Patents

Literature

4044 results about "Terminal point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

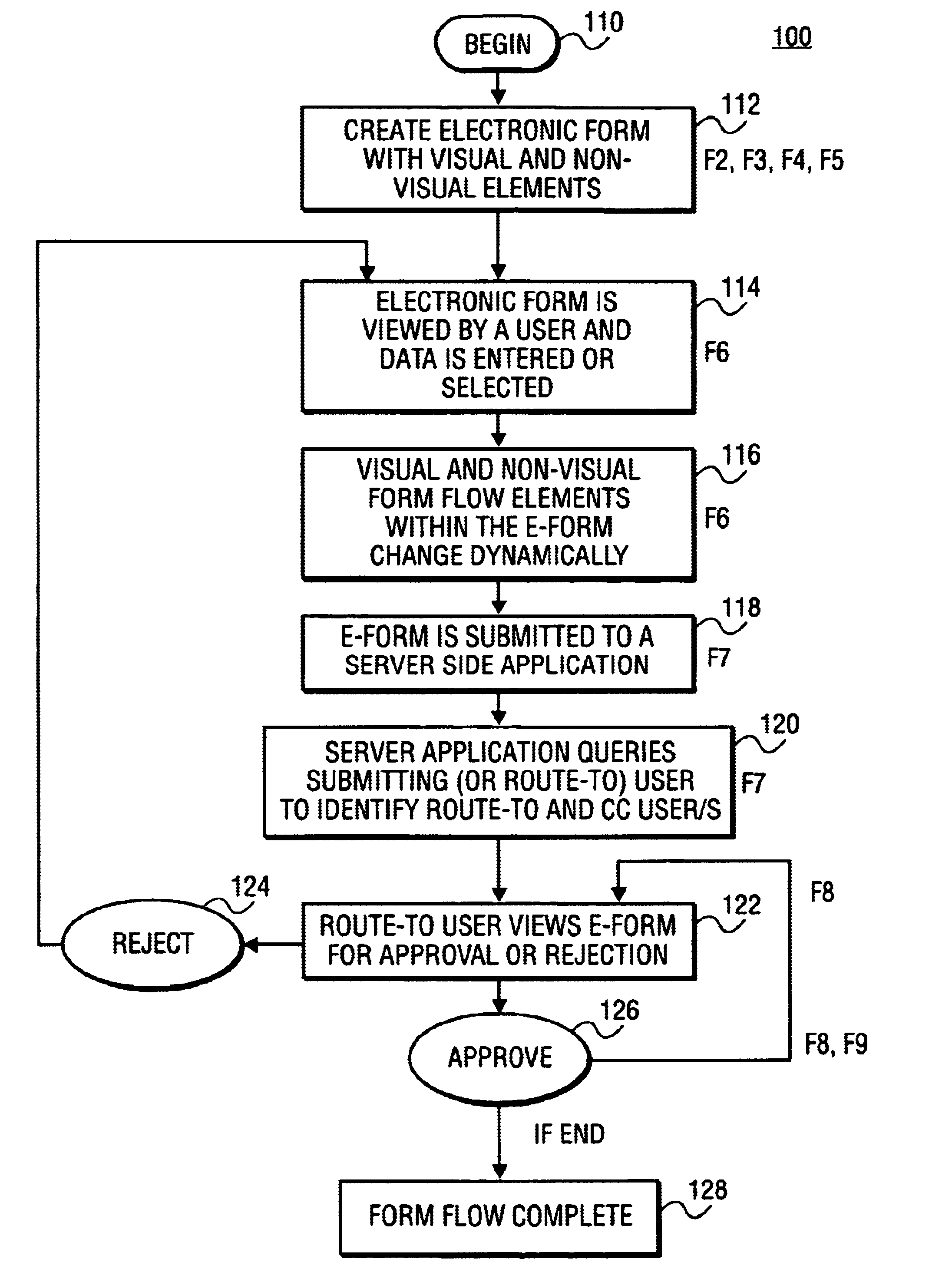

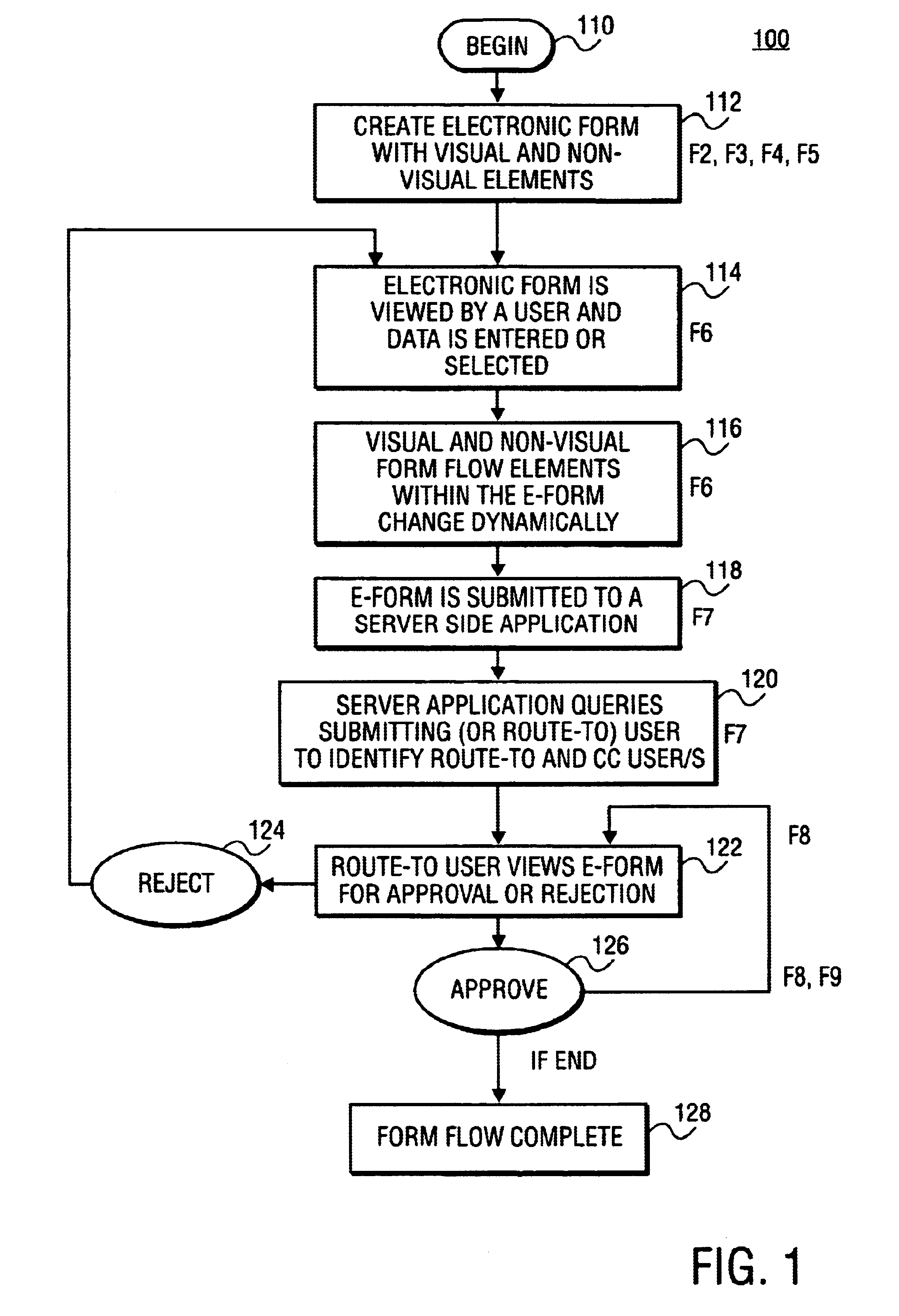

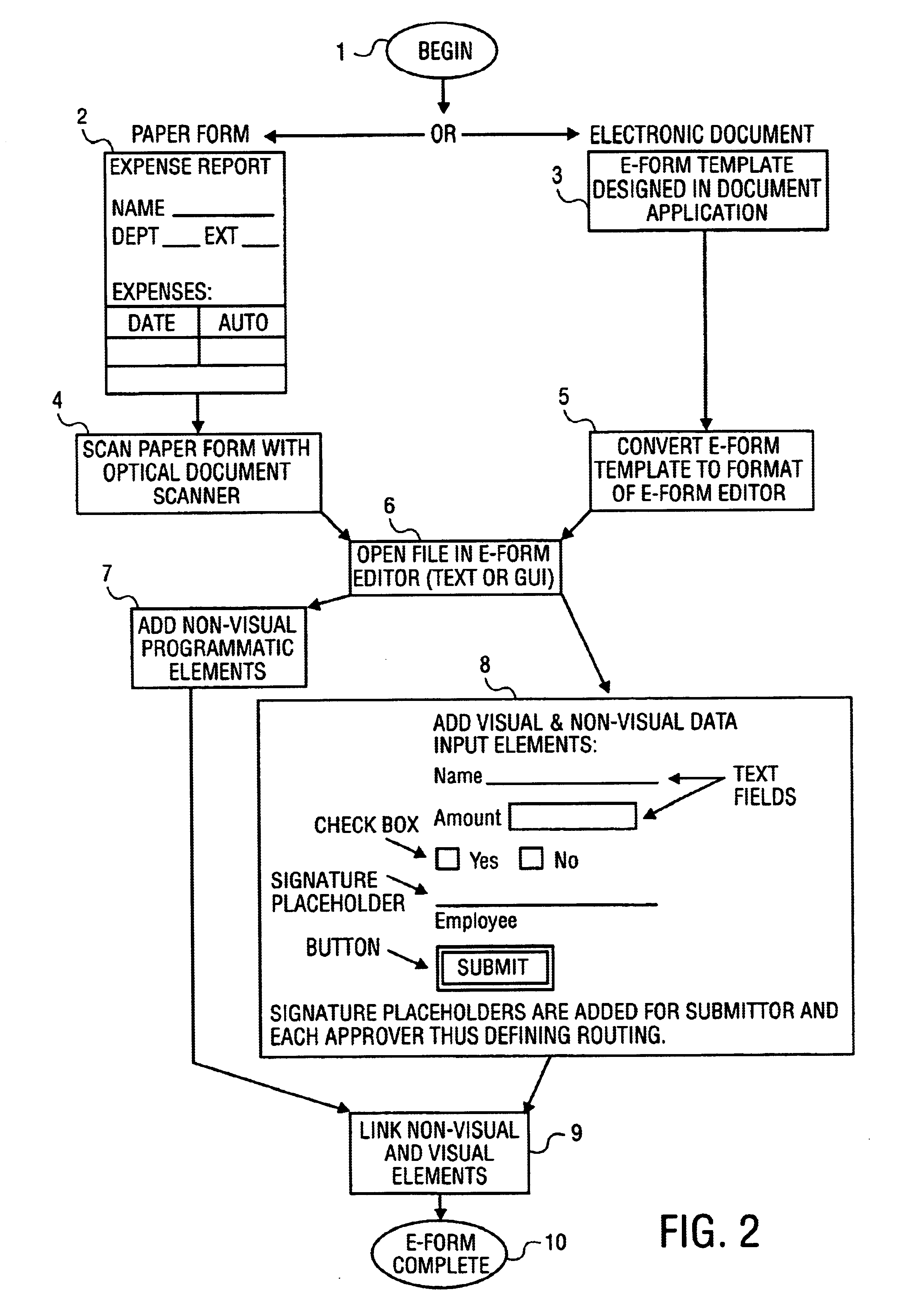

Self-directed routable electronic form system and method

This invention provides for a self-directed routable electronic form generation system and method where each user in the process defines the next, or all the subsequent user routing. The invention resides in providing rules and guidelines that define routing to exist completely within the electronic form itself. Residing in the electronic form these routing rules are dynamically changed based on data input to the form, providing visual clues to the routing based on that input. The present invention generates in the approver's view of the form appropriate visual elements corresponding with allowable actions of this subsequent viewer. The present invention also provides visual clues as to the next routing destination based on the electronics form current fill-in data, or based on any changes the approver makes to fill-in data, all without server interaction. This sequence continues until the electronics "form flow" is complete and an end point is reached.

Owner:END THE PAPERCHASE INC

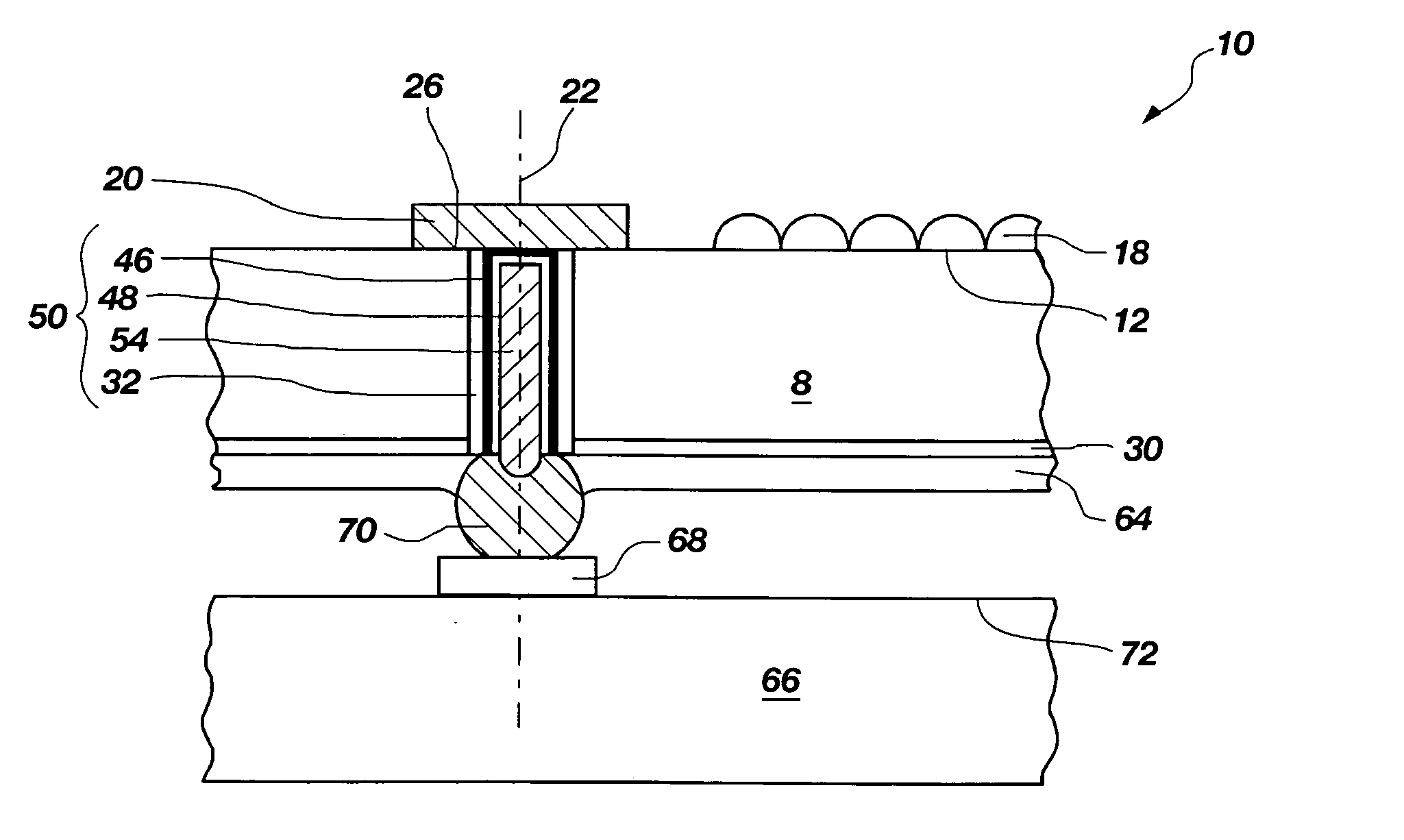

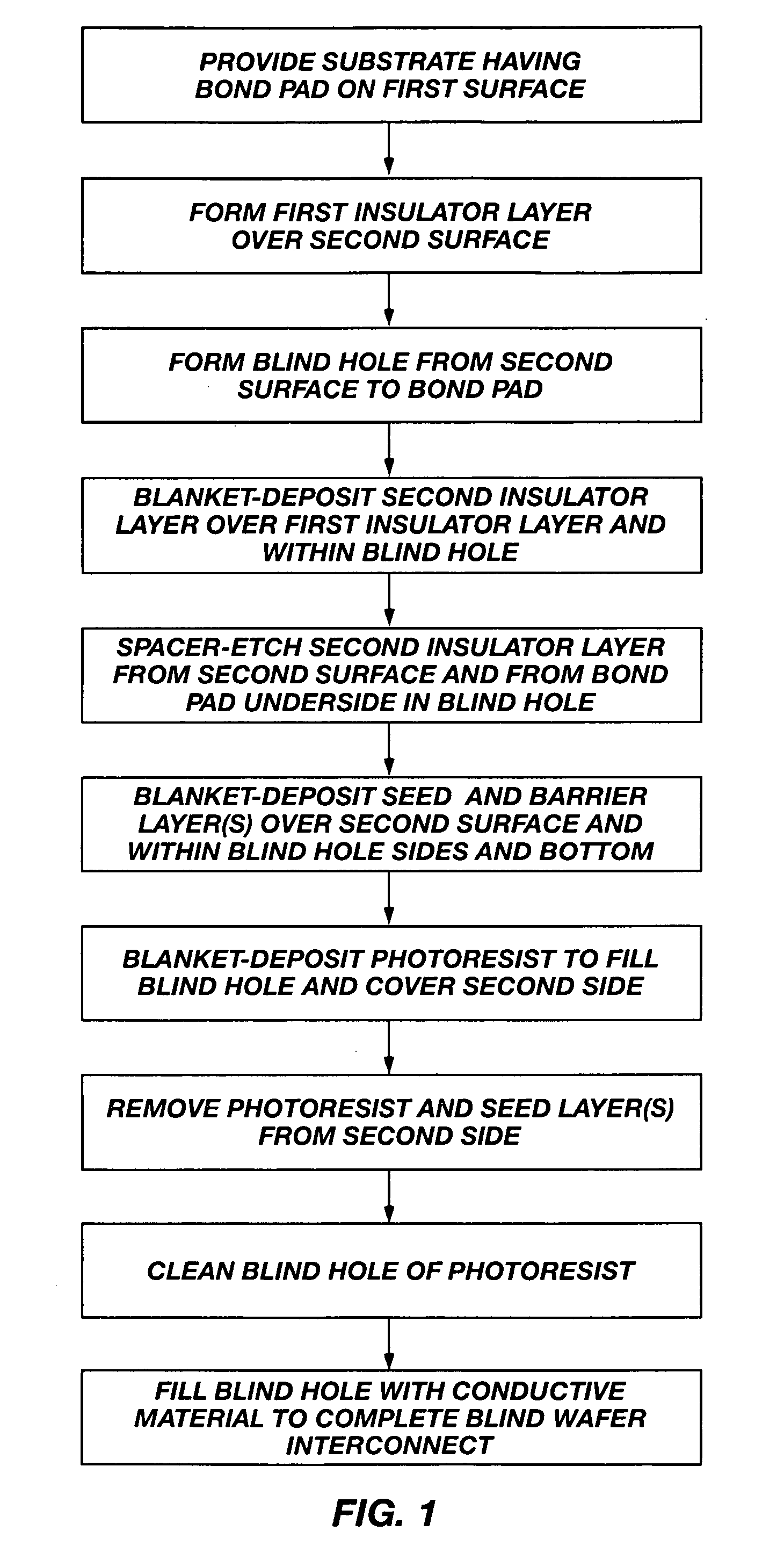

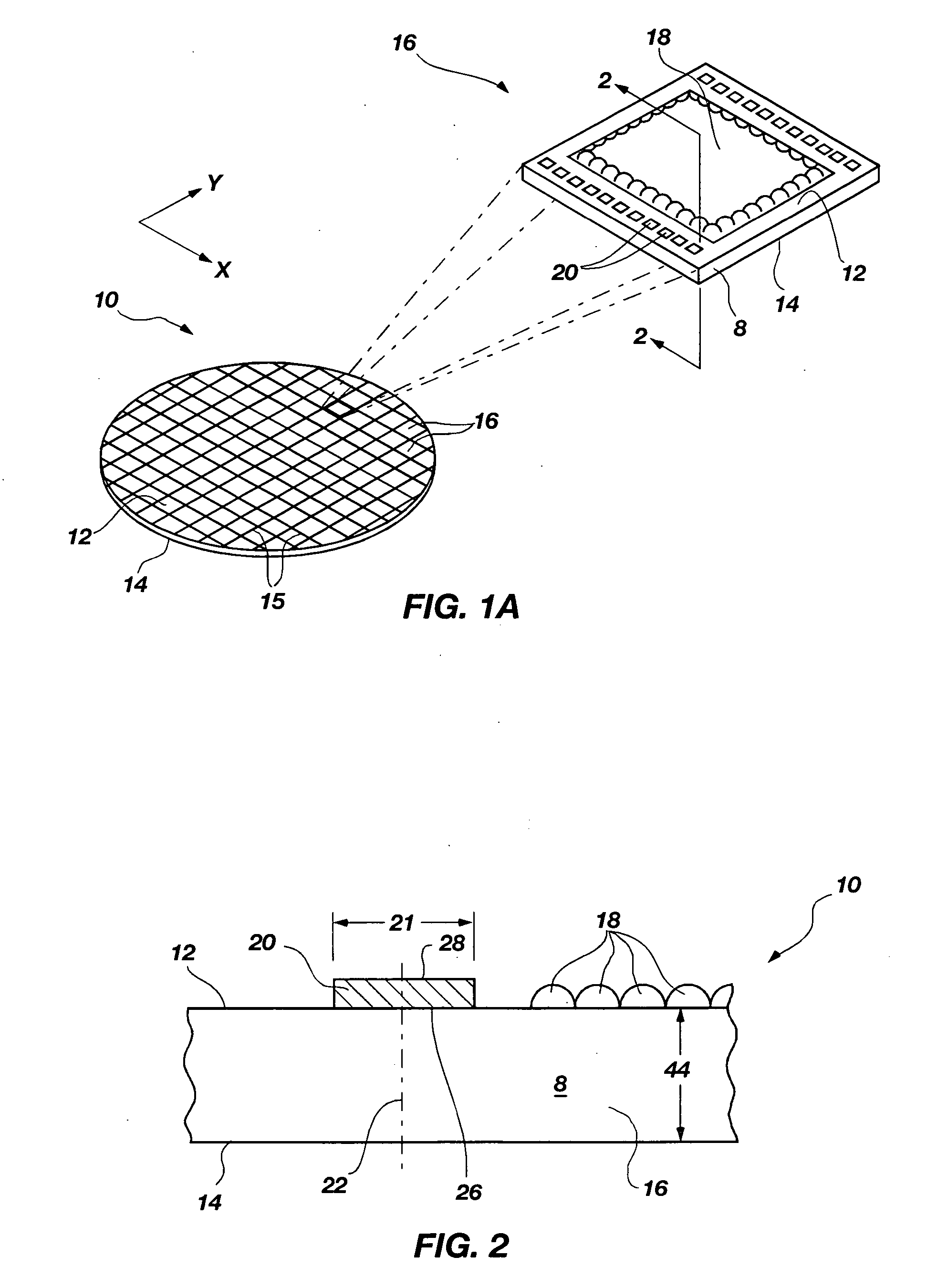

Methods of forming blind wafer interconnects, and related structures and assemblies

InactiveUS20070045780A1Reduce expensesReduce processing timeSemiconductor/solid-state device detailsSolid-state devicesResistSolder ball

Methods for forming blind wafer interconnects (BWIs) from the back side of a previously thinned substrate structure such as a semiconductor wafer to the underside of a bond pad on its active surface includes the formation of a blind hole from the back side, application of a passivating layer therein, anisotropically etching to remove passivation material from the blind hole bottom, blanket-depositing at least one conductive layer within the blind hole and over the back side, blanket-depositing a resist in the blind hole and over the back side, planarizing the back side to remove resist and the at least one conductive layer, removing resist from the blind hole, and filling the blind hole with solder or other conductive material or a dielectric material. Variations in the methods include formation of a conductive pad adjacent the back side surface, disposition of a solder ball or other conductive structure on the BWI, or forming an end thereof in the form of an extended slug protruding from the back side (for ball-less attachment) as the outer terminus of the BWI.

Owner:ROUND ROCK RES LLC

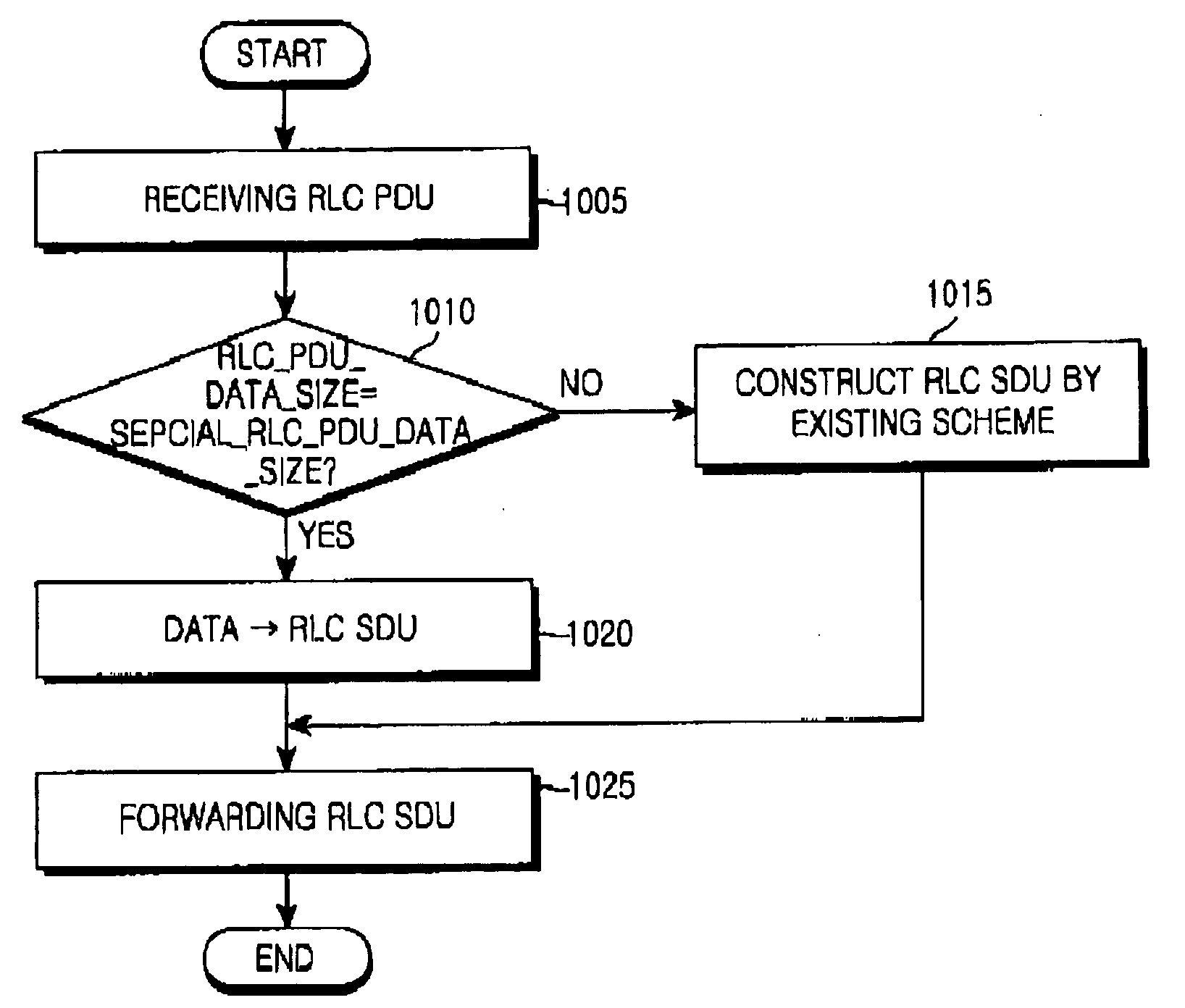

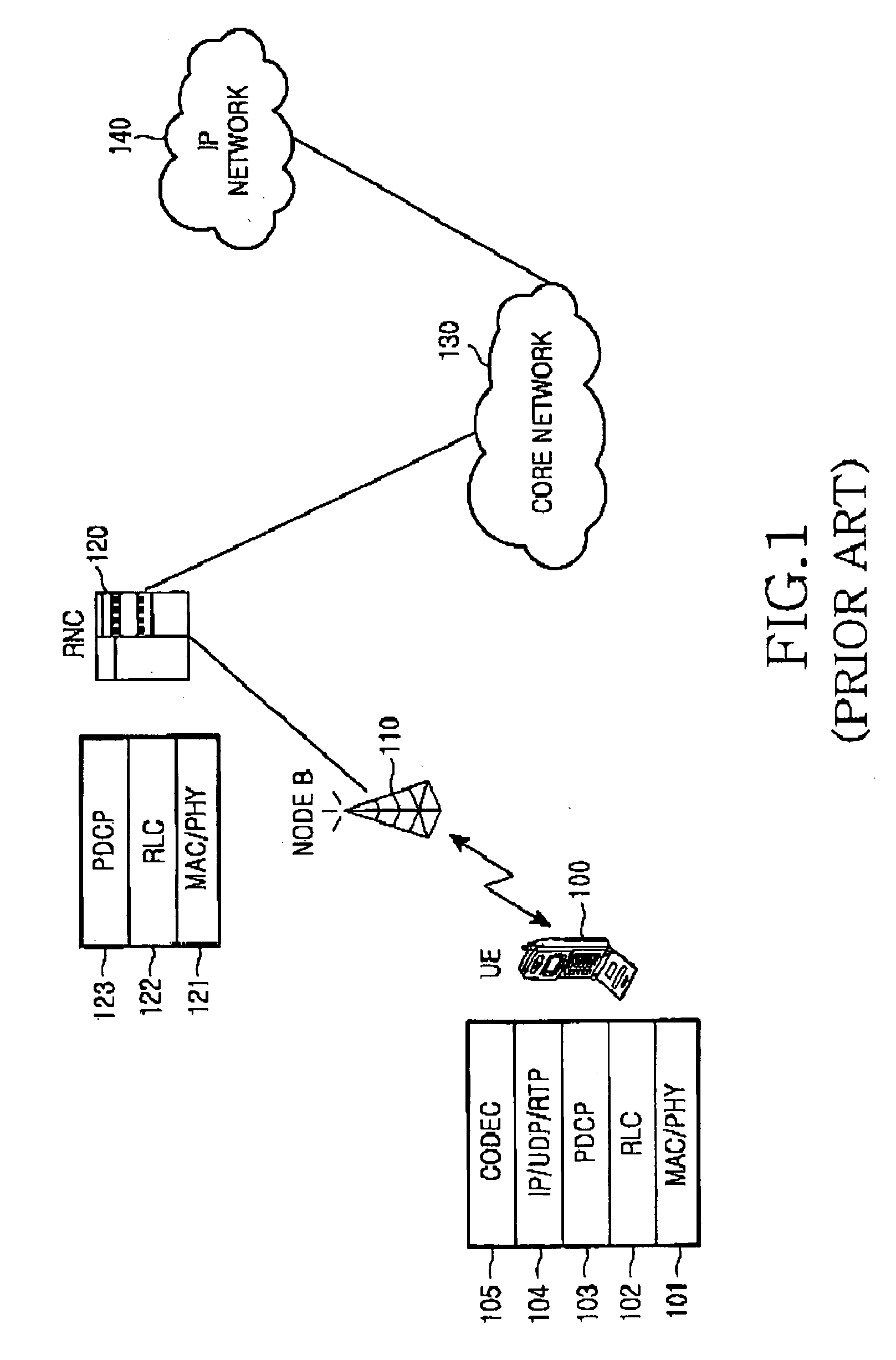

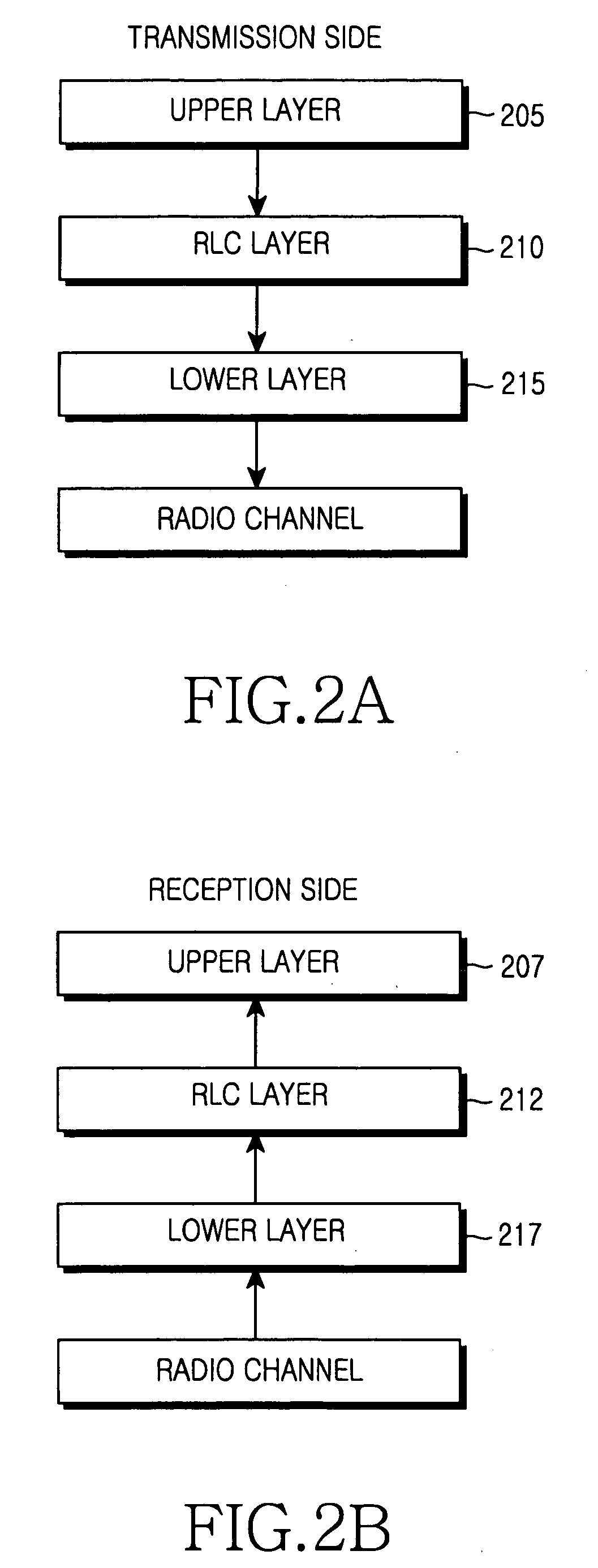

Method for efficiently utilizing radio resources in a mobile telecommunication system providing VoIP service

InactiveUS20050213605A1Easy to useEfficiently formedNetwork traffic/resource managementClosure with auxillary devicesComputer networkMobile communication systems

A method for efficiently utilizing radio resources by reducing a size of a PDU of an RLC layer in a mobile communication system supporting a VoIP service. In the method, an RLC PDU is framed without inserting information regarding a start point and an end point of a voice packet, or existence or absence of padding, such that a size of overhead according to transmission of the voice packet can be reduced. Consequently, restricted radio resources can be efficiently used.

Owner:SAMSUNG ELECTRONICS CO LTD

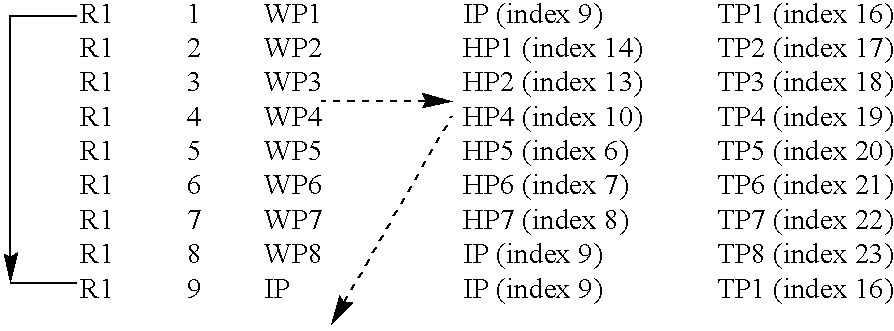

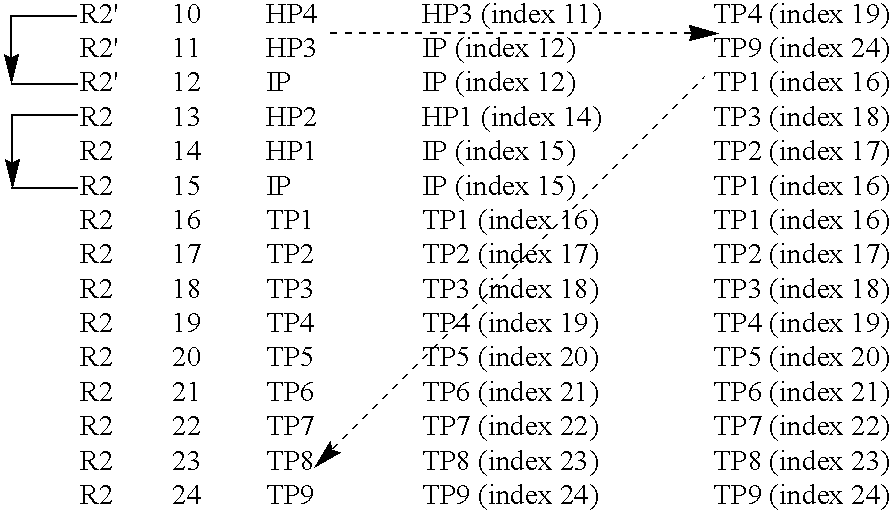

Waypoint navigation

ActiveUS20040193334A1Reduce riskDigital data processing detailsHeight/levelling measurementMode controlRemote control

The invention relates to remote control of an unmanned aerial vehicle, UAV, (100) from a control station (110) by means of a wireless command link (115). The UAV (100) may be controlled in an autonomous mode wherein it flies according to a primary route (R1, R1') defined by a first set of predefined waypoints (WP1-WP8, IP). The UAV (100) may also be controlled in a manual mode wherein it flies according to an alternative primary route (R1') defined in real-time by control commands received via the wireless command link (115). Flight control parameters are monitored in both modes, and in case a major alarm condition occurs, the UAV (100) is controlled to follow an emergency route (R2') defined by a second set of predefined waypoints (HP1-HP7, TP1-TP9, IP). Particularly, a major alarm condition is activated if an engine failure is detected. Then, the emergency route (R2') involves flying the UAV (100) to an air space above a termination waypoint (TP9) on the ground at which it is estimated that the vehicle's (100) flight may be ended without injuring any personnel or causing uncontrolled material damages.

