Patents

Literature

339 results about "Afterburner" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An afterburner (or a reheat) is a component present on some jet engines, mostly those used on military supersonic aircraft. Its purpose is to provide an increase in thrust, usually for supersonic flight, takeoff, and combat situations. Afterburning is achieved by injecting additional fuel into the jet pipe downstream of (i.e., "after") the turbine. Afterburning significantly increases thrust without the weight of an additional engine, but at the cost of very high fuel consumption and decreased fuel efficiency, limiting its practical use to short bursts.

Trapped vortex cavity afterburner

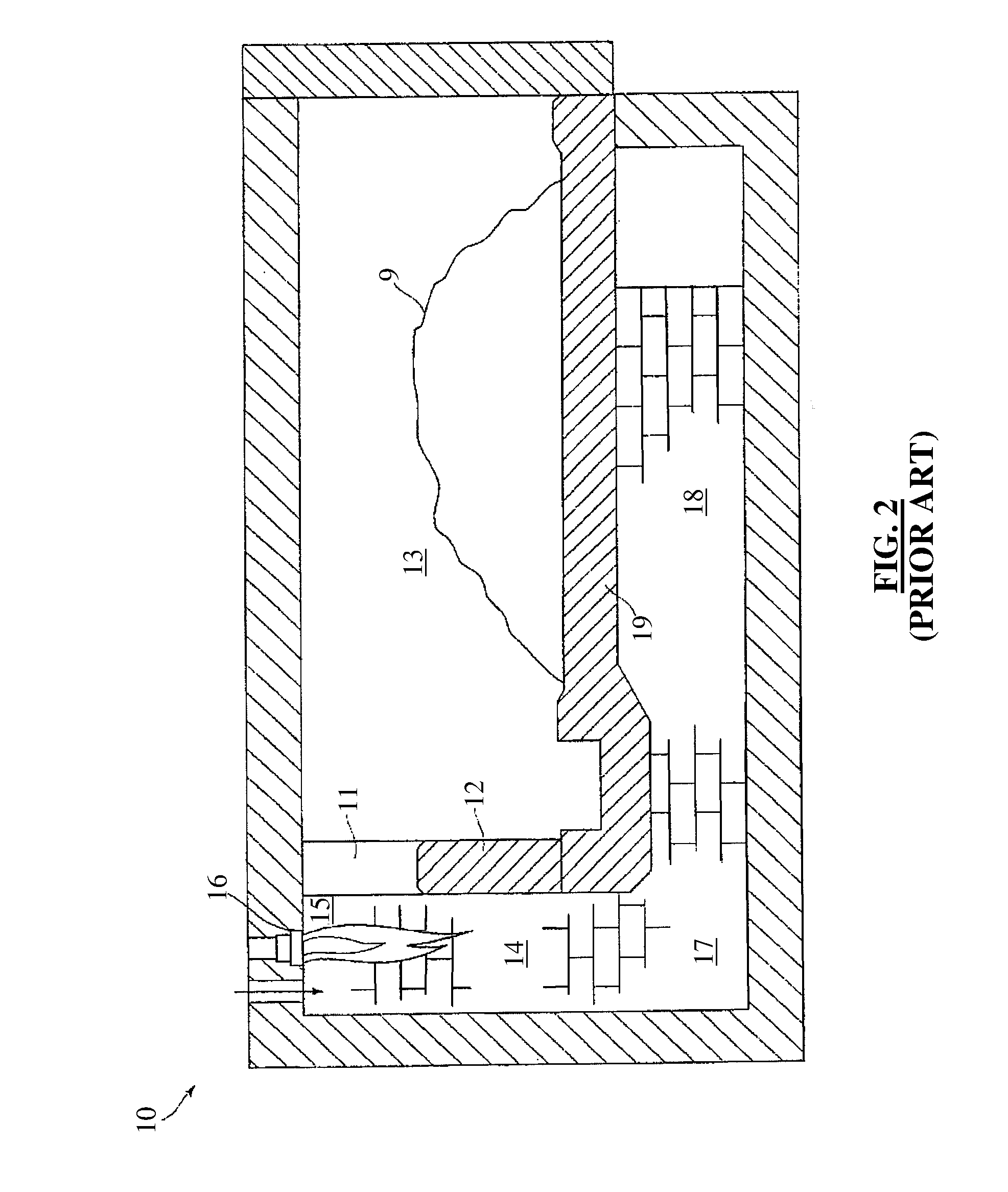

ActiveUS7225623B2Continuous combustion chamberTurbine/propulsion fuel supply systemsTrailing edgeDegree Fahrenheit

A trapped vortex cavity afterburner includes one or more trapped vortex cavity stages for injecting a fuel / air mixture into a combustion zone. The trapped vortex cavity afterburner is operable to provide all thrust augmenting fuel used for engine thrust augmentation. Each stage has at least one annular trapped vortex cavity. The trapped vortex cavity afterburner may be a multi-stage afterburner having two or more trapped vortex cavity stages ganged for simultaneous ignition or operable for sequential ignition. One embodiment of the annular trapped vortex cavity is operable to raise a temperature of an exhaust gas flow through the afterburner about 100 to 200 degrees Fahrenheit. Each of the trapped vortex cavity stages may be operable to produce a single or a different amount of temperature rise of the exhaust gas flow through the afterburner. A chevron shaped trapped vortex cavity and having zig-zag shaped leading and trailing edges may be used.

Owner:GENERAL ELECTRIC CO

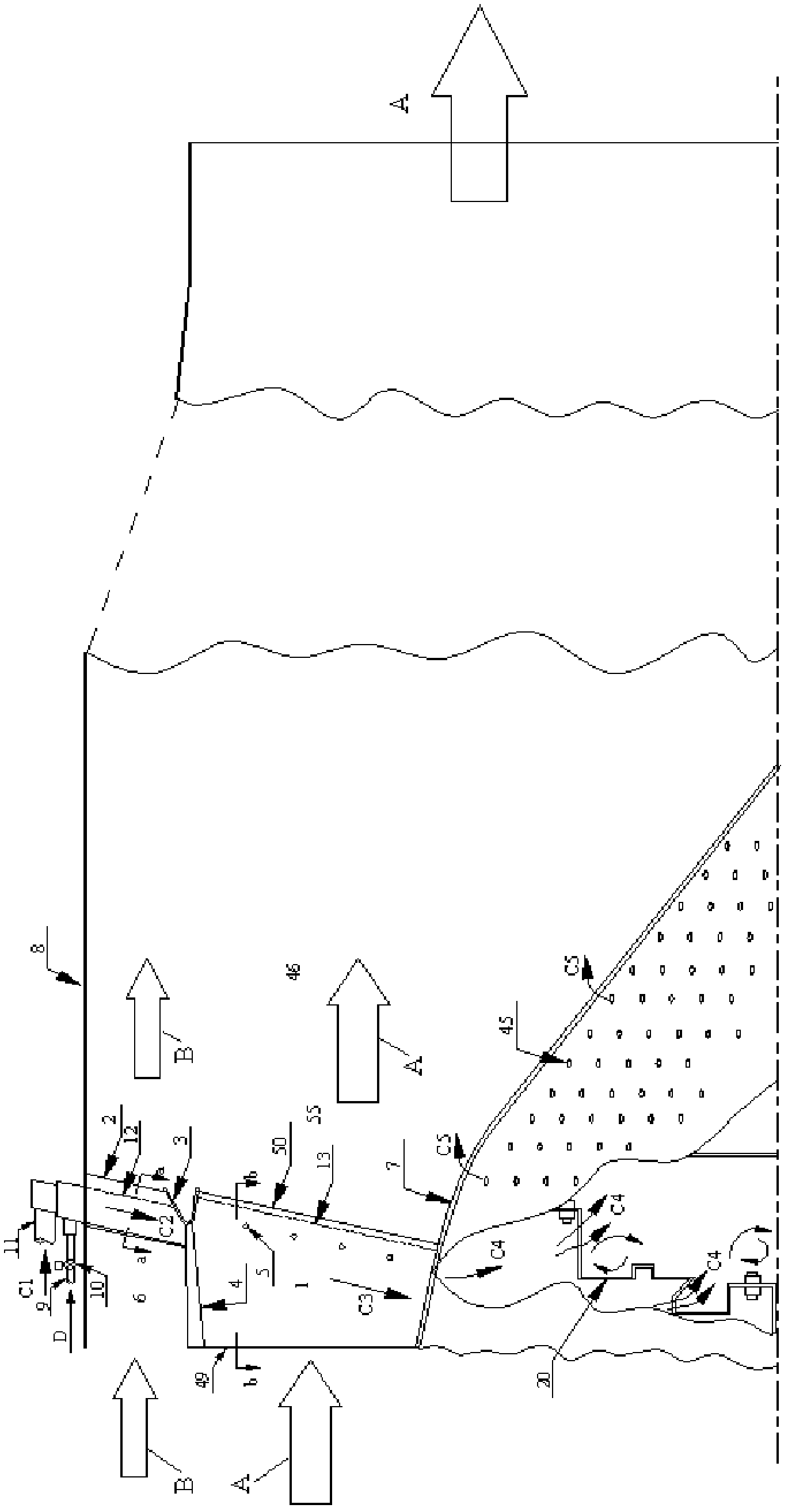

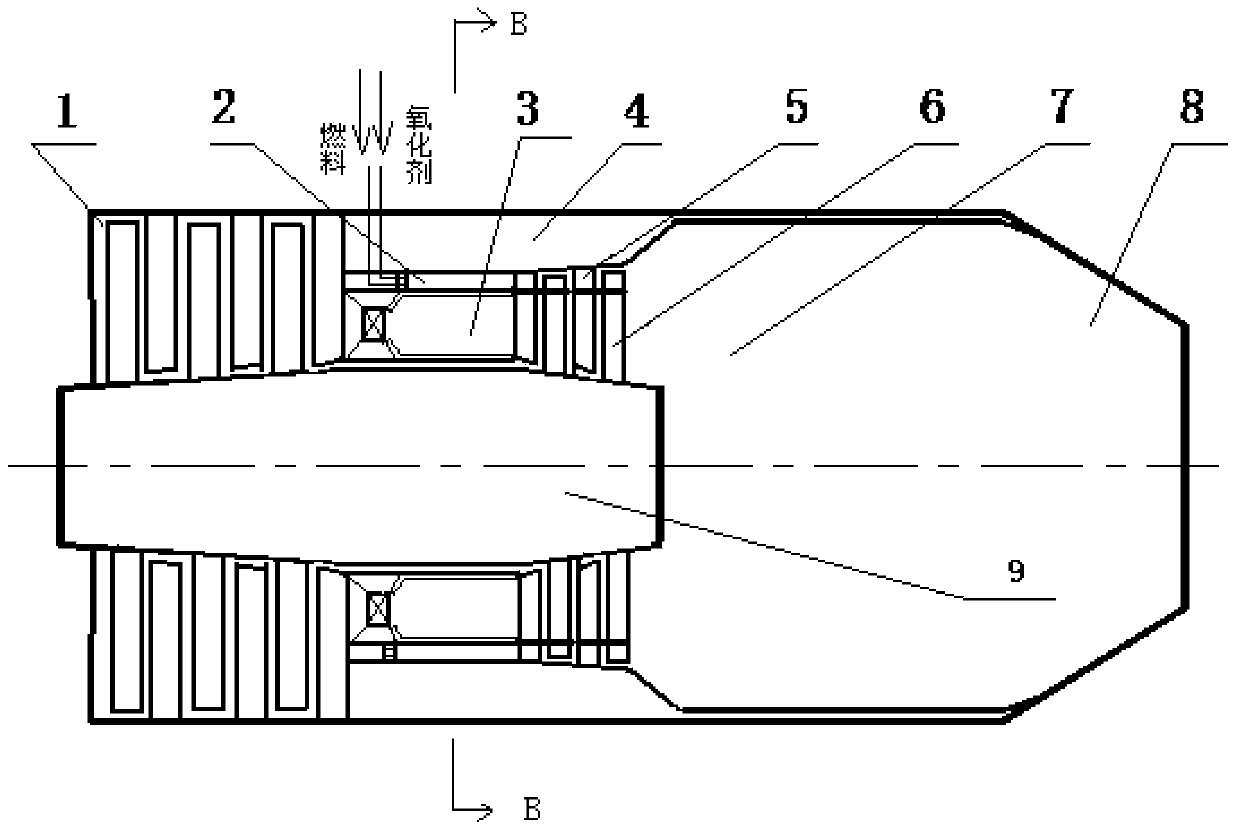

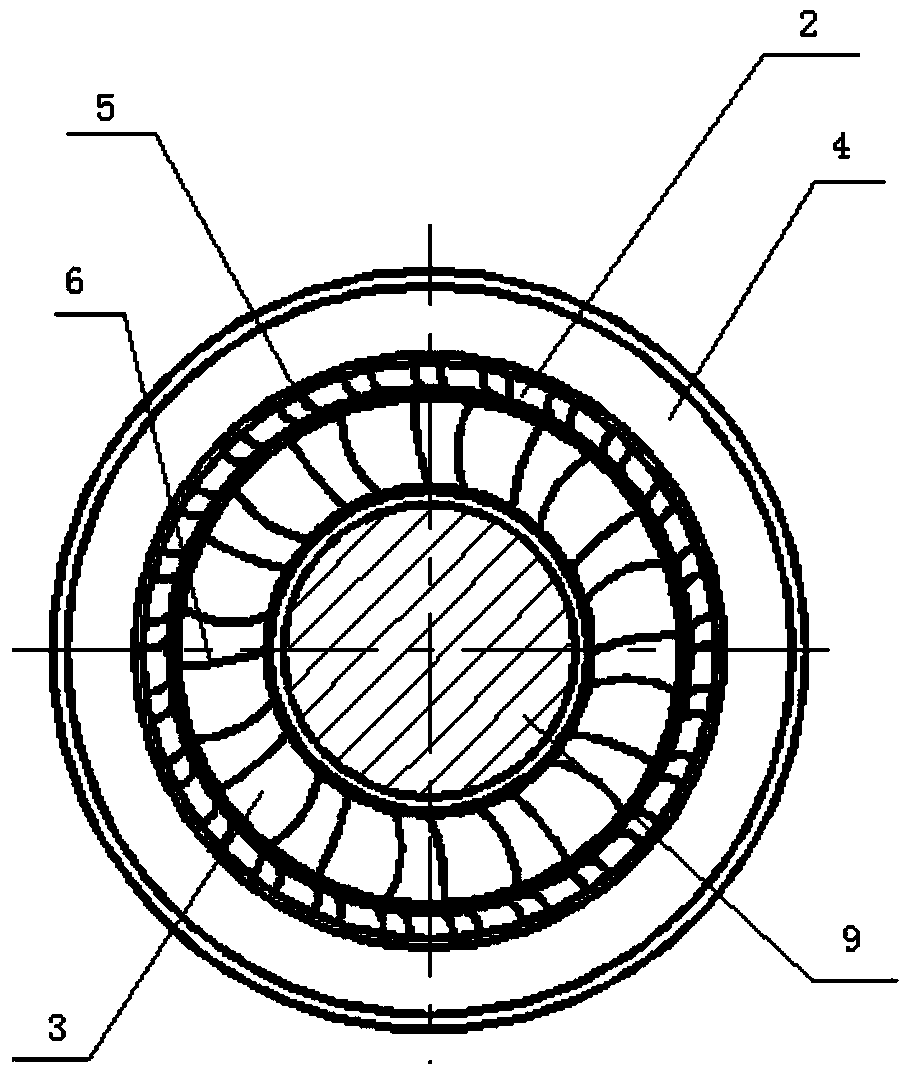

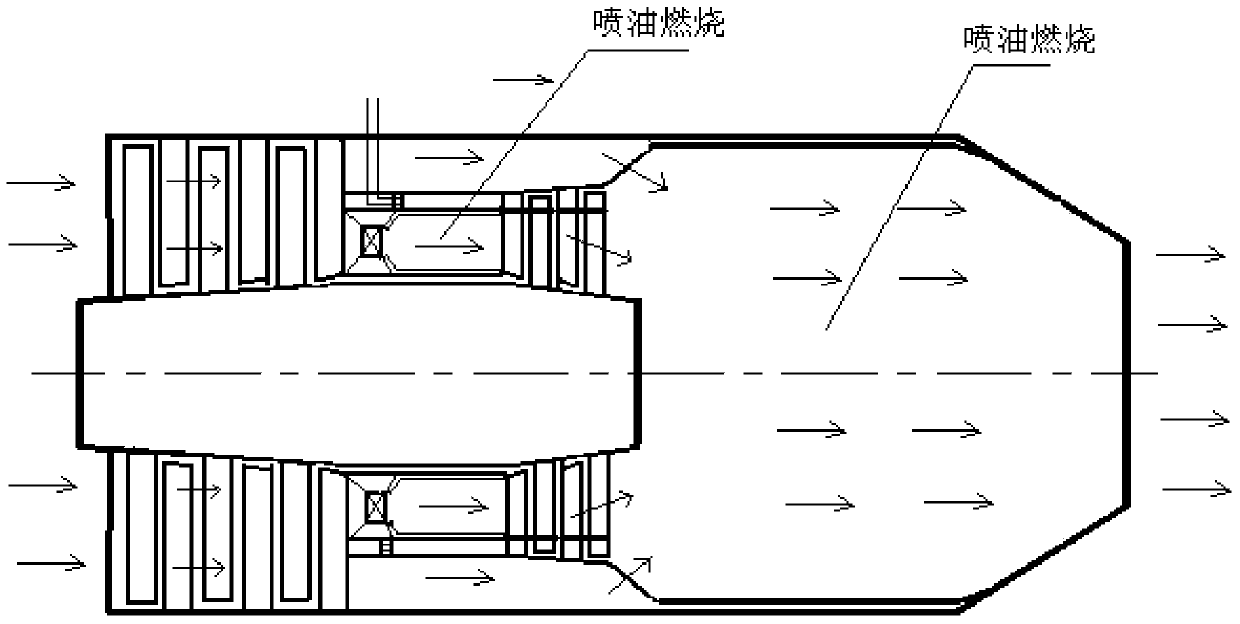

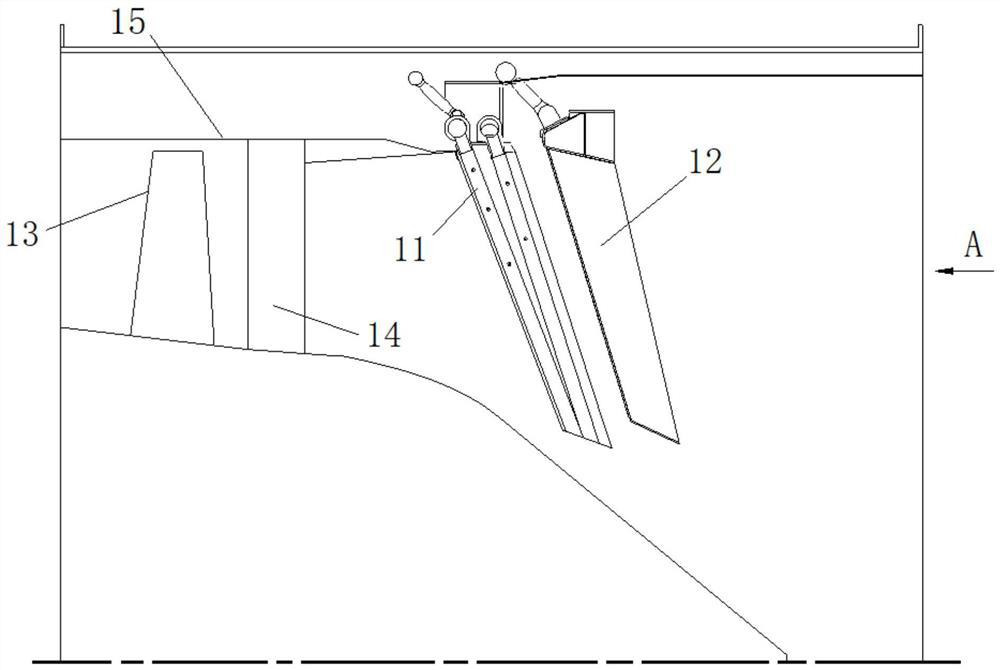

Afterburner integrated with stabilizer and worm wheel rear rectification support plate

InactiveCN102538010ASolve the technical problems of ablationImprove reliabilityContinuous combustion chamberEfficient propulsion technologiesCombustion chamberFuel oil

The invention discloses an afterburner integrated with a stabilizer and a worm wheel rear rectification support plate. A combustion part in the afterburner is integrated with a worm wheel rear load-bearing framework; the worm wheel rear rectification support plate is integrated with an inner culvert flame stabilizer, and cooling air is fed; a fuel oil supply pipe and a fuel oil nozzle are arranged in the rectification support plate; main fuel oil is transversely sprayed out from two sides of the support plate; and duty fuel oil is sprayed out from a groove on the rear surface of the stabilizer to form a duty flame. A pneumatic appearance of an outer culvert flame stabilizer is designed as a V-shaped bluff body, and the cooling air is fed into the outer culvert flame stabilizer; a fuel oil pipeline is arranged in the outer culvert flame stabilizer; the main fuel oil is transversely sprayed by a baffle plate nozzle; and the duty fuel oil is sprayed out from a groove on the rear surface of the outer culvert flame stabilizer. An annular flame stabilizer is arranged between the inner culvert flame stabilizer and the outer culvert flame stabilizer, so that functions of the stabilizer and a flame coupler are realized in a circumferential direction. The internal parts of the afterburner are integrated, so that the part utilization efficiency is improved, and the engine thrust-weight ratio is increased.

Owner:BEIHANG UNIV

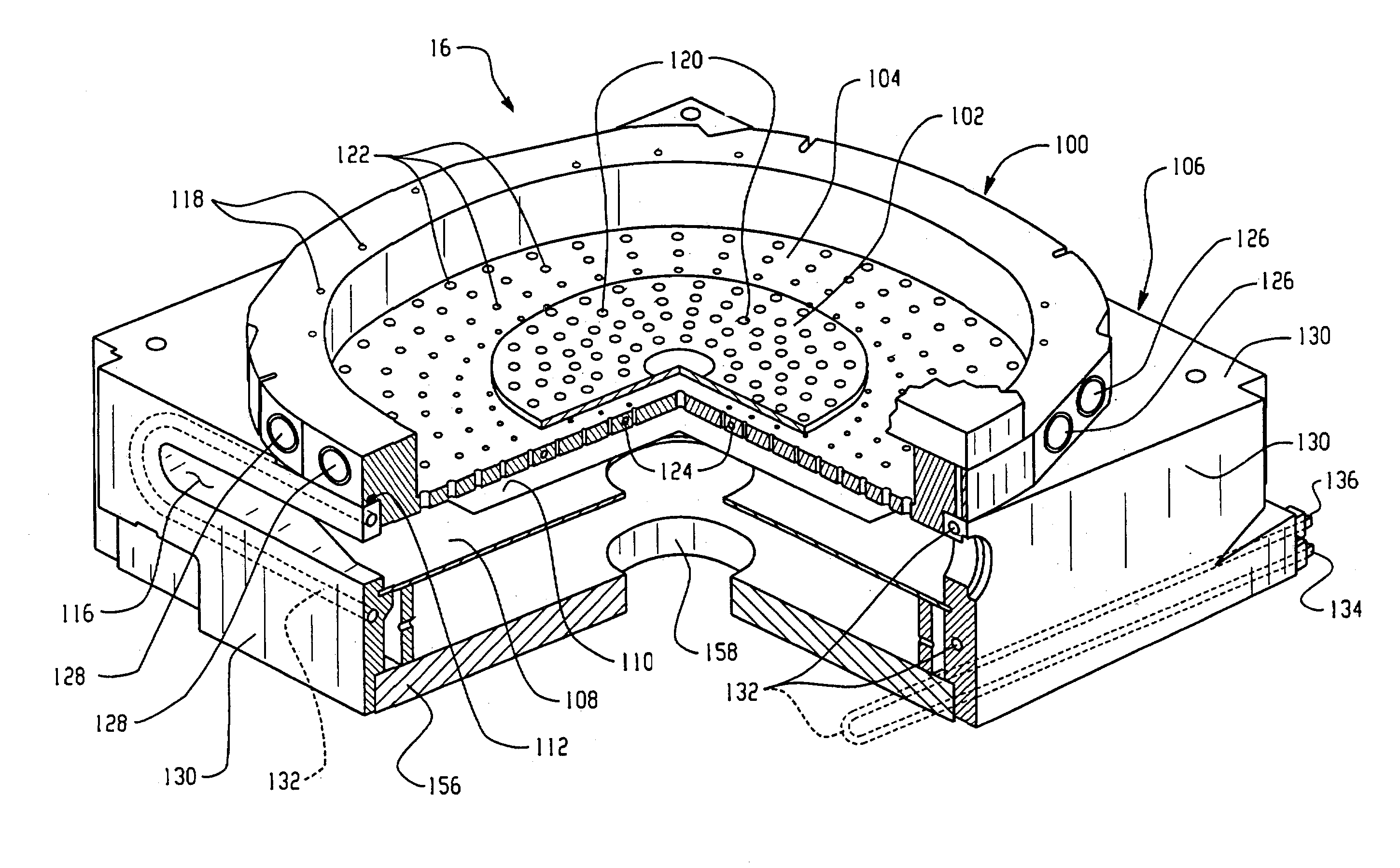

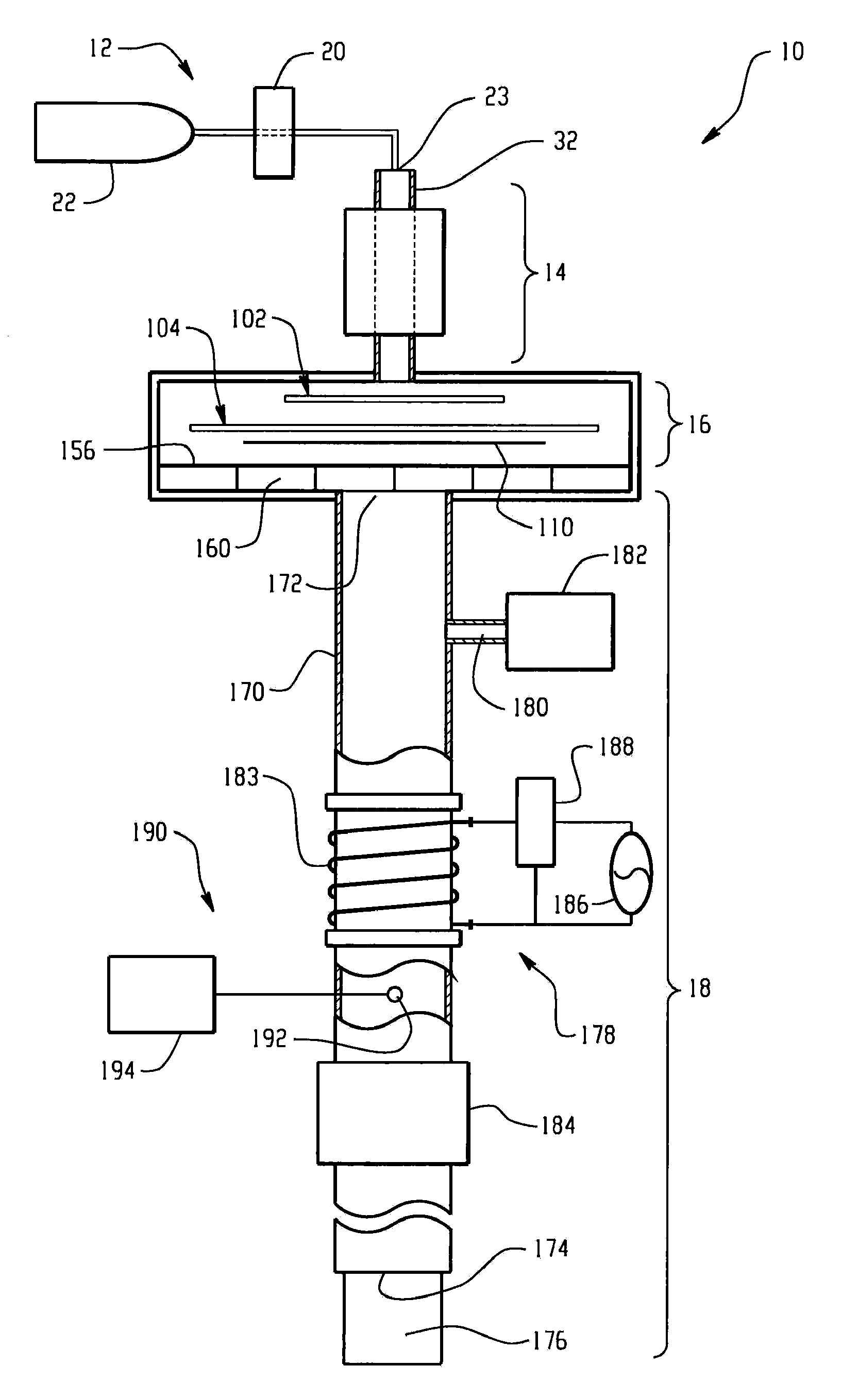

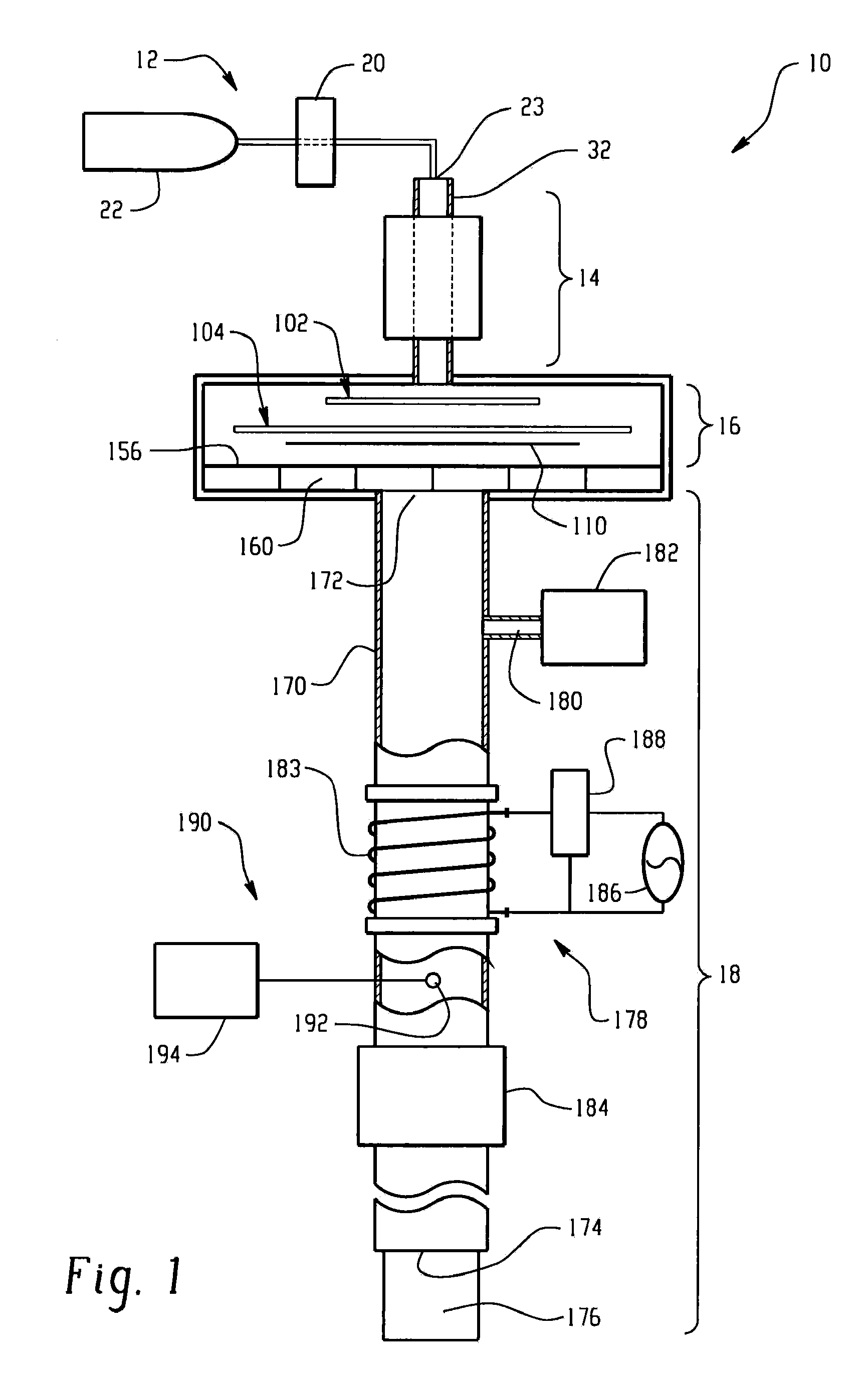

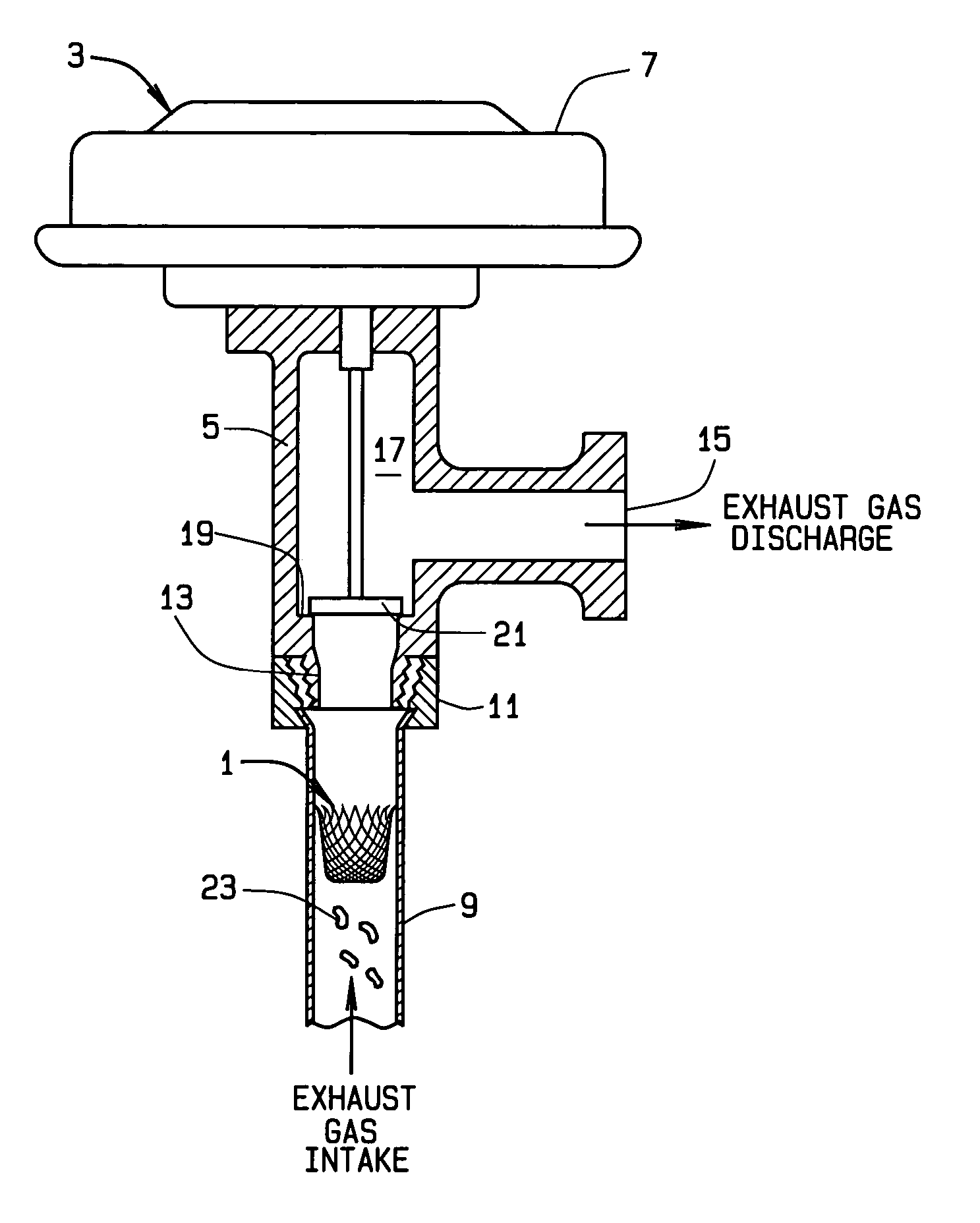

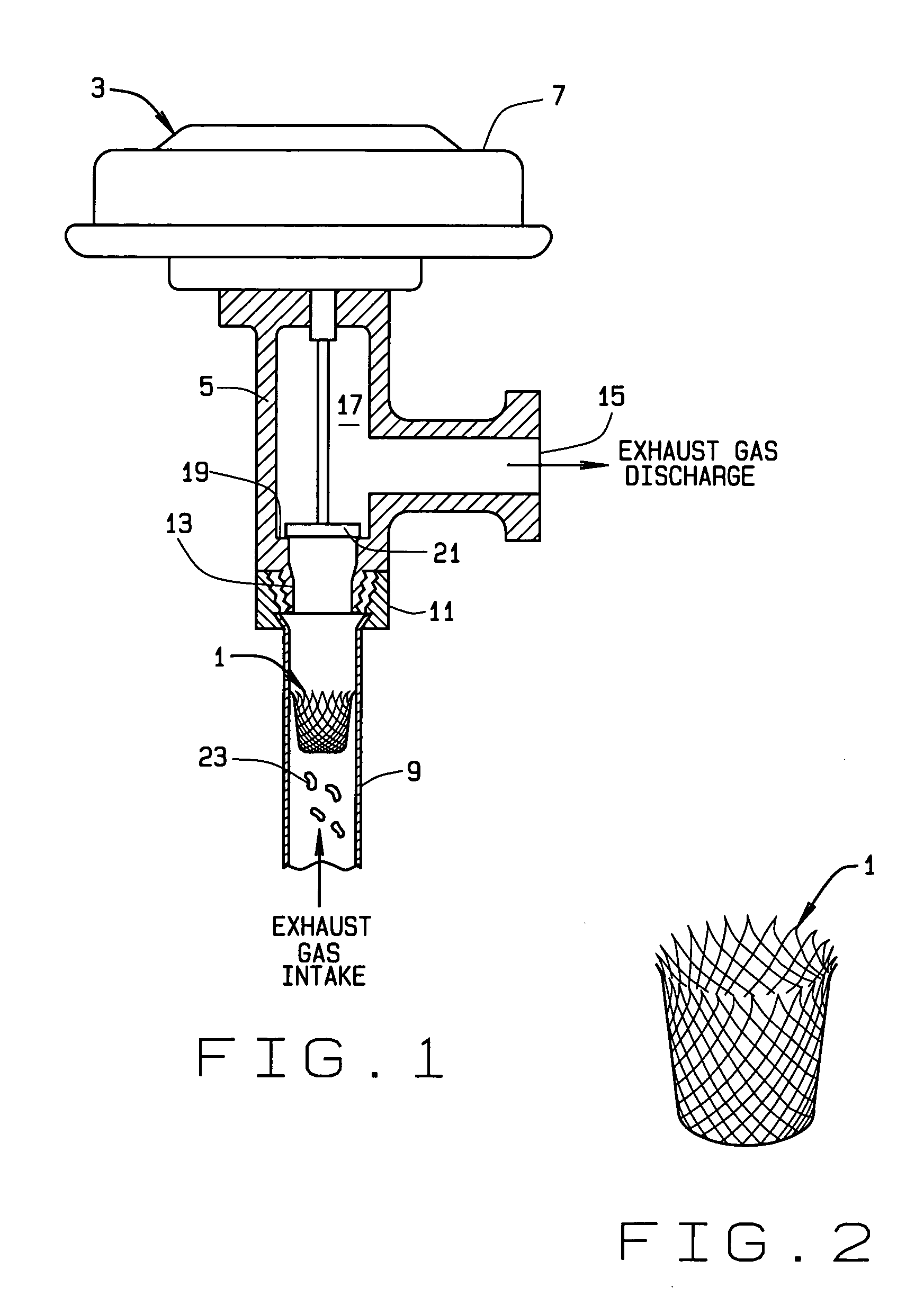

Plasma ashing apparatus and endpoint detection process

InactiveUS20040235299A1Enhance photoresist removalFlexible process platformElectric discharge tubesSemiconductor/solid-state device manufacturingNitrogen plasmaCombustion chamber

A plasma ashing apparatus for removing organic matter from a substrate including a low k dielectric, comprising a first gas source; a plasma generating component in fluid communication with the first gas source; a process chamber in fluid communication with the plasma generating component; an exhaust conduit in fluid communication with the process chamber; wherein the exhaust conduit comprises an inlet for a second gas source and an afterburner assembly coupled to the exhaust conduit, wherein the inlet is disposed intermediate to the process chamber and an afterburner assembly, and wherein the afterburner assembly comprises means for generating a plasma within the exhaust conduit with or without introduction of a gas from the second gas source; and an optical emission spectroscopy device coupled to the exhaust conduit comprising collection optics focused within a plasma discharge region of the afterburner assembly. An endpoint detection process for an oxygen free and nitrogen free plasma process comprises monitoring an optical emission signal of an afterburner excited species in an exhaust conduit of the plasma asher apparatus. The process and apparatus can be used with carbon and / or hydrogen containing low k dielectric materials.

