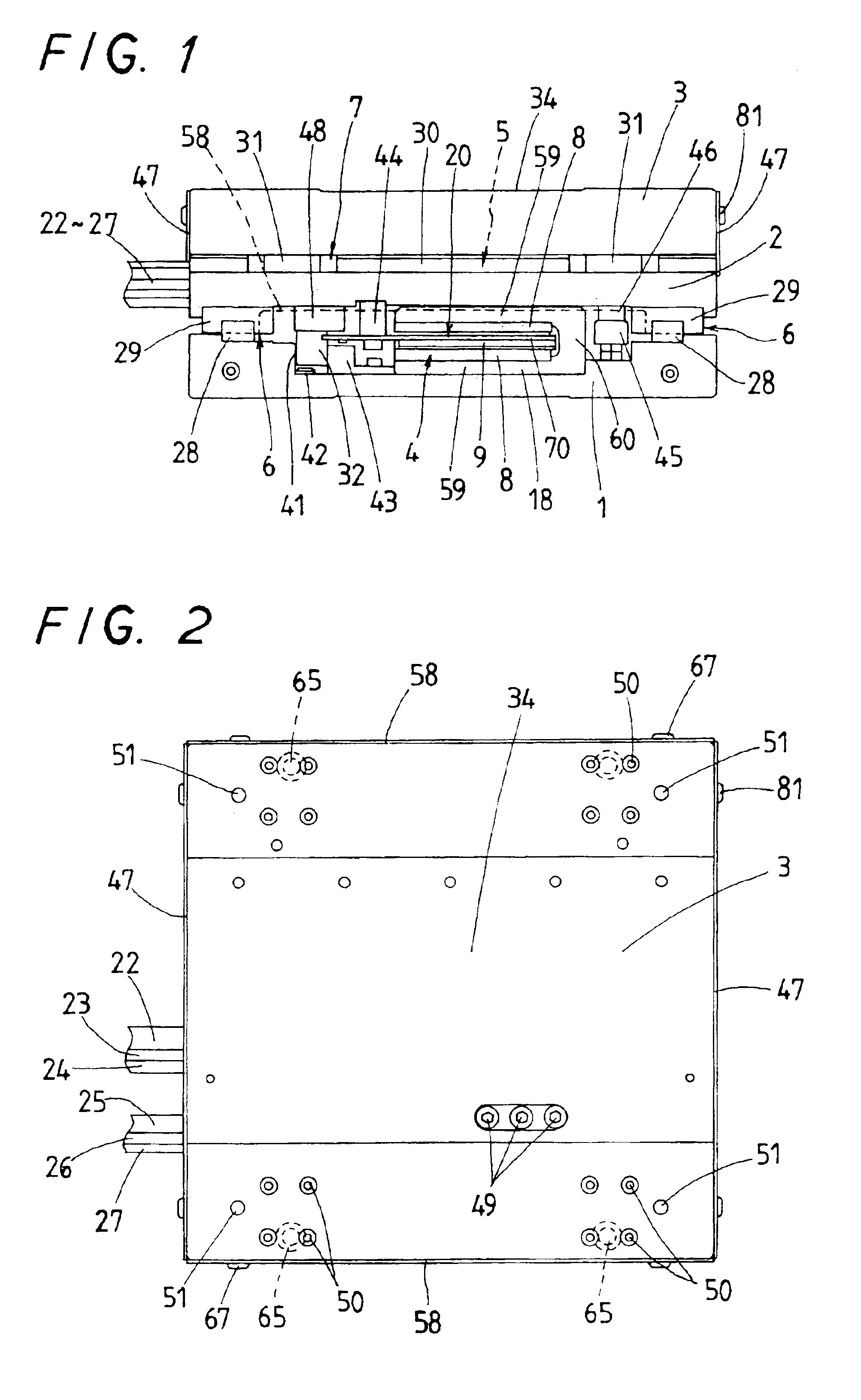

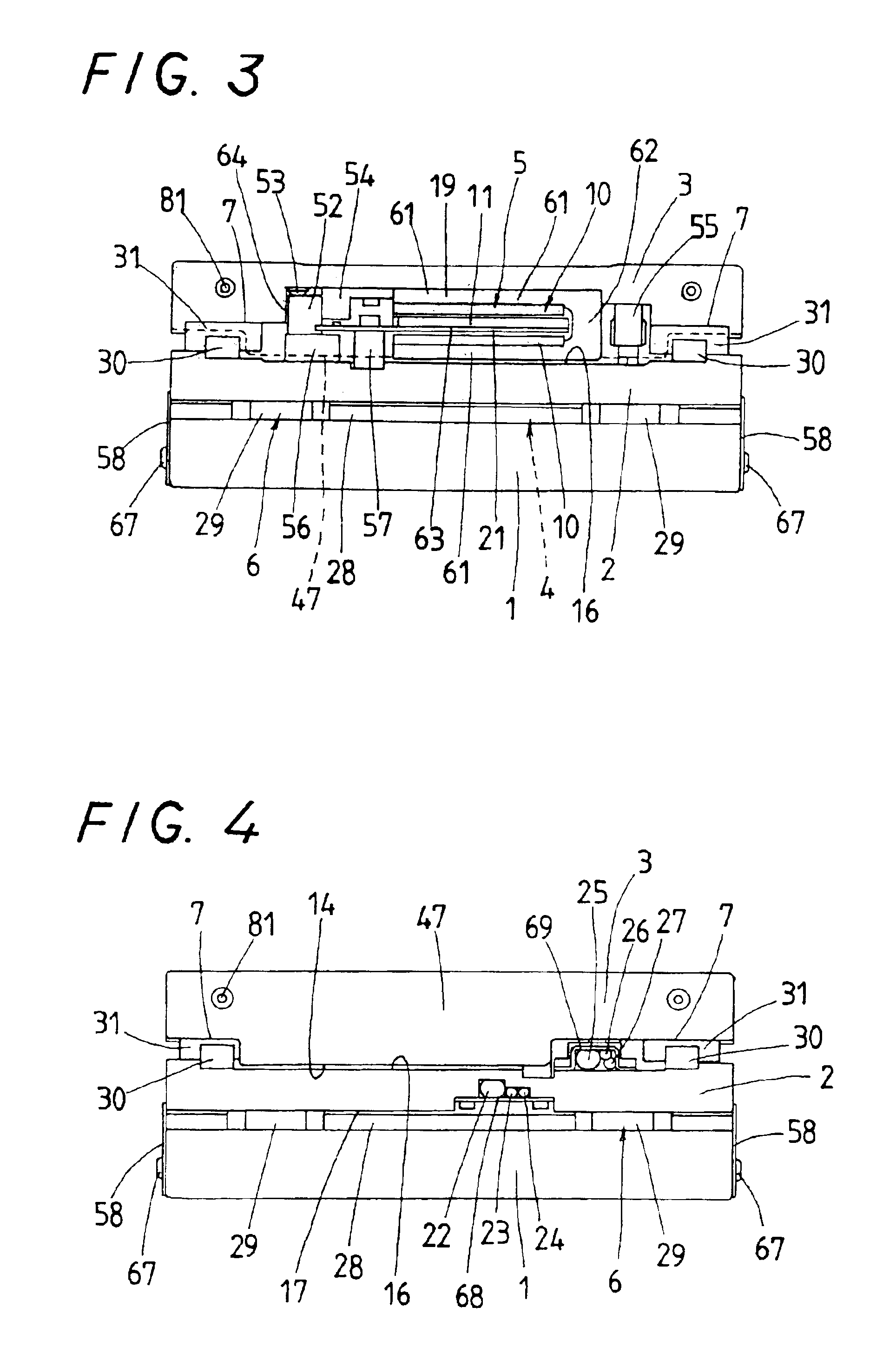

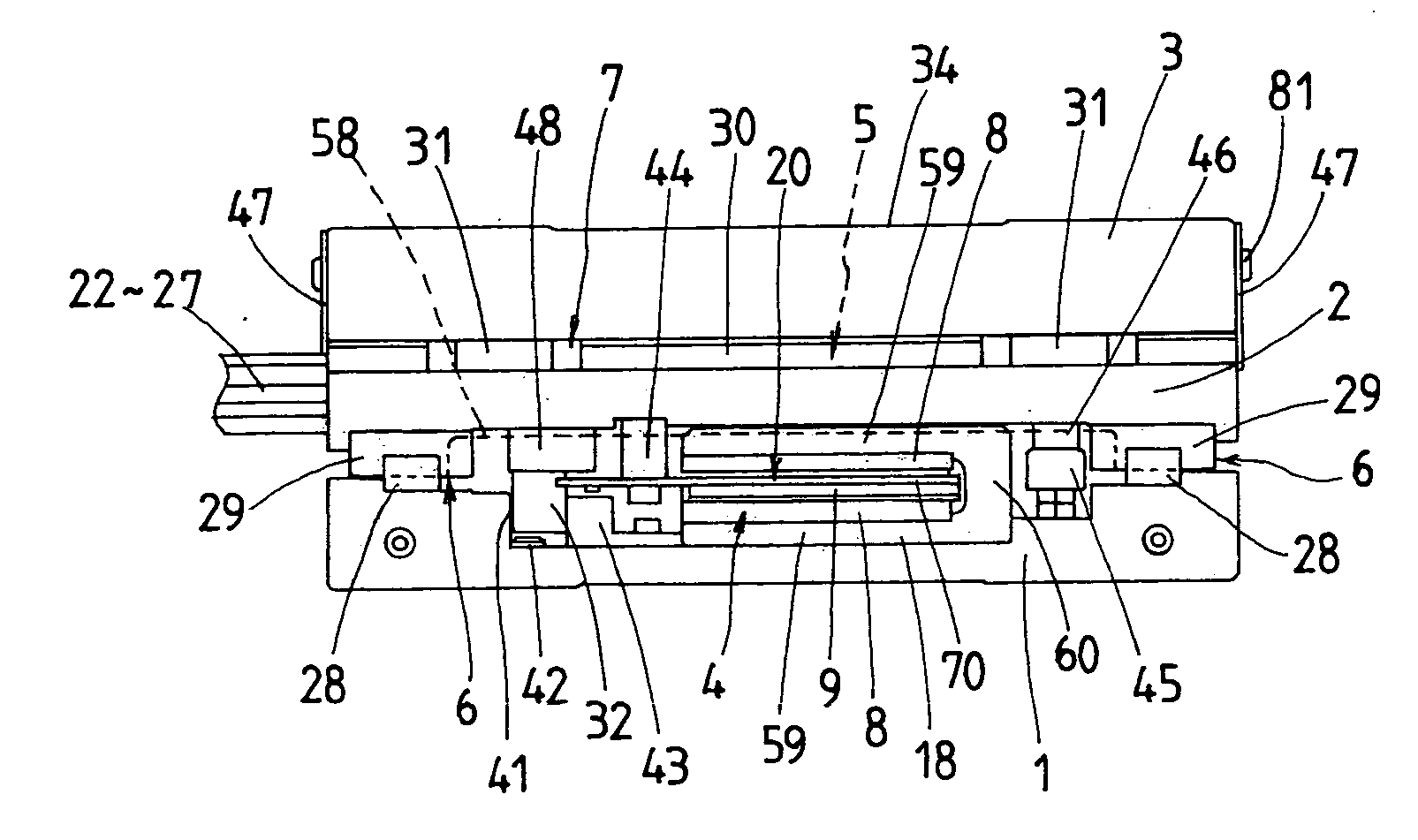

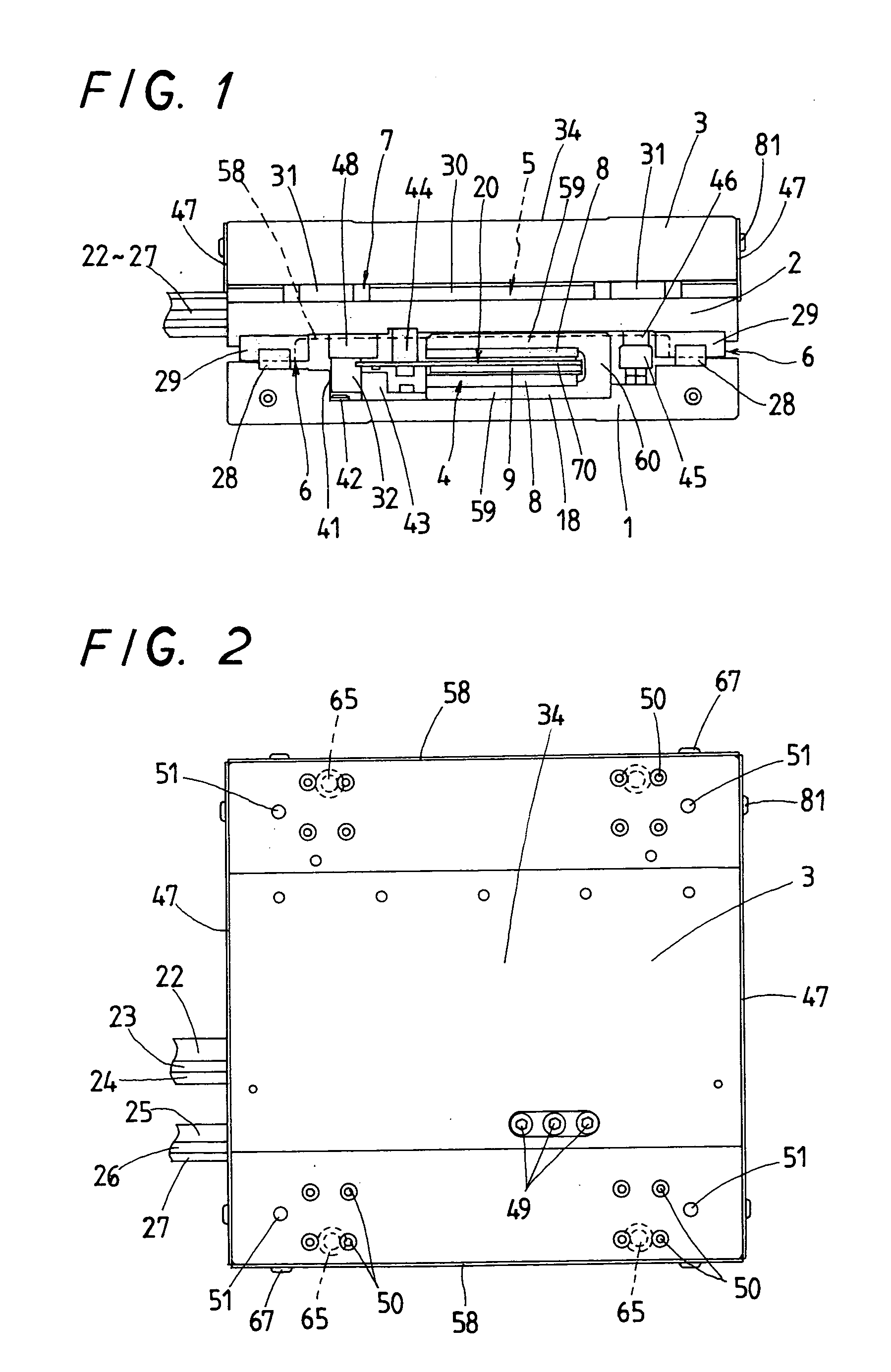

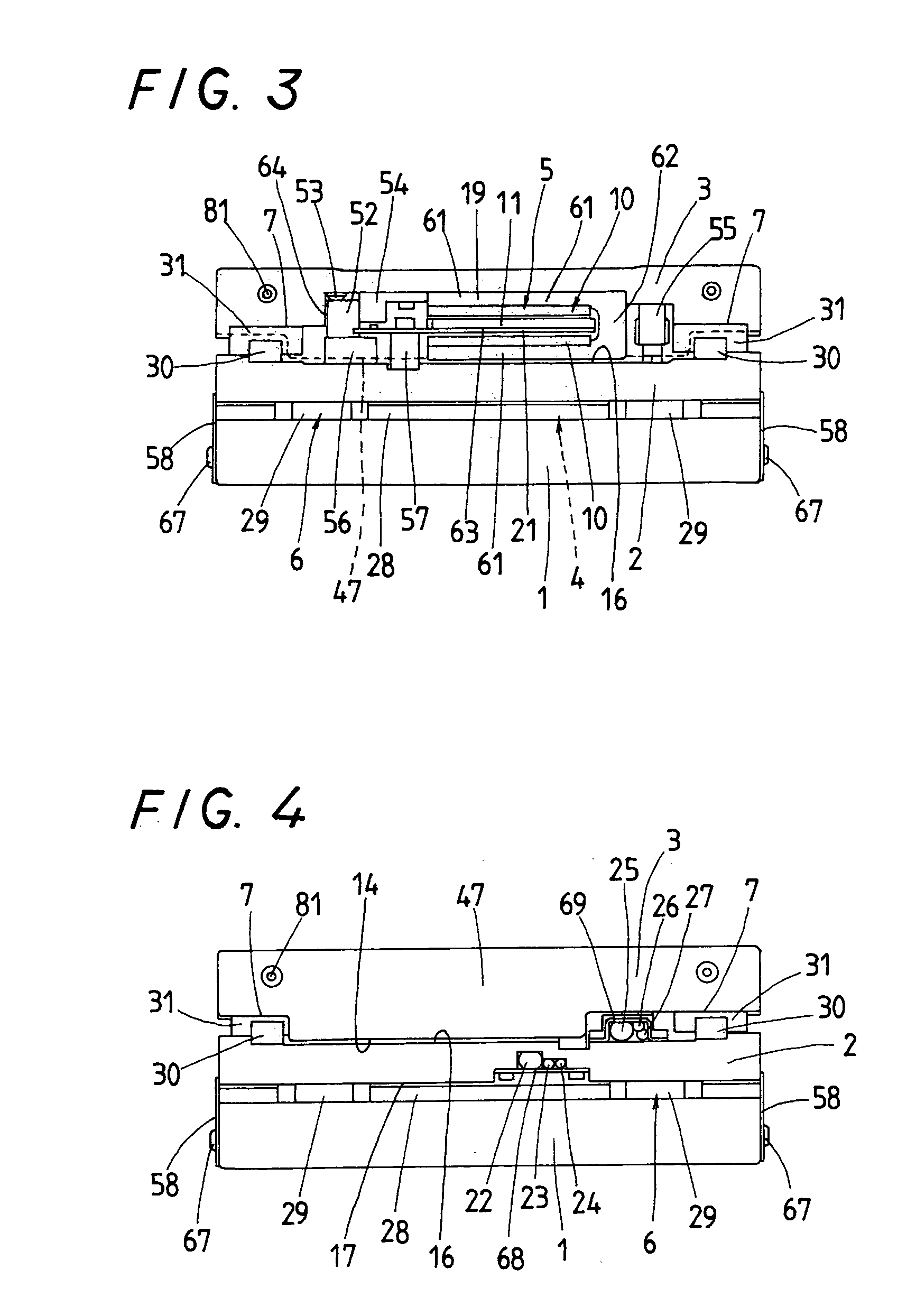

X-Y stage system with onboard linear motor

ActiveUS6911747B2Easy and fast assemblyReduce the overall heightFeeding apparatusLarge fixed membersLinear motionEngineering

An X-Y stage system is disclosed which is easy to assemble and compact or slim in construction. Both the X- and Y-stages are allowed to move without getting influence from the magnetic force created by the field magnets. The X-Y stage system has an X-stage movable relatively to a bed through a linear motion guide unit in an X-direction, and a Y-stage movable relatively to the X-stage through another linear motion guide unit in a Y-direction. The linear motors to force the X- and Y-stages are composed of paired field magnets of secondary side held to the bed and the Y-stage, respectively, and armature windings of primary side supported on the opposite sides of the X-stage in a way lying in clearances between the opposing field magnets.

Owner:NIPPON THOMPSON

Folding bicycle

InactiveUS7591473B2Avoid excessive widthAvoid excessive heightFoot-driven leversWheel based transmissionShaped beamAcute angle

The present invention discloses a folding bicycle, wherein a folding joint is installed on the beam, and the rear fork is hinged with the frame via a hinge axle, on the rear fork is installed a support bar which rests against the frame; and wherein the beam is S-shaped, and the hinge axle is tilted by an acute angle with respect to the central axle of the frame. When the bicycle is folded, the front and rear wheels are located separately, each at one side of the beam and within the concave section of the S-shaped beam, so that the bicycle is more compact and has a less width after being folded.