Owner:SAAB AB

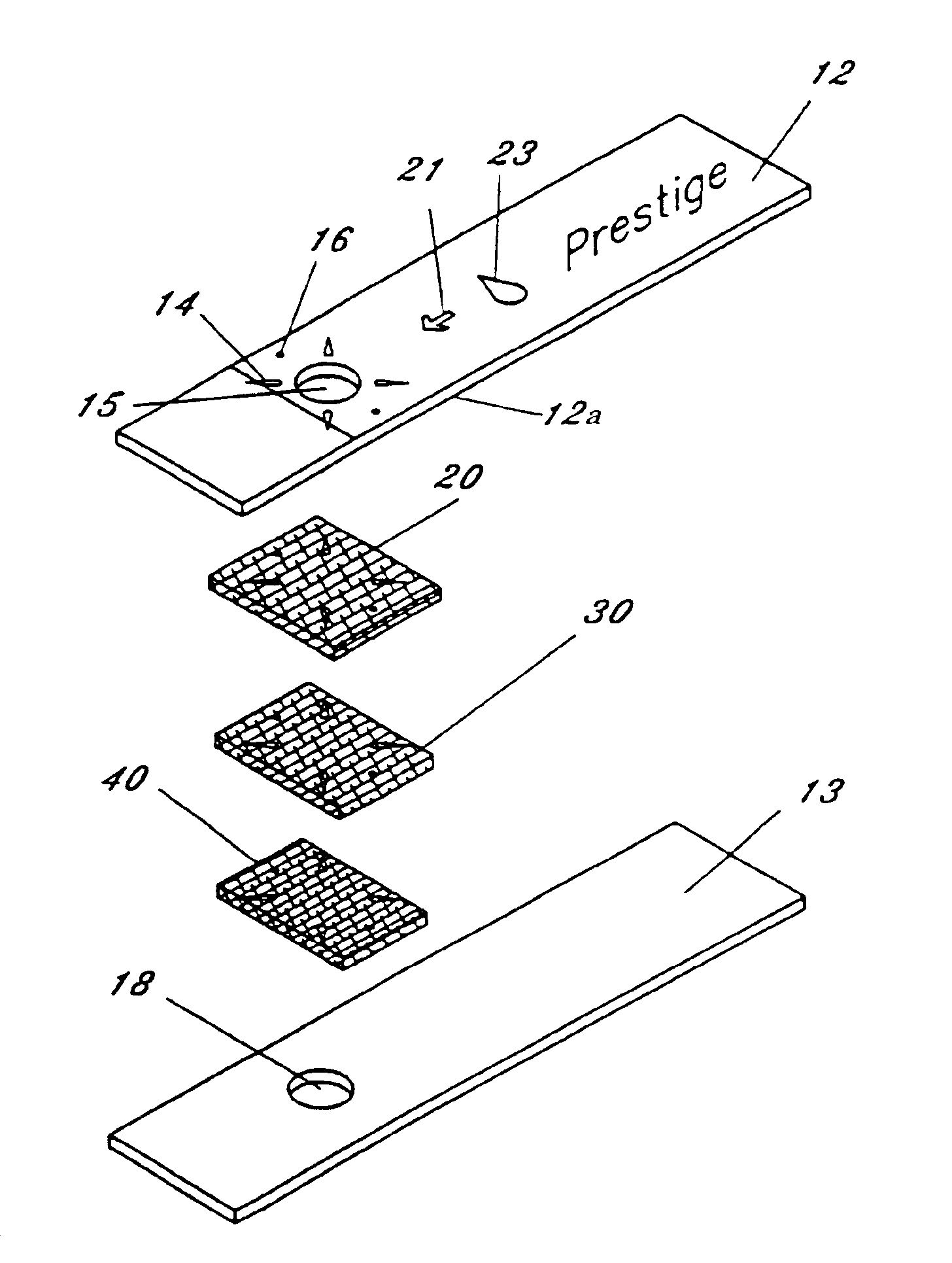

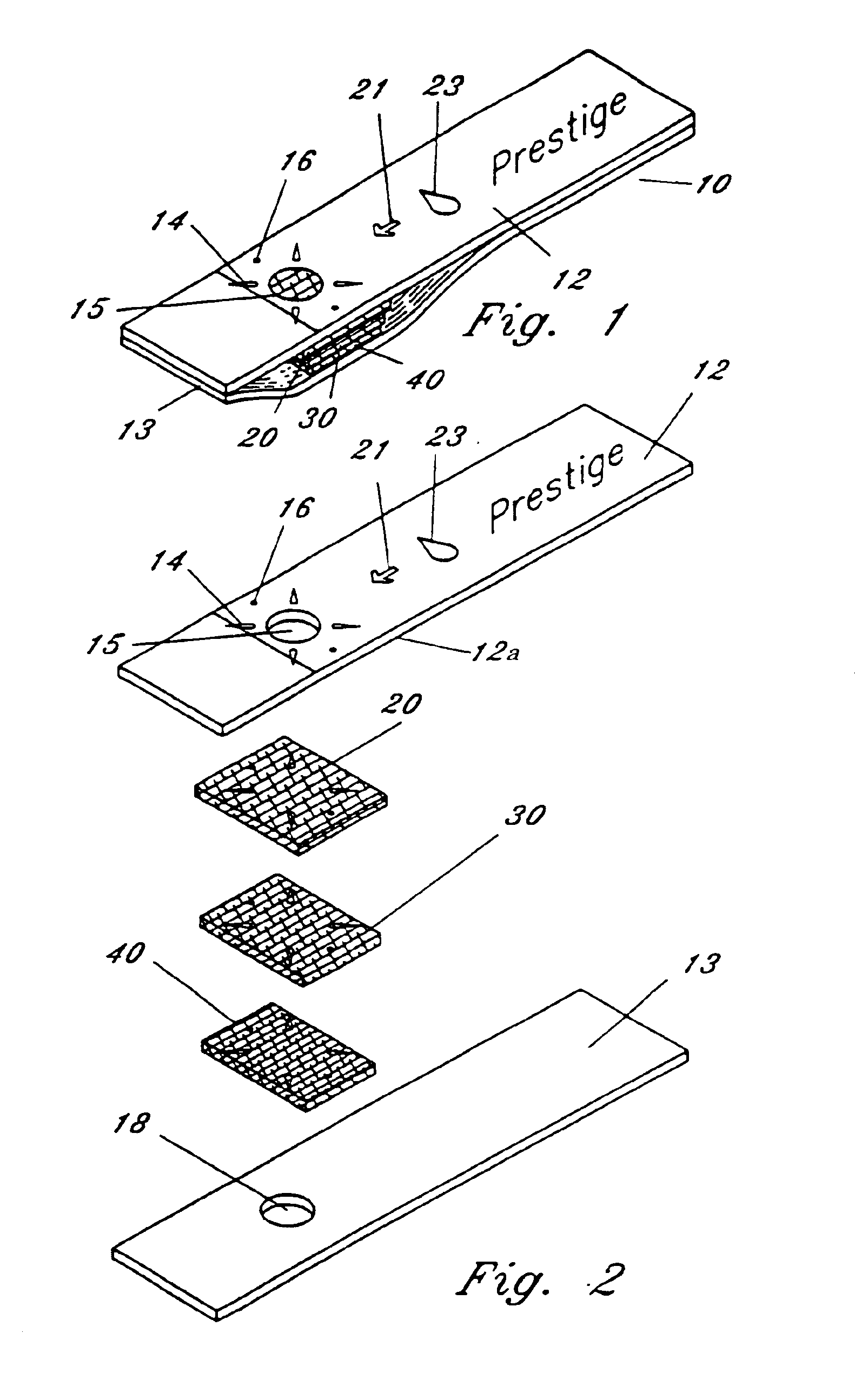

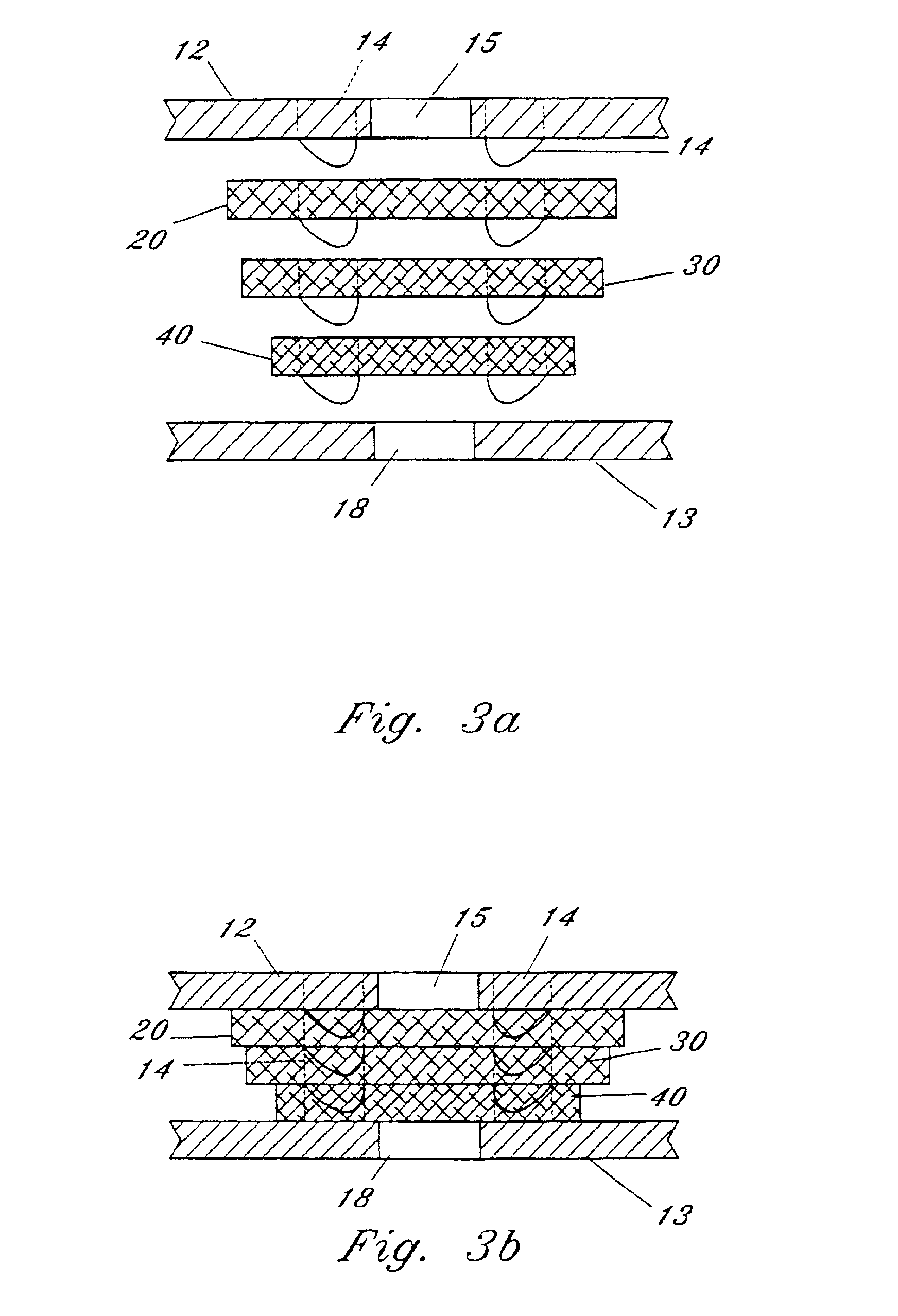

Diagnostic sanitary test strip

InactiveUS6991940B2Easy to useBroaden applicationBioreactor/fermenter combinationsBiological substance pretreatmentsColor changesFluid specimen

An improved multi-layered diagnostic sanitary test strip for receiving a heterogenous fluid, such as whole blood, to test for presence and / or amount of a suspected analyte in the fluid by facilitating a color change in the strip corresponding to the amount of the analyte in the fluid, wherein the test strip includes fluid volume control dams to prevent spillage of the fluid from the strip and a chemical reagent solution that facilitates end-point testing. The improved test strip comprises no more than two operative layers and: (a) a reaction membrane containing a reagent capable of reacting with the analyte of interest to produce a measurable change in said membrane; (b) an upper support layer defining a sample receiving port for receiving the fluid sample thereat; (c) one or more structures for directing the sample containing the analyte of interest through at least a portion of said reaction membrane; and (d) a lower support layer having a reaction viewing port in vertical alignment with said membrane for displaying said measurable change, said lower support being associated with said upper support to secure said reaction membrane in said test strip.

Owner:NIPRO DIAGNOSTICS INC

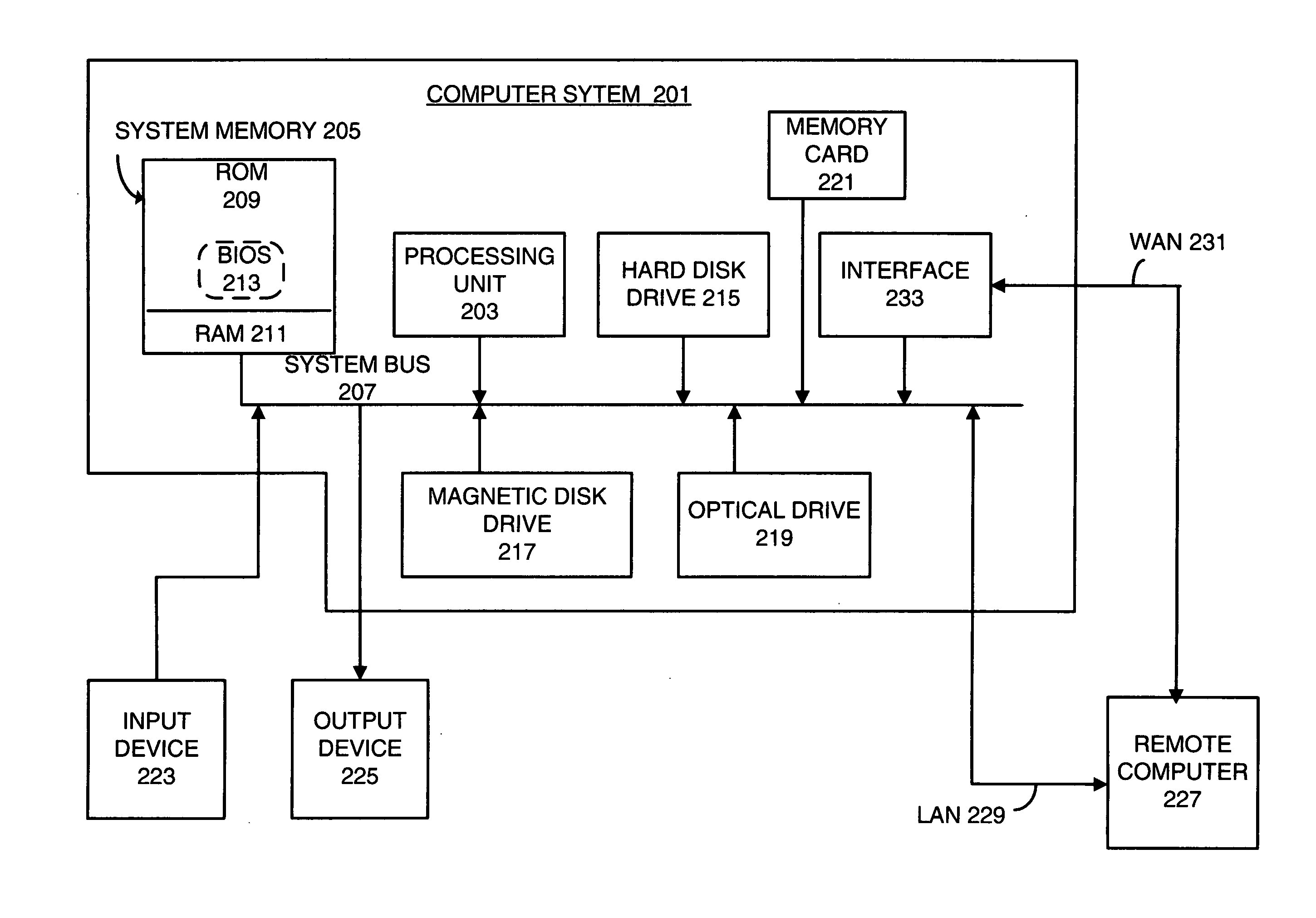

End point control

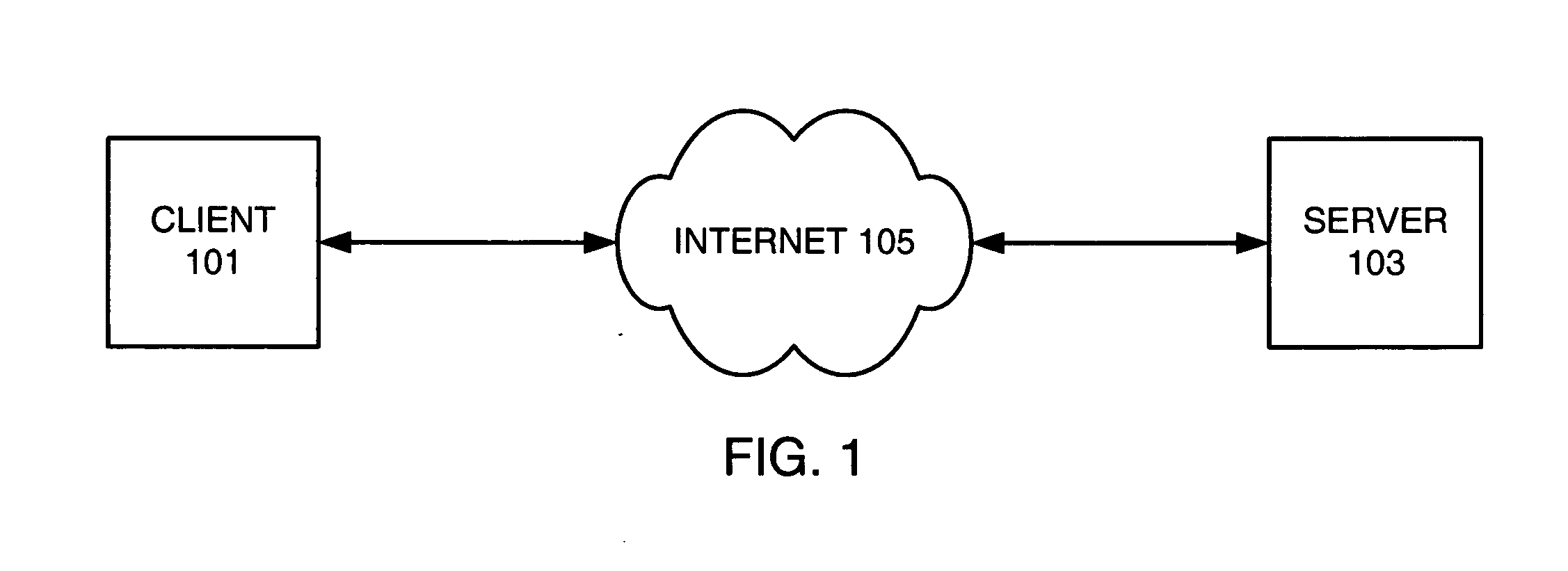

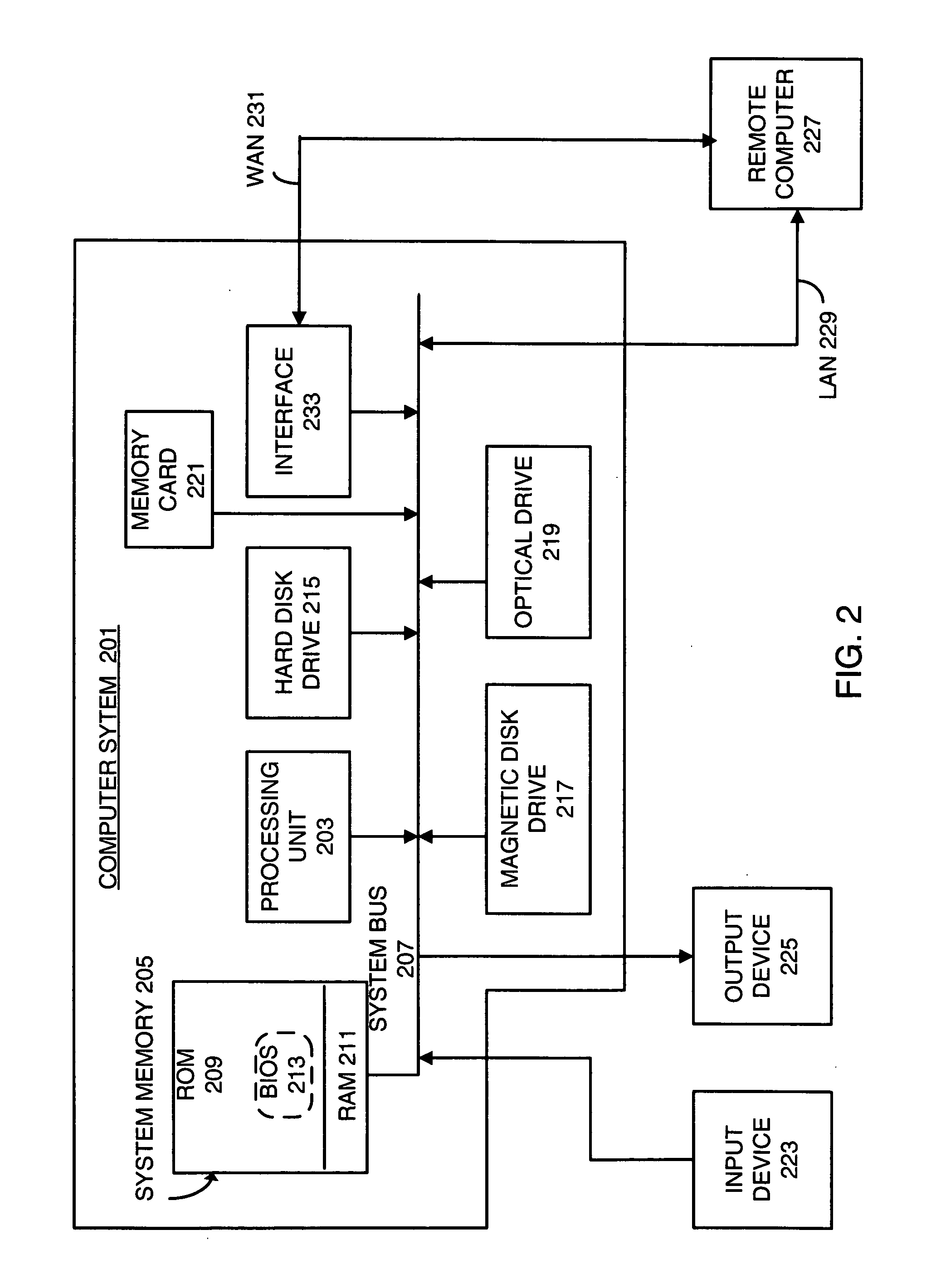

ActiveUS20050144481A1Improved computing environmentDigital data processing detailsComputer security arrangementsControl systemComputer access

Systems and techniques are provided for controlling requests for resources from remote computers. A remote computer's ability to access a resource is determined based upon the computer's operating environment. The computer or computers responsible for controlling access to a resource will interrogate the remote computer to ascertain its operating environment. The computer or computers responsible for controlling access to a resource may, for example, download one or more interrogator agents onto the remote computer to determine its operating environment. Based upon the interrogation results, the computer or computers responsible for controlling access to a resource will control the remote computer's access to the requested resource.

Owner:AVENTAIL A WHOLLY OWNED SUBSIDIARY OF SONICWALL

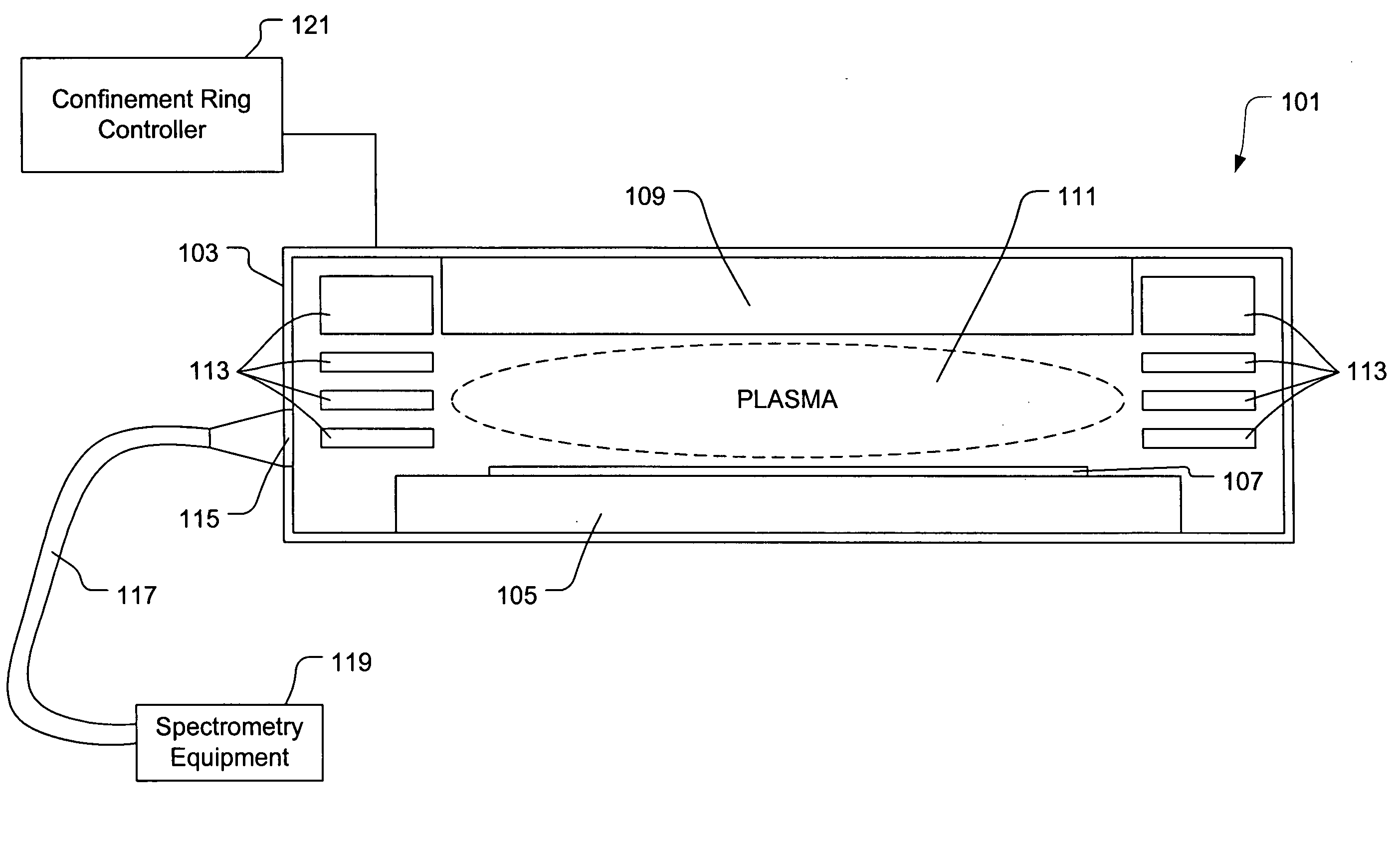

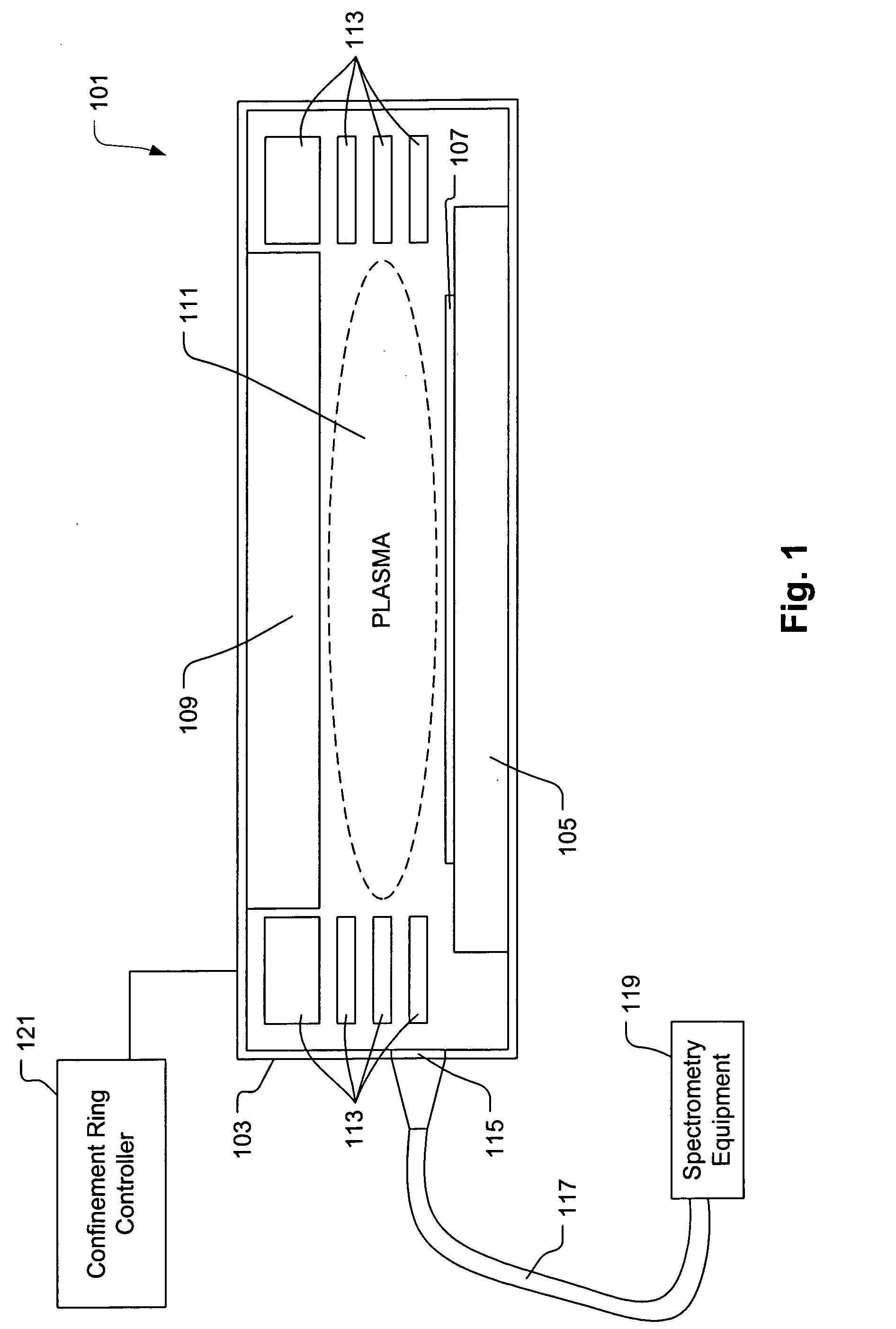

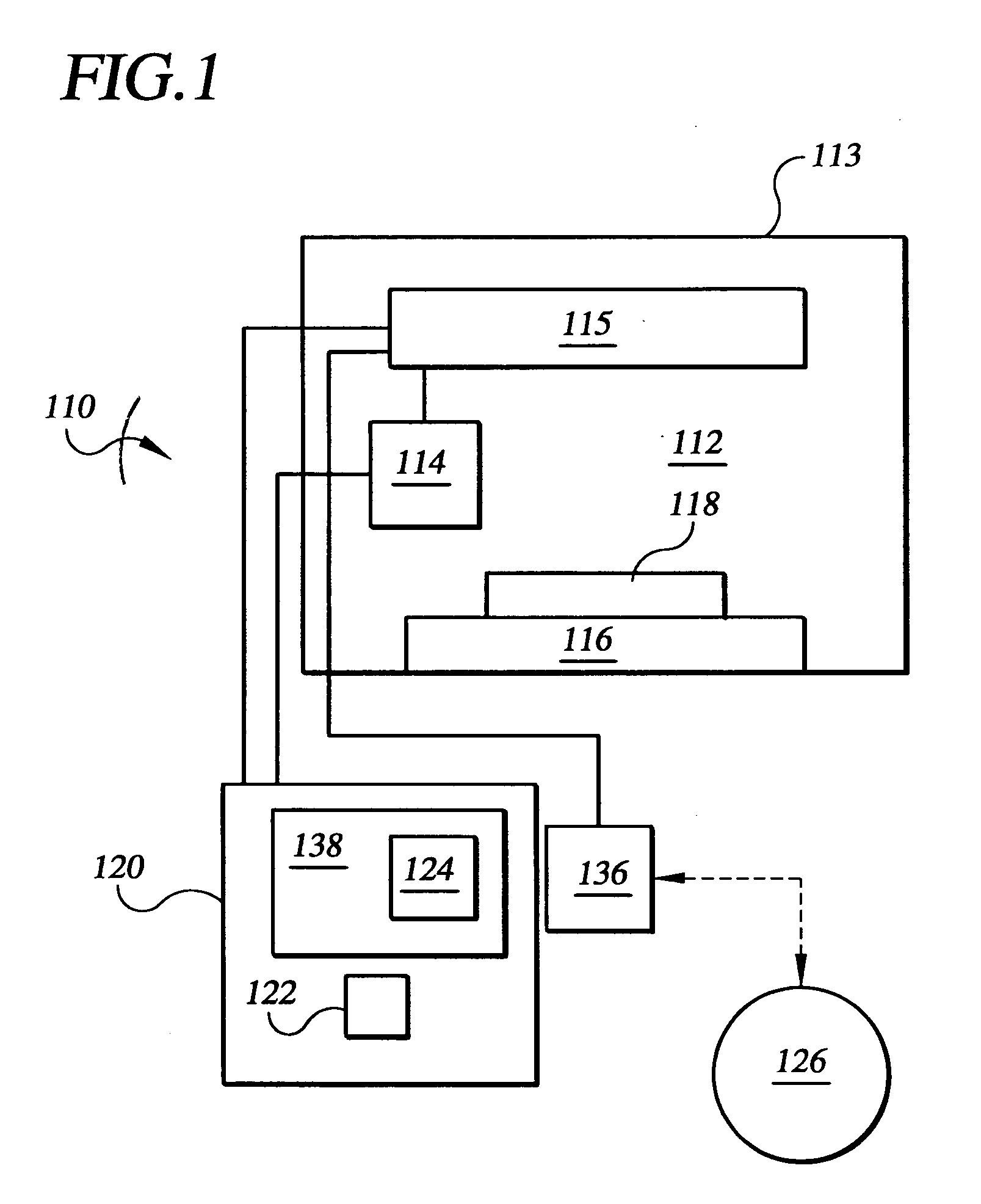

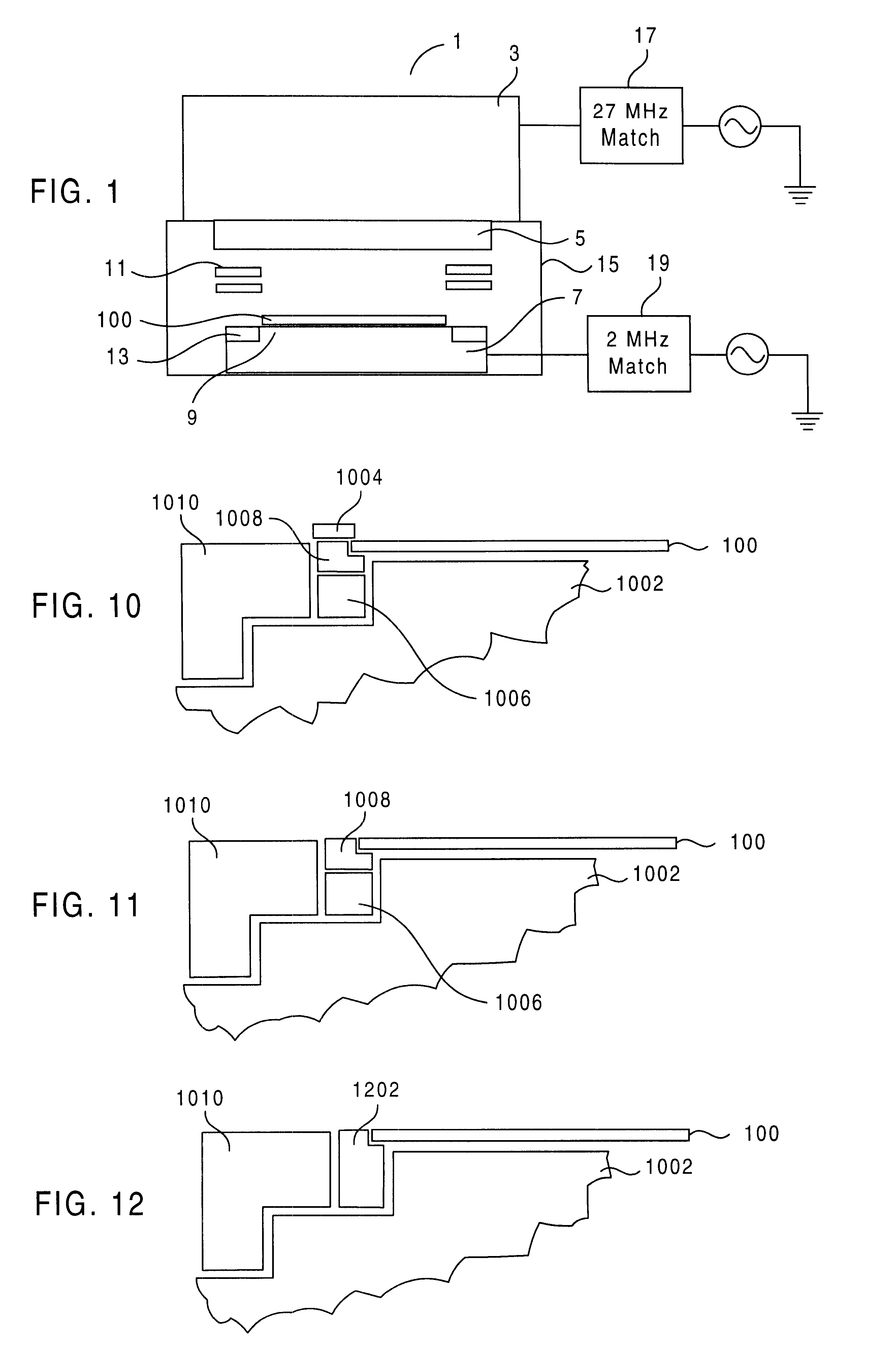

Method and apparatus for etch endpoint detection

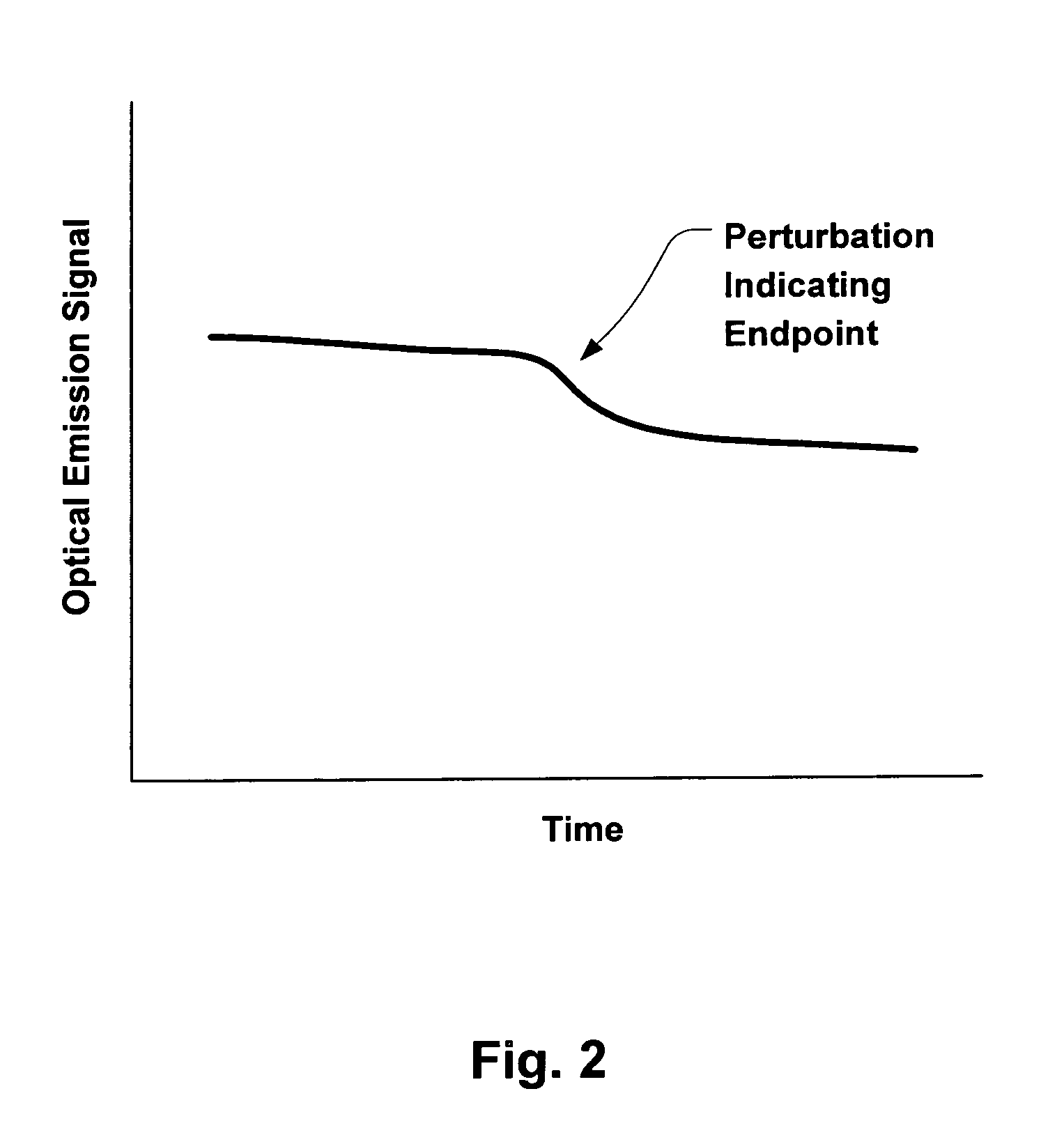

ActiveUS20060087644A1Preventing any perturbationEmission spectroscopyRadiation pyrometryEngineeringSpecific time

Broadly speaking, an invention is provided for monitoring a plasma optical emission. More specifically, the present invention provides a method for monitoring the plasma optical emission through a variable aperture to detect an endpoint of a plasma etching process without interferences that could lead to false endpoint calls. The method includes collecting optical emission data from a plasma through an aperture defined by moveable members. The moveable members are capable of varying a configuration of the aperture. The method also includes holding the moveable members at a particular time to cause the aperture to maintain a fixed configuration. The method further includes detecting a specific perturbation in the plasma optical emission while holding the moveable members.

