Patents

Literature

438 results about "Mixed fatty acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

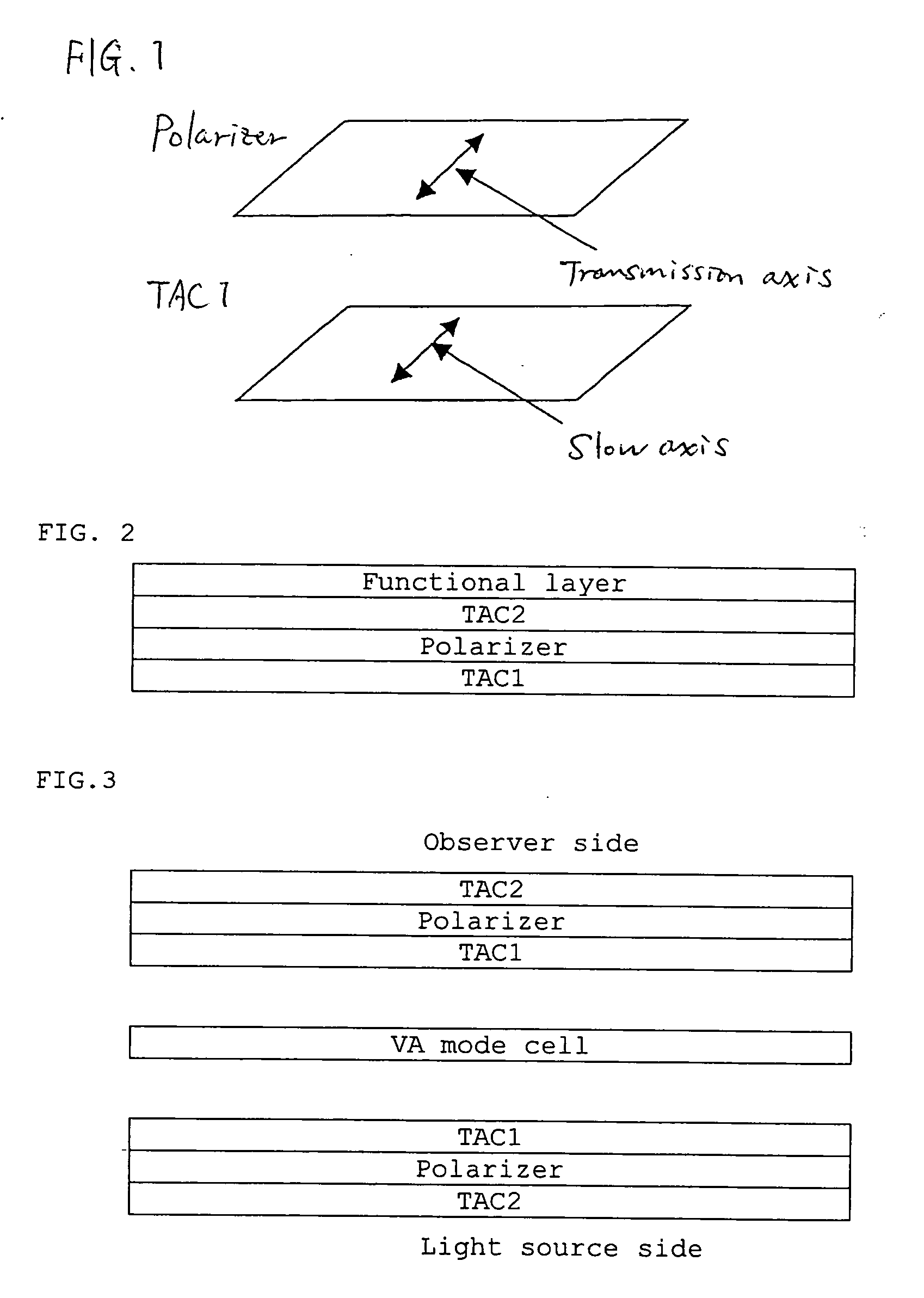

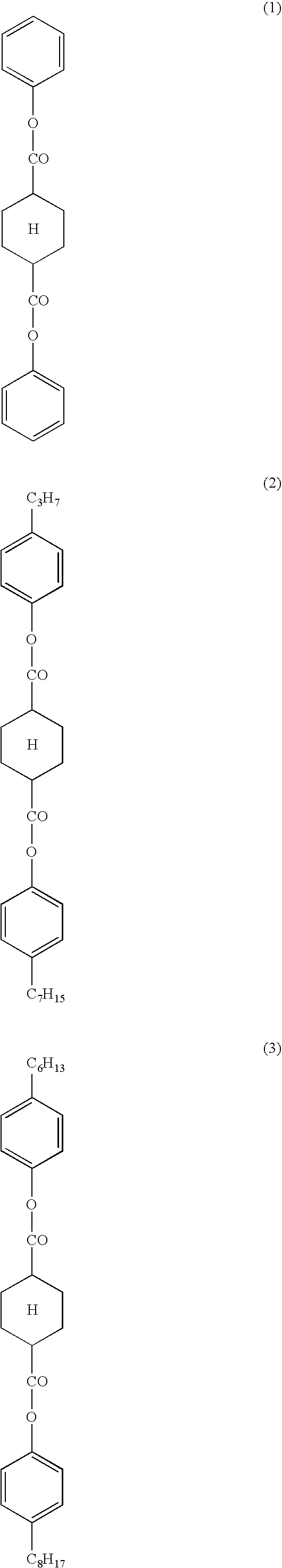

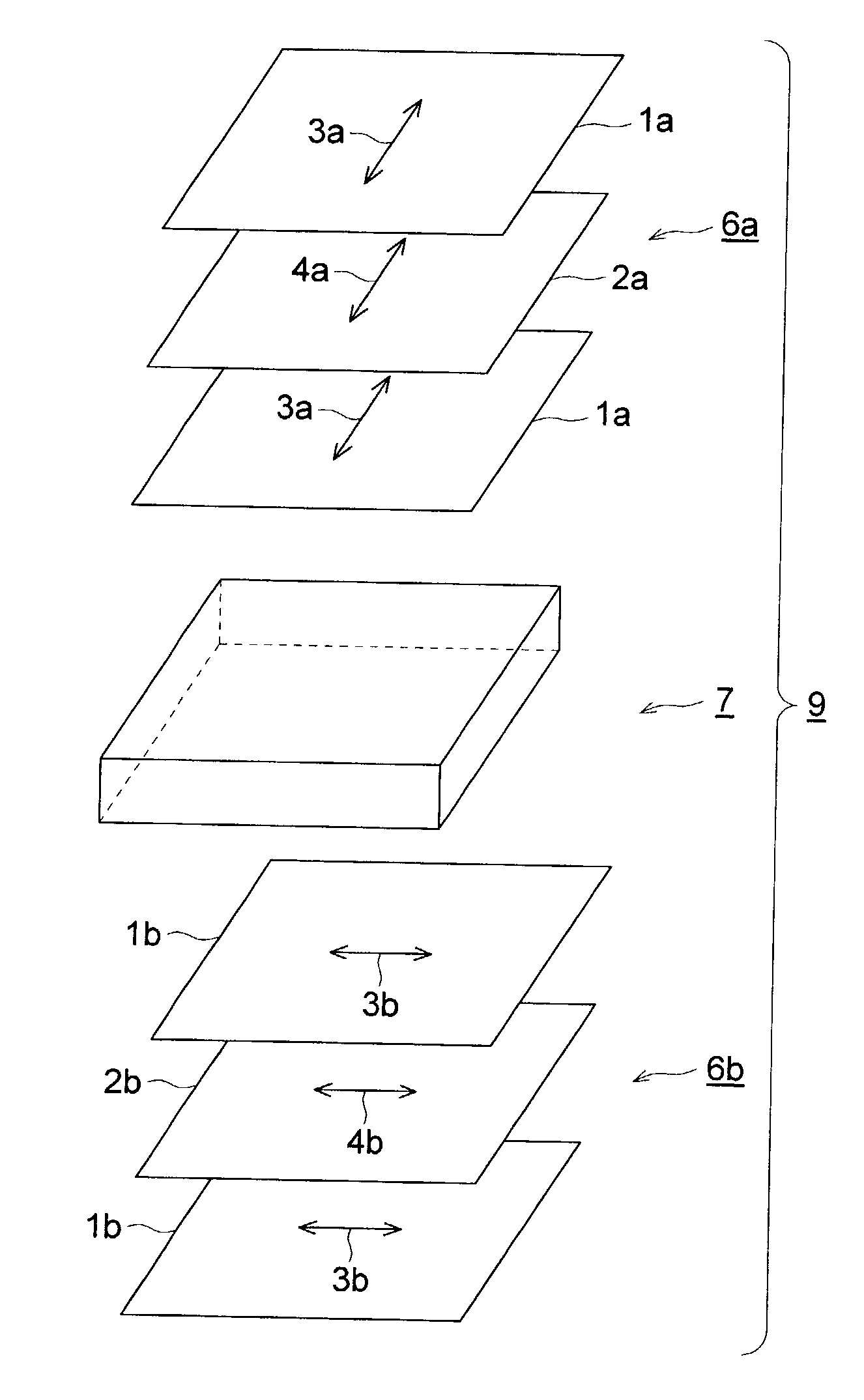

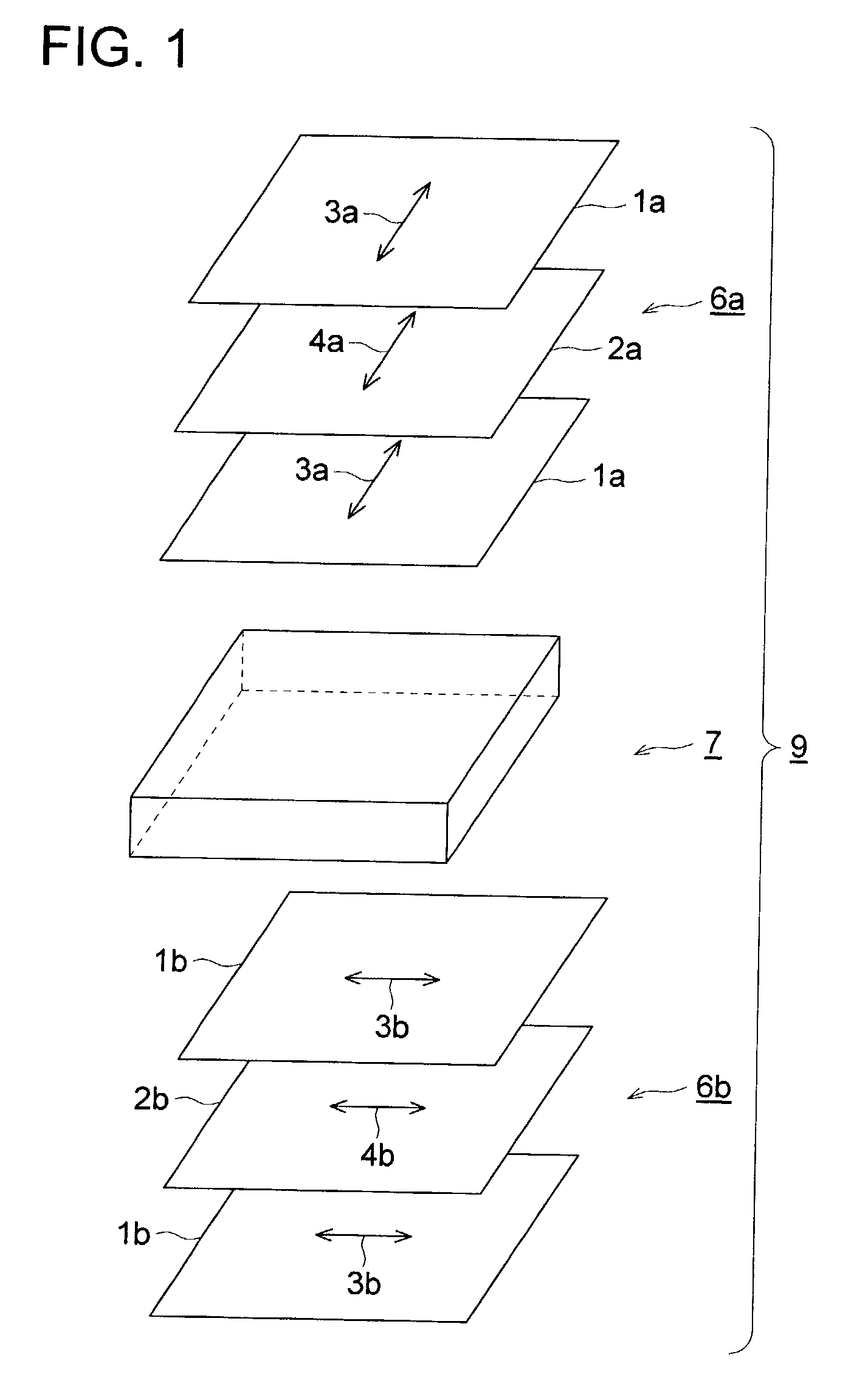

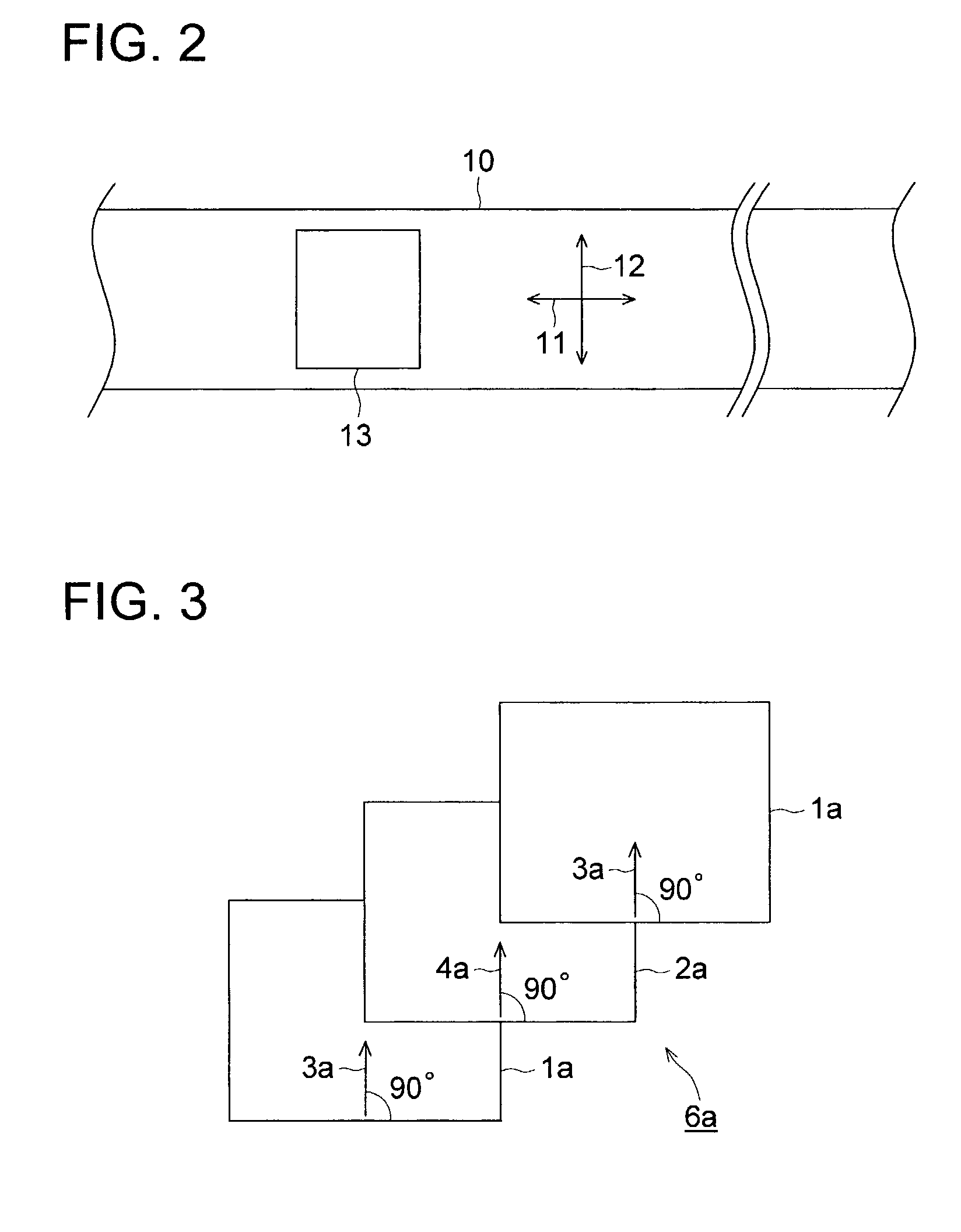