Owner:LAM RES CORP

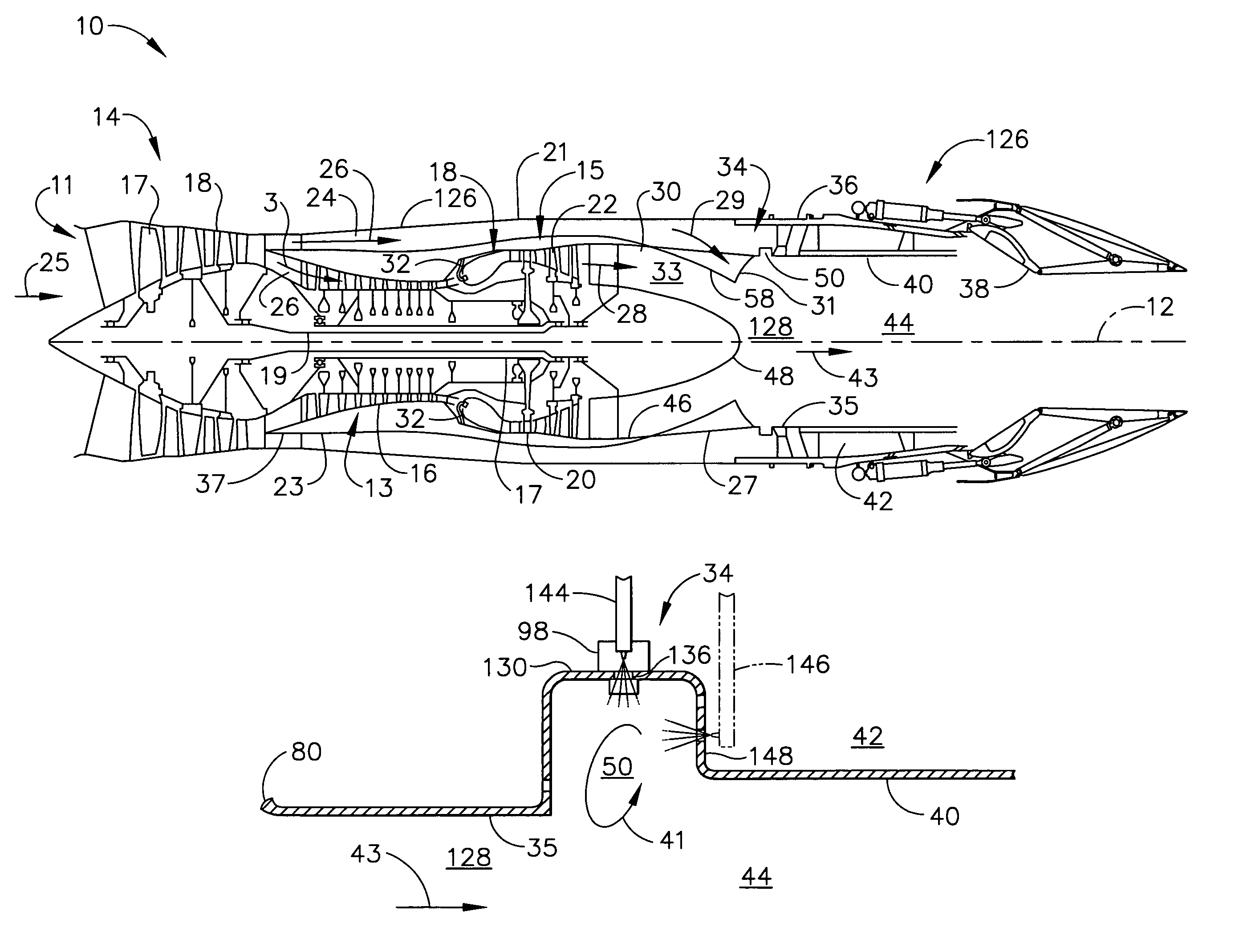

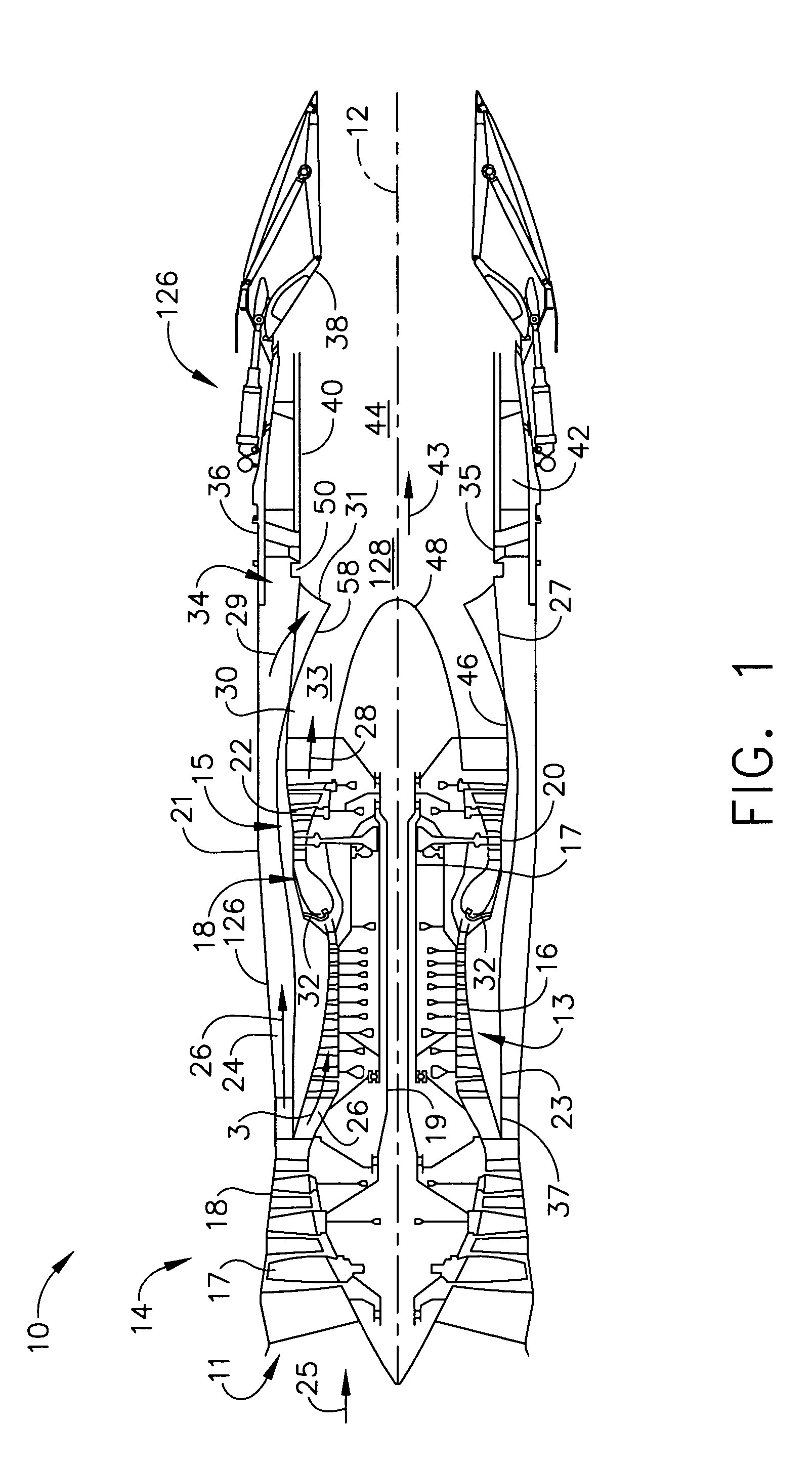

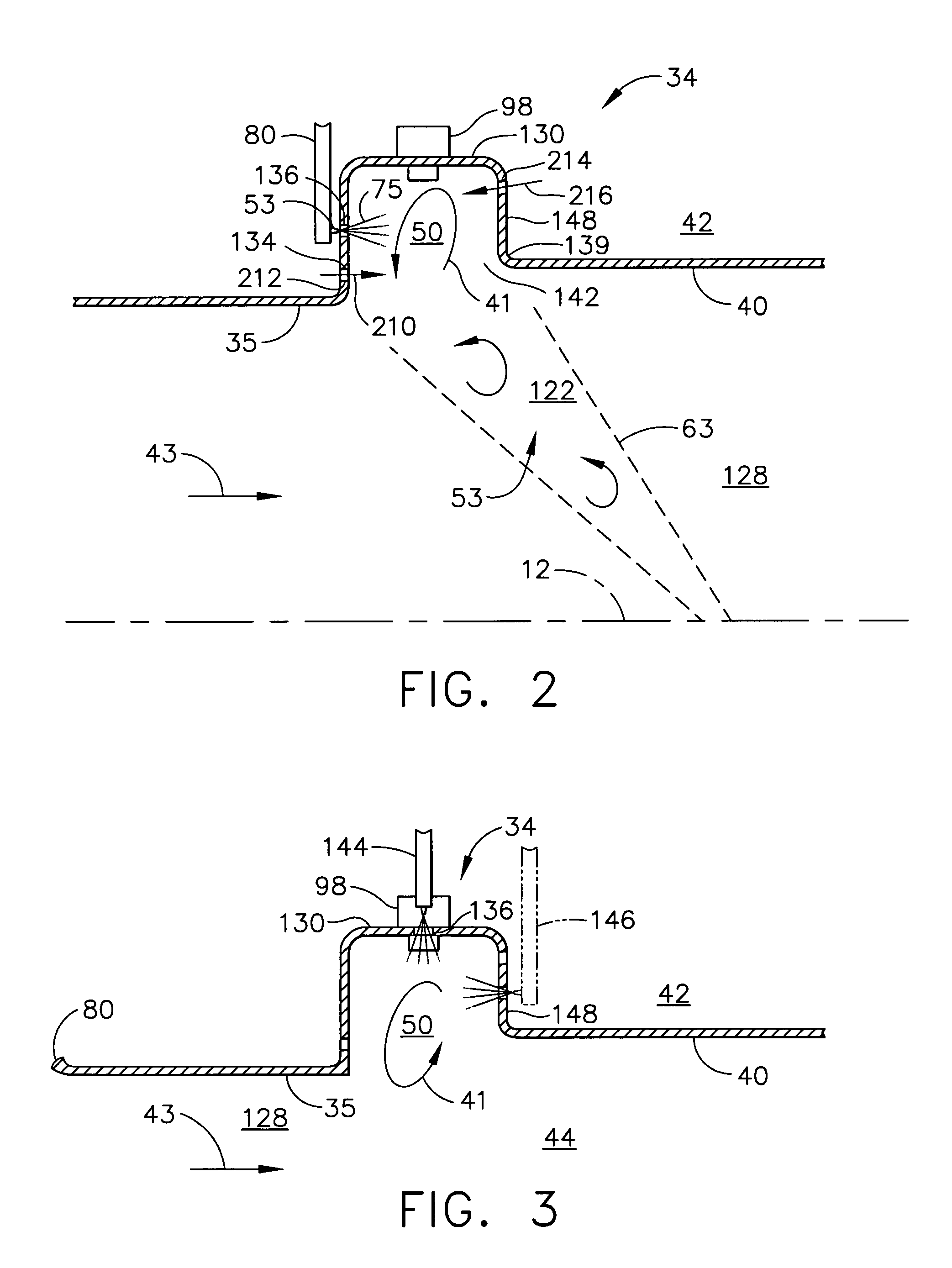

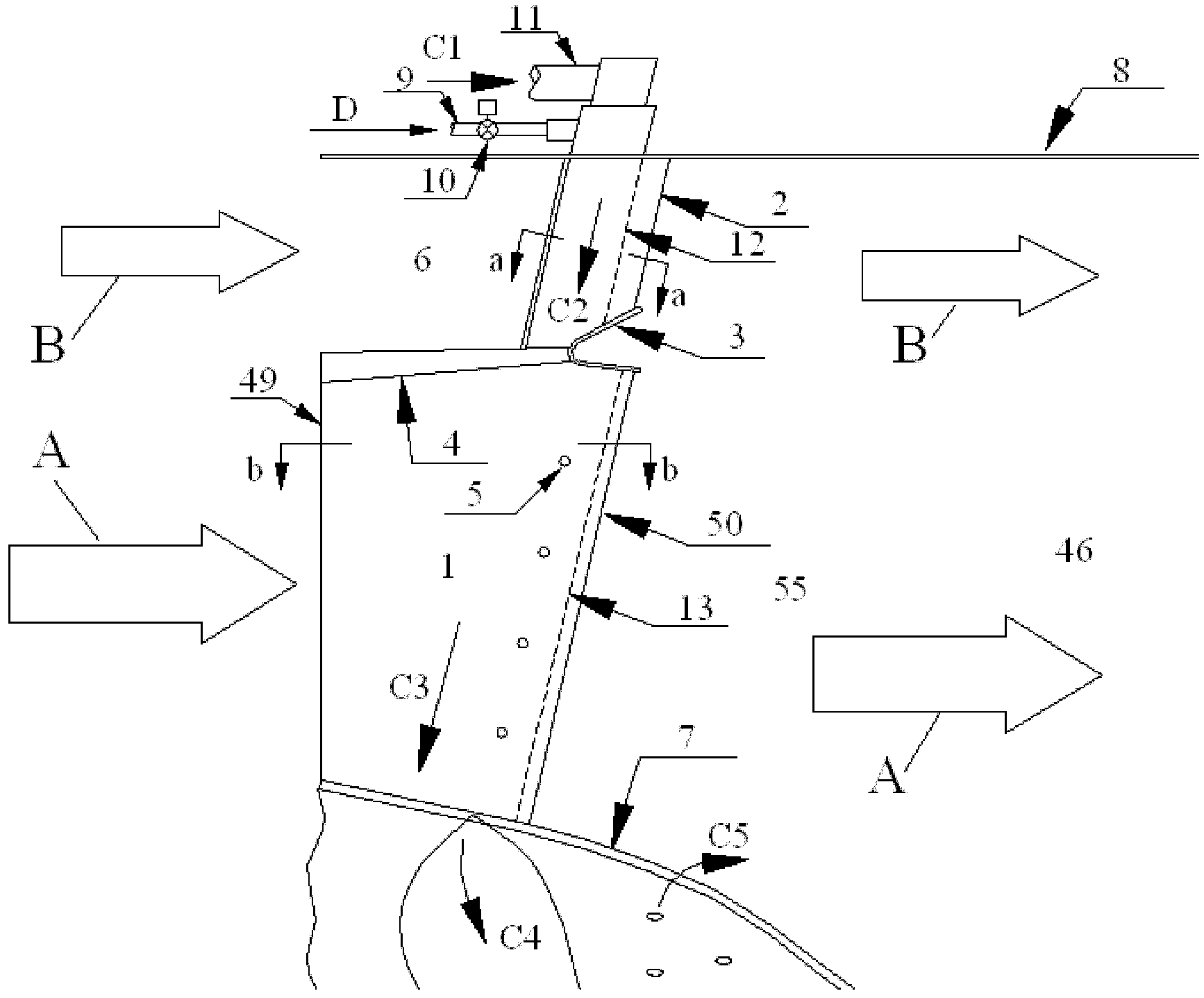

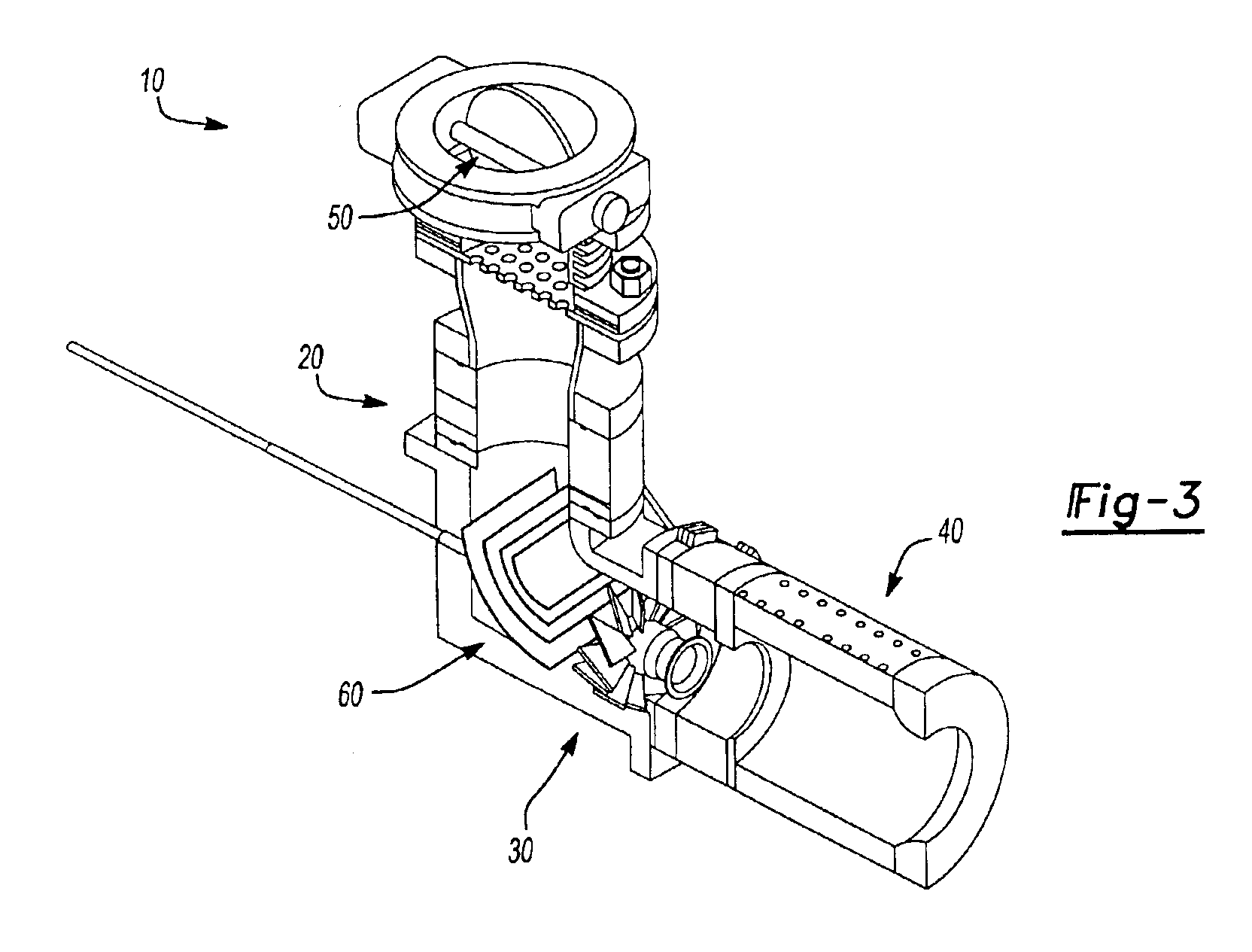

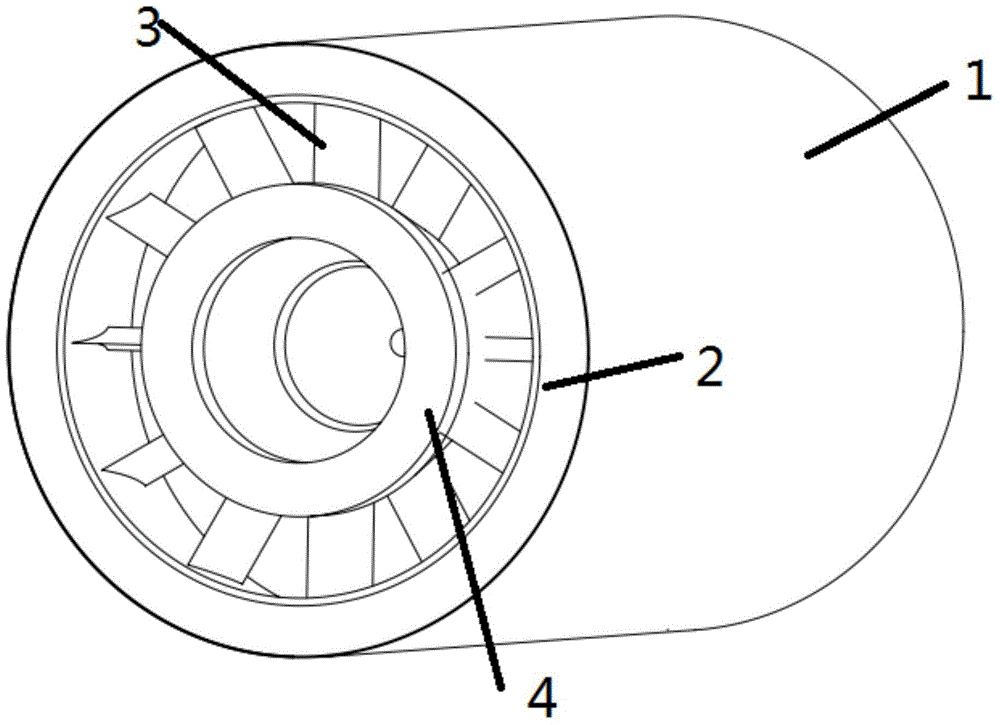

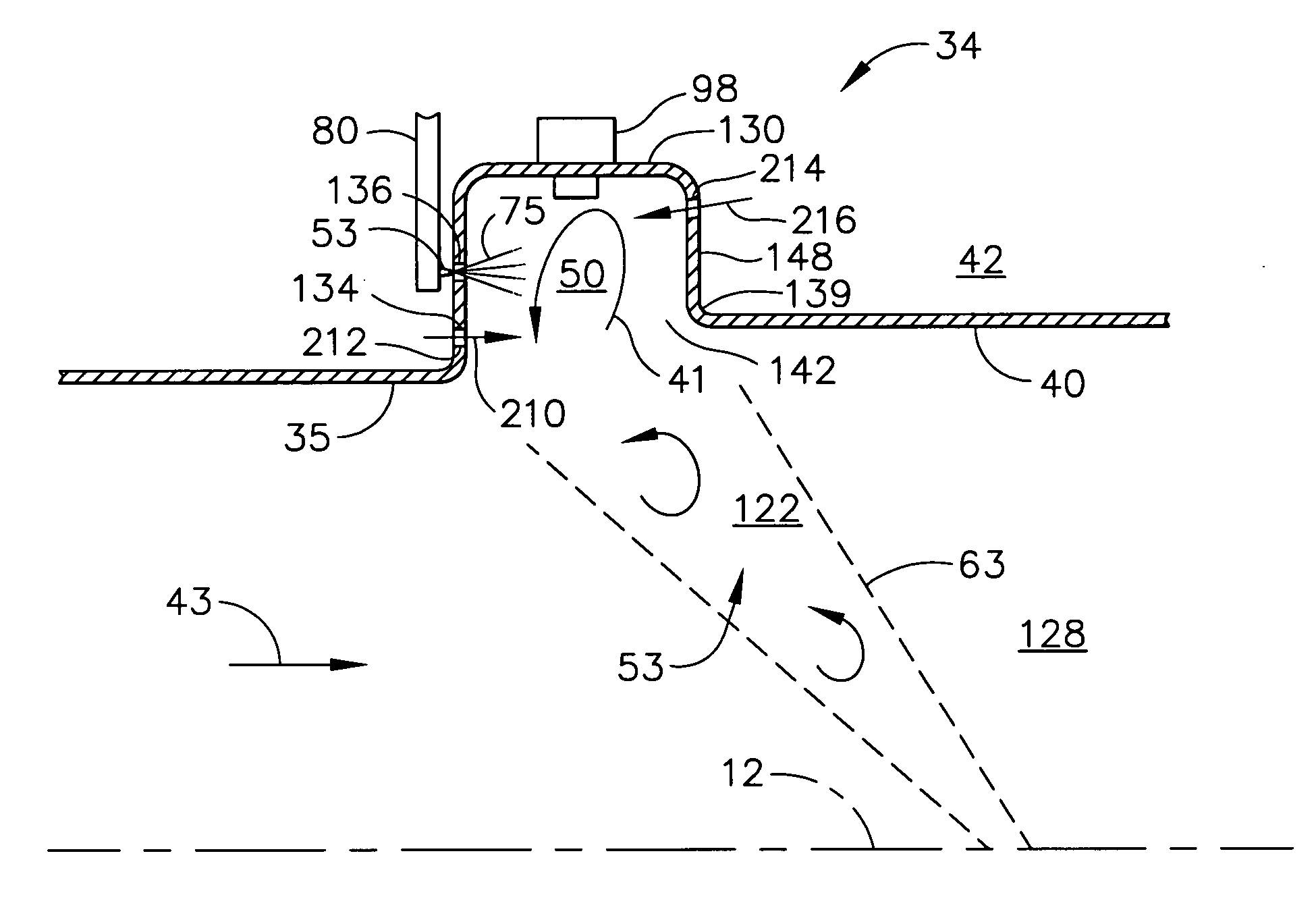

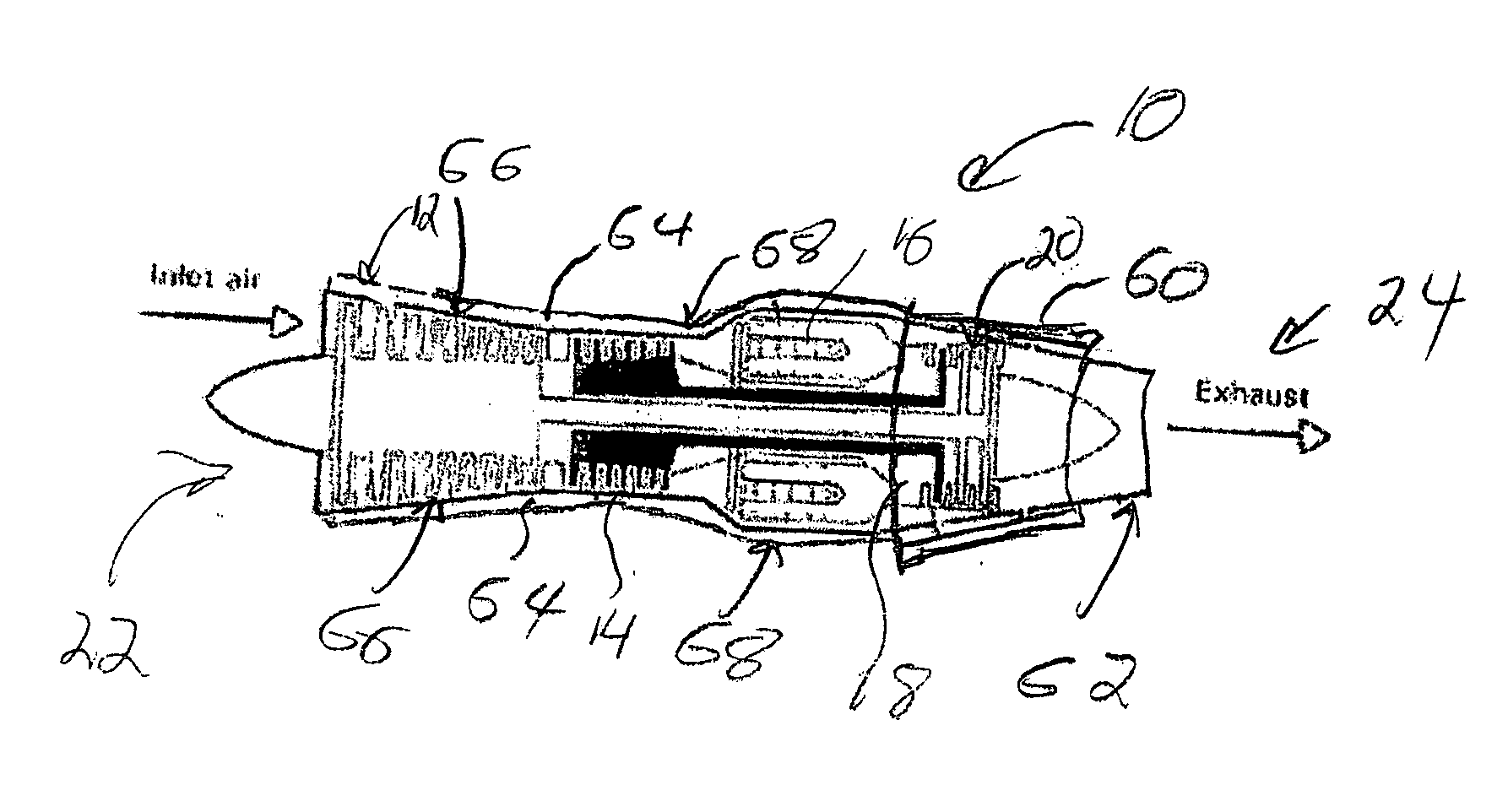

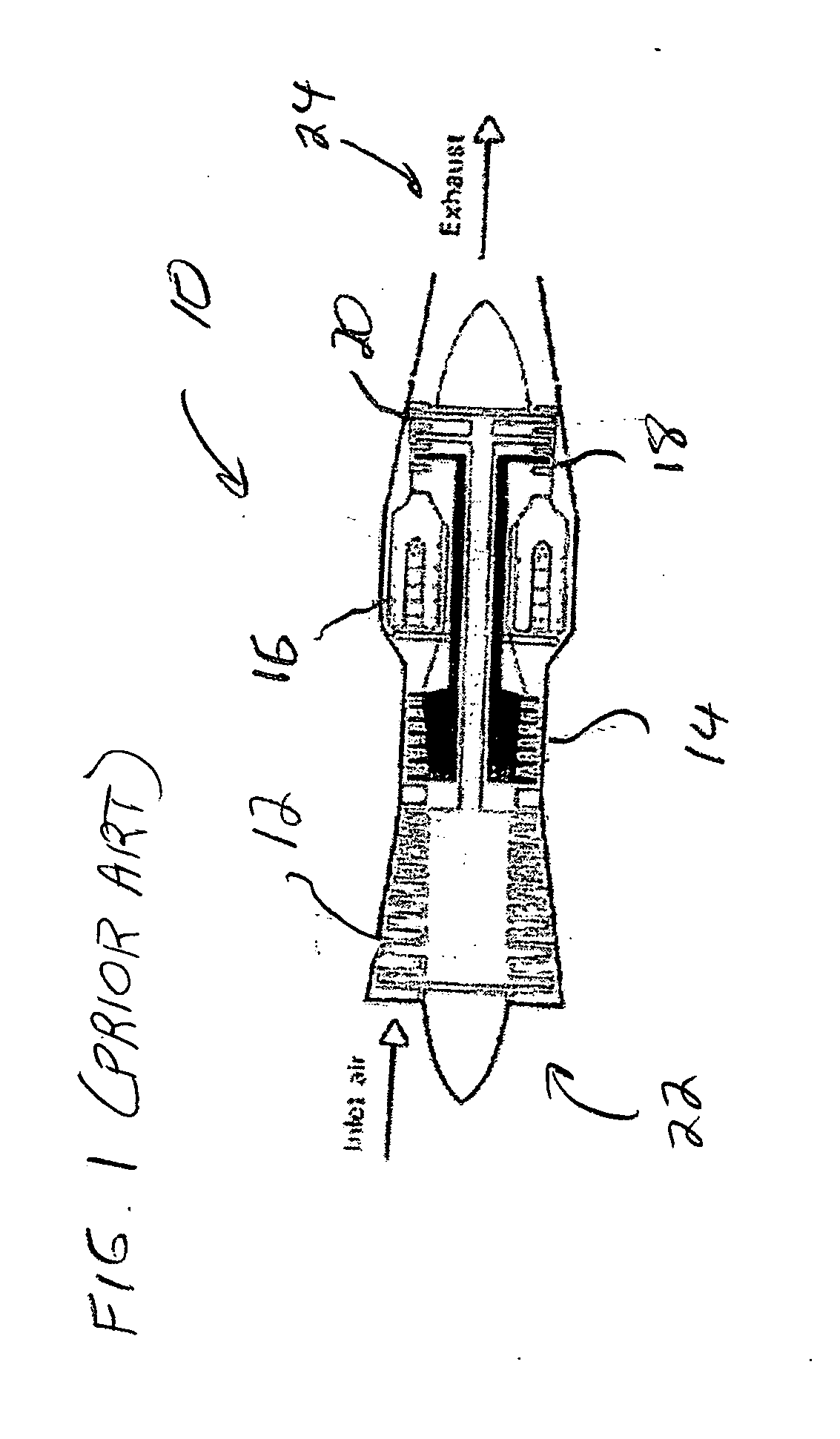

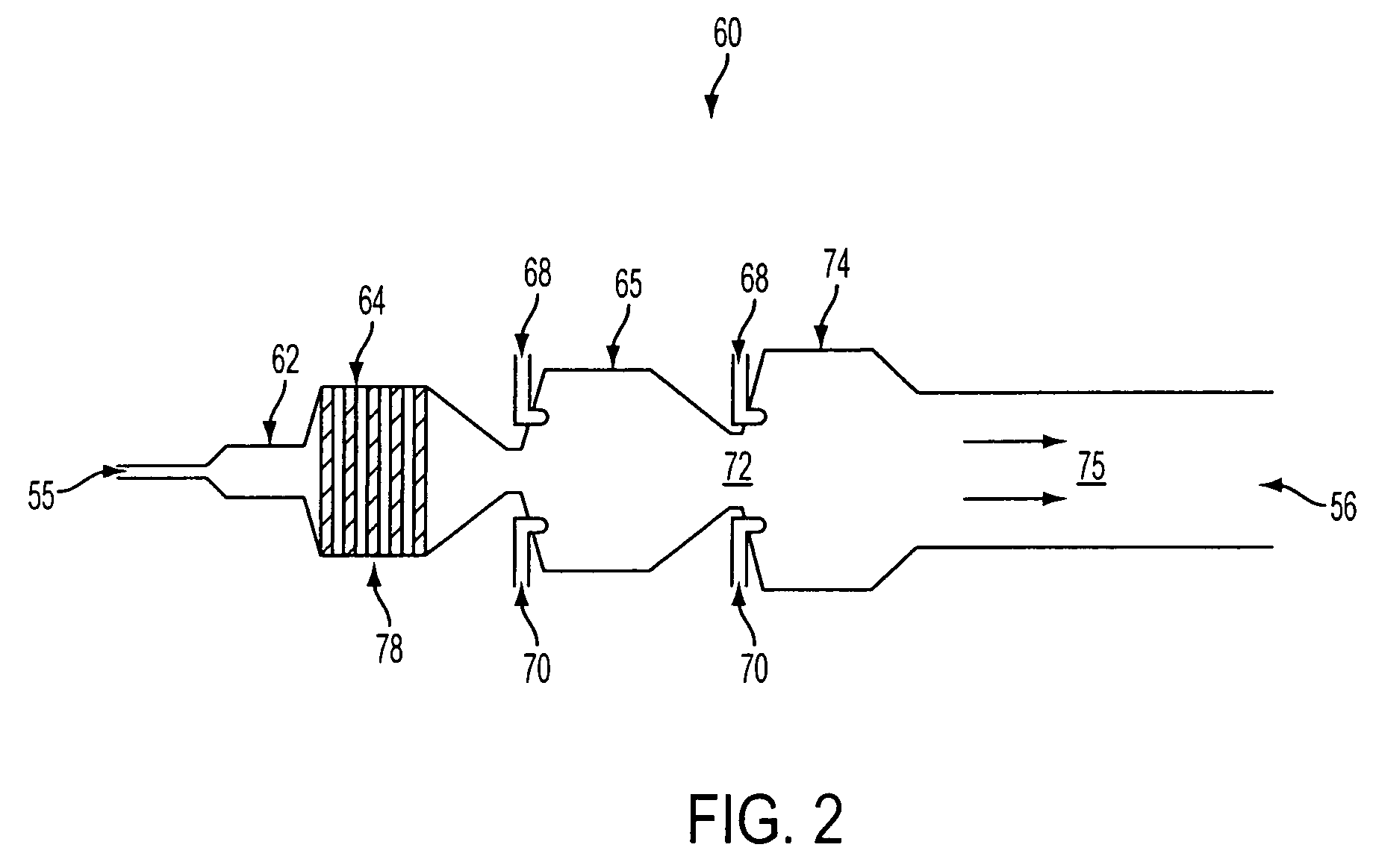

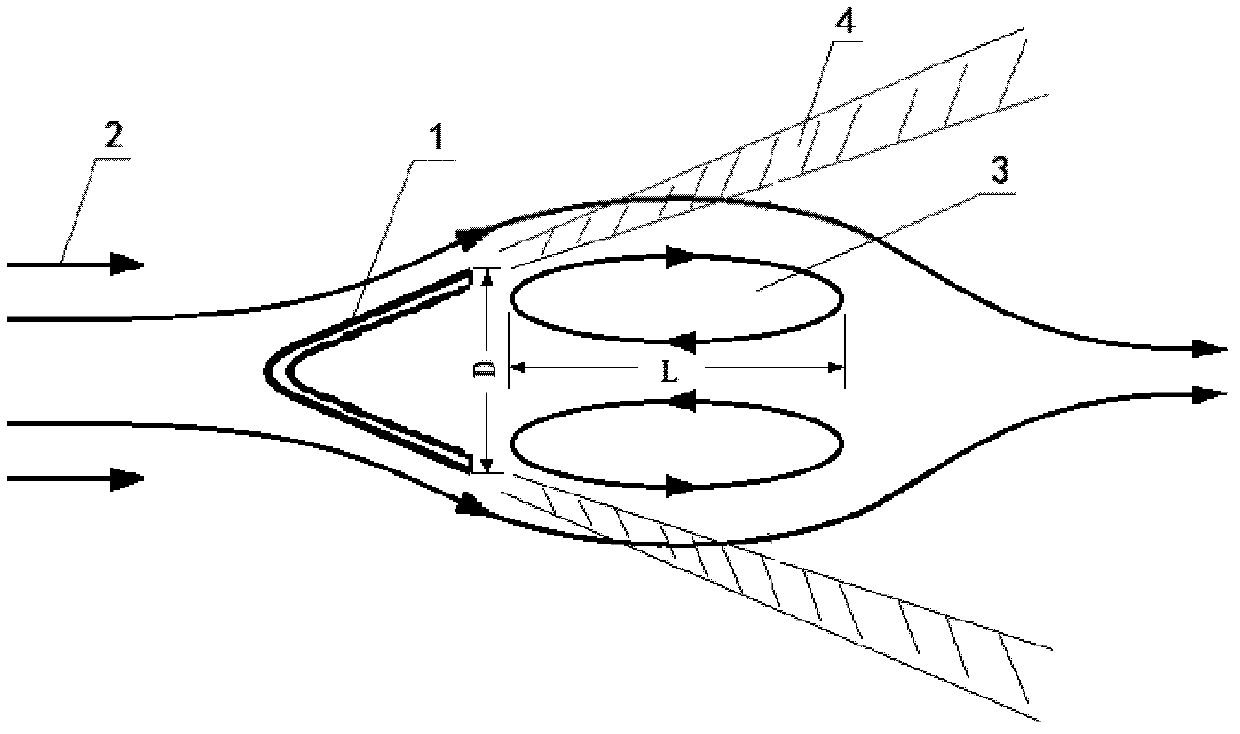

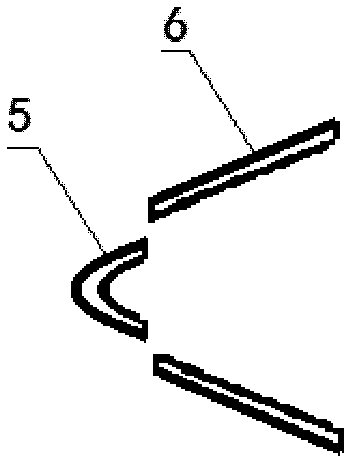

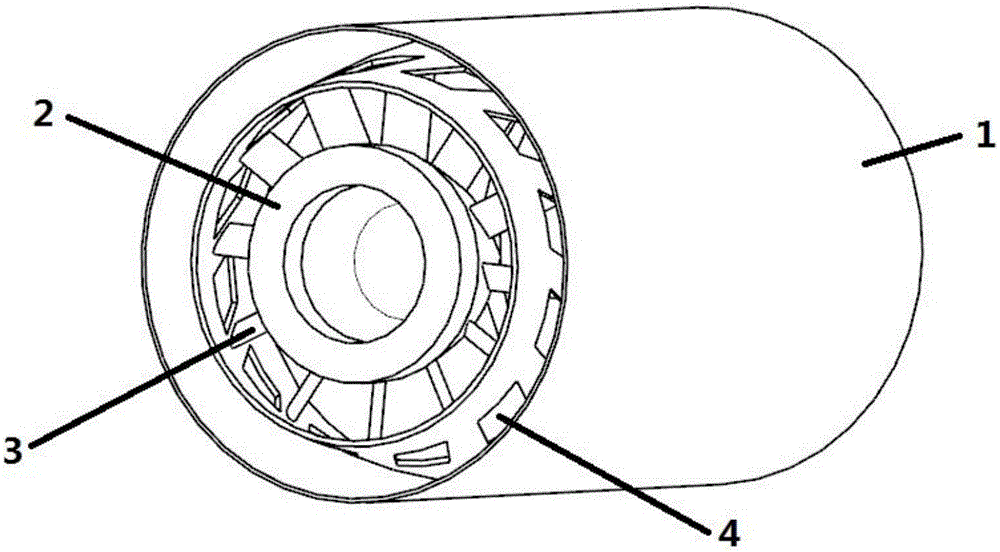

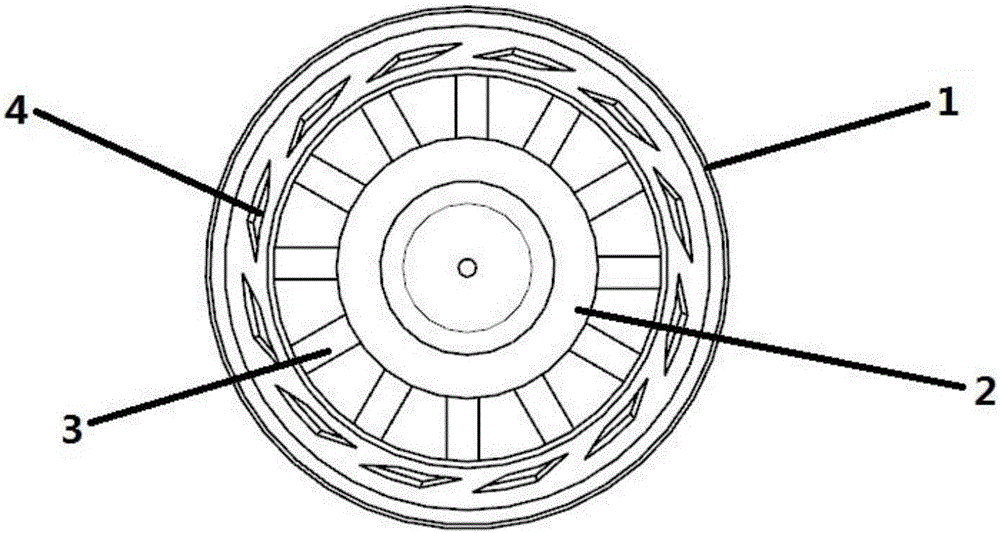

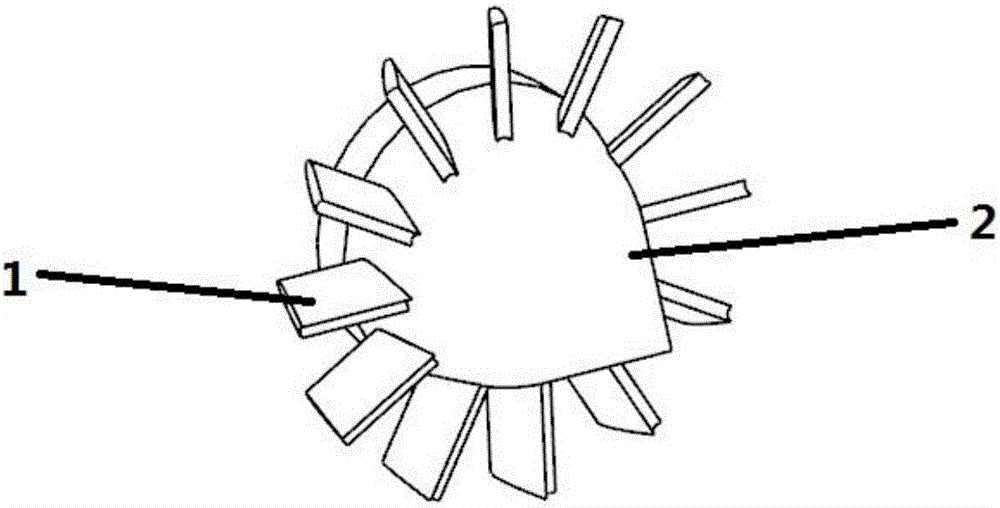

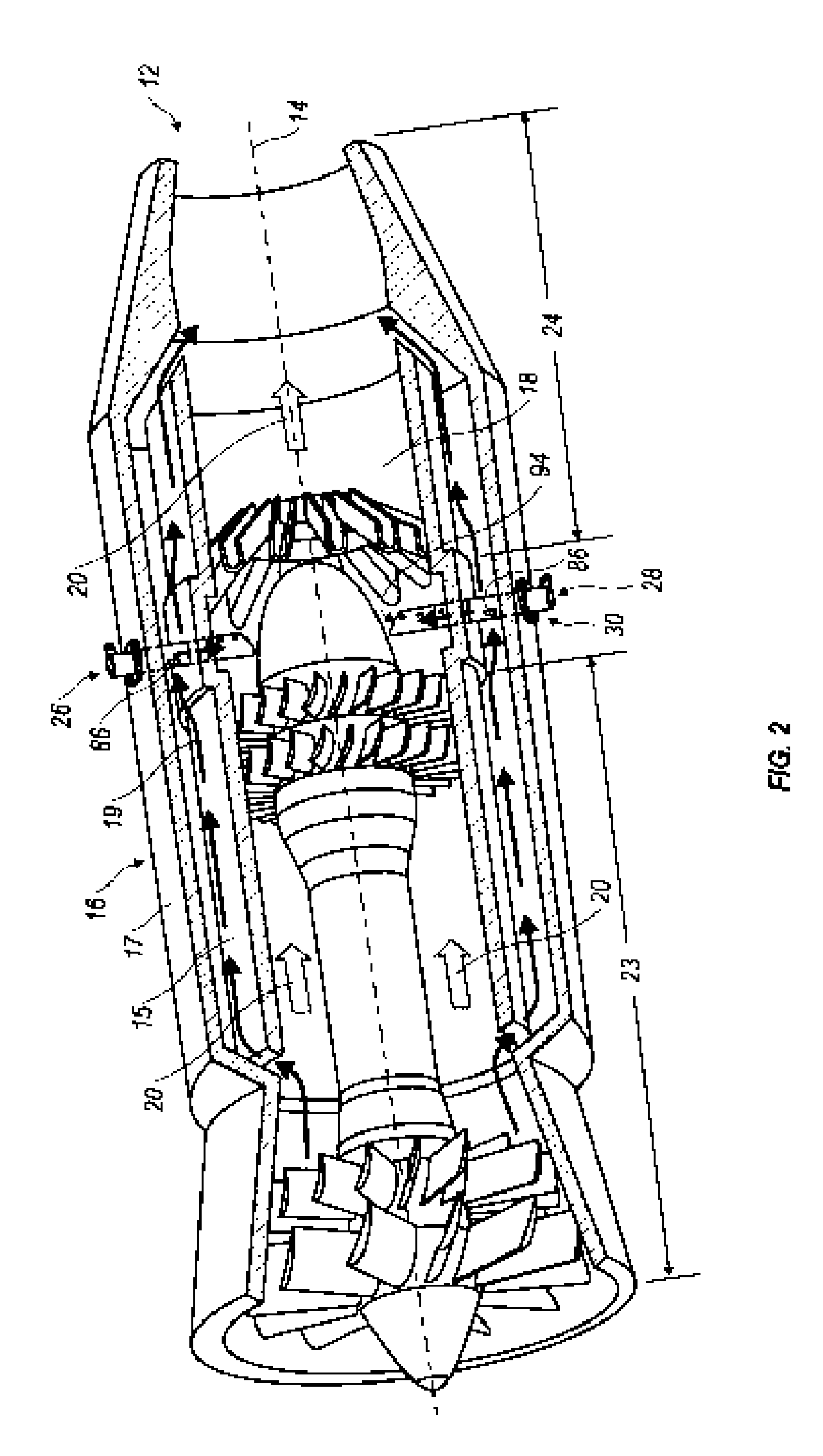

Compact swirl augmented afterburners for gas turbine engines

InactiveUS6895756B2Efficient flame propagationBurn quicklyTurbine/propulsion fuel supply systemsContinuous combustion chamberCombustion instabilityCombustion chamber

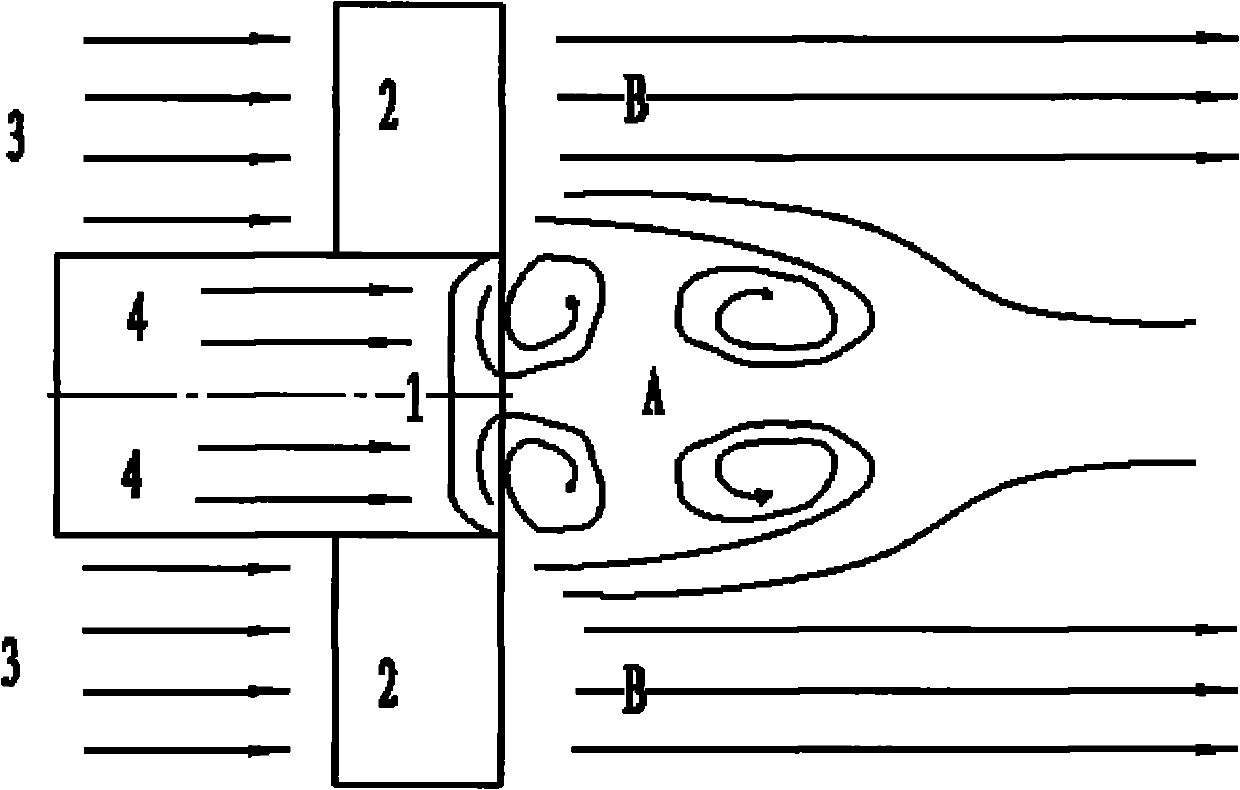

An afterburner apparatus that utilizes a novel swirl generator for rapidly and efficiently atomizing, vaporizing, as necessary, and mixing a fuel into an oxidant. The swirl generator converts an oxidant flow into a turbulent, three-dimensional flowfield into which the fuel is introduced. The swirl generator effects a toroidal outer recirculation zone and a central recirculation zone, which is positioned within the outer recirculation zone. These recirculation zones are configured in a backward-flowing manner that carries heat and combustion byproducts upstream where they are employed