Owner:LAM RES CORP

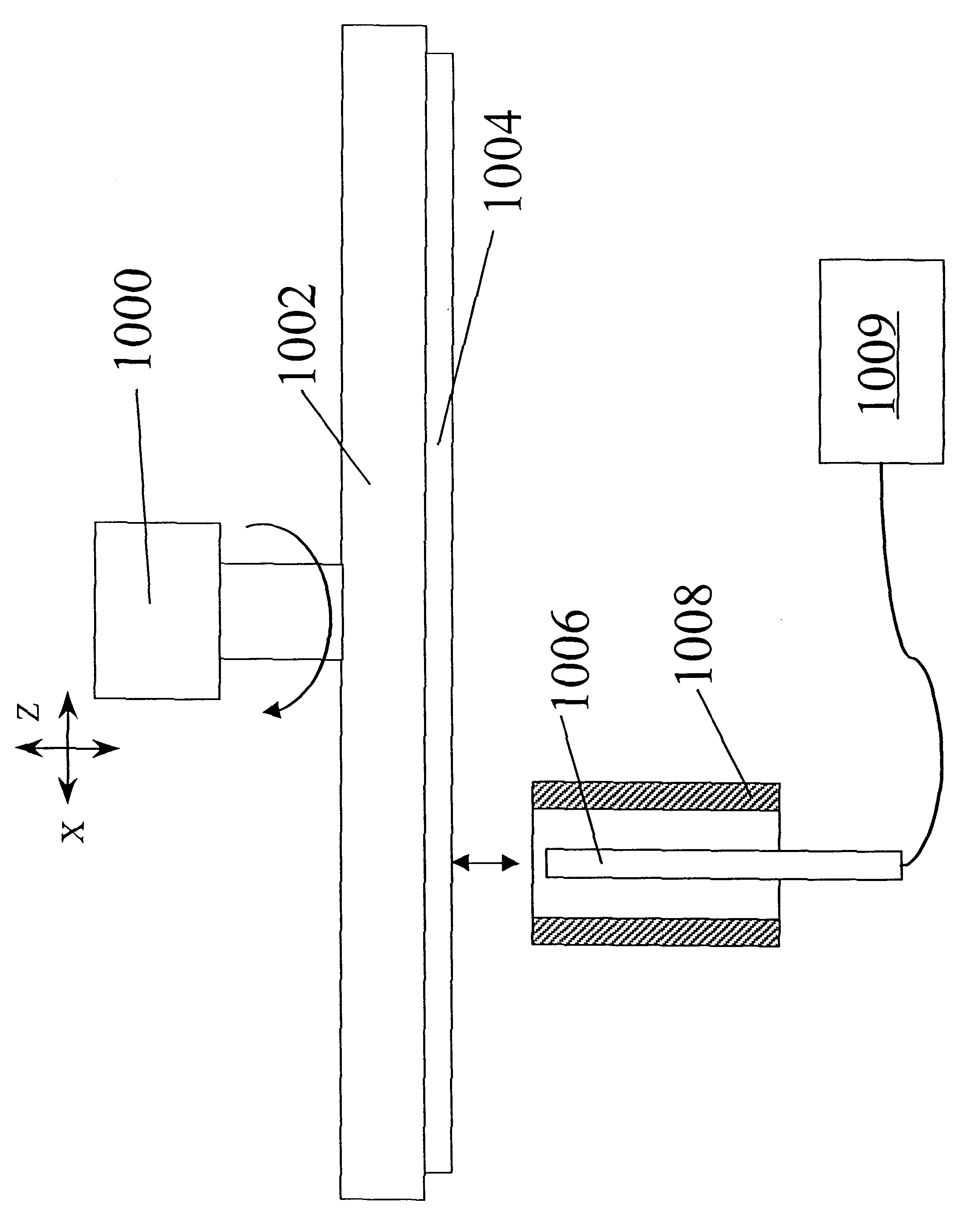

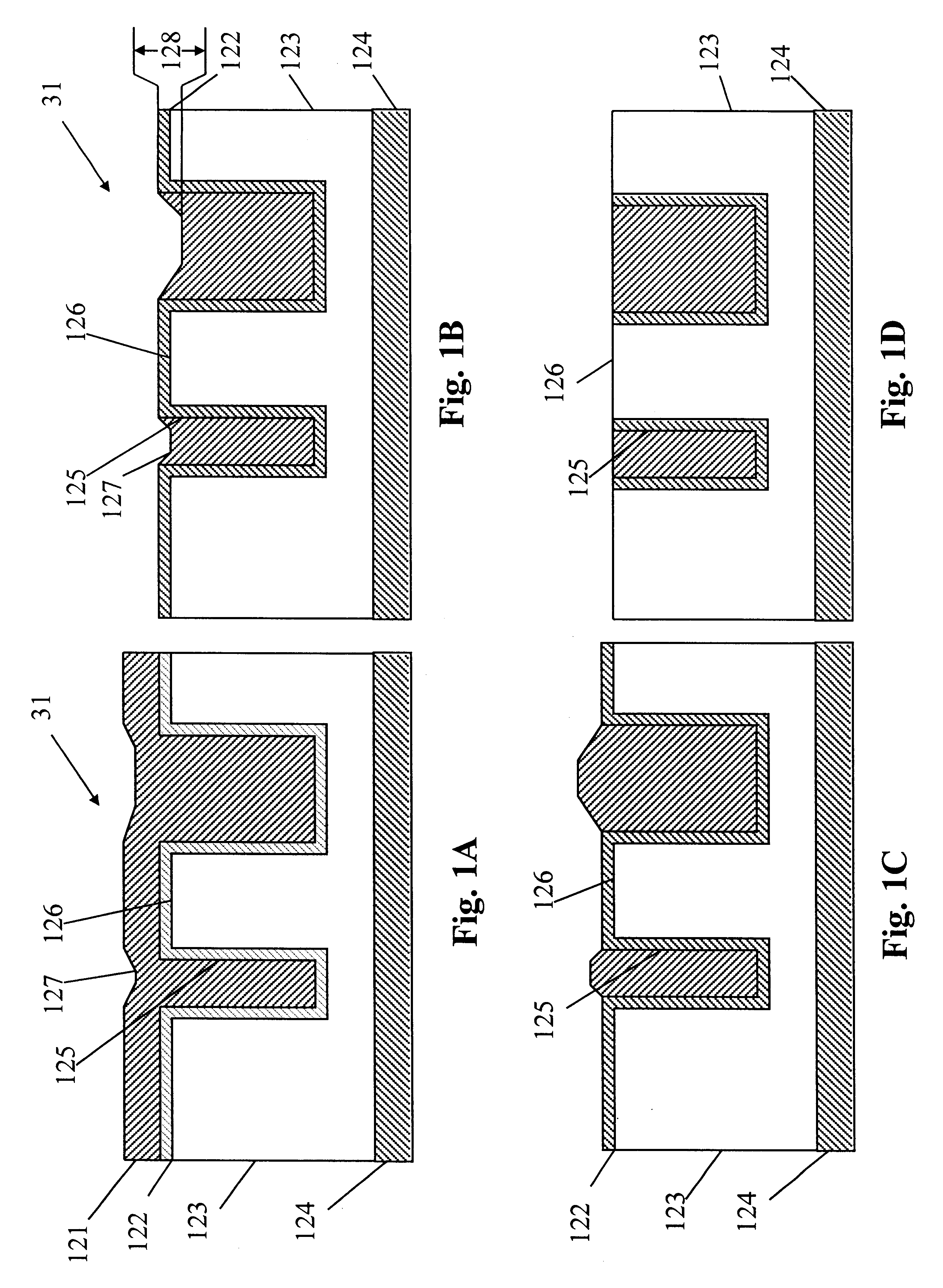

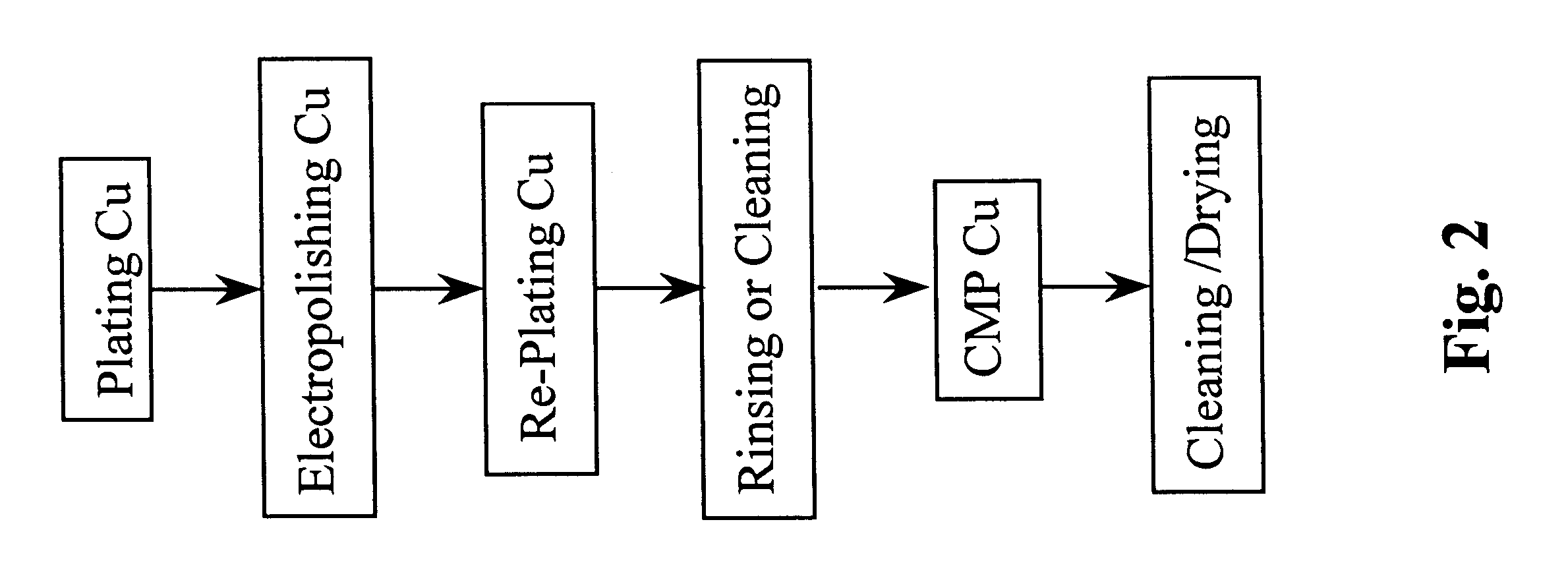

Methods and apparatus for end-point detection

An apparatus for detecting the end-point of an electropolishing process of a metal layer formed on a wafer includes an end-point detector. The end-point detector is disposed adjacent the nozzle used to electropolish the wafer. In one embodiment, the end-point detector is configured to measure the optical reflectivity of the portion of the wafer being electropolished.

Owner:ACM RES

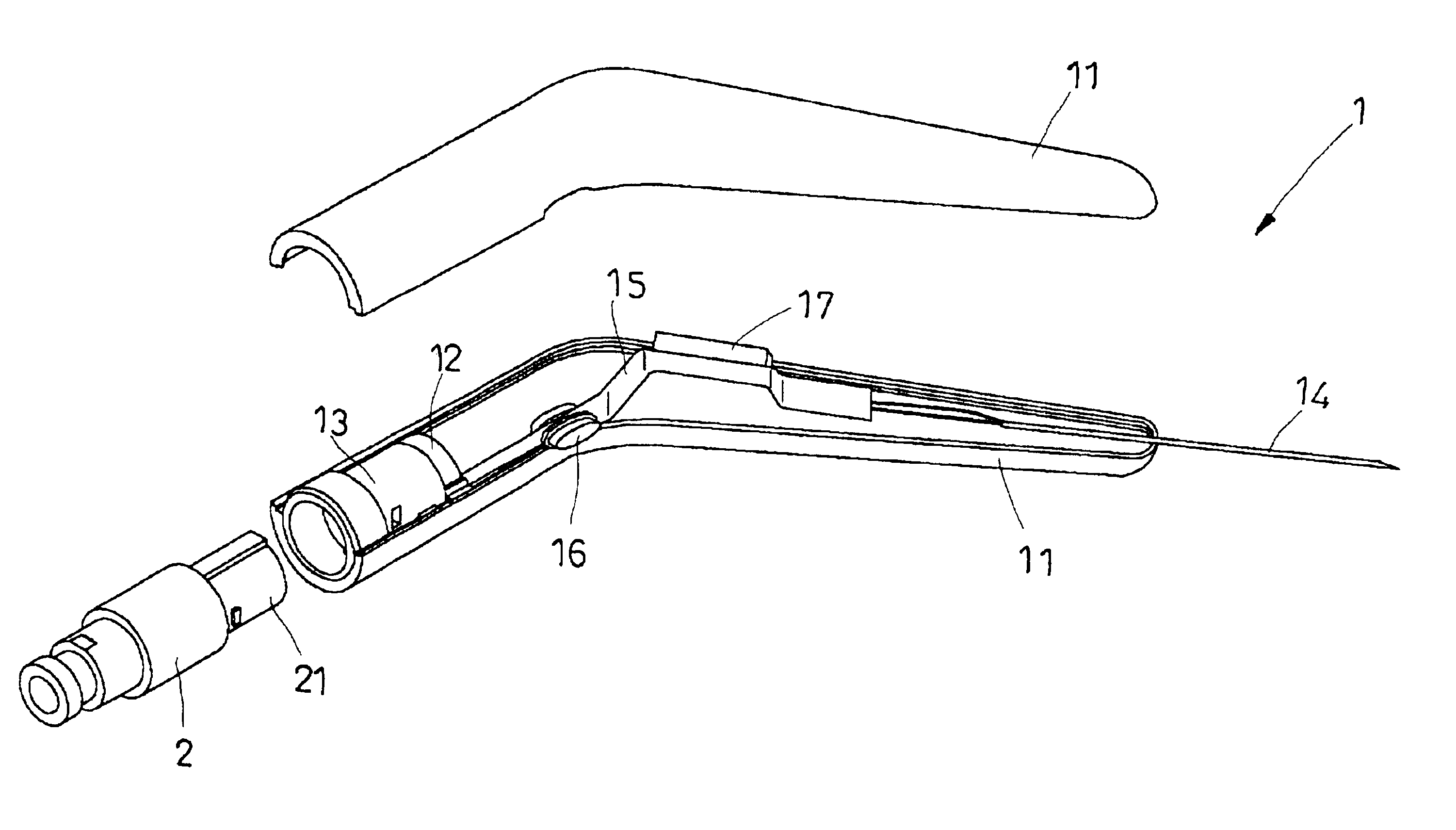

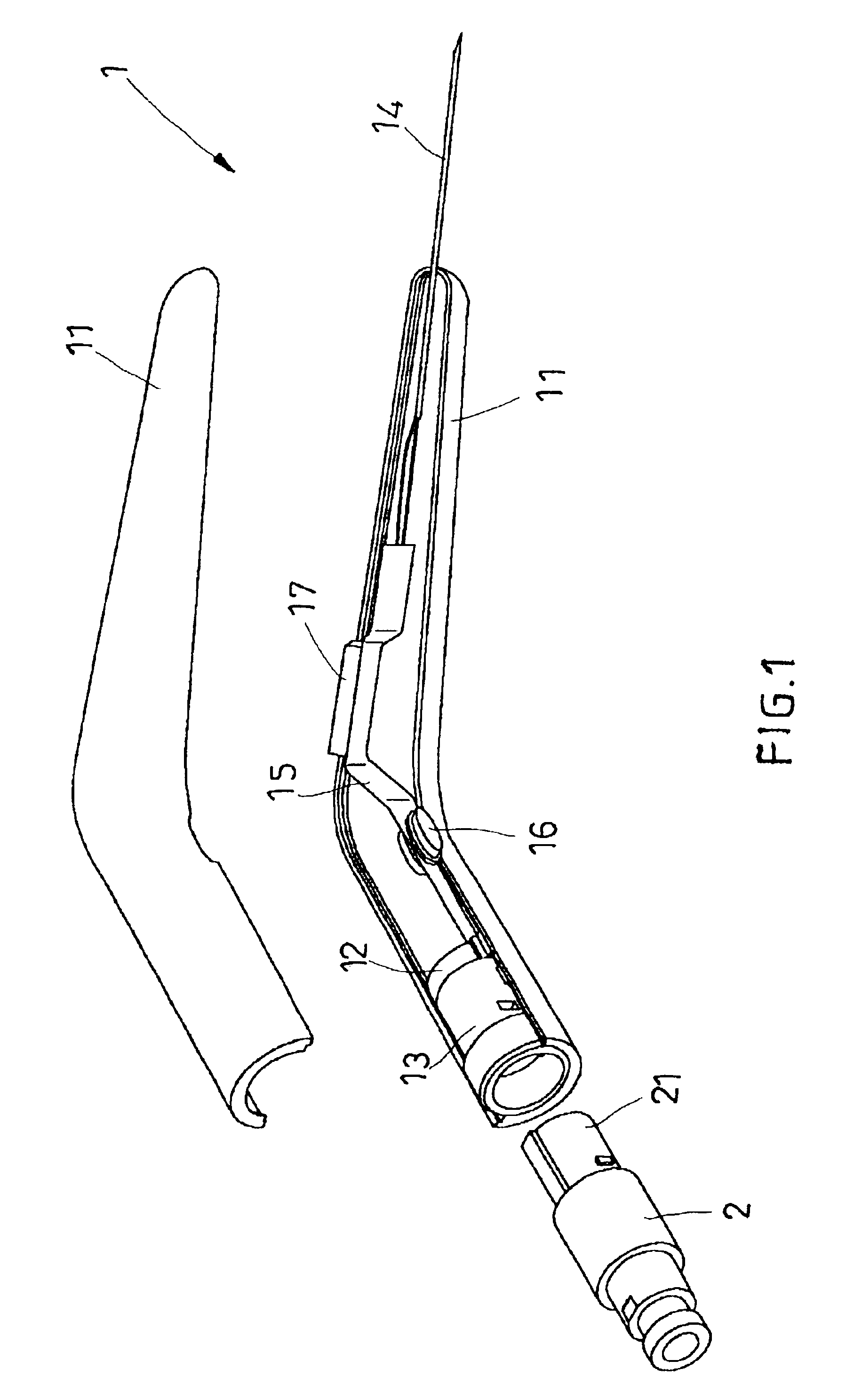

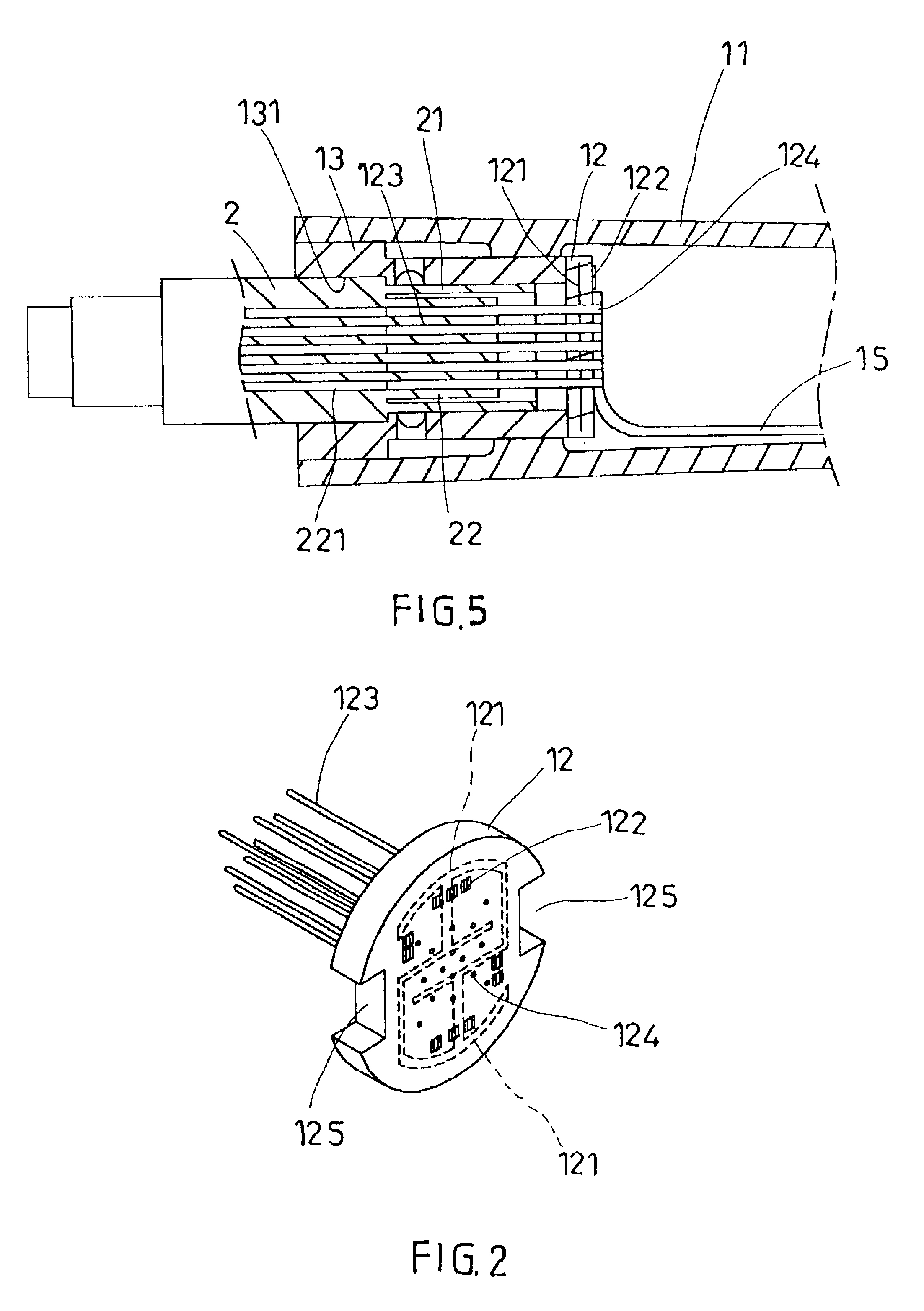

Disposable surgical devices

InactiveUS6849074B2Consume less timeConsume less laborSurgical instruments for heatingElectricityFlexible circuits

A disposable surgical device is constructed to include a shell, a smart block mounted in one end of the shell, the smart block electronic having components mounted to a circuit embedded therein, front contact pins for insertion into respective contact holes in the connector of an industry standard connector interface, and rear wire terminal points, a medical treatment terminal installed in the other side of the shell and adapted for performing surgery and treatments, and a flex circuit termination electrically connected between the smart block and the medical treatment terminal, the flex circuit termination having embedded conductor lines respectively connected to the medical treatment terminal and wire terminal points at the ends of the conductor lines respectively soldered to the wire terminal points of the smart block.

Owner:ATL TECH LLC

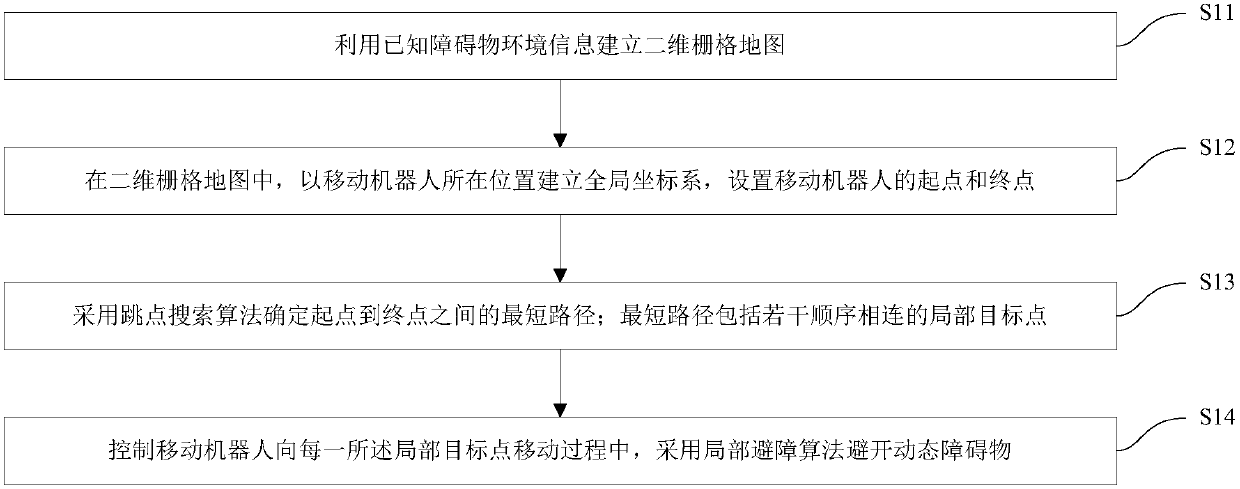

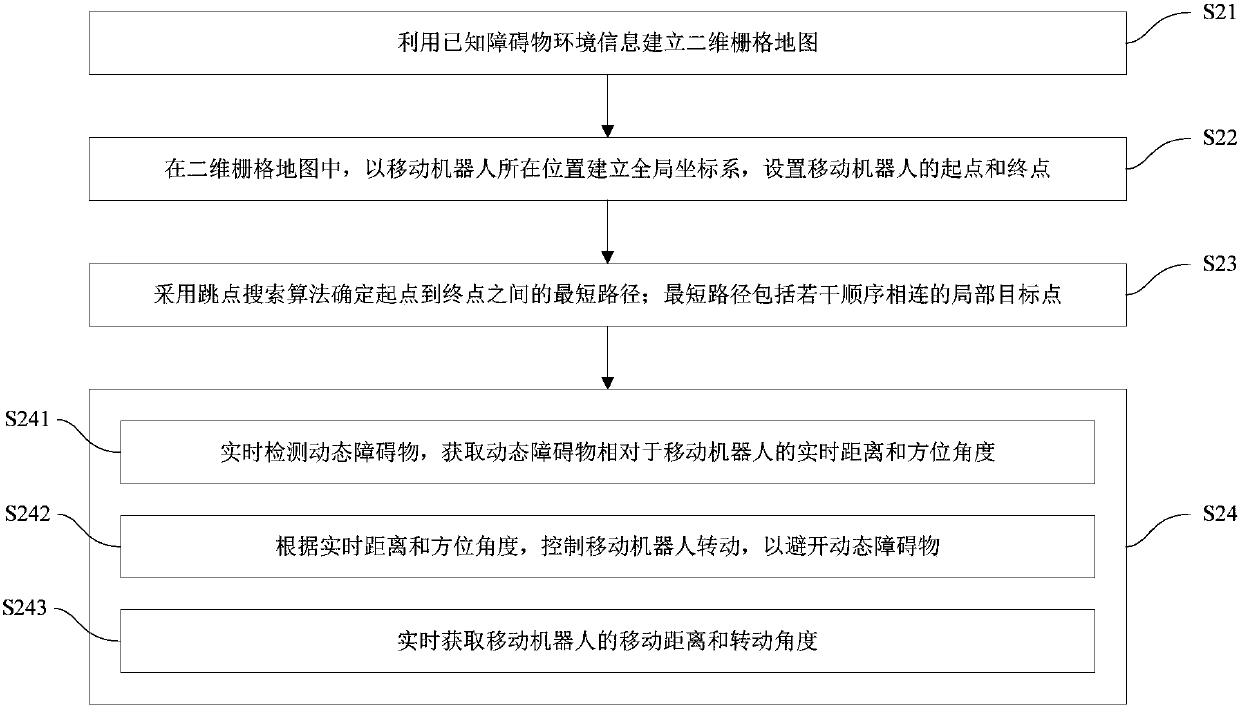

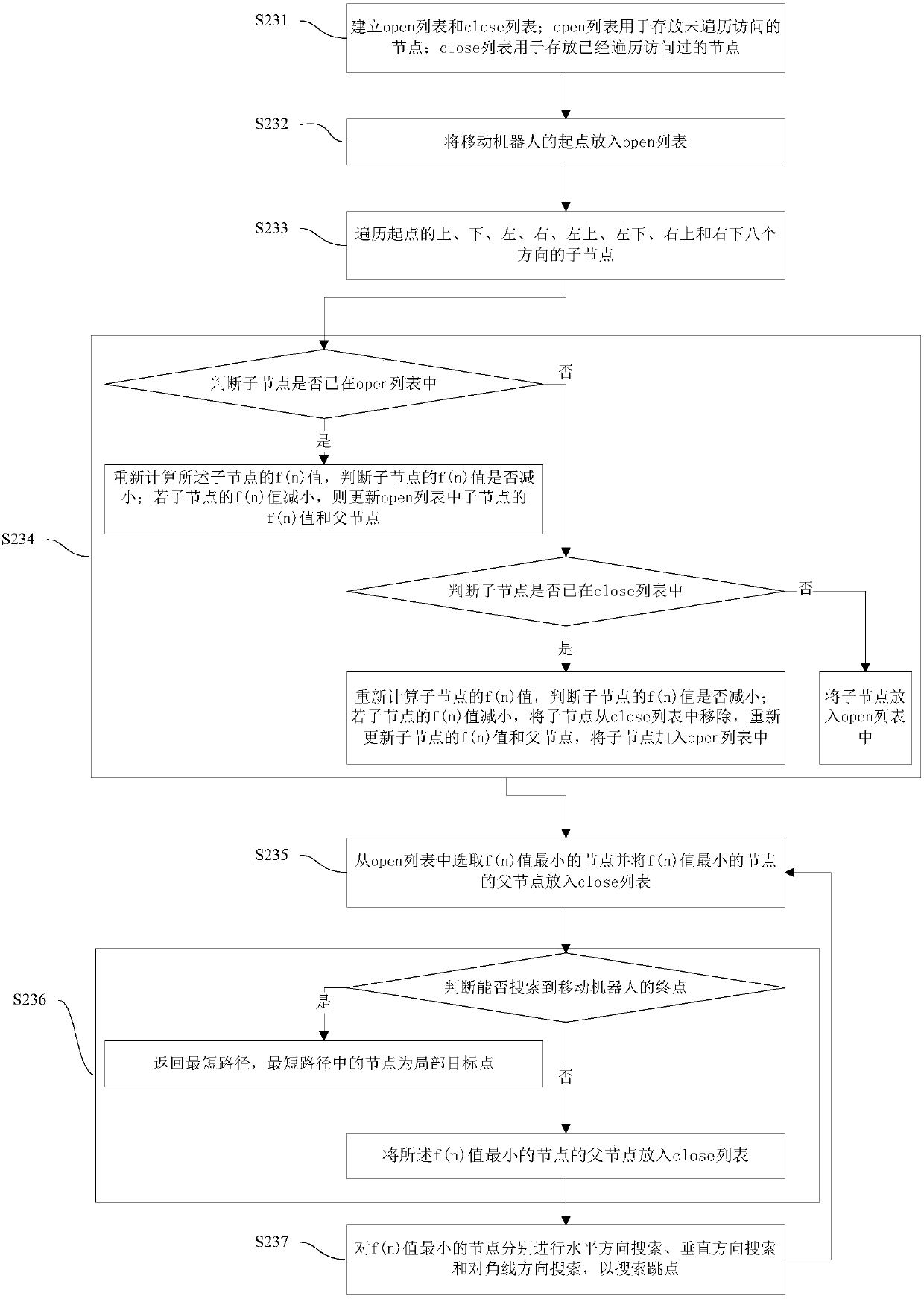

Mobile robot path planning and obstacle avoidance method and system

InactiveCN105955280AReduce path planning timeGuaranteed accuracyPosition/course control in two dimensionsObstacle avoidance algorithmMobile robots path planning

The invention discloses a mobile robot path planning and obstacle avoidance method and system. The mobile robot path planning method comprises the following steps: establishing a two-dimensional grid map by utilizing known obstacle environment information; in the two-dimensional grid map, establishing a global coordinate system at the place of a mobile robot, and setting a starting point and a terminal point of the mobile robot; determining the shortest path between the starting point and the terminal point through a jump point search algorithm, wherein the shortest path comprises a plurality of local target points connected in sequence; and in the process of controlling the mobile robot to move to each of the local target points, utilizing a local obstacle avoidance algorithm to avoid a dynamic obstacle. The mobile robot path planning and obstacle avoidance method adopts the jump point search algorithm to obtain the shortest path quickly, so that path search efficiency can be improved, and storage space is saved; and through the local obstacle avoidance algorithm, accuracy and real-time performance of mobile robot path planning and obstacle avoidance can be ensured, and autonomous navigation of the mobile robot is realized.

Owner:TCL CORPORATION

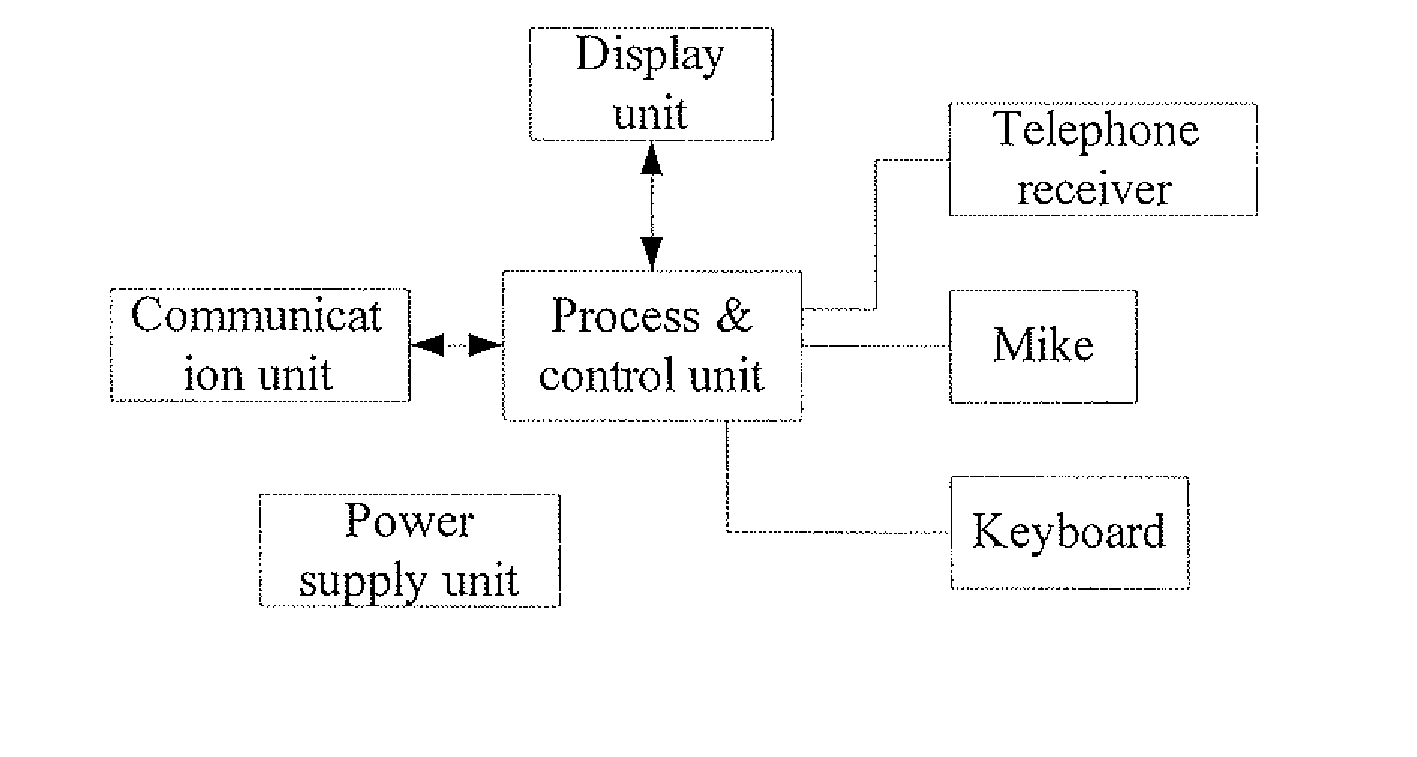

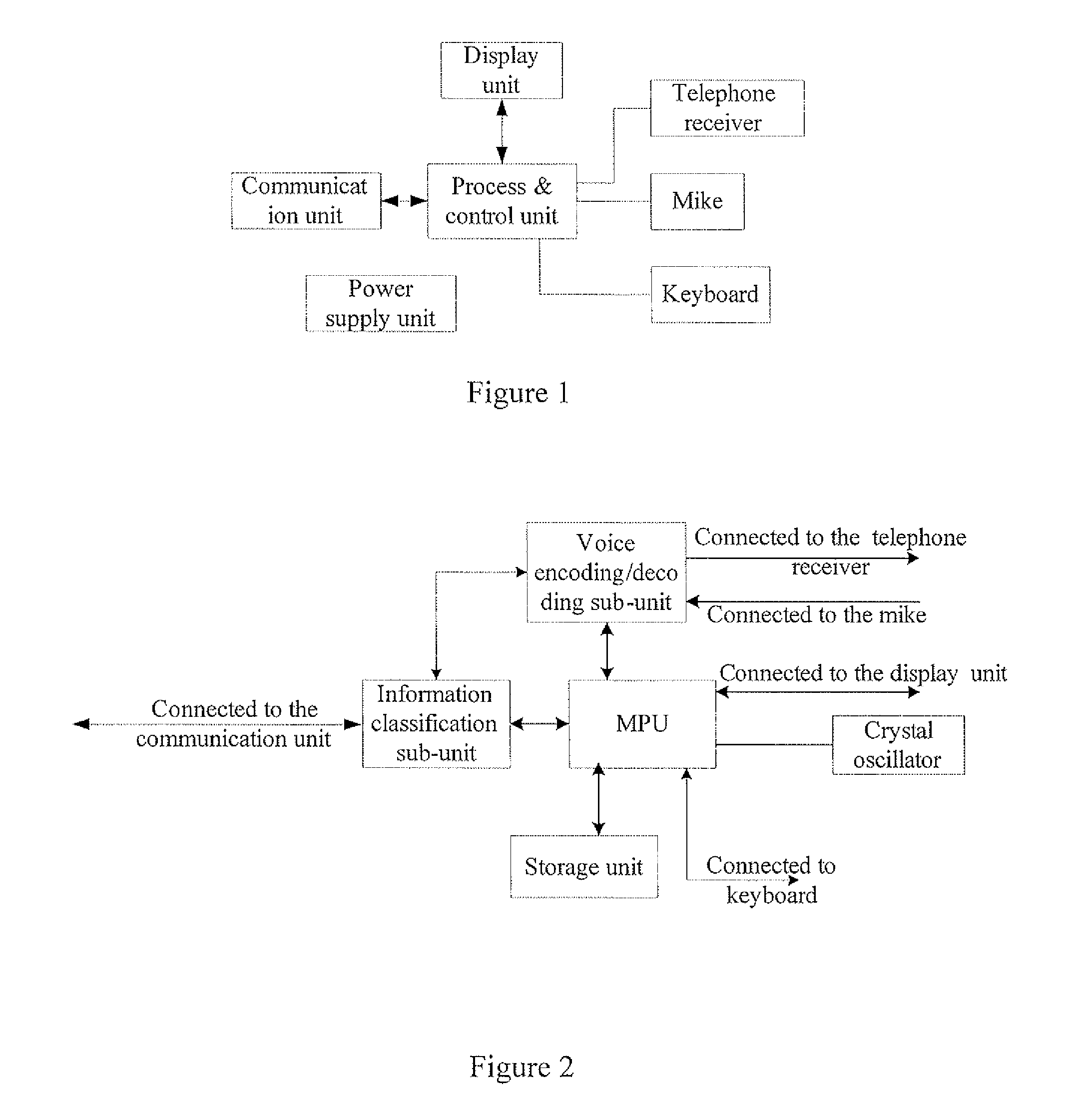

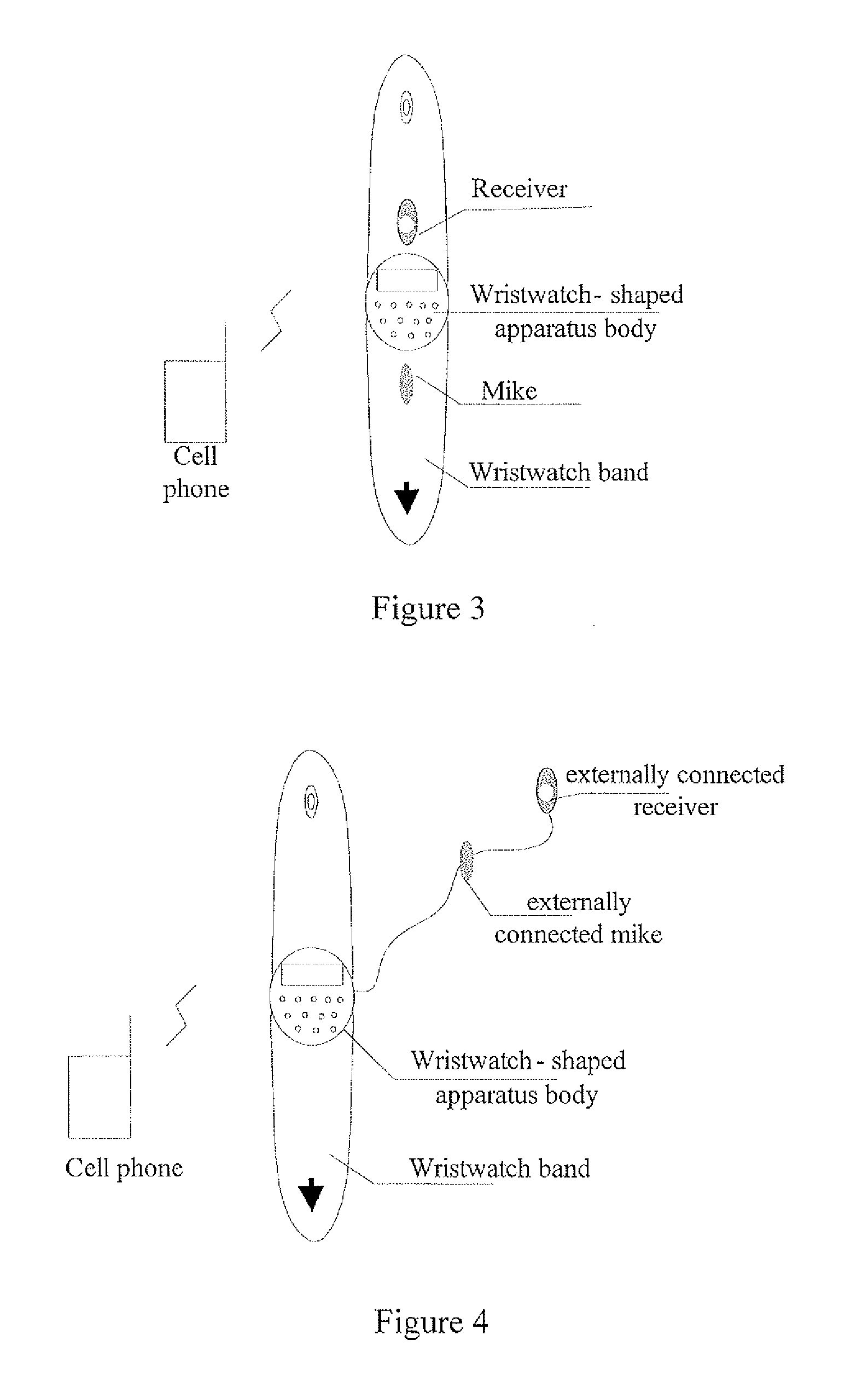

Cell phone peripheral device, communication terminal and method for a cell phone peripheral device communicating with a cell phone

ActiveUS20070191002A1Easy to manufactureLow costSynchronisation arrangementDevices with bluetooth interfacesCommunication unitData information

A cell phone peripheral device comprises a communication unit, for short-distance wireless communicating between said cell phone peripheral device and the cell phone; a processing unit, for receiving information from said communication unit, processing the information to obtain and analyze data information; a display unit, for receiving and displaying said data information. A method for a cell phone perpheral device communicating with a cell phone comprises receiving information from the cell phone by way of short-distance wireless communication; processing the information to obtain and analyze data information; and displaying, by the cell phone peripheral device, the data information. And a communication terminal comprises: a first communication unit for communicating with a cellular network, a processing unit, and a first input / output unit, and further comprising: a second communication unit, for transmitting voice and data information between the processing unit and the first input / output unit by way of short distance wireless communication.

