Patents

Literature

121 results about "Plasma ashing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

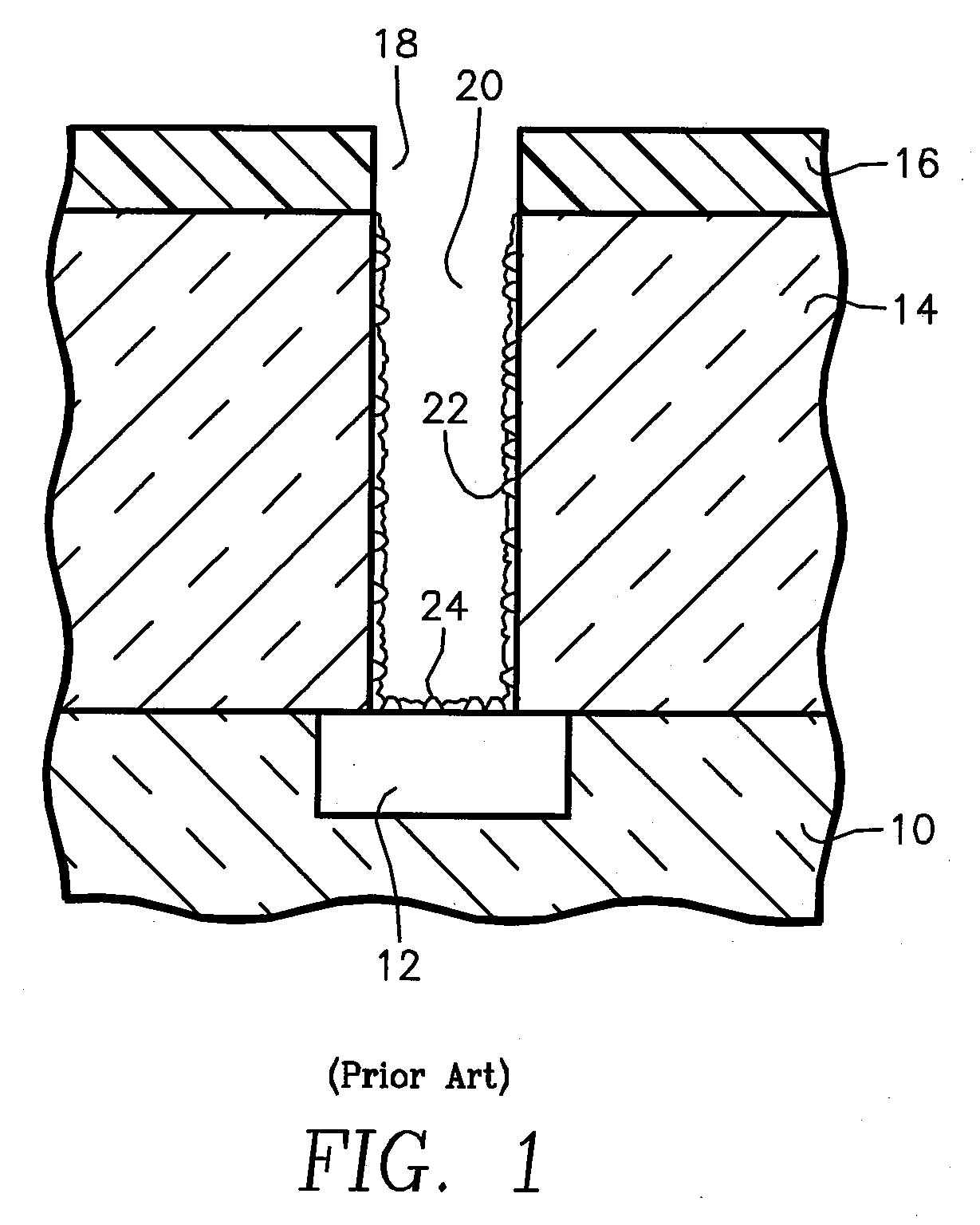

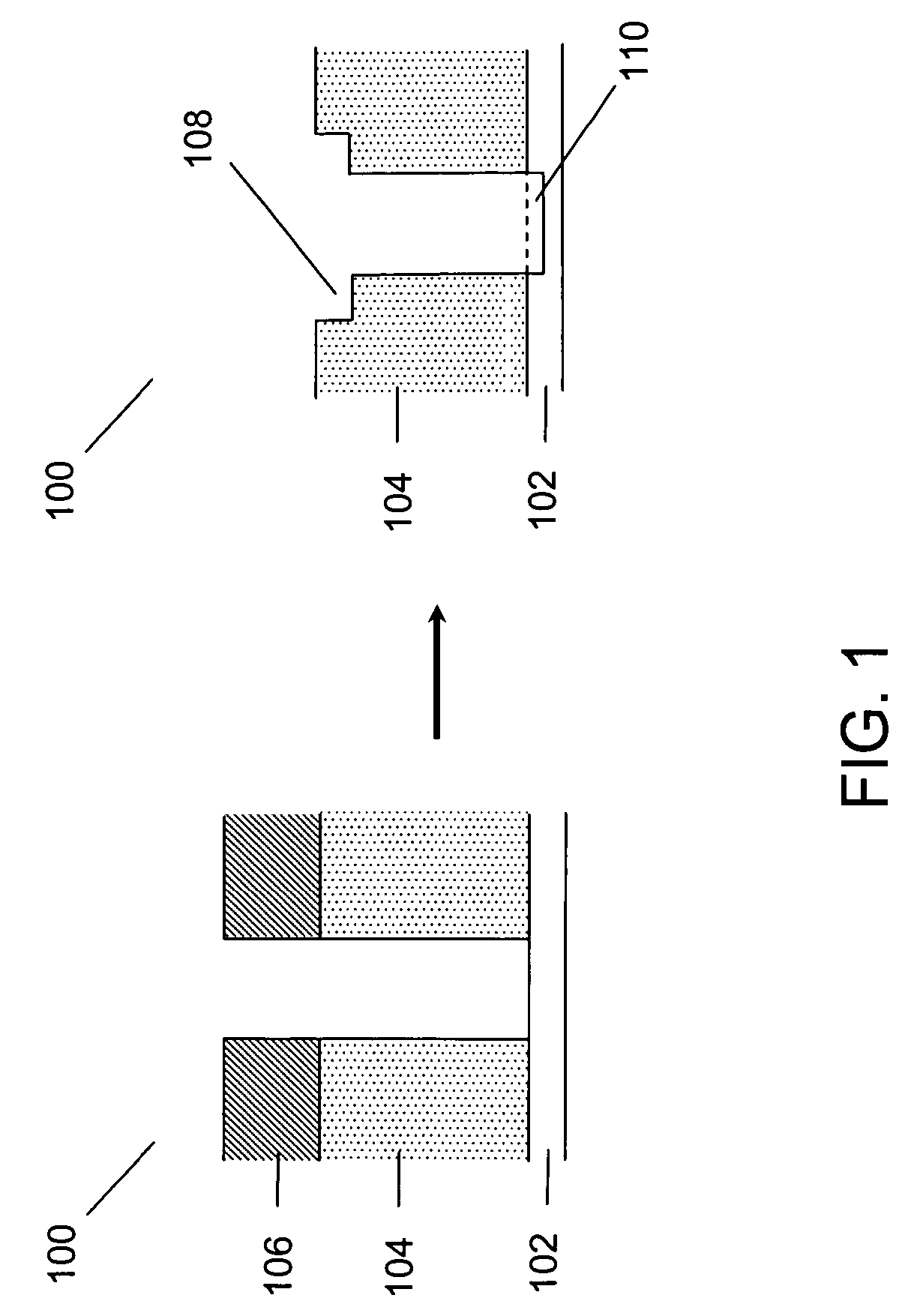

In semiconductor manufacturing plasma ashing is the process of removing the photoresist (light sensitive coating) from an etched wafer. Using a plasma source, a monatomic (single atom) substance known as a reactive species is generated. Oxygen or fluorine are the most common reactive species. The reactive species combines with the photoresist to form ash which is removed with a vacuum pump.

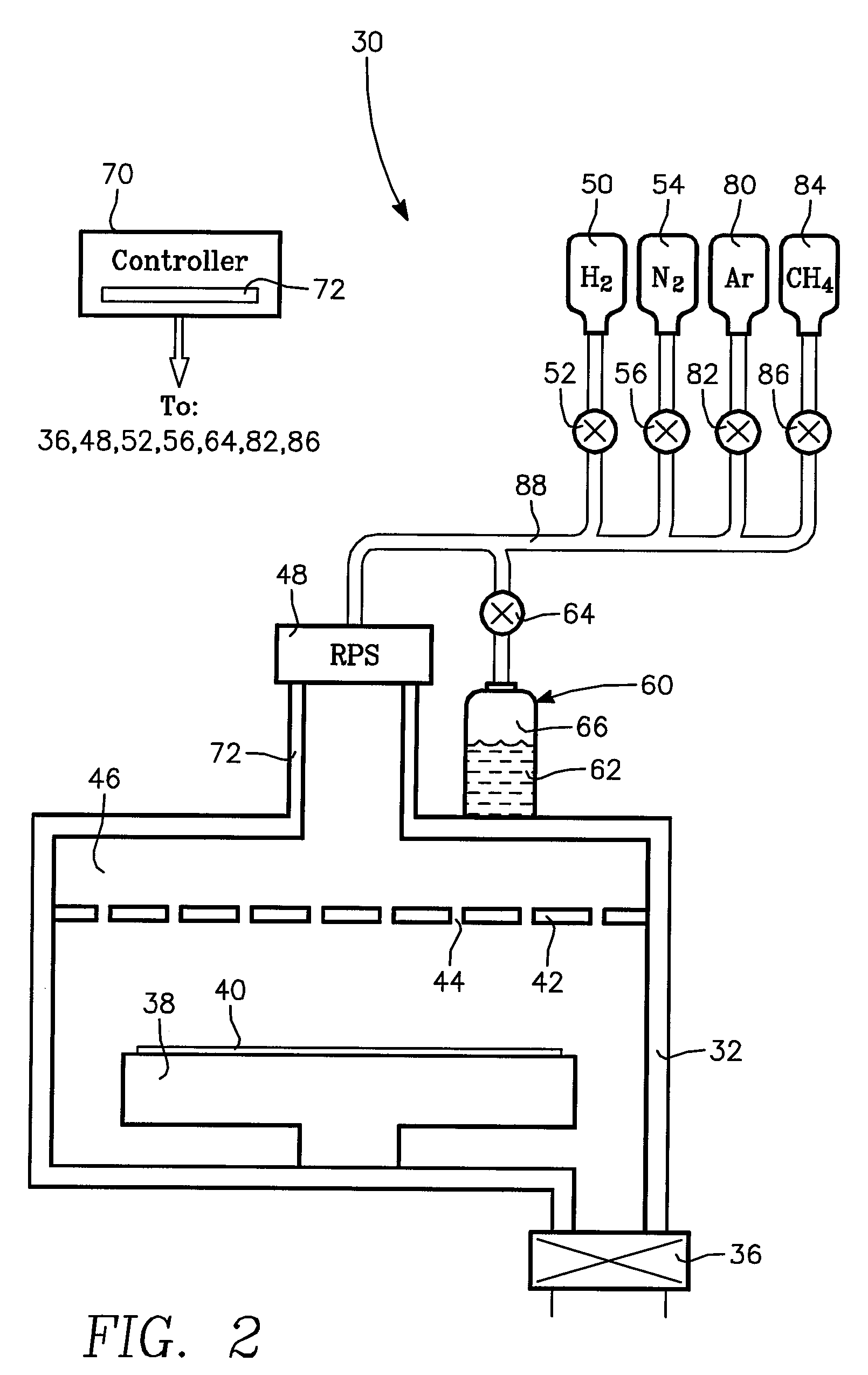

Hydrogen ashing enhanced with water vapor and diluent gas

ActiveUS20080261405A1Decorative surface effectsSemiconductor/solid-state device detailsWater vaporOxygen

An oxygen-free hydrogen plasma ashing process particularly useful for low-k dielectric materials based on hydrogenated silicon oxycarbide materials. The main ashing step includes exposing a previously etched dielectric layer to a plasma of hydrogen and optional nitrogen, a larger amount of water vapor, and a yet larger amount of argon or helium. Especially for porous low-k dielectrics, the main ashing plasma additionally contains a hydrocarbon gas such as methane. The main ashing may be preceded by a short surface treatment by a plasma of a hydrogen-containing reducing gas such as hydrogen and optional nitrogen.

