Patents

Literature

607results about "Railway roofs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

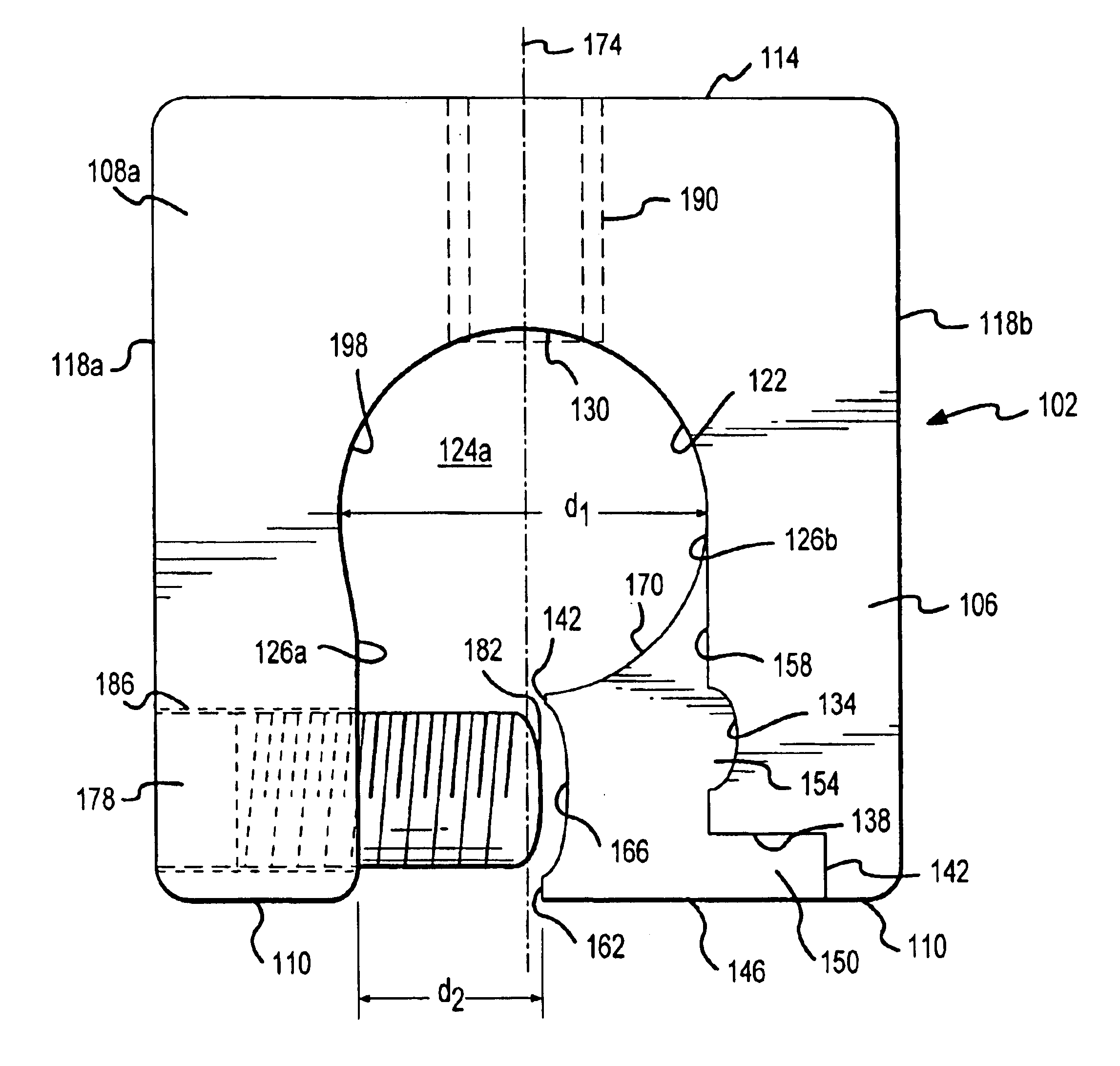

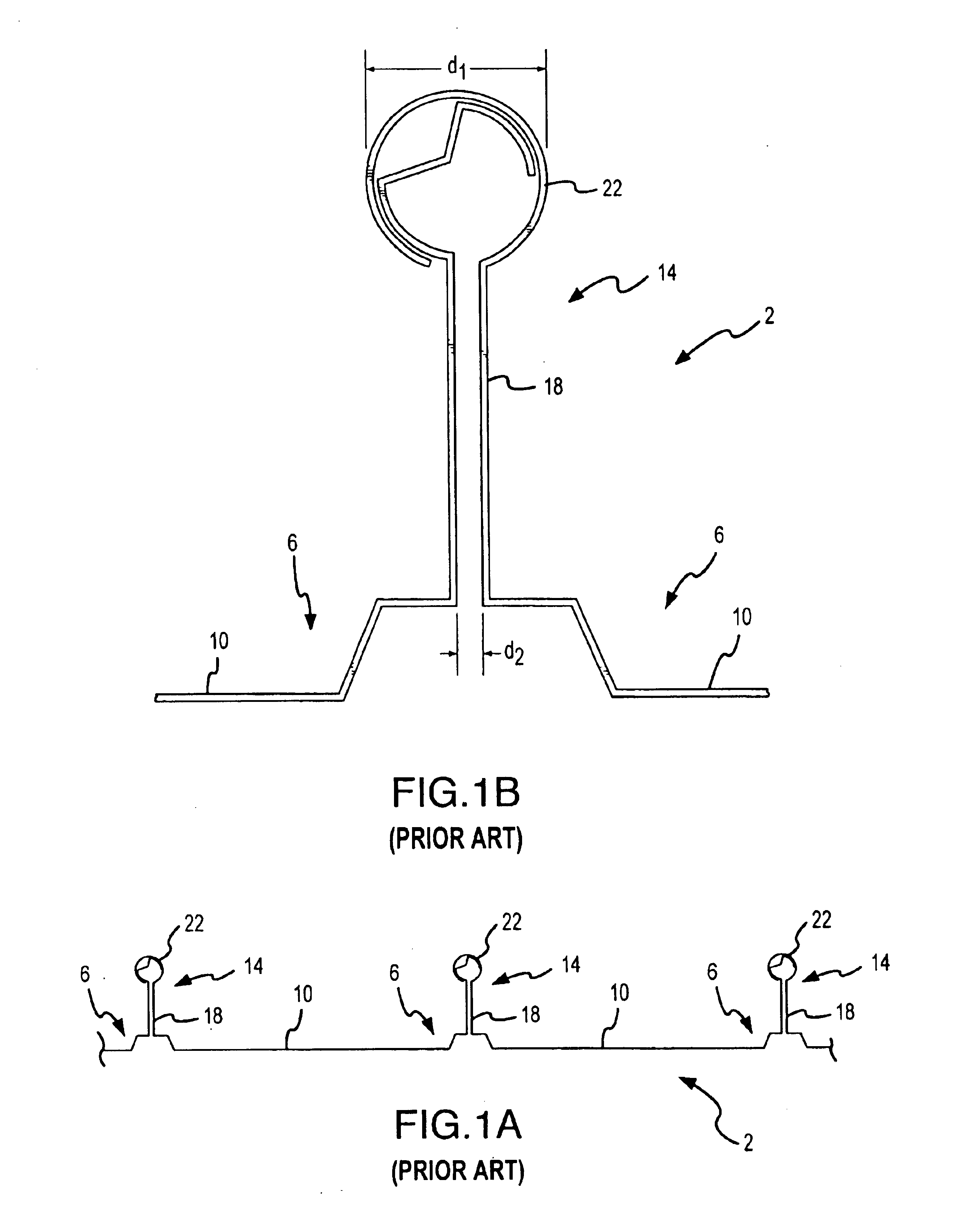

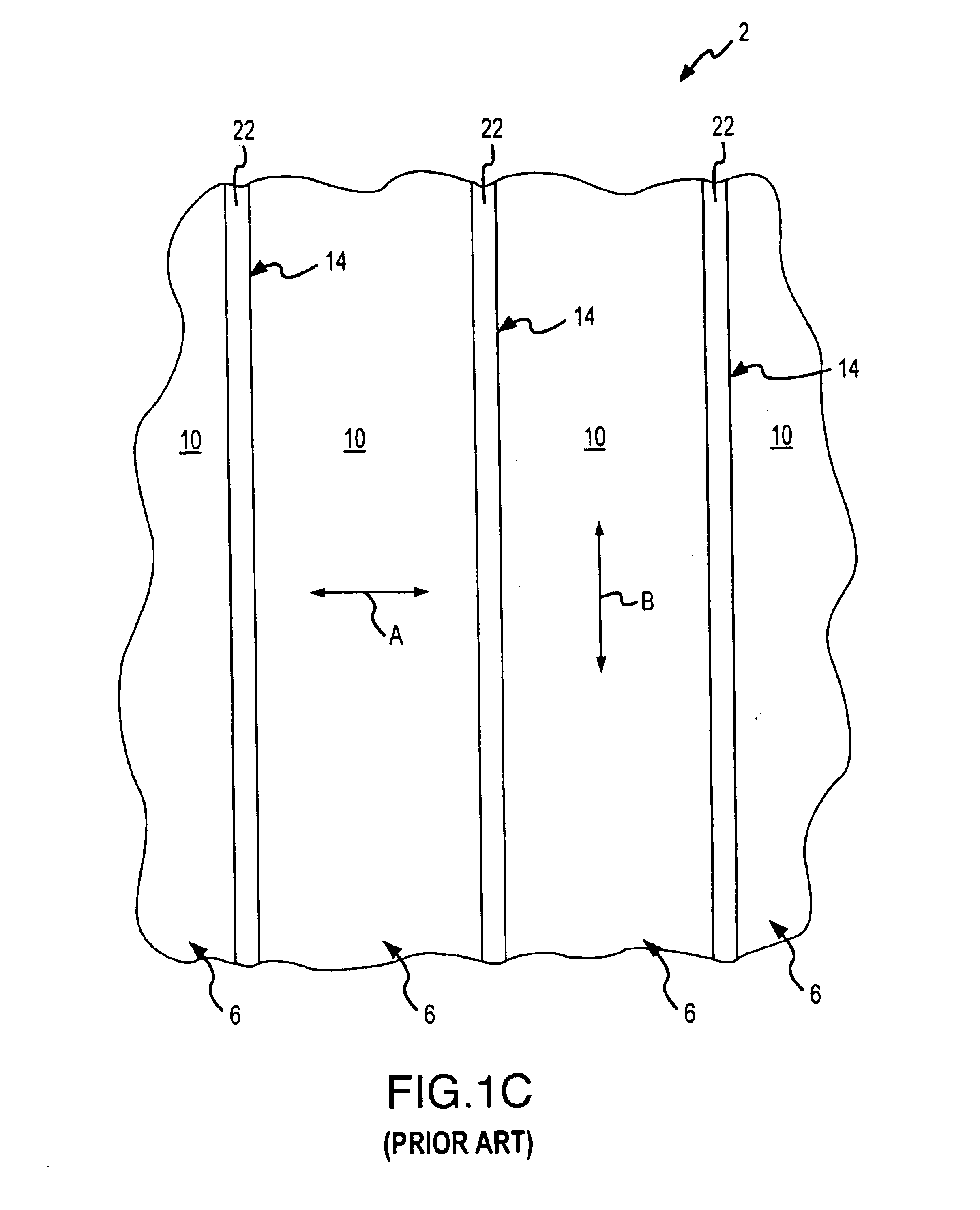

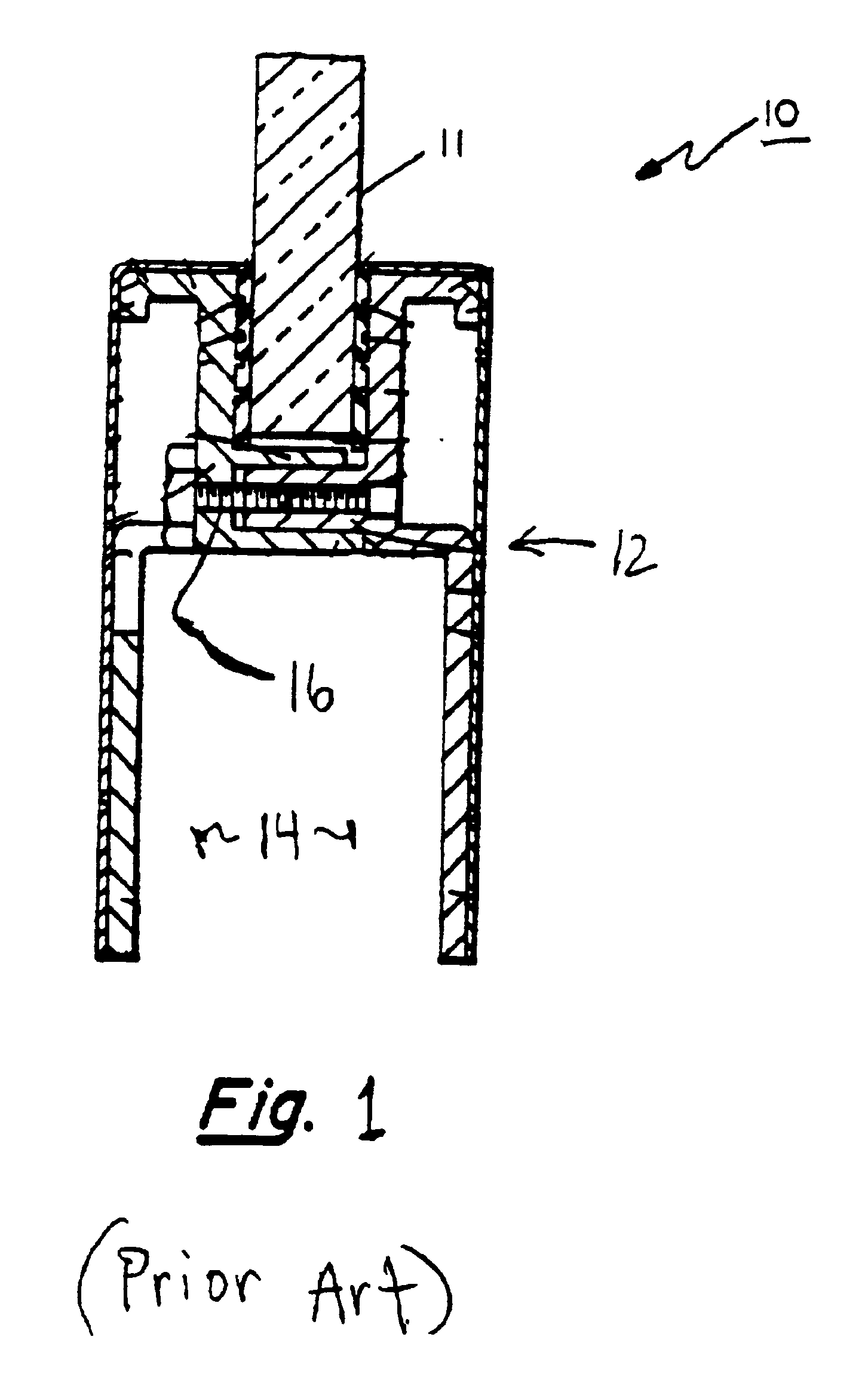

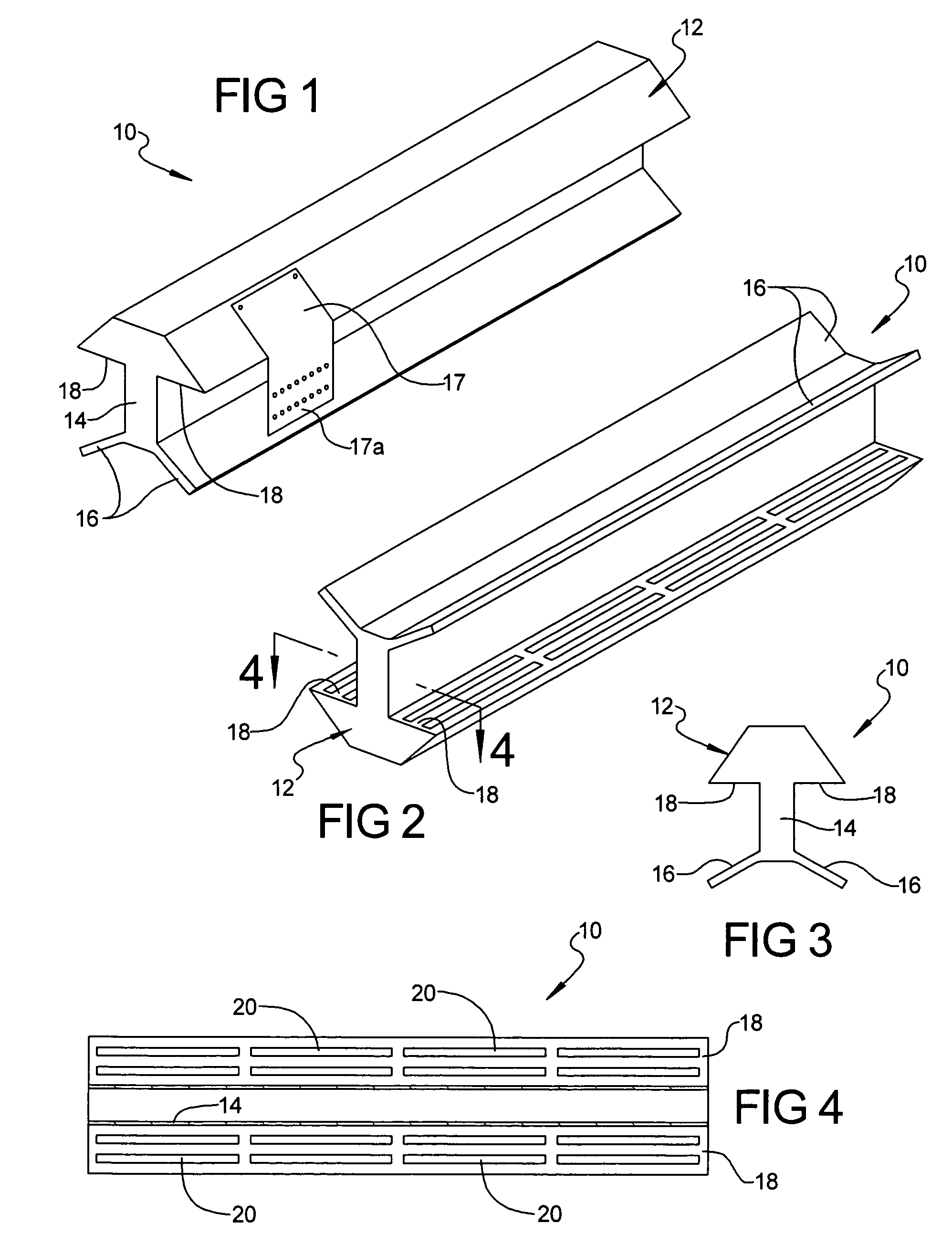

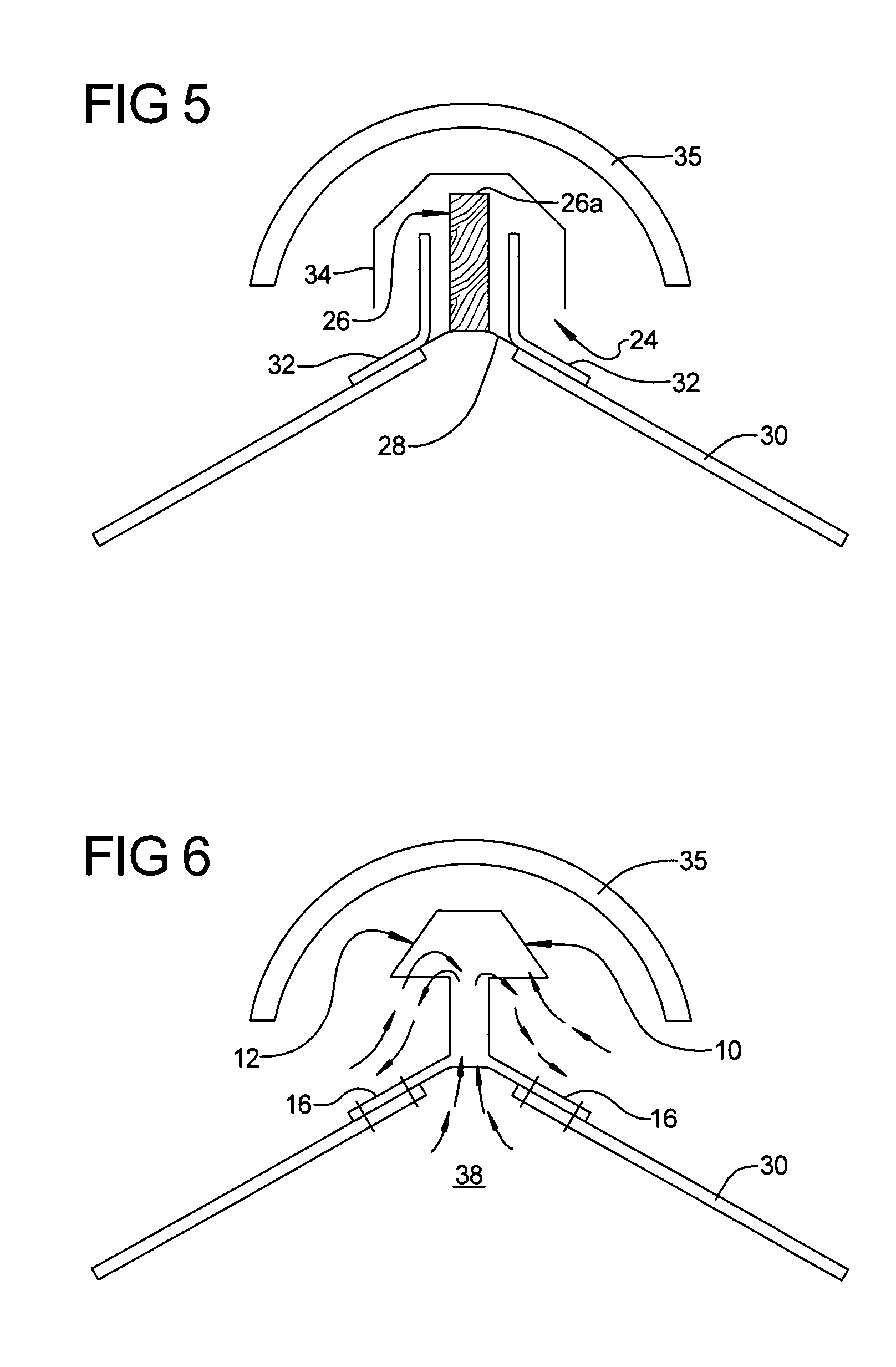

Multi-piece clamp for standing seams

InactiveUS7100338B2Increase volumeImprove the immunityRailway roofsRoof covering using slabs/sheetsBiomedical engineeringFastener

