Patents

Literature

71results about How to "Few teeth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sauces, spreads, cooking oils, and cooking fats made from various ingredients

Sauces, spreads, cooking oils, and cooking fats are created from a wide range of various ingredients. Sauces, spreads, cooking oils, and cooking fats having at least one ingredient, with at least one flavoring, and at least one texture. At least one ingredient is selected from group including of at least one flavoring ingredient, at least one nutritional ingredient, at least one health ingredient, and at least one other ingredient. At least one ingredient is also created as small spherical balls as mixed in. Sauces can be served as appetizer and snack. And served as baby food, for children with less teeth, for old people, and for sick people. Sauces, spreads, cooking oils, and cooking fats are used for food preparation and food flavoring, including condiment and salad dressing. And used in manner selected from group consisting of room temperature, cold, warm, and hot.

Owner:CHANG ALICE

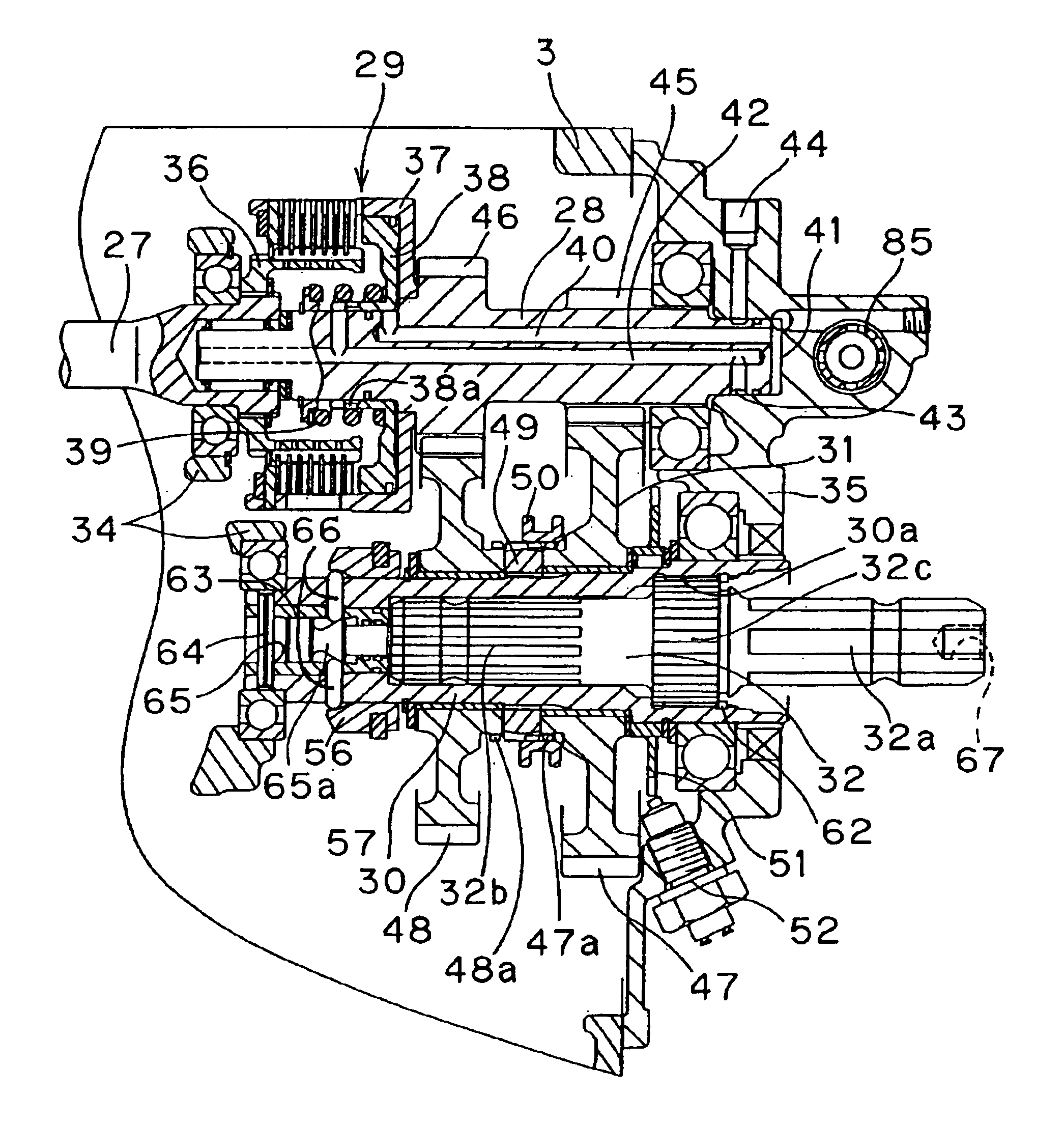

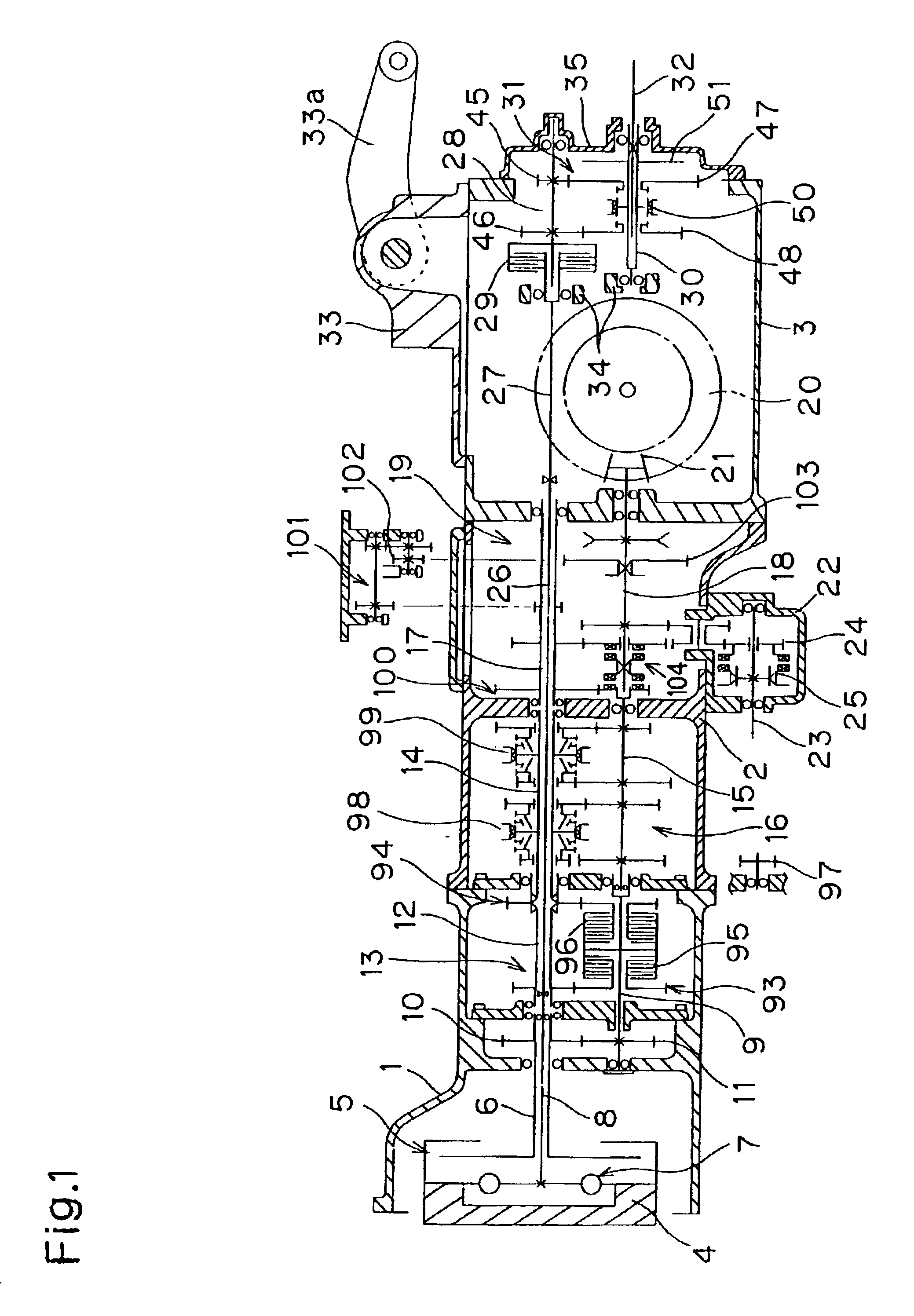

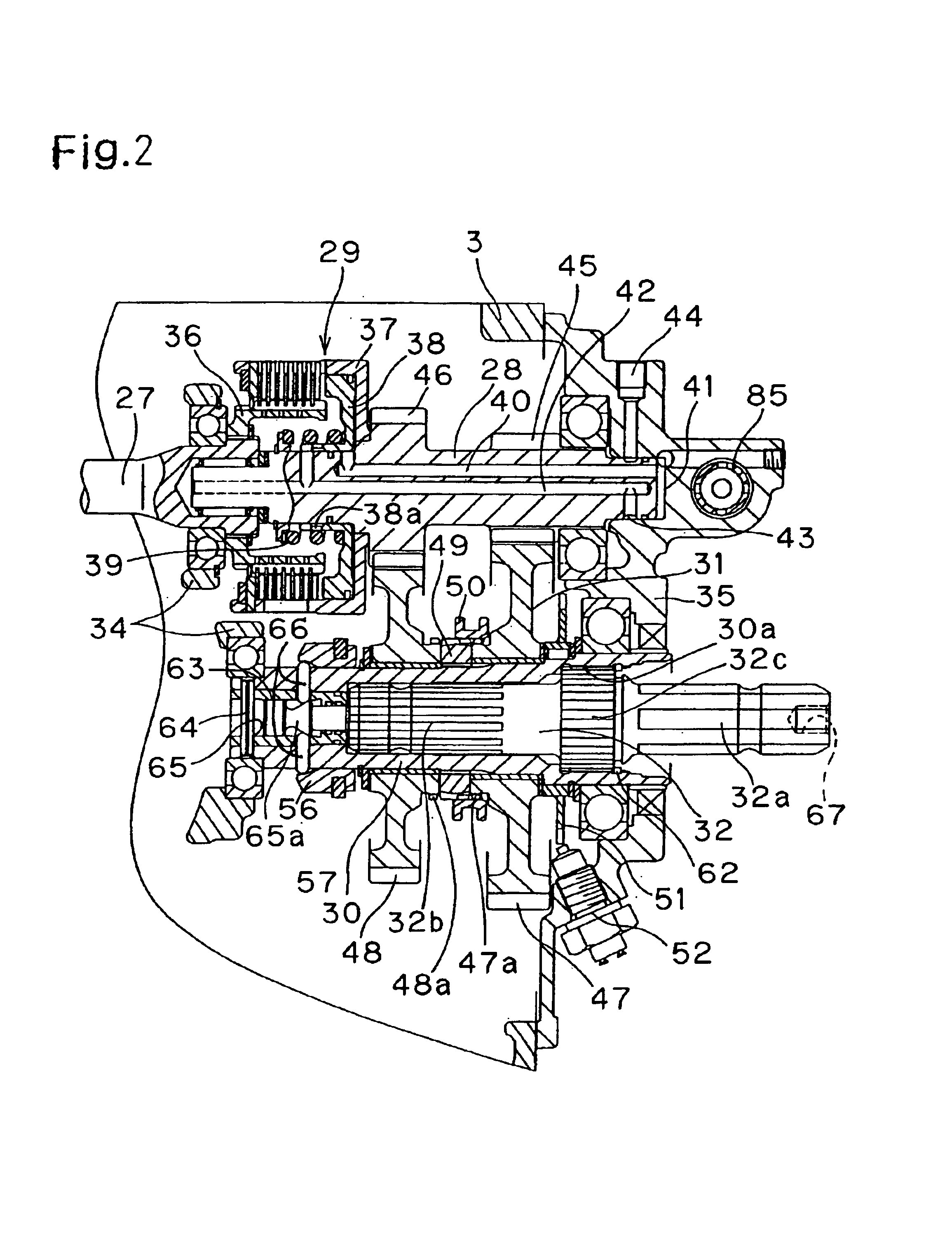

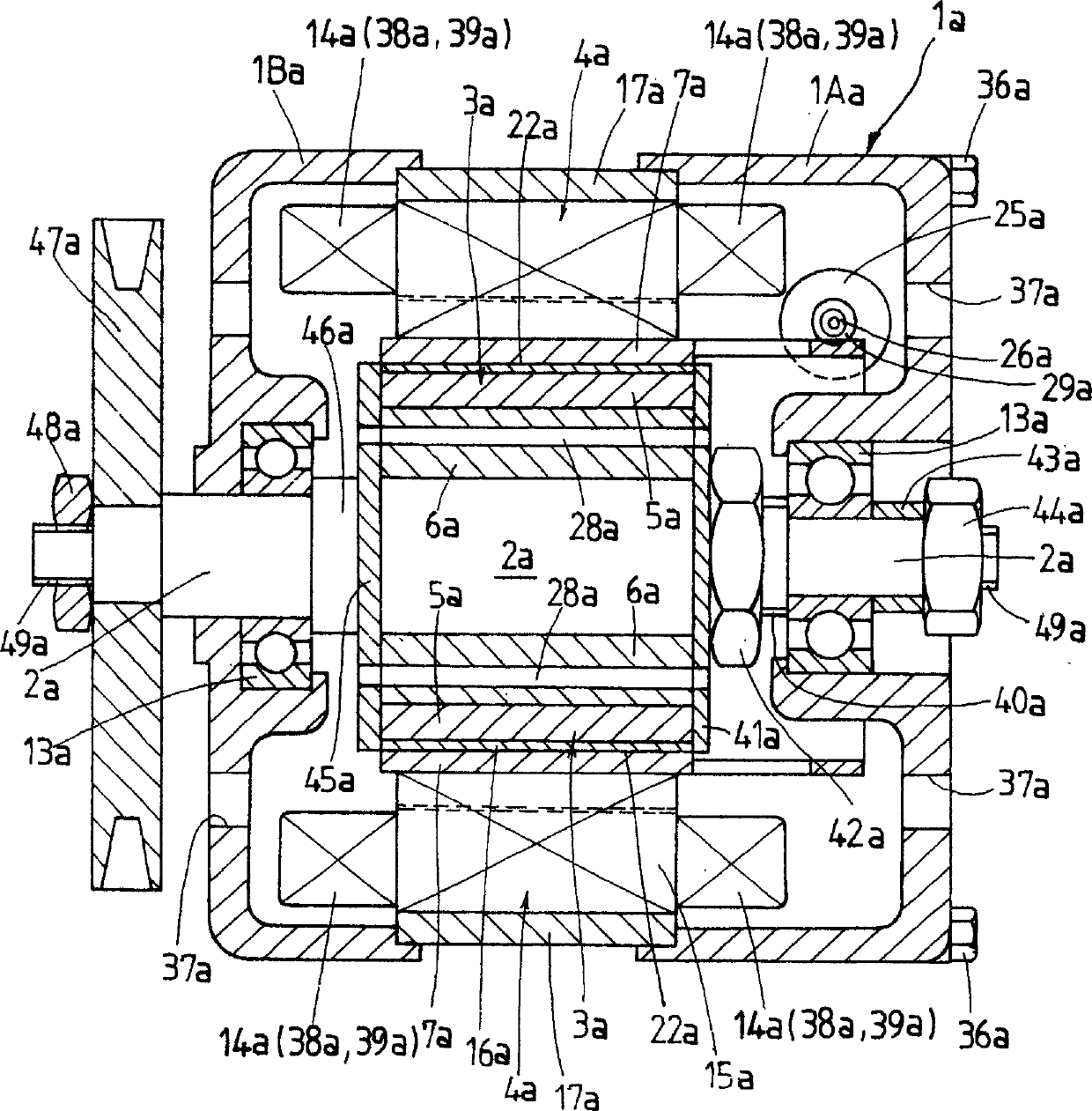

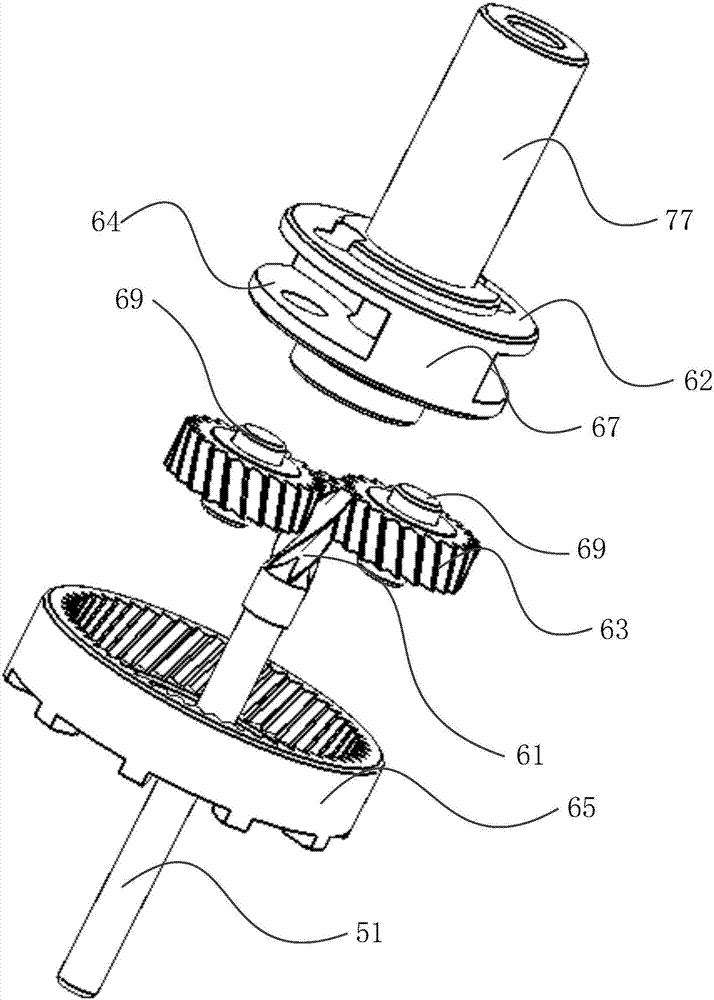

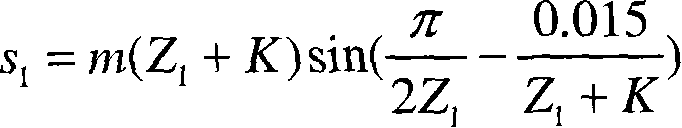

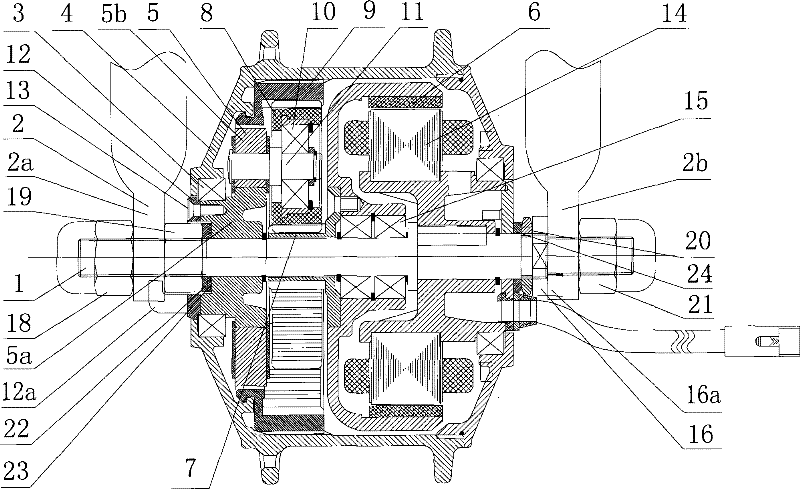

Power take-off assembly of a working vehicle

A reversible PTO shaft having opposite splined ends whose numbers of teeth are different from each other is inserted at one of the splined ends into an output sleeve and not-relatively rotatably connected to the output sleeve. For constituting at a position out of the PTO transmission system an actuator for changing the rotary speed of the output sleeve and holding the output sleeve changed in rotary speed simultaneously to the reversing of PTO shaft, a second collar connected to a shifter collar for changing the rotary speed of output sleeve so as to be slidable integrally with the shifter collar is disposed on an inner end of the output sleeve. When the splined end of PTO shaft having the greater number of teeth is inserted into the output sleeve, a sensor having a cam surface is moved by an end surface of the PTO shaft so as to make a pin project from the output sleeve, thereby holding the second collar at its low speed position. A power take-off assembly which sets the output sleeve into either a low speed mode or a high speed mode simultaneously to the reversing of the PTO shaft is also disclosed.