Owner:APPLIED MATERIALS INC

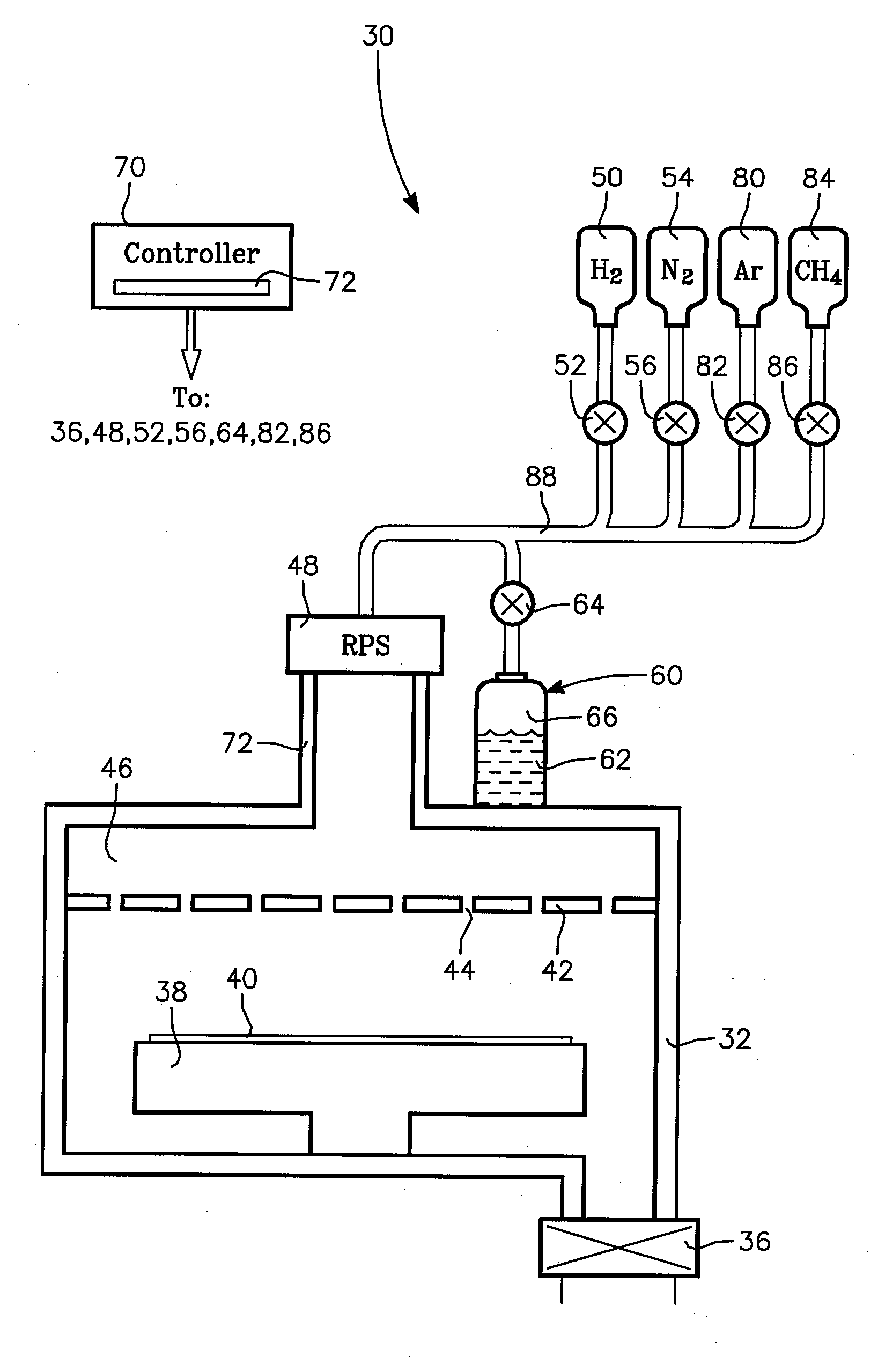

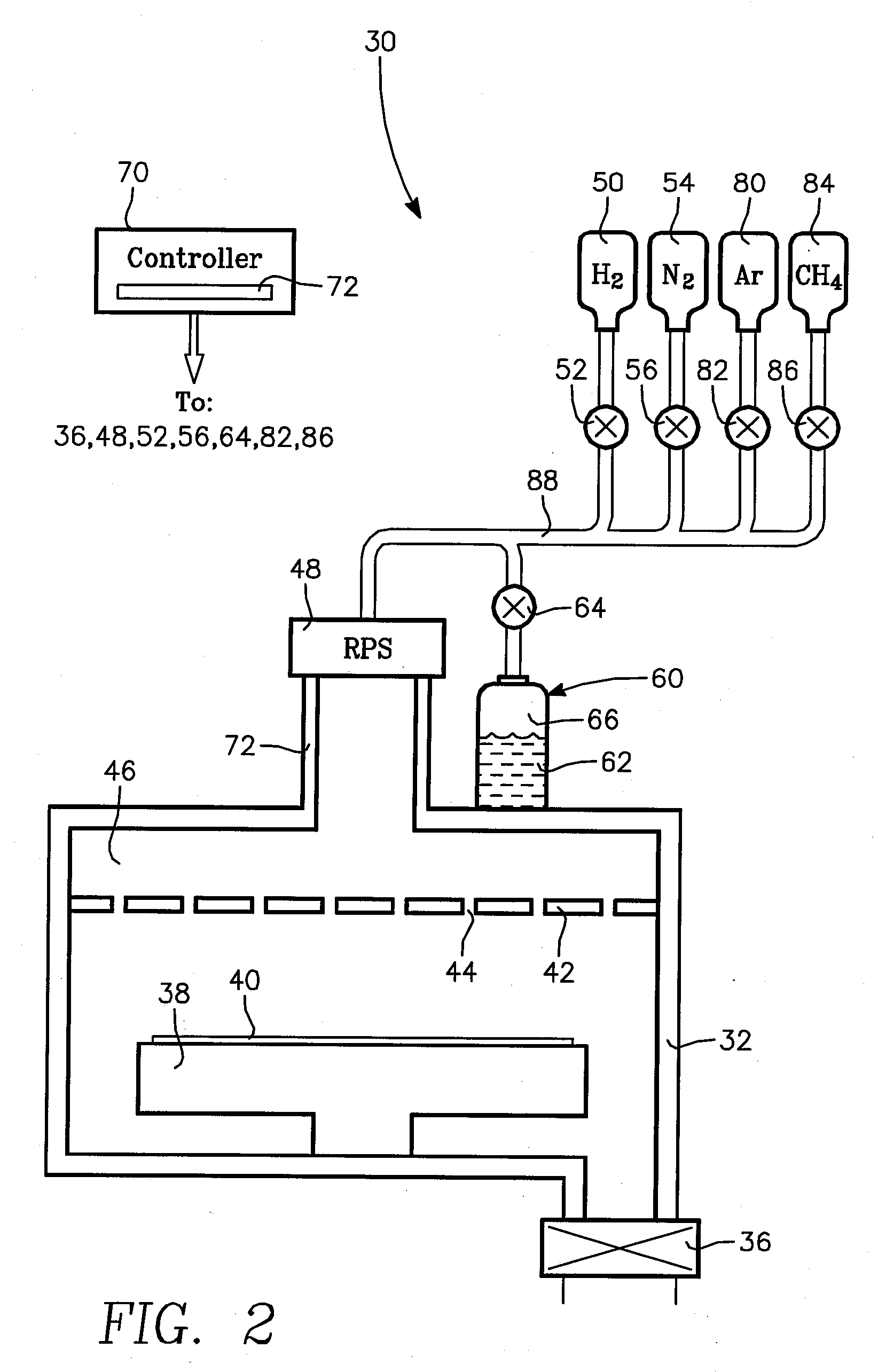

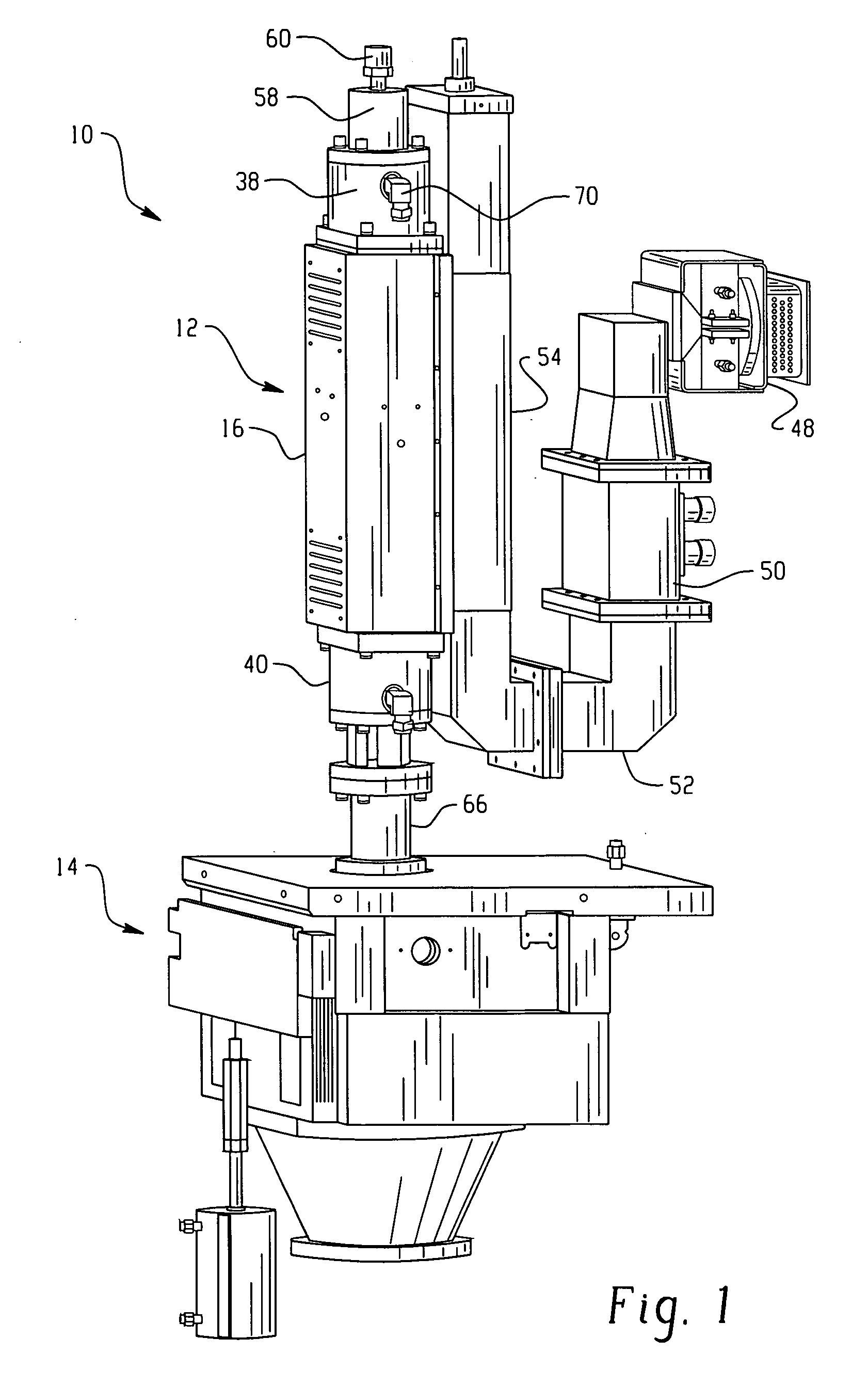

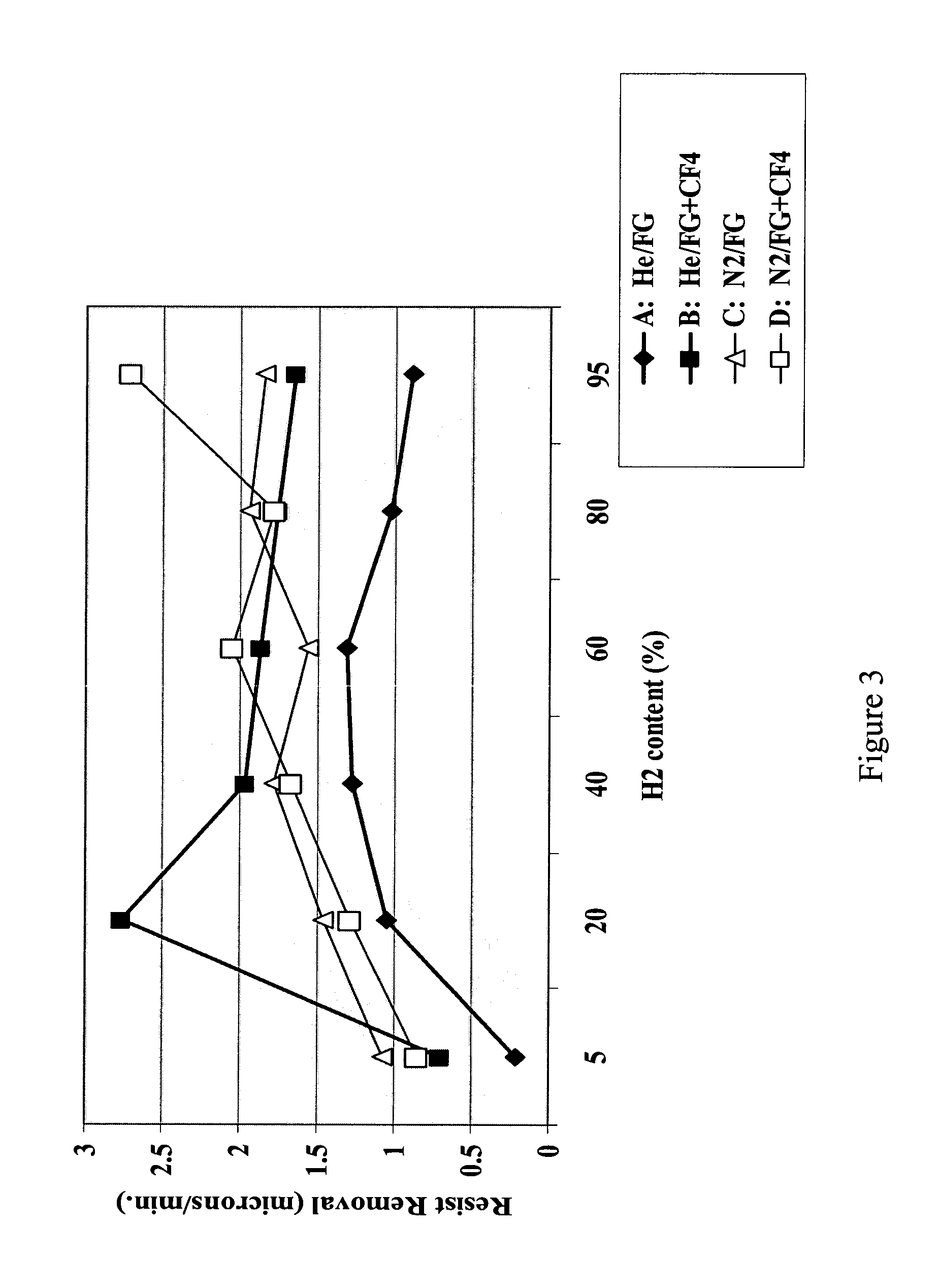

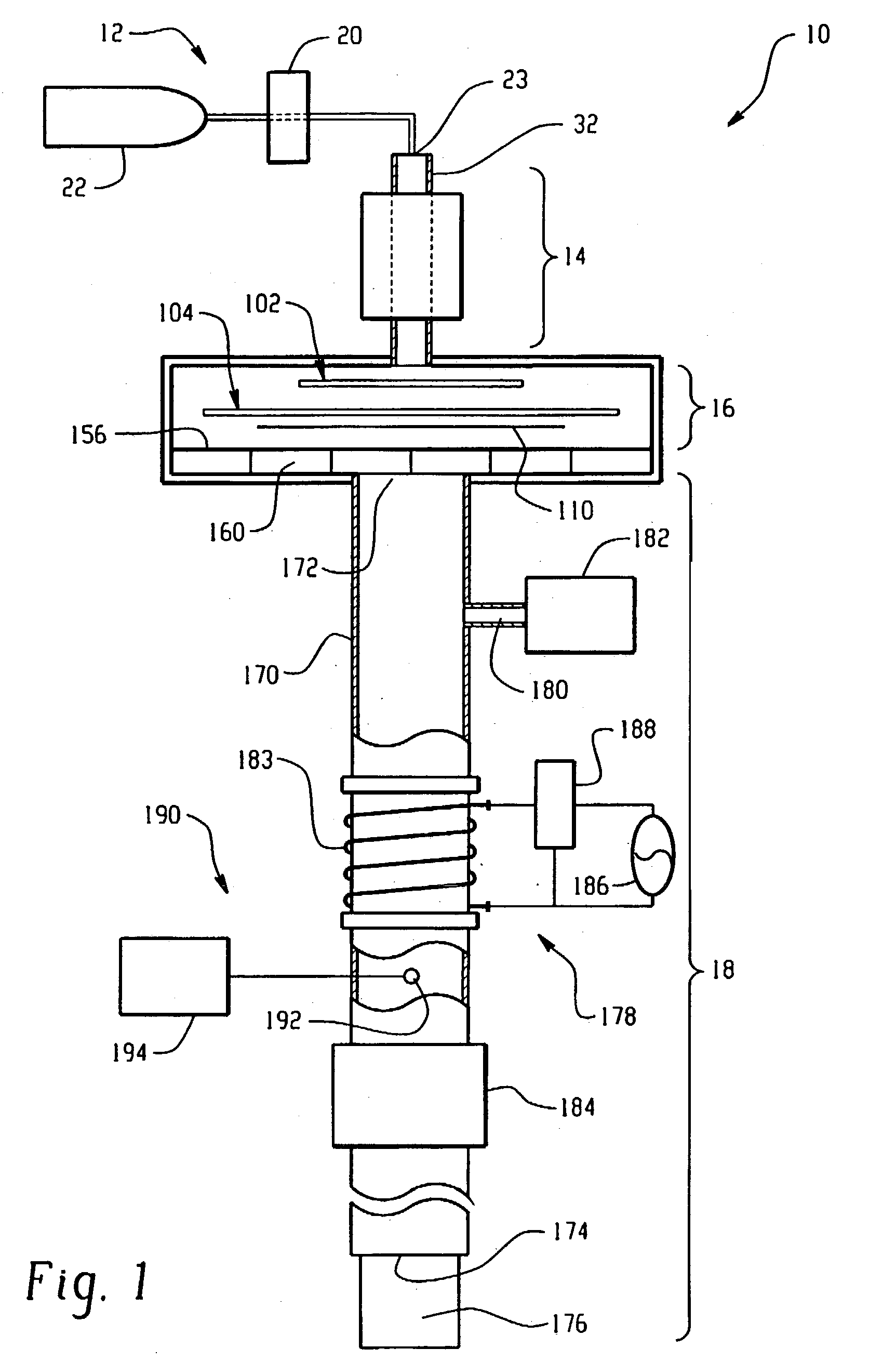

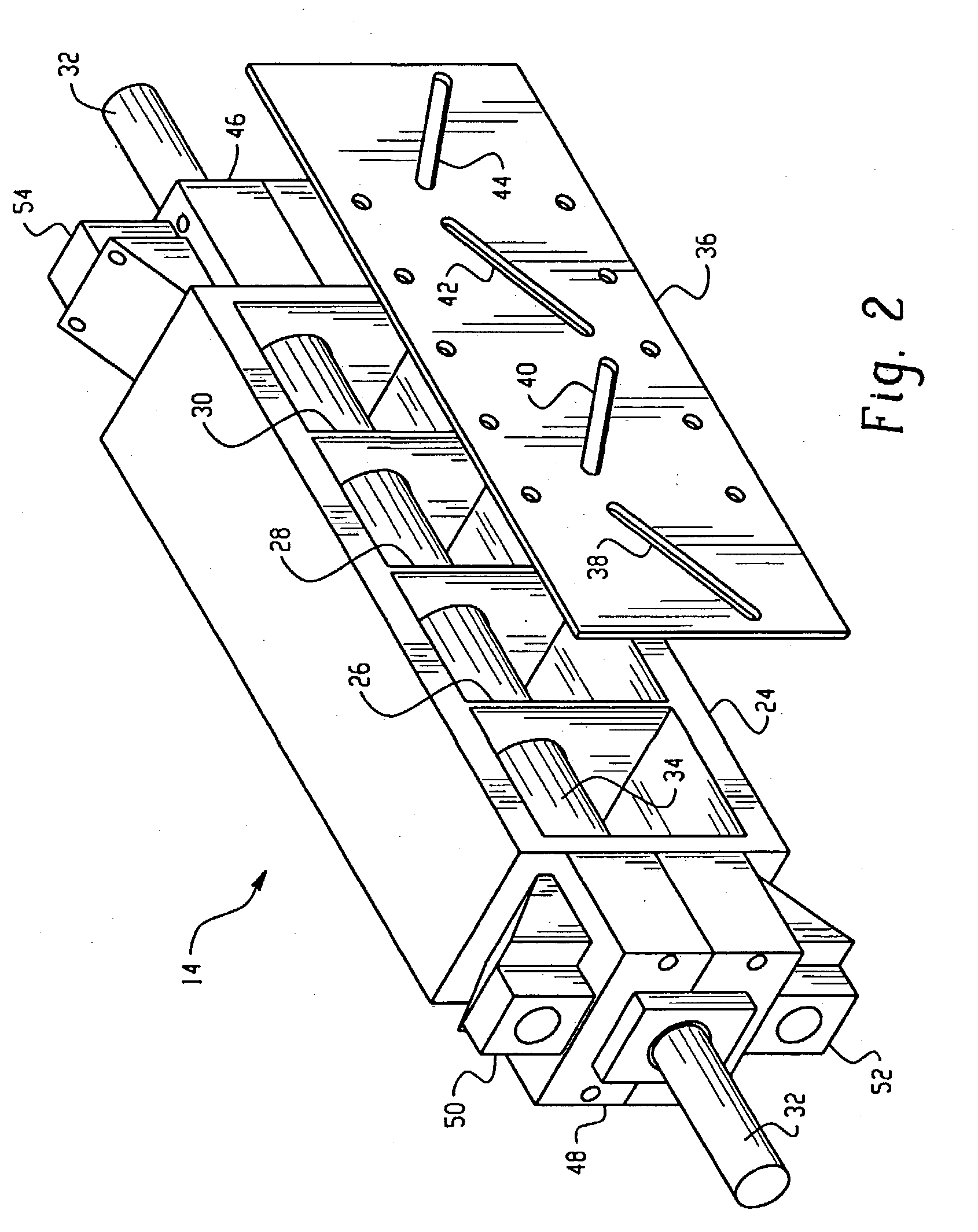

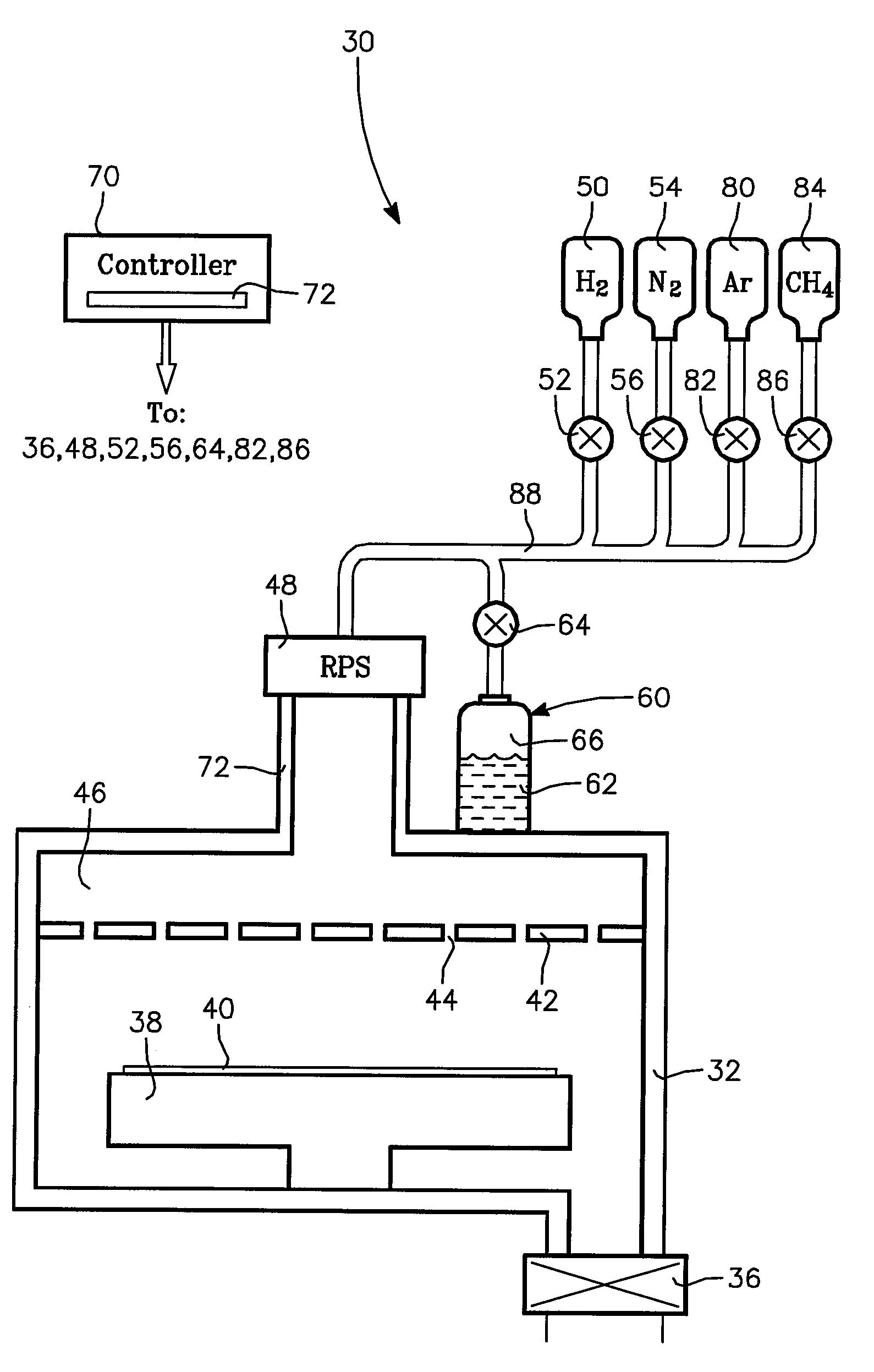

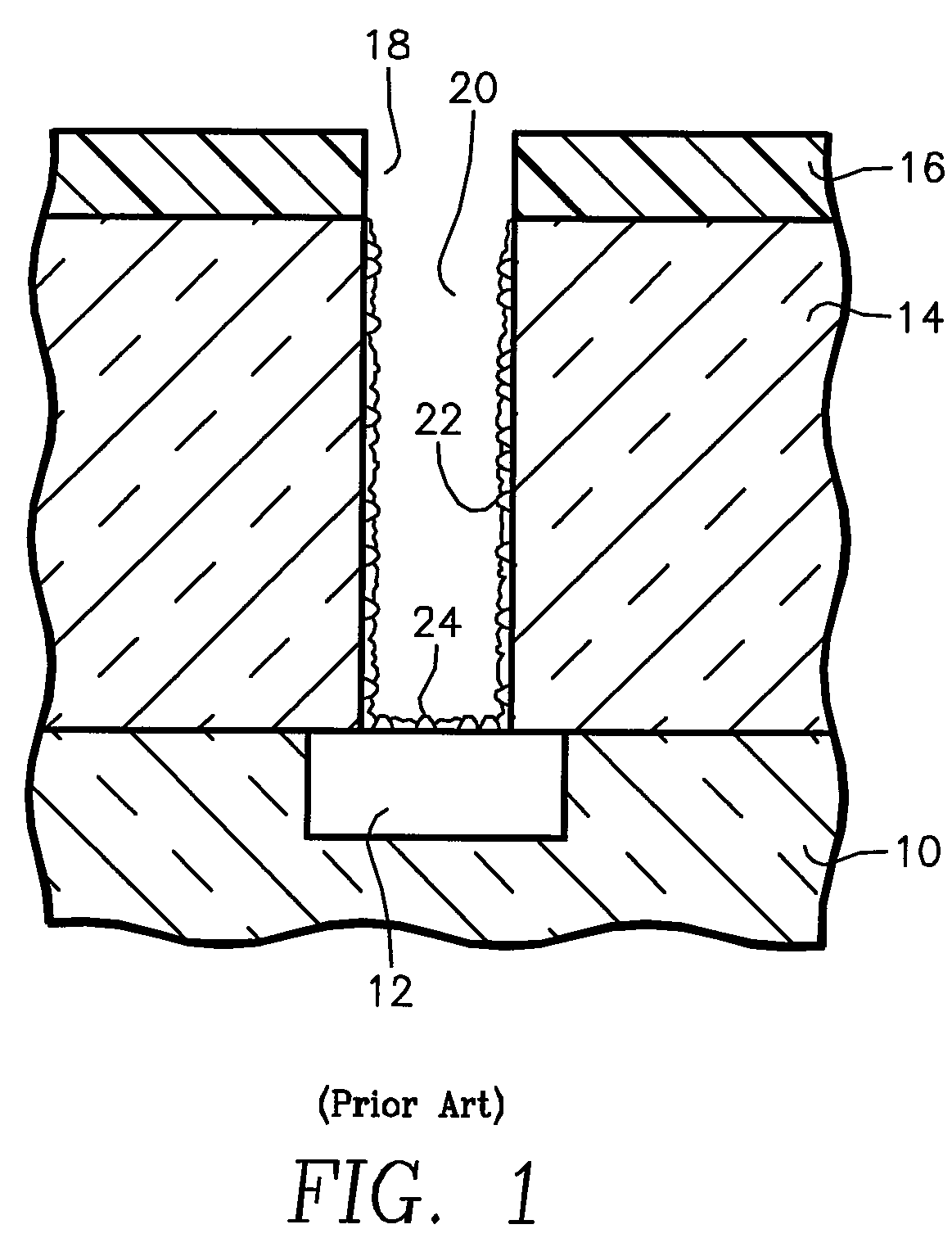

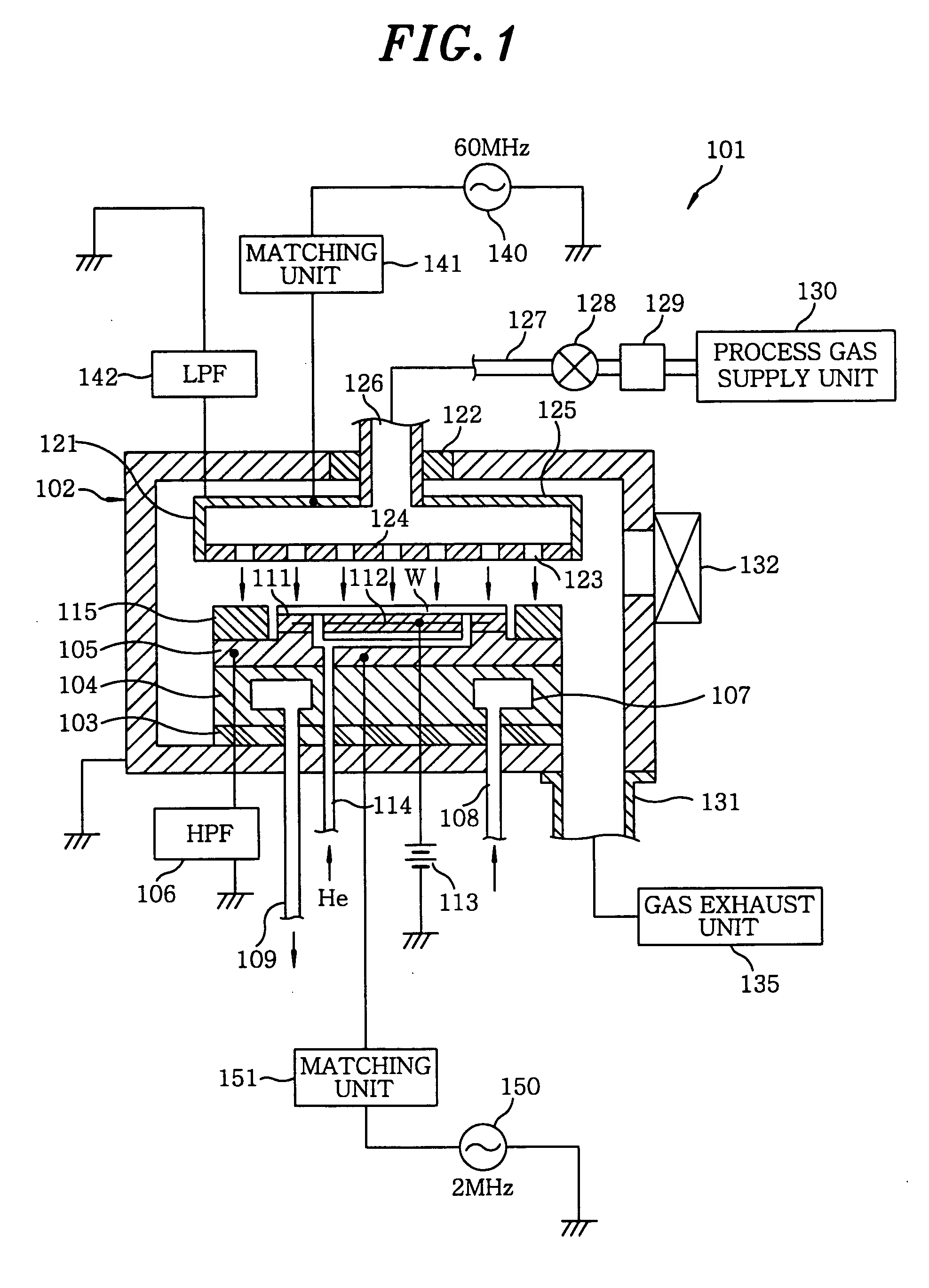

Apparatus and plasma ashing process for increasing photoresist removal rate

InactiveUS20060046470A1Reduce the temperatureAshing rateElectric discharge tubesPhotomechanical apparatusHydrogenOxygen plasma

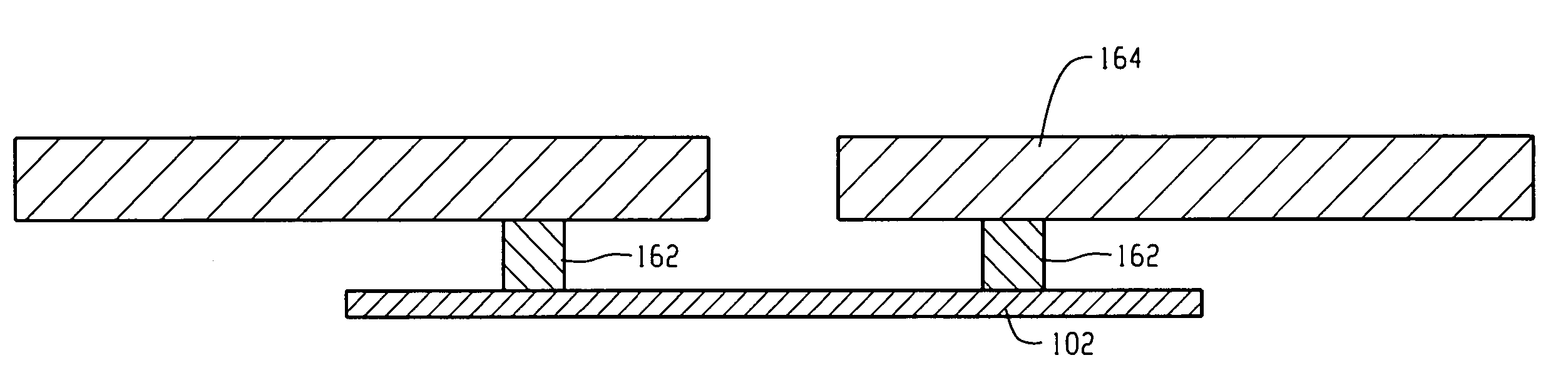

A plasma ashing process for removing photoresist material and post etch residues from a substrate comprising carbon, hydrogen, or a combination of carbon and hydrogen, wherein the substrate comprises a low k dielectric layer, the process comprising forming a plasma from an essentially oxygen free and nitrogen free gas mixture; introducing the plasma into a process chamber, wherein the process chamber comprises a baffle plate assembly in fluid communication with the plasma; flowing the plasma through the baffle plate assembly and removing photoresist material, post etch residues, and volatile byproducts from the substrate; periodically cleaning the process chamber by introducing an oxygen plasma into the process chamber; and cooling the baffle plate assembly by flowing a cooling gas over the baffle plate assembly. A process chamber adapted for receiving downstream plasma, the process chamber comprising an upper baffle plate comprising at least one thermally conductive standoff in thermal communication with a wall of the process chamber; and a lower baffle plate spaced apart from the upper baffle plate.

Owner:LAM RES CORP

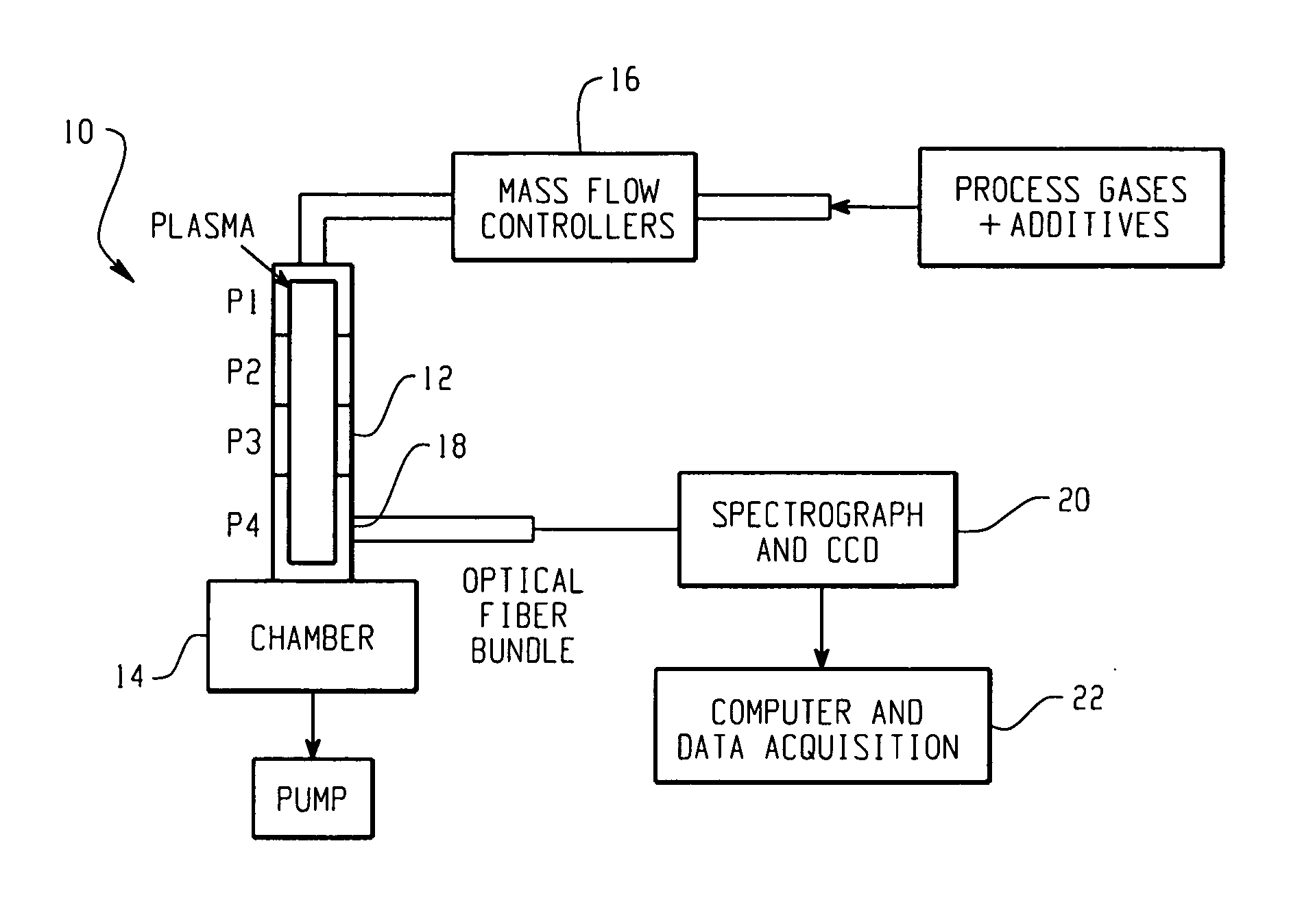

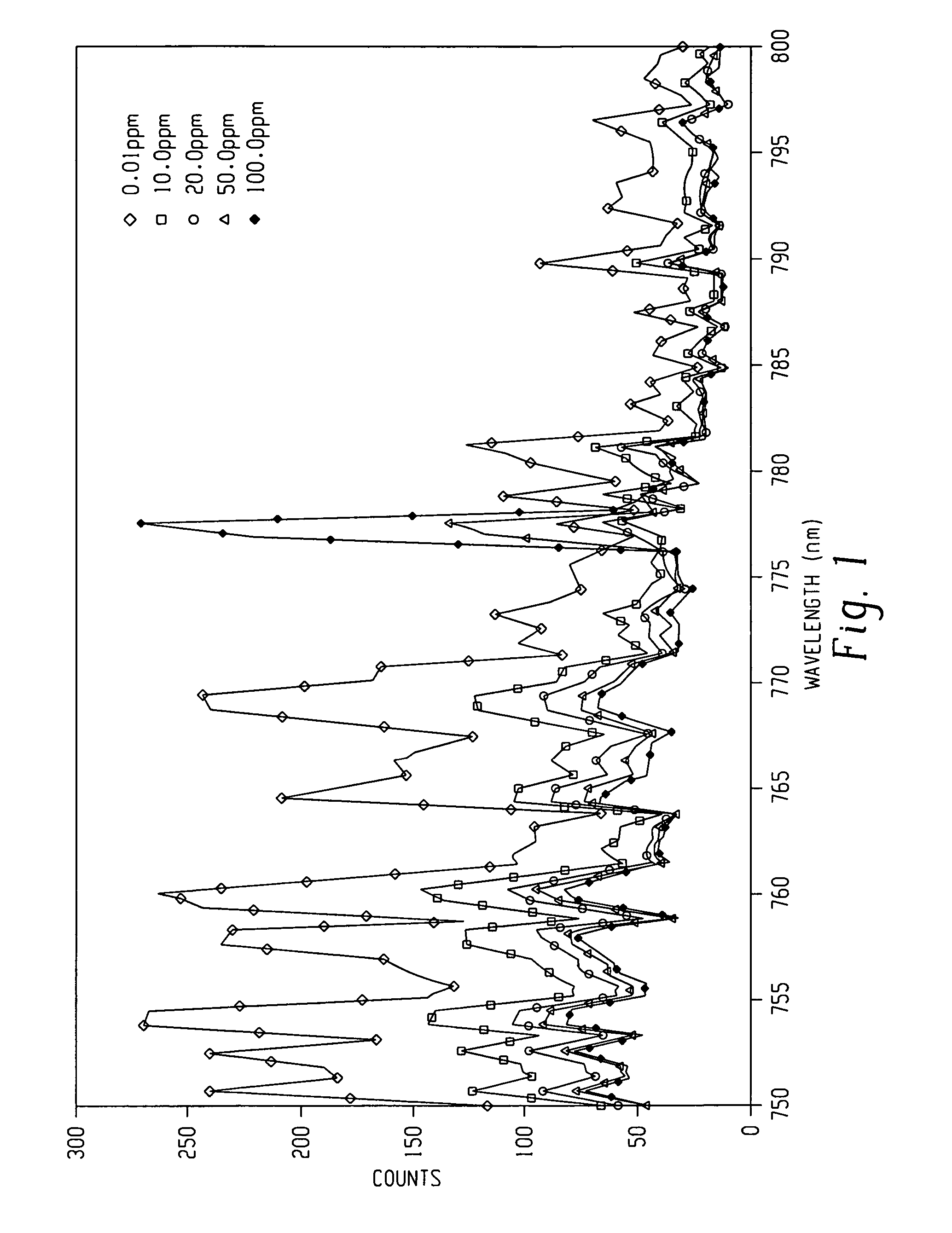

Processes for monitoring the levels of oxygen and/or nitrogen species in a substantially oxygen and nitrogen-free plasma ashing process

ActiveUS20070221620A1Semiconductor/solid-state device testing/measurementElectric discharge tubesOxygenAnalytical chemistry

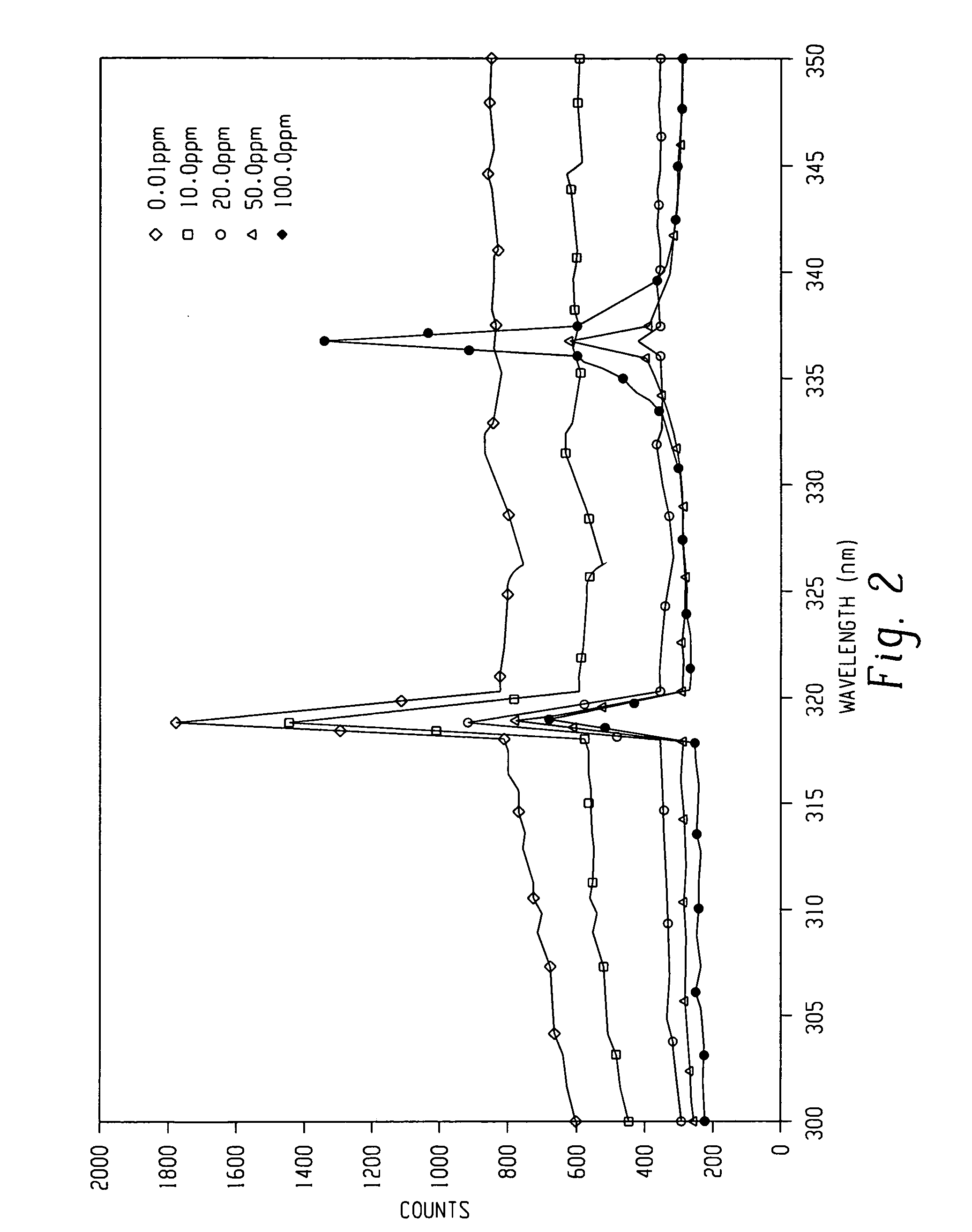

Processes for monitoring the levels of oxygen and / or nitrogen in a substantially oxygen and nitrogen-free plasma ashing process generally includes monitoring the plasma using optical emission. An effect produced by the low levels of oxygen and / or nitrogen species present on other species generally abundant in the plasma is monitored and correlated to amounts of oxygen and nitrogen present in the plasma. This so-called “effect detection” process monitors perturbations in the spectra specifically associated with species other than nitrogen and / or oxygen due to the presence of trace amounts of oxygen and / or nitrogen species and is used to quantitatively determine the amount of oxygen and / or nitrogen at a sensitivity on the order of 1 part per million and potentially 1 part per billion.

Owner:LAM RES CORP

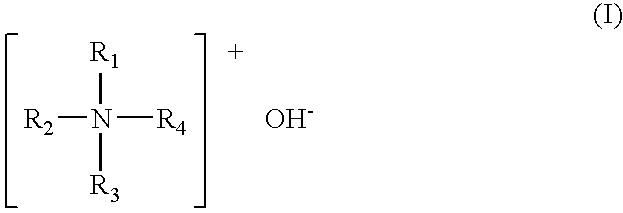

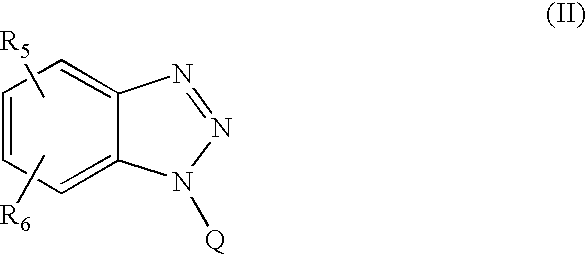

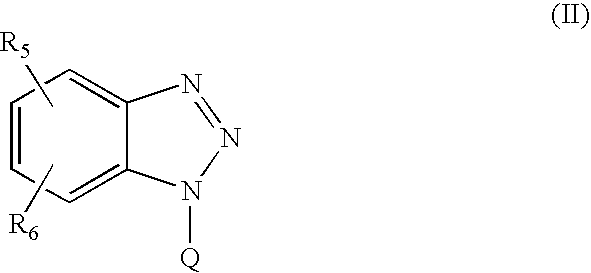

Method for removing photoresist

InactiveUS20050176259A1Improve corrosion resistanceEfficient strippingDecorative surface effectsSemiconductor/solid-state device manufacturingAmmonium hydroxideCopper

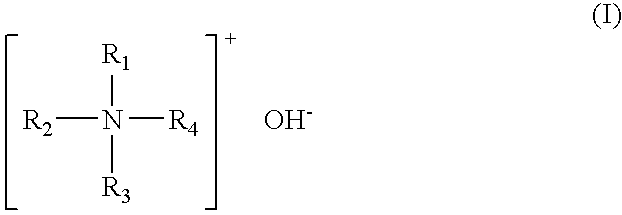

Disclosed is a method for stripping a photoresist comprising: (I) providing a photoresist pattern on a substrate where the substrate has at least a copper (Cu) wiring and a low-dielectric layer thereon, and selectively etching the low-dielectric layer by using the photoresist pattern as a mask; (II) contacting the substrate after the step (I), with ozone water and / or aqueous hydrogen peroxide; and (III) contacting the substrate after the step (II), with a photoresist stripping solution that contains at least a quaternary ammonium hydroxide. The present invention provides a method for stripping a photoresist that enables to strip effectively photoresist films and etching residues after etching step even in a process not including an O2 plasma ashing treatment in micropatterning of a substrate having at least Cu wiring and a low-dielectric layer thereon, as in a dual damascene forming process, and, in addition, the method of the invention does not have any negative influence on the dielectric constant of the low-dielectric layer, and ensures an excellent anti-corrosivity.

