Patents

Literature

415results about How to "Uniform wind" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

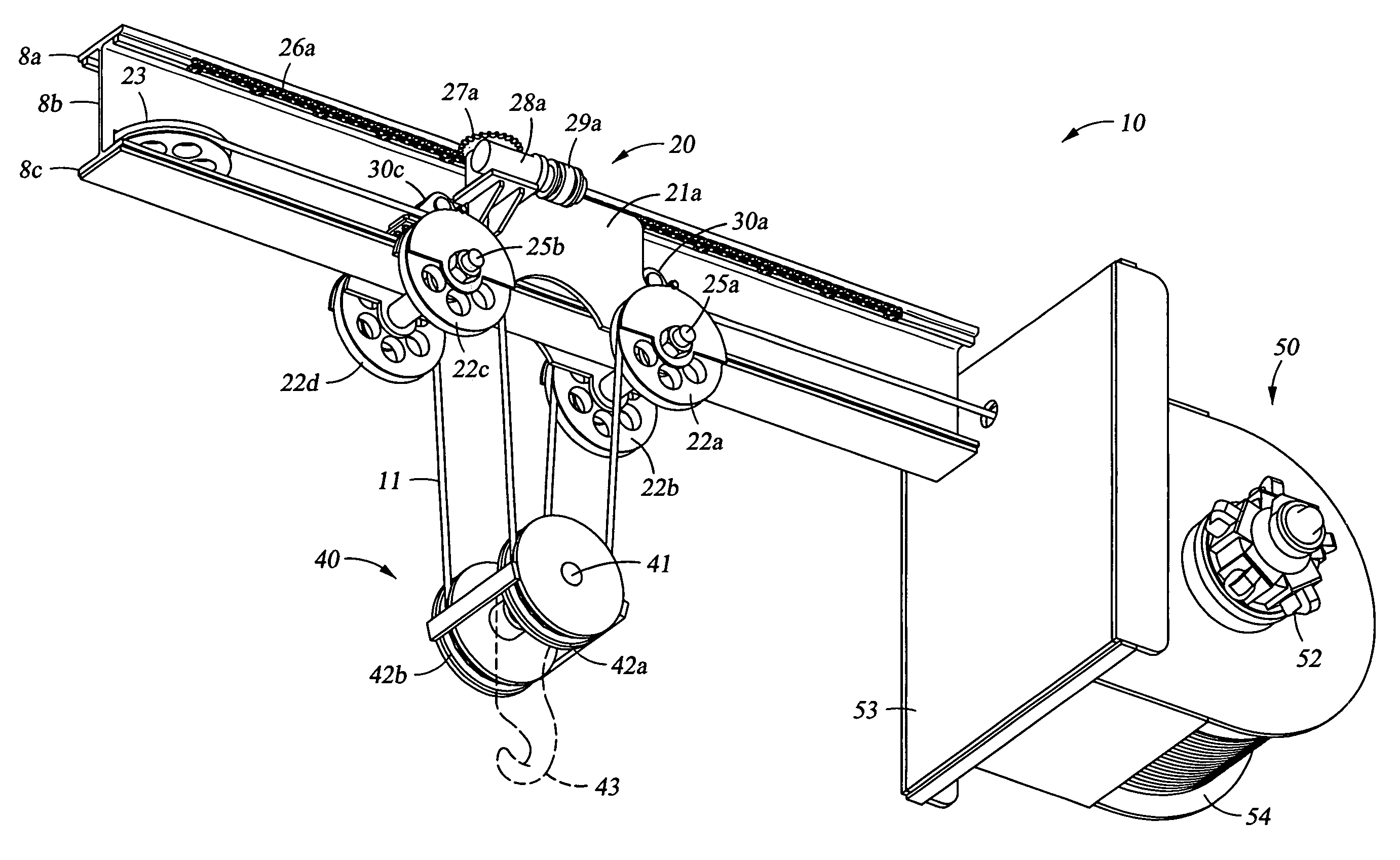

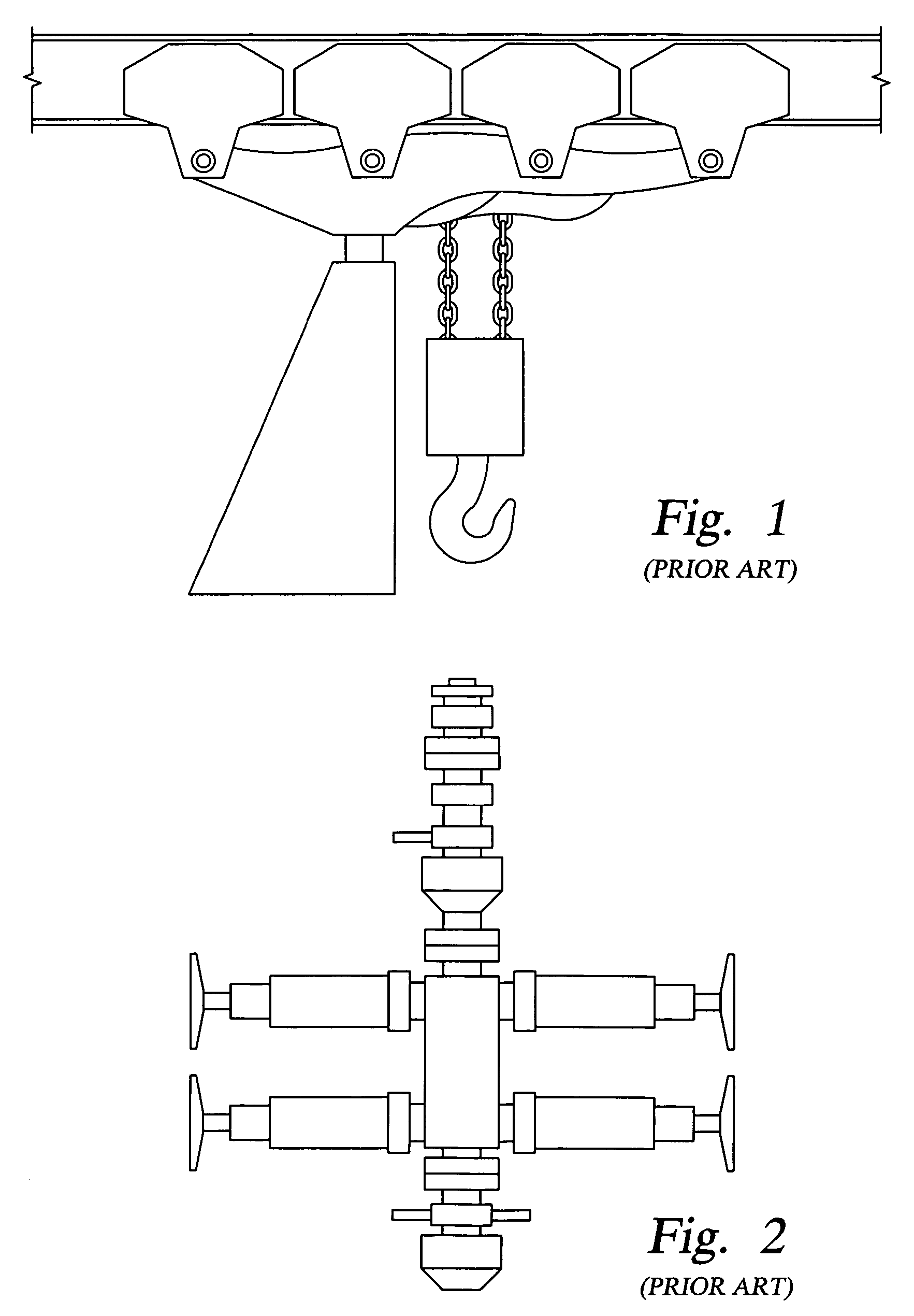

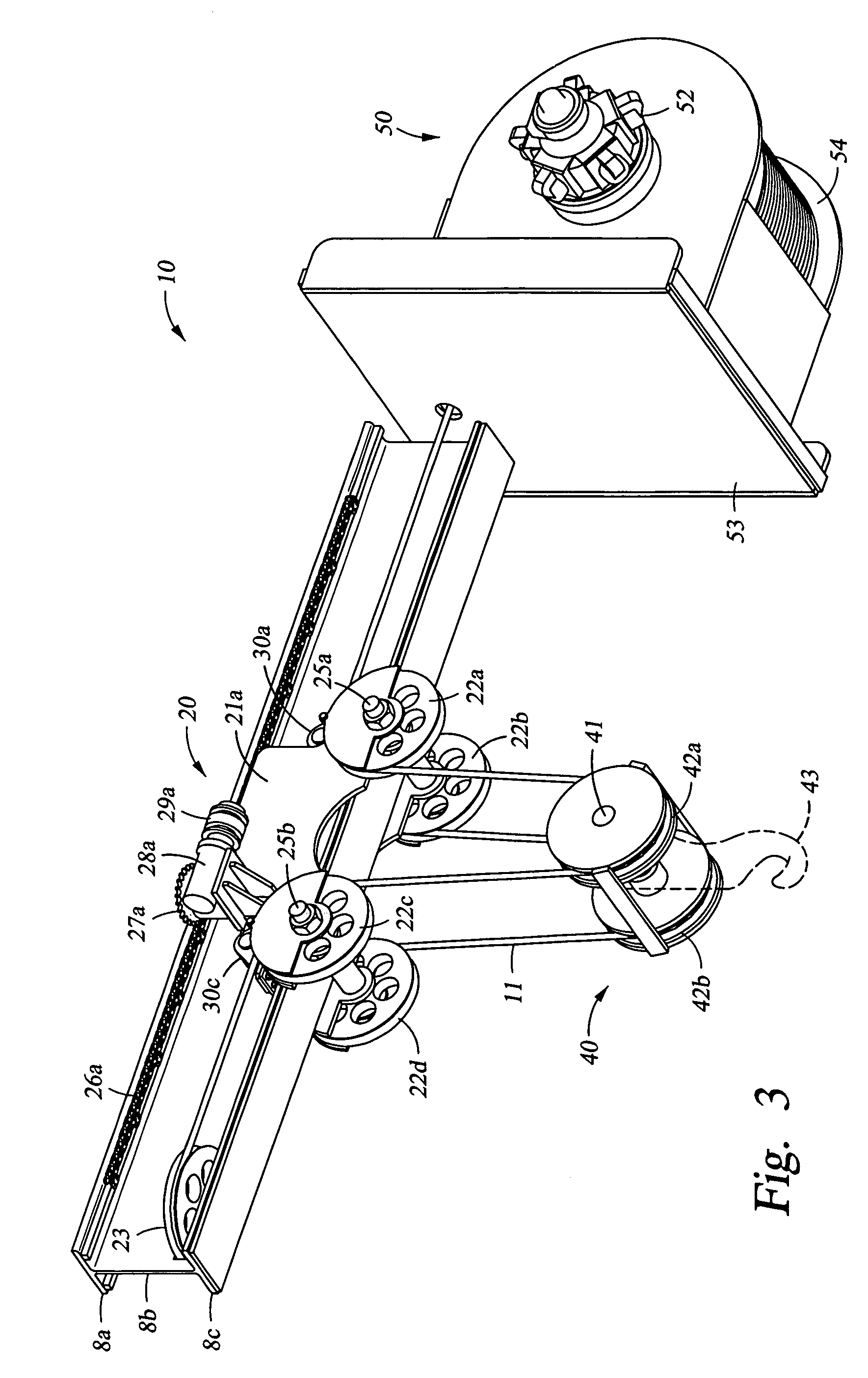

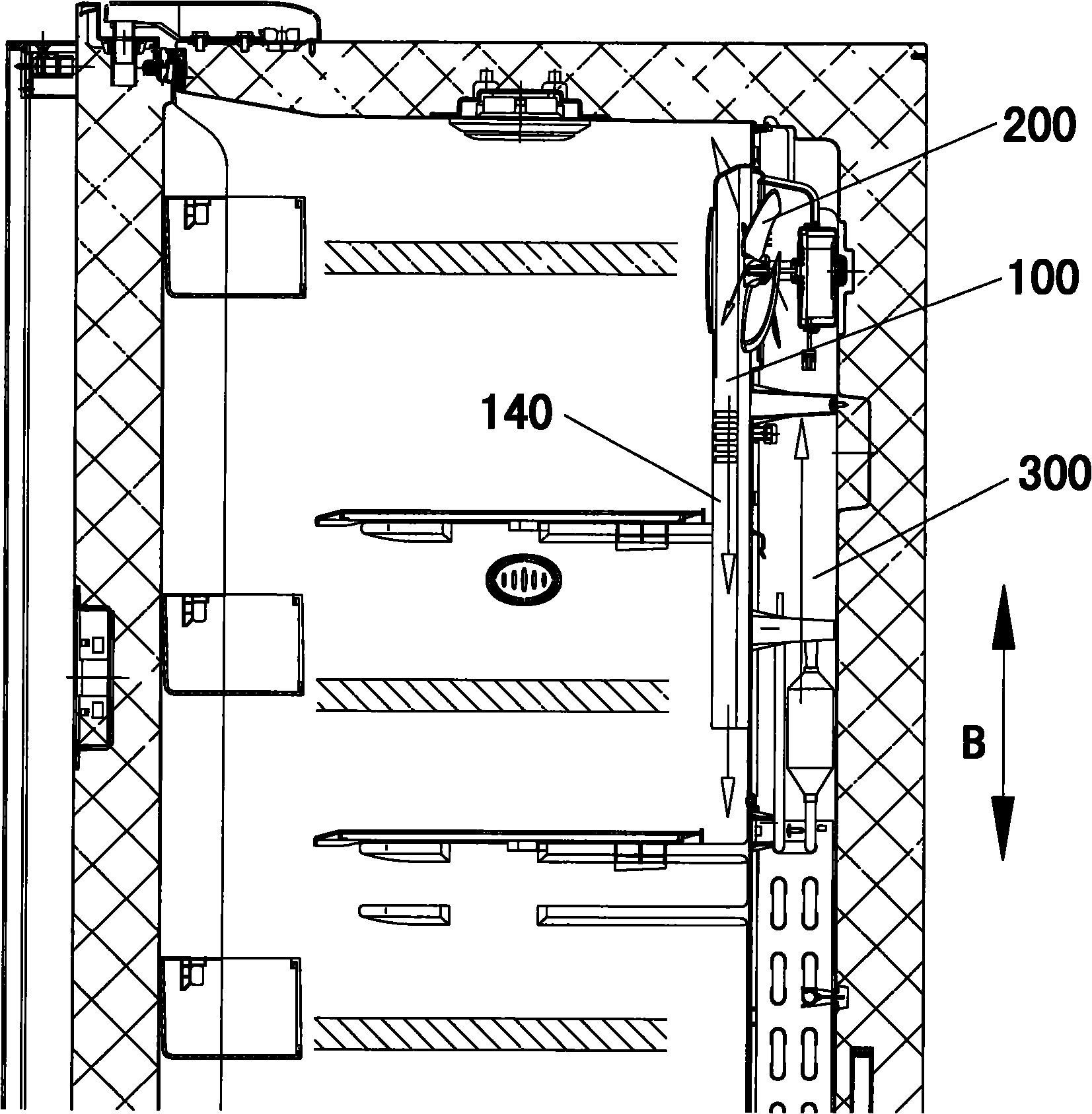

Compact hoist for drilling or workover rig

InactiveUS20060180564A1Expands vertical and horizontal rangeExpanding the range of operation increases usable rig storage spaceTrolley cranesTravelling gearLifting capacityWell drilling

The present invention provides a compact hoist system for use on a drilling or workover rig. The present invention eliminates problems related to chain failures in hoist systems by incorporating wire rope in a vertically and horizontally compacted arrangement to provide maximum vertical lift capacity and improved versatility. Caterpillar bearings, wire rope tension equalizing sheaves and a winch coupled to a axially movable spiral-grooved drum are combined to provide a system that enables cantilever jack-up rigs to handle blow-out preventer stacks of increased height and size.

Owner:KEPPEL JAMES R

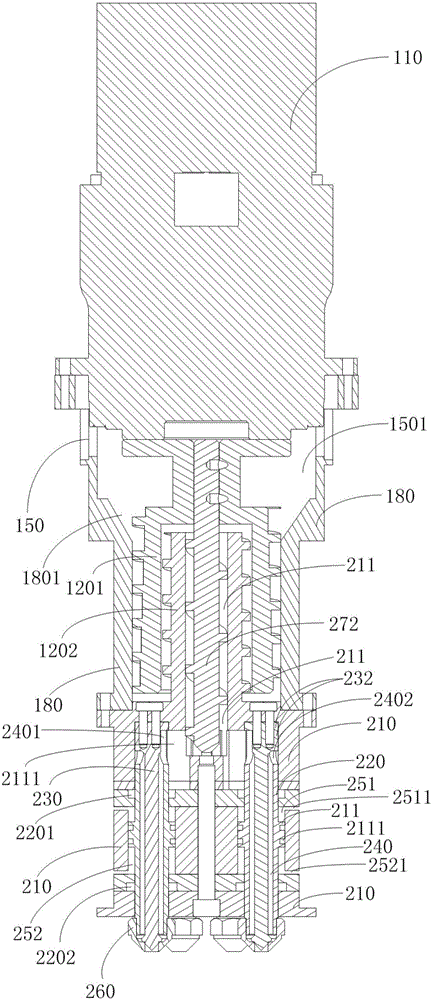

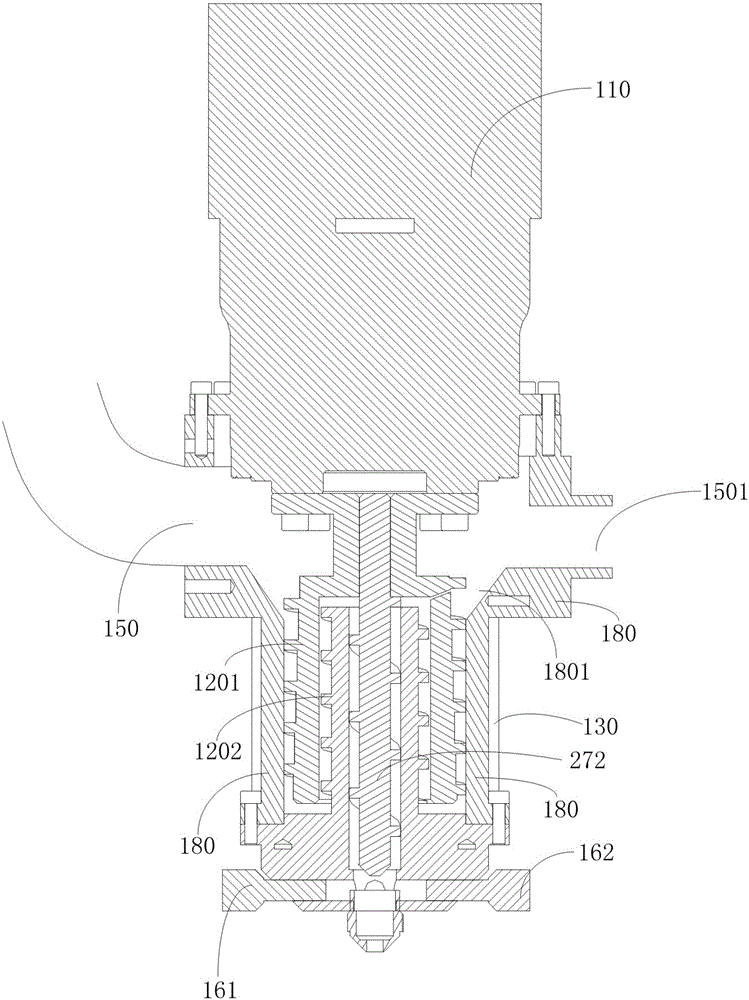

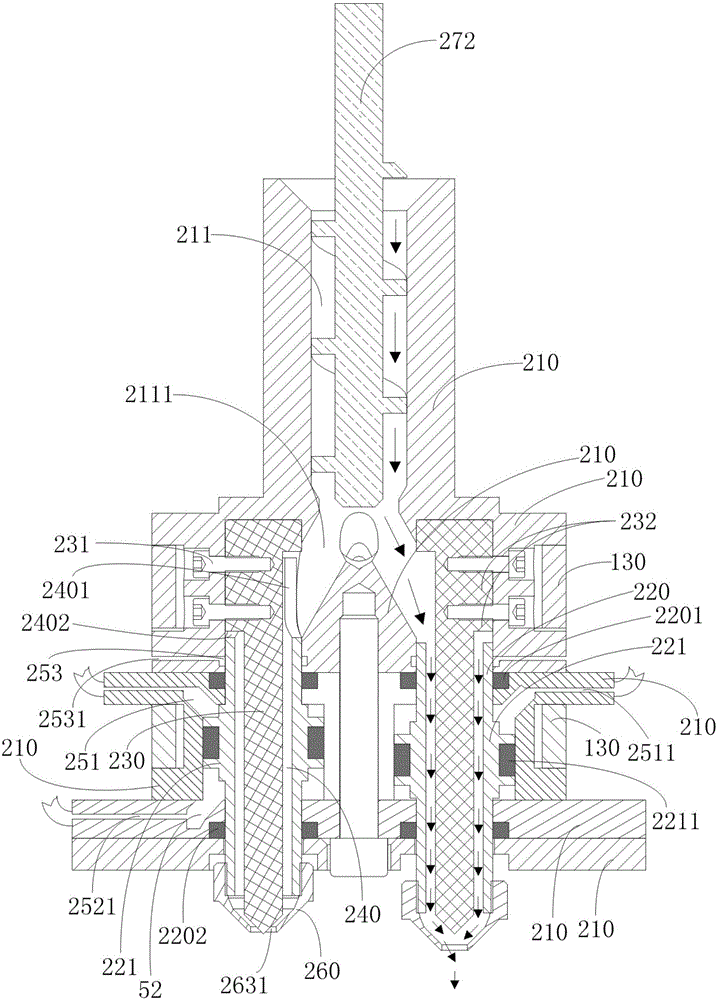

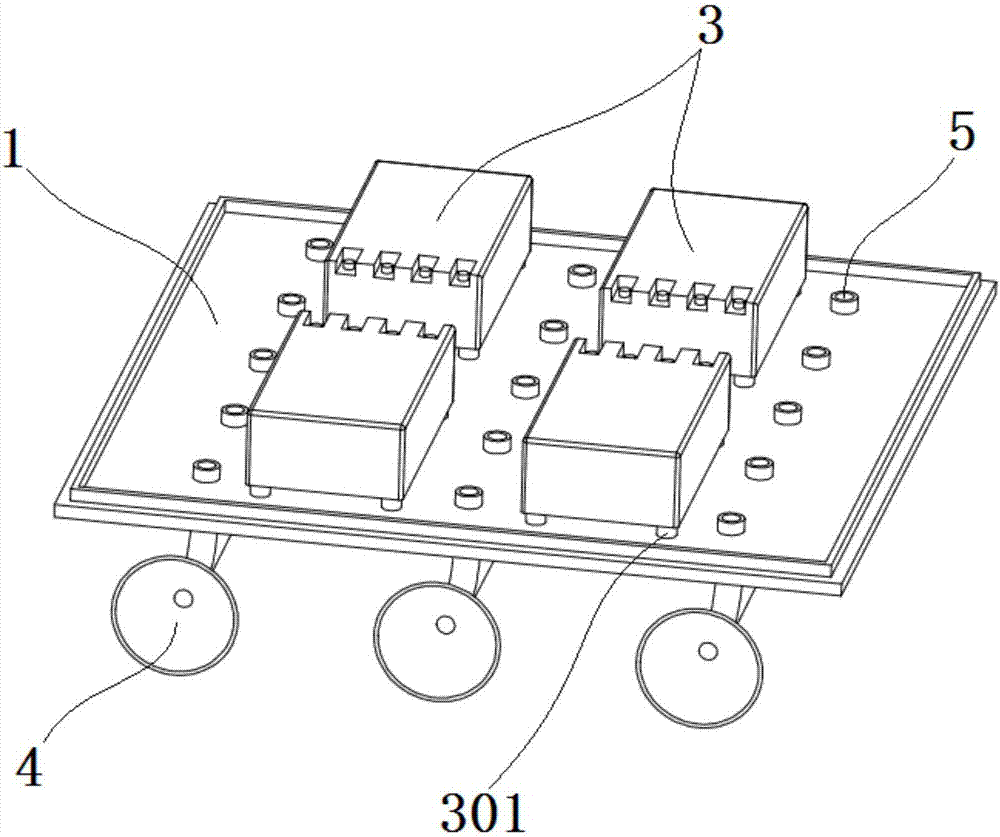

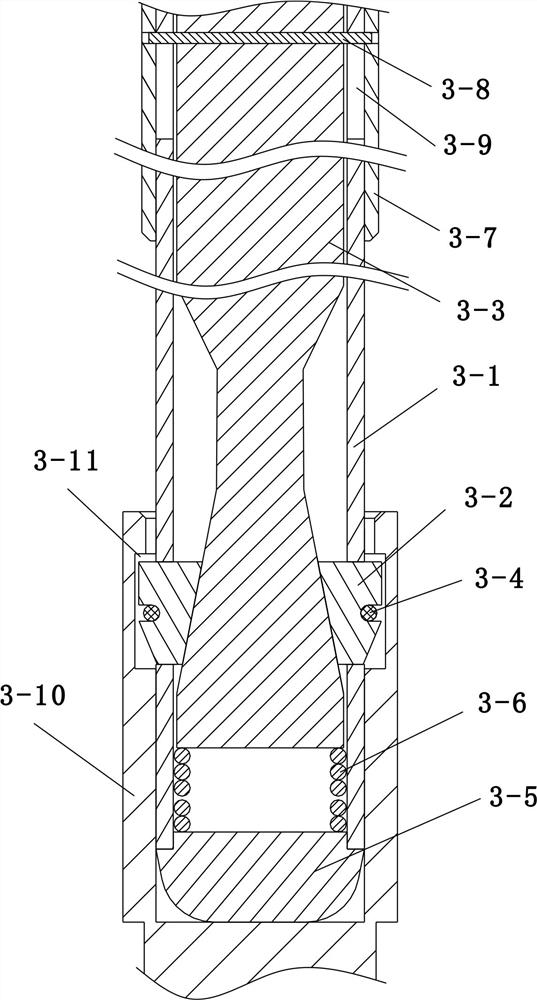

Printing head for 3D printing, control system, 3D printer and printing method

The invention discloses a printing head for 3D printing. The printing head comprises a machine shell, a screw extruding system, an installation seat, barrels, valve needles and spray nozzles. A drive system is arranged at one end of the machine shell. The screw extruding system is arranged in the machine shell and is composed of at least two screws which are embedded internally and externally, and at least one screw is driven by the drive system. The installation seat is mounted below the screw extruding system. One or more inner holes are distributed in the installation seat in the axial direction, and a discharge outlet is formed in the top or the side face of each inner hole. The barrels are mounted in all the inner holes of the installation seat correspondingly, the barrels extend out from one end of the installation seat, and barrel feeding openings are formed in the top ends of the barrels. Valve cavities are formed in the barrels. The valve needles penetrate through all the valve cavities of the barrels to be mounted on the installation seat, and the gaps between the valve needles and the valve cavities form discharging channels communicating with the feeding openings of the barrels. The spray nozzles are arranged at the tail ends of all the barrels. The printing head for 3D printing is light in weight, small in size, capable of achieving high printing precision and printing speed, novel in design, high in practicability and high in economic value.