Owner:CAUGHT FISH ENTERPRISES +1

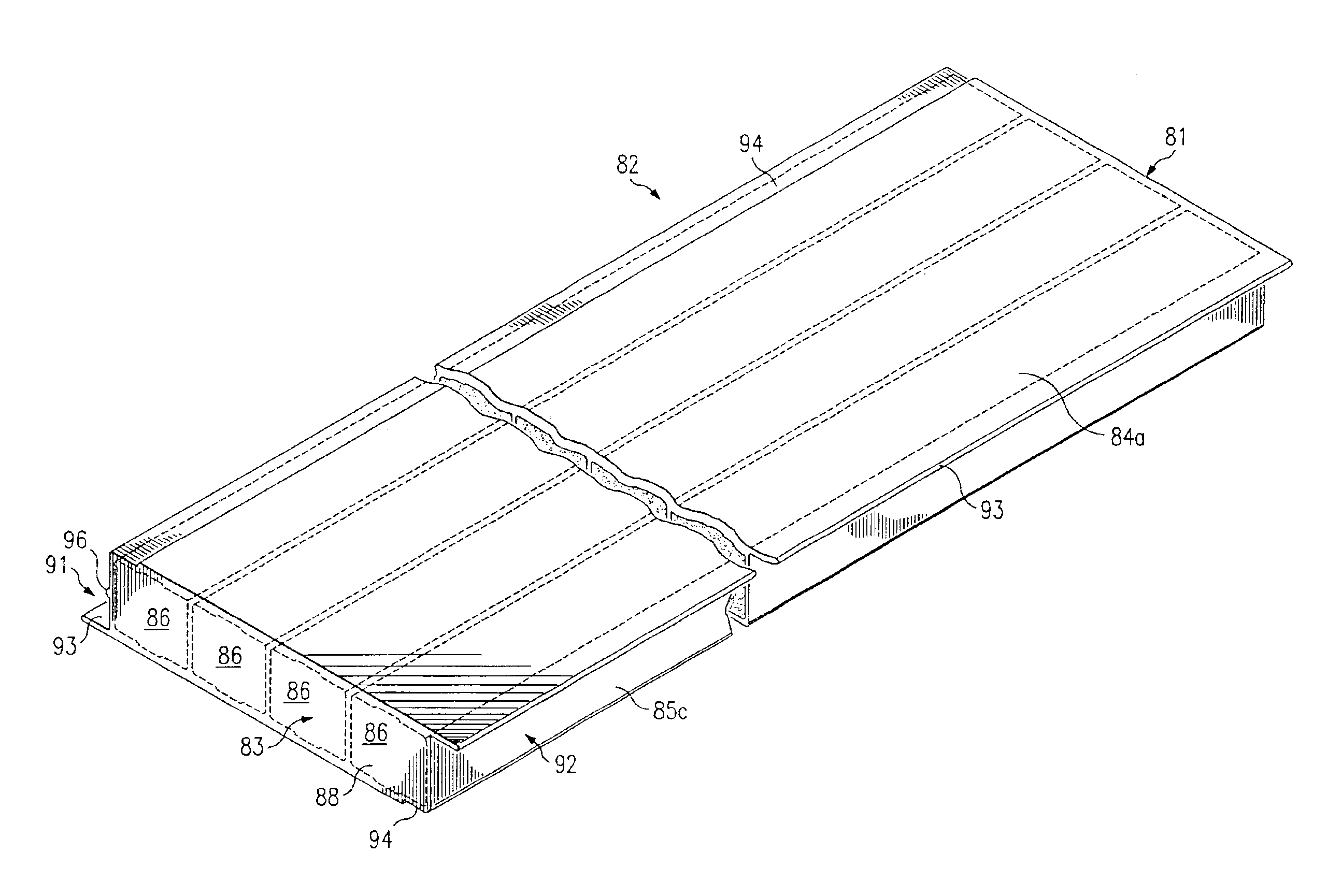

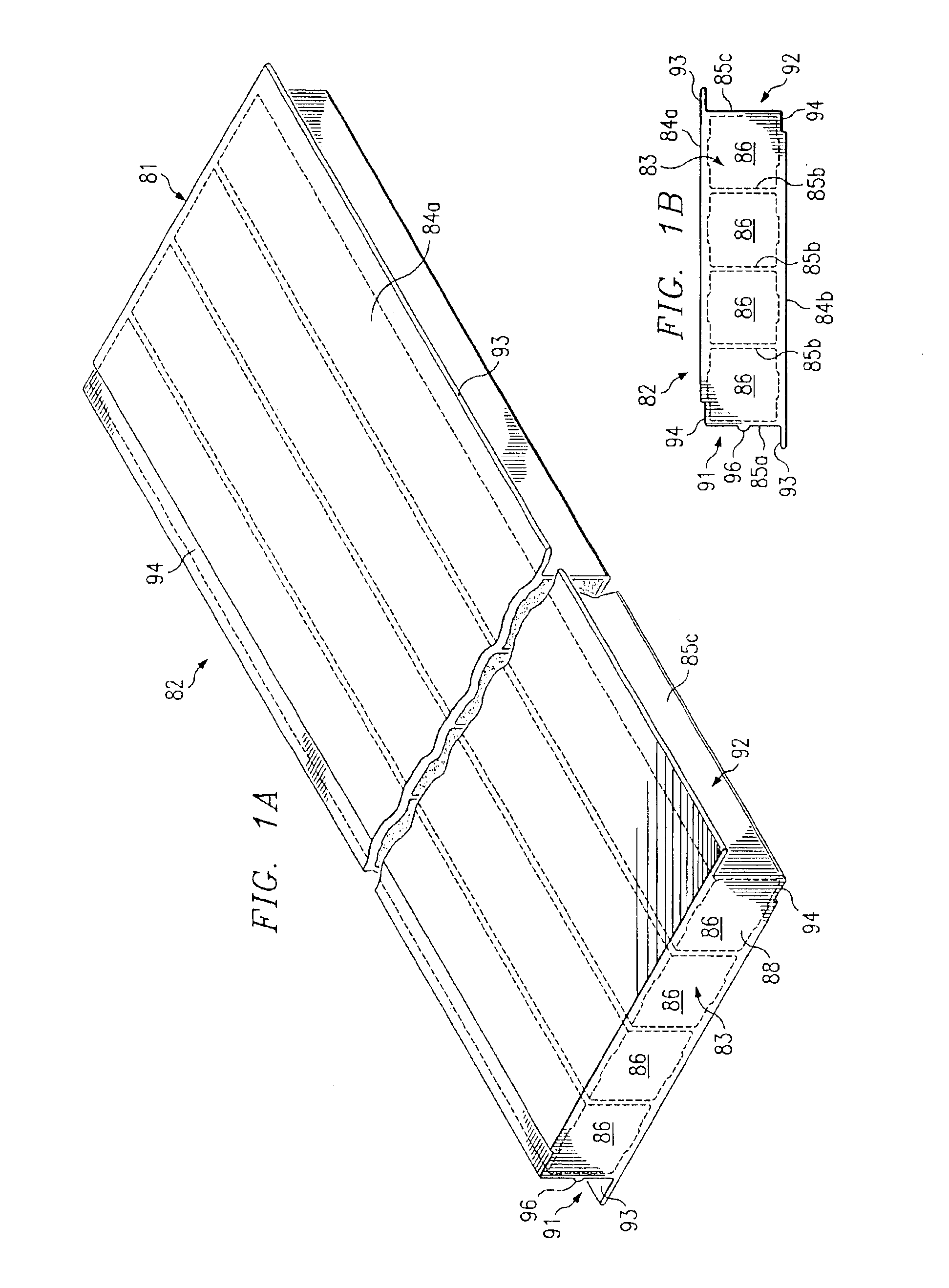

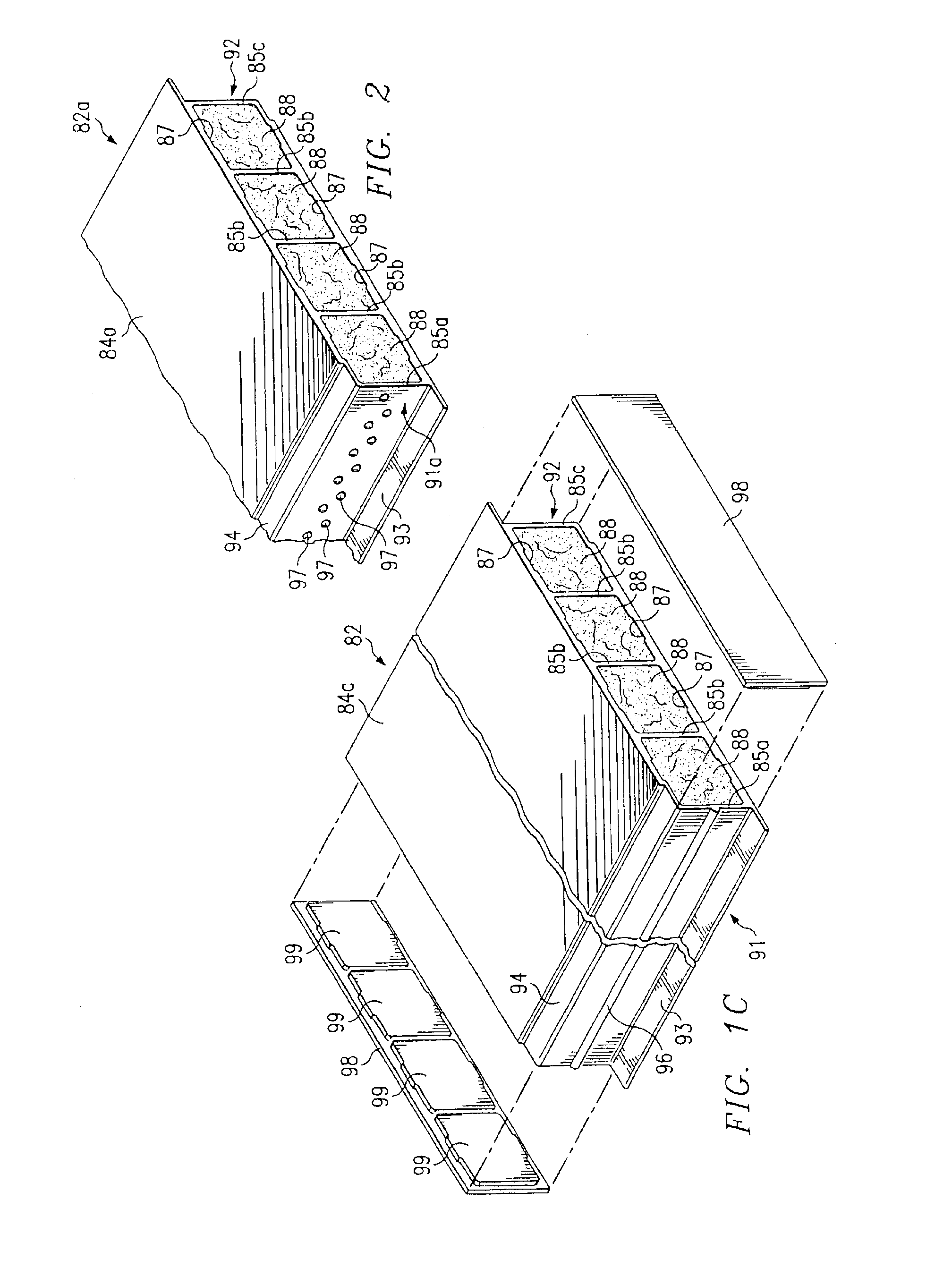

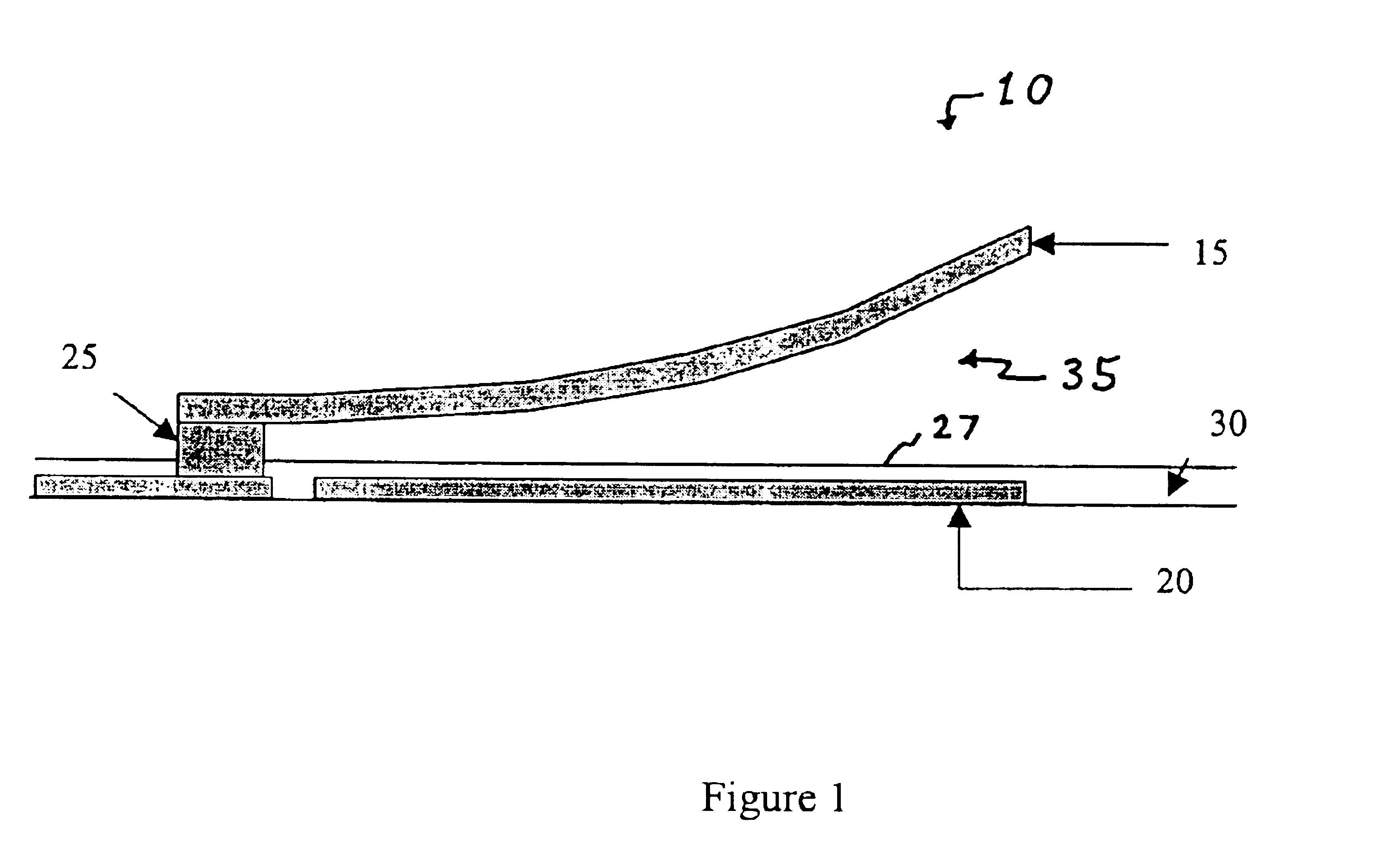

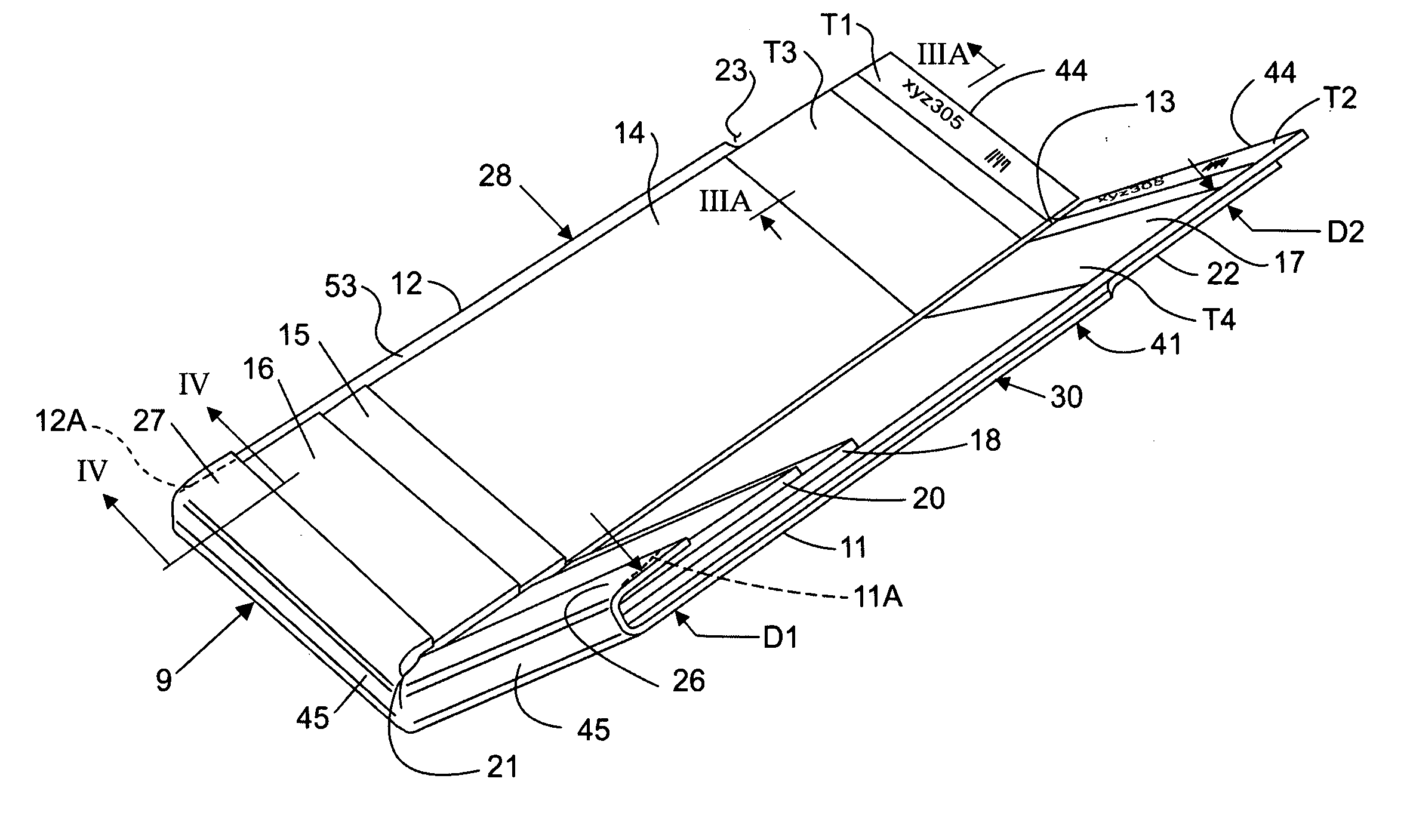

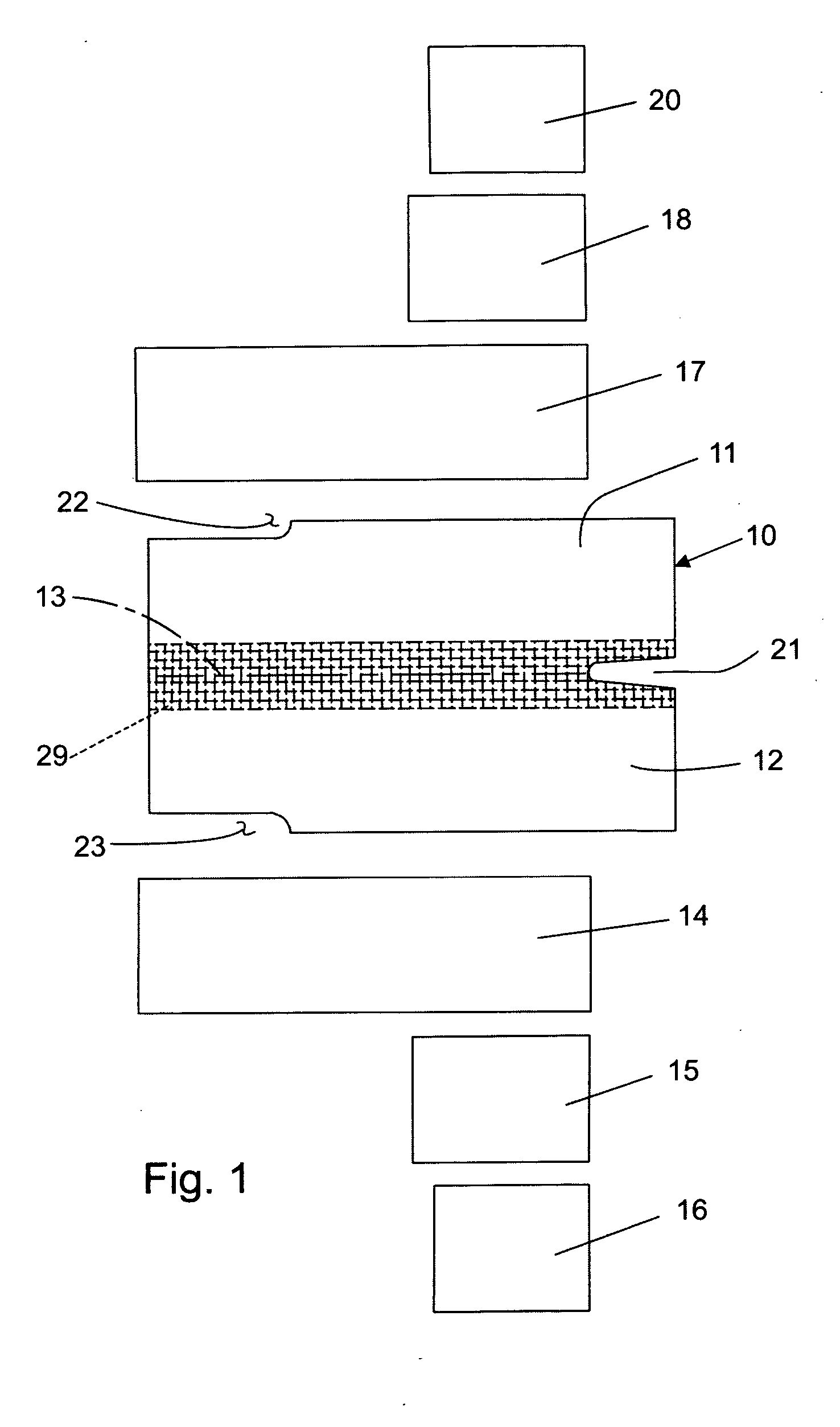

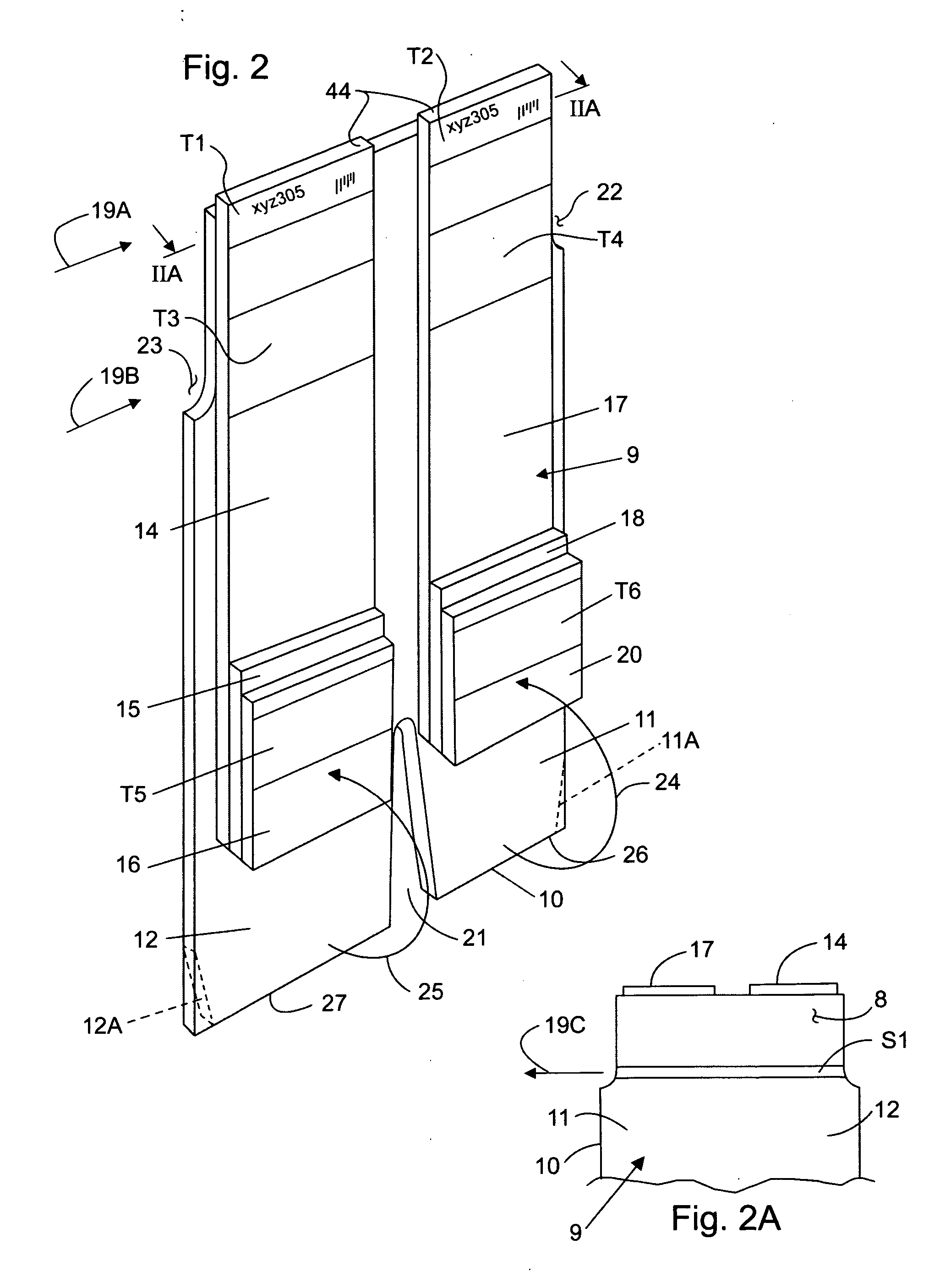

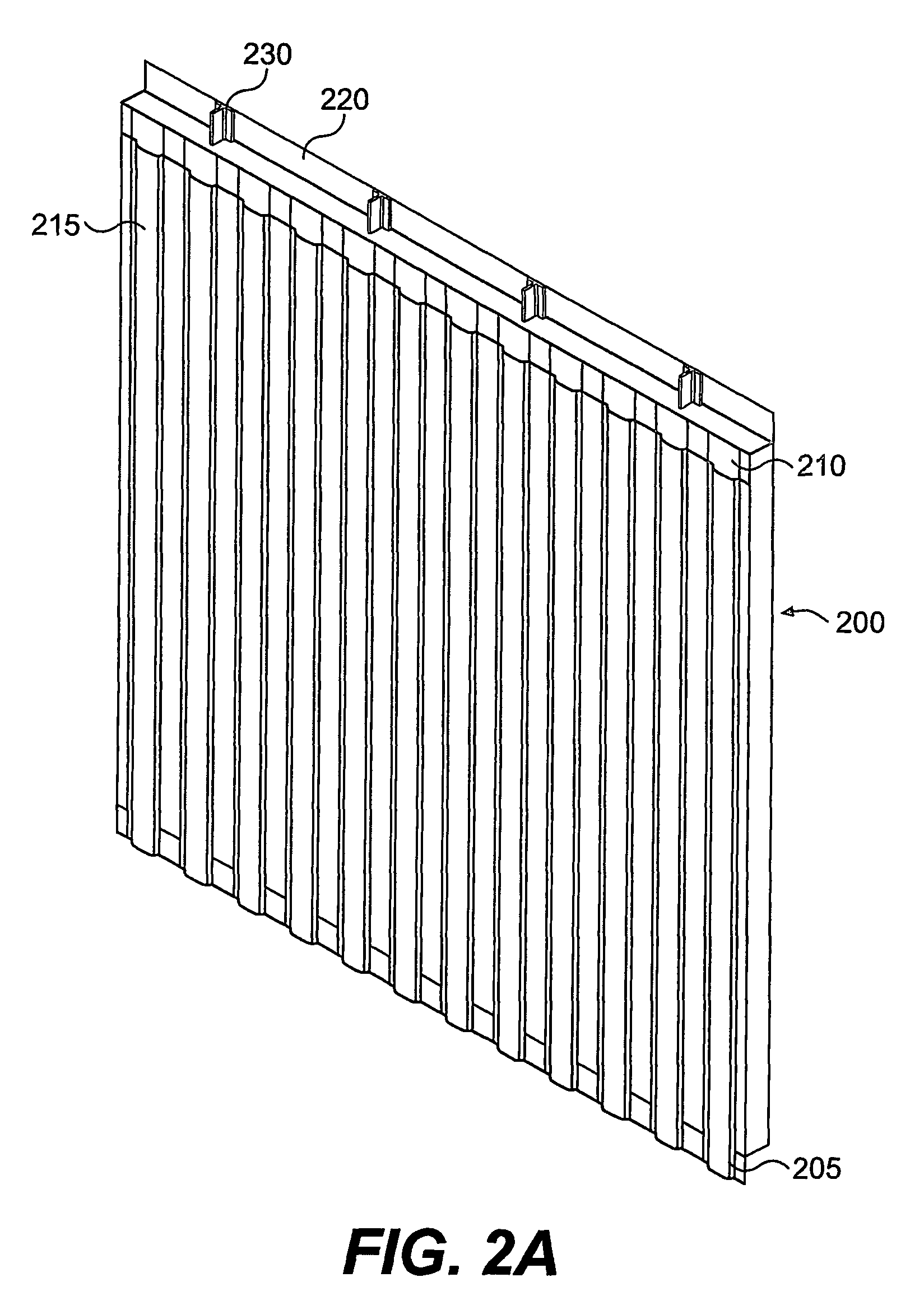

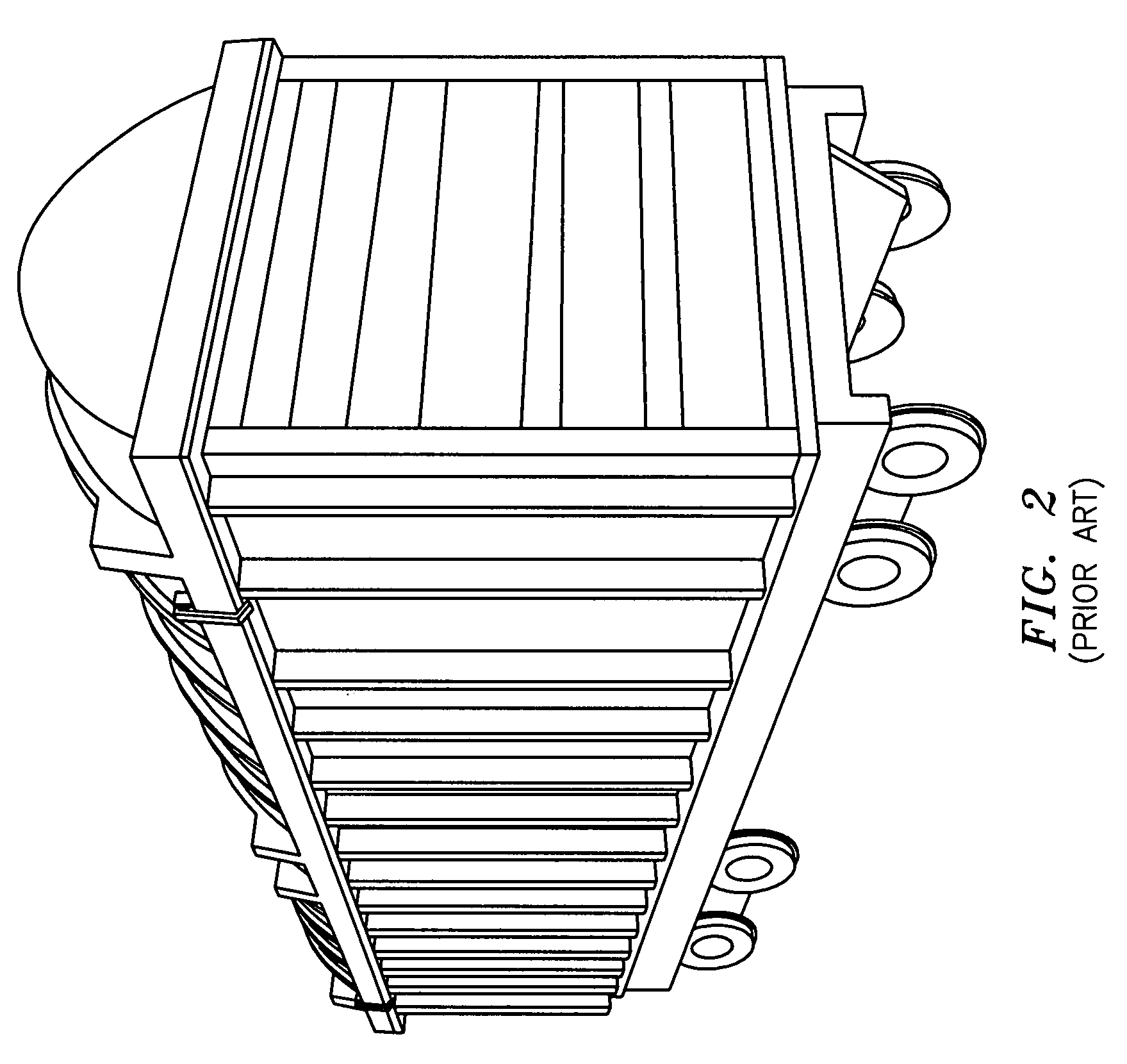

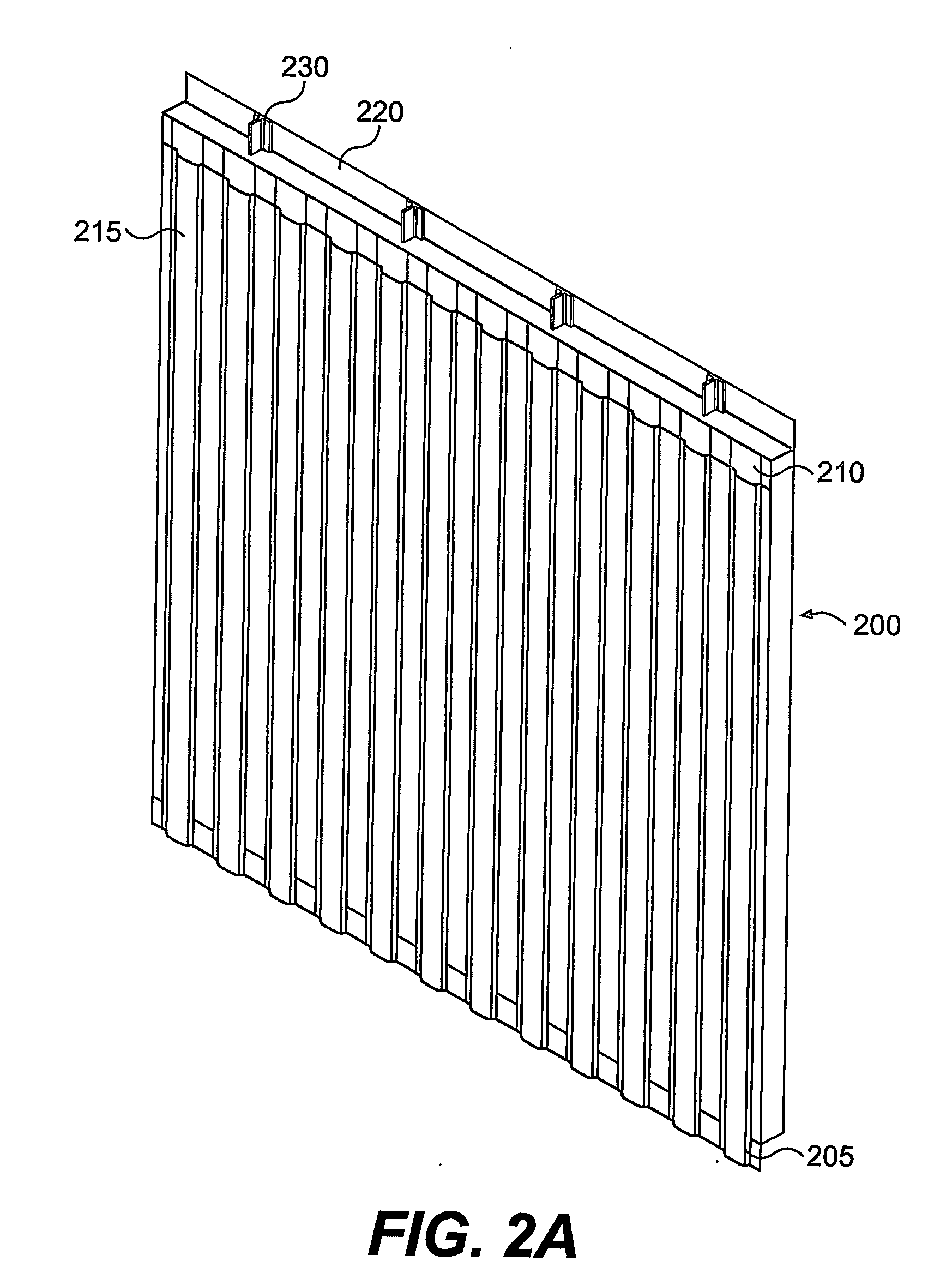

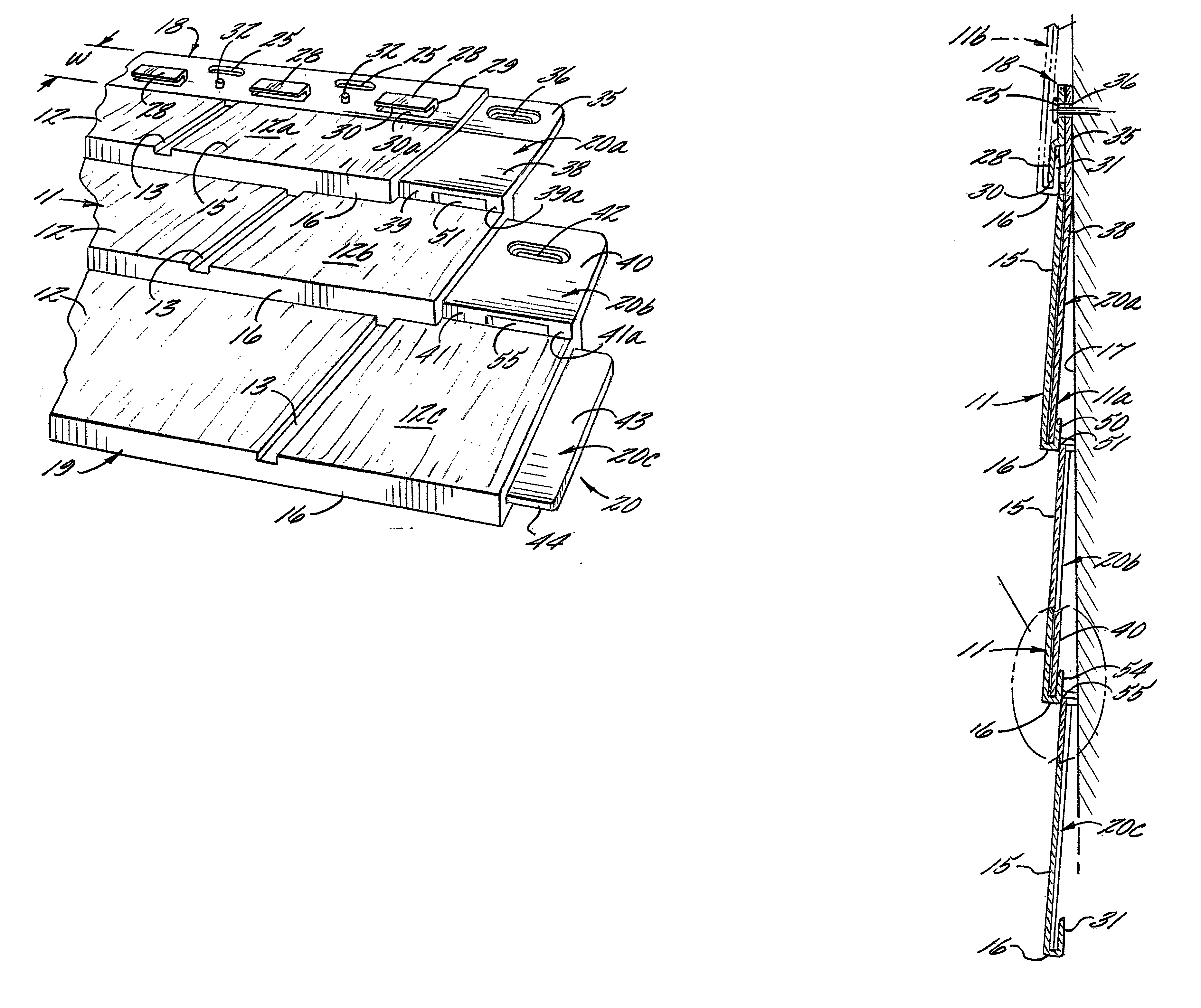

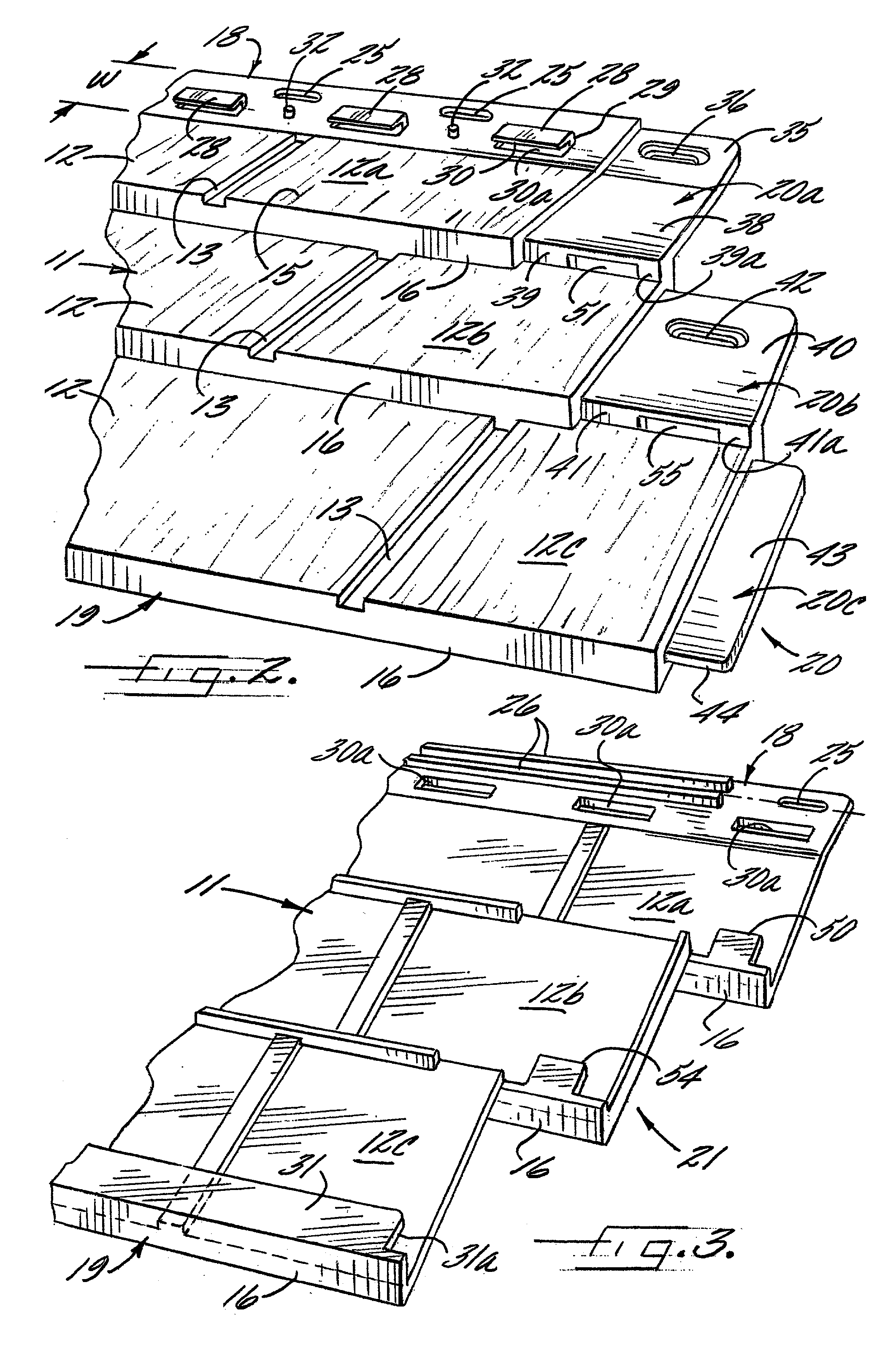

Pultruded panel

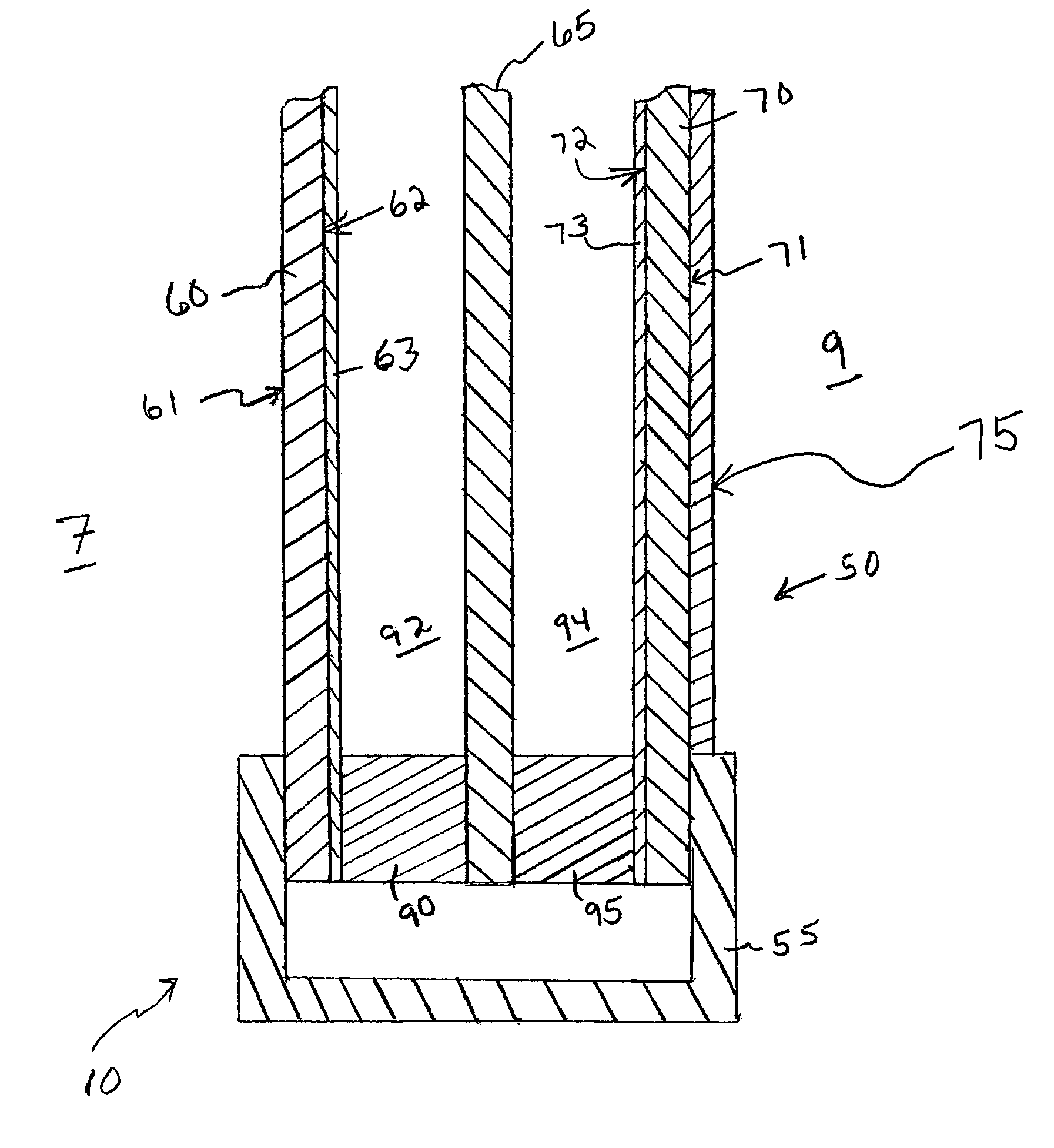

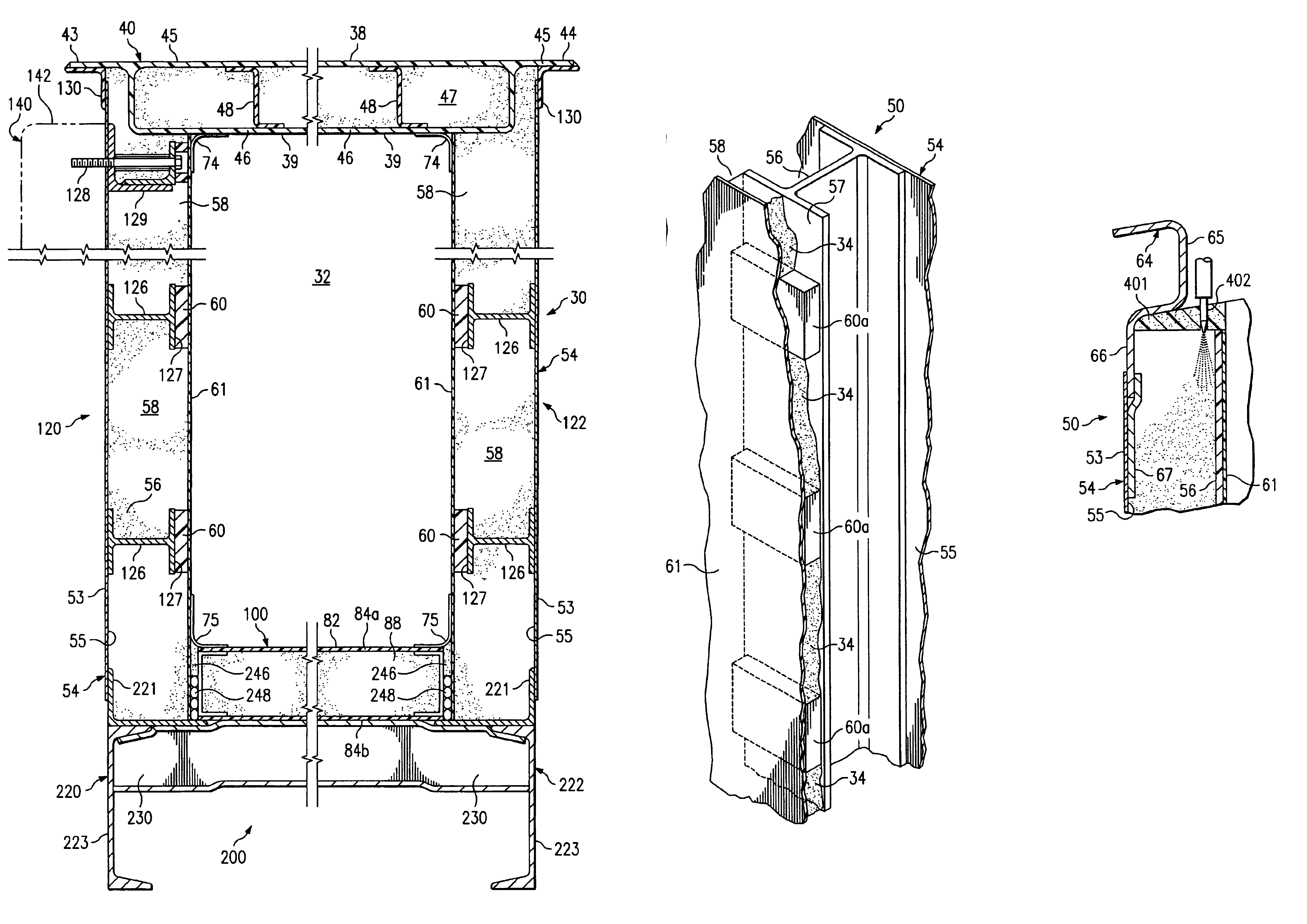

InactiveUS6871600B2Improve insulation performanceImprove carrying capacityRailway roofsRailway heating/coolingAdhesiveEngineering

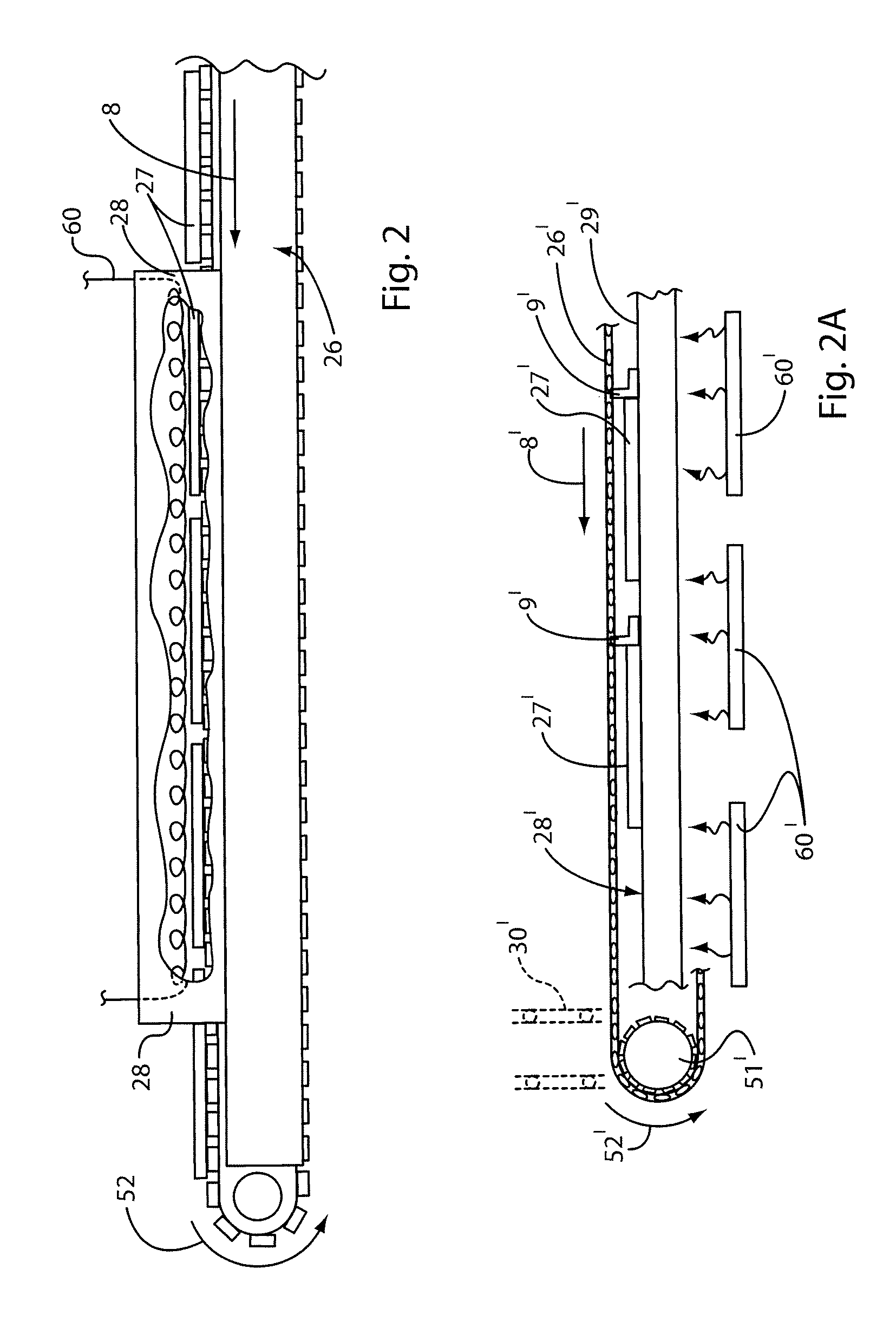

Pultruded panels having a first longitudinal edge profile and a second longitudinal edge profile may be used to form a floor assembly mounted on a railway car underframe. The pultruded panels may also be used to form walkways, bridges, piers and other structures. A bead may be placed on at least one of the longitudinal edge profiles to form a gap between an adjacent pultruded panel. An adhesive may be placed within the gap to couple or bond adjacent pultruded panels with each other. Void spaces may be formed within the pultruded panel and filled with foam to provide improved resistance to heat transfer through the respective panel. Respective coverings may be placed on opposite ends of each panel to block access to the associated void spaces.

Owner:TRINITY IND INC

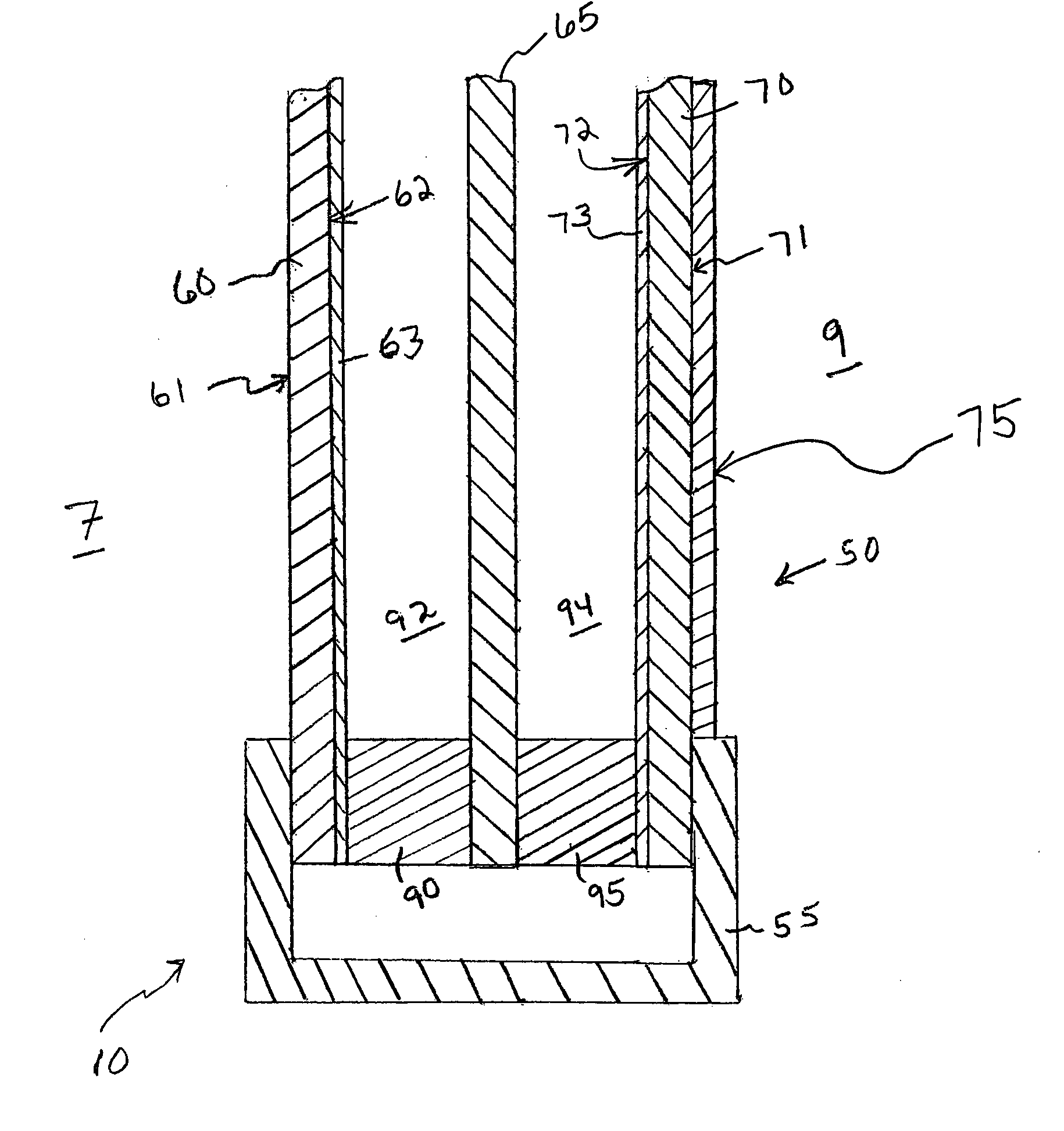

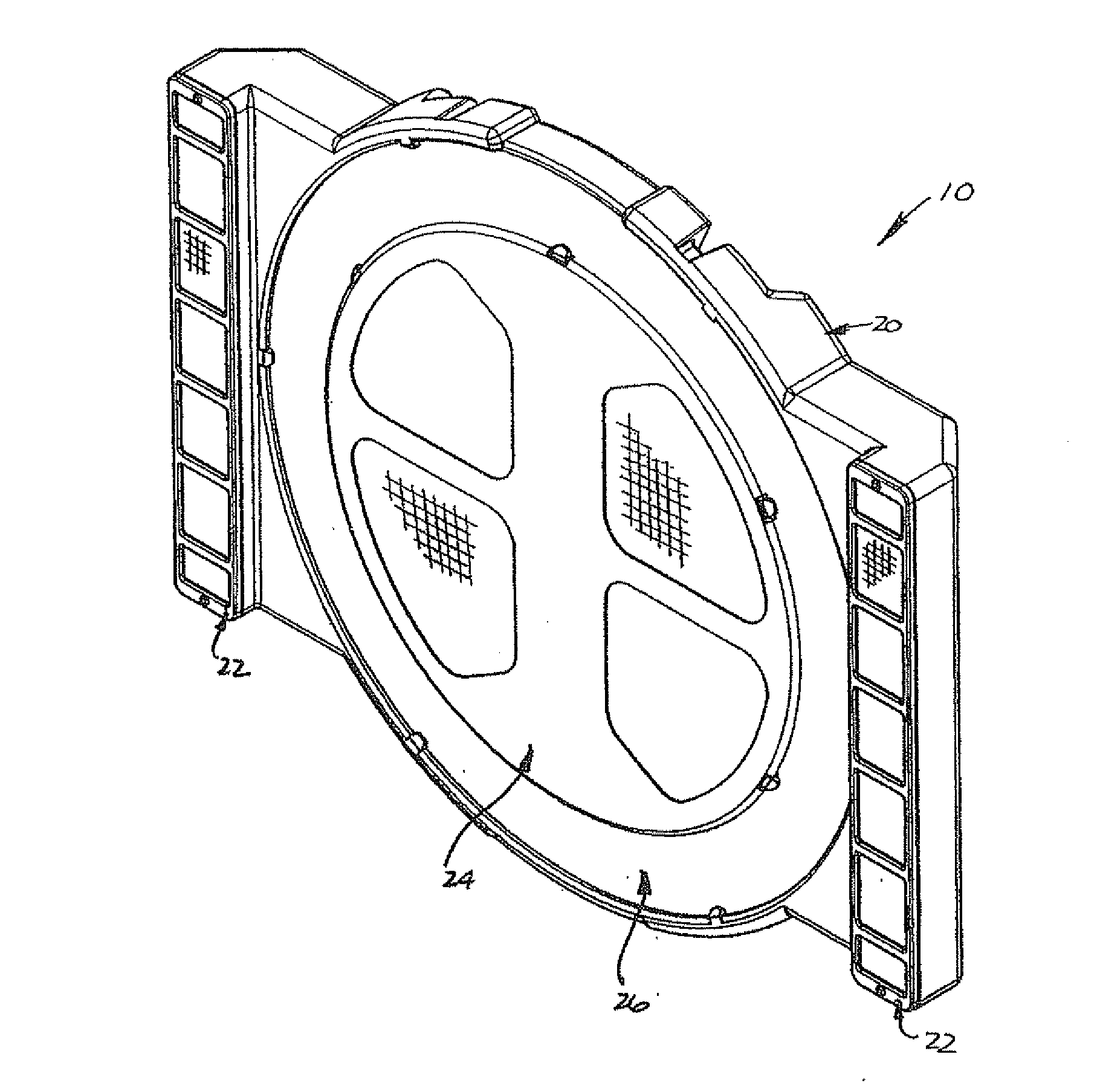

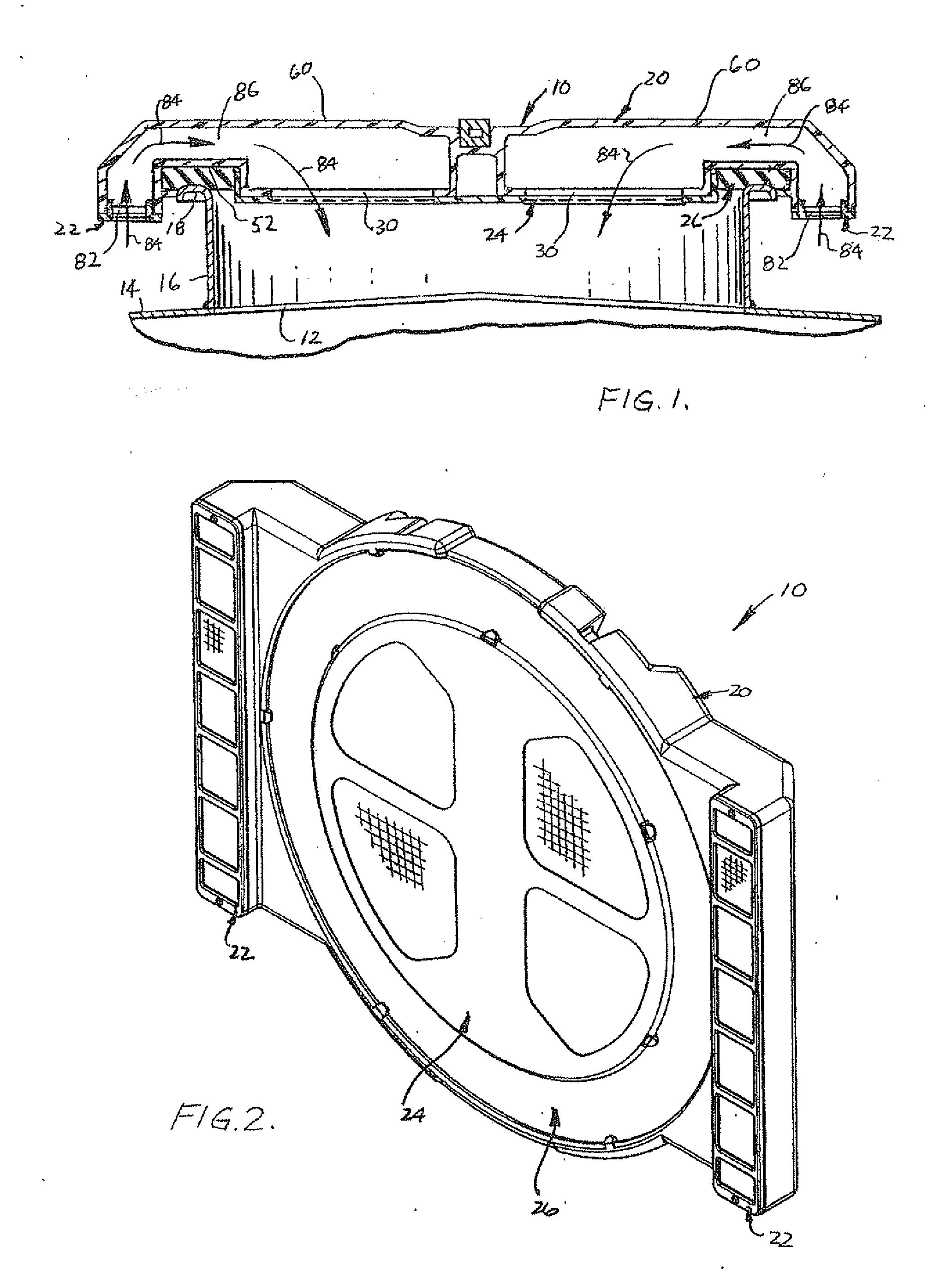

Anti-fog refrigeration door and method of making the same

InactiveUS20060265979A1BurdeningIncreased energy costShow cabinetsRailway roofsThermal insulationLow emissivity

The energy-free refrigeration door of the present application provides a way to control condensation when the door of a refrigeration unit is opened by providing thermal insulation to the door with glass panels which have a low emissivity coating. The door includes a door frame housing and an insulating glass unit comprising inner, middle and outer sheets of glass. A first sealant assembly disposed around the periphery of the inner and middle sheets of glass forms a first chamber between the inner and middle sheets of glass. A second sealant assembly disposed around the periphery of the middle and outer sheets of glass forms a second chamber between the middle and outer sheets of glass. A gas, such as krypton, air, or argon is held in the first and second chambers. The outer sheet of glass and inner sheet of glass each have an unexposed surface that faces the middle sheet of glass. A low emissivity coating is disposed on the unexposed surfaces of the inner and outer sheets of glass so that the glass door as a whole avoids formation of condensation on the outer surface of the outer sheet of the glass door, without the application of electricity to heat the door, while also providing the desired evaporation rate of condensation from the inner side of the inner sheet of the glass door. An anti-fog or anti-frost coating is included on a surface of one of the sheets of glass.