Owner:TAK WEI HON DAVID

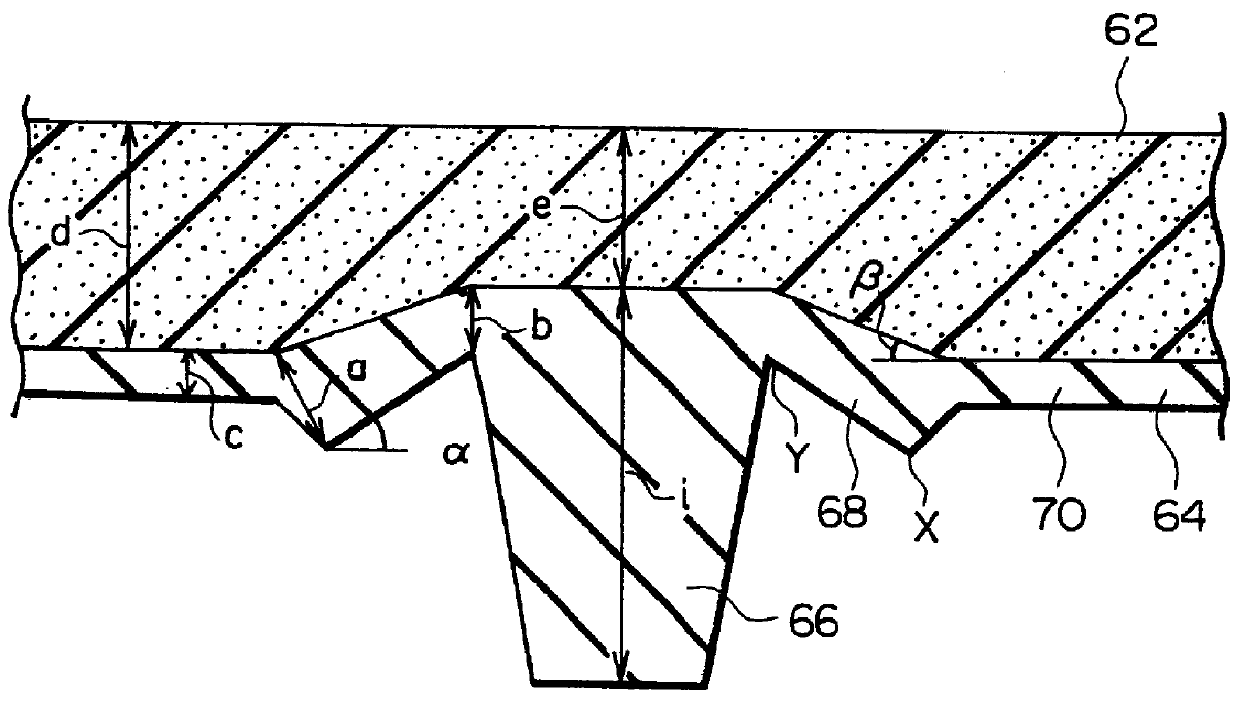

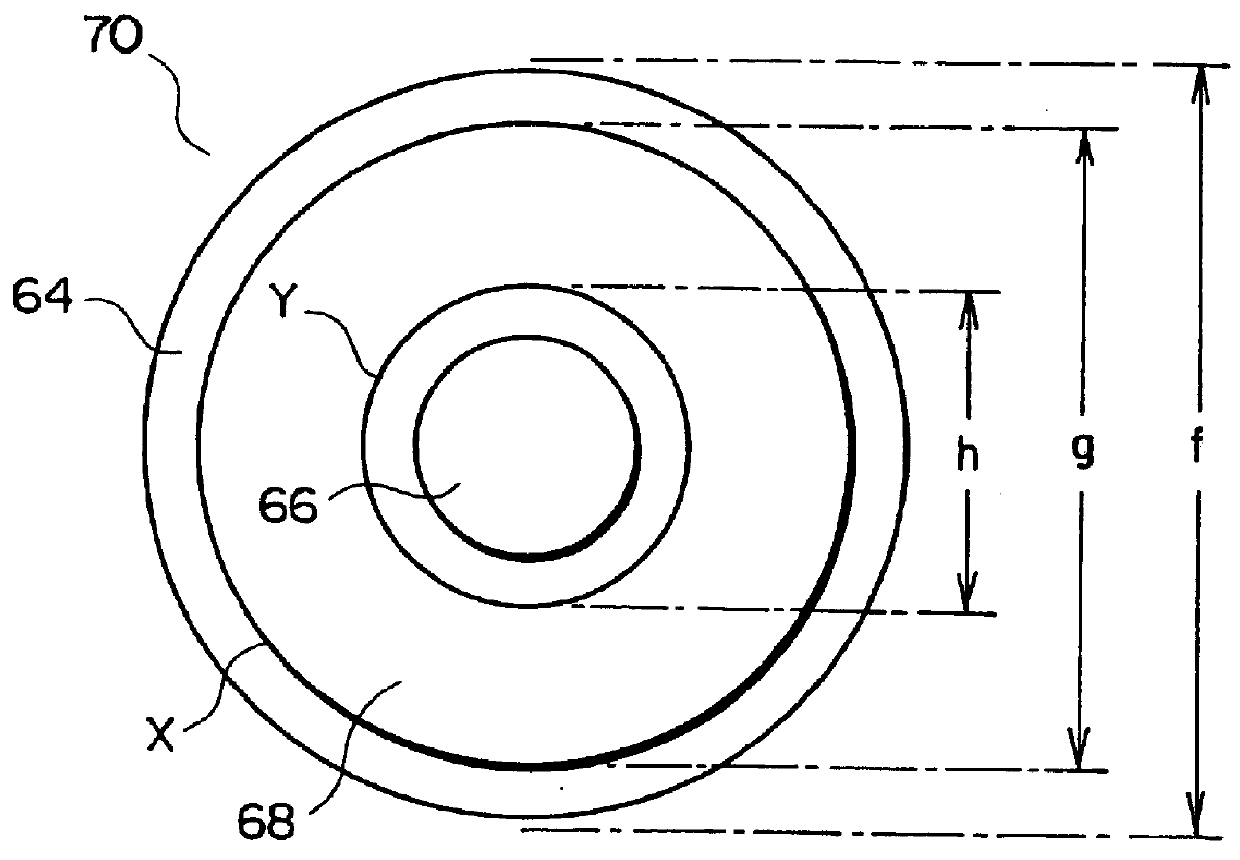

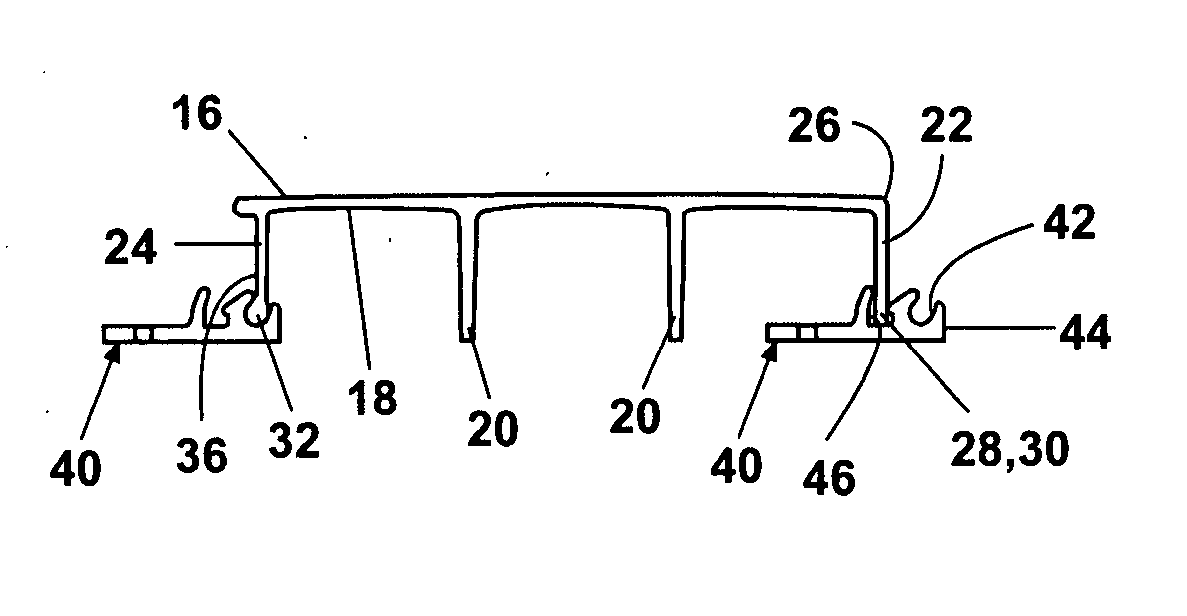

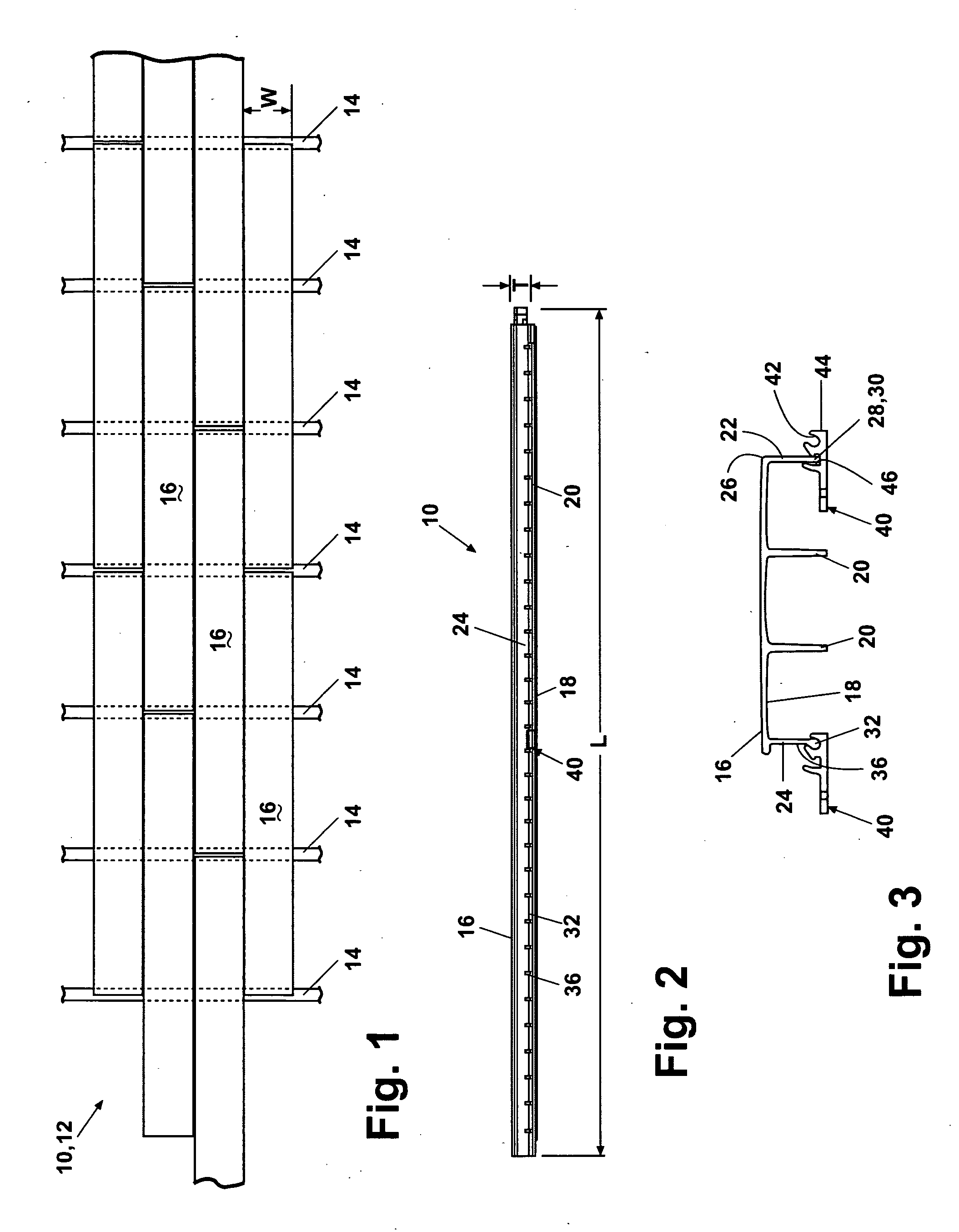

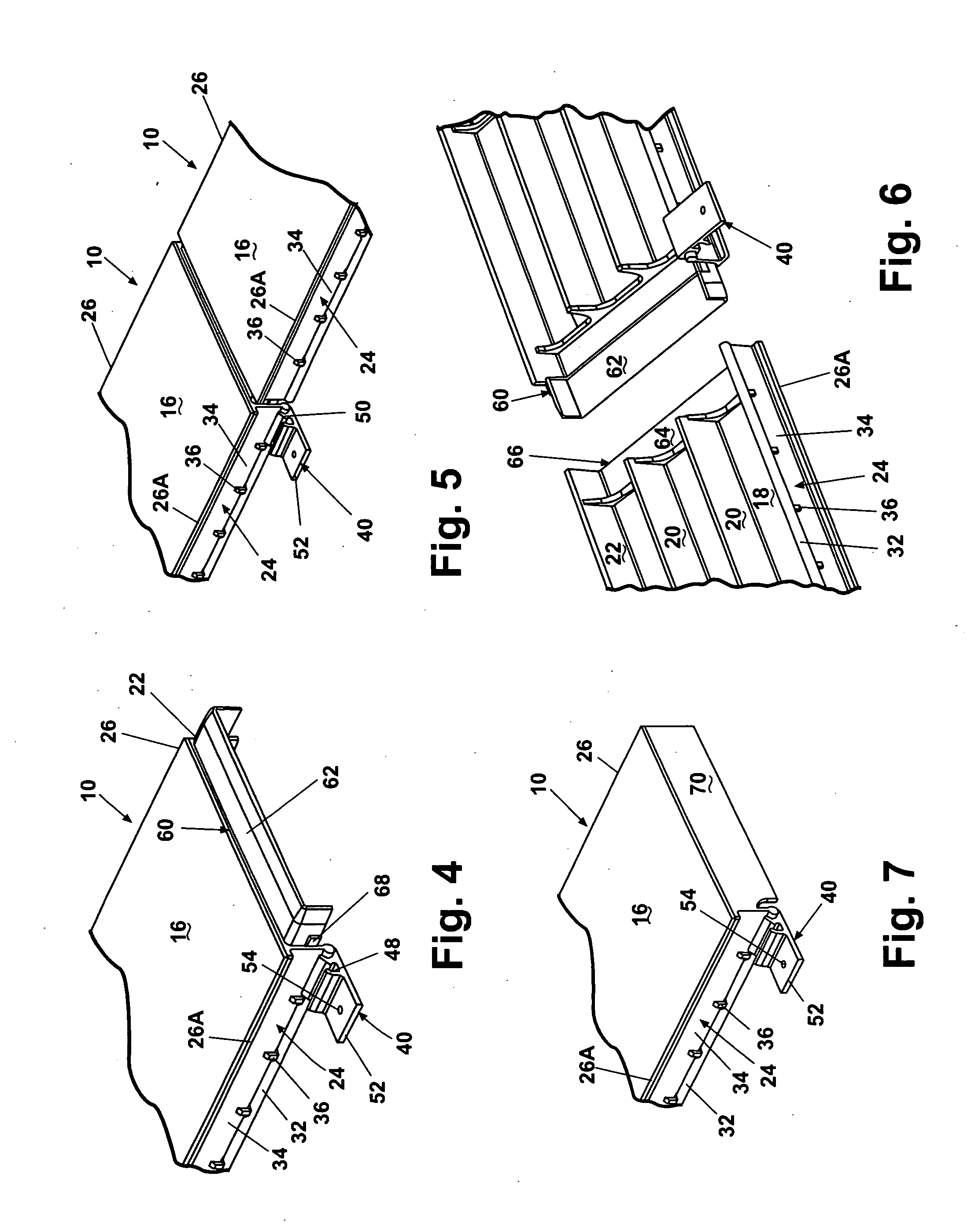

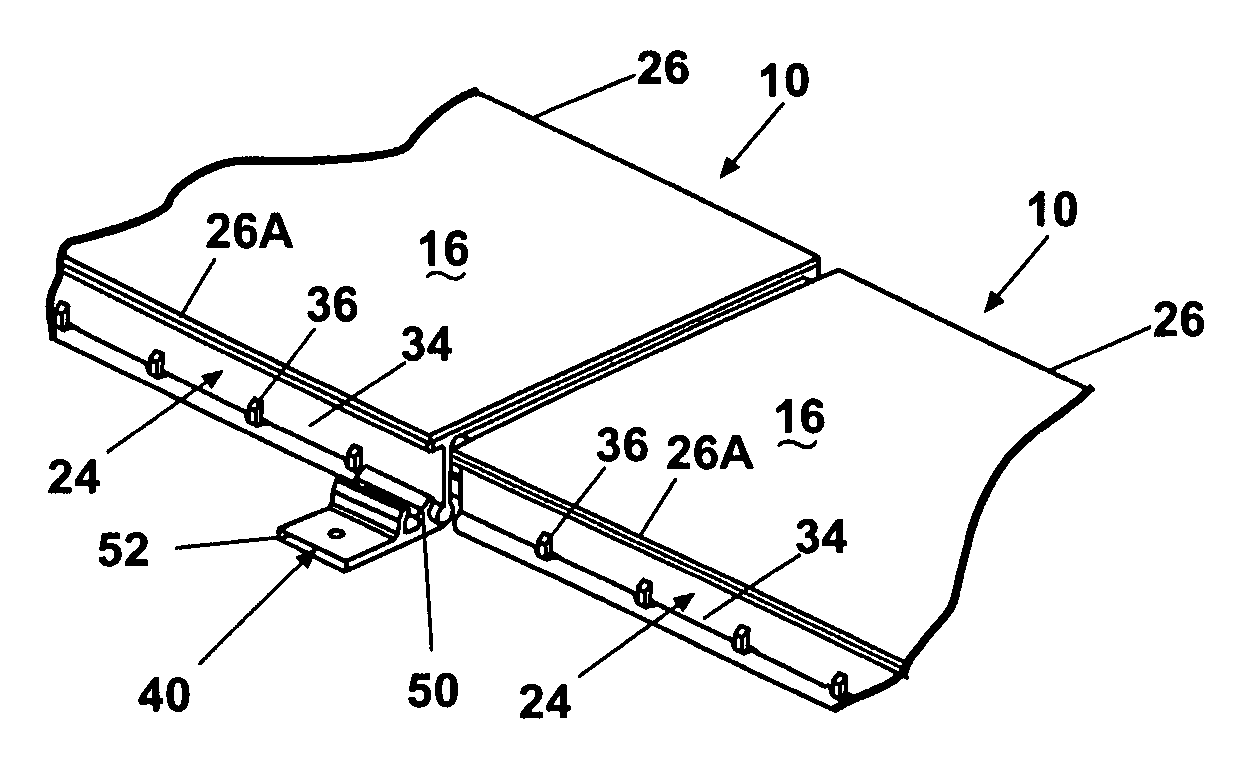

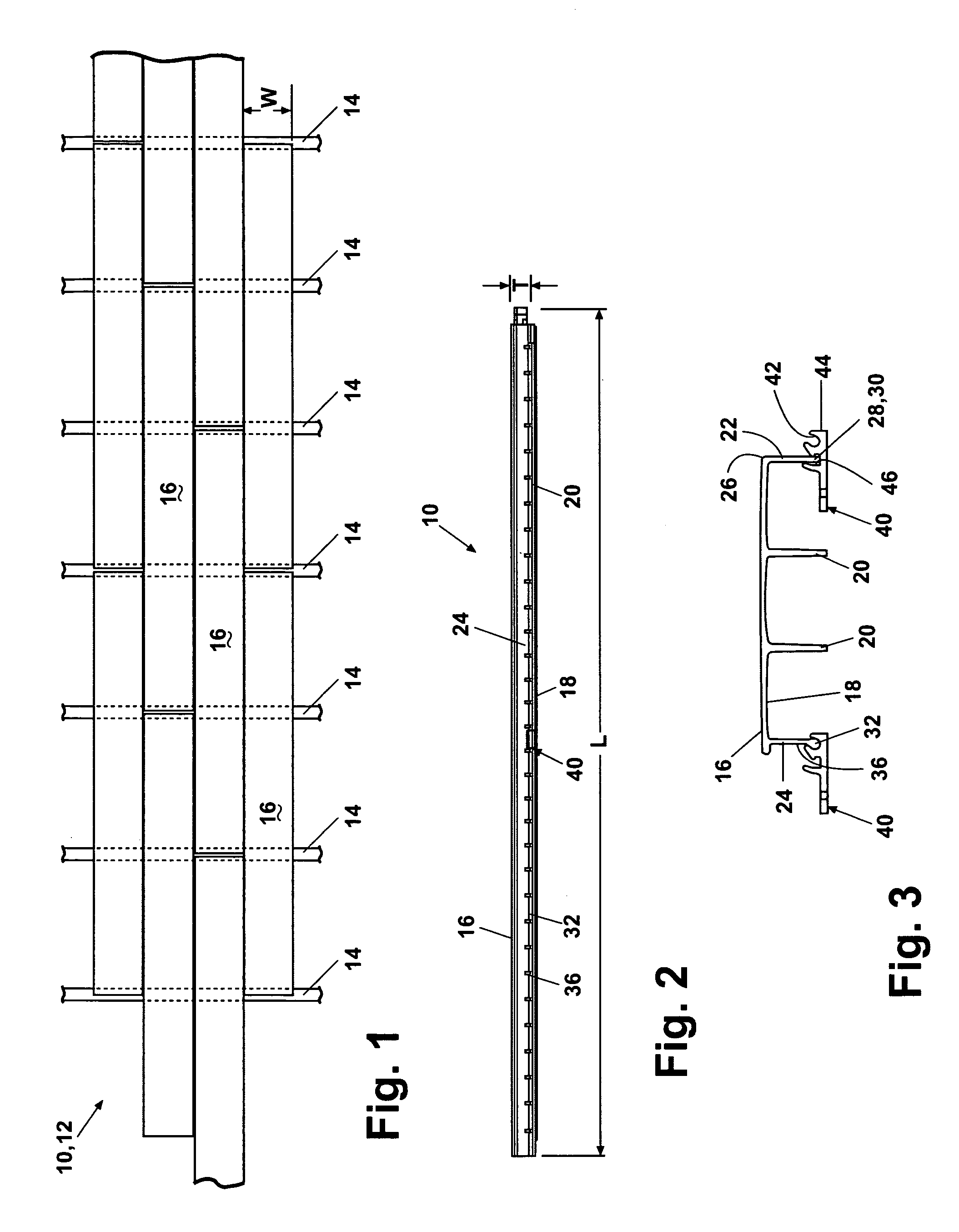

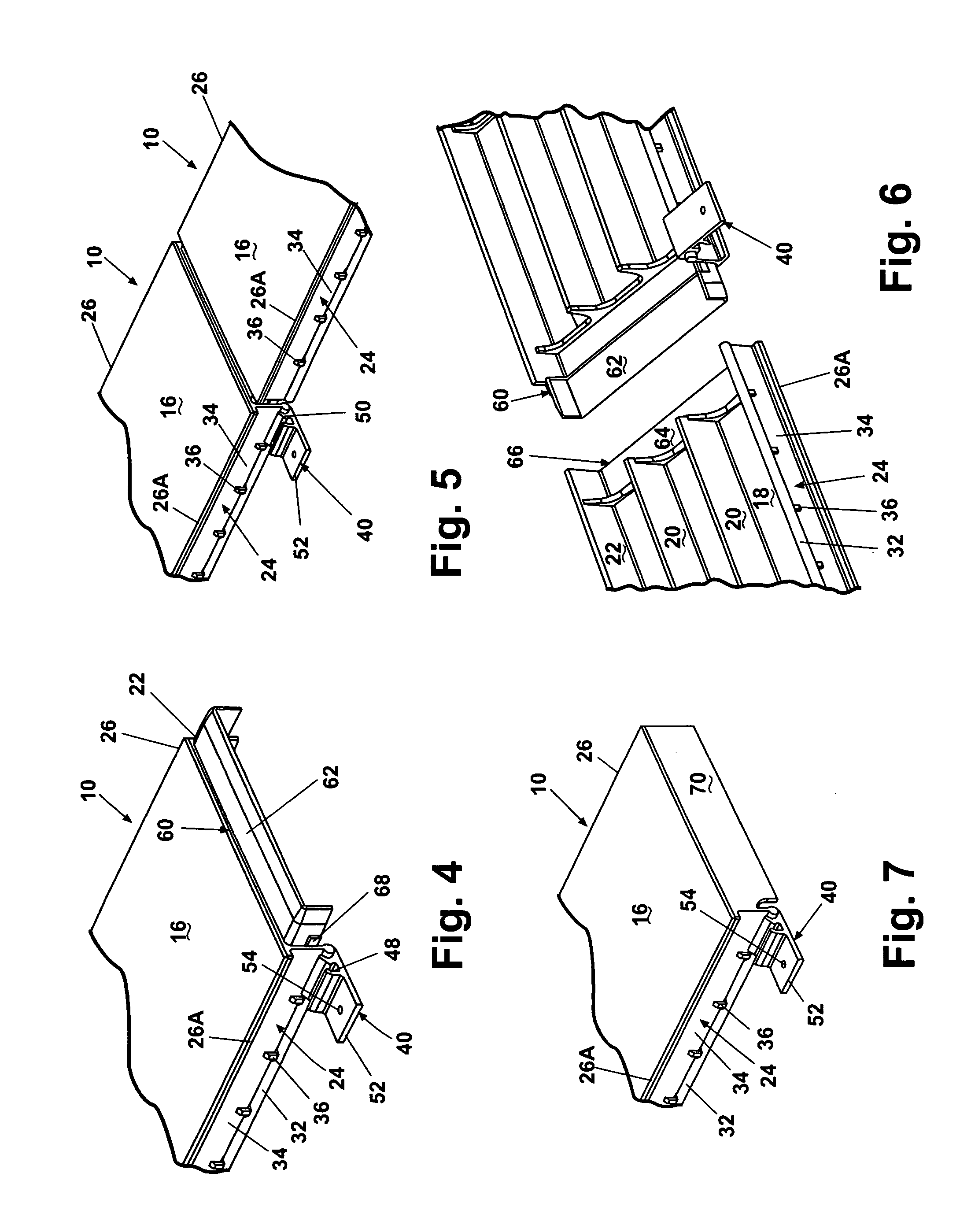

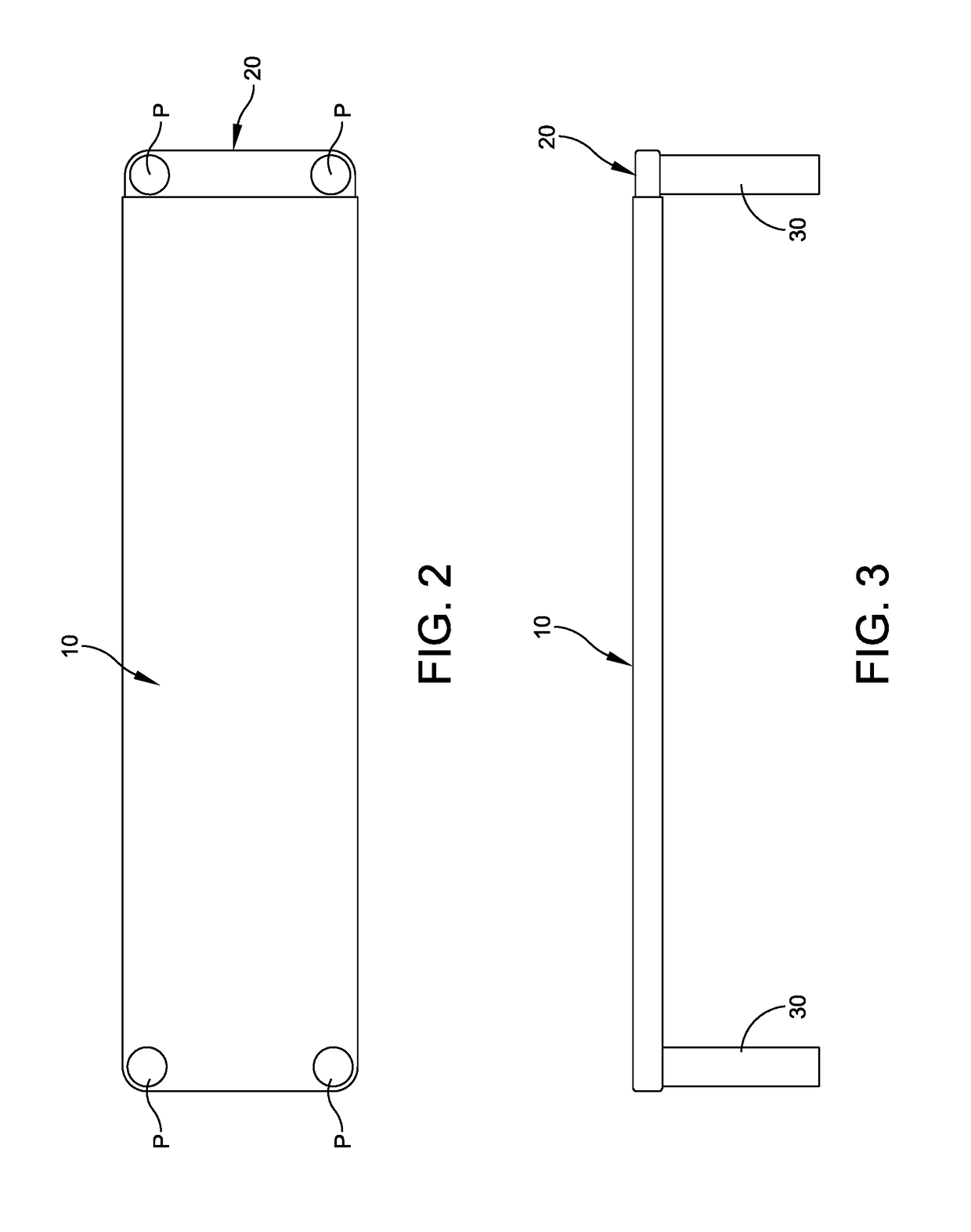

Decking system

InactiveUS20050039413A1Precise positioningAvoid excessive heightRailway roofsCeilingsEngineeringFlange

A floor panel and method of manufacturing wherein each panel comprises a sheet having at least two stiffening members extending from the lower surface and substantially the length of the sheet. A bead is defined along one of the stiffening members while a tab is defined along the other stiffening member. Clips are provided to fasten the bead and tab in a locking relationship to hold the sheet in position. A flange formed at one end of the panel is received within a recess formed at an opposite end of another panel to automatically space one panel from another.

Owner:JIMDI

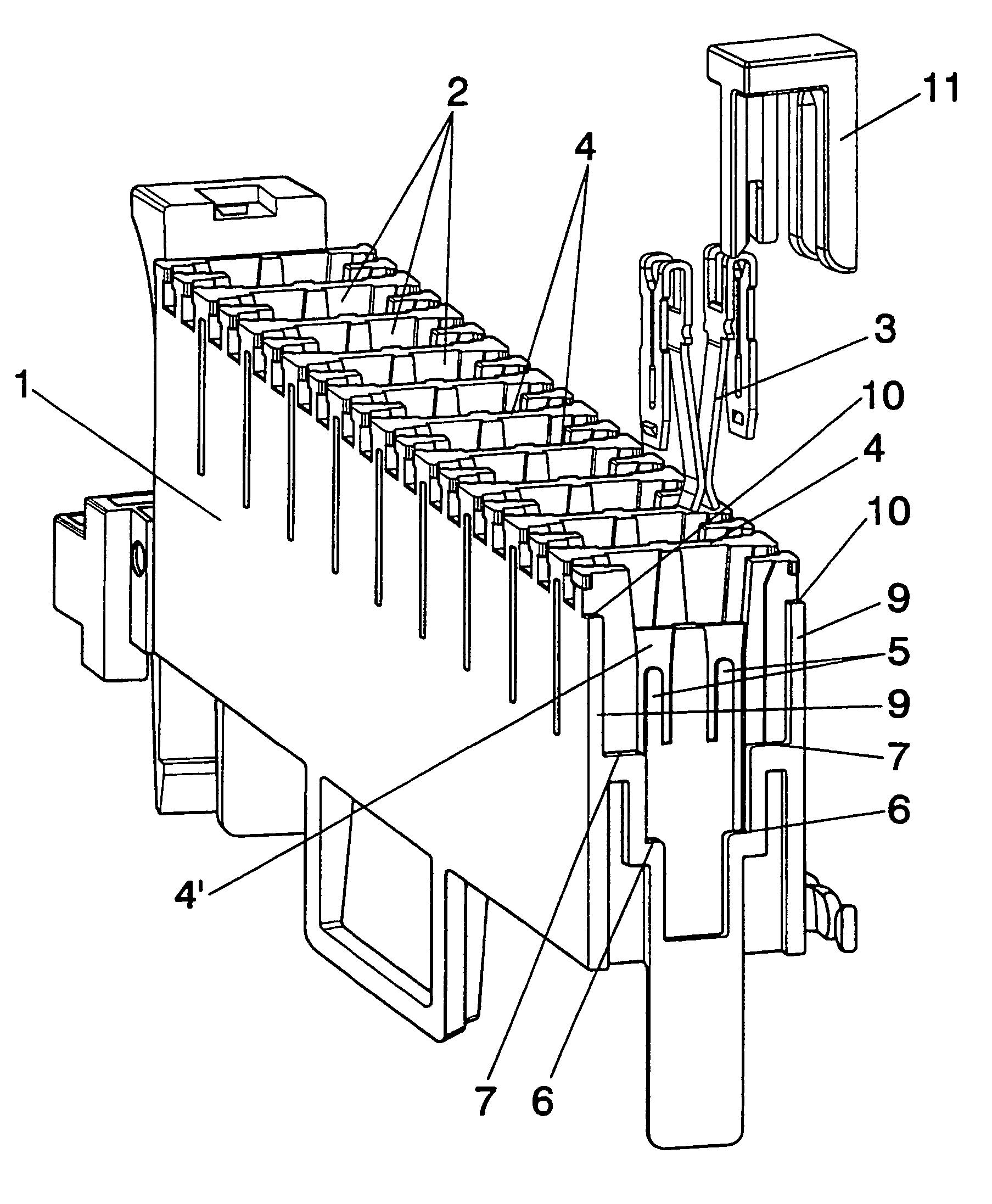

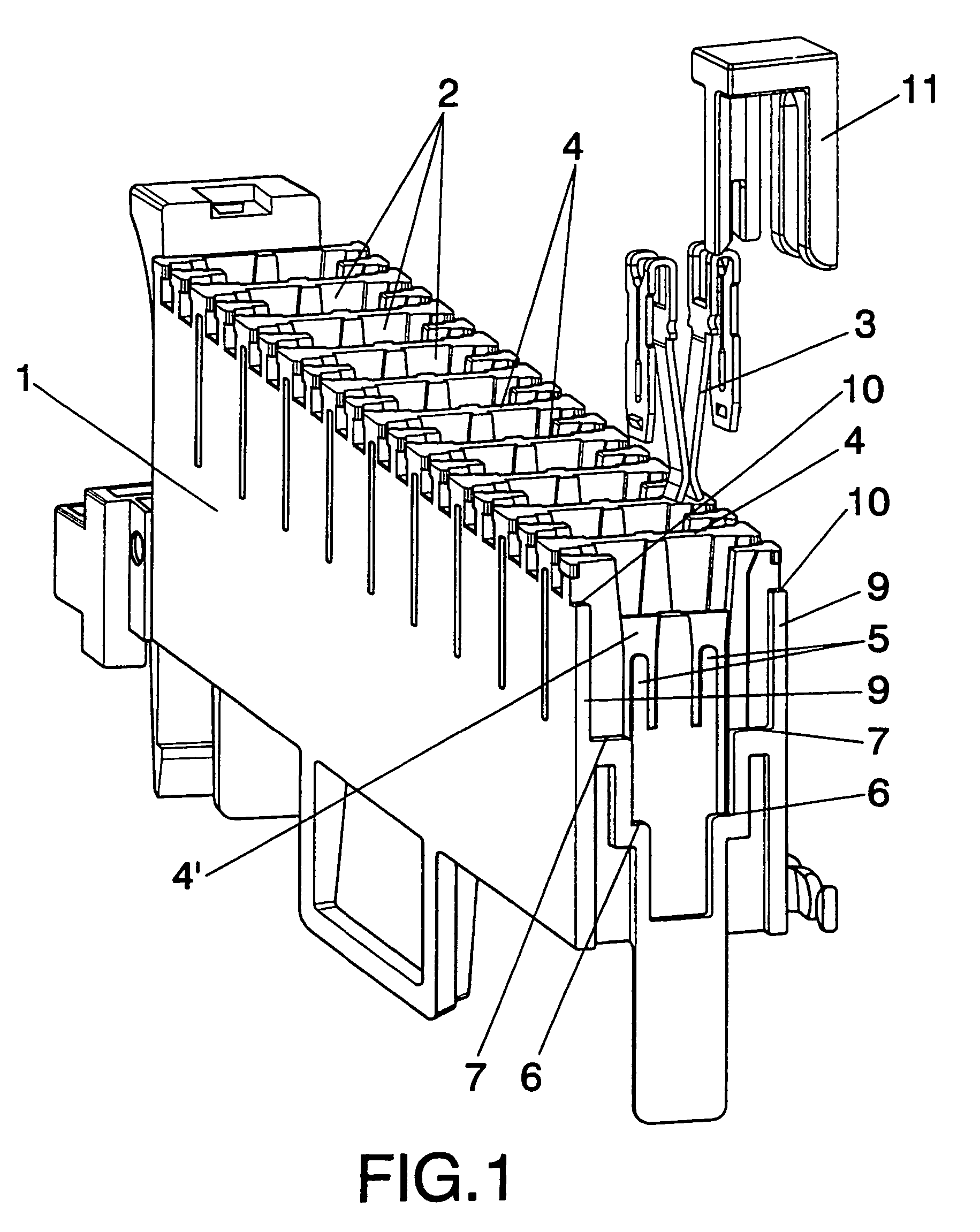

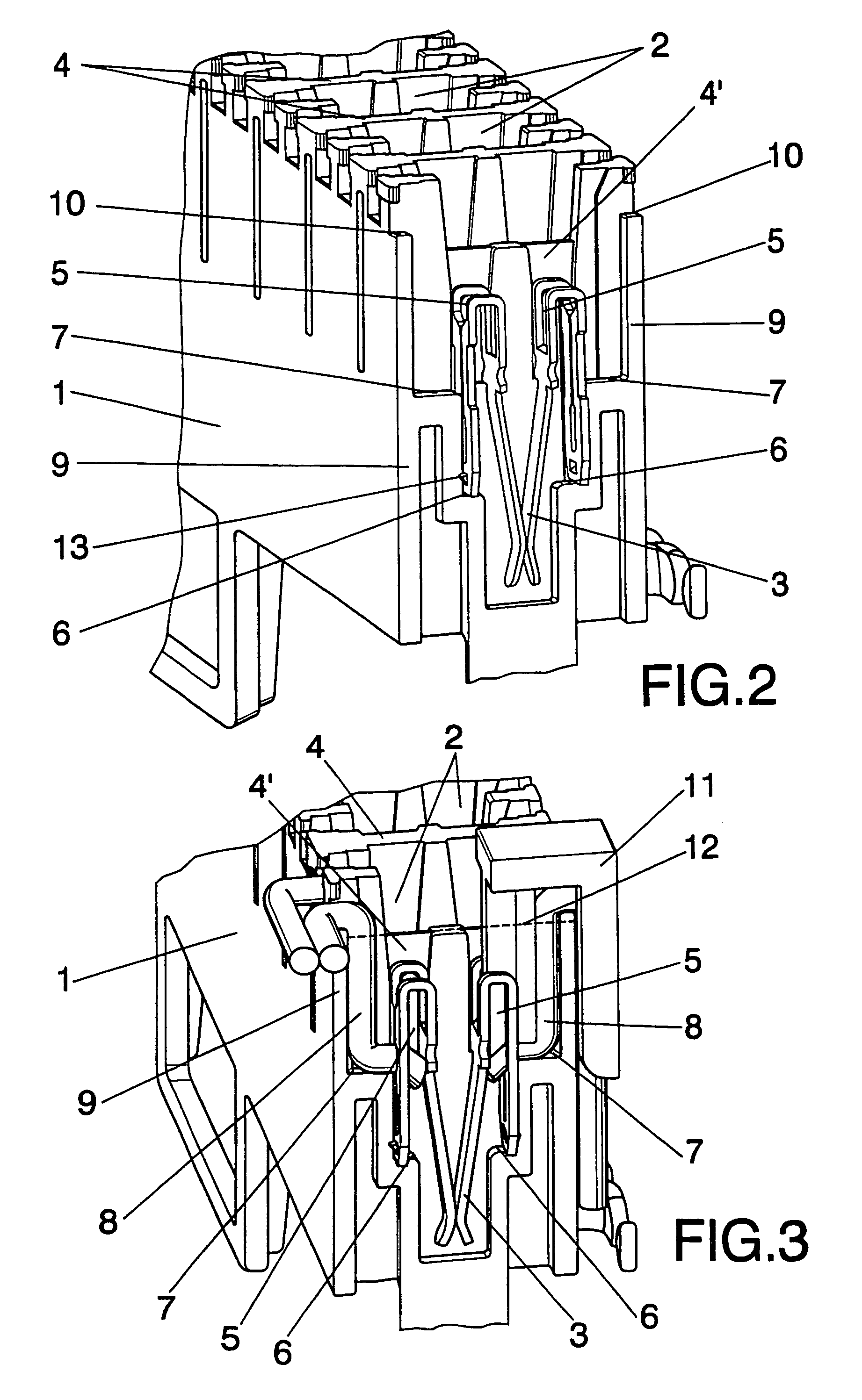

Multi-terminal connector strip and procedure for the sealing thereof

InactiveUS7056147B2Increase volumeImprove efficiencySubstation/switching arrangement detailsCouplings bases/casesElectrical conductorEngineering

Owner:COMMSCOPE CONNECTIVITY SPAIN

Dental implants and dental implant/prosthetic tooth systems

Owner:ELIAN NICHOLAS

Generator of time-variable magnetic fields of a magnetic resonance device and magnetic resonance device

InactiveUS20050099183A1Improve efficiencyReduce weightDiagnostic recording/measuringSensorsElectrical conductorResonance