to continuously ignite a combustible fuel / oxidizer mixture in adjacent shear layers. The recirculation zones accelerate flame propagation to allow afterburning to be completed in a relatively short length. Inherent with this swirl afterburner concept are design compactness, light weight, lower cost, smooth and efficient combustion, high thrust output, wide flammability limits, continuous operation at stoichiometric fuel / oxidizer mixture ratios, no combustion instabilities, and relatively low pressure losses.

Owner:THE BOEING CO +1

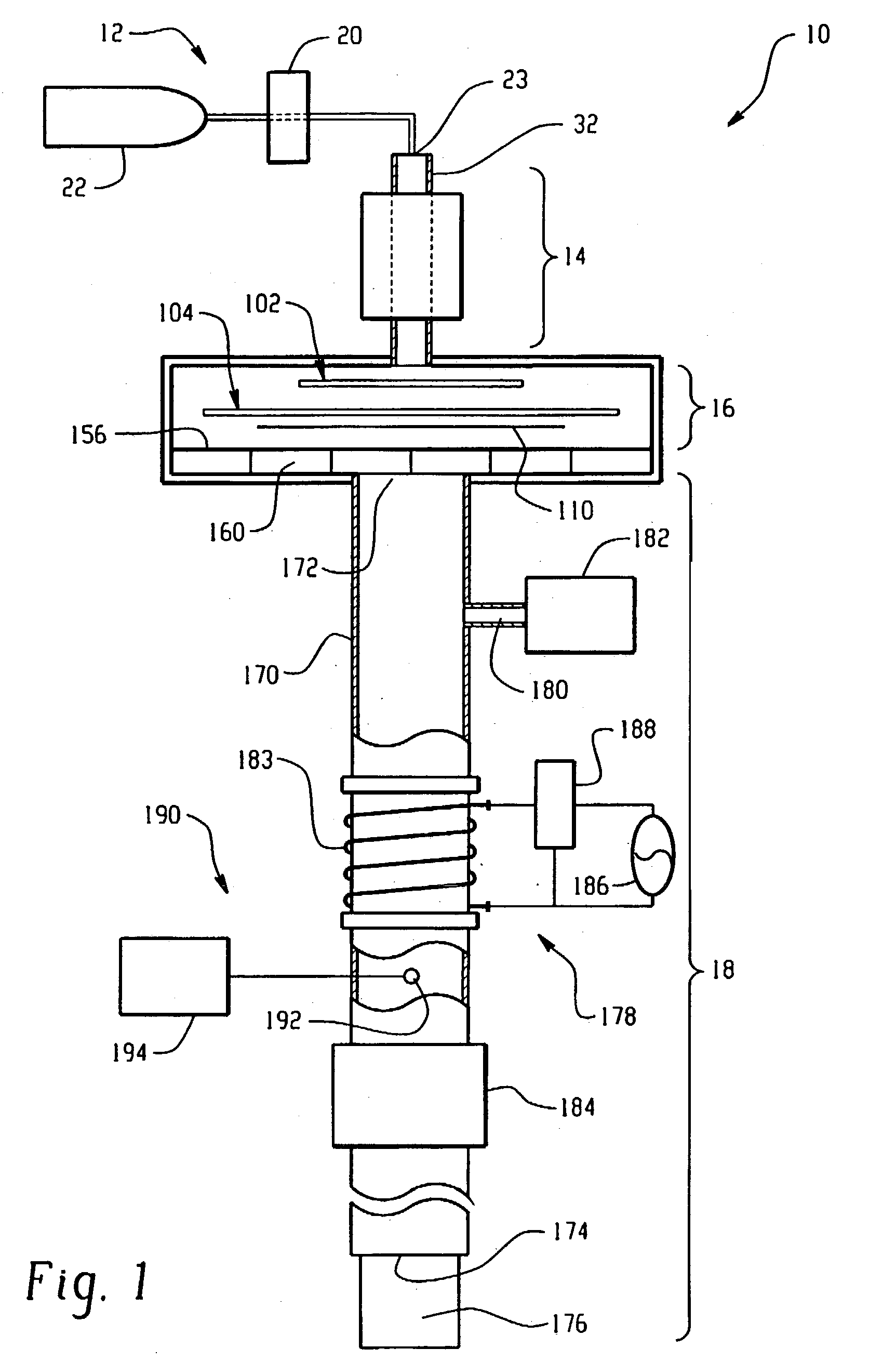

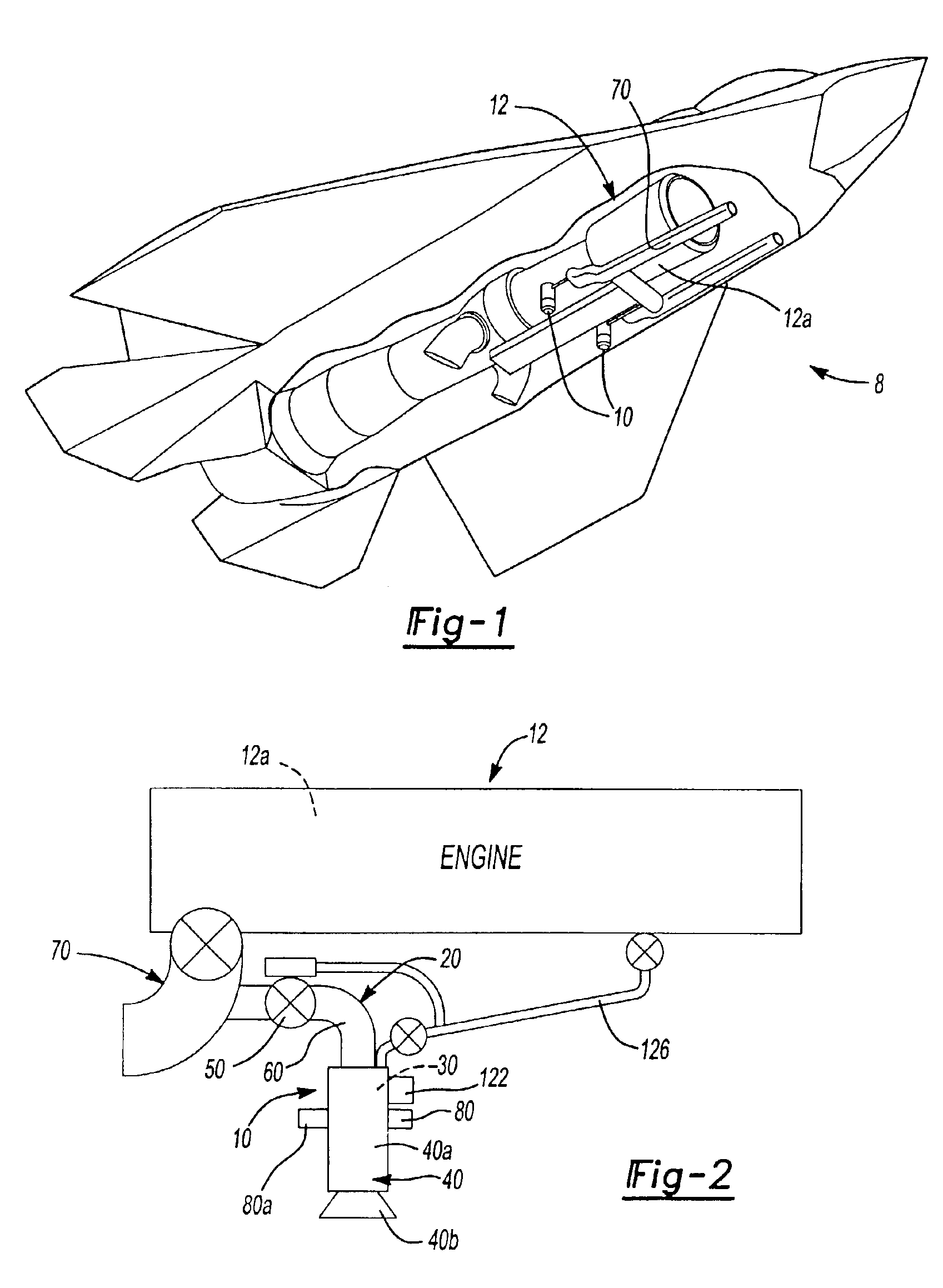

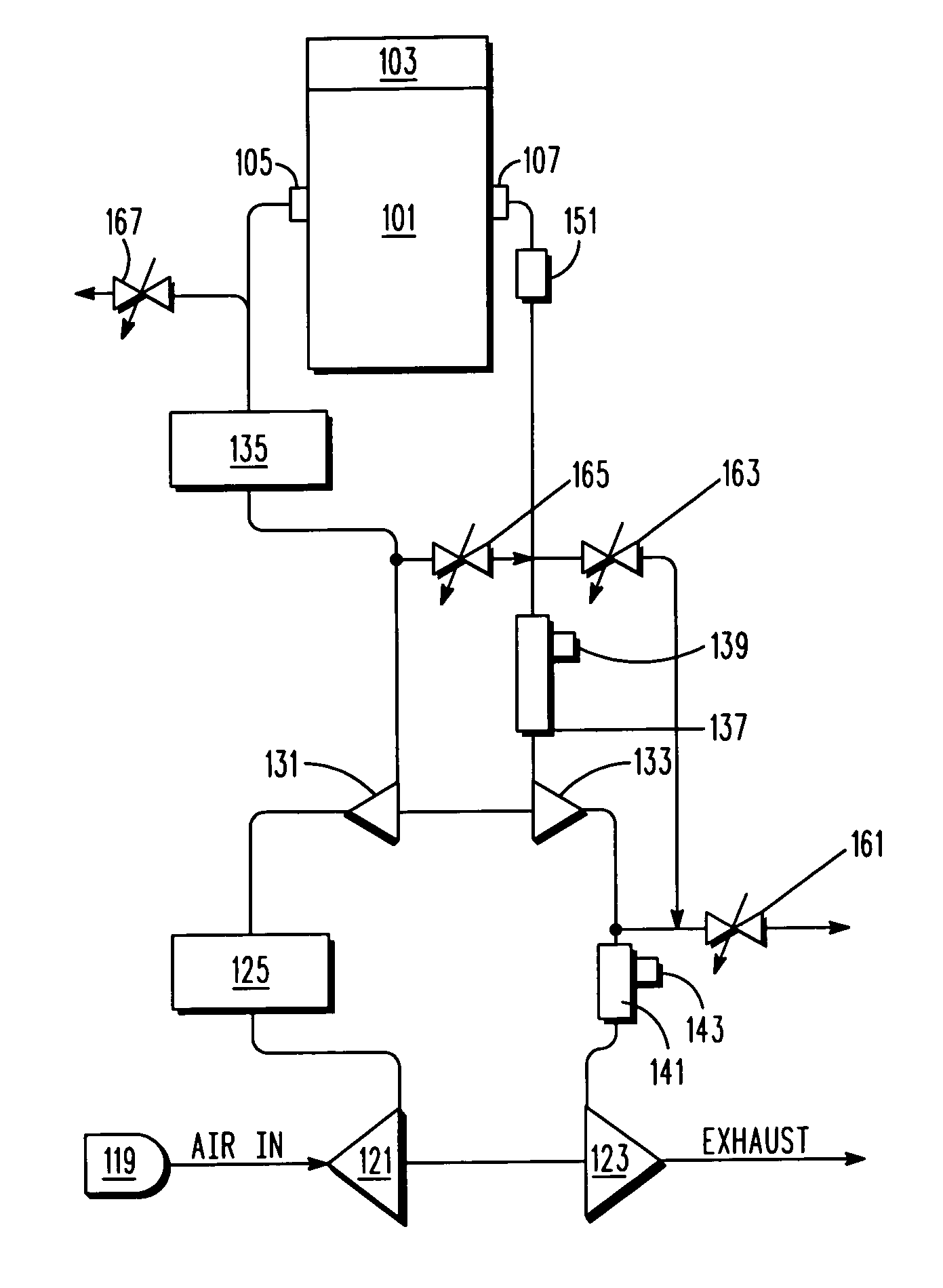

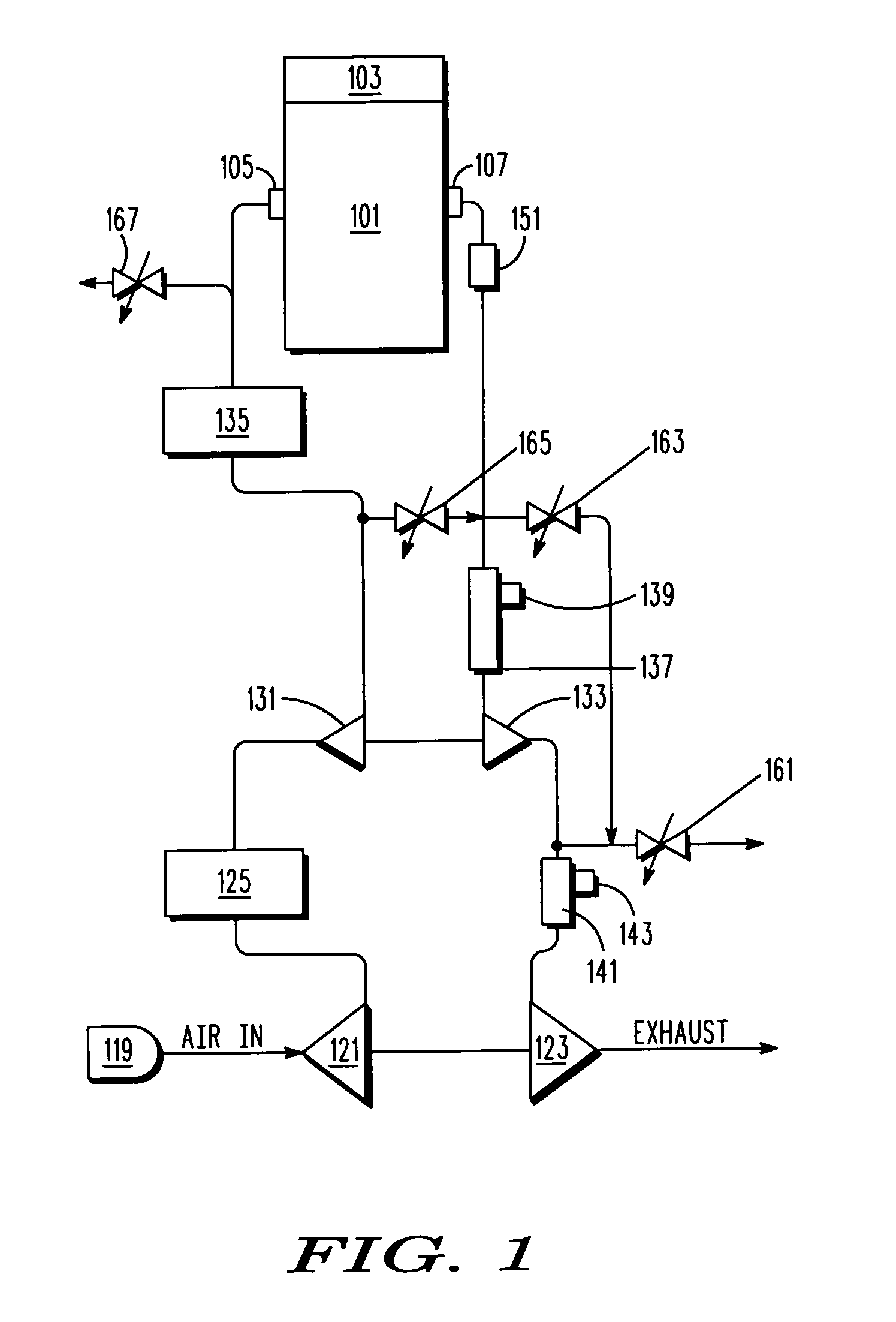

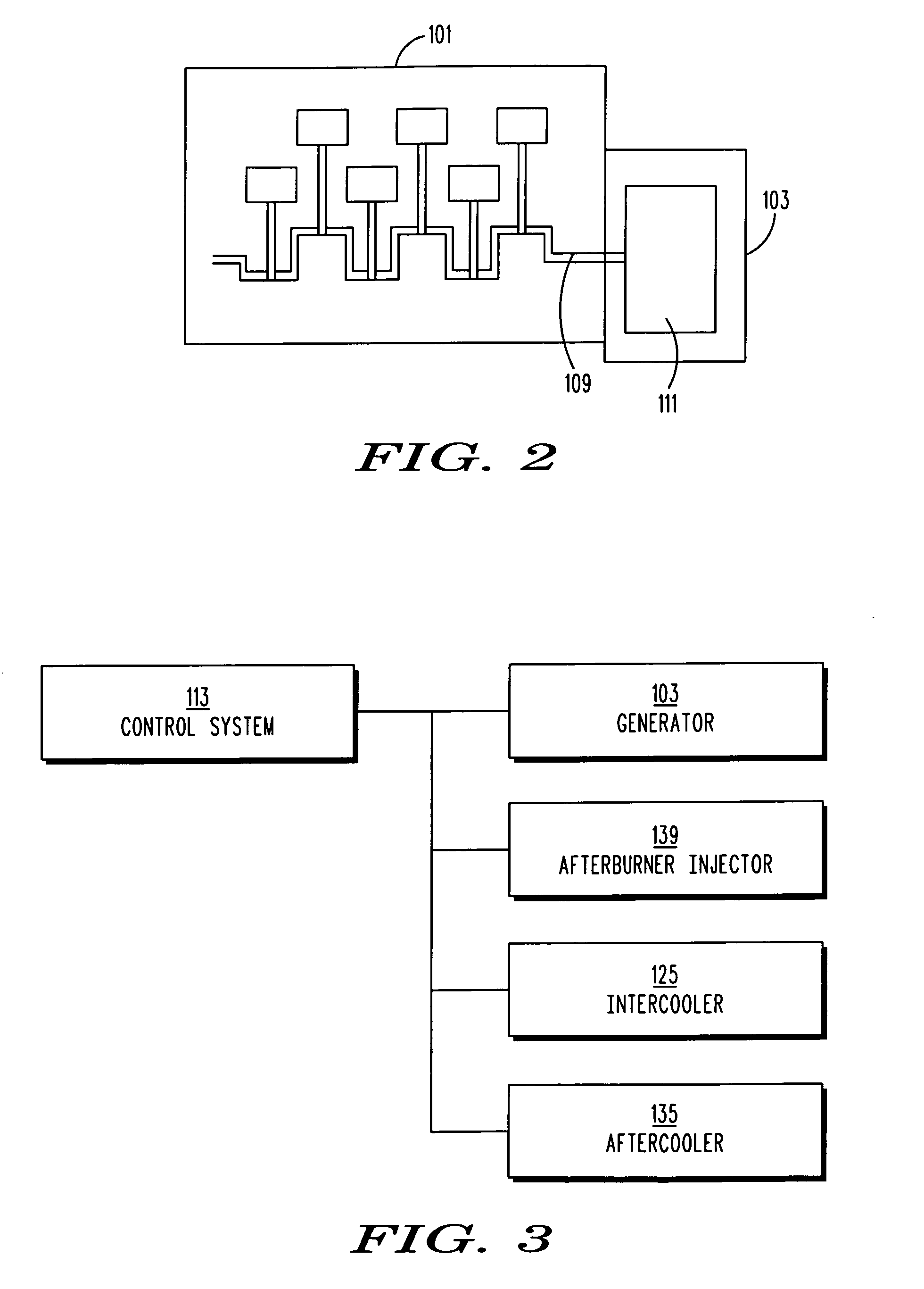

Powerplant and related control system and method

ActiveUS20100100300A1Efficient powerImprove reliabilityInternal combustion piston enginesDigital data processing detailsEquivalence ratioControl system

A hydrogen fueled powerplant including an internal combustion engine that drives a motor-generator, and has a two-stage turbocharger, for an aircraft. A control system controls the operation of the motor-generator to maintain the engine at a speed selected based on controlling the engine equivalence ratio. The control system controls an afterburner, an intercooler and an aftercooler to maximize powerplant efficiency. The afterburner also adds power to the turbochargers during high-altitude restarts. The turbochargers also include motor-generators that extract excess power from the exhaust.

