Patents

Literature

501 results about "Sulfolane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sulfolane (also tetramethylene sulfone, systematic name: 1λ⁶-thiolane-1,1-dione) is an organosulfur compound, formally a cyclic sulfone, with the formula (CH₂)₄SO₂. It is a colorless liquid commonly used in the chemical industry as a solvent for extractive distillation and chemical reactions. Sulfolane was originally developed by the Shell Oil Company in the 1960s as a solvent to purify butadiene. Sulfolane is a polar aprotic solvent, and it is readily soluble in water.

Absorbing liquid for eliminating sulfide from gas mixture

InactiveCN1421264AReduce processing stepsEconomical desulfurization methodDispersed particle separationSulfur preparation/purificationSulfolaneMorpholine

The present invention belongs to gas producing technology. The absorbing liquid for eliminating sulfide from gas mixture includes main absorbent comprising steric hindrance amine and N-methyl diethanolamine; cosolvent of one or several of sulfolane, N-methyl pyrrolidine, polyglycol dialkyl ether, morpholine and its derivative; catalyst of one or several of C2-C12 alkanolamine, piperazine and its derivative, quinoline, urea and metal phthalocyanine complex. Using the absorbing liquid can eliminate H2S, COS, mercaptan, thioether and other sulfide in less steps.

Owner:江苏蓝电环保股份有限公司

Process for preparing 2,3,5,6-Tetrafluoro-para-xylyl alcohol

InactiveCN1458137AOrganic compound preparationHydroxy compound preparationSulfolanePotassium fluoride

The preparation process of 2, 3, 5, 6-tetrafluoro-para-xylyl alcohol with 2, 3, 5, 6-tetrachloro-p-phenyl diformyl chloride as material includes fluorination with potassium fluoride, etc. as fluorination agent, sulfolane, etc. as solvent and calixarene, etc. as catalyst and at 40-230 deg.c; esterification of ester with fatty alcohol or aromatic alcohol as esterifying agent and at 20-120 deg.c; reduction of ester with sodium borohydride, etc. as reductant and sulfolane, etc. as solvent, and at -10 deg.c to 60 deg.c; bromination with HBr acid as brominating agent and dichloromethane as solvent and at 30-160 deg.c; and reduction of bromide with magnesium powder, etc as reductant and fatty alcohol, water, chloride, etc as solvent, and at -10 deg.c to 50 deg.c. The present invention has the advantages of simple process, low production cost, high product yield and purity, and is suitable for industrial production.

Owner:TIANJIN UNIV

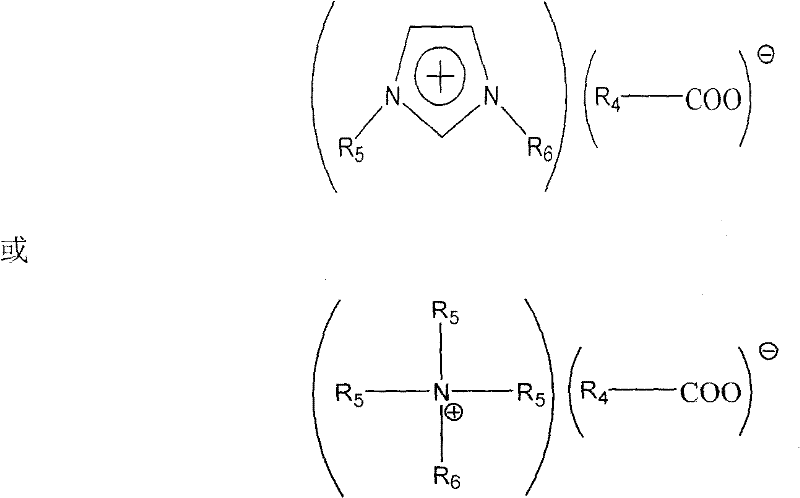

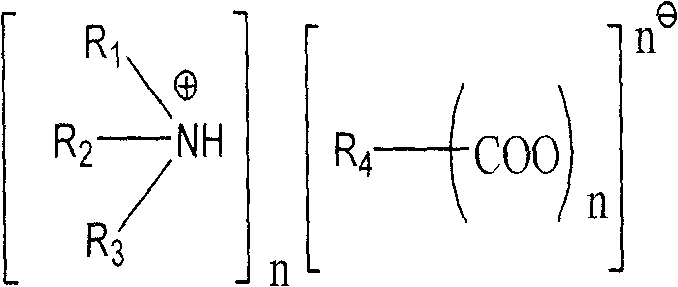

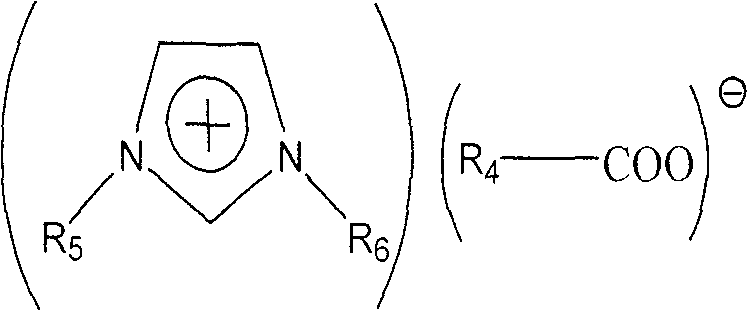

Mixed ionic liquid solution special for absorbing SO2 gas and preparation method thereof

InactiveCN101745290AIncrease molar absorptionLow viscosityDispersed particle separationSulfur compoundsProtonationSulfolane

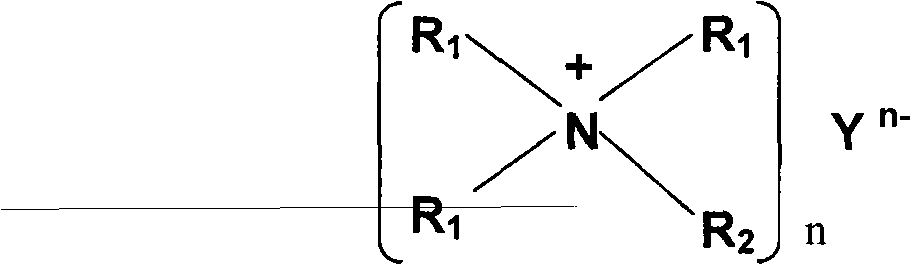

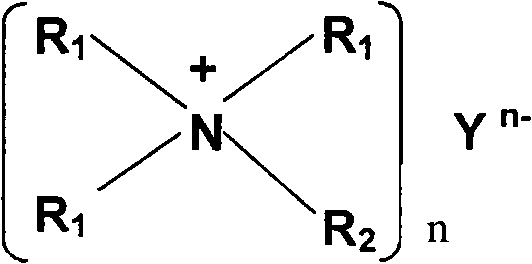

The invention relates to mixed ionic liquid formula solution, which consists of an ionic liquid A, an ionic liquid B and a mixed solvent C, wherein the positive ion of the ionic liquid A is the N,N-dialkyl imidazole positive ion or the N,N,N,N-tetra alkyl quaternary amine positive ion, while the negative ion thereof is the monobasic carboxylic negative ion; the positive ion of the ionic liquid B is the protonated alkylamine positive ion, while the negative ion thereof is the monobasic or binary or ternary carboxylic negative ion; and the mixed solvent C is aqueous solution of water, polyethylene glycol, polyglycol ether, propylene carbonate or tetramethylene sulfone. The mixed ionic liquid formula solution of the invention is strong base-weak acid and weak base-weak acid mixed salt solution, has wide pH buffering capacity, and can greenly efficiently absorb the SO2 gas in a reversible cycle mode. The mixed ionic liquid formula solution of the invention is adopted as a SO2 absorbent so that the requirement for the equipment required by SO2 absorption is simple, the operation condition of absorbing and desorbing SO2 is mild, the desulfurization efficiency is high, and the problems of waste solution and wastewater discharge and the like do not exist. The invention also discloses a preparation method for the mixed ionic liquid formula solution.

Owner:NANJING UNIV +1

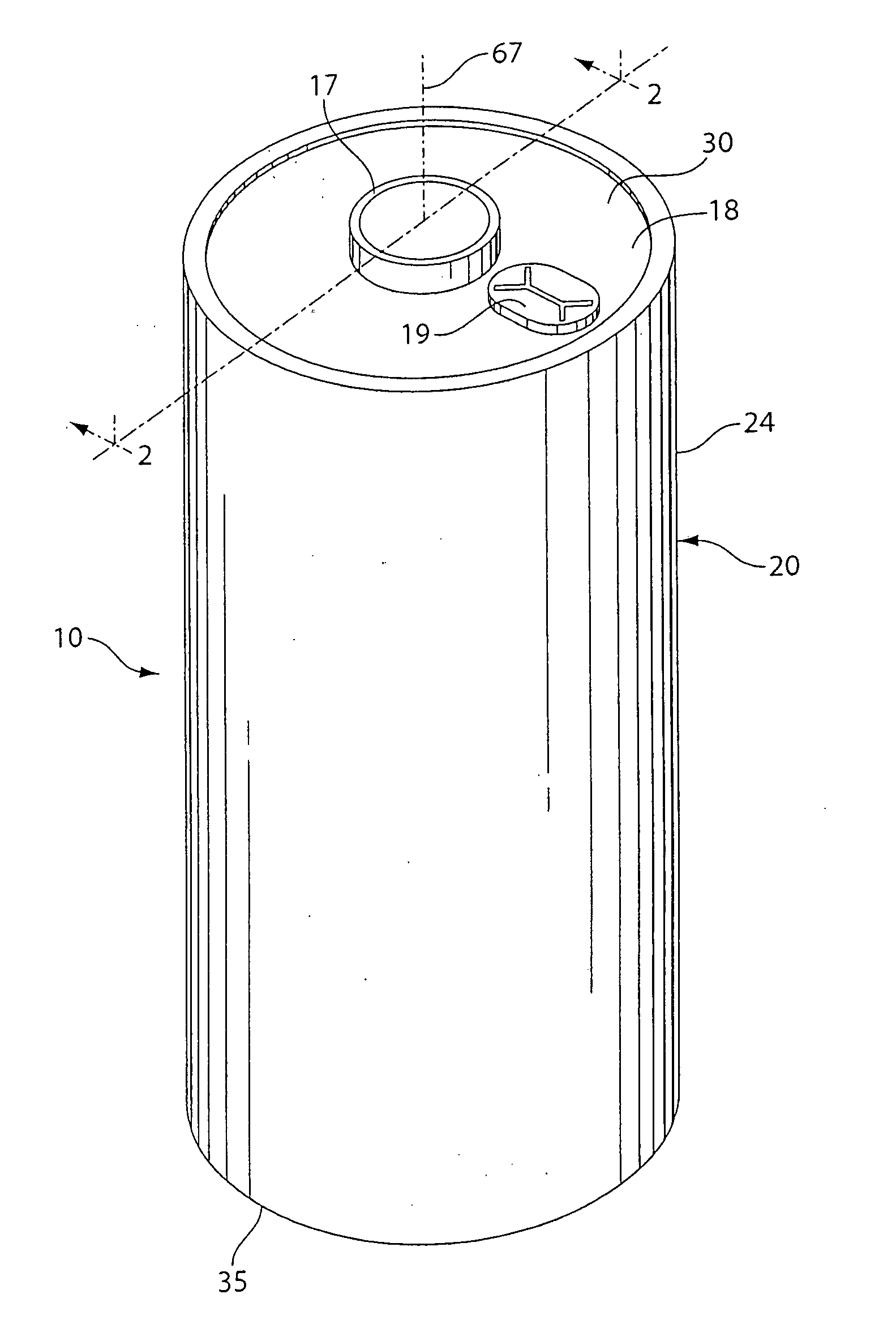

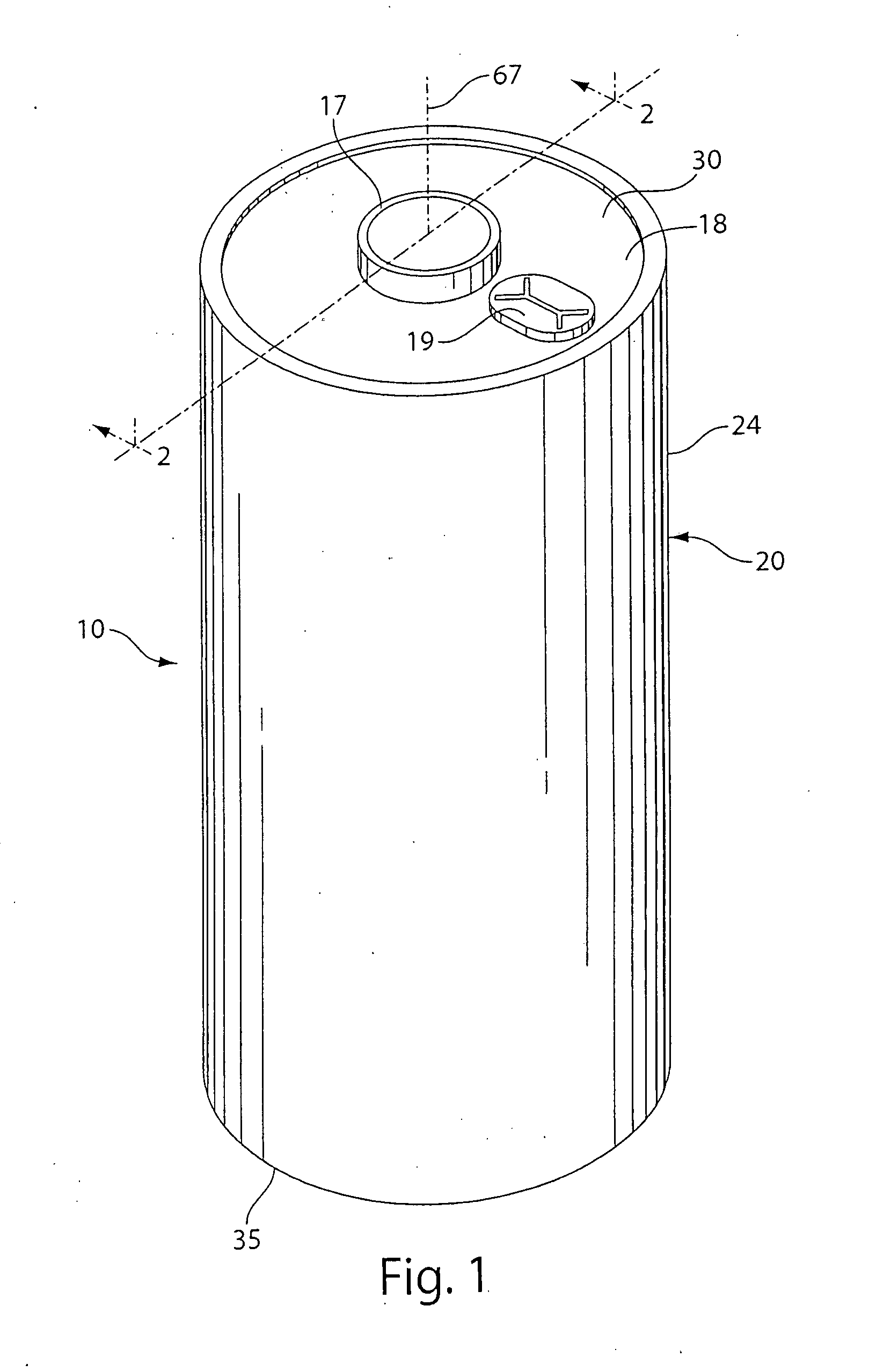

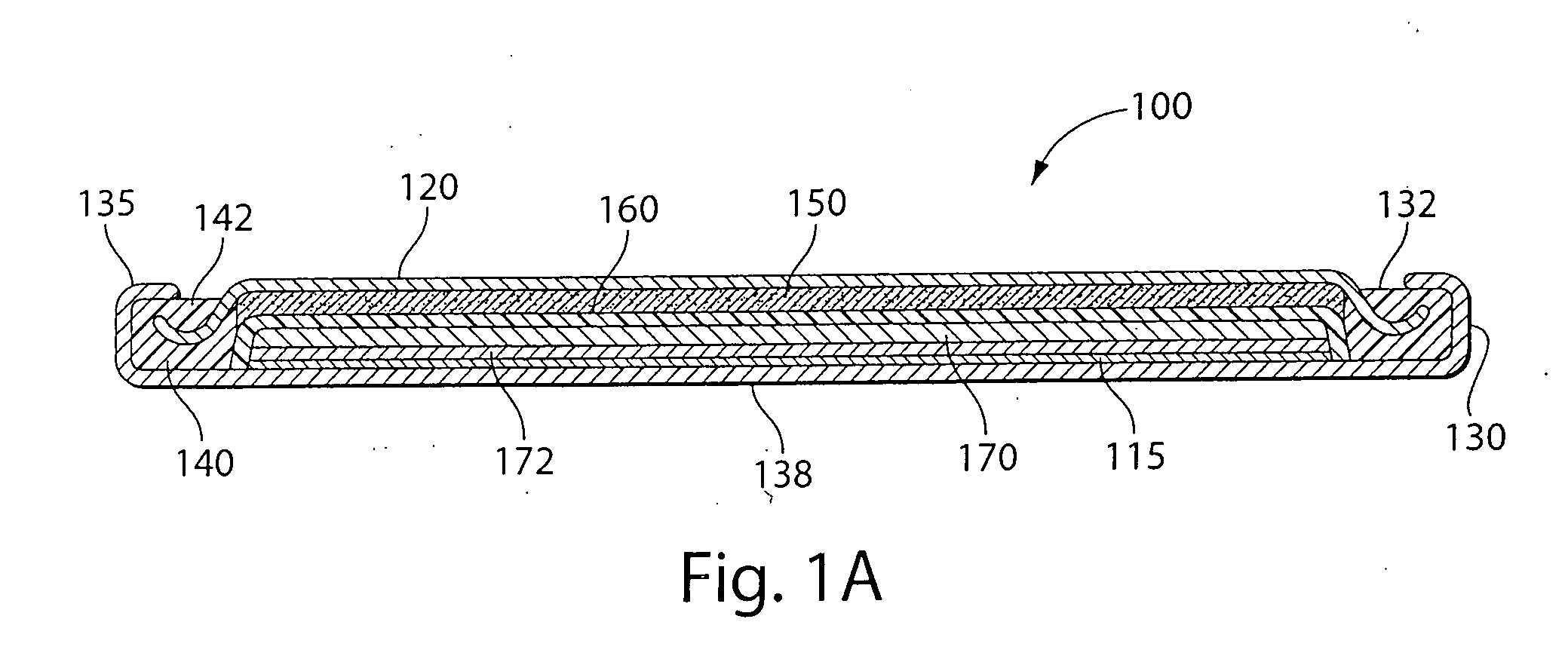

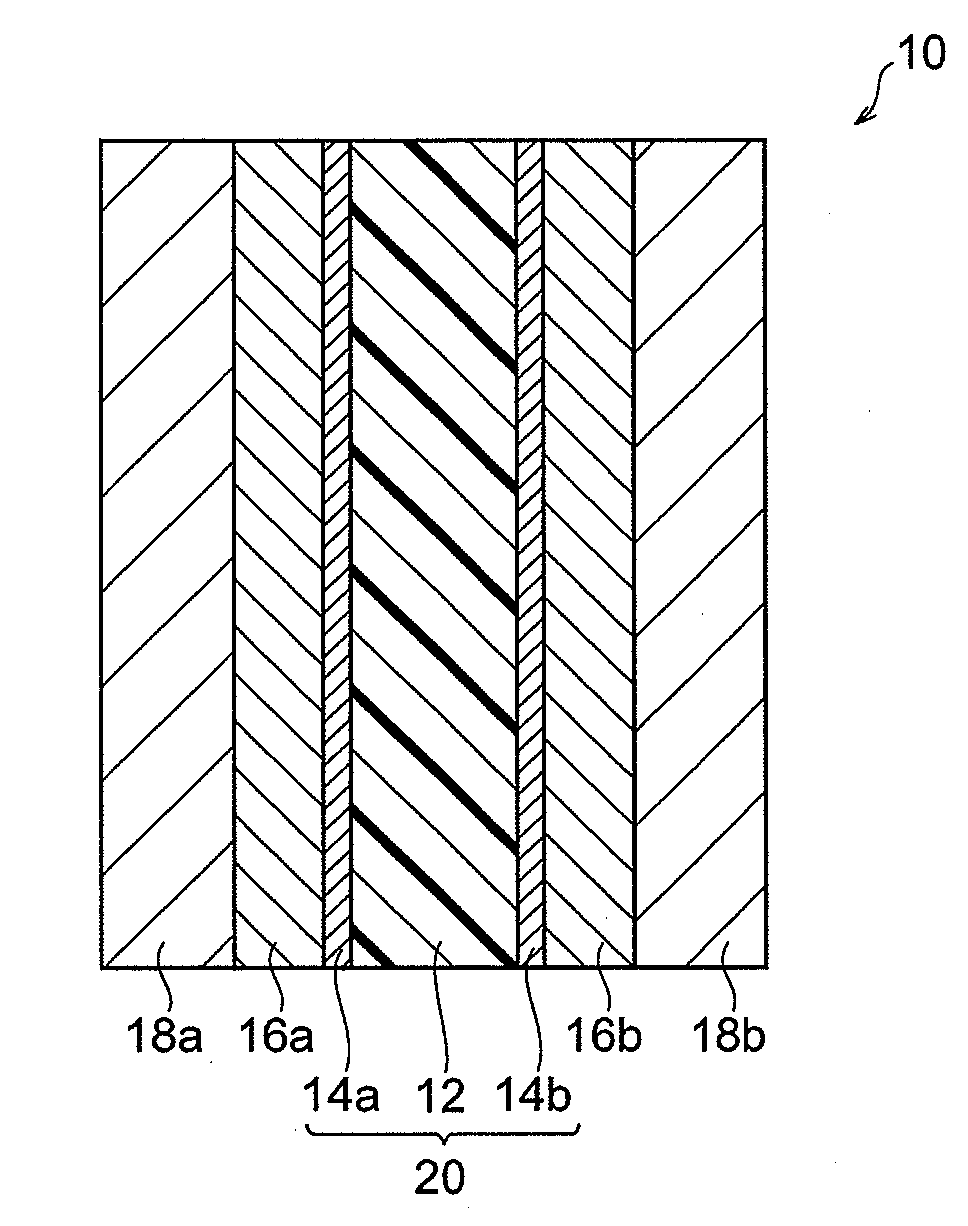

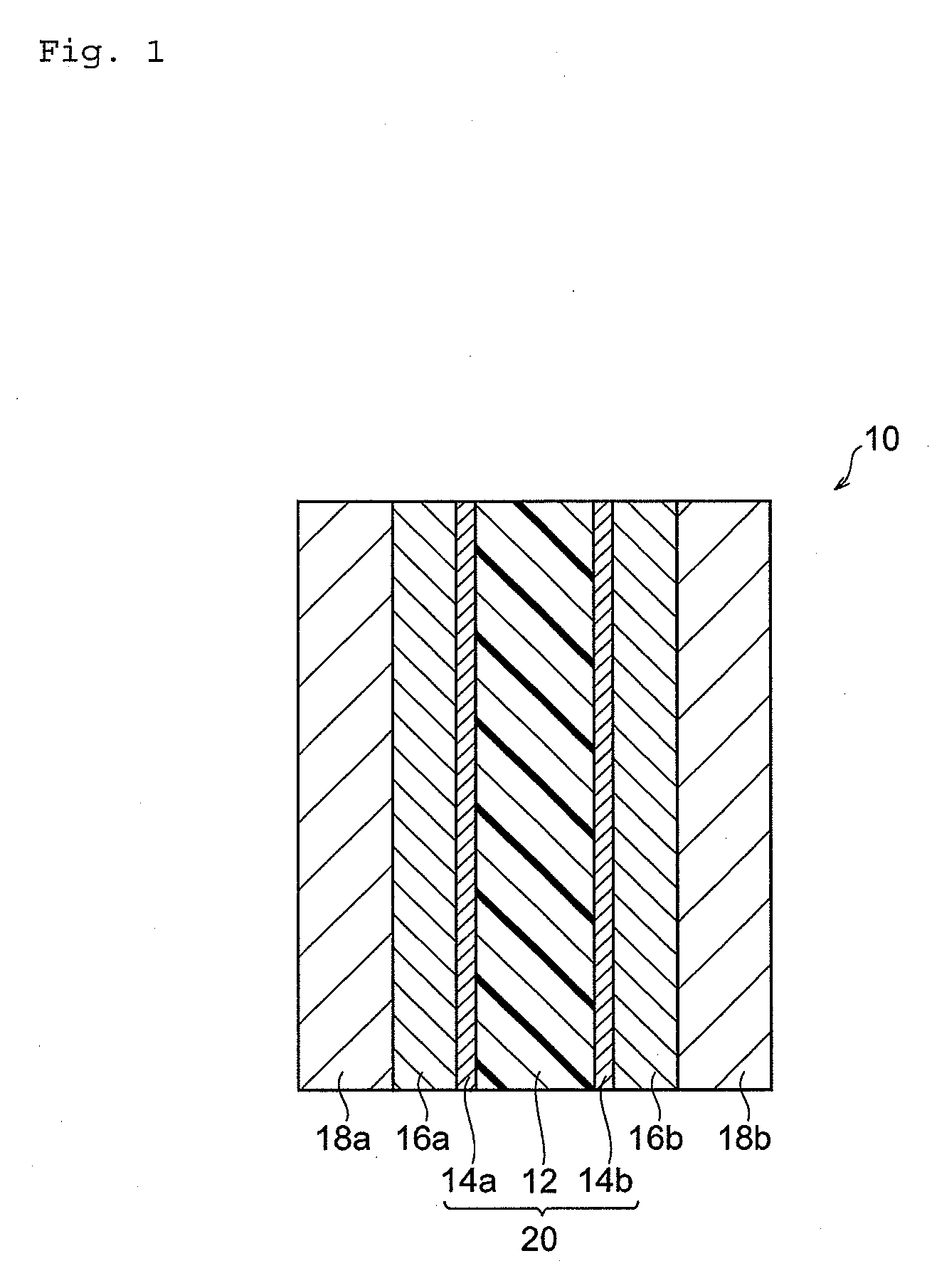

Lithium cell

ActiveUS20090208849A1Reduce passive layer resistanceSlow build ratesPrimary cell maintainance/servicingElectrode carriers/collectorsSulfolaneAlloy

A primary cell having an anode comprising lithium or lithium alloy and a cathode comprising iron disulfide (FeS2) and carbon particles. The electrolyte comprises a lithium salt preferably lithium iodide (LiI) dissolved in an organic solvent mixture. The solvent mixture preferably comprises dioxolane, dimethoxyethane and sulfolane. The electrolyte typically contains between about 100 and 2000 parts by weight water per million parts by weight (ppm) electrolyte therein. A cathode slurry is prepared comprising iron disulfide powder, carbon, binder, and a liquid solvent. The mixture is coated onto a conductive substrate and solvent evaporated leaving a dry cathode coating on the substrate. The anode and cathode can be spirally wound with separator therebetween and inserted into the cell casing with electrolyte then added.