A generator of time-variable magnetic fields of a magnetic resonance device having an examination space for registering at least one area to be examined of an item being examined has the following features: the conductors of a gradient coil arrangement of the generator define an area at least partially surrounding the examination space, said area contains at least a partial area which is free from conductors of the gradient coil arrangement and which contains conductors of a radio frequency antenna of the generator, and a field flowback space, inter alia for fields of the radio frequency antenna, extends proceeding from the partial area away from the examination space and is delimited beyond said partial area by a radio frequency shield.

Owner:SIEMENS HEALTHCARE GMBH

X-Y stage system with onboard linear motor

ActiveUS20040051403A1Easy constructionEasy to assembleFeeding apparatusLarge fixed membersLinear motionEngineering

An X-Y stage system is disclosed which is easy to assemble and compact or slim in construction. Both the X- and Y-stages are allowed to move without getting influence from the magnetic force created by the field magnets. The X-Y stage system has an X-stage movable relatively to a bed through a linear motion guide unit in an X-direction, and a Y-stage movable relatively to the X-stage through another linear motion guide unit in a Y-direction. The linear motors to force the X- and Y-stages are composed of paired field magnets of secondary side held to the bed and the Y-stage, respectively, and armature windings of primary side supported on the opposite sides of the X-stage in a way lying in clearances between the opposing field magnets.

