Patents

Literature

1136results about "Liquid fuel feeder/distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

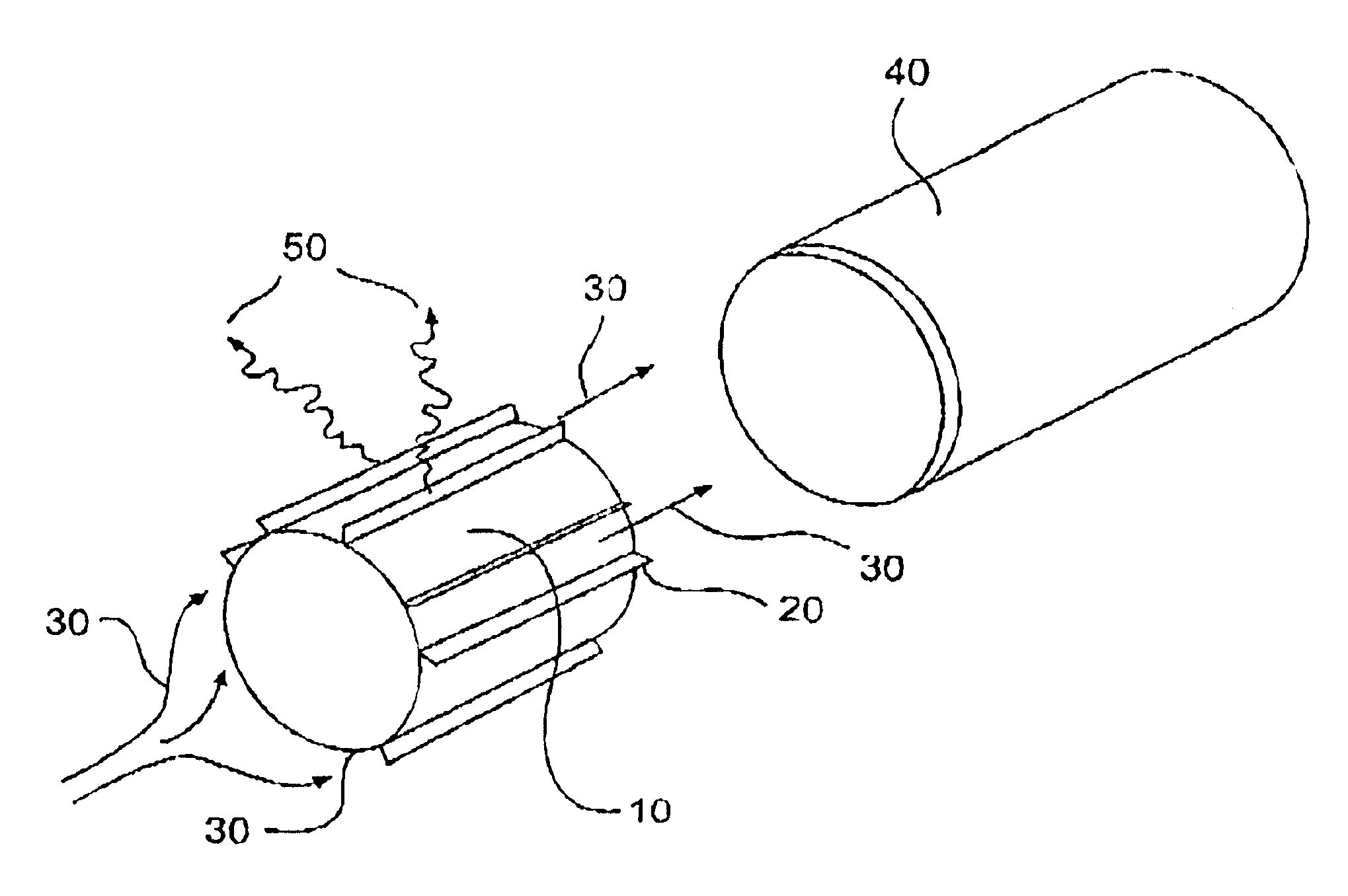

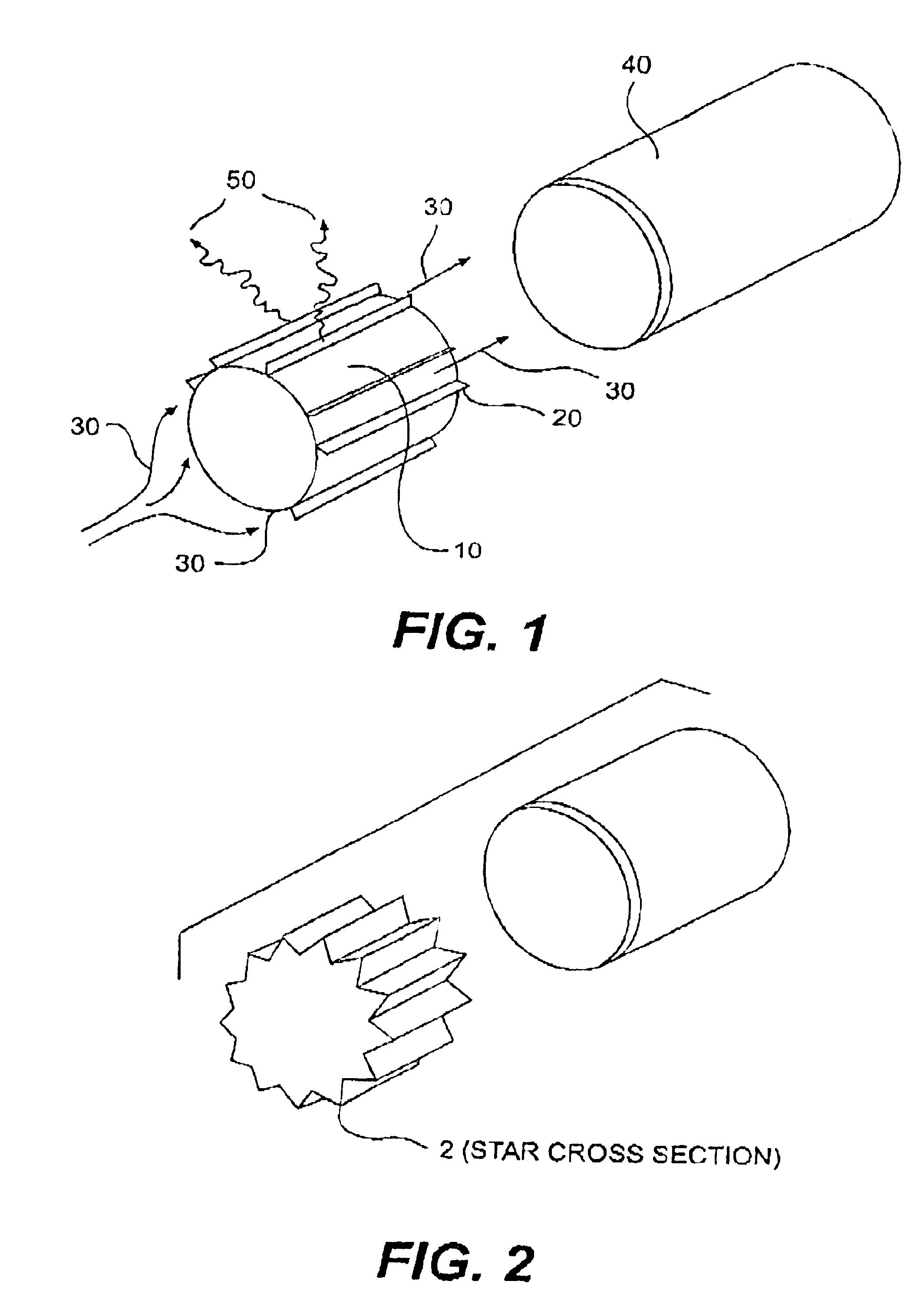

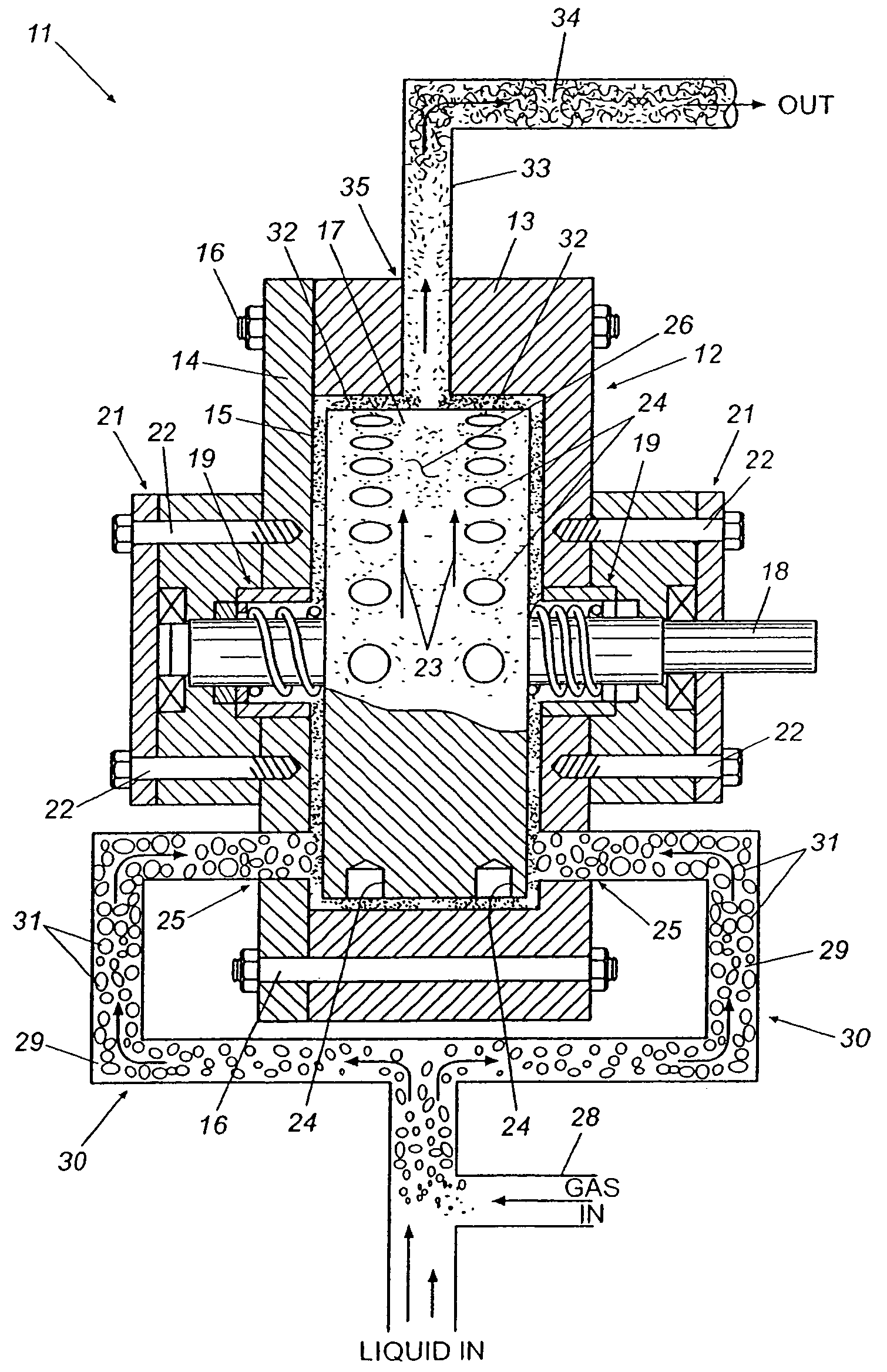

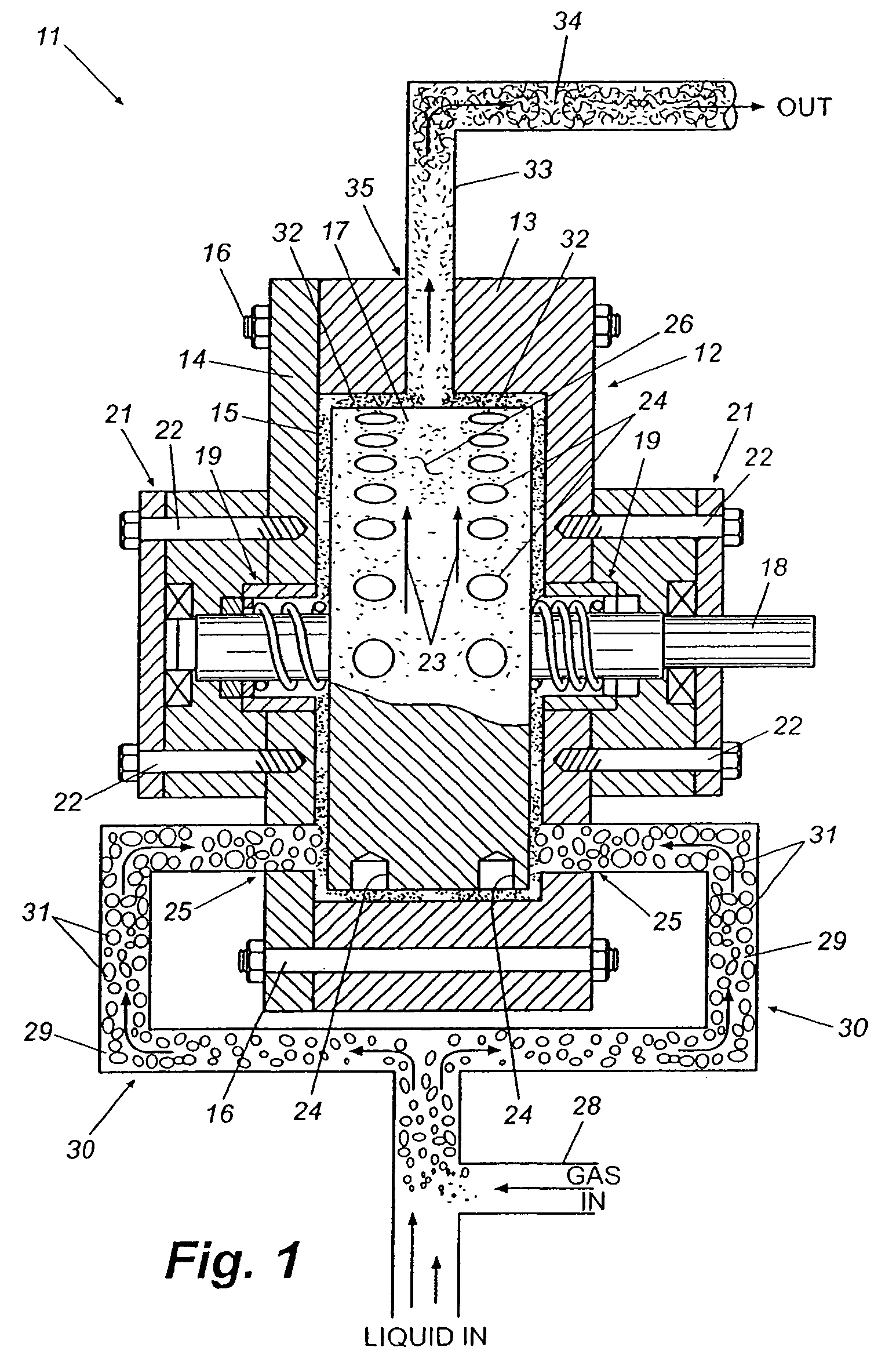

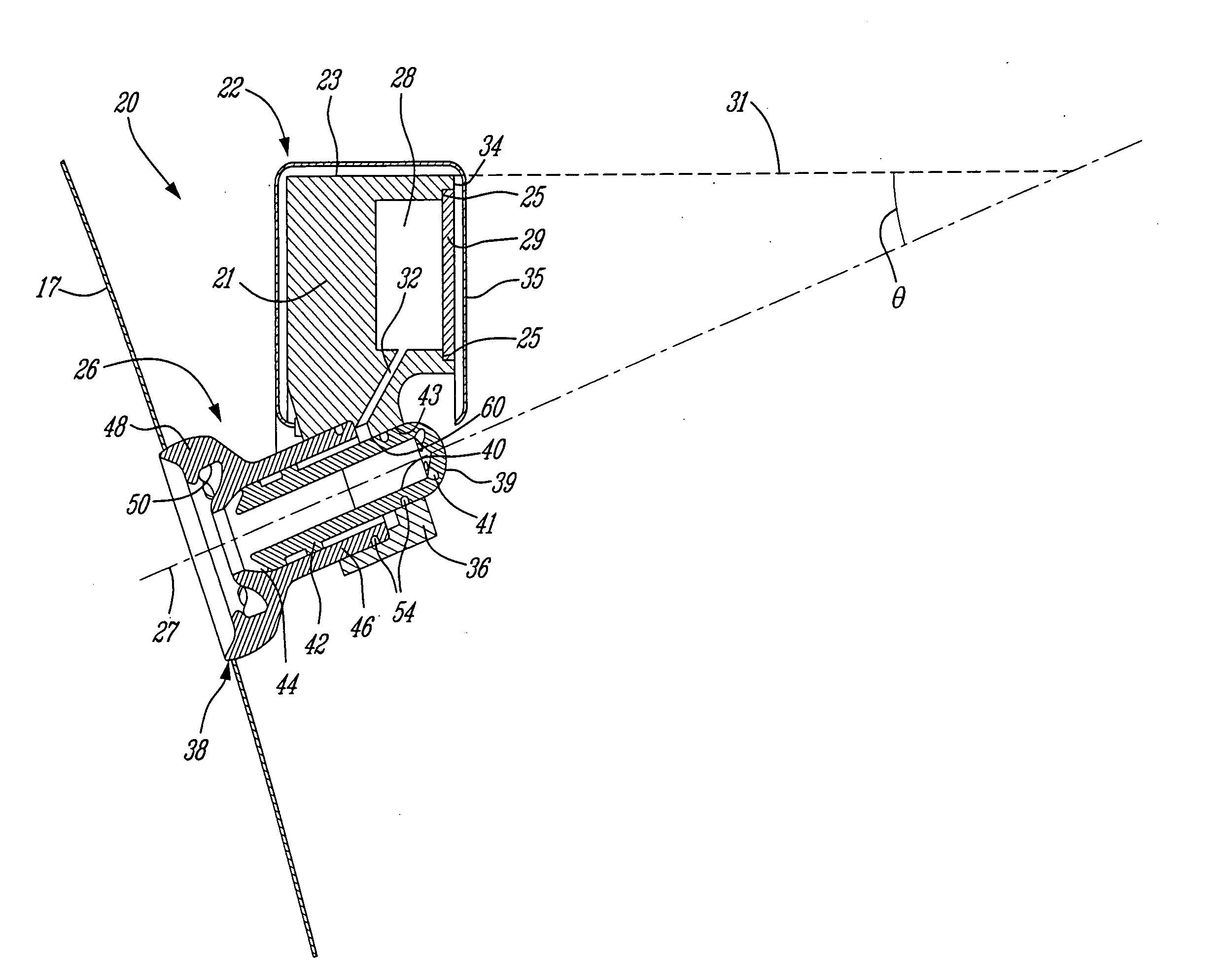

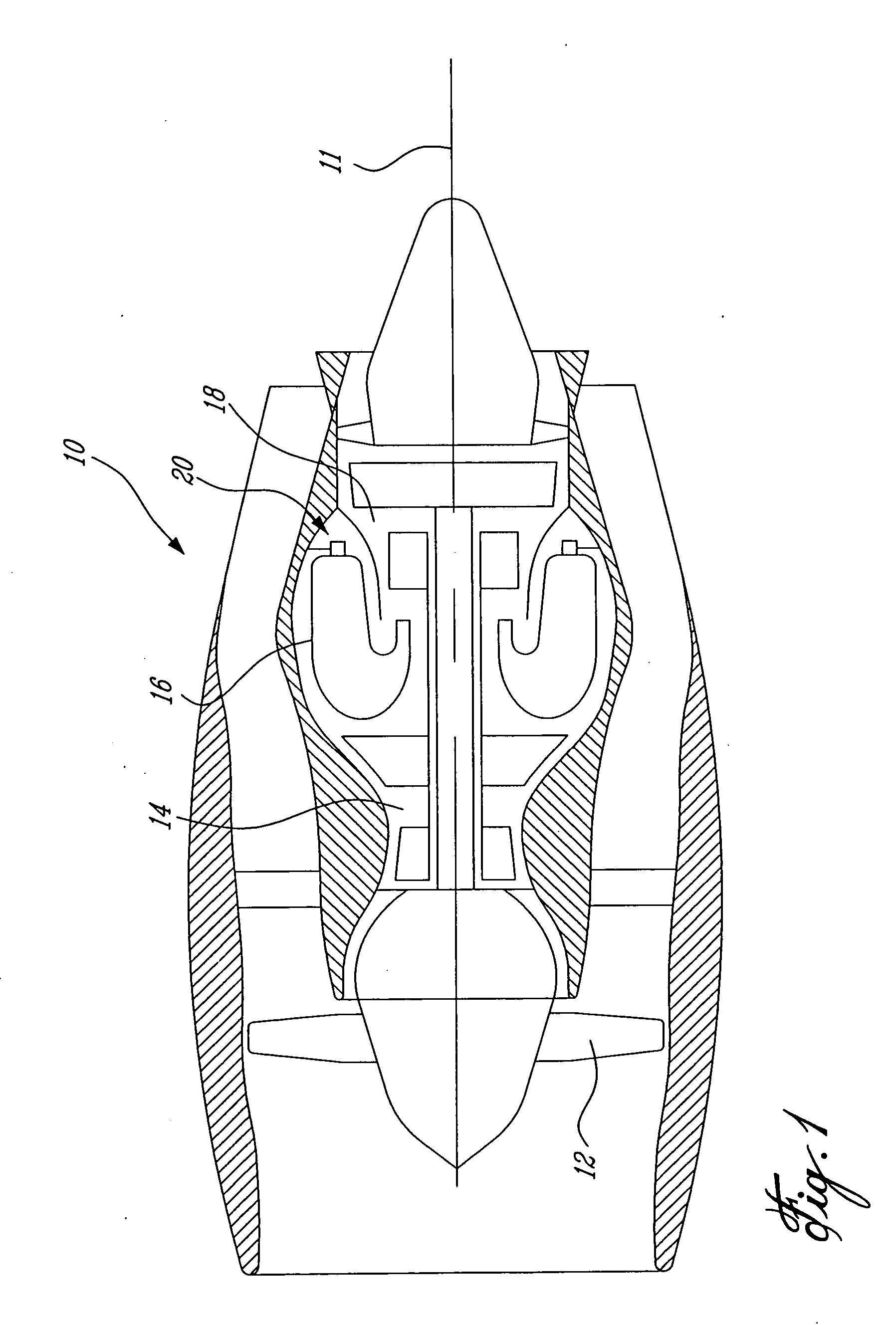

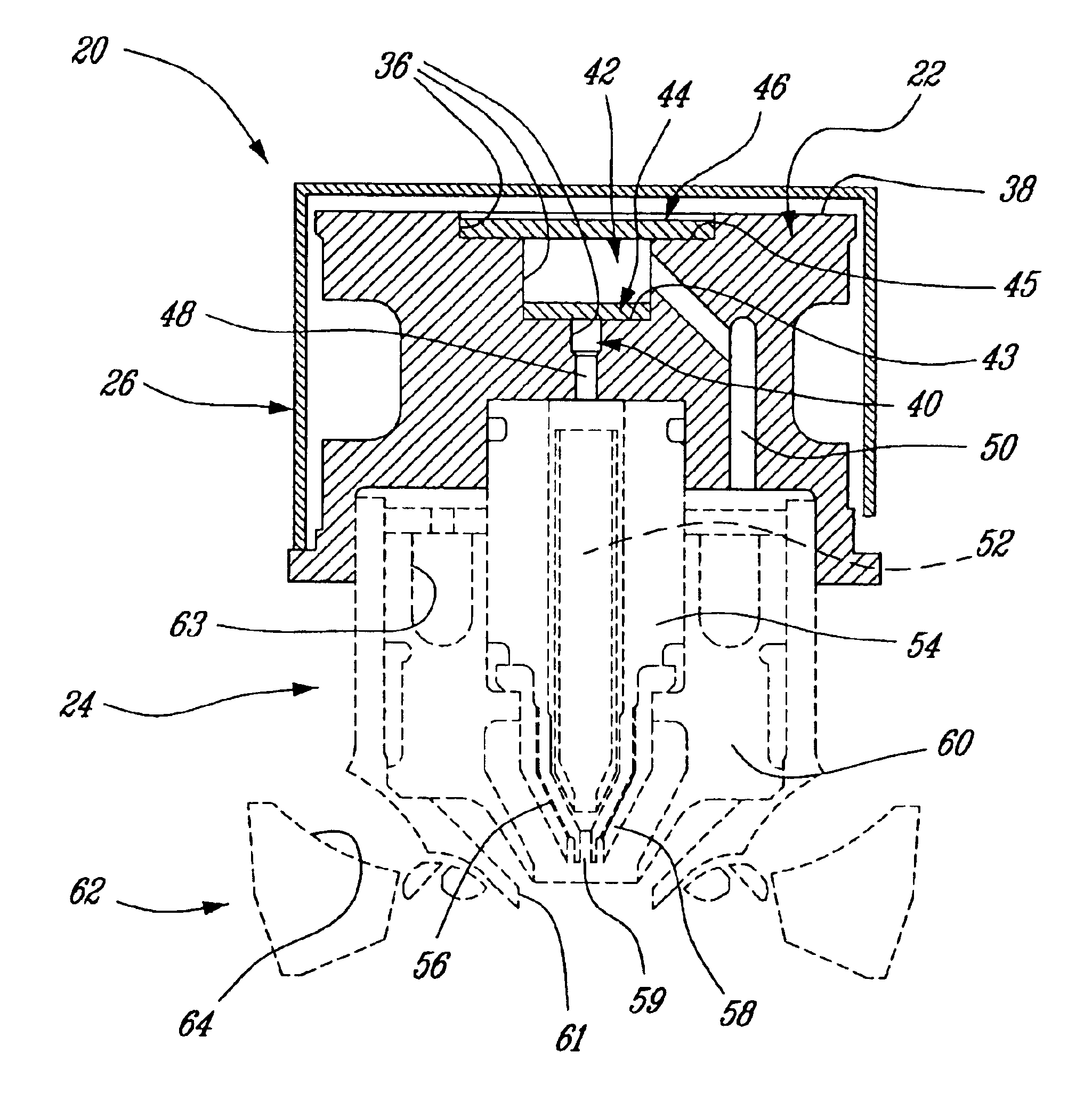

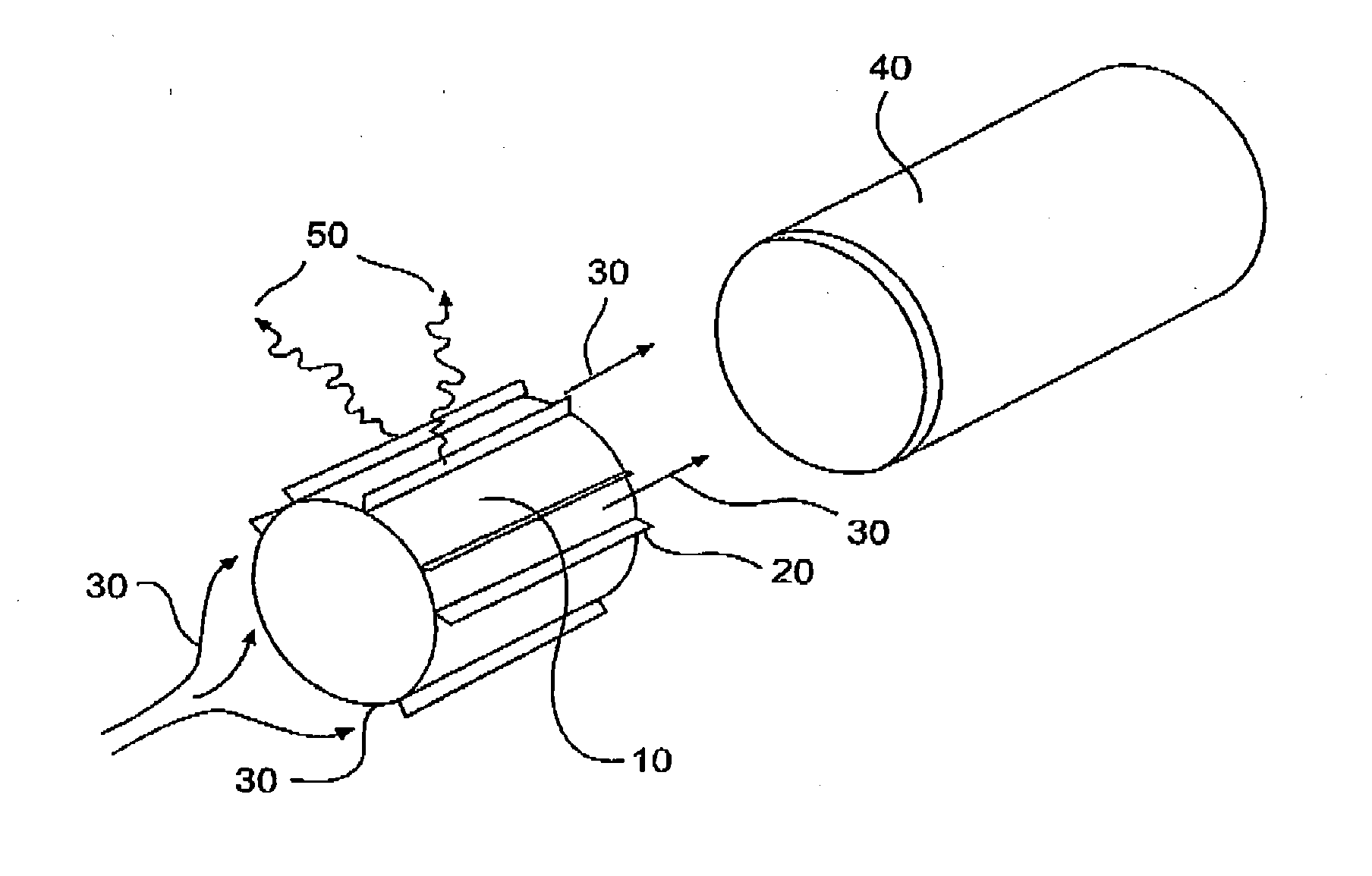

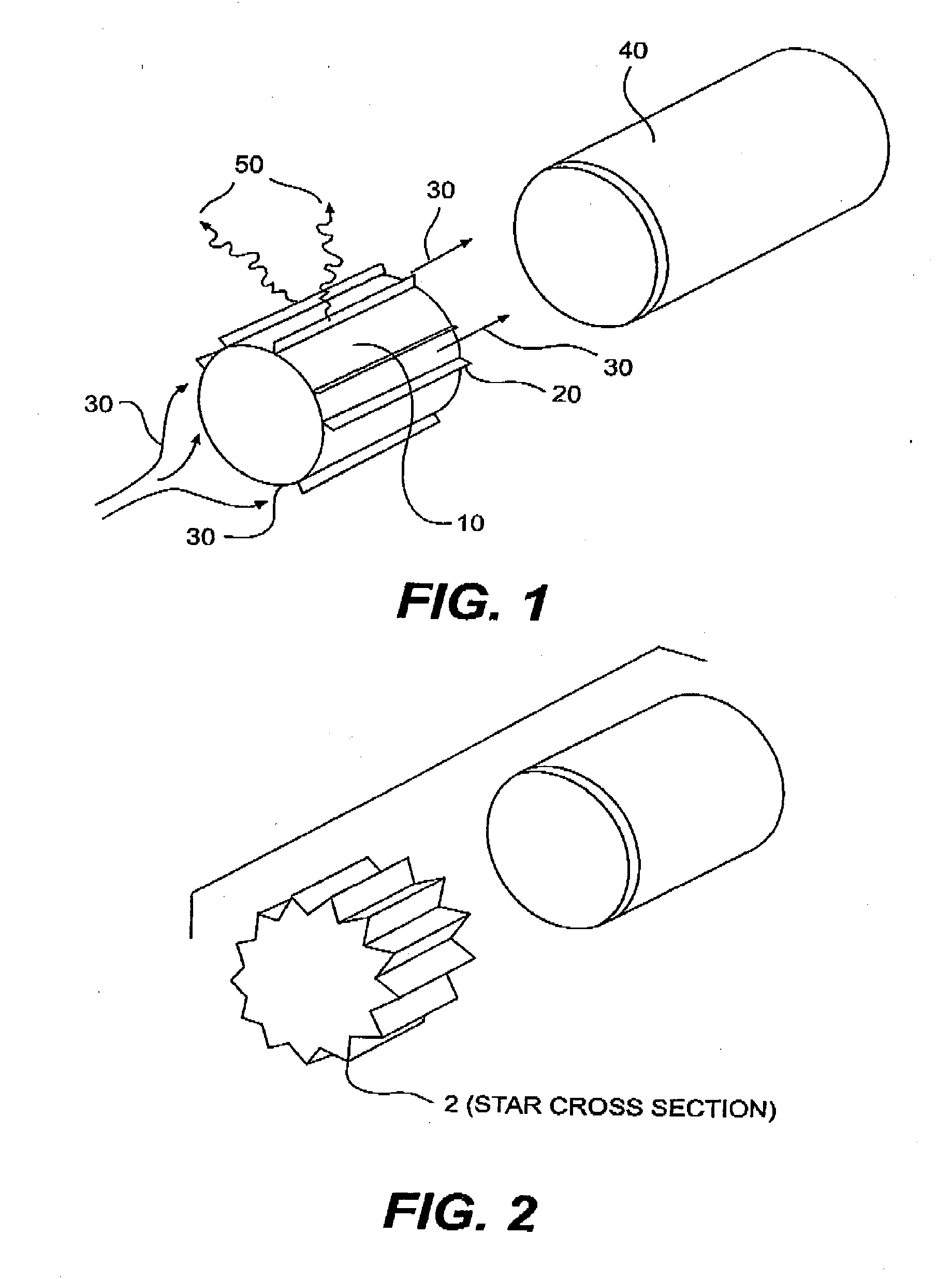

Method and apparatus to increase combustion efficiency and to reduce exhaust gas pollutants from combustion of a fuel

InactiveUS6851413B1Improve combustion efficiencyFacilitate fuel combustionBurnersLiquid fuel feeder/distributionCombustorExhaust fumes

A method and apparatus is disclosed for increasing combustion efficiency in internal combustion engines and external combustors resulting in increased fuel economy and reduced exhaust pollutants. The same principles and apparatus of the invention are used in the exhaust stream to further reduce pollutants.

