Top slab connecting structure inside railway train roof

A railway passenger car and connection structure technology, applied in the direction of railway roof, material-based railway technology, etc., can solve the problems of reducing passenger comfort, inability to reduce noise and vibration isolation, and large temperature difference in carriages, etc., to achieve strong practicability, Improve the fire prevention ability and the effect of uniform air outlet of the air conditioner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The content of the present invention will be described below in conjunction with the accompanying drawings. The following description is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

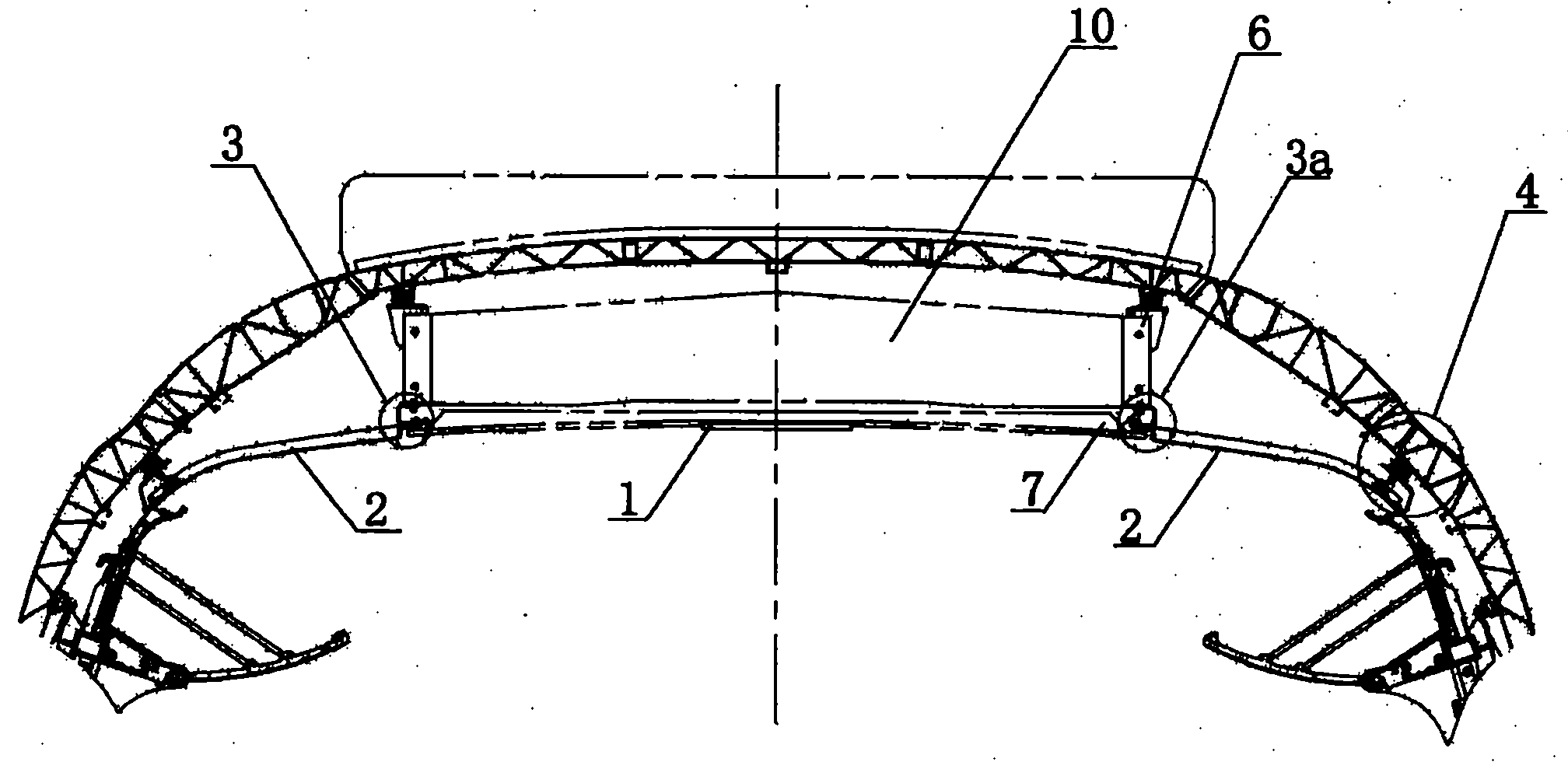

[0017] The section of the curved connection structure of the inner side roof plate of the railway passenger car roof of the present invention is B-shaped. The plate thickness of the side roof is 2.5mm, and the thickness of the connection end with the middle roof is 6mm. The length of the top plate is generally 2015mm.