Owner:HUAWEI TECH CO LTD

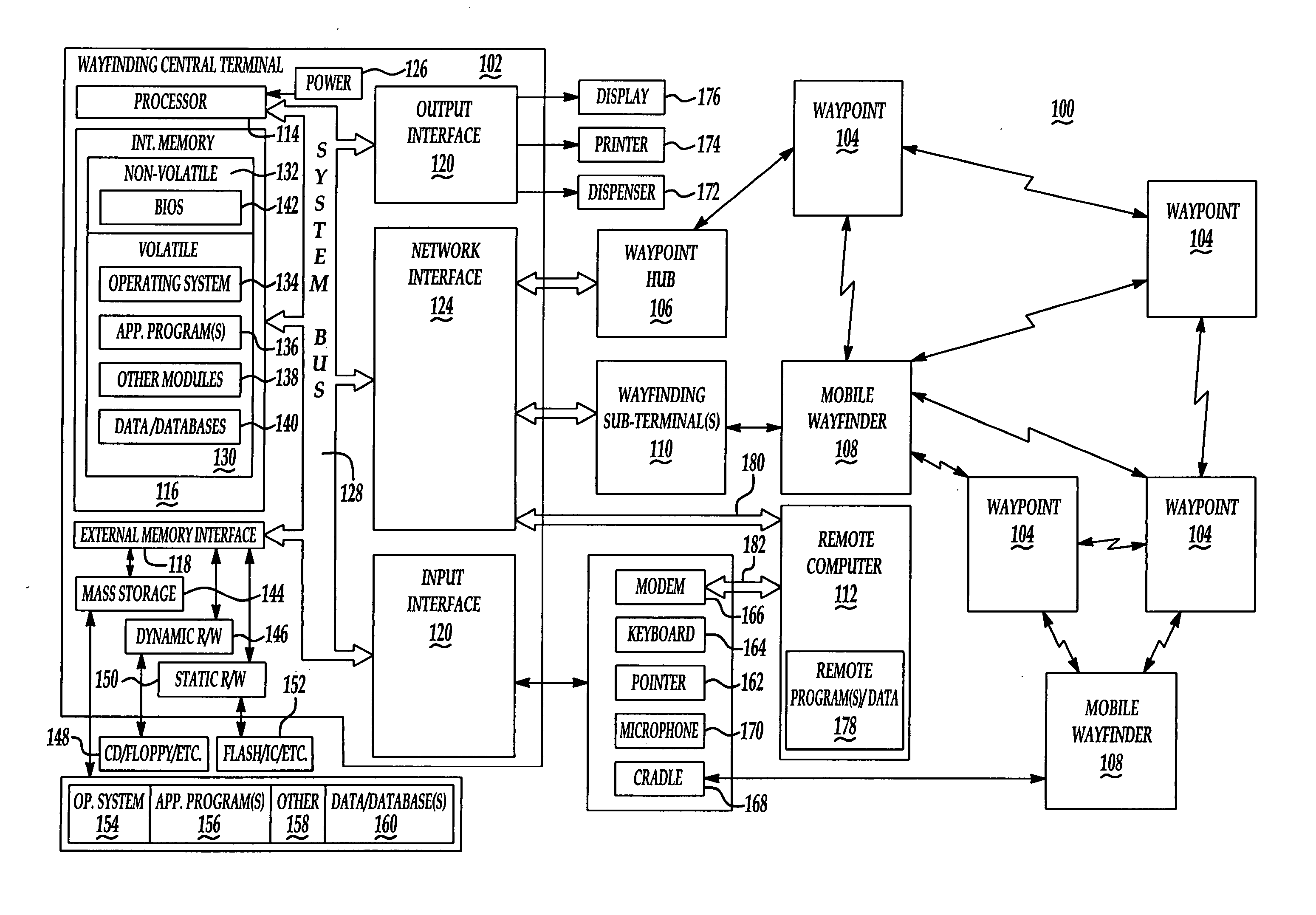

Wayfinding

InactiveUS20060247849A1Instruments for road network navigationNavigational calculation instrumentsMarine navigationReal-time computing

Waypoint navigation for a visitor to a facility is carried out according to the following steps. Distributing waypoint devices in waypoint locations of the facility. Transmitting waypoint identifier signals from the waypoint devices. Providing a mobile wayfinder device in wireless communication with the waypoint devices to receive the waypoint identifier signals. Identifying an origin and a destination in the facility. Generating a route from the origin to the destination and a return route from the destination to the origin. Determining a current location of the mobile wayfinder device. Determining a current navigation instruction along the route(s) based at least in part on the current location of the mobile wayfinder device, and communicating the current location and navigation instruction information to the visitor.

Owner:PROXEMICS

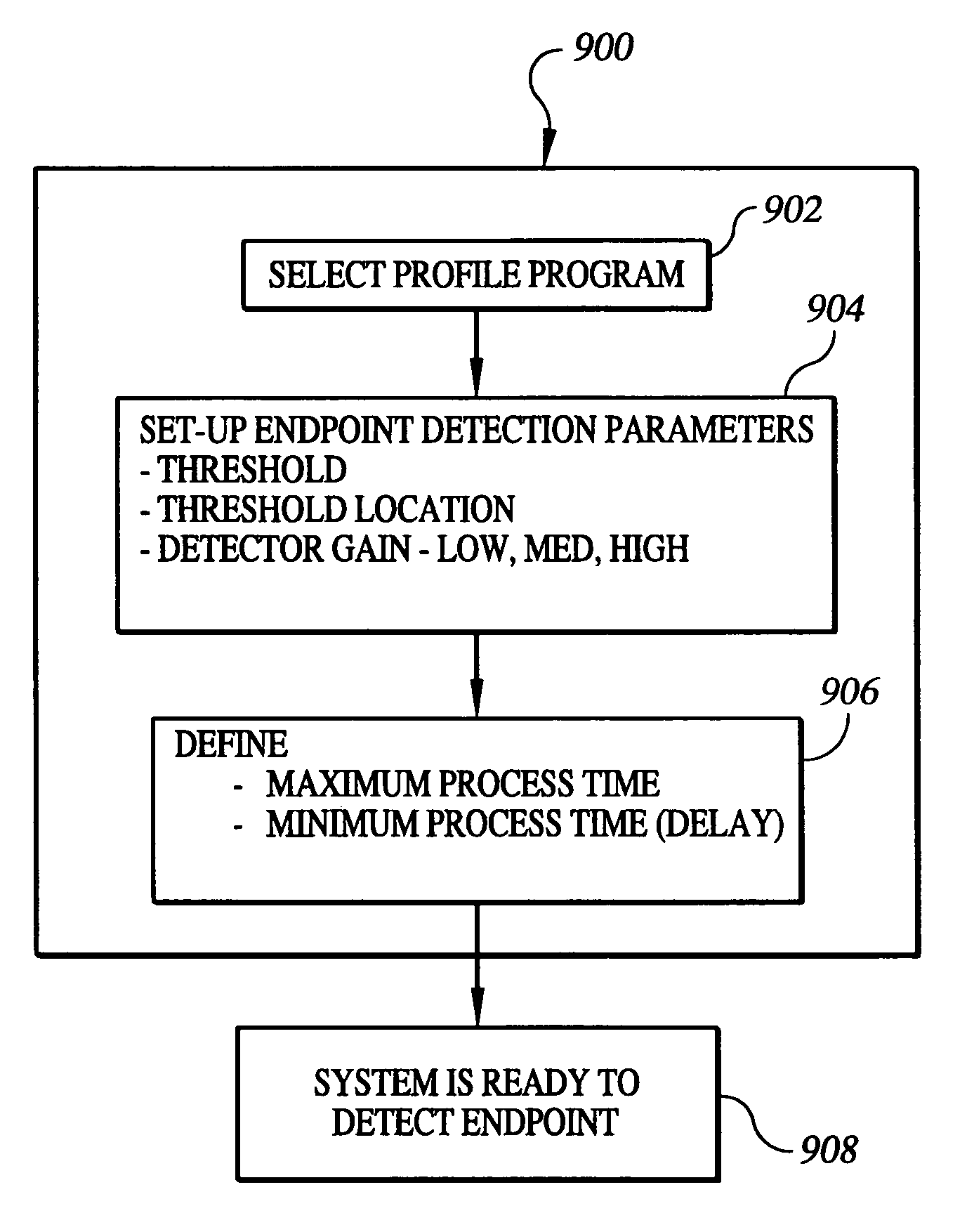

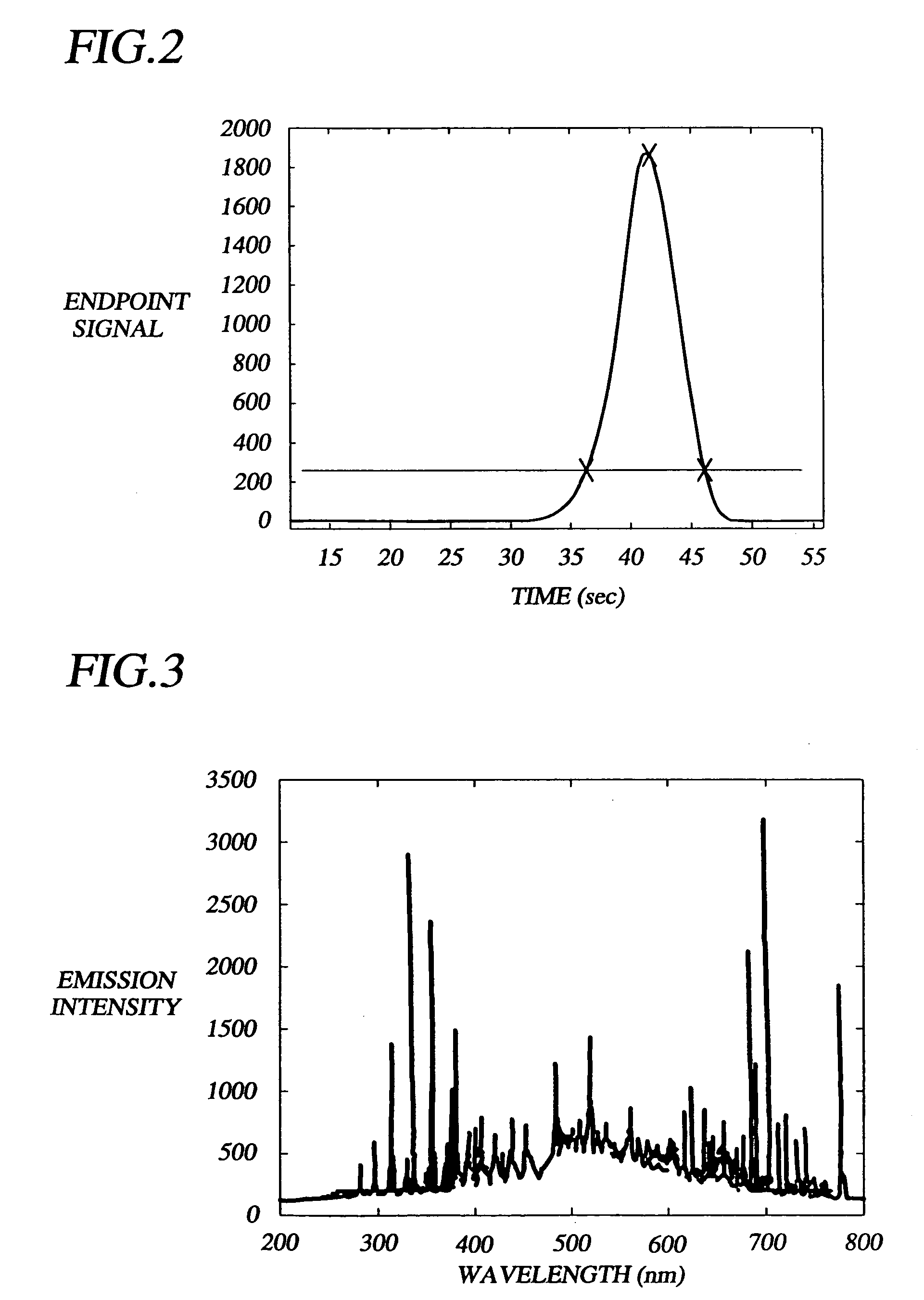

Full spectrum endpoint detection

InactiveUS6969619B1Simplifies parameterPromote useSemiconductor/solid-state device testing/measurementElectric discharge tubesFrequency spectrumOptoelectronics

A method of endpoint detection during plasma processing of a semiconductor wafer comprises processing a semiconductor wafer using a plasma, detecting radiation emission from the plasma during the semiconductor processing, and tracking data points representing changes in spectra of the radiation as a function of time during the semiconductor processing. At any point prior to or during processing a plurality of profiles are provided, each profile representing a different processing condition affecting detection of the desired plasma processing endpoint of the semiconductor wafer. After selecting a desired profile, a first set of parameters are input, representing simplified values for determining when changes in spectra of the radiation indicate that plasma processing of the semiconductor wafer reaches a desired endpoint. The selected profile converts the input first set of parameters into a larger, second set of parameters, and then applies the second set of parameters to an algorithm that converts data points from the spectra of the radiation as a function of time into an endpoint curve. The method then uses the algorithm to track changes in spectra of the radiation as a function of time and determine when plasma processing of the semiconductor wafer reaches a desired endpoint.

Owner:NOVELLUS SYSTEMS

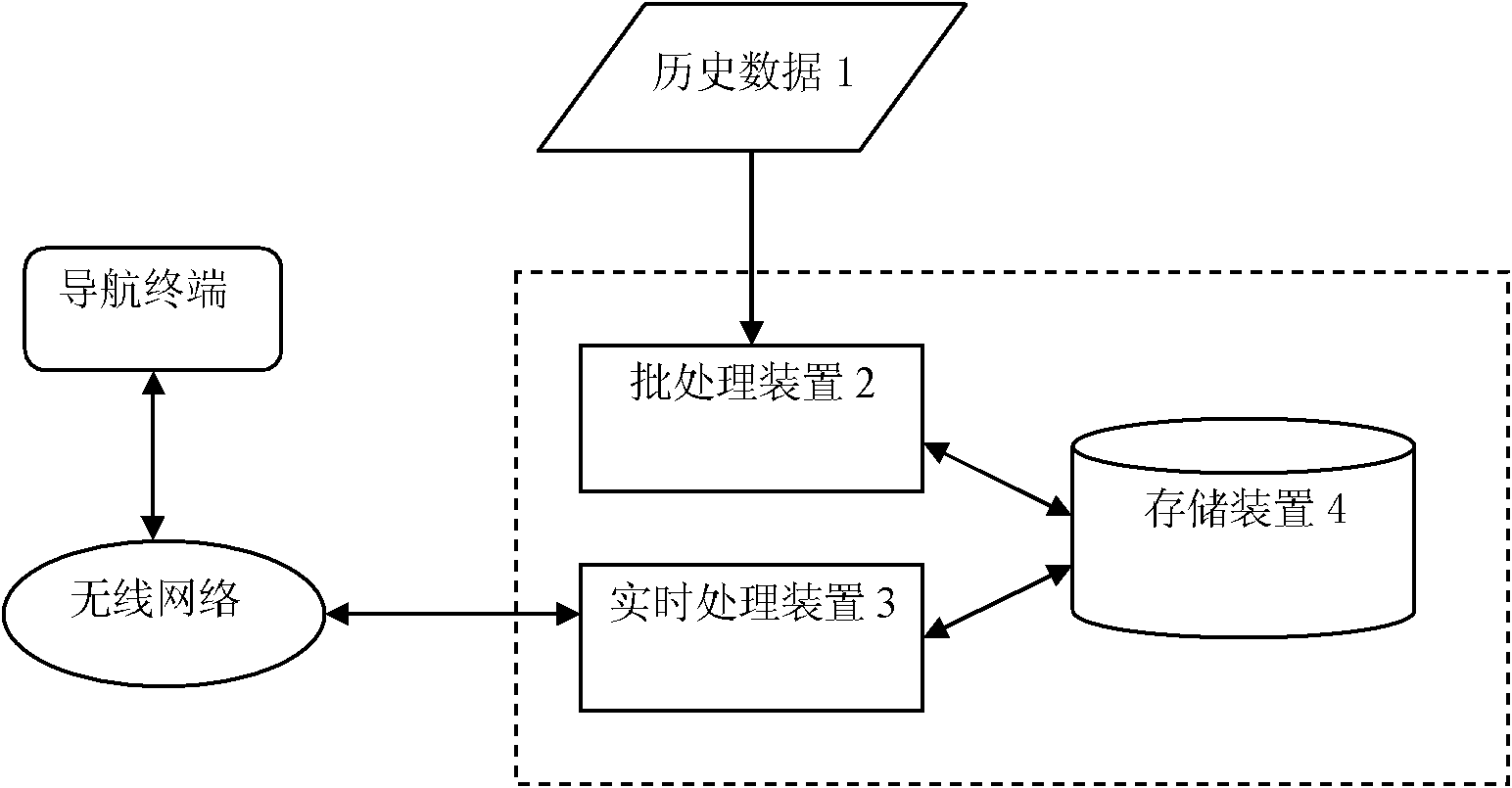

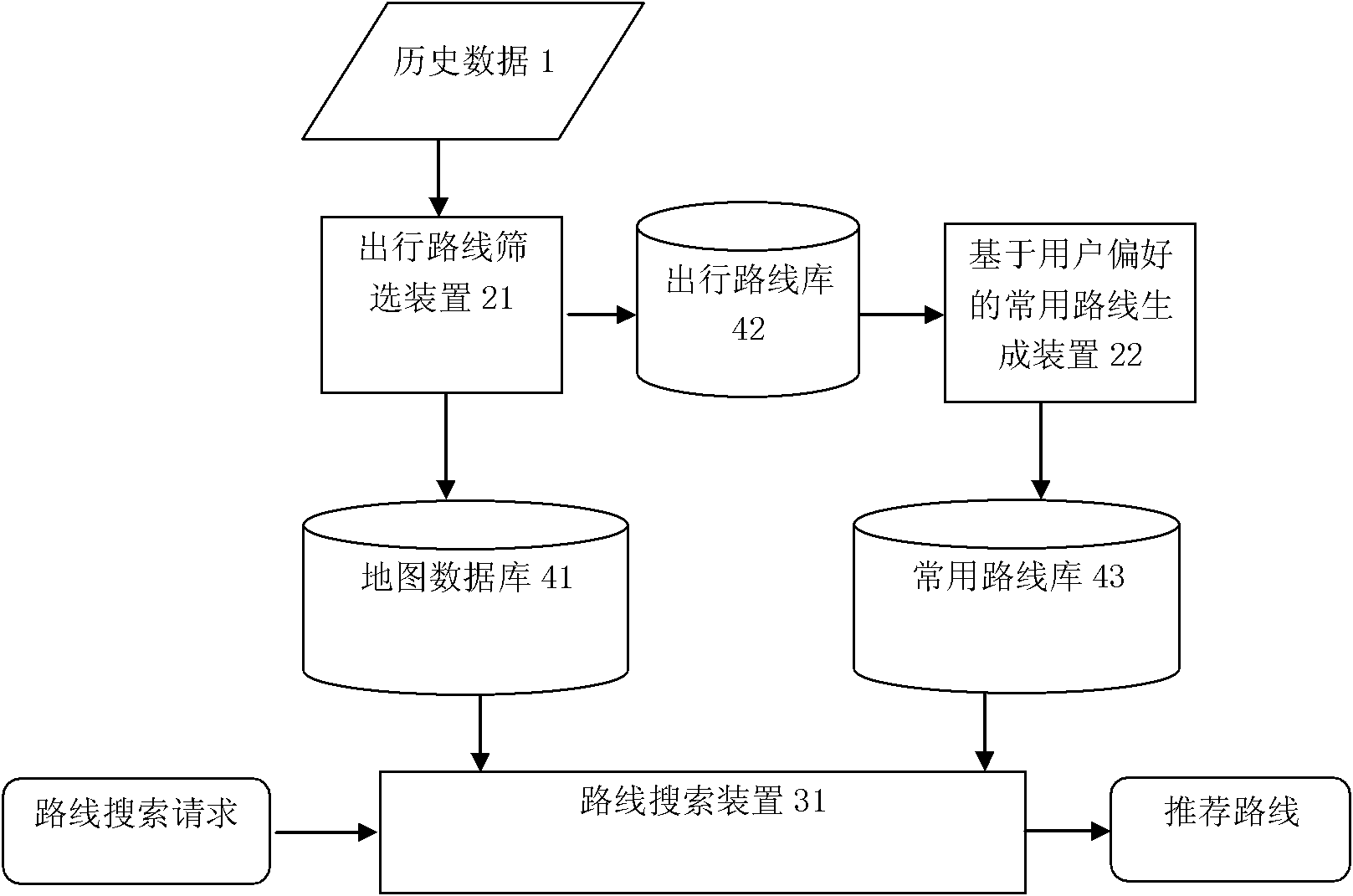

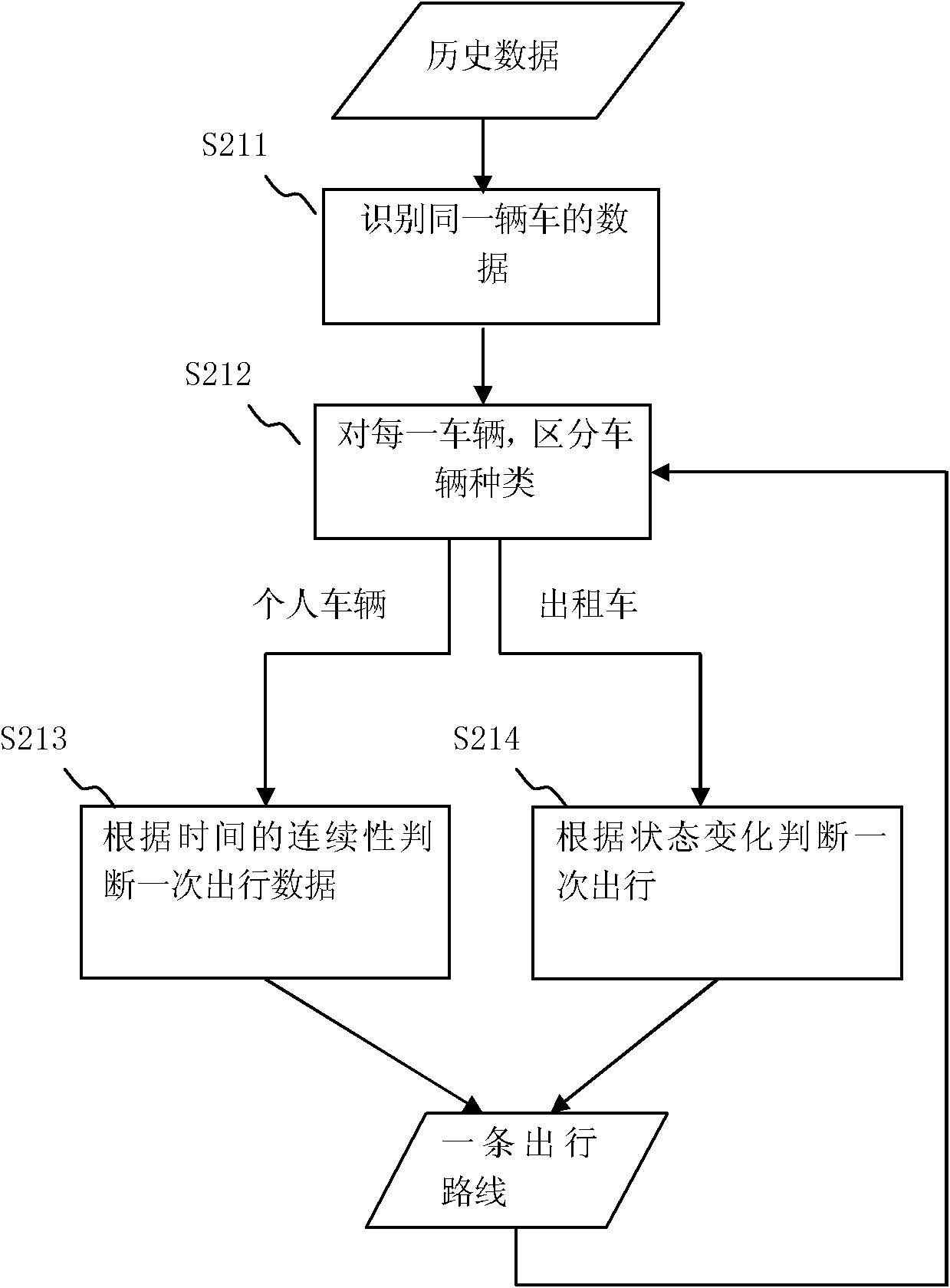

Route searching system and method based on commonly used route

InactiveCN102840867AReduce dependencePersonalized route search resultsInstruments for road network navigationSimulationRoute search

The invention provides a route searching method and a route searching system. The route searching method comprises the following steps: based on a starting point and a terminal point, finding out if there is a matched commonly used route in a commonly used route library, wherein if the matched commonly used route is found out, directly returning to the matched commonly used route to use the matched commonly used route as the final recommended route, if not, calculating an initial route of the starting point and the terminal point by using a route searching algorithm; by aiming at the endpoints of the calculated initial route and all links, finding out a matched common used route in the commonly used route library, and replacing corresponding parts of the initial route to obtain candidate routes; and evaluating all obtained candidate routes, and selecting a candidate route which has a longest length that replacing the initial route to use the candidate route as the final recommended route.

Owner:CLARION CO LTD

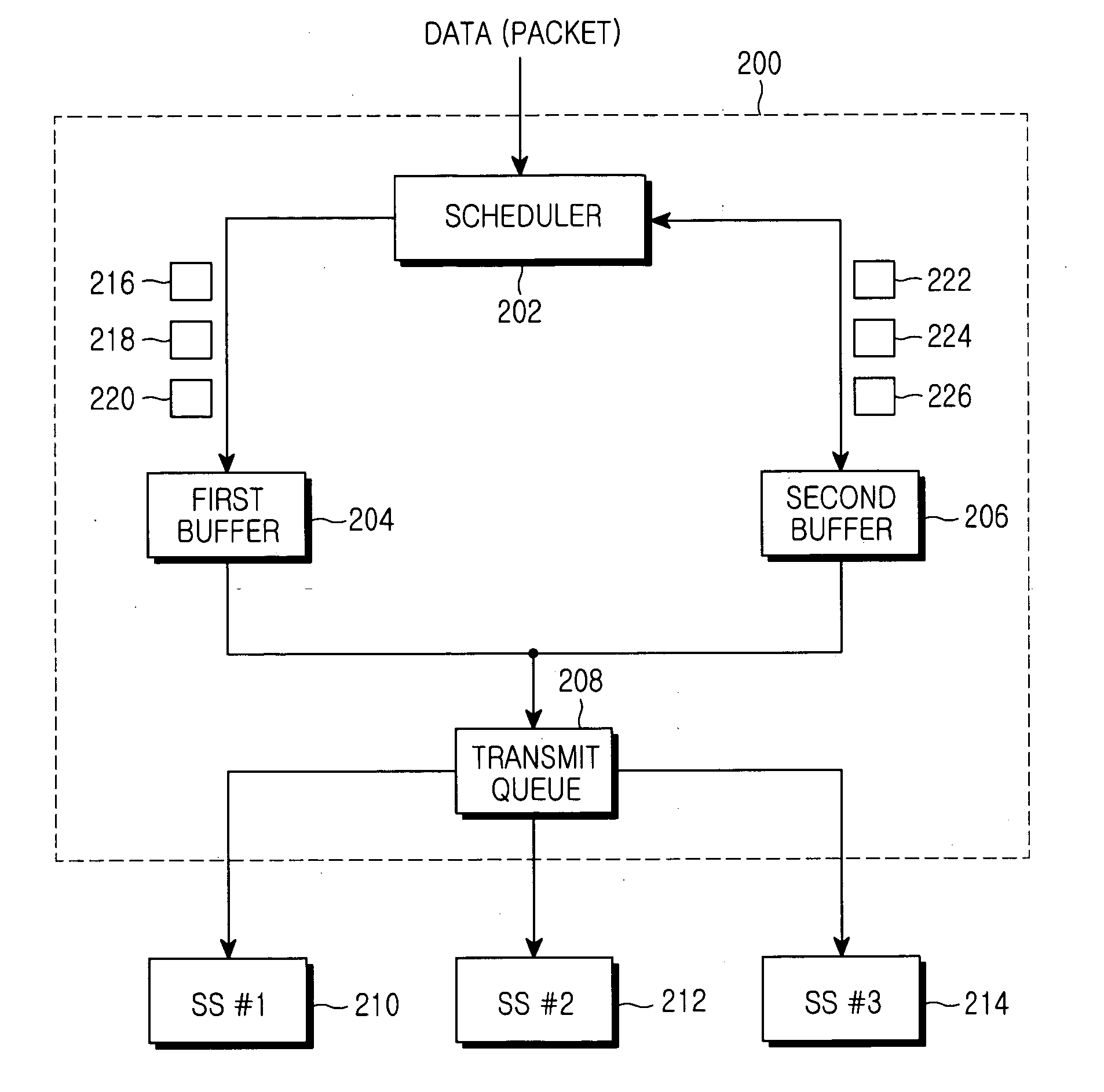

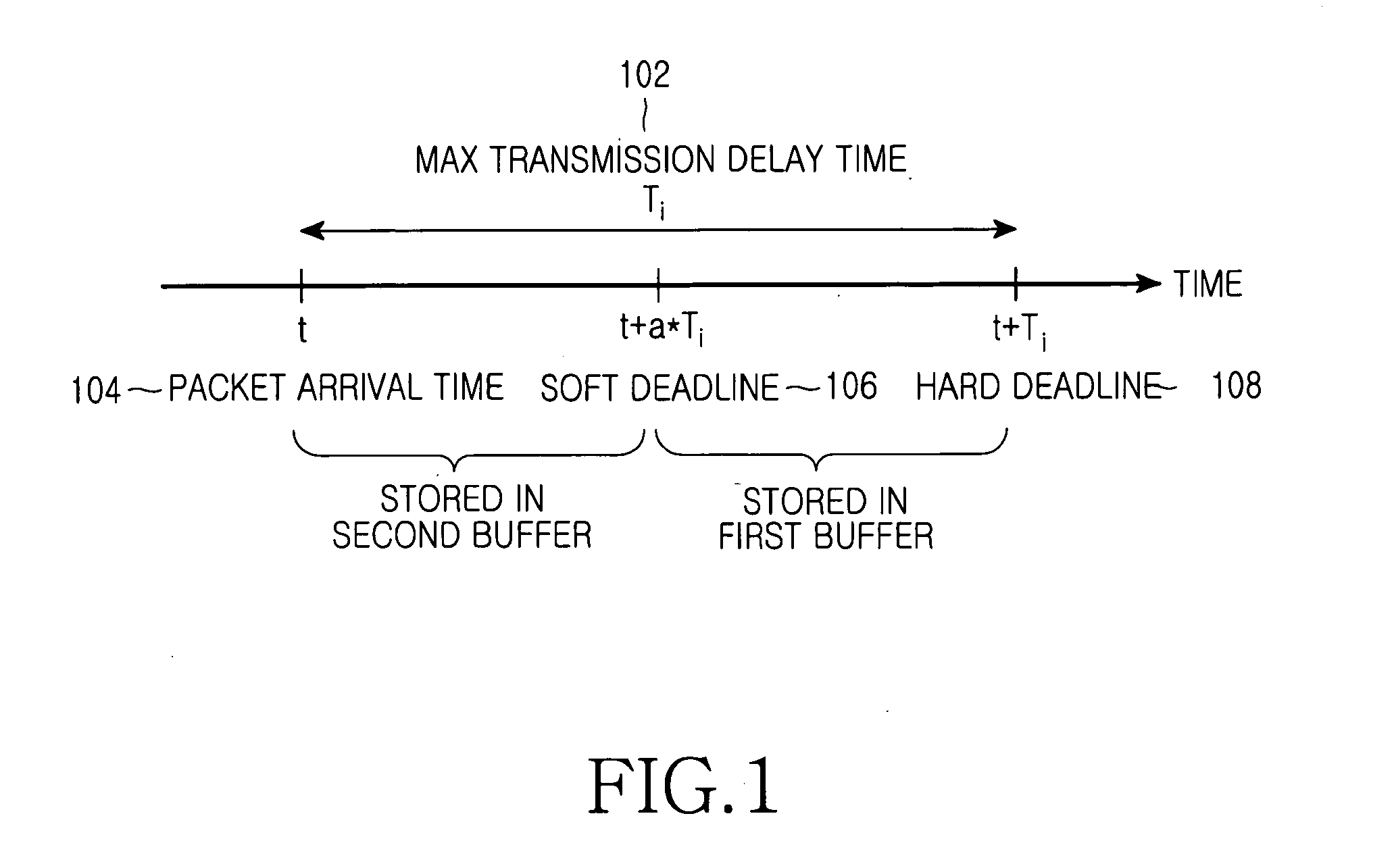

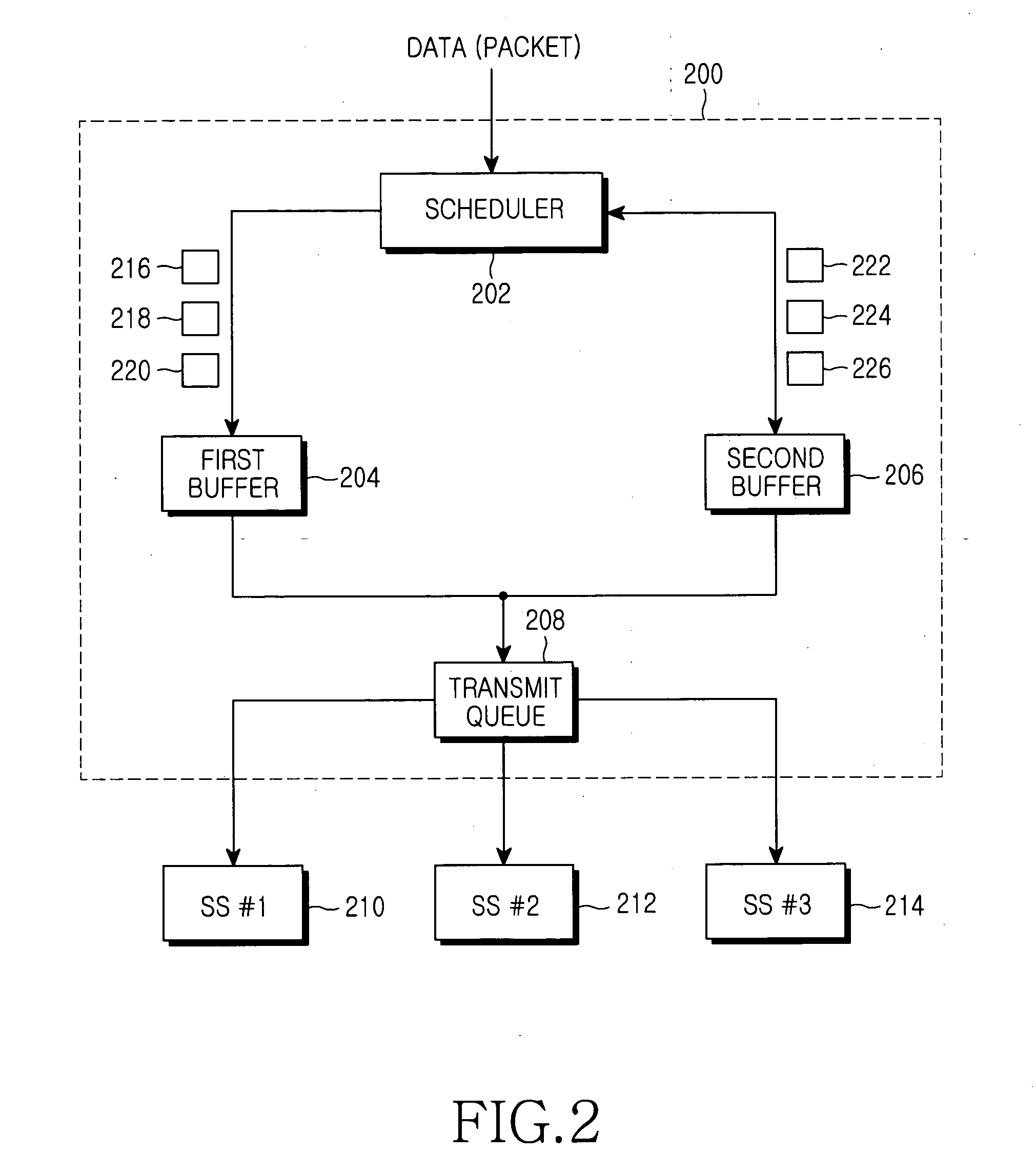

Apparatus and method for scheduling packets in a wireless communication system

InactiveUS20050213587A1Efficient processingConveyorsNetwork traffic/resource managementQuality of serviceCommunications system

An apparatus and a method for scheduling packets in a wireless communication system. The method includes the steps of dividing a transmission deadline of the packets for a destination into a first deadline, which is an end point of the transmission deadline, and a second deadline, which is allocated before the first deadline in consideration of a transmission channel state and a quality of service (QoS) of the packets, scheduling and transmitting the packets according to transmission priorities thereof, which are determined by a predetermined scheme, before the second deadline, and scheduling and transmitting the packets according to an approaching order of the packets with respect to the first deadline, if the packets have passed through the second deadline.