Owner:NIPPON THOMPSON

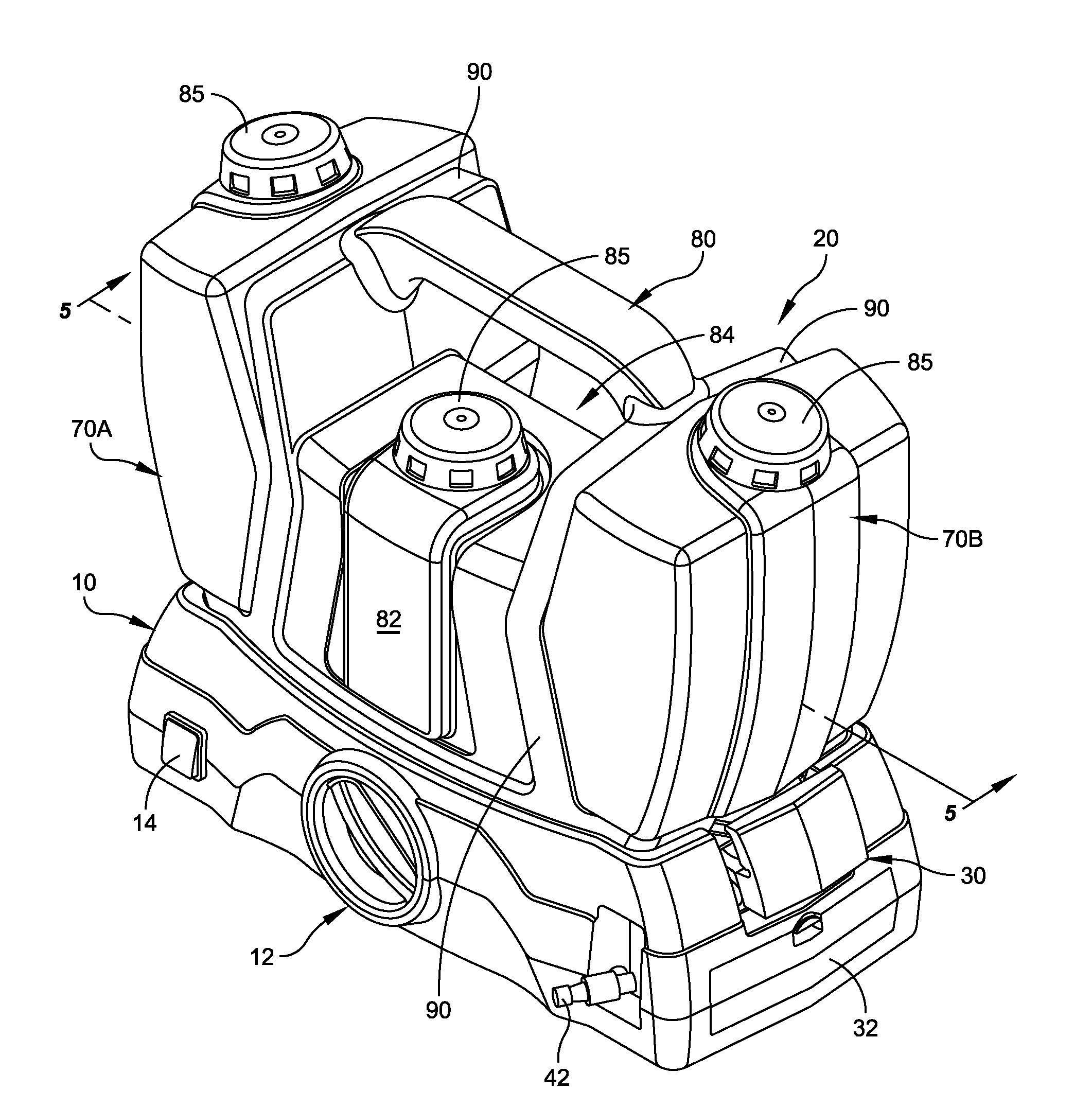

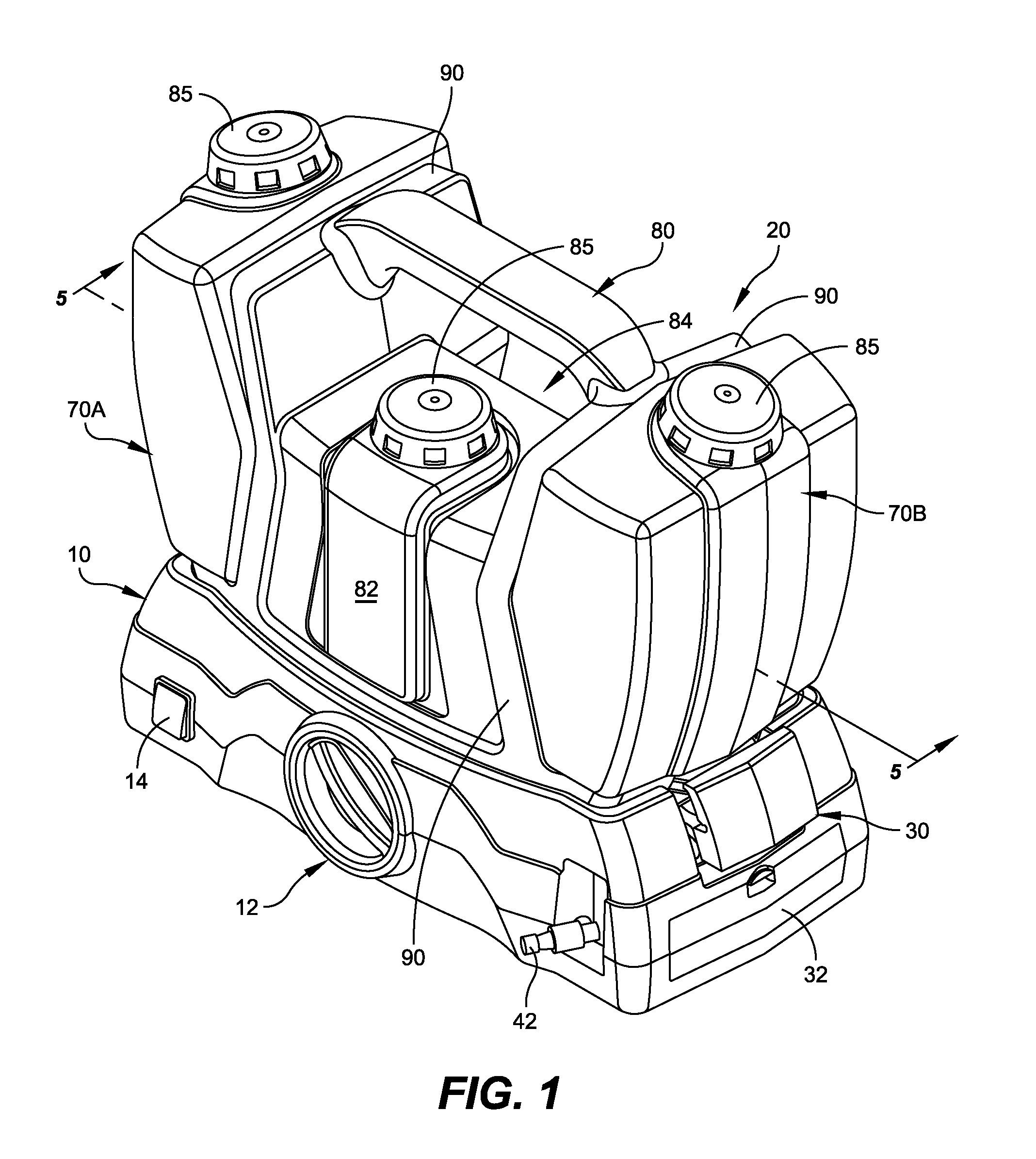

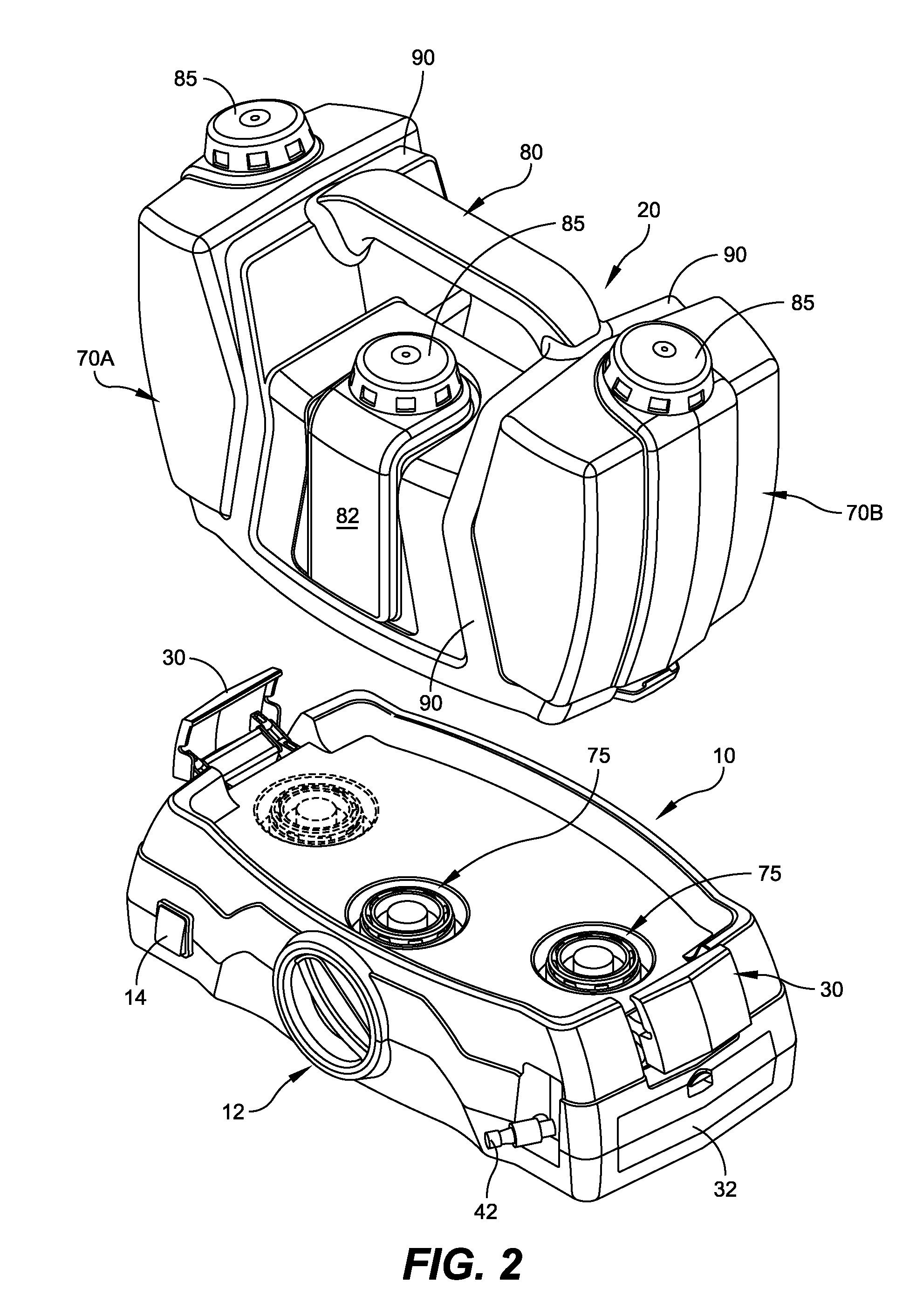

Portable pressure washer

InactiveUS20120241014A1Avoid excessive heightWatering devicesPipeline systemsEngineeringAir compressor

A portable pressure washer that includes a base and a tank assembly formed as a one-piece structure and for engagement with the base. The tank assembly has a pair of water tanks that are disposed separately from each other and a solution tank that is disposed between the pair of water tanks Each of the tanks is provided with a filler cap. A latch mechanism is disposed at opposite ends of the base for releasably securing the tank assembly with the base. The base houses a liquid pump and air compressor. A manual selector is mounted at the base and has separately selectable positions including a first position in which the pump is connected with the water tanks, and a second position in which the pump is connected with the solution tank. A spray hose is coupled from the pump for directing either of the water or solution when the pump is activated.

Owner:WISE TODD W

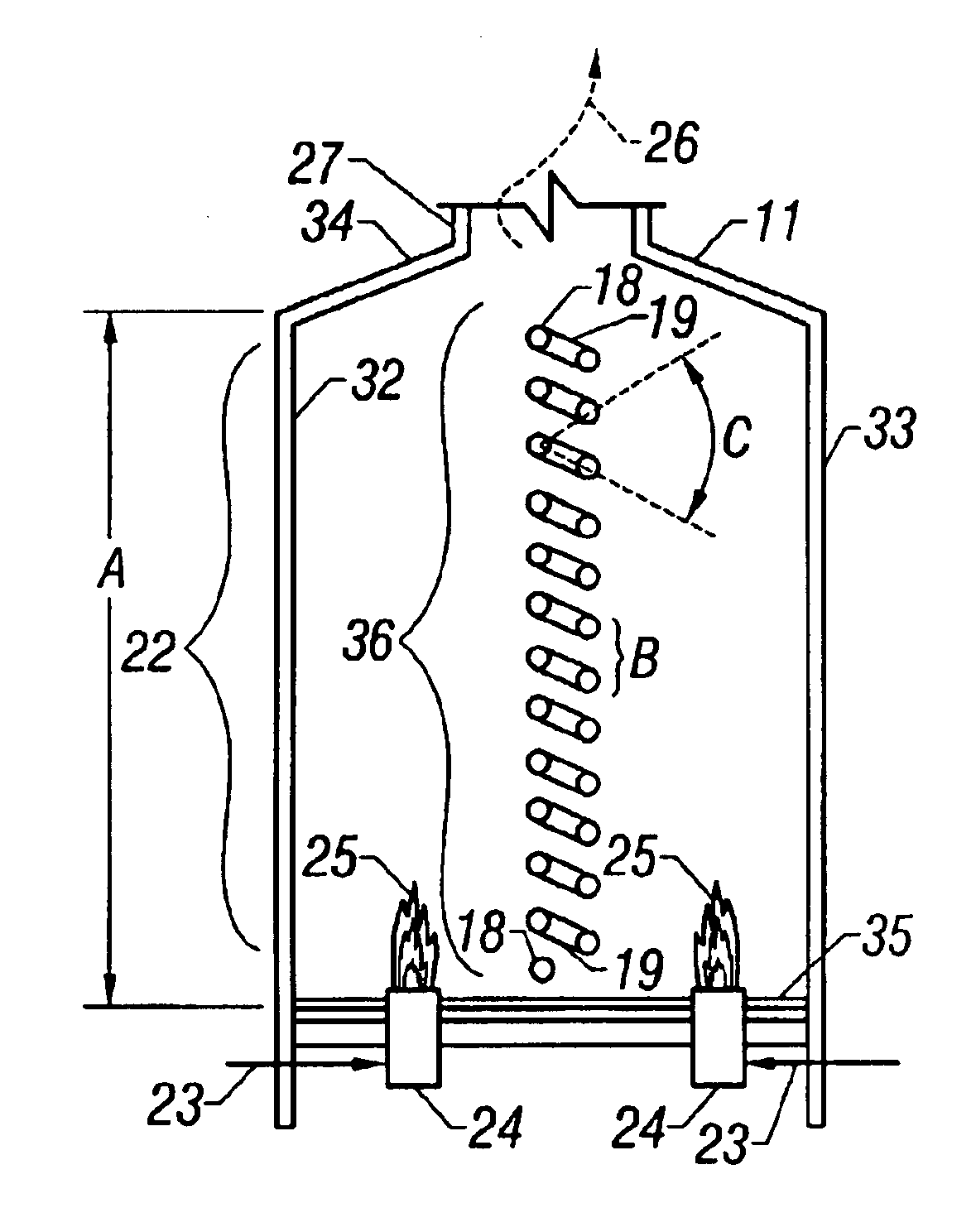

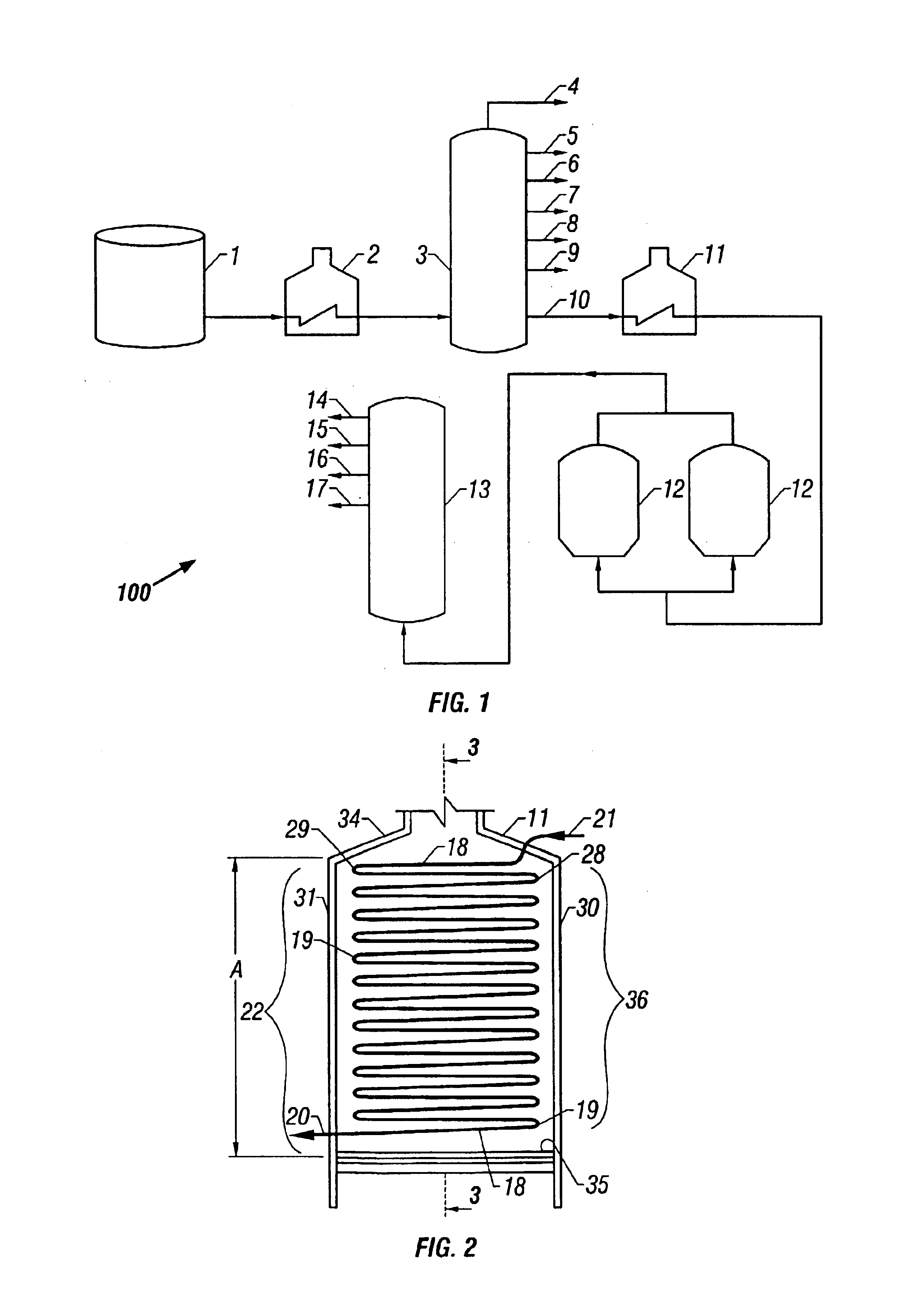

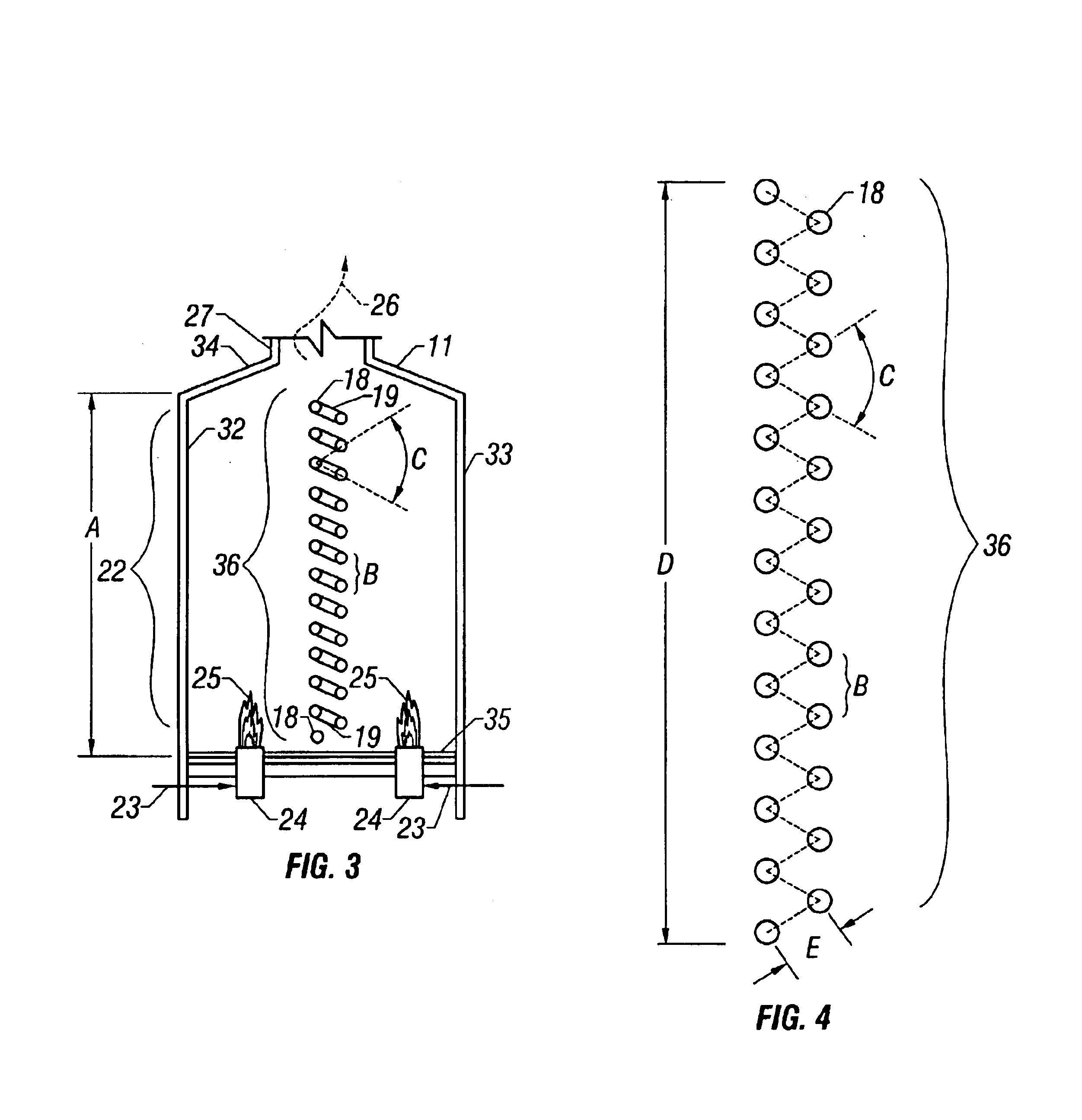

Alternate coke furnace tube arrangement

InactiveUS6852294B2Trend downReduce dwell timeThermal non-catalytic crackingCombustible gas coke oven heatingVaporizationEngineering

Tubes within a radiant heating section of a coking furnace are arranged differently than in a single vertical column and connected together in a simple, planar serpentine pattern. The tubes are arranged in a plurality of offset or staggered vertical columns. This arrangement permits the upper tubes to be close to the radiant heat source and allows the tube bends connecting adjacent tubes to be of greater radius, so that the pressure at which the feedstock is passed through the tube bundle can be lower allowing more vaporization of the cracked process fluids.

Owner:BECHTEL HYDROCARBON TECH SOLUTIONS INC

Decking system

InactiveUS7730693B2Precise positioningAvoid excessive heightCeilingsCovering/liningsEngineeringFlange

A floor panel and method of manufacturing wherein each panel comprises a sheet having at least two stiffening members extending from the lower surface and substantially the length of the sheet. A bead is defined along one of the stiffening members while a tab is defined along the other stiffening member. Clips are provided to fasten the bead and tab in a locking relationship to hold the sheet in position. A flange formed at one end of the panel is received within a recess formed at an opposite end of another panel to automatically space one panel from another.