Owner:RONNELL

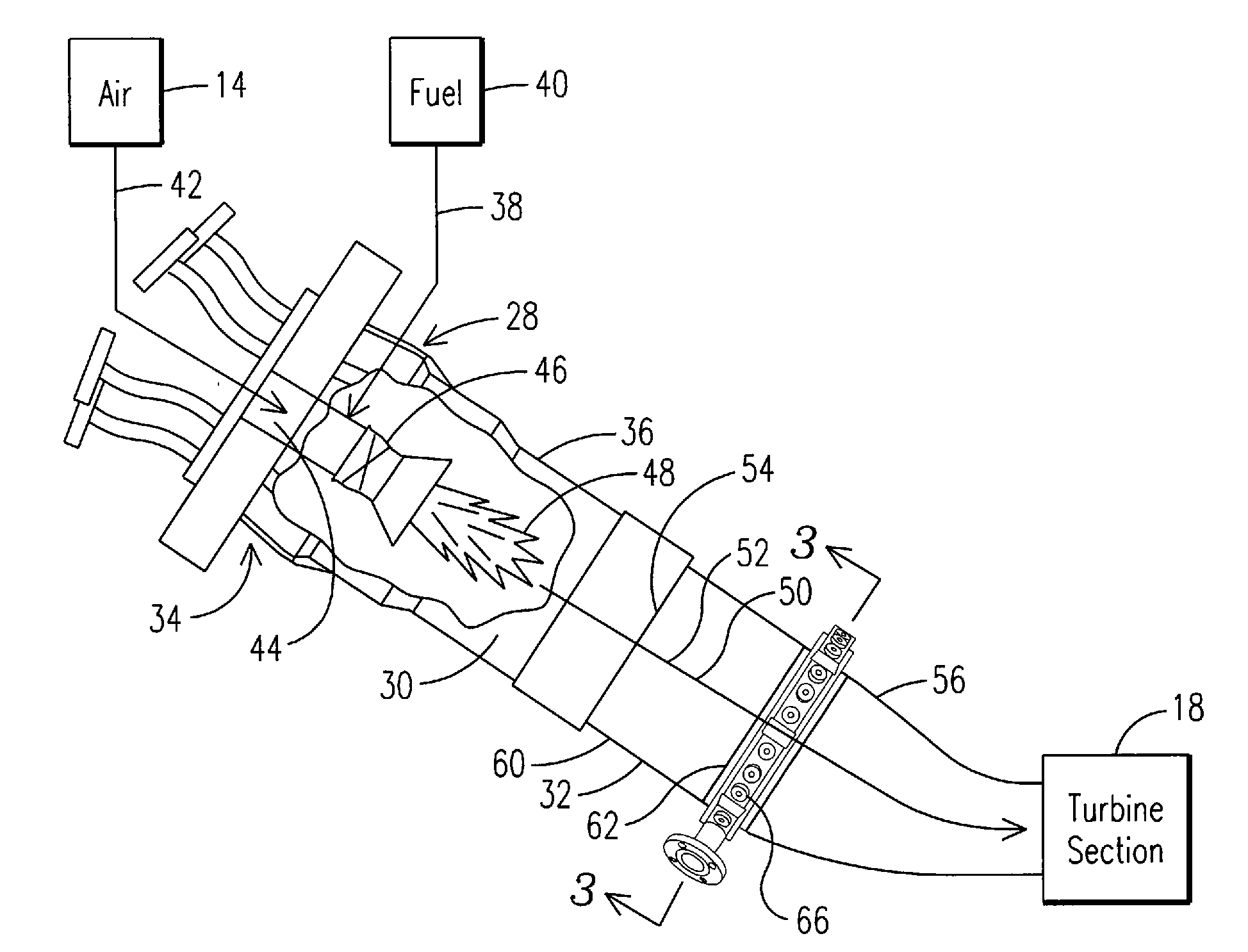

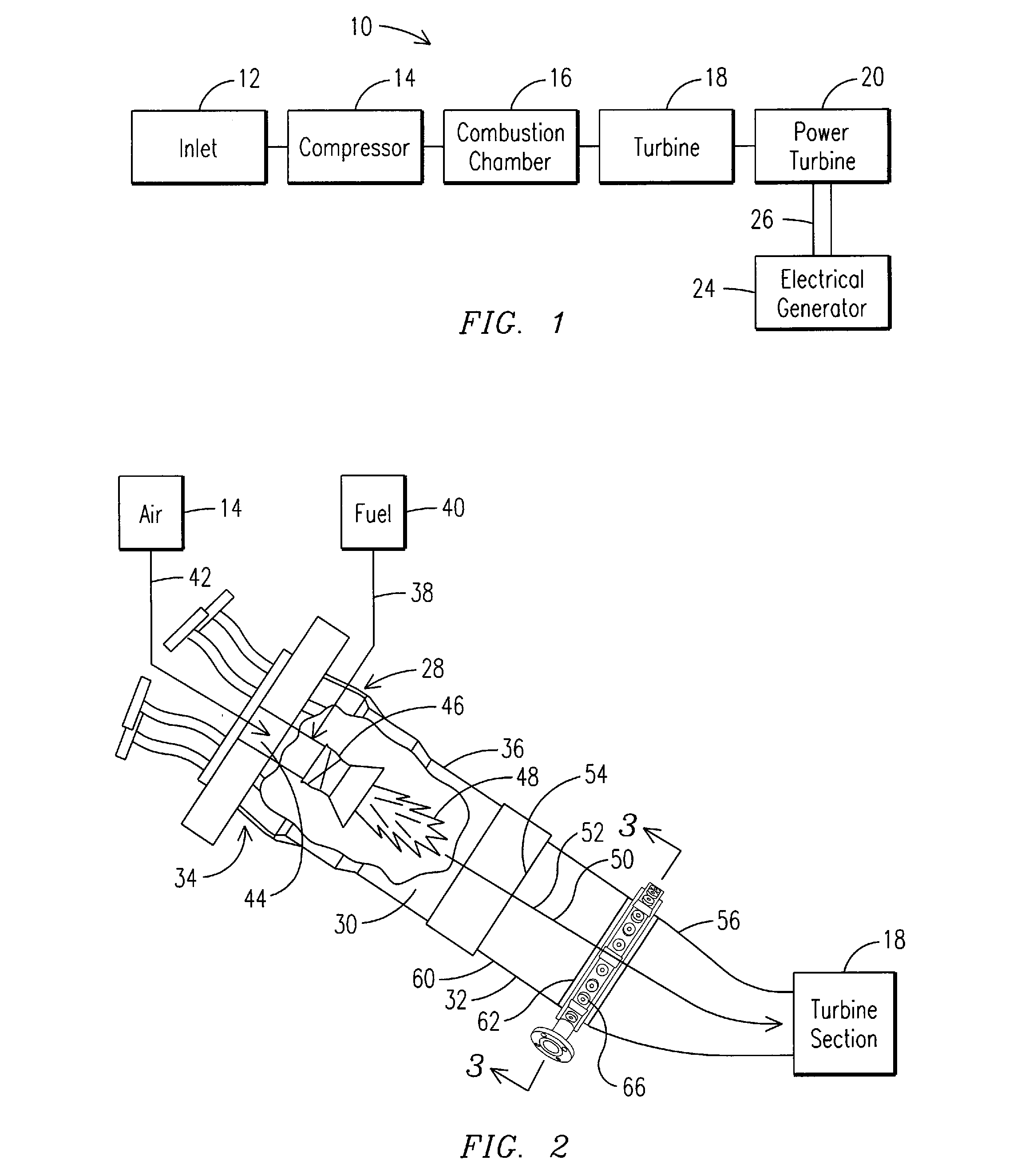

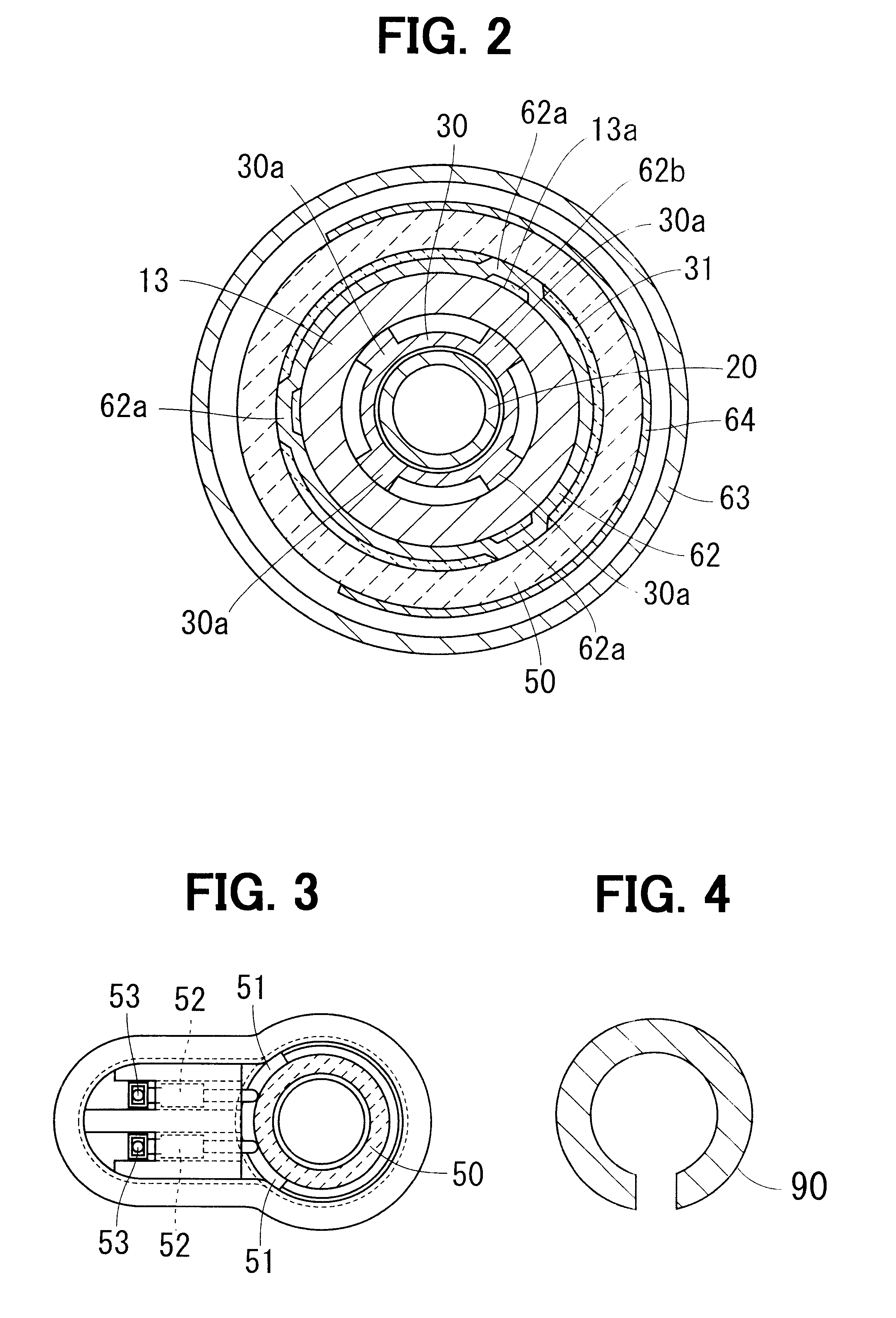

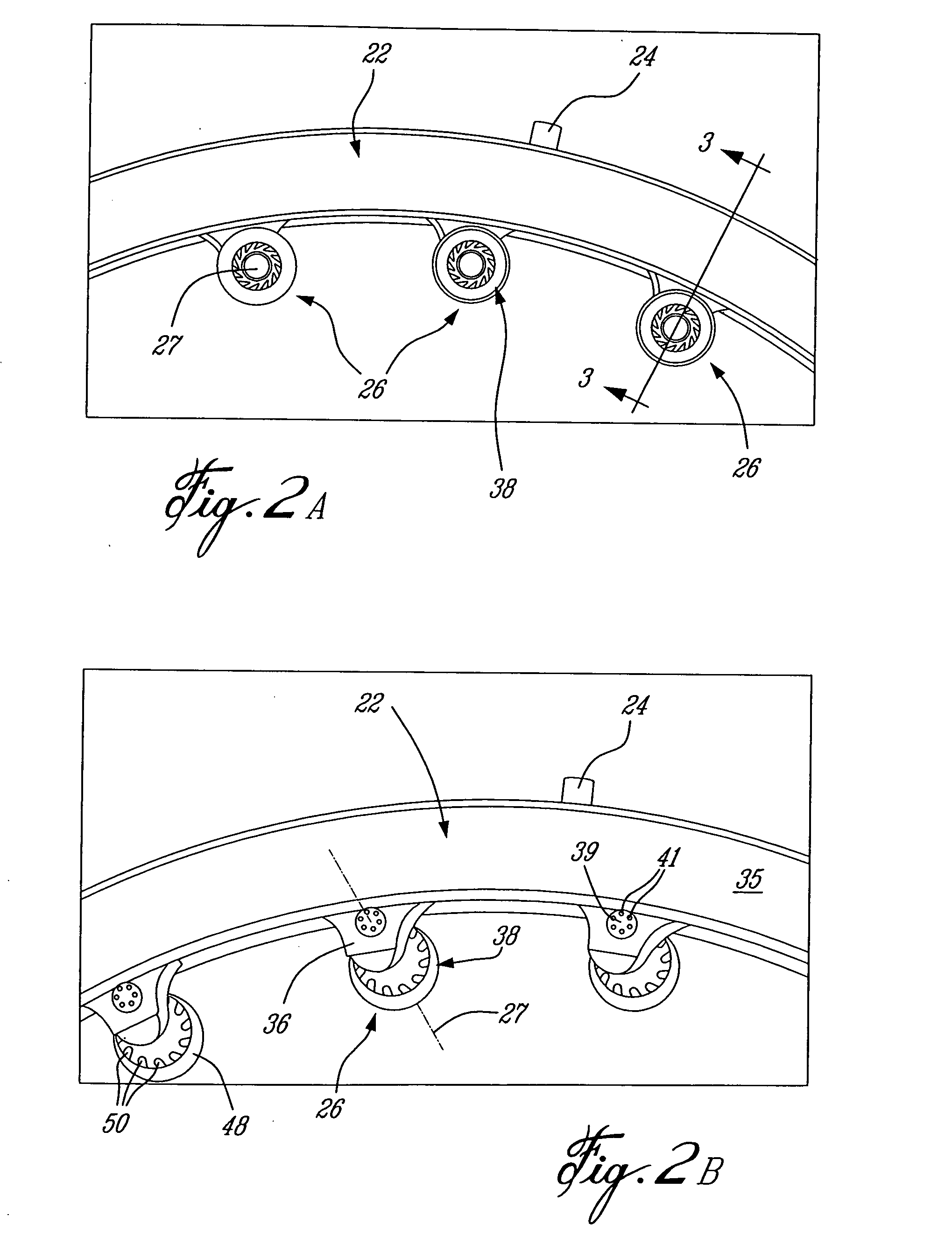

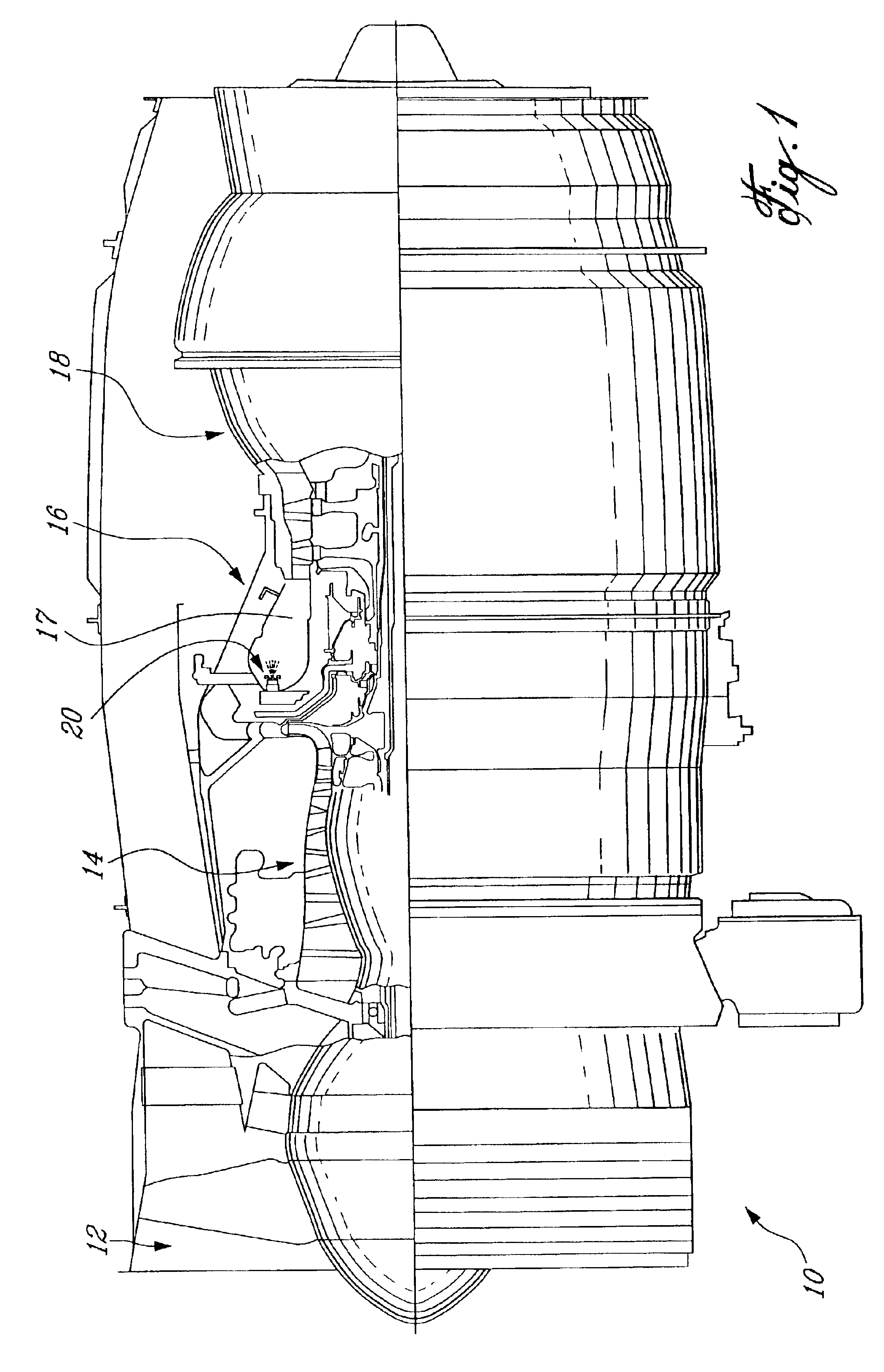

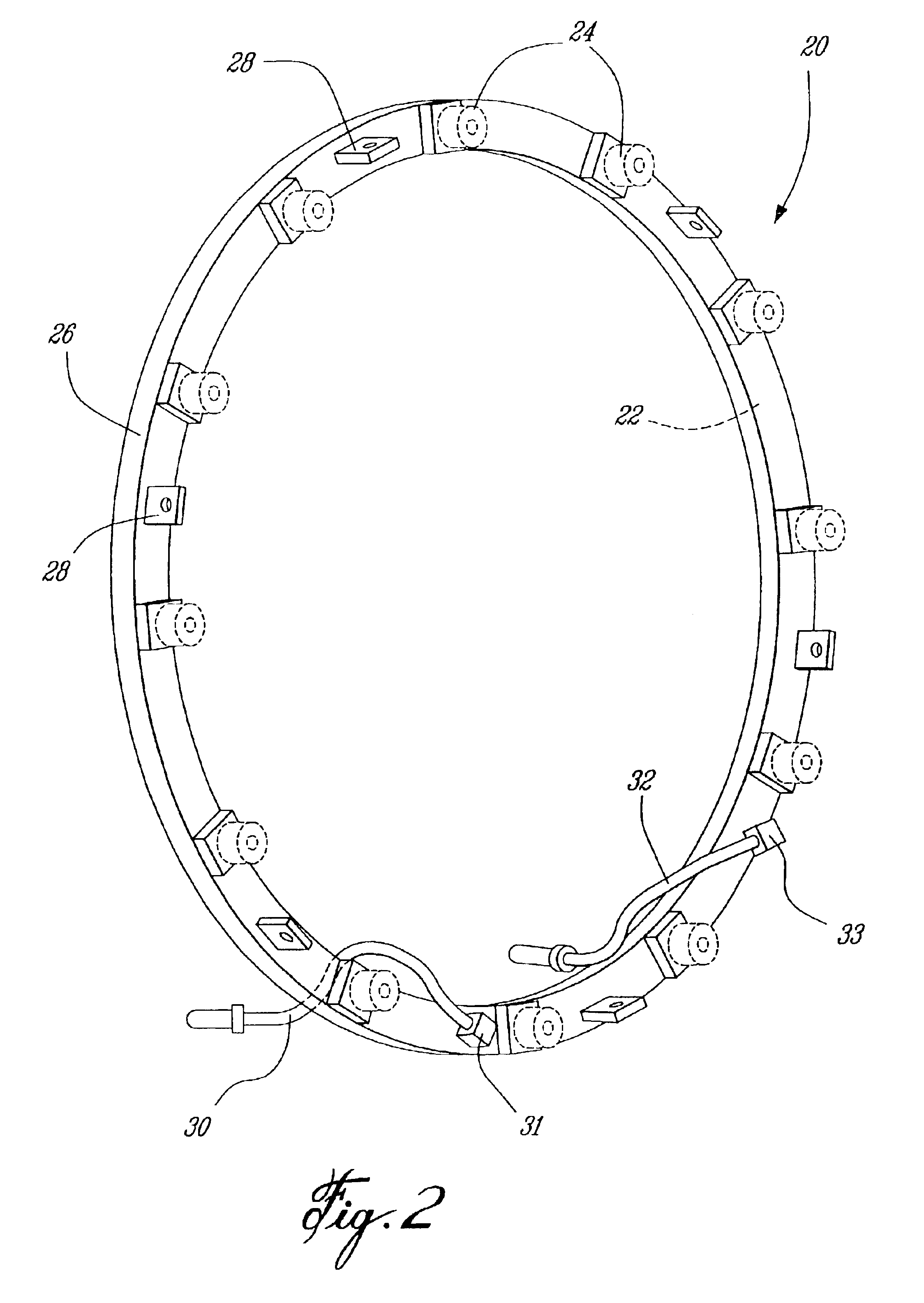

Apparatus and Method for Controlling the Secondary Injection of Fuel

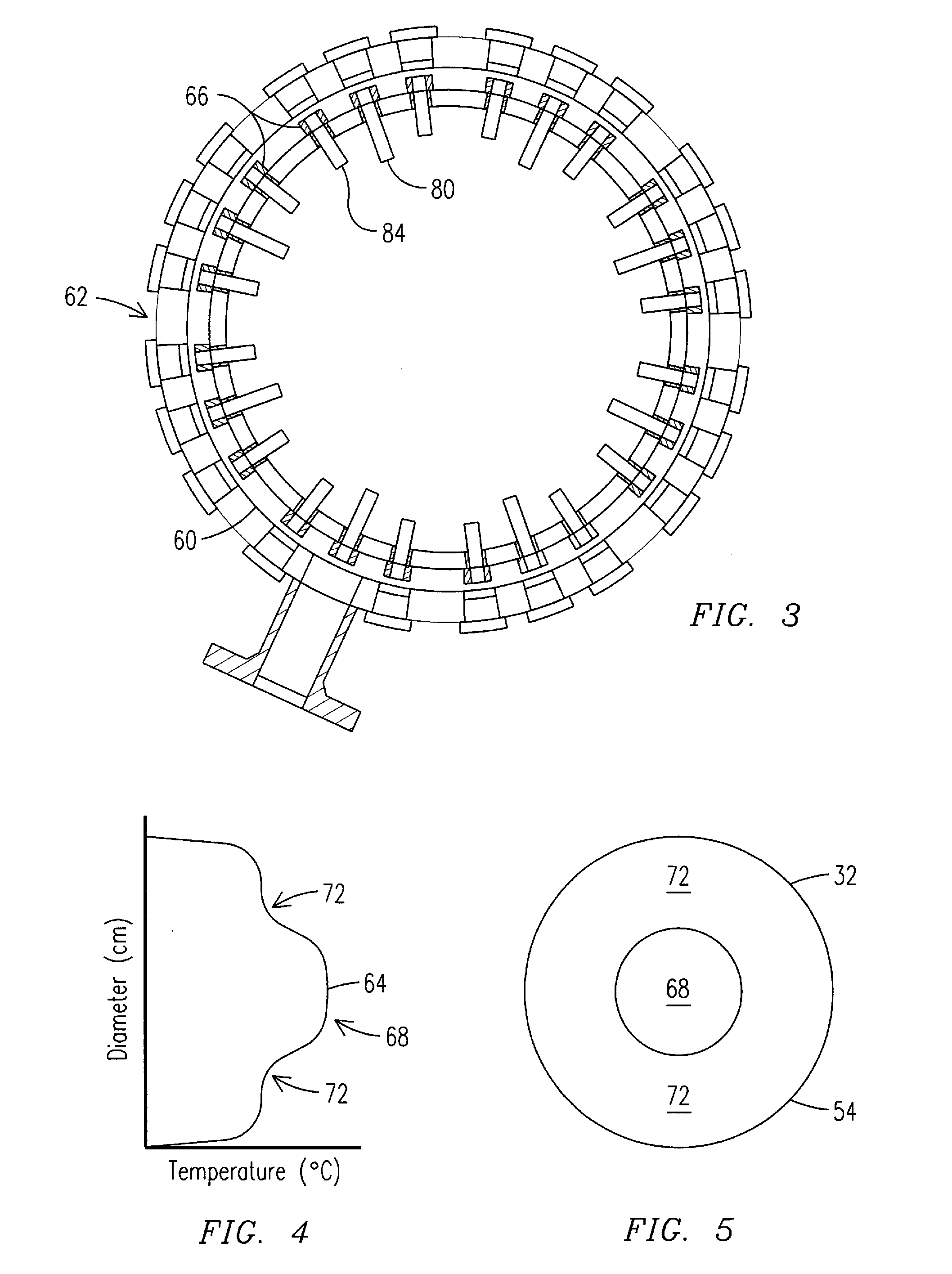

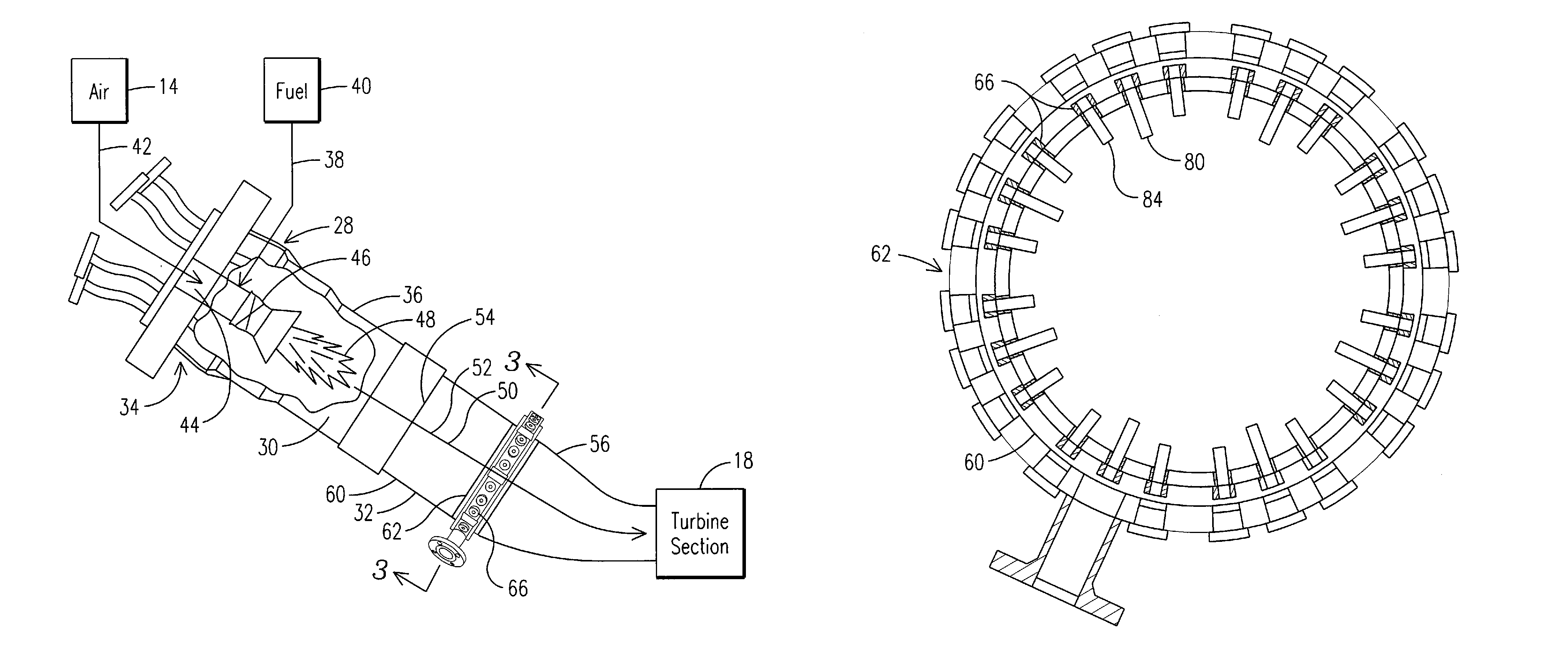

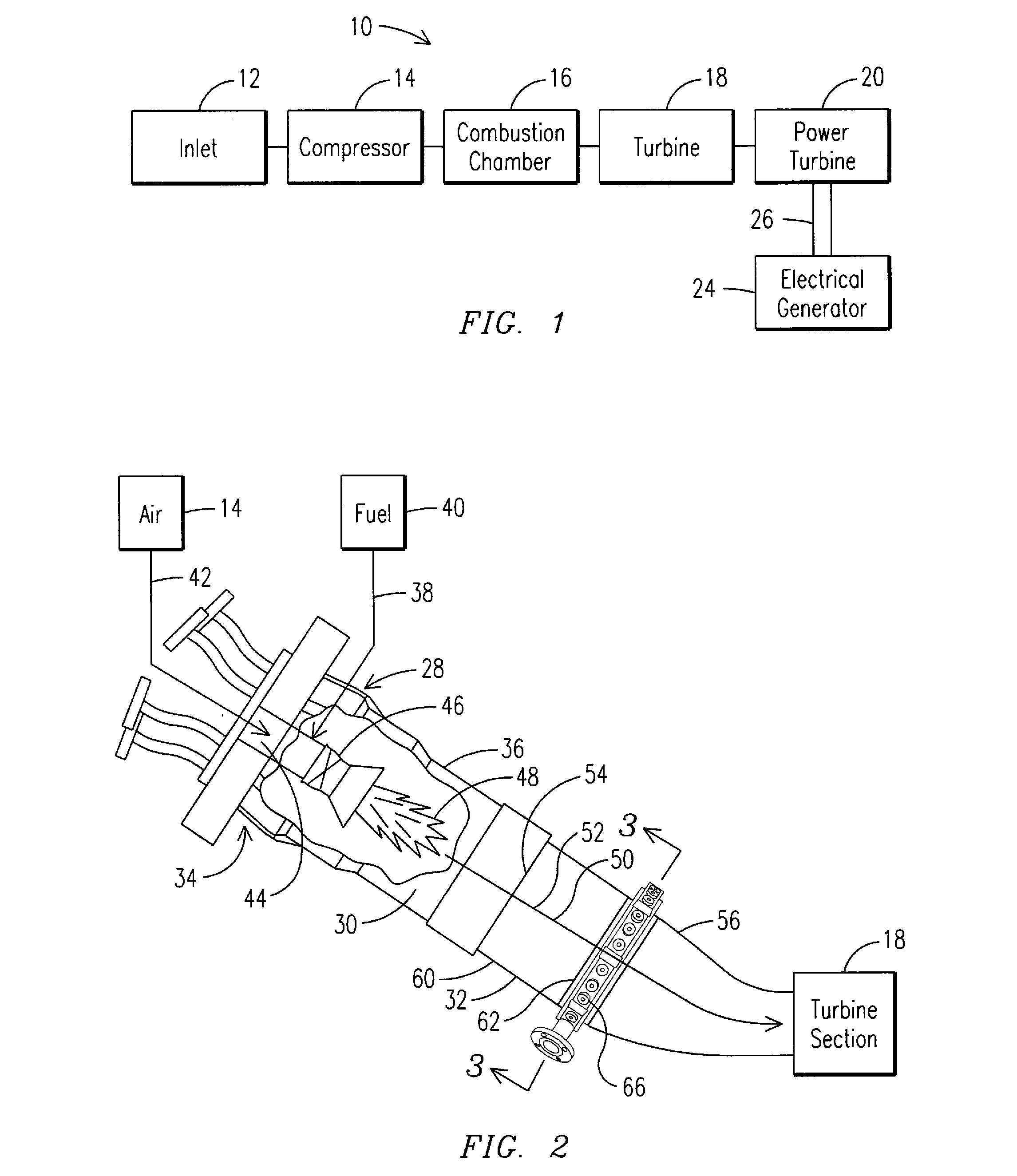

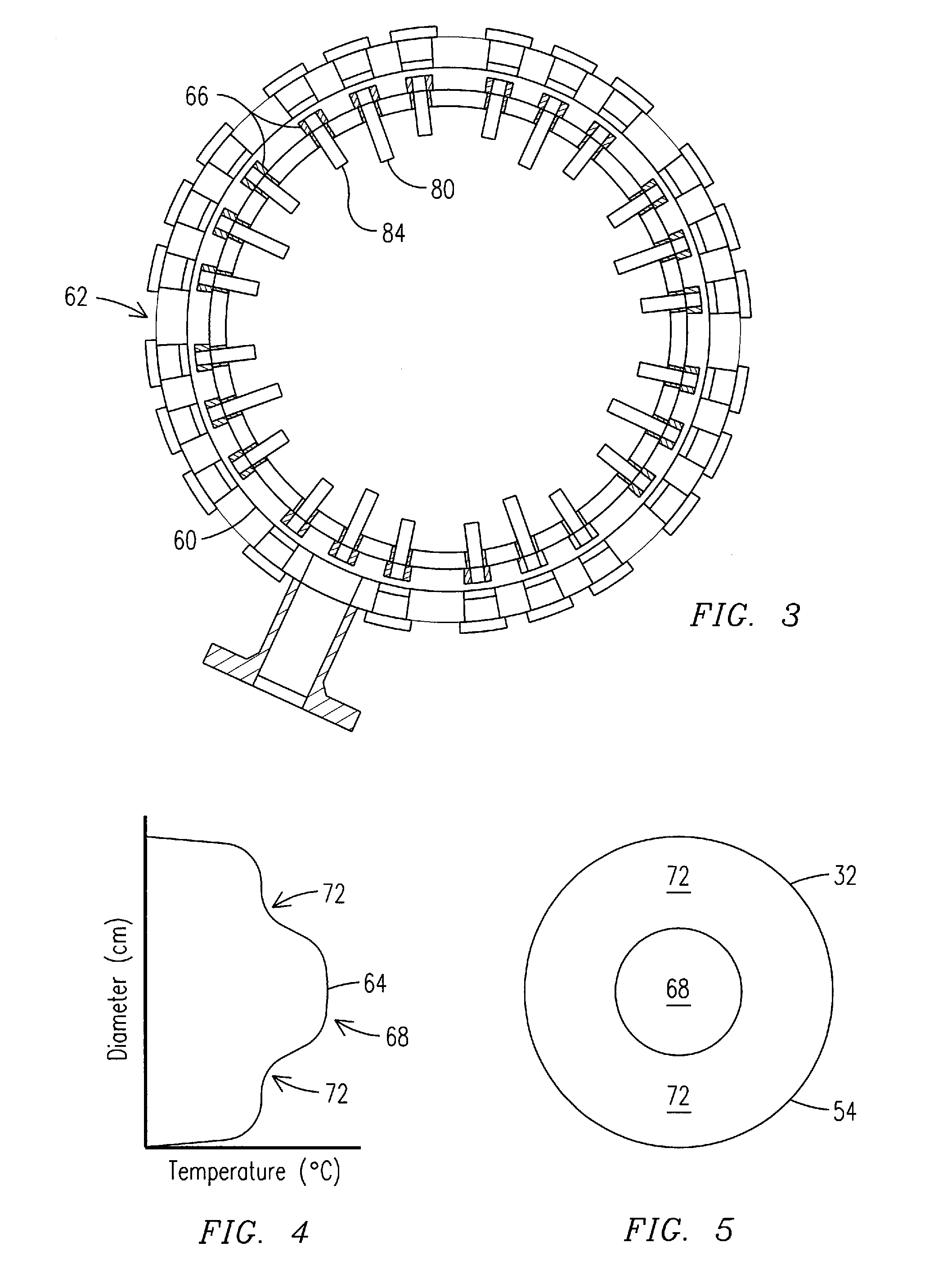

In one embodiment, a combustor (28) for a gas turbine engine is provided comprising a primary combustion chamber (30) for combusting a first fuel to form a combustion flow stream (50) and a transition piece (32) located downstream from the primary combustion chamber (30). The transition piece (32) comprises a plurality of injectors (66) located around a circumference of the transition piece (32) for injecting a second fuel into the combustion flow stream (50). The injectors (66) are effective to create a radial temperature profile (74) at an exit (58) of the transition piece (32) having a reduced coefficient of variation relative to a radial temperature profile (64) at an inlet (54) of the transition piece (32). Methods for controlling the temperature profile of a secondary injection are also provided.

Owner:SIEMENS ENERGY INC

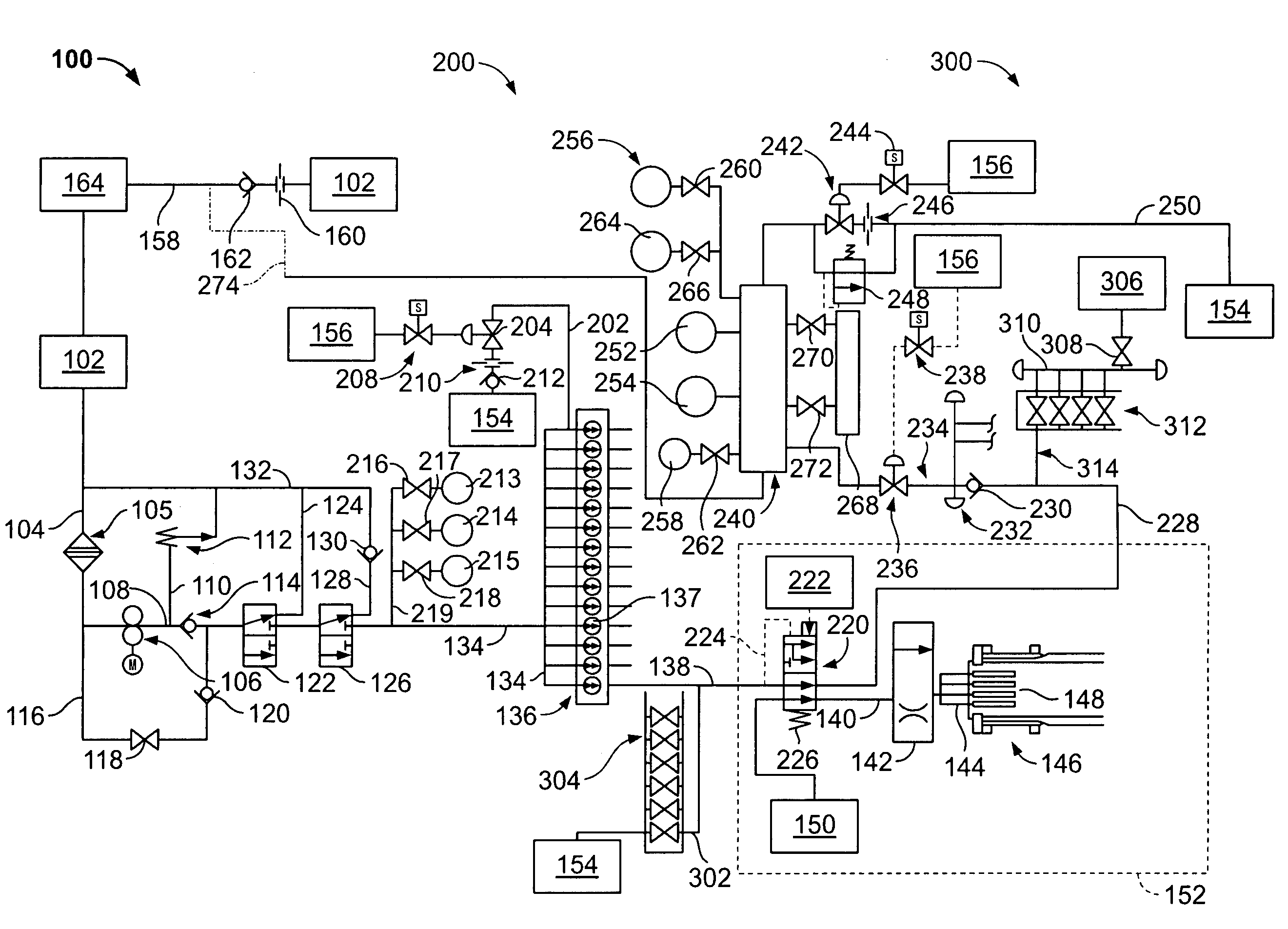

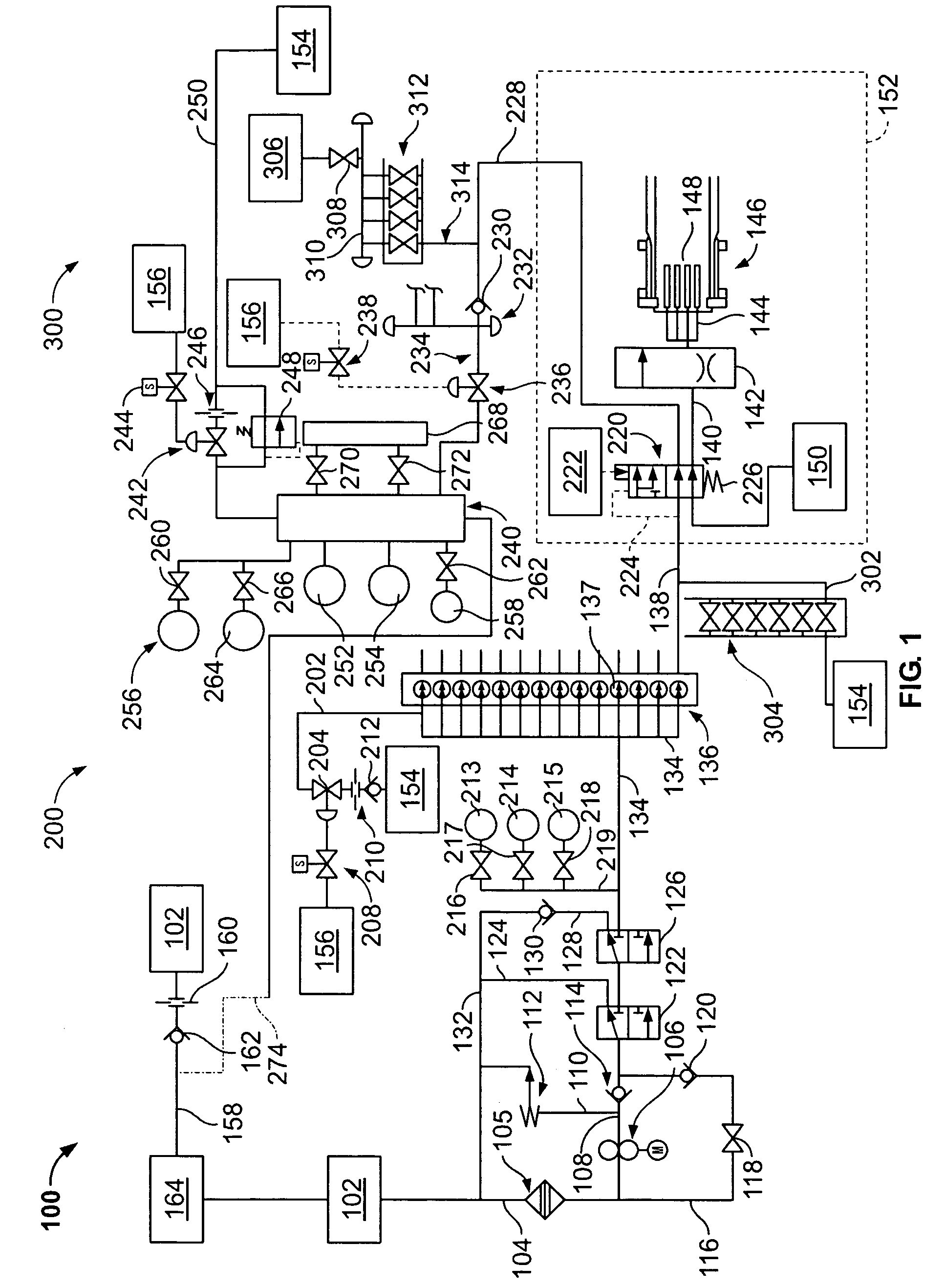

Methods and apparatus for a combustion turbine nitrogen purge system

ActiveUS7730711B2Reduce formationEasy to disassembleLiquid fuel feeder/distributionEngine fuctionsParticulatesCombustion