Owner:YANMAR CO LTD

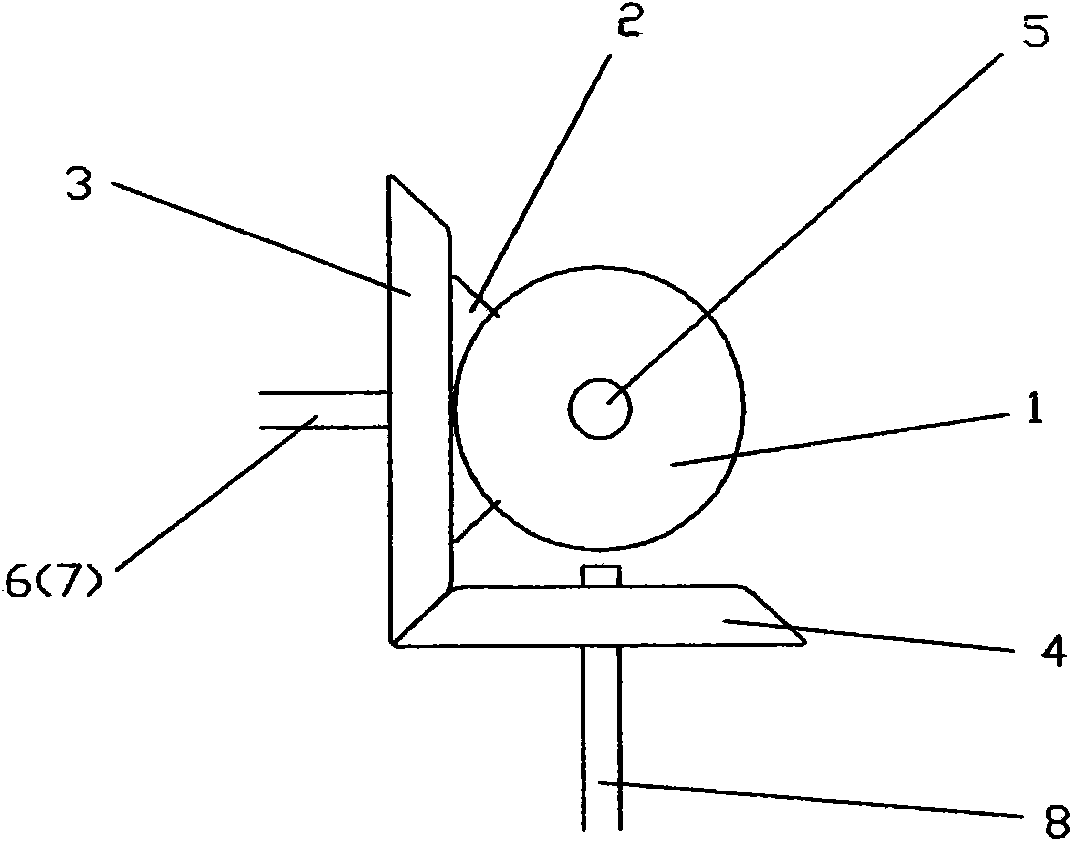

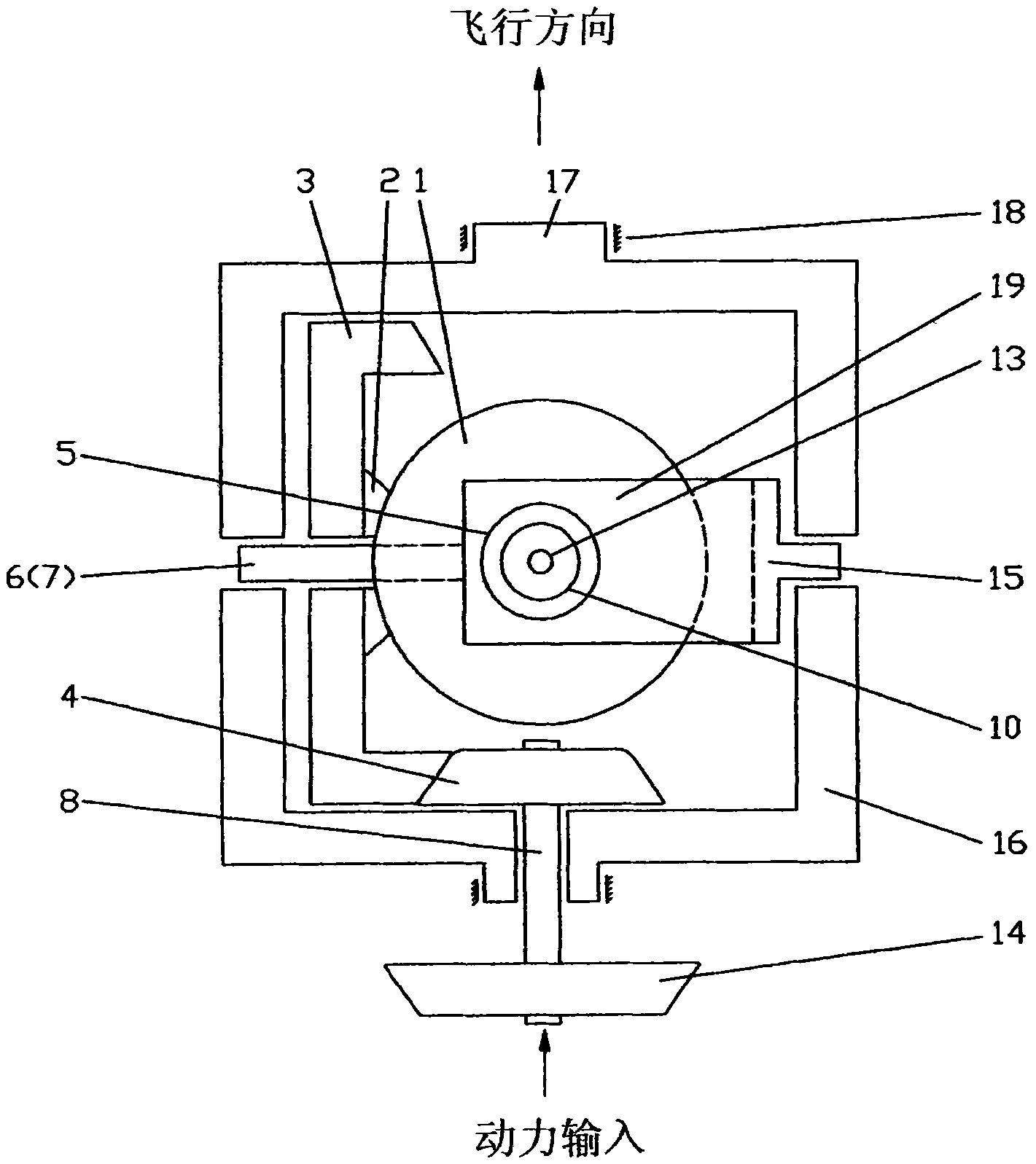

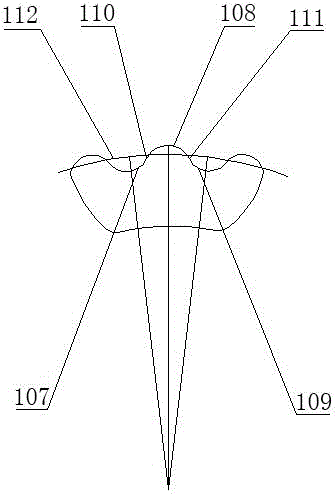

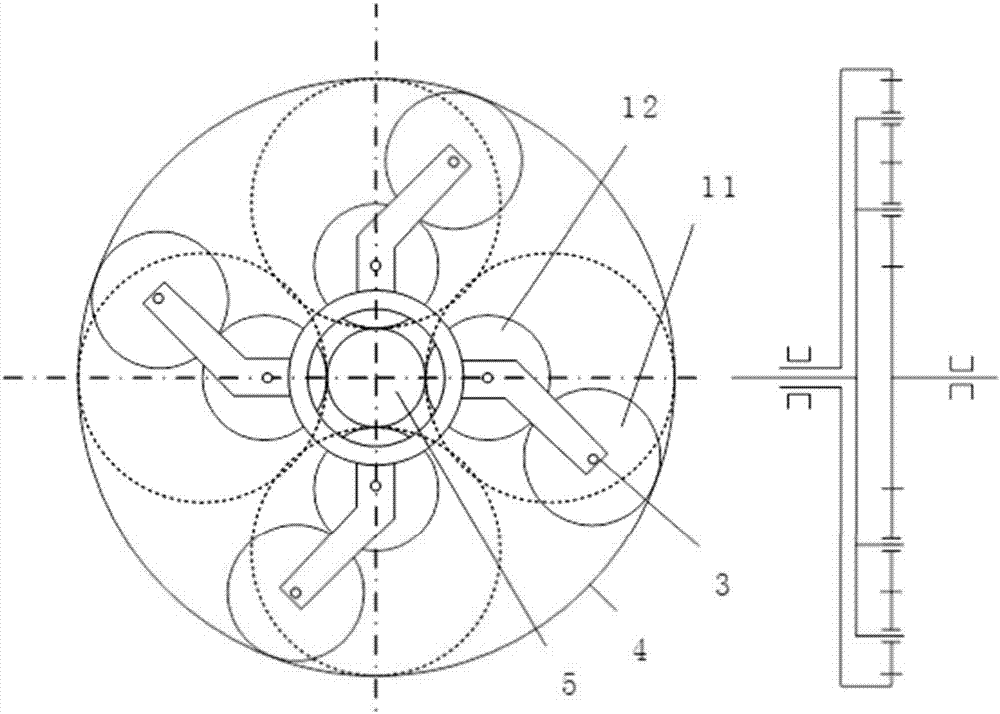

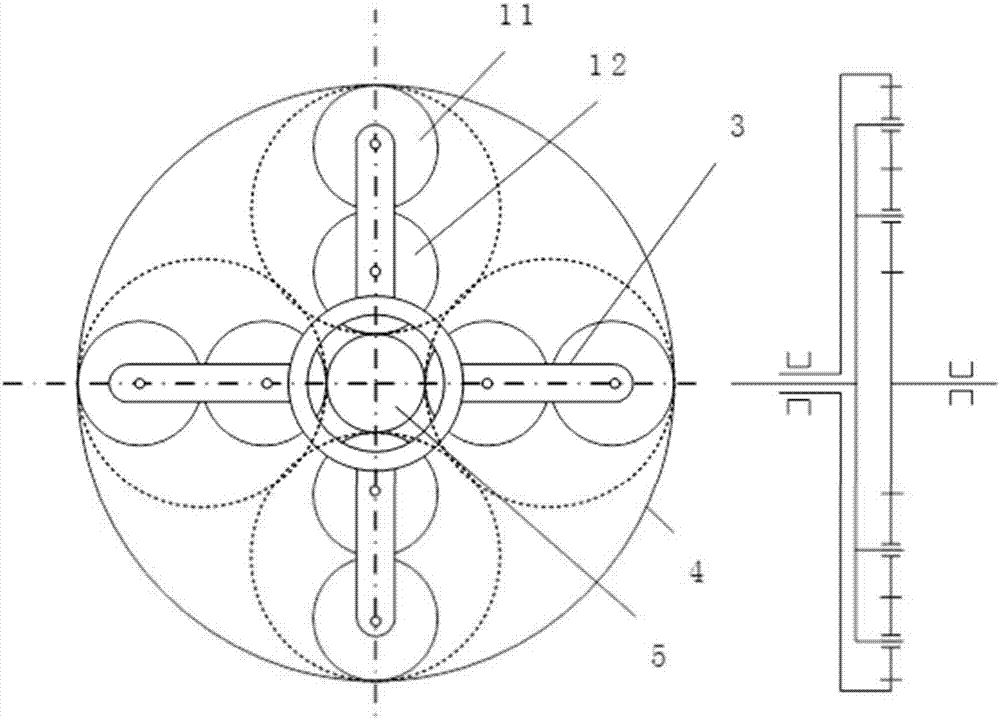

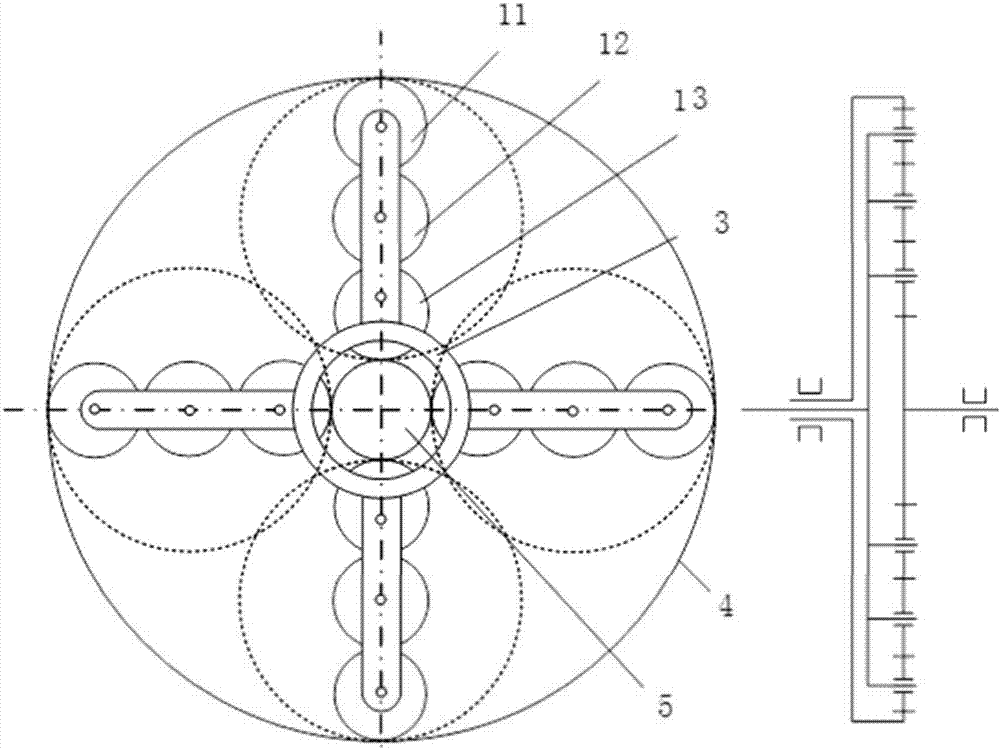

Direct inclination control rotor helicopter

InactiveCN102030105BLarge installation spaceIncrease the number of teethRotocraftPropellerHorizontal axis

Owner:林定荣

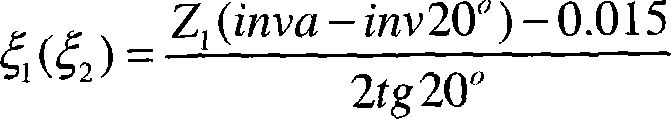

Processing method of involute of gear with large module and a few teeth

Owner:重庆市华丰动力配件有限公司

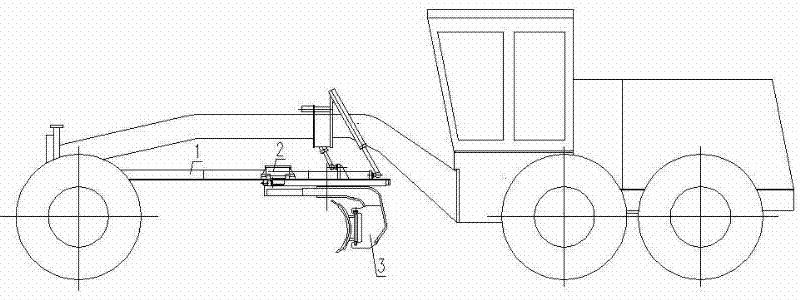

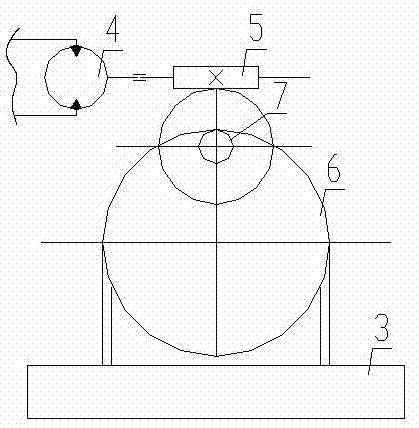

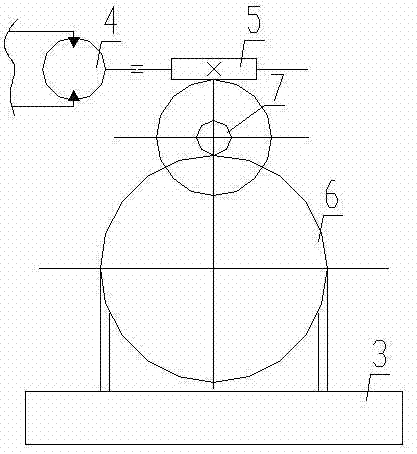

Rotary land leveler operating device based on short-tooth shape

InactiveCN102212996AImprove reliabilitySimple structureSoil-shifting machines/dredgersHydraulic motorGear wheel

The invention relates to a rotary land leveler operating device based on a short-tooth shape. The device consists of a traction frame, a rotary mechanism and a shovel blade body assembly; the rotary mechanism consists of a hydraulic motor, a worm wheel / gear speed reduction box and a rotary gear ring; the hydraulic motor and the worm wheel / gear speed reduction box are integrated into a whole; a co-axial pinion is arranged on a worm wheel of the worm wheel / gear speed reduction box; the co-axial pinion is engaged with the rotary gear ring; the rear end of the traction frame lifts the rotary gear ring to the lower part of the traction frame through a guide plate; the rotary gear ring can do rotary motion on the lower part of the traction frame; the shovel blade body assembly consists of a support, an angle retainer and a shovel blade; the support is fixed on the rotary gear ring; the angle retainer is fixed on an angle retainer installation shaft positioned on the support; the shovel blade is connected with a horizontal hydraulic oil cylinder and arranged on a sliding rail; the angle retainer is connected with one end of the sliding rail; and the rotary gear ring can be replaced by a rotary support structure with an internal ring and an external ring, and a connection mode is also required to be correspondingly adjusted. By the device, a land leveler rotary mechanism is simple in structure and has long service life, the reliability of the rotary land leveler working device is greatly improved, and the reliability of the whole land leveler is greatly and correspondingly improved.

