Patents

Literature

249results about "Fatty substance recovery/refining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

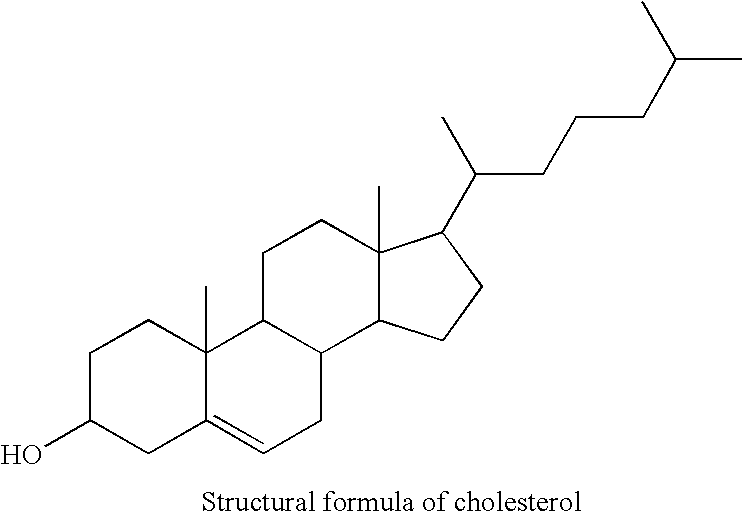

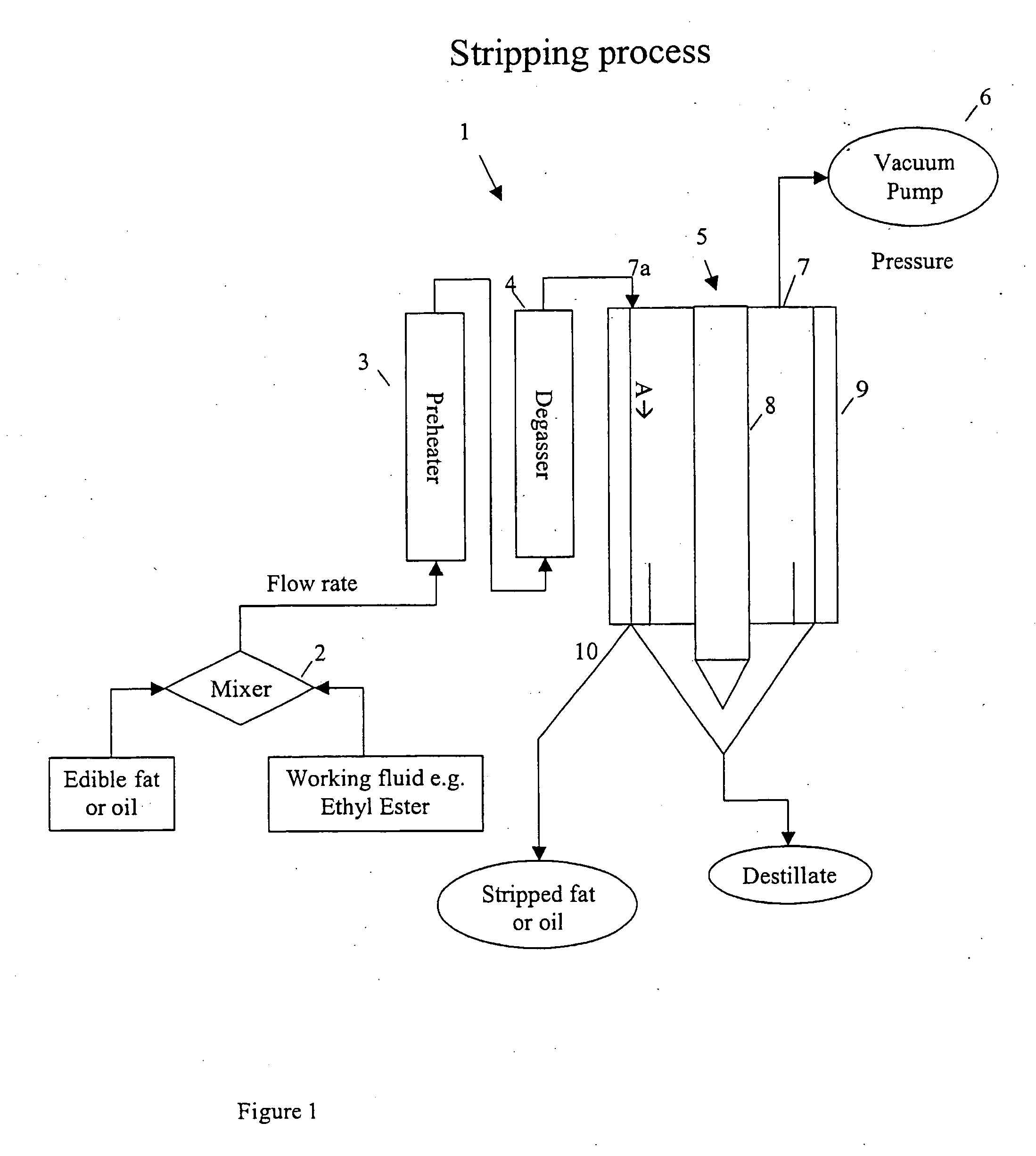

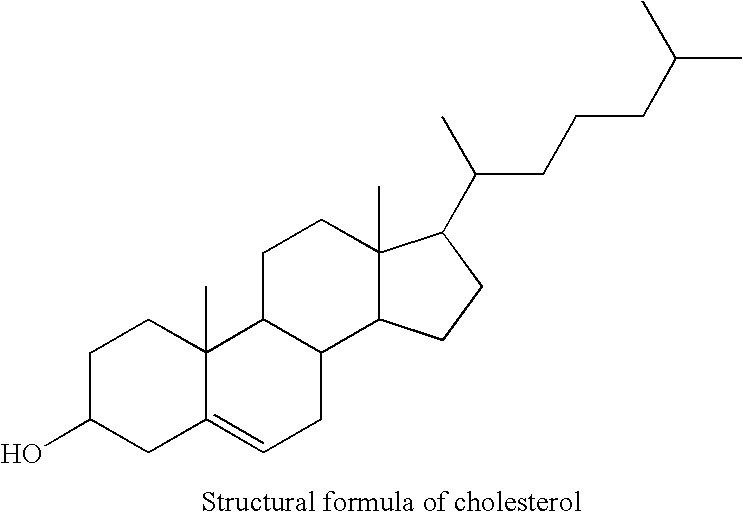

Process for decreasing the amount of cholesterol in a marine oil using a volatile working fluid

ActiveUS7678930B2Lower cholesterol levelsPoint becomes highCosmetic preparationsNervous disorderWorking fluidFree form

The invention relates to a process for decreasing the amount of cholesterol in a mixture comprising a marine oil, the marine oil containing the cholesterol, which process comprises the steps of adding a volatile working fluid to the mixture, where the volatile working fluid comprises at least one of a fatty acid ester, a fatty acid amide and a hydrocarbon, and subjecting the mixture with the added volatile working fluid to at least one stripping processing step, in which an amount of cholesterol present in the marine oil in free form is separated from the mixture together with the volatile working fluid. The present invention also relates to a volatile cholesterol decreasing working fluid and a health supplement and a pharmaceutical, based on a marine oil, prepared according to the process mentioned above.

Owner:PRONOVA BIOPHARMA NORGE

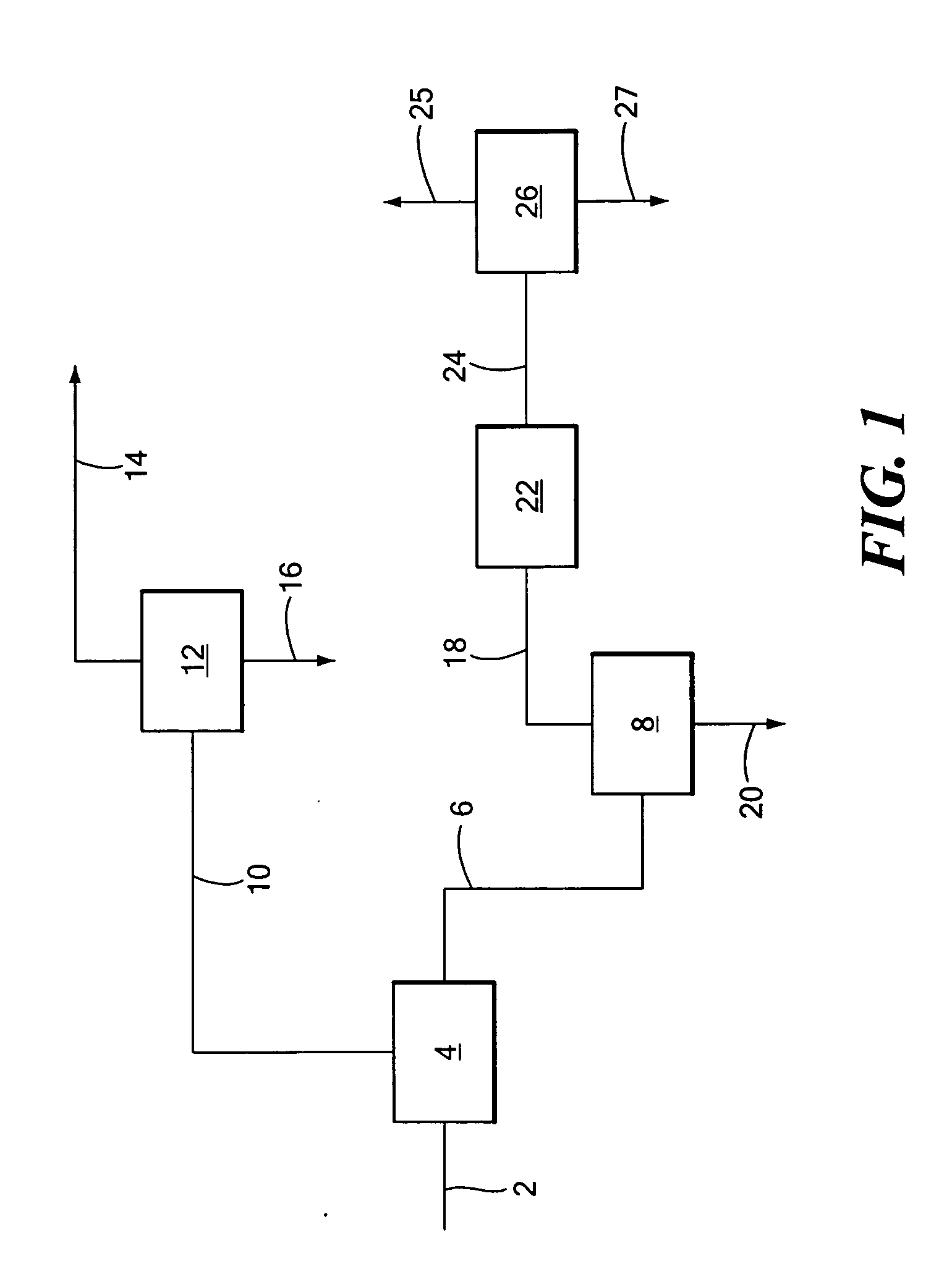

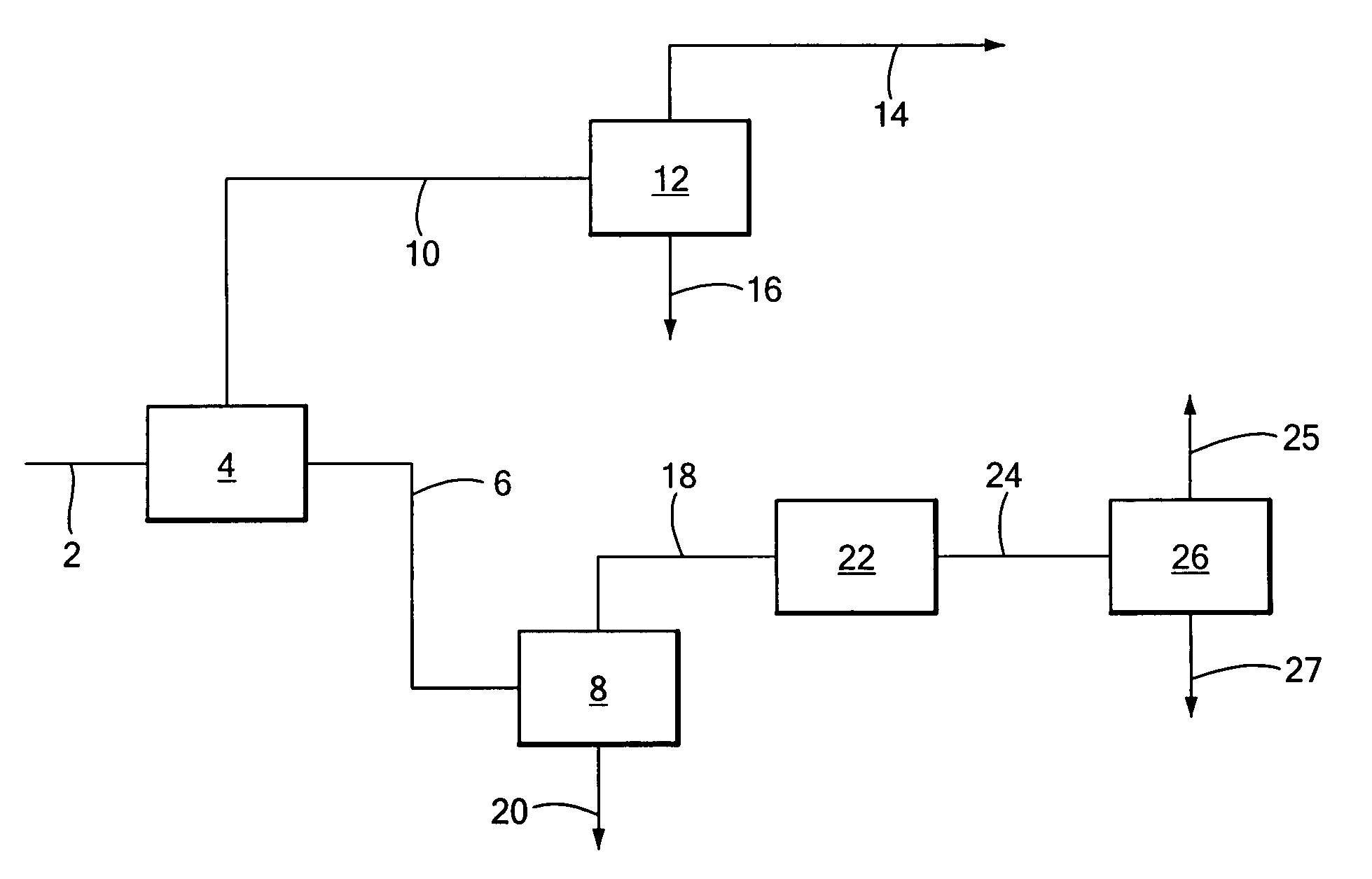

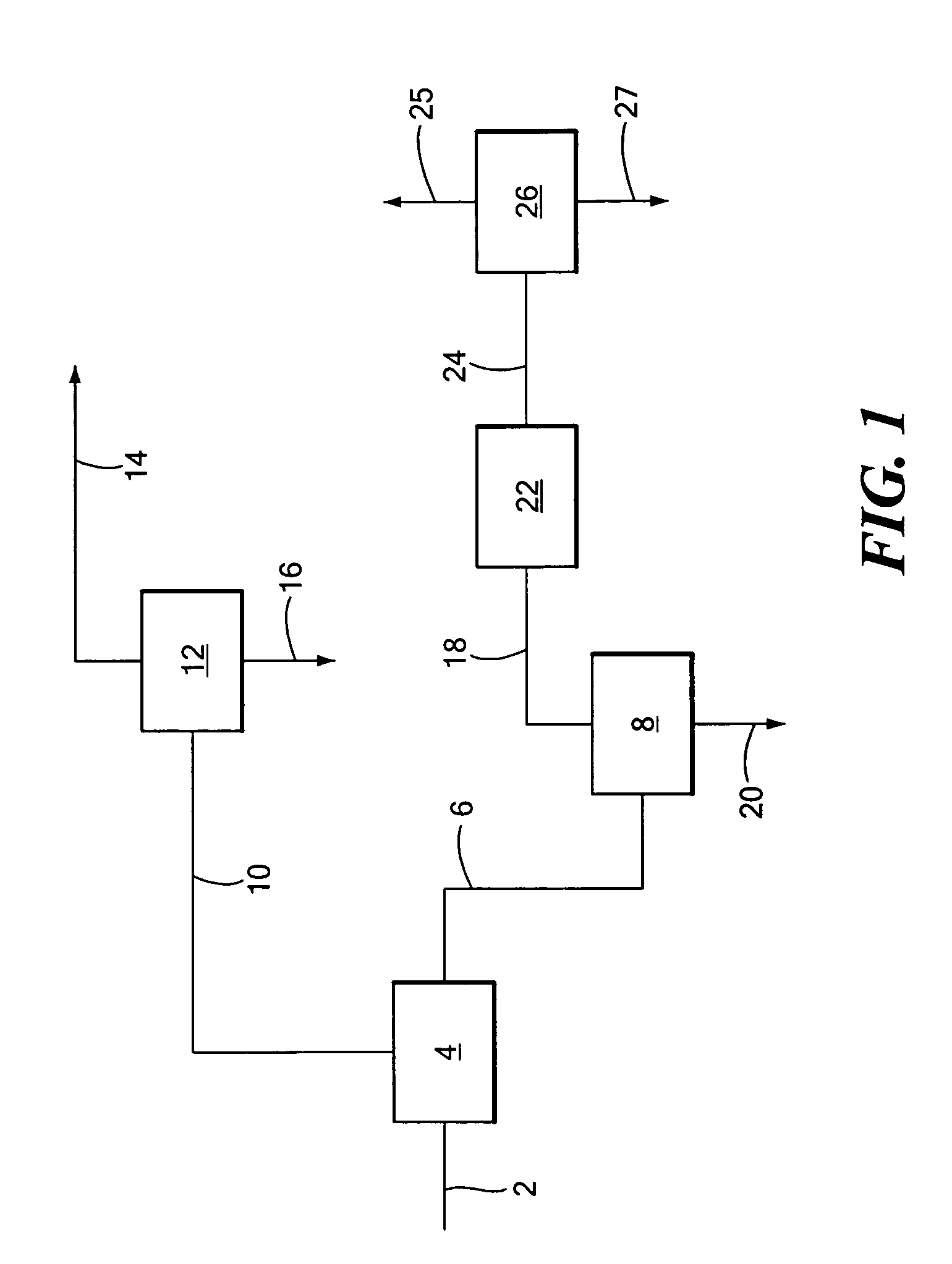

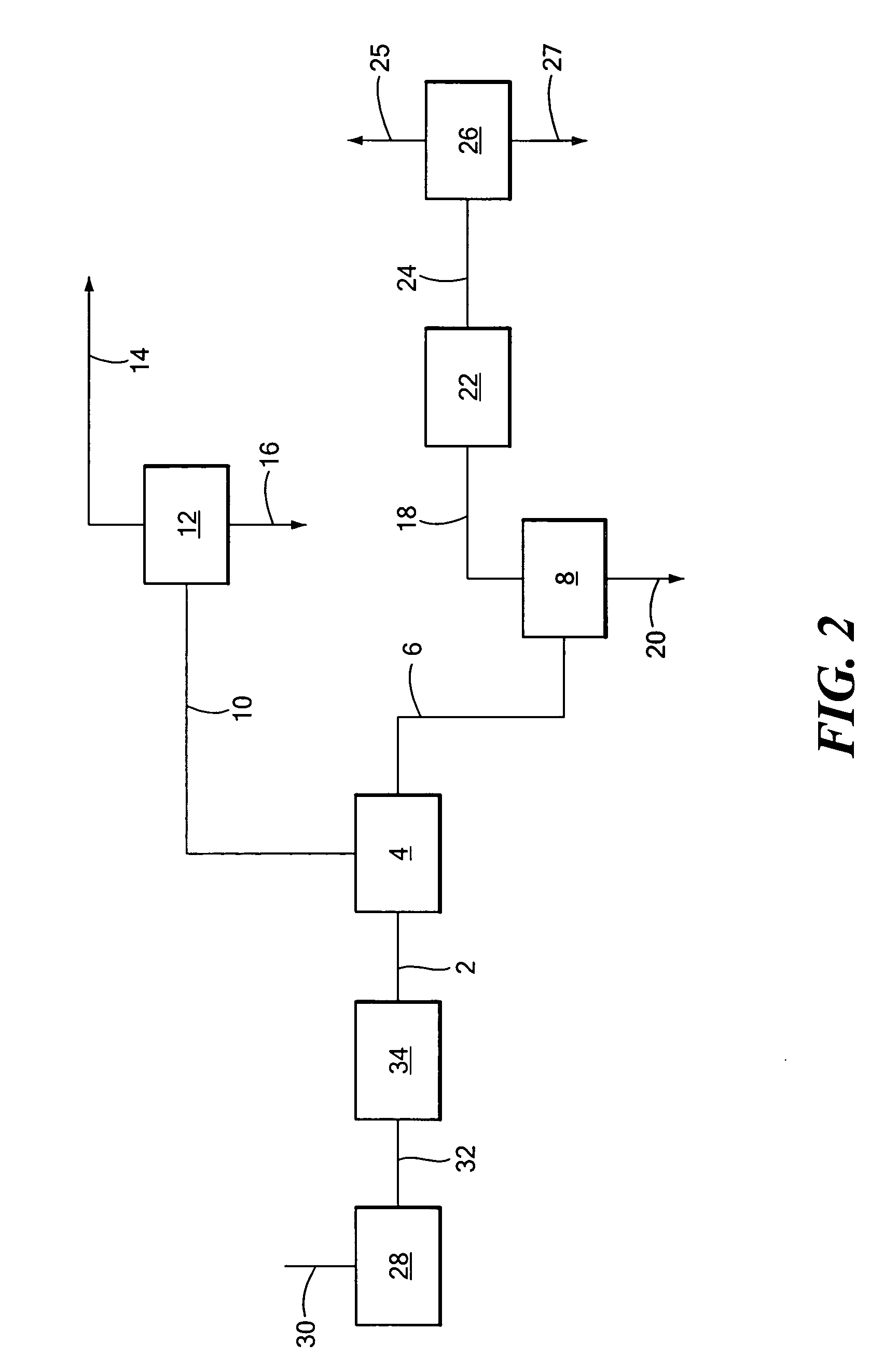

Biodiesel process

InactiveUS20060074256A1Overcomes shortcomingFatty oils/acids recovery from wasteFatty substance recovery/refiningBiodieselAlcohol

The present invention provides a biodiesel process capable of yielding a mono-alkyl ester biodiesel. In one embodiment, a process for yielding biodiesel comprises providing a feed stream. Preferably, the feed stream comprises mono-alkyl esters, salts, alcohol and glycerol. The process also comprises substantially separating alcohol from the feed stream to yield a first stream. The first stream comprises mono-alkyl esters, glycerol and salts. A separation of alcohol from the first stream is performed by volatility. Furthermore, the process of the invention comprises substantially separating salts from the first stream to yield a vapor stream. The vapor stream also comprises mono-alkyl esters and glycerol. Separation of salts of the vapor stream is also performed by volatility. Glycerol and mono-alkyl esters of the vapor stream are also substantially separated so as to yield a biodiesel. Preferably, the biodiesel is a fuel grade biodiesel comprising fatty acid mono-alkyl esters.

