Patents

Literature

115 results about "Poly(ethylene glycol) dimethyl ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Citric acid polymers

InactiveUS20090325859A1Peptide/protein ingredientsGenetic material ingredientsPoly(ethylene glycol) dimethyl etherPolyethylene glycol

The present invention provides polymers (e.g., elastomeric citric acid polymers) and methods of making and using these polymers (e.g., as a biologically active molecule delivery platform). In certain embodiments, the polymer has adsorbed biologically active molecules. In particular embodiments, the polymer comprises pores that are between about 7 and 15 nanometers in diameter. In other embodiments, the polymer comprises poly(1,8 octanediol-co-ctric acid). In certain embodiments, the polymers are made by employing polyethylene glycol dimethyl ether (PEGDM).

Owner:NORTHWESTERN UNIV

Process for the purification of gases

InactiveUS6277345B1Improve efficiencyIncreased gas throughputHydrogenOrganic chemistryPoly(ethylene glycol) dimethyl etherHydrogen

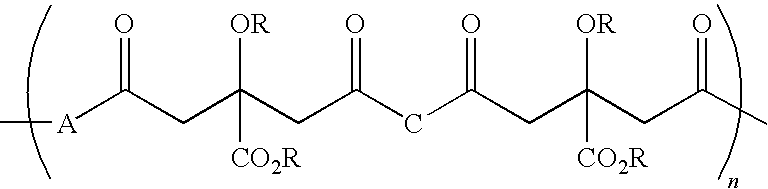

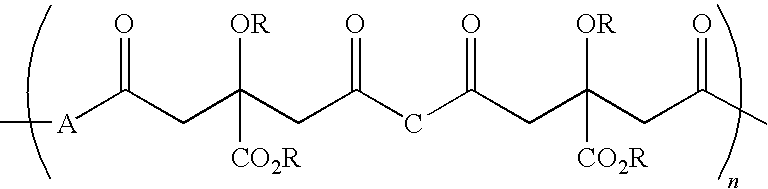

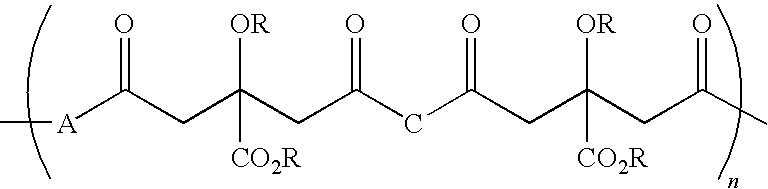

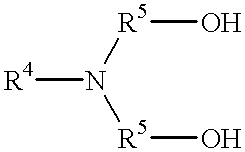

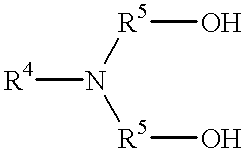

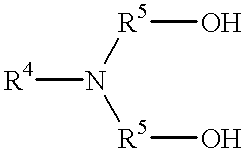

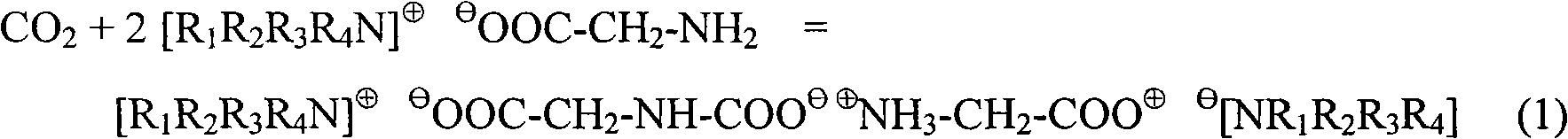

The present invention relates to the use of an absorption liquid for purifying a gas by removal of gaseous, acidic impurities. The gas to be purified can be any gas, such as synthesis gas or natural gas, which contains gaseous, acidic impurities such as CO2, H2S, SO2, CS2, HCN, COS or mercaptans. The absorption liquid comprises:A) from 0.01 to 4% by weight of at least one compound of the formulaB) from 0.001 to 8.0% by weight of water, andC) at least one polyalkylene glycol alkyl ether of the formulato 100% by weight,whereR1 is C1-C4-alkyl,R2 is ethylene or 2-methylethylene,R3 is hydrogen or C1-C4-alkyl,R4 is hydrogen or C1-C4-alkyl,R5 is C1-C4-alkylene andX is an integer from 1 to 10. The amine may be N-methyldiethanolamine and the ether may be polyethylene glycol dimethyl ether.

