Patents

Literature

6588 results about "Lap joint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

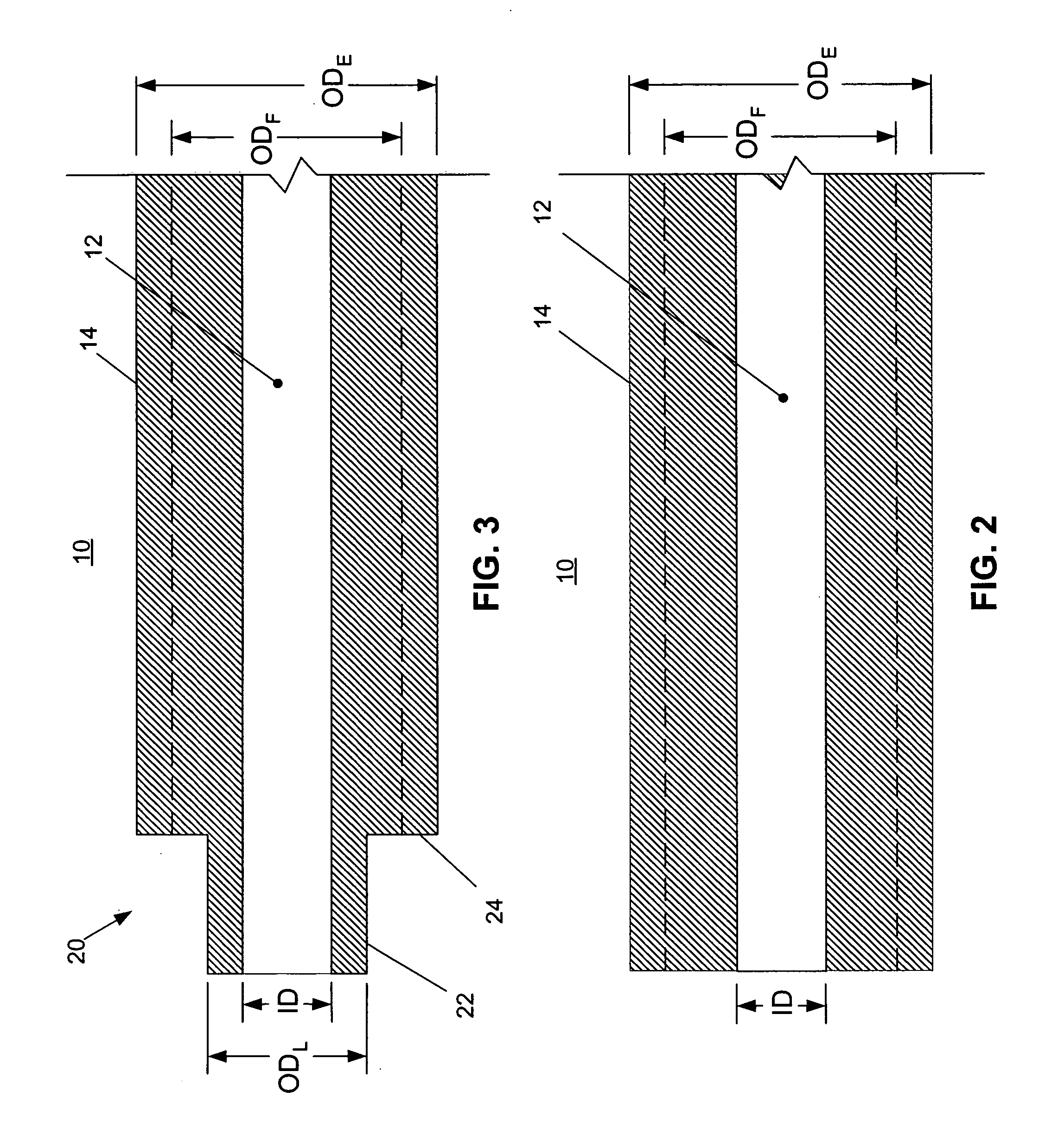

A lap joint or overlap joint is a joint in which the members overlap. Lap joints can be used to join wood, plastic, or metal. A lap joint may be a full lap or half lap. In a full lap, no material is removed from either of the members that will be joined, resulting in a joint which is the combined thickness of the two members. In a half lap joint or halving joint, material is removed from both of the members so that the resulting joint is the thickness of the thickest member. Most commonly in half lap joints, the members are of the same thickness and half the thickness of each is removed.

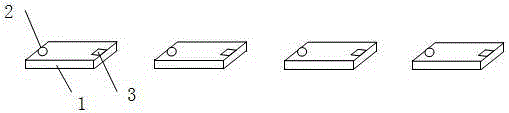

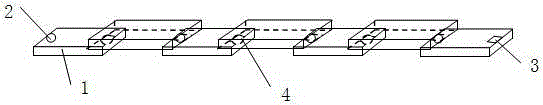

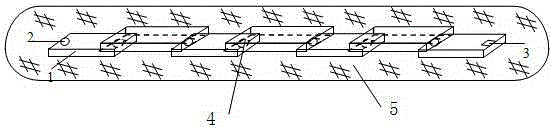

LED lamp filament illuminating strip and preparation method therefor

ActiveCN105161608AImprove yieldImprove uniformitySolid-state devicesSemiconductor devicesFluorescenceLap joint

The invention discloses an LED lamp filament illuminating strip and a preparation method therefor. The illuminating strip comprises LED chips in upper and lower rows, wherein all LED chips in the lower row are distributed at intervals, and all LED chips in the upper row are respectively connected between two adjacent LED chips in the lower row in a lap joint manner. The illuminating surfaces of the LED chips in the upper and lower rows are opposite to each other. The positive and negative electrodes of all LED chips in the upper row are respectively welded with the negative and positive electrodes of two adjacent LED chips, in lap joint connection with the LED chips in the upper row, in the lower row. The preparation method comprises the steps: coating solder paste on the positive and negative electrodes of all LED chips in the lower row; heating the solder paste and enabling the solder paste to be melted, welding the corresponding electrodes, coating the front and back surfaces of chip strips in series connection with fluorescent glue, and solidifying the fluorescent glue. The illuminating strip employs the chips which are not overlapped with each other, and the illuminating surfaces of the chips are arranged oppositely, thereby improving the light-emitting uniformity and facilitating heat dissipation. The wire crossing and tandem among chips is avoided, the packaging cost is reduced, and the yield of finished products is improved.

Owner:SHANDONG INSPUR HUAGUANG OPTOELECTRONICS

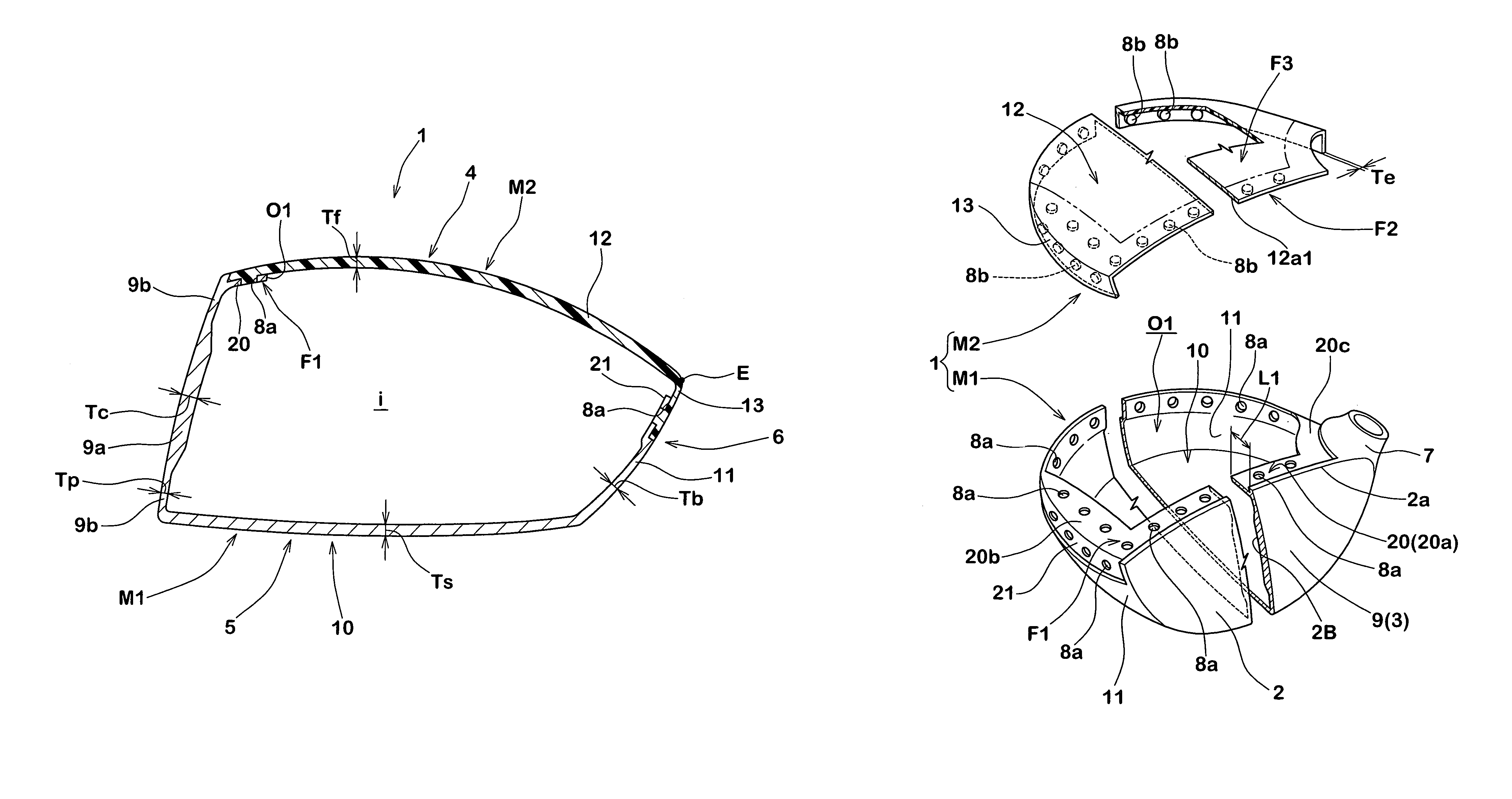

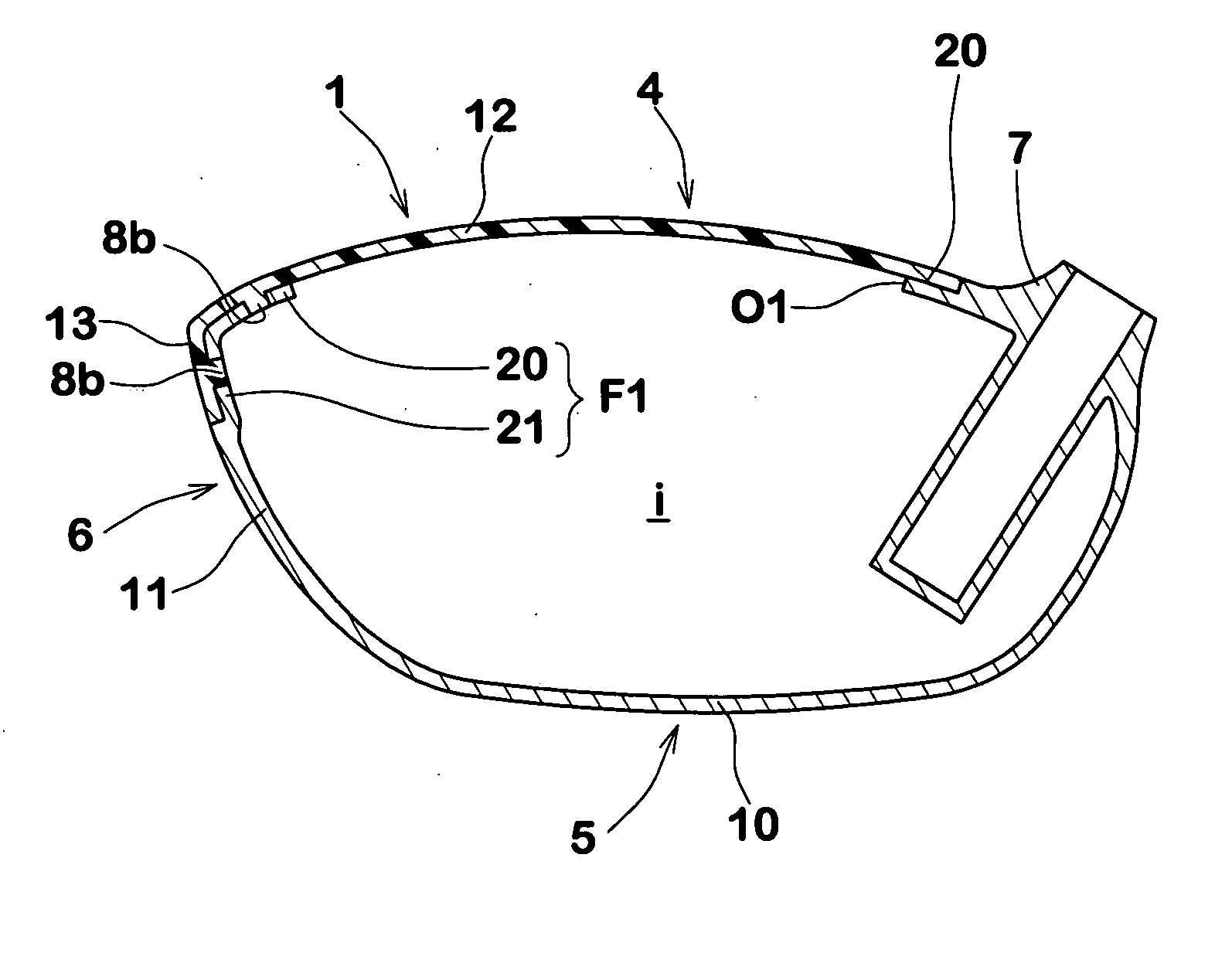

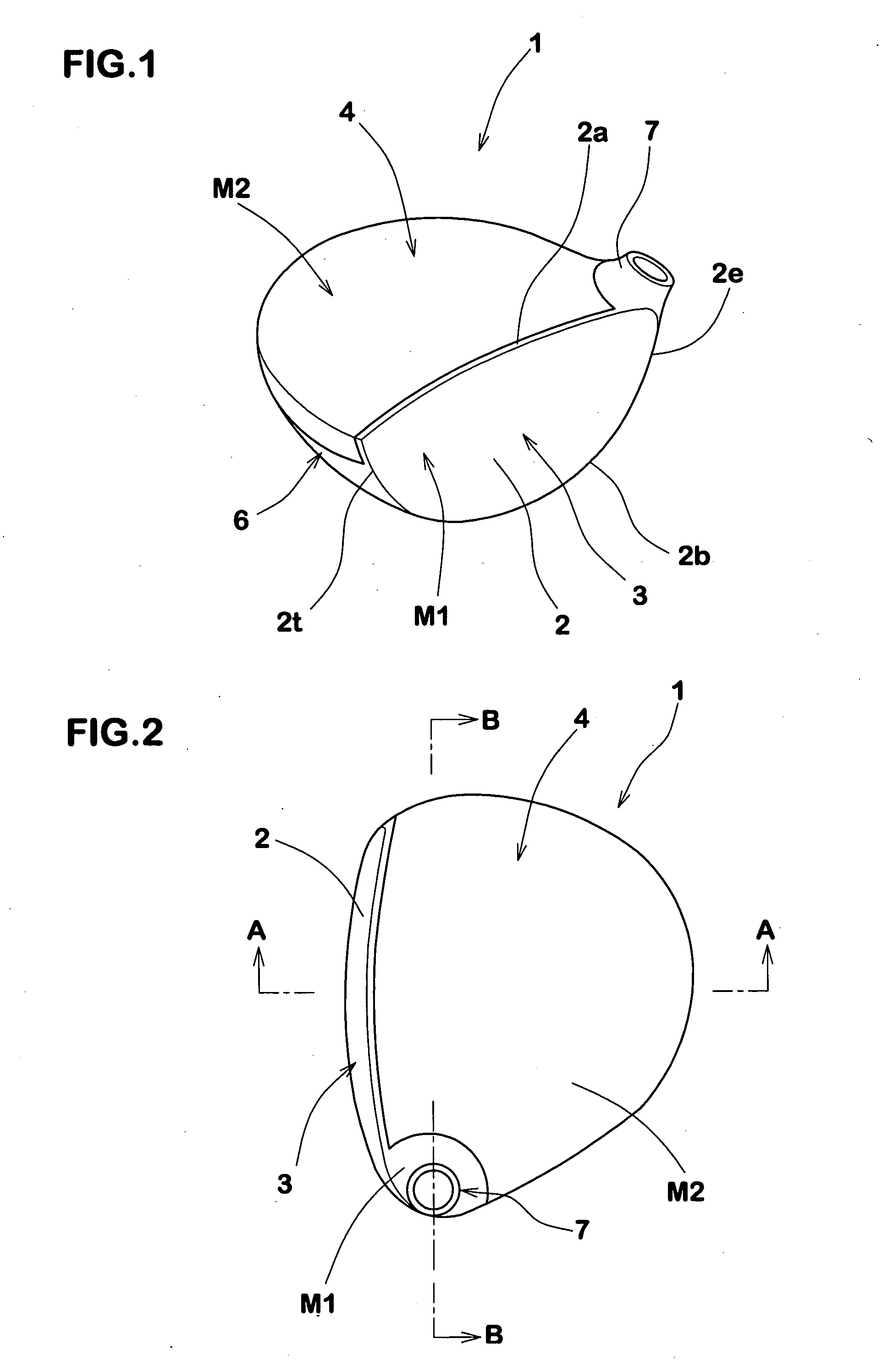

Golf club head

ActiveUS7128662B2Increased durabilityHigh strengthGolf clubsStringed racketsLap jointMetallic materials

The present invention relates to a golf club head composed ofa metal member made of at least one kind of metal material and a FRP member made of a fiber reinforced resin, the metal member having a first lap joint part, and the FRP member having a second lap joint part lap-jointed with the first lap joint part and a non-lap joint part, wherein the resin content of the second lap joint part is larger than the resin content of the non-lap joint part.

Owner:SUMITOMO RUBBER IND LTD

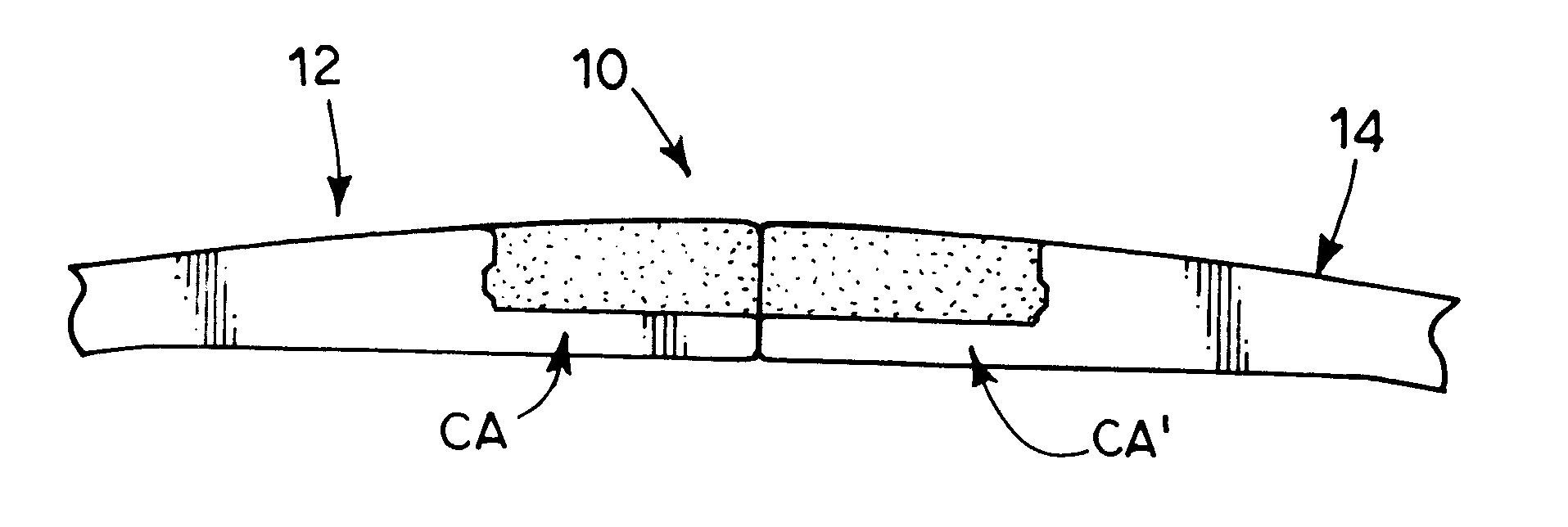

Joint for pre-cast concrete twin-leaf arch sections

InactiveUS6243994B1Efficiently and accurately formForming accuratelyUnderground chambersBuilding material handlingControl theoryPrecast concrete

A joint for pre-cast concrete twin-leaf arch sections is self-aligning when the two arch sections are initially brought into abutting contact with each other. The joint provides a rigid connection between the twin units and is achieved on site by means of re-inforced cast-in-place concrete. Reinforcement splices for the connection are lap splices, and the joint allows pouring the cast-in-place concrete without the need of formwork. For load distributing purposes, a continuous connection of individual arch rings in the longitudinal direction at the arch crown is possible. An initial abutting contact between the twin units is provided by the joint of the present invention. The contact provided by the joint of the present invention is self-aligning, locking, allows the controlled transmission of the abutting force and allows for a temporary connection. The joint includes mechanical elements for aligning and locking the two arch sections together. The mechanical elements include, in the preferred embodiment, a projection on one arch section and a depression on the other arch section. Cast-in-place concrete is placed in boxed-out, or step, sections located adjacent to the mechanical elements and completes the joint.

Owner:CONTECH ENGINEERED SOLUTIONS

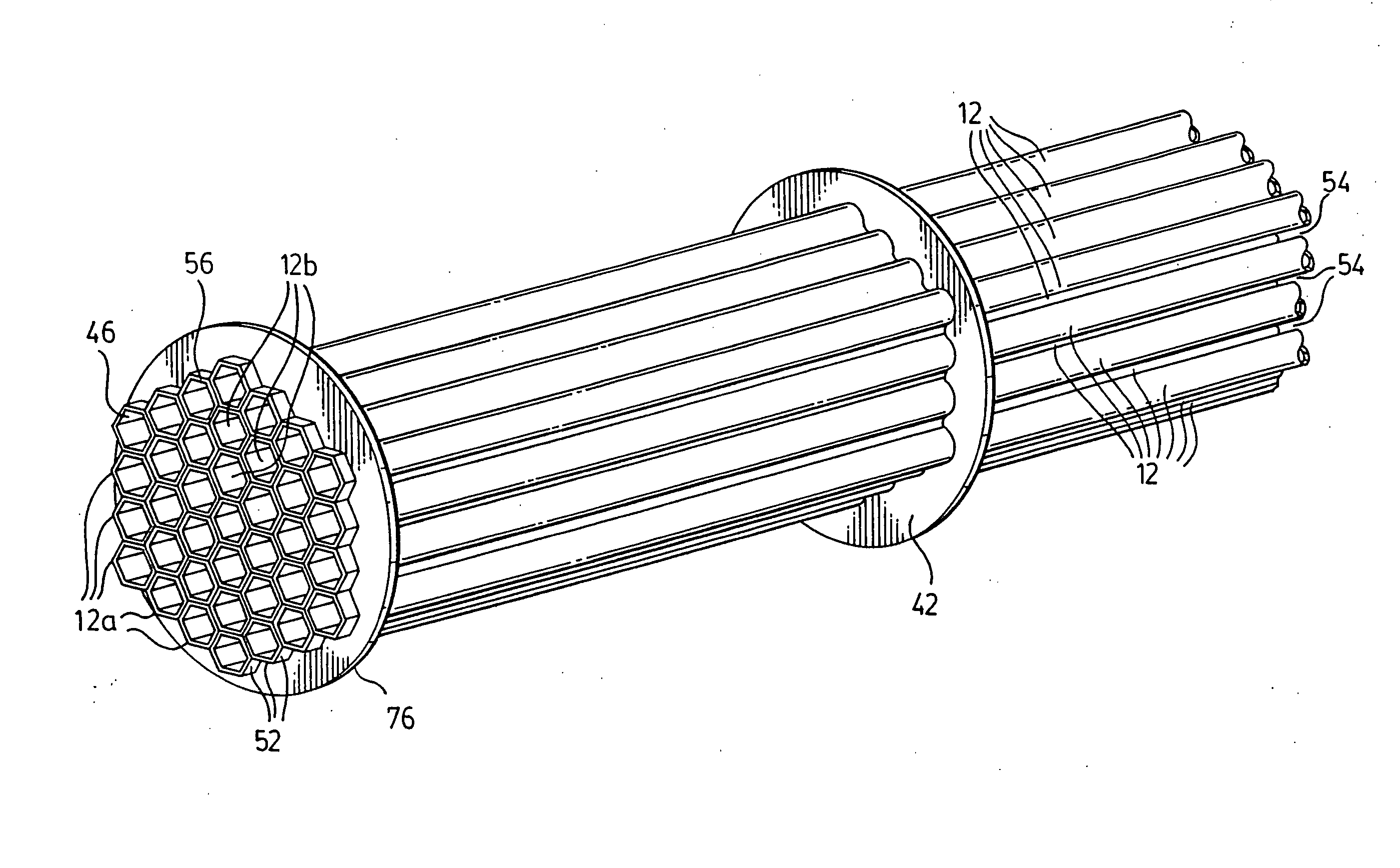

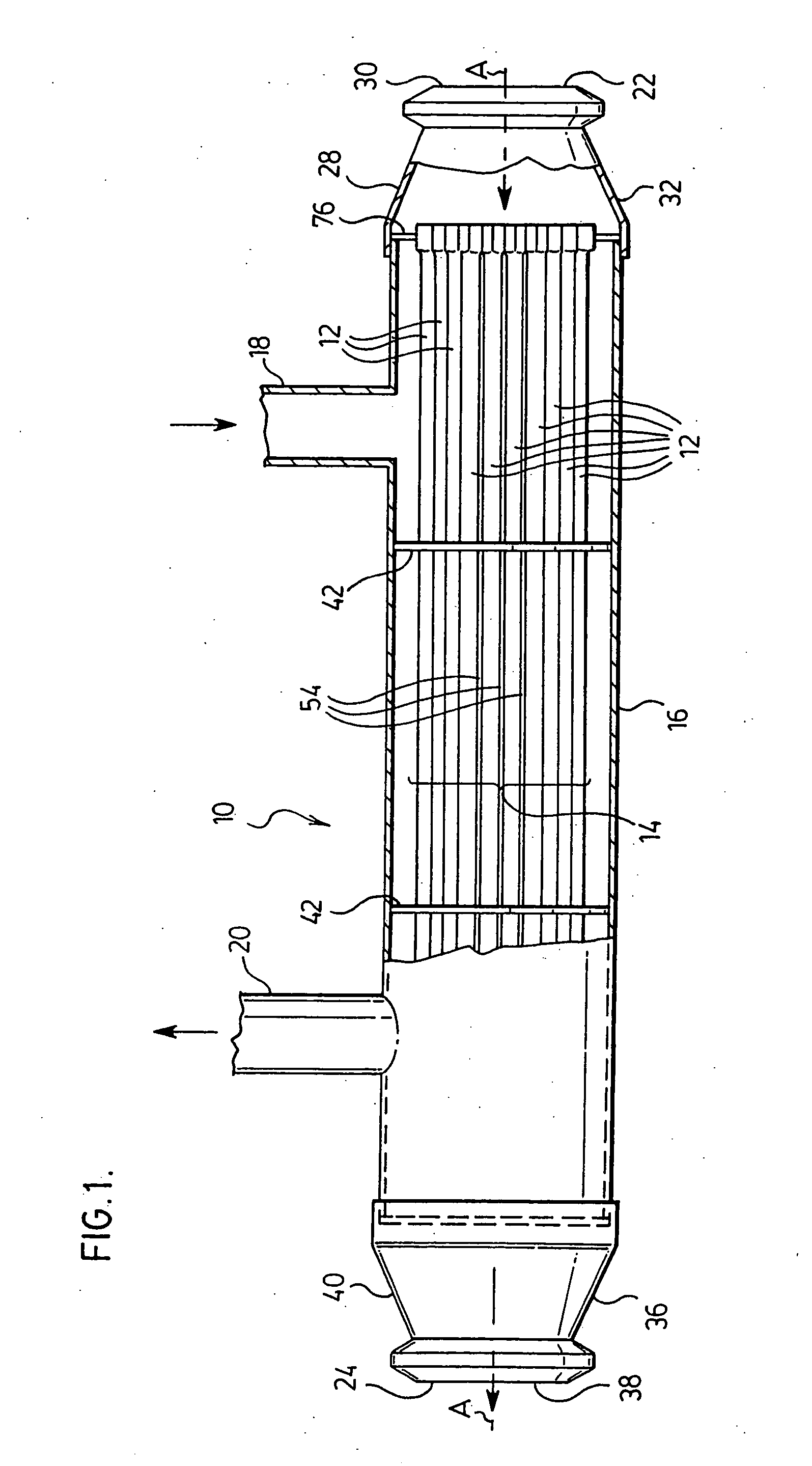

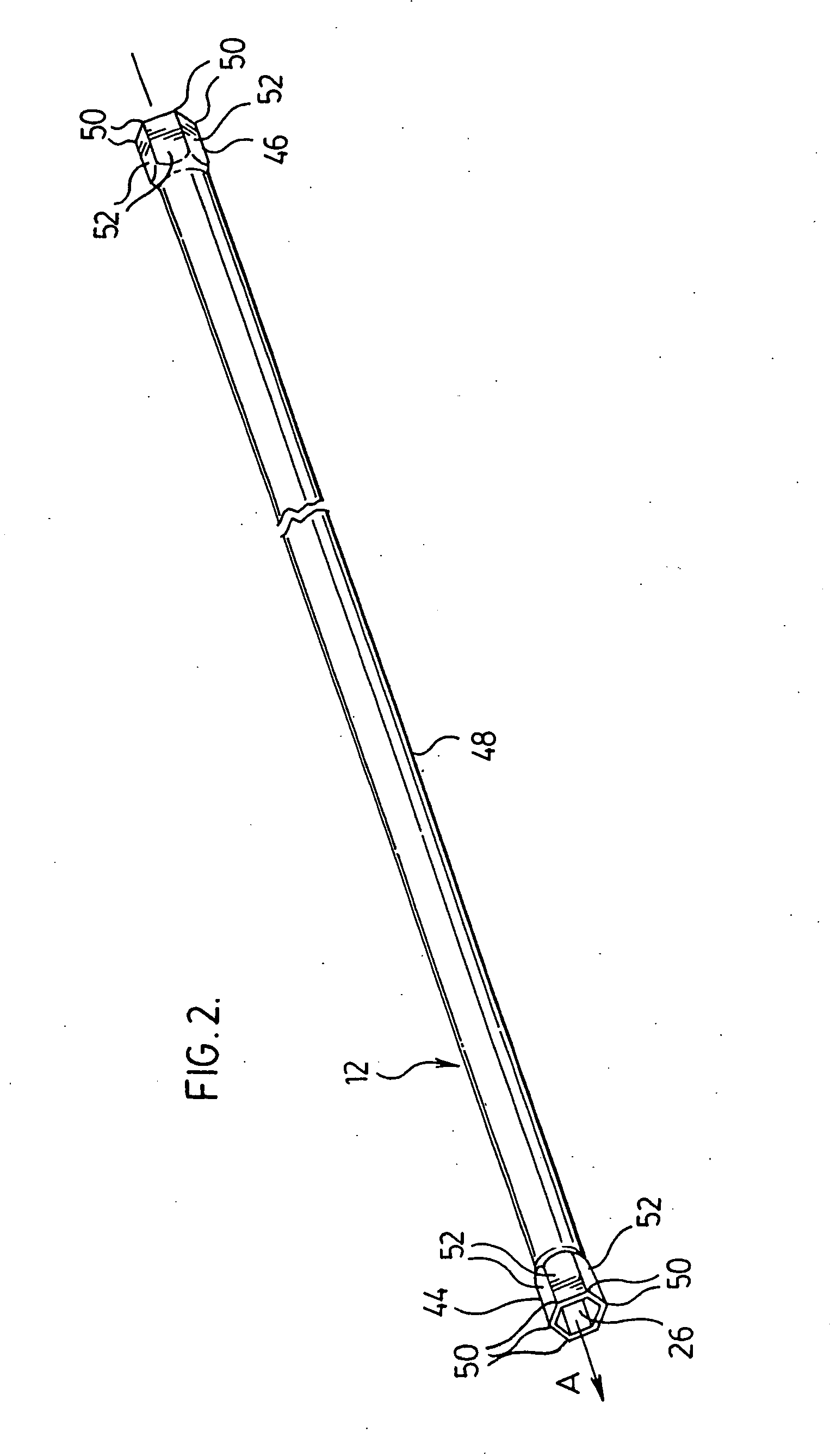

Tube bundle heat exchanger comprising tubes with expanded sections

InactiveUS20050067153A1Increase the cross-sectional areaReduce the cross-sectional areaInternal combustion piston enginesNon-fuel substance addition to fuelLap jointMechanical engineering

A heat exchanger useful for high temperature applications such as EGR cooling and fuel reformer applications comprises a tube bundle made up of a plurality of tubes, each having at least one end expanded to an enlarged polygonal cross-section, and having central portions with a generally smaller cross section. When the tubes are formed into a bundle, the enlarged end portions nest with one another and interstitial spaces are provided between the central portions of the tube. The enlarged end portions are preferably retained by a header ring having a multifaceted inner peripheral sidewall which is adapted to form brazed lap joints with the outward facing surfaces of the peripheral tubes end portions in the tube bundle. In one preferred arrangement, axially aligned enlarged portions are provided intermediate the ends of at least some of the tubes. These enlarged intermediate portions nest with one another and eliminate or reduce the need for baffle plates.