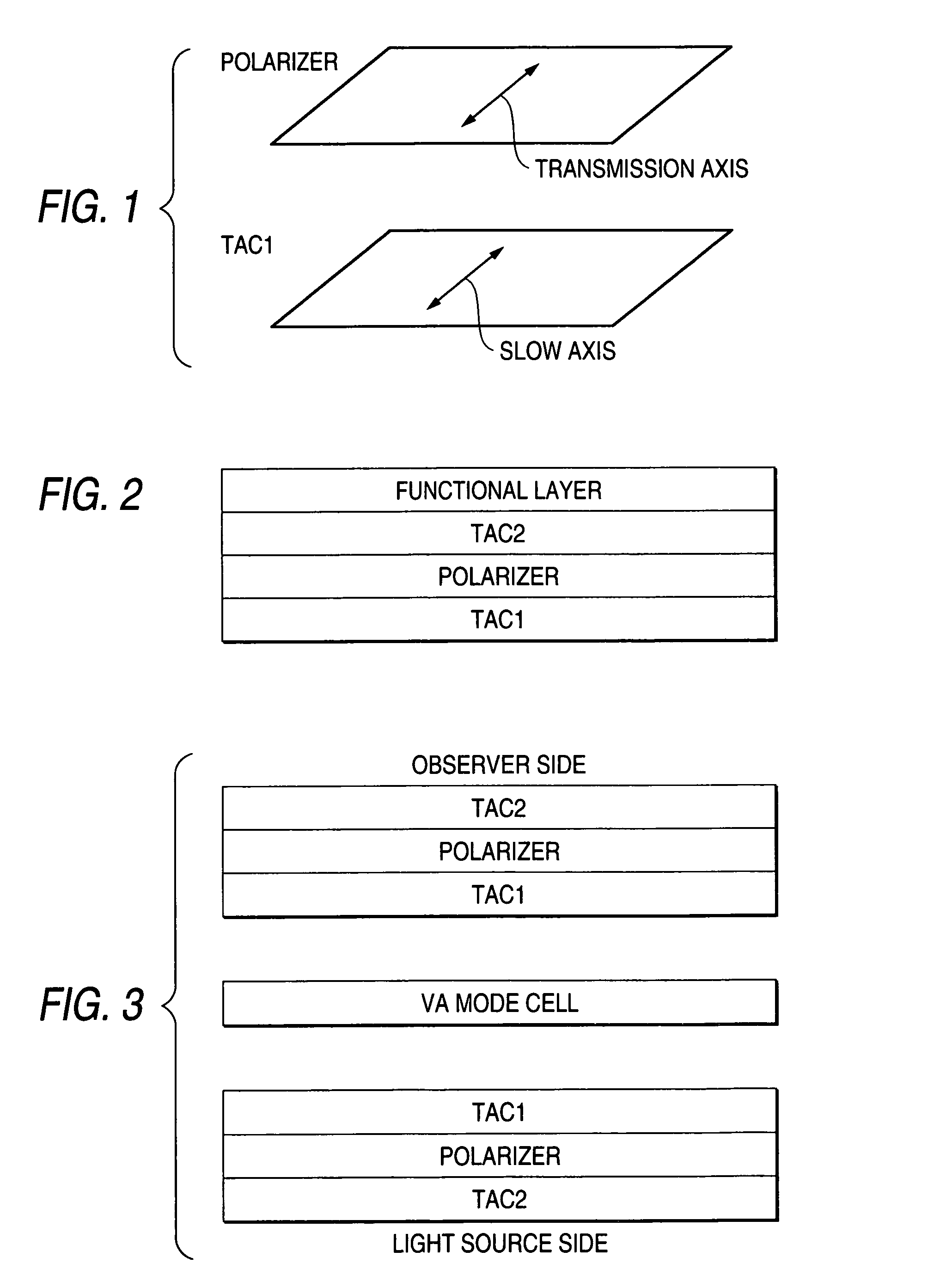

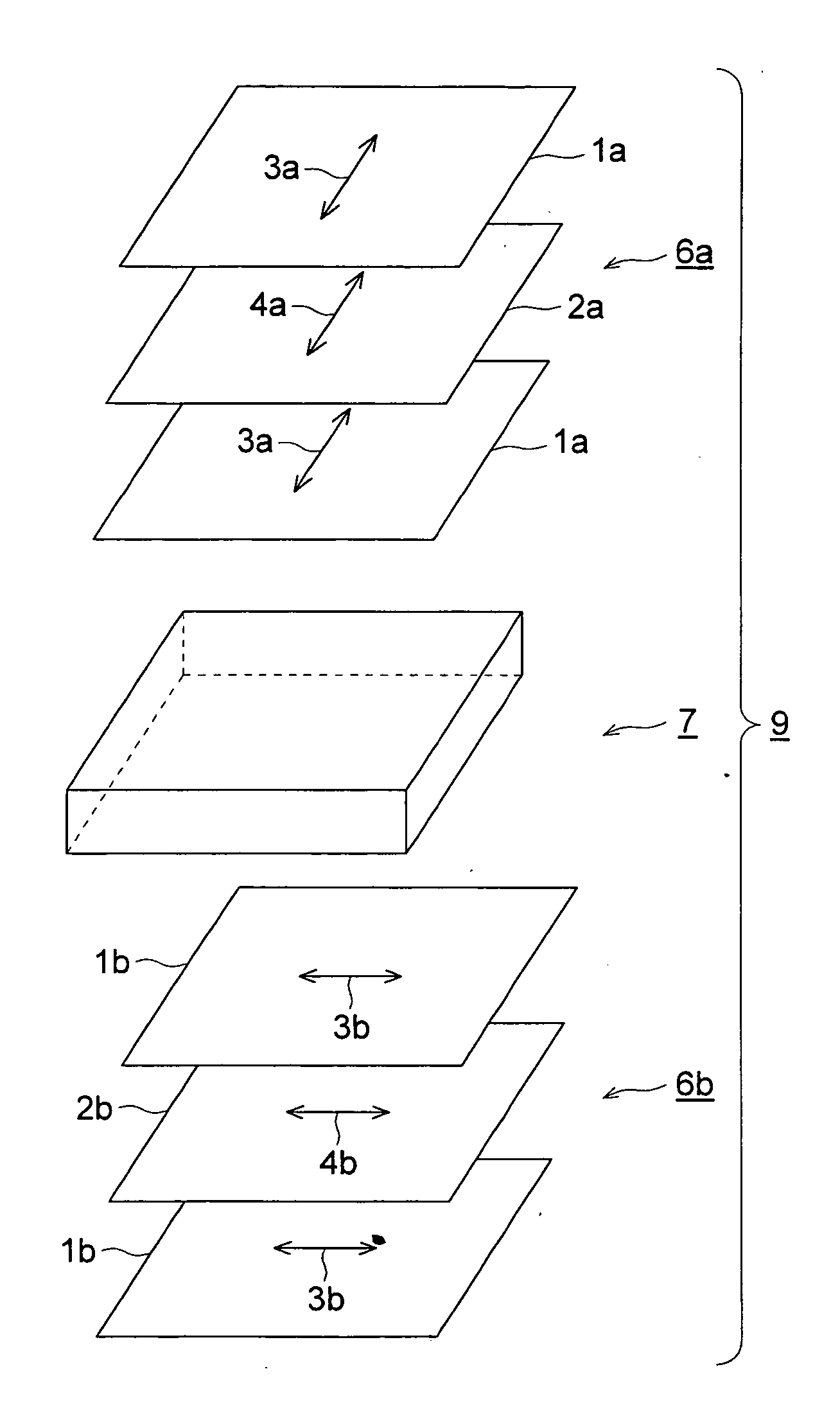

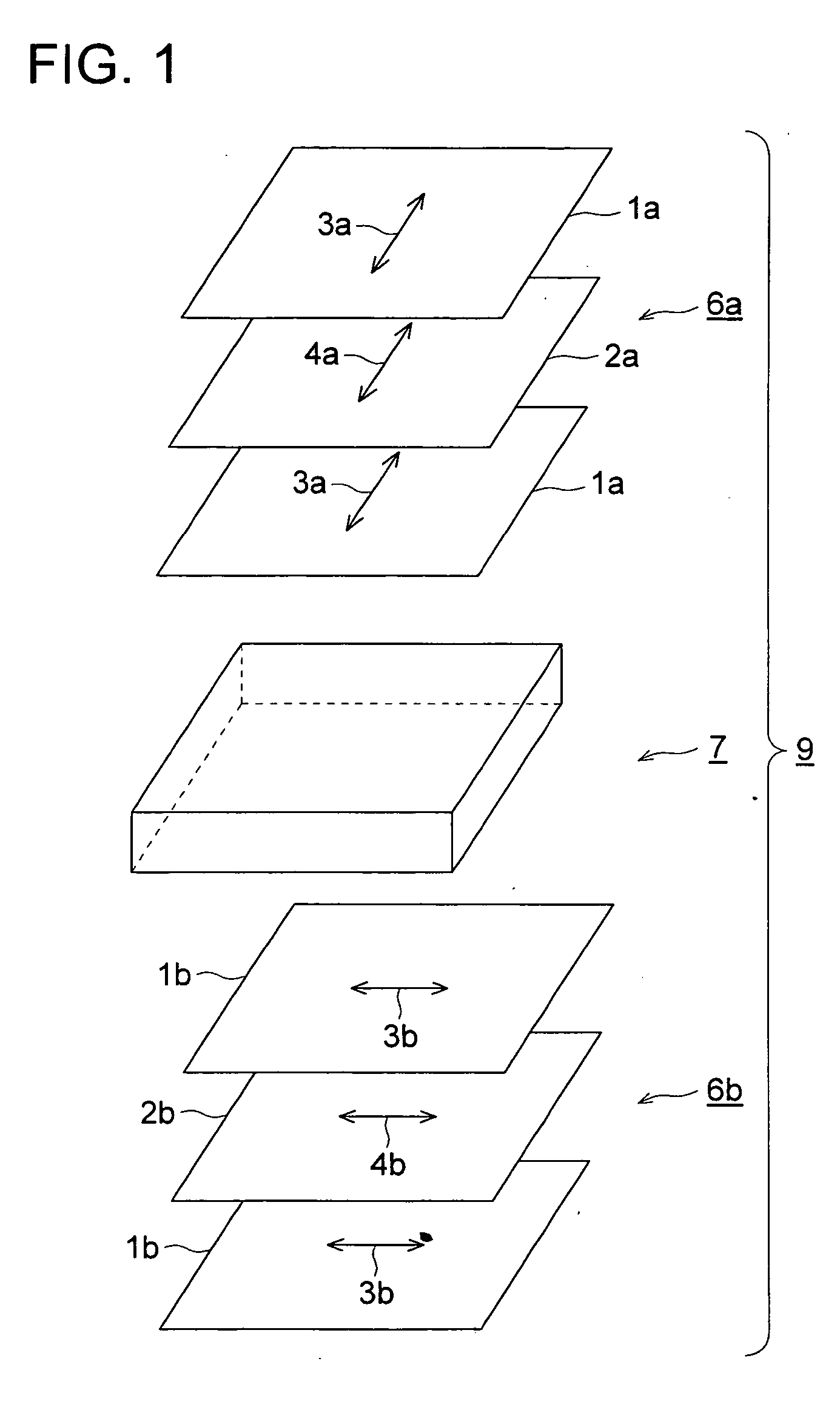

Optical cellulose acylate film, polarizing plate and liquid crystal display

ActiveUS20050142304A1Favorable retardation valueLittle changeLiquid crystal compositionsPolarising elementsCelluloseMixed fatty acid

