Patents

Literature

756 results about "Heating oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heating oil is a low viscosity, liquid petroleum product used as a fuel oil for furnaces or boilers in buildings. Home heating oil is often abbreviated as HHO. Heating oil consists of a mixture of petroleum-derived hydrocarbons in the 14- to 20-carbon atom range that condense between 250 and 350 °C (482 and 662 °F) during oil refining. Heating oil condenses at a lower temperature than petroleum jelly, bitumen, candle wax, and lubricating oil, but at a higher temperature than kerosene, which condenses between 160–250 °C (320–482 °F). The heavy (C20+) hydrocarbons condense between 340–400 °C (644–752 °F).

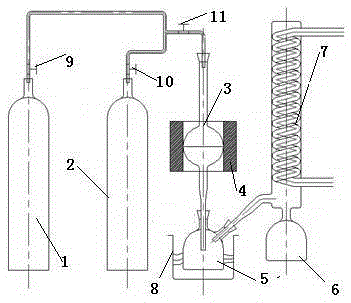

Method for preparing precursor for chemical vapor deposition of metallic rhenium

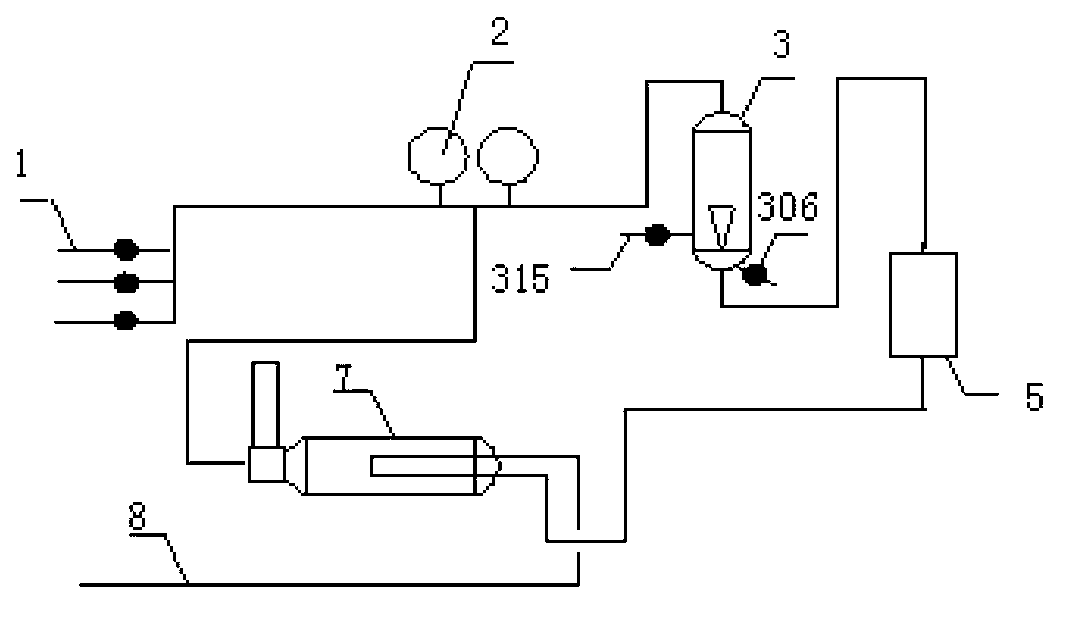

The invention discloses a method for preparing a precursor for chemical vapor deposition of metallic rhenium and belongs to the technical field of material preparation. According to the method, ReCl5 is made to react in an oxidizing atmosphere, efficient solid-liquid-gas separation is conducted on reactants and products with a sand core filter bulb so that reactants, reaction products and waste gas can be effectively separated, the reaction products ReOCl4 and ReO3Cl are gathered in a collection vessel heated by an oil bath pan at the same time, oxygen introduction is stopped after reaction ends, circulation of inert gases is maintained, a tube furnace is cooled, the oil bath pan is heated at the same time to enable ReO3Cl to volatilize to enter a rectification unit to be collected, ReOCl4 is purified, and then the high-purity precursor ReOCl4 for chemical vapor deposition of metallic rhenium is obtained. By the adoption of the method, reaction efficiency is high, ReOCl4 and ReO3Cl are separated through rectification, and the purity of the product ReOCl4 is improved.

Owner:海朴精密材料(苏州)有限责任公司

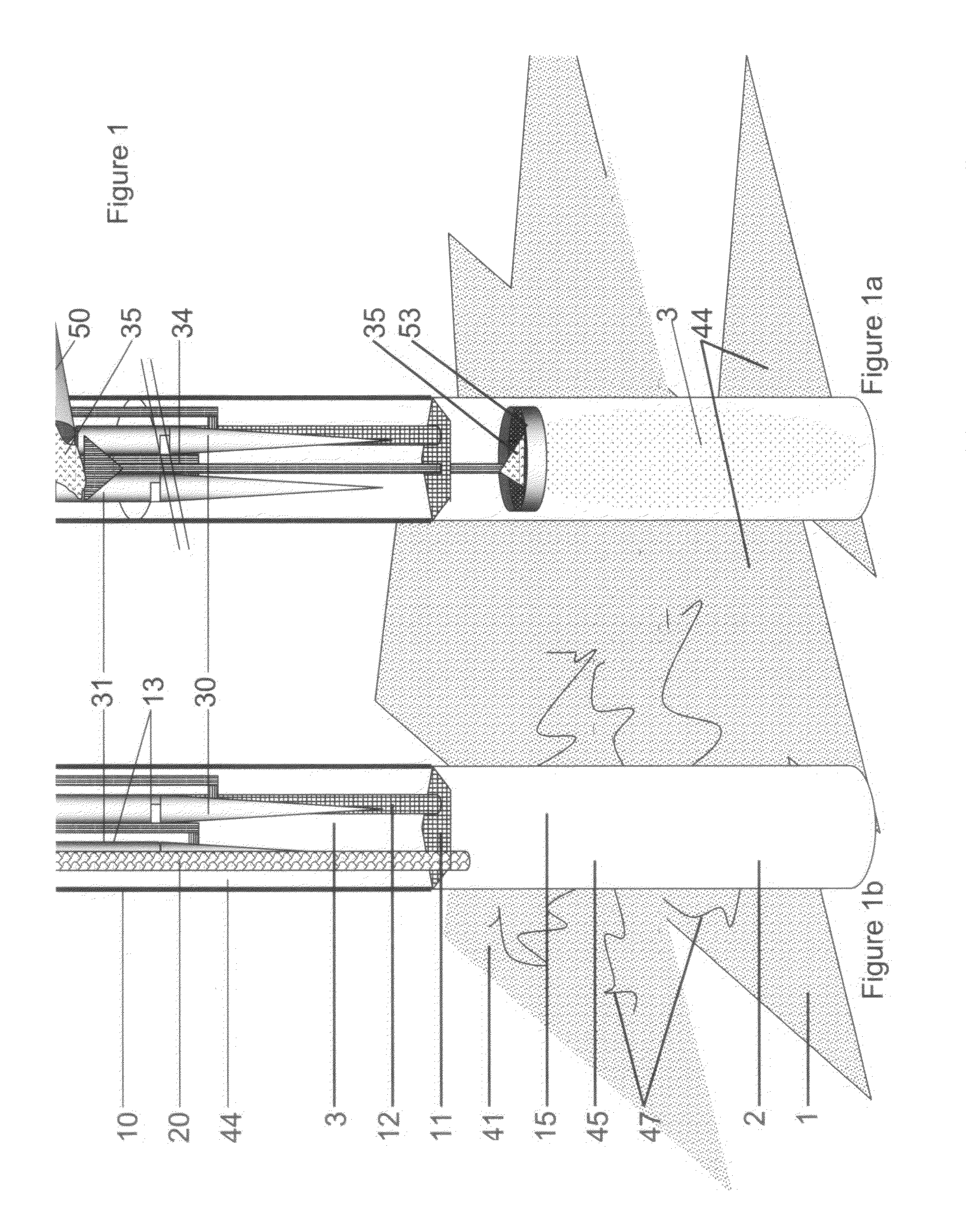

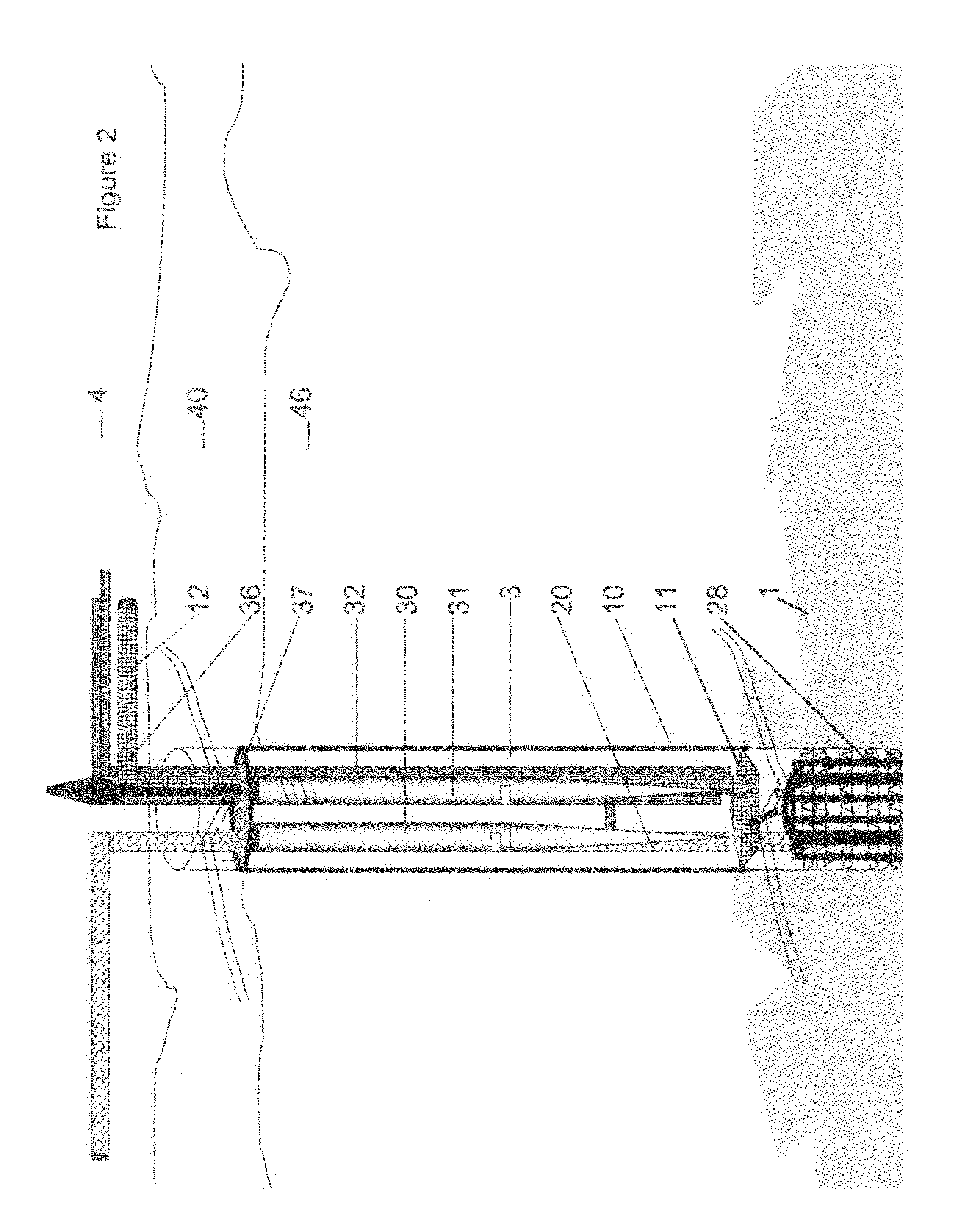

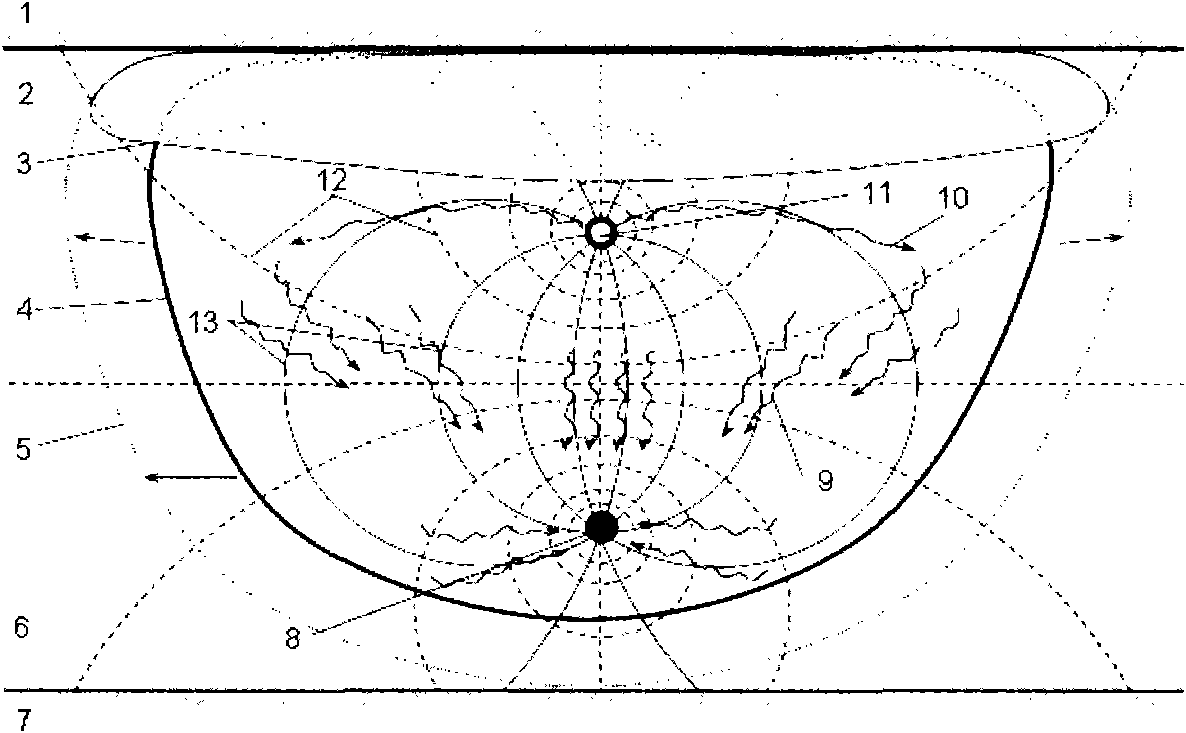

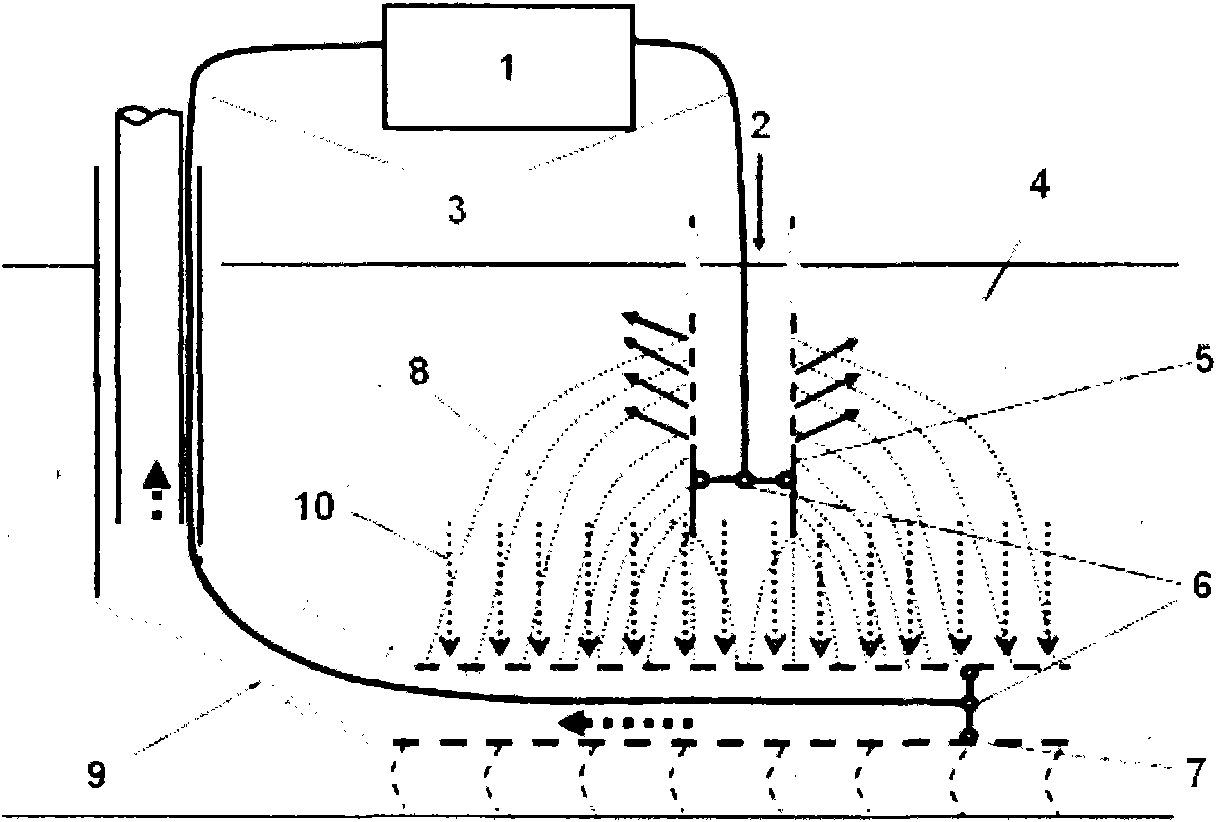

Harvesting hydrocarbons and water from methane hydrate deposits and shale seams

InactiveUS20100006281A1Low extraction temperatureLess waterConstructionsMultiple-effect/fractional condensationNoble gasKerosene

A method of extraction of fuels, organic pollutants, and elements from Methane hydrate deposits, shale seams and the soil is described which freezes the zone and heats the center carrying the fuel, chemicals and water in these deposits and seams from where they are found, be it deep in the sea or on land, and carries them into the condensing unit in inert Nitrogen gas. Required drilling on the surface or sea bottom includes a main shaft and with auxiliary narrow drillings widely spaced from the shaft. The extraction zone, which is first cooled to brittle cold using the evaporation of Liquid Nitrogen and fractured with vibrations, is heated to the highest temperature of the hydrocarbon fraction desired to be extracted. The evaporating hydrocarbons are extracted in a Nitrogen gas carrier, a recognized fire suppressant (NFPA Code 2000). To speed the extraction rate, tonal input from two or more sounding units vibrates the seam structure freeing the evaporated hydrocarbons allowing more rapid escape into the shaft. To prevent air loss in aquifers, ice barriers seal the zone periphery. These hydrocarbons are separated into the hydrocarbons fractions, into fuel fractions as heating oil, kerosene, gasoline, ethers, and fuel gas including methane, Argon / Oxygen and rare gas segments, or, if pollutants, into the separate chemicals by boiling point. The thermal gradient of the extraction pipe is implemented by sourcing the Nitrogen from Liquid Nitrogen and bundling those pipes with the extraction pipe condensing its contents by hydrocarbon fractions into vessels and gas drums depending on boiling points of fractions. Water is separated from the gasoline segment and purified first by separation and then by freezing. The extraction of deep deposits layer the extraction zones as well as work neighboring extraction zones covering many acres. Fuel gases can be liquefied or burned in an on-site electric generating plant.