Owner:DANA CANADA CORP

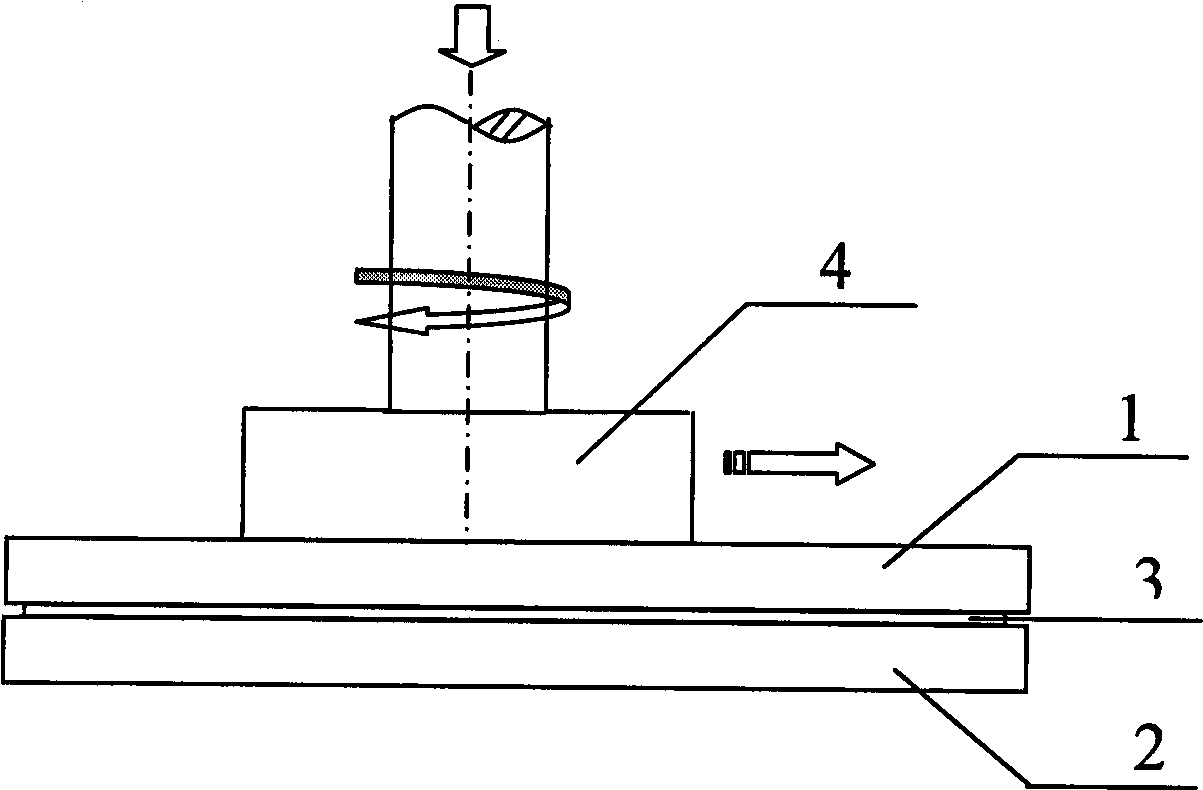

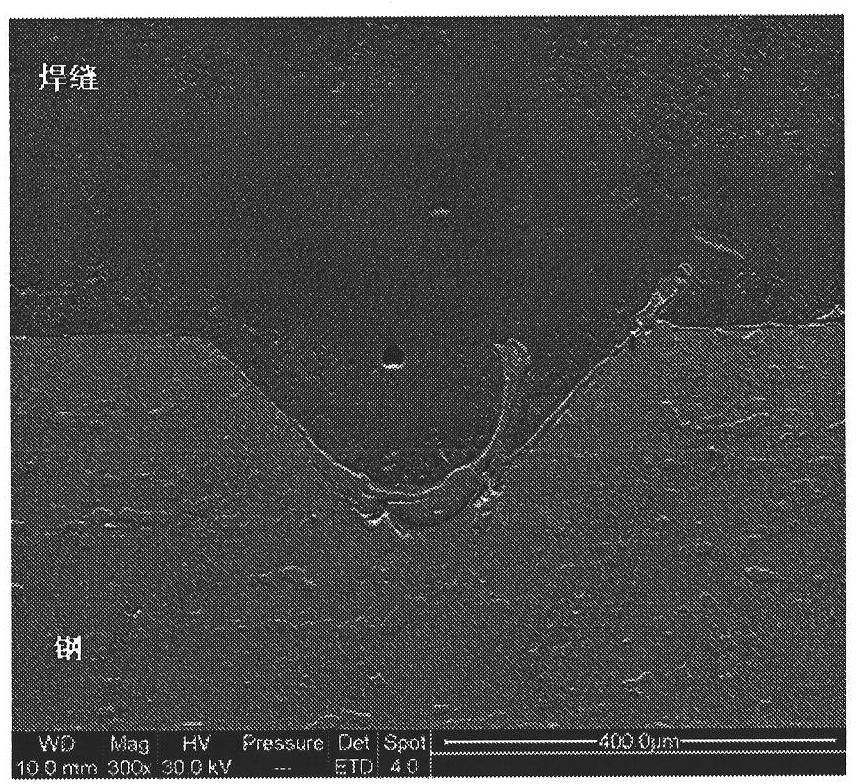

Method for preparing bimetal composite plate by stirring friction braze welding

InactiveCN101530947APrevent thinningAvoid direct contactNon-electric welding apparatusSurface layerShielding gas

The invention discloses a method for preparing a bimetal composite plate by stirring friction braze welding. The method comprises that: a plate with small hardness is used as a covering layer metal plate; a plate with high hardness is used as a base layer metal plate; the covering layer metal plate and the base layer metal plate are horizontally fixed on a working platform surface in a lap joint mode; solders which can generate eutectic reaction with one of the upper / base layer metal plates are preset between the upper / base layer metal plates; a non-needle type cylinder friction device is arranged over the covering layer metal plate; the non-needle type cylindrical friction device is made to rotate and be pressed to be closely contacted with the surface layer of the covering layer metal plate, but not penetrate the covering layer metal plate, and the non-needle type cylindrical friction device rotates in the original position or moves forward along the surface of the covering layer metal plate while rotating; by utilizing frictional heat to melt the solders, the upper / base layer metal plates are both quickly melted in the solders, thereby achieving excellent interface combination; and the excessive solders are squeezed out, and a thin and dense soldering seam is formed, so that the bimetal composite plate is prepared. Compared with the braze welding in a furnace, the method has the advantages of high efficiency, energy conservation, pressure lead-in, unnecessary soldering flux and gas protection and short holding time at a high temperature.

Owner:XI AN JIAOTONG UNIV

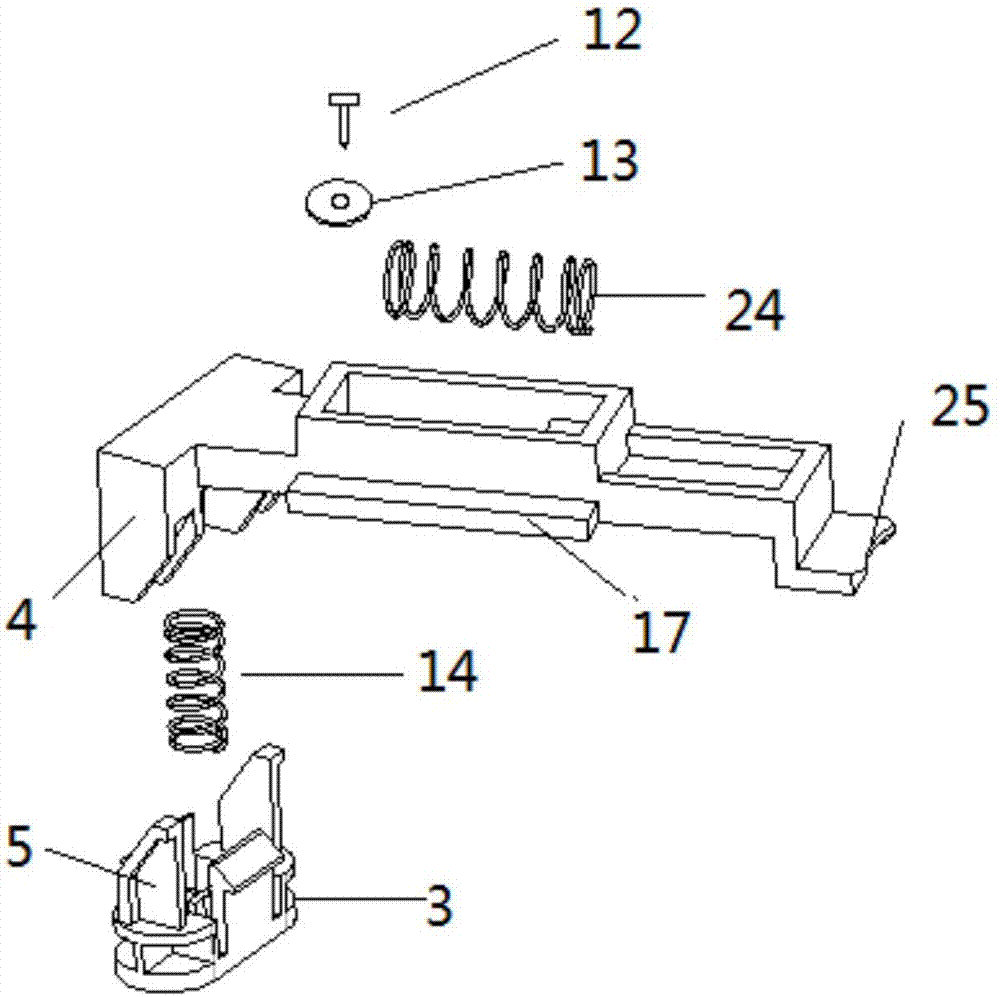

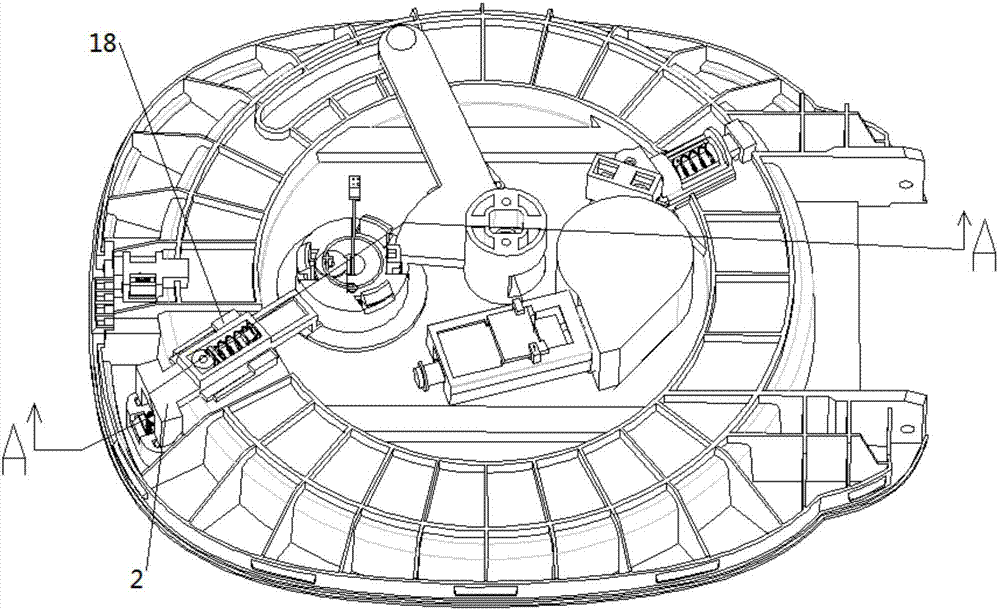

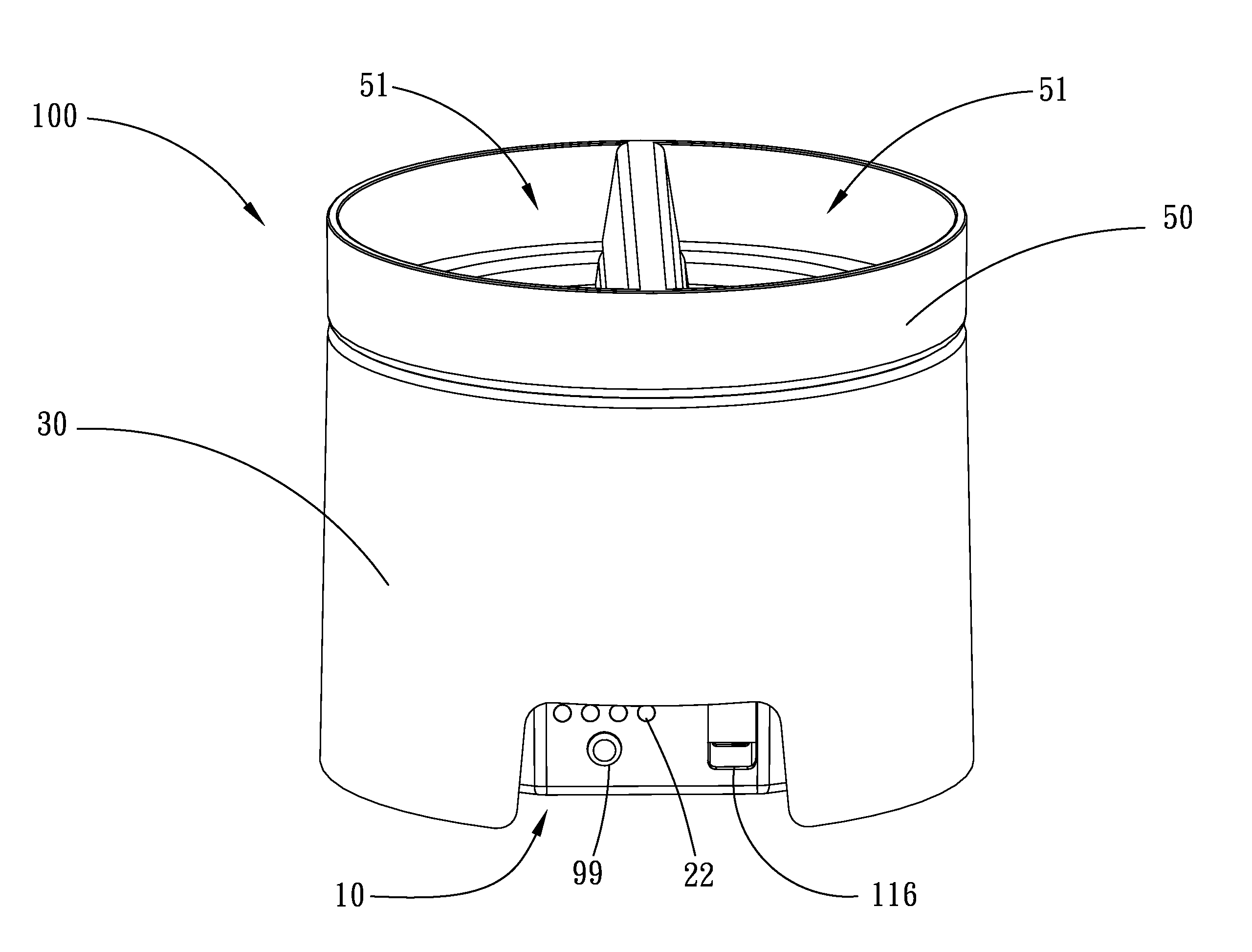

Buckle structure, heat-preservation cover plate installation structure of pressure cooker and pressure cooker

ActiveCN107361637ASimple structureEasy to assemble and disassemblePressure-cookersLap jointEngineering

The invention provides a buckle structure, a heat-preservation cover plate installation structure of a pressure cooker and the pressure cooker. The buckle structure is provided with a locking structure body arranged on a first structural piece and a lock catch assembly arranged on a second structural piece. The heat-preservation cover plate installation structure of the pressure cooker is provided with one buckle structure and a lap-joint buckle. The first structural piece of the buckle structure is a heat-preservation cover plate of the pressure cooker, and the second structural piece of the buckle structure is an inner cover of the pressure cooker; and the pressure cooker is provided with the heat-preservation cover plate installation structure of the pressure cooker. The heat-preservation cover plate installation structure of the pressure cooker is simple in structure, convenient to dismantle, safe and reliable.

Owner:GREE ELECTRIC APPLIANCES INC

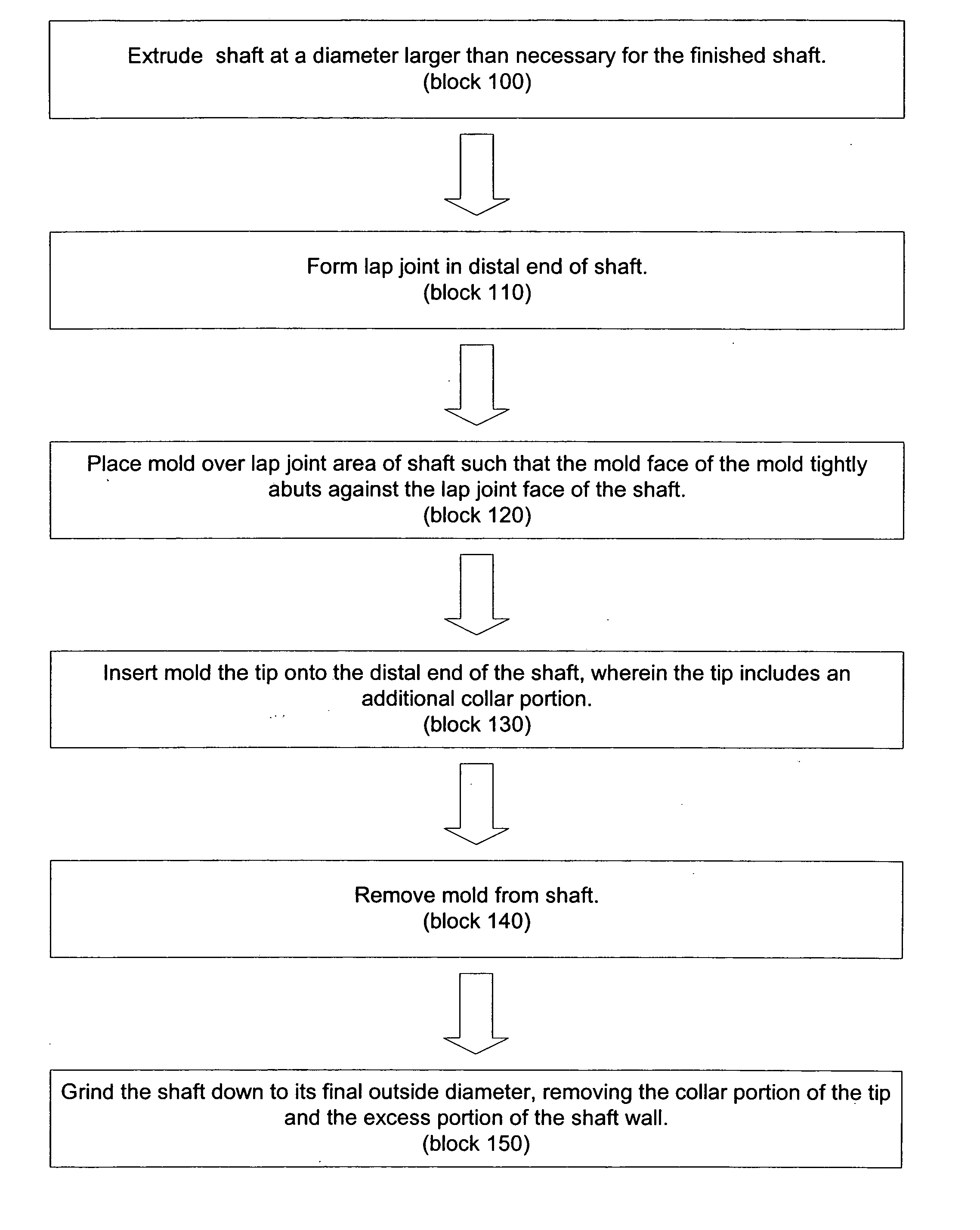

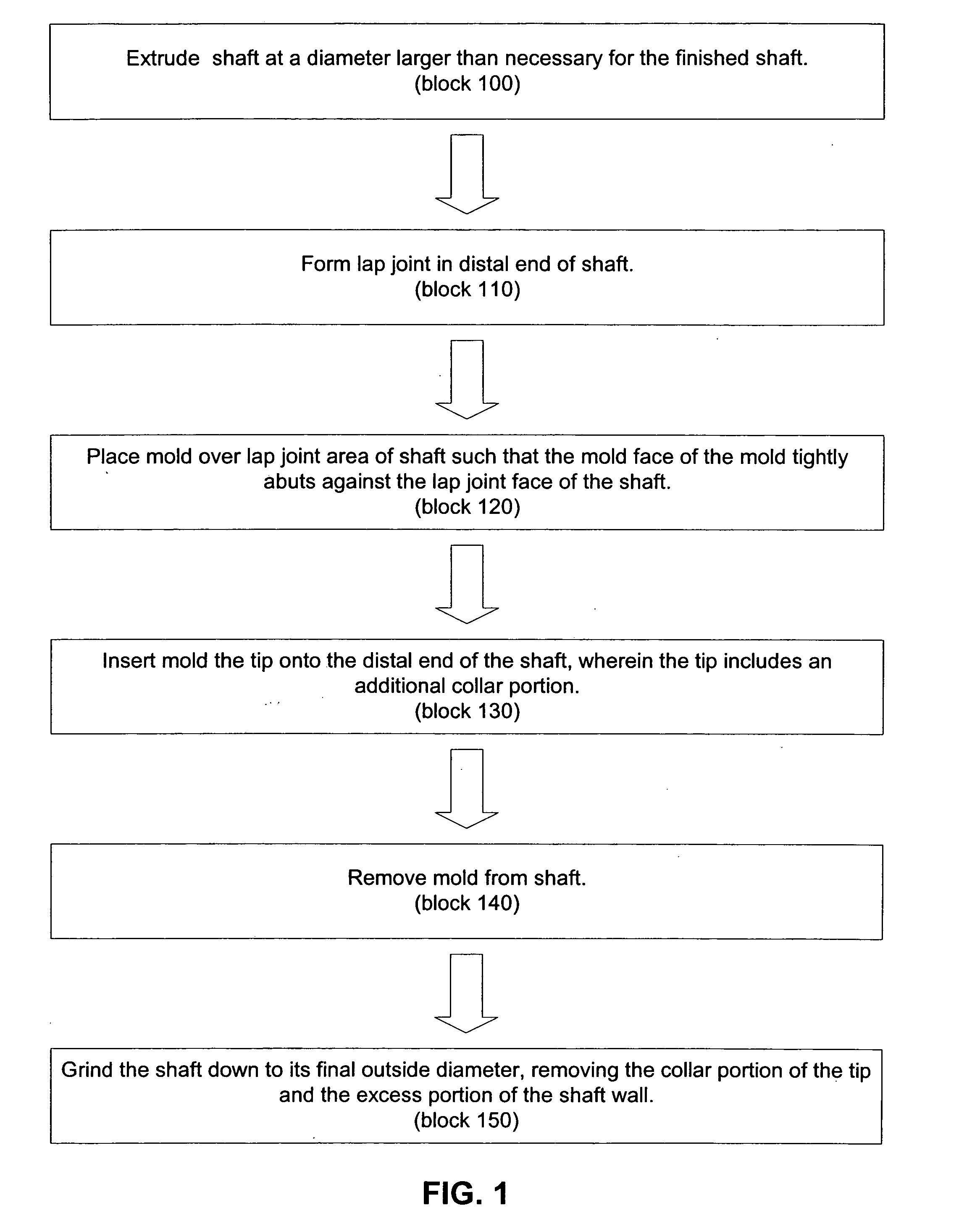

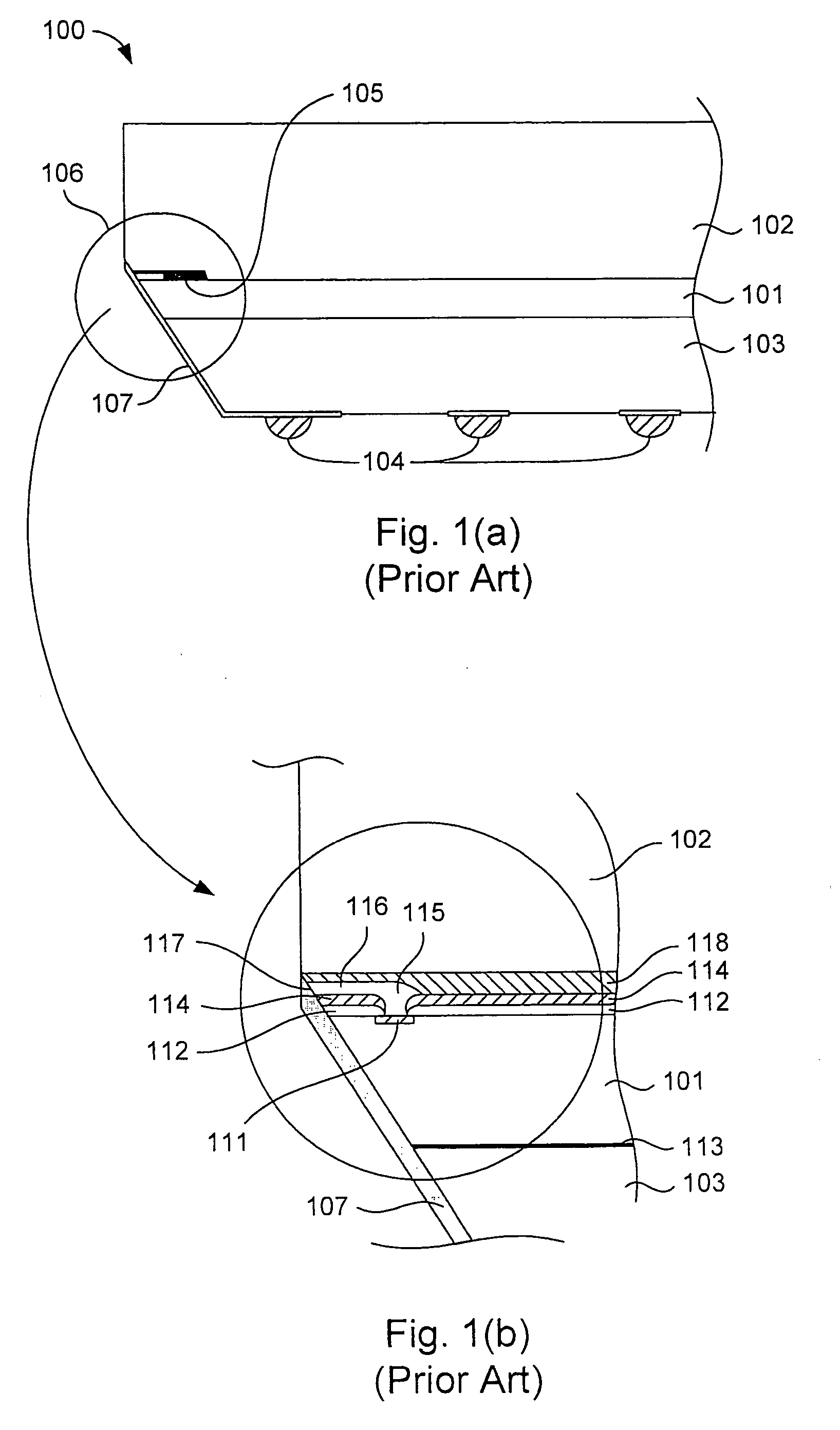

Catheter tip and method of attaching a catheter tip to a catheter shaft

The present invention is a method of bonding a shaft tip to a distal end of a catheter or sheath shaft. The method includes extruding a shaft to have an initial outside diameter that is greater than an outside diameter the shaft will have when finished. A lap joint area is then ground into the distal end of the shaft. The tip is then insert molded over the lap joint area. The tip includes a collar at a proximal end of the tip that provides additional thermal mass to facilitate the bonding of the tip to the shaft. The shaft is then ground from its initial outside diameter to its finished outside diameter.

Owner:FORSBERG ANDREW

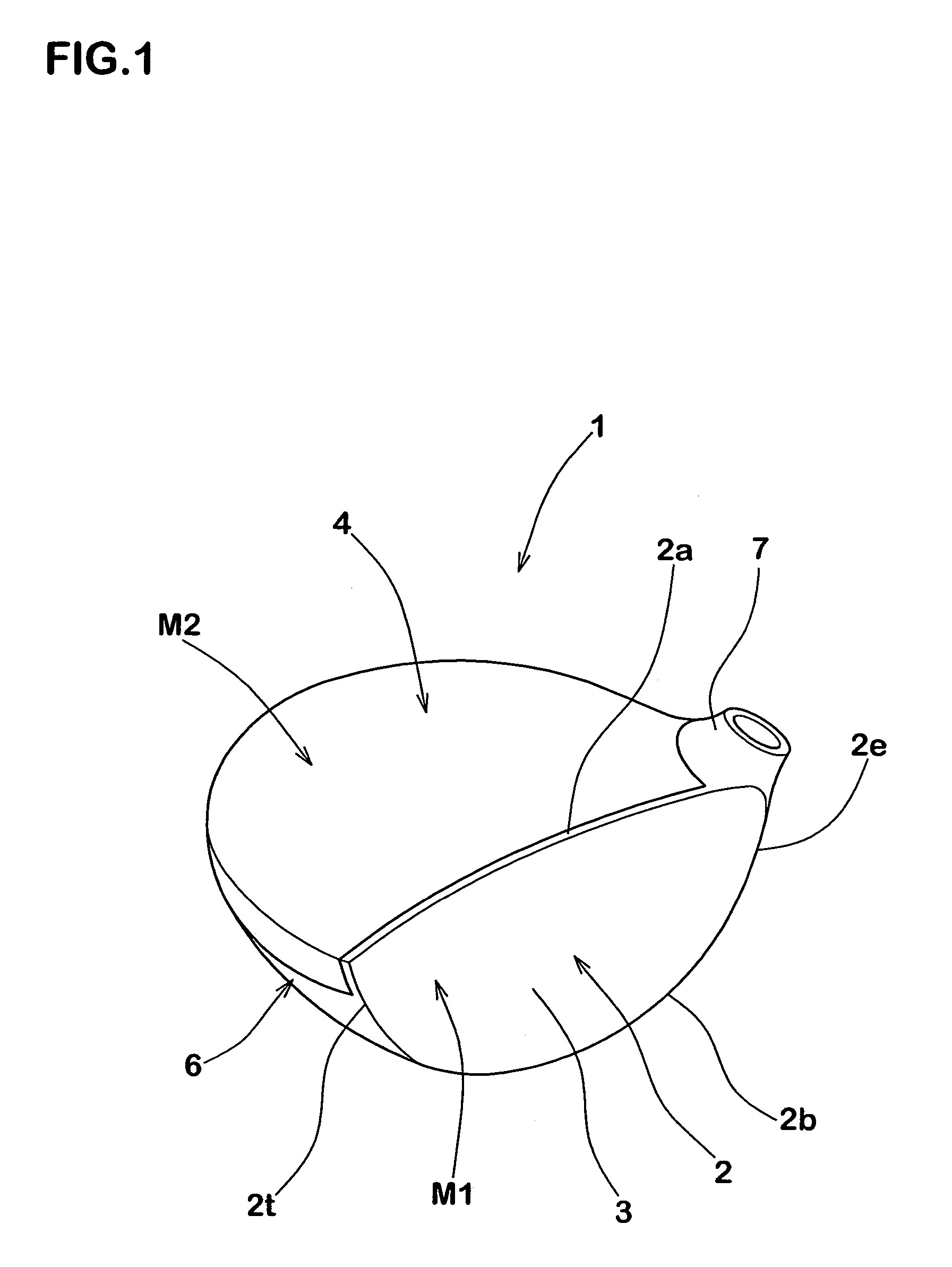

Golf club head

InactiveUS20050026723A1Reduce material thicknessLarge elastic deformationGolf clubsRacket sportsFiberLap joint

