Patents

Literature

1221 results about "Cooking oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glycerol Feedstock Utilization for Oil-Based Fuel Manufacturing

InactiveUS20090004715A1Bioreactor/fermenter combinationsFatty acid chemical modificationMicroorganismTransesterification

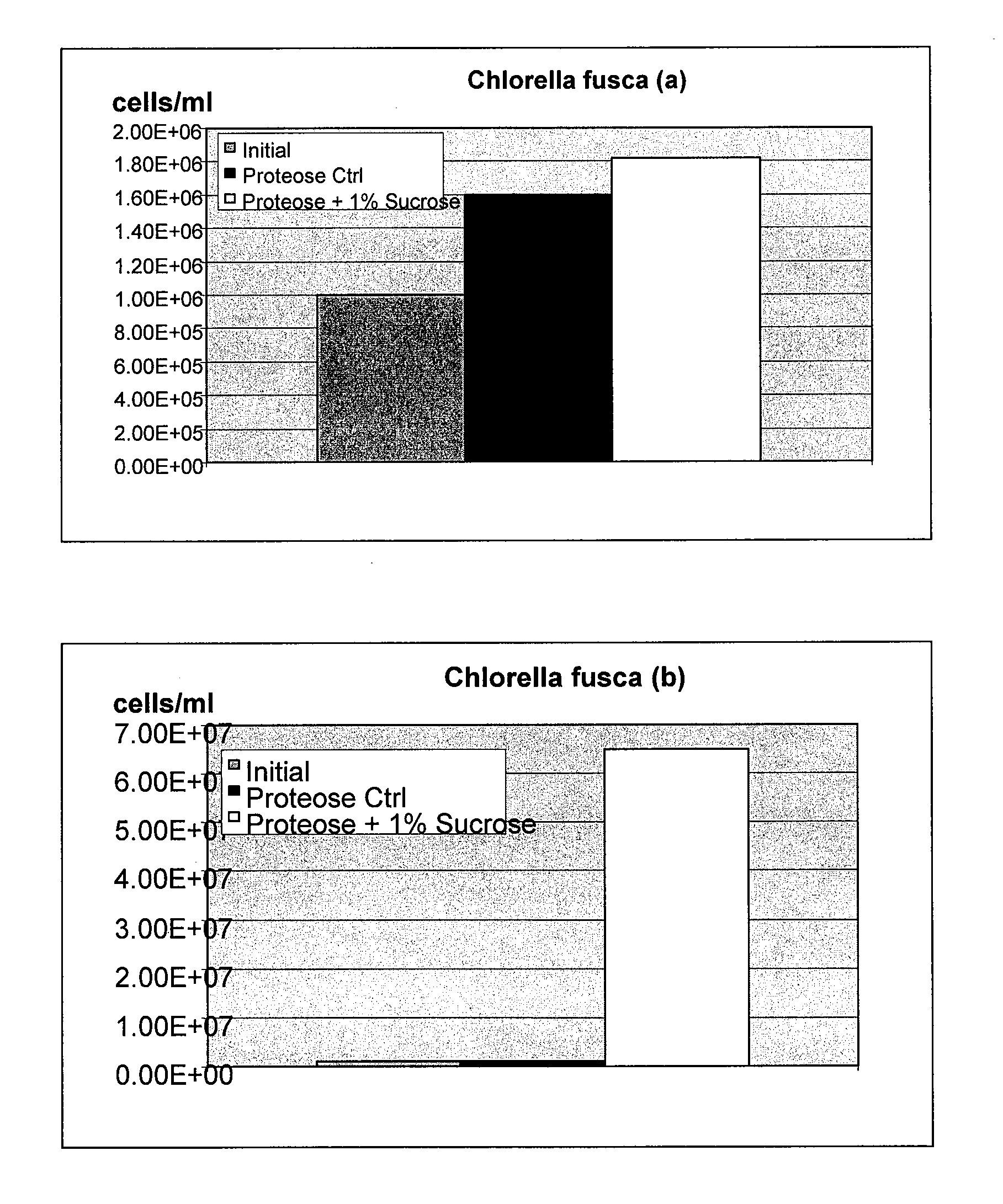

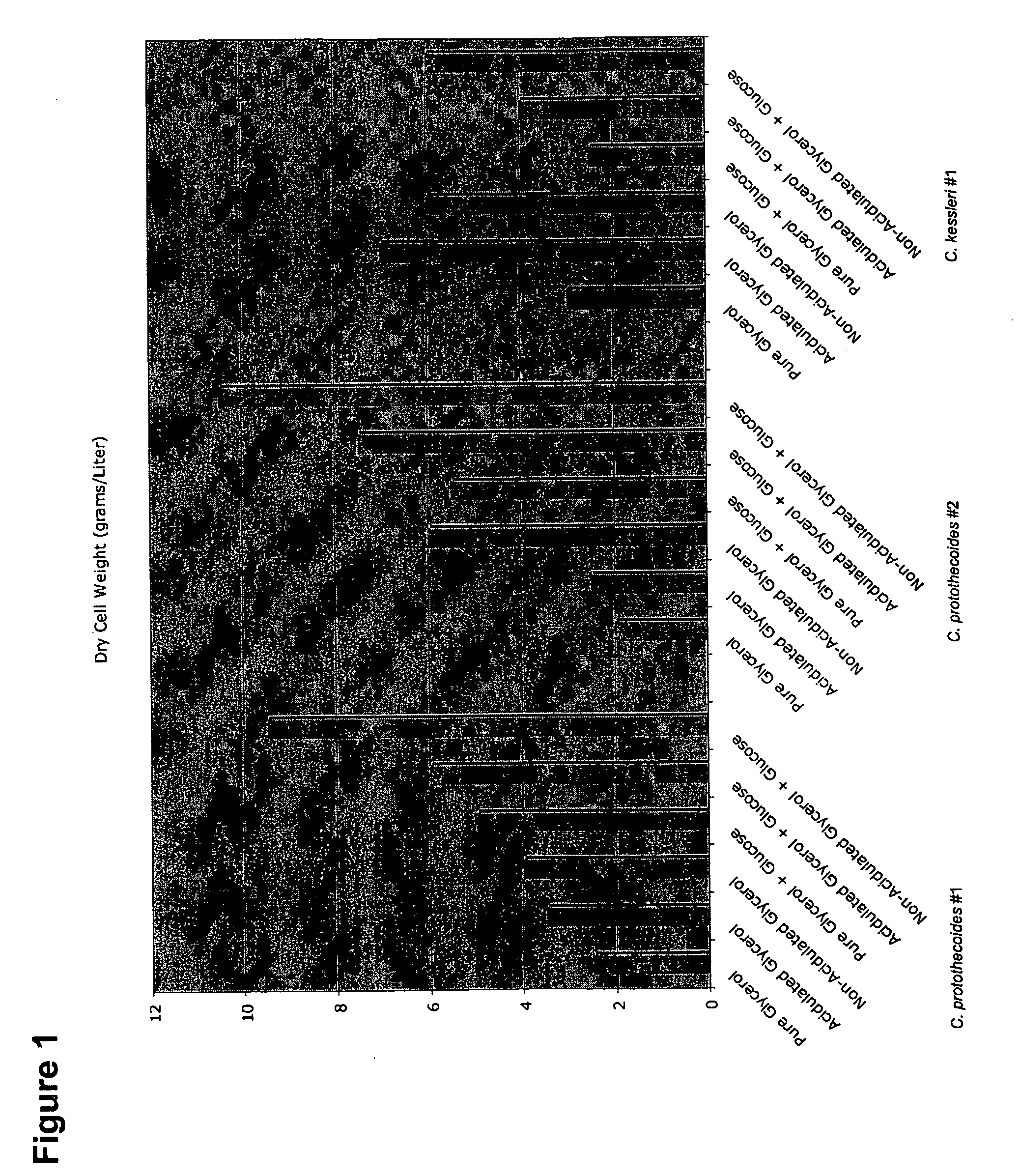

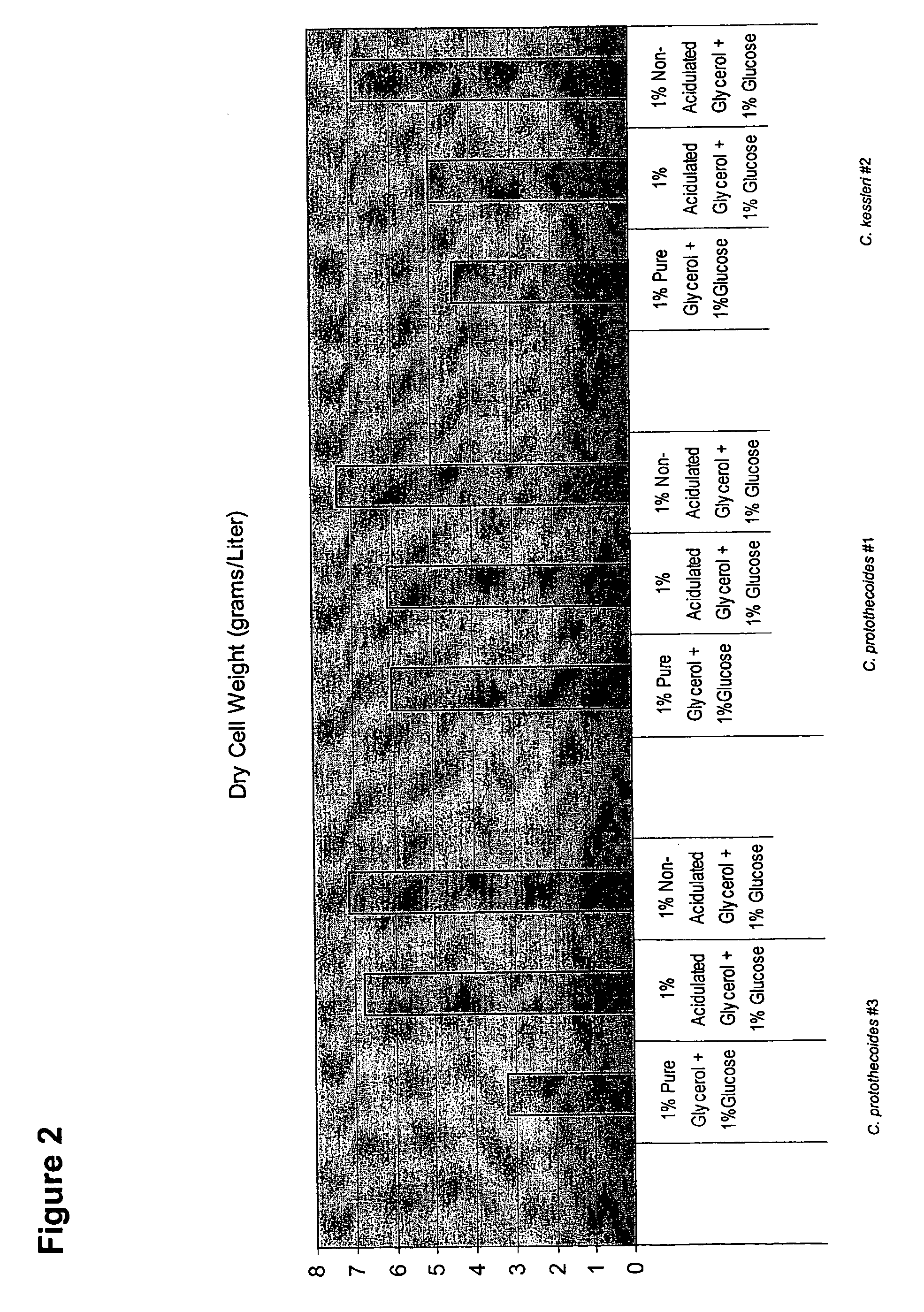

The invention provides methods of manufacturing biodiesel and other oil-based compounds using glycerol and combinations of glycerol and other feedstocks as an energy source in fermentation of oil-bearing microorganisms. Methods disclosed herein include processes for manufacturing high nutrition edible oils from non-food feedstock materials such as waste products from industrial waste transesterification processes. Also included are methods of increasing oil yields by temporally separating glycerol and other feedstocks during cultivation processes. Also provided herein are oil-bearing microbes containing exogenous oil production genes and methods of cultivating such microbes on glycerol and other feedstocks.

Owner:TERRAVIA HLDG INC

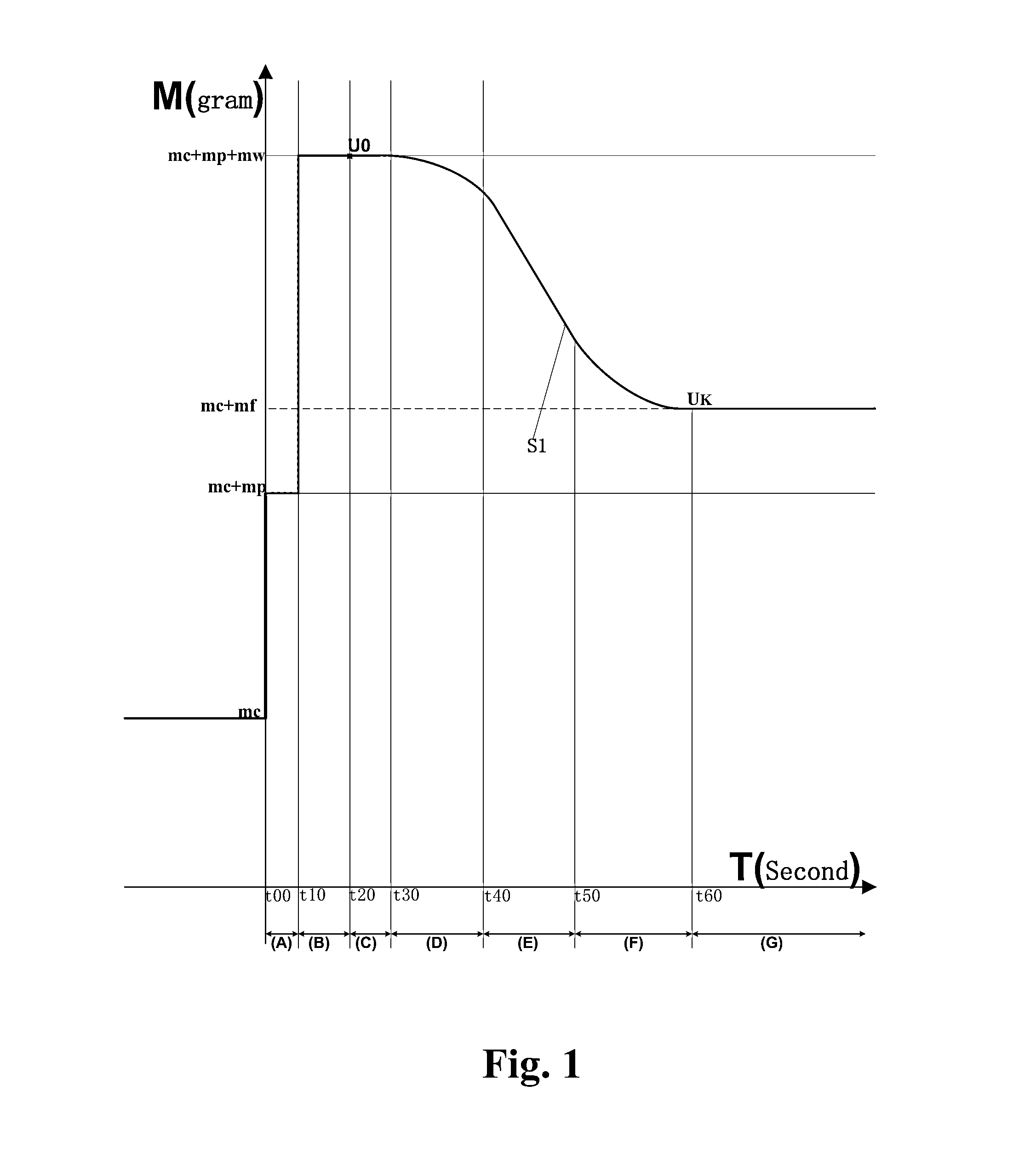

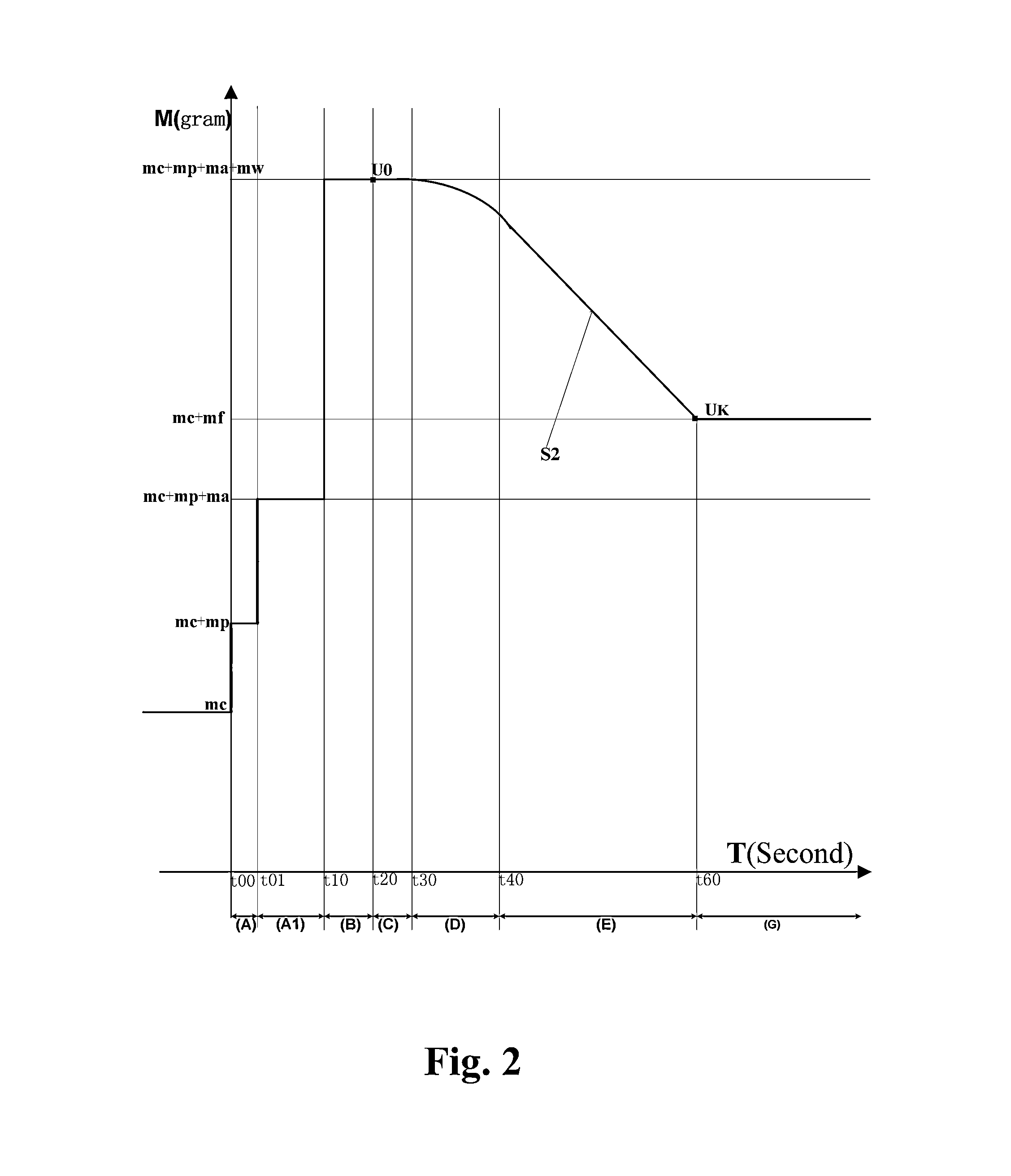

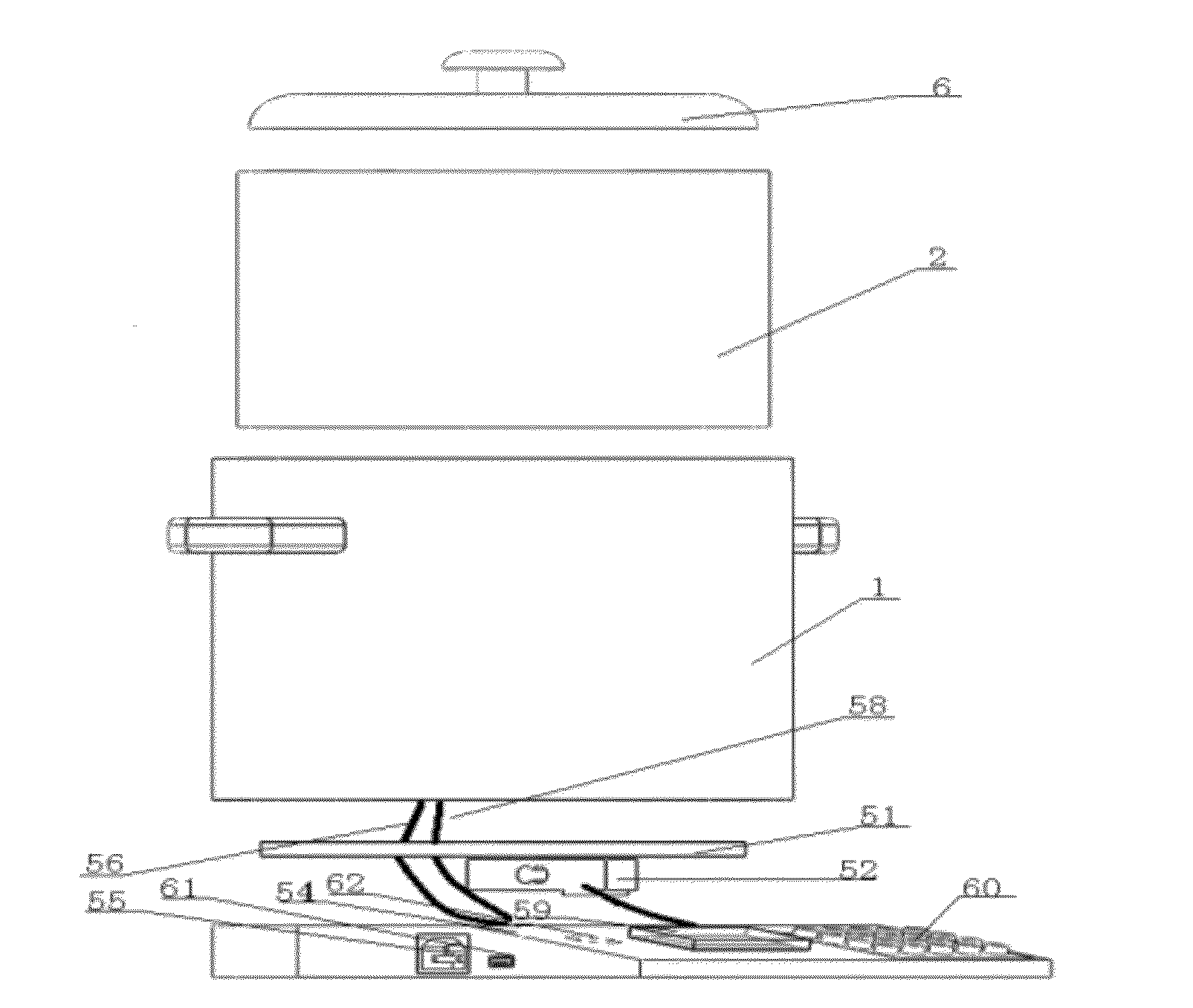

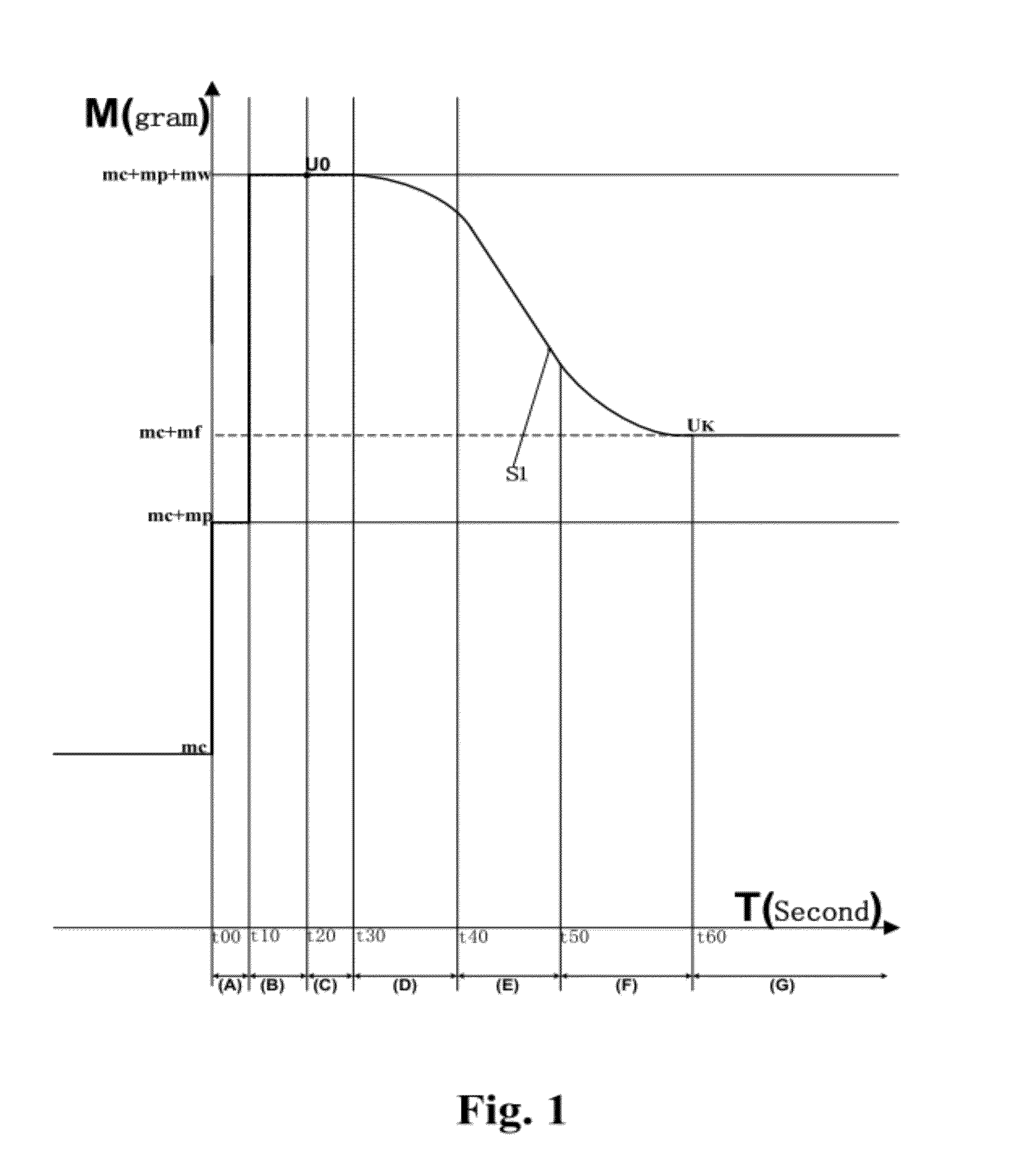

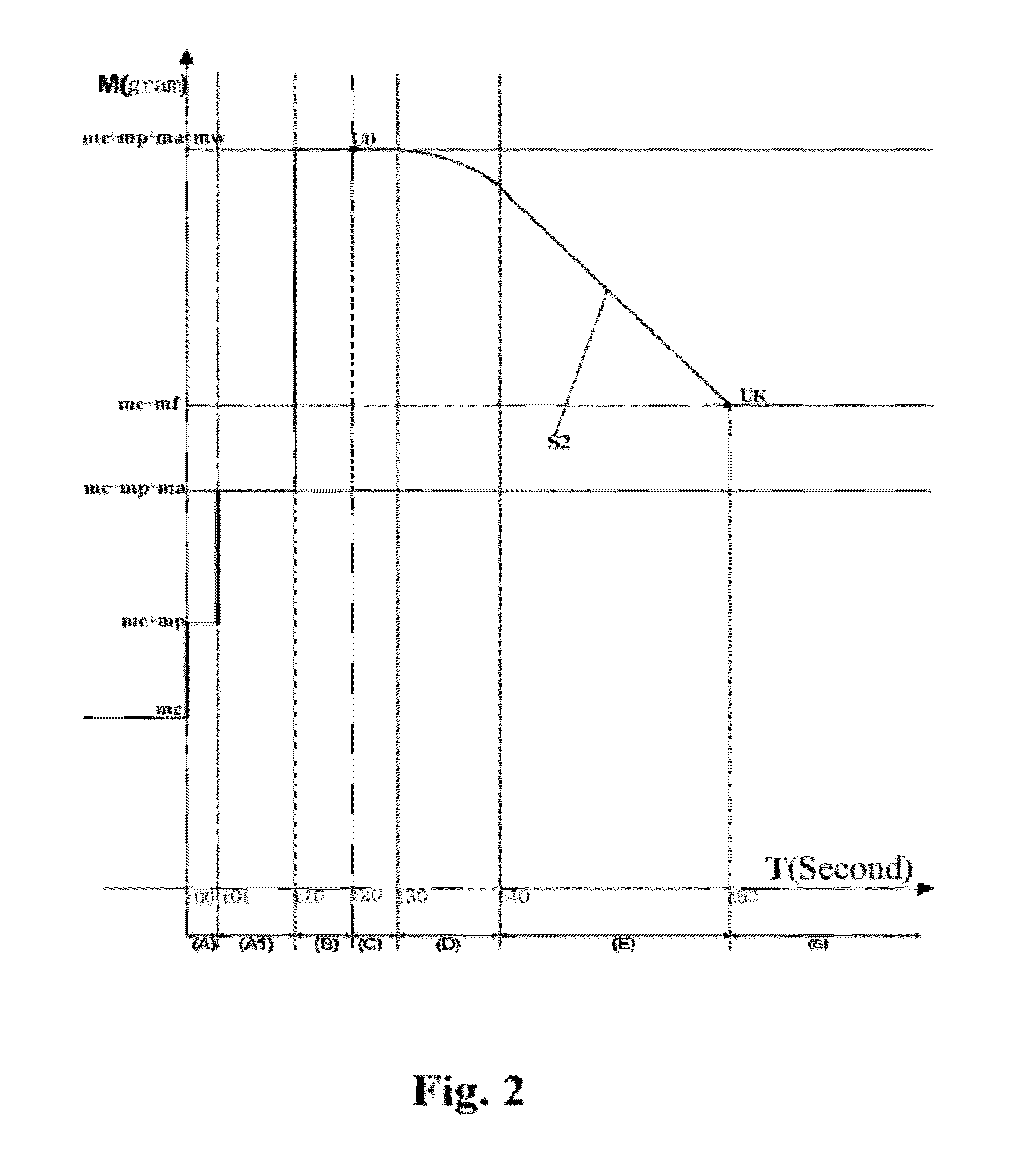

Electric heating cooker with weighing function and weighing control method thereof

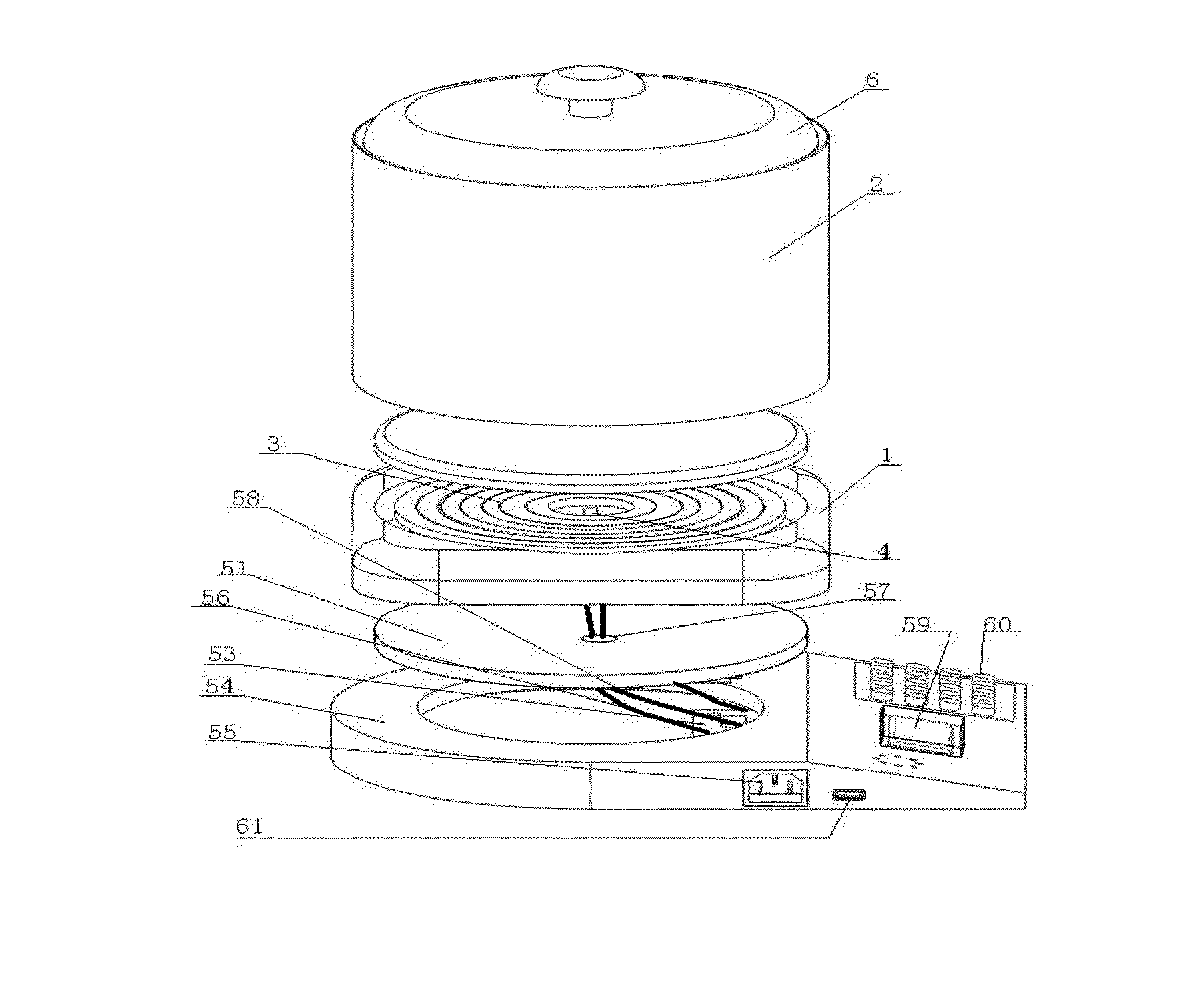

ActiveUS9119501B2Increase and decrease valueEasy to controlWeighing apparatus detailsOhmic-resistance heatingCholesterolAdditive ingredient

An electric heating cooker with weighing function and a weighing control method thereof are provided. An electronic scale (5) with weighing function is added under the traditional electric heating cooker and stores cooking experience database and food information database. It solves the problem that users aren't accurate about the amount of water to add for a given weight of ingredient. And experience curve of heating power are designed at different weight points for food such as rice or meat, and also it makes the cooker to intelligently adjust parameters according to the taste feedback of the user so as to be more closer to the user's taste for the cooking next time; additionally it is capable of showing the total and average content of heat quantity, cholesterol, protein, fat, salt and cook oil of various foods in current cooking or if there are unmatched foods.