Owner:CLARIANT PROD DEUT GMBH

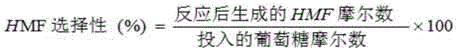

Special MDEA formula solution activated by functional ion liquid for CO2 gas absorption separation

InactiveCN101804292AReduce lossOvercome the disadvantage of high energy consumptionDispersed particle separationBy chemical separationSulfolanePoly(ethylene glycol) dimethyl ether

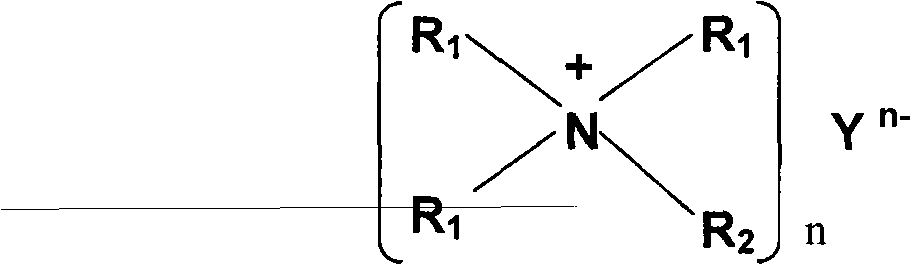

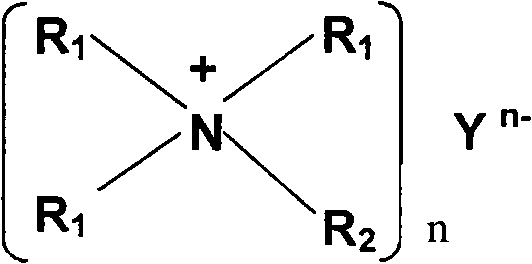

The invention relates to a special N-methyldiethanolamine formula solution activated by ion liquid for CO2 gas absorption separation, which consists of the following ingredients in mass percent: 35 to 50 percent of N-methyldiethanolamine, 5 to 20 percent of low-viscosity kalescent functional ion liquid, 15 to 30 percent of dimethyl ether of polyethlene glycol and / or sulfolane and 15 to 30 percent of water, wherein cations of the low-viscosity kalescent functional ion liquid are tetraalkylammonium ions, and anions of the low-viscosity kalescent functional ion liquid are amino acid radicals or organic carboxylate anions. The formula solution of the invention has the advantages that the high mass transfer performance of the absorption-desorption process is improved, the material consumption in the use process is low, the defect of high energy consumption because a large amount of water vapor is brought away during the absorbing agent regeneration, and the invention belongs to an energy-saving formula with high green degree. The regeneration temperature of the solution is lower than that of the traditional absorbing liquid, the grade of a heat source required to be provided in the regeneration process is reduced, energy sources can be saved, the stability of the absorbing agent solution in the operation is high, the consumption of each absorption-desorption circulation is low, and in addition, the cost is low.