Owner:TONGJI UNIV

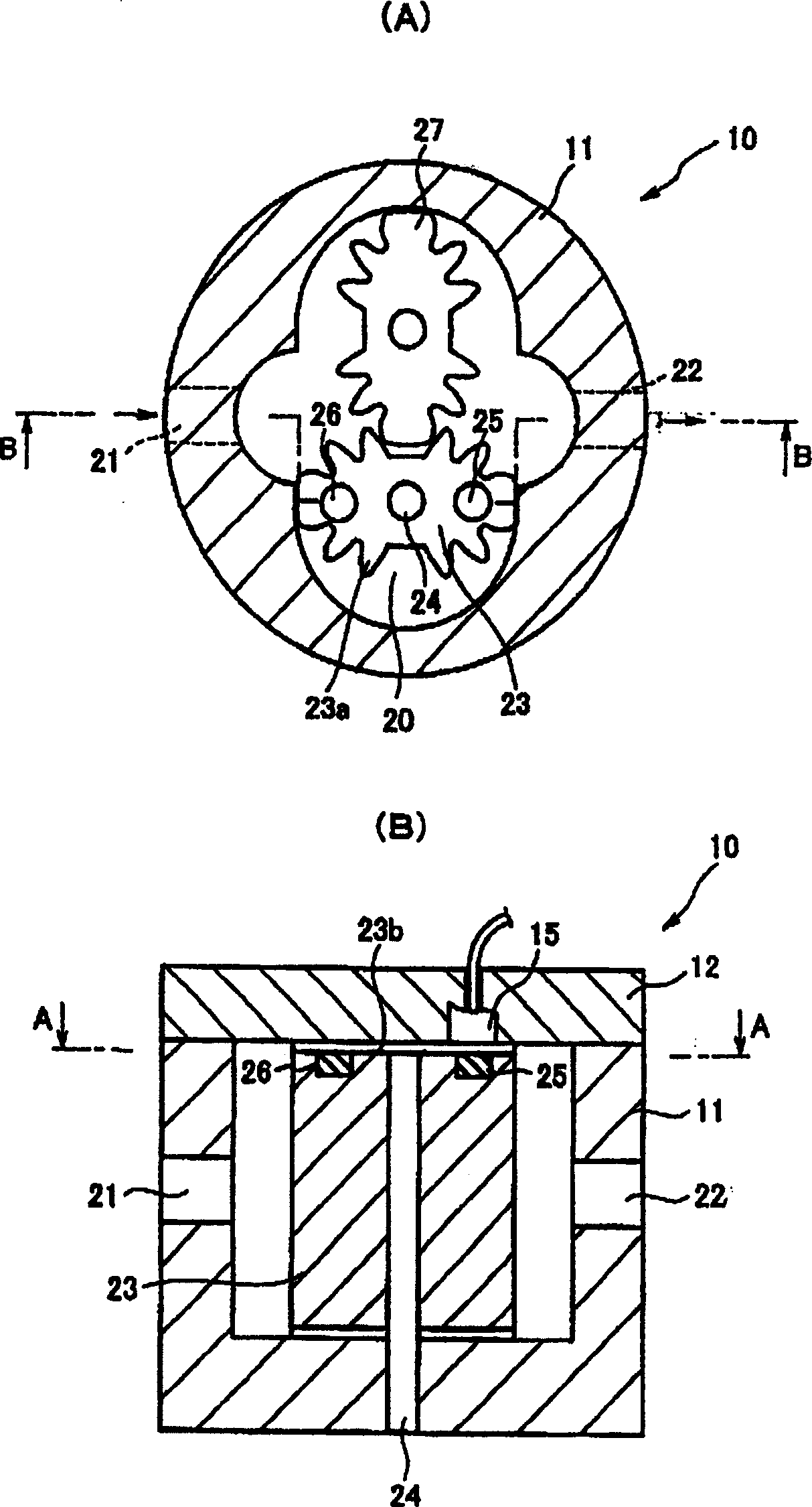

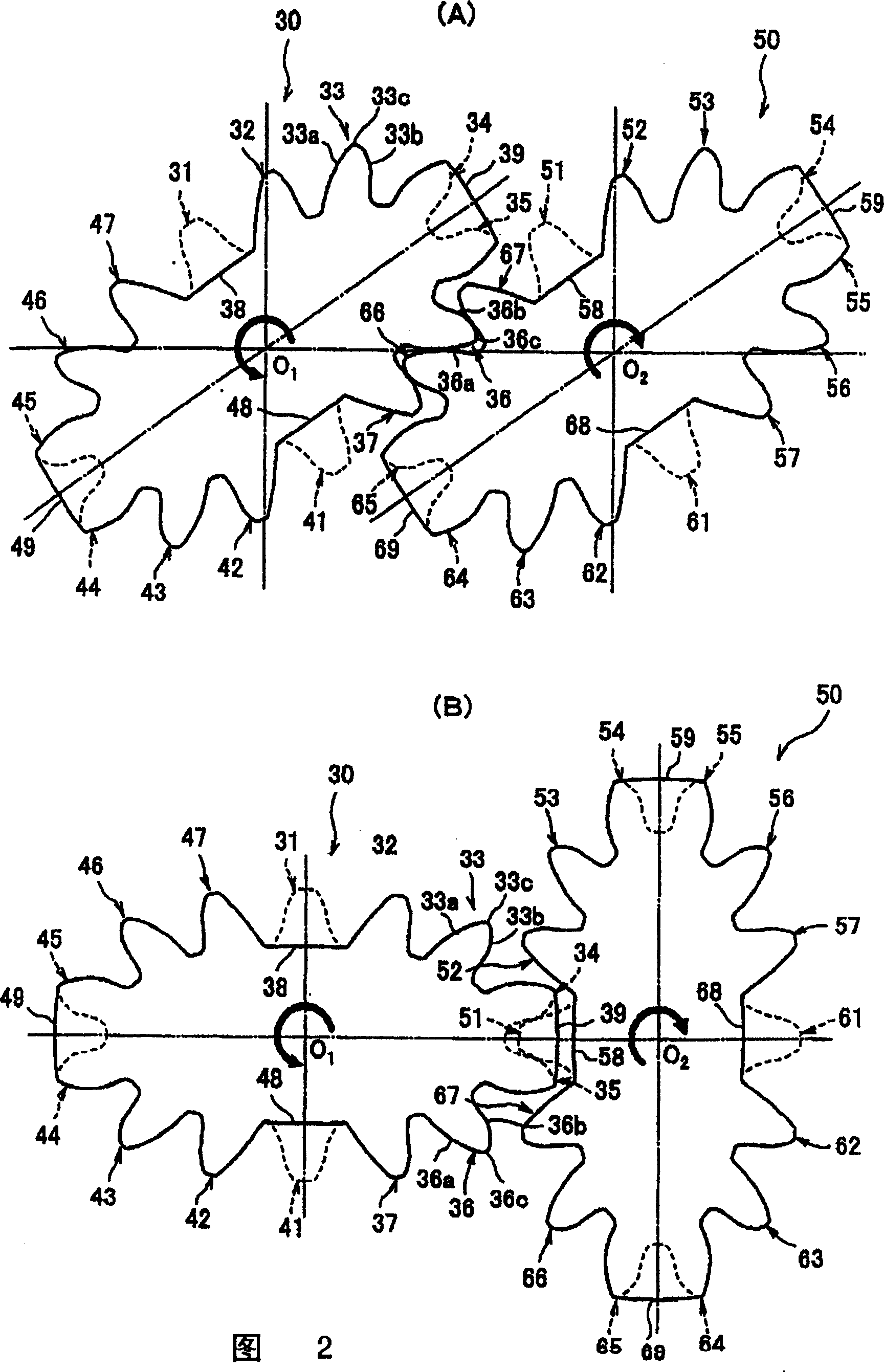

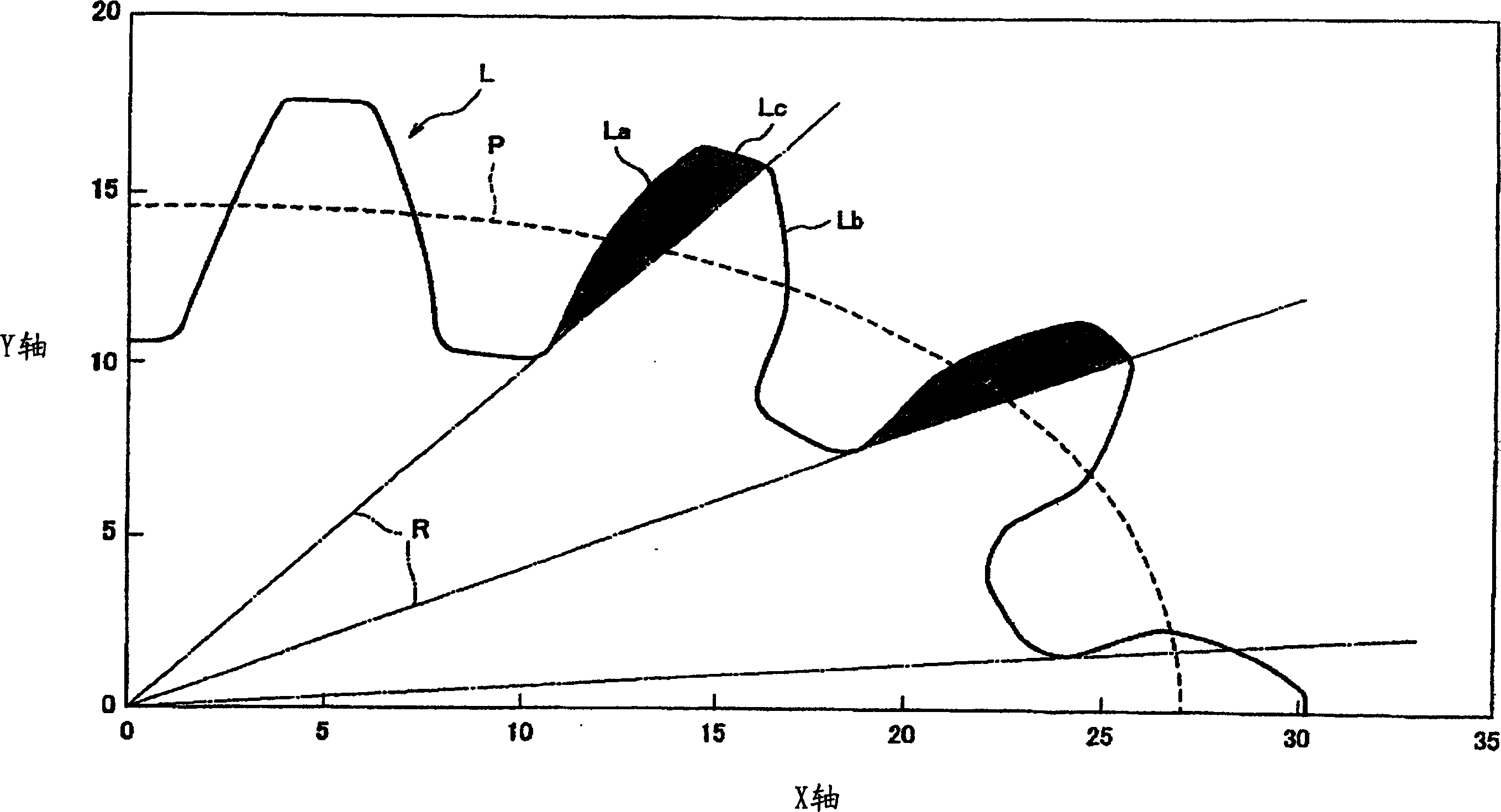

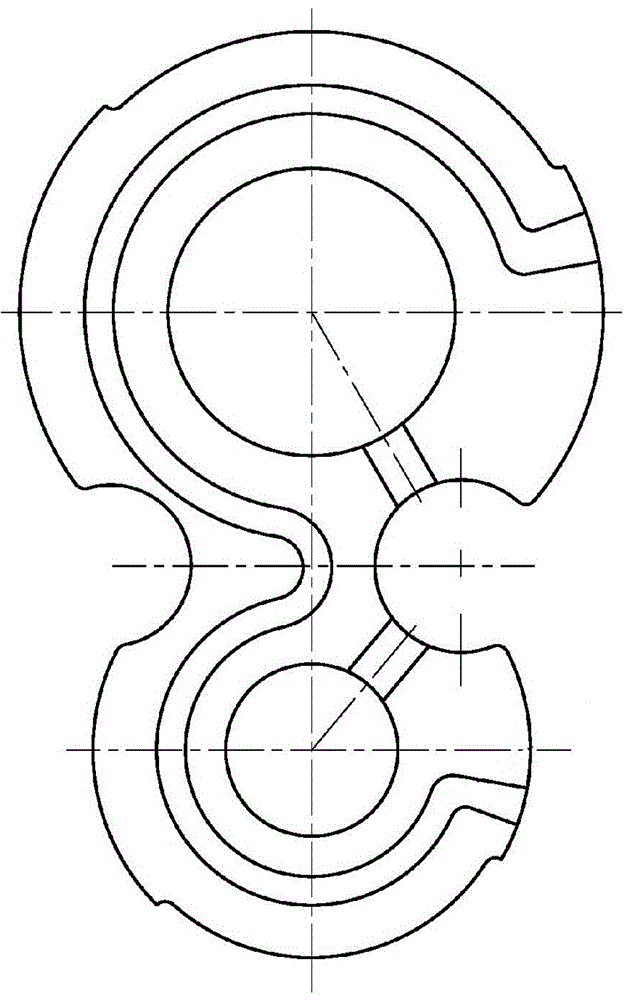

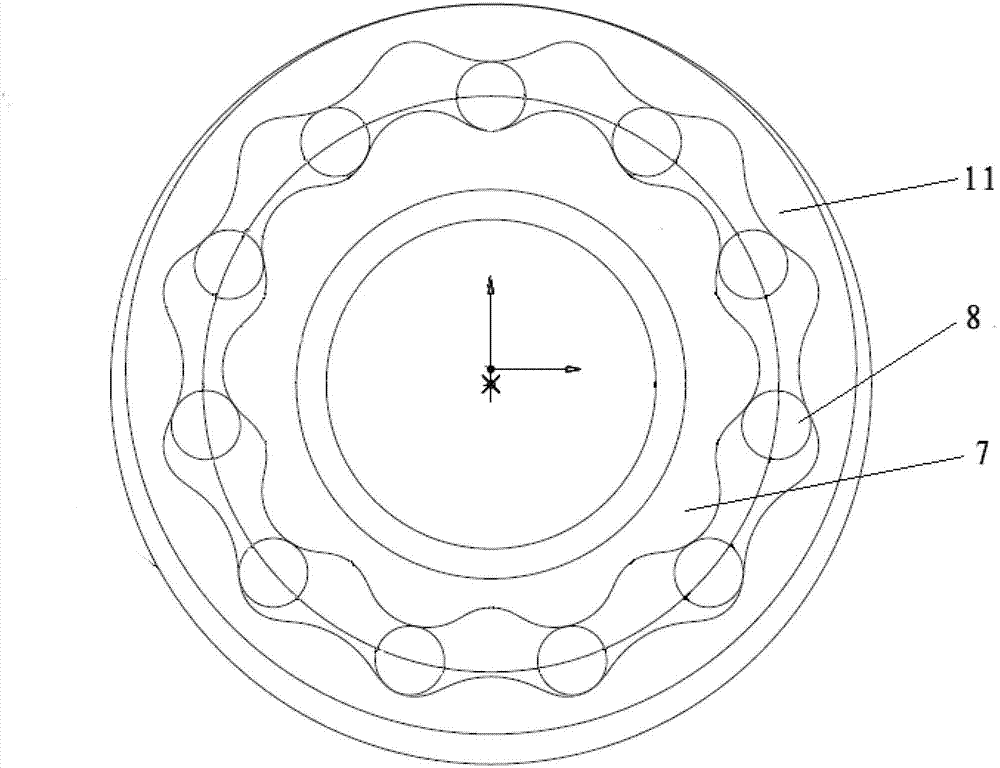

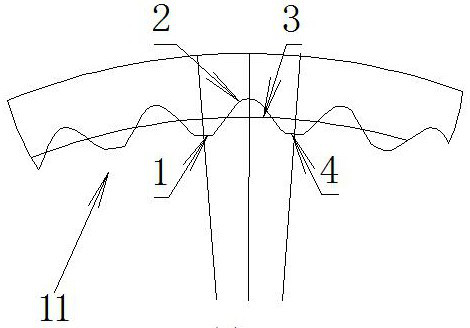

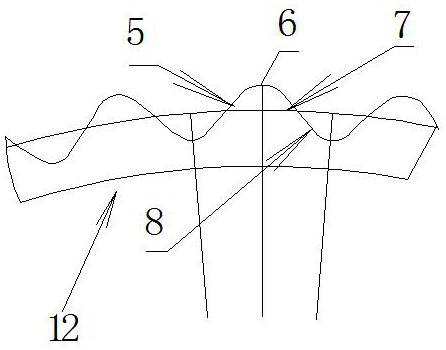

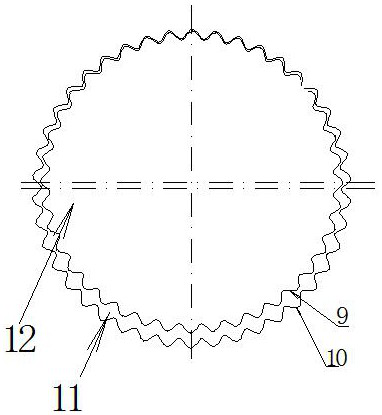

Non round gear and volumetric flowmeter using same

InactiveCN1573302ALittle changeEasy to set upVolume/mass flow measurementRotary piston pumpsEllipseEngineering

The number of teeth is set to 4n+2 (n is a natural number), both the ends on a long axis are set to be teeth grooves, both the ends on a short axis are set to be tips, a pitch curve is set to be, for example, an ellipse, and tooth marks 31-37, 41-47 are set to be basic tooth mark curves. With the tooth mark curve, the engagement teeth surface is set to be an involute curve, a non-engagement tooth surface is set to be a cycloid curve, and the tool pressure angle of each tooth mark is set by an undercut limit and a point limit. The non-circular gears 30, 50 bury the recess between two tooth marks, holding the tooth space located at both the ends on the long axis, based on the basic tooth mark curve, and have a shape, where the tooth section including the tip at both the ends on the short axis are scraped off, and the number of teeth completed is finally set to 4n-2. Accordingly, it is able to obtain a non-circular gear that reduces the change in an engagement pressure angle, is advantageous for setting the tool pressure angle of an engagement teeth surface, can reduce the number of teeth without forming an overhang section, and can fully secure the sealing performance with the inner wall of a casing to be installed.

Owner:OVAL CORP

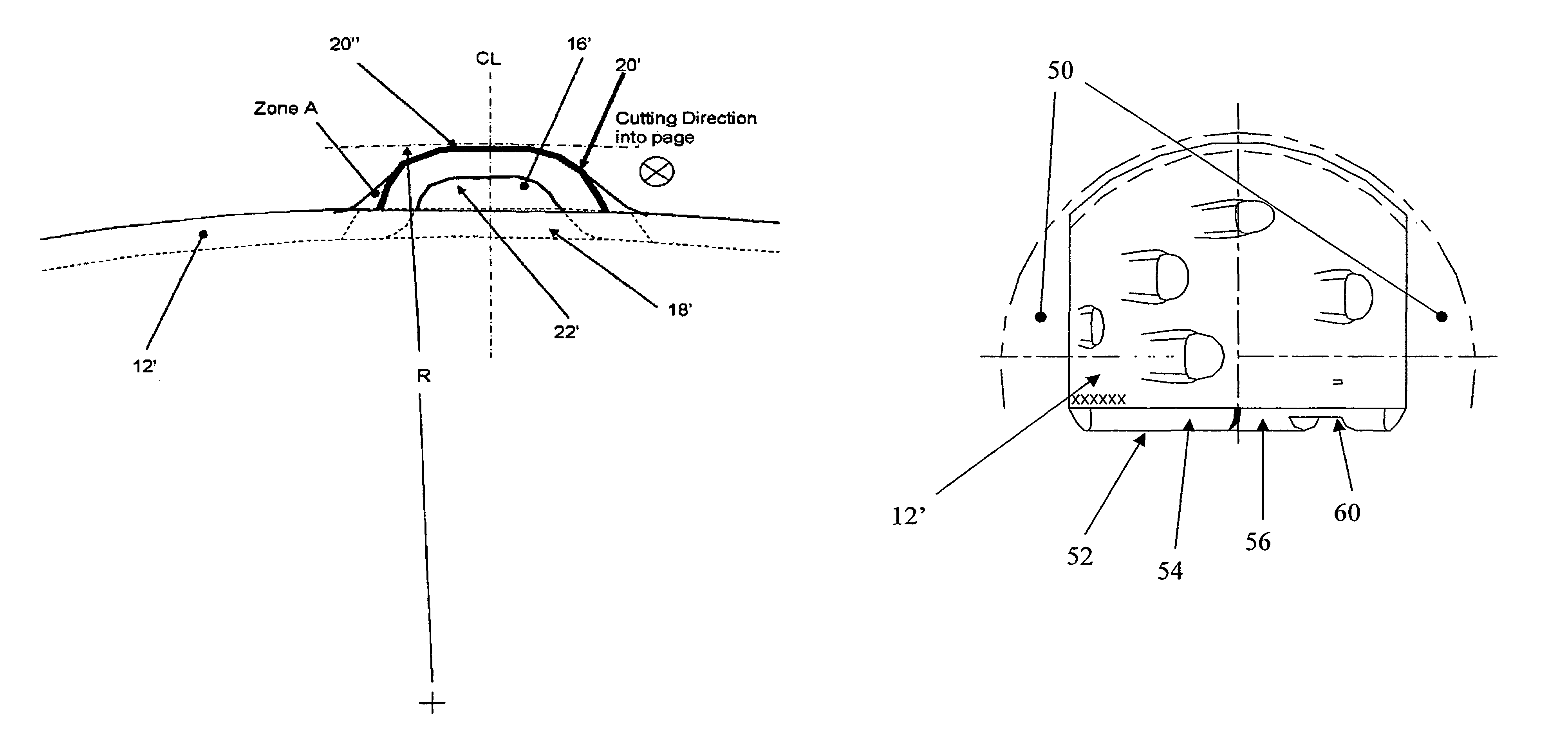

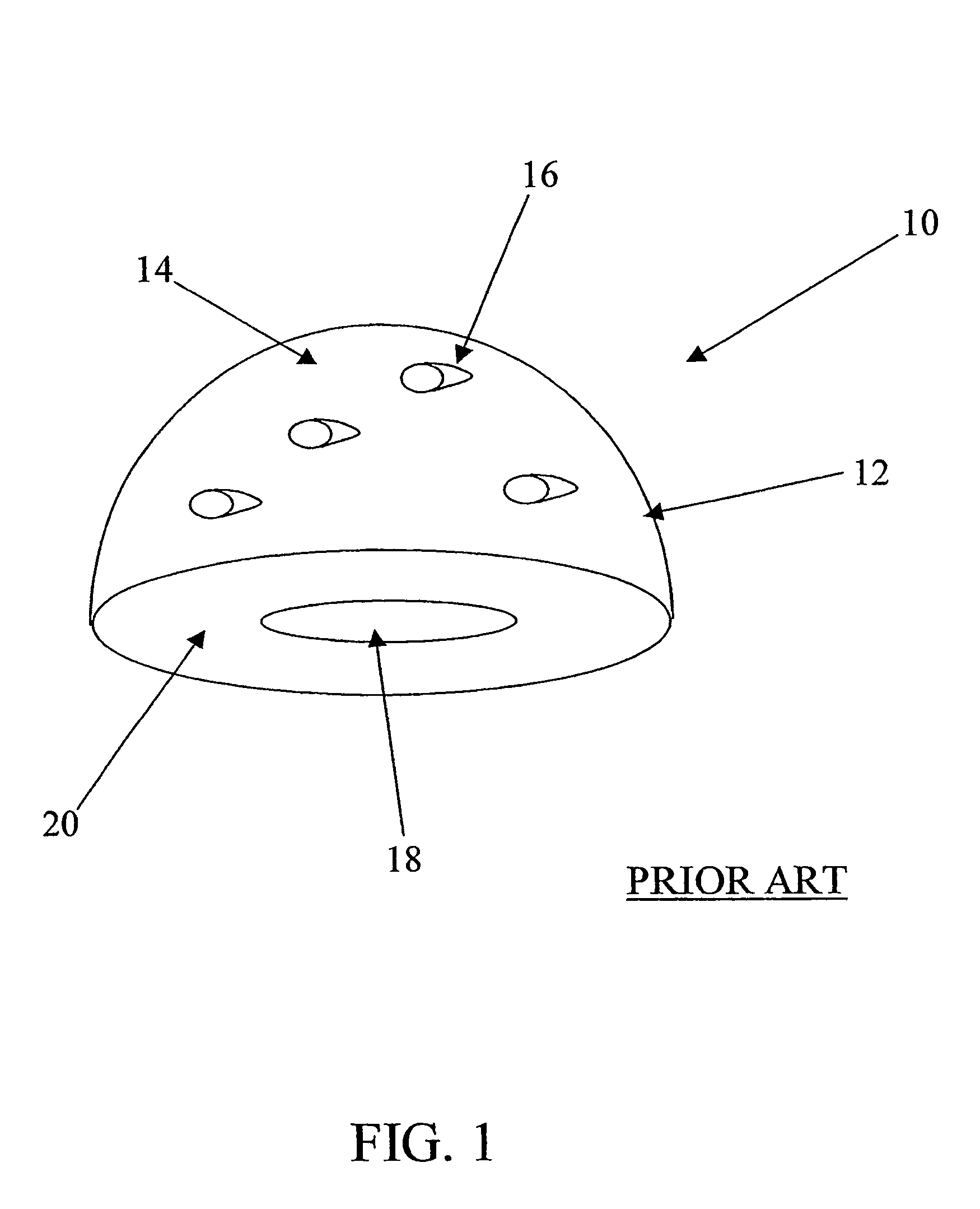

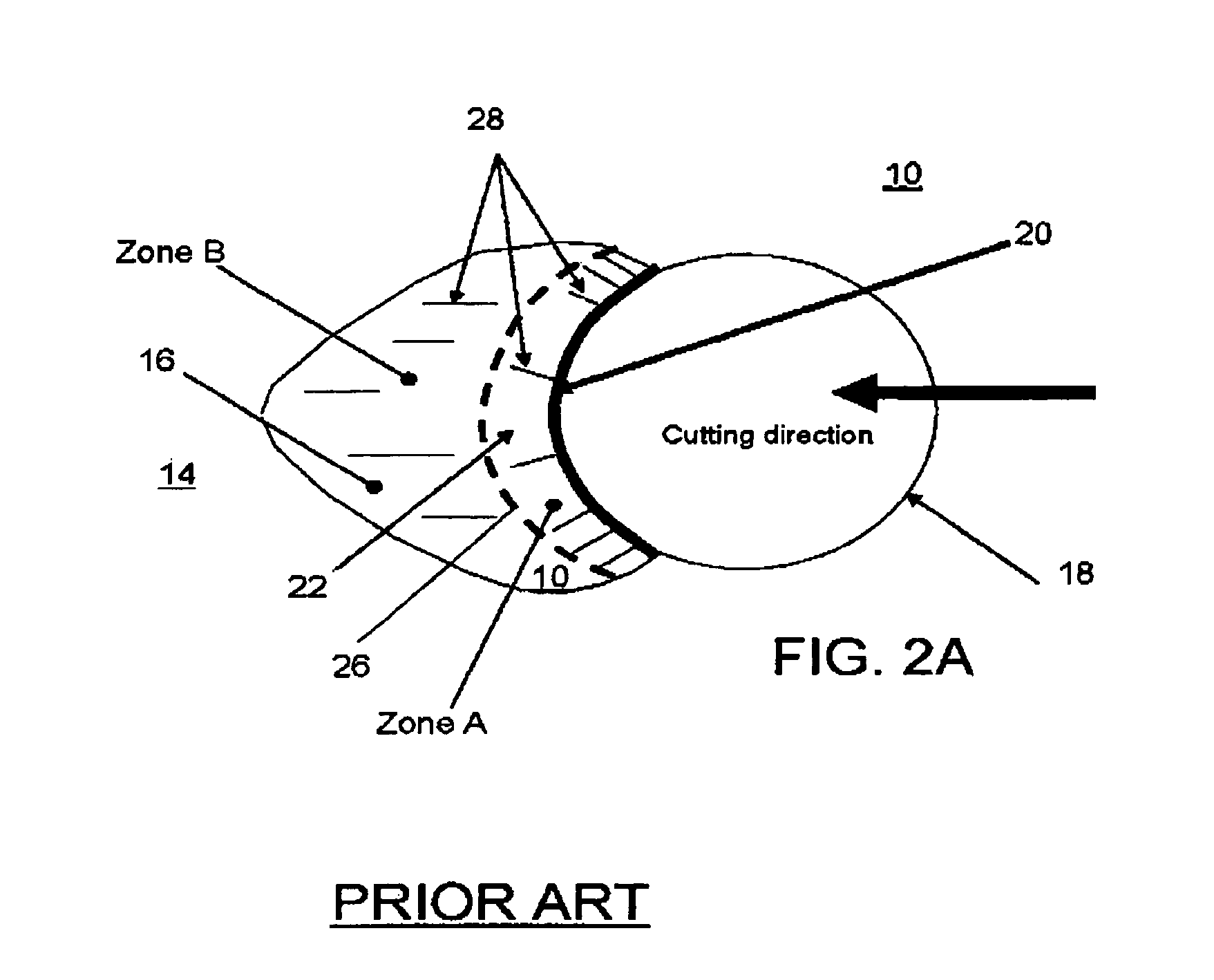

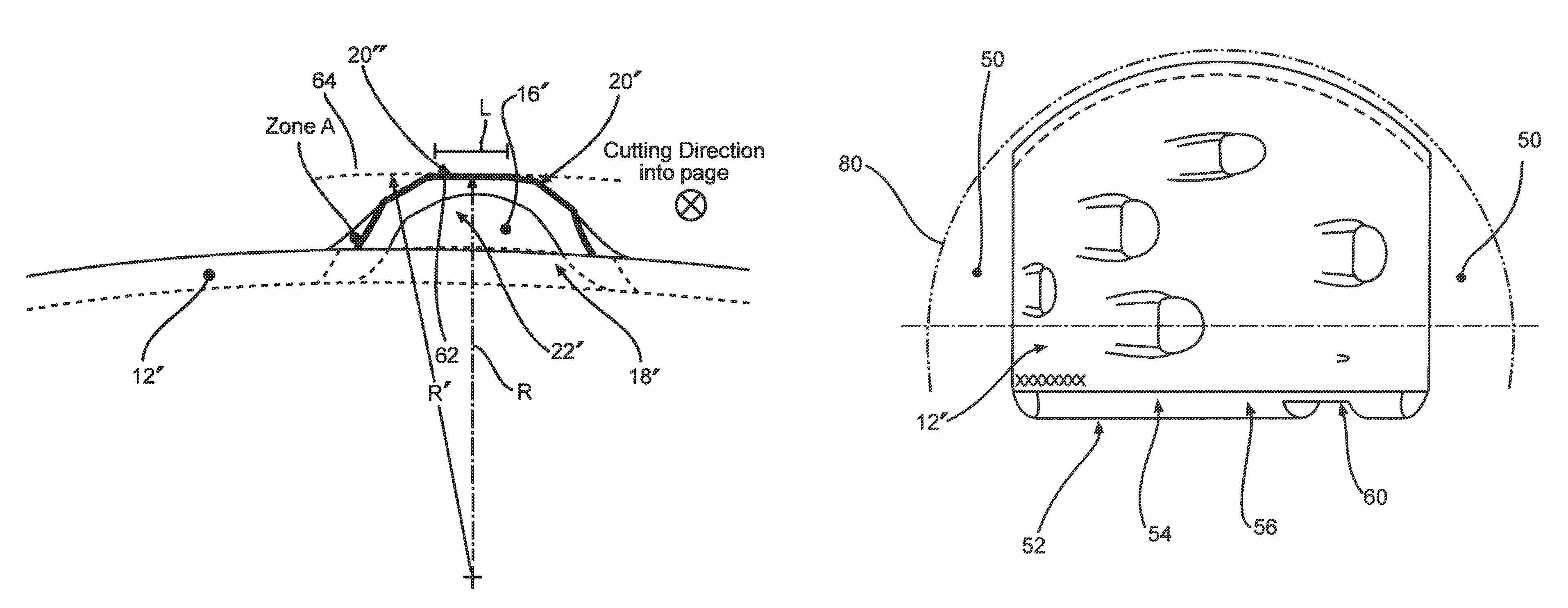

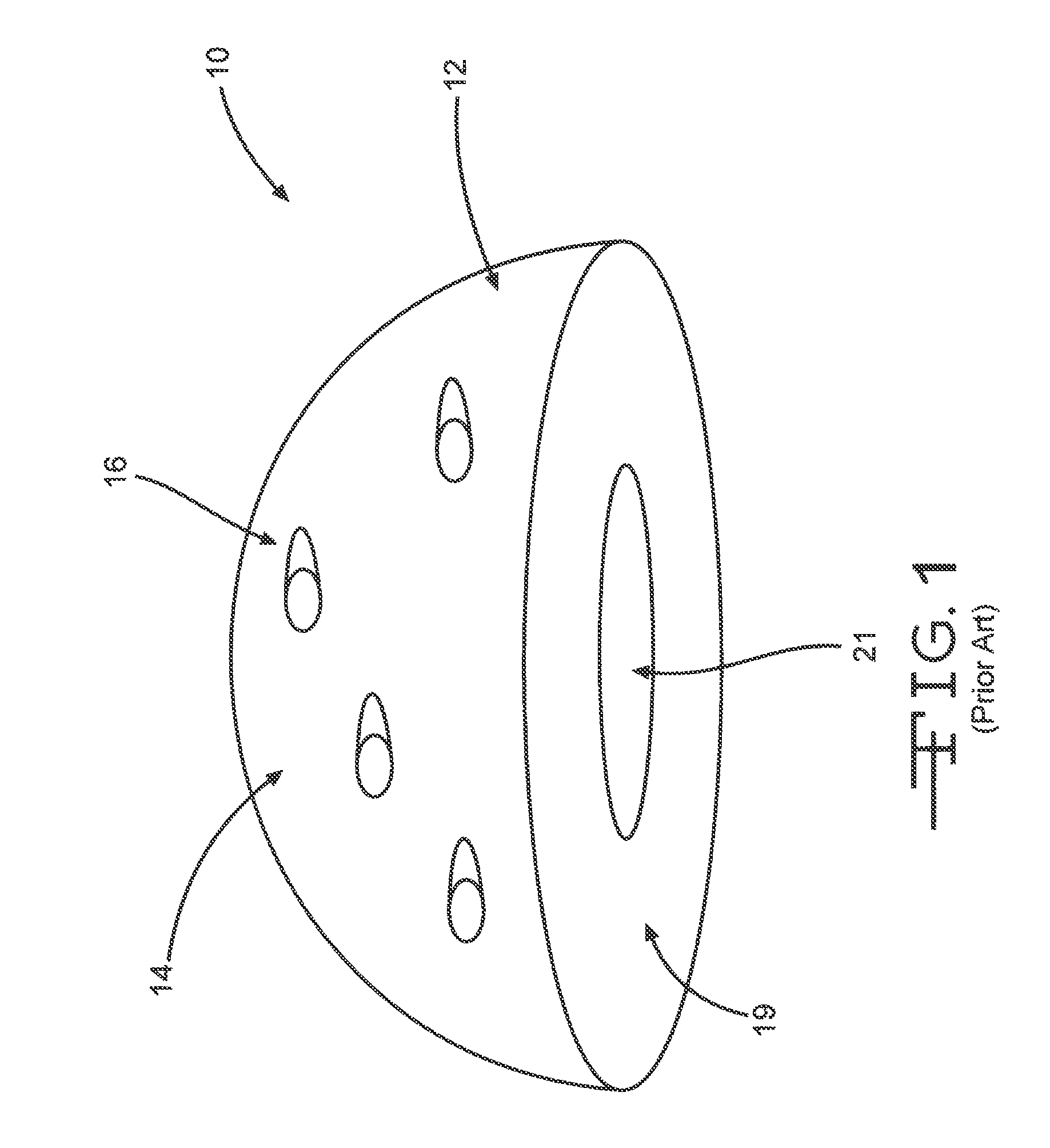

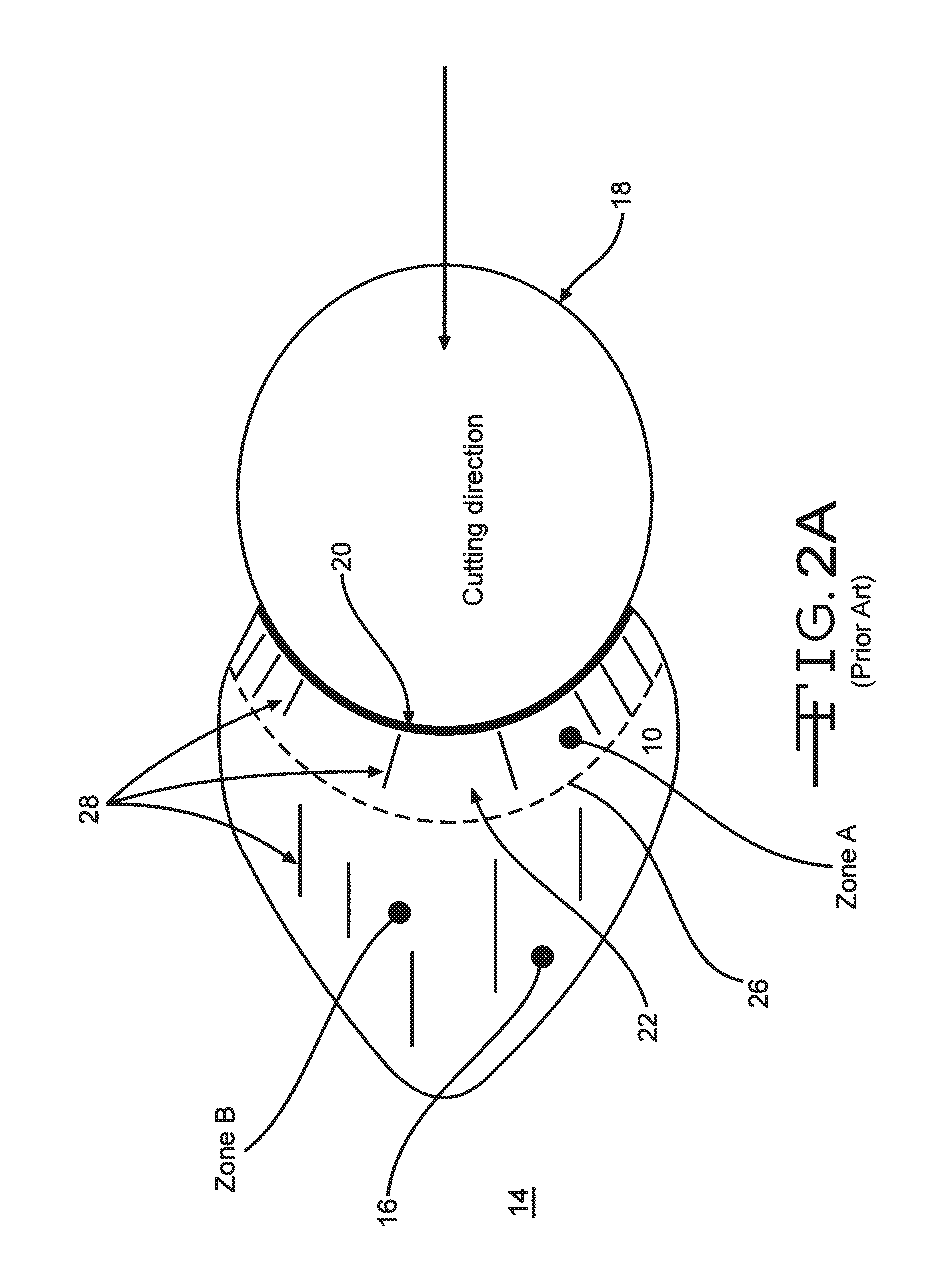

Contoured reamer teeth

An acetabular reamer (10′) for cutting a required cut shape. The reamer has a cutting shell (12′) having a series of doubly curved cutting teeth (16′) thereon of a quantity to substantially reduce a cutting pressure on each tooth as well as to reduce a size of a typical chip generated upon cutting. Substantially all the teeth each have a matched arc cutting edge (20′) of substantial length that has a cutting profile which substantially matches a profile of a shape to be cut. Such a configuration reduces the number of teeth required to cut the shape.