Owner:TOKYO OHKA KOGYO CO LTD

Plasma ashing process

InactiveUS20040084412A1Ashing rate can be increasedEfficient removalElectric discharge tubesDecorative surface effectsPlasma ashingLow-k dielectric

A substantially oxygen-free and nitrogen-free plasma ashing process for removing photoresist in the presence of a low k material from a semiconductor substrate includes forming reactive species by exposing a plasma gas composition to an energy source to form plasma. The plasma gas composition is substantially free from oxygen-bearing and nitrogen-bearing gases. The plasma selectively removes the photoresist from the underlying substrate containing low k material by exposing the photoresist to substantially oxygen and nitrogen free reactive species. The process can be used with carbon containing low k dielectric materials.

Owner:LAM RES CORP

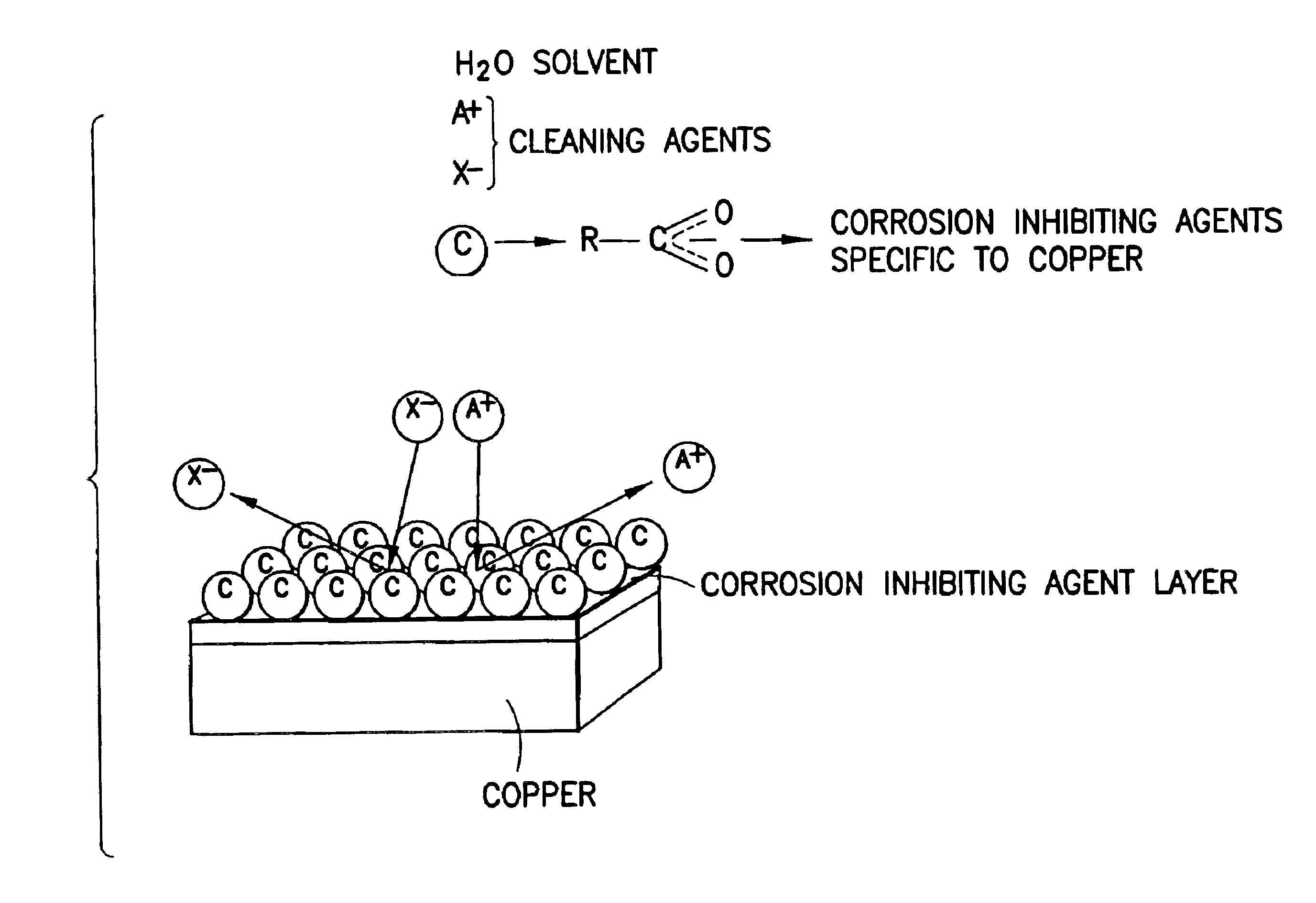

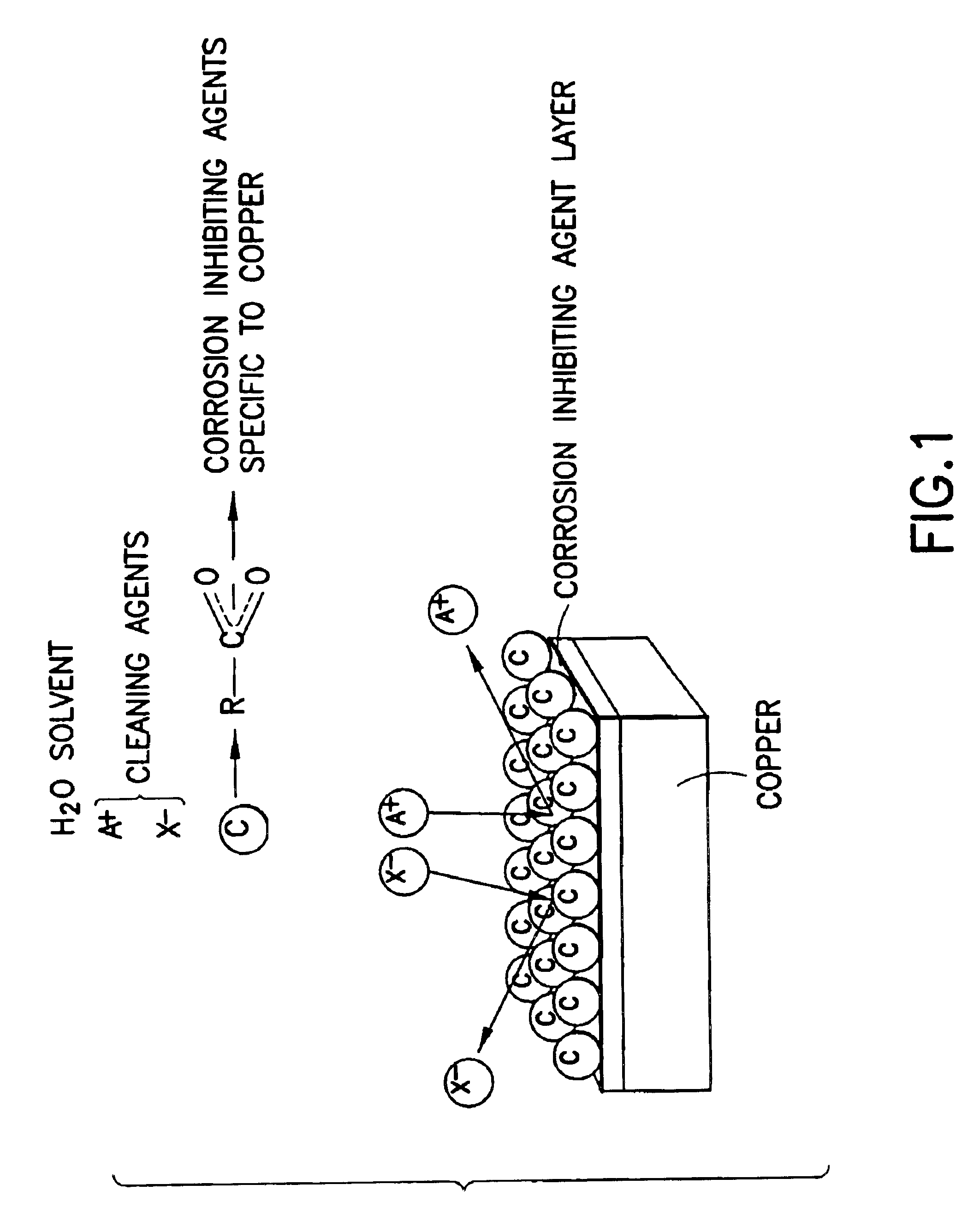

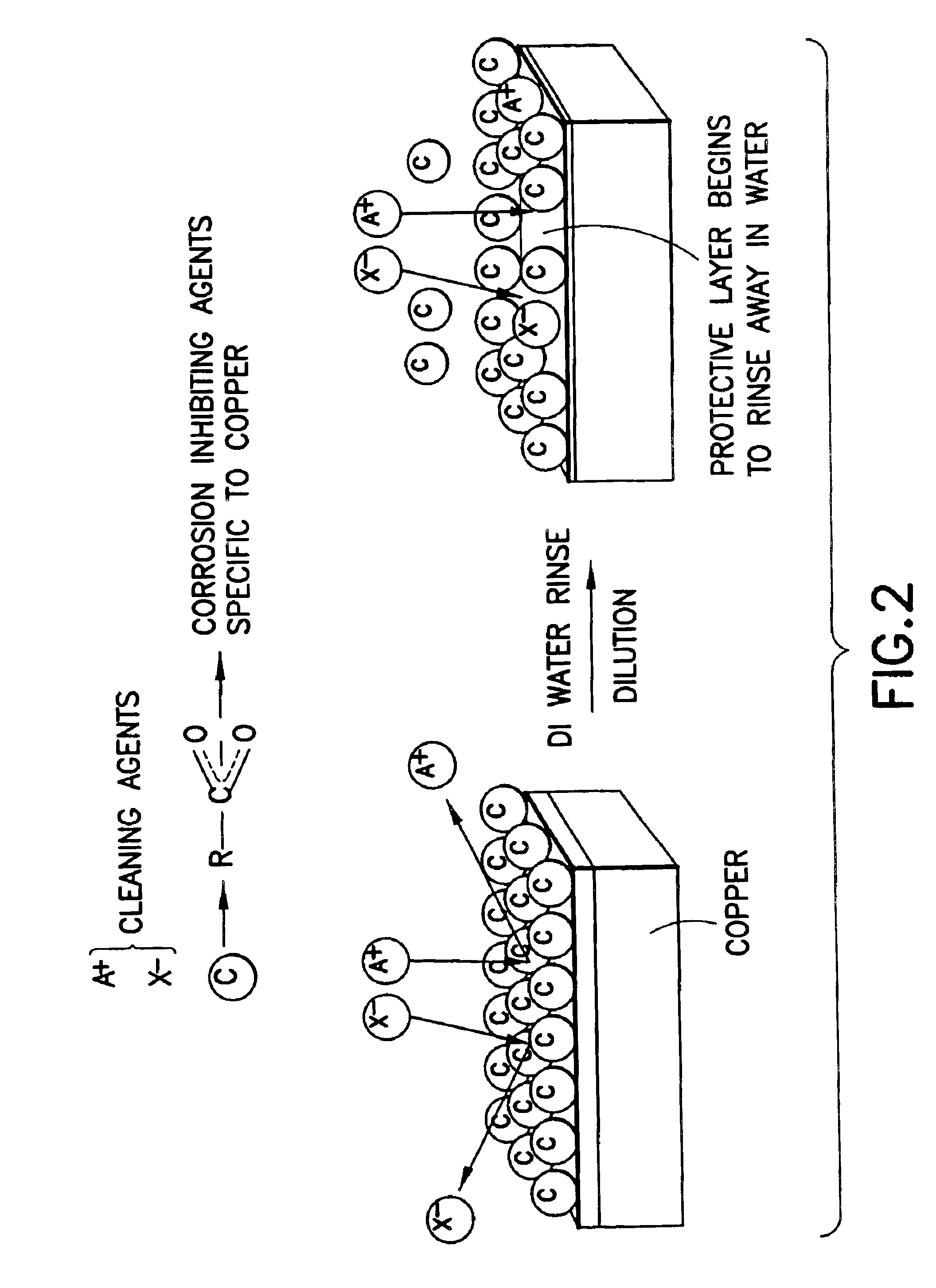

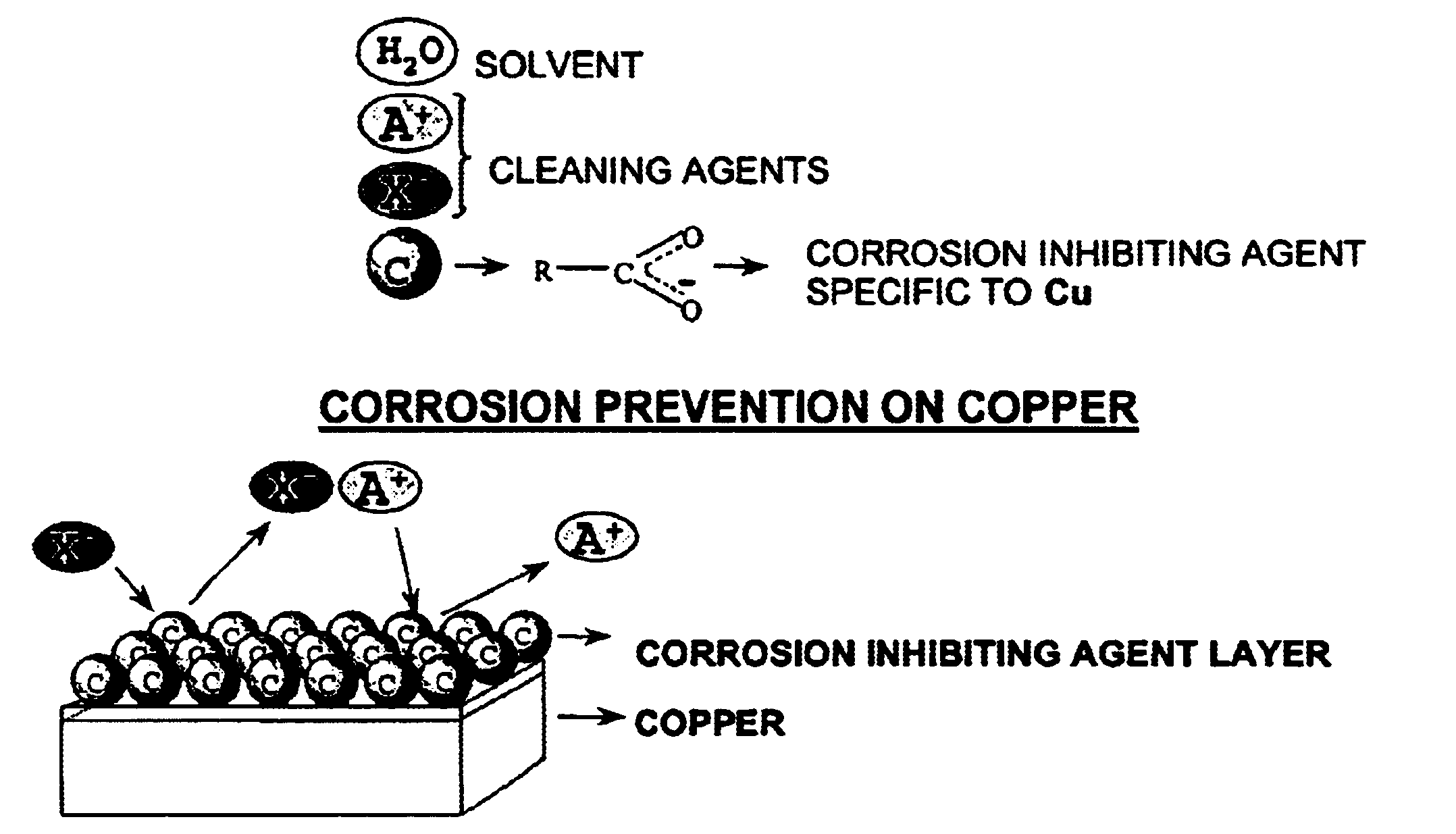

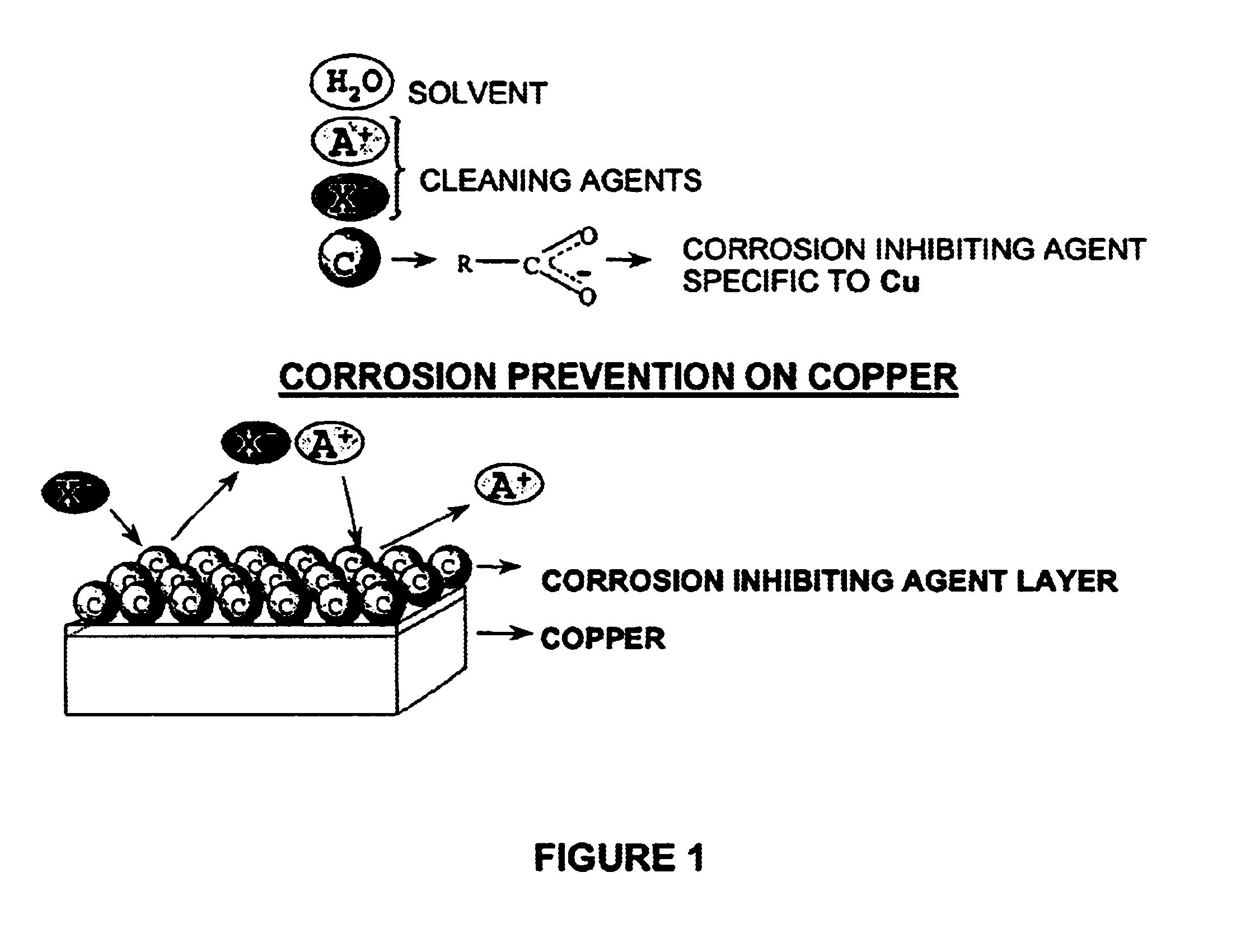

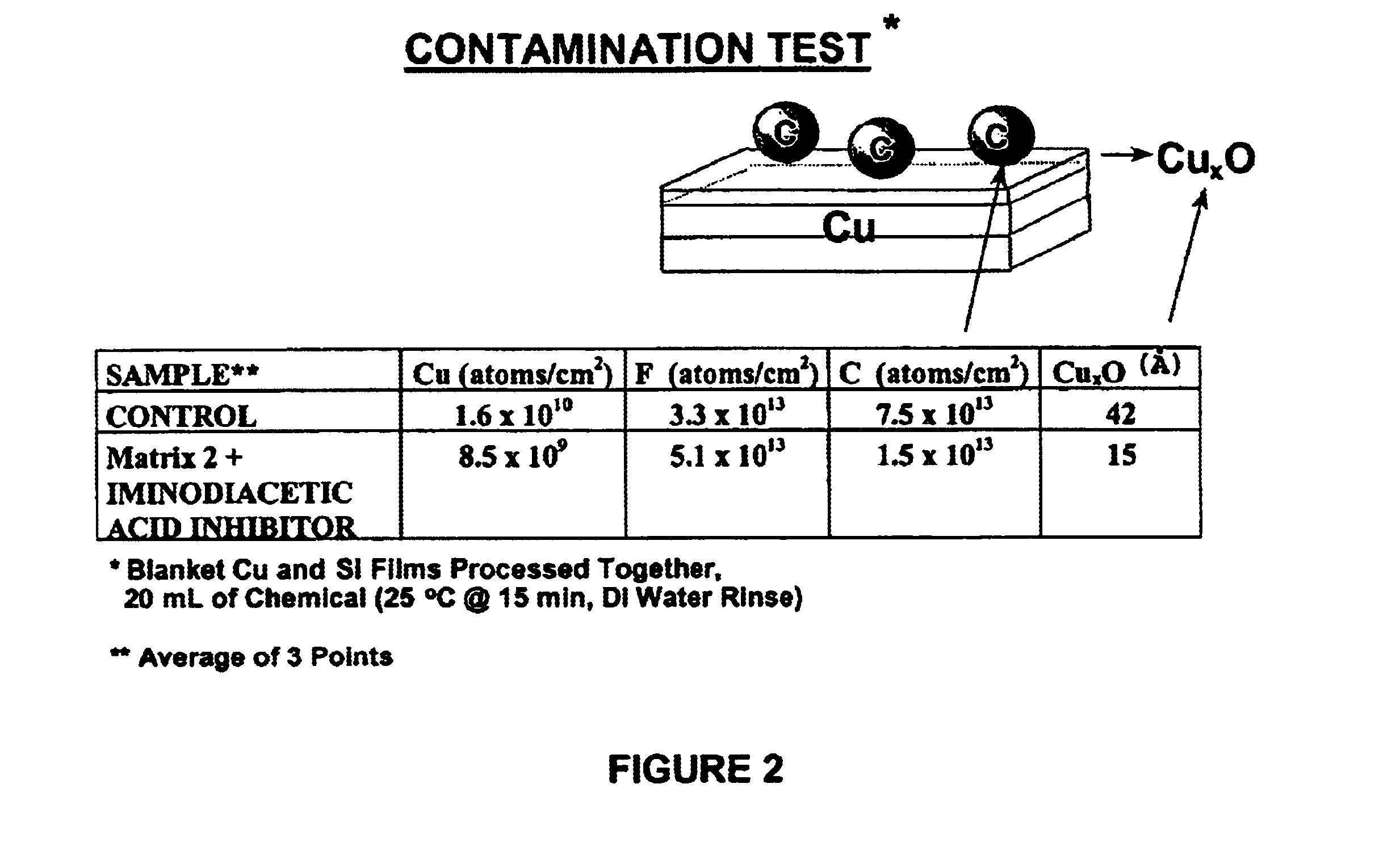

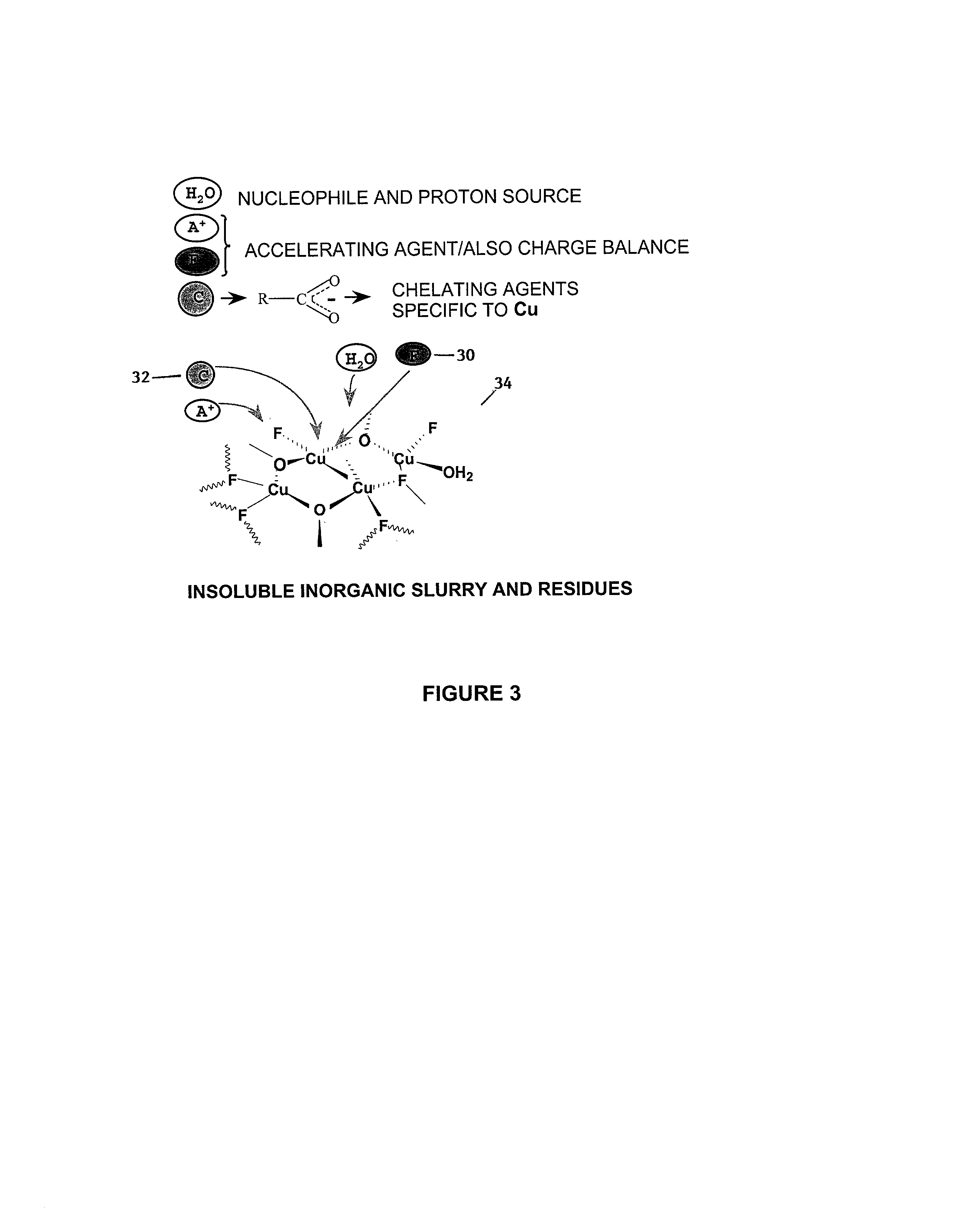

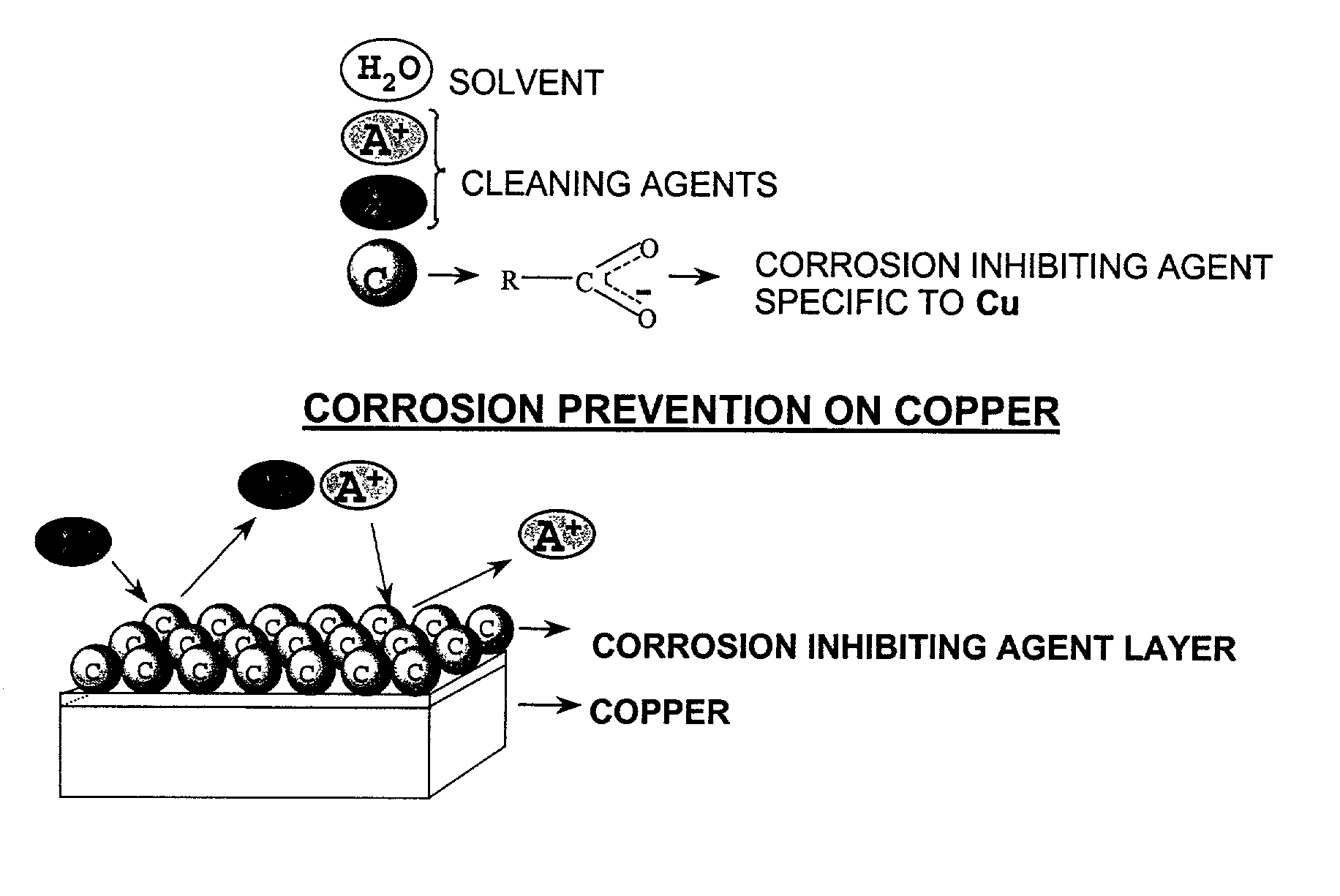

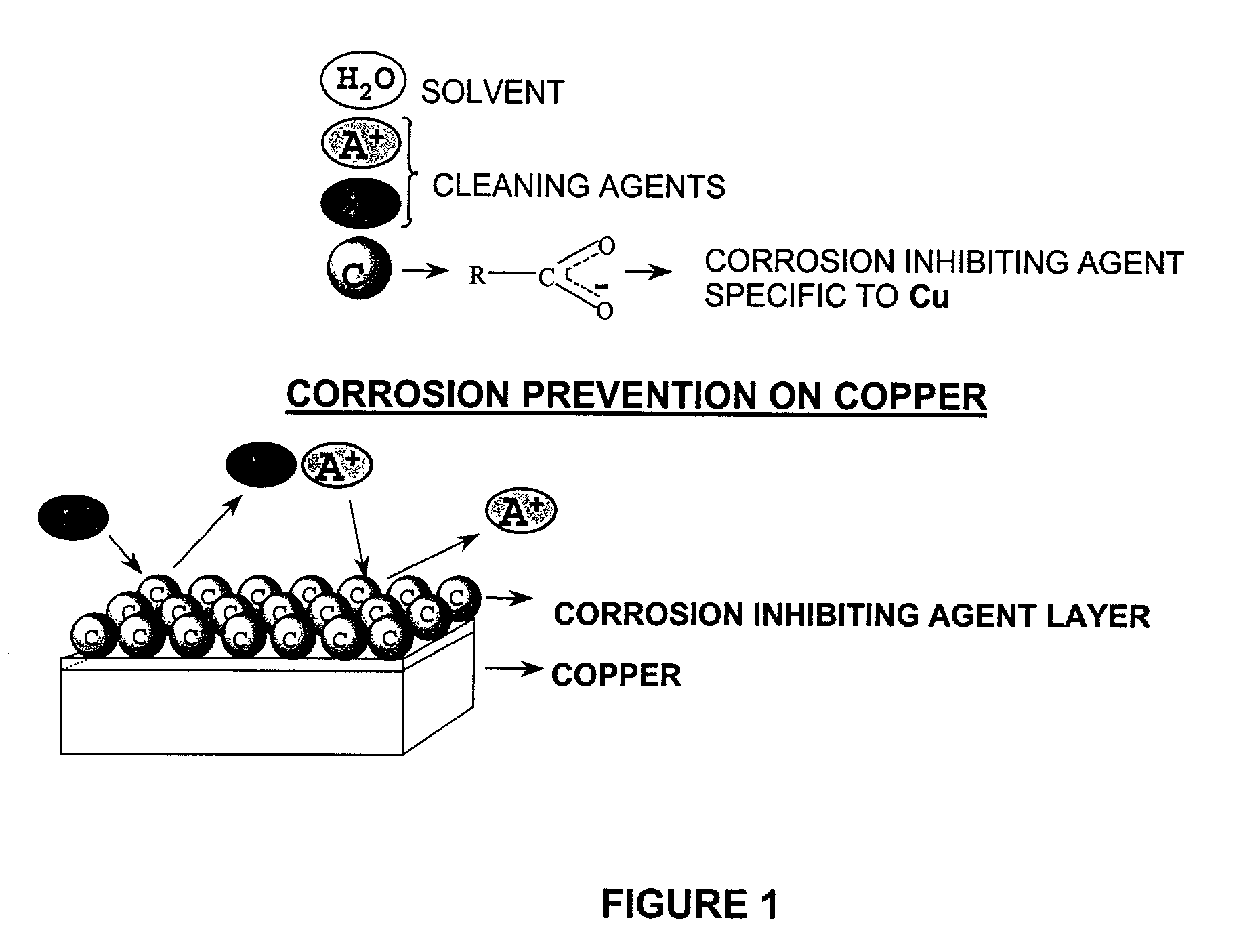

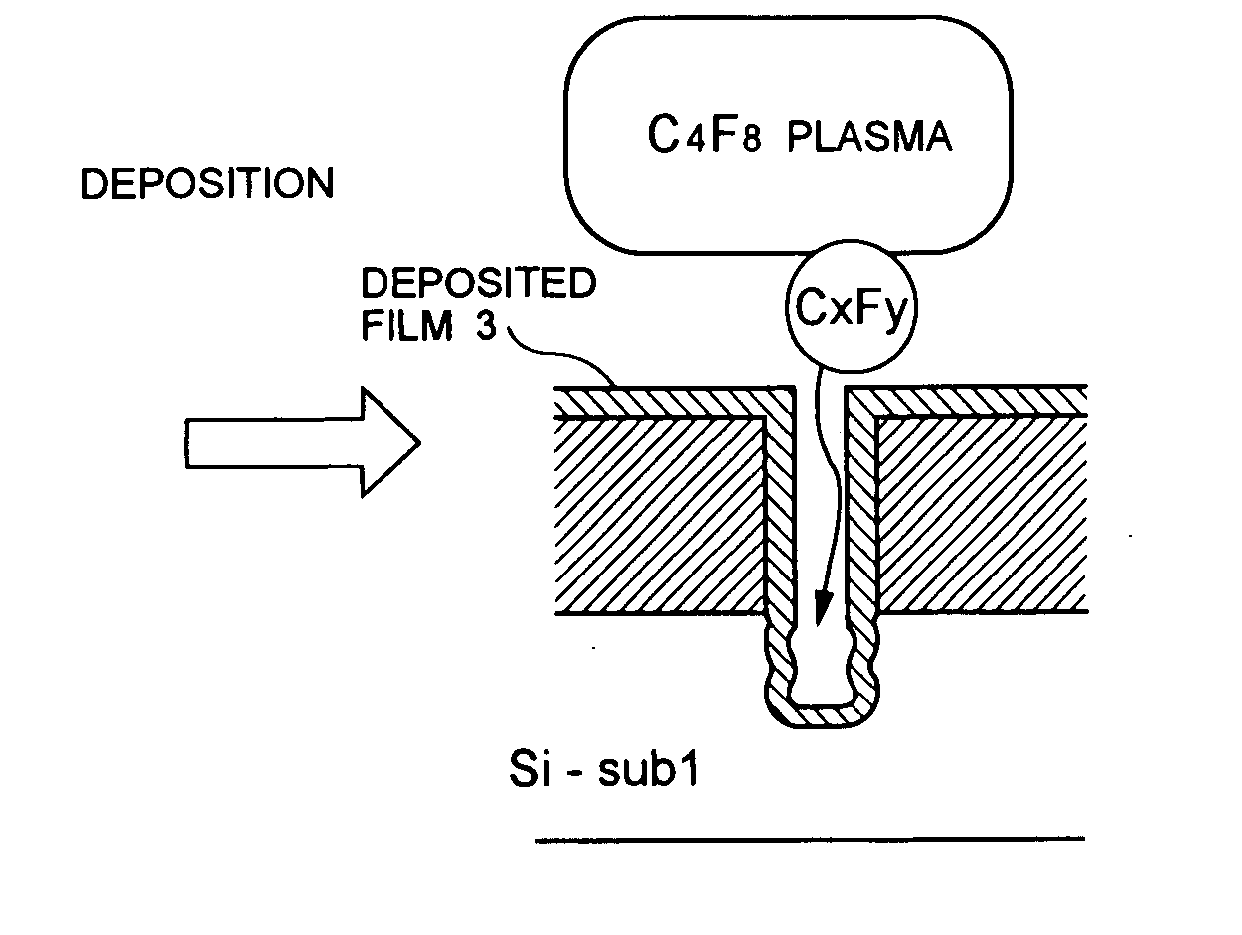

Aqueous cleaning composition containing copper-specific corrosion inhibitor for cleaning inorganic residues on semiconductor substrate

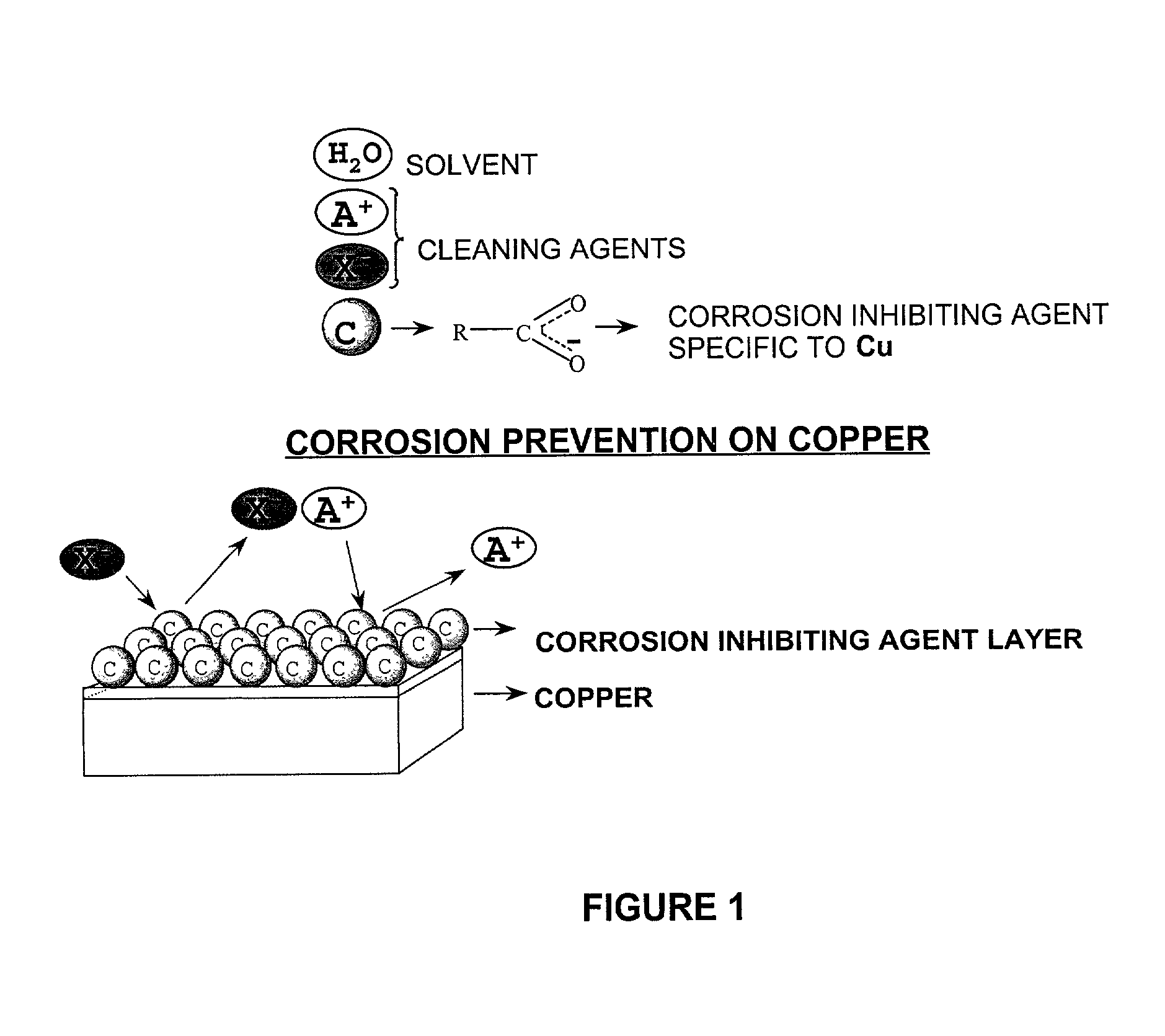

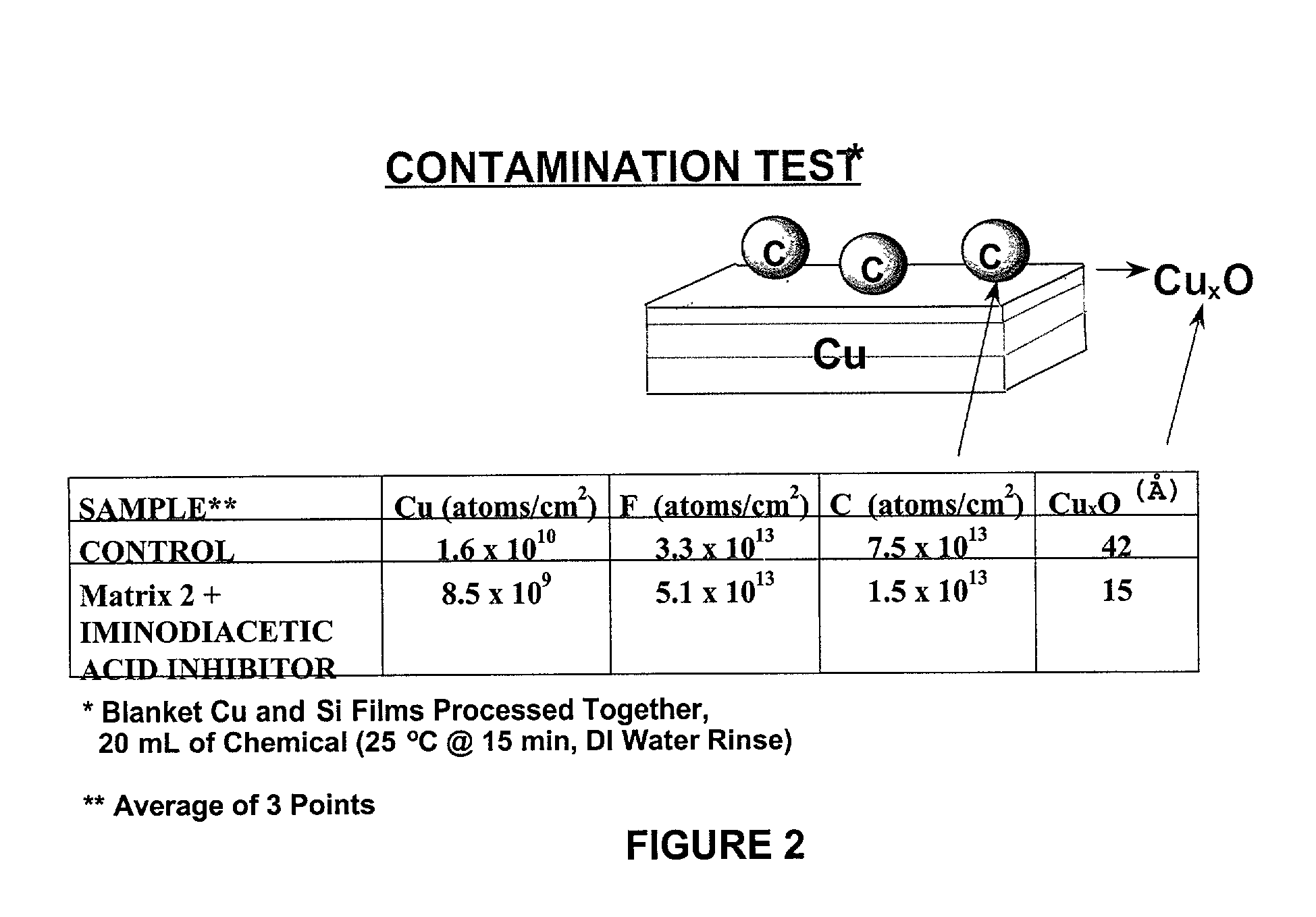

InactiveUS6896826B2Efficient removalExcellent peelabilityInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsResistNitrogen

Owner:ENTEGRIS INC