Owner:DUO AI JIA BEIJING SCI & TECH

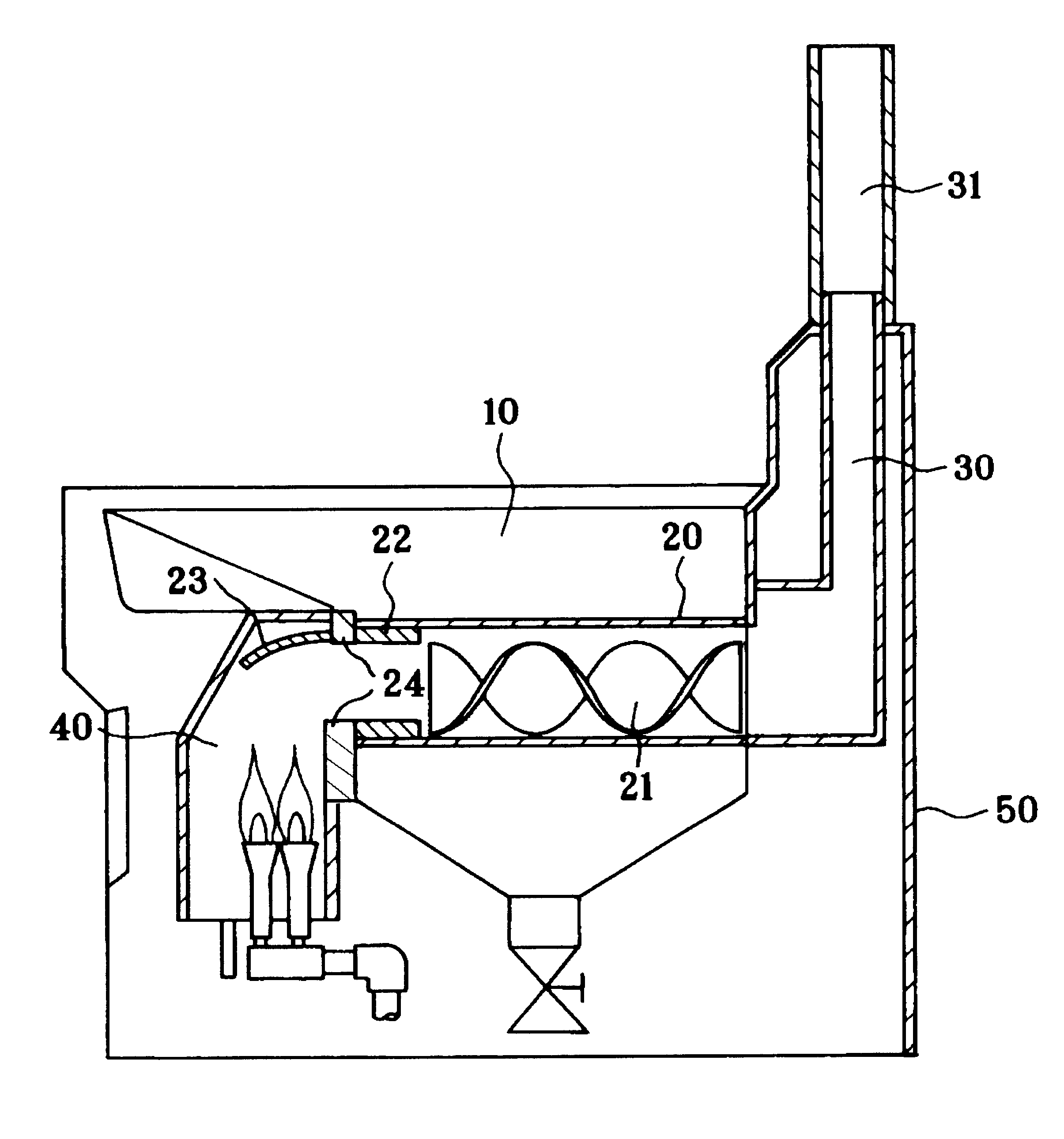

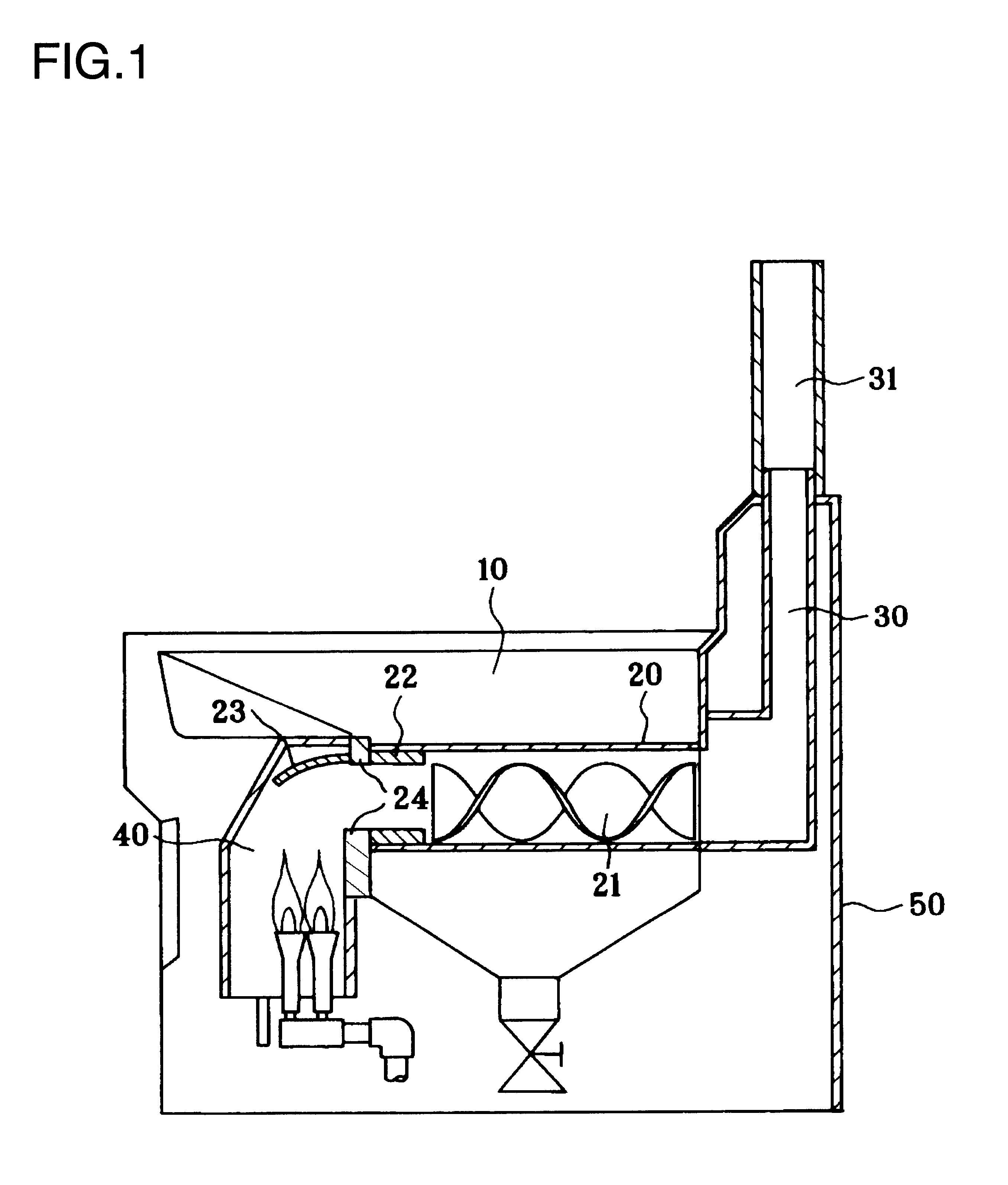

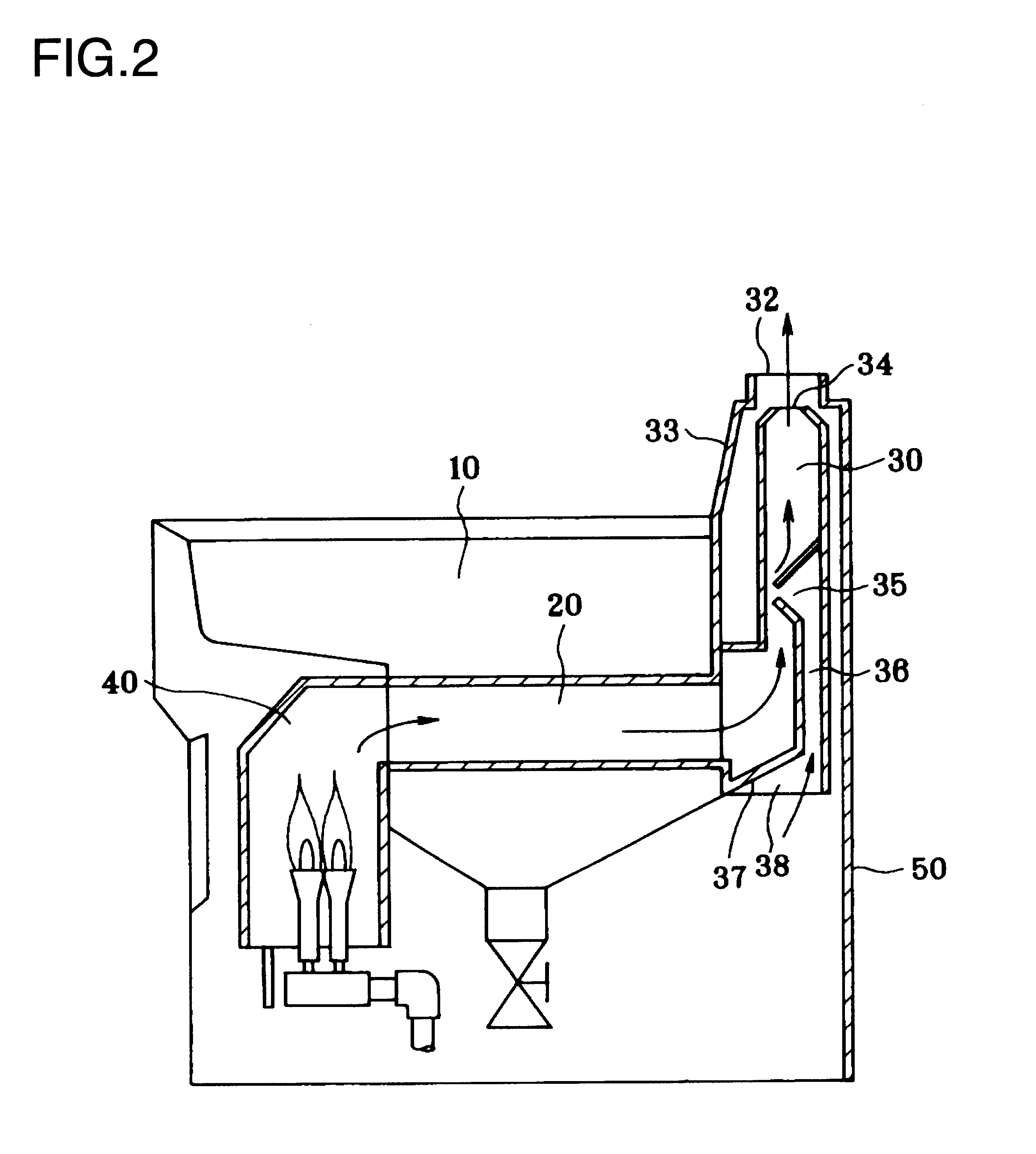

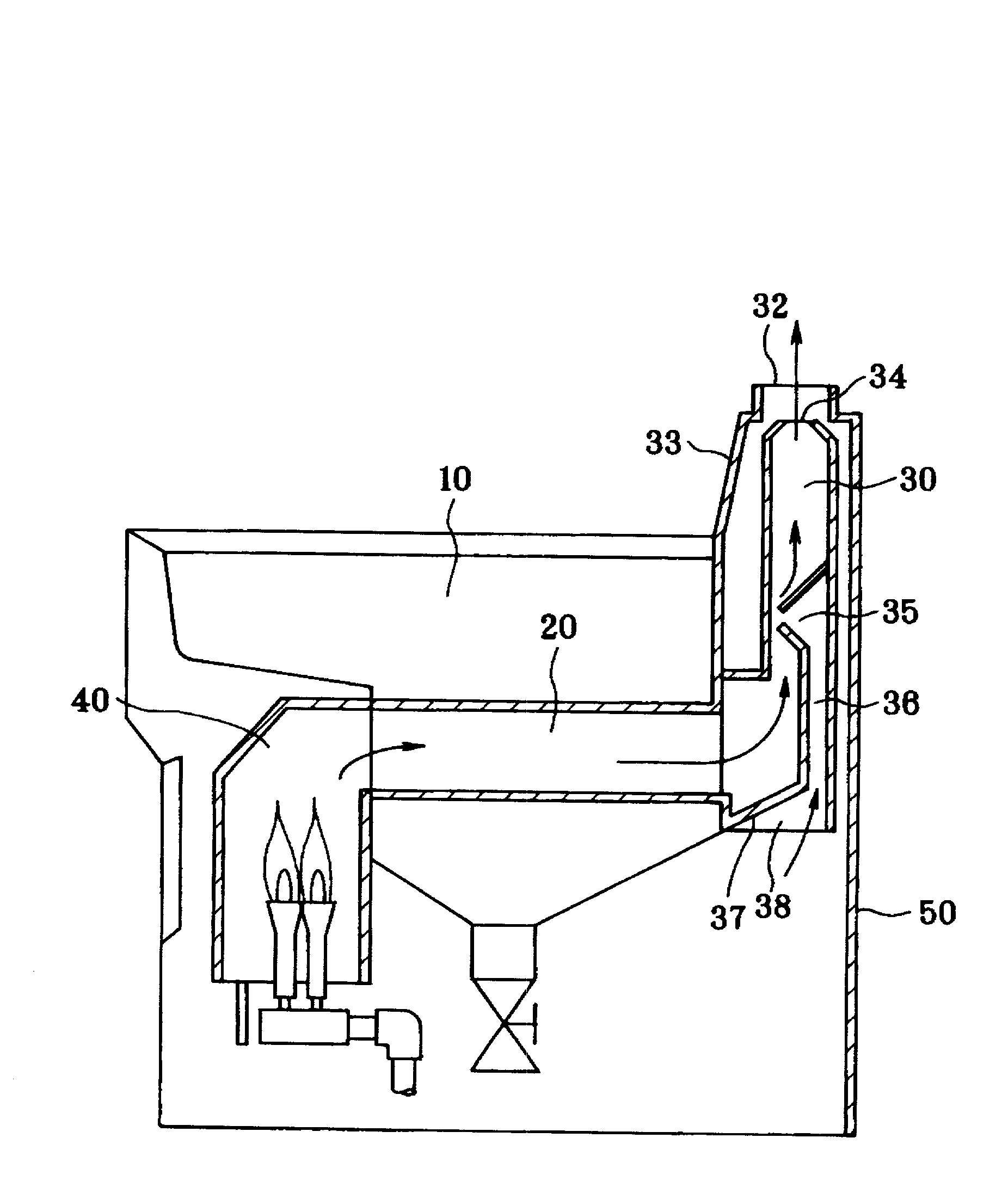

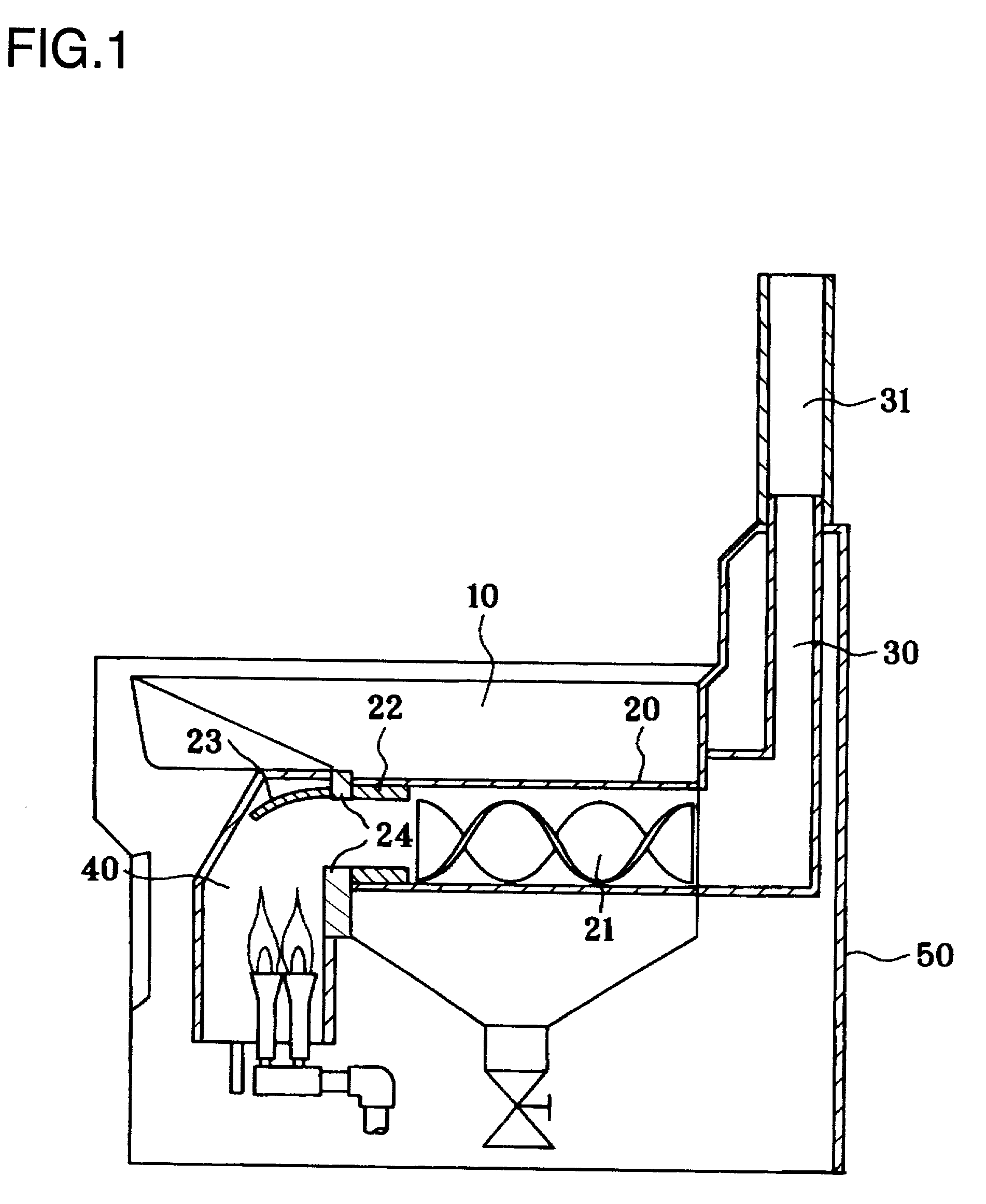

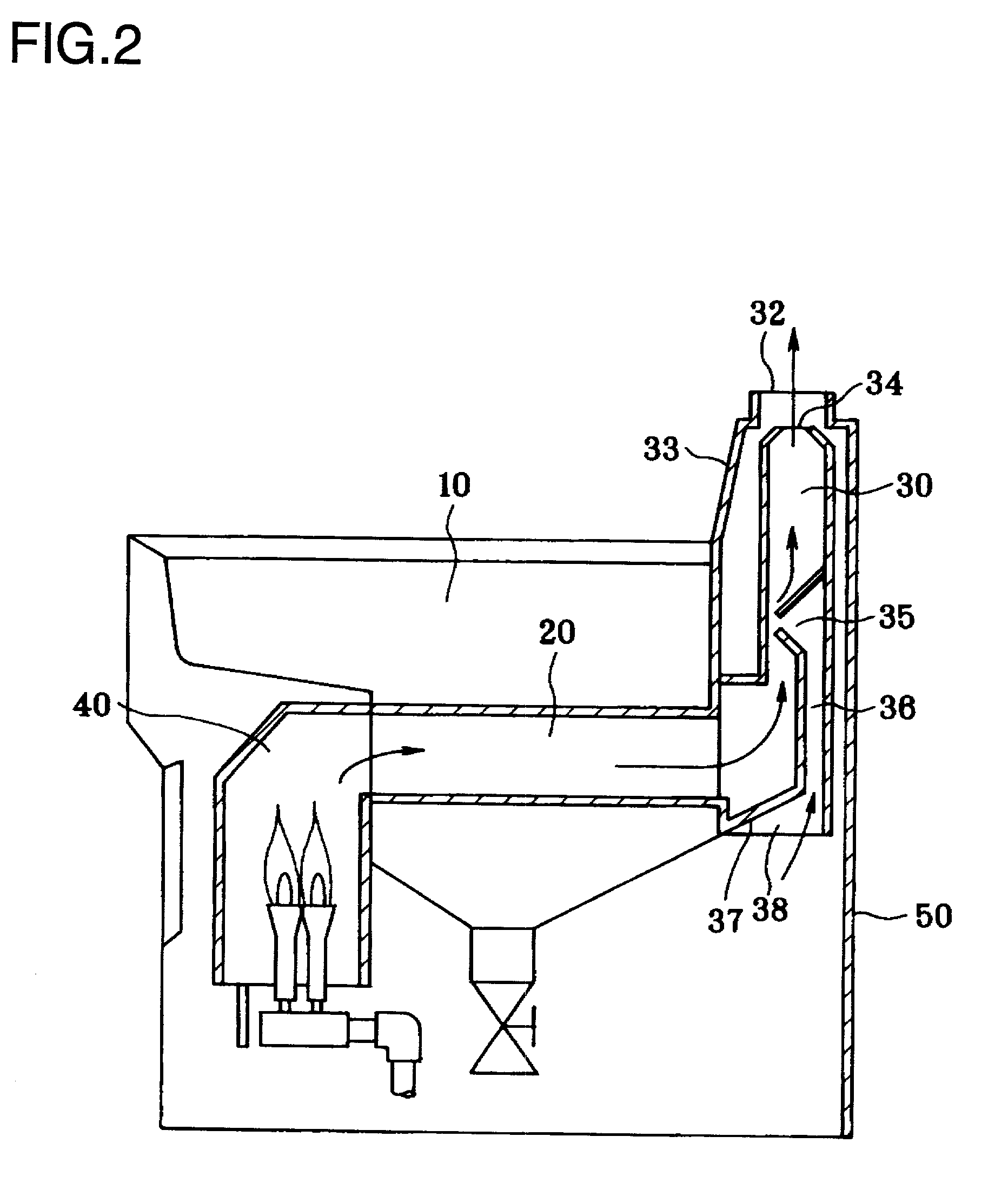

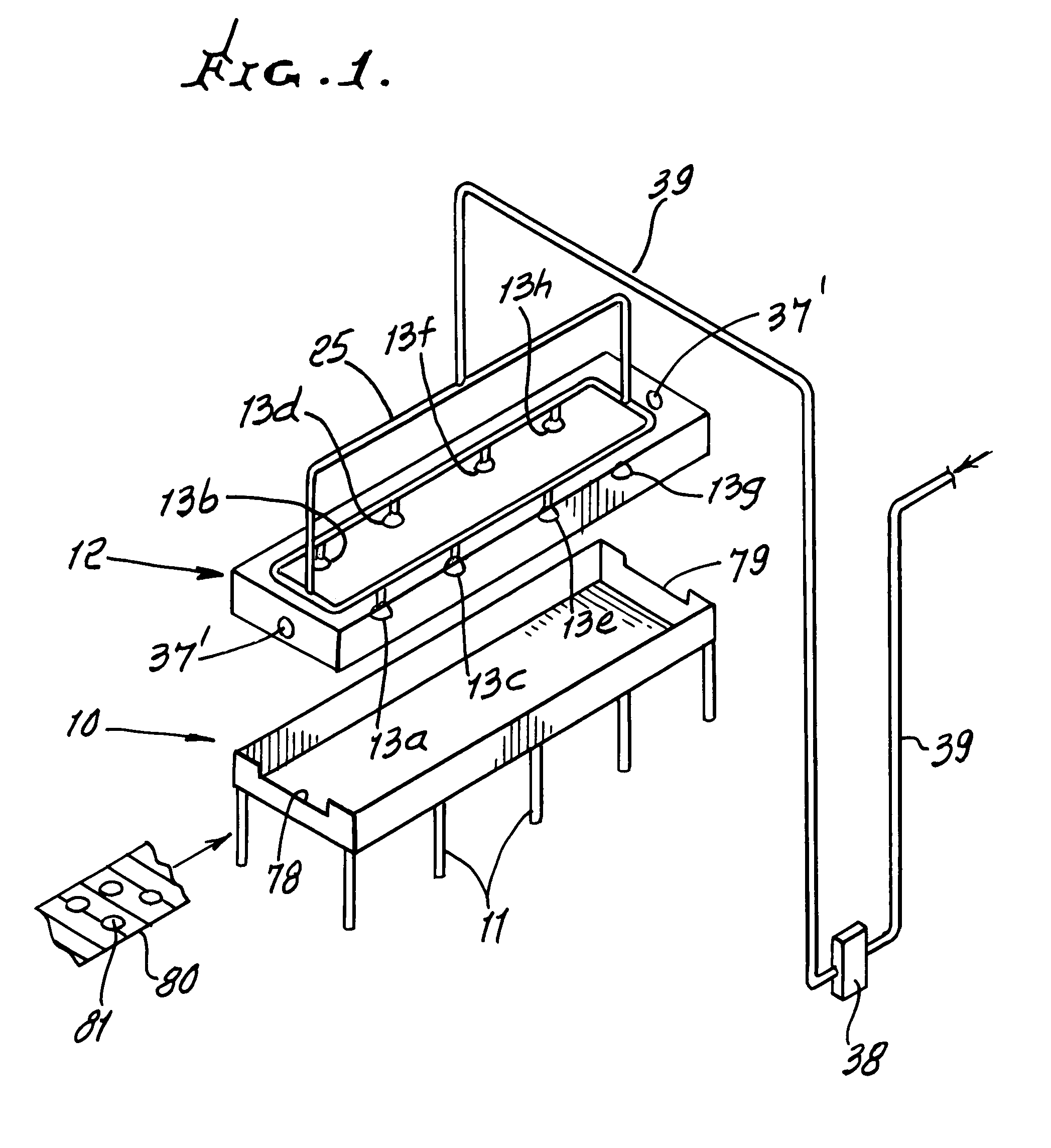

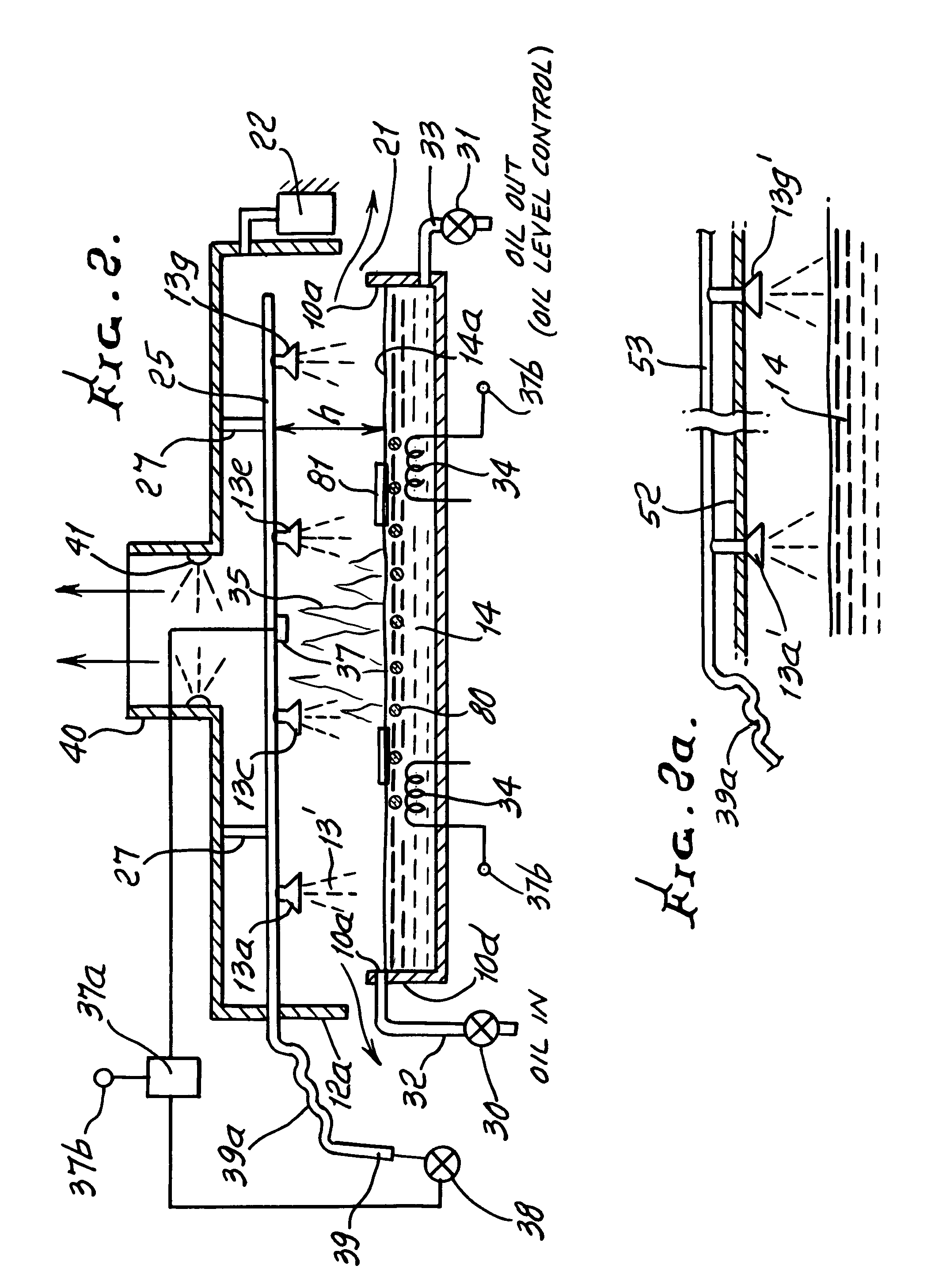

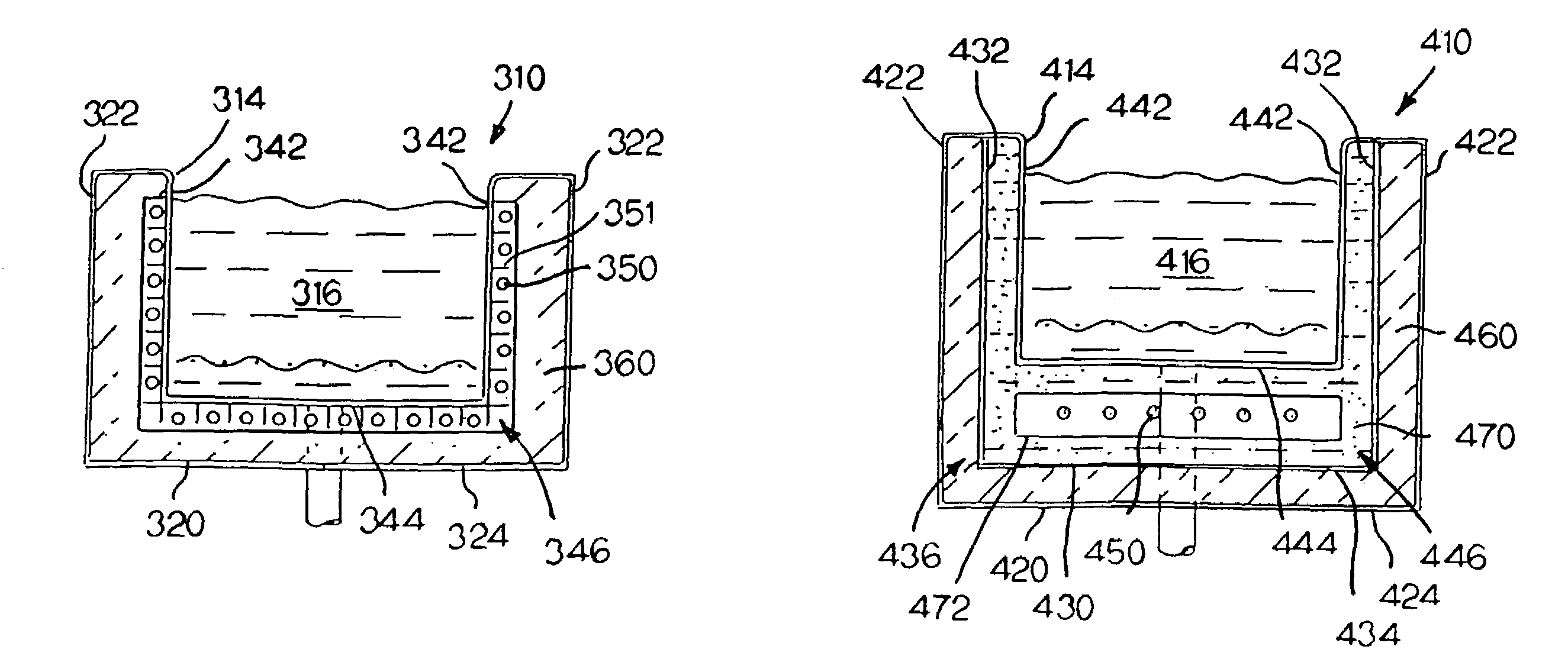

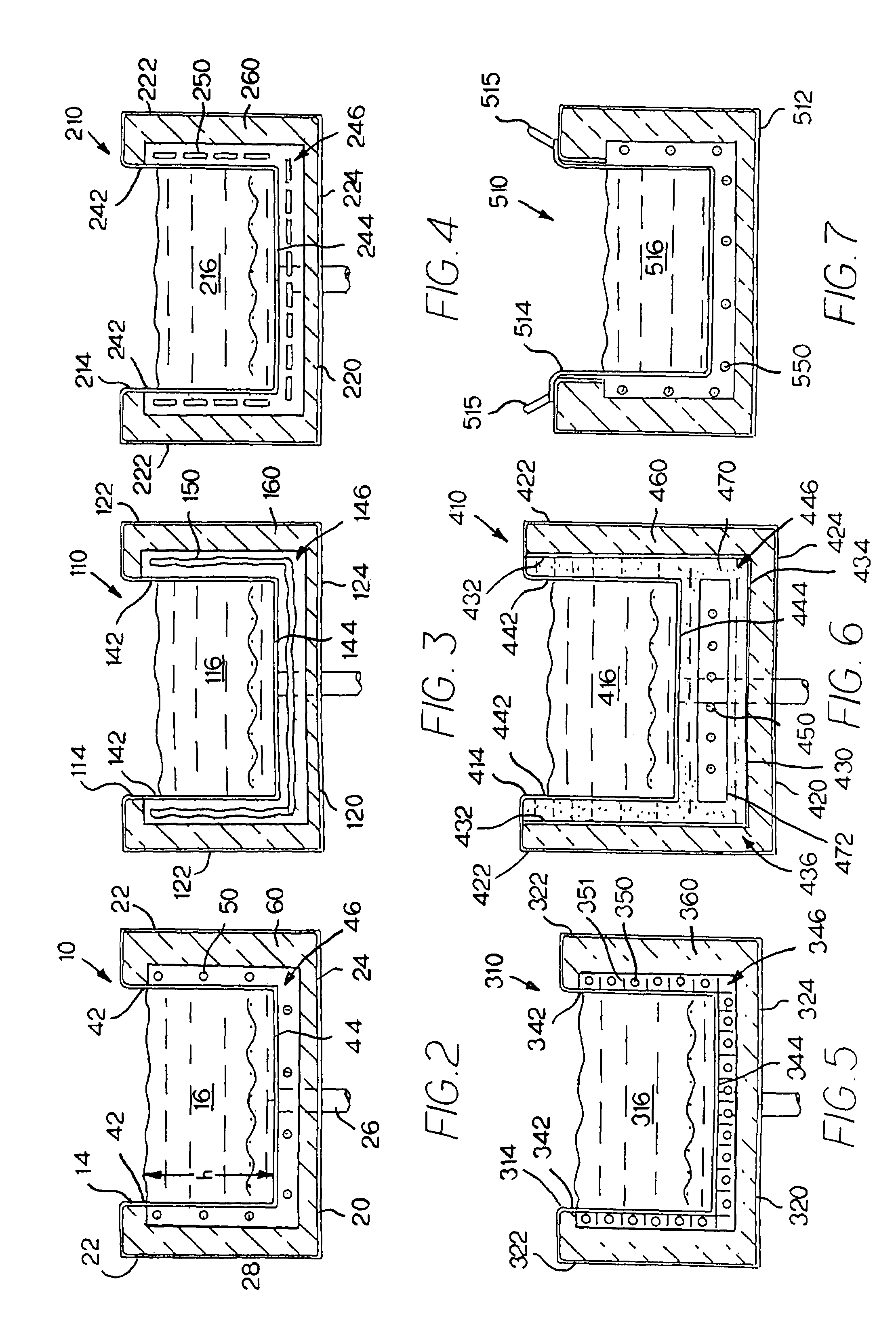

Gas fryer with improved heat-exchange properties

InactiveUS6736131B2Prevent degradationUneven temperature of gasEnlarged heating surface vesselsWater heatersCombustionFresh air

A gas fryer includes a tank for holding cooking oil, a heat pipe located in the middle depth of the tank so that the heat pipe is soaked in the cooking oil, a combustion chamber located at the combustion gas inlet side of the heat pipe, and a flue located at a combustion gas outlet side of the heat pipe. The heat pipe has a sleeve fitted in the inner wall of the heat pipe, and a spirally shaped mixer installed in the heat pipe. The flue also has an introduction system for fresh air, with a blowing nozzle of the fresh air positioned proximate to a narrowed region located about in the middle of the flue along a longitudinal axis, an inlet of fresh air located at a part of the flue, and a passage of fresh air provided along the inner and / or outer wall of the flue.

Owner:K K FUJI ENTERPRIZE +1

Gas fryer with improved heat-exchange properties

InactiveUS20030034027A1Prevent degradationUneven temperature of gasEnlarged heating surface vesselsWater heatersCombustion chamberFresh air

A gas fryer comprising: a tank for holding cooking oil, a heat pipe located proximate in the middle depth of said tank so that said heat pipe is soaked in said cooking oil, a combustion chamber located at the combustion gas inlet side of said heat pipe, and a flue located at a combustion gas outlet side of said heat pipe, wherein said heat pipe comprises a sleeve fitted in the inner wall of said heat pipe, and a spirally shaped mixer installed in said heat pipe, and wherein said flue comprises an introduction system of fresh air, said system comprising of a blowing nozzle of the fresh air positioned proximate to a narrowed region located proximate in the middle of said flue along a longitudinal axis, an inlet of fresh air located at a part of said flue, and a passage of fresh air provided along the inner and / or outer wall of said flue was provided.