Owner:VIANT AS&O HLDG LLC

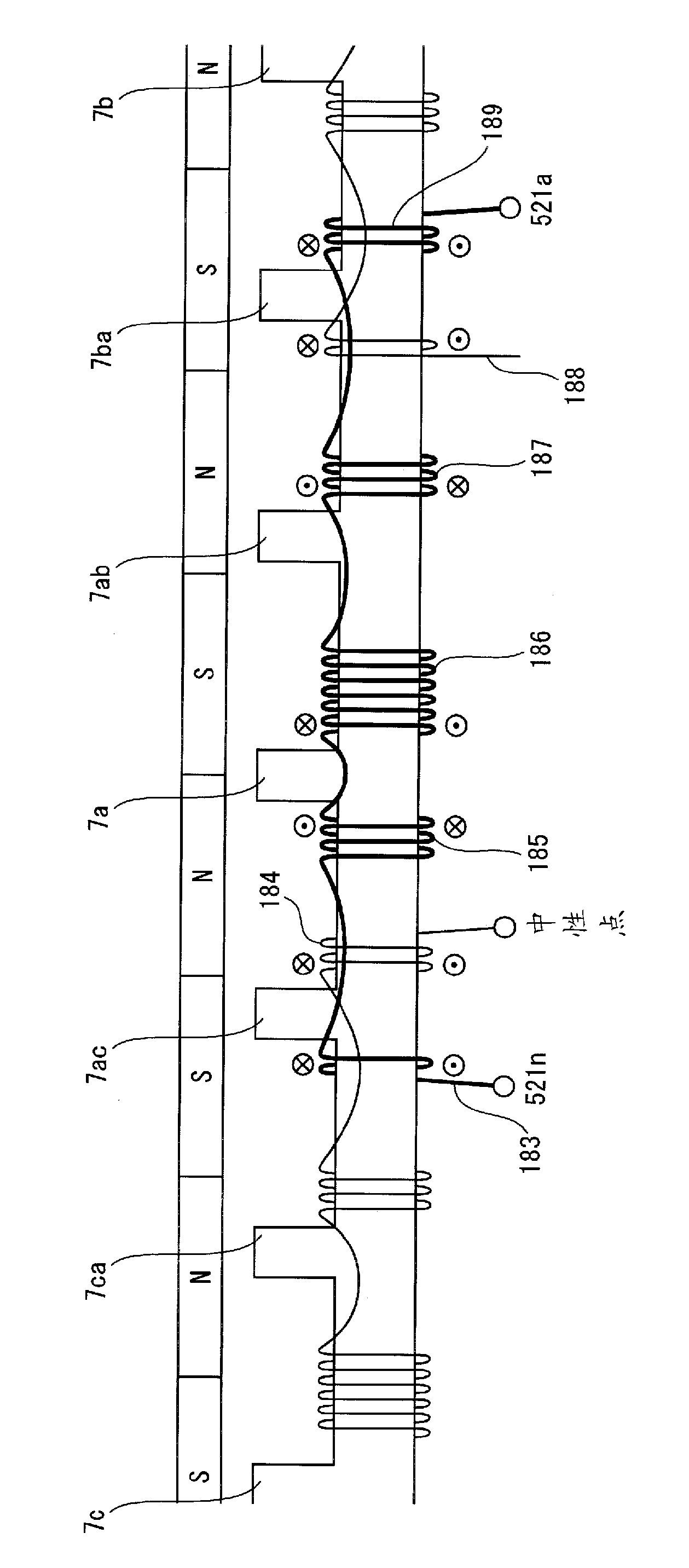

Magneto generator

InactiveCN1610222ALow costSuppress noiseSynchronous machines with stationary armatures and rotating magnetsMagnetic fluxElectric power

A permanent-mannet generator, setting a pectination front end part on a stator and a pectination teeth part on a magnetic flux control loop locating opposite with the stator. To make the magnetic flux control loop rotate and swing, and to change area of the pectination teeth part opposite to the pectination front end part, and to restrain magnetic flux through the magnetic circuit as well as to generate electric power of constant voltage. Forming chamfering edges parts on two turning parts in cycle direction of the pectination teeth part and the pectination front end part, so as to form gap of magnetic flux interspace with accuracy.

Owner:FUJI CERA TECH

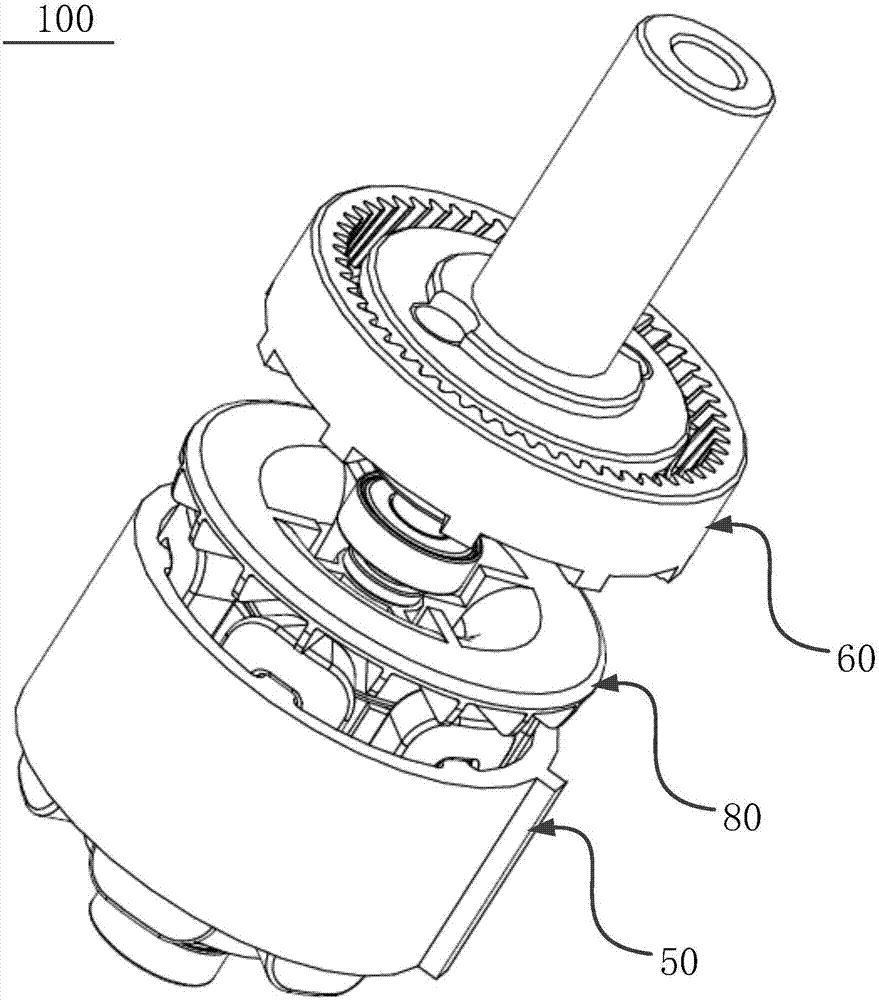

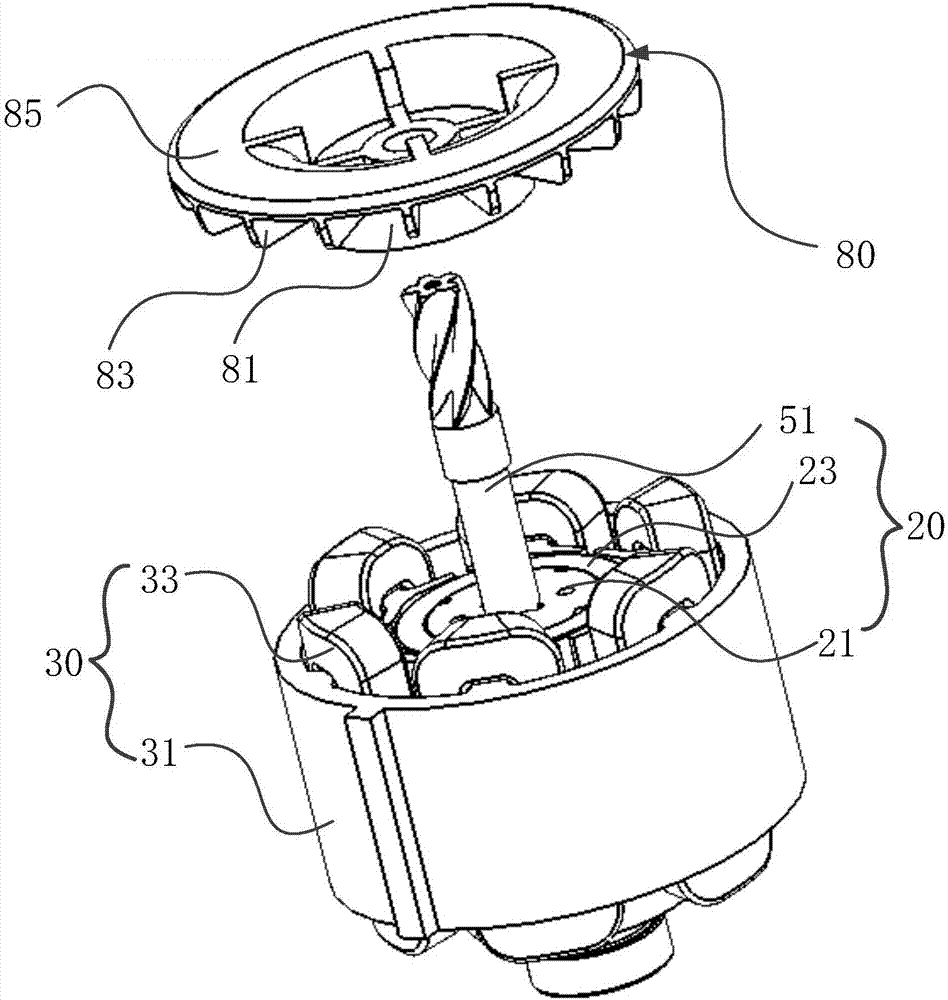

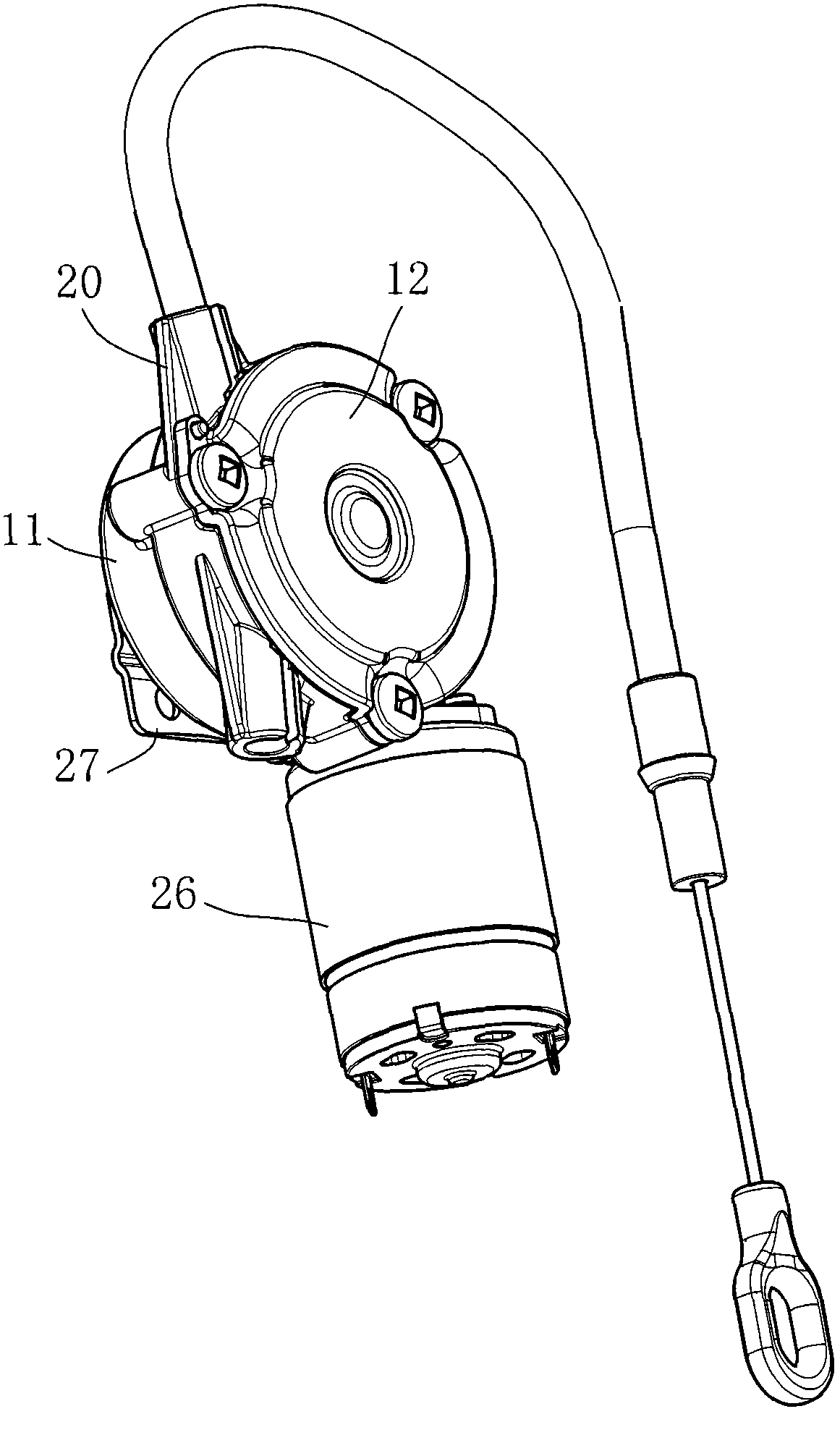

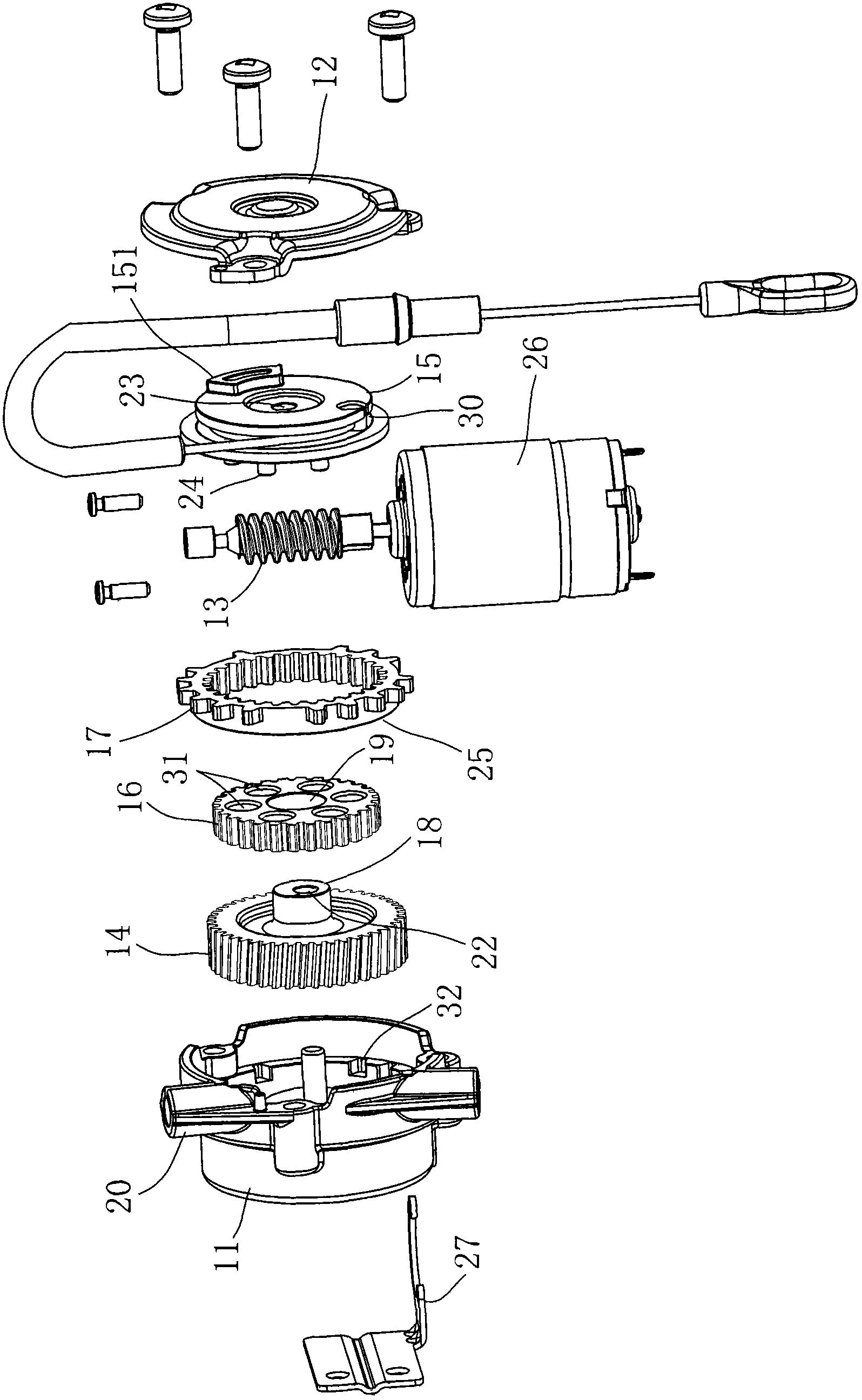

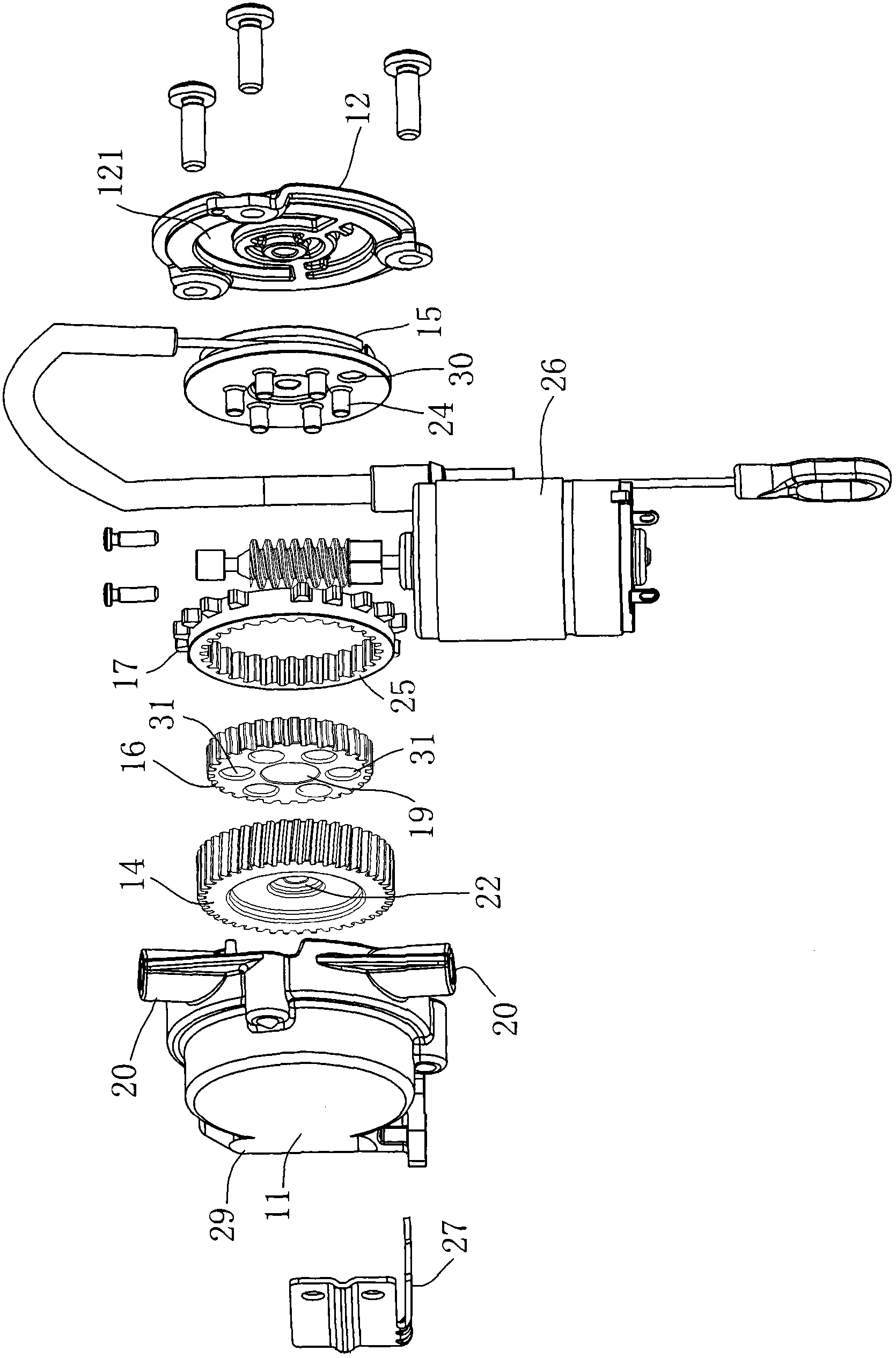

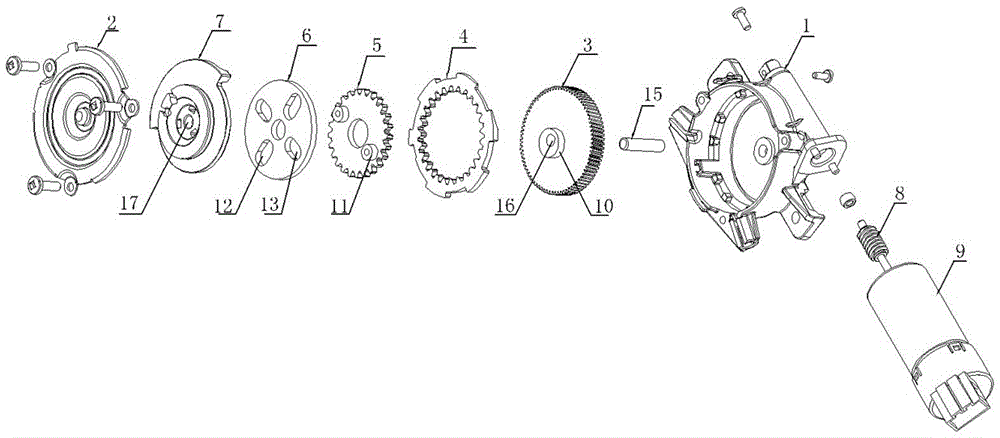

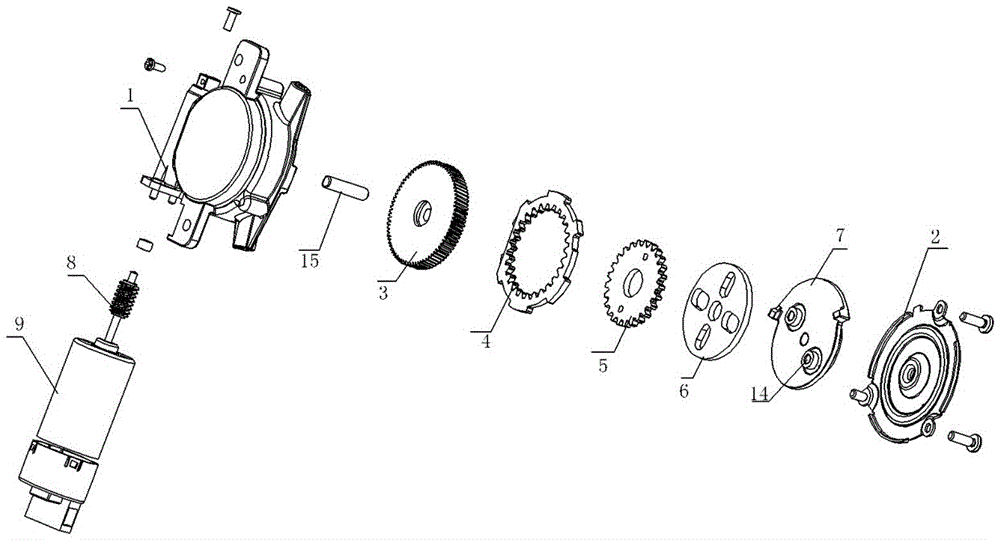

Driving device and electric tool applying same

InactiveCN107355528AFew teethLarge transmission ratioMagnetic circuitToothed gearingsGear wheelElectric machine

The invention provides a driving device comprising a motor being a single-phase motor and a gearbox. The gearbox comprises a sun gear, a plurality of planetary gears surrounding and engaged with the sun gear, and a plurality of internal gear rings surrounding and engaged with the plurality of planetary gears, wherein the sun gear integrally forms a rotating shaft on the motor. The invention further provides an electric tool comprising the driving device, a work head driven by the driving device and an impact unit arranged between the driving device and the work head. In the driving device and the electric tool applying the driving device, the sun gar is combined with the motor rotating shaft and an integrally-formed gear shaft is formed, so a number of teeth of the sun gear can be reduced to 5 or less; and gearbox transmission ratio can be effectively improved when a maximum geometrical external diameter is remained the same.