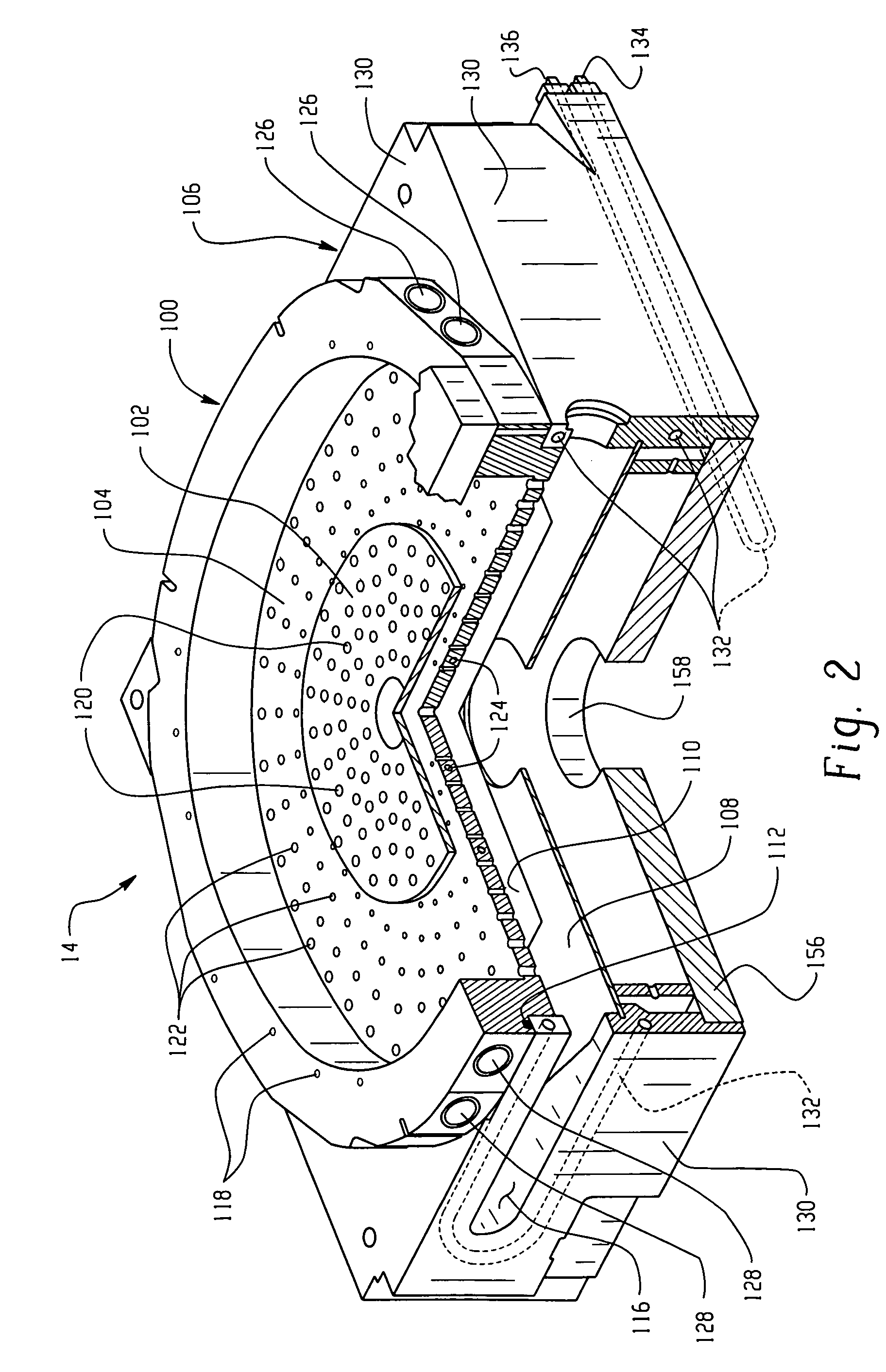

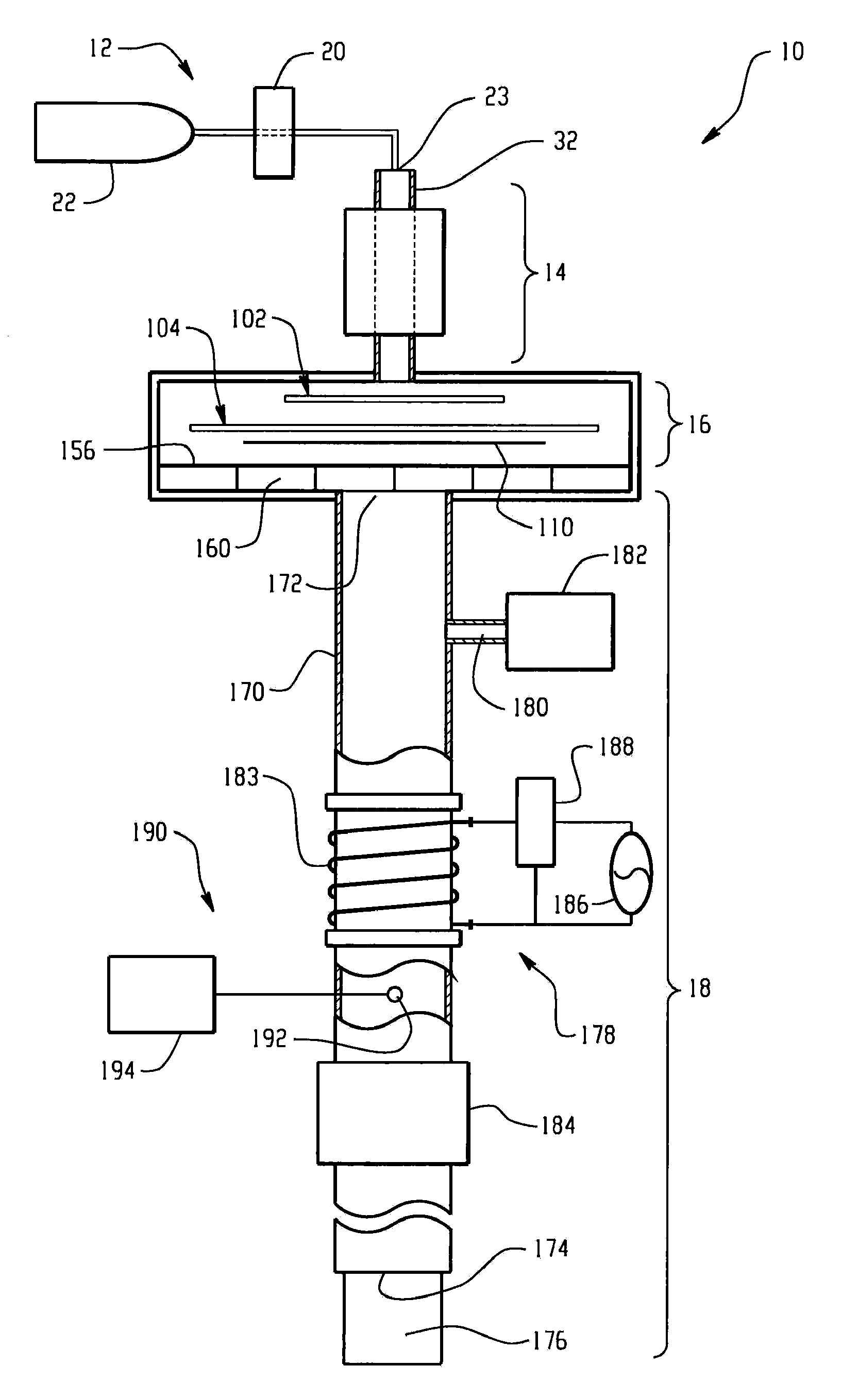

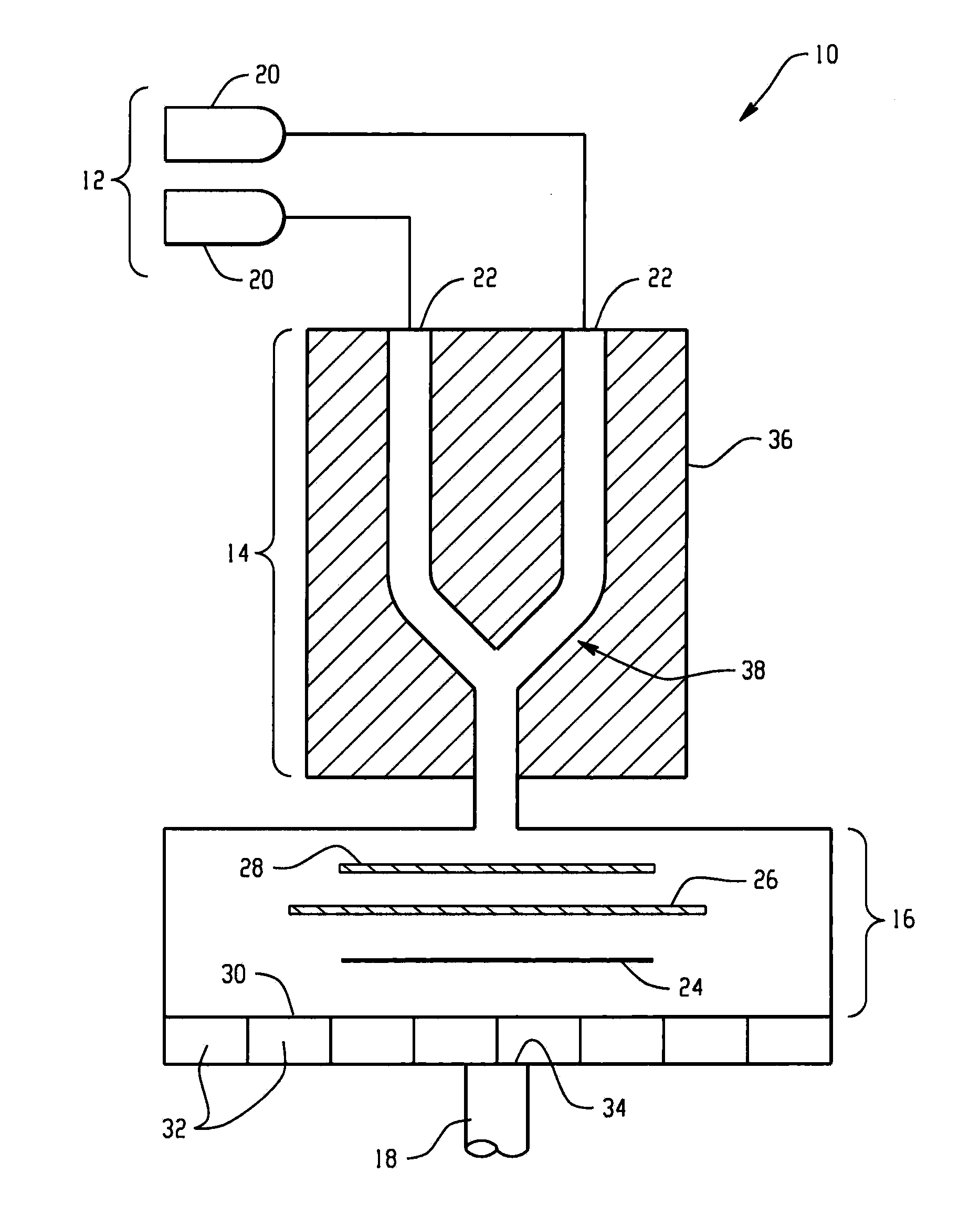

Plasma ashing apparatus and endpoint detection process

InactiveUS20040235299A1Enhance photoresist removalFlexible process platformElectric discharge tubesSemiconductor/solid-state device manufacturingNitrogen plasmaCombustion chamber

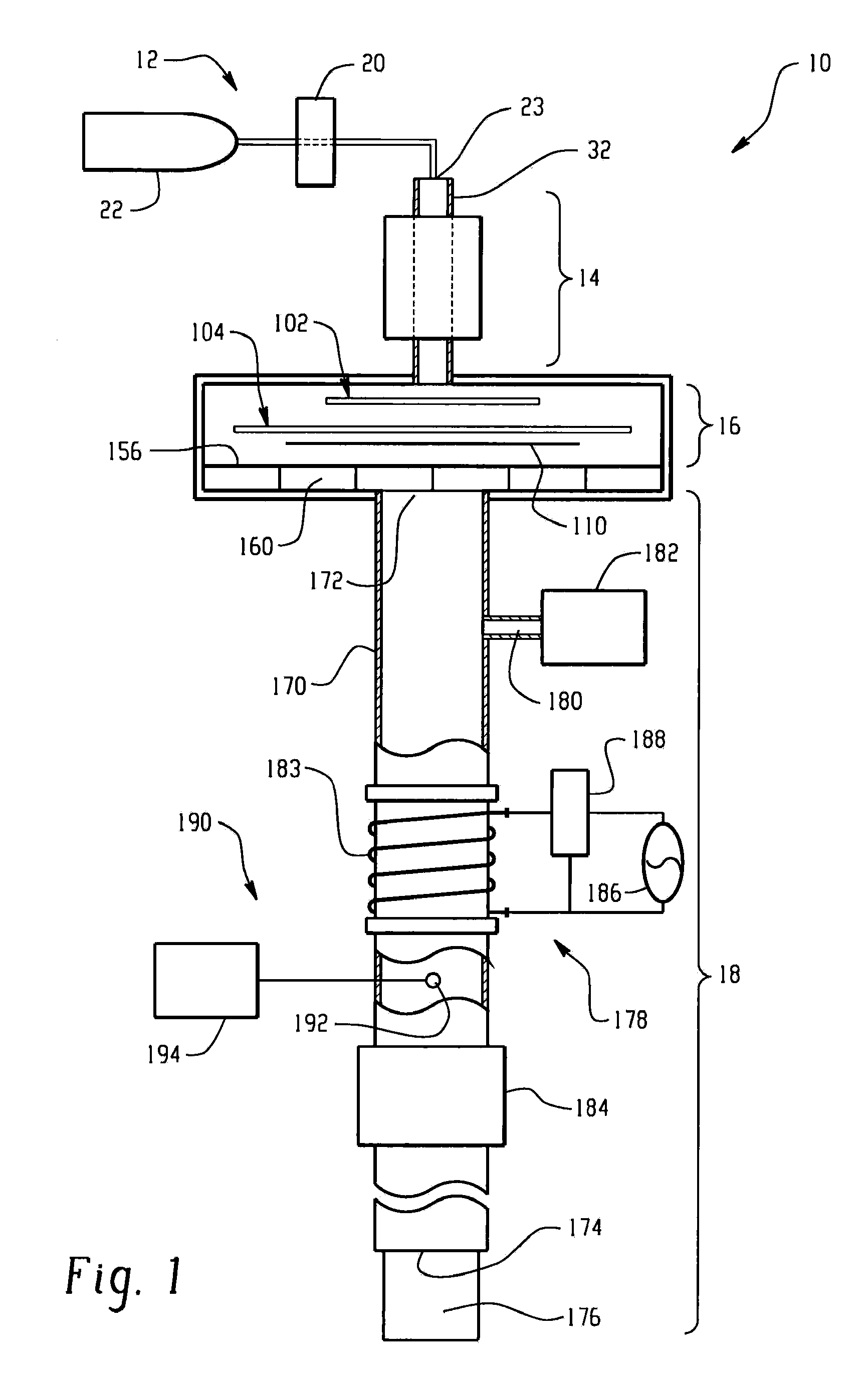

A plasma ashing apparatus for removing organic matter from a substrate including a low k dielectric, comprising a first gas source; a plasma generating component in fluid communication with the first gas source; a process chamber in fluid communication with the plasma generating component; an exhaust conduit in fluid communication with the process chamber; wherein the exhaust conduit comprises an inlet for a second gas source and an afterburner assembly coupled to the exhaust conduit, wherein the inlet is disposed intermediate to the process chamber and an afterburner assembly, and wherein the afterburner assembly comprises means for generating a plasma within the exhaust conduit with or without introduction of a gas from the second gas source; and an optical emission spectroscopy device coupled to the exhaust conduit comprising collection optics focused within a plasma discharge region of the afterburner assembly. An endpoint detection process for an oxygen free and nitrogen free plasma process comprises monitoring an optical emission signal of an afterburner excited species in an exhaust conduit of the plasma asher apparatus. The process and apparatus can be used with carbon and / or hydrogen containing low k dielectric materials.

