Method for preparing mixed fatty acid from hogwash oil and use method of mixed fatty acid

A technology of mixing fatty acids and hogwash oil, which is applied in the fields of fatty acid production, fatty acid preparation/refining, carboxylate/lactone preparation, etc. It can solve the problems of immaturity, large investment, lipase not suitable for oil hydrolysis industrial production, etc., and achieve Strong fluidity, less investment in equipment, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: Utilize hogwash oil to prepare mixed fatty acids

[0049] Specifically include the following steps

[0050] 1) The hogwash oil recovered from the catering industry is separated and removed from protein and other food residues, and after pretreatment such as precipitation and impurity removal, acidification degumming, steam cooking deodorization, vacuum dehydration, etc., it is poured into the acidification tank, the hogwash oil is heated and stirred, and sulfuric acid is added Perform acidification treatment, let the lower layer of wastewater stand still, collect it for acidification, then wash it with hot water until it is neutral, then discharge the wastewater, and collect it for acidification.

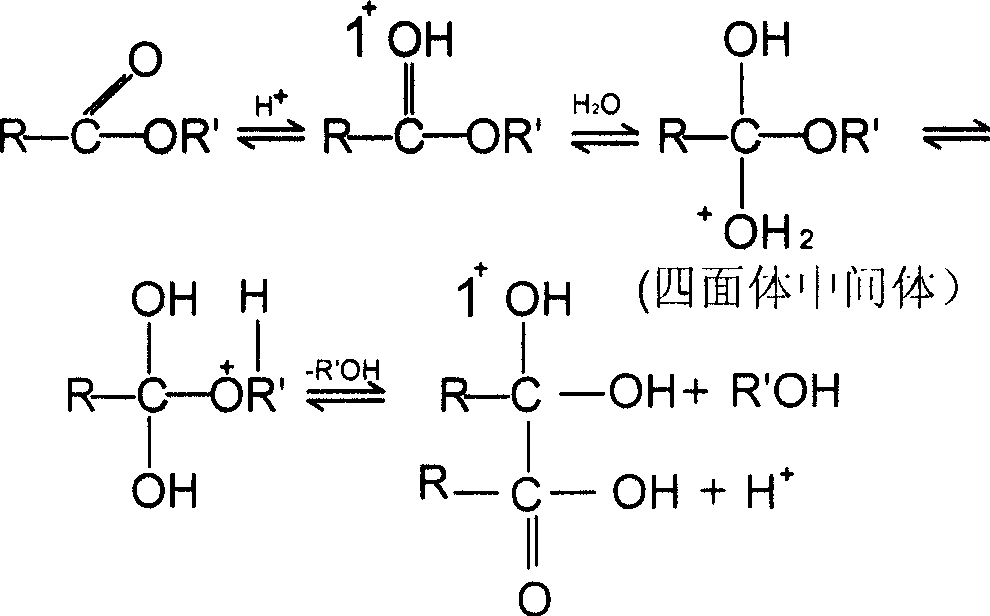

[0051] 2) The neutral acidified oil is metered and injected into the hydrolysis tank 1, 10% sulfuric acid, 1% catalyst and 50% distilled water are added in proportion, the temperature of the oil bath is controlled at 101-110° C., and the hydrolysis is carried ou...

Embodiment 2

[0055] Embodiment 2: Utilize the mixed fatty acid prepared by hogwash oil of the present invention to produce products such as unsaturated and saturated fatty acids. The specific steps 1) to 5) of this example are the same as those in Example 1, and step 6) is also included. Step 6) is as follows: put the mixed fatty acid obtained in the above step 5) into a freezing pot, control the temperature at 0-4°C, and freeze for 24 hours , process the frozen mixed fatty acid by cloth extrusion method, the liquid part is mixed unsaturated fatty acid, and the solid part can be heated to 95 ℃ to obtain saturated fatty acid such as stearic acid, which can be used in industrial fields such as rubber, printing and dyeing, plastic additives, etc. .

Embodiment 3

[0056] Example 3: Production of oleic acid and linoleic acid products using the mixed fatty acid prepared from hogwash oil according to the present invention.

[0057] The specific steps 1) to 5) of this embodiment are the same as in Example 1, and also include step 6), and step 6) is as follows: the mixed fatty acid obtained in the above step 5) is pumped into a freezing pot, stirred continuously, and the fatty acid is frozen , emulsification separation and distillation treatment, the qualified oleic acid and linoleic acid are distilled out, which is a product of deep processing of the unsaturated part of mixed fatty acids and is widely used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com