To provide an optical film which exhibits excellent retardation values both in the film plane and along the direction perpendicular to the film plane and shows little change in retardation values depending on environmental factors such as humidity, a liquid crystal display showing little change in viewing angle characteristics due to an environmental (humidity) change, and a polarizing plate to be used in the liquid crystal display, the cellulose acylate contains a cellulose acylate which is a mixed fatty acid ester of a cellulose and satisfies formulae specified in the specification, and a polarizing plate and a liquid crystal display using this cellulose acylate film.

Owner:FUJIFILM CORP

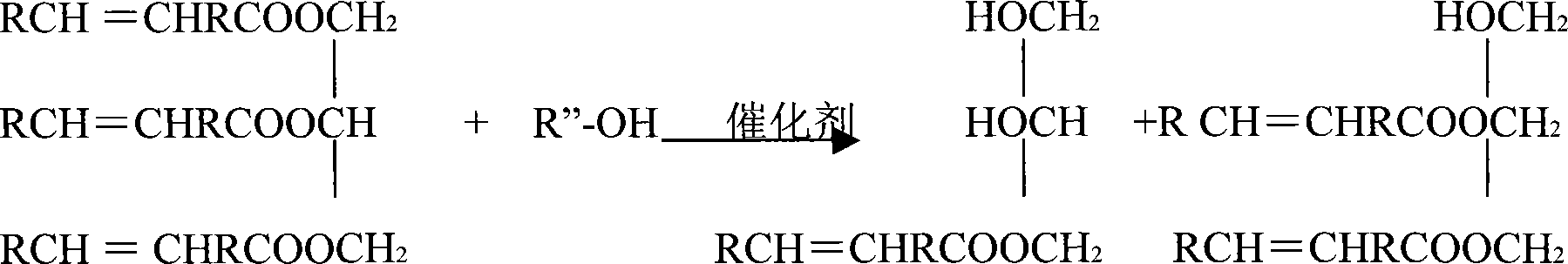

Preparation method of grease with humanized structure

ActiveCN102776077AHuge market potentialHigh number of reusesMilk preparationFatty acid esterificationVegetable oilMolecular rearrangement

The invention discloses a preparation method of grease with a humanized structure. The preparation method comprises the following steps: carrying out intra-molecular rearrangement reaction to palm oil with palmitic acid content of higher than 50% under the action of catalyst to obtain Sn-2 locus triglyceride with palmitic acid content of higher than 50%; and carrying out ester exchange reaction to the Sn-2 locus triglyceride with palmitic acid content of higher than 50% with mixed fatty acid or non-glyceride under the action of 1,3 locus Specificity lipase, and then subjecting the reaction product to after treatment, so as to obtain the grease with humanized structure, wherein the mixed fatty acid is mixture of at least two selected from the group consisting of decanoic acid, lauric acid,myristic acid, palmitoleic acid, stearic acid, oleic acid, linoleic acid and linolenic acid. The vegetable oils are used as the raw material according to the method, so the safety is high; the preparation process is simple, the reaction time is short, the enzyme dosage is low, and the cost is low; and the prepared grease with the humanized structure is very similar to the beast milk fat in the composition of fatty acid and the structural distribution of triglyceride, so the grease can be added in infant formula or formula foods and used as breast milk fat substitute.

Owner:ZANYU TECH GRP CO LTD

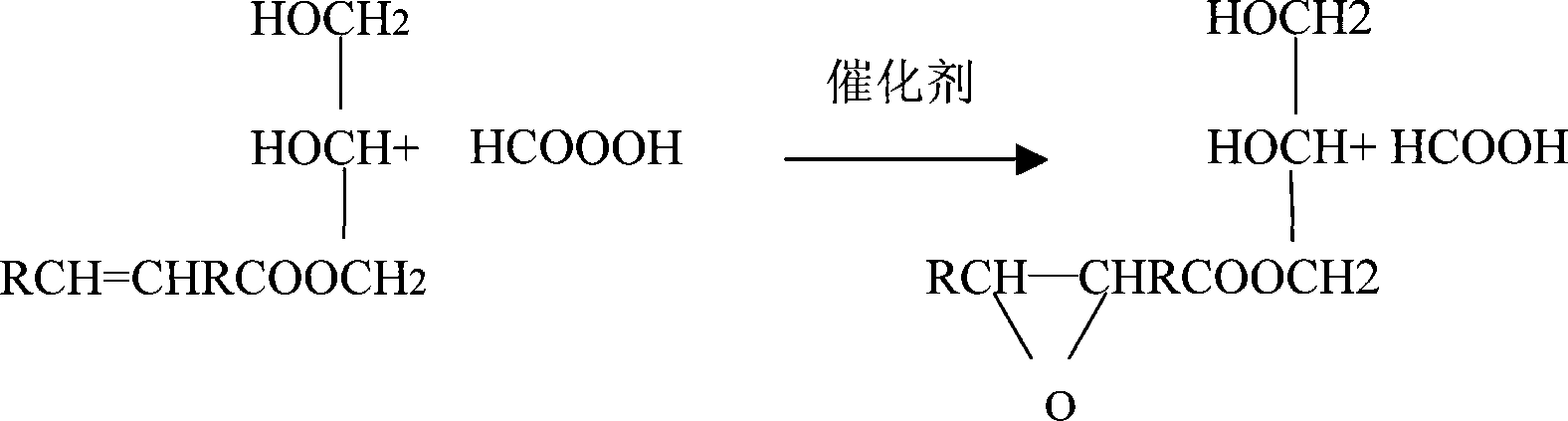

Biological radical polyatomic alcohol prepared by Jatropha curcas oil

The present invention relates to a preparation method for a biological polybasic alcohol by using of an aleurites fordii. The preparation method is as follows: an alcohol-decomposing agent is added into the aleurites fordii to make the alcohol-decomposing reaction in the catalyzing environment to create a mixing ester of fatty acid; and then an epoxidizing agent is added into the mixing ester of fatty acid to make the epoxidizing reaction in the catalyzing environment to create a mixing epoxidizing ester of fatty acid; the mixing epoxidizing ester of fatty acid takes the opening reaction of epoxidizing key with an opening agent to create a mixing hydroxylic ester of fatty acid, i.e. a biological polybasic alcohol. The biological polybasic alcohol takes the addition reaction with an oxidation alkene in the catalyzing environment to create a biological polybasic alcohol with much higher molar weight. The preparation technics and operation of the present invention are more convenient; the adjustability for the product function is much better with much better performance. The aleurites fordii materials used in the present invention is a reproducible materials; so the cost is much lower and the material is abundant, which can replace the petrifaction polyether glycol to prepare the polyurethane foam plastic so that the dependence to the polyurethane product decreases.

Owner:HONGBAOLI GRP CO LTD

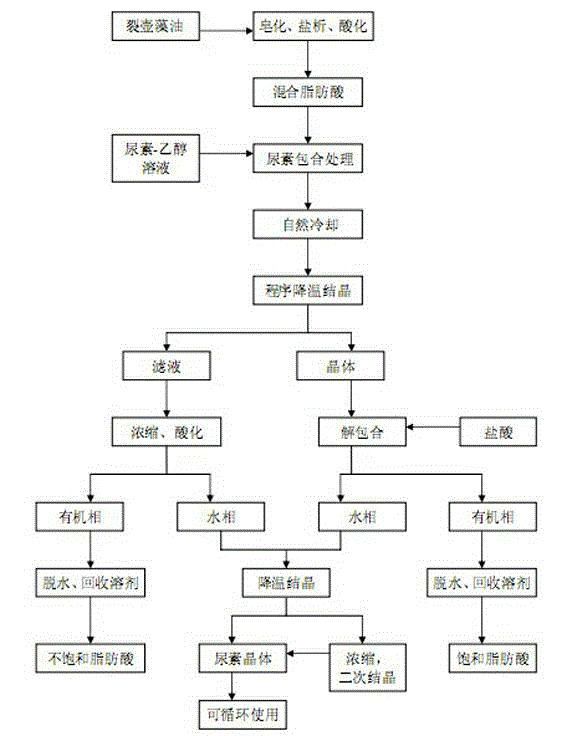

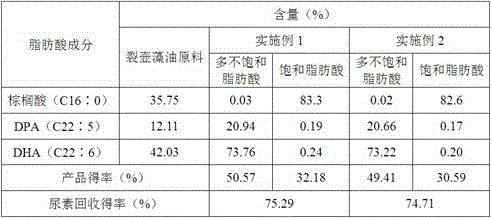

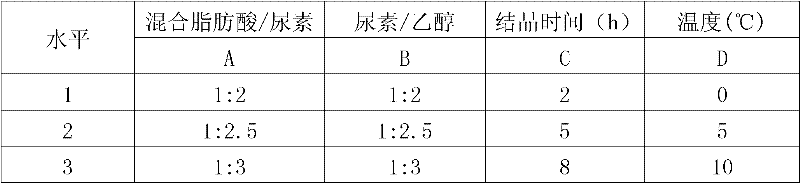

Method for separating and purifying DHA (docosahexaenoic acid) and saturated fatty acid from schizochytrium limacinum oil

ActiveCN102746947AIncrease contentPrevent oxidationPreparation from carboxylic acid saltsFatty acids production/refiningMixed fatty acidSalting out

The invention discloses a method for separating and purifying DHA (docosahexaenoic acid) and saturated fatty acid from schizochytrium limacinum oil. The method includes: firstly, saponifying, salting out and acidizing the schizochytrium limacinum oil under protection of nitrogen so as to obtain free mixed fatty acid, and separating the fatty acid different in degree of saturation by urea adduction fractionation so as to obtain filtrate and solids after filtration; concentrating and extracting the filtrate so as to obtain polyunsaturated fatty acid rich in DHA and DPA (docosapentenoic acid); and allowing the solids to leach by means of acidolysis, extracting the saturated fatty acid (mainly comprising palmic acid) and recovering urea, wherein the urea is recyclable. The method is performedat a low temperature, oxidization of the unsaturated fatty acid is avoided, biological activity and nutrition of the unsaturated fatty acid are kept intact, and the problem of residual solvent is avoided. Products are high in purity, and the obtained polyunsaturated fatty acid mainly comprises the DHA and the DPA and hardly comprises EPA (eicosapentaenoic acid), the content of the DHA and the DPAis higher than 93%, and the content of the palmic acid of the saturated fatty acid is higher than 82%.

Owner:福建华尔康生物科技有限公司

Refining method of camellia oil

ActiveCN1746283AReduce consumptionEmission reductionFatty-oils/fats refiningMixed fatty acidWater discharge

A refinery method of camellia oil is carried out by removing impurities for tea seed crude oil, degumming, physically depickling with free fatty acid<0.5% in crude oil, adding sodium carbonate and sodium hydrate into oil, washing, laying aside, washing, drying, decolouring, and deodorizing to obtain refined camellia oil. Its advantages include low cost, higher output rate, short deodorization time, less consumption and waste- water discharge.