Owner:浙江光镀智造科技有限公司

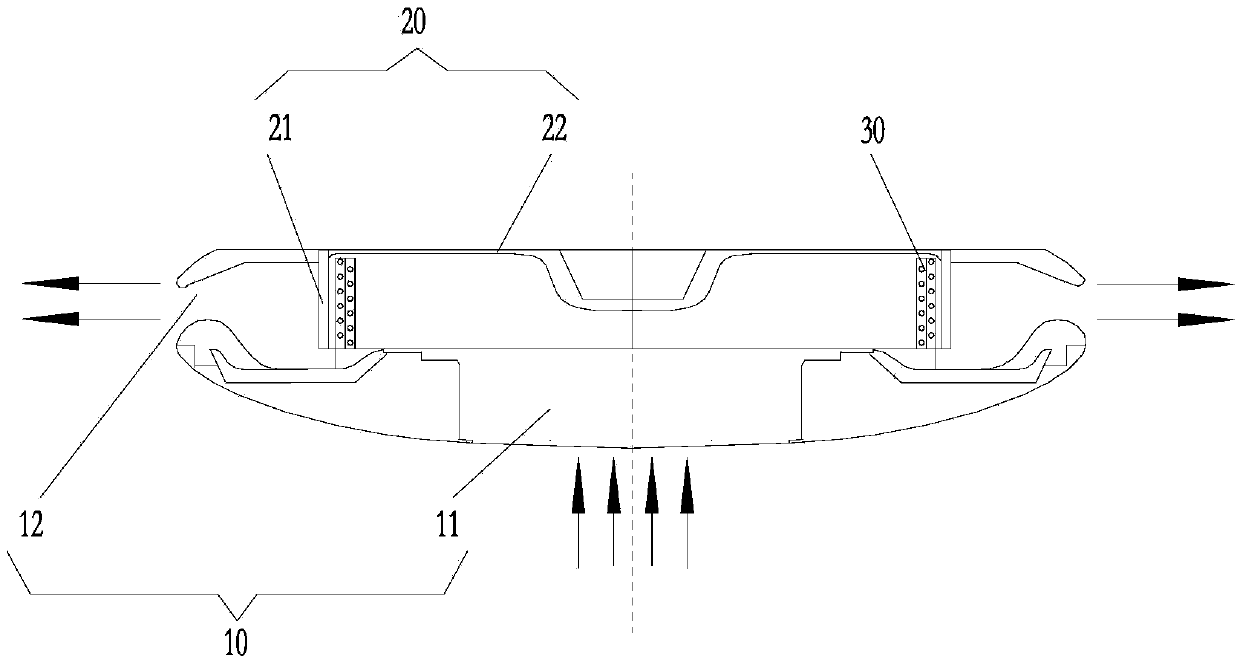

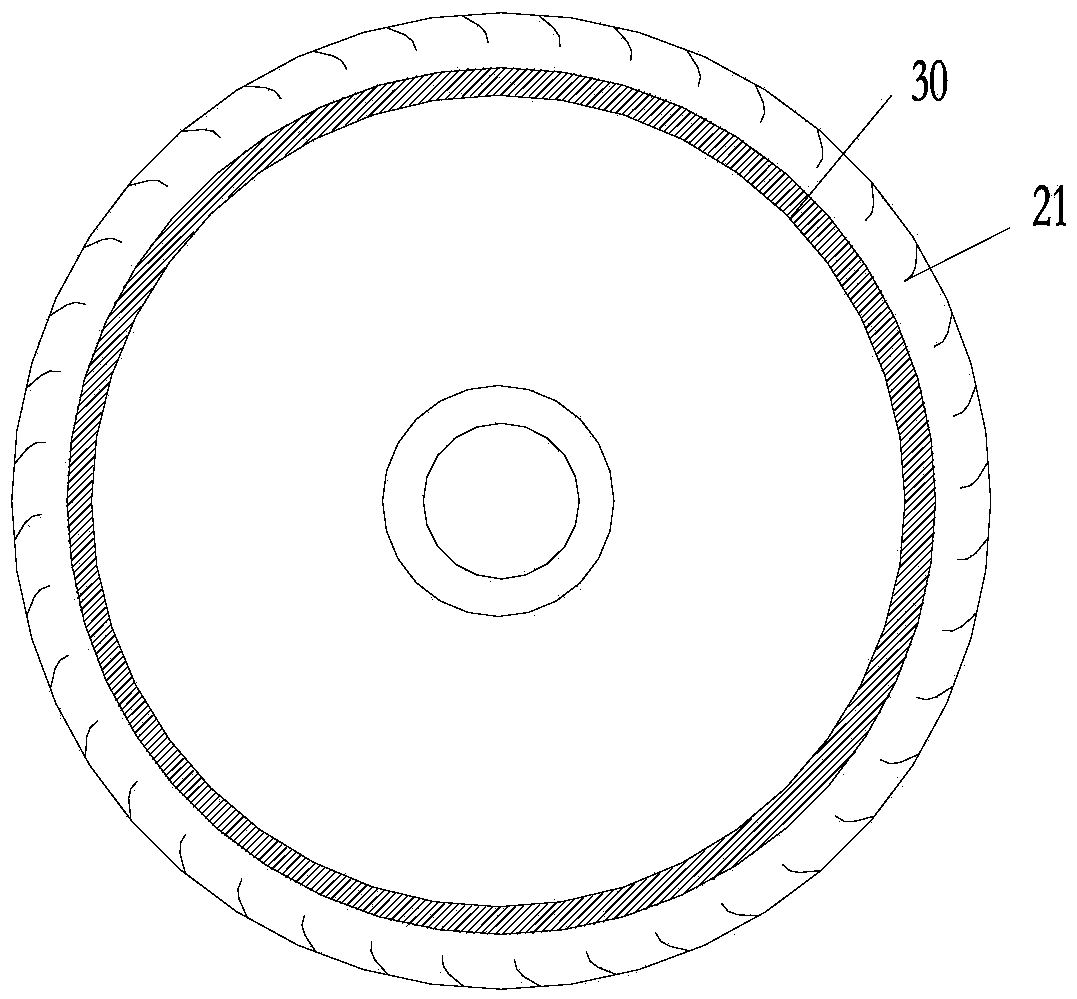

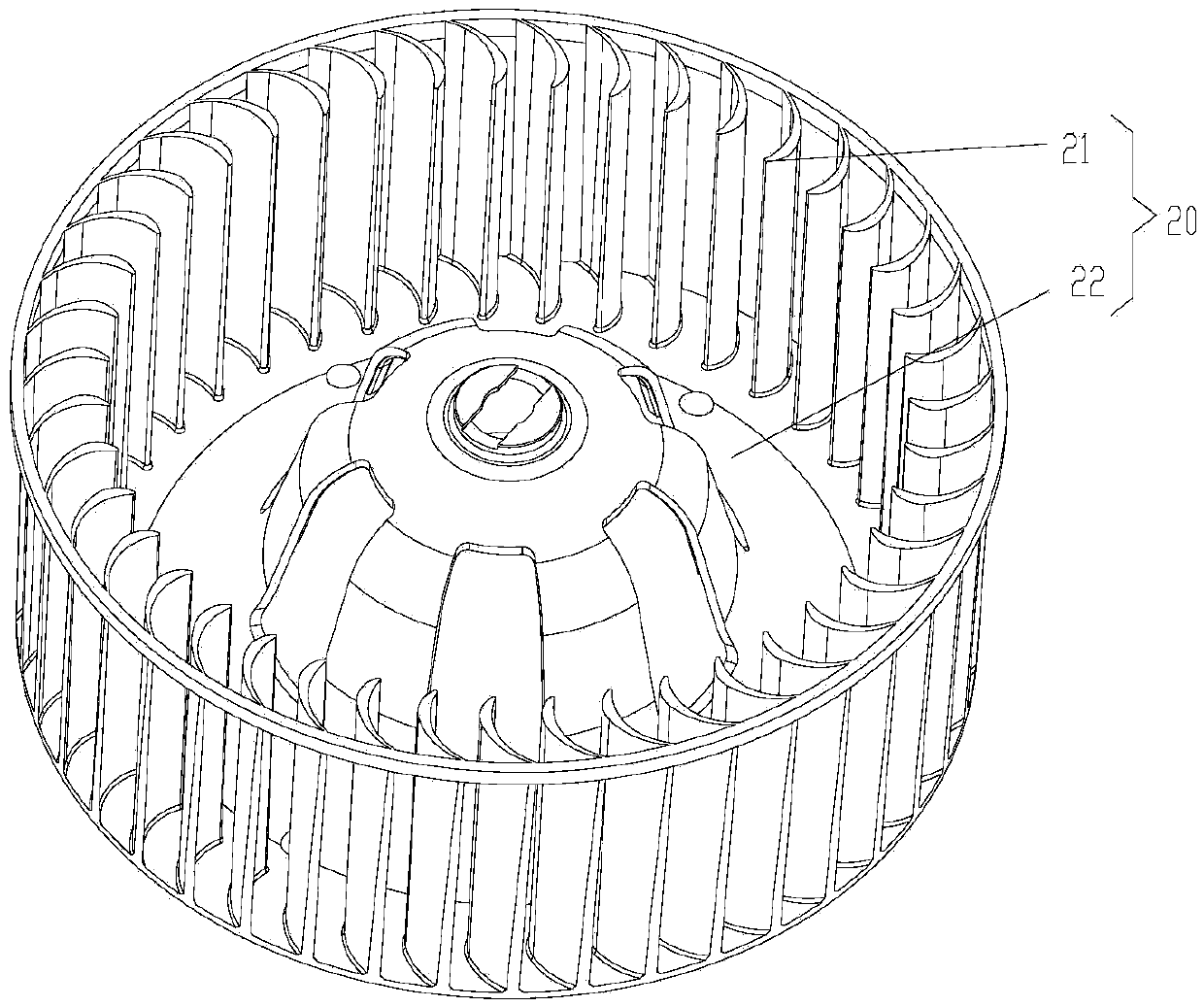

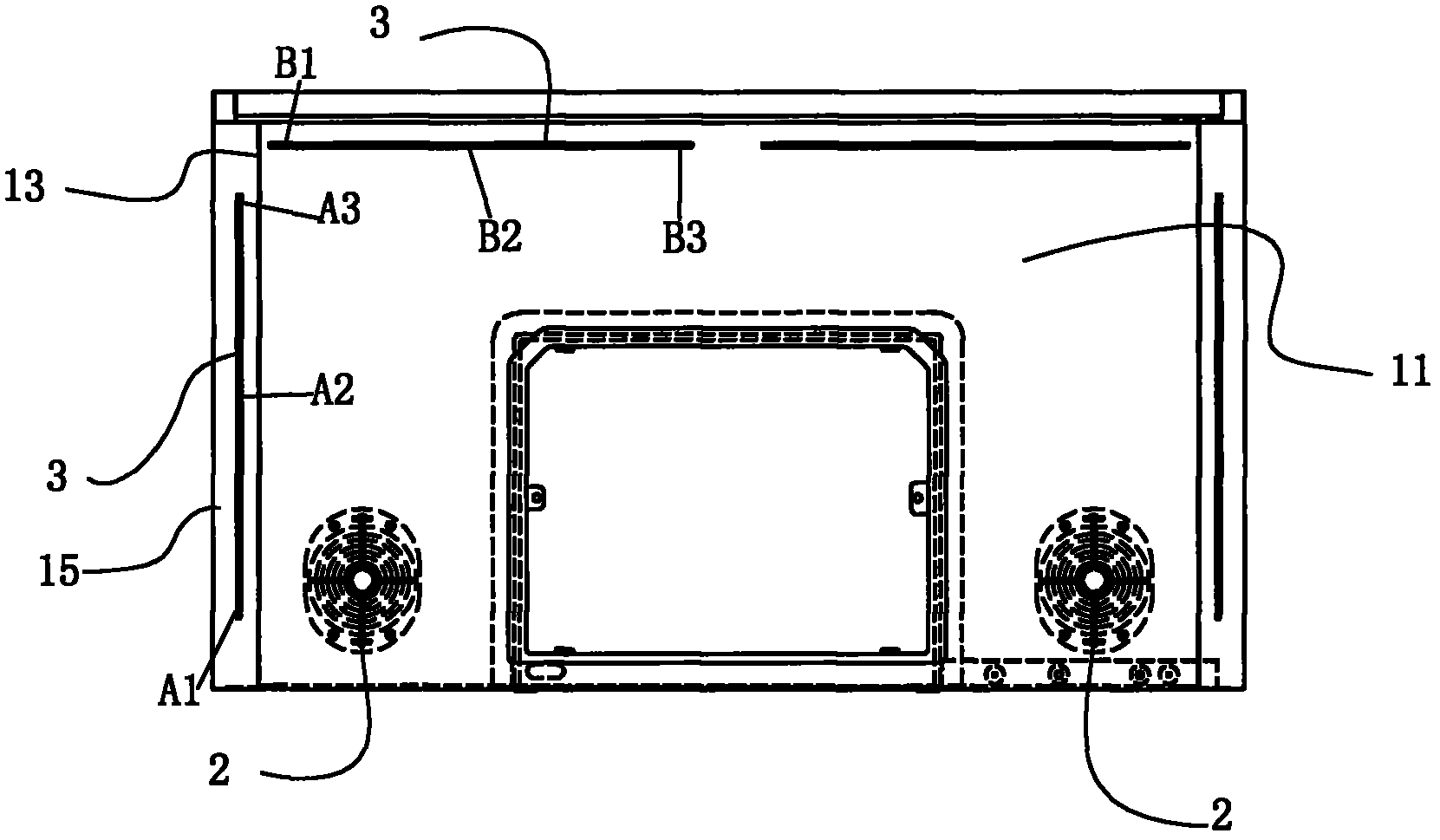

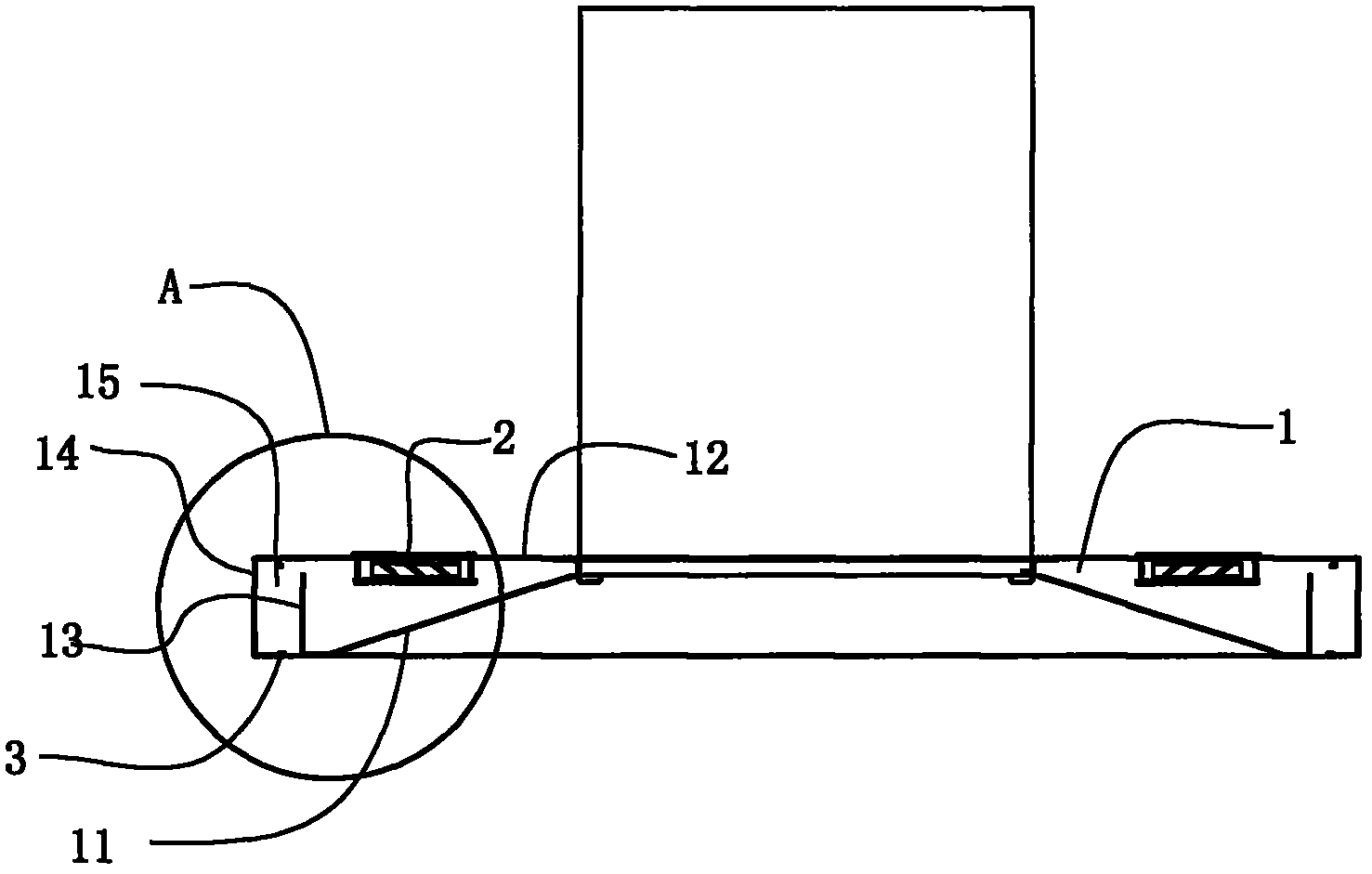

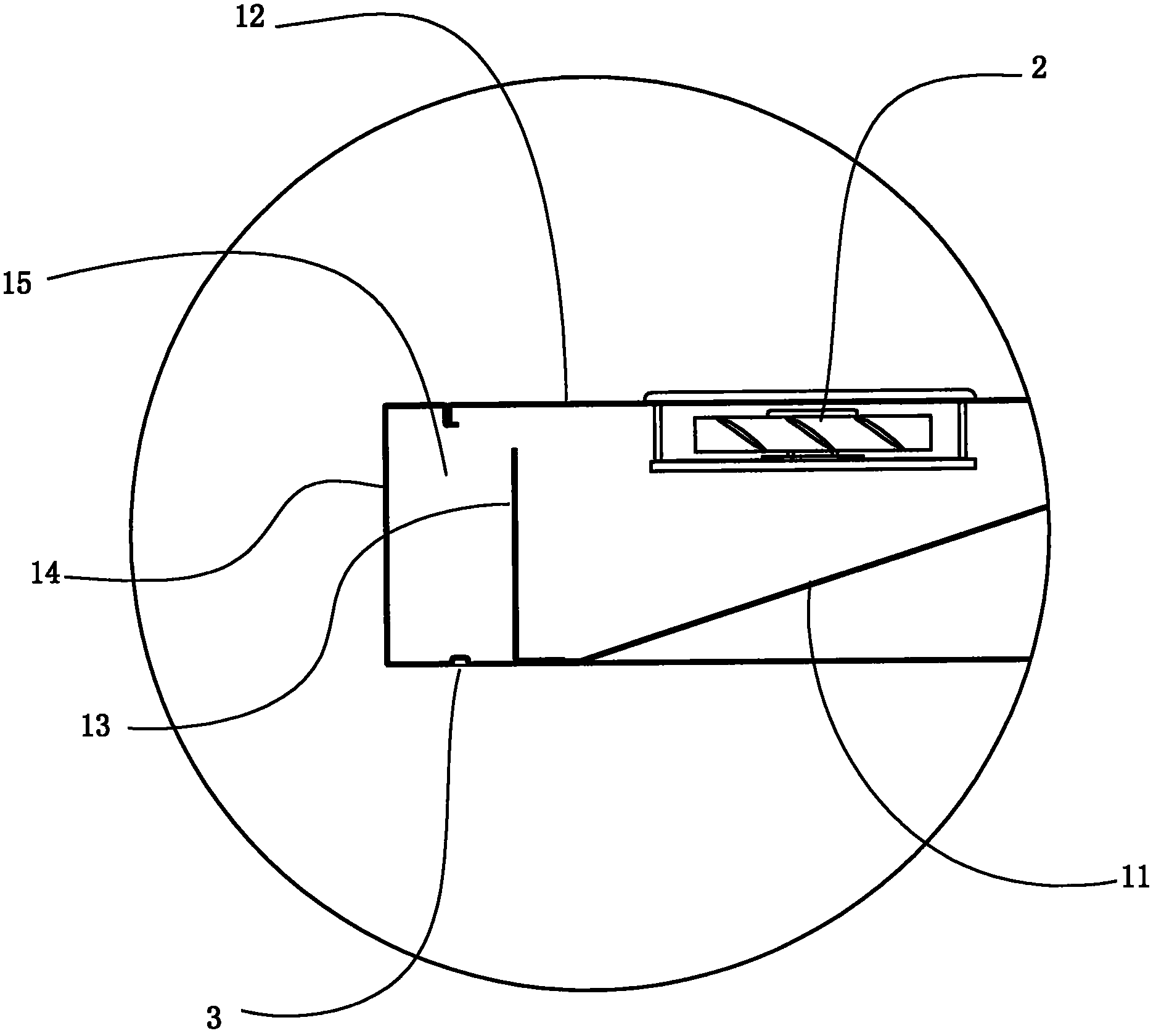

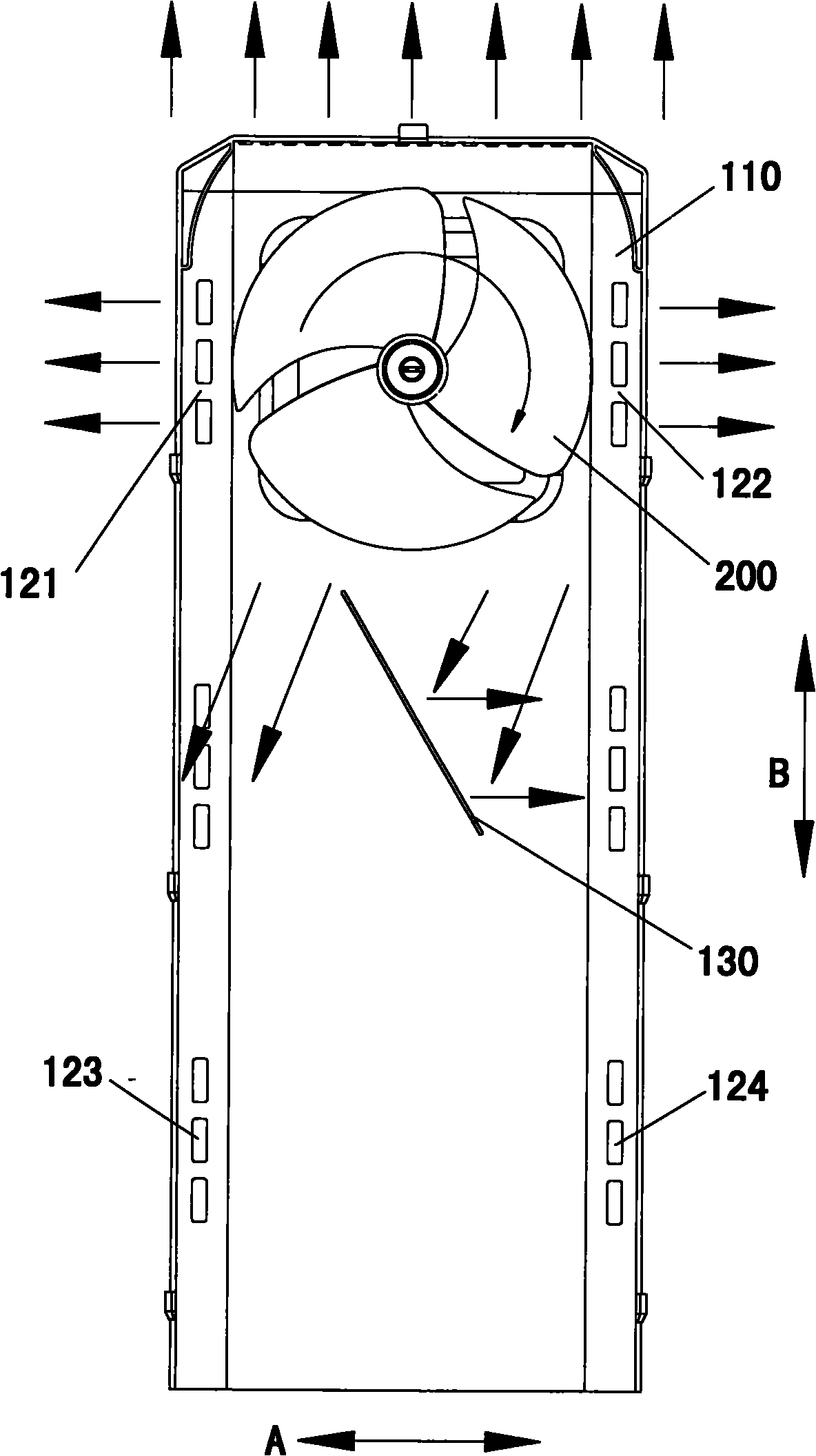

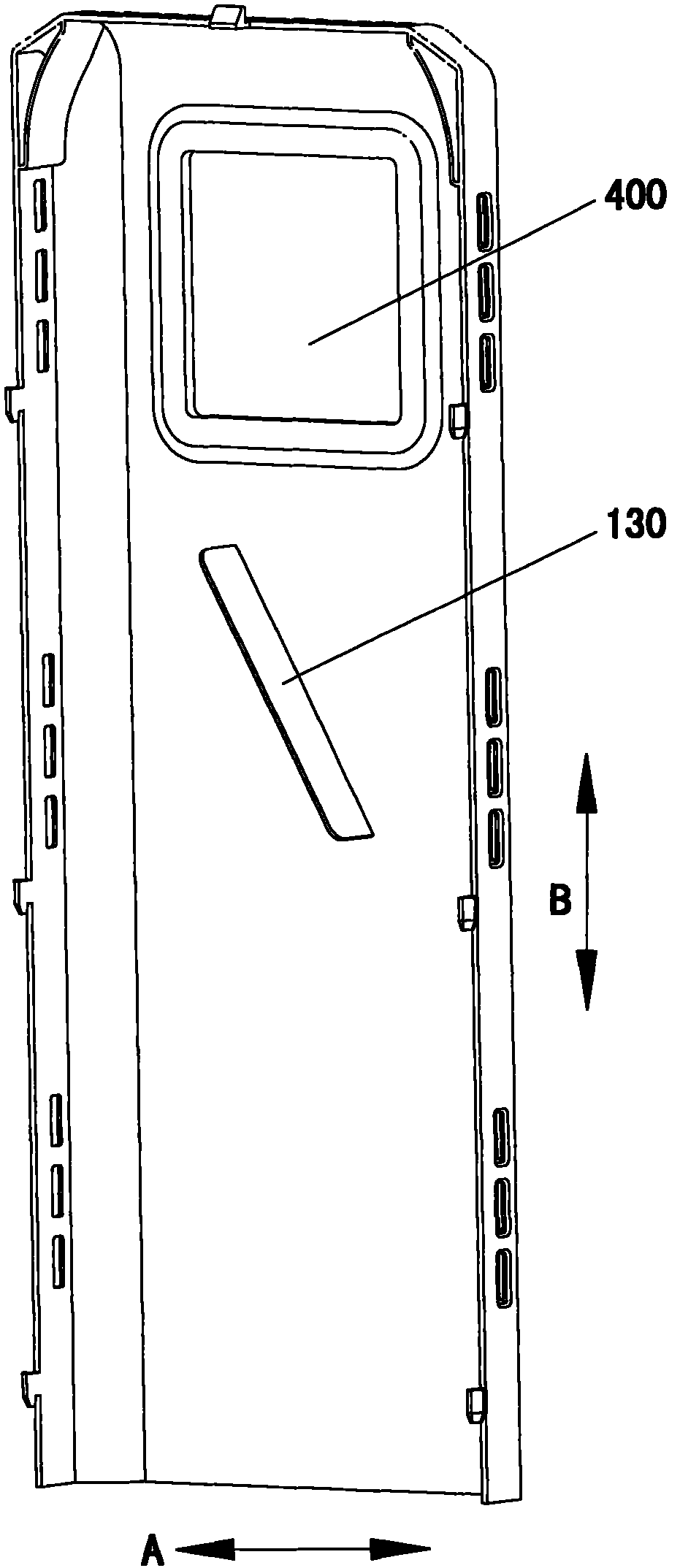

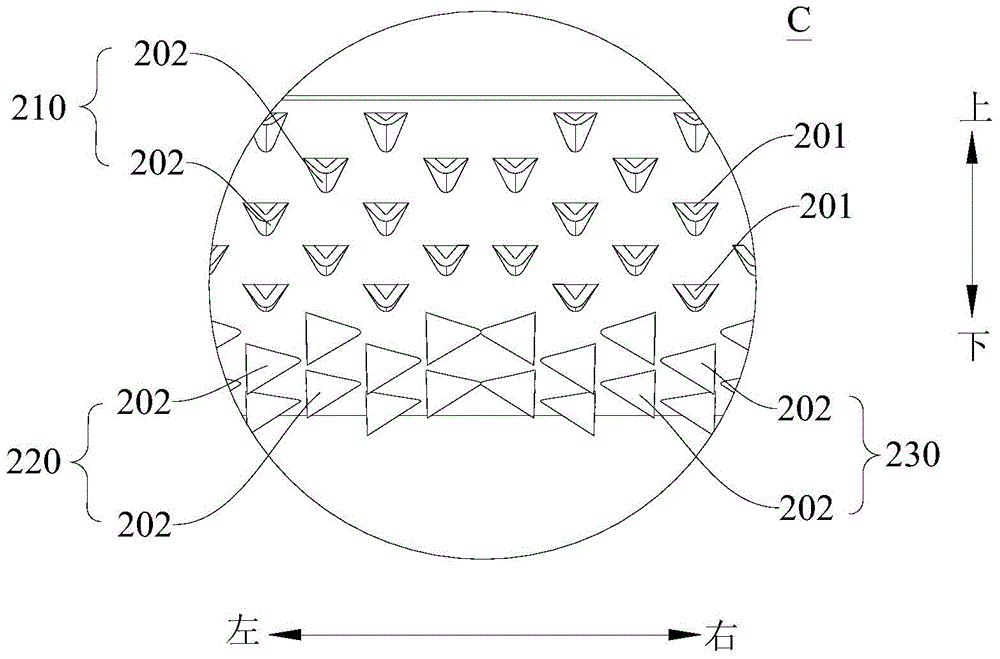

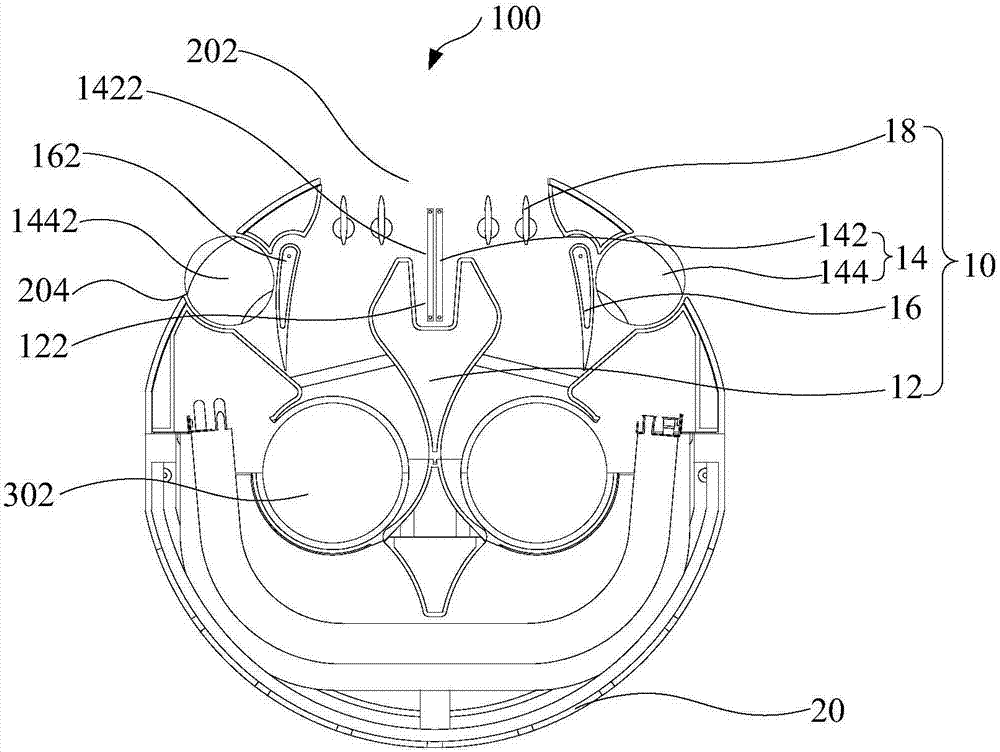

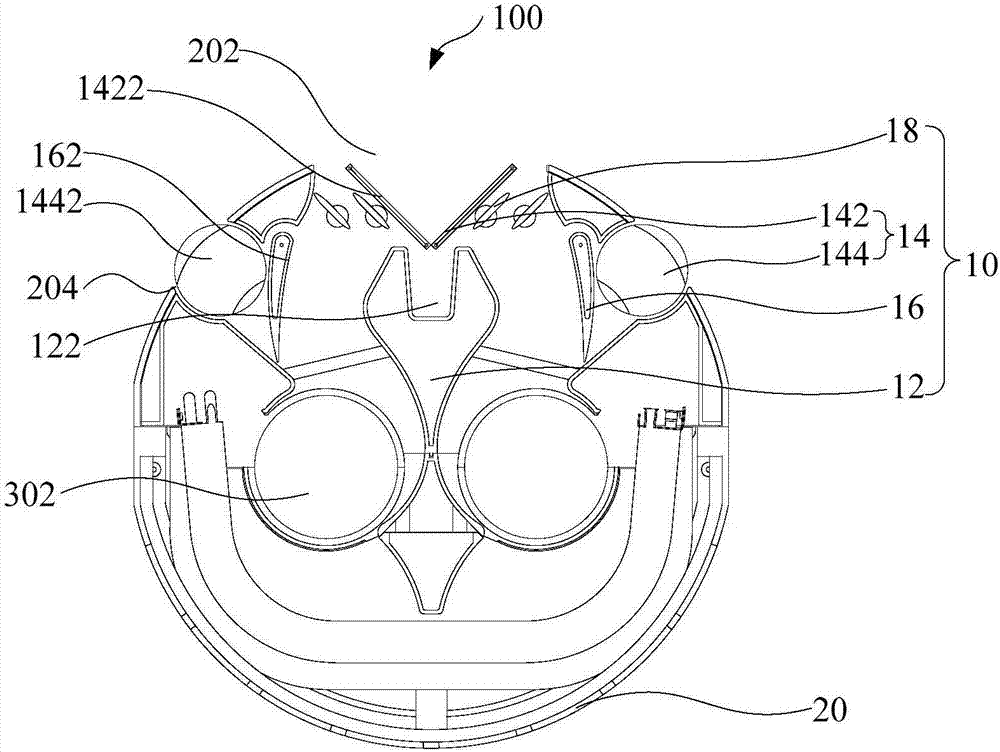

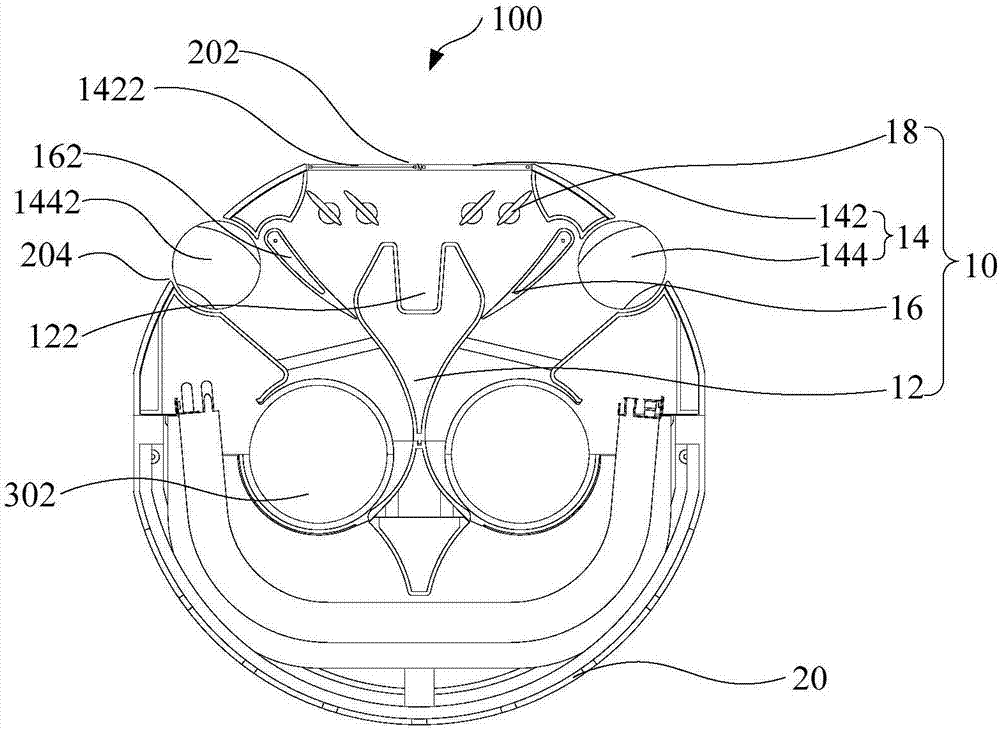

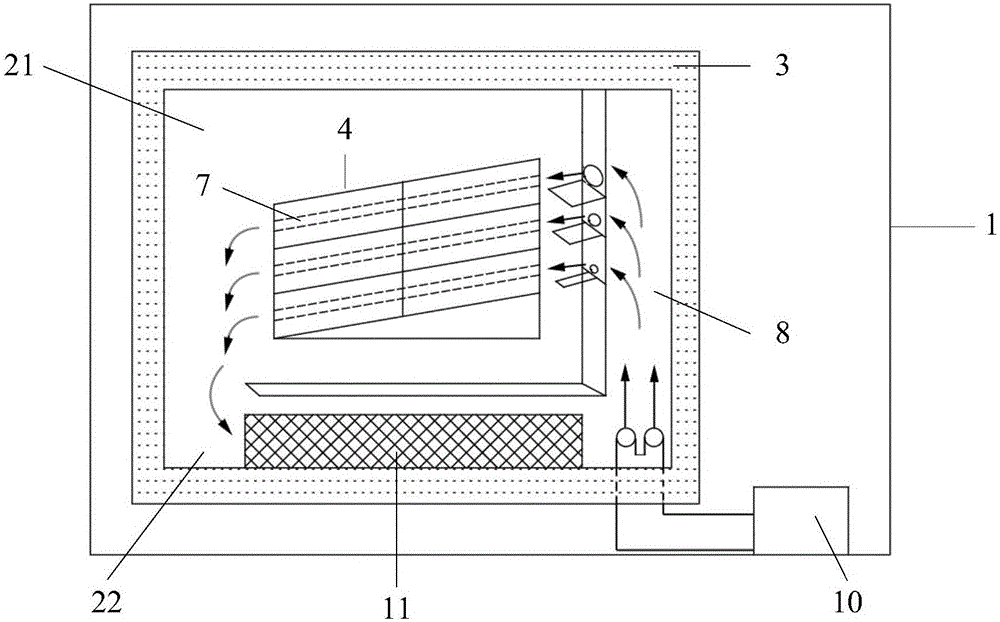

Air conditioner

ActiveCN105371374AConsistent speedUniform windCondensate preventionLighting and heating apparatusEngineeringFan blade

The invention provides an air conditioner. The air conditioner comprises a shell (10), a centrifugal fan (20) and a heat exchanger (30), wherein the shell (10) is provided with an air inlet (11) and an air outlet (12); the centrifugal fan (20) is arranged in the shell (10), and comprises a fan blade (21); and the heat exchanger (30) is arranged on the inner side of the periphery of the fan blade (21). By adopting the technical scheme disclosed by the invention, the problem of an air conditioner in the prior art that the noise is large, and air outlet is non-uniform are solved.

Owner:GREE ELECTRIC APPLIANCES INC

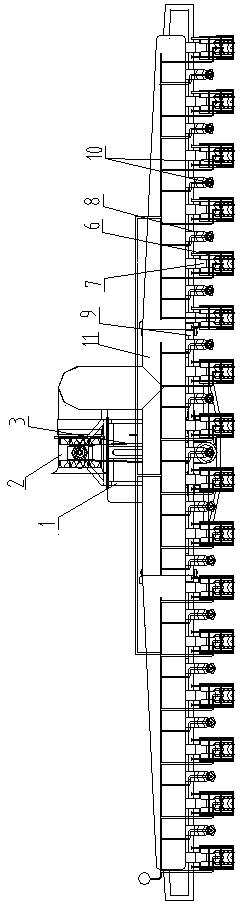

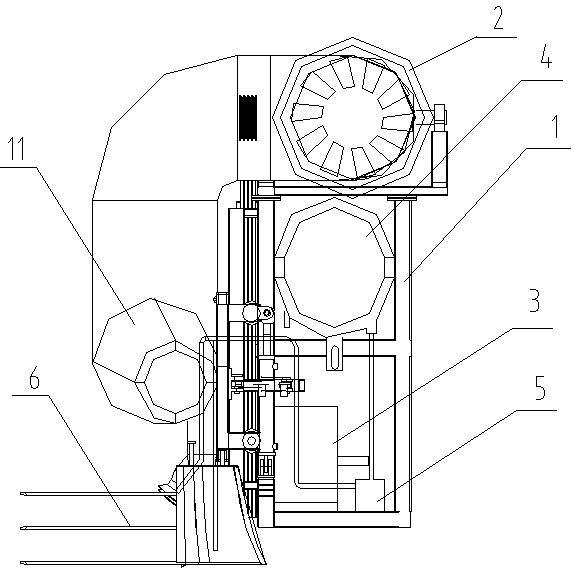

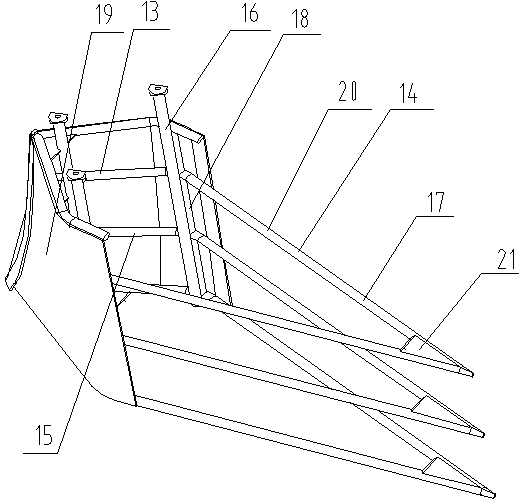

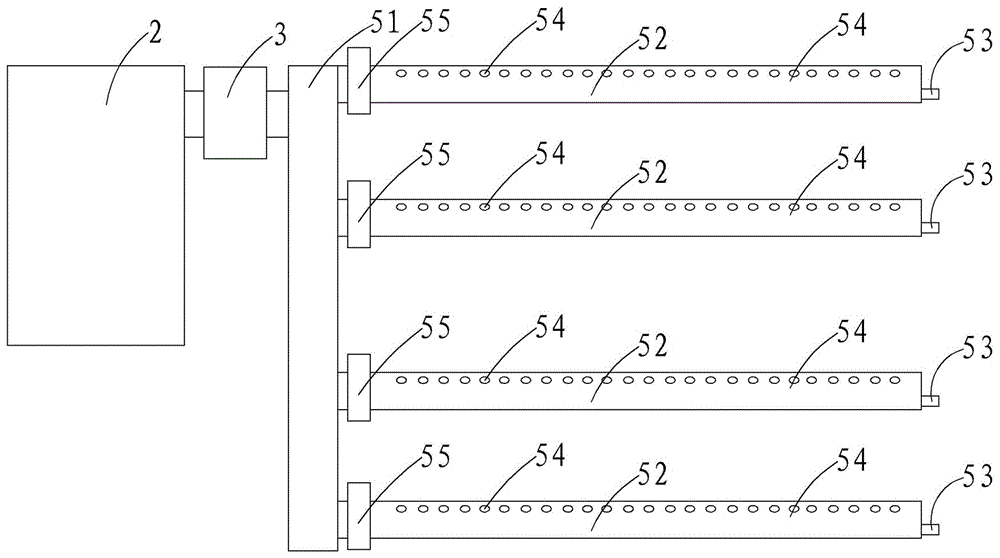

Efficient spraying machine suitable for cotton fields

InactiveCN104012508AUniform adhesiveAvoid pollutionInsect catchers and killersAgricultural engineeringEngineering

The invention provides an efficient spraying machine suitable for cotton fields and relates to farm machinery. The efficient spraying machine comprises a bracket, a draught fan, a draught fan power system, a pesticide box and a pesticide pump, wherein the draught fan, the pesticide box and the draught fan power system are respectively and fixedly arranged on the bracket; the outlet of the pesticide box is connected with the inlet end of the pesticide pump through a pipeline; the draught fan power system is in drive connection with the draught fan through a belt wheel rotation mechanism; the bracket is provided with a nozzle mounting bracket; the nozzle mounting bracket is provided with a plurality of row dividing devices, straight spraying barrels and inclined spraying barrels; air outlets of the direct spraying barrels and the inclined spraying barrels are provided with medicine feeding nozzles; wind