Owner:LAM RES CORP

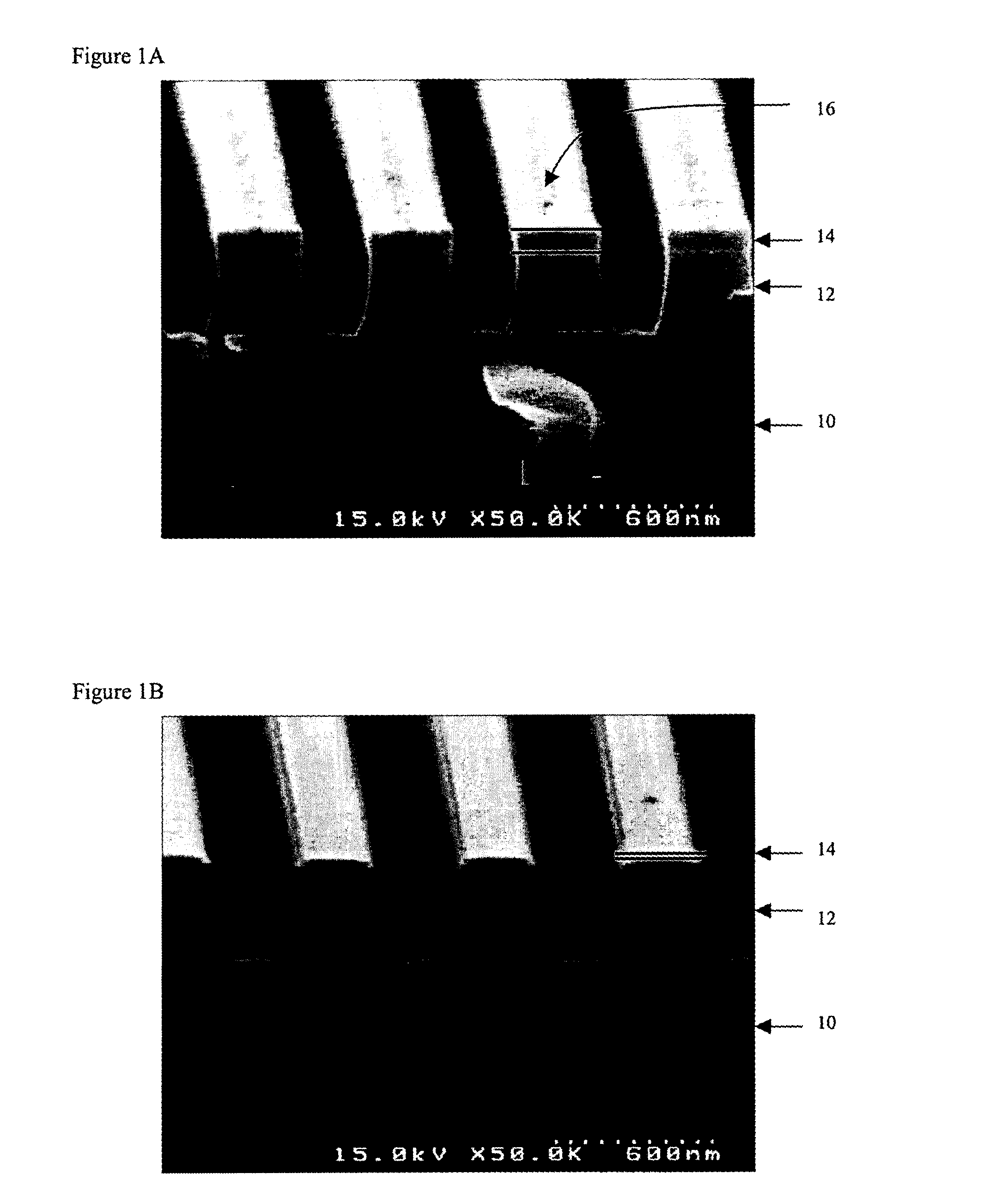

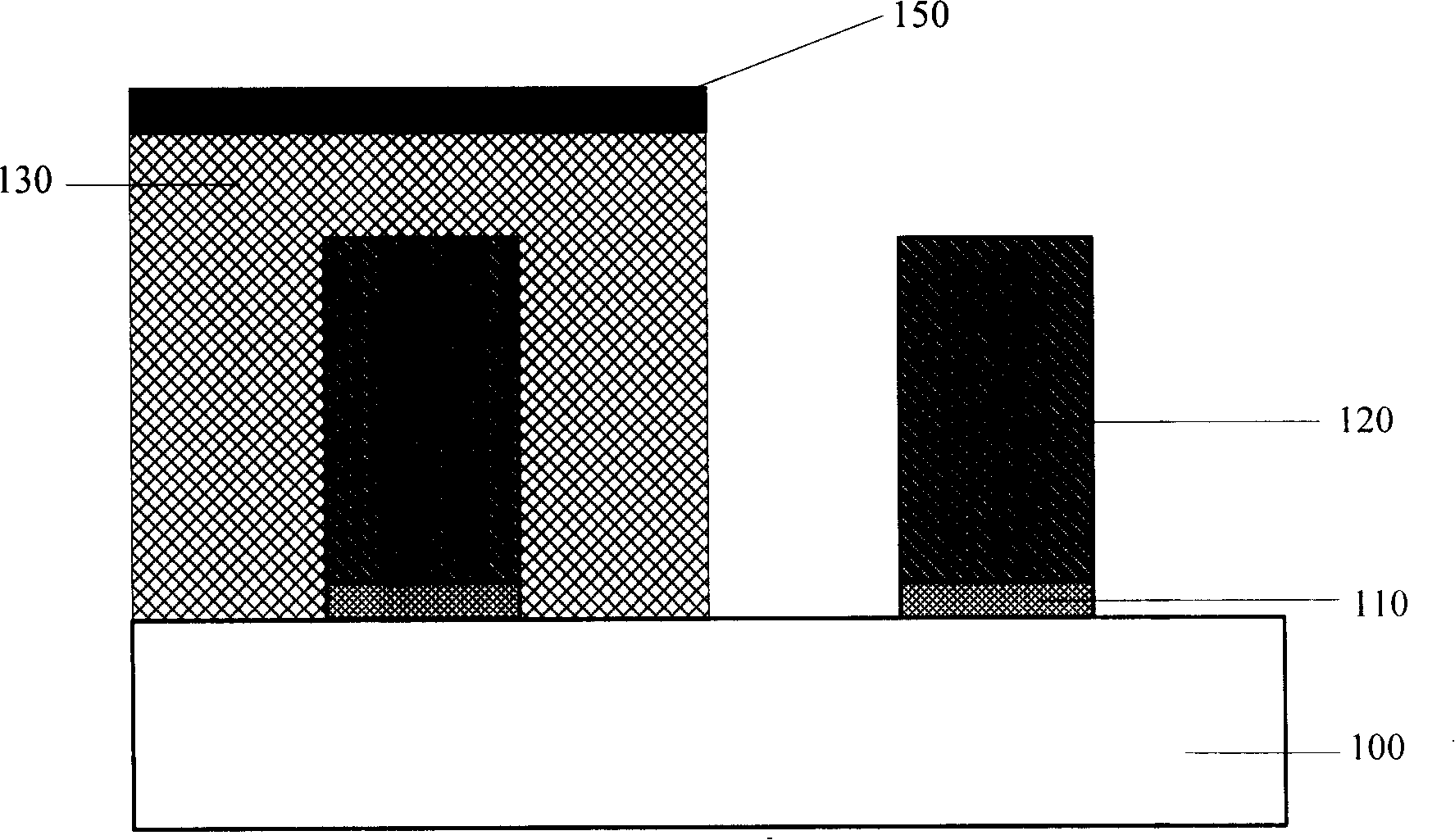

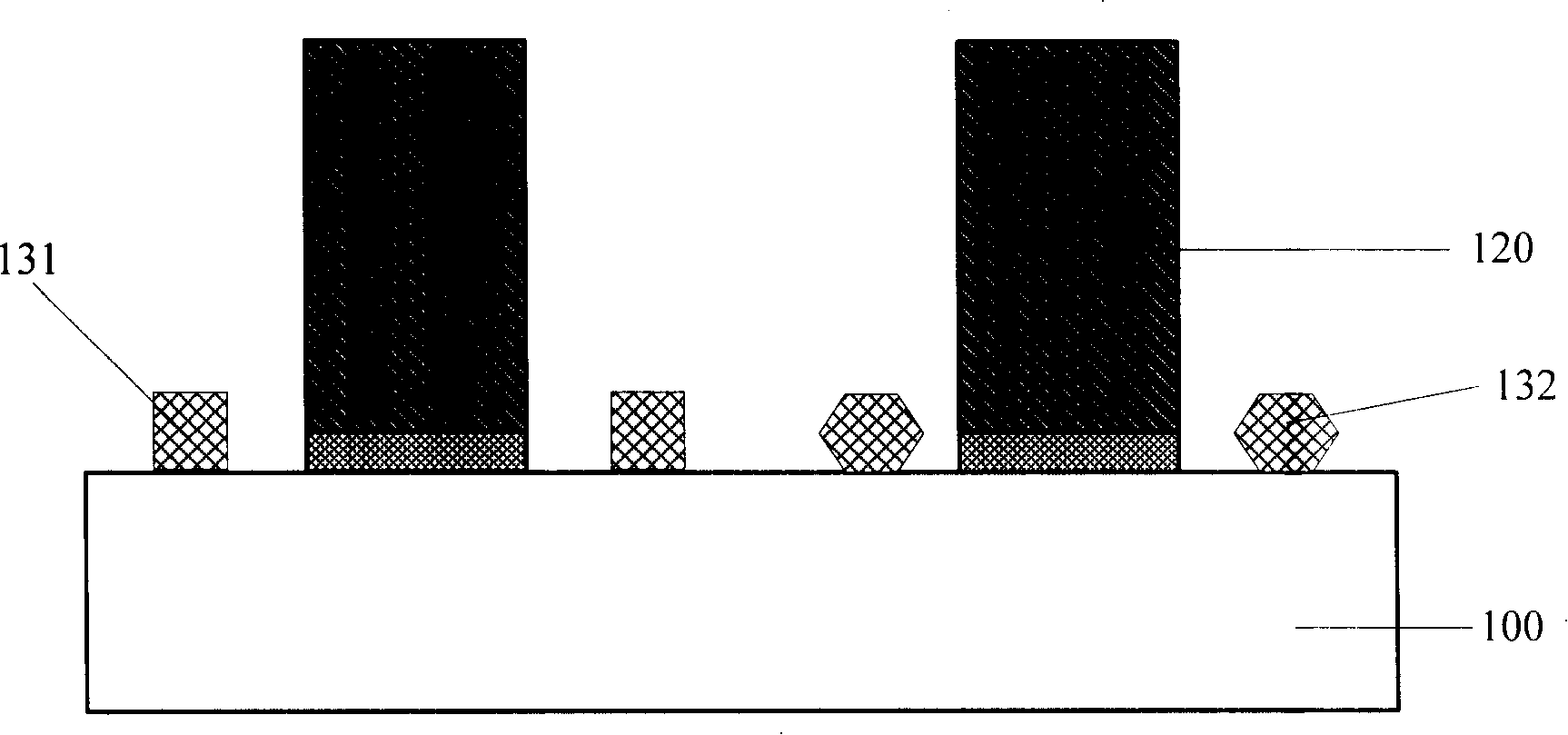

Method of manufacturing a semiconductor device having air gaps

InactiveUS20080124917A1Excellent electrical propertiesWell formedSemiconductor/solid-state device manufacturingCapacitanceResistance capacitance

In a method of manufacturing a semiconductor device having air gaps, an organic sacrificial layer pattern is formed on a semiconductor substrate, wherein the organic sacrificial layer pattern includes openings. Metal structures are formed in the openings. The organic sacrificial layer pattern is removed by a plasma ashing treatment using a source gas including oxygen (O2) and carbon monoxide (CO). An insulating interlayer is formed to have air gaps between the metal structures. Resistance-capacitance (RC) delay and crosstalk between the metal structures may be efficiently suppressed.

Owner:SAMSUNG ELECTRONICS CO LTD

Aqueous cleaning composition containing copper-specific corrosion inhibitor for cleaning inorganic residues on semiconductor substrate

InactiveUS6755989B2Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsCopper interconnectCarboxylic acid

A semiconductor wafer cleaning formulation, including 1-21% wt. fluoride source, 20-55% wt. organic amine(s), 0.5-40% wt. nitrogenous component, e.g., a nitrogen-containing carboxylic acid or an imine, 23-50% wt. water, and 0-21% wt. metal chelating agent(s). The formulations are useful to remove residue from wafers following a resist plasma ashing step, such as inorganic residue from semiconductor wafers containing delicate copper interconnecting structures.

Owner:ENTEGRIS INC

Method for thinning grapheme layer by layer

The invention relates to a method for thinning grapheme layer by layer, which is characterized in that the method comprises the following steps of: firstly utilizing the plasma ashing technology, bombarding multi-layer grapheme by plasma and then annealing in a high-temperature furnace to remove the grapheme on the top layer so as to realize the effect of precisely thinning the grapheme. Through more times of plasma bombarding and high-temperature annealing, the effect of thinning the multi-layer grapheme layer by layer can be realized. The method is characterized in that in combination with the grapheme modification and grapheme anisotropic oxidation process conducted by adopting the plasma technology, the method accurately etches the multi-layer grapheme and can realize the effect of precisely thinning the multi-layer grapheme on a monoatomic layer and keep the excellent performance of the thinned grapheme. The method is applied to the preparation of a grapheme nanostructure, a grapheme electronic device and the like.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Plasma ashing process

InactiveUS6951823B2Electric discharge tubesSemiconductor/solid-state device manufacturingNitrogenPlasma Gases

A substantially oxygen-free and nitrogen-free plasma ashing process for removing photoresist in the presence of a low k material from a semiconductor substrate includes forming reactive species by exposing a plasma gas composition to an energy source to form plasma. The plasma gas composition is substantially free from oxygen-bearing and nitrogen-bearing gases. The plasma selectively removes the photoresist from the underlying substrate containing low k material by exposing the photoresist to substantially oxygen and nitrogen free reactive species. The process can be used with carbon containing low k dielectric materials.

Owner:LAM RES CORP

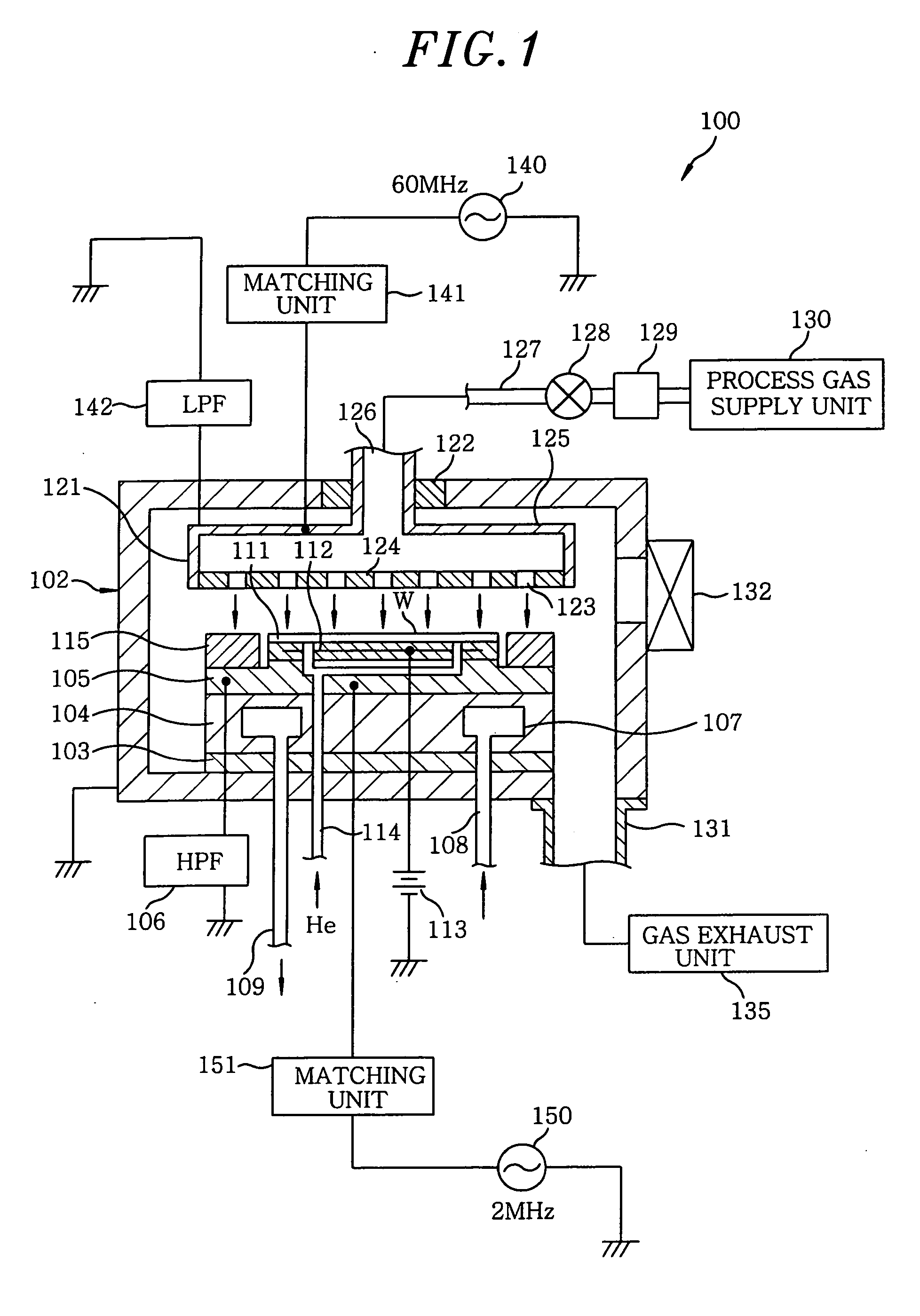

Low-pressure removal of photoresist and etch residue

ActiveUS7344993B2Reduce erosionErosion minimizationSemiconductor/solid-state device testing/measurementElectric discharge tubesResistHydrogen

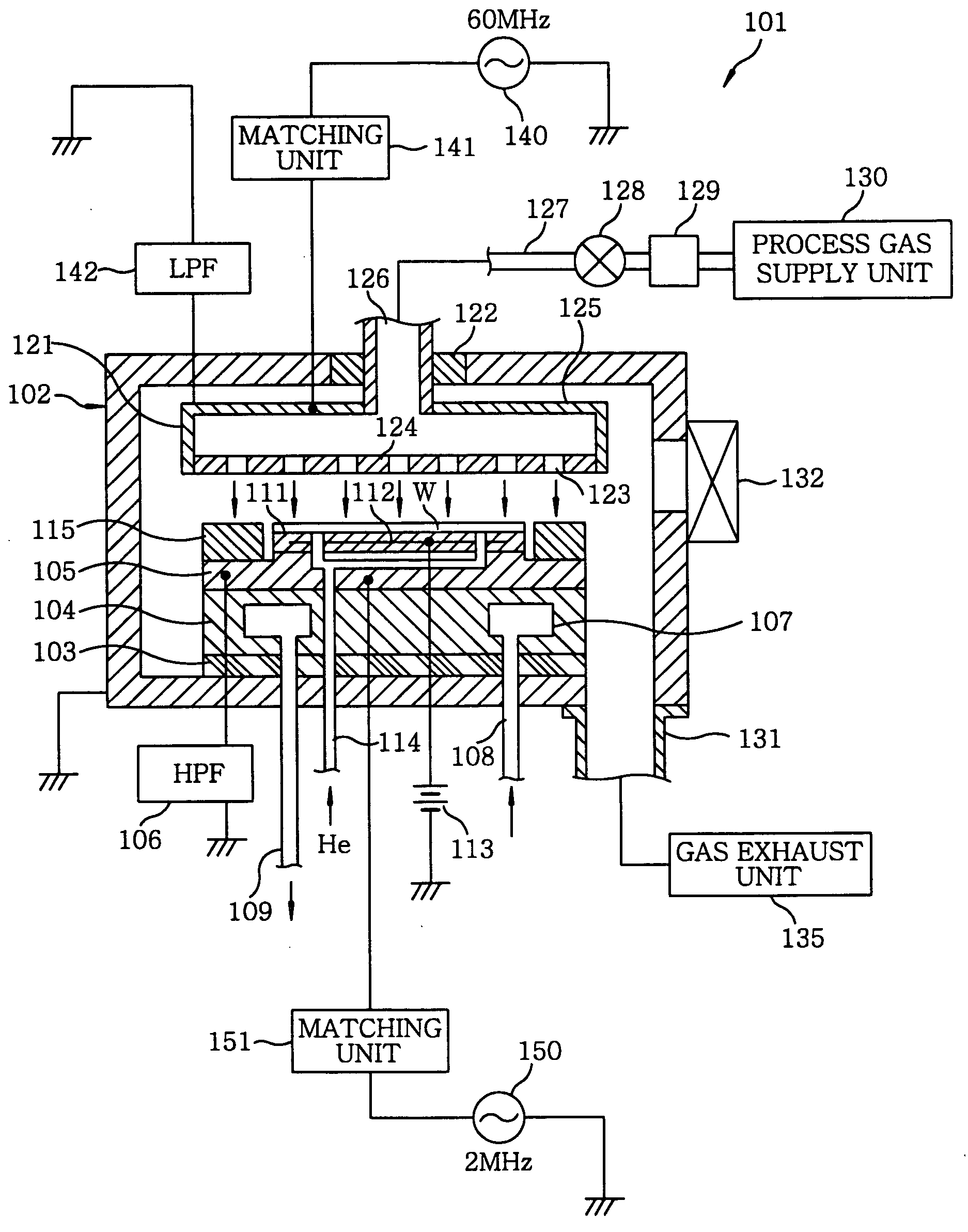

A method is provided for plasma ashing to remove photoresist remnants and etch residues formed during preceding plasma etching of dielectric layers. The ashing method uses a two-step plasma process involving a hydrogen-containing gas, where low or zero bias is applied to the substrate in the first cleaning step to remove significant amount of photoresist remnants and etch residues from the substrate, in addition to etching and removing detrimental fluorocarbon residues from the chamber surfaces. An increased bias is applied to the substrate in the second cleaning step to remove the remains of the photoresist and etch residues from the substrate. A chamber pressure less than 20 mTorr is utilized in the second cleaning step. The two-step process reduces the memory effect commonly observed in conventional one-step ashing processes. A method of endpoint detection can be used to monitor the ashing process.

Owner:TOKYO ELECTRON LTD

Plasma ashing apparatus and endpoint detection process

InactiveUS20100055807A1Semiconductor/solid-state device testing/measurementElectric discharge tubesNitrogen plasmaHydrogen

A plasma ashing apparatus for removing organic matter from a substrate including a low k dielectric, comprising a first gas source; a plasma generating component in fluid communication with the first gas source; a process chamber in fluid communication with the plasma generating component; an exhaust conduit in fluid communication with the process chamber; wherein the exhaust conduit comprises an inlet for a second gas source and an afterburner assembly coupled to the exhaust conduit, wherein the inlet is disposed intermediate to the process chamber and an afterburner assembly, and wherein the afterburner assembly comprises means for generating a plasma within the exhaust conduit with or without introduction of a gas from the second gas source; and an optical emission spectroscopy device coupled to the exhaust conduit comprising collection optics focused within a plasma discharge region of the afterburner assembly. An endpoint detection process for an oxygen free and nitrogen free plasma process comprises monitoring an optical emission signal of an afterburner excited species in an exhaust conduit of the plasma asher apparatus. The process and apparatus can be used with carbon and / or hydrogen containing low k dielectric materials.

Owner:LAM RES CORP

Aqueous cleaning composition containing copper-specific corrosion inhibitor for cleaning inorganic residues on semiconductor substrate

InactiveUS20010050350A1Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsResistNitrogen

A semiconductor wafer cleaning formulation, including 1-21% wt. fluoride source, 20-55% wt. organic amine(s), 0.5-40% wt. nitrogenous component, e.g., a nitrogen-containing carboxylic acid or an imine, 23-50% wt. water, and 0-21% wt. metal chelating agent(s). The formulations are useful to remove residue from wafers following a resist plasma ashing step, such as inorganic residue from semiconductor wafers containing delicate copper interconnecting structures.

Owner:ENTEGRIS INC

Hydrogen ashing enhanced with water vapor and diluent gas

ActiveUS7807579B2Decorative surface effectsSemiconductor/solid-state device detailsWater vaporOxygen

An oxygen-free hydrogen plasma ashing process particularly useful for low-k dielectric materials based on hydrogenated silicon oxycarbide materials. The main ashing step includes exposing a previously etched dielectric layer to a plasma of hydrogen and optional nitrogen, a larger amount of water vapor, and a yet larger amount of argon or helium. Especially for porous low-k dielectrics, the main ashing plasma additionally contains a hydrocarbon gas such as methane. The main ashing may be preceded by a short surface treatment by a plasma of a hydrogen-containing reducing gas such as hydrogen and optional nitrogen.

Owner:APPLIED MATERIALS INC

Aqueous cleaning composition containing copper-specific corrosion inhibitor for cleaning inorganic residues on semiconductor substrate

InactiveUS20030078173A1Efficient removalExcellent peelabilityInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsCopper interconnectCarboxylic acid

A semiconductor wafer cleaning formulation, including 1-35% wt. fluoride source, 20-60% wt. organic amine(s), 0.140% wt. nitrogenous component, e.g., a nitrogen-containing carboxylic acid or an imine, 20-50% wt. water, and 0-21% wt. metal chelating agent(s). The formulations are useful to remove residue from wafers following a resist plasma ashing step, such as inorganic residue from semiconductor wafers containing delicate copper interconnecting structures.