Owner:DURACELL U S OPERATIONS

Process for separating aromatics by extractive distillation and a composite solvent used therein

InactiveUS7078580B2Improve solubilityWide boiling rangeDistillation purification/separationHydrocarbonsSulfolaneAlkalinity

This application relates to a composite solvent for separating aromatics by extractive distillation, comprising a main solvent, a solutizer and a modifier. Said solutizer is selected from any one or mixtures of any two of C8–C11 aromatics having different number of carbon atoms, the content of which is 3–39 wt %, and the number of carbon atoms of the lowest aromatic in the solutizer should be greater than that of the highest aromatic in the aromatics to be separated. When the solutizer is selected from any one of C8–C11 aromatics, the composite solvent contains 0.01–10.0 wt % of the modifier; when the solutizer is selected from mixtures of any two of C8–C11 aromatics having different number of carbon atoms, the composite solvent contains 0–10.0 wt % of the modifier. Said main solvent and modifier are independently selected from sulfolane derivatives, N-formyl morpholine, and N-methyl pyrrolidone, provided that the acidity and basicity of the modifier are opposite to those of the main solvent. When the composite solvent is used to recover aromatics by extractive distillation, it is possible to moderate the operation conditions of solvent recovery, increase the yield of aromatics, and make the separated aromatics to be neutral.

Owner:CHINA PETROCHEMICAL CORP +1

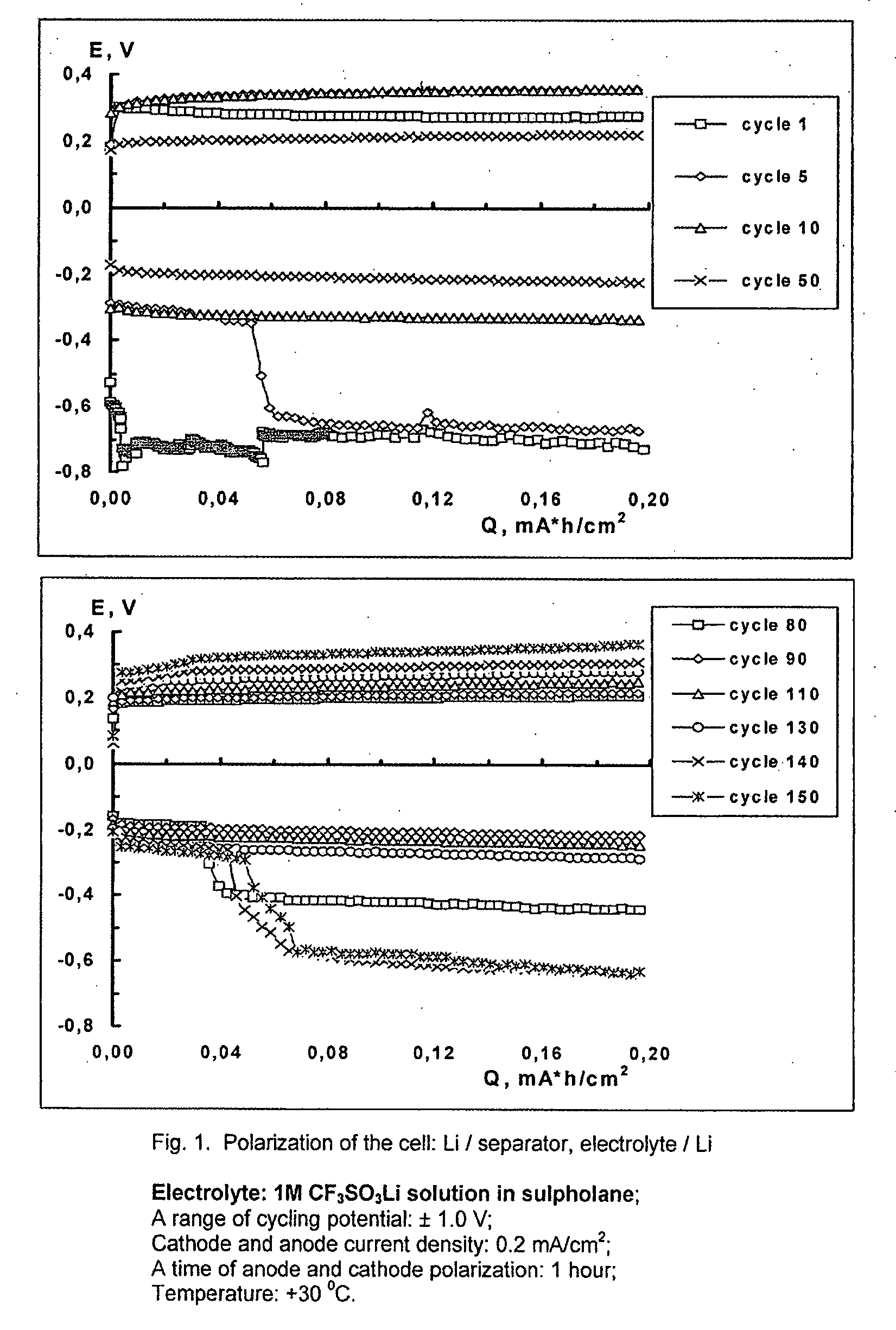

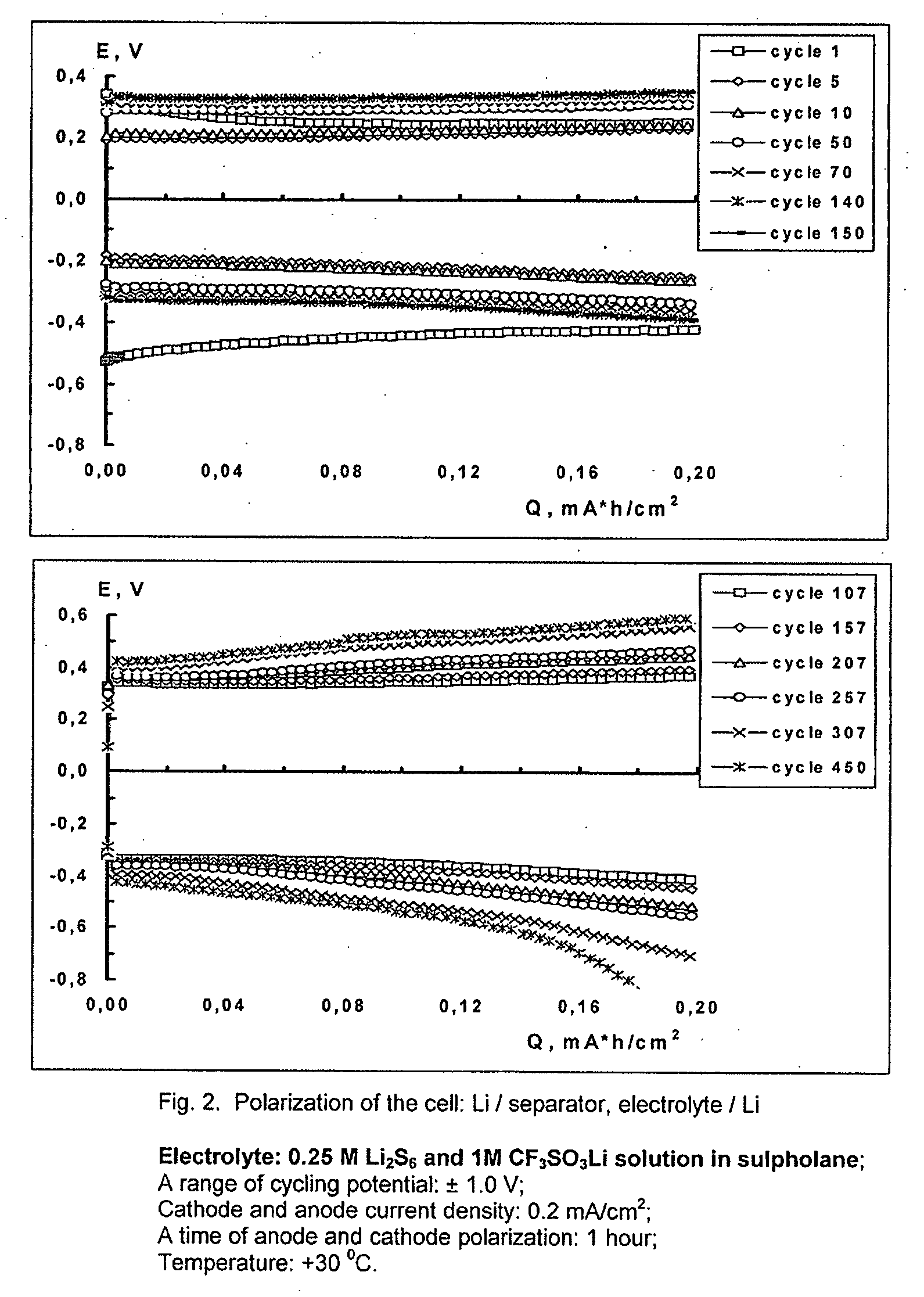

Cell or battery with a metal lithium electrode and electrolytes therefor

InactiveUS20080038645A1Improve cycle lifeOrganic electrolyte cellsLi-accumulatorsSulfolaneMetallic lithium

An electrolyte for rechargeable batteries with a negative electrode of lithium or lithium containing alloys comprising: one or several non-aqueous organic solvents, one or several lithium salts and one or several additives increasing the cycle life of the lithium electrode. The electrolyte solution may comprise one or several solvents selected from the group comprising: tetrahydrofurane, 2-methyltetrahydrofurane, dimethylcarbonate, diethylcarbonate, ethylmethylcarbonate, methylpropylcarbonate, methylpropylpropyonate, ethylpropylpropyonate, methylacetate, ethylacetate, propylacetate, dimetoxyethane, 1,3-dioxalane, diglyme (2-methoxyethil ether), tetraglyme, ethylenecarbonate, propylencarbonate, γ-butyrolactone, and sulfolane. The electrolyte solution may further comprise at least one salt or several salts selected from the group consisting of lithium hexafluorophosphate (LiPF6), lithium hexafluoroarsenate (LiAsF6), lithium perchlorate (LiClO4), lithium sulfonylimid trifluoromethane (LiN(CF3SO2)2)) and lithium trifluorosulfonate (CF3SO3Li) or other lithium salts or salts of another alkali metal or a mixture thereof. Also disclosed is an electrochemical cell or battery with an anode of metallic lithium or a lithium-containing alloy, and such an electrolyte.

Owner:OXIS ENERGY

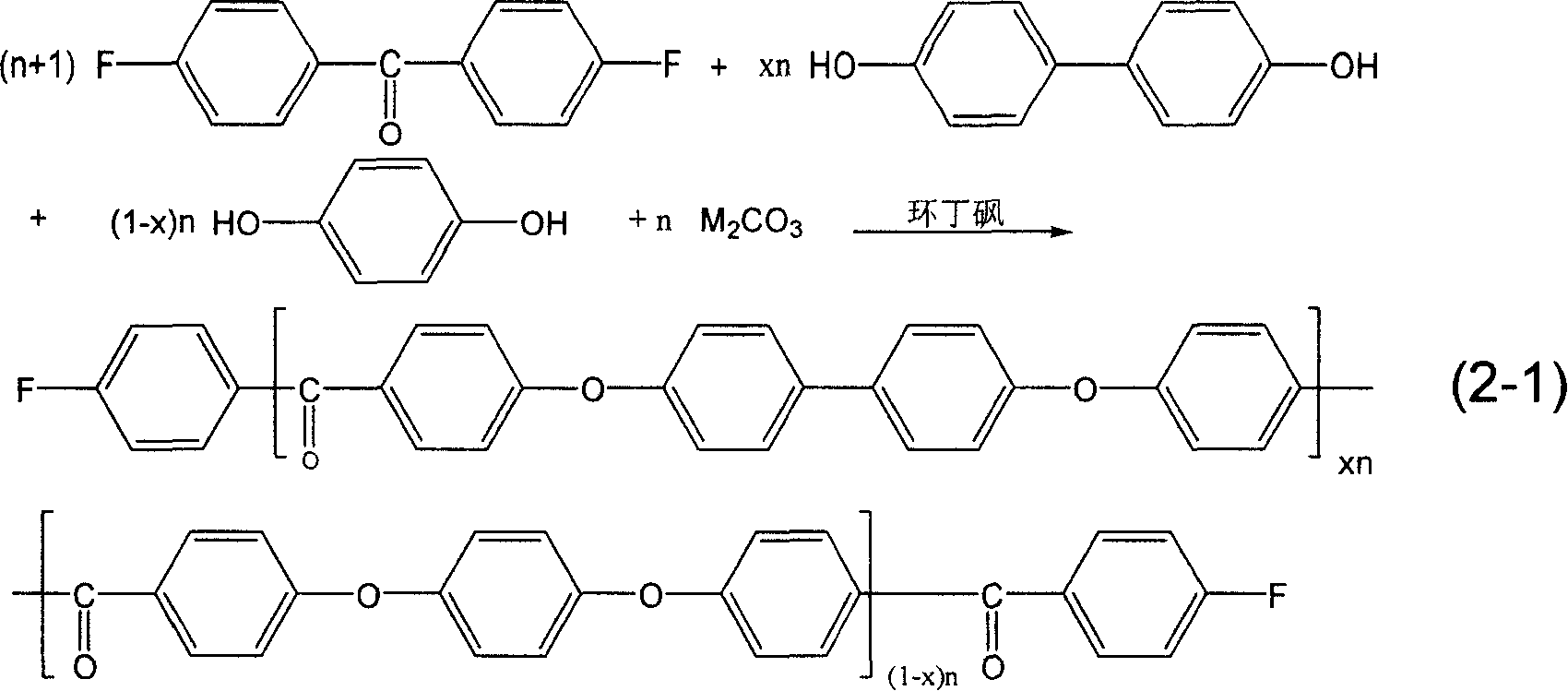

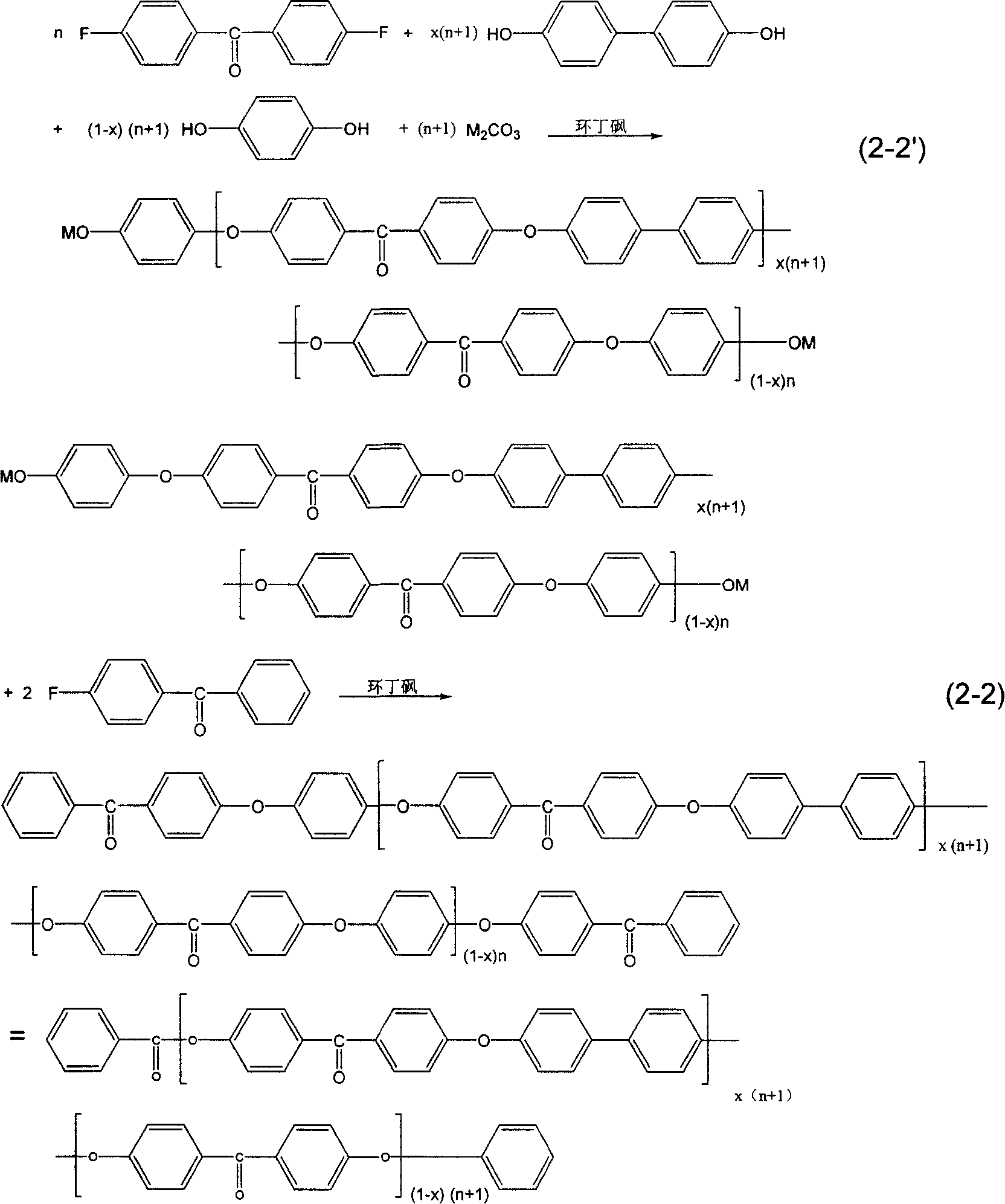

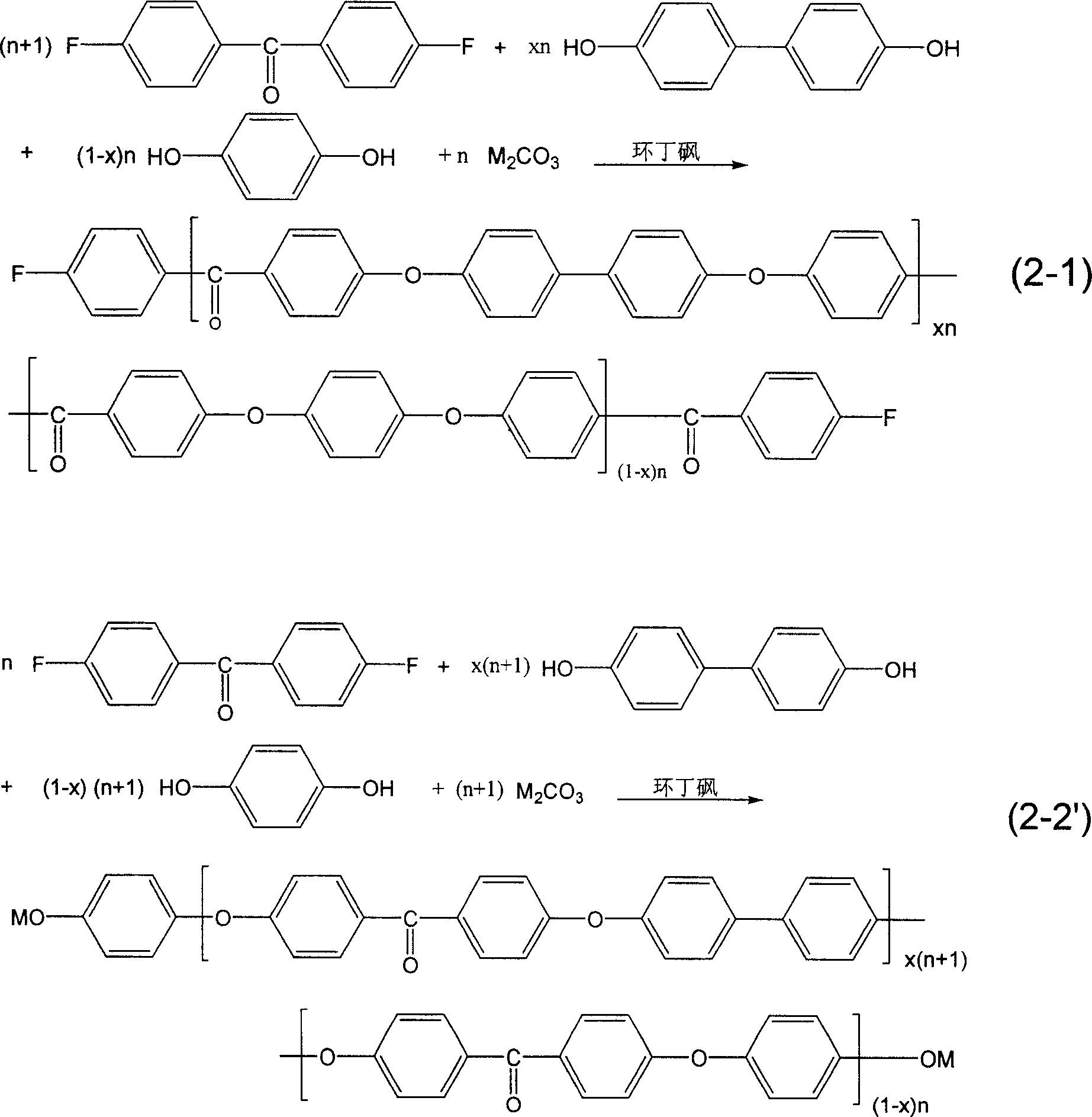

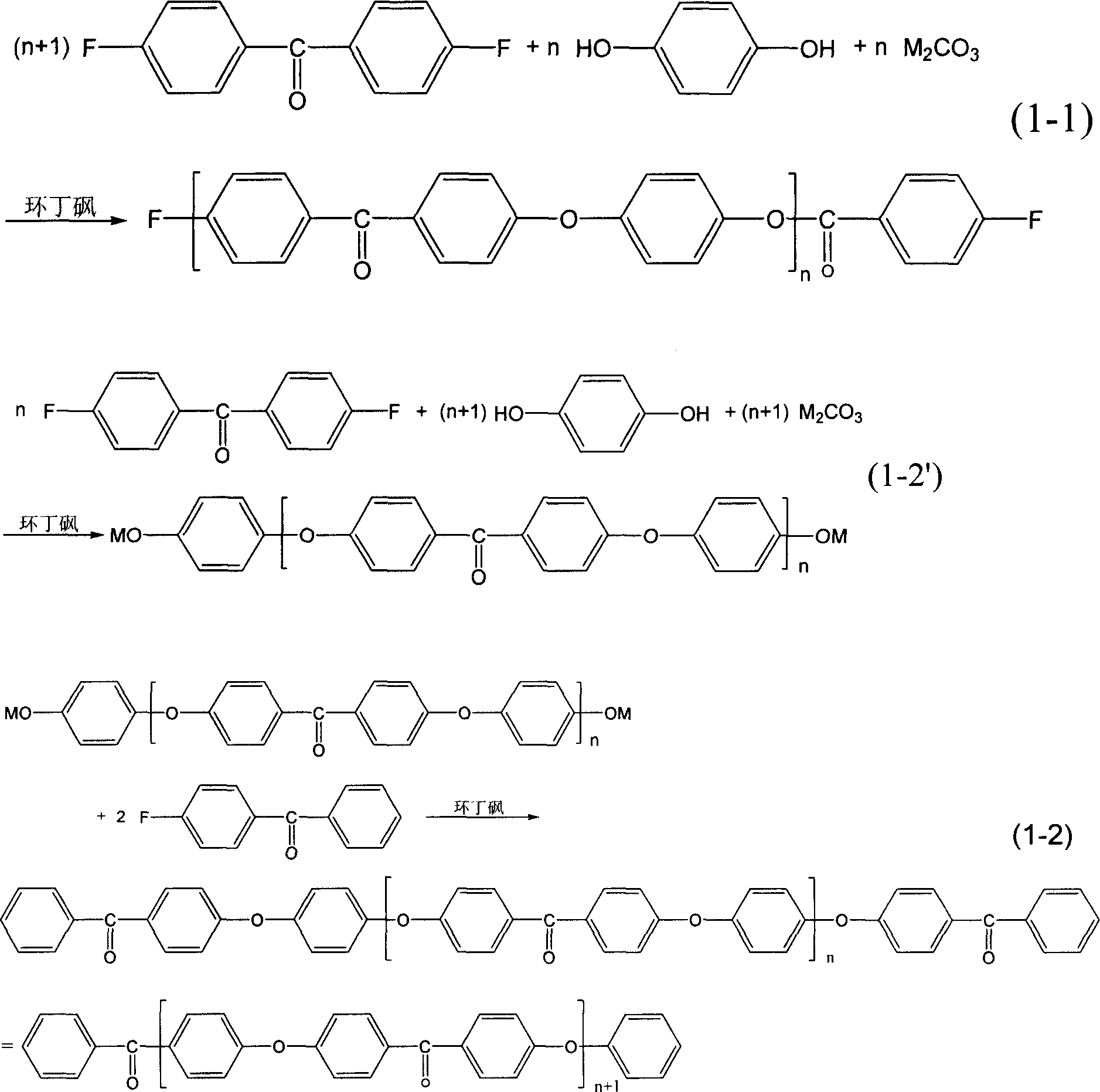

Synthesis method of ternary copolymer containing PEDEK and PEEK using sulfolane as solvent

The invention relates to a method for preparing polyetheretherketone and polyetheretherketone terpolymer by using sulfolane. It comprises following steps: the mole number of 4, 4'- difluoro diphenyl ketone is more than that of eldopaque and diphenol by 0.1-1%, the solid content in reaction system is 15-30%; filling dimethylbenzene with its mass being 10-20% of that of organic solvent, stirring, heating, adding mixed salt of alkali metal carbonate when monomer is totally dissolved and the temperature is between 75 to 85 Deg. C, reacting at constant temperature 230-260 Deg. C for 1-3 hours, stopping reaction, pouring product into cold water, cooling and disintegrating and filtering, boiling solid product with deionized water for several times, drying refined powder material in baking box, and getting said final product.