Owner:AIR WARS DEFENSE

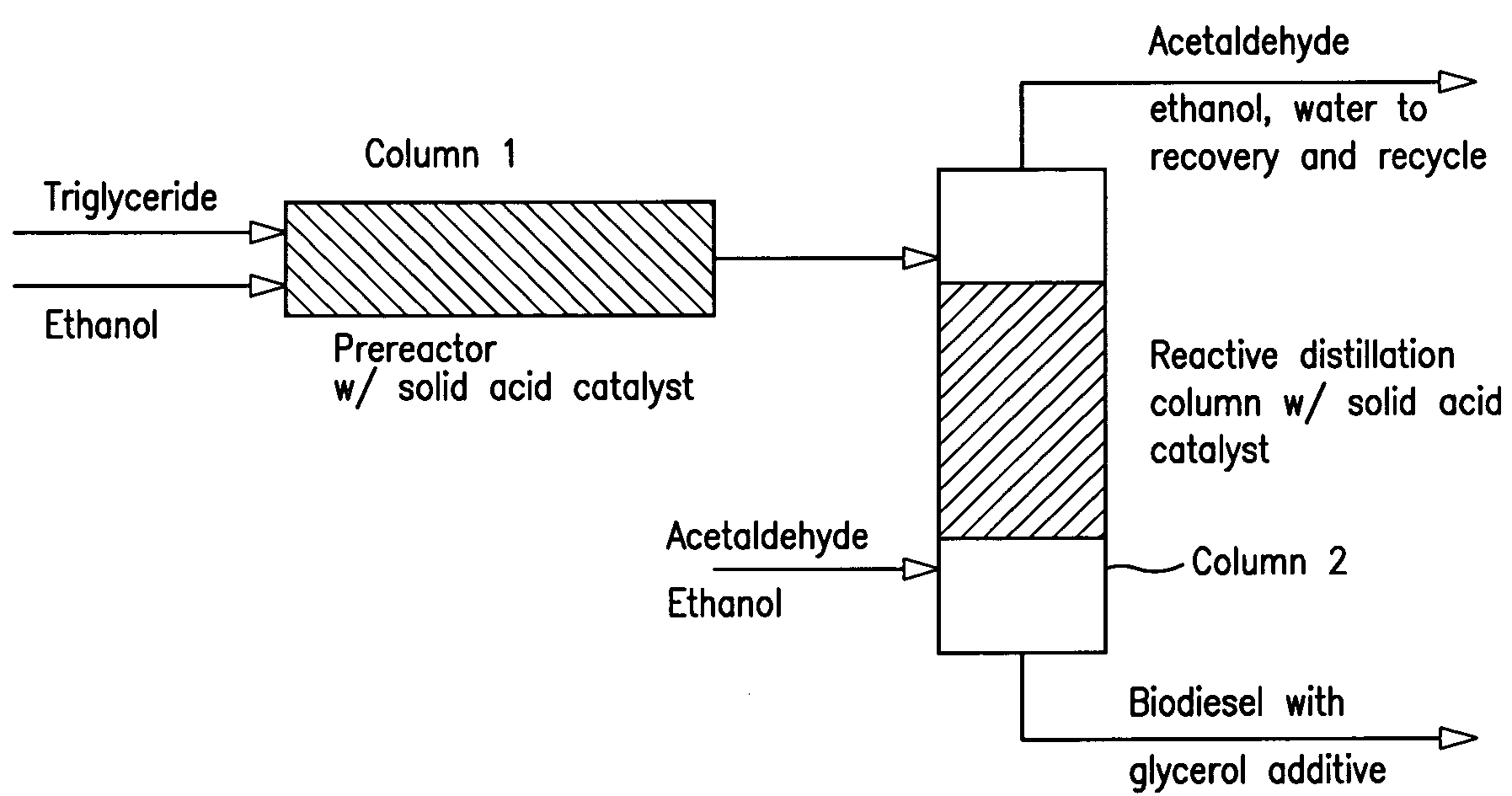

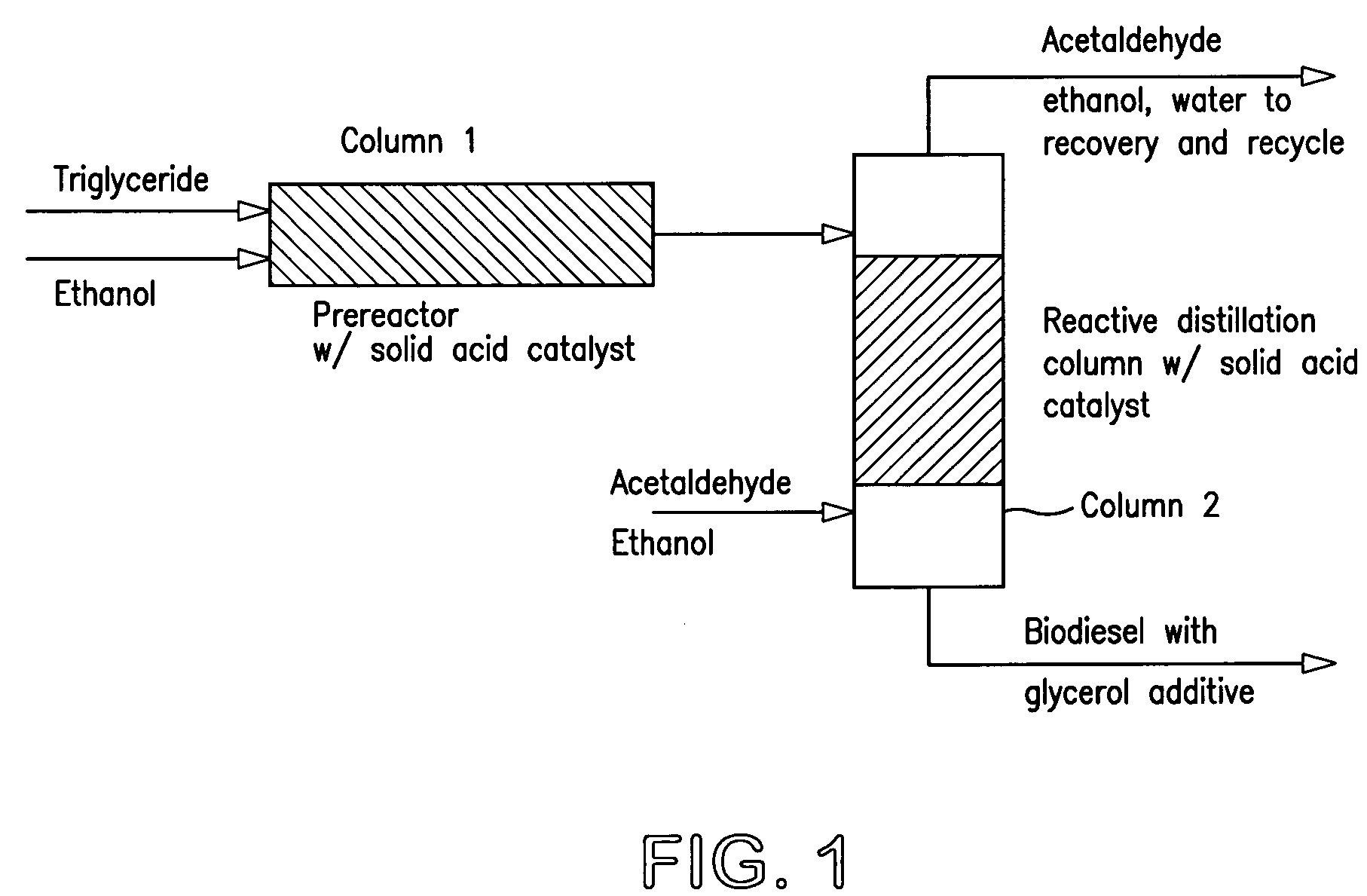

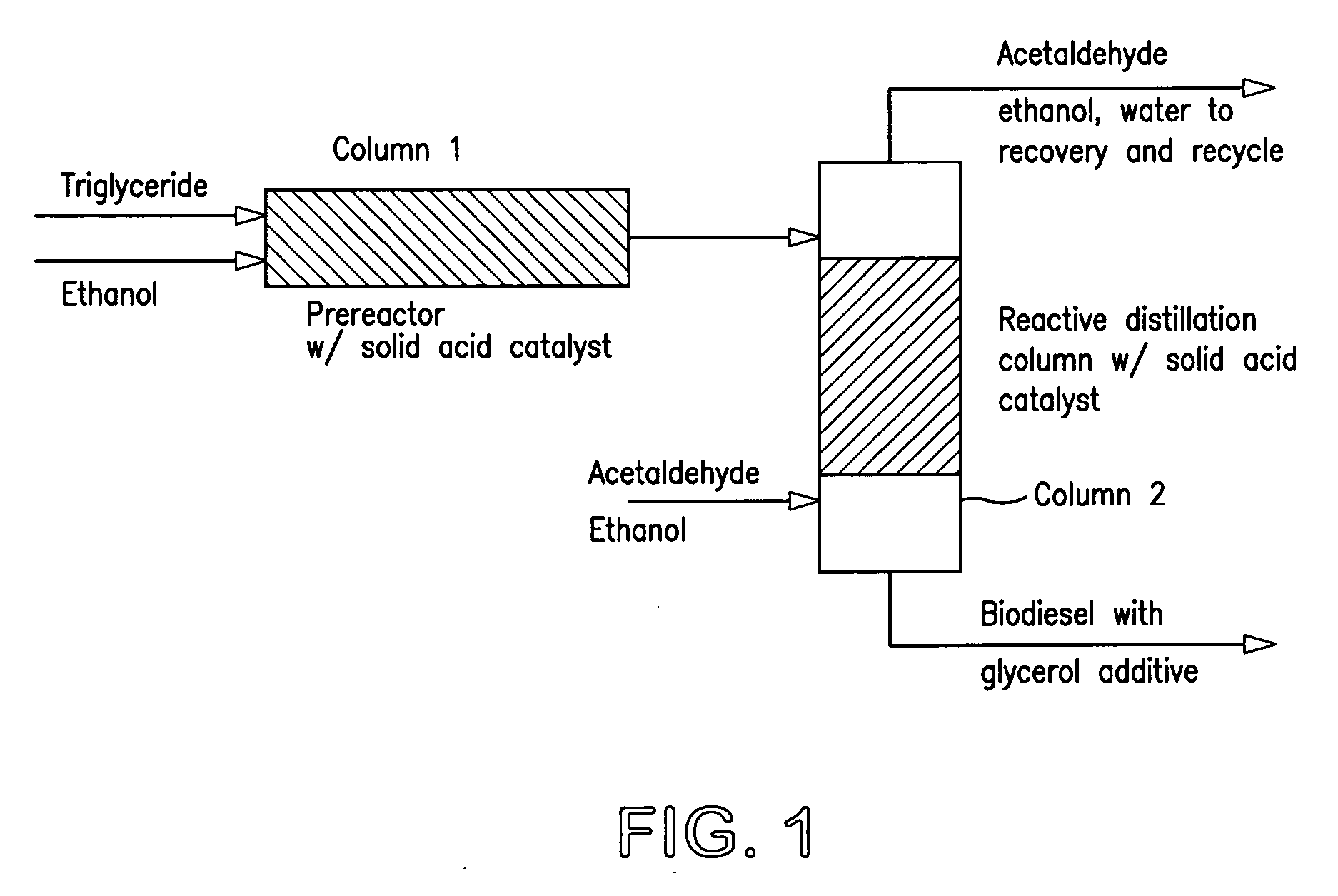

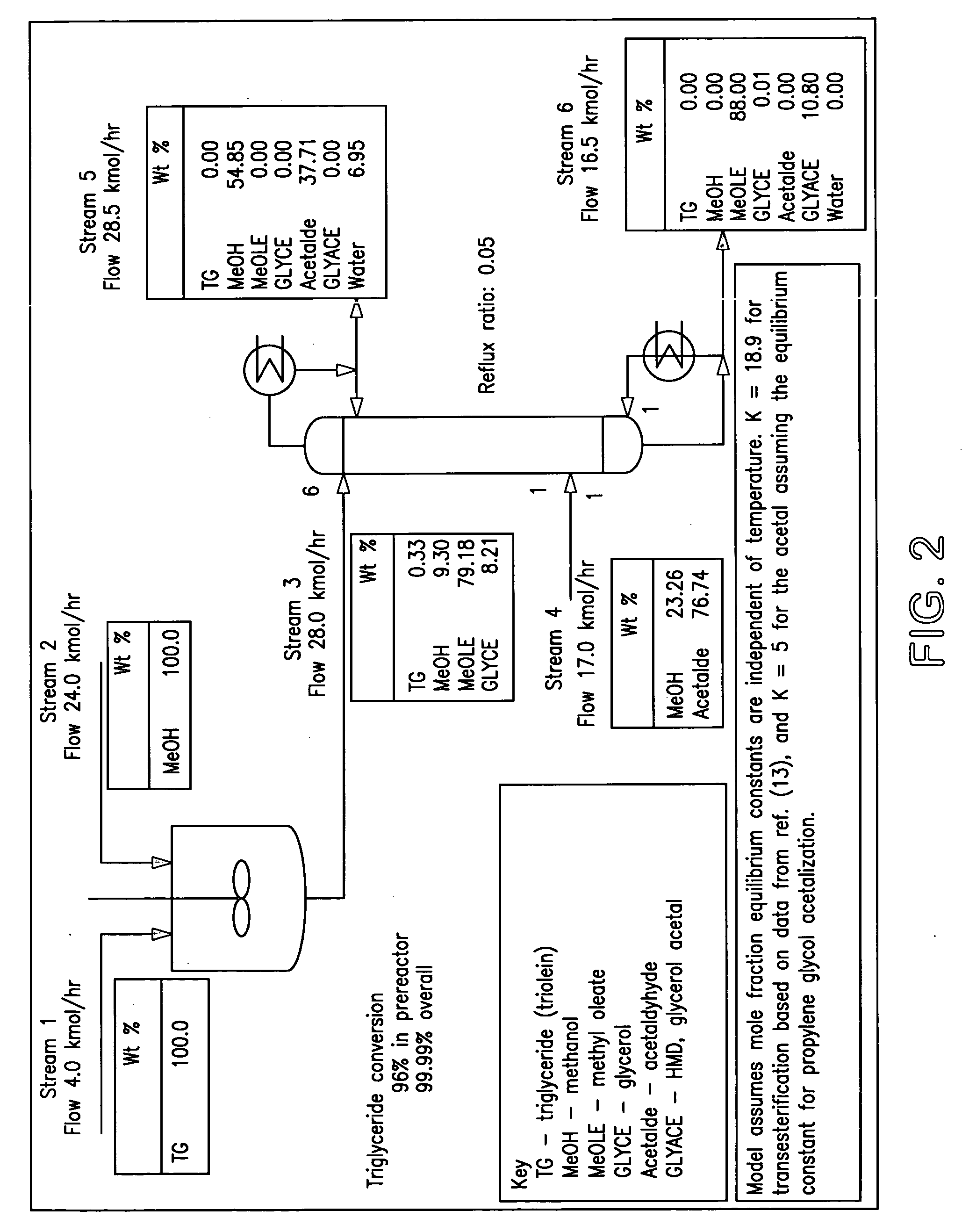

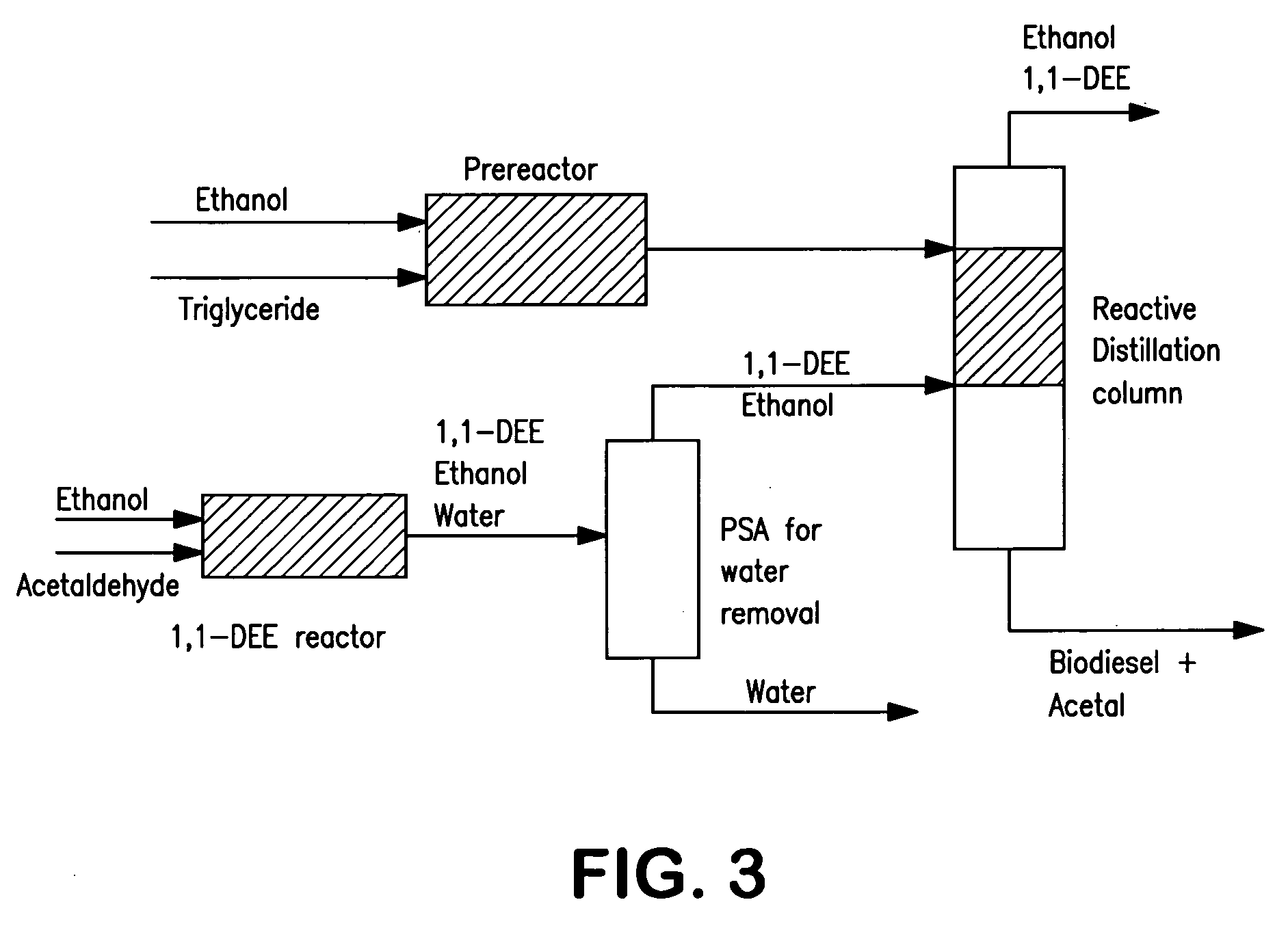

Process for production of a composition useful as a fuel

InactiveUS7321052B2Easy to operateFuel propertyFatty oils/acids recovery from wasteFatty acid esterificationHeating oilTG - Triglyceride

A process for the preparation of a fuel oil (diesel fuel or heating oil) composition which is a mixture of an alkanol tranesterified fatty acid ester triglyceride and an acetal of glycerol is described. The process preferably provides a prestep of the formation of at least some of the alkanol transesterified triglyceride containing the glycerol for use in the formation of the acetal of glycerol. The composition can also be formed from a reaction of 1,1-dimethoxy- or 1,1-diethoxyethane and glycerol to form the acetal in the alkanol transesterified triglyceride.

Owner:MICHIGAN STATE UNIV

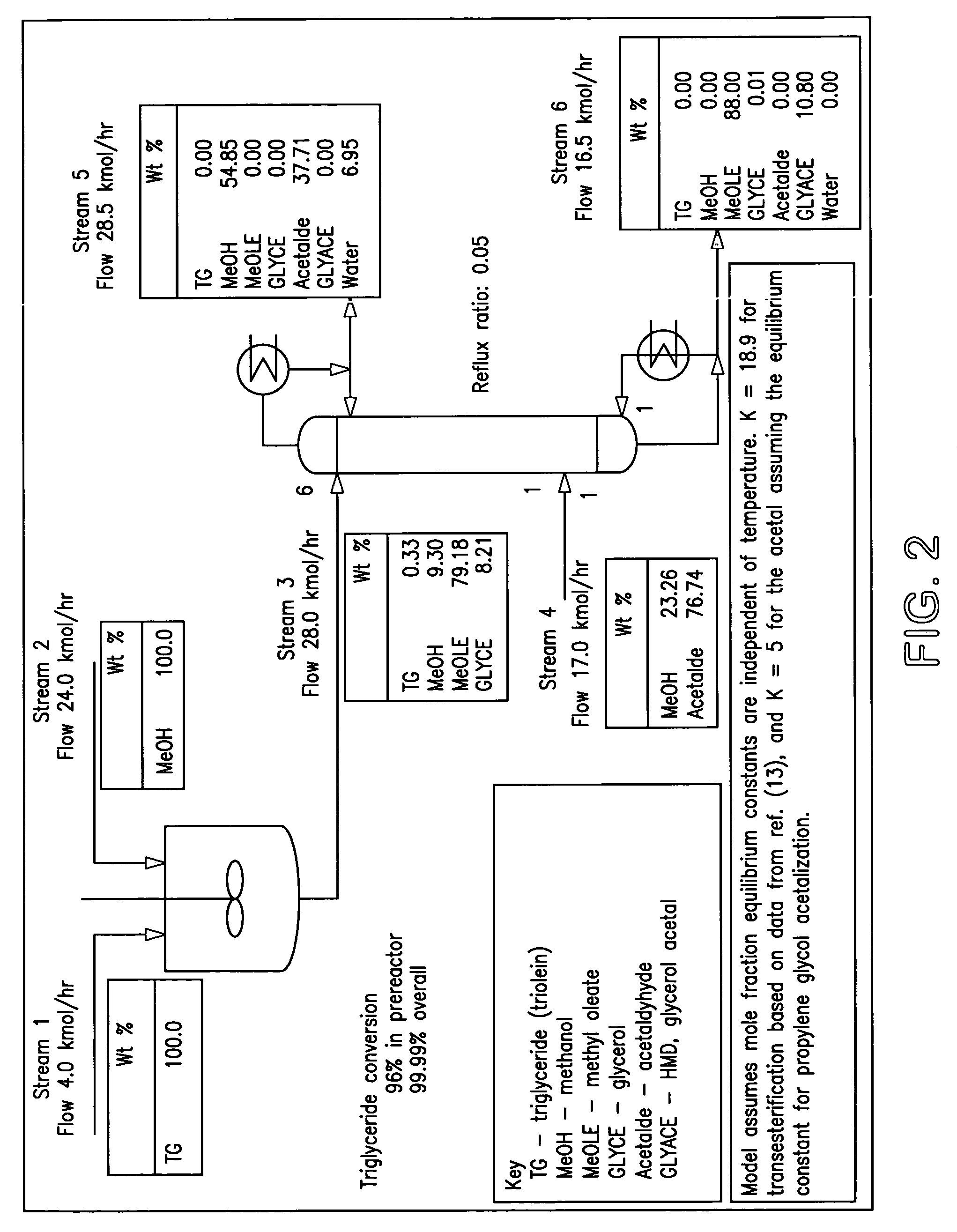

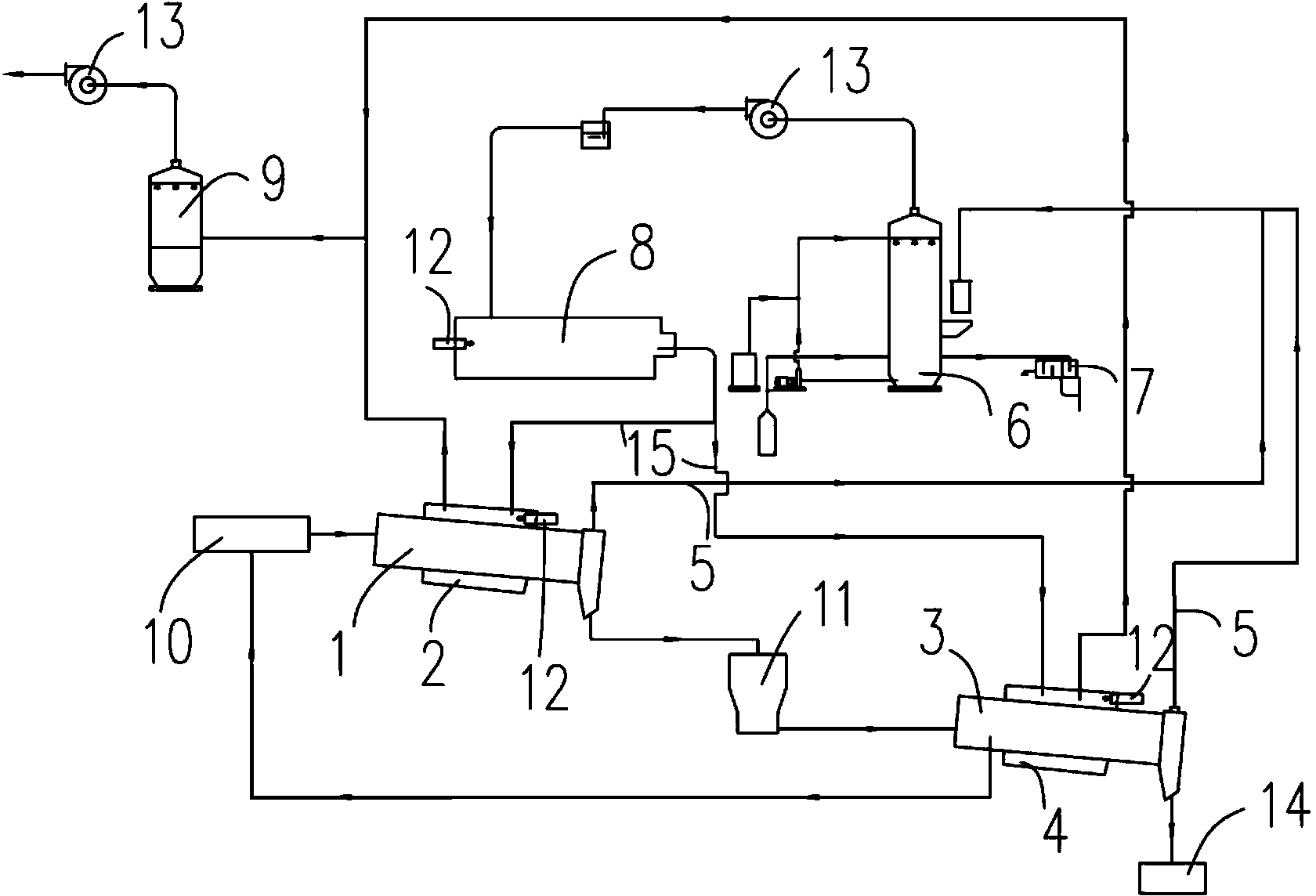

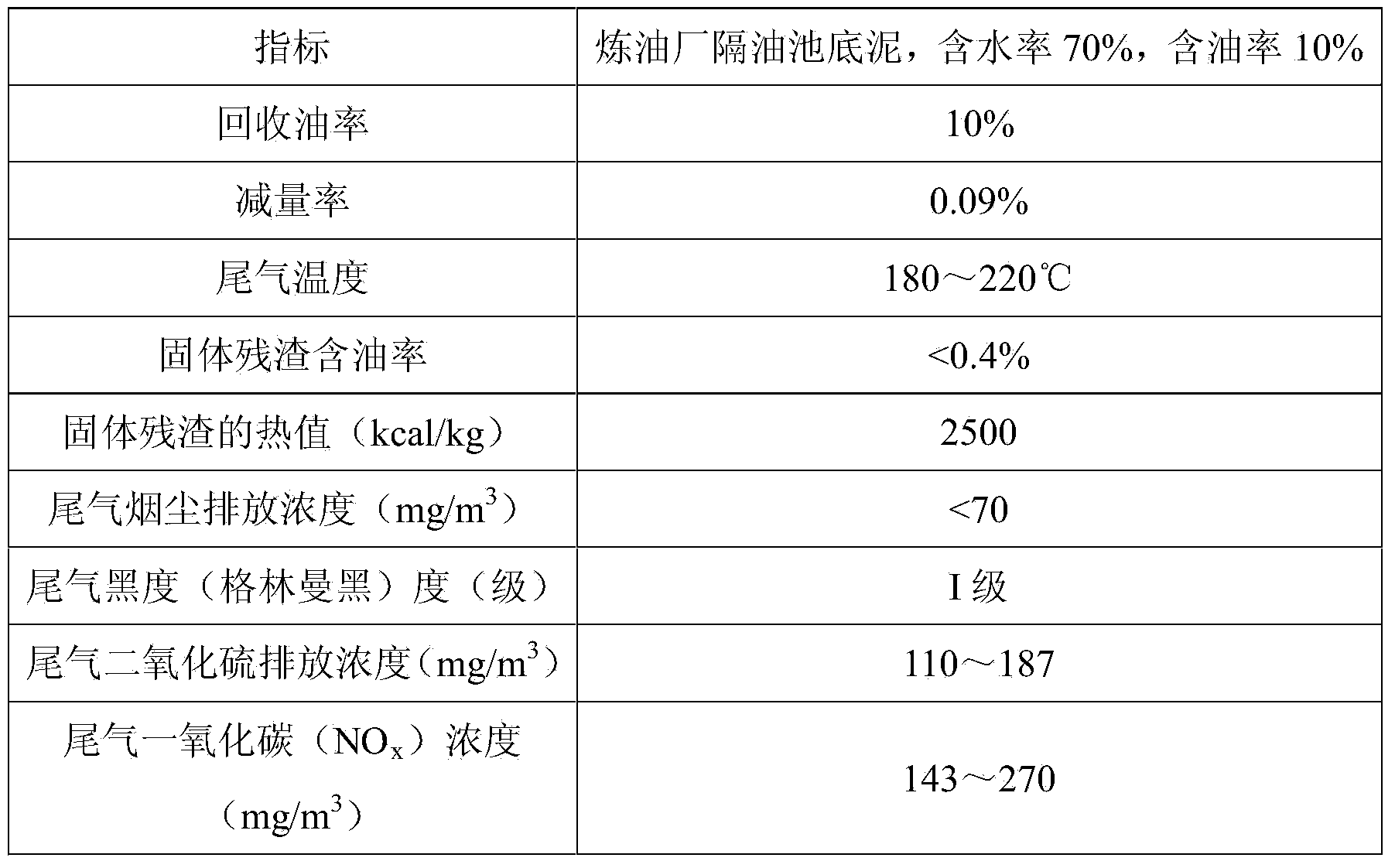

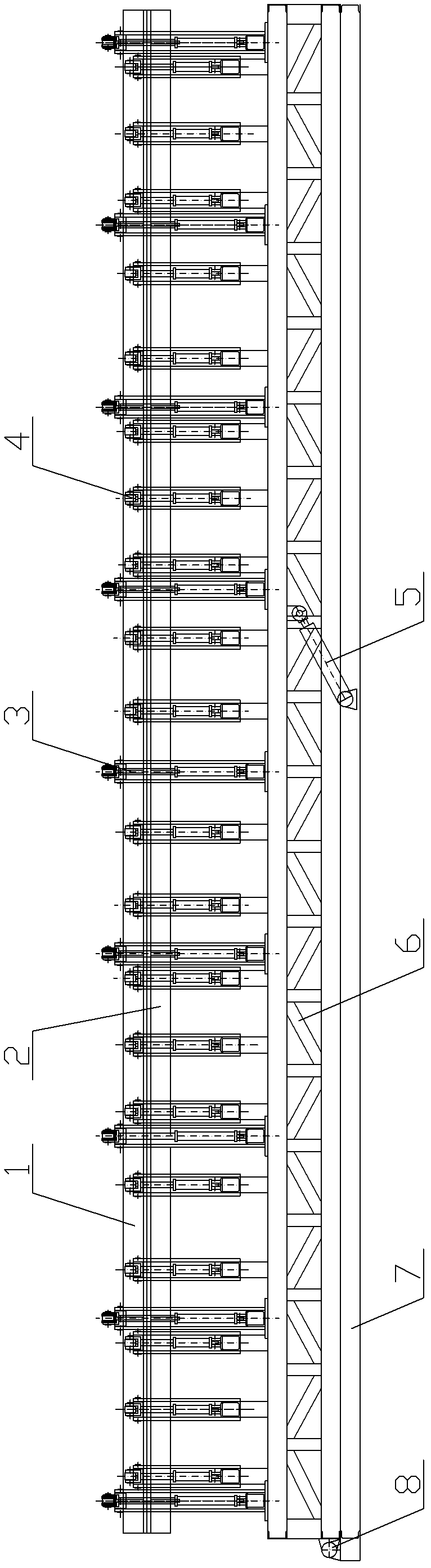

Method and device for refinery sludge carbonization treatment and carbon recovery

ActiveCN103449701AReduce the difficulty of process controlEfficient process operationSludge treatment by thermal conditioningCarbon preparation/purificationSludgeGas phase

The invention relates to a method and device for refinery sludge carbonization treatment and carbon recovery. The method comprises the following steps: pre-treatment: heating oil-containing sludge to 160-180 DEG C in an external heating manner while isolating air, and ensuring that the water content of the oil-containing sludge is controlled at 20% or below; carbonization: carbonizing the oil-containing sludge at 600-650 DEG C for 30-45 minutes, and recovering the solid residue generated by carbonization; condensation and oil-water separation: collecting gas-phase products generated by pre-treatment and carbonization, condensing in a water spray manner to obtain carbonization liquid and non-condensable gas, and performing oil-water separation on the carbonization liquid to obtain carbonization oil; utilization of combustible gas: performing combustion treatment on the non-condensable gas, enabling high temperature generated by combustion to provide heat energy for pre-treatment and carbonization, and performing purification treatment on the tail gas before discharging. The invention also provides a device for realizing the method. According to the invention, the advantages of high oil content recovery rate and stable and reliable process operation are achieved.