screens are arranged between the draught fan and the straight spraying barrels and between the draught fan and the inclined spraying barrels; air inlets of the wind screens are connected with an air outlet of the draught fan; air outlets of the wind screens are respectively connected with the straight spraying barrels and the inclined spraying barrels. The spraying machine can uniformly apply pesticides and has strong penetrating power; the pesticide utilization amount per unit area is little.

Owner:NANTONG HUANGHAI CHEM MACHINERY

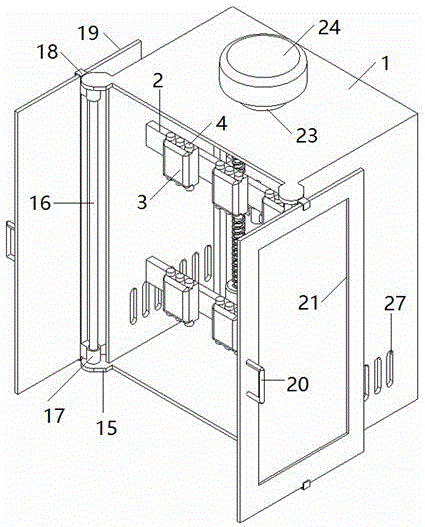

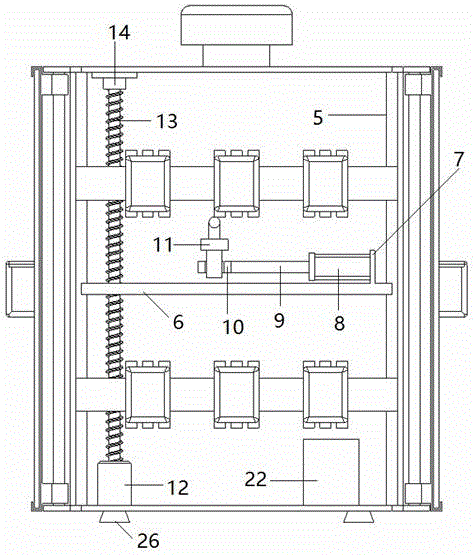

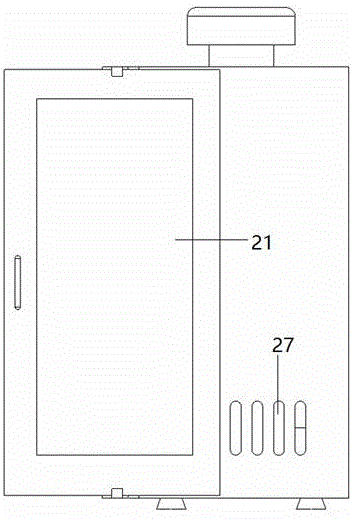

Power switch cabinet with directional fire extinguishing function

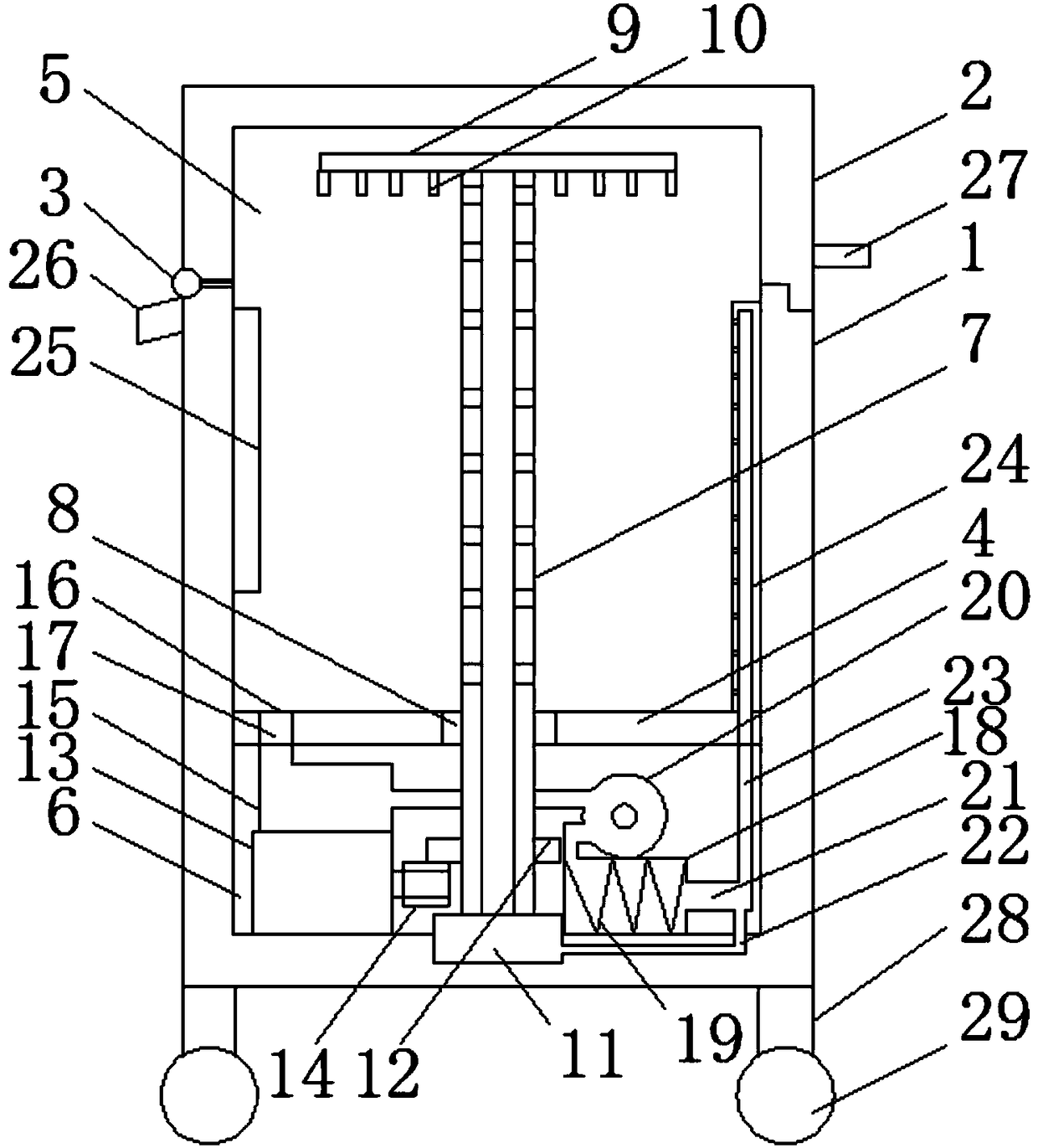

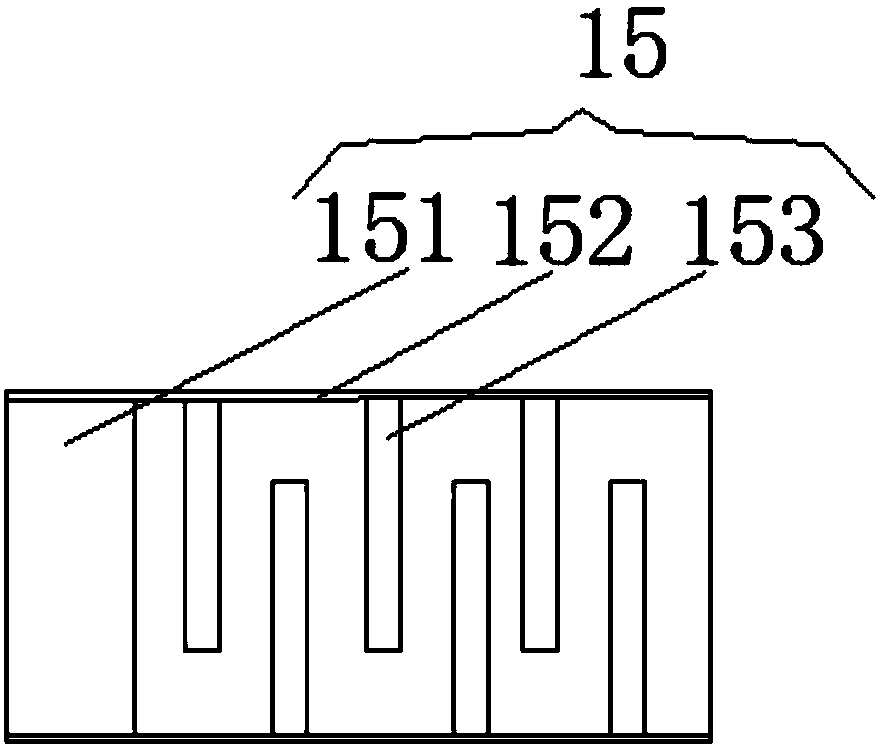

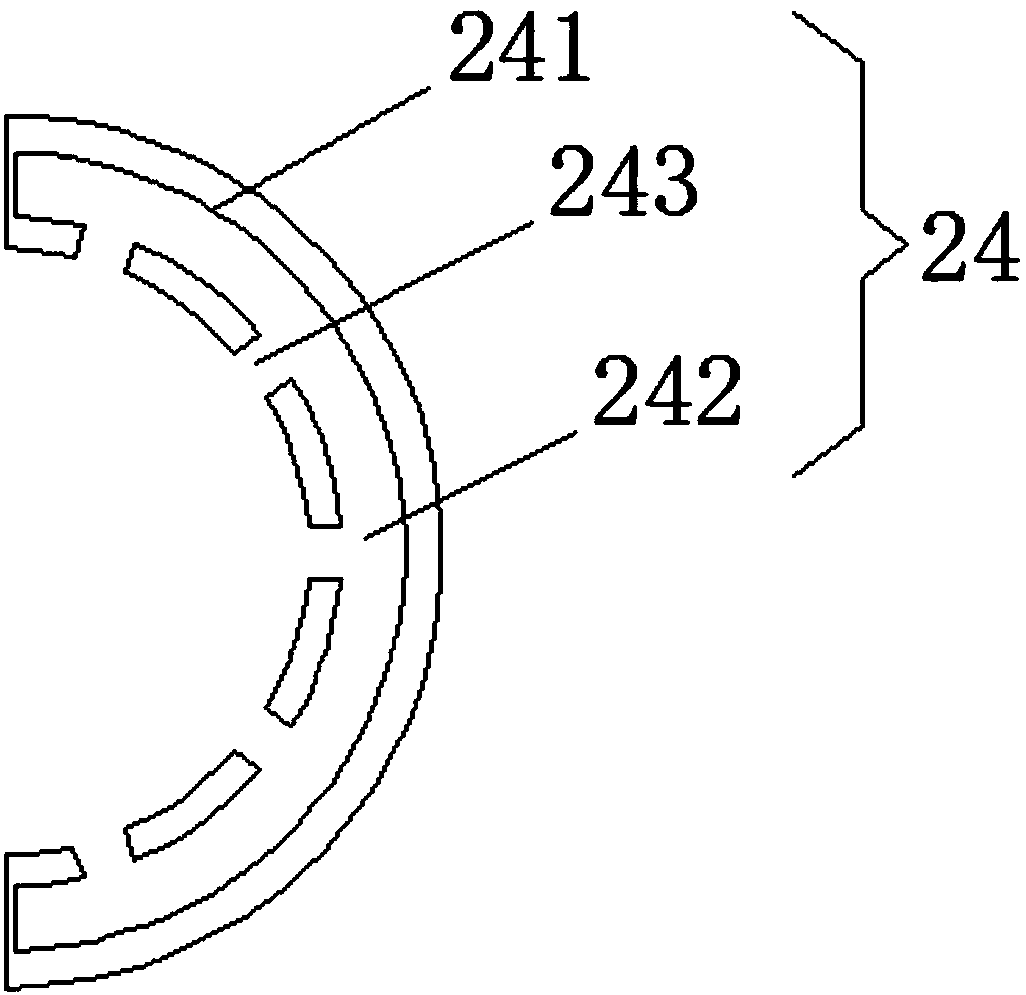

InactiveCN106300064AMove quickly and accuratelyReduce the impactSubstation/switching arrangement cooling/ventilationFire rescueHydraulic cylinderChinese characters

The invention discloses a power switch cabinet with a directional fire extinguishing function. The power switch cabinet comprises a cabinet body, wherein a plurality of connecting plates are uniformly arranged on the inner wall of the middle part of the cabinet body; a plurality of power switches are uniformly arranged on the connecting plates; wiring terminals are respectively arranged at the two ends of each power switch; slide rails are vertically arranged on the inner walls of the two sides of the back end of the cabinet body; a slide plate is horizontally arranged at the back end of the cabinet body and is matched with the slide rails; a bulge is arranged at one end of the slide plate, and a hydraulic cylinder is horizontally arranged at one side of the bulge. The power switch cabinet has the advantages that a high-pressure spray head is controlled by a driving motor and a bidirectional screw rod to move along the vertical direction, and is controlled by a hydraulic cylinder and a piston rod to move along the horizontal direction, the high-pressure spray head can be quickly and accurately moved to the fire location, the enough liquid carbon dioxide is sprayed to extinguish the fire source, and the influence to the other positions of the cabinet body is reduced; by adopting the combination of a rotary shaft and a groove which is in a shape like Chinese character of hui, a cabinet door is slide along the groove in the shape like Chinese character of hui, the space occupation is reduced, and the convenience in use is realized.