Owner:长春吉大特塑工程研究有限公司

Special MDEA formula solution activated by functional ion liquid for CO2 gas absorption separation

InactiveCN101804292AReduce lossOvercome the disadvantage of high energy consumptionDispersed particle separationBy chemical separationSulfolanePoly(ethylene glycol) dimethyl ether

The invention relates to a special N-methyldiethanolamine formula solution activated by ion liquid for CO2 gas absorption separation, which consists of the following ingredients in mass percent: 35 to 50 percent of N-methyldiethanolamine, 5 to 20 percent of low-viscosity kalescent functional ion liquid, 15 to 30 percent of dimethyl ether of polyethlene glycol and / or sulfolane and 15 to 30 percent of water, wherein cations of the low-viscosity kalescent functional ion liquid are tetraalkylammonium ions, and anions of the low-viscosity kalescent functional ion liquid are amino acid radicals or organic carboxylate anions. The formula solution of the invention has the advantages that the high mass transfer performance of the absorption-desorption process is improved, the material consumption in the use process is low, the defect of high energy consumption because a large amount of water vapor is brought away during the absorbing agent regeneration, and the invention belongs to an energy-saving formula with high green degree. The regeneration temperature of the solution is lower than that of the traditional absorbing liquid, the grade of a heat source required to be provided in the regeneration process is reduced, energy sources can be saved, the stability of the absorbing agent solution in the operation is high, the consumption of each absorption-desorption circulation is low, and in addition, the cost is low.