Owner:AGC FLAT GLASS NORTH AMERICA INC

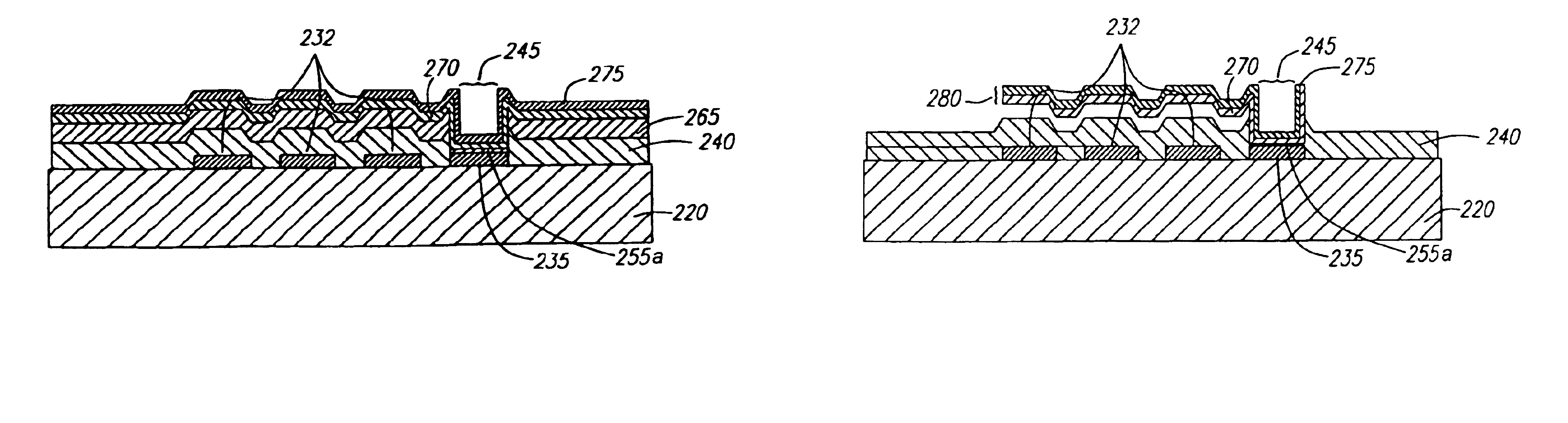

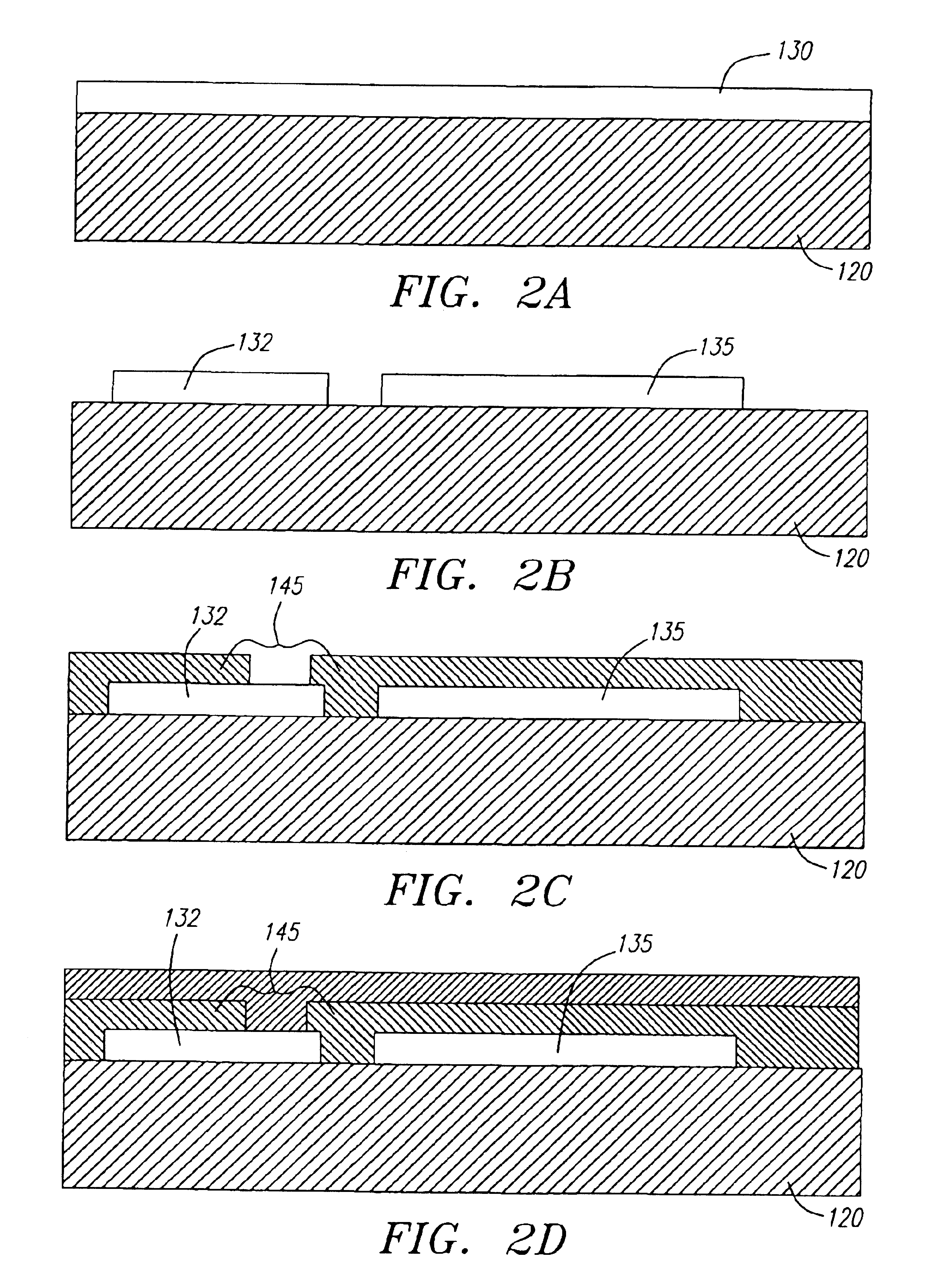

Method of making an electrostatic actuator

InactiveUS6933165B2Reduce stress concentrationHigh stressRailway roofsMaterial nanotechnologyElectrostatic actuatorOptoelectronics

A method of fabricating an electrostatic actuator with an intrinsic stress gradient is provided. An electrode is formed on a substrate and a support layer is formed over the electrode. A metal layer is deposited onto the support layer via a deposition process. Deposition process conditions are varied in order to induce a stress gradient into the metal layer. The intrinsic stress in the metal layer increases in the direction from the bottom to the top of the metal layer. The support layer under the electrode is removed to release the electrostatic actuator.

Owner:SUPERCONDUCTOR TECHNOLOGIES INC

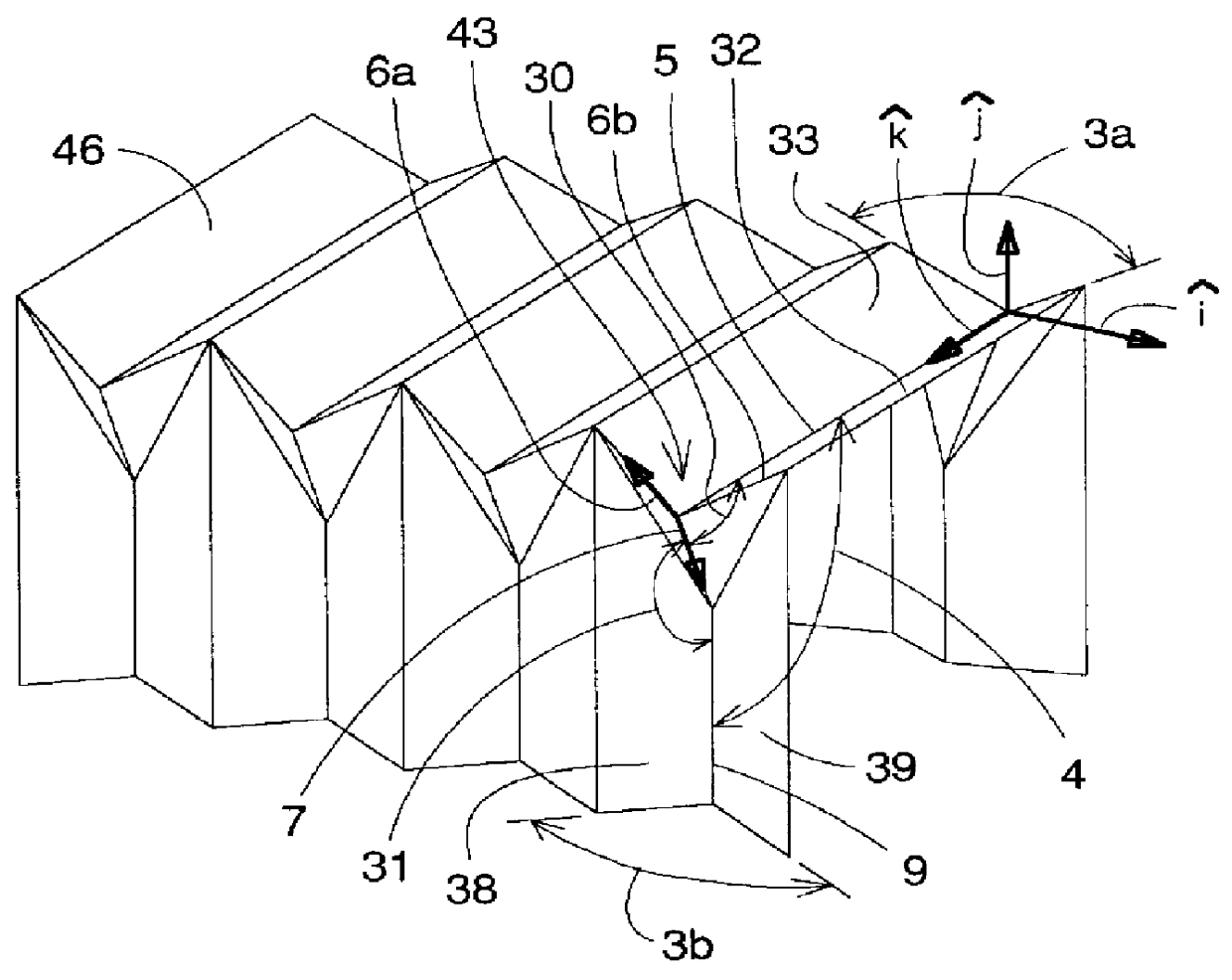

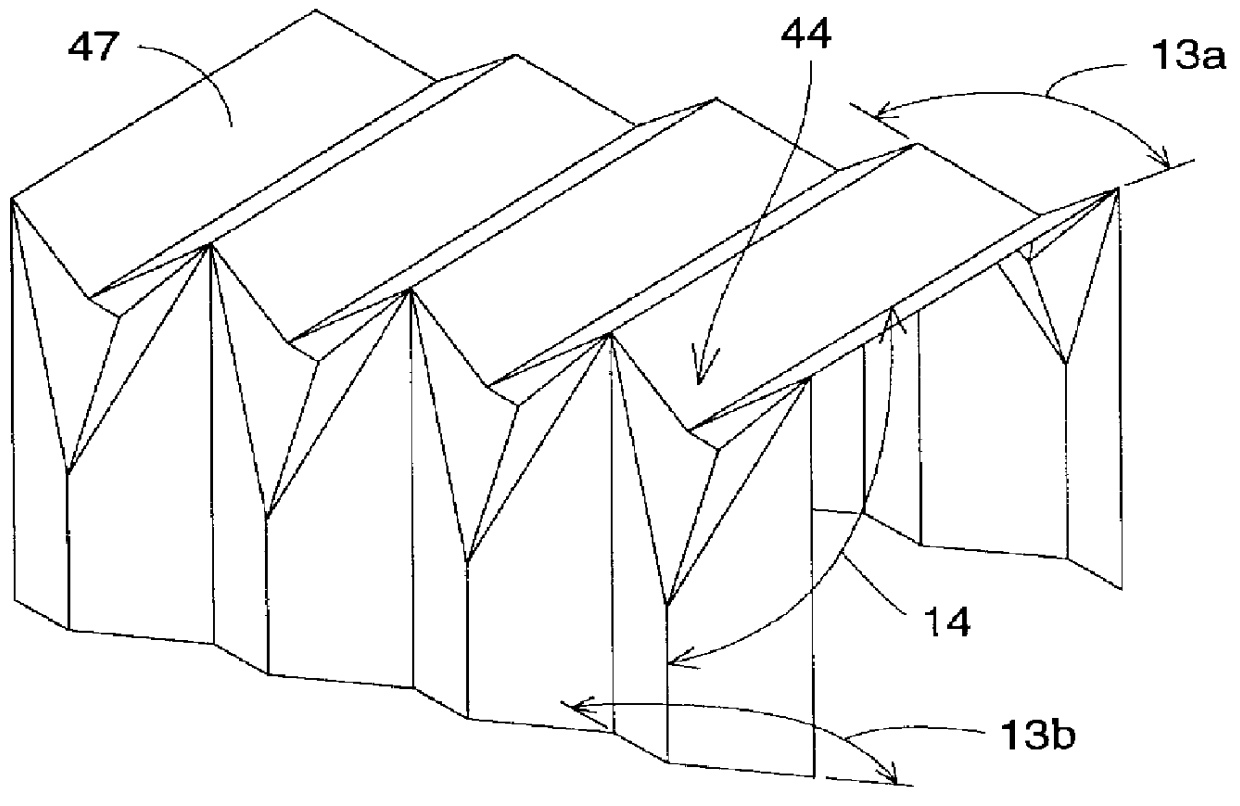

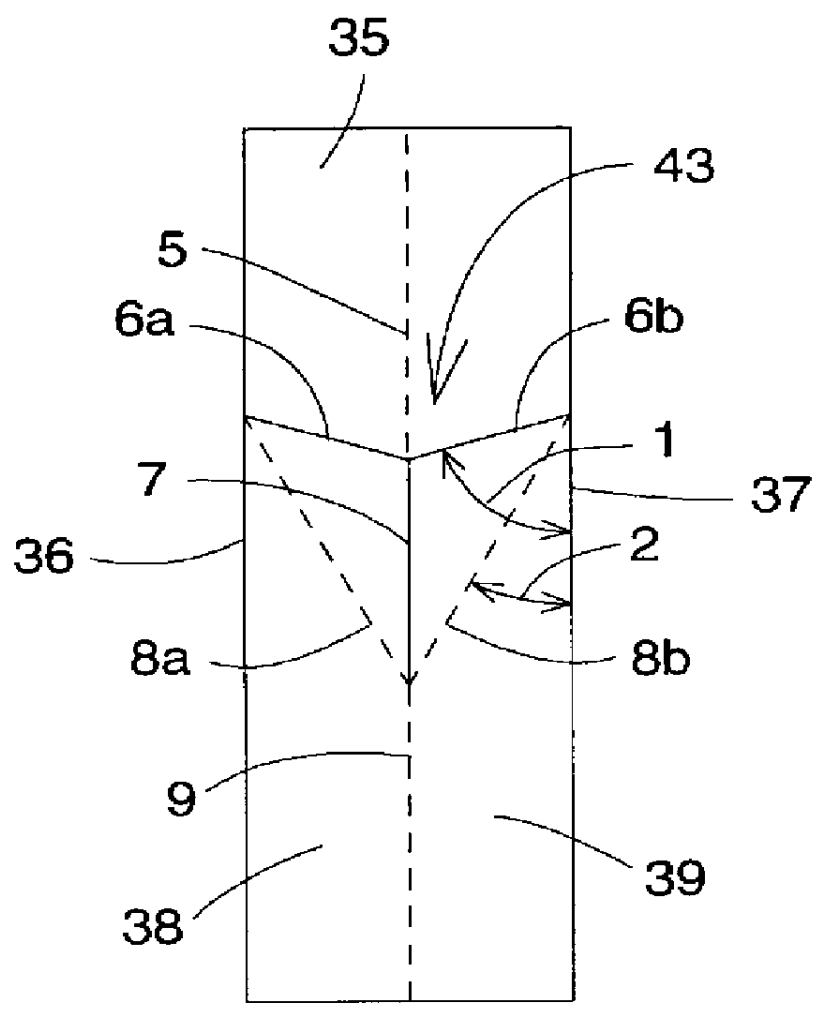

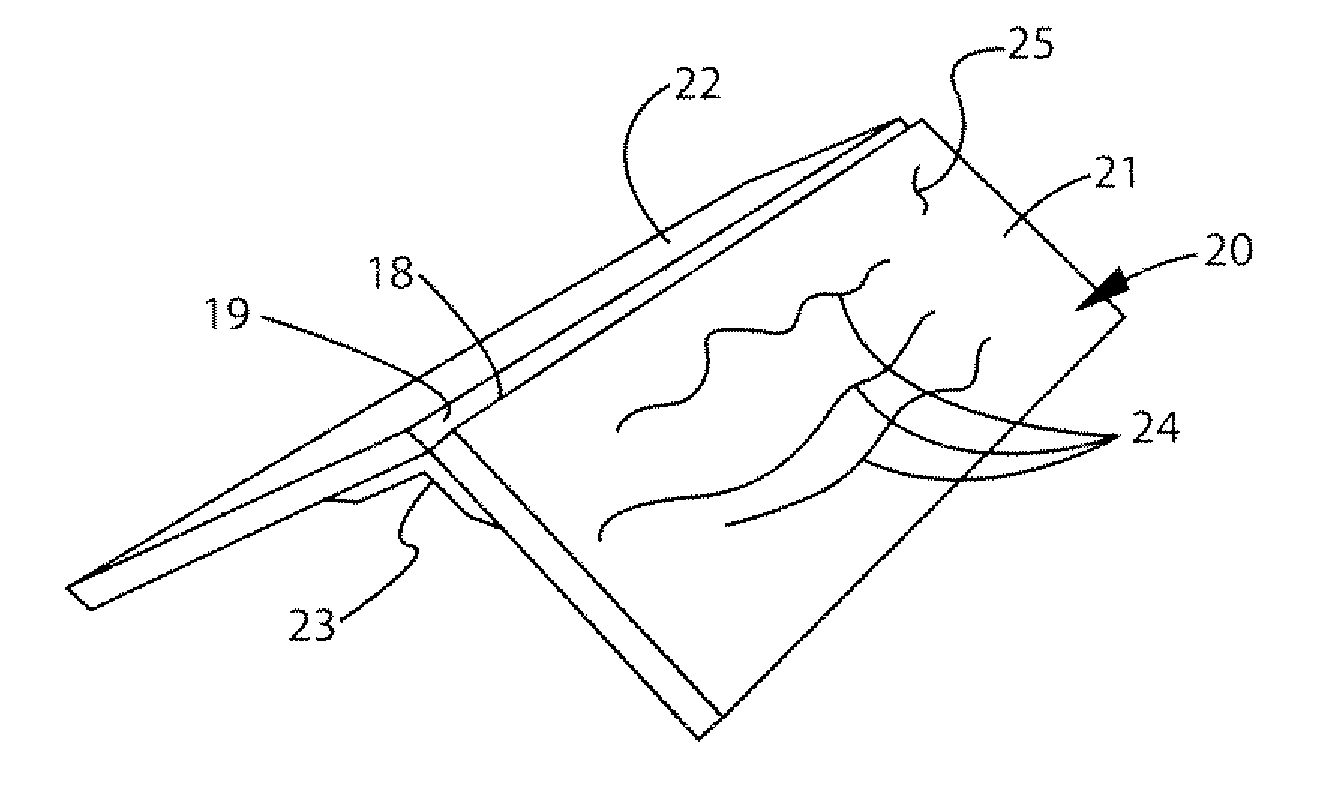

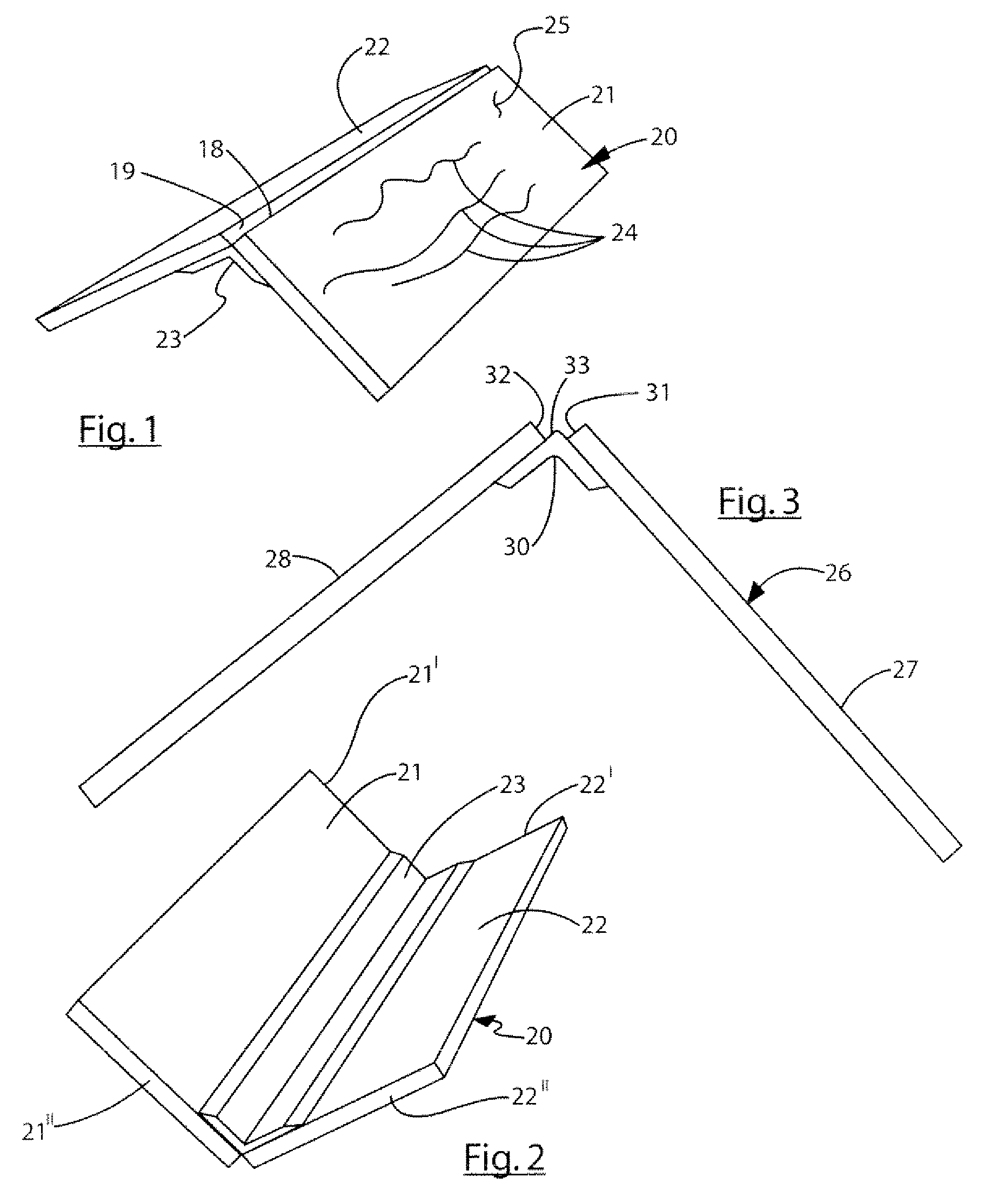

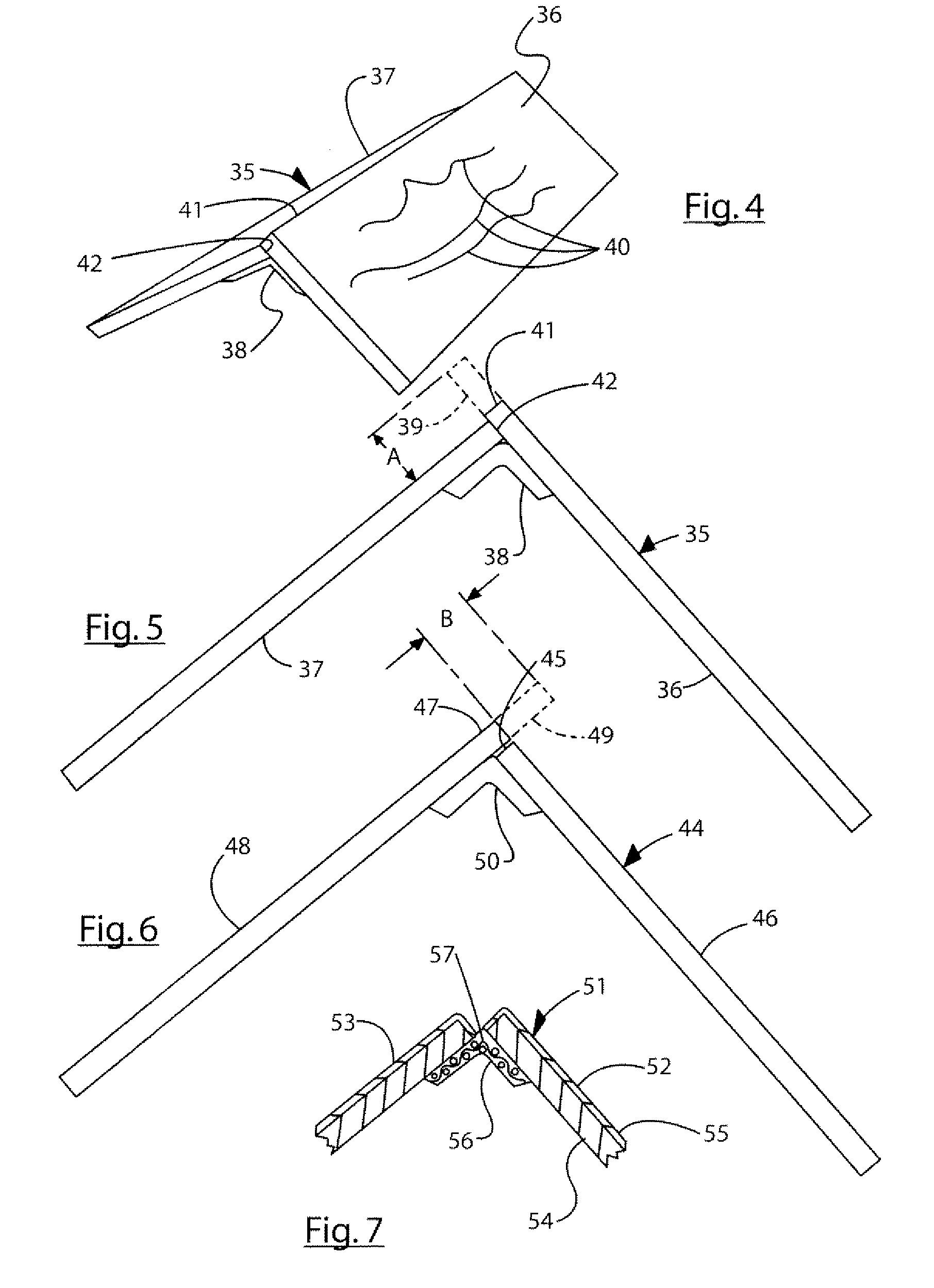

Mathematically optimized family of ultra low distortion bellow fold patterns

An improved mathematically modeled family of bellow fold patterns, useful for making bellows from stiff but foldable materials, which forms a corner of a bellow consisting of a series of several single inversion fold patterns, each having a characteristic design angle which is mathematically computed to provide a desired initial wall angle for the bellow and to minimize wall tilting over a predetermined extension angle range, thereby allowing low cost bellows to be made which can extend long distances while using a minimal amount of stiff but foldable material. In addition, each characteristic design angle can be computed to provide exactly zero tilting of the bellow walls at one or more non-zero extension lengths specified by a designer, thus allowing, unlike all other prior art folds, a structurally stiff, long extending bellow to be formed in an extended state using fast production techniques such as vacuum forming, blow molding or injection molding, while also allowing the bellow to be free of distortion in the compressed state.