Owner:广东新大地生物科技股份有限公司

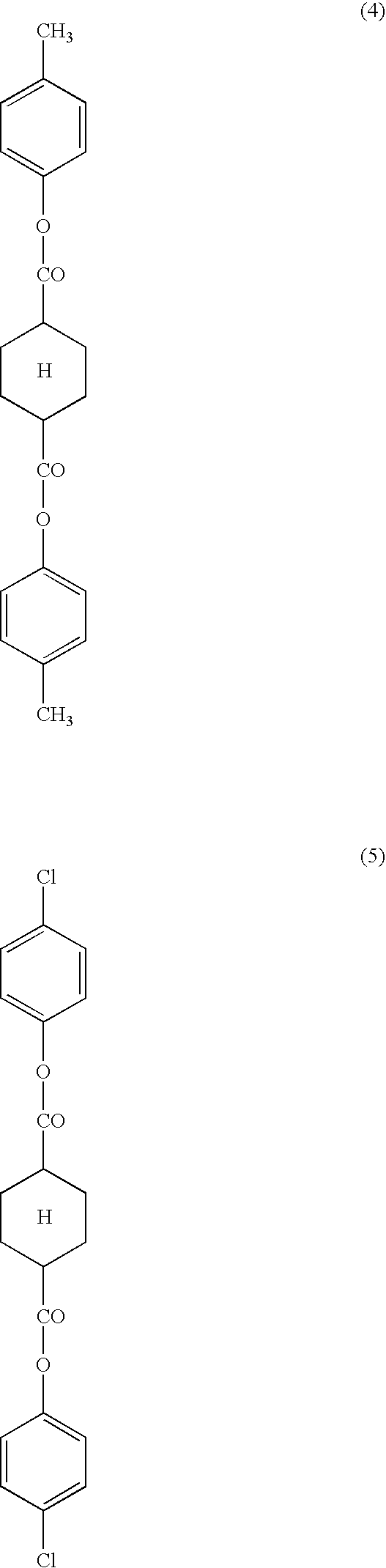

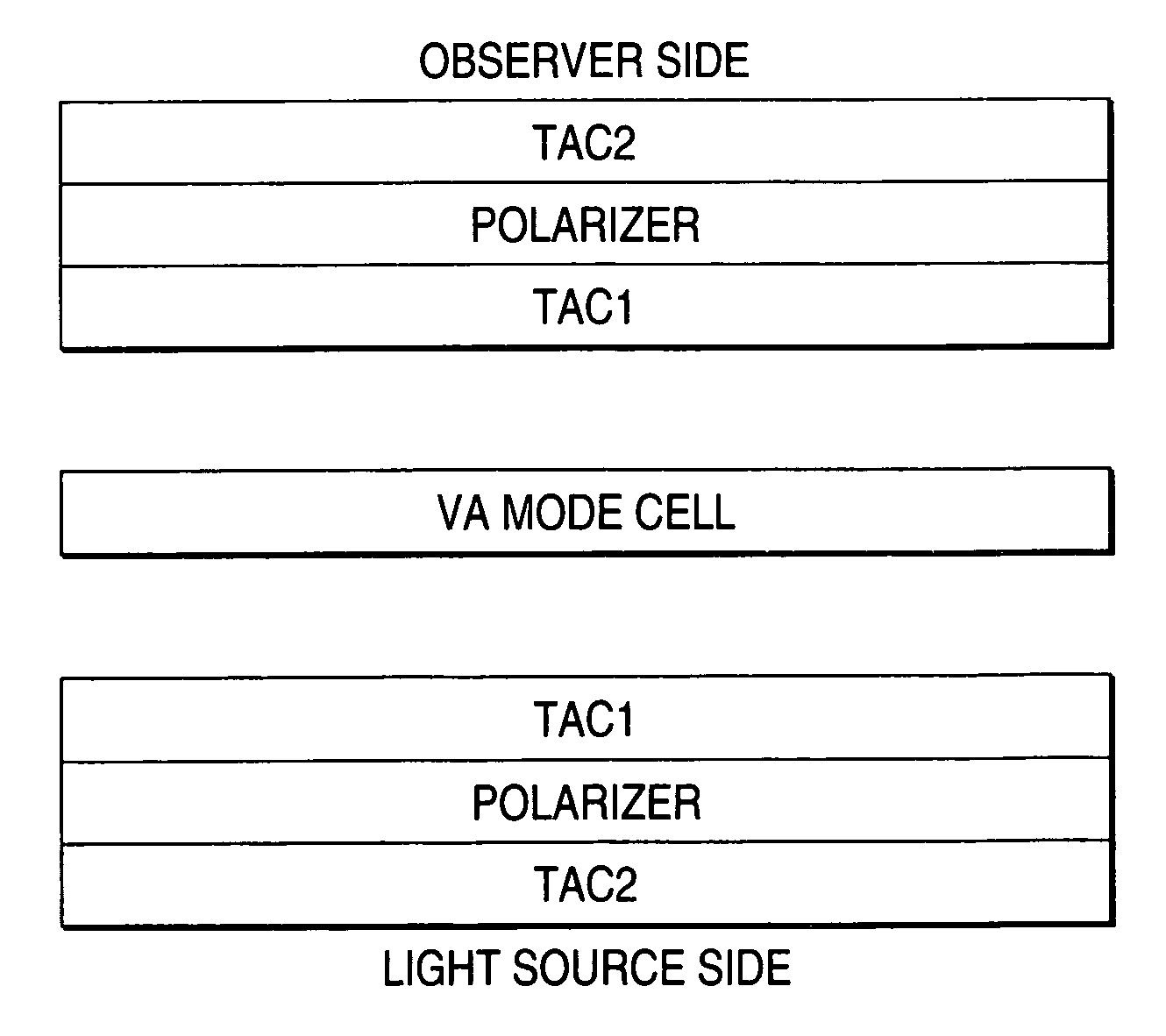

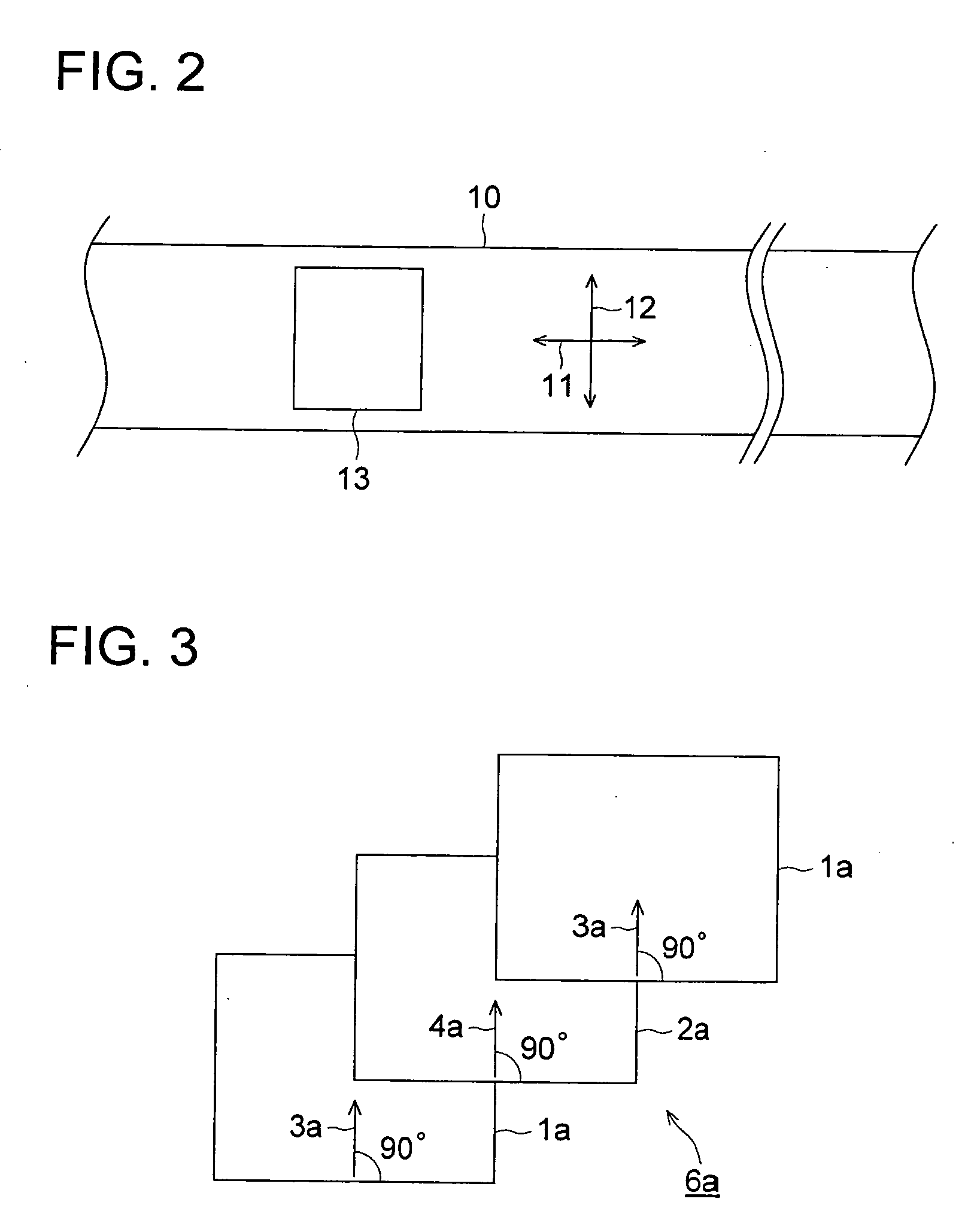

Polarizing plate having a stretched film on a side thereof and liquid crystal display employing the same

InactiveUS7038744B2Good effectLiquid crystal compositionsPolarising elementsIn planeMixed fatty acid

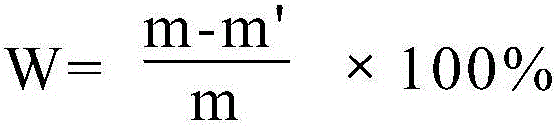

A polarizing plate used in a vertical alignment mode liquid crystal display comprising a liquid crystal cell is disclosed, wherein the polarizing plate comprises a polarizing film and a mixed fatty acid cellulose ester film with optical biaxiality provided between the polarizing film and the liquid crystal cell, and wherein the mixed fatty acid cellulose ester film has a retardation in plane R0 of from 31 to 120 nm, and a retardation in the thickness direction Rt of from 60 to 300 nm, in which R0 is represented by the following formula (1) and Rt is represented by the following formula (2):R0=(nx−ny)×d formula (1)Rt={(nx+ny) / 2−nz}×d formula (2)

Owner:KONICA CORP

Separation method of silkworm pupa oil polyunsaturated fatty acid by gradient freezing crystallization

InactiveCN101892119APrevent oxidationHigh yieldFatty acids production/refiningFatty-oils/fats productionPolyunsaturated fatty acidPupa

The invention discloses a separation method of silkworm pupa oil polyunsaturated fatty acid by gradient freezing crystallization, comprising the following steps of preprocessing silkworm pupas, extracting silkworm pupa oil with ultrasonic waves, preparing silkworm pupa oil mixed fatty acid, preparing a urea ethanol solution, and conducting urea inclusion treatment and then gradient freezing crystallization. Compared with the traditional separation methods of the silkworm pupa oil polyunsaturated fatty acid, the problem of fatty acid oxidation caused by overhigh temperature can be avoided because the whole operation process is conducted under low temperature all along. The silkworm pupa oil polyunsaturated fatty acid prepared by the invention contains 96.5% of polyunsaturated fatty acid (including 4.2% of linoleic acid, 91.3% of alpha-linoleic acid, and 1.0% of arachidonic acid), and can be served as principal components of relative drugs or health food. The invention has the advantages of simple processing step, high product yield, excellent quality, high purity of the polyunsaturated fatty acid and the like, and can be used for preparing the polyunsaturated fatty acid from silkworm pupa oil.

Owner:SHAANXI NORMAL UNIV

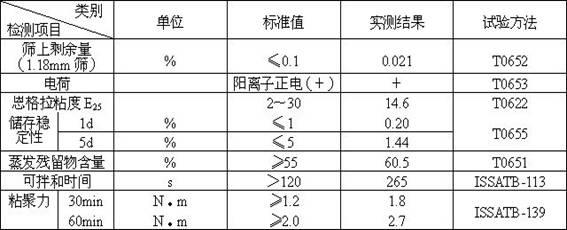

Technology for synthesizing bisquaternary ammonium salt slow-breaking quick-setting asphalt emulsifier

InactiveCN102580607AWide applicabilityGood emulsifying effectTransportation and packagingMixingQuaternary ammonium cationDistillation

The invention relates to a technology for synthesizing a bisquaternary ammonium salt slow-breaking quick-setting asphalt emulsifier. The technology comprises the steps of: (1) adding mixed fatty acid, long-chain aliphatic amine, an aromatic hydrocarbon solvent and a catalyst in a reaction vessel for backflow reaction, then removing the solvent through reduced pressure distillation, cooling and adding an alcohol solvent to obtain an amide or multi-acyl amide intermediate; (2) mixing aliphatic tertiary amine with hydrochloric acid, then dripping epoxy chloropropane, mixing for a reaction and cooling to a room temperature to obtain a quaternary ammonium salt intermediate; and (3) dripping the quaternary ammonium salt intermediate into the amide or multi-acyl amide intermediate for reaction so as to obtain the bisquaternary ammonium salt type cationic asphalt emulsifier. The technology for synthesizing the bisquaternary ammonium salt slow-breaking quick-setting asphalt emulsifier, disclosed by the invention, has the advantages of wide raw material source, high cost performance, wide application range and convenience in popularization and application. The asphalt emulsion has uniform and fine particles and good storage stability; and wide slow-breaking quick-setting use performances can be obtained.