Owner:JOHNSON ELECTRIC SHENZHEN

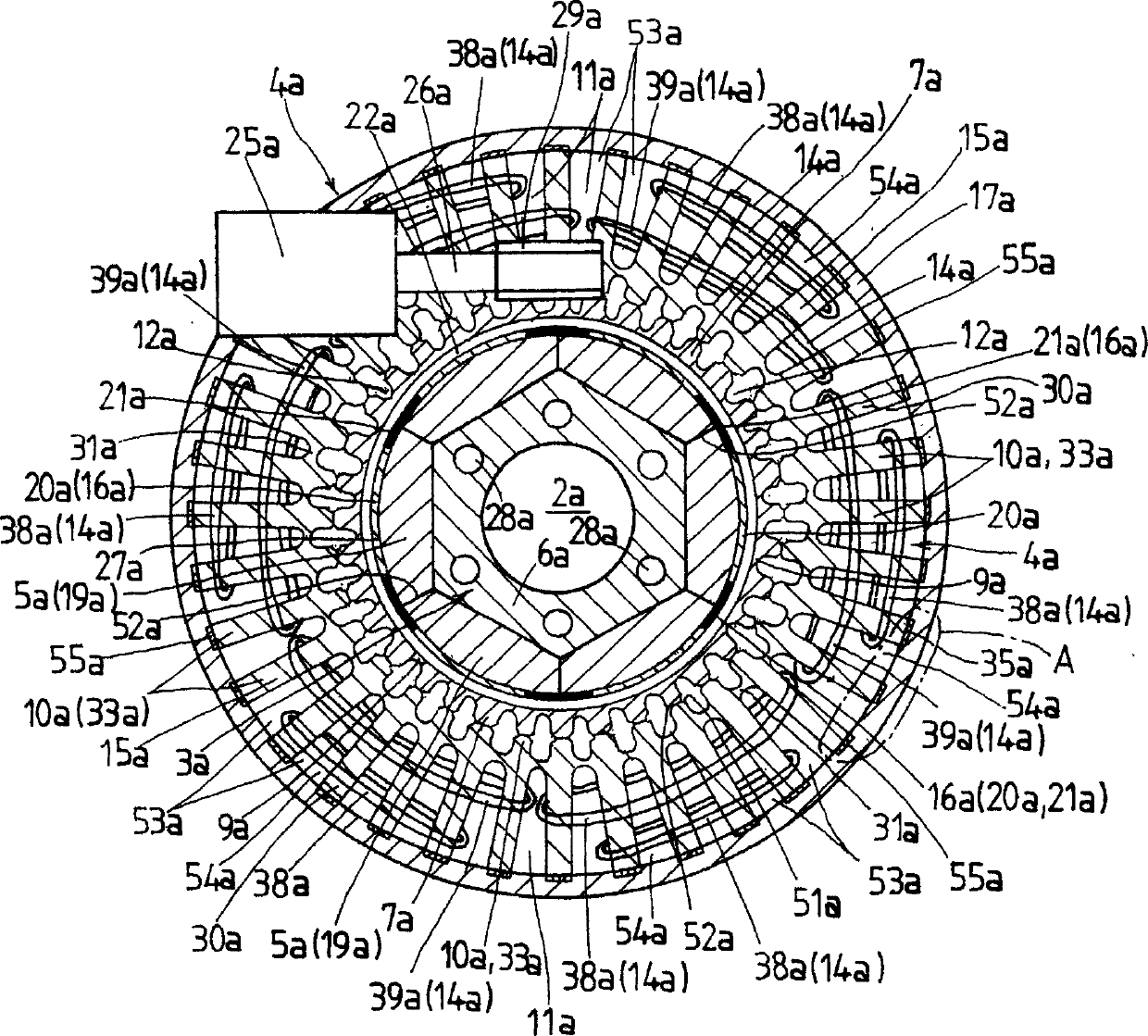

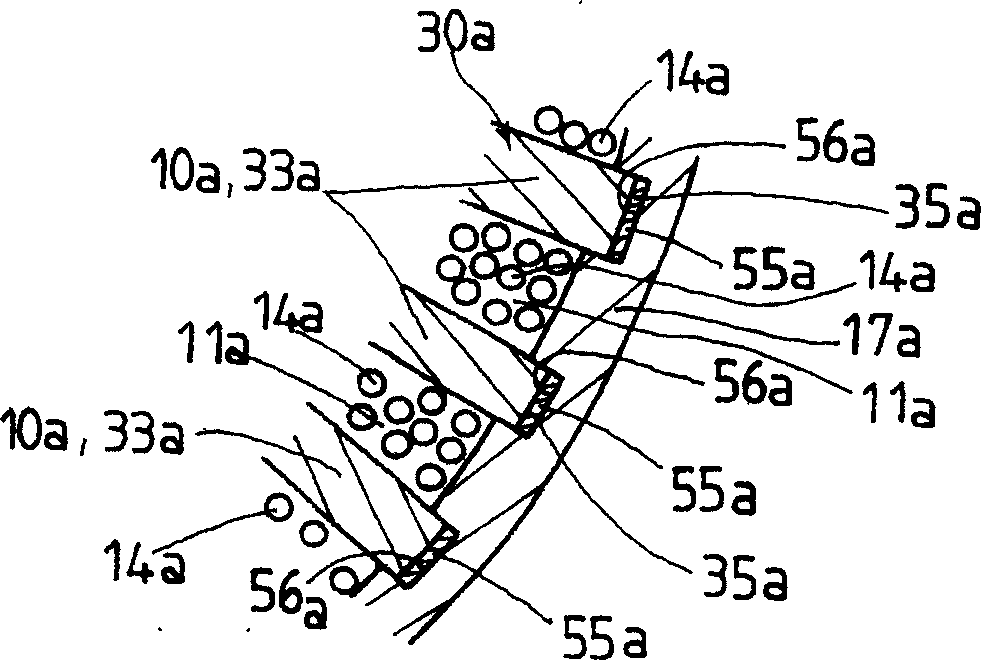

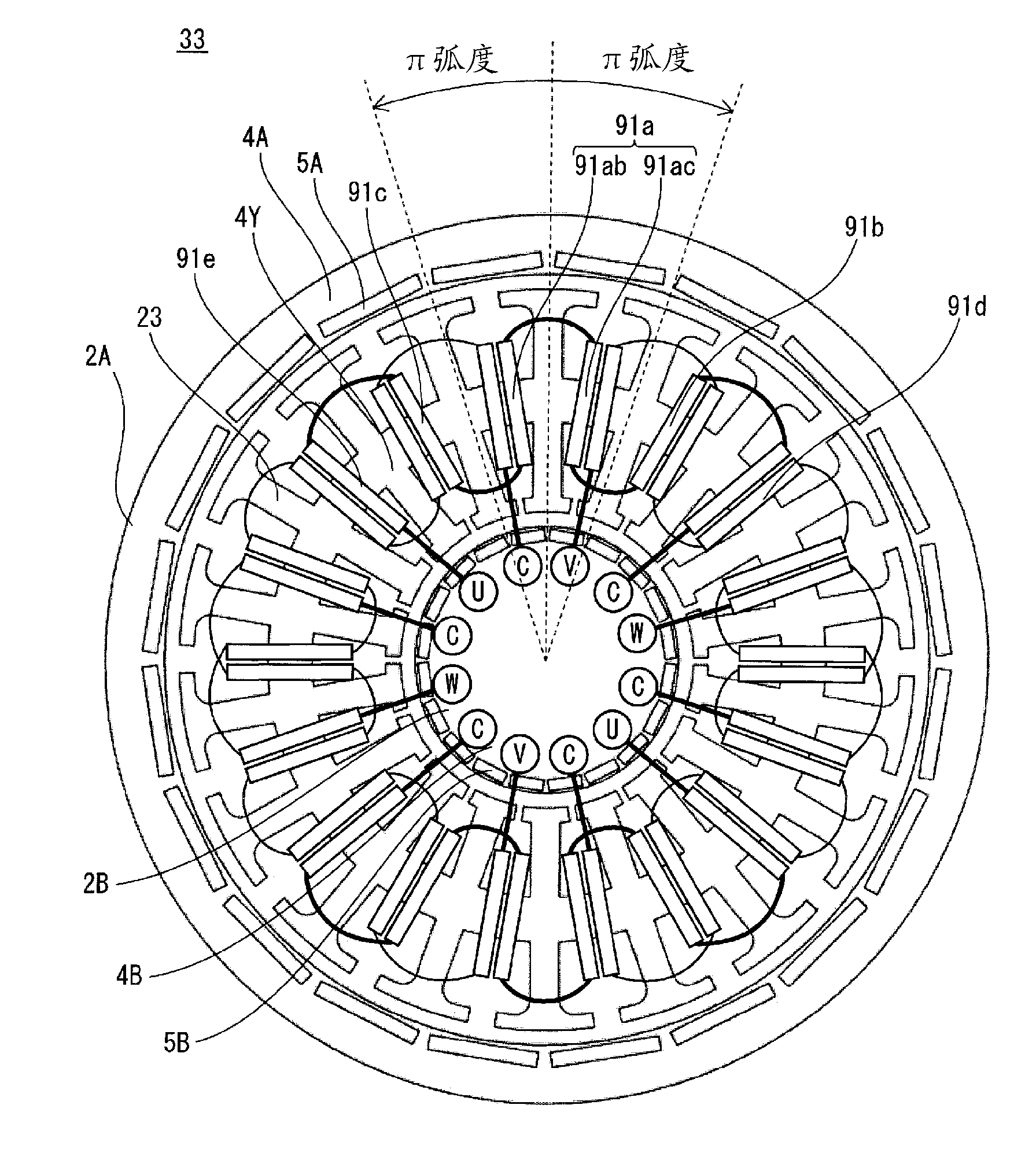

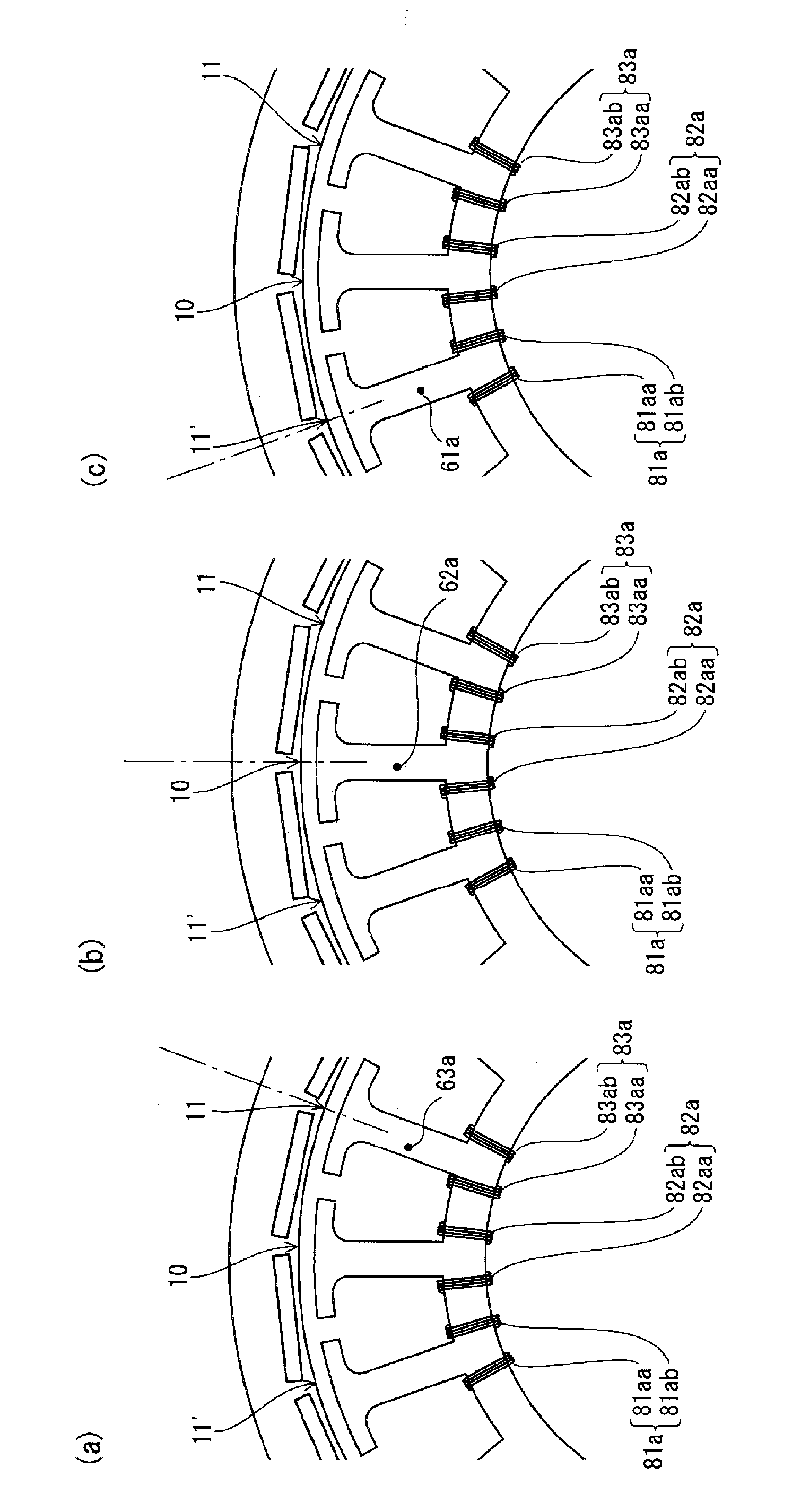

Synchronous motor and system for driving synchronous motor

ActiveCN102498645ASmall torqueIncrease torqueTorque ripple controlAC motor controlSynchronous motorStator

Disclosed are a synchronous motor having reduced torque pulsation while having a high torque and a system for driving a synchronous motor. Specifically disclosed is a synchronous motor which comprises a rotor (2) and a stator(3), and U-phase windings (91; 91a, 91b, and the like), V-phase windings (92; 92ab and the like), and W-phase windings (93; 93ac and the like) are wound around stator yoke portions each located between two adjacent stator teeth (7; 7a, 7ab, and the like). Each of the windings is wound in predetermined turns and in a predetermined direction such that timing differences between the timings at which a magnetic field generated at each of the stator teeth is maximized and those at which portions (10, 11, 11, and the like) between magnetic poles pass the stator teeth while the rotor (2) rotates, the timing differences being caused by a difference between the interval between the magnetic poles and that between the stator teeth, are compensated.

Owner:PANASONIC CORP

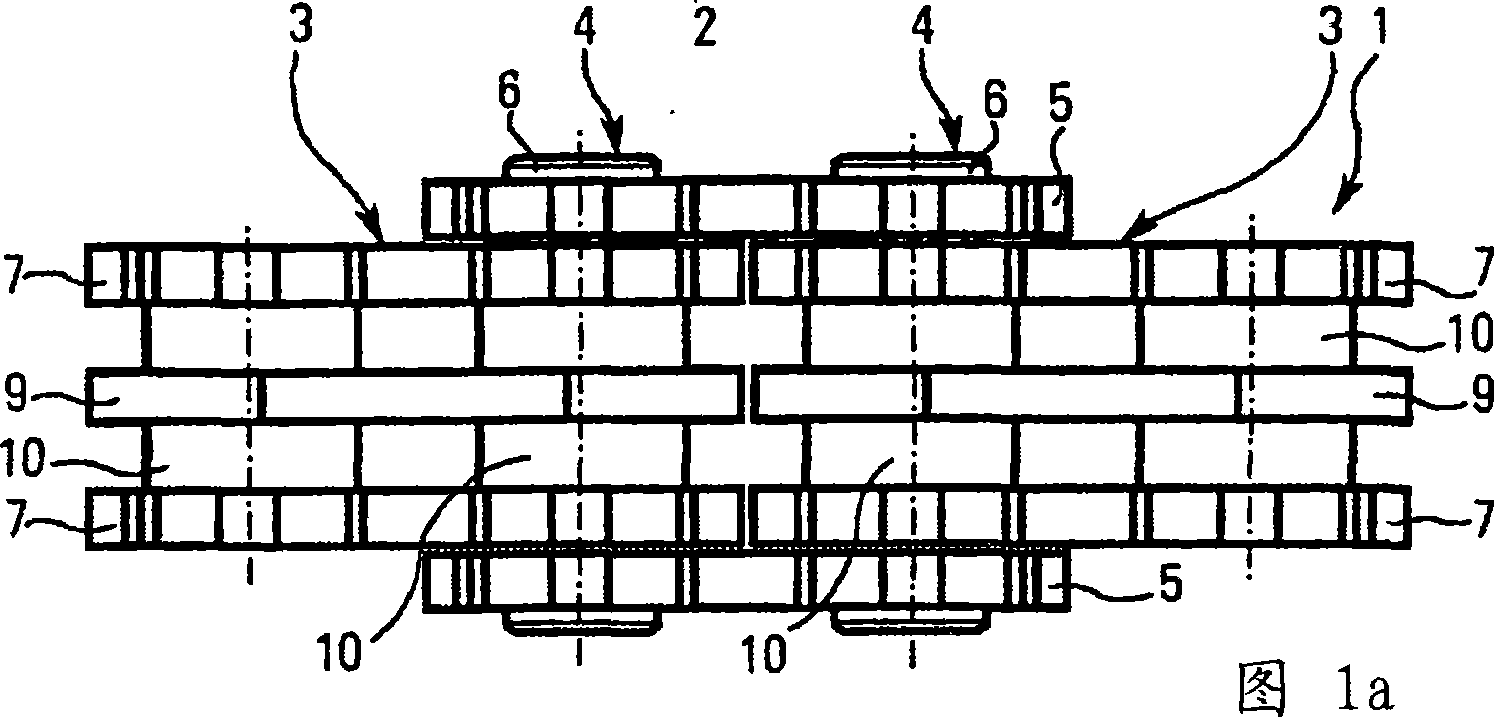

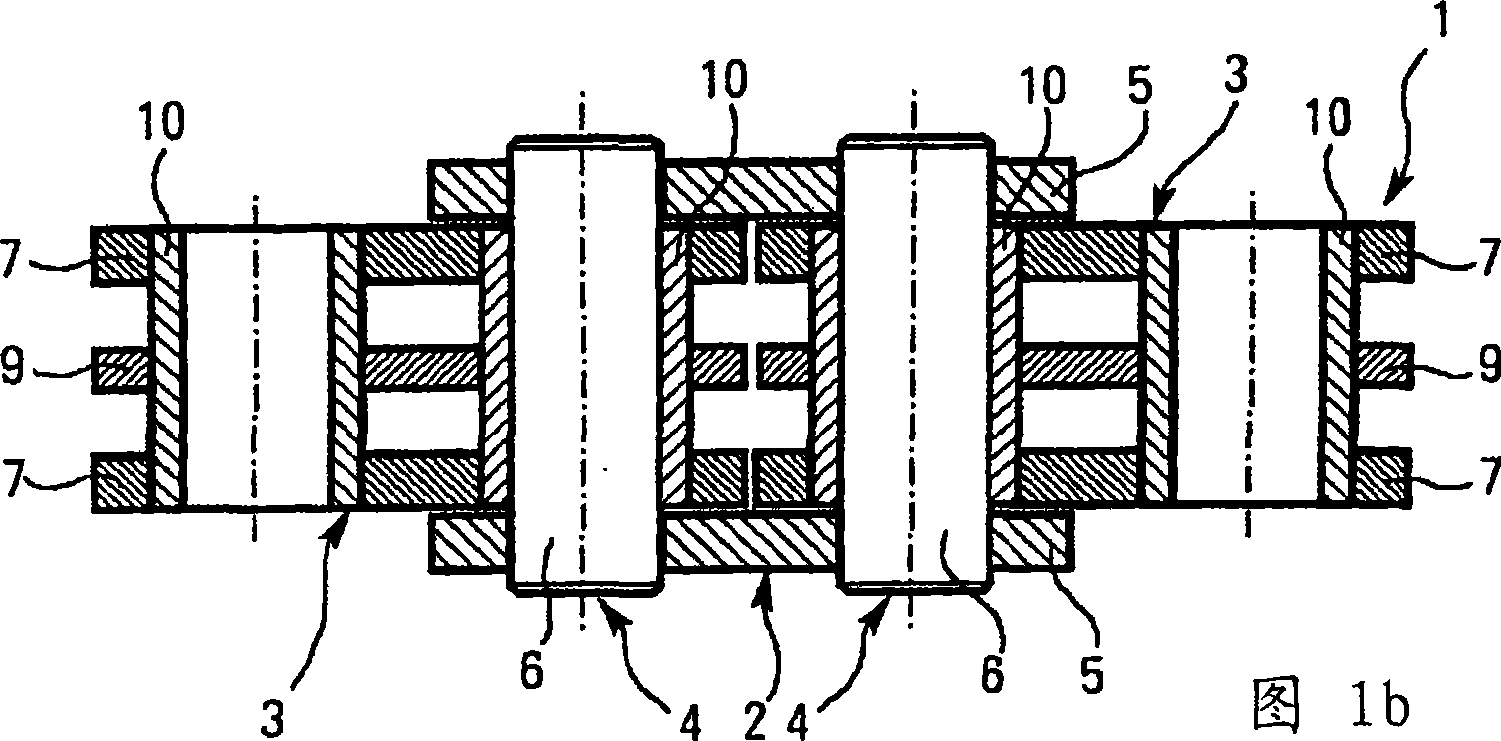

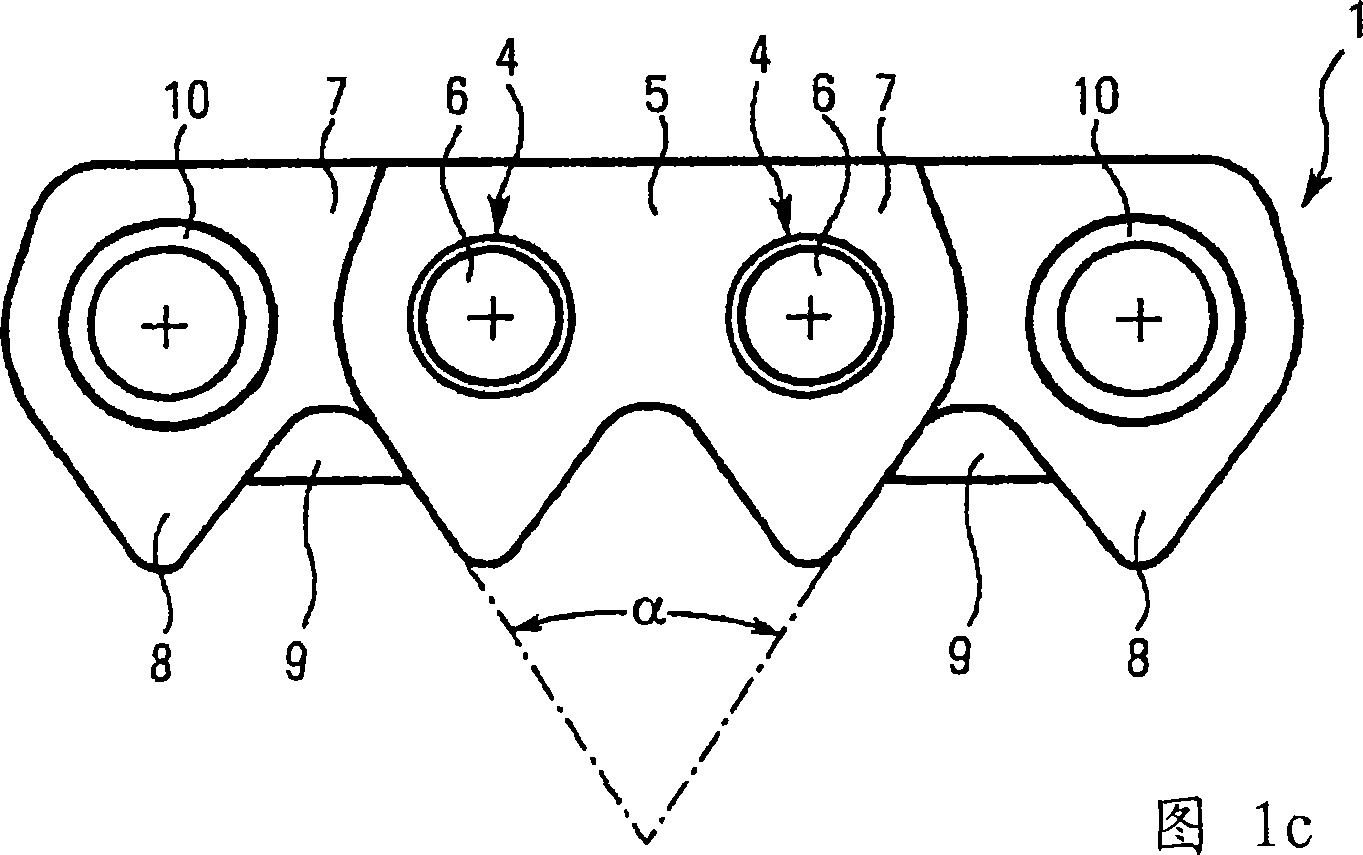

Toothed chain with optimised chain joint and increased external flank angle

InactiveCN101421536AImprove stabilityIncrease the articulation surfaceDriving chainsDrivetrainEngineering

The invention relates to a toothed chain (1) with alternating inner and outer chain links (2, 3), joined by means of a chain joint (4), wherein the inner chain links (3) comprise at least one inner plate (7) and at least two joint bushes (10) running perpendicularly through the above, the outer chain links (2) comprise at least two outer plates (5) and at least two joint pins (6) running perpendicularly through the same. To form a chain joint a joint pin of the outer chain link (5) extends through a joint bush of the inner chain link and at least one inner plate (7) of the inner chain link and / or at least one outer plate of the outer chain link is embodied as a toothed plate with each having two teeth defined by an outer flank and an inner flank.; According to the invention, a toothed chain with improved life and improved design for the complete chain drivetrain can be achieved, wherein an outer flank angle given for both outer flanks of a toothed plate (5,7), is a = 65 DEG and = 75 DEG and the ratio VBa between a pitch T of the toothed chain (1) and the outer diameter dBa of the joint pin is = 2.65.