Owner:ARTISAN IND

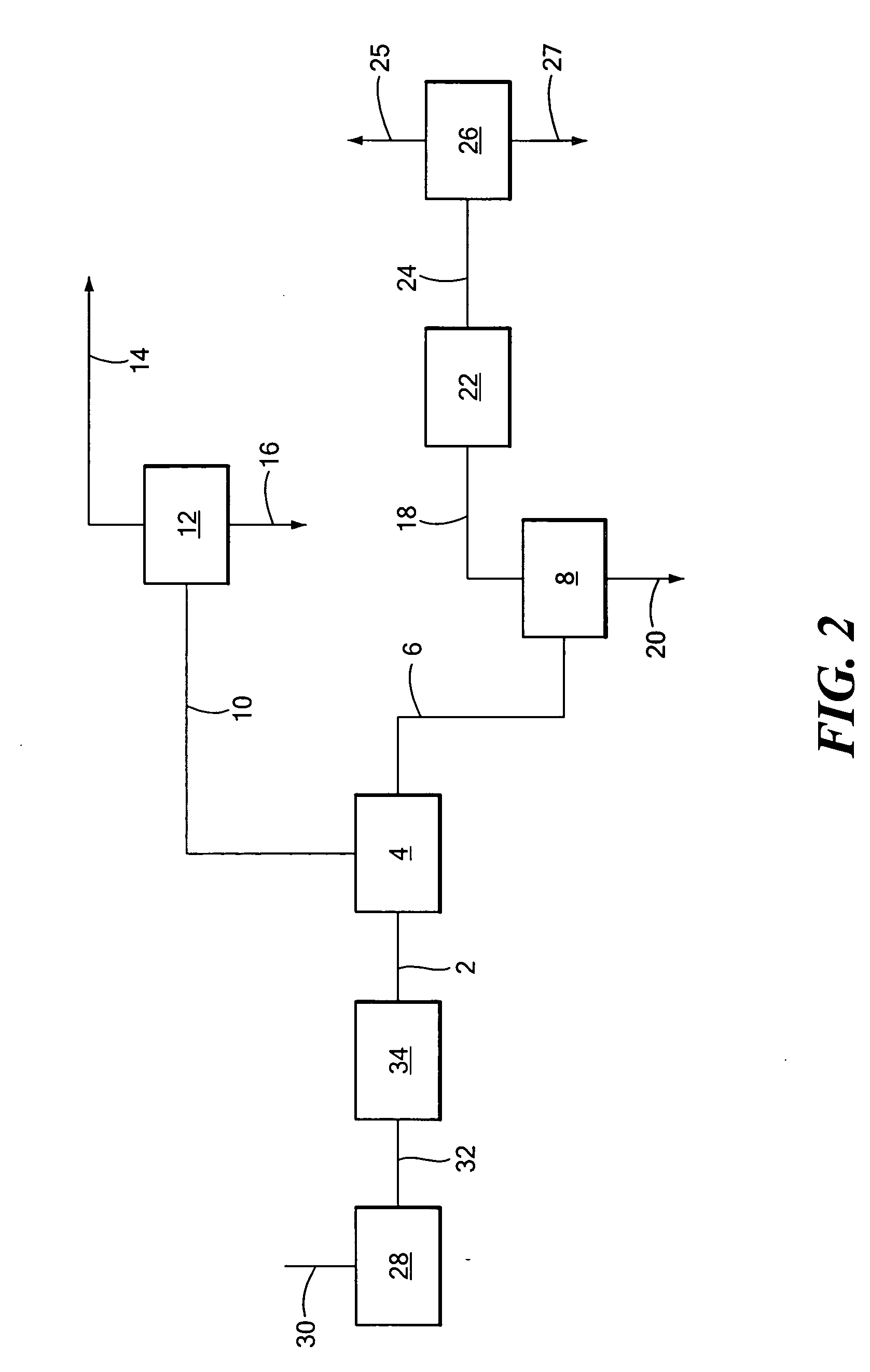

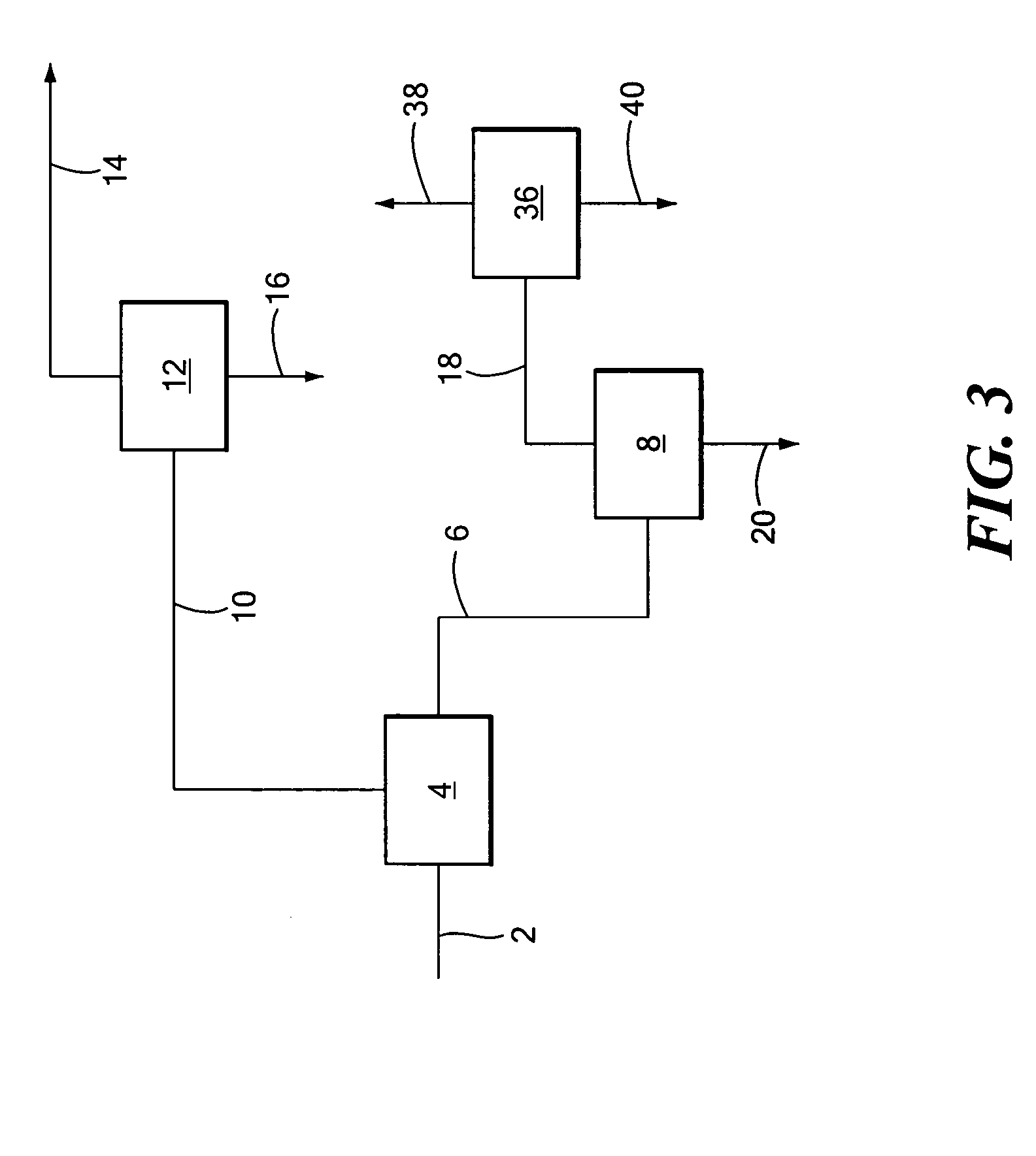

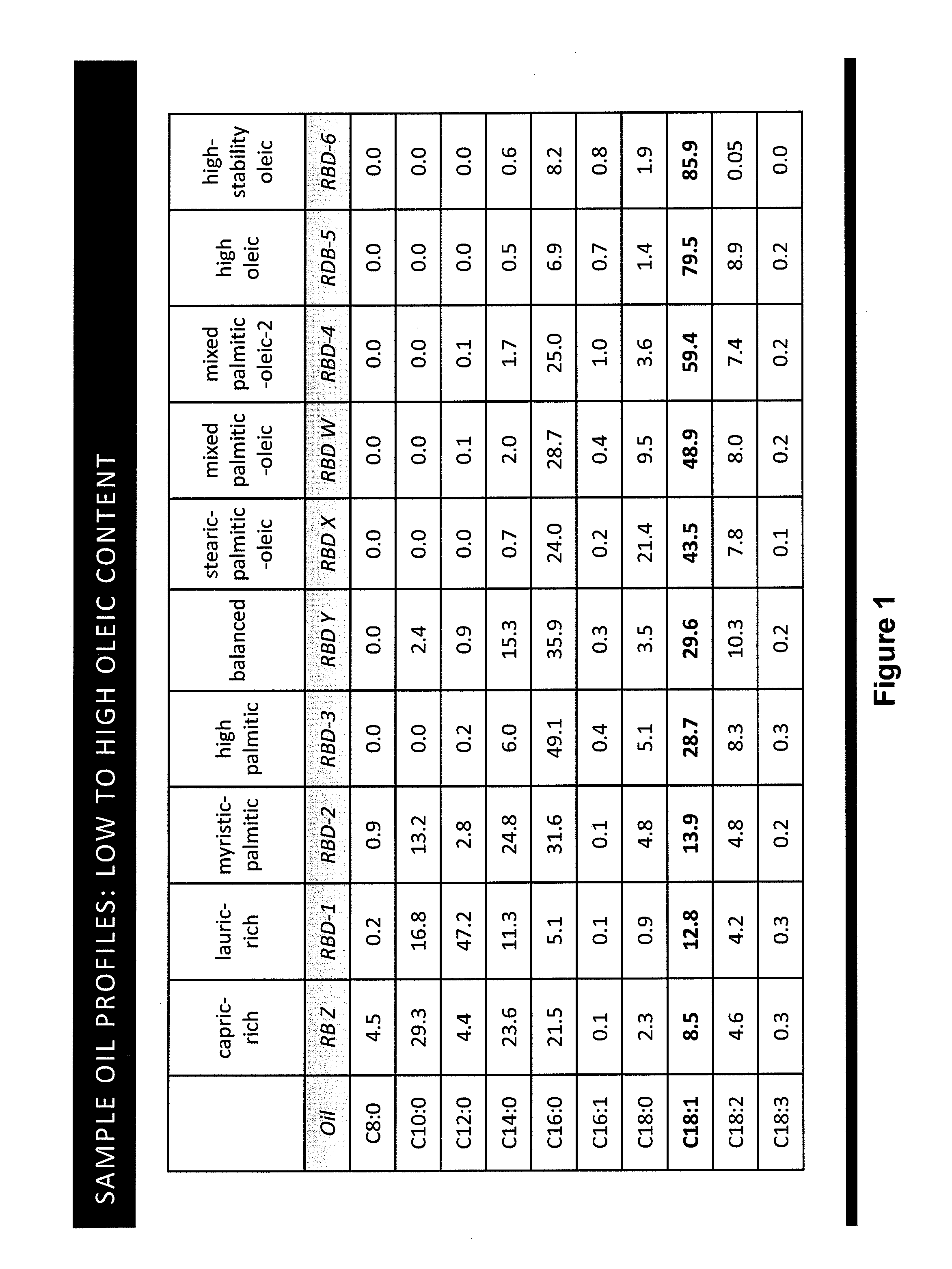

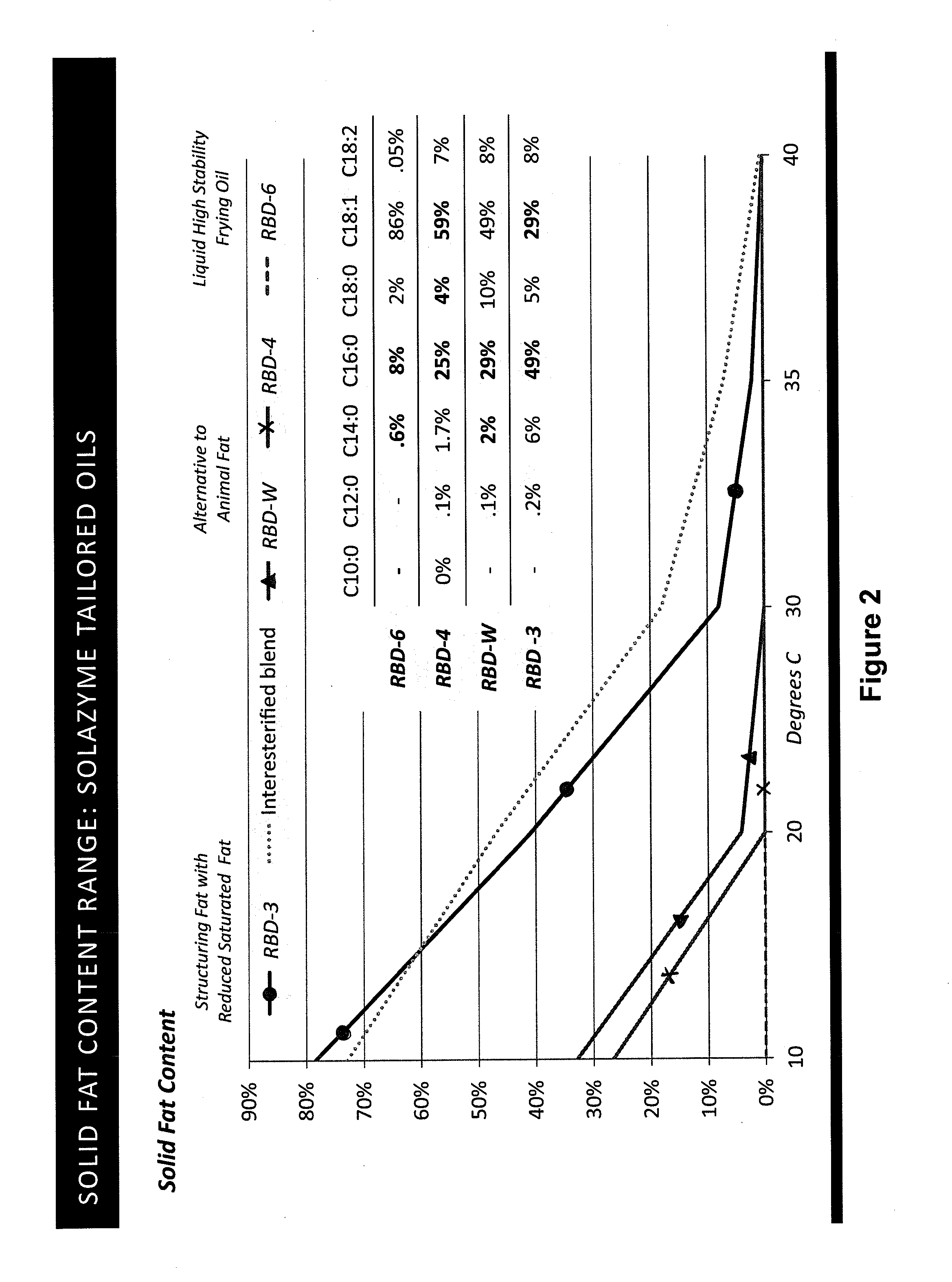

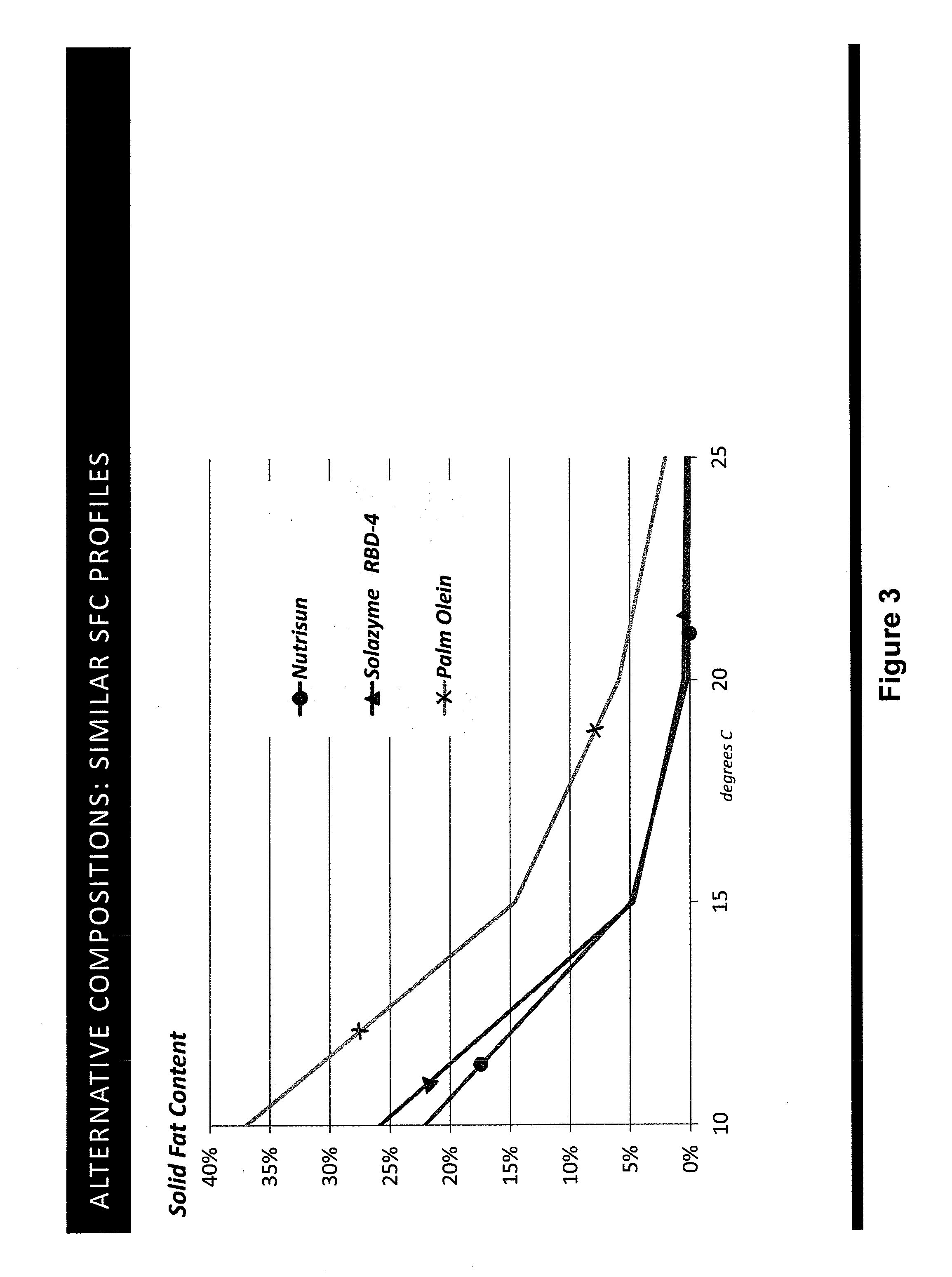

Tailored Oils

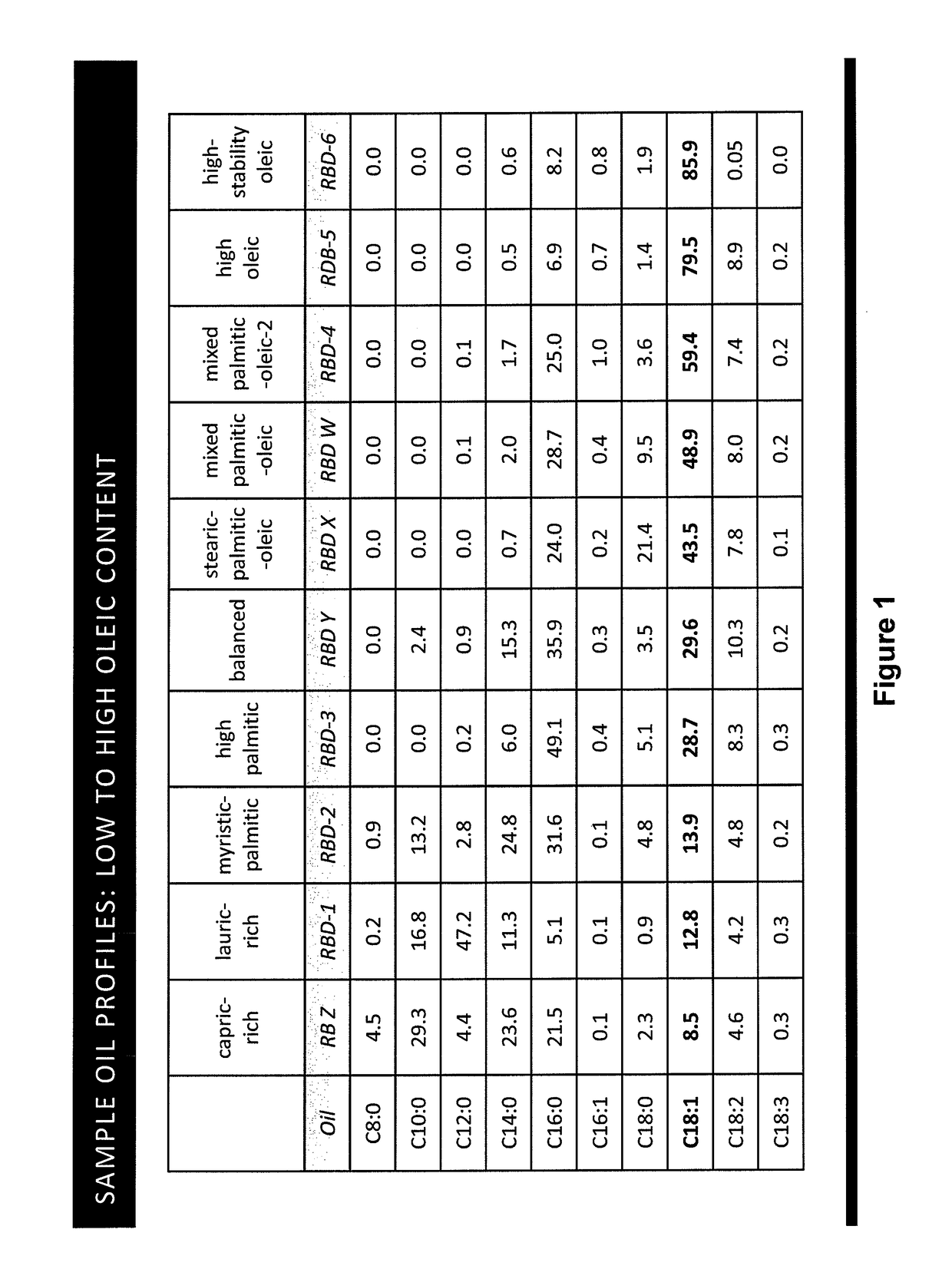

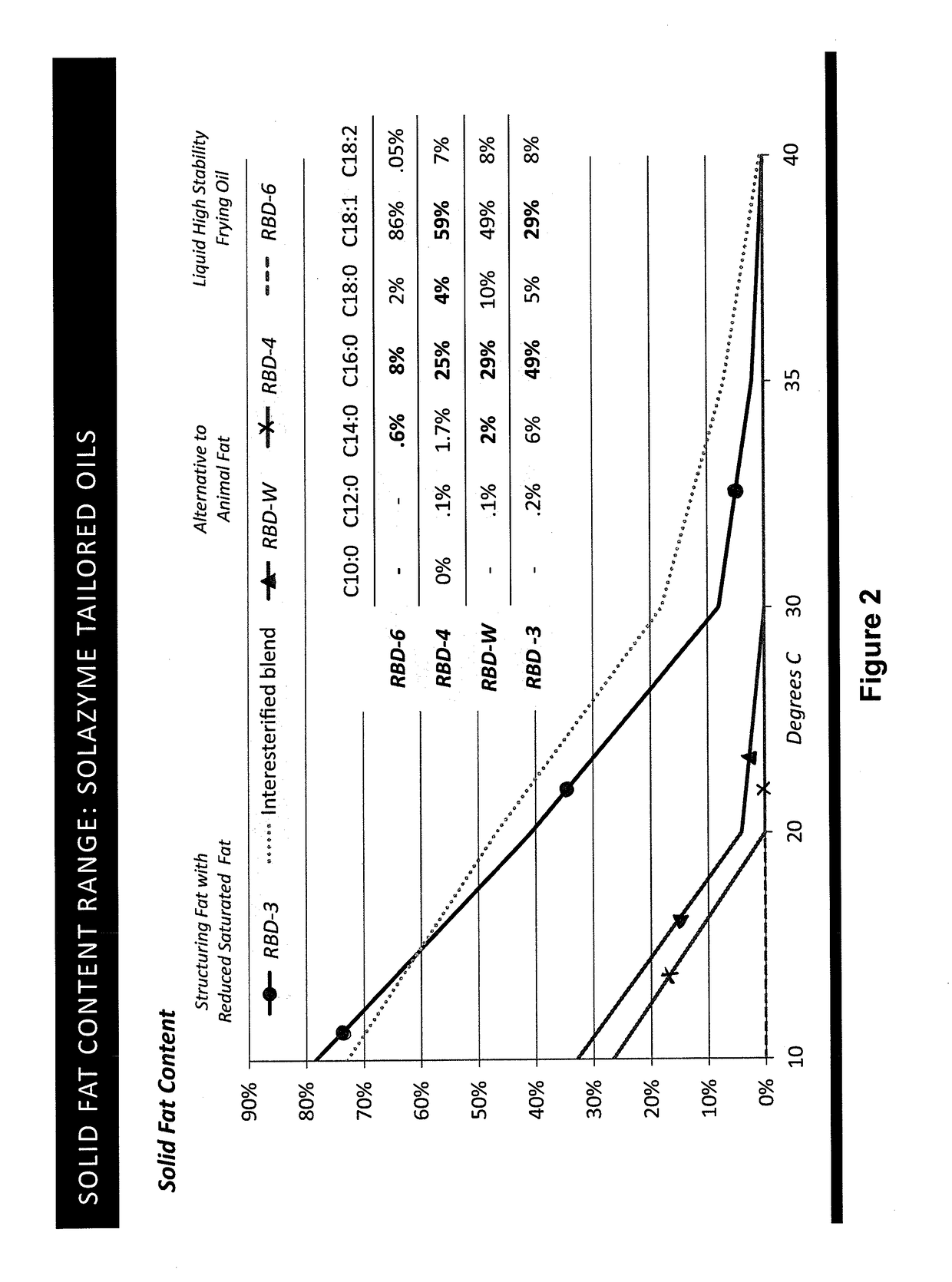

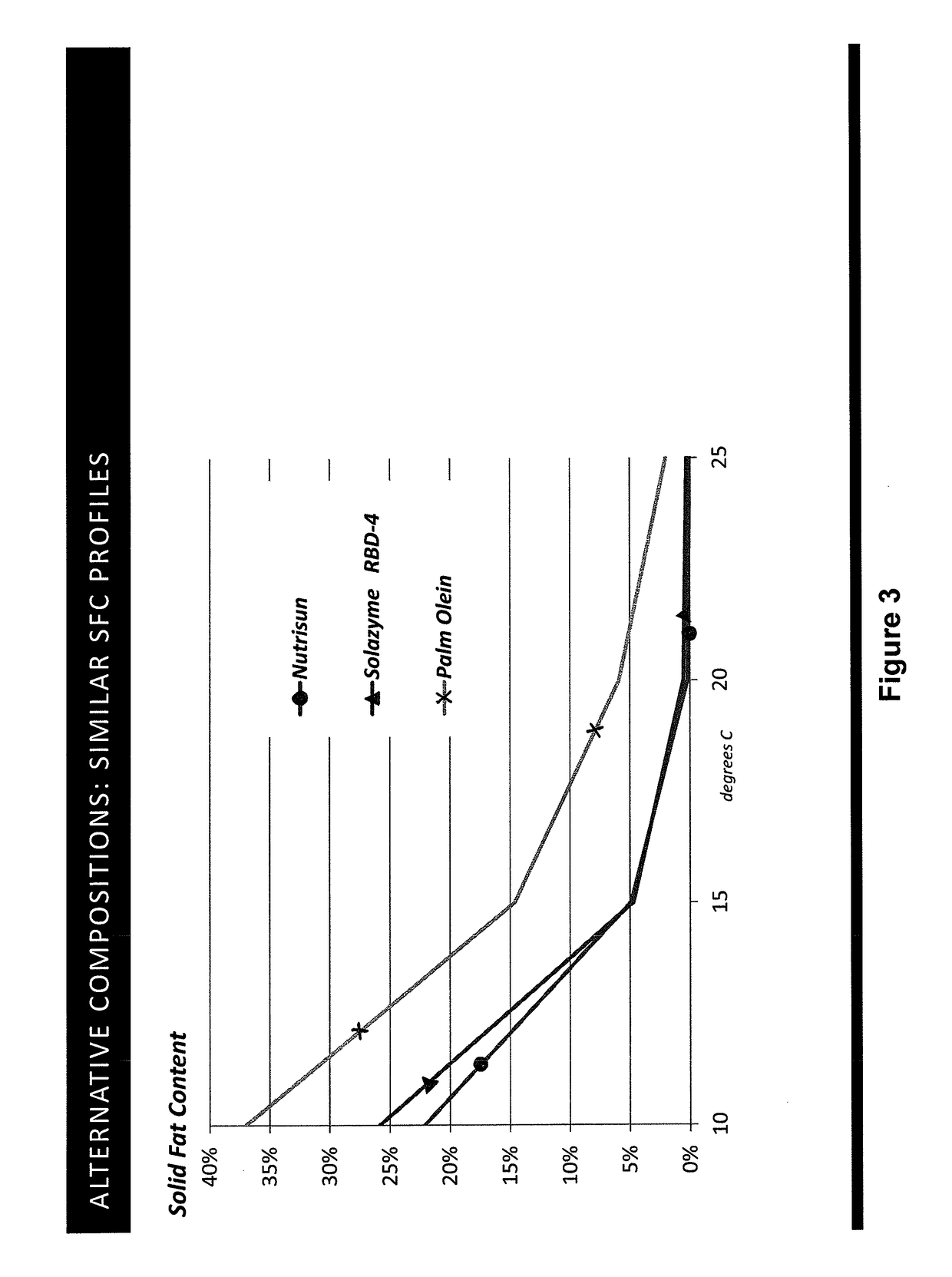

ActiveUS20130338385A1Raise the ratioReduced activityOrganic chemistryFatty substance recovery/refiningButter cocoaACP desaturase

Recombinant DNA techniques are used to produce oleaginous recombinant cells that produce triglyceride oils having desired fatty acid profiles and regiospecific or stereospecific profiles. Genes manipulated include those encoding stearoyl-ACP desturase, delta 12 fatty acid desaturase, acyl-ACP thioesterase, ketoacyl-ACP synthase, and lysophosphatidic acid acyltransferase. The oil produced can have enhanced oxidative or thermal stability, can be useful as a frying oil, shortening, roll-in shortening, tempering fat, cocoa butter replacement, as a lubricant, or as a feedstock for various chemical processes. The fatty acid profile can be enriched in midchain profiles or the oil can be enriched in triglycerides of the saturated-unsaturated-saturated type.

Owner:CORBION BIOTECH INC

Process for the isolation of glycolipids