Owner:KANE NATHAN R

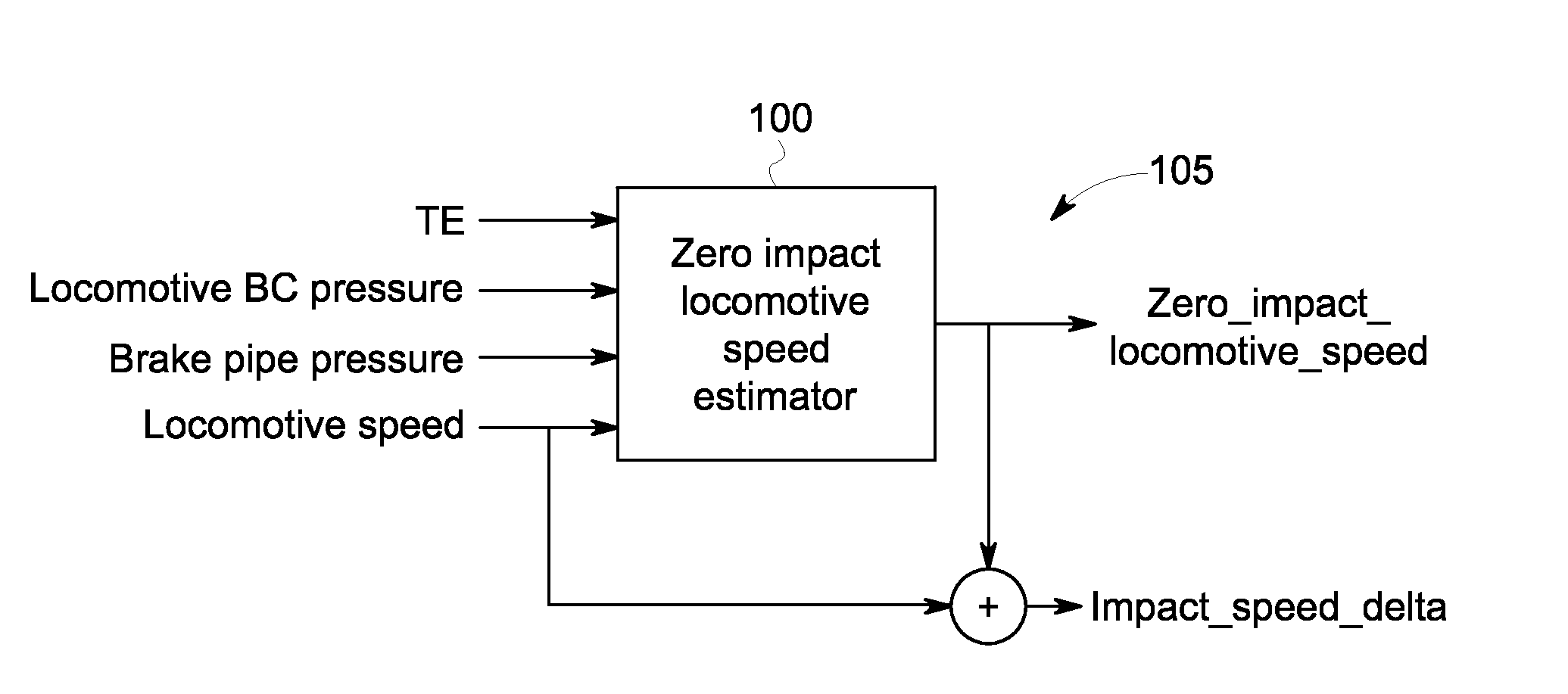

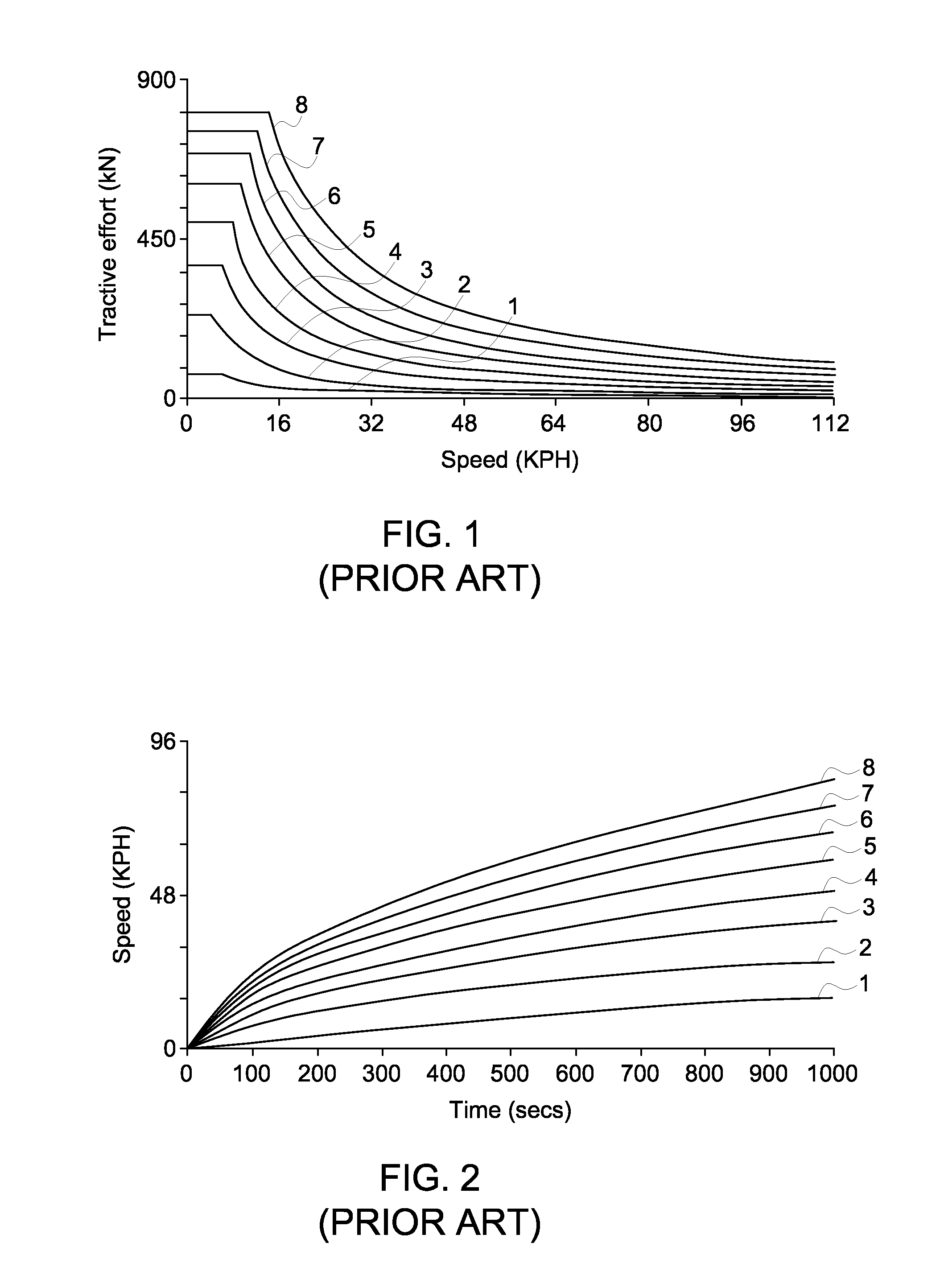

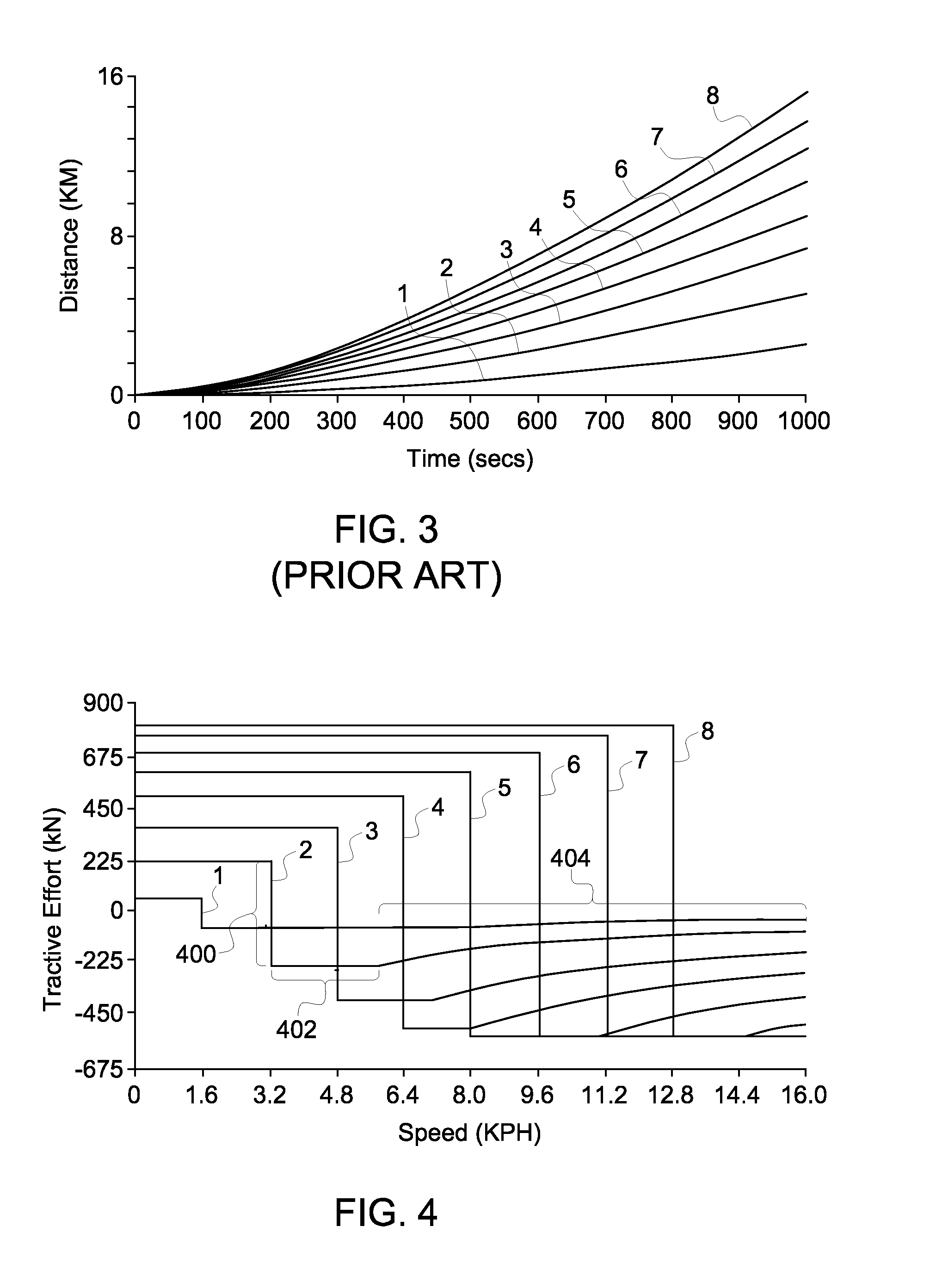

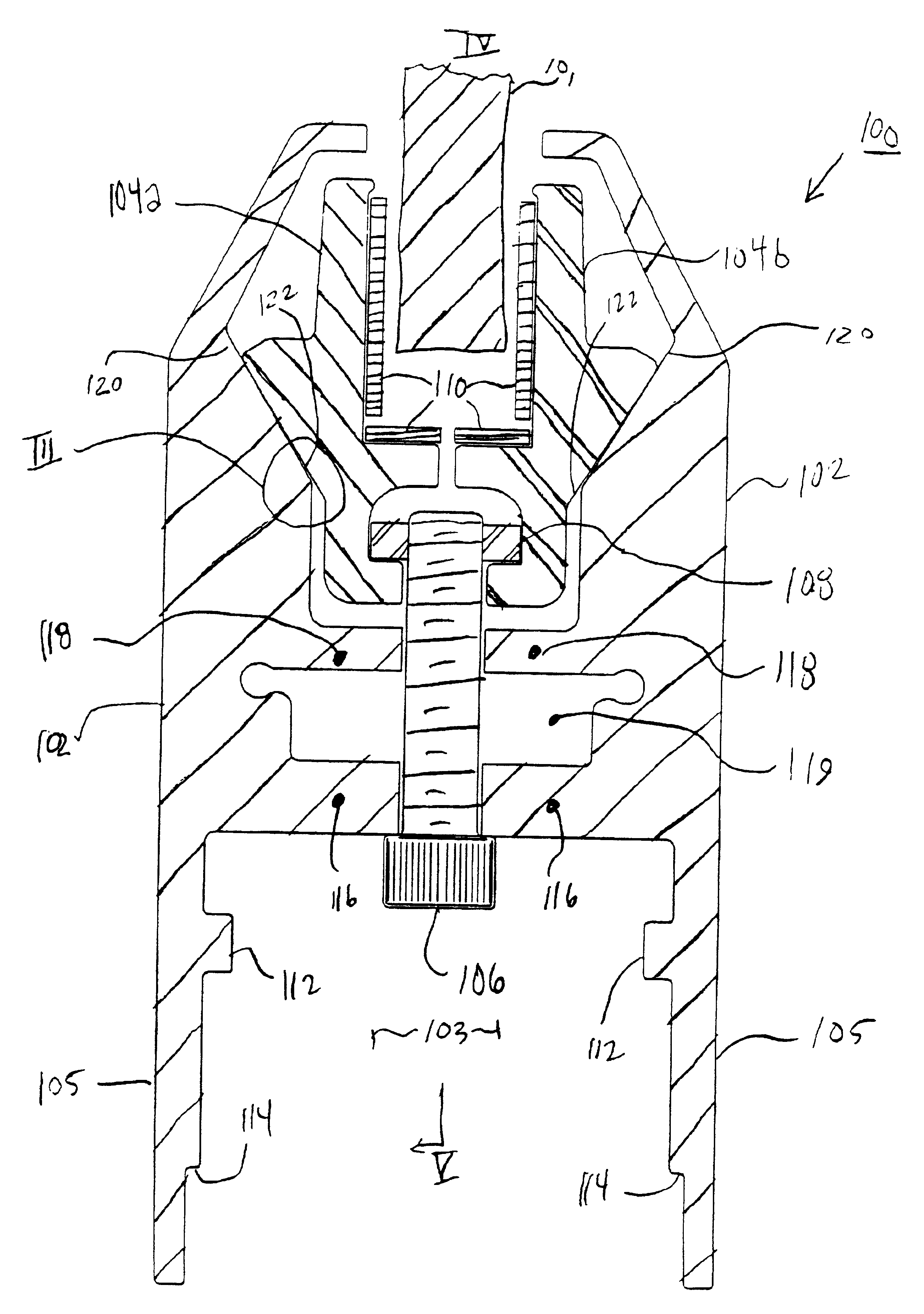

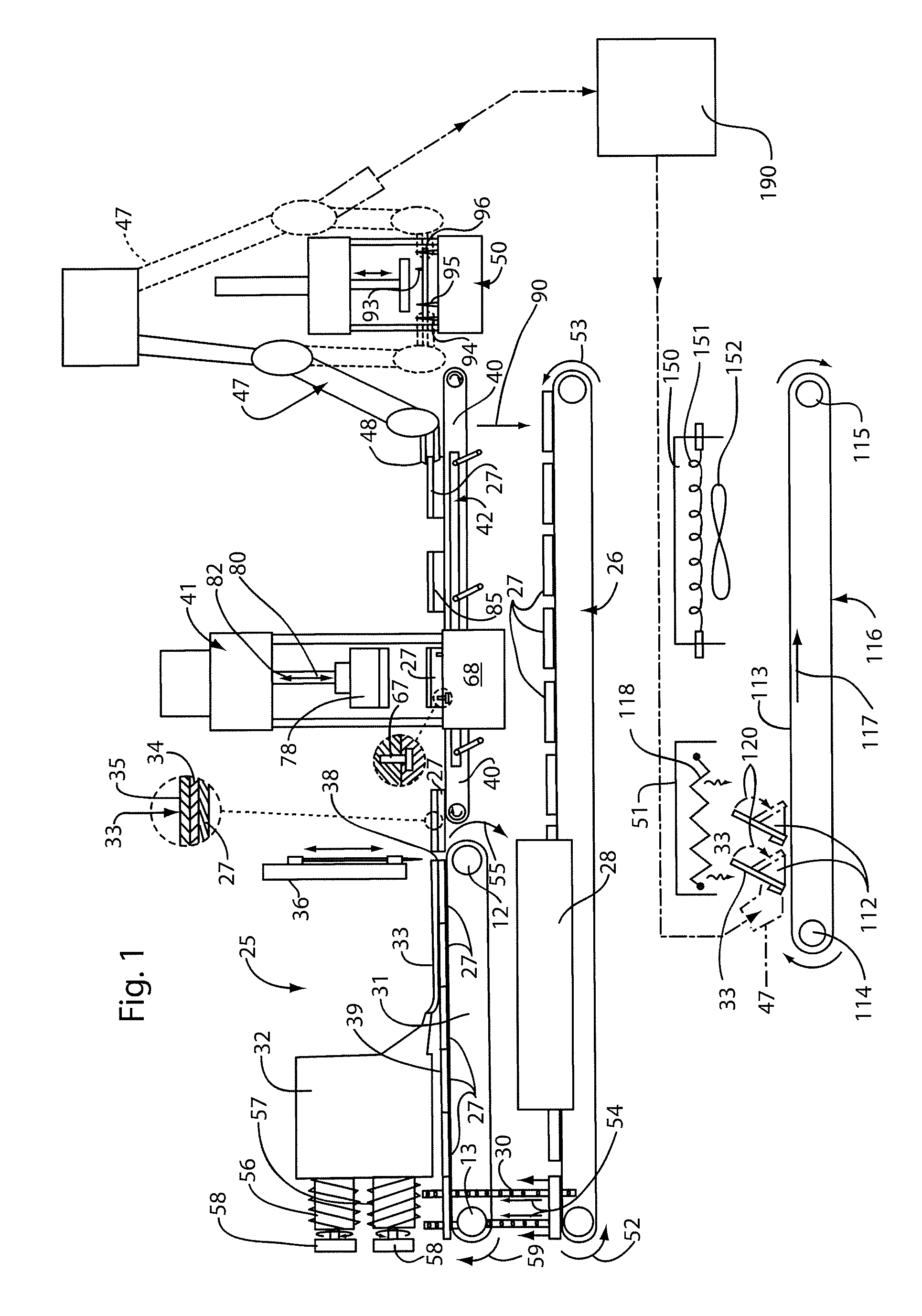

Methods and systems for throttle control and coupling control for vehicles

A multi-mode control system for a locomotive includes a throttle control device having notch settings corresponding to, for a first, long haul mode, control signals for providing respective tractive effort or power from the locomotive, a master controller in communication with the throttle control device and adapted to receive said control signals from the throttle control device and to transmit respective command signals to power-train components of the locomotive to achieve the respective tractive effort or power, the master controller also adapted for sending alternative command signals when a user-operable mode selector is set to one of one or more alternative modes. The user-operable mode selector includes one or more user interface devices in communication with the master controller for selecting one alternative mode of the one or more alternative modes.

Owner:GE GLOBAL SOURCING LLC

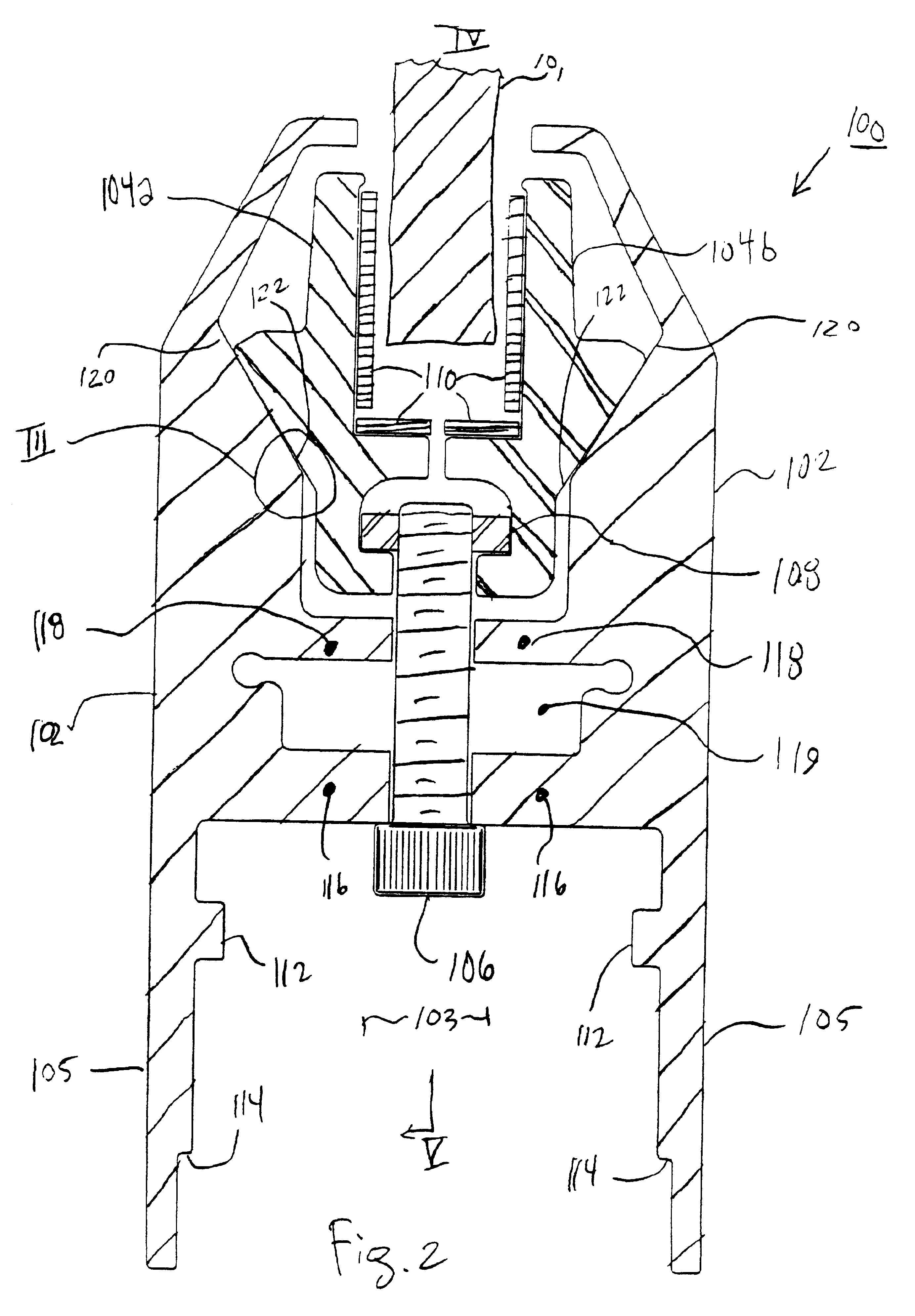

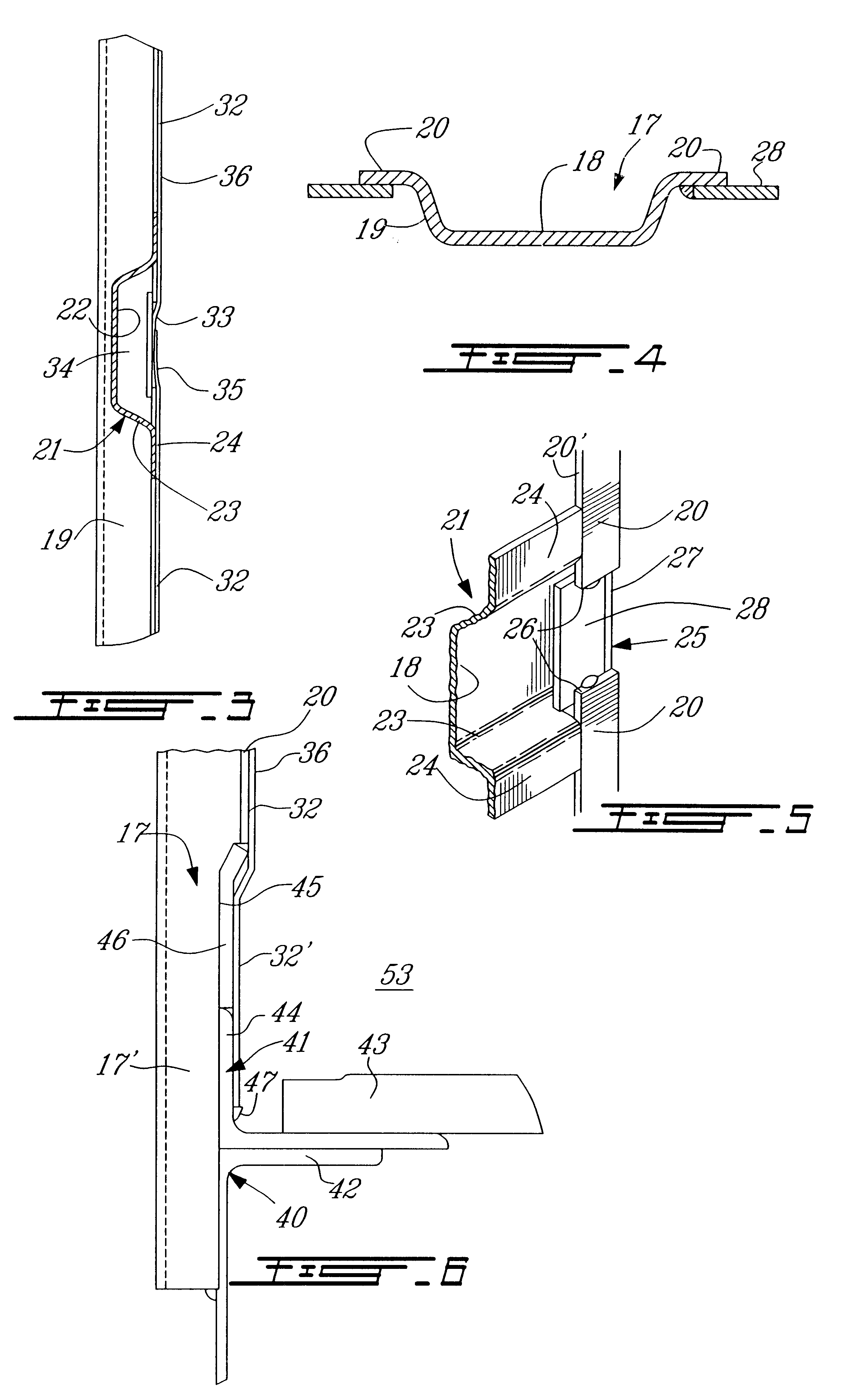

Door rail system

InactiveUS6912818B2Easy to disassembleConvenient to accommodateRailway roofsCorner/edge jointsFlat glassEngineering

A rail system for holding a panel, such as a plate glass pane, in a door and / or wall partition. The rail system includes a housing and a clamp member having a wedging geometry so that when the clamp member is actuated with respect to the housing in a first direction, at least a portion of the clamp member will move in a clamping direction, which is different than the first direction to clamp the panel.

Owner:C R LAURENCE

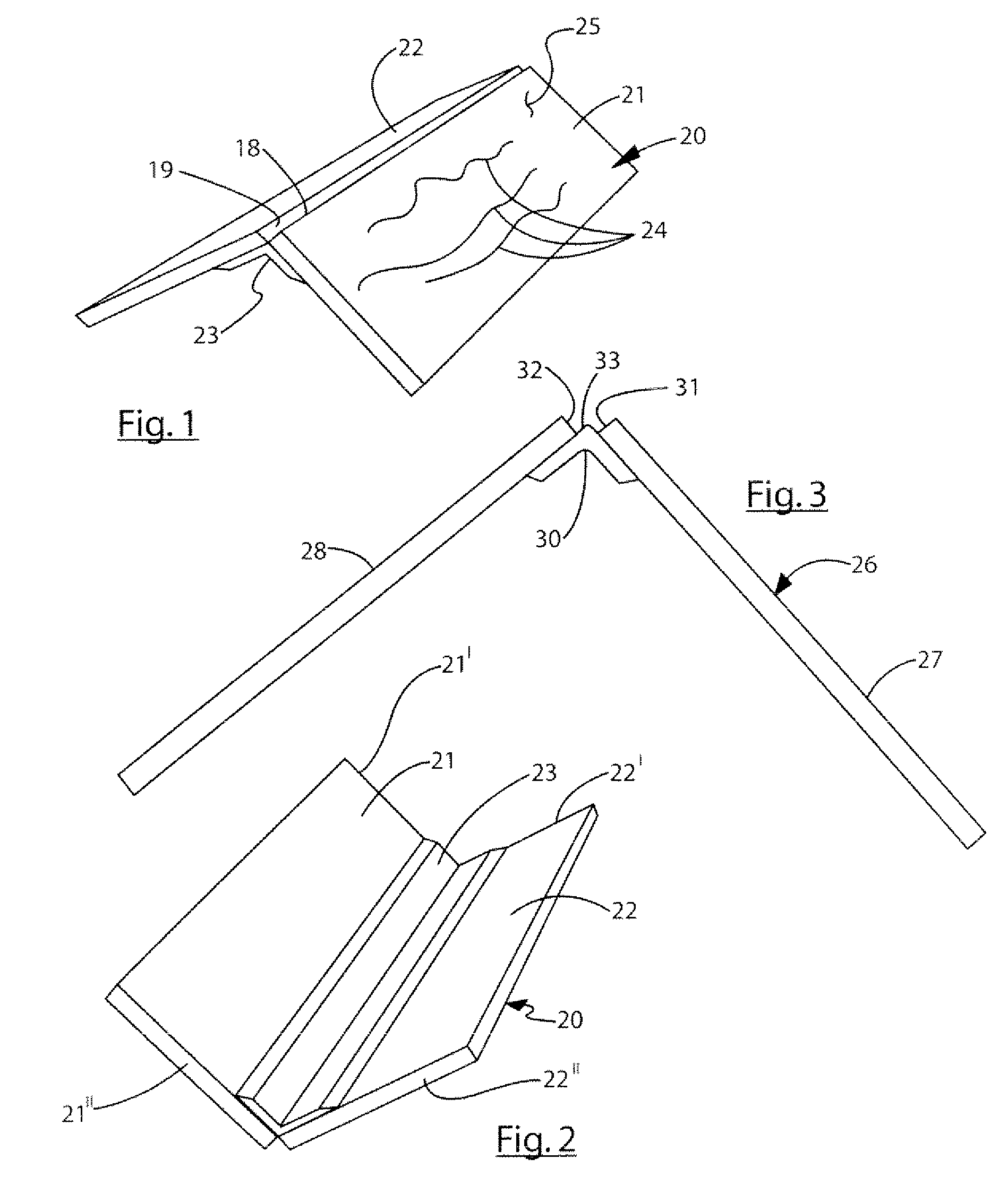

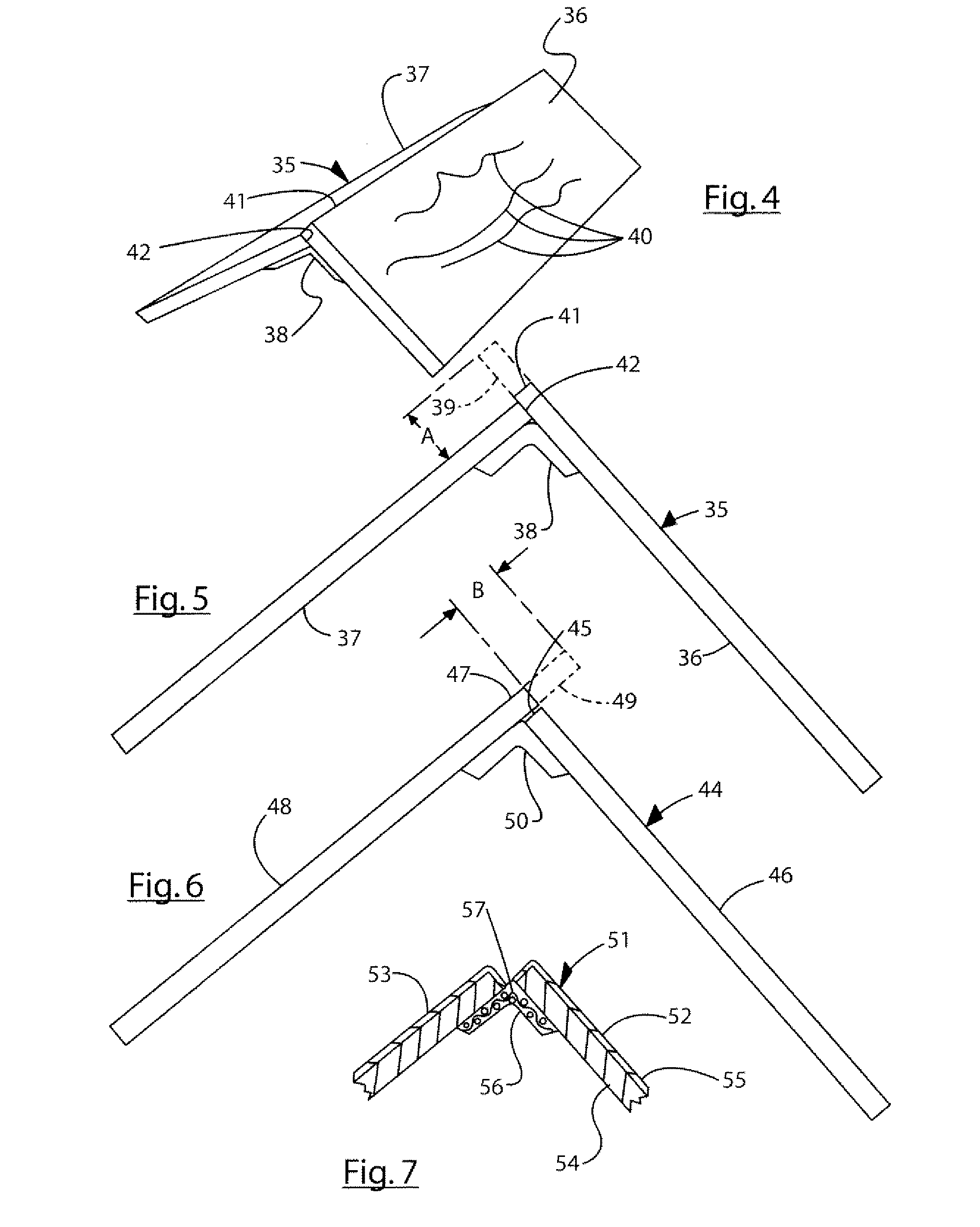

Hip, ridge or rake shingle

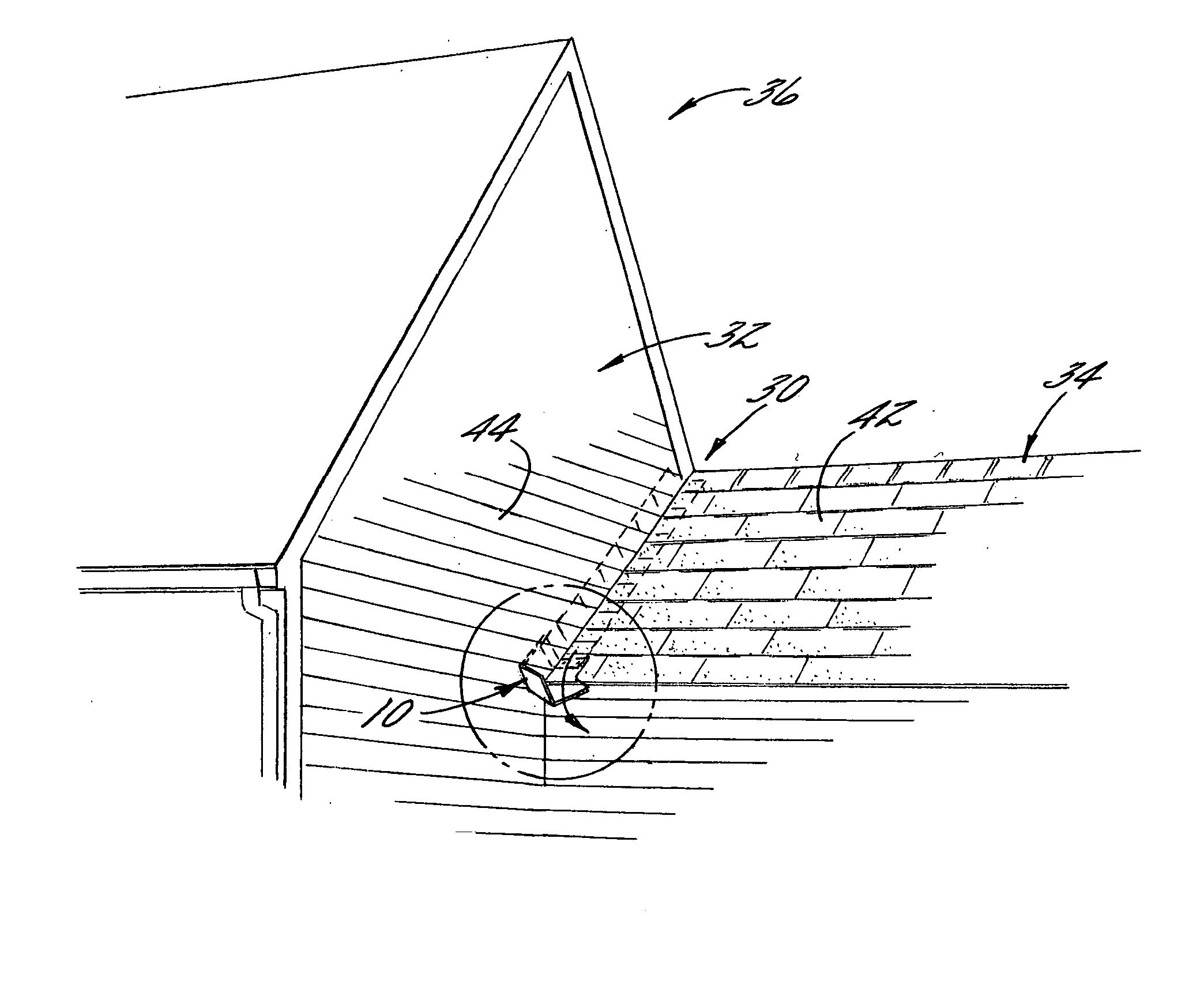

ActiveUS20070144077A1Reduce the possibilityThick appearanceRailway roofsBuilding roofsEngineeringElectrical and Electronics engineering

A hip, ridge or rake shingle comprised of a plurality of panels sandwiched on each panel portion side of a layer of shingle material, such that each panel portion can be folded along a fold line, and wherein tabs are provided for each panel portion, adapted to be bent backwardly upon themselves, sandwiching thickening panels therebetween. The shingles can be laid up on a hip, ridge or rake of a roof, to yield desirable thickened features.

Owner:CERTAINTEED CORP

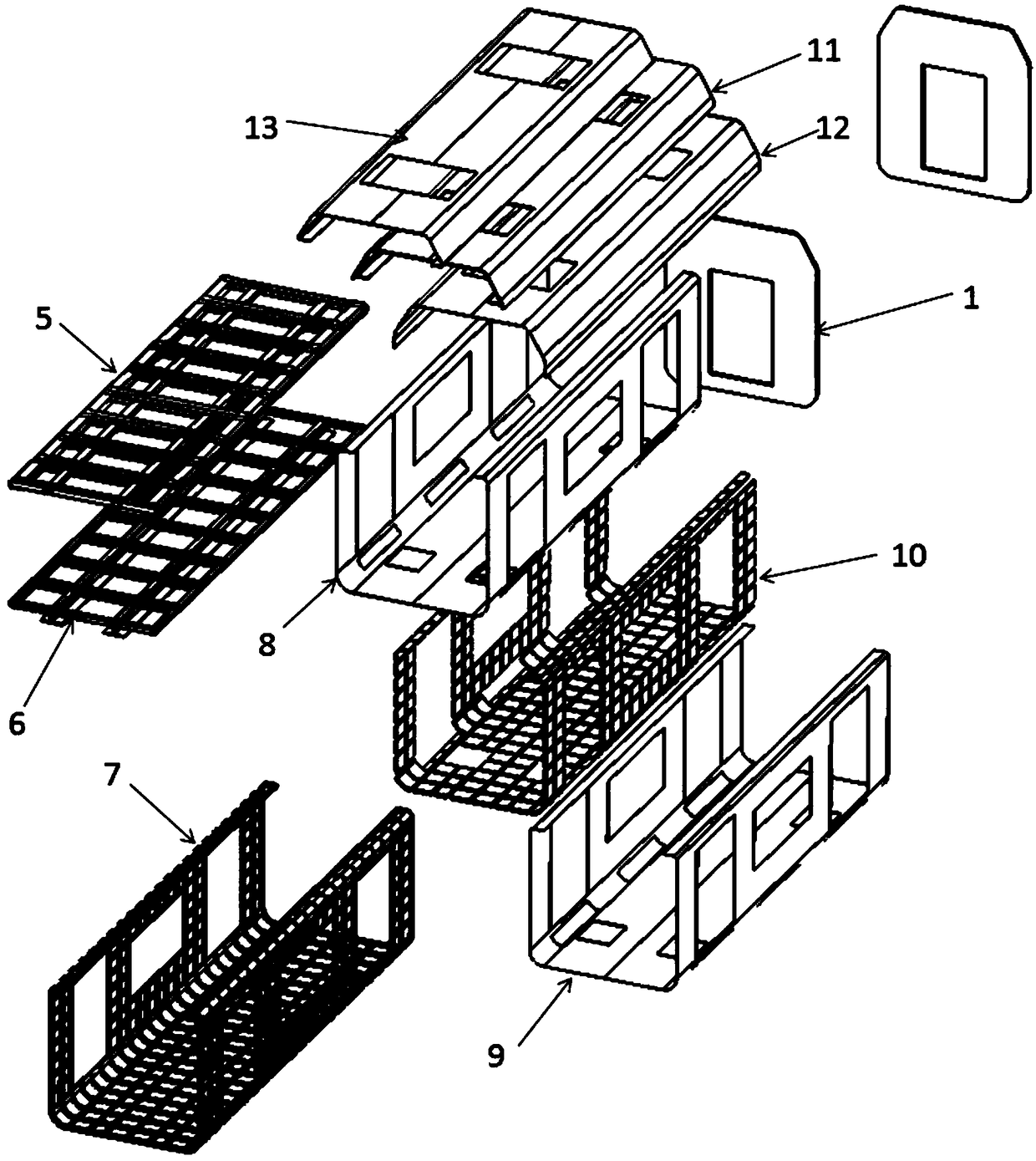

Top slab connecting structure inside railway train roof

ActiveCN101804818AReduce noiseImprove fire performanceRailway roofsMaterial based railway technolgyRailway passenger carFireproofing

The invention relates to the technical field of railway train roofs and discloses a modular designing and manufacturing method of a top slab curved connecting structure in a railway train roof. The top slab connecting structure inside the train proof comprises an intermediate top slab, side top slabs, connecting assemblies of the intermediate top slab and the side top slabs and connecting assemblies of the side top slabs and a train body. Connecting parts of the side top slabs and the intermediate top slab are arranged on air duct affiliated hanging codes through large-stroke screw parts; top slab hanging codes are arranged on an air-conditioning air duct; and the connecting parts of the side top slabs and the train body are fixed on inserts of a C-shaped groove of the train body through fixing clamping pieces of the side top slabs. The curved connecting structure can effectively reduce noise in the train body, improve the fireproofing capability in the train body, can be convenient to overhaul air-conditioning air outlet duct components at the upper part of the top slab in a carriage, ensures uniform air outlet of an air conditioner and greatly improves the comfort and the practicability for passengers to take a seat.