Owner:NANJING UNIV

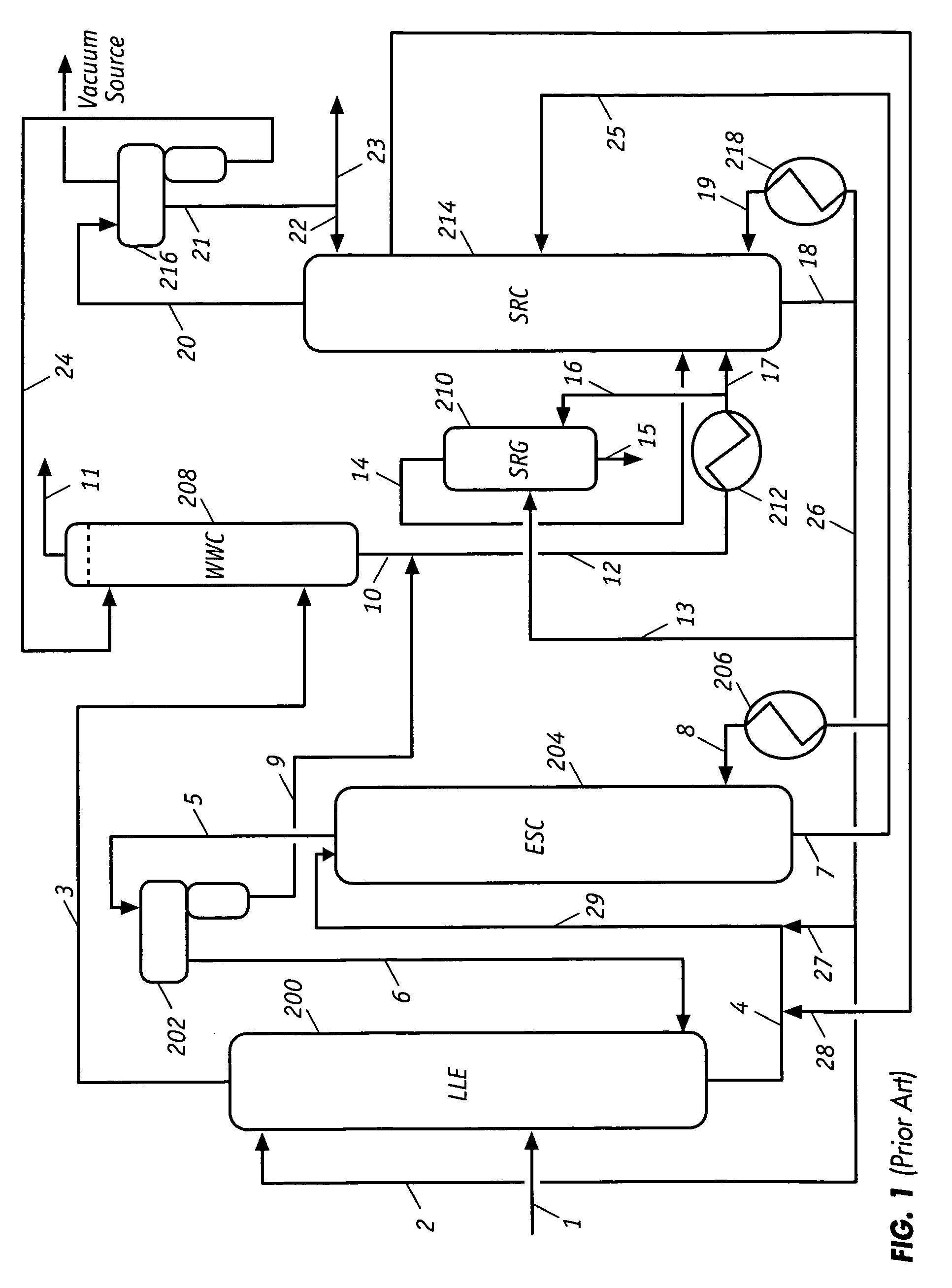

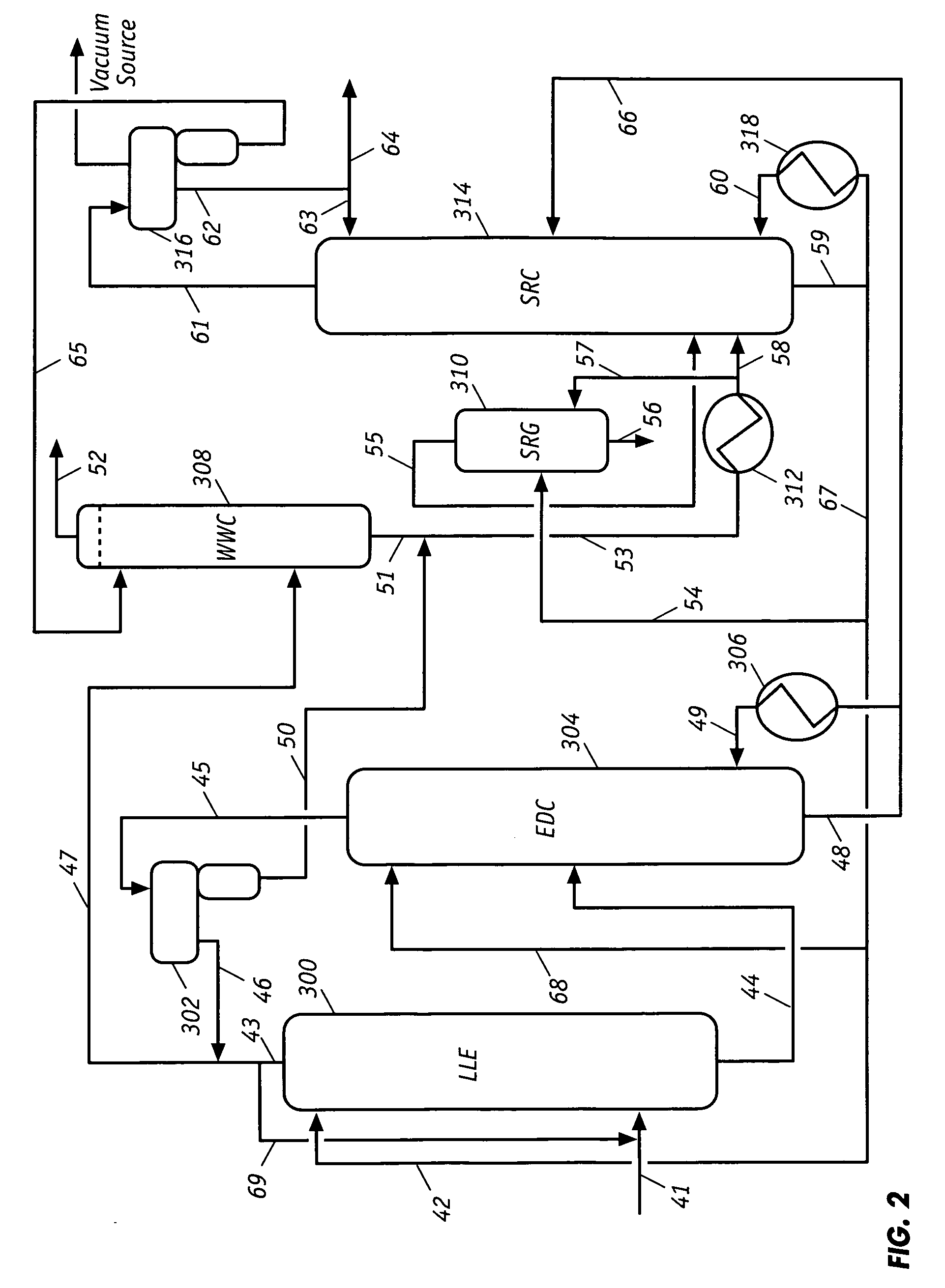

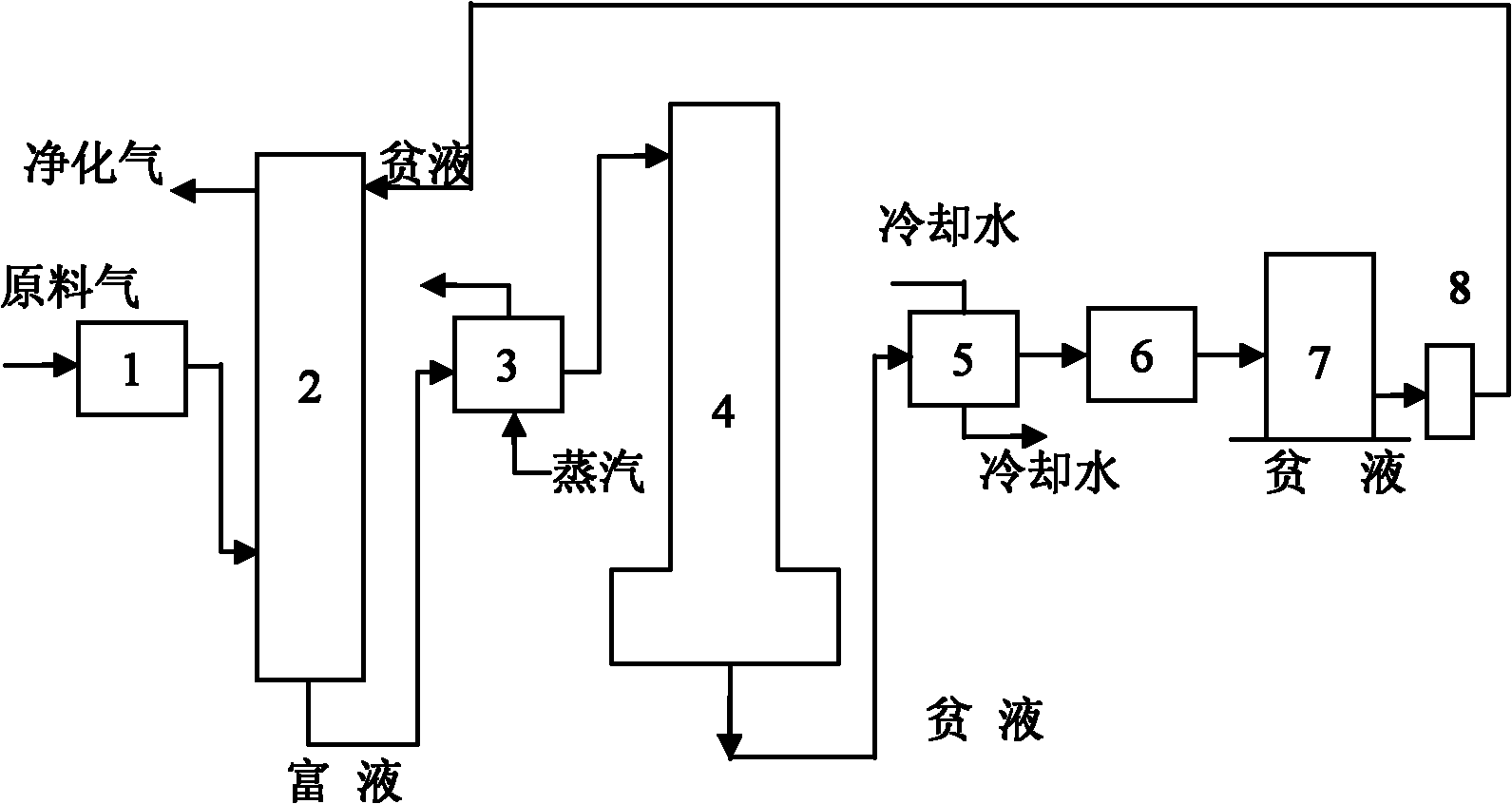

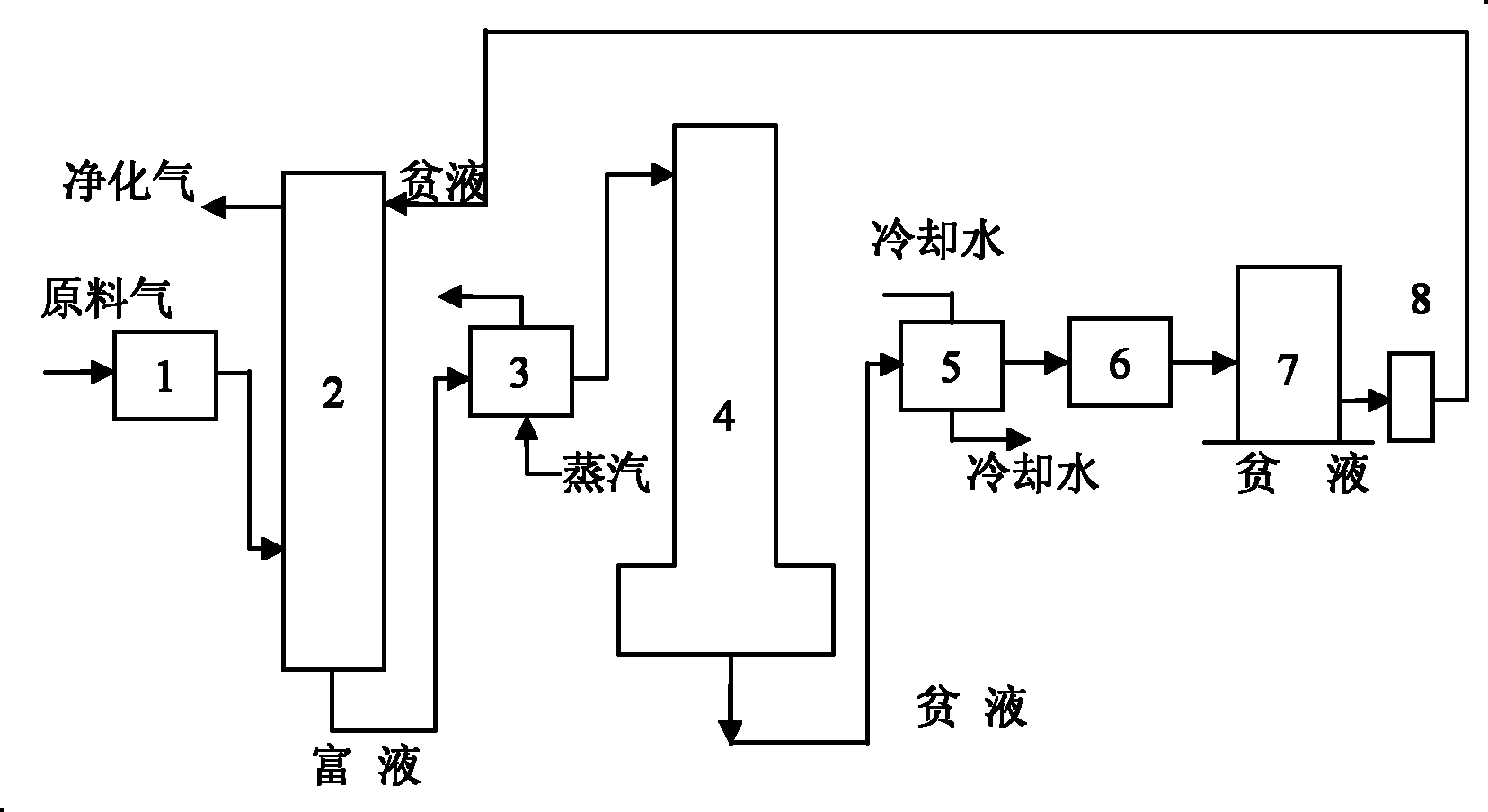

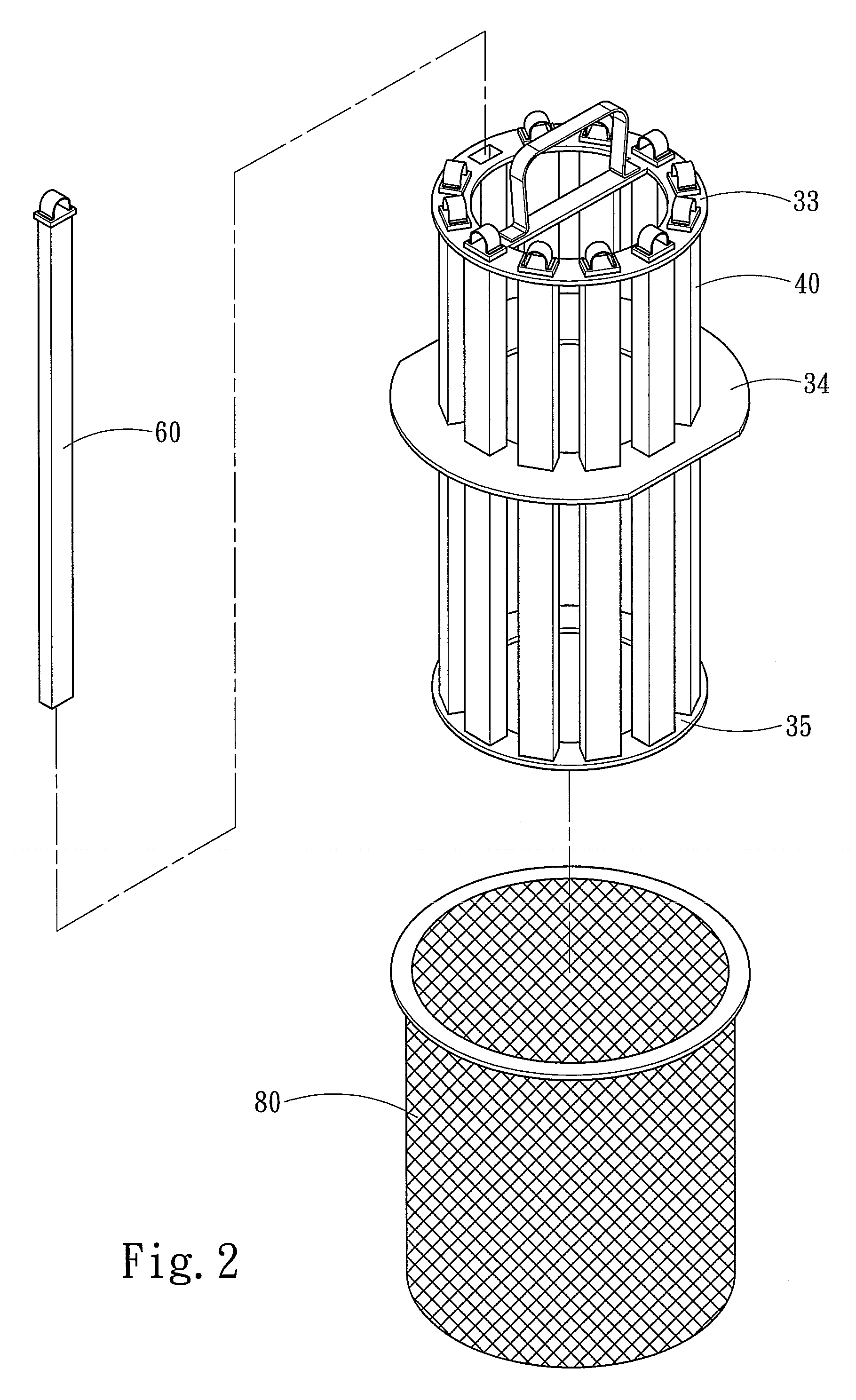

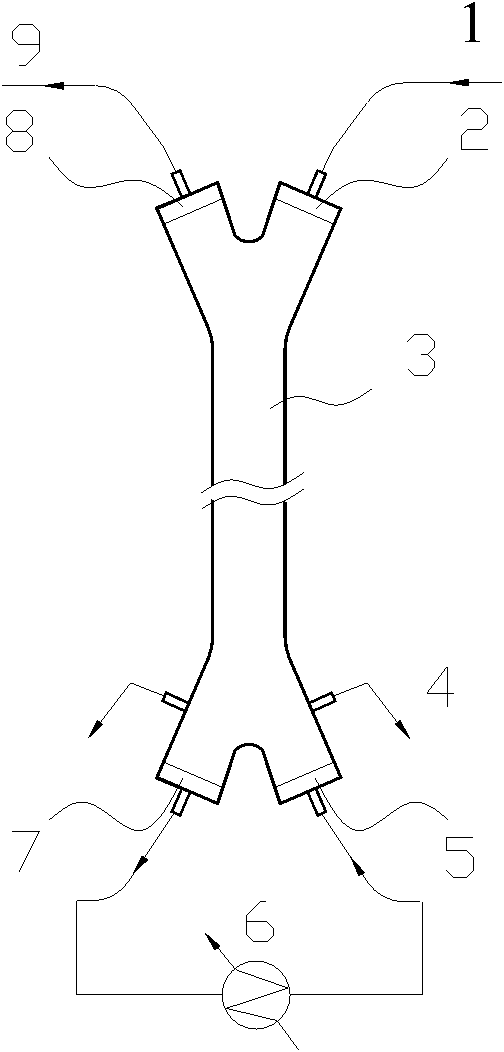

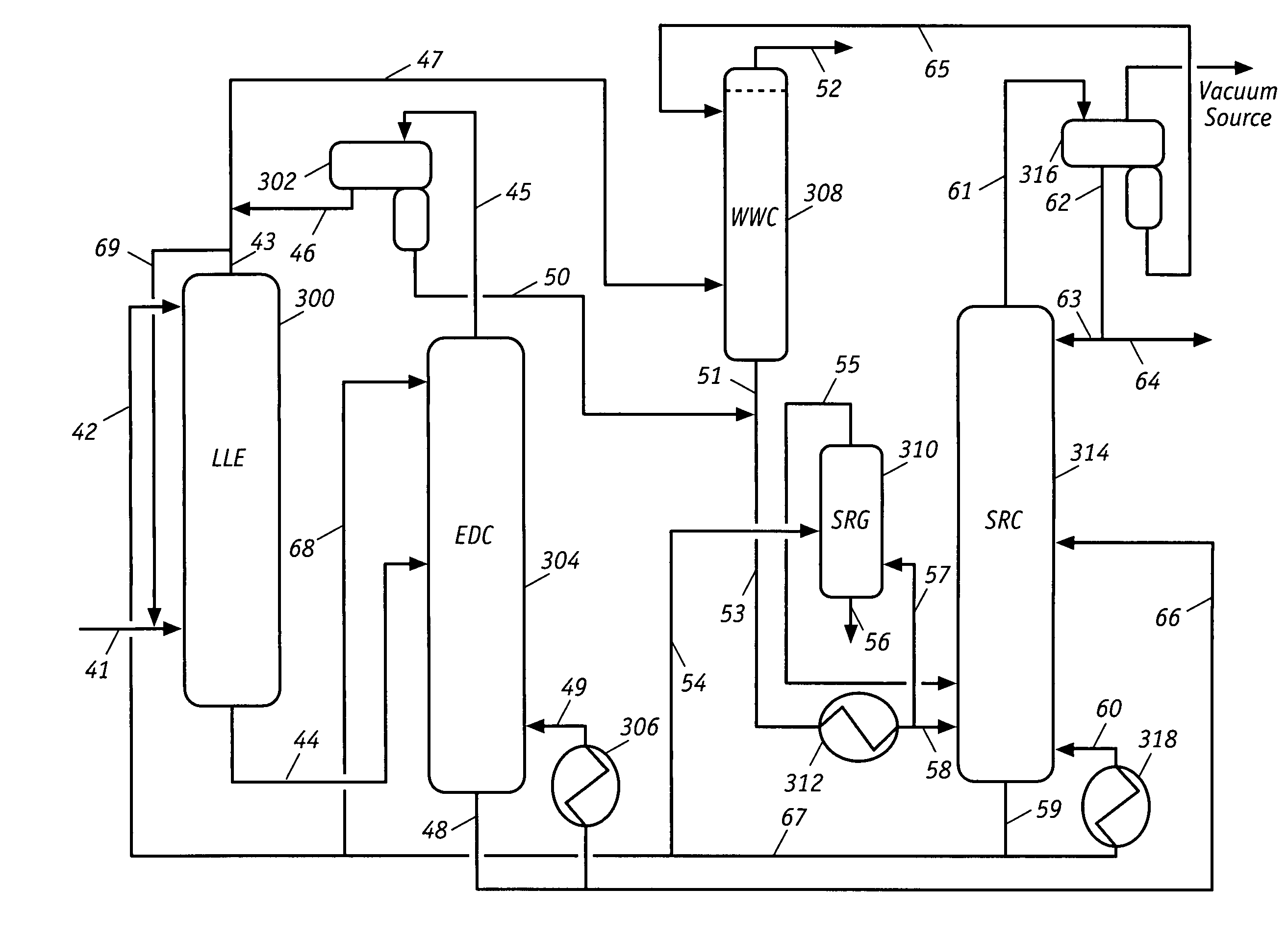

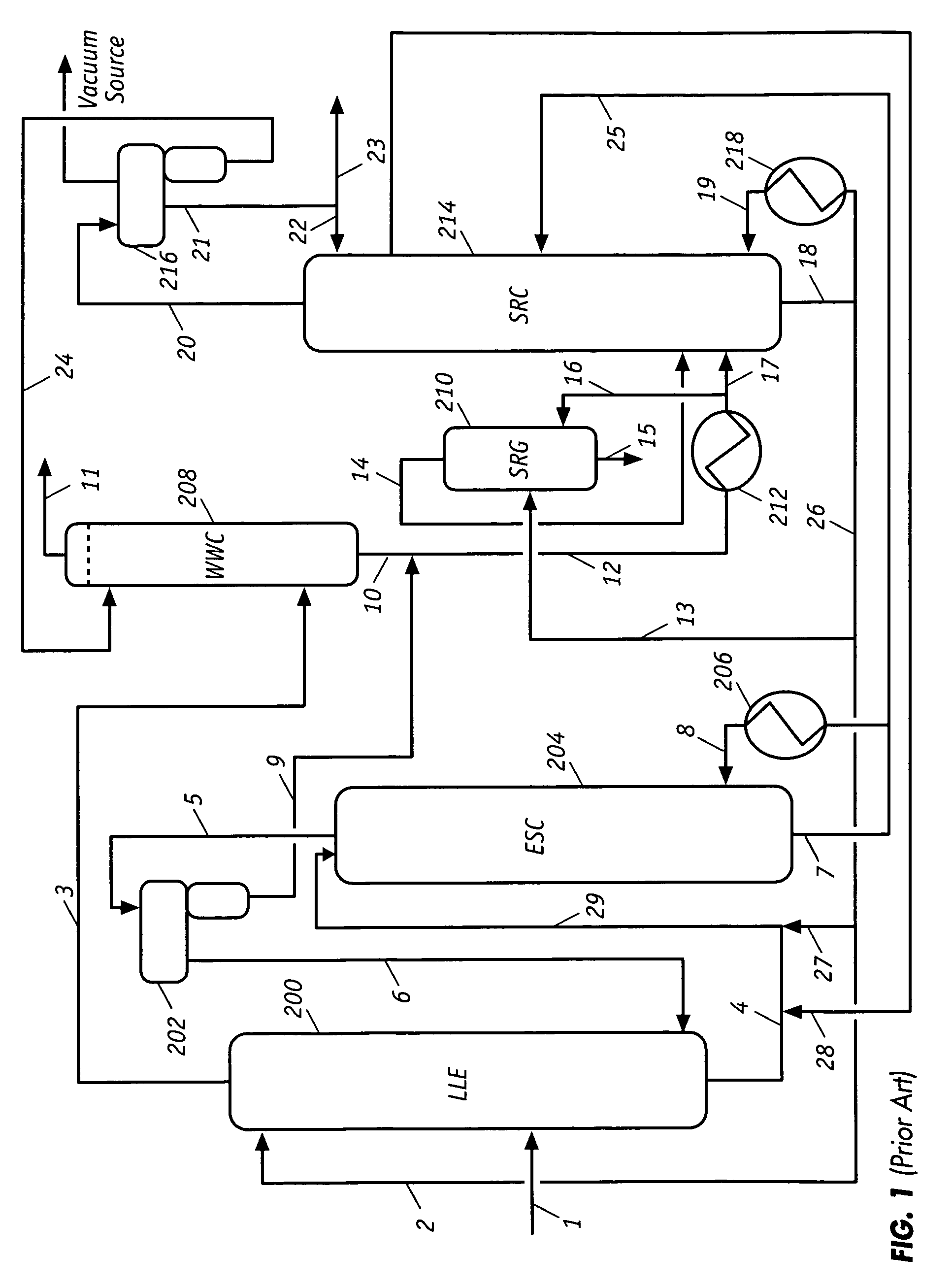

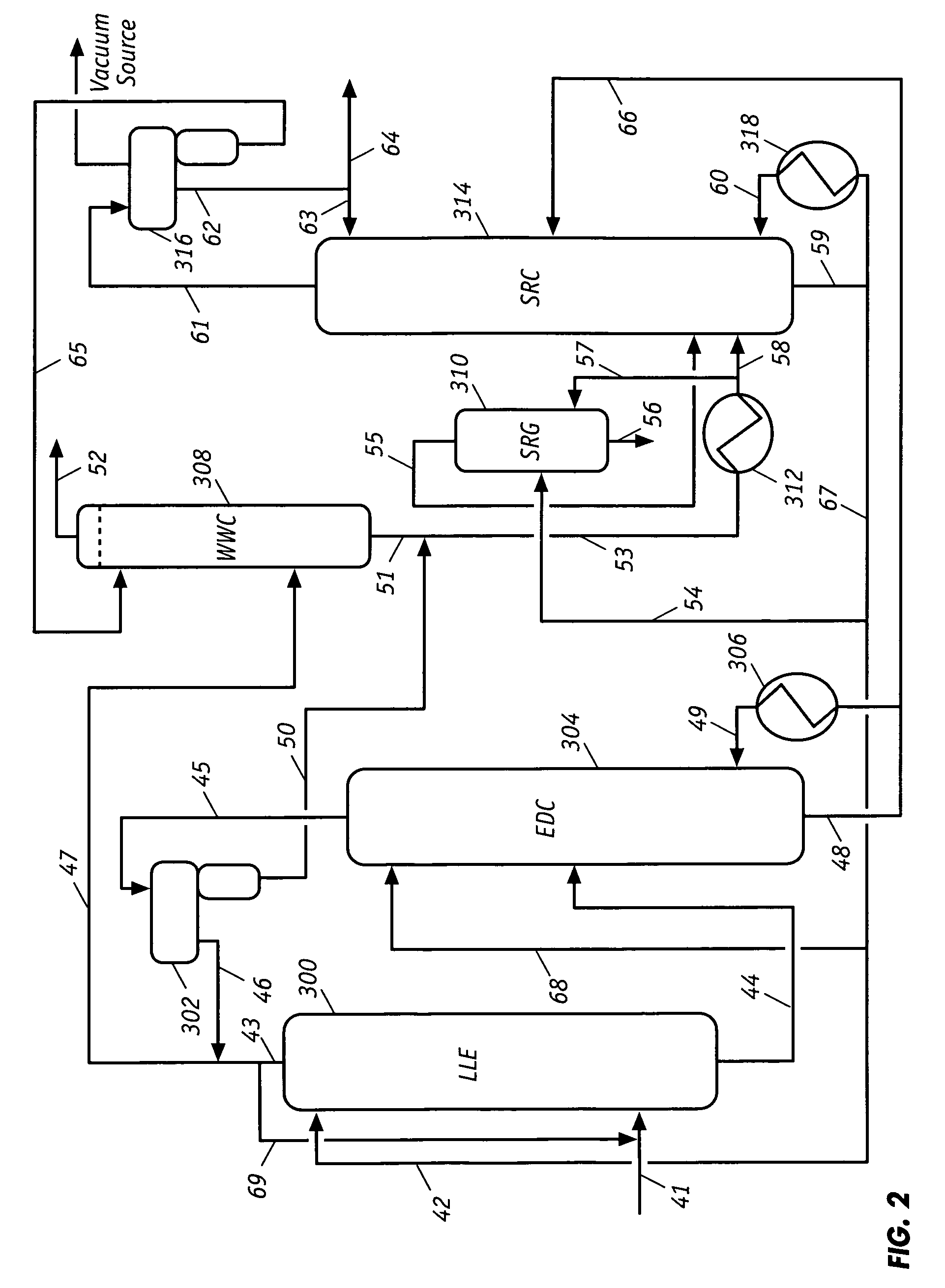

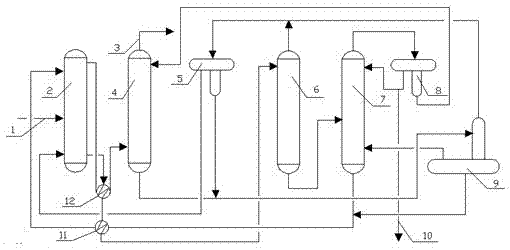

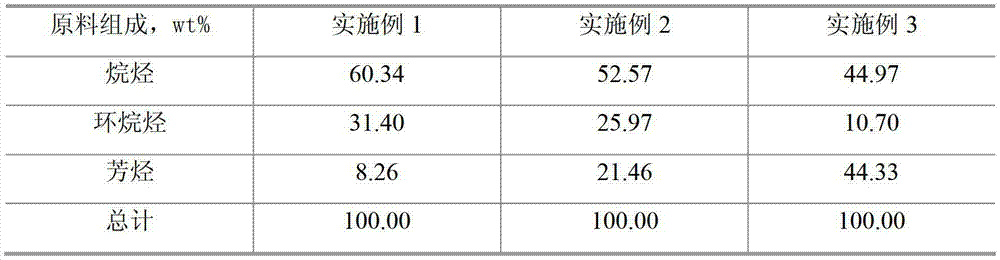

Novel energy efficient and throughput enhancing extractive process for aromatics recovery

InactiveUS20090255853A1Satisfactory aromatic puritySatisfactory recoveryHydrocarbon distillationRefining with acid-containing liquidsSulfolaneExtractive distillation

An energy efficient, high throughput process for aromatics recovery can be readily implemented by revamping existing sulfolane solvent extraction facilities, or constructing new ones, so as to incorporate unique process operations involving liquid-liquid extraction and extractive distillation. Current industrial sulfolane solvent based liquid-liquid extraction processes employ a liquid-liquid extraction column, an extractive stripping column, a solvent recovery column, a raffinate wash column, and a solvent regenerator. The improved process for aromatic hydrocarbon recovery from a mixture of aromatic and non-aromatic hydrocarbons requires transformation of the extractive stripping column into a modified extractive distillation column. The revamping incorporates the unique advantages of liquid-liquid extraction and extractive distillation into one process to significantly reduce energy consumption and increase process throughput. The revamp entails essentially only piping changes and minor equipment adjustments of the original liquid-liquid extraction facility, and is therefore, reversible.

Owner:CPC CORPORATION +1

High-efficient desulfurizing agent for removing hydrogen sulfide and organic mercaptan from mixed gas

InactiveCN101844035AHigh mercaptan removalHigh acid gas loadDispersed particle separationSulfolaneTert-Butylamine

The invention discloses a high-efficient desulfurizing agent for removing hydrogen sulfide and organic mercaptan from mixed gas, which comprises serotonin, wherein the serotonin consists of N-methyl diethanolamine and ethoxy ethanol tert-butylamine, and also comprises sulfolane and N-Hydroxyethyl piperidine. The weight ratio of the serotonin in the desulfurizing agent is 70 to 85 percent; the weight ratio of the sulfolane in the desulfurizing agent is 5 to 10 percent; and the weight ratio of the N-Hydroxyethyl piperidine in the desulfurizing agent is 10 to 20 percent. By mixing physical and chemical solvent and abstracting the advantages of the physical and chemical solvent, so on the premise that the removal effect of H2S is ensured, the organic sulfur can be removed high efficiently; and the desulfurizing agent has large acid gas load, strengthens the reaction speed between the H2S and MDEA and TBEE, so the consumption of the desulfurizing agent is small during the gas purification process, and the regeneration energy consumption of the solvent is low.

Owner:四川省精细化工研究设计院

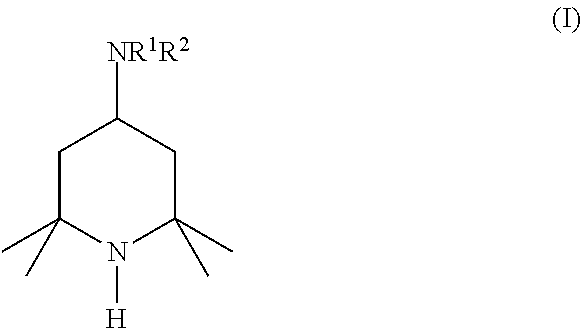

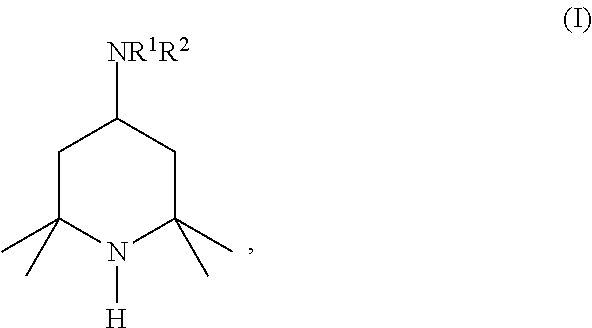

Co2 absorption from gas mixtures using an aqueous solution of 4-amino-2,2,6,6-tetramethylpiperidine

InactiveUS20120017762A1Easy loadingLess corrosiveGas treatmentOther chemical processesSulfolaneHydrogen

CO2 is absorbed from a gas mixture by bringing the gas mixture into contact with an absorbent that comprises water and at least one amine of the formula (I), wherein R1 and R2, independently of each other, are hydrogen or an alkyl group. According to the invention, absorption media comprise sulfolane or an ionic liquid in addition to water and an amine of the formula (I). A device according to the invention for removing CO2 from a gas mixture comprises an absorption unit, a desorption unit, and an absorption medium according to the invention that is conducted in the circuit.

Owner:EVONIK DEGUSSA GMBH

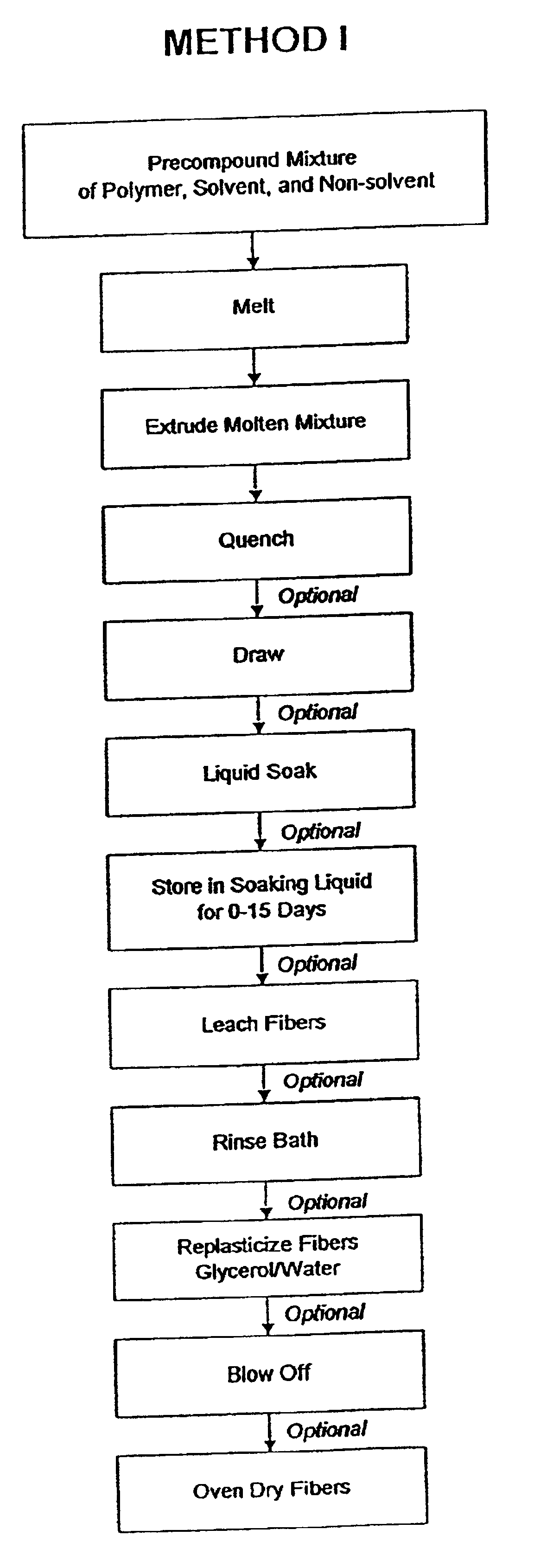

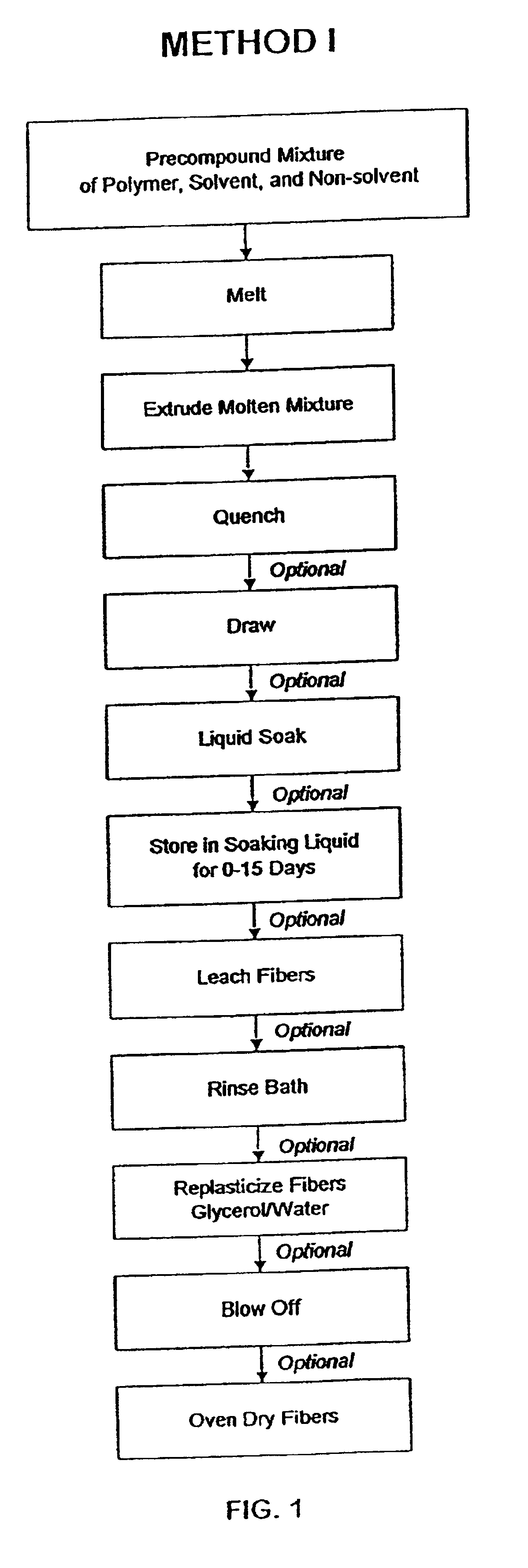

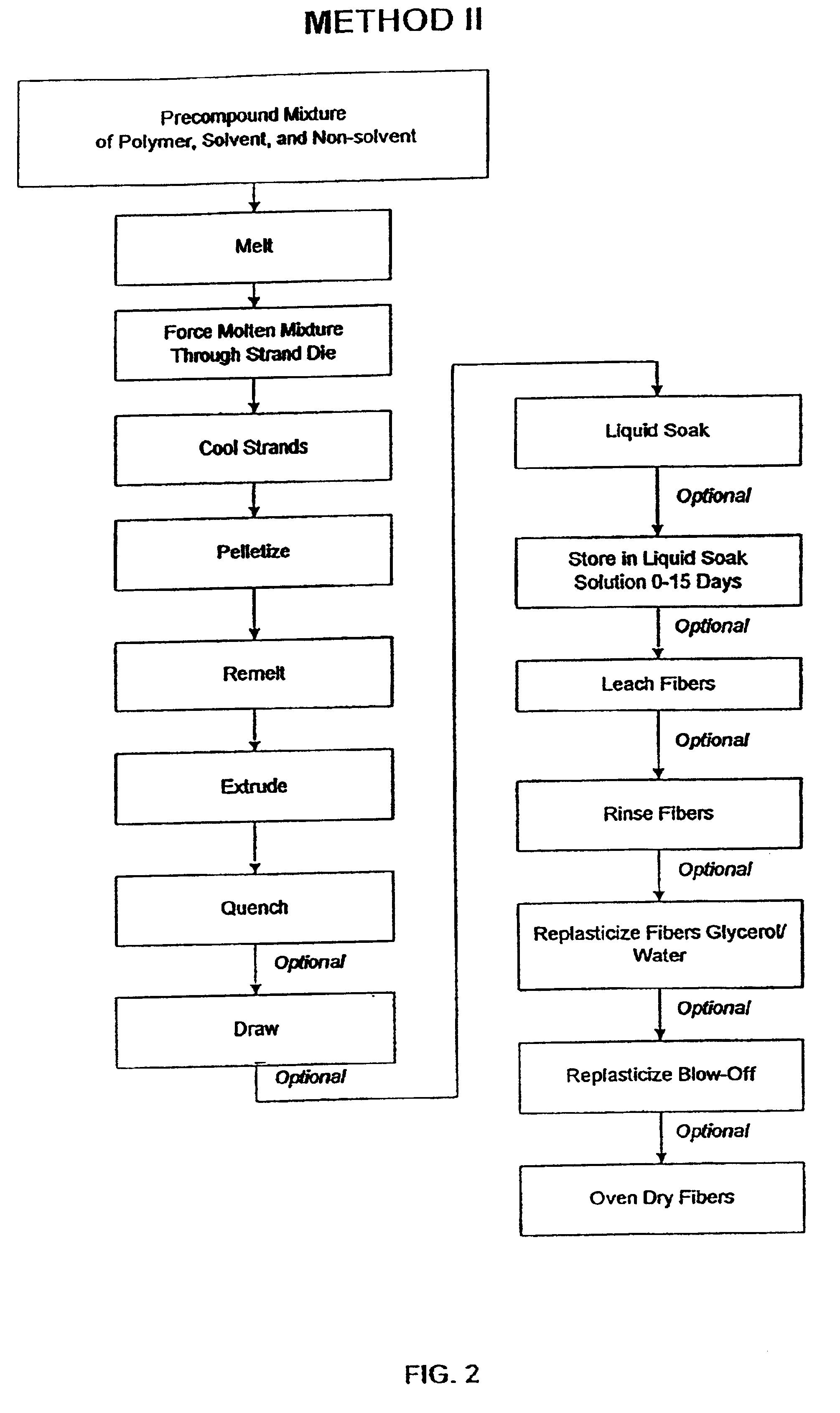

Melt-spun polysulfone semipermeable membranes and methods for making the same

The present invention discloses, inter alia, a composition useful for producing a hemogeneous, semipermeable membrane, the composition comprising (1) a polysulfone compounds, (2) a solvent, such as sulfolane, antypyrine, δvalerolactam, diethyl phthalate, and mixtures thereof, and (3) a non-solvent, such as poly(ethylene glycol), di(ethylene glycol), tri(ethylene glycol), glycerol, and mixtures thereof. Another aspect of this invention discloses methods for fabricating semipermeable membranes by homogeneously mixing the composition of the polysulfone compound, solvent, and non-solvent, melting the composition, and melt-spinning the molten composition. Another aspect of the present invention includes homogeneous, melt-spun, semipermeable membranes useful for liquid separation processes, such as, but not limited to, microfiltration, ultrafiltration, dialysis, and reverse osmosis.