InactiveUS6953849B2Simple methodEsterified saccharide compoundsFatty substance recovery/refiningSludgeRice Bran Extract

Owner:COUNCIL OF SCI & IND RES

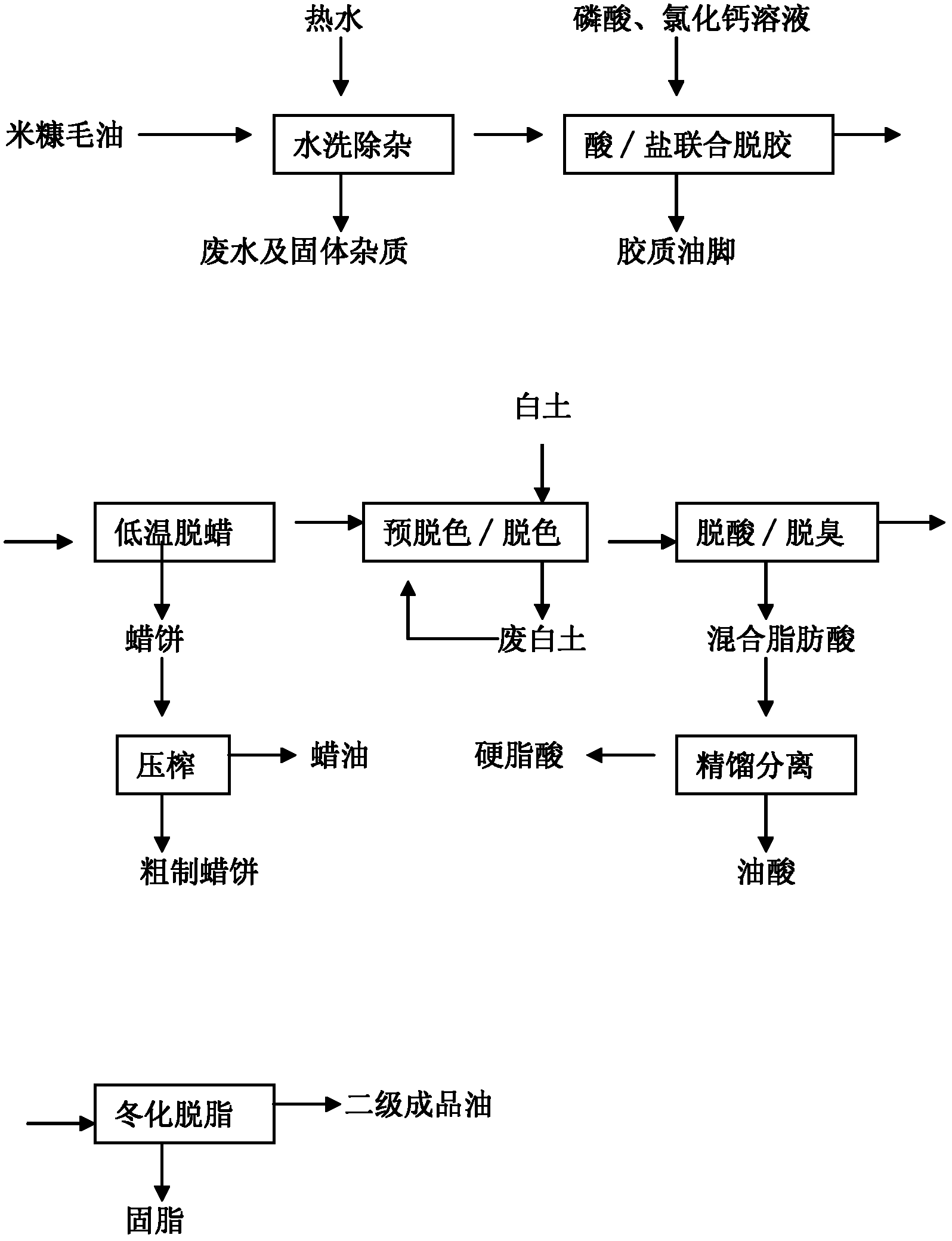

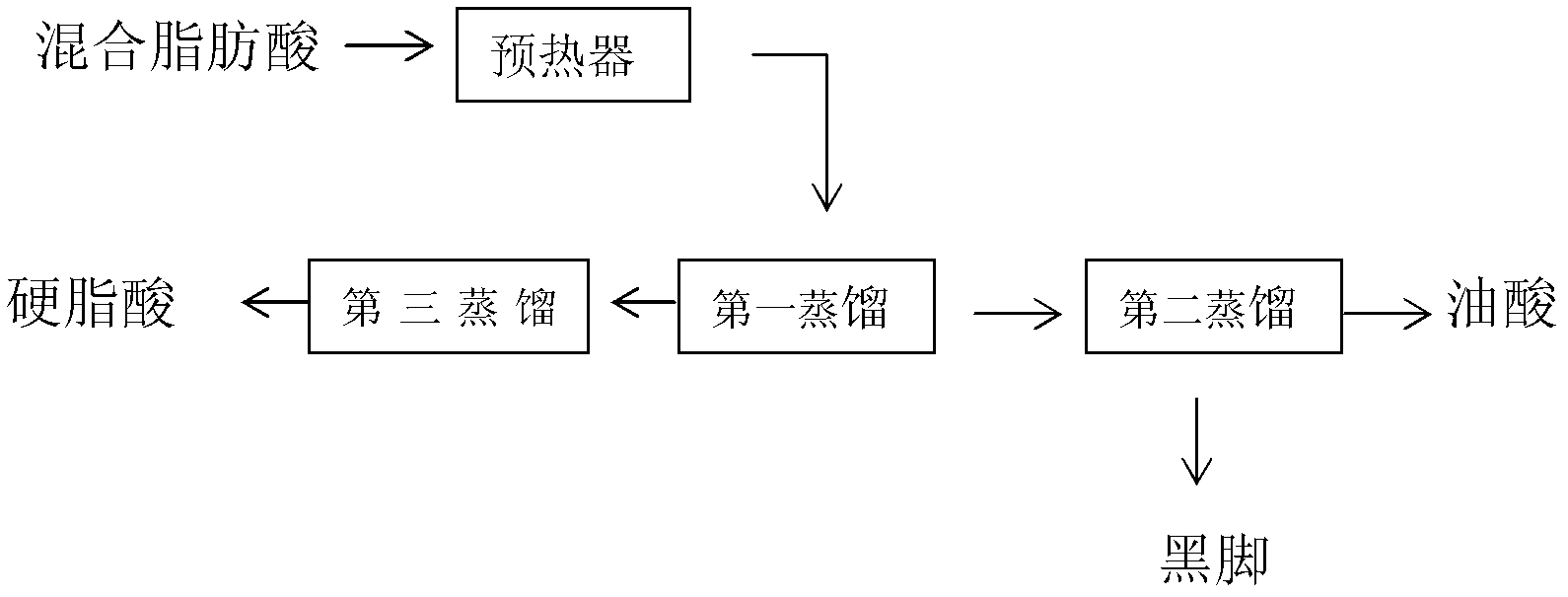

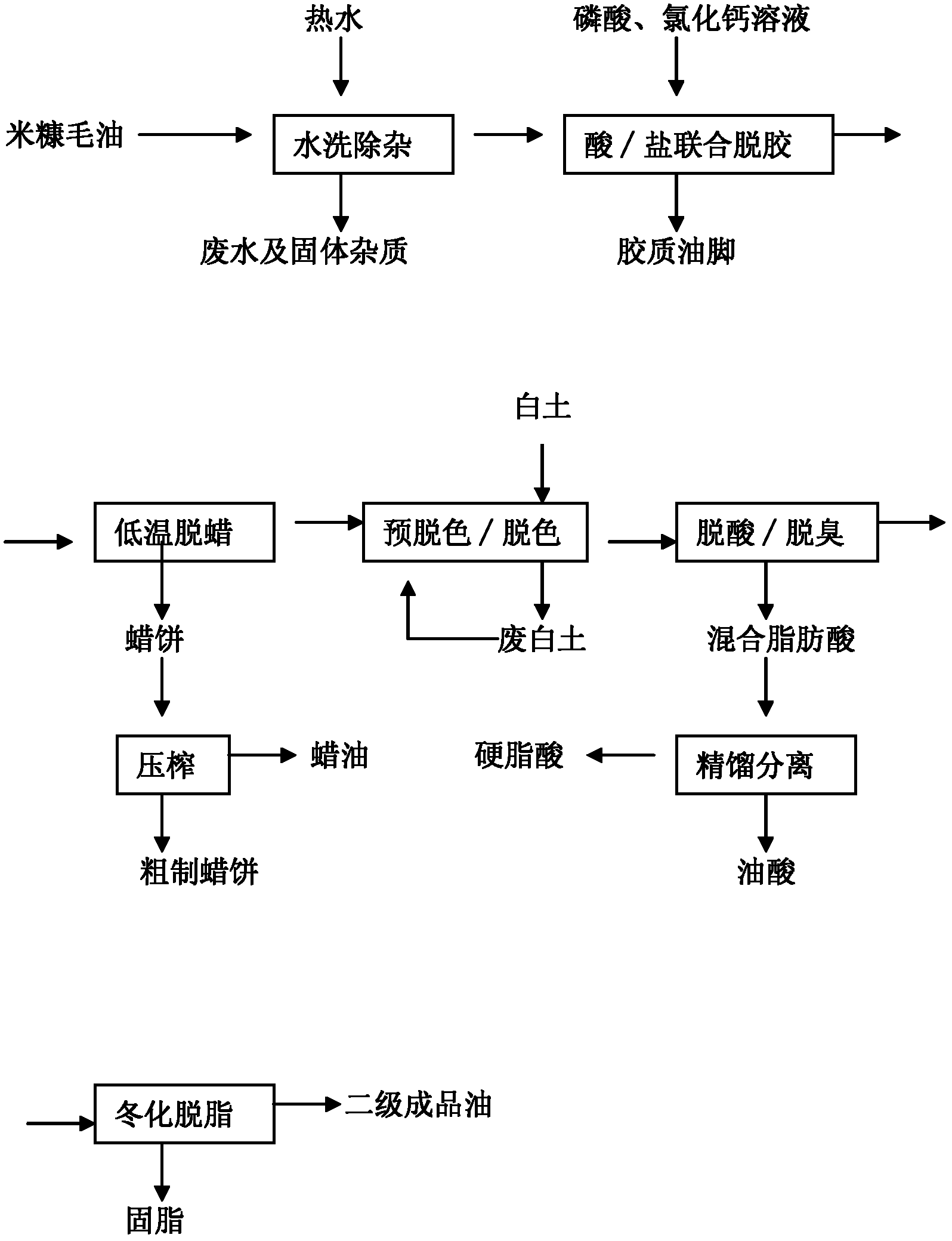

Rice bran oil refinement and byproduct production method

InactiveCN102492546AOvercome efficiencyOvercome the cycleFatty substance recovery/refiningFatty acids production/refiningWaxMixed fatty acid

The invention relates to a rice bran oil refinement and byproduct production method, and solves the problems of poor quality, low product and byproduct yield, low purity, complex technique, small production scale and the like in the existing product oil refined from rice bran oil. The technical scheme is as follows: the method comprises the following steps: carrying out acid / salt combined degumming on rice bran raw oil, dewaxing at low temperature, decolorizing, deacidifying / deodorizing, and degreasing by winterization to obtain tertiary rice bran oil and byproducts (crude wax cake, mixed fatty acids and solid grease). The technique provided by the invention is simple to control, can stably obtain Chinese standard tertiary rice bran oil and byproducts thereof, and can implement large-scale production.