Owner:ENTEGRIS INC

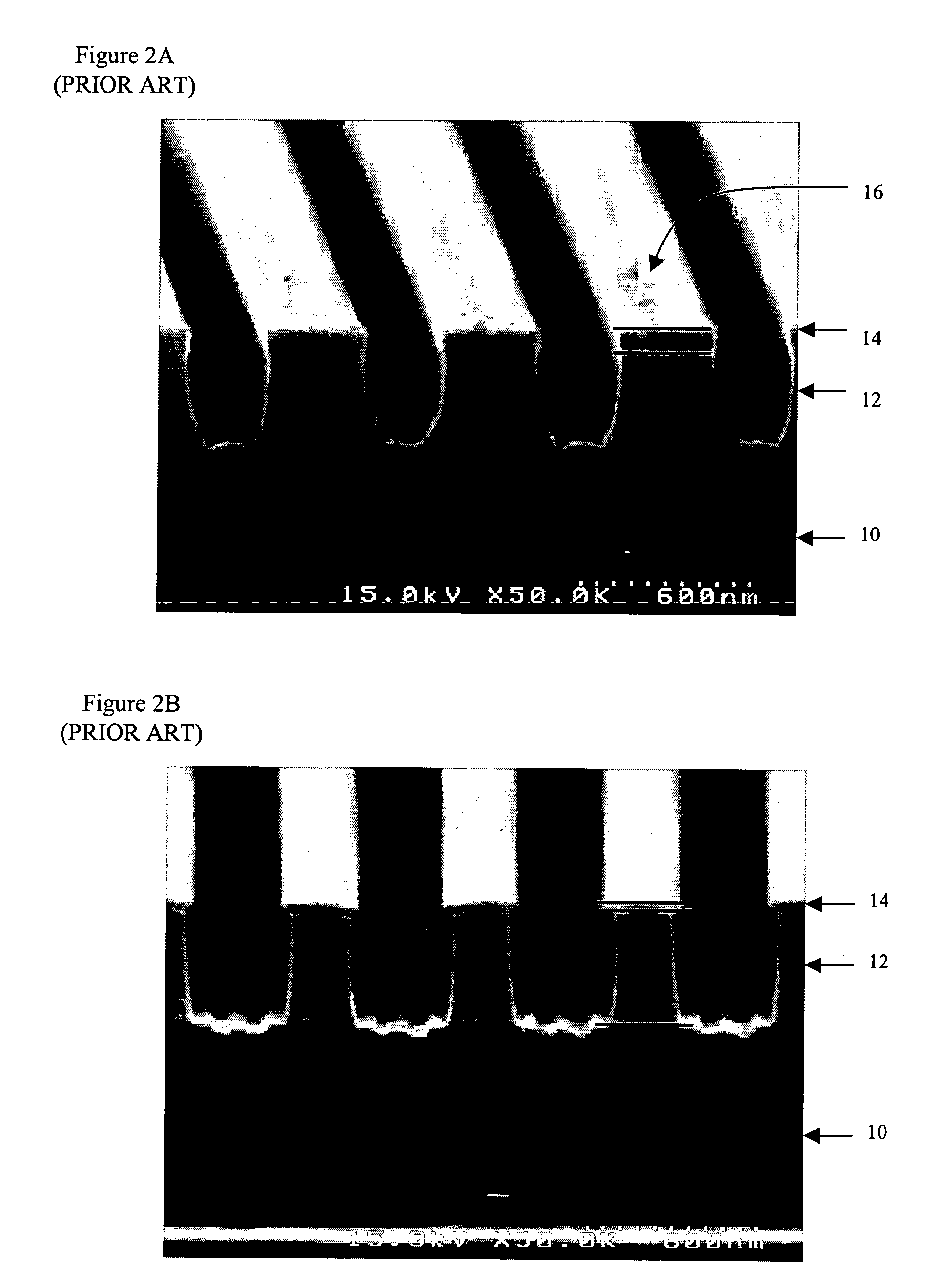

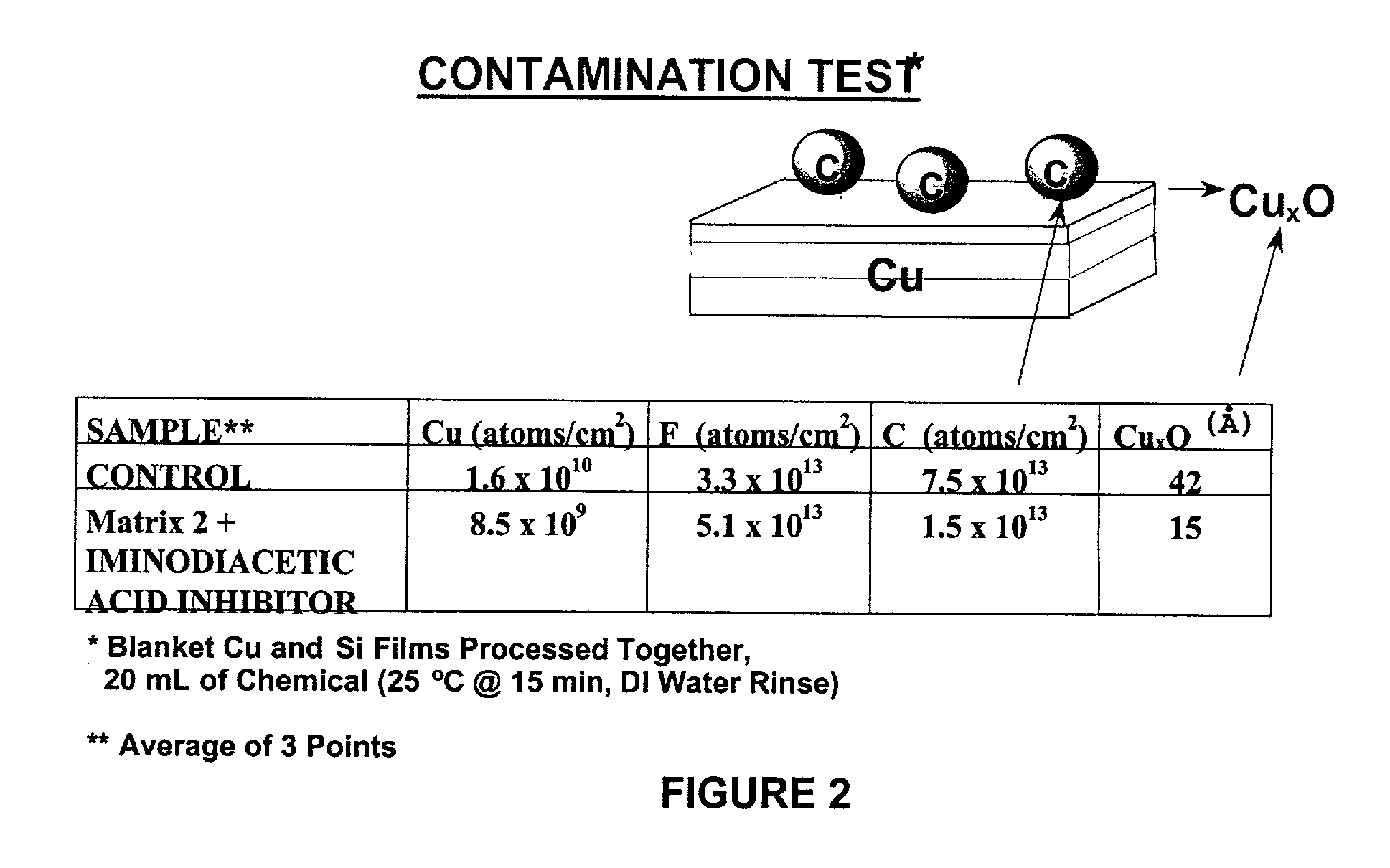

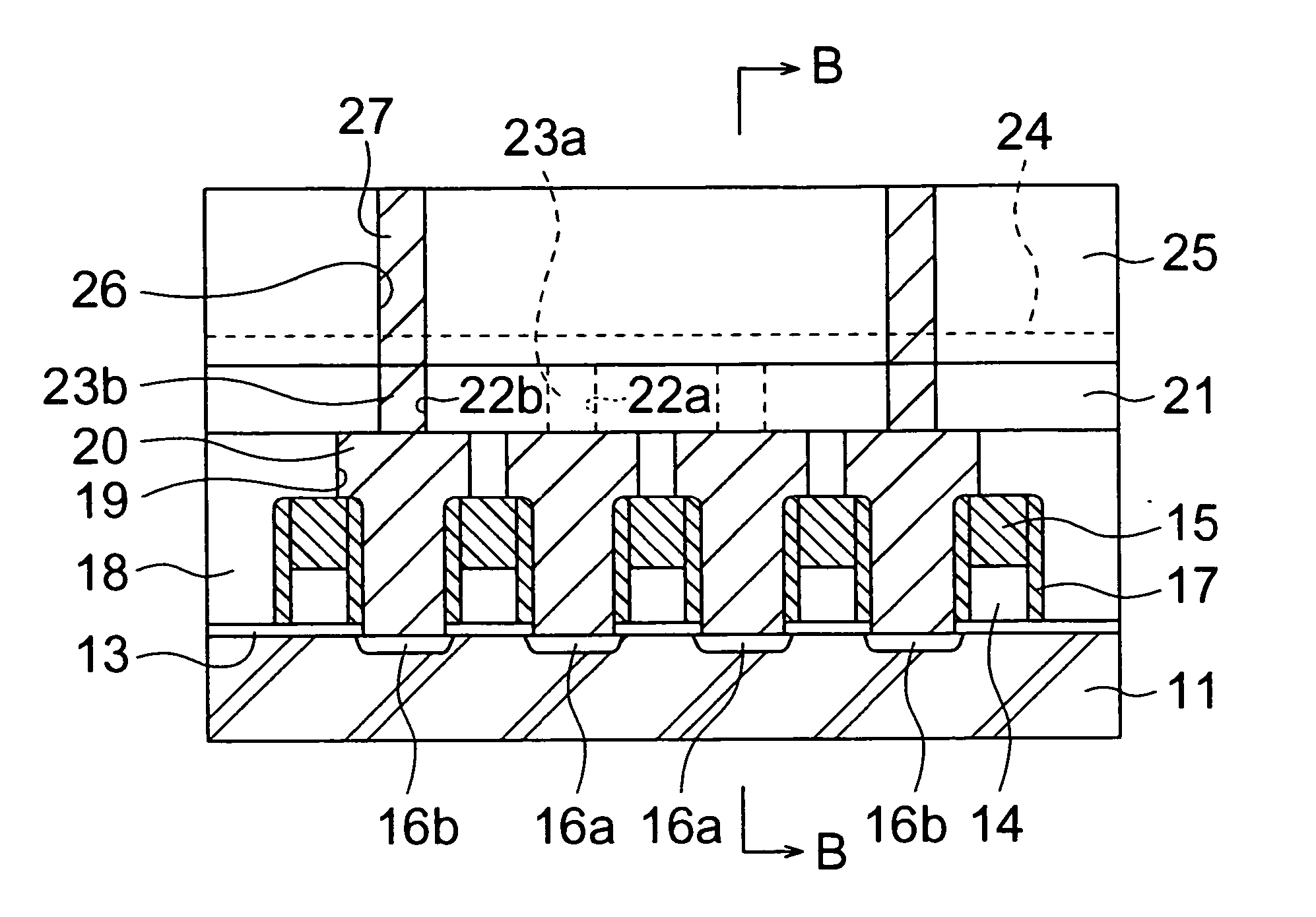

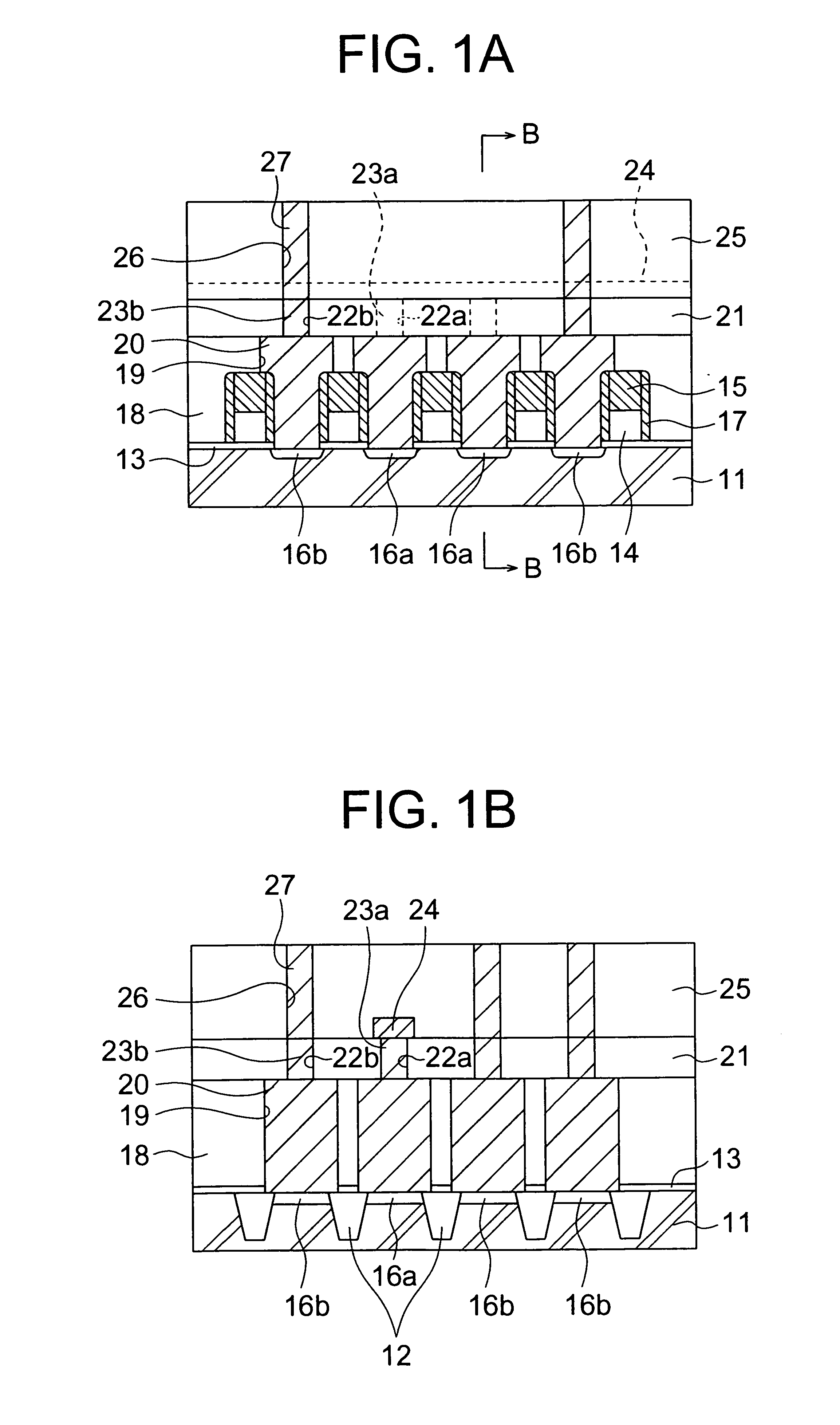

Method of fabricating semiconductor device

InactiveUS20060223324A1Increase in detachmentSemiconductor/solid-state device manufacturingTransmissionDevice materialSemiconductor

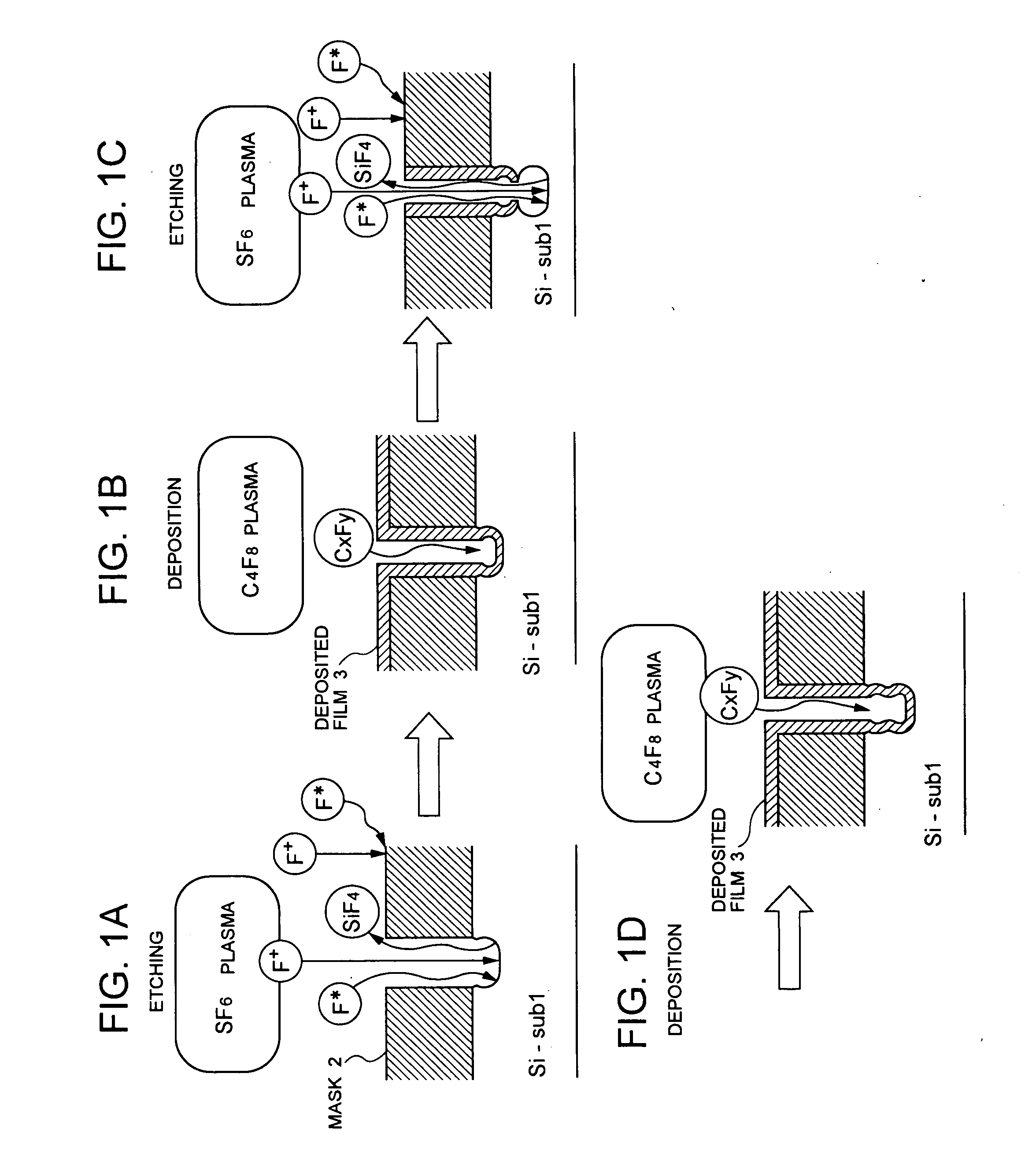

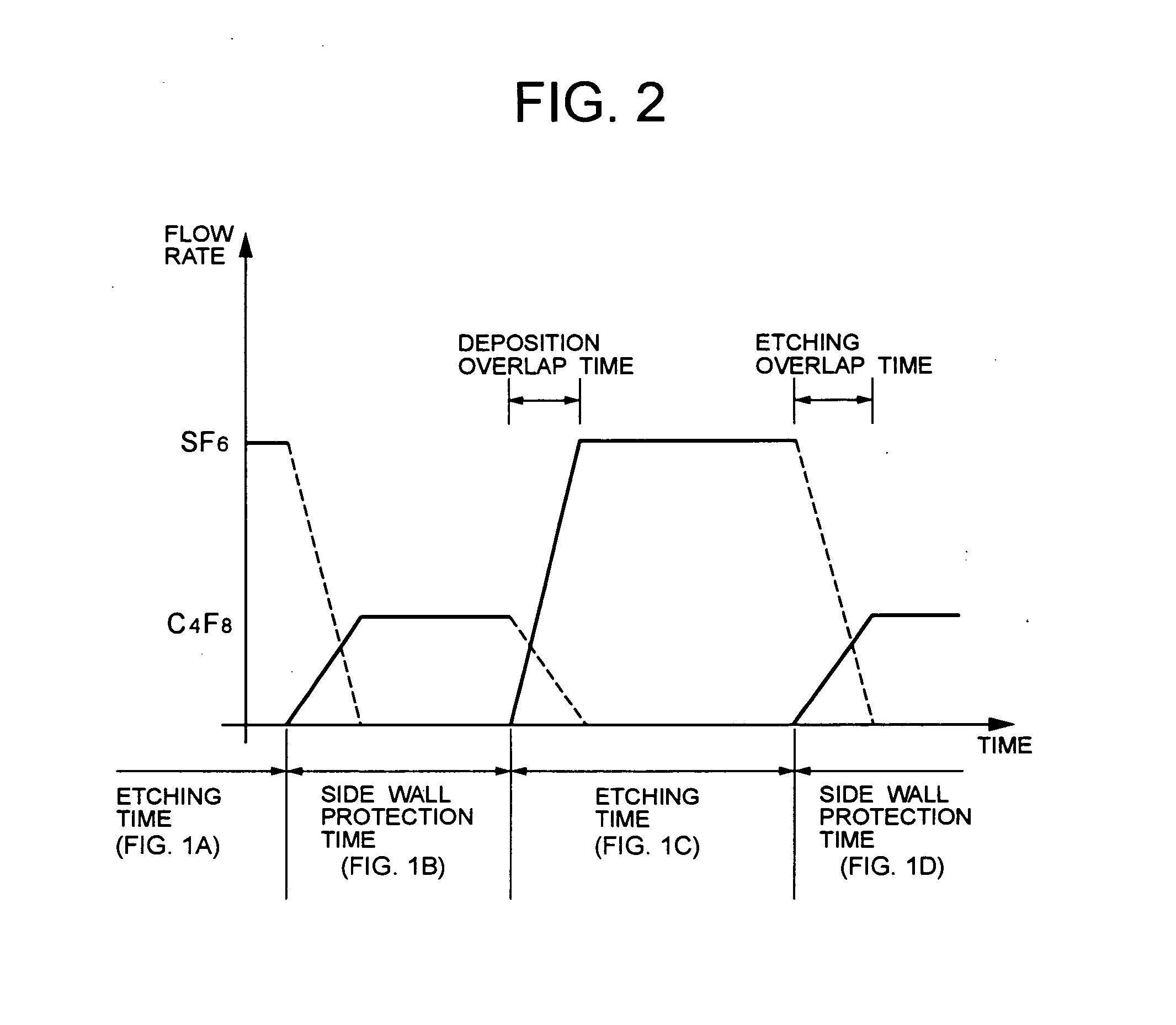

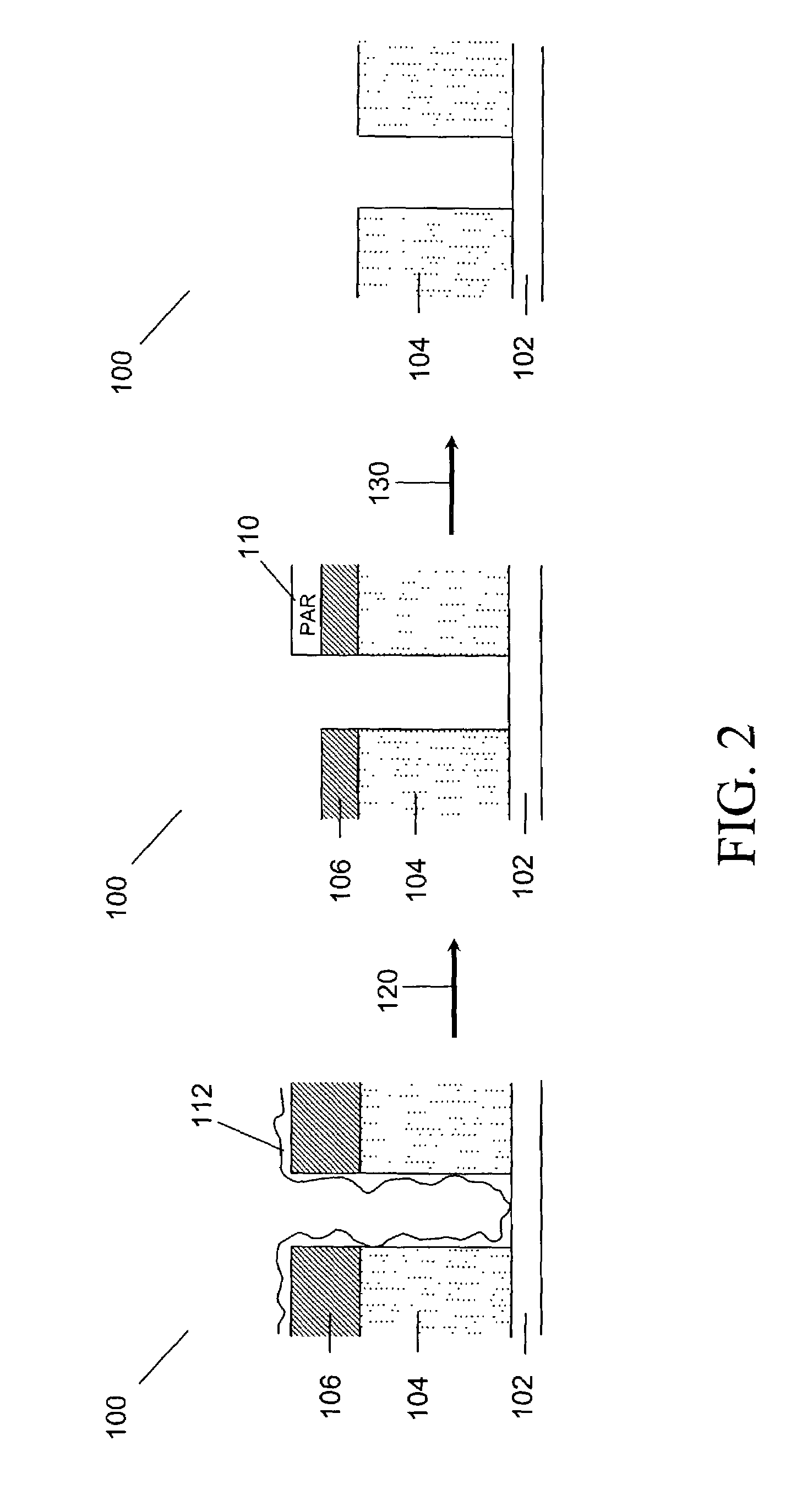

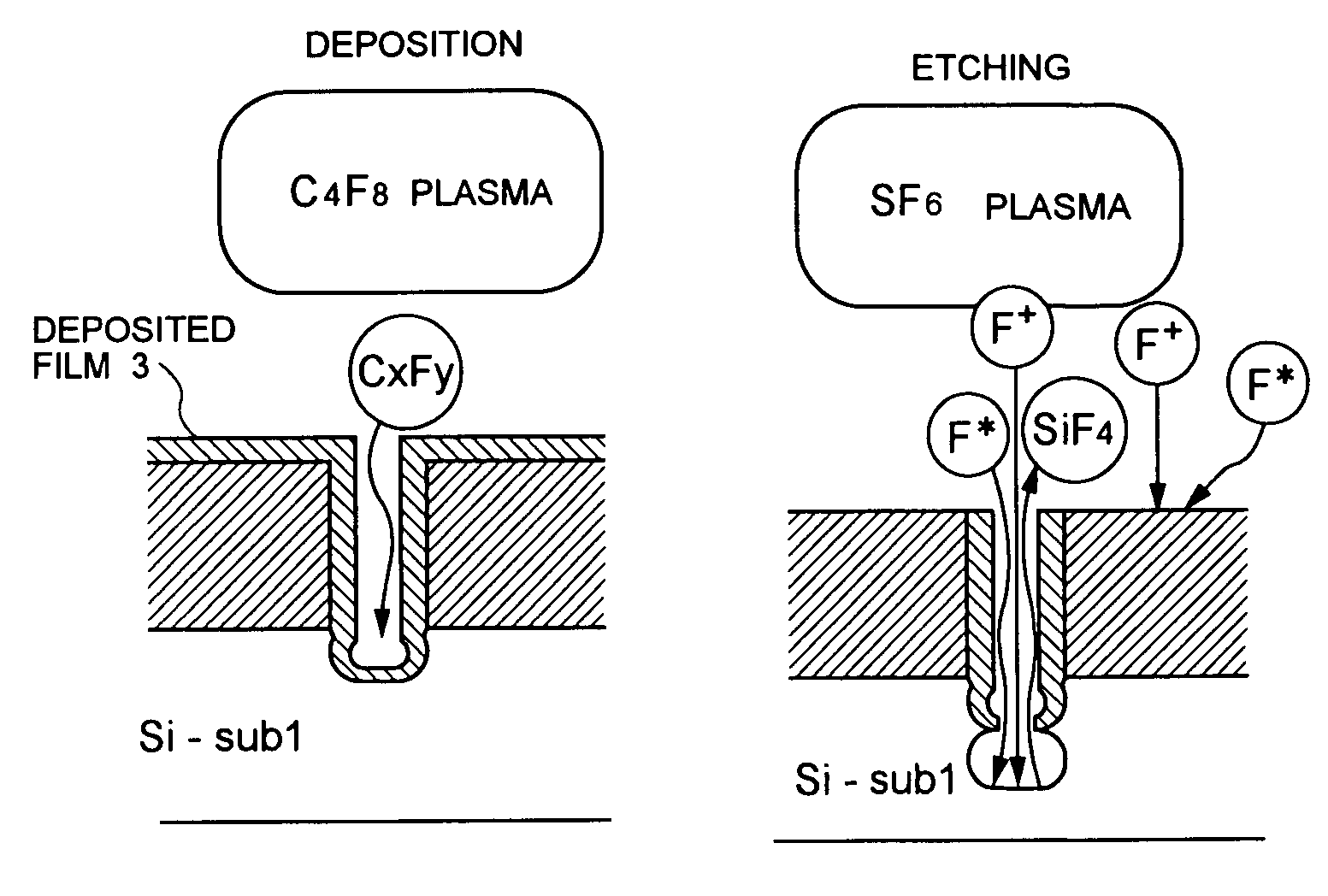

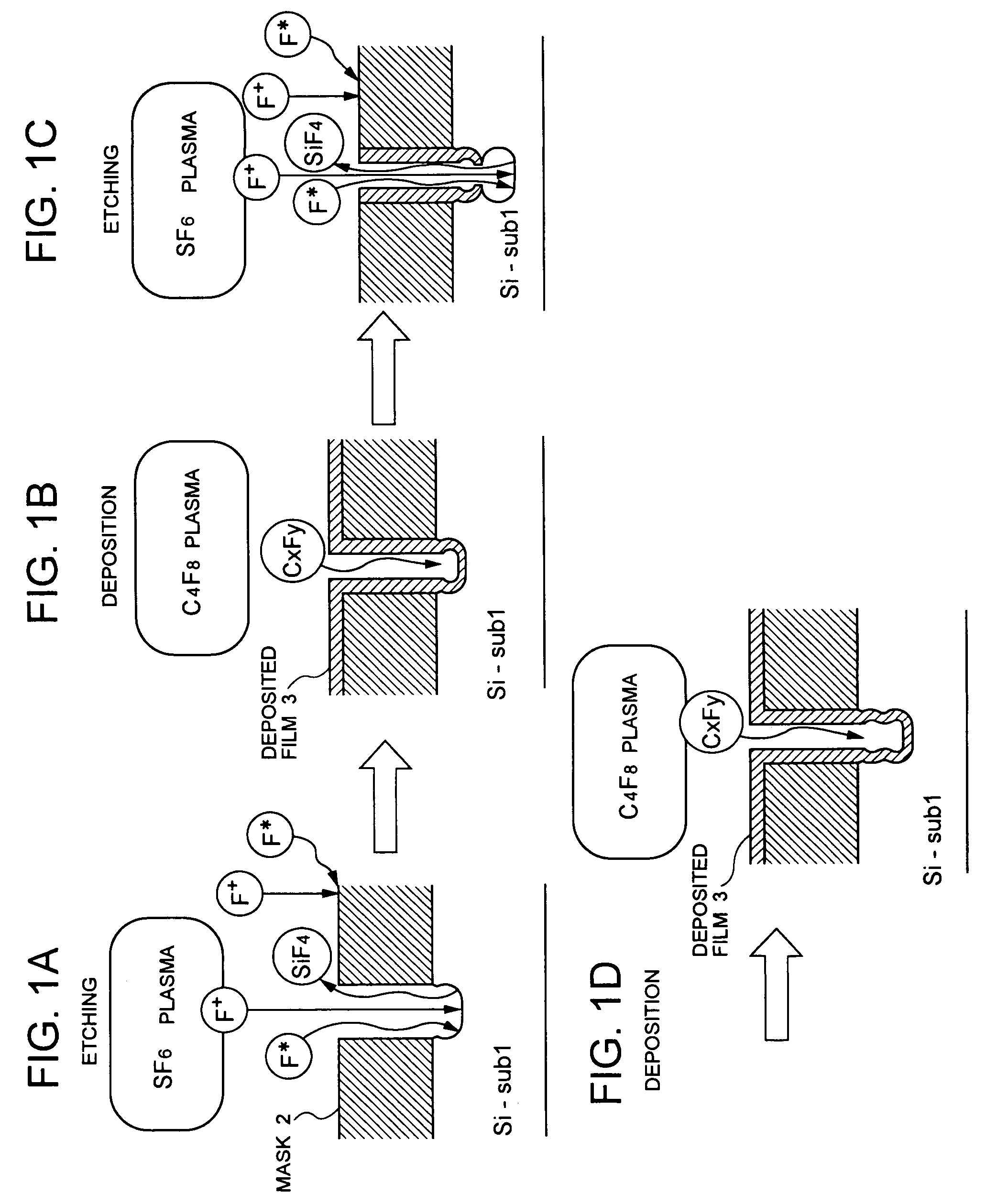

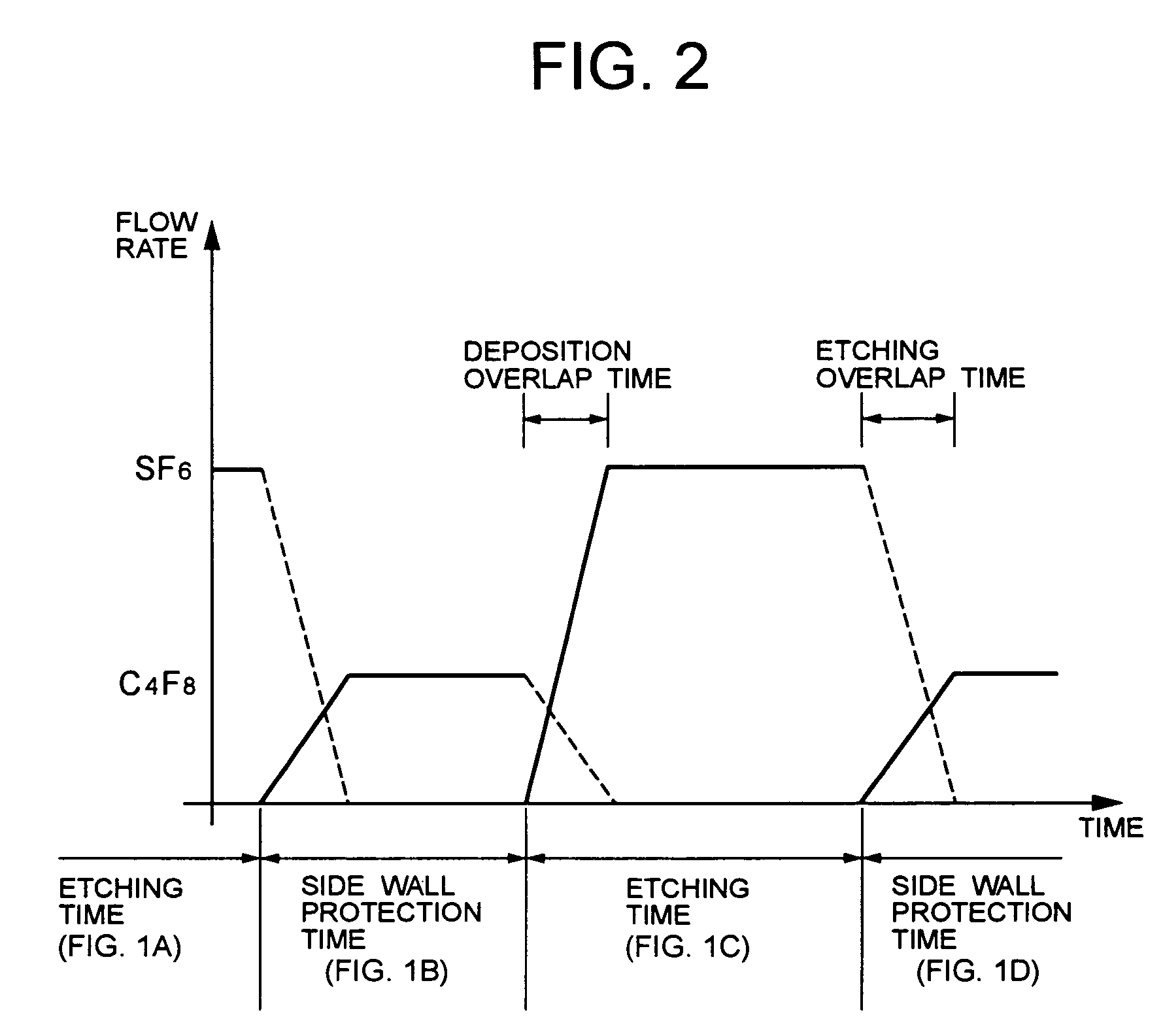

The method of fabricating a semiconductor device includes subjecting a semiconductor substrate to trench etching by alternately repeating an etching step and a deposition step. The etching step creates a trench structure by dry-etching the exposed surface of the semiconductor substrate. An etching mask is formed on the surface of the semiconductor substrate so that the semiconductor substrate has the exposed portion. The deposition step deposits a protection film for suppressing etching of the trench side walls. The method of fabricating a semiconductor device also includes subjecting the semiconductor substrate that has just undergone the trench etching to a heat treatment at a predetermined temperature. The semiconductor substrate is heat-treated within a temperature range of 300 to 500° C. immediately following the trench etching, for example. Plasma ashing is then performed.

