Method for eliminating glass wind spots and wind grating swing mechanism

A swing mechanism and glass technology, applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as complex wind spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A method for eliminating wind spots on glass. A number of air grilles are arranged above and below the conveying roller table, and the air grilles are evenly distributed along the glass conveying direction to form a blowing coverage area. During the cooling process, the conveying roller table drives the glass to blow air. Within the coverage area, it moves back and forth along the glass conveying direction; when the moving direction of the glass changes, the air grid is moved to make it move relative to the glass in the direction of glass conveying. When the glass changes its moving direction, the relative movement between the wind grille and the glass is still guaranteed, and it will not stay on the glass surface, which effectively reduces the formation of wind spots. The moving speed of the air grid is equal to the speed of the glass during the reciprocating movement. Make the glass maintain a constant relative speed with the wind grid during the whole process of reci...

Embodiment 2

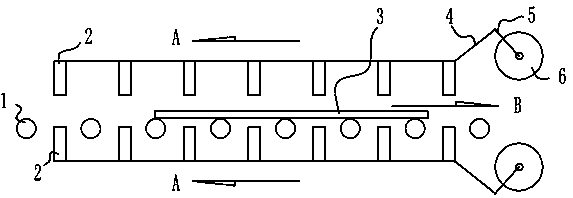

[0015] Such as figure 1 As shown, an air grid swing mechanism includes a conveying roller table 1, a number of air grilles 2 are arranged above and below the conveying roller table 1, and the air grilles 2 are evenly distributed along the conveying direction of the glass 3 to form a blowing coverage area. During the cooling process, the conveying roller table 1 drives the glass 3 to move back and forth along the conveying direction of the glass 3 within the blowing coverage area; the air grille 2 is movable, and the air grille 2 is connected with a drive that can push the air grille 2 to move back and forth along the conveying direction of the glass 3 mechanism, the drive mechanism is connected with a power mechanism that provides power for it, and the swing mechanism of the air grid 2 also includes a speed detection device (not shown in the figure), which is used to detect the speed of the glass 3 and generate When changed, a signal is sent to the drive mechanism. The moving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com