Owner:BAXTER INT INC

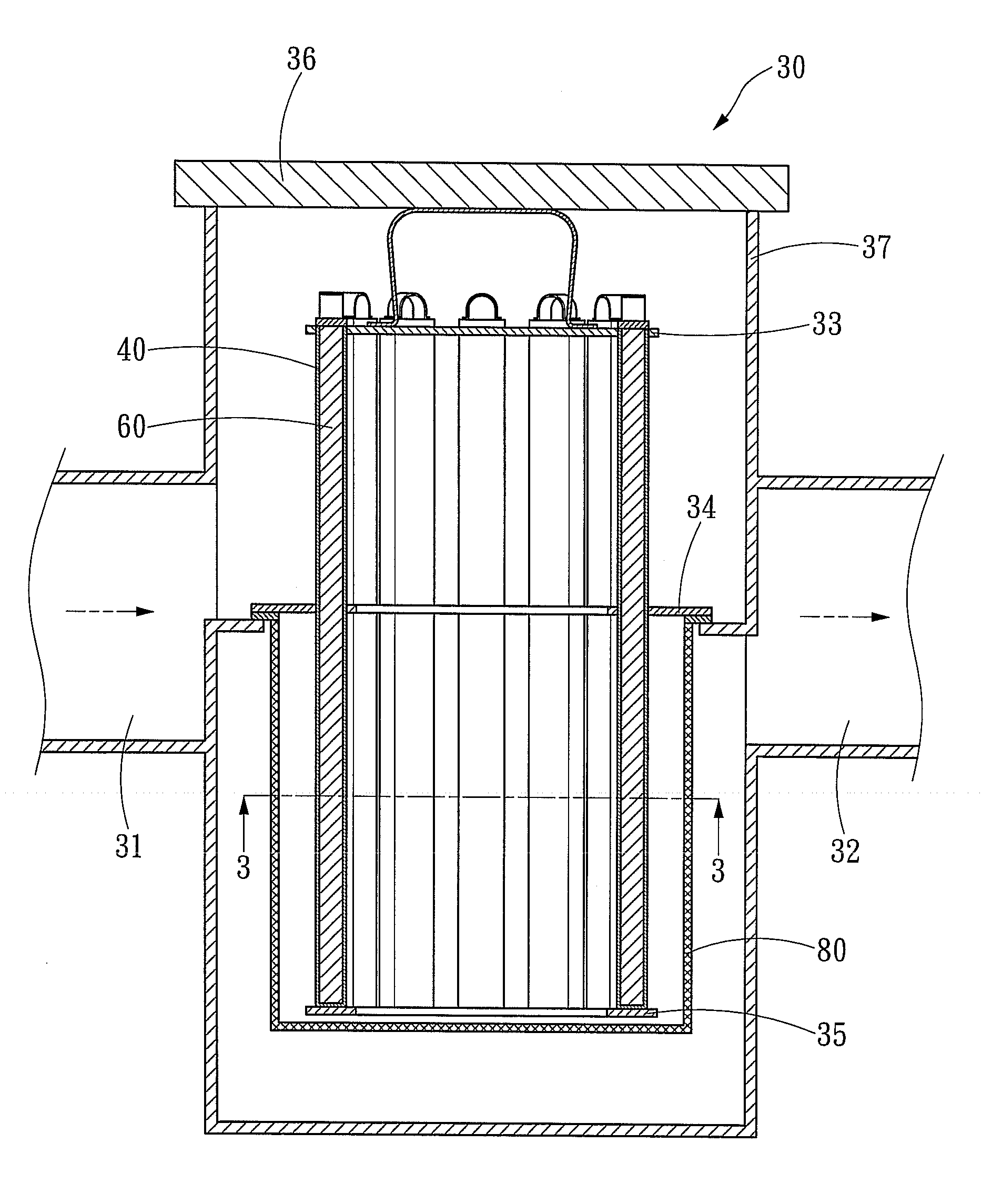

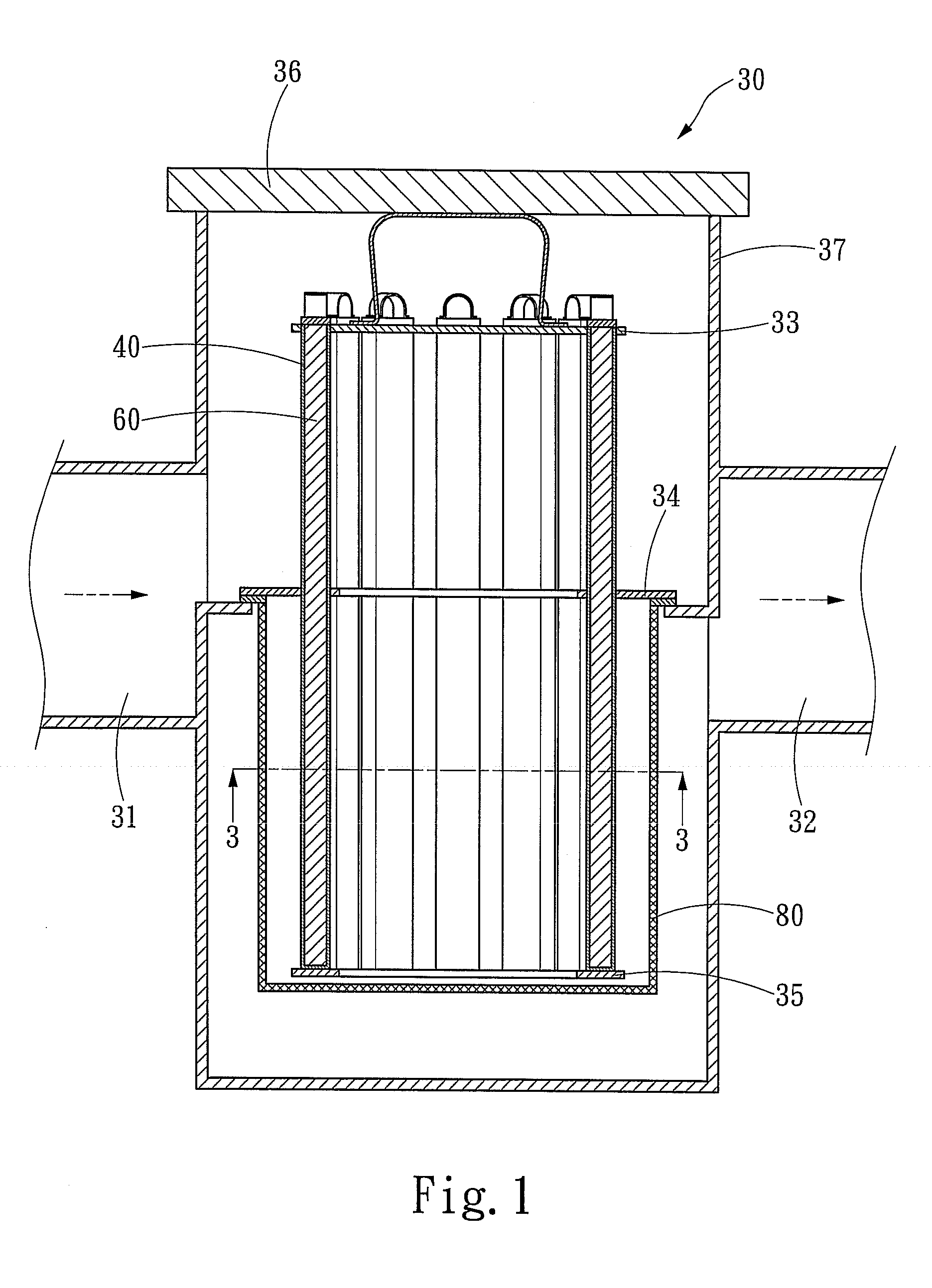

Process and apparatus for online rejuvenation of contaminated sulfolane solvent

InactiveUS20090272702A1Increase capacityImprove efficiencyWater/sewage treatment by magnetic/electric fieldsMagnetic separationSulfolaneEngineering

A continuous online process for rejuvenating whole stream of contaminated lean sulfolane in an extraction system is provided. In particular, a rejuvenator is installed in the solvent circulation loop to remove the contaminants continuously to keep the solvent clean, effective and less corrosive. Specifically, the rejuvenator comprises a high pressure vessel with a removable cover and a round rack with vertical stainless steel tubes fitted in the high pressure vessel. A magnetic bar is placed in each stainless steel tube. A screen cylinder is installed inside the ring of stainless steel tubes. As the contaminated sulfolane is passed through the rejuvenator, the rejuvenator picks up its contaminants. The rejuvenator can be dissembled to remove the contaminants periodically. The rejuvenator is characterized by simple in construction, reliable in operation, and low in operation and maintenance costs. With this rejuvenator, the extraction system can be operated at high efficiency and high capacity without the dreaded corrosion.

Owner:CPC CORPORATION

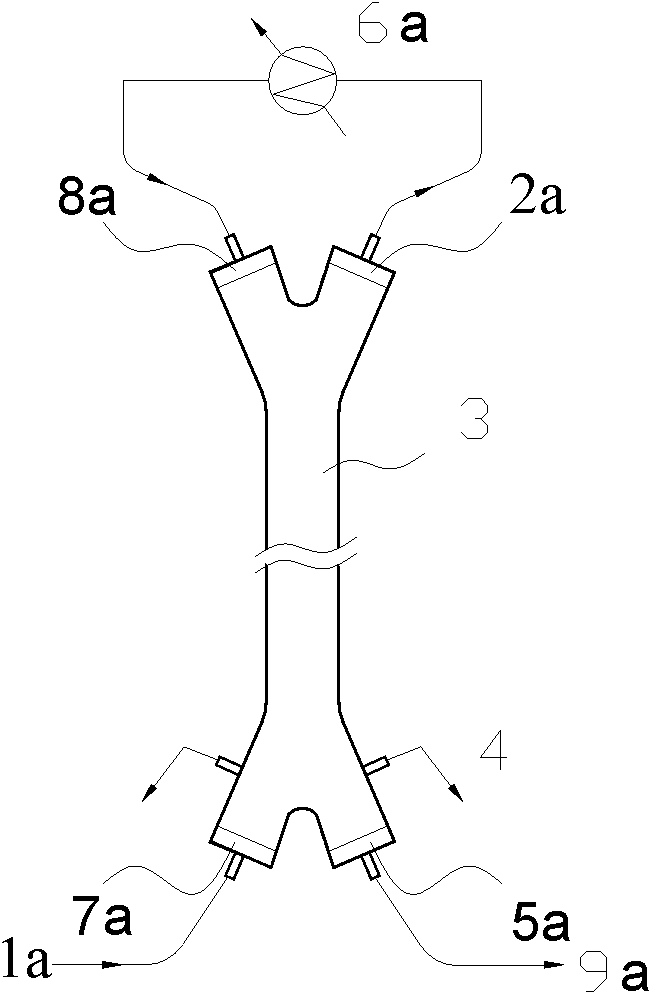

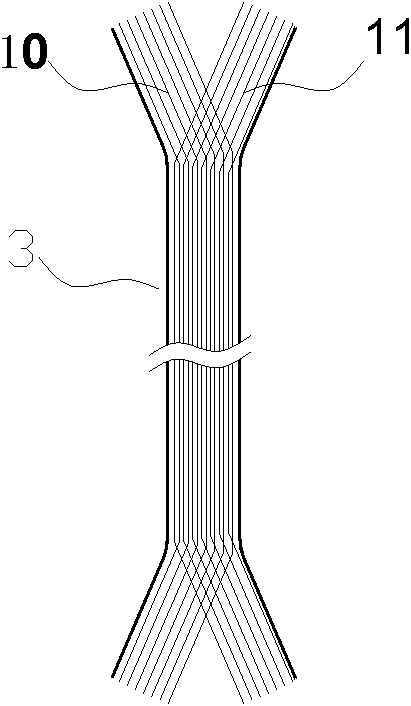

Multi-effect membrane distillation device with efficient internal heat reclamation function and method

ActiveCN102085454AExcellent heat transferExcellent mass transfer effectGeneral water supply conservationEnergy based wastewater treatmentSulfolaneFiber

The invention relates to a multi-effect membrane distillation device with efficient internal heat reclamation function and a method. The middle part of a membrane shell is provided with a cavity, two ends of the membrane shell are provided with an inlet and an outlet respectively, hollow fibrous membranes and hollow fiber pipes arranged uniformly are arranged in the cavity of the membrane shell, joints at two ends of the hollow fibrous membranes and the hollow fiber pipes are connected with the inlet and the outlet respectively, the lower end of the membrane shell is provided with a distillate outlet, and an external heat exchanger is connected in series between the inlet and the outlet of the water return end of a membrane assembly. The device has compact structure, simple and mild operating condition, low energy consumption and high water making rate, and can be used for small-scale dispersed implementation and integrated application; the method can be used in the fields of sea water desalinization, bitter water desalinization, concentration treatment of aqueous solution of nonvolatile or semi-volatile solutes, environmental protection and the like; and particularly when the method is used for concentration of aqueous solution of nonvolatile and semi-volatile solutes such as sodium chloride, ammonium sulfate, ammonium nitrate, sodium nitrate, sodium carbonate, sodium hydroxide, sulfuric acid, hydrochloric acid, glucose, xylitol, urea, glycerol, ethylene glycol, lactic acid, glyoxylic acid, dimethyl sulfoxide, sulfolane and the like, normal pressure steam or hot water is used as a heat source, and the highest water making rate can reach 13.7.

Owner:天津凯铂能膜工程技术有限公司

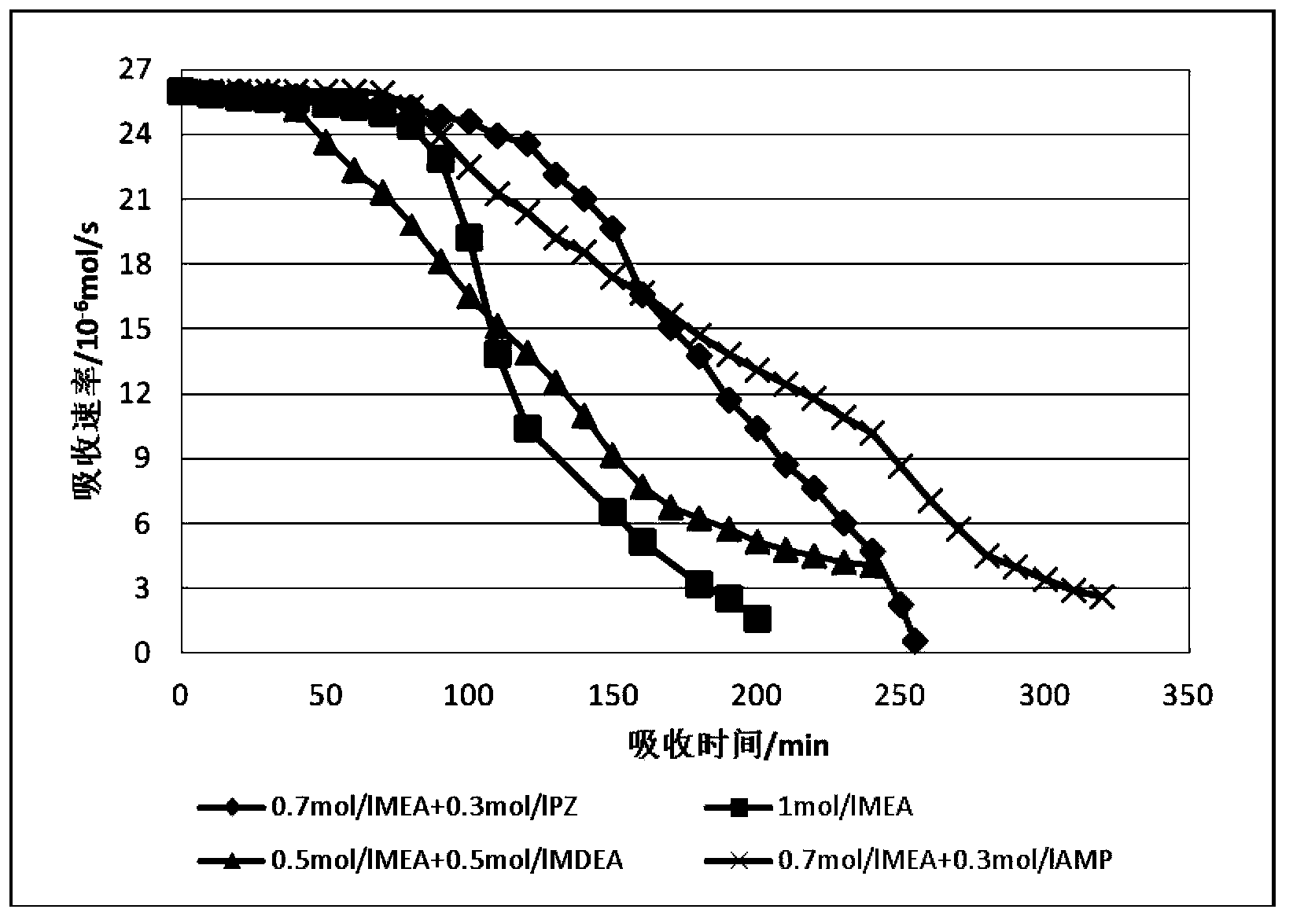

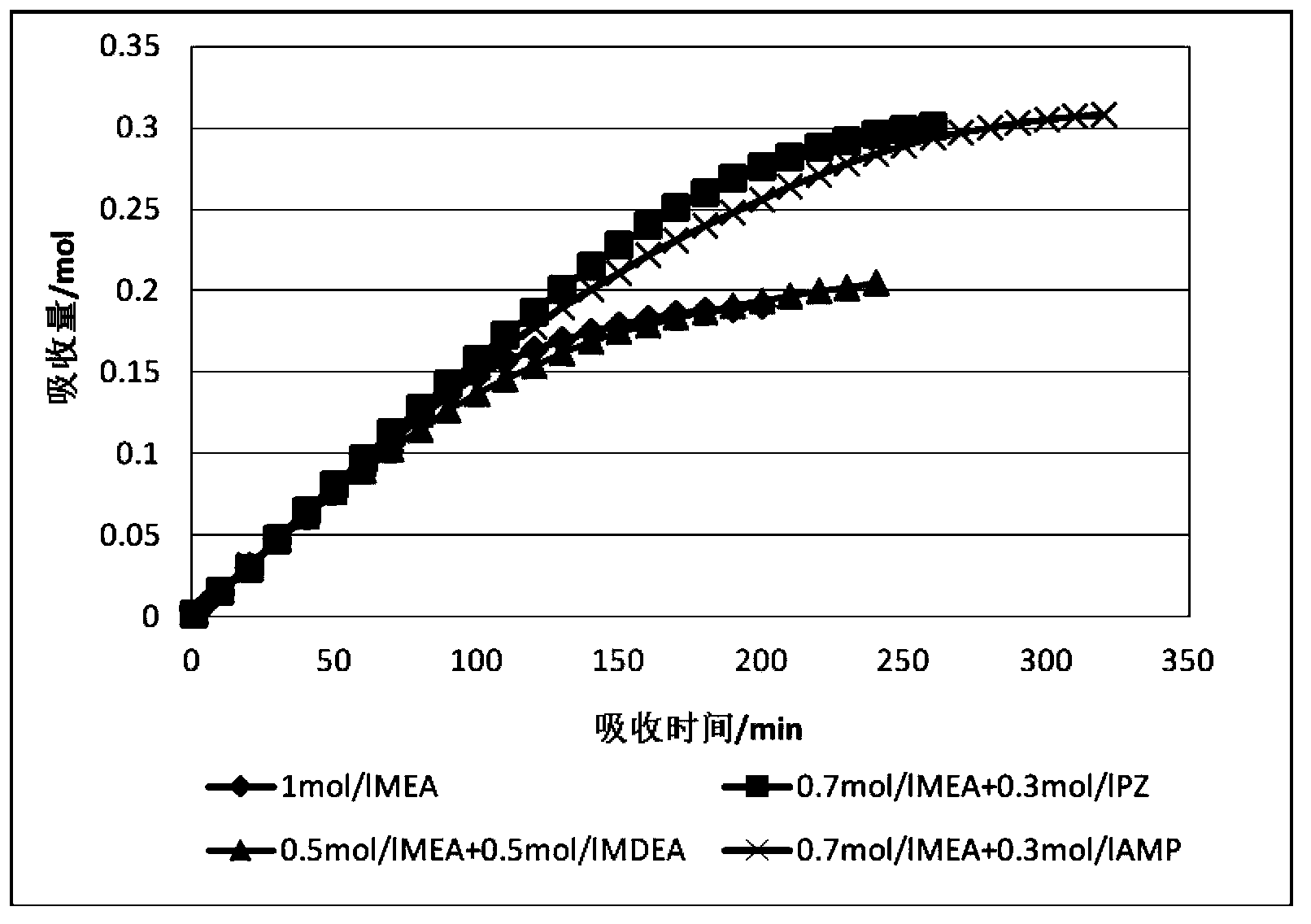

Organic amine compound absorbent for removal of carbon dioxide in fire coal flue gas

ActiveCN103394277AImprove protectionSolving Corrosion ProblemsDispersed particle separationBy chemical separationSulfolaneAbsorption capacity

The invention discloses an organic amine compound absorbent for removal of carbon dioxide in fire coal flue gas; the organic amine compound absorbent comprises the following components: by mass, 10%-45% of a main absorbent component, 0-10% of an assistant absorbent component, 0.01%-6% of a corrosion inhibitor, 0.01-3% of an antioxidant, 0-5% of a defoaming agent and the balance of water; wherein the main absorbent component comprises the following components: account for the total mass percentage of the organic amine composite absorbent, 3%-20% of monoethanolamine MEA, 0-12% of 2-amino-2-methyl-1-propanol AMP, 1%-15% of sun of piperazine PZ and N-aminoethyl piperazine AEP and 1%-12% of sum of aminoethyl ethanolamine AEEA and N-methyl monoethanolamine MMEA; and the assistant absorbent comprises one or a plurality of component selected from the group comprising diethanol amine DEA, diethylenetriamine DETA, triethylene tetramine TETA, N-methyldiethanolamine MDEA, sulfolane and tertbutylaminoethoxyethanol TBEE. The organic amine compound absorbent has the advantages of good stability, large absorption capacity, high purification degree, low regeneration energy consumption, good desorption effect, great reduction of degradation loss of the compound absorbent in the process of using, and the like.

Owner:STATE GRID CORP OF CHINA +1

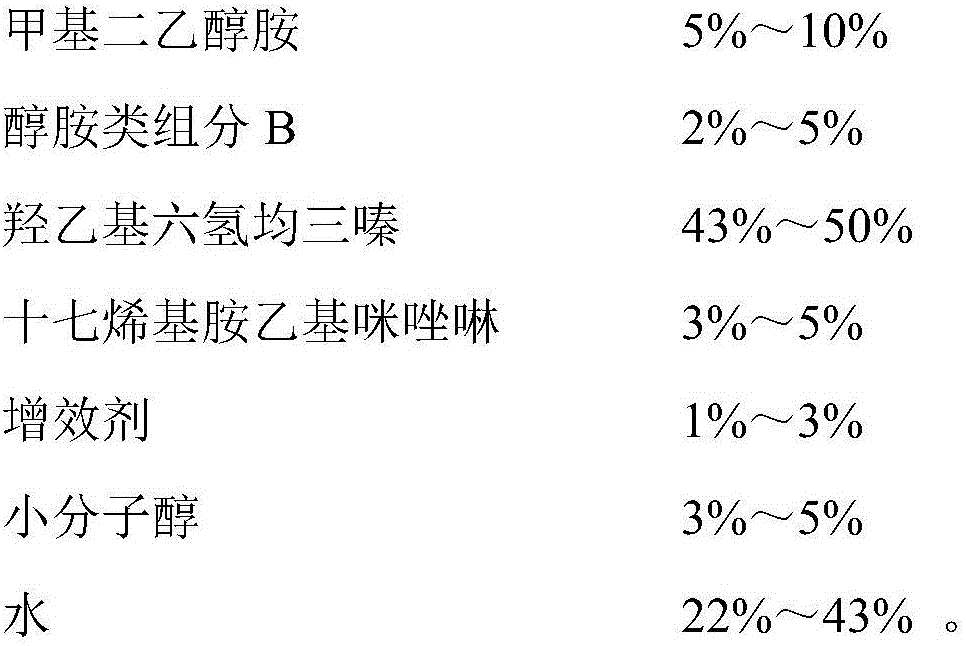

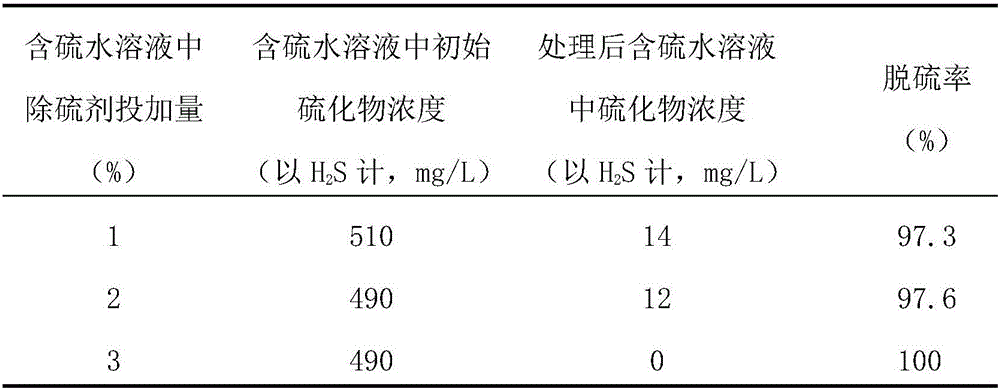

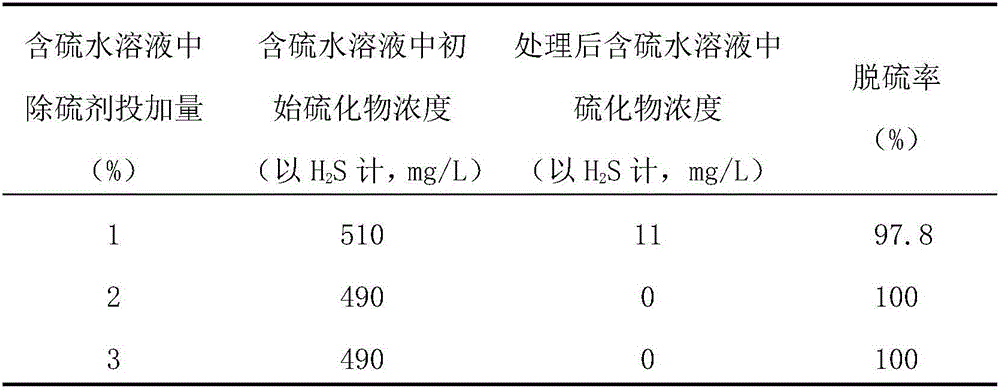

Organic composite efficient sulfur removal agent for oil-gas field and preparation method and application of organic composite efficient sulfur removal agent

ActiveCN106479468AEfficient removalReduce contentGaseous fuelsDrilling compositionDecompositionGlycerol

The invention discloses an organic composite efficient sulfur removal agent for oil-gas field and preparation method and application of the organic composite efficient sulfur removal agent. The sulfur removal agent is characterized in that water serves a solvent and comprises an alcohol amine component A, an alcohol amine component B, a triazine derivative, inhibiter, synergist and low-molecular mass alcohols; the alcohol amine component A refers to methyldiethanolamine, the alcohol amine component B refers to one of triethanolamine and diethanolamine or a mixture of triethanolamine and diethanolamine; triazine derivative refers to hexahydro-1,3,5-tris-s-triazine; the inhibiter refers to seventeen alkenyl amide ethyl imidazoline; the synergist refers to sulfolane; the low-molecular mass alcohols refer to one of ethylene glycol and glycerol or a mixture of ethylene glycol and glycerol. The sulfur removal agent has the advantages of good selectivity on sulfuretted hydrogen, small dosage, quick effect, high sulfur removal efficiency, no corrosion of steel, stable product performance, difficulty in heating decomposition, capability of being biodegradable and the like; sulfide like sulfuretted hydrogen existing in extraction of an oil-gas well can be effectively removed or reduced to safety threshold value range in content, corrosion of sulfide on pipelines and equipment is inhibited, and safety on the equipment and operation personnel is guaranteed.