Owner:JIMDI

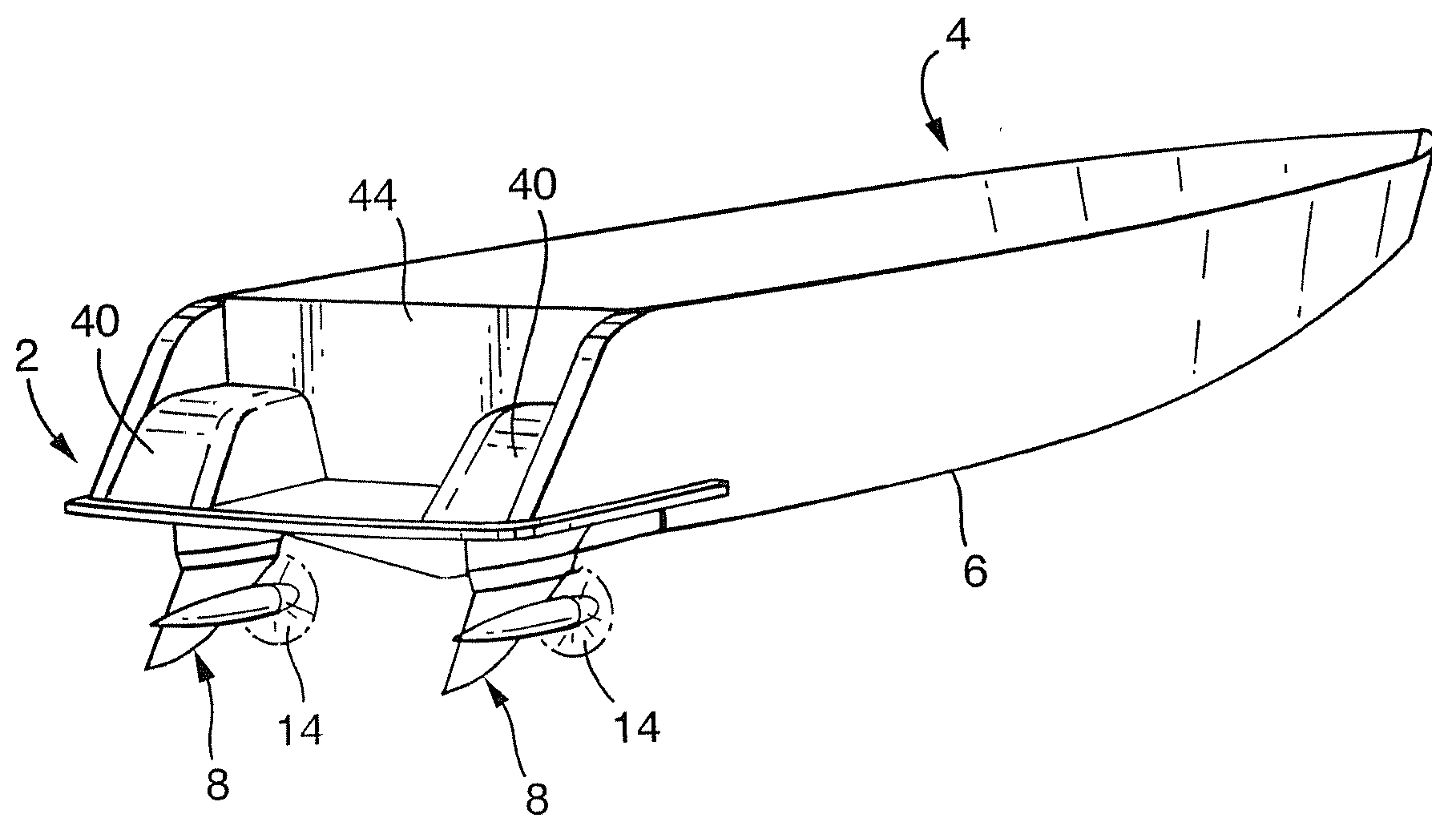

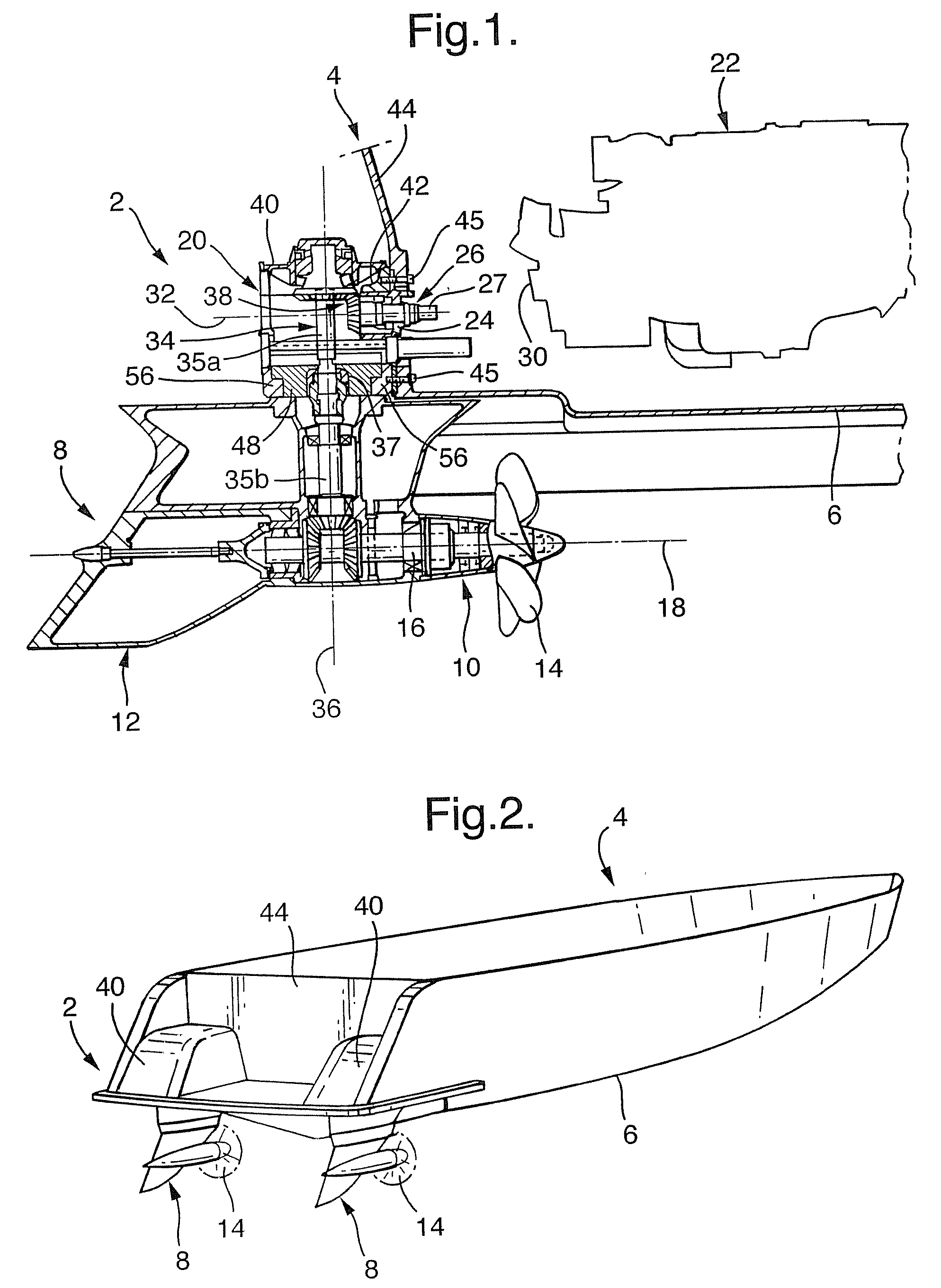

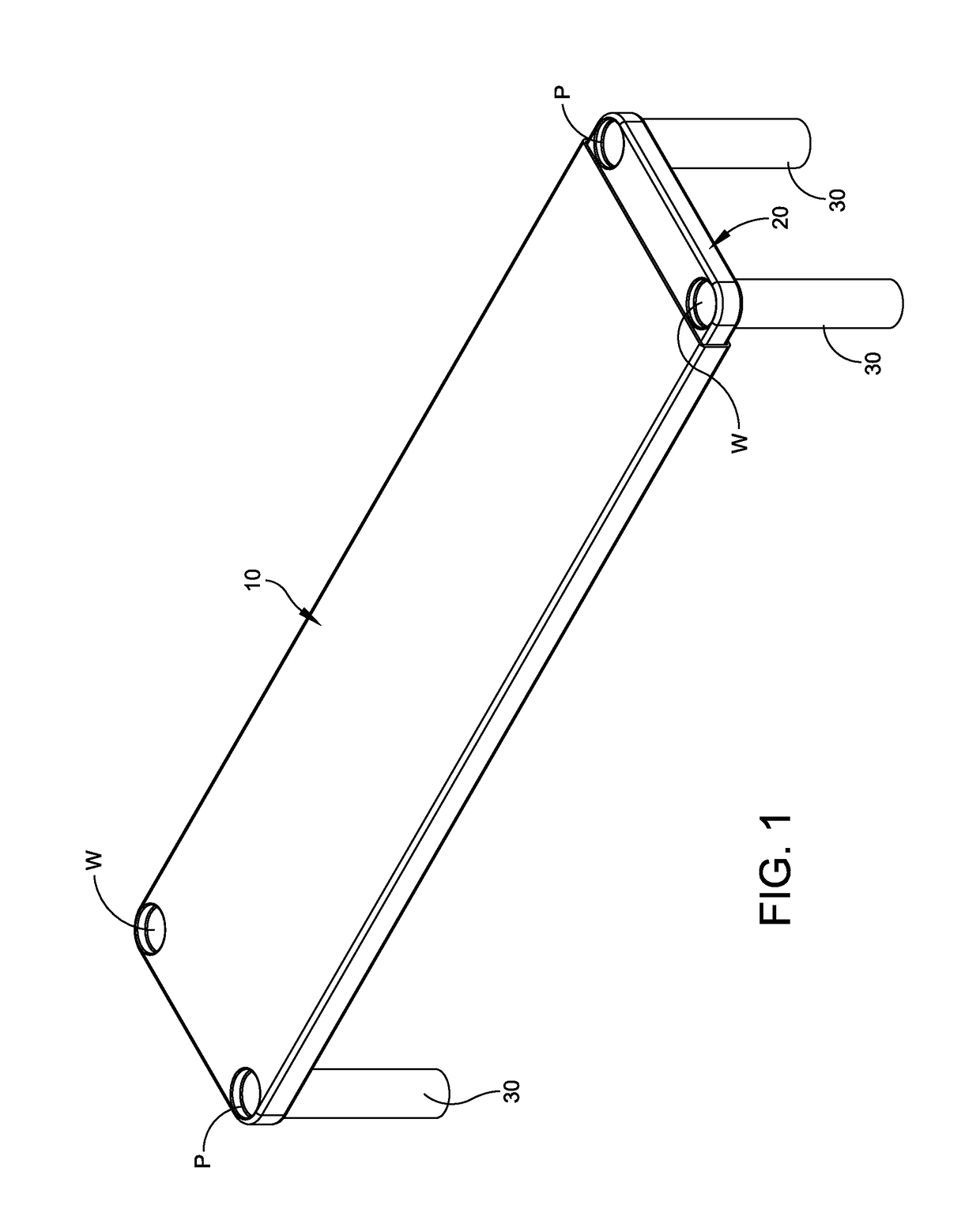

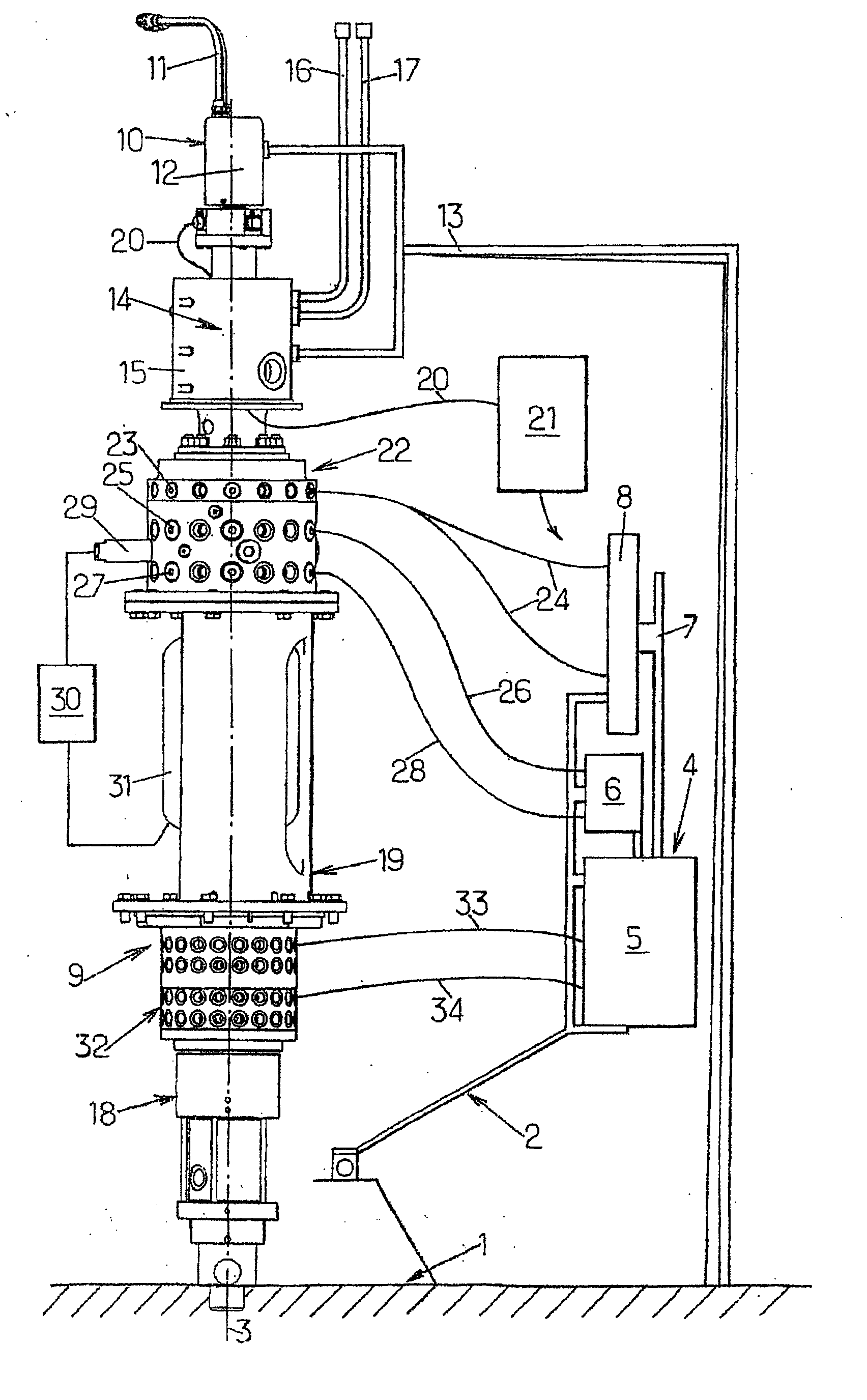

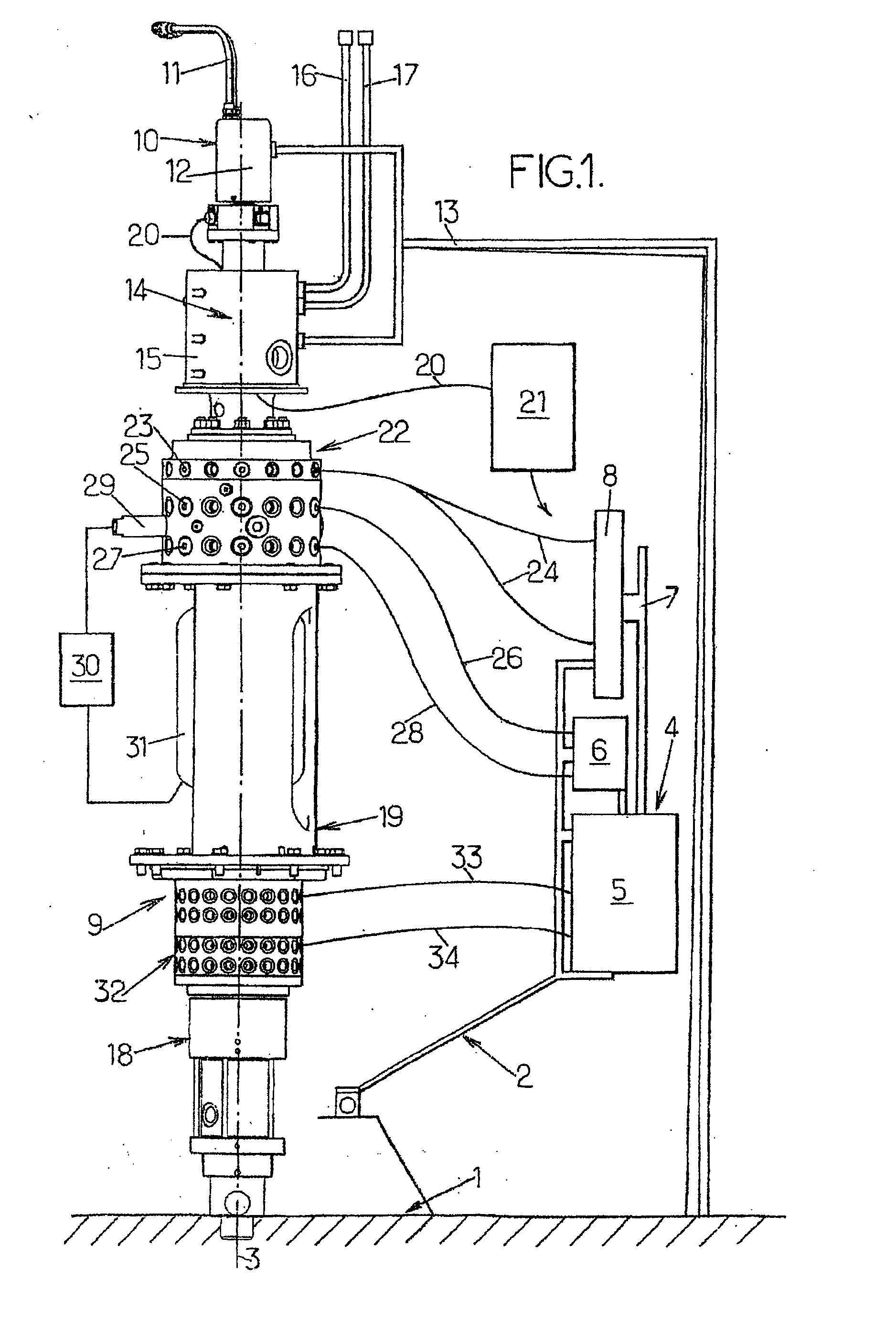

Means for bearing a propulsion unit and a propulsion system for a waterbourne vessel

ActiveUS20070123118A1More spaceGood accessPropulsion power plantsOutboard propulsion unitsPropellerPower unit

A propulsion system 2 for a waterborne vessel 4 comprises a hull structure 6, typically for a full or semi planing boat. The propulsion system 2 comprises a pod housing 8 having a front end 10 and a rear end 12, a propeller 14 and a propeller shaft 16. The propeller 14 is disposed externally at the front end 10 of the pod 8 and is rotatable about a longitudinal axis 18 of the propeller shaft 16, the propeller shaft 16 being drivingly connected to drive means. The drive means comprises a transmission unit 20 and a power unit 22 in the form of a diesel engine. In FIG. 1 the diesel engine is shown disconnected from the transmission unit 20. The power unit 22 is disposed within the structure of the hull 6 and, in this particular embodiment; the transmission unit 20 is disposed substantially outside the structure of the hull 6. The hull 6 is formed with a port 24 through which an interface unit 26 extends. The interface unit 26 provides means to transmit the torque of the power unit 22 to the transmission unit 20.

Owner:KONGSBERG MARITIME

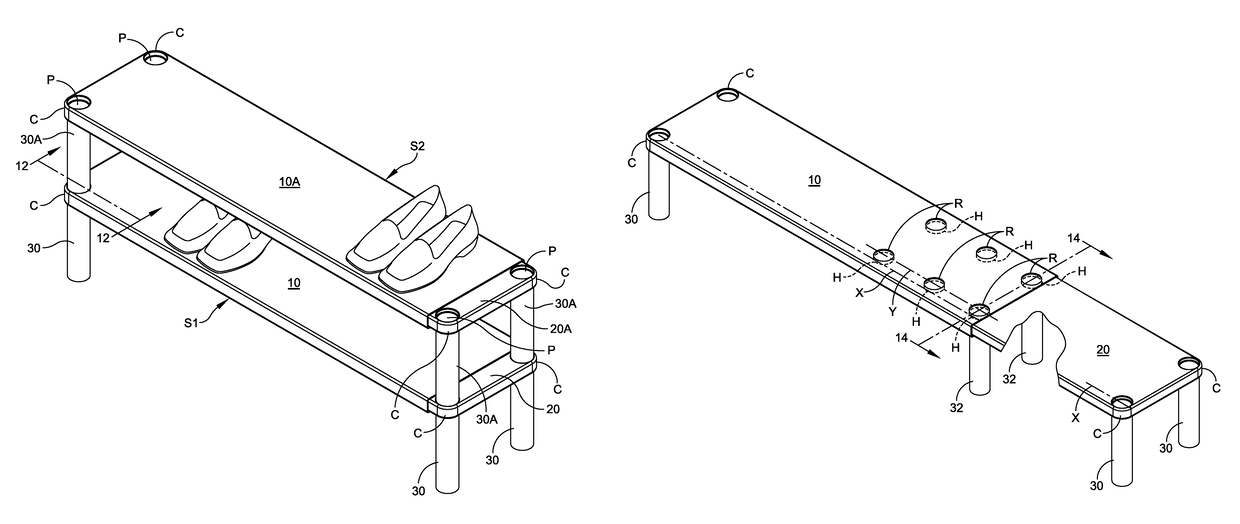

Adjustable shelving

A rack for supporting items and comprising a first shelf and a second shelf that slideably interlocks with the first shelf and a plurality of support legs including at least two support legs for each of the first shelf and second shelf. Each of the first and second shelves has one end that includes a pair of spaced apart receiving ports with each receiving port for accommodating a corresponding support leg. Each of the first and second shelves further has an opposite end with the opposite ends for respective sliding engagement therebetween in order to provide the slideable interlocking.

Owner:LINARI RONALD +1

Semiconductor package

InactiveUS20050062148A1Lesser footprintAvoid excessive heightSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipSemiconductor package

A semiconductor package is disclosed that bonds a semiconductor chip to a leadframe using a flip chip technology. An exemplary semiconductor package includes a semiconductor chip having a plurality of input-output pads at an active surface thereof. A plurality of leads are superimposed by the bond pads and active surface of the semiconductor chip. The leads have at least one exposed surface at a bottom surface of the package body. A plurality of conductive connecting means electrically connect the input-output pads of the chip to the leads. A package body is formed over the semiconductor chip and the conductive connecting means. The bottom surface portions of the leads are exposed to the outside.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