Owner:GE INFRASTRUCTURE TECH INT LLC

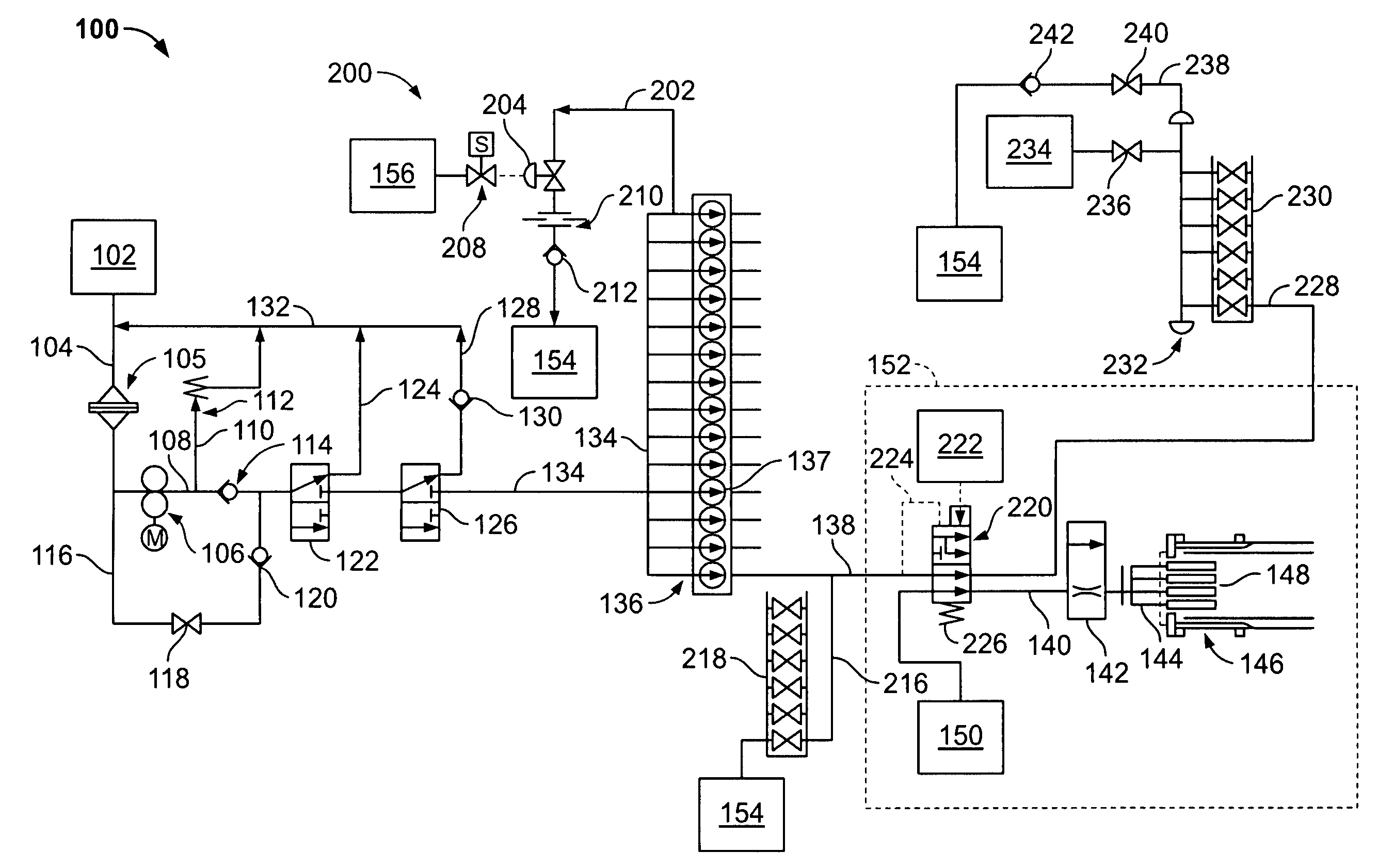

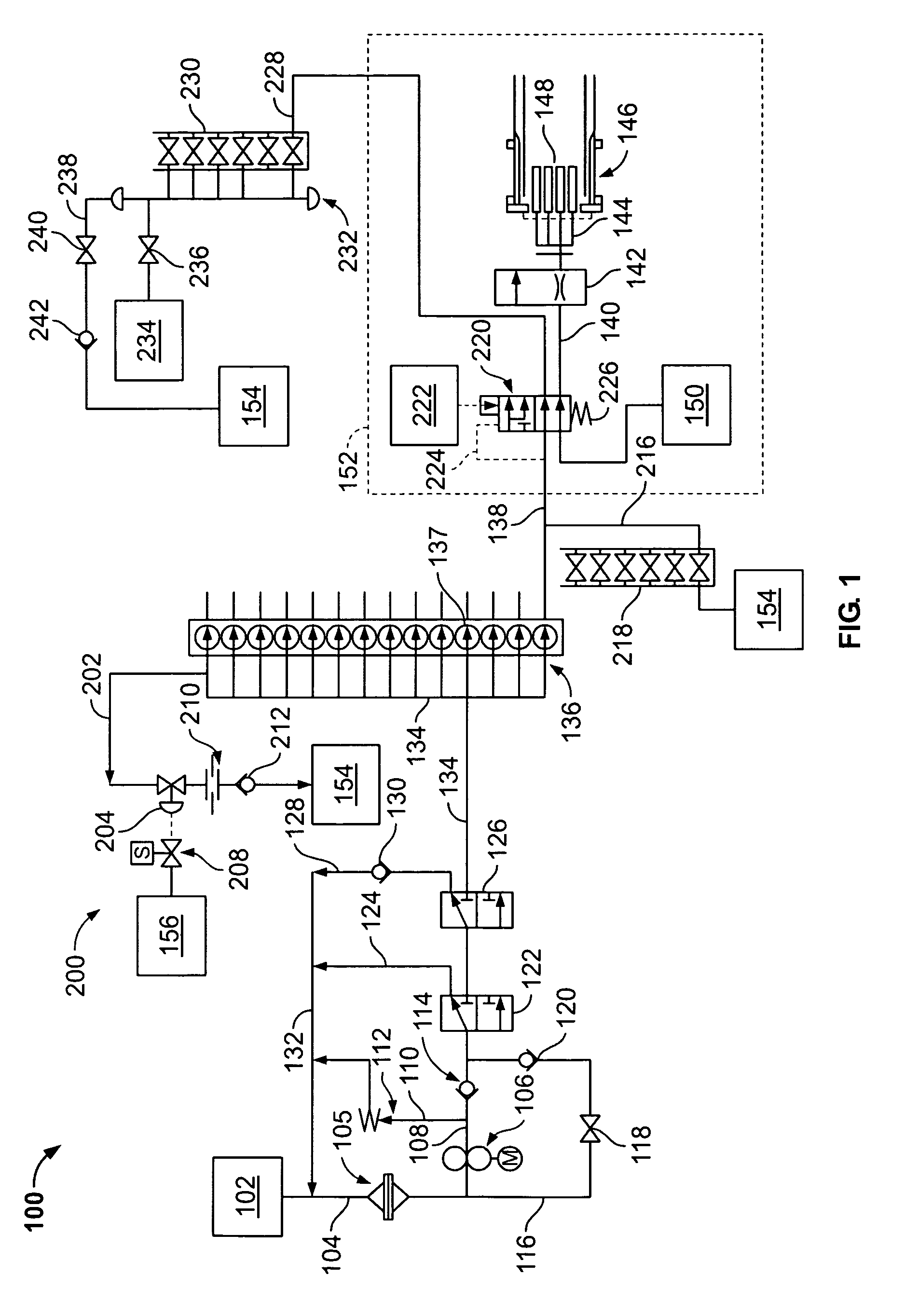

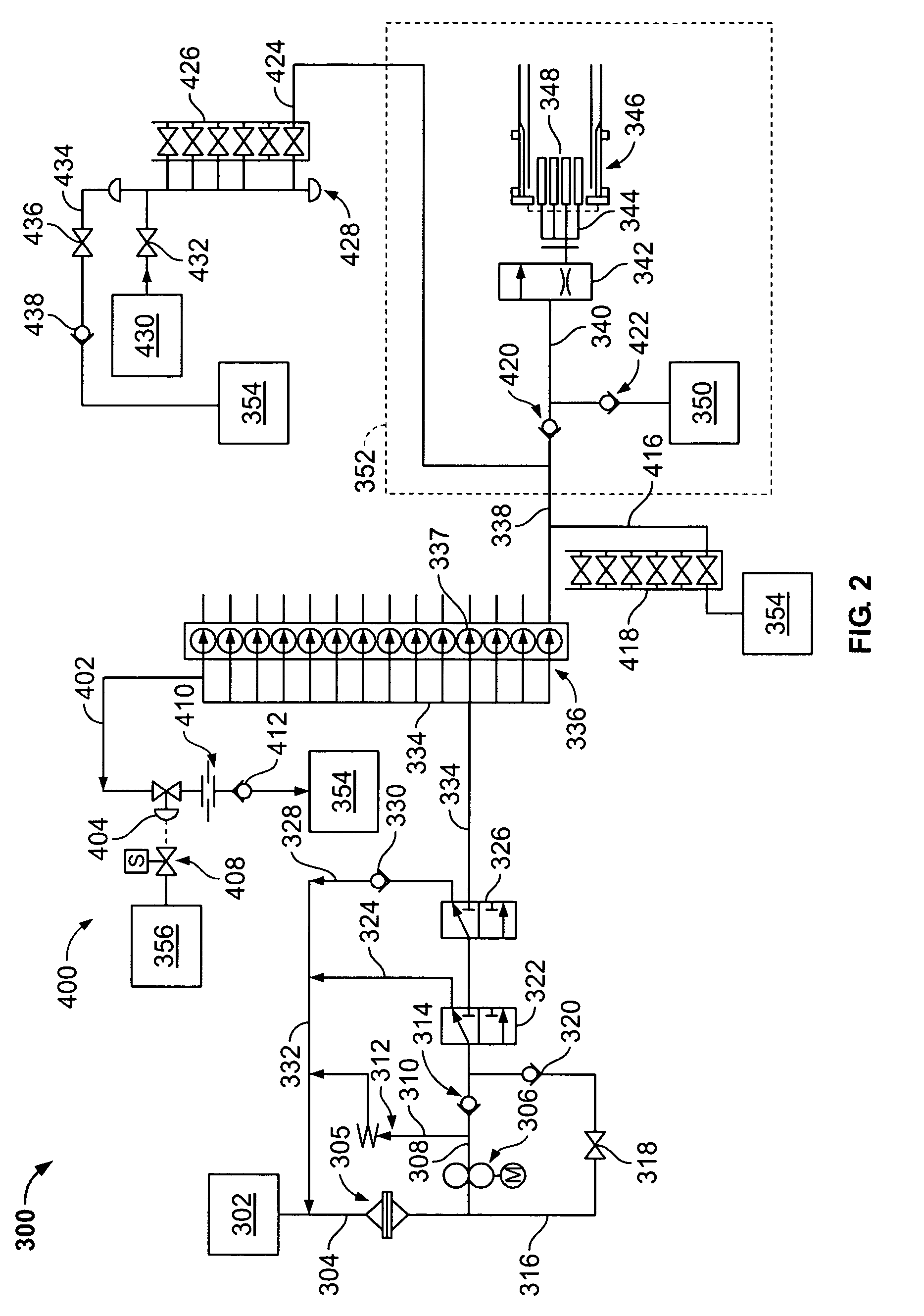

Methods and apparatus for a combustion turbine fuel recirculation system and nitrogen purge system

ActiveUS7721521B2Reduce formationEasy transferLiquid fuel feeder/distributionContinuous combustion chamberParticulatesCombustion

A method of operating a fuel system is provided. The method includes removing fuel from at least a portion of the fuel system using a gravity drain process. The method also includes channeling nitrogen into at least a portion of the fuel system to facilitate removing air and residual fuel from at least a portion of the fuel system, thereby mitigating a formation of carbonaceous precipitate particulates. The method further includes removing air and nitrogen from at least a portion of the fuel system during a fuel refilling process using a venting process such that at least a portion of the fuel system is substantially refilled with fuel and substantially evacuated of air and nitrogen. The method also includes removing air from at least a portion of the refilled fuel system using a venting process. The method further includes recirculating fuel within at least a portion of the fuel system, thereby removing heat from at least a portion of the fuel system and facilitating a transfer of operating fuel modes.

Owner:GENERAL ELECTRIC CO

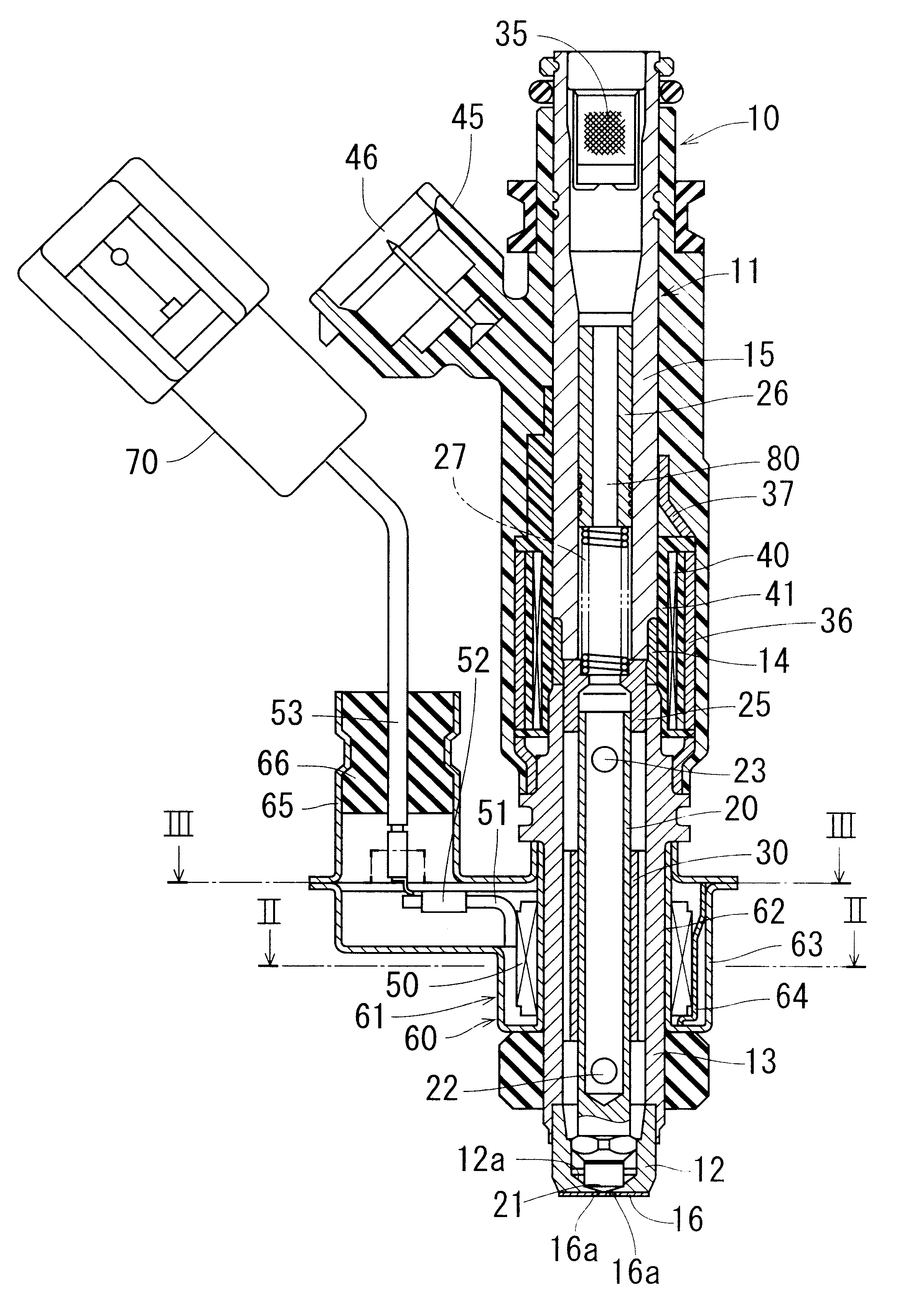

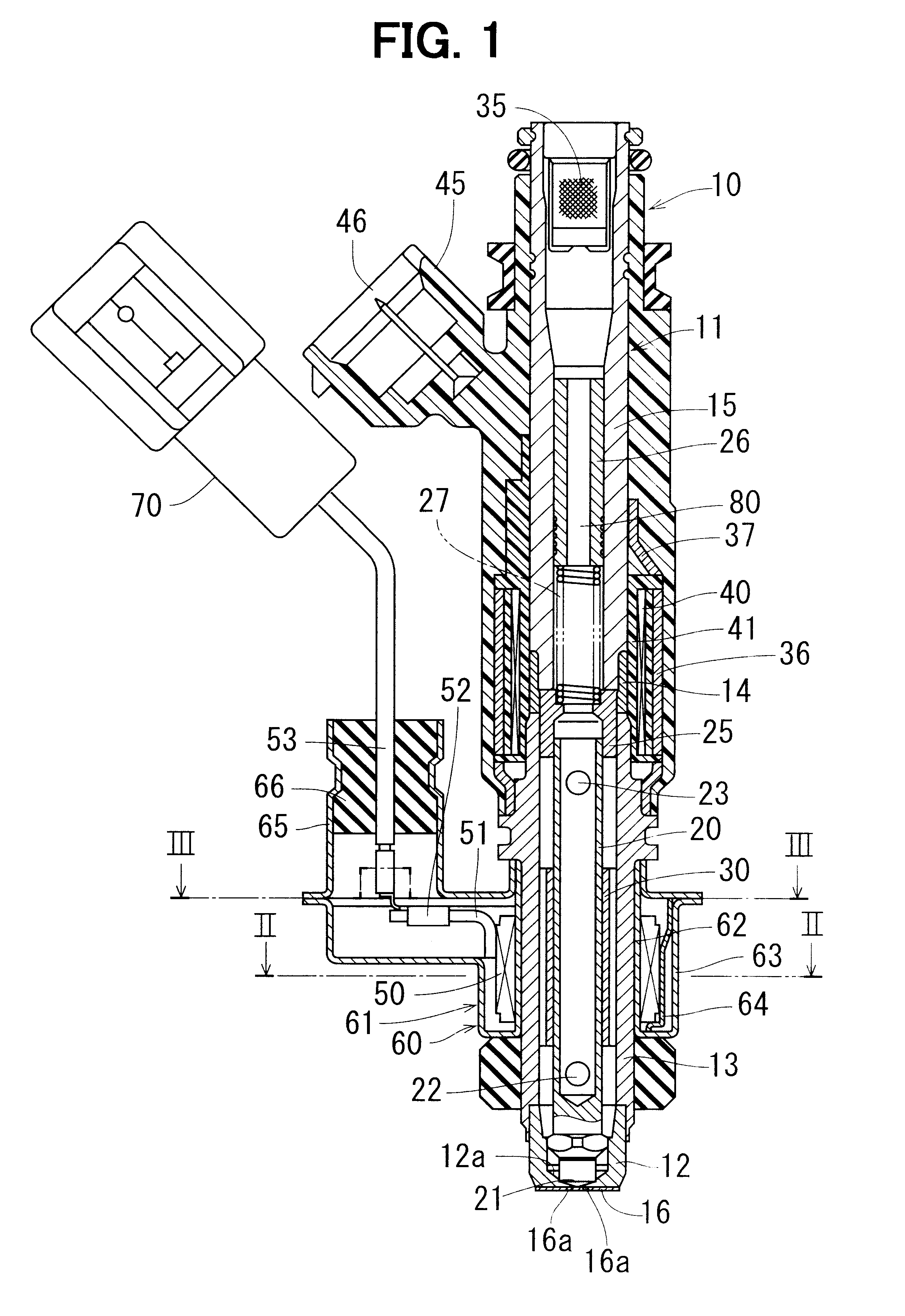

Fuel injection device having heater

InactiveUS6561168B2Liquid fuel feeder/distributionLiquid surface applicatorsEngineeringHeat transfer tube

A nozzle needle has a hollow tubular form having a closed base end. A heat transfer tube is press fitted into a first magnetic portion. The heat transfer tube surrounds an outer peripheral surface of the nozzle needle. A ceramic heater is formed as an integral cylindrical body by sintering a ceramic material together with a heat generating resistive element. A case covers the heater and protects the heater from externally applied water. An inner tube of the case is resiliently engaged with both the heater and the first magnetic portion. Heat of the heater is conducted to the nozzle needle through the inner tube, the first magnetic portion and the heat transfer tube to heat fuel inside the nozzle needle.

Owner:DENSO CORP

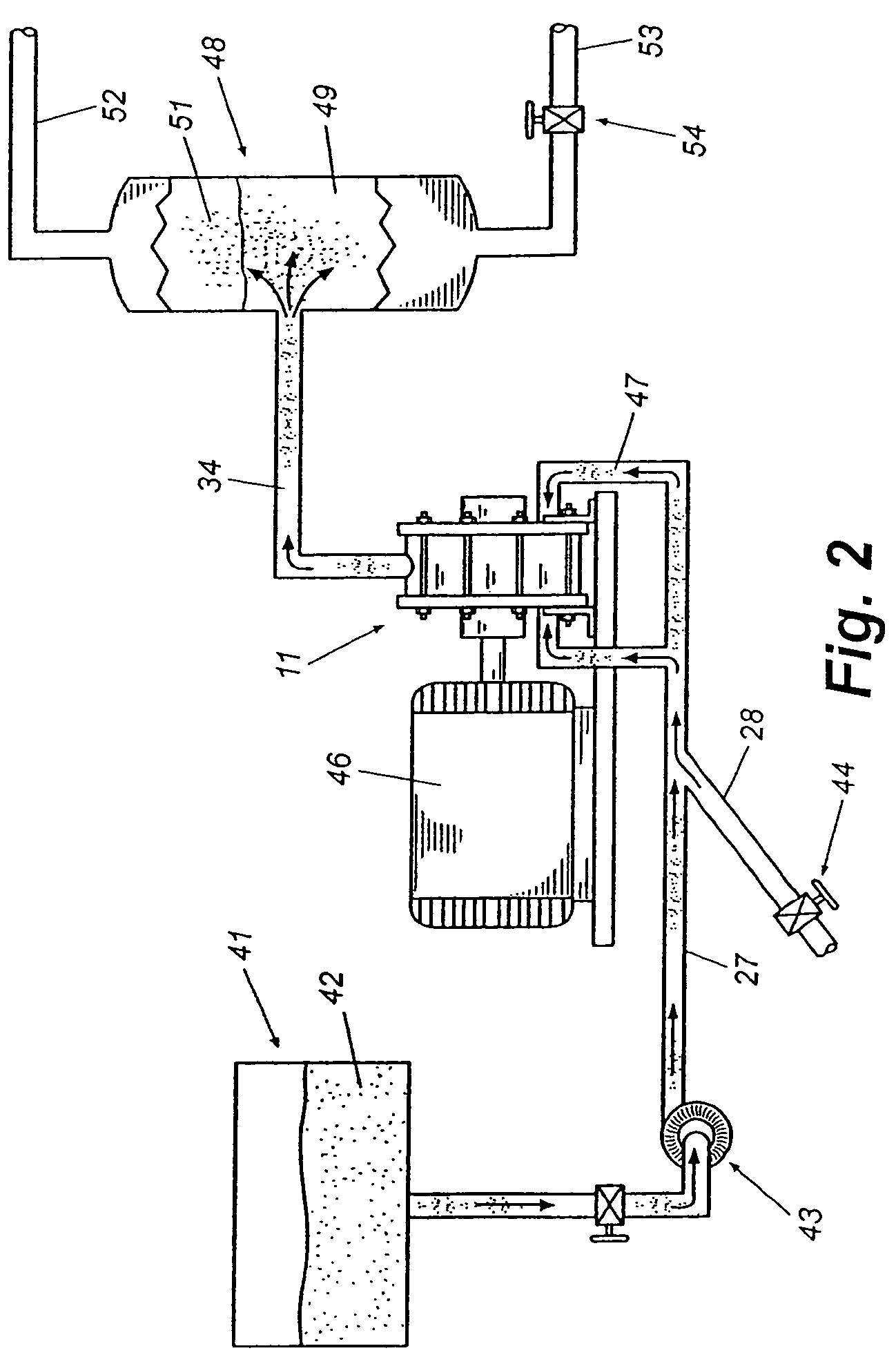

Cavitation device with balanced hydrostatic pressure

InactiveUS7360755B2Improve efficiencyEvenly distributedBurnersLiquid fuel feeder/distributionCavitationHydrostatic pressure

A method of mixing two or more dissimilar fluids such a gas and a liquid is provided. The method includes the steps of introducing one fluid into the other to form a mixture, inducing cavitation in the mixture to reduce at least one of the fluids to a large number of relatively small units, and distributing the small units uniformly throughout the mixture. In a preferred embodiment, the step of inducing cavitation comprises introducing the mixture into a chamber having a rotating disk formed with a plurality of irregularities such as bores. The irregularities on the rotating disk induce cavitation in the mixture. The cavitation also breaks down van der Waals attractions within the mixture to enhance mixing.

Owner:HYDRODYNAMICS

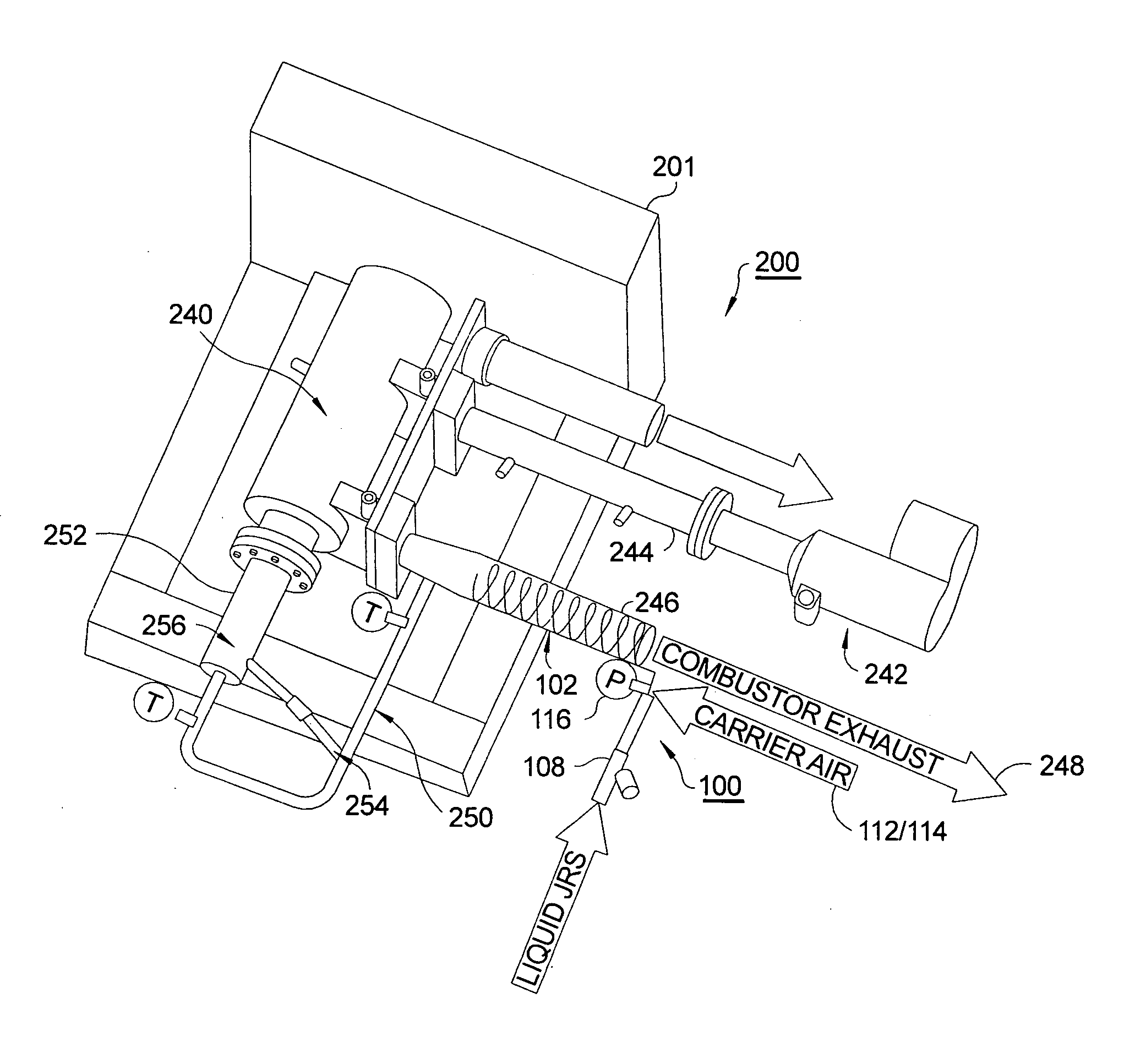

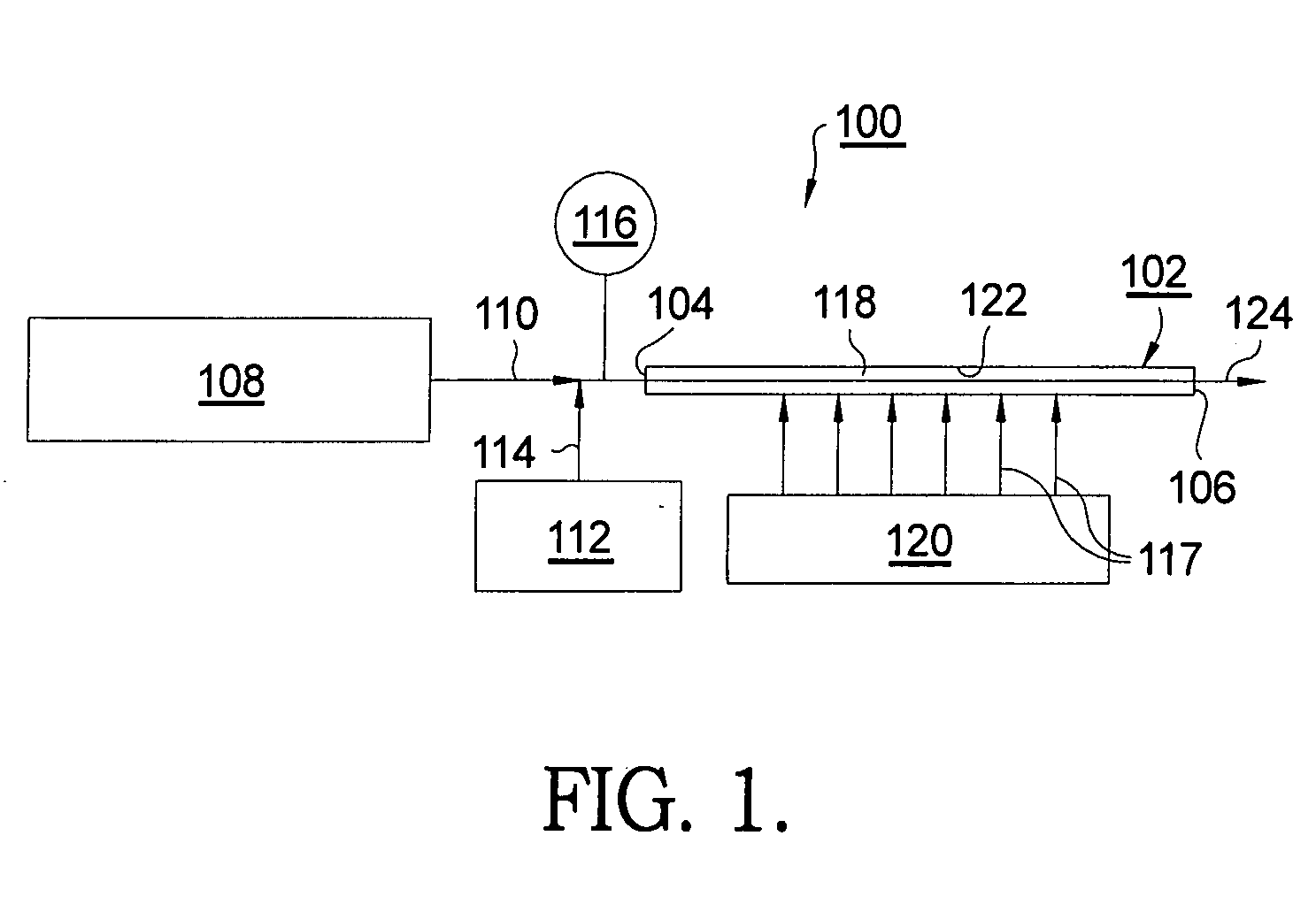

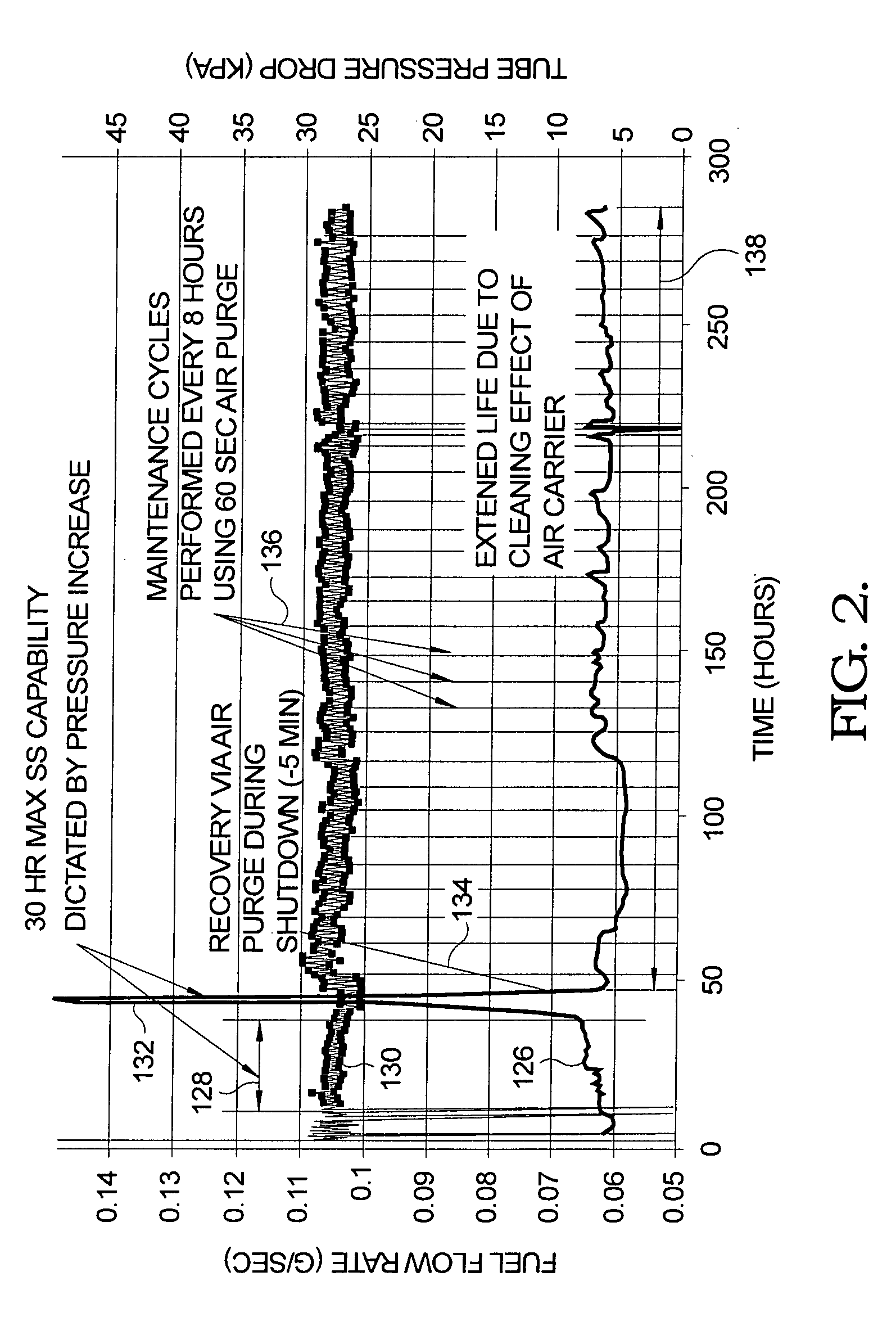

Continuous liquid fuel vaporizer

InactiveUS20080230039A1Reduce rateEasy to disassembleLiquid fuel feeder/distributionMachines/enginesEngineeringVaporization

A tubular vaporizer for vaporizing volatile liquids, and especially hydrocarbon fuels. Liquid fuel is passed into the vaporizer tube, is vaporized by heat transferred through fuel contact with the hot walls, and vaporized fuel exits the vaporizer tube. A hot carrier air stream is passed through the vaporizer with the vaporized fuel, greatly reducing the rate of buildup of deposits on the vaporizer walls; however, fueling of the vaporizer eventually must be shut down to remove the deposits. The deposits are easily removed, and the vaporizer tube completely regenerated, by passing hot air alone through the tube for a period of time. In a preferred embodiment, two parallel-path vaporization tubes and switching means therebetween are provided for alternate use and regeneration cycles, affording a continuous flow of vaporized fuel from the apparatus. The vaporizer is especially useful in providing gaseous fuel for a catalytic hydrocarbon reformer.