Owner:AEROVIRONMENT INC

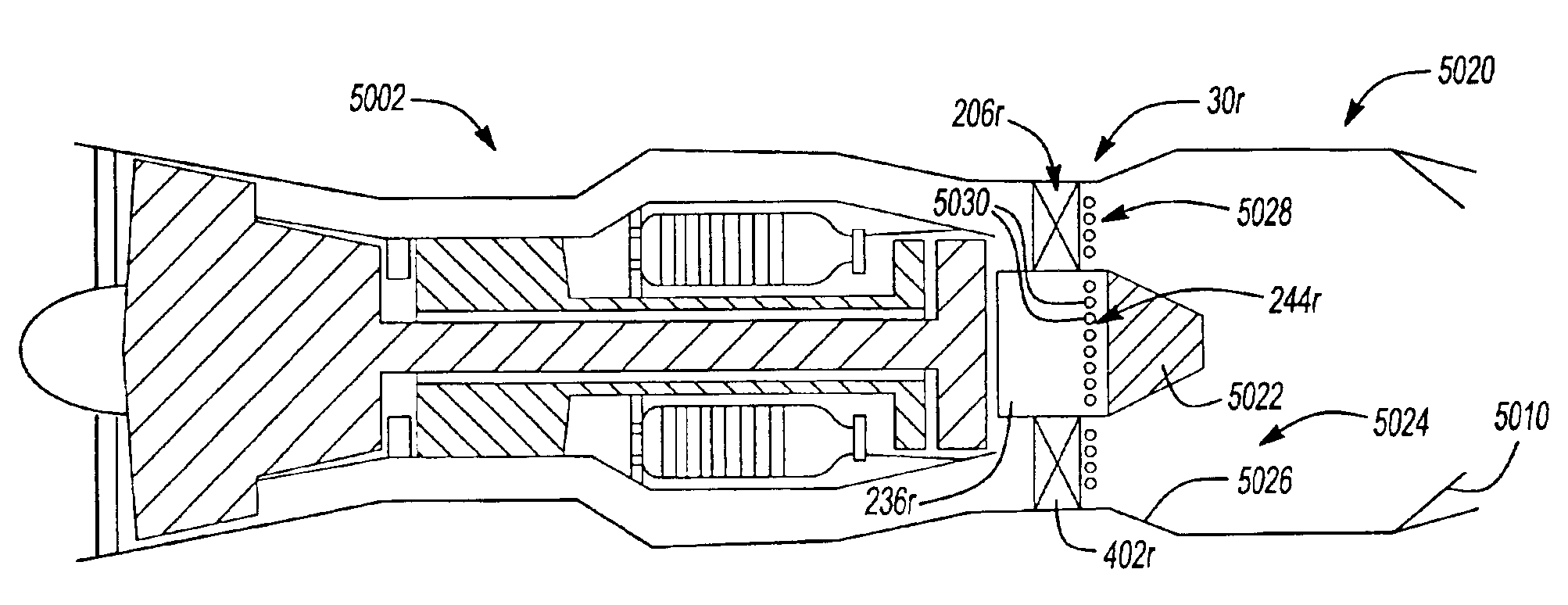

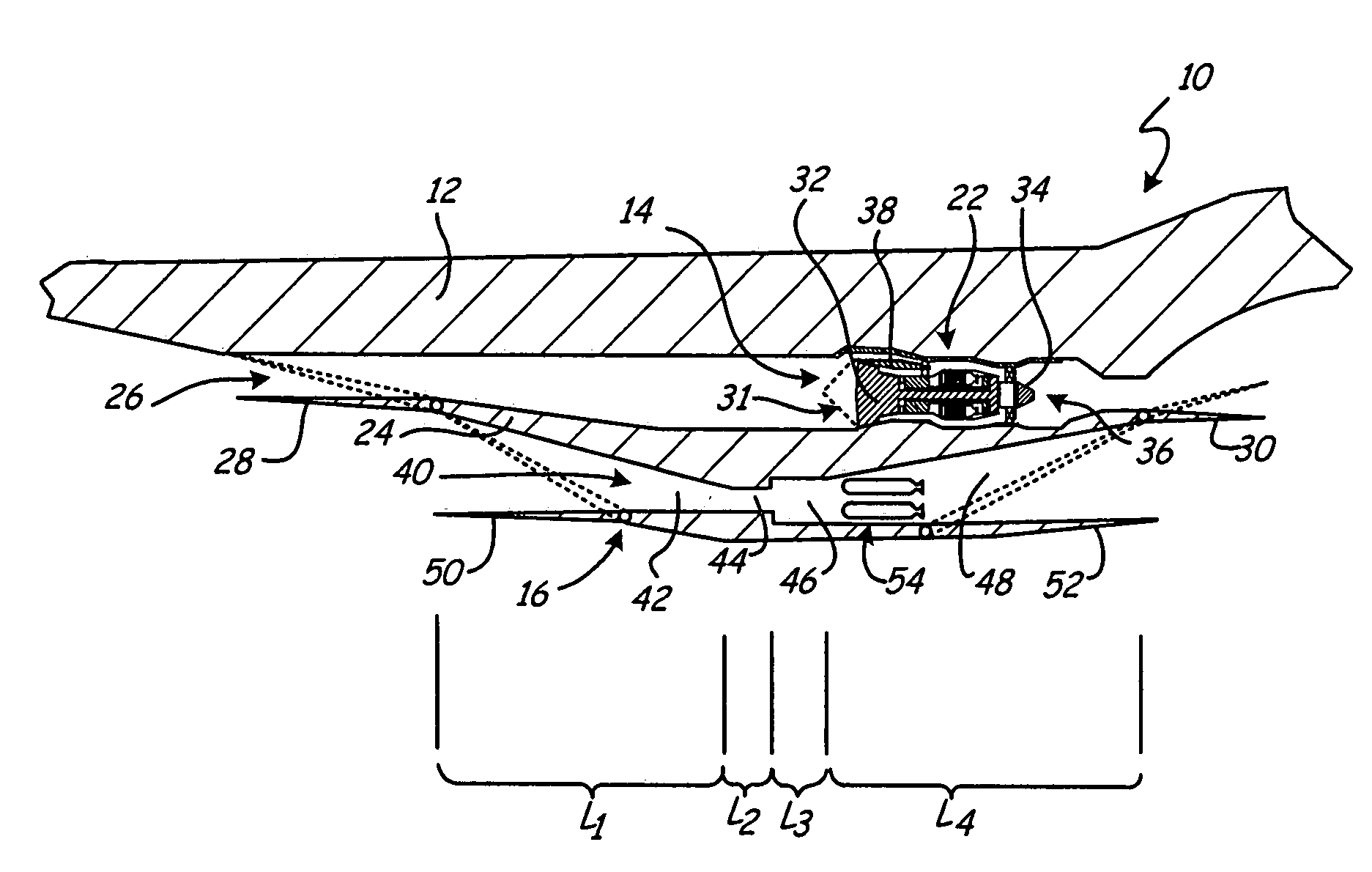

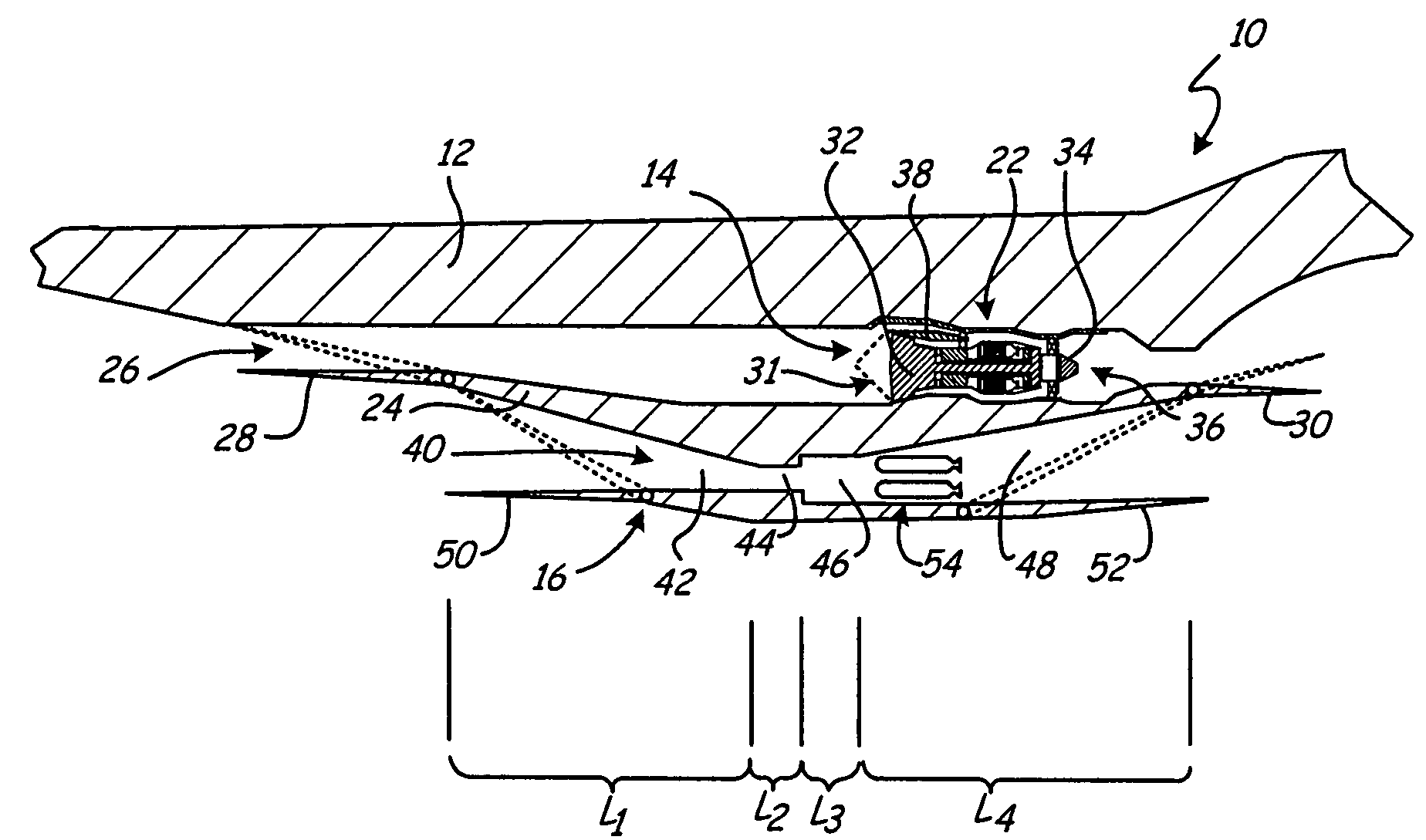

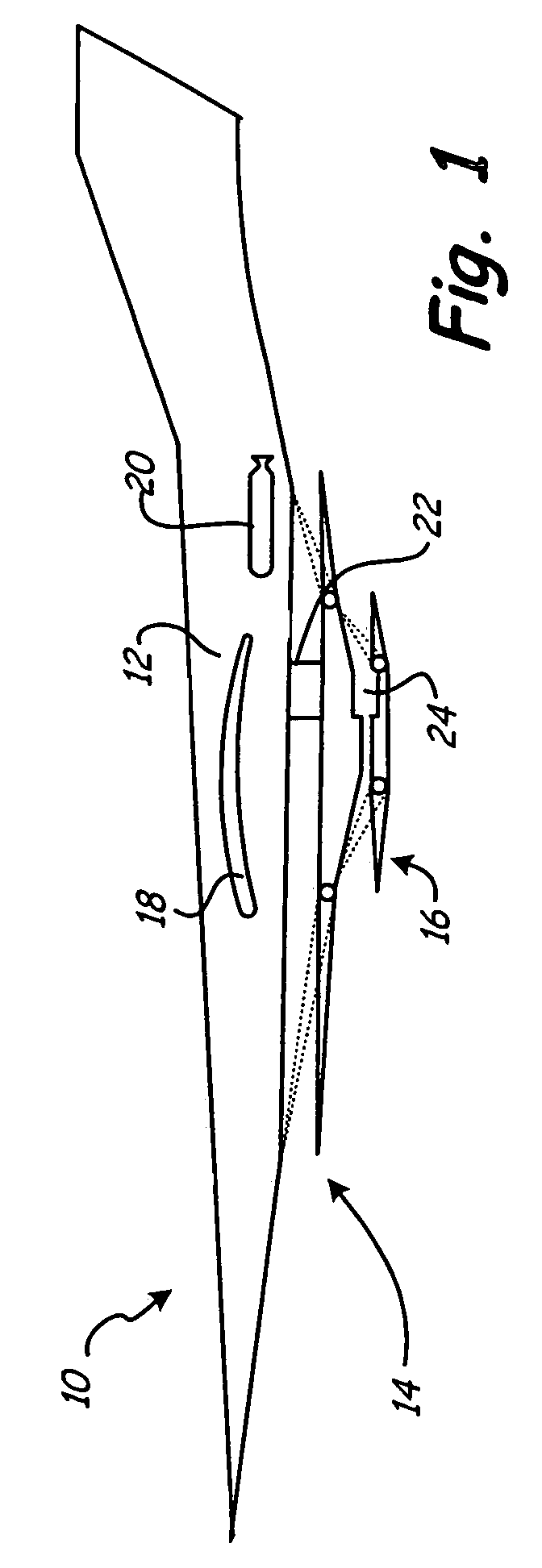

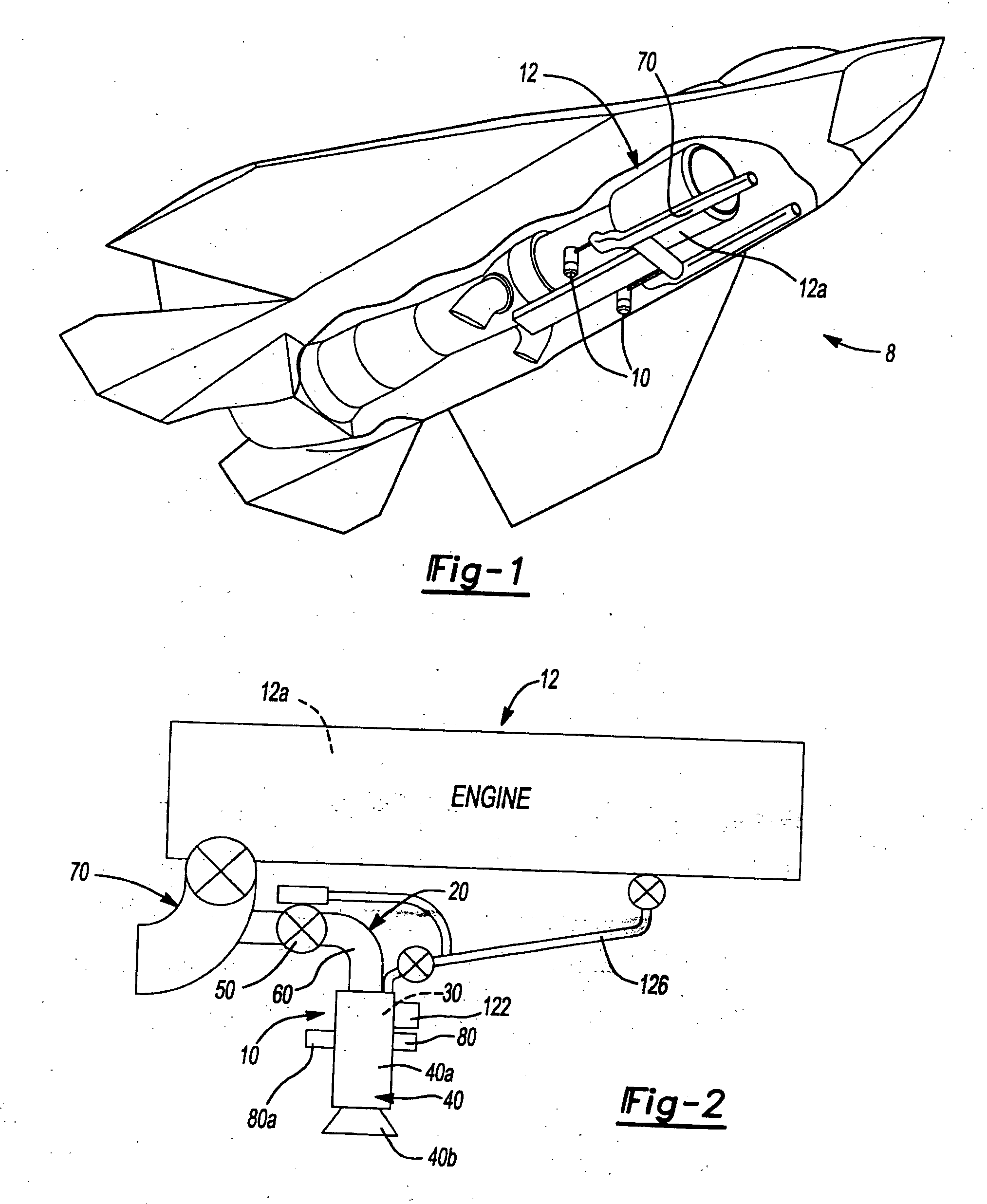

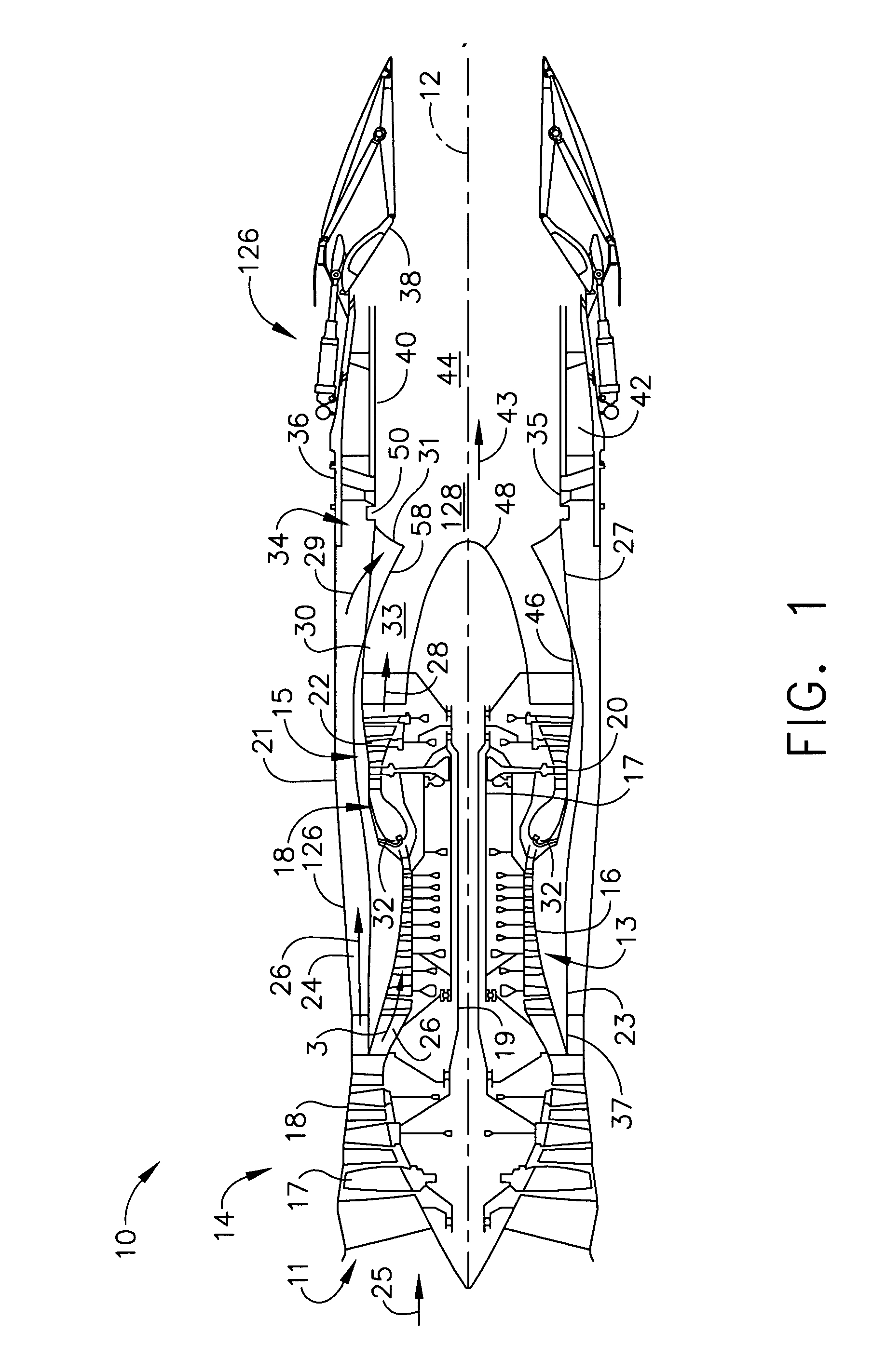

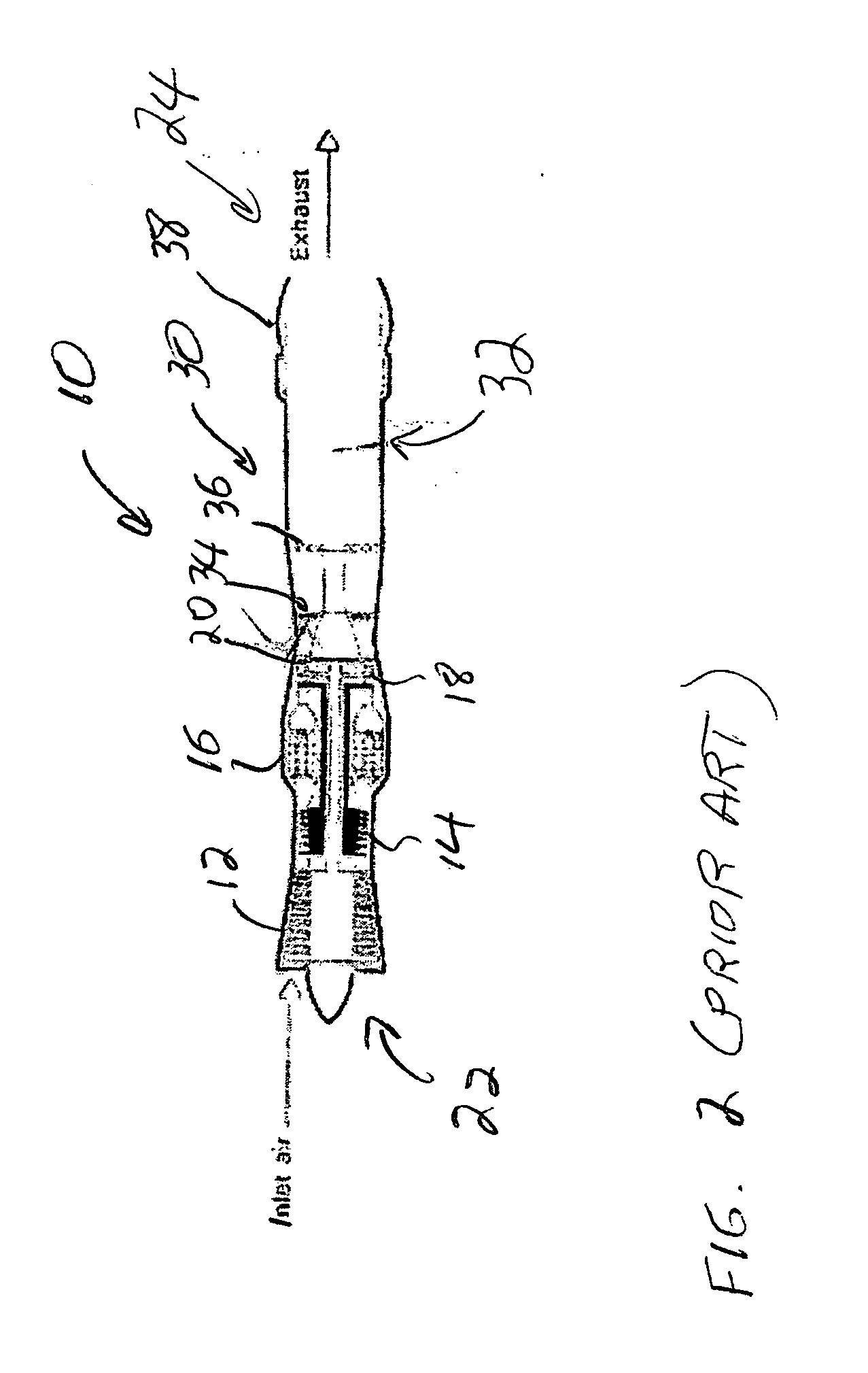

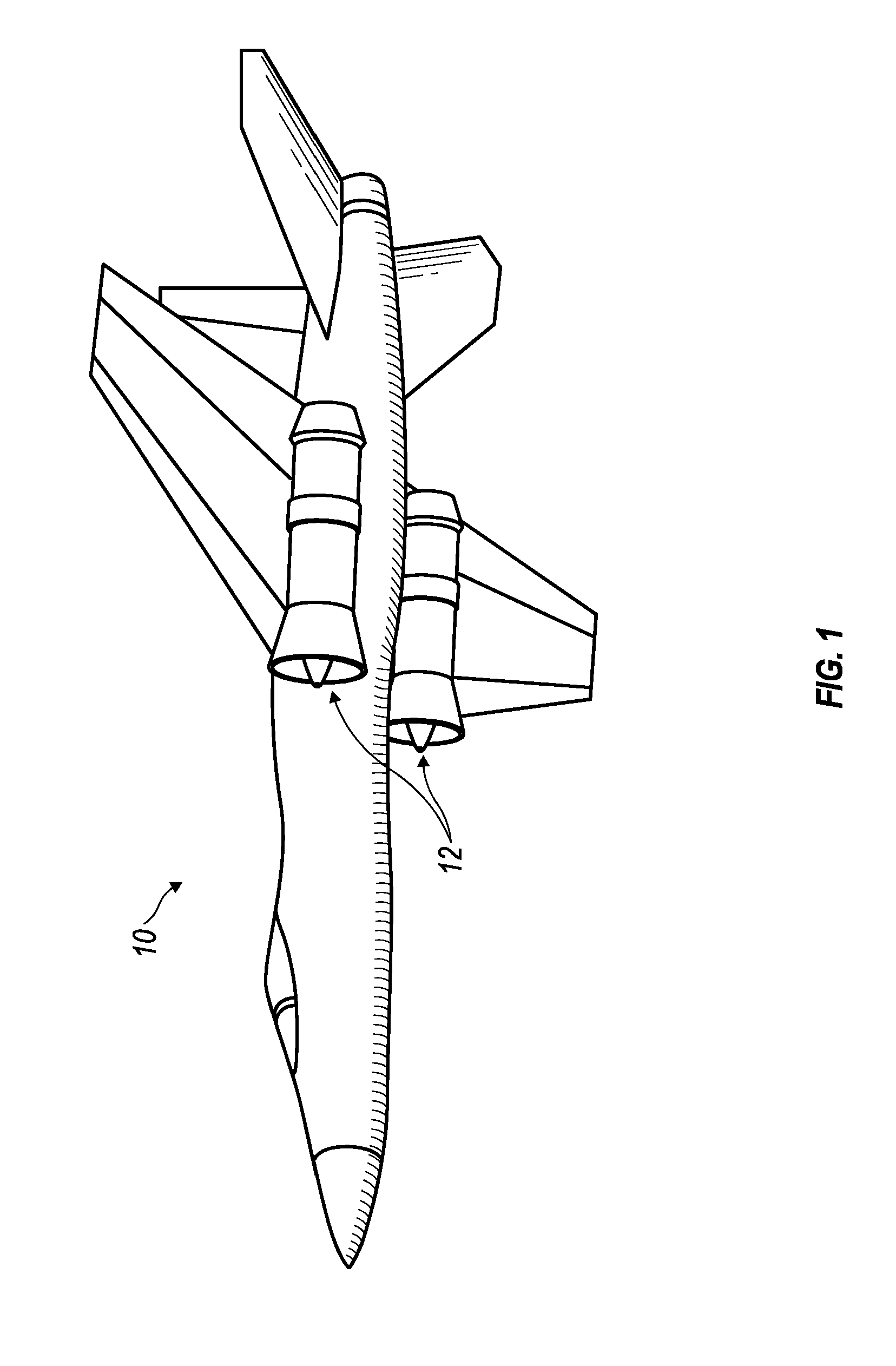

Single-stage hypersonic vehicle featuring advanced swirl combustion

InactiveUS20080283677A1Reduce complexityShorten the lengthAircraft navigation controlPower plant exhaust arrangementsRamjetLow speed

A single-stage hypersonic vehicle is comprised of a low-speed and a high-speed propulsion system. The low-speed propulsion system propels the single-stage vehicle to a threshold velocity, after which the high-speed propulsion system then takes over. The low-speed propulsion system includes a combined-cycle engine featuring a swirl generator that is integrated into a turbojet engine to provide a compact turbojet and swirl afterburner-ramjet propulsion system. The high-speed propulsion system includes a hypersonic engine that is operable at the threshold takeover velocity and beyond. In various embodiments, the high-speed propulsion system comprises a scramjet, rocket, or scramjet / rocket engine depending requirements. Benefits of the swirl generator design include its ability to rapidly and efficiently atomize, vaporize, mix and burn the fuel and oxidizer for the low speed propulsion system, significantly reduce length, weight, cooling requirements and complexity for both propulsion systems, while maintaining high propulsion performance and reducing propulsion and launch costs.

Owner:UNITED TECH CORP

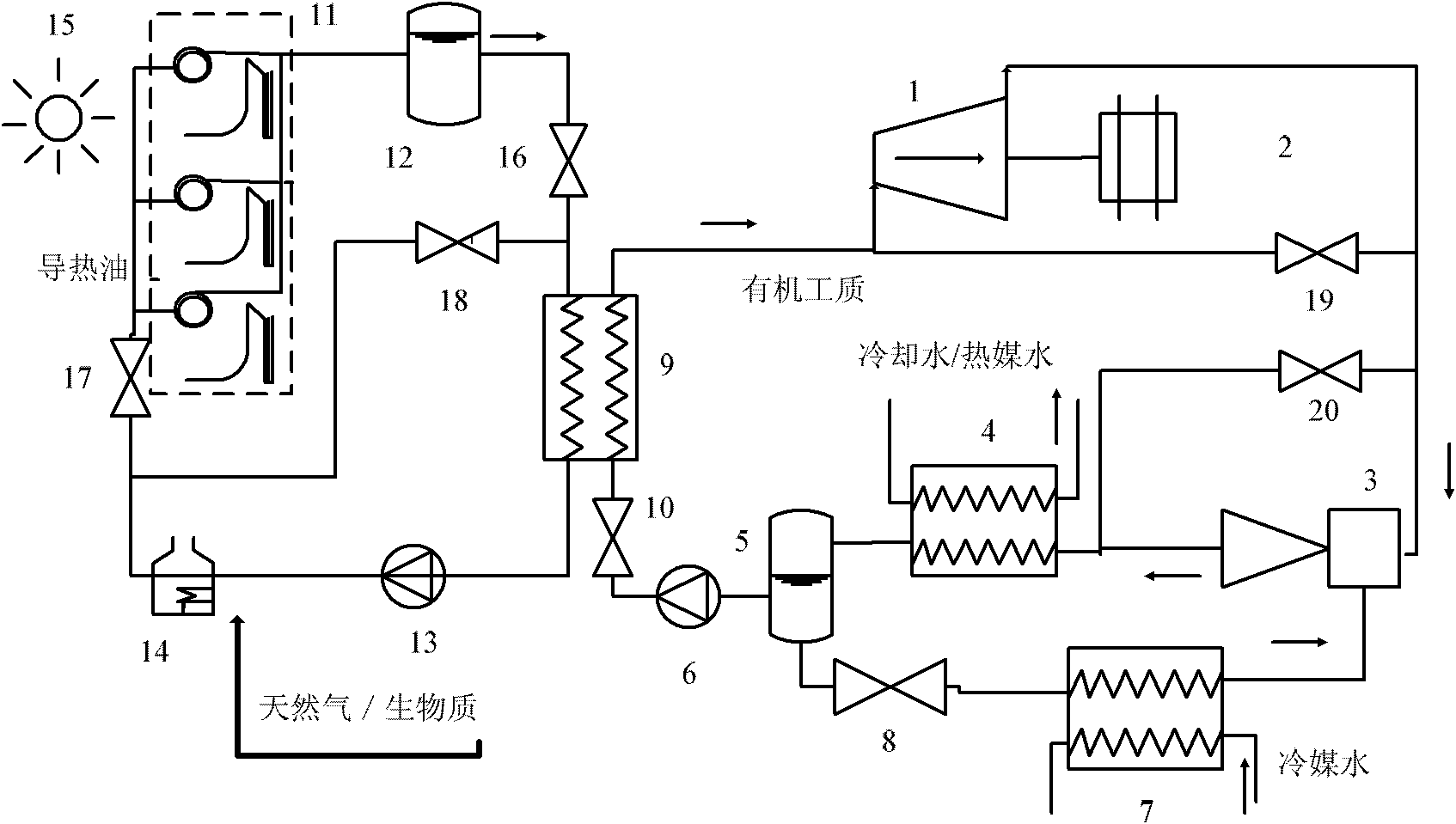

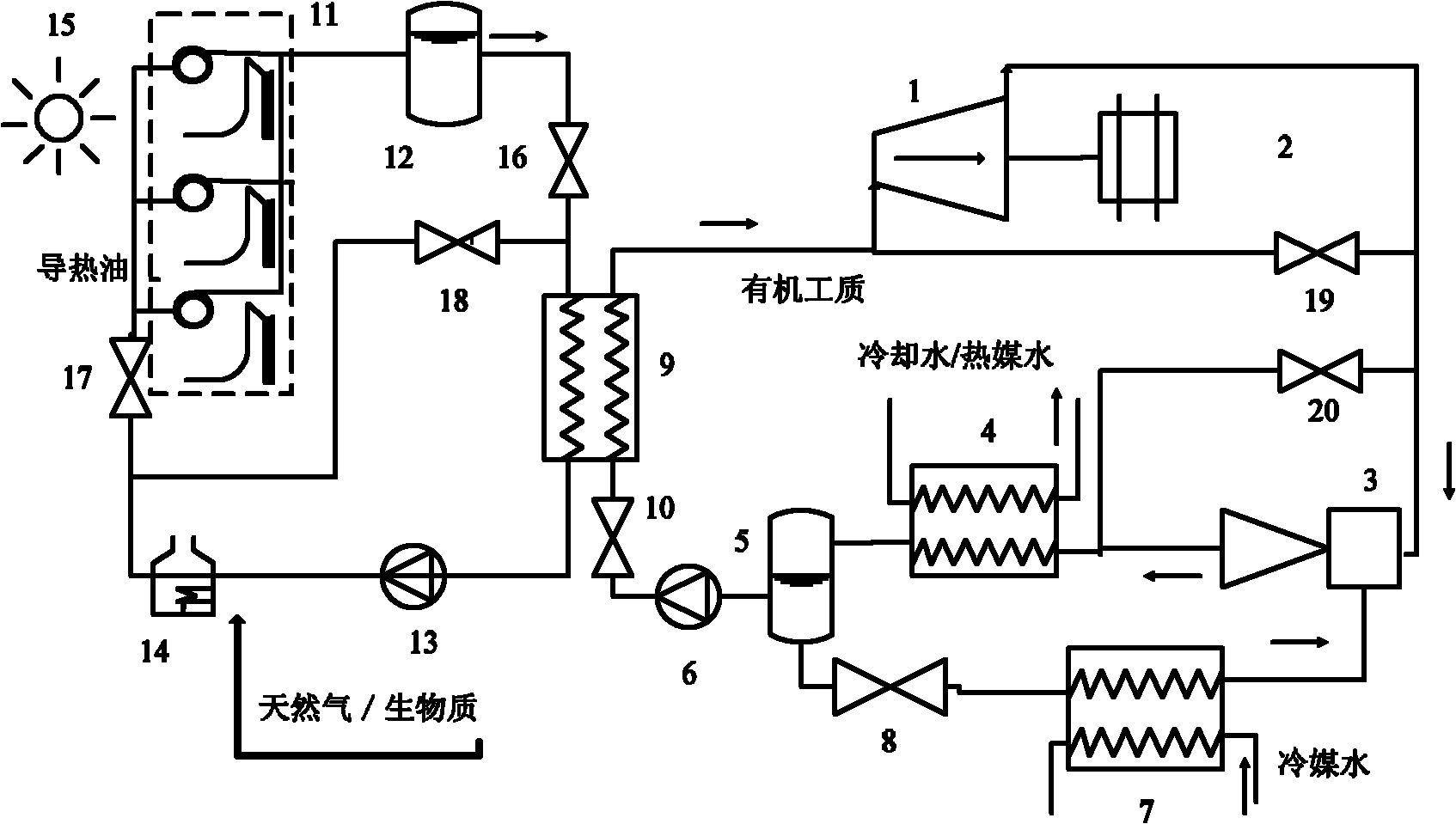

Solar energy-natural gas complementary injection type distributed combined cold heat and power supply device

InactiveCN101871440AImprove cooling effectSimple structureFrom solar energySolar heat devicesCyclic processShuttle valve

The invention provides a solar energy-natural gas complementary injection type distributed combined cold heat and power supply device, comprising a turbine expansion engine, a generator, an ejector, a condenser, a working medium storage tank, a working medium pump, a refrigerating evaporator, a throttle valve, a heat source exchanger, a first valve, a solar thermal collector, a conduction oil storage tank, an oil pump, an afterburner, a second valve, a third valve, a fourth valve, a first bypass valve and a second bypass valve. Electric powder required by the whole circulating process can be supplied by the system self, and extra electric energy and cold can be outputted to meet the load requirement of a user of a cold and power supply distributed energy supply system.

Owner:SHANGHAI JIAO TONG UNIV

Ceramic-encased hot surface igniter system for jet engines

InactiveUS20080141651A1Increased voltageIncreasing power flowBurnersIncandescent ignitionCeramicSilicon nitride

A ceramic-encased hot surface igniter system for jet engines is presented. The advanced ceramic-encased hot surface igniter system comprises at least one electrical resistance heated element encased in a durable, thermal and mechanical shock resistant, high temperature advanced ceramic compound such as silicon nitride. The one or more advanced ceramic-encased hot surface igniter elements are mounted proximally upstream or within a combustion chamber of a jet engine enclosure or within the afterburner section of a jet propulsion engine's exhaust. The surface temperature of each ignition element's encasement being of sufficient temperature to cause the ignition of a gaseous, atomized, or liquid fuel.

Owner:STATE OF FRANKLIN INNOVATIONS

Single-stage hypersonic vehicle featuring advanced swirl combustion

InactiveUS7762077B2Reduce complexityShorten the lengthPower plant exhaust arrangementsEfficient propulsion technologiesRamjetLow speed

A single-stage hypersonic vehicle is comprised of a low-speed and a high-speed propulsion system. The low-speed propulsion system propels the single-stage vehicle to a threshold velocity, after which the high-speed propulsion system then takes over. The low-speed propulsion system includes a combined-cycle engine featuring a swirl generator that is integrated into a turbojet engine to provide a compact turbojet and swirl afterburner-ramjet propulsion system. The high-speed propulsion system includes a hypersonic engine that is operable at the threshold takeover velocity and beyond. In various embodiments, the high-speed propulsion system comprises a scramjet, rocket, or scramjet / rocket engine depending requirements. Benefits of the swirl generator design include its ability to rapidly and efficiently atomize, vaporize, mix and burn the fuel and oxidizer for the low speed propulsion system, significantly reduce length, weight, cooling requirements and complexity for both propulsion systems, while maintaining high propulsion performance and reducing propulsion and launch costs.