Owner:LAPIS SEMICON CO LTD

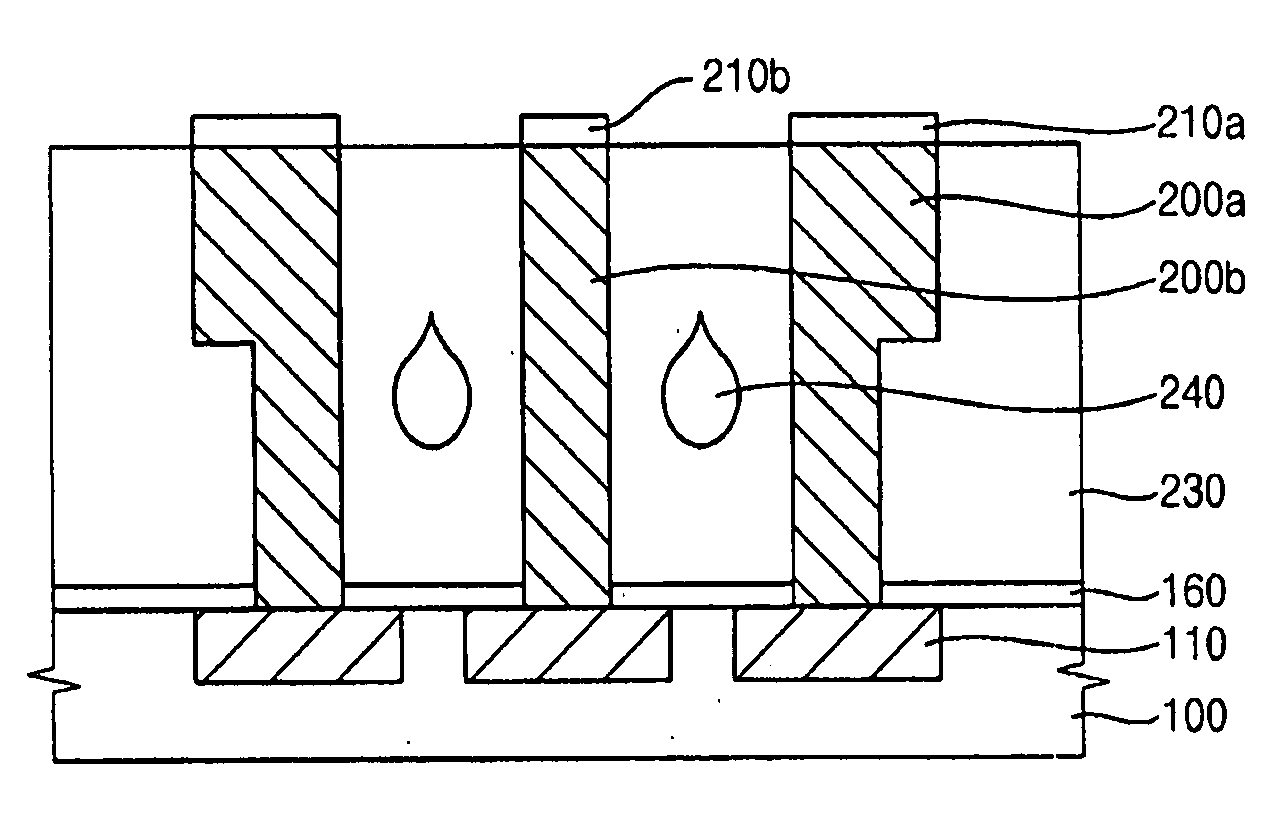

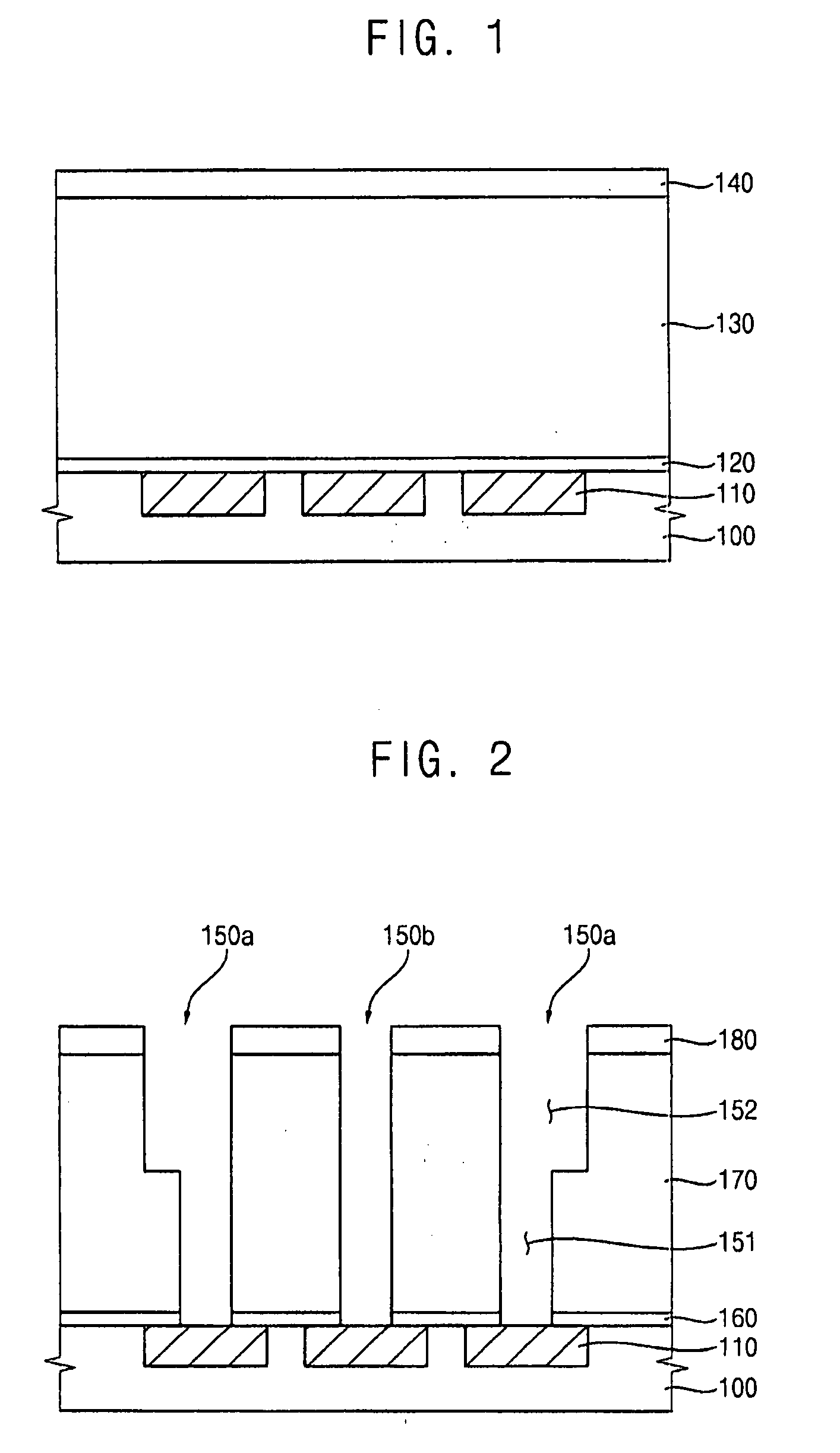

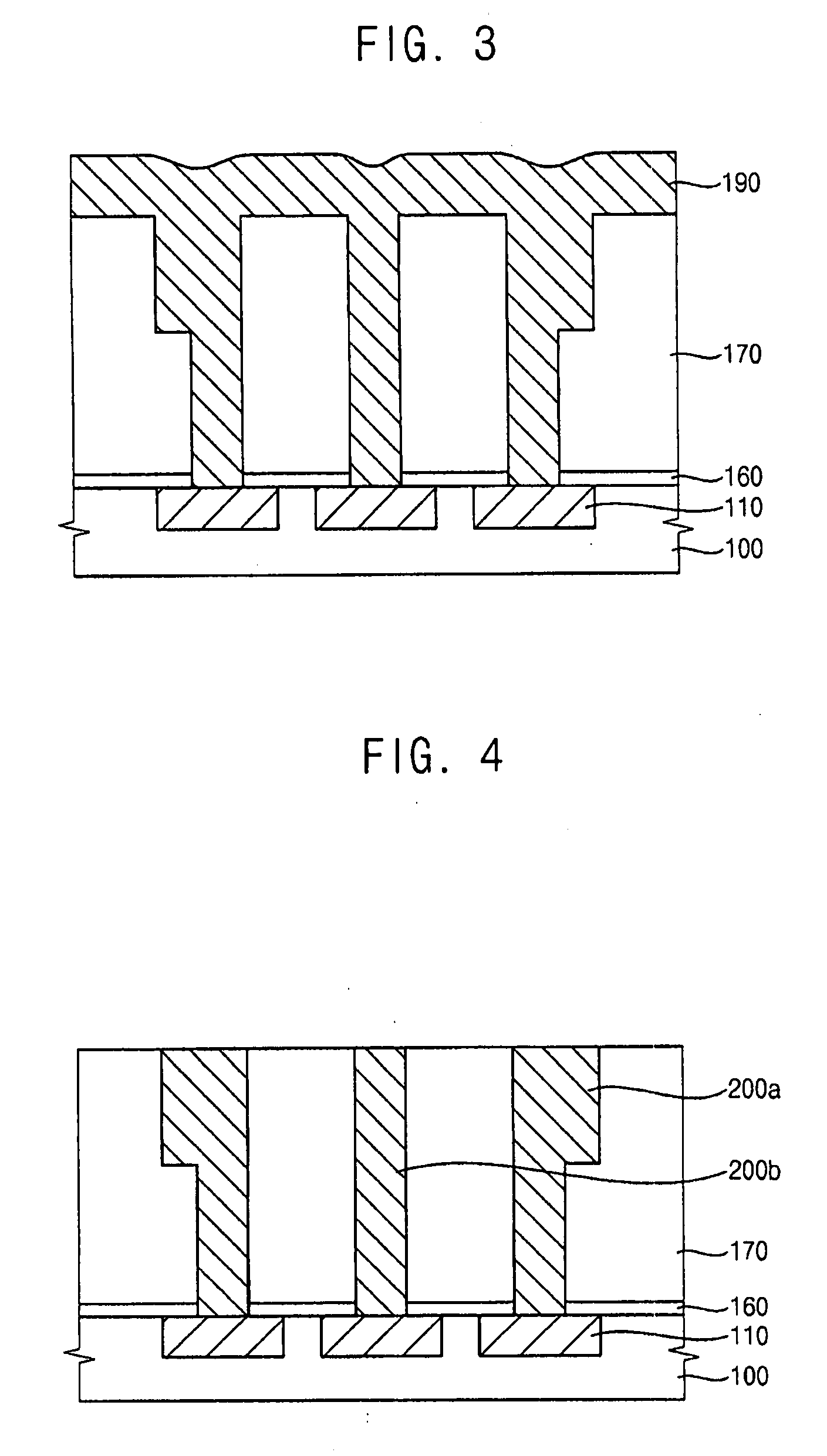

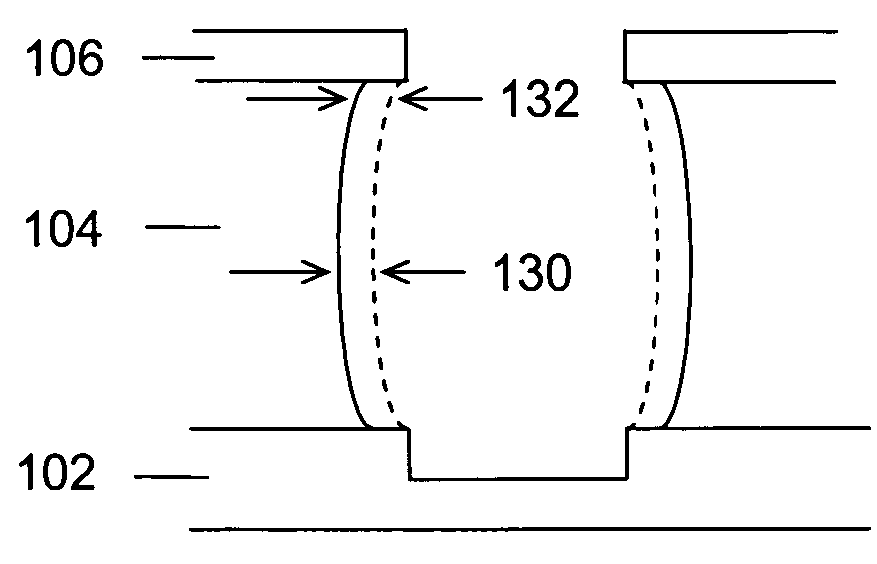

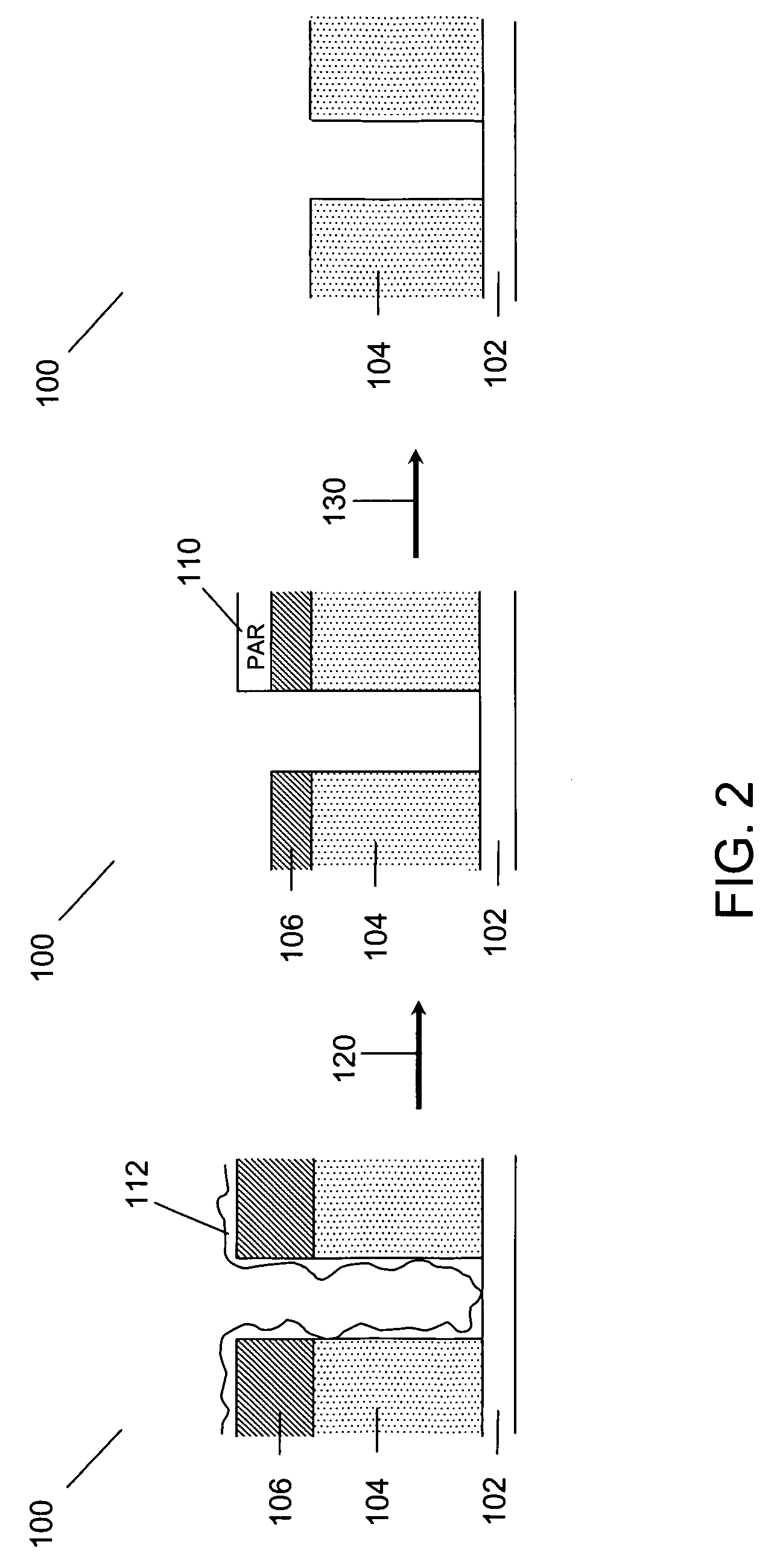

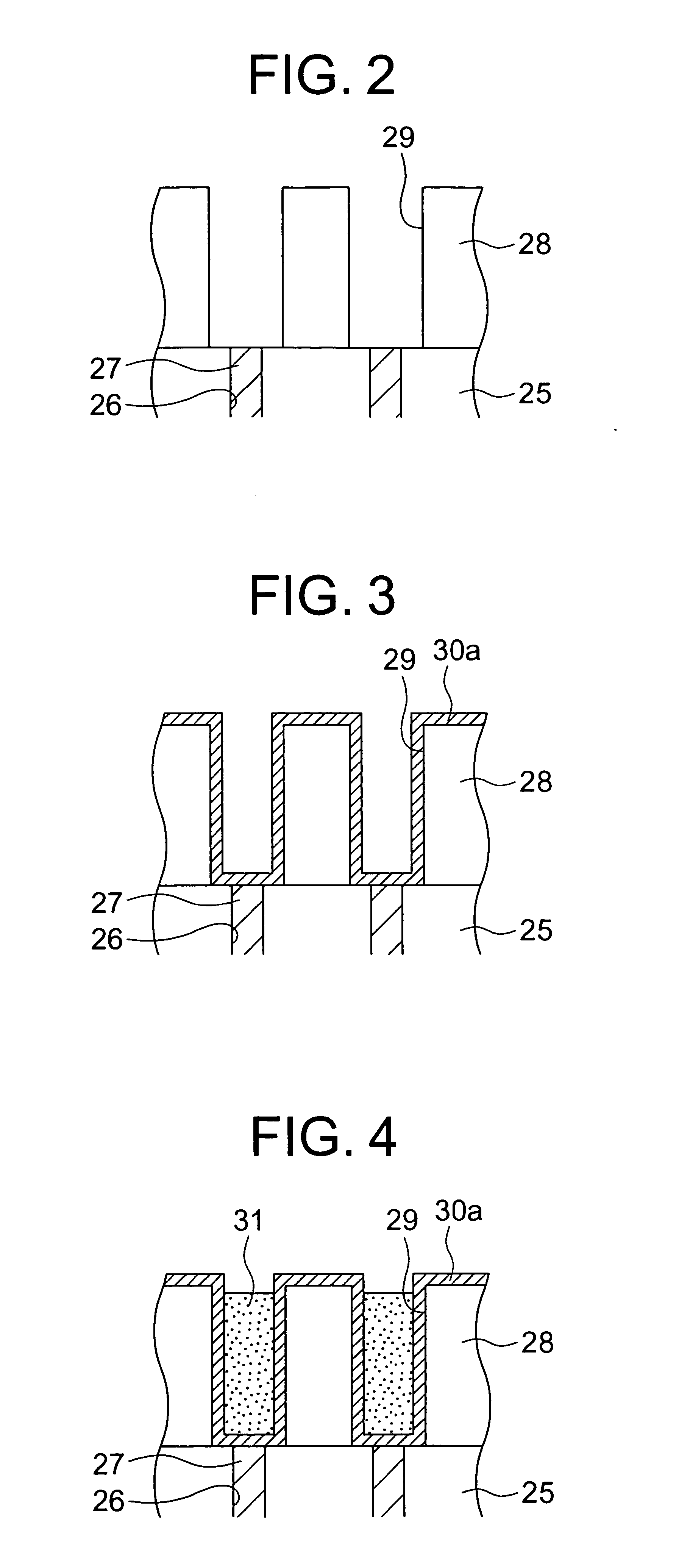

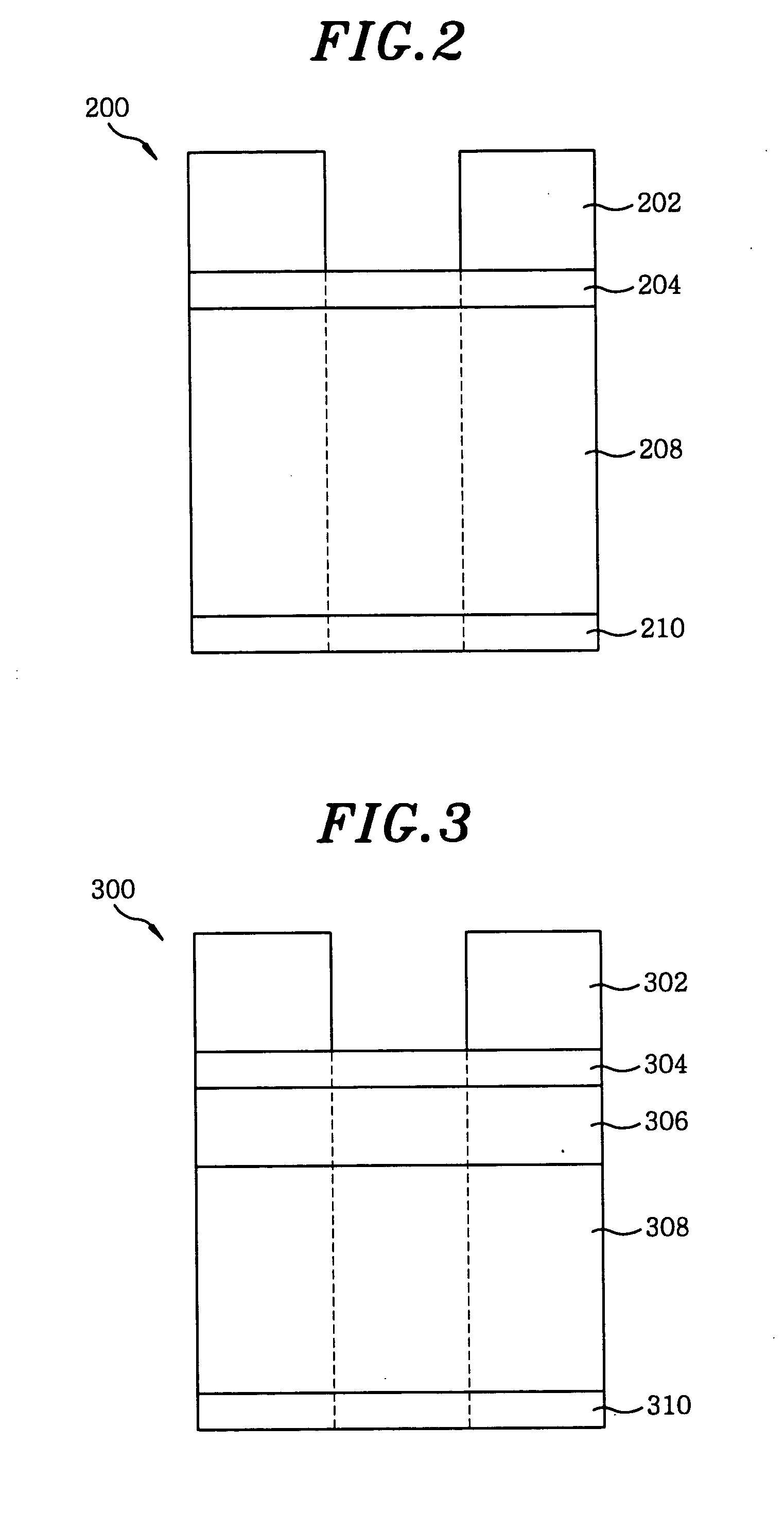

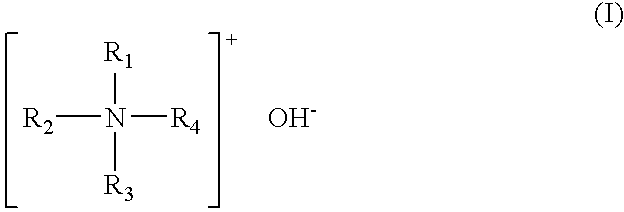

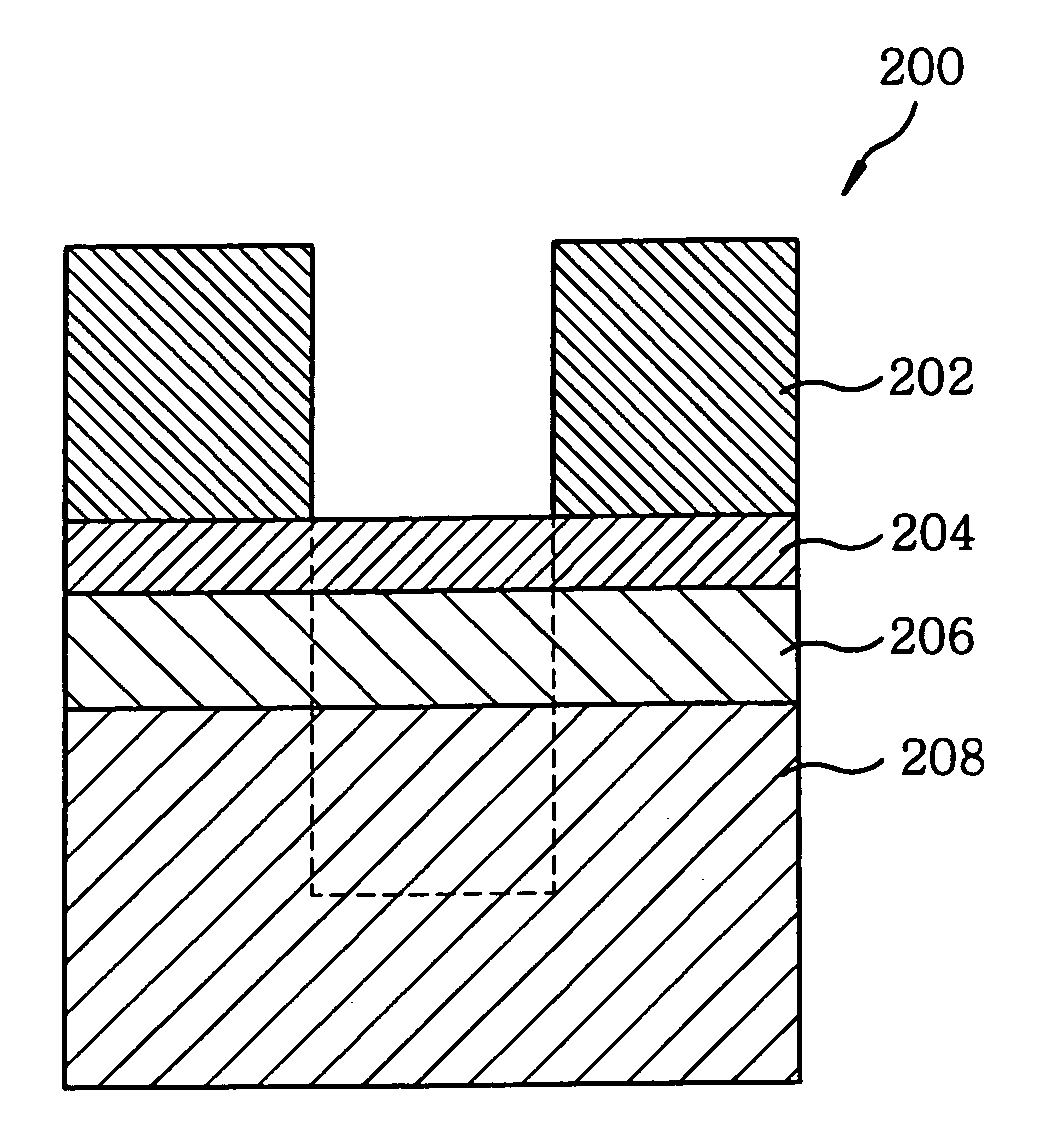

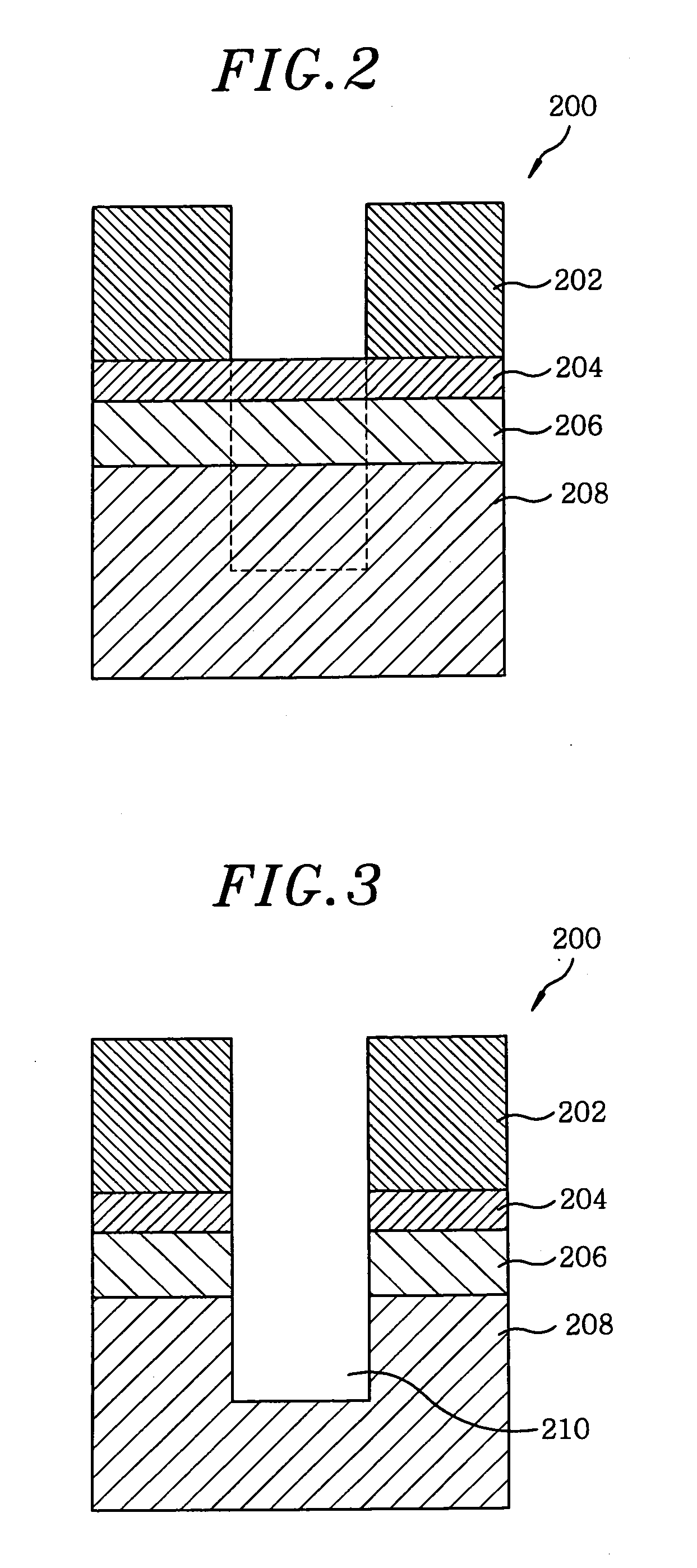

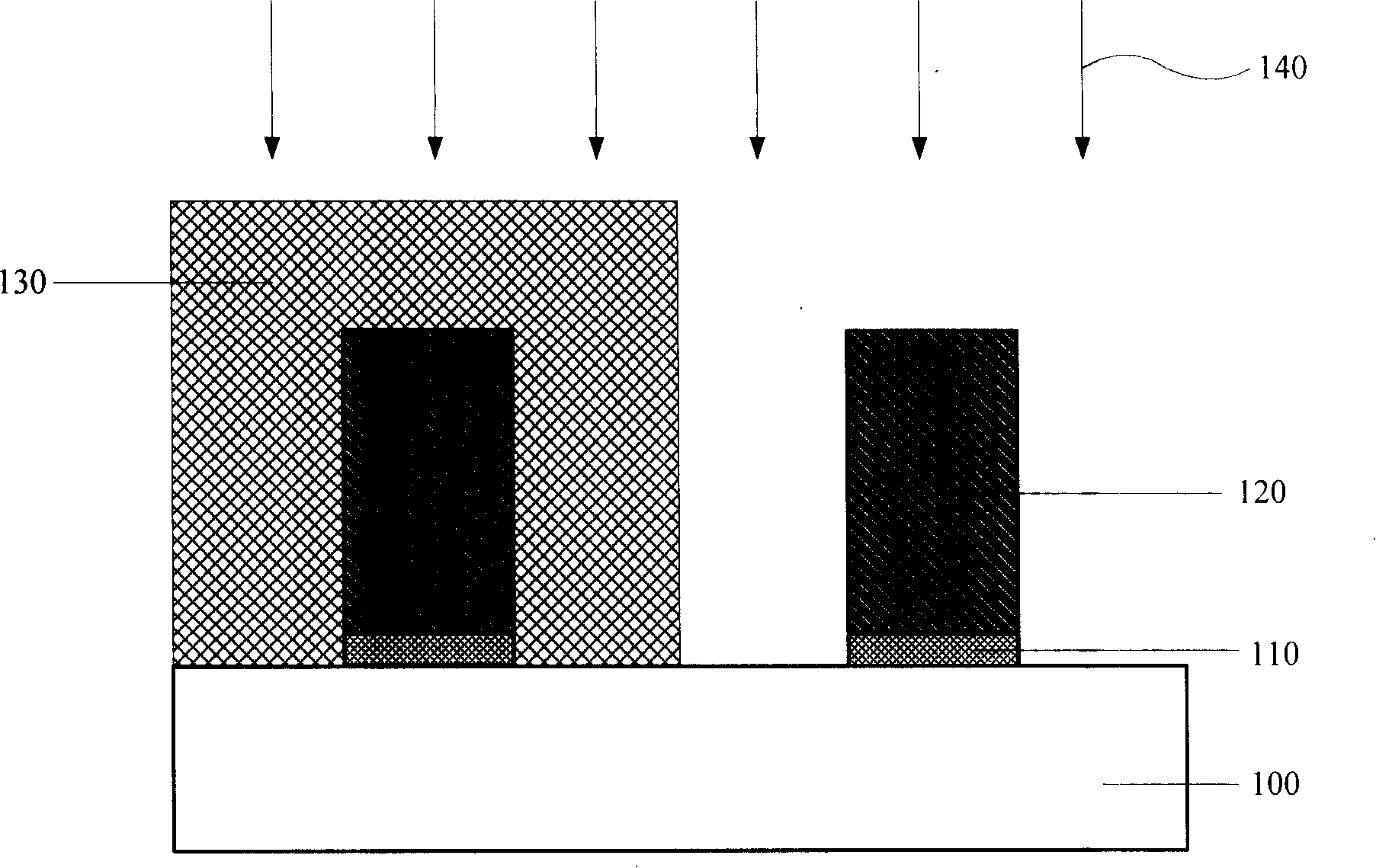

Method for forming a semiconductor device including a plasma ashing treatment for removal of photoresist

InactiveUS20060234511A1Increase capacitanceQuality improvementSolid-state devicesPhotomechanical apparatusEngineeringPlasma Gases

A method for forming a cylindrical capacitor having a metal-nitride bottom electrode, capacitor insulation film and a top electrode in a DRAM device includes the step of forming a photoresist film on the bottom electrode in a cylindrical hole, removing the photoresist film by using a plasma ashing treatment using non-oxygen gas, and consecutively forming the insulation film and the top electrode on the bottom electrode. The plasma ashing treatment uses a bias power for accelerating the plasma gas into the cylindrical trench.