Owner:DELPHI TECH INC

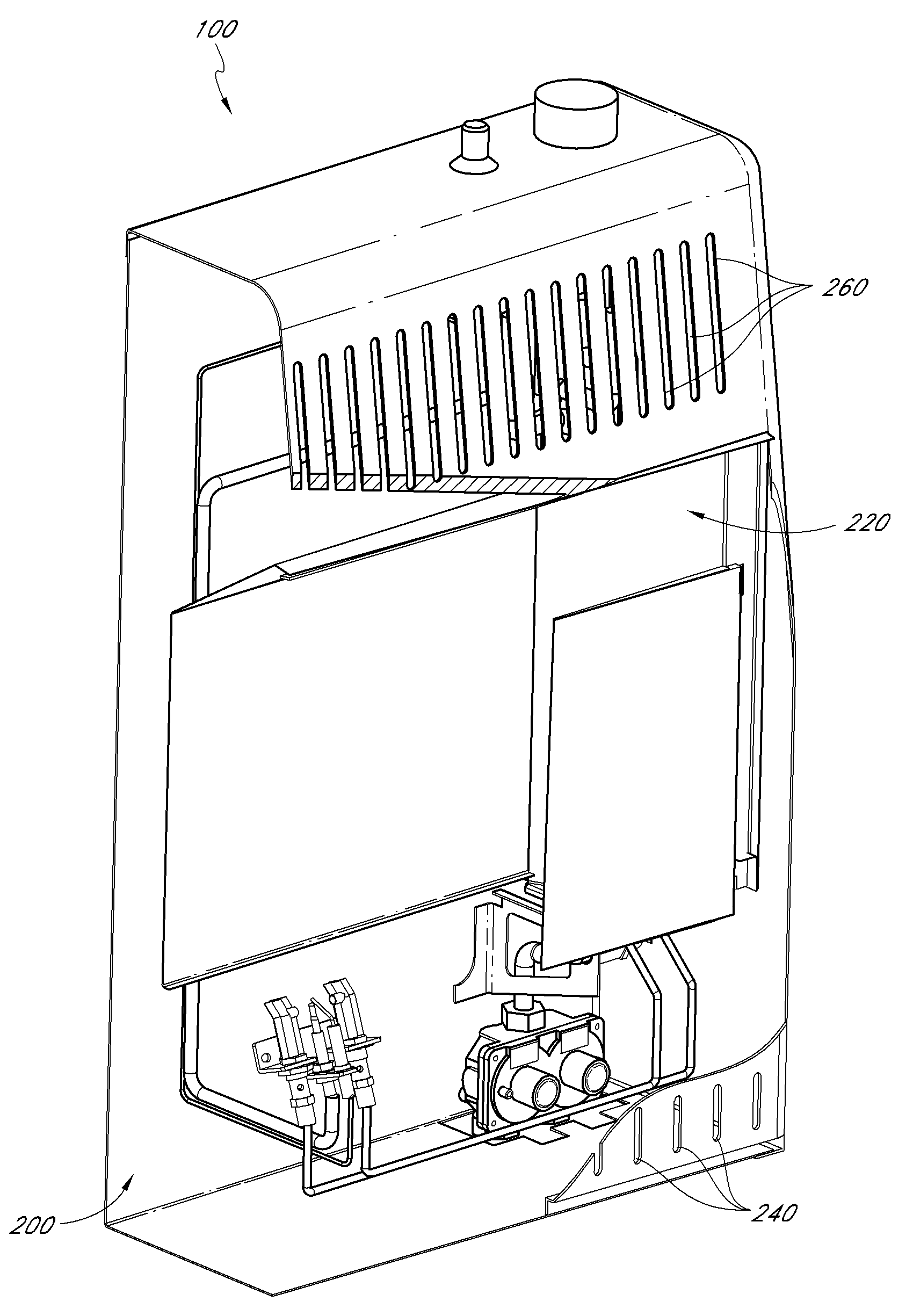

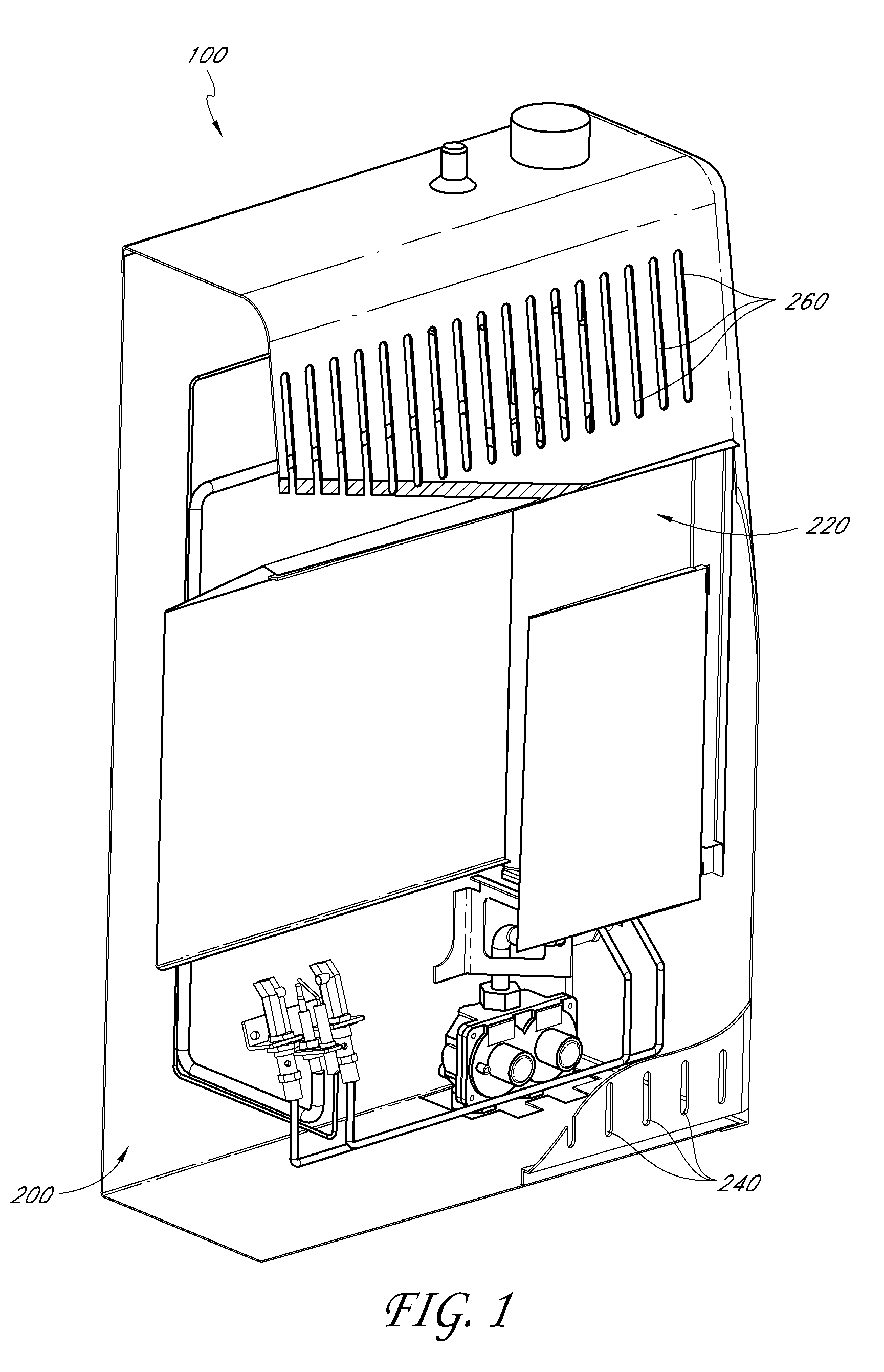

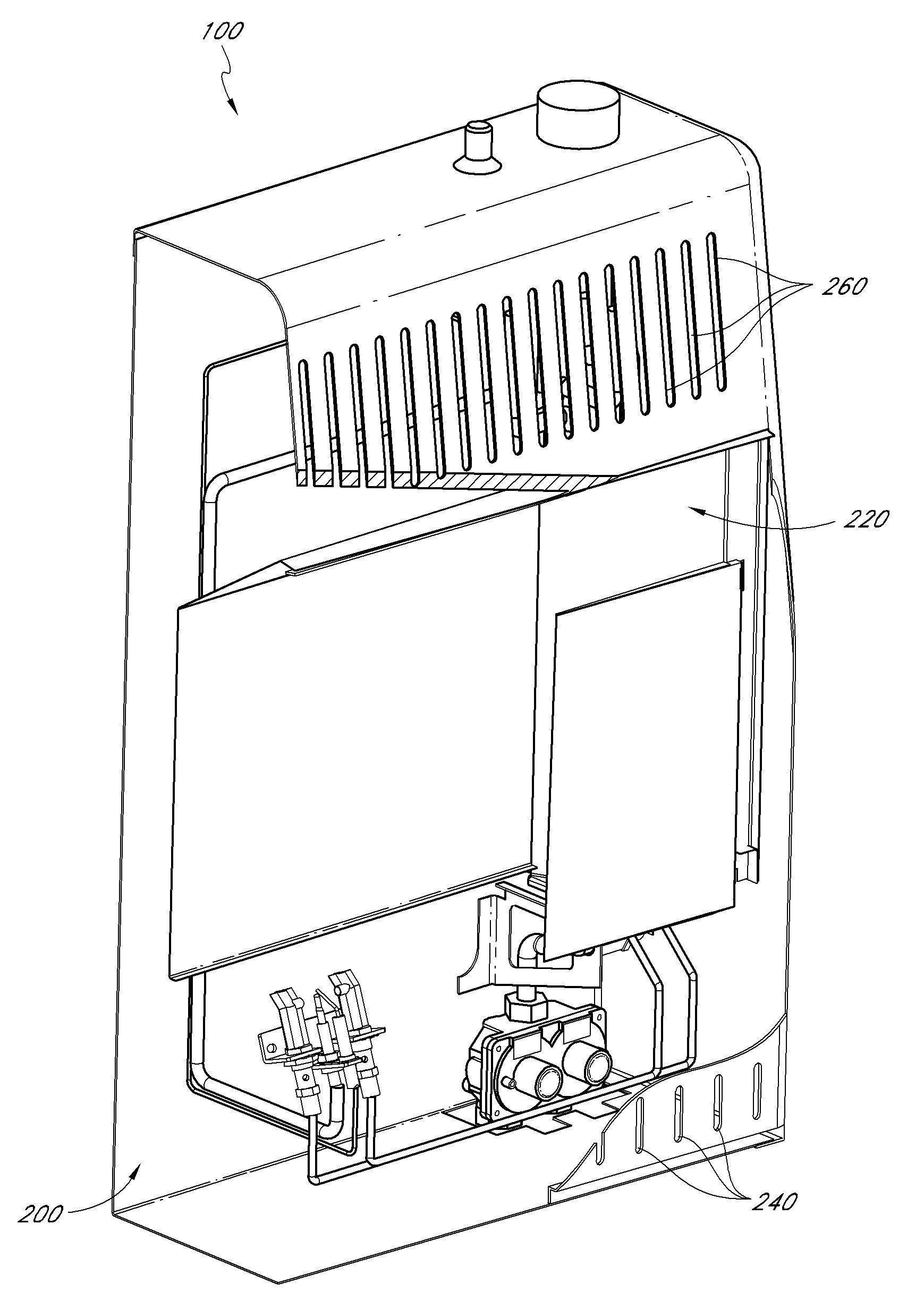

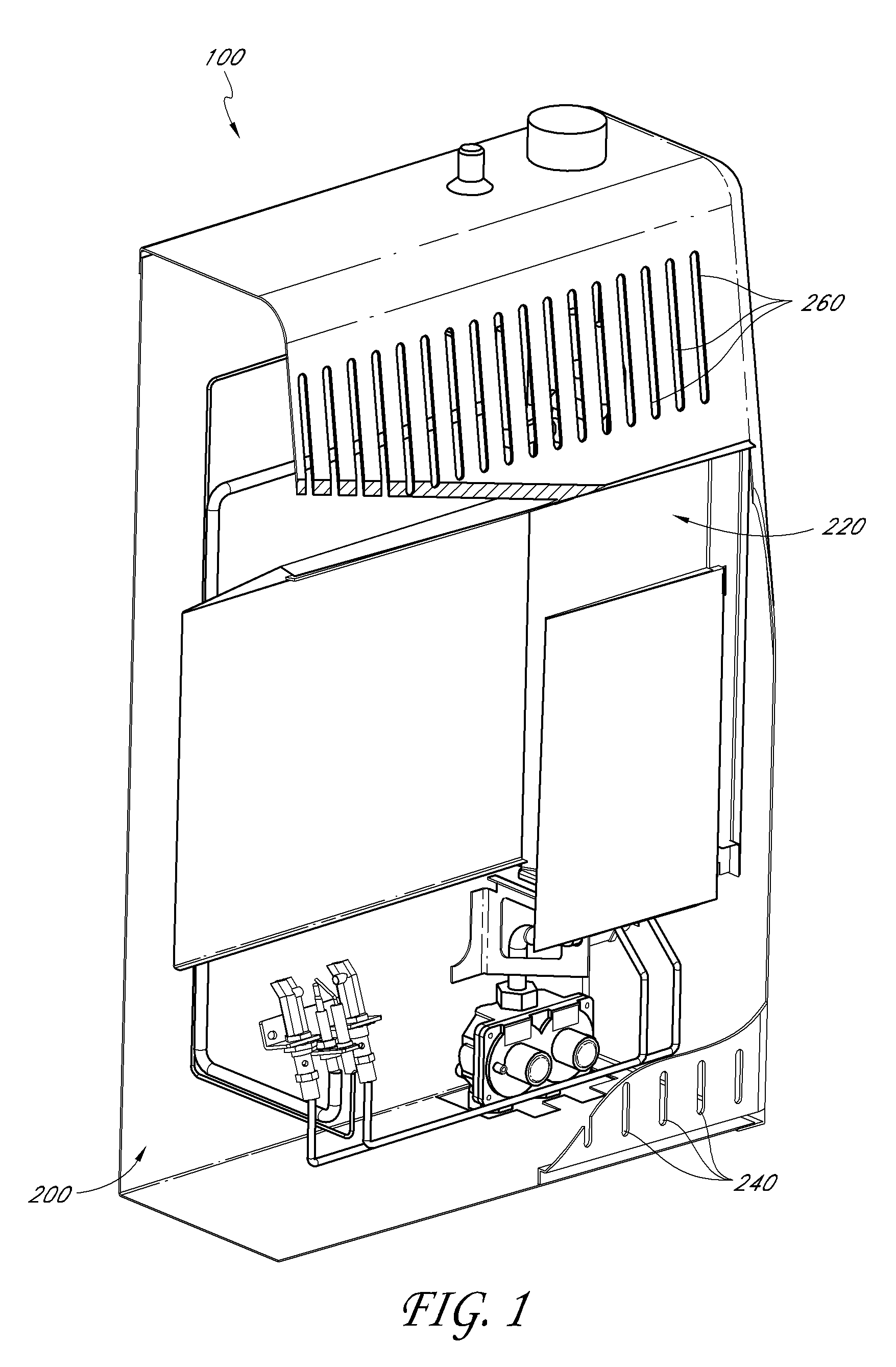

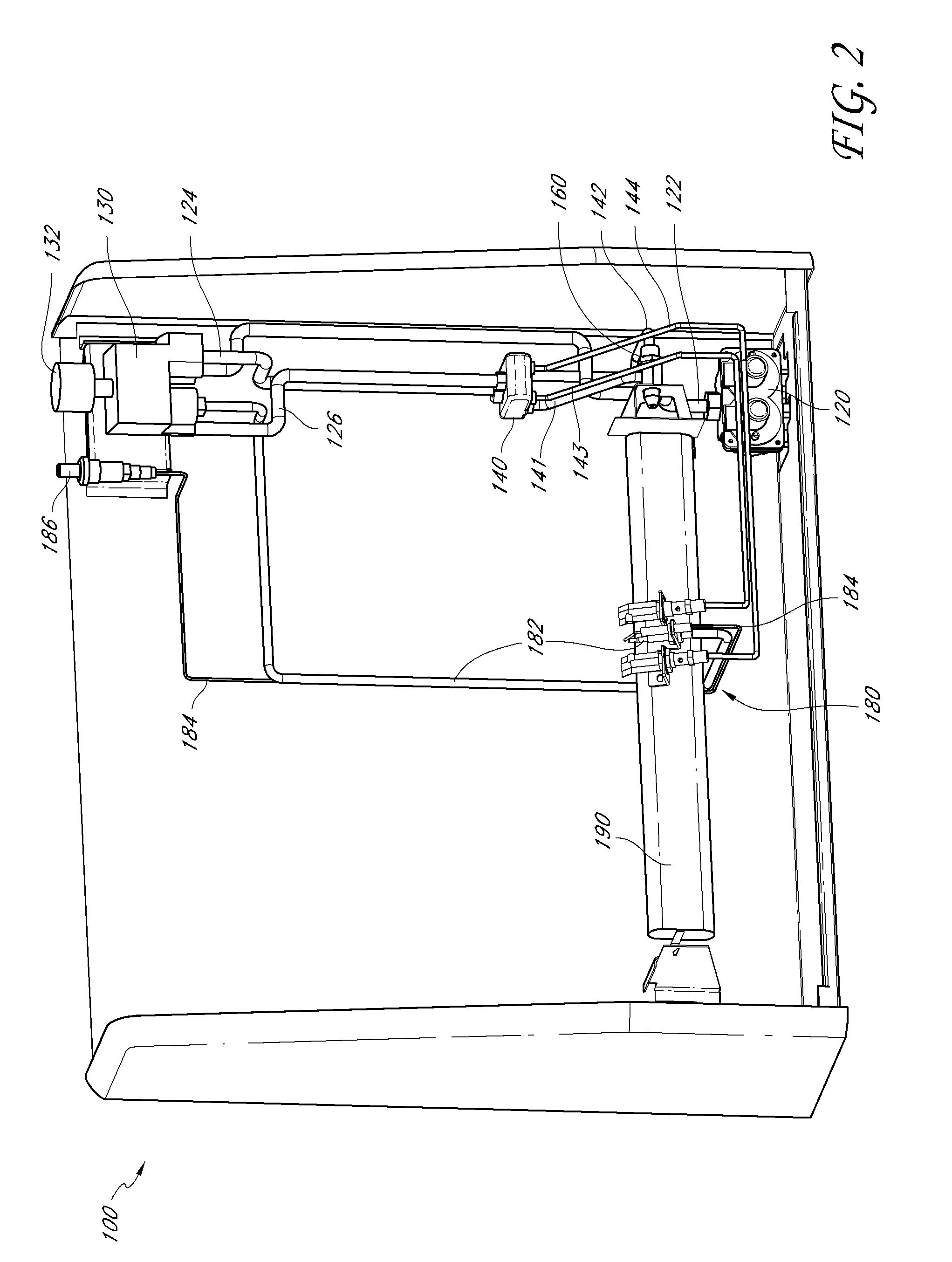

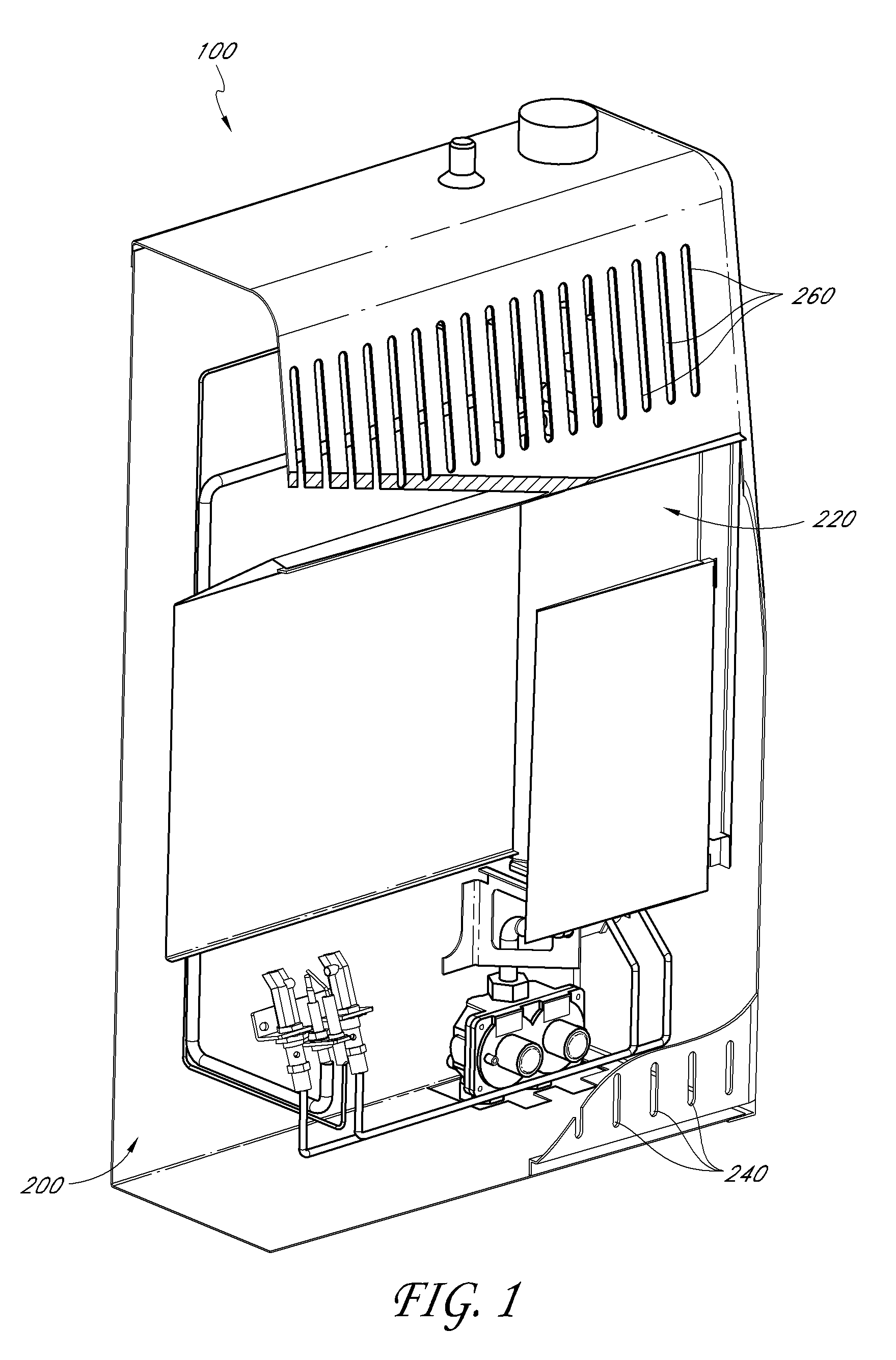

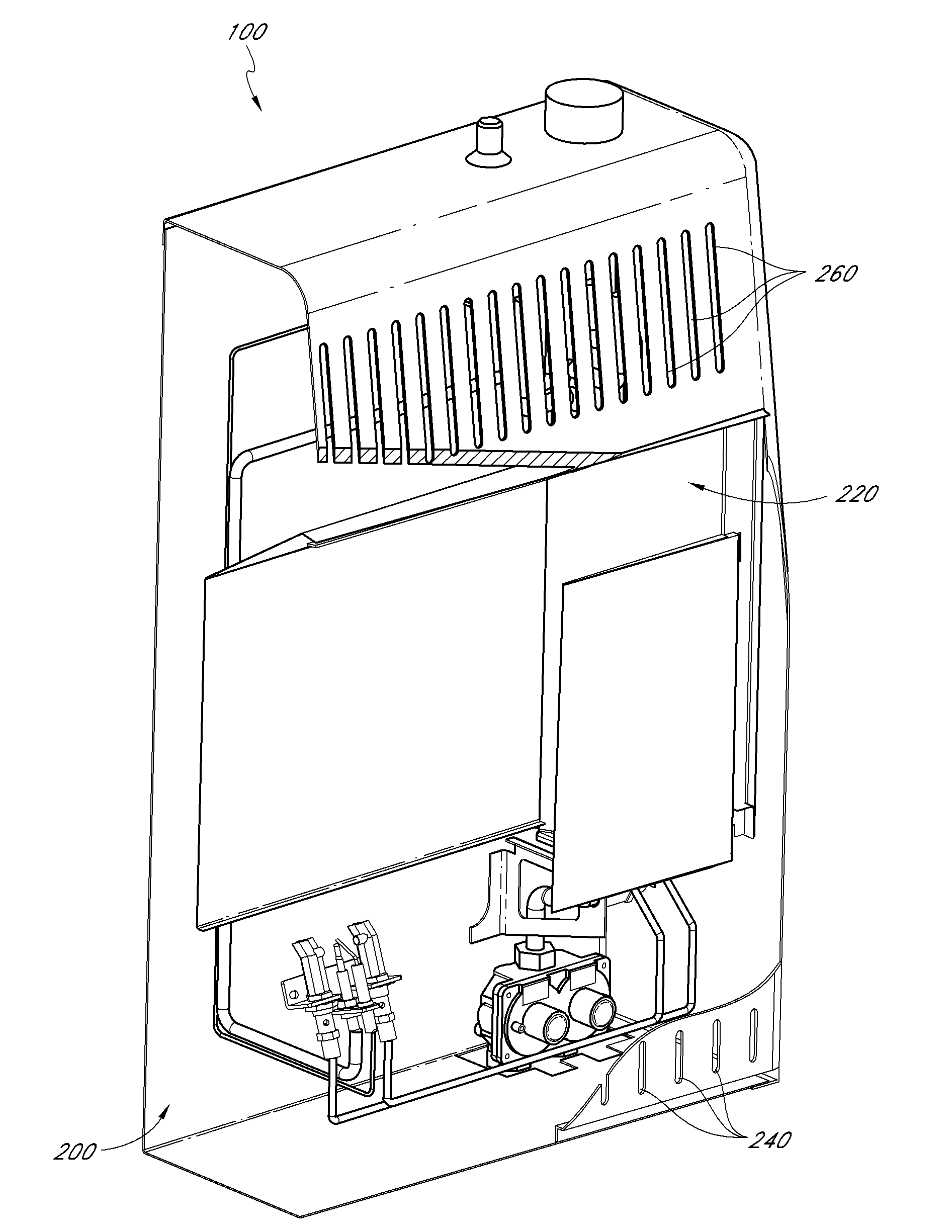

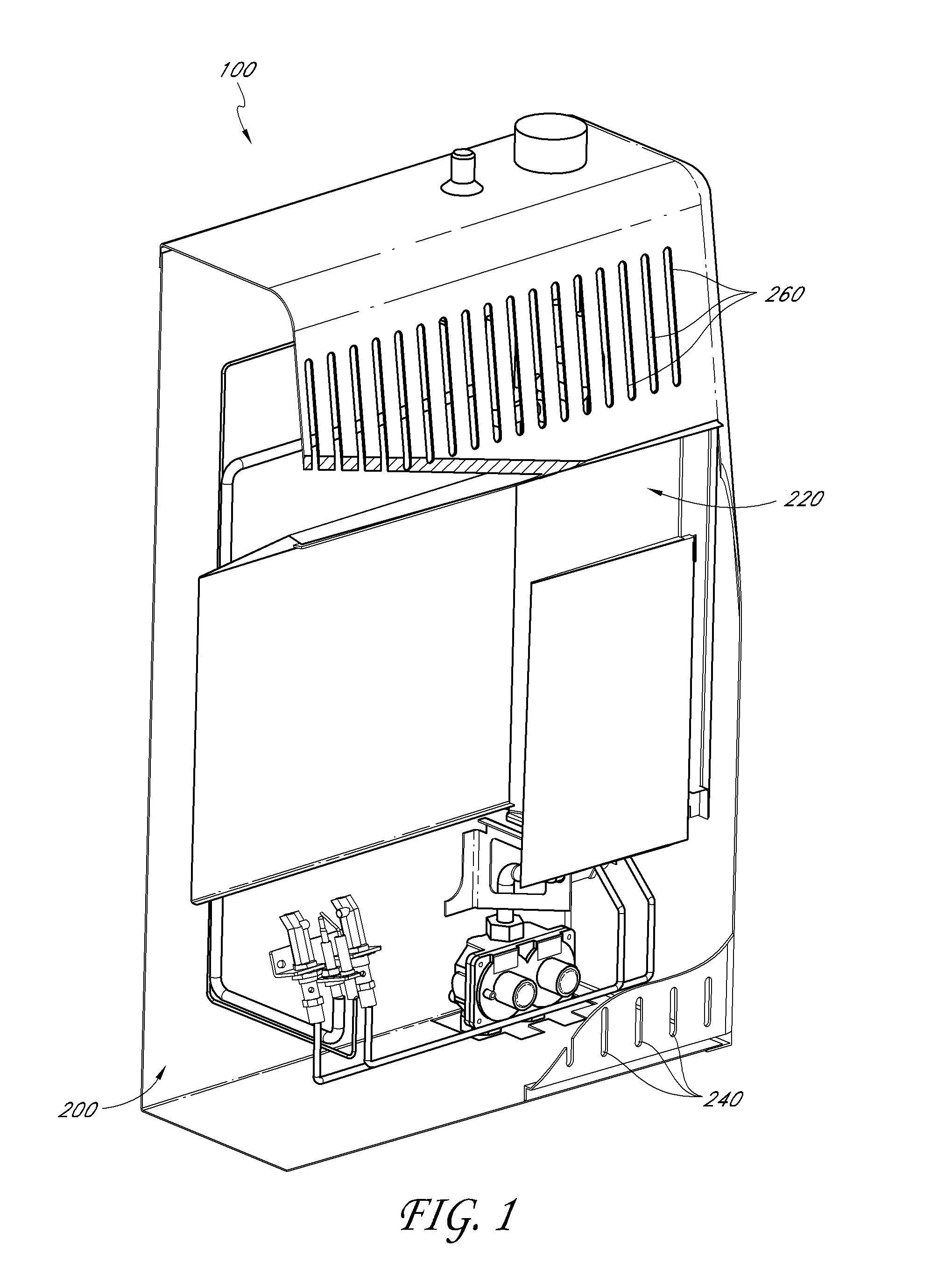

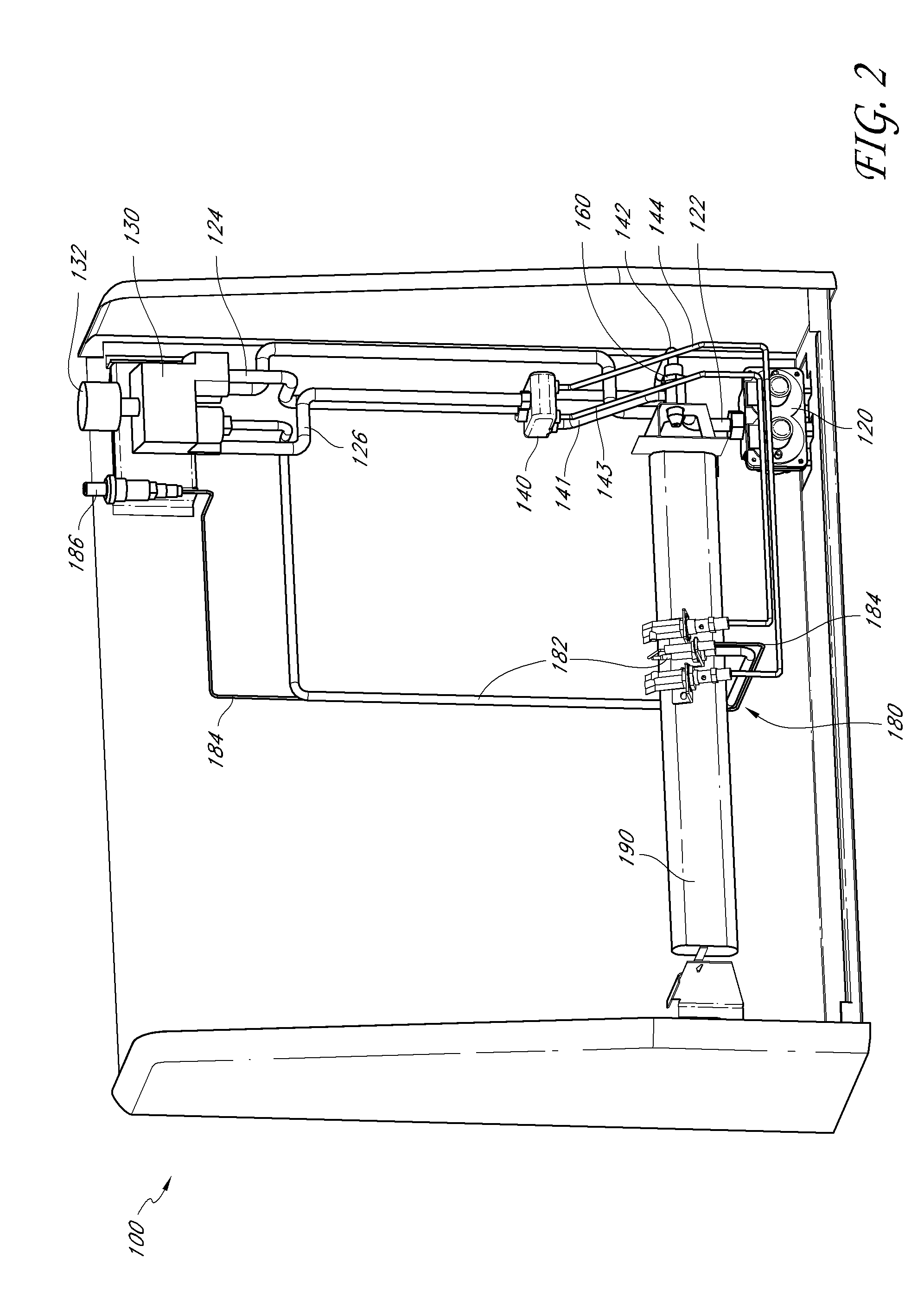

Dual fuel heating source

ActiveUS20100330513A1Avoid flowLiquid fuel feeder/distributionFuel supply regulationEngineeringMechanical engineering

A dual fuel heating source can have a fuel selector valve for selecting between a first fuel and a second fuel different from the first. The dual fuel heating source may selectively have a regulator unit, and an outlet valve. The regulator unit can be configured to regulate the pressure of two different fuels. The outlet valve can be connected to the fuel selector valve such that selecting a fuel can determine the path fuel will flow through the outlet valve and also out of the heating source.

Owner:DENG DAVID

Nested channel ducts for nozzle construction and the like

InactiveUS7028484B2Simpler and economical to manufactureLiquid fuel feeder/distributionContinuous combustion chamberGuide tubeGas turbines

A multiple conduit system for a gas turbine engine, the multiple conduit system extending between a plurality of conduit inlet and outlets. A channel is formed in a surface of a gas turbine engine component, and the channel is adapted for conveying a fluid flow from an inlet to an outlet. At least a first sealing member is disposed within the channel and divides the channel into at least a first discrete conduit and a second discrete conduit. A second sealing member encloses the channel to define the second discrete conduit. The first and second discrete conduits are each adapted to direct an independent fluid flow from respective inlets to respective outlets.

Owner:PRATT & WHITNEY CANADA CORP

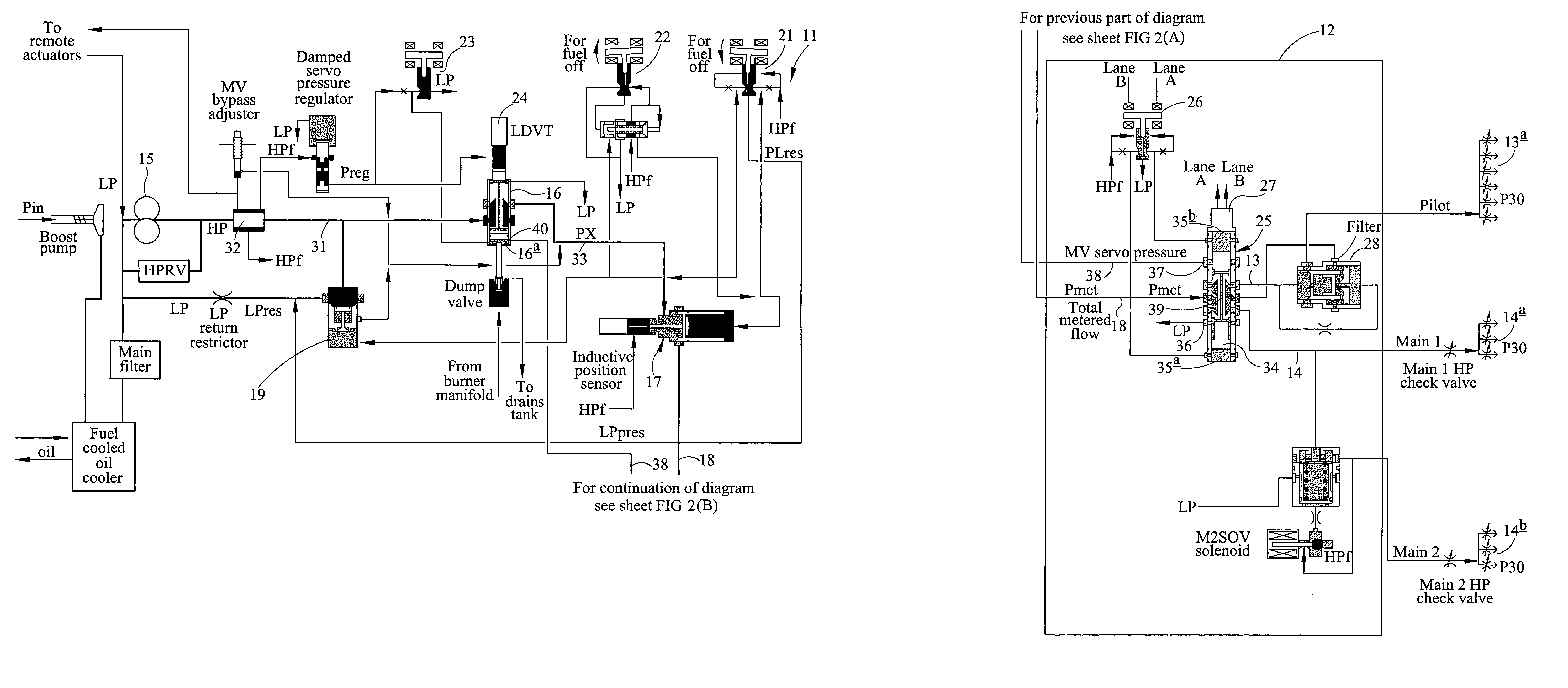

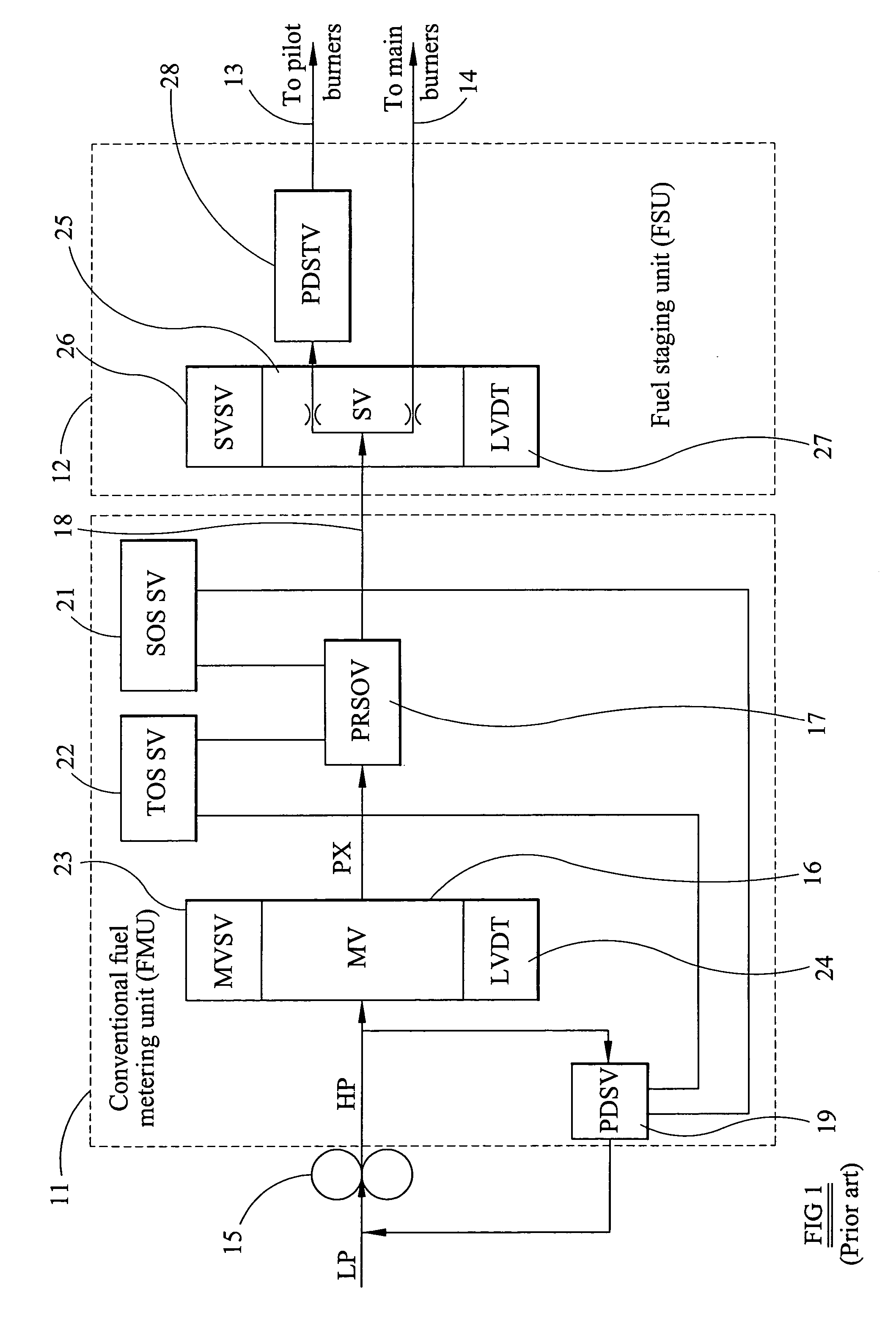

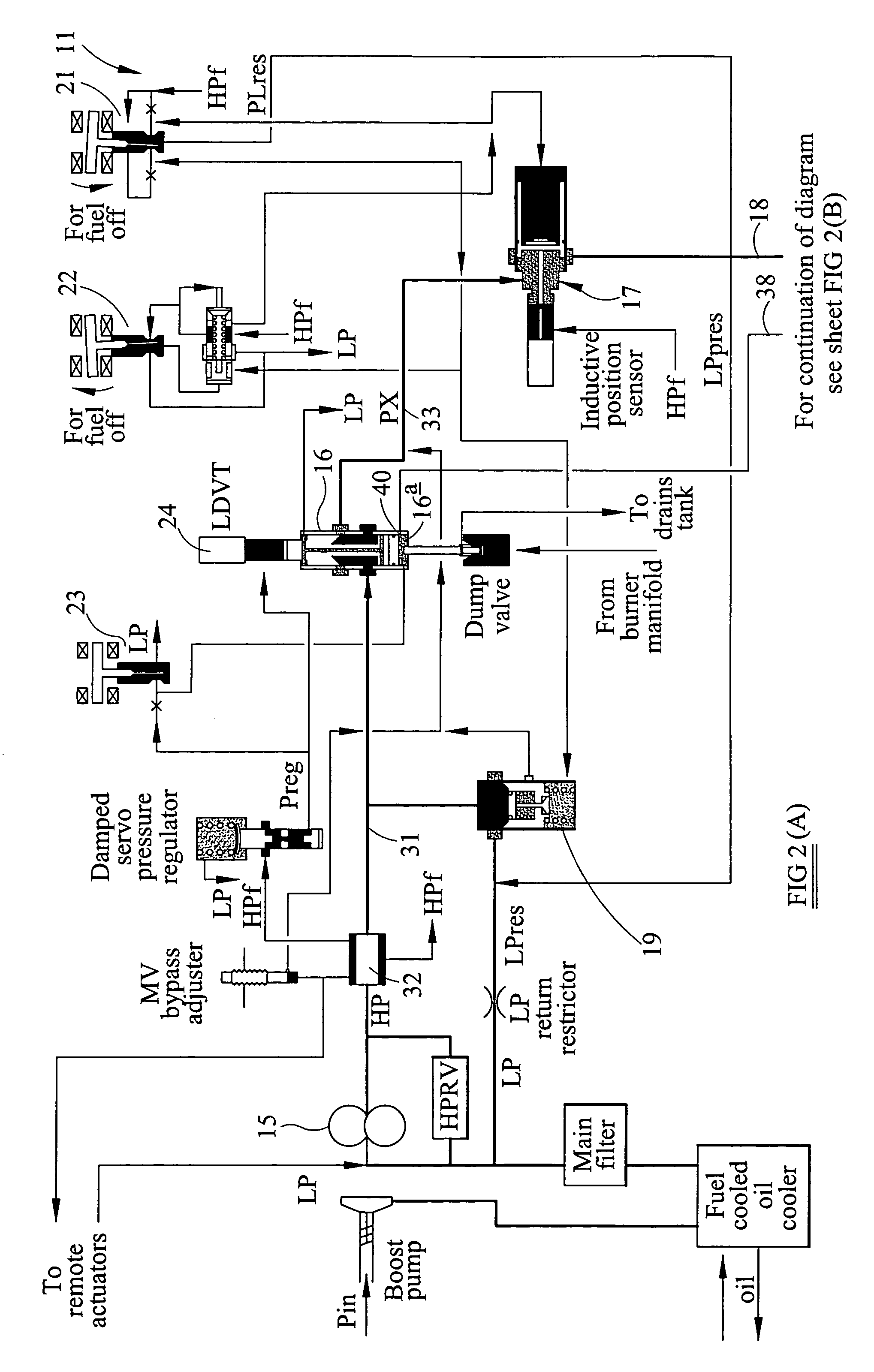

Fuel system

InactiveUS7137242B2Reduce the amount requiredFuel supply regulationLiquid fuel feeder/distributionCombustorControl system

A fuel control system for a staged combustion engine comprising, a fuel metering unit including a fuel metering valve having a fuel metering orifice the opening of which is varied to meter the flow of fuel through the metering valve in use, a fuel staging unit receiving fuel from the metering valve of the fuel metering unit and incorporating a staging valve for dividing the flow of fuel from the fuel metering unit to pilot burner and main burner output lines, a connection between a fuel pressure region of said fuel metering unit and a port of said staging valve, and, overthrust detection means causing said staging valve, in response to overthrust detection, to connect said port of said staging valve to low pressure, whereby to drain fuel under pressure from said pressure zone of said fuel metering unit to low pressure to limit or reduce the fuel supplied from the fuel metering unit to the fuel staging unit and thus to the engine in use.