Owner:UNITED TECH CORP

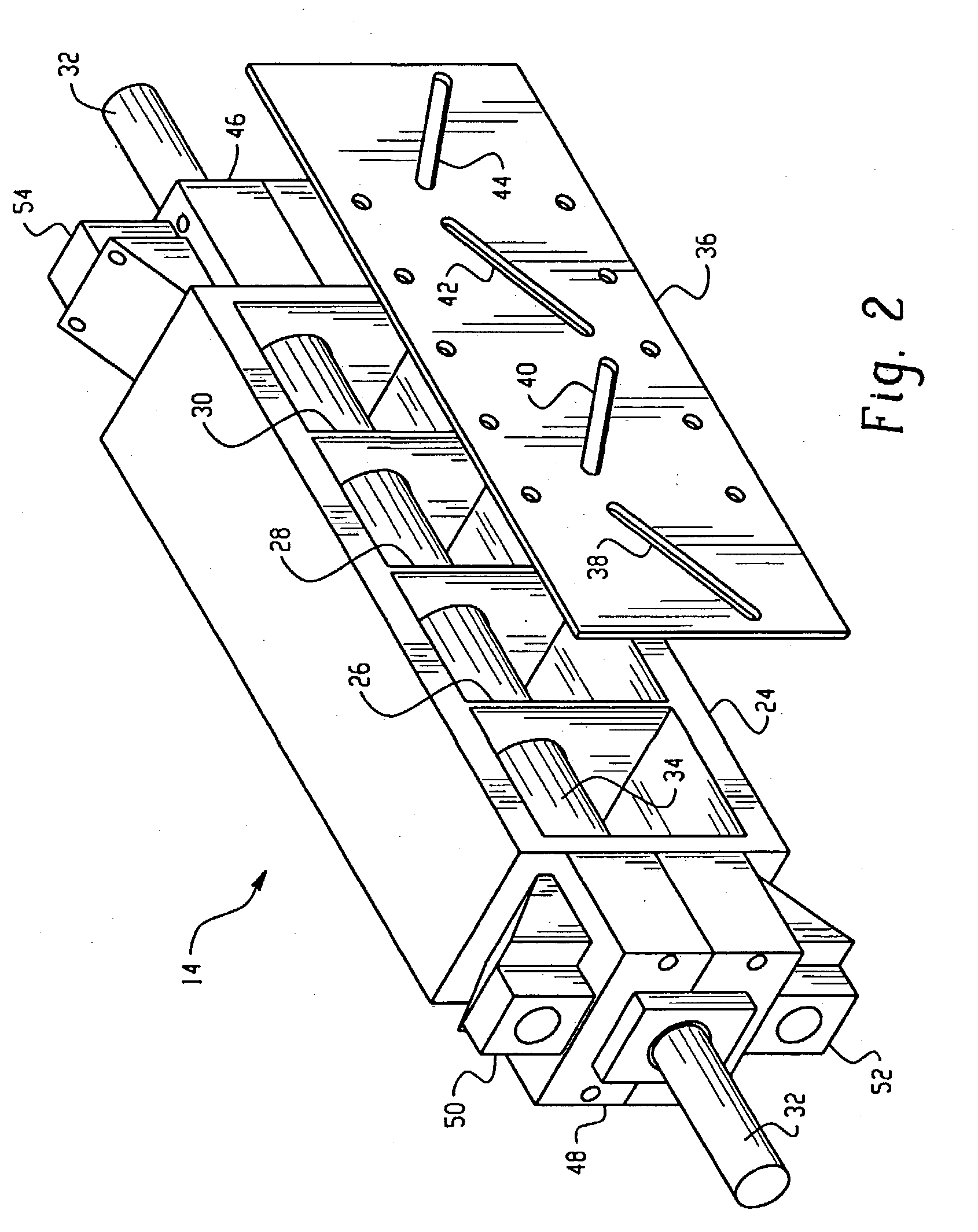

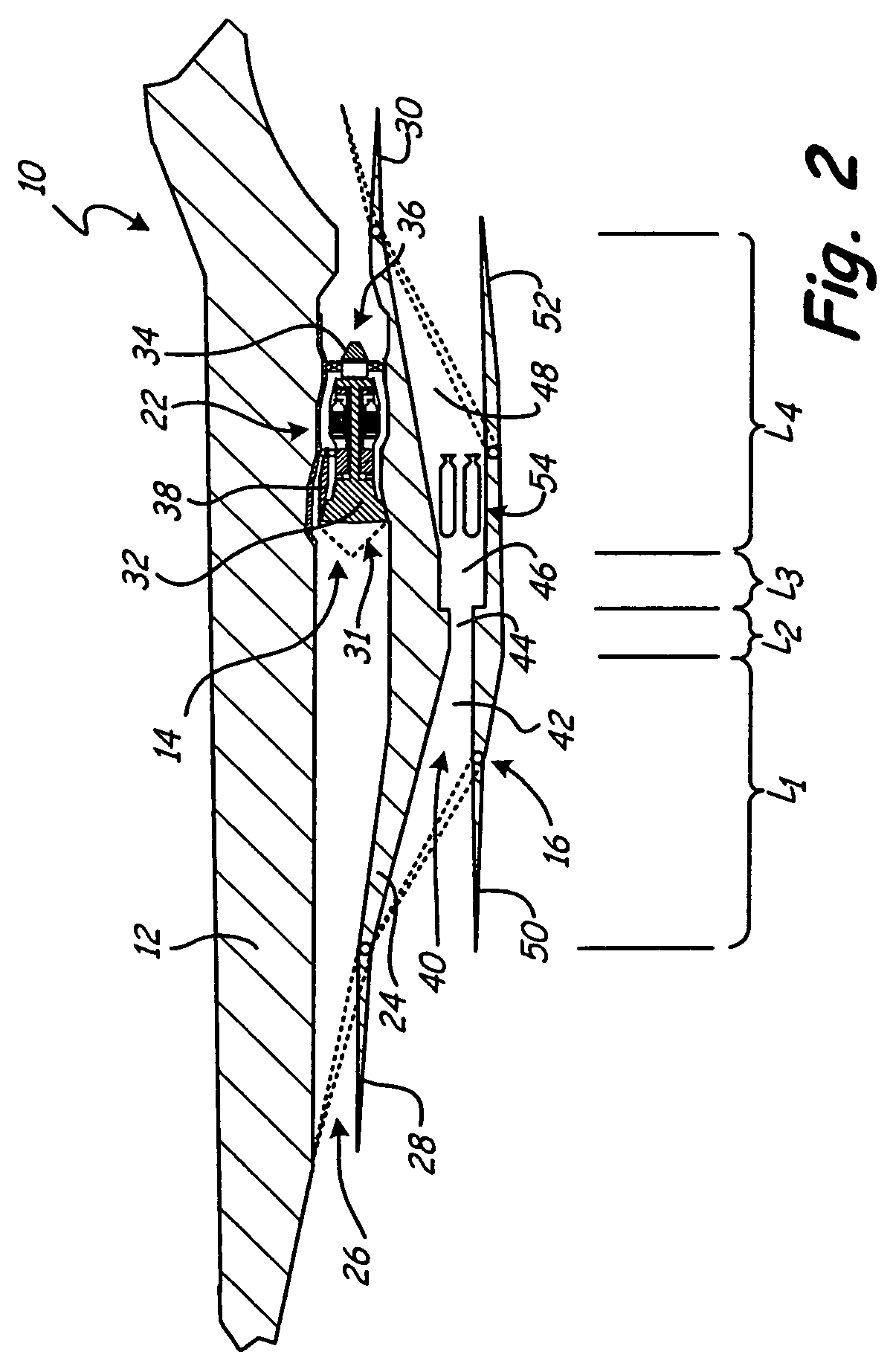

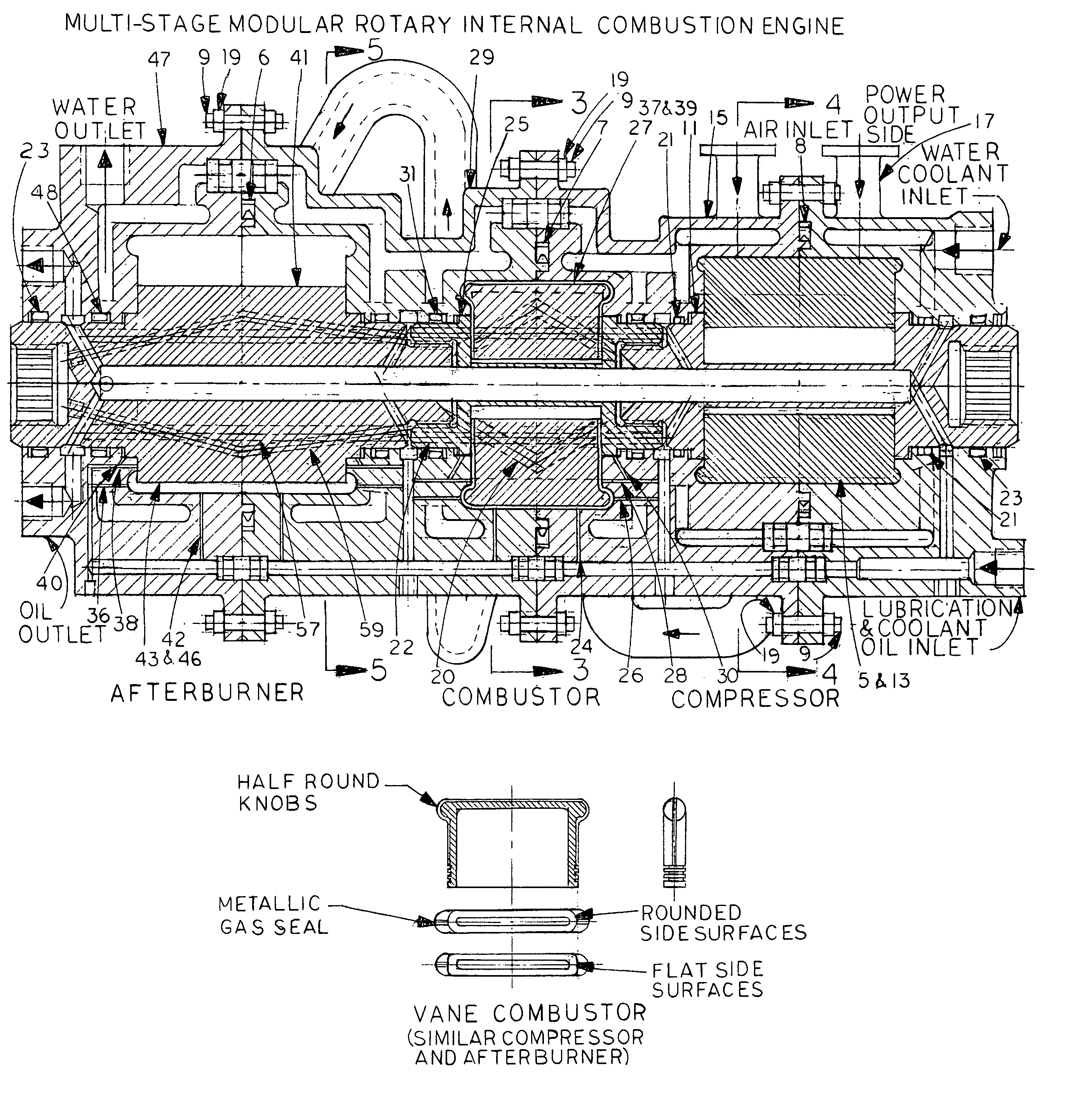

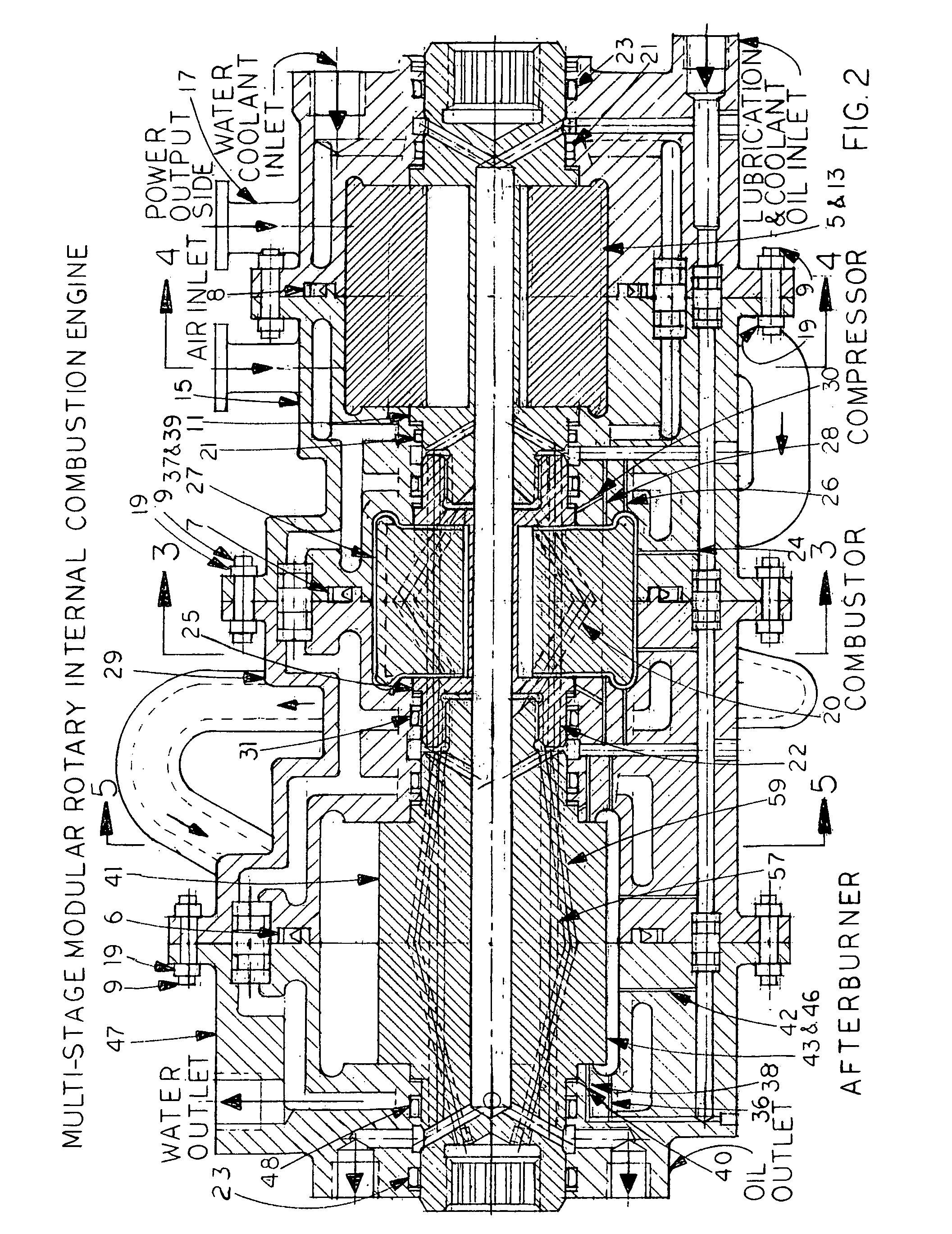

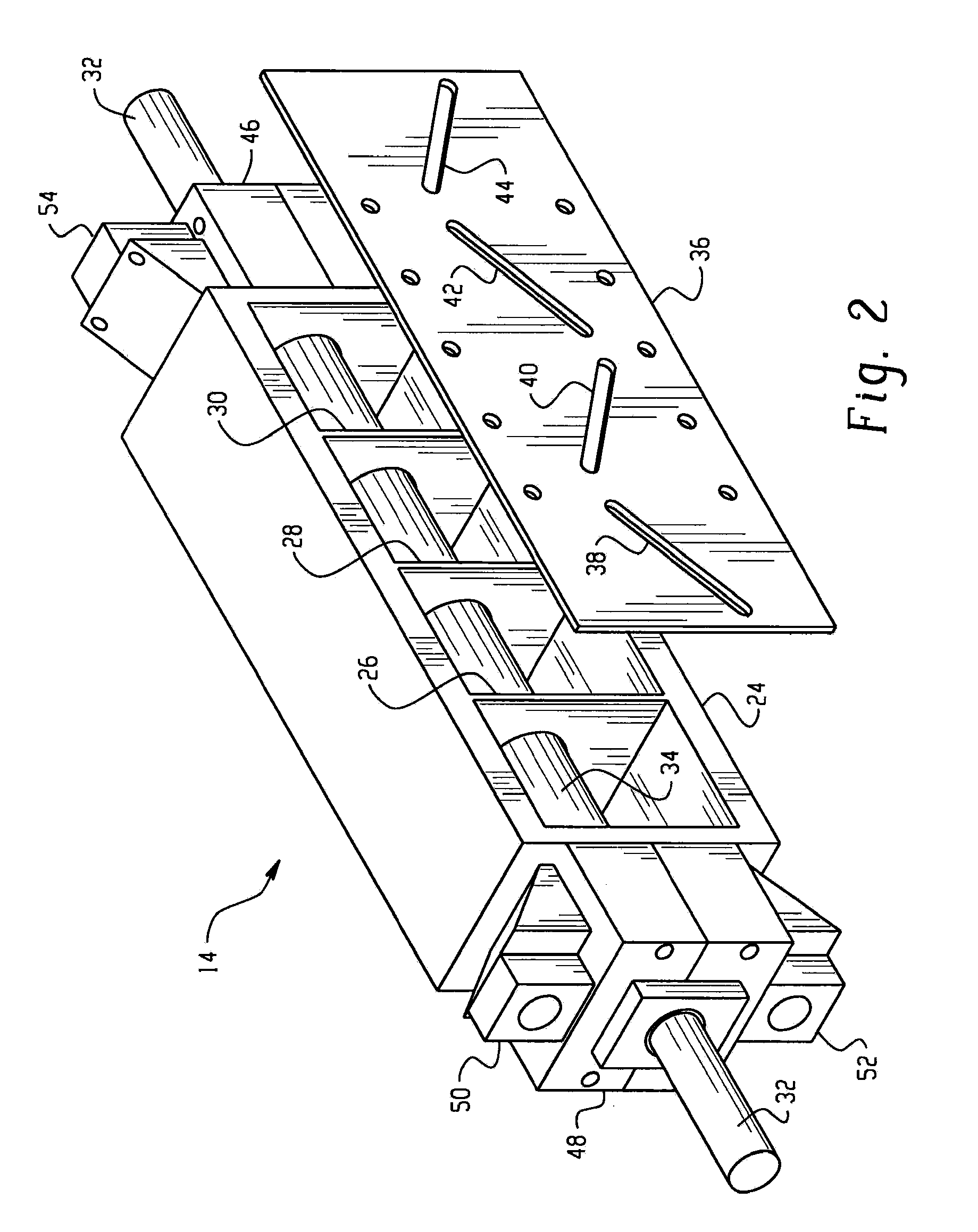

Multi-stage modular rotary internal combustion engine

ActiveUS7117839B2Easy constructionRobust designInternal combustion piston enginesOscillating piston enginesCombustorThree stage

A three-stage internal combustion rotary engine, comprised of: a compressor feeding compressed air to a combustor for compression, fuel injection, combustion, and expansion of gases which rotate the rotor. The combustor rotor generates torque and drives the compressor and afterburner rotors simultaneously. The afterburner receives the combusted gases and scavenged air from the combustor for secondary combustion and expels the exhaust gases. Each unit consists of a housing joined together on a common axis and a rotor with a shaft mounted in an eccentric position of the housing side-walls. The shafts are interconnected by splines. The rotors have radial blind slots which contain slidable, movable vanes fitted with half-round knobs on opposite sides, aligned with the top surface and fit in the hemispherical grooves on the interior side-walls of the housing. This maintains a permanent contact with the interior housing periphery, regardless of gas pressures and rotating speed.

Owner:HORSTIN ABRAHAM H

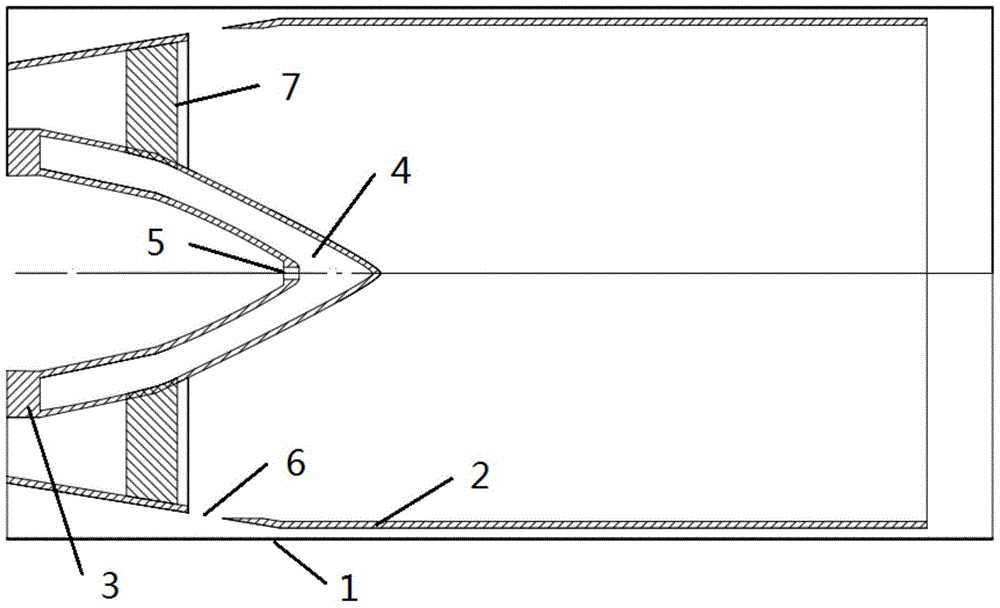

Pre-evaporation type integrated afterburner

InactiveCN105674332AIncrease the degree of mixingReduce the temperatureContinuous combustion chamberCombustion chamberEvaporation

The invention provides a pre-evaporation type integrated afterburner. An oil cavity is formed inside an afterburning inner cone, and is connected with a fuel oil channel inside a rectification support plate flame stabilizer. Fuel oil is heated in the oil cavity to become gas or a supercritical body, and then the gas or the supercritical body enters the fuel oil channel inside the rectification support plate flame stabilizer and is sprayed out from direct-injection type spraying nozzle small holes in the two sides. The spraying nozzle small holes are reasonably formed so that the mixing effect of the fuel oil and the gas can be effectively improved, and the burning efficiency is improved. In addition, a large amount of heat is transmitted to the fuel oil through the afterburning inner cone, so that the self temperature is decreased, and the infrared stealth performance is effectively improved. The pre-evaporation type integrated afterburner has the beneficial effects that on the basis of an integrated afterburner structure, by reasonably leading in the structure of the oil cavity inside the afterburning inner cone and the structure of the fuel oil channel inside the rectification support plate flame stabilizer and reasonably forming the direct-injection type spraying nozzle small holes, the burning efficiency is effectively improved, and the infrared stealth performance is effectively improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