Owner:SAMSUNG ELECTRONICS CO LTD

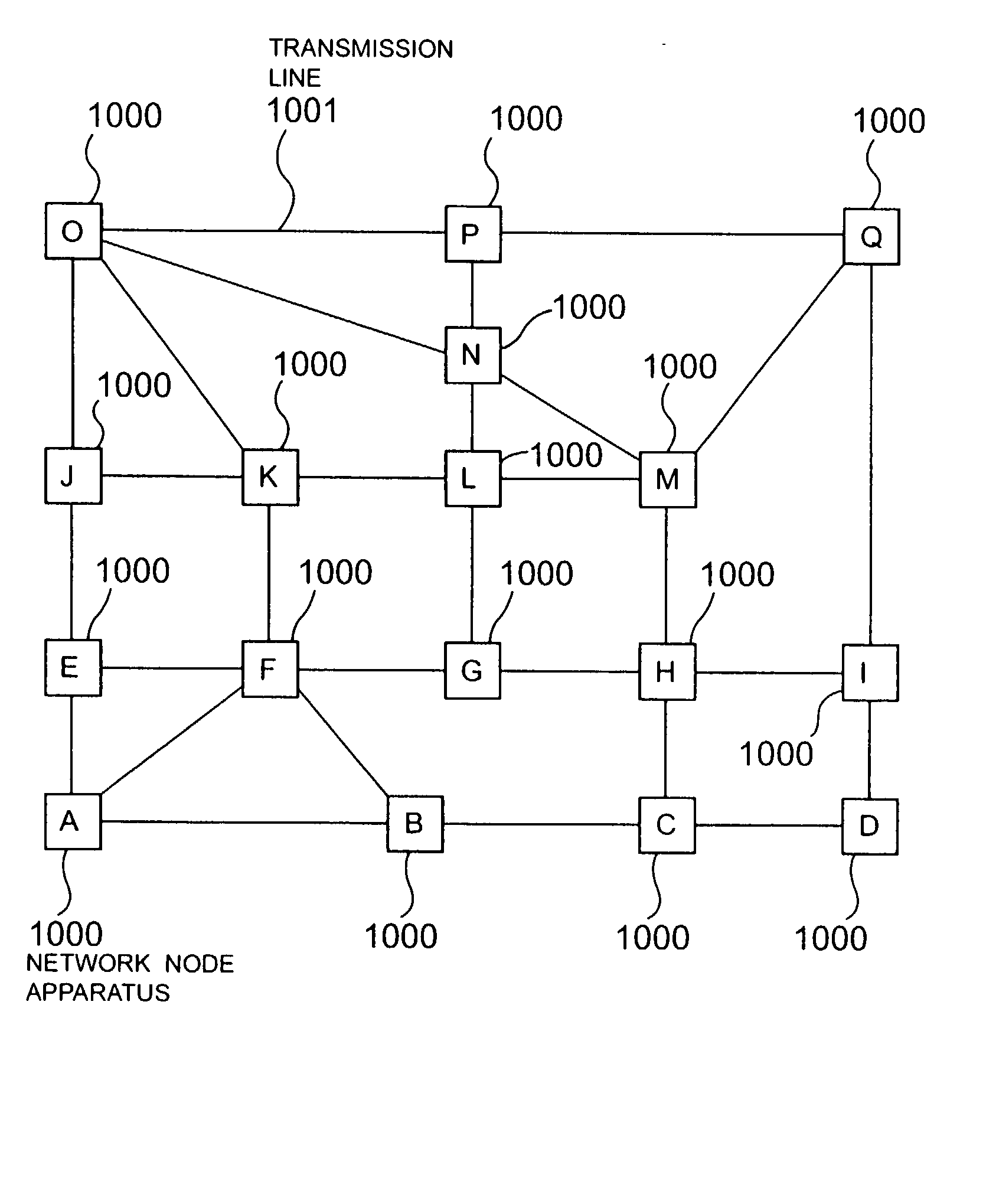

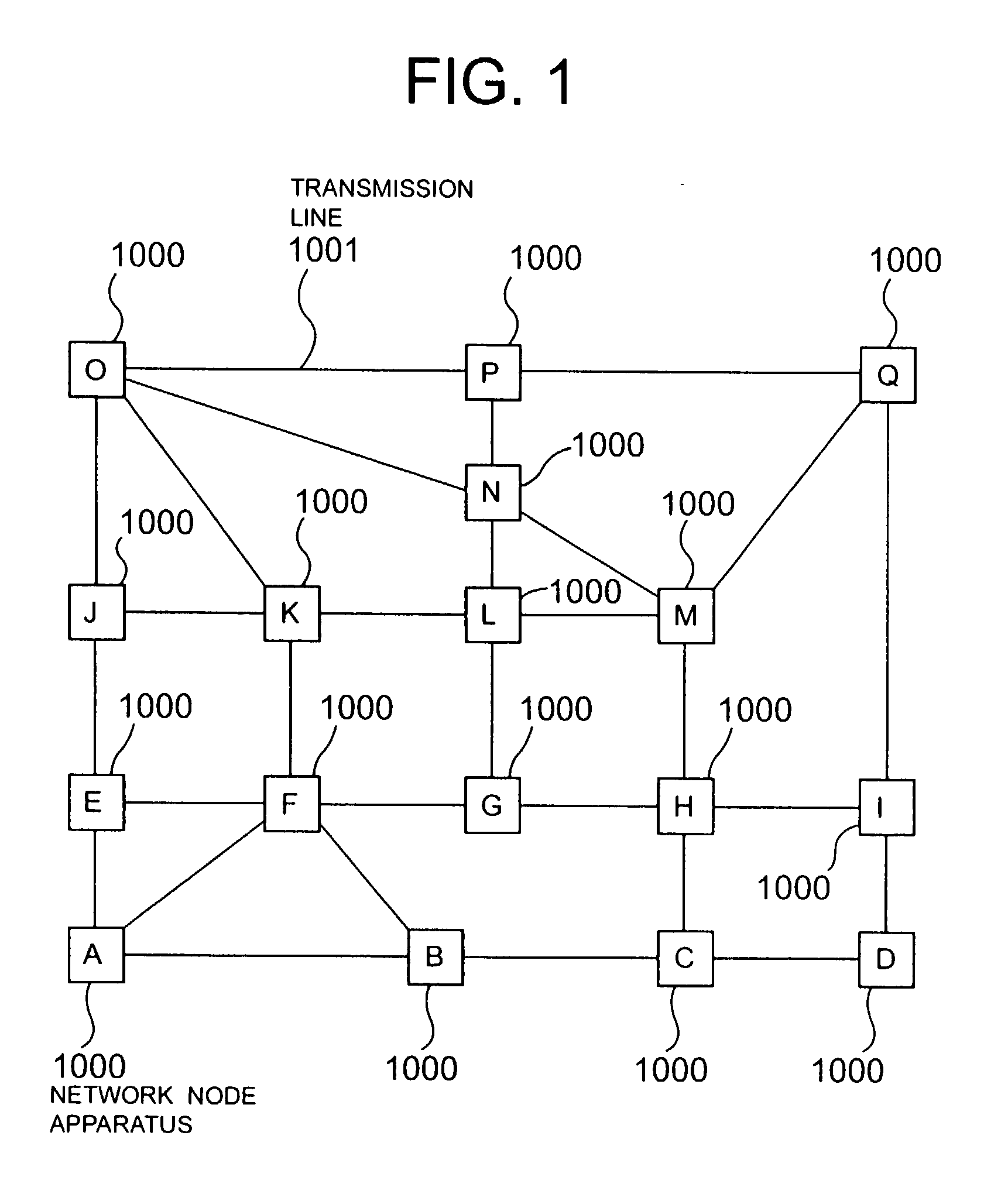

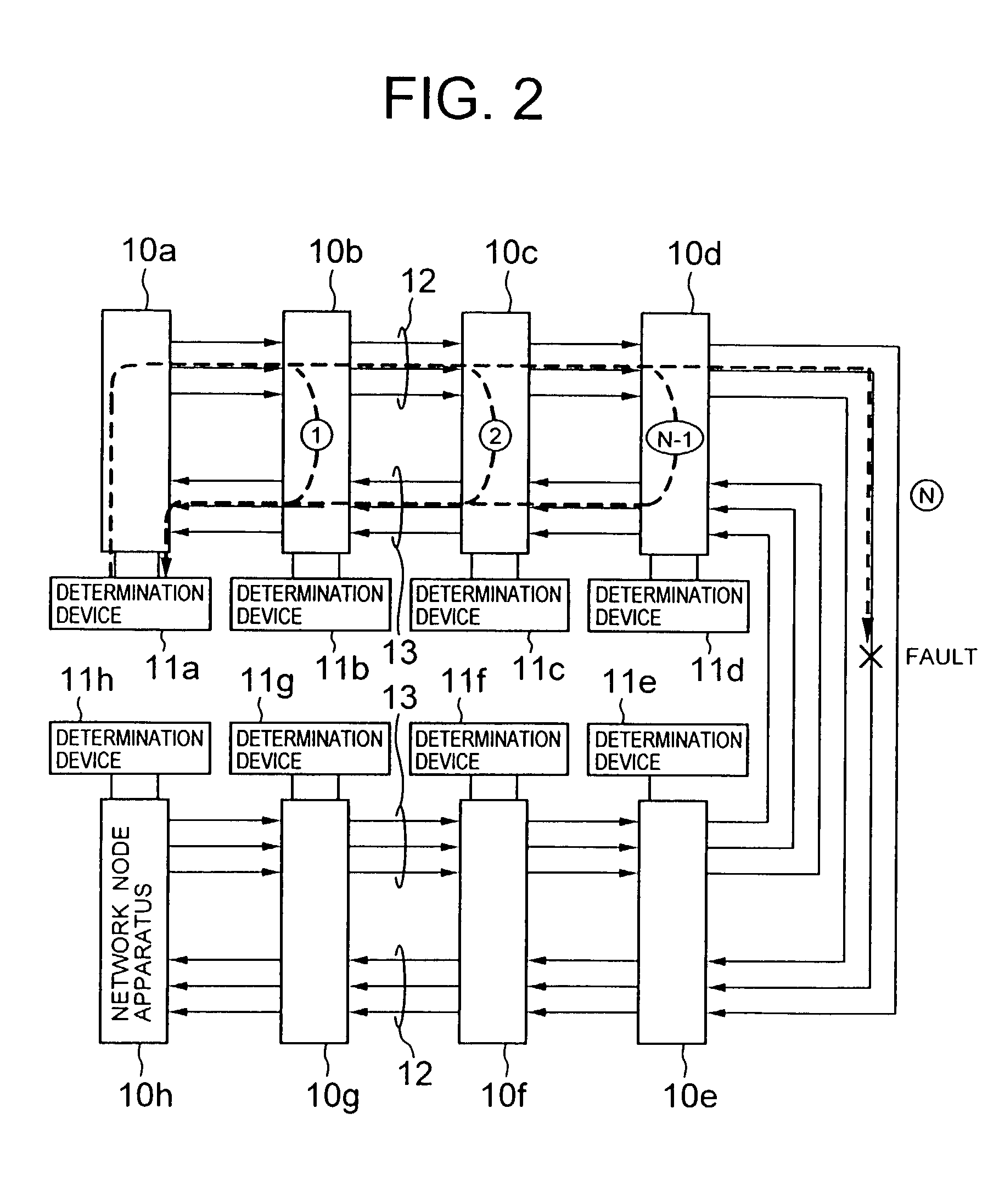

Network node apparatus, network system using the same and fault location detecting method

InactiveUS20020129295A1Easy to identifyReduce in quantityError preventionError detection/correctionLocation detectionOptical test

To identify a fault location easily if there is any fault detected in a network. If an optical path is switched from a working system to an auxiliary system due to a fault, an optical test signal originated from a network node apparatus located at an end point of the optical path is looped back by another network node apparatus on the optical path for the working system. This looped back optical signal is received by the network node apparatus of an originator, in which the signal quality of the optical test signal is measured by a determination device, thereby detecting the presence or absence of the fault on the path through which the optical test signal has been passed. A test receiver within the determination device measures a BER, an S / N ratio, an optical power, or an optical wavelength, whereby it is possible to detect not only the fault location due to disconnection of a link but also degradation in the signal quality.

Owner:NEC CORP

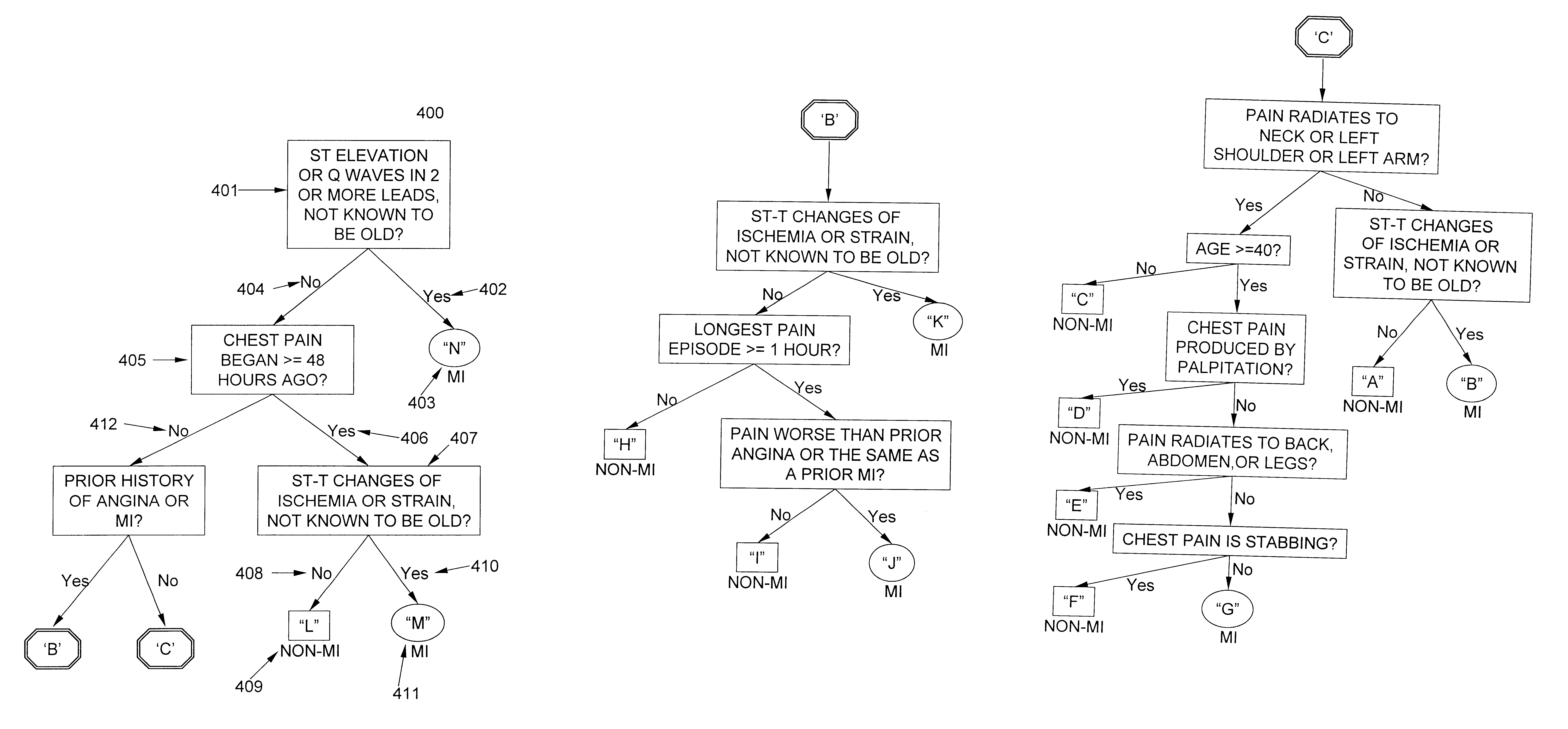

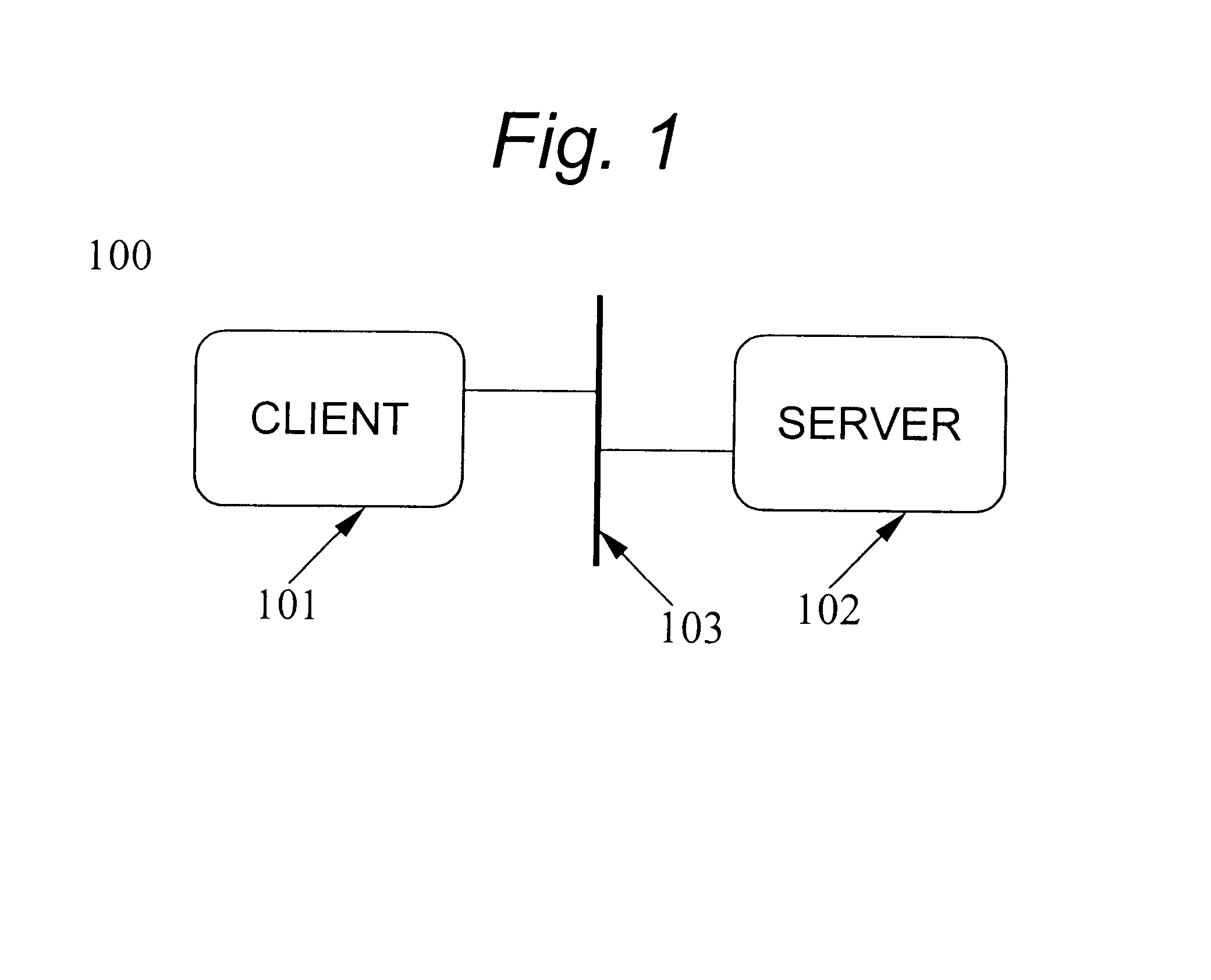

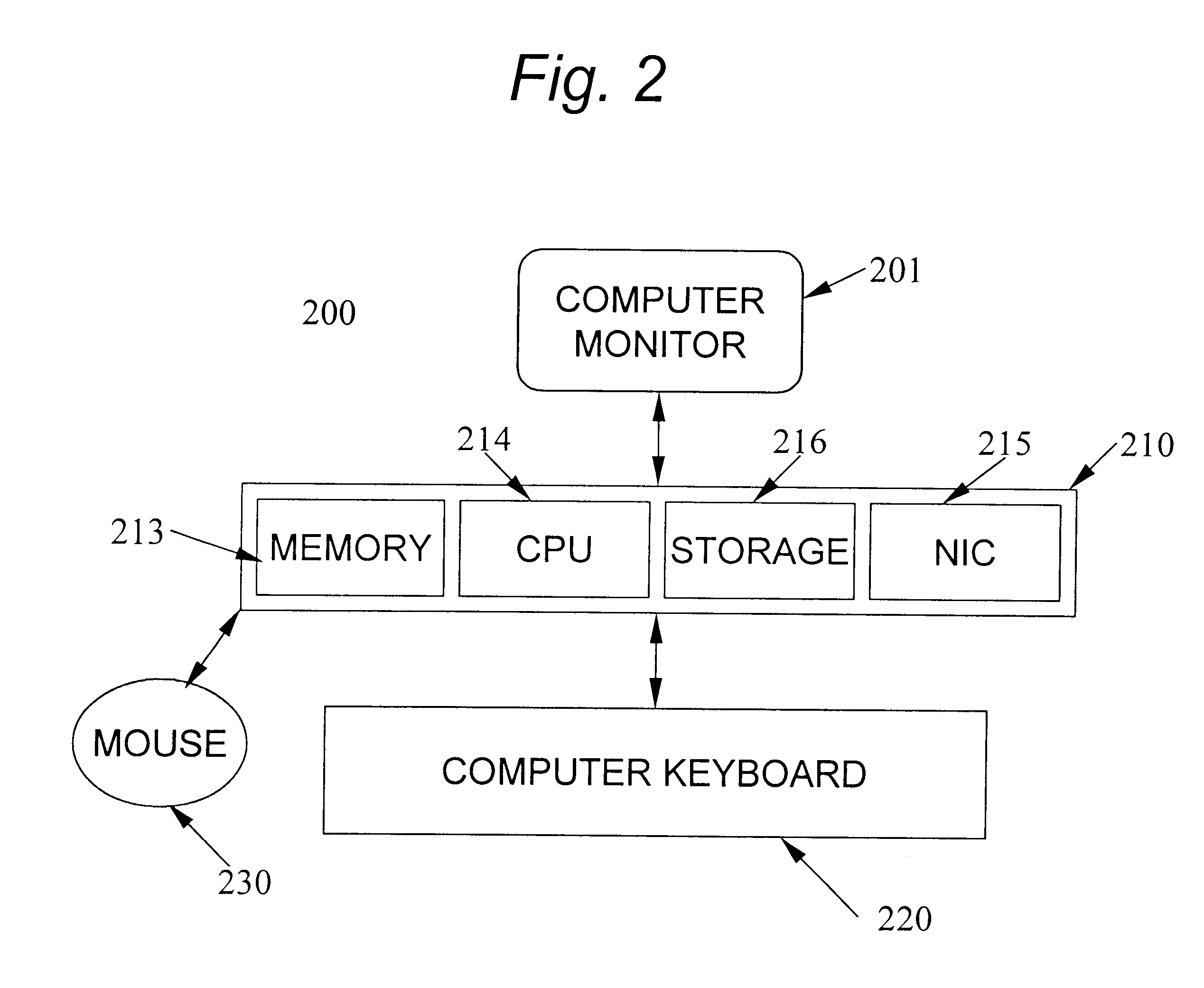

Computer system and method for a self administered risk assessment

InactiveUS6334192B1SurgeryComputer-assisted medical data acquisitionComputer monitorComputerized system

A computer system for performing an interactive assessment of the risk of an event, has a computer monitor to present to a user of the system a series of questions and potential responses, and a keyboard or other device to select a response to the question. The system can administer complex inverted tree type decision algorithms, in which the questions that are presented to the user, depend upon the response to the previous question, and an assessment of the risk of an event is presented to the user whenever they reach the terminus point in the decision tree. The risk assessment algorithm is data driven and a risk assessment is defined by entries in a file, which is available over a network. The system provides options so each user may view the path through the sequence of questions and answers, and interact with the risk assessment, in a manner customized for their own interactive session.

Owner:KARPF RONALD S

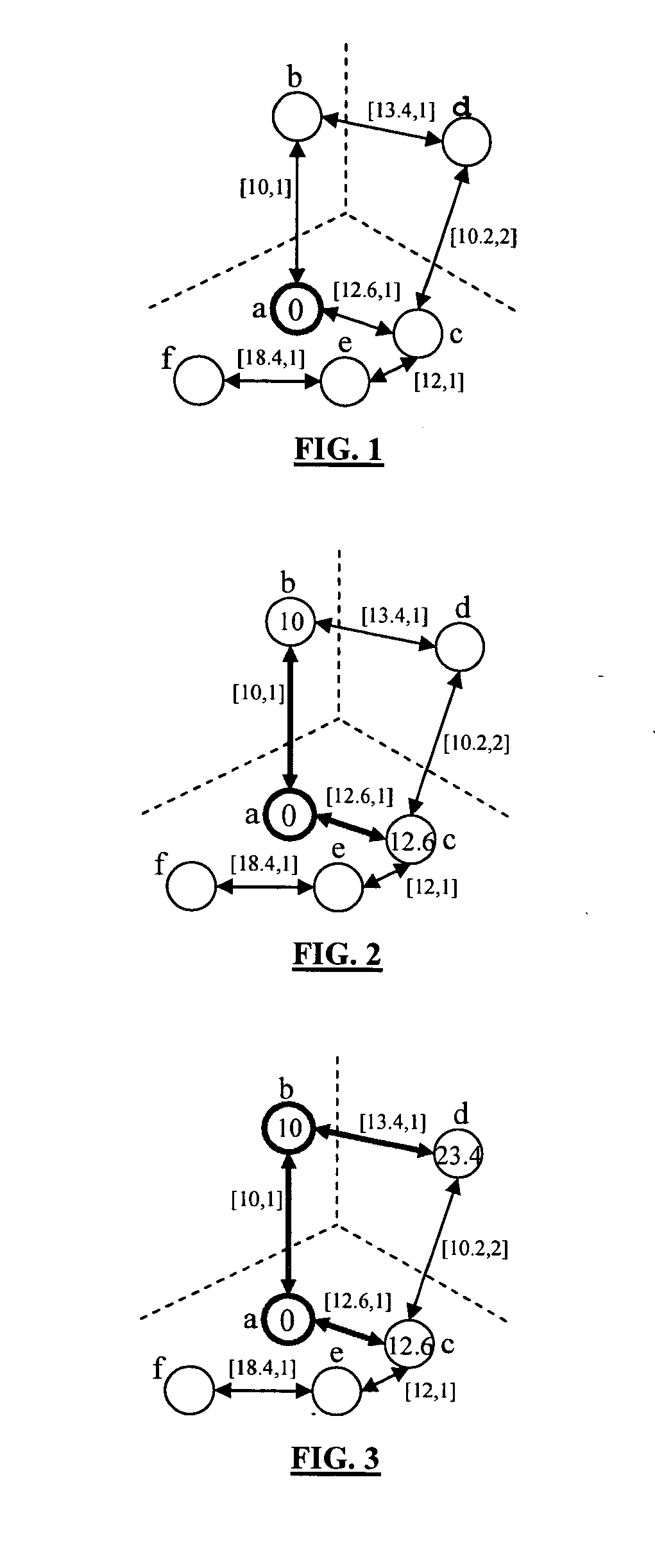

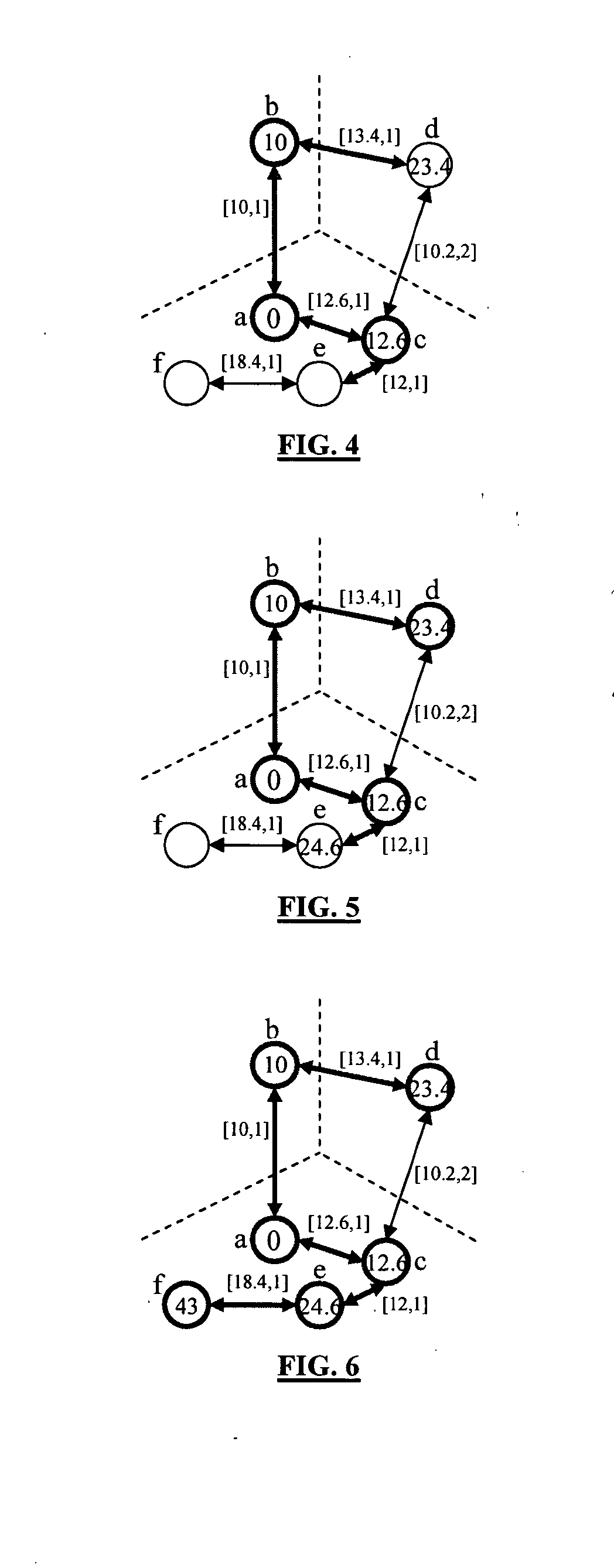

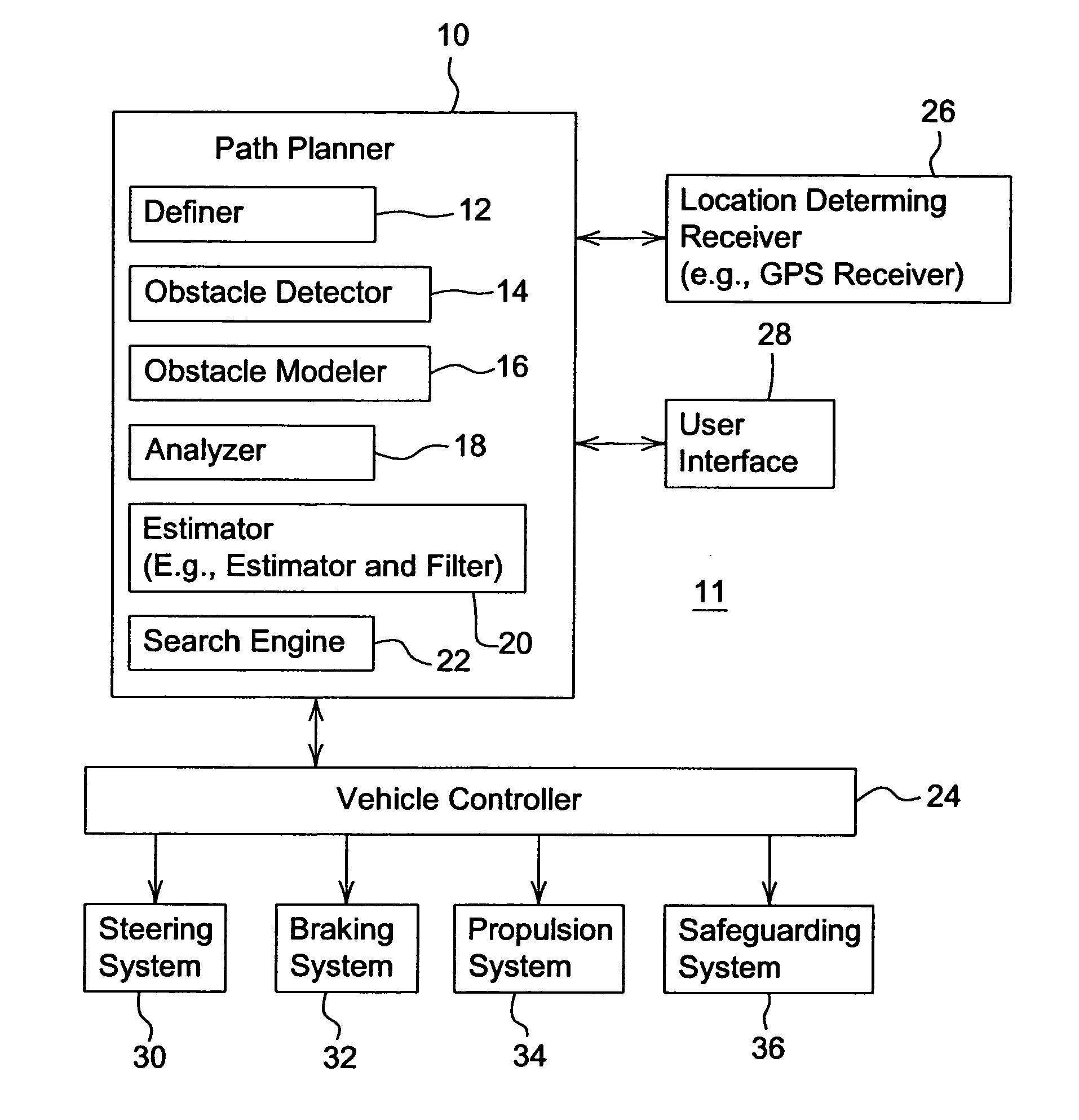

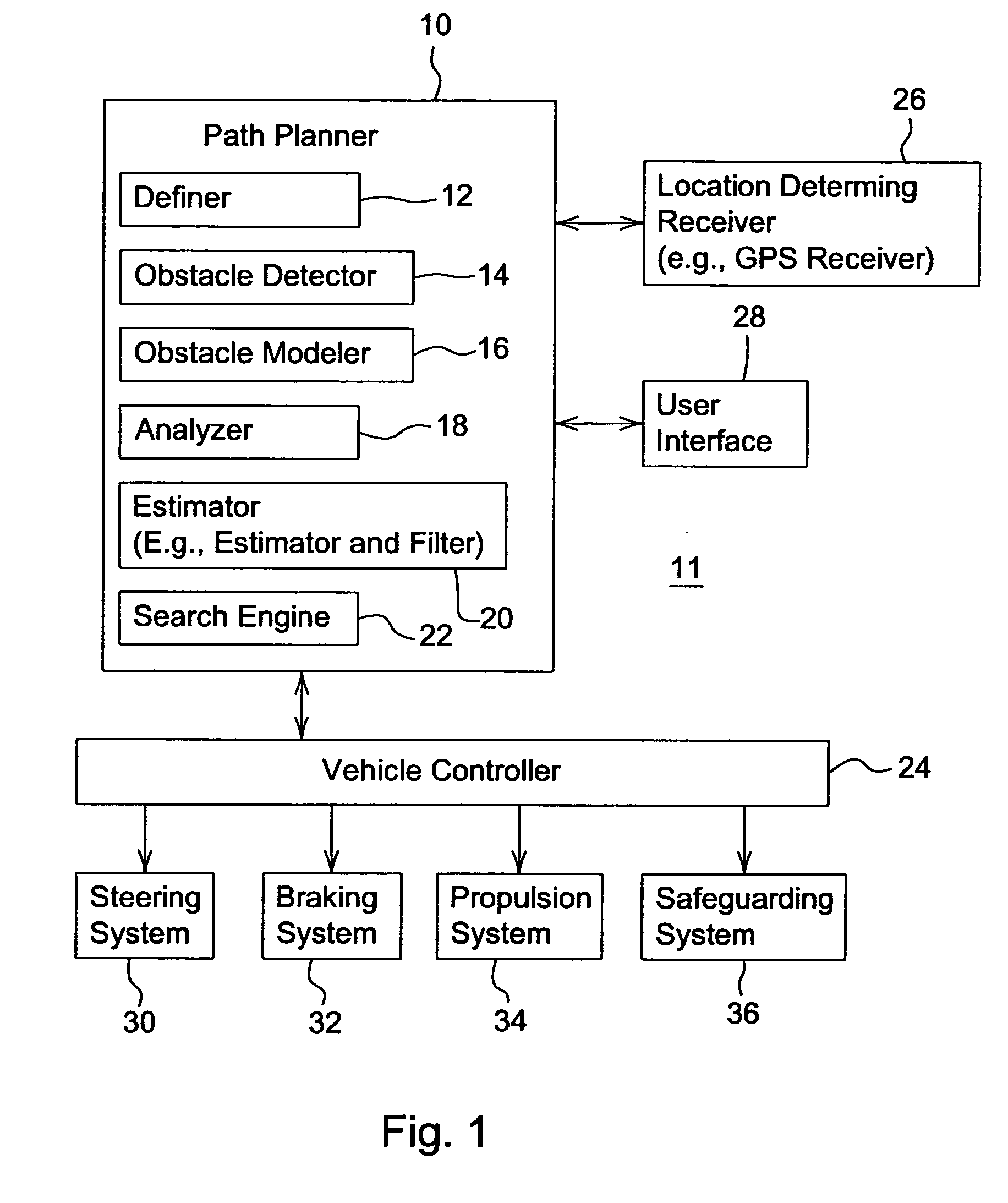

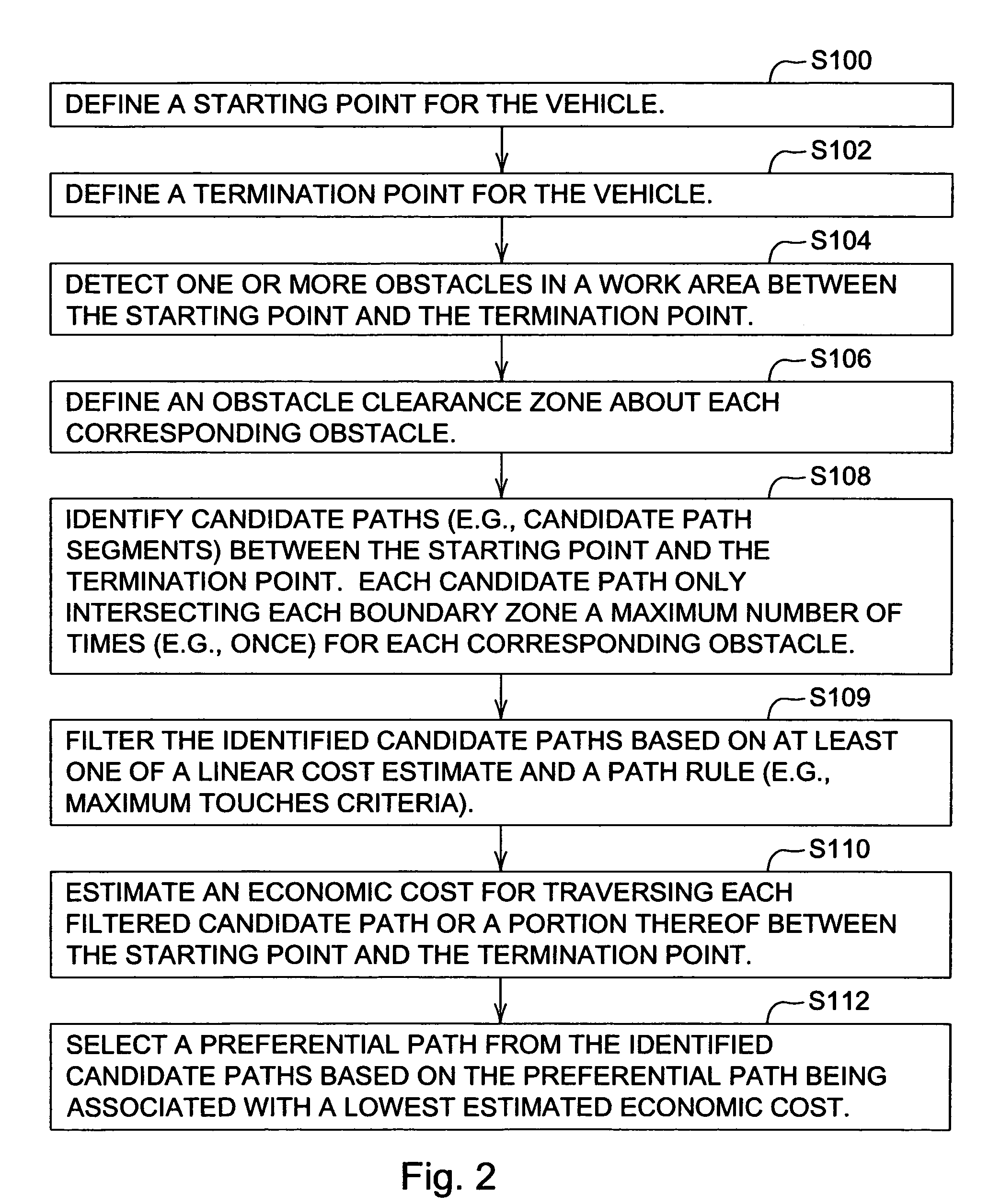

Point-to-point path planning

InactiveUS7079943B2Instruments for road network navigationAnalogue computers for trafficComputer scienceCost (economic)

A path planner and a method for determining a path for a vehicle comprises defining a starting point for the vehicle. A termination point is defined. An obstacle detector detects one or more obstacles in a work area between the starting point and the termination point. A boundary zone is defined about each corresponding obstacle. Candidate paths are identified between the starting point and the termination point. Each candidate path only intersects each boundary zone once for each corresponding obstacle. An economic cost is estimated for traversing each candidate path or a portion thereof between the starting point and the termination point. A preferential path is selected from the identified candidate paths based on the preferential path being associated with a lowest estimated economic cost.