Owner:WUHAN UNIV OF TECH

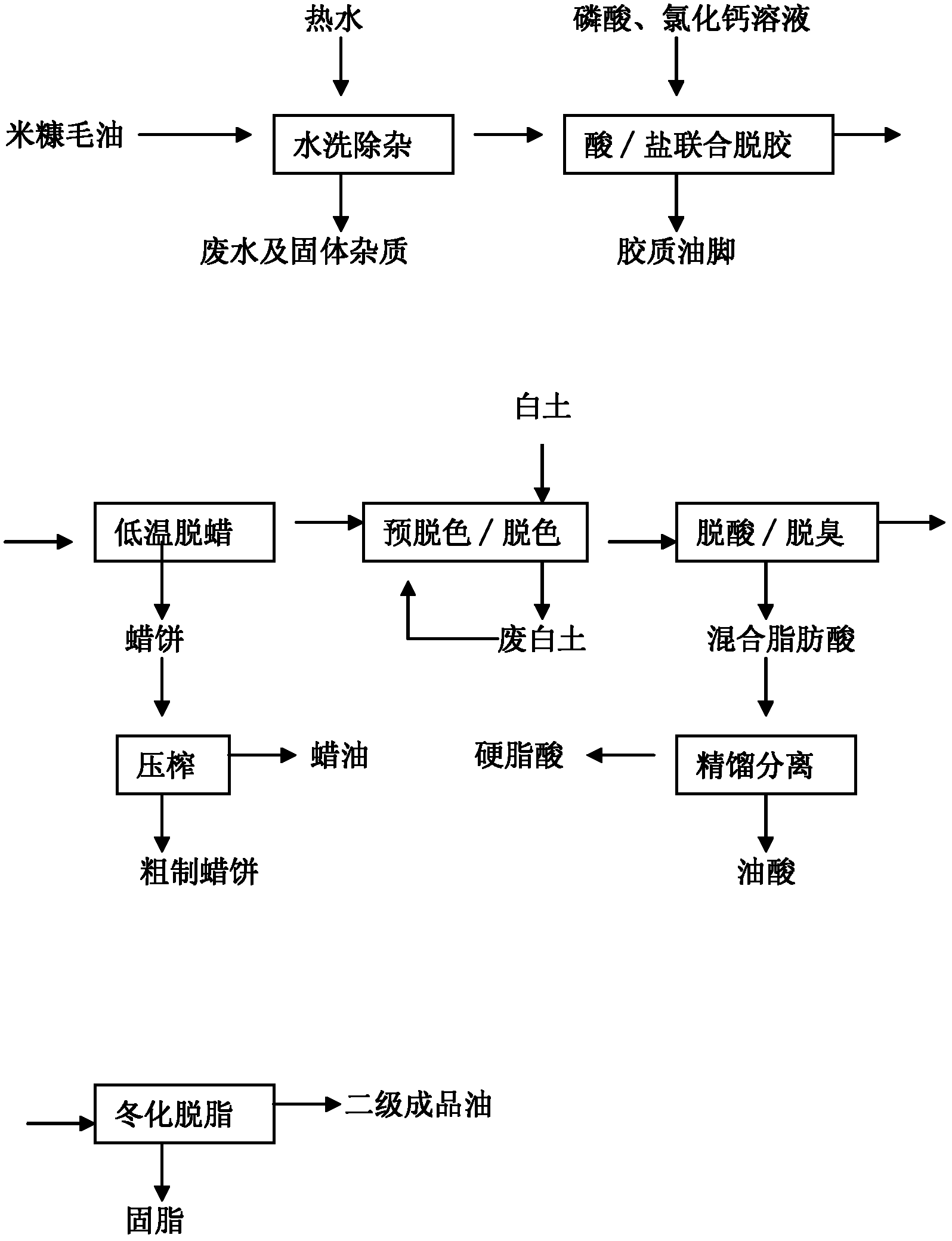

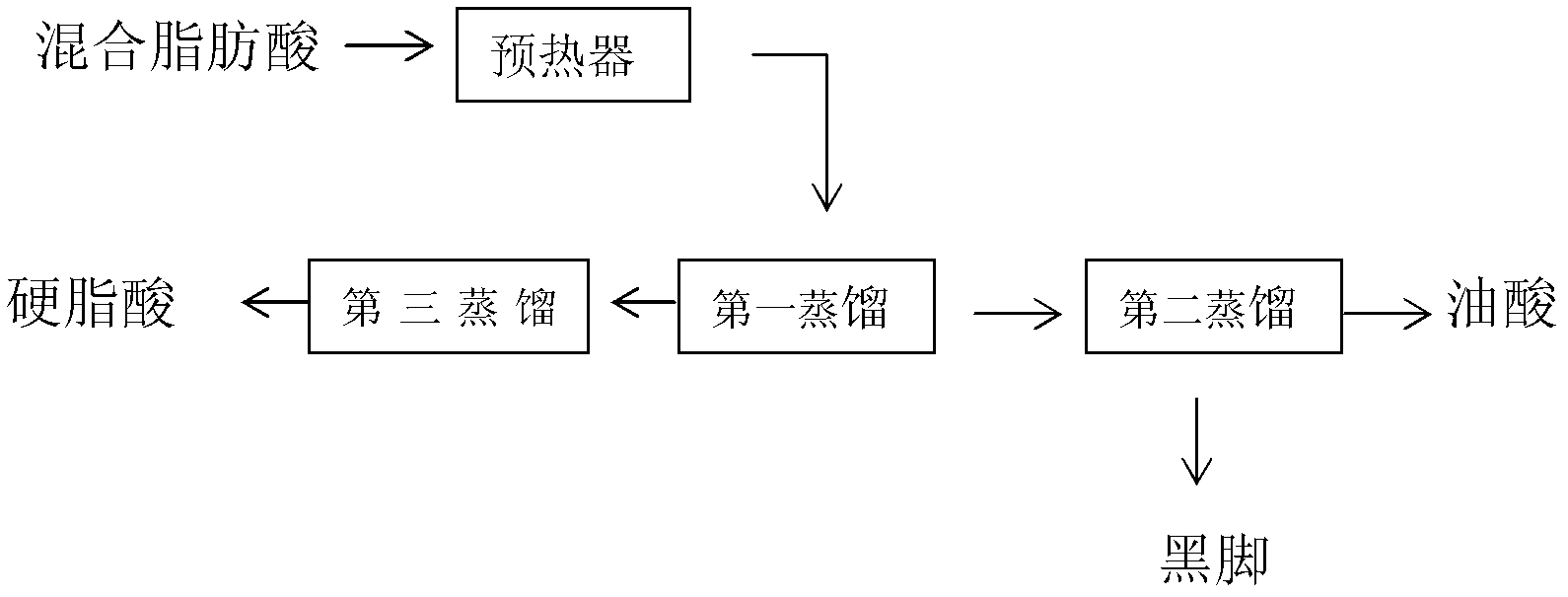

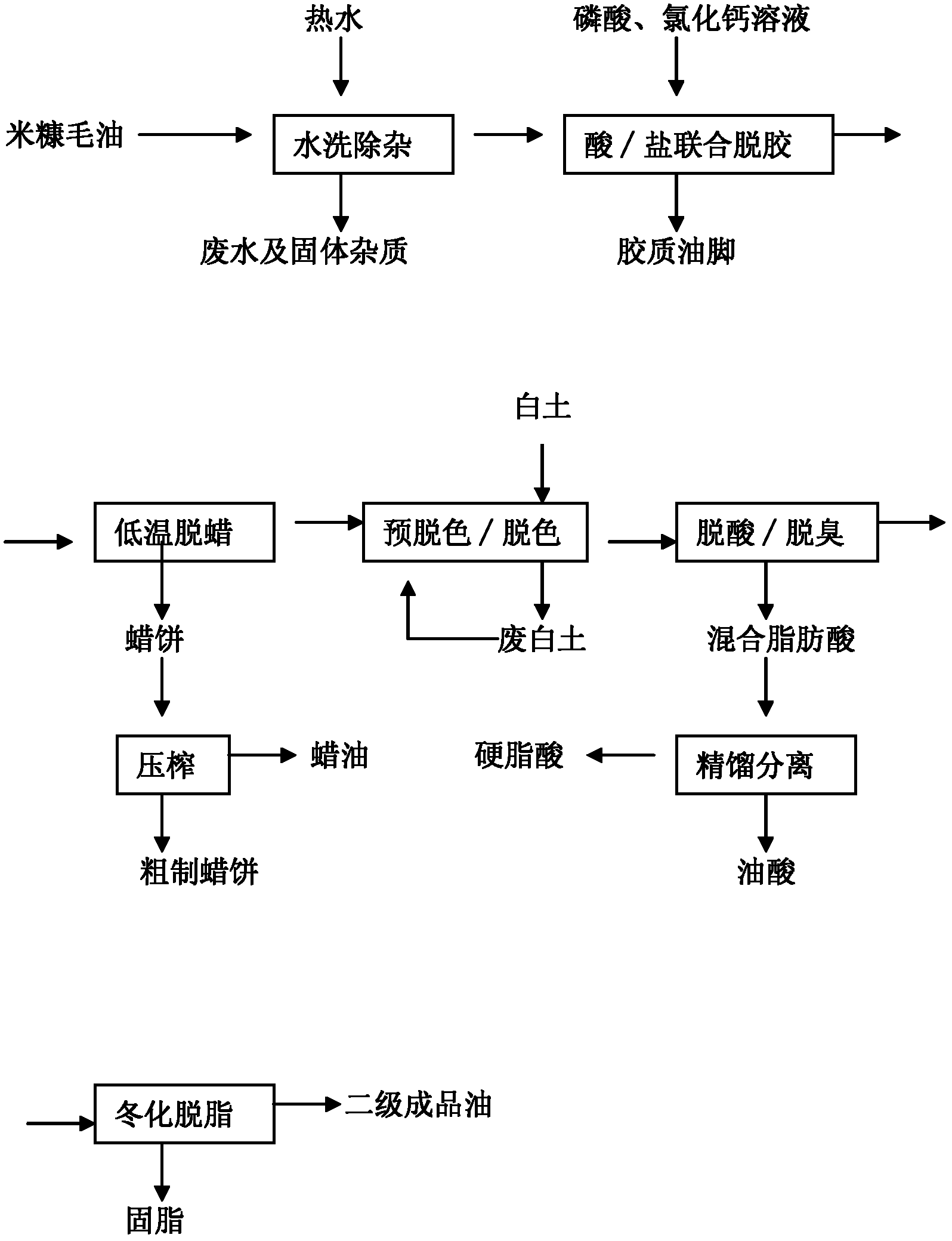

Rice bran oil refinement and byproduct production method

InactiveCN102492546AOvercome efficiencyOvercome the cycleFatty substance recovery/refiningFatty acids production/refiningWaxMixed fatty acid

The invention relates to a rice bran oil refinement and byproduct production method, and solves the problems of poor quality, low product and byproduct yield, low purity, complex technique, small production scale and the like in the existing product oil refined from rice bran oil. The technical scheme is as follows: the method comprises the following steps: carrying out acid / salt combined degumming on rice bran raw oil, dewaxing at low temperature, decolorizing, deacidifying / deodorizing, and degreasing by winterization to obtain tertiary rice bran oil and byproducts (crude wax cake, mixed fatty acids and solid grease). The technique provided by the invention is simple to control, can stably obtain Chinese standard tertiary rice bran oil and byproducts thereof, and can implement large-scale production.

Owner:WUHAN POLYTECHNIC UNIVERSITY +2

Optical cellulose acylate film, polarizing plate and liquid crystal display

ActiveUS7504139B2Increase valueLittle changeLiquid crystal compositionsPolarising elementsMixed fatty acidCellulose

To provide an optical film which exhibits excellent retardation values both in the film plane and along the direction perpendicular to the film plane and shows little change in retardation values depending on environmental factors such as humidity, a liquid crystal display showing little change in viewing angle characteristics due to an environmental (humidity) change, and a polarizing plate to be used in the liquid crystal display, the cellulose acylate contains a cellulose acylate which is a mixed fatty acid ester of a cellulose and satisfies formulae specified in the specification, and a polarizing plate and a liquid crystal display using this cellulose acylate film.