Owner:K K FUJI ENTERPRIZE +1

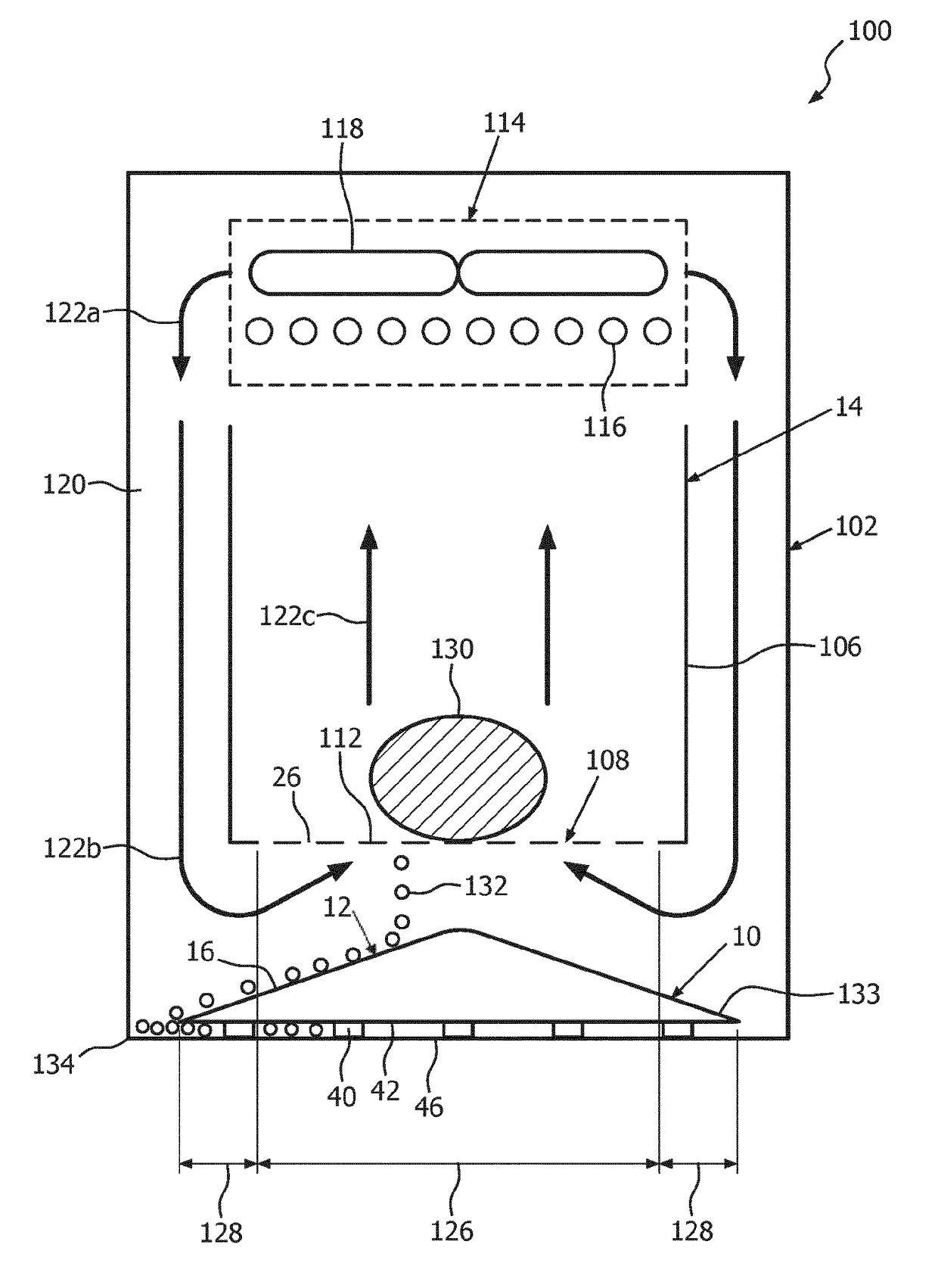

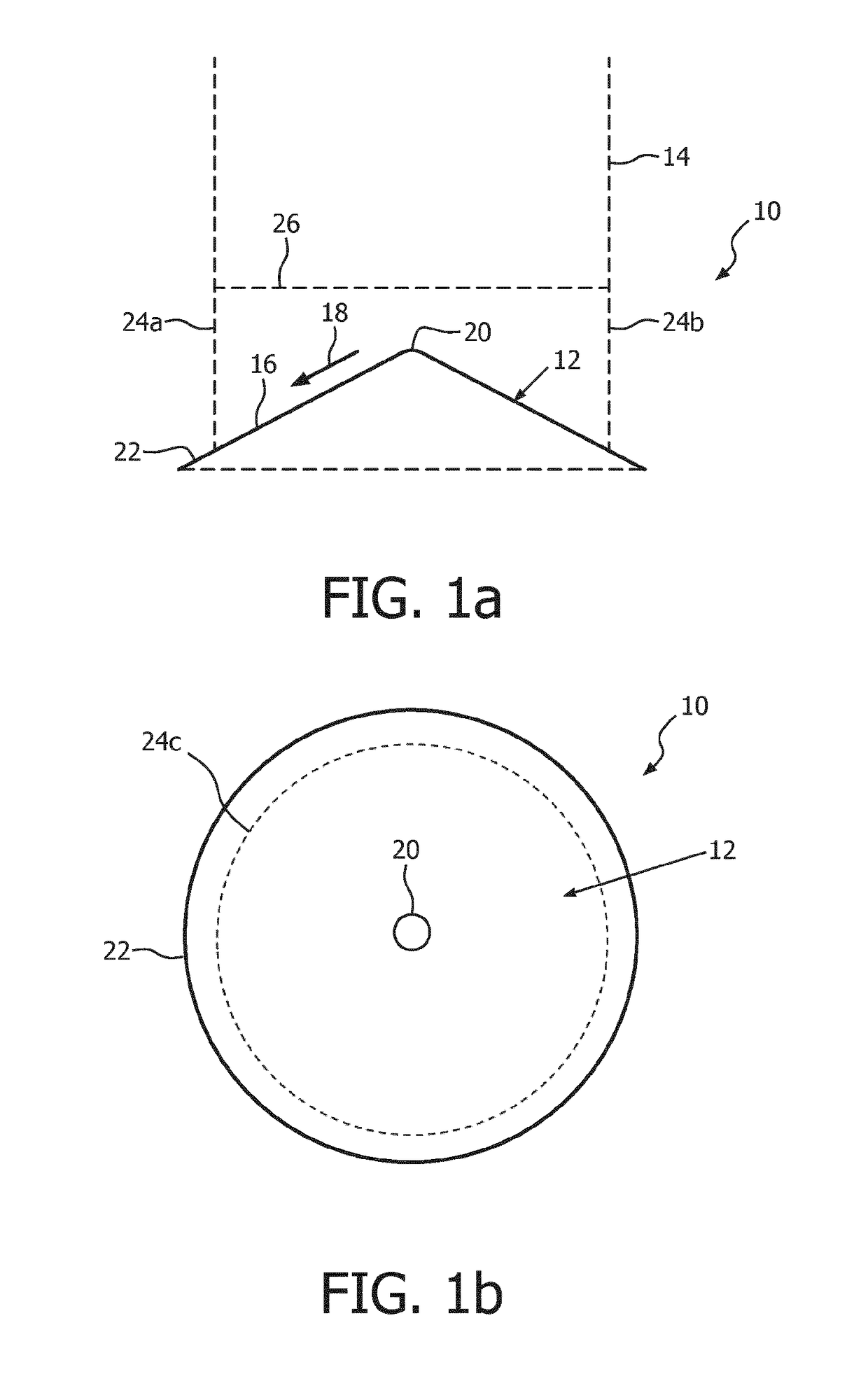

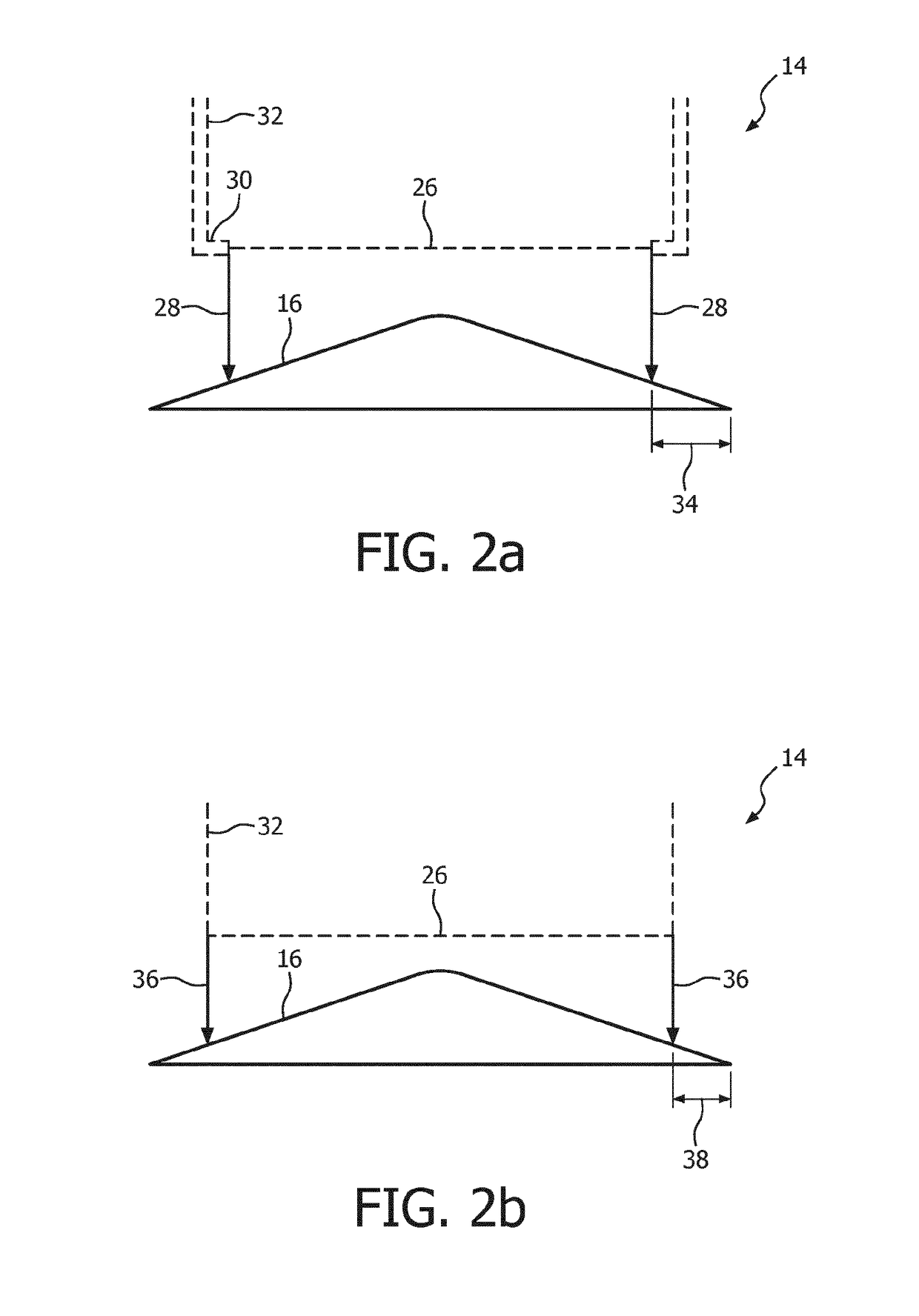

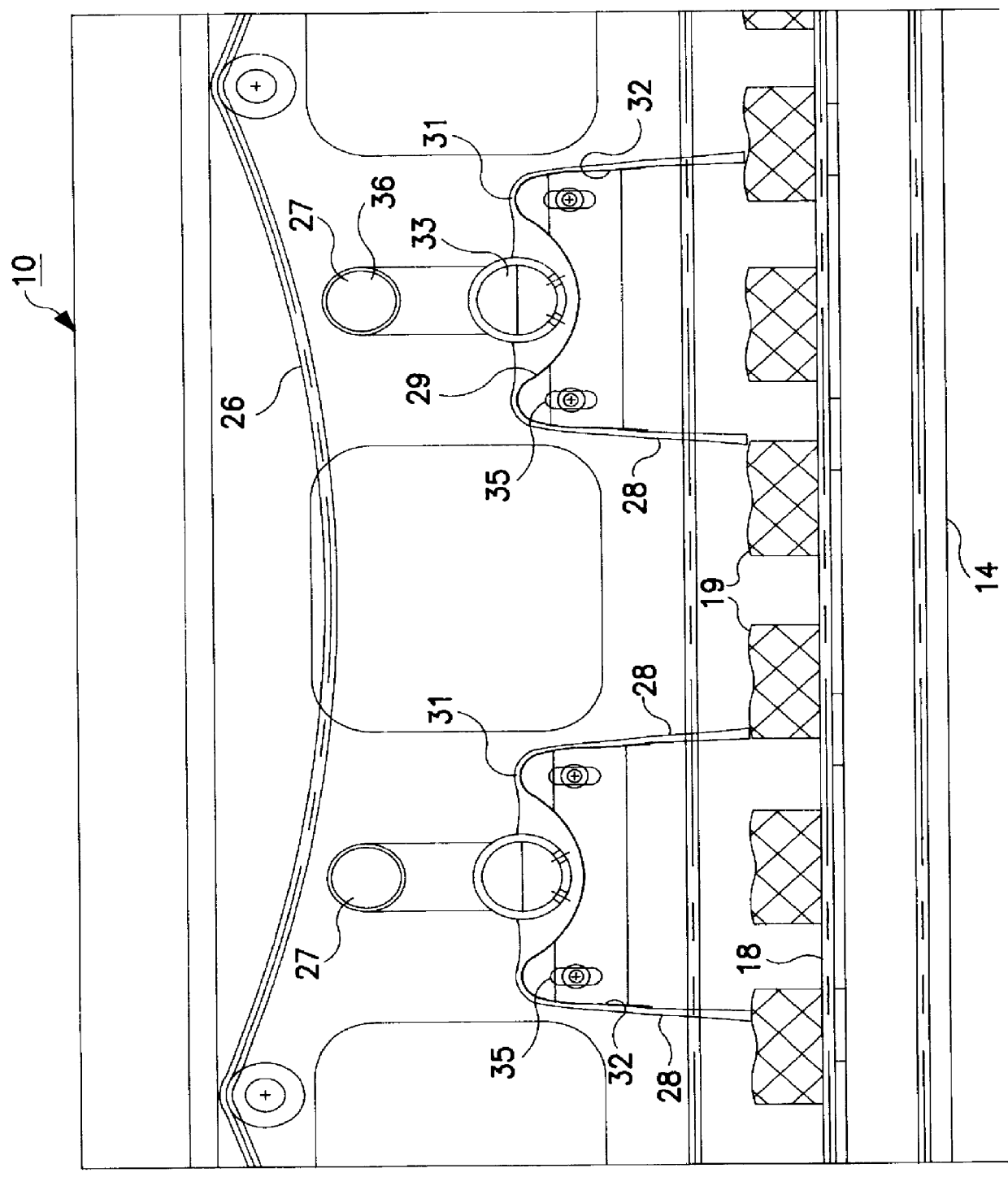

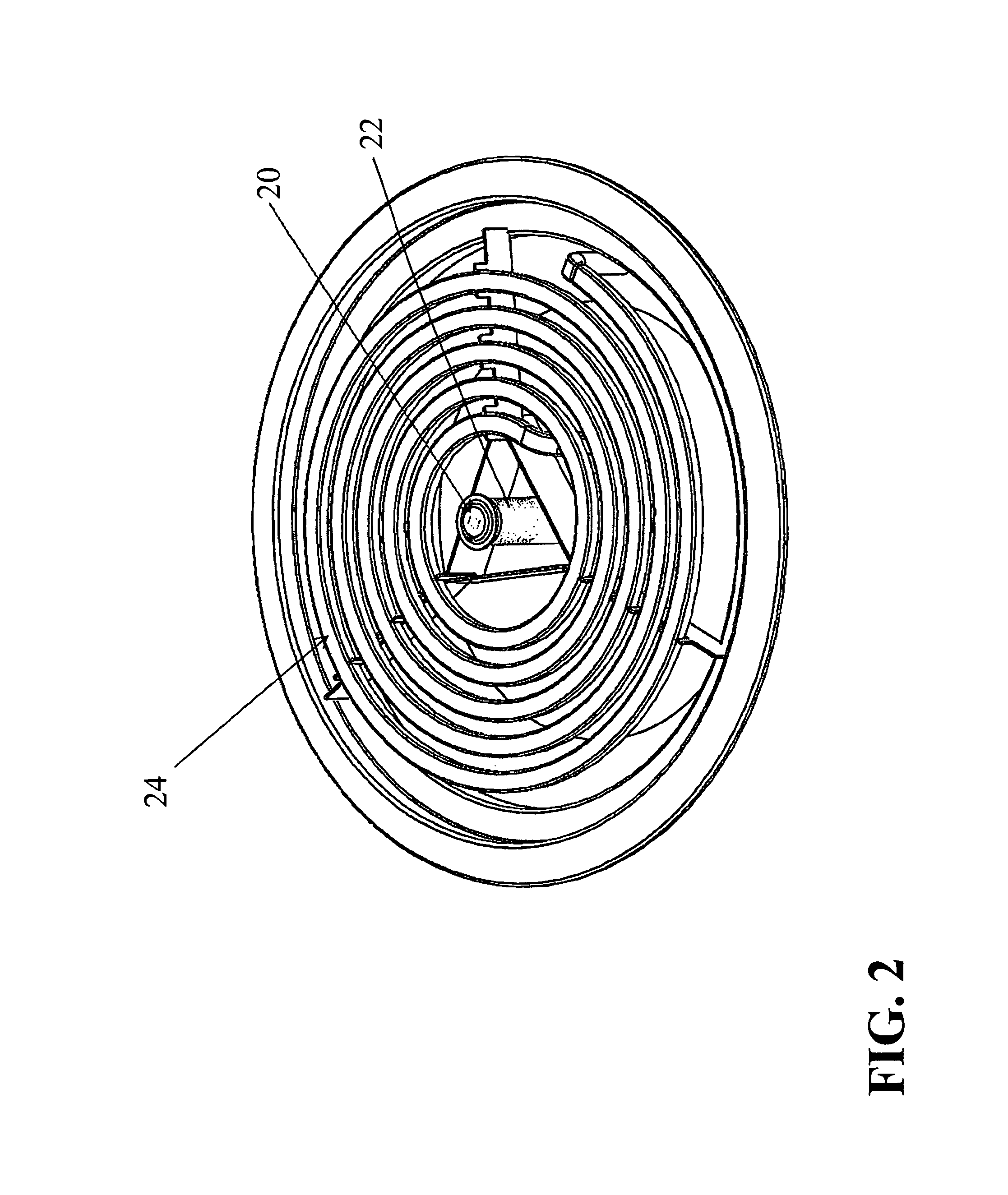

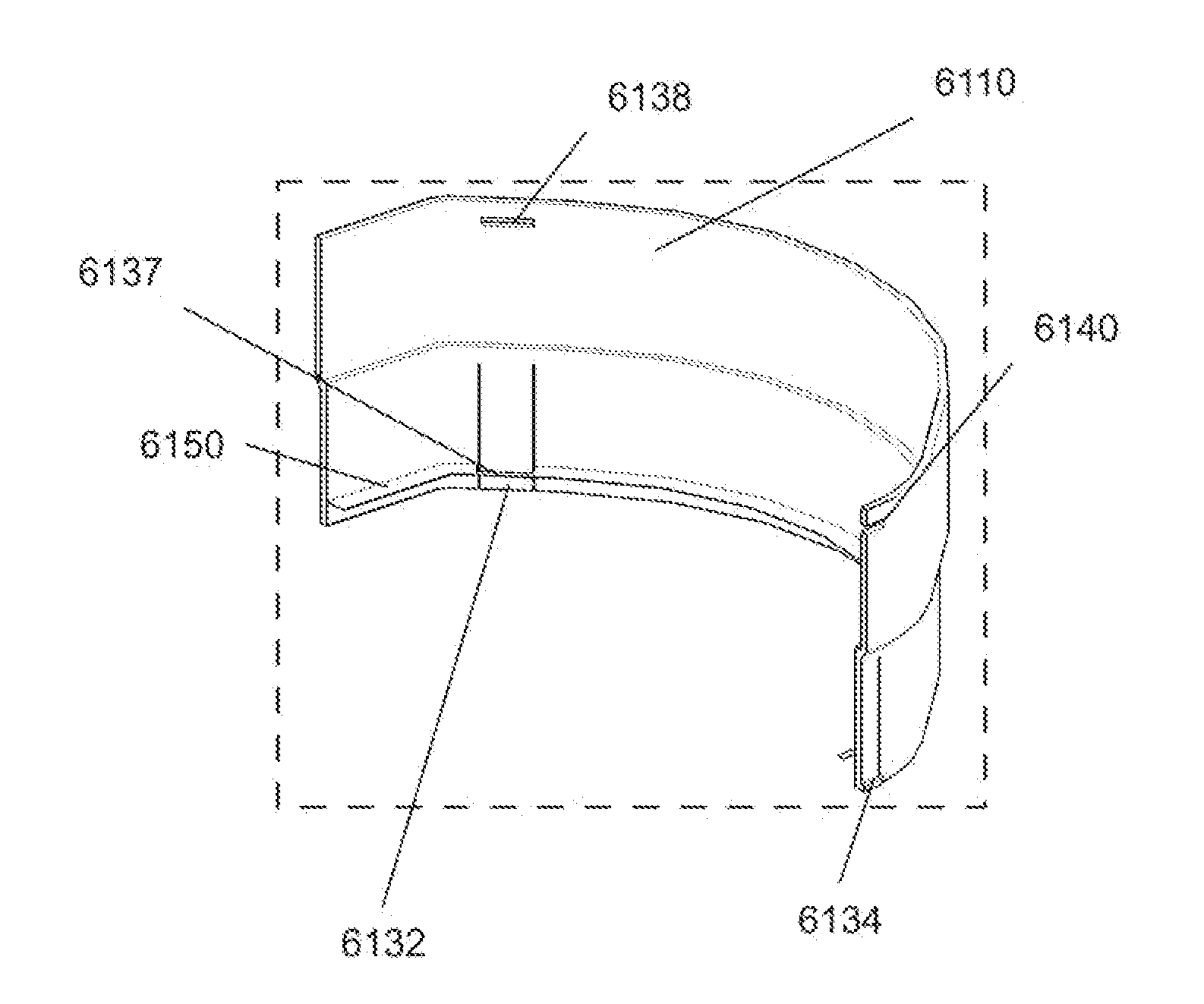

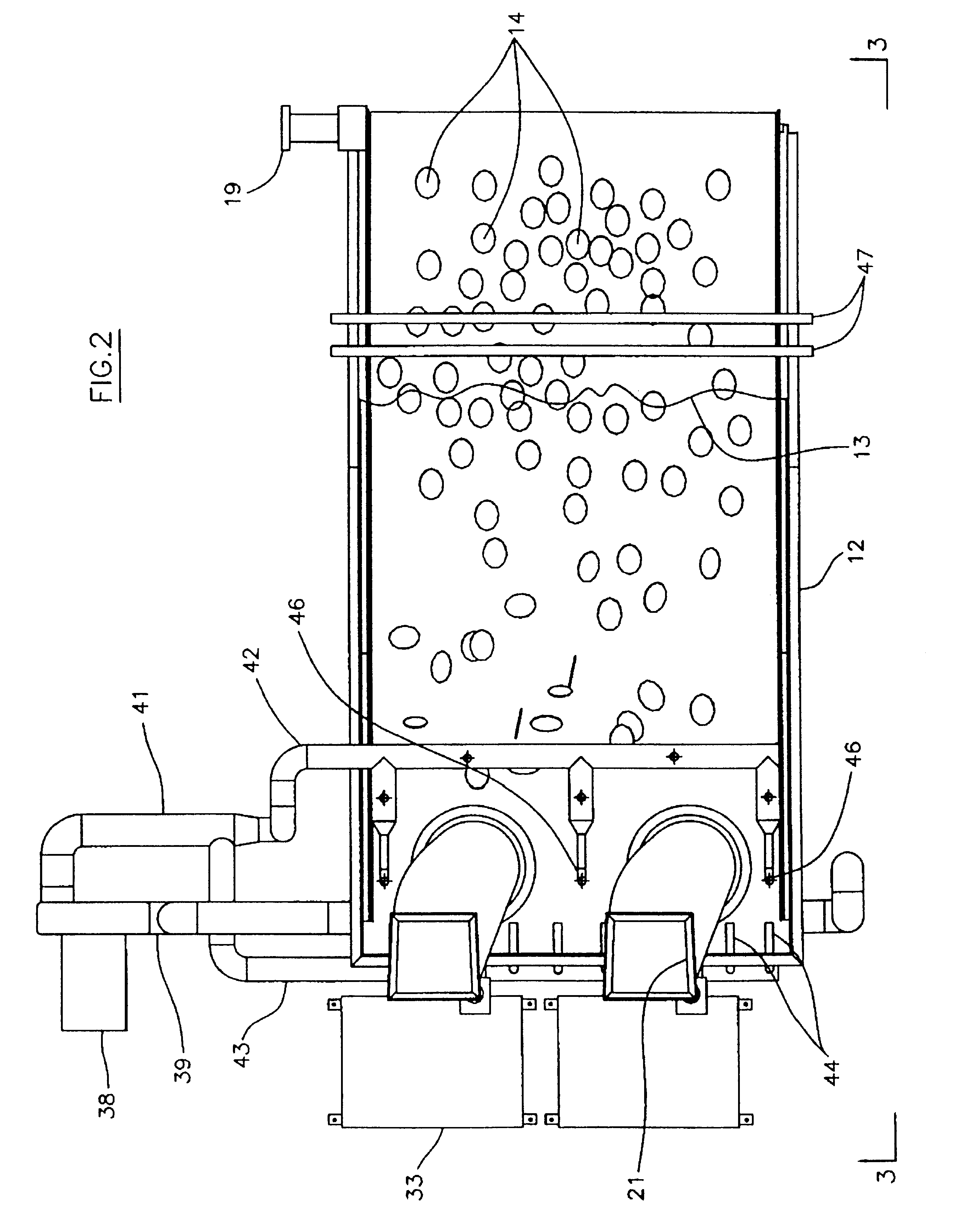

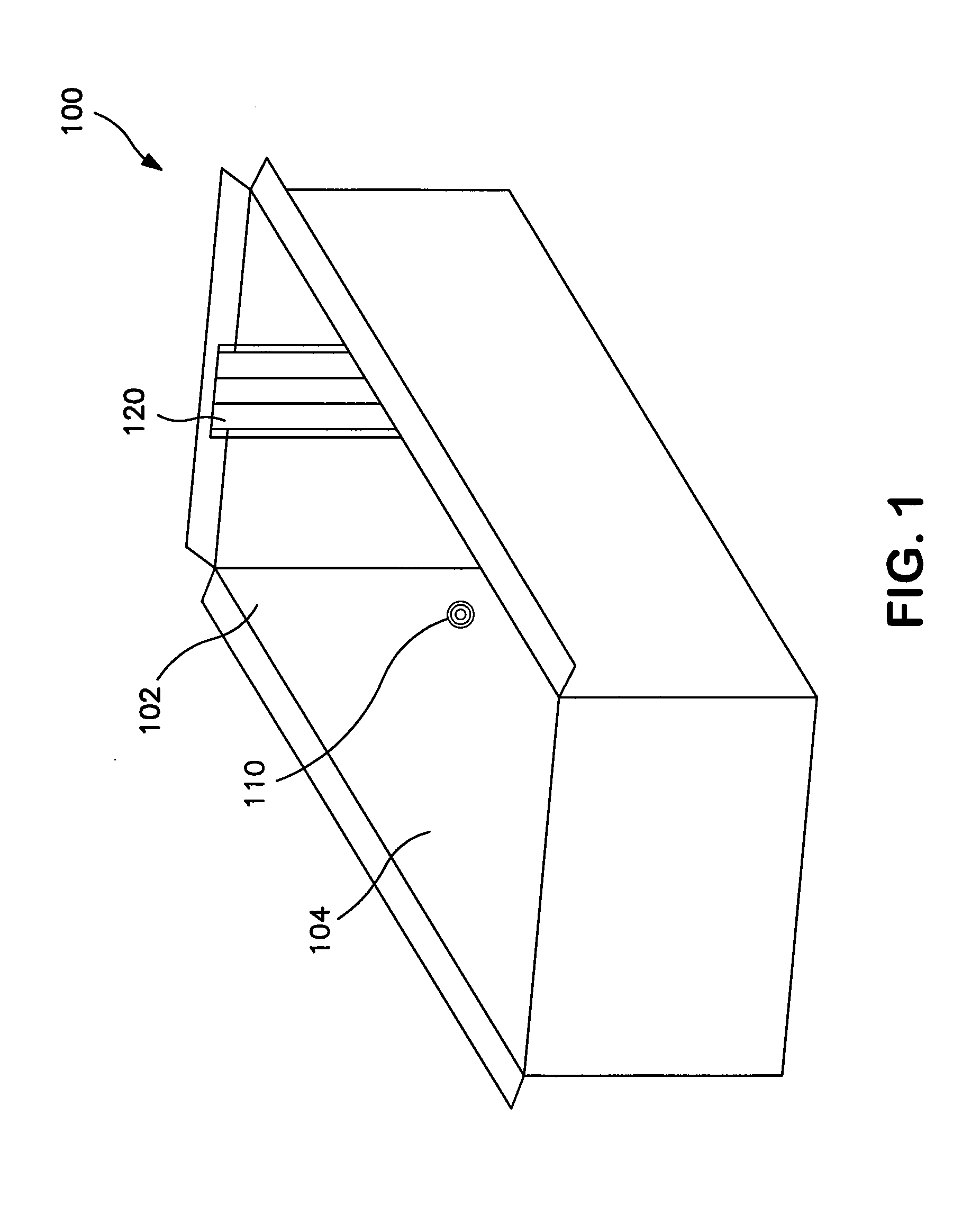

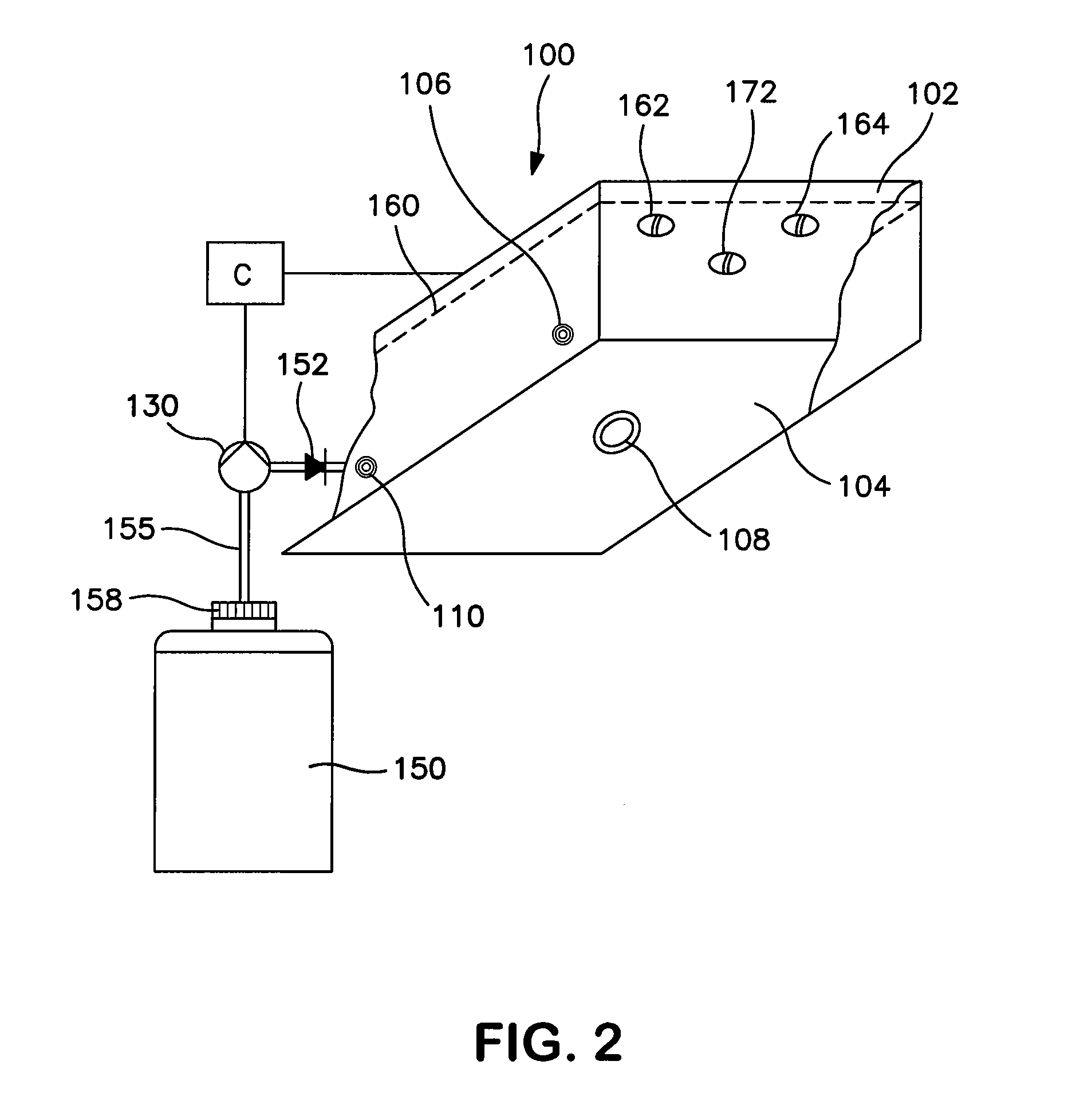

Insert for an air-based fryer, apparatus comprising such insert

ActiveUS20170303740A1Generation of fume can be reducedReduce generationRoasters/grillsVertical projectionEngineering

The invention relates to an insert (10) for an apparatus (100) for preparing food by circulation of a flow of hot air in a food basket (14) placed inside a food preparation chamber and having a bottom part (108) with a lower opening area (26) for the circulation of the flow of hot air. The insert comprises an upper surface (12) intended to be arranged below the food basket. The upper surface (12) defines an inclined surface (16) having a downward inclination extending outwards from a middle zone towards a perimeter of the insert. The inclined surface (16) is provided such that the inclination extends at least beyond a vertical projection of the lower opening area (26). The insert further comprises spacers (40) provided on a lower side (42) of the insert to create a clearance gap (44) between the lower side (42) and a bottom surface (46) of the food preparation chamber. This invention allows improving food preparation while minimizing the emission of cooking oil fumes.

Owner:VERSUNI HLDG BV

Industrial oil cooker fire protection system

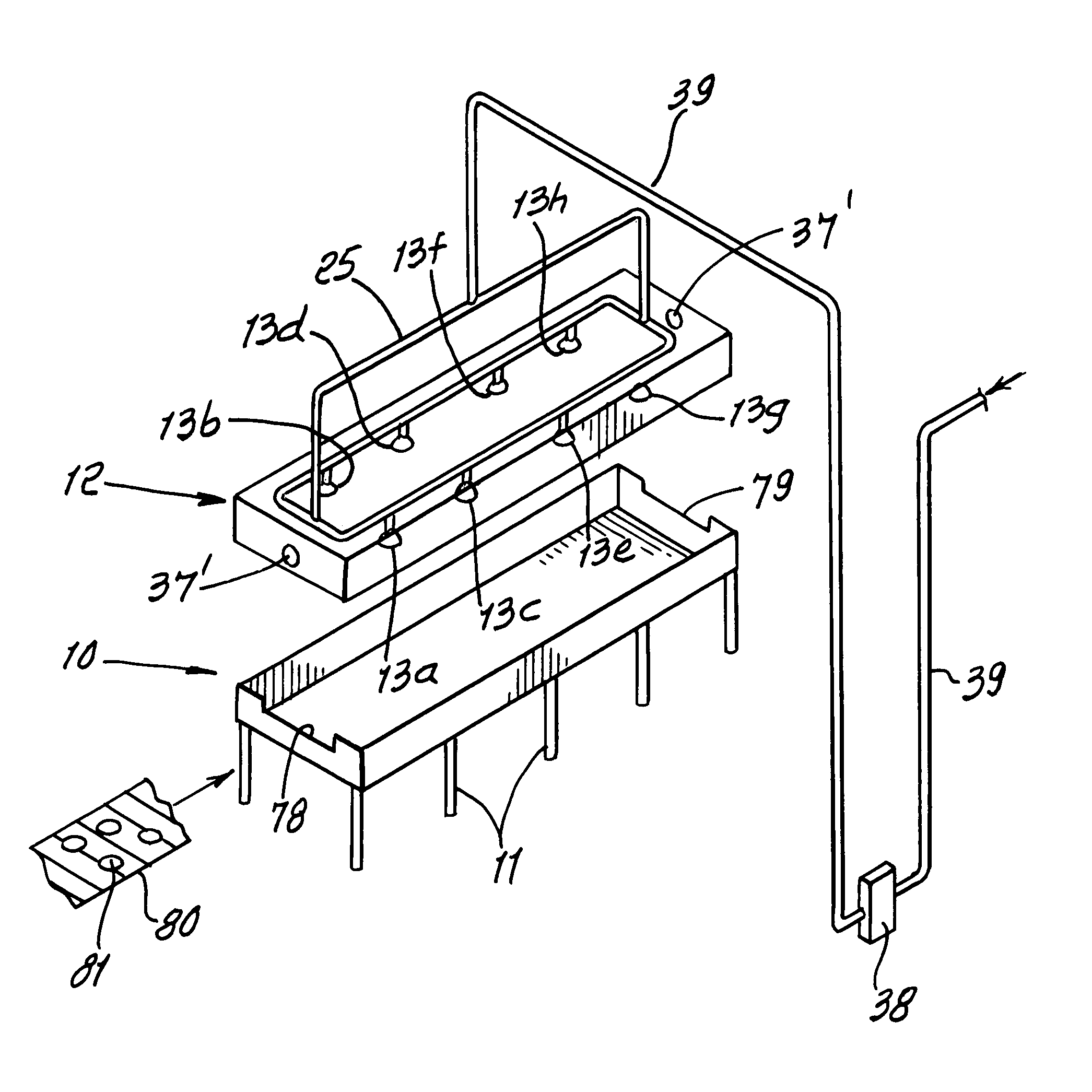

InactiveUS7789165B1Efficient and effectiveNon toxicFluid heatersBoiling over preventionWater deliveryEdible oil

A cooker system, comprising a relatively wide pan containing cooking oil at high temperatures, the pan extending longitudinally, for cooking edibles located longitudinally, single or multiple row water mist producing nozzles supported above the pan, there being one or more laterally spaced nozzles at longitudinally spaced locations above the pan, each nozzle producing mist substantially covering an area of at least about one square foot, at oil surface level in the pan, and control means to control pressurized water delivery to the nozzles, in the event of fire in or associated with oil in the pan.