Owner:STATE GRID CORP OF CHINA +1

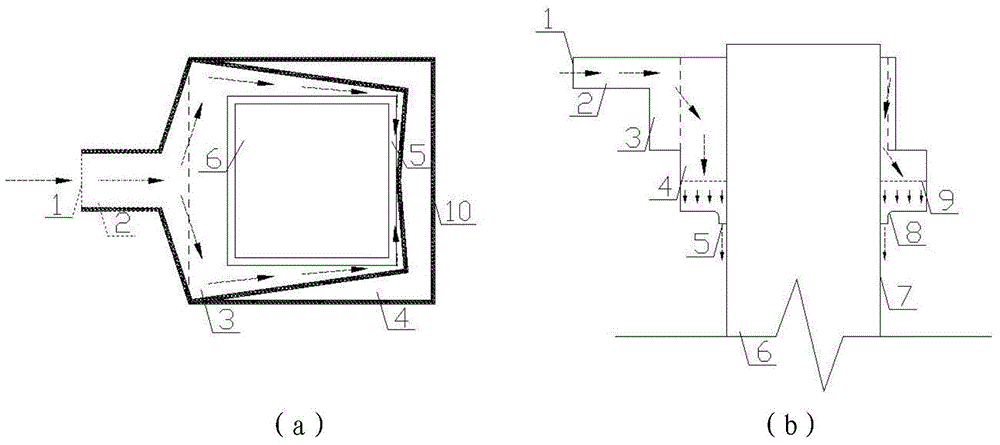

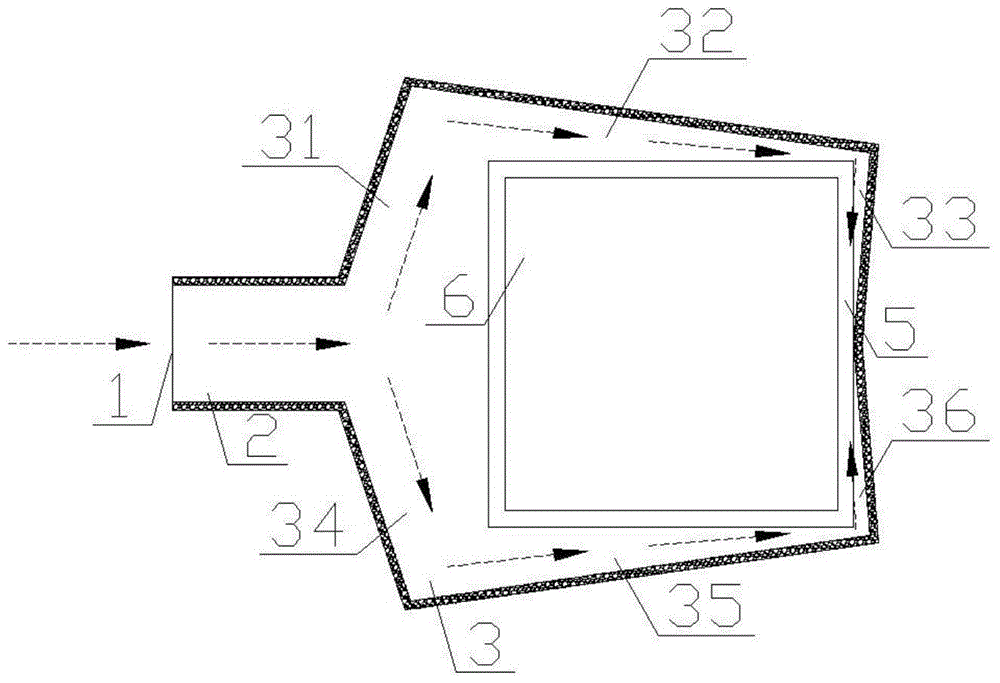

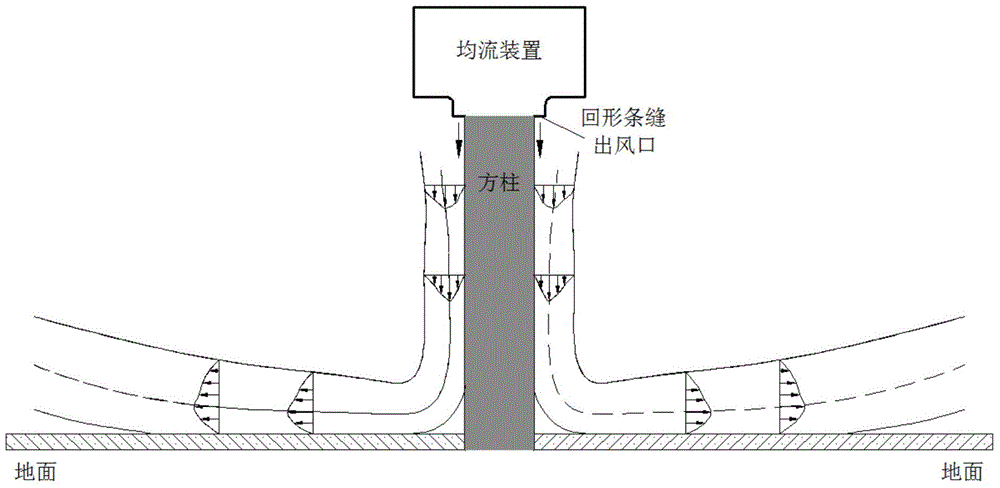

Variable cross-section flow rectifier for square column wall surface attached type uniform air feeding

ActiveCN104930635AImprove effectivenessUniform windLighting and heating apparatusNoise suppressionIndoor air qualityThermal comfort

The invention discloses a variable cross-section flow rectifier for square column wall surface attached type uniform air feeding. The variable cross-section flow rectifier for square column wall surface attached type uniform air feeding comprises an air inlet pipe and a shell, and further comprises a variable cross-section air feeding passage. The shell is a concentric-square-shaped barrel with a sealed upper end, and the lengths of the four sides of the barrel are the same. A square column is sleeved with the shell and the inner wall of the inner barrel of the shell is closely attached to the outer wall of the square column. The air inlet pipe is installed at the upper end of the variable cross-section air feeding passage and communicated with the variable cross-section air feeding passage. The axis of the air inlet pipe and the axis of the shell perpendicularly intersect. The variable cross-section air feeding passage is barrel-shaped and located in the upper half of the shell, and the lower end port of the variable cross-section air feeding passage is communicated with the shell. The variable cross-section flow rectifier for square column wall surface attached type uniform air feeding can improve the indoor air quality of buildings and hot comfort and health of people, and is applicable to a building ventilation air-conditioning system which comprises a square column structure and realizes attached air feeding through a concentric-square-shaped seam air port.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

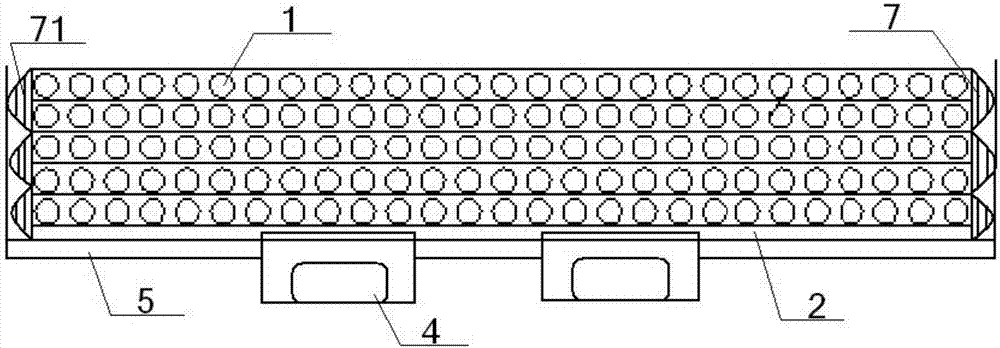

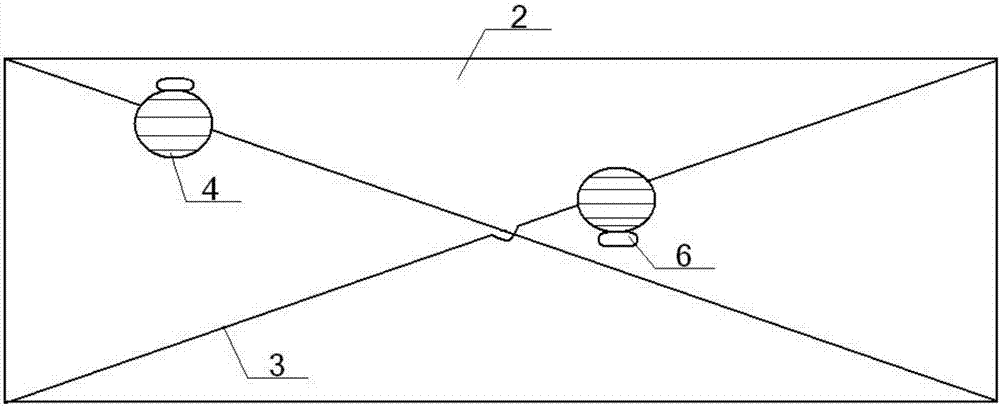

Multifunctional mattress

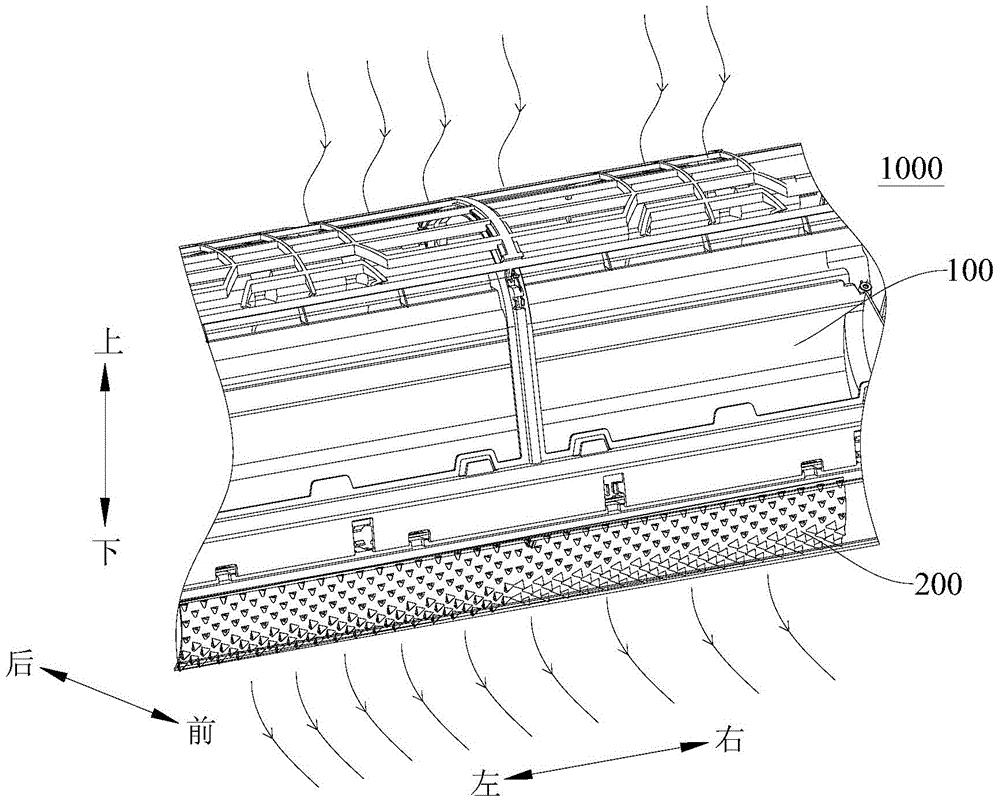

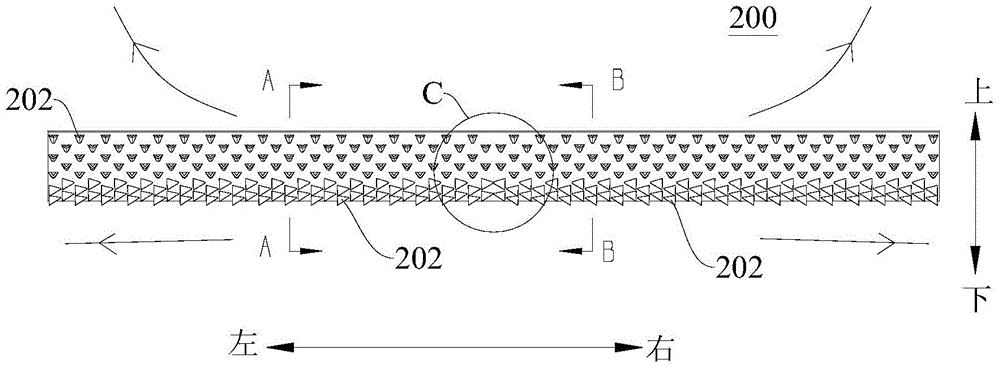

InactiveCN107307672AImprove breathabilityIncrease elasticityStuffed mattressesSpring mattressesHoneycombEngineering

A multifunctional mattress comprises a cotton layer and a shelf, the top of the cotton layer is in contact with the air, the bottom of the cotton layer is connected to the top of the shelf, and the bottom of the shelf is connected to the bed frame; The cotton layer is made of bionic honeycomb cotton; the bottom of the shelf is provided with two sliding rods that cross each other, and the two sliding rods correspond to a diagonal line of the shelf respectively. The sliding rods are made of elastic materials, and the sliding rods are provided with A hair dryer with a sliding fit, the air outlet of the hair dryer is arranged opposite to the bottom of the cotton layer directly above it, and a temperature sensor is arranged on the hair dryer, which includes a metal casing, an input wire, an input conductive plate, an output wire, an output conductive plate and power sheet. This design not only has a strong ventilation effect, but also has a better ventilation effect.