Owner:IWIS MOTORSYSTEME GMBH & CO KG

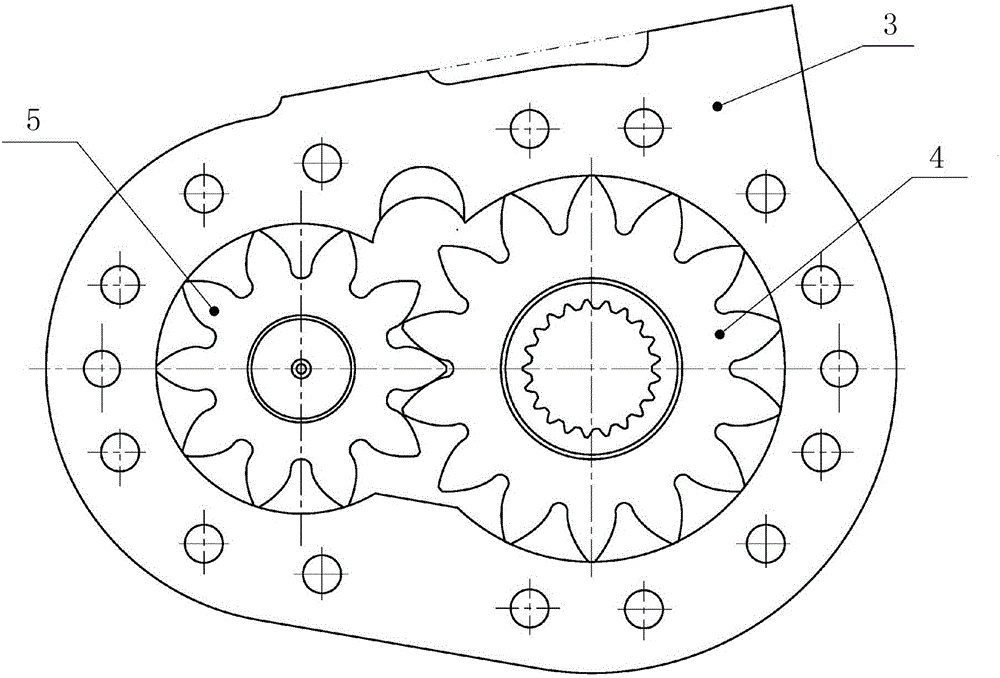

Large displacement high pressure gear pump with driving and driven wheels in different sizes

InactiveCN105952637AImprove the state of radial stressReduce volumeRotary piston pumpsRotary piston liquid enginesDrive wheelGear pump

The invention discloses a large displacement high pressure gear pump with driving and driven wheels in different sizes. A conventional external engaging gear pump is relatively great in flow pulsation, high in noise, low in efficiency and low in pressure. The large displacement high pressure gear pump with driving and driven wheels in different sizes disclosed by the invention comprises a pump body, a front cover and a rear cover connected to the pump body, a pair of gear pairs with driving and driven wheels in different sizes and two symmetrical floating side plates, wherein two roller bearings are arranged at the driving wheel, two DU bearings are arranged at the driven wheel, a set of E-shaped seal ring is arranged on the back of each floating side plate, and an outer seal ring is arranged between the pump body and the front cover and between the pump body and the rear cover, respectively. When the gear pump disclosed by the invention is in a large displacement high pressure operation, the bearing areas of the pump body and the front and back covers are effectively reduced, and the stress environments of parts such as gears, the floating side plates and bearings are greatly improved, so that the working pressure of the gear pump is improved to 1.5 times of that of a common gear pump, the rated working pressure of the gear pump reaches 16MPa and the highest pressure of the gear pump reaches 20MPa.

Owner:江苏国瑞液压机械有限公司

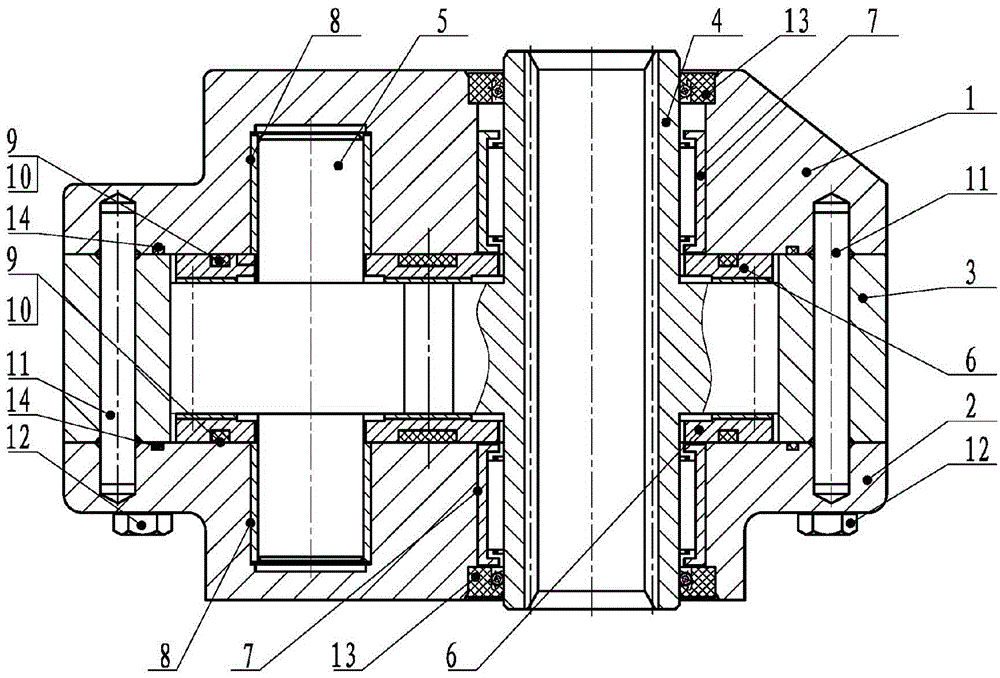

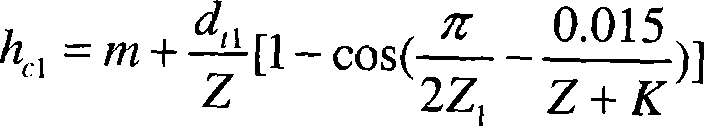

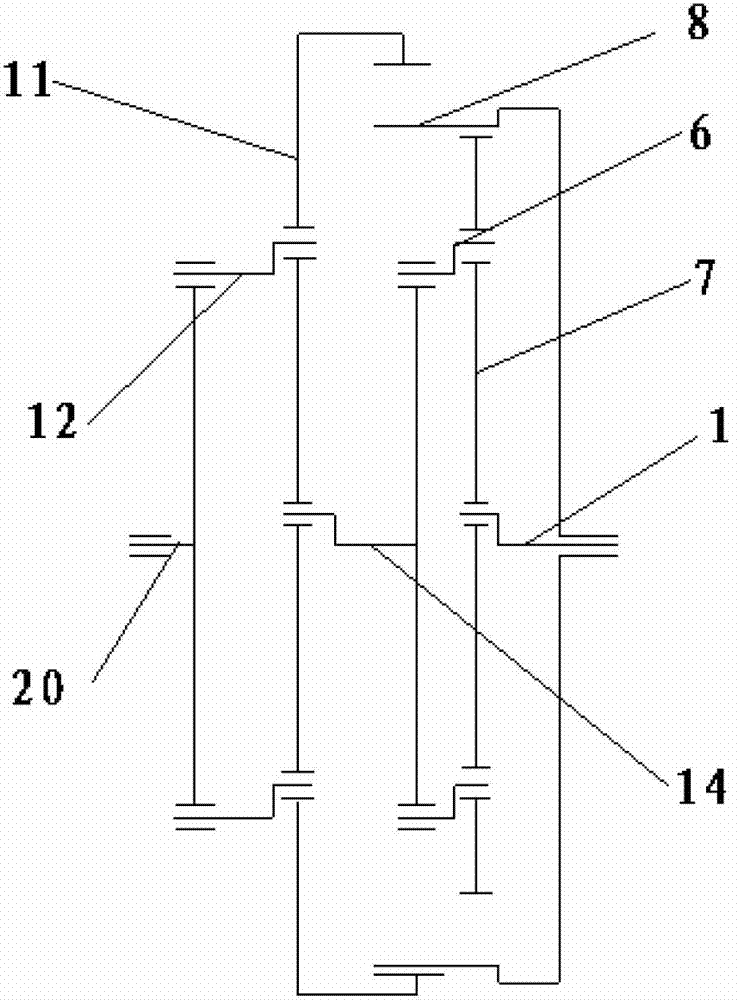

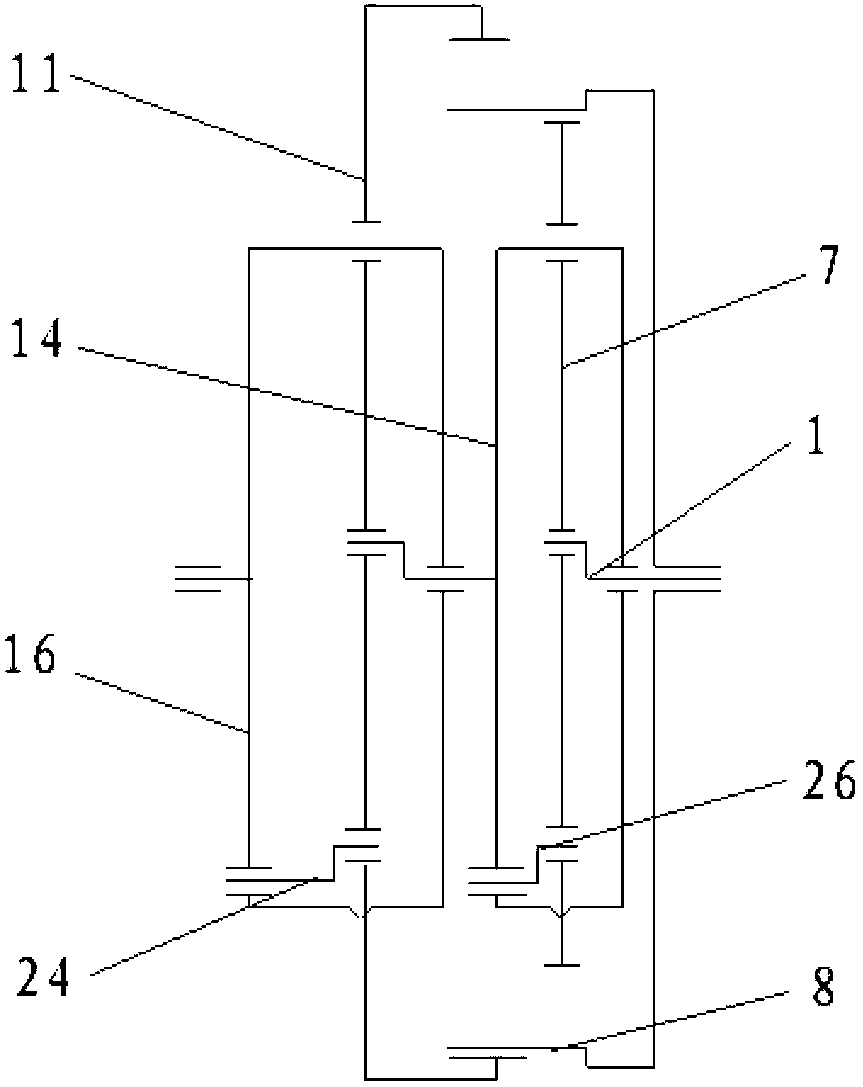

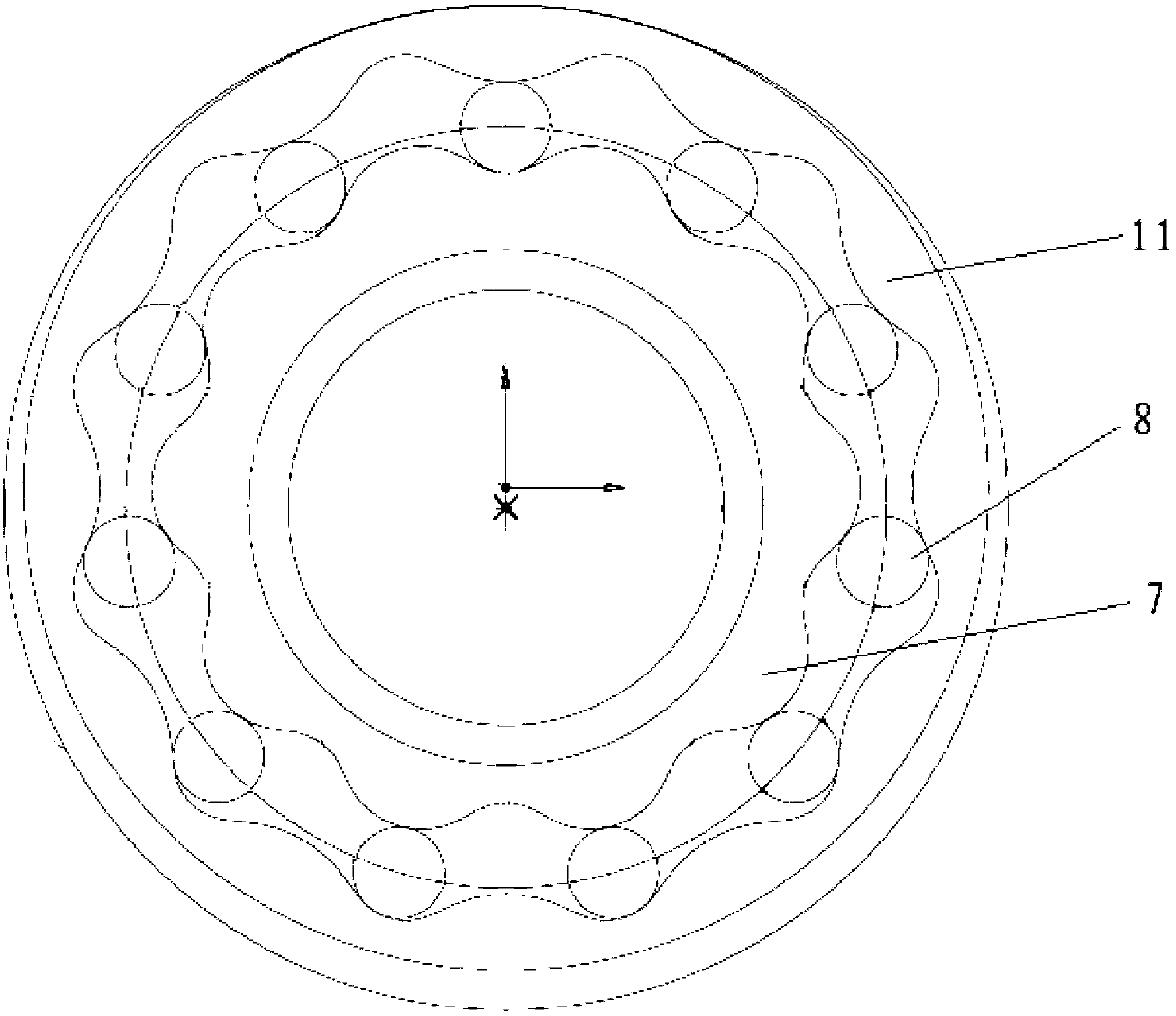

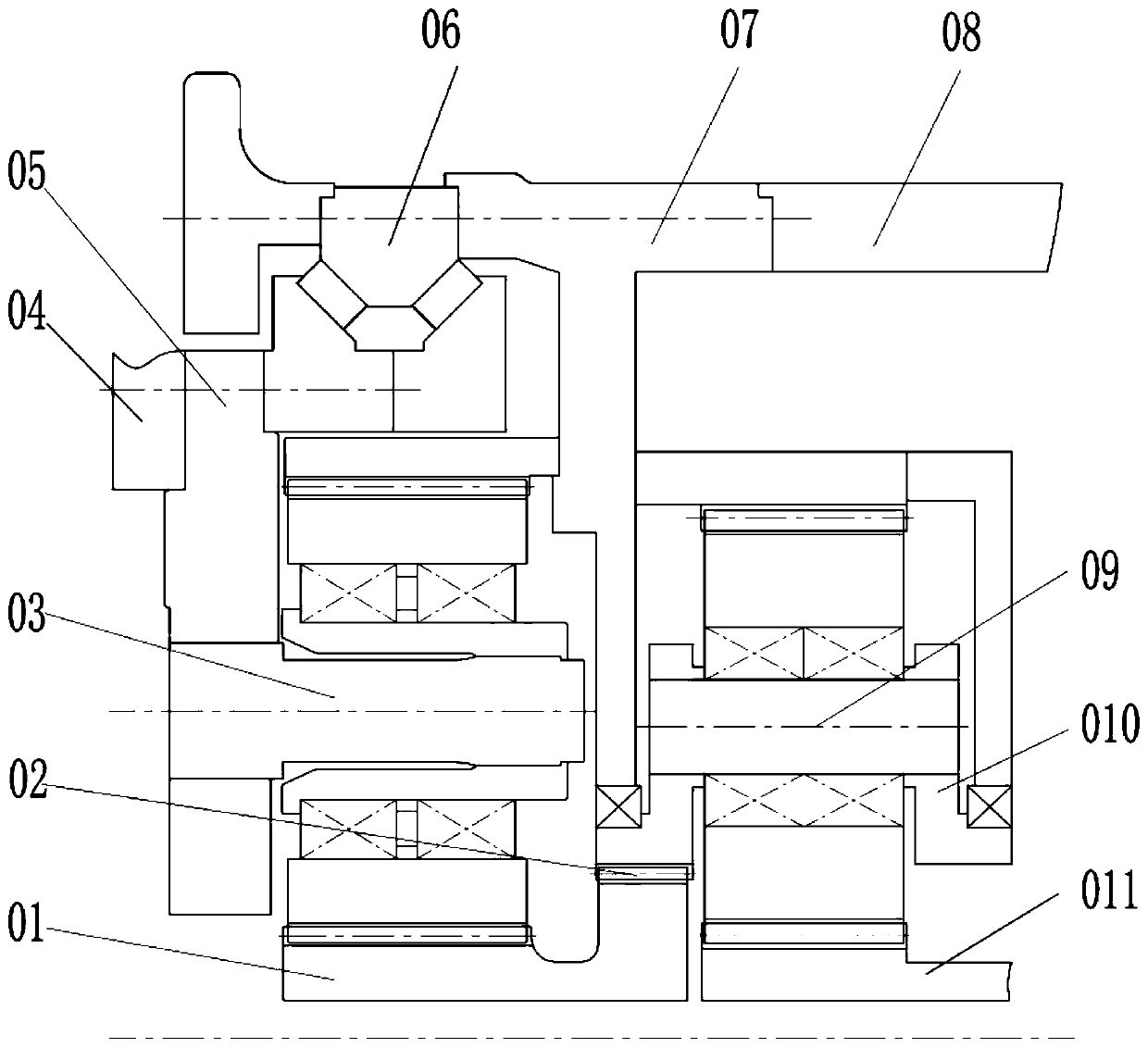

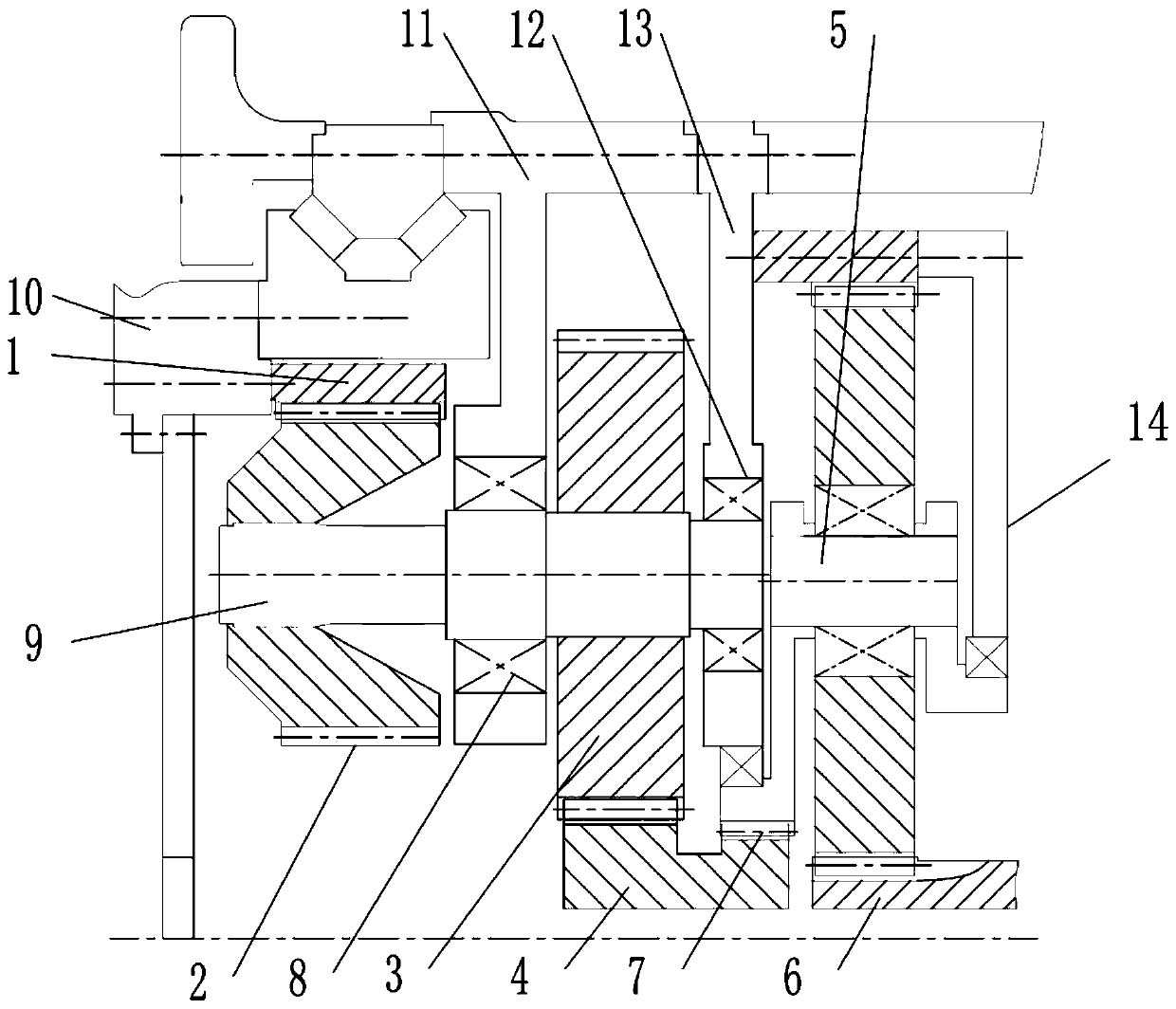

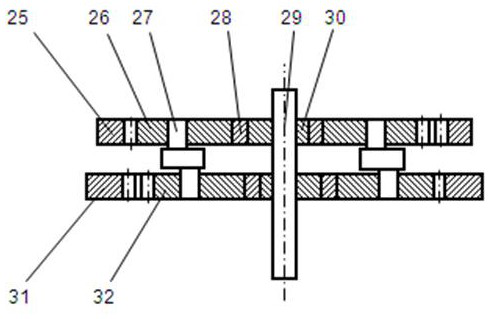

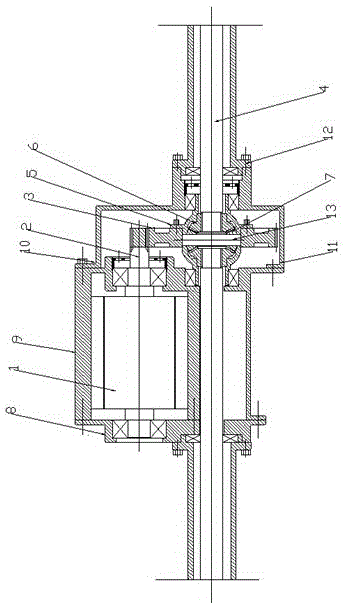

Single-eccentric short transmission chain speed reducer

The invention discloses a single-eccentric short transmission chain speed reducer. The single-eccentric short transmission chain speed reducer comprises a fixed main body, a bearing sleeve, a power input shaft, a power output shaft and a duplicate gear; the power input shaft comprises positive axis parts at the two ends and an off-axis part in the middle, the axes of the positive axis parts and the off-axis part do not coincide, the duplicate gear is arranged on the off-axis part of the power input shaft in a sleeving mode through a third bearing, and the duplicate gear comprises a first external gear and a second external gear; a first inner gear ring is arranged on the portion, corresponding to the first external gear, of the fixed main body, a second inner gear ring is arranged on the portion, corresponding to the second external gear, of the power output shaft, the first external gear and the first inner gear ring are in internal meshed transmission, and the second external gear and the second inner gear ring are in internal meshed transmission. The single-eccentric short transmission chain speed reducer has the advantages of being simple in structure, short in transmission chain, high in transmission efficiency, stable in transmission, large in transmission moment, wide in speed reducing ratio range and the like.