Owner:YEN PING LI

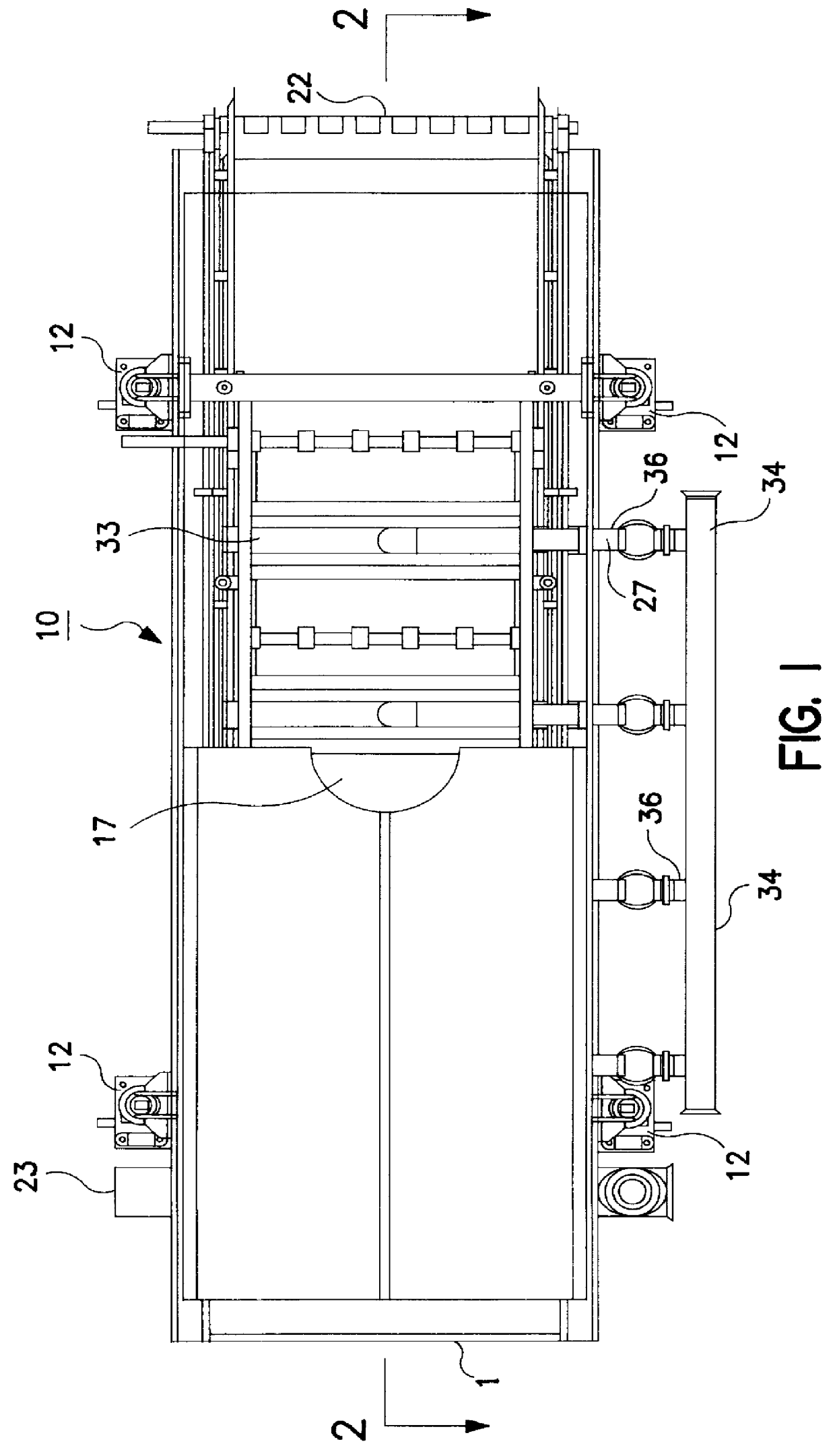

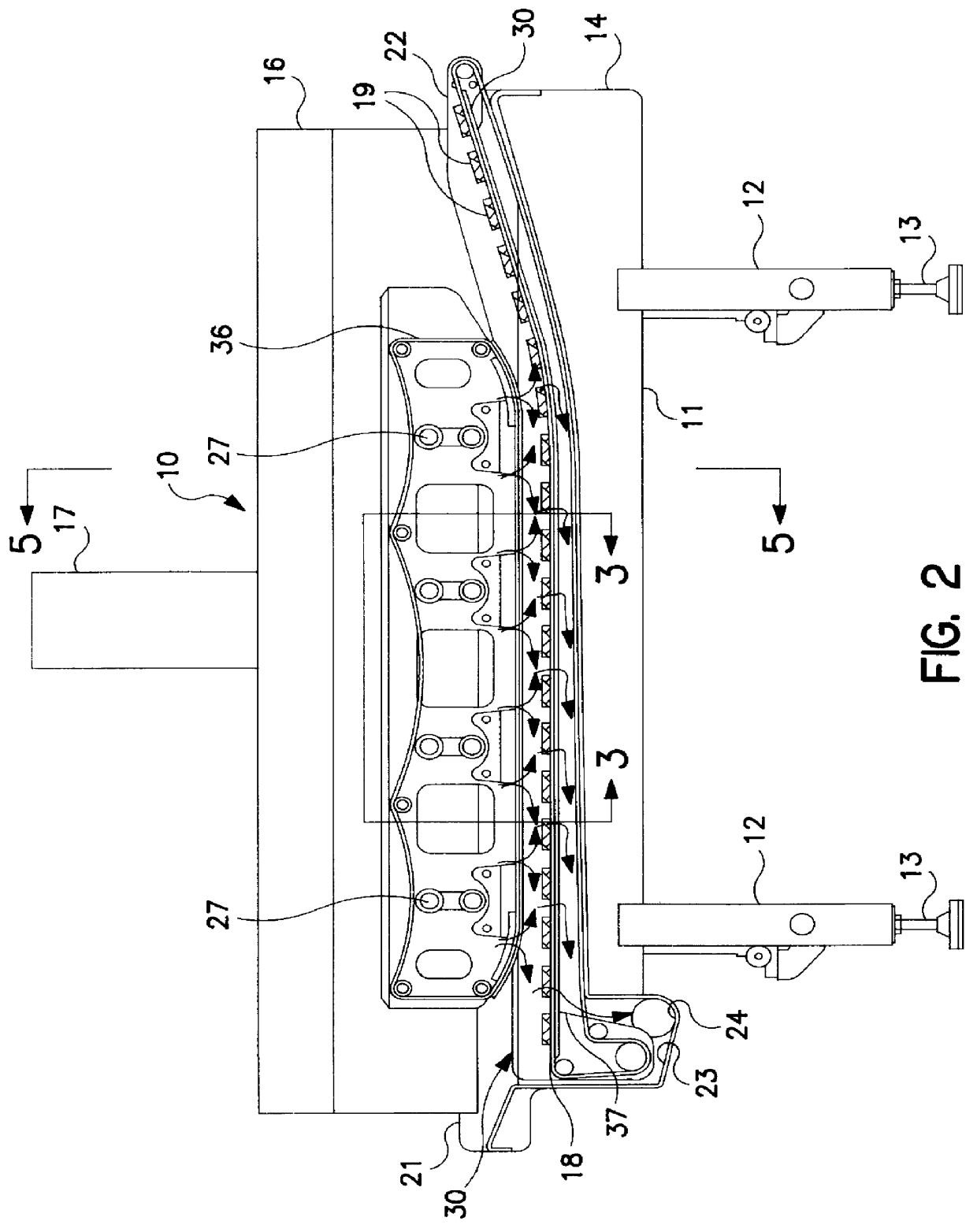

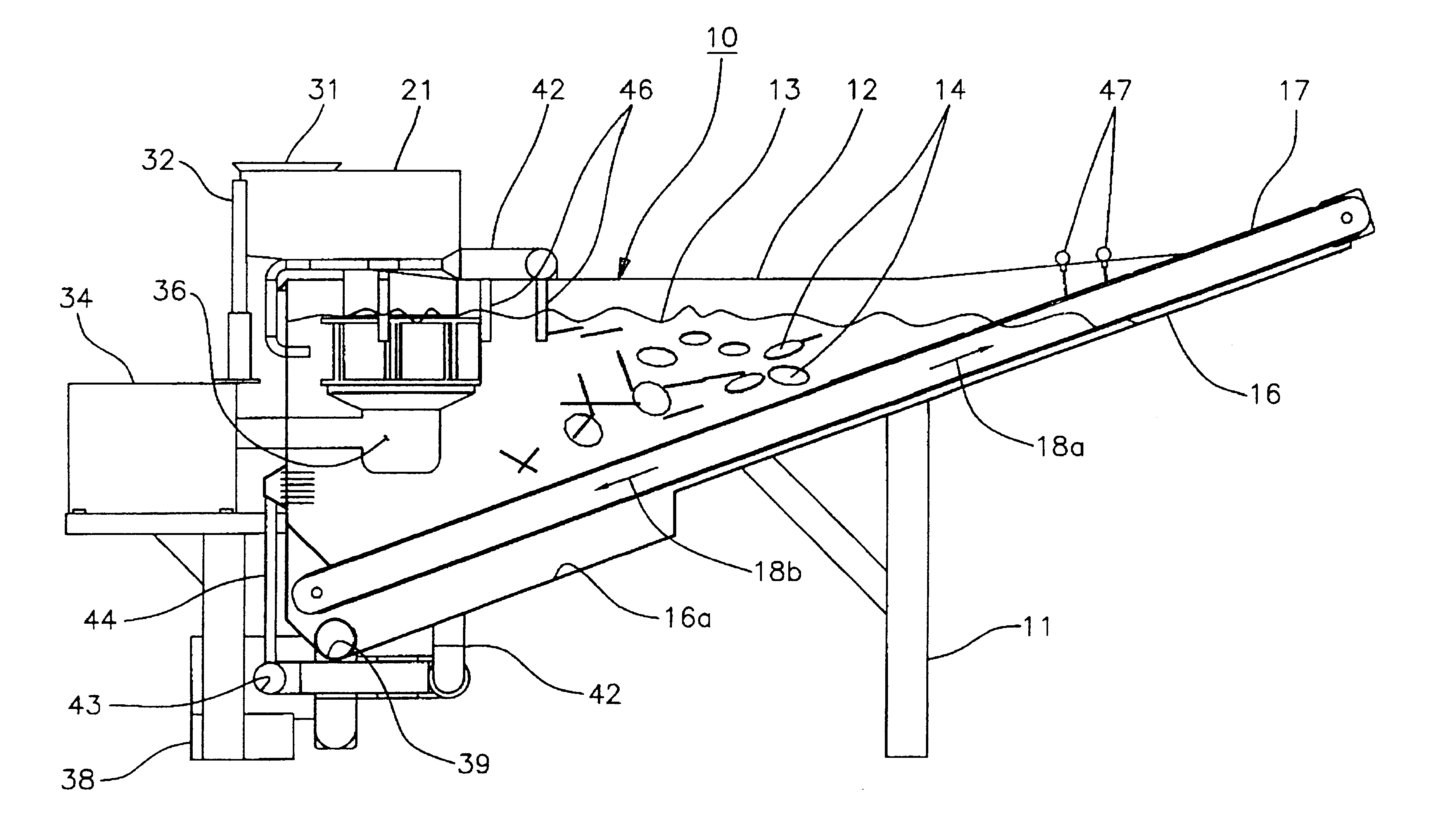

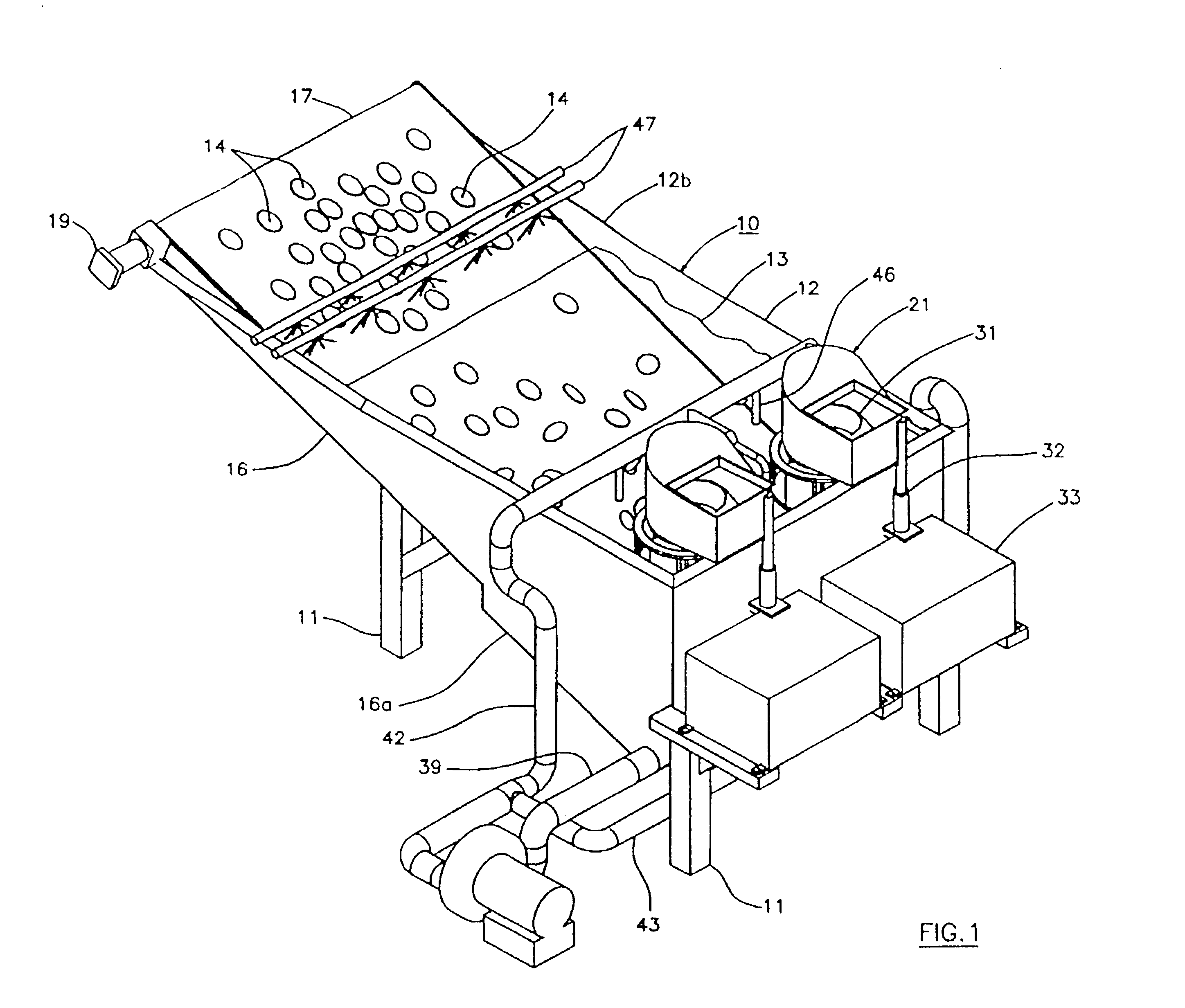

Breaded products fryer

InactiveUS6067899AUniform and accurate vertical flow patternSpeed up the flowFood preservationCooking vesselsCooking oilFood products

A fryer for food products such as battered and breaded pieces of meat has a main conveyor with forward and return belt paths inside the fryer pan, the belt return dragging the pan bottom sweeping fines to one end for removal. A submerger conveyor prevents products from floating in the cooking oil which enters the fryer from above through oil inlet weirs. A plurality of weirs supply curtains of hot cooking oil in non-turbulent flow onto the food product covering the product as the product is conveyed on the main conveyor. The cooking oil is returned along defined lanes in the pan for reheating outside of the fryer. The food products are removed from the fryer in a cooked condition with the bread coatings intact.

Owner:HEAT & CONTROL

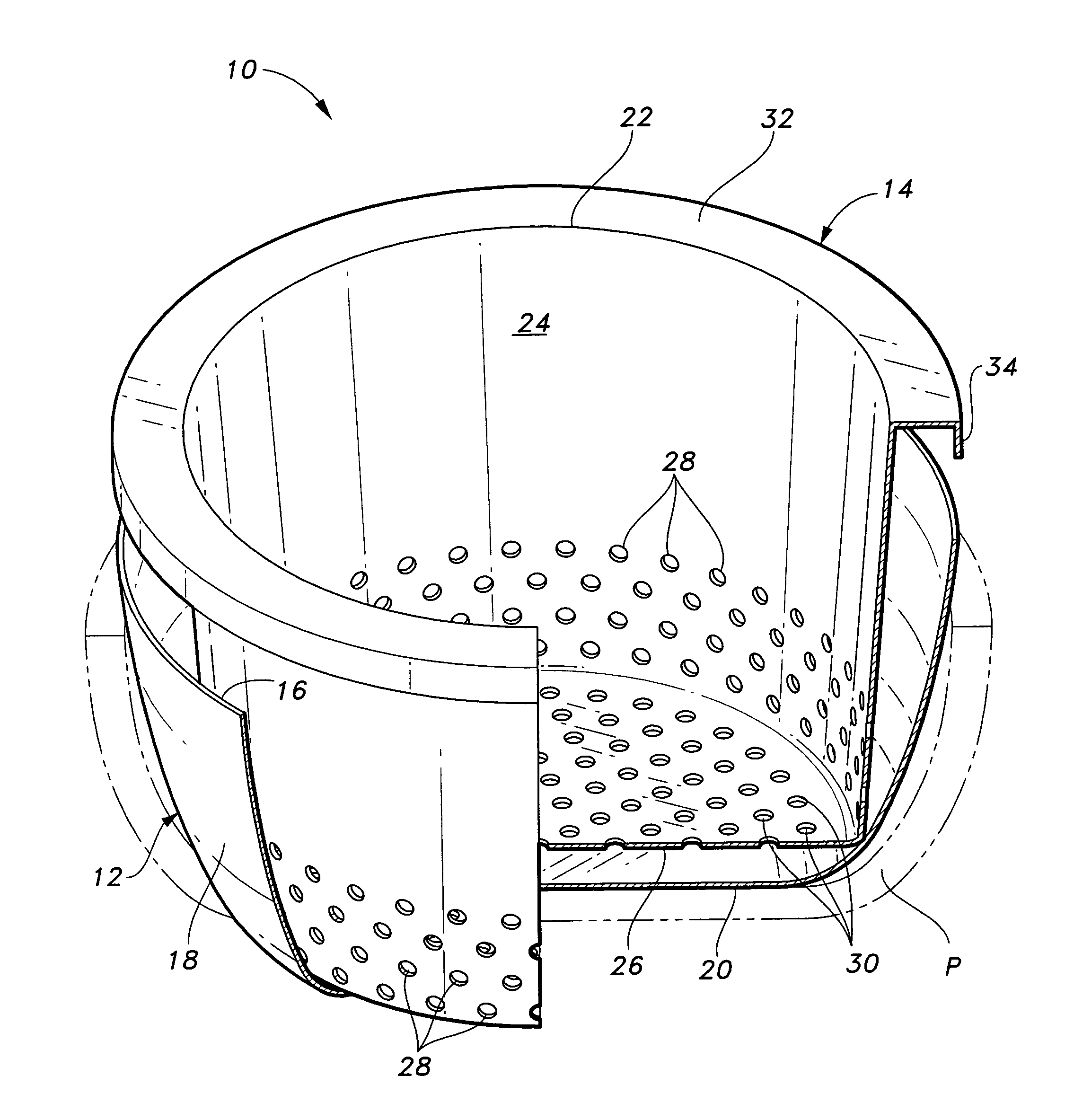

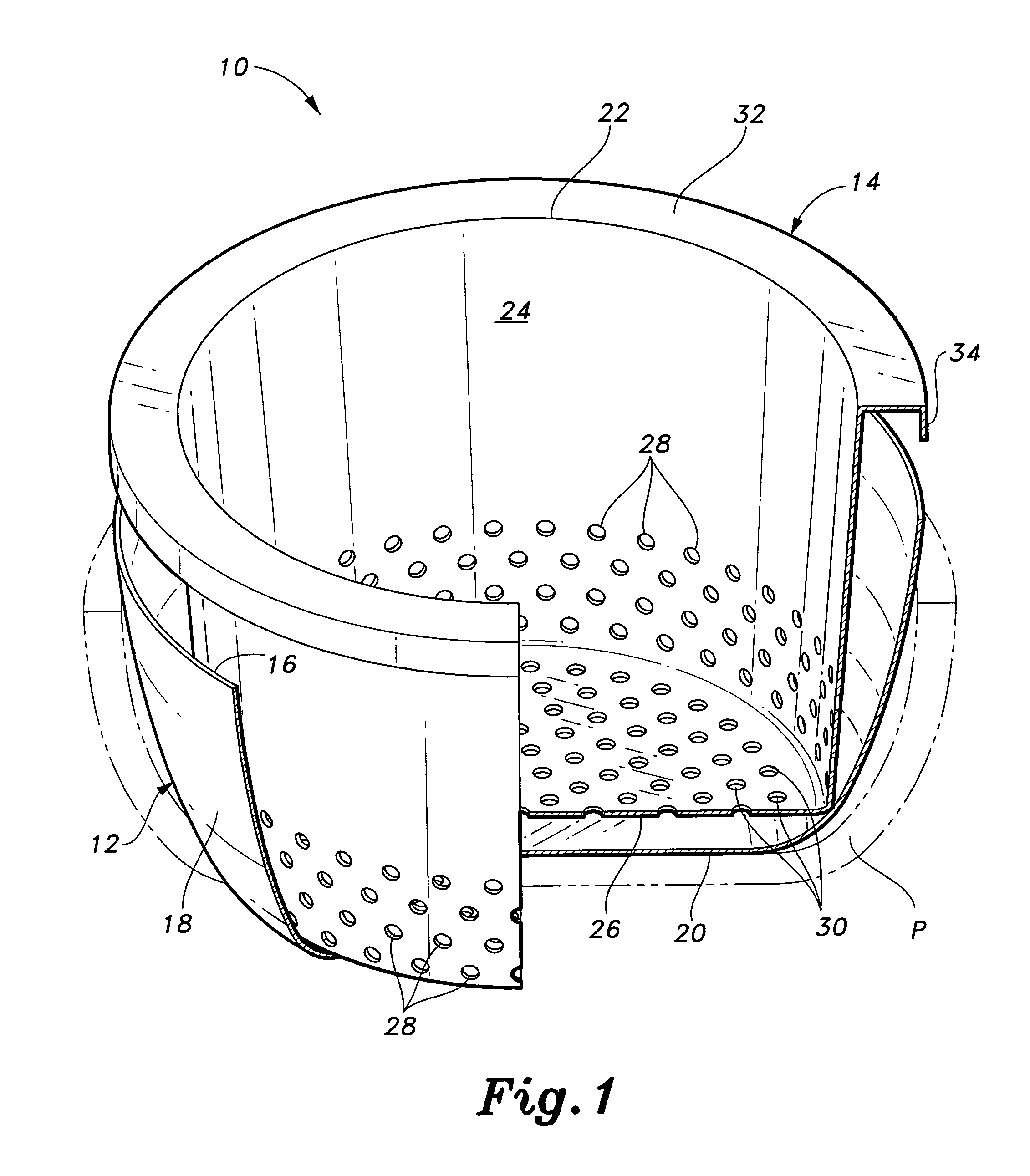

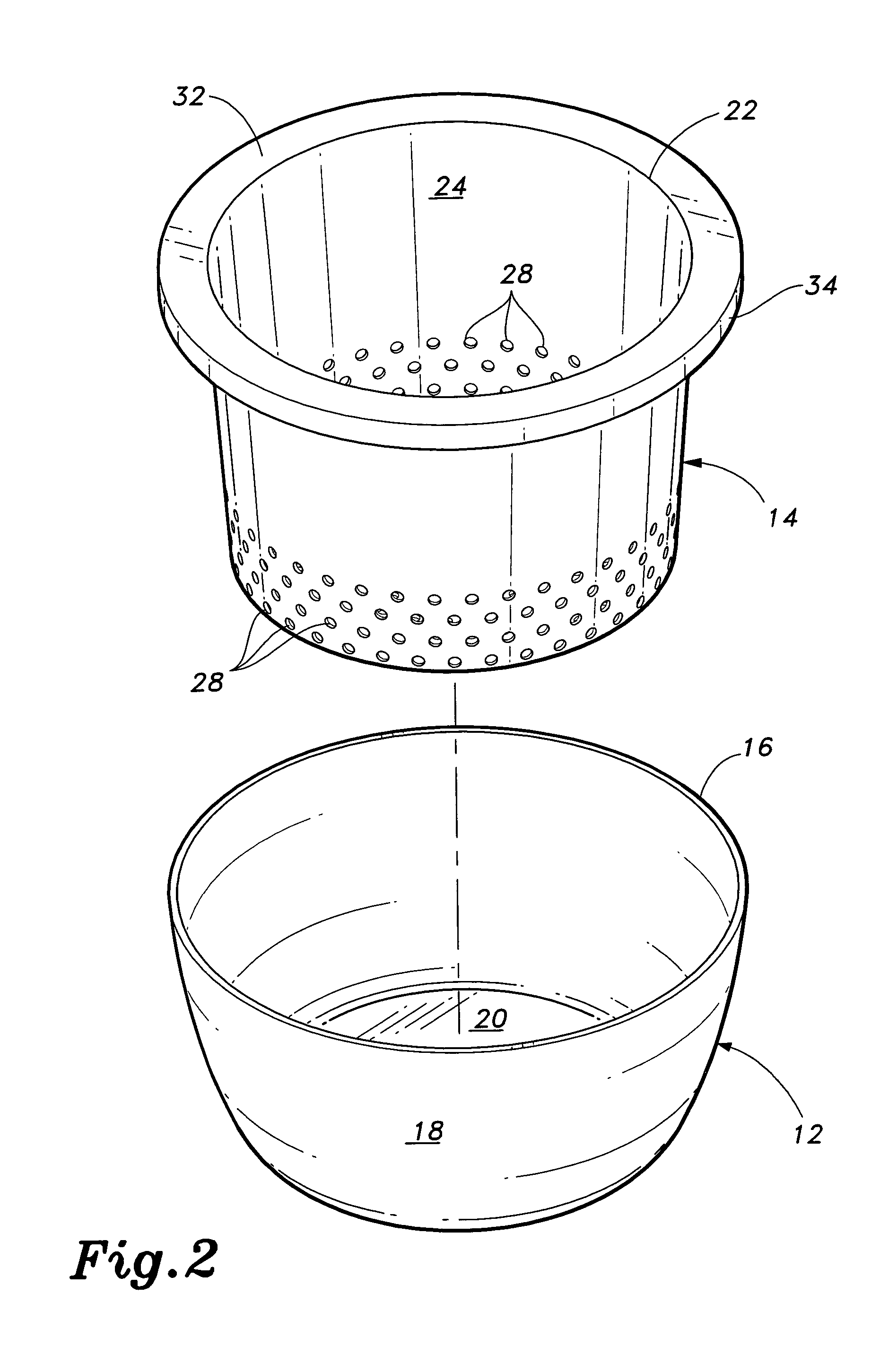

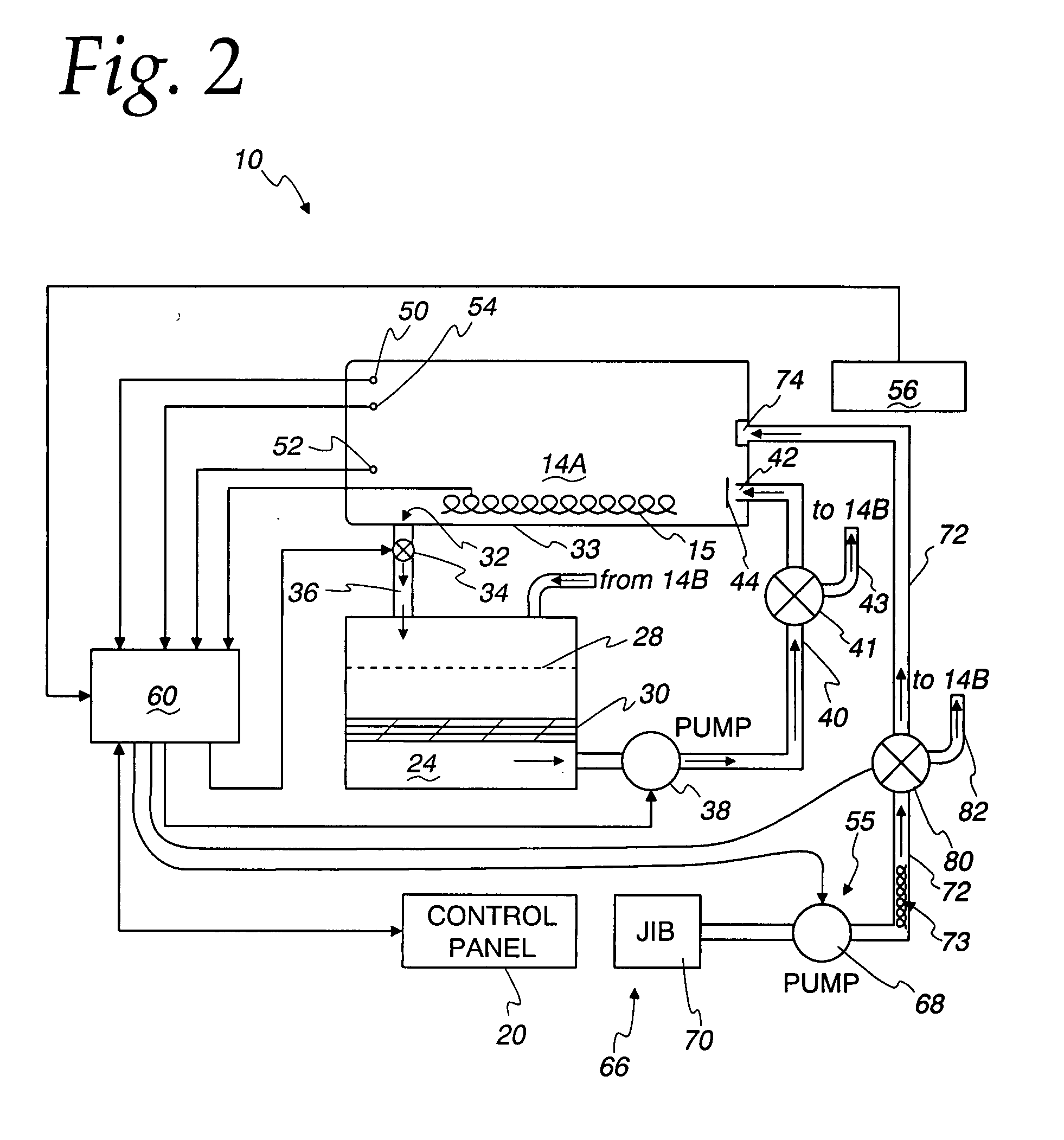

Disposable frying pan insert

A disposable pan, pot, or kettle liner system for deep-frying foods and includes a disposable pot liner and a disposable strainer fitting into the pot liner made of thin aluminum, aluminum alloy or other metal material having a stiffness adequate to be free-standing upon filling with cooking oil and heating to cooking temperatures while being sufficiently inexpensive to be disposable after use. The strainer is made of similar material and fits within the liner, holding foods to be cooked, and has a circular, flange-like upper rim extending upward, beyond the rim of the liner, to serve as a handle for lifting and straining the cooked food from the liner. The inventive disposable system is designed to be used within a non-disposable pot or kettle, but is freestanding. The system may also be used as a stand-alone unit directly on a heating surface such as a stove heating element.