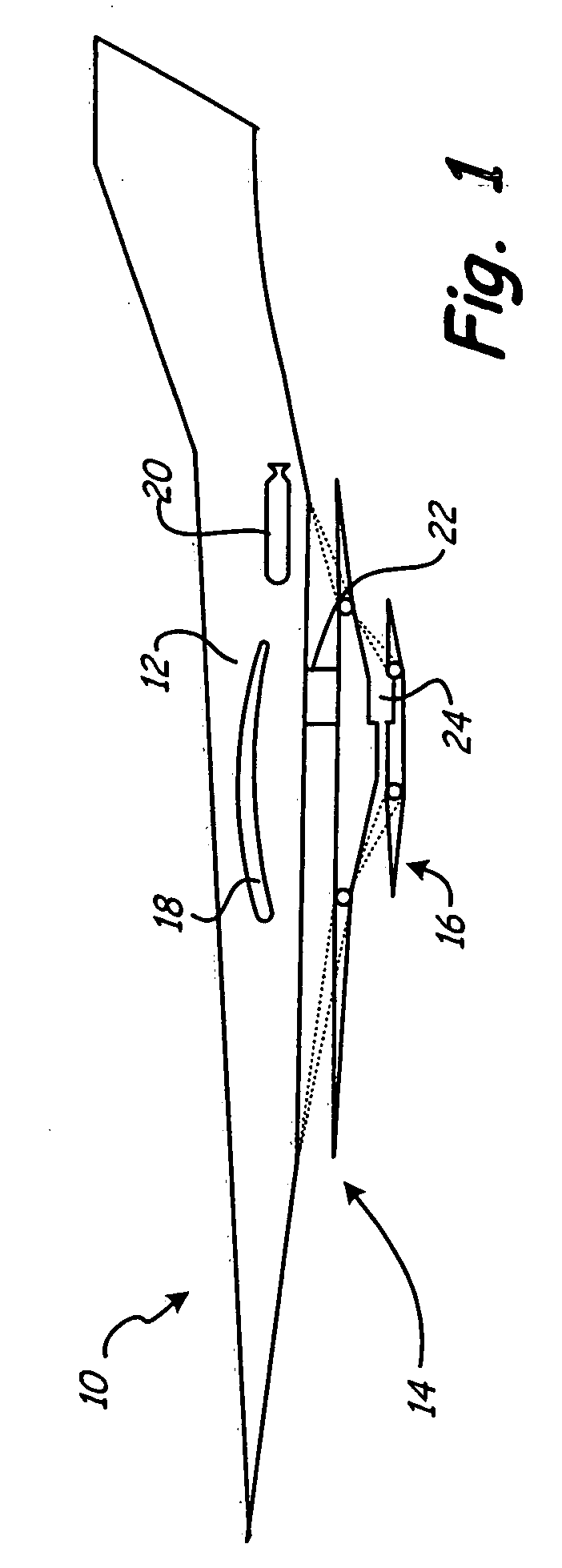

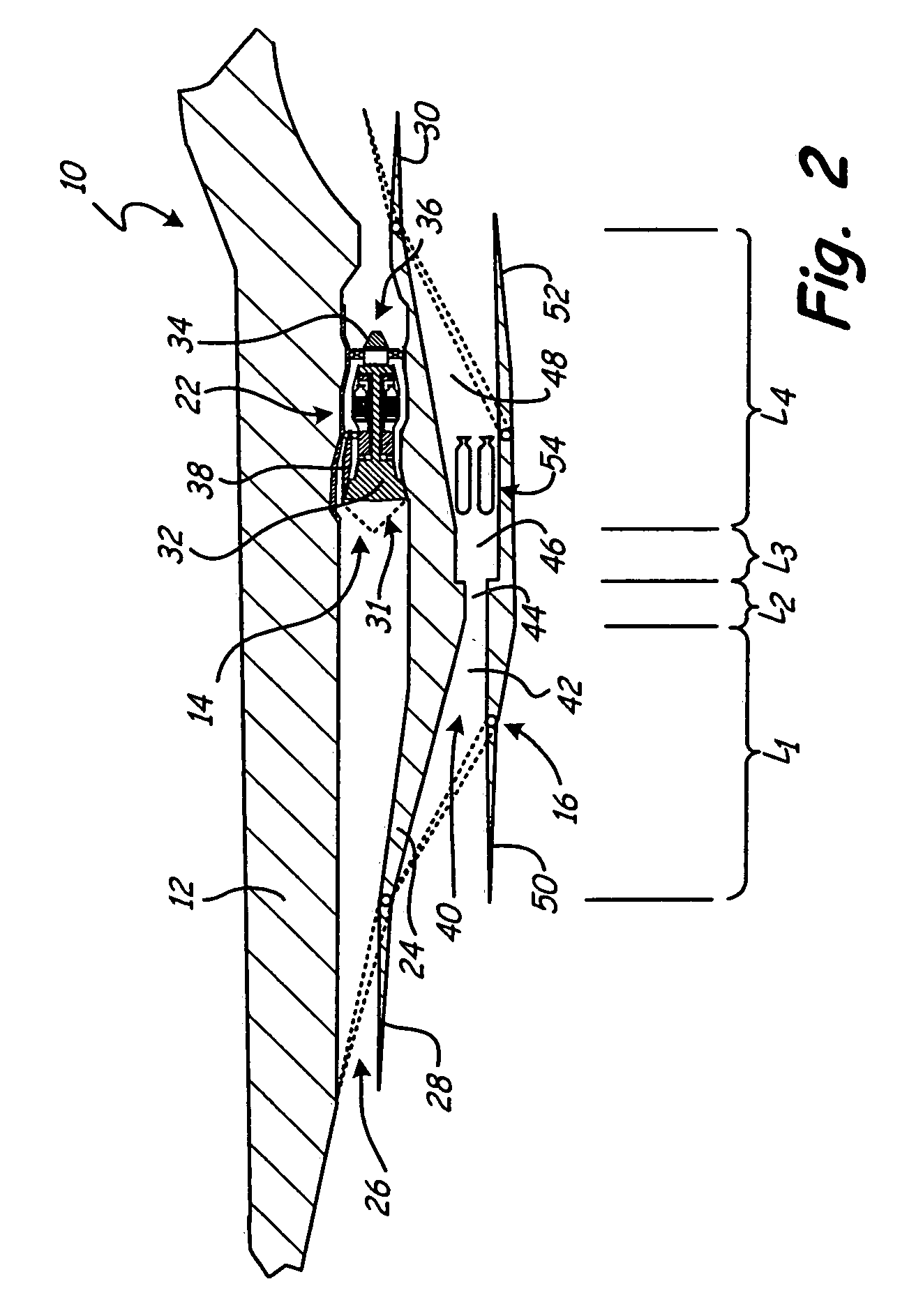

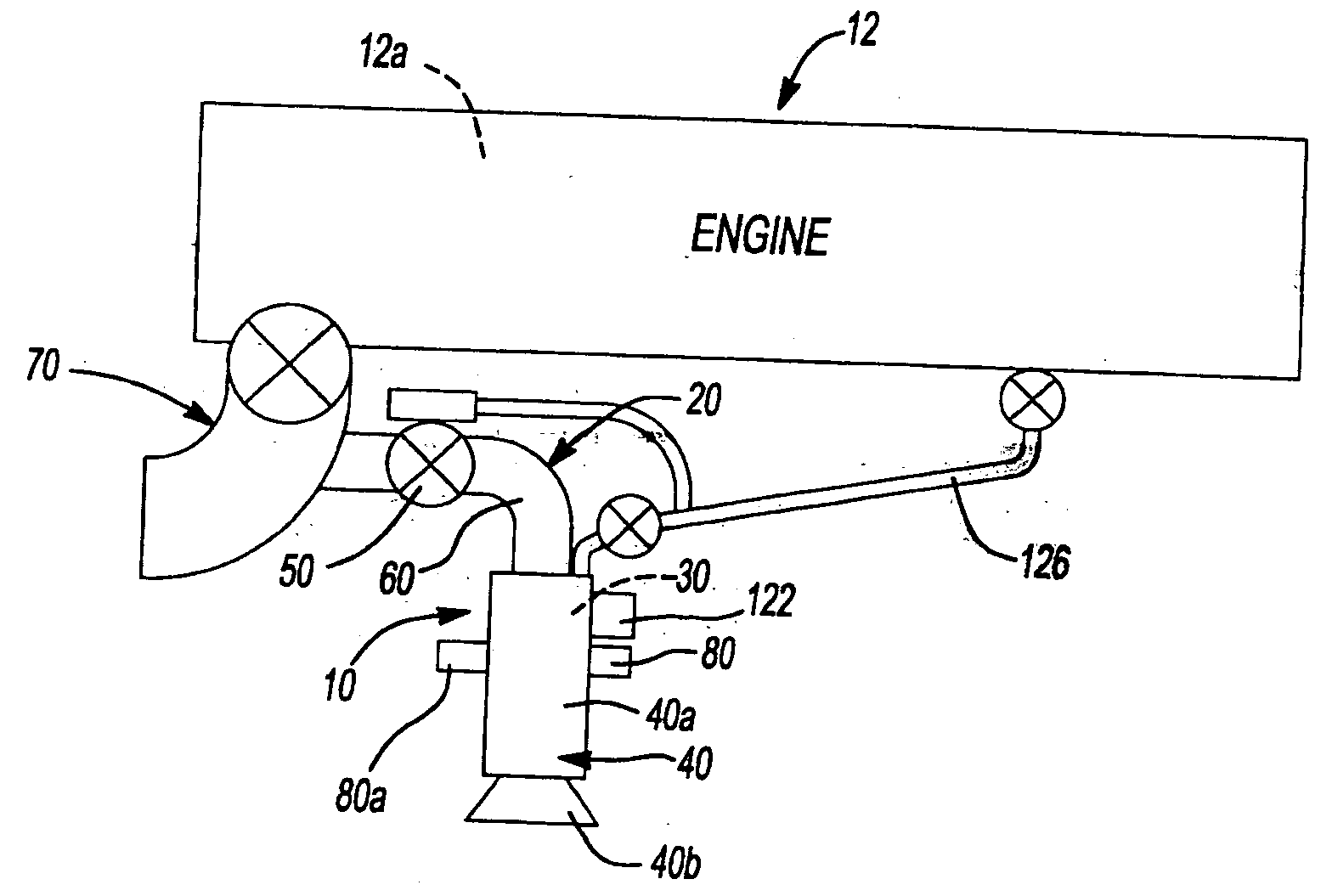

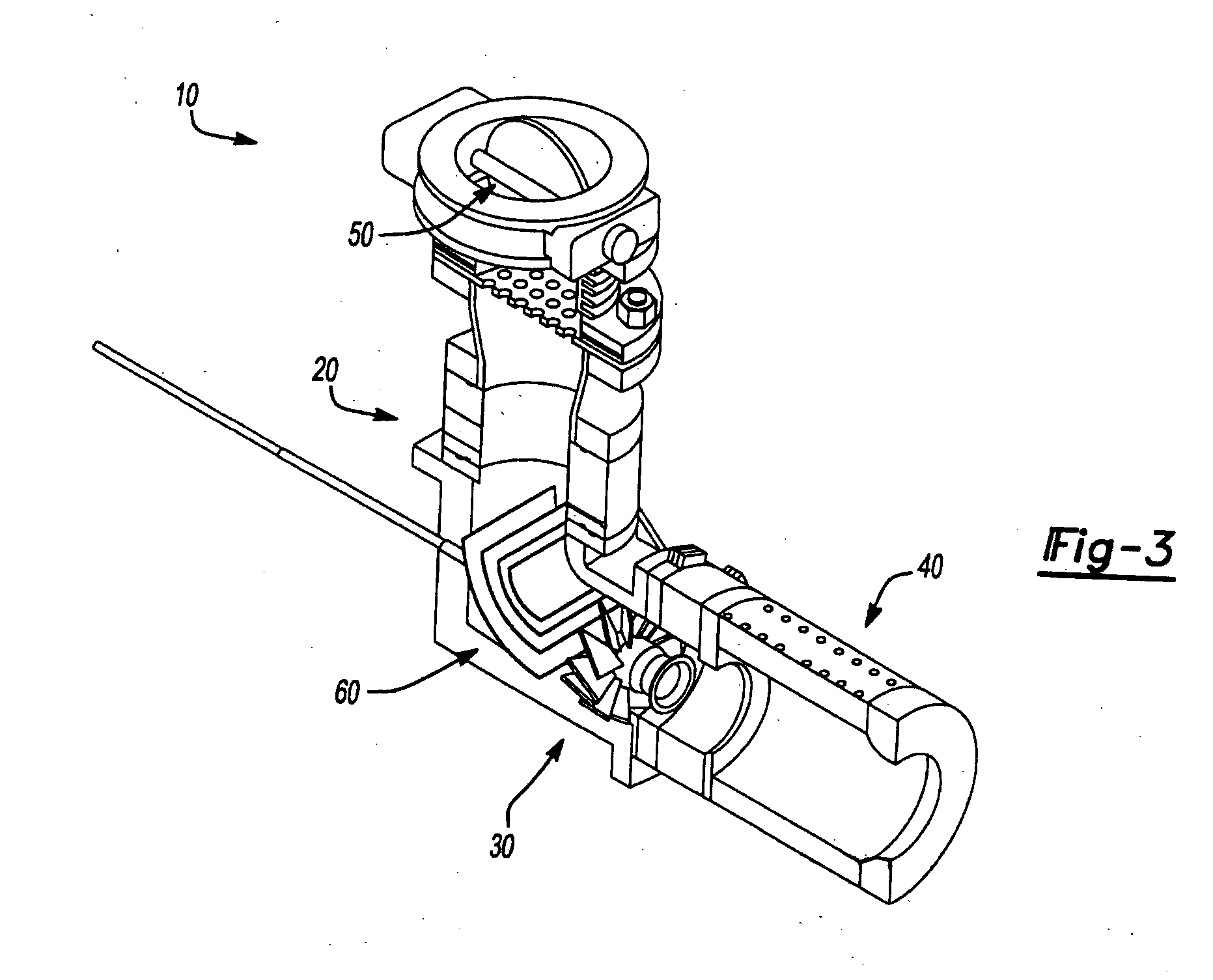

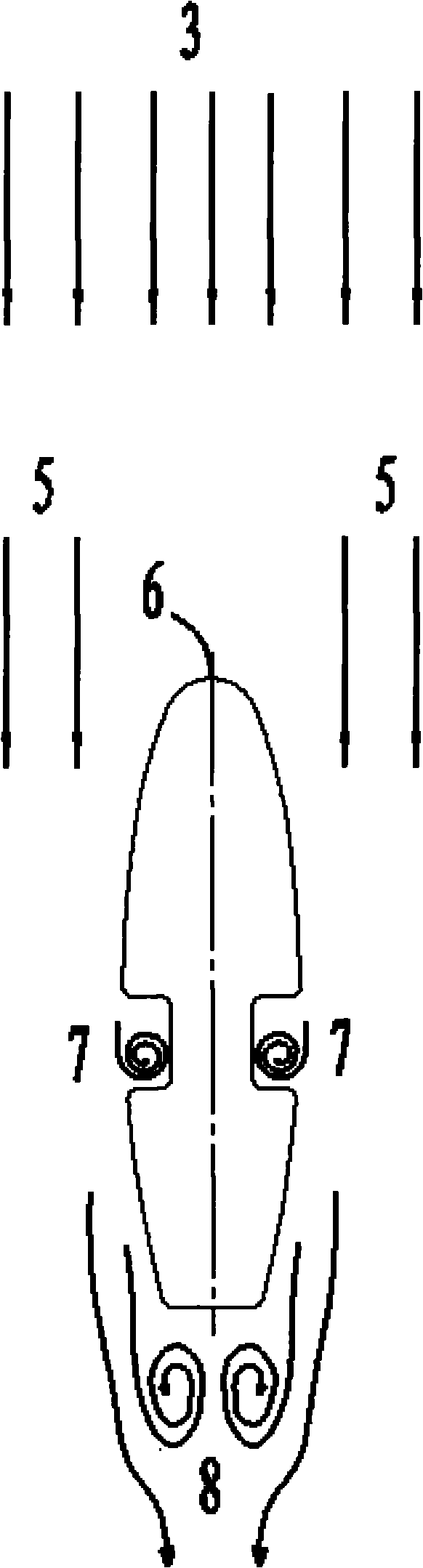

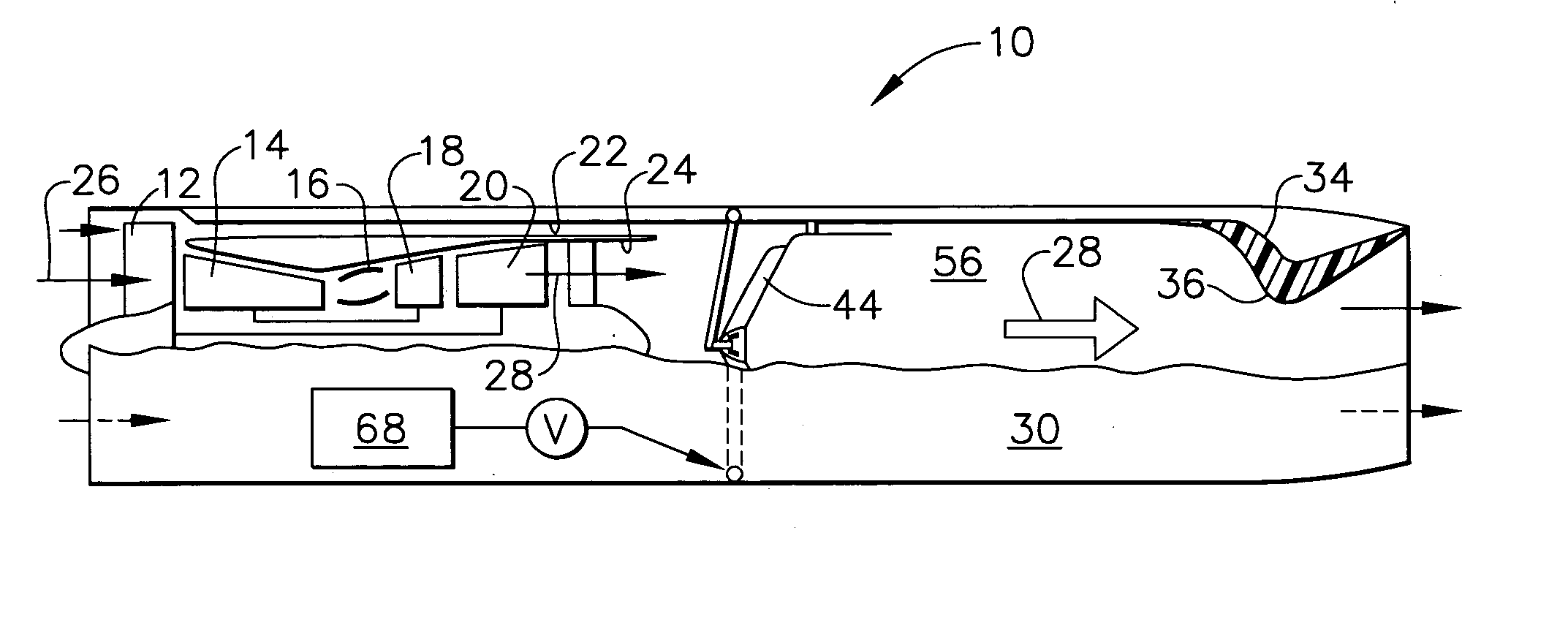

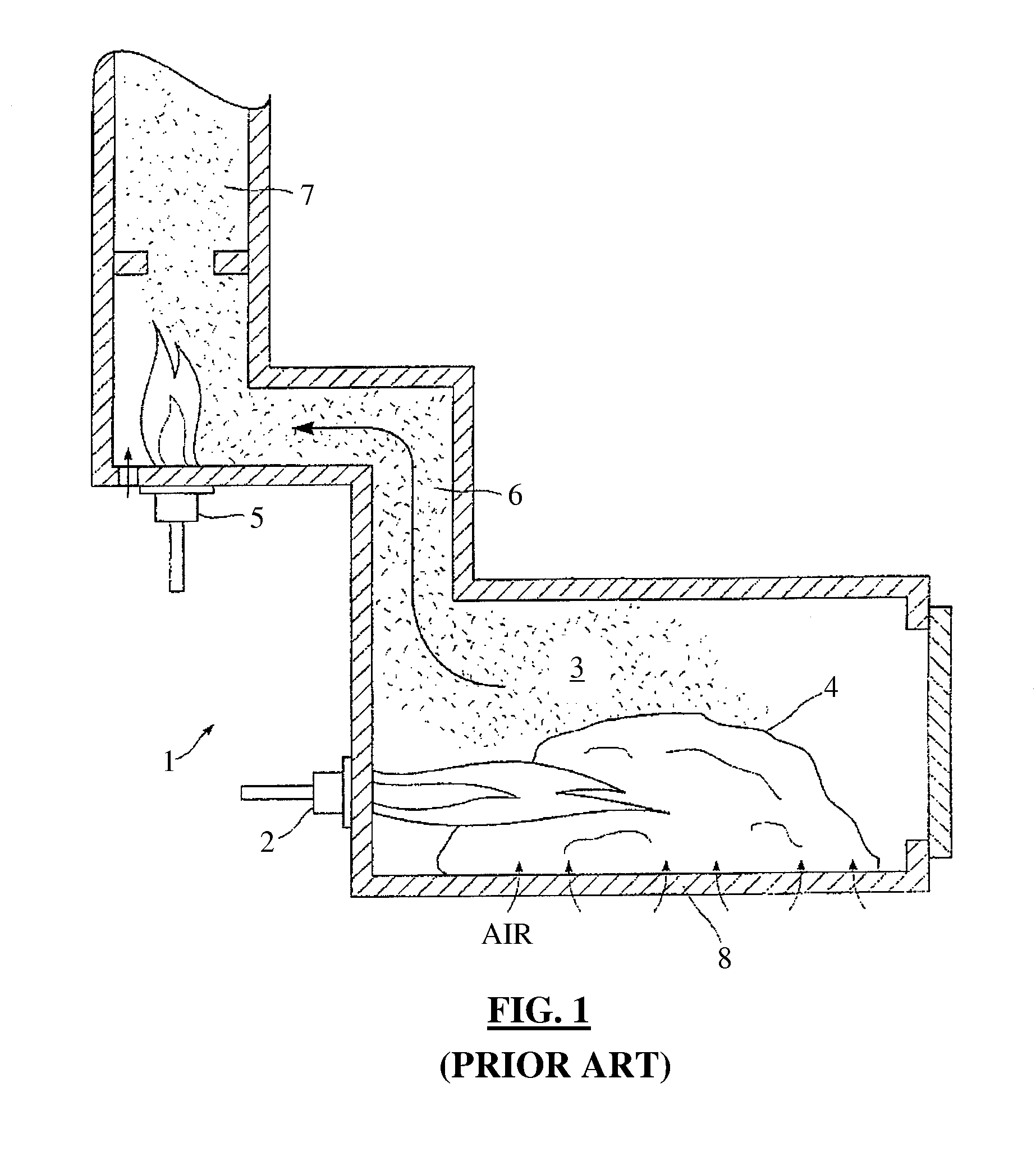

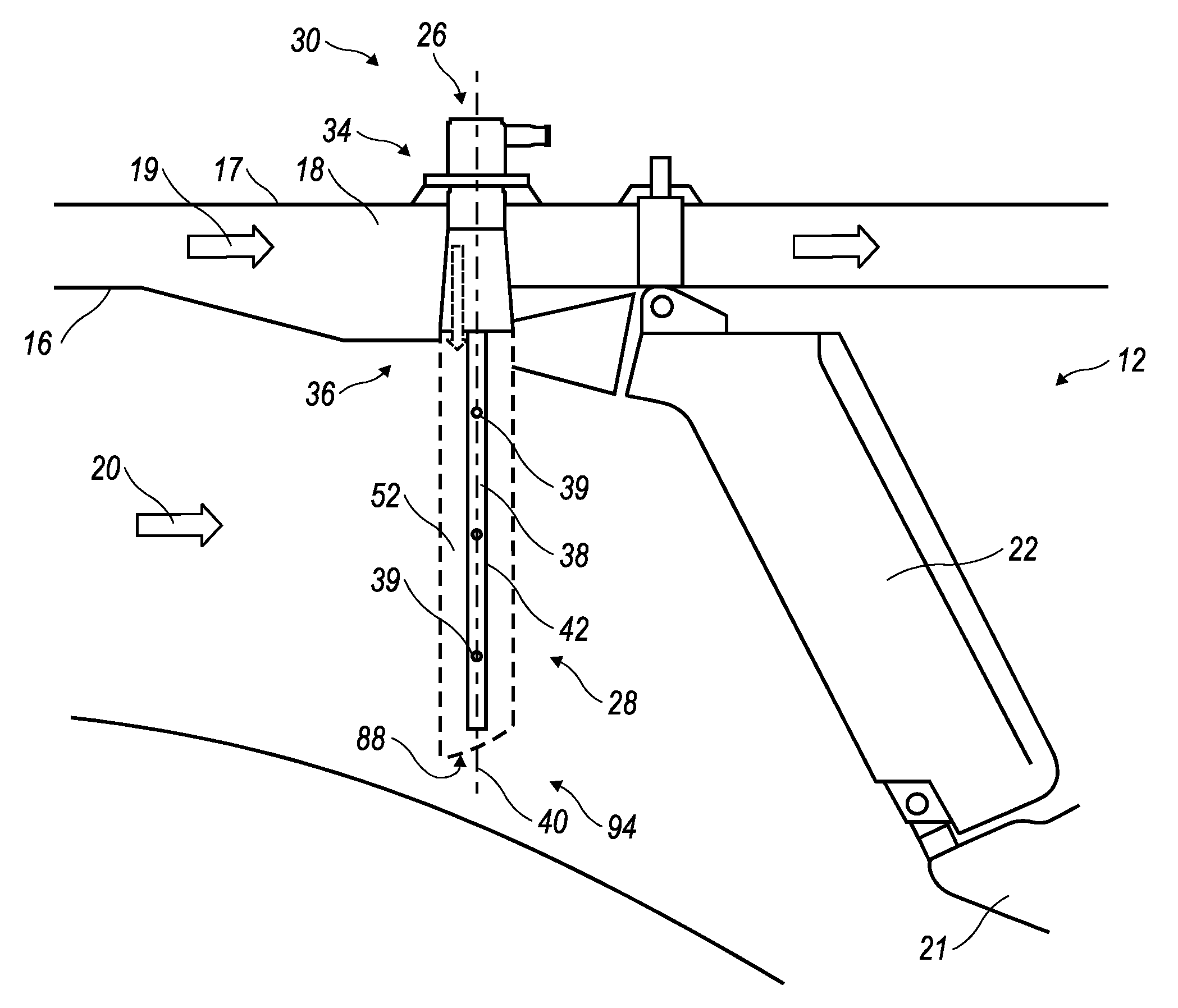

Compact swirl augmented afterburners for gas turbine engines

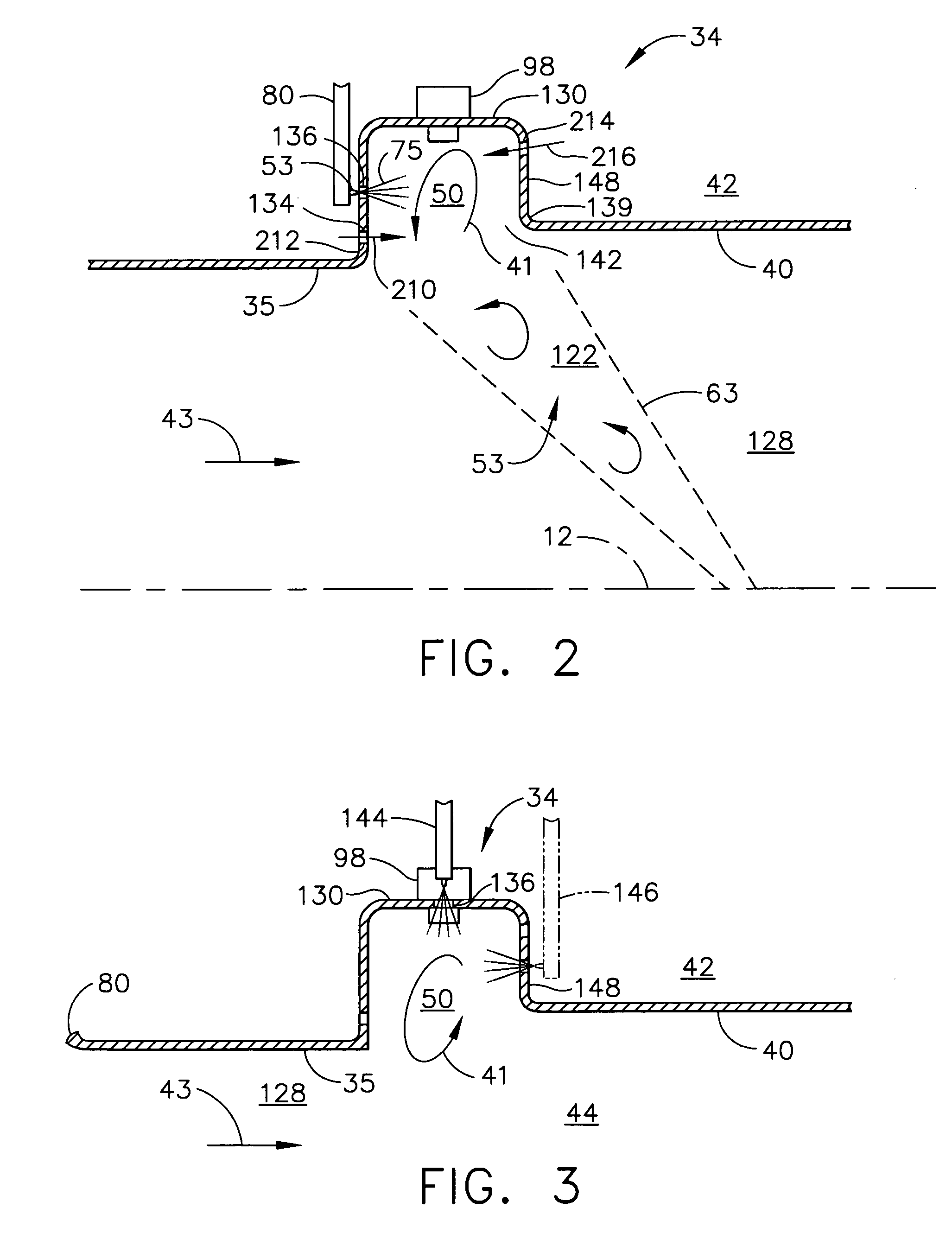

InactiveUS20060230764A1Promotes rapid and efficient atomization and mixingBurn quicklyTurbine/propulsion fuel supply systemsContinuous combustion chamberCombustion instabilityFlame propagation

An afterburner apparatus that utilizes a novel swirl generator for rapidly and efficiently atomizing, vaporizing, as necessary, and mixing a fuel and an oxidant. The swirl generator converts an oxidant flow into a turbulent, three-dimensional flowfield into which the fuel is introduced. The swirl generator effects a toroidal outer recirculation zone and a central recirculation zone, which is positioned within the outer recirculation zone. These recirculation zones are configured in a backward-flowing manner that carries heat and combustion byproducts upstream where they are employed to continuously ignite a combustible fuel / oxidizer mixture in adjacent shear layers. The recirculation zones accelerate flame propagation to allow afterburning to be completed in a relatively short length. Inherent with this swirl afterburner concept are design compactness, light weight, lower cost, smooth and efficient combustion, high thrust output, wide flammability limits, continuous operation at stoichiometric fuel / oxidizer mixture ratios, no combustion instabilities, and relatively low pressure losses.

Owner:UNITED TECH CORP

Plasma ashing apparatus and endpoint detection process

InactiveUS20100055807A1Semiconductor/solid-state device testing/measurementElectric discharge tubesNitrogen plasmaHydrogen

A plasma ashing apparatus for removing organic matter from a substrate including a low k dielectric, comprising a first gas source; a plasma generating component in fluid communication with the first gas source; a process chamber in fluid communication with the plasma generating component; an exhaust conduit in fluid communication with the process chamber; wherein the exhaust conduit comprises an inlet for a second gas source and an afterburner assembly coupled to the exhaust conduit, wherein the inlet is disposed intermediate to the process chamber and an afterburner assembly, and wherein the afterburner assembly comprises means for generating a plasma within the exhaust conduit with or without introduction of a gas from the second gas source; and an optical emission spectroscopy device coupled to the exhaust conduit comprising collection optics focused within a plasma discharge region of the afterburner assembly. An endpoint detection process for an oxygen free and nitrogen free plasma process comprises monitoring an optical emission signal of an afterburner excited species in an exhaust conduit of the plasma asher apparatus. The process and apparatus can be used with carbon and / or hydrogen containing low k dielectric materials.

Owner:LAM RES CORP

Trapped vortex cavity afterburner

ActiveUS20070044476A1Increase temperatureContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustion chamberTrailing edge

A trapped vortex cavity afterburner includes one or more trapped vortex cavity stages for injecting a fuel / air mixture into a combustion zone. The trapped vortex cavity afterburner is operable to provide all thrust augmenting fuel used for engine thrust augmentation. Each stage has at least one annular trapped vortex cavity. The trapped vortex cavity afterburner may be a multi-stage afterburner having two or more trapped vortex cavity stages ganged for simultaneous ignition or operable for sequential ignition. One embodiment of the annular trapped vortex cavity is operable to raise a temperature of an exhaust gas flow through the afterburner about 100 to 200 degrees Fahrenheit. Each of the trapped vortex cavity stages may be operable to produce a single or a different amount of temperature rise of the exhaust gas flow through the afterburner. A chevron shaped trapped vortex cavity and having zig-zag shaped leading and trailing edges may be used.

Owner:GENERAL ELECTRIC CO

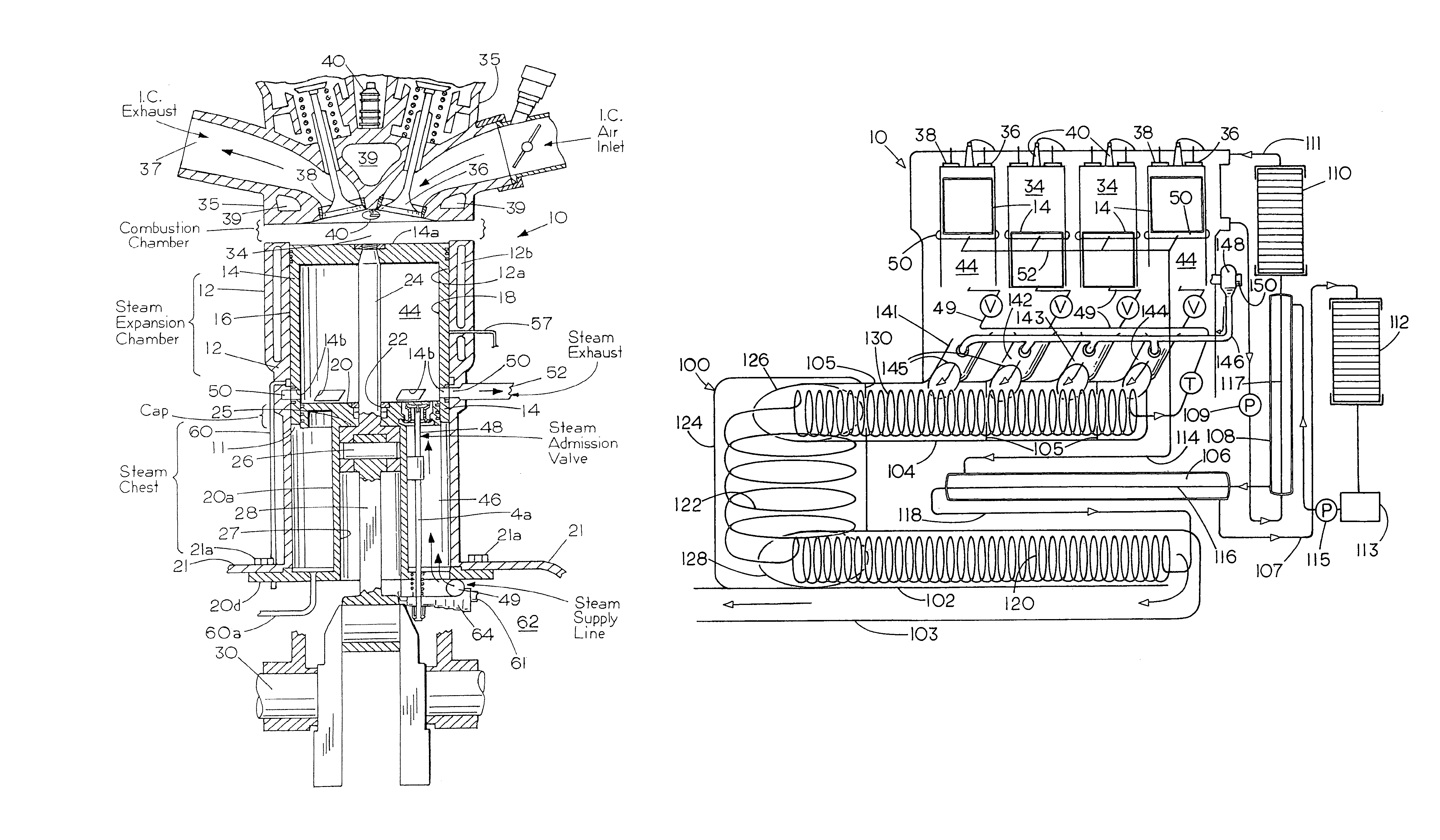

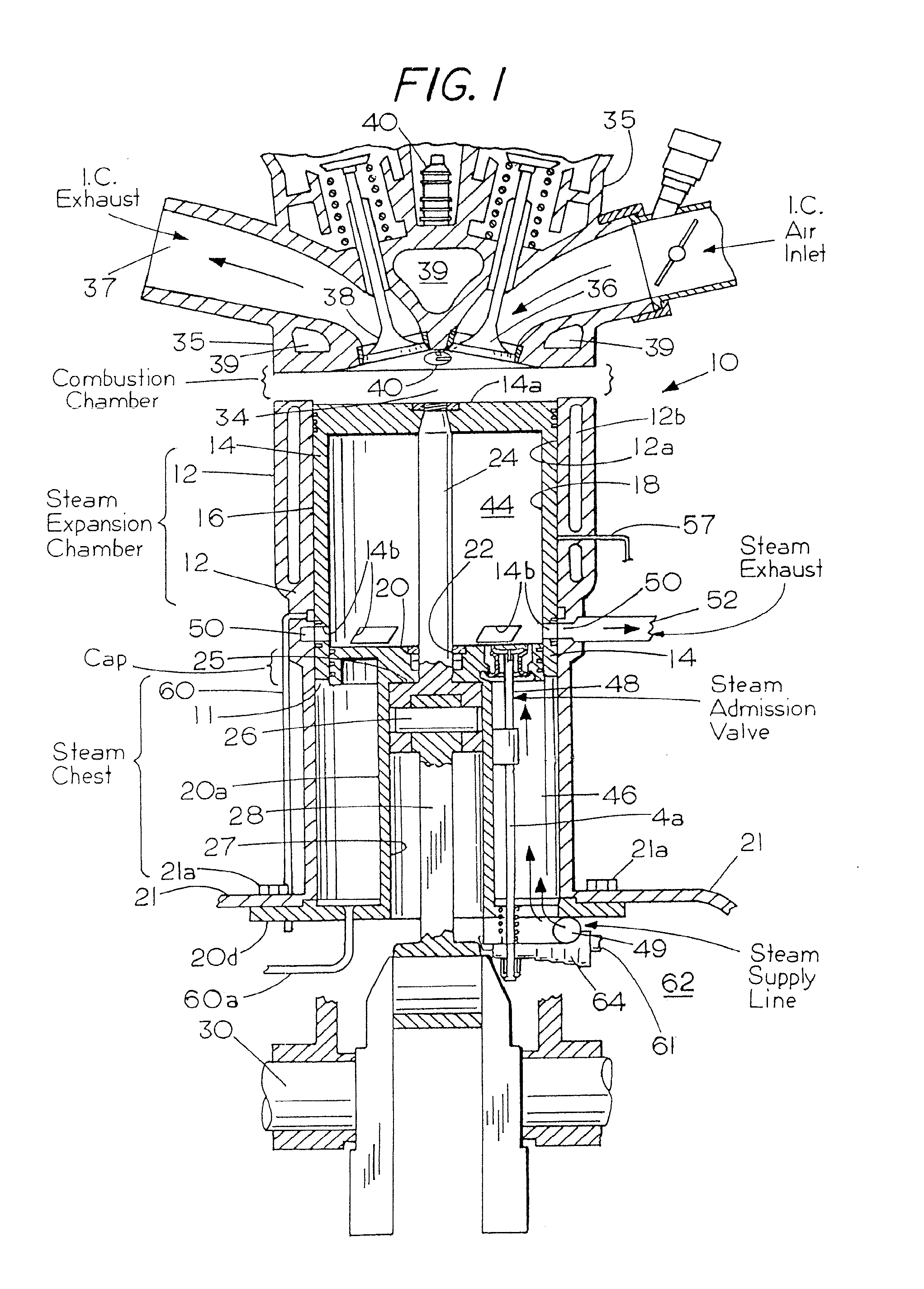

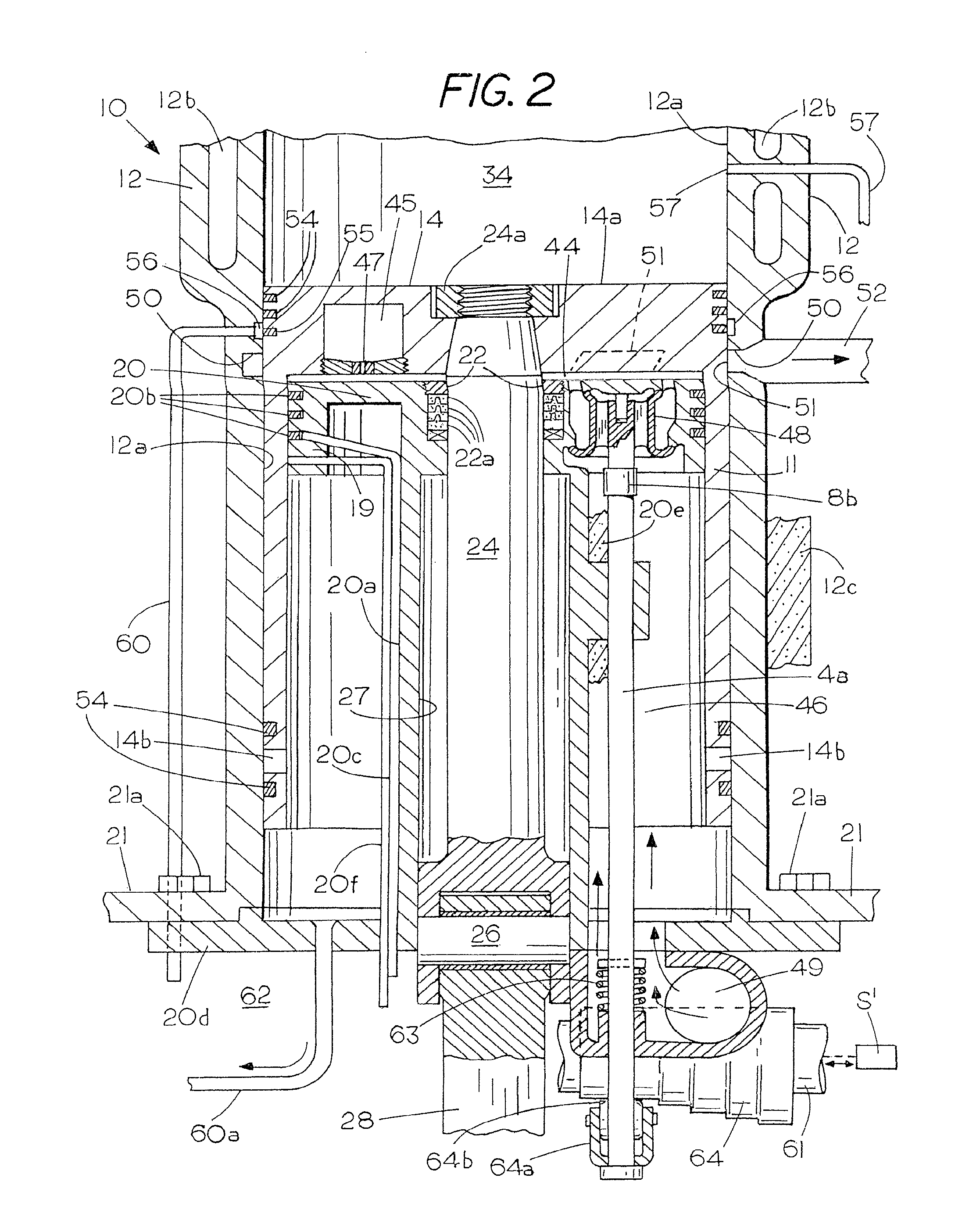

Internal combustion engine with auxiliary steam power recovered from waste heat

ActiveUS7997080B2Effectively economizeImprove efficiencyInternal combustion piston enginesSteam regenerationExternal combustion engineEngineering

Owner:THERMAL POWER RECOVERY

Afterburning, recuperated, positive displacement engine

ActiveUS7028476B2Low costEasy to manufactureSteam engine plantsHot gas positive displacement engine plantsWorking fluidEngineering

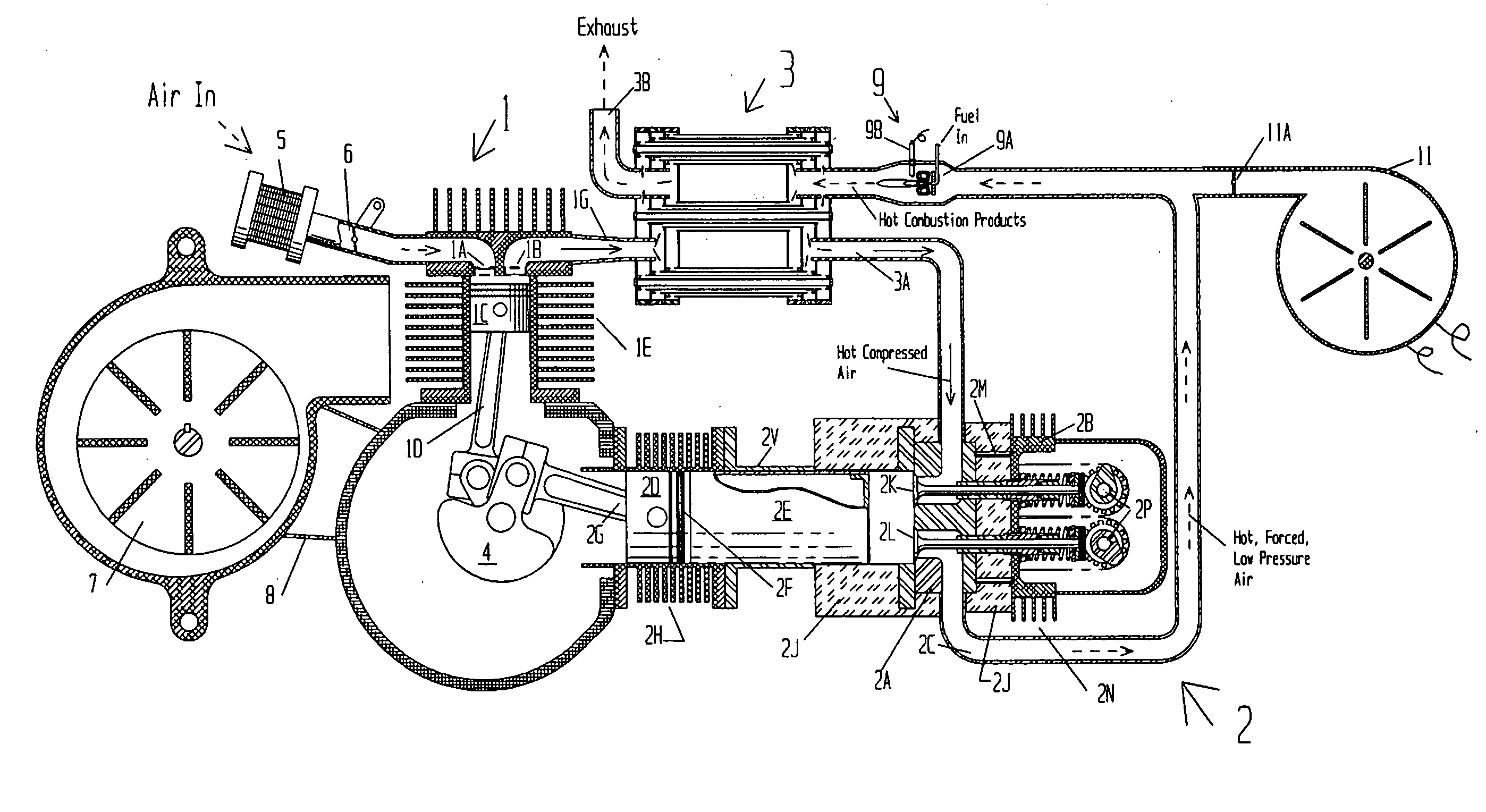

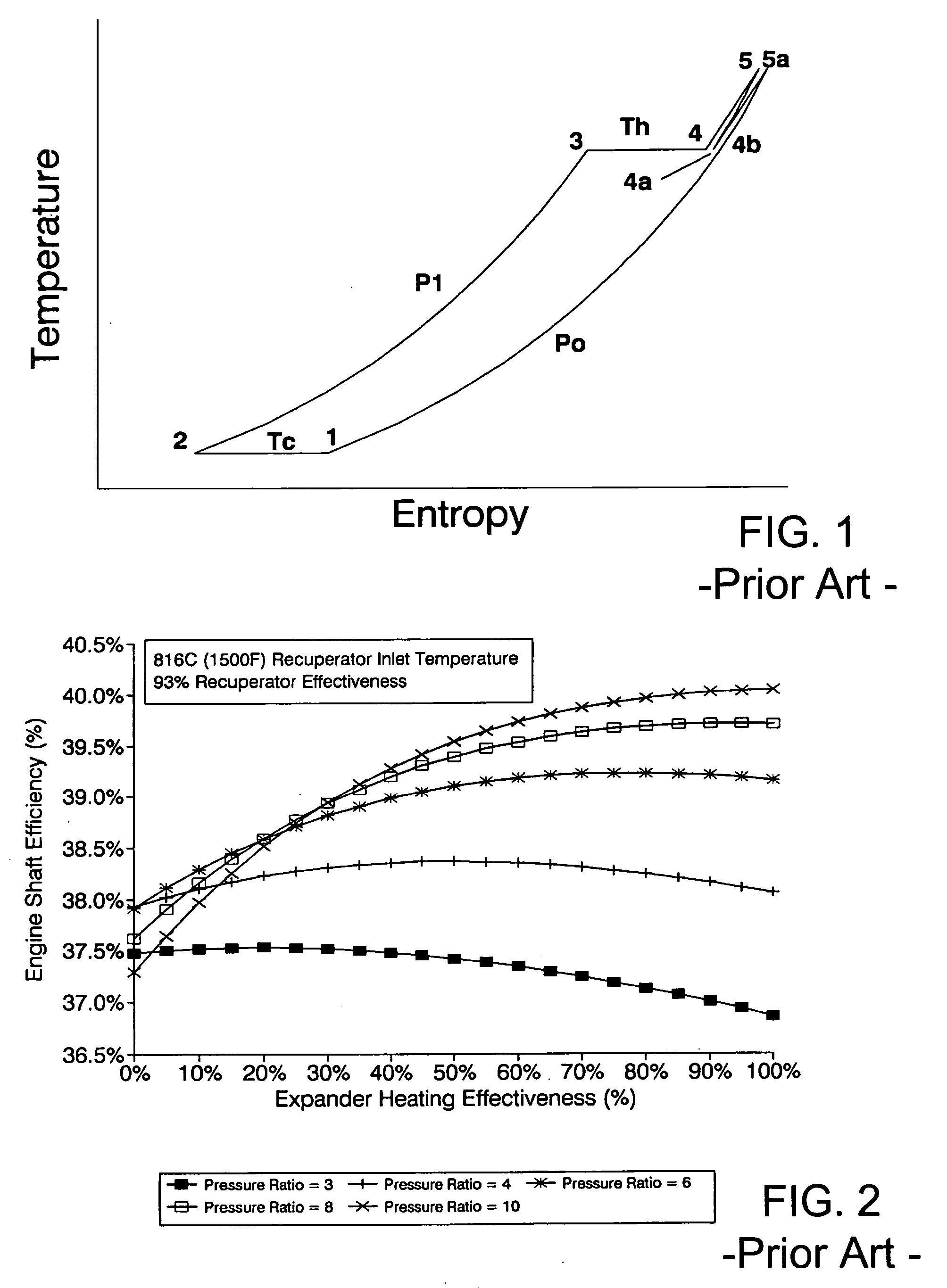

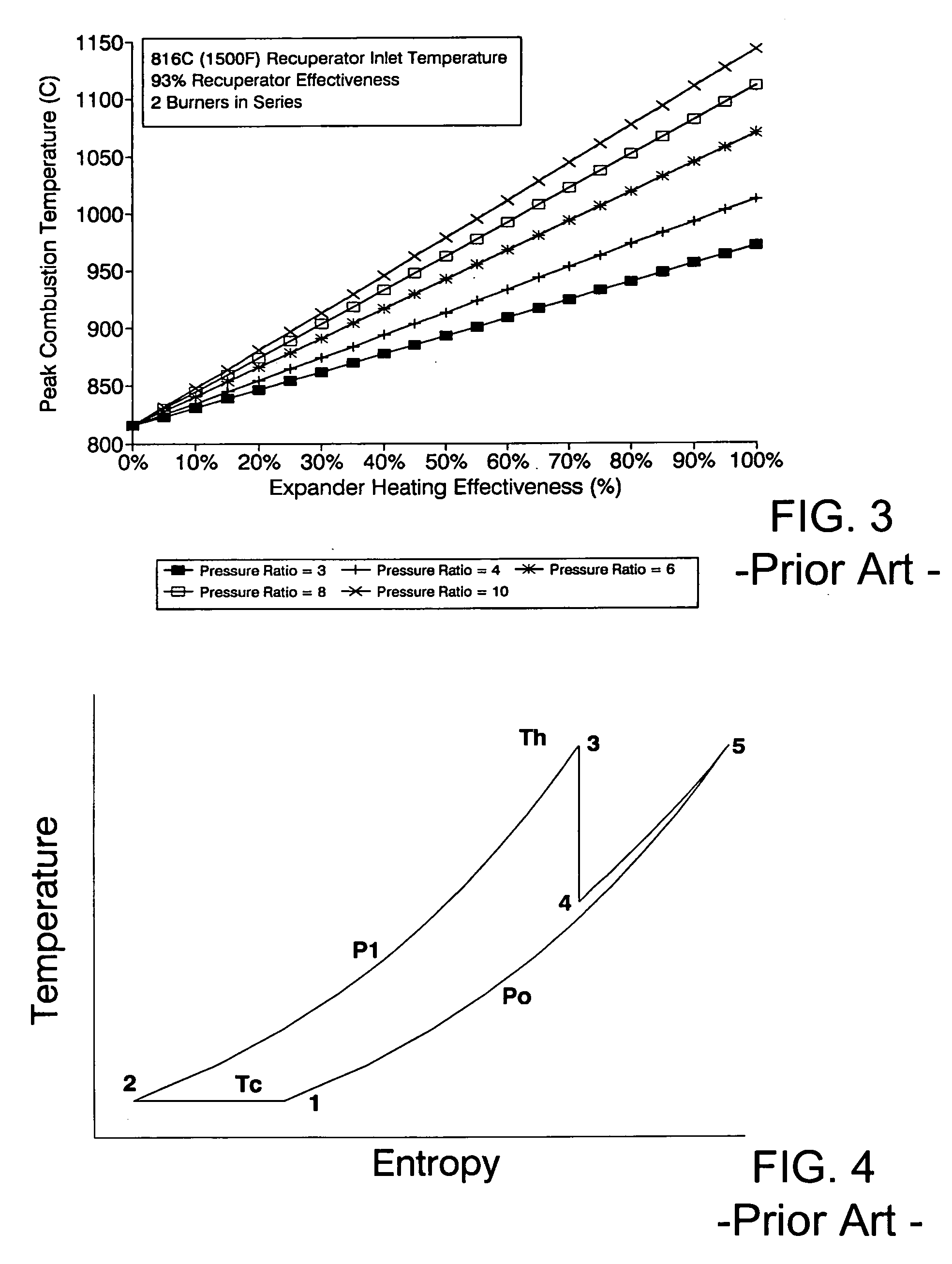

The invention is a positive displacement heat engine; where the engine cycle comprises the steps of Ericsson (isothermal) compression, recuperative heat addition, Brayton (adiabatic) expansion, and recuperative heat removal; whose principle is heat addition to the cycle by an afterburner in which fuel is burned with the low pressure air working fluid exhausted by the expander. The resulting combustion gases are used in a counterflow heat exchange recuperator to continually heat the high pressure air compressed by the compressor. All moving parts are only exposed to clean air, and the expander valves can be operated at temperatures comparable to current internal combustion engines. Liquid, solid or gaseous fuels can be used and control of speed and power is simple, based on keeping engine temperatures constant. The low-pressure continuous combustion avoids fuel pressurization problems and allows high efficiency, low emission combustion processes.