Owner:DUNLOP SPORTS CO LTD

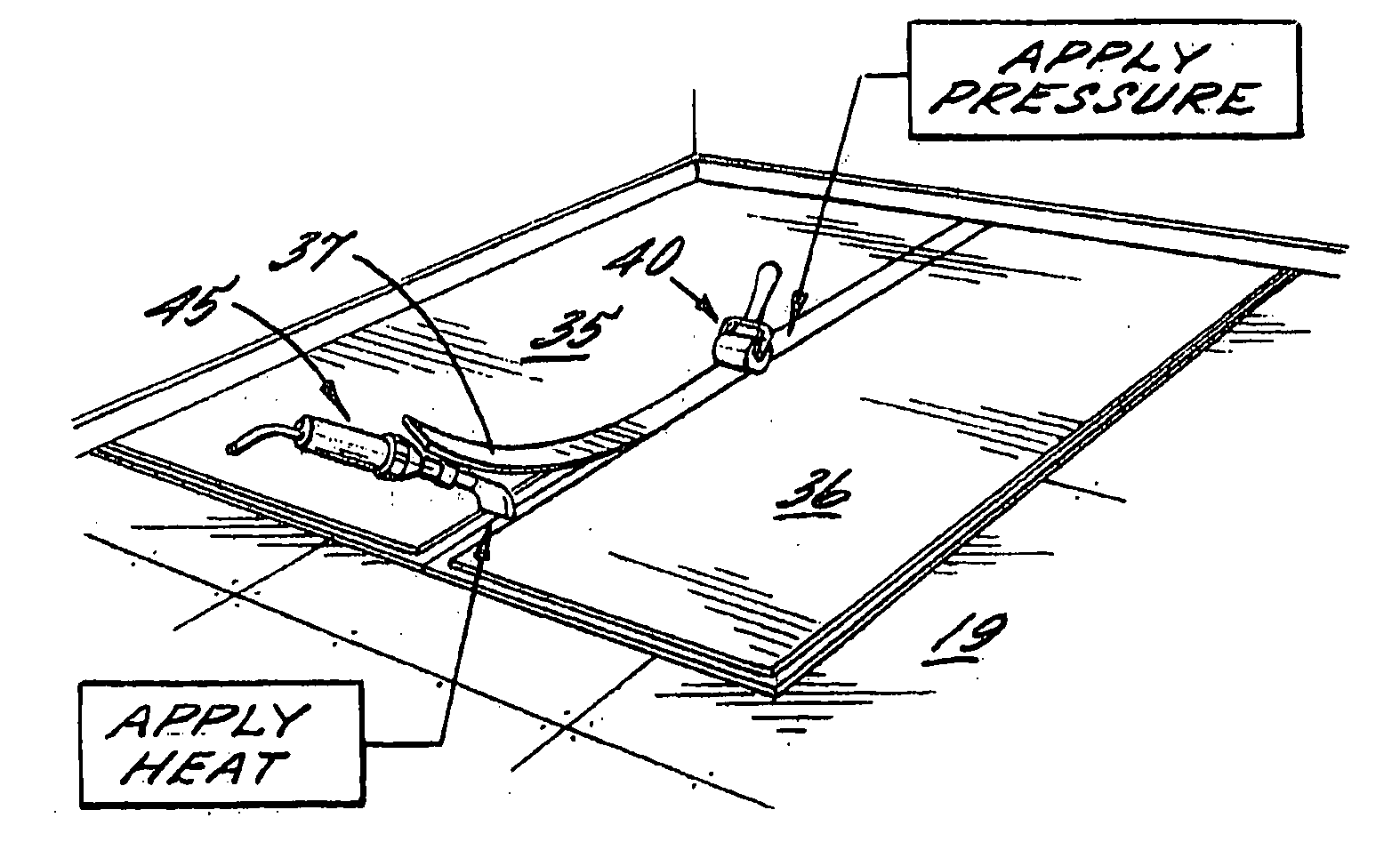

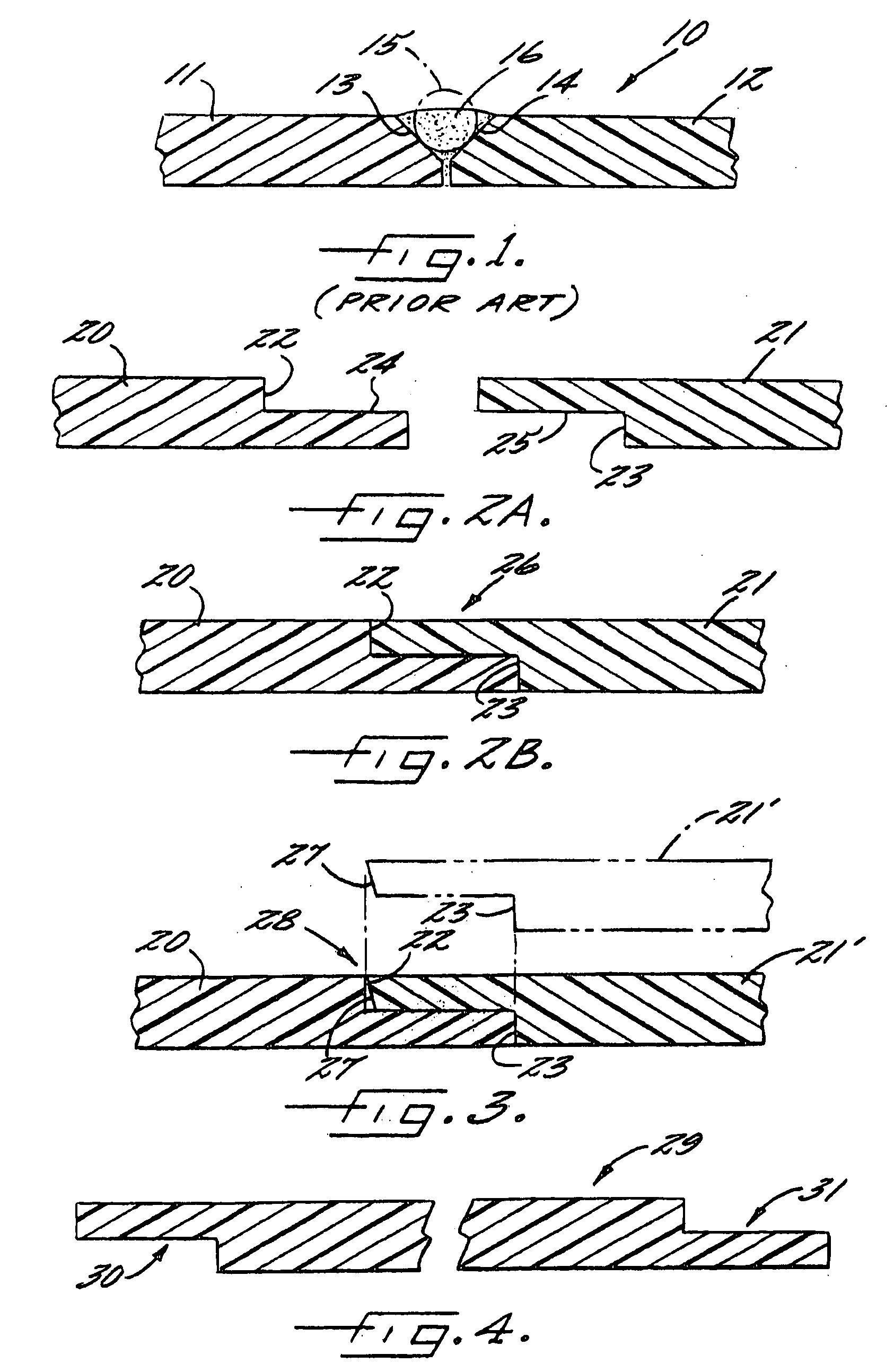

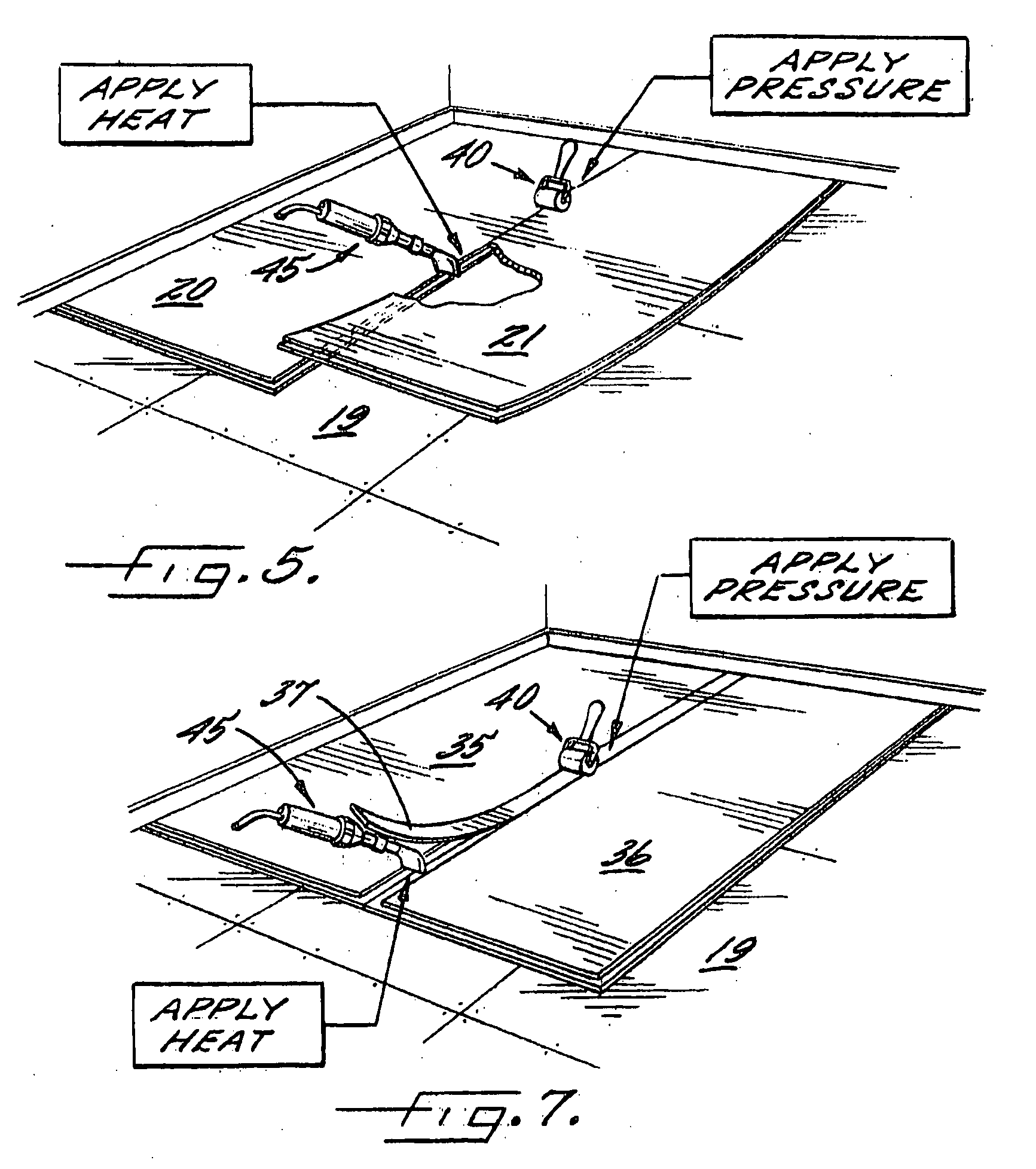

Installation Method for Non-Slip Sanitary Flooring

A method of installing flooring and resulting structure are disclosed. The method is particularly useful for sanitary nonslip (or slip resistant) applications such as kitchens. The method includes the steps of positioning a first sheet of polymer flooring material with an upwardly-facing step cut along one edge of the first sheet on a floor to be covered, and applying a second sheet of polymer flooring material with a complementary downwardly-facing step cut along one edge of the second sheet to the upwardly facing step cut of the first sheet and to the floor adjacent the first sheet while concurrently sealing or bonding the respective faces to one another in a step lap joint.

Owner:MARTIN JOEL E JR +1

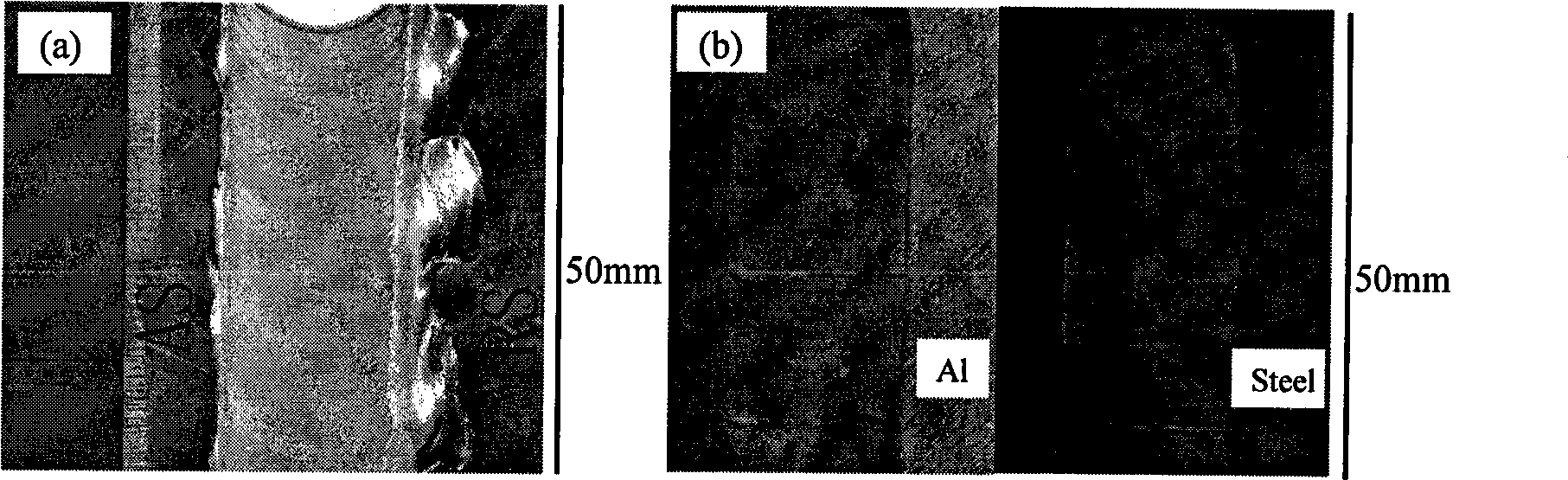

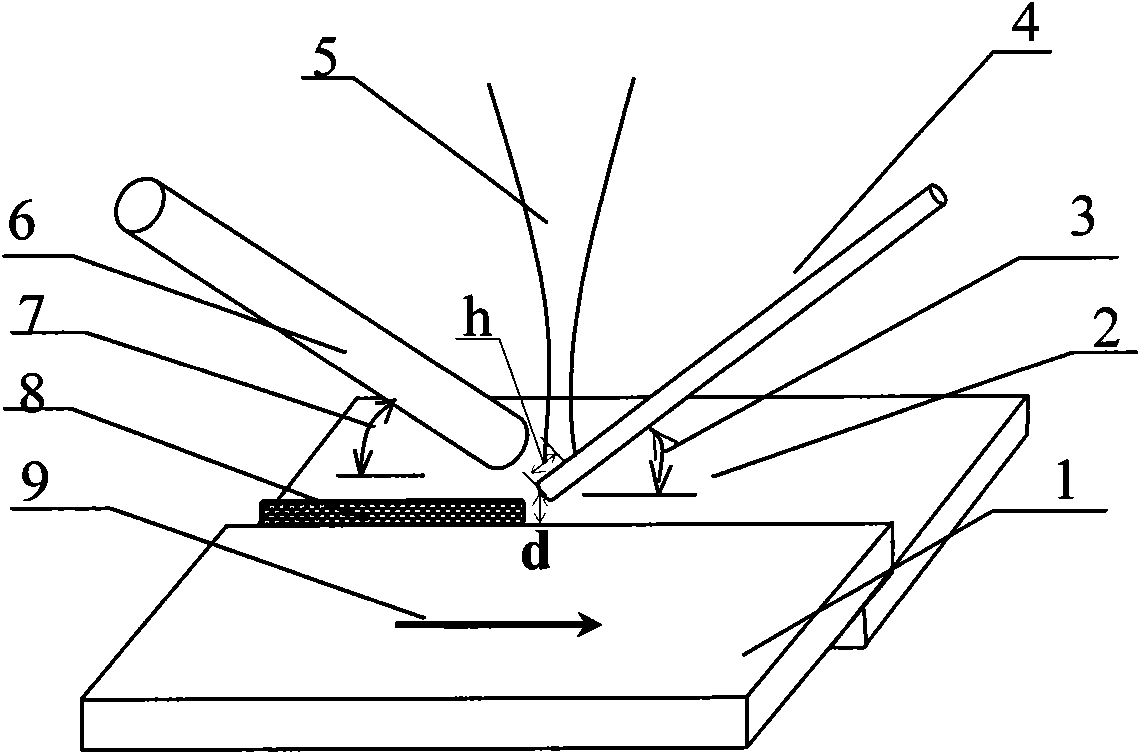

Method for connecting aluminum alloy and steel by laser filler wire

InactiveCN101941119AAchieve fusion-braze connectionPrecise control of heat inputLaser beam welding apparatusLap jointLaser beams

The invention relates to a method for connecting an aluminum alloy and steel by a laser filler wire, which is suitable for the field of dissimilar material connection and particularly suitable for the connection between dissimilar materials of which fusion points and thermal physical properties differ from each other greatly. The method comprises the following steps of: assembling a lap joint in which an aluminum plate is arranged on a steel plate, wherein a laser beam, a wire feeding nozzle and a protective gas nozzle are fixed in the same plane, the laser beam is vertically incident, and a laser focus, a wire dropping point of a welding wire and a protective gas feeding point are guaranteed to be consistent during welding; and melting the fed aluminum welding wire by using the laser to ensure that the molten aluminum welding wire is in fusion connection with the aluminum plate, simultaneously a micro fusion layer is formed on one side of the steel plate and then a fusion-braze welding connection is formed, thus the lap joint between dissimilar metals such as the aluminum alloy and the steel is realized. The method improves the connection efficiency between the dissimilar metals such as the aluminum alloy and the steel, and the tensile strength of the joint is over 149.6N / mm. The method solves the problems of long preparation time, low automation degree and poor reproducibility of welding results in the process of connecting pre-coated layers of the dissimilar materials such as welded-aluminum and the steel.

Owner:BEIJING UNIV OF TECH

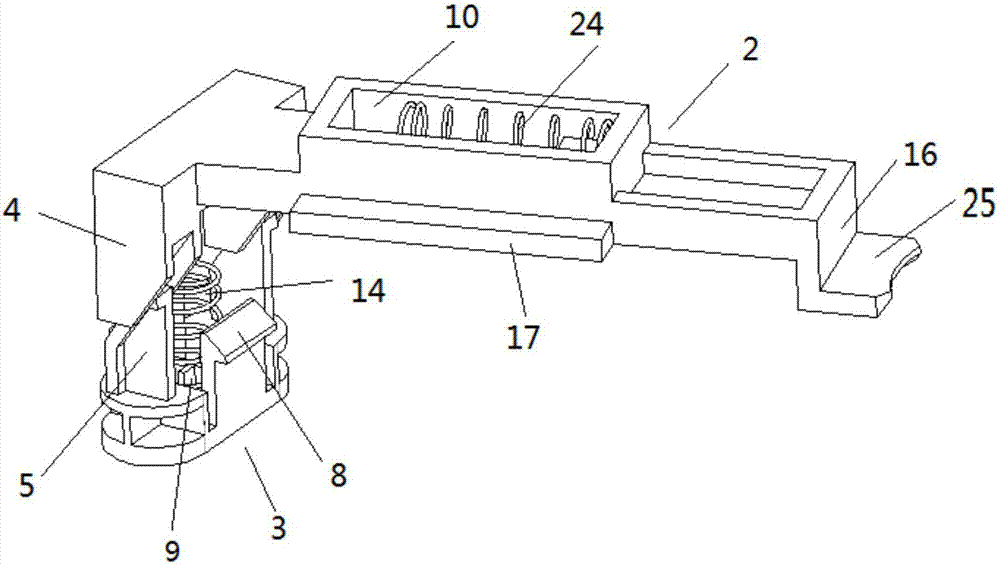

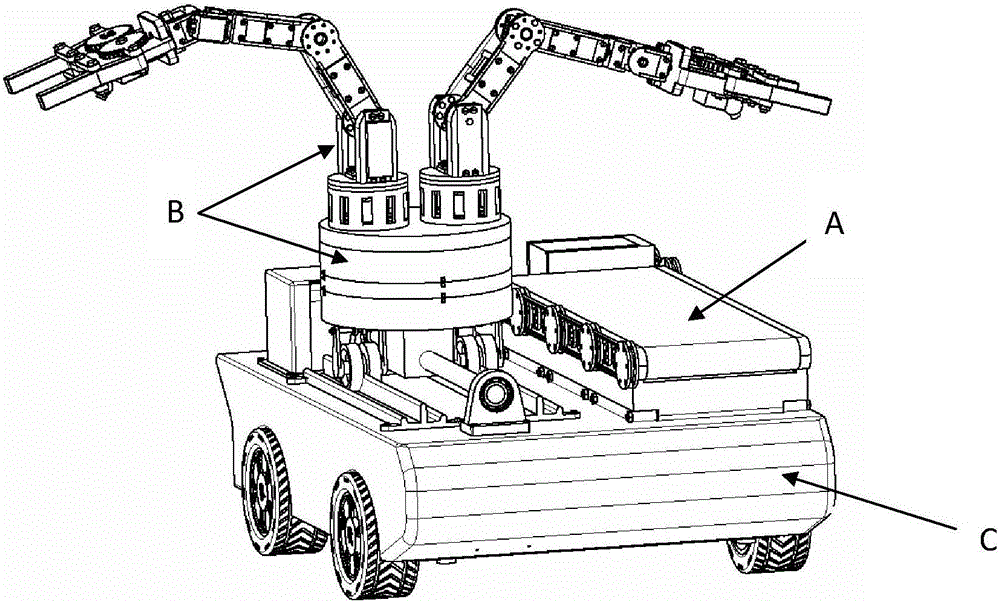

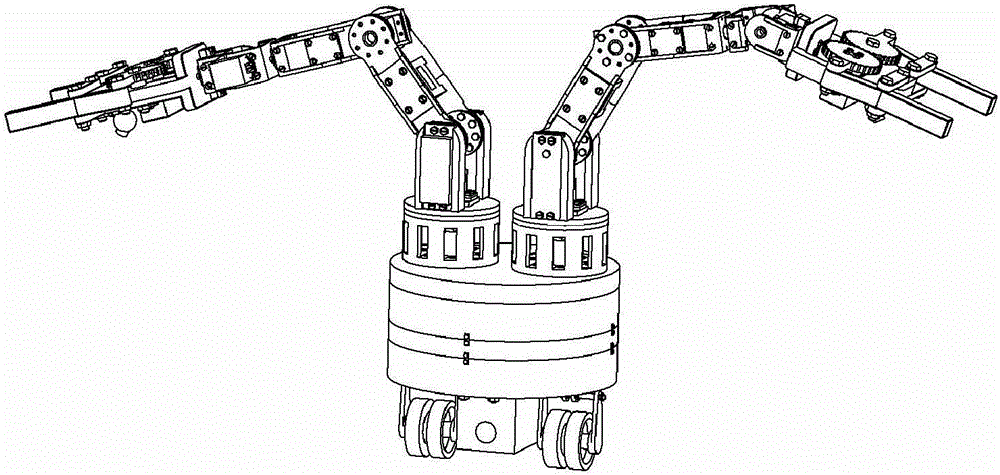

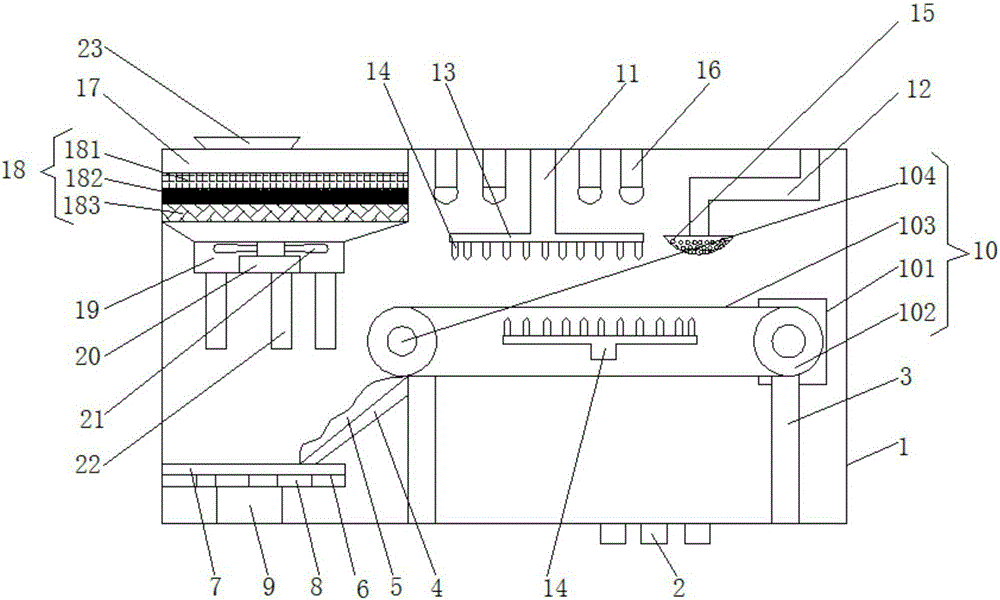

Double-arm loading and transferring robot

ActiveCN106112952AUninterrupted gripping of packagesImprove securityProgramme-controlled manipulatorCircular discTransmission belt

The invention discloses a double-arm loading and transferring robot and belongs to the field of robot structure design. Fast package loading during air transportation is achieved through the double-arm loading and transferring robot. The robot comprises a clamping module composed of mechanical arms, a disc mechanism and a guide rail mechanism, a conveying belt module used for transferring, a chassis module capable of making the robot move freely, and a sorting module located at the transferring terminal point. During transferring, a double-arm rotary structure is adopted by the robot, the two mechanical arms are fixed to a rotatable disc, the included angle between the two mechanical arms is 180 degrees, after a package is clamped by one mechanical arm, 180-degree fixed-angle rotation of the rotatable disc is achieved through the cooperation of a clutch and an incomplete gear mechanism in the disc, the package is placed onto a small conveying belt, the other mechanical arm starts clamping simultaneously, and in this way, the double mechanical arms can conduct clamping and placing alternately so that the packages can be clamped continuously. Meanwhile, the clamped packages are transferred through the conveying belt, and the efficiency is improved. After the packages reach a transfer location, the conveying belt can be in lap joint with an airport large conveying belt by adjusting the angle and heights, and the packages are separated from a sorting device and moved to a cabin.

Owner:BEIJING UNIV OF TECH

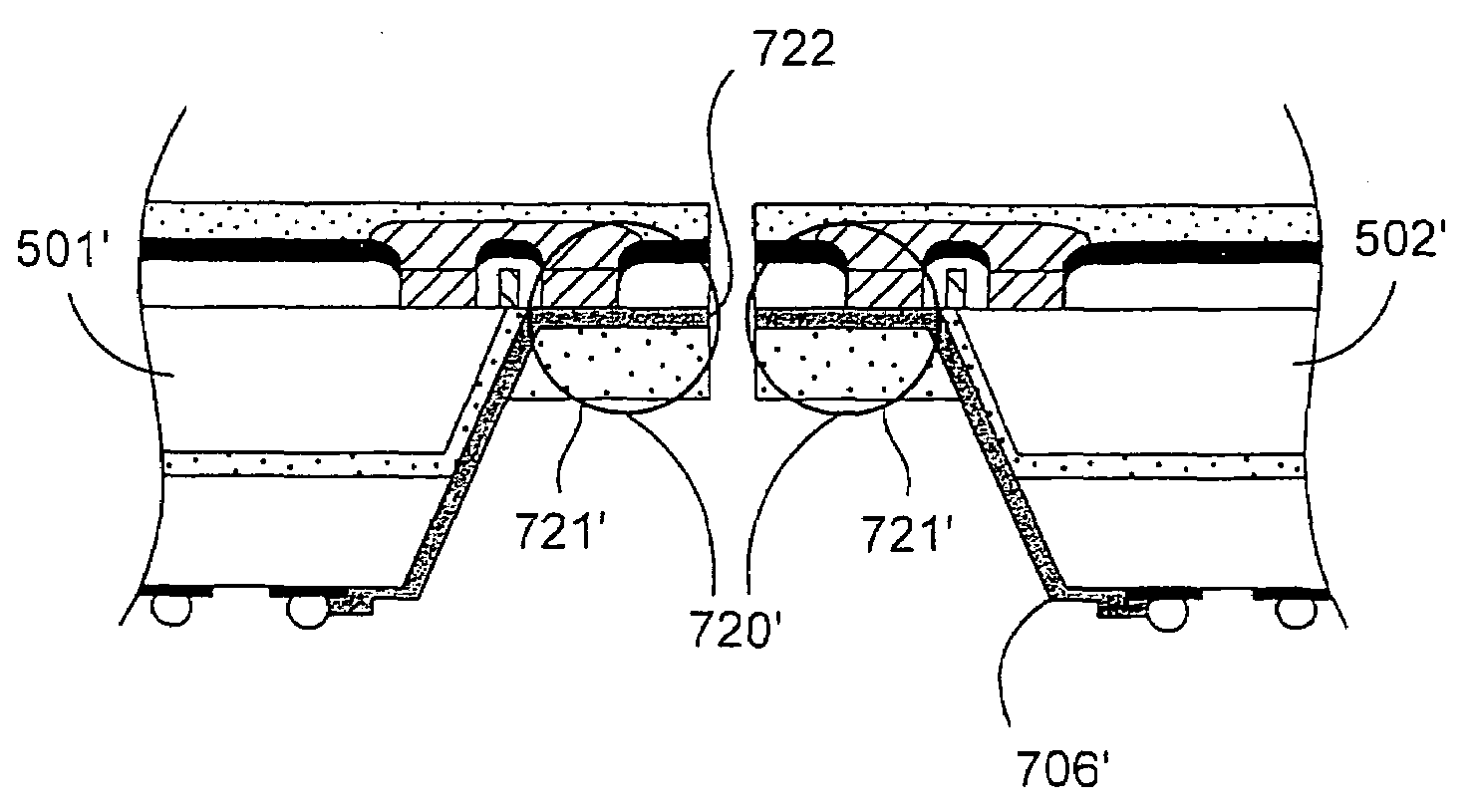

Electrical die contact structure and fabrication method

InactiveUS7067354B2Semiconductor/solid-state device detailsSolid-state devicesElectrical connectionLap joint

A semiconductor device of the invention includes an integrated circuit formed on a semiconductor substrate having first and second surfaces and edges. The first surface includes electrical contact pads electrically connected with the integrated circuit. The first surface of the semiconductor substrate includes a top protective layer that has a surface portion extending beyond the edges of the semiconductor substrate. The surface portion of the top protective layer includes electrical contact pads that are electrically connected with electrical contact pad extensions and with the integrated circuit. The second surface of the semiconductor substrate includes a multiplicity of backside electrical connectors that are in overlapping electrical contact with corresponding electrical contact pad extensions forming lap joint electrical connections between the backside electrical connectors and the corresponding electrical contact pad extensions. Methods for constructing such devices and connections are also disclosed.

Owner:NAT SEMICON CORP

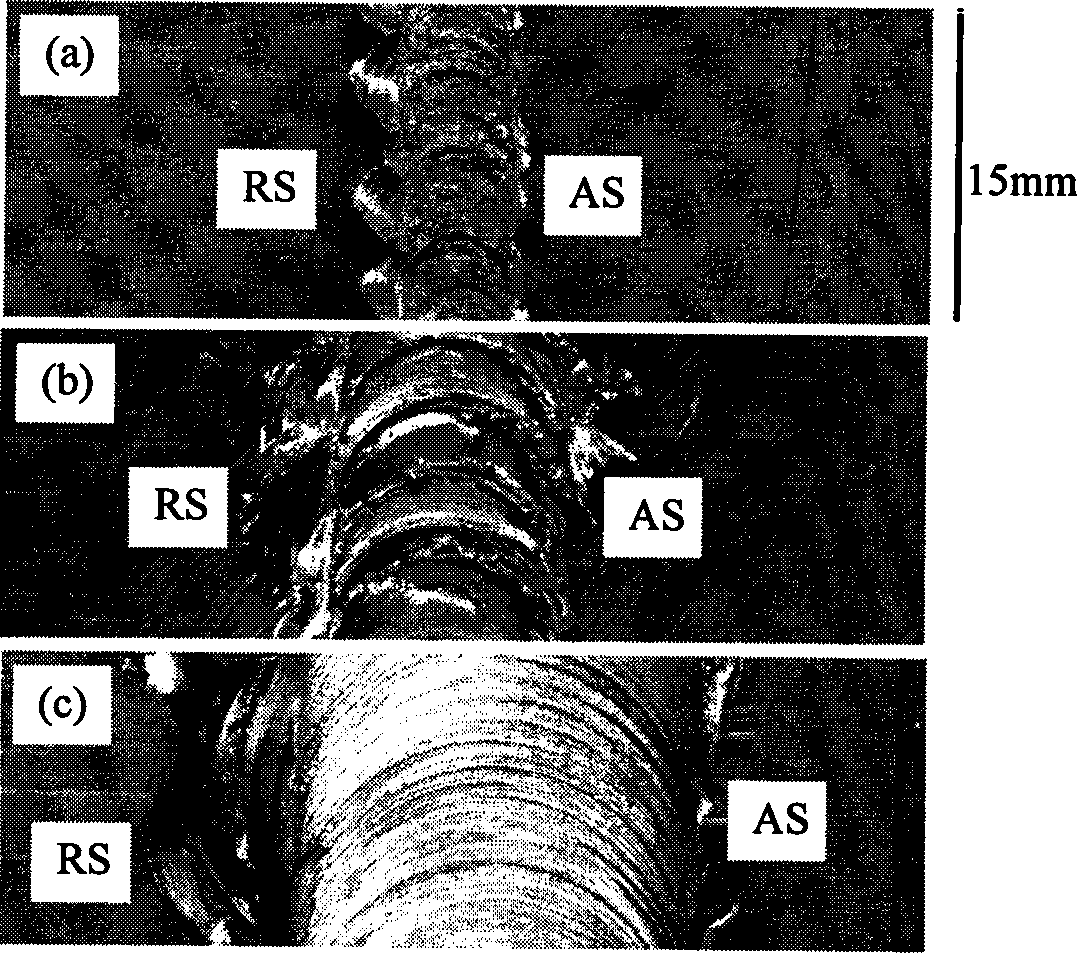

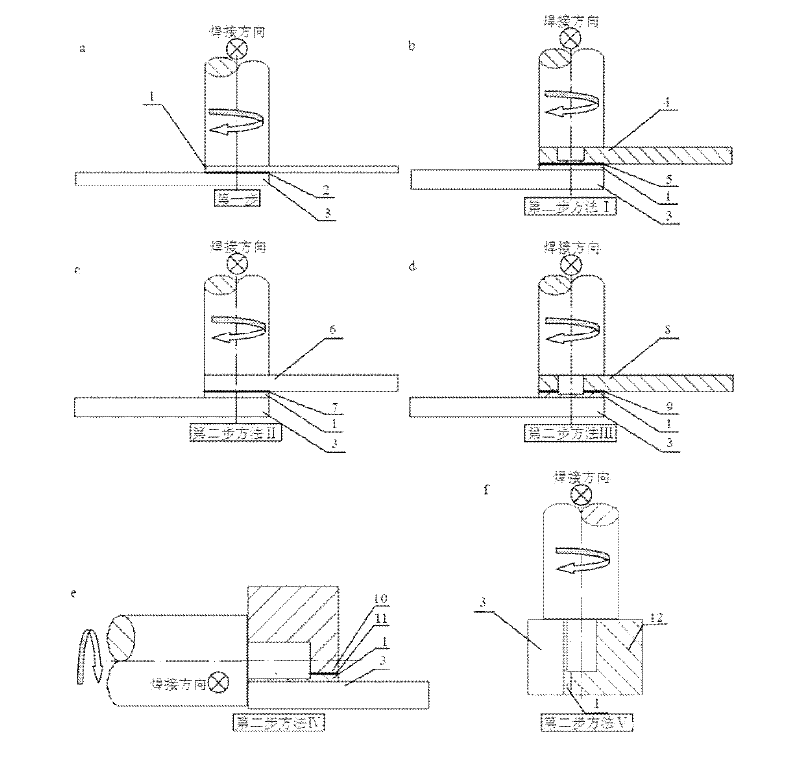

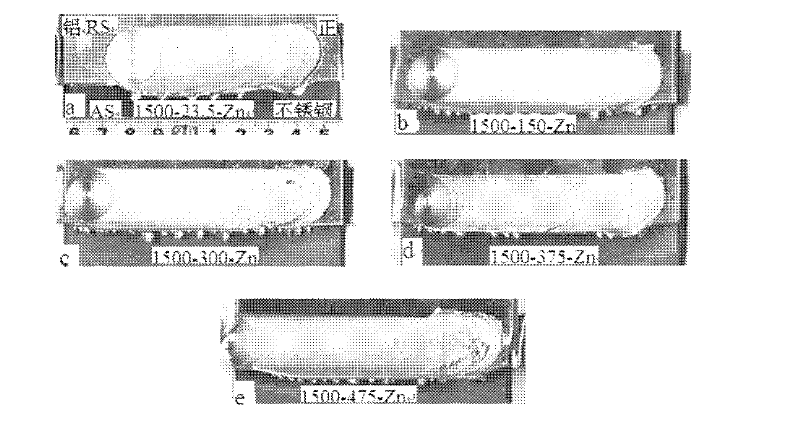

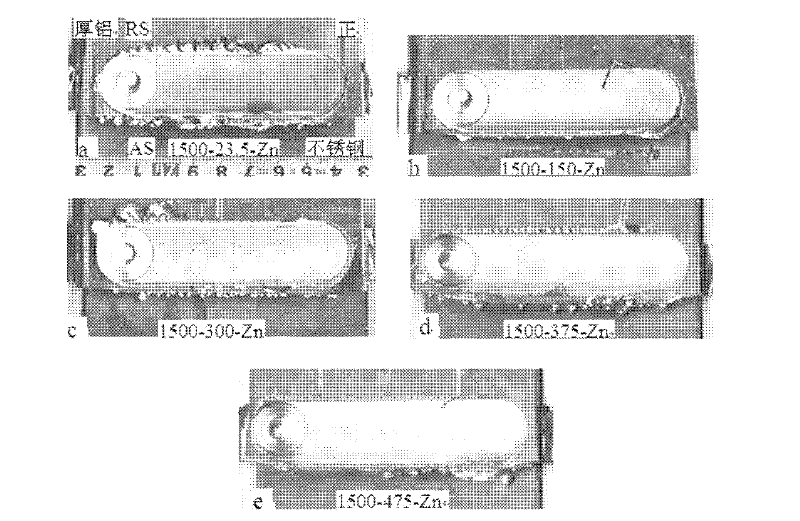

Step-by-step friction stir brazing method for thick aluminium plate and rigid dissimilar material

ActiveCN102513638AHigh strengthSoldering apparatusNon-electric welding apparatusNeedle freeLap joint

The invention discloses a step-by-step friction stir brazing method for a thick aluminium plate and a rigid dissimilar material. The method can be used for avoiding various problems such as needle abrasion (when a tool with a needle is used), insufficient interface heat, poor mechanical membrane rupture effect and the like existing in the direct friction stir brazing process of the thick aluminium plate and the rigid dissimilar material (such as stainless steel, copper, titanium and steel). The method comprises the following steps of: firstly brazing a thin aluminium plate on the to-be-brazed surface of a rigid dissimilar material through needle-free friction stir brazing, striping by virtue of a metallurgical factor and a mechanical factor, and extruding brazing filler metal, thus realizing a compact joint between the thin aluminium plate and the rigid dissimilar material; and welding the thin aluminium plate brazed on the rigid dissimilar material and a thick aluminium plate through friction stir brazing or friction stir welding, wherein when friction stir brazing is utilized to weld lap joint in the second step, the welding-on area can be obviously enlarged. The process can be used for completely preventing rigid parent metal from abrading a tool; and the interface welding-on of the thin aluminium plate and the dissimilar material is reliable. The method disclosed by the invention can be used for preparing aluminium / stainless steel contact rails and aluminium / copper transition joints.