Owner:FUJIFILM CORP

Preparation method of breast milk fat structural fat substitute

The invention discloses a preparation method of a breast milk fat structural fat substitute, and belongs to the field of food additives and structural fat preparation. In the method, palm stearin is used as a raw material, the content of palmitic acid at the sn-2 position is improved through a random ester exchange reaction, and then the palm stearin and mixed fatty acid subjected to the random ester exchange reaction are catalyzed by sn-1,3 specific lipase to prepare a structural fat similar to breast milk fat, namely a breast milk fat structural fat substitute mainly comprising 1,3-dioleoicacid-2-palmitic acid triglyceride (OPO). An enzymatic reaction in the method provided by the invention adopts a solvent-free system, the repeated utilization rate of an enzyme preparation is high, andthe safety is good; therefore, the method provided by the invention has the advantages of stable source, low price, simple reaction process, short reaction time, high product content, 84.33% similarity of composition and components between an obtained product and the breast milk fat, controllable quality and the like in the production of the structural fat, and is suitable for large-scale industrial production.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of conjugated linoleic acid

InactiveCN101565367AHigh yieldReduce manufacturing costFatty acid isomerisationOrganic compound preparationIsomerizationVegetable oil

The invention relates to a preparation method of conjugated linoleic acid, comprising the following steps: placing the vegetable oil containing linoleic acid glyceride or mixed fatty acid containing linoleic acid or extracted and separated linoleic acid product as raw material, low boiling point alcohols solvent and base catalyst into a reaction kettle and performing the isomerization reaction at a certain temperature. The reaction product is subjected to evaporating, acidifying, extracting and vacuum drying to obtain the conjugated linoleic acid. The conversion of the linoleic acid is above 97.5% and the total yield of the conjugated linoleic acid is above 85%, the proportions of the cis-9, trans-11 isomer and trans-10, cis-12 isomer in the total conjugated linoleic acid are above 96%. The preparation method has features of less reaction steps, easy recovery and repeated use of solvent, simple follow-up separation, low production cost, and easy industrialization.

Owner:ZHEJIANG UNIV

Method for preparing conjugate linolic acid using idesia polycarpa maxim. var. vestita diels oil

InactiveCN101381298AQuality improvementLow costCarboxylic compound separation/purificationIsomerizationPhospholipid

The invention discloses a method for preparing conjugated linoleic acid by using Idesia polycarpa Maxim oil, which belongs to the fields of medicine, food and feedstuff. The technology comprises four aspects of acid-process degumming of crude oil, preparation of mixed fatty acid, extraction of linoleic acid and conjugation. The method is characterized in that degummed oil is obtained through acid degumming process, and phospholipid is thoroughly removed; direct saponification preserves dissociative linoleic acid and avoids the yield loss; the technical processes of carbamide inclusion, alkali isomerization of the linoleic acid and the like are optimized to avoid the application of toxic reagents so as to obtain the conjugated linoleic acid with high quality and high conversion rate; at the same time, the technical processes are simple with low equipment requirement, recover the solvent effectively, reduce the cost significantly, and have wider application prospect in the production of high-quality conjugated linoleic acid.

Owner:四川省毛叶山桐子科技股份有限公司

Separation method of oleic acid and linoleic acid in tea seed oil

ActiveCN105316107AHigh purityAchieving Synchronous SeparationFatty acids production/refiningFatty-oils/fats separationOleic Acid TriglyceridePolyunsaturated fatty acid

The invention discloses a separation method of oleic acid and linoleic acid in tea seed oil, which includes the steps of: saponifying and acidifying the tea seed oil to obtain mixed fatty acid; pre-removing saturated fatty acid through a freezing crystallization method; and finally purifying the oleic acid and the linoleic acid through a urea inclusion method. In the method, the saturated fatty acid is separated in a certain degree by means of difference of melting point of the saturated fatty acid and unsaturated fatty acid for the first time, and then saturated and monounsaturated fatty acids are separated from polyunsaturated fatty acids through the urea inclusion to further prepare the oleic acid and the linoleic acid at high purity. Compared with the prior art, synchronous separation of the oleic acid and the linoleic acid in the tea seed oil is achieved. The method not only enriches the oleic acid in the tea seed oil but also separates the linoleic acid, and meanwhile increases the purities of the oleic acid and the linoleic acid. The method solves the problem that only is the oleic acid or the linoleic acid can be separated individually in the prior art and increases the additional value of products and raw material utilization rate.

Owner:GUIZHOU ZHOUYIQING BIOTECH +1

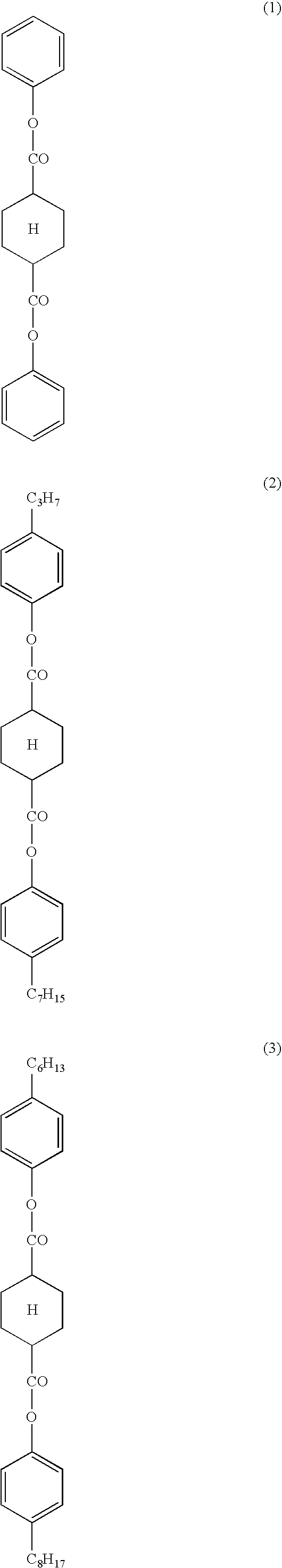

Base for electric insulating oil

InactiveUS7795193B2Low viscosityImprove liquidityLiquid organic insulatorsHeat-exchange elementsElectricityMixed fatty acid

A base for electric insulating oil comprising an esterification product from a C8-C20 higher fatty acid and a C6-C14 branched aliphatic monohydric alcohol; or a base for electric insulating oil comprising an esterification product from a mixed fatty acid derived from palm oil and / or mixed fatty acid derived from soybean oil and a C1-C5 aliphatic monohydric alcohol or C6-C14 branched aliphatic monohydric alcohol. The thus provided base for electric insulating oil excels in viscosity, fluidity, chemical stability, etc. and is capable of satisfactorily exhibiting electrical characteristics of electric insulating oil.

Owner:FUJI ELECTRIC CO LTD +1

Fatty acid mixture amide propyl betaine and preparation method thereof

ActiveCN103524370AReduce manufacturing costExcellent oil-water interface performanceOrganic compound preparationSulfonic acids salts preparationMixed fatty acidBetaine

The invention relates to a fatty acid mixture amide propyl betaine and a preparation method thereof. The structure of the fatty acid mixture amide propyl betaine is presented as (I). The fatty acid mixture amide propyl betaine is prepared with natural oil or derivatives of the natural oil, such as fatty acid methyl ester, fatty acid mixture and the like; and compared with single-carbon-chain fatty acid amide propyl betaine, the fatty acid mixture amide propyl betaine has the advantages that the production cost can be reduced remarkably, and the oil-water interface performance is excellent when the fatty acid mixture amide propyl betaine is applied to chemical compound flooding composition formula systems.

Owner:PETROCHINA CO LTD

Suppository for treating piles and other anorectal diseases and its prepn

InactiveCN1403142AEasy accessImprove absorption rateOrganic active ingredientsAnthropod material medical ingredientsMixed fatty acidCurative effect

The present invention is one kind of suppository for treating piles and other anorectal diseases and its preparation process. The medicine is prepared with bezoar, pearl, muskone, notoginseng, gallnut, borneol, belladonna fluid extract and calamine. The preparation process includes crushing pearl, notoginseng and gallnut; mixing and stoving balladonna fluid extract and calamine; mixing all the medicine powder except muskone; further grinding and the mixed medicine powder; heating and melting fatty glyceride; and mixing all the components via stirring. The present invention has high treating effect on internal pile external pile, mixed pile and anal fissure.

Owner:MAYINGLONG PHARMA GROUP

Methanol diesel fuel complex additive and preparation method thereof

ActiveCN101709234AGood compatibility stabilityStable in natureLiquid carbonaceous fuelsCyclohexanoneN-Butylamine

The invention discloses a methanol diesel fuel complex additive and a preparation method thereof. The complex additive is prepared from the following raw materials in parts by volume: 1-4 parts of diethyl phthalate, 1-8 parts of n-butylamine, 1-9 parts of isooctanol, 1-6 parts of cyclohexanone, 13-42 parts of lauryl methacrylate, 7-30 parts of mixed fatty glyceride, 1-5 parts of phenyl propargyl ether, 1-8 parts of dihexadecyl dimethyl ammonium chloride, 2-12 parts of ethyl formate, 2-14 parts of isooctyl nitrate and 1-6 parts of polyoxyethylene hexadeeylalkyl ether selies. The methanol diesel fuel complex additive can enable methanol diesel fuel to be evenly mixed and to be stably stored for more than 6 months, which effectively improves the fire behaviour of the methanol diesel fuel and inhibits the volatilization when the methanol content is higher; moreover, the production process is simple and the use is convenient, thereby being beneficial to the popularization and application of the methanol diesel fuel.

Owner:临沂星火知识产权服务有限公司

Lubricating oil and preparation method thereof

The invention provides a lubricating oil and a preparation method thereof. The preparation method concretely comprises the following steps: taking 50-60wt% of mineral base oil and 15-40wt% of poly-alpha-olefin (PAO), stirring at T1 DEG C for t1 h to obtain mixed base oil A; adding 7wt% of neopentyl polyol mixed fatty acid ester and 1wt% of borated fatty acid ester to the mixed base oil A, and stirring at T2 DEG C for t2 h to obtain base oil B; adding 2wt% of zinc dialkyl dithiophosphate to the mixed base oil B, and reacting at T3 DEG C for t3 h to obtain base oil C; and adding x% of rare earth oxide powder to the base oil C, and reacting at 50-60DEG C for t4 h to obtain the finished lubricating oil. The lubricating oil has the advantages of simple preparation method and simple component.

Owner:黑龙江三维润滑油科技有限公司

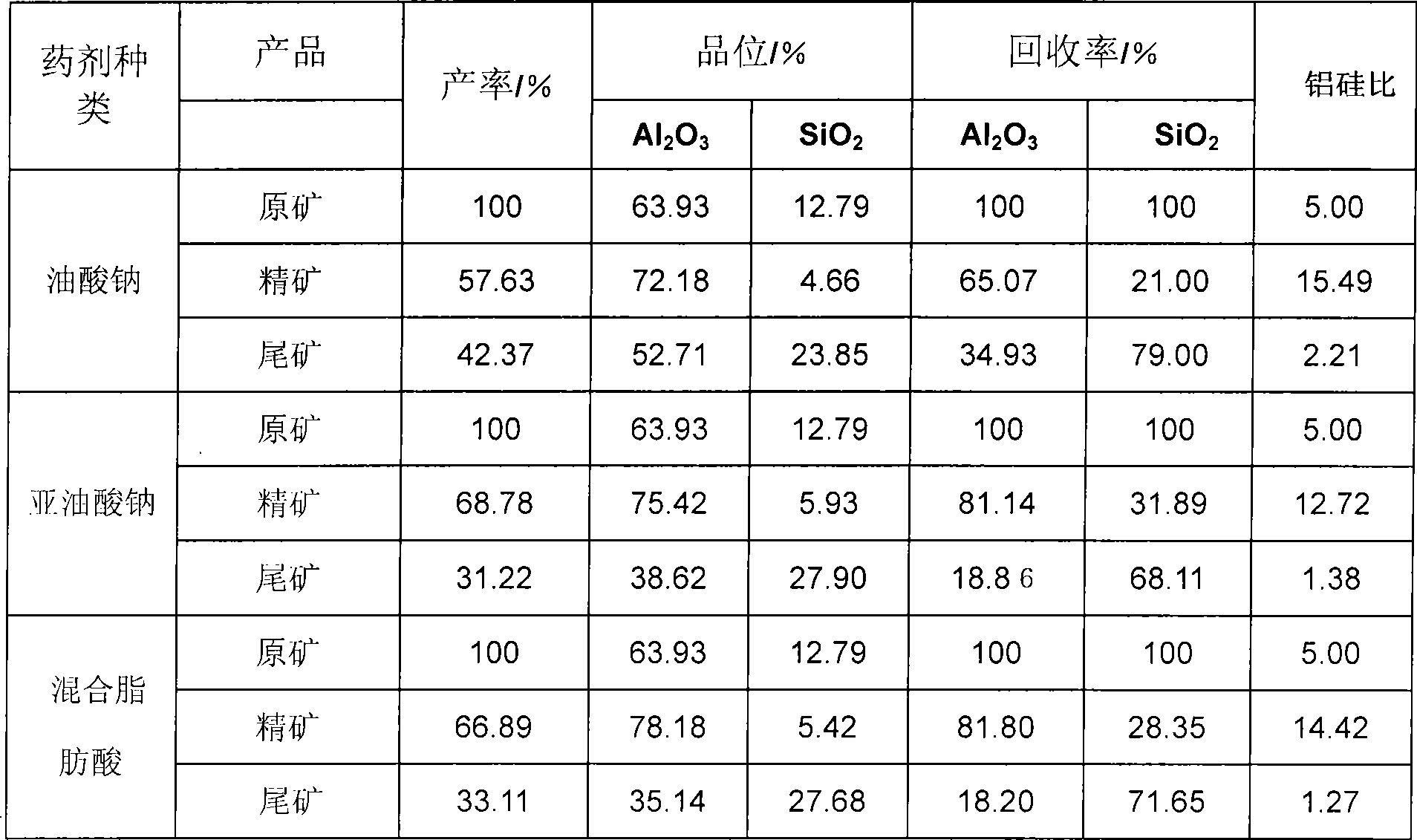

Method for preparing mixed fatty acid from hogwash oil and use method of mixed fatty acid

InactiveCN101462938AFatty acids production/refiningPreparation from carboxylic acid esters/lactonesDistillationHydrolysis

The invention discloses a method for preparing mixed fatty acid by using waste cooking oil and the application method of the mixed fatty acid. The preparation method comprises: 1) the waste cooking oil is pretreated; 2) concentrated sulfuric acid is added into an oil layer which is then turned over and cooked and stands; the mixture is washed by hot water and stands, and the waste water at the lower layer is discharged; the obtained product is washed by water repeatedly until acidated oil with the pH value of 6-8 is obtained; 3) the acidated oil, distilled water, sulphuric acid and a catalyst are added in a reaction vessel, heated, stirred, and hydrolyzed and then stand; the waste water at the lower layer is discharged; the mixture is washed by hot water and stands, and the waste water at the lower layer is discharged; the product is washed by water repeatedly until the discharged water is neutral; 4) the step 3 is carried out again, and crude fatty acid can be obtained by secondary hydrolysis; 5) the mixed fatty acid product is obtained by thermal dehydration and negative pressure distillation. The method has high synthetic efficiency, low requirements for equipment as well as low investment and preparation cost; the prepared mixed fatty acid has high activity, strong fluidity and remarkable flotation performance when being applied to the aspect of ore dressing flotation, thereby having stronger competition strength and good application prospect.