Owner:ZHE JIANG ECO ENVIRONMENTAL TECH CO LTD

Method and apparatus for burning oils of varying viscosity

InactiveUS6132203AEfficient combustionPrevents possibility of fire and explosionLiquid fuel feeder/distributionSpraying apparatusHeating oilCombustor

Disclosed is an oil burning system that is capable of burning oils of varying viscosities, including high viscosity waste oils and low viscosity heating oils. Suitable as a new installation or a retrofit modification, the present invention incorporates the use of a variable rate, high-pressure oil delivery system, along with an oil pre-heater, in conjunction with a modified high-pressure atomizing nozzle. Installed in a sliding drawer burner arrangement that allows for quick and easy access, the oil burning system also includes a means by which particulate matter and carbonization build-ups are removed from the burner nozzle automatically, thereby eliminating the need for frequent cleaning.

Owner:MASIN RADEK

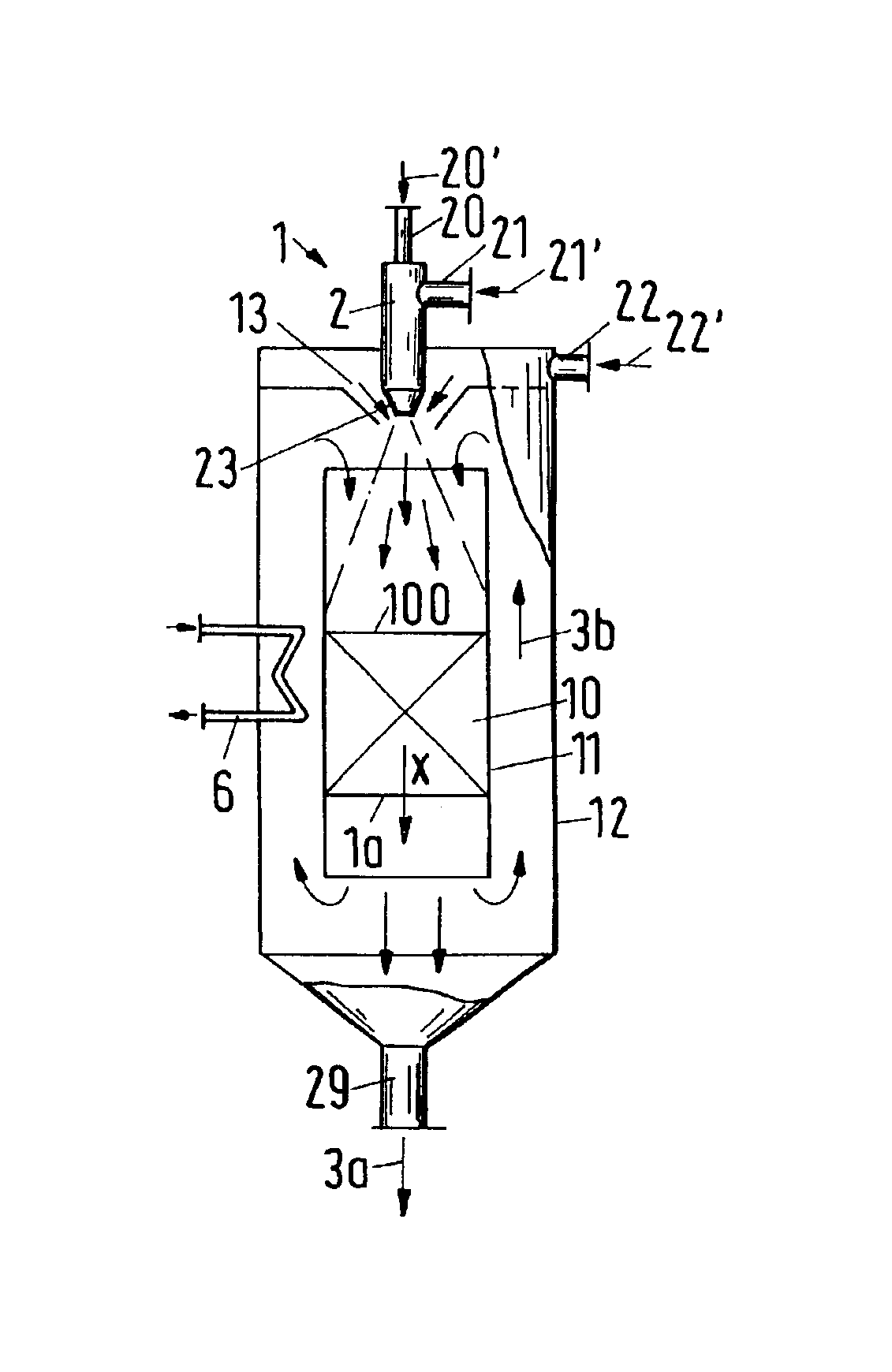

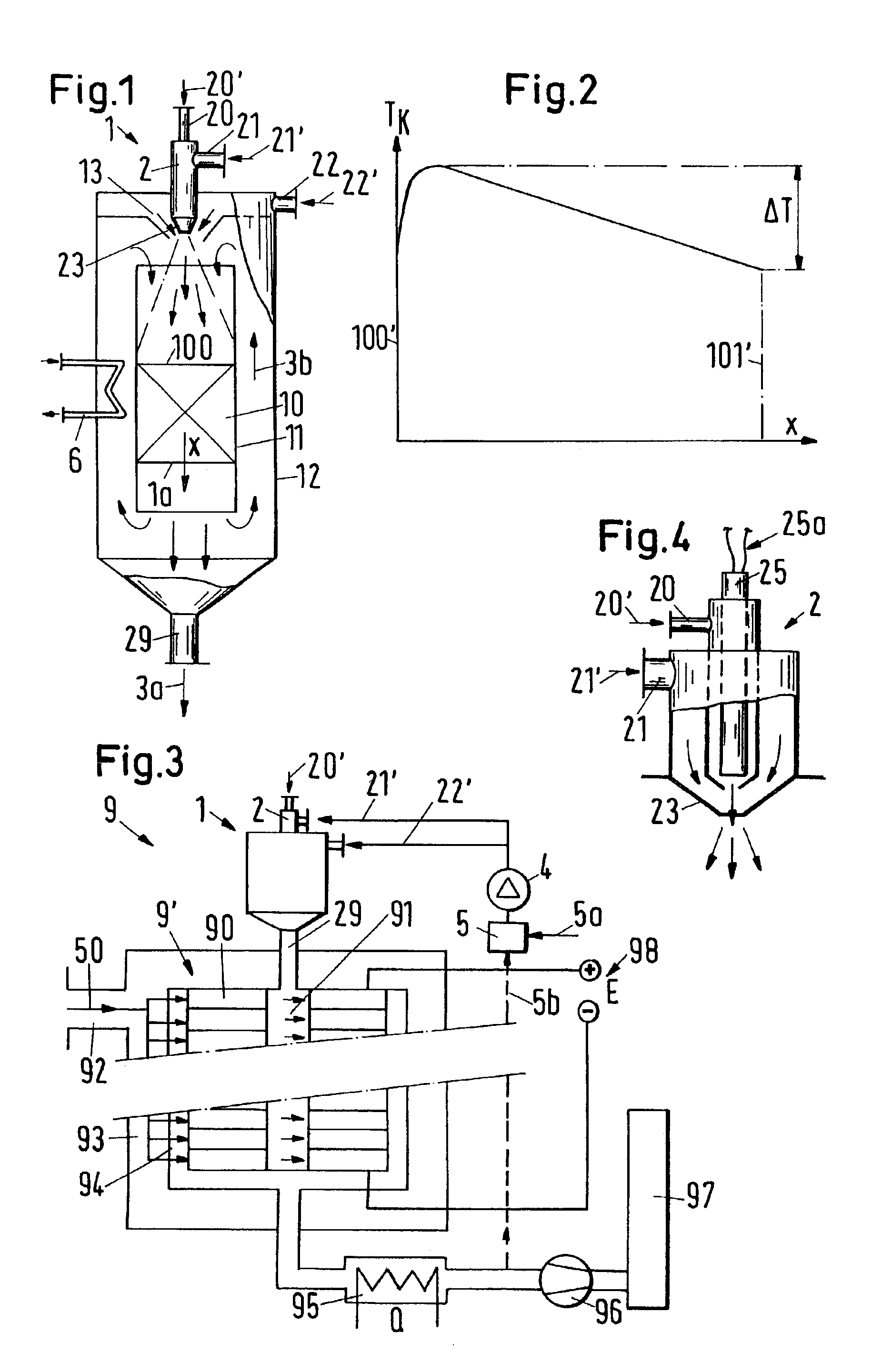

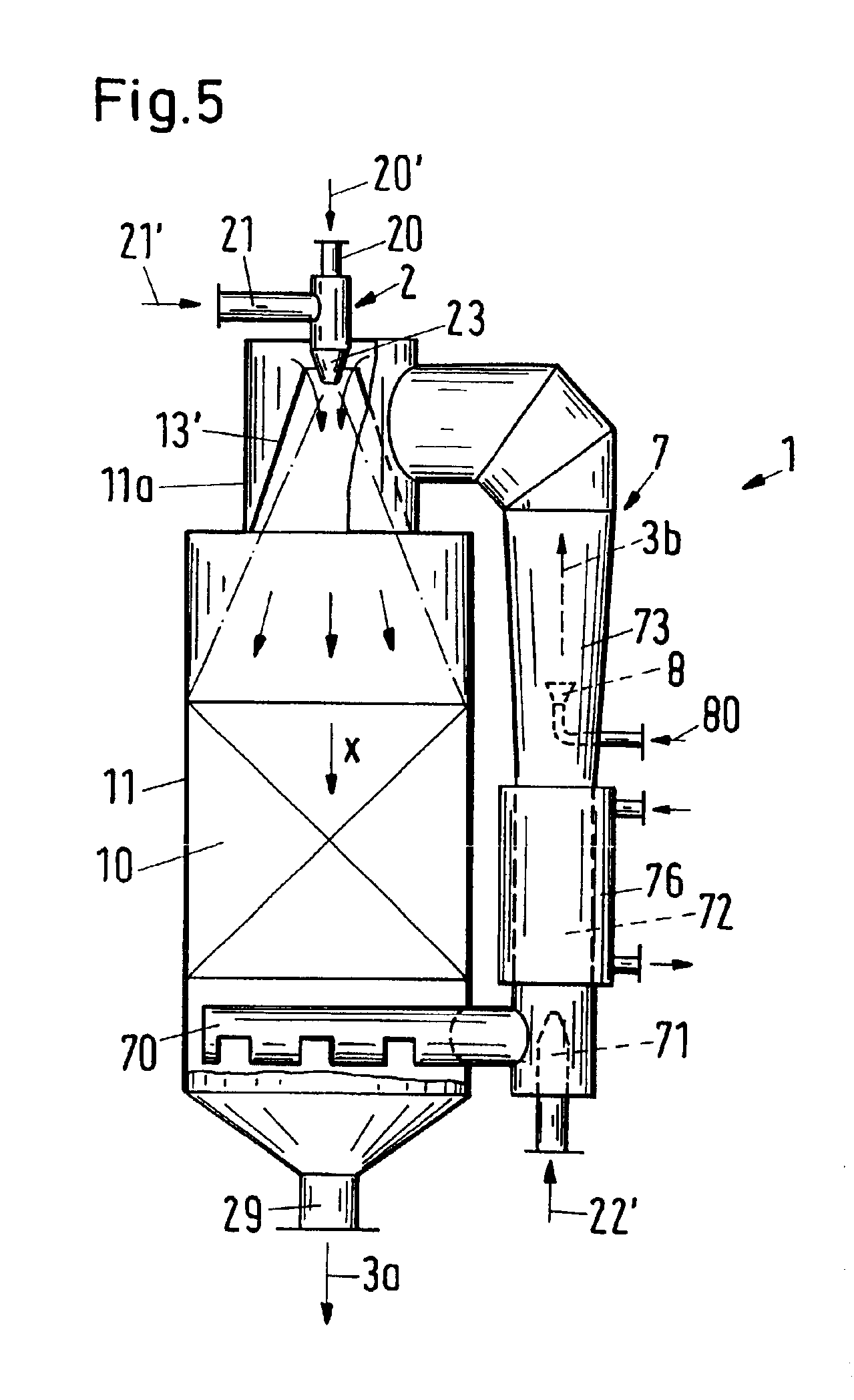

Method for the reformation of fuels, in particular heating oil

InactiveUS6872379B2Avoid damaging effectsReduce the temperatureHydrogenHydrocarbon from carbon oxidesHeating oilForming gas

The method for the reformation of fuels, in particular of heating oil (20′) and of another liquid fuel is carried out using an oxygen containing gas (5a, 5b, 21′, 22′). The method includes the following steps:formation of a fuel / gas mixture by dispersing of the fuel in a jet of the oxygen containing gas (21′);additionally an admixture of gas of a return flow (3b) and vaporization of the dispersed fuel;generation of synthesized gas from the gas mixture by means of partial oxidation and also reformation processes by heterogeneous catalysis;branching off of the produced synthesized gas into a product flow (3a) and the return flow (3b) for a recirculation; anda regulated extraction of heat from the return flow for the setting of a predetermined temperature of a catalyst support (10) on which the heterogeneous catalysis takes place.

Owner:SULZER HEXIS AG

Mixed alcohol fuels for internal combustion engines, furnaces, boilers, kilns and gasifiers

Mixed alcohol formulas can be used as a fuel additive in gasoline, diesel, jet fuel, aviation gasoline, heating oil, bunker oil, coal, petroleum coke or as a neat fuel in and of itself. The mixed alcohols formulations can contain C1-C5 alcohols, or in the alternative, C1-C8 alcohols or higher C1-C10 alcohols in order to boost energy content. The C1-C5 mixed alcohols contain more ethanol than methanol with declining amounts of propanol, butanol and pentanol. C1-C8 mixed alcohols contain the same, with declining amounts of hexanol, heptanol and octanol. C1-C10 mixed alcohols contain the same, with declining amounts of nananol and decanol. Synthetically produced mixed alcohol formulas feature higher octane and energy densities than either MTBE or fermented grain ethanol; more stable Reid Vapor Pressure blending characteristics; and increased soluablizing effects on condensate water. The primary benefits of mixed alcohols are increased combustion efficiencies, reduced emissions profiles and low production costs.

Owner:STANDARD ALCOHOL COMPANY OF AMERICA

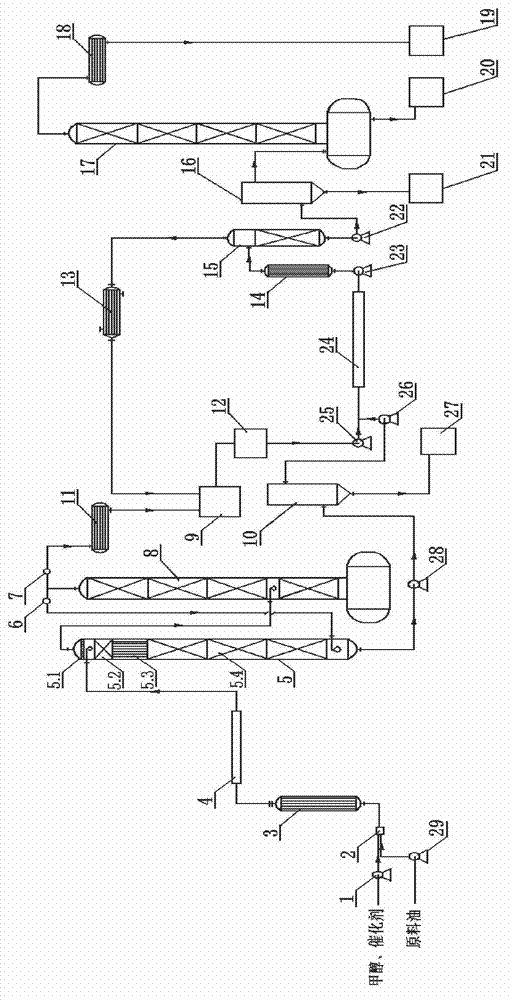

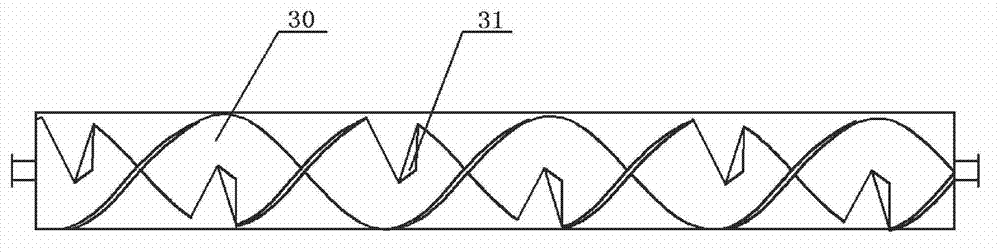

Continuous production device and method of biodiesel

The invention discloses a continuous production device of biodiesel, which comprises a biodiesel reaction device, a connecting pipeline, and a metering pump, a delivery pump and a flow meter, wherein the metering pump, the delivery pump and the flow meter are arranged in the pipeline; the biodiesel reaction device comprises a mixer 2, a heater I3, a pipeline reactor I4, an esterification reaction tower 5, a catalyst separator 10, a methanol storage tank 9, a pipeline reactor II24, a flash column 15, a glycerin separator 16, a distillation tower 17 and a biodiesel storage tank 19. A method for preparing the biodiesel by the continuous production device comprises the steps of: pretreating high acid value raw oil, carrying out first stage esterification reaction and second stage esterification reaction, separating by a catalyst, carrying out transesterification, and finally separating and distilling flash and glycerin which are obtained by heating oil after transesterification to obtain the biodiesel. The method disclosed by the invention is simple in production technology, wide in application scope of equipment for the raw oil quality, low in production energy consumption, higher in conversion rate and more environment-friendly, and more effectively improves the production quality and the yield of the biodiesel.

