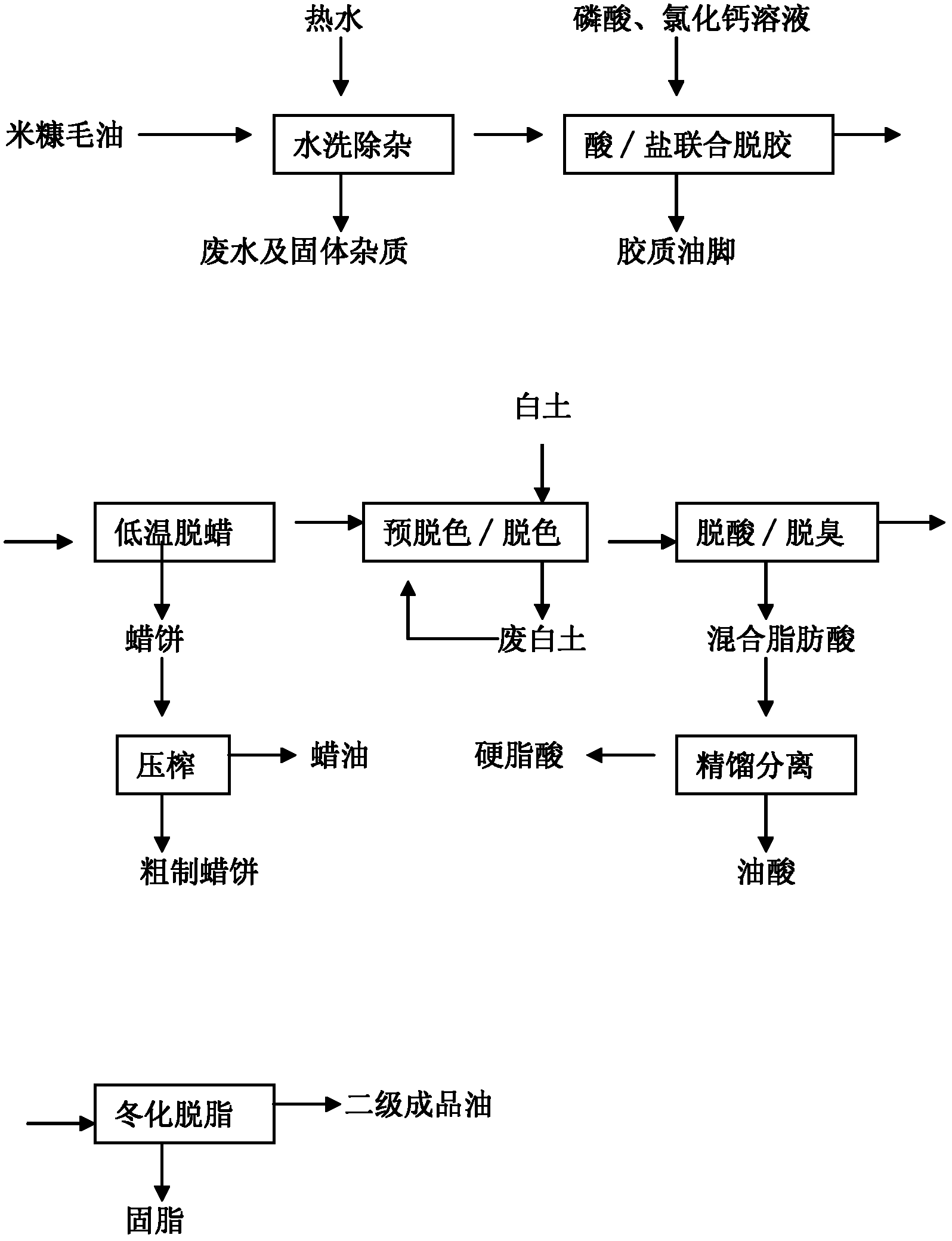

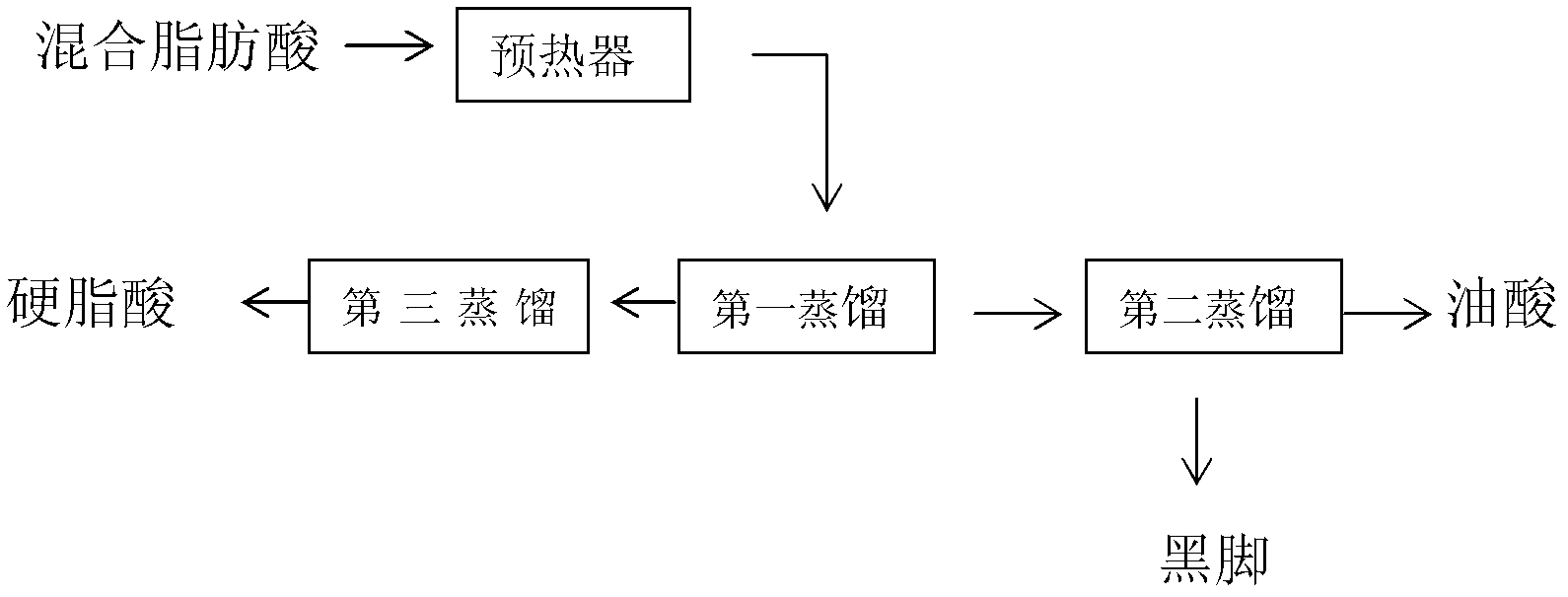

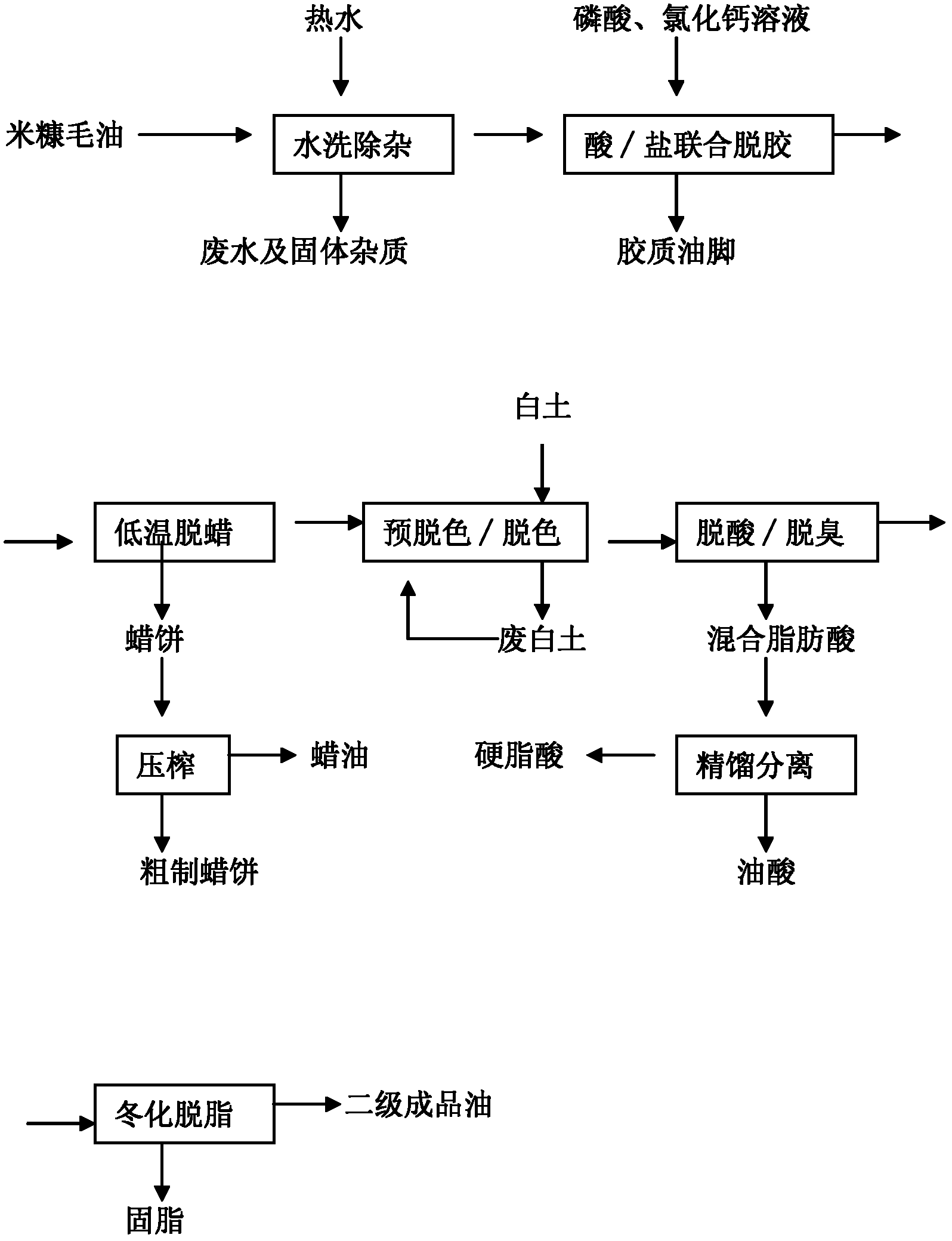

Rice bran oil refinement and byproduct production method

A production method and technology of rice bran oil, applied in the field of oil processing, can solve the problems of low purity of by-products, poor economic benefits, difficult production, etc., and achieve the effects of simple process, low power consumption, and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Washing and removing impurities: pump crude rice bran oil into the refining pot, and heat the oil to 65°C with indirect steam while stirring. Add hot water at a temperature of 75°C, the amount of water added is 5% (w / w) of the oil weight, add water to wash, let it stand for precipitation for 1 hour, and obtain the rice bran crude oil after the upper layer has been removed, and release the lower layer of waste washing water and all the oil at the same time. Contains solid impurities.

[0025](2) Acid / salt joint degumming: Put the crude rice bran oil after washing and removing impurities in the refining pot, and heat the oil temperature to 65°C with indirect steam while stirring. Add