Owner:DEERE & CO

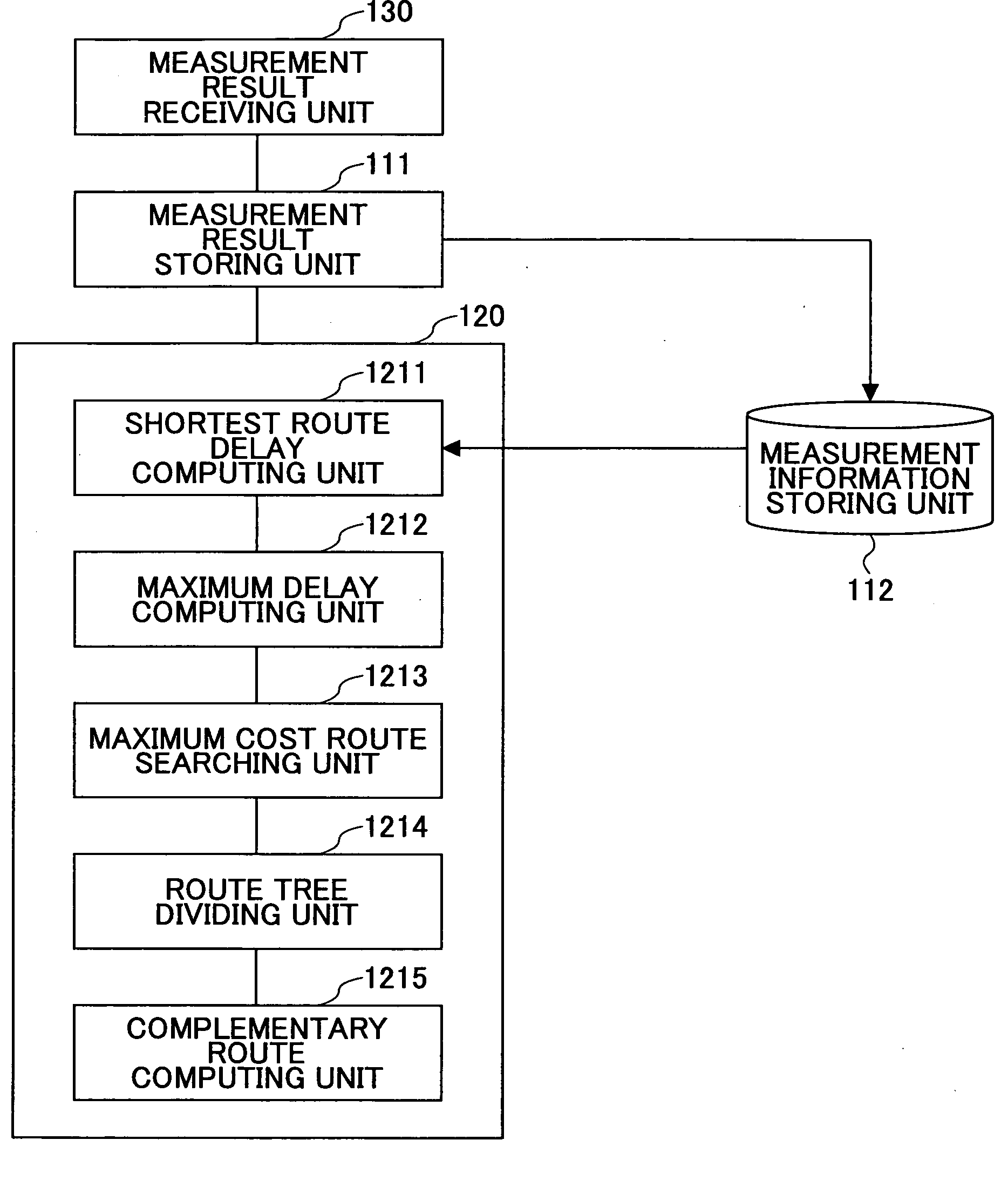

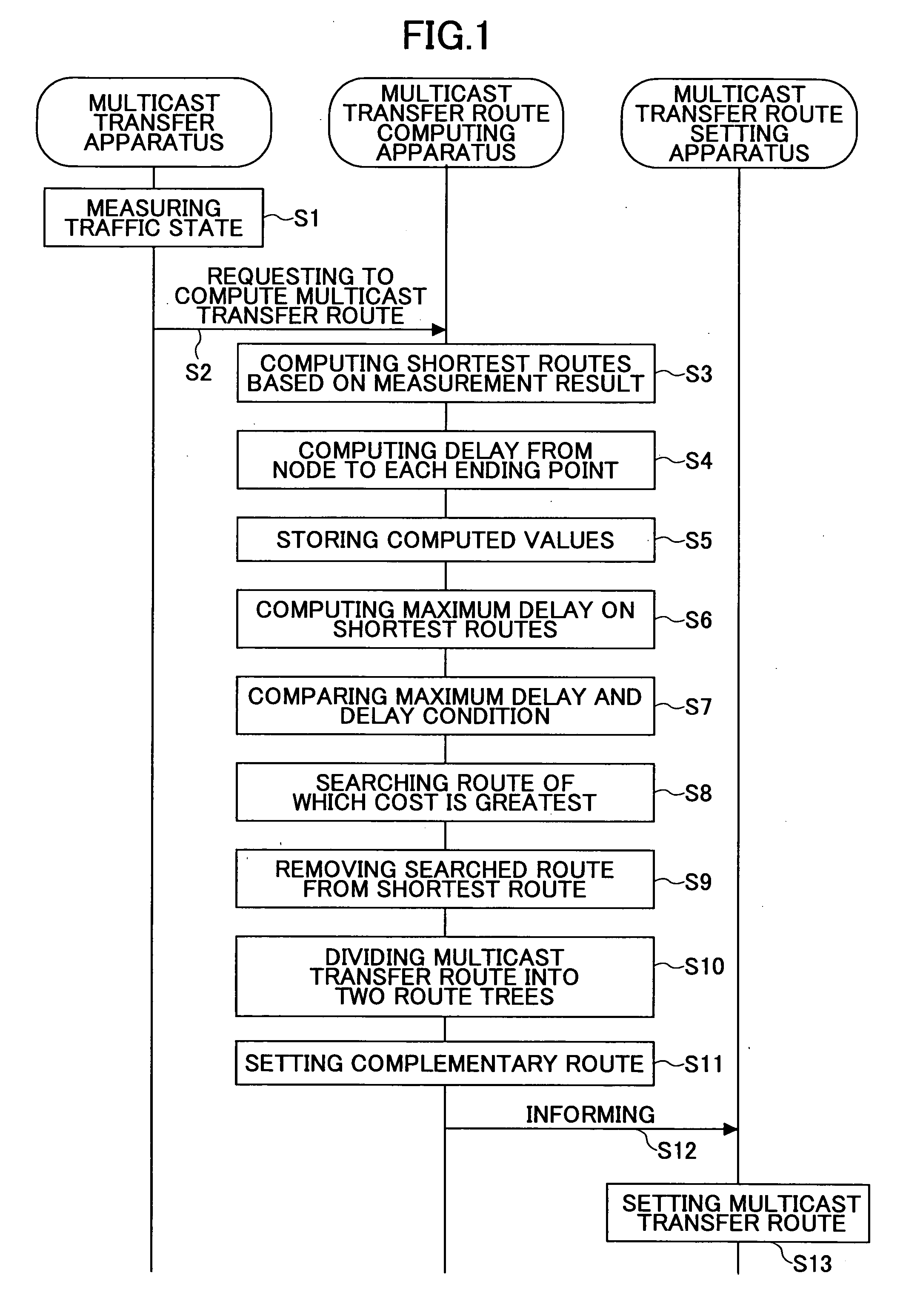

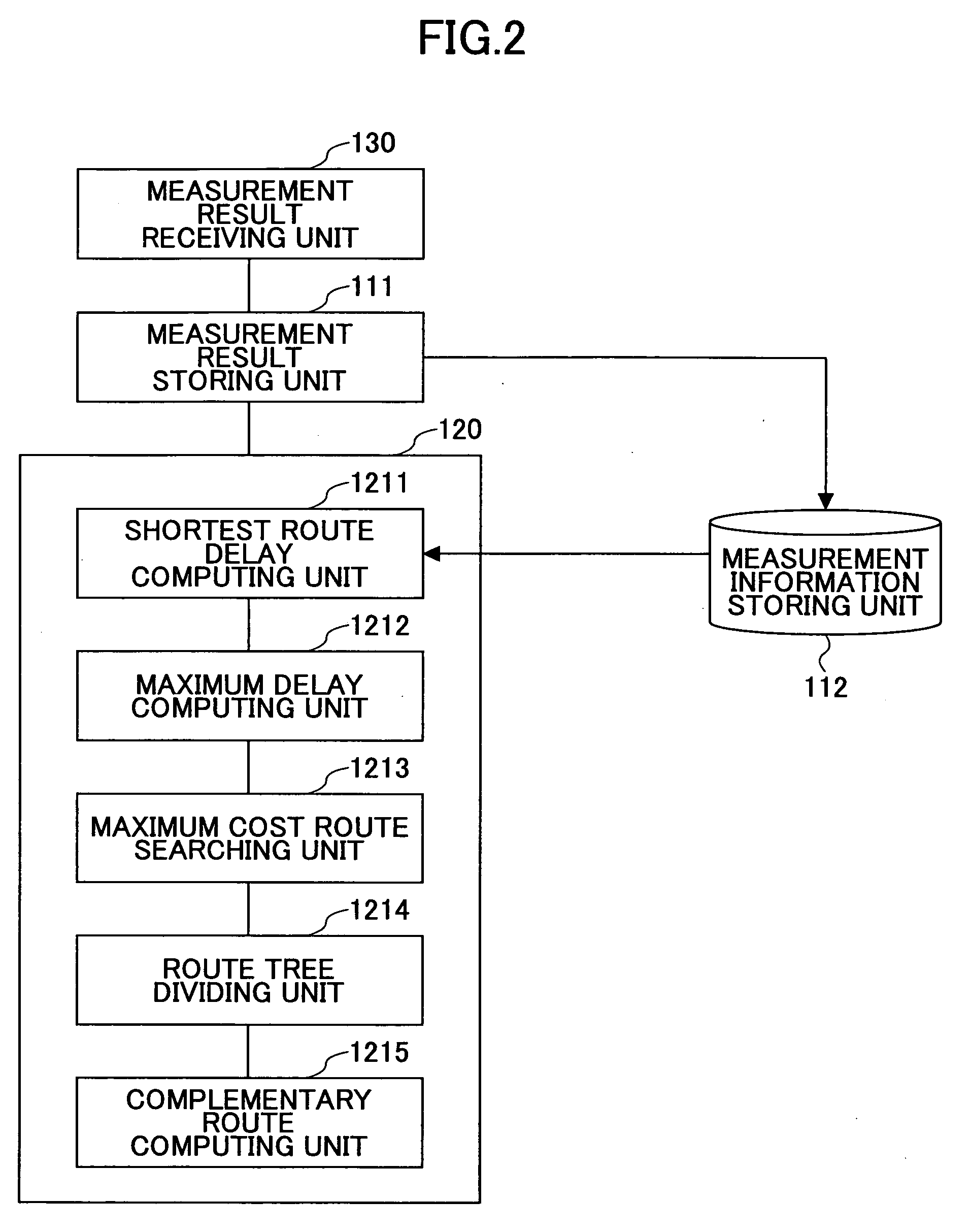

Multicast transfer route setting method, and multicast label switching method for implementing former method

InactiveUS20060147204A1Increase computing speedLow costTransmission monitoringTransmission monitoring/testing/fault-measurement systemsSelection criterionLabel switching

A method of establishing a multicast transfer route is disclosed that can reduce the cost of entire route under a constraint on delay incurred between starting point and ending points. The method includes the steps of: computing the shortest route with respect to delay connecting the starting point and the plural ending points based on measurement result; computing delay from a node on the shortest route to each ending point and the greatest delay; removing, if the greatest delay satisfies a delay condition, the greatest-cost route from the shortest route in accordance with selection criteria effective for cost reduction; dividing the multicast transfer route into two route trees; and establishing separately computed route as a complementary route that complement the removed route for connecting the two route trees. A method of multicast label switching for realizing the above method is also disclosed. A multicast label switching route is established using hierarchical labels by establishing a common multicast label switching route using a first layer label and establishing plural partial multicast label switching routes for subgroup destinations using lower layer labels. A relay node recognizes the hierarchical labels thereby to label-switch using all hierarchical labels.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

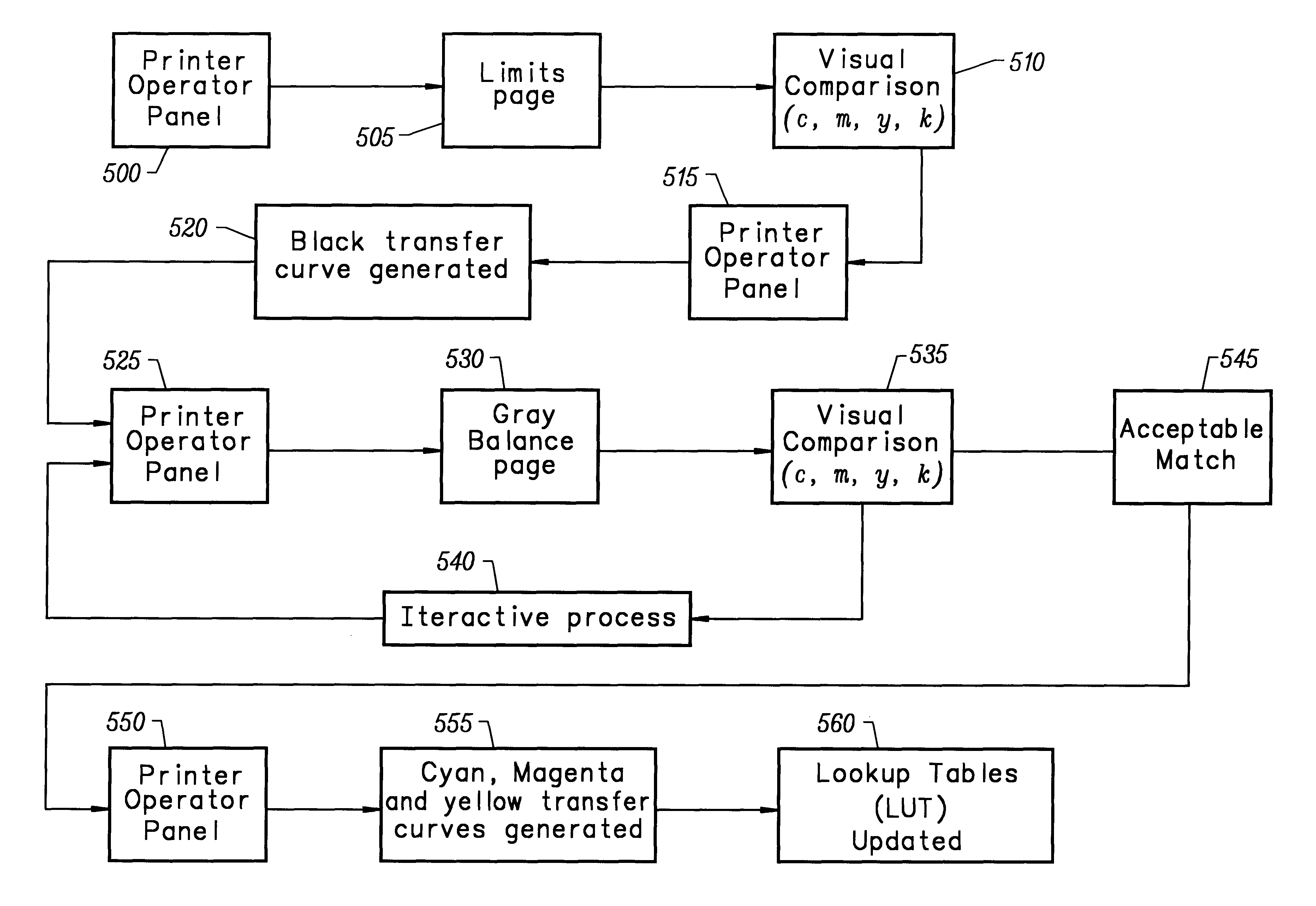

Visual calibration

InactiveUS6215562B1Digitally marking record carriersDigital computer detailsMeasuring instrumentMagenta

A calibration apparatus and method for a color printer that allows a user to calibrate a printer without the use of expensive measuring instruments and prior user training is provided. The calibration process prints out two target layouts. On the first target the user selects the primary inks start and end points (highlights and shadows), and the black ink only input value that generates a 30% gray. The primary inks are the device-dependent colorants, cyan, magenta and yellow. The second target compares the 30% black ink with grays made of a combination of cyan, magenta and yellow inks. The user selects the best match in an iterative process. Using this data, calculations are made of the corrections to the original input signal values for the printer. A look up table is updated with corrected input values to compensate for the printer deviation from its standard behavior.

Owner:ELECTRONICS FOR IMAGING

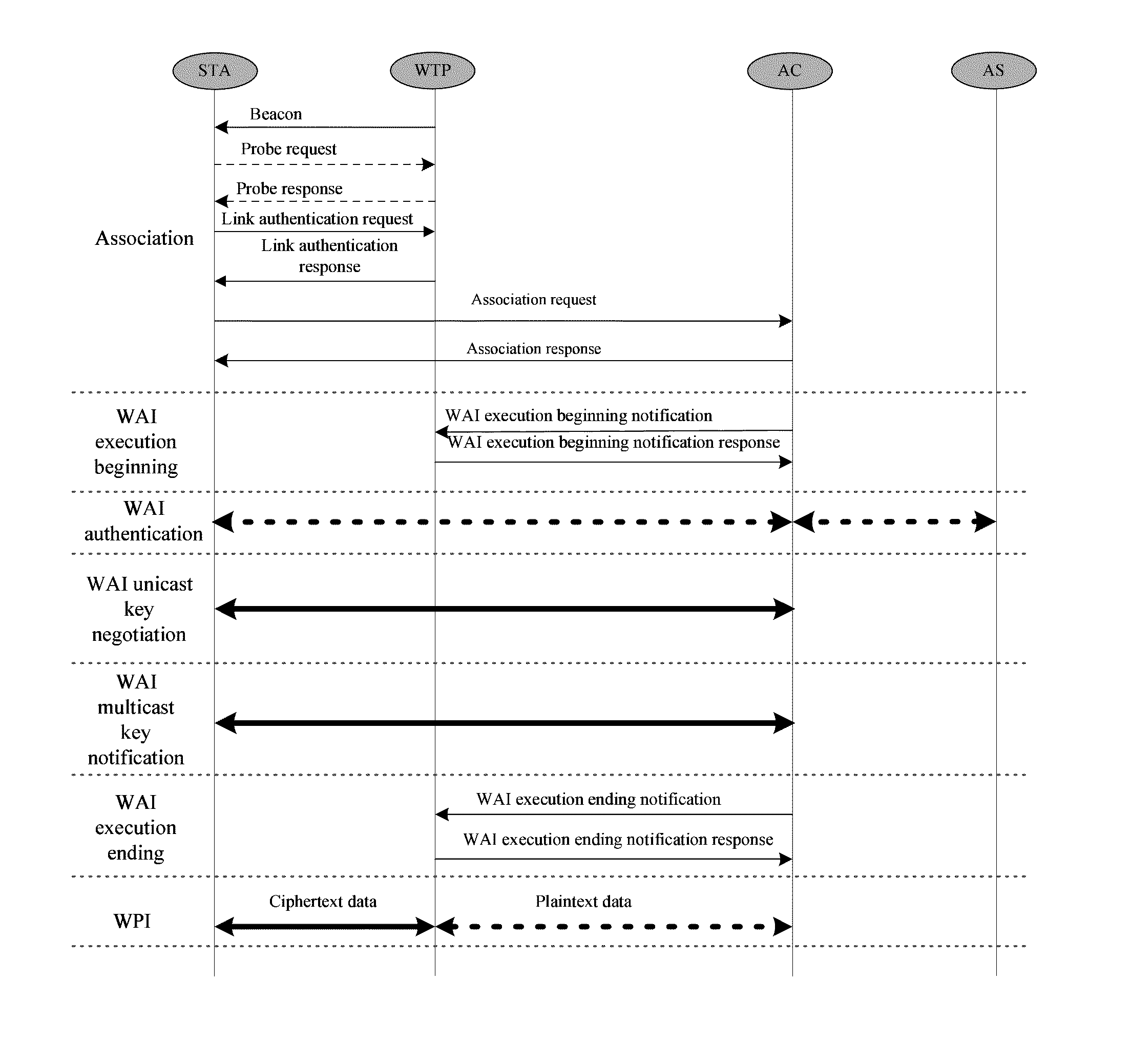

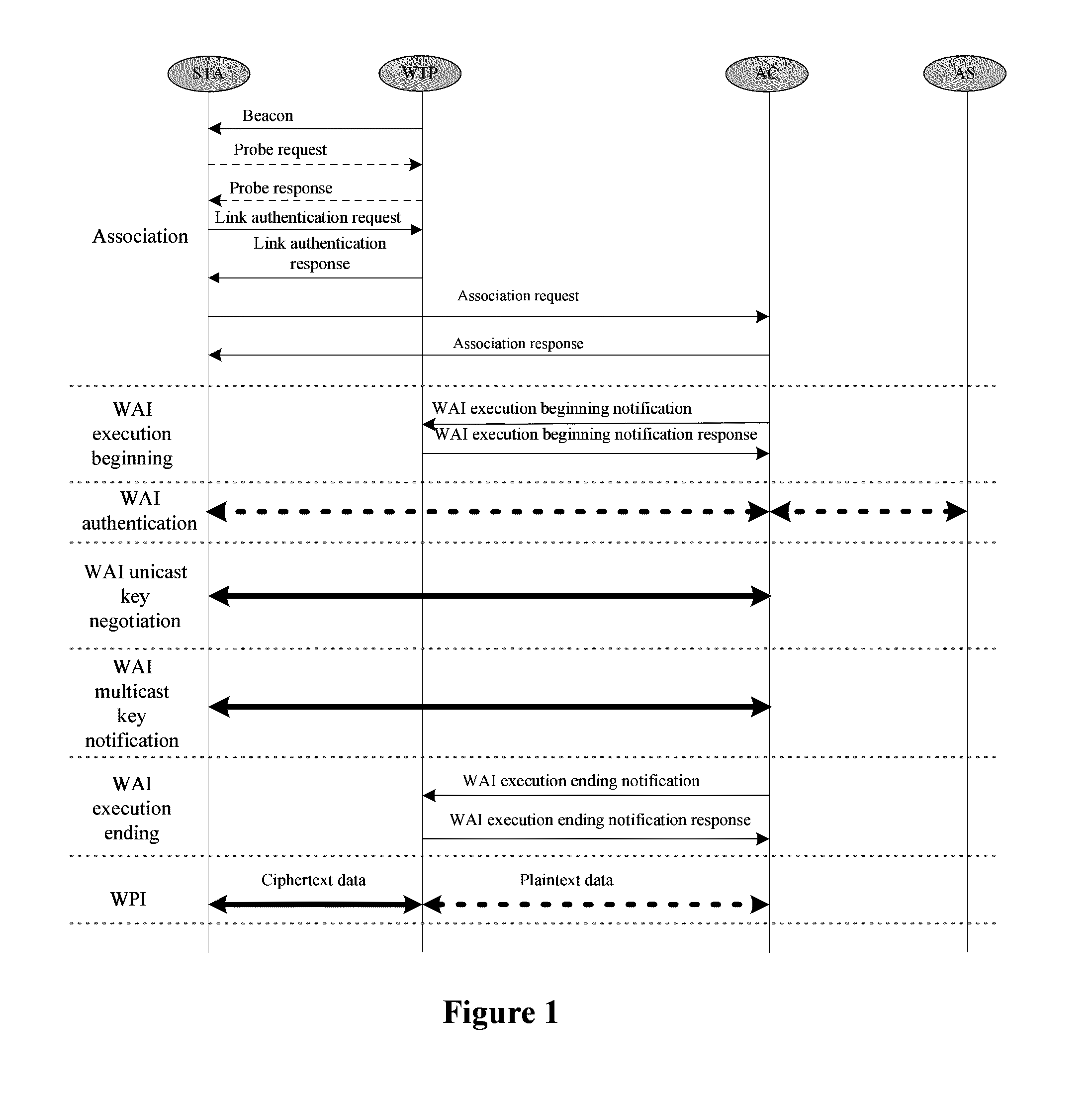

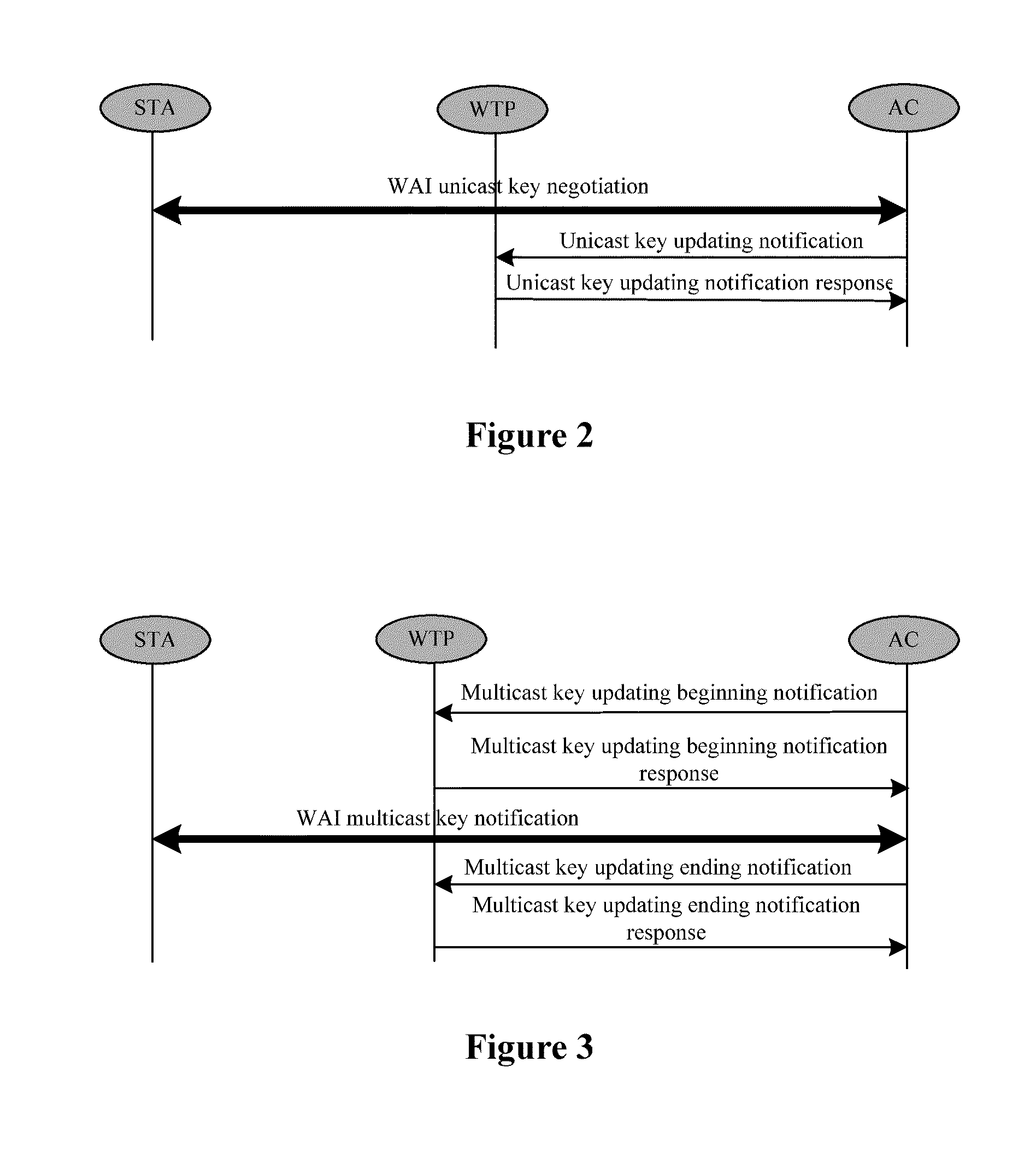

Method for implementing a convergent wireless local area network (WLAN) authentication and privacy infrastructure (WAPI) network architecture in a local MAC mode

ActiveUS9015331B2Security of the WLAN is ensuredBreak the limitationsNetwork topologiesMultiple digital computer combinationsNetwork architectureMedia access control

A method for implementing a convergent Wireless Local Area Network (WLAN) Authentication and Privacy Infrastructure (WAPI) network architecture in a local Medium Access Control (MAC) mode is provided and includes the following steps: the MAC function and WAPI function of Access Point (AP) are divided between Wireless Terminal Point (WTP) and Access Controller (AC) to construct a local MAC mode; the convergence of WAPI protocol and the convergent WLAN network architecture is implemented in the local MAC mode; the process of association and connection between Station (STA), WTP and AC is performed; the process of notification of the beginning of the execution of the WLAN Authentication Infrastructure (WAI) protocol between AC and WTP is performed; the process of the execution of the WAI protocol between STA and AC is performed; the process of notification of the end of the execution of the WAI protocol between AC and WTP is performed; the process of encrypted communication between WTP and STA is performed by use of WPI.

Owner:CHINA IWNCOMM

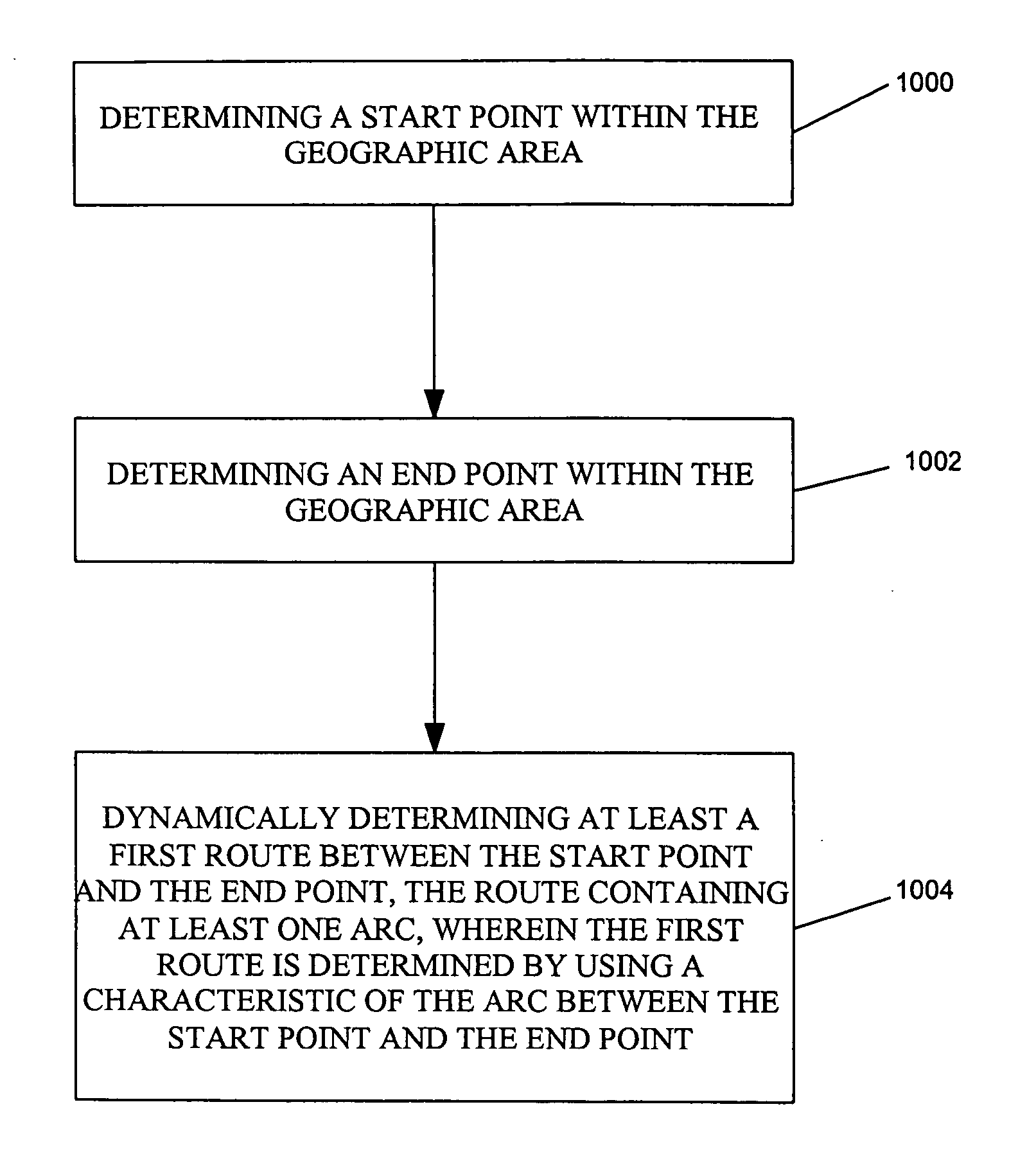

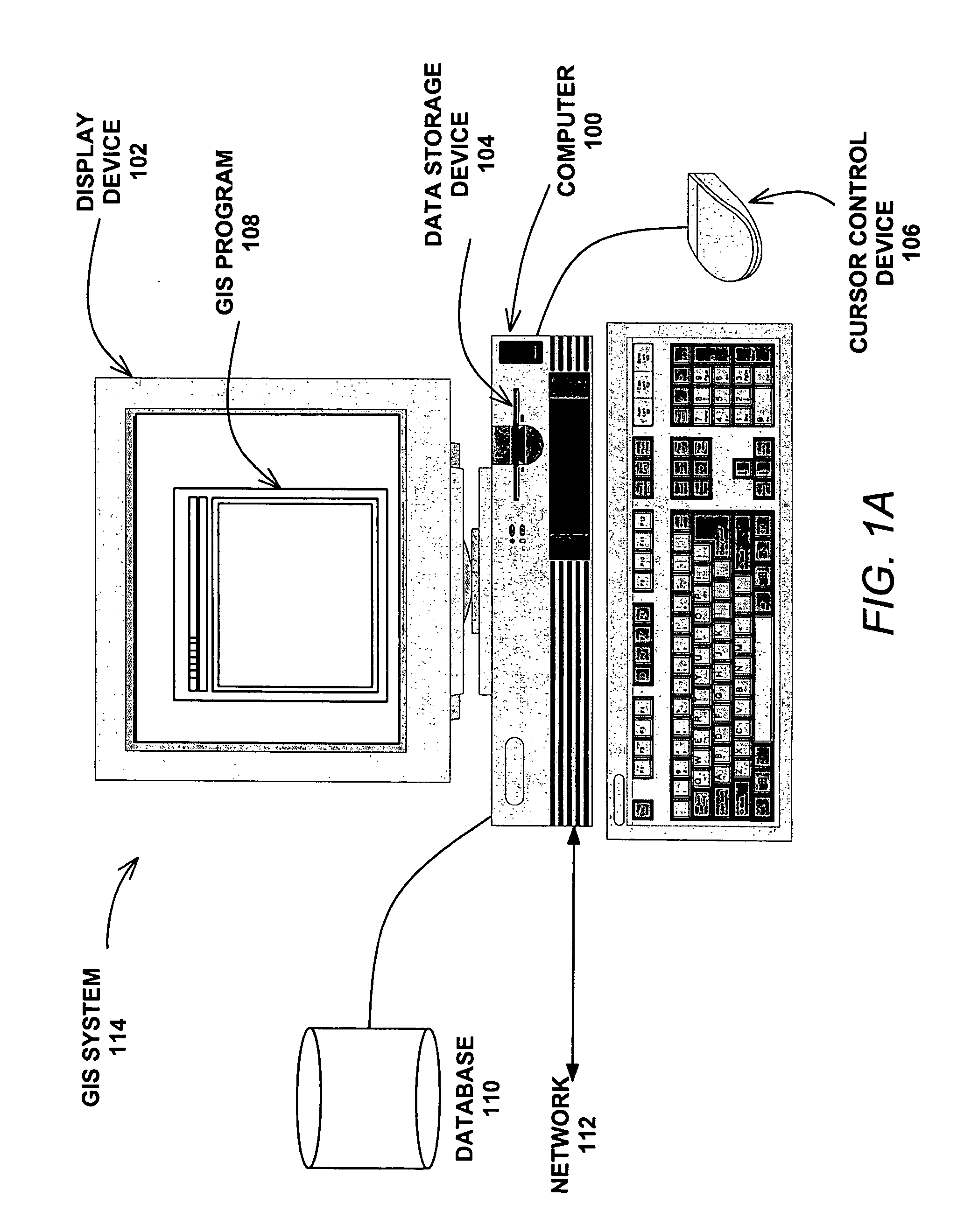

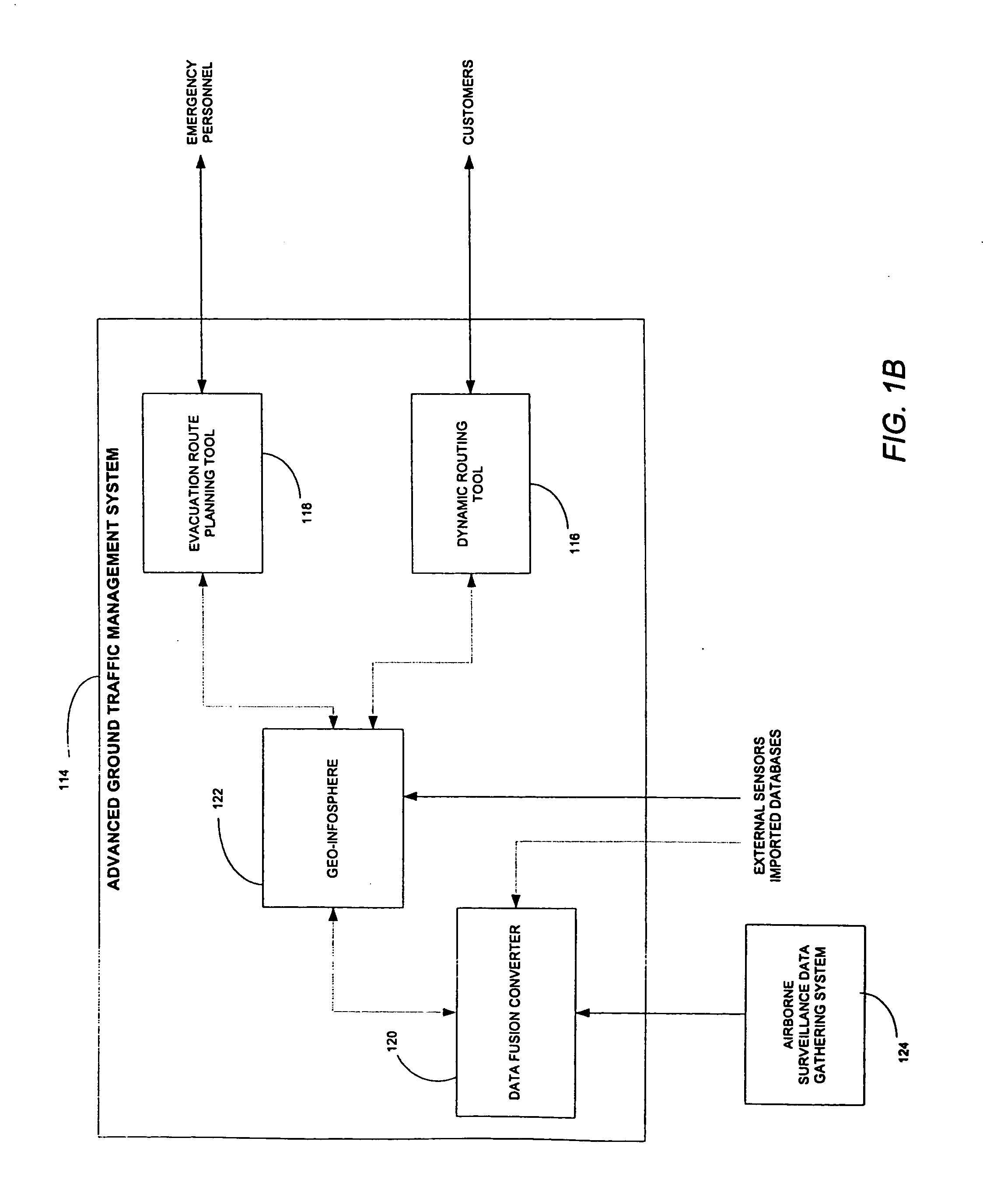

Dynamic routing tool

InactiveUS20060241855A1Maximizing traffic flowMinimize timeInstruments for road network navigationRoad vehicles traffic controlAdaptive routingComputer science

GIS-based methods and apparatuses for determining transportation routes are disclosed. A method in accordance with the present invention comprises determining a transportation route using a geographical information systems (GIS) database that represents a geographical area, wherein the GIS database includes at least one node representing at least one geographical location within the geographic area and at least one arc representing at least one street within the geographic area. The method further comprises determining a start point within the geographic area, determining an end point within the geographic area, and dynamically determining at least a first route between the start point and the end point, the route containing at least one arc, wherein the first route is determined by using a characteristic of the arc between the start point and the end point.