Owner:XUCHANG UNIV

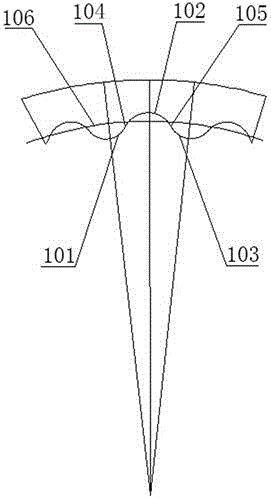

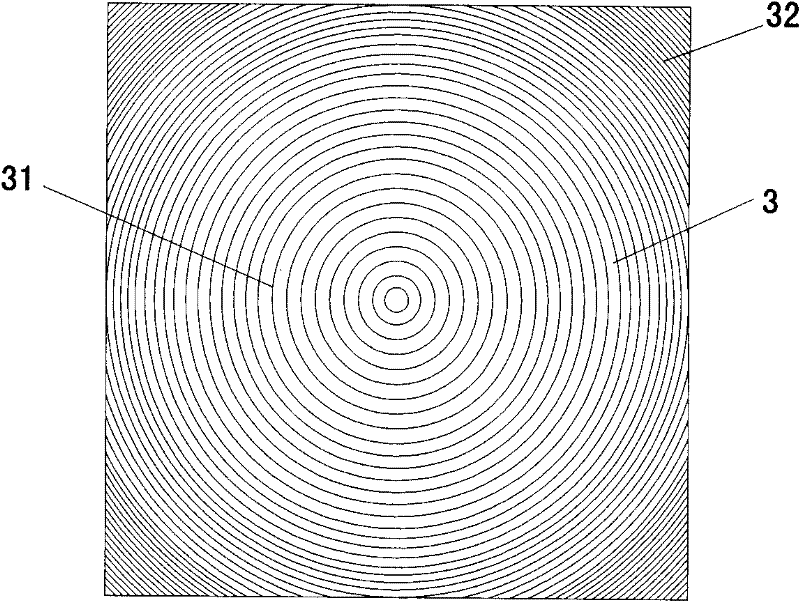

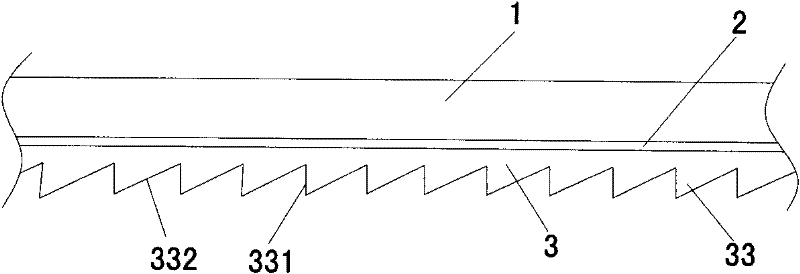

Composite-structure Fresnel lens

InactiveCN102681047AGood weather resistanceHigh surface hardnessGlass/slag layered productsCondensersPhysicsWeather resistance

The invention relates to a composite-structure Fresnel lens which is formed by sequentially connecting tempered panel ultra-white glass, a bonding layer and a silica gel layer, wherein the outer surface of the silica gel layer forms a Fresnel tooth-form surface, the Fresnel tooth-form surface is composed of a plurality of tooth-form concentric rings or broken rings, the tooth-form section of each ring is respectively in a right-angled triangle shape, one right-angled edge of the right-angled triangle is perpendicular to the upper surface of the Fresnel lens, namely the incident plane of sunlight, and the surface where the inclined edge locates forms the refraction plane of sunlight. The inclined angle of each tooth-form refraction plane in the Fresnel tooth-form surface is increased ring by ring from the center to the outside. Compared with the prior art, the composite-structure Fresnel lens has the advantages of being high in optical transmittance, good in weather resistance, high in surface hardness, strong in sand and wind resistance, low in material cost and the like.

Owner:上海合瑞新能源科技有限公司

High-speed transmission correcting gear

InactiveCN101033791AFew teethImprove meshing conditionsPortable liftingGearing elementsWorking lifeEngineering

Owner:CHENDU KEDA AUTOMATION CONTROL ENG

Variable-speed flywheel

PendingCN108482572AReliable high-speed motionFew teethChain/belt transmissionFreewheelMaximum diameter

The invention discloses a variable-speed flywheel. The variable-speed flywheel comprises a tower wheel, a wheel hub and a freehub, and further comprises a connecting ring and a ring end cap, wherein multiple layers of gear rings of which diameters are increased successively are in lap joint to form the tower wheel; the tower wheel comprises a first gear ring with the maximum diameter and a secondgear ring with the minimum diameter; the tower wheel is in transmission connection with the wheel hub; the inner diameter 2r of the second gear ring is smaller than the outer diameter 2R of the freehub; one end of the freehub is detachably connected with the connecting ring; the ring end cap comprises a column and a cover; the column is connected with the connecting ring; and the cover is in contact with the second gear ring. The variable-speed flywheel has the advantages that the flywheel is universal to a standard freehub, and is low in cost and wide in transmission velocity ratio.

Owner:HUNAN NAITE MATERIAL TECH CO LTD

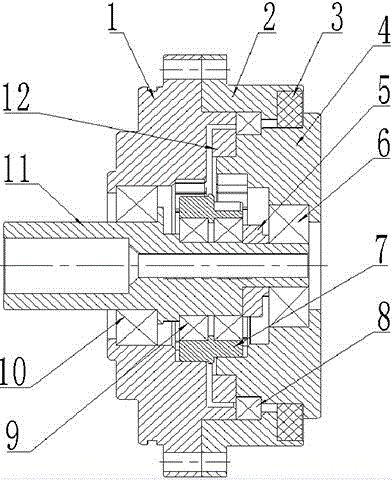

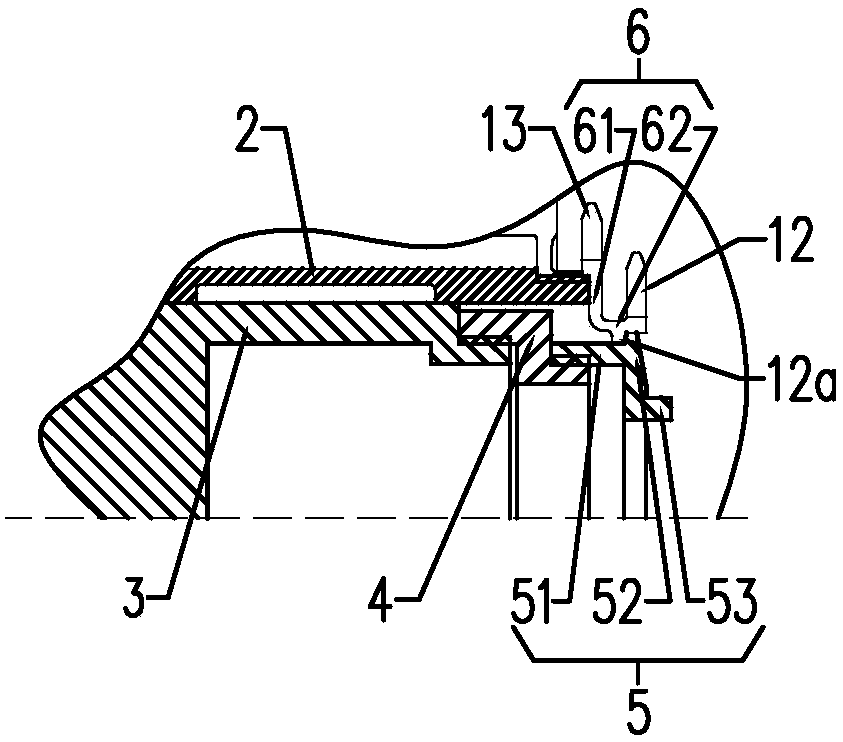

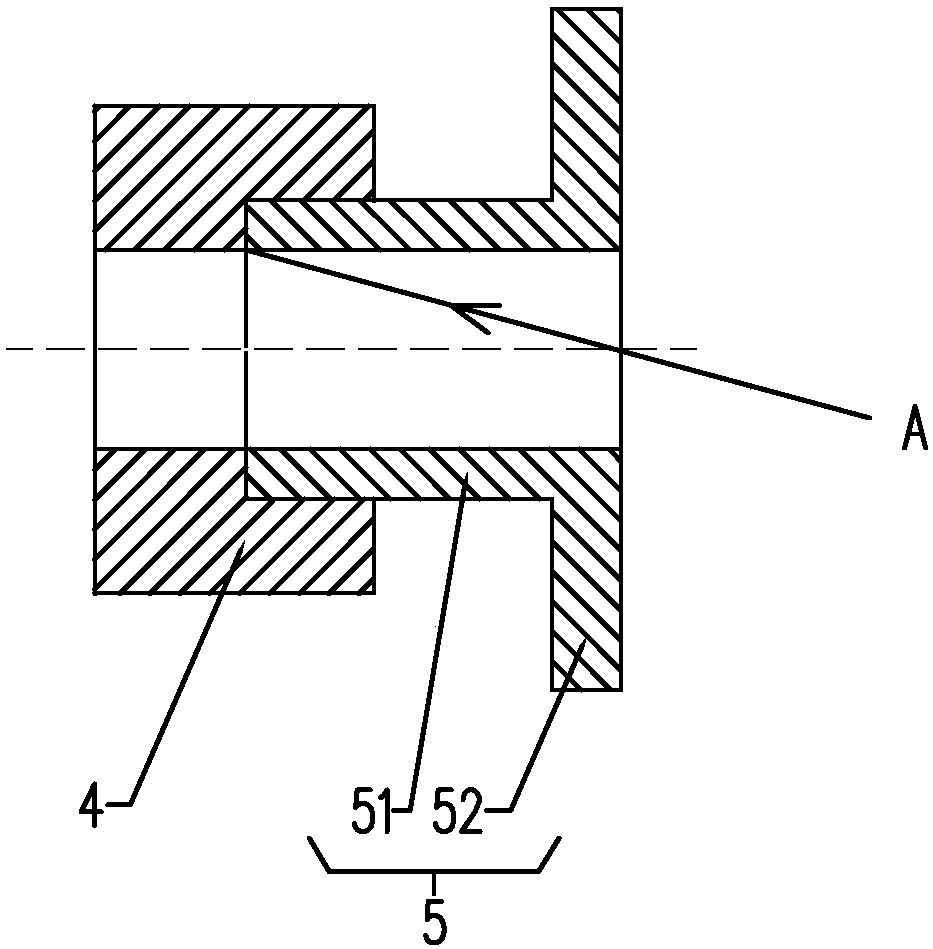

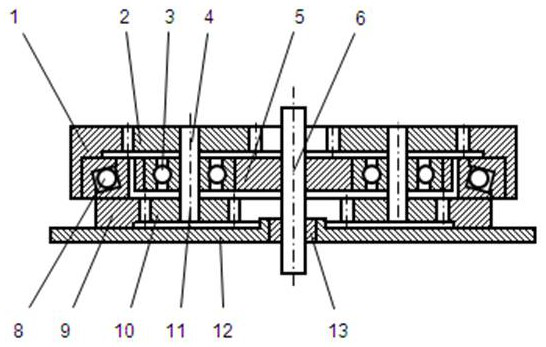

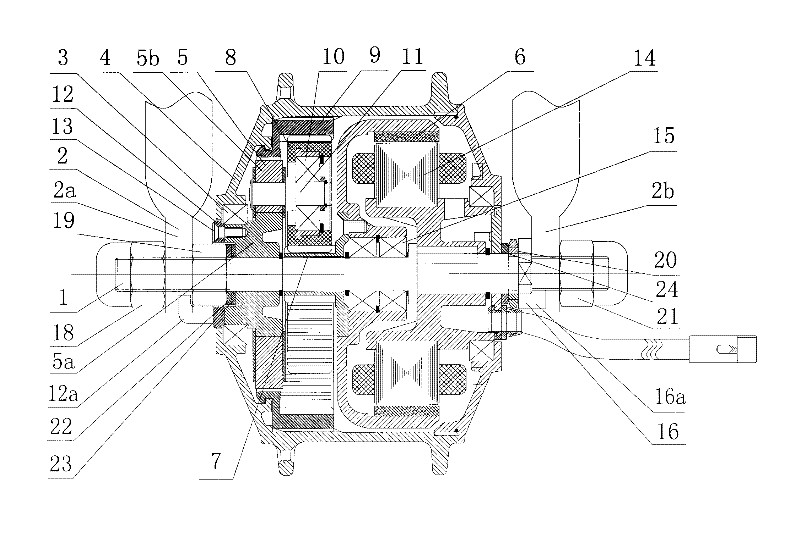

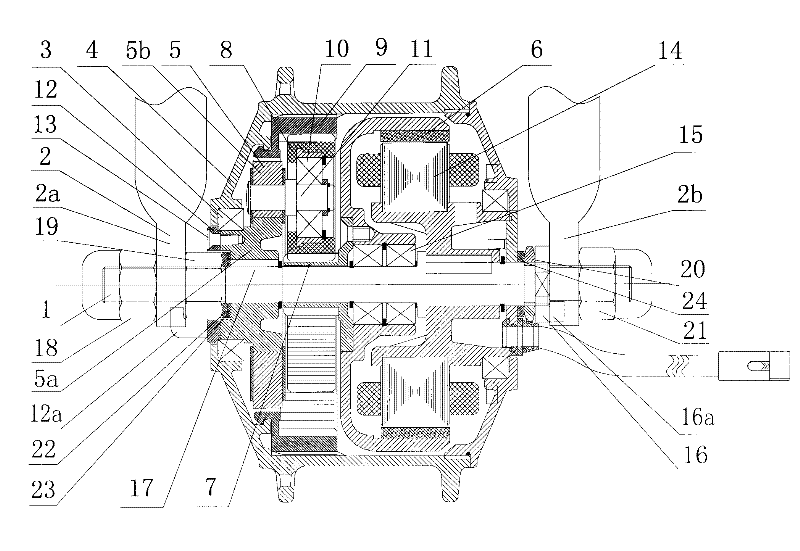

Driving device for electric lumbar system

The invention relates to the technical field of a reeling-unreeling device and particularly relates to a driving device for an electric lumbar system. The driving device comprises a box body, an upper cover, a worm, a worm gear, a wire wheel and an eccentric wheel, wherein the box body and the upper cover are assembled to form a case body; the case body is provided with a wire outlet groove; the box body is internally provided with the worm gear; the worm gear is matched with the worm; the eccentric wheel doing eccentric movement is axially driven by the worm gear; and the wire wheel is axially driven by the eccentric wheel. A scheme that the eccentric wheel doing eccentric movement is driven by the worm gear and the wire wheel is driven by the eccentric wheel is adopted, the outer diameter of the worm gear can be greatly lessened, the quantity of teeth outside the worm gear is remarkably reduced, the difference between the quantity of teeth of the eccentric wheel and the quantity of teeth of the wire wheel is small, the whole size is small, and the rigidity of the worm gear is improved; and cascade type multi-step transmission is adopted, a high transmission ratio is achieved, the whole stability is good and the service life is long.

Owner:东莞市凌锐汽车零部件有限公司 +1

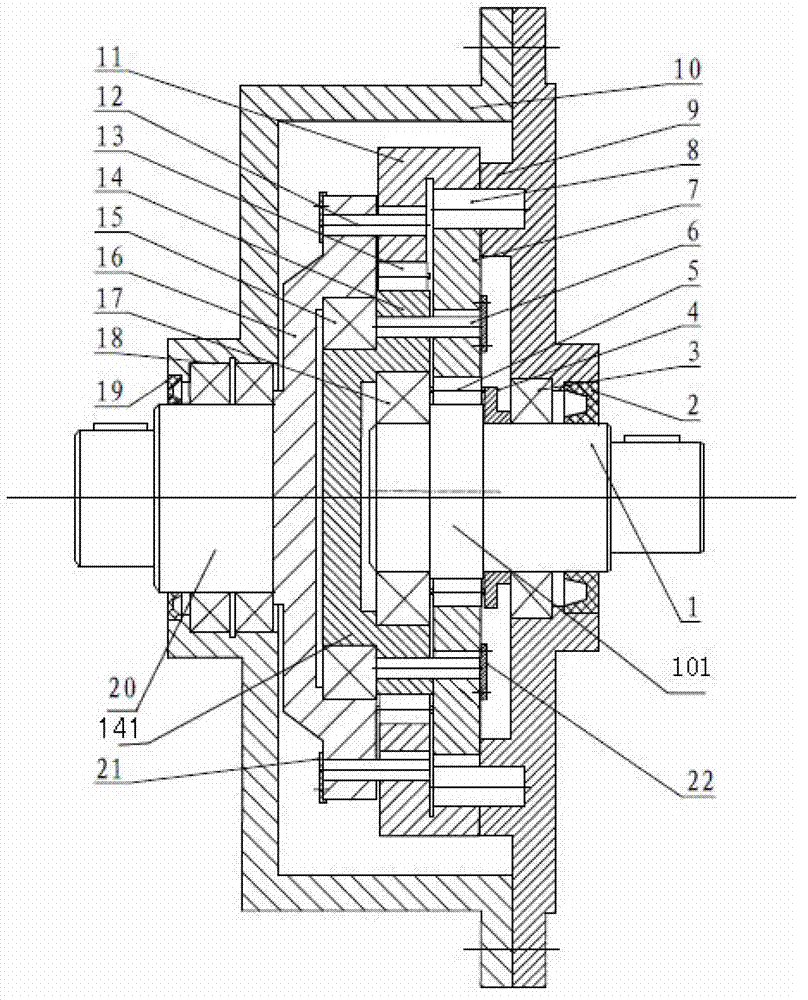

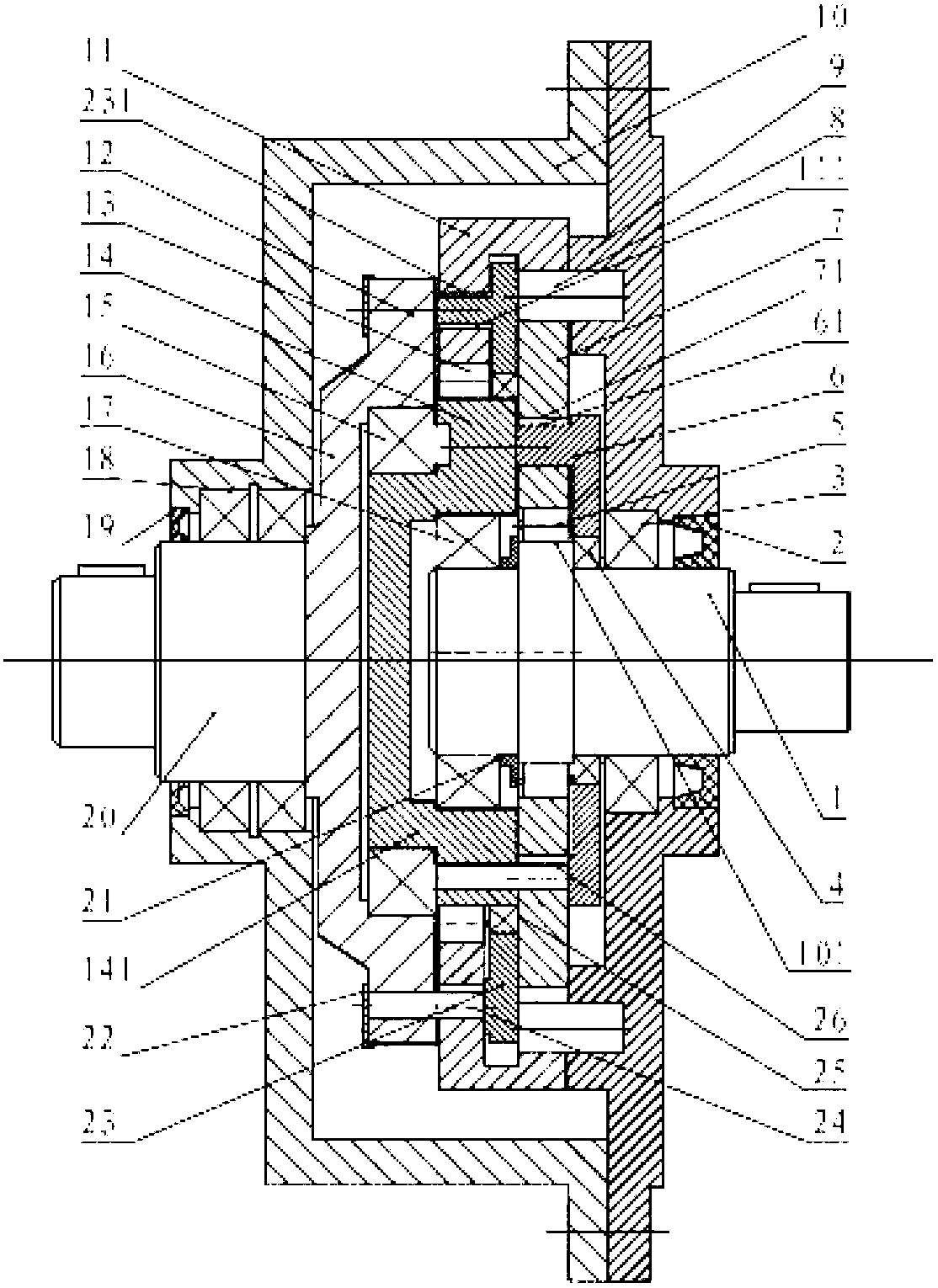

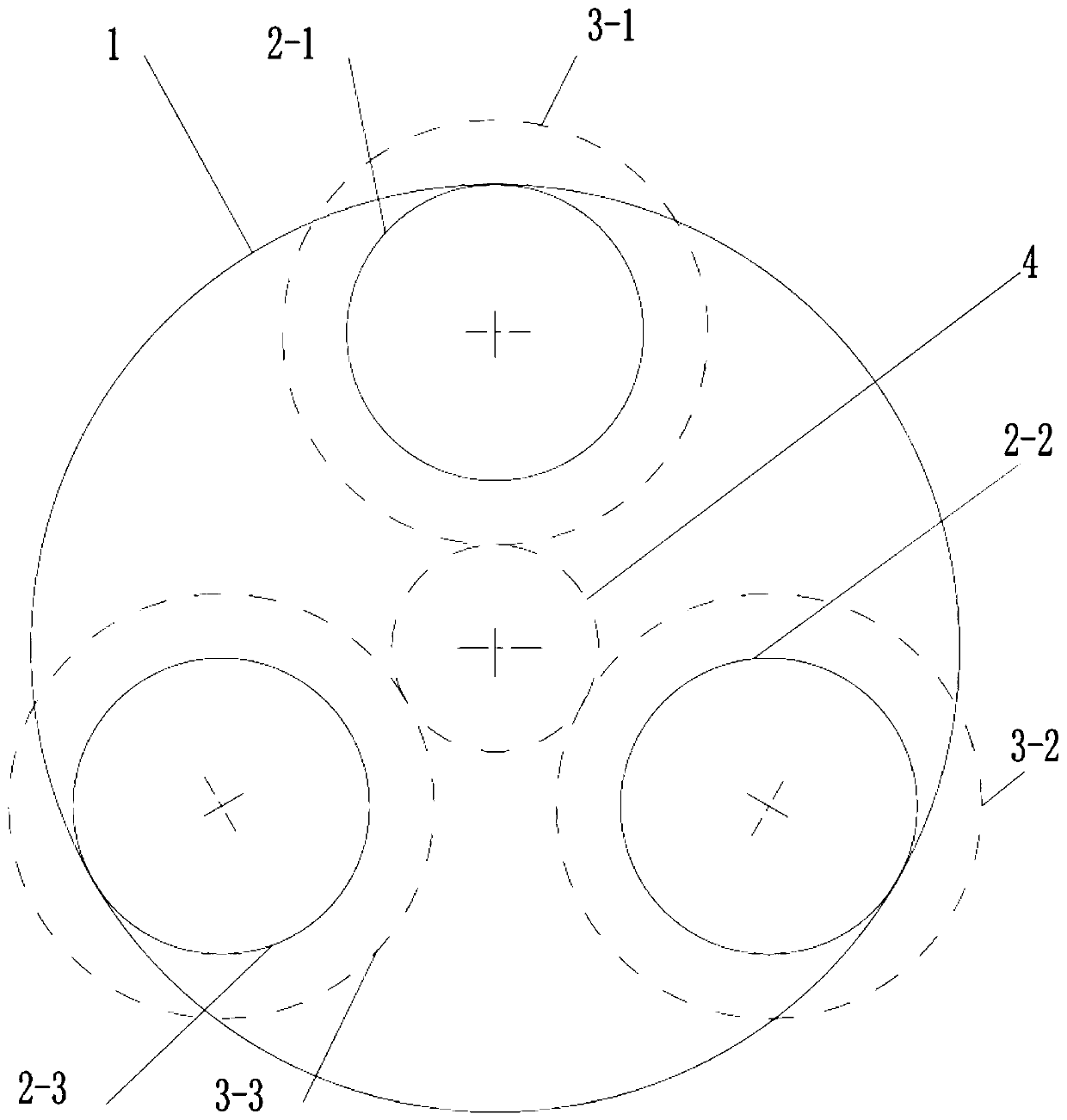

Inner and outer tooth form meshing gear reducer

ActiveCN103115112AHigh machining accuracy requirementsImprove transmission efficiencyToothed gearingsGearing detailsDrive wheelReduction drive

The invention relates to an inner and outer tooth form meshing gear reducer comprising a first-level reducing mechanism and a second-level reducing mechanism. The first-level reducing mechanism comprises an eccentric wheel (101), a first turning bearing(5), an outer-meshing curve wheel (7) and a gear pin (8); the gear pin is fixed on a first support (9) and externally meshes with the outer-meshing curve wheel (7). The second-level reducing mechanism comprises an eccentric driving wheel (14), a second turning bearing (13) sleeved on the eccentric driving wheel (14), an outer-meshing curve wheel (11), and an output plate (16) in linkage with an output shaft (20). The outer-meshing curve wheel (11) is sleeved on the second turning bearing (13) and internally meshes with the gear pin (8). The eccentric driving wheel (14) is in linkage with the outer-meshing curve wheel (7) through a pin (6), and the outer-meshing curve wheel (11) is in linkage with the output plate (16) through a driving pin (12). The inner and outer tooth form meshing gear reducer has the advantages of few tooth numbers, high speed ratio, small size, high load bearing, high efficiency and long service life, and is especially applicable to reducers by industrial robots.