Owner:SIZER LATOYA E

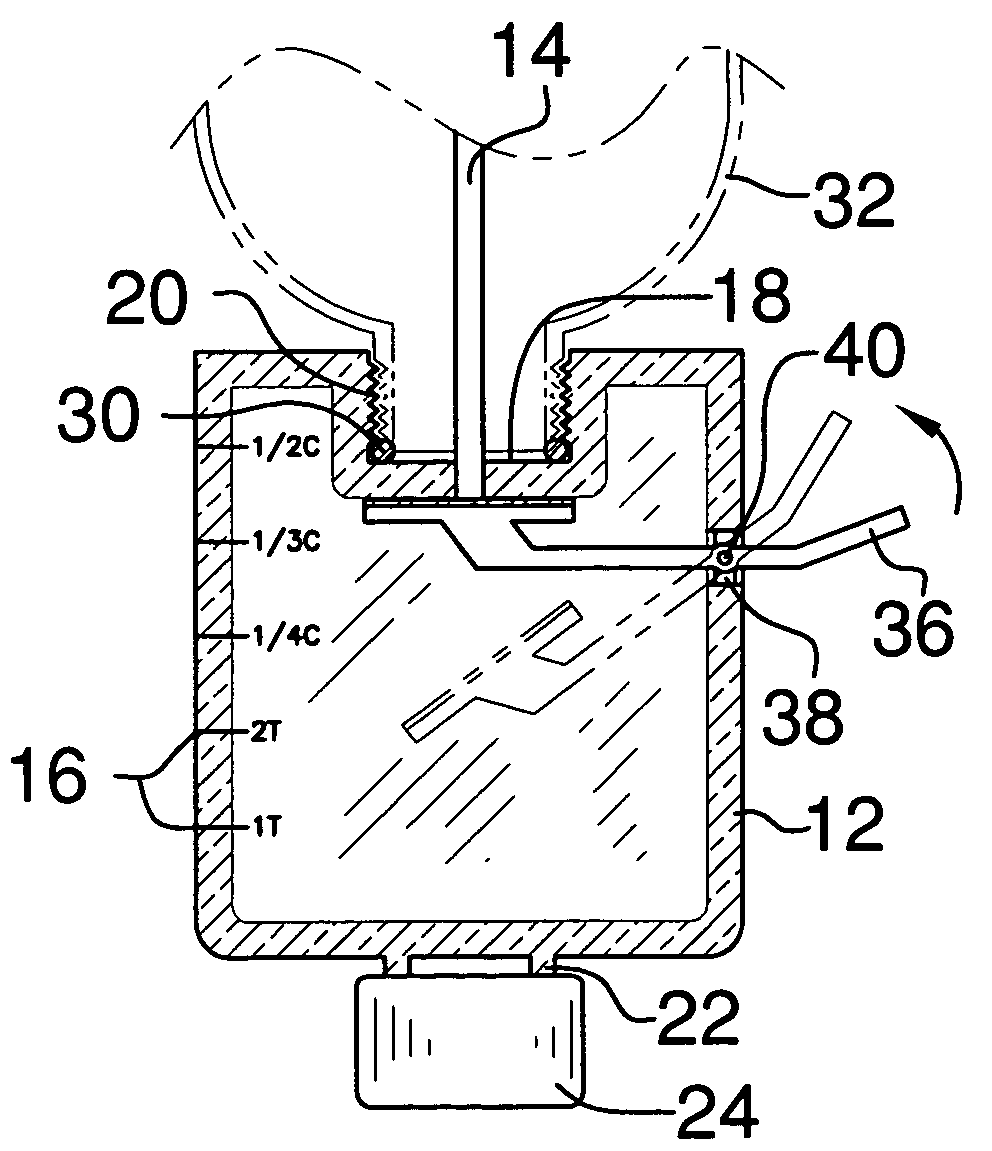

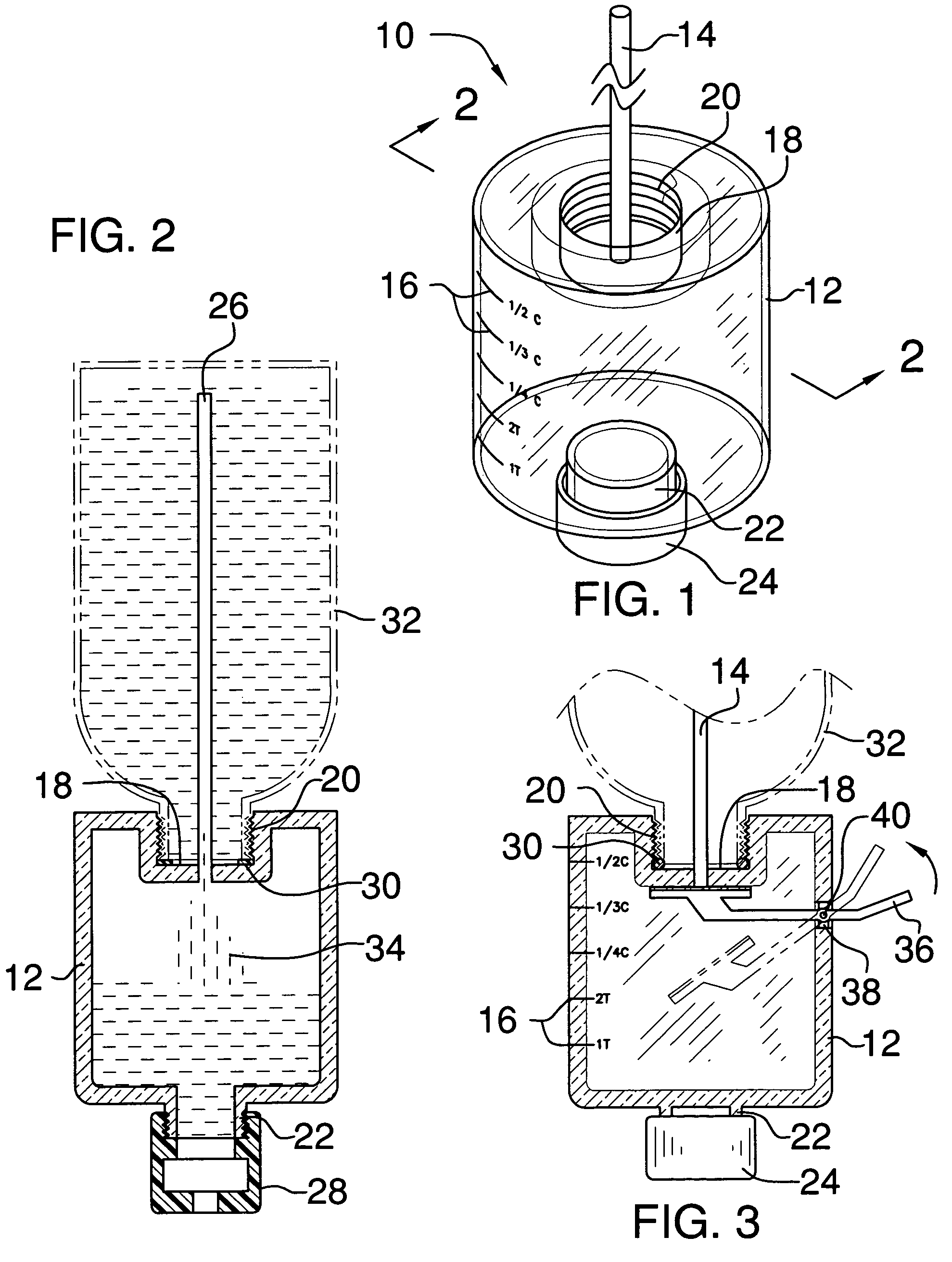

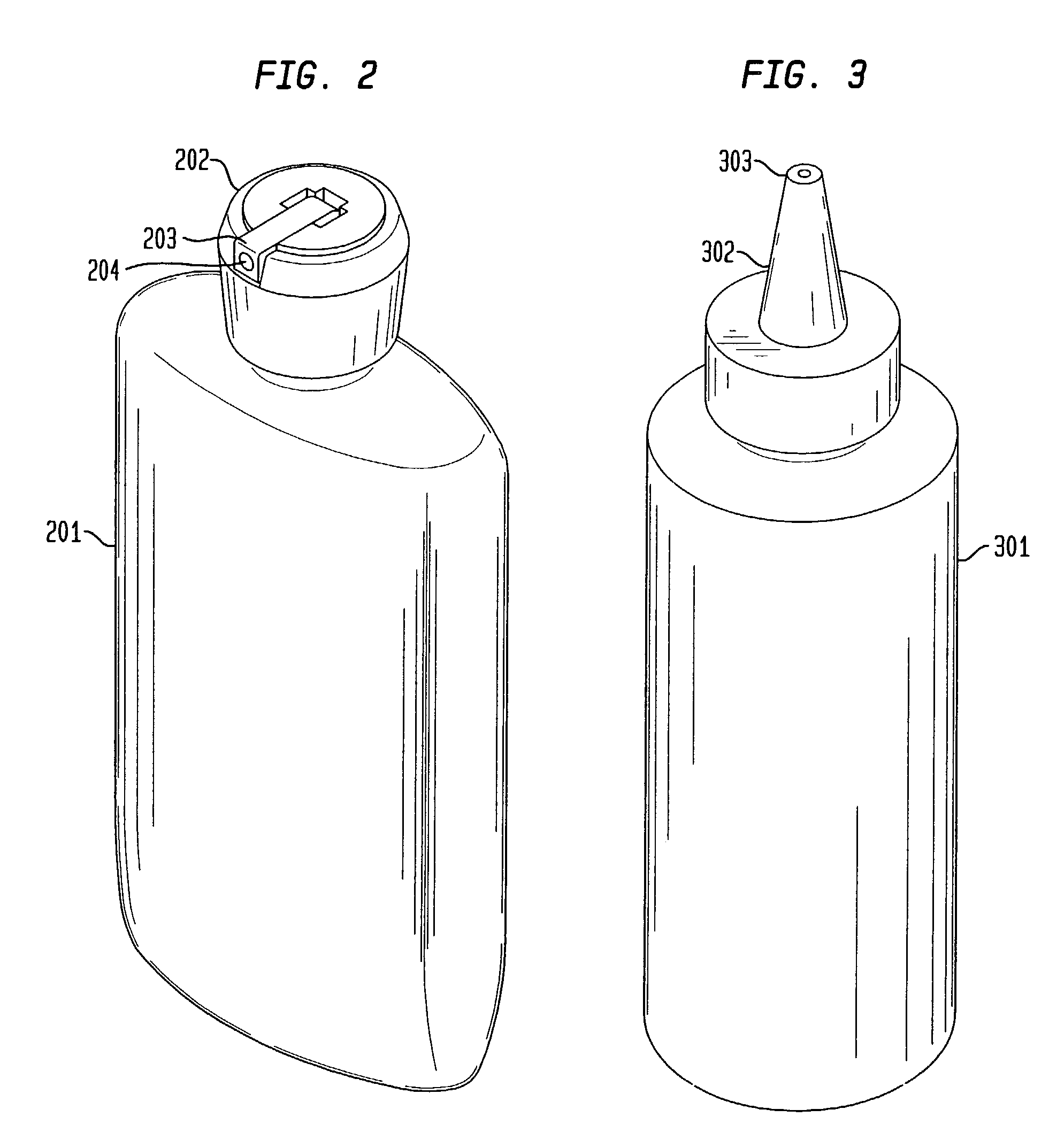

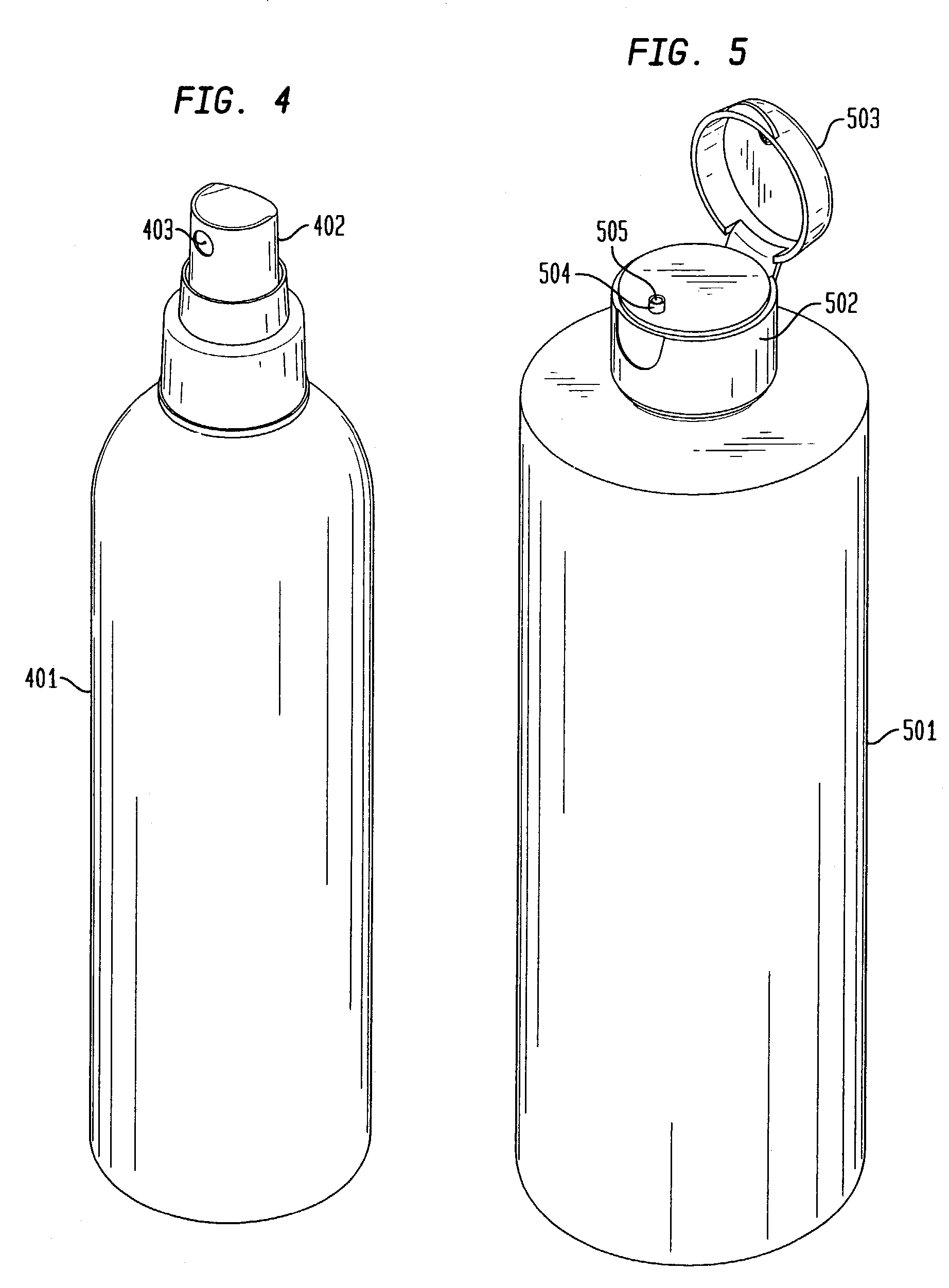

Liquid measuring and dispensing device

InactiveUS6877639B1Without risk of spillageRemove cleanContracting/expanding measuring chambersMovable measuring chambersMeasuring instrumentBottle

Liquid measuring and dispensing devices measure and dispense a quantity of cooking oil or other liquids or flowable powders. The liquid measuring and dispensing device attaches directly to the bottle containing the material, eliminating the need to search for measuring instruments when one desires to measure a quantity of material. Because of the direct bottle attachment, it is impossible to spill the material during the measuring process. Furthermore, because the use of external measuring instruments is eliminated, there is no cleaning process required after measuring and dispensing a quantity of material.

Owner:HANSON TINA R

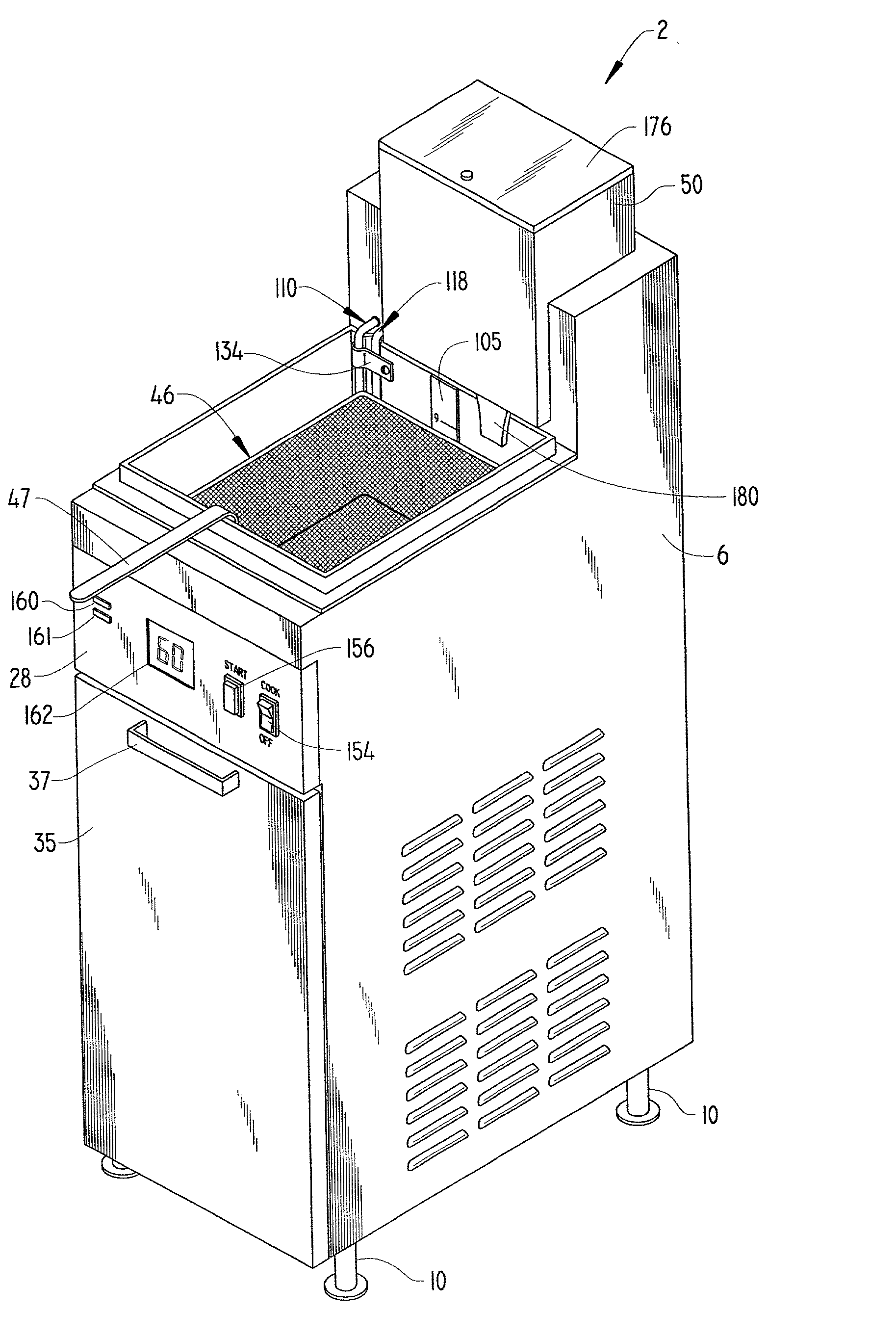

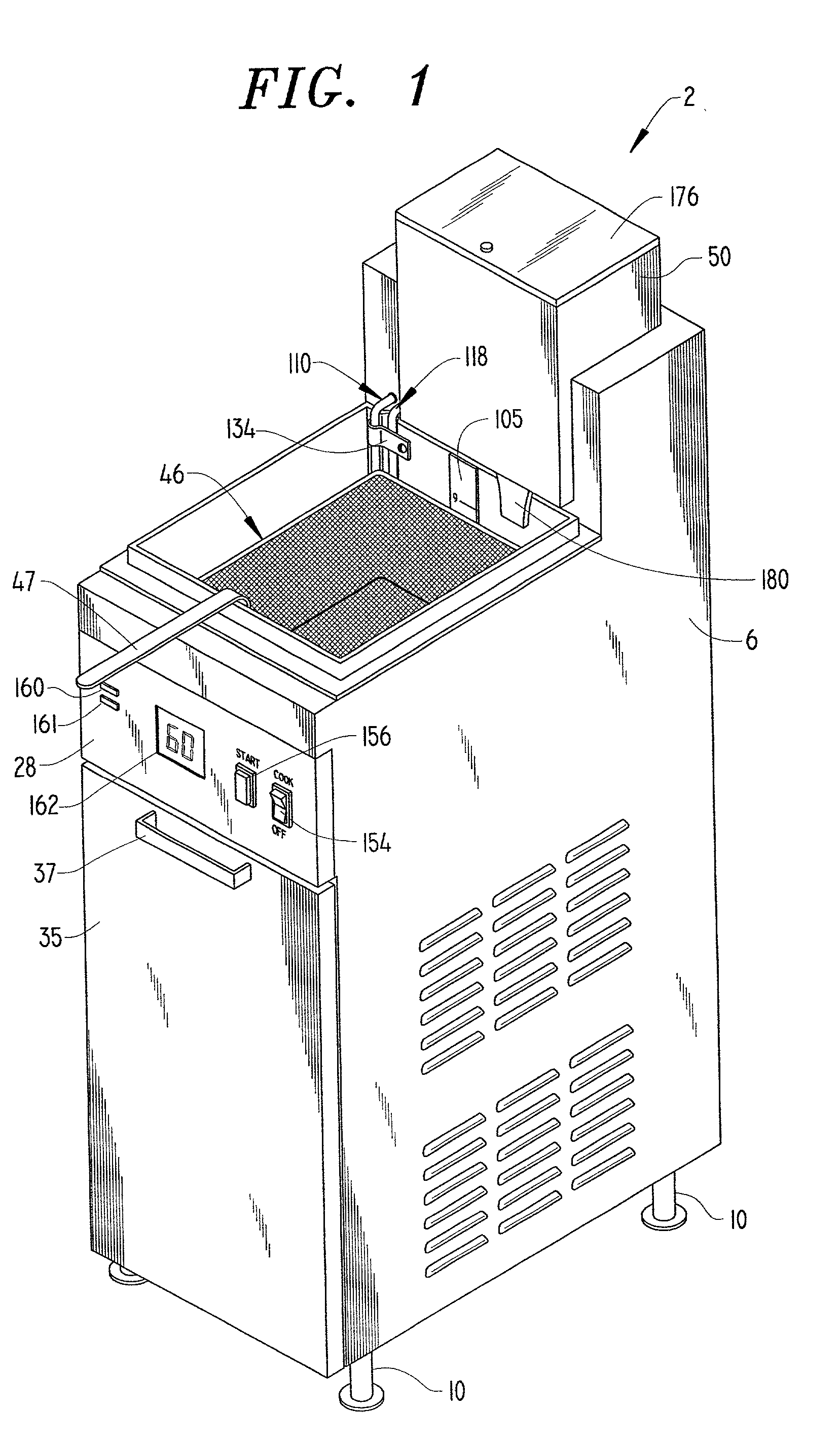

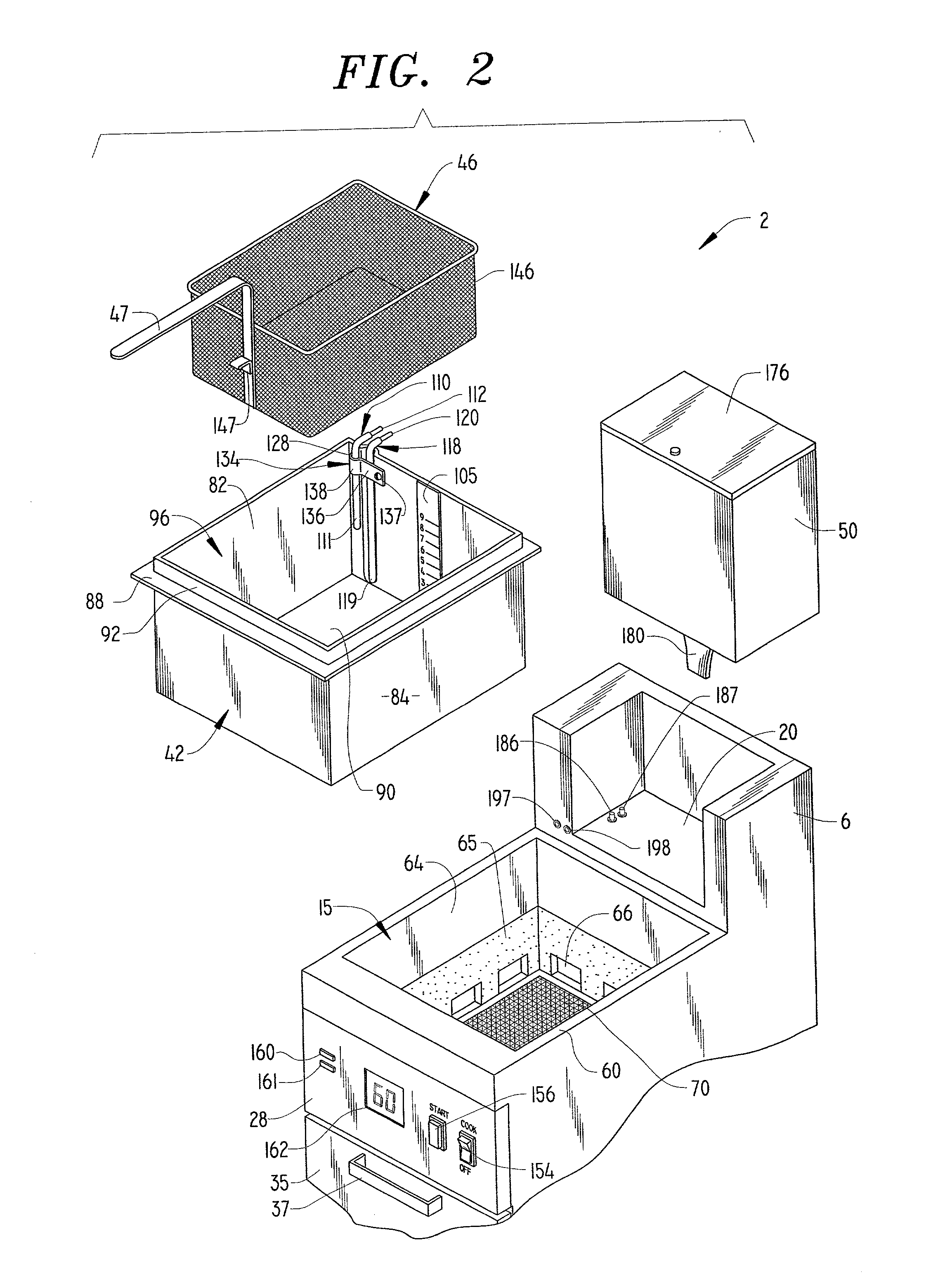

High temperature, oil saving, rapid cook fryer system

A deep fat fryer able to quickly cook food items, in about one-third to one-half of a typical cook time in the art for corresponding food items, includes a high powered, preferably high efficiency heating unit utilized to establish a cooking oil temperature in the order of about forty or more degrees Fahrenheit above a typical cook time, while preferably remaining lower than or equal to 410° F. A controller regulates the heat input from the heating unit so as to keep the temperature of the oil from dropping drastically after a product to be fried is placed in the oil for cooking. The amount of cooking oil employed is minimized. A sensing arrangement is utilized to input sensed operating conditions to the controller in order to maintain a desired operating temperature and oil level.

Owner:PITCO FRIALATOR LLC

Cooking oil antioxidant composition, method of preparation and use

InactiveUS7320809B2Edible oils/fats ingredientsFatty substance preservation using additivesAntioxidantCooking oil

Frying processes utilizing cooking oil at elevated temperatures can cause various degradation effects in the oil including oxidation, hydrolysis and / or polymerization. In the absence of additives to protect the oil, the nutritional profile and cooking performance of degraded oil diminishes the quality of food cooked therein. The disclosed methods and compositions provide beneficial and cost effective improvements in the cooking performance of oil used at elevated temperatures, for example, in food frying equipment.

Owner:OIL PROCESS SYST

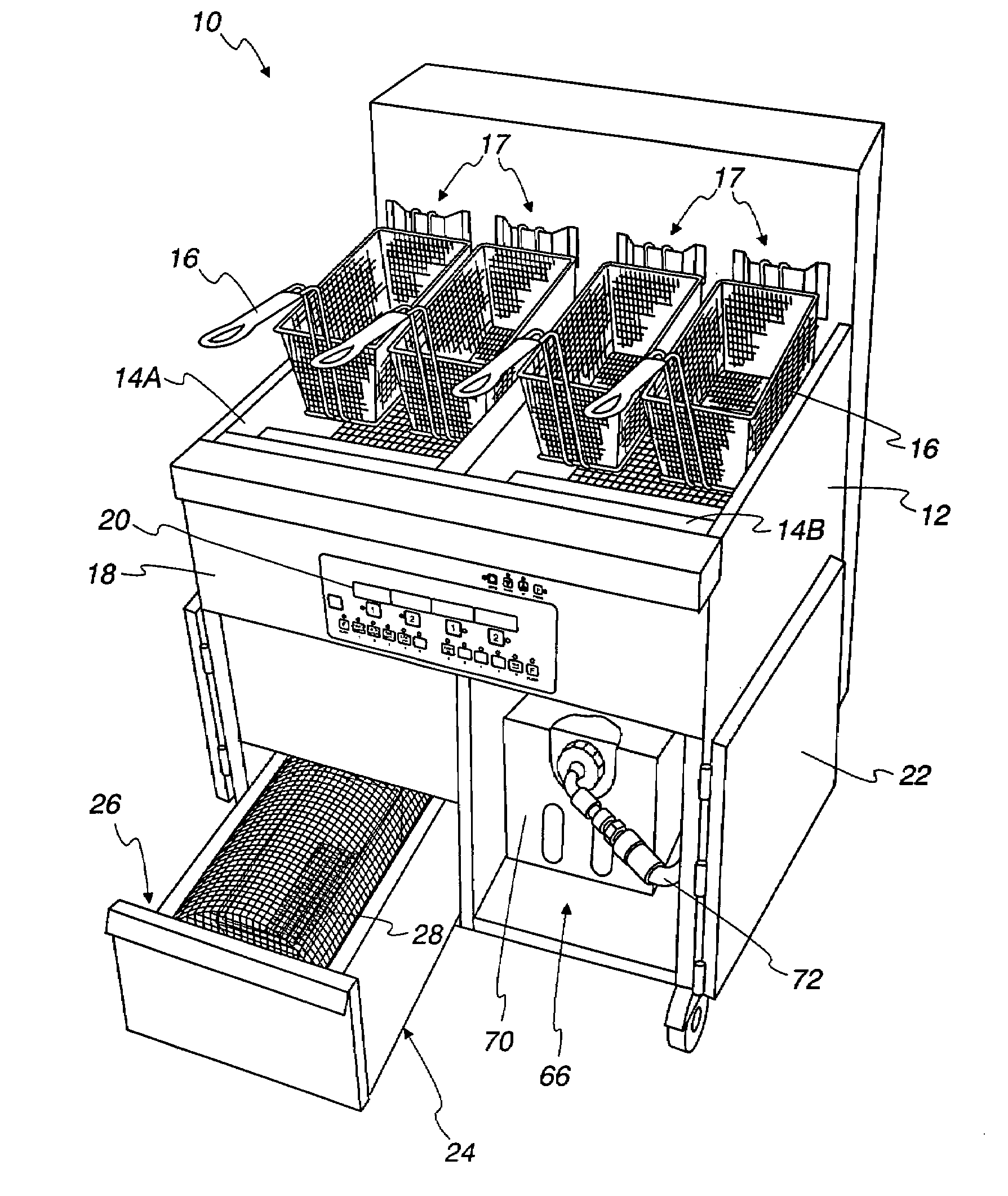

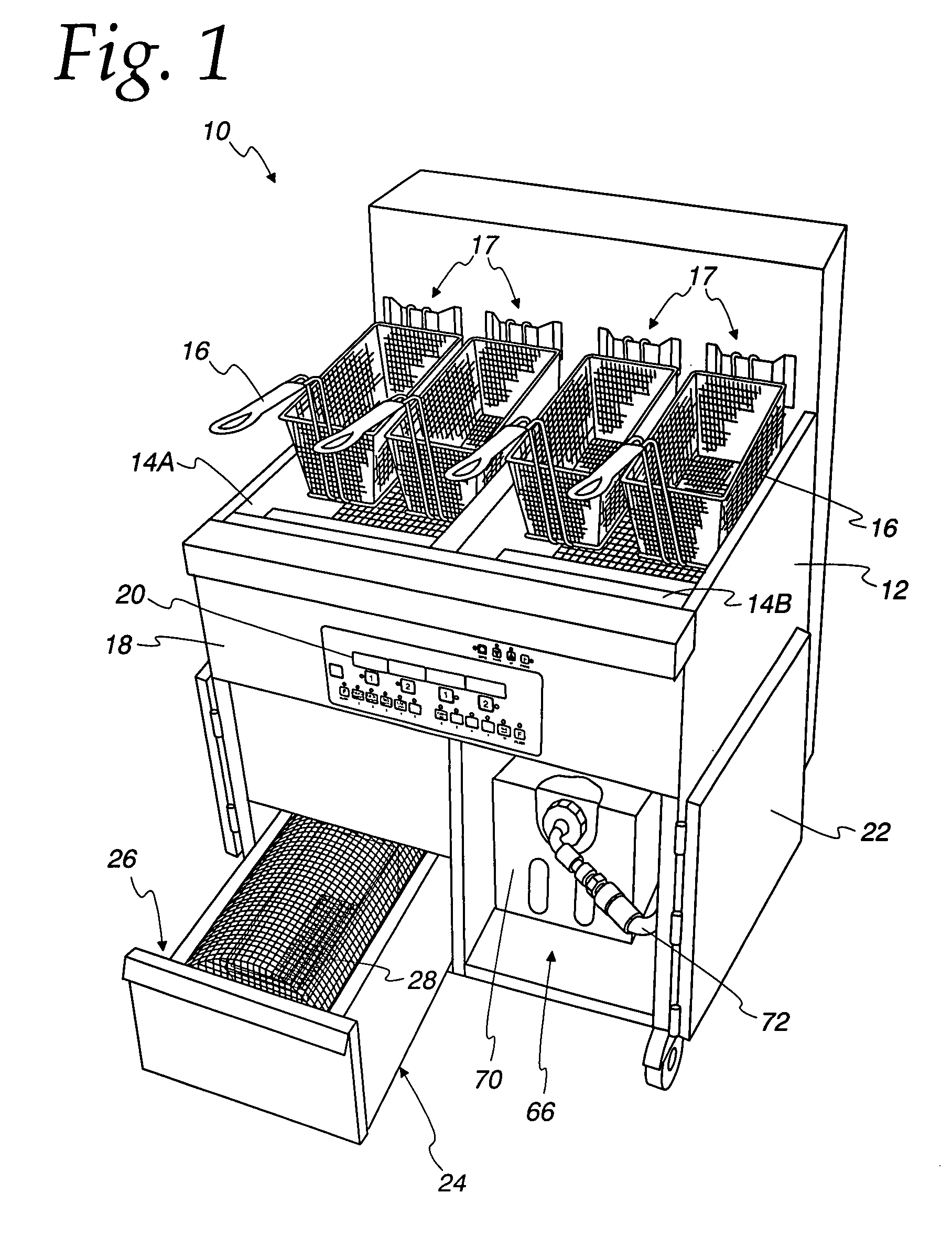

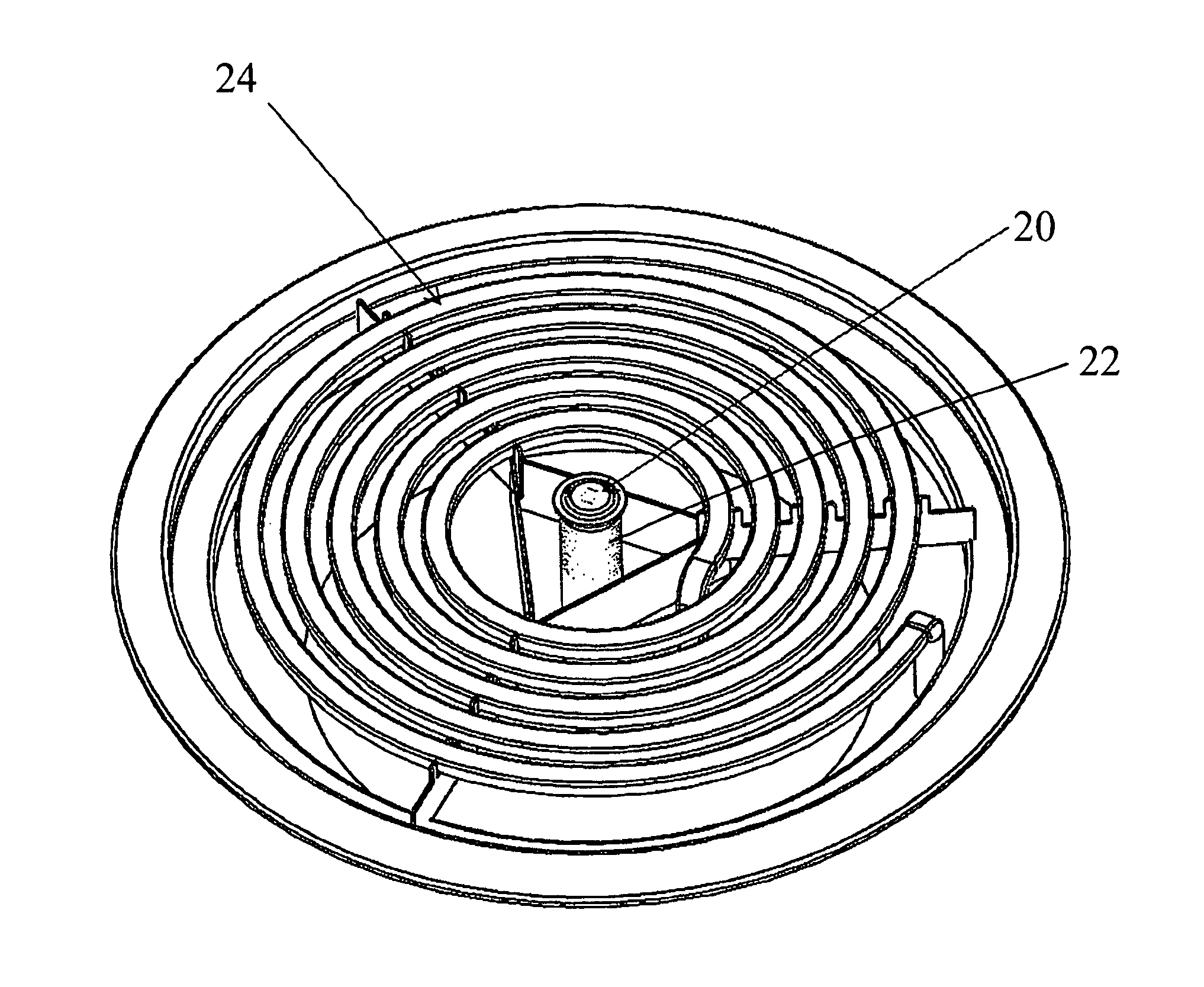

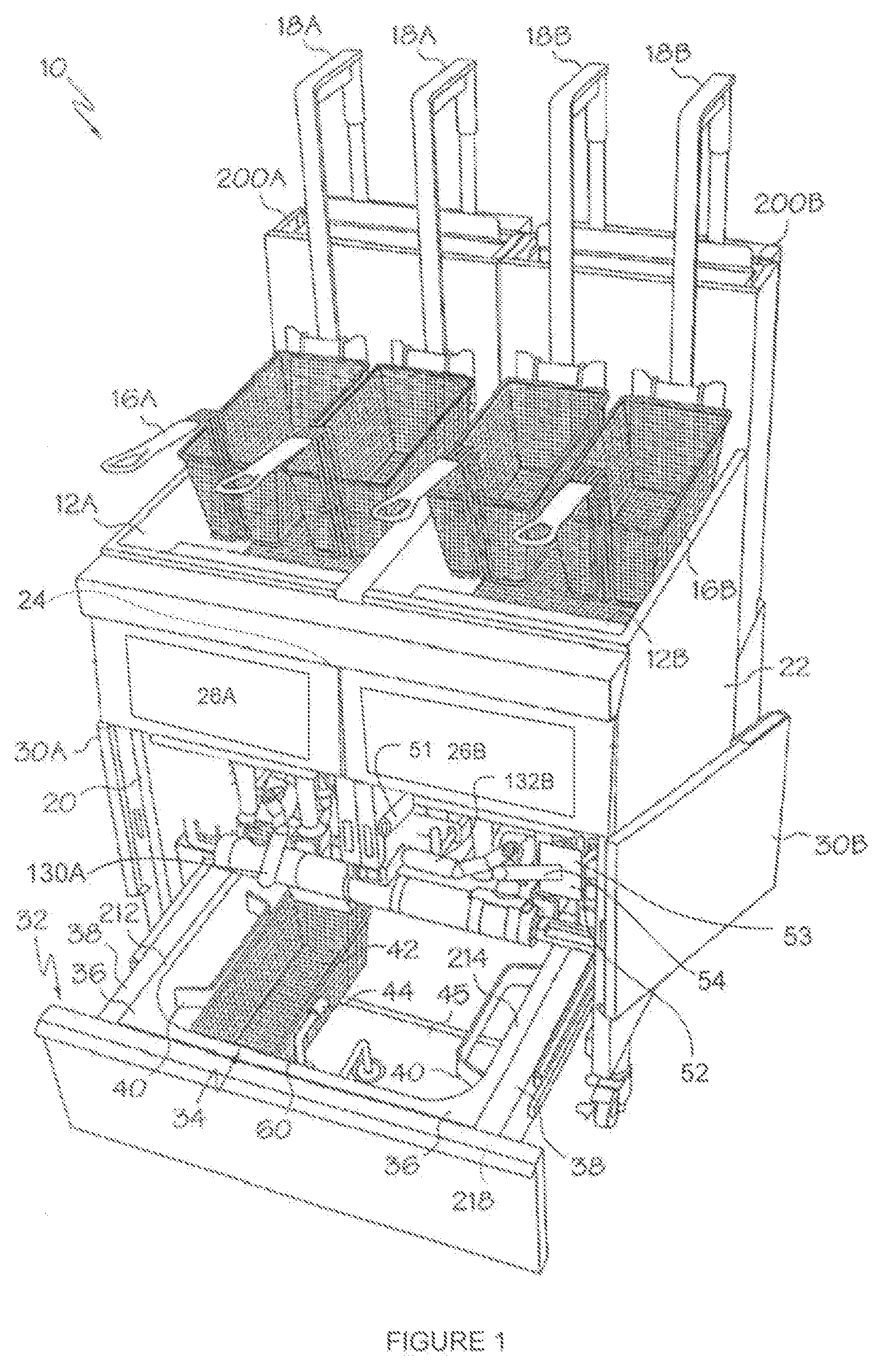

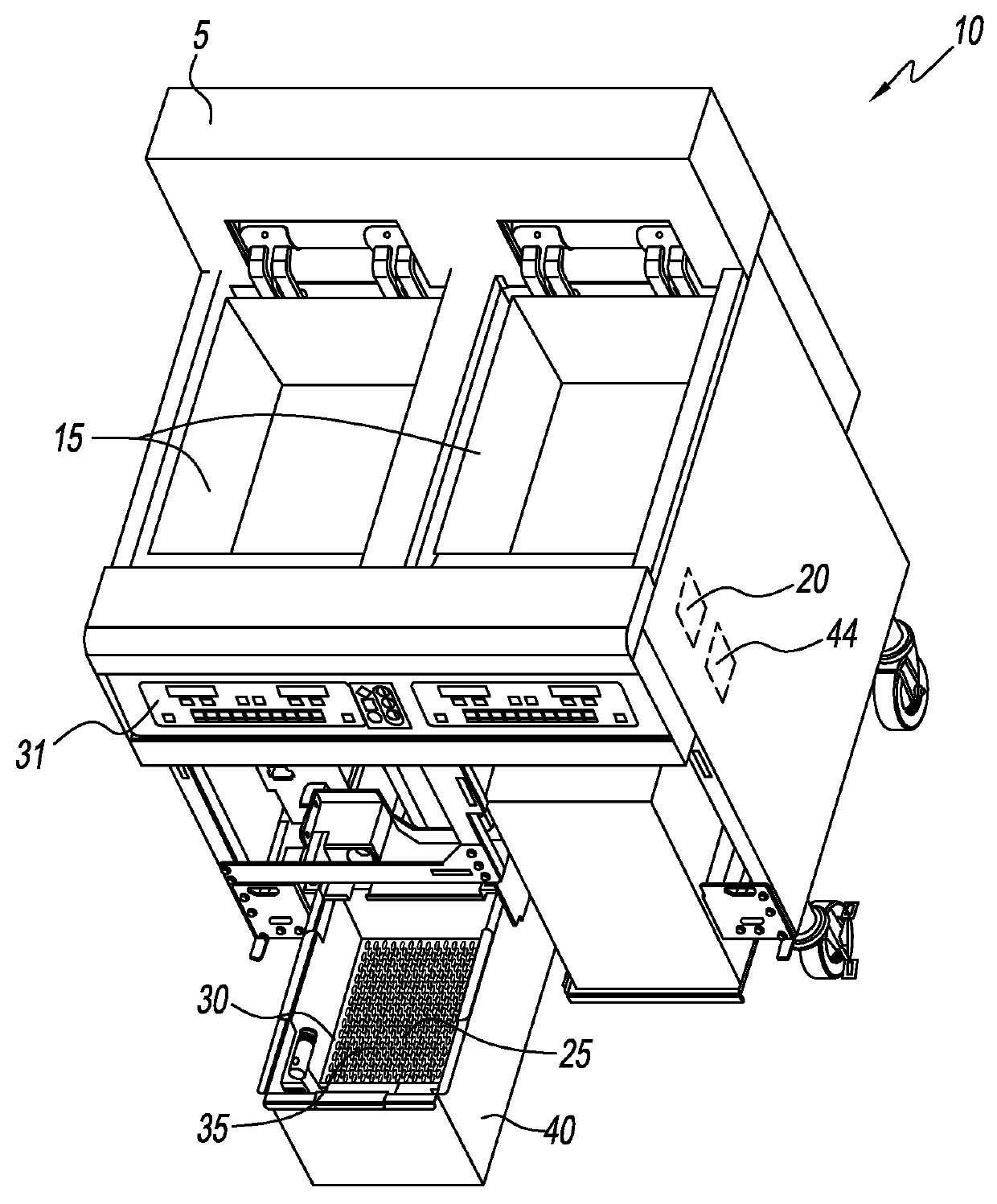

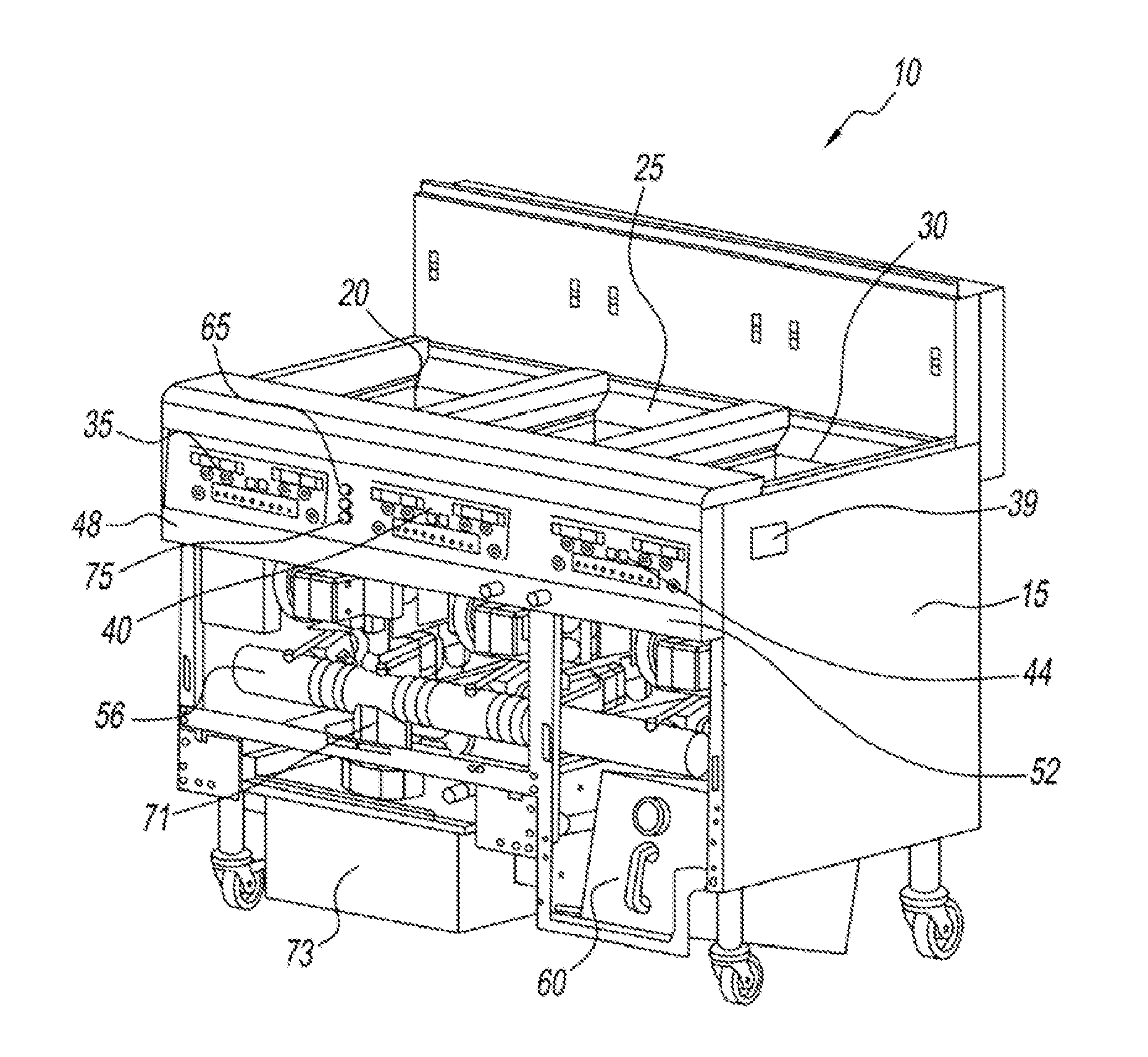

Automated fryer refilling device and method

InactiveUS20080213446A1Quality improvementOil consumption is minimizedFatty oils/acids recovery from wasteCooking vesselsUncooked FoodsFiltration