Owner:PROE POWER SYST

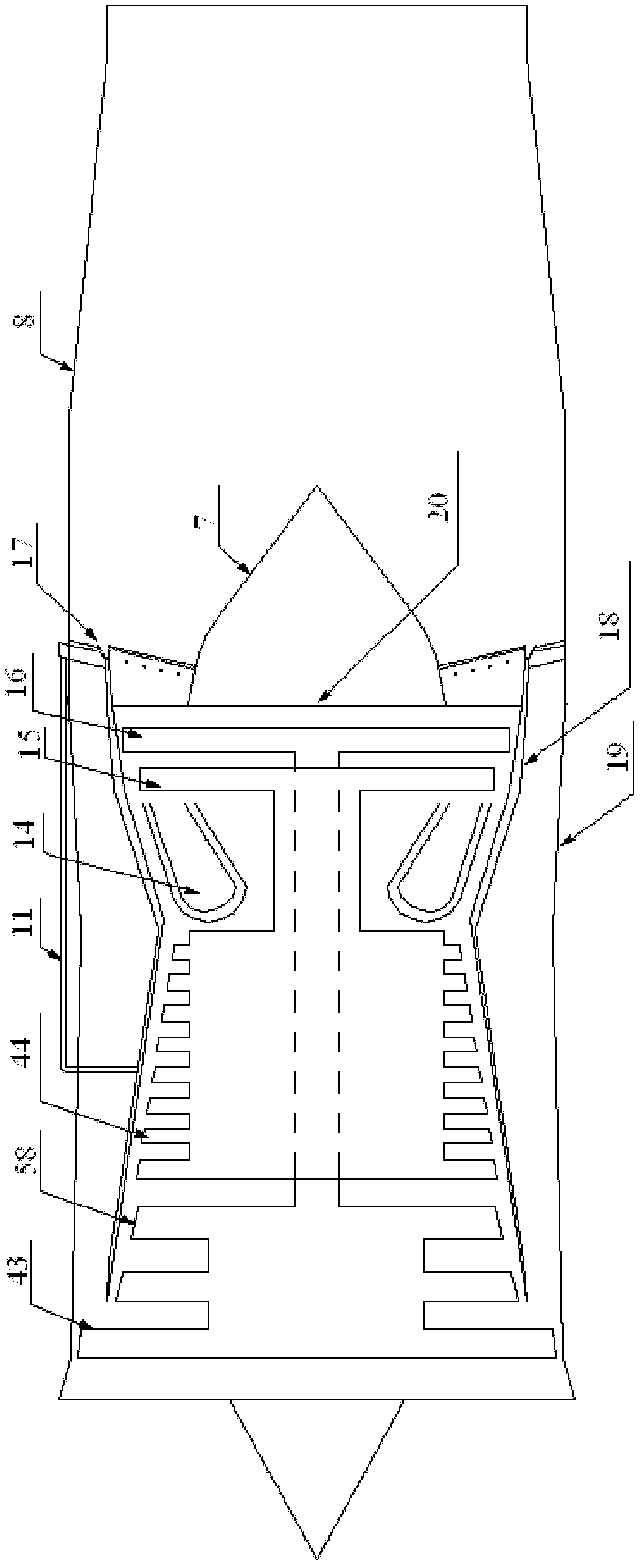

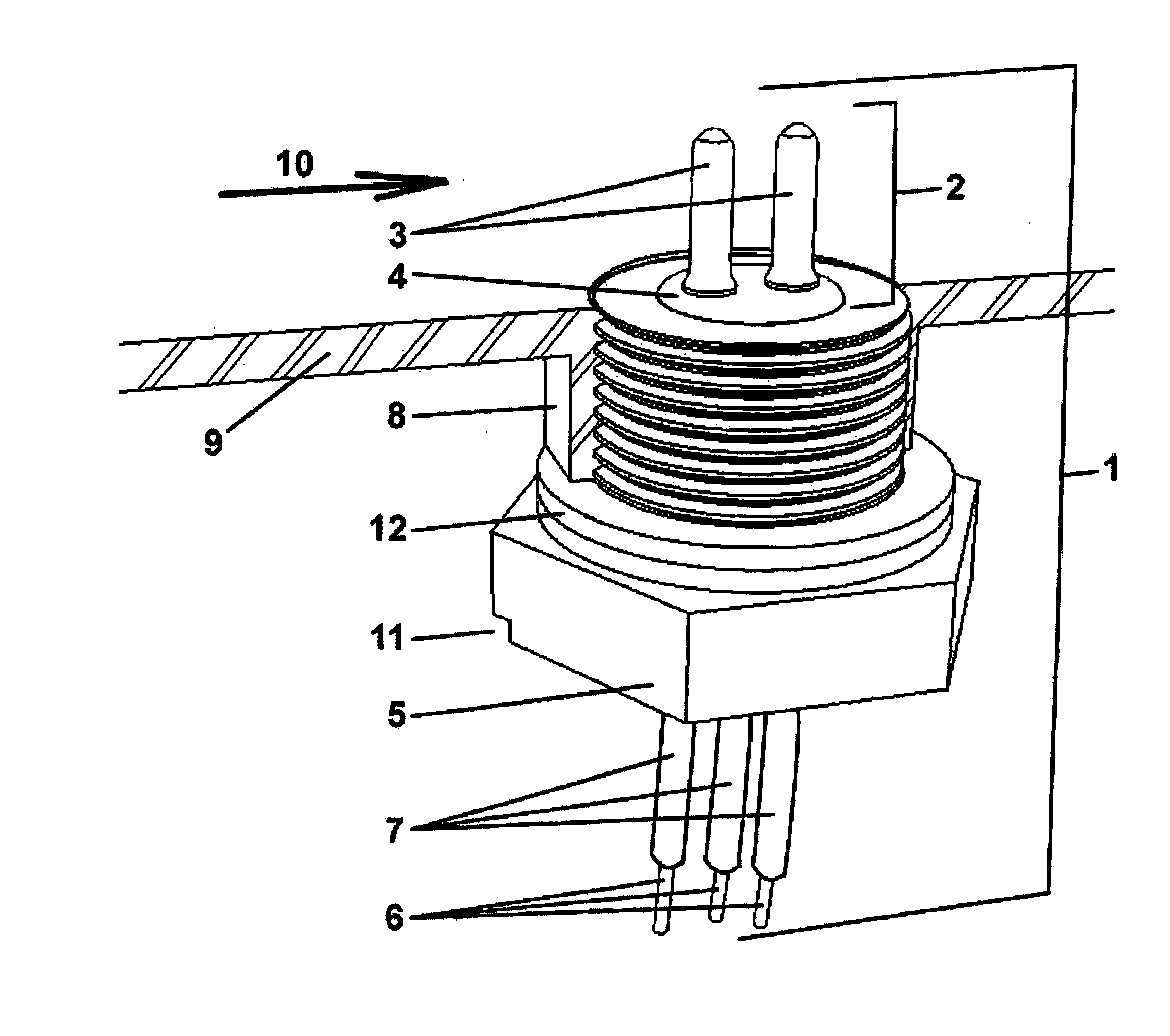

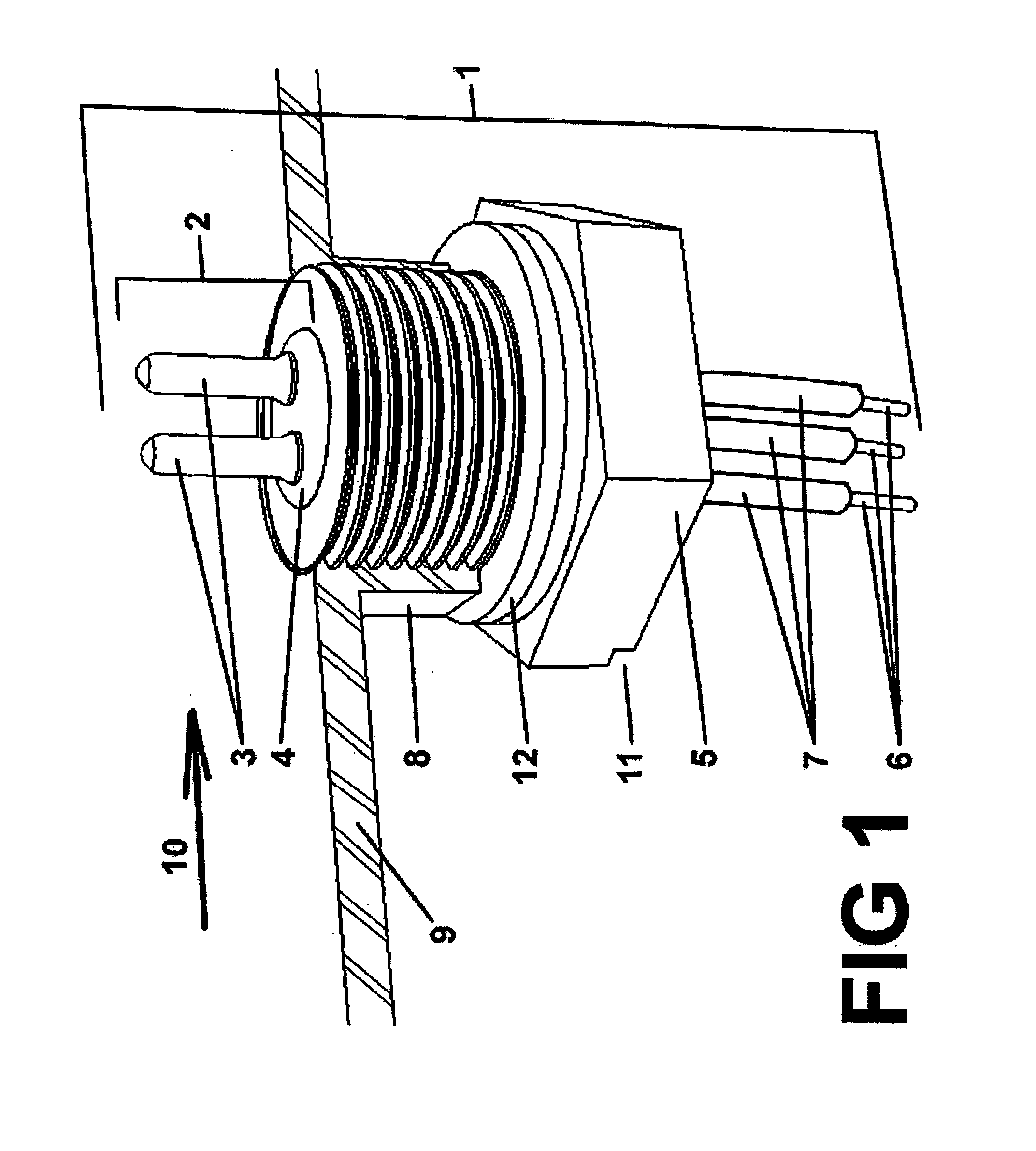

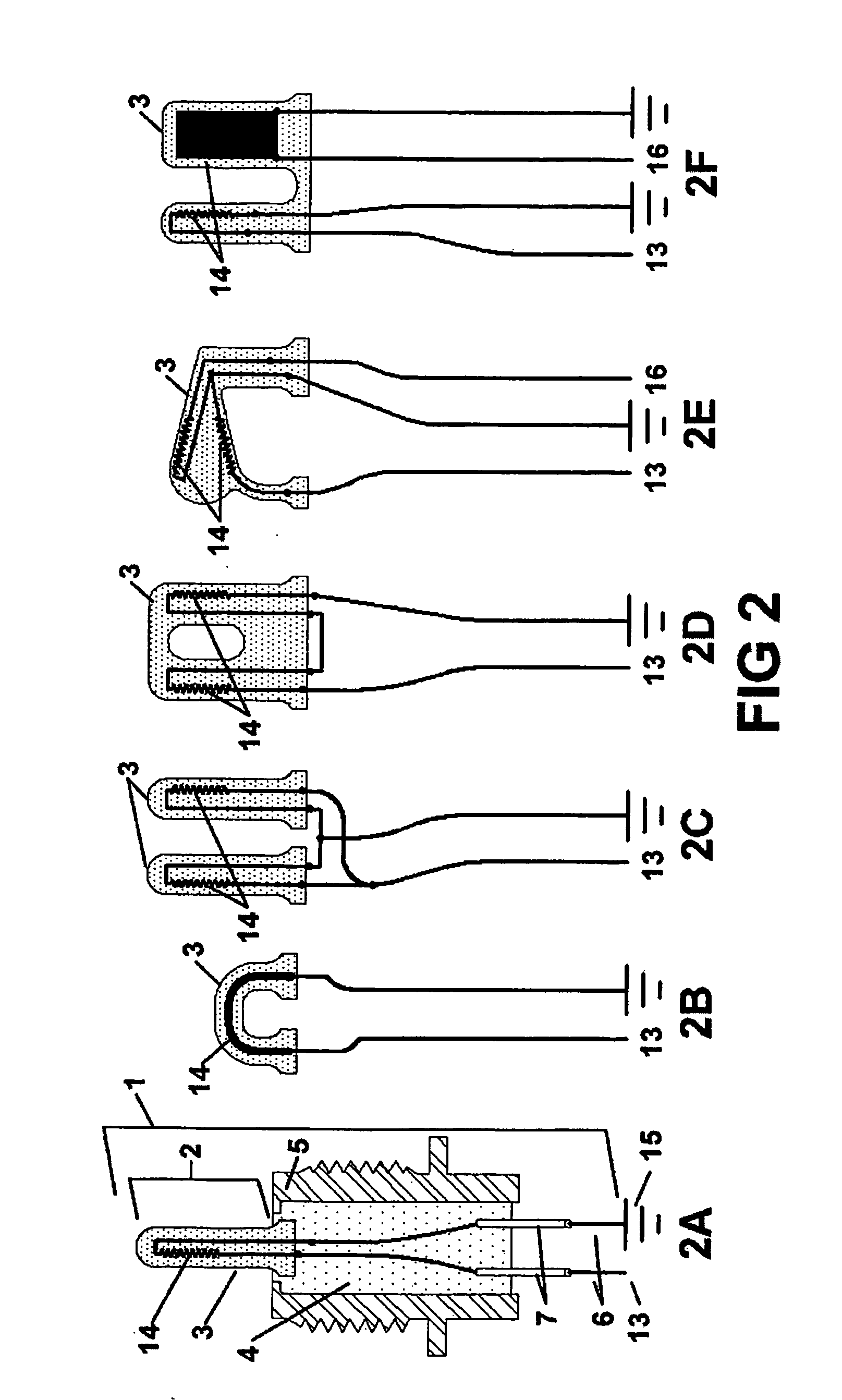

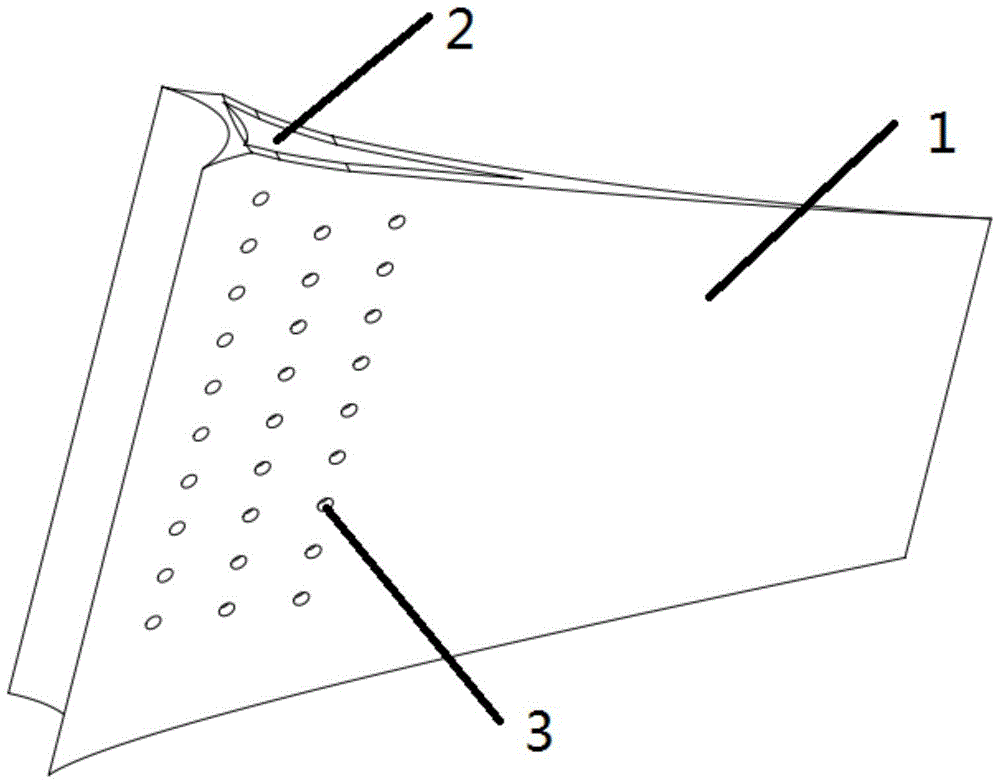

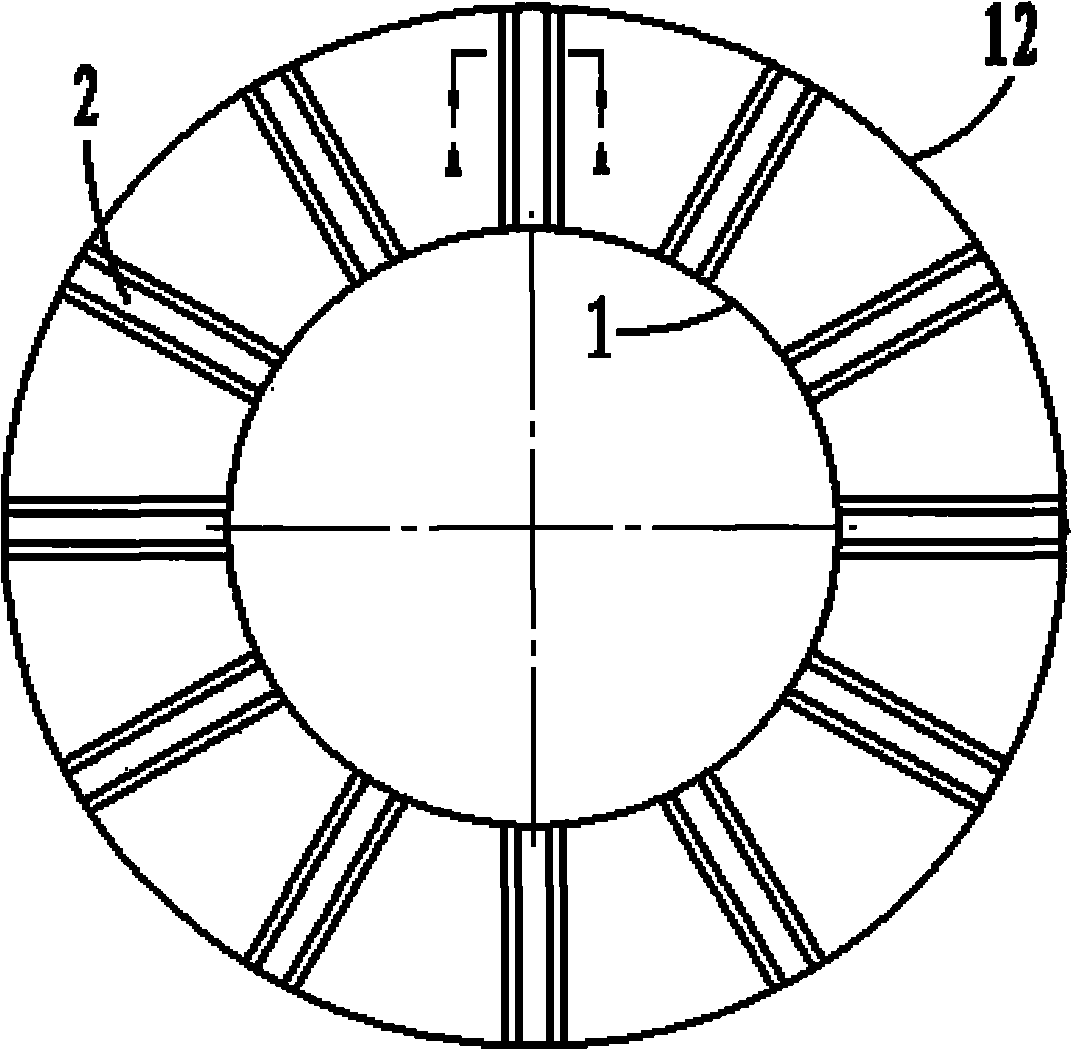

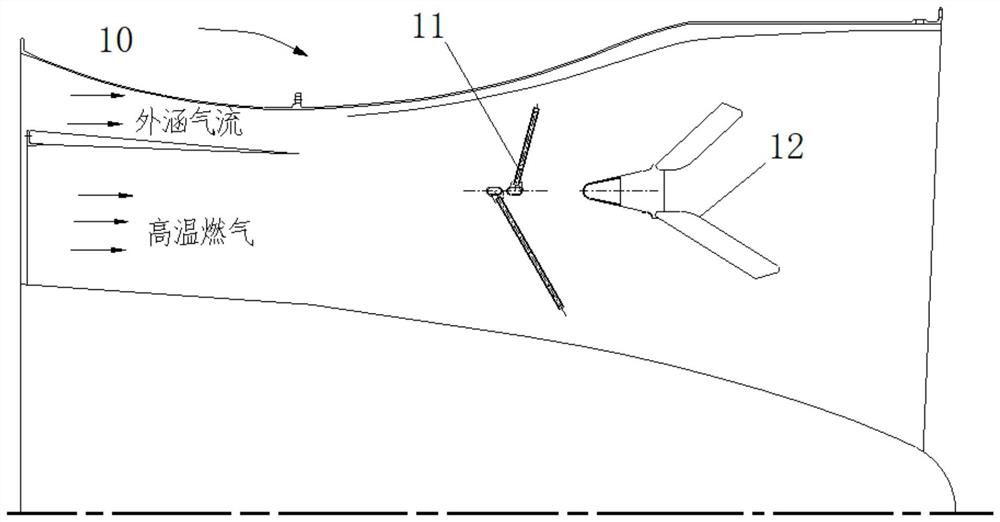

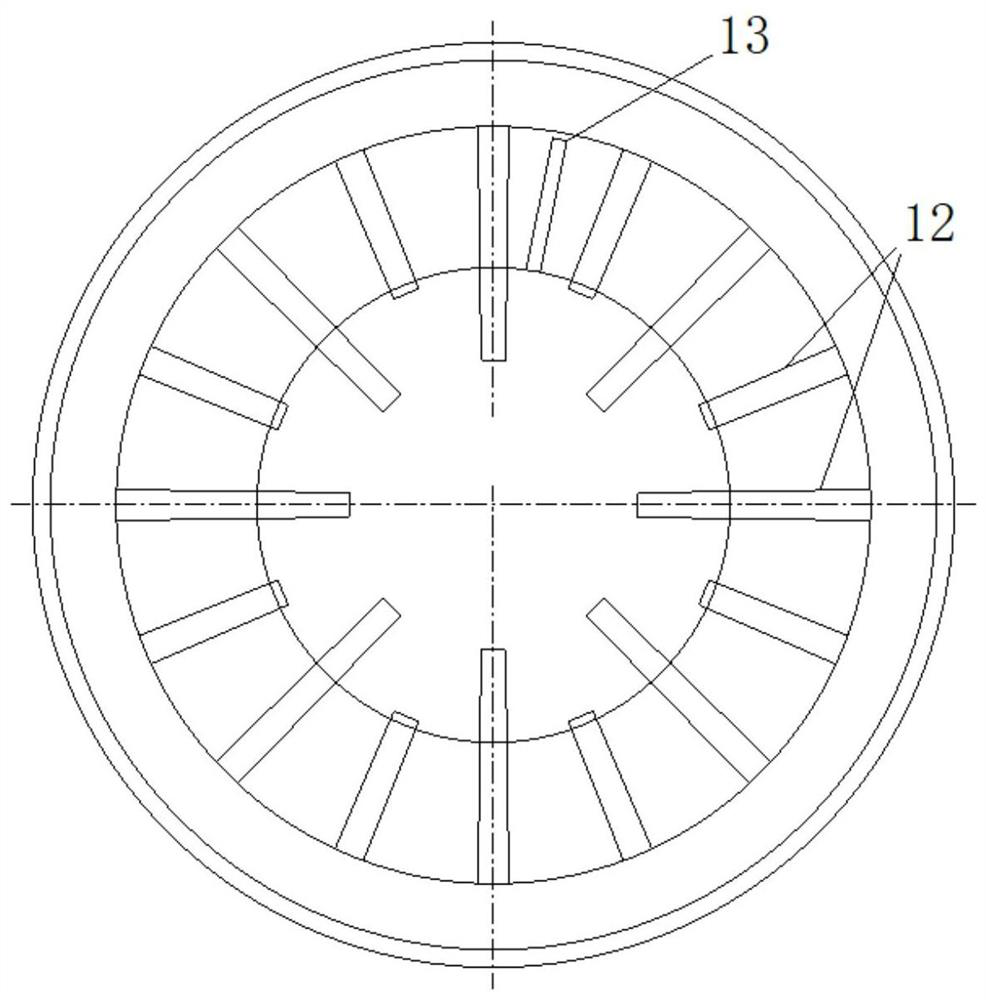

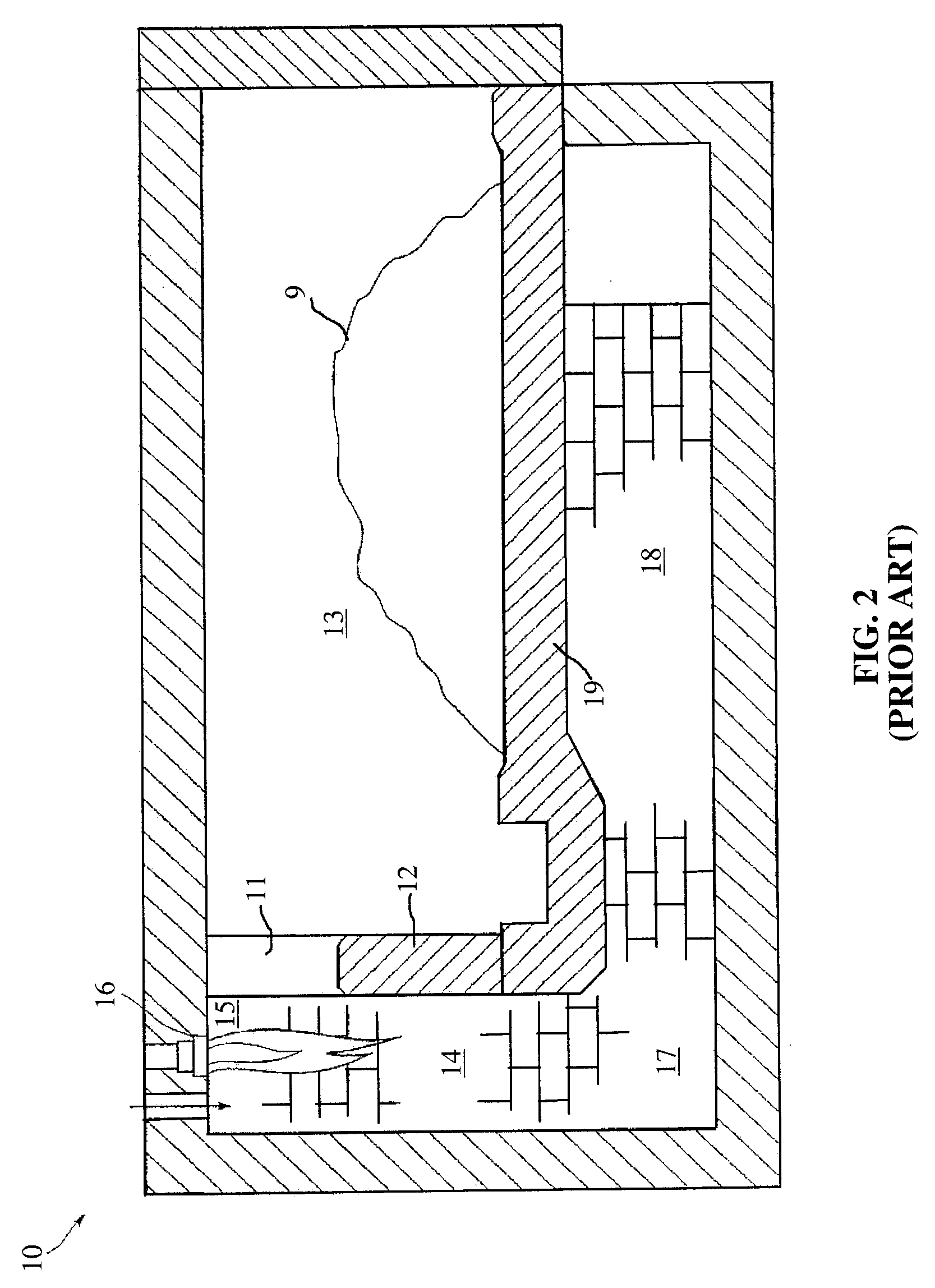

Flame stabilizing device and method for supporting plate with cavities

InactiveCN102200292AIncrease swirl areaExtended Radial Coverage AreaContinuous combustion chamberCombustion chamberLow speed

The invention provides a flame stabilizing device and method of an afterburner for a gas turbine engine. In the device, the original turbine rear frame supporting plate is replaced with the supporting plate with the cavities; and the device is characterized in that: the section of the supporting plate is in the shape of a wing with a suddenly expanded trailing edge and is provided with the cavities. The aim of stabilizing flame is fulfilled through a low-speed backflow region formed by flowing gas flow through the cavities of the supporting plate and the suddenly expanded part of the trailing edge. The invention provides the turbine rear frame supporting plate (2) of the afterburner for the gas turbine engine; the afterburner comprises a case (12), a turbine rear frame inner wall (1) and a plurality of turbine rear frame supporting plates (2), wherein the turbine rear frame supporting plates (2) are connected with the case (12) and the turbine rear frame inner wall (1); and the turbine rear frame supporting plate (2) is characterized by being provided with the cavities (9).

Owner:BEIHANG UNIV

Retractable afterburner for jet engine

The present invention is a retractable afterburner shroud for use upon a jet engine. The retractable shroud conforms to an outer surface of a jet engine. The afterburner shroud is affixed by a plurality of moveable support arms. The afterburner shroud is retractable. During operation of the afterburner shroud, the afterburner shroud is extended rearward toward the exhaust of the jet engine. A storage tank provides liquid oxygen through the support arms to a mixing ring located within the afterburner shroud. The mixing ring mixes the liquid oxygen and fuel to form a combustible mixture. The combustible mixture is injected into the exhaust wherein the mixture is ignited. The ignited mixture provides additional thrust for the jet engine.

Owner:ADTECH

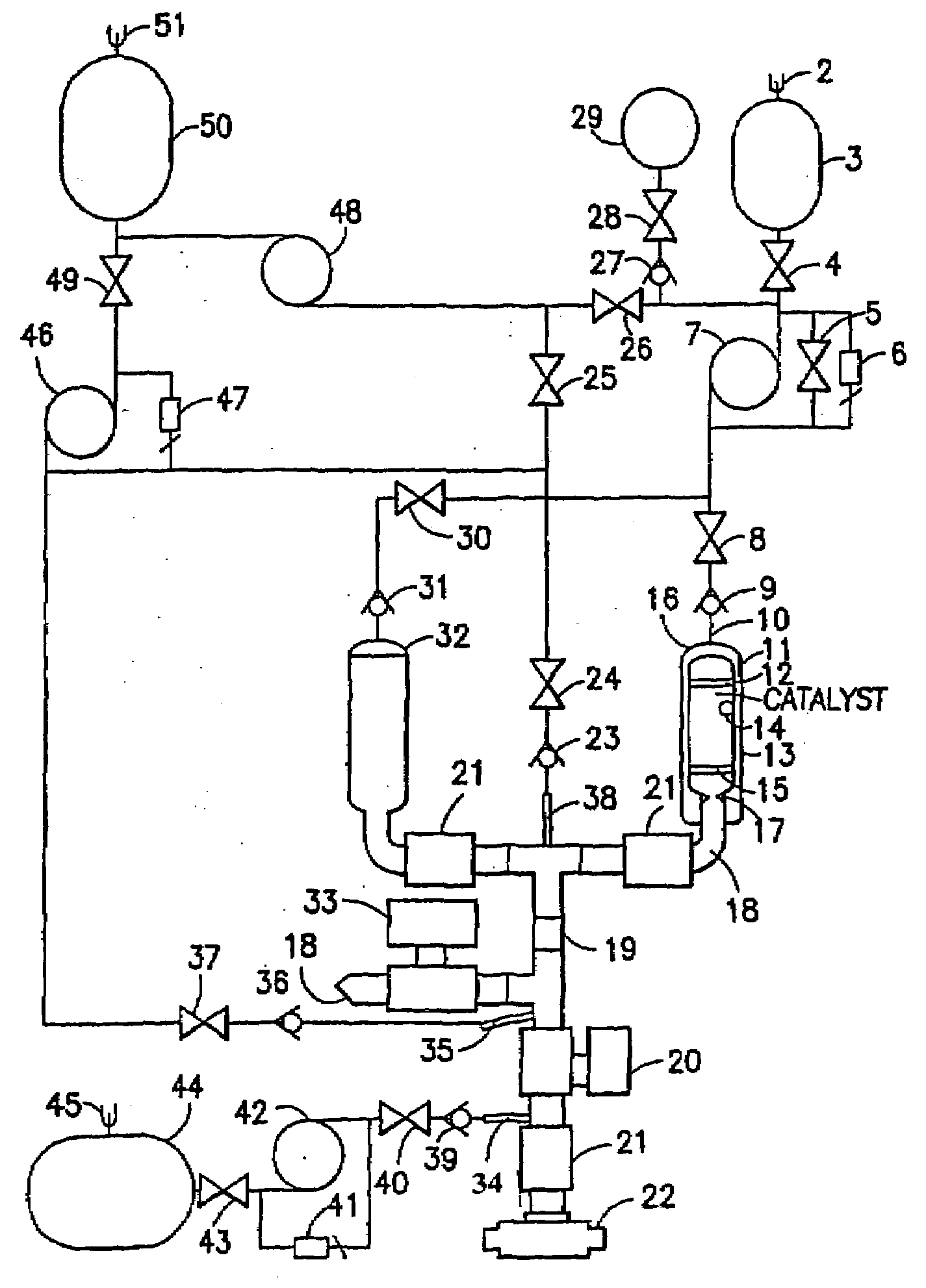

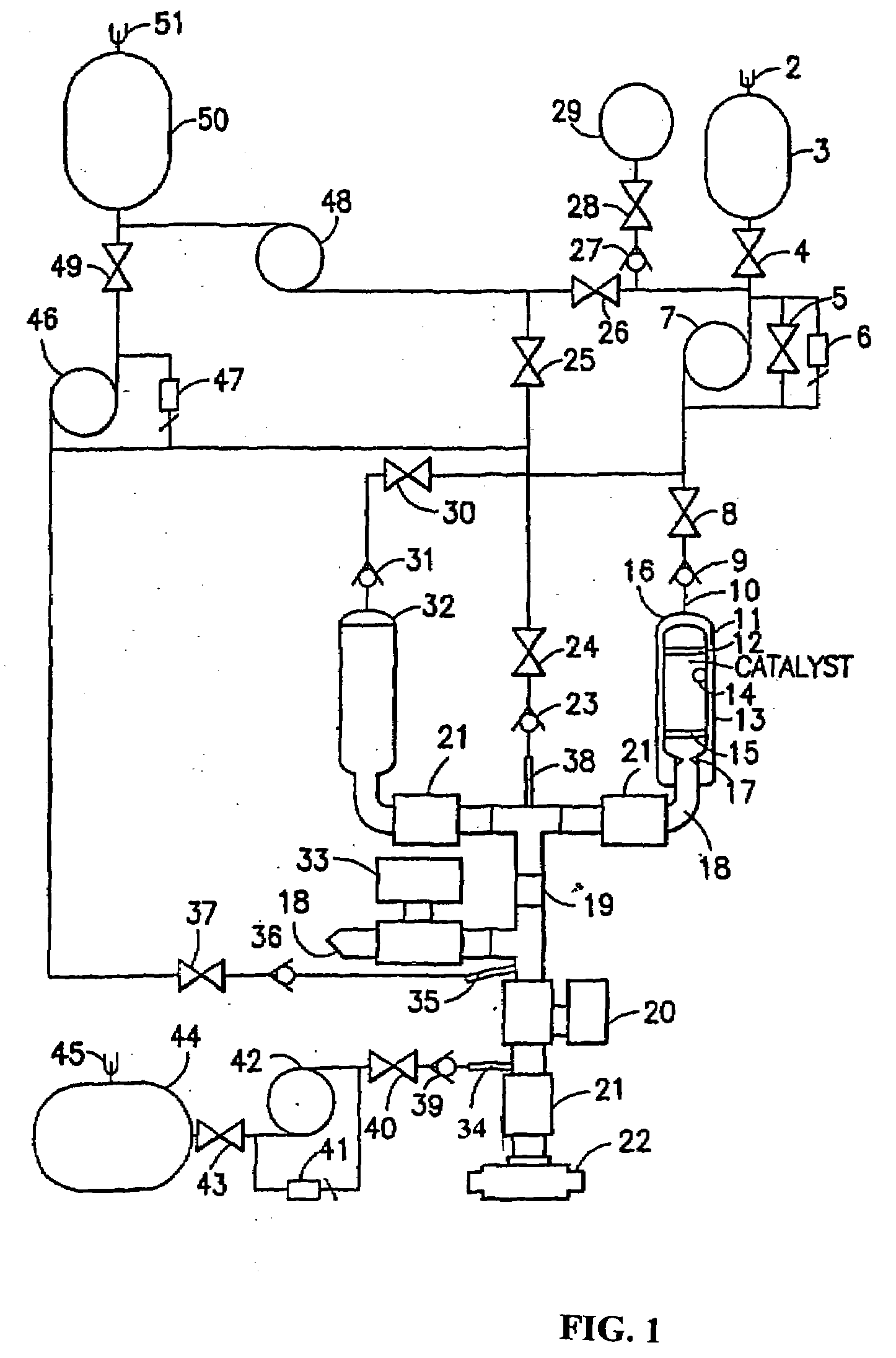

Engine/steam generator with afterburner

InactiveUS20080087434A1Efficient use ofReduce the possibility of corrosionExothermal chemical reaction heat productionDrilling rodsChemical storageCombustion chamber

An engine / steam generator which converts hydrogen peroxide to superheated steam and oxygen and having an afterburner that together with a reducing agent, utilizes the oxygen, thereby supplying oxygen free super-heated steam under pressure for oil well stimulation. Fluids such as water and KH30 can be injected into the engine / stem generator. The invention also relates to an apparatus and methods of incineration, soil remediation, land fill remediation, controlled vault burning, chemical atomization / vaporization, home heating, generation of electricity, diesel engine exhaust cleaning, steam turbine, gas path cleaner for jet engines, steam cleaning, natural gas engine power booster emission reducer, chemical storage tank cleaning, portable gas drive, and metal tempering.

Owner:UNITED ENERGY CORP

Self-air-entrainment-based plasma jet igniter of aero-engine

ActiveCN108005790ASimplify the intake structureReduce weightGas turbine plantsJet propulsion plantsPlasma jetCombustion chamber

The invention discloses a self-air-entrainment-based plasma jet igniter of an aero-engine. The plasma jet igniter comprises an outer pipe, an insulating inner pipe, a conducting copper pipe, a cathodeand an anode; the lower end of the outer pipe is fixedly connected with the upper end of the anode; the outer pipe is internally sleeved with the insulating inner pipe; the insulting inner pipe is internally sleeved with the conducting copper pipe; the upper part of the cathode has threaded connection with a groove formed in the lower part of the conducting copper pipe; a hollow structure insidethe upper part of the cathode is an ionization region; the hollow structure inside the lower part of the anode is a flow jet region; the outer sidewall of the ionization region is provided with an igniter air inlet for leading air which is inside a main combustion chamber or mixed rotational air flow which is inside an afterburner into the ionization region; the upper part of the cathode is positioned inside the conducting copper pipe; and the lower part of the cathode is positioned inside the ionization region. The plasma jet igniter disclosed by the invention needs not to be externally connected with an air entraining device; the air flow in two channels of the main combustion chamber or the air flow in the afterburner is directly led into the plasma jet igniter, so the structure of an igniting device is simplified, and the weight and volume of the igniting device are reduced.