Owner:THE BOEING CO

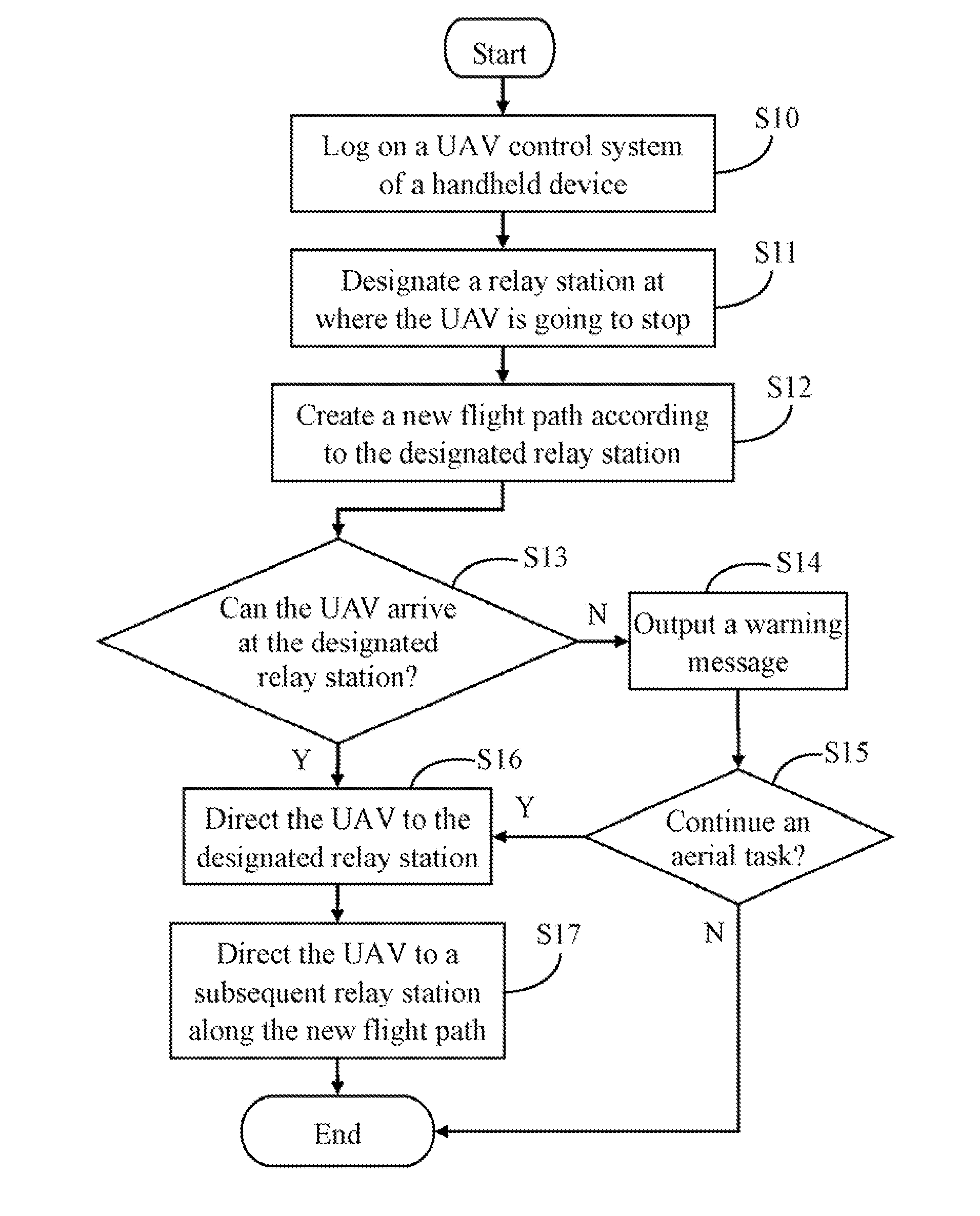

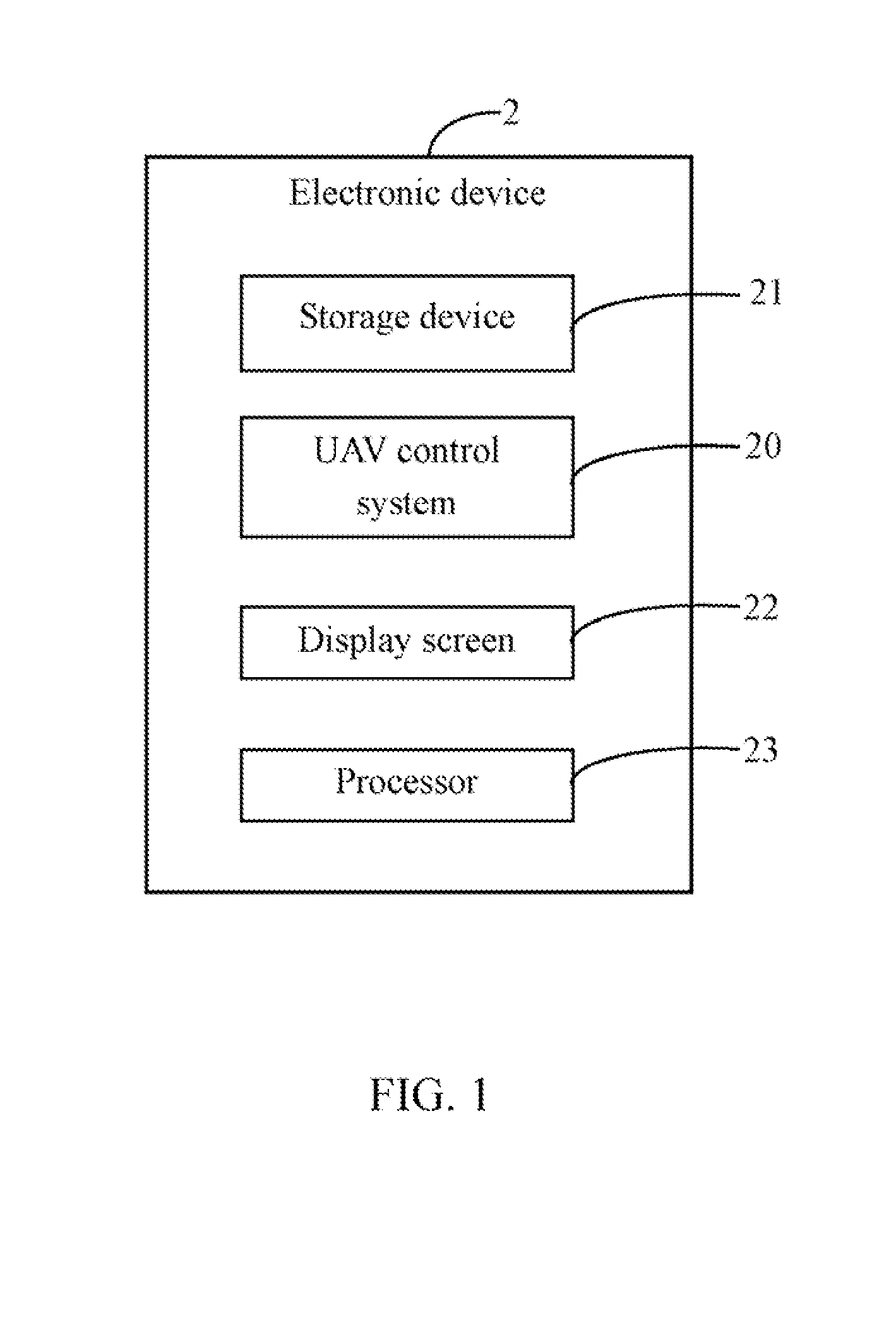

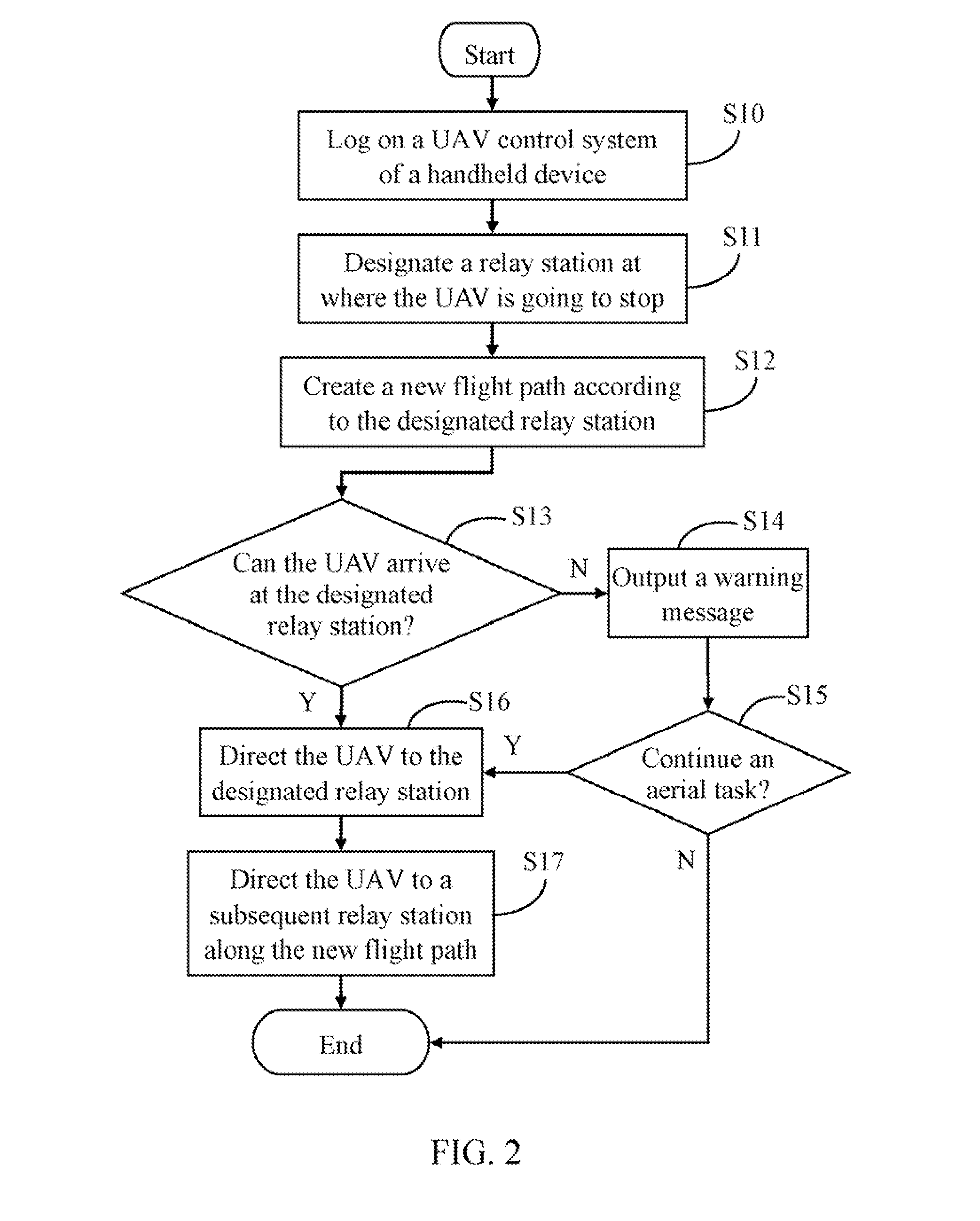

Electronic device and method for controlling unmanned aerial vehicle using the same

ActiveUS20110320068A1Digital data processing detailsVehicle position/course/altitude controlUncrewed vehicleRelay

A method for controlling an unmanned aerial vehicle (UAV) using an electronic device determines a designated relay station of the UAV using the electronic device, and creates a new flight path for the UAV according to the designated relay station. The method further directs the UAV to fly to the designated relay station upon the condition that the UAV can arrive at the designated relay station, and directs the UAV to fly to a subsequent relay station along the new flight path upon the condition that the UAV has not arrived at an endpoint of the new flight path.

Owner:BEIJING JINGDONG CENTURY TRADING CO LTD

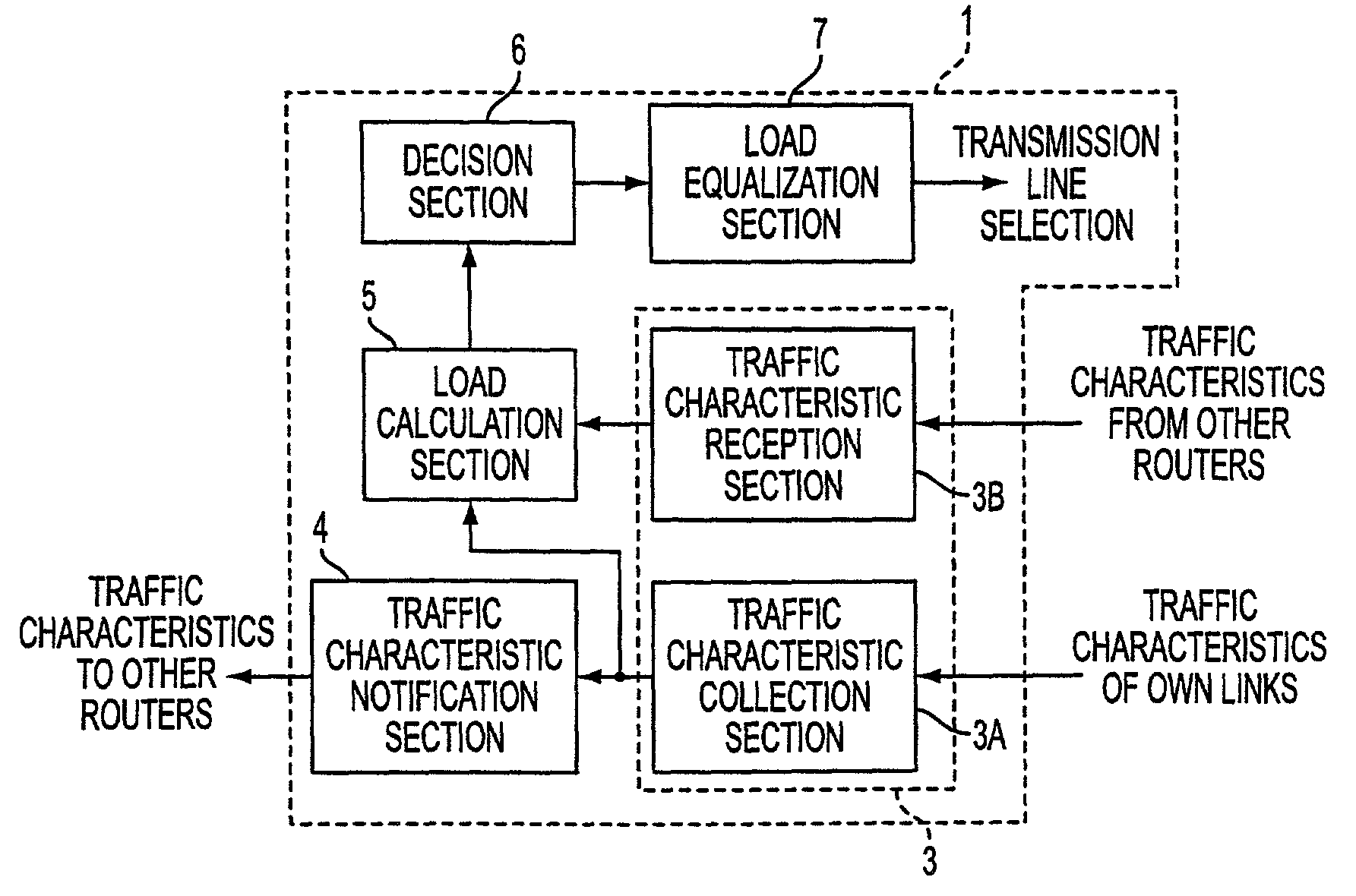

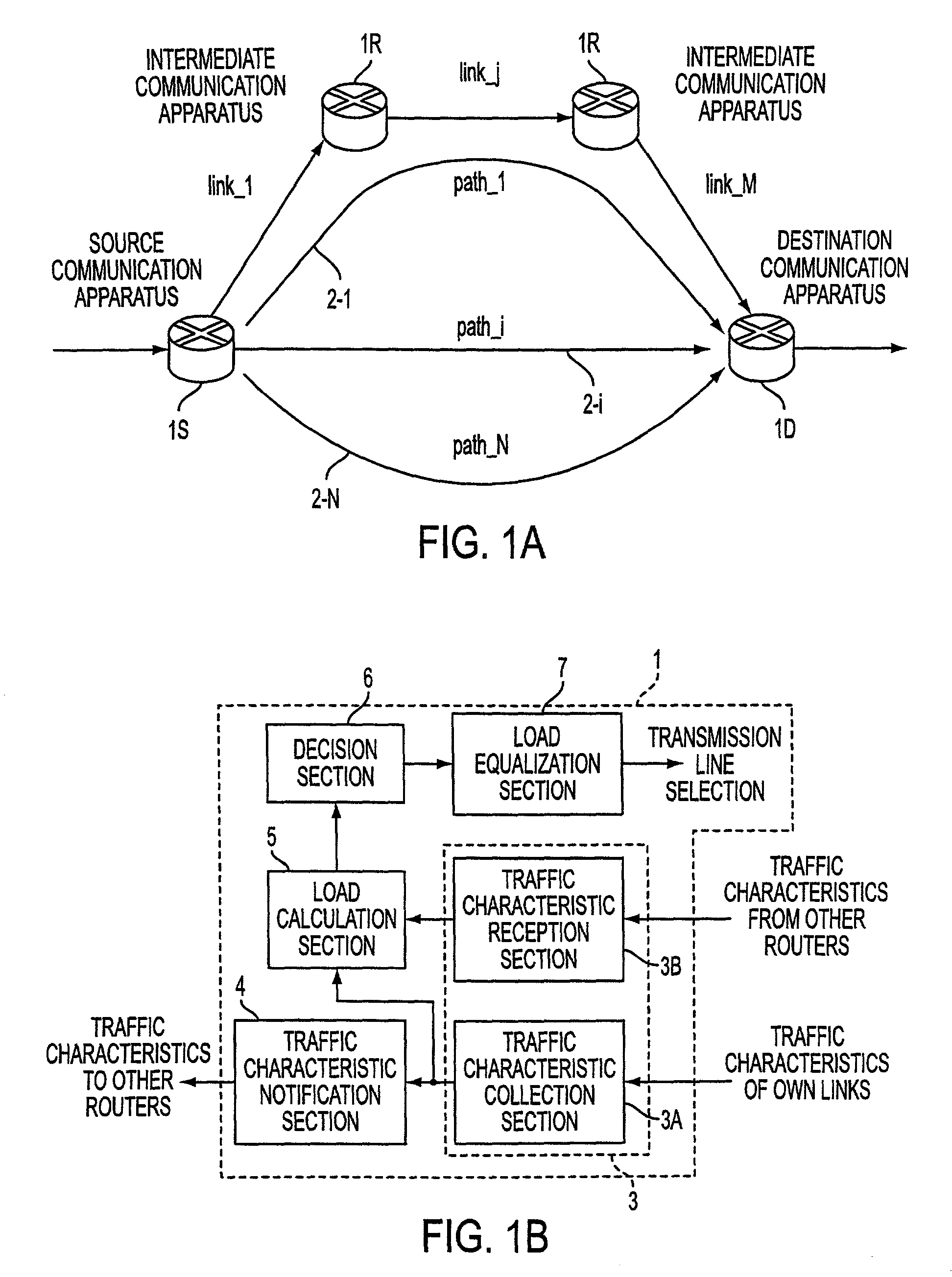

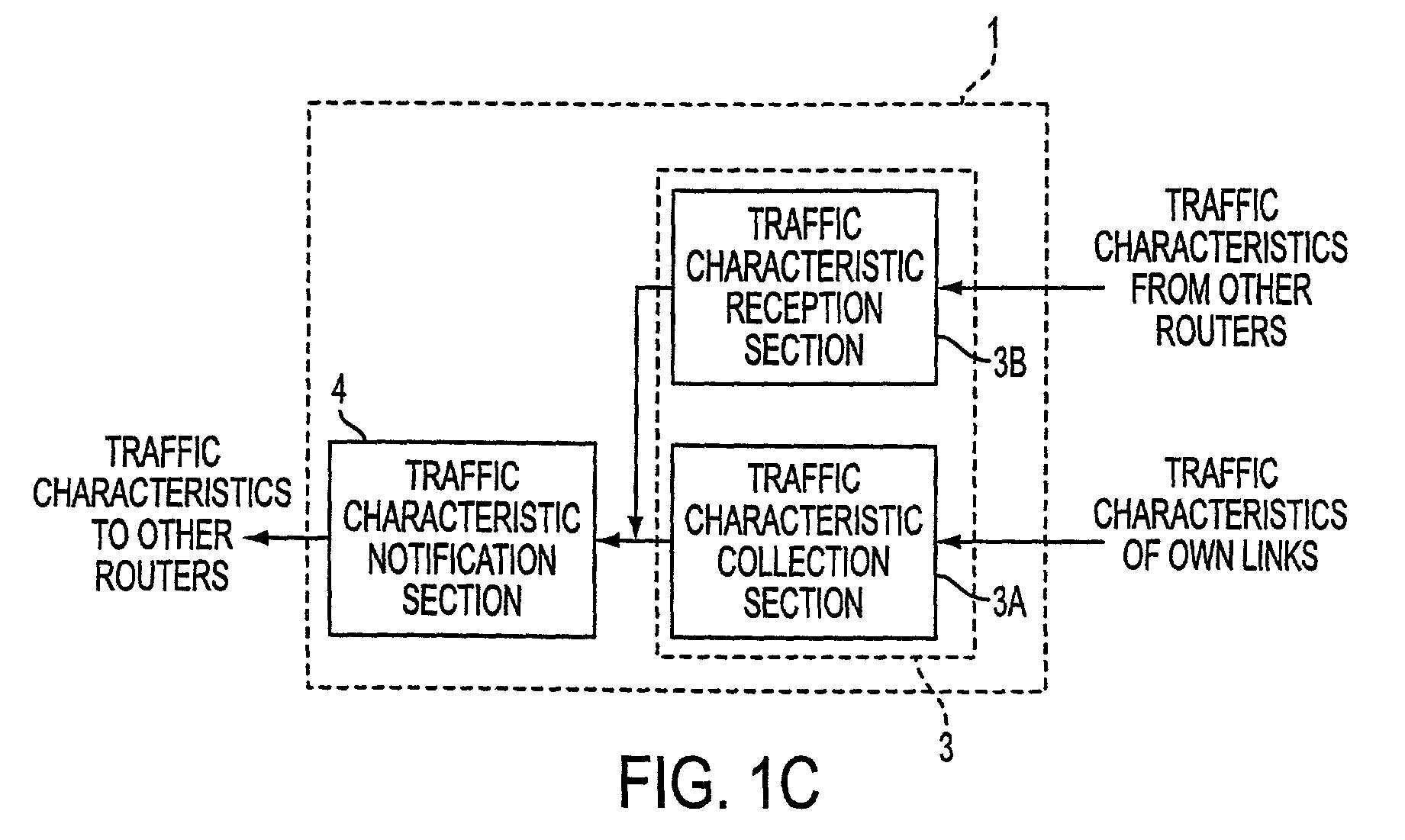

Transmission path controlling apparatus and transmission path controlling method as well as medium having transmission path controlling program recorded thereon

The present invention relates to distributing the load between the set routes among a plurality of routes between a communication apparatus which serves as a start point to another communication apparatus which serves as an end point. An apparatus provided in a router in a network collects traffic characteristics of transmission paths connected to the router, notifies other routers of the collected traffic characteristics, calculates load based on the collected traffic characteristics, decides based on the calculated load information whether or not a transmission path should be added or deleted, and equalizes the load among the plurality of transmission paths.

Owner:FUJITSU LTD

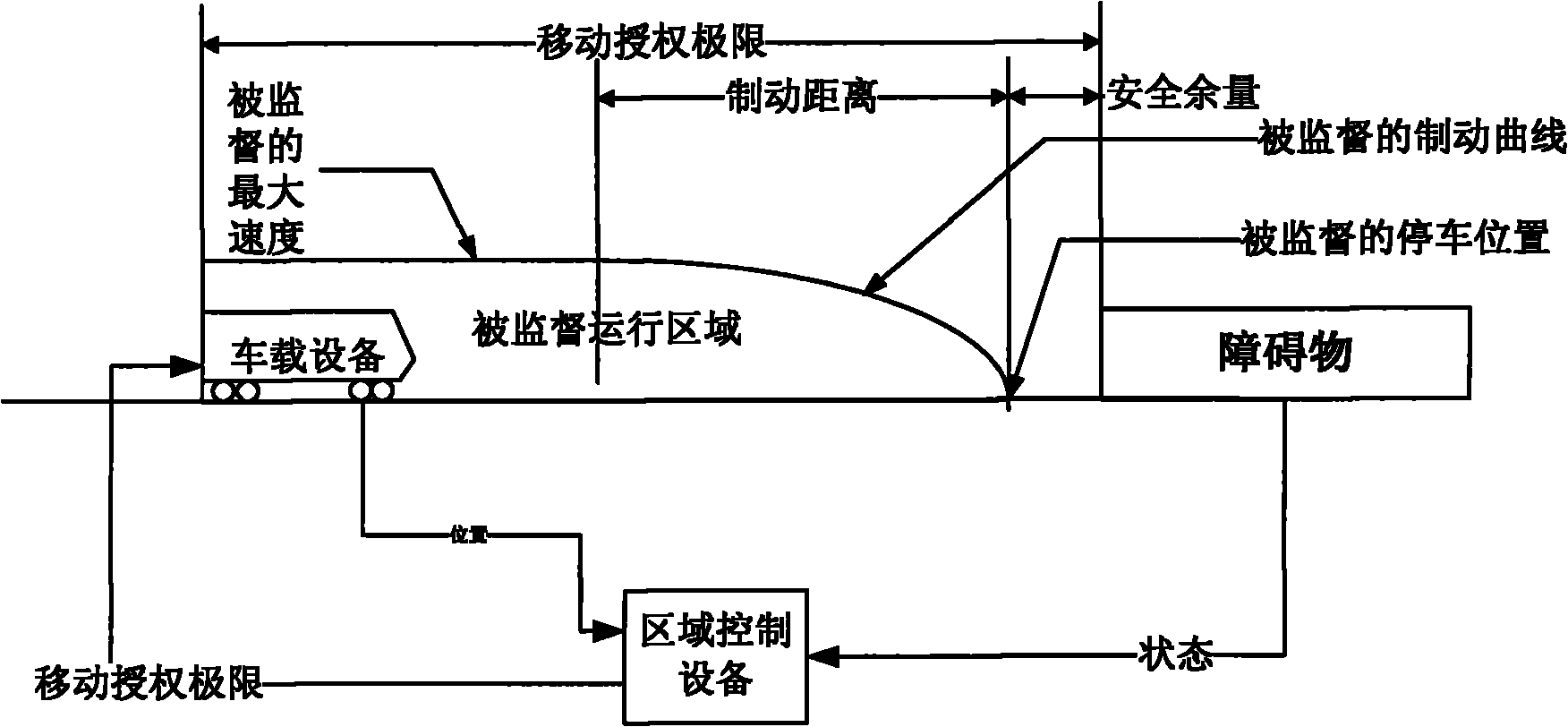

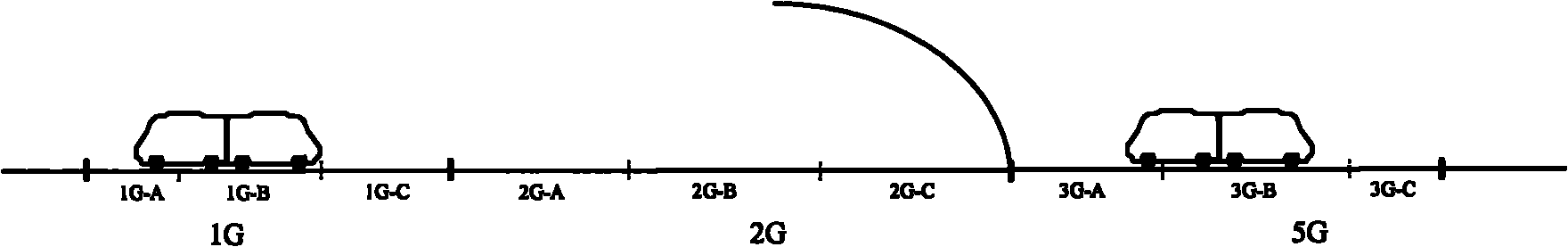

Train control system-based mobile authorization calculating method

ActiveCN101934807AAchieve precise positioningReduce run timeRailway traffic control systemsControl systemSafe operation

The invention discloses a train control system-based mobile authorization calculation method. The method comprises the following steps of: reading route information of a train; determining a traversal range of the train according to the route information; initializing a terminal point of mobile authorization as a terminal point position in the traversal range; searching static obstacles in the traversal range; judging whether each of the static obstacles meets the requirement on safe operation of the train in turn; if not, setting the position of the last static obstacle in the traversal range as the terminal point of the mobile authorization; otherwise, changing the terminal point of the mobile authorization into a matched route terminal point; searching dynamic obstacles in the traversal range and judging the existence of a tracking train; if the tracking train exists, modifying the terminal point of the mobile authorization into the initial terminal of an axle section in which the train is positioned; and if no dynamic obstacle exists in the traversal range, modifying the final terminal point of the mobile authorization into the position of the last static obstacle in the traversal range. The method can improve the precision of a train tracking interval and improve the operating efficiency of the train.

Owner:TRAFFIC CONTROL TECH CO LTD

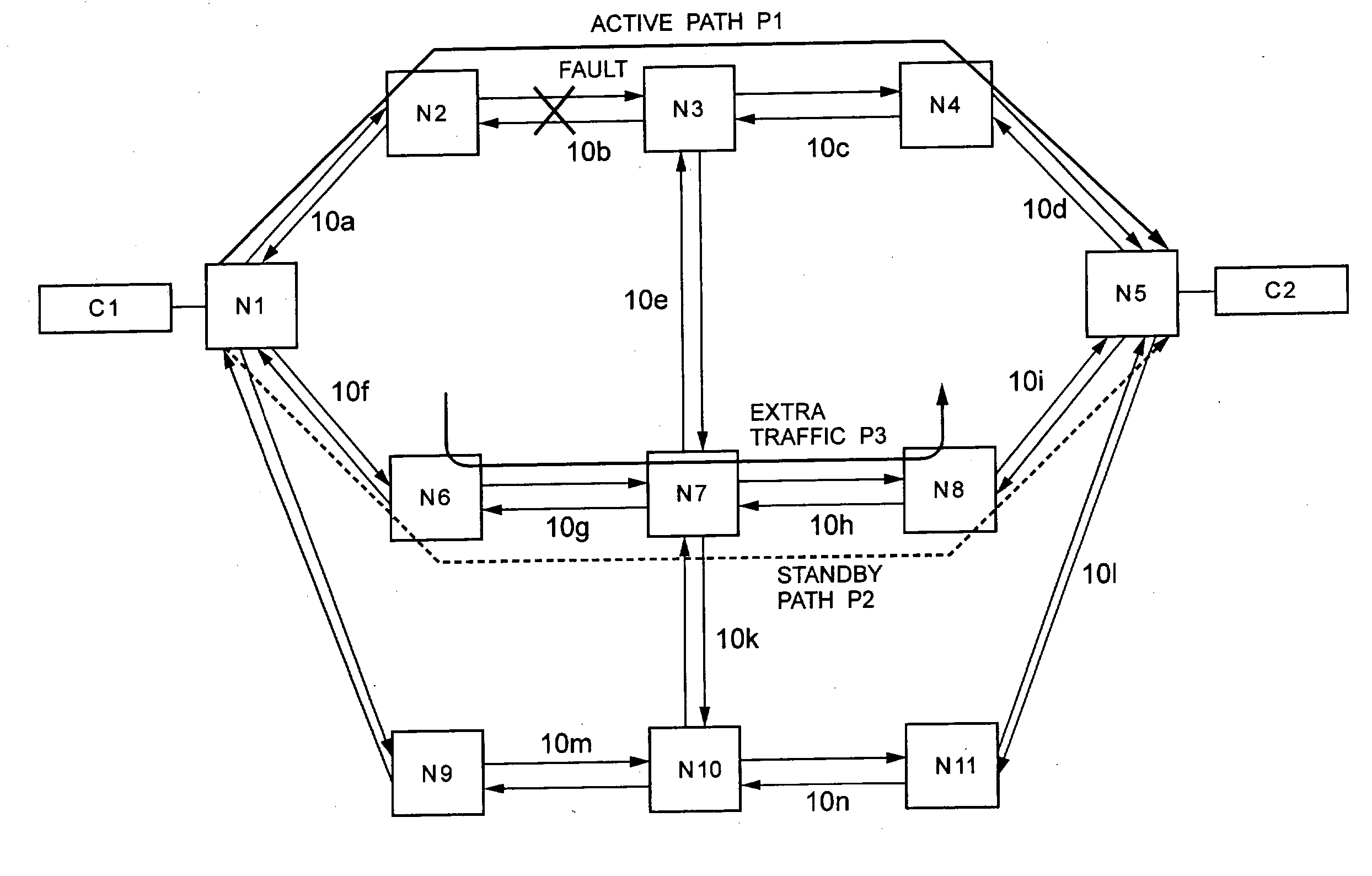

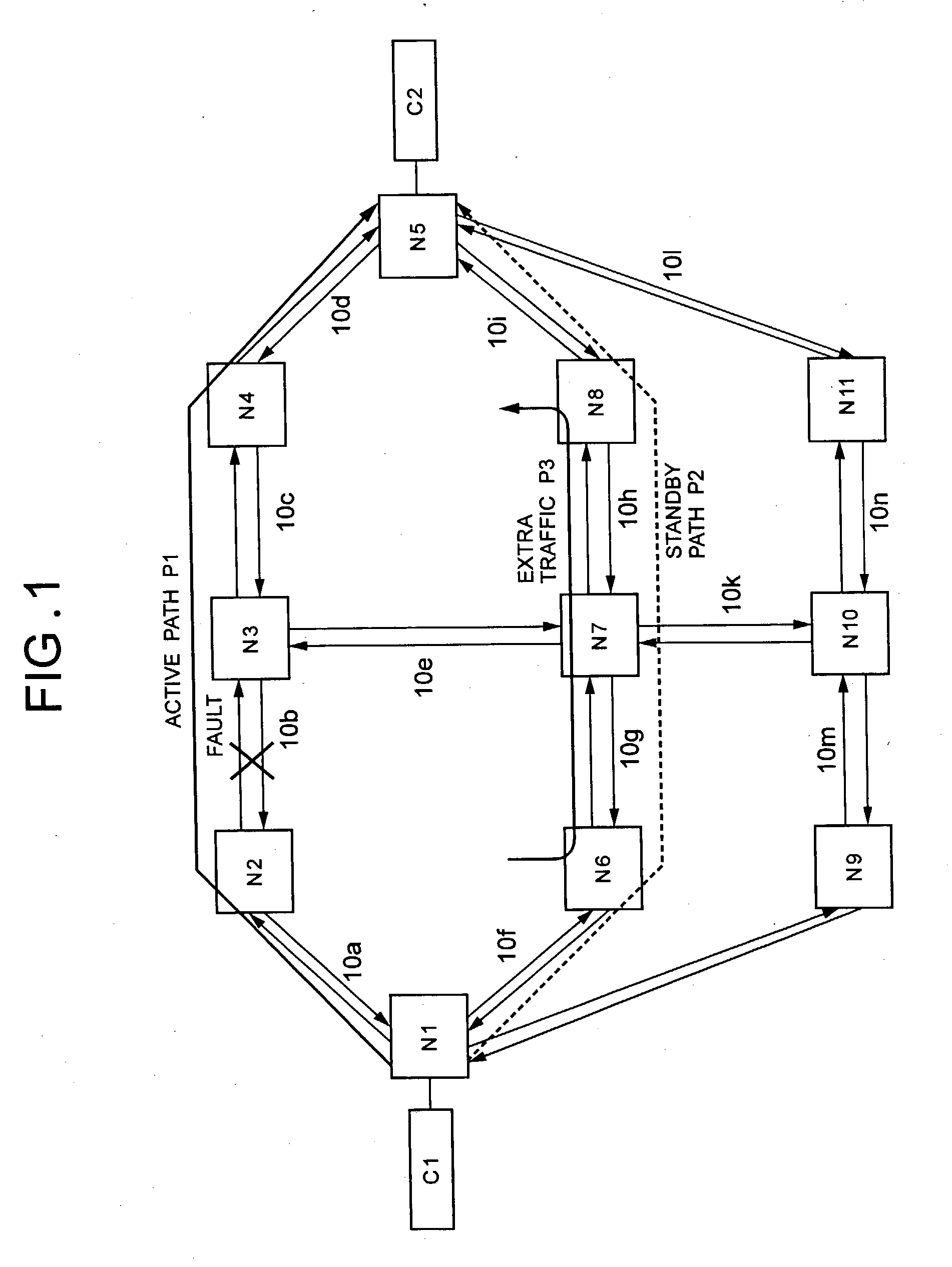

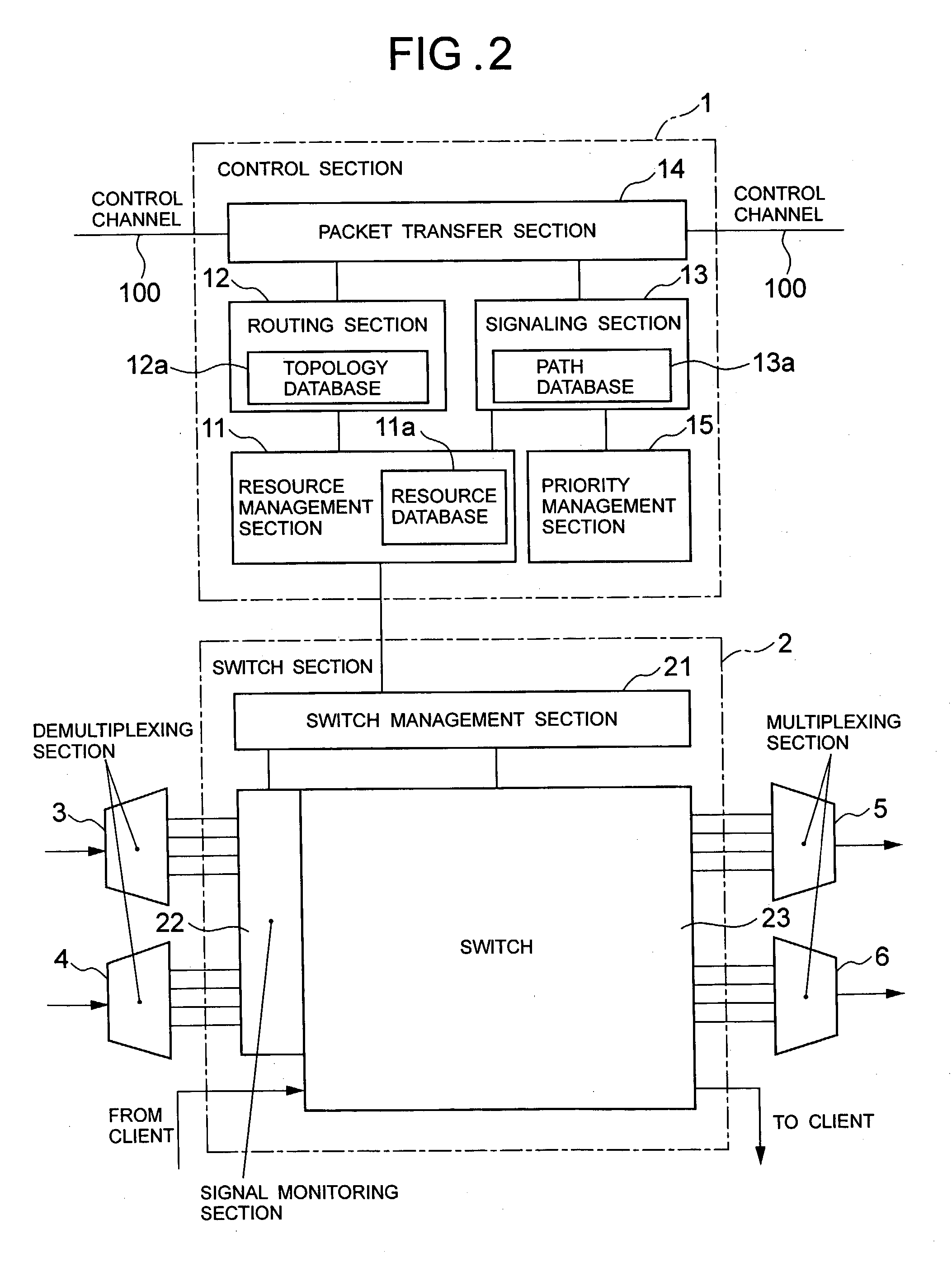

Path fault recovery method, switching-back method after recovery from fault, and node using the same

InactiveUS20030137932A1Improve reliabilityError preventionTransmission systemsRecovery methodRestoration method

This invention provides another optical path fault recovery method by which when the resources of a standby path are used by extra traffic, the standby path can be set quickly and an active path can be switched to the standby path without any improper connection in the event of a fault on the active path. An end point node of a path having received fault notification issues a resource securing request message transferred hop by hop to a start point node along the standby path. In the case where resources of the standby path are secured, when the resources are used by the extra traffic, the nodes on the standby path and the start point node that have received the message release the extra traffic and then secure the resources. When the resource securing request message reaches the start point node, the start point node issues a switch changeover request message, and the end point node, the start point node, and the nodes on the standby path set switches according to the secured resources.