Owner:ELPIDA MEMORY INC

Method for stripping photoresist

InactiveUS20070298619A1Efficient strippingImprove corrosion resistanceSemiconductor/solid-state device manufacturingPhotosensitive material processingAmmonium hydroxideCopper

Disclosed is a method for stripping a photoresist comprising: (I) providing a photoresist pattern on a substrate where the substrate has at least a copper (Cu) wiring and a low-dielectric layer thereon, and selectively etching the low-dielectric layer by using the photoresist pattern as a mask; (II) contacting the substrate after the step (I), with ozone water and / or aqueous hydrogen peroxide; and (III) contacting the substrate after the step (II), with a photoresist stripping solution that contains at least a quaternary ammonium hydroxide. The present invention provides a method for stripping a photoresist that enables to strip effectively photoresist films and etching residues after etching step even in a process not including an O2 plasma ashing treatment in micropatterning of a substrate having at least Cu wiring and a low-dielectric layer thereon, as in a dual damascene forming process, and, in addition, the method of the invention does not have any negative influence on the dielectric constant of the low-dielectric layer, and ensures an excellent anti-corrosivity.

Owner:YOKOI SHIGERU +2

Plasma mediated ashing processes

InactiveUS20110226280A1Suppressing and/or reducing fast diffusing speciesPhotomechanical apparatusSemiconductor/solid-state device manufacturingOxygenAshing

A plasma ashing process for removing photoresist, polymers and / or residues from a substrate comprises placing the substrate including the photoresist, polymers, and / or residues into a reaction chamber; generating a plasma from a gas mixture comprising oxygen gas (O2) and / or an oxygen containing gas; suppressing and / or reducing fast diffusing species in the plasma; and exposing the substrate to the plasma to selectively remove the photoresist, polymers, and / or residues from the substrate, wherein the plasma is substantially free from fast diffusing species.

Owner:LAM RES CORP

Post plasma ashing wafer cleaning formulation

InactiveUS7534752B2Increase productionImprove adhesionDetergent mixture composition preparationSemiconductor/solid-state device manufacturingSulfolaneInorganic compound

A semiconductor wafer cleaning formulation for use in post plasma ashing semiconductor fabrication comprising at least one organic chelating agent and at least one polar solvent, wherein the chelating agent and polar solvent are in sufficient amounts to effectively remove inorganic compound residue from a semiconductor wafer. Preferably, the chelating agent is selected from the group consisting of 2,4-Pentanedione, Malonic acid, Oxalic acid, p-Toluenesulfonic acid, and Trifluoroacetic acid; and the polar solvent is selected from the group consisting of Water, Ethylene glycol, N-Methylpyrrolidone (NMP), Gamma butyrolactone (BLO), Cyclohexylpyrrolidone (CHP), Sulfolane, 1,4-Butanediol, and Butyl carbitol.

Owner:ENTEGRIS INC

Method for removing photoresist and etch residues

InactiveUS7169440B2Erosion minimizationReduce erosionPaper/cardboard articlesVacuum gauge using ionisation effectsResistOxygen

A method is provided for plasma ashing to remove photoresist remnants and etch residues that are formed during preceding plasma etching of dielectric layers. The ashing method uses a two-step plasma process involving an oxygen-containing gas, where low or zero bias is applied to the substrate in the first cleaning step to remove significant amount of photoresist remnants and etch residues from the substrate, in addition to etching and removing detrimental fluoro-carbon residues from the chamber surfaces. An increased bias is applied to the substrate in the second cleaning step to remove the remains of the photoresist and etch residues from the substrate. The two-step process reduces the memory effect commonly observed in conventional one-step ashing processes. A method of endpoint detection can be used to monitor the ashing process.

Owner:TOKYO ELECTRON LTD

Method of fabricating semiconductor device including forming a protective layer and removing after etching a trench

InactiveUS7622394B2Increase in detachmentSemiconductor/solid-state device manufacturingTransmissionDry etchingSemiconductor

The method of fabricating a semiconductor device includes subjecting a semiconductor substrate to trench etching by alternately repeating an etching step and a deposition step. The etching step creates a trench structure by dry-etching the exposed surface of the semiconductor substrate. An etching mask is formed on the surface of the semiconductor substrate so that the semiconductor substrate has the exposed portion. The deposition step deposits a protection film for suppressing etching of the trench side walls. The method of fabricating a semiconductor device also includes subjecting the semiconductor substrate that has just undergone the trench etching to a heat treatment at a predetermined temperature. The semiconductor substrate is heat-treated within a temperature range of 300 to 500° C. immediately following the trench etching, for example. Plasma ashing is then performed.

Owner:LAPIS SEMICON CO LTD

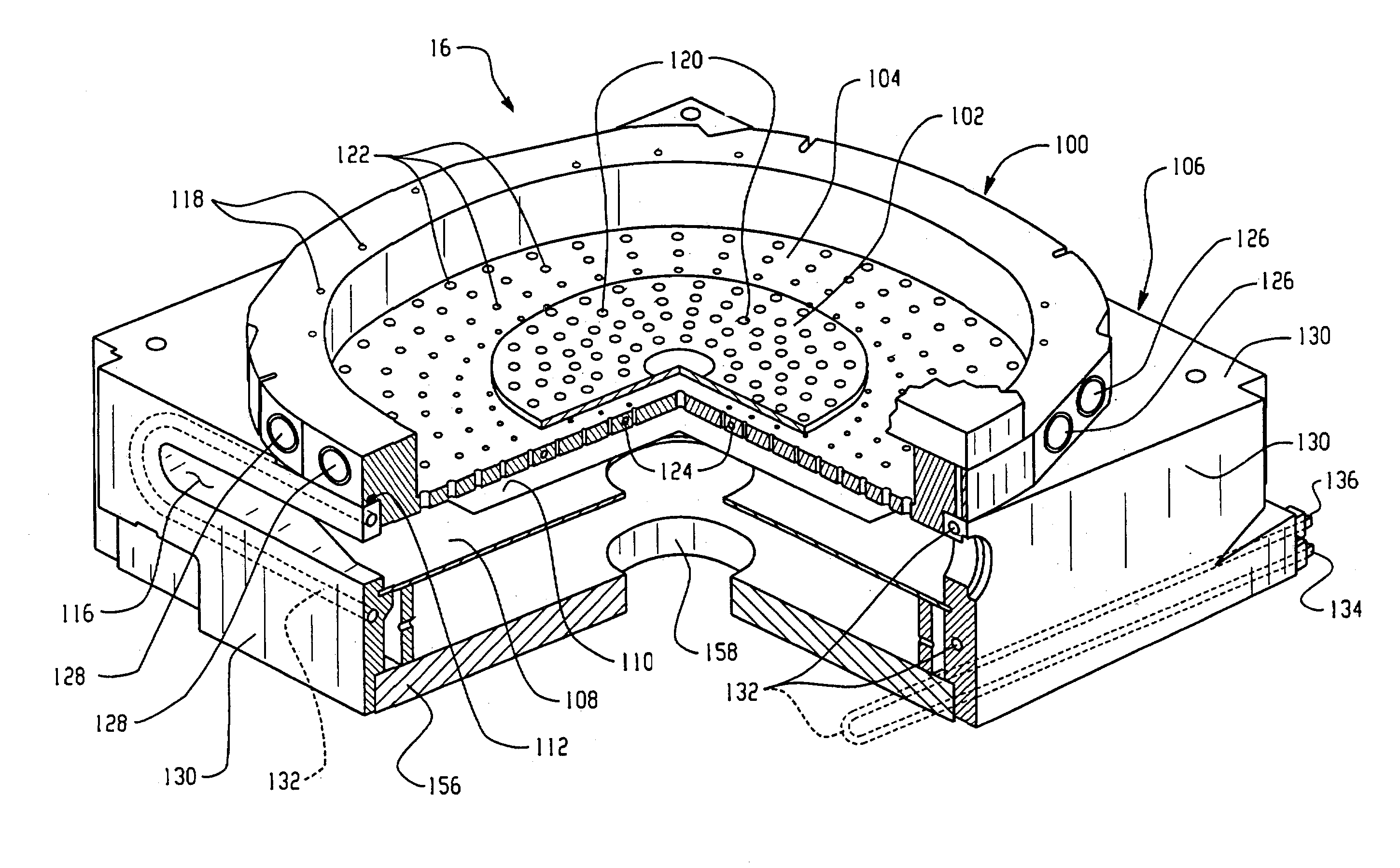

Method for improving ash rate uniformity in photoresist ashing process equipment

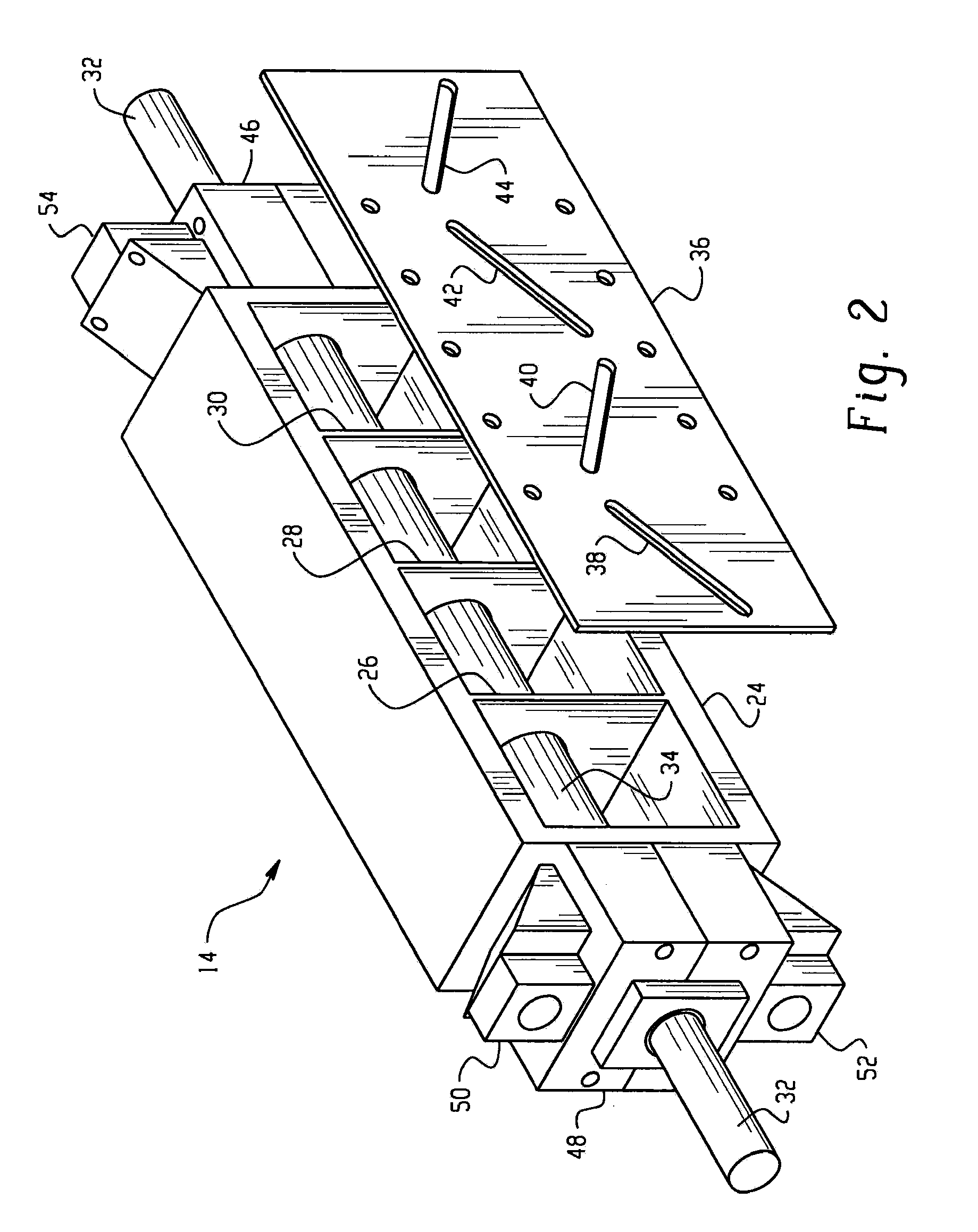

InactiveUS6878898B2Increase ratingsAmount of undesirableElectric discharge tubesBaking ovenProcess equipmentEngineering

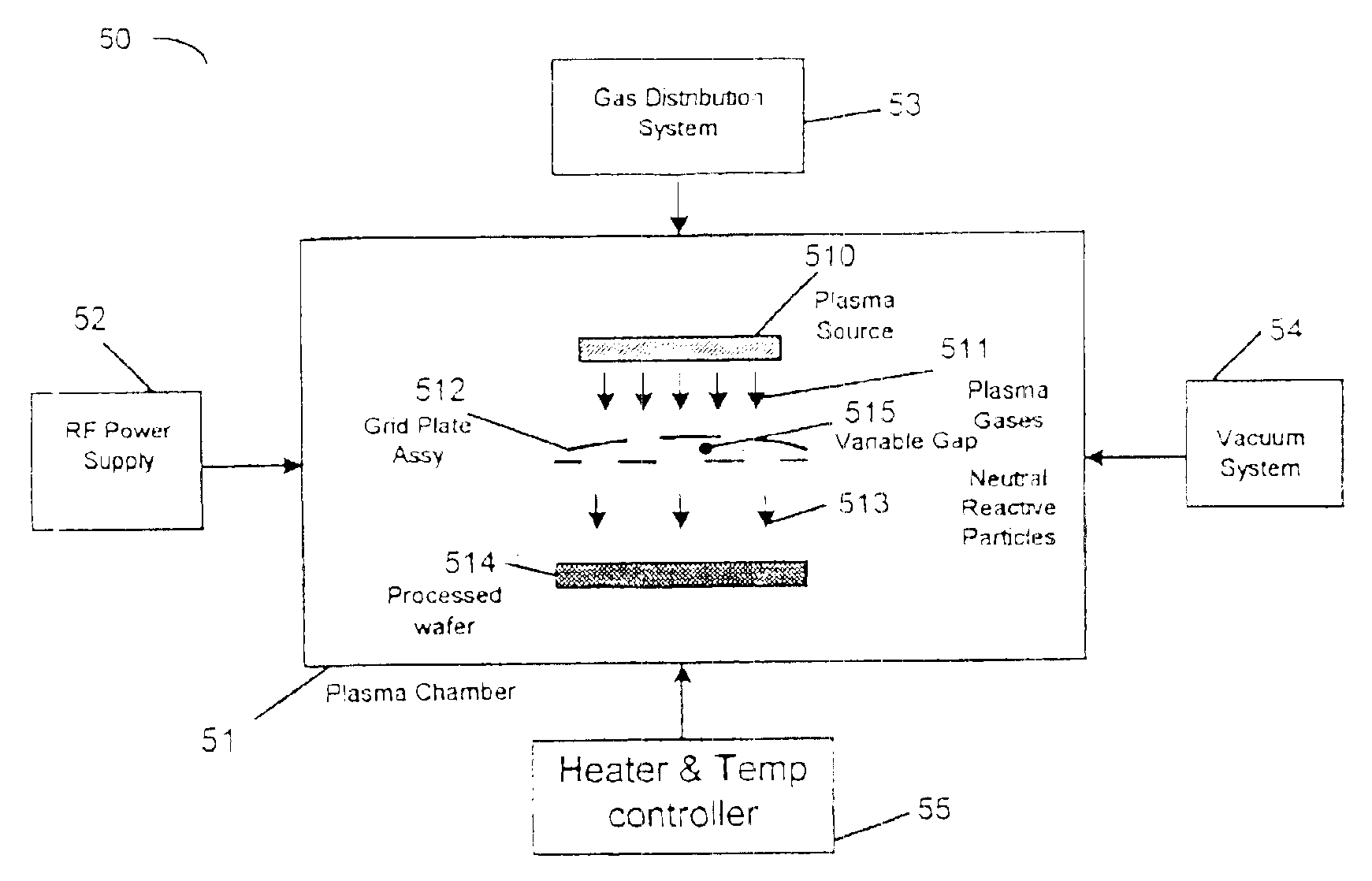

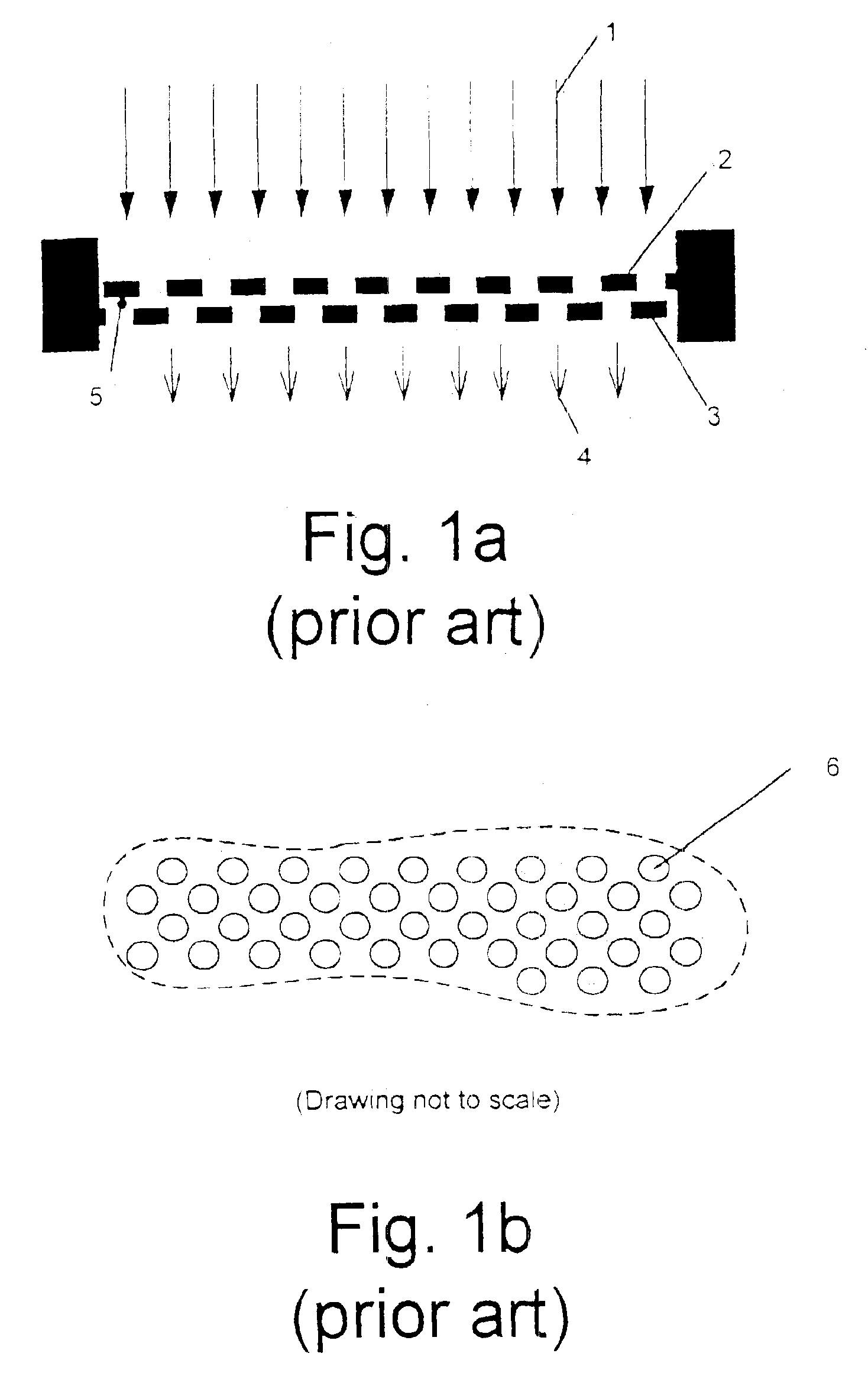

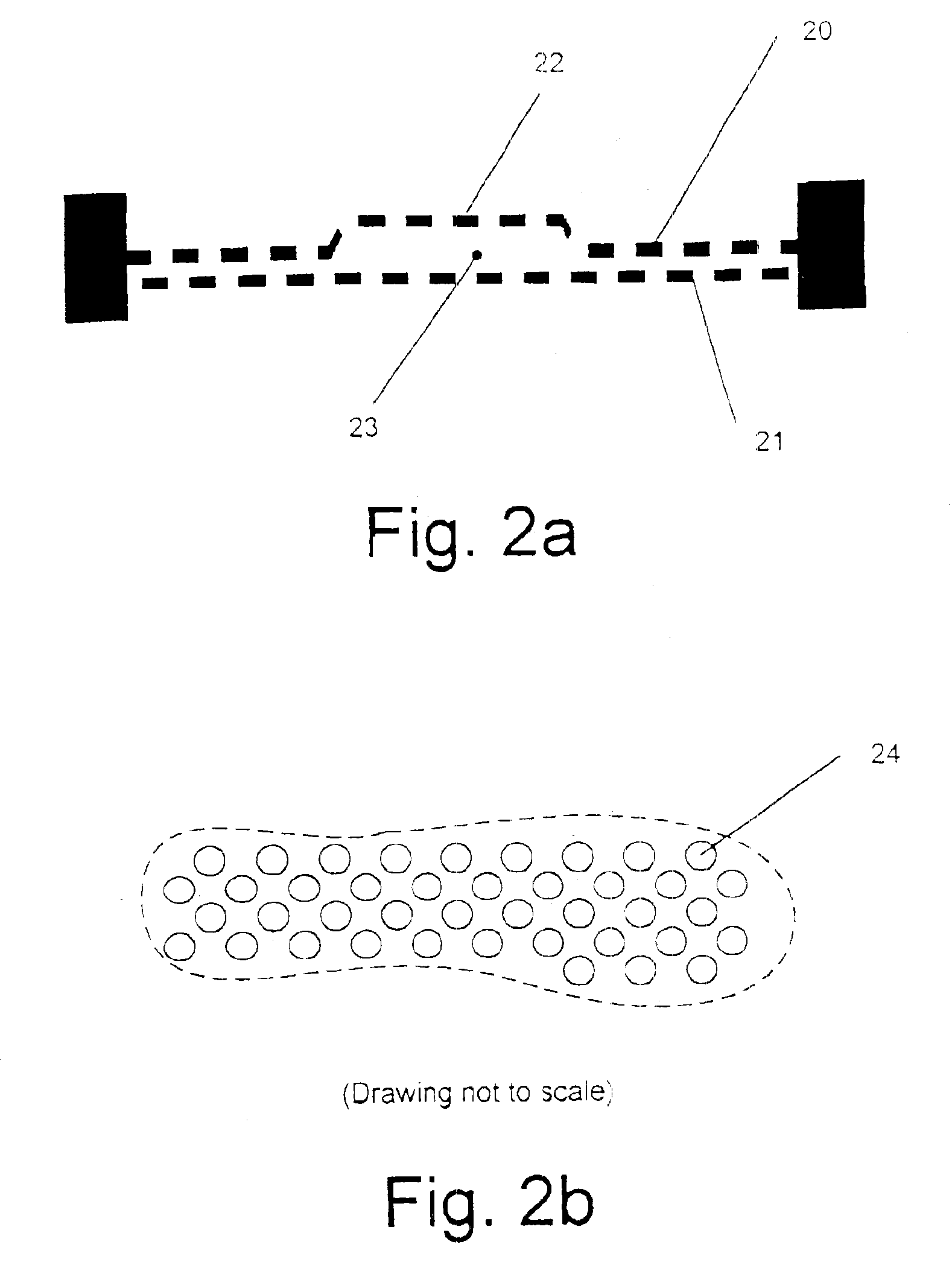

A method for improving the edge-to-center photoresist ash rate uniformity in lower temperature (typically, but not limited to <100° C.) processing of integrated circuits and micro-electro-mechanical devices. A varying gap distance 32 from the edge-to-center of the upper and lower grid plates, 30 and 31, of a plasma ashing machine is provided to allow additional flow of plasma gases into the normally semi-stagnated area near the center of the wafer being processed. This improvement overcomes the problem of slower photoresist removal in the center of the wafer. Three configurations of the invention is described, including both stepwise and continuous variation of the grid plate gap spacing and optionally, the variation of the size of grid plate holes in a parallel grid plate assembly.

Owner:TEXAS INSTR INC

Plasma ashing method

InactiveUS20050106875A1Efficient removalAvoid quality lossElectric discharge tubesSemiconductor/solid-state device manufacturingResistAshing

A plasma ashing method of an object to be processed removes a resist film therefrom in a processing vessel after etching a part of a low dielectric constant film with the resist film having a pattern thereon as a mask in the processing vessel. The plasma ashing method includes a first and a second ashing processes. The first ashing process removes deposits off an inner wall of the processing vessel by using a first processing gas including at least O2 gas while controlling the pressure in the processing vessel to be smaller than or equal to 20 mTorr. The second ashing process removes the resist film by using a second processing gas including at least O2 gas.

Owner:TOKYO ELECTRON LTD

Treating liquid for photoresist removal, and method for treating substrate

InactiveUS20060110690A1High dissolution rateImprove corrosion resistancePhotomechanical apparatusSemiconductor/solid-state device manufacturingPropylene carbonateAqueous solution

Disclosed are a treating liquid for photoresist removal, containing (a) an oxidizing agent (e.g., aqueous hydrogen peroxide), (b) at least one selected from alkylene carbonates and their derivatives (e.g., propylene carbonate), and (c) water; and a method for treating with the treating liquid a substrate having a photoresist film deteriorated after dry-etching treatment thereof or a substrate optionally subjected to plasma-ashing treatment after the dry-etching treatment, and then treating it with a photoresist-stripping liquid for stripping off the photoresist.

Owner:TOKYO OHKA KOGYO CO LTD

Plasma ashing method

InactiveUS20070059933A1Damage suppressionDecorative surface effectsPhotomechanical apparatusResistHigh frequency power

A plasma ashing method is used for removing a patterned resist film in a processing chamber after etching a portion of a low-k film from an object to be processed in the processing chamber by using the patterned resist film as a mask. The method includes a first step of supplying a reaction product removal gas including at least CO2 gas into the processing chamber, generating plasma of the reaction product removal gas by applying a high frequency power for the plasma generation, and removing reaction products deposited on an inner wall of the processing chamber; and a second step of supplying an ashing gas into the processing chamber, generating plasma of the ashing gas by applying a high frequency power for the plasma generation, and removing the resist film.

Owner:TOKYO ELECTRON LTD

Photoresist removeing method

ActiveCN101211125AGuaranteed performanceAvoid churnSemiconductor/solid-state device manufacturingPhotosensitive material processingCMOSSurface layer

The invention discloses a photoresist removal method, which comprises the methods of partial ashing and wet cleaning, i.e. removing a hard surface layer generated on the surface of a photoresist during the ion implantation process through plasma ashing technique, and cleaning the photoresist with SOM cleaning agent. The method can completely remove the photoresist, and can effectively prevent great loss of silicon on the substrate surface and avoid the appearance of severe sag, so as to ensure the performance of CMOS devices.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Gas for plasma reaction, process for producing the same, and use

InactiveUS20050092240A1High purityImprove efficiencyPreparation by hydrogen halide split-offSolid-state devices2-PentyneProduct gas

A gas for plasma reaction comprising a chainlike perfluoroalkyne having 5 or 6 carbon atoms, preferably perfluoro-2-pentyne. This plasma reaction gas is suitable for dry etching for formation of a fine pattern, for plasma CVD for formation of a thin film, and for plasma ashing. The plasma reaction gas is synthesized by contacting a dihydrofluoroalkane compound or a monohydrofluoroalkene compound with a basic compound.

Owner:ZEON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com