Owner:AIR FORCE UNIV PLA

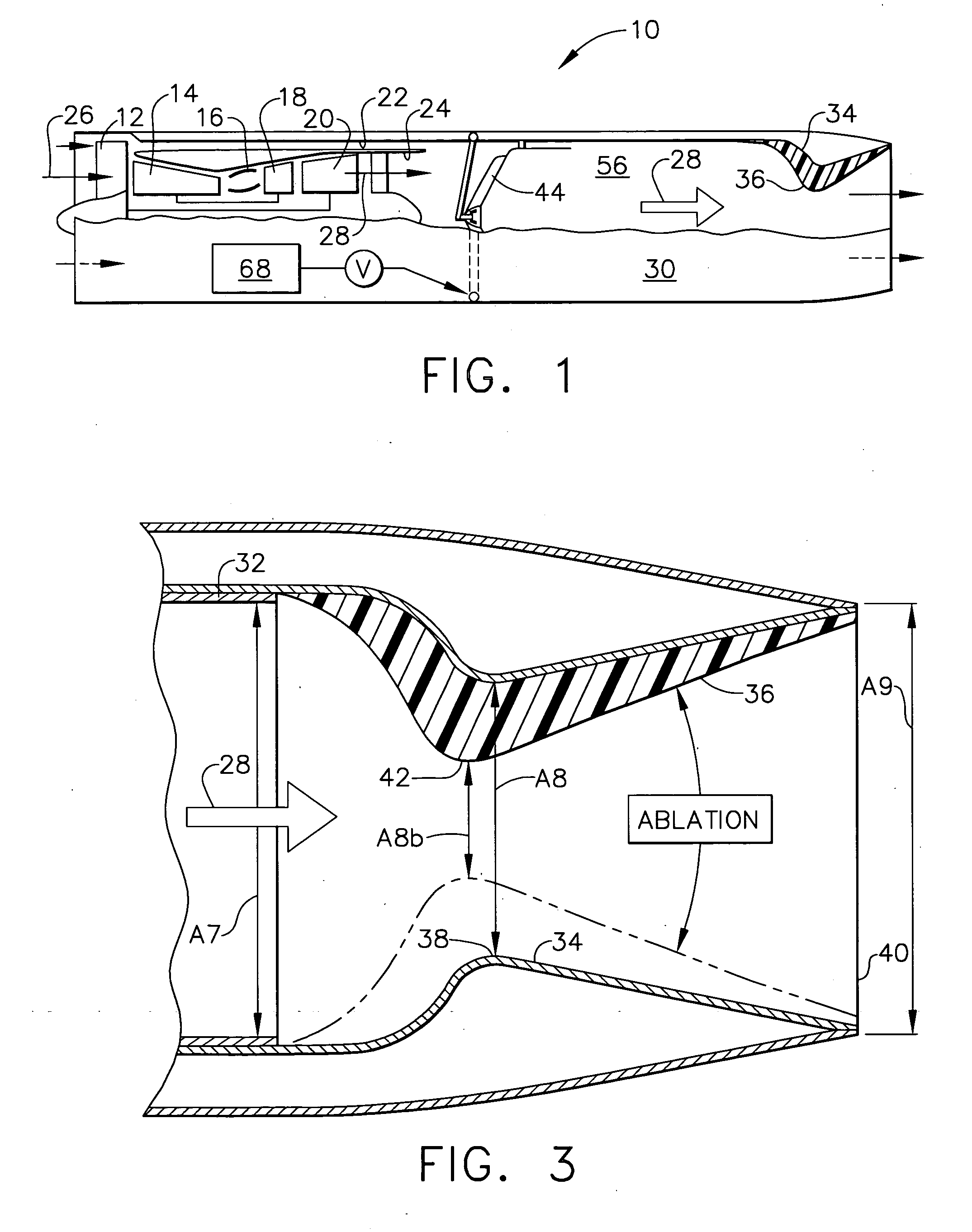

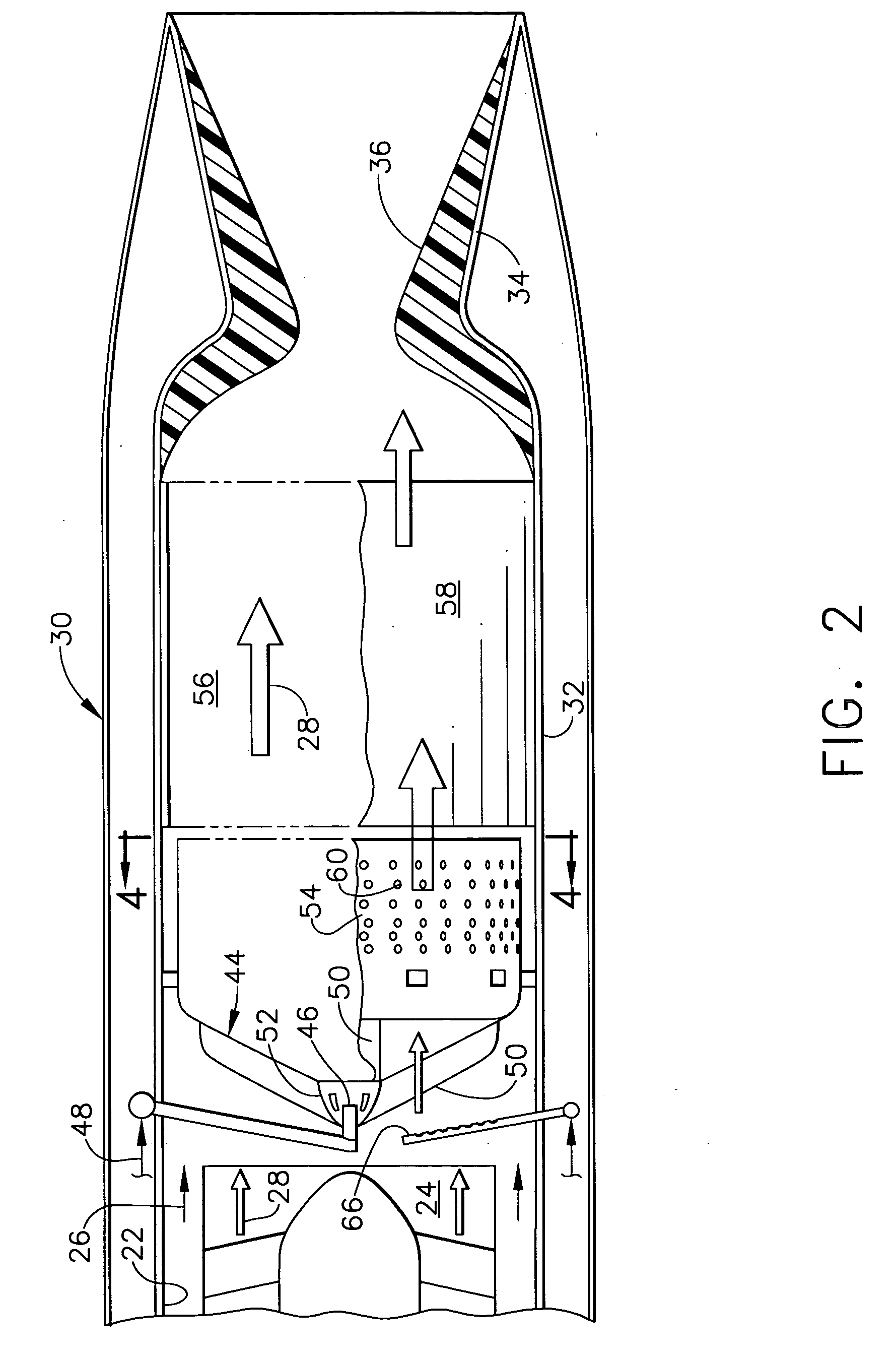

Ablative afterburner

InactiveUS20050198940A1Continuous combustion chamberPower plant exhaust arrangementsAfterburnerNozzle

An afterburner includes an exhaust duct with a fixed area outer nozzle at an aft end thereof, and an ablative inner nozzle therein. The smaller inner nozzle is consumed during reheat operation to expose the larger outer nozzle for increased propulsion thrust.

Owner:GENERAL ELECTRIC CO

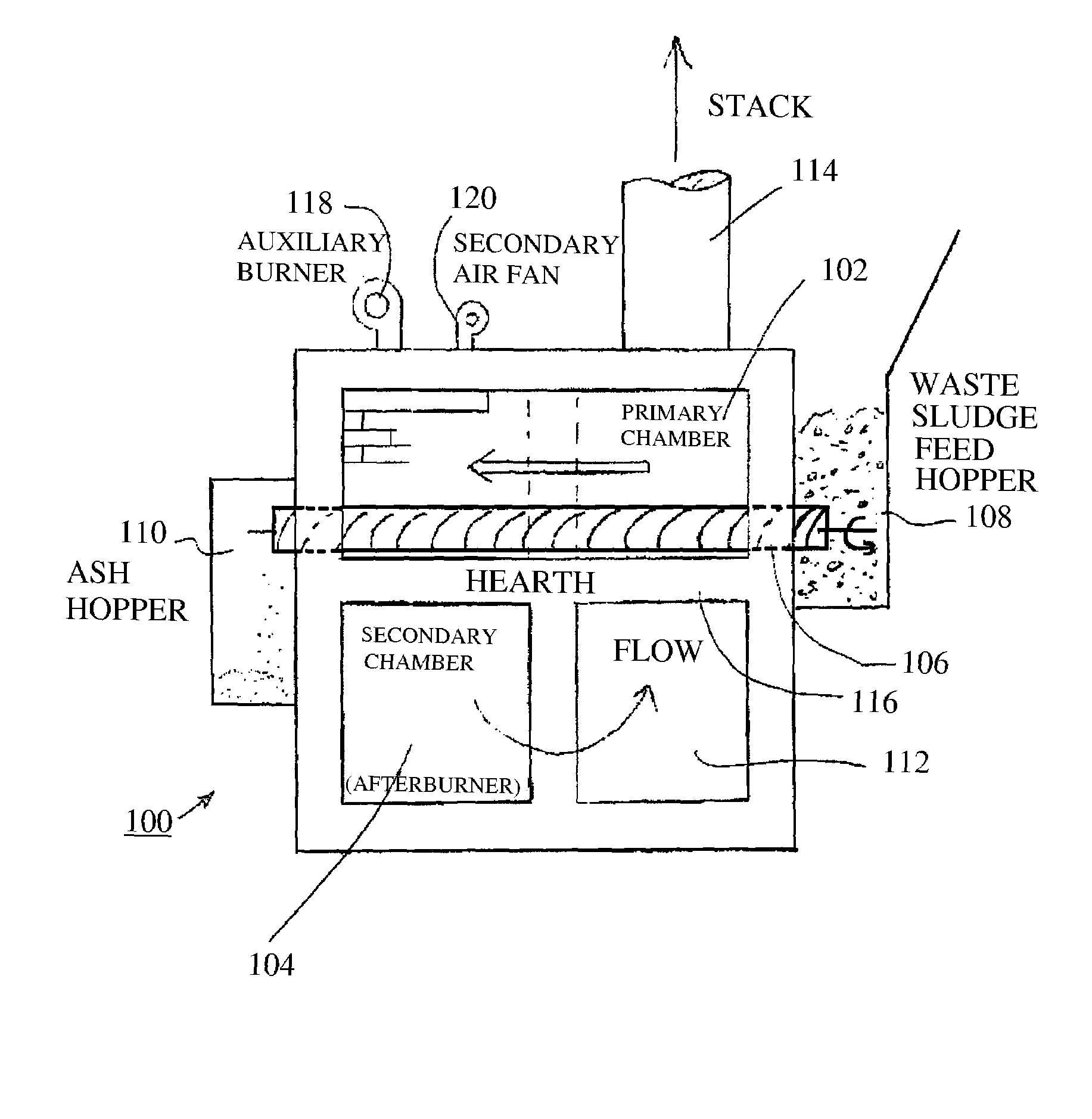

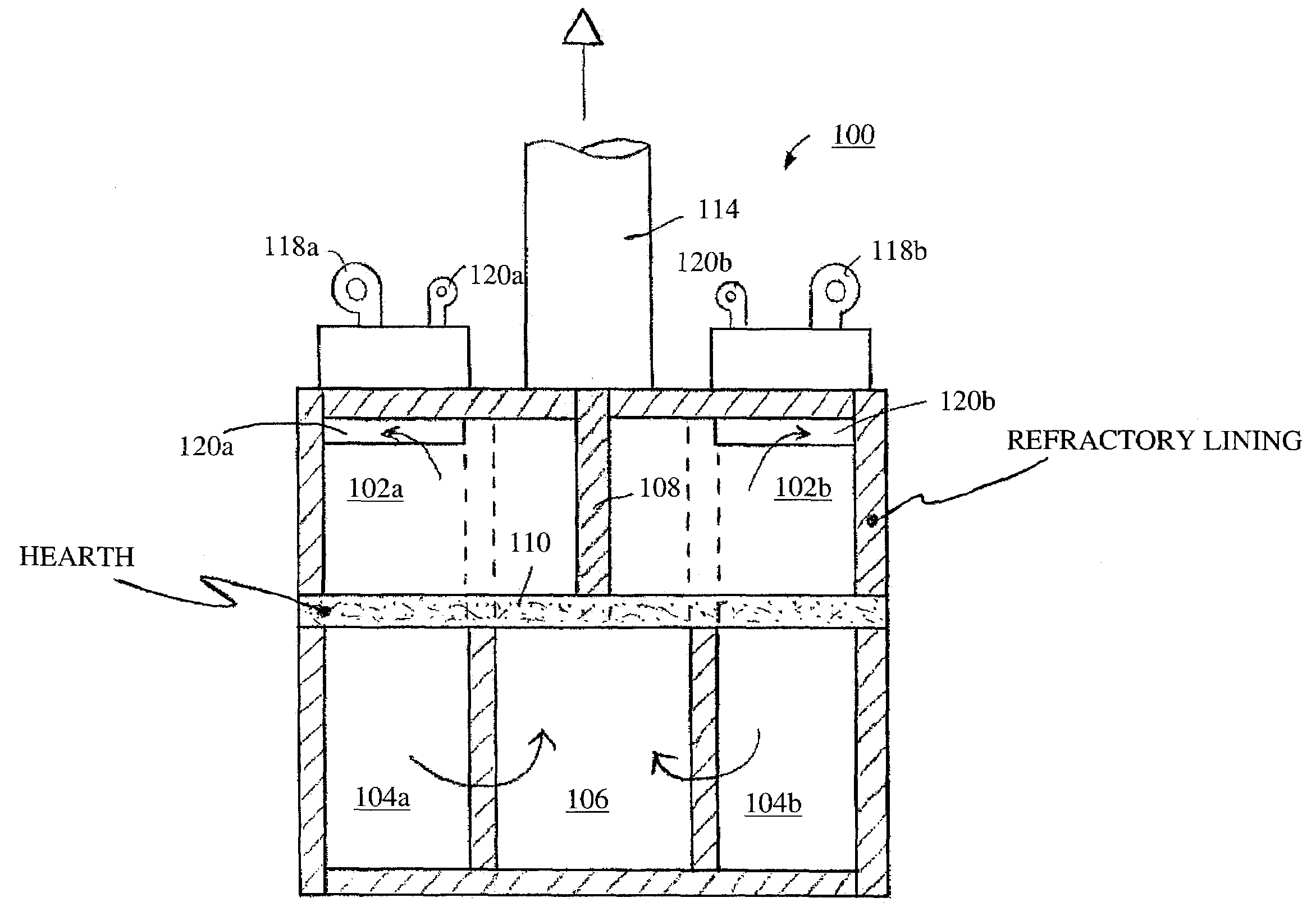

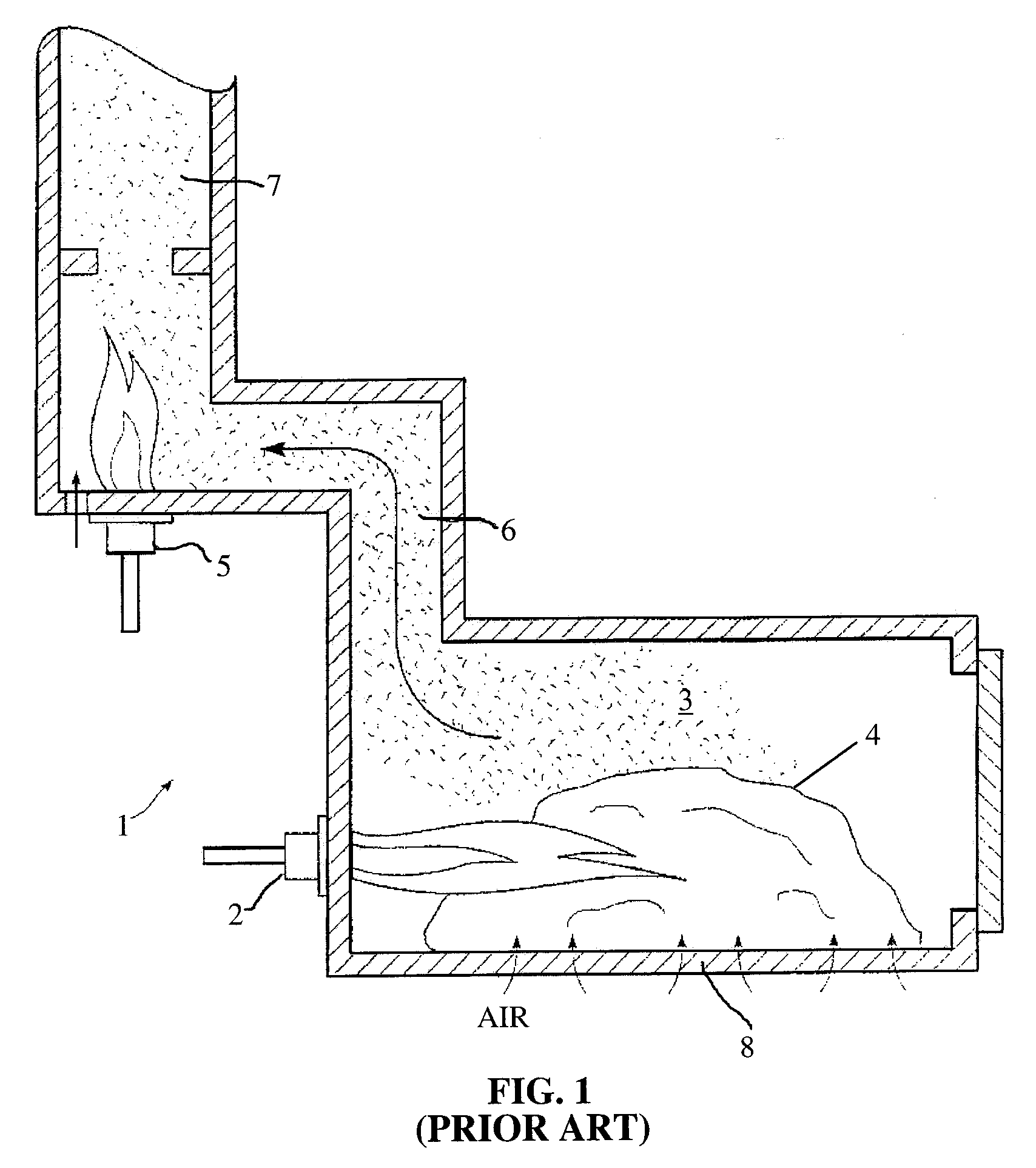

Gasifier and Incinerator for Biomass Sludge Destruction

A device for gasifying biomass sludge having particle size less than 1 cm, and 20% to 100% solids content has a primary chamber, a fume transfer vent, a mixing chamber which accepts fumes from the primary chamber, and an afterburner chamber in fluid communication with the mixing chamber. A secondary burner produces an initial heating flame within a vertical portion of the afterburner chamber. A heat transfer chamber is in fluid communication with the afterburner chamber. Heated gases from the afterburner chamber cause heating of the heat transfer chamber. The primary chamber has a heat conductive floor superimposed over the heat transfer chamber so that conductive and convective heating of the primary chamber occur. At least one primary auger is located crosswise in the primary chamber between a sludge feed hopper and an ash hopper. The heat transfer chamber underlies the primary auger near the end at the ash hopper.

Owner:ZEBREX ENVIRONMENTAL SYST

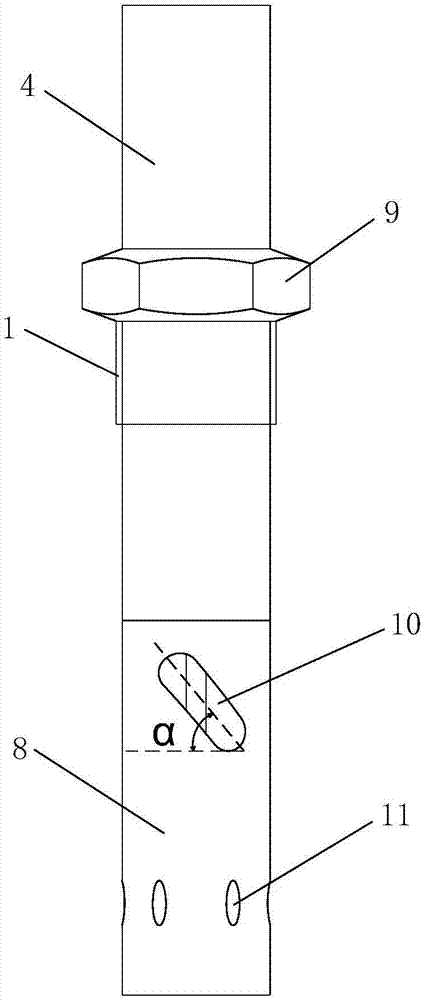

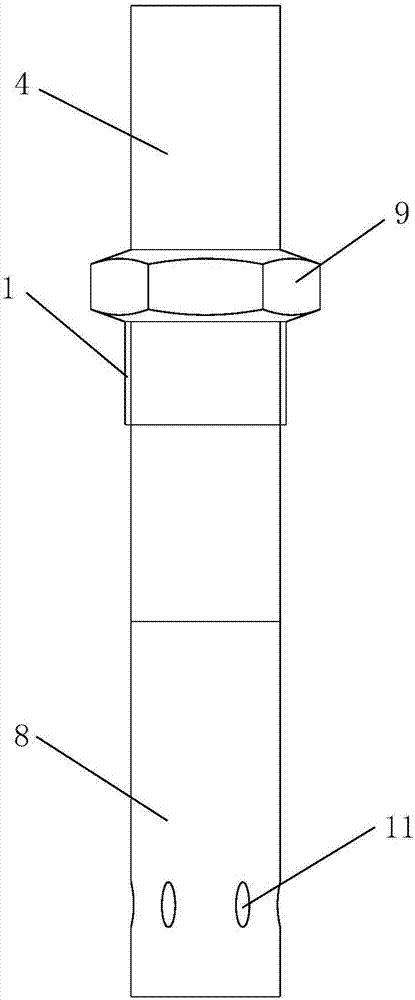

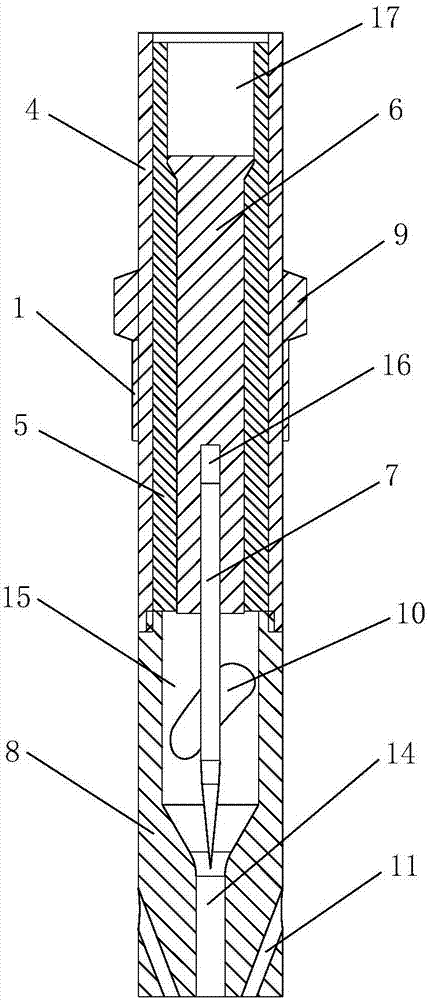

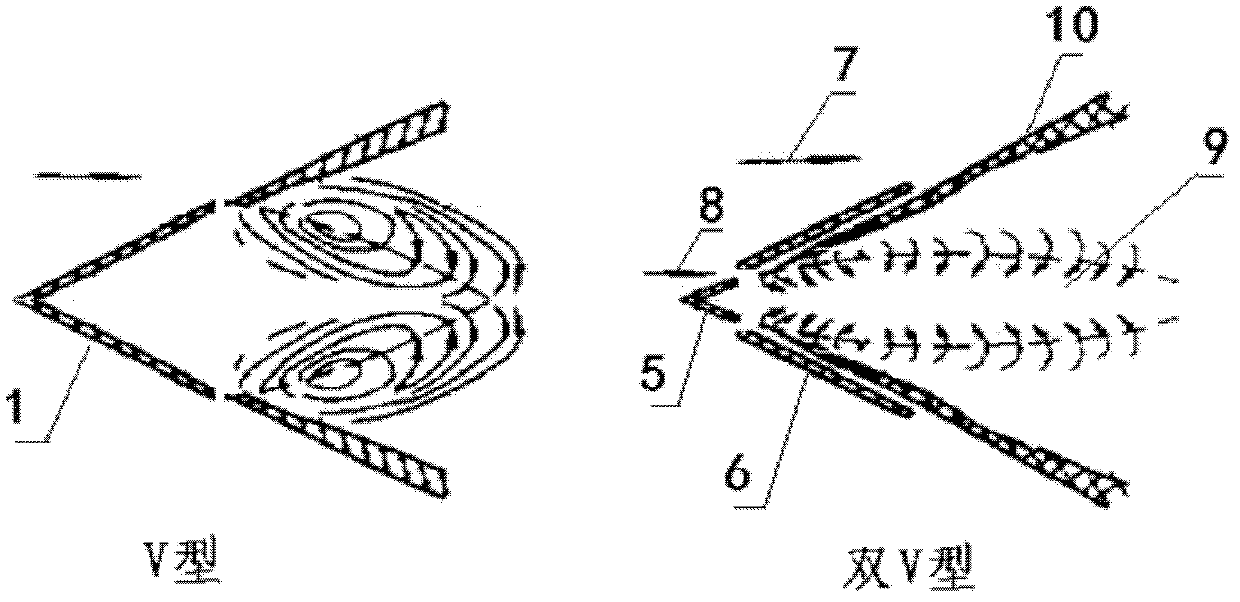

Geometrical variable flame stabilizing device

InactiveCN102607061ALow flow resistanceImprove thrust performanceContinuous combustion chamberCombustion chamberEngineering

The invention discloses a geometrical variable flame stabilizing device and belongs to the technical field of afterburner flame stabilization of aircraft engines. The geometrical variable flame stabilizing device disclosed by the invention utilizes a V-shape as a basic bluff body structure and consists of a main body part and a transmission power part, wherein the main body part is vertically installed in an afterburner cartridge receiver, the afterburner cartridge receiver comprises a front streamline head part, a blade A with a rotating shaft A, a blade B with a rotating shaft B, a rotating shaft supporting plate and a mounting seat, and the two ends of the streamline head part are fixedly connected between the mounting seat and the rotating shaft supporting plate. The geometrical shape of the flame stabilizing device provided by the invention can be changed to effectively reduce the flow resistance of the flame stabilizing device if necessary, or the flow resistance is increased within a short time to improve the ignition success rate, or the geometrical shape of the flame stabilizing device is adjusted to consistently keep the flame stabilizing device at the optimal combination point of the flame stabilization and flow resistance loss so as to obtain the maximal thrust performance of the afterburner.

Owner:BEIHANG UNIV

Variable-cycle air turbine combined engine of rocket

The invention discloses a variable-cycle air turbine combined engine of a rocket. The variable-cycle air turbine combined engine of the rocket comprises an axial compressor, a shaft, a main combustion chamber, an air duct, a turbine, an afterburner and an exhaust nozzle, wherein the axial compressor is arranged on the side, with an air inlet, of the main combustion chamber, the turbine is arranged on the side, with an air outlet, of the main combustion chamber, the axial compressor is connected with the turbine through the shaft, the air duct is arranged on the outer side of the main combustion chamber, and is used for communicating the axial compressor with the afterburner, the afterburner is arranged on the exhaust side of the turbine, and the exhaust nozzle is communicated with the afterburner. The variable-cycle air turbine combined engine of the rocket further comprises a fuel gas generator and a second turbine, wherein the fuel gas generator is arranged between the air duct and the main combustion chamber, the second turbine is arranged at the blade tip position of the turbine, and is connected with the axial compressor through the shaft, and an outlet of the fuel gas generator exactly faces the second turbine. The variable-cycle air turbine combined engine of the rocket provides a power system solution scheme for a spacecraft, wherein according to the power system solution scheme, the spacecraft can carry out the long-time economical cruise, and can carry out high-speed maneuver in a short time in a high comprehensive performance mode, and the problem that an existing aviation turbine engine can not carry out self-starting can be solved.

Owner:NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH

Air-cooling shielding integrated afterburner

InactiveCN113357670AImprove cooling effectRealize full occlusion of rear viewContinuous combustion chamberCombustion chamberFuel oil

The invention provides an air-cooling shielding integrated afterburner. The air-cooling shielding integrated afterburner comprises a diffuser casing; the inner cone is arranged in the diffuser casing; a plurality of hollow flow guide supporting plates are installed on the inner cone and connected to the diffuser casing through pull rods, flame stabilizers are arranged at the rear ends of the flow guide supporting plates, the flow guide supporting plates extend in the axis direction of the engine in a bent and twisted mode, and the he front end and the rear end of the flow guide supporting plate are deflected by a preset angle in the circumferential direction, so that a shielding structure is formed; an oil injection rod extending into the flow guide support plates communicates with the oil injection rod outside the diffuser casing through an annular fuel oil main pipe; a confluence ring is installed on the flow guide supporting plates and divides a flow channel between the diffuser casing and the inner cone into a fuel gas flow channel and a cold gas flow channel, fuel gas flows into the fuel gas flow channel and is mixed with fuel oil flowing out of the oil injection rod for combustion, one part of cold gas flows into the cold gas flow channel, and the other part of the cold gas flows into the flow guide supporting plates from a communicating hole formed in the confluence ring; a cooling flow path is formed.

Owner:AECC SHENYANG ENGINE RES INST

Exhaust gas recirculation afterburner

InactiveUS20050109017A1Non-fuel substance addition to fuelInternal combustion piston enginesCombustion chamberExhaust fumes

An embodiment of the invention includes an exhaust gas recirculation (EGR) valve, an intake pipe, and an afterburner. As the intake valve communicates an exhaust gas stream to an EGR valve, an afterburner affixed to an inside wall of the intake pipe captures and burns large particles contained in the exhaust gas stream to prevent obstruction of the EGR valve.

Owner:GSI ENGINE MANAGEMENT GROUP

Integrated afterburner provided with deflected rectification support plate

ActiveCN106678868AWell mixedEasy to organizeContinuous combustion chamberCombustion chamberSpray nozzle

The invention provides an integrated afterburner provided with a deflected rectification support plate. The integrated afterburner provided with the deflected rectification support plate can effectively enlarge a backflow area, prolong the staying time of a gas mixture and improve the combustion efficiency. Gas flows from an inner duct and an outer duct are mixed between rectification support plate flame stabilizers through sliding baffle type back duct ejectors. Blades of the rectification support plate flame stabilizers are periodically and evenly arranged, and each blade and the axial direction form a certain included angle. Fuel oil enters a fuel oil channel inside the rectification support plate flame stabilizers through an oil supply channel. The fuel oil is sprayed out through direct-injection type spray nozzle small holes on the two sides and mixed with the gas mixture of the inner duct and the outer duct, and then the fuel oil is combusted behind the rectification support plate flame stabilizers. Under the action of the rectification support flame stabilizers, the backflow area is enlarged, the staying time of oil and gas is prolonged, the oil and the gas are more evenly mixed, combustion is more complete, and then the combustion efficiency is effectively improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

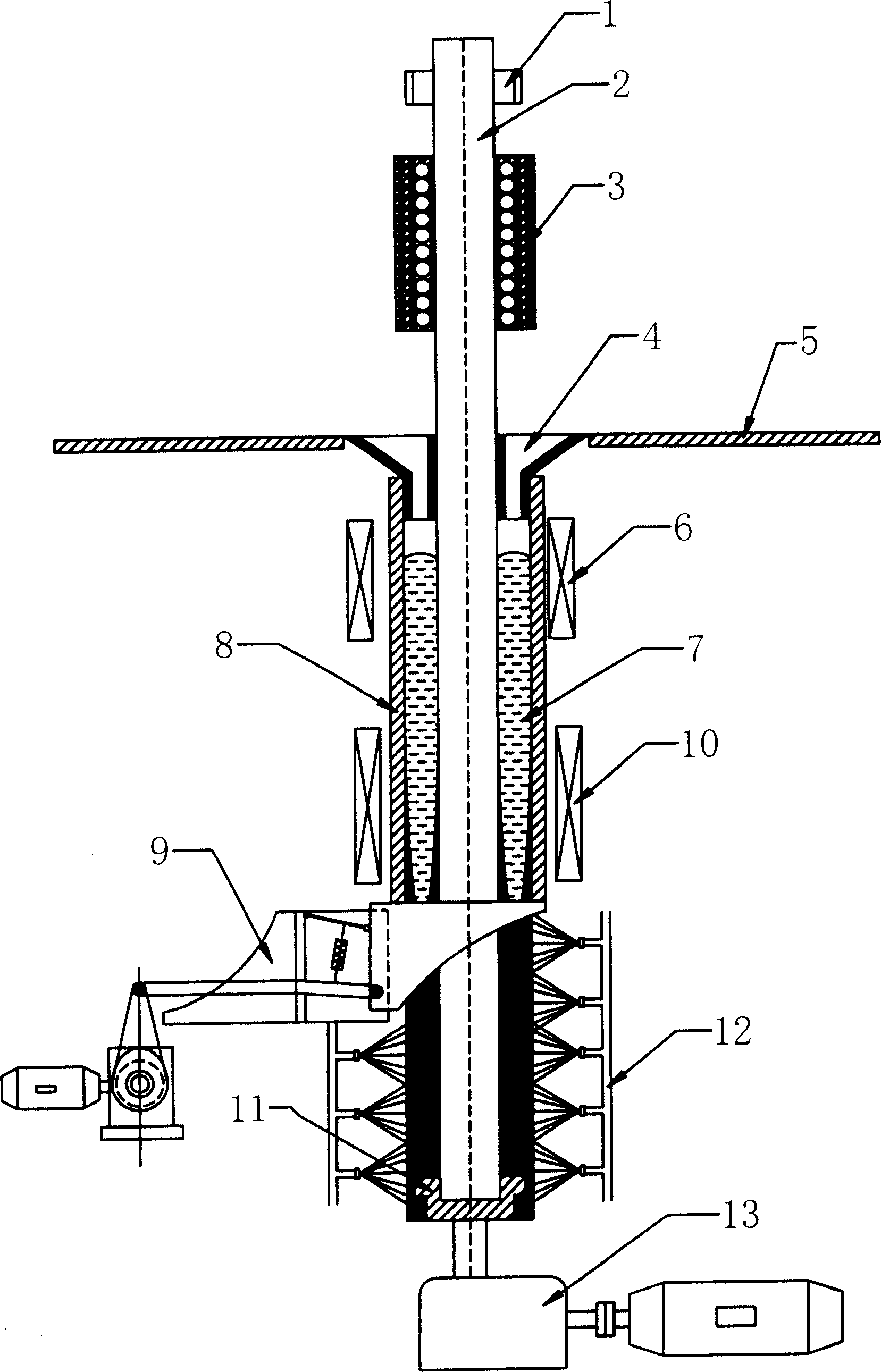

Electromagnetic continuous casting method of composite roller and its casting equipment

An electromagnetic conticasting apparatus for casting composite rolling roller is composed of dual-electromagnetic crystallizer cooled by water, induction afterburner, electromagnetic stirrer, preheating induction furnace, and vibrating system. Its casting method includes such steps as prefabricating roller core, locating in preheating induction furnace, preheating, arranging it at lower end of said crystallizer, installing filling bath, turning on said induction afterburner filling the molten metal for working layer from filling bath in the crystallizer, turning on secondary cooling system, vibrating system, electromagnetic stirrer and billet puller, continuously pulling out billet and spraying water for cooling.

Owner:NORTHEASTERN UNIV

Method and apparatus for providing an afterburner fuel-feed arrangement

InactiveUS20060032231A1Extended service lifeVibration minimizationContinuous combustion chamberTurbine/propulsion fuel flow conduitsEngineeringAerodynamics

Method and apparatus for providing an afterburner fuel-feed arrangement including an elongate fuel spraybar for distributing fuel to the afterburner section of a turbo-combustion engine. The spraybar has a longitudinal axis and includes a fuel-receiving spray head in fluid communication with a plurality of elongate fuel pipes surrounded by an elongate, aerodynamic-shaped shroud. The spray head is configured to be mounted in a casing of a turbo-combustion engine which projects the surrounded fuel pipes into an interior through-core of the engine in cross-wise orientation to a core gas flow thereof. The shroud has an interior lateral sidewall that includes a pipe-receiving portion configured to abuttingly engage a corresponding shroud-engaging portion of an exterior surface of one of the fuel pipes. The pipe-receiving portion is configured to substantially radially fix a fuel pipe, received therein, relative to the shroud. In this manner, the fuel pipes are supported along their length, and when the pipes are abuttingly engaged with the shroud, the braced configuration is stiffened which raises the eigenfrequencies of the assembly into ranges higher than those of the incorporating engine.

Owner:VOLVO AERO CORP

Dual Chamber System for Gasifying Biomass Waste

A device for gasifying biomass waste has two each of primary chambers, fume transfer vents, mixing chambers which accept fumes from the primary chamber, afterburner chambers in fluid communication with the mixing chambers, and an exhaust duct. Each secondary burner produces an initial heating flame within a vertical portion of the respective afterburner chamber, and secondary chambers are in fluid communication with the afterburner chambers. Heated gases from the afterburner chambers cause heating of the secondary chambers. A portion of each primary chamber has a heat conductive floor superimposed over the respective secondary chamber, and the partition between the primary chambers is heat conductive, so that conductive and convective heating of the primary chambers occurs.

Owner:ZEBREX ENVIRONMENTAL SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com