Owner:陕西森瑞石油技术开发有限公司

Post plasma ashing wafer cleaning formulation

InactiveUS7534752B2Increase productionImprove adhesionDetergent mixture composition preparationSemiconductor/solid-state device manufacturingSulfolaneInorganic compound

A semiconductor wafer cleaning formulation for use in post plasma ashing semiconductor fabrication comprising at least one organic chelating agent and at least one polar solvent, wherein the chelating agent and polar solvent are in sufficient amounts to effectively remove inorganic compound residue from a semiconductor wafer. Preferably, the chelating agent is selected from the group consisting of 2,4-Pentanedione, Malonic acid, Oxalic acid, p-Toluenesulfonic acid, and Trifluoroacetic acid; and the polar solvent is selected from the group consisting of Water, Ethylene glycol, N-Methylpyrrolidone (NMP), Gamma butyrolactone (BLO), Cyclohexylpyrrolidone (CHP), Sulfolane, 1,4-Butanediol, and Butyl carbitol.

Owner:ENTEGRIS INC

Solvent for eliminating H2S from gas mixture

InactiveCN1887406APromote absorptionImprove the desorption effectDispersed particle separationSulfolaneOrganic sulfide compound

The present invention is method of adding one kind of secondary amine and one kind of organic amine with steric effect into water or sulfolane solution of N-methyl diethanolamine to obtain the activator for removing H2S from gas mixture with or without CO2. The present invention provides two solution recipes. The recipe I for the solution suitable for removing H2S from gas mixture containing no or less organic sulfide consists of N-methyl diethanolamine 30-50 wt%, secondary amine 1-10 wt%, steric amine 1-15 wt% and water for the rest. The recipe II for the solution suitable for removing H2S from gas mixture containing organic sulfide consists of N-methyl diethanolamine 30-40 wt%, secondary amine 1-5 wt%, steric amine 1-15 wt%, water 5 wt% and sulfolane for the rest.

Owner:HUAXI CHEM INST CHENGDU CITY

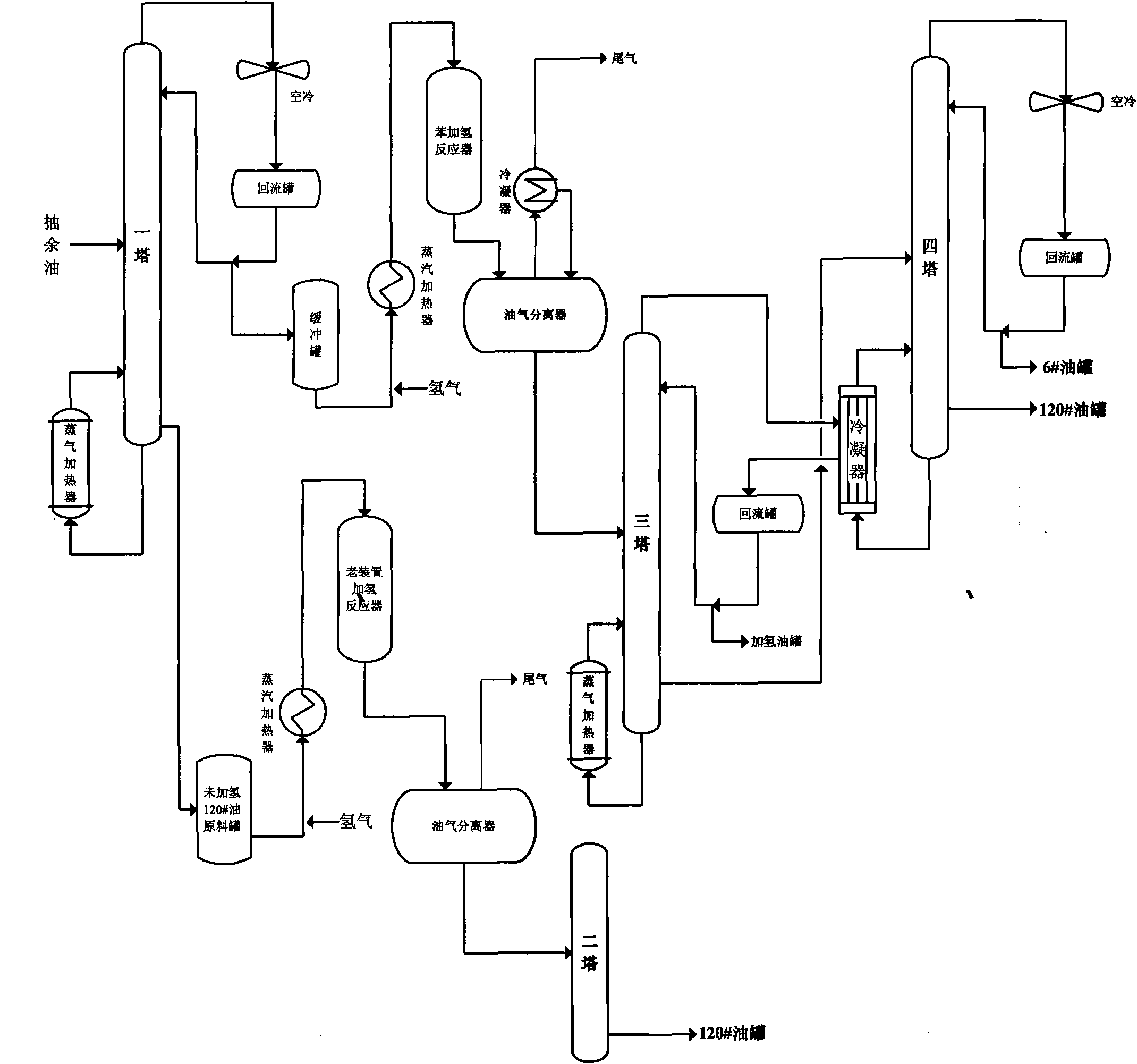

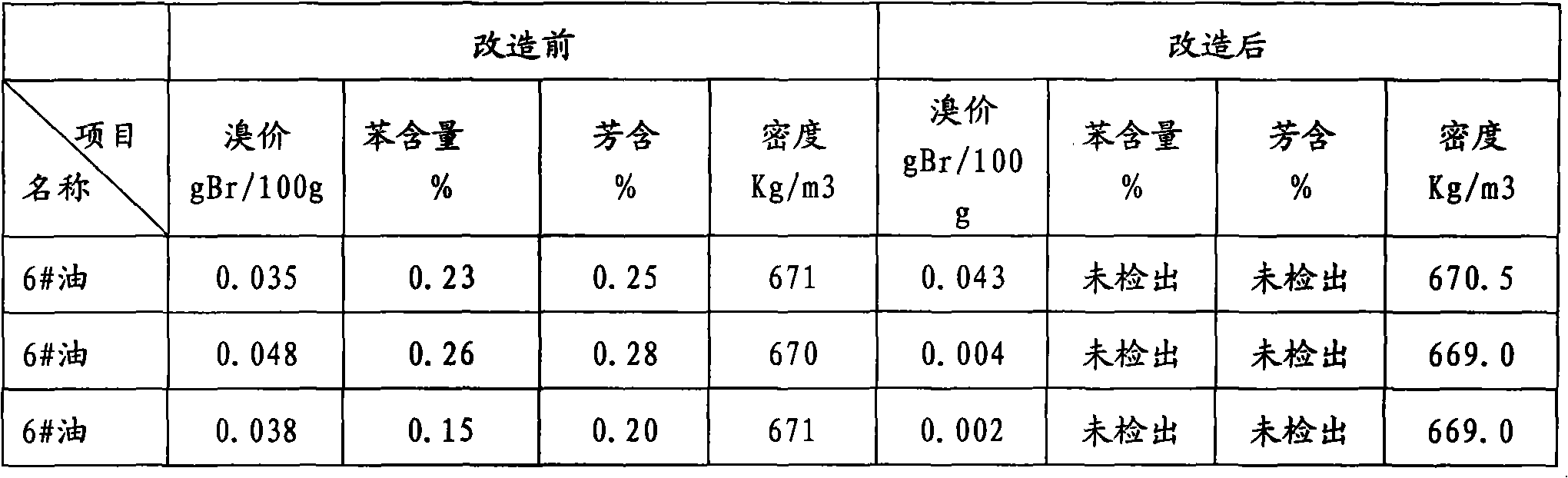

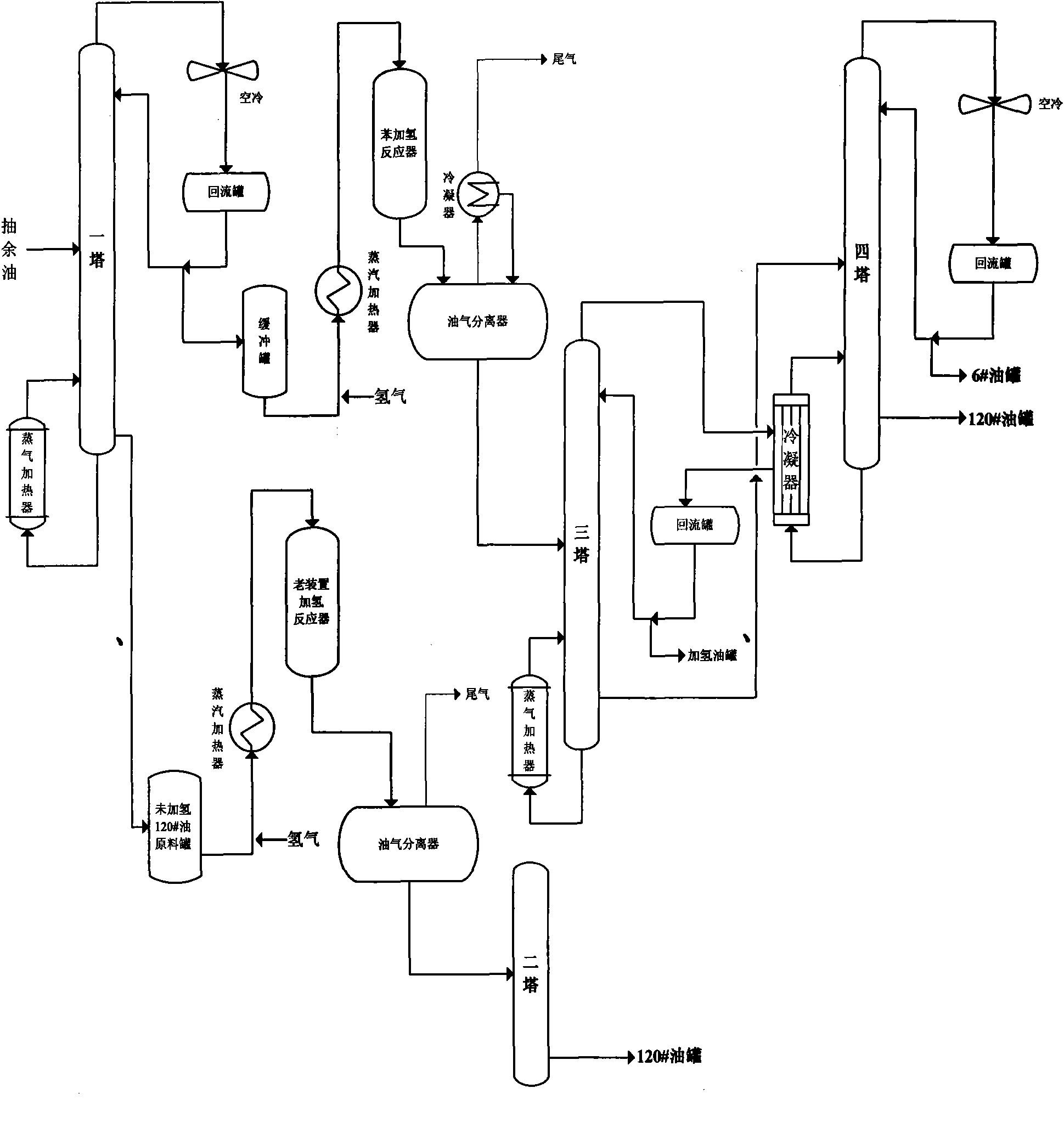

Process for producing solvent oil by removing aromatic hydrocarbon from raffinate oil

ActiveCN101974347ANot easy to cokeHigh activityTreatment with hydrotreatment processesBromine numberSulfolane

The invention discloses a process for producing solvent oil by removing aromatic hydrocarbon from raffinate oil, which comprises the following steps of: (1) rectifying raffinate oil, and removing sulfolane, water and colloid substances from the raffinate oil; (2) completely hydrogenating the raffinate oil obtained in the step (1) under the action of a benzene hydrogenation catalyst; and (3) removing excessive hydrogen from the product of the step (2) by separating, rectifying and collecting the product at the top of a rectifying tower to obtain solvent oil No.6 or normal hexane. In the method, all the raw materials are cleaned, hydrogenated and separated, reformed circulating hydrogen can be used, and the distillation range of the product is controllable. The content of aromatic hydrocarbon in the obtained product is trace, and the bromine number is lower than 100 mgBr / 100g.

Owner:TIANJIN JINGHUA PETROCHEM

Synthesis of polyether-ether-ketone resin with sulfolane as solvent

Synthesis of poly ether-ether-ketone resin as sulfolane as solvent is carried out by adding into 4,4,-difluoro-benzophenone and hydroquinone related to excessive dihydroxy-benzene 0.1~1%( or insufficient 0.1~1% ) successively, agitating, heating to 75~85 degrees C, adding into K2CO3 and Na2CO3 mixed salt, constant-temperature reacting at 230~260 degrees C for 1~3hrs, putting the reactant into cool water, cooling, freezing, crushing, filtering, boiling the solid product by non-ionic water repeatedly, removing solvent and by-product and drying the refined materials in oven to obtain final product. It can acquire poly ether-ether-ketone resin with two different hydroxyl terminal groups.

Owner:PANJIN ZHONGRUN SUPER ENG PLASTICS

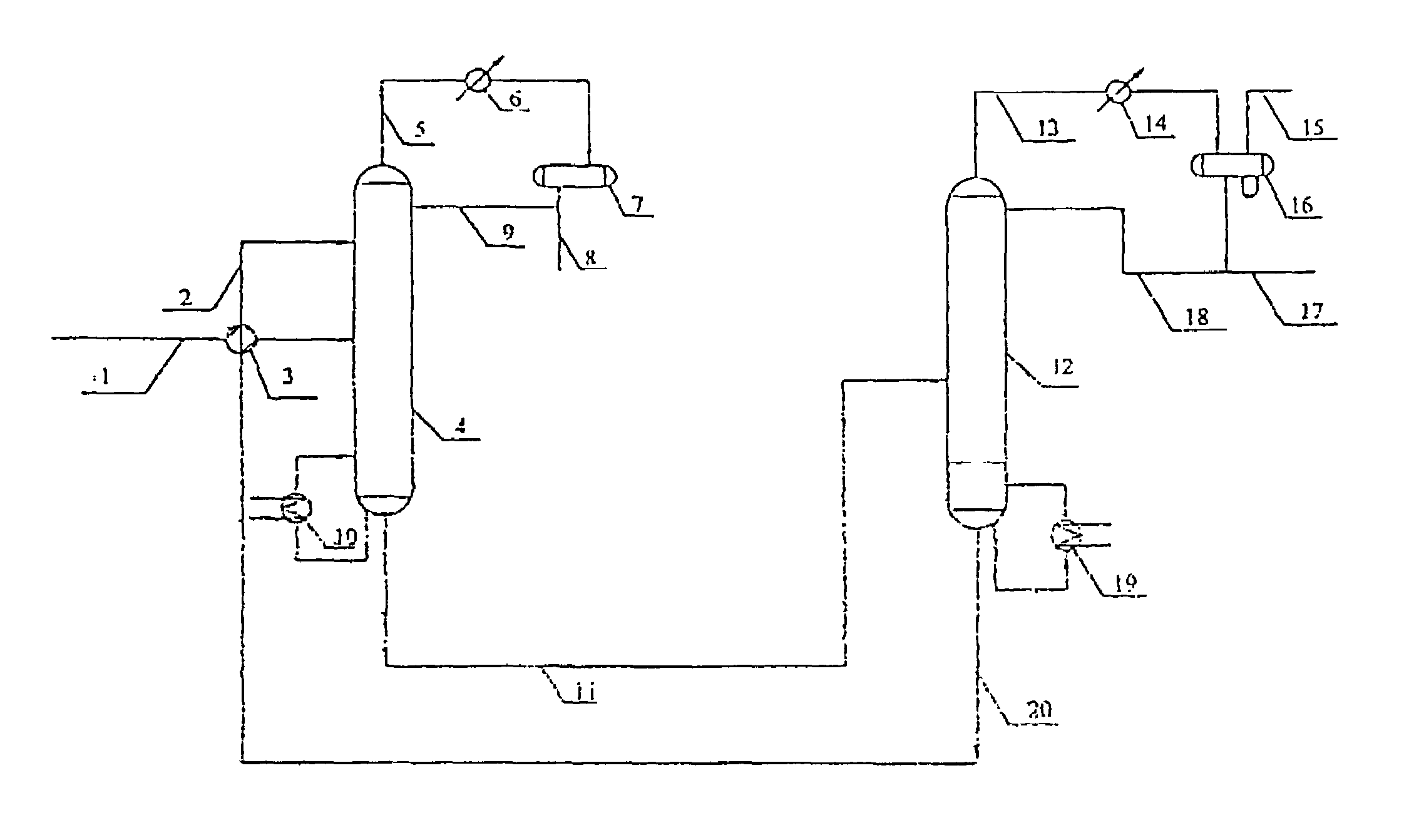

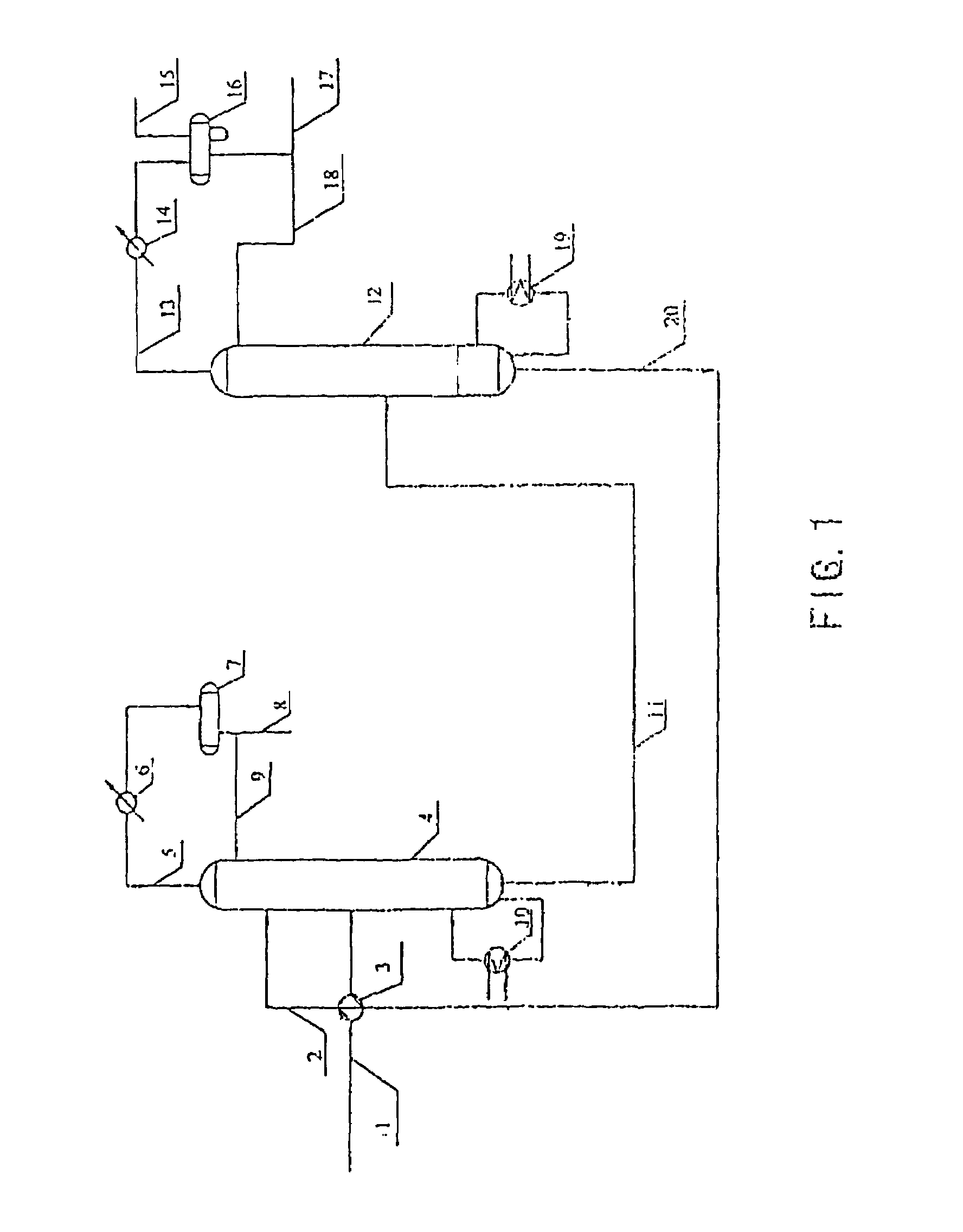

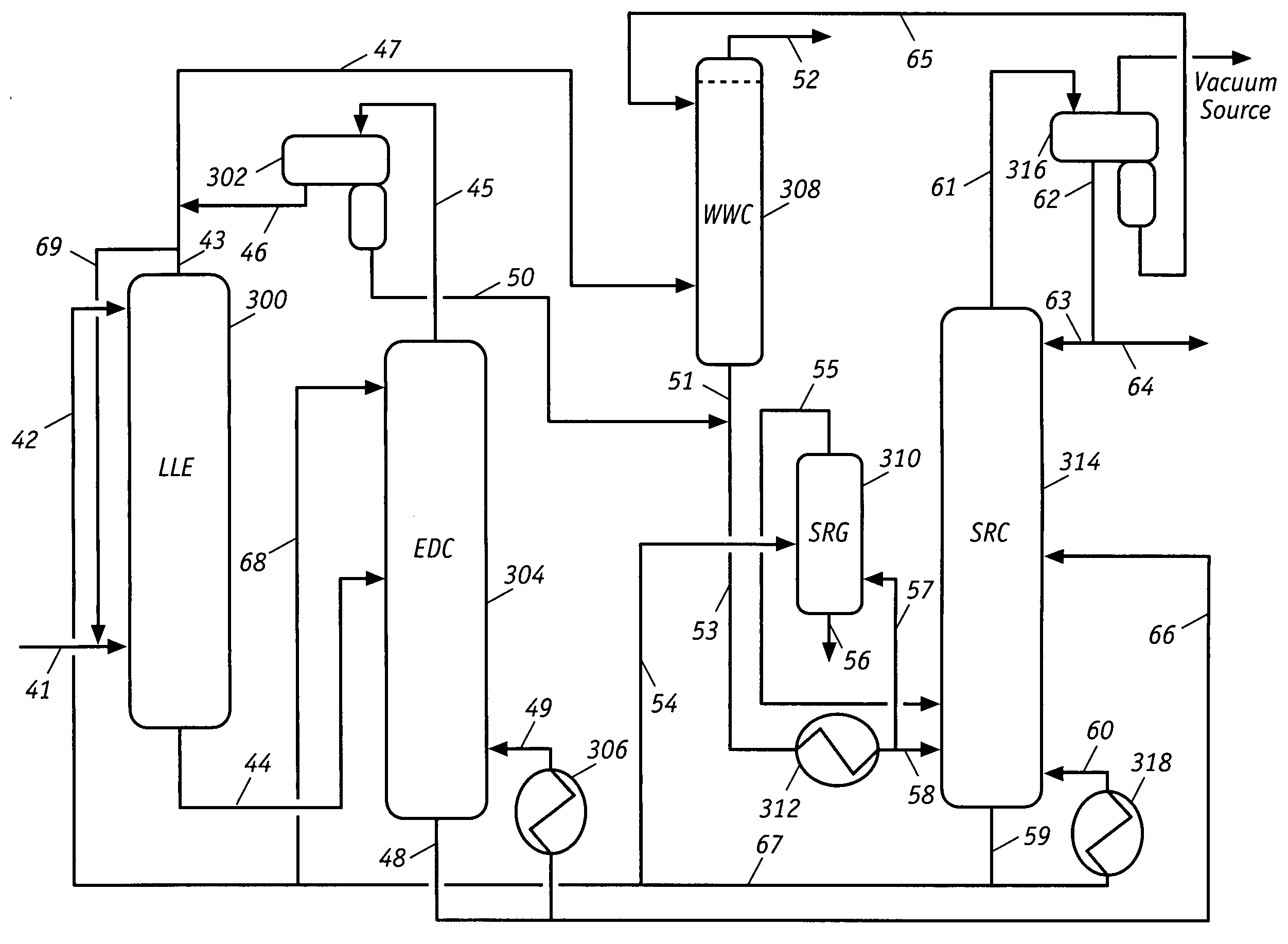

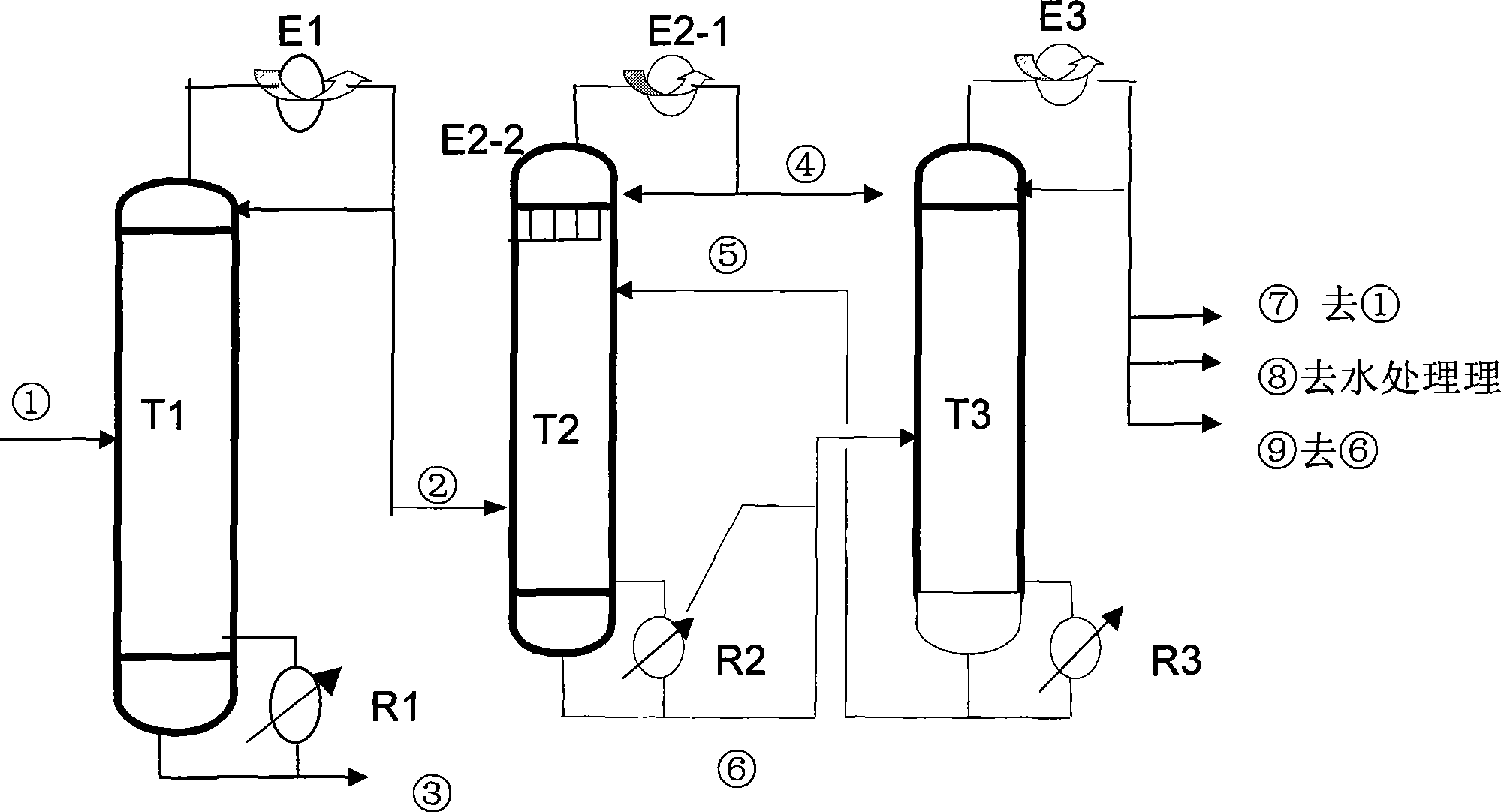

Energy efficient and throughput enhancing extractive process for aromatics recovery

InactiveUS7879225B2Significant energy savingImprove throughputHydrocarbon distillationRefining with acid-containing liquidsSulfolaneExtractive distillation

An energy efficient, high throughput process for aromatics recovery can be readily implemented by revamping existing sulfolane solvent extraction facilities, or constructing new ones, so as to incorporate unique process operations involving liquid-liquid extraction and extractive distillation. Current industrial sulfolane solvent based liquid-liquid extraction processes employ a liquid-liquid extraction column, an extractive stripping column, a solvent recovery column, a raffinate wash column, and a solvent regenerator. The improved process for aromatic hydrocarbon recovery from a mixture of aromatic and non-aromatic hydrocarbons requires transformation of the extractive stripping column into a modified extractive distillation column. The revamping incorporates the unique advantages of liquid-liquid extraction and extractive distillation into one process to significantly reduce energy consumption and increase process throughput. The revamp entails essentially only piping changes and minor equipment adjustments of the original liquid-liquid extraction facility, and is therefore, reversible.