Owner:CENT SOUTH UNIV

Method for preparing nonane diacid catalyzed by solid acid

InactiveCN101077856AEasy to separateFacilitate the realization of industrial productionMolecular sieve catalystsOrganic compound preparationTemperature controlMixed fatty acid

The solid acid catalyzed process of preparing azelaic aid includes the following steps: mixing unsaturated fatty acid or mixed fatty acid produced through hydrolyzing animal and vegetable oil, solid acid catalyst and ammonium hexadecyl trimethyl chloride; stirring, heating to 50-70 deg.c, introducing gas mixture containing 2-10 wt% ozone in the flow rate of 500 ml / min, stepped adding 20-40 wt% concentration hydrogen peroxide solution at temperature controlled below 70 deg.c; heating to 95-110 deg.c for reaction for 5-12 hr; and separating the resultant liquid mixture and purifying to obtain pure azelaic aid. The used solid acid catalyst may be separated from other materials for reuse, and the process has facile materials and environment friendship, and is suitable for industrial production.

Owner:SHANGHAI UNIV

Supercritical CO2 extraction separation purification method for silkworm chrysalis alpha-linolenic acid

InactiveCN101121654AAvoid destructionHigh technical contentFatty acids production/refiningBulk chemical productionCelsius DegreePurification methods

The invention relates to an extraction and purification method of the pupa alpha-linolenic acid with the supercritical CO2 technology. The natural biological pupa powder is used as the raw material; the supercritical CO2 is used as the extraction agent to get the pupa oil; the pupa oil is added into the sodium hydroxide alcohol solution, and then to be stired, water-added and clarified; besided, the pupa oil is extracted by the organic solvent; the mixed fatty acid and urea are put into the urea methanol solution; at minus 15 to minus 20 Celsius system, and then to be stired 12 to 36 hours, next to be filtered and washed with the methanol;finally, the product is dried and the product can be got. The invention can be operated at a low temperature, avoiding the damage to the polyunsaturated fatty acid; the purity of the product quality is high and the extraction time is short; the operation is simple and convenient; compared with the traditional solvent method and squeezing method, the collection rate is high and the efficiency is high; the CO2 can be reused; no solvent is left; the product quality is high; the invention can be used in the mass production of the industrial mechanization.

Owner:SHANDONG UNIV

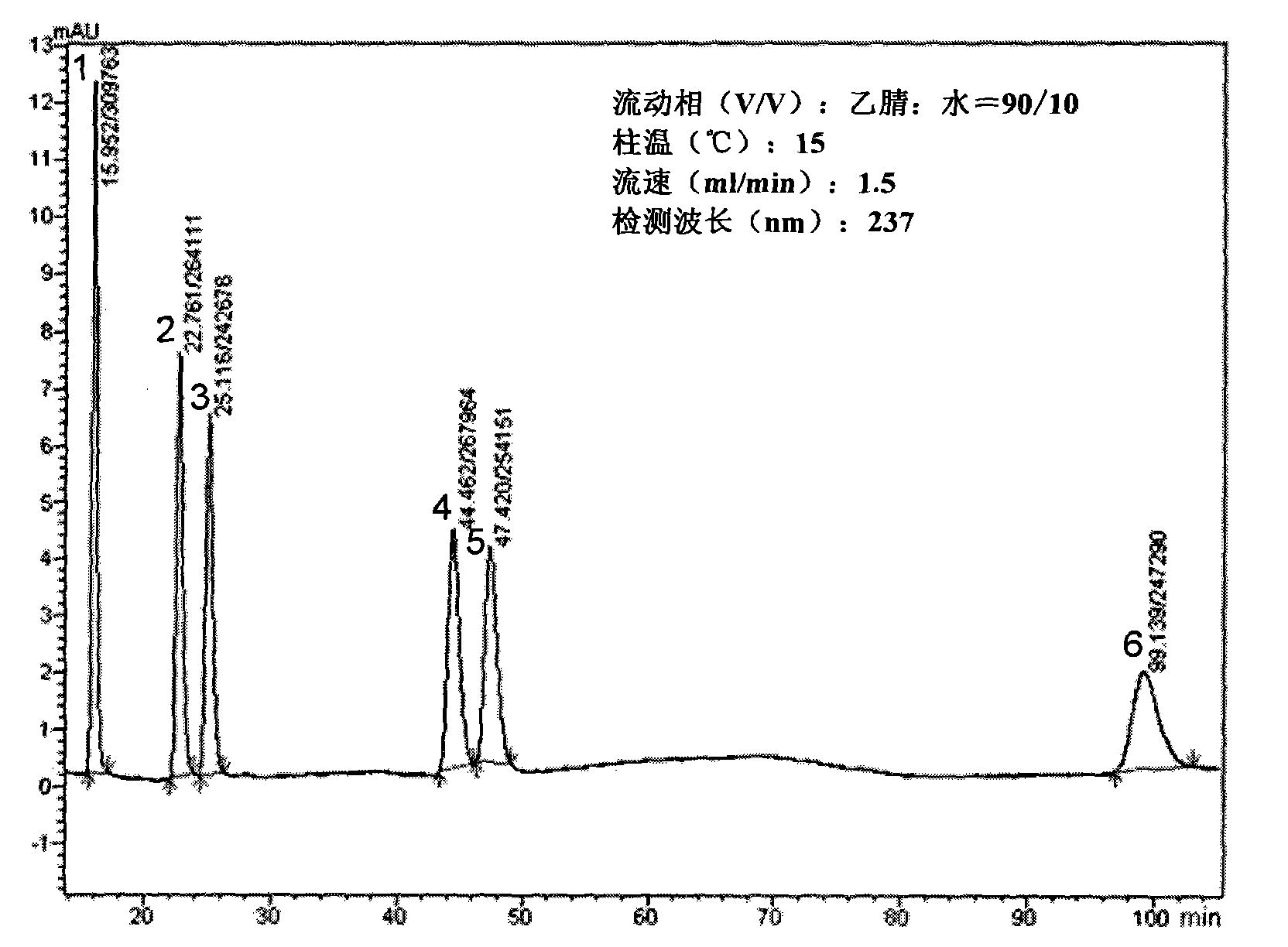

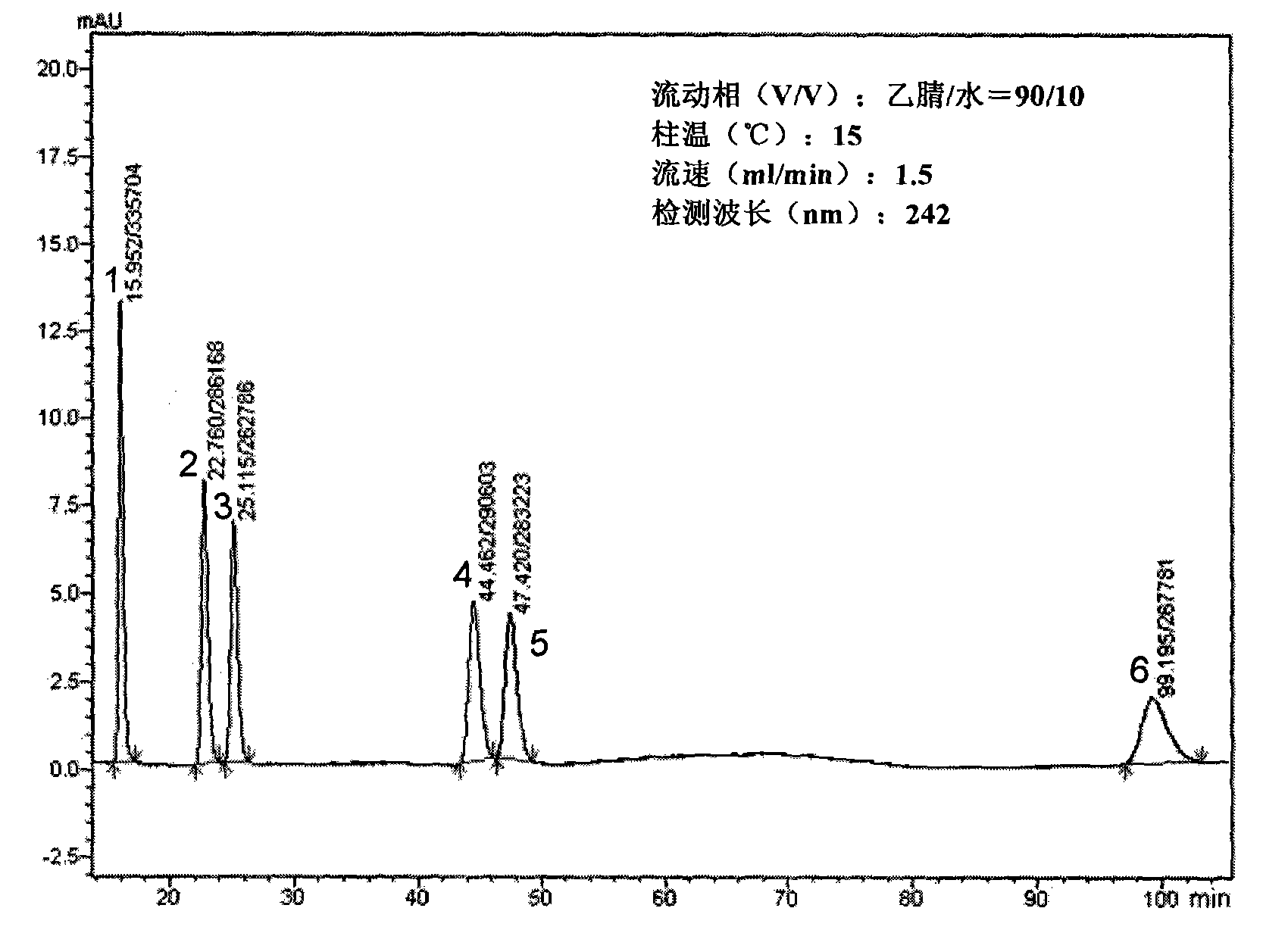

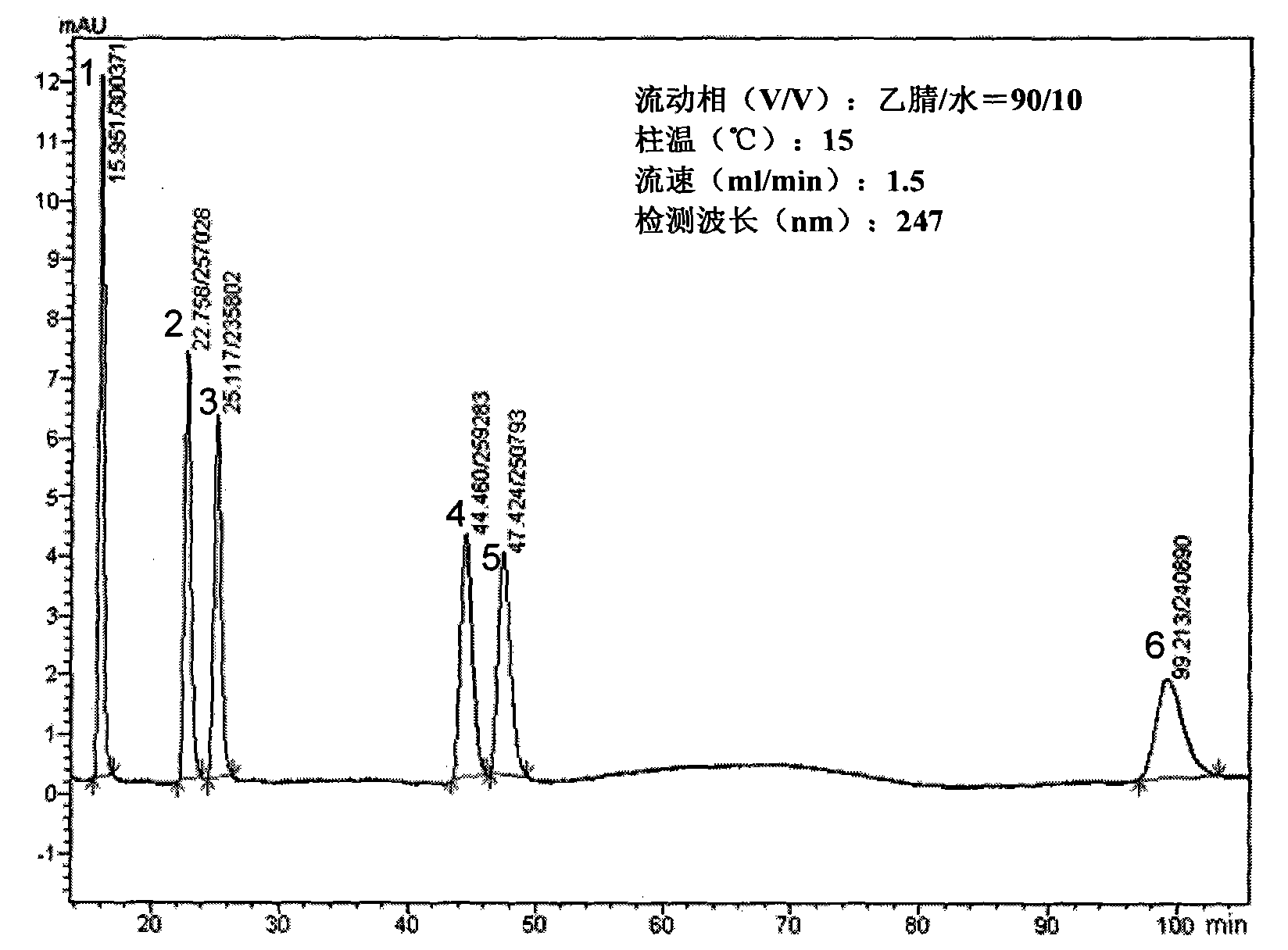

Mixed fatty acid high performance liquid phase chromatography method and application