Owner:西安英特金属复合材料有限公司

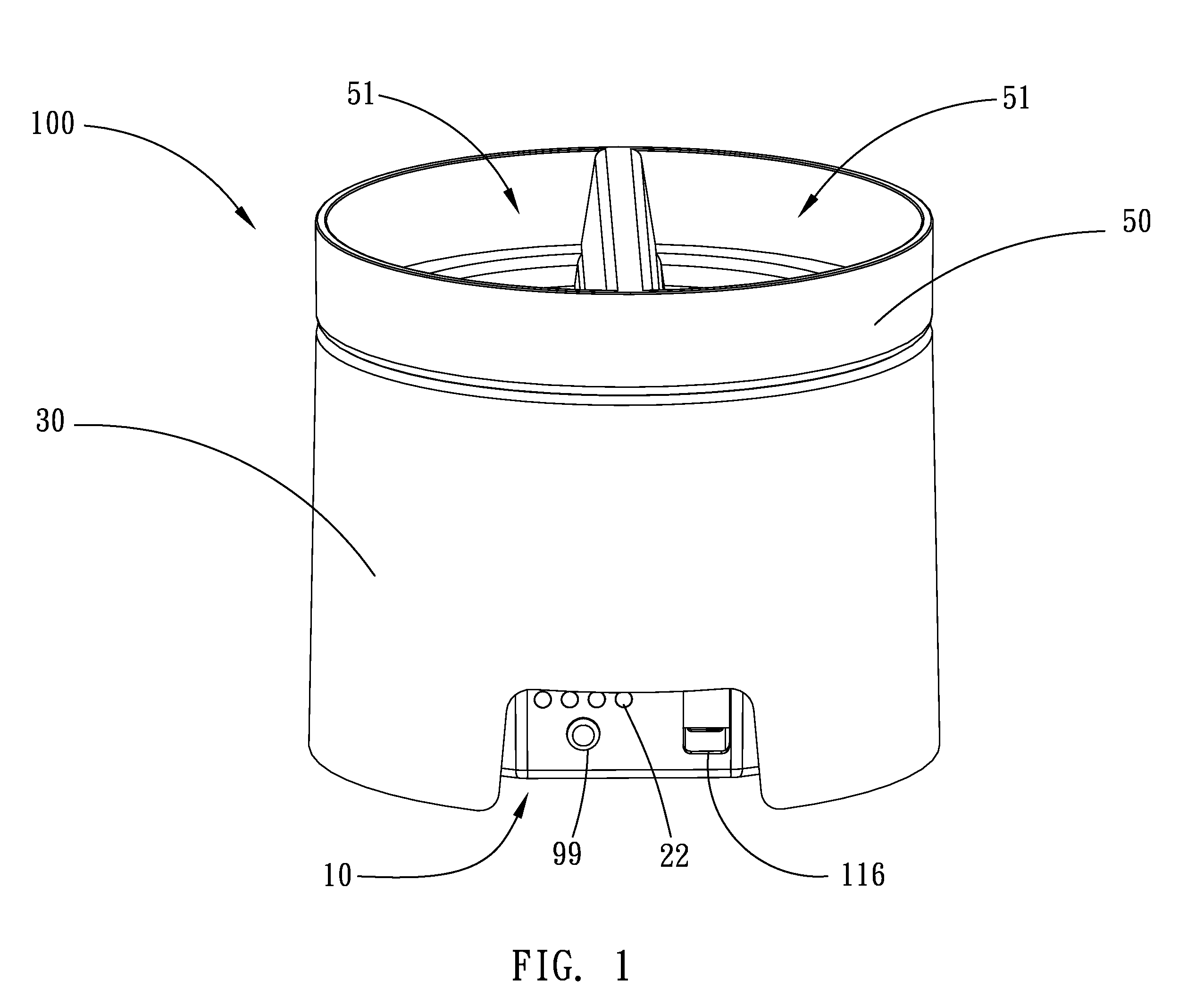

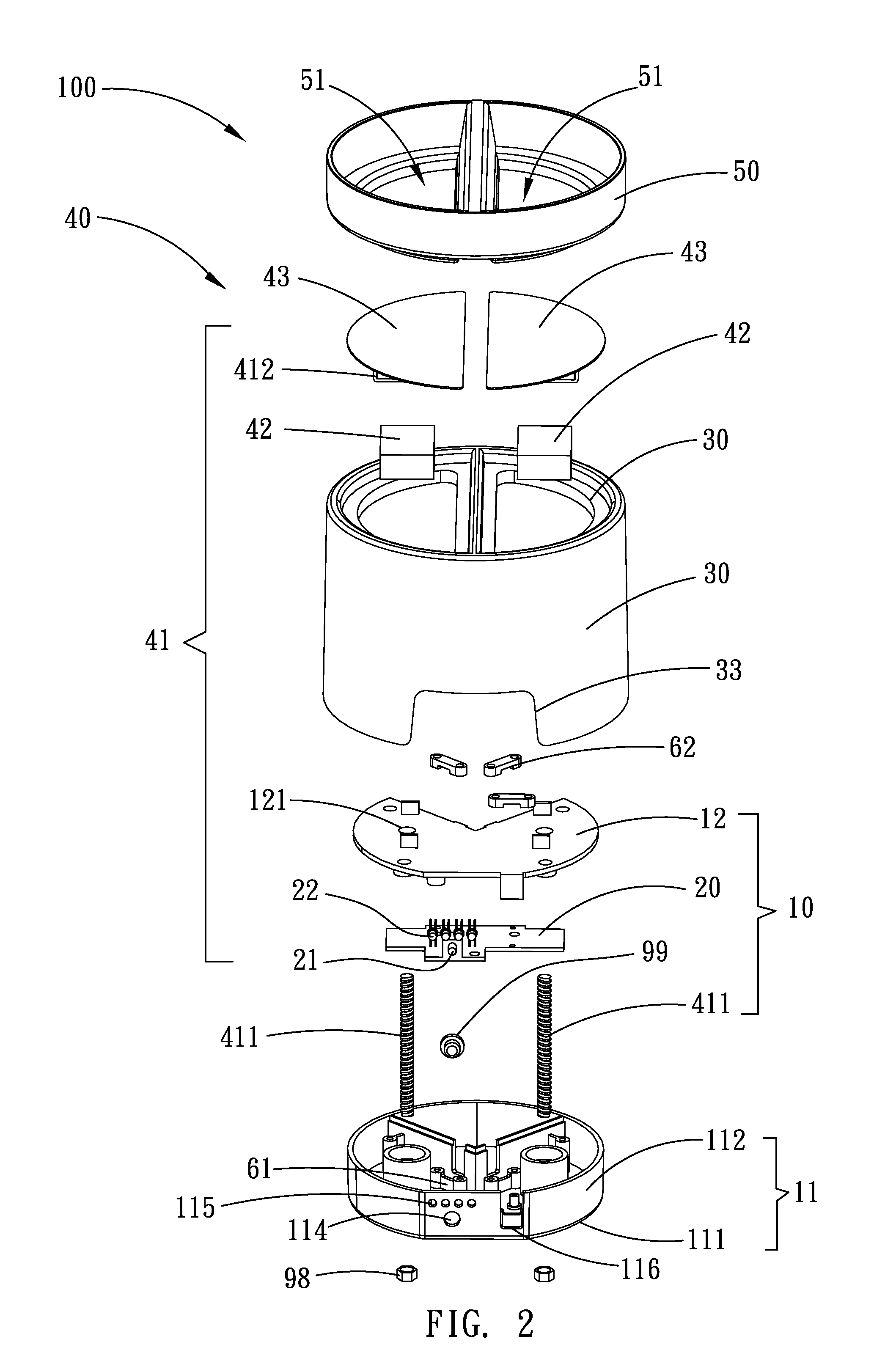

Aromatic device

InactiveUS20110110824A1Blunting smellTransform or excite users' emotionFire rescueGaseous substancesPower switchingLap joint

An aromatic device has a base, a timing control circuit board, a hollow housing, at least two electric heaters and an aromatic container. The timing control circuit board is mounted inside the base and connected with an external power source. The hollow housing shields the base and has a touch slot for fixing and accessing to operate a power switch. The aromatic container is lap-jointed on the hollow housing and has two separately isolated aromatic chambers respectively receiving an aromatic material therein. Each of the electric heaters heats the corresponding aromatic chamber continuously or on schedule so as to generate continuous or scheduled fragrance or mix up new fragrance. The touch slot is recessed into the hollow housing to prevent accidental touch of the function selection button and enhance safety.

Owner:HSIAO MING JEN

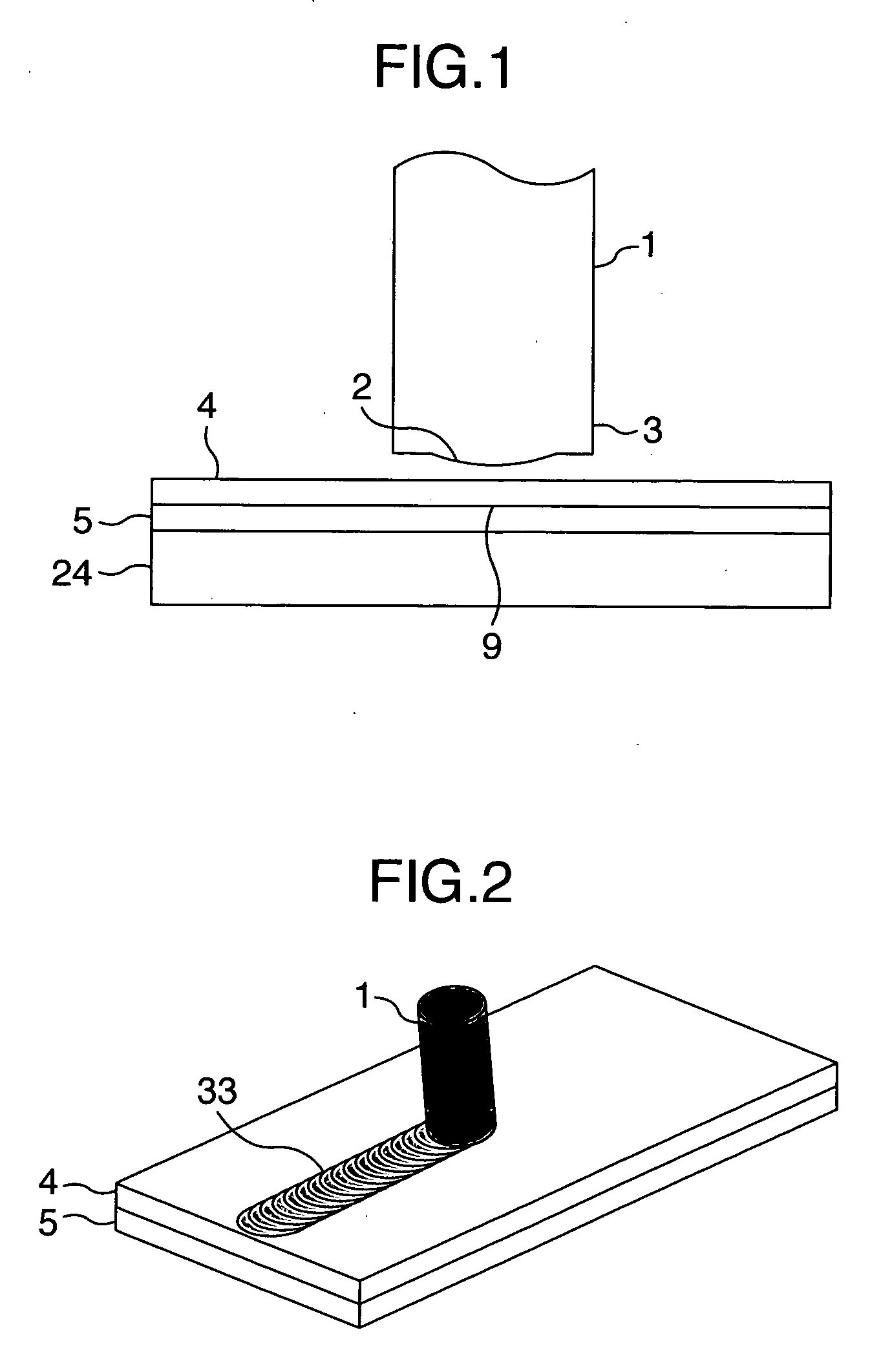

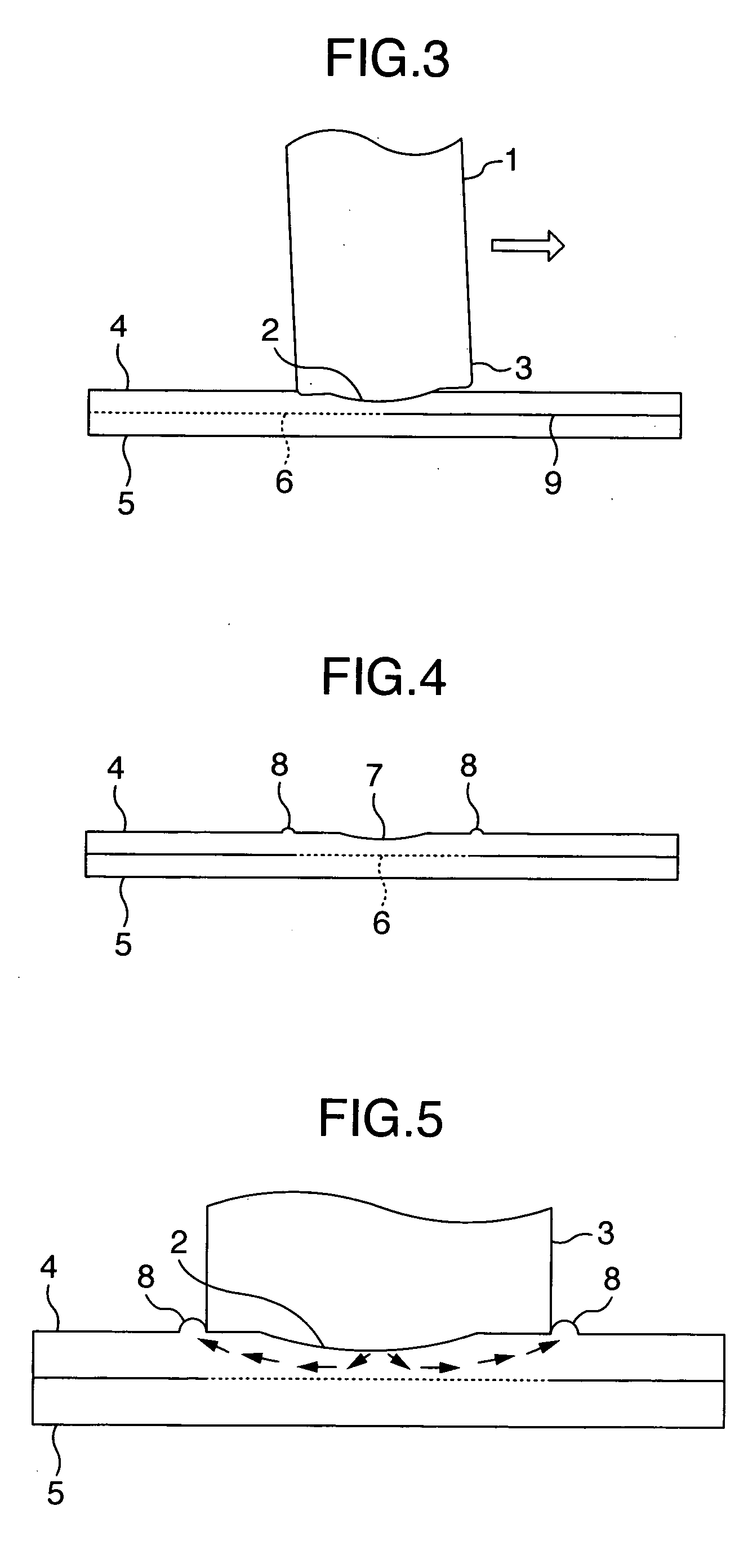

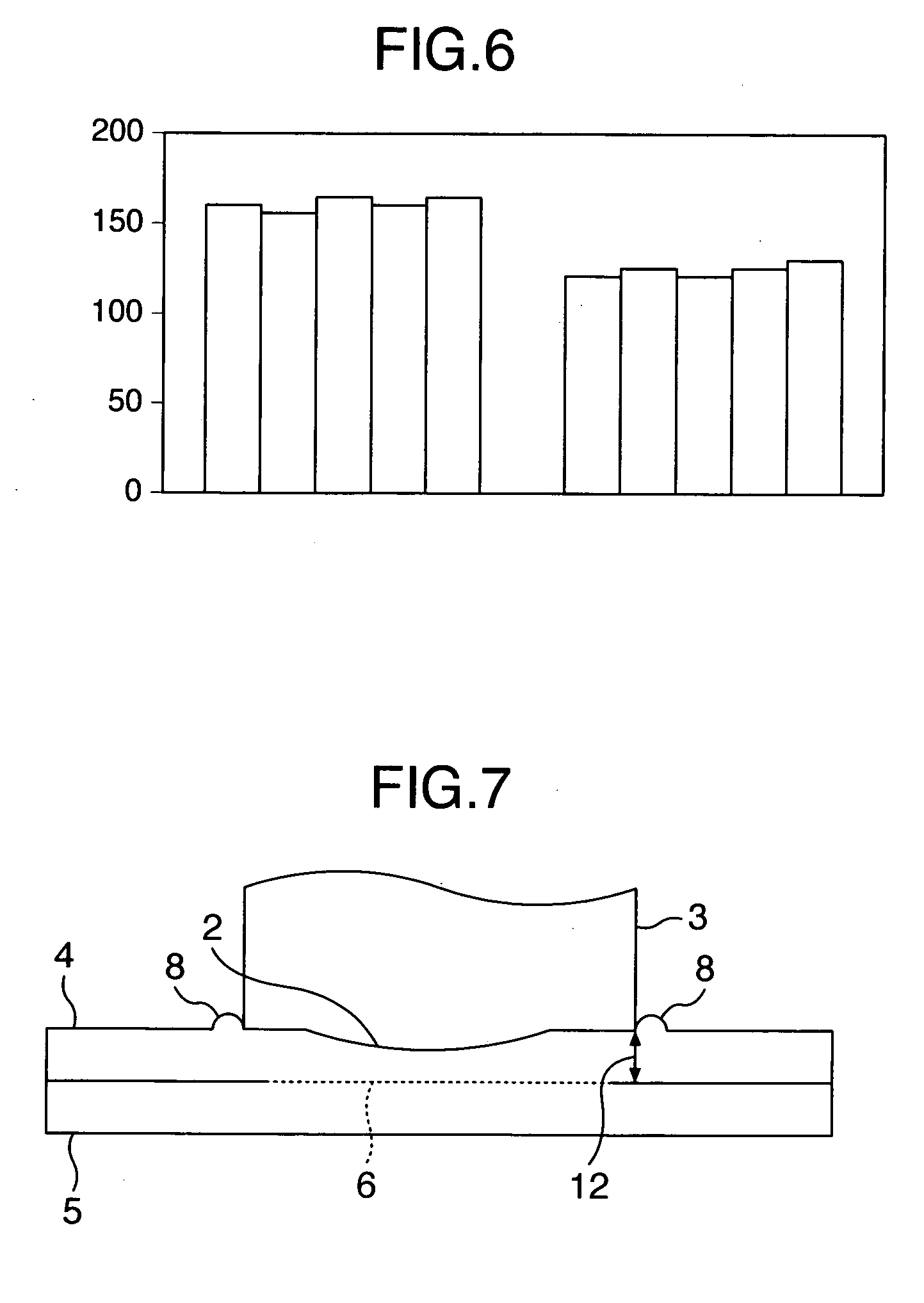

Friction stirring-welding method

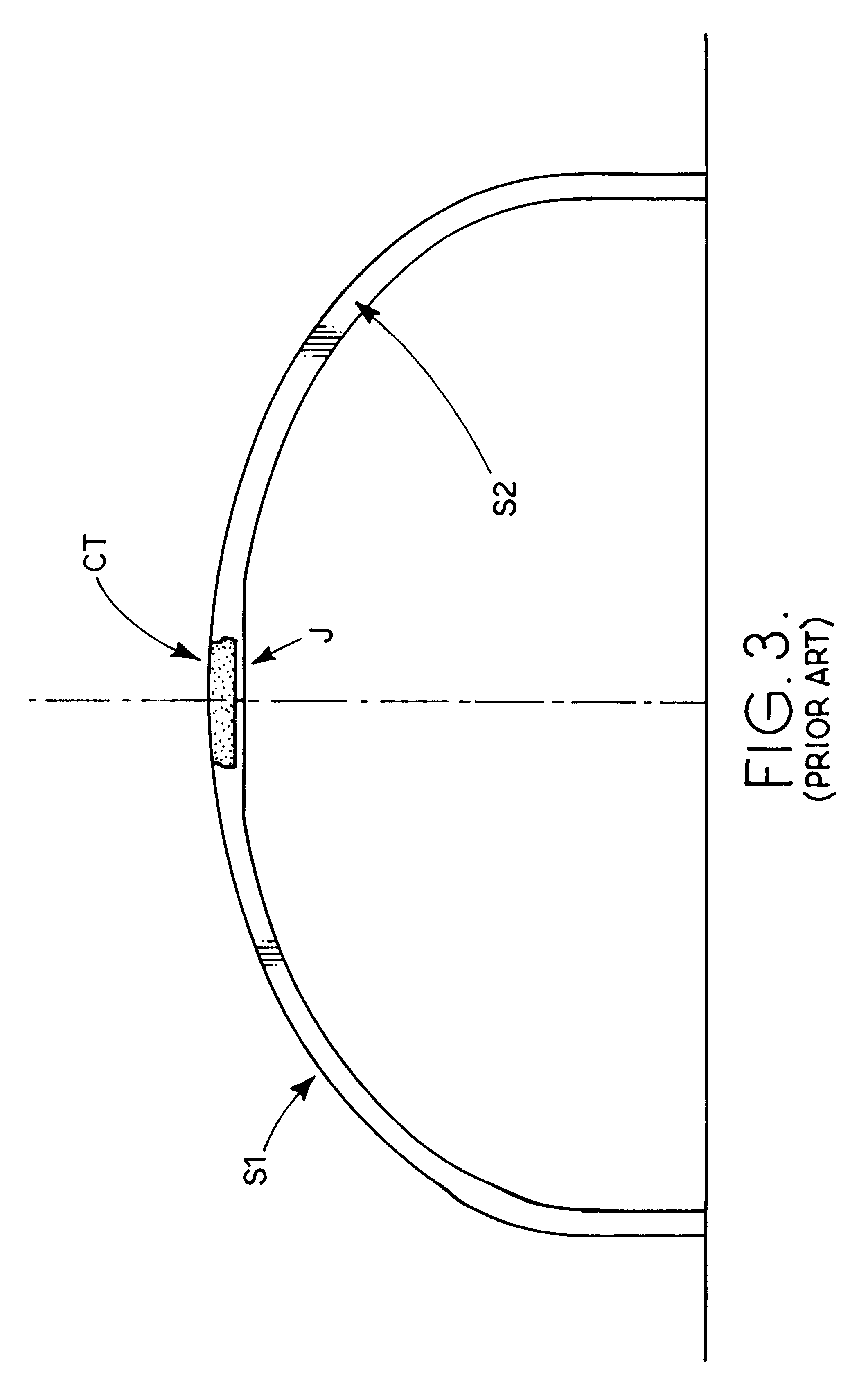

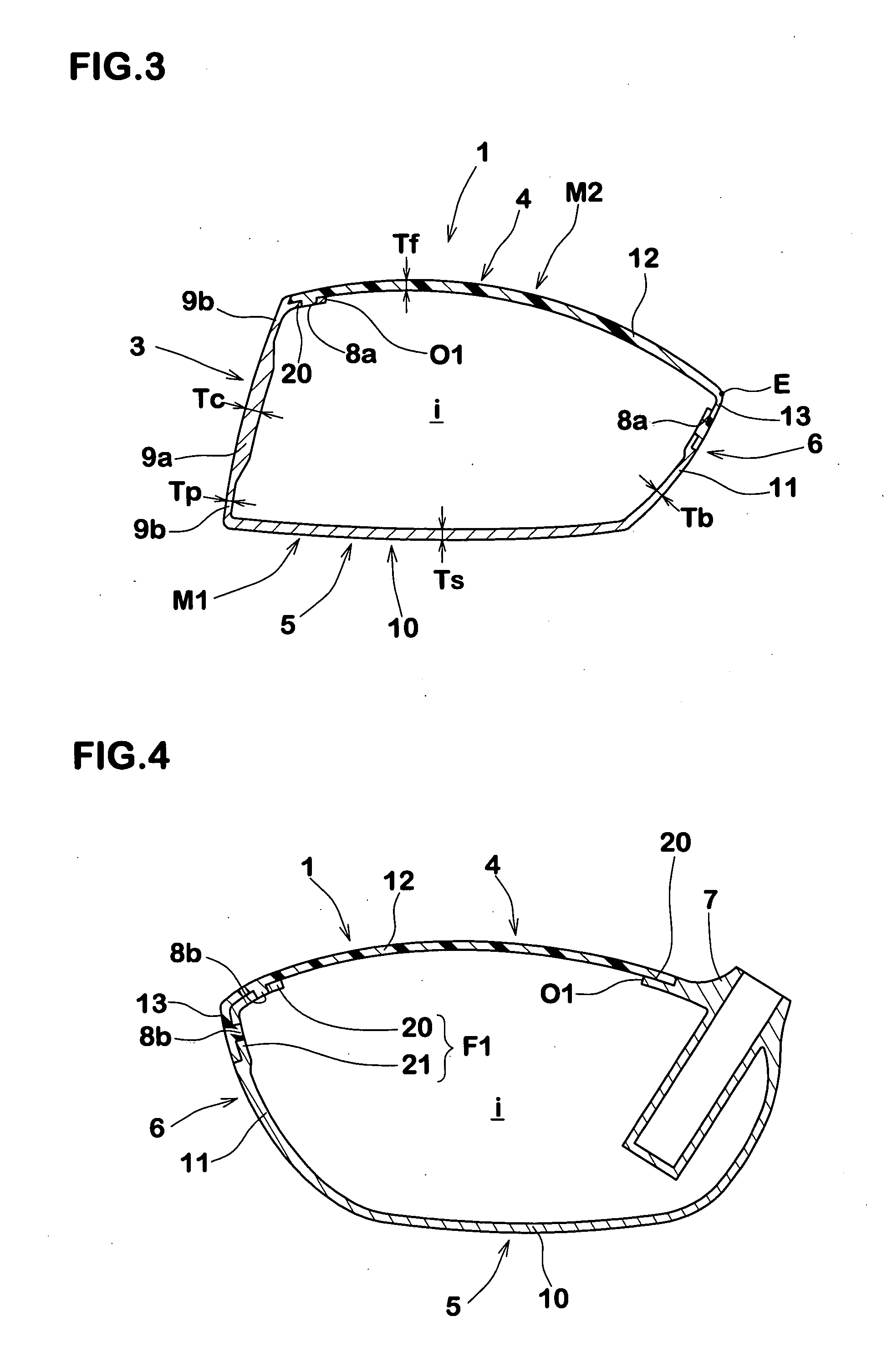

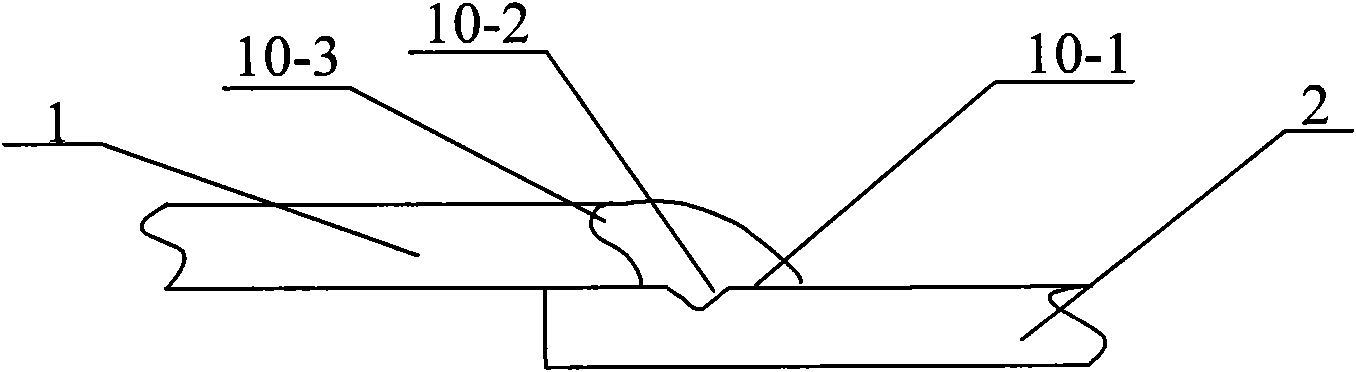

InactiveUS20060138197A1Easy to disassembleEfficient methodNon-electric welding apparatusLap jointSurface oxidation

A friction stirring-welding method capable of increasing the welding strength of a lap joint. A welding tool (1) comprises a small diameter projected part (2) at the tip of a shoulder (3). The welding tool is press-fitted to the upper plate (4) of the lap joint while being rotated. By a friction stirring action, an upper plate side welding boundary surface (6) plastically flows, a surface oxidation film on a lapped surface is peeled off, and the boundary surface is activated to provide an excellent welding part. Also, since the welding tool is formed in a shape having the small diameter semispherical projected part (2) at the tip thereof, the thickness (12) of an upper plate welding part is increased, and a lap joint part with high welding strength can be provided.