Owner:GUANGXI HEZHONG ENERGY +1

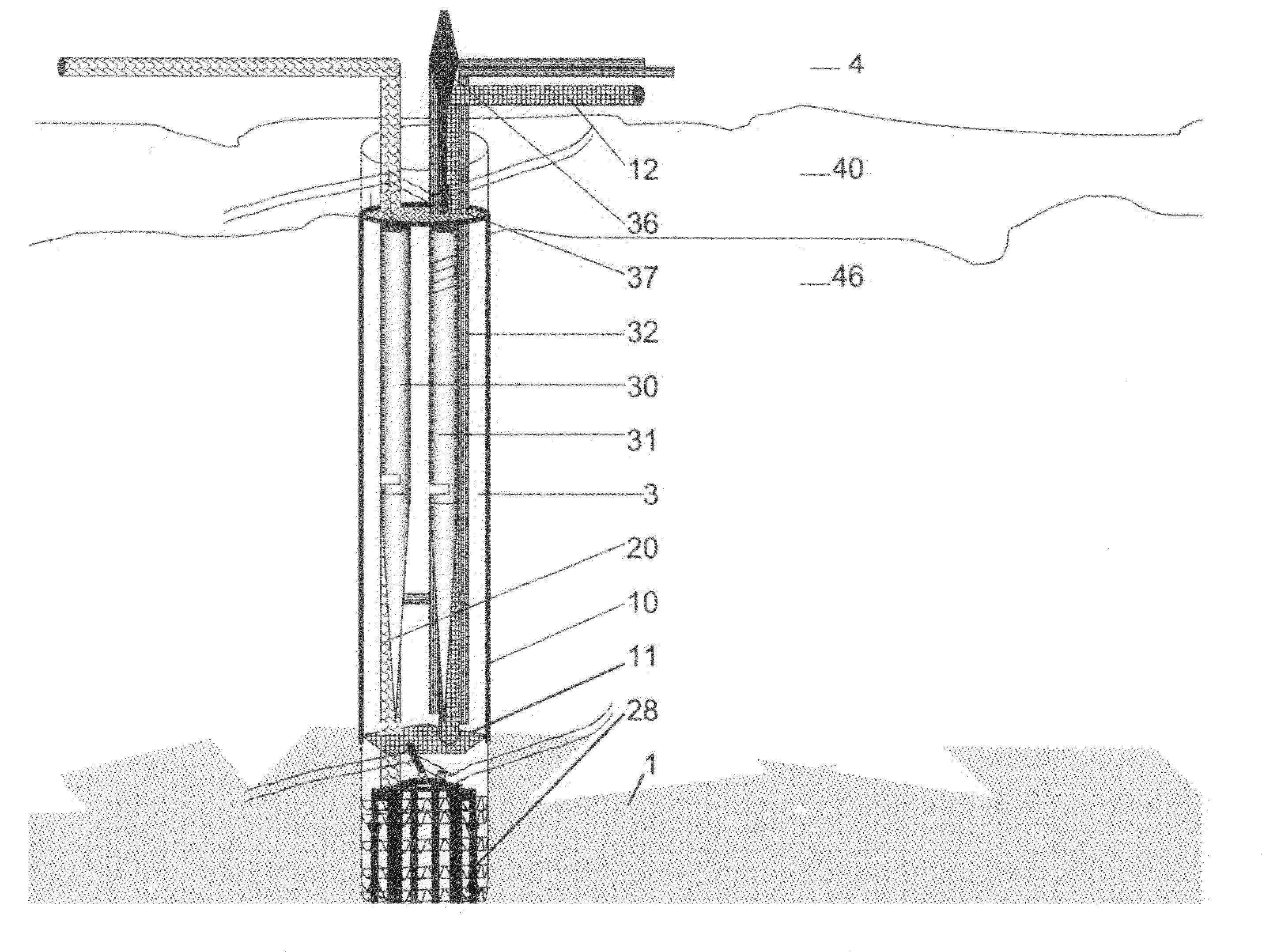

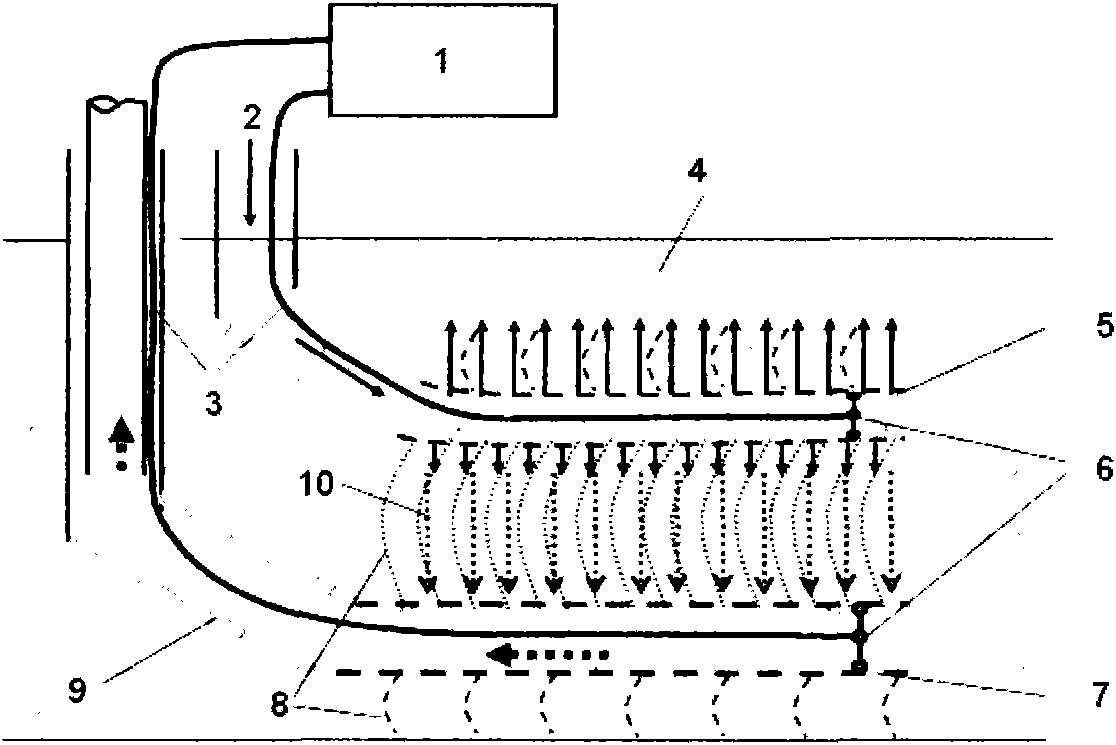

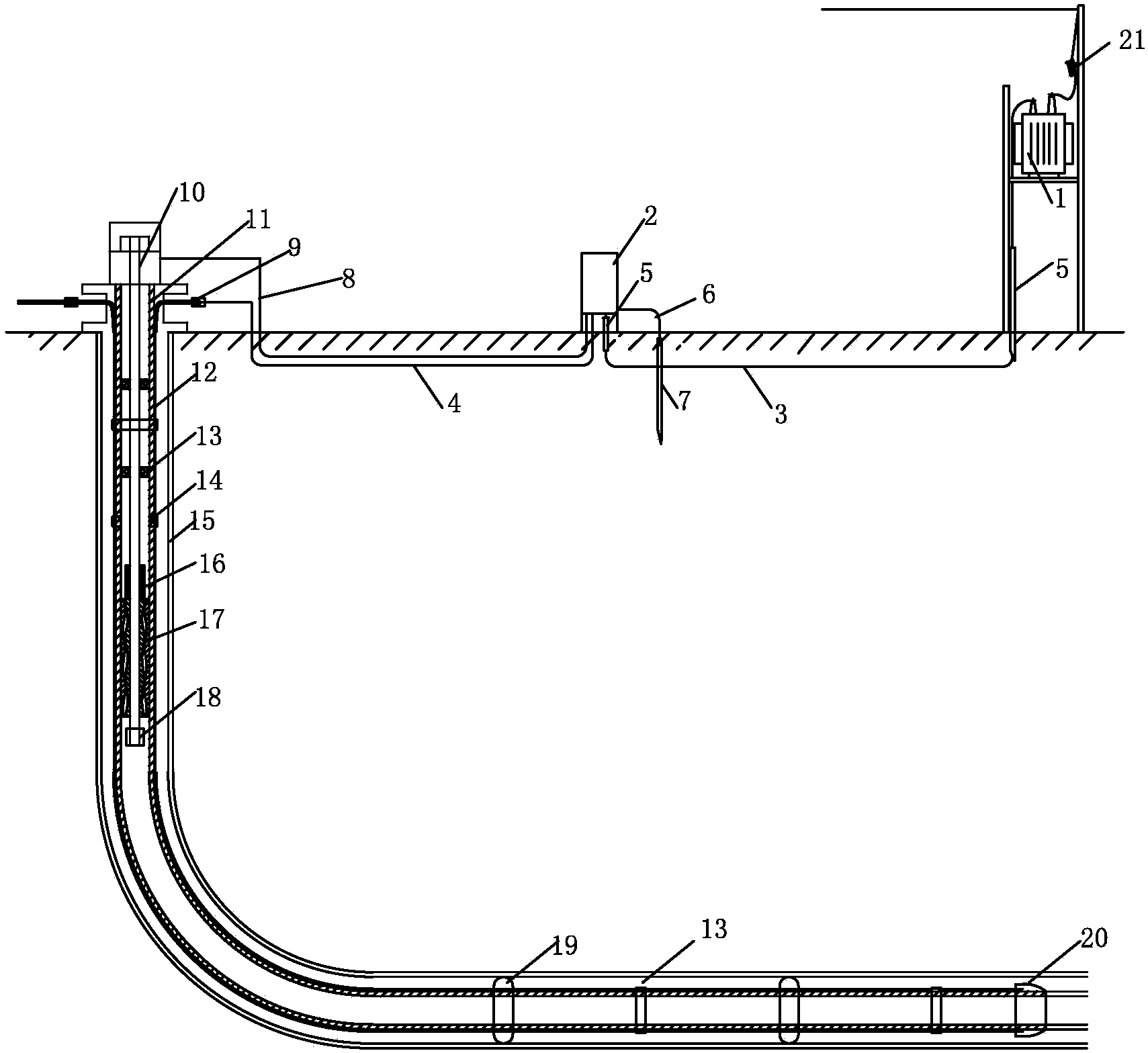

Gas and electric heating assisted gravity oil drainage technology

The invention belongs to a technology of well drilling, well completion and oil extraction in oil fields, which is mainly applied to exploitation of thick oil reservoirs, in particular relates to a gas and electric heating assisted gravity oil drainage technology. By adopting an upper horizontal well and a lower horizontal well or combining a straight well at the upper part and a horizontal well at the lower part, the two wells perform the double electrode action for heating oil reservoirs (mainly oil reservoirs among wells) in a distributed way on the spot, thereby avoiding the heat loss of the ground and shafts, improving the heating efficiency and obviously weakening the adverse effect of two-phase flow of oil water because of no injected water; and on the other hand, gas (N2, CO2, flue gas or natural gas and the like) is injected into the well at the upper part, wherein on the one hand, the gas is collected at the tops of the oil reservoirs to form gas caps, thereby increasing the stratum energy, keeping the stratum pressure, assisting the gravity oil drainage and simultaneously performing the action of heat insulation; and on the other hand, the injected gas can properly enlarge heat waves and volume, thereby improving the heating effect. The technology of the invention can be used as a technology of conversion and exploitation of thick oil in old areas or a technology of production and exploitation of thick oil in new areas.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Process for production of a composition useful as a fuel

InactiveUS20060199970A1Easy to operateImprove solubilityFatty oils/acids recovery from wasteFatty acid esterificationHeating oilGlycerol

A process for the preparation of a fuel oil (diesel fuel or heating oil) composition which is a mixture of an alkanol tranesterified fatty acid ester triglyceride and an acetal of glycerol is described. The process preferably provides a prestep of the formation of at least some of the alkanol transesterified triglyceride containing the glycerol for use in the formation of the acetal of glycerol. The composition can also be formed from a reaction of 1,1- dimethoxy- or 1,1-diethoxyethane and glycerol to form the acetal in the alkanol transesterified triglyceride.

Owner:MICHIGAN STATE UNIV

Method of high temperature hydrocarbon gas convection heating oil shale for exploiting oil gas

InactiveCN101122226AAlleviate the contradiction of convection heating waterLow costFluid removalHeating oilCapacitance coefficient

An oil and gas exploitation method for an oil shale through high-temperature convection-heating of the hydrocarbon gas relates to a mineral exploitation method. The high-temperature overheating water steam convection heating is used by the prior art to exploit oil and gas of an oil shale. As the temperature capacitance coefficient of the high temperature overheating water steam is low, heating of a mineral layer is slow, which increases the cost and reduces the efficiency. Some oil shale deposits are in the desert, and much water is needed by the overheating water steam heating, so the deposits cannot be exploited. The invention uses the hydrocarbon gas as the convection heating fluid. The high temperature hydrocarbon gas is injected into the oil shale along a heat injection well, and the heated mineral layer causes pyrogenation of the kerogen to form oil and gas, which is carried by the low-temperature gas or water along a production well to the ground. After the oil and gas is separated from the water, gas will be separated independently to from the oil and gas product, and the hydrocarbon gas will enter a storage tank to be pressurized and heated to the designed pressure and temperature. Then the hydrocarbon gas will be injected into the oil shale mineral layer for circulating exploitation of oil and gas. Thus, the oil and gas exploitation method for an oil shale through high-temperature convection-heating of the hydrocarbon gas is economical and more convenient for application in the industry.

Owner:TAIYUAN UNIV OF TECH

Method for stabilizing heating oil or diesel oil, particularly heating oil or diesel oil from the depolymerization of hydrocarbon-containing residues, or pyrolysis oil

ActiveUS20090008296A1Refining with oxygen compoundsHydrocarbon distillationHeating oilDepolymerization

In order to keep diesel or heating oil obtained by fractional distillation, in particular after depolymerization of residues, or pyrolysis oil that was obtained by pyrolysis of rubber or organic substances, permanently clear and light, first, the process of discoloration (darkening) is allowed and then a second distillation is carried out, through which a permanently clear and light heating, diesel or heavy oil is obtained.

Owner:DEPO SOLUTIONS GMBH

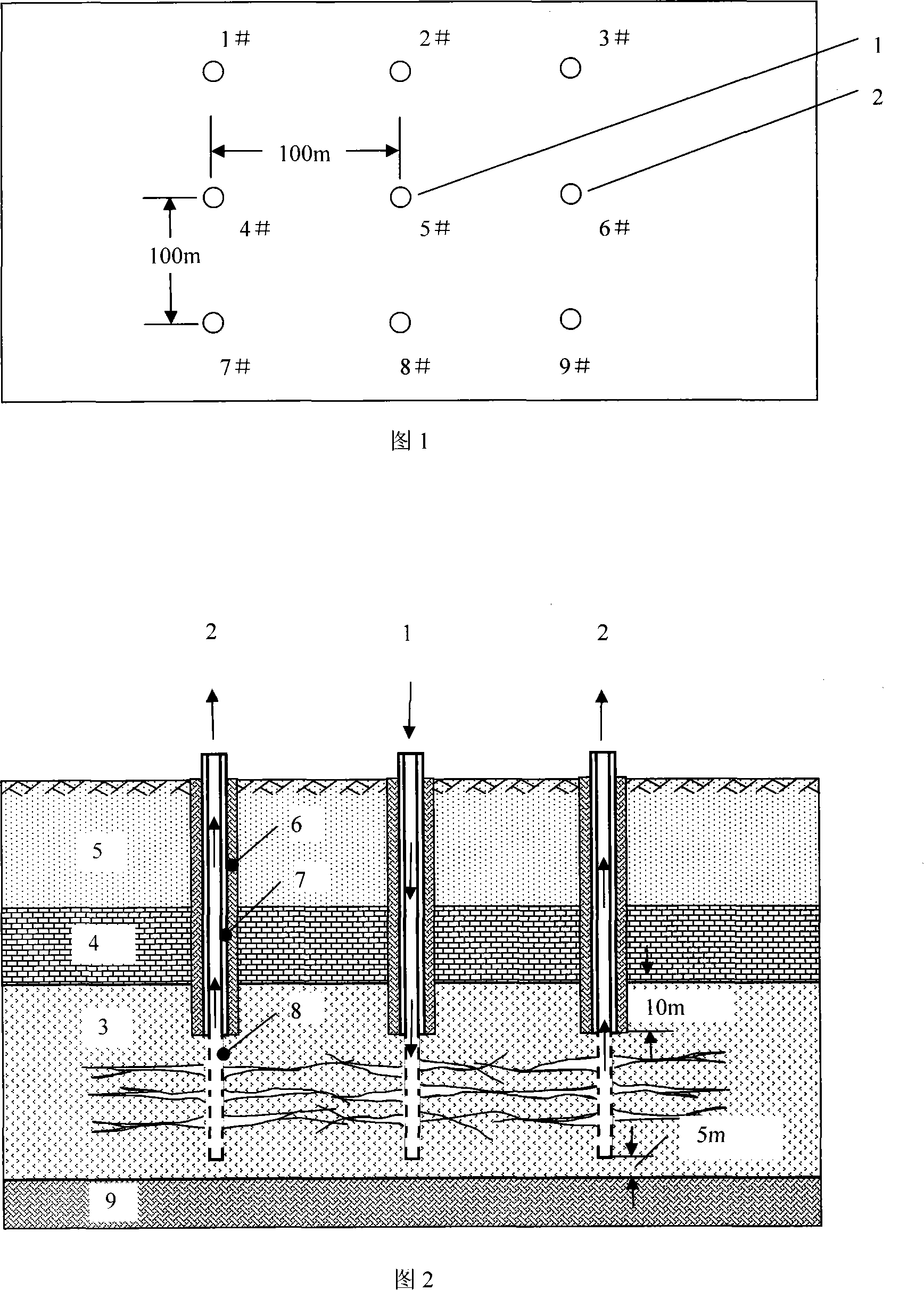

Method for heating oil shale underground in situ

ActiveCN103174406ALower resistanceNo fracking requiredElectric discharge heatingFluid removalElectricityHeating oil

The invention discloses a method for heating oil shale underground in situ. According to the method, shale oil and fuel gas can be obtained from an underground oil shale seam in situ, and the fuel gas can also be obtained from an underground coal seam in situ. Wells are drilled downwardly from the ground surface, and the drilling depth of each well reaches the inside of an operation region of an underground oil shale ore bed. At least two wells are drilled, and electrodes are placed in the wells. Firstly, high-voltage electricity which is sufficient to cause partial discharge of the oil shale ore bed is conducted into the electrodes, and then a plasma channel is formed in the oil shale ore bed and can be subjected to breakdown by the high-voltage electricity; after the resistance of each of two electrode regions is lowered, the two electrodes are used for conducting currents into the plasma channel in the oil shale ore bed; the oil shale ore bed is heated under the resistance heating function of the plasma channel; and released heat is used for realizing thermal cracking and gasification of fixed organic carbon in the oil shale ore bed. Through the method for heating the oil shale underground in situ, the heating speed of an underground ore bed can be increased, hydraulic fracturing does not need to be carried out on a rock stratum, and the use of poisonous conductive materials is avoided at the same time.

Owner:JILIN UNIV

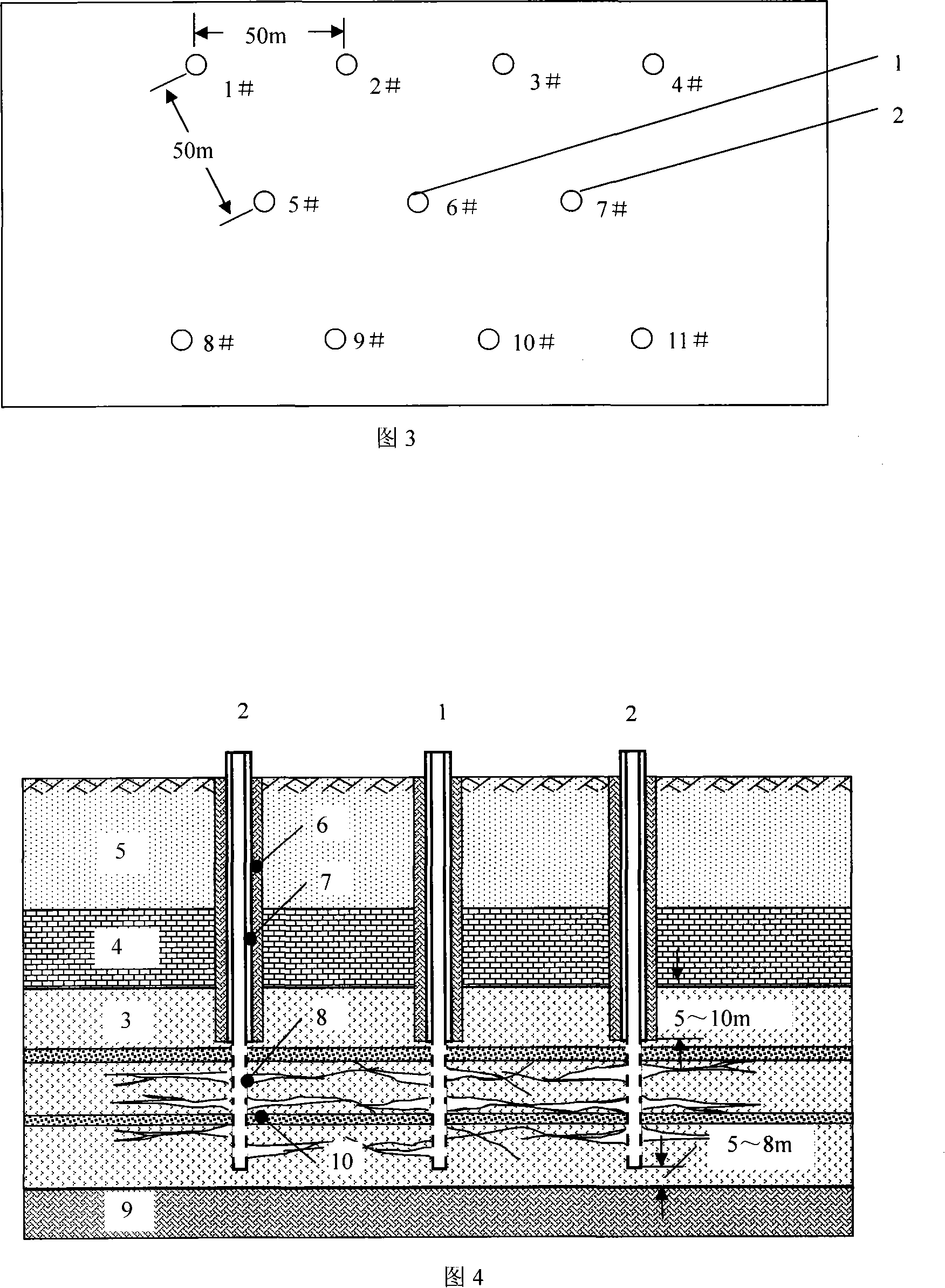

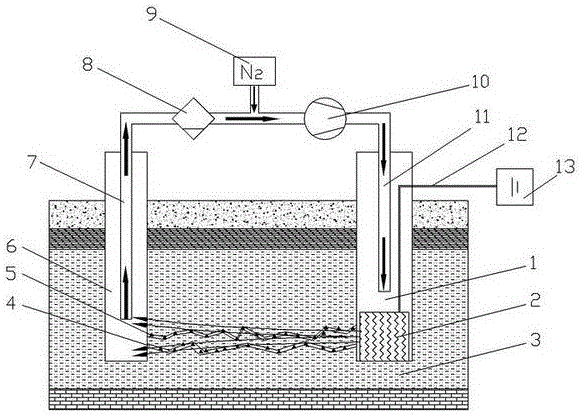

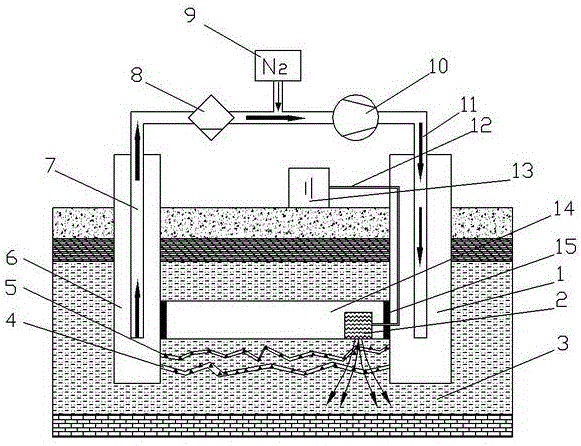

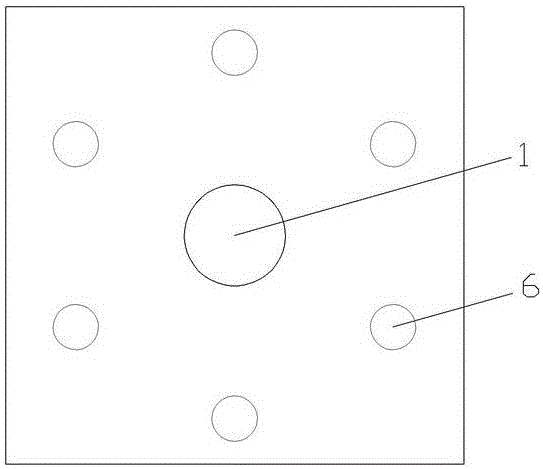

Eddy current heating oil shale underground in-situ mining method

ActiveCN106437667AHeating fastImprove energy utilizationFluid removalInduction current sourcesOil shale gasNitrogen gas

The invention discloses an eddy current heating oil shale underground in-situ mining method. The method comprises the steps that a mining well is drilled from the ground to a target oil shale layer, a propping agent containing ion particles is adopted during fracturing, and the iron particles are pressed into clearances of the oil shale layer; then a gas injection well is drilled again to the target oil shale layer within the fracturing range with the fracturing well as the center; an eddy current effect magnetic field generator is tripped in the well bottom of the gas injection well; nitrogen is introduced into the gas injection well for system internal circulation; the eddy current effect magnetic field generator is started to generate a high-frequency strong magnetic field, the iron particles in the oil shale layer are heated due to the eddy current effect at this moment, and then oil shale is heated to carry out in-situ fracturing on kerogen; nitrogen can carry shale oil and combustible gas and returns to the ground from the mining well, and after oil and the combustible gas are separated through a comprehensive separator, remaining gas is injected into the gas injection well again for circulating. The heating process of the oil shale can be effectively accelerated, the energy utilization rate can be increased, and the heating cost can be reduced.