A commercial device and method for cooking food product in cooking oil includes a fry vat containing an amount of cooking oil used to cook discrete batches of uncooked food in discrete batches of a weight relative to the amount of cooking oil in the range of from about 0.0375 to about 0.1, with the total amount of food being cooked at any one time relative to the amount of oil in the fry vat being about 0.1 or less. Cooking the food results in an uptake of oil by the food in an amount of from about 5.5% to about 13% by weight of the uncooked food, and an oil turnover ratio of from about 0.0026 to about 0.007 per discrete batch. Replacement oil is periodically added, and a sufficient number of batches are cooked over 60 hours of operation to achieve at least one vat oil turnover.Automated intermittent filtration is employed in the device and method that can include monitoring the elapsed time since the last filtration of the cooking oil, monitoring the amount of food by number of batches or by weight of food product cooked in the oil since the last filtration, and filtering the oil when a predetermined threshold value is reached based on the elapsed time since the last filtration and the amount of food cooked.An automated device and method for maintaining a level of oil in a fry vat having a volume includes sensing the level of oil in the vat. When the sensed level of oil in the vat is less than or equal to a first predetermined level, replacement oil is automatically added to the fry vat, typically when at ambient temperature at a low average flow rate in the range of about 0.008 to about 0.08 gallons per minute per gallon of the oil present in the vat at the first predetermined level. The low average flow rate of added oil avoids a temperature drop of more than 15° F., 10° F. or 5° F. in the bulk oil present in the fry vat as result of adding the oil as desired.

Owner:RESTAURANT TECH

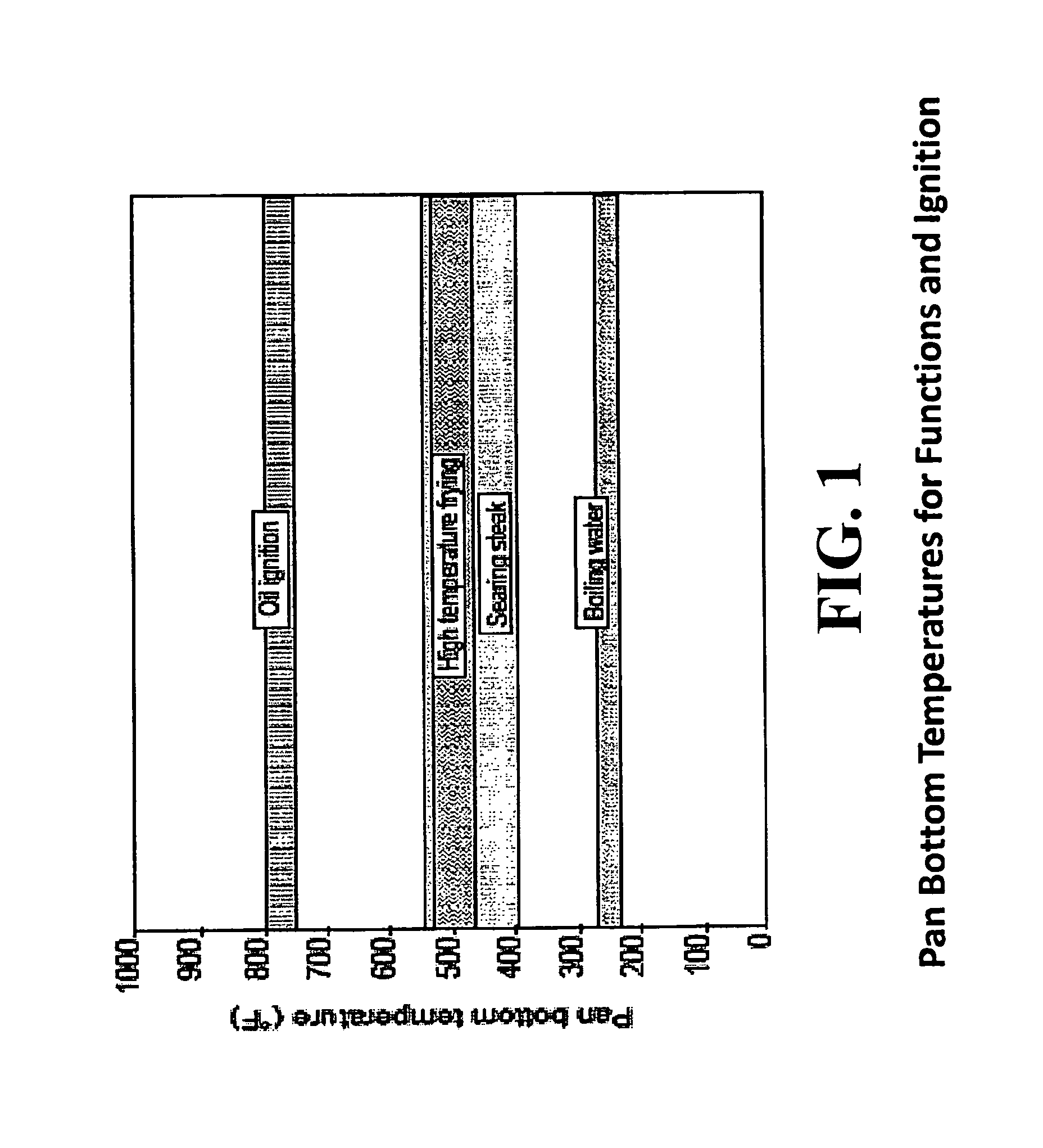

Device and method for cooktop fire mitigation

ActiveUS9132302B2Reduce riskWithout riskBoiling over preventionDomestic stoves or rangesEngineeringCooking oil

A device for limiting the temperature of cookware on a cooktop to a threshold level that corresponds to an oil ignition temperature. The device includes a temperature sensor that is positioned adjacent a bottom of the cookware on the cooktop. A control device in combination with each of the temperature sensor and the cooktop monitors the temperature and adjusts a heating element of the cooktop as needed to avoid cooking oil ignition. The temperature sensor can be a spring loaded temperature sensor to ensure and / or absorb contact with the cookware.

Owner:PRIMAIRA

Oil reclamation device and process

A fryer filtration arrangement includes an oil reclamation system to reclaim used filtered cooking oil.

Owner:ILLINOIS TOOL WORKS INC

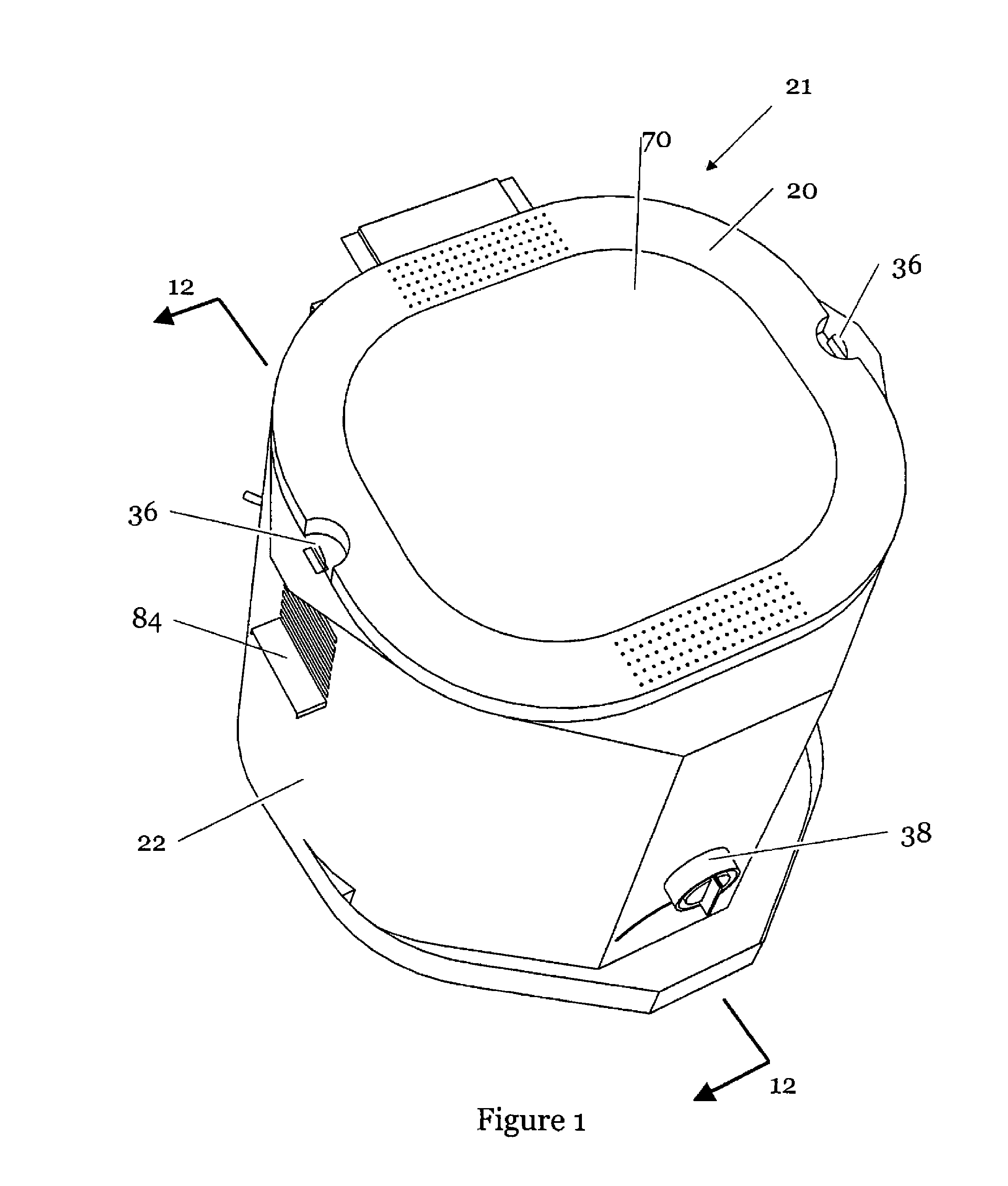

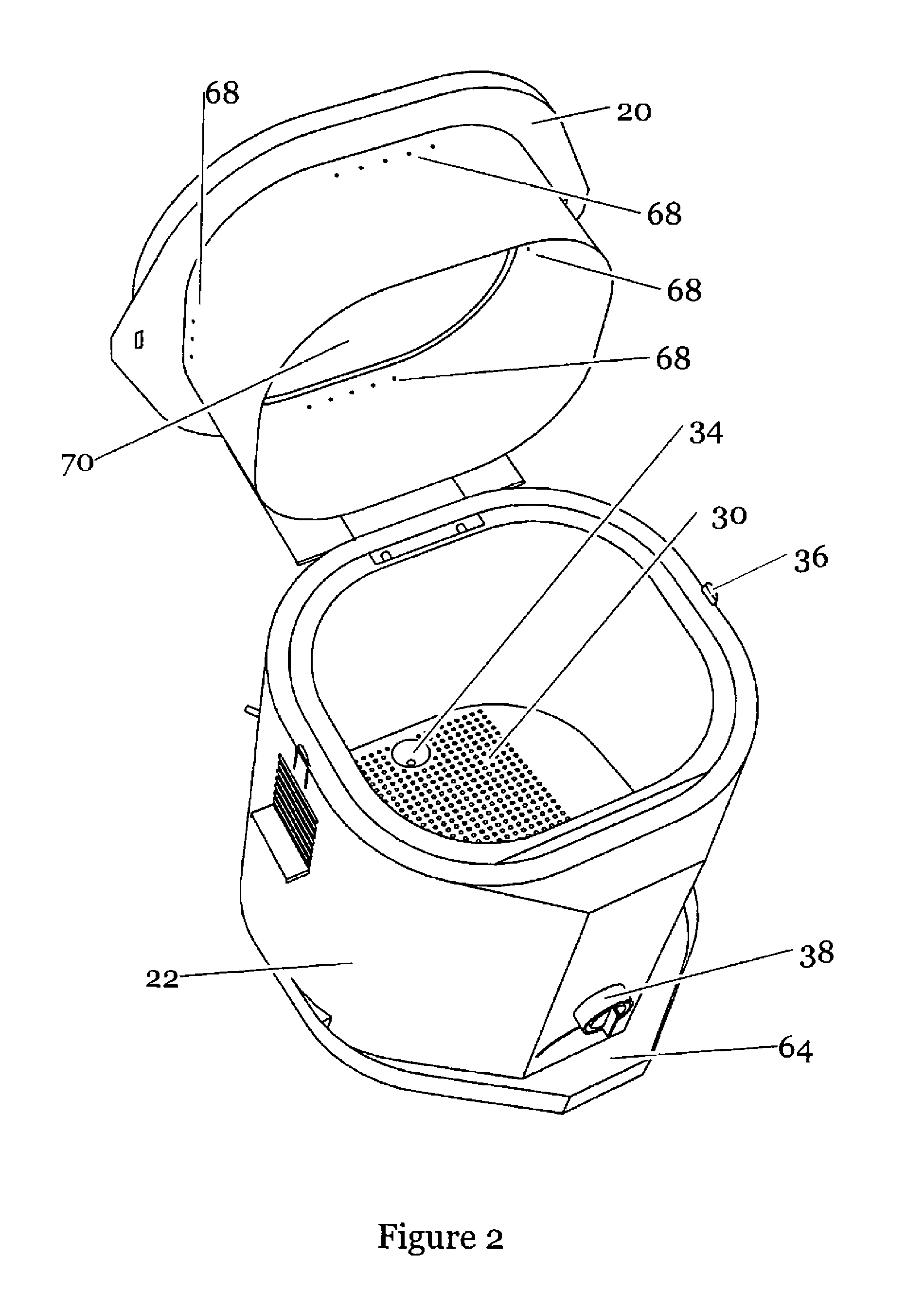

Device to efficiently cook foods using liquids and hot vapors

InactiveUS20120167778A1Low costReduce needSteam cooking vesselsDeep fat fryersMarine engineeringCooking oil

A combination food steamer and deep fryer cooking apparatus includes a vessel, a heat source, and first and second support structures. The vessel is configured to hold, at different times, associated water and associated cooking oil therein. The heat source is configured to heat the associated water within the vessel to a first selected temperature sufficient to boil the associated water held within the vessel. The heat source is further configured to heat the associated cooking oil within the vessel to a second selected temperature sufficient to deep fry associated food submerged in the associated cooking oil. The first support structure is separate from the second support structure and supports the associated food while submerged within the heated cooking oil which is contained within the vessel. The second support structure supports the associated food while being steamed by the boiling water.

Owner:RONS ENTERPRISES

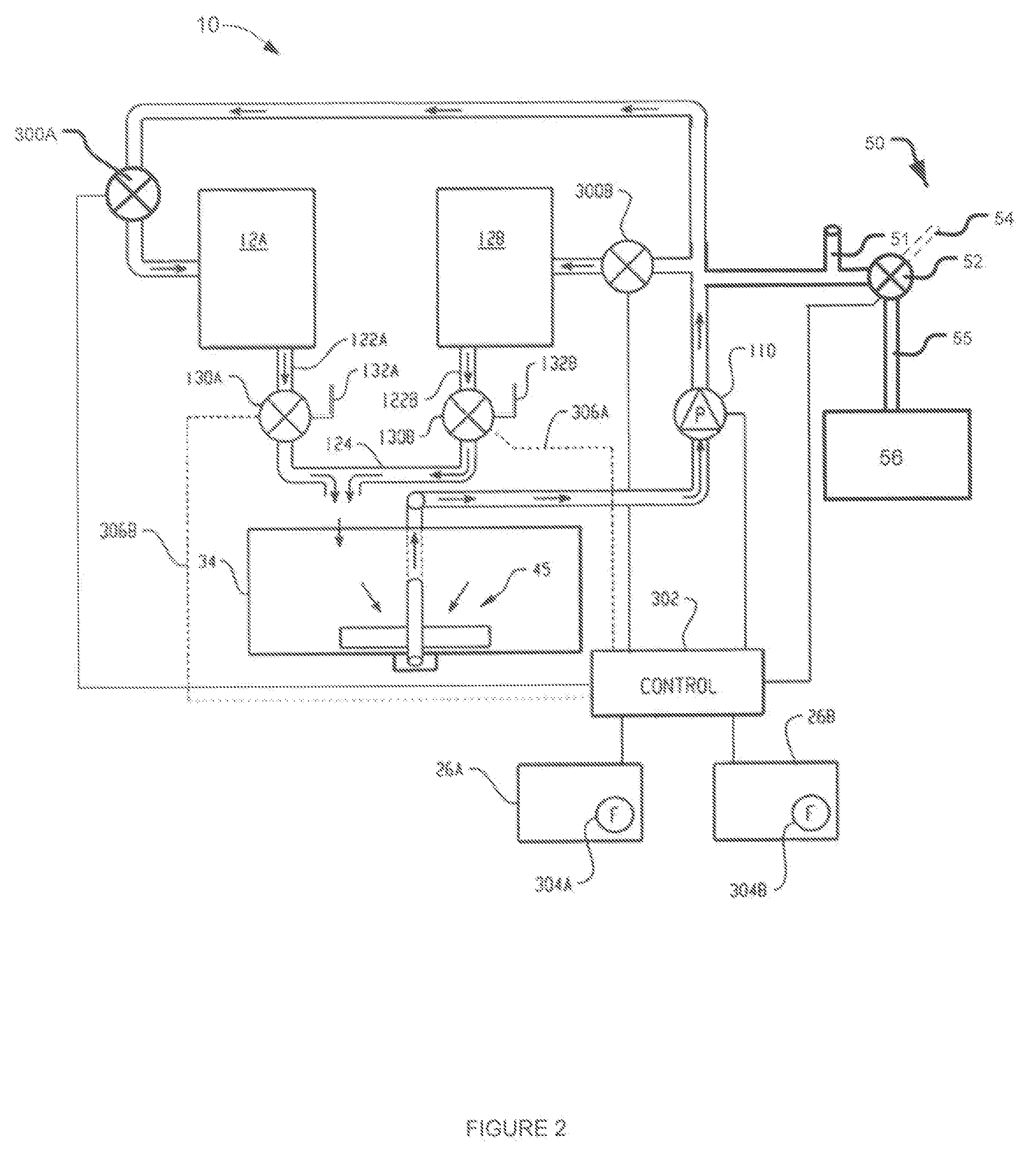

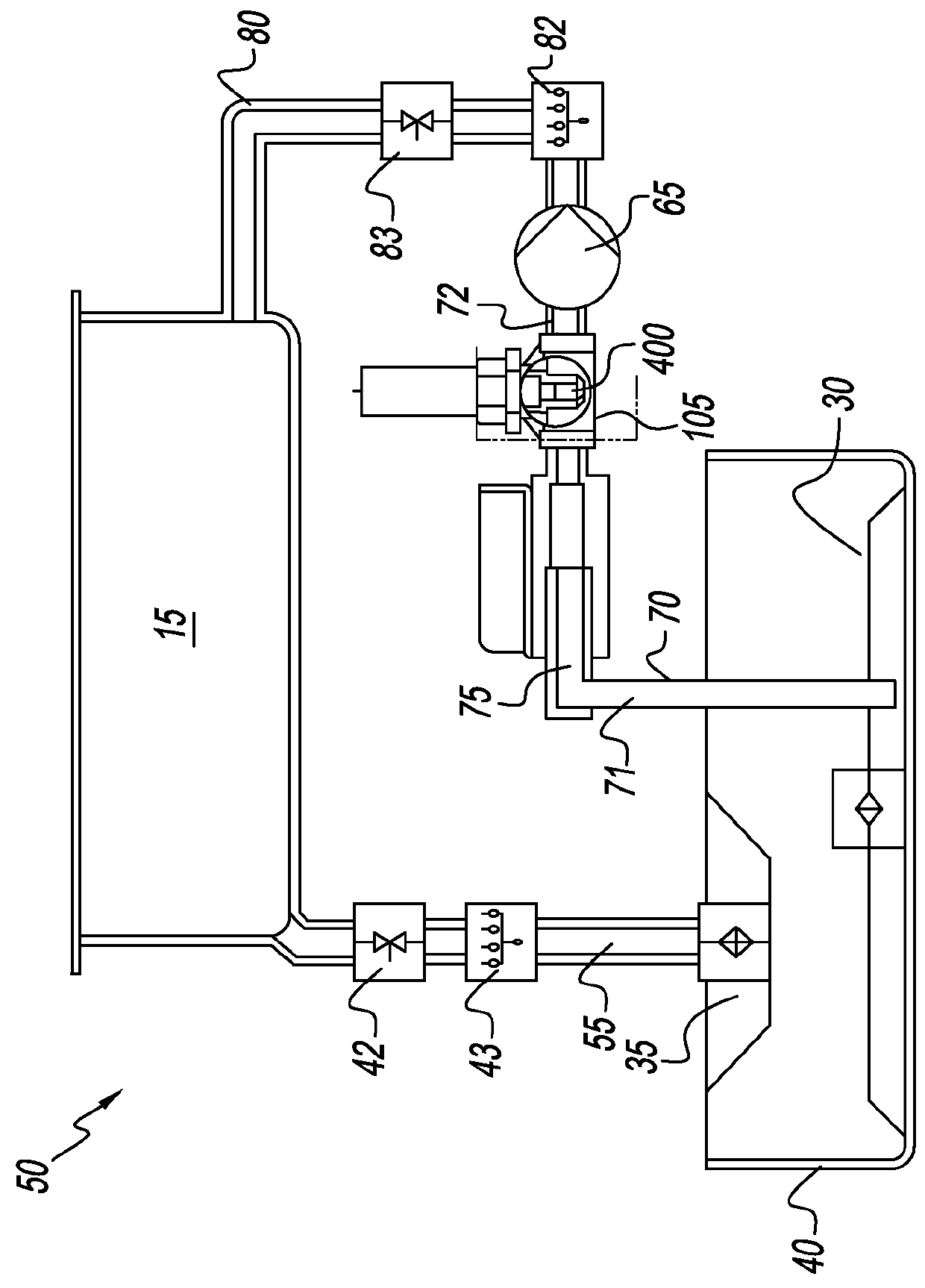

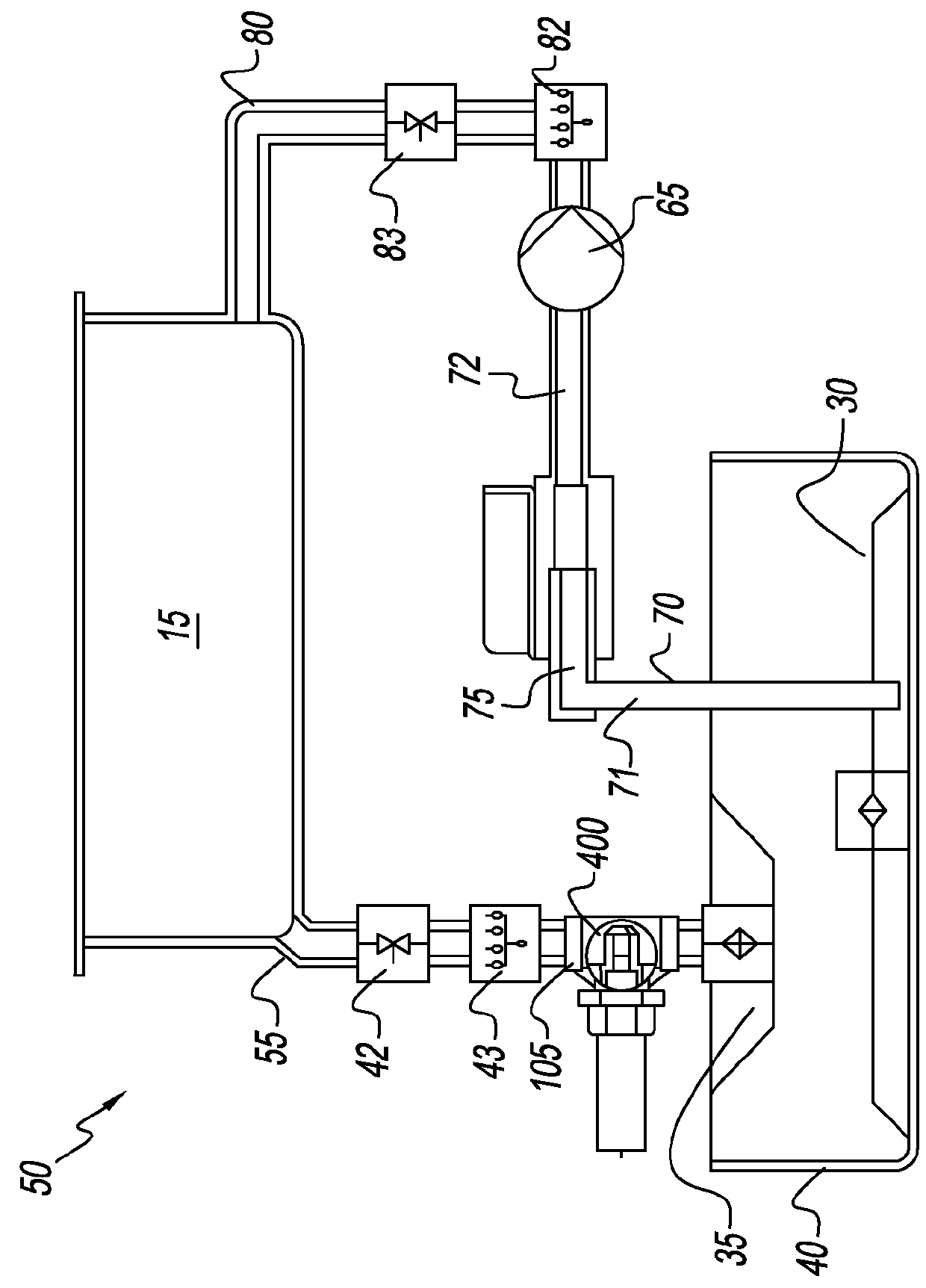

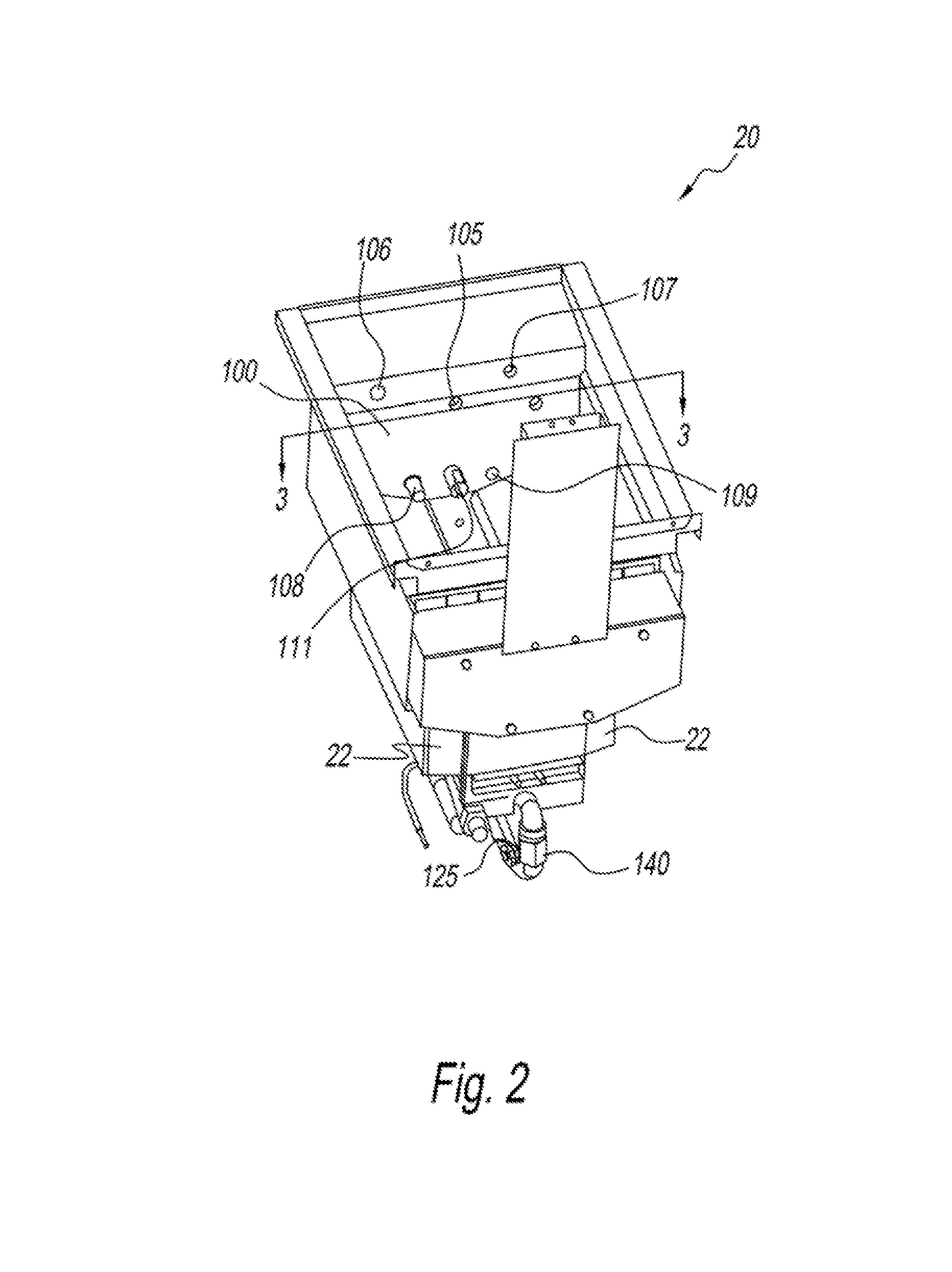

Method and apparatus for a cooking oil quality sensor

A fryer includes a fryer pot, a filter pan connected to the fryer pot by a drain conduit and a return conduit forming a filtration loop, a cooking oil quality sensor being in the filtration loop, and a controller that controls operation of a filtration cycle of the fryer. The filtration cycle has a circulation sequence and a fill sequence. The circulation sequence circulates cooking oil through the filtration loop and the fill sequence fills the fryer pot with the cooking oil from the filter pan. The controller stops the fill sequence after filling the fryer pot with a predetermined amount of cooking oil during a partial fill and resumes the fill sequence after a predetermined amount time elapses to complete the fill sequence. The cooking oil quality sensor measures a cooking oil quality to obtain a cooking oil quality measurement during the predetermined amount time.