Owner:GOODRICH CONTROL SYST LTD

Dual fuel heating system and air shutter

InactiveUS20100326430A1Liquid fuel feeder/distributionFuel supply regulationCombustionHeating system

A dual fuel heating system can be used in a gas appliance. The system can have an air shutter to regulate an amount of air that can mix with the fuel for combustion. The air shutter can be configured to have different positions depending on the type of fuel to be used.

Owner:DENG DAVID

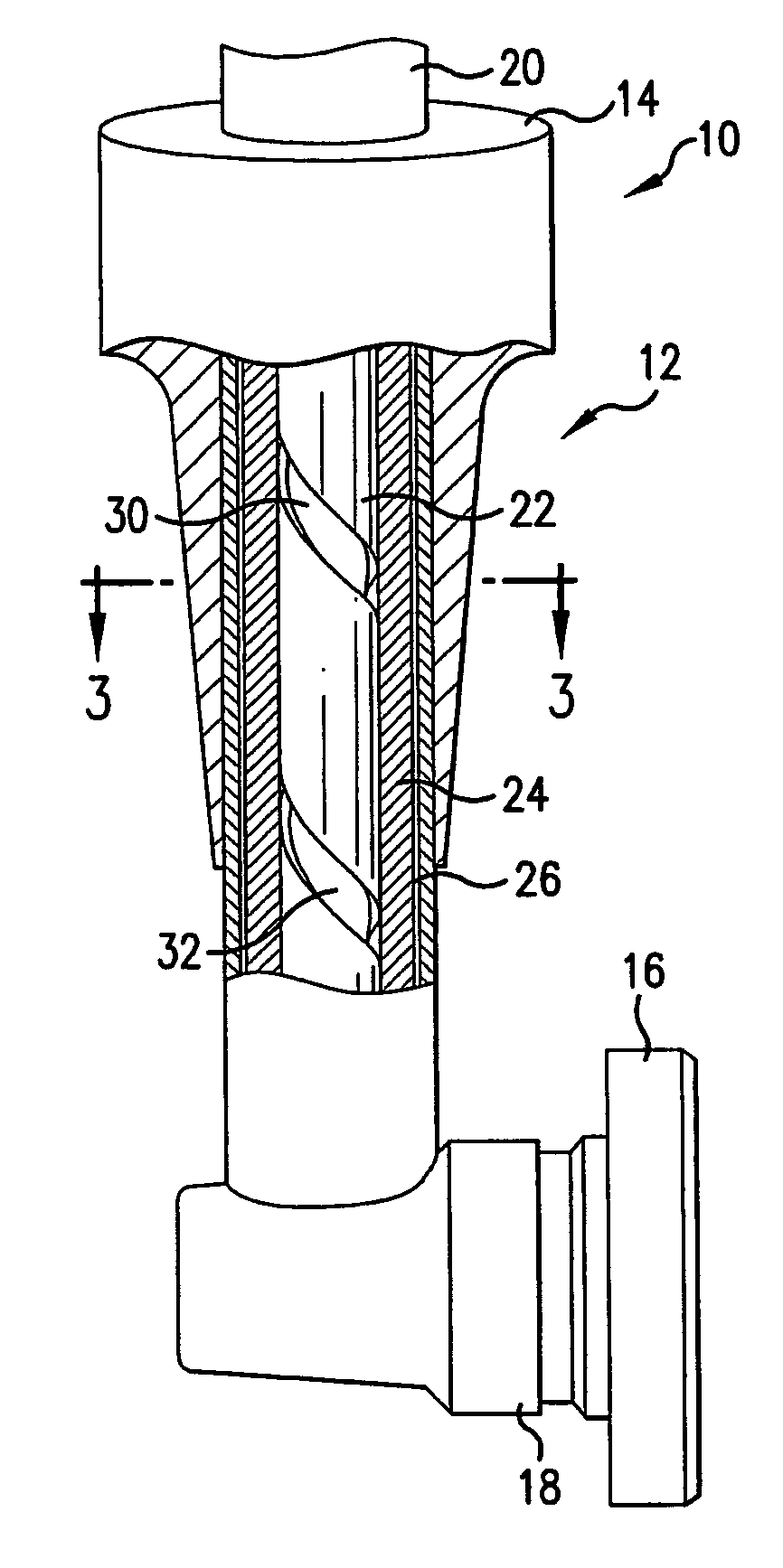

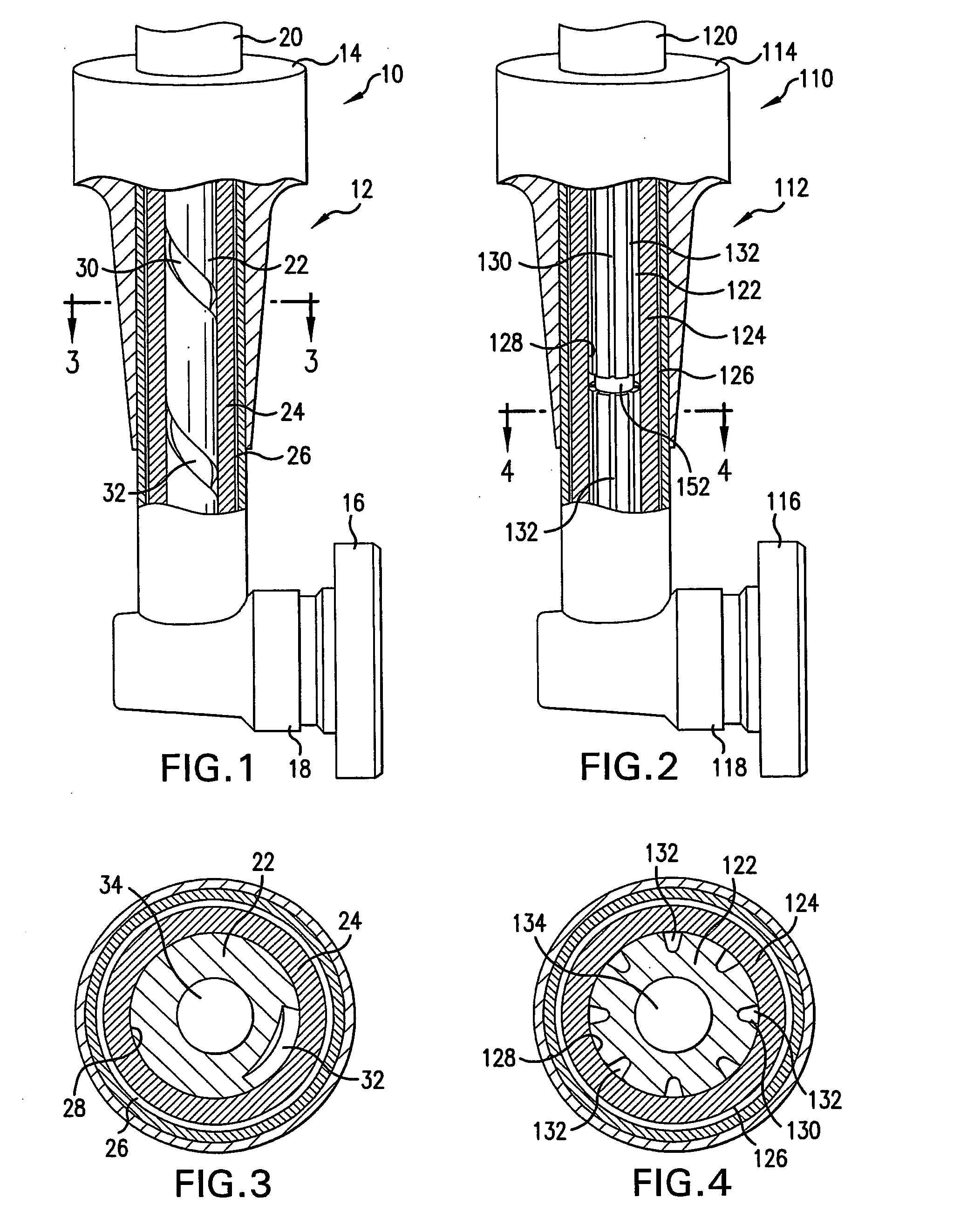

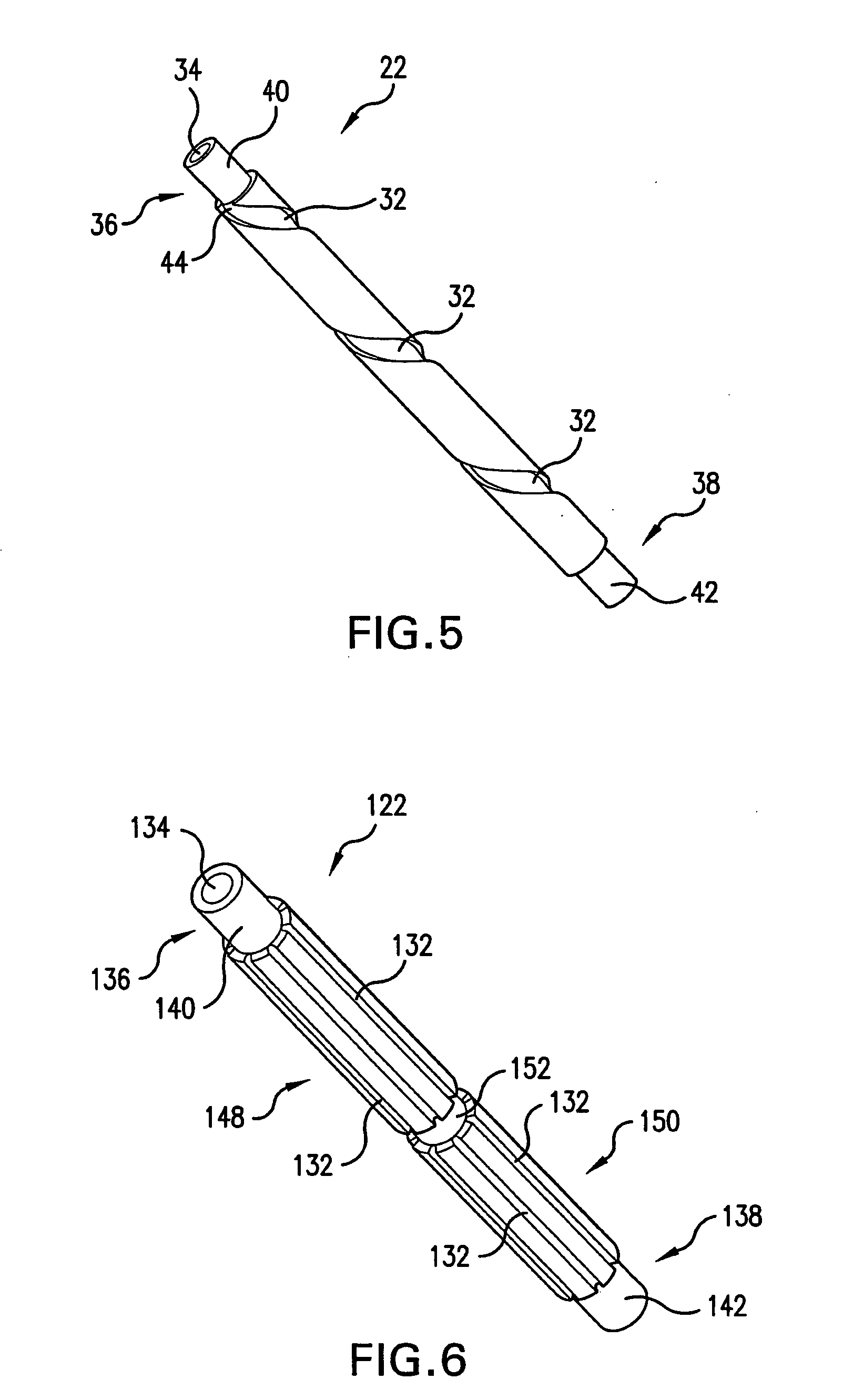

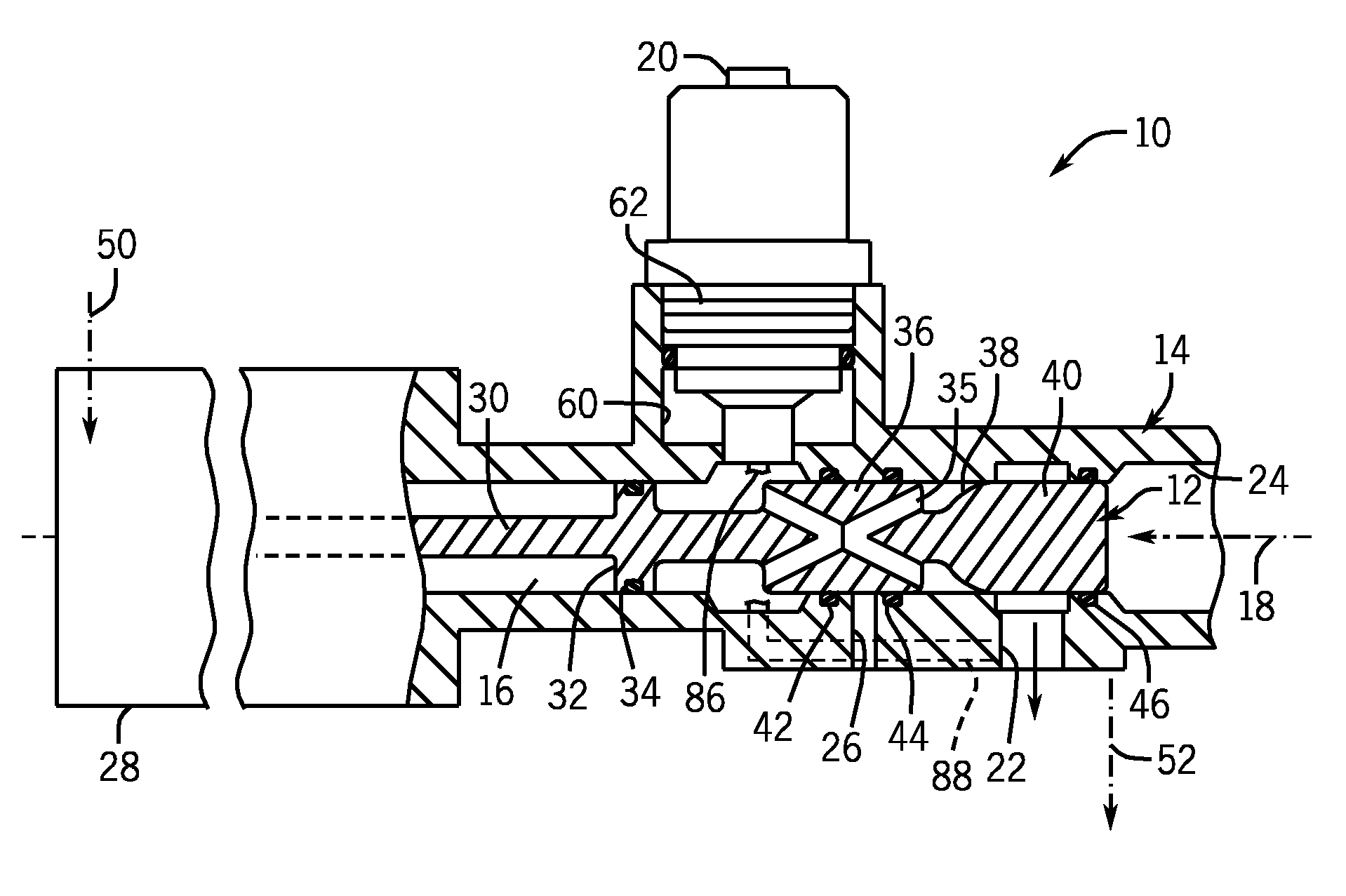

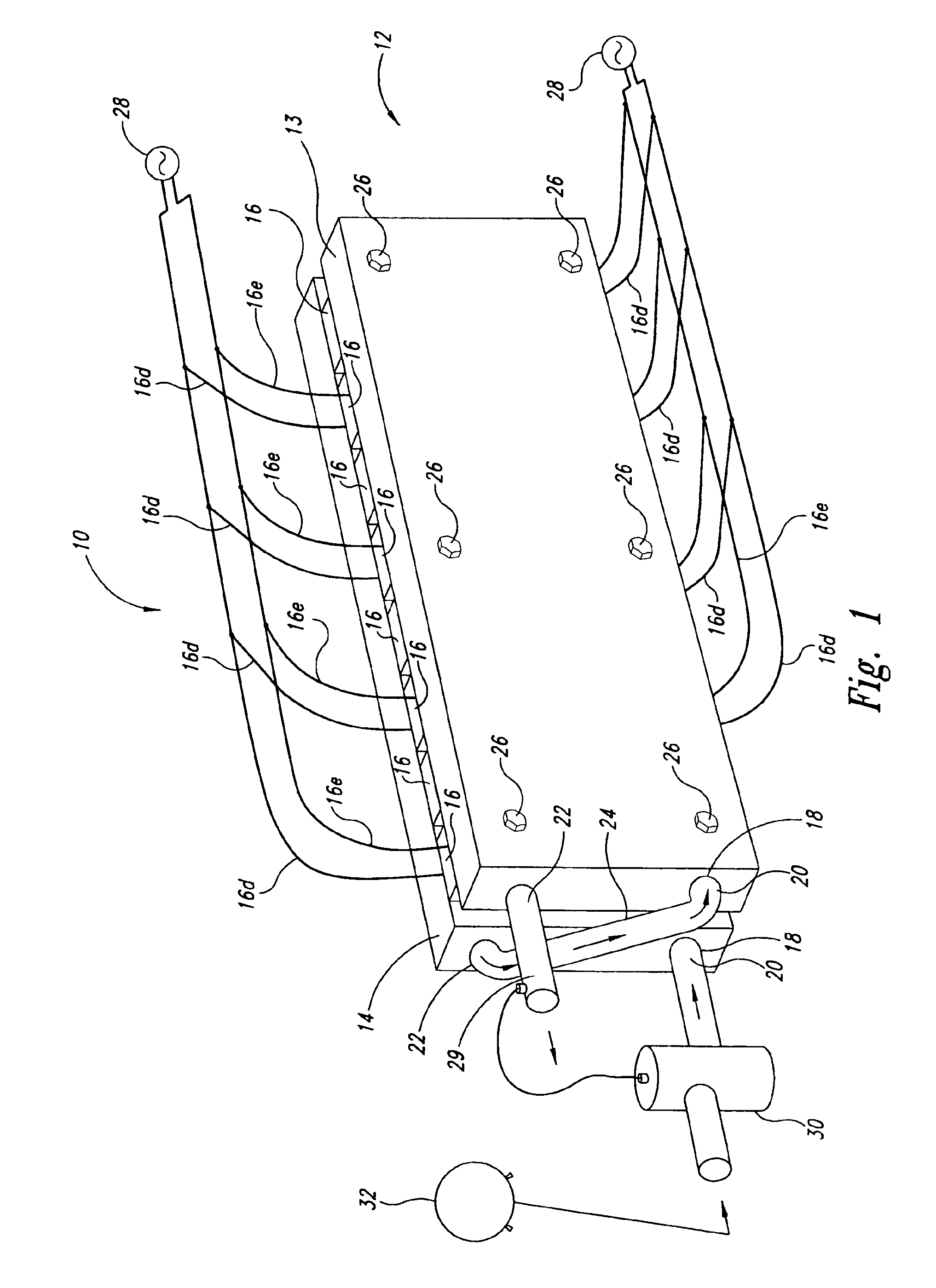

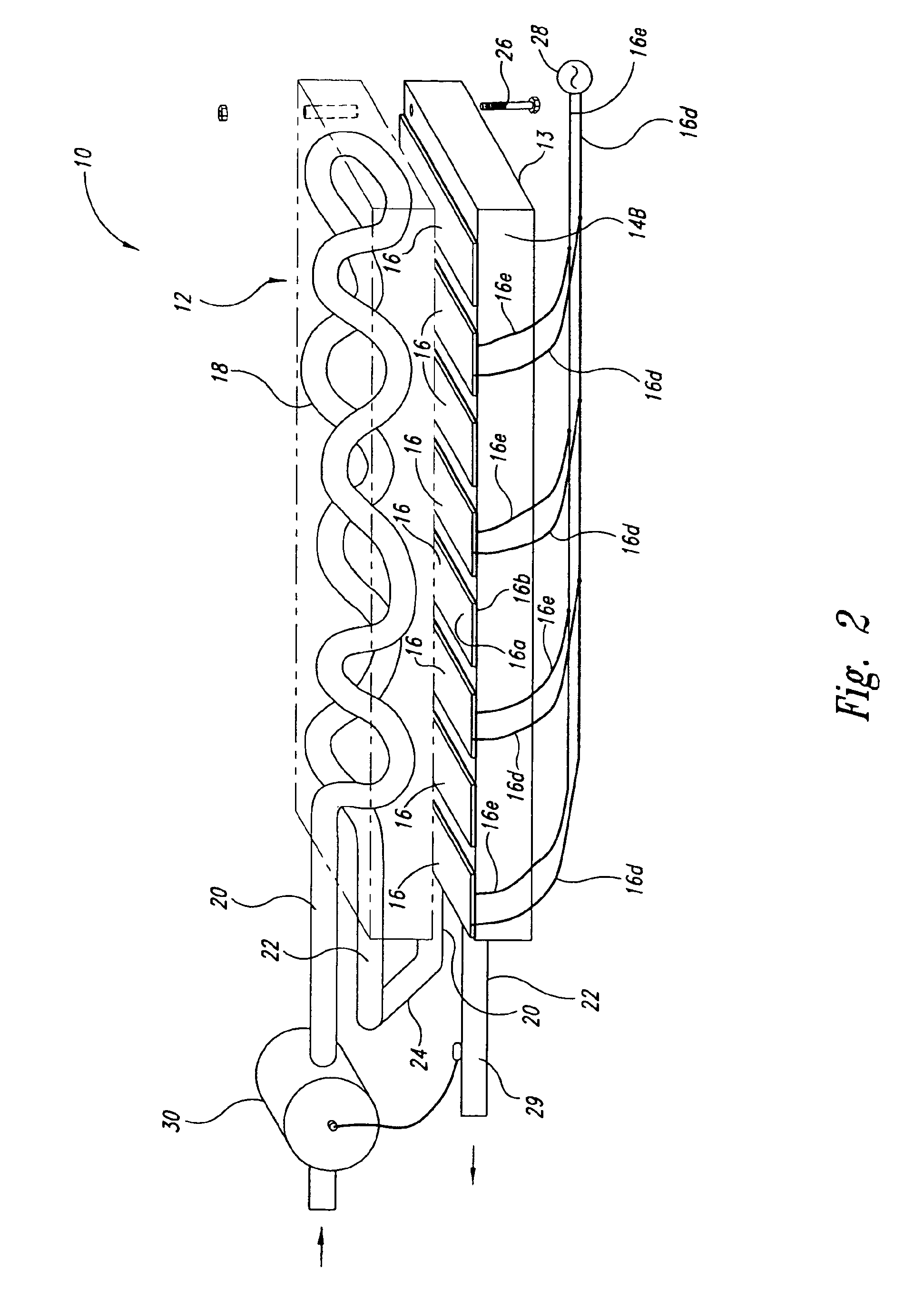

Method and apparatus to increase combustion efficiency and to reduce exhaust gas pollutants from combustion of a fuel

InactiveUS20050016507A1Improve combustion efficiencyFacilitate fuel combustionBurnersLiquid fuel feeder/distributionCombustorExhaust fumes

A method and apparatus is disclosed for increasing combustion efficiency in internal combustion engines and external combustors resulting in increased fuel economy and reduced exhaust pollutants. The same principles and apparatus of the invention are used in the exhaust stream to further reduce pollutants.

Owner:RONNELL

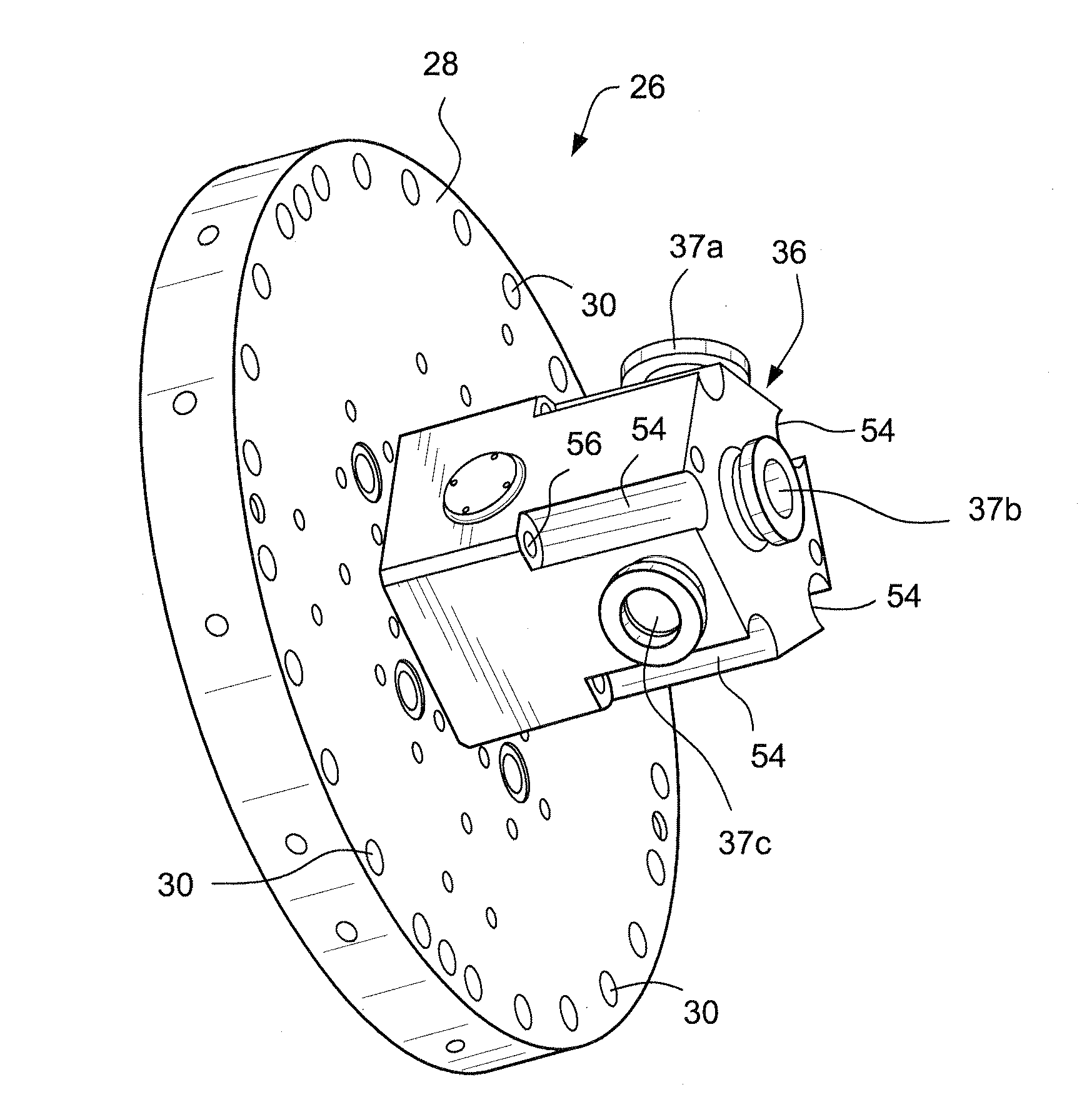

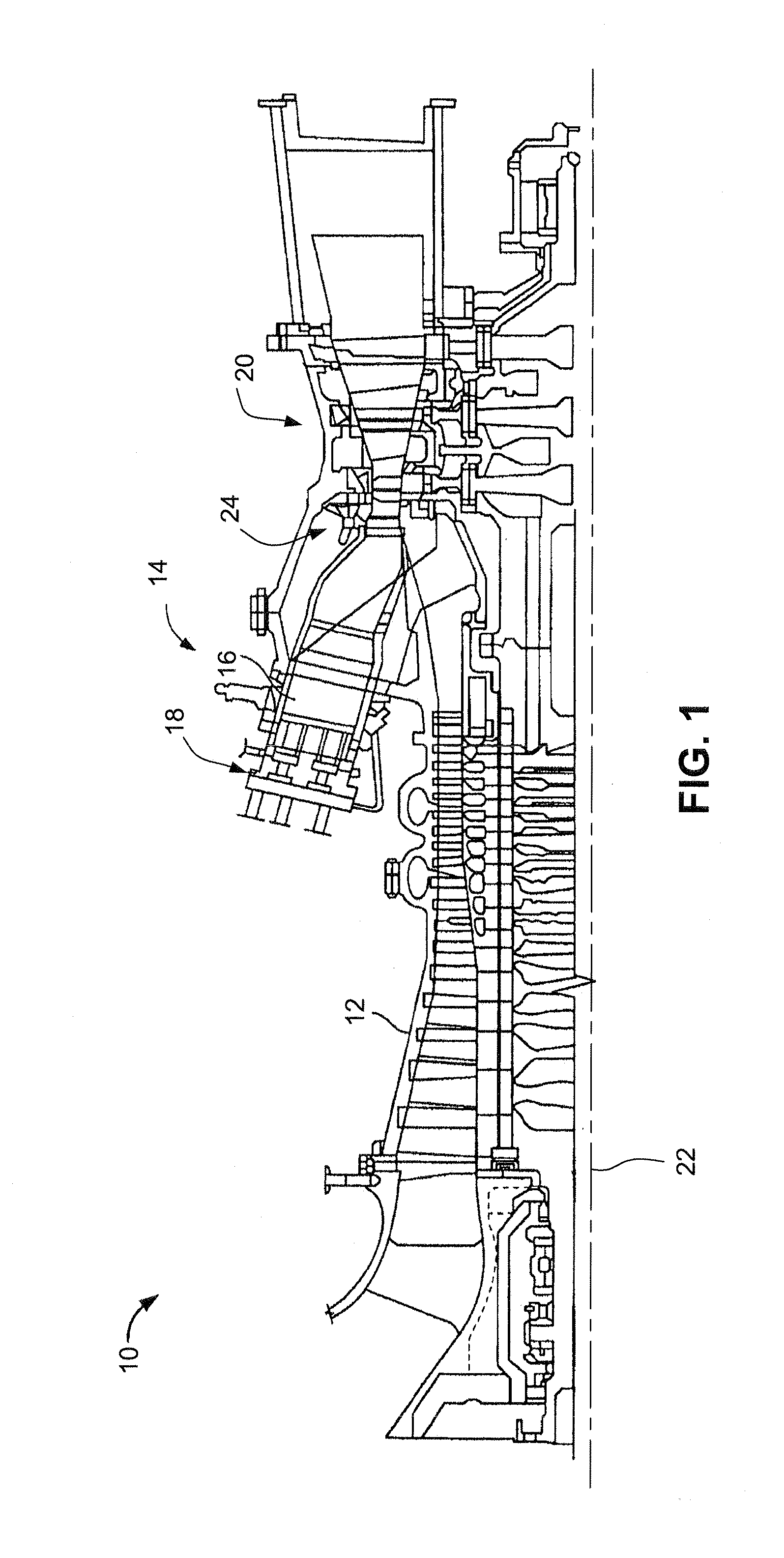

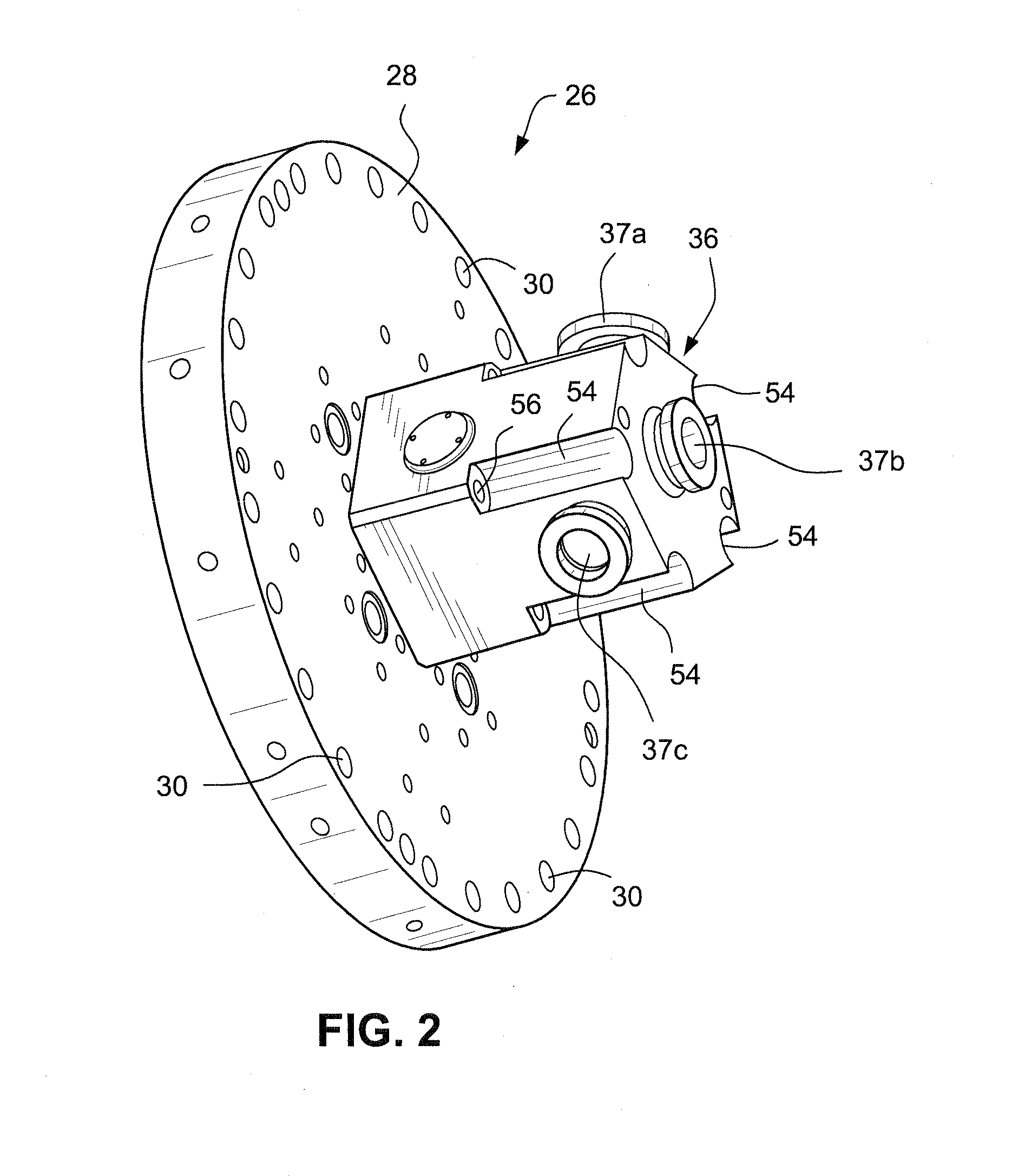

Apparatus and method for controlling the secondary injection of fuel

A combustor (28) for a gas turbine engine is provided comprising a primary combustion chamber (30) for combusting a first fuel to form a combustion flow stream (50) and a transition piece (32) located downstream from the primary combustion chamber (30). The transition piece (32) comprises a plurality of injectors (66) located around a circumference of the transition piece (32) for injecting a second fuel into the combustion flow stream (50). The injectors (66) are effective to create a radial temperature profile (74) at an exit (58) of the transition piece (32) having a reduced coefficient of variation relative to a radial temperature profile (64) at an inlet (54) of the transition piece (32). Methods for controlling the temperature profile of a secondary injection are also provided.