Owner:JILIN UNIV

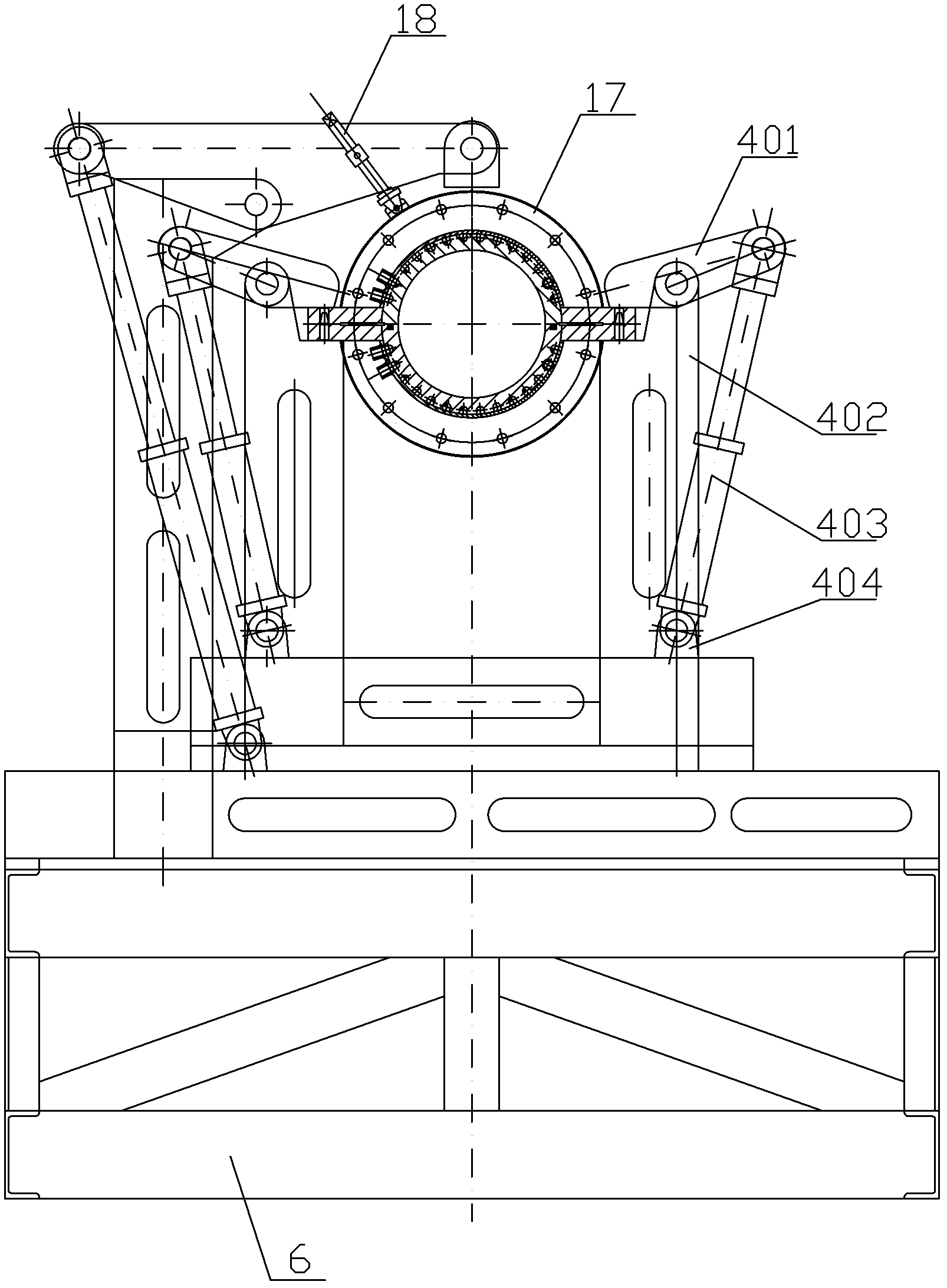

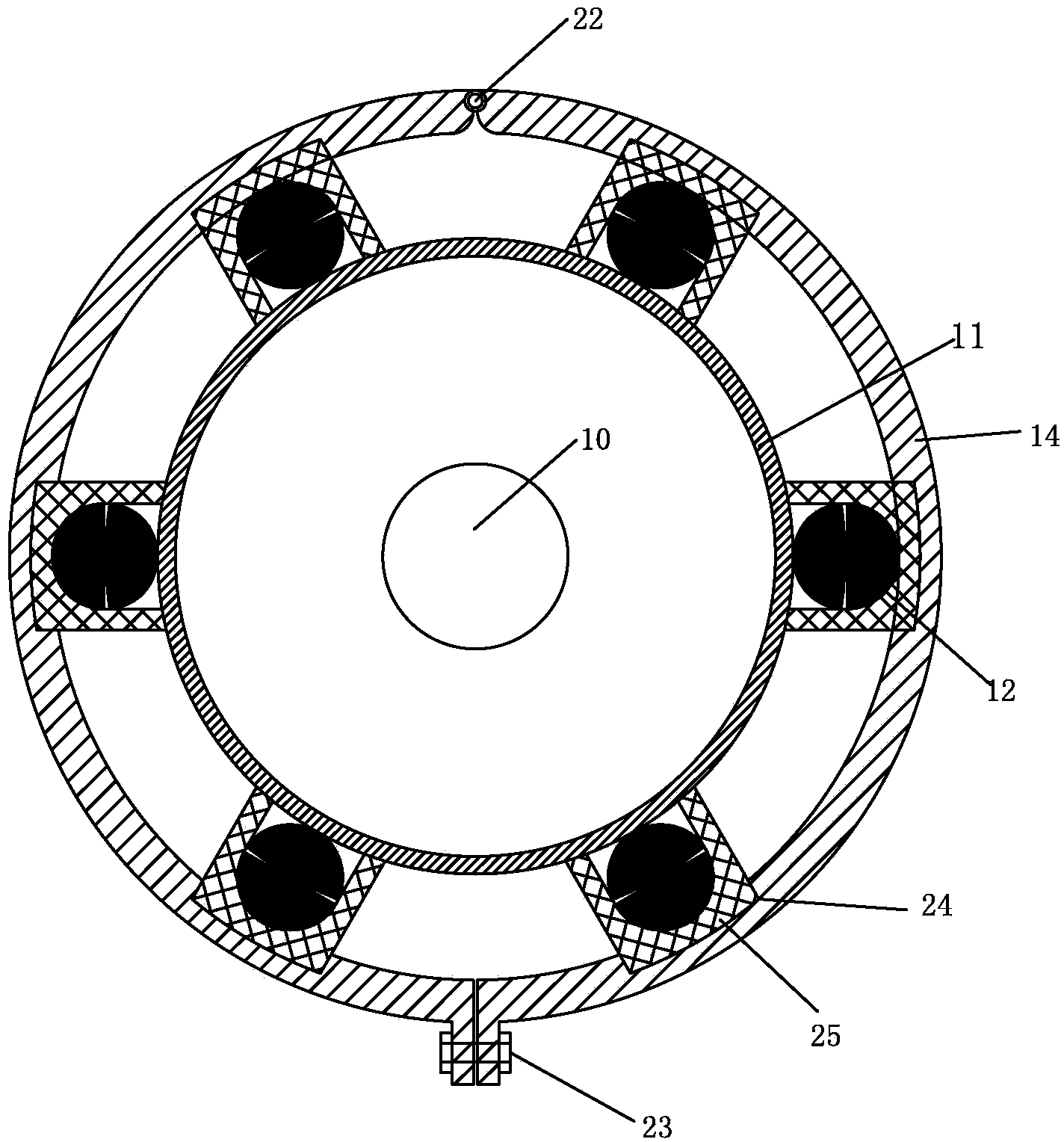

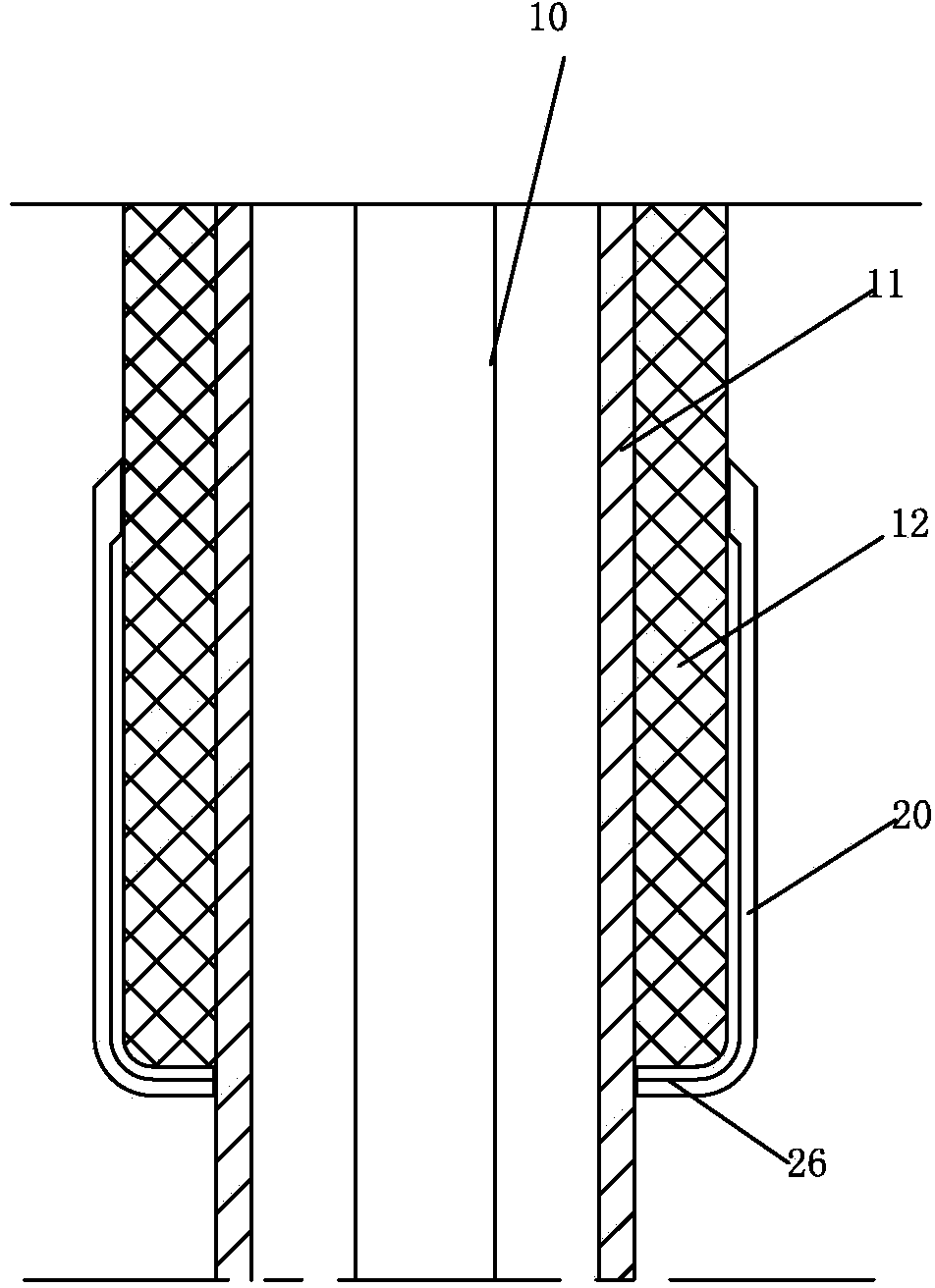

Deep water pipeline composite polyurethane elastomer heat insulation layer casting molding device

The invention discloses a deep water pipeline composite polyurethane elastomer heat insulation layer casting molding device. A subsection machining and integral assembly mode is adopted in a die, heating temperature control devices are arranged corresponding to subsection assemblies in subsections, and heating oil passages are arranged opposite; a positioning structure and a sealing structure arearranged in the parting surface of the die; and the die is provided with a die opening device, a die closing and an inclination device controlled by a hydraulic system. The device realizes mechanicaloperation of casting molding of a product, and has practical structure and strong operability; by adopting subsection machining in the die, the machining difficulty and the machining cost are reduced, and the machining precision and the machining quality are improved; and meanwhile, three sets of heating devices are used corresponding to three sections of assemblies, so that the heating temperature difference is reduced, the quality of the cast product is improved, automatic control of the temperature of the casting die can be realized, the heat insulation time of the polyurethane heat insulation layer in the die is shortened, and the service efficiency of the casting die is improved.

Owner:CHINA NAT OFFSHORE OIL CORP +2

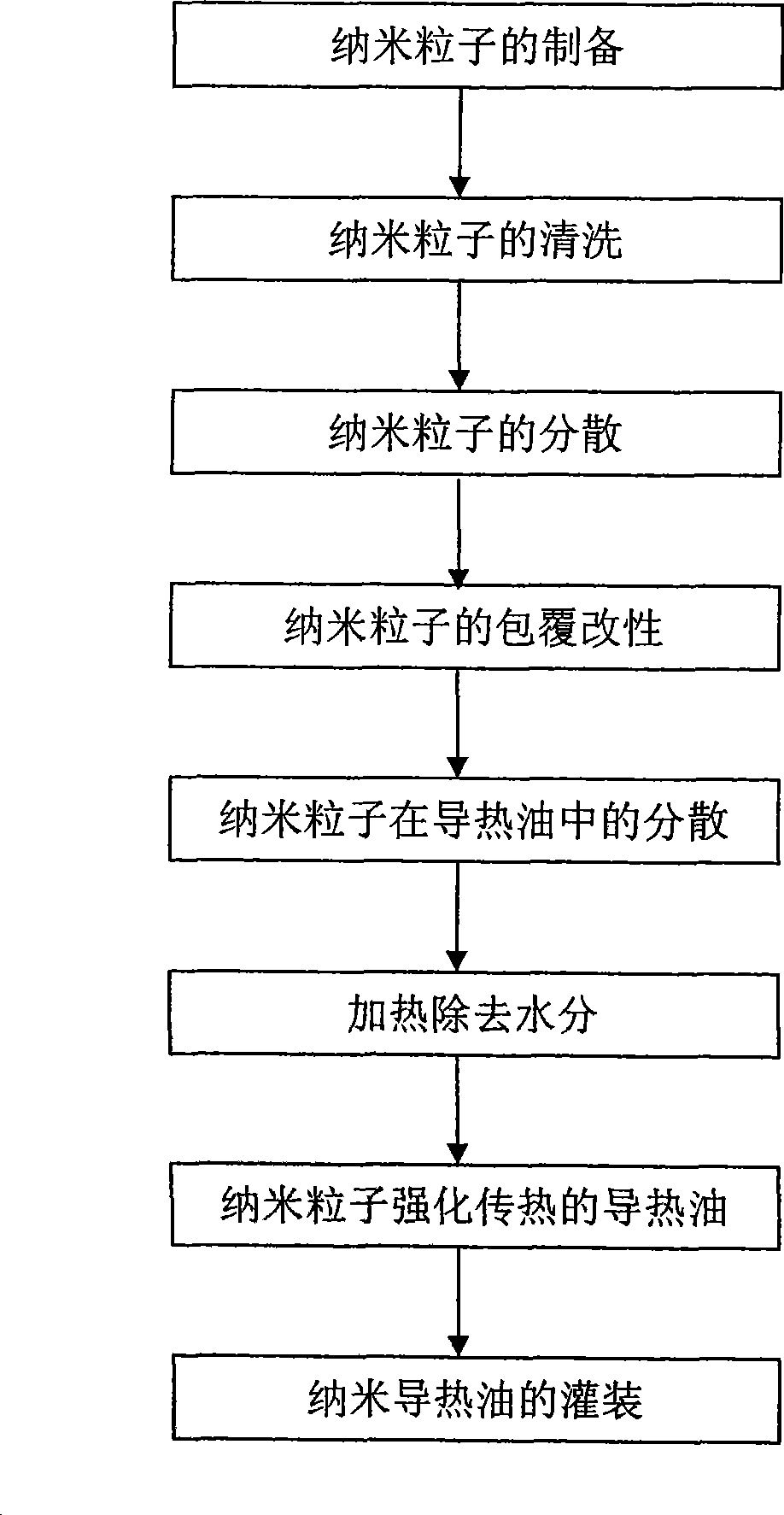

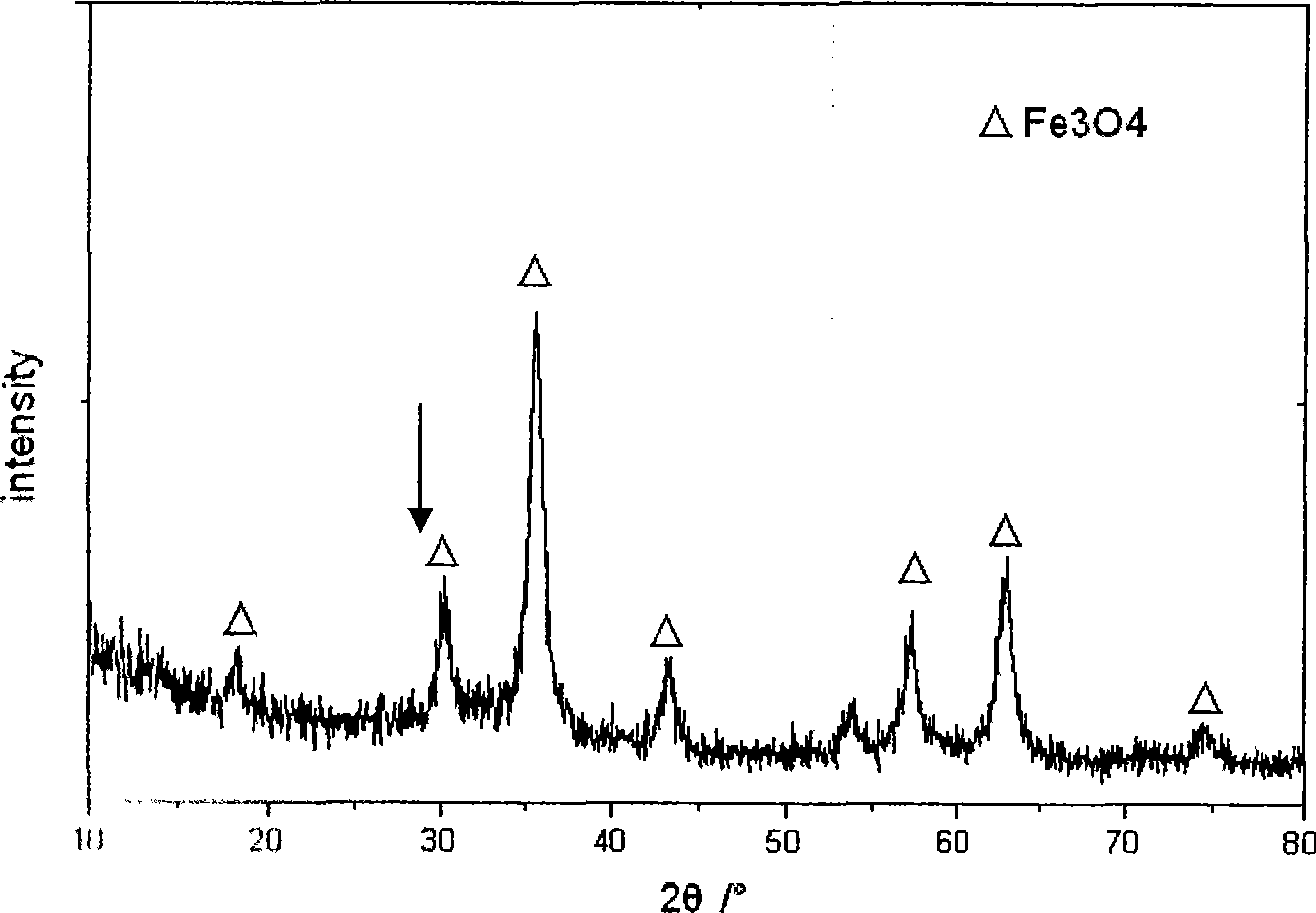

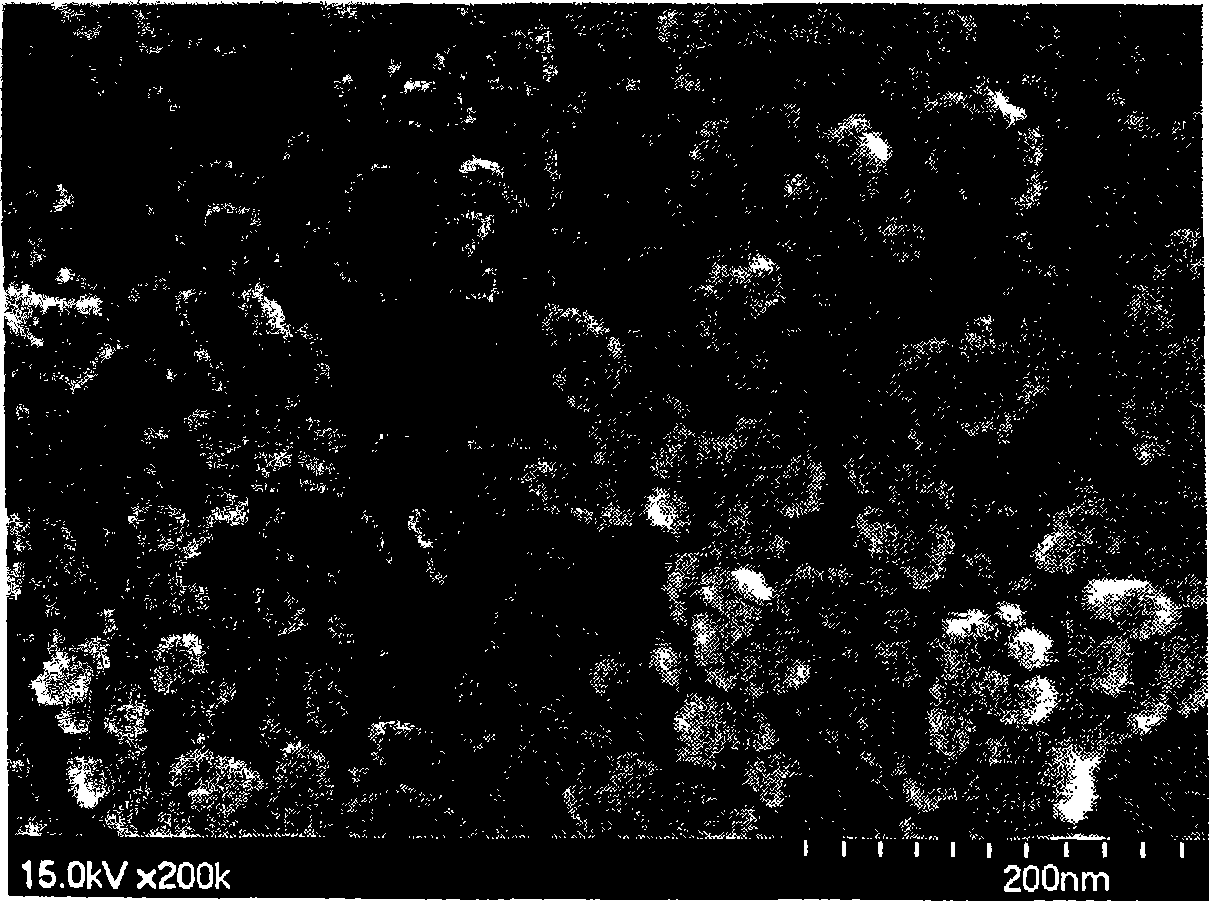

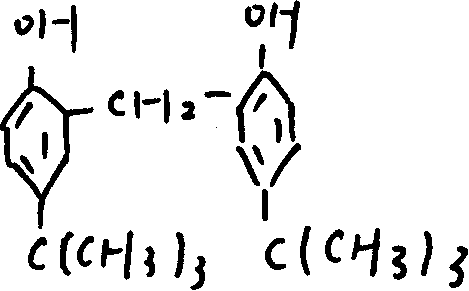

Preparation of heat conducting oil with nano-particle for strengthening heat transfer and use thereof in electric oil-filled radiator

InactiveCN101440273AReduce heating time for electric heatingReduce power consumptionHeat-exchange elementsHeating oilHeat conducting

The invention discloses a method for preparing conduction oil with strengthened heat transfer by adopting nano-particles and application of the method to electrical heating oil lights. The preparation method comprises the steps of the preparation of the nano-particles, the washing of the nano-particles, the dispersion of the nano-particles, coating modification of the nano-particles, the dispersion of the nano-particles in conduction oil, moisture removal by heating, and the filling and storage of nanometer conduction oil, the prepared conduction oil is dispersed with the nano-particles, and the nano-particles are subjected to surface coating modification through an oleophilicsurfactant to accelerate the nano-particles to be dispersedly suspended in the conduction oil. The thermal coefficient of the conduction oil is remarkably improved, the conduction oil still has steady suspension after two years of storage and is uniform and steady novel heat transfer medium with high thermal coefficient, the density of the conduction oil reaches between 0.85 and 1.0g / cm<3>, the open flash point is more than or equal to 180 DEG C; the conduction oil can improve the rate of temperature increase, reduce the electrified heating and temperature increase time of the oil lights, and play roles in power conservation and material conservation when applied to the electrical heating oil lights; and practice proves that the temperature increase rates of the electrical heating oil lights with the application of the conduction oil are improved by more than 15 percent than those of common oil lights.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

High temperature steam and oil resistant fluororubber pad

ActiveCN1702112AGuaranteed low temperature resistanceMeet the use requirementsHeating oilEngineering

The invention relates to a thermostable viton gasket, which is mainly used as sealing element in plate exchanger using high temperature steam and heating oil. The viton gasket comprises 70-75 wt% of F26 ready-mixed glue and 25-30 wt% of HNBR ready-mixed glue. Said F26 ready-mixed glue comprises 100 wt% of 26-style rubber, 2-2.2 wt% of hexaflurate bisphenol A and so on. HNBR ready-mixed glue comprises 100 wt% of hydrogenated rubber, 48-52 wt% of black pigment and so on. The invention can resist high temperature steam and oil.