Owner:CRRC TANGSHAN CO LTD

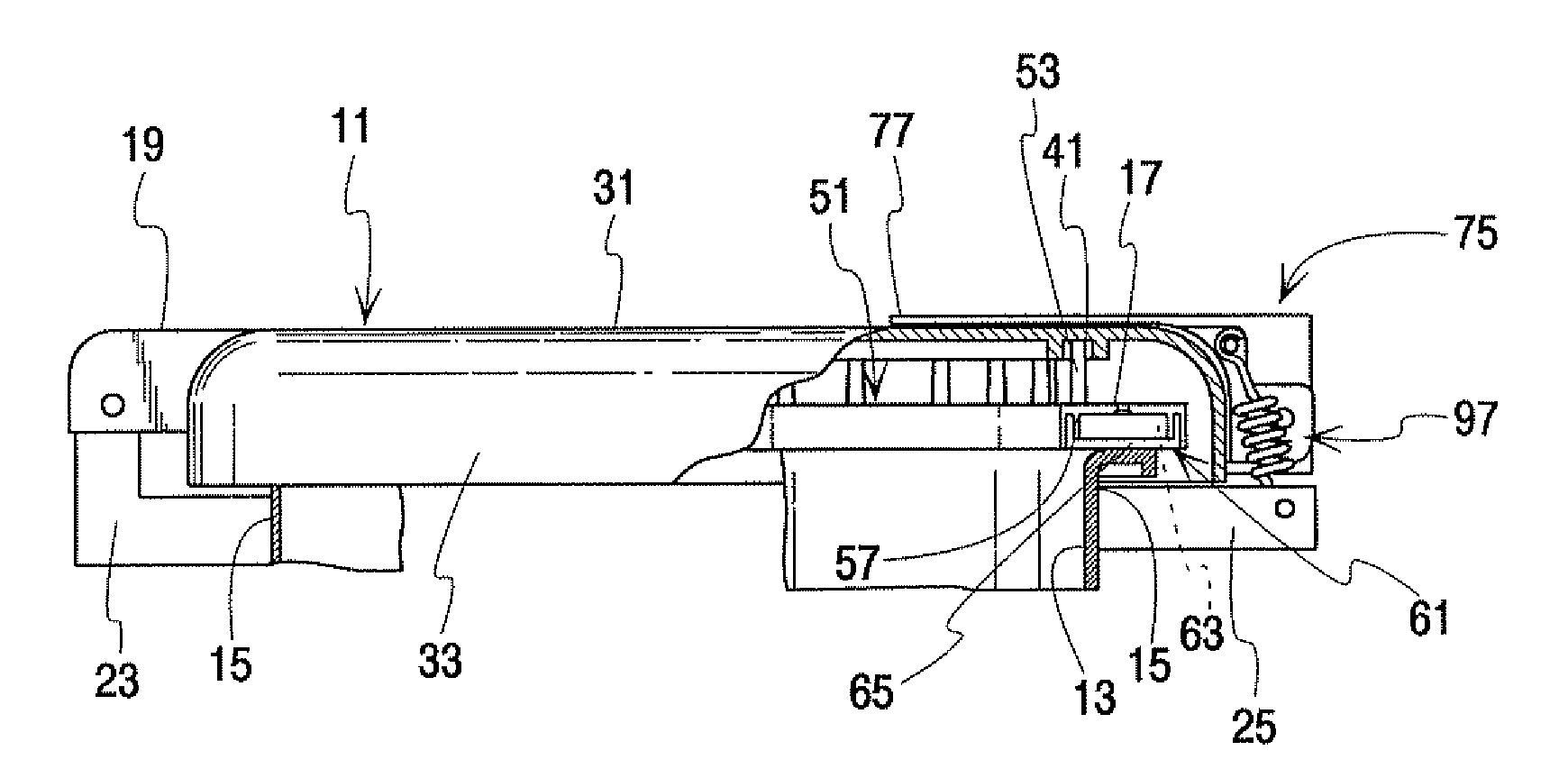

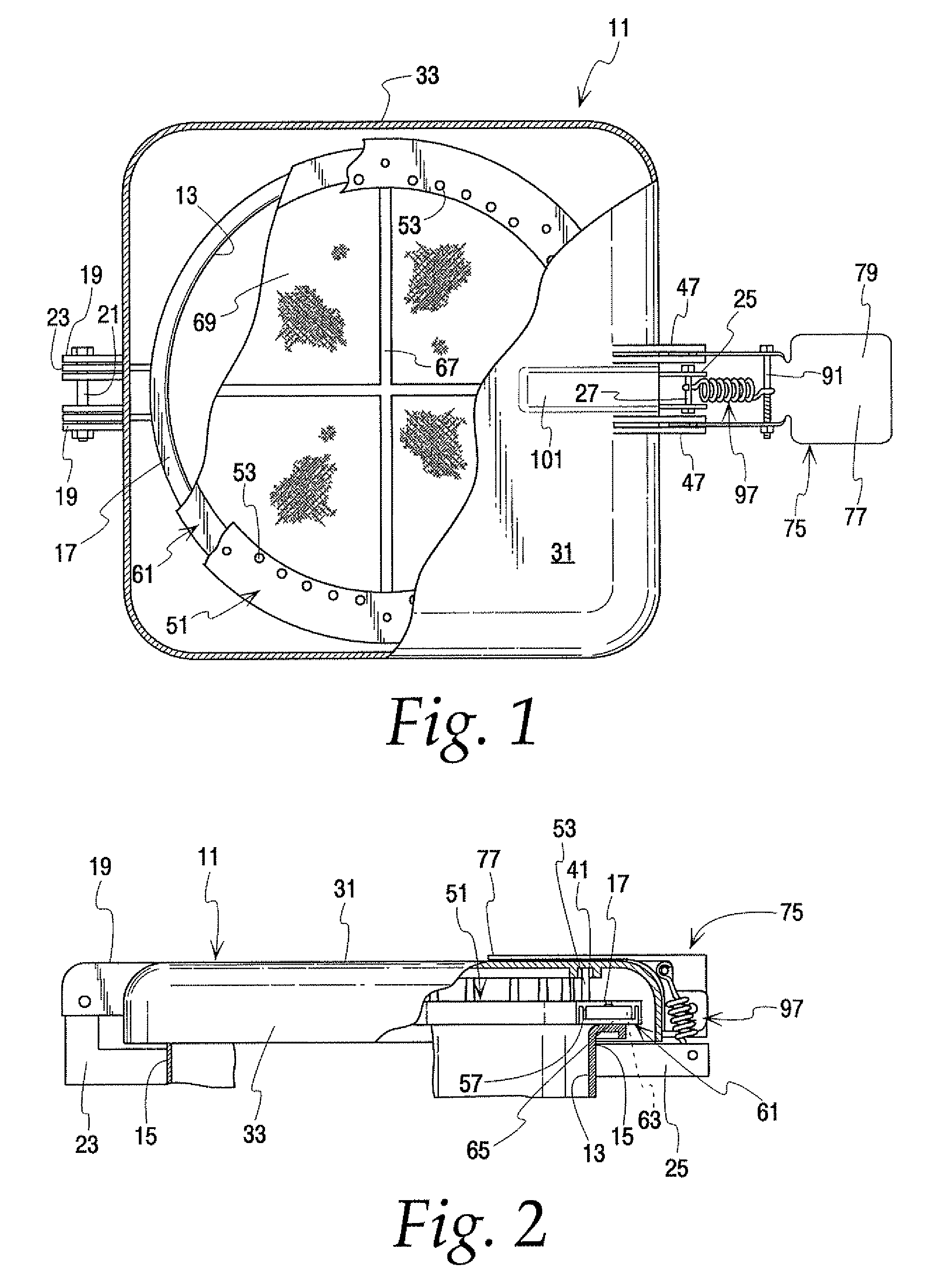

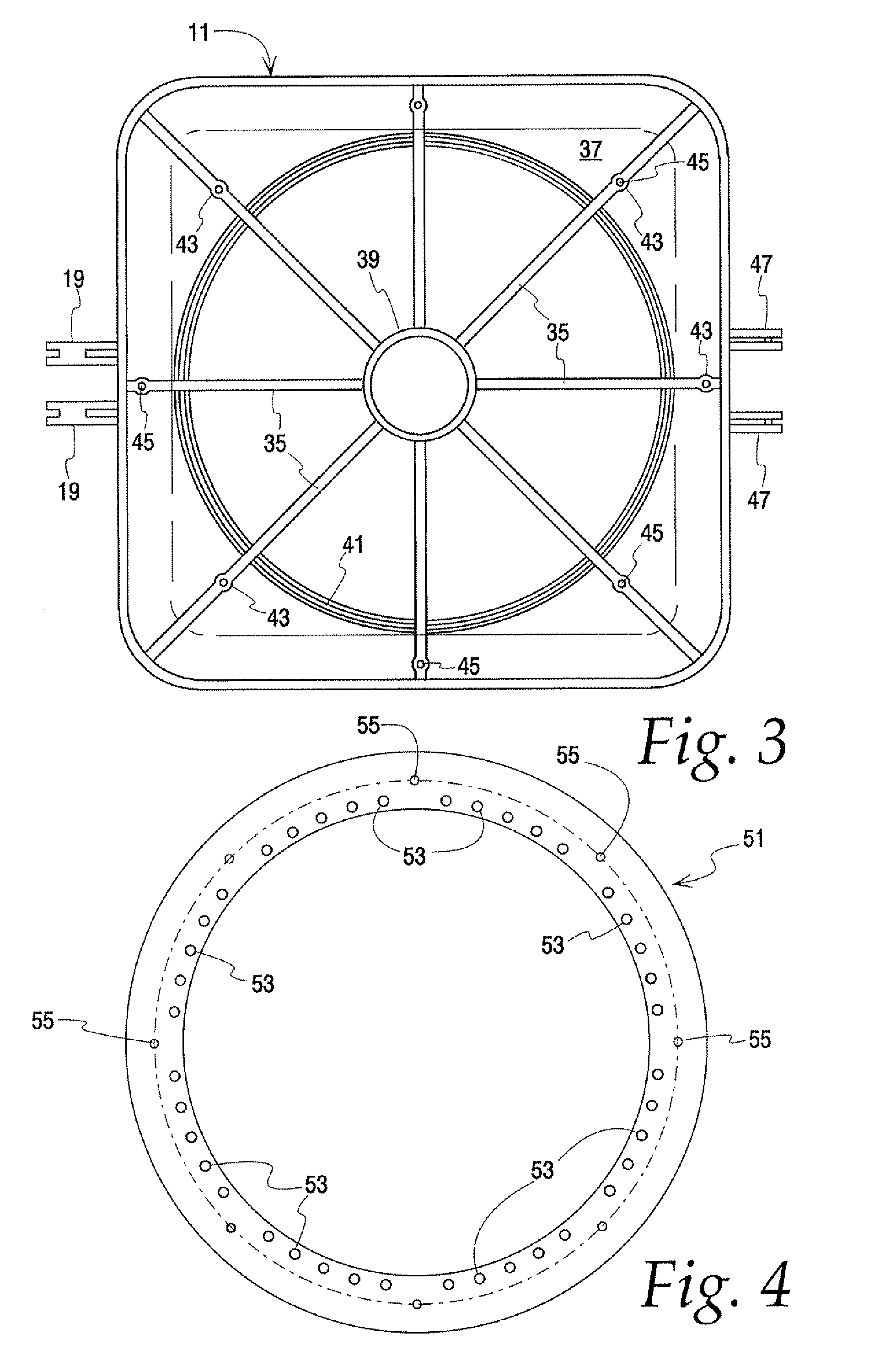

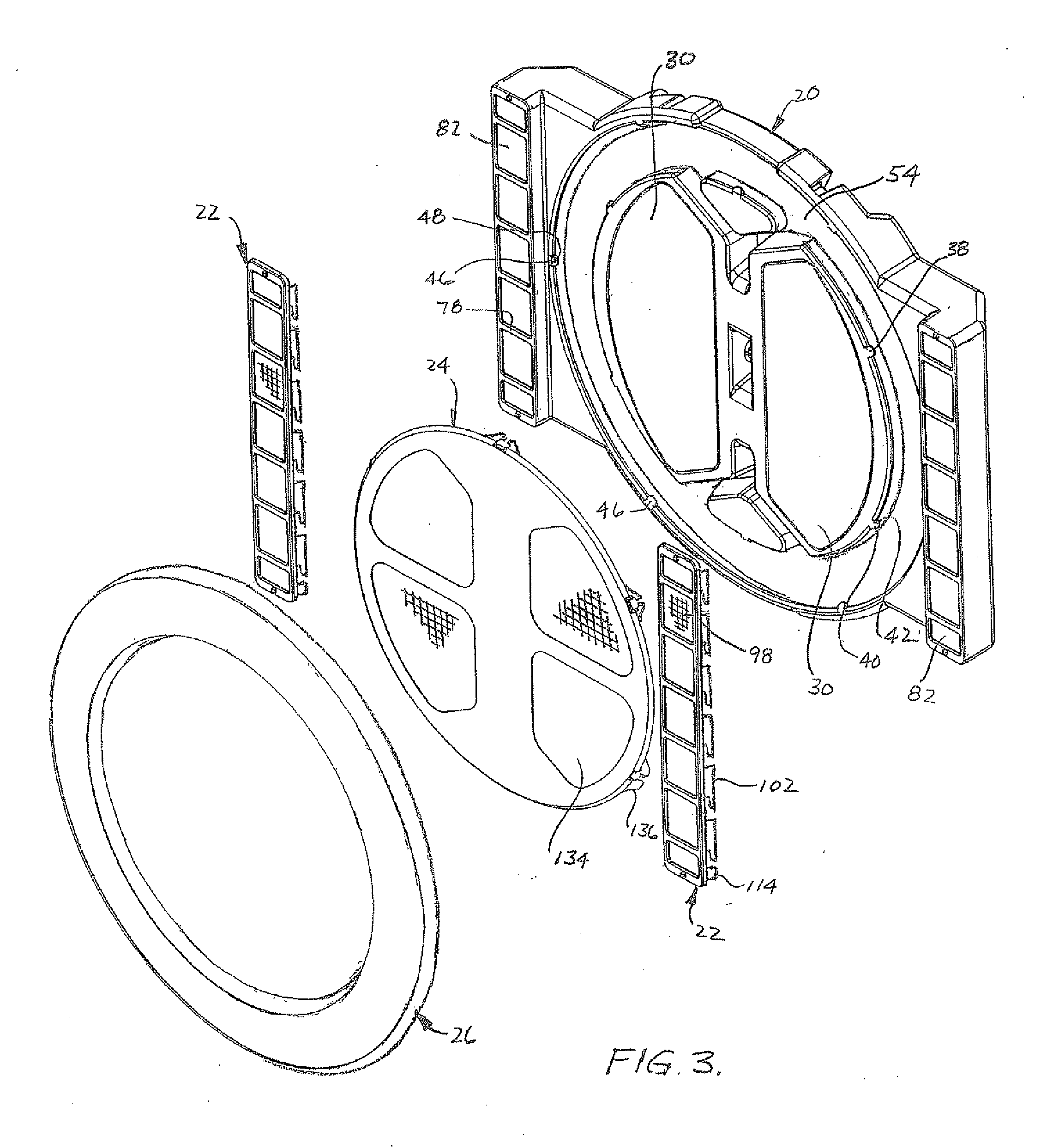

Hatch Cover For A Covered Railroad Car Having Removable Closure and Screen Member

InactiveUS20090158959A1Facilitate opening and closingEliminate needRailway roofsCoil springEngineering

A hatch cover for hopper compartment opening with a coaming surrounding the opening. The hatch cover includes a peripheral skirt with a portion of the skirt spaced outwardly of the coaming when the hatch cover is closed to allow air flow from the exterior of the hatch cover to the opening. A frame has a center portion and an annular gasket which seats on the coaming with the center portion over the opening. The center portion of the frame may be a screen or may be solid. An annular ring is attached to the underside of the hatch cover. A press fit attachment is provided between the frame and the annular to permit attachment and removal of the frame from the annular ring. A latch mechanism is provided for the hatch cover. A spring anchor pin is supported on coaming brackets and a latching pin is supported on the hatch cover. A latch mechanism includes a handle having a pair of uprights located at one end of the handle. An outwardly opening slot is formed in each upright with the slots aligned with each other to be removeably engagable and pivot on the hatch cover latching pin. The mechanism also includes a compressibly loaded helical spring connected between the latch handle and the coaming spring anchor.

Owner:STANRAIL CORP

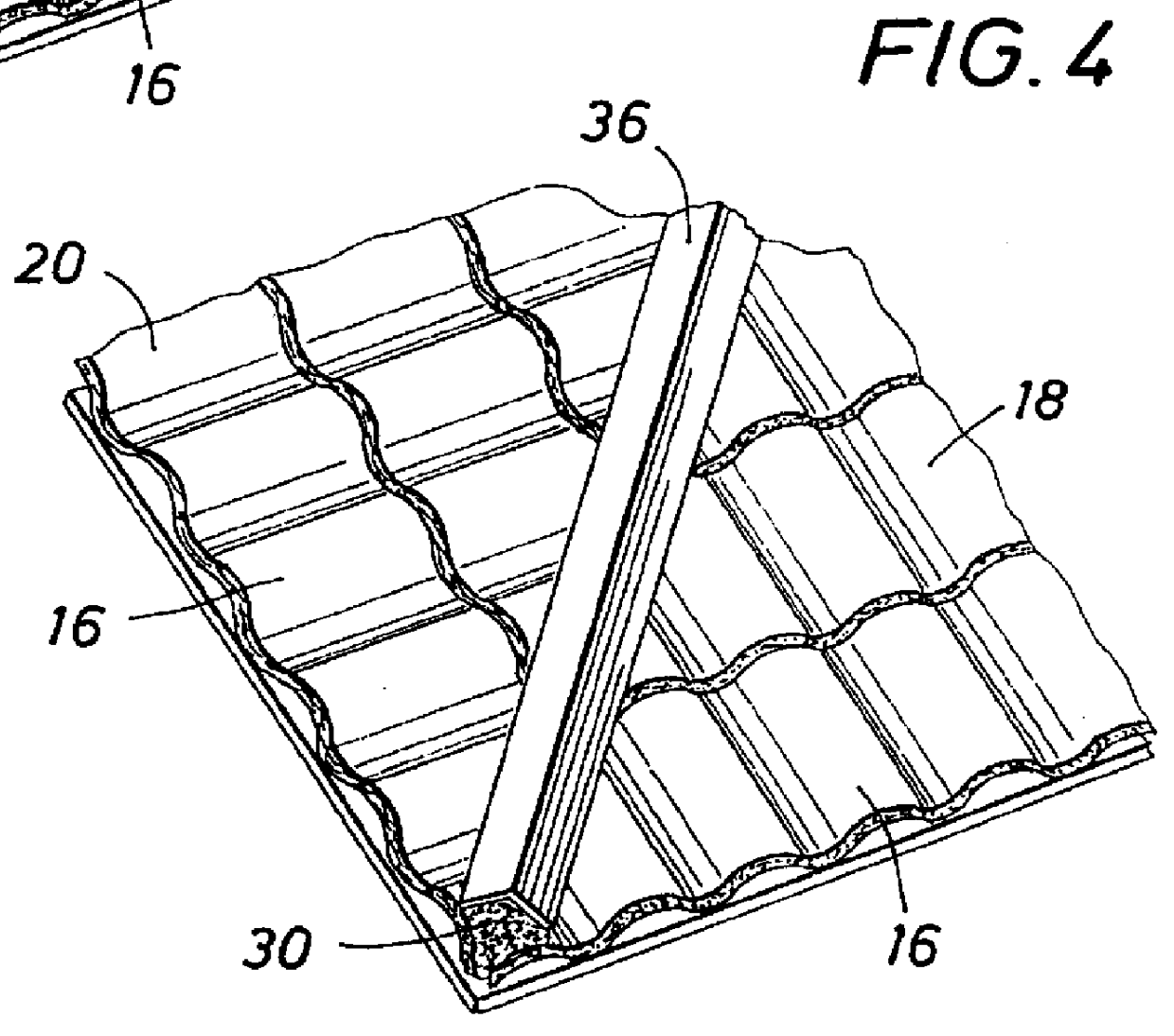

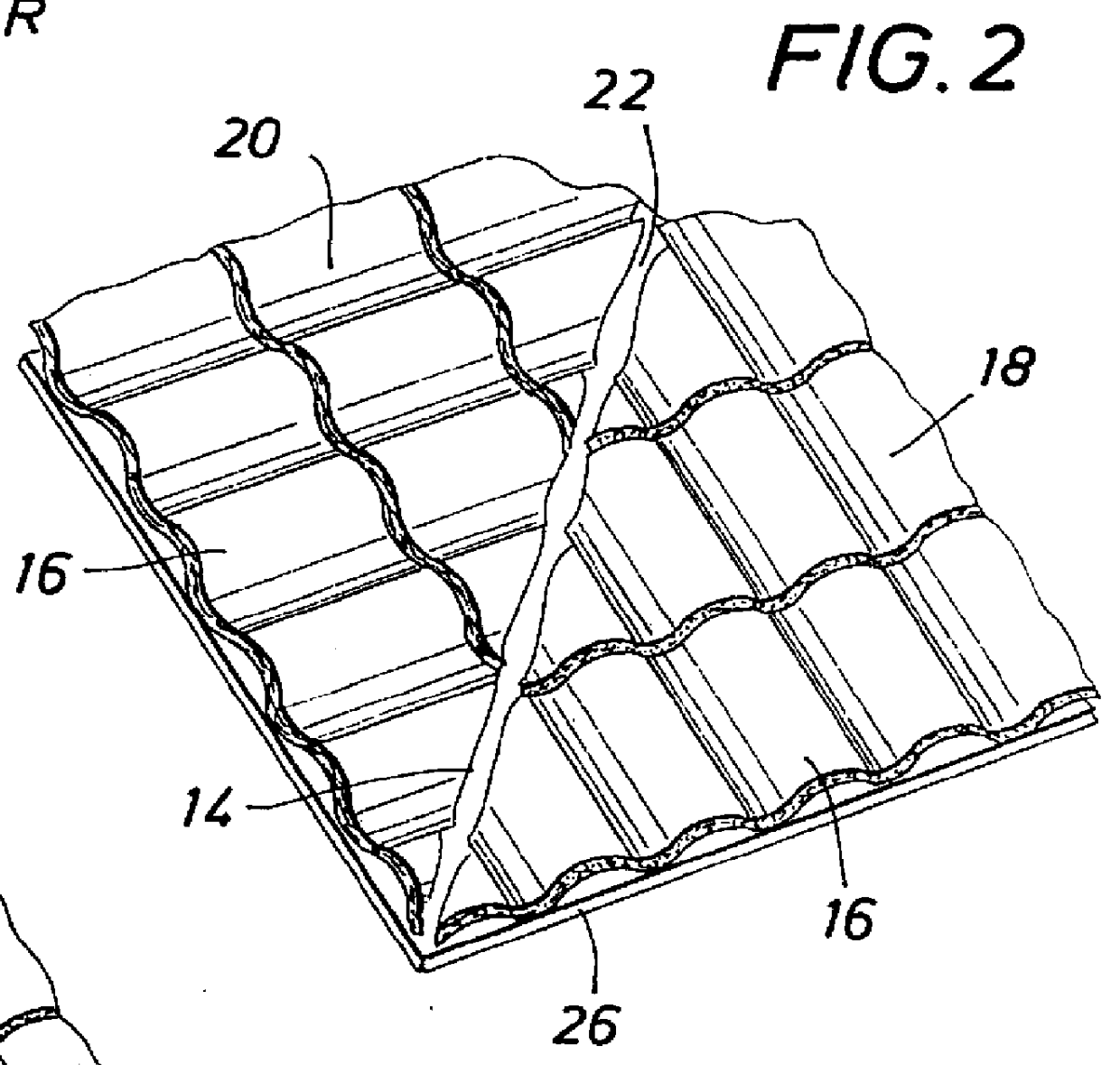

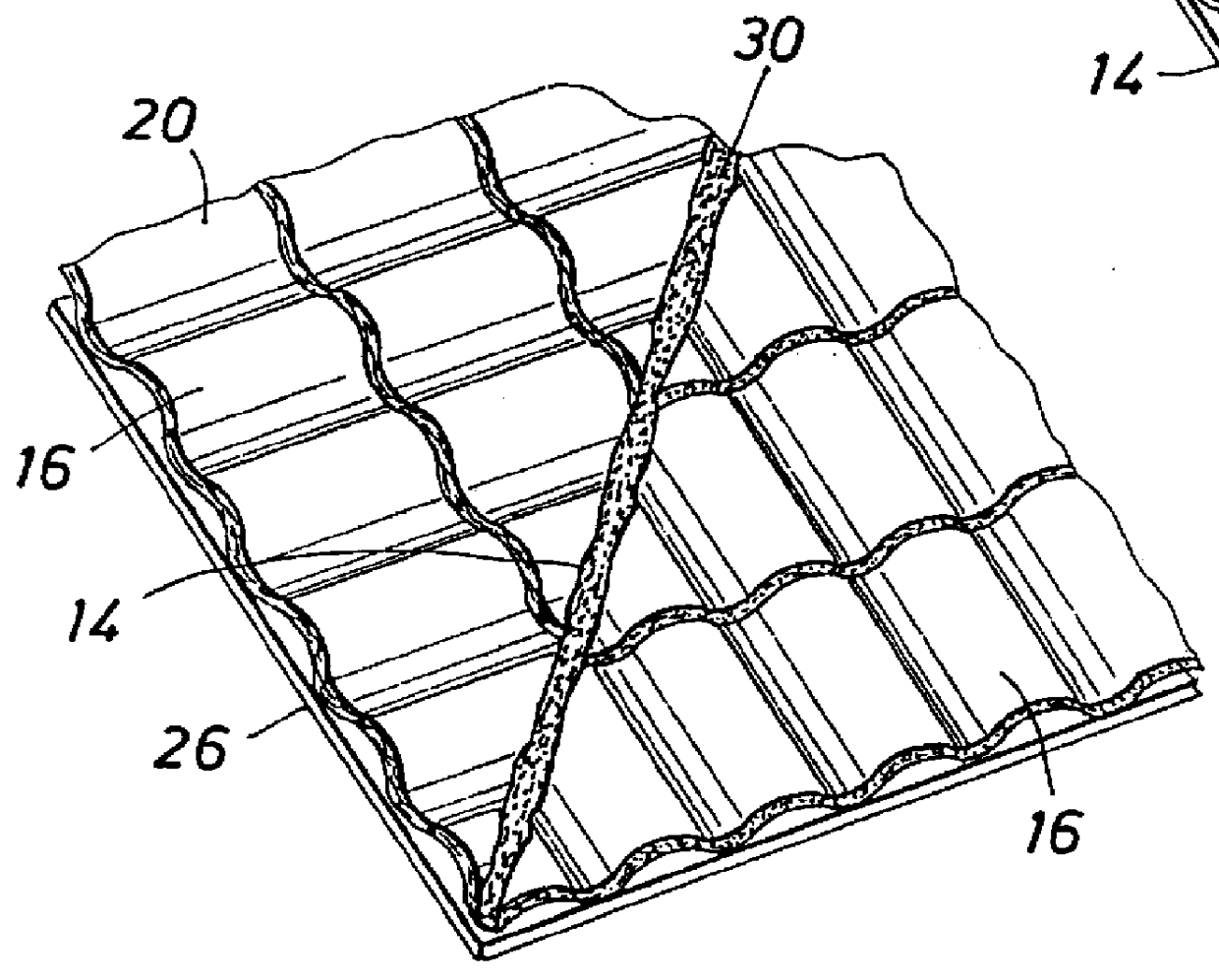

Hip and ridge sealing and attachment system and method of using same

A hip and ridge roof sealing and attachment system including a polyurethane foam adhesive first applied in a space between adjacent roof tiles along a hip or ridge of the roof. The first application of the polyurethane foam adhesive fills the space between the adjacent roof tiles. The polyurethane foam adhesive applied in a second application to adhere a lower surface of a hip or ridge tile to the first application of polyurethane foam adhesive and the adjacent roof tiles. The method of installing the hip and ridge roofing system includes the steps of applying a first layer of urethane foam adhesive in the space between adjacent roof tiles at a hip or ridge of a roof and adhering a hip or ridge tile to the first layer of urethane foam adhesive.

Owner:ICP CONSTR INC

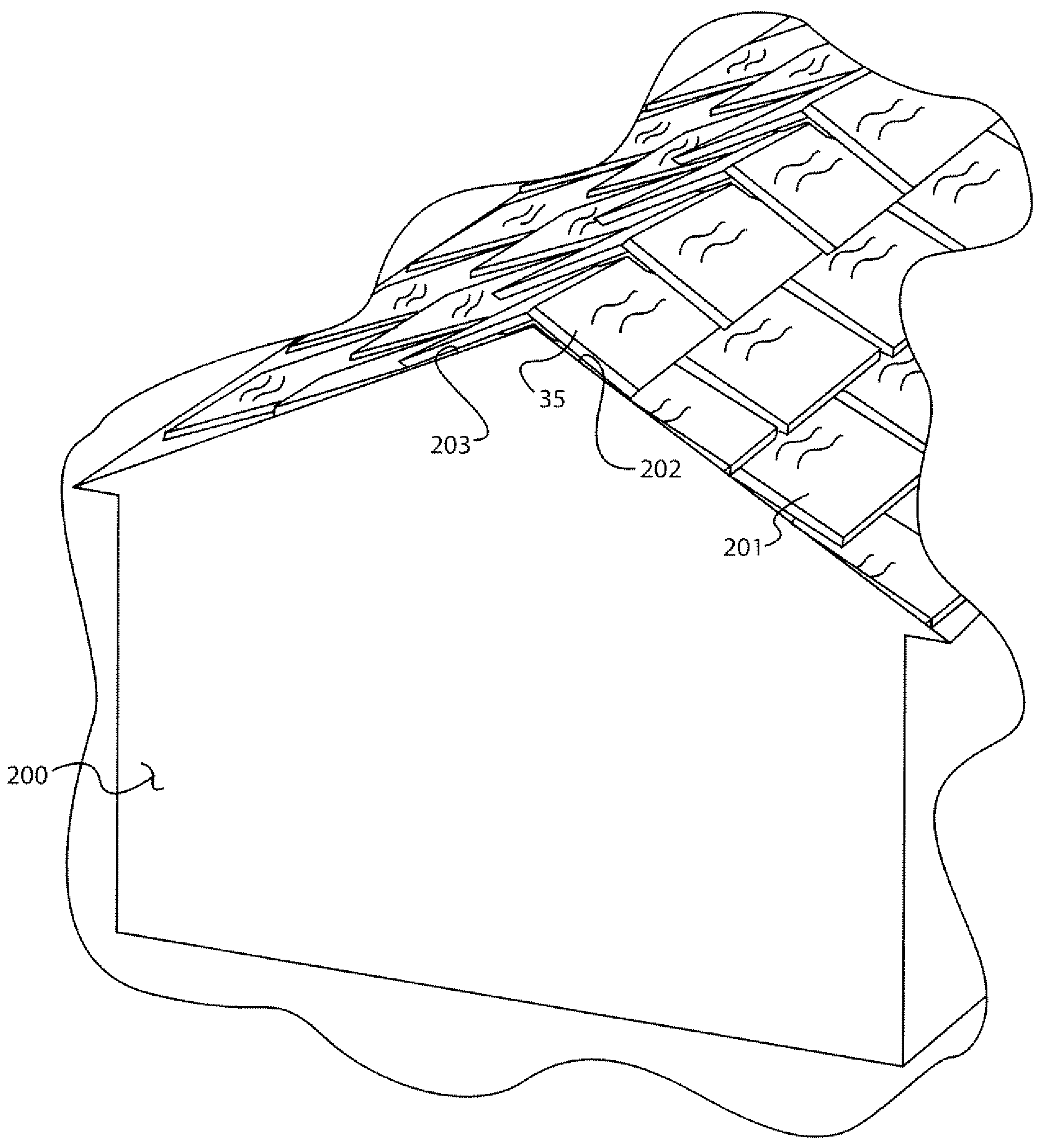

Pre-Assembled Hip, Ridge or Rake Shingle

InactiveUS20080229695A1Facilitate stacking of the shinglesEasy to operateRailway roofsRoof covering using tiles/slatesBiomedical engineeringRidge

A hip ridge or rake shingle is provided in which a pair of substantially rigid panel portions are connected by a hinge portion, and wherein the shingle is pre-assembled, but can conform to a variety of different angles to accommodate different angular relationships between surfaces of a hip, ridge or rake of a roof.