Owner:SIEMENS ENERGY INC

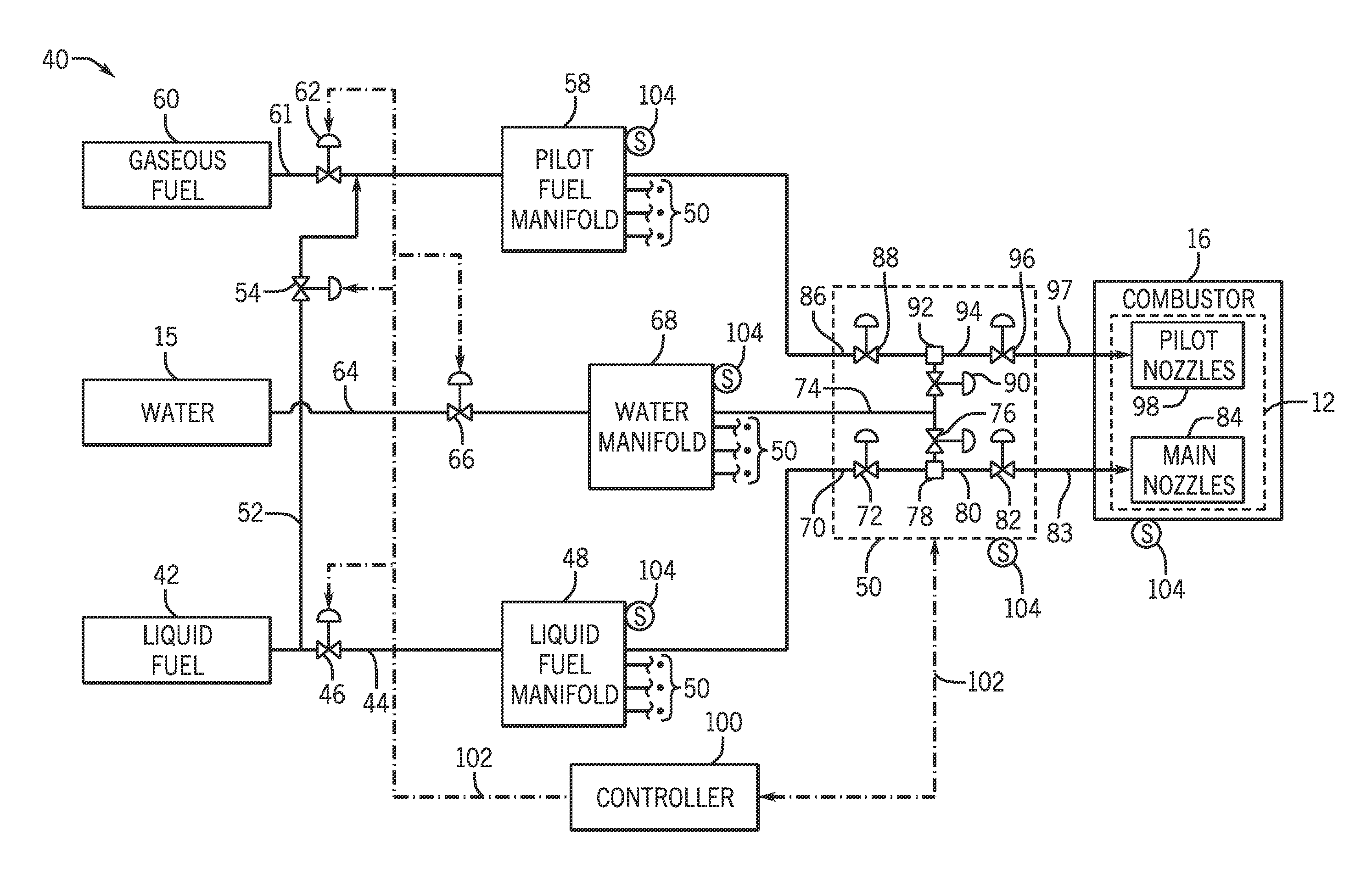

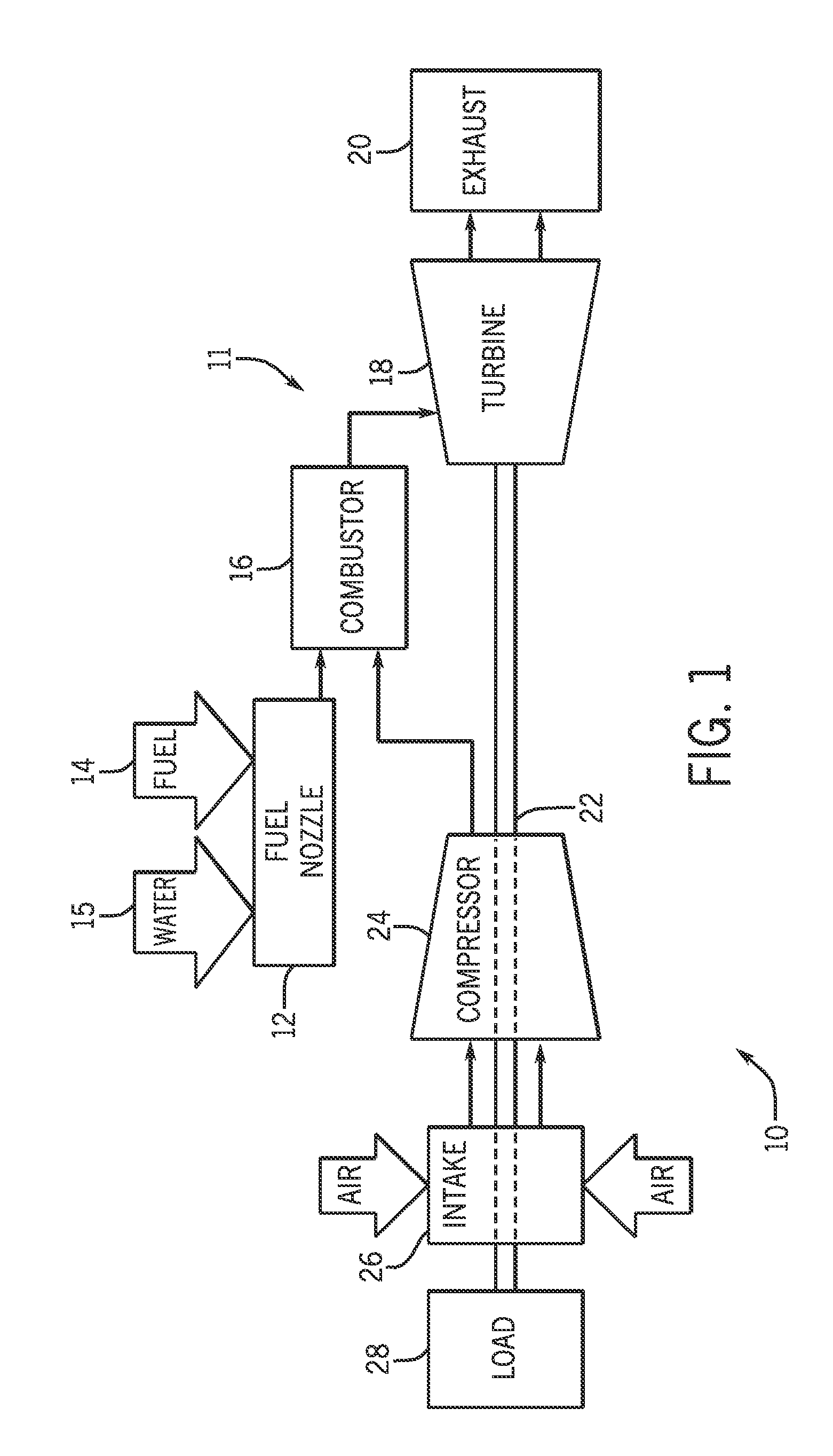

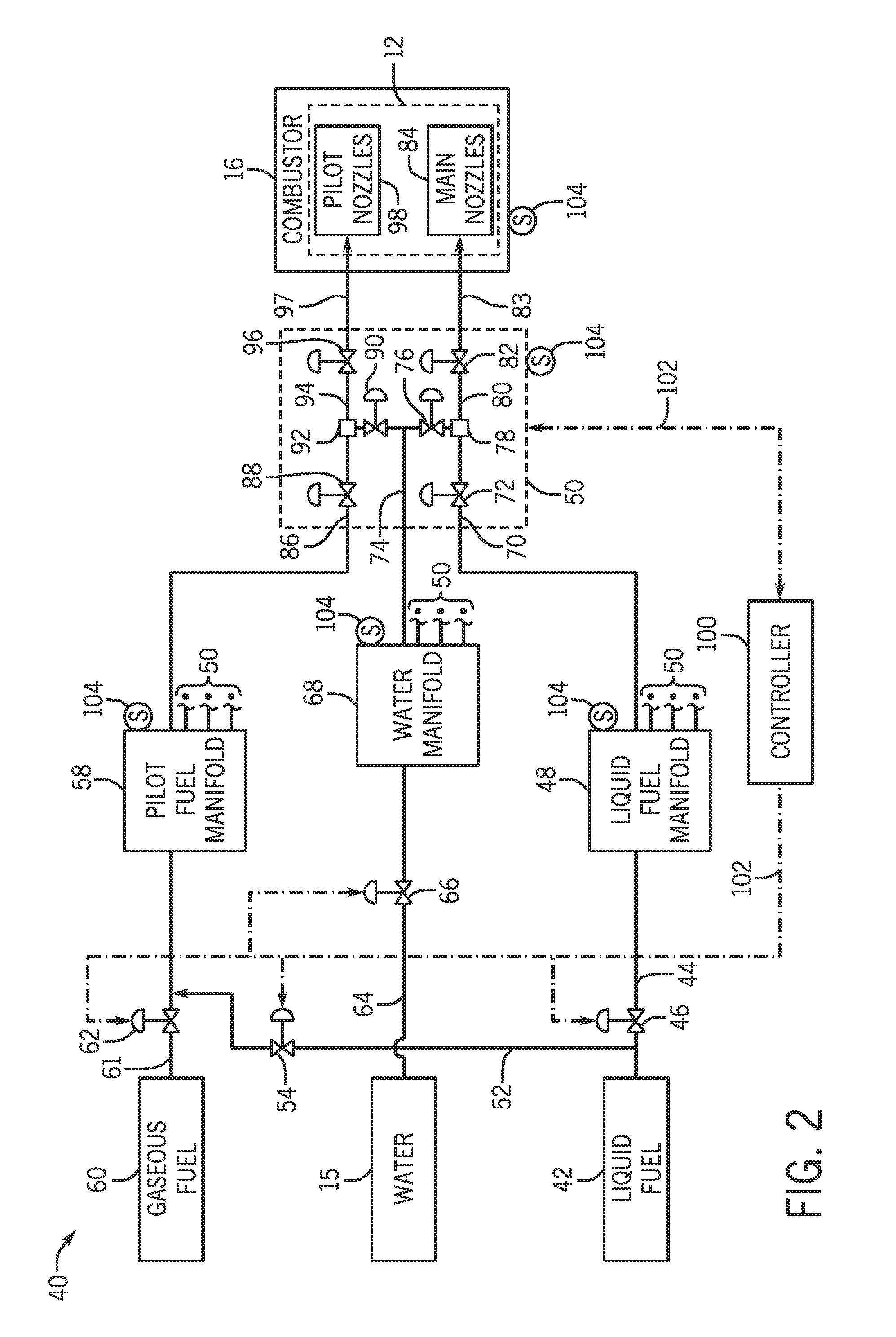

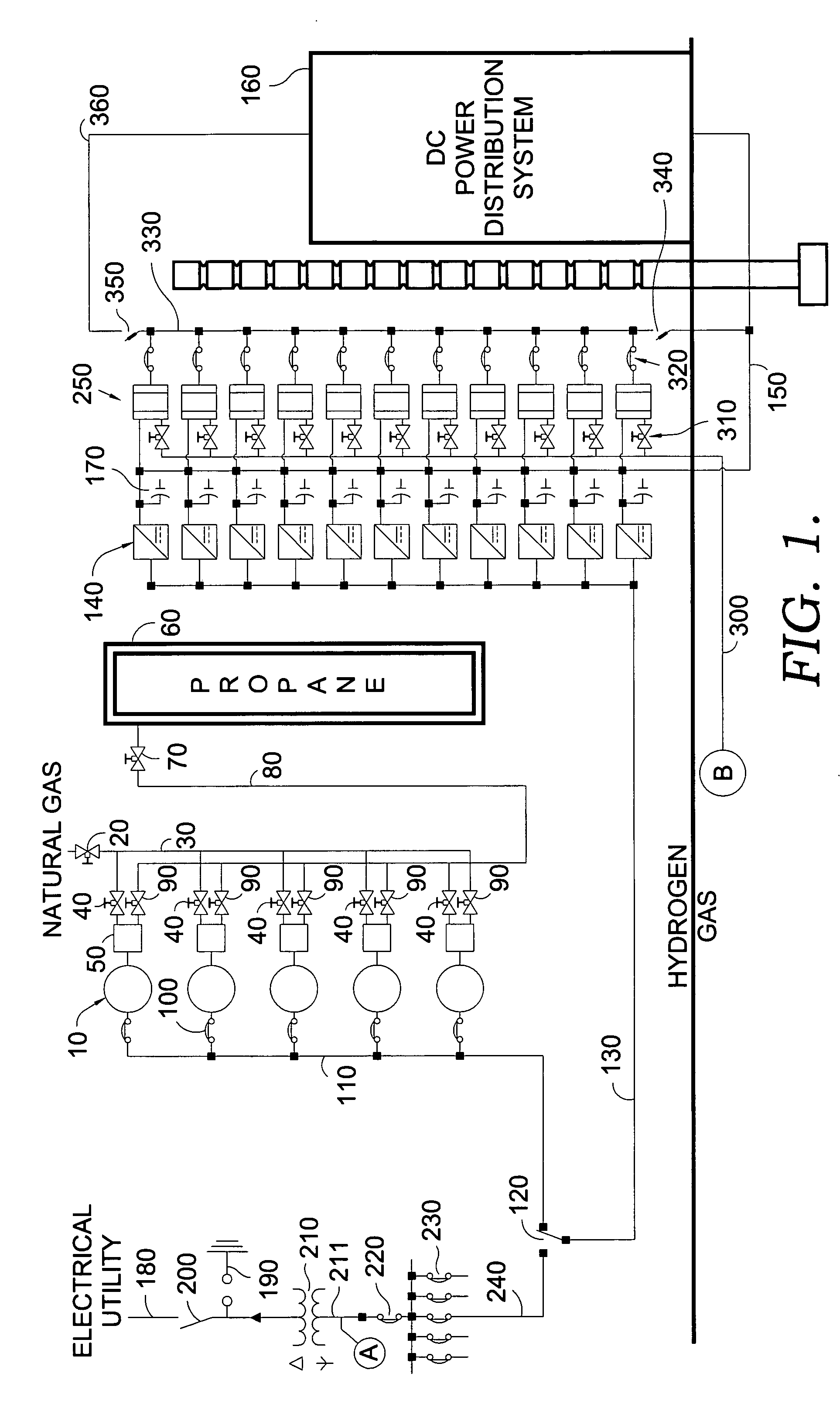

System for turbine combustor fuel mixing

ActiveUS20130097991A1Liquid fuel feeder/distributionTurbine/propulsion fuel flow conduitsCombustorLiquid fuel

A system includes a mixing assembly configured to mix a liquid fuel and a water to generate a fuel mixture. The fuel mixture is configured to combust in a combustor of a gas turbine. The mixing assembly includes a liquid fuel passage disposed in an integrated housing. The liquid fuel passage is configured to flow the liquid fuel and to exclude liquid traps. The mixing assembly also includes a water passage disposed in the integrated housing. The water passage is configured to flow the water and to exclude liquid traps. The mixing assembly also includes a mixer disposed in the integrated housing and coupled to the liquid fuel passage and the water passage. The mixer is configured to mix the liquid fuel and the water to form the fuel mixture.

Owner:GENERAL ELECTRIC CO

Heat engine with nozzle

A heat engine can have a fuel selector valve for selecting between a first fuel and a second fuel. Making the selection with the fuel selector valve can also determine a flow path through the heat engine, there being two different paths, each configured for a different fuel. A burner nozzle can form a single unit with the fuel selector valve. In some embodiments the burner nozzle can also form a single unit with an outlet valve.

Owner:DENG DAVID

Feed arm for a multiple circuit fuel injector

A feed arm for a multiple circuit fuel injector of a gas turbine engine. The feed arm includes an elongated tubular sleeve having a central bore with an interior wall defining an inner diameter, and an elongated fuel tube positioned within the bore of the tubular sleeve. The fuel tube includes a tubular wall defining an outer diameter, which is substantially equal to the inner diameter of the central bore. A primary fuel flow passage is formed within the tubular wall of the fuel tube and bounded by the interior wall of the tubular sleeve, and the primary fuel flow passage circumferentially extends around the fuel tube at least once along the axial length of the fuel tube. A secondary fuel flow passage extends through a central portion of the fuel tube, and the fuel tube is configured to facilitate heat transfer by conduction and / or convection.

Owner:COLLINS ENGINE NOZZLES INC

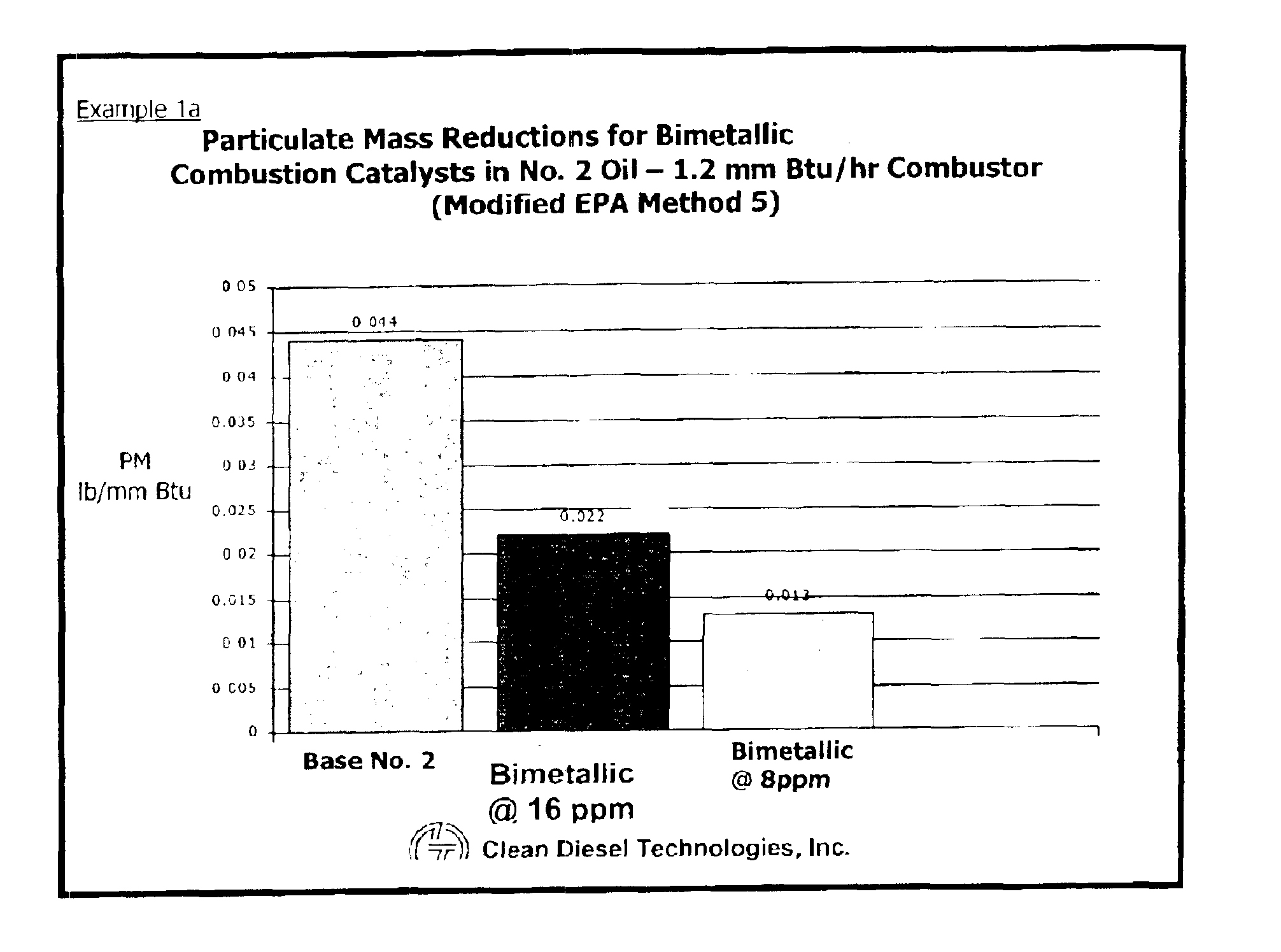

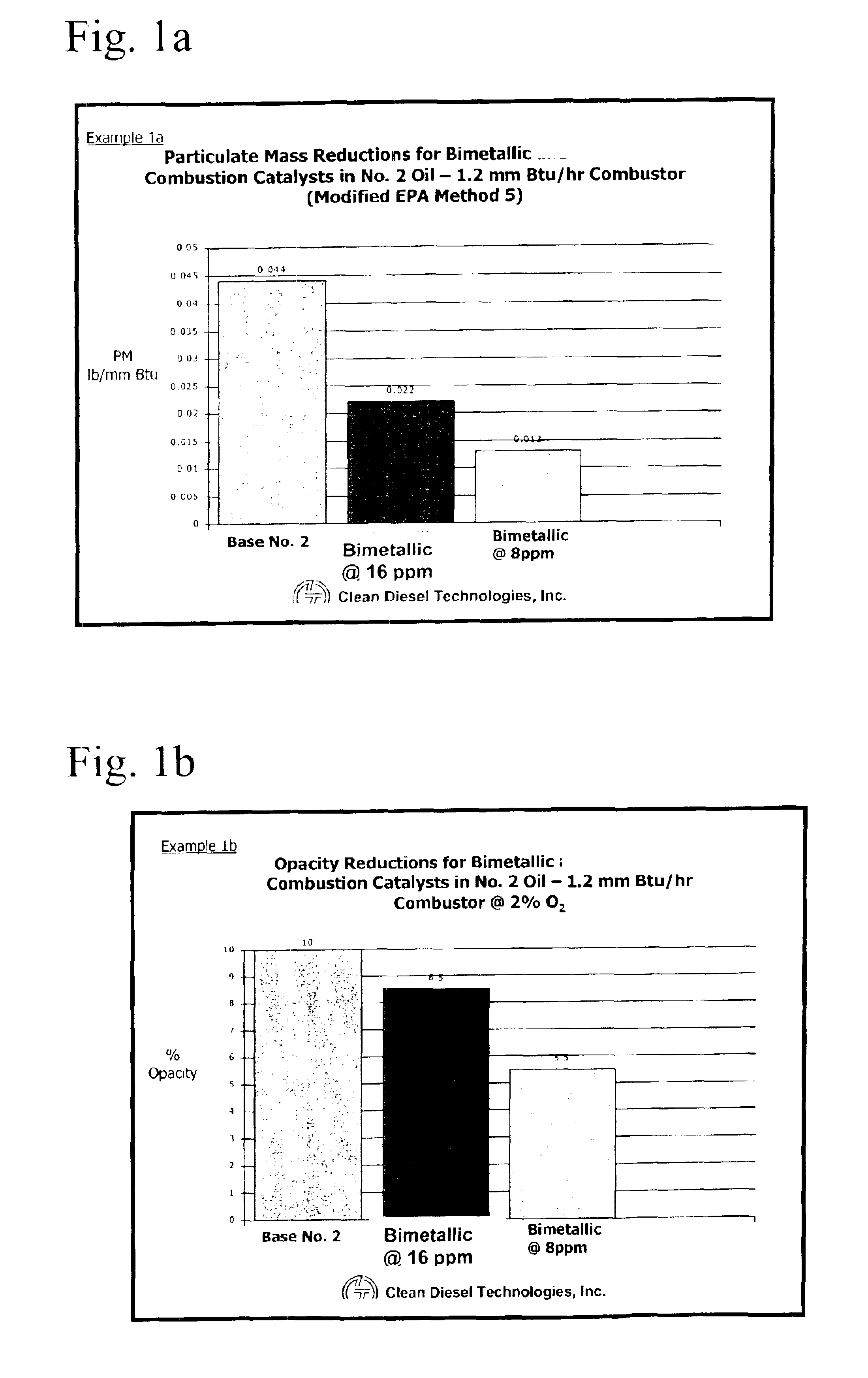

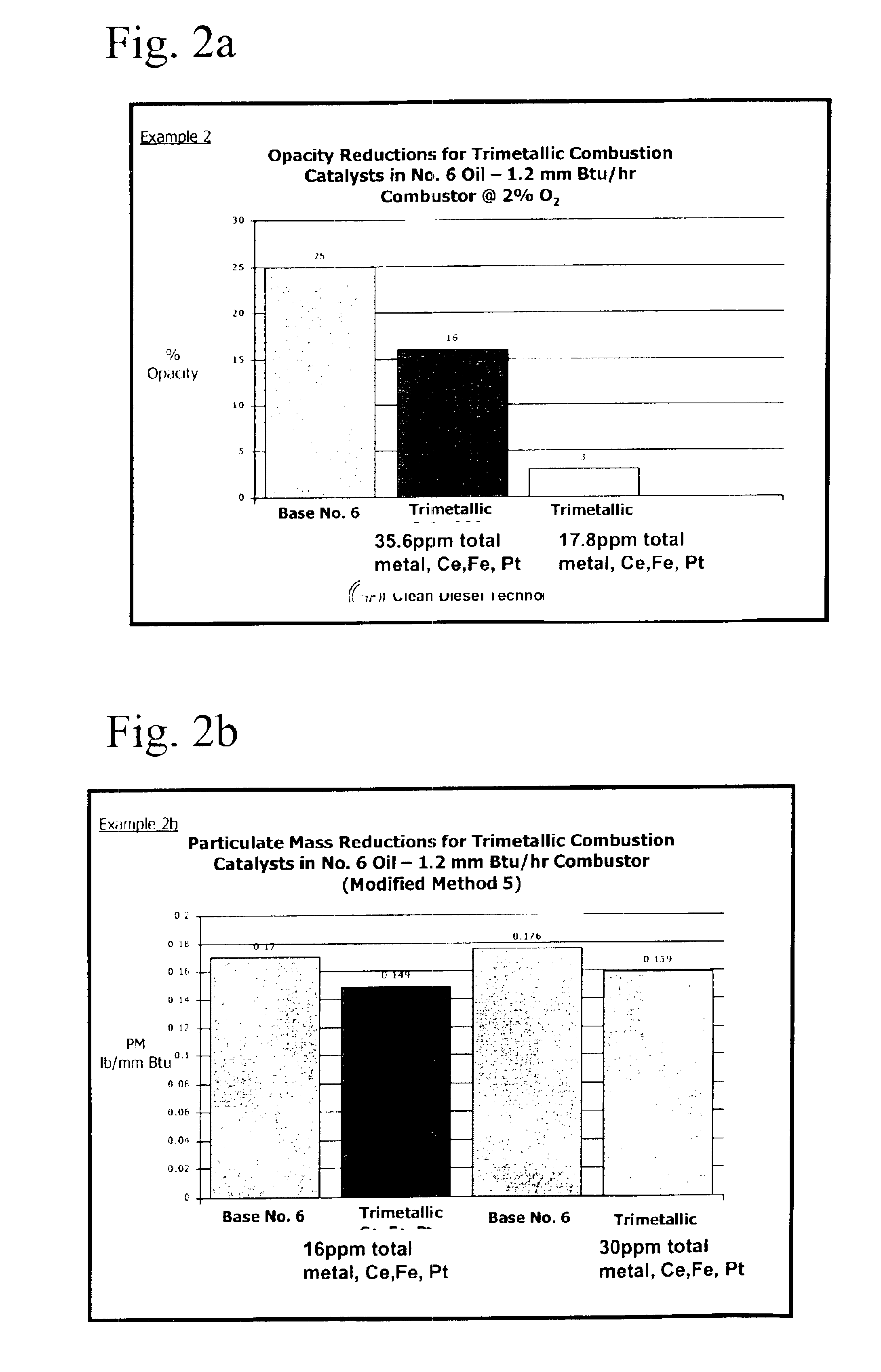

Reduced-emissions combustion utilizing multiple-component metallic combustion catalyst

InactiveUS6948926B2Increase dosePromote combustionLiquid fuel feeder/distributionExhaust apparatusParticulatesCerium

Residual fuels, as well as lighter distillate fuels, are combusted with greater efficiency by utilizing low concentrations of specific bimetallic or trimetallic fuel-borne catalysts. The catalysts reduce fouling of heat transfer surfaces by unburned carbon while limiting the amount of secondary additive ash which may itself cause overloading of particulate collector devices or emissions of toxic ultra fine particles when used in forms and quantities typically employed. By utilizing a fuel containing a fuel-soluble catalyst comprised of platinum and at least one additional metal comprising cerium and / or iron, production of pollutants of the type generated by incomplete combustion is reduced. Ultra low levels of nontoxic metal combustion catalysts are able to be employed for improved heat recovery and lower emissions of regulated pollutants.

Owner:CLEAN DIESEL TECHNOLOGIES

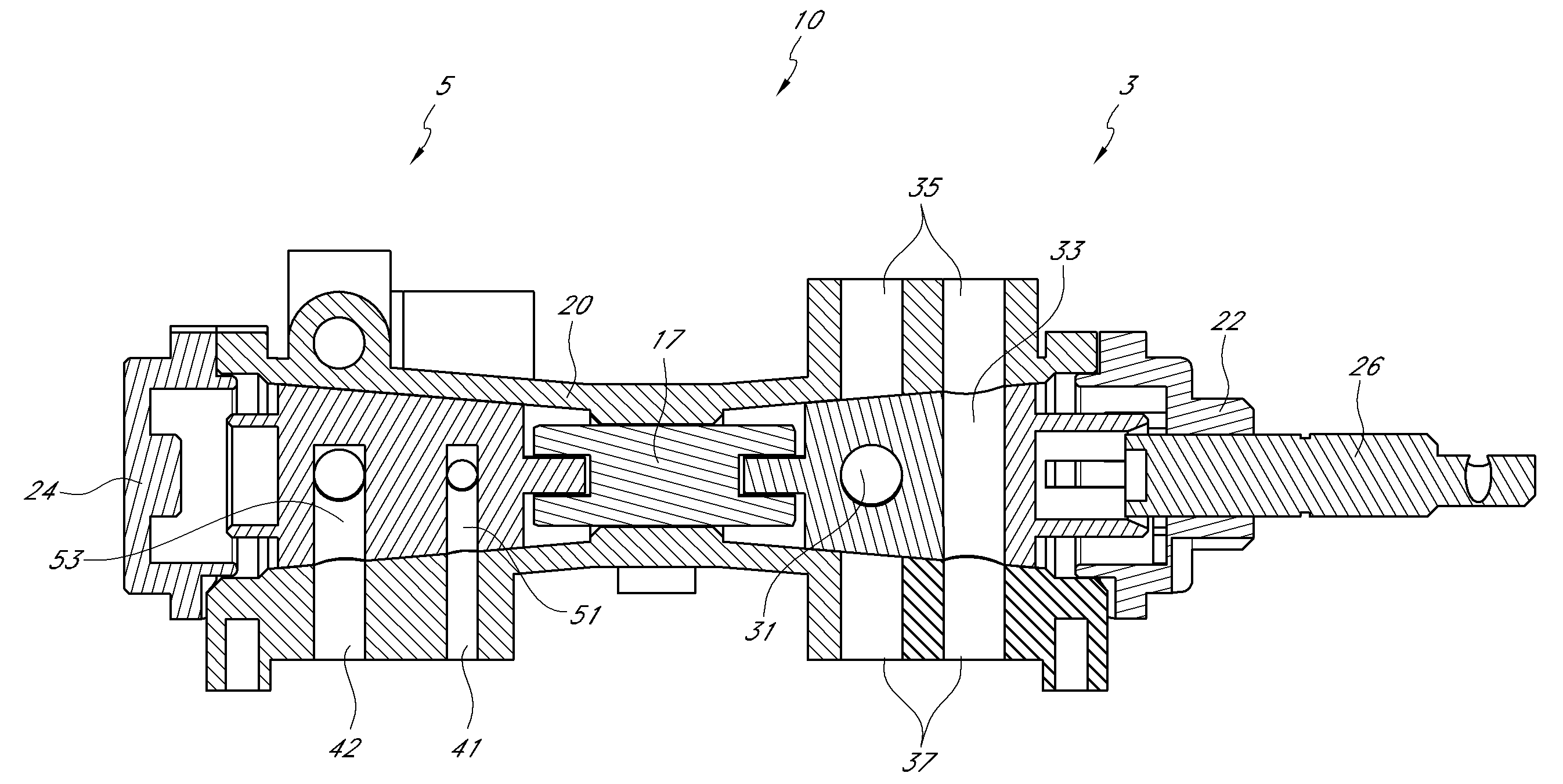

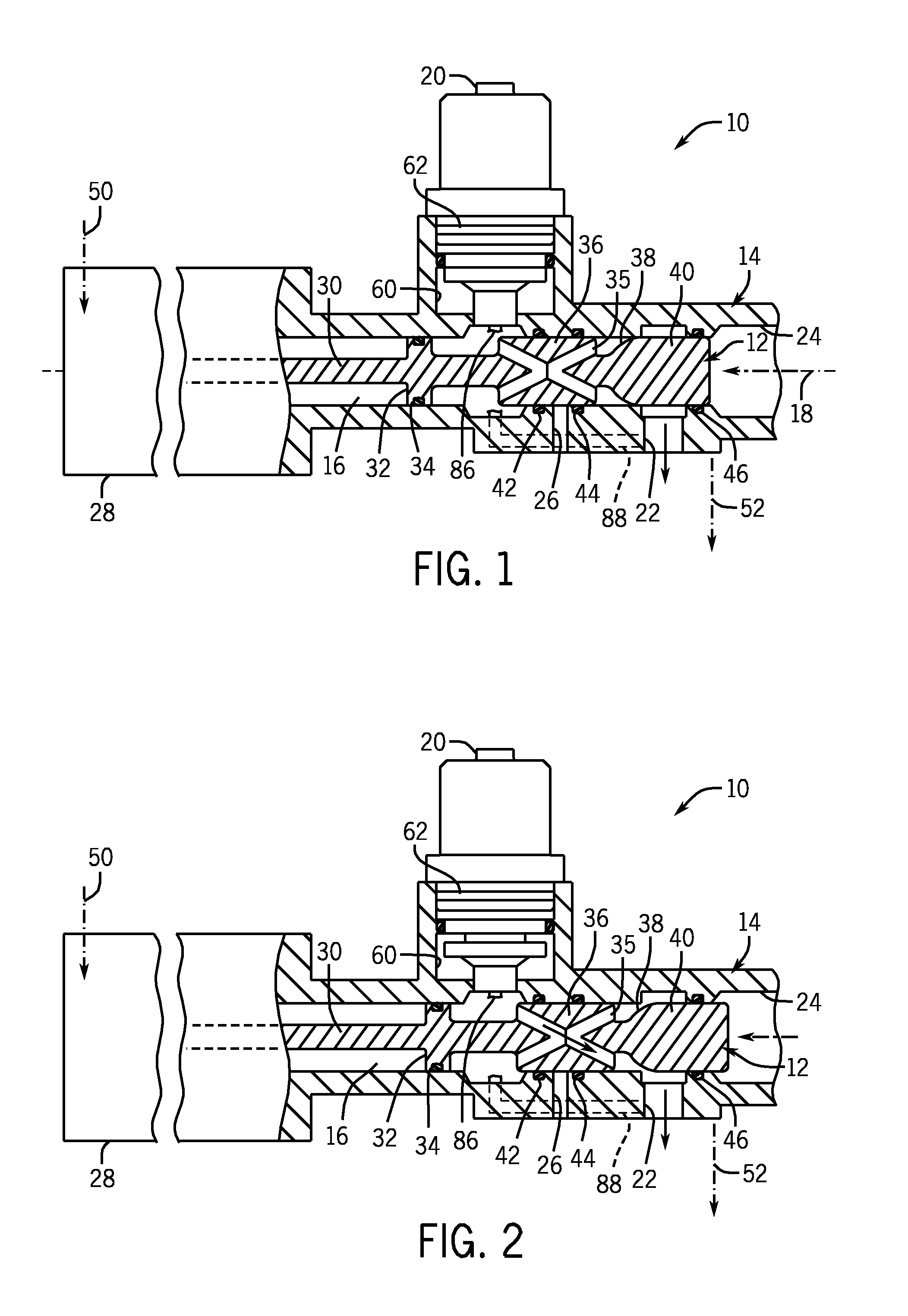

Fuel control system with metering purge valve for dual fuel turbine

ActiveUS8104258B1Reduce sensitivityPlug valvesLiquid fuel feeder/distributionCrossbar switchSpool valve

The fuel system of a dual fuel turbine includes a flow control valve having a metering purge valve that in one state directly meters fuel to injectors of the turbine, in another state closes of fuel flow and passes purge air to the injectors and in another state positively closes of flow of both fuel and purge air. The metering purge valve is a pressure compensated spool valve that has a unique cross-ported interchange that passes fuel from the inlet through the spool to the metering edge. The direct metering of the valve to the injectors eliminates the need for additional shut off valves, and if used with a combining valve having an integral distributor section metering fuel to multiple injectors, the need for a separate flow divider is also eliminated. The valve can be actively cooled by dedicated coolant lines or lines shared with other flow control components such as additional metering valves for either the primary or secondary fuel.