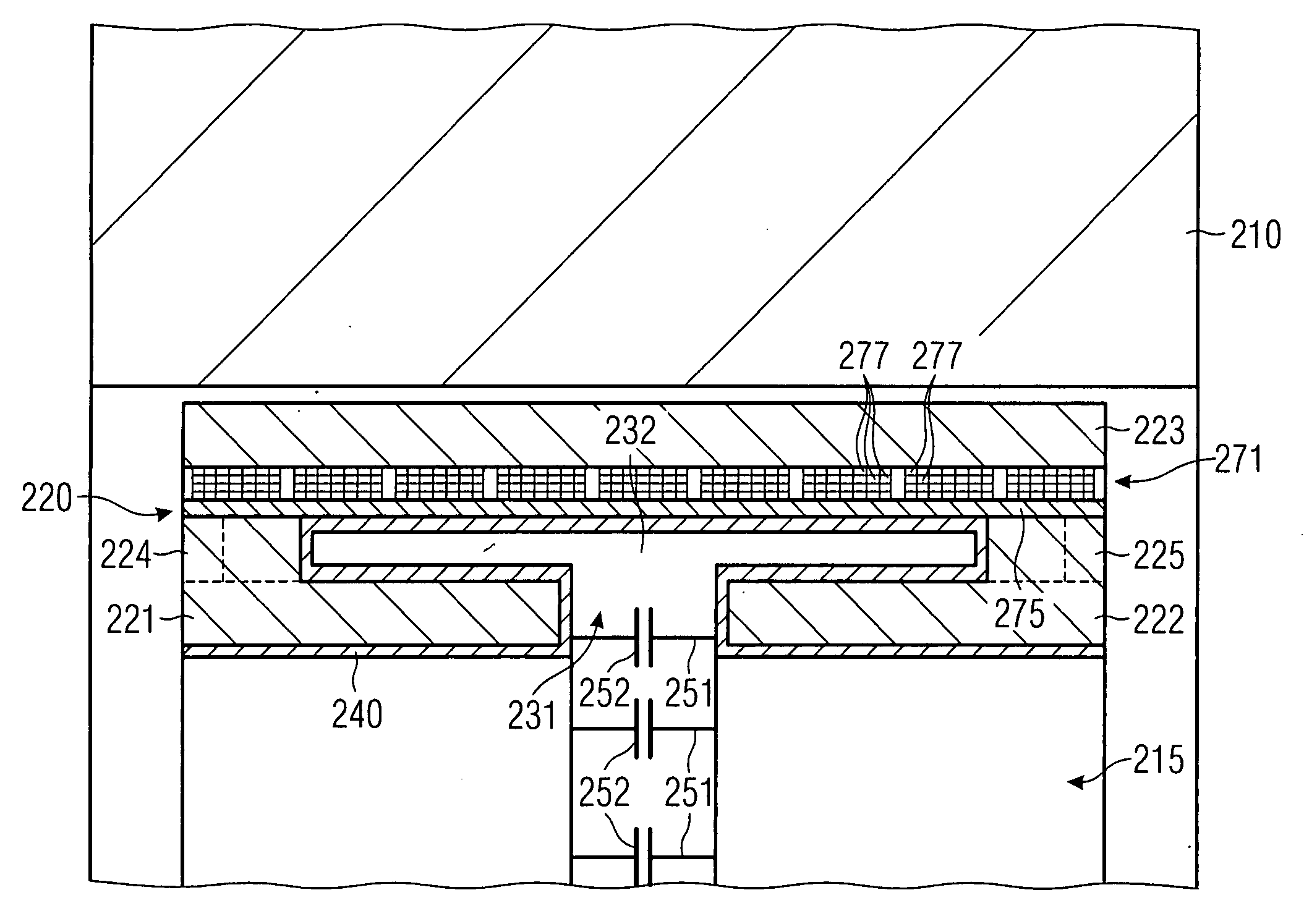

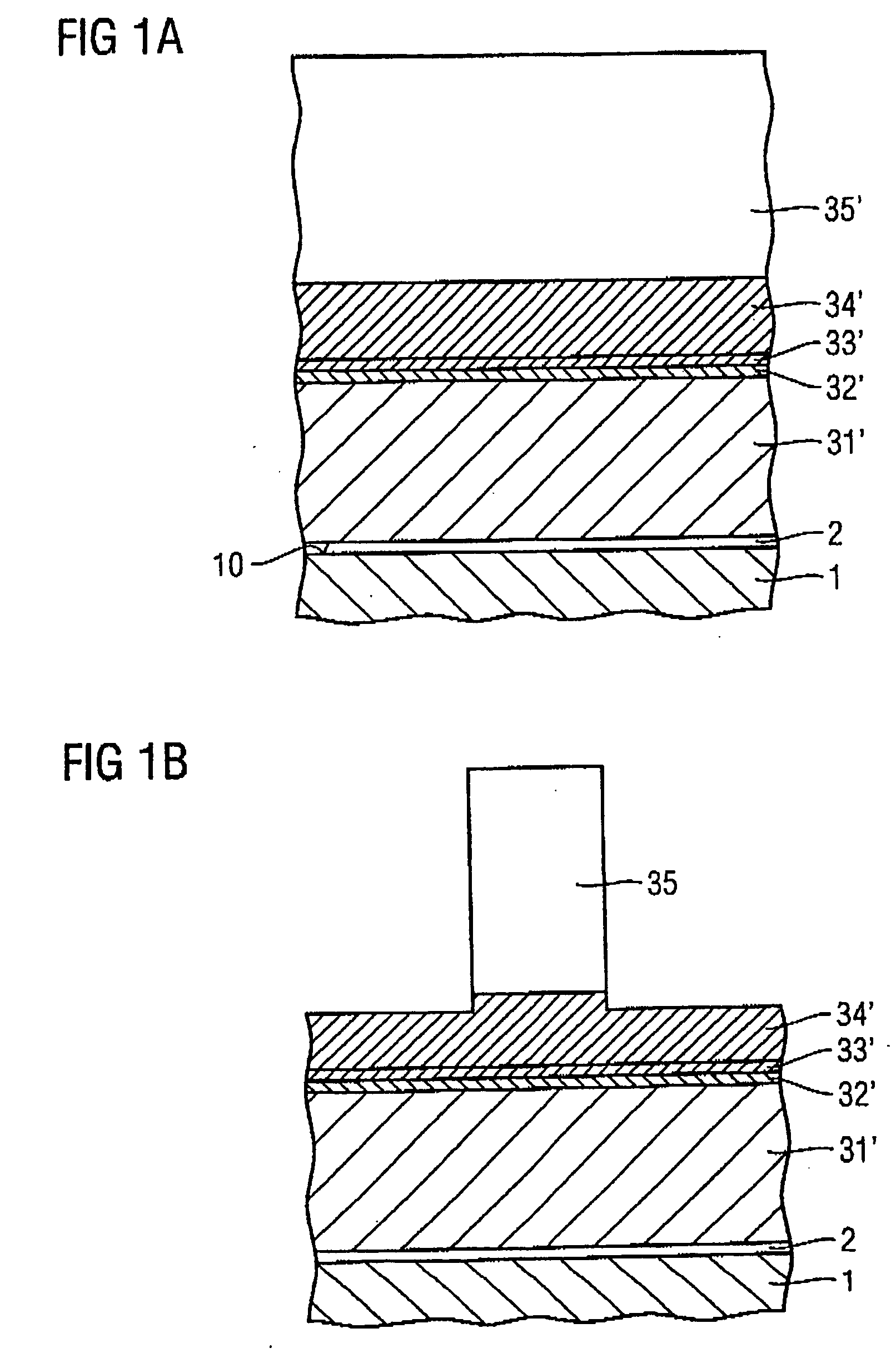

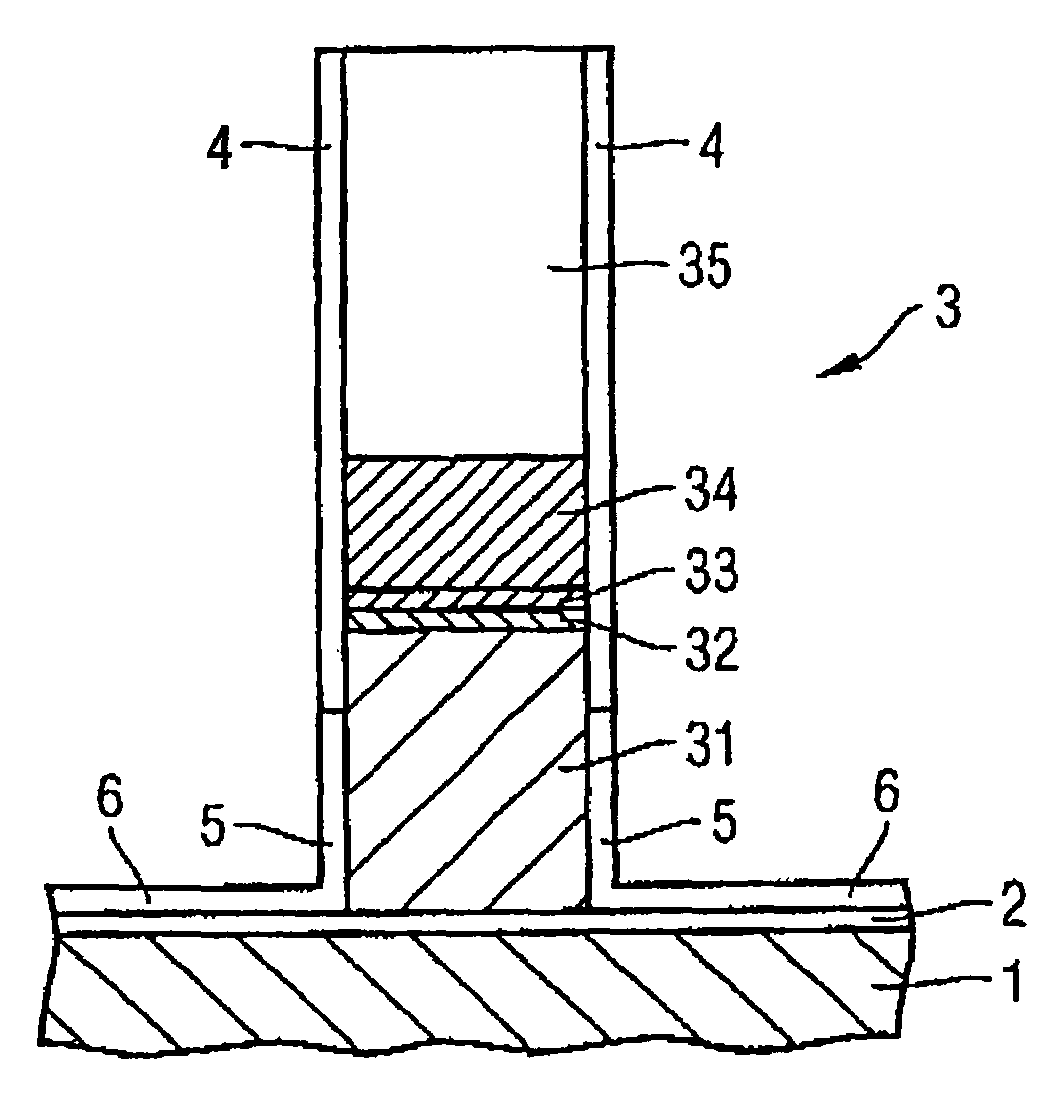

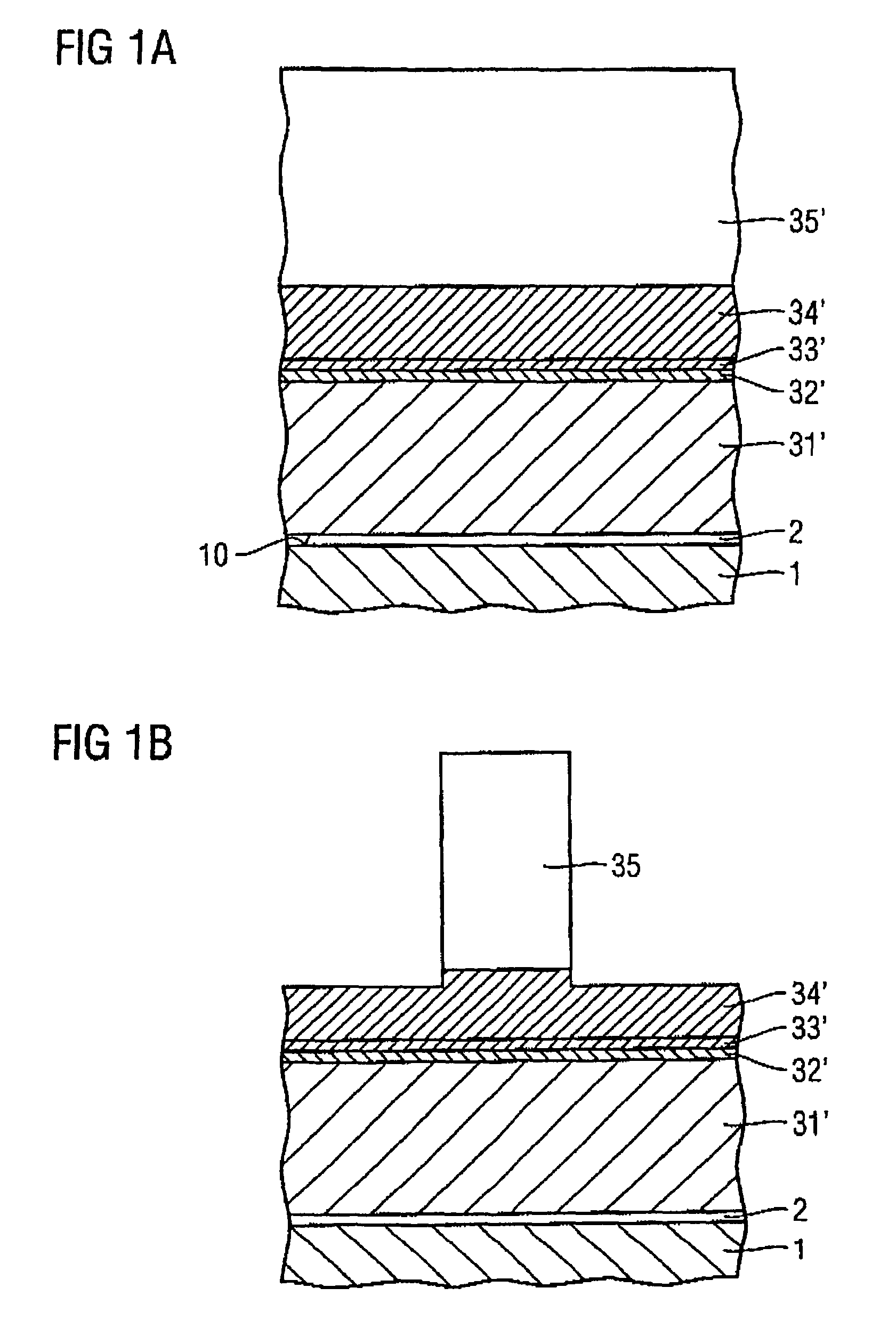

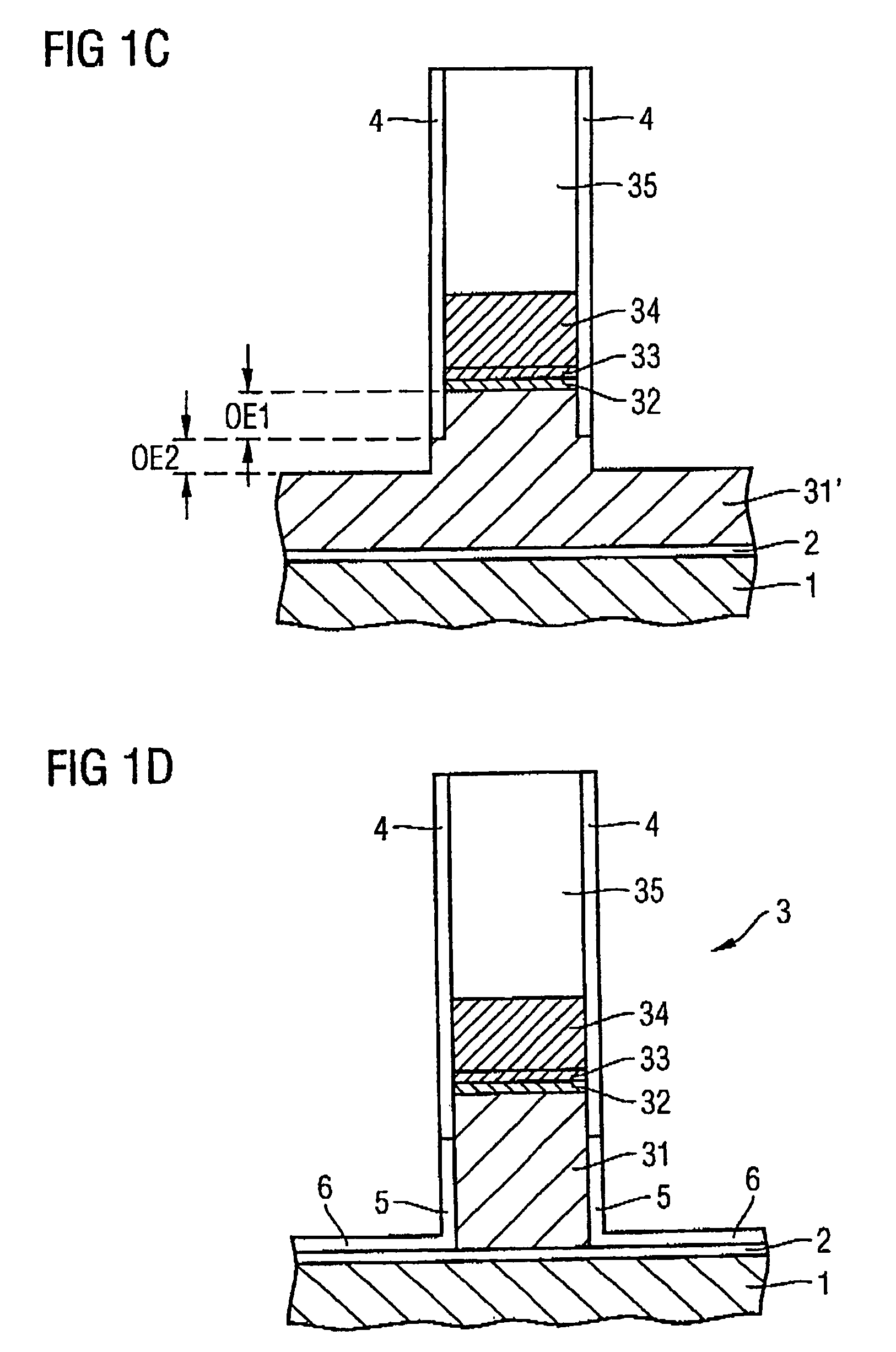

Multi-layer gate stack structure comprising a metal layer for a fet device, and method for fabricating the same

InactiveUS20050275046A1Reduce the overall heightAvoid excessive heightSolid-state devicesSemiconductor/solid-state device manufacturingGate dielectricGate stack

A multi-layer gate stack structure of a field-effect transistor device is fabricated by providing a gate electrode layer stack with a polysilicon layer, a transition metal interface layer, a nitride barrier layer and then a metal layer on a gate dielectric, wherein the transition metal is titanium, tantalum or cobalt. Patterning the gate electrode layer stack comprises a step of patterning the metal layer and the barrier layer with an etch stop on the surface of the interface layer. Exposed portions of the interface layer are removed and the remaining portions are pulled back from the sidewalls of the gate stack structure leaving divots extending along the sidewalls of the gate stack structure between the barrier layer and the polysilicon layer. A nitride liner encapsulating the metal layer, the barrier layer and the interface layer fills the divots left by the pulled-back interface layer. The nitride liner is opened before the polysilicon layer is patterned. As the requirement for an overetch into the polysilicon layer during the etch of the metal layer, the barrier layer and the interface layer is omitted, the height of the polysilicon layer can be reduced. The aspect ration of the gate stack structure is improved, the feasibility of pattern and fill processes enhanced and the range of an angle under which implants can be performed is extended.