Owner:岳聪阳

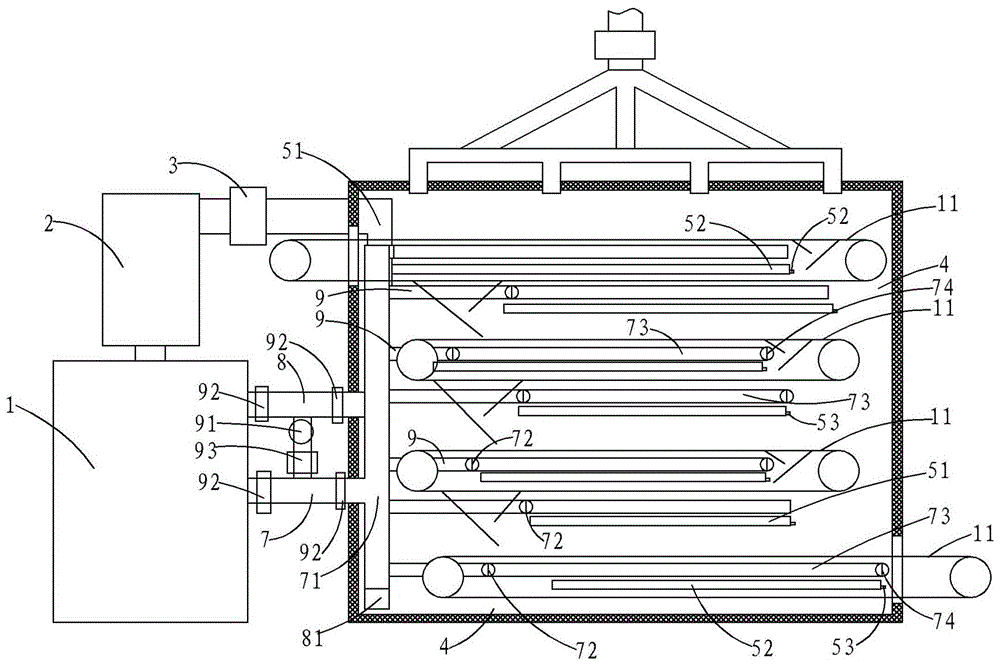

Broken yarn protection system of warp knitting machine

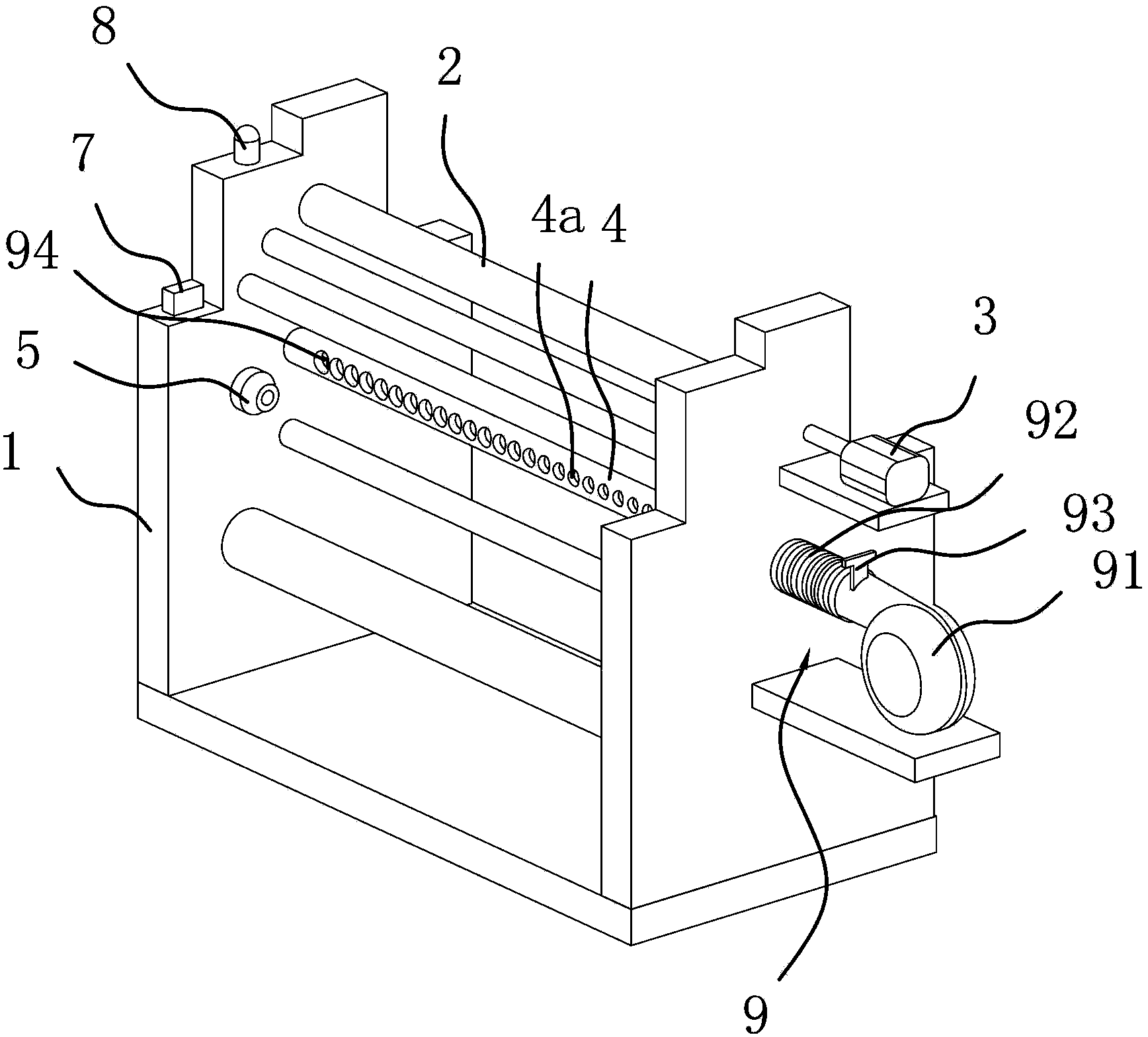

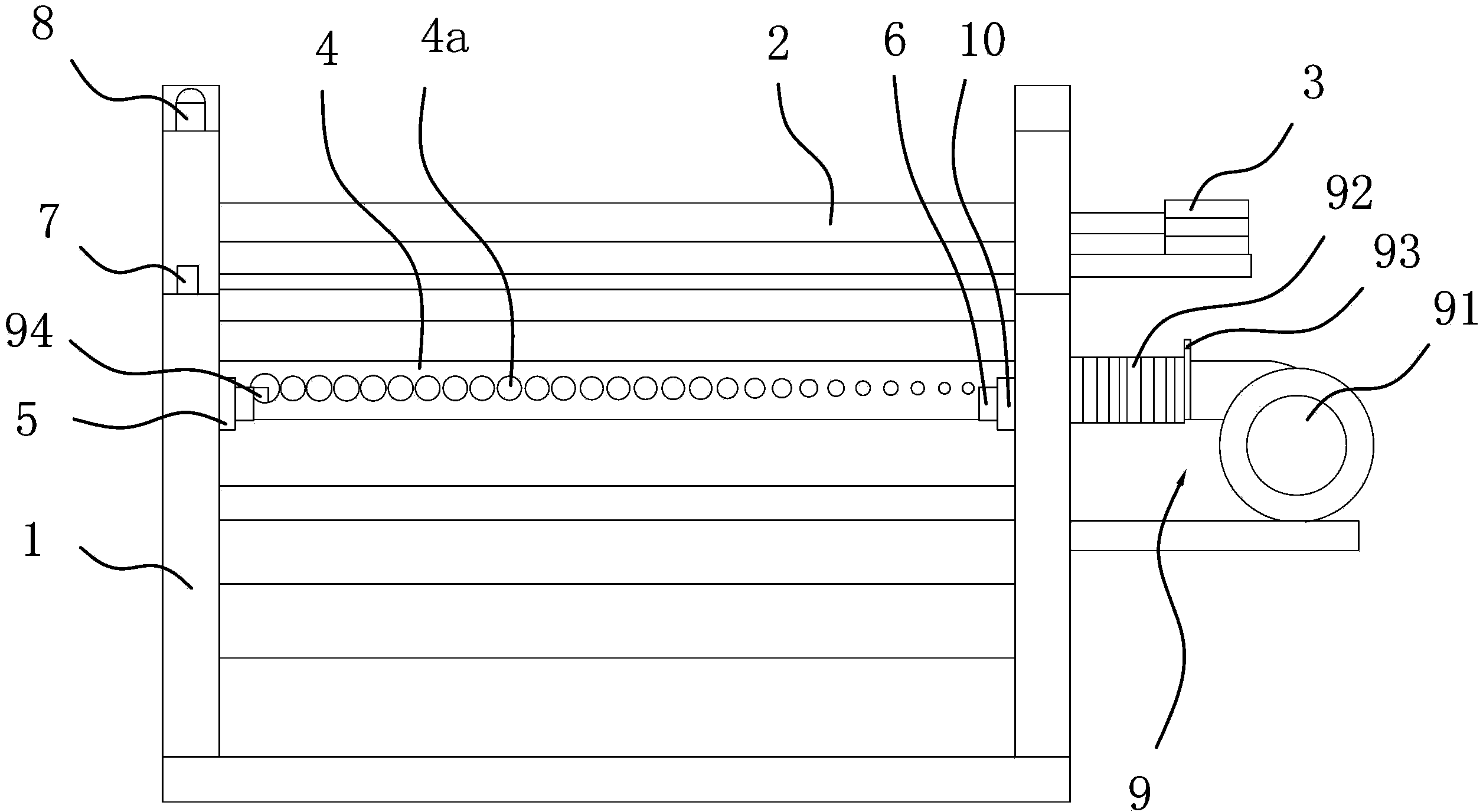

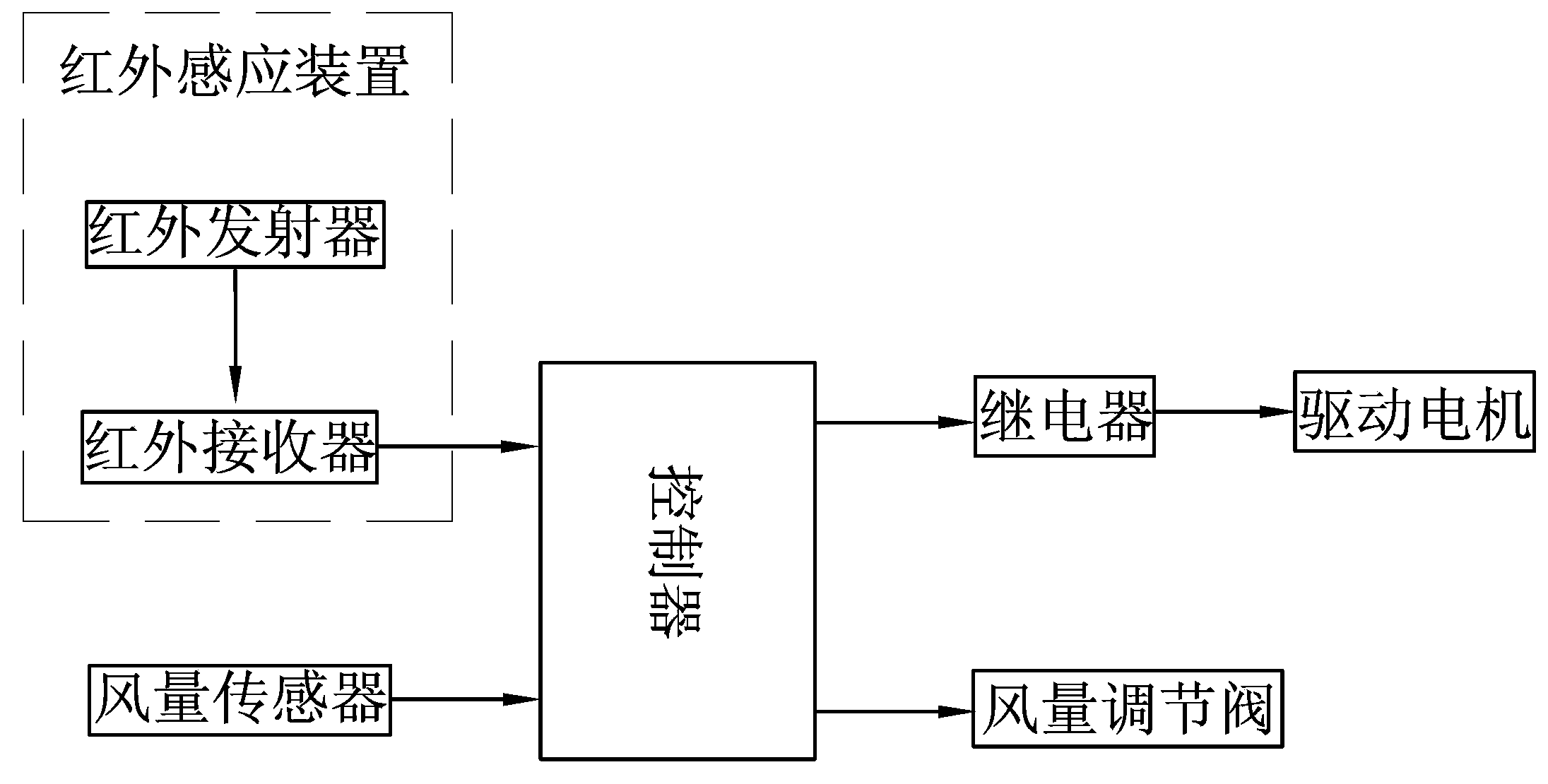

The invention provides a broken yarn protection system of a warp knitting machine, and belongs to the technical field of spinning. The broken yarn protection system of the warp knitting machine solves the problems that yarn in an existing warp knitting machine is easy to break, and therefore machine faults can easily happen in a following mode. According to the broken yarn protection system of the warp knitting machine, the warp knitting machine comprises a machine frame and a yarn-feeding rolling barrel arranged on the machine frame, and the yarn-feeding rolling barrel is driven to rotate by a drive motor. The broken yarn protection system comprises an air outlet pipe, an infrared emitter and an infrared receiver, wherein the air outlet pipe is fixed to the machine frame and is parallel to the yarn-feeding rolling barrel, the infrared emitter is fixed to one end of the machine frame, the infrared receiver is fixed to the other end of the machine frame, the infrared emitter faces the infrared receiver, an inducing straight line is located on one side of yarn, the air outlet pipe is located on the other corresponding side of the yarn, and a plurality of air outlet holes facing the yarn are formed in the pipe body of the air outlet pipe. According to the broken yarn protection system of the warp knitting machine, when yarn is broken in the operating process, the drive motor can be automatically controlled to stop working so as to remind working personnel to replace the yarn, and accordingly machine faults are avoided.

Owner:ZHEJIANG JINSHIDA ENTERPRISE

Air curtain apparatus for smoke ventilator

InactiveCN102200313ADoes not affect appearanceBeautify the appearanceDomestic stoves or rangesLighting and heating apparatusSmoke hoodAir channel

Disclosed is an air curtain apparatus for a smoke ventilator, comprising blower fans fixed in the housing of the smoke ventilator. A smoke collecting cover is provided on the bottom of the housing. Between the smoke collecting cover and the top board and lateral walls of the housing forms a space for wind to pass through, and the blower fan is located in the space. The air curtain apparatus is characterized in that: along two sides of the smoke collecting cover are arranged air outlets and extend separator plates which are located in the housing and separate the outlets from the blower fans; the separator plates extend from the smoke collecting cover towards the top board, and there are gaps between the tops of the separator plates and the top board, thereby forming air channels between the separator plates and the lateral walls. The installation of the separator plates enables a uniform air curtain with a wide scope of an air-out speed to appear around the smoke collecting cover, thereby preventing oil smoke from going out without extra installation of air curtain pipelines. The air curtain apparatus provided in the invention has a beautiful shape and a simple structure.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

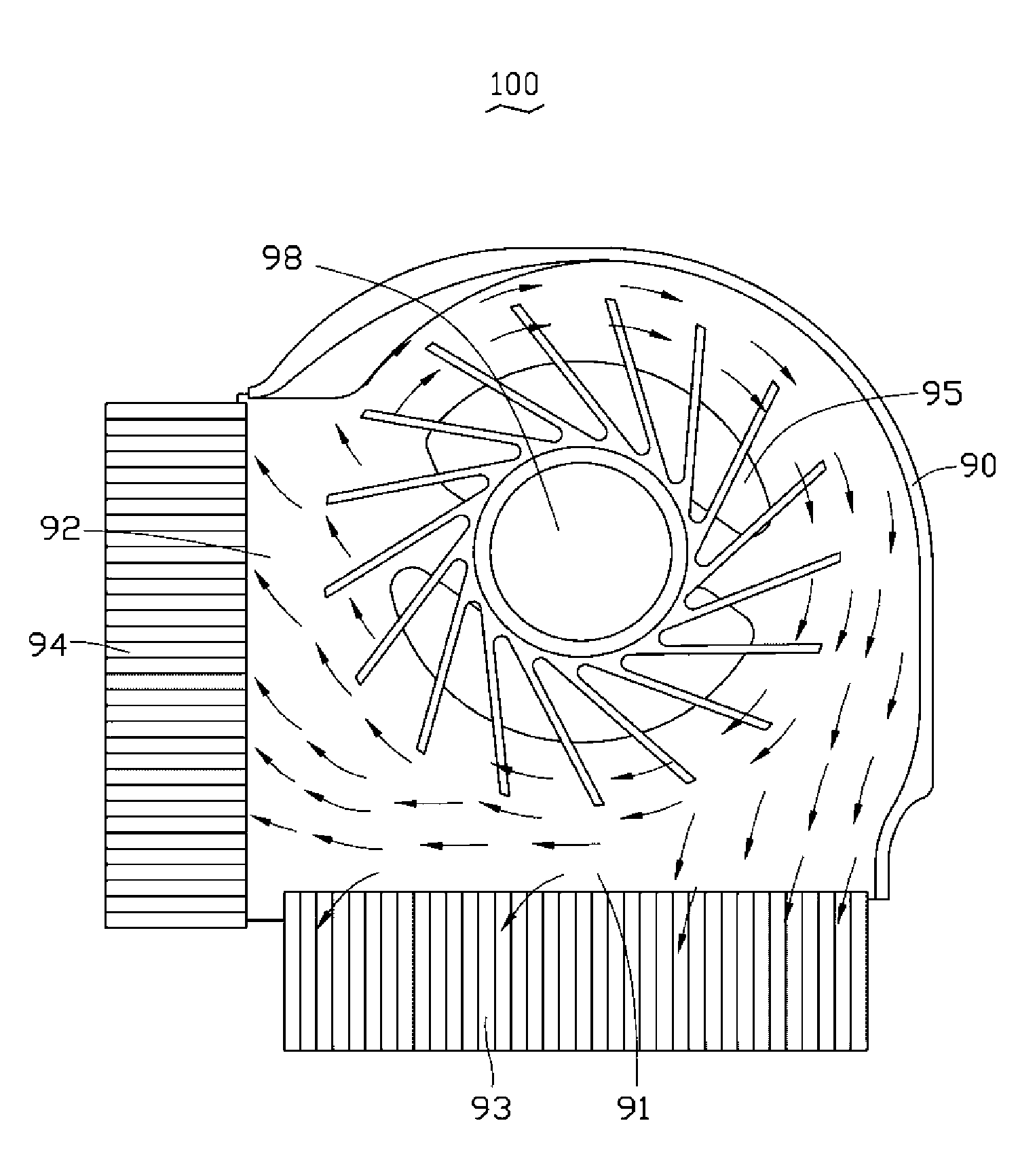

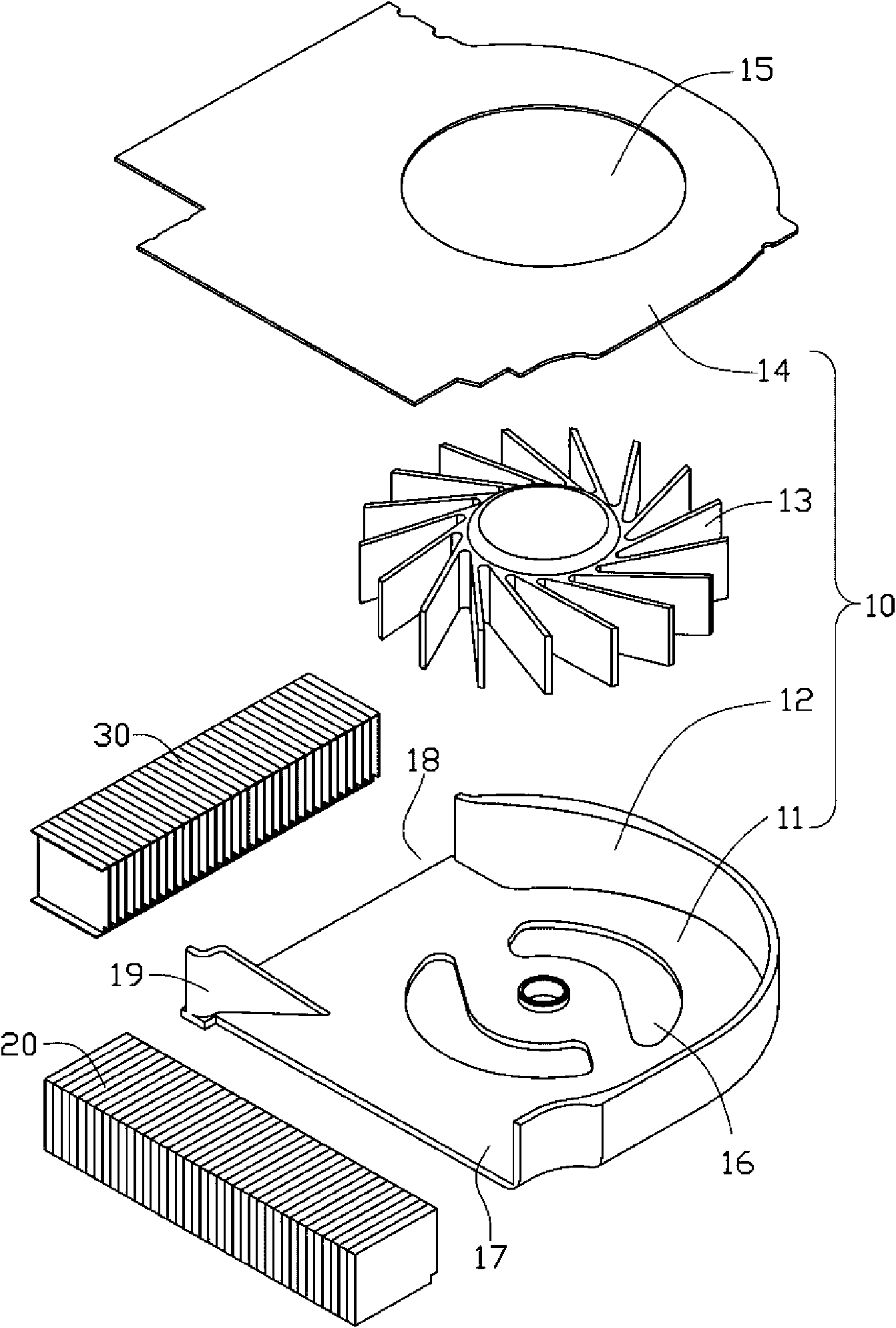

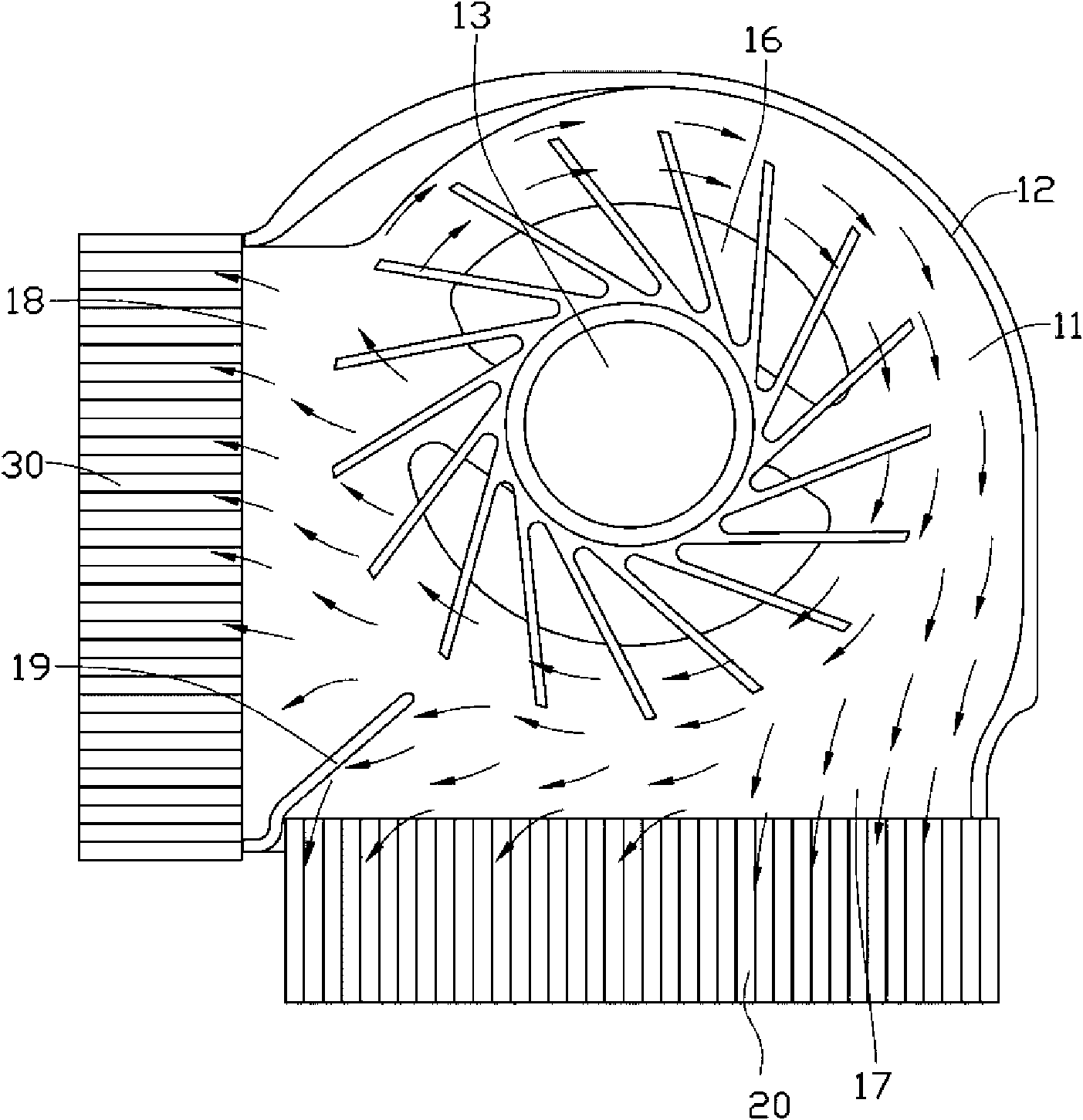

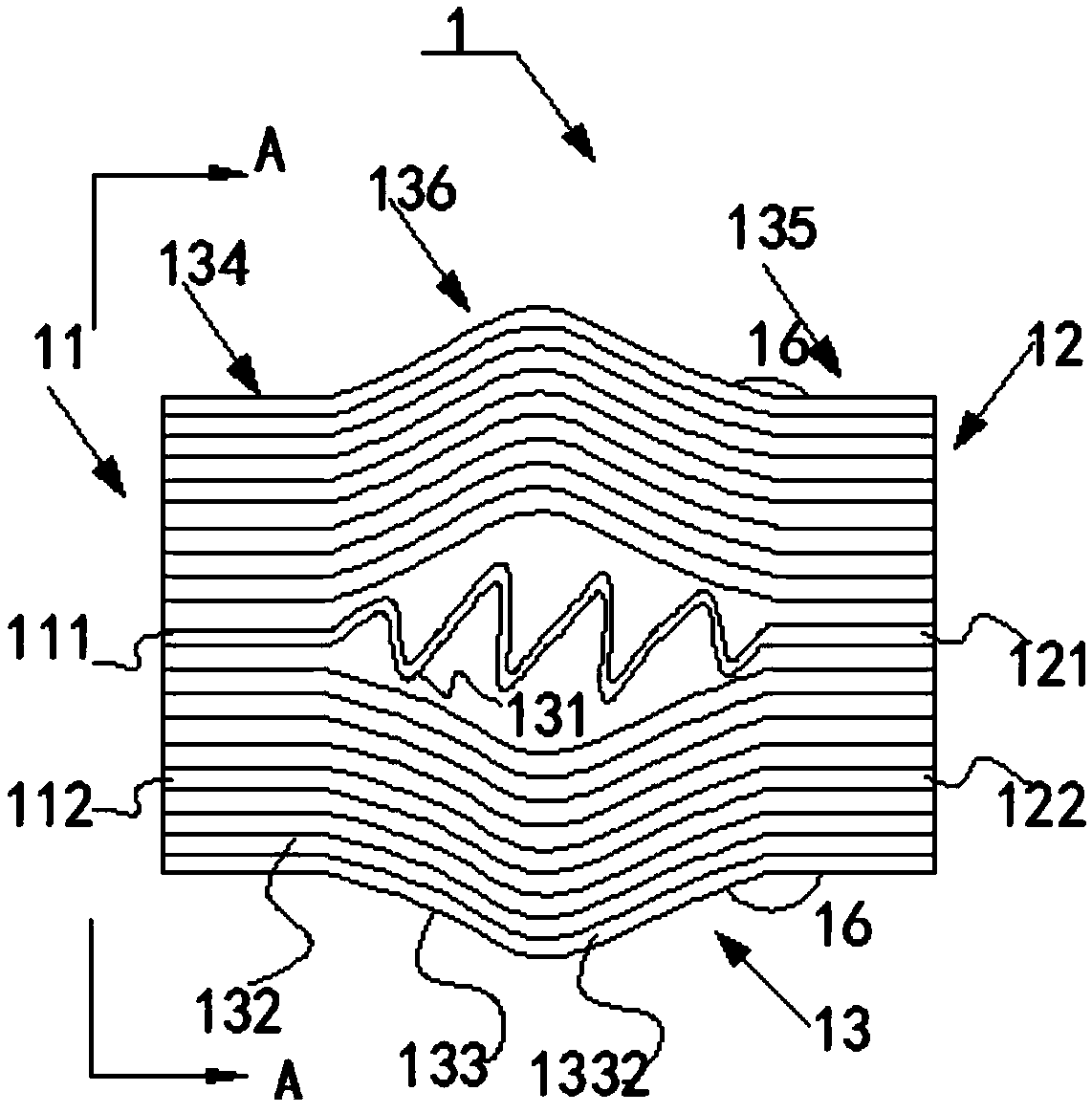

Heat sink and centrifugal fan applied by same

InactiveCN101676569AUniform windLarge air volumePump componentsDigital data processing detailsImpellerAir bearing

A heat sink comprises a centrifugal fan, a first fin group and a second fin group; the centrifugal fan comprises an impeller, a baseboard and a lateral wall surrounding the baseboard; the lateral wallis provided with a first air outlet and a second air outlet; the first fin group and the second fin group are respectively arranged at the first air outlet and the second air outlet; the air flow generated by the impeller is exhausted towards the first air outlet and the second air outlet; a lug is arranged between the first air outlet and the second air outlet; the lug extends from the exteriorof the centrifugal fan towards the interior of the centrifugal fan, changes the quantity of the air flow flowing out of the first air outlet and the second air outlet, guides the air flow towards thefirst fin group and the second fin group at the first air outlet and the second air outlet, thus ensuring the air bearing of the first fin group and the second fin group to be more even, enhancing utilization rate of fins and improving heat sinking effect.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

Air-cooling system for automobile power supply

ActiveCN107394078AUniform windEven heat dissipationSecondary cellsCell component detailsEngineeringAir cooling system

The invention discloses an air-cooling system for an automobile power supply and relates to the field of electric cars. The air-cooling system comprises a battery base, a battery cover which is fixed on the battery base and can be detached, and a plurality of battery modules fixed on the battery base; the battery modules are positioned on the inner side of the battery cover; a plurality of air collection devices are arranged on the front side of the battery base and take the shapes of trumpets with running-through interiors; the big mouths of the air collection devices face a car running direction; a plurality of air inlets are formed in the battery base in a penetrating manner; the upper ends of the air inlets are communicated with the inner side of the battery cover; the lower ends of the air inlets are connected with the small mouths on the rear sides of the air collection devices through connecting pipes; each air collection device is communicated with at least one of the air inlets; and a heat dissipation opening is formed in the battery cover. According to the air-cooling system for the automobile power supply, the effects from of an air source on the different battery modules inside are equal, all the battery modules can well dissipate heat, and the battery performance is guaranteed.

Owner:六安市匠心信息科技有限公司

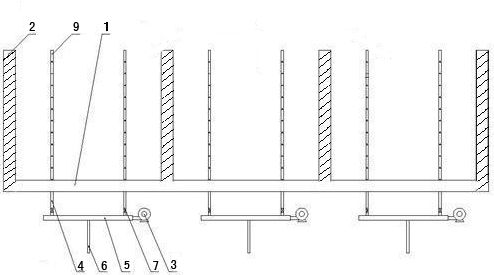

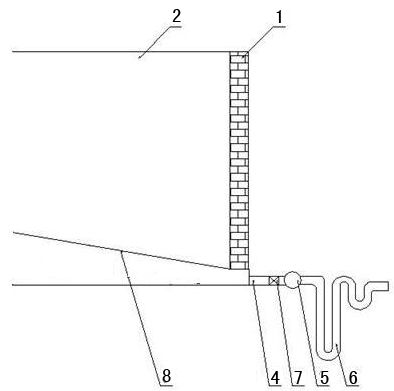

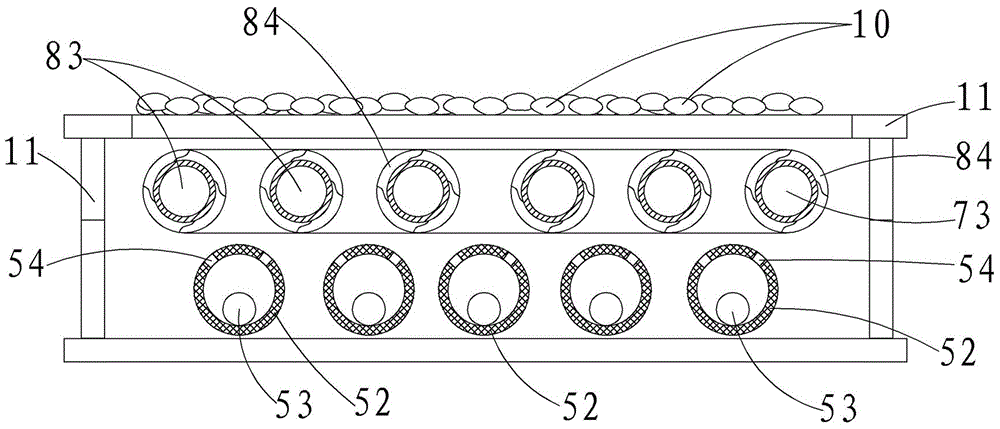

Static aerobic fermentation reactor for domestic garbage

InactiveCN102503599AIncreased load-bearing capacityNot easy to damageClimate change adaptationOrganic fertilisersAgricultural engineeringAir blower

The invention relates to a static aerobic fermentation reactor for domestic garbage. The reactor comprises a fermentation cabin, drainage and ventilation pipes and air blowers, wherein the fermentation cabin has a three-grid type masonry-concrete structure and is enclosed by a main wall and side walls formed at equal intervals; according to the reactor, the drainage and ventilation pipes, main drainage and ventilation pipes and U-shaped drainage pipes are respectively arranged on the ground outside the main wall of a three-grid cabin body correspondingly in a connection mode; the ground of the fermentation cabin is inclined towards outlets of the U-shaped drainage pipes; a drainage and ventilation groove is formed on the ground in each grid of the cabin body parallel to the side walls; cover plates are arranged on the upper end surfaces of the drainage and ventilation grooves respectively; the drainage and ventilation grooves are communicated with the drainage and ventilation pipes corresponding to the drainage and ventilation grooves at the intersections of the bottom of the main wall; the other ends of the drainage and ventilation pipes are communicated with the main drainage and ventilation pipes arranged on the outer side of the main wall; the air blowers are connected to the tail ends of the main drainage and ventilation pipes parallel to the outer side of the main wall; and one U-shaped drainage pipe is vertically arranged on one side of each main drainage and ventilation pipe in a connection mode. The reactor has a simple structure and low cost, is easy and convenient to use and maintain and effectively improves the composting efficiency of produced garbage.

Owner:TIANJIN INST OF AGRI RESOURCES & ENVIRONMENTAL

Heat cycle type clothes processing drying device and method

InactiveCN108103748AReduce heat lossUniform windTextiles and paperLaundry driersMotor driveEngineering

The invention discloses a heat cycle type clothes processing drying device in the clothes processing field. A rotating rod is inserted in a partition plate in a penetrating mode. A drying device is arranged on the top of a motor. An air blower is arranged on the top of a heating pipe. A flow dividing plate is arranged on the right side of a drying chamber. According to the heat cycle, air enters the drying device from the drying chamber, and the dried air enters the heating pipe through the air blower to be heated, then enters the rotating rod and the flow dividing plate, is discharged from air outlets to enter the drying chamber, and enters the drying device from air inlets to form the heat cycle; heat loss is reduced, wind bearing is uniform, hot air enters air ducts of the flow dividingplate and the rotating rod and is divided through the air outlets, the motor drives the rotating rod to rotate, and clothes on a hanging rod rotate around the rotating rod, pass by the air outlet face of the flow dividing plate by turns and bear wind uniformly to be rapidly dried; wind is blown to the front sides and the back sides of the clothes through the flow dividing plate and the rotating rod, and the clothes are rapidly dried.