Owner:JANSENS AIRCRAFT SYST CONTROLS

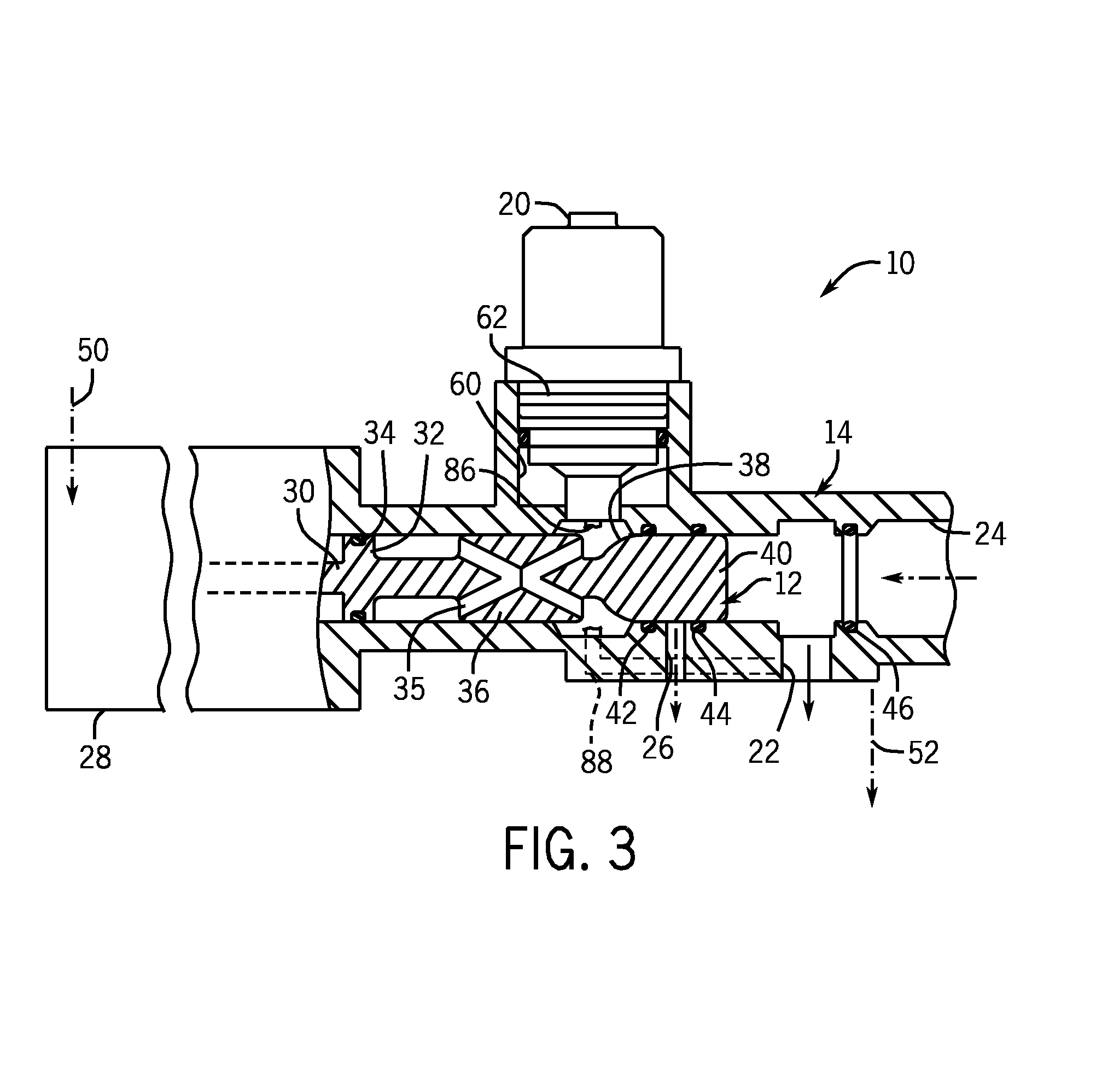

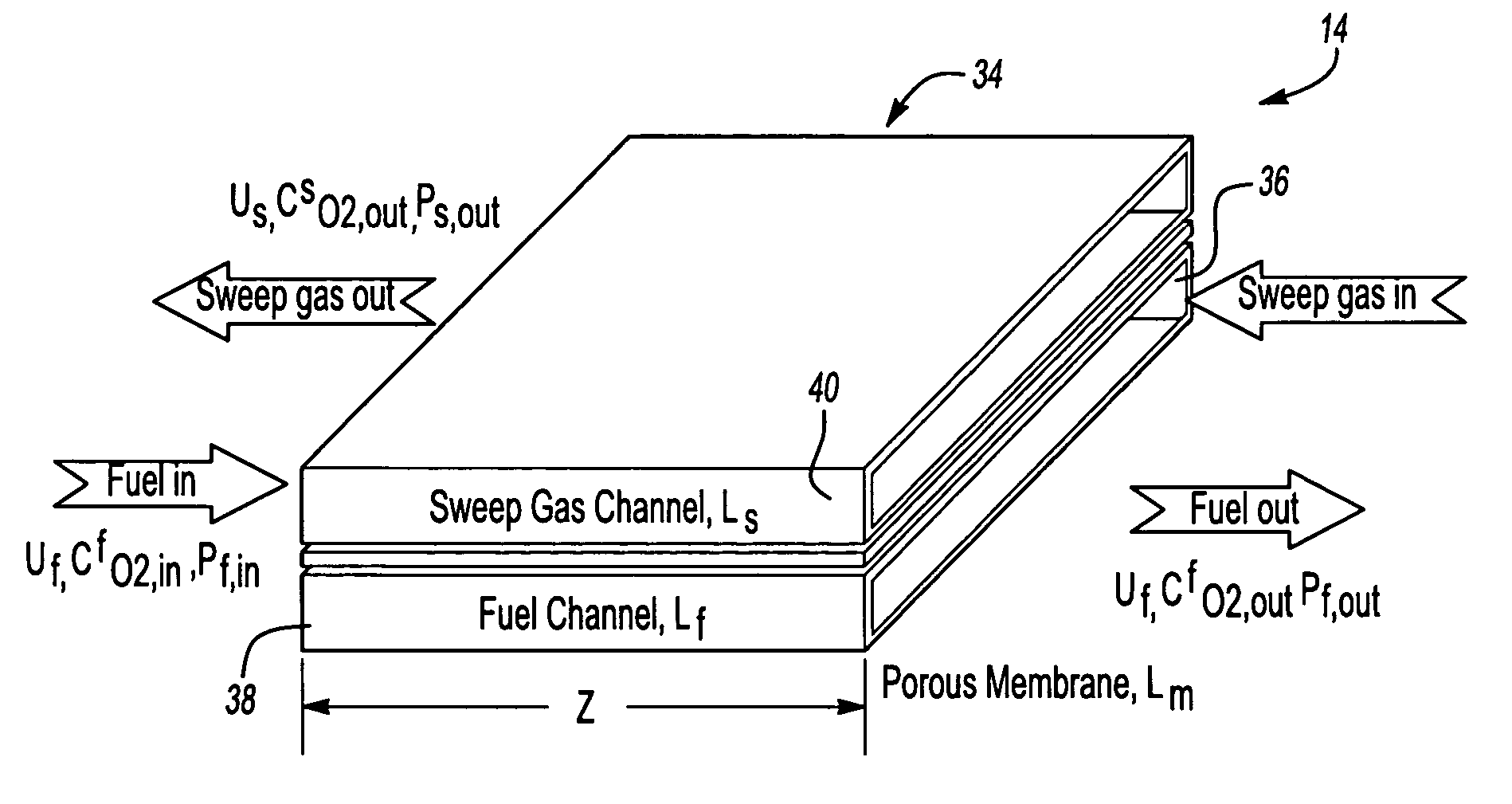

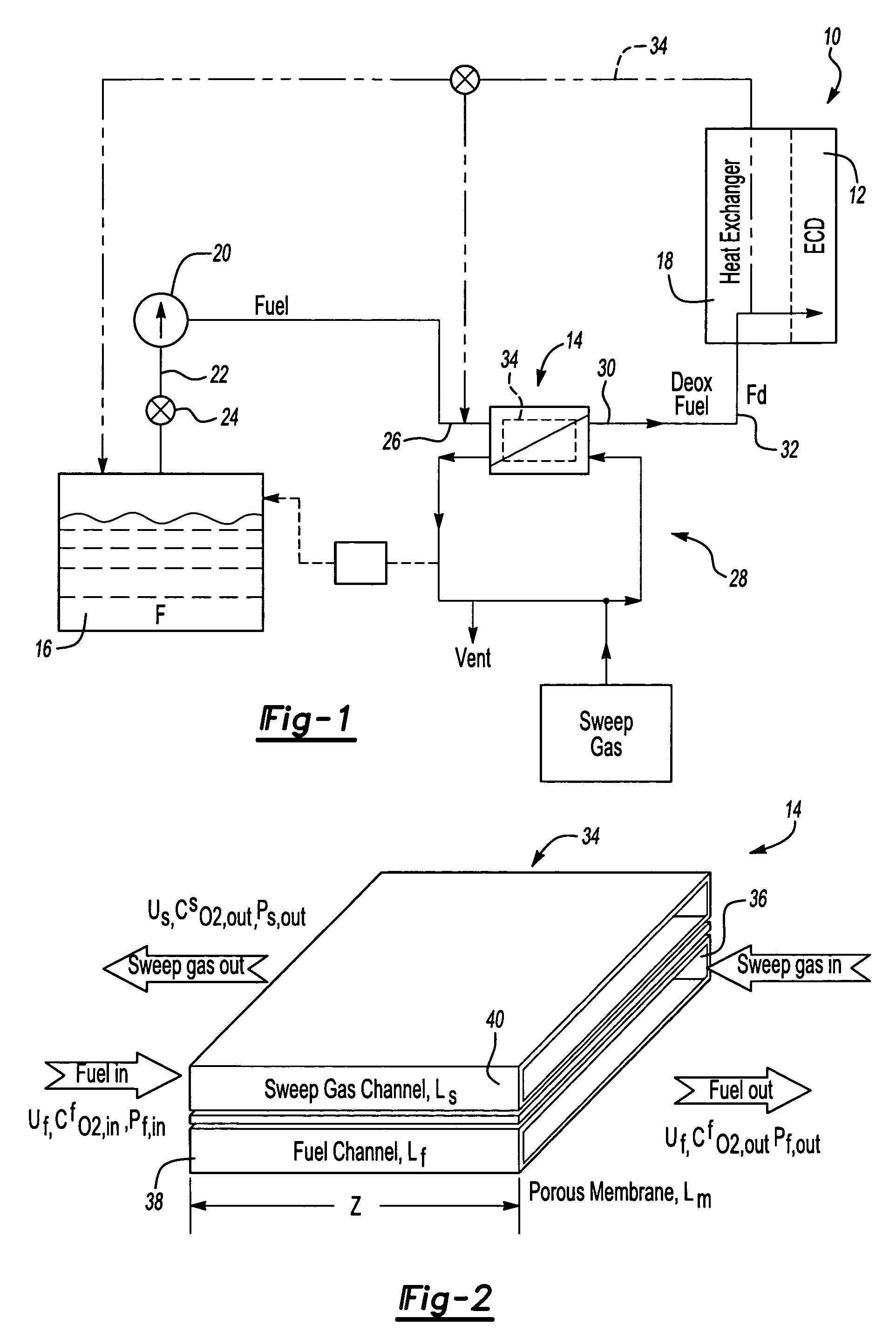

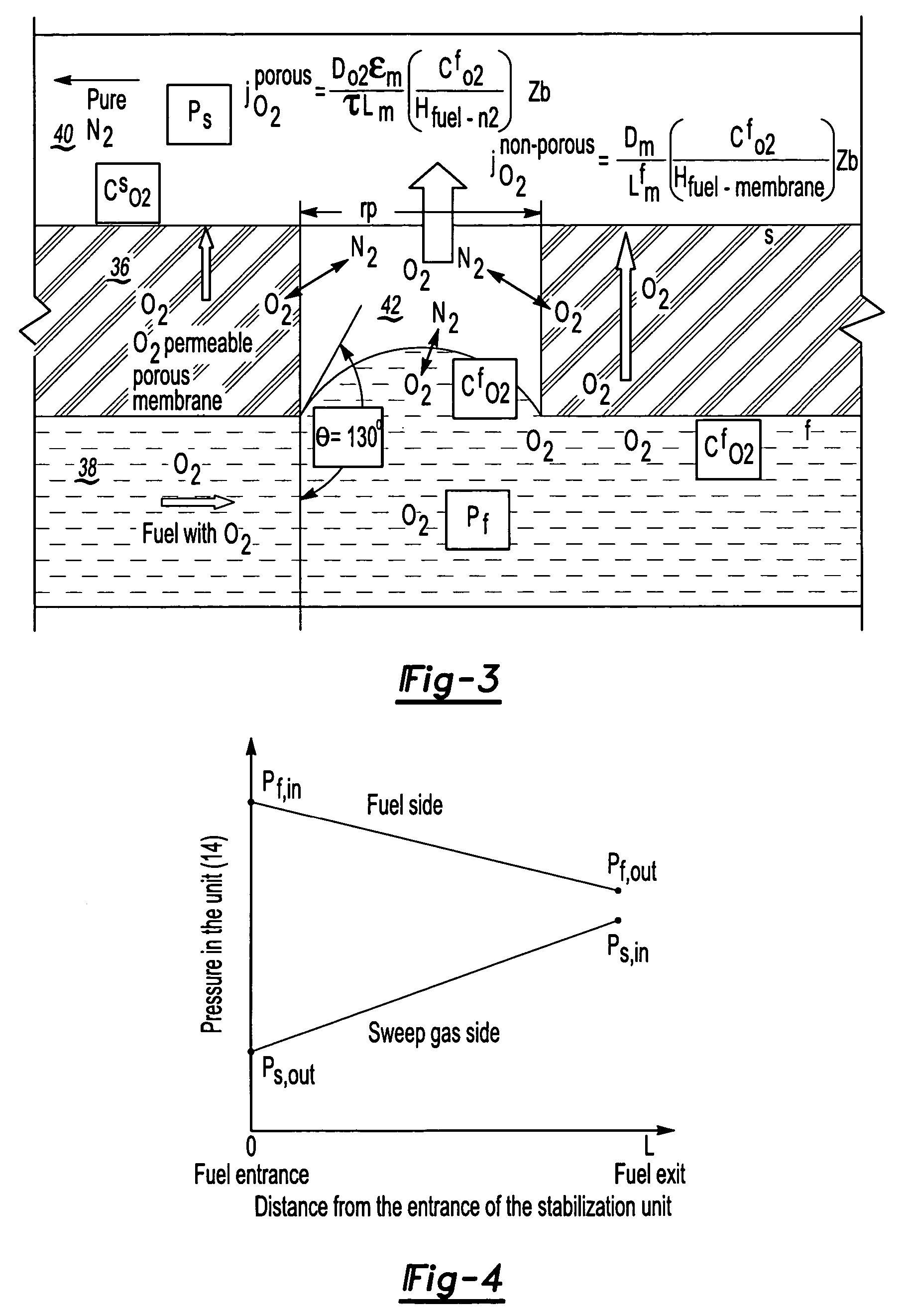

Fuel deoxygenation system

ActiveUS7153343B2Inexpensive sizeInexpensive weightLiquid fuel feeder/distributionSemi-permeable membranesPorous membraneEngineering

A fuel system for an energy conversion device includes a deoxygenator system with a porous membrane. The deoxygenator includes an oxygen receiving channel separated from the fuel channel by the porous membrane. The capillary forces counteract the pressure differential across the membrane, preventing any leakage of the fuel, while the oxygen concentration differential across the membrane allows for deoxygenation of the fuel through the porous membrane.

Owner:RTX CORP

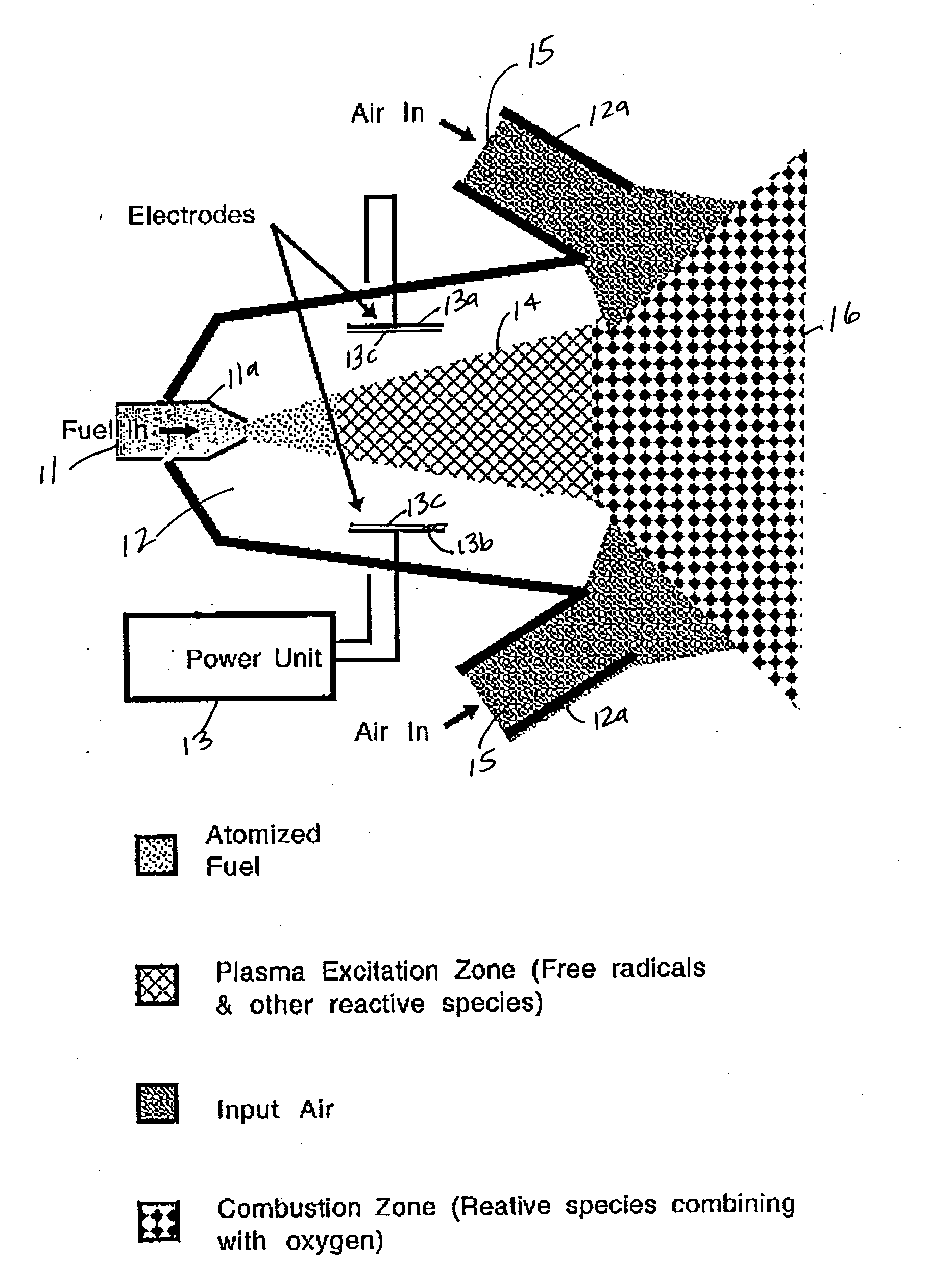

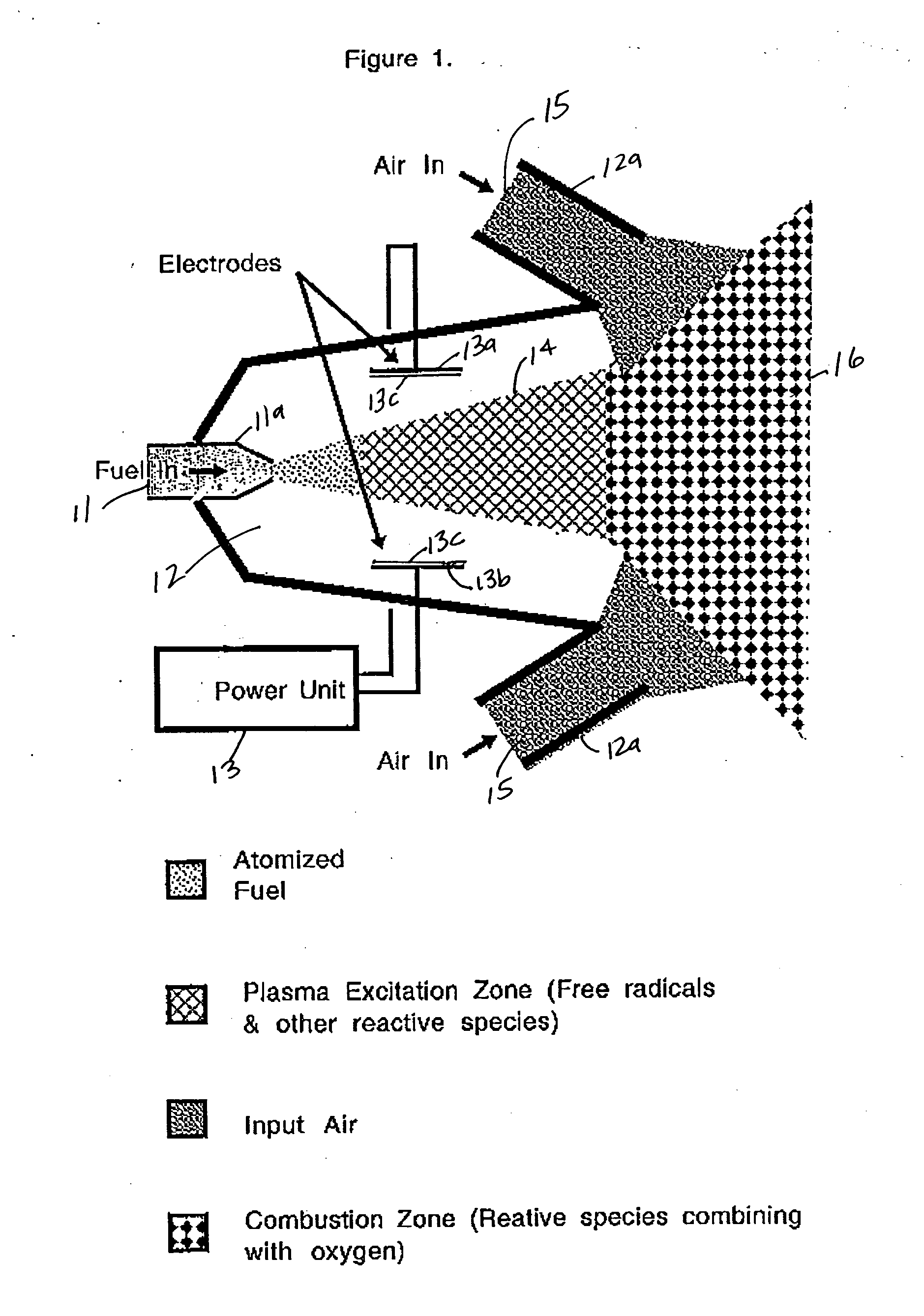

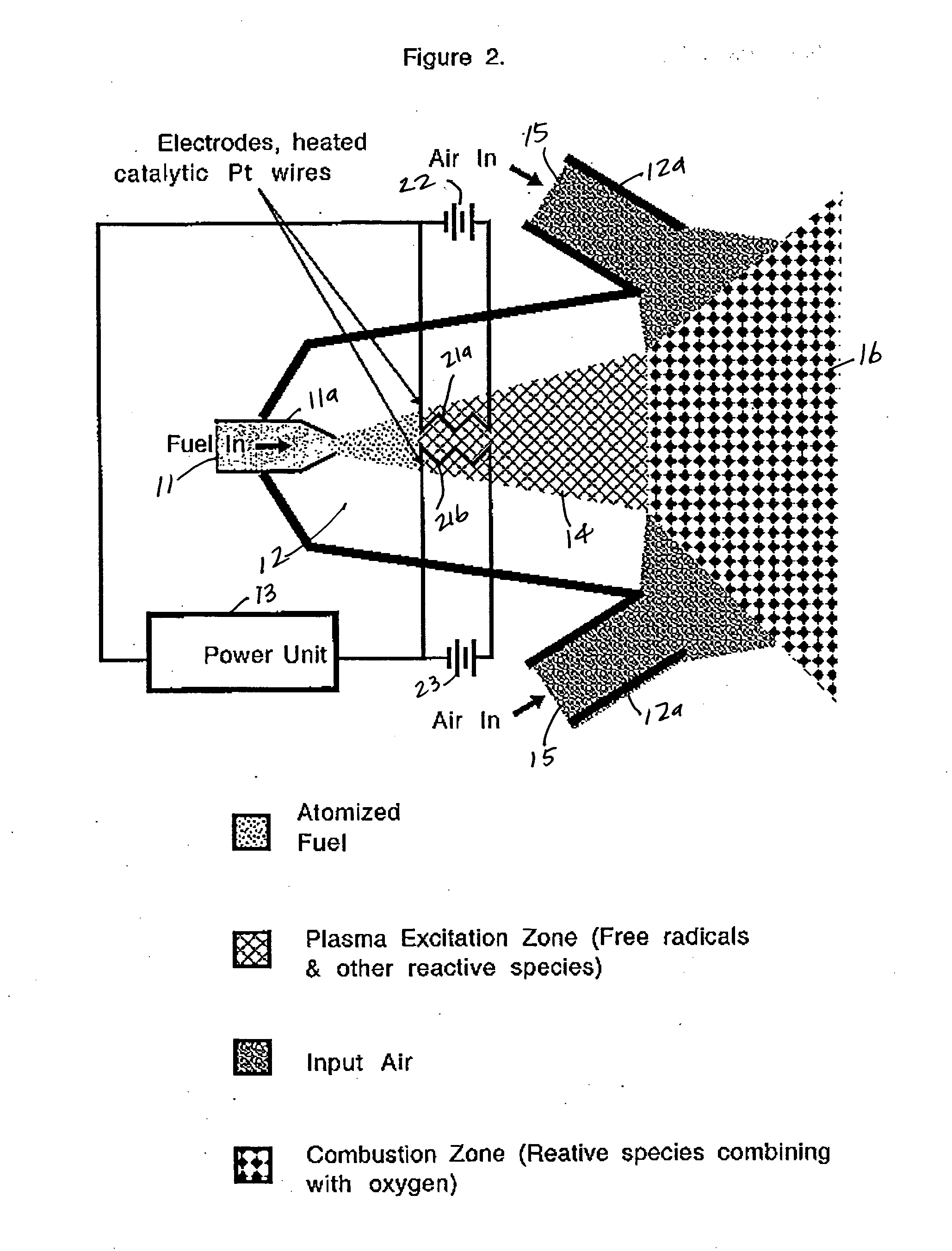

Plasma catalytic fuel injector for enhanced combustion

InactiveUS20050019714A1Improve efficiencyPromote combustionLiquid fuel feeder/distributionGaseous fuel feeder/distributionEngineeringElectric power

Apparatus and method for enhancing combustion comprises an enclosure defining an opening for introduction of a gas and openings for the introduction of air, with a nozzle in the opening for introduction of a fuel gas into the enclosure. First and second electrodes are located in the enclosure, the first and second electrodes being coated with dielectric material, and being connected to an electrical power supply. With electrical power applied to the first and second electrodes and with the fuel gas sprayed into the enclosure, an atmospheric pressure plasma created by a dielectric barrier discharge is produced in the enclosure that cracks the fuel gas prior to its mixing with air introduced through the openings for the introduction of air.

Owner:RGT UNIV OF CALIFORNIA

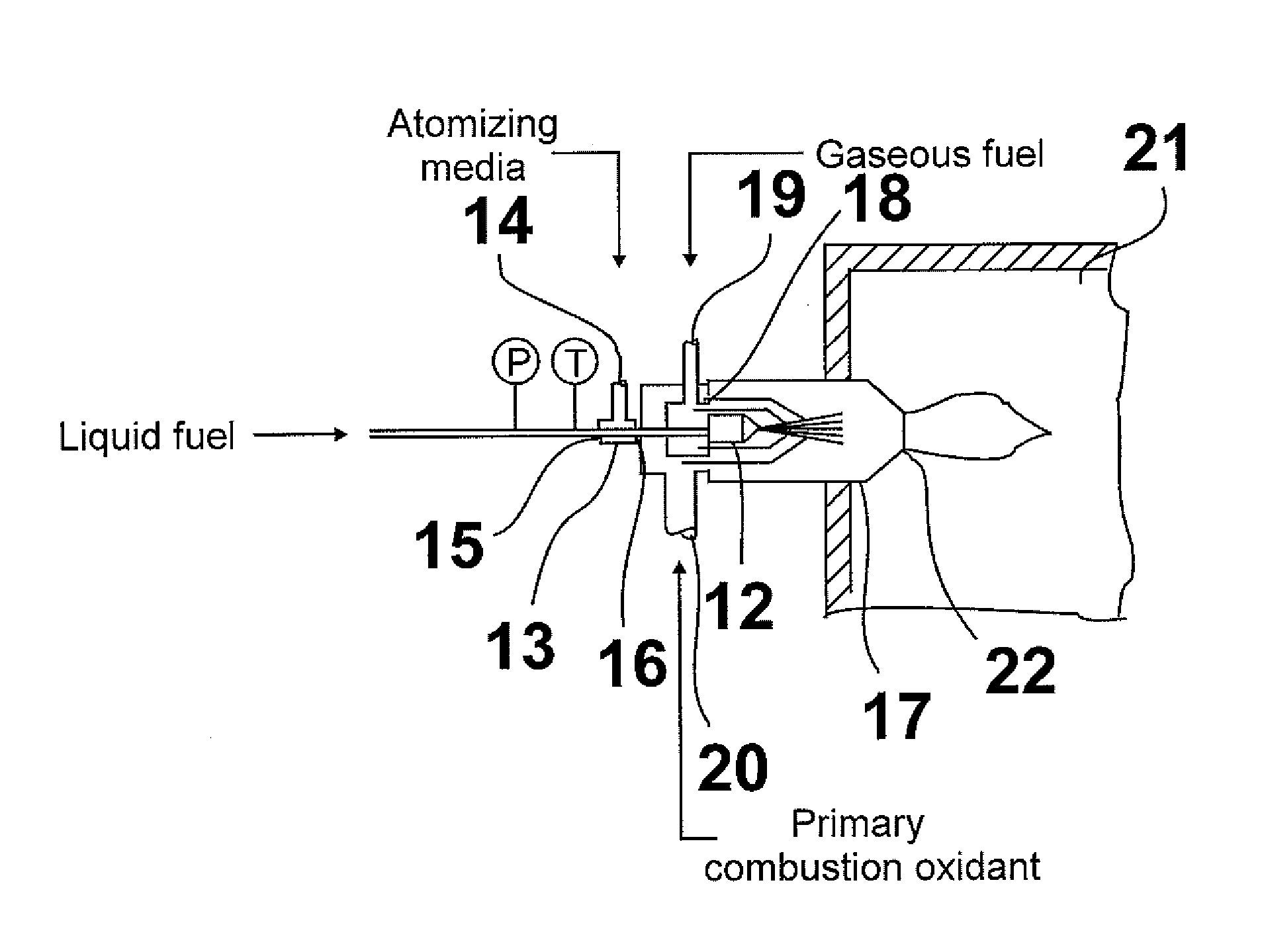

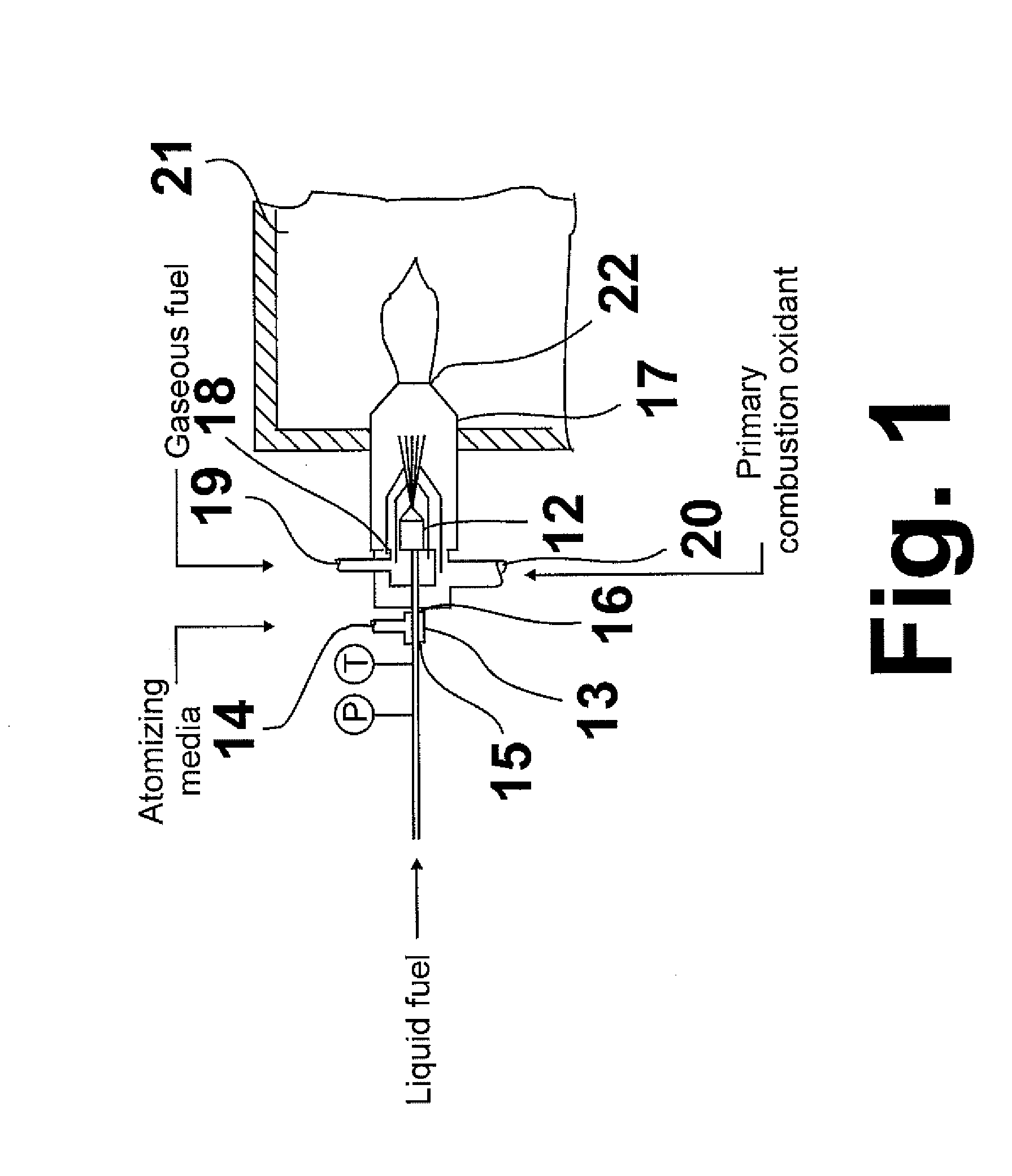

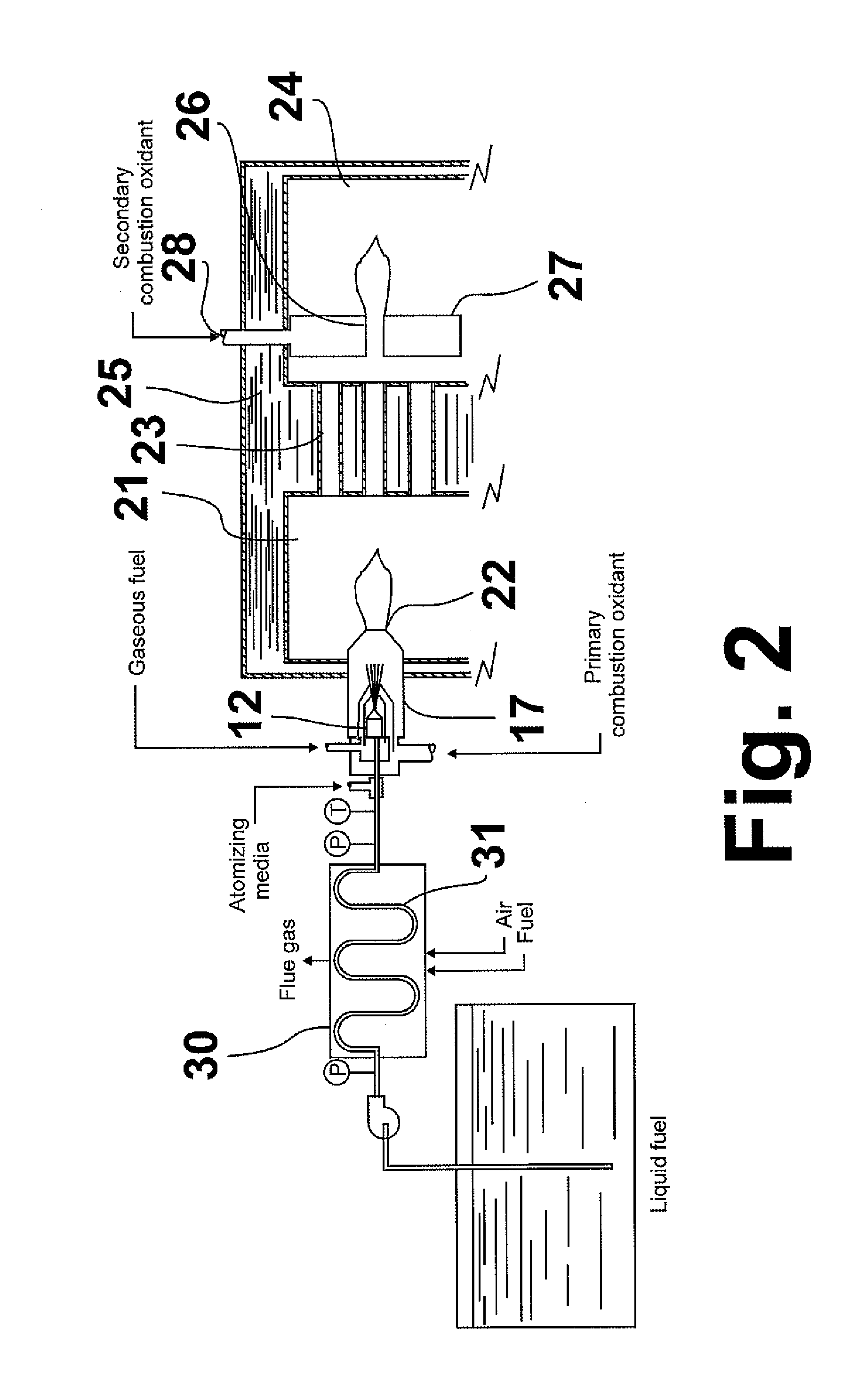

METHOD AND SYSTEM FOR LOW-NOx DUAL-FUEL COMBUSTION OF LIQUID AND/OR GASEOUS FUELS

ActiveUS20120315586A1Improve efficiencyEmission reductionLiquid fuel feeder/distributionFuel supply regulationFlueProcess engineering

A method and apparatus for combustion in which a pressurized preheated liquid fuel is atomized and a portion thereof flash vaporized, creating a mixture of fuel vapor and liquid droplets. The mixture is mixed with primary combustion oxidant, producing a fuel / primary oxidant mixture which is then injected into a primary combustion chamber in which the fuel / primary oxidant mixture is partially combusted, producing a secondary gaseous fuel containing hydrogen and carbon oxides. The secondary gaseous fuel is mixed with a secondary combustion oxidant and injected into the second combustion chamber wherein complete combustion of the secondary gaseous fuel is carried out. The resulting second stage flue gas containing very low amounts of NOx is then vented from the second combustion chamber.

Owner:GAS TECH INST

Gas turbine combustor endcover assembly with integrated flow restrictor and manifold seal

ActiveUS20120180488A1Liquid fuel feeder/distributionContinuous combustion chamberCombustorCombustion chamber

An endcover assembly for a turbine combustor adapted to support one or more combustor nozzles includes a substantially flat plate having one side which in use, faces a combustion chamber and an opposite side which, in use, faces away from the combustion chamber. At least one fuel passage extends through the substantially flat plate. A fuel manifold porting block is secured to the opposite side of the flat plate with at least one port aligned with the at least one passage. A fuel restrictor insert formed with multiple flow orifices is located between the flat plate and the fuel manifold porting block in alignment with the at least one fuel passage and the at least one port.