Owner:WUHAN POLYTECHNIC UNIVERSITY +2

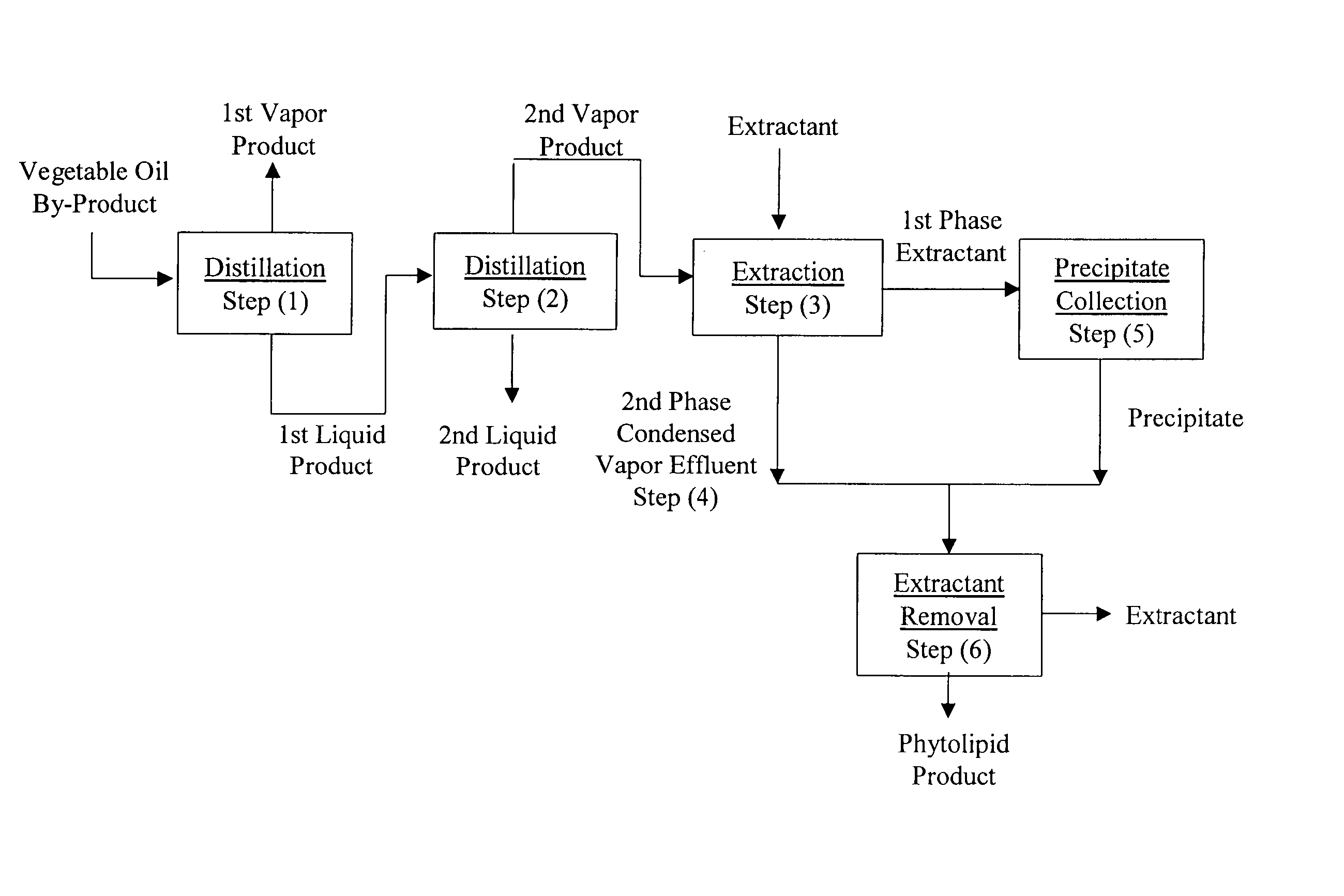

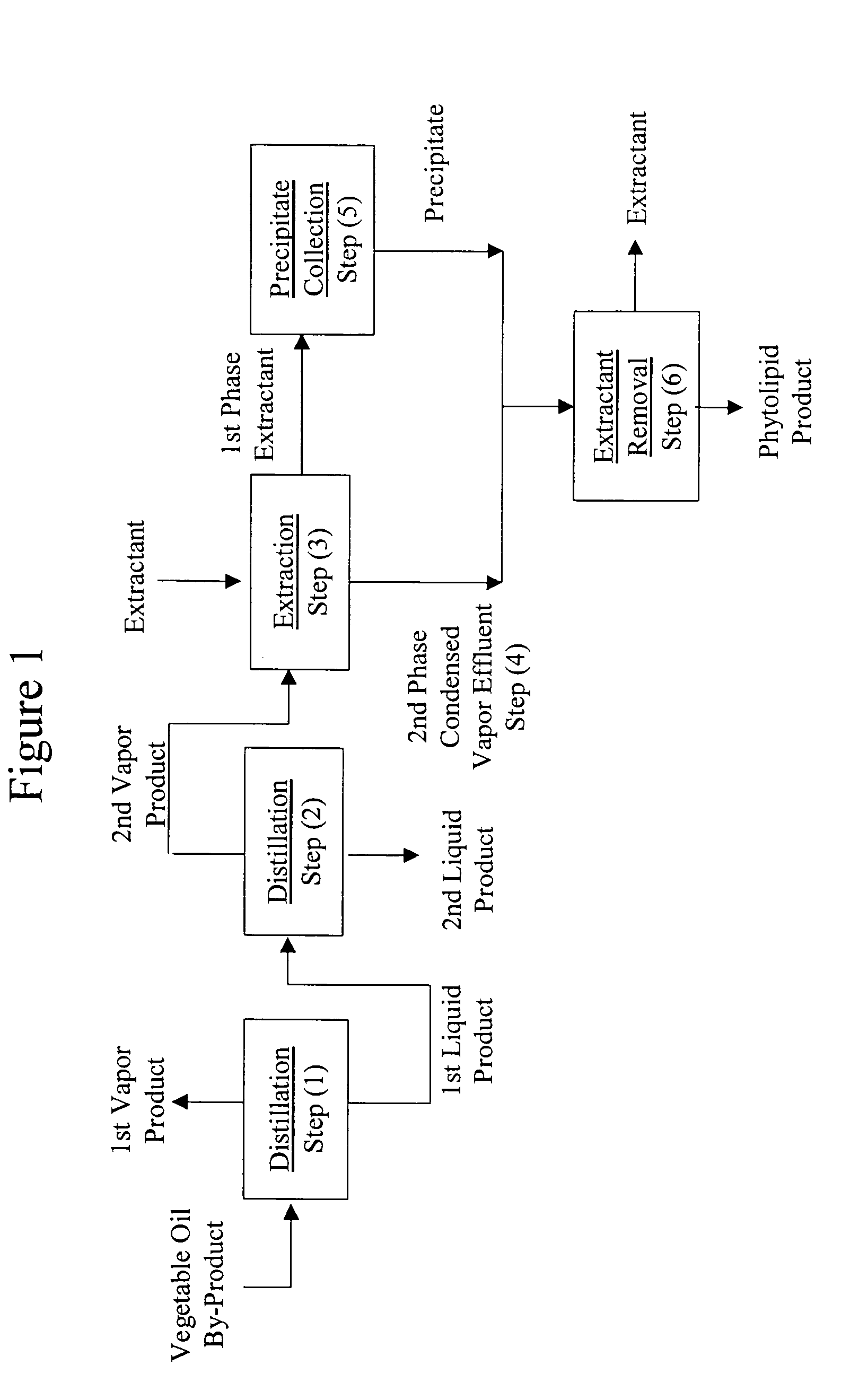

Process for the recovery of a phytolipid composition

InactiveUS20050051419A1Easy to prepareLow viscosityFatty oils/acids recovery from wasteEdible oils/fats ingredientsVegetable oilMedicine

Disclosed is a process for the recovery of a phytolipid composition from a vegetable oil by-product. The phytolipid composition produced comprises squalene, phytosterols, mixed tocopherols and tocotrieneols, and vegetable wax and is useful as an emollient. The phytochemical composition may be applied directly to the skin to provide emolliency. Alternatively, the phytolipid composition may be formulated in various aqueous or anhydrous cosmetic compositions such as creams, lotions, gels, ointments, lip balms, sticks, or pencils for treatment of the skin and lips. The phytolipid composition also may be incorporated into foods, beverages, and nutraceuticals to provide health benefits.

Owner:EASTMAN CHEM CO

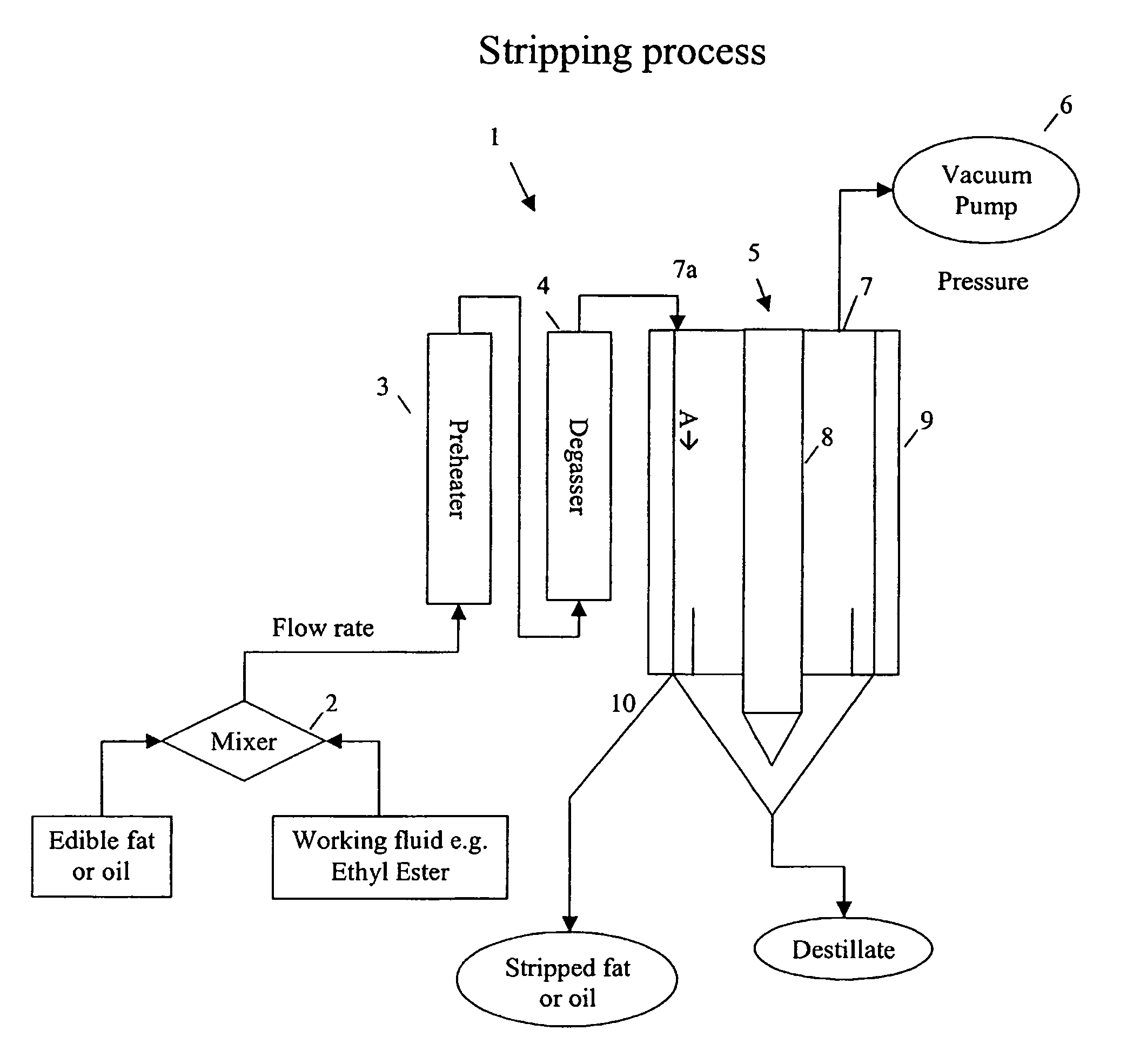

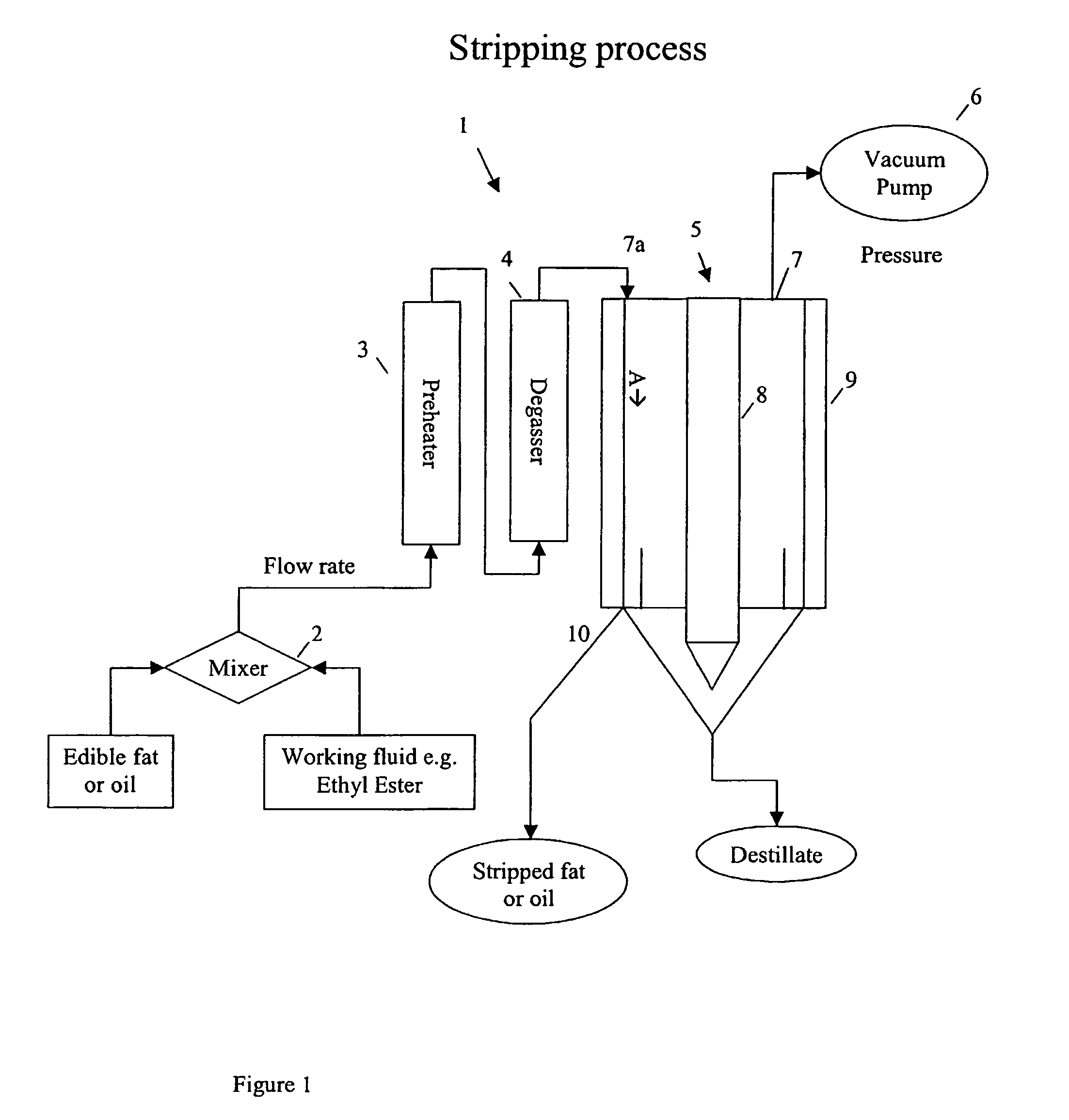

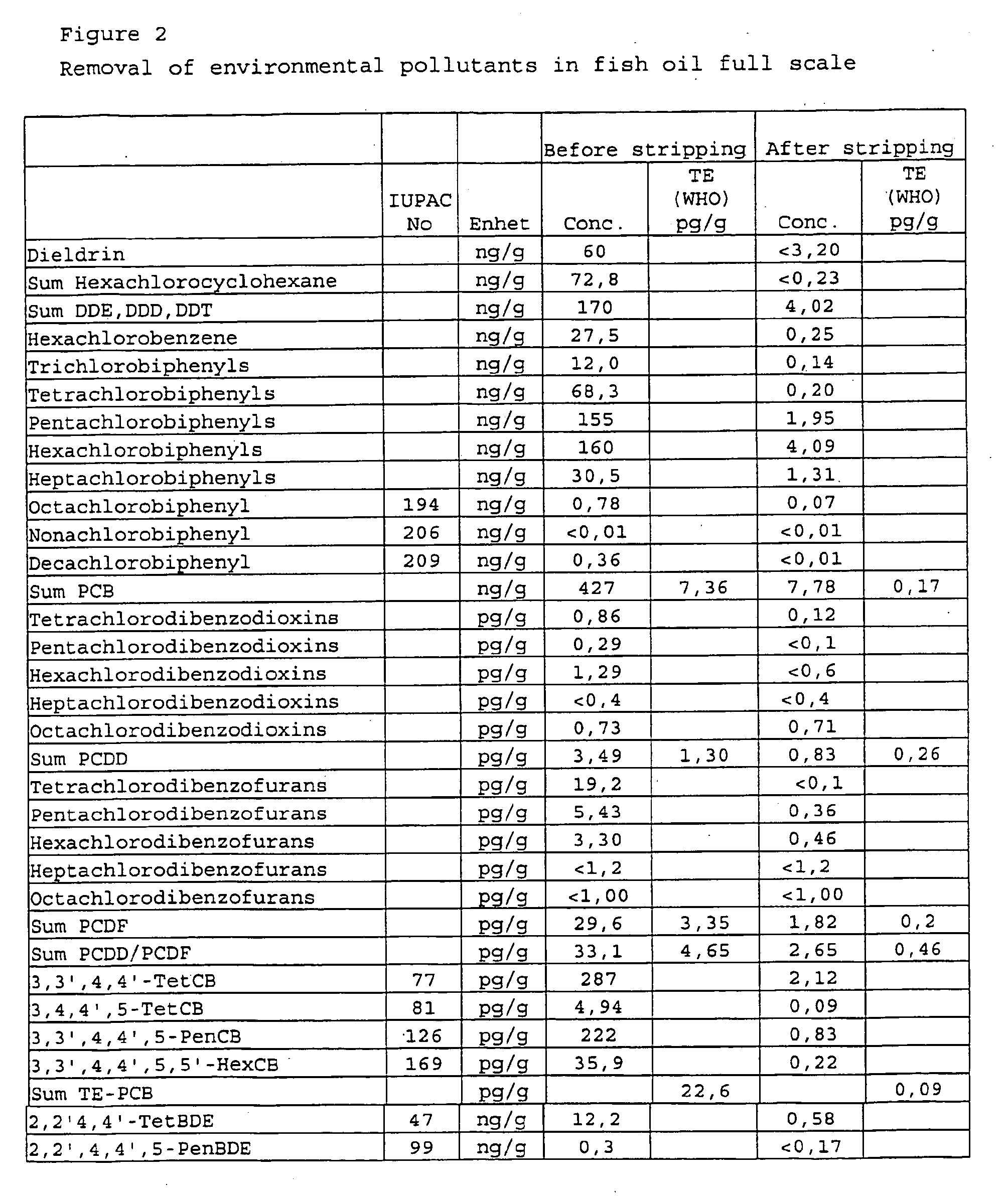

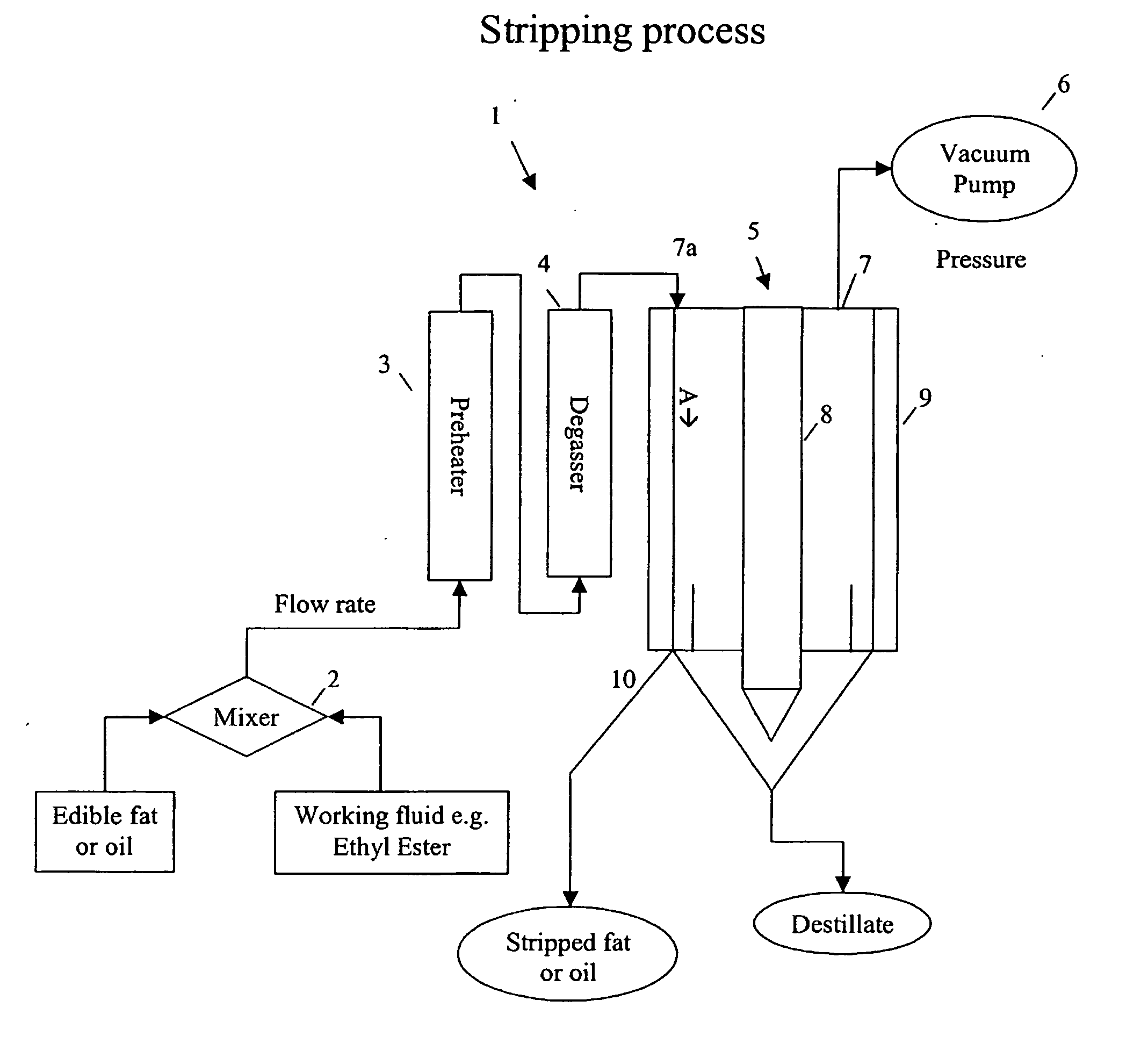

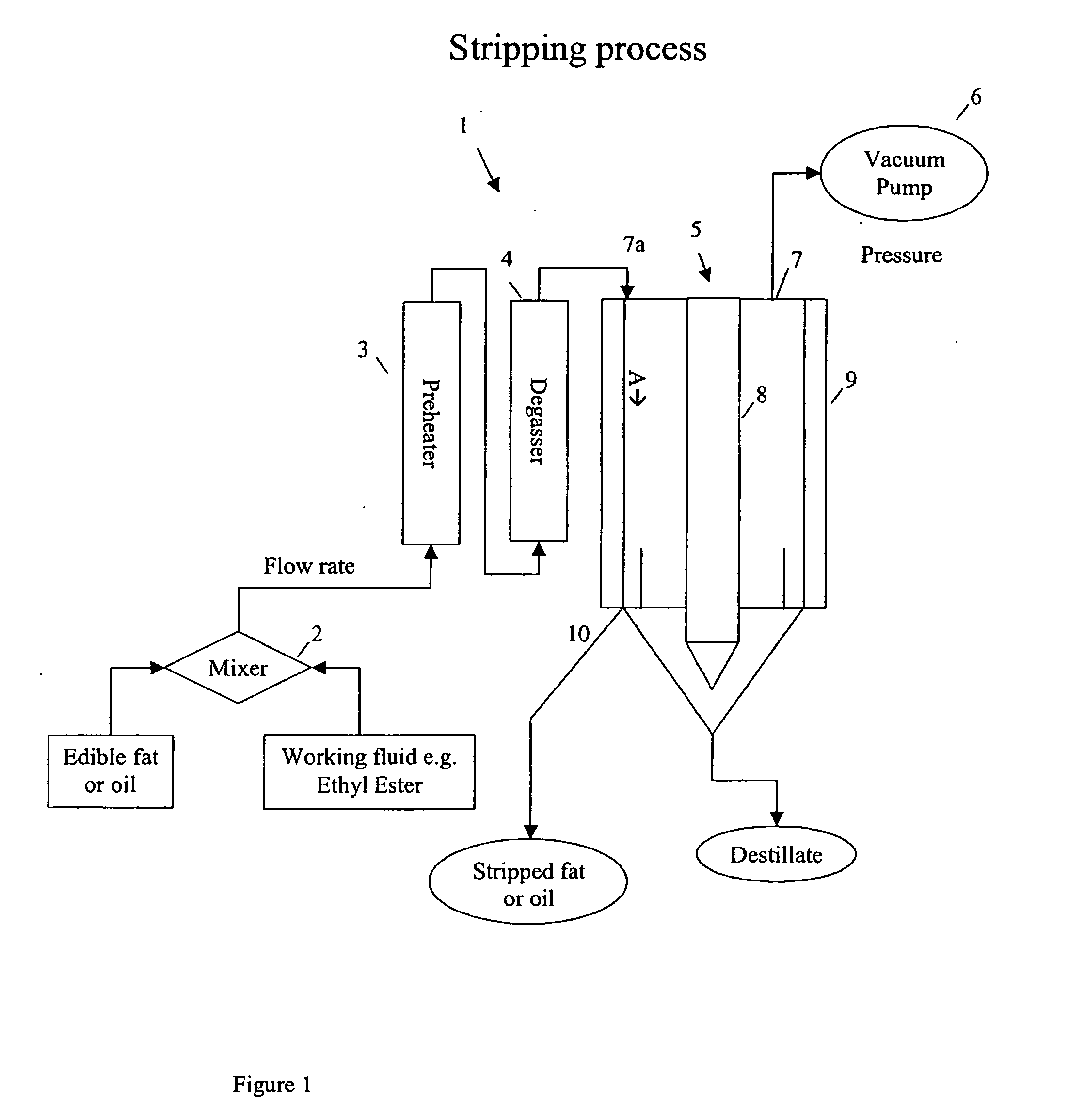

Process for decreasing environmental pollutants in an oil or a fat, a volatile environmental pollutants decreasing working fluid, a health supplement, and an animal feed product

ActiveUS20050256326A1Fatty oils/acids recovery from wasteOrganic active ingredientsOil and greaseWorking fluid

The invention relates to a process for decreasing the amount of environmental pollutants in a mixture comprising a fat or an oil, being edible or for use in cosmetics, the fat or oil containing the environmental pollutants, which process comprises the steps of adding a volatile working fluid to the mixture, where the volatile working fluid comprises at least one of a fatty acid ester, a fatty acid amide, a free fatty acid and a hydro-carbon, and subjecting the mixture with the added volatile working fluid to at least one stripping processing step, in which an amount of environmental pollutant pre-sent in the fat or oil, being edible or for use in cosmetics, is separated from the mixture together with the volatile working fluid. The present invention also relates to a volatile environmental pollutants decreasing working fluid, for use in decreasing an amount of environmental pollutants present in a fat or oil, being edible or for use in cosmetics. In addition, the present invention relates to a health supplement, a pharmaceutical and an animal feed product prepared according to the process mentioned above.