Owner:CPC CORPORATION +1

Lithium ion battery and preparation method thereof

ActiveCN103022555ALow costConsiderable reversible capacityFinal product manufactureCell electrodesSulfolaneSulfate

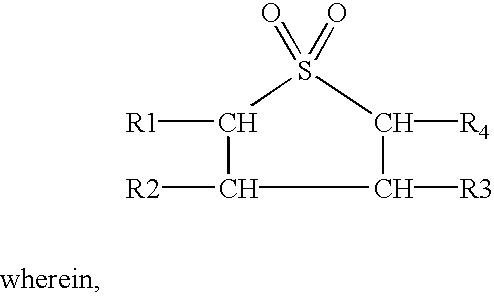

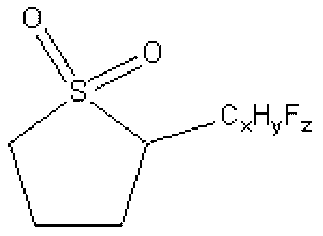

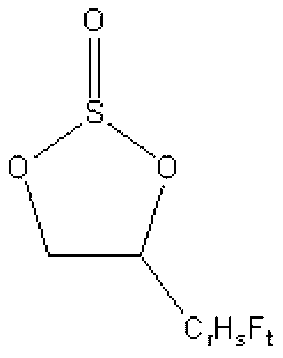

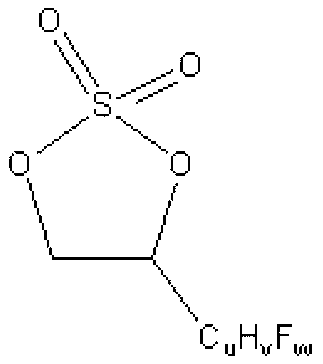

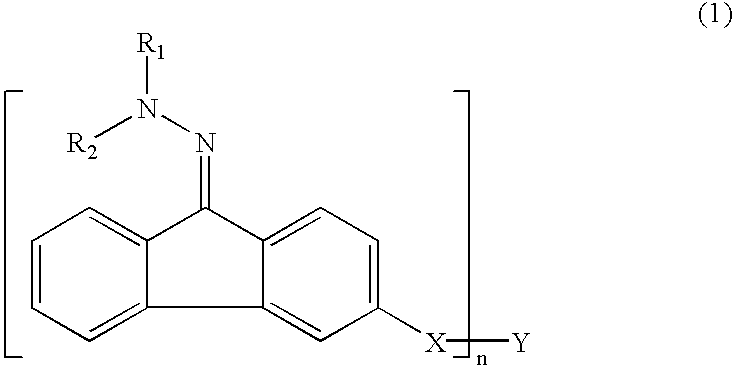

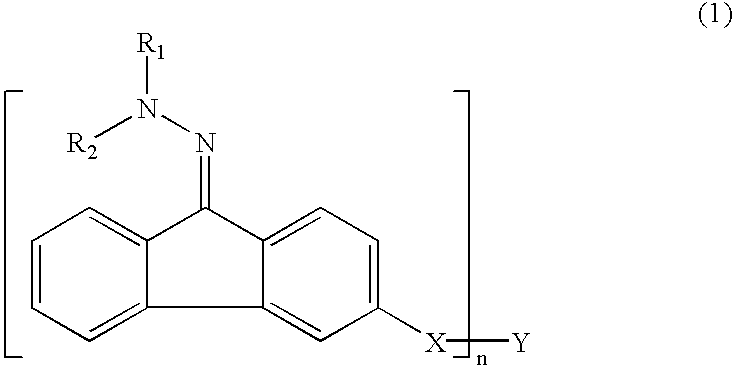

The invention relates to a lithium ion battery and a preparation method thereof. The lithium ion battery comprises a solvent which includes a fluoro carbonic ester and additives. The additives include fluoro methyl ethylene sulfate or derivatives thereof, or fluoro methyl ethylene sulfate or derivatives thereof and fluoro methyl sulfolane or derivatives thereof, or ethylene sulfate or derivatives thereof and fluoro methyl ethylene sulfite or derivatives thereof, or fluoro methyl sulfolane or derivatives thereof and fluoro methyl ethylene sulfite or derivatives thereof and fluoro methyl ethylene sulfate or derivatives. The additives comprises the following formulas: the fluoro methyl sulfolane derivatives are shown in the formula (1), wherein x=1-5, y+z=2x+1, x, y, z are positive integers; the fluoro methyl ethylene sulfite derivatives are shown in the formula (2), wherein r=1-5, s +t =2r+1, r, s and t are positive integers; and the fluoro methyl ethylene sulfate derivatives are shown in the formula (3), wherein u=1-5, v+w=2u+1, and u, v, and w are positive integers.

Owner:WUXI FUHONG TECH +1

Composite solvent and extraction method for extracting and separating aromatic hydrocarbons

InactiveCN103160310AReduce dosageImprove solubilityExtraction purification/separationHydrocarbon oils refiningSolubilitySulfolane

The invention relates to a composite solvent and extraction method for extracting and separating aromatic hydrocarbons from a hydrocarbon mixture in industries of oil refining and chemical engineering, which can achieve the advantages of high aromatic hydrocarbon separation efficiency, favorable heat stability and convenient recovery process. The technical scheme is as follows: the composite solvent comprises the following solvents in percentage by mass: 45-95% of main solvent, 4.5-40% of auxiliary solvent and 0.5-15% of modifier, wherein the main solvent is one of sulfolane or N-formyl morpholine or dimethylsulfoxide or tetraethylene glycol, the auxiliary solvent is one of N-methylpyrrolidone or N,N-dimethylformamide, and the modifier is one of ethylene glycol or polyethyleneglycol; and a preparation method of the composite solvent comprises the following steps: proportionally adding the modifier into the auxiliary solvent, evenly mixing, proportionally adding the mixed solvent into the main solvent, and evenly mixing to prepare the composite solvent. The composite solvent obviously enhances the solubility and selectivity of the solvent on aromatic hydrocarbons, avoids the increase of energy consumption and the occurrence of hydrolysis reaction caused by the situation that water is contained in the solvent, reduces the consumption of the solvent and increases the aromatic hydrocarbon recovery rate.

Owner:SOUTHWEST PETROLEUM UNIV

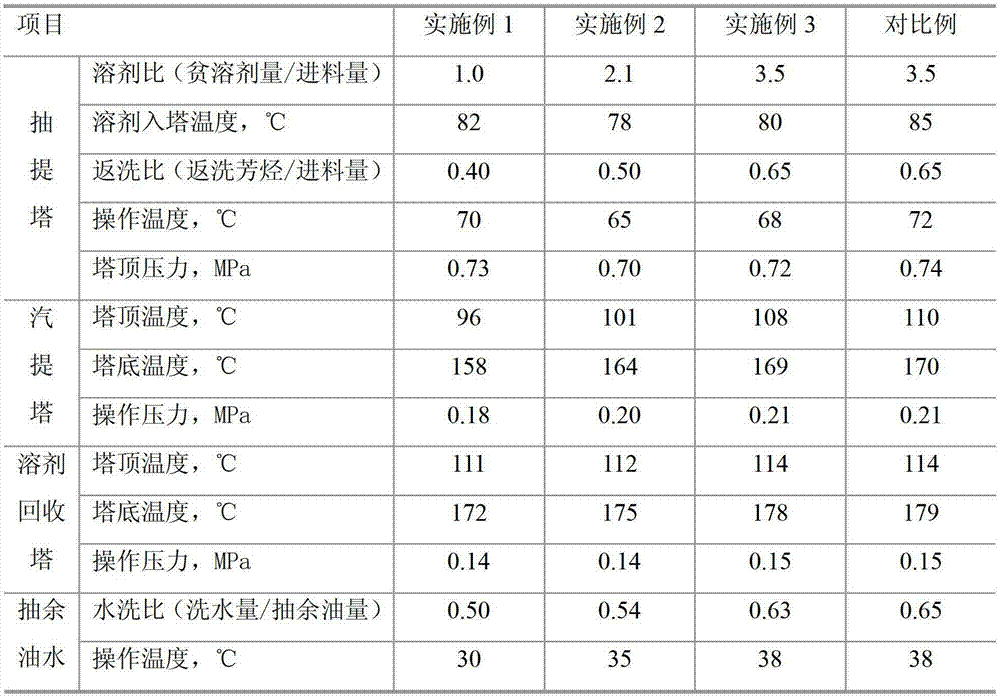

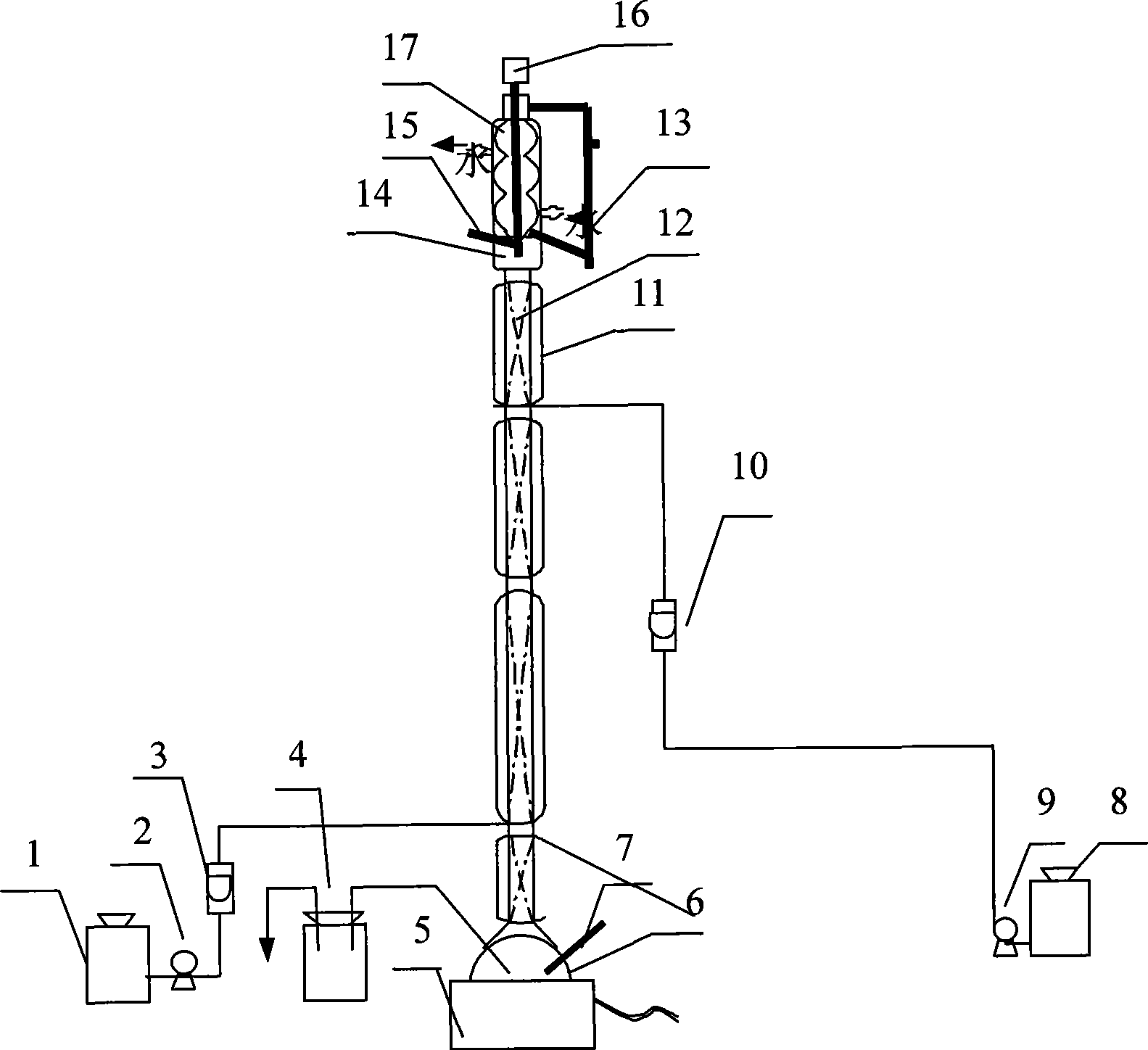

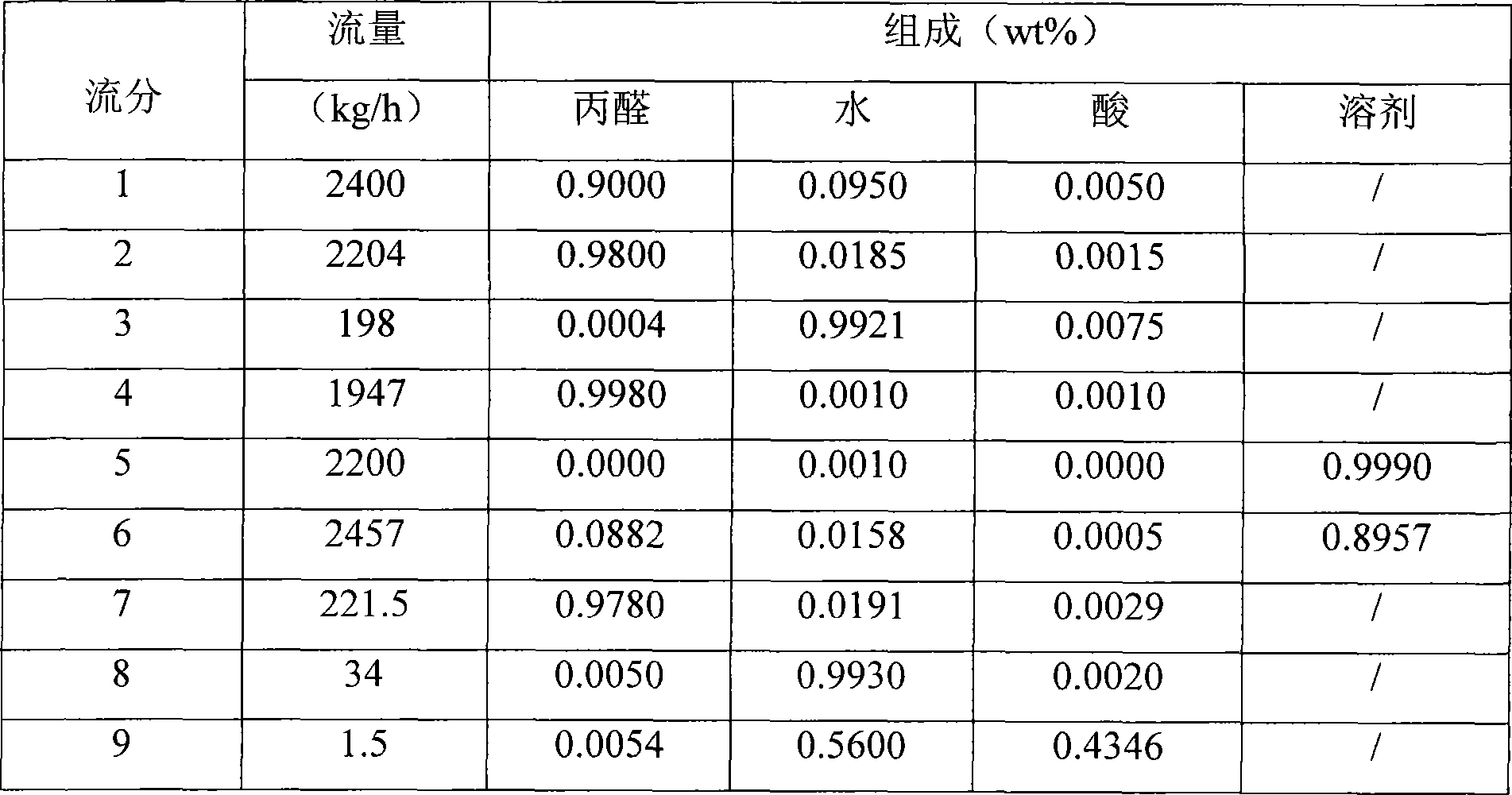

Method and equipment for separating propionaldehyde-water-acetic acid mixed liquid by combining azeotropic distillation and extraction distillation by saliferous mixed extracting agent

InactiveCN101544549ANo emissionsThe process steps are simpleDistillation separationCarbonyl compound separation/purificationSulfolaneLiquid waste

The invention discloses a method and equipment for separating propionaldehyde-water-acetic acid mixed liquid by combining azeotropic distillation and extraction distillation by saliferous mixed extracting agent. The steps are as follows: (1) performing azeotropic distillation to propionaldehyde-water-acetic acid mixed liquid, and obtaining about 98 percent of propionaldehyde at the top of an extracting and rectifying tower; (2) extracting and separating the about 98 percent of propionaldehyde by the mixed solvent of saliferous sulfolane and glycerin, obtaining over 99.8 percent of propionaldehyde at the top of the extracting and rectifying tower, and flowing out the saliferous mixed extracting agent from a tower kettle; (3) processing the saliferous mixed extracting agent by a regeneration tower and respectively obtaining 98 percent of propionaldehyde, aqueous solution containing acid and distillate containing the extracting solvent at the top of the regeneration tower; (4) returning 98 percent of propionaldehyde into a material tank of an azeotrope tower for circulation use; and (5) dewatering the aqueous solution containing acid, returning the distillate containing the extracting solvent to a mixed solvent storage tank and circularly using the saliferous mixed extracting agent. The invention has simpler process steps, high product purity, circular utilization of the mixed extracting solvent, no waste liquid emission in the production process and low energy consumption.

Owner:滨海火炬科技有限公司

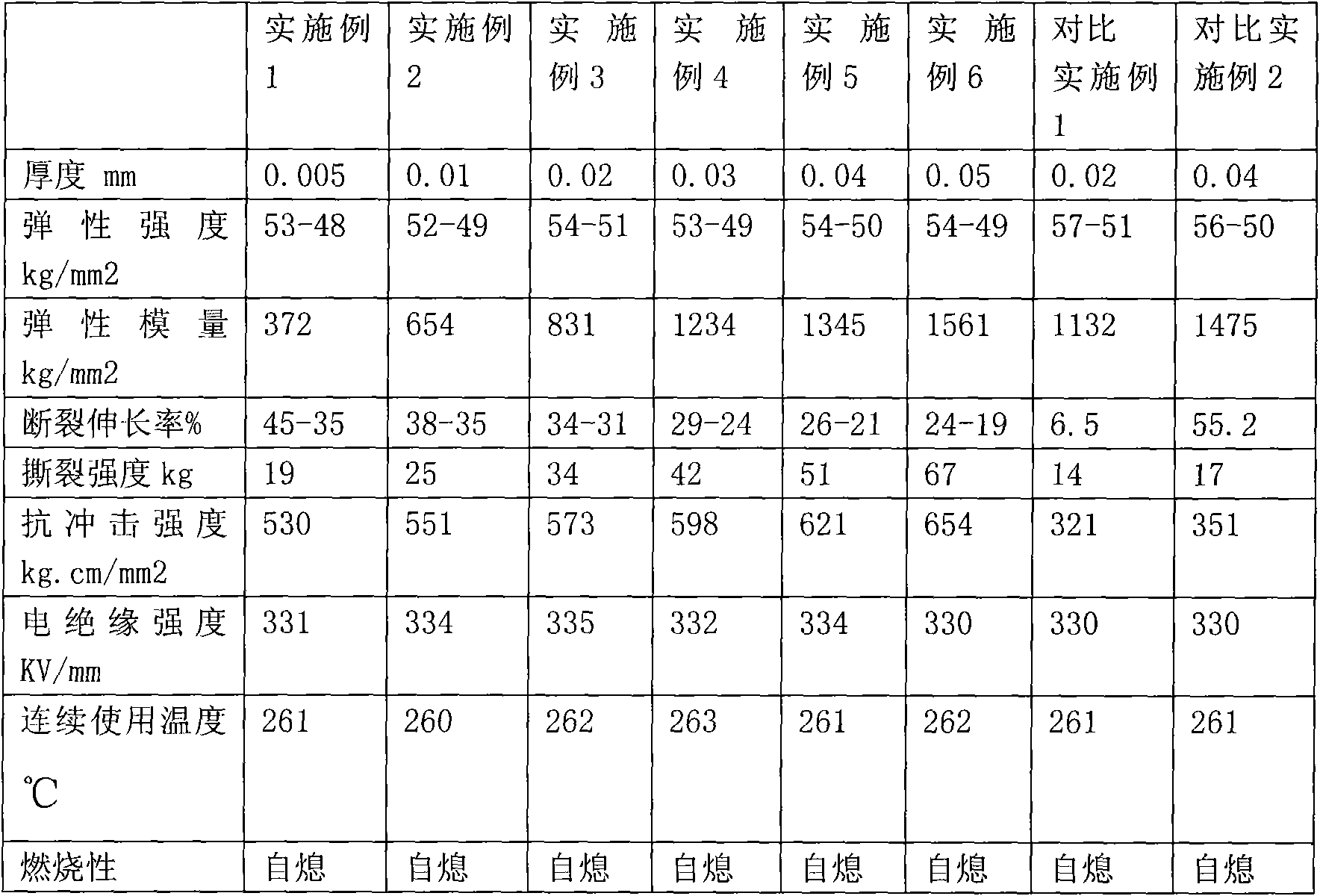

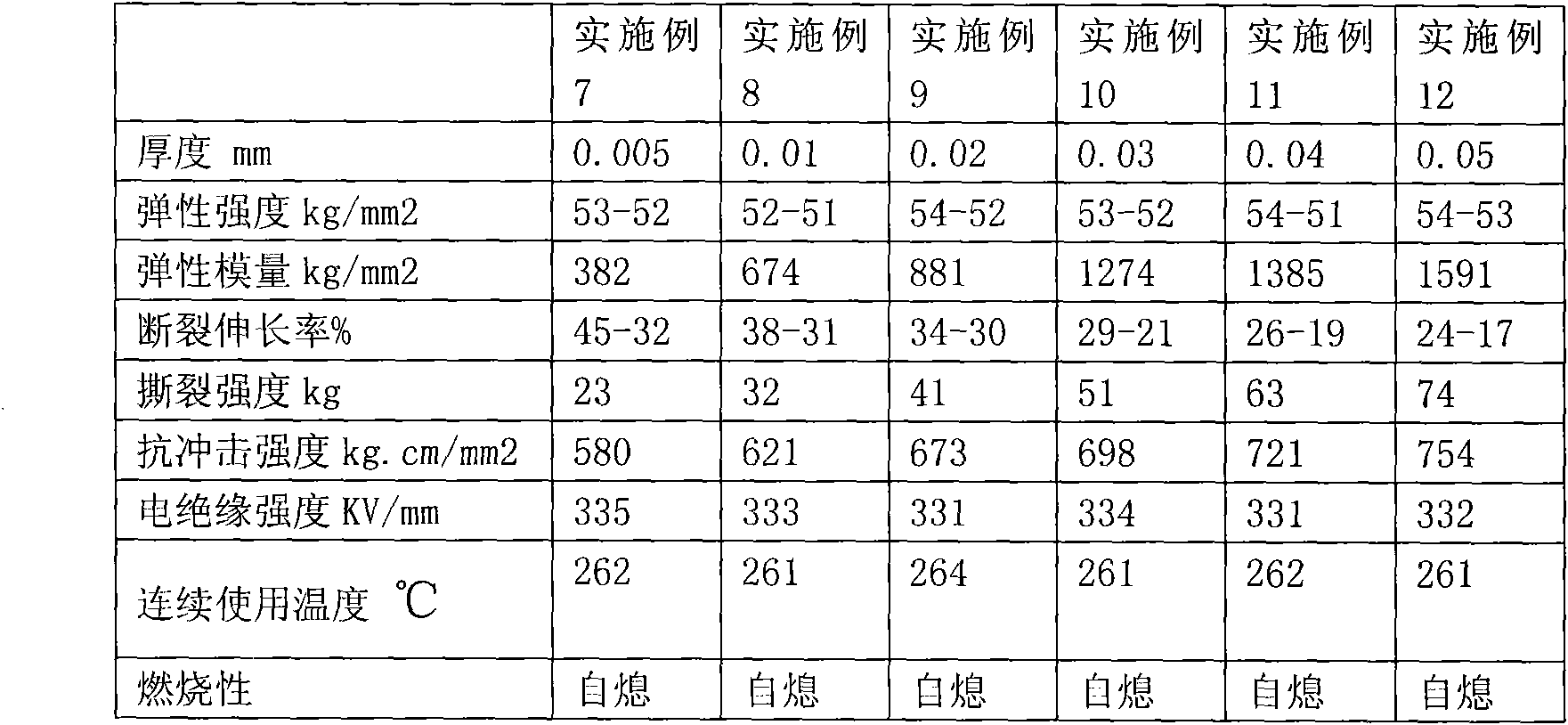

Manufacturing method of polyether-ether-ketone thin film

The invention discloses a manufacturing method of a polyether-ether-ketone thin film, which comprises the following steps: adopting 4,4'-difluoro benzophenone and bisphenol A as raw materials, adopting sulfolane as a solvent, carrying out condensation polymerization under the action of an alkali metal carbonate assistant for synthesizing polyether-ether-ketone resin; then adding 0.2-0.3% of inorganic nano-material and 5.0-8.1% of organic filler and other compounds or high-temperature elastomer material into the polyether-ether-ketone resin, mixing the substances into thin film raw materials according to a certain proportion, extruding the materials by a twin-screw extruder, passing through a T-shaped die with the width of 1-5mm and the length of 150-200mm, andfurther increasing the breadth of the thin film to 1000-2000m via two-way drafting and finally to obtain the polyether-ether-ketone thin film. The manufacturing method can be widely used in electronic and electrical appliances, war industry, aerospace, aviation and the like.