Owner:HITACHI LTD

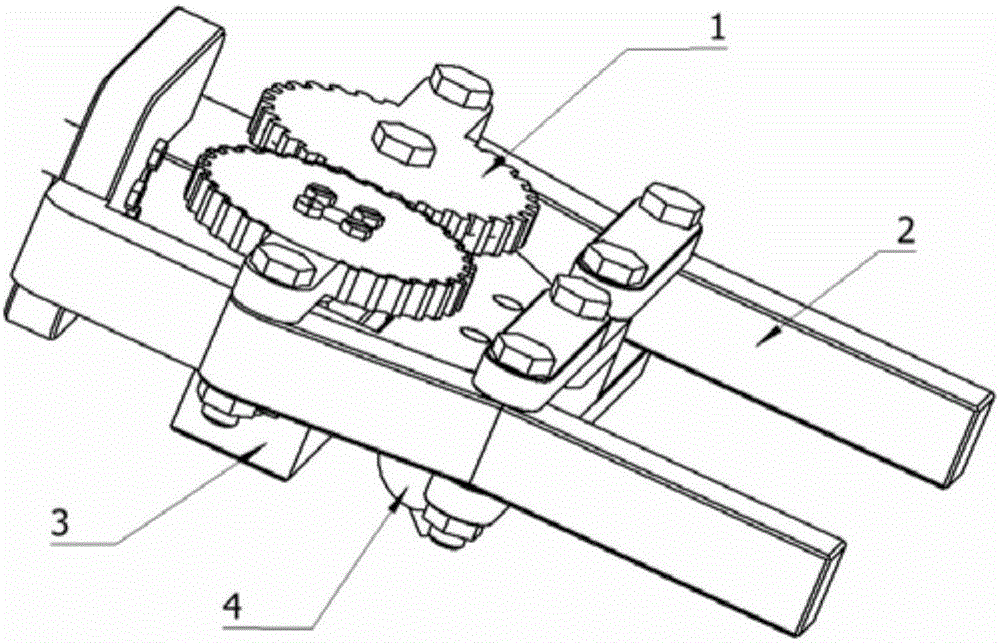

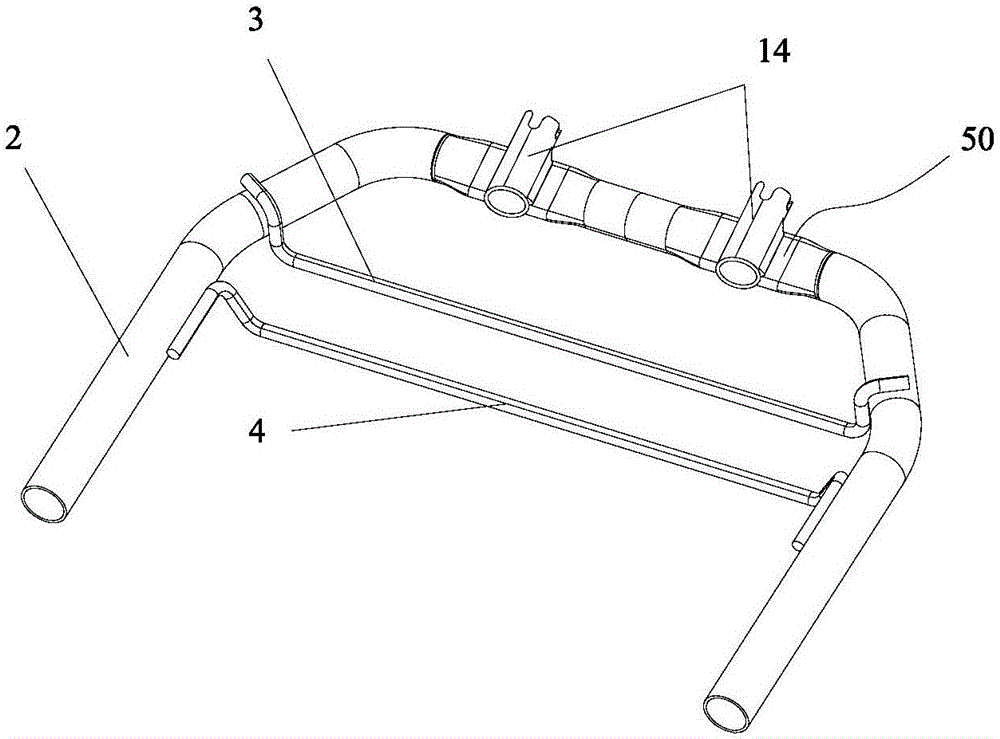

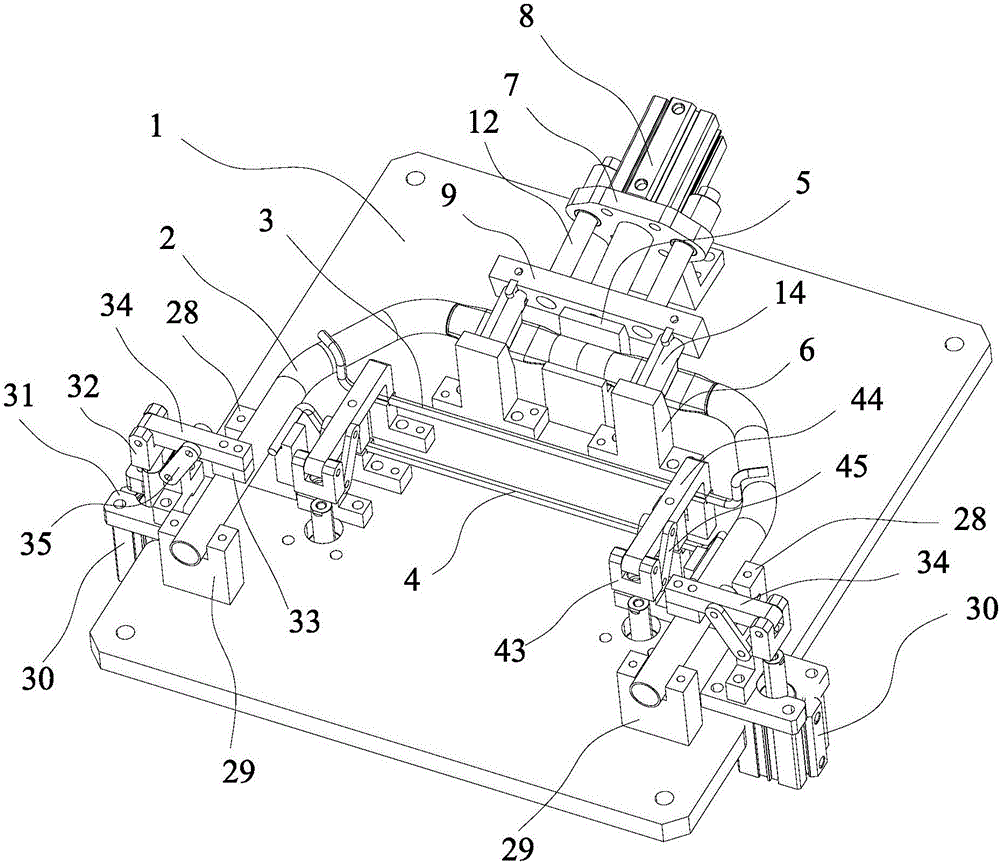

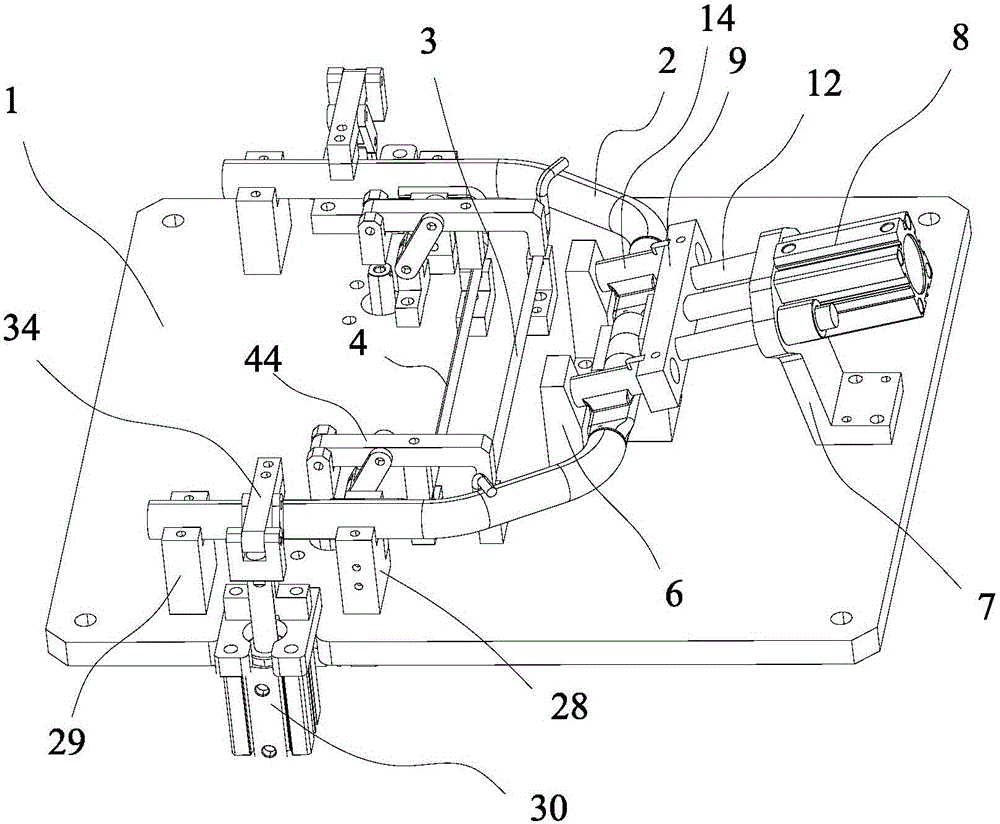

Welding tool for production of automobile seat framework

ActiveCN106112371AEnsure consistencyGuaranteed accuracyWelding/cutting auxillary devicesAuxillary welding devicesLap jointEngineering

The invention discloses a welding tool for production of an automobile seat framework. The welding tool for production of the automobile seat framework comprises a base (1), a feed clamping device, two side section clamping devices and a supporting bar clamping device, wherein the feed clamping device is provided with a sleeve (14) in advance and pushes the sleeve to the position above a slope (50) of the bottom section of a U-shaped bent pipe (2) in the automobile seat framework, the two side section clamping devices are used for fixedly clamping two side sections of the U-shaped bent pipe (2), and the supporting bar clamping device is used for fixedly clamping a first supporting bar (3) and a second supporting bar (4) so that the two ends of the first supporting bar (3) and the two ends of the second supporting bar (4) can be in fixed lap joint to the two side sections of the U-shaped bent pipe (2) correspondingly. By the adoption of the structure, the U-shaped bent pipe, the first supporting bar and the second supporting bar can be fixedly clamped, and therefore the welding tool for production of the automobile seat framework can guarantee fixed clamping of the U-shaped bent pipe and the welding precision and the product consistency of the first supporting bar and the second supporting bar during automatic welding.

Owner:宁波明望汽车饰件有限公司

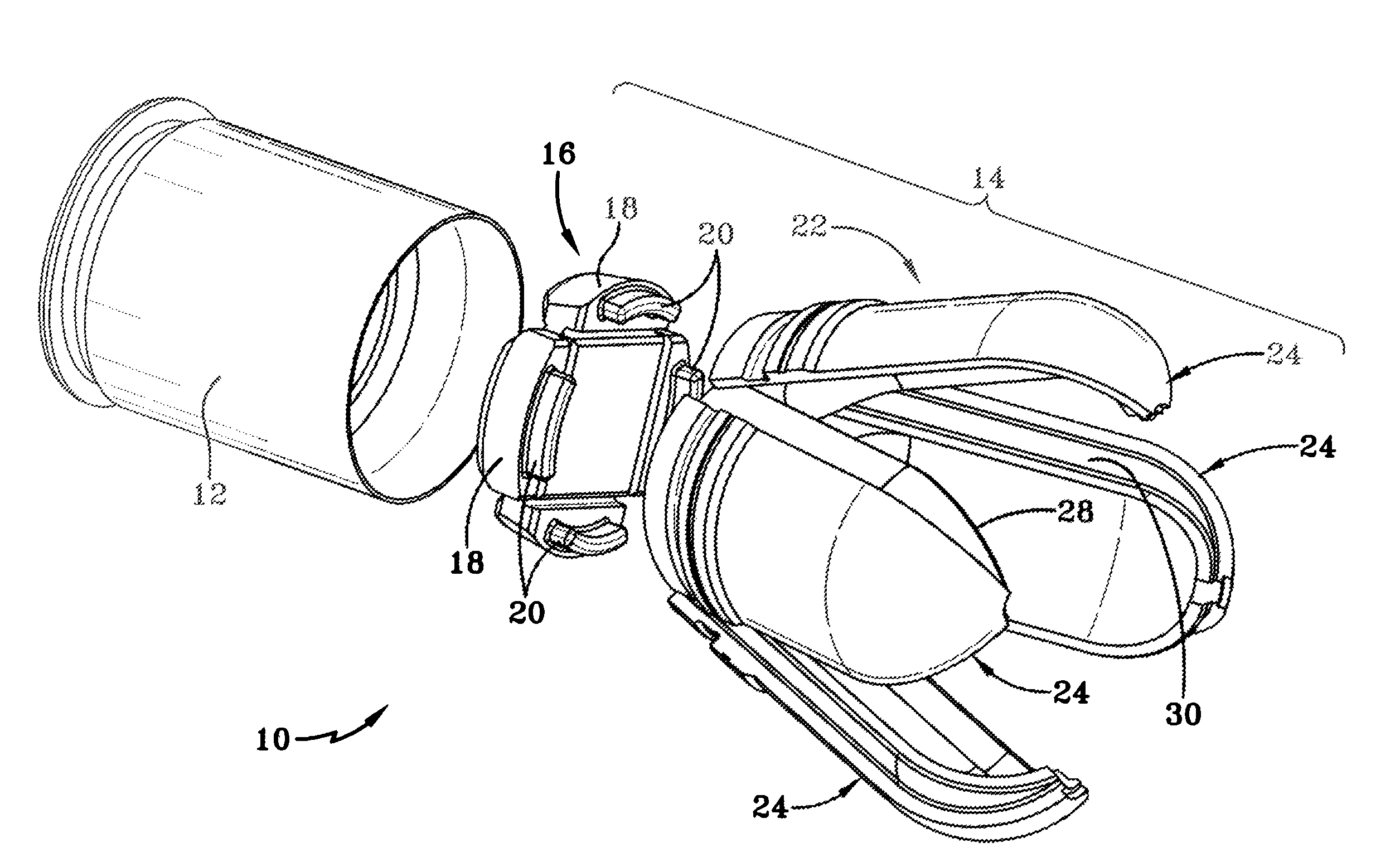

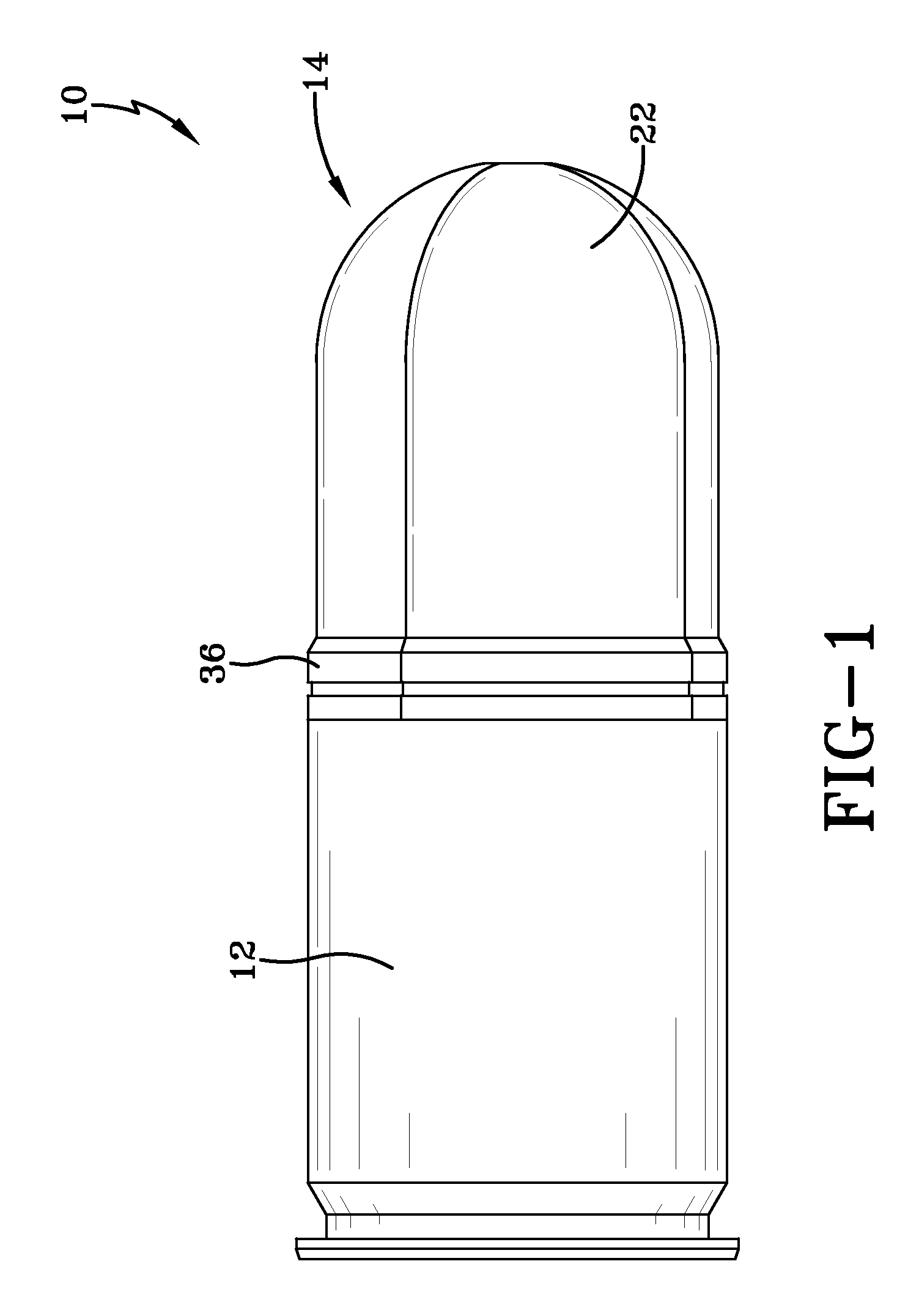

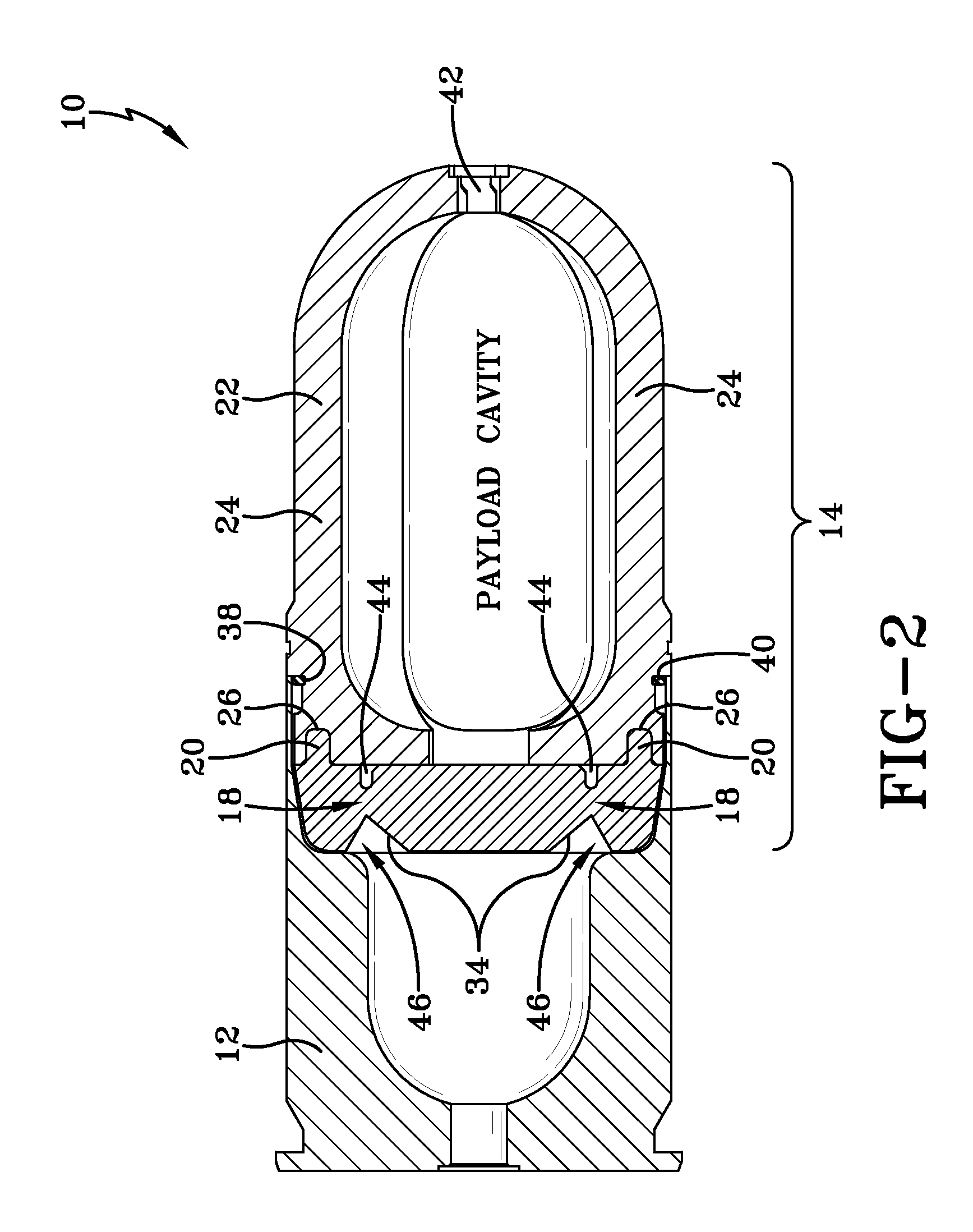

Non-lethal projectile carrier

A non-lethal projectile carrier includes a base having a plurality of hinges, each hinge including a tab; and a payload case attached to the base, the payload case comprising a plurality of petaloid members, each petaloid member including an opening in a rear surface for insertion of a corresponding tab; wherein upon exiting a gun tube the petaloid members open and fold toward the base. Each petaloid member includes a lip on one edge and an undercut on another edge so that adjacent petaloid members form lap joints. The hinges are defined by zones of small cross-sectional area in the base.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Cleaning and drying device for medical instruments

InactiveCN105170527AQuick washQuick cleaningDrying gas arrangementsCleaning using liquidsLap jointEngineering

The invention discloses a cleaning and drying device for medical instruments. The cleaning and drying device comprises a box. Water outlets are formed in the bottom of the inner wall of the box. A support is fixedly arranged at the bottom of the inner wall of the box. One side of the support is fixedly connected with a lower sliding plate. The surface of the lower sliding plate is covered with a water absorption sponge. The bottom end of the lower sliding plate is in lap joint with the upper surface of a bearing plate. A containing groove is formed in the upper surface of the bearing plate, and a heating piece is arranged in the bearing plate. According to the cleaning and drying device for the medical instruments, a high-pressure spray head is arranged, so that the medical instruments are cleaned fast; ultraviolet lamps are arranged, so that the effect of disinfecting the medical instruments is achieved; the sliding plate and the water absorption sponge are arranged, so that the effects of sliding down and water absorption on the instruments are achieved; a filter device is arranged in an air chamber, so that the effect of filtering out impurities in air is achieved; and the heating piece is arranged, so that the effect of heating the bearing plate and the instruments on the bearing plate is achieved.

Owner:THE FIRST AFFILIATED HOSPITAL OF ZHENGZHOU UNIV

Narrow lap joint welding process for cold-rolled dual-phase steel strips

InactiveCN104842056AImprove welding strengthImprove plasticityResistance welding apparatusProduction linePower flow

The invention discloses a narrow lap joint welding process for cold-rolled dual-phase steel strips and belongs to the technical field of steel strip welding processes. A narrow lap joint resistance welding machine is utilized to weld the cold-rolled dual-phase steel strips. According to the technical scheme, the welding process conditions include that welding current is 9-26 KA, welding speed is 6-13m / min, the welding wheel pressure of the welding machine is 6.5-13KN, the lap joint amount of the tail portion of a previous steel strip roll and the heat portion of a later steel strip roll is 0.4-2.0 mm, and compensation amount is 0.25-0.7 mm. The narrow lap joint welding process is a bold trial, the design limits on the strength, component and the like of the narrow lap joint resistance welding machine are broken through, and narrow lap joint welding operation of the cold-rolled dual-phase steel strips is achieved through innovative operation. The narrow lap joint resistance welding machine on an existing processing line of an enterprise can be used for welding the cold-rolled dual-phase steel strips, the functions of the existing production line are greatly widened, the fund cost, production cost and device cost of the cold-rolled dual-phase steel strips are effectively reduced, and huge economic benefit is brought to the enterprise.

Owner:TANGSHAN IRON & STEEL GROUP

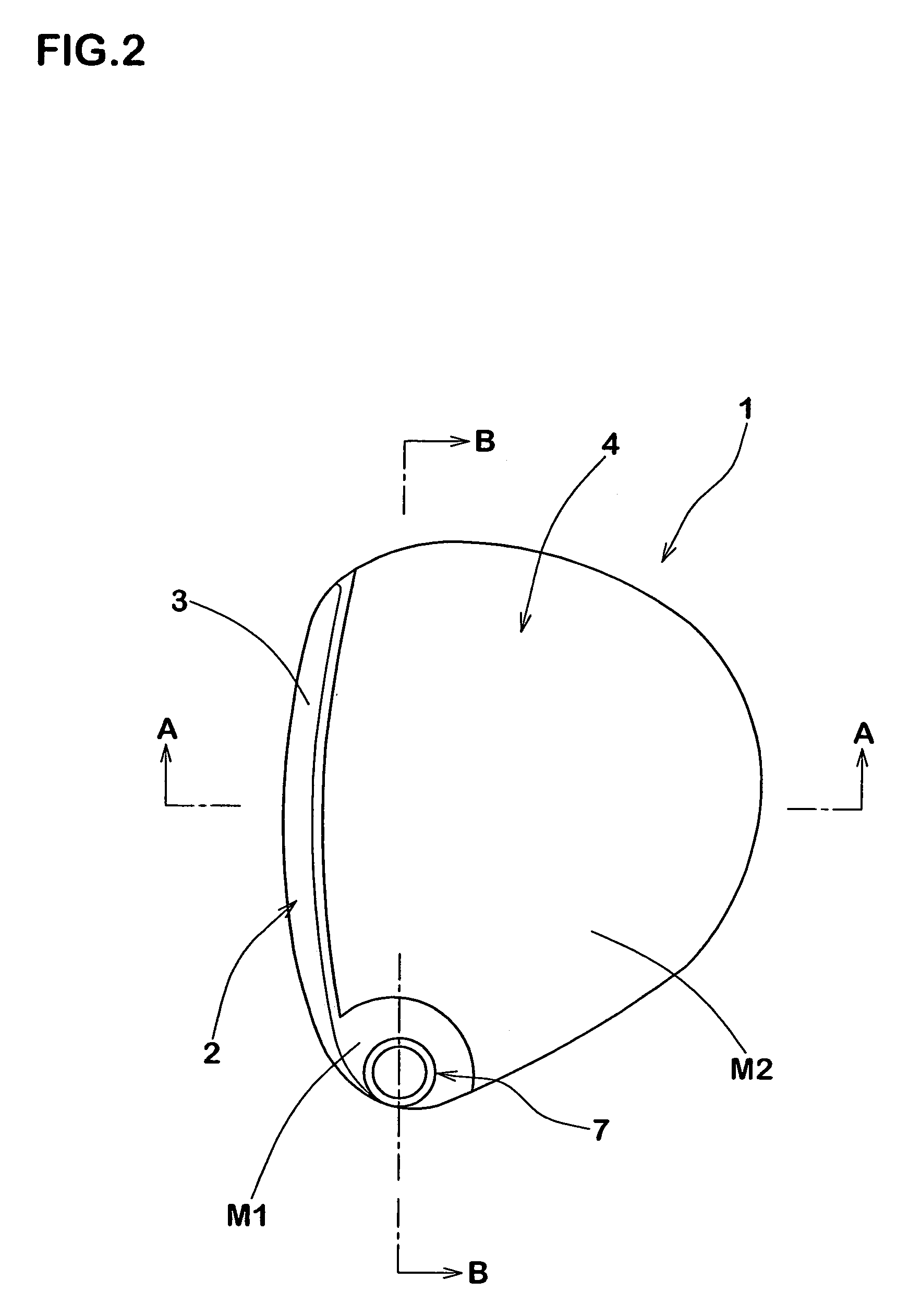

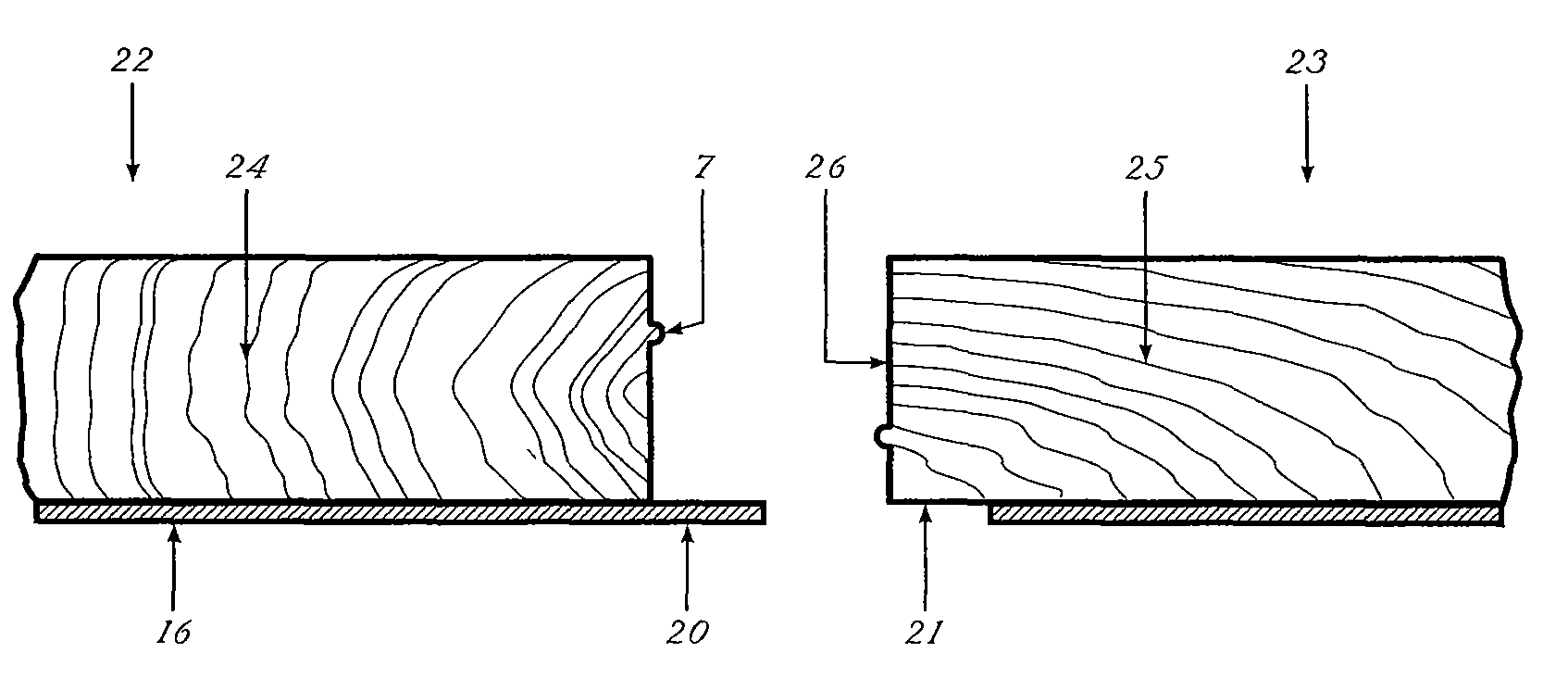

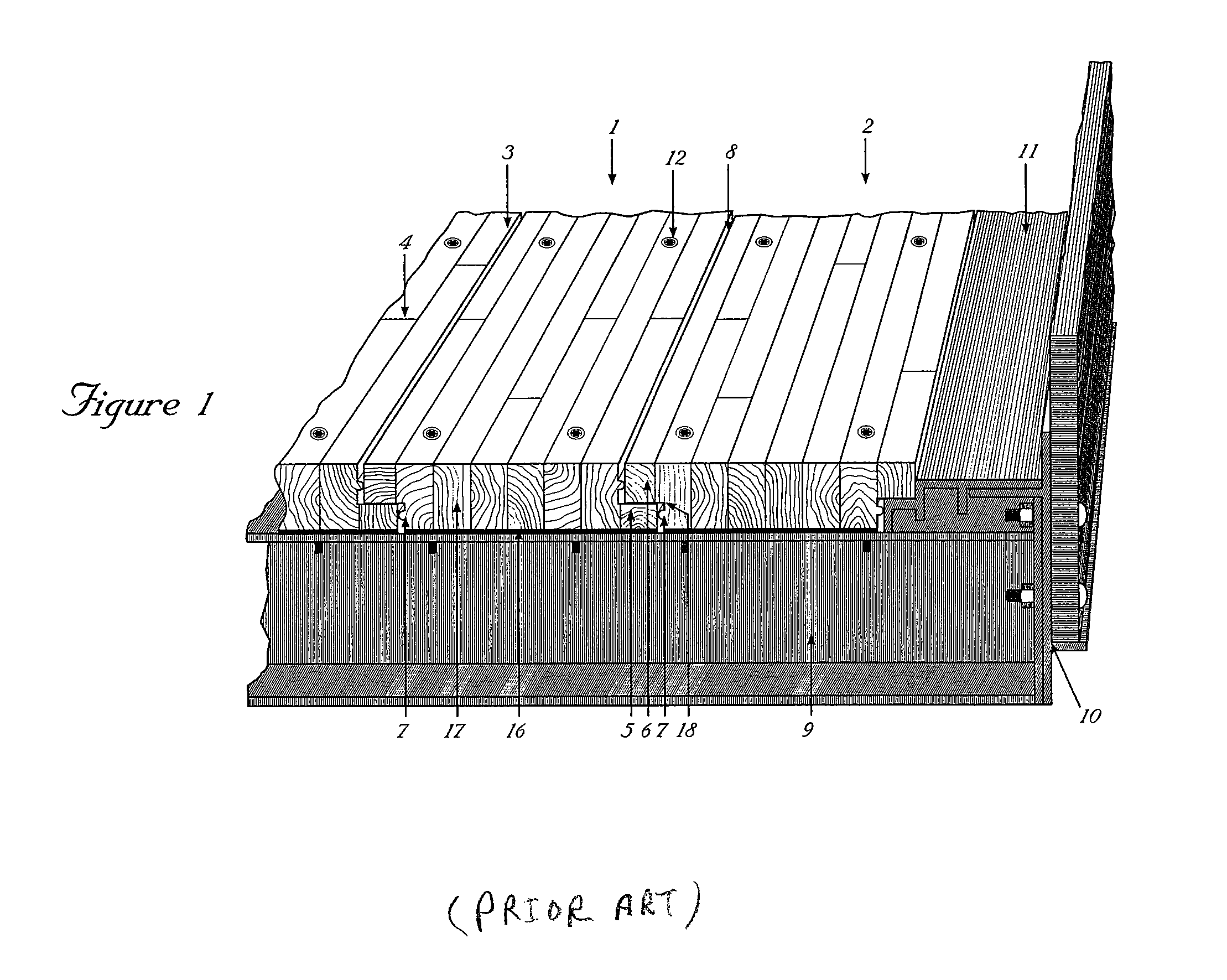

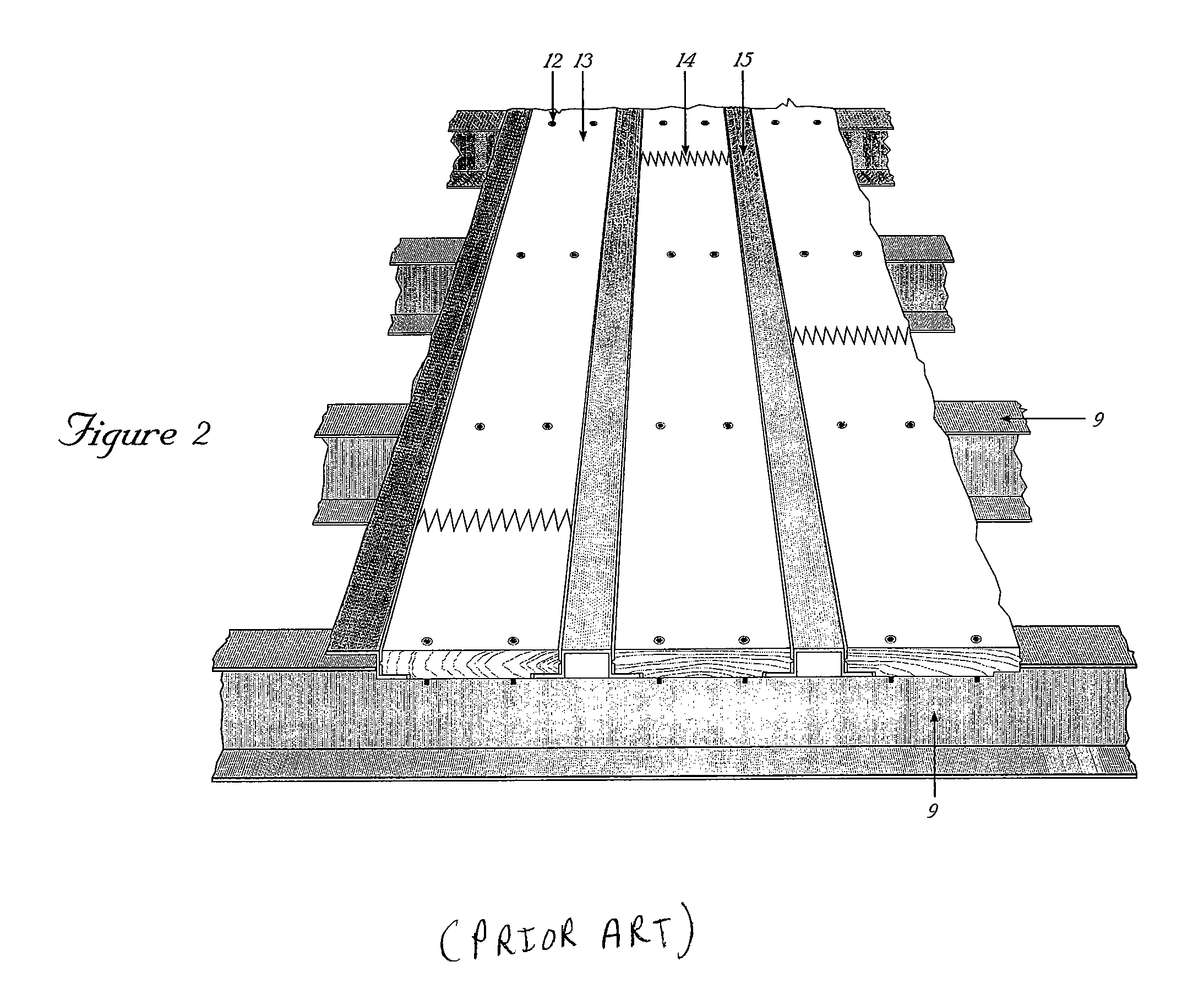

Flexible composite lap joint for trailer flooring

A composite lap joint for the assembly of a first and a second floor board from a plurality of boards, used to make the floor for a vehicular trailer, each board composed of a layer of wood at the top side and a layer of fiber reinforced composite at the bottom side, wherein the composite layer is at least partly bonded to the wood layer; the composite layer of a first board forming a lip, wherein the lip is a lateral extension of the composite layer and the lip is disposed under the bottom side recess of an adjacent second board to form a composite joint, whereby the joint provides improved flexibility, moisture sealing ability at the seam of the joint and higher strength to the edges of the boards.