Owner:PRONOVA BIOPHARMA NORGE

Method for preparing wax tree wax with wax tree seed

InactiveCN101319168AHigh yieldHigh purityFatty substance recovery/refiningEssential-oils/perfumesTweelFiltration

The invention belongs to the technical field of preparing a Japan wax from Japanese wax tree seeds. The invention is characterized in that: a two-time filtration process is adopted for filtration; that is to say, a primary filtration adopts a 400-mesh stainless steel net to carry out extraction filtration through a barrel type filter; a secondary filtration is a composite filtration carried out by a plate frame filter press, filter liquor is firstly filtrated by a piece of tweel cotton filter cloth, then is filtrated by a piece of industrial filter paper and is finally filtrated by a piece of industrial filter cloth, and the temperature during the whole filtration process is controlled from 70 to 80 DEG C; No. 120 solvent naphtha is taken as an extraction solvent, the addition quantity ratio between the extraction solvent and the Japan wax tree seed powder is 3 to 1 (volume ratio), and extraction is carried out for 50-60min when a temperature is raised to 90-100 DEG C; 320-mesh active carbon is taken as a decolorizer, the addition quantity of the active carbon is about 5 percent of the weight of leaching liquor, a decolorizing temperature is controlled from 110 to 115 DEG C, and the active carbon decolorizing time is controlled from 45 to 55min. Due to the technologies of raw material decladding separation, absorbent decolorizing, two-time filtration, etc., a Japan wax product has higher yield, better purity and quality, higher added value and comprehensive utilization rate, lower production cost and more environmental protection.

Owner:汤小林

Method for producing pepper seed oil

InactiveCN101870918AEasy to process and useReduce oxidationFatty substance recovery/refiningFatty acids production/refiningWaxOrganic solvent

The invention discloses a method for producing pepper seed oil, mainly comprising the steps of crushing pepper seeds, frying seeds, expelling, dewaxing, extracting low-polarity organic solvent, processing extraction liquid on the upper and lower layers, wherein the upper layer is recycled by recovering organic solvent; the material obtained from concentration is free fatty acid; the lower-layer liquid is grease with low acid value, drying, decolouring and filtering at low temperature by a regular refining process to obtain the qualified oil product with the acid value within the range of national standard. In the invention, the pepper seed skin and kernel are expelled together, the crude oil contains a great amount of alpha-linolenic acid in the kernel and volatile oil in the skin, the crude oil is firstly dewaxed and then a great amount of free fatty acid is extracted with the organic solvent, then alkaline refining is performed, the yield of the product is improved, the additional value of the secondary product of wax and the free fatty acid is high, and the loss of volatile oil and oxidization of alpha-linolenic acid are reduced via the low-temperature refining process. The produced pepper seed oil contains above 30 percent of the alpha-linolenic acid and has intense spicy smell. The invention ensures that the pepper seed is comprehensively processed and utilized.

Owner:卢英坚

Tailored oils

ActiveUS9719114B2Raise the ratioReduced activityOrganic chemistryFatty substance recovery/refiningButter cocoaLysophosphatidic acid acyltransferase

Recombinant DNA techniques are used to produce oleaginous recombinant cells that produce triglyceride oils having desired fatty acid profiles and regiospecific or stereospecific profiles. Genes manipulated include those encoding stearoyl-ACP desturase, delta 12 fatty acid desaturase, acyl-ACP thioesterase, ketoacyl-ACP synthase, and lysophosphatidic acid acyltransferase. The oil produced can have enhanced oxidative or thermal stability, can be useful as a frying oil, shortening, roll-in shortening, tempering fat, cocoa butter replacement, as a lubricant, or as a feedstock for various chemical processes. The fatty acid profile can be enriched in midchain profiles or the oil can be enriched in triglycerides of the saturated-unsaturated-saturated type.

Owner:CORBION BIOTECH INC

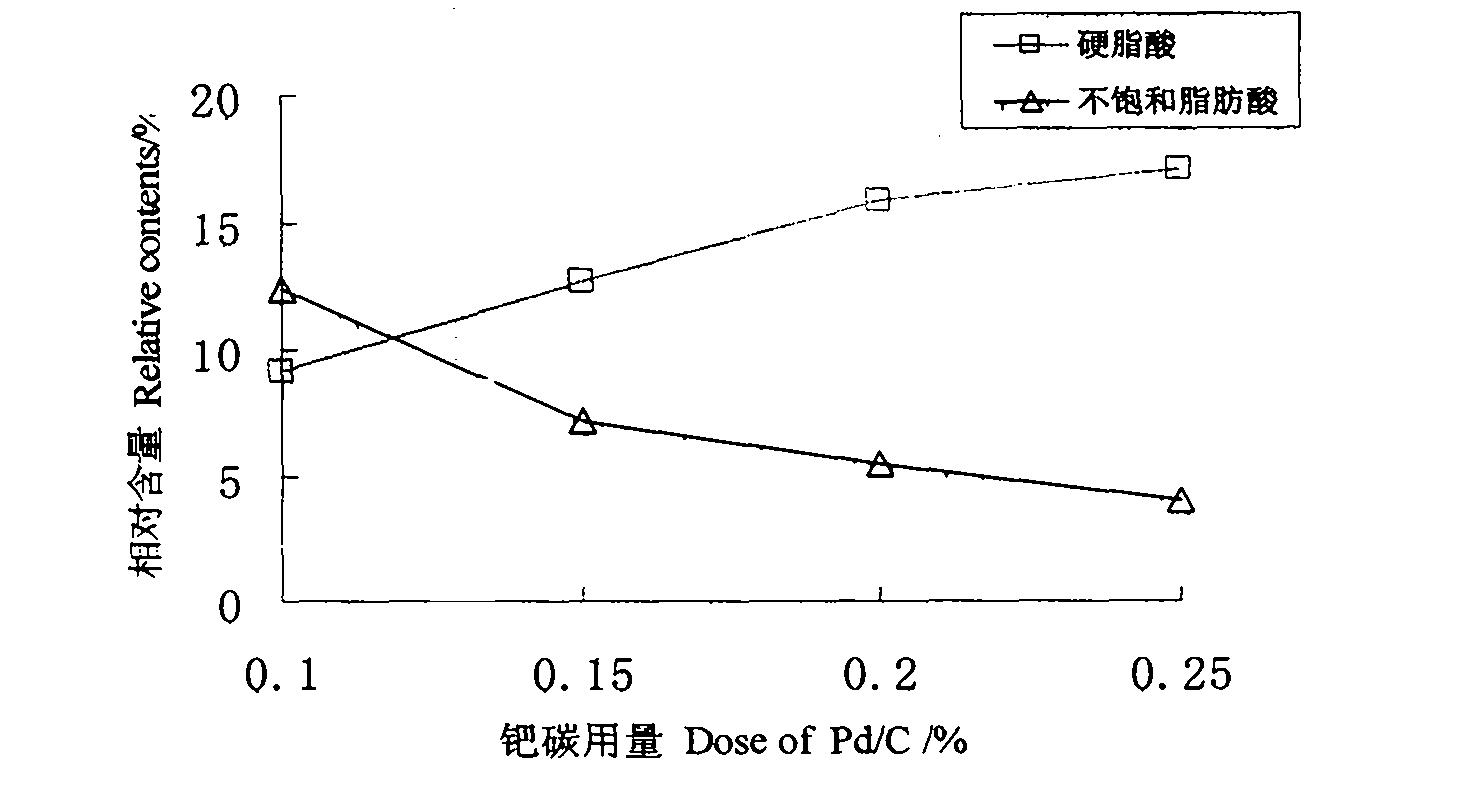

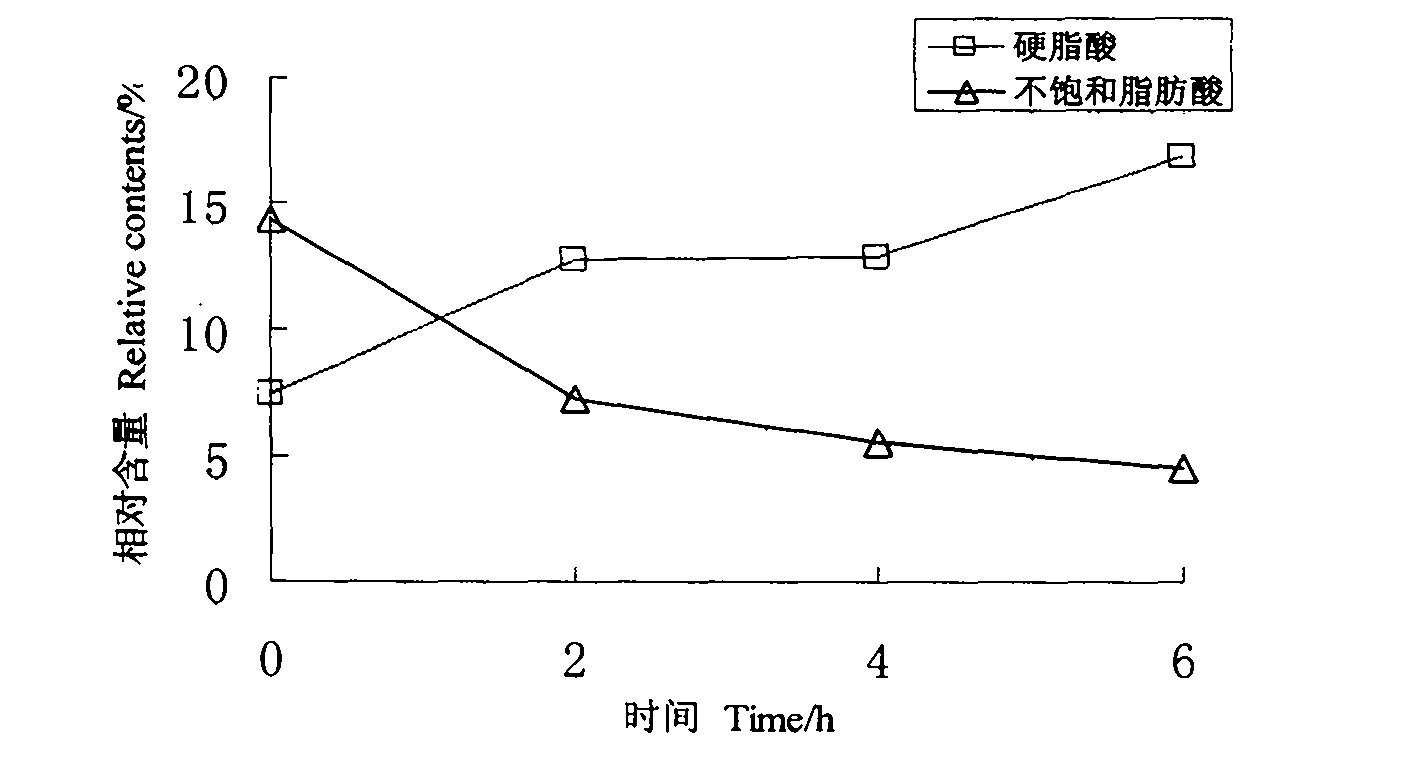

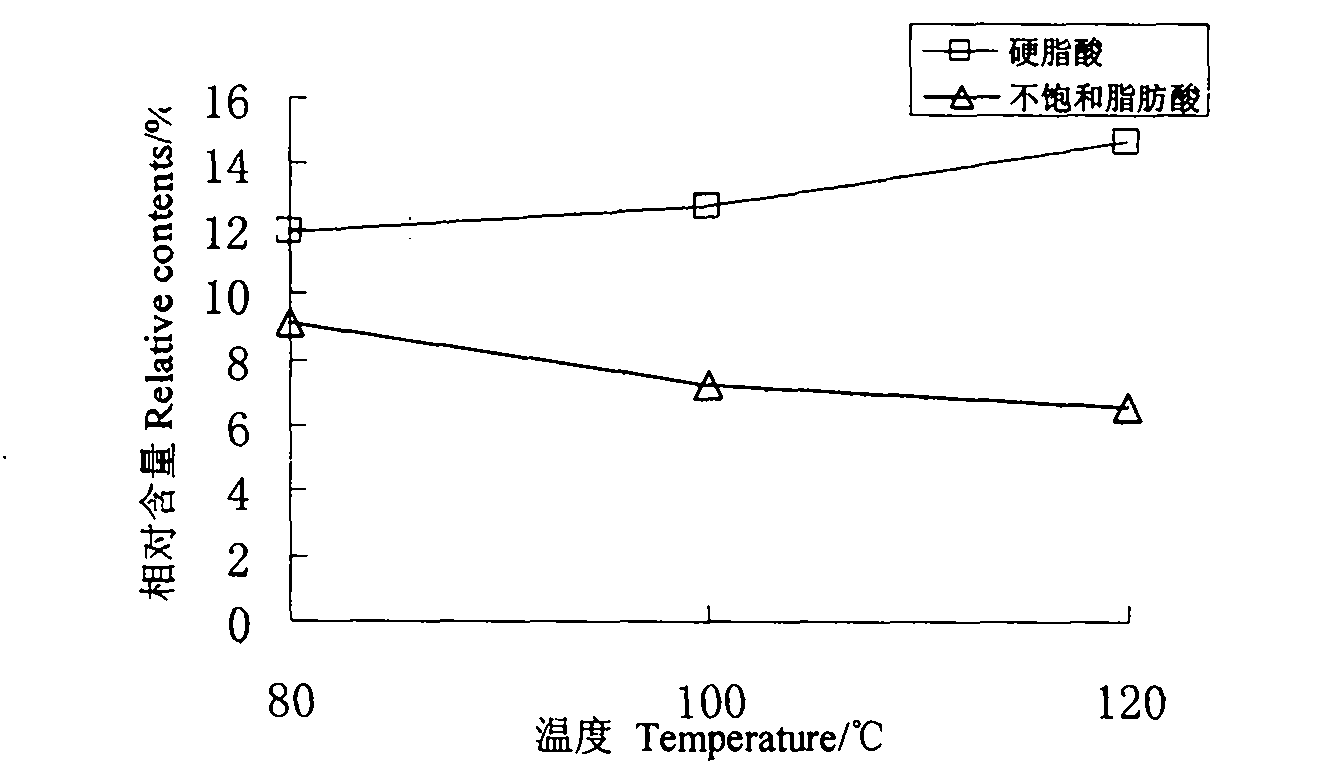

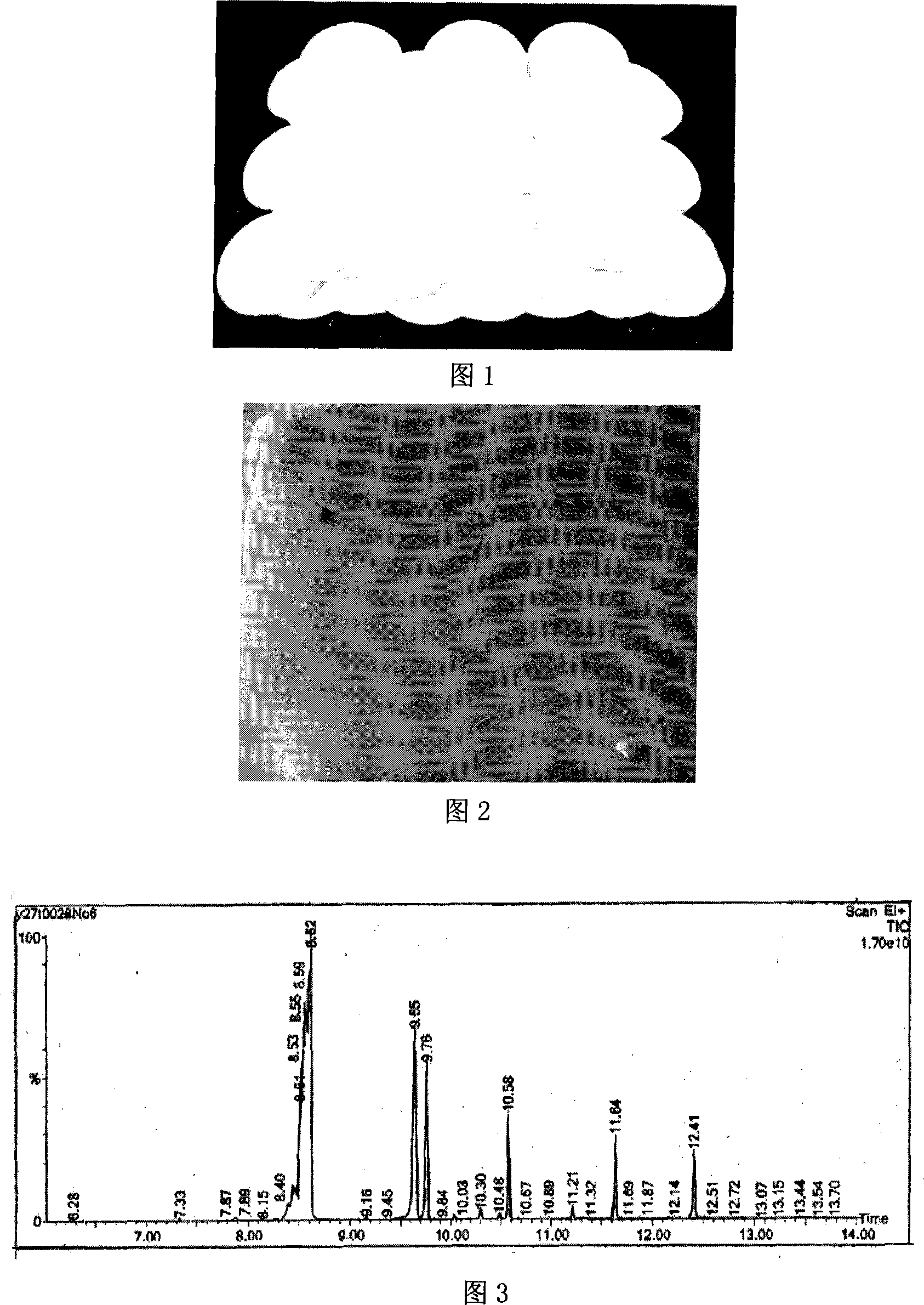

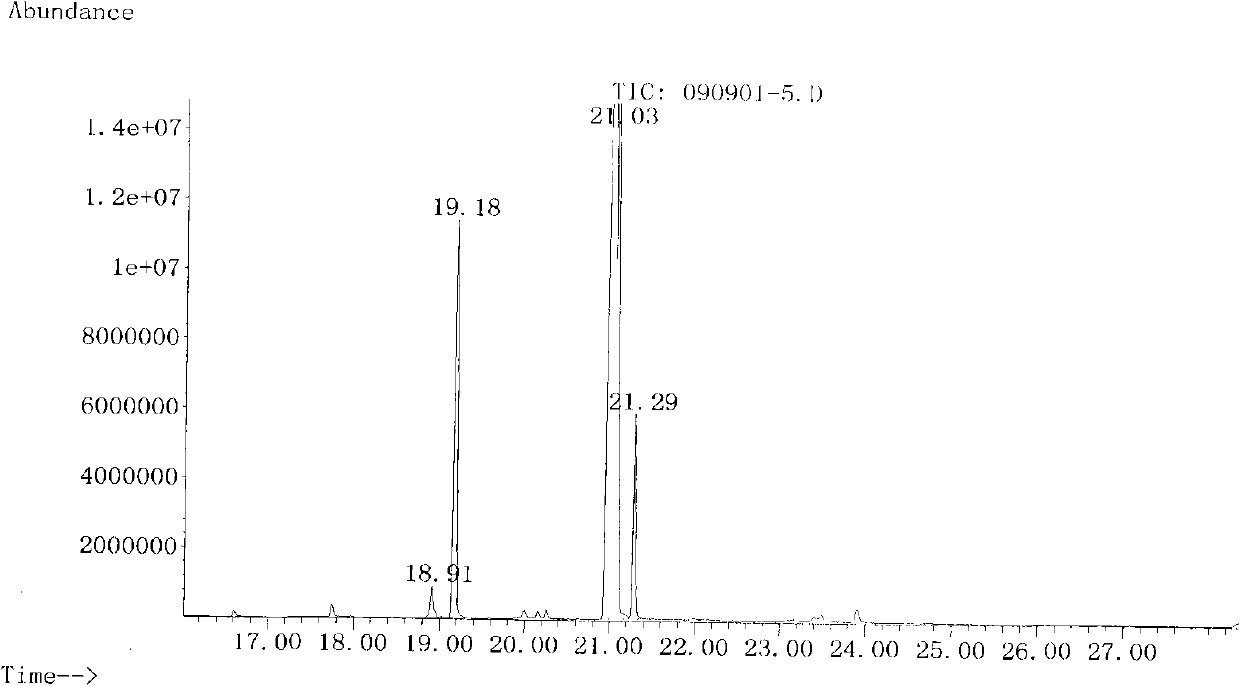

Method for preparing high-quality fine lacquer wax product

ActiveCN102329693APrevent mildewReduce moisture contentFatty substance recovery/refiningFatty substance recoveryPalladium on carbonLacquer

The invention discloses a method for preparing high-quality fine lacquer wax product, which comprises the following steps of: firstly, microwave drying lacquer seeds, separating skin and cores, and lixiviating the skin and flesh part of the lacquer seeds by using a non-polar solvent to obtain rough lacquer wax; heating and uniformly mixing the lacquer wax and a certain proportion of Pd / C catalyst in a high-temperature high-pressure reactor, charging hydrogen gas and maintaining a certain hydrogen gas pressure for reaction; after the reaction is completed, and filtering and discoloring the product while hot to obtain highly saturated lacquer wax; and detecting the variation of fatty acid content in the lacquer wax, by using gas chromatography. The method is simple and convenient, and the problems of low lacquer wax melting point, easy rancidity and the like caused by high content of unsaturated fatty acid in rough lacquer wax can be effectively solved. The obtained hydrogenated fine lacquer wax product has similar physical and chemical properties to Star Cherry-A white wax processed by Japan Araki Wax Manufacturing Company and can be widely applied to the field of daily chemicals.