Owner:石卫祥

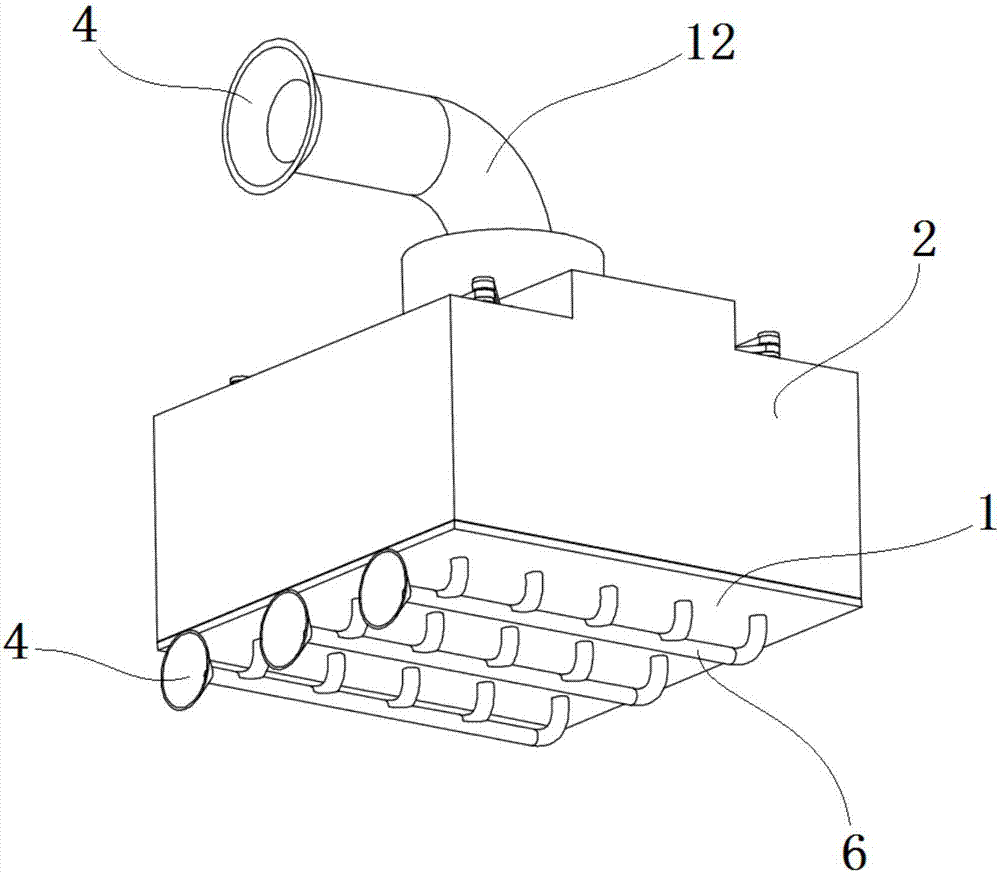

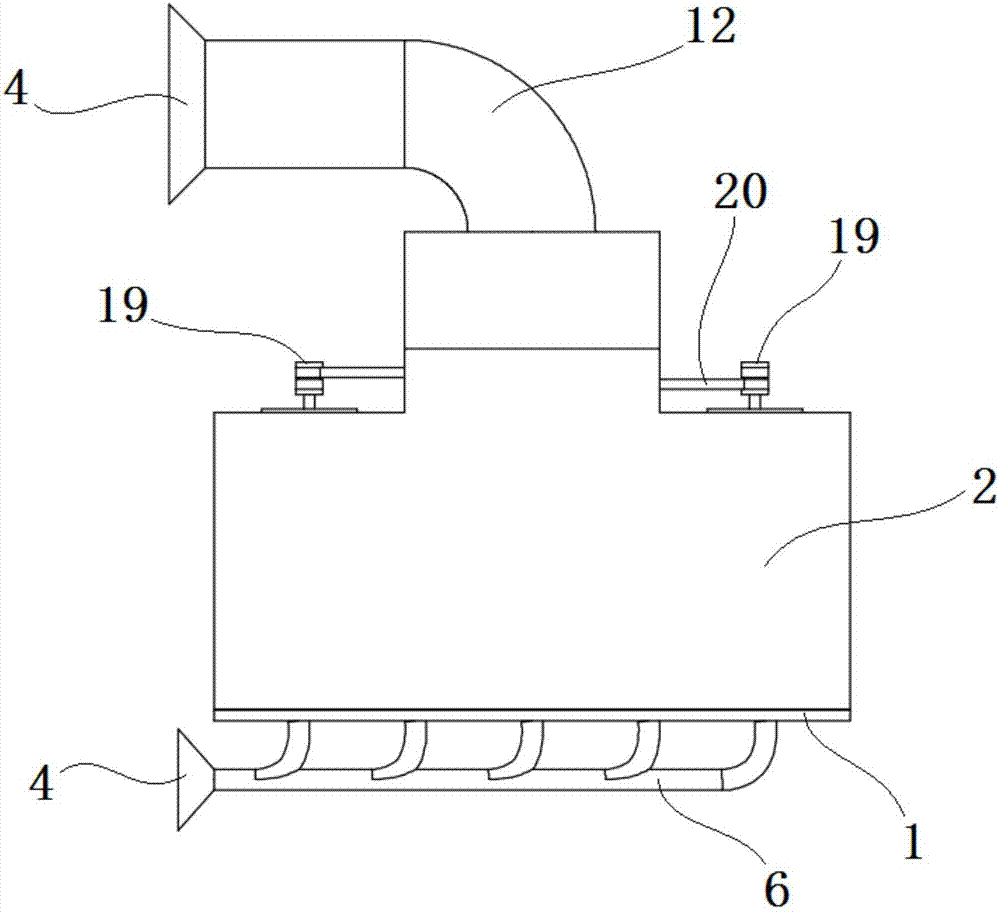

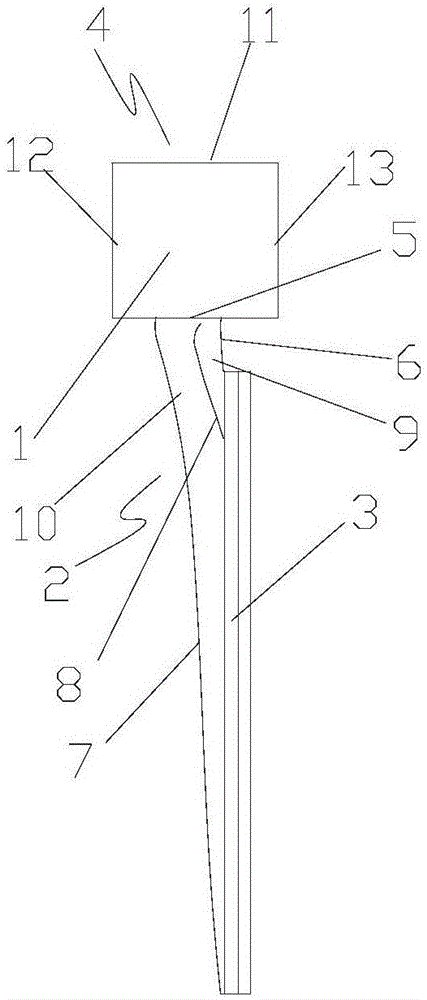

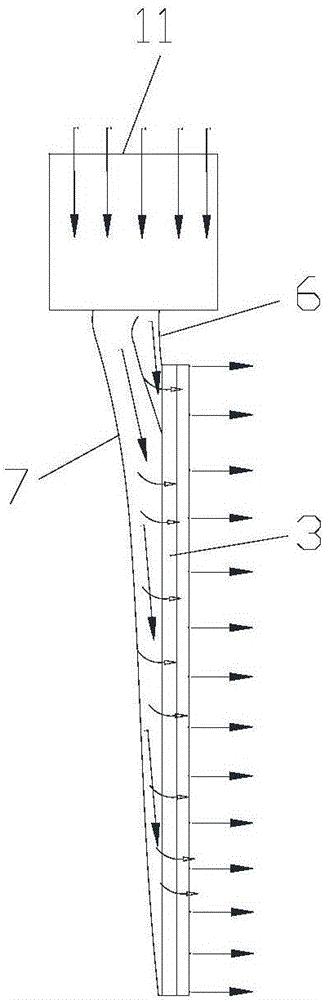

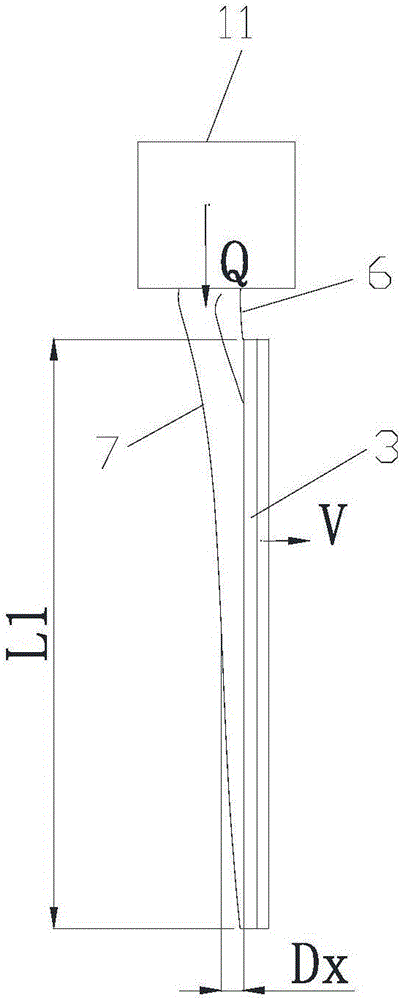

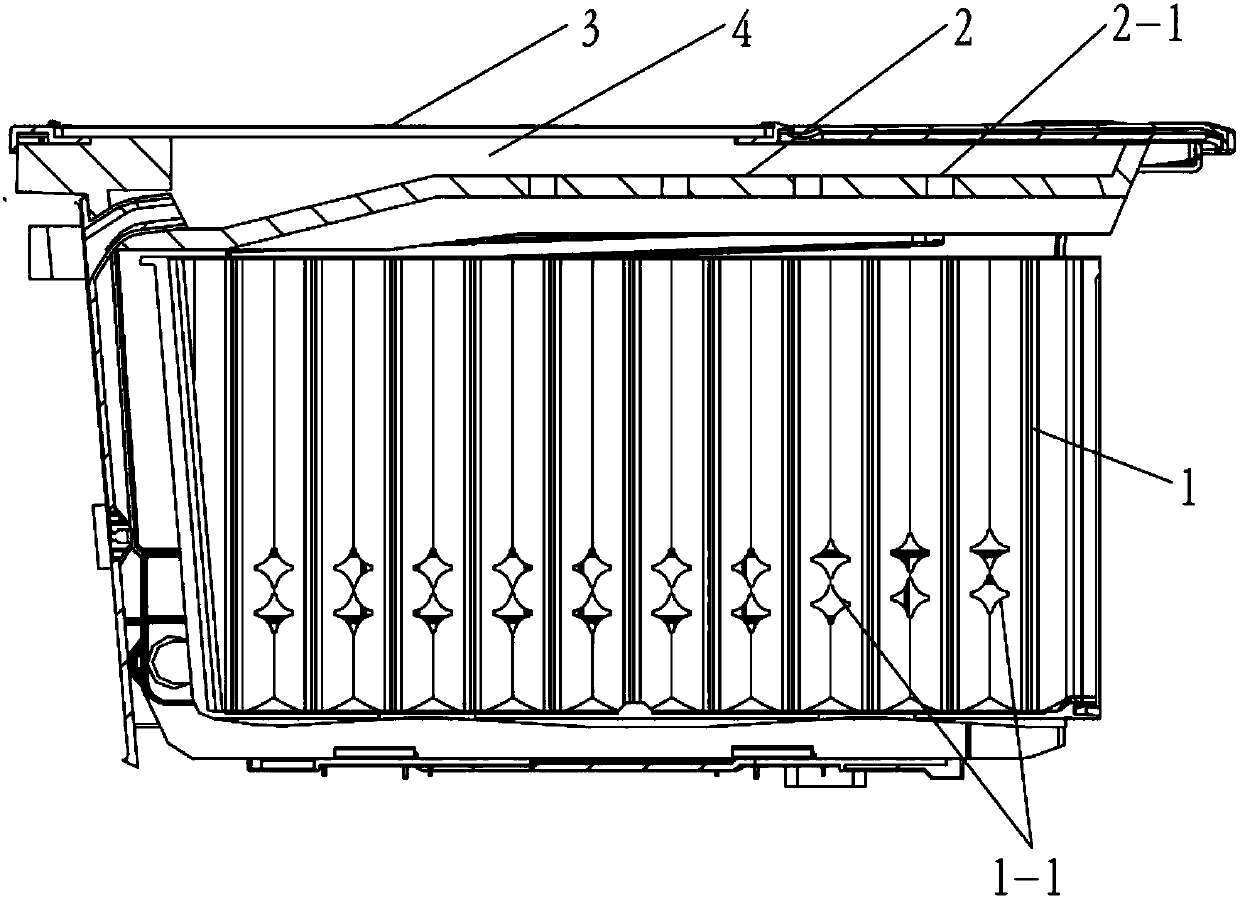

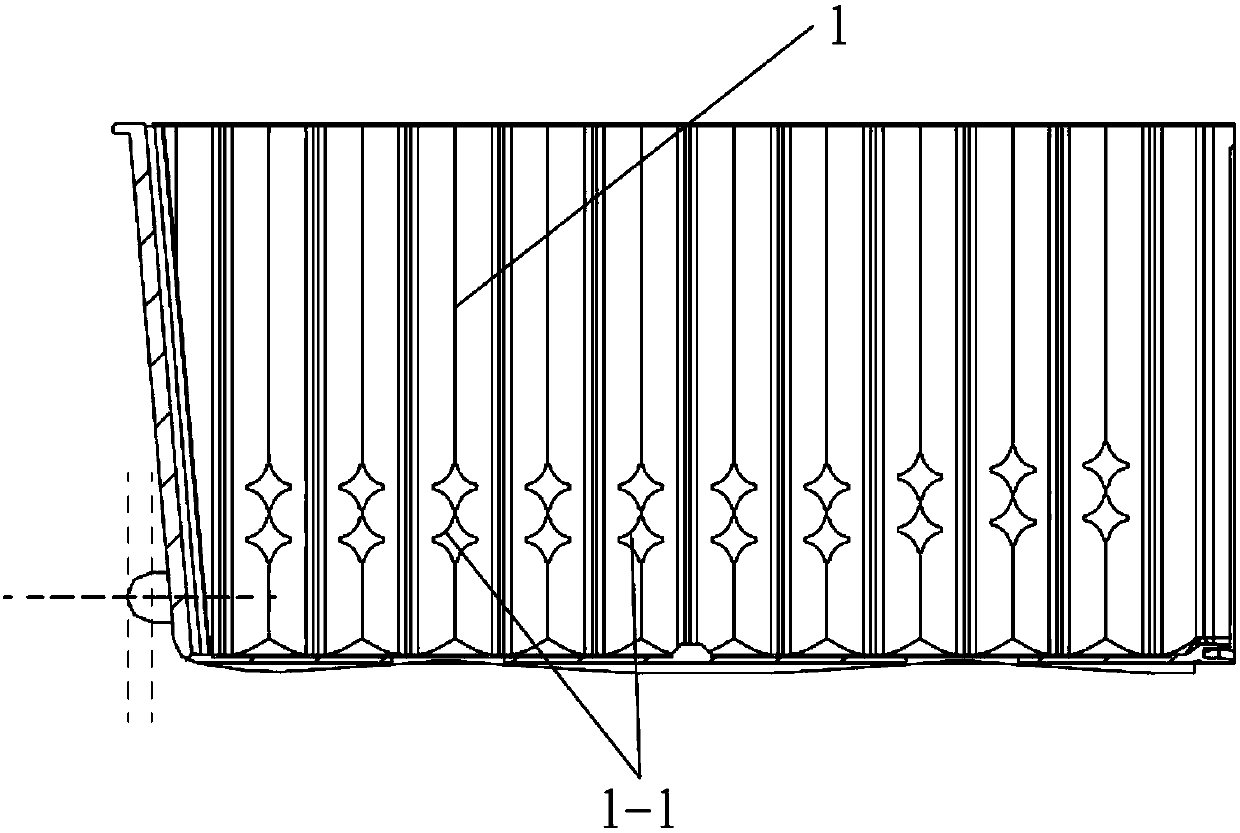

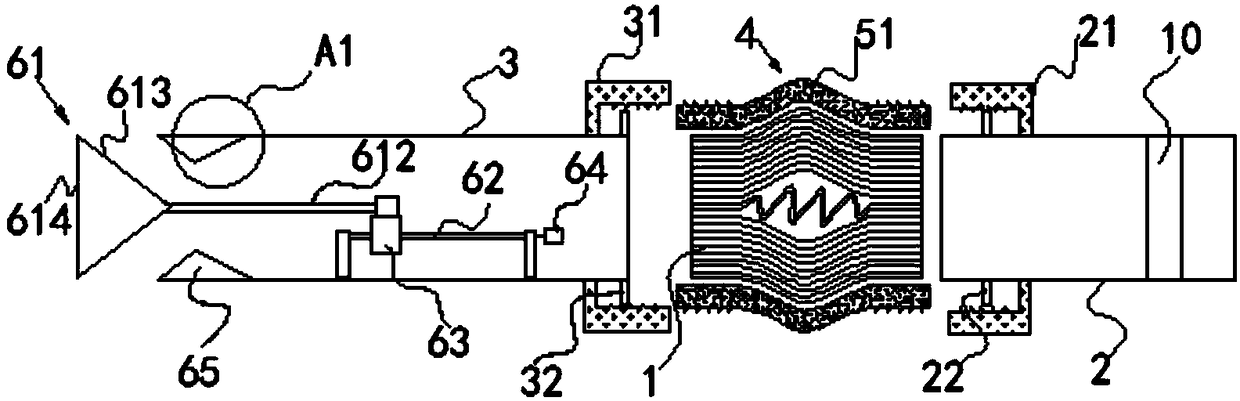

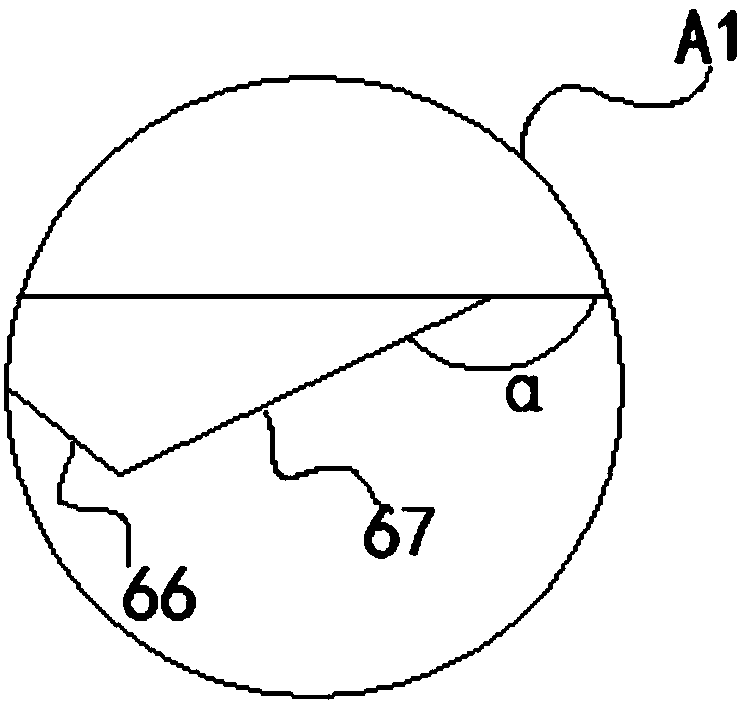

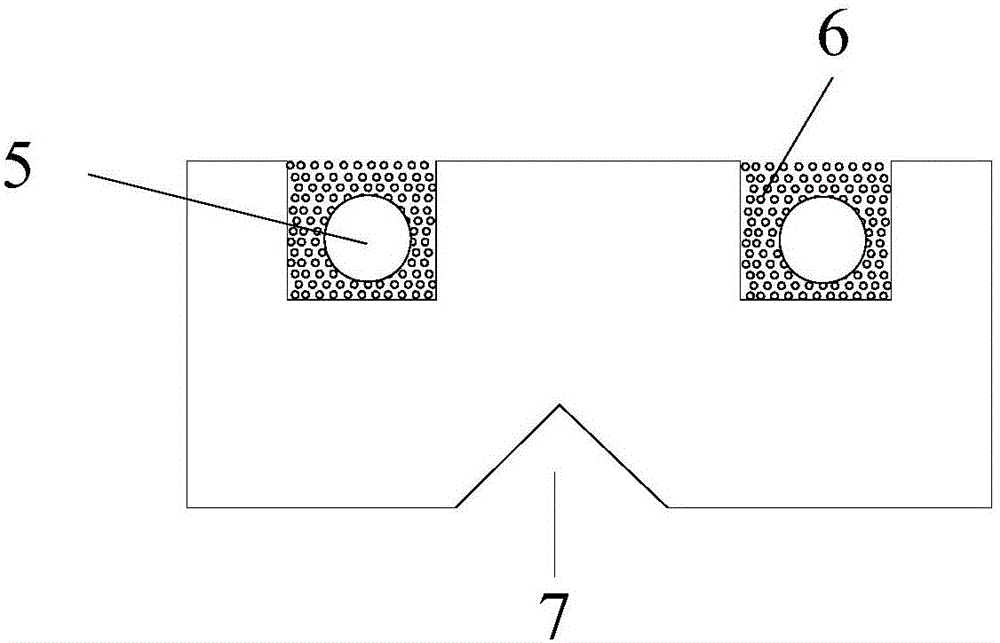

Air conditioner air outlet structure and air conditioner

InactiveCN106403040AReduce flow inertiaUniform windDucting arrangementsLighting and heating apparatusHeat exchangerAerospace engineering

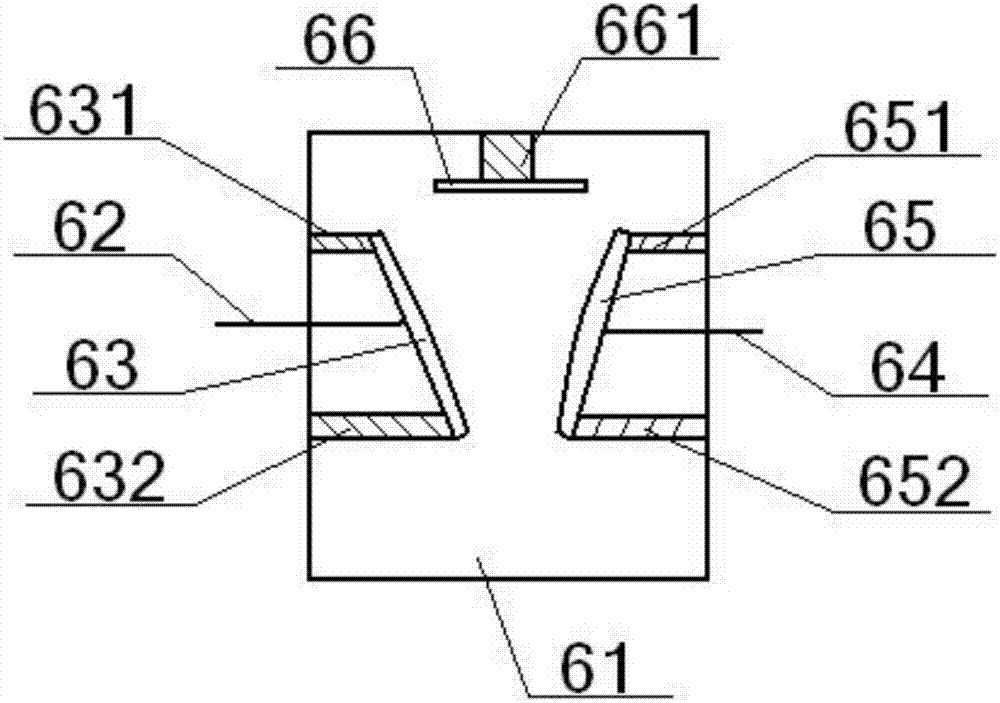

The invention discloses an air conditioner air outlet structure and an air conditioner. The air conditioner air outlet structure comprises a fan (1), an air supply duct (2) and a heat exchanger (3), wherein the fan (1) comprises a fan air inlet (4) and a fan air outlet (5), the air supply duct (2) is connected to the fan air outlet (5), the front side wall (6) of the air supply duct (2) extends to the side, close to the fan air outlet (5), of the heat exchanger (3) from the fan air outlet (5), and the rear side wall (7) of the air supply duct (2) extends to the other side, away from the fan air outlet (5), of the heat exchanger (3) from the fan air outlet (5). The heat exchanger (3) is arranged at an outlet of the air supply duct (2), and the section of the air supply duct (2) is gradually reduced in the direction away from the fan air outlet (5). The air conditioner air outlet structure is uniform in air output, and can effectively guarantee the air output efficiency of the air conditioner.