Owner:CERTAINTEED CORP

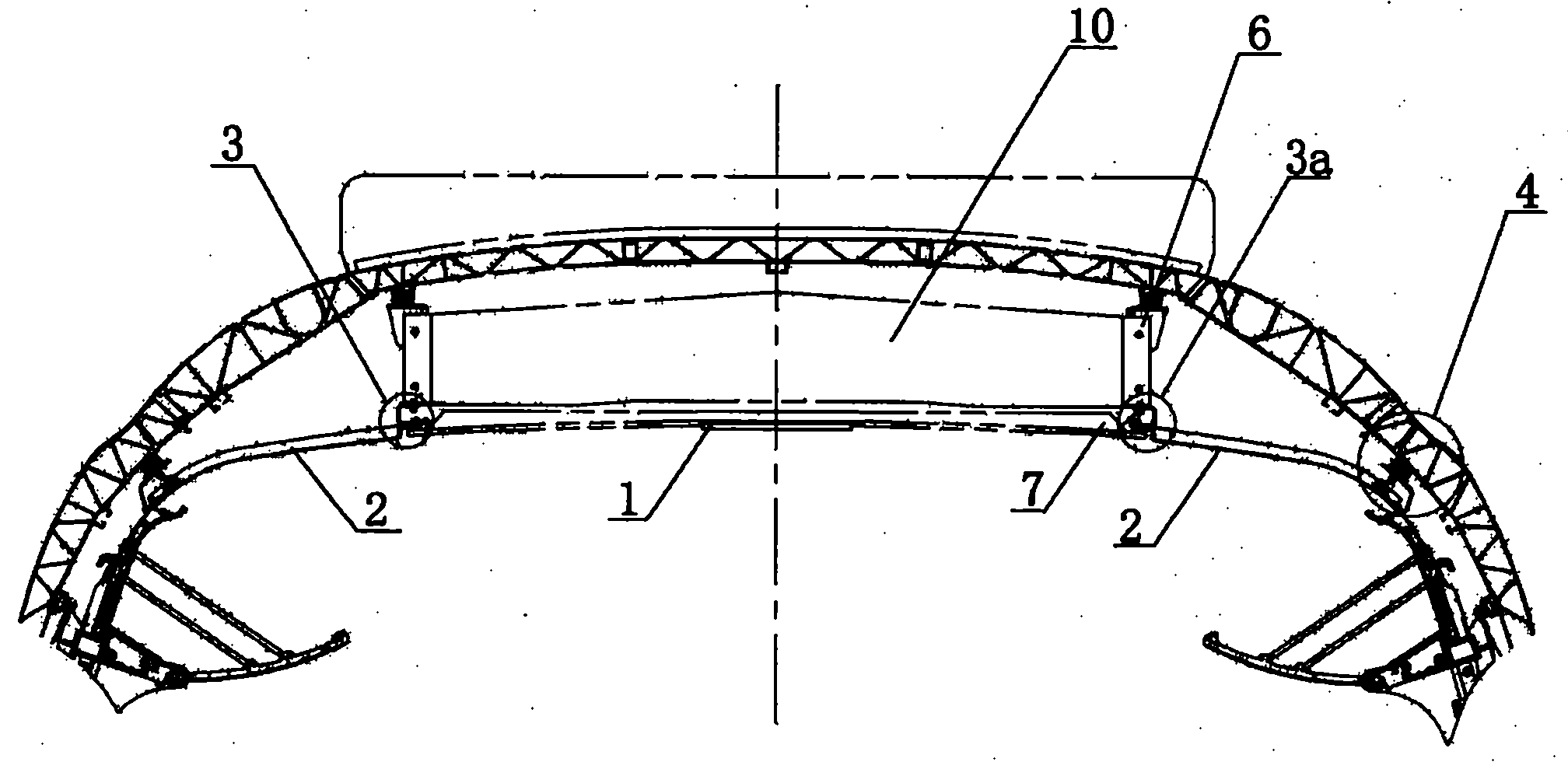

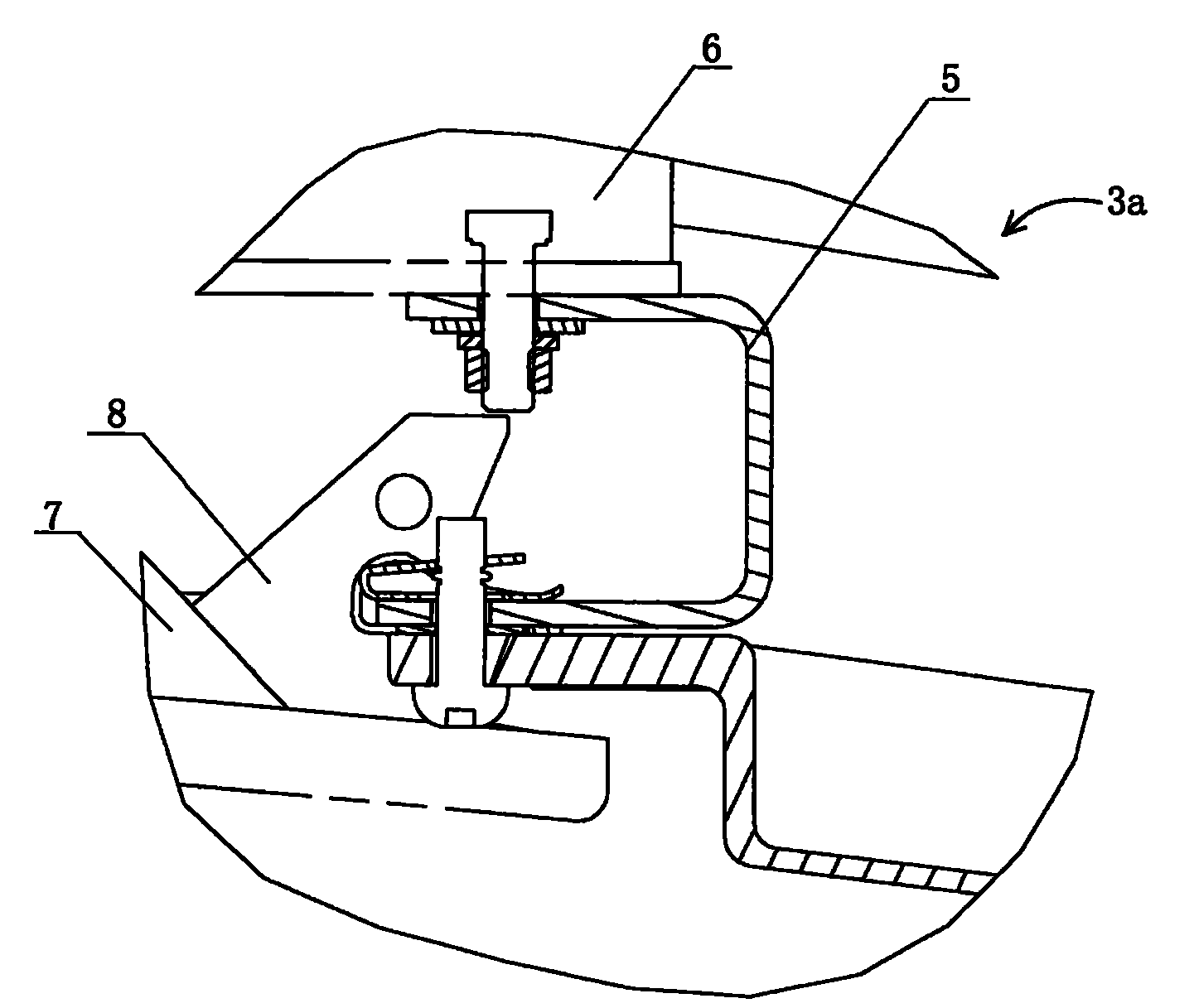

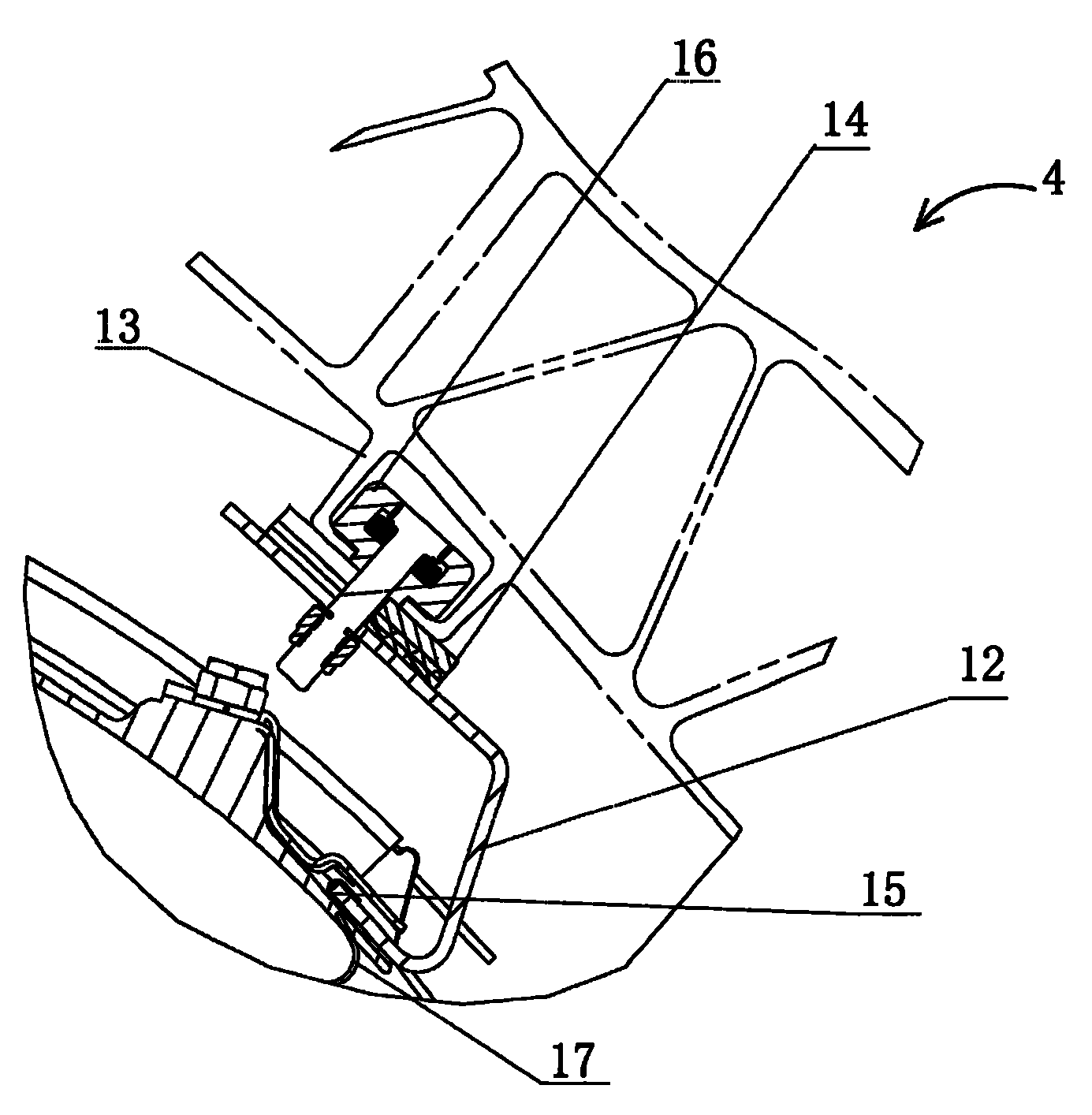

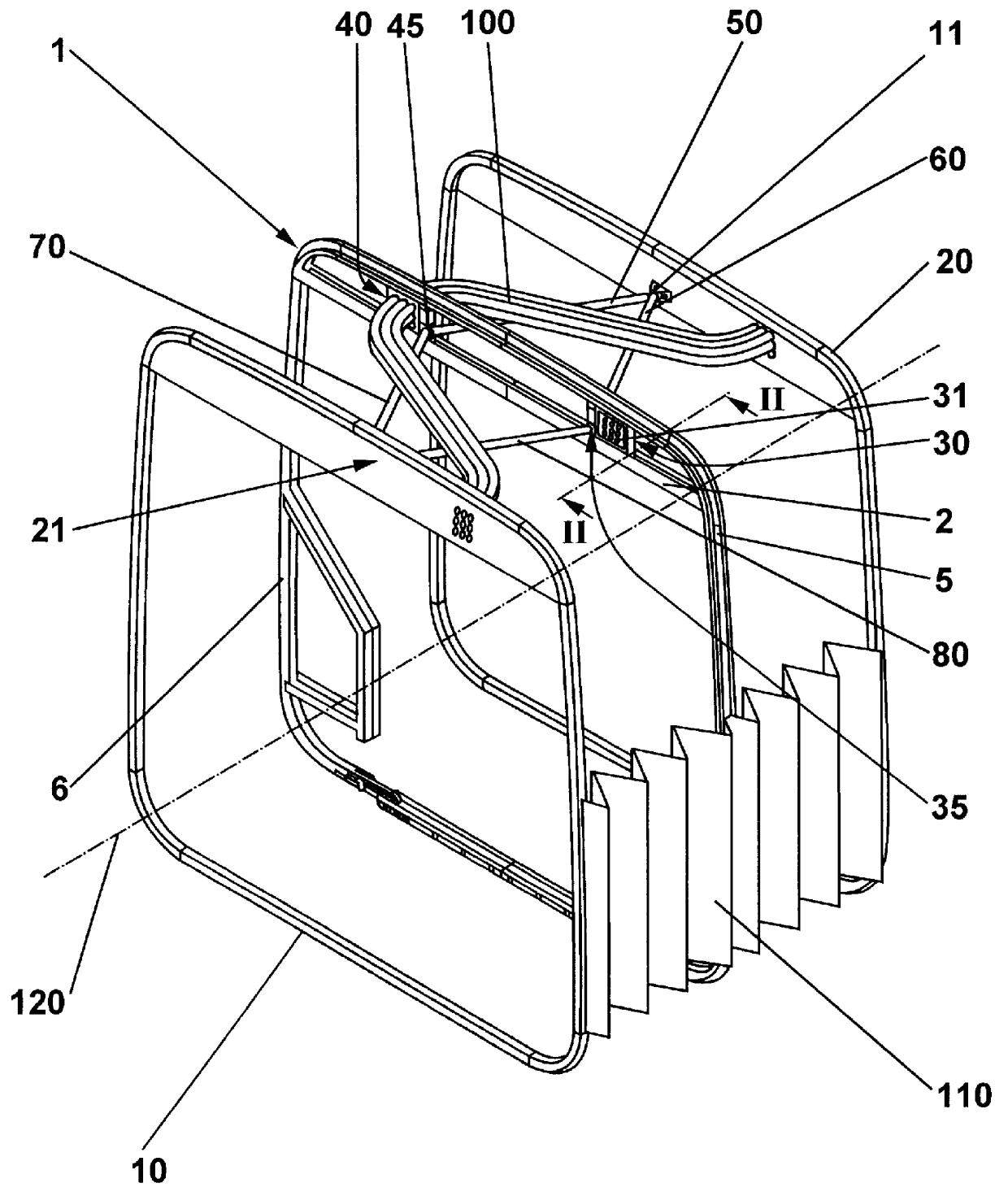

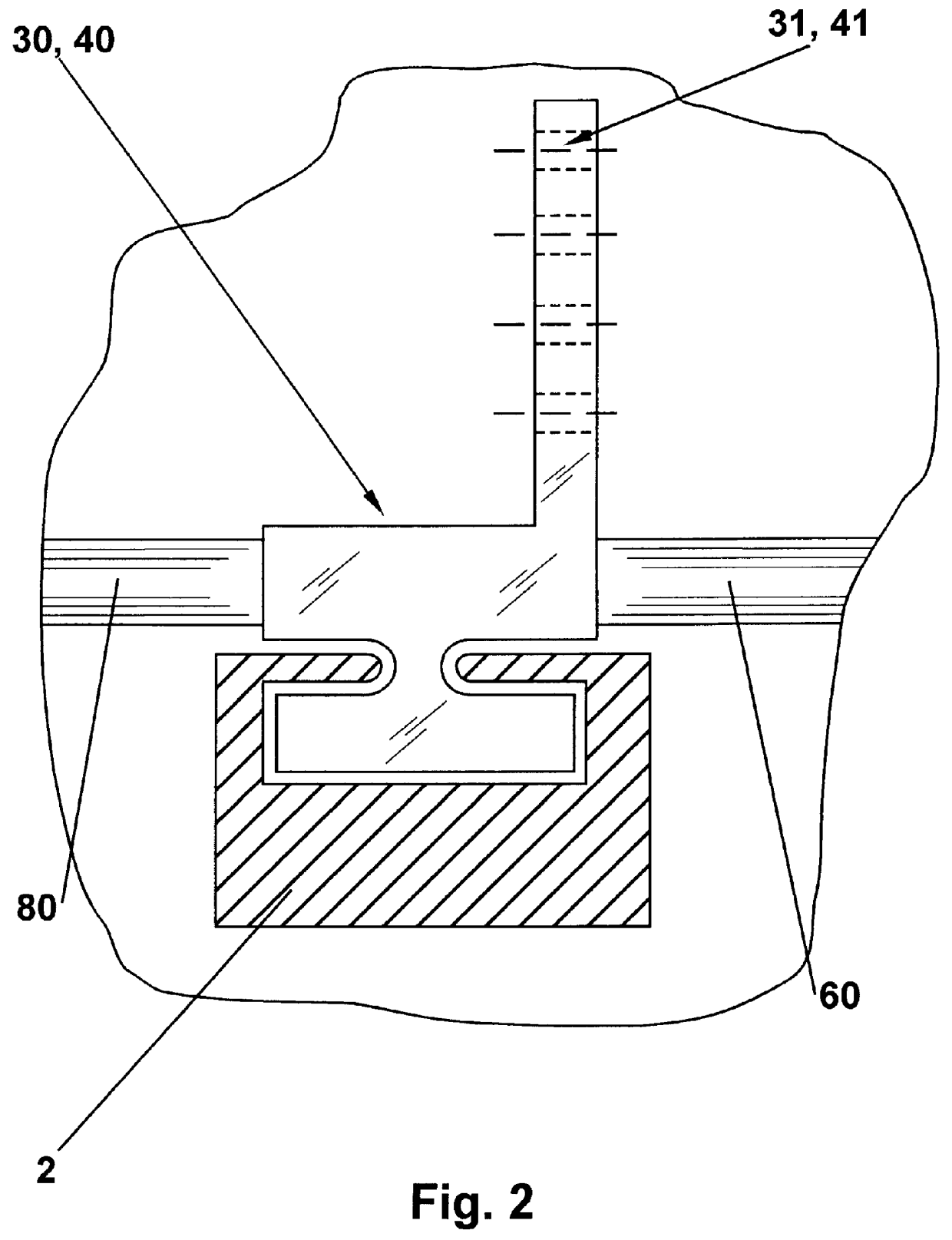

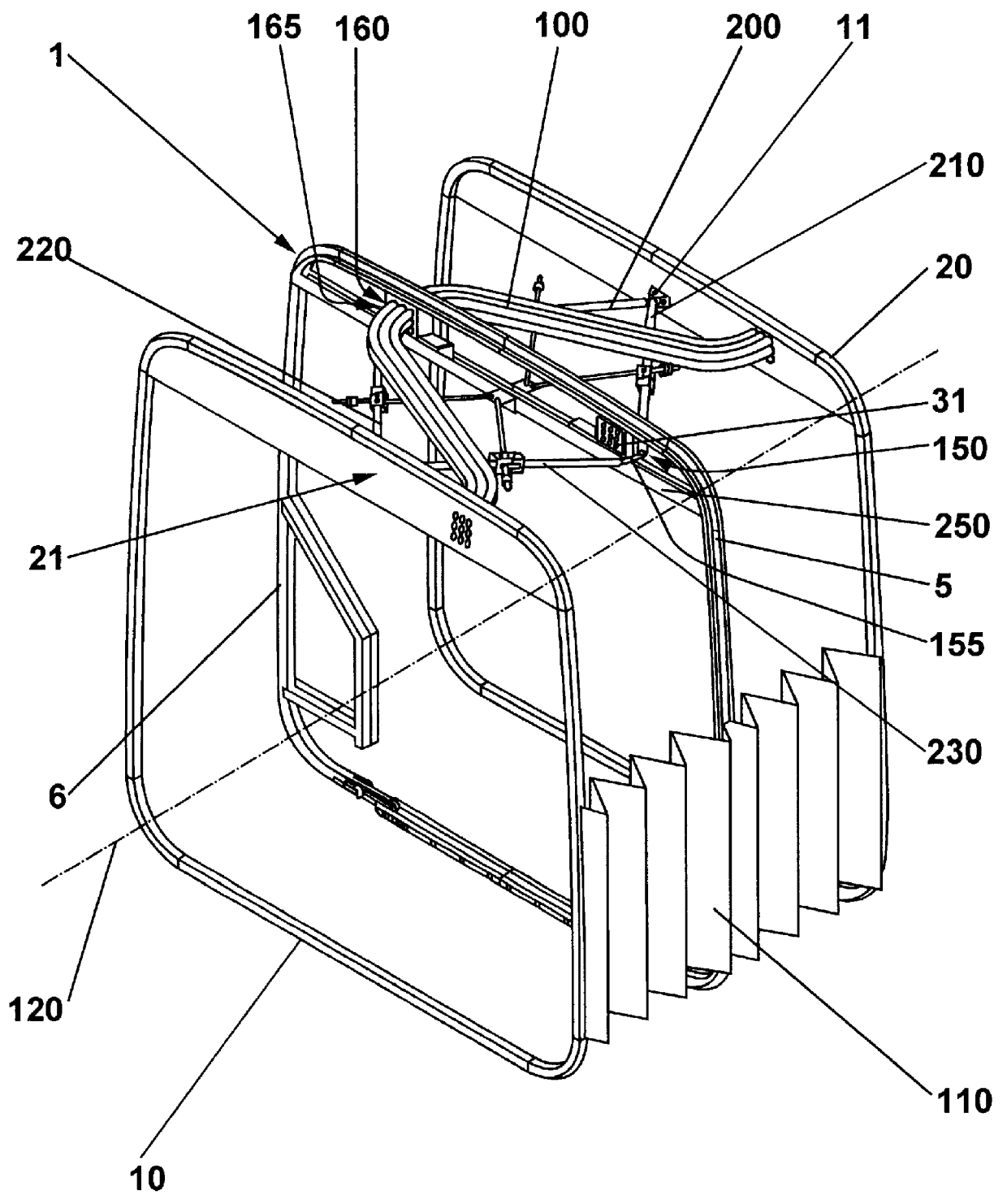

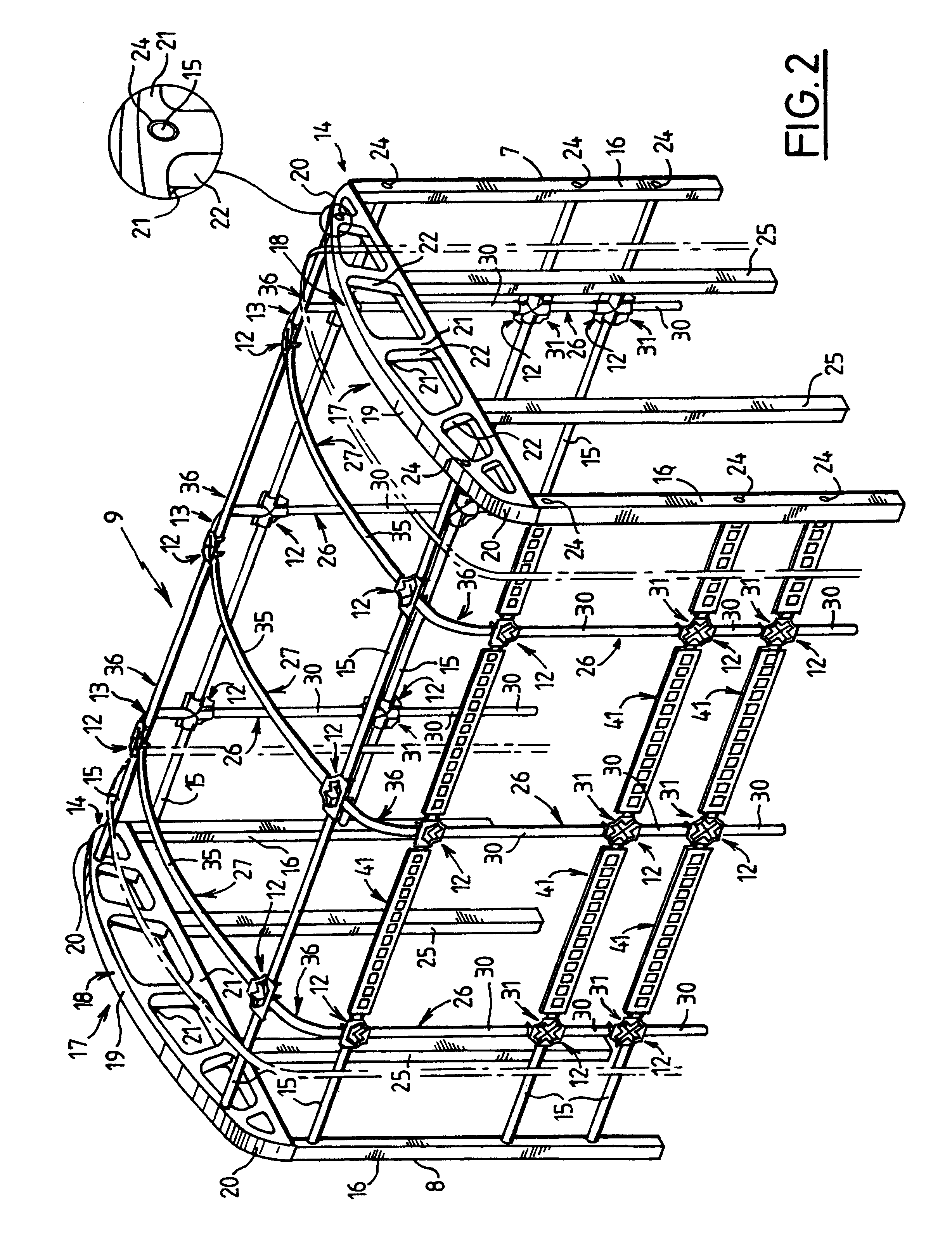

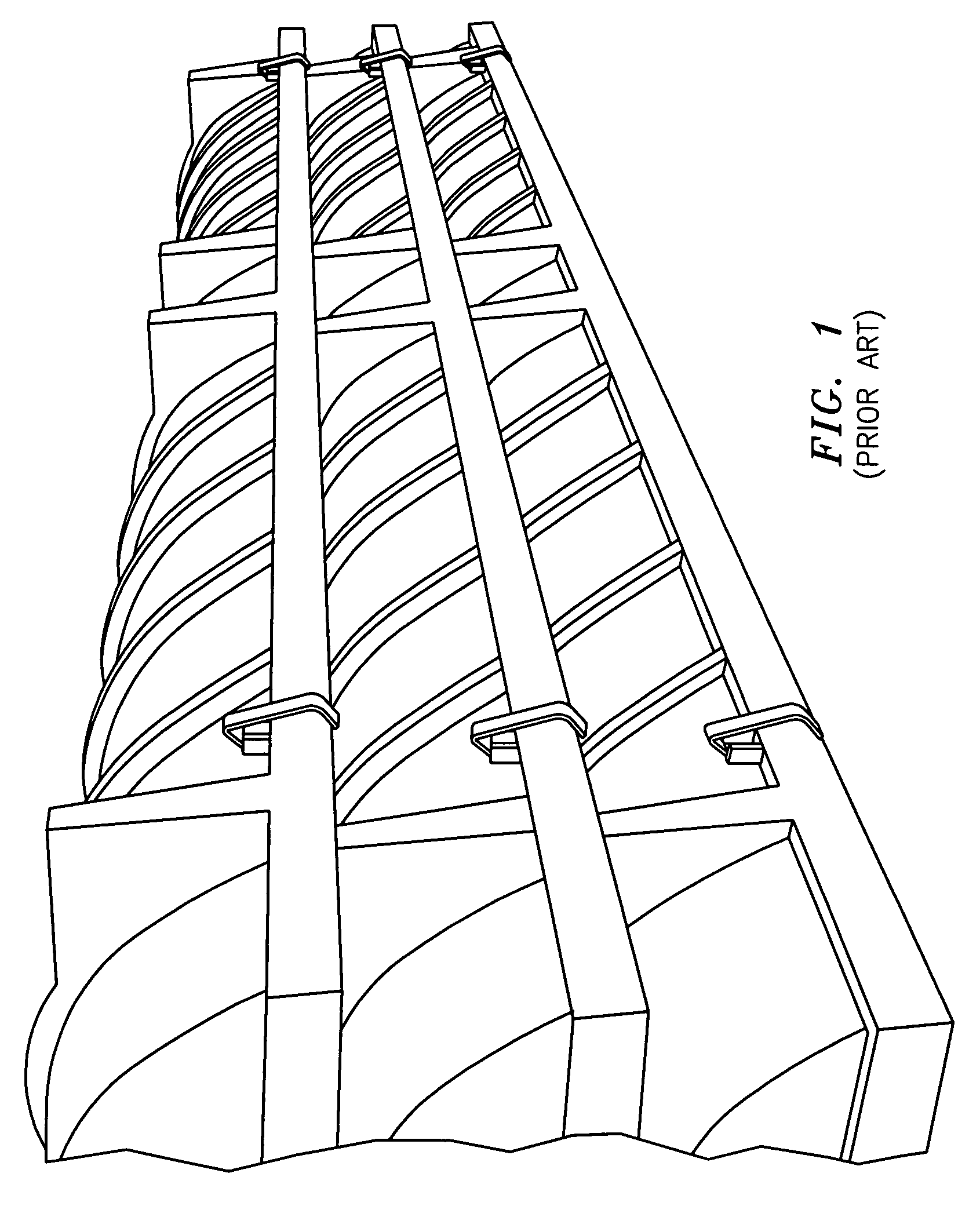

Central frame of a connecting corridor bellows subdivided in two halves

InactiveUS6076470AAvoid disadvantagesRailway roofsAxle-box lubricationArticulated vehicleEngineering

The subdivided bellows of a connecting element is provided between two articulated vehicle components. The halves of the bellows are coupled at their ends to a vehicle component, and a middle frame (1) has a device for guiding supply lines (100), e.g. tubes, cables, etc., in a ceiling area of the connecting element which is movable relative to the middle frame (1).

Owner:HUBNER GUMMI UND KUNST

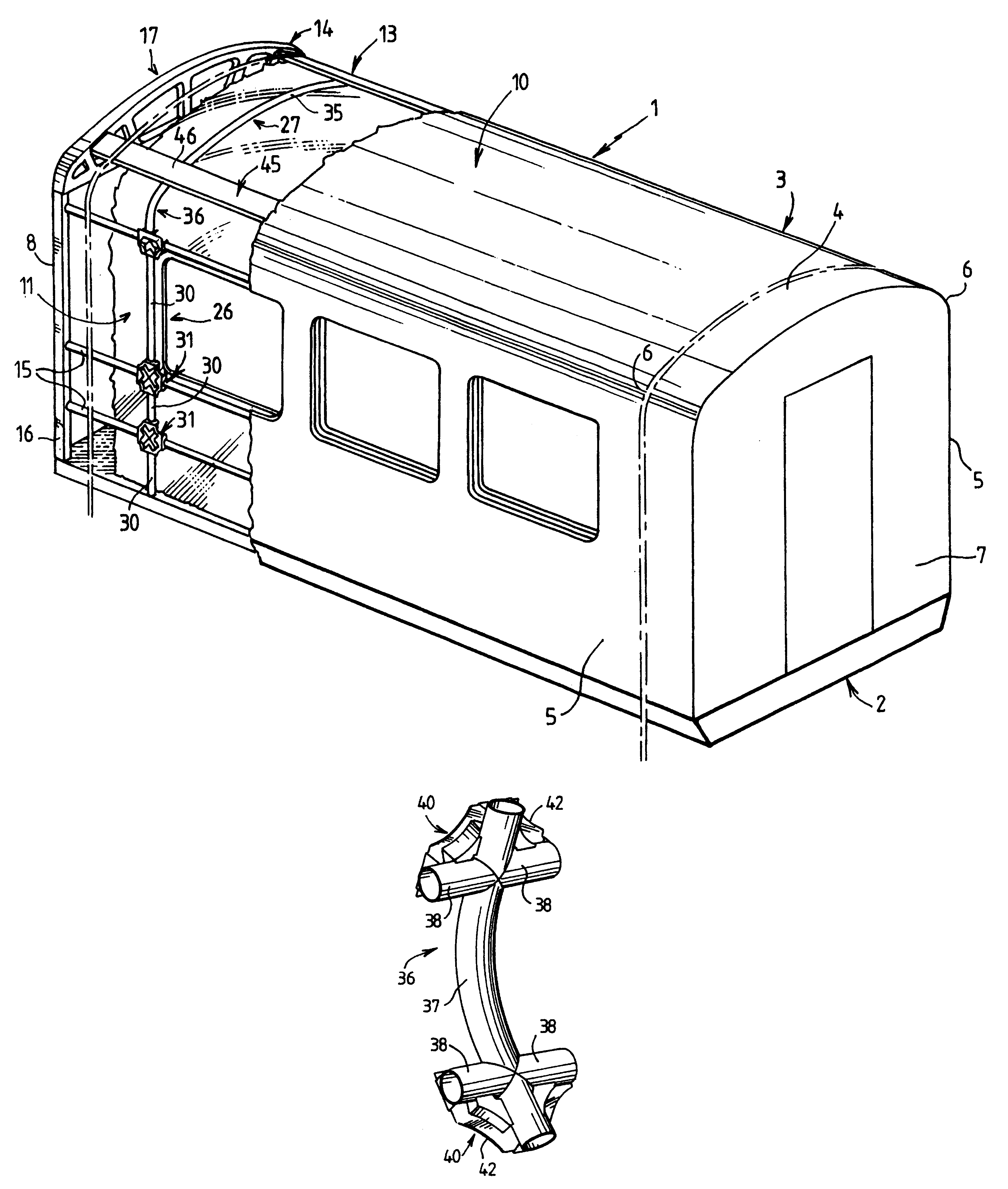

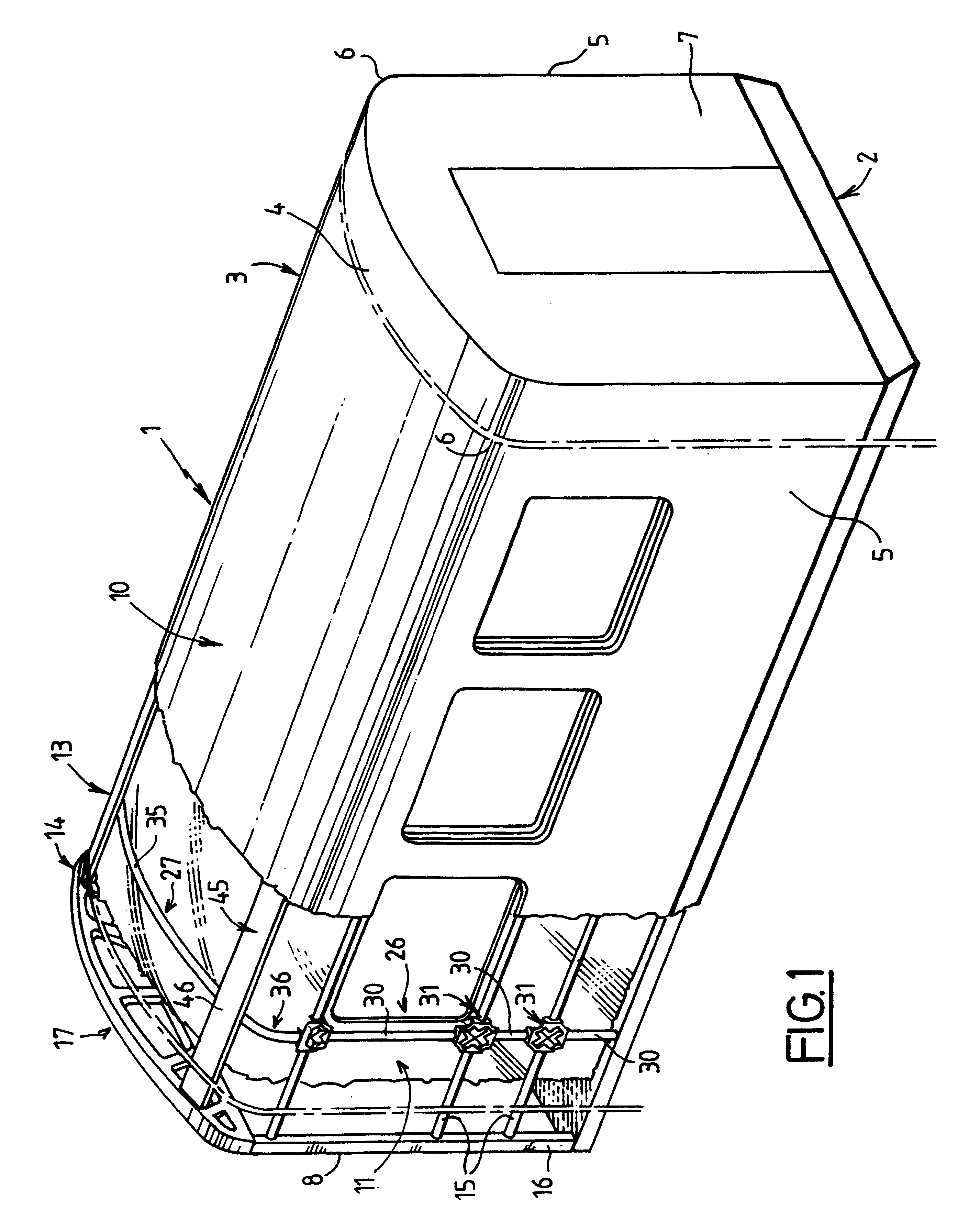

Rail vehicle body, a rail vehicle, and corresponding assembly methods

InactiveUS6378444B1Limiting design costLow costRailway roofsVehicle seatsEngineeringMechanical engineering

The invention relates to a rail vehicle body of the type comprising a grid structure, itself comprising longitudinal elements and cross elements interconnected at nodes, and supporting outer and inner coverings. Longitudinal and cross elements are circular section tubes. At at least some of its nodes, the grid structure comprises connections for interconnecting longitudinal and cross tubes of circular section. These connections have longitudinal and cross circular section sleeves which receive longitudinal and cross tubes respectively. Longitudinal tubes pass right through the connections made of longitudinal and cross tubes.

Owner:ALSTOM TRANSPORT TECH SAS

Vented Hatch Cover

A vented hatch cover comprising a cover body, an intake filter element, a discharge filter element and a gasket. The cover body has a plurality of walls defining an air intake passage, an air discharge passage, and a plenum extending from the air intake passage to the air discharge passage. The cover body includes a plurality of ribs extending across the air intake passage. The intake filter element is disposed over the air intake passage and includes a plurality of latches engaging the ribs to secure the intake filter element to the cover body. The cover body further includes an inner rim and an outer rim located radially outward of the inner rim. The inner rim and the outer rim define a pocket. The gasket is retained in the pocket of the cover body. The discharge filter element is disposed over the air discharge passage and includes a plurality of upward extending portions or latches located radially between the inner rim and the gasket. The latches of the discharge filter element releasably secure the discharge filter element to the cover body

Owner:SALCO PRODS

Anti-fog refrigeration door and method of making the same

InactiveUS7891154B2Burdening the cooling systemEasy and economical to manufacture and operate and maintainShow cabinetsRailway roofsElectricityFrost

The energy-free refrigeration door of the present application provides a way to control condensation when the door of a refrigeration unit is opened by providing thermal insulation to the door with glass panels which have a low emissivity coating. The door includes a door frame housing and an insulating glass unit comprising inner, middle and outer sheets of glass. A first sealant assembly disposed around the periphery of the inner and middle sheets of glass forms a first chamber between the inner and middle sheets of glass. A second sealant assembly disposed around the periphery of the middle and outer sheets of glass forms a second chamber between the middle and outer sheets of glass. A gas, such as krypton, air, or argon is held in the first and second chambers. The outer sheet of glass and inner sheet of glass each have an unexposed surface that faces the middle sheet of glass. A low emissivity coating is disposed on the unexposed surfaces of the inner and outer sheets of glass so that the glass door as a whole avoids formation of condensation on the outer surface of the outer sheet of the glass door, without the application of electricity to heat the door, while also providing the desired evaporation rate of condensation from the inner side of the inner sheet of the glass door. An anti-fog or anti-frost coating is included on a surface of one of the sheets of glass.

Owner:AGC FLAT GLASS NORTH AMERICA INC

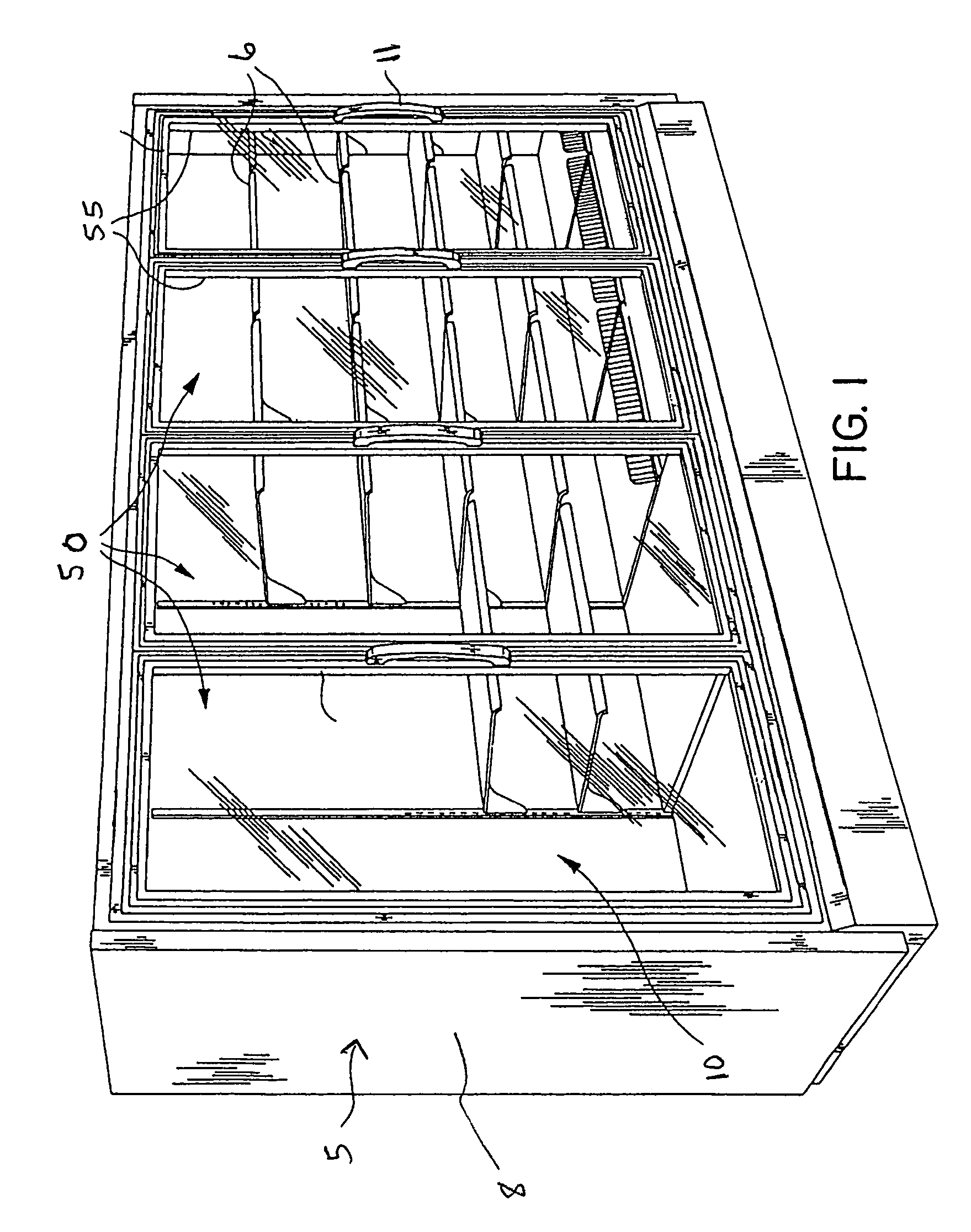

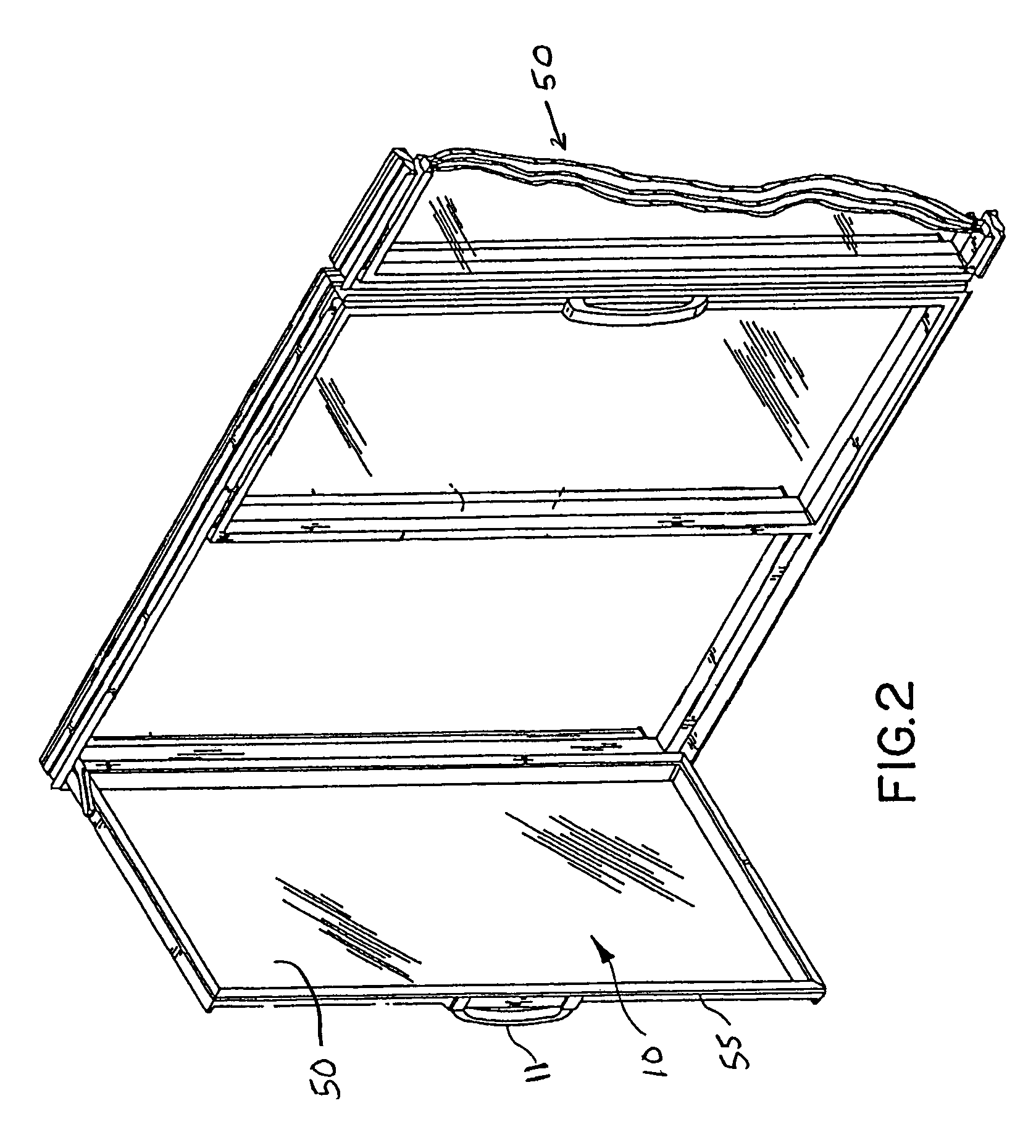

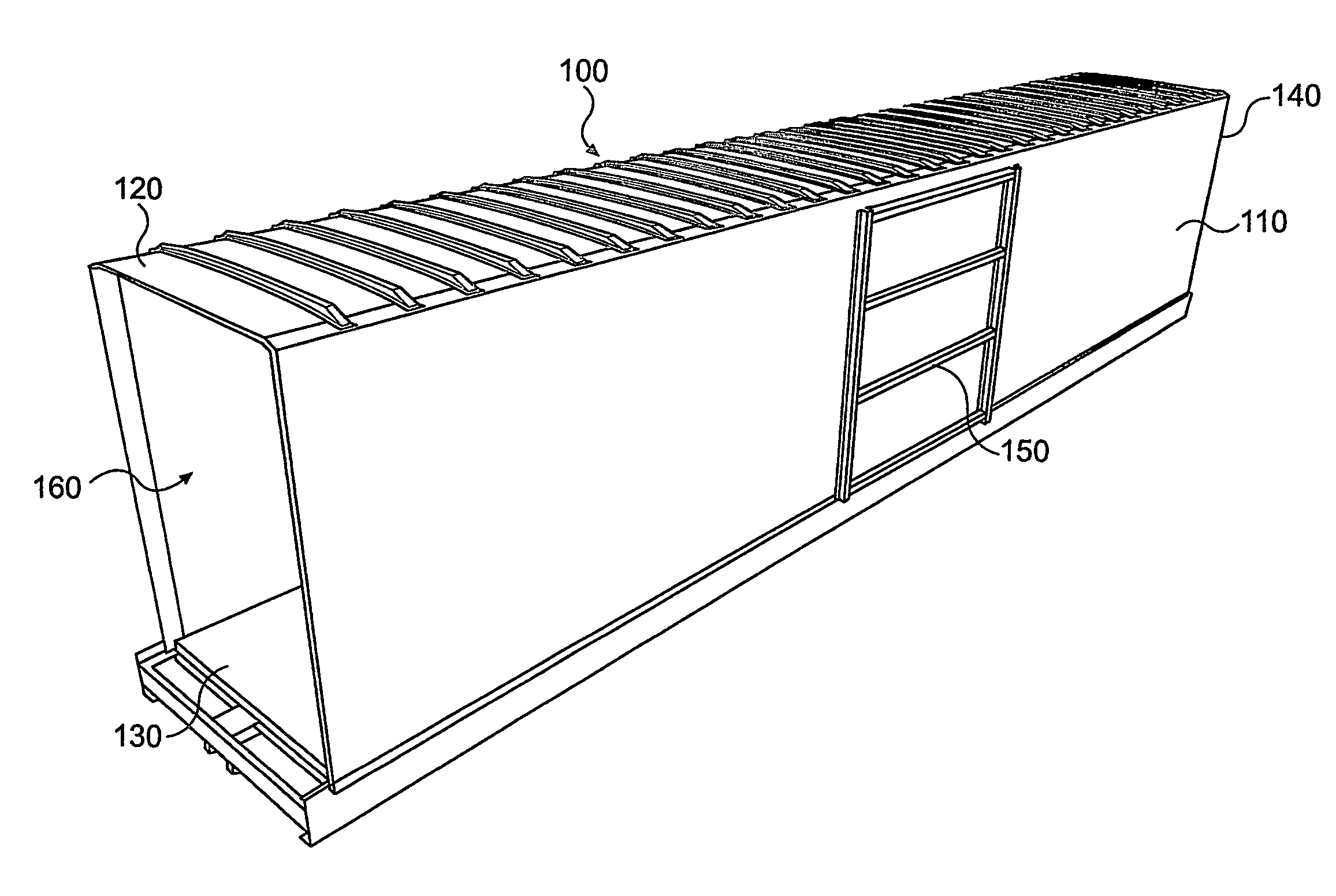

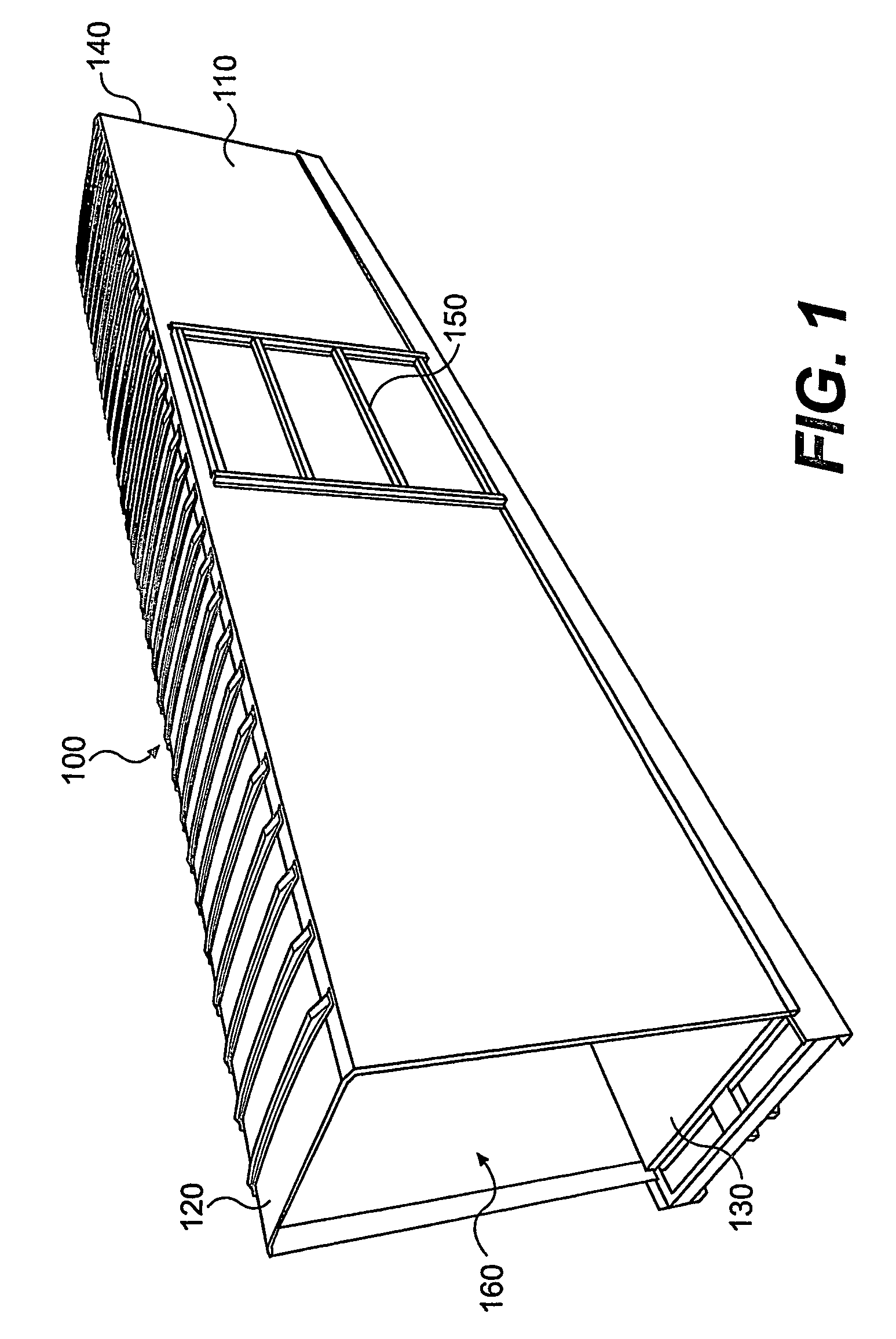

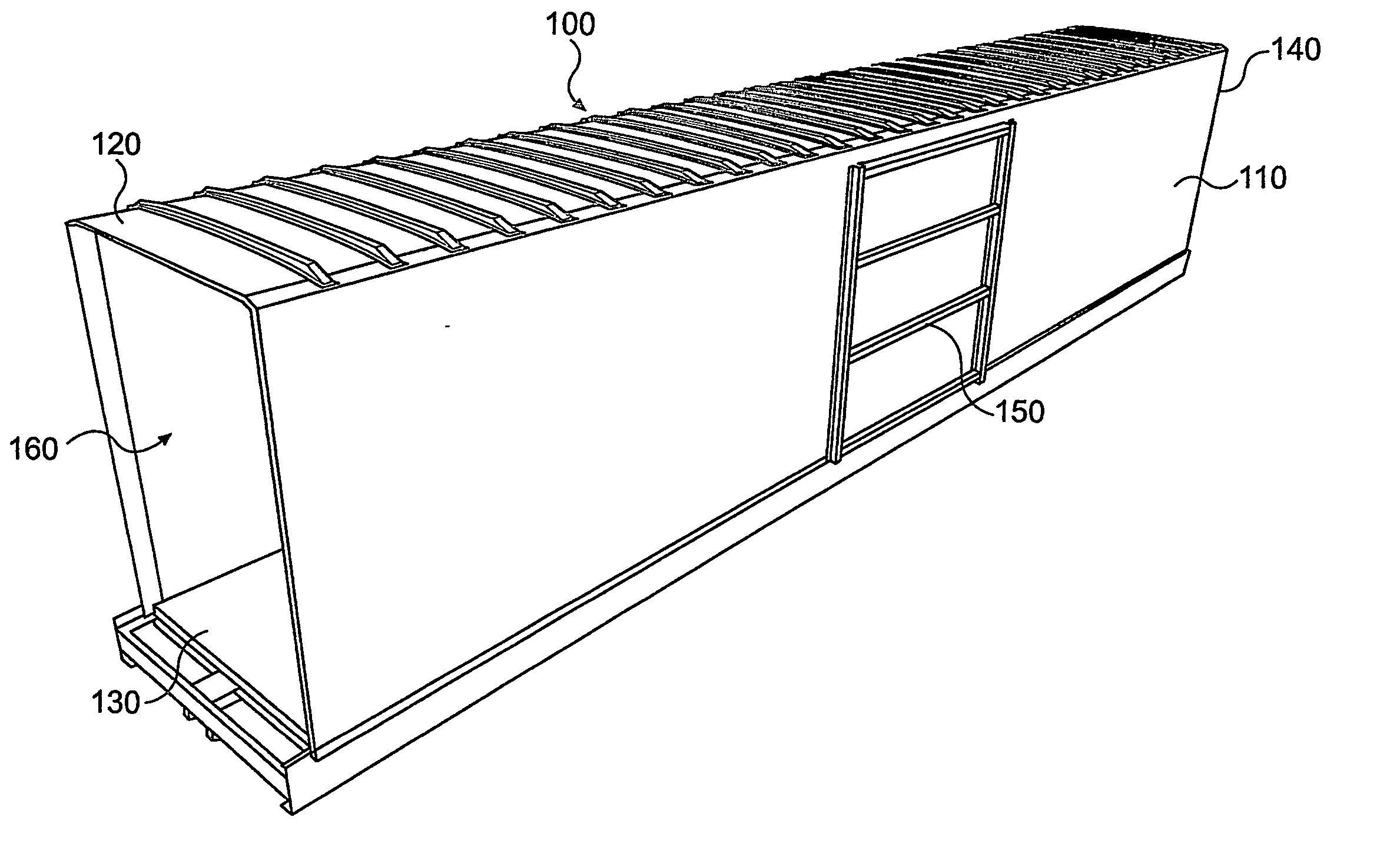

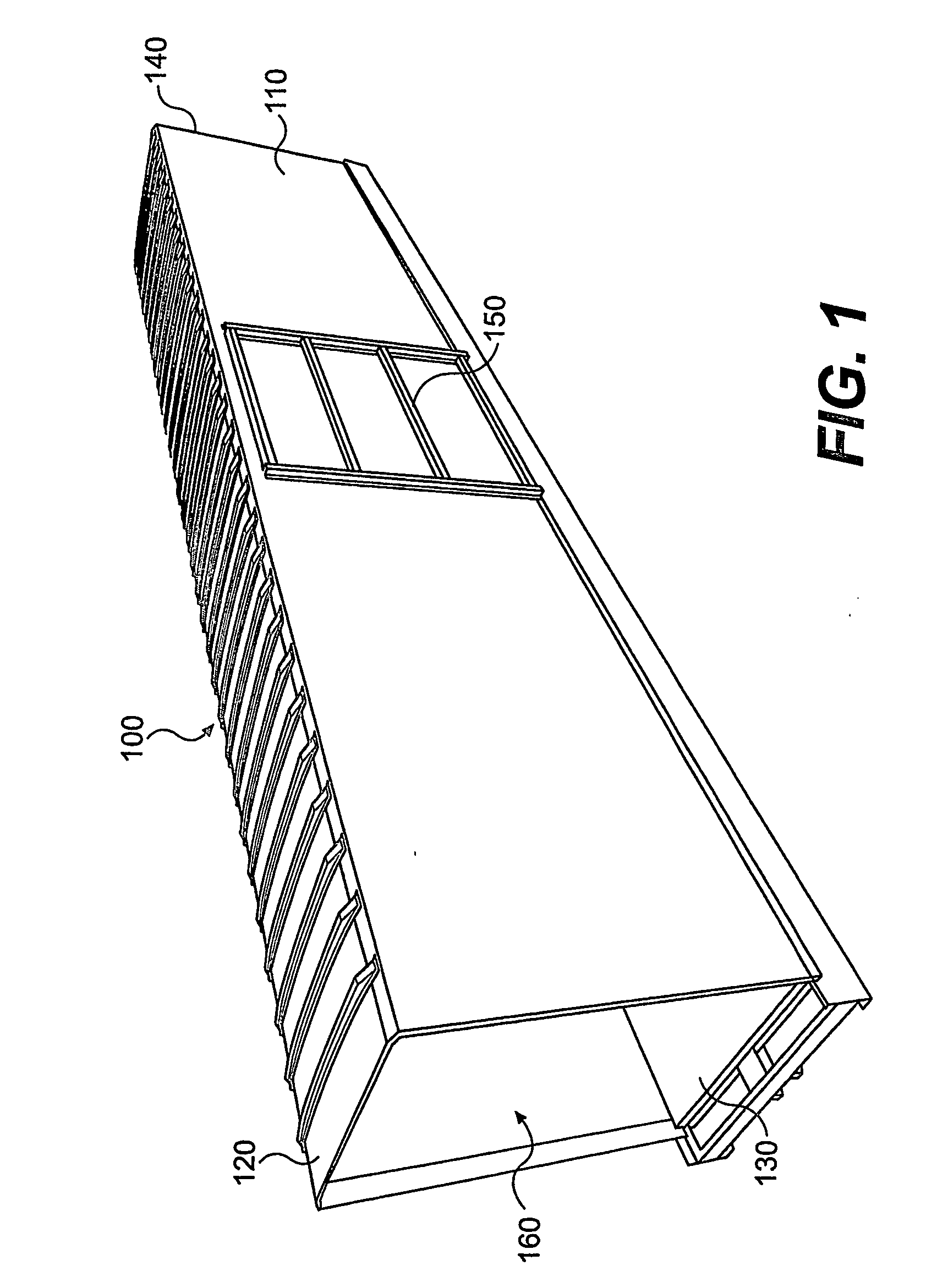

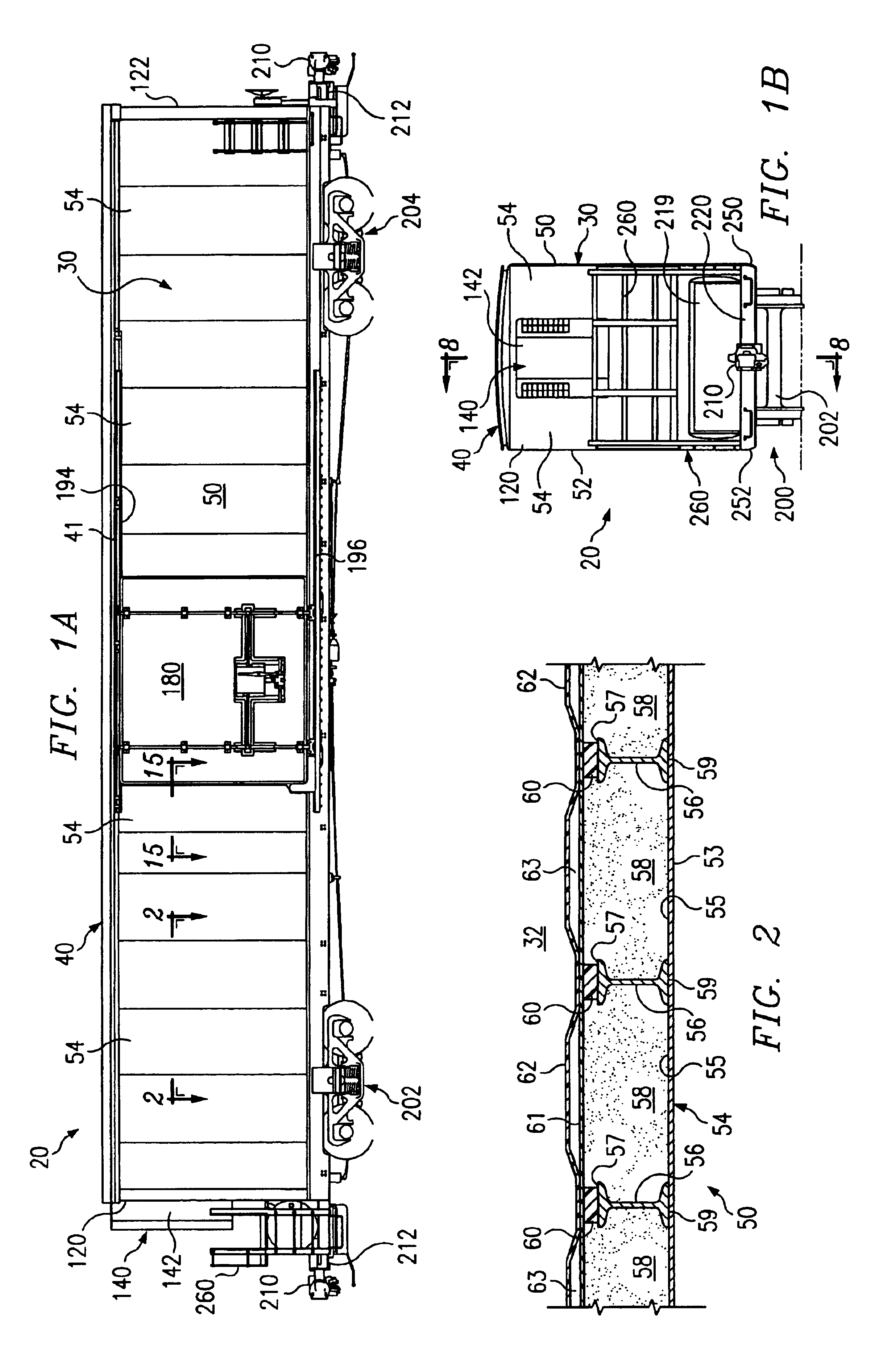

Insulated cargo containers

The present invention relates to an insulated cargo container that may have, in combination, an interior panel covering a layer of thermal insulation that has an air-impermeable layer thereon. The thermal insulation is attached to the exterior panel of the container, which may have structural supports on its interior surface. In one embodiment, the insulated cargo container is an insulated railroad boxcar.