Owner:NAN YA TECH +1

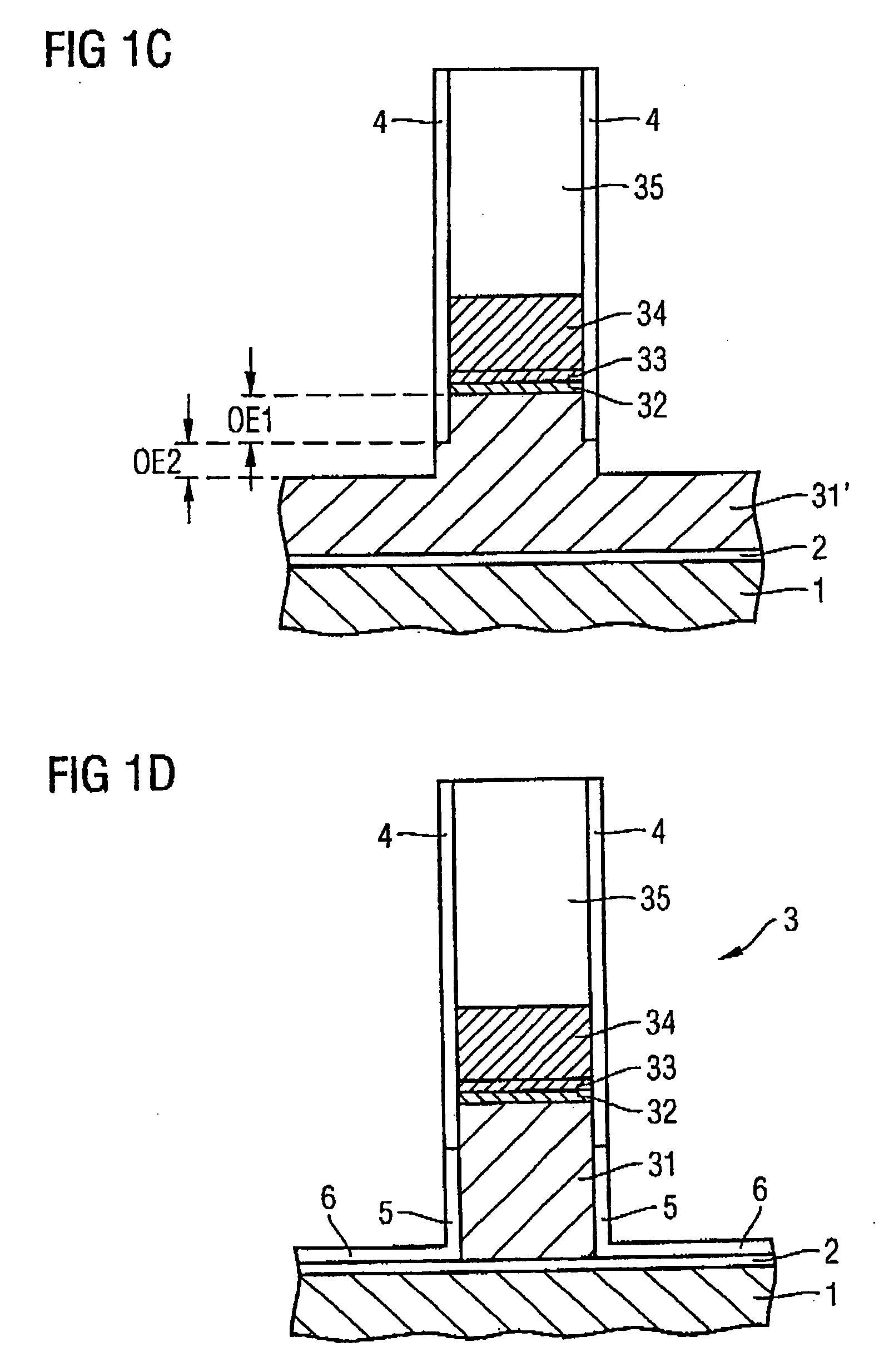

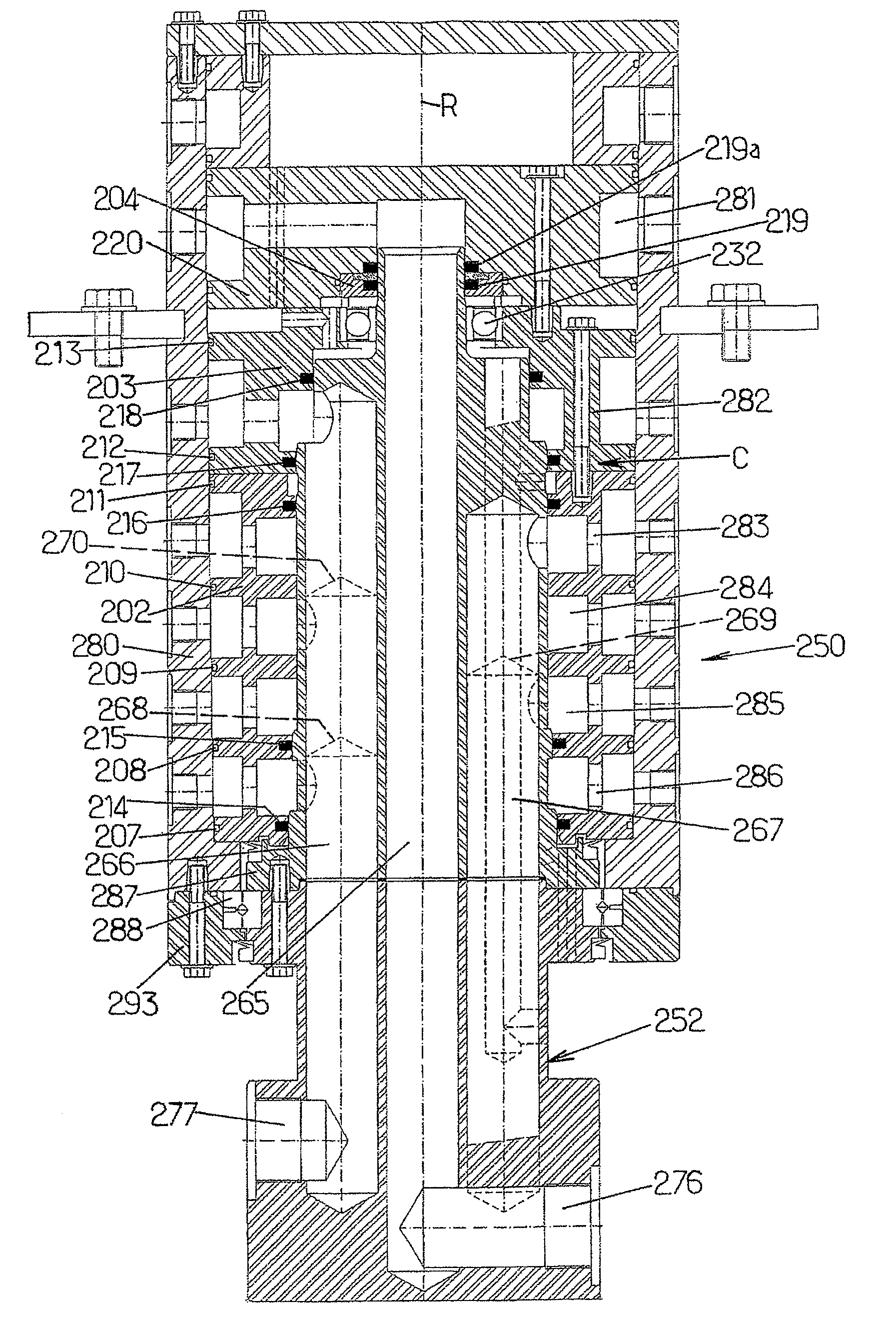

Rotating Machine With a Fluid Supply Rotating Column

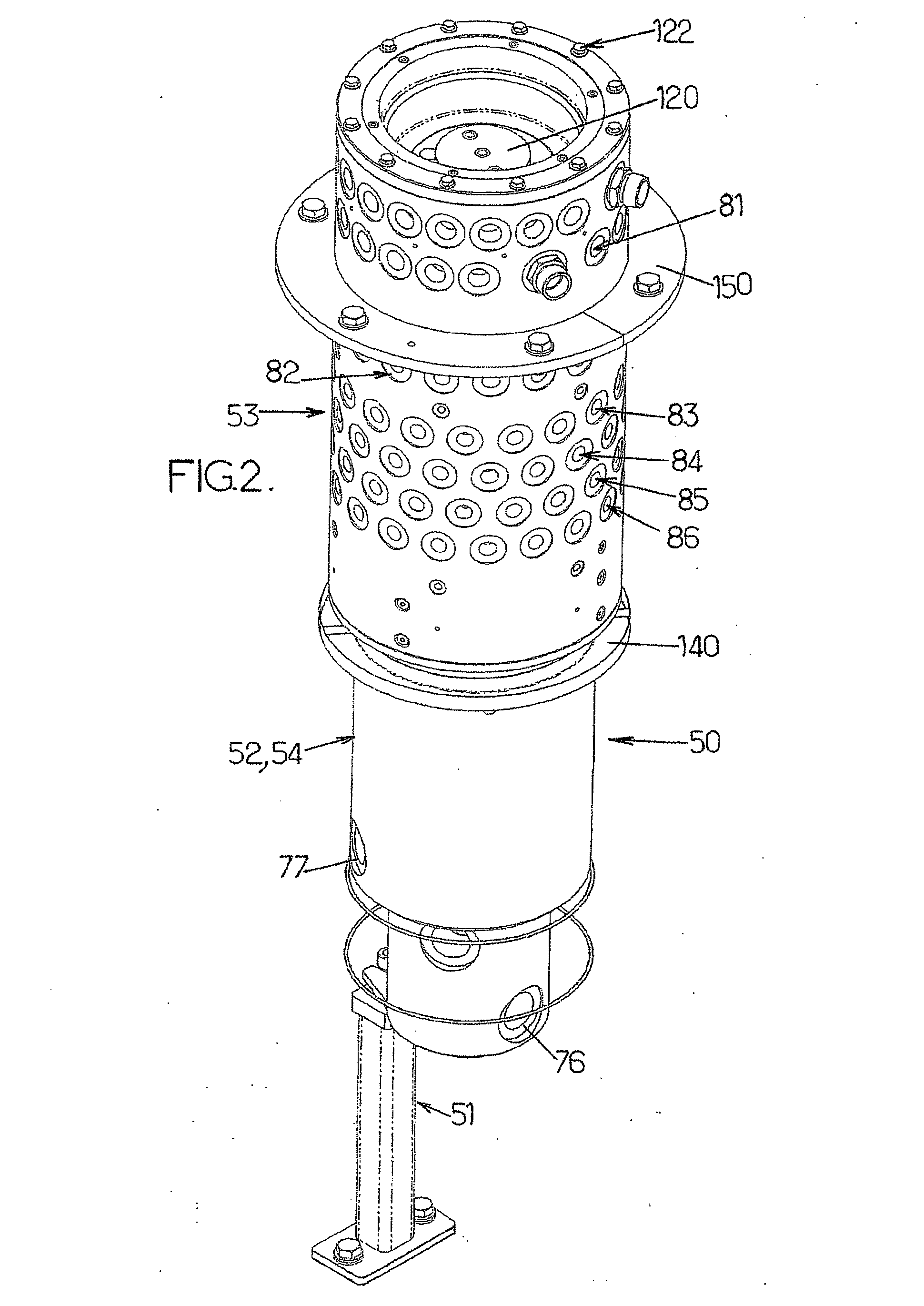

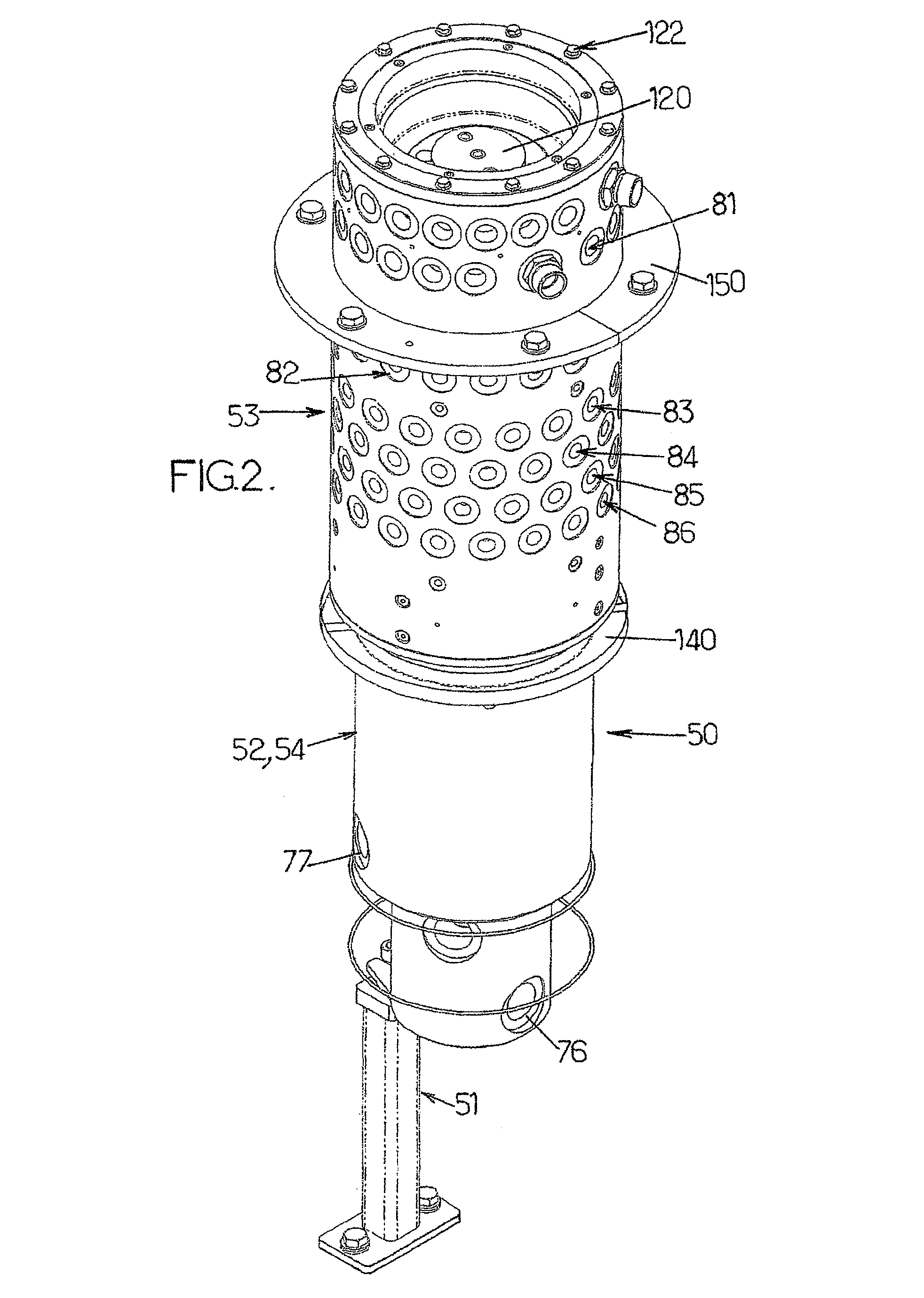

The invention concerns a rotating machine such as a carrousel comprising a rotating frame driven in rotation about an axis of rotation, several working stations supported by the rotating frame, a fluid supplying rotating column, coaxial to the axis column element (50, 250) provided with two assemblies (52, 252, 53) mobile in rotation relative to each other, about said axis of rotation, a first assembly (52, 252) including an axial tubular body (80, 280) provided with at least two tiers of radial through holes (81-86, 281-286), the axial conduits of the first assembly (52, 252) extending over different lengths in the space delimited by said tubular body (80, 280), each conduit (65a, 70-73, 75) emerging perpendicularly to one specific tier of radial through holes (81-86, 281-286), the column element (50, 250) thereby defining a rotating connection dispensing at least two fluids towards the working stations of the machine, and in that a sleeve C is interposed between said tubular body (80, 280) of the second assembly (53) and said first assembly (52, 252).

Owner:SIDEL PARTICIPATIONS SAS

Multi-layer gate stack structure comprising a metal layer for a FET device, and method for fabricating the same

InactiveUS7078748B2Reduce the overall heightAvoid excessive heightSolid-state devicesSemiconductor/solid-state device manufacturingGate dielectricGate stack

A multi-layer gate stack structure of a field-effect transistor device is fabricated by providing a gate electrode layer stack with a polysilicon layer, a transition metal interface layer, a nitride barrier layer and then a metal layer on a gate dielectric, wherein the transition metal is titanium, tantalum or cobalt. Patterning the gate electrode layer stack comprises a step of patterning the metal layer and the barrier layer with an etch stop on the surface of the interface layer. Exposed portions of the interface layer are removed and the remaining portions are pulled back from the sidewalls of the gate stack structure leaving divots extending along the sidewalls of the gate stack structure between the barrier layer and the polysilicon layer. A nitride liner encapsulating the metal layer, the barrier layer and the interface layer fills the divots left by the pulled-back interface layer. The nitride liner is opened before the polysilicon layer is patterned. As the requirement for an overetch into the polysilicon layer during the etch of the metal layer, the barrier layer and the interface layer is omitted, the height of the polysilicon layer can be reduced. The aspect ration of the gate stack structure is improved, the feasibility of pattern and fill processes enhanced and the range of an angle under which implants can be performed is extended.

Owner:NAN YA TECH +1

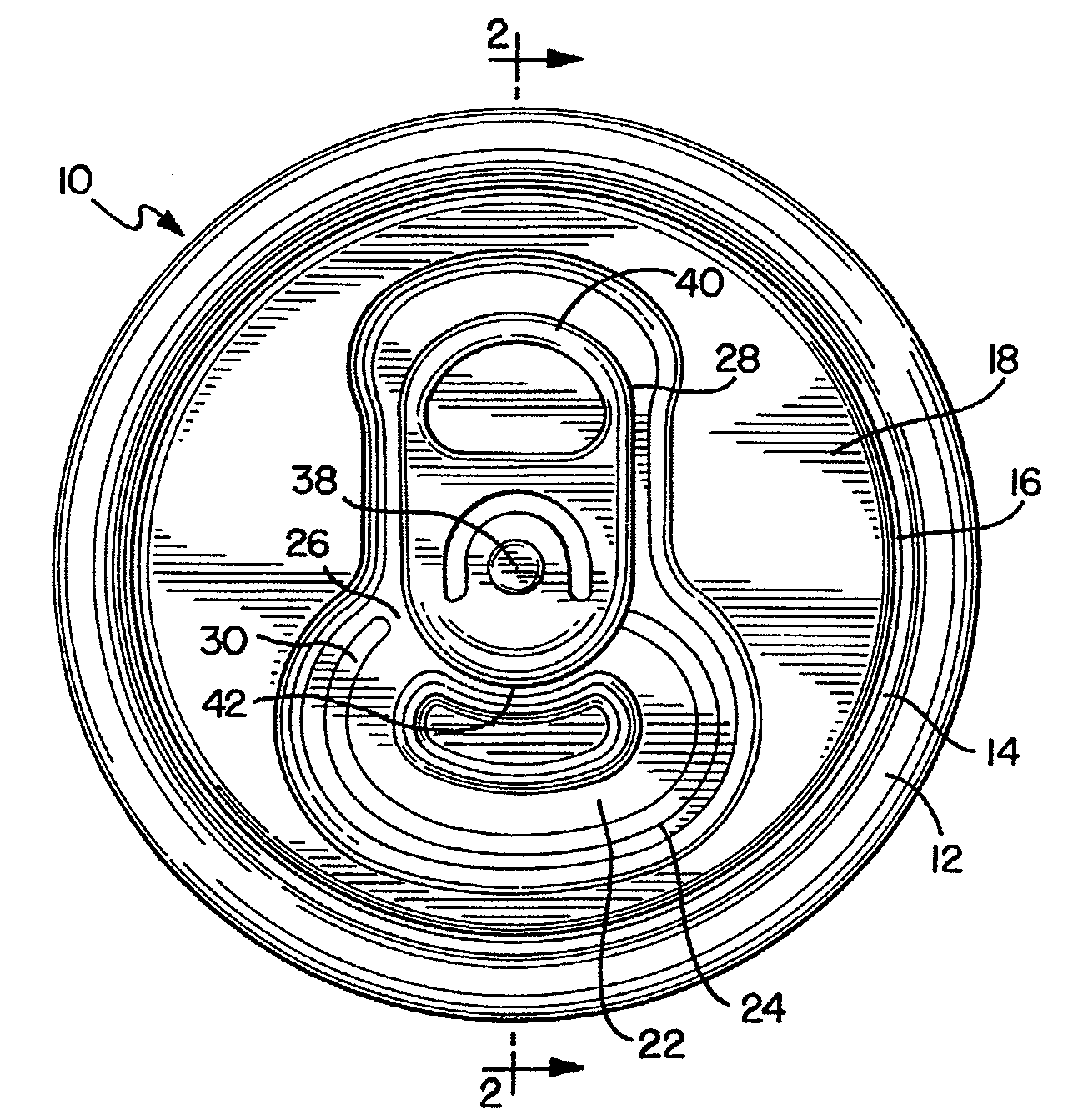

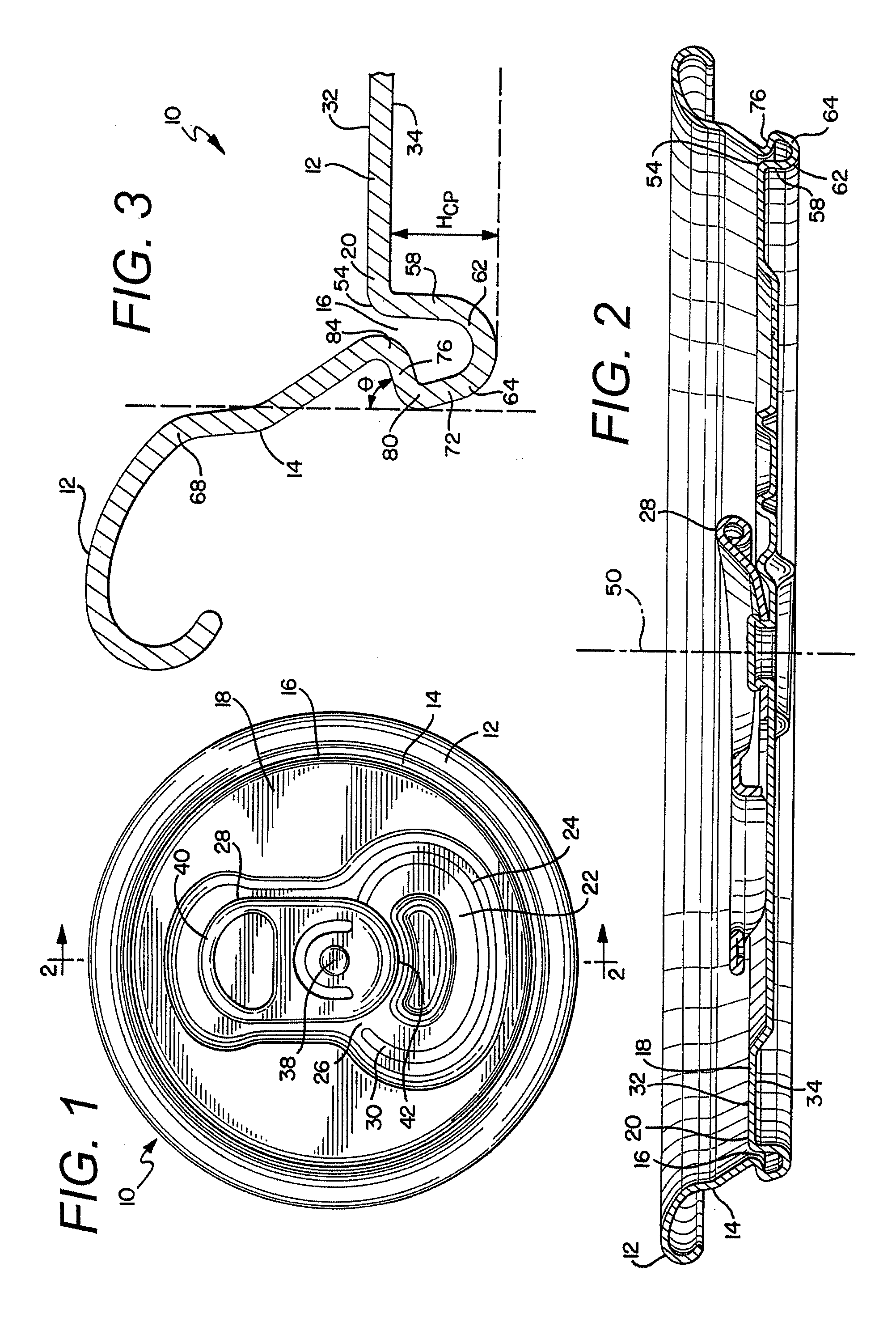

Can End With Negatively Angled Wall

InactiveUS20080257900A1Less lengthAvoid excessive heightContainer/bottle contructionRigid containersEngineeringCountersink

An end for a beverage can is described. The end has a product side, an opposing public side, a center panel, an annular countersink, a circumferential wall, and a curl. The center panel has a means for opening the end. The annular countersink extends circumferentially about the center panel. The circumferential wall extends upwardly from the countersink and has an angled portion extending radially inwardly toward the center panel. The curl is located radially outward relative to the center panel and defines an outer perimeter of the end.

Owner:REXAM BEVERAGE CAN

Generator of time-variable magnetic fields of a magnetic resonance device and magnetic resonance device

InactiveUS7109715B2Improve efficiencyReduce weightDiagnostic recording/measuringSensorsElectrical conductorResonance

A generator of time-variable magnetic fields of a magnetic resonance device having an examination space for registering at least one area to be examined of an item being examined has the following features:the conductors of a gradient coil arrangement of the generator define an area at least partially surrounding the examination space,said area contains at least a partial area which is free from conductors of the gradient coil arrangement and which contains conductors of a radio frequency antenna of the generator, anda field flowback space, inter alia for fields of the radio frequency antenna, extends proceeding from the partial area away from the examination space and is delimited beyond said partial area by a radio frequency shield.