Owner:NANJING ZHONGSEN BIOLOGICAL TECH CO LTD

Extraction method of japan wax, japan wax composite nano material and preparation method

InactiveCN101205505ASolve shell separationHigh purityFatty substance recovery/refiningThermal insulationLacquer

The invention discloses a leaching method for wild sumac wax which comprises the following procedures: seeds of the wild sumac are purified to obtain flesh parts of the seeds of the wild sumac, then the flesh parts are crushed into fine powder, the non-polar solvent is used to make a rotary type continuous leaching to the fine powder to obtain the leaching liquor, the leaching liquor is made thermal insulation, decolored, cylindrical type and plate type secondary filtration and vacuum condensation; the invention also provides a wild sumac wax composite nanometer material which comprises the wild sumac wax vacuum condensate and inorganic nanometer material. The invention also provides a preparation method for the wild sumac wax composite nanometer material, which comprises the following steps: the wild sumac wax vacuum condensate is heated, added with the inorganic nanometer material, made thermal insulation and stirred to form the homogeneous wax liquid, spherical liquid drops are formed in the high-temperature area of a spherical granulator through a nozzle of the spherical granulator, and gradually cooled in a water cooling tower to dehydrate partial free water to obtain white sumac wax particles which are dehydrated then, and spherical sumac wax particles are formed. The invention has the advantages that the invention prepares the wild sumac wax with high purity, and particularly improves the performance of the wild sumac wax nanometer material.

Owner:NANJING ZHONGSEN BIOLOGICAL TECH CO LTD

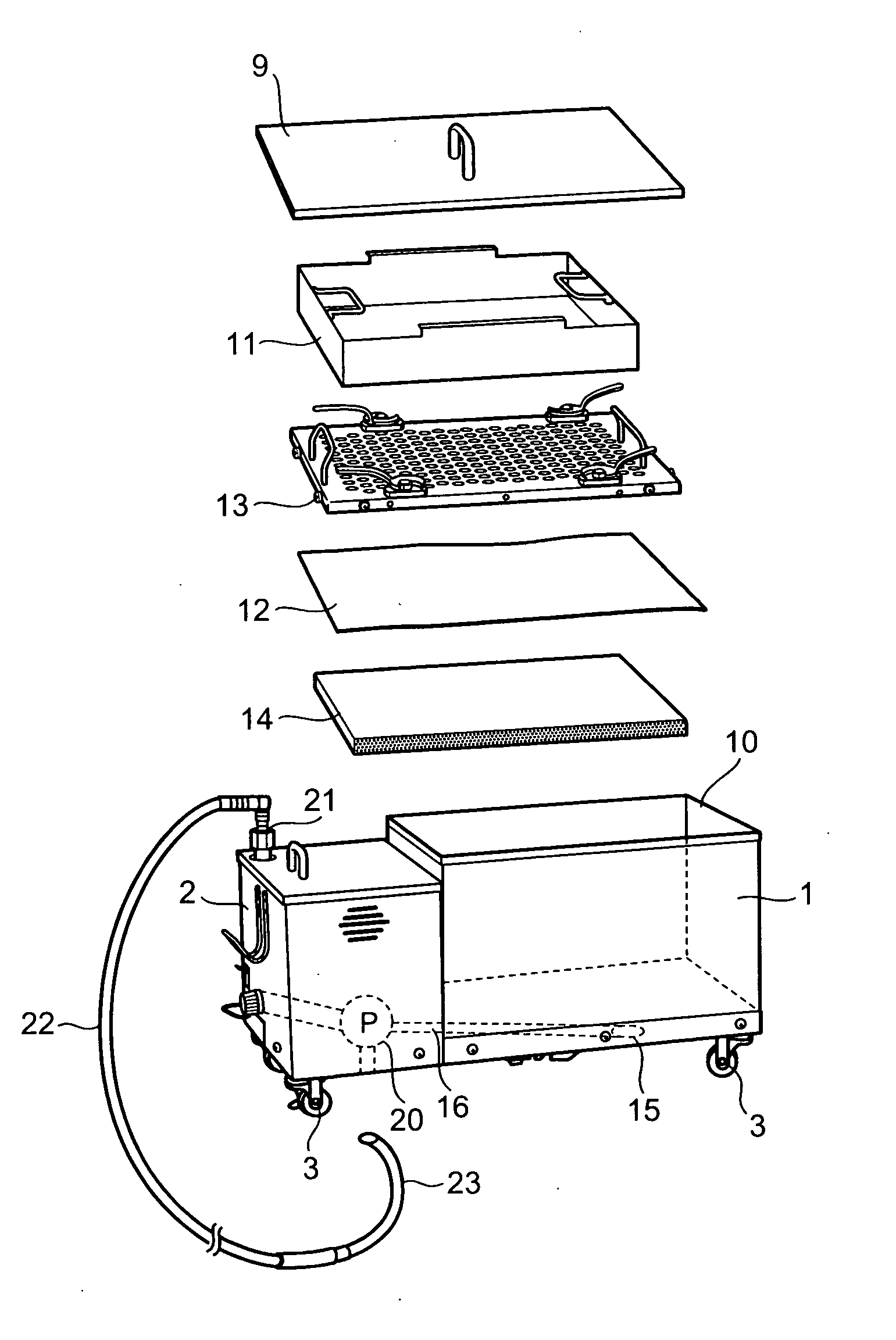

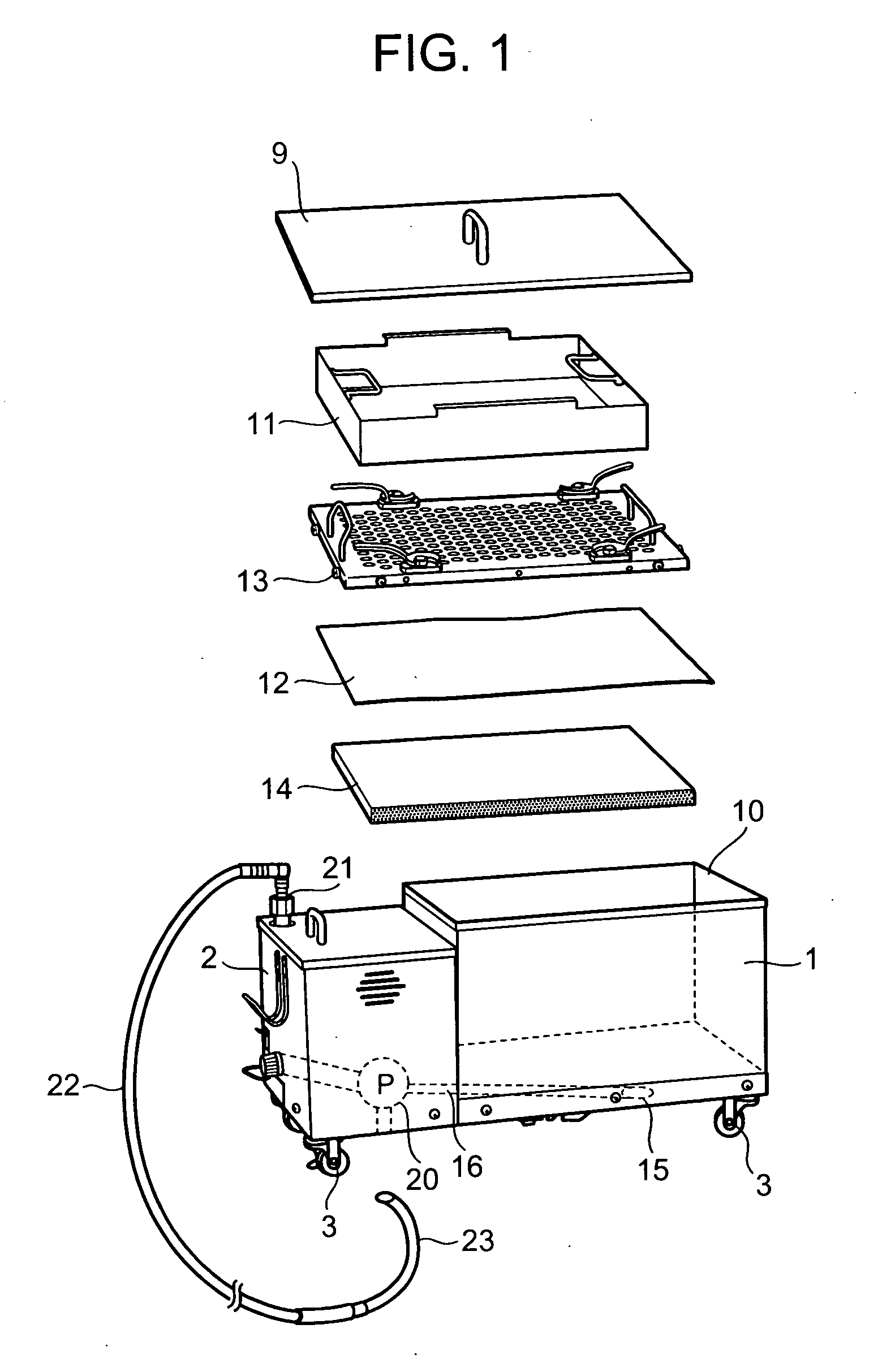

Method for purifying cooking oil and cooking oil filter apparatus

InactiveUS20050223909A1Prevent degradationSuitable materialFatty substance recovery/refiningFiltration separationOxidation resistantFilter material

To use cooking oil repeatedly for a long time while maintaining quality of the cooking oil in a good condition, a cooking oil filter apparatus according to this invention filters the cooking oil collected from a fryer in using a filtering material. A fragment of granite porphyry containing amphibole is used as the filtering material. The granite porphyry containing the amphibole indicates a good antioxidant effect against the cooking oil, and the cooking oil is recycled upon contact with the granite porphyry, thereby prevented from degrading. As a structure, for example, the apparatus has a filter cartridge containing the fragment of the granite porphyry containing the amphibole, in which a basket and a paper filter respectively in a mesh form are disposed on the filter cartridge.

Owner:KURATA KATSUHIKO

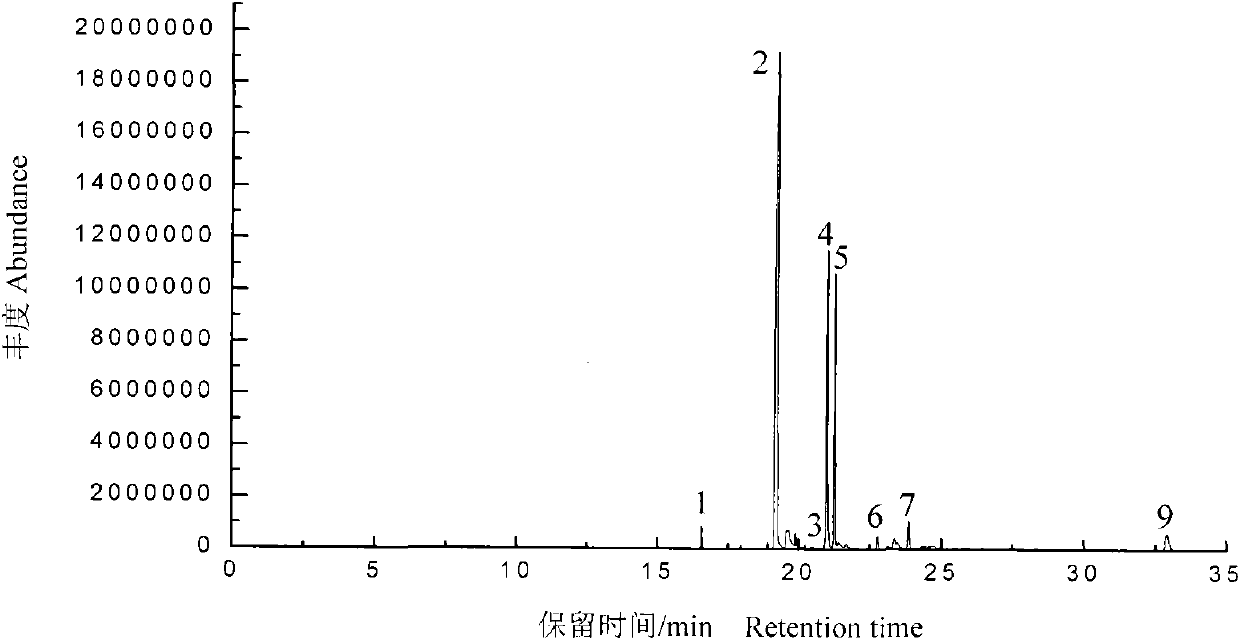

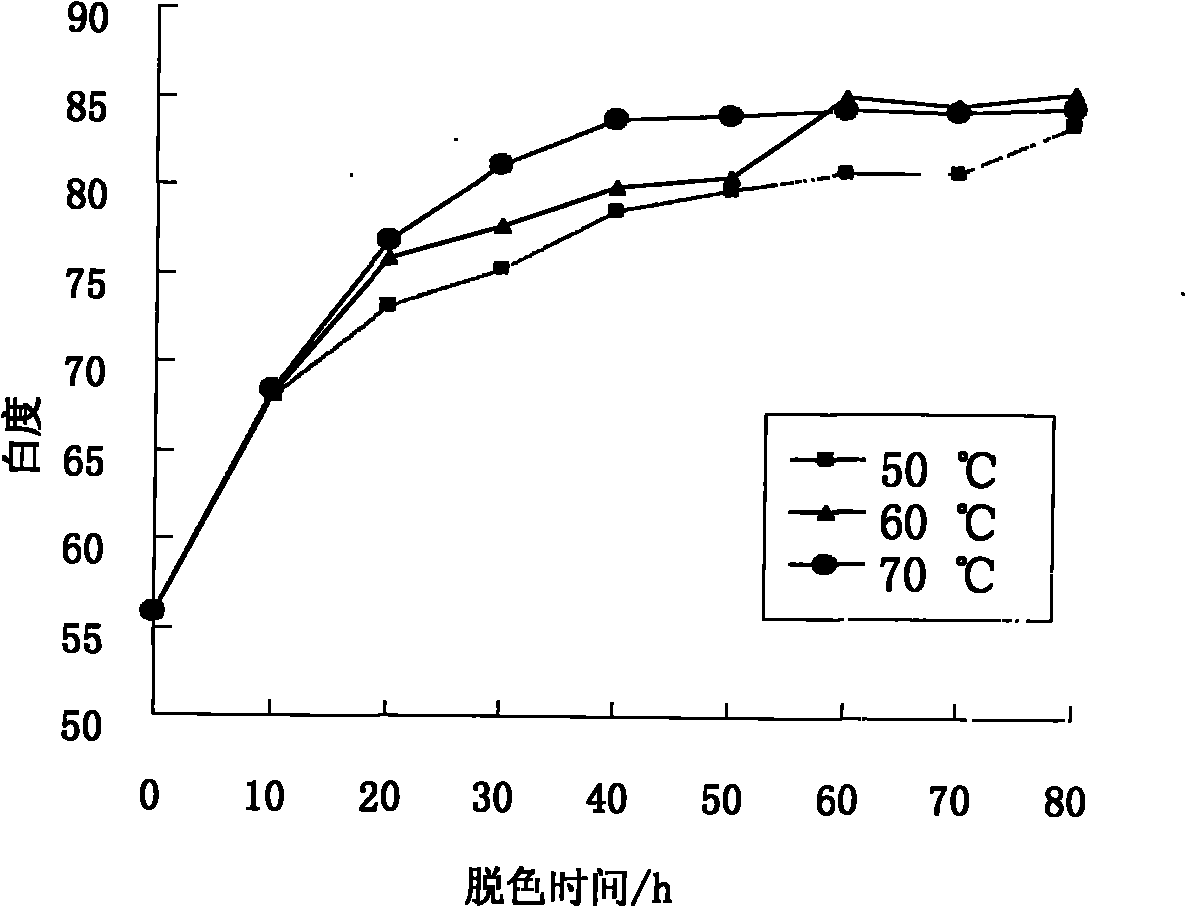

Method for preparing high-quality colorless lacquer wax quickly by ultraviolet decoloring

ActiveCN101906354AControl hungerControl fatty acid contentFatty substance recovery/refiningFatty-oils/fats productionWaxActivated carbon

The invention discloses a method for preparing high-quality colorless lacquer wax quickly by ultraviolet decoloring, which comprises the following steps: separating the pulp from the peel of crushed sumach seeds, extracting with a nonpolar solvent to obtain coarse lacquer wax, decoloring the coarse lacquer wax under the irradiation of a 100 to 1,000W ultraviolet lamp and controlling the decoloring temperature at different stages, wherein each stage is 5 to 15 hours; measuring the whiteness and chromaticity of the decolored lacquer wax, monitoring the change of fatty acid in the lacquer wax by using GC-MS and reducing the unsaturated fatty acid content of the colorless lacquer wax to improve product quality. The method can prepare the colorless lacquer wax quickly and avoid using active cargon or carclazyte to prevent lacquer wax loss. The method is simple, convenient, economic, environmentally-friendly and effective and can be used for decoloring and refining industrial coarse wax.

Owner:陕西秦乔农林生物科技有限公司

Fat composition

InactiveUS20070122452A1Promote absorptionSufficient exhibition of pharmacological effectBiocideOrganic active ingredientsFatty acids.polyunsaturatedPhospholipid

Provided is a composition permitting high systemic absorption of n-3 polyunsaturated fatty acids and high transfer of them to tissues and capable of fully exhibiting pharmacological effects which the fatty acids have. A fat composition containing one or more phospholipids having, as a constituent fatty acid, an n-3 polyunsaturated fatty acid selected from docosahexaenoic acid, docosapentaenoic acid and eicosapentaenoic acid; and α-linolenic acid and / or a fat containing α-linolenic acid.

Owner:WAKUNAGA PHARMA CO LTD

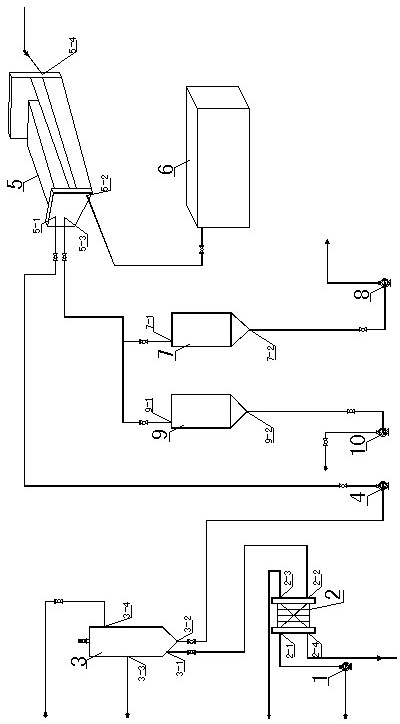

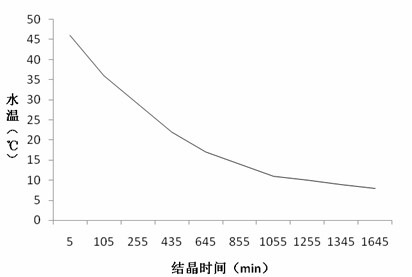

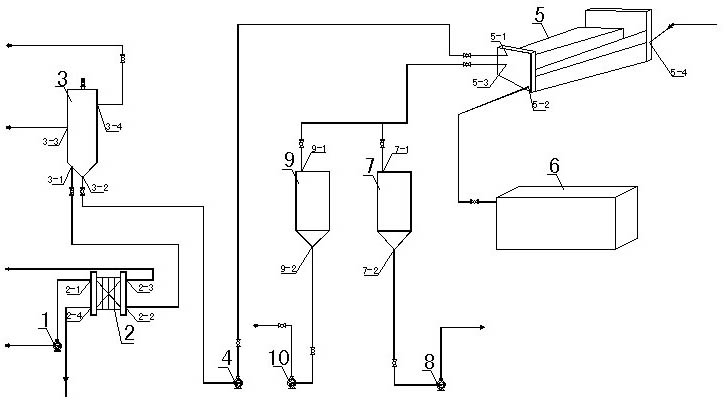

Oil dewaxing process and device

InactiveCN102433220AReduce lossNo pollution in the processFatty substance recovery/refiningFatty-oils/fats refiningWaxOil and grease

The invention discloses an oil dewaxing process and an oil dewaxing device. The process comprises: heating oil to be dewaxed till the wax is molten completely, transferring the oil to a crystallizing tank, and subjecting the oil to crystallization and crystal growing according to preset crystallization menu in the crystallization tank; delivering the crystallized oil into a membrane filter press, filtering, transferring the separated dewaxed oil into a dewaxed oil tank, and thus, completing dewaxing. The dewaxing device comprises the crystallization tank, wherein the crystallization tank is connected with the membrane filter press through a feeding pump; and the discharging port of the membrane filter press is connected with the dewaxed oil tank. Compared with the conventional dewaxing process, the process and the device have the advantages that: the need of any aid filtering agent is obviated, so the production cost is effectively reduced; the oil product is natural and environment-friendly, and the loss of oil is low; by wax by product is pure, does not contain any aid filtering agent, can be directly used in industrial production of edible wax, avoids any environment pollution and requires little equipment investment; and the automation degree of the device is high, and the device is more suitable for large-scale industrial production.

Owner:郑州远洋油脂工程技术有限公司

Process for decreasing the amount of cholesterol in a marine oil using a volatile working fluid

ActiveUS20060134303A1Efficient processingLower cholesterol levelsCosmetic preparationsNervous disorderWorking fluidFree form

The invention relates to a process for decreasing the amount of cholesterol in a mixture comprising a marine oil, the marine oil containing the cholesterol, which process comprises the steps of adding a volatile working fluid to the mixture, where the volatile working fluid comprises at least one of a fatty acid ester, a fatty acid amide and a hydrocarbon, and subjecting the mixture with the added volatile working fluid to at least one stripping processing step, in which an amount of cholesterol present in the marine oil in free form is separated from the mixture together with the volatile working fluid. The present invention also relates to a volatile cholesterol decreasing working fluid and a health supplement and a pharmaceutical, based on a marine oil, prepared according to the process mentioned above.