Owner:GREE ELECTRIC APPLIANCES INC

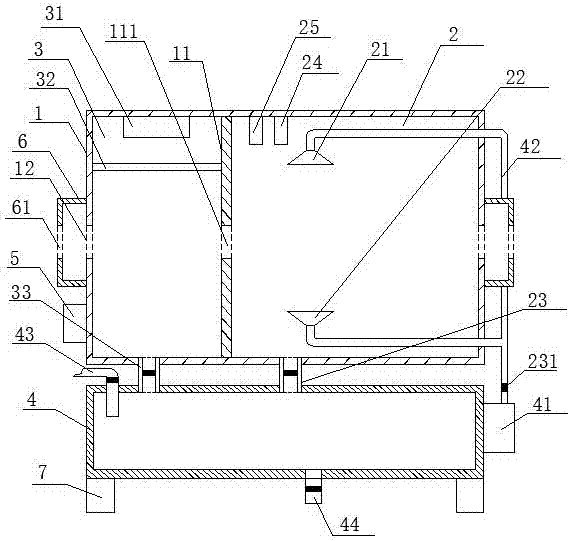

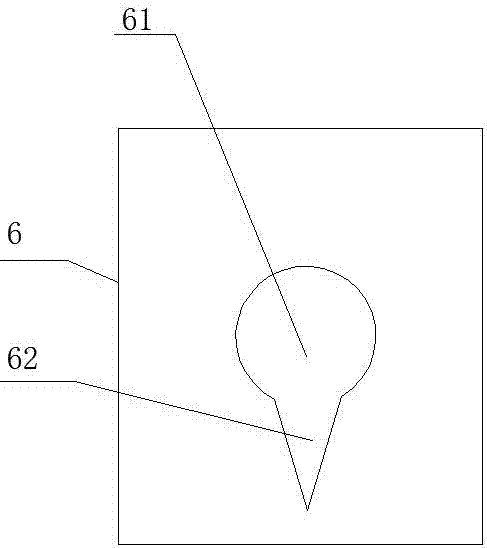

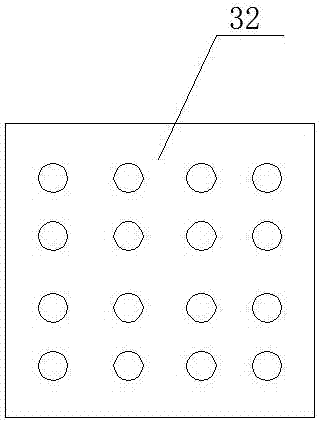

Drawer and refrigerator

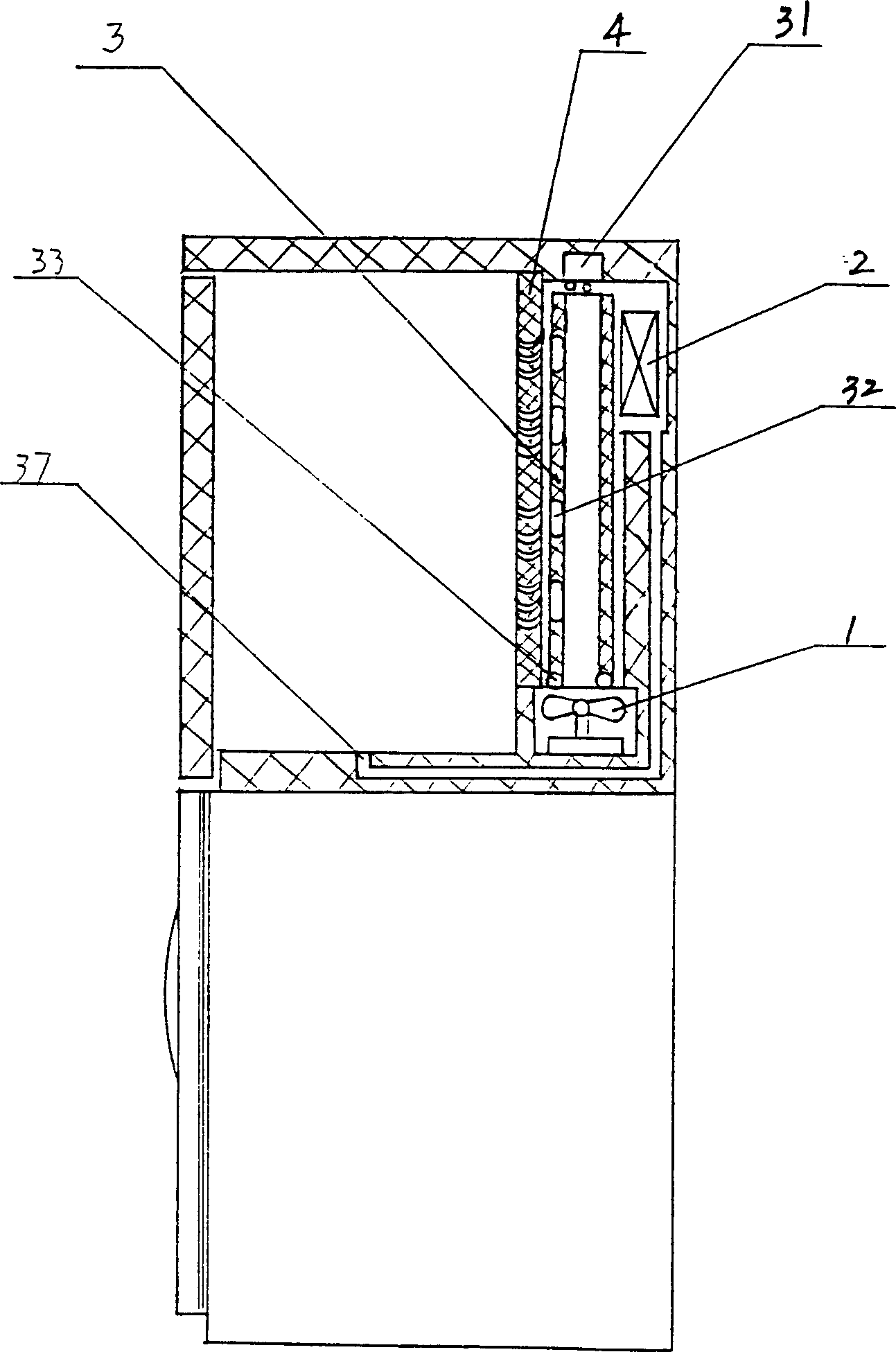

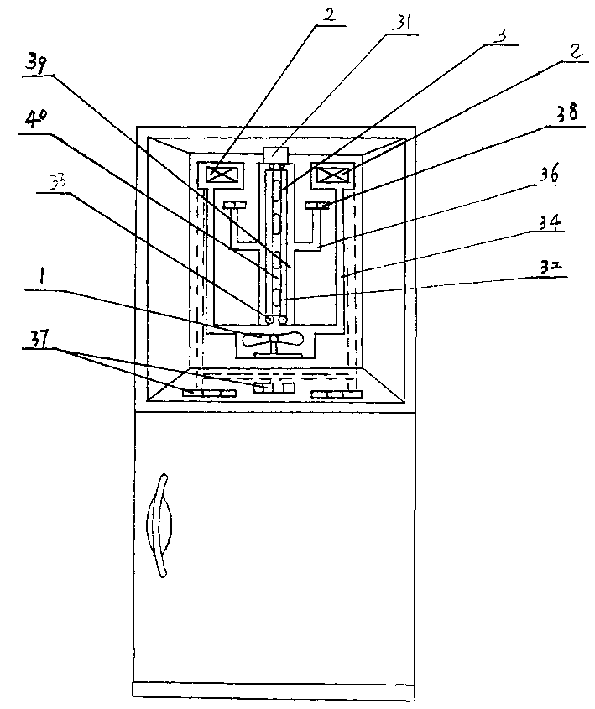

InactiveCN107606868ARealize independent temperature control functionUniform windLighting and heating apparatusCooling fluid circulationTemperature controlRefrigerated temperature

The invention relates to the technical field of refrigerating equipment, in particular to a drawer and a refrigerator. The drawer is mounted in a storage compartment of the refrigerator and comprisesa drawer body with the open upper portion and a storage cavity, and an air duct cover plate used for covering an opening. The air duct cover plate and a shelf of the storage compartment are connectedand then jointly form an air inlet cavity in a defining mode. The air inlet cavity is connected with an air supply opening of the refrigerator, and an air door assembly used for switching the communicating state and the blocking state of the air inlet cavity and the air supply opening is arranged in the connecting position of the air inlet cavity and the air supply opening. An air inlet communicating with the storage cavity is formed in the air duct cover plate. An air outlet communicating with the storage cavity is formed in the side wall of the drawer body. Thus the independent temperature control function inside the drawer can be achieved; and meanwhile, air blowing of the area in the drawer body is uniform, the air outlet path is shortened, the temperature gradient is small, temperature uniformity inside the drawer is effectively improved, and thus foods placed in the drawer can be in the environment with the constant and uniform temperature all the time so as to keep fresh and nutritive for a long time.

Owner:HEFEI HUALING CO LTD +2

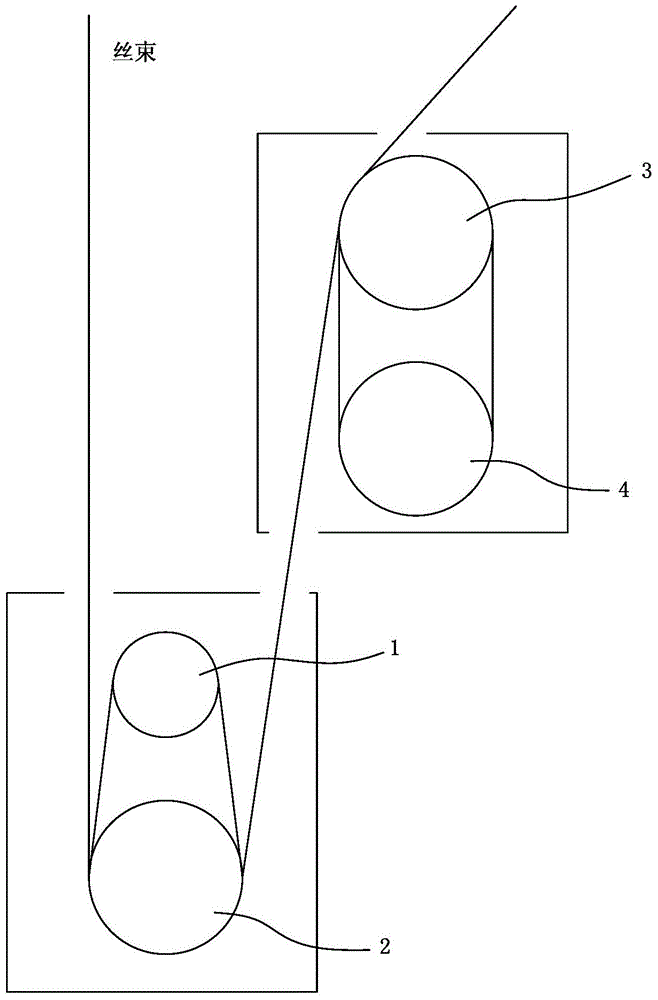

Production process of nylon-6 coarse-denier high-strength yarns

InactiveCN104695033AReduced drawabilityPromote crystallizationArtificial thread manufacturing machinesFilament manufactureBreaking strengthYarn

A production process of nylon-6 coarse-denier high-strength yarns includes slicing, melting, metering, spinning, cooling, oiling, pre-interlacing, drafting and setting, main interlacing, and winding. In the slicing step, nylon-6 slices 2.8 to 3.2 in viscosity are selected. Melting is performed at the temperature of 270 DEG C to 280 DEG C. In the spinning step, pore diameter of a spinneret plate is 0.36mm, pore length is 1.08 mm, and initial pressure of a component is 135 bars to 142 bars. In the oiling step, oil resistant to high temperature, anti-static and high in cohesion is adopted. The nylon-6 slices of specific viscosity are used, the temperature of the melting step is adjusted, and a melt pipe, a spinning component, an oiling device, pre-interlacing and drafting and setting are modified, and the nylon-6 coarse-denier high-strength yarns up to 6.2Cn / dtex in breaking strength are produced.

Owner:QUANZHOU TIANYU CHEM FIBER WEAVING IND

Air-out cover and refrigerator with same

ActiveCN102080909AUniform temperatureEfficient use ofLighting and heating apparatusCooling fluid circulationWaste management

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

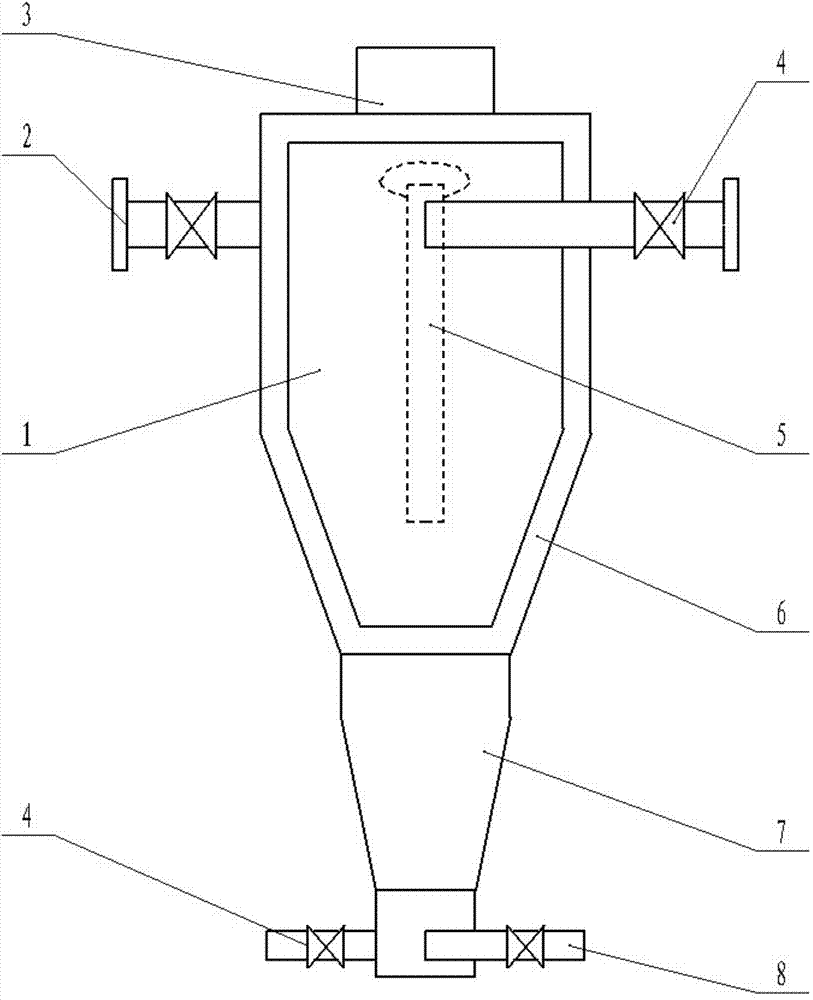

Electrolytic manganese dioxide cyclone separator

InactiveCN103586144ASmall pressure lossAvoid the phenomenon of irregular rotation and swingReversed direction vortexCycloneElectrolysis

The invention discloses an electrolytic manganese dioxide cyclone separator which comprises a barrel body, two air inlet pipes A and an air outlet pipe, wherein the upper part of the barrel body is a cylinder, and the lower part of the barrel body is a cone; the air inlet pipes A are arranged at tangent positions on the outer wall of the cylinder at the upper end of the barrel body; the air outlet pipe is arranged at the cover of the upper end of the barrel body; a vortex stabilization pipe is arranged under the air outlet pipe in the barrel body; a cyclone joint is arranged at the lower end of the barrel body; two air inlet pipes B are arranged on the cyclone joint. According to the electrolytic manganese dioxide cyclone separator, the structure of an inner flow field of the cyclone separator is effectively improved, and the pressure loss of the cyclone separator is reduced; furthermore, the electrolytic manganese dioxide cyclone separator can effectively implement secondary separation, so that the quality of a separated material is improved, and the requirement on electrolytic manganese dioxide production is met. The electrolytic manganese dioxide cyclone separator is simple and reasonable in structure, wide in application range and suitable for popularization and application.

Owner:GUANGXI GUILIU CHEM CO LTD

Beef jerk automatic drying device

InactiveCN107726795AUniform windIncrease air flowDrying gas arrangementsDrying chambers/containersFlavorCam

The invention relates to the technical field of food processing, and discloses a beef jerk automatic drying device. The beef jerk automatic drying device comprises a rack, an air supply box and a beefjerk manufacturing box. The air supply box and the beef jerk manufacturing box are both mounted on the rack. The beef jerk manufacturing box communicates with the air supply box. A hollow plate is arranged on the rack. Turbines are rotationally connected in the hollow plate. Beef hanging rods are arranged in the beef jerk manufacturing box. A shaft rod is arranged in the beef jerk manufacturing box and provided with beef beating hammers. A motor is arranged in the beef jerk manufacturing box. The output end of the motor is connected with a cam abutting against the beef hanging rods. First spline teeth are arranged on the shaft rod. A sliding rod is arranged on the rack. A spring is connected between the sliding rod and the rack. Second spline teeth and gear teeth are arranged on the sliding rod. The sliding rod is engaged with the first spline teeth on the shaft rod through the second spline teeth. A sector gear coaxial with the cam is arranged in the beef jerk manufacturing box. Thesliding rod is engaged with the sector gear through the gear teeth. The beef jerk automatic drying device solves the problems that in the prior art, a hot air drying device is adopted for air-drying beef jerk, and consequently the beef jerk loses the special flavor.

Owner:贵州务川仡苗特色食品有限公司

Cable cooling device

InactiveCN107195390AReduce processImprove work efficiencyInsulating conductors/cablesPetroleum engineeringResidual moisture

The invention discloses a cable cooling device, which relates to the technical field of cable preparation, and comprises a cooling box. Openings are respectively arranged in the middle of the left and right side walls of the cooling box, and the center lines of the openings overlap. The side and the inner cavity of the cooling box form a water-cooled cooling chamber, and the left side of the partition forms a drying chamber with the inner cavity of the cooling box. There is a hole in the center of the partition that coincides with the center line and the opening, and the water-cooled cooling chamber is connected to the drying chamber through the hole. The invention uses water cooling to cool down the temperature of the cable, and then performs drying treatment to remove the residual moisture on the surface of the cable, saves procedures, improves work efficiency, and is easy to operate.

Owner:山东励仙电力工程有限公司

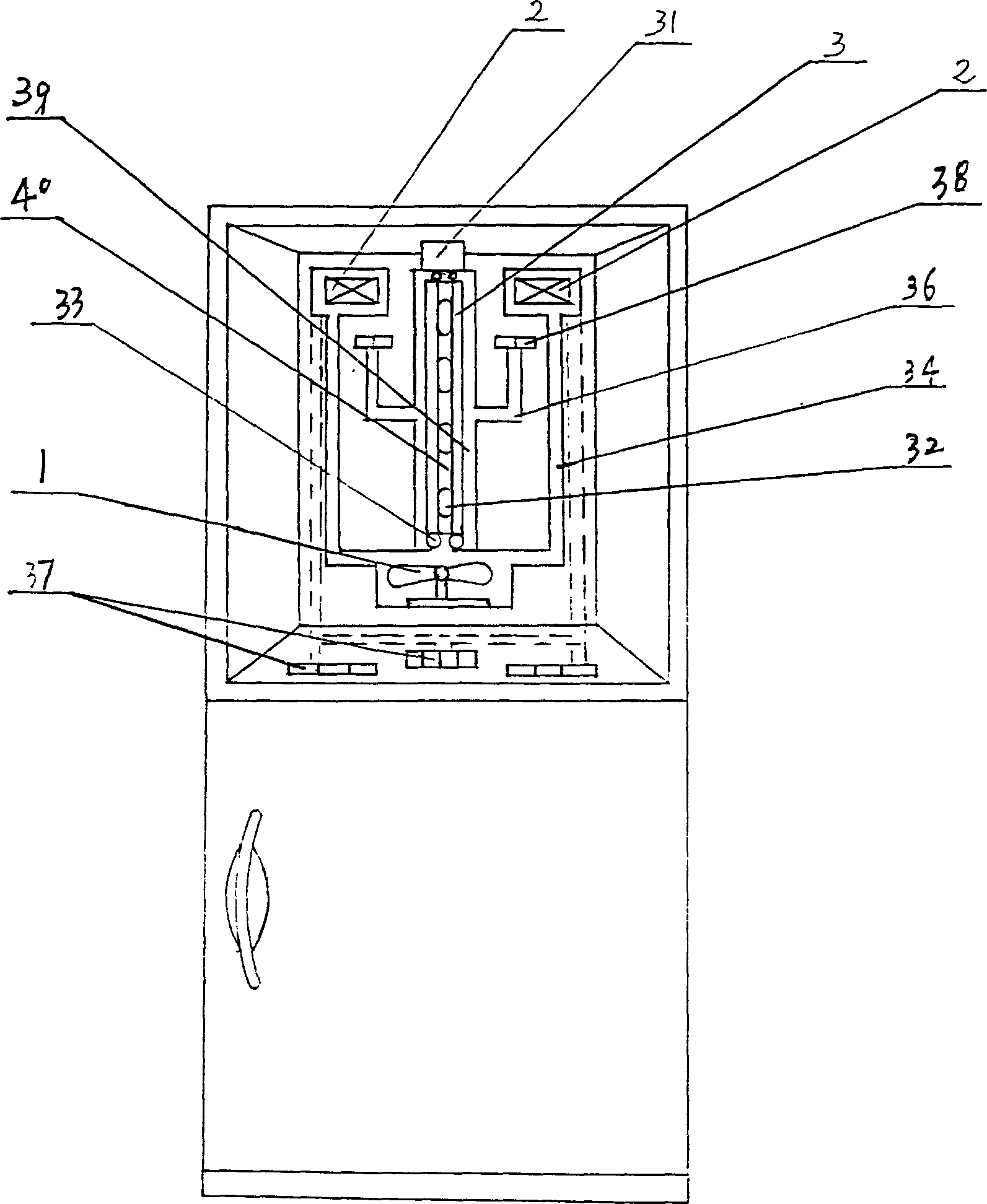

Blower cooling system for blower cooled refrigerator

InactiveCN1421665AUniform temperaturePrevent spoilageLighting and heating apparatusDomestic refrigeratorsCold airEngineering

The blower cooling system for blower cooled refrigerator has one increased rotary wind channel to the back wall of the refrigerator. The rotary wind channel is communicated to original wind channel. Inside the rotary wind channel, there are one wind column with several wind holes, one motor to drive the wind column to rotate at one end of the wind column, and one bearing at the other end. The wind column has one axial notch with wind outlet. One wind lattice with arced blades is set between the wind channel and the refrigerator compartment. The blower cooling system may form rotary stereo wind to deliver cold air everywhere in the compartment of refrigerator to ensure temperature homogeneous and no rot of food.

Owner:HAIER GRP CORP +1

Indoor unit of air conditioner and wind board

ActiveCN104697057AReduce wind speedNo wind effectLighting and heating apparatusAir conditioning systemsEngineering

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

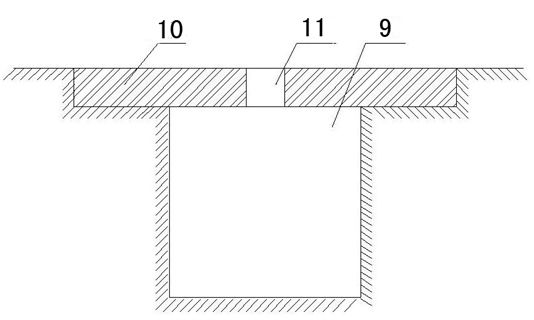

Through-wall purification ventilation pipe with induced draft fan

ActiveCN108180592AAir volume adjustmentEasy to useDucting arrangementsMechanical apparatusVentilation tubeAir volume

The invention discloses a through-wall purification ventilation pipe with an induced draft fan. The through-wall purification ventilation pipe comprises a ventilation pipe, a filter device and a pipefan; the ventilation pipe comprises a first section of ventilation pipe and a second section of ventilation pipe; the pipe fan is arranged on the first section of ventilation pipe; the filter device comprises a filter screen and a filter screen mounting shell; the filter screen mounting shell comprises two half mounting shells with the same structures; the first section of ventilation pipe is provided with a first mounting cover; and the second section of ventilation pipe is provided with a second mounting cover. The through-wall purification ventilation pipe is provided with the induced draftfan for achieving a suction function; the novel filter screen is arranged in the ventilation pipe to achieve a filter function; through extension of a gas filter path, the designed filter screen achieves the purpose of prolonging the contacted time of gas with the filter screen, so that the purifying efficiency of the filter screen is high, and the filter screen can be singly used by deviating from a purifier when the air purifying effect is improved; and in addition, an air volume adjusting device is designed to achieve less mounting space, simple operation, reliable structure and high automation degree.

Owner:KUNSHAN SILAIMU ENERGY SAVING TECH CO LTD

Wind guide device, wind guide control method and air conditioner

PendingCN106958860AAffect comfortGuaranteed comfortMechanical apparatusSpace heating and ventilation safety systemsWind directionBlow out

The invention provides a wind guide device, a wind guide control method and an air conditioner. The wind guide device comprises a wind channel assembly and a wind door assembly. The wind channel assembly is connected with a wind wheel assembly and arranged in a shell at two wind outlet areas. The wind door assembly is mounted on the shell and comprises multiple wind doors used for opening or closing a middle wind outlet or two side wind outlets. The multiple wind doors comprise at least one folding door and at least one cylindrical rotating door. By means of the wind guide device, wind generated by working of the wind wheel assembly is blown out to the outer environment by different parts of the middle wind outlet or the side wind outlets opened through expansion or contraction of the folding door to different positions, and the middle wind outlet or the side wind outlets can blow out wind in different directions in the wind outlet state; the cylindrical rotating doors rotate so that ventilation channels can be located at different positions to communicate the inner portion of the shell with the outer portion of the shell to open the middle wind outlet or the side wind outlets; the wind outlet direction can be changed; the wind outlet range can be widened; and the use experience of a user can be improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

Solid heat storage device

ActiveCN105783564ASpeed up the flowAverage fully utilizedSafety devices for heat exchange apparatusHeat storage plantsFlueOperations management

The embodiment of the invention discloses a solid heat storage device. The solid heat storage device is characterized by comprising a shell, an inner container arranged in the shell and divided into a heat storage bin and a heat supply bin which communicate with each other, solid heat storage bodies arranged in the heat storage bin, heating pipes arranged in the solid heat storage bodies, ventilation channels arranged in the solid heat storage bodies and penetrating the solid heat storage bodies, an air flue making the heat storage bin and the heat supply bin communicate with each other, and a draught fan used for driving gas in the air flue to flow, wherein the air flue communicates with the heat storage bin through vents formed in the side wall of the heat storage bin and increased from bottom to top sequentially; and the ventilation channels are obliquely arranged, and the two ends of each ventilation channel face an upper opening and a lower opening. Therefore, through the oblique arrangement of the ventilation channels, the heat storage and supply efficiency is improved, the vents are sequentially increased from bottom to top, air force obtained at the positions away from the vents and air force obtained at the positions close to the vents are basically balanced, and the situation that the heat storage and supply efficiency is affected due to the generation of turbulent flow is avoided.

Owner:北京嘉能智创科技有限公司

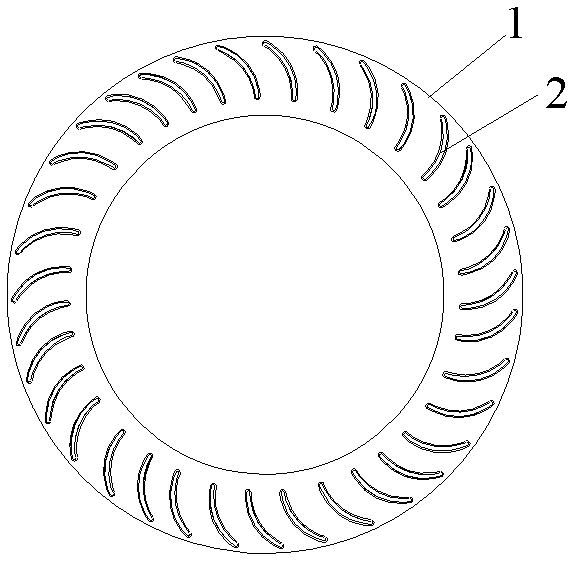

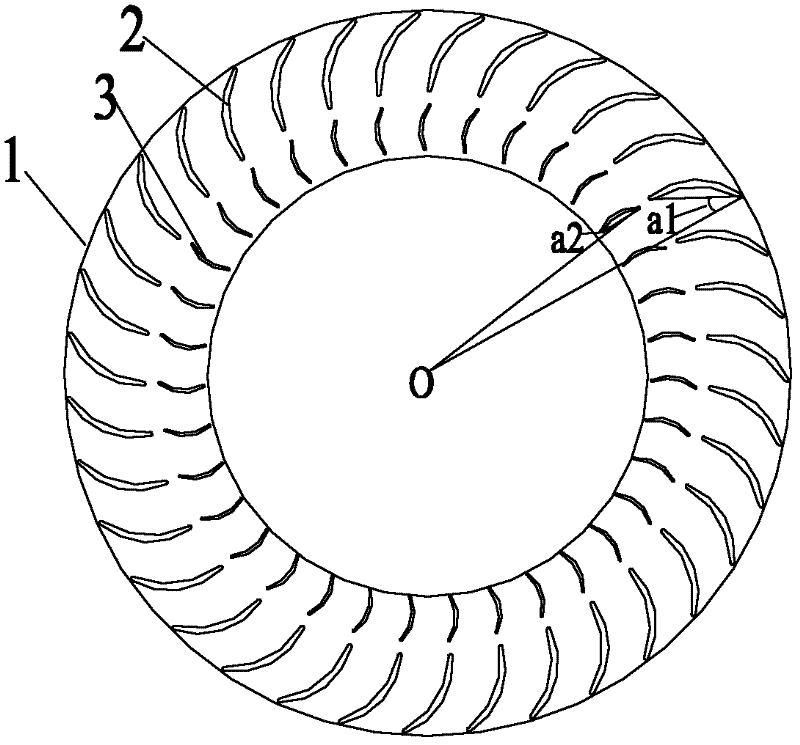

A kind of impeller structure and cross-flow fan

The invention discloses an impeller structure, which includes a fixed frame, in which at least two rows of blade groups are arranged, each row of blade groups includes a plurality of blades, and each row of blade groups is arranged around the axis of the fixed frame. The impeller structure of the present invention is provided with at least two rows of blade groups, so that the air flow is subjected to the force of the blades four times at least four times. Among the at least two rows of blade groups, the blades in the second row of blade groups play an auxiliary role and can play a role. The role of breaking the vortex and guiding the airflow, thereby reducing the eccentric vortex in the cross-flow wind wheel, thereby reducing the air volume of the secondary return flow of the cross-flow fan, increasing the outlet air volume, improving the flow field characteristics, and making the air output more uniform , At the same time, this at least two rows of blades can also break up the large vortex, thereby reducing noise. Wherein, the second row of blade sets plays a role in guiding the airflow, which can change the original flow direction of the airflow, guide the airflow to flow to the other side of the impeller and then flow out of the impeller. The invention also discloses a cross-flow fan.