Owner:蒋惠成

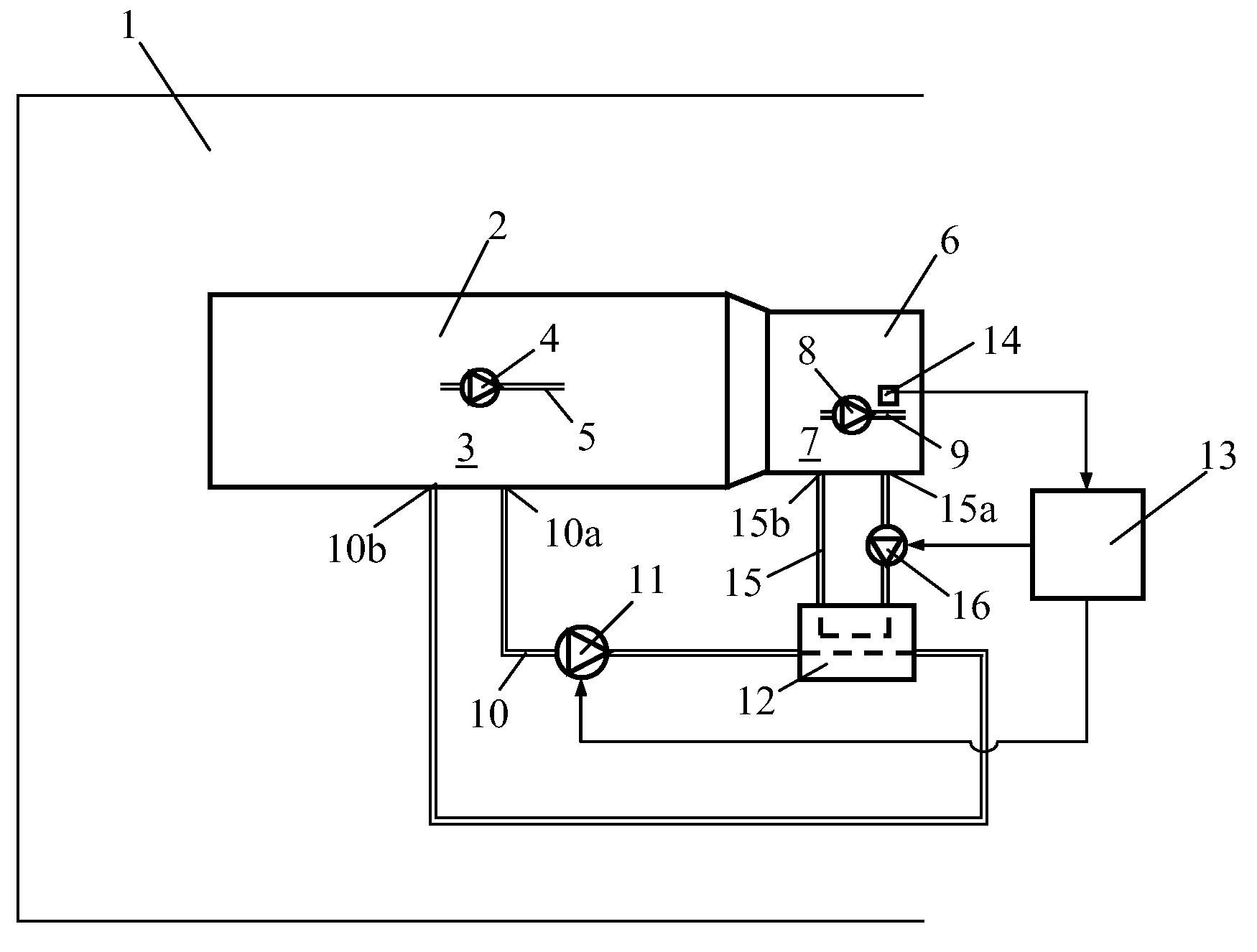

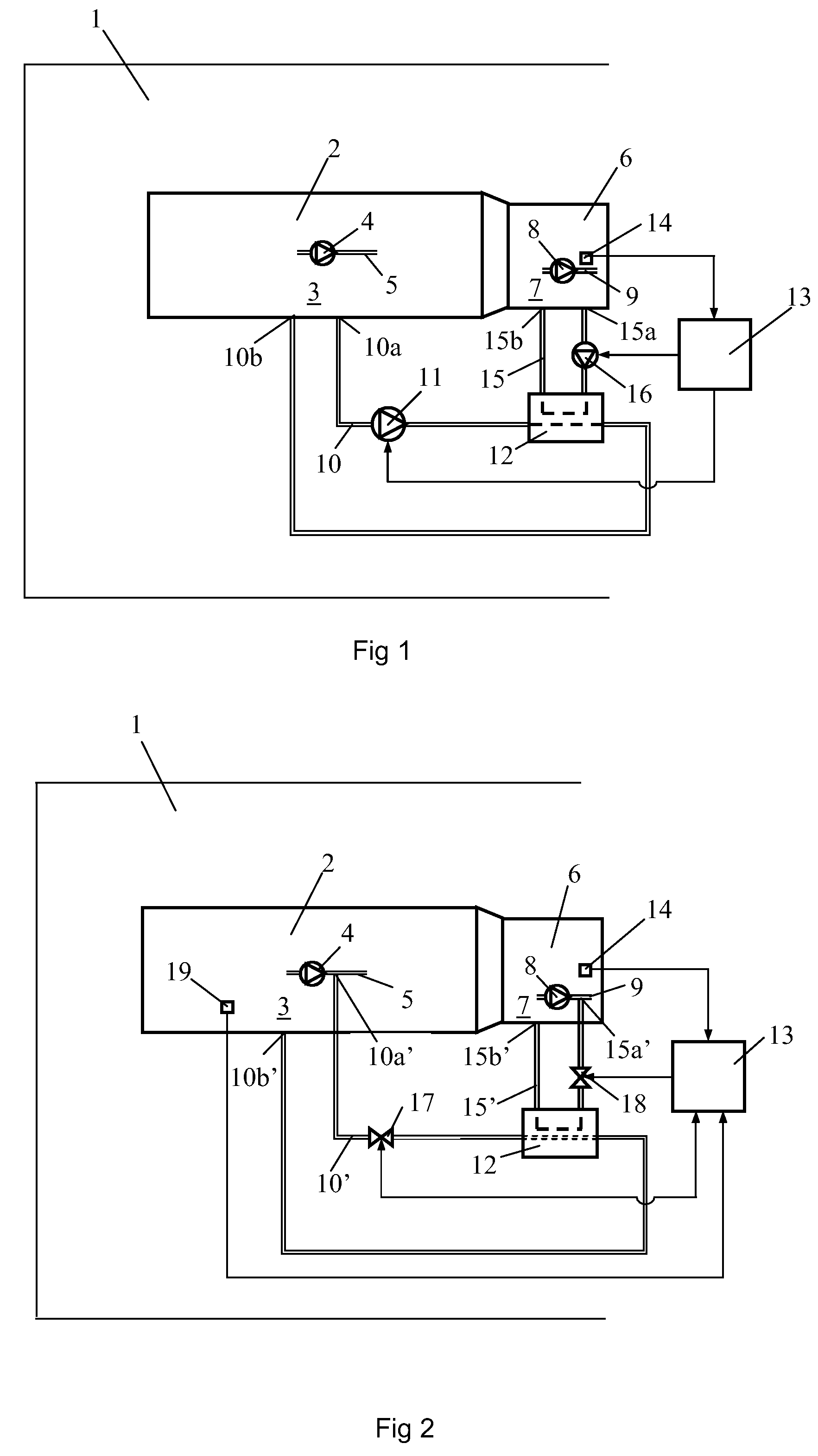

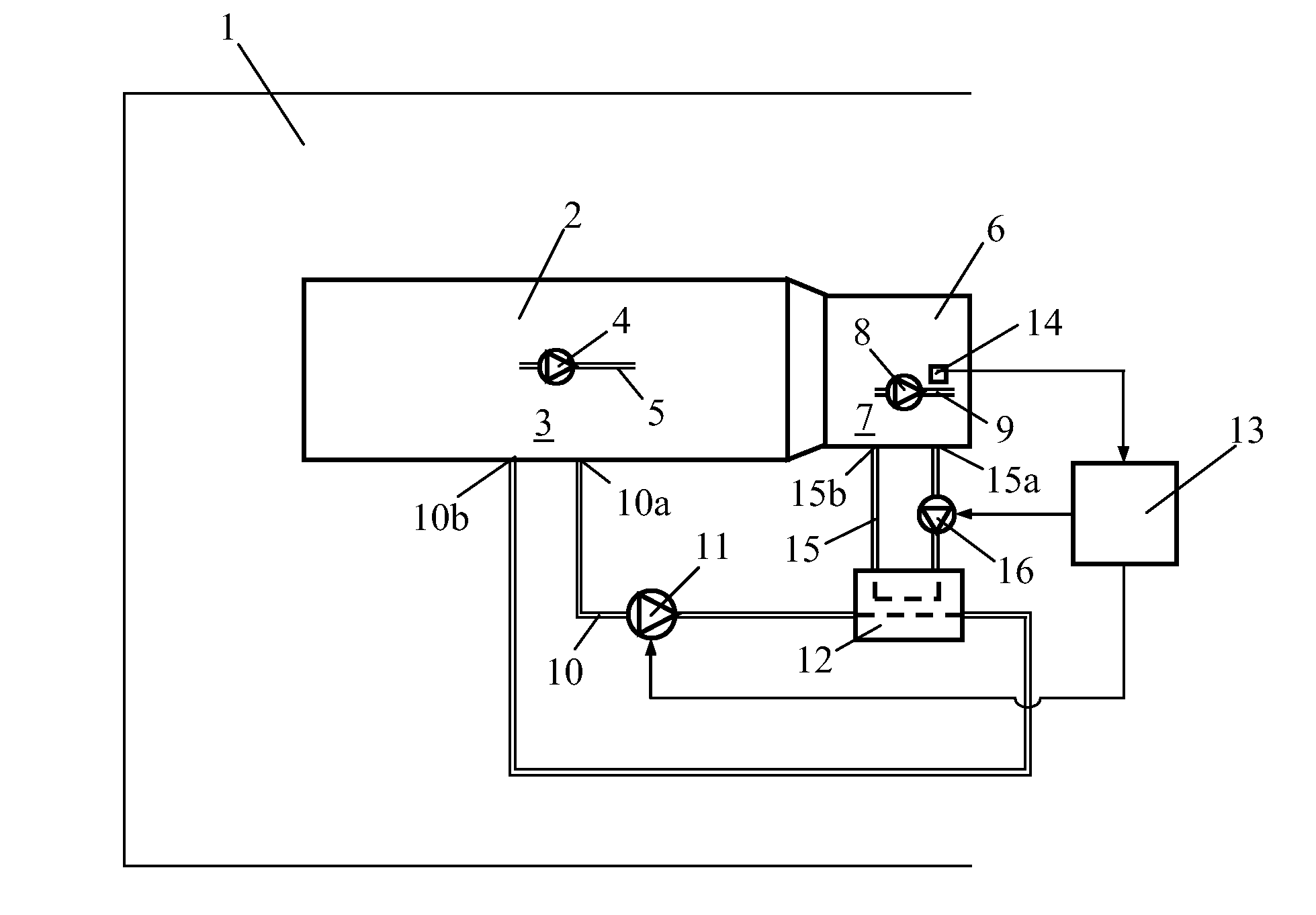

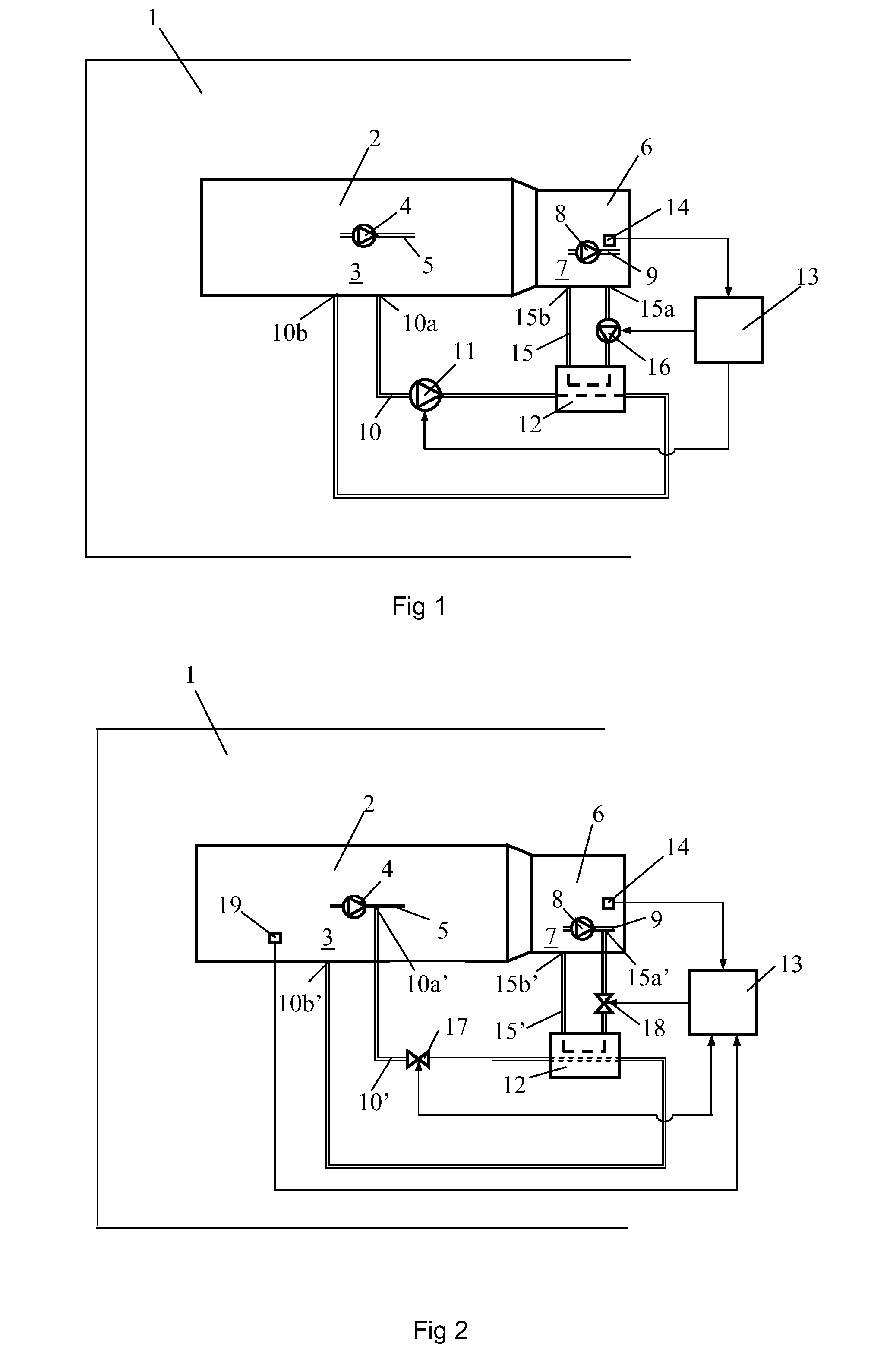

Arrangement for heating oil in a gearbox

InactiveUS8100106B2Reduce fuel consumptionHeating up fastAir-treating devicesLubrication of auxillariesHeating oilCombustion

An arrangement for warming the oil in a gearbox in a vehicle powered by a combustion engine. A first pipe system with a first flow device which makes possible circulation of oil from the combustion engine through a heat exchanger. A second pipe system with a second flow device makes possible circulation of oil from the gearbox through the heat exchanger. A control device controls the flow devices so that flow of oil through the heat exchanger is obtained in situations in which the oil in the gearbox is at a too low temperature with respect to a desired temperature. The motor oil in the combustion engine can thus be used for heating the oil in the gearbox during cold starts of the combustion engine.

Owner:SCANIA CV AB

Arrangement for heating oil in a gearbox

InactiveUS20100000475A1Reduce fuel consumptionHeating up fastLubrication of auxillariesAir coolingHeating oilCombustion

An arrangement for warming the oil in a gearbox in a vehicle powered by a combustion engine. A first pipe system with a first flow device which makes possible circulation of oil from the combustion engine through a heat exchanger. A second pipe system with a second flow device makes possible circulation of oil from the gearbox through the heat exchanger. A control device controls the flow devices so that flow of oil through the heat exchanger is obtained in situations in which the oil in the gearbox is at a too low temperature with respect to a desired temperature. The motor oil in the combustion engine can thus be used for heating the oil in the gearbox during cold starts of the combustion engine.

Owner:SCANIA CV AB

Mixed alcohol fuels for internal combustion engines, furnaces, boilers, kilns and gasifiers

Mixed alcohol formulas can be used as a fuel additive in gasoline, diesel, jet fuel, aviation gasoline, heating oil, bunker oil, coal, petroleum coke or as a neat fuel in and of itself. The mixed alcohols formulations can contain C1-C5 alcohols, or in the alternative, C1-C8 alcohols or higher C1-C10 alcohols in order to boost energy content. The C1-C5 mixed alcohols contain more ethanol than methanol with declining amounts of propanol, butanol and pentanol. C1-C8 mixed alcohols contain the same, with declining amounts of hexanol, heptanol and octanol. C1-C10 mixed alcohols contain the same, with declining amounts of nananol and decanol. Synthetically produced mixed alcohol formulas feature higher octane and energy densities than either MTBE or fermented grain ethanol; more stable Reid Vapor Pressure blending characteristics; and increased soluablizing effects on condensate water. The primary benefits of mixed alcohols are increased combustion efficiencies, reduced emissions profiles and low production costs.

Owner:STANDARD ALCOHOL COMPANY OF AMERICA

Process for producing water soluble capsanthin pigment

The process of producing water soluble capsanthin pigment includes heating oil soluble capsanthin pigment to 45 deg.c, adding hydrating agent preheated to 45 deg.c, stirring at 45 deg.c for 1 hr, and lowering the temperature to below 30 deg.c to obtain water soluble capsanthin pigment. The said hydrating agent consists of sucrose ester and Tween-80. The water soluble capsanthin pigment has high stability and may be stored at room temperature or low temperature without turbidity and floc separation.

Owner:晨光生物科技集团天津有限公司

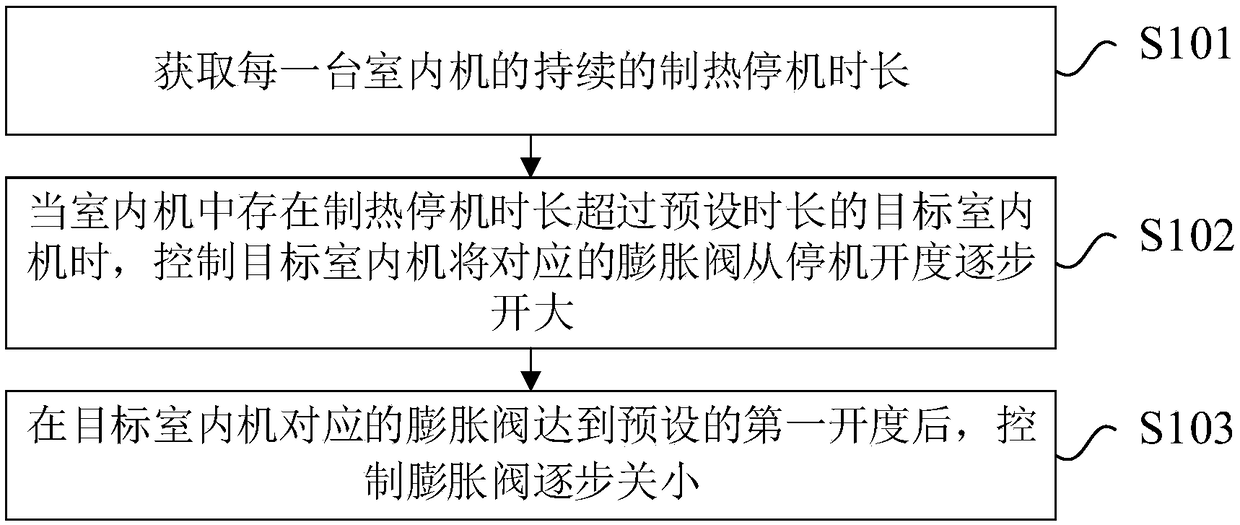

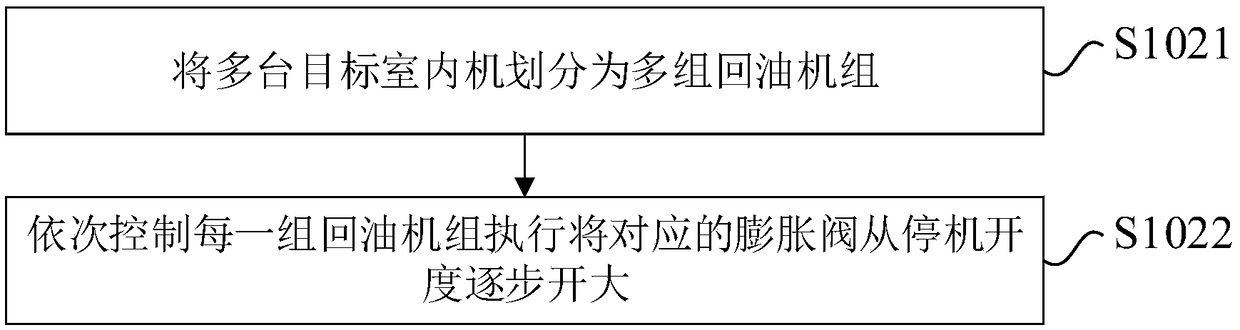

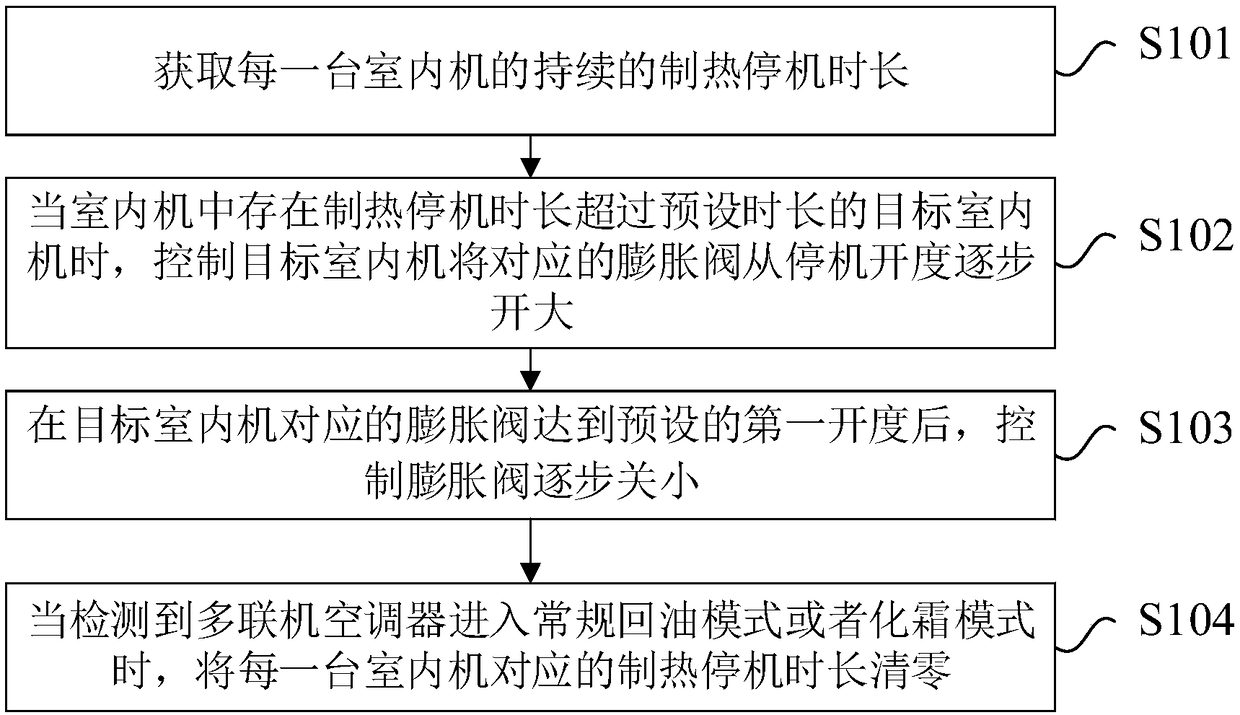

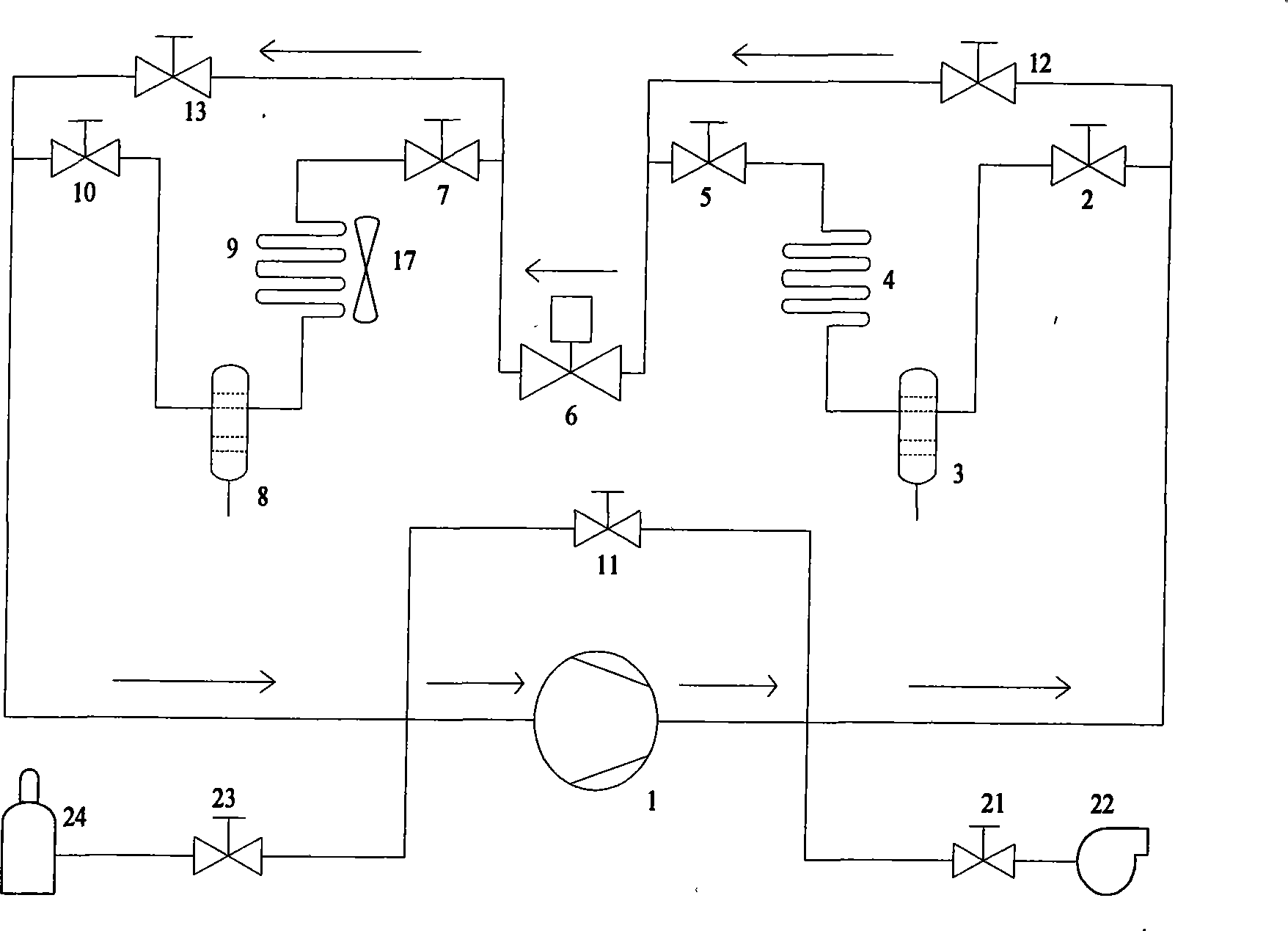

Multi-split heating oil return control method and multi-split air conditioner

ActiveCN109357440AAvoid oil shortageDoes not affect working statusCompressorMechanical apparatusHeating oilProcess engineering

The invention provides a multi-split heating oil return control method and a multi-split air conditioner. The multi-split heating oil return control method comprises the steps that the continuous heating halt duration of each indoor unit is obtained; when the target indoor unit with the heating halt duration exceeding the preset time duration exists in the indoor units, the target indoor unit is controlled to gradually increasing the opening of a corresponding expansion valve from the halt opening; and after the expansion valve corresponding to the target indoor unit reaches the preset first opening, the opening of the expansion valve is controlled to be gradually decreased. By means of the multi-split heating oil return control method, in the multi-split air conditioner heating operationprocess, oil return can be achieved in time in a targeted mode, and the problem that a compressor is lack of oil is avoided; the pressure relief phenomenon is effectively prevented from being producedin the oil return process, and the operation effects of other indoor units operated normally are ensured.