Owner:PRONOVA BIOPHARMA NORGE

Biodiesel process

InactiveUS7528272B2Fatty oils/acids recovery from wasteFatty substance recovery/refiningBiodieselAlcohol

The present invention provides a biodiesel process capable of yielding a mono-alkyl ester biodiesel. In one embodiment, a process for yielding biodiesel comprises providing a feed stream. Preferably, the feed stream comprises mono-alkyl esters, salts, alcohol and glycerol. The process also comprises substantially separating alcohol from the feed stream to yield a first stream. The first stream comprises mono-alkyl esters, glycerol and salts. A separation of alcohol from the first stream is performed by volatility. Furthermore, the process of the invention comprises substantially separating salts from the first stream to yield a vapor stream. The vapor stream also comprises mono-alkyl esters and glycerol. Separation of salts of the vapor stream is also performed by volatility. Glycerol and mono-alkyl esters of the vapor stream are also substantially separated so as to yield a biodiesel. Preferably, the biodiesel is a fuel grade biodiesel comprising fatty acid mono-alkyl esters.

Owner:ARTISAN IND

Method for decolorizing rice bran wax

ActiveCN103981032ALow costReduce manufacturing costFatty substance recovery/refiningEvaporationWastewater

The invention discloses a method for decolorizing rice bran wax. The method comprises the steps of dehydrating rice bran wax paste, adding an industrial hexane solvent for removing oil, then adding an adsorption decolorizing agent for decolorizing in the presence of the industrial hexane solvent, and finally performing solid-liquid separation and evaporation to remove the solvent, thus obtaining decolorized rice bran wax. Compared with the prior art, the method has the advantages that the method does not adopt any oxidant, no heavy metals are left, a large amount of wastewater is not produced, the production cost is reduced, and the pollutants are reduced; and meanwhile, a white rice bran wax product with the whiteness of nearly 32 can be obtained by adopting the method, the purity of the product is high, and the application range of the product is expanded.

Owner:舒城县金禾油脂科技开发有限公司

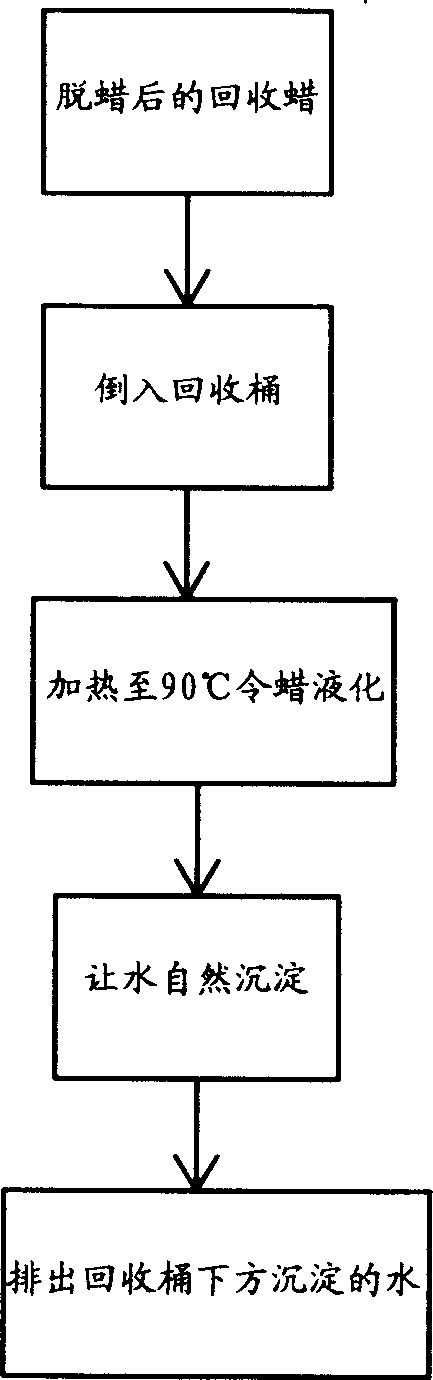

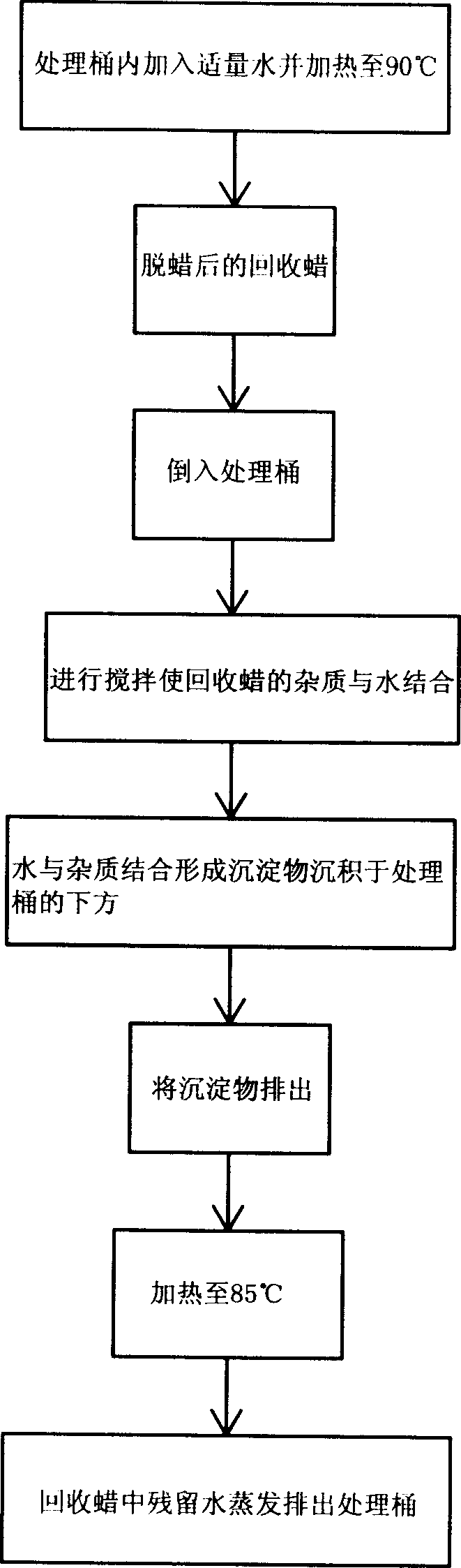

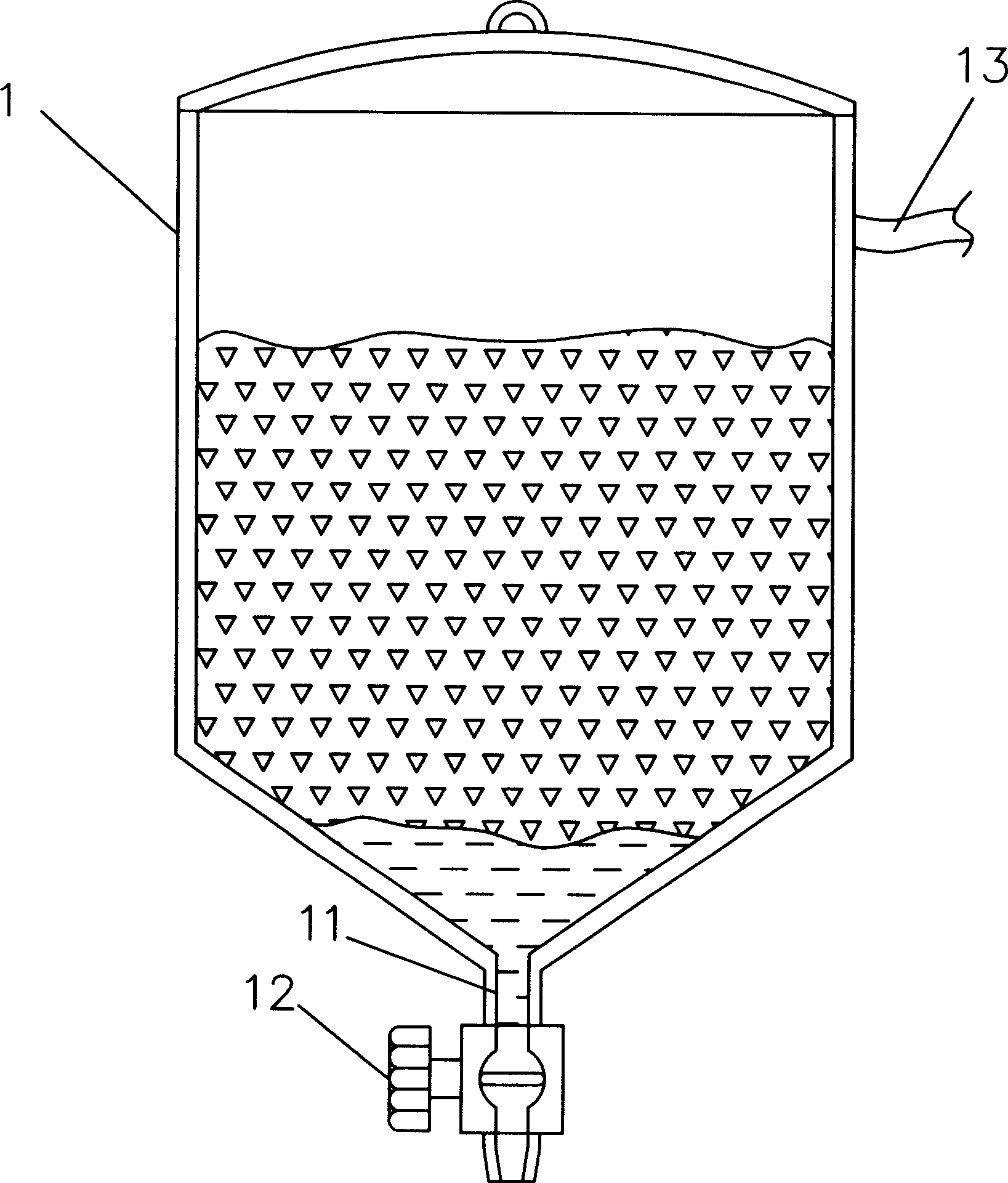

Method for processing recovered wax

InactiveCN1796518AHigh purityReduced settling timeFatty substance recovery/refiningFatty substance recoveryWaxVacuum pumping

This invention describes a process for treating recovered wax, comprising the steps of: adding water whose amount is at least 10% that of the recovered wax into a treating barrel, and heating the water to higher than or erqual to 85 deg.C and lower than100 deg.C; adding the recovered wax into the barrel, keeping the recovered wax in liquid state and stirring in order that the impurities in the wax combine with water and precipitate to the bottom of the treating barrel due to a higher specific weight than the wax; discharging the precipitant, and vacuum-pumping and heating the treating barrel so that the residual water is vaporized and discharged. The process can recover pure wax within a short time, thus shortening the operation time and reducing the cost, and can increase the purify of the recovered wax.

Owner:洪静升

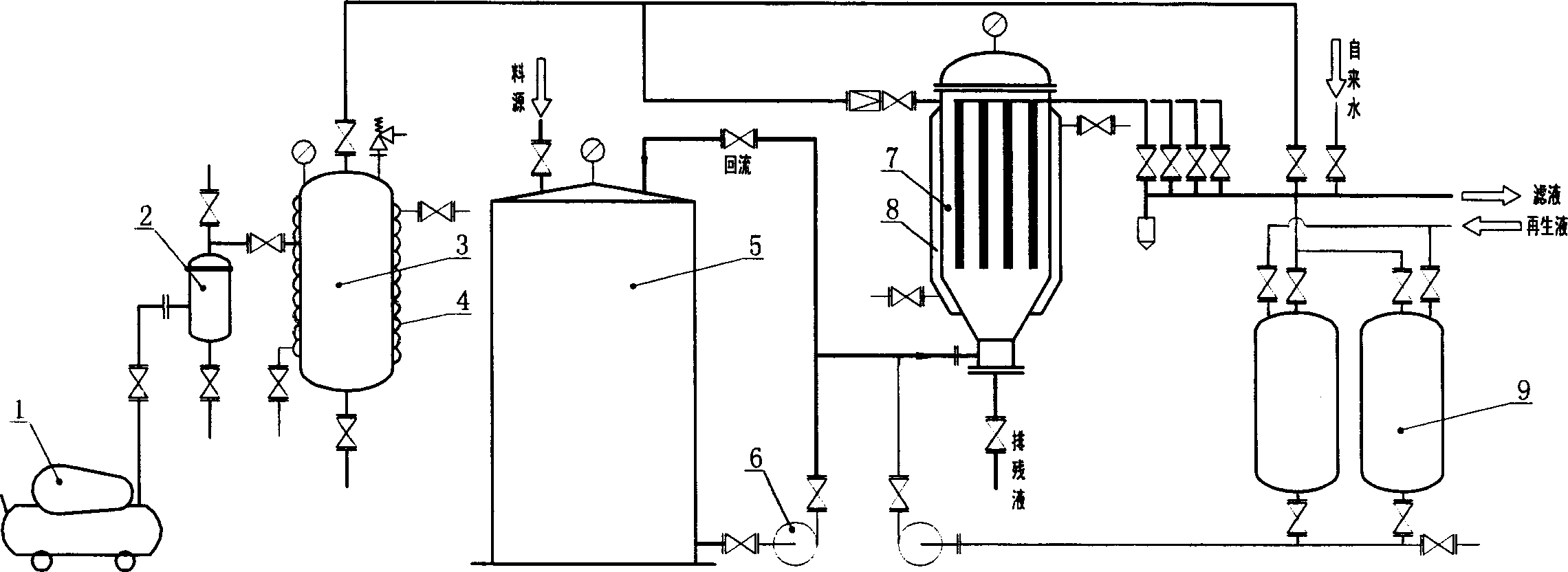

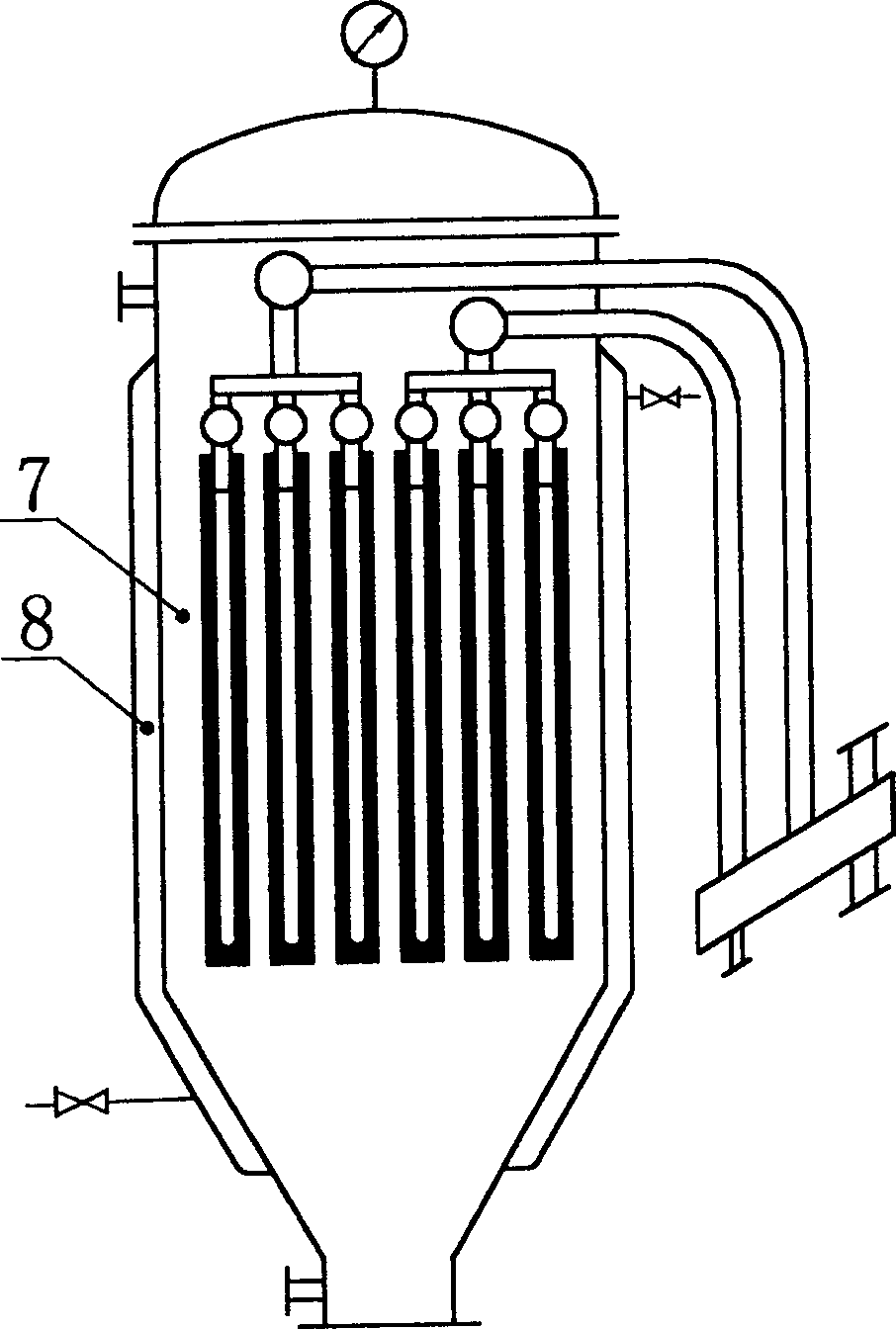

Precision micro hole filtering method and device for winterization edible oil defatted wax

InactiveCN1605617ARemove completelyReduce resistanceFatty substance recovery/refiningFatty-oils/fats refiningWaxPhospholipid

The present invention is the precise microporous filtering process and apparatus for defatting and dewaxing winterized edible oil. The process includes the following steps: filtering the winterized edible oil in precise microporous filtering machine to obtain filtrate as refined edible oil; back blowing with normal temperature compressed air for 4-6 times or back blowing with hot compressed air at 65-70 deg.c in raised filtering pressure difference; and chemical regeneration of the precise microporous filtering machine with regenerating solution capable of dissolving niger and phospholipid from regenerating solution tanks. The apparatus includes compressor tank with outer coiled pipe jacket, precise microporous filtering machine with water cooling jacket, and rigid microporous filtering pipe. The present invention has the advantages of complete defatting and dewaxing, high filtering precision, high filtering efficiency, high regeneration efficiency, etc.

Owner:宋志骥

Light rice bran cerotic acid wax and preparation method thereof

PendingCN108048222AEffective oxidation removalGood emulsifying effectFatty substance recovery/refiningFatty substance recoveryAcetic acidEthyl ester

The invention provides a preparation method of light rice bran cerotic acid wax. The method includes the following steps of deoiling, oxidation and acid pickling and water scrubbing. During deoiling,deoiled rice bran wax to be discolored is soaked in ethyl acetate, heated for melting and then cooled and sliced for use. During oxidation, the sliced rice bran wax and dilute sulphuric acid are heated to enable the rice bran wax to be melted, then the rice bran wax is added into a sodium bichromate solution and then constantly stirred, the color of the rice bran wax turns light from brown, and natural cooling and standing are conducted to make the wax delaminated from a chromium slurry solution. During acid pickling and water scrubbing, the oxidized rice bran wax is heated into a liquid thenput into dilute sulphuric acid and stirred, standing is carried out to make the wax delaminated from a water scrubbing liquid, then the mixture is added with water, stirred and heated at the same timetill the wax is totally melted, stirring continues to be conducted, standing is carried out to make the wax delaminated from the water scrubbing liquid, and the oxidized rice bran wax at the upper layer is sliced and packed after being cooled. The invention further provides the light rice bran cerotic acid wax. According to the method, the rice bran wax is oxidized by sodium bichromate to generate the rice bran cerotic acid wax which is light in color, odorless and hard in texture, micromolecular materials are effectively removed, the emulsibility and the luster are obviously improved, and deep processing is facilitated.

Owner:重庆合才化工科技有限公司

Decolorizing and dewaxing process for vegetable oil with one-step method

InactiveCN101338249AAvoid lostReduce manufacturing costFatty substance recovery/refiningFatty-oils/fats refiningVegetable oilRe absorption

The invention provides a technology which can finish decolorization and dewaxing of vegetable oil within one step. The technology is described as following: after being heated, the vegetable oil needed to be treated is mixed with argil and active carbon; the mixture is sent into a decolorization tower for absorption; the materials after being absorbed then is sent into a deacidification tower for re-absorption; the materials after being re-absorbed then is pumped into a crystallizer for crystallization; the materials after being crystallized then is sent into a separator to separate the vegetable oil. The technology finishes decolorization and dewaxing treatment within one step. The materials after being decolorized directly enter into the decolorization tower without separating, with the result that the intermediate links between the decolorization and the dewaxing processes are reduced. The technology saves the equipment input and steam, power and manpower consumption necessary during the separation process, avoids the loss of the vegetable oil produced by the separation, has good decolorization and dewaxing effects, can recycle the argil and the active carbon when dewaxing, does not need to add filter acid any more, saves consumption costs of the filter acid, and greatly reduces the production cost of the vegetable oil.

Owner:SHANDONG SANXING CORN IND SCI CO LTD

Method for recovering lac and extracting lac wax

InactiveCN101392147AMeet lacFulfil requirementsFatty substance recovery/refiningNatural resin processWaxOrganic solvent

The invention relates to a method for recovering a lac and extracting a lac-wax, which comprises: water or a dilute sodium carbonate solution is utilized for dissolving red dregs containing the lac and the lac-wax which are generated during the production process of a bleached lac, the dissolving temperature is between 70 DEG C and 100 DEG C and heat filtration is carried out so as to obtain a sodium carbonate solution containing the lac and the lac-wax removed from lots of mechanical substances; the solution is cooled and a dilute sodium hypochlorite solution is added for bleaching; the bleached solution stands to separate into layers and a lac-wax crude product is obtained by taking out the surface coagulum; the solution is filtered with diatomite or active floridin, the filtrate is added with dilute sulphuric acid so as to separate out a white floc and a bleached lac-wax is obtained after washing, solid-liquid separation and drying; the lac-wax crude product is covered with a piece of filter paper or filter cloth and put into a soxhlet extractor, an organic solvent is added to carry out refluxing extraction so as to obtain a mixture of organic substances and the lac-wax; the mixture of the organic substances and the lac-wax is carried out with normal pressure or reduced pressure volatilization and distillation and after the organic solvent is recovered, the rest is cooled and a refined lac-wax product is obtained.