Owner:HAVCO WOOD PRODS

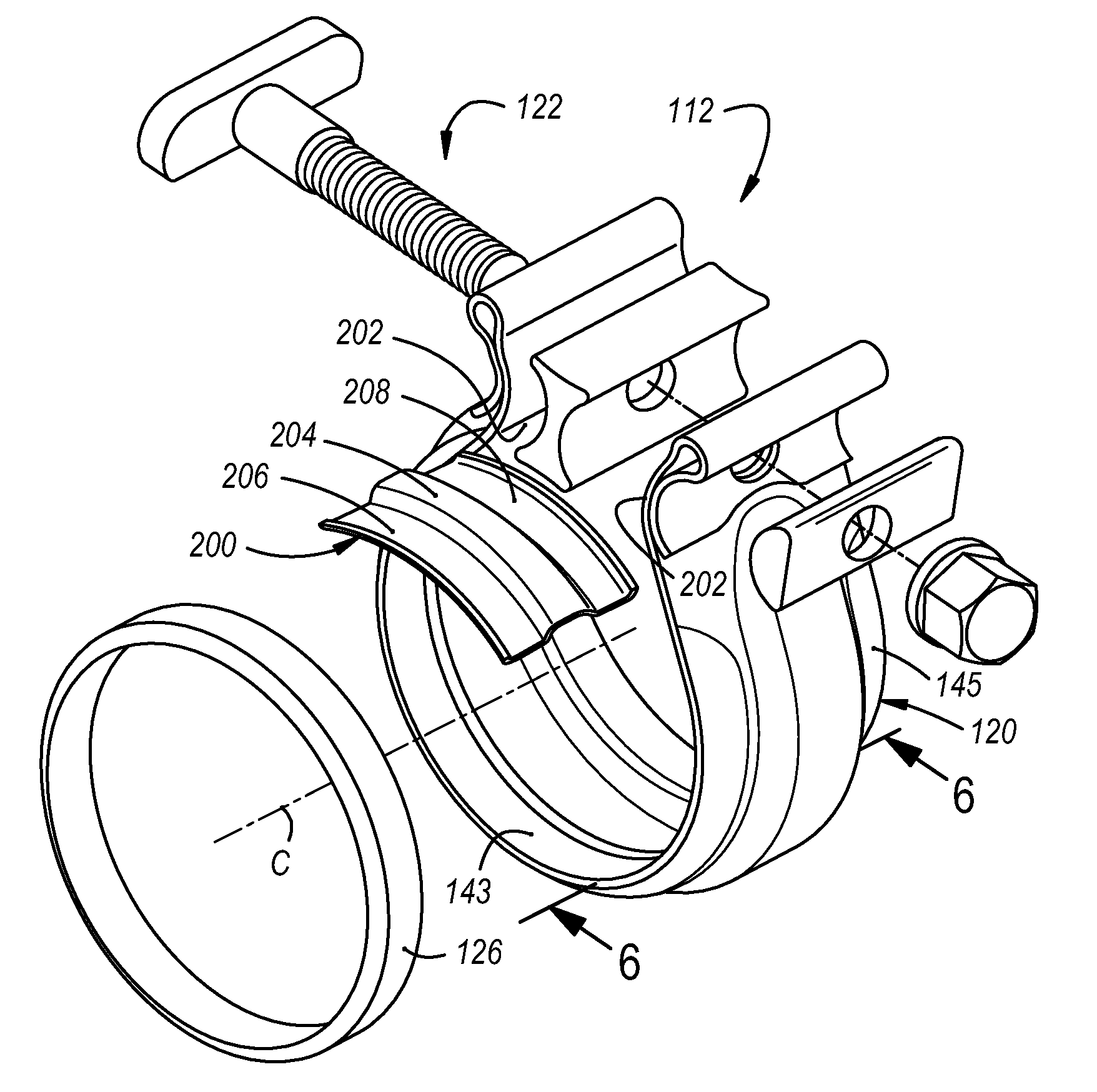

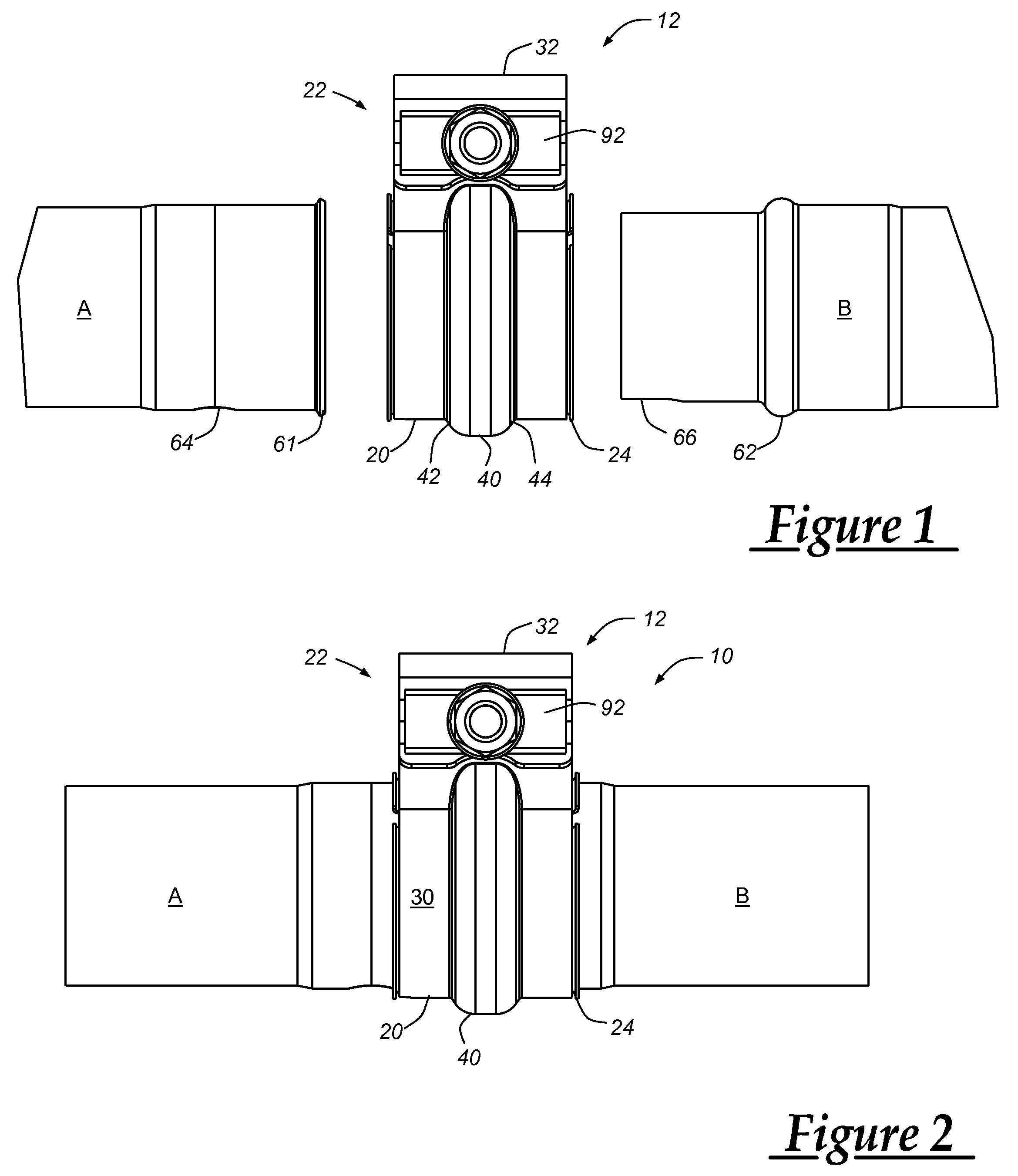

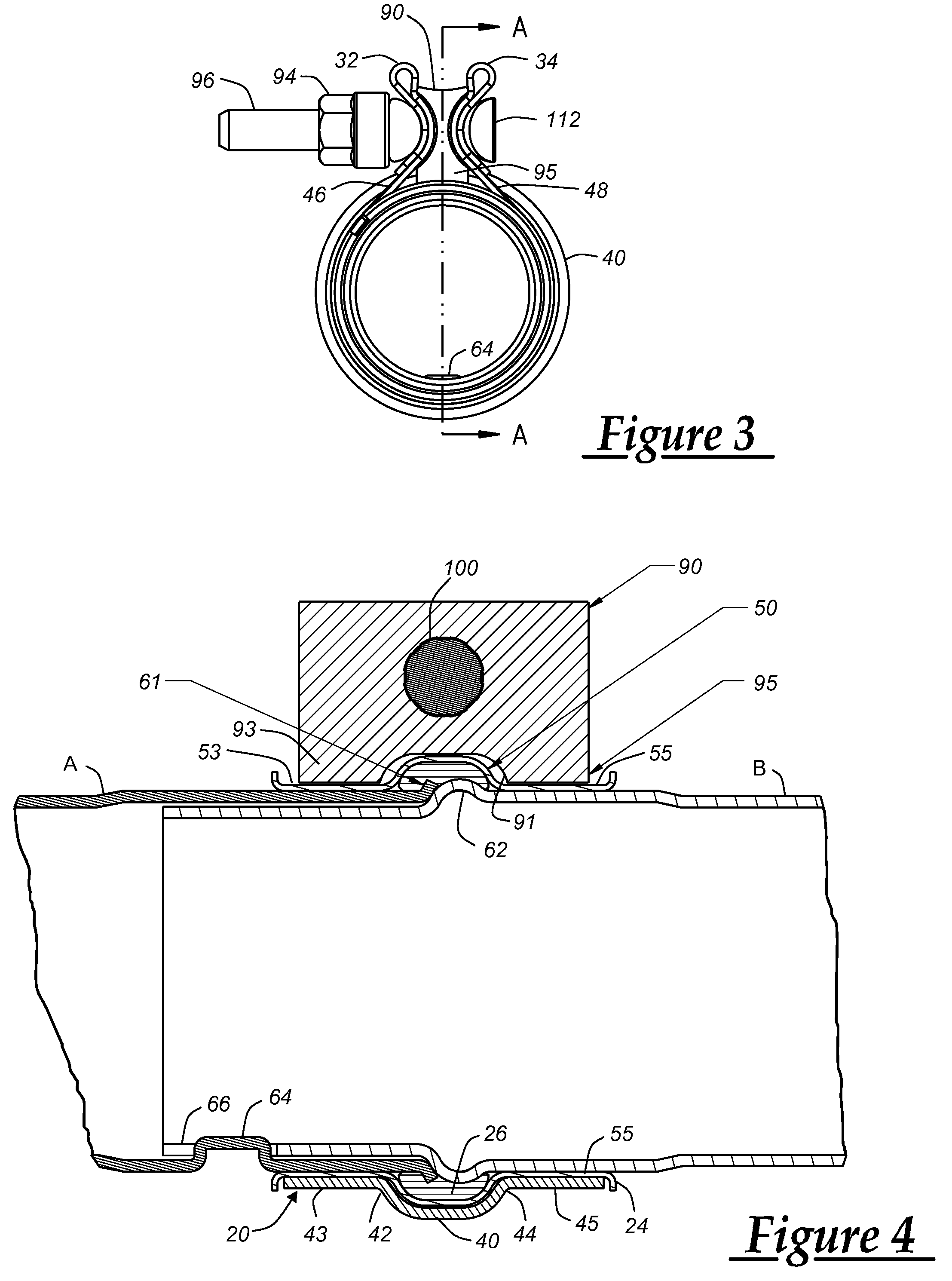

Single-bolt band clamp with gasketed center rib and pipe lap joint using the same

A band clamp that connects overlapping pipe ends includes a band, a tightening mechanism, and a gasket. The band has a radially protruding rib, a first lateral section that extends from a side of the rib, and a second lateral section that extends from another side of the rib. The tightening mechanism connects to the band and is operable to tighten the band, and the gasket is received in the rib. In one example, an axial width of the lateral sections are within a range relative to an axial width of the rib, and in another example, the lateral sections are angled inwardly with relative to an axis of the band.

Owner:NORMA US HOLDING LLC

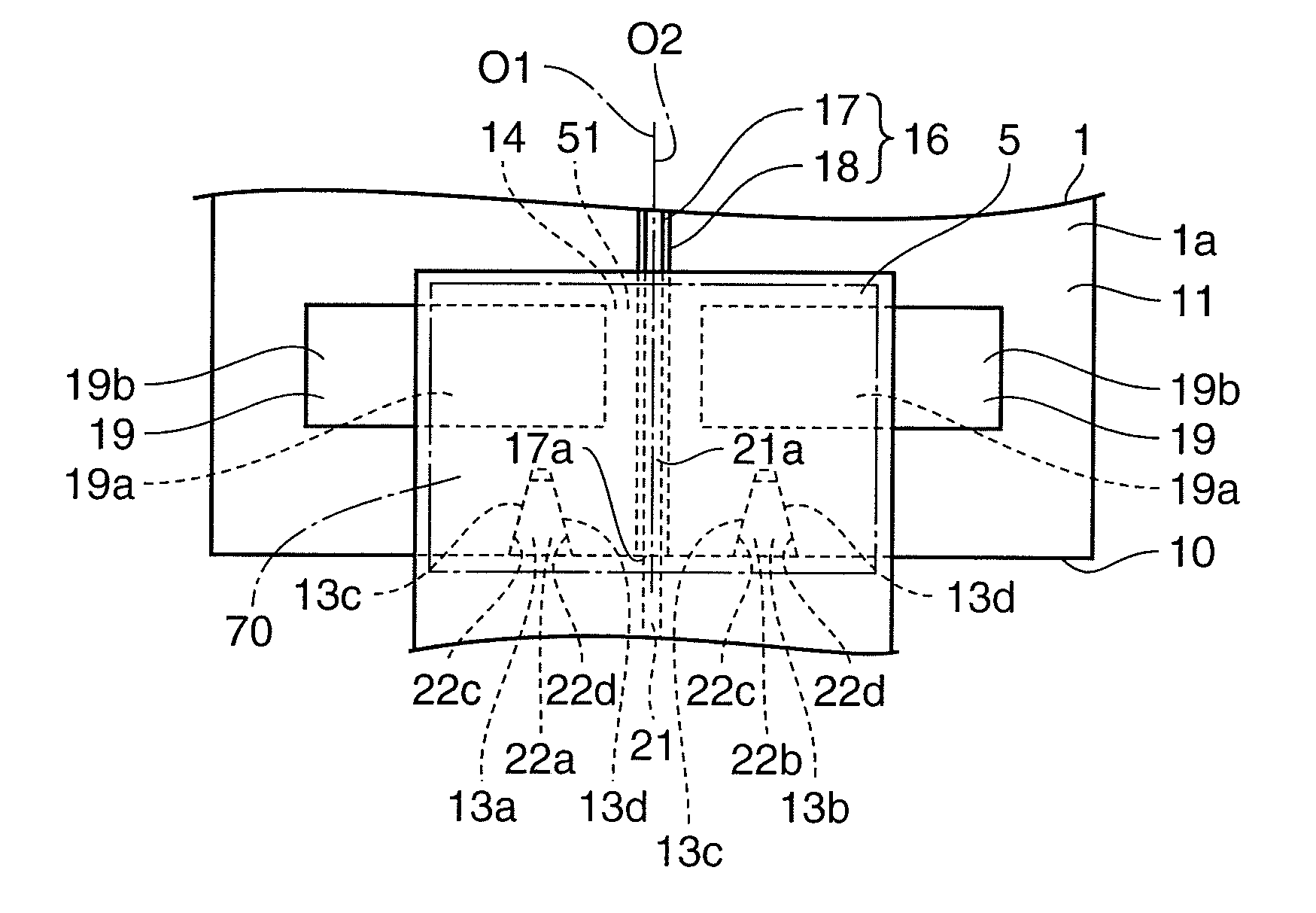

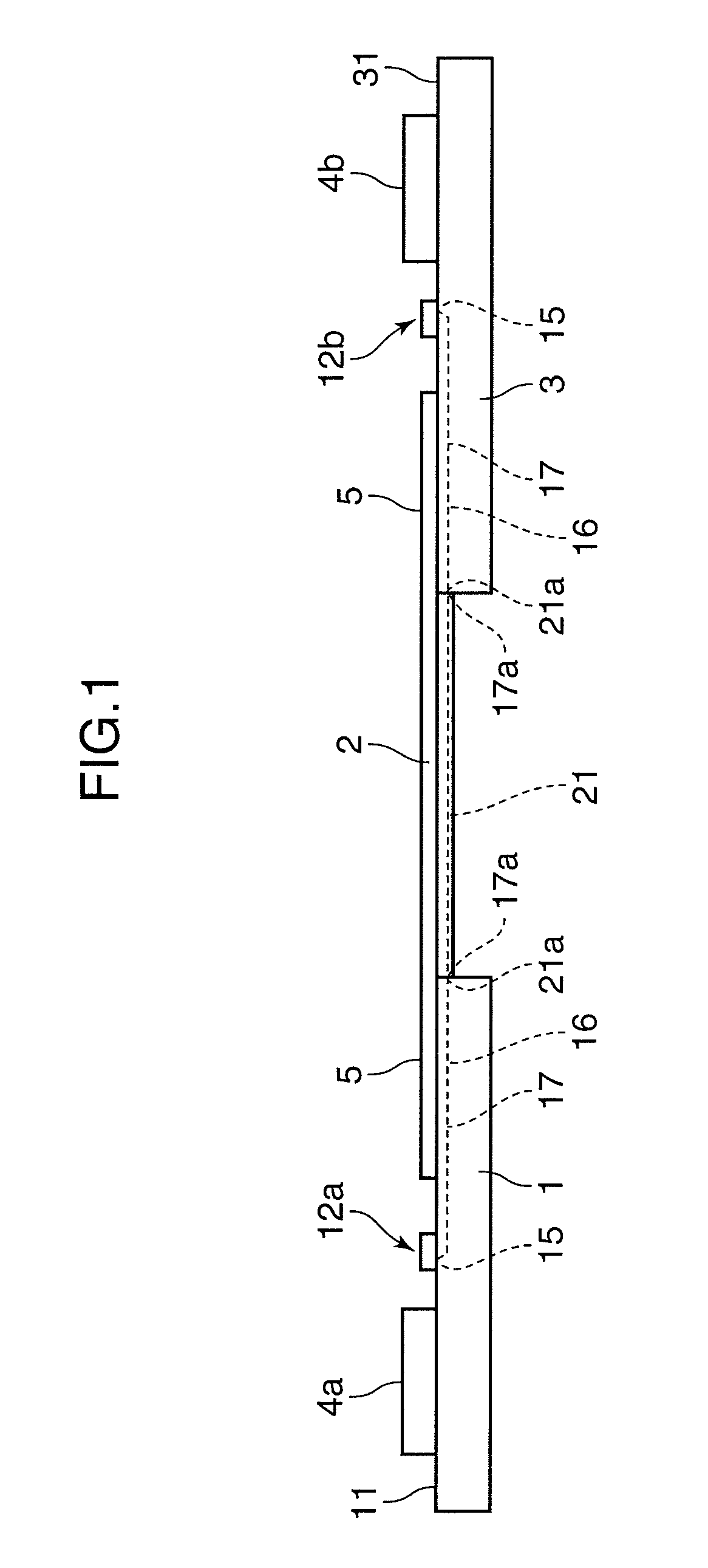

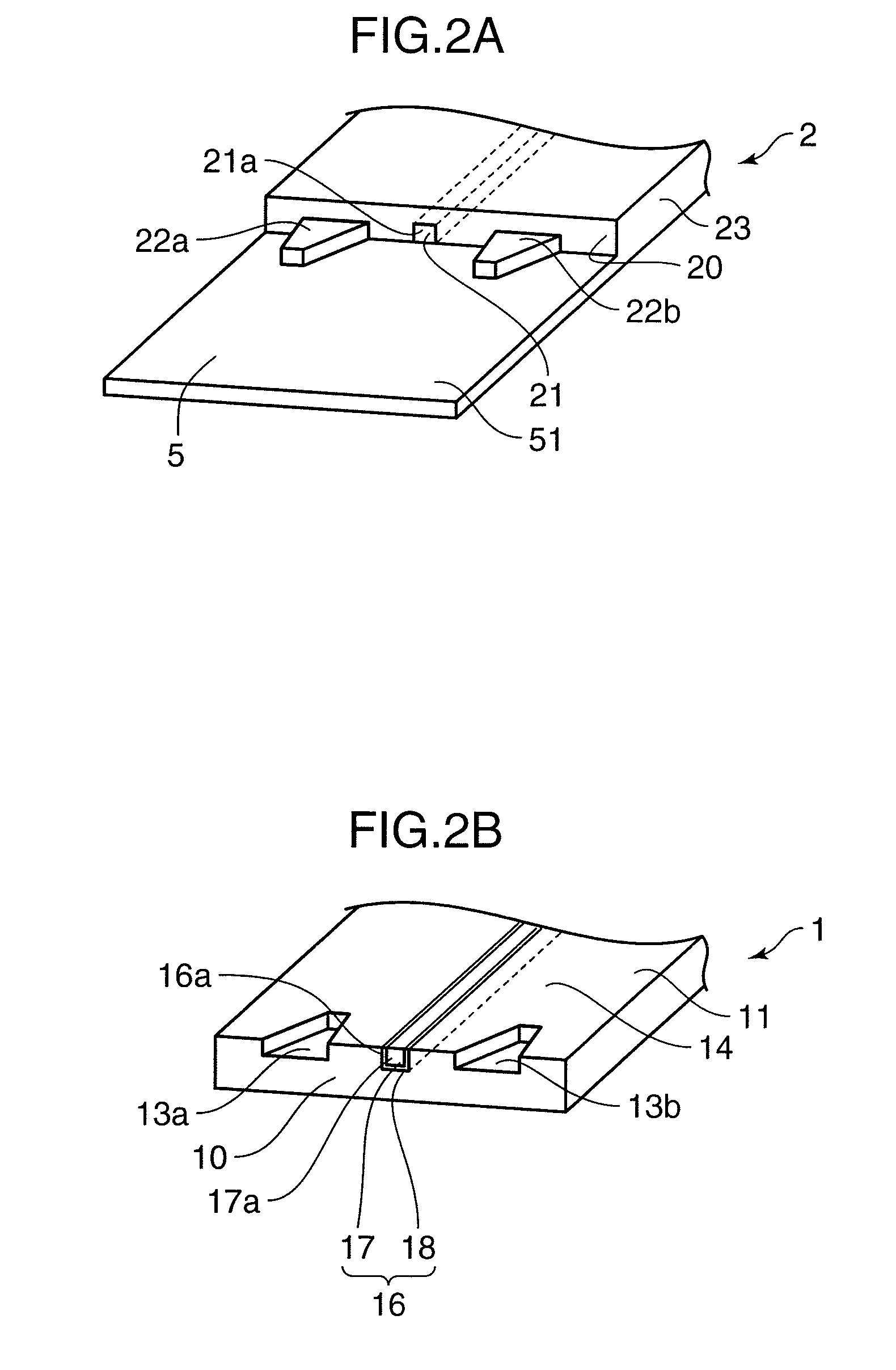

Optical module

InactiveUS20100220957A1High bonding strengthReduce riskCoupling light guidesOptical waveguide light guideOptical ModuleLap joint

An optical module includes an emitter-side mounting substrate, a receiver-side mounting substrate and an external waveguide substrate. The mounting substrate is provided with a waveguide having a core and a pair of fitting recesses. The external waveguide substrate is provided with an external waveguide having a core, a pair of fitting tabs and a lap joint portion. As the fitting tabs are fitted into the respective fitting recesses, the mounting substrate and the external waveguide substrate are joined together, the two cores are aligned with each other, and the lap joint portion is positioned to overlap the mounting substrate.

Owner:PANASONIC CORP

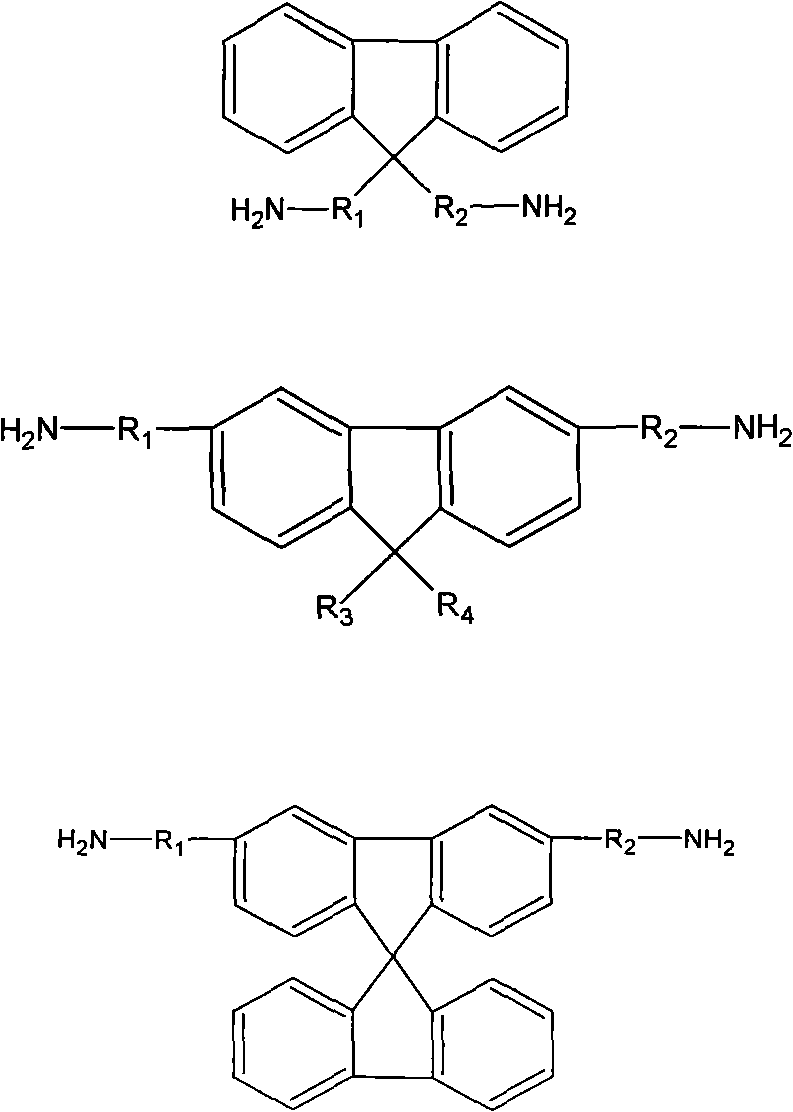

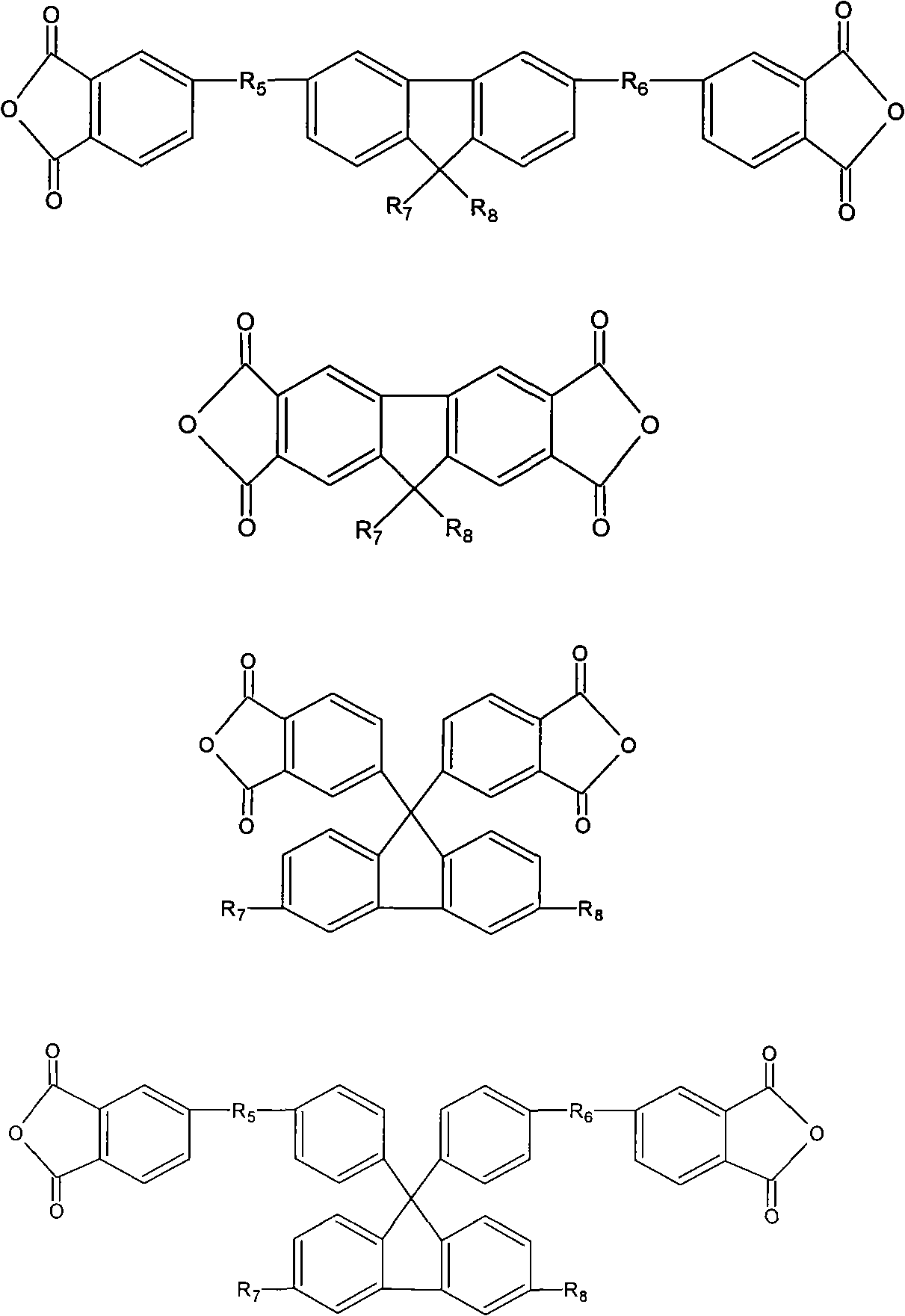

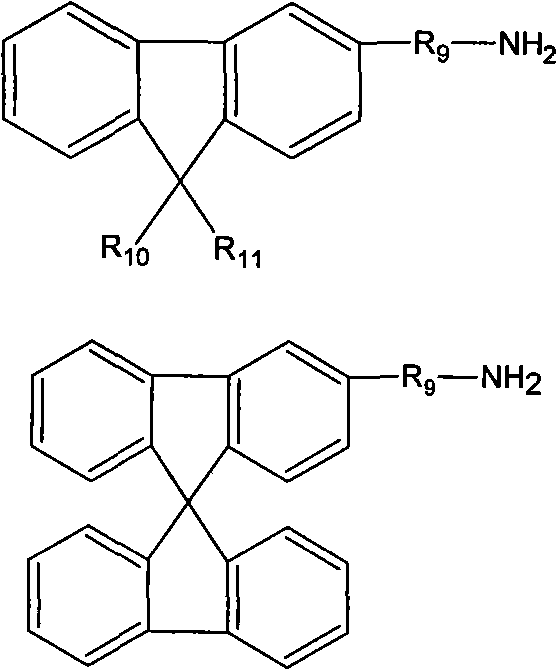

Fluorene-containing polyimide adhesive and preparation method thereof

The invention provides a fluorene-containing polyimide adhesive having good adhesivity with metal, which is characterized in that: the adhesive at least comprises a fluorene-containing diamine monomer, a fluorene-containing dianhydride monomer and / or a fluorene-containing end capping agent, and at least one of other fluorene-containing diamine monomers, other fluorene-containing dianhydride monomers and / or other end capping agents. A preparation method for the fluorene-containing polyimide adhesive comprises the following steps: A, dissolving a certain amount of diamine, dianhydride or the end capping agent in organic solvent, stirring at room temperature, and obtaining even polyamic acid solution; B, preparing polyimide powder or a partial imidization polyimide film by a chemical imidization method or a heat imidization method; and C, arranging the powder with certain thickness or the film between two metal sheets, and performing hot pressing on a press for a certain period of time to obtain a single-lap joint bonded part with firm adhesivity. The fluorene-containing polyimide adhesive provided by the invention is applied in the fields of high-tech such as aviation, space flight, microelectronics, etc.