Owner:NINGBO AUX ELECTRIC +1

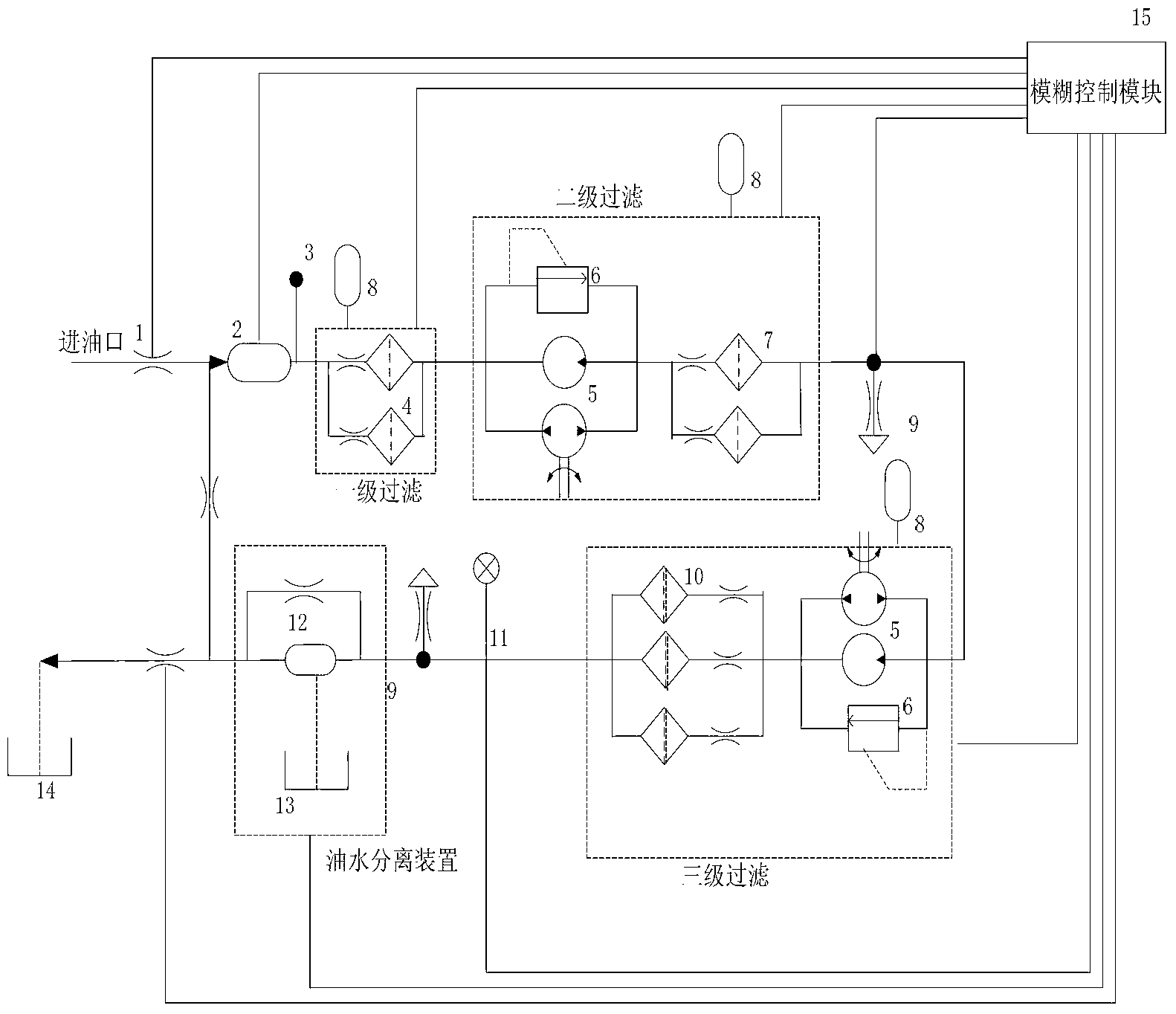

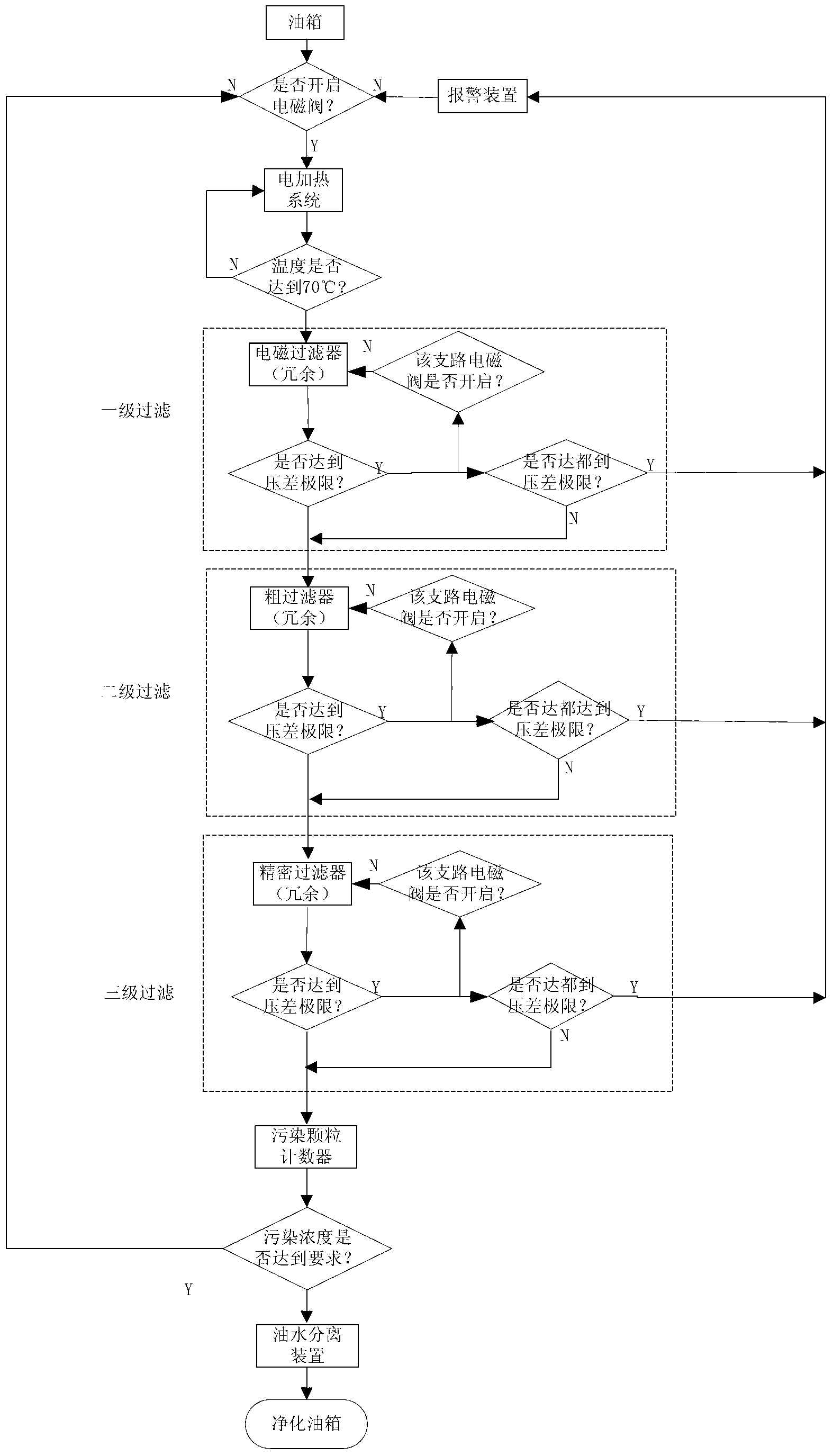

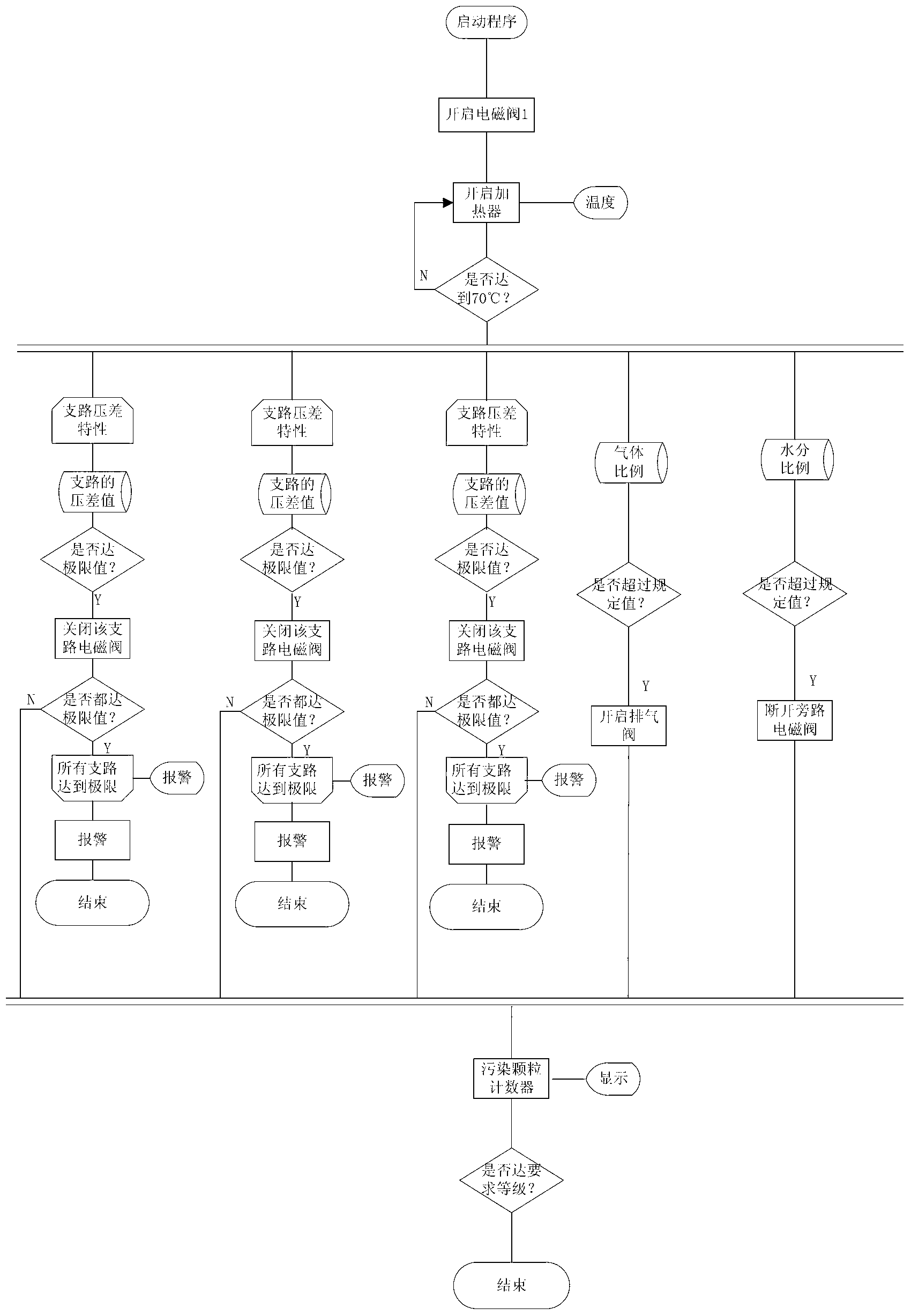

Method for filtering and purifying hydraulic oil

InactiveCN103321988AImprove reliabilityHigh reliabilityFluid-pressure actuator componentsExhaust valveSolenoid valve

A method for filtering and purifying hydraulic oil comprises the steps of (1) using an electrical heating system for heating oil to 60 DEG C; (2) performing primary filtering through a first filtering device which comprises novel high-gradient electromagnetic filters connected in parallel so as to filter ferromagnetic corrosion products in the oil and macromolecules generated by oxidation during usage of the hydraulic oil; (3) performing secondary filtering through a second filtering device to remove large solid particles; (4) subjecting the oil to tertiary filtering through a third filtering device which comprises common parallelly-connected filters high in filtering accuracy to form redundancies; (5) opening exhaust valves which are mounted after filtering of all stages to remove gas impurities in the oil and bubbles generated during filtering; (6) removing moisture in the oil through an oil-water separation system; (7) monitoring the oil cleanliness class in real time through a contamination particle counter, and closing a solenoid valve of an oil return pipe when the purification class requirement is reached.

Owner:BEIHANG UNIV

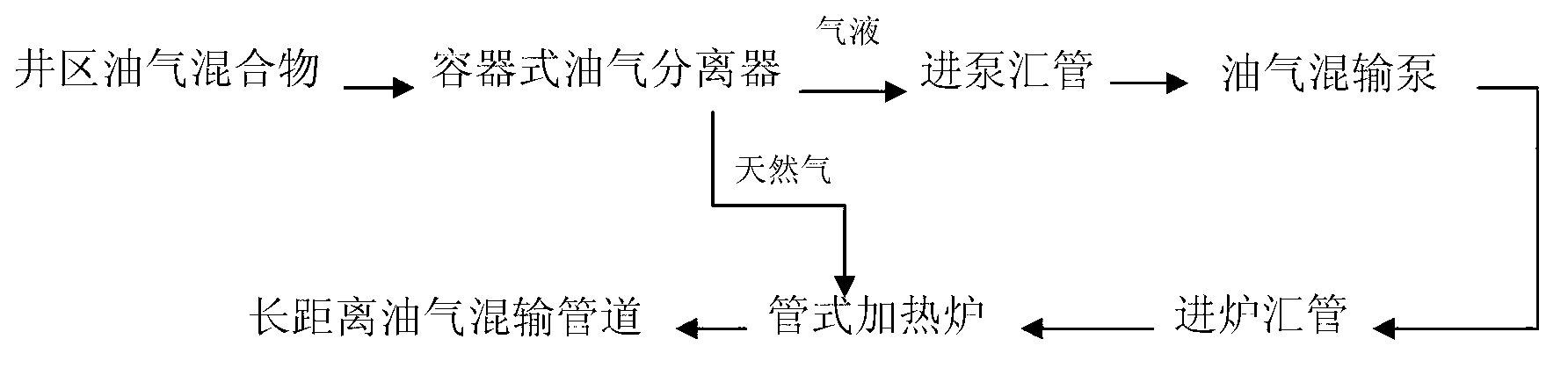

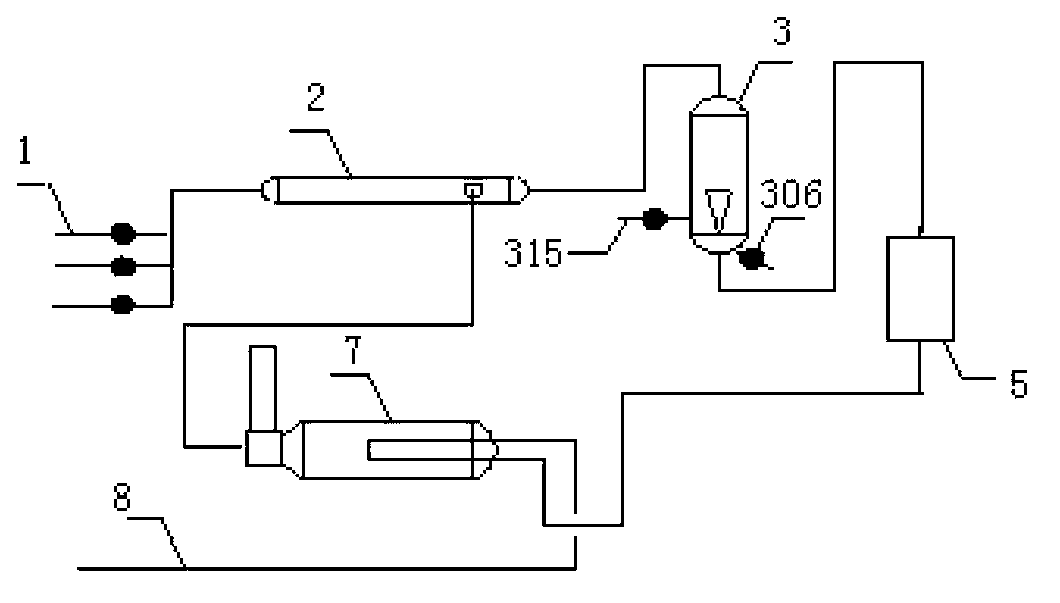

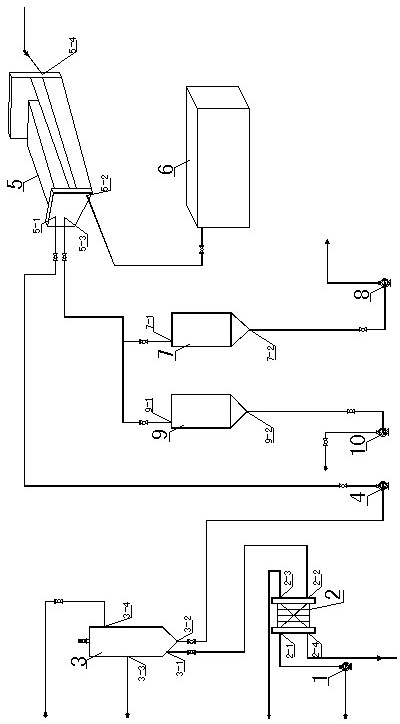

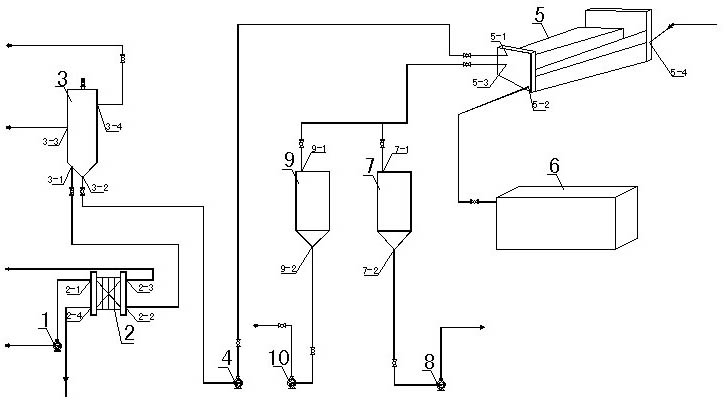

Pressurizing heating oil gas mixing transportation system and method

The invention relates to a pressurizing heating oil gas mixing transportation system and method. The system comprises an in-station valve group, a fuel gas separator, an oil gas mixing transportation pump, a pipe type heating furnace and a long-distance oil gas mixing transportation pipe which are sequentially communicated through a pipe. A multi-phase shock excitation sand remover, a multi-phase mixing transportation pump group inlet uniform flow device and a gas liquid separation flow divider. Gas and liquid mixture from an oil field well area enters the pipe type fuel gas separator, a part of natural gas is separated to serve as fuel of the heating furnace, surplus gas liquid mixture enters the multi-phase shock excitation sand remover to be subjected to sand removing, enters the multi-phase mixing transportation pump group inlet uniform flow device to be subjected to uniform flow distribution and is delivered to the gas liquid separation flow divider through the oil gas mixing transportation pump, and the separated liquid enters the pipe type heating furnace to be heated and is mixed with the separated gas to enter the long-distance oil gas mixing transportation pipe. Safe stable high-efficiency operation of the system is guaranteed, service life of devices is prolonged, and project investment, energy consumption, operation maintenance and operation cost are reduced.

Owner:PETROCHINA CO LTD +2

Oyster product and preparation method thereof

InactiveCN1543869ASolve the inconvenience of eatingAdapt to needsFood preparationHeating oilChemistry

A process for preparing oyster product comprises the steps of, (1) beating oyster meat, (2) shredding the processed vegetable into pulp, mixing the oyster pulp with the vegetable pulp, adding in seasoning, mixing homogeneously into size mixture, (3) heating oil, charging seasoning and the size mixture and frying.

Owner:MARICULTURE INST OF SHANDONG PROVINCE

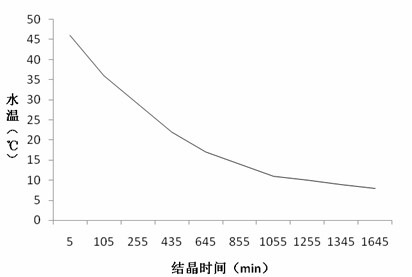

Oil dewaxing process and device

InactiveCN102433220AReduce lossNo pollution in the processFatty substance recovery/refiningFatty-oils/fats refiningWaxOil and grease

The invention discloses an oil dewaxing process and an oil dewaxing device. The process comprises: heating oil to be dewaxed till the wax is molten completely, transferring the oil to a crystallizing tank, and subjecting the oil to crystallization and crystal growing according to preset crystallization menu in the crystallization tank; delivering the crystallized oil into a membrane filter press, filtering, transferring the separated dewaxed oil into a dewaxed oil tank, and thus, completing dewaxing. The dewaxing device comprises the crystallization tank, wherein the crystallization tank is connected with the membrane filter press through a feeding pump; and the discharging port of the membrane filter press is connected with the dewaxed oil tank. Compared with the conventional dewaxing process, the process and the device have the advantages that: the need of any aid filtering agent is obviated, so the production cost is effectively reduced; the oil product is natural and environment-friendly, and the loss of oil is low; by wax by product is pure, does not contain any aid filtering agent, can be directly used in industrial production of edible wax, avoids any environment pollution and requires little equipment investment; and the automation degree of the device is high, and the device is more suitable for large-scale industrial production.