Owner:THE FRYMASTER CORP LLC

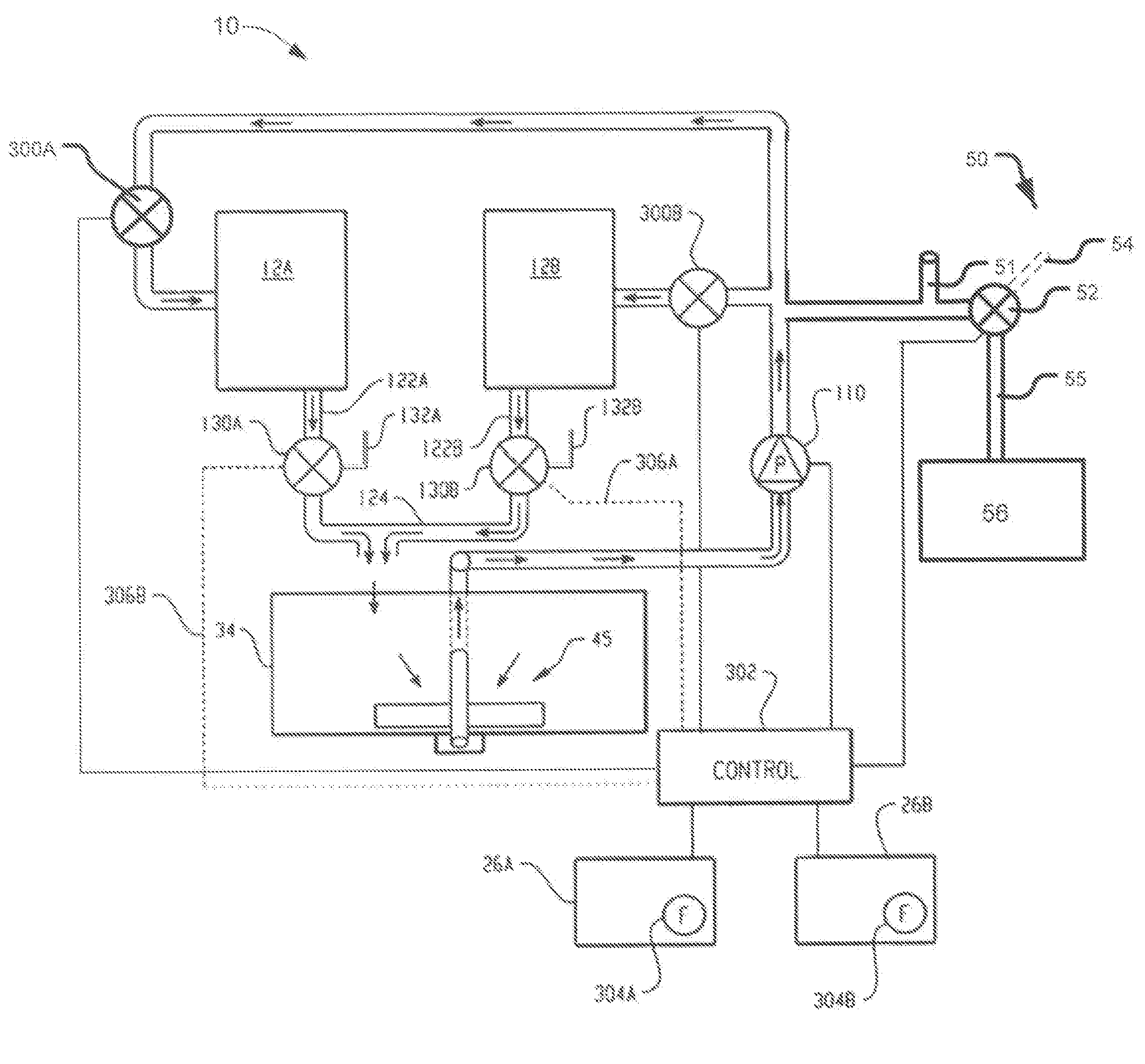

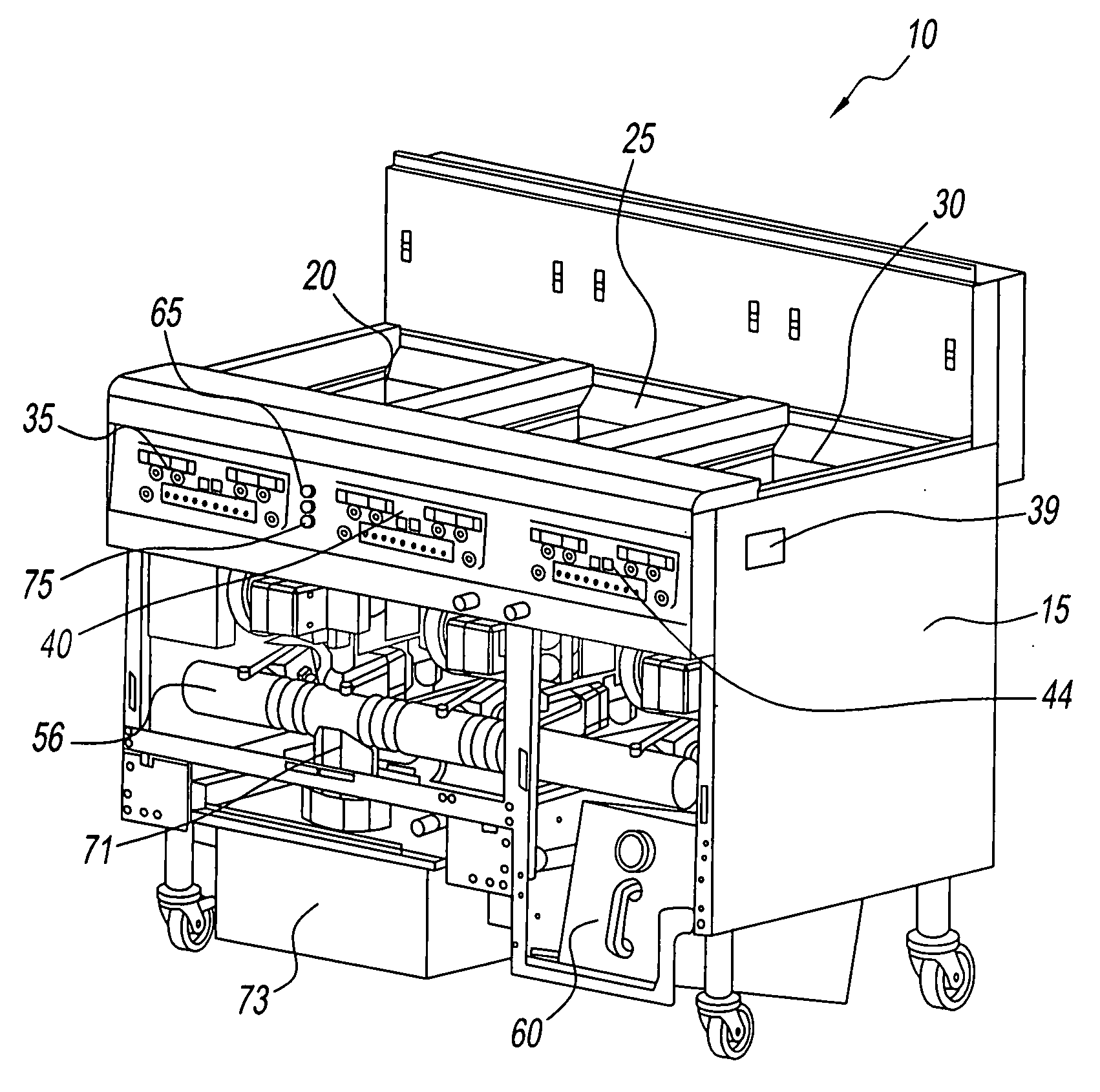

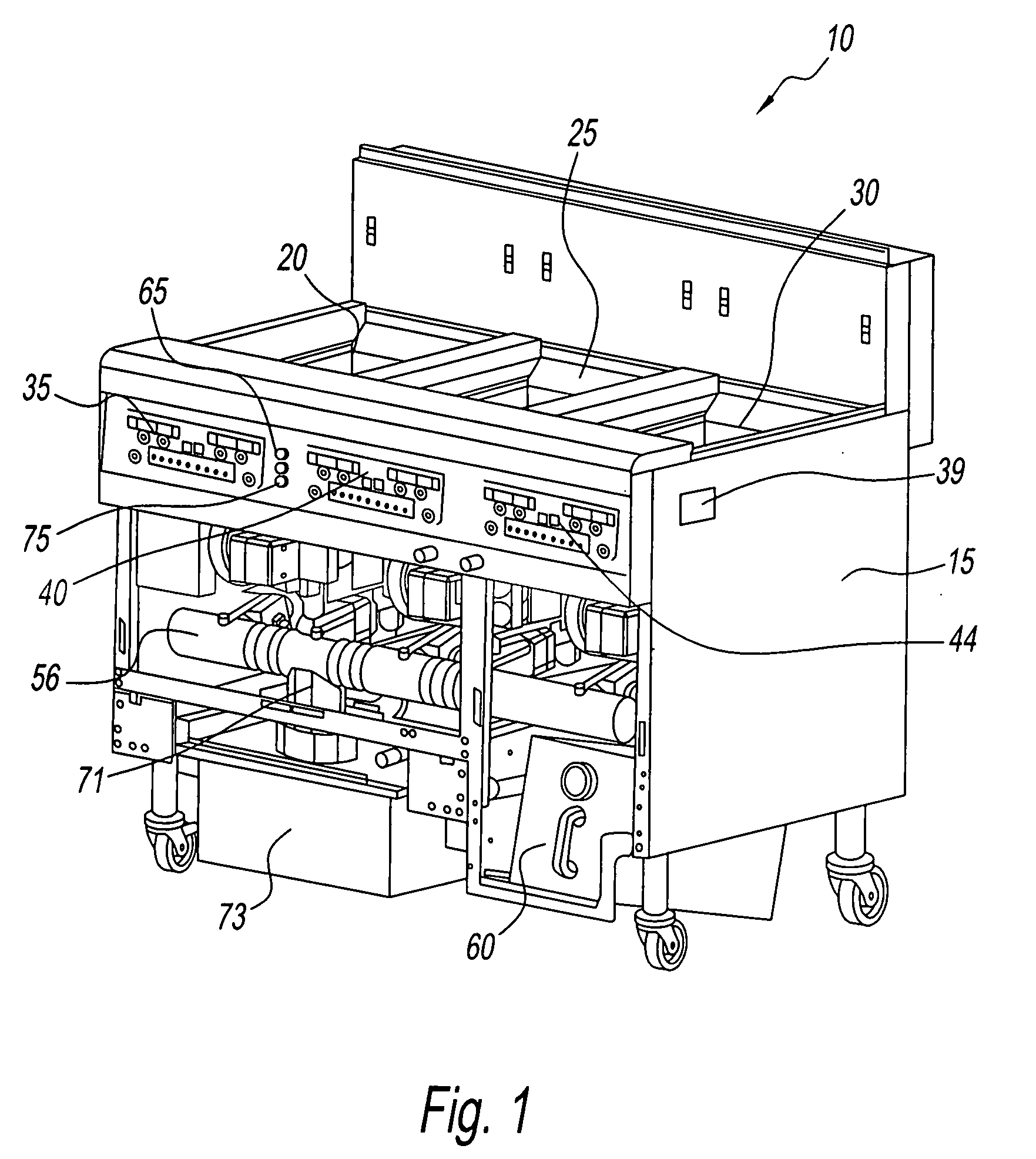

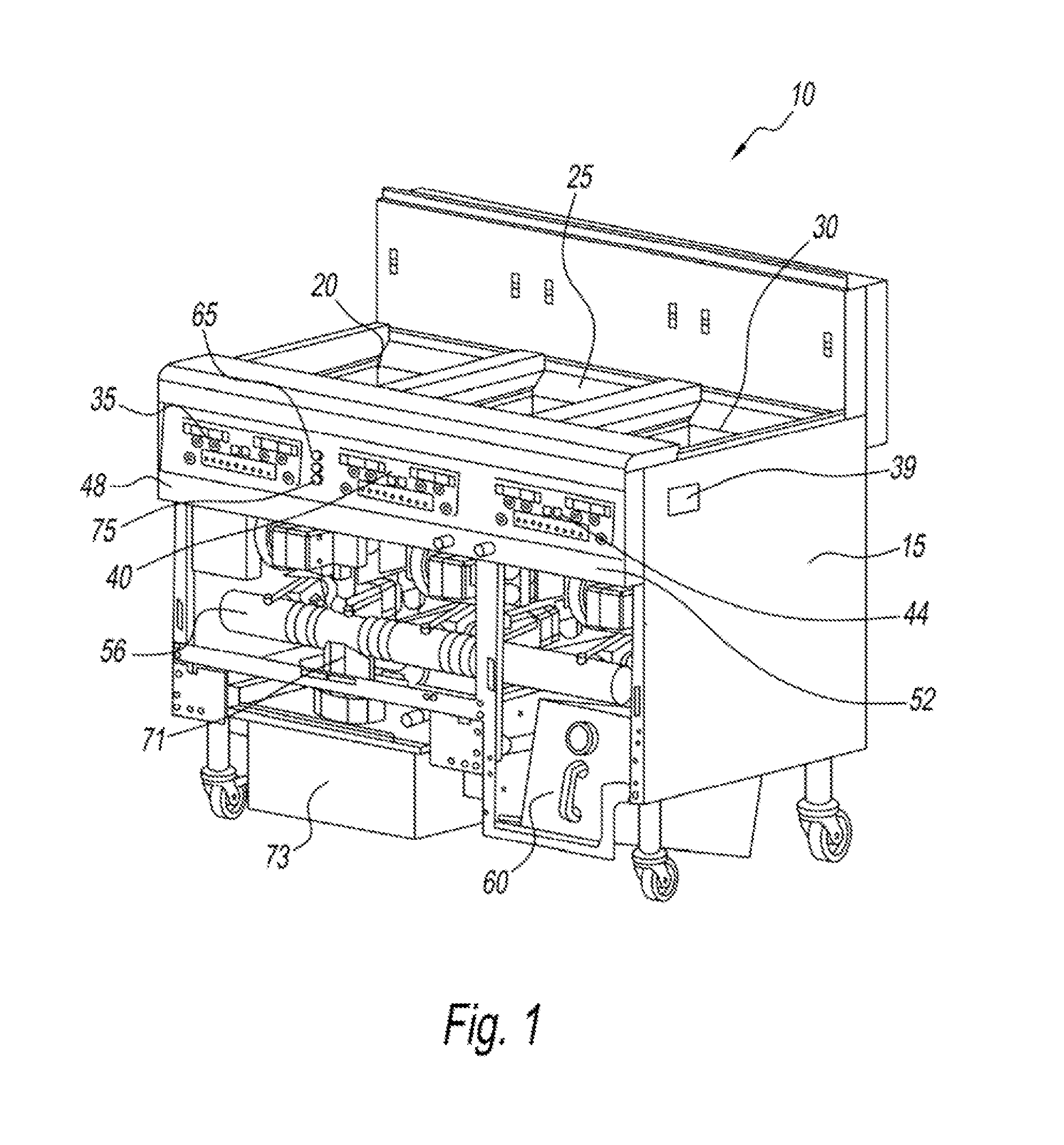

Low oil volume fryer with automatic filtration and top-off capability

A multi-function system for automatically filtering and maintaining cooking oil in fryer pots of a deep fryer having a deep fryer and a plurality of fryer pots is provided. Each of the plurality of fryer pots contains at least a first temperature sensor and a second temperature sensor. The deep fryer is capable of operating in an automatic filling mode to maintain an oil level when the first sensor senses a first predetermined oil temperature and an automatic filtration mode to allow filtration of oil in one of the plurality of fryer pots after the first sensor senses a first predetermined oil temperature.

Owner:RESTAURANT TECH

Sauces, spreads, cooking oils, and cooking fats made from various ingredients

Sauces, spreads, cooking oils, and cooking fats are created from a wide range of various ingredients. Sauces, spreads, cooking oils, and cooking fats having at least one ingredient, with at least one flavoring, and at least one texture. At least one ingredient is selected from group including of at least one flavoring ingredient, at least one nutritional ingredient, at least one health ingredient, and at least one other ingredient. At least one ingredient is also created as small spherical balls as mixed in. Sauces can be served as appetizer and snack. And served as baby food, for children with less teeth, for old people, and for sick people. Sauces, spreads, cooking oils, and cooking fats are used for food preparation and food flavoring, including condiment and salad dressing. And used in manner selected from group consisting of room temperature, cold, warm, and hot.

Owner:CHANG ALICE

Method for producing epoxy fatty acid methyl ester by using illegal cooking oil

InactiveCN102161938AHigh speedEasy to control and adjust the dosageFatty acid esterificationPreparation by alcoholysisEpoxyDistillation

Owner:河北金谷增塑剂有限公司

Simultaneous slicing and washing of vegetables

InactiveUS6413566B2Save equipmentShorten the timeClimate change adaptationMeat/fish preservation by freezing/coolingVegetable matterWater flow

Owner:HEAT & CONTROL

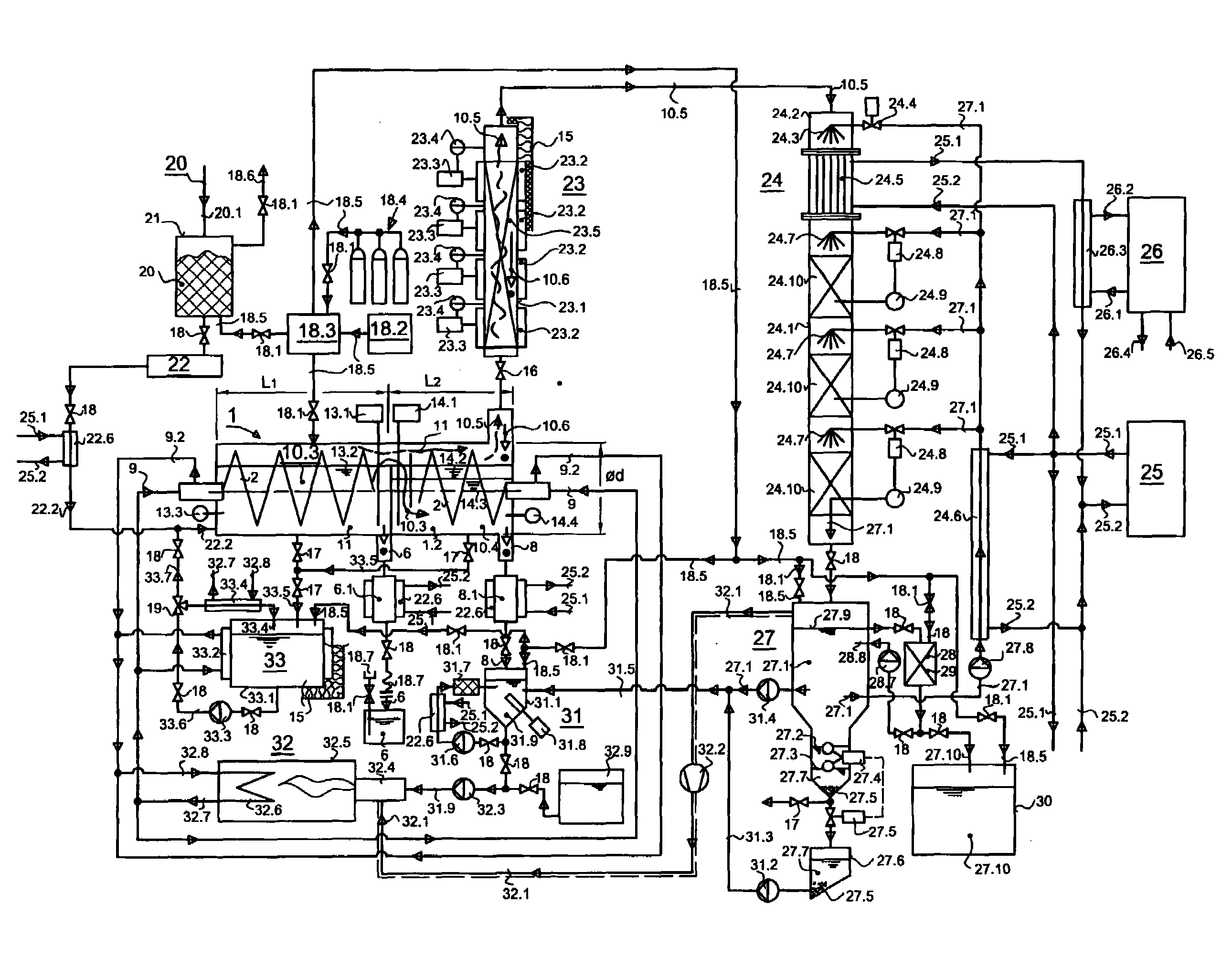

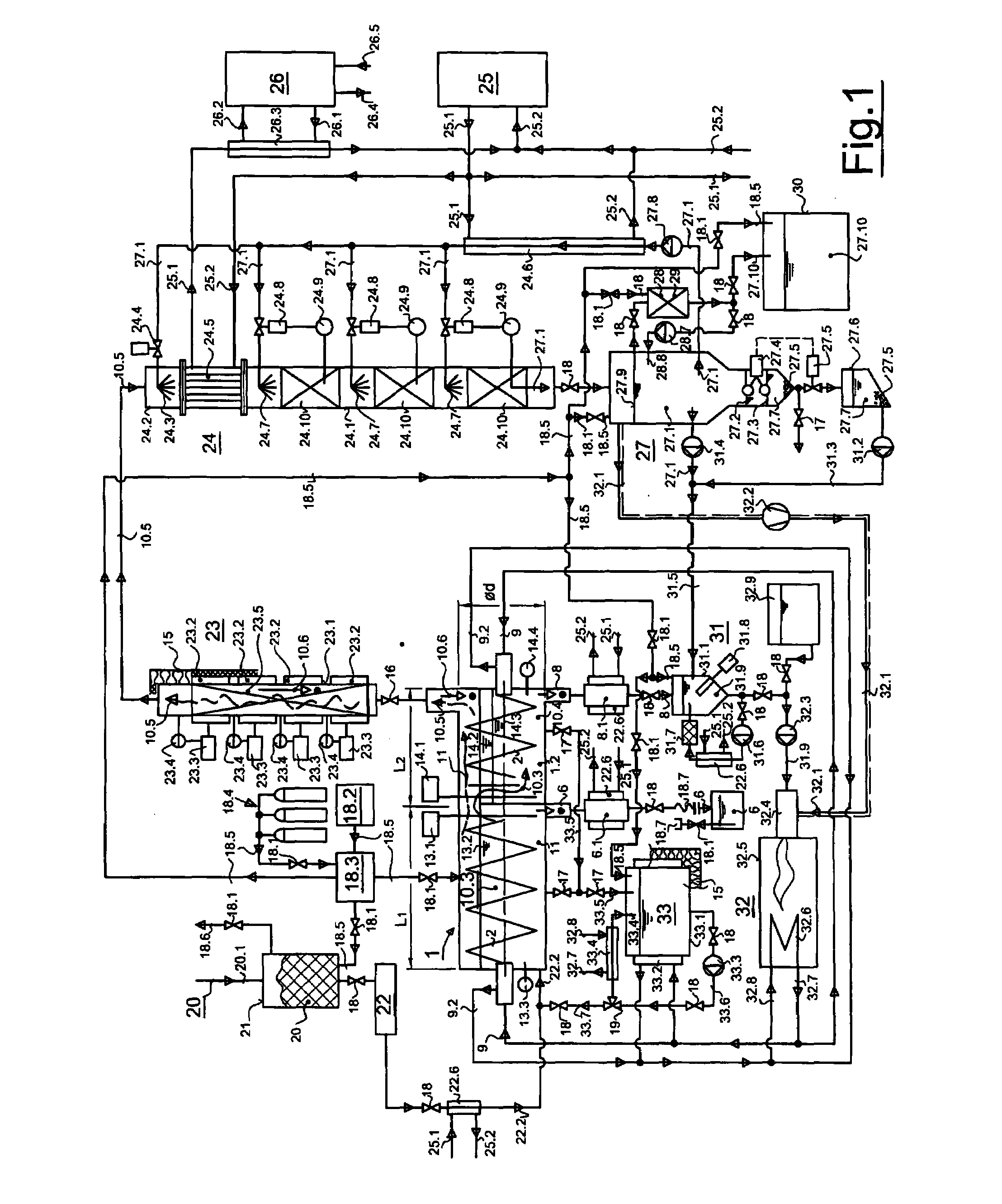

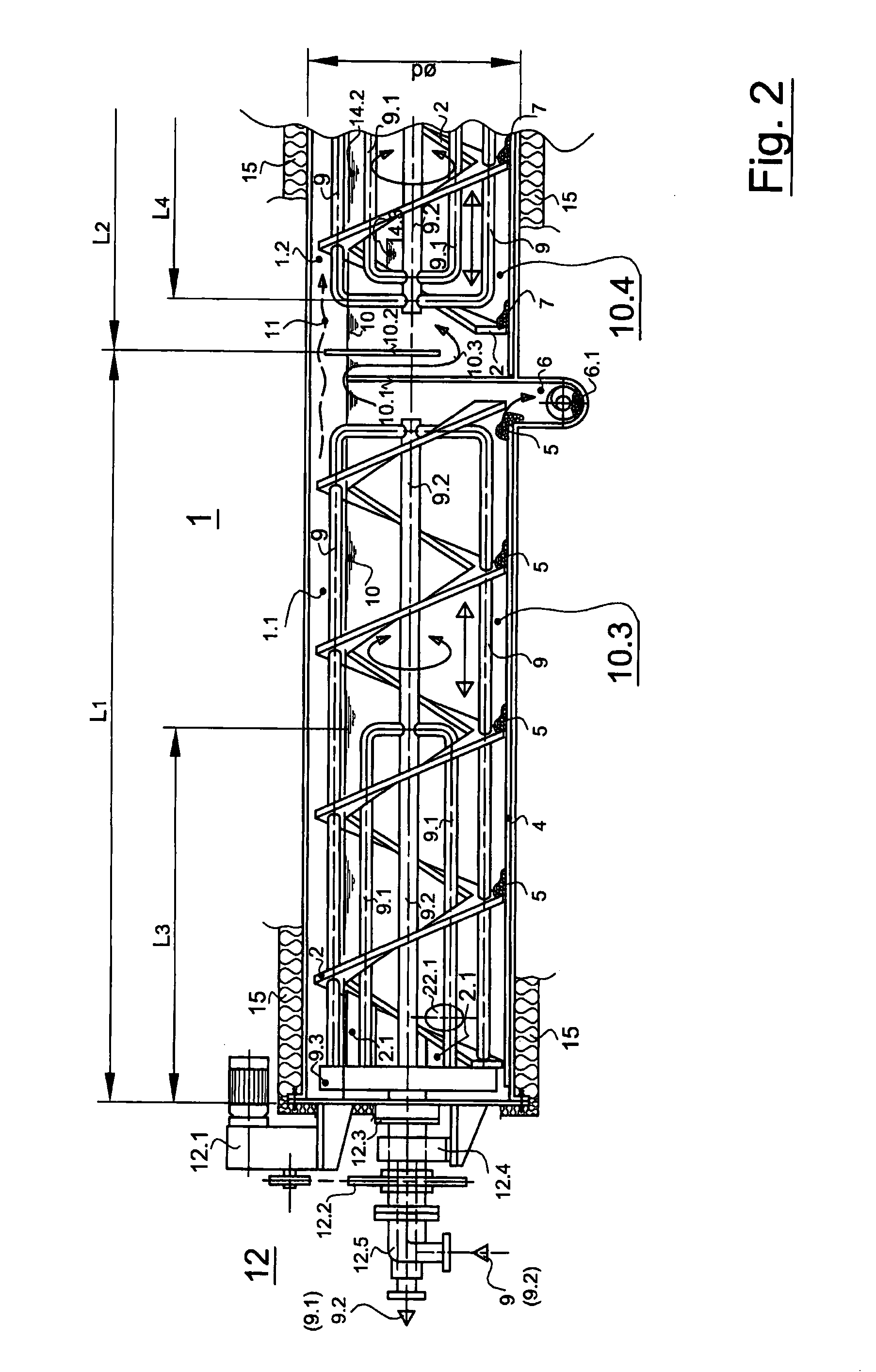

Method and device for processing plastic-containing waste

InactiveUS20090321317A1Improve heat transfer performanceReduce decreaseGaseous chemical processesCatalytic crackingGas phaseOrganic fluid

The invention relates to a method and device for processing plastic-containing and organic fluids based on crude oil, cooking oil, fats or the like, wherein the substance mixture is fed into a reactor, is then melted in the melting zone of the reactor and the interfering substances are discharged from the melt. The long-chained polymers still present in the melt are cracked in a crack zone of the reactor until they assume a gaseous state. Then the gas phase is discharged from the reactor an condensed in a cooler. Impurities are then removed from the volatile liquid present after cooling and the volatile liquid is stored.

Owner:WESER GEROLD +1

Maotai-flavor peanut thick chilli sauce and its preparation method

The invention discloses a peanut butter and its preparing process, wherein the raw materials include (by weight ratio) peanut 45-55 parts, dried soybean paste 15-25 parts, refined pork 30-50 parts, fermented soybean 35-45 parts, dried pepper 10-30 parts, soaked pepper 45-55 parts, chilli-paste with broad bean 45-55 parts, sesame 10-20 parts, catsup 25-35 parts, Chinese prickly ash 3-6 parts, white sugar 15-25 parts, green onion 10-20 parts, fresh ginger 10-20 parts, garlic 10-20 parts, cooking oil 80-120 parts, water or soup 200-300 parts.

Owner:安艳涛

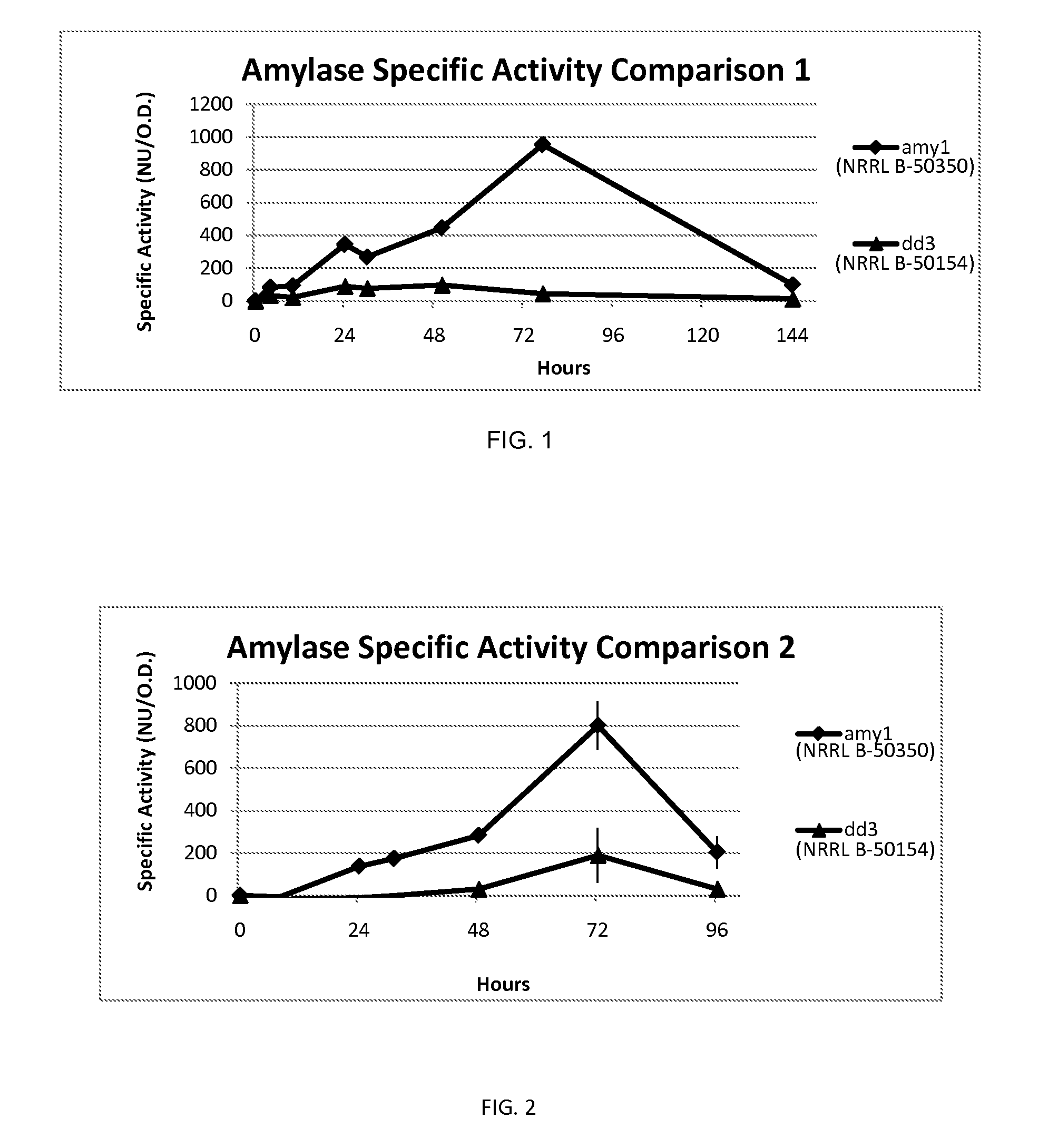

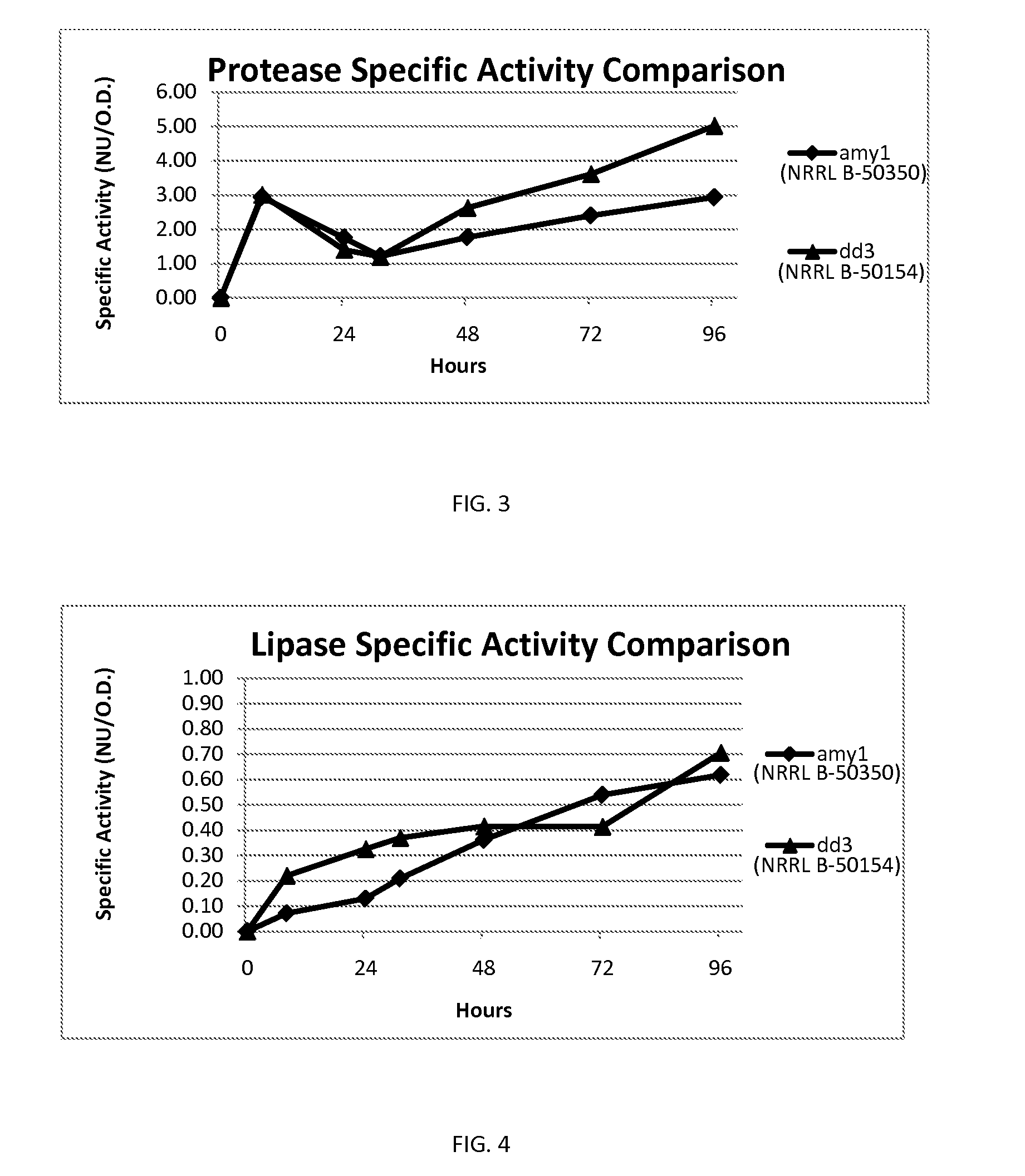

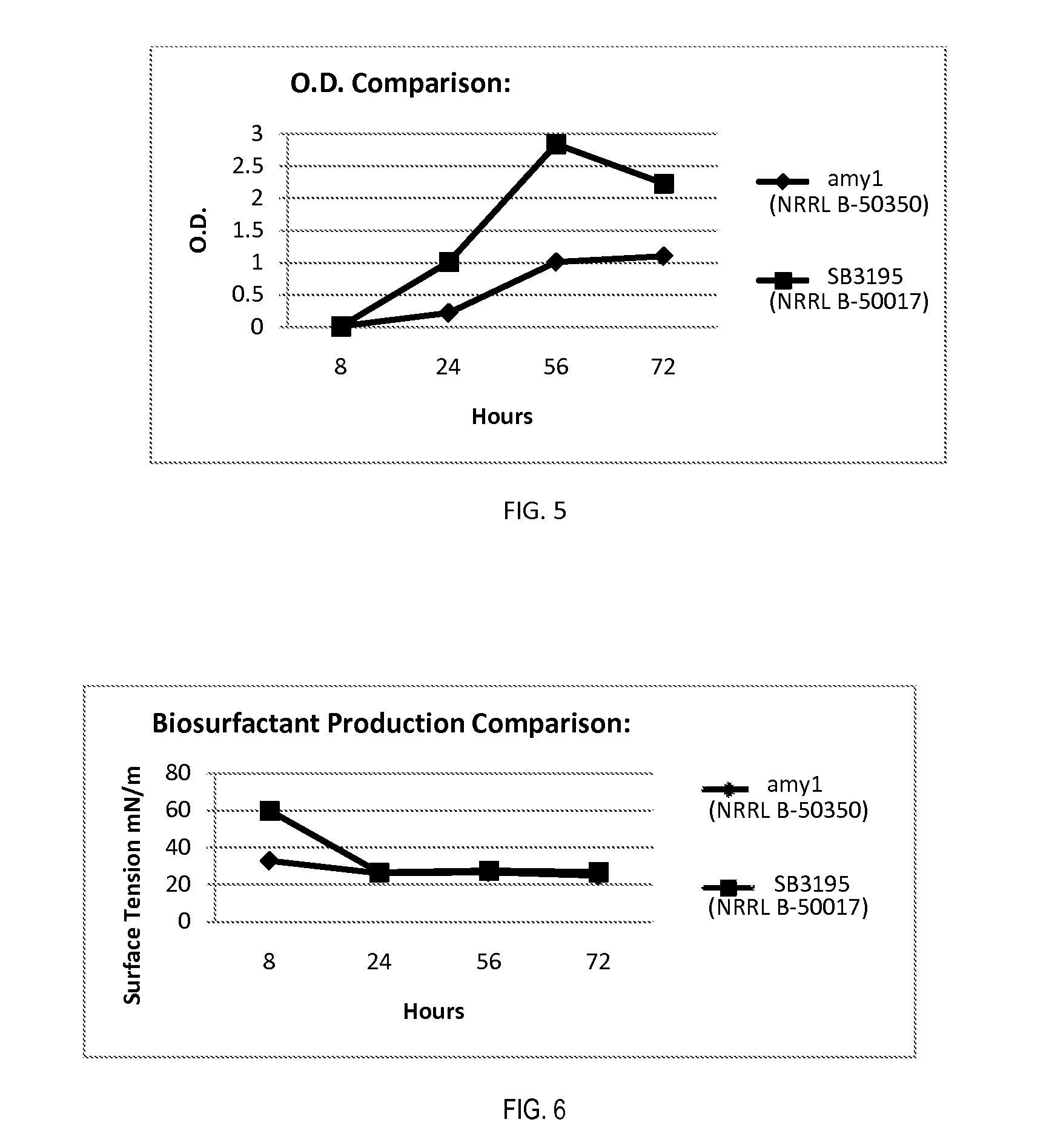

Bacillus amyloliquefaciens Strain

ActiveUS20110274673A1Preventing and alleviating and undesirable conditionImprove seed qualityBiocideBacteriaBiotechnologyBacteroides

The present disclosure relates to a strain of Bacillus amyloliquefaciens bacteria that hyperproduces amylase enzyme and protease enzyme. The strain is also suitable for producing lipase for the degradation of oleaginous materials such as fats, greases and cooking oils. The strain also has excellent fungicidal and / or fungistatic qualities. The strain of the present disclosure and the enzymes produced thereby have a number of applications, including agricultural uses, laundry and dish detergents, drain cleaners and spot removers, and among other things, baking applications.