Owner:陈逊

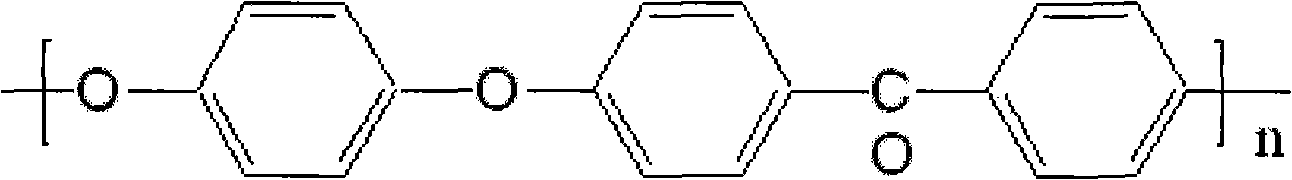

Electrophotographic organophotoreceptors with novel charge transport materials

InactiveUS6905804B2High quality imagingQuality improvementOrganic chemistryOrganic compound preparationArylHydrazone

Owner:S PRINTING SOLUTION CO LTD

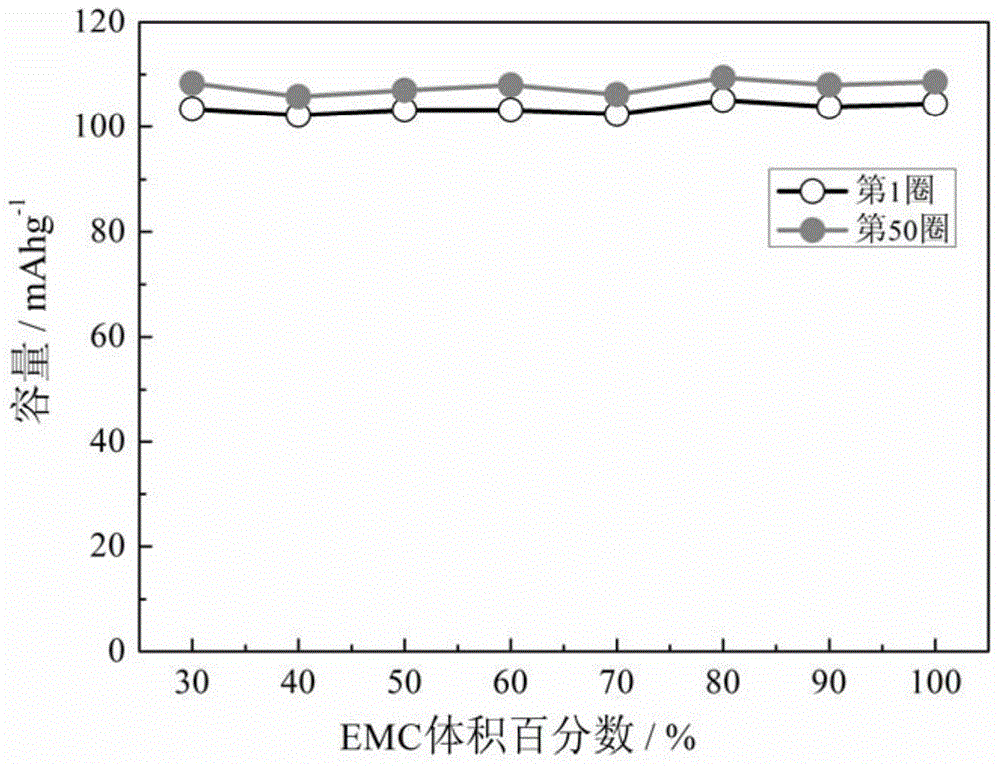

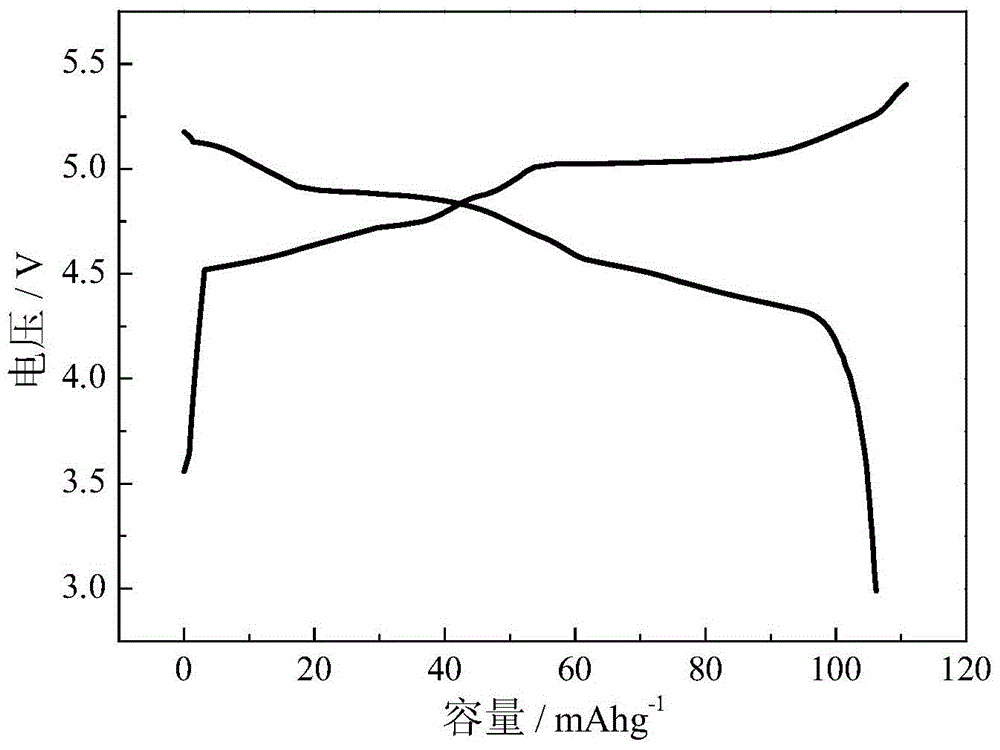

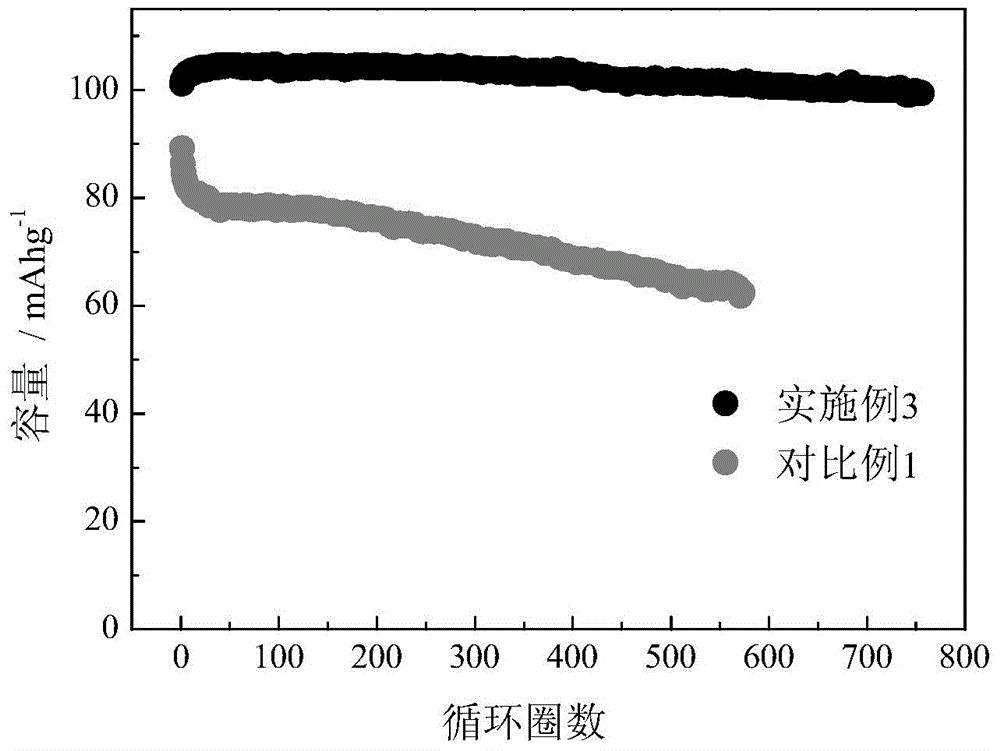

Dual-ion battery

The present invention provides a dual-ion battery, which comprises a graphite positive electrode, a negative electrode, a separation member and an electrolytic solution, wherein the separation member and the electrolytic solution are positioned between the positive electrode and the negative electrode, and the electrolytic solution comprises an electrolyte and an organic solvent. According to the present invention, the chain-like carbonate is adopted as the organic solvent of the electrolytic solution and has excellent anti-oxidation property so as to significantly increase the anti-oxidation capacity of the electrolytic solution, and the chain-like carbonate has low viscosity and further has characteristics of electrolyte solubility increase, substantial electrolytic solution conductivity improving, and substantial dual-ion battery rate property improving, such that the capacity and the cycle performance of the dual-ion battery are effectively improved; sulfolane is added to the organic solvent so as to improve the anti-oxidation capacity of the electrolytic solution and the coulombic efficiency of the dual-ion battery; and the experimental results show that the capacity of the dual-ion battery of the present invention is 10-110 mAh / g, and the capacity attenuation is not obvious after cycle 750 times.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI +1

Polymer electrolyte, and polymer electrolyte membrane, membrane-electrode assembly and fuel cell that are using the polymer electrolyte

InactiveUS20090117438A1Improve proton conductivitySmall size changeSolid electrolytesFinal product manufactureSulfolaneN dimethylformamide

The present invention provides polymer electrolyte that has the ion-exchange capacity of 1.7 meq / g or more and has the reduced viscosity of 160 mL / g or more at 40° C. when being made to be 1% by weight solution with at least one kind of solvent selected from the group consisting of N,N-dimethylformamide, N-methyl-2-pyrrolidone, dimethyl sulfoxide, N,N-dimethylacetamide, sulfolane, and γ-butyrolactone, and polymer electrolyte that has the ion-exchange capacity of 1.7 meq / g or more and the reduced viscosity of 160 mL / g or more at 40° C. when being made to be 1% by weight solution with at least one kind of solvent selected from the group consisting of N,N-dimethylformamide, N-methyl-2-pyrrolidone, and dimethyl sulfoxide.

Owner:SUMITOMO CHEM CO LTD

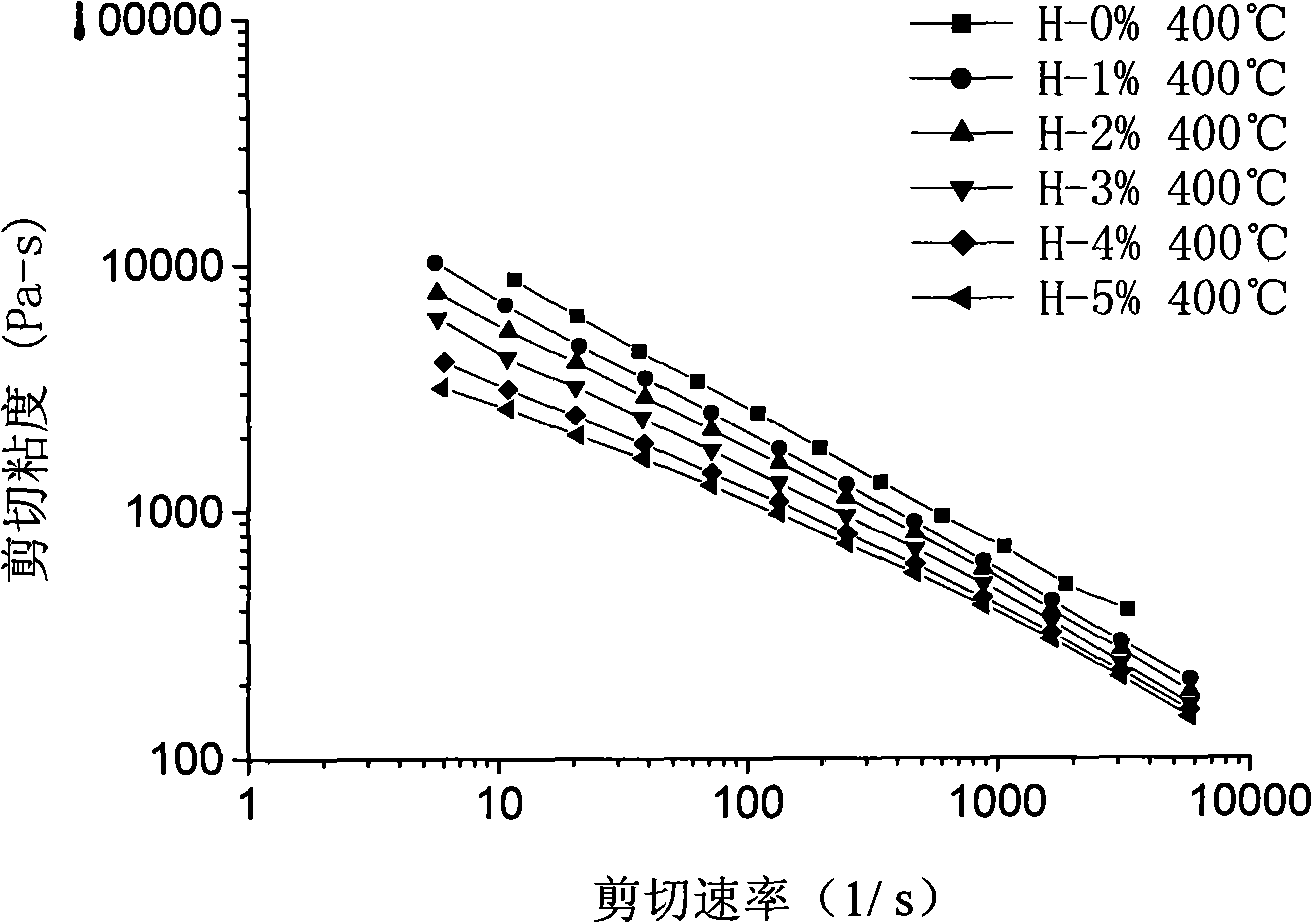

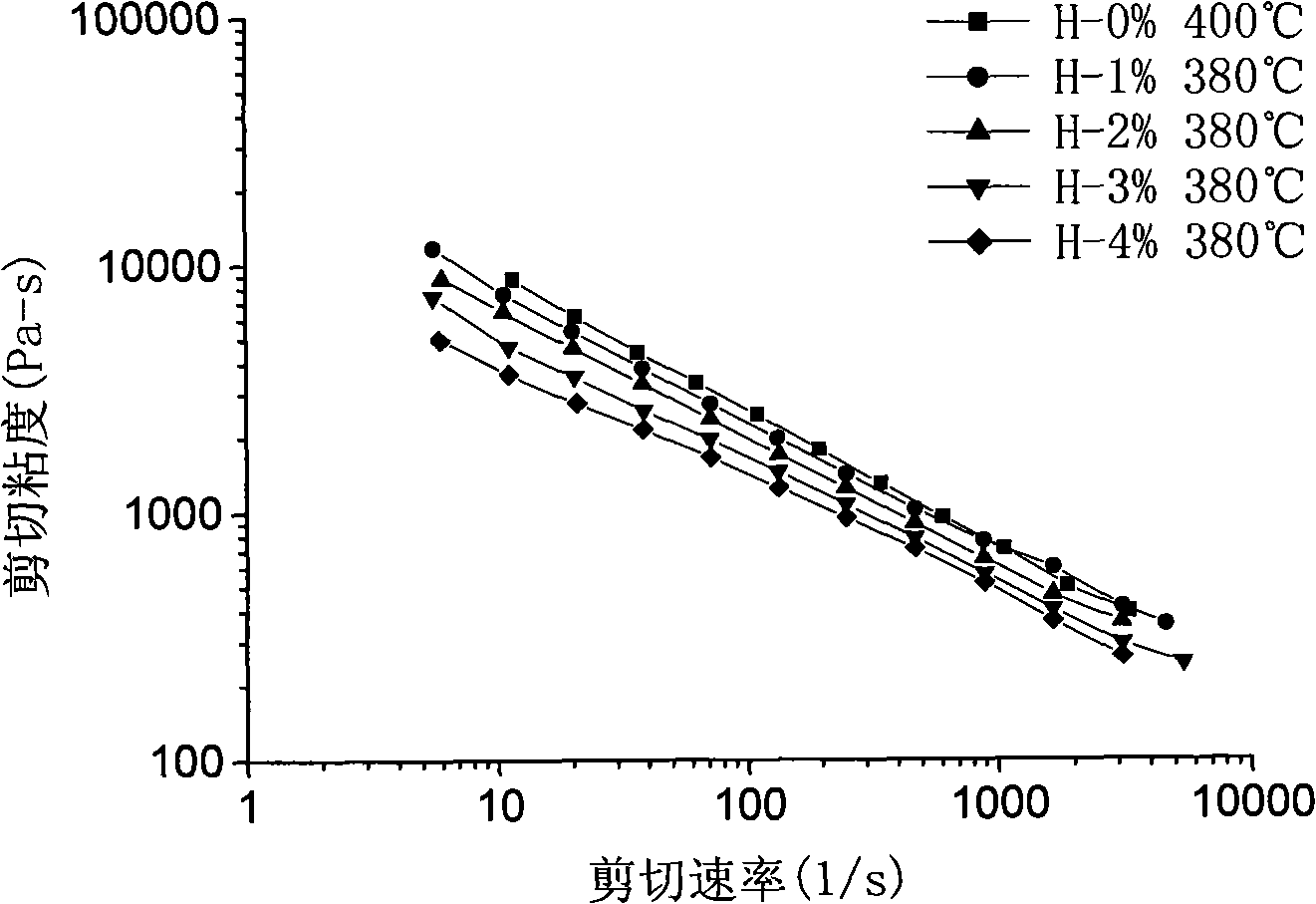

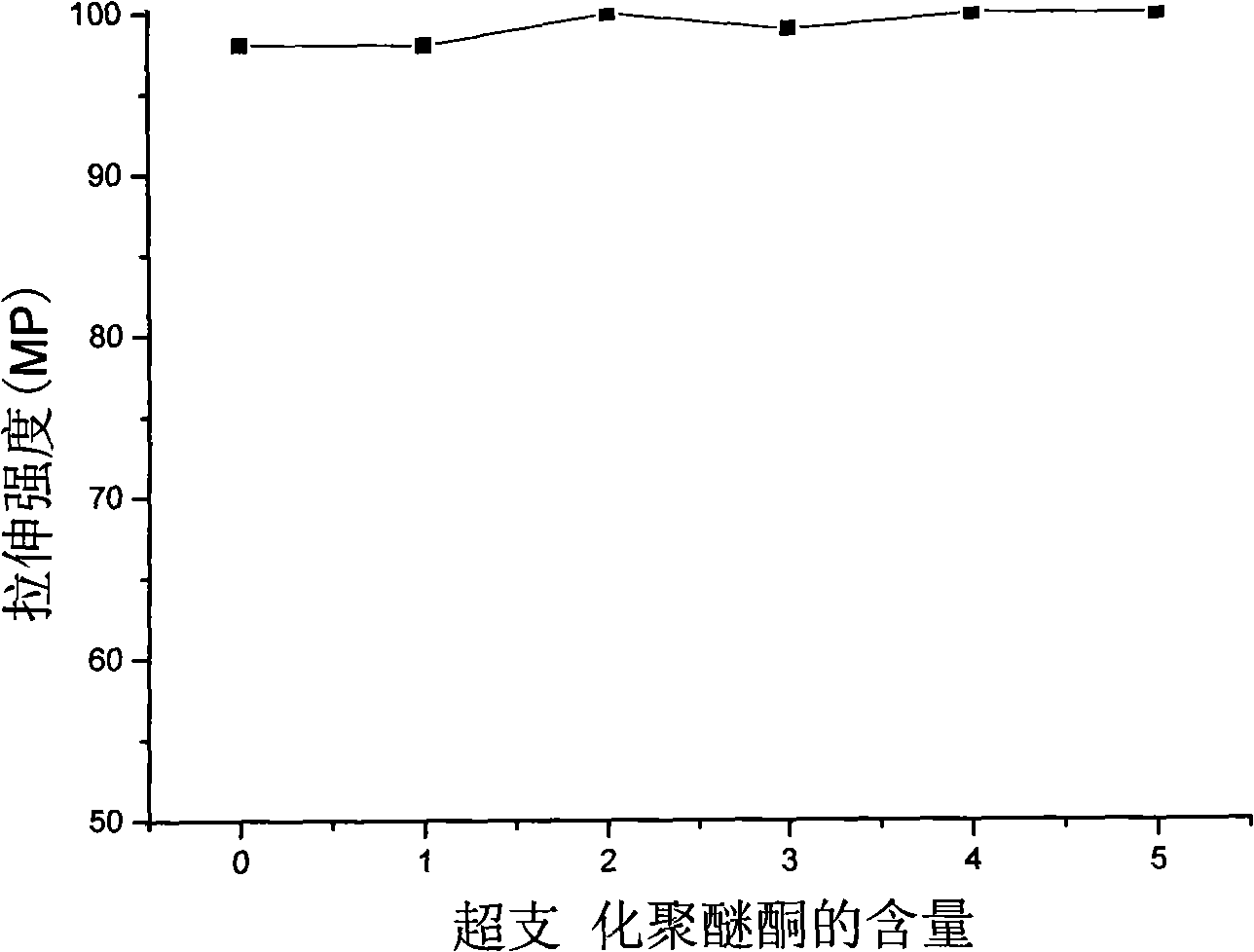

Hyperbranched poly(aryl ether ketone), preparation method and application thereof in viscosity modifier

The invention relates to a hyperbranched poly (ether ketone), a preparation method thereof and application of the material in viscosity modifiers. The hyperbranched poly(ether ketone) is prepared wit BB2-type monomers 2, 4, 6 trifluoro phenyl ketone and A2-type monomers hydroquinone, resorcin, bisphenol A, and hexafluoro-bisphenol A or biphenyl diphenol as reactants, potassium carbonate or sodium carbonate or the mixture of the potassium carbonate and the sodium carbonate as a salification agent, and sulfolane or N, N-dimethyl ketopyrrolidine as a solvent through mixing, salification, polycondensation reaction and after treatment. The solid content is 20 to 30 percent; the dosage of the salification agent is 1 to 1.1 time of the dosage of the A2 monomers. Fluorine terminated hyperbranched polyaryletherketone and hydroxy terminated superbranched polyaryletherketone are got respectively by adjusting the ratio of the dosages of the BB2-type and A2-type monomers. The hyperbranched poly (ether ketone) is characterized in that by adding the superbranched polyaryletherketone, the mechanical property and the thermostability of linear polyaryletherketone are not reduced while the melt viscosity of the linear polyaryletherketone is reduced.

Owner:JILIN UNIV

Co2 absorption from gas mixtures using an aqueous solution of 4-amino-2,2,6,6-tetramethylpiperidine

Owner:EVONIK DEGUSSA GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com