Owner:NEC CORP

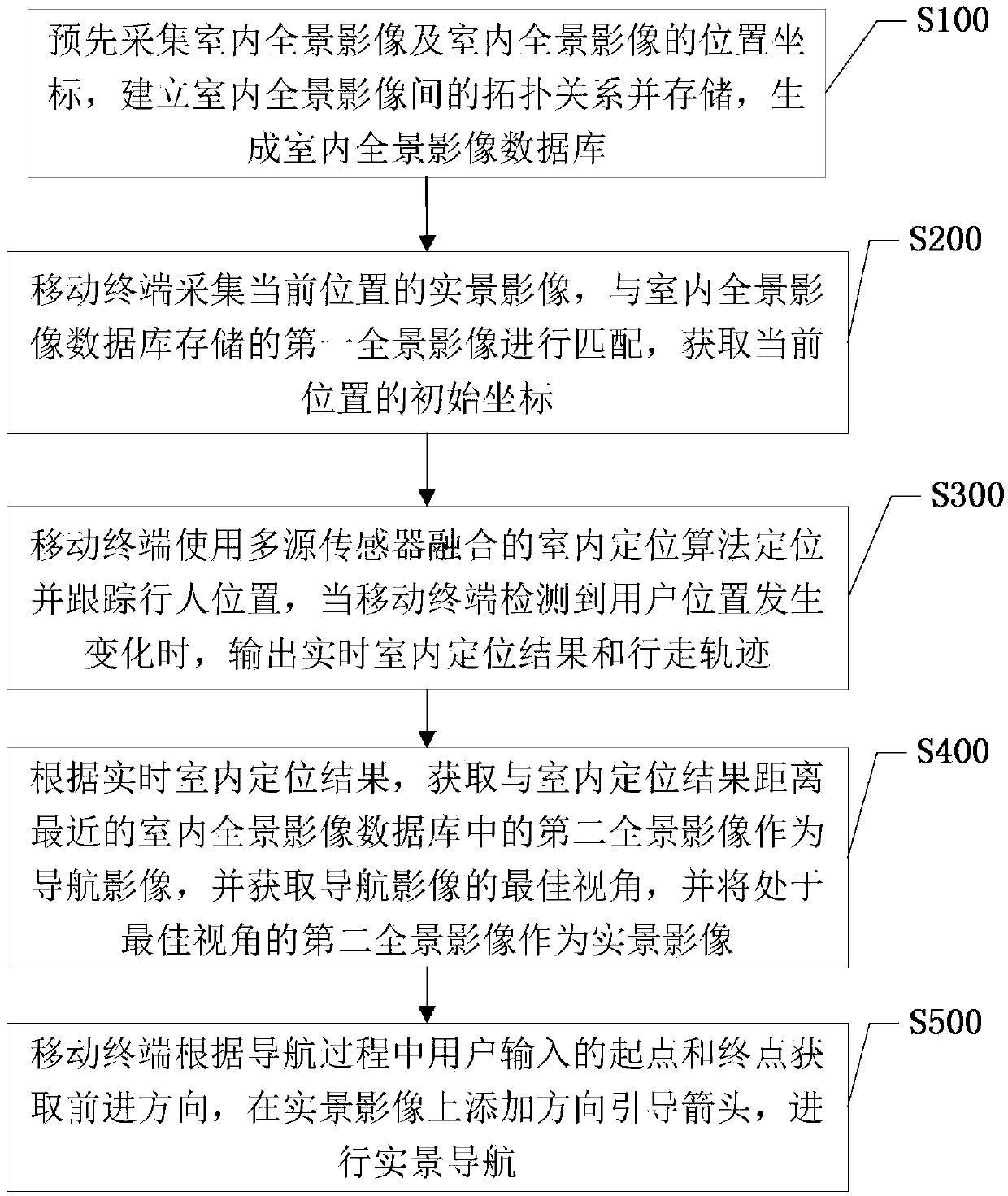

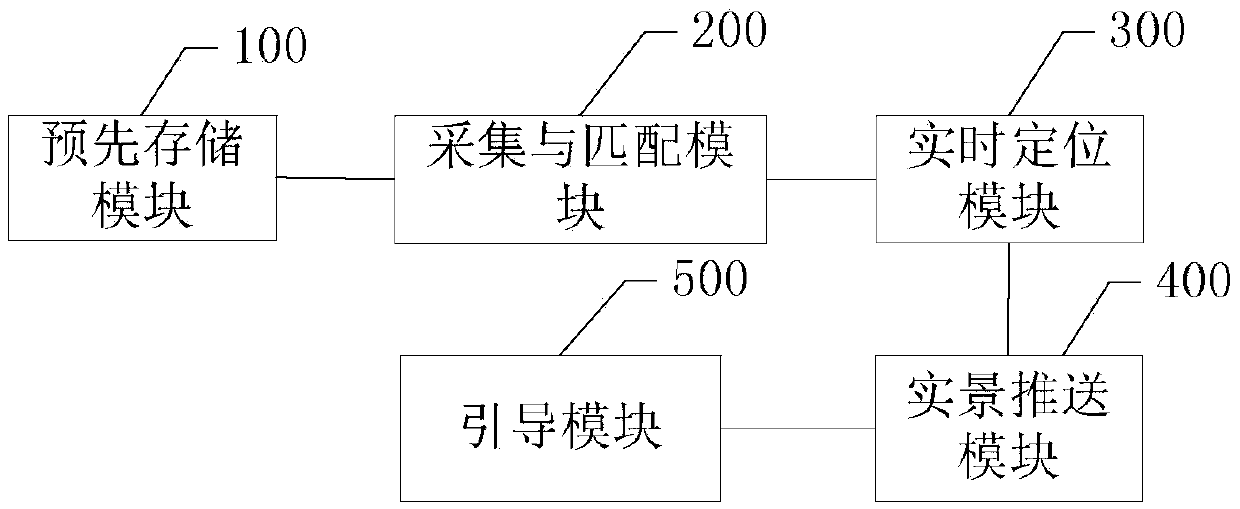

Indoor live-action navigation method and system

The invention discloses an indoor live-action navigation method and system. The method comprises the steps that a mobile terminal collects live-action images of the current position, the live-action images are matched with a first live-action image stored in an indoor live-action image database, and an initial coordinate of the current position is obtained; the position of a pedestrian is positioned and tracked in real time through a multi-source sensor fused position algorithm, and when the mobile terminal detects that the position of a user changes, a real-time position result and a walking trajectory are output; a second live-action image, closest to the indoor position result, in the indoor live-action image database is obtained according to the real-time indoor position result; the mobile terminal obtains a starting point and an ending point which are input by the user in the navigation process, a forward direction is obtained, a direction guided arrow is added on the second live-action image, and live-action navigation is conducted. By means of the indoor live-action navigation method and system, according to the position where the pedestrian is located, the live-action navigation images can be pushed automatically, the best navigation image visual angle can be judged automatically, and route guidance information such as the arrow is overlapped on the navigation images.

Owner:SHENZHEN UNIV

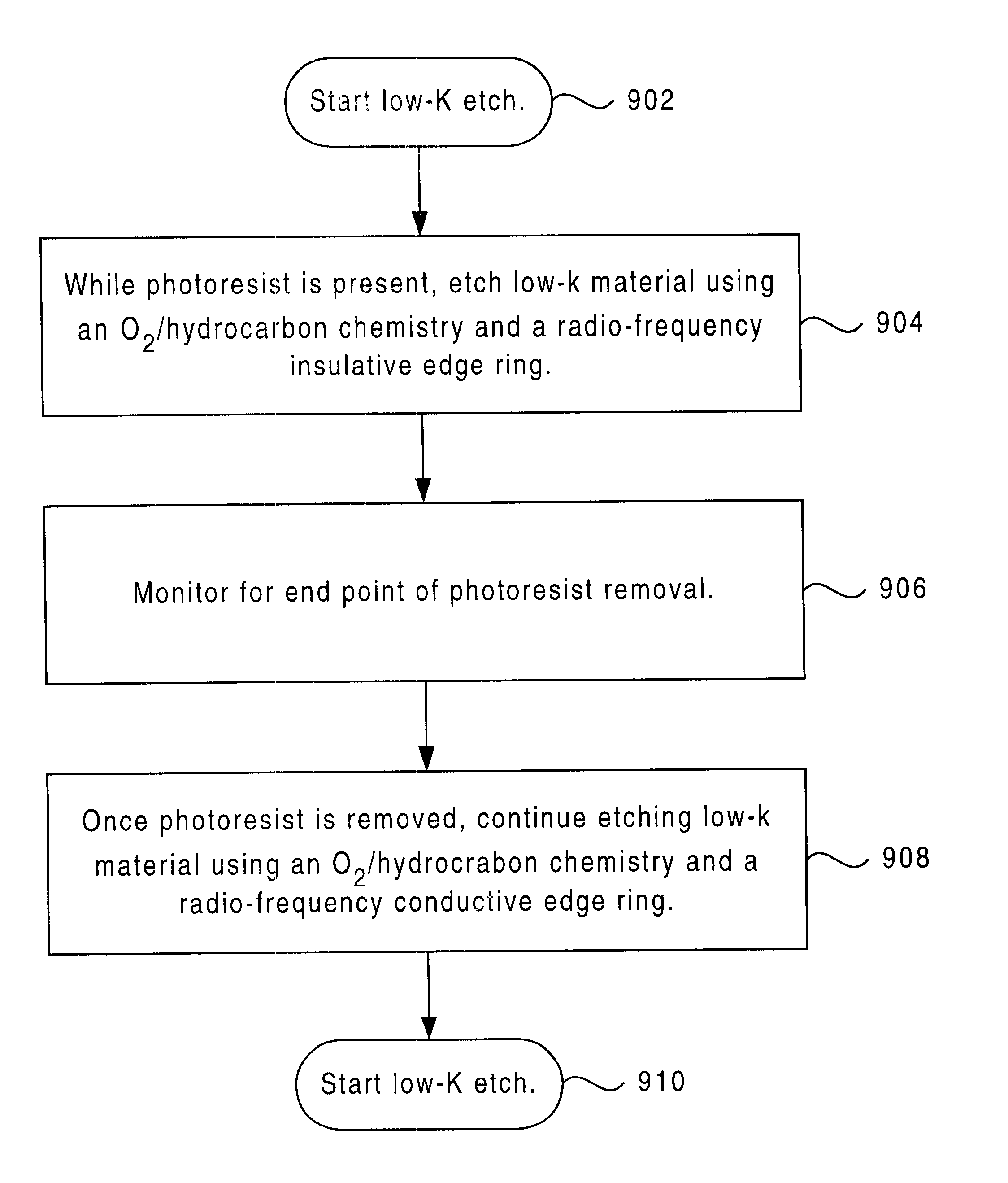

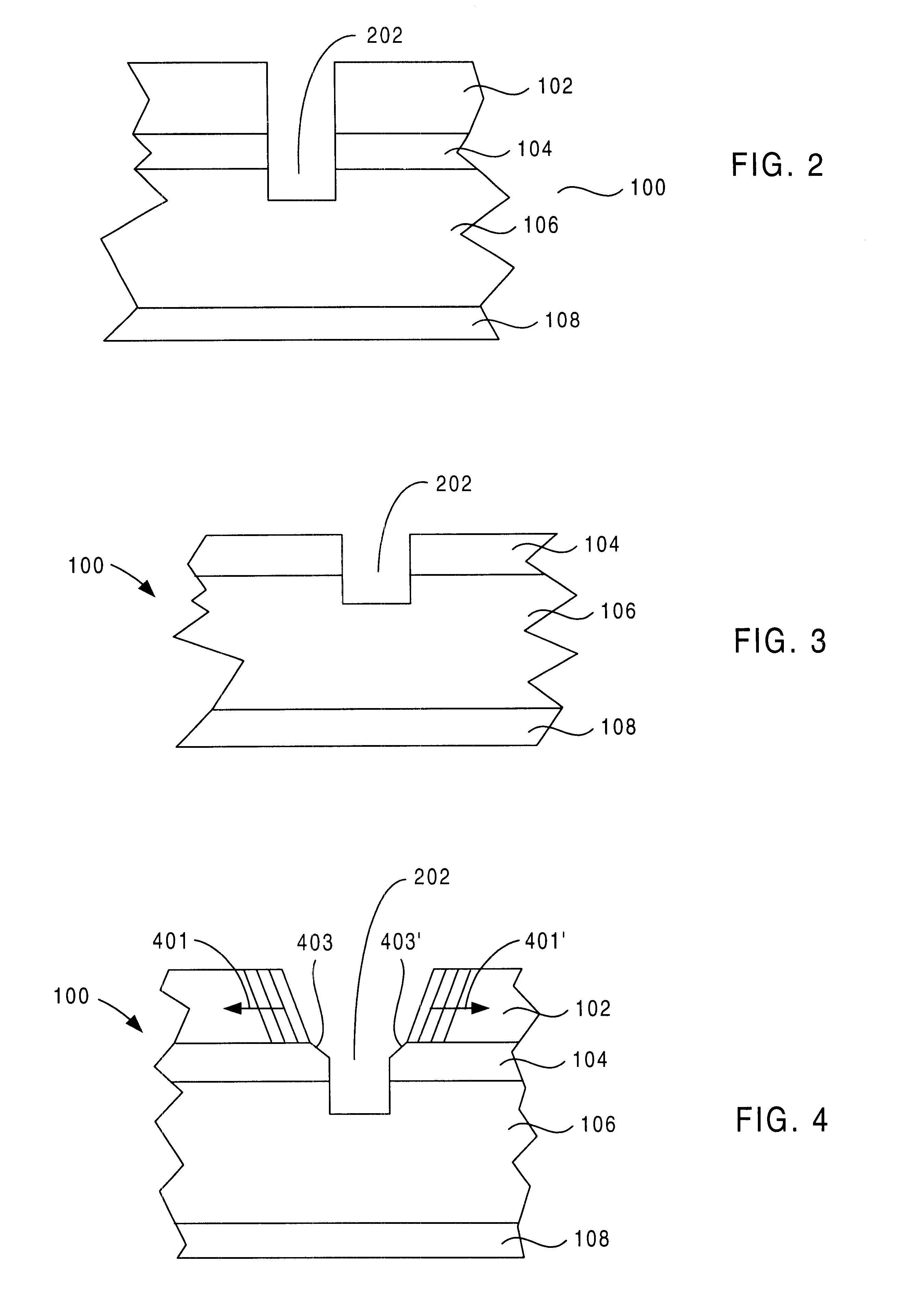

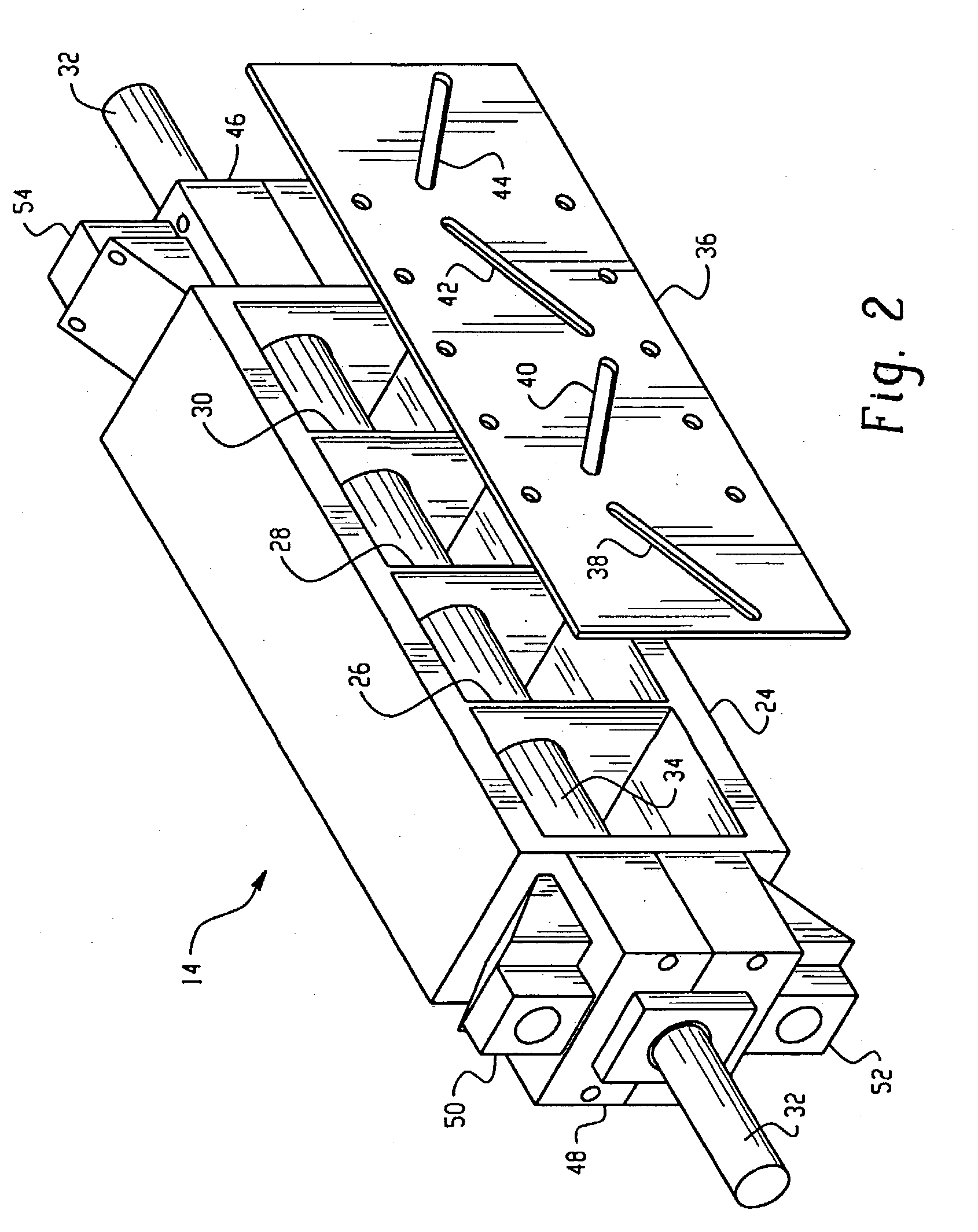

Convertible hot edge ring to improve low-K dielectric etch

Two-step process to improve low-K dielectric etch uniformity, apparatus to perform the method, and semiconductor devices formed in accordance with the method. In a first etching step, an insulating hot edge ring is provided. When the photoresist clearing signal is observed using end-point software, the insulating cover is moved aside to expose the conductive edge ring for the remainder of the etch. One aspect of this invention contemplates an insulator cover over a conductive edge ring at the start of wafer etching, which cover is removed after end-pint detection. The present invention contemplates a number of physical configurations whereby the insulator ring is urged into, and away from, its masking of the conductive edge ring. Alternatively, the etching of a wafer bearing low-K material may be conducted using two edge rings, where the first etch step is conducted using an insulating hot edge ring, and a second etch step is conducted using a conductive hot edge ring. According to this aspect, the two step process may thus be performed in a plurality of reactor vessels, or in one reactor vessel having a plurality of processing stations. Different low-K materials may require differing etchant / passivant / diluent combinations. Accordingly, the two-step etch process is taught in conjunction with any number of different etch chemistries.

Owner:LAM RES CORP

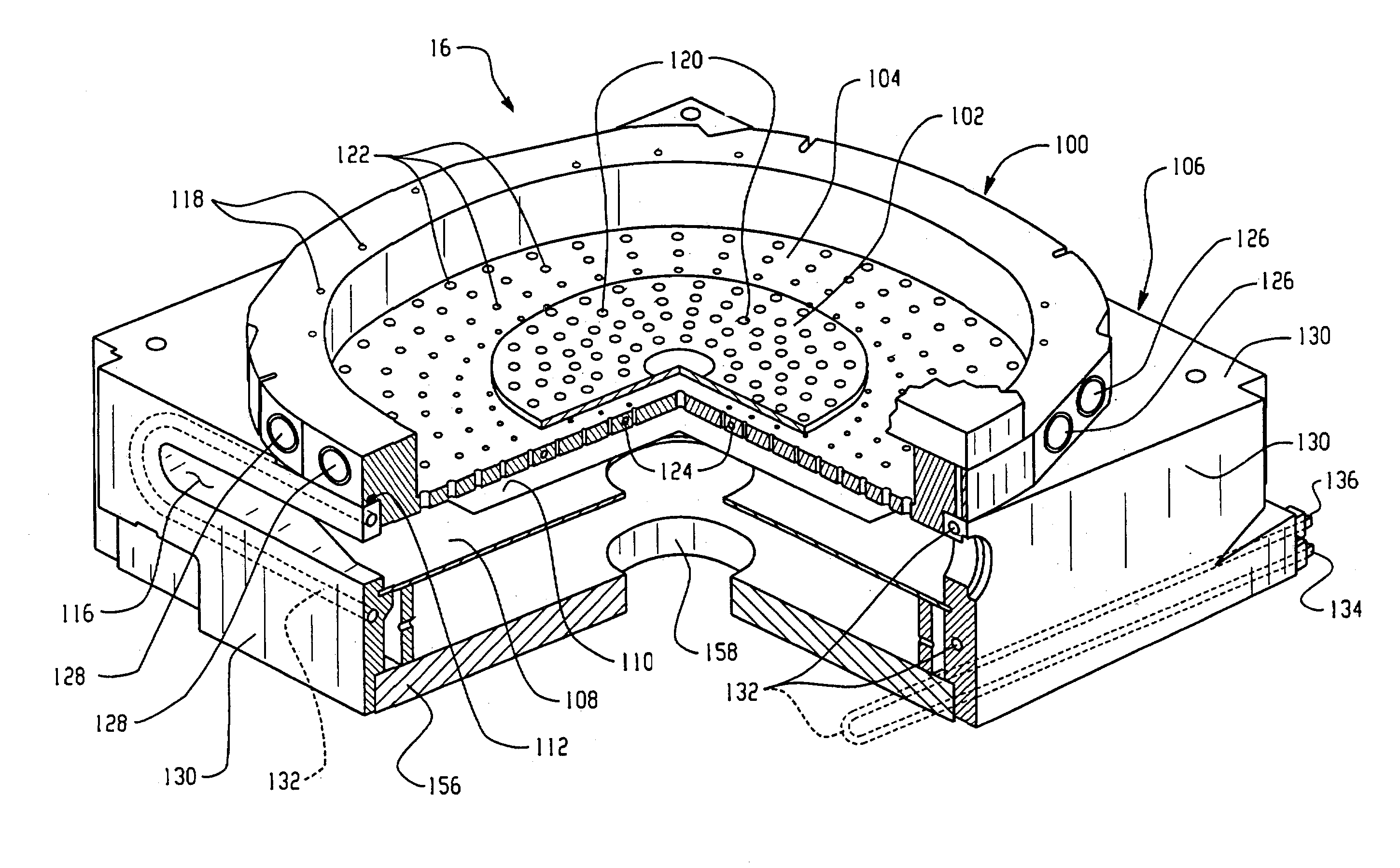

Plasma ashing apparatus and endpoint detection process

InactiveUS20040235299A1Enhance photoresist removalFlexible process platformElectric discharge tubesSemiconductor/solid-state device manufacturingNitrogen plasmaCombustion chamber

A plasma ashing apparatus for removing organic matter from a substrate including a low k dielectric, comprising a first gas source; a plasma generating component in fluid communication with the first gas source; a process chamber in fluid communication with the plasma generating component; an exhaust conduit in fluid communication with the process chamber; wherein the exhaust conduit comprises an inlet for a second gas source and an afterburner assembly coupled to the exhaust conduit, wherein the inlet is disposed intermediate to the process chamber and an afterburner assembly, and wherein the afterburner assembly comprises means for generating a plasma within the exhaust conduit with or without introduction of a gas from the second gas source; and an optical emission spectroscopy device coupled to the exhaust conduit comprising collection optics focused within a plasma discharge region of the afterburner assembly. An endpoint detection process for an oxygen free and nitrogen free plasma process comprises monitoring an optical emission signal of an afterburner excited species in an exhaust conduit of the plasma asher apparatus. The process and apparatus can be used with carbon and / or hydrogen containing low k dielectric materials.

Owner:LAM RES CORP

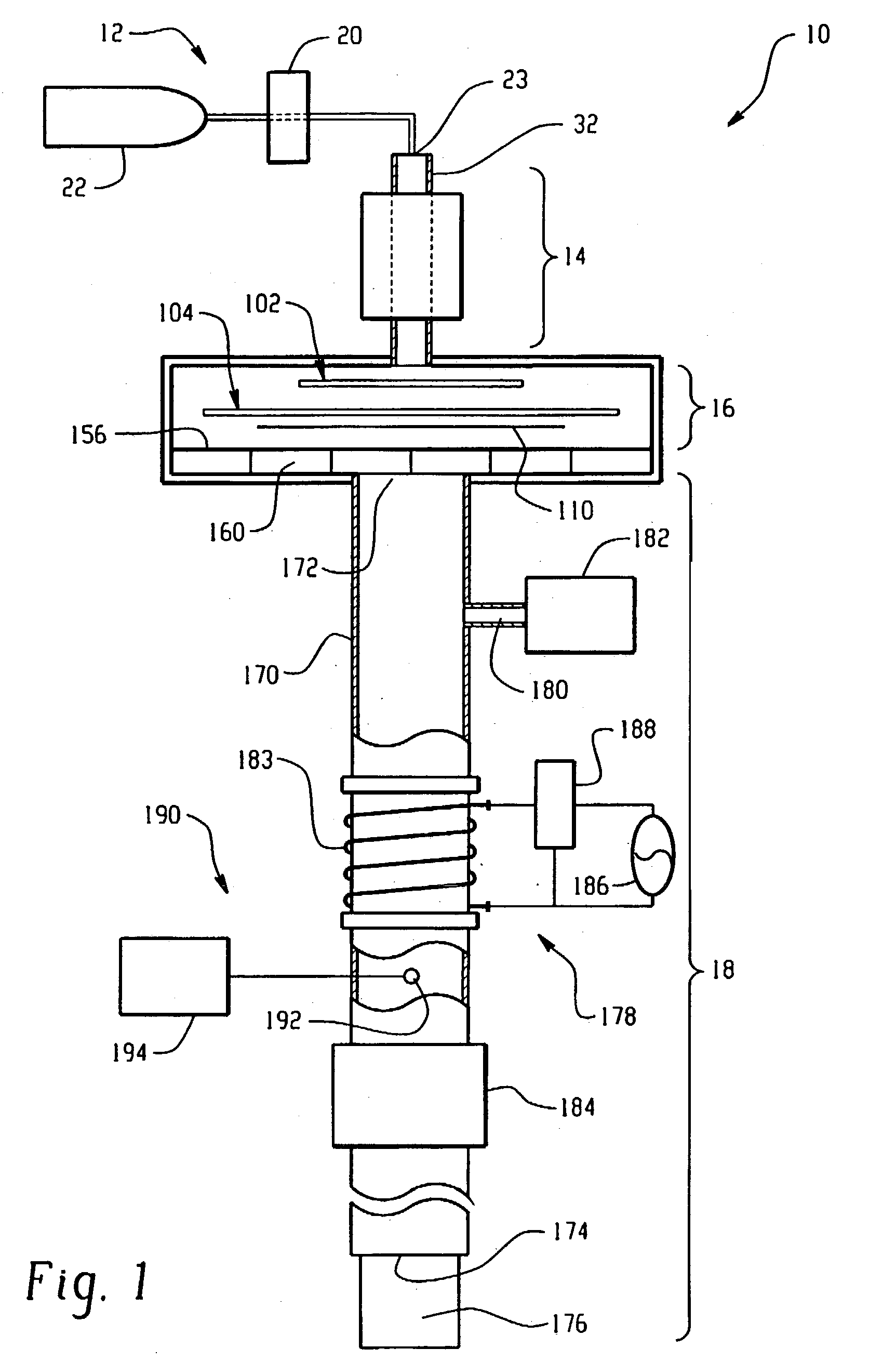

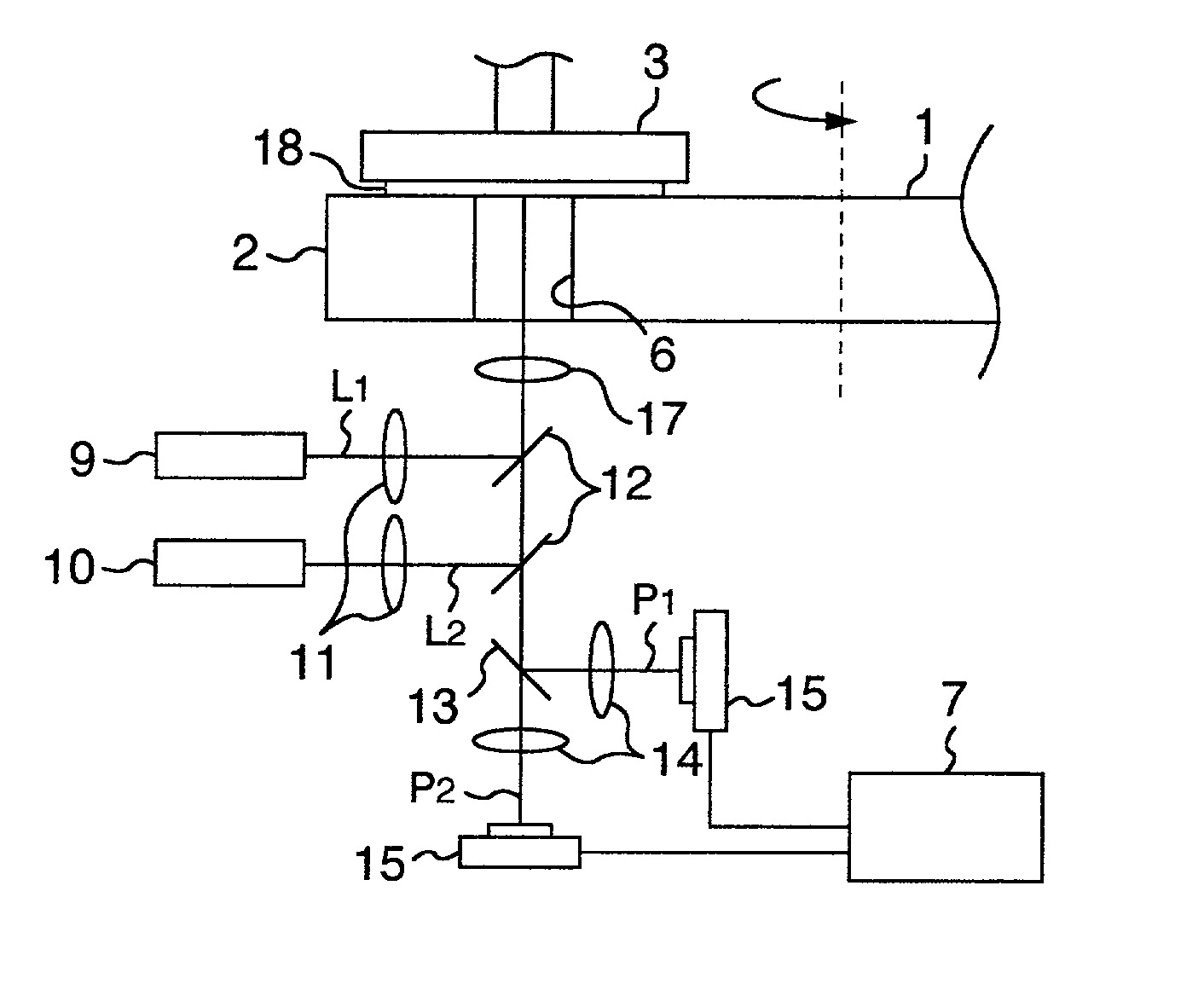

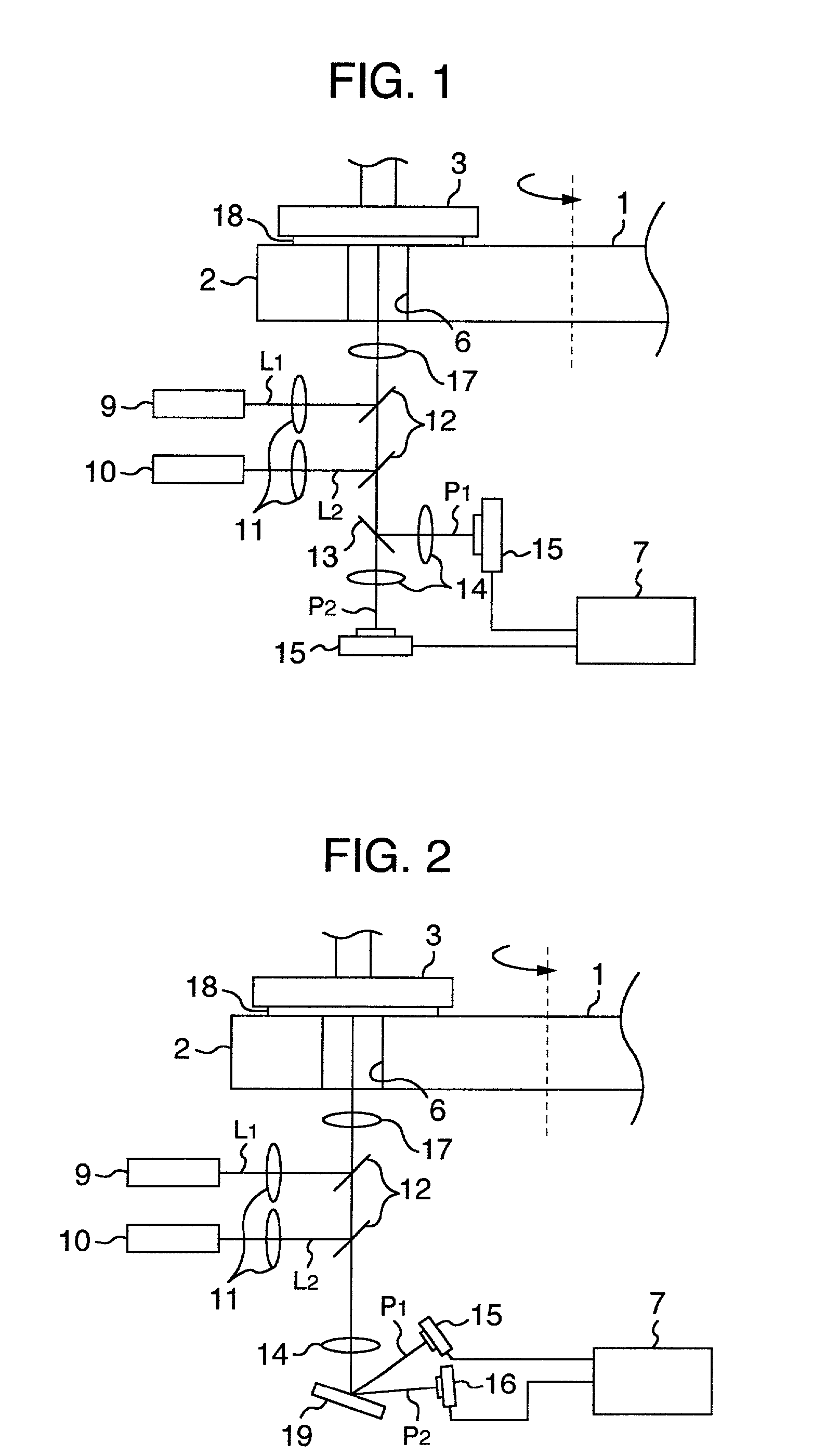

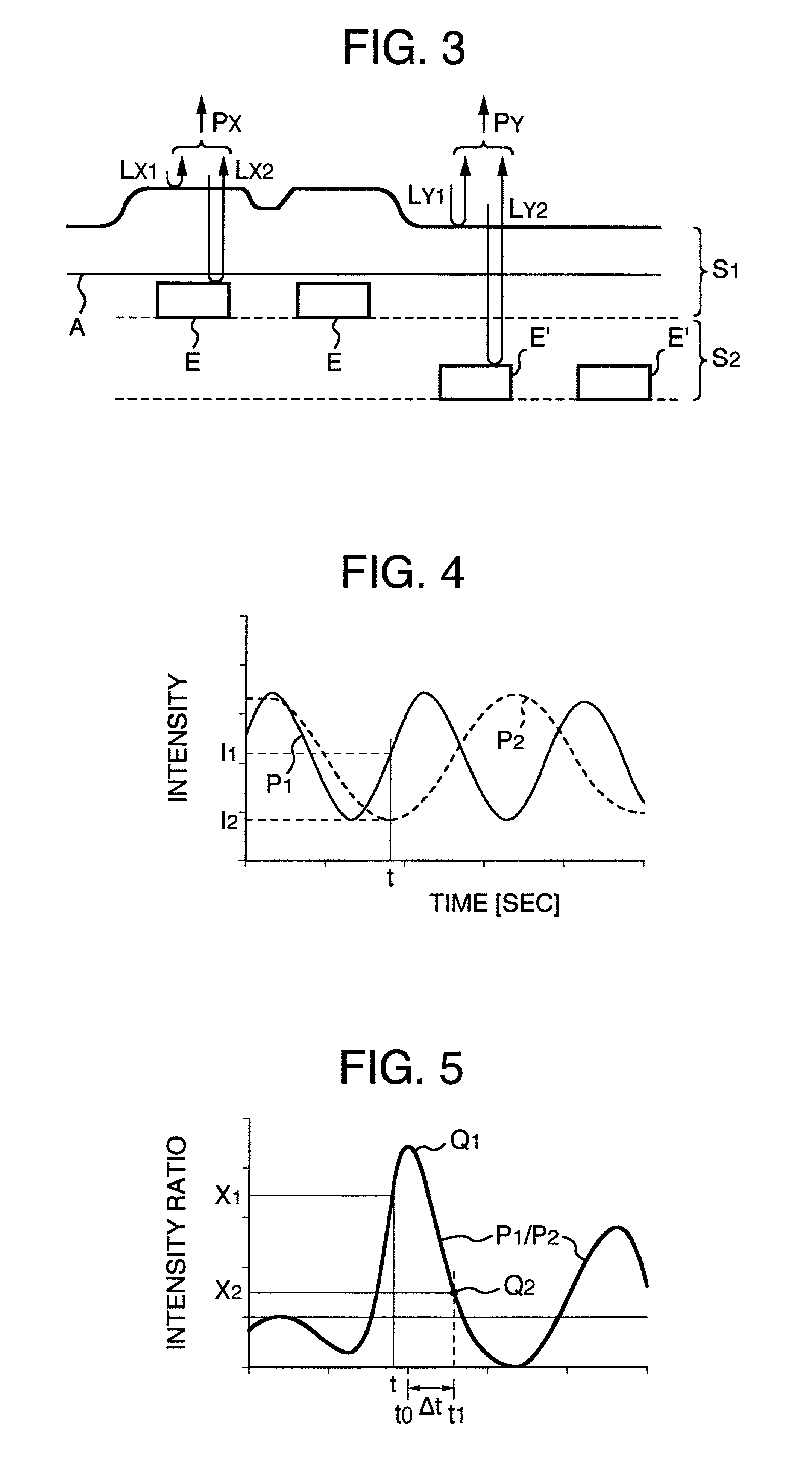

Method of detecting and measuring endpoint of polishing processing and its apparatus and method of manufacturing semiconductor device using the same

InactiveUS20020127950A1Improve accuracyImprove throughputSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingBeam splitterLaser light

Laser sources output laser lights L.sub.1 and L.sub.2 having different wavelengths so as to increase an accuracy of an endpoint detection of polishing processing by enabling an accurate detection of a film thickness of a layer insulating film on a surface of a wafer to be polished by the CMP processing, the lights are emitted from a detection window via a beam splitter to the layer insulating film formed on the surface of the wafer to be polished by a pad, different optical detectors detect interference lights corresponding to the laser lights L.sub.1 and L.sub.2 reflected and generated from a surface of the layer insulating film and a pattern under the surface via the detection window, the beam splitter, and a dichroic mirror, the detection results are supplied to a film thickness evaluation unit 7, a film thickness of the layer insulation film is detected on the basis of a relationship between intensities of the reflected interference lights to the laser lights L.sub.1 and L.sub.2 or the intensity ratio, and an endpoint of polishing processing is determined when the film thickness is equal to a predetermined value.

Owner:HITACHI LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com