Owner:BEIHANG UNIV

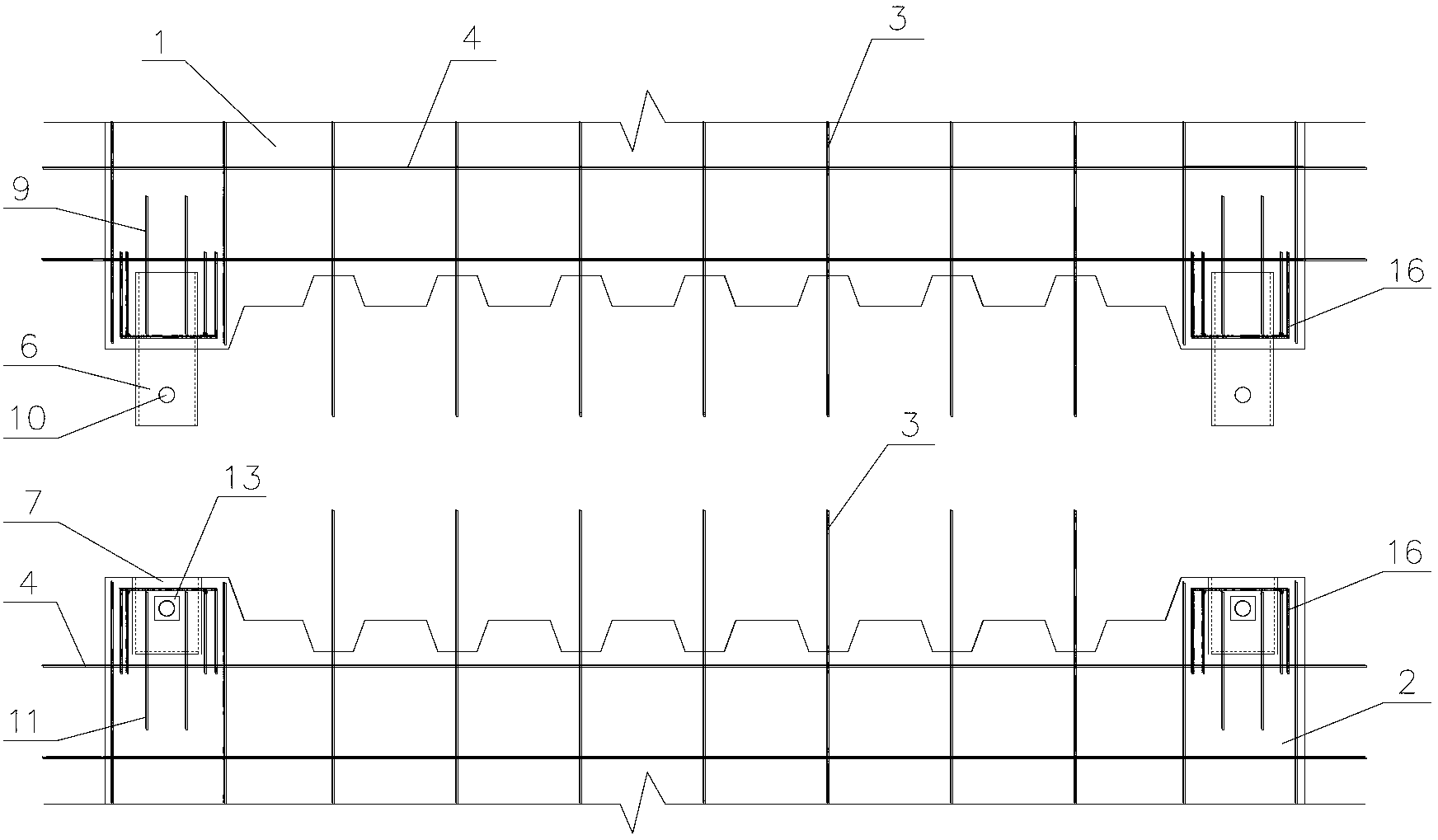

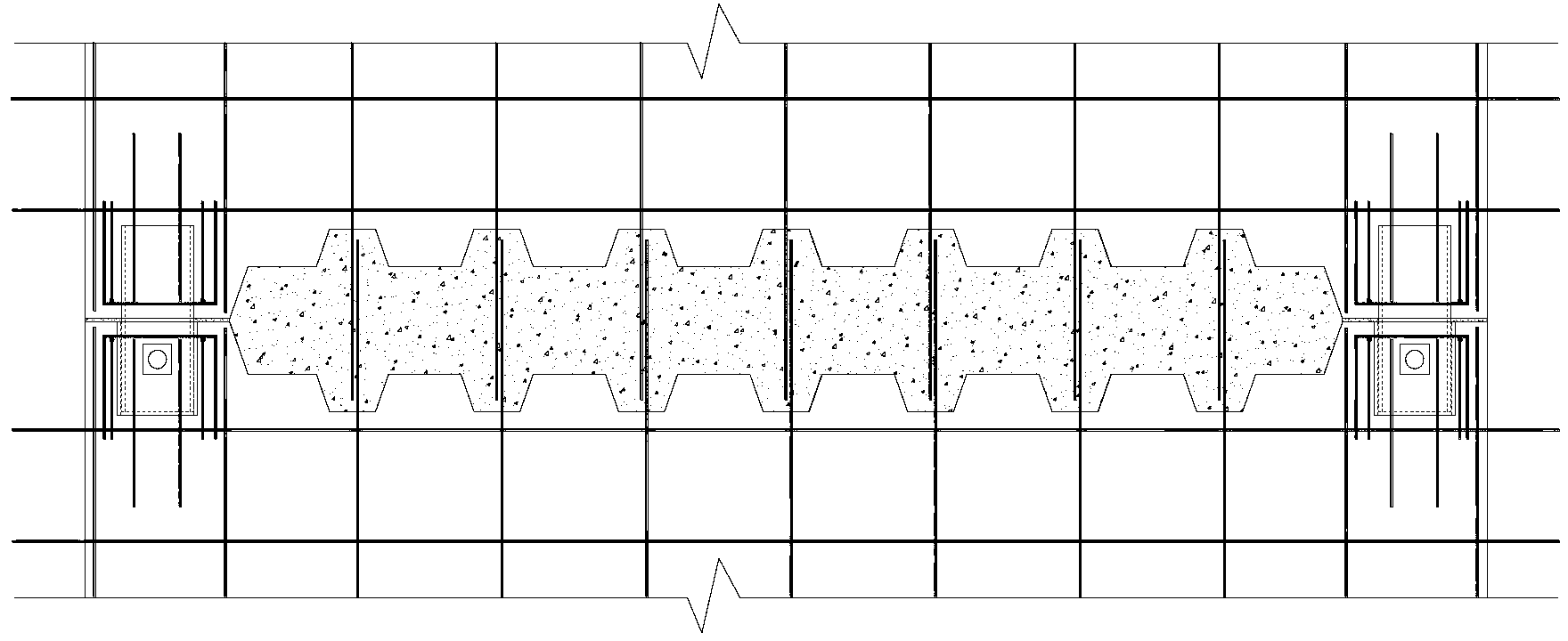

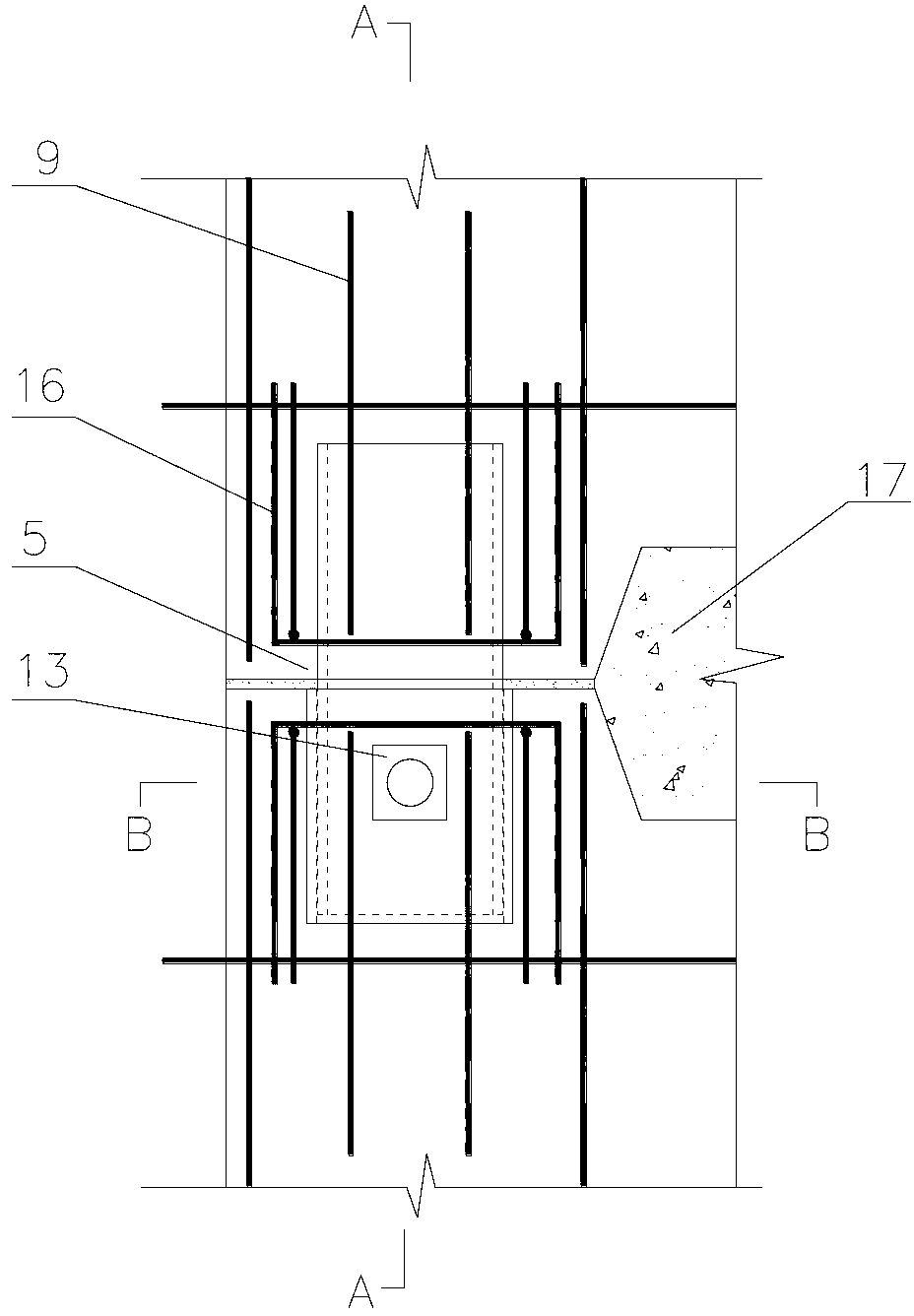

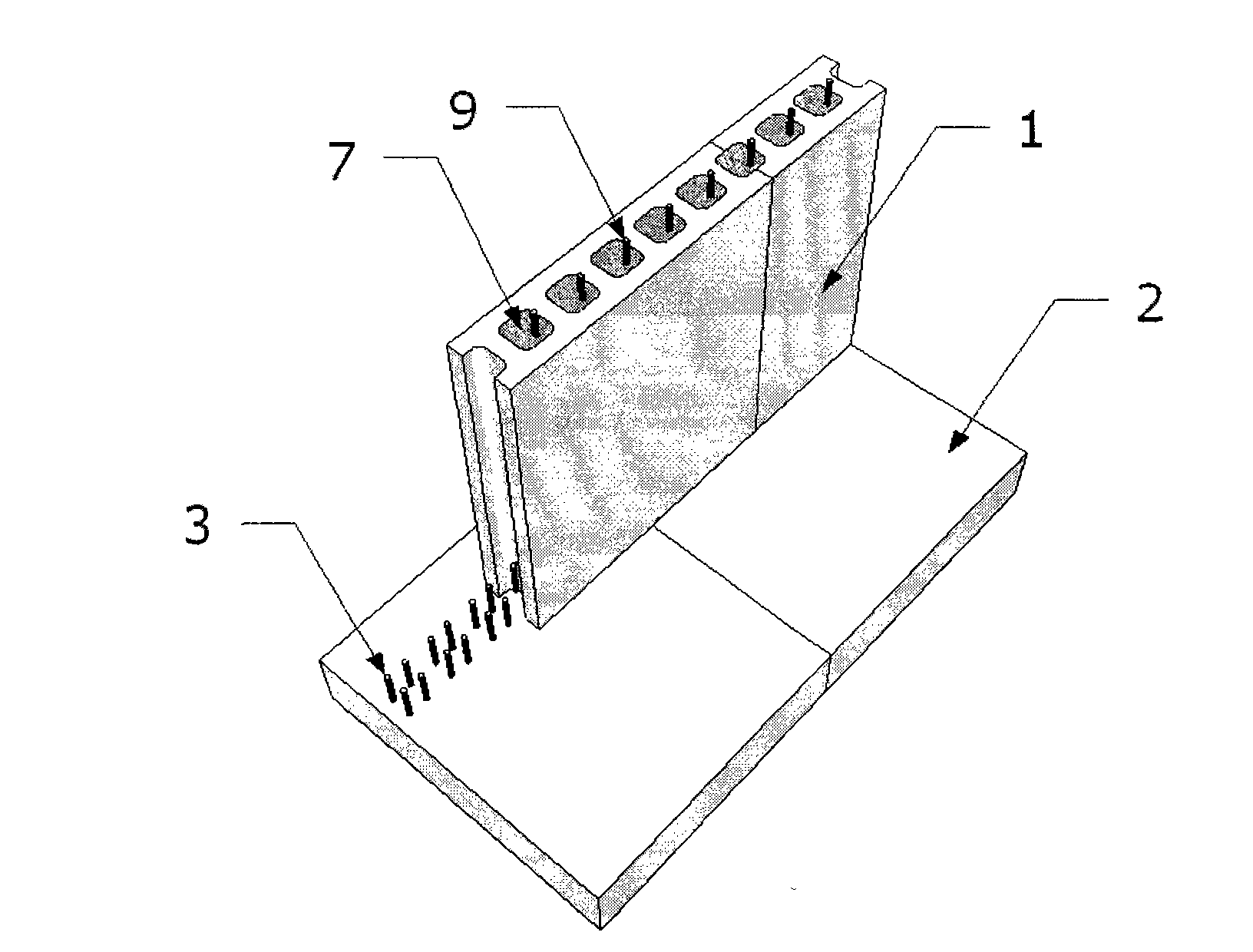

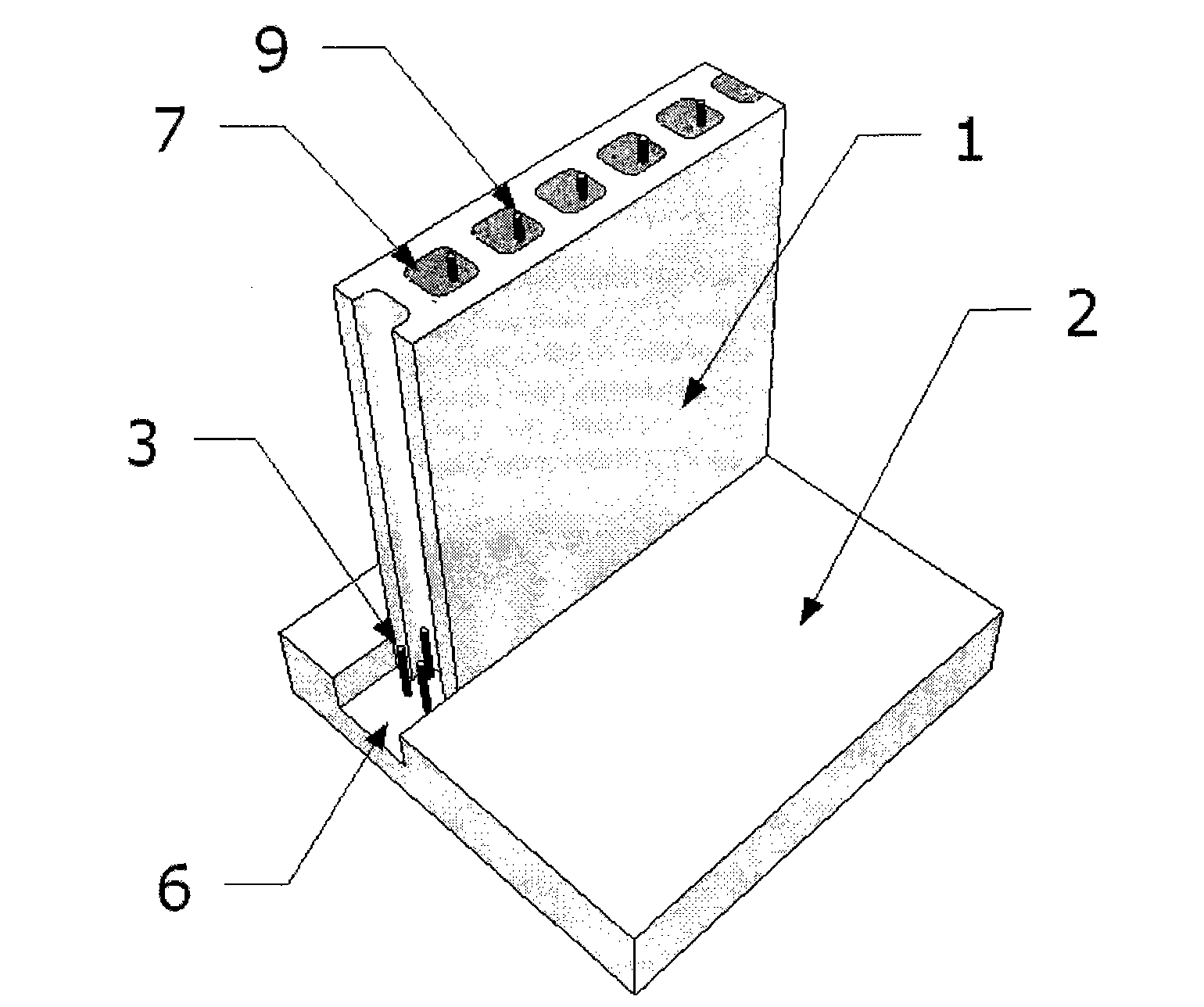

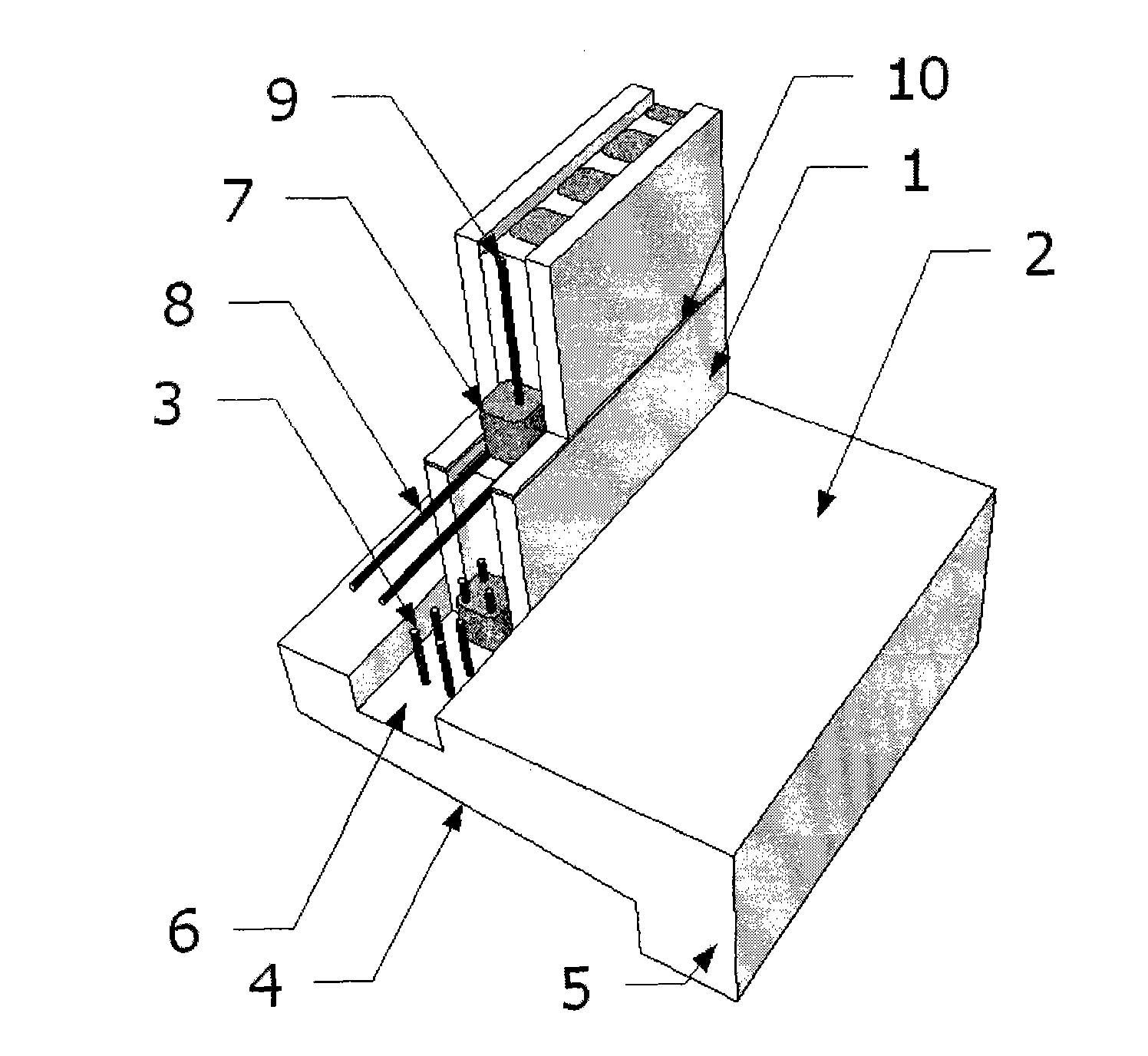

Tooth-groove-type connection structure of upper-layer inner wallboard of assembly-type shear wall and lower-layer inner wallboard of assembly-type shear wall

The invention discloses a tooth-groove-type connection structure of an upper-layer inner wallboard of an assembly-type shear wall and a lower-layer inner wallboard of the assembly-type shear wall. Each inner wallboard comprises two contact locating structures of the upper-layer inner wallboard which are respectively arranged at two ends of each wallboard and a post-pouring concrete structure. The post-pouring concrete structure is located between the two contact locating structures. Upper grooves are formed in the bottom surface of the upper-layer inner wallboard, upper tooth-shaped grooves are formed in the bottoms of the upper grooves, and vertically-distributed rebars of the upper-layer inner wallboard stretch out from the upper grooves. Lower grooves are formed in the top surface of the lower-layer inner wallboard, lower tooth-shaped grooves are formed in the bottoms of the lower grooves, and vertically-distributed rebars of the lower-layer inner wallboard stretch out from the lower grooves. When the upper-layer inner wallboard is connected with the lower-layer inner wallboard, notches of the upper grooves are connected with notches of the lower grooves in a butt joint mode, forming grooves of the post-pouring concrete structure are formed, and the vertically-distributed rebars of the lower-layer inner wallboard and the vertically-distributed rebars of the upper-layer inner wallboard are correspondingly connected in a lap joint mode. The tooth-groove-type connection structure of the upper-layer inner wallboard of the assembly-type shear wall and the lower-layer inner wallboard of the assembly-type shear wall is easy and convenient to construct and reliable in structure.

Owner:TIANJIN UNIV RES INST OF ARCHITECTRUAL DESIGN & URBAN PLANNING +1

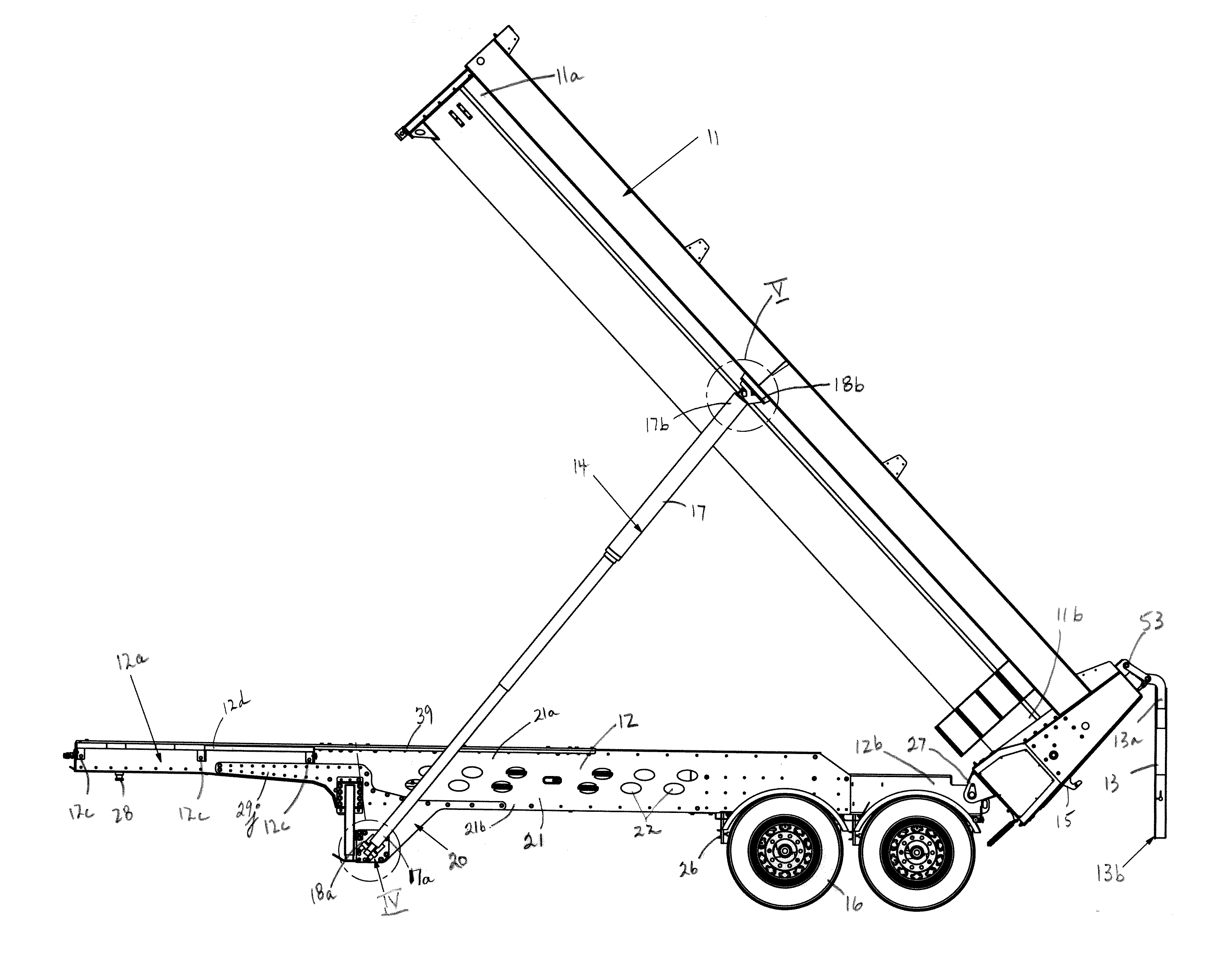

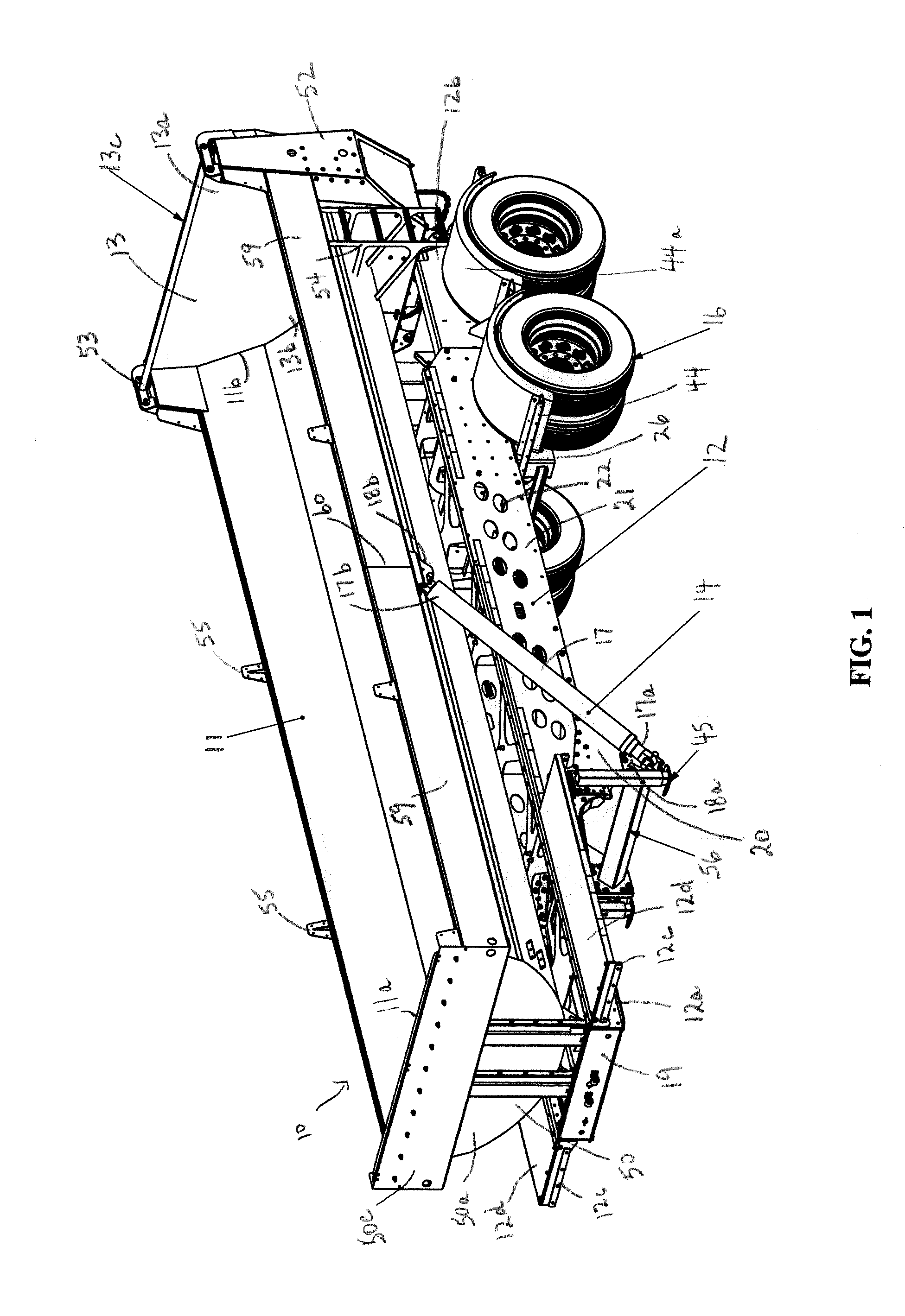

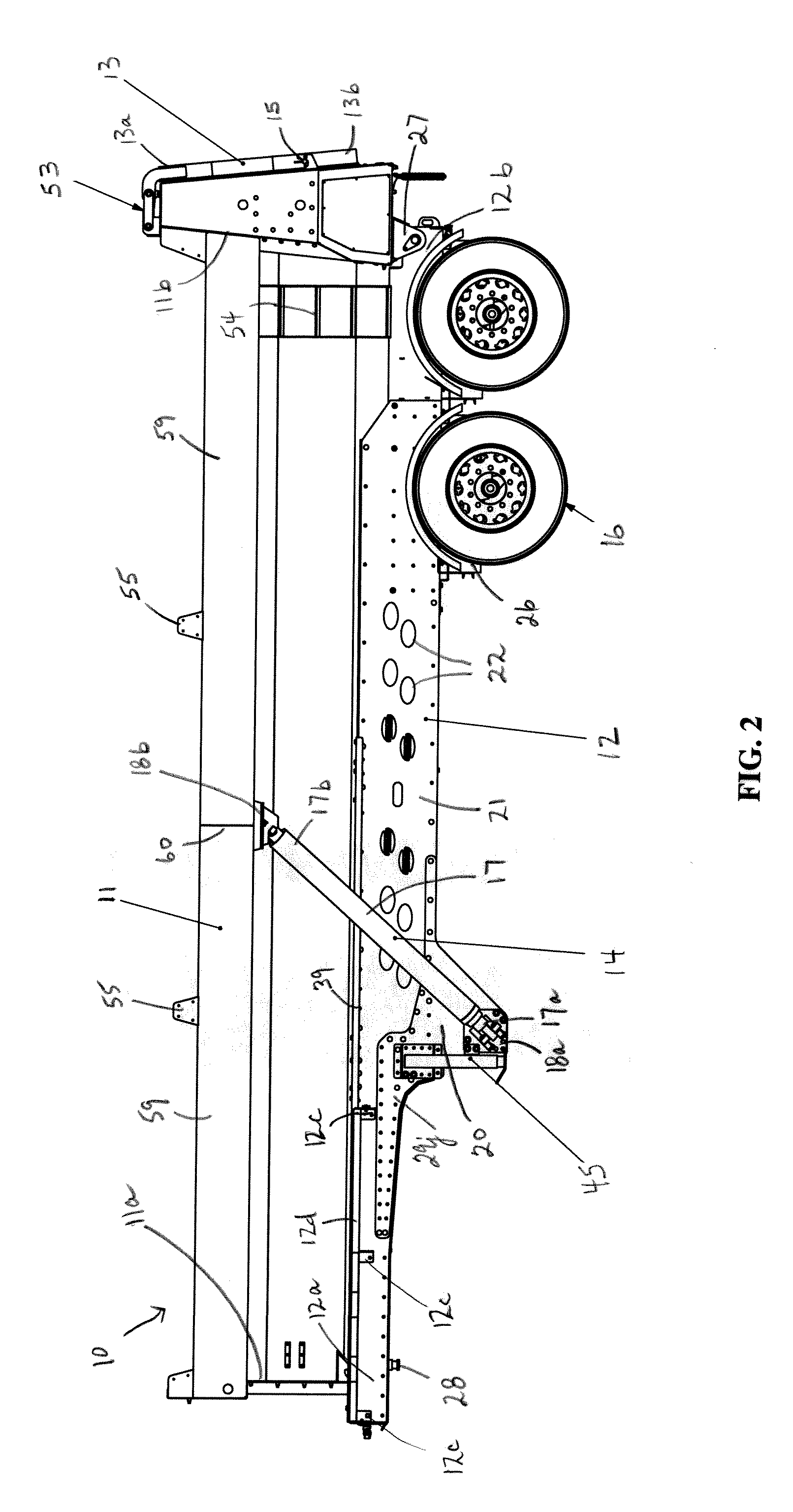

End dump trailer

ActiveUS20120086185A1Provide structural strengthUnderstructuresTractor-trailer combinationsRear quarterEngineering

A trailer frame assembly for a fifth wheel trailer frame in which at least a portion of the frame is torsionally stiffened with a rectangular closed section in a transverse cross section. The rectangular closed section is formed by longitudinal, parallel spaced vertical side plates, a top pan extending between top portions of the side plates, and a bottom pan between bottom portions of the side plates. Overlap joints between the side plates and the top and bottom pans allow for connection with threaded or rivet fasteners. An end dump semi trailer is also provided with a double acting lift cylinder on each side of the trailer. Also provided is a latch lift assembly for a dump gate using a linkage assembly to impart vertical upward movement to dump gate to unlatch the dump gate from a cradle catch.