Owner:NANJING UNIV

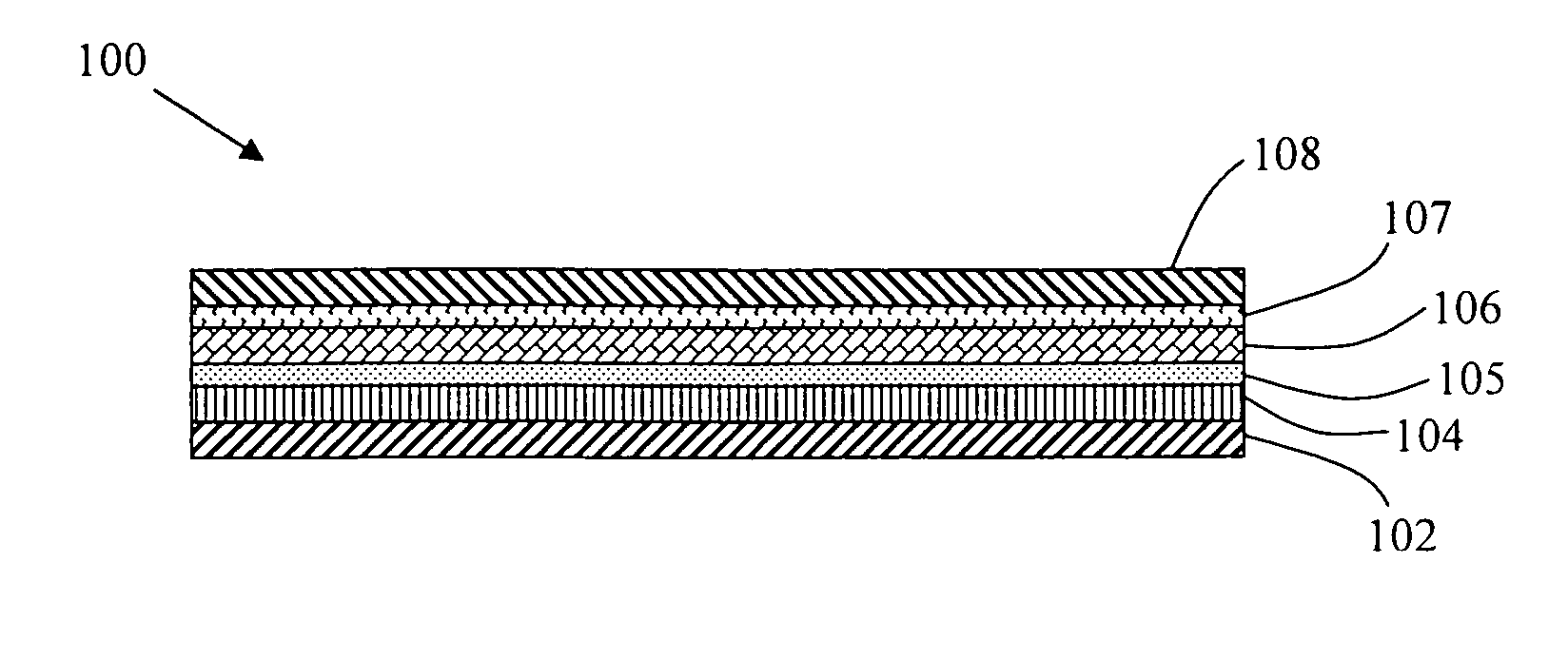

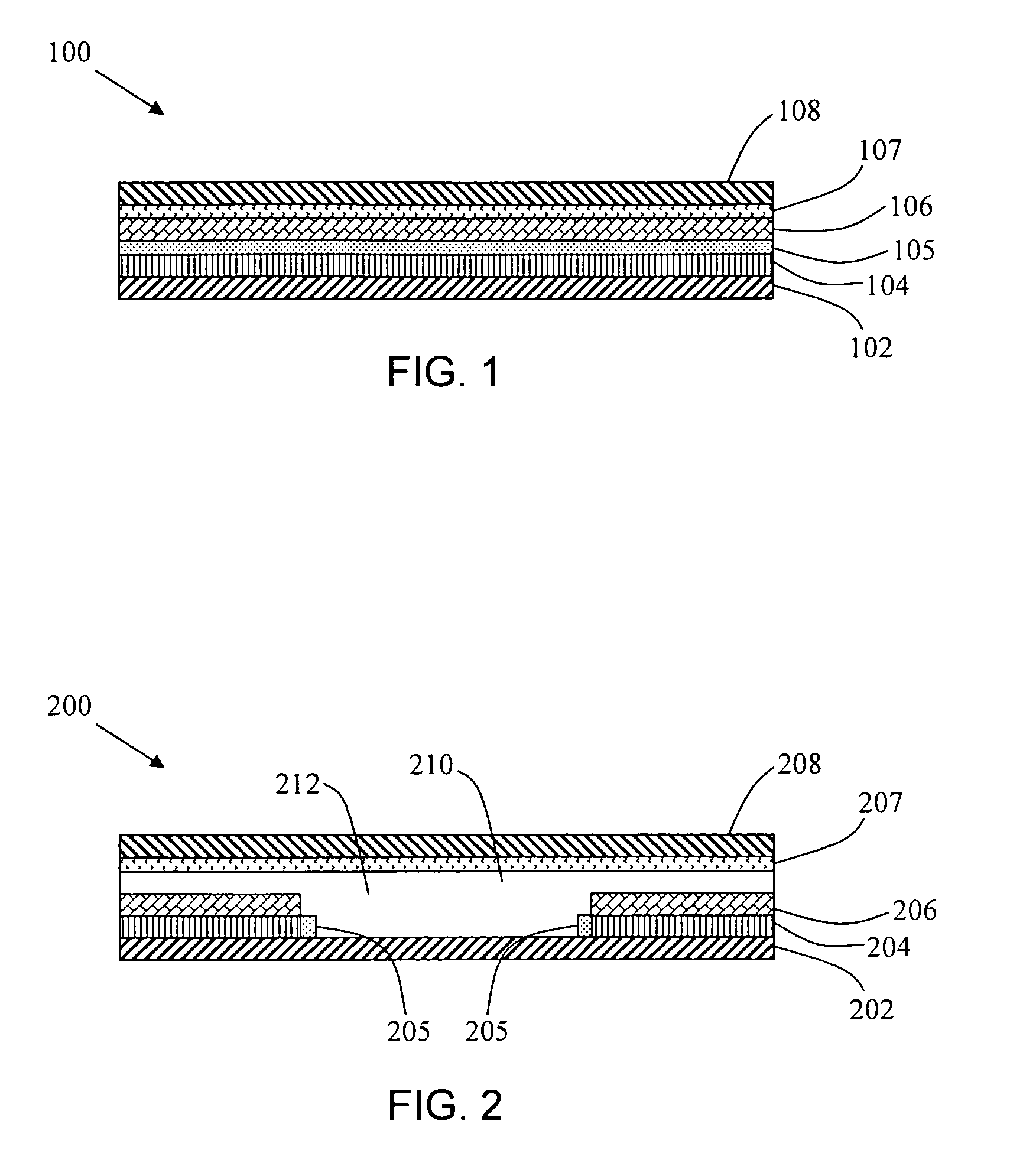