Owner:GENERAL ELECTRIC CO

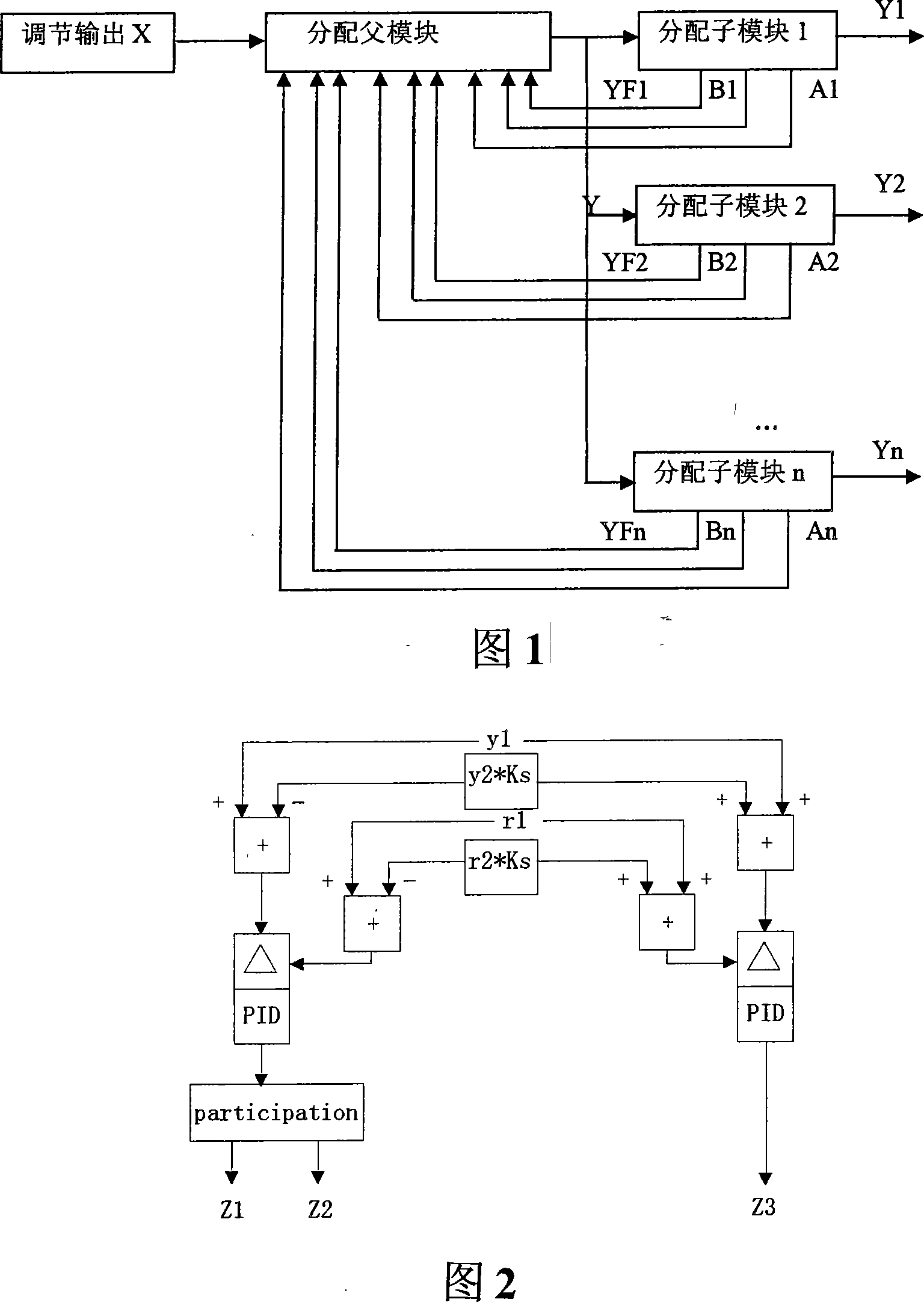

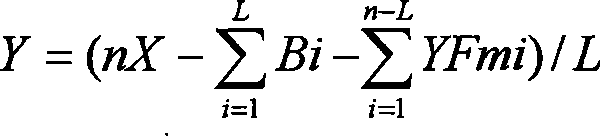

Automatic control method of 300 MW grading circulating fluidized bed units

ActiveCN101225955AKeep the economy runningAvoid cokingFluidized bed combustionLiquid fuel feeder/distributionAir volumeAutomatic control

The invention relates to an automatic control method of 300MW grade circulating fluid bed unit, which sets the automatic control methods for the coordination of machine and furnace, the deviation of single bed pressure and double bed pressure, the water level of the deaerator and the condenser, the secondary air quantity / oxygen quantity and the secondary air pressure, the boiler bed temperature, the fuel flow and the limerock feeding during making the first 300 MW circulating fluid bed unit as the localization of manufactures, meanwhile, the 300 MW circulating fluid bed unit has the advantages of stable operation, safety, reliable and remarkable economic operation passing through the coordination and control for the system.

Owner:云南电力试验研究院(集团)有限公司

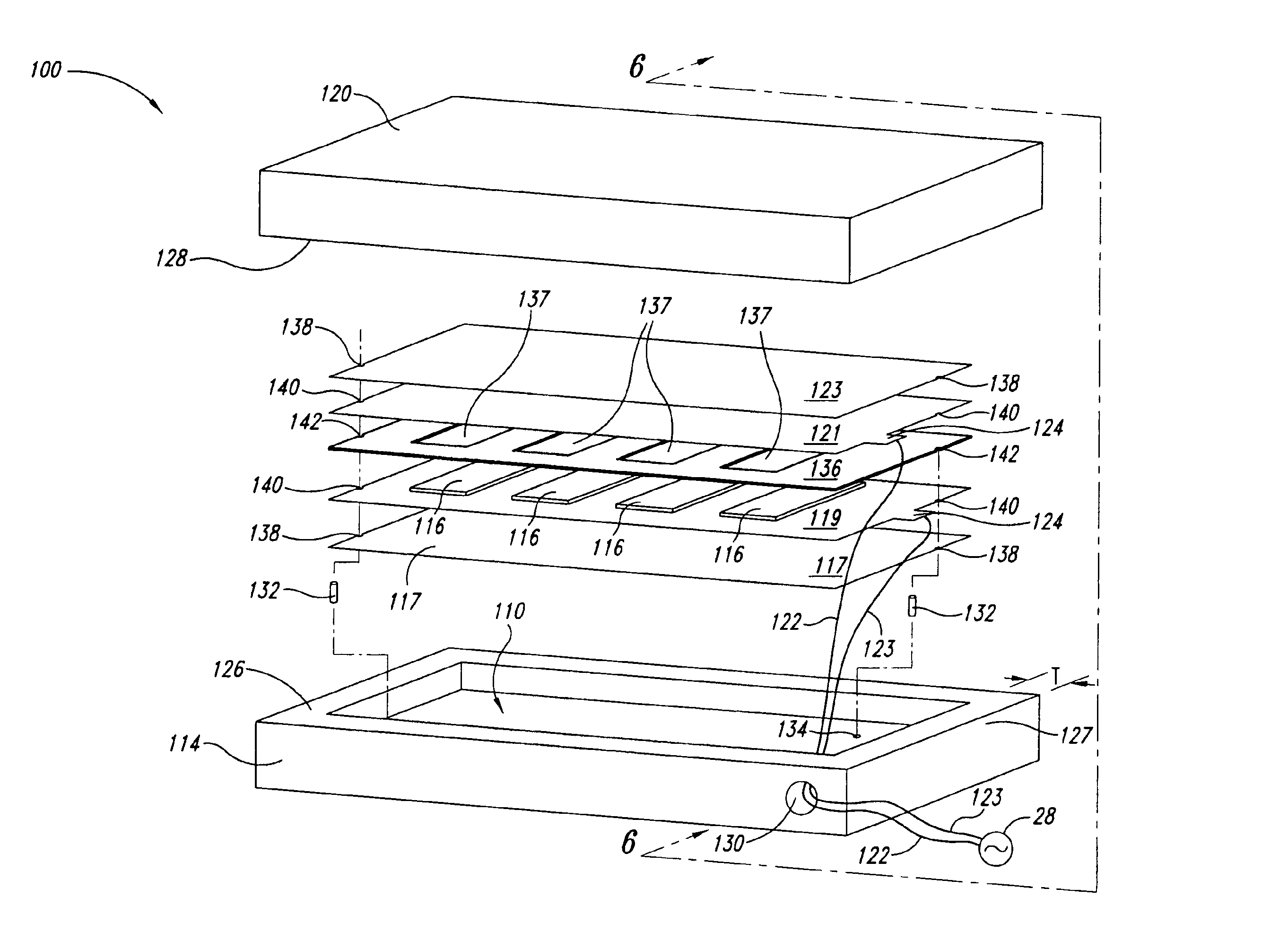

Fluid heater

A fluid heater having a first heat exchanger block with a fluid heating tube encased therein, and having a first surface, a second heat exchanger block with a fluid heating tube encased therein and having a second surface adjacent to the first surface. A cavity is formed in the surface of the first block, or, alternatively, formed in each of the surfaces of the first and second blocks. A heating element is positioned within the cavity and completely encapsulated by the first and second blocks. The heating element may include first and second bus plates and a plurality of PTC elements sandwiched between the bus plates in an electrically parallel configuration, each PTC element including first and second conductive plates, and a plurality of positive temperature coefficient heating stones sandwiched between the conductive plates in an electrically parallel configuration.

Owner:ALGAS SDI INT

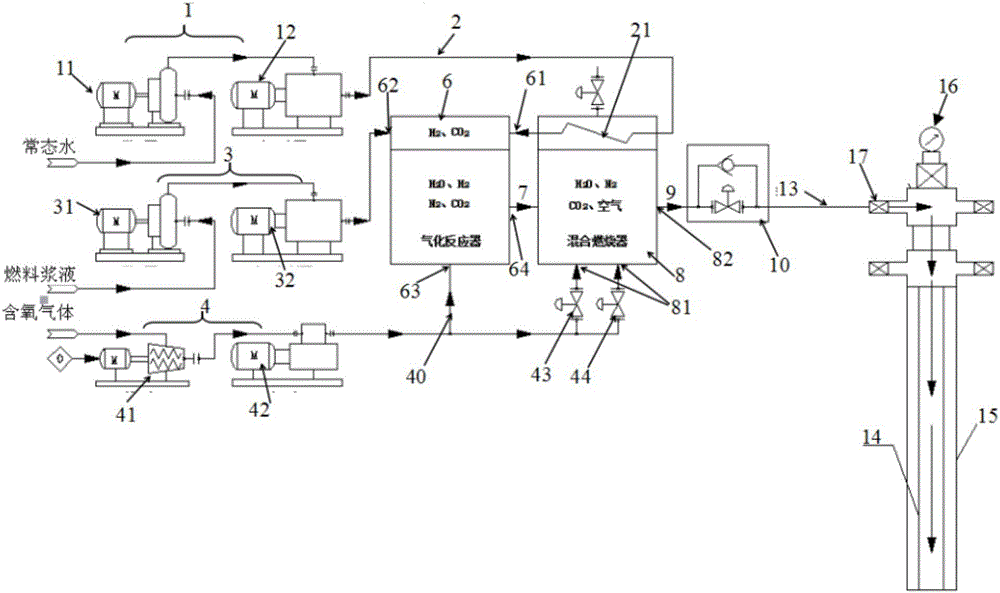

Supercritical multisource multielement thermal fluid injection-production system and injection-production method

InactiveCN106640008AImprove insulation effectLow thermal conductivityLiquid fuel feeder/distributionFluid removalCombustionProduct gas

The invention discloses a supercritical multisource multielement thermal fluid injection-production system and injection-production method. The system comprises a supercritical multisource multielement thermal fluid generating system and an oil tube. The oil tube is arranged in an exploiting shaft; the supercritical multisource multielement thermal fluid generating system comprises a supercritical gasification reactor and a supercritical mixed combustion reactor; in the presence of supercritical water, a gasification reaction is performed on fuel slurry in the supercritical gasification reactor, and the gasification product of the reaction and oxygen-containing gas dissolved in the supercritical water combust in the supercritical mixed combustion reactor to form a supercritical multisource multielement thermal fluid containing supercritical water and carbon dioxide; the supercritical mixed combustion reactor is connected to the oil tube. The supercritical multisource multielement thermal fluid injection-production system provided by the invention has the effects that thermal efficiency is high, the viscosity of thickened oil is reduced, the flowability of the thickened oil is improved and the recovery efficiency is increased.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Method and apparatus for burning oils of varying viscosity

InactiveUS6132203AEfficient combustionPrevents possibility of fire and explosionLiquid fuel feeder/distributionSpraying apparatusHeating oilCombustor

Disclosed is an oil burning system that is capable of burning oils of varying viscosities, including high viscosity waste oils and low viscosity heating oils. Suitable as a new installation or a retrofit modification, the present invention incorporates the use of a variable rate, high-pressure oil delivery system, along with an oil pre-heater, in conjunction with a modified high-pressure atomizing nozzle. Installed in a sliding drawer burner arrangement that allows for quick and easy access, the oil burning system also includes a means by which particulate matter and carbonization build-ups are removed from the burner nozzle automatically, thereby eliminating the need for frequent cleaning.

Owner:MASIN RADEK

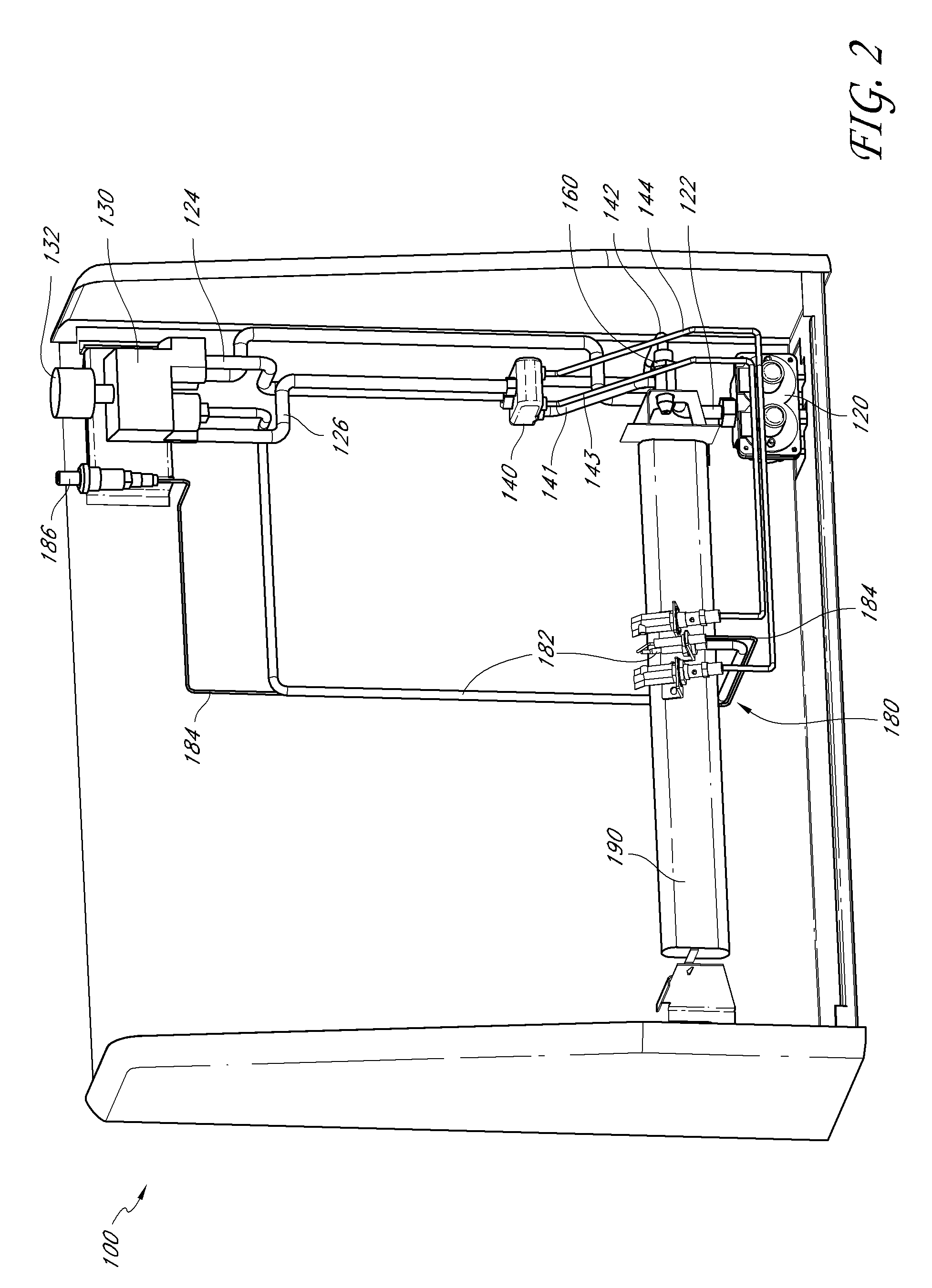

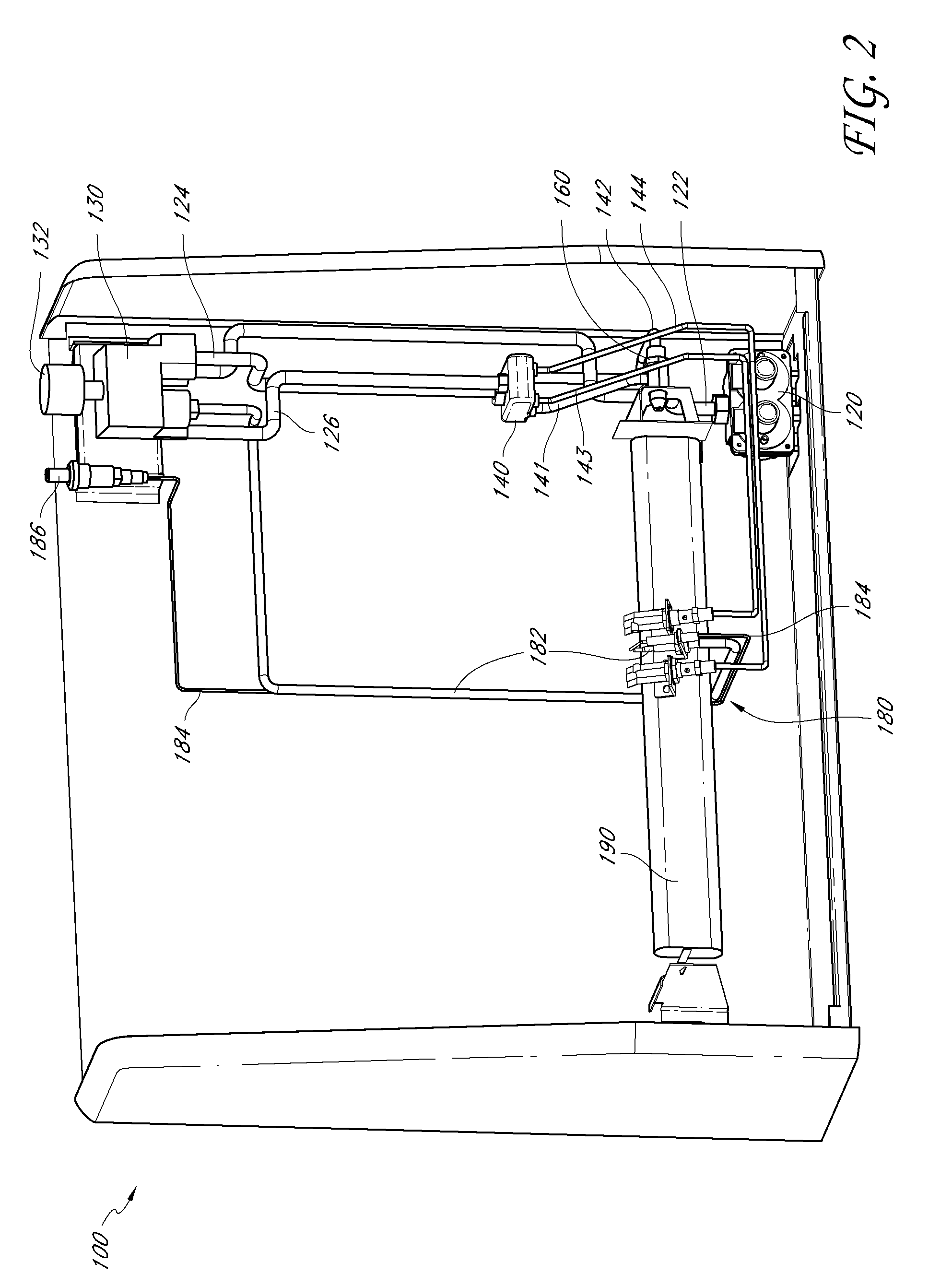

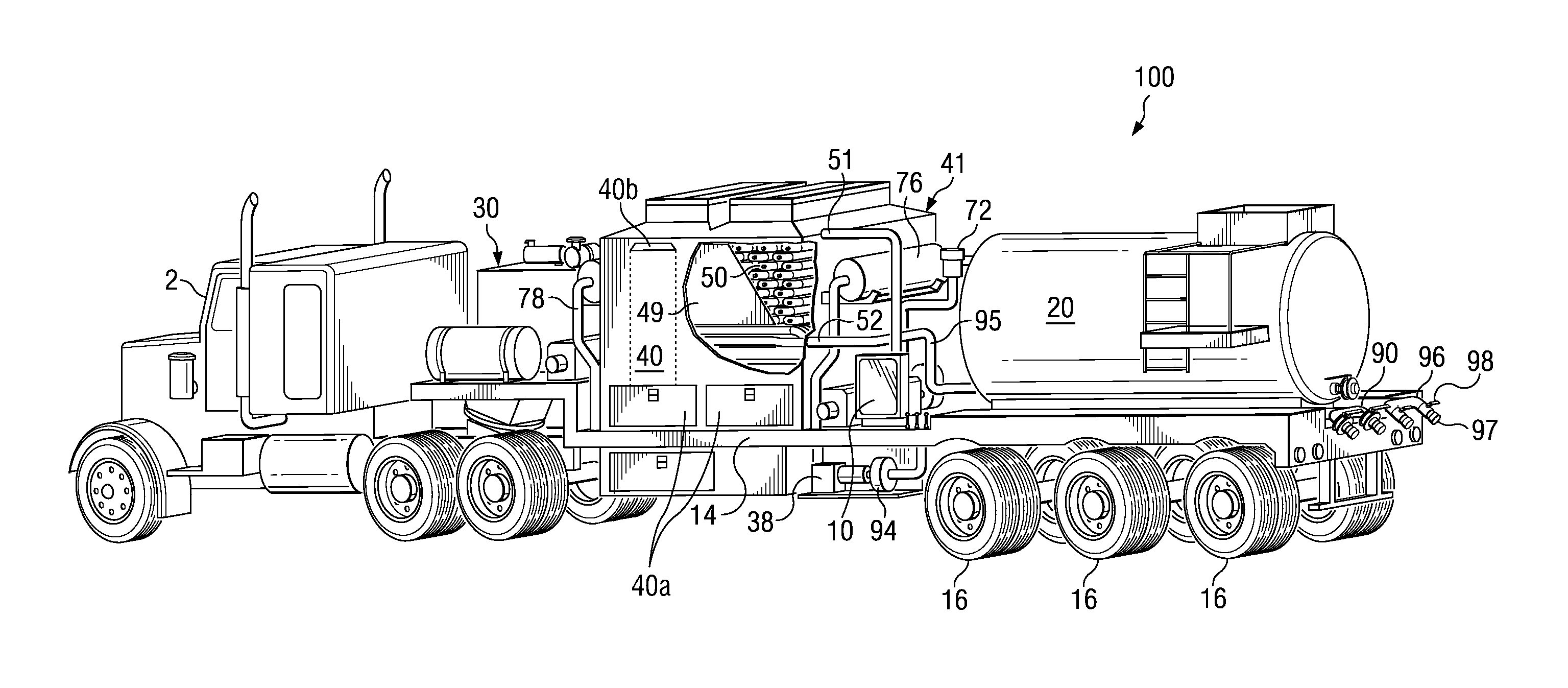

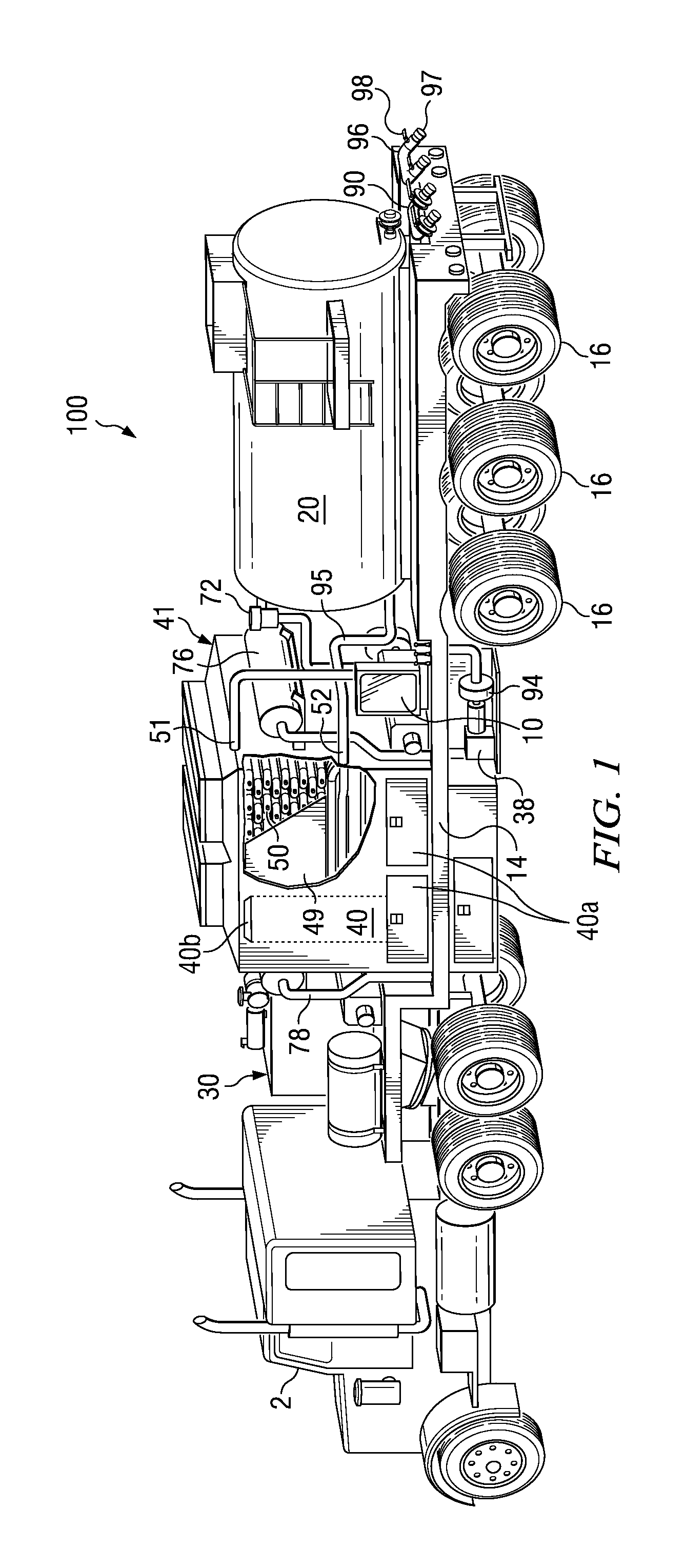

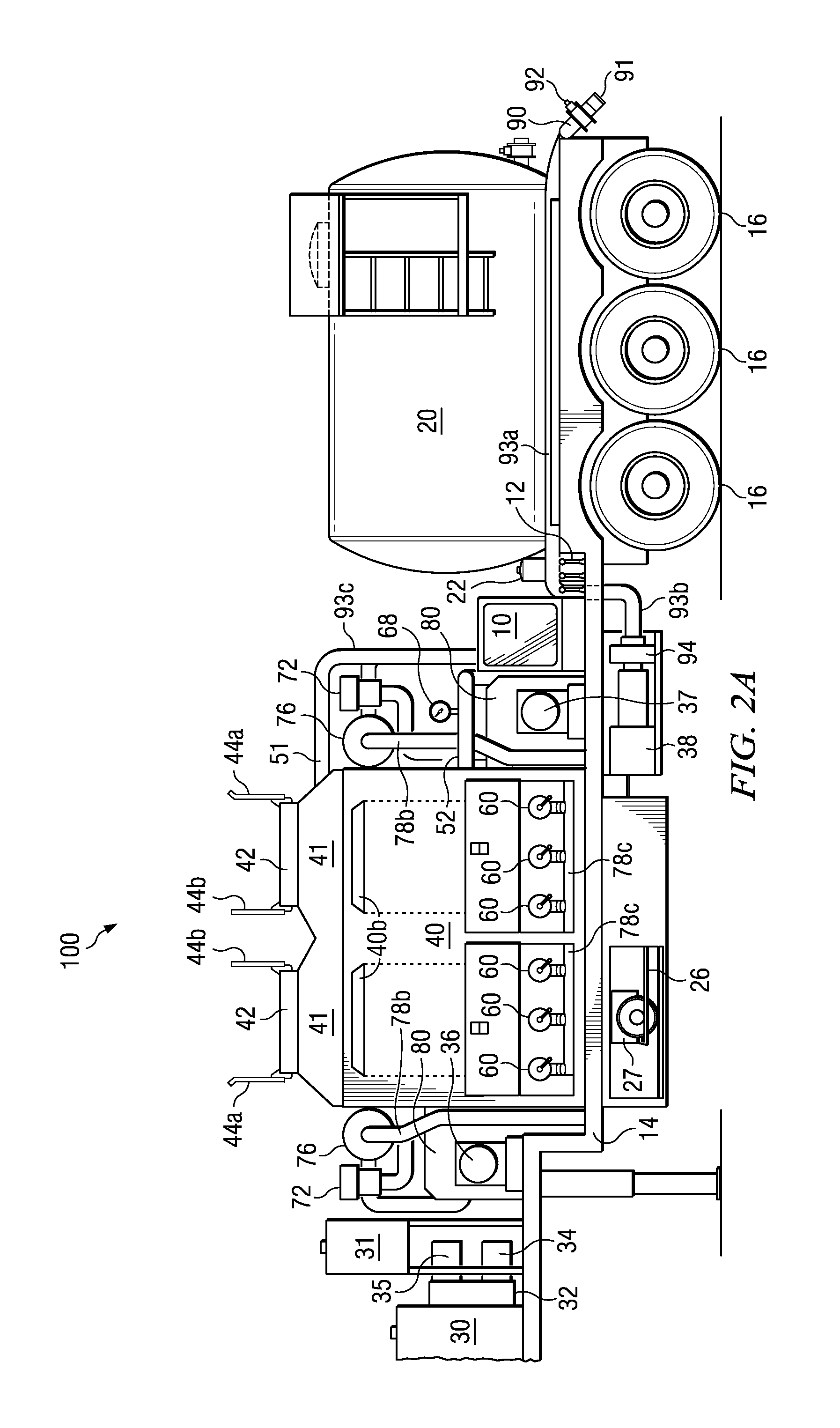

Frac water heater and fuel oil heating system

InactiveUS20130189629A1Maximize atomization and combustionMaximize combustionBurnersLiquid fuel feeder/distributionCombustion chamberFuel oil

An accessory heat exchanger unit for heating the fuel oil used by the frac oil heater system of the invention prior to combustion. The accessory heat exchanger unit receives and distributes the fuel oil through a plurality of heat exchanger tubes prior to directing the oil to the combustion chamber. The unit also includes an inlet for receiving heated treatment fluid from the frac water heater system of the present invention. The heated treatment fluid passes over the plurality of heat exchanger tubes of the accessory heat exchanger unit prior to being directed to the outlet of the accessory heat exchanger unit. By heating the fuel oil prior to combustion, the accessory heat exchanger unit greatly improves the viscosity and flow rate of the fuel oil, thereby allowing cheaper, less cold-tolerant grades of fuel oil to be used in extreme cold climates with no degradation in the operation of the frac water heater system of the present invention.

Owner:CHANDLER RONALD L

Dual fuel heating source

InactiveUS20100330519A1Liquid fuel feeder/distributionFuel supply regulationControl valvesPressure regulator

A dual fuel heating source can have a dual entry valve unit with a main body at least partially defining a certain flow paths or channels therethrough. The dual entry valve can have first and second inlets and first and second outlets. The dual fuel heating source may also include a pressure regulator, an exit valve, a control valve and / or a manifold connected to the dual entry valve unit.

Owner:DENG DAVID

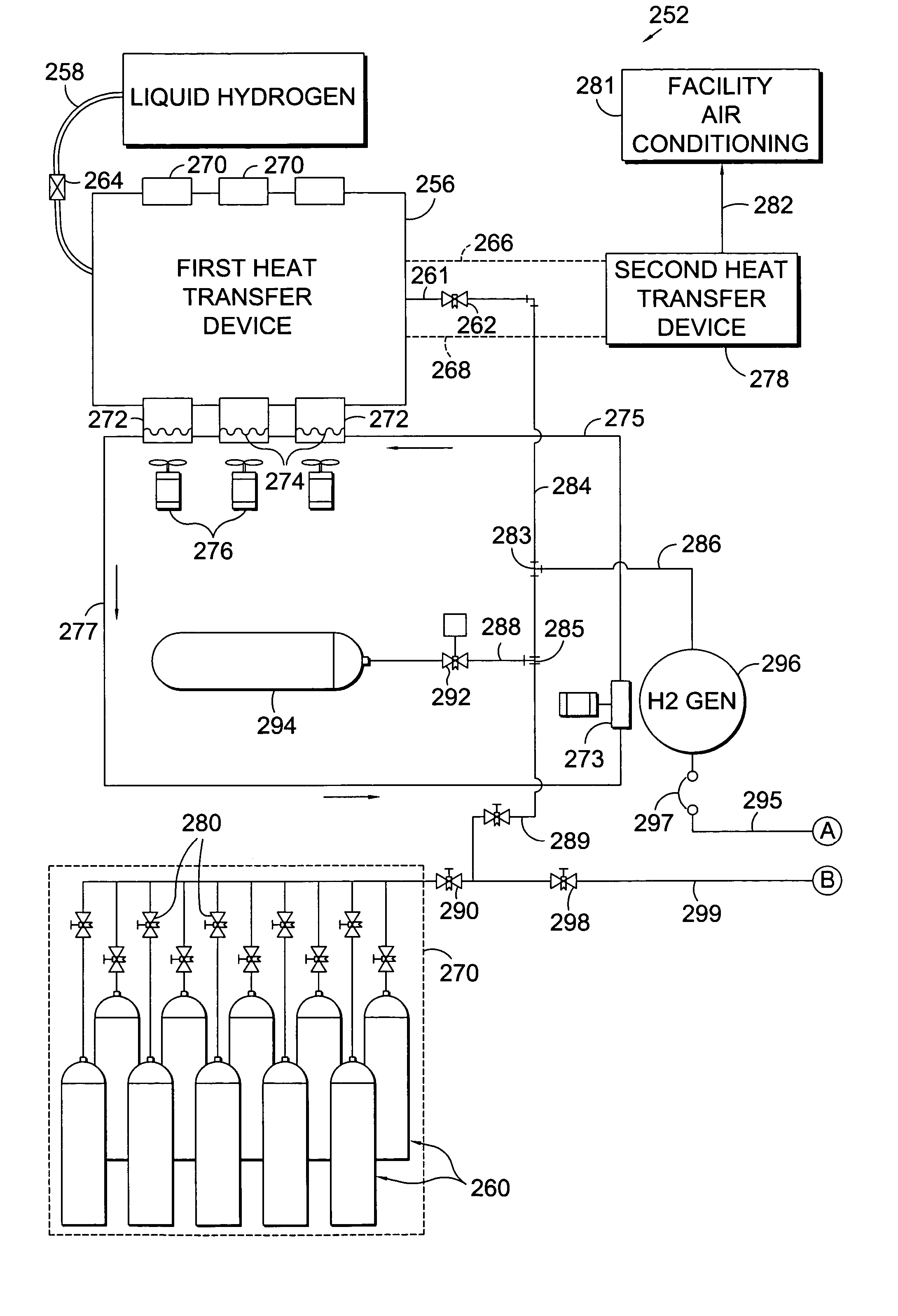

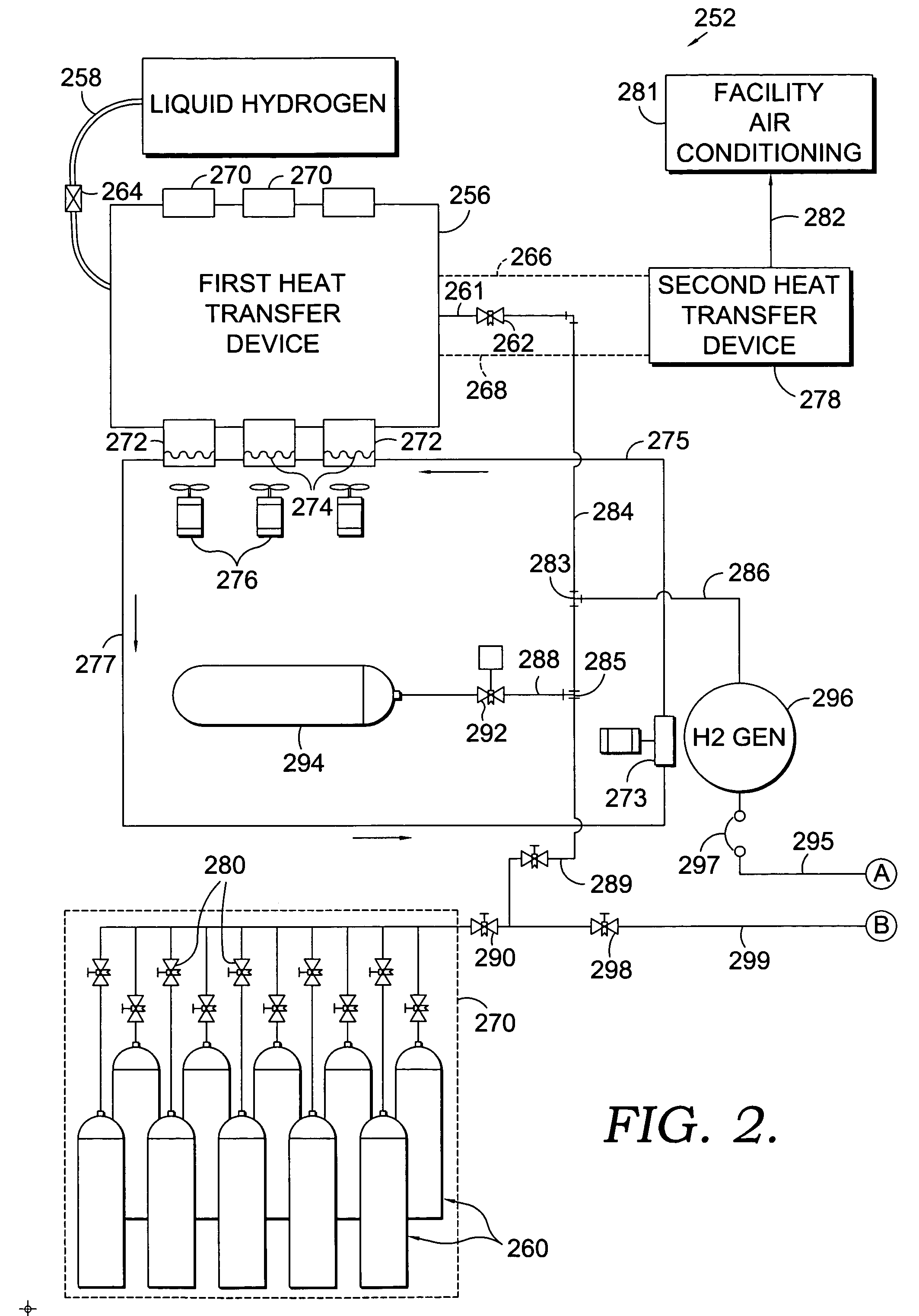

Fuel system used for cooling purposes

ActiveUS20060016189A1Liquid fuel feeder/distributionSteam engine plantsNuclear engineeringHydrogen fuel

A hydrogen fuel system in which the fuel is transformed from liquid to gas is used to administer cooling, e.g., air conditioning. The system incorporates first and second stage heat exchangers. The first stage exchanger is used to benefit from the endothermic reaction created when liquid hydrogen transforms into gas. The cooling provided from this state change is transferred into a second medium which is delivered into a second stage heat transfer device and then used for cooling purposes.

Owner:T MOBILE INNOVATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com