Double-arm loading and transferring robot

A technology for handling robots and robots, which is applied in the field of robots, can solve problems such as violent transfer and damaged packages, and achieve the effect of improving transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

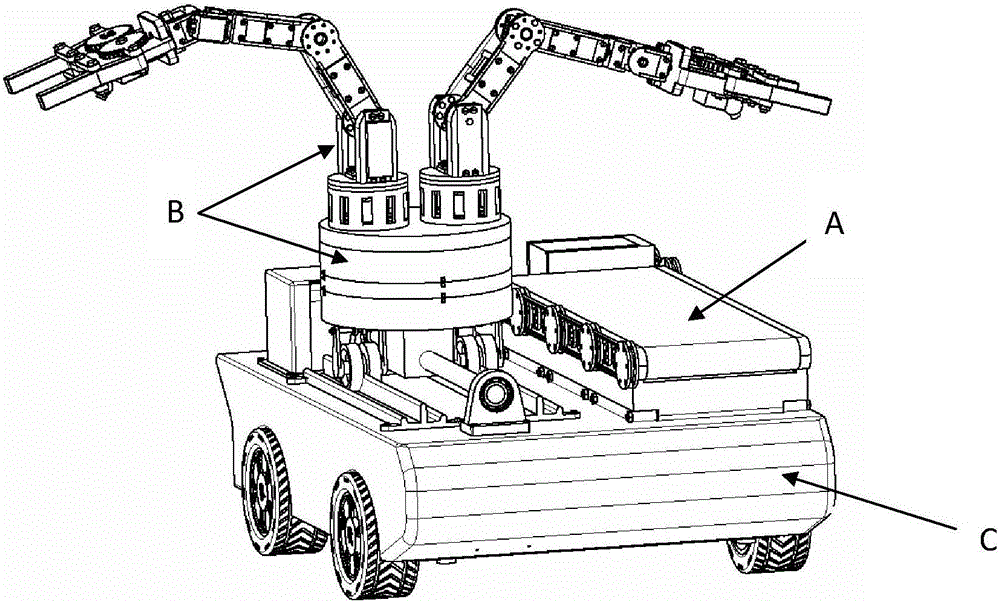

[0028] The robot as a whole figure 1 As shown, it is mainly composed of three parts: A, B, and C. Part A is the small conveyor belt part for transportation, part B is the mechanical arm and disc mechanism part for gripping, and part C is the chassis part with guide rail mechanism and moving function.

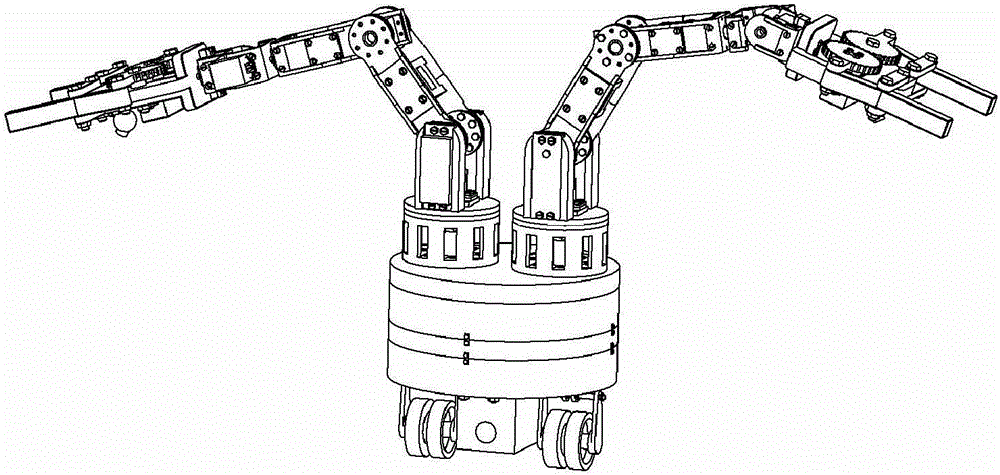

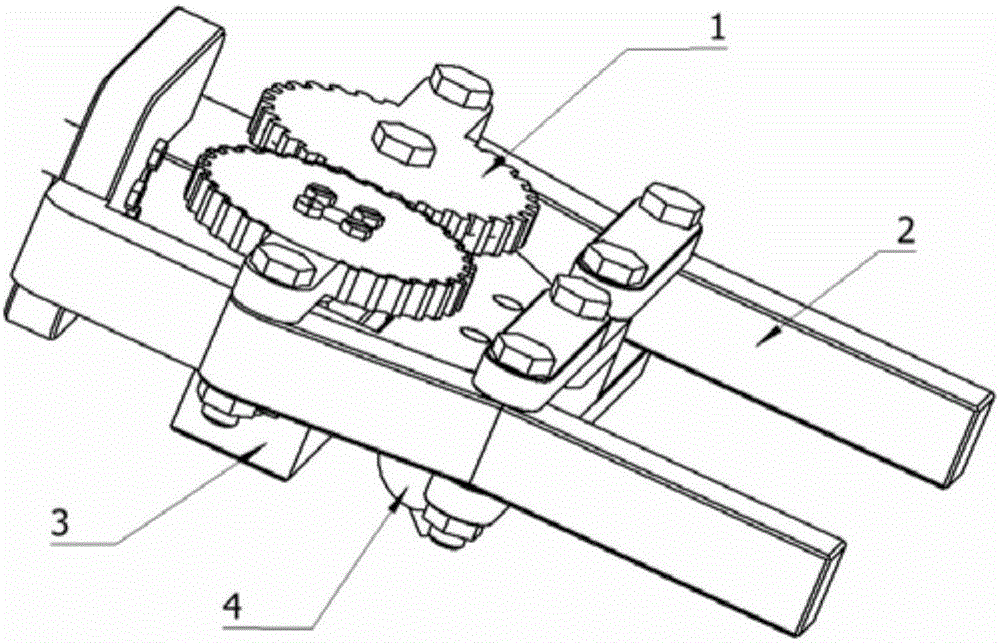

[0029] The mechanical arm is a six-axis mechanical arm assembled from 6 parts. Each part is controlled by a servo motor. The clamping head adopts gear meshing and a parallelogram mechanism to form a clamping mechanism, which is driven by a motor. The disc rotating part is composed of a clutch mechanism and an incomplete gear mechanism. The bottom of the disc is connected with the guide rail with a lead screw nut, so that the whole disc mechanism can slide on the guide rail. The overall overlapping of the conveyor belt mechanism is driven by a rotatable support rod, and the surface operation of the conveyor belt is realized by belt transmission. The chassis adopts two-wheel dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com