InactiveCN101776666AImprove efficiencyShort separation timeComponent separationStearic acidPalmitoleic acid

The invention discloses a mixed fatty acid high performance liquid phase chromatography method and application thereof. In order to solve the problems that the prior art has single method in separating linolenic acid, palmitic acid, linoleic acid and other three fatty acid mixtures with very similar chemical and physical properties with HPLC, and defects in elution method, mobile phase composition selection and the like, the invention provides a method for simultaneously separating six fatty acid mixtures, i.e. linolenic acid, palmitic acid, linoleic acid, oleic acid, palmitic acid and stearic acid with HPLC. The method esterifies fatty acid solution to be tested with the acetone solution of omega-bromoacetophenone and the acetone solution of triethanolamine, and separates the solution with HPLC. The HPLC adopts an isocratic elution method, and the mixture of acetonitrile and CTAB solution or acetonitrile-water solution is selected to serve as the mobile phase. Compared with the priorart, the invention has the advantages of simple and feasible operation, good separation effect, high detection sensitivity, accurate and reliable results, and simultaneous separation of 6 fatty acids.

Owner:SICHUAN AGRI UNIV

Method for gathering oleic acid from tea-seed oil

The invention relates to a method for gathering high-purity oleic acid from tea-seed oil, which comprises the following steps: preparation of tea-seed oil mixed fatty acid and separation of saturated fatty acid, and is characterized by also comprising the following steps that: tea-seed oil is saponified and acidified to prepare tea-seed oil mixed fatty acid; urea and mixed fatty acid are sequentially added into short-chain alcoholic phase, are frozen to form urea inclusion compound and then are filtered or centrifugally separated to obtain liquid-phase non-urea inclusion part, and unsaturated fatty acid product is obtained after the solvent is steamed. With the method, total content of 18-carbon unsaturated fatty acid reaches 95 to 99.3 percent, the content of the oil acid reaches 90 to 93.3 percent, and the obtained oil acid can be directly used in the fields such as cosmetics, medical and the like. The method has low cost, simple process and environmental protection and is convenient for the mass production.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Process for extracting alpha-linolenic acid

InactiveCN101337880AUndamagedImprove oil yieldFatty acids production/refiningCarboxylic compound separation/purificationMixed fatty acidLinseed oil

Owner:TONGWEI XIAOLING TRADE

Method for extracting and separating safflower seed oil

ActiveCN101744237AReduce dosageHigh purityEdible oils/fatsFood preparationOil processingFractionation

The invention relates to a method for extracting and separating safflower seed oil, belonging to the technical field of grain and oil processing. The invention uses safflower seed oil as raw material and adopts multifrequency ultrasonic synergy to extract safflower seed oil. The extracting method has simple technology, low operation temperature, short extraction time, less solvent dosage and high recovery ratio, the obtained crude oil has high quality and is easy to refine; and the obtained safflower seed oil is used to prepare mixed fatty acid through saponification and acidification, firstly urea adduction fractionation is adopted to perform primary separation of the mixed fatty and prepare crude linoleic acid, and then the molecular distillation of the crude linoleic acid is performed to prepare refined linoleic acid. The separation method combines the urea adduction fractionation with the molecular distillation method, the prepared linoleic acid has high purity, good quality, high yield and low cost and the obtained product can be used in medicines, health care products, foods and other industries.

Owner:吉林省百利生物科技有限公司

Method for extracting gamma-linoleic acid from blue algae in water bloom

InactiveCN1562943ALow priceSimple methodOrganic compound preparationCarboxylic compound preparationWater bathsEutrophication

The invented prodn. process contains steps of: (1) raw material algal bloom blue green algare is concentrated, dewatered, dried and crushed to obtain algare powder; (2). said powder is soaked in mineral ether at room temp. to break the cells, and continuously soaked after a night, refluxing in water bath, then removing leavings of the cell to obtain gamma-linoleates mixed ester; (3). said ester is saponified after adding saponifier in water bath, then cooled to room temp., (4). adjusting said solution pH value to 3-4, then methoxycarbonylation and urea packing reaction to abtain gamma-linoleic acid. Advantages are: simple process, high obtg. rate, easy to obtain raw material, with social, environment and economic benefits.

Owner:INST OF AQUATIC LIFE ACAD SINICA

Polarizing plate and liquid crystal display employing the same

InactiveUS20060082703A1Shrinking and dimensional changeGood optical performanceLiquid crystal compositionsPolarising elementsCelluloseMixed fatty acid

A polarizing plate used in a vertical alignment mode liquid crystal display comprising a liquid crystal cell is disclosed, wherein the polarizing plate comprises a polarizing film and a mixed fatty acid cellulose ester film with optical biaxiality provided between the polarizing film and the liquid crystal cell, and wherein the mixed fatty acid cellulose ester film has a retardation in plane R0 of from 31 to 120 nm, and a retardation in the thickness direction Rt of from 60 to 300 nm, in which R0 is represented by the following formula (1) and Rt is represented by the following formula (2): R0=(nx−ny)×d formula (1) Rt={(nx+ny) / 2−nz}×d formula (2)

Owner:KONICA CORP

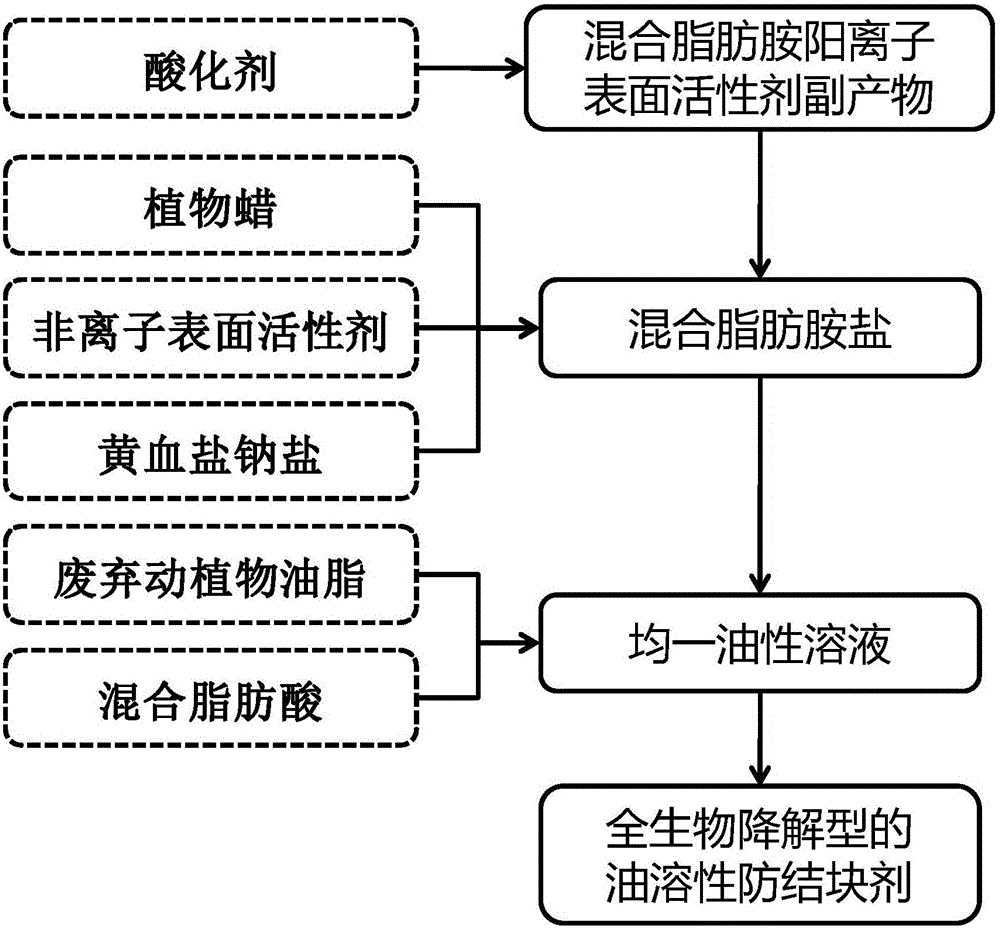

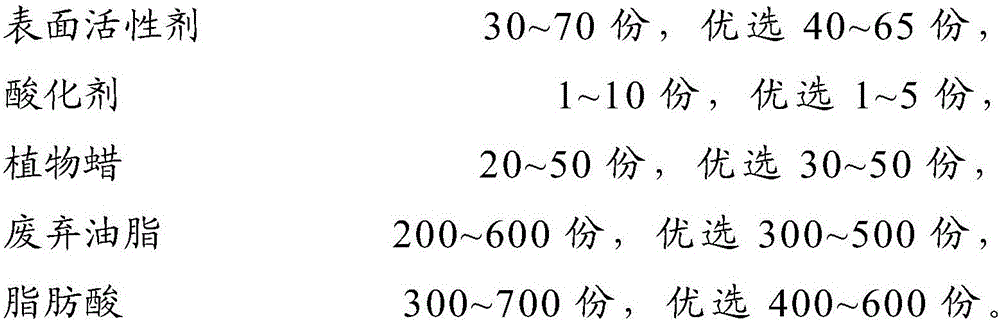

Environment-friendly oil-soluble anti-caking agent for compound fertilizer and preparation method thereof

The invention relates to a full-biodegradable oil-soluble anti-caking agent for a compound fertilizer and a preparation method and application thereof. The anti-caking agent consists of the following raw materials: a surfactant, an acidifier, vegetable wax, waste oil and fatty acid mixture and more preferentially also comprises a nonionic surfactant and / or sodium ferrocyanide. In the invention, the prepared anti-caking agent can be completely bio-degraded in natural environment, the preparation technology is relatively simple, the cost performance is relatively high, the caking of a chemical compound fertilizer caused by dampness and extrusion can be effectively prevented, and the anti-caking rate of the most easy-to-cake potassium sulfate compound fertilizer and high-nitrogen compound fertilizer is greater than 96%, preferentially greater than 98% and more preferentially greater than 99% and approaches and even reaches 100%.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Extraction method for unsaturated fatty acid

ActiveCN102311882AImprove extraction efficiencyHigh purityFatty acids production/refiningFatty-oils/fats refiningFatty liverIodo fatty acid

The invention relates to a method of extracting unsaturated fatty acid from abdominal fat of geese with fatty liver. The method comprises the steps of preparation of crude goose oil of abdominal fat of geese with fatty liver, refining of the crude goose oil and extraction of unsaturated fatty acid, and is characterized in that: there is a step of extraction of goose oil mixed fatty acid between the step of refining of the crude goose oil and the step of extraction of unsaturated fatty acid. According to the invention, refining technological parameters of degumming, decolouring and deodorization for the goose oil are improved in the method, thereby removing non-glyceride components in the unsaturated fatty acid, substantially abating influence of impurities on subsequent processes and improving stability of the unsaturated fatty acid; the step of extraction of goose oil mixed fatty acid is added before the step of extraction of unsaturated fatty acid, thereby substantially improving efficiency of subsequent extraction of the unsaturated fatty acid and purity of the unsaturated fatty acid and reducing cost. The method enables waste abdominal fat of geese with fatty liver to be fullyutilized, having an important social benefit and economic value. The extracted unsaturated fatty acid can be used in a wide variety of fields like foodstuffs, medicines and cosmetics.

Owner:山东雁王食品科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com