Owner:WRT EQUIP

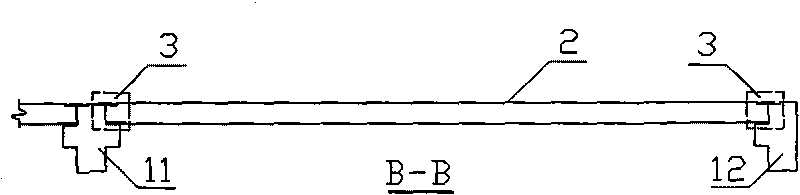

Integrally-assembled cantilever-type retaining wall and construction method thereof

InactiveCN101787708AReduce the degree of impactFast impactArtificial islandsUnderwater structuresReinforced concreteLap joint

The invention discloses an integrally-assembled cantilever-type retaining wall and a construction method thereof. A prefabricated reinforced concrete hollow wall plate (1) is adopted as a wall surface plate, and a base of the retaining wall adopts a prefabricated reinforced concrete bottom plate (2) with vertical lap-joint reinforcing steel bars (3). When the prefabricated reinforced concrete hollow wall plate (1) is in assembling, the vertical lap-joint reinforcing steel bars (3) are stretched into holes in the prefabricated reinforced concrete hollow wall plate (1); vertical stressed reinforcing steel bars (9) are inserted into the holes of the prefabricated reinforced concrete hollow wall plate (1) and concrete (7) is poured to form the integrally-assembled cantilever-type retaining wall. The provided construction method of the integrally-assembled cantilever-type retaining wall in the invention includes the following steps in sequence: (a) preparation work; (b) foundation excavation; (c) hoisting; (d) inserting of the reinforcing steel bars and concrete pouring; (e) backfilling.

Owner:黄靓

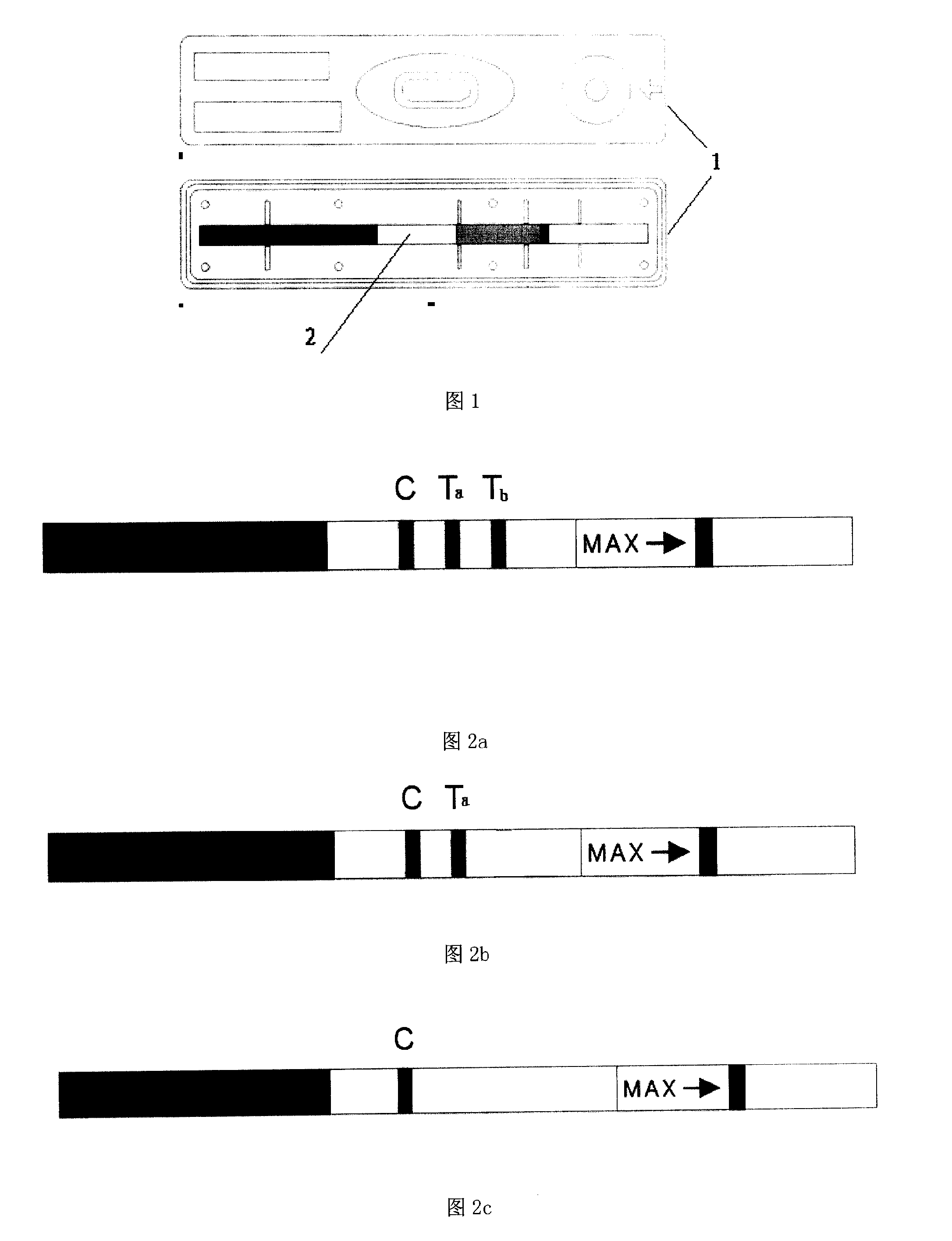

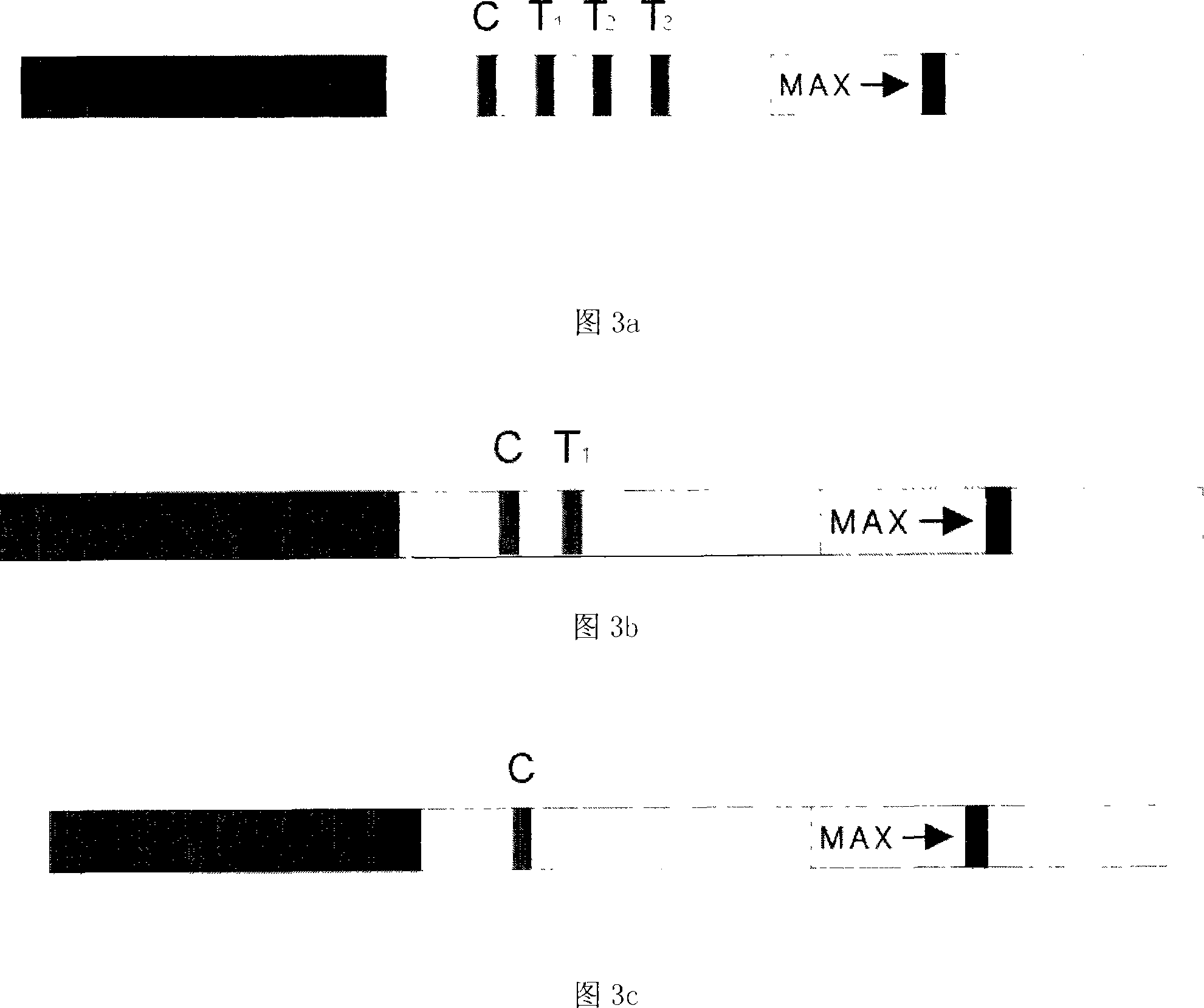

Multi-linked immunity chromatography test paper for detecting saliva abusing drug, system and its preparation method

InactiveCN101241136ANo pollution in the processOperational securityMaterial analysisAntigenAbuse drugs

The present invention discloses a multi-linked chromatographic test paper bar for detecting drug abuse in saliva and preparation thereof. The testing paper bar is a reaction film bar made of sample mats lap jointed mutually in turn pasted on the base, glass fiber film coated with colorful latex, colloidal gold or colloid selenium particles labeled protein, custodite film and absorbent paper. Control region coated anti-rat antibody, at least two detecting region of which coated with corresponding drug antigen are set on custodite film. The present invention has merits of safety and simple operation, suitable for detecting by single person / share and high detecting speed, and multi-detection of drug antigen in saliva at the same time.

Owner:GUANGZHOU WONDFO BIOTECH

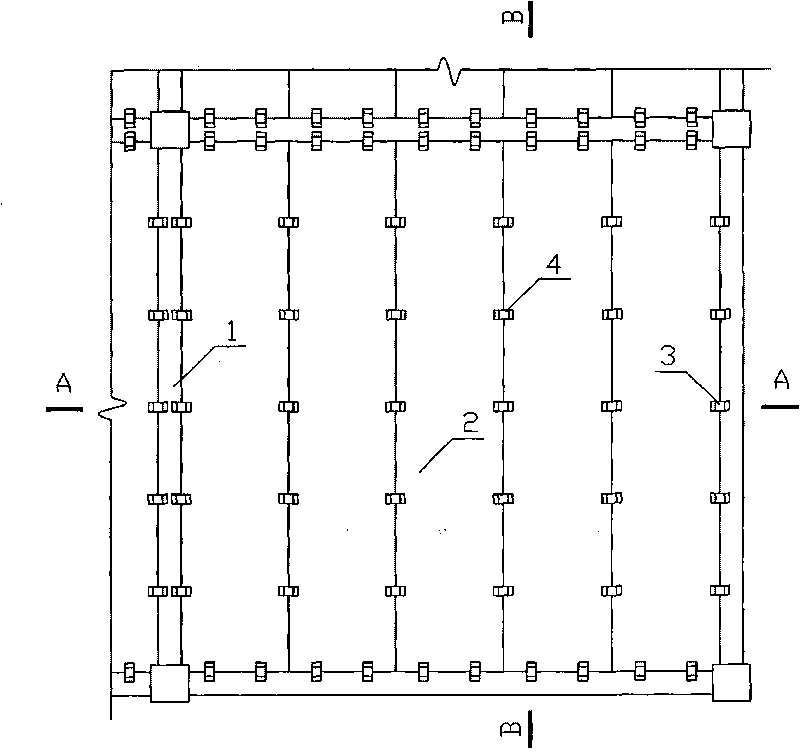

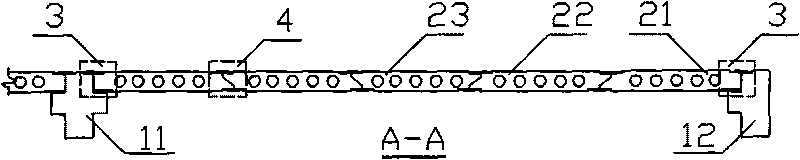

Totally-prefabricated assembling type reinforced concrete floor system

The invention discloses a totally-prefabricated assembling type reinforced concrete floor system which consists of girders, prefabricated slabs, girder-slab connecting pieces, and slab-slab connecting pieces. The invention is characterized in that: the prefabricated girders are cornice girders, and the prefabricated slabs are matchboards; the prefabricated slabs are fixedly connected by the girder-slab connecting pieces after being arranged on the prefabricated girders; and the prefabricated slabs are fixedly connected by the slab-slab connecting pieces after being lap-jointed with each other. The prefabricated slabs can be prefabricated prestressed concrete cored slabs, superimposed slabs or other flat slabs. The invention realizes the bidirectional force bearing performance of the unidirectional prefabricated slabs and the four-edge fixed-end limiting form of the floor system, and can effectively meet the requirement for large span and heavy load; moreover, belonging to a totally-assembled system, the invention has the characteristics of less field operation, high construction speed, good earthquake resisting performance, and obvious effects of energy saving and environmental protection.

Owner:SOUTHEAST UNIV

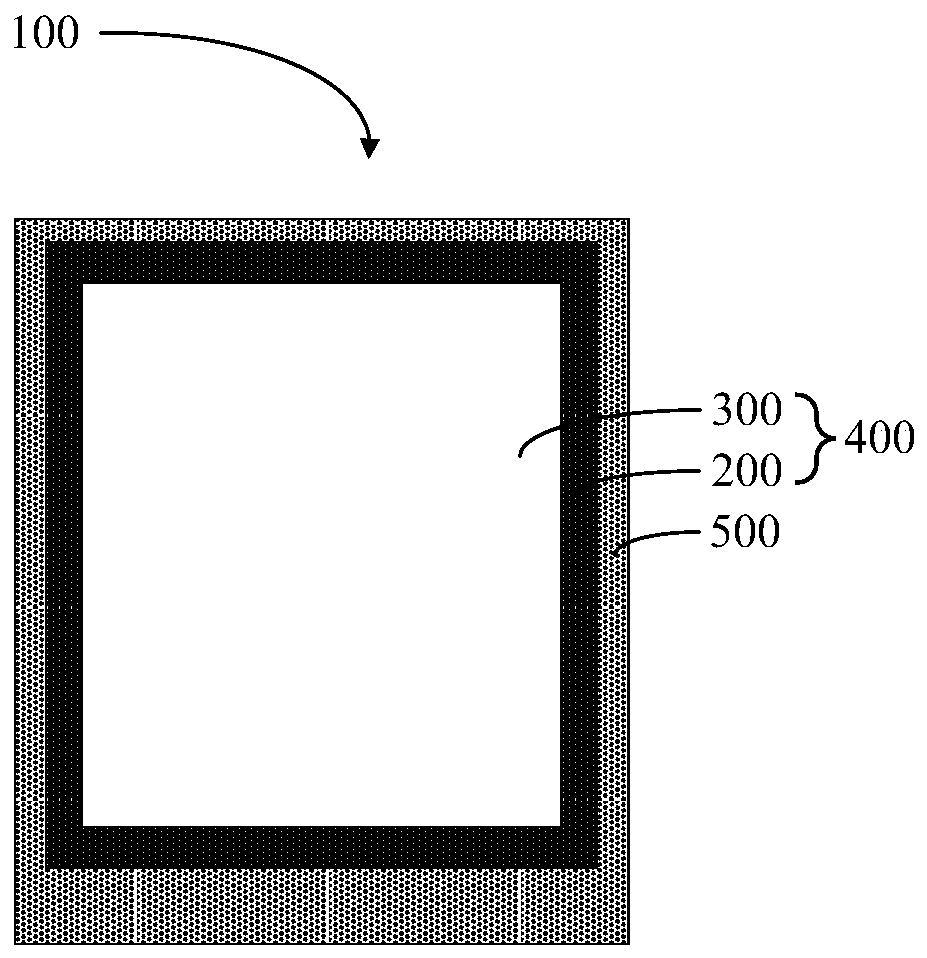

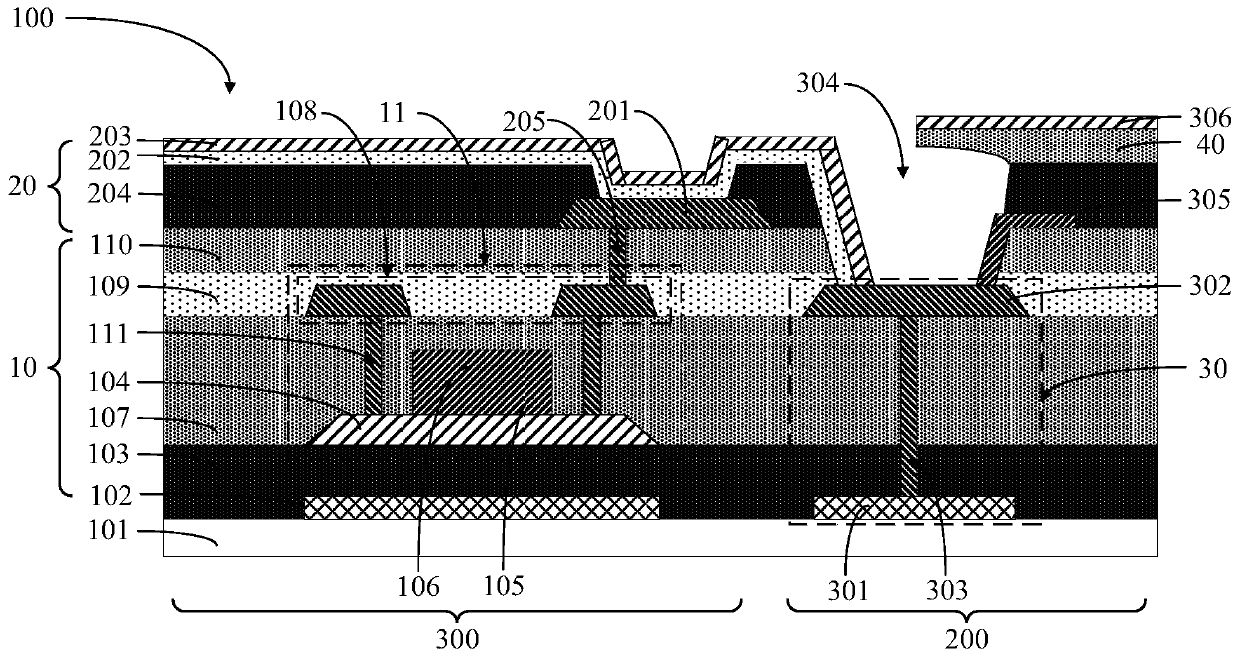

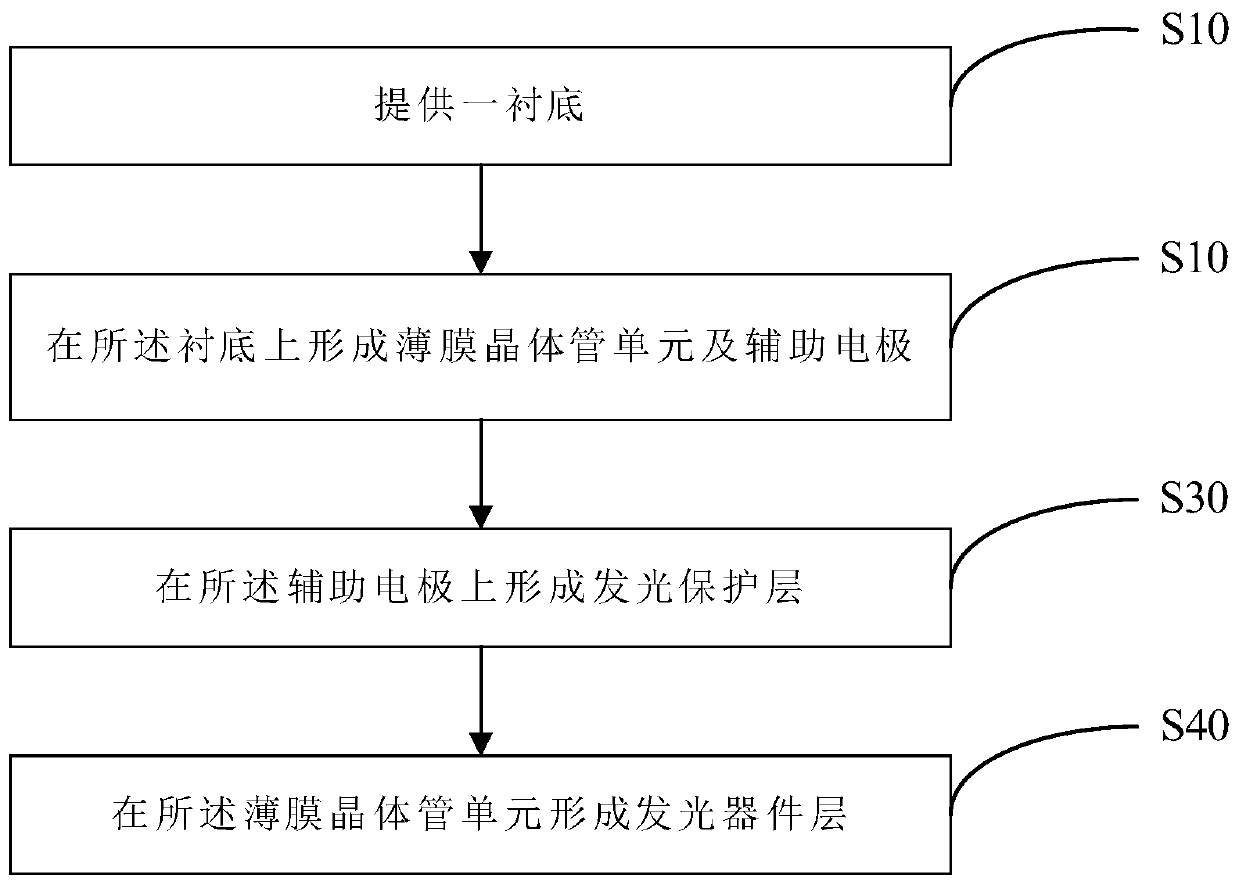

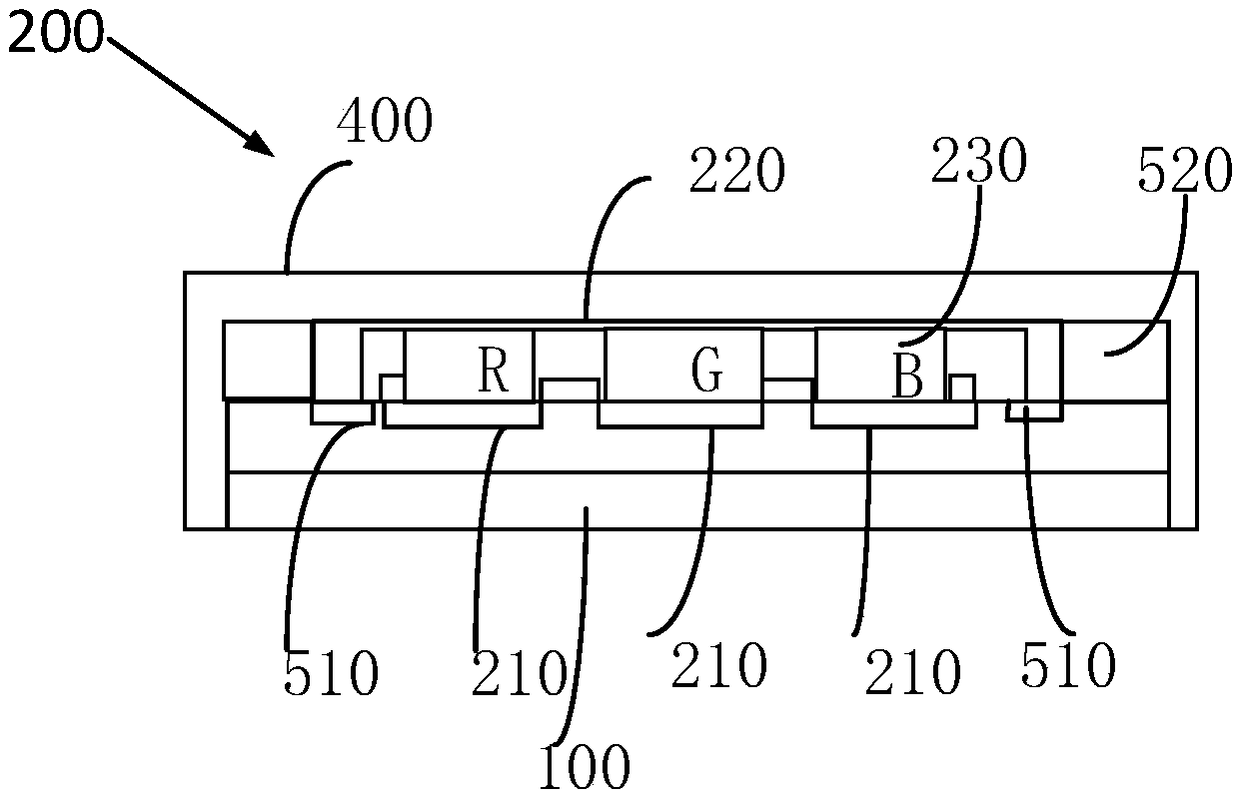

Display panel and manufacturing method

InactiveCN110071225AIncrease brightnessRaise the potentialSolid-state devicesSemiconductor/solid-state device manufacturingVoltage dropLap joint

The invention provides a display panel and a manufacturing method thereof, wherein a display area of the display panel comprises a first area positioned at the edge of the display area; and an auxiliary electrode and a light-emitting protection layer positioned on the auxiliary electrode are arranged in the first area, and orthographic projection of the light-emitting protection layer on the auxiliary electrode is partially overlapped with the auxiliary electrode. According to the invention, an auxiliary electrode is arranged in the edge area of a display panel, and cathode layer is in lap joint with the auxiliary electrode, so that the potential of the cathode layer is increased, the voltage drop of the cathode layer is slowed down, and the brightness uniformity of the display panel is improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

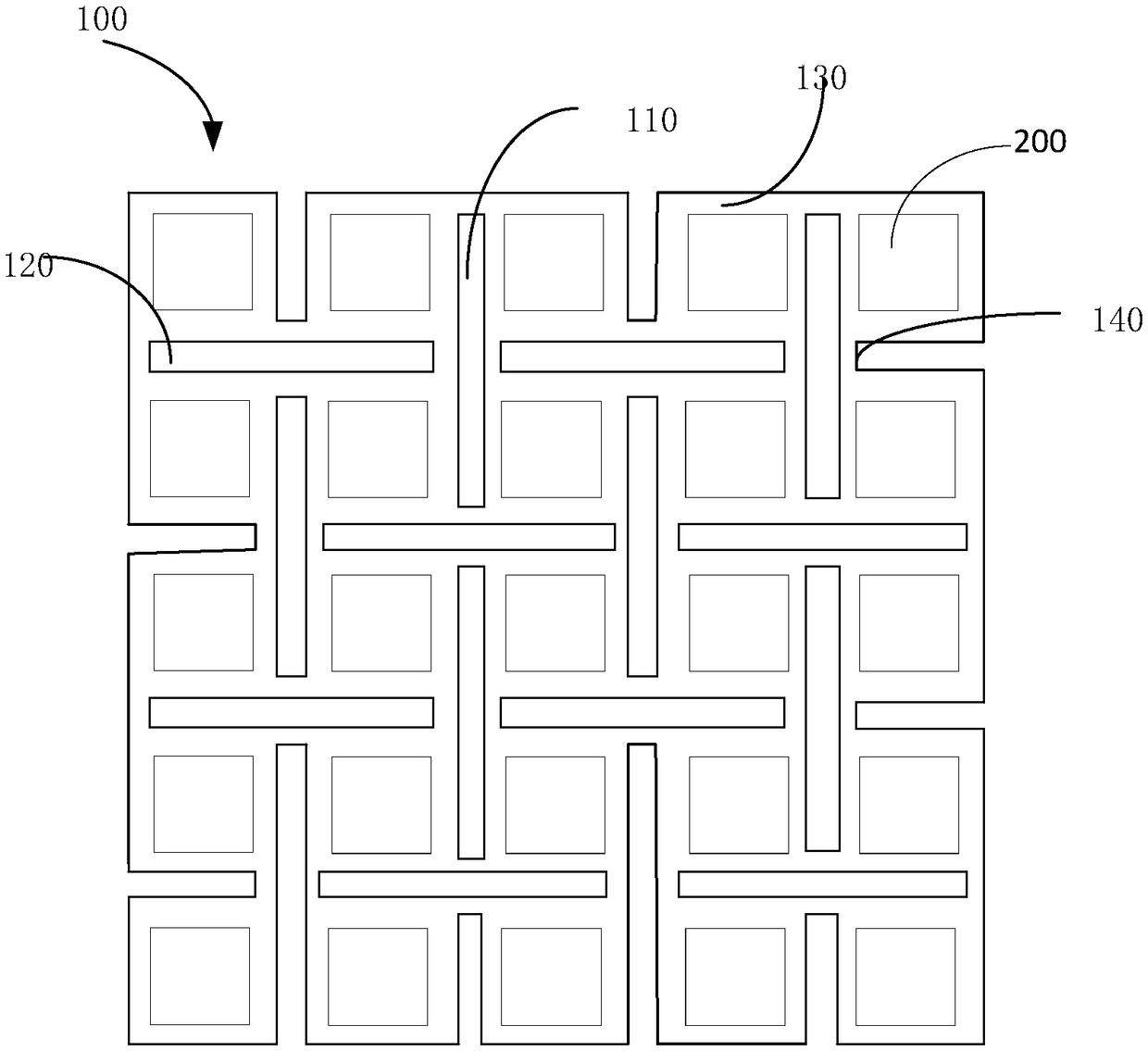

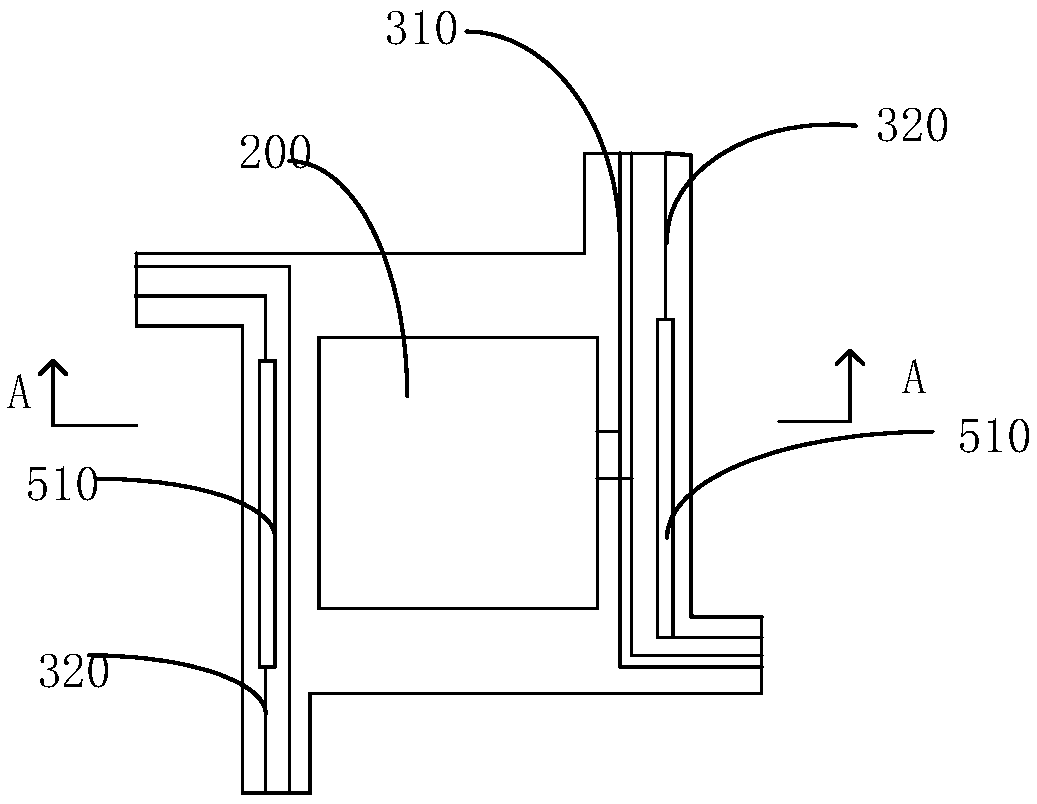

Stretchable display substrate, manufacturing method thereof and display device

ActiveCN109308851AIntegrity guaranteedImprove bending resistanceFinal product manufacturePhotovoltaic energy generationDisplay deviceLap joint

The invention provides a stretchable display substrate, a manufacturing method thereof and a display device. The stretchable display substrate comprises a substrate body, multiple display pixel unitsdistributed in an array and multiple wires; multiple first split bands and multiple second split bands which are crossed and not mutually penetrated are distributed on the substrate body and split thesubstrate body into multiple islands arranged in an array and multiple bridges connected with all the islands; each island is at least provided with one display pixel unit; the multiple wires are electrically connected with the display pixel units; at least part of the display pixel units comprise first electrodes, second electrodes and luminescent layers, the multiple wires comprise the first wires and the second wires, the first electrodes are connected through the first wires laid on the bridges and the islands, and the second electrodes are connected through the second wires laid on the bridges and the islands. Accordingly, the problem that in the prior art, the stretchable display device adopts negative poles of the whole surface for conducting level lap joint on the screen edge, andthen potential is unstable can be solved.

Owner:BOE TECH GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com