Owner:MARTIN MARIETTA MATERIALS

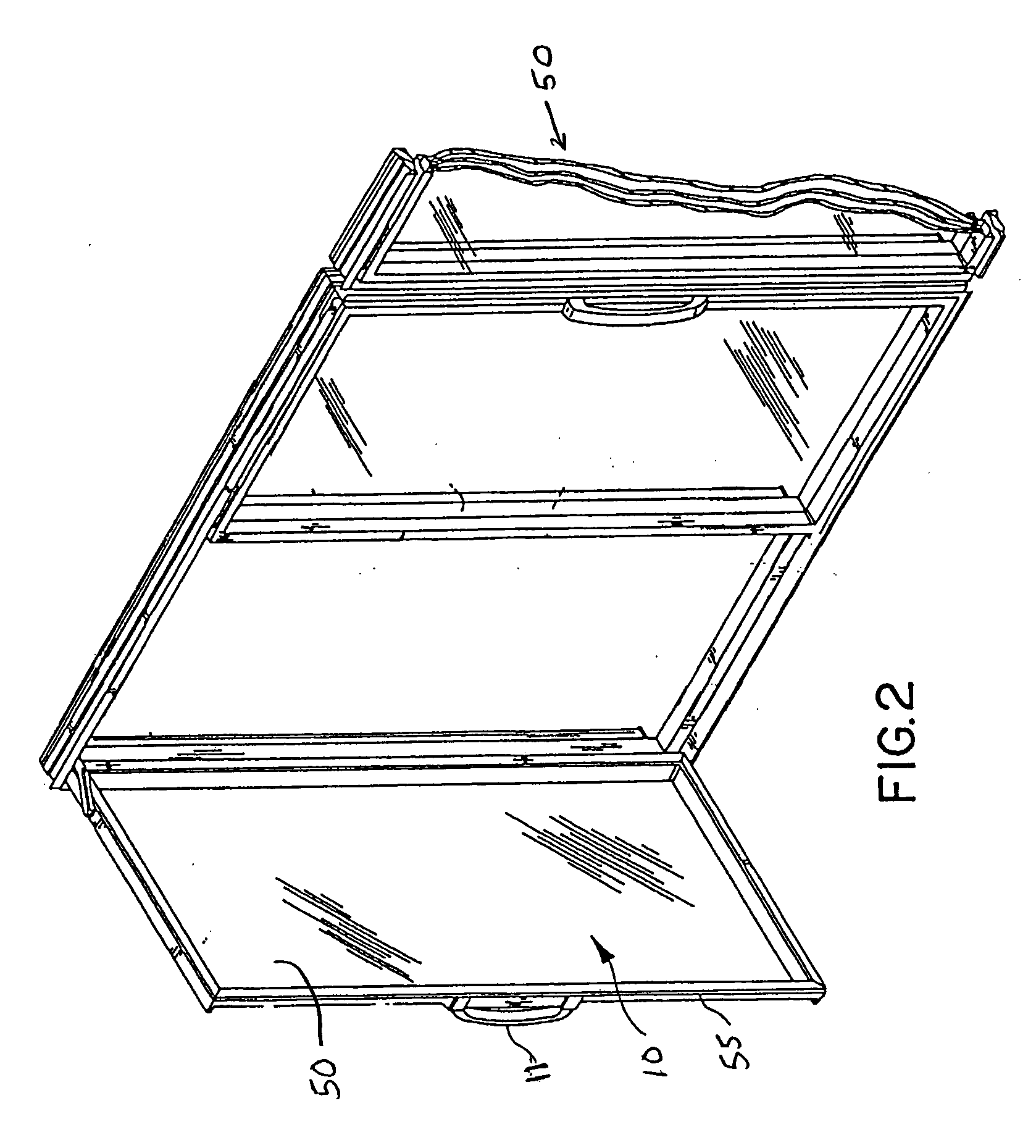

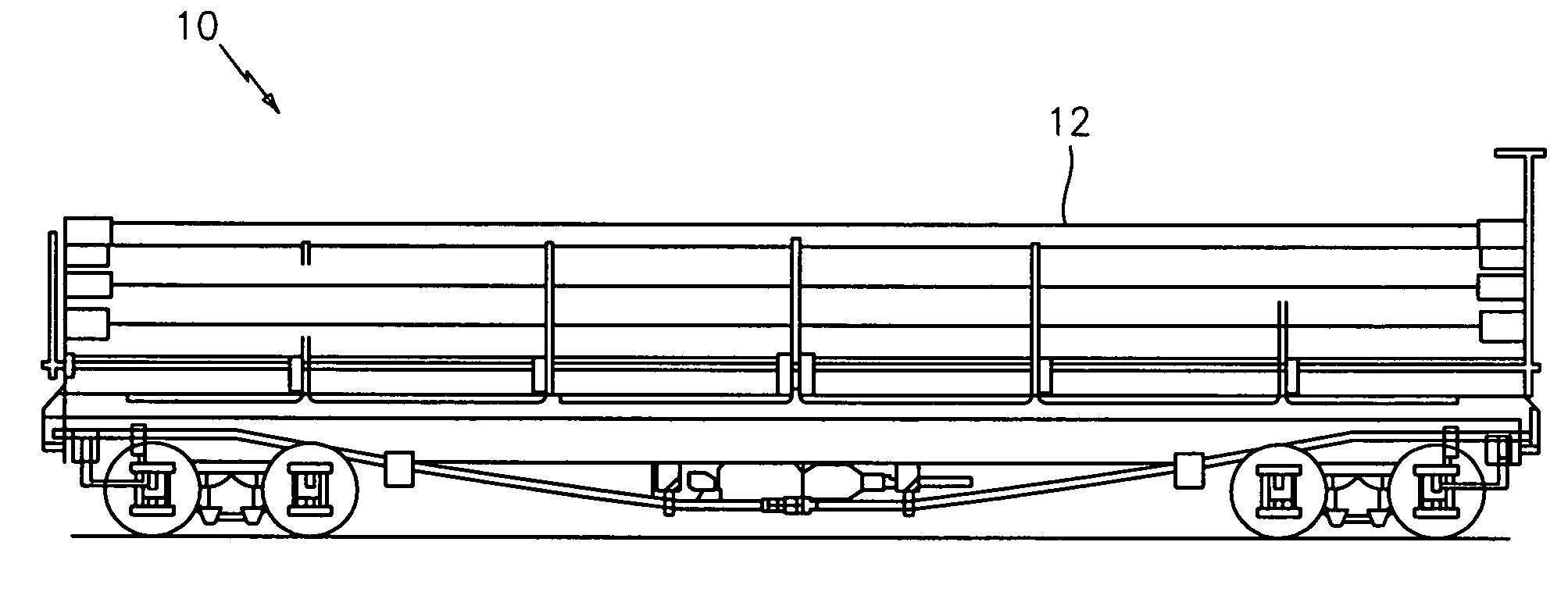

Open-top rail car covers and open-top rail cars employing the same

An open-top rail car cover is defined by a frame having dimensions sufficient to fit an open-top freight car designed in accordance with the Association of American Railroads, a roof and a pair of end walls. A latch disposed about a side of the frame includes a first flange and a second flange that combine to define a means for receiving an engagement member of a rail car. Both the first and second flanges include a at least one first aperture and at least one second aperture designed to receive a means for securing the car cover to the rail car. The first and second apertures have dimensions sufficient to permit movement of the first and second flanges about the means for receiving.

Owner:MARTIN MARIETTA MATERIALS

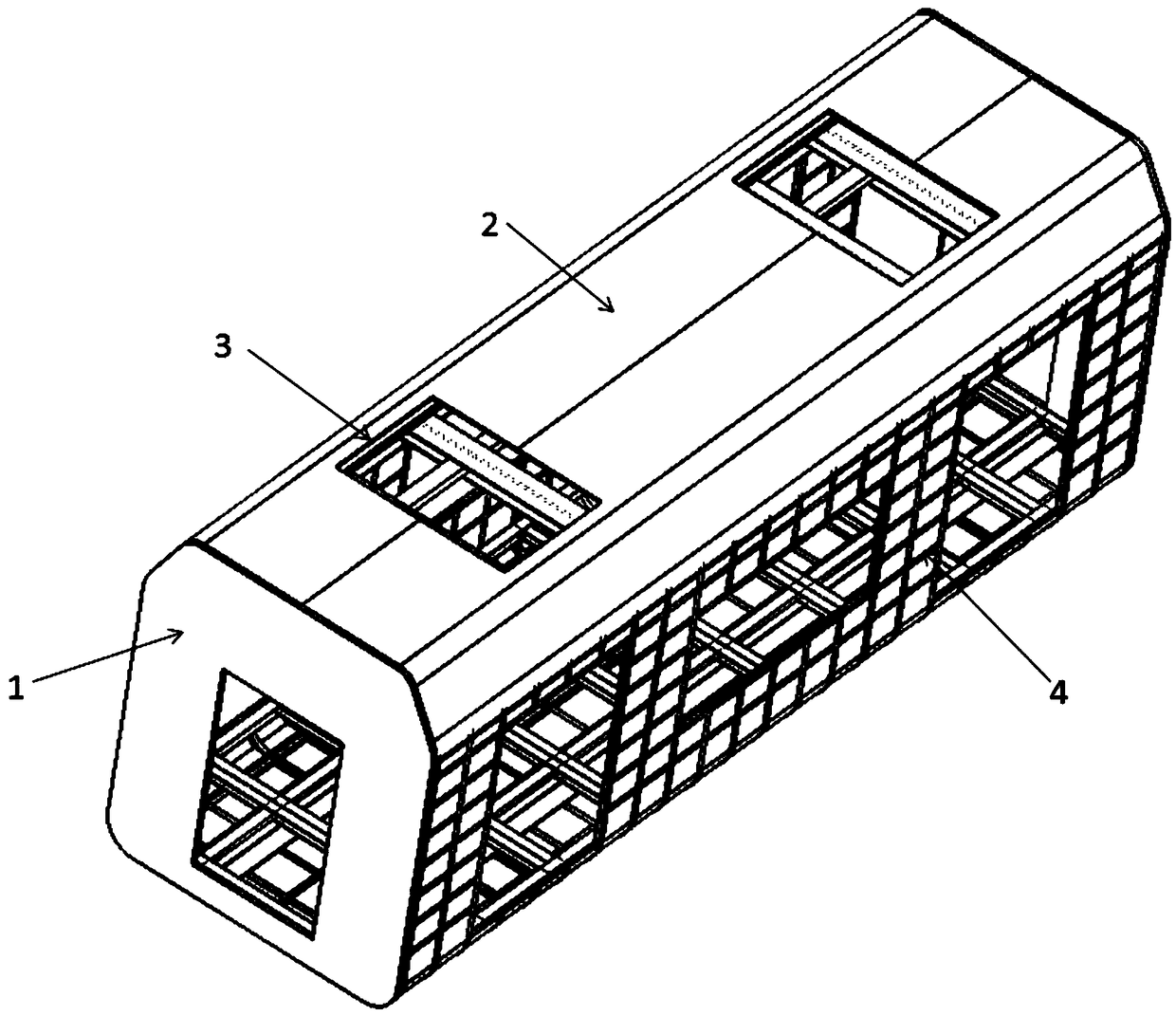

Structure and manufacturing process of low-cost carbon fiber composite material sky railway train body

ActiveCN108622123AAchieve lightweightIncrease stiffnessRailway roofsAxle-box lubricationBogieEngineering

The invention discloses a structure and a manufacturing process of a low-cost carbon fiber composite material sky railway train body, and belongs to the technical field of application of composite materials on rail vehicles. The structure comprises a train body side wall, wherein end walls are assembled and connected to the both ends of the train body side wall; a top frame and a bottom frame arecorrespondingly assembled and connected to the inner top surface and the inner bottom surface of the train body side wall, a ceiling is assembled and connected to the outer top surface of the train body side wall, and a bogie mounting hole is formed in the ceiling; the train body side wall and the end walls both comprise reinforced rib frames, inner skins and outer skins, and grids of the reinforcing rib frames are filled with sandwich foam blocks; the ceiling comprises a sandwich panel, an upper skin and a lower skin, and the top frame, the bottom frame, the reinforcing rib frame, the inner skins, the outer skins, the upper skin and the lower skin are all integrally molded from carbon fiber composite materials; and the inner portions of the reinforcing rib frames are filled with sandwichfoam, and the purpose of satisfying the function and structure of the load bearing mode of a suspension-type train body on the premise of light weight of the train body is achieved.

Owner:SOUTHWEST JIAOTONG UNIV

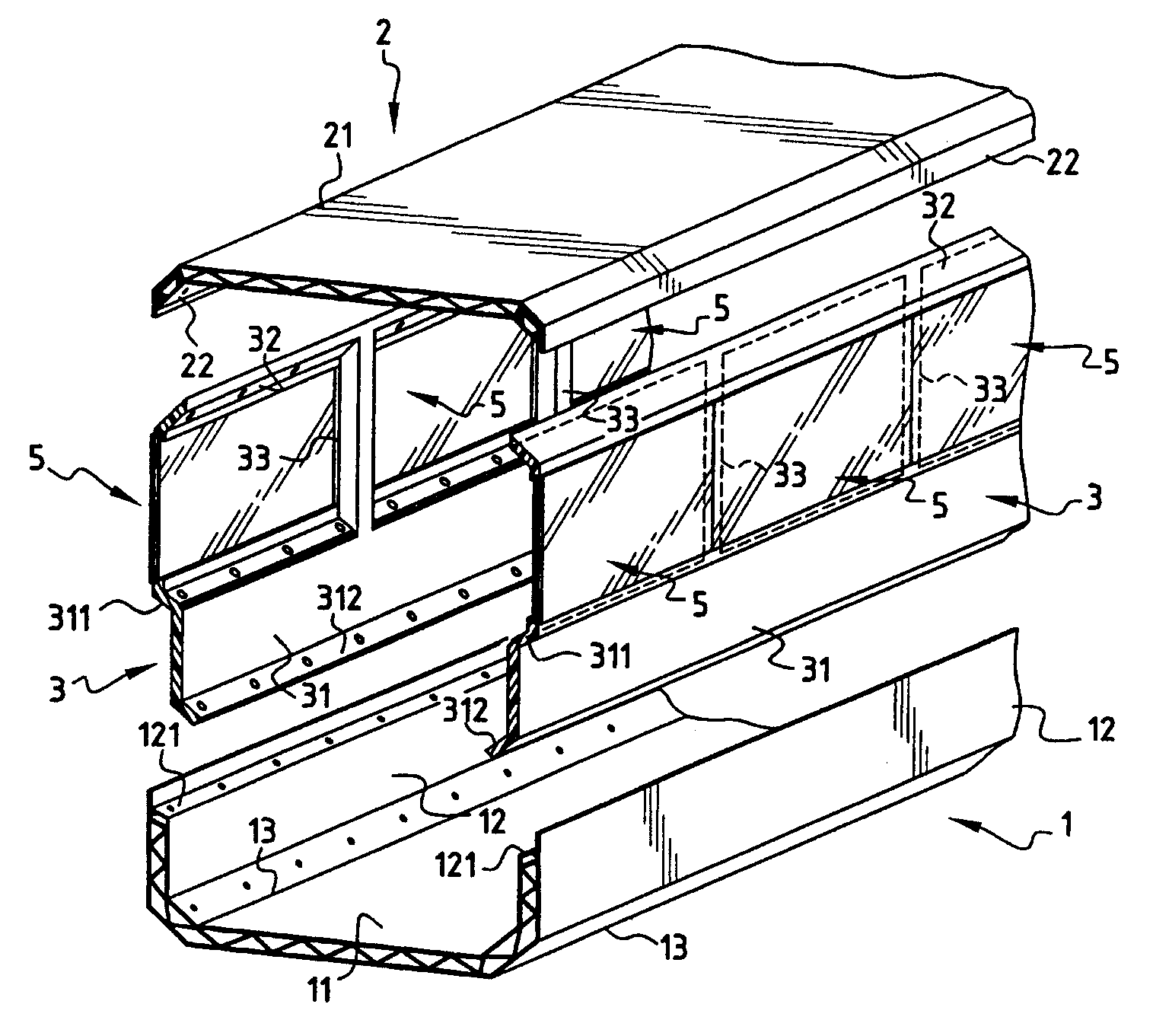

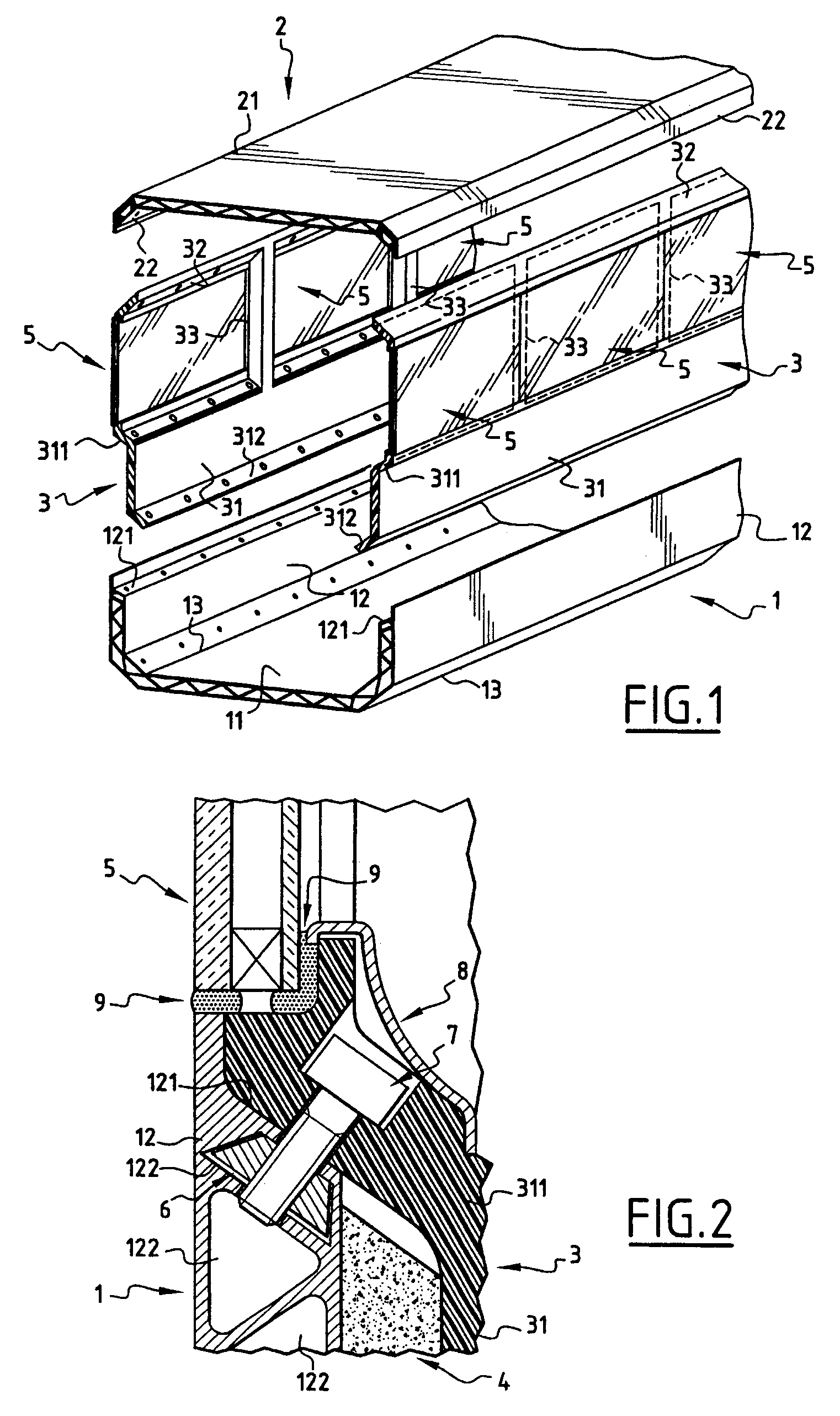

Rail vehicle body

In order to increase the robustness and reliability of the vehicle, reduce the time taken to manufacture it, to enable certain stages of such manufacture to be performed by robots, and to be able easily to adapt the appearance of the vehicle on demand, the body is of hybrid structure comprising an aluminum or aluminum alloy "frame assembly", an aluminum or aluminum alloy "roof assembly", and two "fitted-out face assemblies" of composite material each fixed both to the frame assembly and to the roof assembly. The invention is particularly suitable for manufacturing cars for trains.

Owner:ALSTOM TRANSPORT TECH SAS

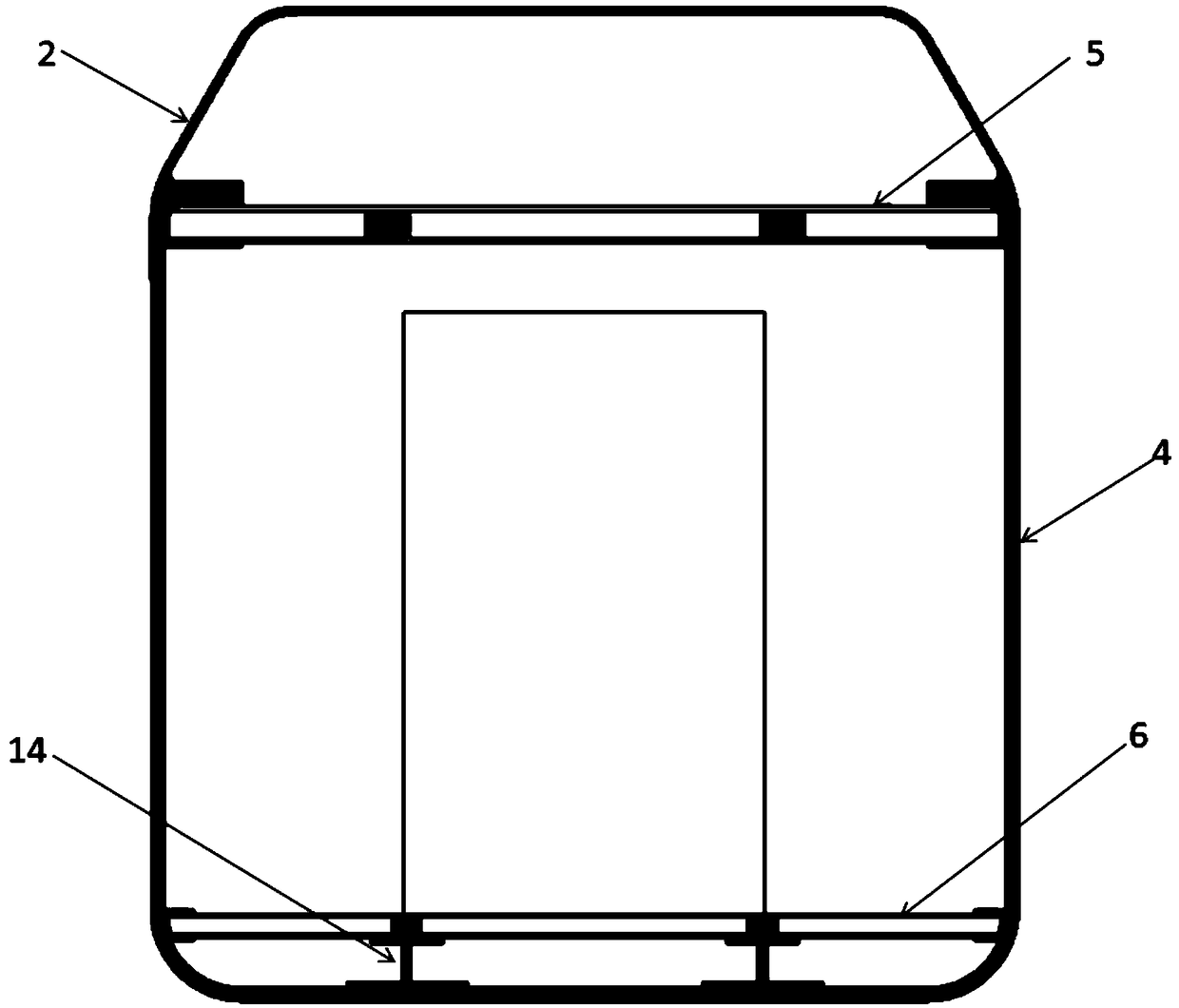

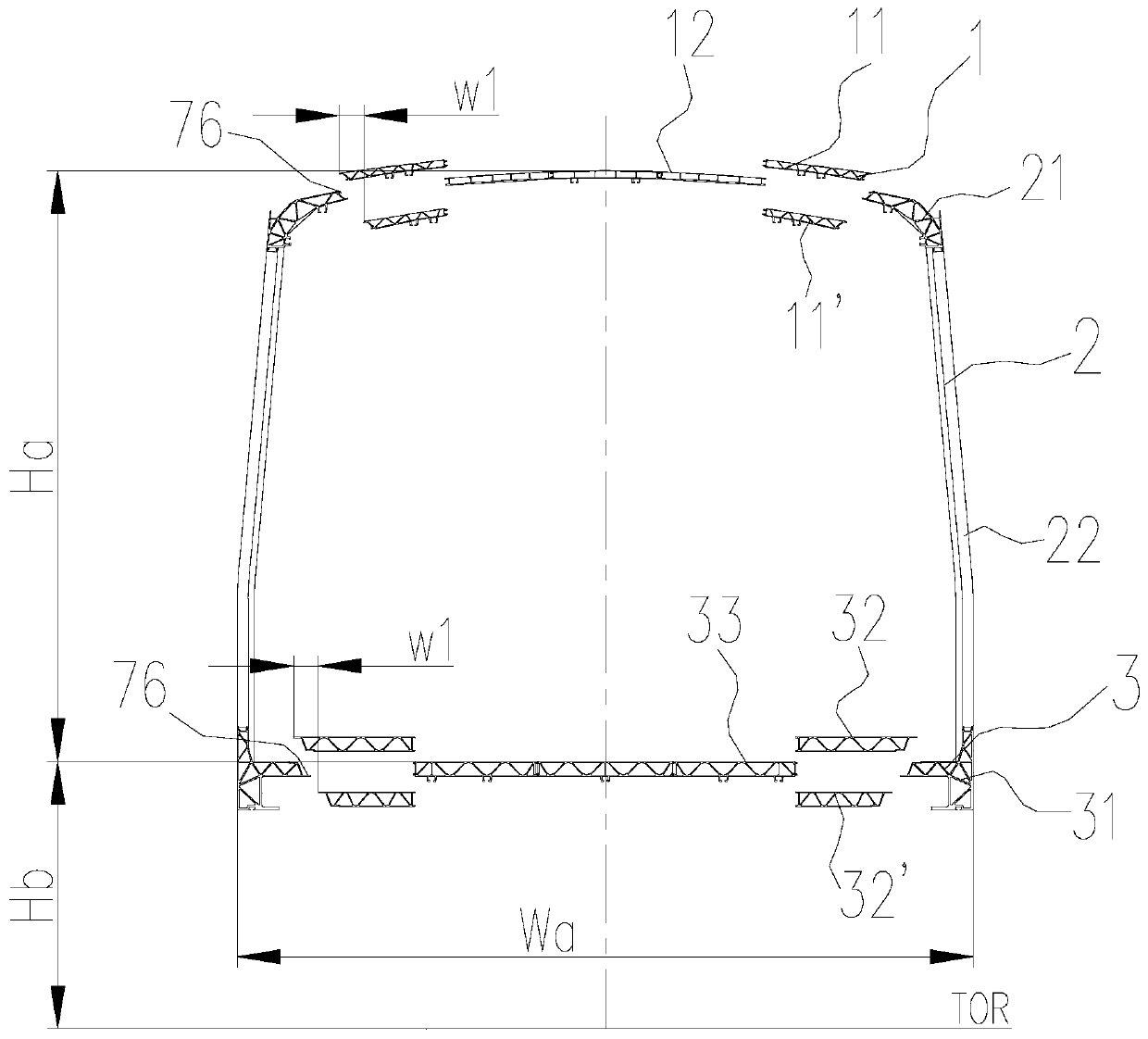

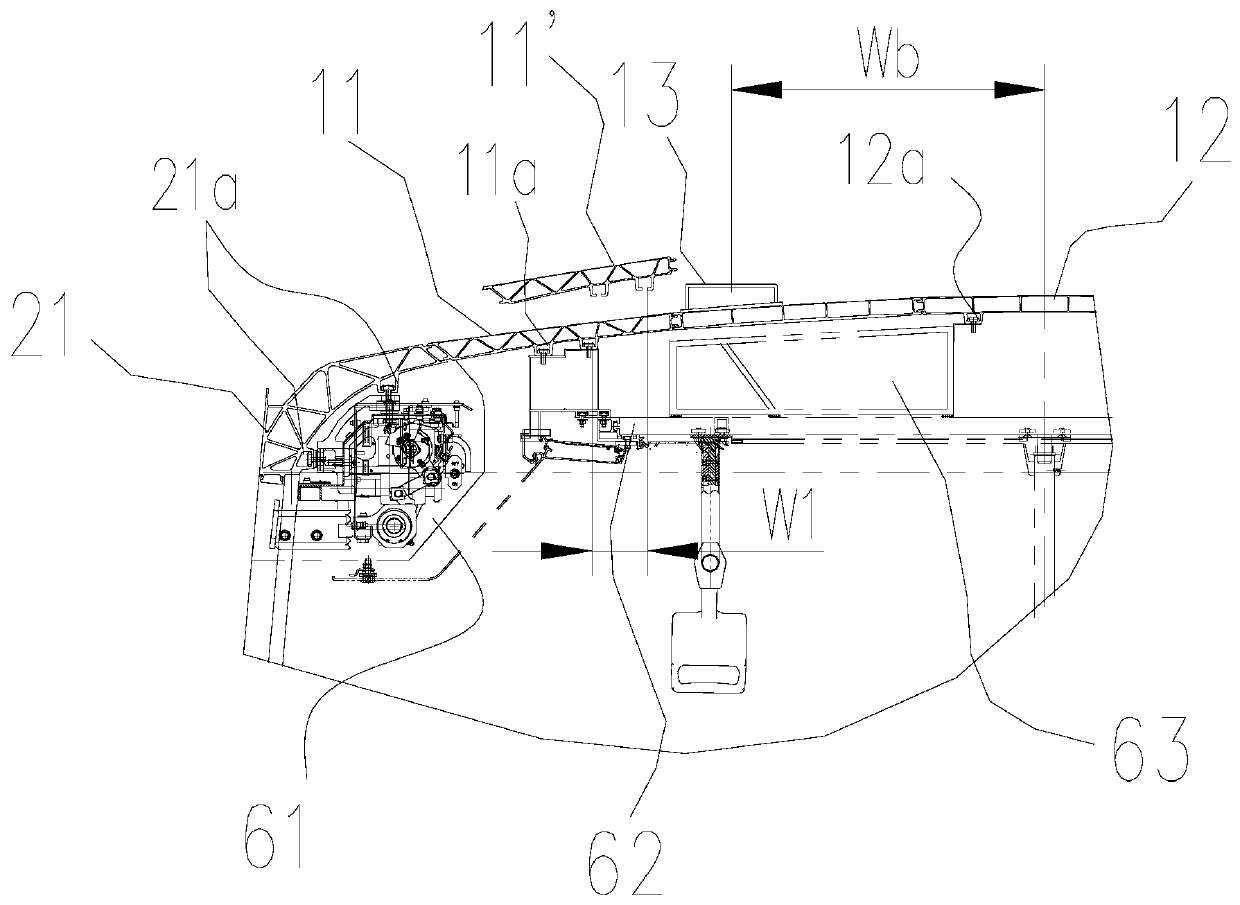

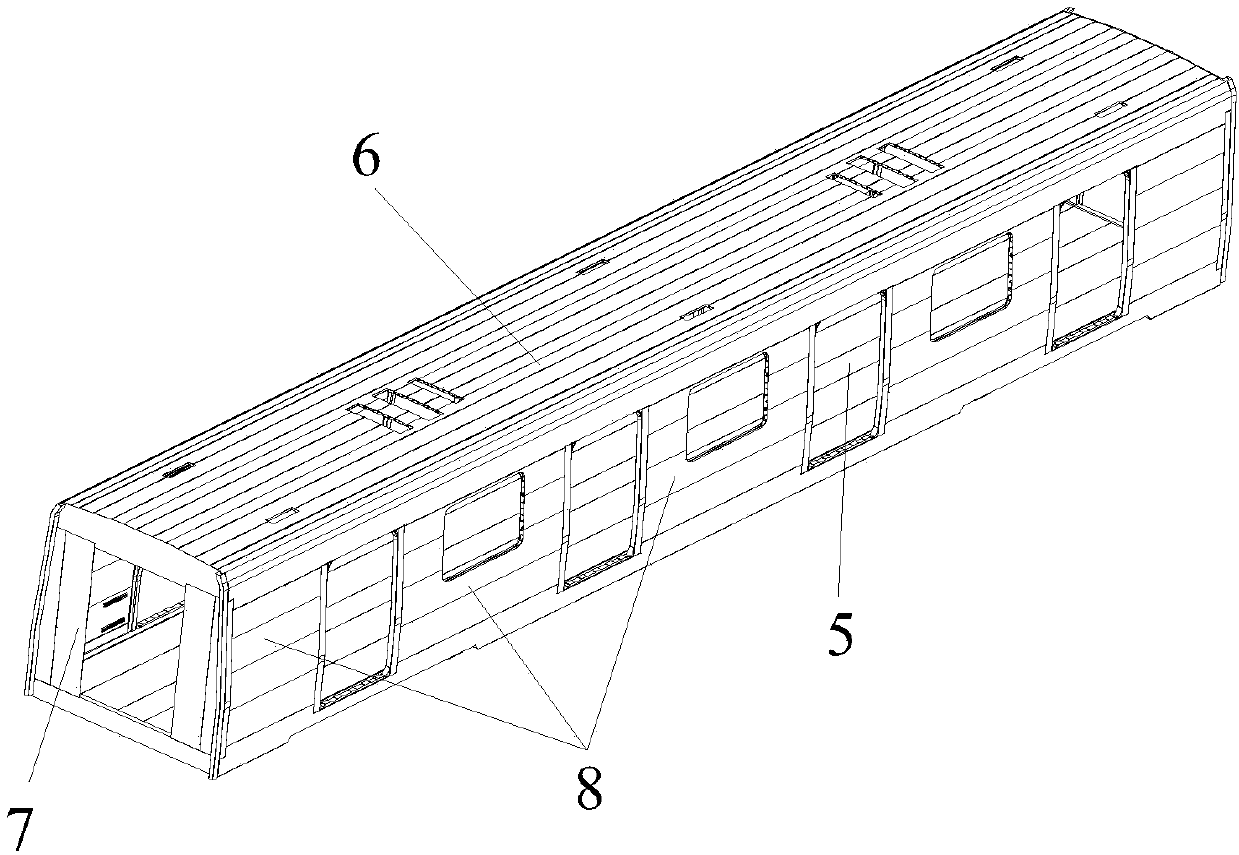

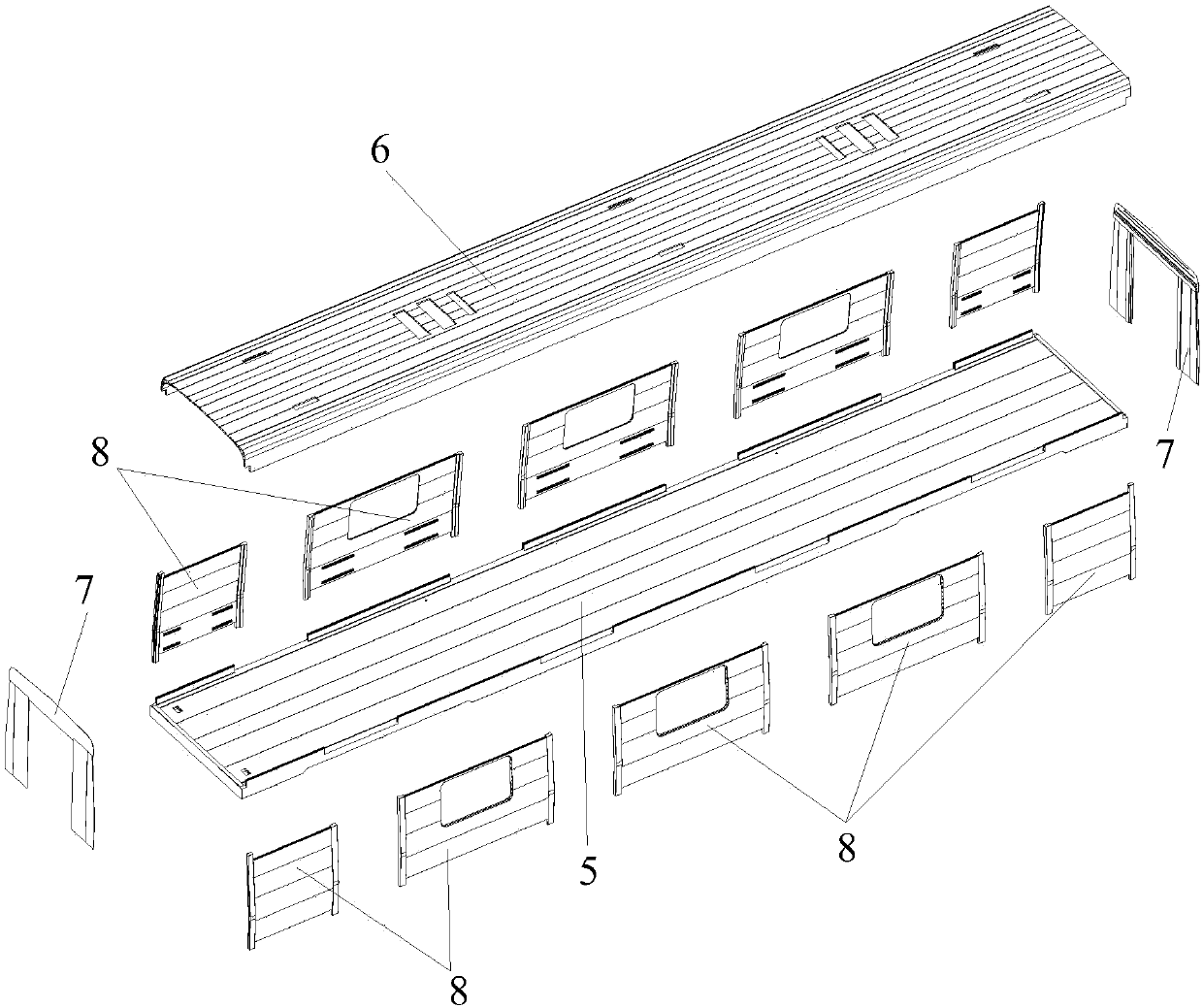

Modularized railway vehicle body

ActiveCN111232002AAchieve sharingAchieve high demandsRailway roofsRailway transportLap jointWall plate

The invention discloses a modular railway vehicle body. The vehicle body comprises a vehicle roof, side walls, a bottom frame, end walls and a cab framework. The roof adopts a full-length arc roof structure; the side wall is of an integral structure or a split structure, and the side wall is mainly composed of a side wall top profile and a plurality of side wall units. Each side wall unit is formed by assembling and welding a plurality of parallel door stand columns and side wall plate sectional materials, and the extending directions of the door stand columns and the side wall plate sectionalmaterials are perpendicular to the side wall top sectional materials. The bottom frame is mainly composed of bottom frame edge beams, floor middle profiles, sleeper beams, traction beams and anti-side-rolling installation bases. The roof and the side walls, the underframe edge beams and the floor edge section bars, and the floor edge section bars and the floor middle section bars are connected through lap joints or butt joint joints. According to the vehicle body, through the design of the top layer, the vehicle body structure and the section bar section are optimized, and the universality and the sharing rate are improved.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

Insulated cargo containers

The present invention relates to an insulated cargo container that may have, in combination, an interior panel covering a layer of thermal insulation that has an air-impermeable layer thereon. The thermal insulation is attached to the exterior panel of the container, which may have structural supports on its interior surface. In one embodiment, the insulated cargo container is an insulated railroad boxcar.