Owner:NOVOZYMES BIOLOGICALS

Anion collecting agent prepared from illegal cooking oil

InactiveCN102179311AReduce manufacturing costReduce security threatsFlotationCooking oilWaste material

The invention relates to an anion collecting agent prepared from illegal cooking oil, belonging to an environment processing technique for waste material utilization. The anion collecting agent is prepared through the following steps: adding 92.5wt% industrial concentrated sulfuric acid into the illegal cooking oil, wherein the mass ratio of the illegal cooking oil to the concentrated sulfuric acid is 1:(0.05-0.1), so that the illegal cooking oil is layered; carrying out demulsification and dust removal on coarse oil by utilizing a saturated sodium chloride solution, wherein the mass ratio of the coarse oil to the sodium chloride solution is 1:(0.1-0.12); sulfonating a pure oil material by utilizing the 98wt% industrial concentrated sulfuric acid, wherein the mass ratio of the pure oil material to the concentrated sulfuric acid is 1:(0.7-1); and saponifying by utilizing a 10wt% industrial sodium hydroxide solution so as to obtain the anion collecting agent, wherein the mass ratio of the sulfonated oil material to the sodium hydroxide solution is 1:1.6. According to the invention, the production cost of the anion collecting agent is reduced, and the food security threat is reduced, so that waste is turned into wealth, harm is turned into benefit, and a novel way is created for the comprehensive utilization of the illegal cooking oil.

Owner:NEIMENGGU BAOGANG RARE EARTH LINFENG TECH

System and method to extend cooking oil life in fryers

A fryer system and method of extending oil life in fryer pots by minimizing the effects of oxygenization, hydrolysis and lack of oil replenishment during the cook cycle. The fryer system includes a controller that controls an on time and an off time of the fryer pots according to a use schedule. The use schedule levels or equalizes the on time use among all of the fryer pots. The controller includes a processor that executes instructions stored in a memory to control the on time use and off time use of the fryer pots as well as the use of filtration based on an elapse of a predetermined number of cook cycles of a stopped fryer pot since the oil was last filtered.

Owner:THE FRYMASTER CORP LLC

Electric heating cooker with weighing function and weighing control method thereof

ActiveUS20120321760A1Increase and decrease valueEasy to controlWeighing apparatus detailsOhmic-resistance heatingElectricityCholesterol

An electric heating cooker with weighing function and a weighing control method thereof are provided. An electronic scale (5) with weighing function is added under the traditional electric heating cooker and stores cooking experience database and food information database. It solves the problem that users aren't accurate about the amount of water to add for a given weight of ingredient. And experience curve of heating power are designed at different weight points for food such as rice or meat, and also it makes the cooker to intelligently adjust parameters according to the taste feedback of the user so as to be more closer to the user's taste for the cooking next time; additionally it is capable of showing the total and average content of heat quantity, cholesterol, protein, fat, salt and cook oil of various foods in current cooking or if there are unmatched foods.

Owner:DUO AI JIA BEIJING SCI & TECH

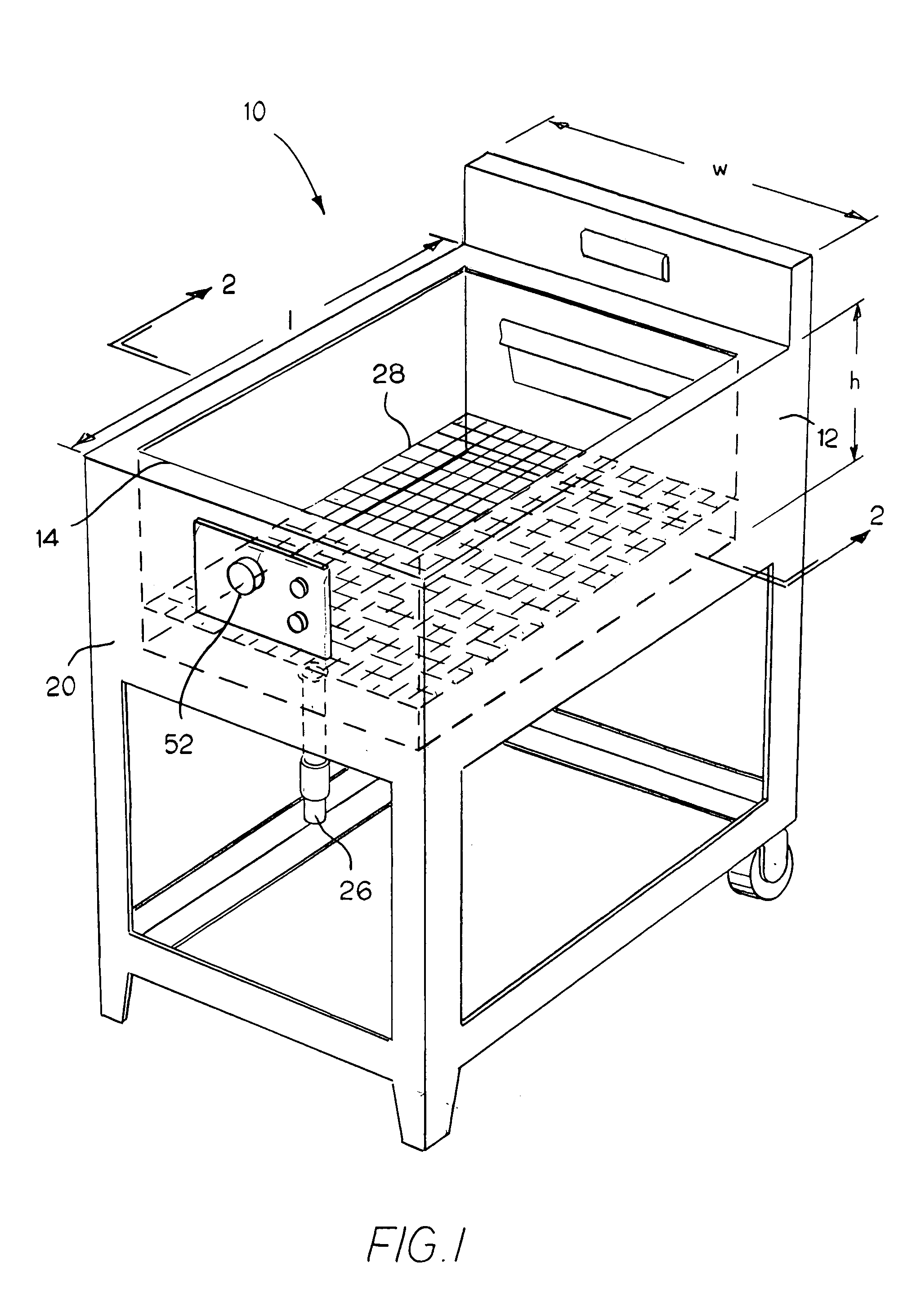

Externally heated deep fat fryer

InactiveUS7141764B1Improve efficiencyHeating evenlyCooking-vessel materialsElectric heating for furnacesHeat lossesCooking oil

An externally heated deep fat fryer includes a tank defined by a plurality of side walls and at least one bottom wall for receiving and holding a volume of cooking oil. Heating elements are positioned adjacent to a substantial portion of the external surfaces of the walls of the tank for providing substantially uniform heating through the walls and to the cooking oil, while insulation material surrounding the heating elements minimizes heat losses.

Owner:BRIAN T SHUMATE TRUSTEE OF THE SHUMATE FAMILY IRREVOCABLE TRUST DATED AUGUST 15 2018

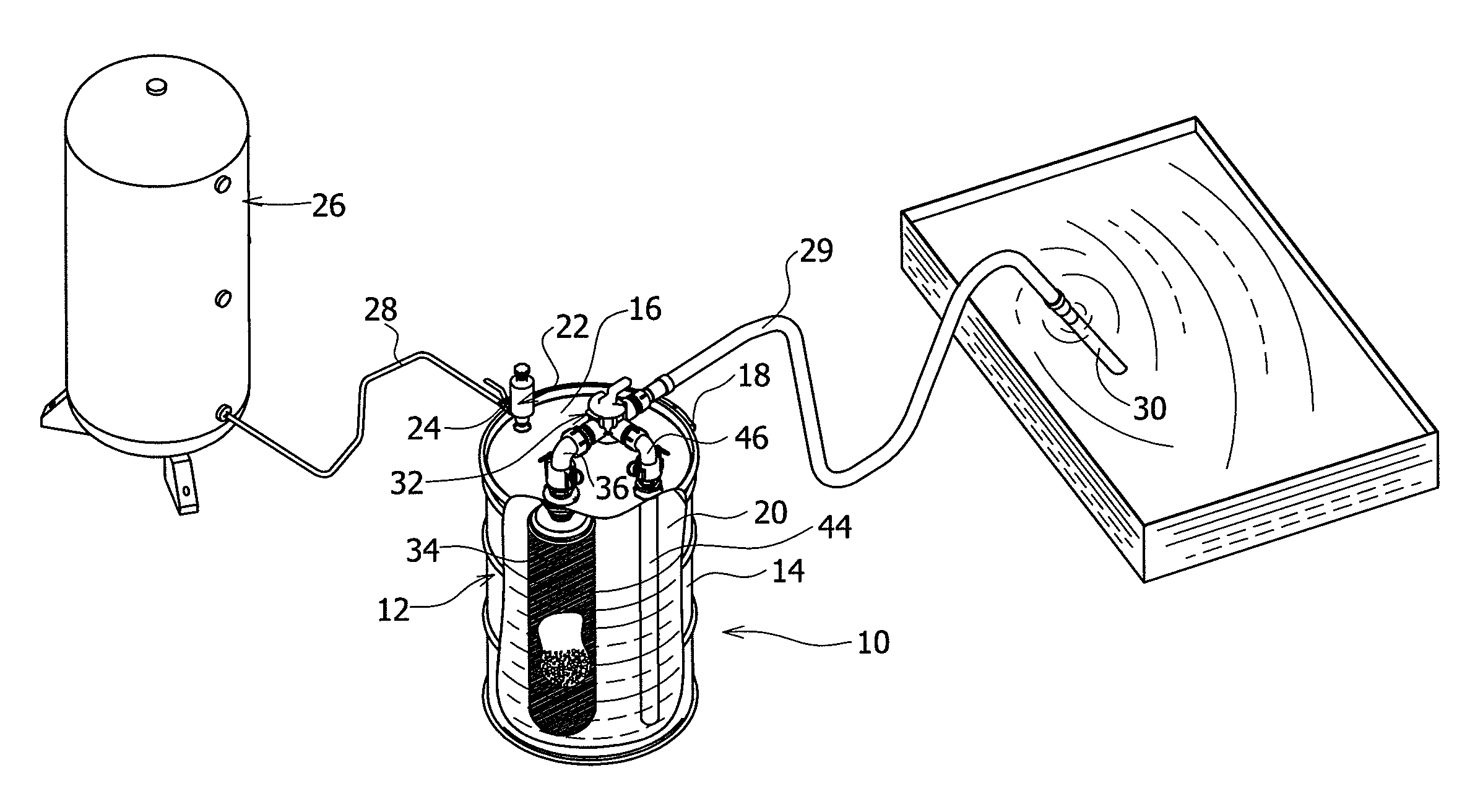

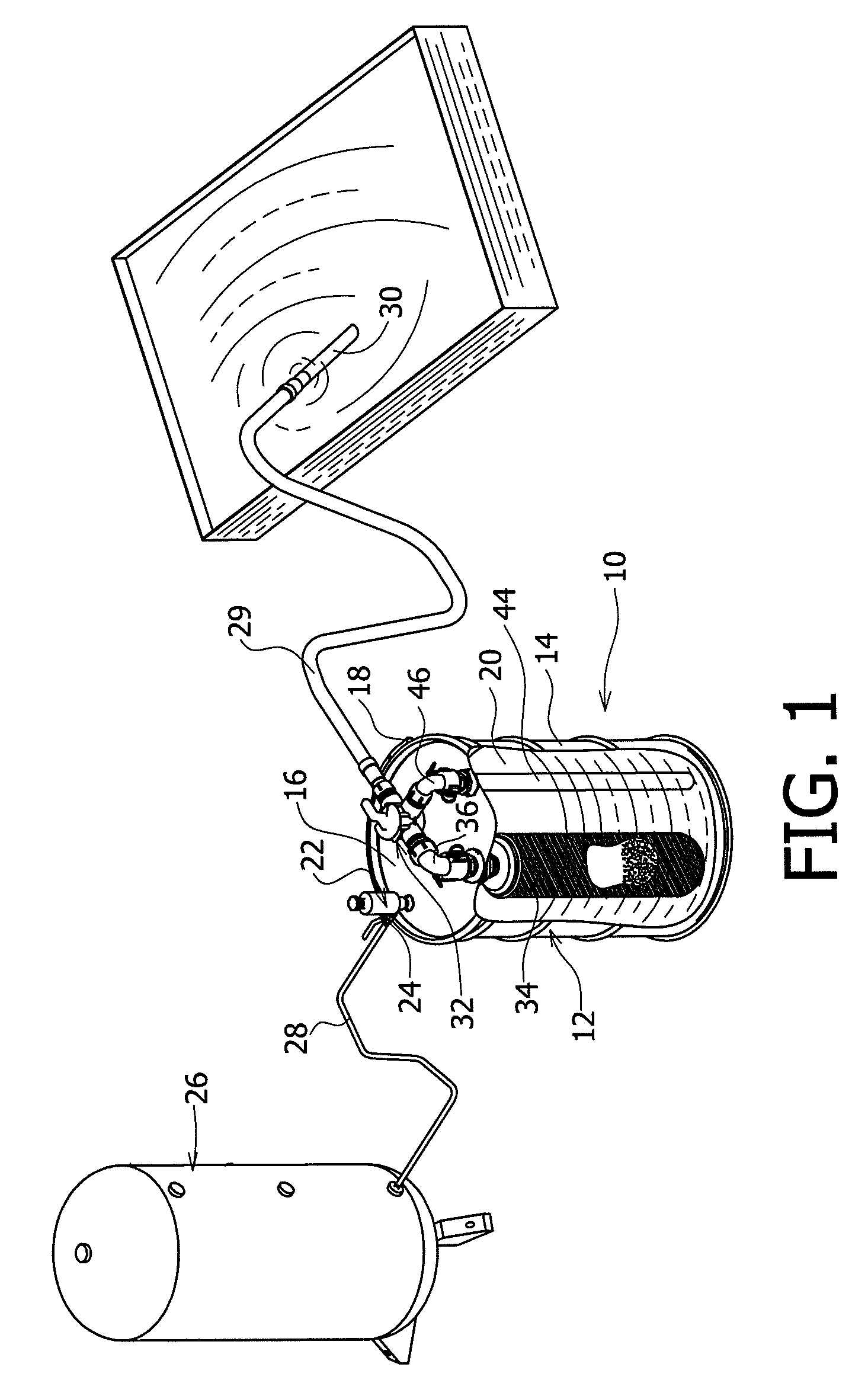

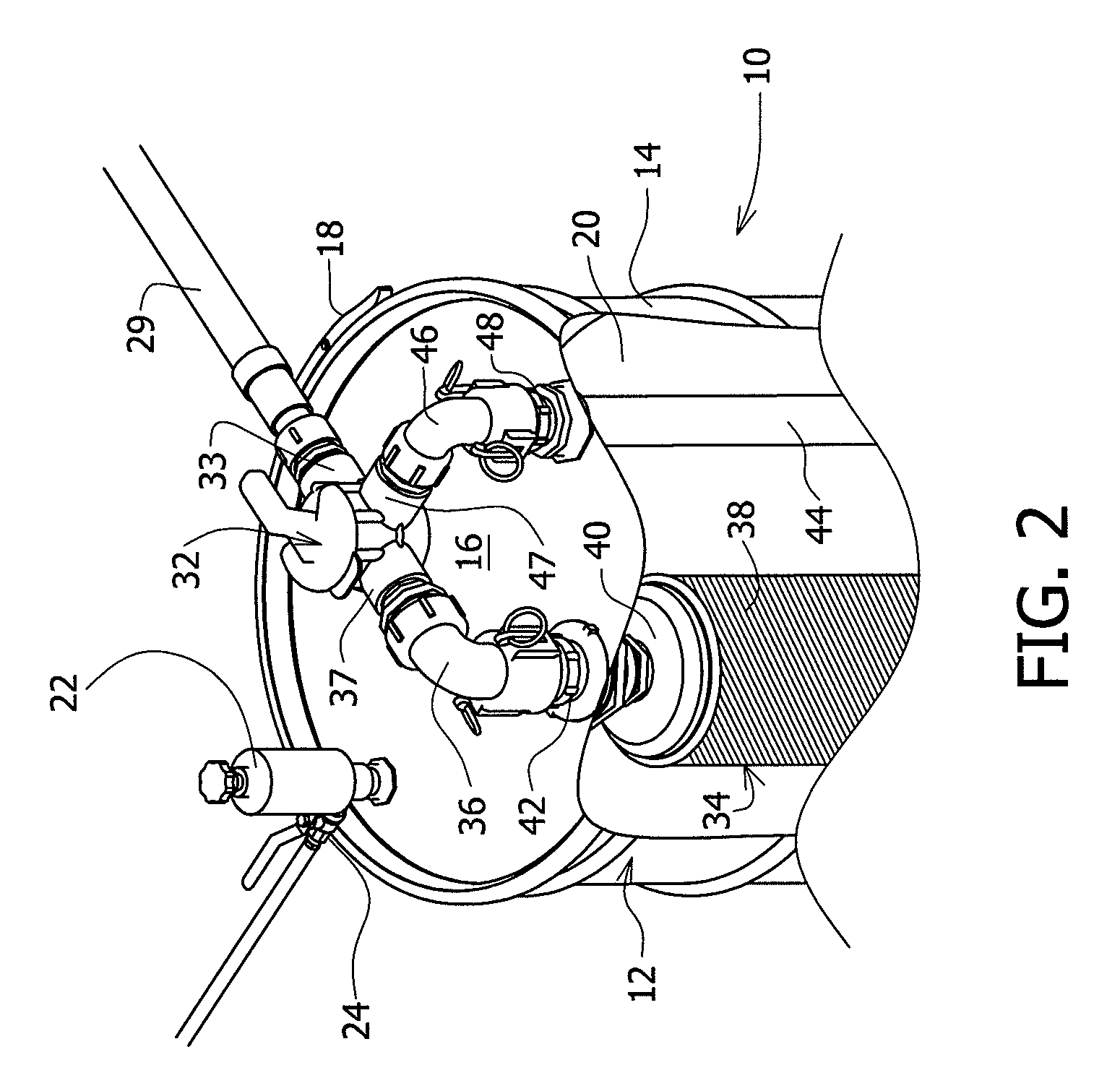

Liquid vacuuming and filtering device and method

ActiveUS8153001B2Increase vacuumEasy disposalSettling tanks feed/dischargeWater/sewage treatmentParticulatesEngineering

A liquid vacuuming and filtering device may include a container having an interior sealed from the ambient, a vacuum pump in communication with the interior, a two-way valve connected to the container interior, a flexible hose connected to the valve, a filter positioned within the container interior and connected to the valve and a standpipe positioned within the interior and connected to the valve. The vacuum pump may be adjusted to a filling configuration in which the pump evacuates the container interior to a pressure below ambient, which causes fluid to be drawn through the hose, valve and through the filter, which may collect particulates that contaminate the fluid. Filtered fluid then collects within the container. The vacuum pump also may be adjustable to a discharge configuration in which the pump pressurizes the interior to a pressure above ambient, wherein the valve is adjusted to allow filtered fluid within the container to flow through the standpipe, valve and be discharged from the container through the hose. The device may be suitable for reclaiming contaminated fluid used in machining operations, oil or coolant reservoirs, cooking oil and the like.

Owner:EXAIR CORP

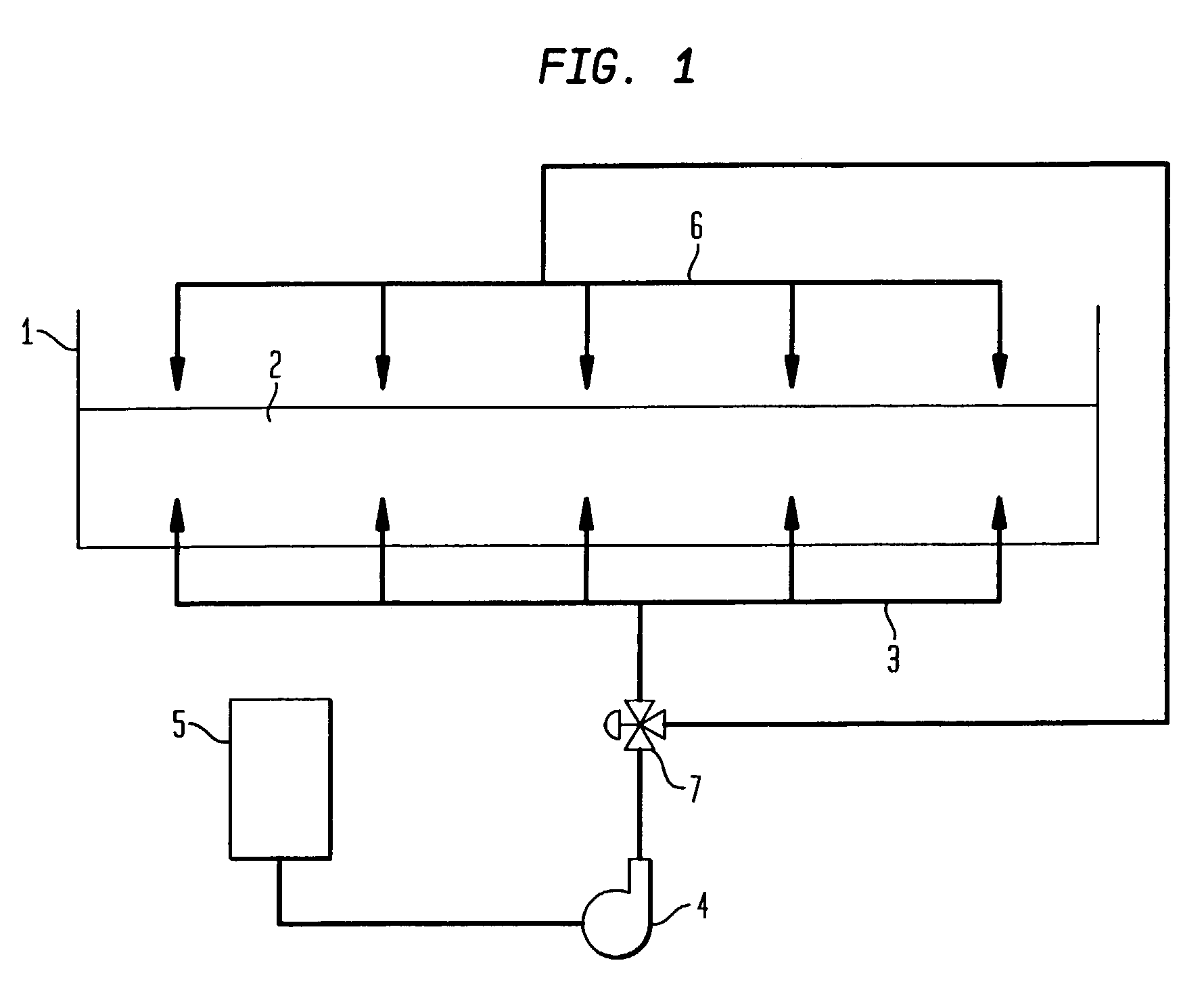

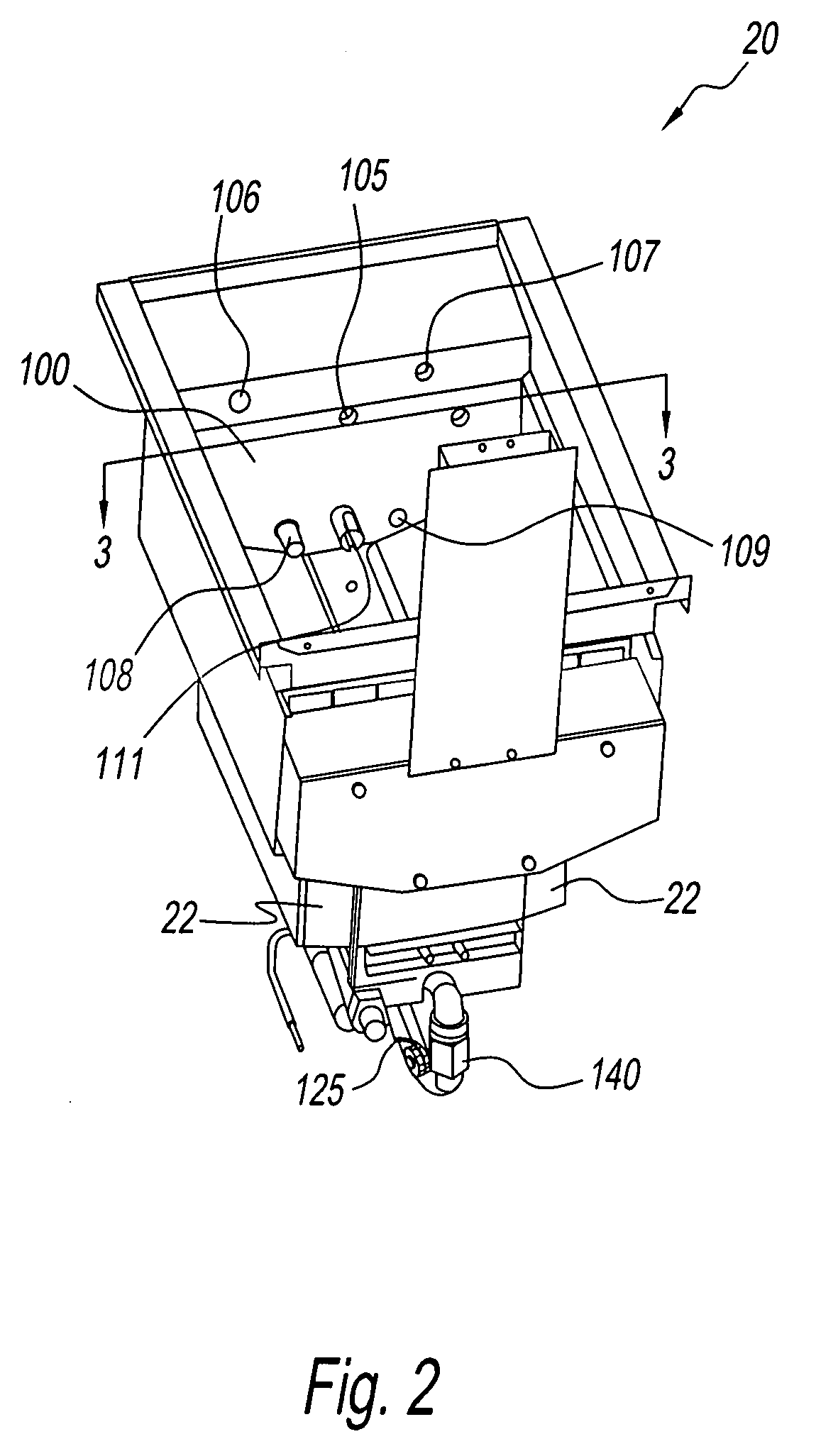

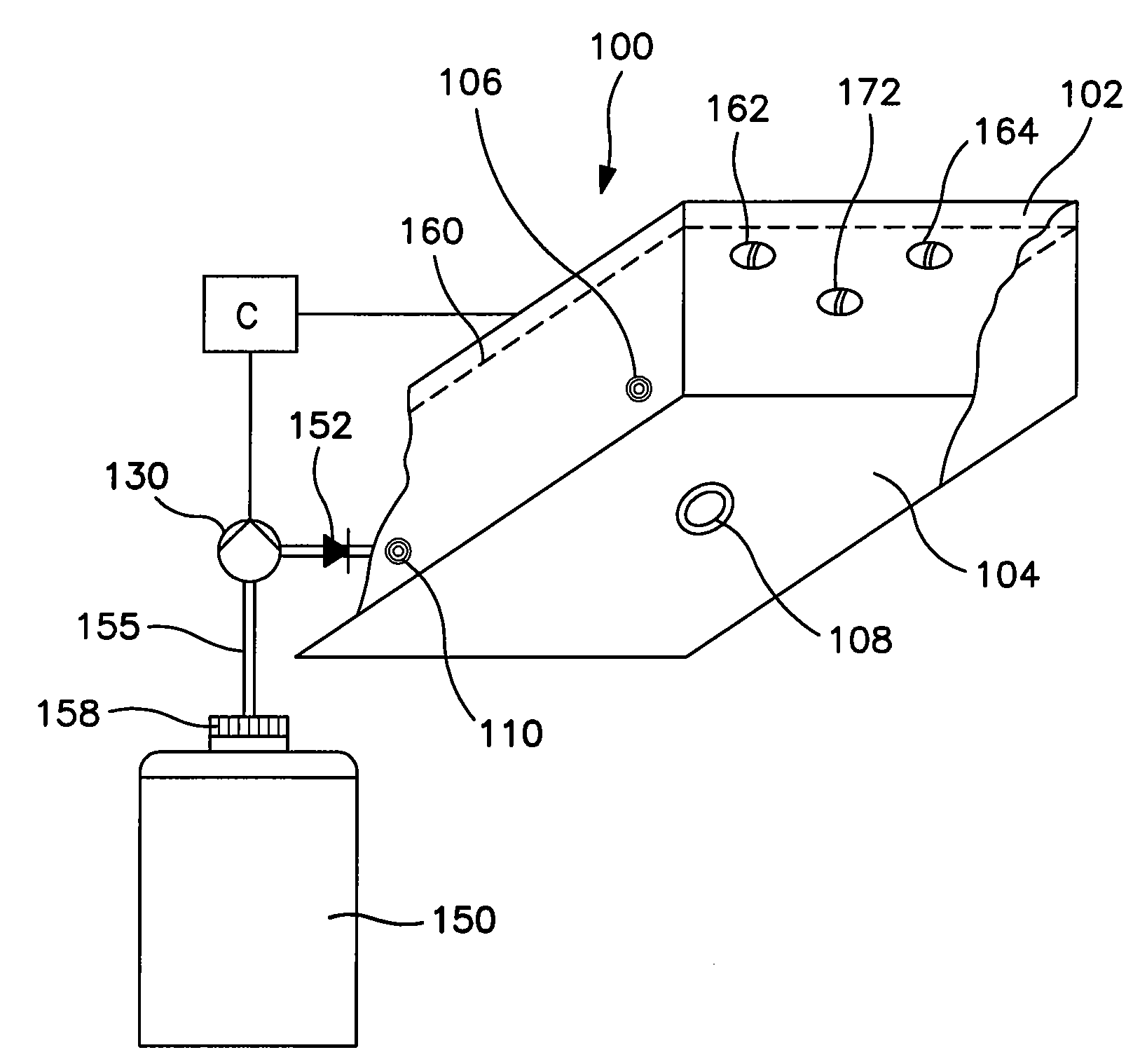

Automatic cooking medium level control systems and methods

ActiveUS20080121115A1Insufficient levelPrevents overcyclingBread-toastersDeep fat fryersControl systemProcess engineering

An automatic cooking medium level control system for a cooking apparatus, e.g., a fryer, may include a cooking vessel having a first temperature sensor at a first level of the cooking vessel and a second temperature sensor at a second level of the cooking vessel. A reservoir holding a cooking medium, such as cooking oil, may be in fluid communication with the cooking vessel. A controller may monitor temperature data from the first and second temperature sensors to determine whether the level of cooking oil in the cooking vessel has lowered. Upon determining that the cooking oil level has lowered, the controller may actuate a supply mechanism, such as a pump, which may be disposed on a fluid communication path between the reservoir and cooking vessel, which may enable the introduction of cooking medium from the reservoir to the to the cooking vessel.

Owner:HENNY PENNY

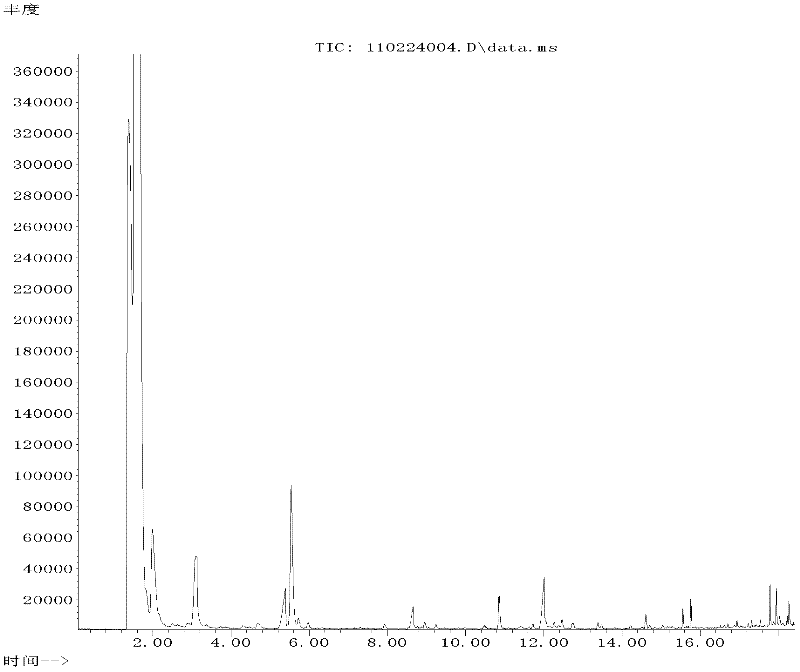

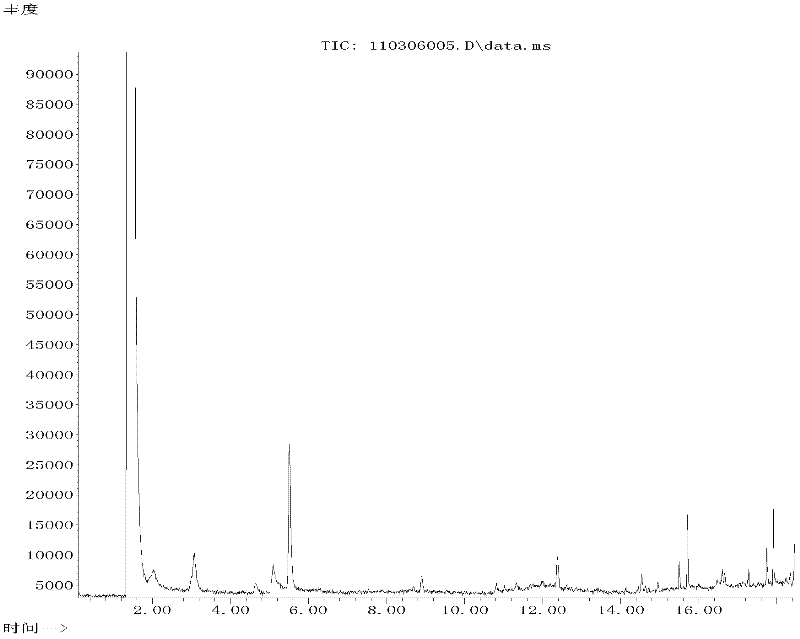

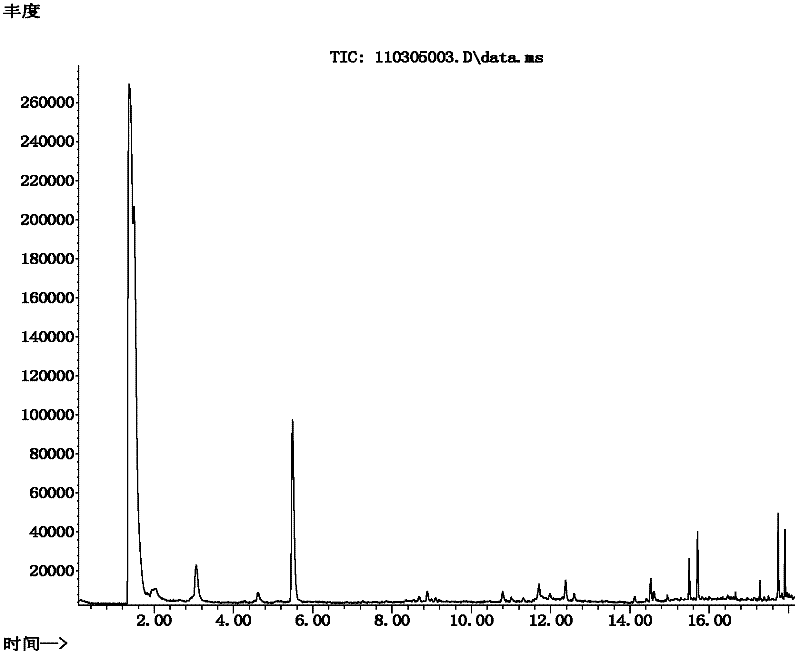

How to detect gutter oil

The invention discloses a method for detecting gutter oil. The method comprises: ①adding the oil sample to be tested into a headspace bottle, shaking the headspace bottle at a temperature of 40°C-150°C, and then balancing for 10min-120min; ②use The syringe absorbs the gas in the upper layer of the balanced headspace bottle and injects it into the gas chromatography-mass spectrometry instrument, and obtains the gas chromatography-mass spectrometry spectrum under the set chromatographic conditions and mass spectrometry conditions; Chromatography-mass spectrometry is used for qualitative analysis; when it is detected that the oil sample to be tested contains fatty acids, it is determined that the oil sample to be tested is waste oil or contains waste oil; the fatty acids are acetic acid, propionic acid, butyric acid, One or two or more of valeric acid and caproic acid. The method of the invention has good accuracy and is applicable to the detection of all waste oils.

Owner:同码信息科技(常州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com