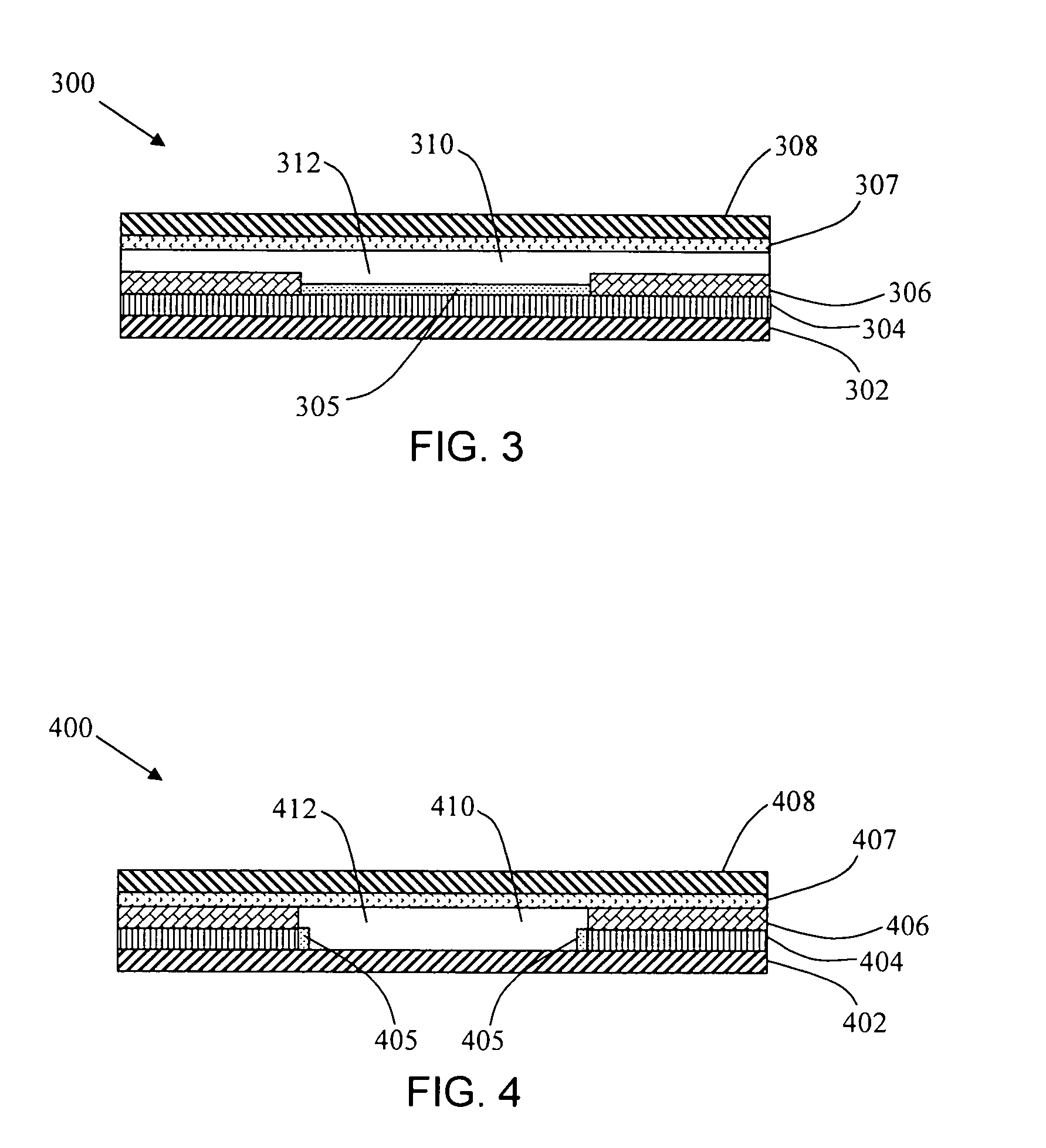

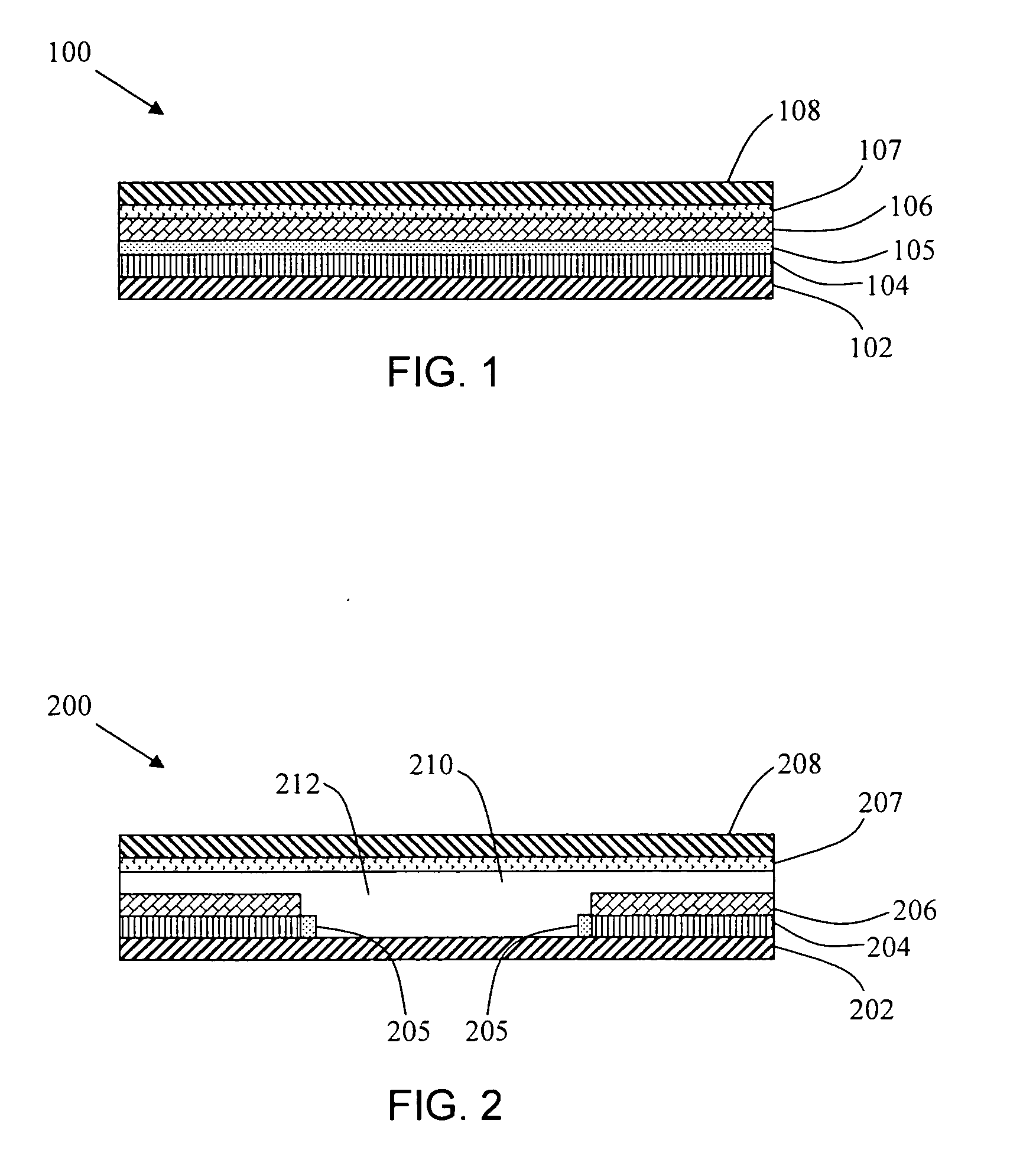

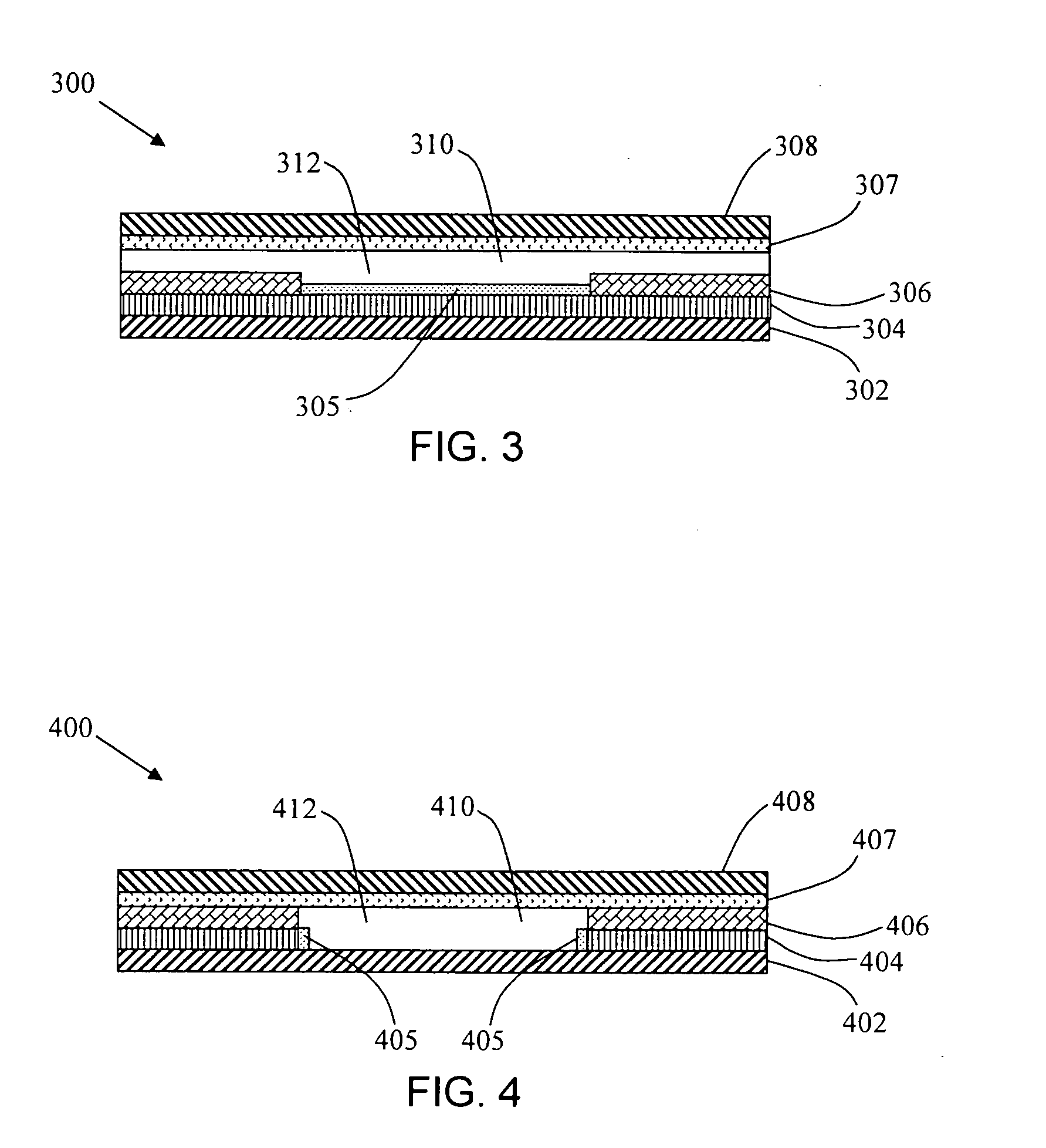

High efficiency electroluminescent devices and methods for producing the same

InactiveUS8574937B2High-efficiency and bright displaySolid-state devicesSemiconductor/solid-state device manufacturingElectricityPoly(ethylene glycol) dimethyl ether