hot water at a temperature of 75°C, the amount of water added is 5% (w / w) of the oil weight; then add industrial phosphoric acid with a concentration of 85% (w / w), and the amount added is 0.1% (w / w) of the oil weight Then add the calcium chloride solution of concentration 5% (w / v), the a...

Embodiment 2

[0032] (1) Washing and removing impurities: pump crude rice bran oil into the refining pot, heat the oil to 75°C with indirect steam while stirring. Add hot water at a temperature of 85°C, the amount of water added is 8% (w / w) of the oil weight, add water to wash, let it stand for precipitation for 2 hours, and obtain the rice bran crude oil after the upper layer has been removed, and release the lower layer of waste washing water and all the oil at the same time. Contains solid impurities.

[0033] (2) Acid / salt joint degumming: Put the crude rice bran oil after washing and removing impurities in the refining pot, and heat the oil temperature to 75°C with indirect steam while stirring. Add hot water at a temperature of 85°C, the amount of water added is 10% (w / w) of the oil weight; then add industrial phosphoric acid with a concentration of 85% (w / w), and the amount added is 0.3% (w / w) of the oil weight Then add the calcium chloride solution of concentration 10% (w / v), and t...

Embodiment 3

[0040] (1) Washing and removing impurities: pump crude rice bran oil into the refining pot, heat the oil to 70°C with indirect steam while stirring. Add hot water at a temperature of 80°C, the amount of water added is 8% (w / w) of the oil weight, add water to wash, let it stand for precipitation for 1 hour, and obtain the rice bran crude oil after the upper layer has been removed, and release the lower layer of waste washing water and all the oil at the same time. Contains solid impurities.

[0041] (2) Acid / salt joint degumming: Put the crude rice bran oil after washing and removing impurities in the refining pot, and heat the oil temperature to 72°C with indirect steam while stirring. Add hot water at a temperature of 80°C, the amount of water added is 7% (w / w) of the oil weight; then add industrial phosphoric acid with a concentration of 85% (w / w), the amount added is 0.5% (w / w) of the oil weight Then add the calcium chloride solution of concentration 20% (w / v), the additio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com