Owner:GUANGDONG CHIGO AIR CONDITIONING

Method for eliminating glass wind spots and wind grating swing mechanism

ActiveCN103833201AReduce formationAvoid relative stillnessGlass tempering apparatusEngineeringGrating

The primary purpose of the invention is to discloses a method for eliminating glass wind spots, especially a method for eliminating wind spots formed when glass swinging stops; several wind gratings are disposed above and below a conveying roller; the wind gratings are uniformly distributed in the glass conveying direction to form a wind blowing covering area; during cooling, the glass is driven by the conveying roller to reciprocate in the wind blowing covering area in the glass conveying direction; when the moving direction of the glass changes, the wind gratings are moved to perform relative movement to the glass in the glass conveying direction. At the moment when the glass swings back, the phenomenon of nonuniform stress caused by glass stop is eliminated by the relative movement of the wind gratings. The secondary purpose of the invention is to discloses a wind grating swing mechanism.

Owner:LUOYANG LANDGLASS TECH CO LTD

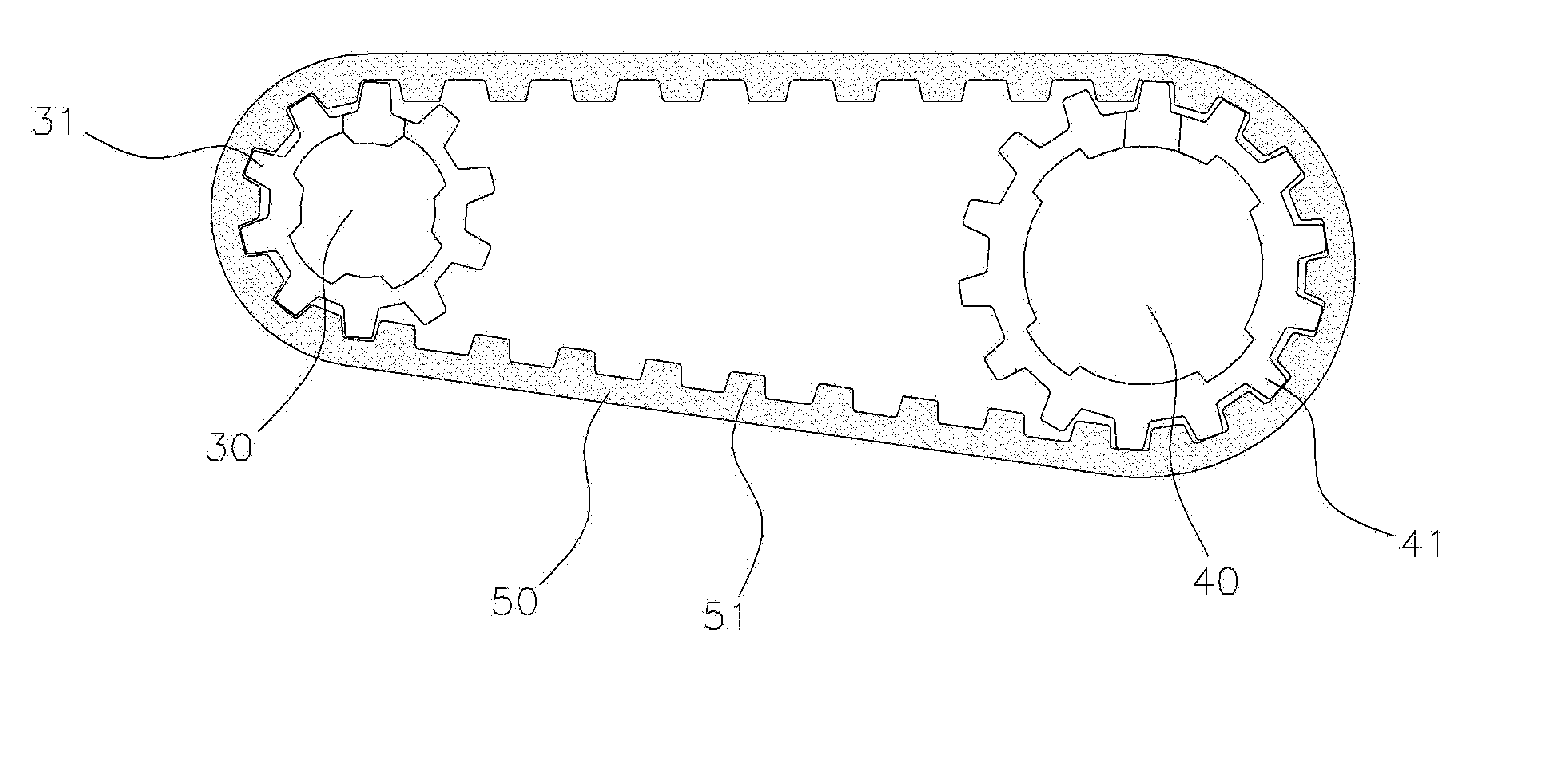

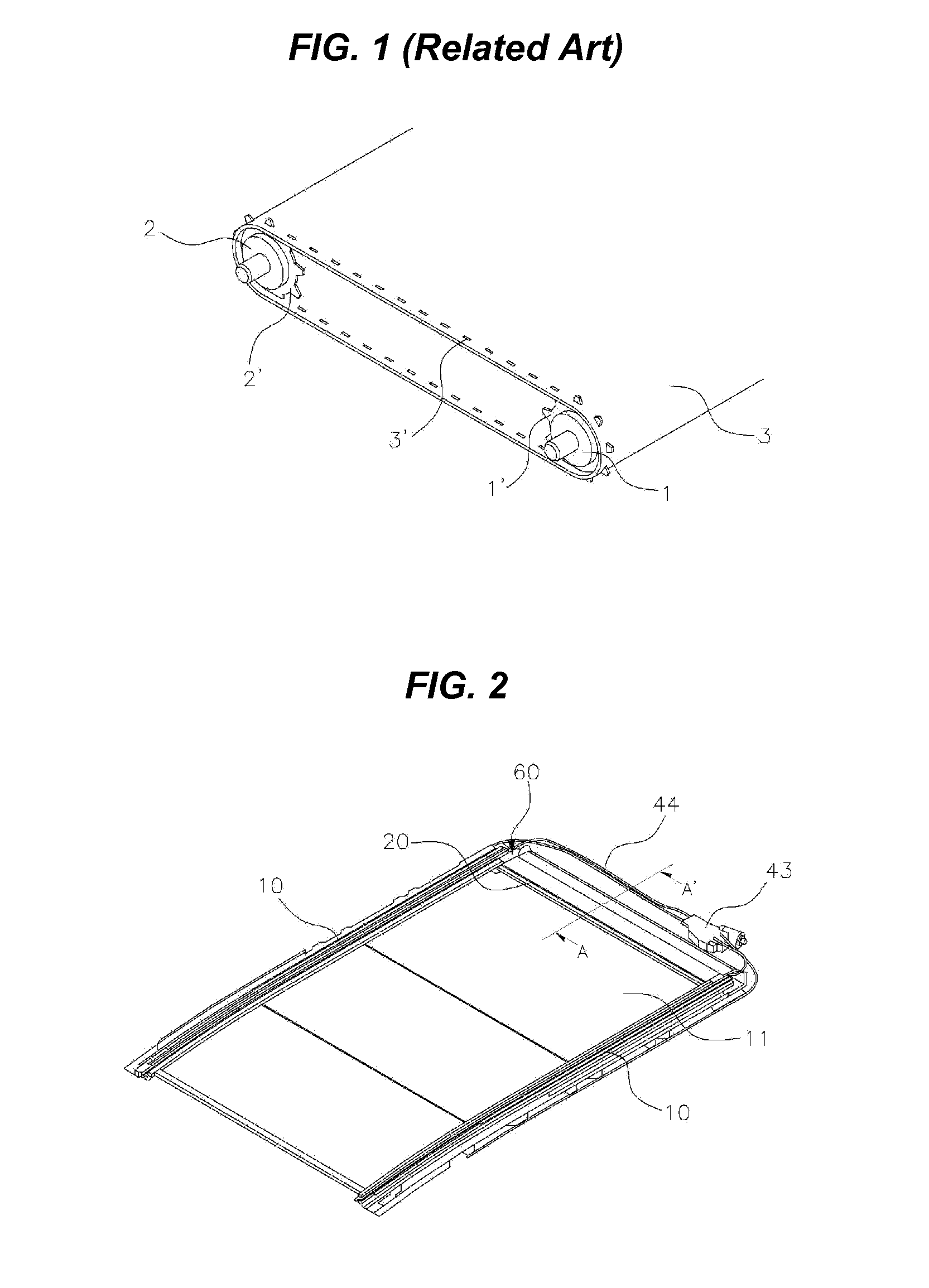

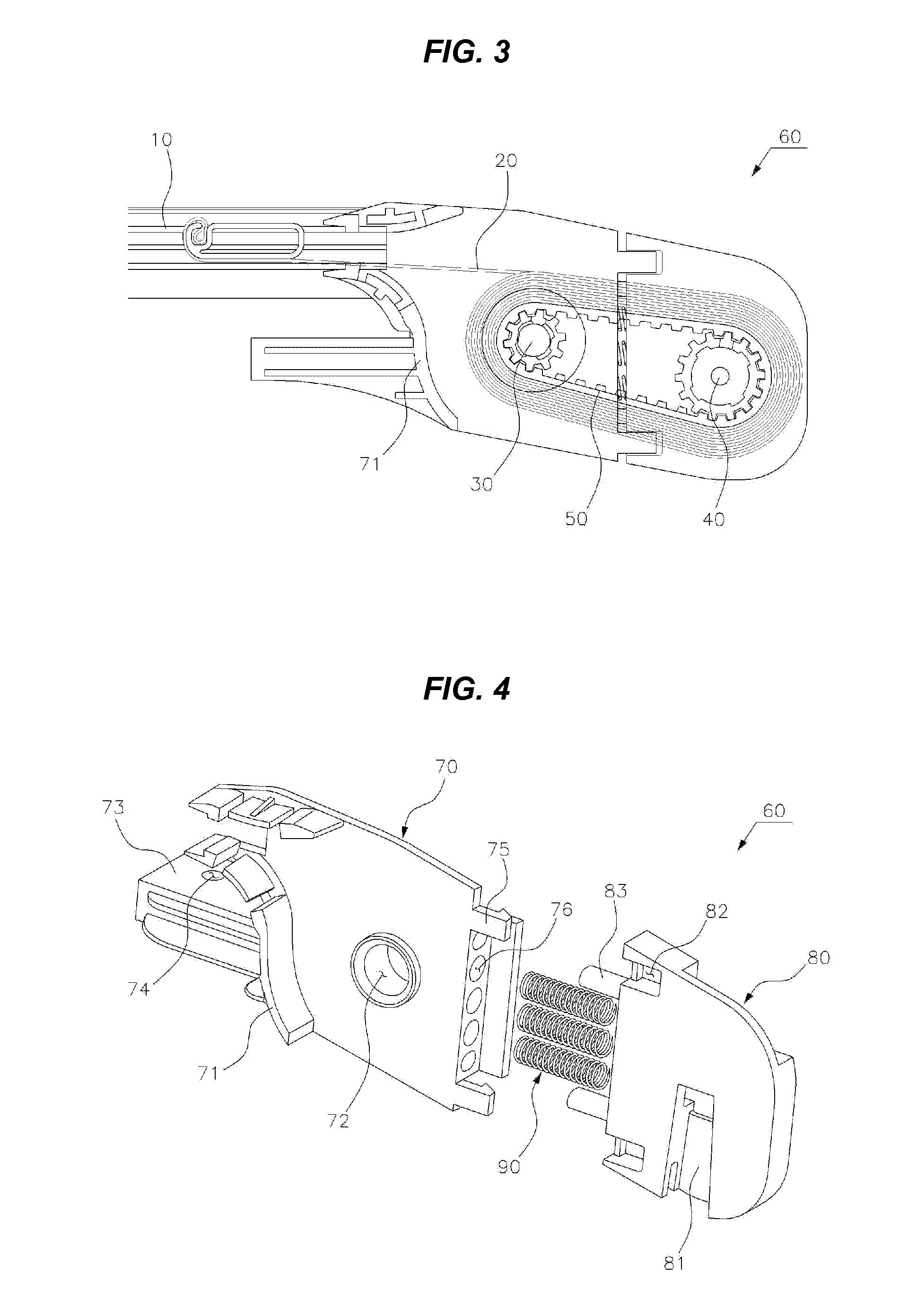

Structure of roll blind using dual roller

A structure of a roll blind that moves in a front-back direction of a vehicle to selectively shade a sunroof glass may include a pair of sunroof frames formed on both lower sides of the sunroof glass in a longitudinal direction of the vehicle, a main roller disposed at the one end of the sunroof frame in a vehicle width direction and can rotate through a motor, an idle roller disposed in the vehicle width direction adjacent to the main roller, a roller tube coupled to and wrapping the main roller and the idle roller to form a closed loop, and a roller guide coupled to both ends of the main roller and the idle roller and including a guide portion formed to protrude so that the blind maintains a constant height.

Owner:HYUNDAI MOTOR CO LTD

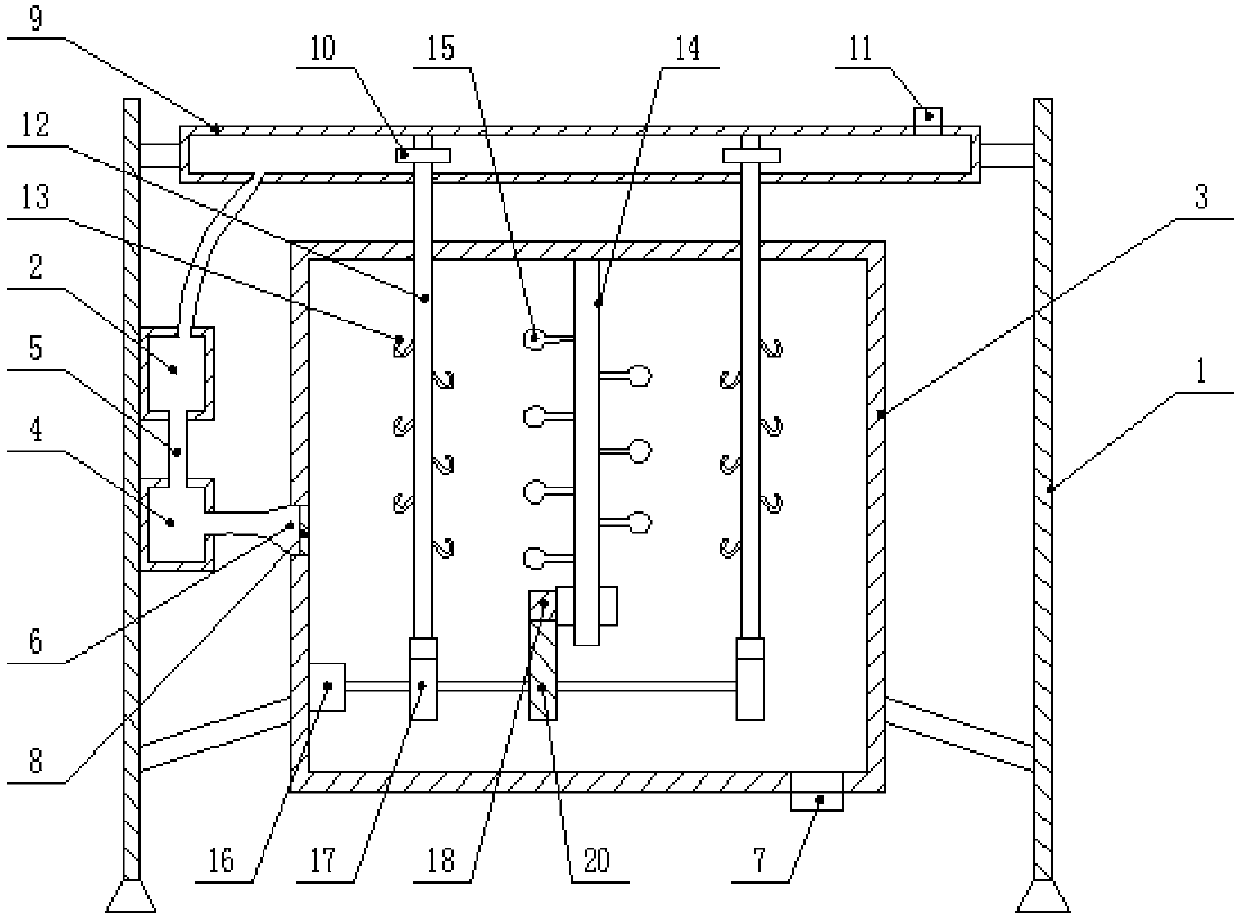

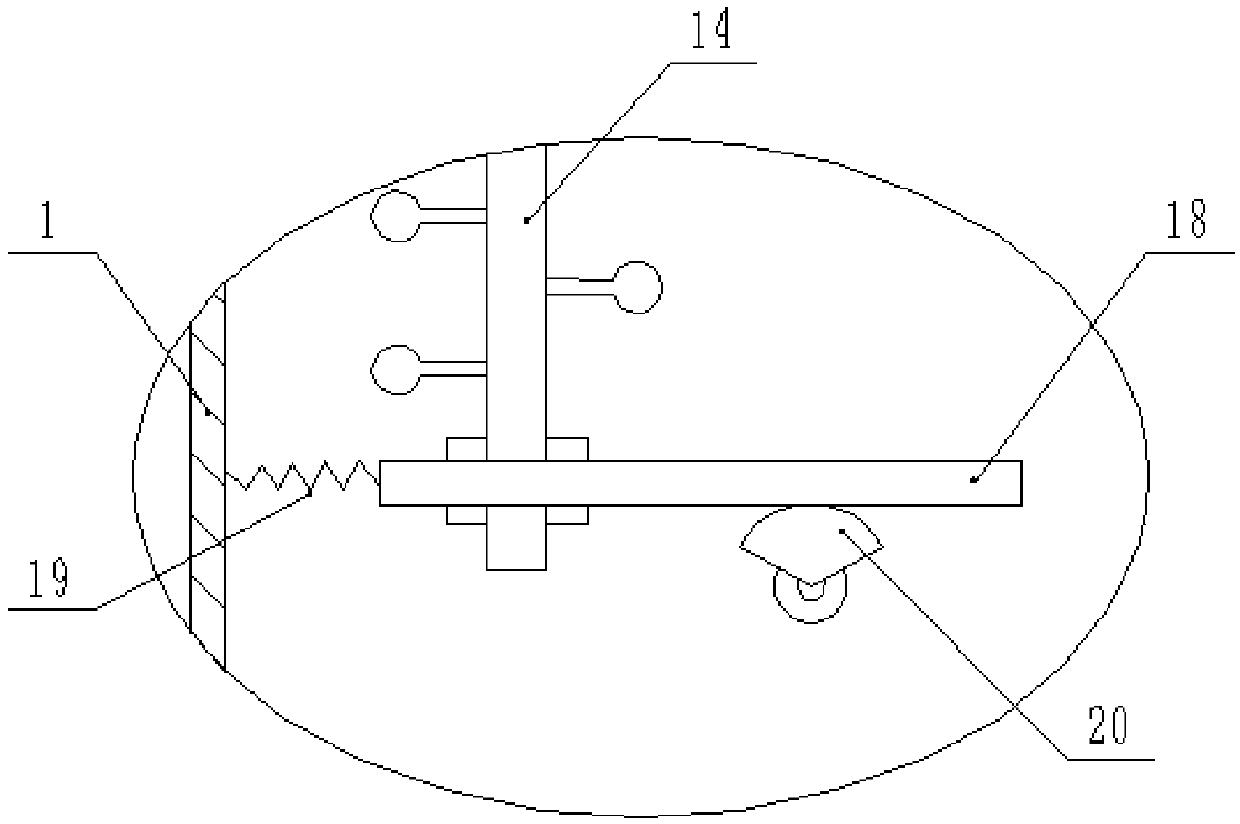

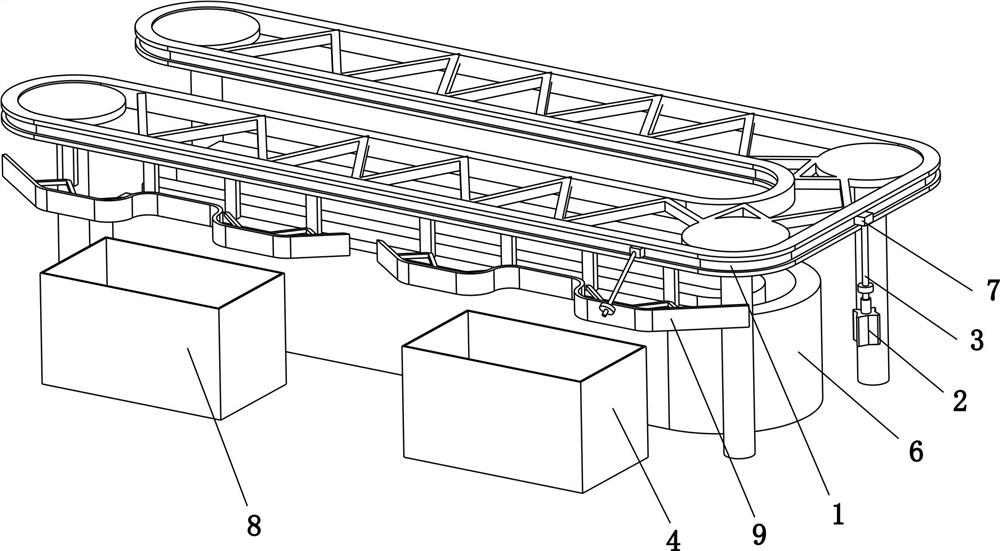

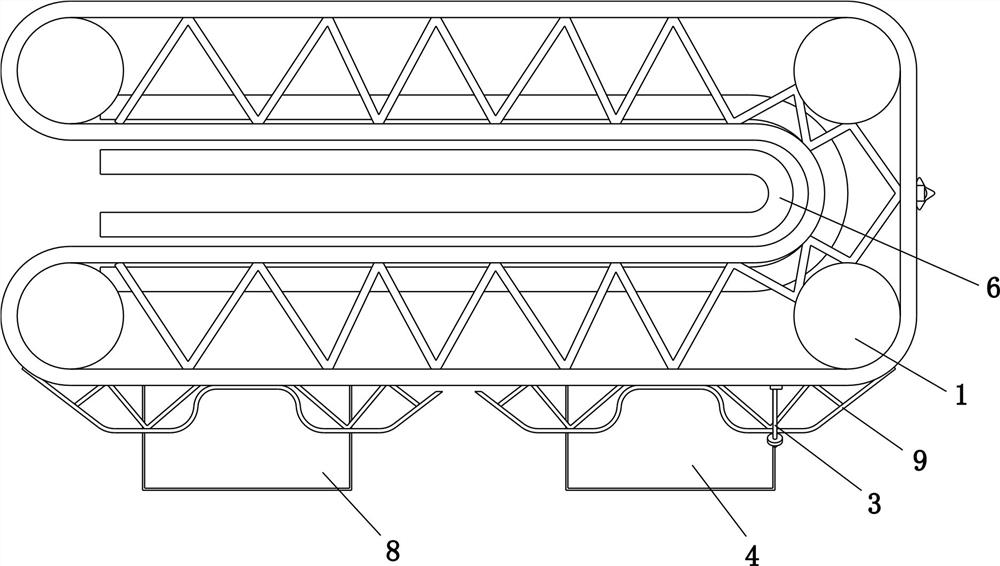

Silica sol mold shell drying system

InactiveCN113714466ASimple structureIncrease productivityMoulding toolsFoundry mouldsInvestment castingSlurry

The invention discloses a silica sol mold shell drying system relating to the technical field of investment casting. The silica sol mold shell drying system comprises a circulating conveyor chain device, an air drying box, hanging mechanisms and a slurry dipping pool, wherein the circulating conveyor chain device is composed of a support frame and a conveyor chain and used for conveying a wax mold; the air drying box is used for air drying of a silica sol mold shell wrapping the wax mold; a chain body of the conveyor chain of the circulating conveyor chain device is evenly hinged to a plurality of hanging mechanisms used for hanging the wax mold at intervals through hinge assemblies; a hinge shaft of each hinge assembly is correspondingly parallel to the axis of the conveyor chain of the circulating conveyor chain device in the length direction; each hanging mechanism comprises an inserting assembly I and an inserting assembly II which can be correspondingly inserted to form a whole; and each inserting assembly I comprises an inserting pipe of which one end is correspondingly hinged with one hinge assembly. The silica sol mold shell drying system is simple in structure and high in production efficiency, the operation of automatically coating silica sol paint on the outer surface of the wax mold and automatically covering the silica sol paint with quartz sand can be achieved, and the labor intensity of operators is effectively reduced.

Owner:洛阳市钢峰工程机械制造有限公司

Rapid briquette coal drying system and briquette coal drying furnace

InactiveCN105758148AAdd liquid spoilerAvoid dirt depositsDrying gas arrangementsDrying machines with progressive movementsBriquetteAirflow

The invention relates to a rapid briquette coal drying system and a briquette coal drying furnace.The drying system and a hot oil system are included.The hot oil system comprises an oil inflow pipe, an oil return pipe and a heat dissipation system located in a drying cavity.The heat dissipation system comprises an oil distributing pipe communicated with the oil inflow pipe, and an oil collecting pipe communicated with the oil return pipe.The oil distributing pipe and the oil collecting pipe are communicated with multiple sets of heat dissipation coil pipes through oil guide pipes respectively.The heat dissipation coil pipes are arranged on the lower portions of briquette coal chain plate conveying device grid plates and located on the upper portions of branch air pipes.A hot air source directly conveys hot air to the bottom of briquette coal through an air distributing device via pipelines, dry air is fully utilized, it is guaranteed that the briquette coal directly makes contact with the dry hot air flow, briquettes enter the drying cavity to make contact with the dry high-temperature airflow all the time, the drying speed is increased, drying efficiency is improved, and the hot air from an air outlet of an induced draft fan is guided by the air distributing pipe, conveyed by the branch air pipes layer by layer and dispersed to the position below each briquette coal layer of the drying furnace.

Owner:石家庄市矿区丰旺机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com