Owner:ZHEJIANG HENGFENGTAI REDUCER MFG

Rigid inside and outside tooth-profile-wrapped tooth reducer

Owner:ZHEJIANG HENGFENGTAI REDUCER MFG

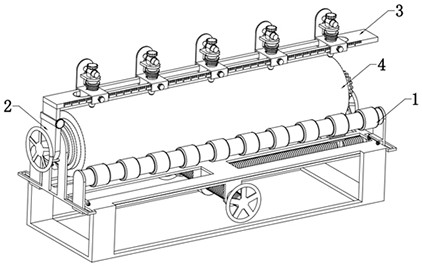

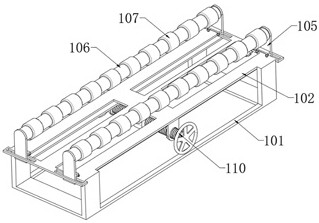

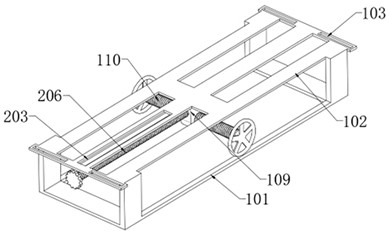

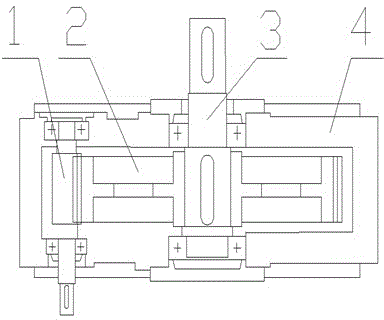

Straightness detection device for geological exploration drill rod

ActiveCN114877829APlay a supporting roleQuick checkWork holdersUsing optical meansStructural engineeringGeological exploration

The invention discloses a straightness detection device for a geological exploration drill rod, and relates to the technical field of drill rod detection equipment, the straightness detection device comprises a supporting assembly, clamping assemblies, a detection assembly and a drill rod body, the clamping assemblies are arranged at the two ends of the upper surface of the supporting assembly, and the detection assembly is arranged at the top ends of the clamping assemblies; a drill rod body is arranged in the middle of the upper surface of the supporting assembly, the supporting assembly can support the drill rod, the clamping assembly is arranged above the supporting assembly, the clamping assembly can clamp the two ends of the drill rod, the drill rod can be driven to rotate through the clamping assembly, and the drill rod can be clamped through the clamping assembly. The detection assembly is arranged at the top end of the clamping assembly, the detection assembly can detect multiple parts of the outer side of the drill rod, the supporting assembly, the clamping assembly and the detection assembly are matched, multi-directional rapid detection of the drill rod can be achieved, compared with manual detection, the detection efficiency can be effectively improved, and the drill rod detection device is more suitable for rapid detection of multiple drill rods.

Owner:LANZHOU CITY UNIV

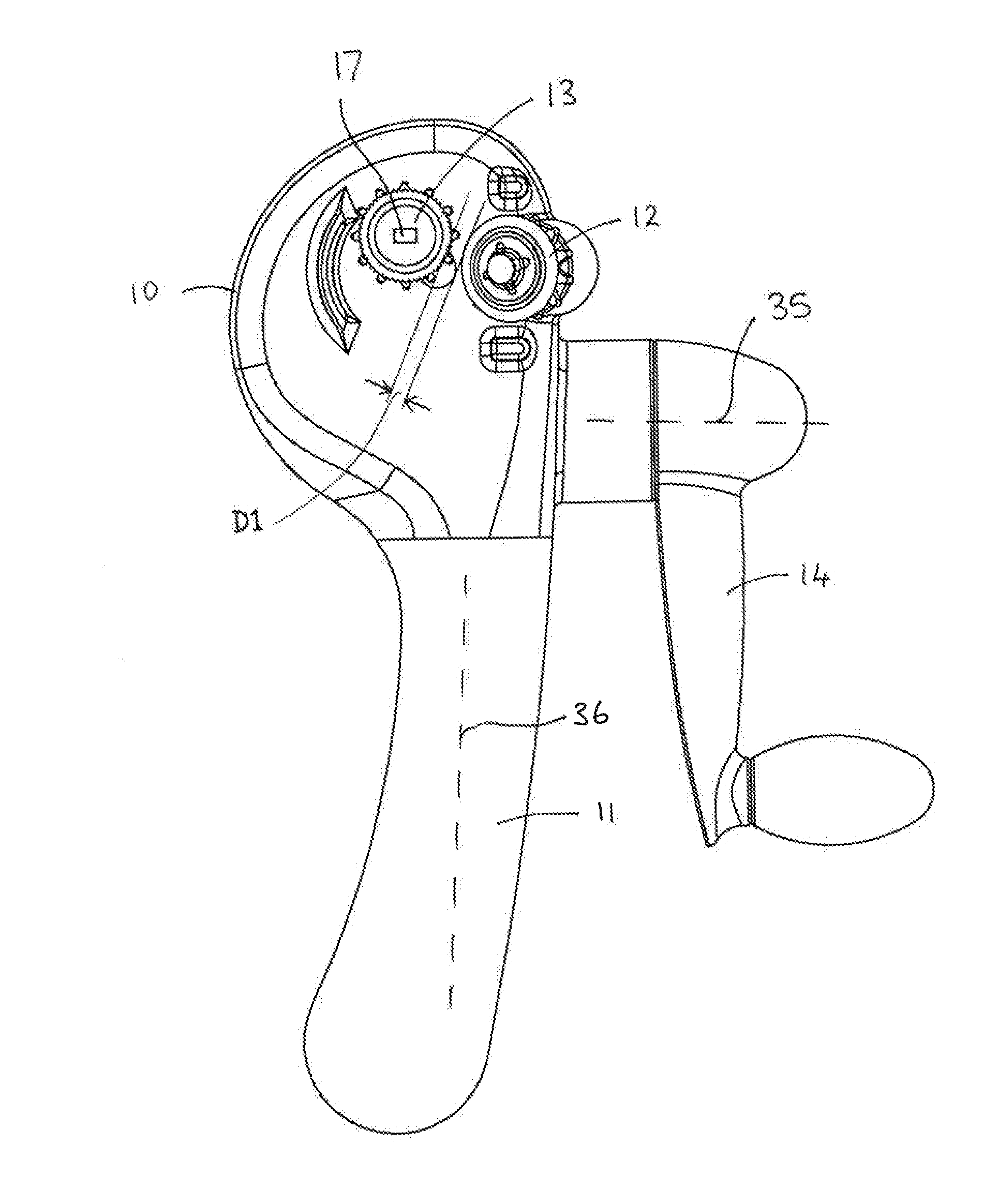

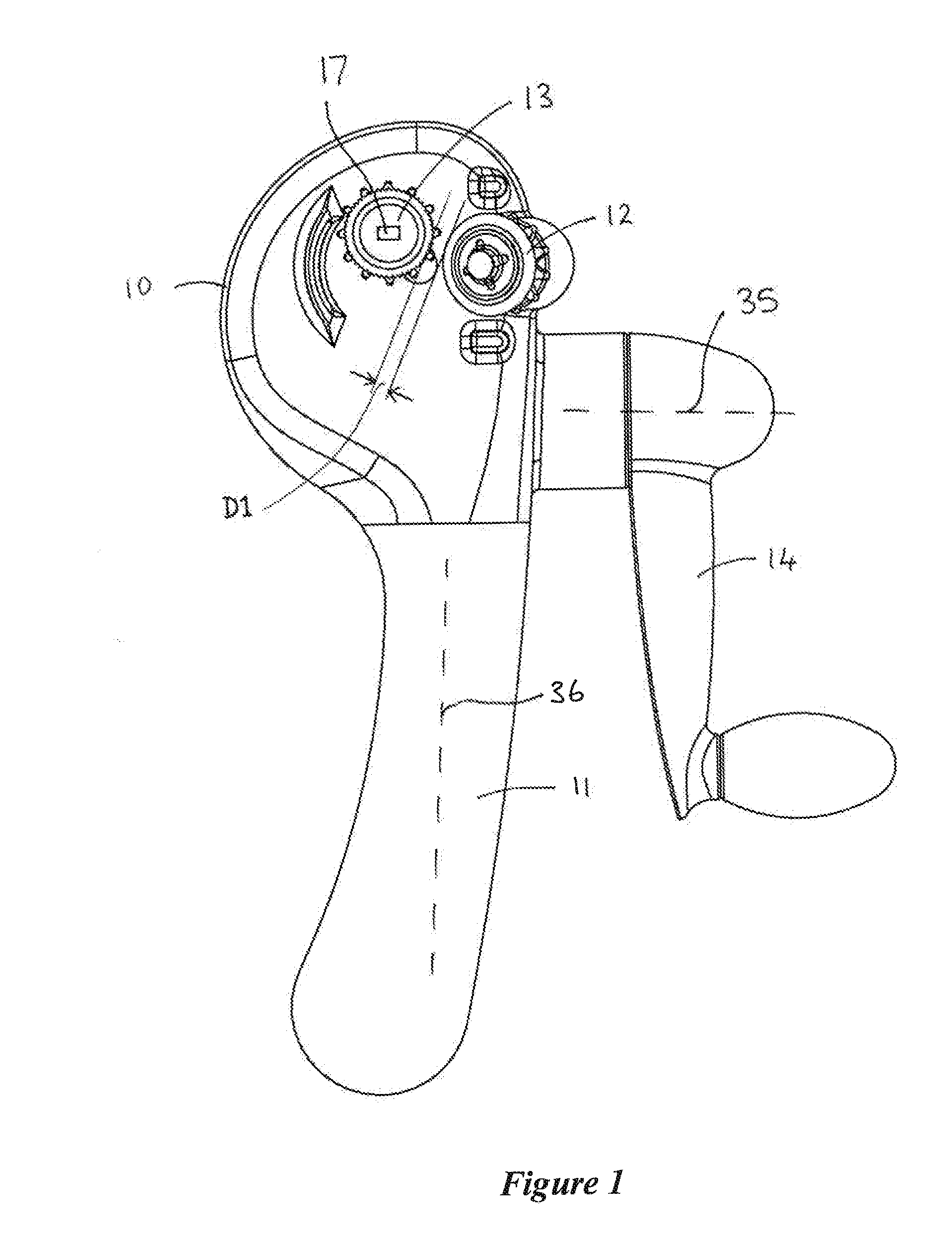

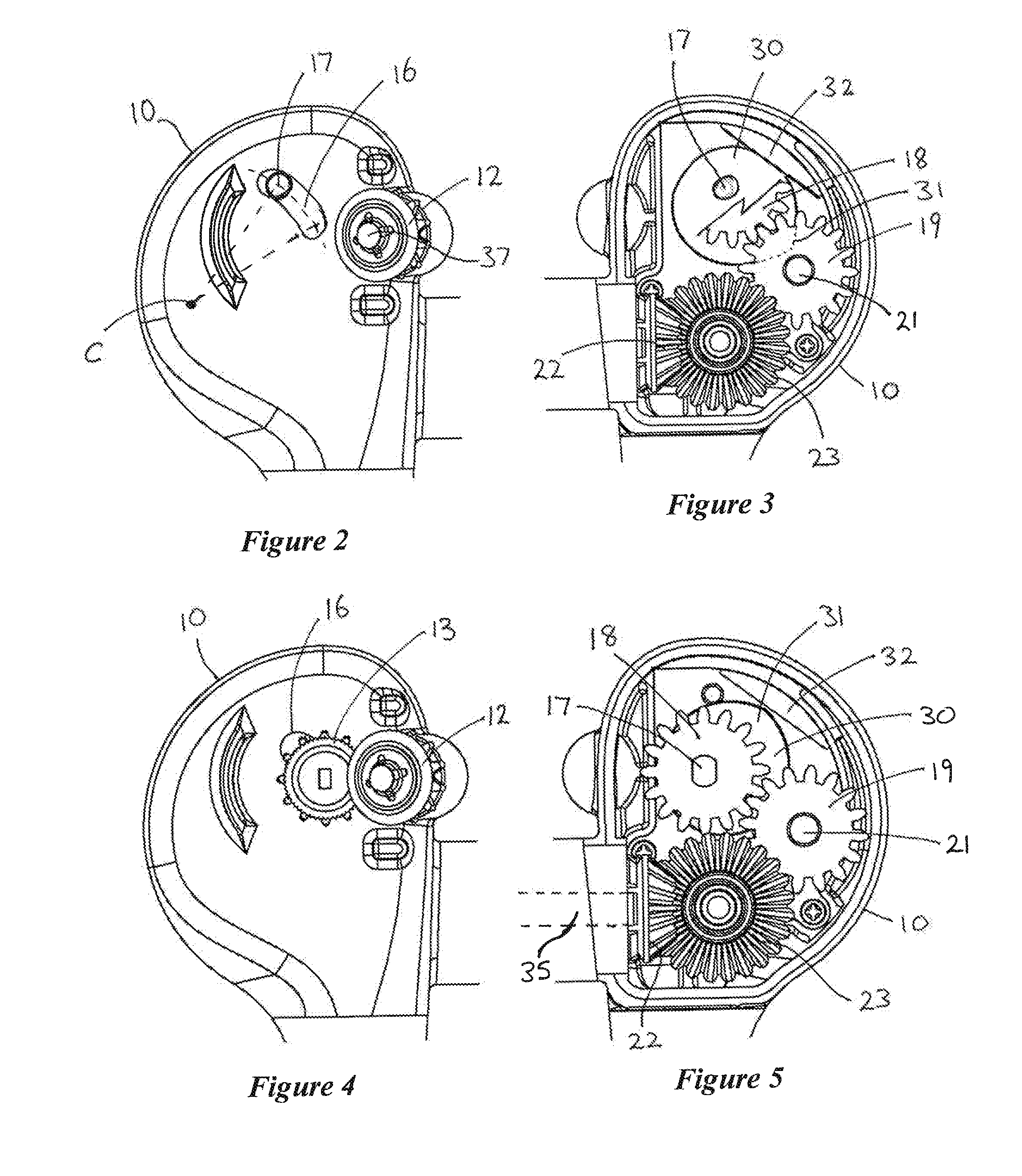

Can opener

InactiveUS20110283551A1Few teethBottle/container closurePower operated devicesKnife bladesEngineering

Owner:UNION LUCKY IND LTD

Multi-planet-wheel transmission mechanism

InactiveCN106870646AImprove power densityCompact structureGeometric CADToothed gearingsGear wheelEngineering

The invention discloses a multi-planet-wheel transmission mechanism which comprises a sun gear, a gear ring and a planet carrier and further comprises a plurality of planet wheel sets, wherein each planet wheel set comprises at least two gears; the gears are all mounted on the planet carrier and can rotate relative to the planet carrier; and two ends of each planet wheel set are meshed with the sun gear and the gear ring. According to the embodiment of the invention, a planet wheel is replaced by a planet wheel set formed by a plurality of small gears to increase the split flow number of a planetary gear train to further increase the power density of the planetary gear train; and in addition, as the small planet wheels are unlikely to intervene in the peripheral direction, the teeth number of the sun gear can be further reduced to increase the transmission ratio of the planetary gear train.

Owner:TSINGHUA UNIV

Contoured reamer teeth

An acetabular reamer (10′) for cutting a required cut shape. The reamer has a cutting shell (12′) having a series of doubly curved cutting teeth (16′) thereon of a quantity to substantially reduce a cutting pressure on each tooth as well as to reduce a size of a typical chip generated upon cutting. Substantially all the teeth each have a matched arc cutting edge (20′) of substantial length that has a cutting profile which substantially matches a profile of a shape to be cut. Such a configuration reduces the number of teeth required to cut the shape.

Owner:VIANT AS&O HLDG LLC

Compact hybrid drive wind generating set gearbox transmission structure

PendingCN111536203AReduced bending capacityImprove carrying capacityToothed gearingsGearing detailsGear driveGear wheel

The invention discloses a compact hybrid drive wind generating set gearbox transmission structure. The structure comprises a first-stage planetary gear transmission system, a second-stage planetary gear transmission system and a third-stage planetary gear transmission system; the first-stage transmission system adopts fixed shaft internal meshing transmission, and power is input through an inner gear ring of the first-stage transmission system and averagely distributed and output through multiple outer gears of the first-stage transmission system; the second-stage transmission system adopts fixed shaft external meshing transmission, and the power is input through multiple large gears and converged to a central small gear to be output; and the third-stage planetary gear transmission systemis an NGW planetary transmission system, a planet carrier of the third-stage planetary gear transmission system is connected with a central small gear through a spline pair, and a sun gear of the third-stage planetary gear transmission system is connected with a generator. According to the structure, the radial space of original second-stage planetary transmission of a traditional compact hybrid wind generating set gearbox is fully utilized, and the wind power generation power and the gearbox speed ratio can be improved while the space of the gearbox is unchanged, which provides a solution forthe compact hybrid drive wind power generation transmission structure.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

Co-location differential speed reducer

InactiveCN112013094ASmall backlash angleRich selection of gear ratiosDifferential gearingsReduction driveReducer

The invention discloses a co-location differential speed reducer which is a speed reducer with a co-location differential gear train. A transmission structure of the co-location differential speed reducer is designed by combining differential logics and multiple logics, the reduction ratio is negatively correlated with the difference value of two contrast rotating speeds, and the difference valuecan be infinitely close to zero from the positive direction and the negative direction, so that the reduction ratio can tend to be infinitely great or infinitely small, how large the reduction ratio is is not mainly determined by how large the multiple of geometrical parameters of assemblies of a transmission gear train is and is mainly determined by how approaches the multiple of geometrical parameters of two transmission gear trains is, under the condition that the sizes are equal, a wide output range and a large reduction ratio can be obtained, or under the same reduction ratio, the size issmaller or the load capacity is larger. On the basis, multiple zero-backlash transmission methods are adopted to reduce return difference, and multiple other technical means are matched to obtain more excellent comprehensive performance and a larger application range.

Owner:周承岗

Composite cosine tooth form internal meshing transmission gear

PendingCN111853203AIncreasing the thicknessStrong contact strengthPortable liftingGearing elementsGear wheelHigh transmission

The invention relates to the technical field of gears, and provides a composite cosine tooth form internal meshing transmission gear. The composite cosine tooth form internal meshing transmission gearcomprises an inner gear and an outer gear, and a single tooth profile of a composite cosine inner gear is formed by sequentially connecting a first inferior arc, a first cosine curve segment and a second inferior arc; the single tooth profile of a composite cosine inner gear is smoothly connected by the first inferior arc and the first cosine curve segment, and the second inferior arc is smoothlyconnected with the first cosine curve segment; and the circle center of a circle where the first inferior arc and the second inferior arc of the single tooth profile of the composite cosine inner gear is located is concentric with a reference circle of the composite cosine inner gear, and the radii of the first inferior arc and the second inferior arc are the same. The composite cosine tooth forminternal meshing transmission gear has the advantages of high transmission efficiency and stable power transferring.

Owner:XUCHANG UNIV

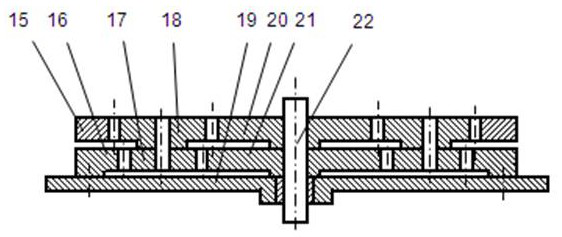

Electric lumbar support driver

The invention discloses an electric lumbar support driver. The electric lumbar support driver comprises a shell and an end cover, wherein the shell and the end cover are combined into a box body, and an outlet line is formed on the box body. The electric lumbar support driver is characterized in that a worm gear, a fixed gear ring, an external gear, a drive disc and an inhaul cable disc are arranged in the box body, the worm gear rotates by virtue of worm drive, a worm is driven by a power source, an eccentric shaft is arranged on the worm gear, the external gear is arranged on the eccentric shaft, a drive pin is arranged on the external gear, the fixed gear ring is fixedly arranged in the box body and is arranged outside the external gear to be eccentrically meshed with the external gear, the drive disc is arranged on the external gear, a first driving groove and a second driving groove are formed in the drive disc, the first driving groove is matched with the drive pin, the inhaul cable disc is rotatably arranged above the drive disc, a driving column is accordingly arranged on the inhaul cable disc, and the driving column is matched with the second driving groove. The electric lumbar support driver disclosed by the invention adopts stacked multi-drive, a large drive ratio is realized, the overall stability is better, and the service life is longer.

Owner:ZHEJIANG YAHU AUTO PARTS

Hub of electric bicycle

ActiveCN101797950BIncrease output torqueHigh torqueVehicle transmissionRider propulsionGear wheelElectric machinery

The invention discloses a hub of an electric bicycle, comprising a main shaft fixed on a frame. The main shaft is provided with a hub shell by a hub shell bearing; a motor, a planet wheel reducing mechanism and a clutch are arranged in the hub shell; the motor adopts a structure with an inner stator and an outer rotor; a sun gear sleeved on the main shaft is fixed on the rotor; the sun gear is meshed with a planet gear; the planet gear is meshed with a hub inner gear ring fixed on the hub shell; the planet gear is arranged on a planet shaft by a planet bearing; the planet shaft is fixed on the clutch; and the clutch and the frame are fixed with each other. Compared with the prior art, the torsion of the clutch in work is borne by using the frame, the torque force borne by the main shaft is greatly reduced, and thereby, the main shaft is made thin to reduce the tooth number of the sun gear under the premise of ensuring the strength of the main shaft to achieve the goals of increasing the reduction ratio of the sun gear to the hub inner gear ring, further increasing the output torque of the main shaft and reducing the volume of the hub.

Owner:BAFANG ELECTRIC (SUZHOU) CO LTD

Driving rear axle of mini electric vehicle

InactiveCN106379164AHigh strengthImprove the feature of lack of spaceControl devicesInterior spaceGear wheel

The invention discloses a driving rear axle of a mini electric vehicle. The driving rear axle of the mini electric vehicle adopts a transmission structure with a motor, a single-reduction gearbox and a differential, is simple and compact in structure and high in transmission efficiency as compared with the prior art, and is more suitable for mini electric vehicles. Simultaneously, a motor output gear shaft which is processed by a cold extrusion molding technique has the characteristics of low number of teeth and high strength, and is suitable for the transmission structure with the motor, single-reduction gearbox and differential. The motor and reduction gearbox integrated case is convenient for mounting and disassembly, reduces the required space for arrangement, and solves the problem that the inner space of the mini electric vehicle is insufficient.

Owner:CHANGCHUN UNIV OF TECH

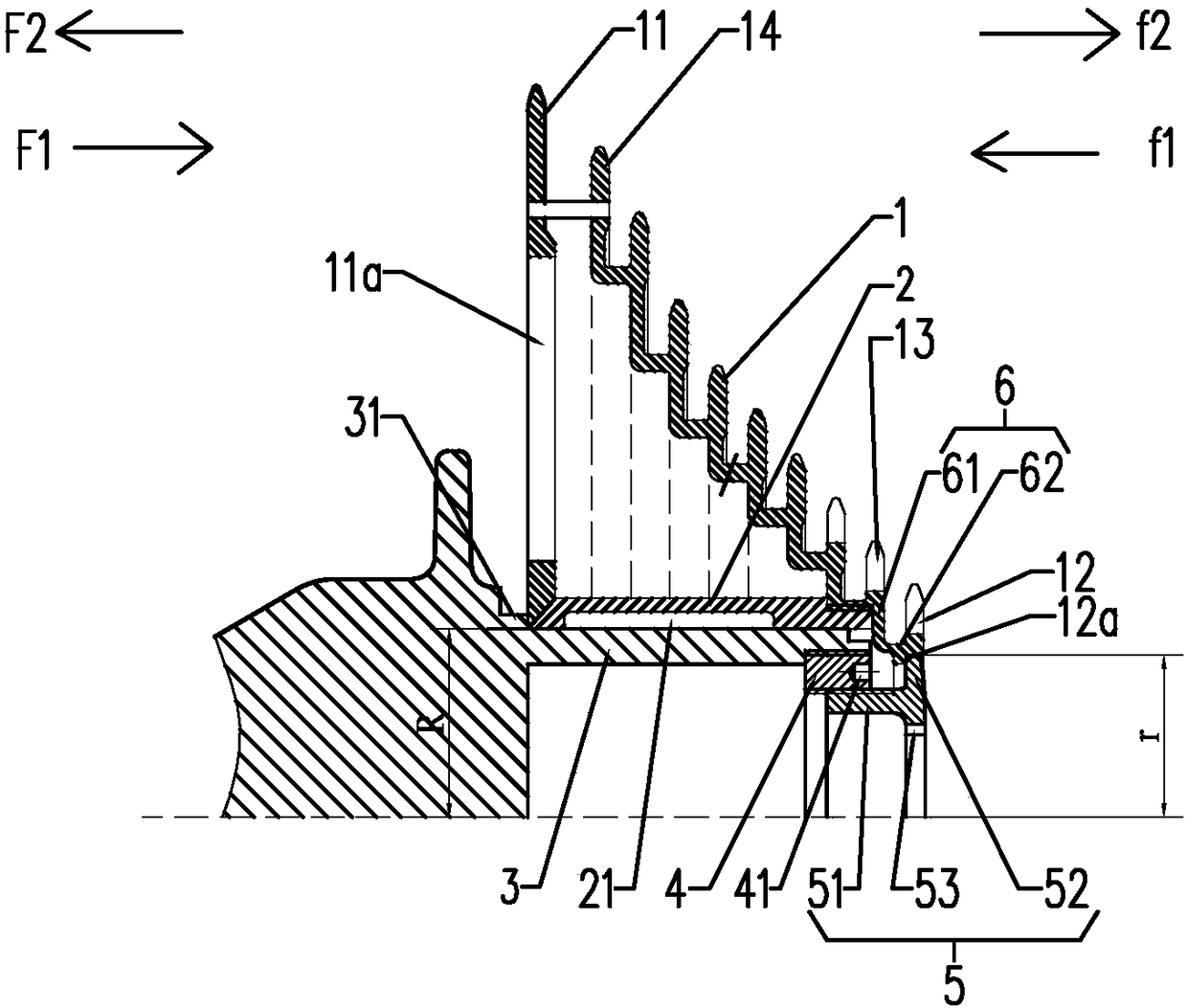

Speed reducer of novel conveyor

The invention discloses a speed reducer of a novel conveyor. The speed reducer of the novel conveyor comprises a worm (1), a worm wheel (2), an output shaft (3) and a box body (4); an input torque drives the worm (1) for rotating, the worm wheel (2) is engaged with the worm (1), the worm wheel (2) is mounted on the output shaft (3), the output shaft (3) is driven by the worm wheel (2) for outputting torque, the worm (1) and the output shaft (3) are mounted on the box body (4); the speed reducer is mainly applied to the coal mine conveyor, which adopts the involute few teeth gear transmission mechanism, the single transmission ratio is increased, the structure size volume is reduced, the speed reducer of the novel conveyor has the advantages of low cost, simple structure, high transmission efficiency, big bearing capability, resistance to wear and strong adhesive resisting capability.

Owner:XIAN LIYUAN INTELLIGENT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com