Owner:SIEMENS HEALTHCARE GMBH

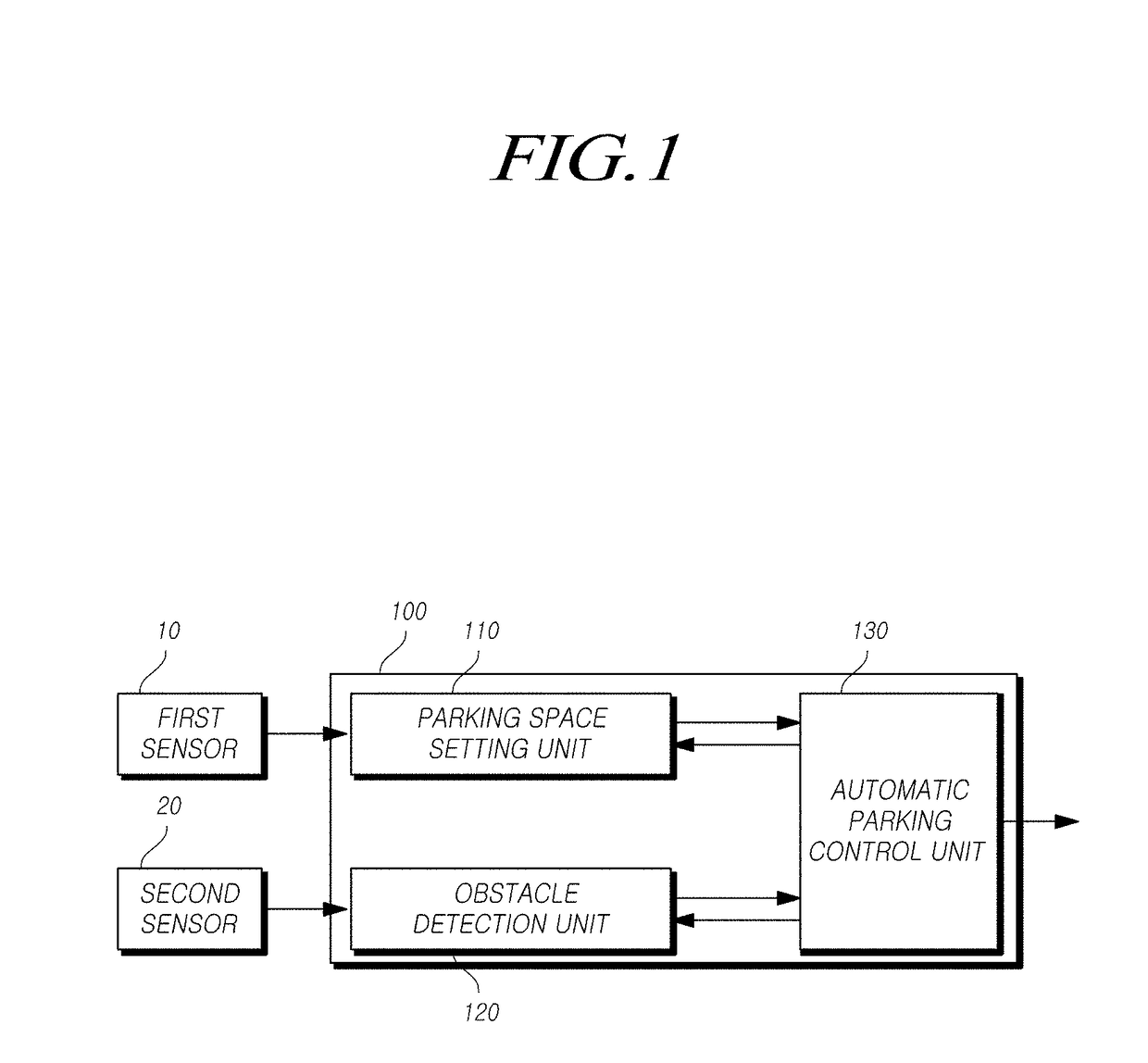

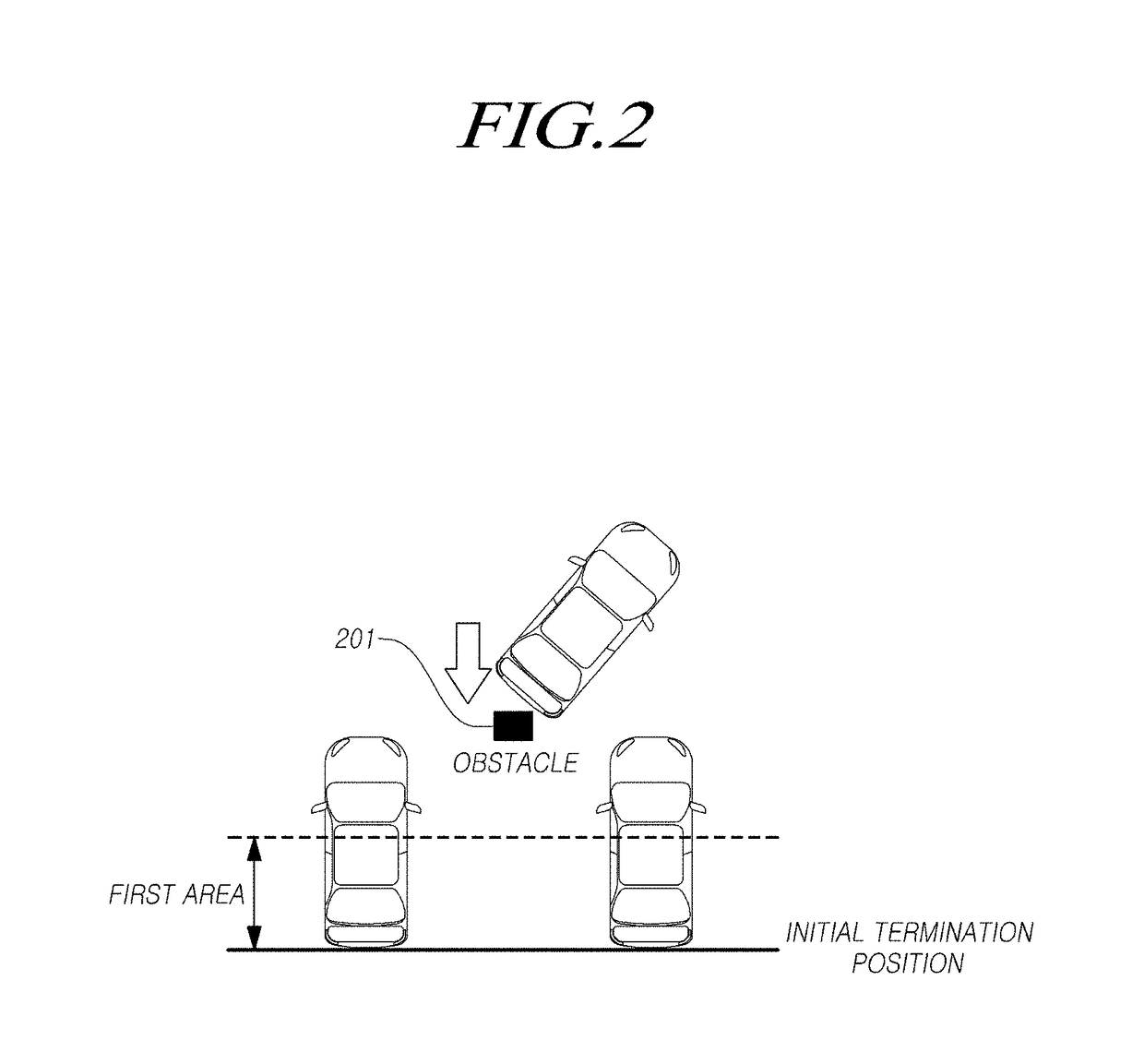

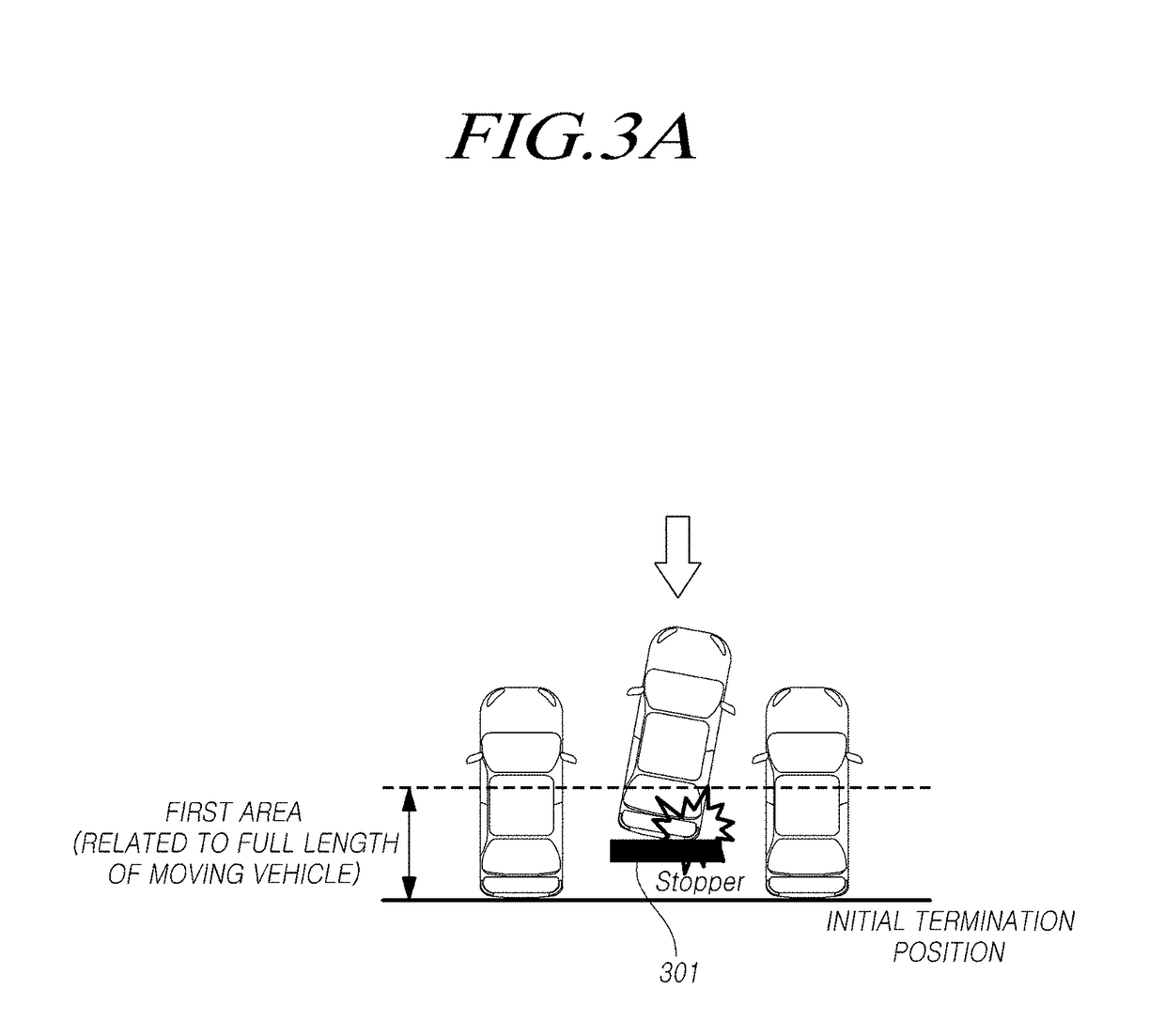

Smart parking assist system and method of controlling the same

ActiveUS20180339702A1Avoid excessive heightRoad vehicles traffic controlScene recognitionParking spaceEngineering

The present disclosure relates to a smart parking assist system (SPAS) and a method of controlling the smart parking assist system. The system and method detect an obstacle that is located on a path to a parking space for automatic parking and is not detected by a sensor of a vehicle using a target speed, a moving speed, and a driving torque of the vehicle, control the vehicle to pass over the obstacle according to a position of the detected obstacle, or change an automatic parking termination condition and complete the automatic parking, thereby detecting the obstacle even though the obstacle is not detected by a sensor in the process of controlling the automatic parking and completing the automatic parking.

Owner:HL KLEMOVE CORP

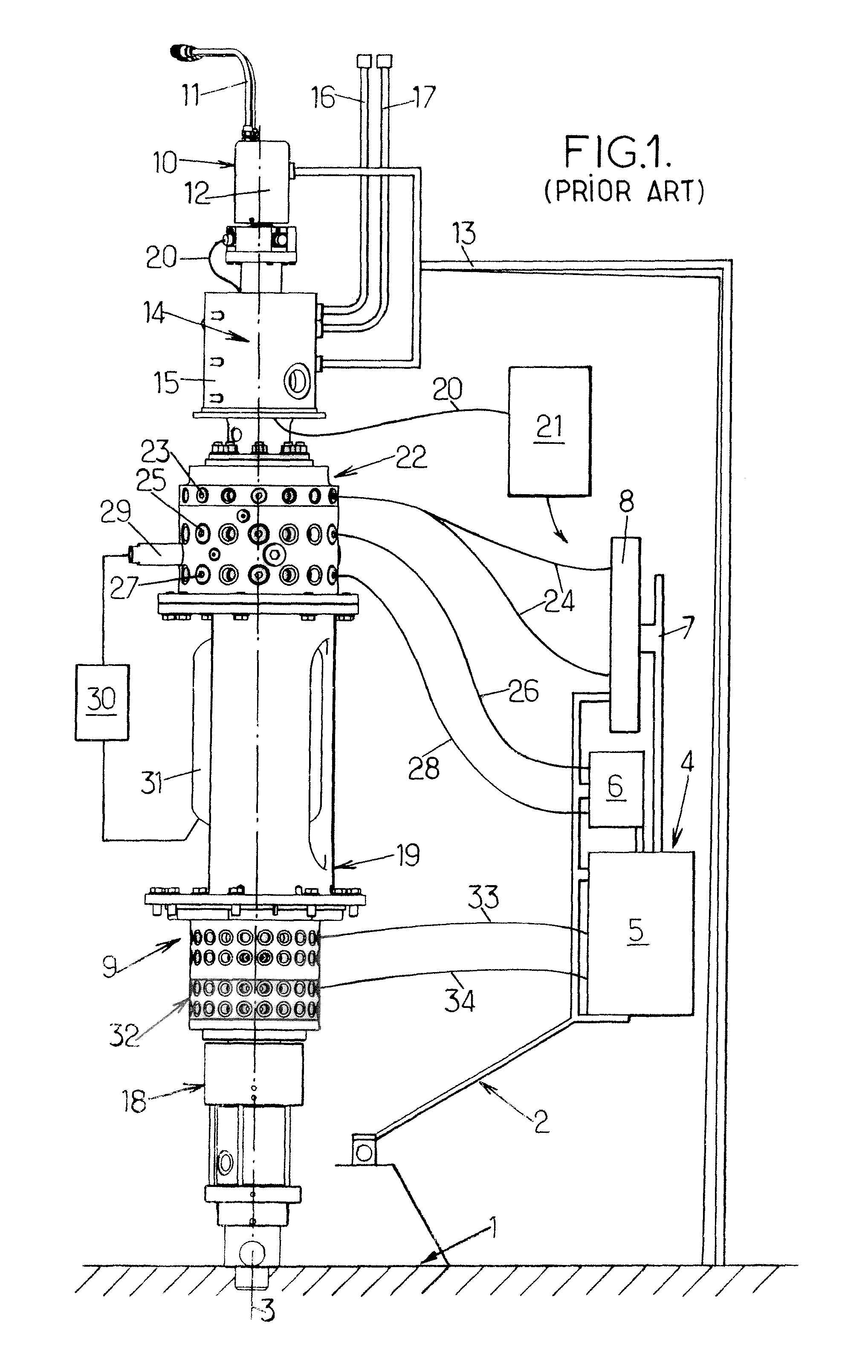

Riserless, pollutionless drilling system

ActiveUS9062498B2Reduce riskAvoid excessive heightUnderwater drillingFlushingWell drillingEngineering

Owner:ENHANCED DRILLING

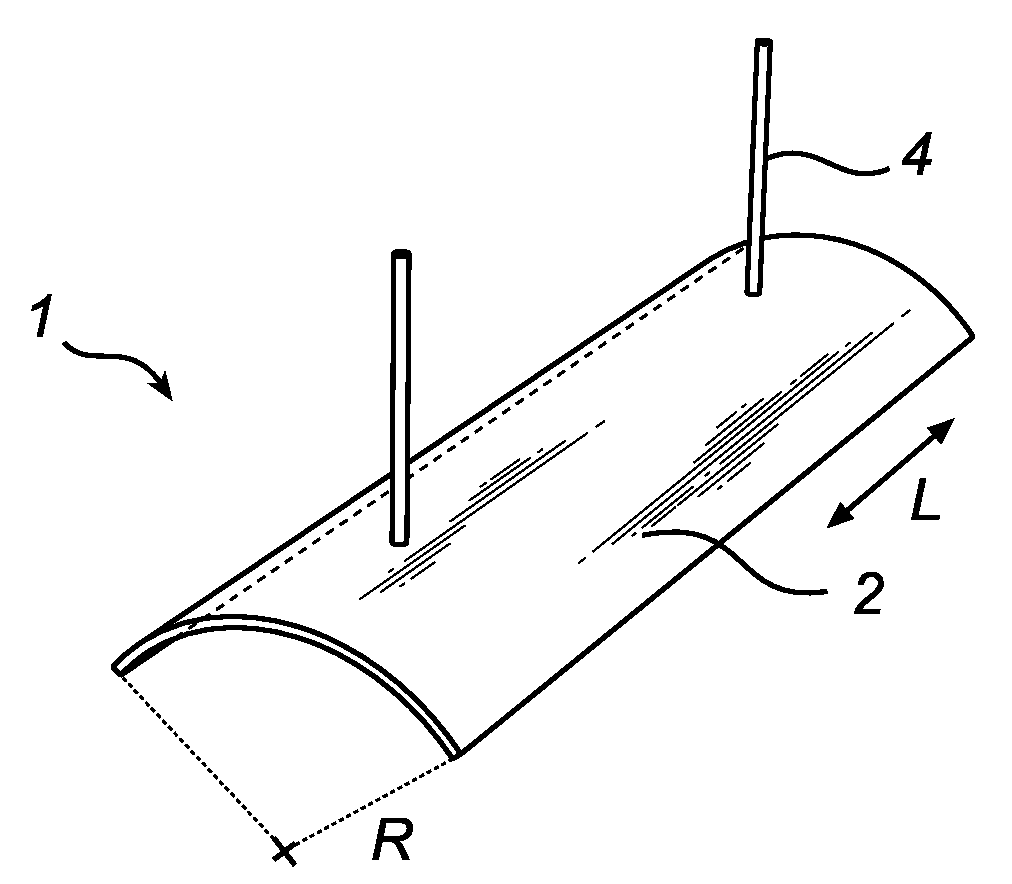

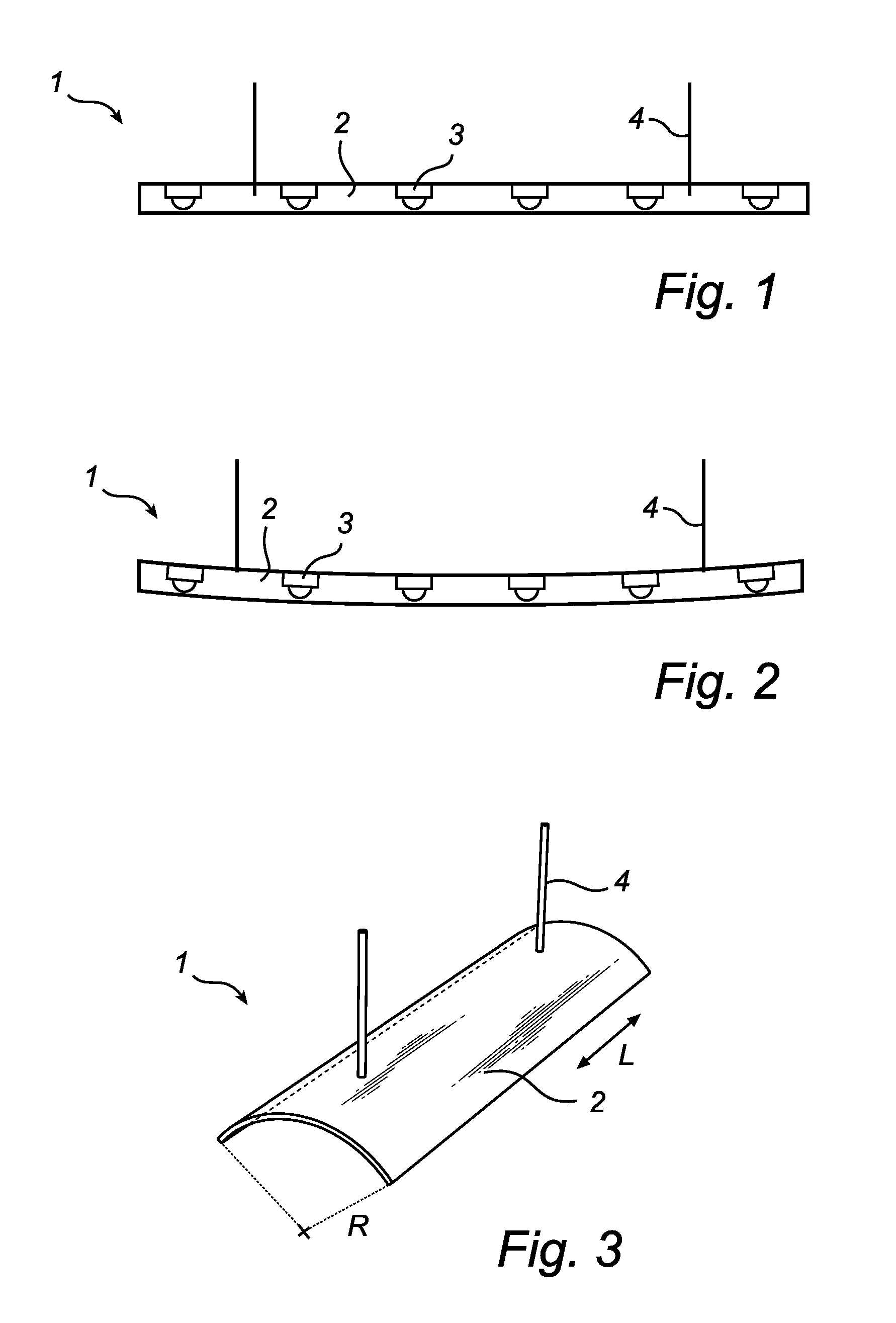

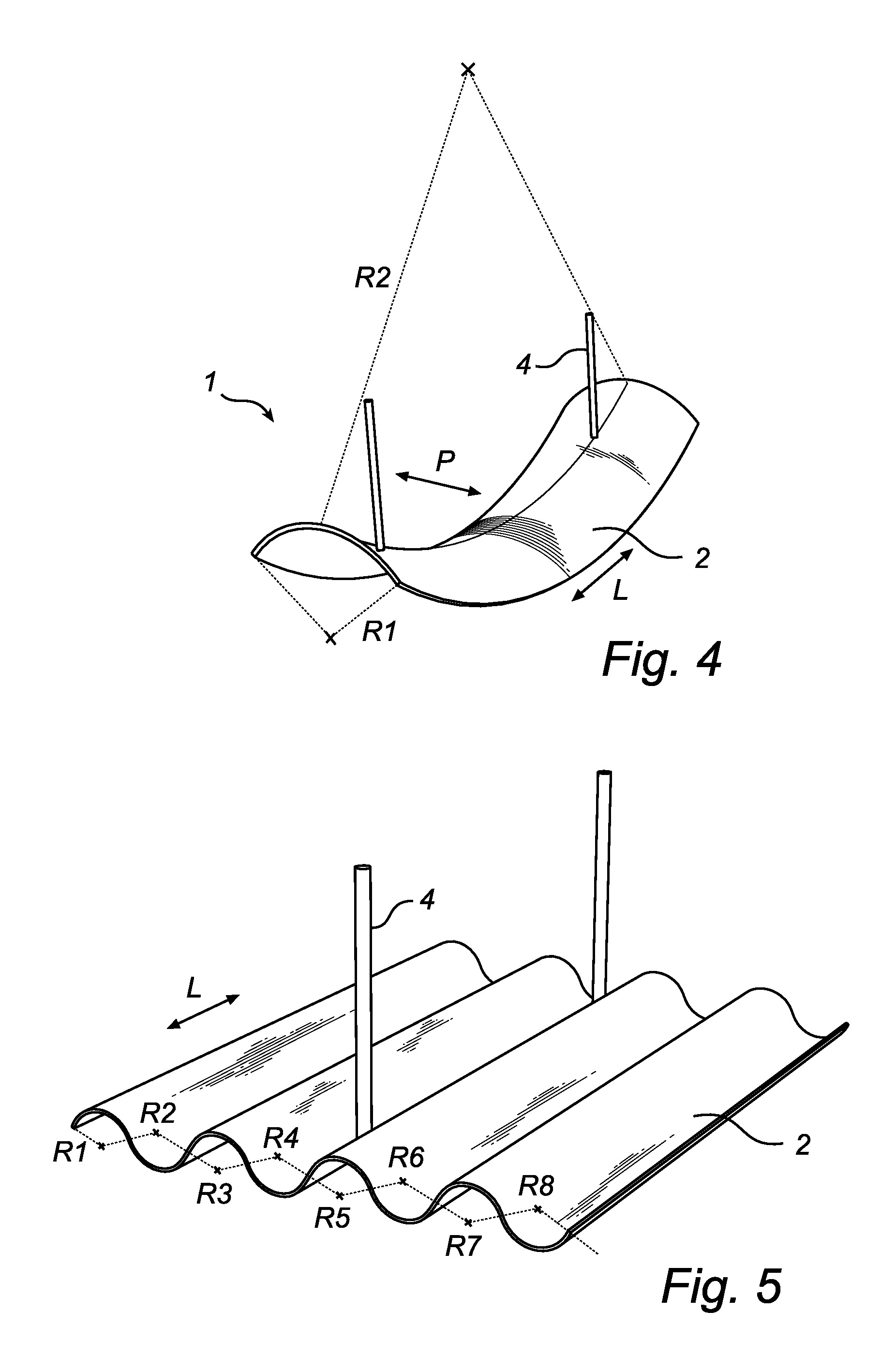

Lighting system

InactiveUS20110051416A1High mechanical stiffnessAppealing designNon-electric lightingPoint-like light sourceLight equipmentLight guide

The present invention relates the field of illumination devices, in particular to a lighting system (1) comprising an elongated light guiding plate (2), comprising at least one light source (3). The light source (3) is enclosed in the light guiding plate (2). Furthermore, the light guiding plate (2) has at least one curvature (R).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Rotating machine with a fluid supply rotating column

The invention concerns a rotating machine such as a carrousel comprising a rotating frame driven in rotation about an axis of rotation, several working stations supported by the rotating frame, a fluid supplying rotating column, coaxial to the axis of rotation of the rotating frame. The invention is characterized in that it comprises a column element (50, 250) provided with two assemblies (52, 252, 53) mobile in rotation relative to each other, about said axis of rotation, a first assembly (52, 252) including an axial tubular body (80, 280) provided with at least two tiers of radial through holes (81-86, 281-286), the axial conduits of the first assembly (52, 252) extending over different lengths in the space delimited by said tubular body (80, 280), each conduit (65a, 70-73, 75) emerging perpendicularly to one specific tier of radial through holes (81-86, 281-286), the column element (50, 250) thereby defining a rotating connection dispensing at least two fluids towards the working stations of the machine, and in that a sleeve C is interposed between said tubular body (80, 280) of the second assembly (53) and said first assembly (52, 252).

Owner:SIDEL PARTICIPATIONS SAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com