Owner:KUNMING UNIV OF SCI & TECH

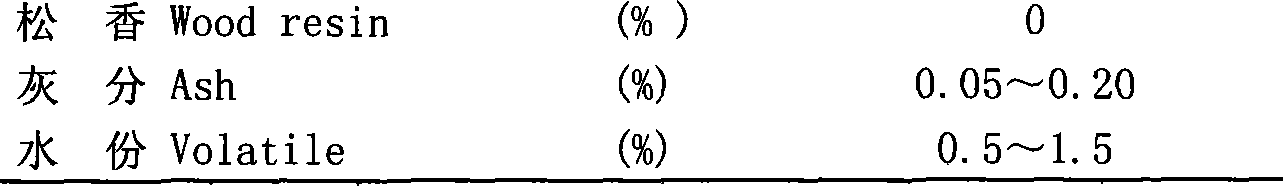

Device and method for dewaxing textile and recovering wax

InactiveCN1715384AHigh dewaxing rateReduce pollutionFatty substance recovery/refiningFatty substance recoveryWaxChemical industry

Owner:DONGHUA UNIV +1

Preparation method of lacquer tree seed wax oil

InactiveCN103849470AEasy to separateNot easy to stickFatty substance recovery/refiningAgricultural engineeringLacquer tree

The invention discloses a preparation method of lacquer tree seed wax oil. The preparation method comprises the following steps: cooling lacquer tree seeds, rubbing the seeds, screening, crushing, pneumatically conveying and selecting, cooking, solvent extracting, filtering, separating and finally obtaining the lacquer tree seed wax oil. The preparation method of the lacquer tree seed wax oil can enable preparation, extraction and separation of the lacquer tree seed wax oil to be continuous, improves production efficiency, material utilization rate and wax quality, and improves wax market competitiveness. By applying the method, the husk-core separating efficiency of the lacquer tree seeds reaches over 95%, and the lacquer tree seed core perfectness ratio reaches over 90%; and moreover, compared with the existing separating method, the whole set of process flow is reliable in operation and strong in economical efficiency, so that processing cost for per tonnage of seeds is lowered by over 15%.

Owner:云南省轻工业科学研究院有限公司 +1

Method for extracting lipid mixture containing phospholipids comprising polyunsaturated fatty acids from viscera of fish, method for preserving viscera prior to extraction, and lipid mixture extracted thereby

InactiveUS7189418B2Simple and low-cost methodReduce lossesFatty substance recovery/refiningGroup 5/15 element organic compoundsLipid formationHigh concentration

The present invention provides a method for extracting a lipid mixture having a high percentage of phospholipids comprising polyunsaturated fatty acids. The method comprises the steps of (a) heating the viscera of fish with hot water or steam; and (b) extracting from the heated viscera of fish, using a solvent, the lipid mixture containing phospholipids comprising polyunsaturated fatty acids. The lipid mixture obtained by the present method contains phosphatidylserine comprising docosahexaenoic acid and phosphatidylethanolamine comprising docosahexaenoic acid in high concentration.

Owner:MARUHACHI MURAMATSU +1

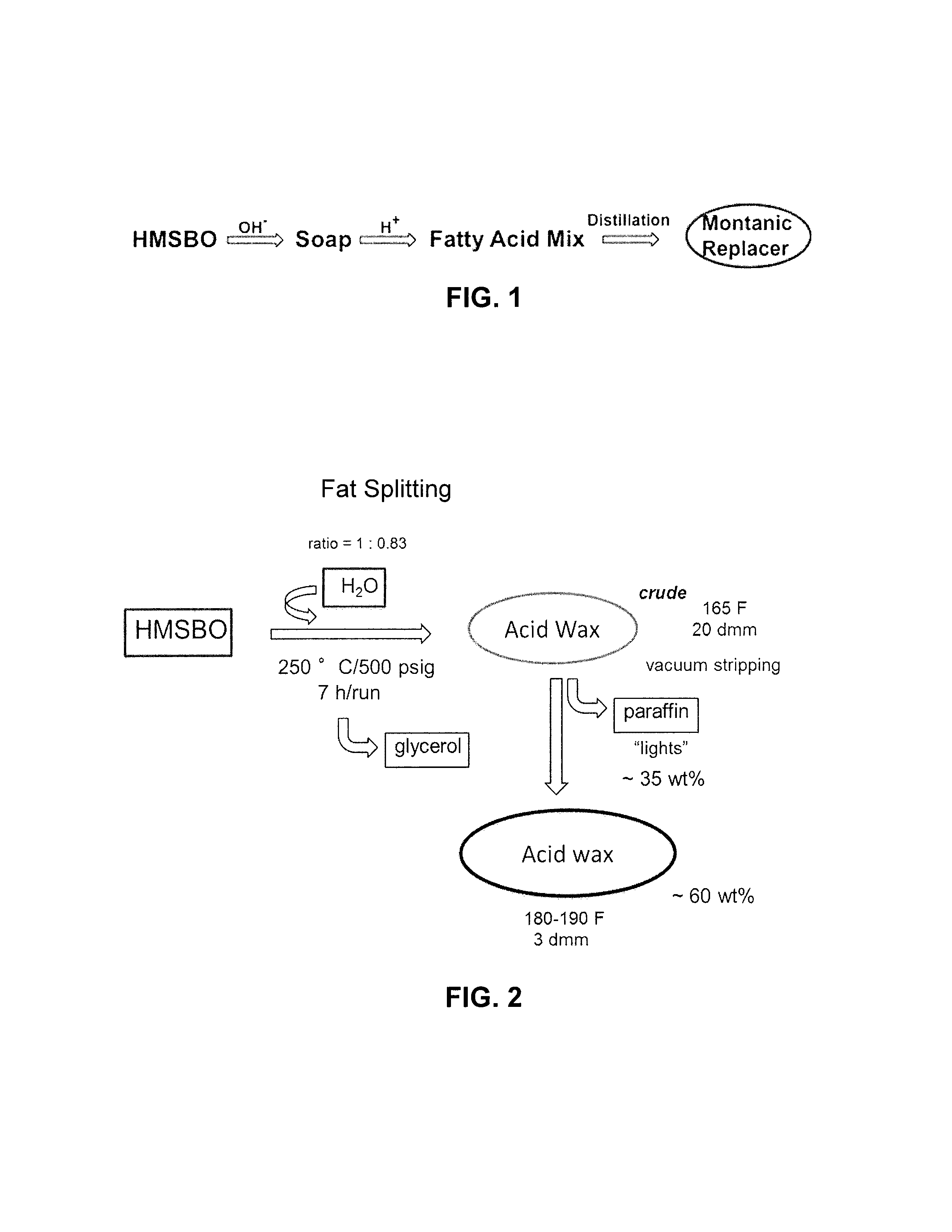

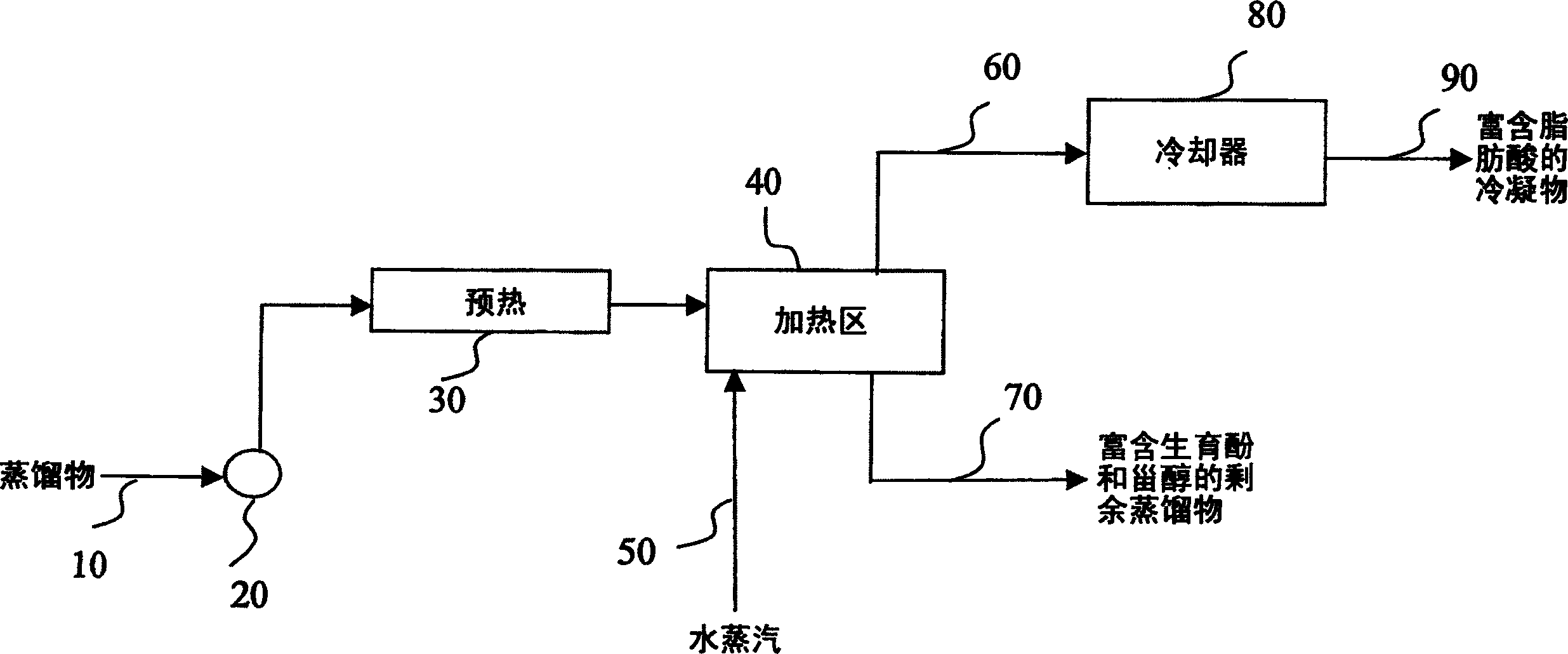

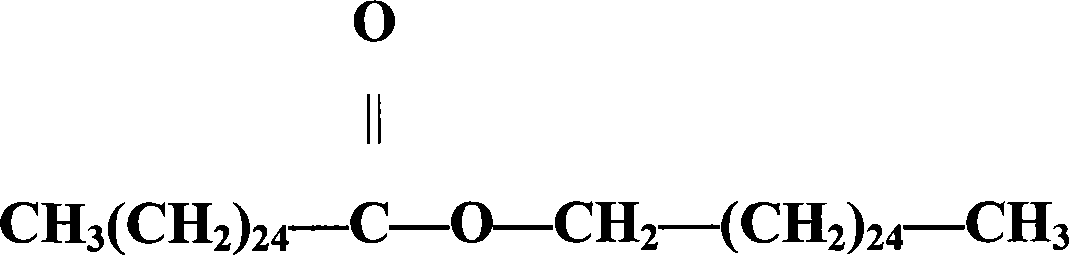

Renewable fatty acid waxes and methods of making

ActiveUS20130178640A1Fatty oils/acids recovery from wasteFatty acid hydrogenationParaffin waxLong chain fatty acid

Natural oil based fatty acid wax compositions and their methods of making are provided. The methods comprise providing a natural oil, and hydrogenating and metathesizing the natural oil, and then converting the hydrogenated metathesized natural oil to obtain a fatty acid wax comprising free fatty acids and / or salts of fatty acids, glycerol and / or alcohol, and paraffin, wherein the fatty acid wax has at least 50 wt % of carbon chain compositions with at least 18 carbon atoms. The compositions may comprise 85-100 wt % long-chain fatty acids, 0-15 wt % esters, wherein the fatty acid comprises between 15-60 wt % long chain di-acids and 40-85 wt % long chain mono-acids. The compositions may comprise about 50-100 wt % long-chain fatty acids and about 0-50 wt % esters, wherein the fatty acid may comprise between about 15-80 wt % long chain di-acids and about 20-85 wt % long chain monoacids.

Owner:WILMAR TRADING PTE LTD

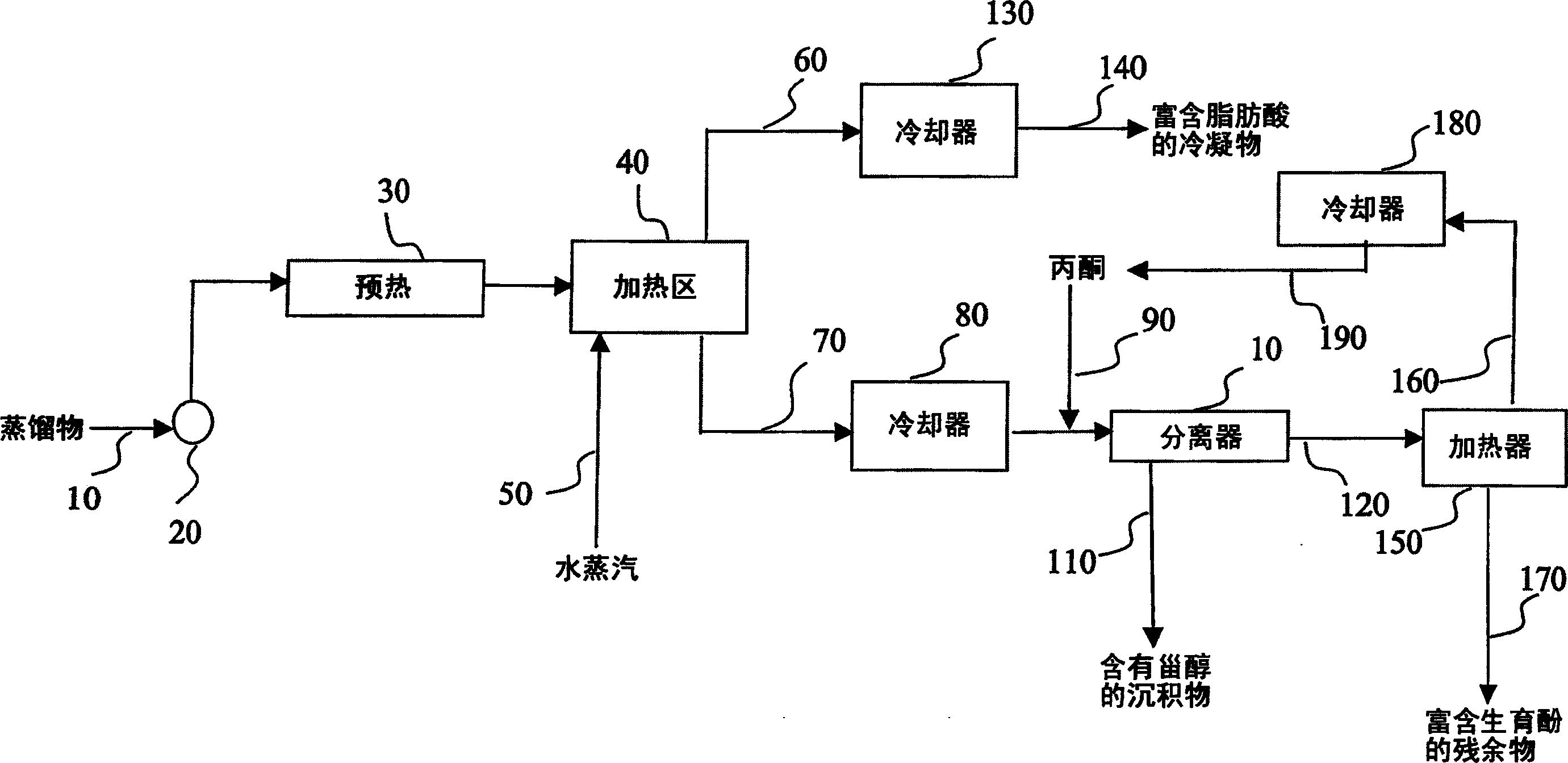

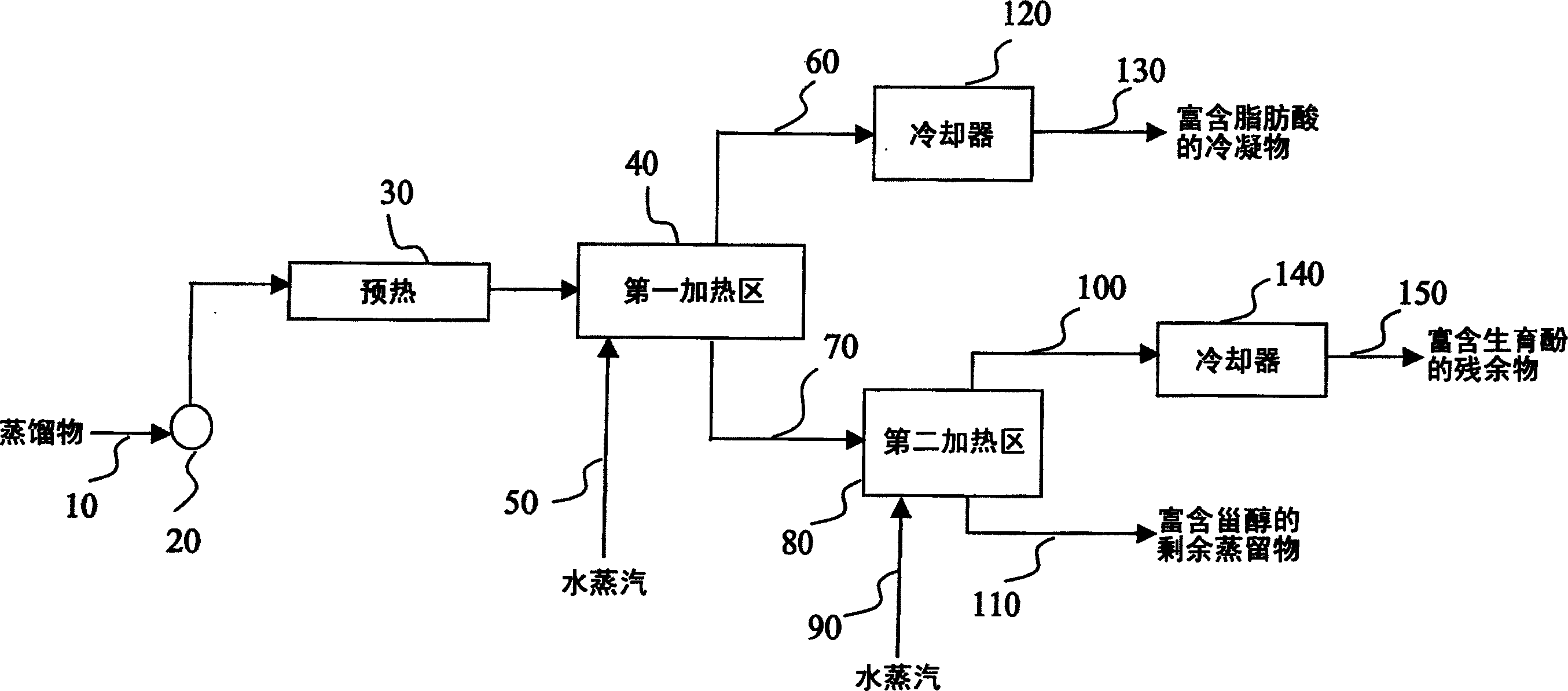

Methods for treating deodorizer distillate

Owner:IP HLDG LLC

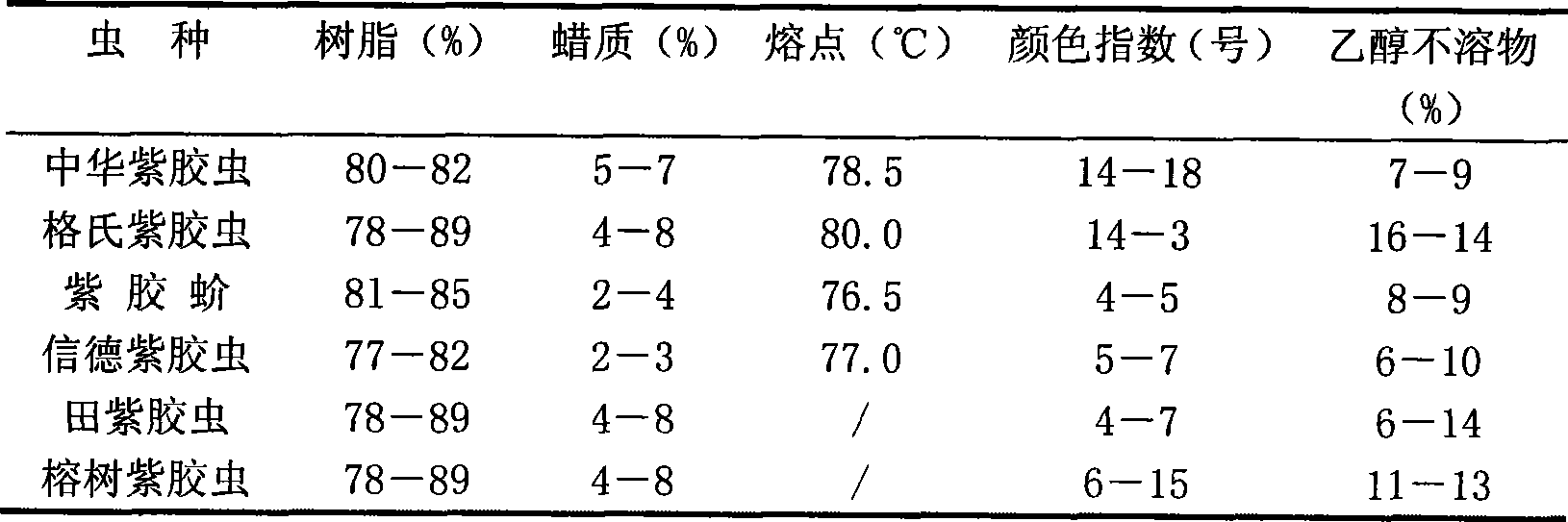

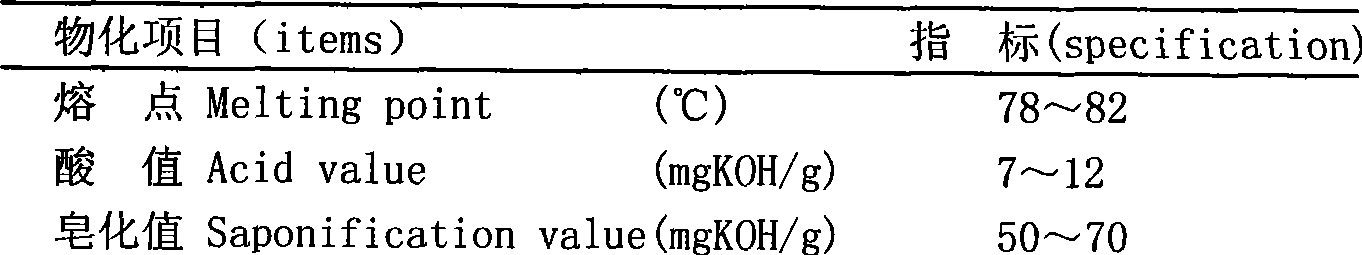

Refining method for insect wax

InactiveCN101225345AImprove refining yieldHigh melting pointFatty substance recovery/refiningFatty substance recoveryWaxMinor metals

The invention discloses a refined method of Chinese wax, comprising 1) acid cleaning to removal impurity, which means acidic solution is adopted to removal the phospholipids and micro metal ion in the liquated raw wax; 2) adsorbing to decolor, which means the floridin and the silicon dioxide are adopted to decolor and removal the protein in the liquated raw Chinese wax under vacuum state. The refined method of Chinese wax has the advantages of simple technique and convention operation. The appearance of the made Chinese wax and the physicochemical index can reach the first wax standard set by < trading cooperative standards of P.R.C- Chinese wax [GH011-80] >, and also has the advantages of increasing the productive rate and the purity of the Chinese wax and lowering the productivity energy consumption.

Owner:THE RES INST OF RESOURCES INSECTS RIRI OF THE CHINESE ACADEMY OF FORESTRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com