Owner:MARTIN MARIETTA MATERIALS

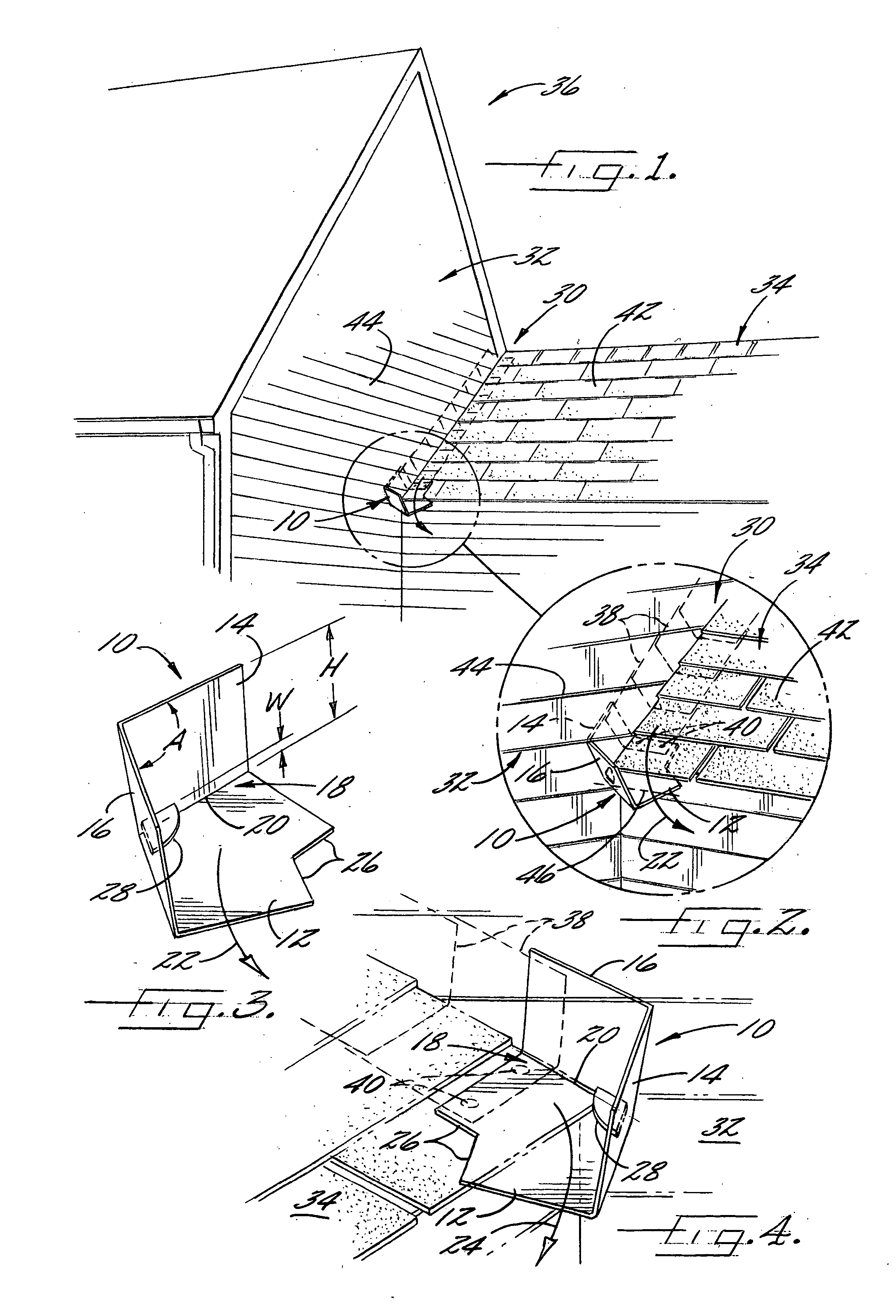

Pre-assembled hip, ridge or rake shingle

InactiveUS8453408B2Facilitate stacking of the shinglesEasy to operateRailway roofsRoof covering using tiles/slatesEngineeringElectrical and Electronics engineering

A hip, ridge or rake shingle is provided, in which a pair of substantially rigid panel portions are connected by a hinge portion, and wherein the shingle is pre-assembled, but can conform to a variety of different angles to accommodate different angular relationships between surfaces of a hip, ridge or rake of a roof.

Owner:CERTAINTEED CORP

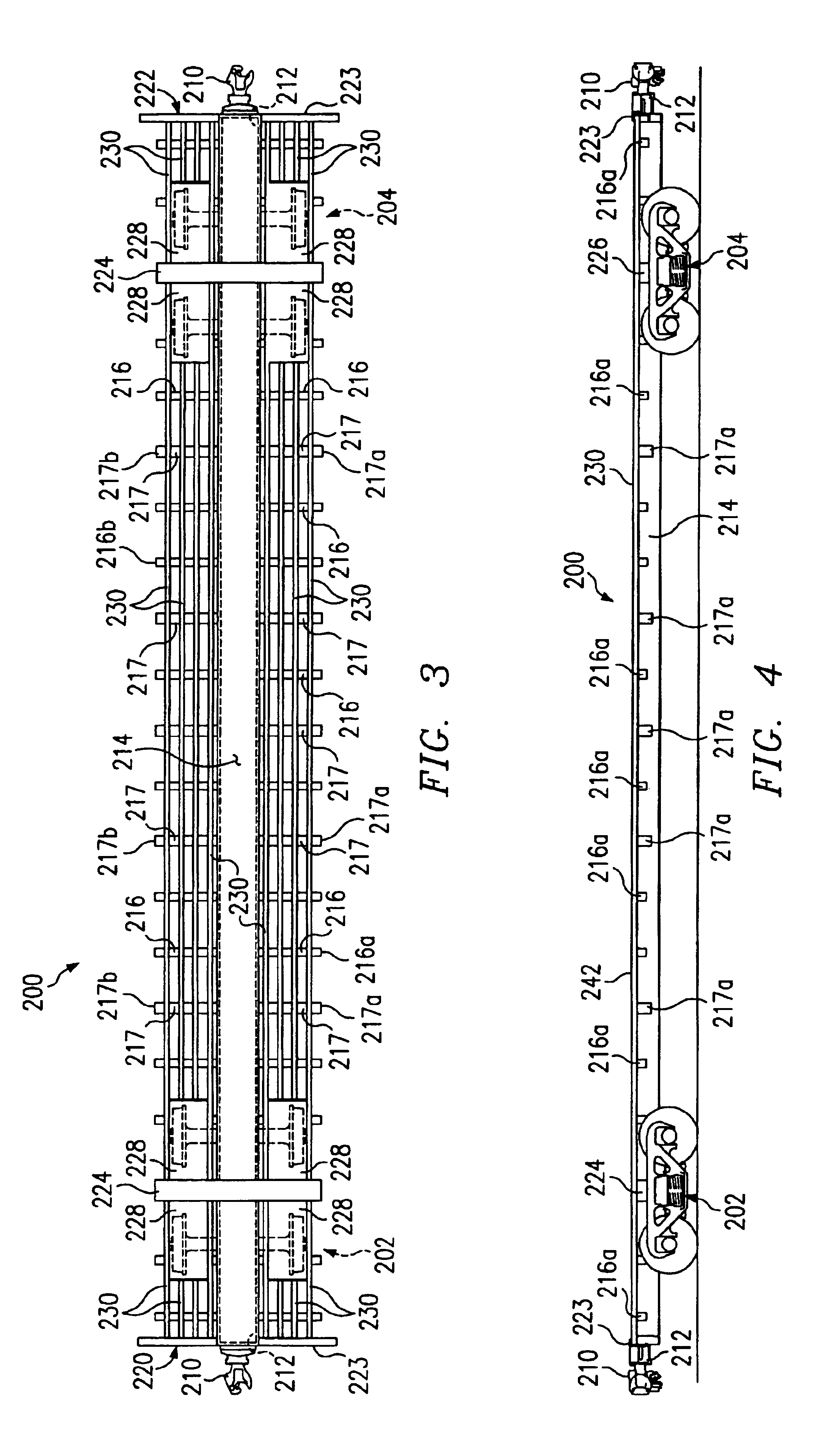

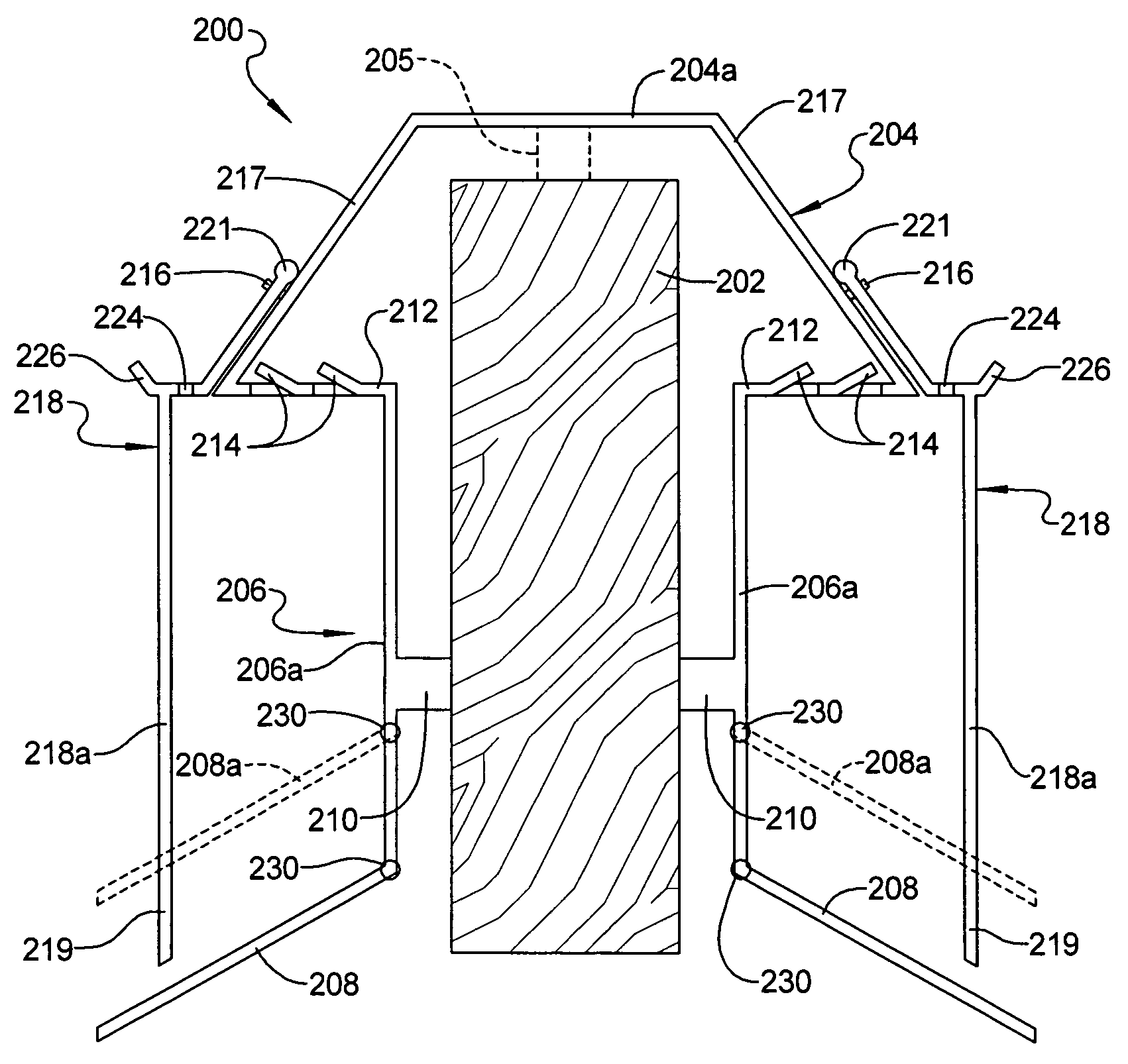

Temperature controlled railway car

A composite box structure assembled on and securely attached to a railway car underframe to form a temperature controlled railway car or on insulated boxcar. The composite box structure defined in part by an exterior metal surface, interior side stakes and at least one layer of fiber reinforced plastic attached to the side stakes. Foam insulation may be disposed between the side stakes, the exterior metal surface and the at least one layer of fiber reinforced plastic. The foam insulation provides improved resistance to heat transfer between the interior and the exterior of the composite box structure. An airflow management system may be incorporated into the composite box structure.

Owner:TRINITY IND INC

Ridge vent for tile roofs

A ridge vent adapted specifically for use with tile roofs having a nailer board installed at a ridge of a roof. The ridge vent includes a main body portion having a pair of eaves and a neck portion. The neck portion includes a plurality of projections on opposing inner walls thereof to maintain a minimum predetermined spacing between the inner walls and the nailer board, to thereby create airflow paths around opposing sides of the nailer board. A pair of weather blocking panels are secured to the nailer boards to help block rain, snow, etc. from entering though openings in the eaves. Each weather blocking panel includes a laterally extending portion with a plurality of slots and an upwardly extending edge portion. The upwardly extending edge portion creates a venturi effect over the slots to help draw air out therethrough when wind is blowing over the upwardly extending edge portions. The weather blocking panels may be formed with finger-like projections or arcuate shaped cutouts, depending on the specific contour of the roof tiles used on the roof to which the ridge vent is attached.

Owner:DIXON DAVID J

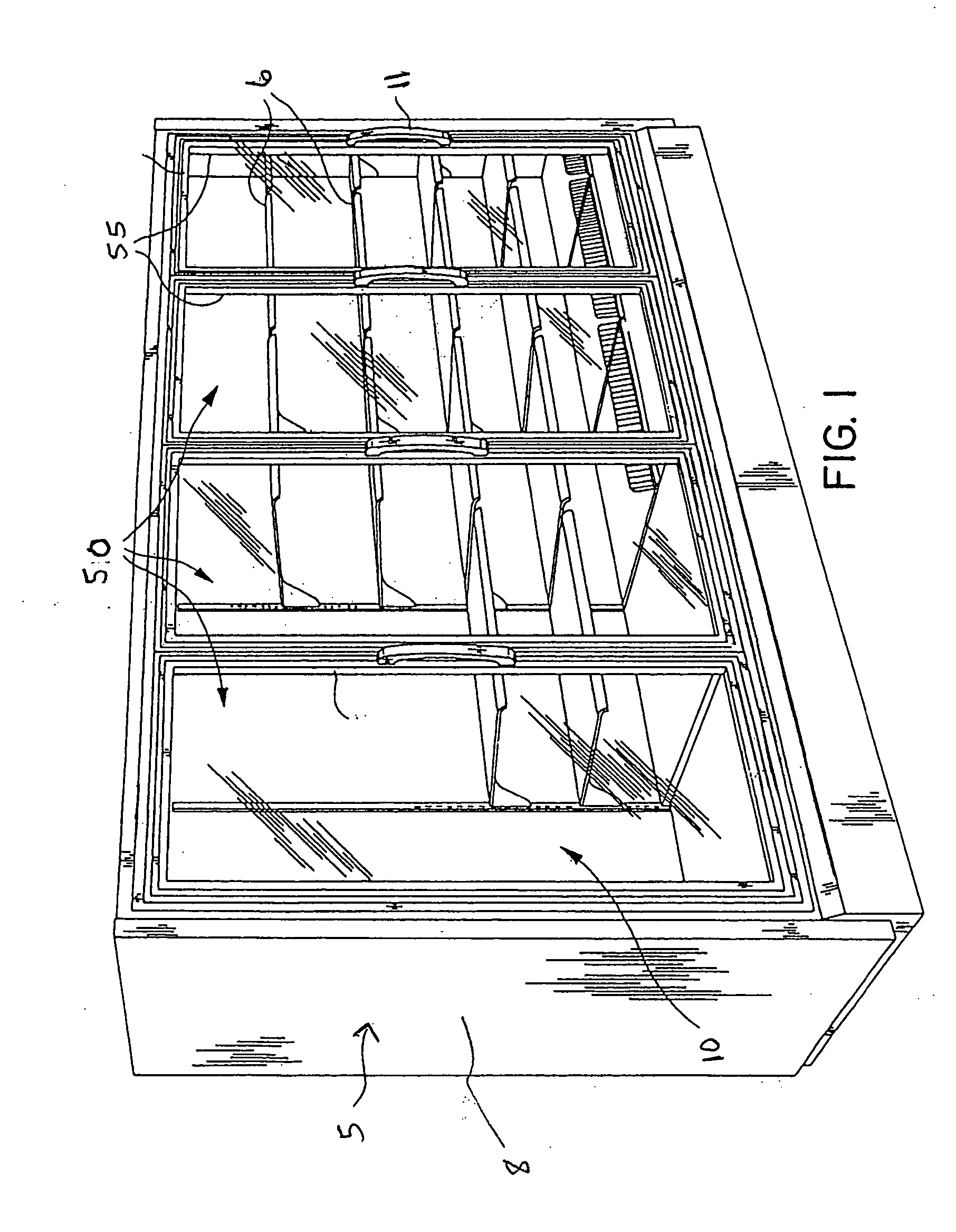

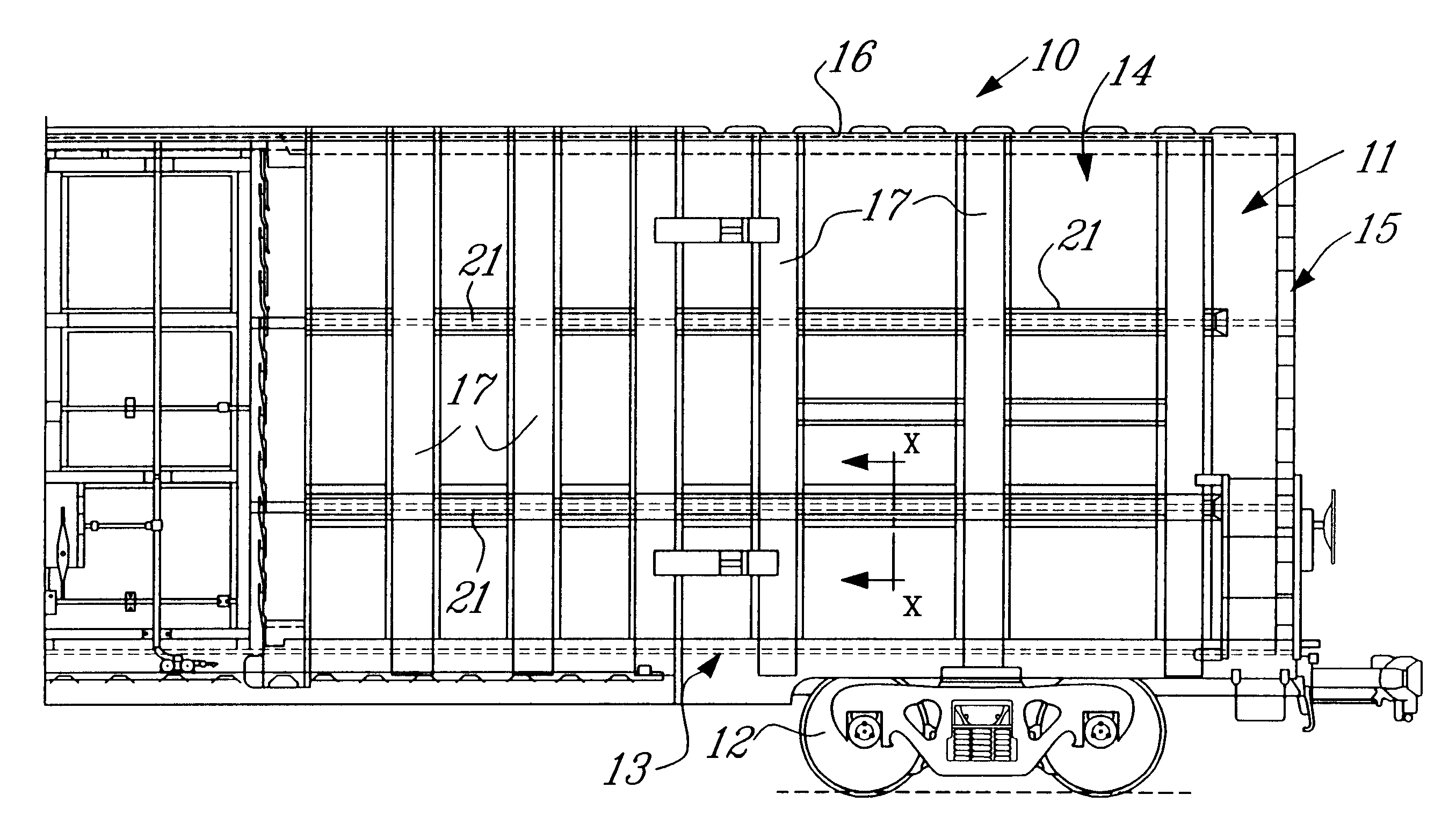

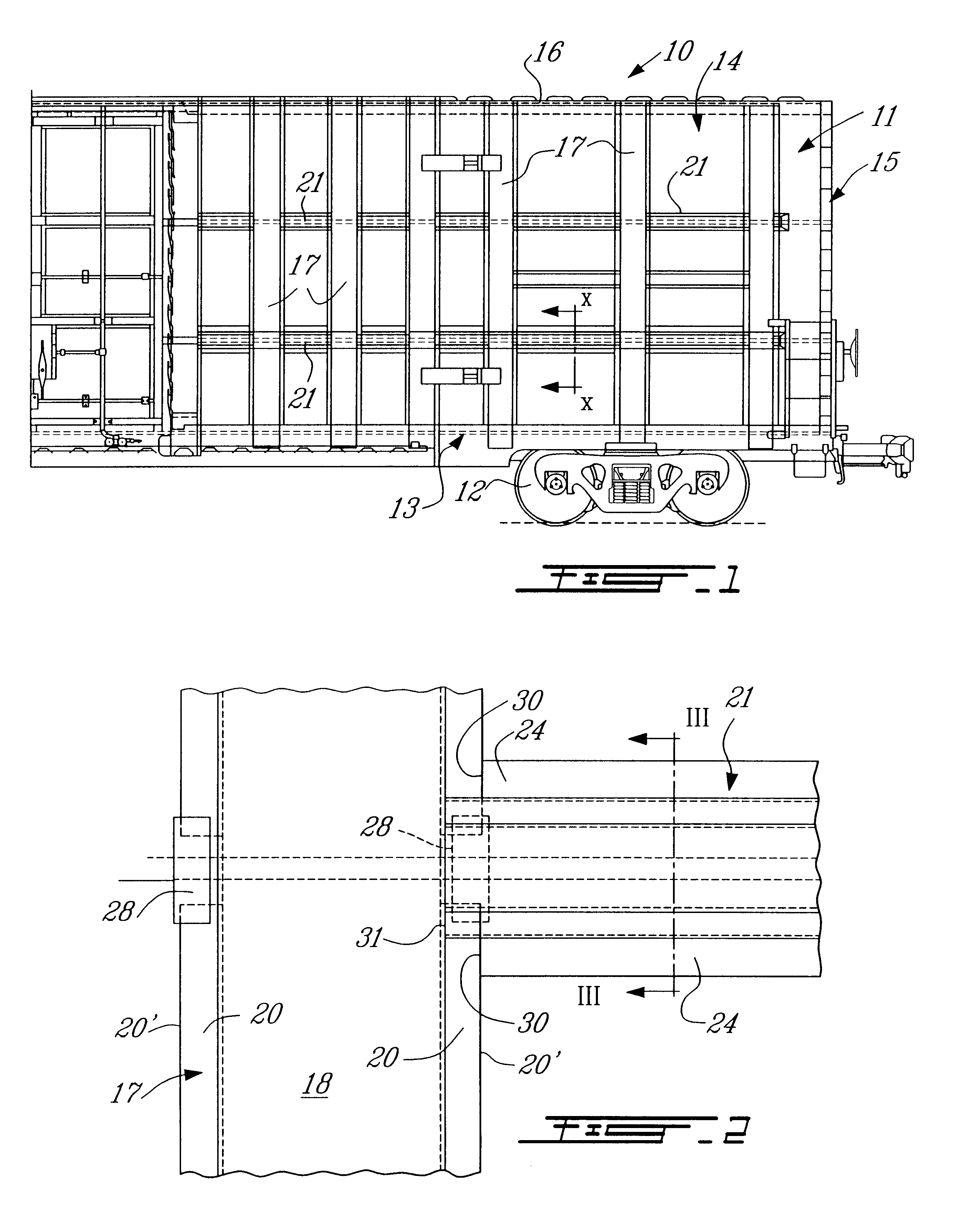

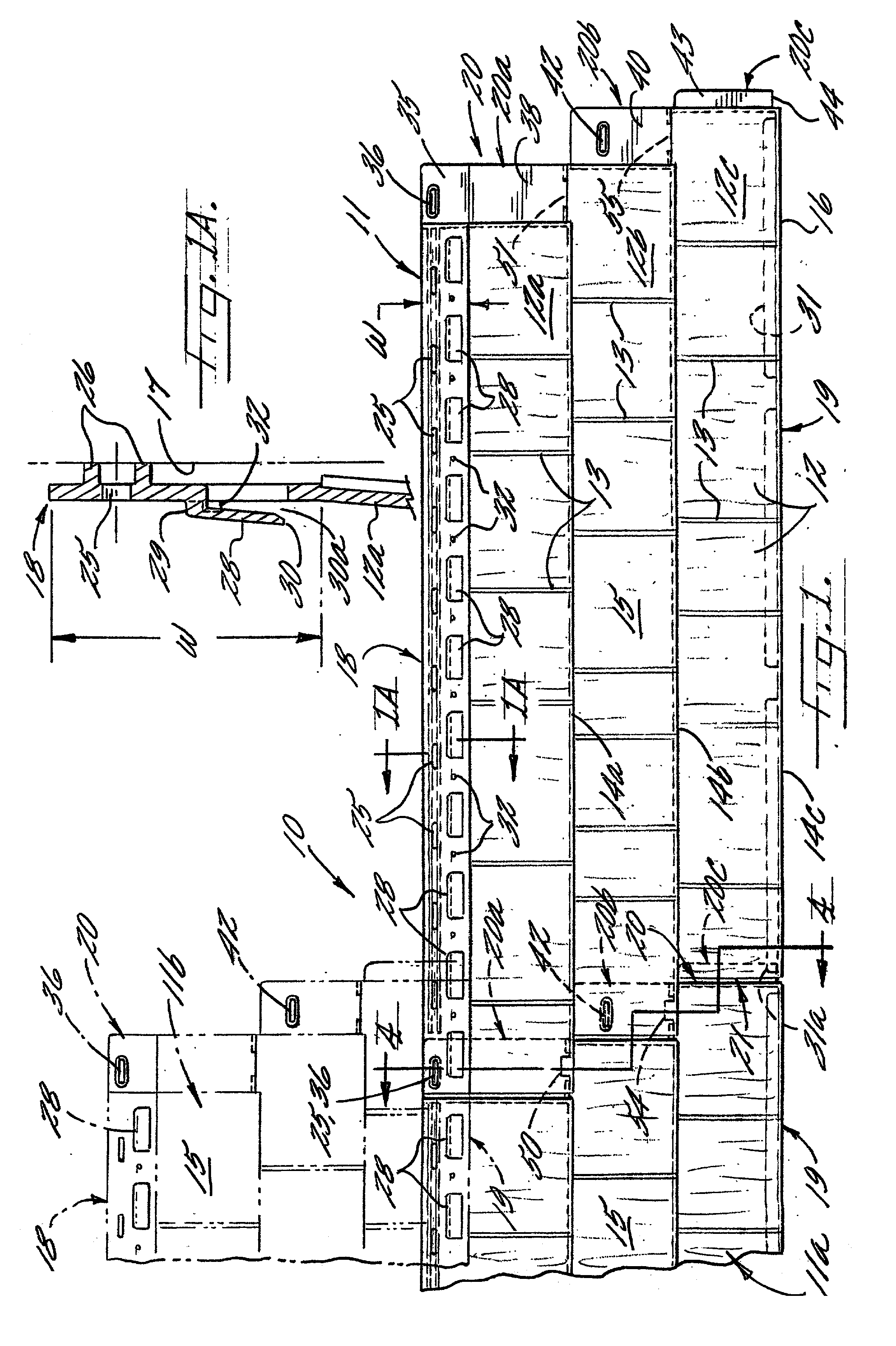

Railway box car structure

InactiveUS6422156B1Improved longitudinal side wall structureSimple designRailway roofsTank wagonsAirplaneFlange

An improved railway car body structure is described. One of the features of the box car is that the longitudinal side walls are formed by a plurality of spaced apart vertical side posts which are hat-shaped in cross-section and define a bottom wall portion, opposed side walls and opposed end flanges extending in a common plane. Horizontal structural stiffeners are secured between the vertical side posts. The stiffeners define a recessed wall portion aligned with a recessed formation formed in the opposed end flanges of the vertical side posts. Ferrous sheet members are secured to the side wall and also to the end frames by welds disposed in the recess wall portion of the stiffeners and recessed formation of the vertical posts to form flush, unobstructed, inner side and end walls of the railway car. A new roof structure is also described and incorporates improved skylight designs.

Owner:IEC HOLDEN INC

Decorative wall covering with upward movement panel interlock system

InactiveUS20040159062A1Easy and reliable panel installationEasy to engageRailway roofsCeilingsSupport surfaceFlange

A wall covering comprising a plurality of plastic panels each having a body portion formed with rows of simulated building elements. The panels are mounted on a support surface with a lower marginal edge region of one panel overlying an upper marginal edge region of a previously mounted panel in a lower course and with a side marginal edge region of one panel overlying the side marginal edge region of a previously mounted adjacent panel in the same course. The marginal edge regions are provided with interlocks which engage and secure both the overlapping upper and lower marginal edge regions and the overlapping side marginal edge regions as an incident to upward movement of the panel relative to the underlying previously mounted panels. In the illustrated embodiment, the overlying lower marginal edge region and side marginal edge region of each panel are formed with upwardly directed locking flanges which are respectively engageable with downwardly directed flanges on the upper marginal edge region and apertures in the side marginal edge region of the underlying panels.

Owner:NOVIK INC

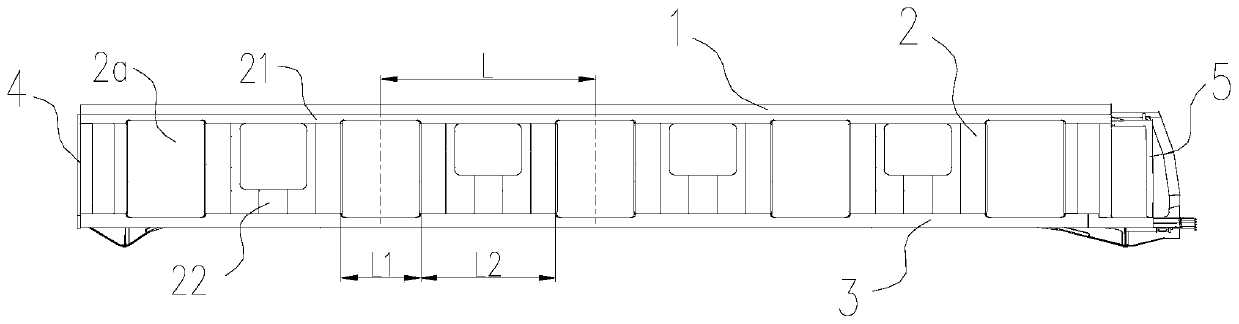

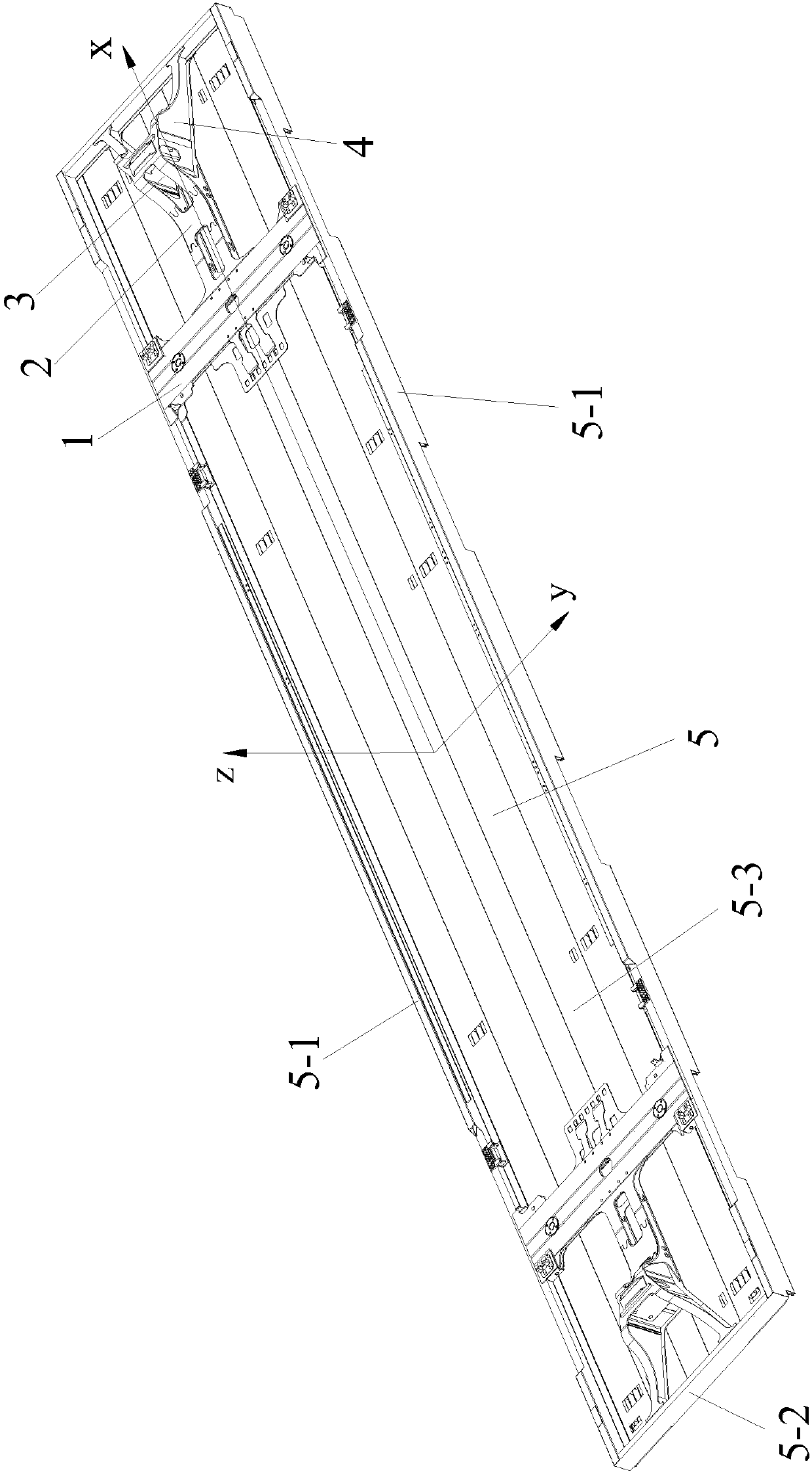

Light-weight metro vehicle body with novel traction sleeper buffer structure

ActiveCN107856688AImprove accessibilityImprove welding qualityRailway roofsUnderframesEngineeringUltimate tensile strength

The invention provides a light-weight metro vehicle body with a novel traction sleeper buffer structure and belongs to the field of full-aluminum product metro vehicle body devices. The light-weight metro vehicle body comprises a chassis, a vehicle roof, two end walls, multiple side wall boards and a full-aluminum product traction sleeper buffer device. The chassis comprises a rectangular floor frame jointly defined by two side beams and two end beams and a floor located in the floor frame. The traction sleeper buffer device comprises a sleeper beam, a traction beam, a draw gear installation seat and two buffer beams. A traction beam lower cover plate and a buffer beam lower cover plate of the full-aluminum product traction sleeper buffer device of the light-weight metro vehicle body are both made of a profile aluminum plate material which is low in density, light in weight and good in bending performance, the draw gear installation seat is made from aluminum plates high in yield stress, other straight plate structures are all made of an aluminum plate material high in yield stress, overall selected materials of the traction sleeper buffer device meet the strength standard, and theprocessing property of welding and manufacturing of the traction sleeper buffer device is the best; and all lightening holes can be simultaneously used as auxiliary holes in the inner cavity weldingoperation process, so that the accessibility and welding quality of inner cavity welding joints are improved.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

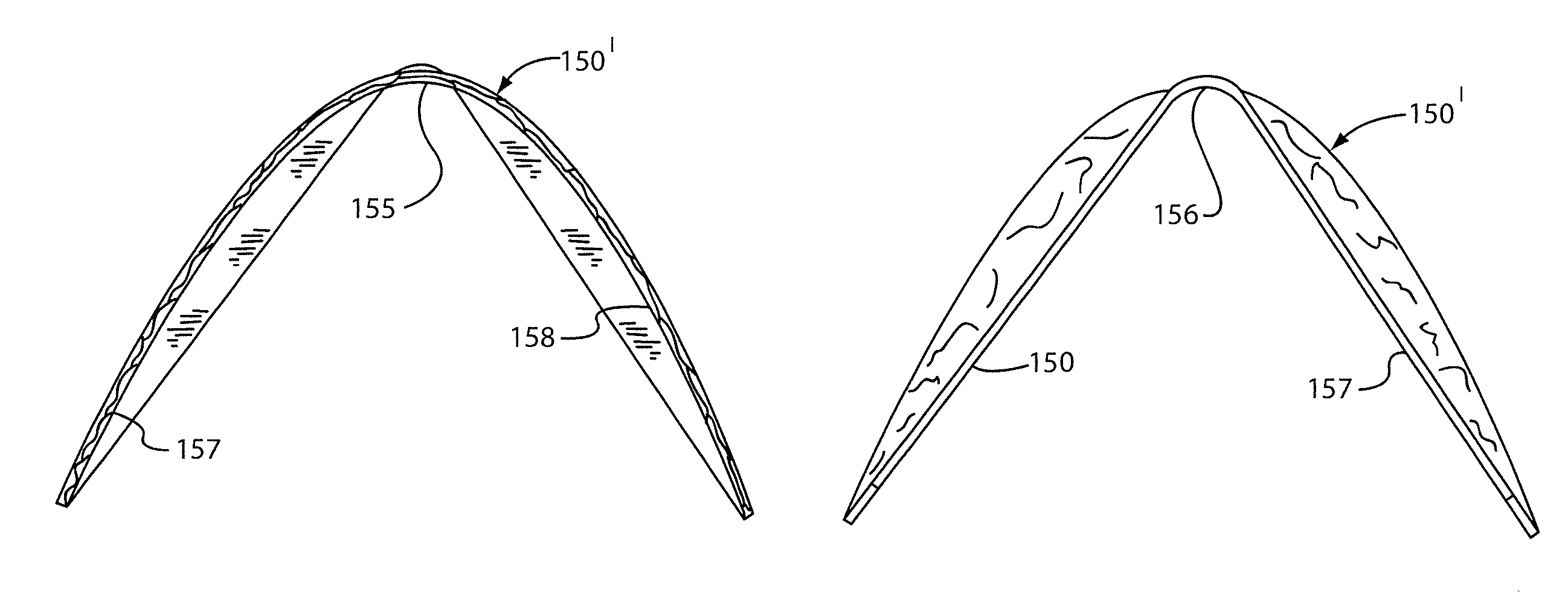

Molded synthetic hip, ridge or rake shingle and process and apparatus for molding same

A molded hip, ridge or rake shingle is provided that is shaped to fit over angled intersecting planar surface of a roof hip, ridge or rake, by making a shingle precursor and draping it in heated condition over a rack having surfaces that have an included angle therebetween to cool and take form, such that portions of the shingle precursor conform to the surfaces of the rack, at a desired predetermined included angle between the shingle precursor portions, to form a hip, ridge or rake shingle with shingle portions having the desired included angle between the shingle portions. The shingle is formed according to the process, and on an apparatus, to produce the shingles that can be applied to a roof, in an array of shingles.

Owner:CERTAINTEED CORP

Kickout flashing and associated assembly and method

A flashing and associated assembly and method for directing water along an interface between a roof and a wall are provided. The flashing, which can be formed as a unitary molded plastic member, has an angled configuration. In particular, a roof portion of the flashing is configured to be disposed on the roof, and first and second flanges extend perpendicularly from the roof portion to define a continuous passage for receiving water. The flanges define an obtuse angle therebetween so that when one flange is disposed against the wall the other flange is configured to direct water flowing along the passage away from the wall. The flashing can be reversible so that the same flashing can be selectively installed at wall-roof interfaces of different configurations.

Owner:ALLEN L ROSS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com