Owner:郑州远洋油脂工程技术有限公司

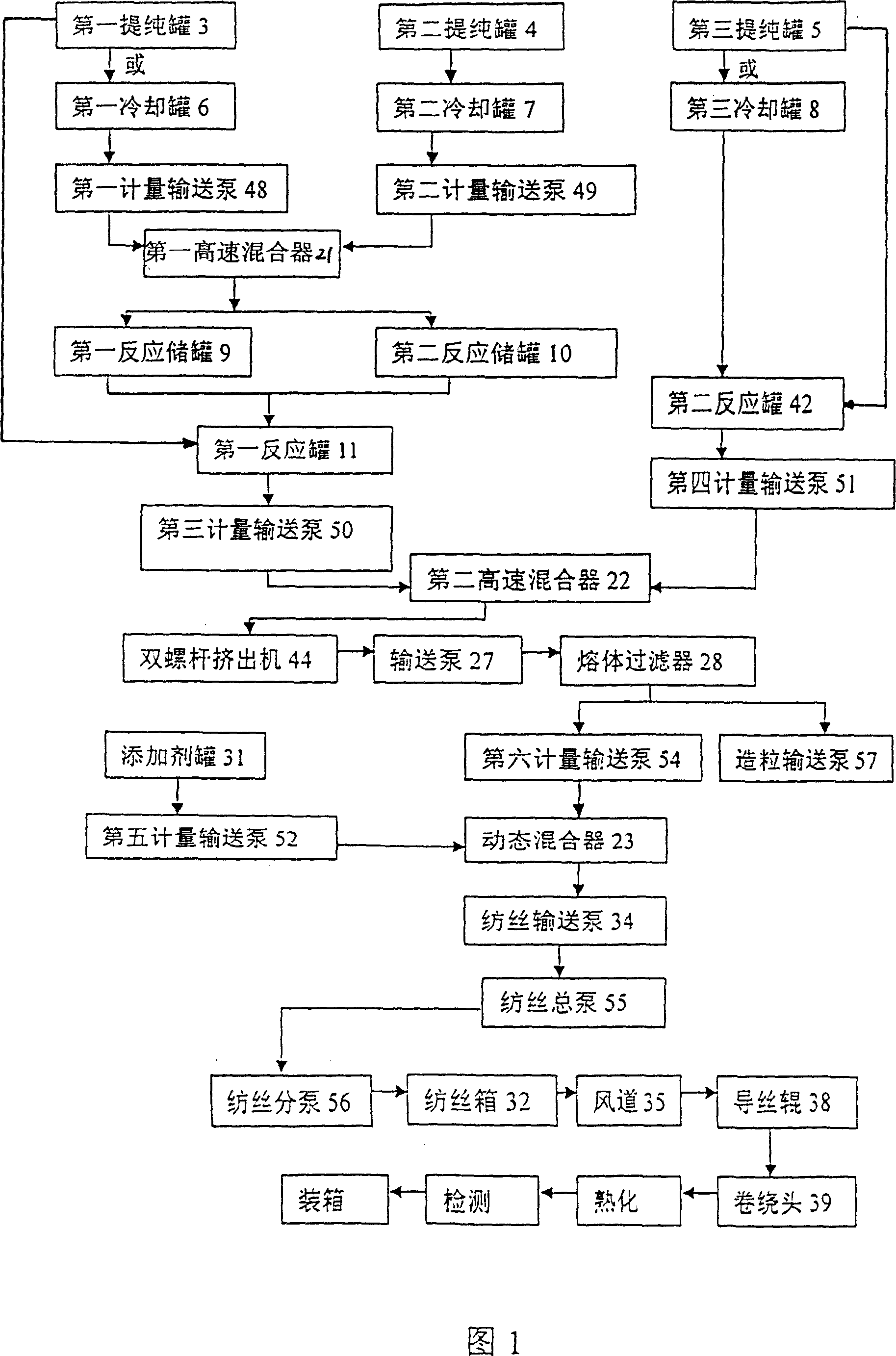

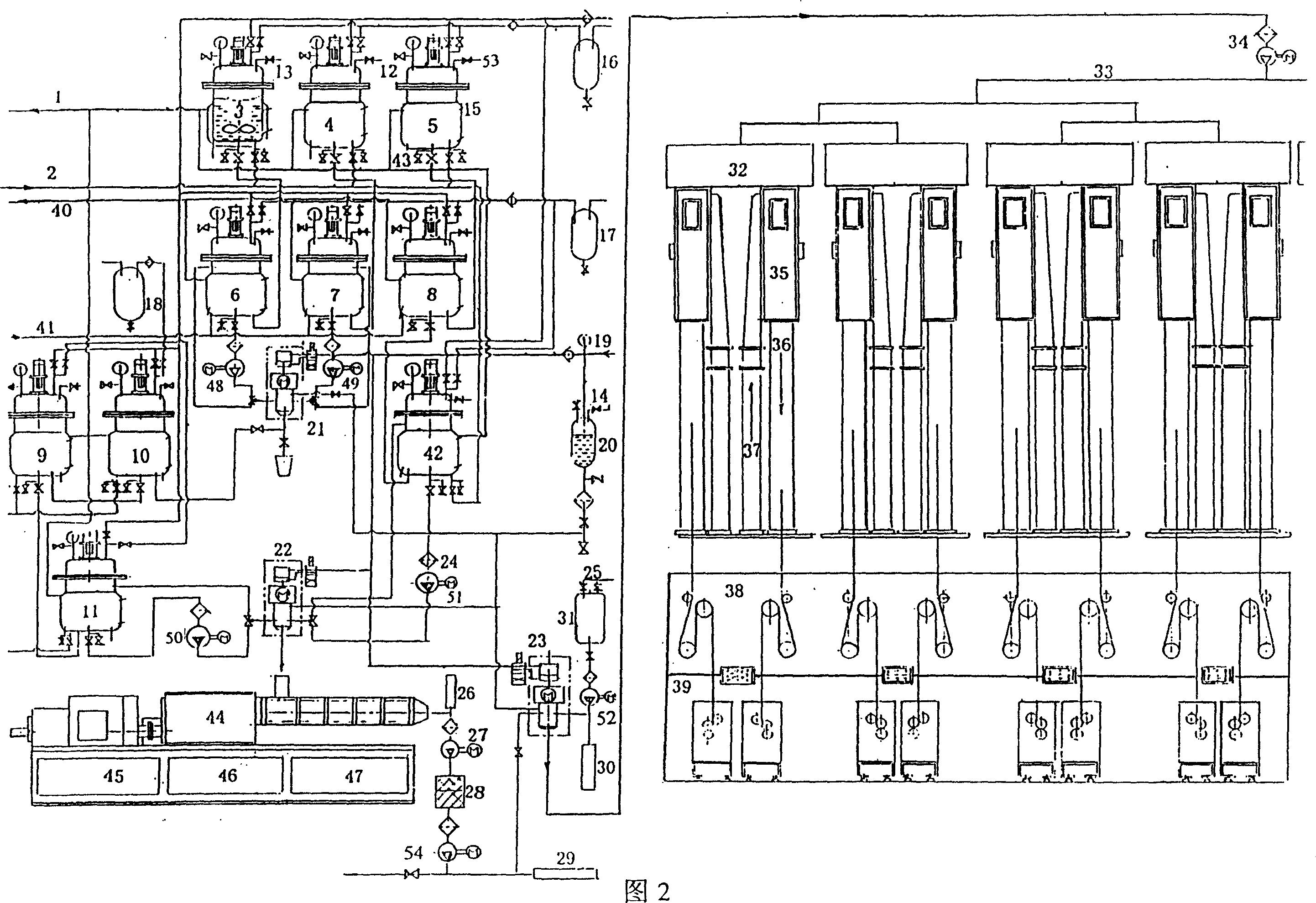

Method of fusion spinning fire resistant special type elastic spandex fiber and producing device thereof

InactiveCN1924123AImprove heat resistanceHigh elongationMonocomponent polyurethanes artificial filamentFilament forming substance formingState of artHeating oil

This invention relates to one method and device for melt straight pin against high temperature of special spandex, which comprises the following steps: original materials weight laying; loading voltage with materials; heating oil; metering, mixing, reacting and extruding; mixing by melting. This invention has advantages of low production cost with about half of current one and two thirds energy consumption than current one while it improves pad by 15 percentage and anti-heat water by 24 percentage and spring reset by 8 percentage.

Owner:江苏省产业技术研究院

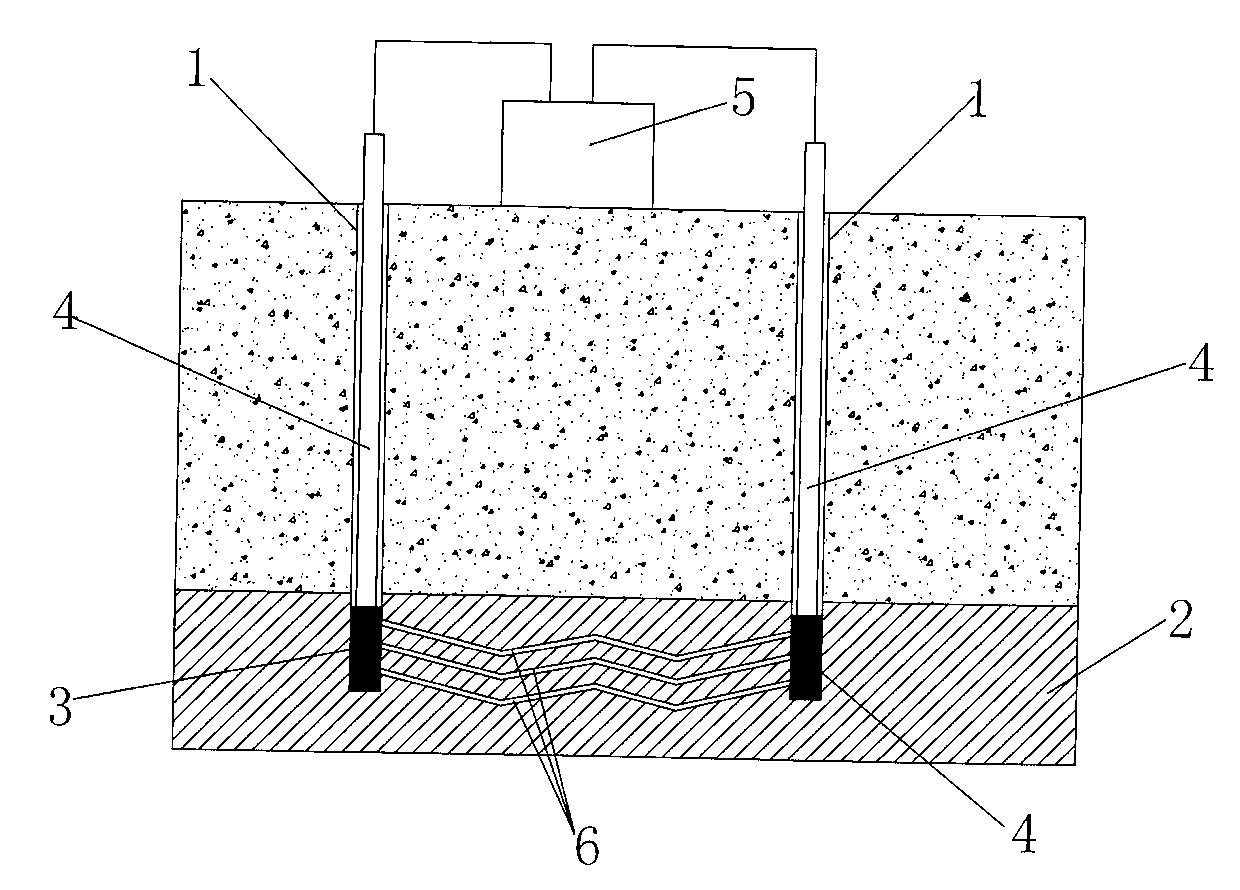

Oil layer electrical heating oil extracting device and using method thereof

The invention discloses an oil layer electrical heating oil extracting device. The oil layer electrical heating oil extracting device comprises a special transformer, a control cabinet, an input cable used for connecting the special transformer and the control cabinet, an output cable, an oil pipe used for outputting thickened oil and a hollow screw pump. A plurality of steel armor heating cables are tightly fixed on the outer wall face of an oil conveying pipe through a plurality of cable clamps and are evenly distributed on the periphery of the oil pipe, and the ends, inside a pumping well, of the steel armor heating cables are connected through a heat tracing cable clamp to form a closed loop.

Owner:LIAONING HUAFU PETROLEUM HIGH TECH

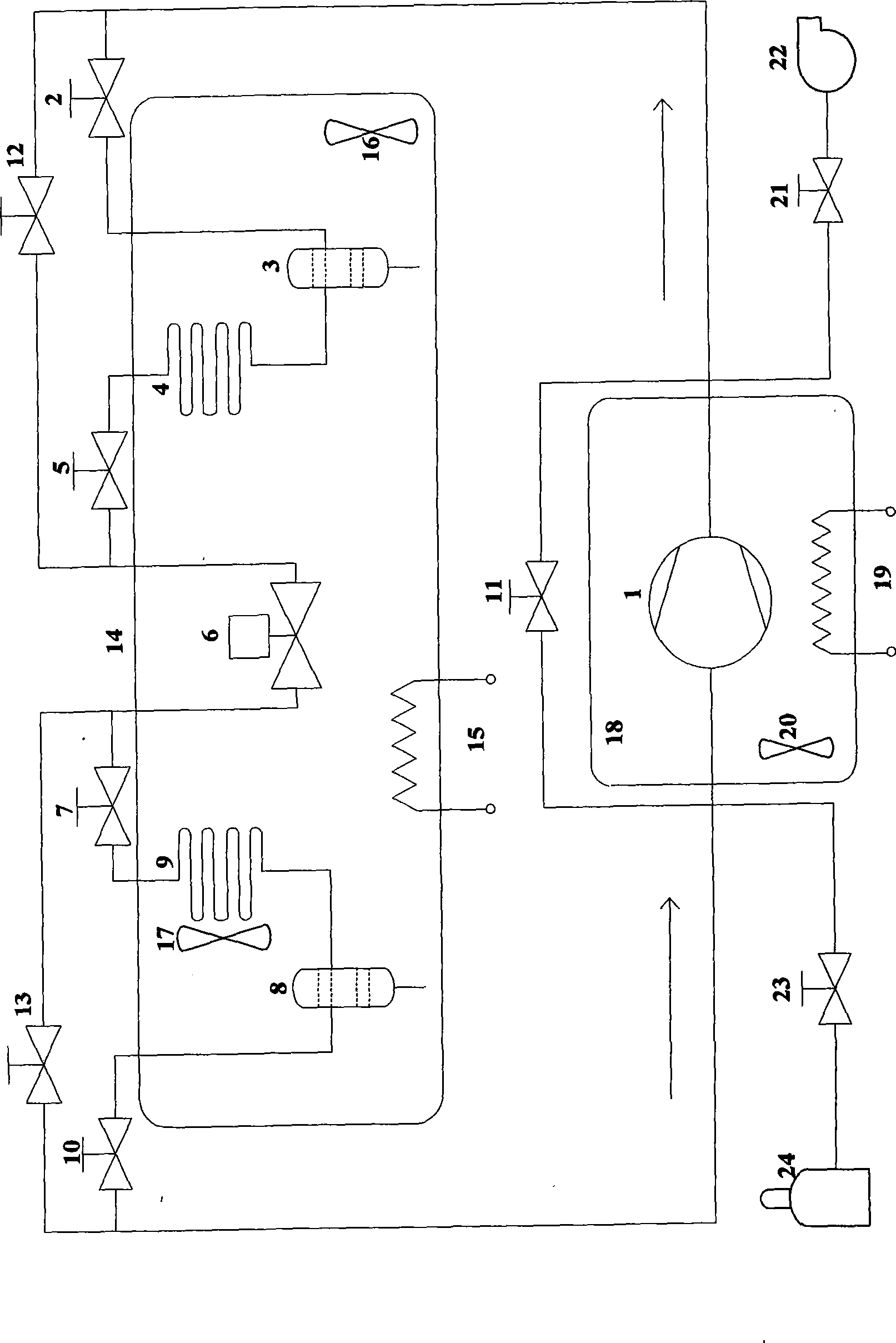

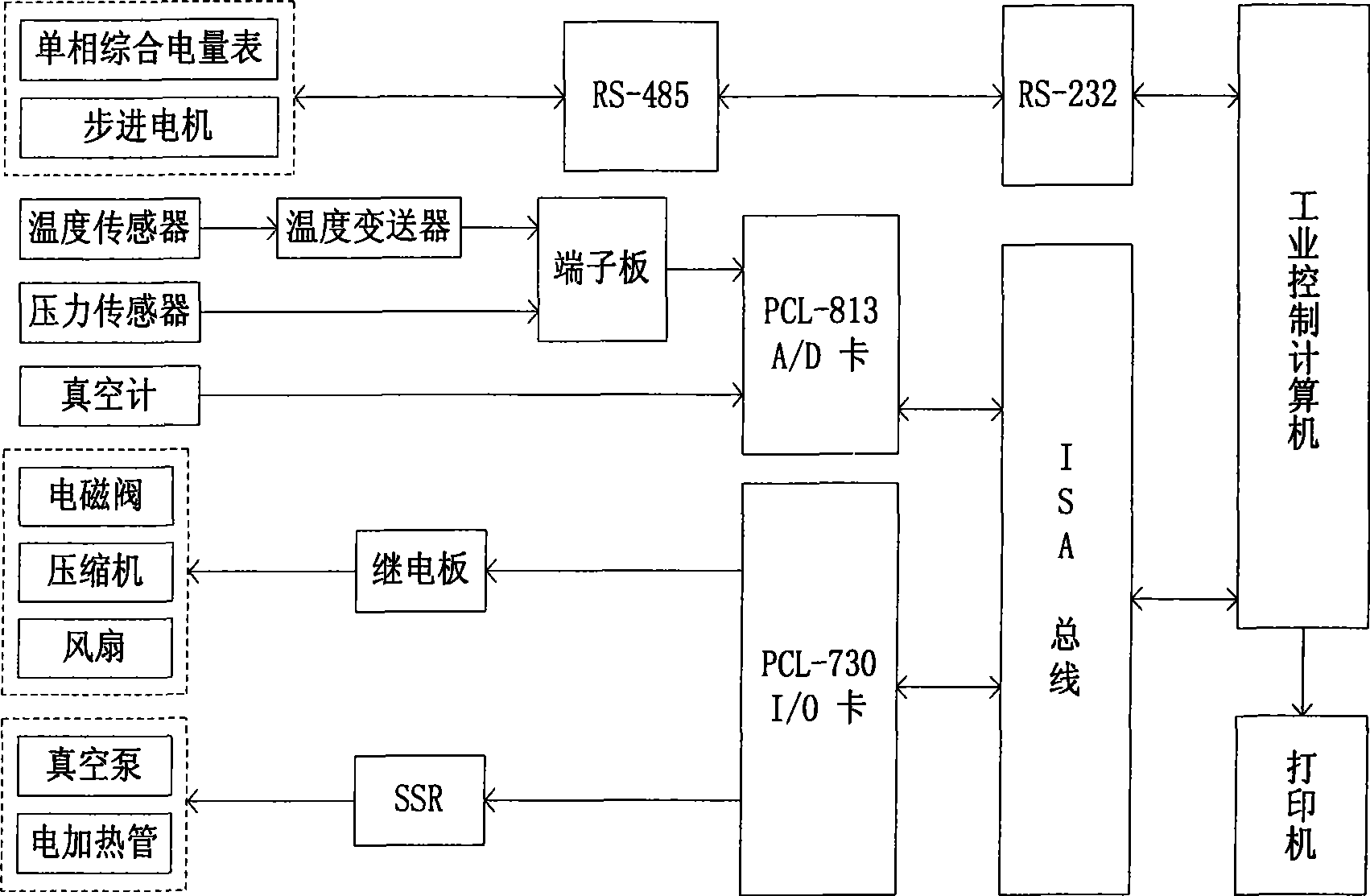

Apparatus and method for measuring small-sized cold compressor oil circulation amount

ActiveCN101498298APump testingPositive-displacement liquid enginesRefrigeration compressorHeating oil

The invention relates to a device and a method for measuring the oil circulating load of a small-sized refrigeration compressor. The device replaces a refrigeration subsystem to adopt a two-stage heating oil separating structure. In a refrigerating and operating unit, an exhaust hole and an inhalation hole of a measured compressor are respectively sequentially connected with an exhaust oil content inlet valve, an exhaust oil and gas separator, a condenser pipe, an exhaust oil content outlet valve, an expansion valve, an inhalation oil content inlet valve, an evaporating pipe, an inhalation oil and gas separator and an inhalation oil content outlet valve through an exhaust interface and an inhalation interface to form a loop, exhaust bypass valves are connected with both ends of the exhaust oil content inlet valve and the exhaust oil content outlet valve in parallel, inhalation bypass valves are connected with both ends of the inhalation oil content inlet valve and the inhalation oil content outlet valve in parallel, and balanced valves are connected with both ends of the exhaust interface and the inhalation interface. The device and the method carry out two-stage heating oil separation for the refrigerating loop by mainly using a method that the compressor is operated in a continuous and discontinuous circulation stopping and starting mode under a variable working condition state.

Owner:ZHEJIANG UNIV OF TECH

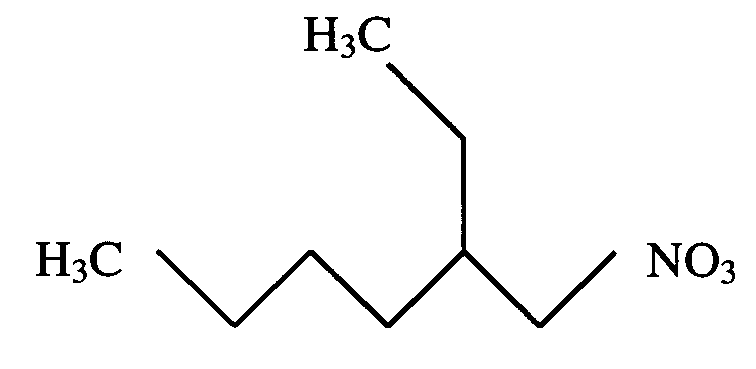

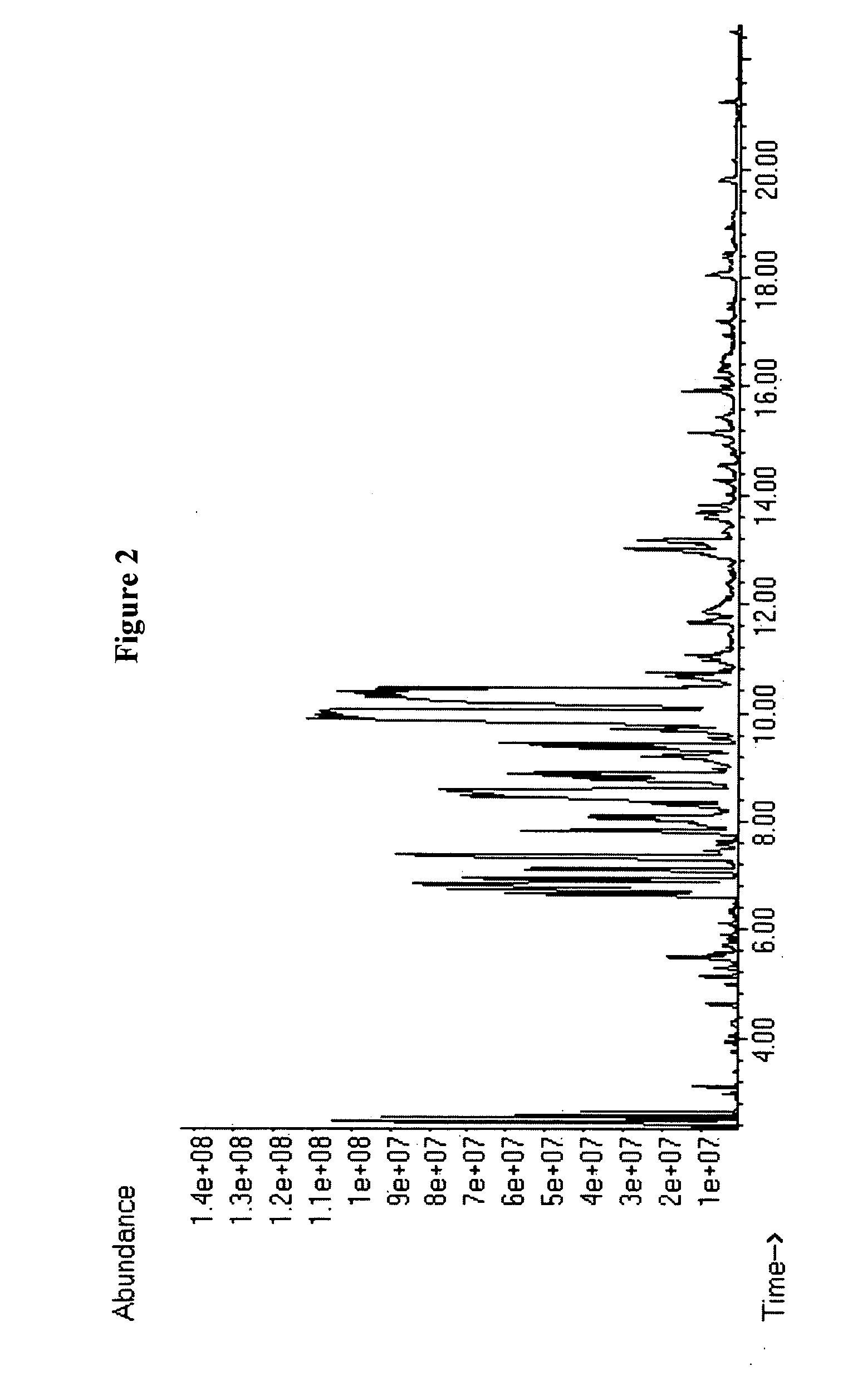

Nitrated non-cyclic N-Alkane scaffolds with differentiated-mean combustive equivalencies as high energy density fuel improvers

A non-ring, non-alkene, nitrated n-alkane base scaffold combined with at least one trioxynitrate provides a differentiated-mean combustive performance in a stabilized and sufficiently polar molecule as to be miscible, and thus serve as a high-energy-density component of a fuel additive that, when mixed with existing fuels at appropriate dilution ratios, will impart equivalent combustive efficiency to that of standardized, petroleum distillate, gasoline and diesel in various blends including aviation fuel and heating oil over the full-temperature-range of use; and a specific embodiment of this non-ring, non-alkene nitrated n-alkane base scaffold is described which, when blended with a petroleum diesel, biodiesel, or combination of B-20 standard biodiesel (80% diesel, 20% biodiesel) wherein the additive comprises less than 5% of the total mix, produces at least a 10% or greater combustive energy density as compared to the base fuel.

Owner:FUELTEC INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com