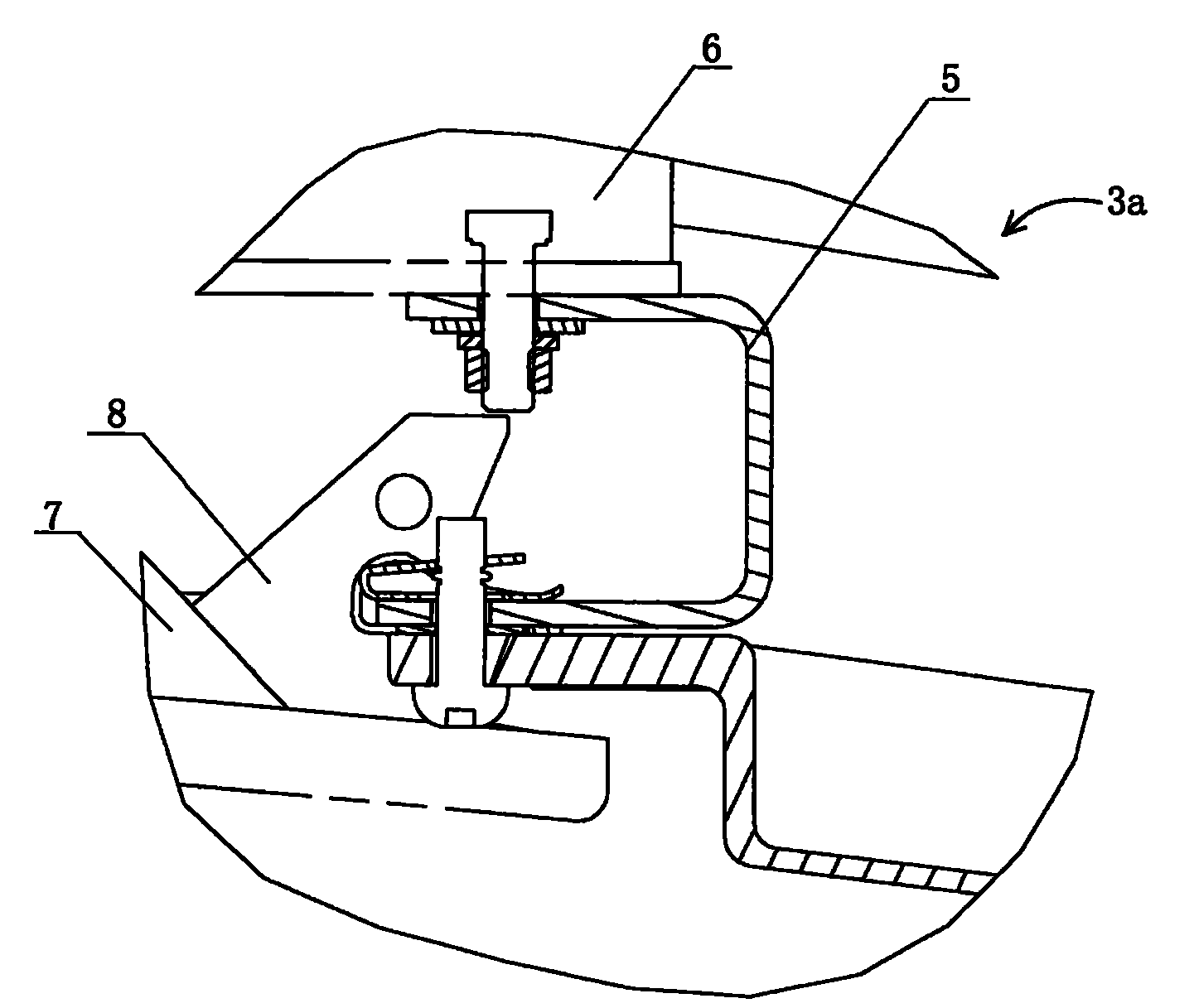

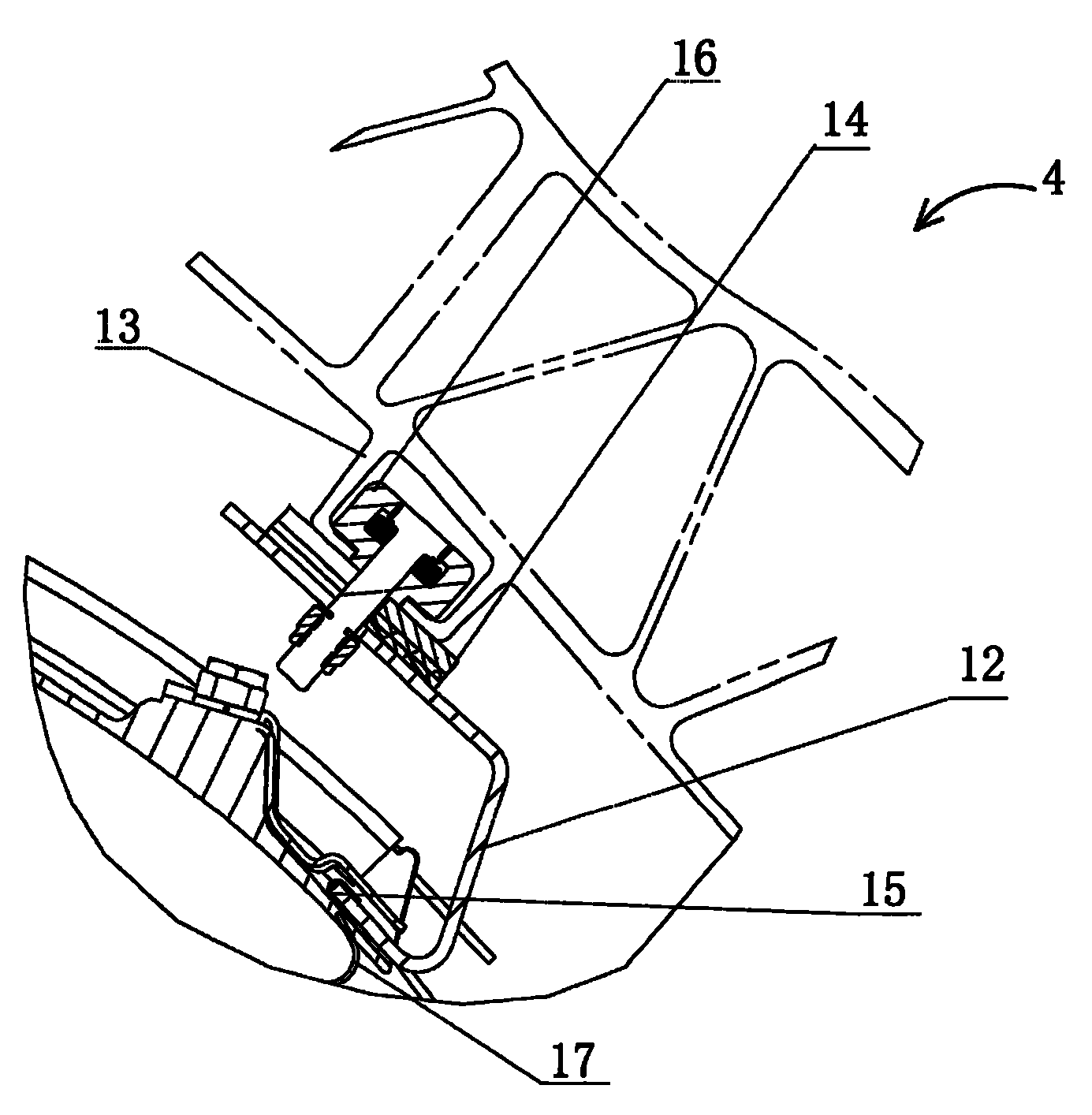

[0018] The roof inner roof connection structure of the railway passenger car of the present invention comprises the connection assembly 3 (or 3a) of the middle roof 1, the side roof 2, the luggage rack rear cover 17, the middle roof and the side roof, the side roof and the car body Connection assembly 4.

[0019] The connection assembly 3 (or 3a) between the middle roof and the side roof includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com