Aspects of the disclosure include electroluminescent devices and methods for making the same. The devices include a substrate, a hole-injection electrode layer, an electroluminescent layer, and an electron-injection electrode layer, such as a layer that includes an air-stable, low work function material, which layer is capable of achieving efficient electron injection with reduced current leakage. In certain embodiments, the devices may contain an efficient electron injection layer that includes a composition comprising a polymer, e.g., a polymer that contains polar components (such as a polar functional group), and a metal diketonate. In certain embodiments, the devices may contain an electron injection layer that includes polyethylene glycol dimethyl ether and barium or calcium acetylacetonate. Methods of manufacturing such devices, for instance, employing a solution processing step for the deposition of an electron injection layer, as well as the use of the produced device(s) in electroluminescent displays is also provided herein.

Owner:SRI INTERNATIONAL

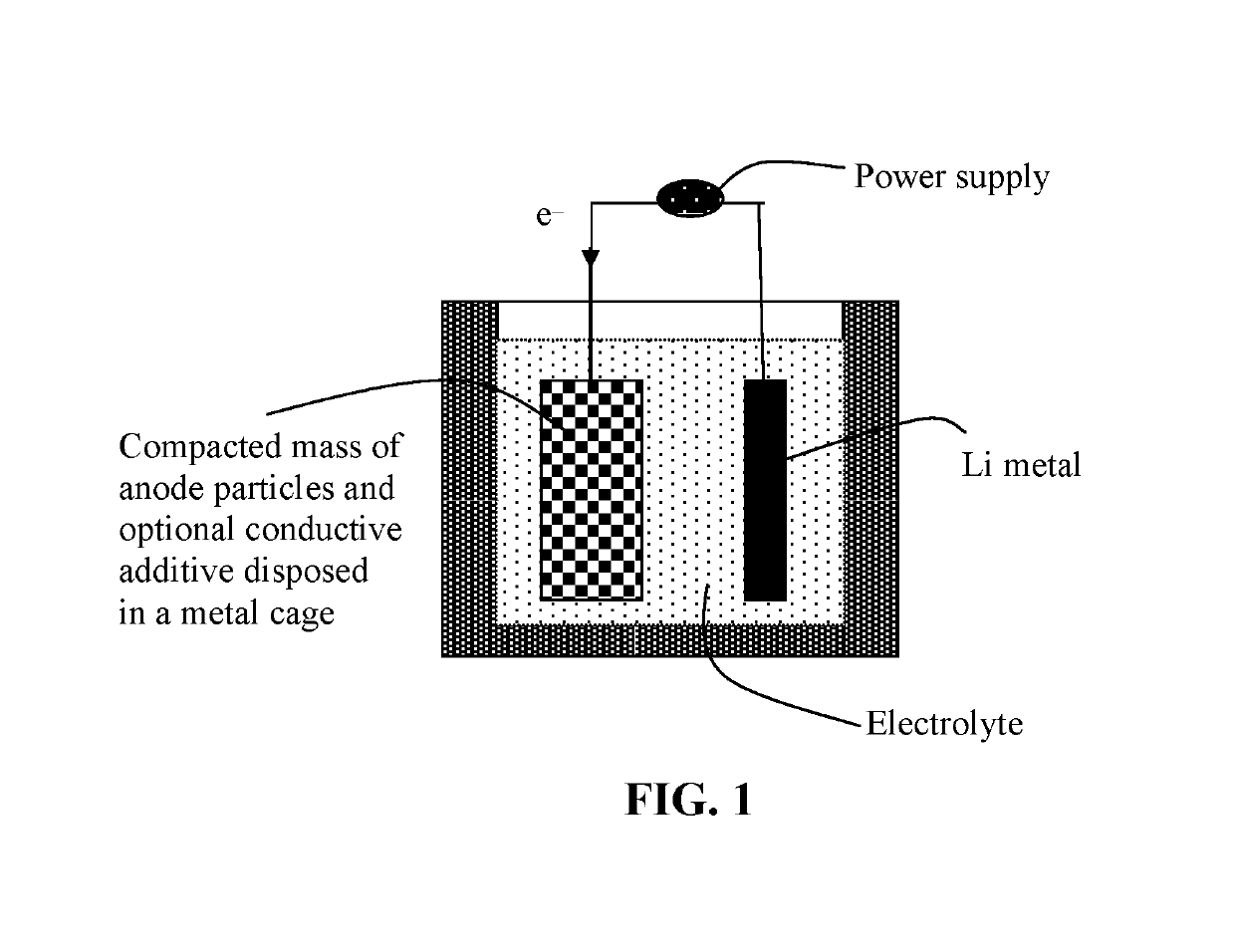

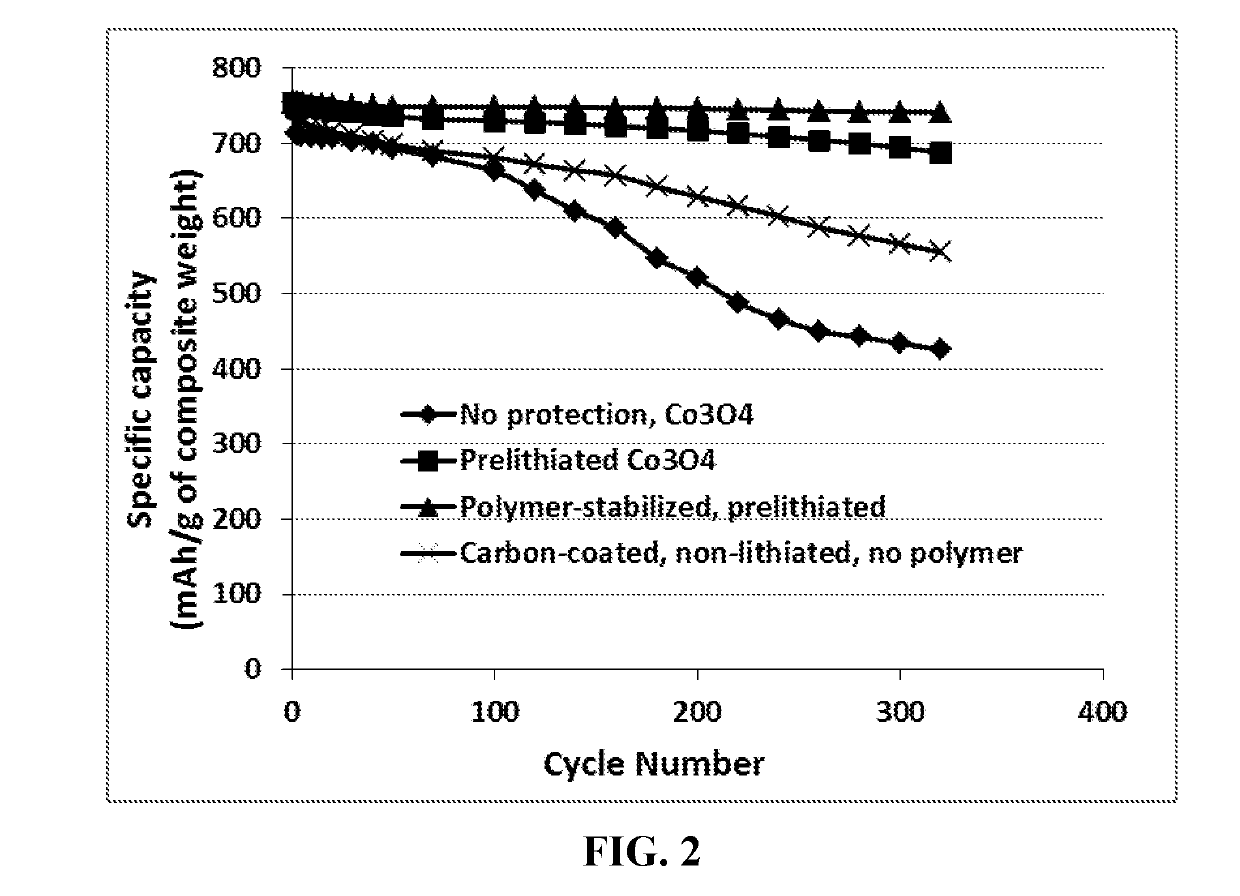

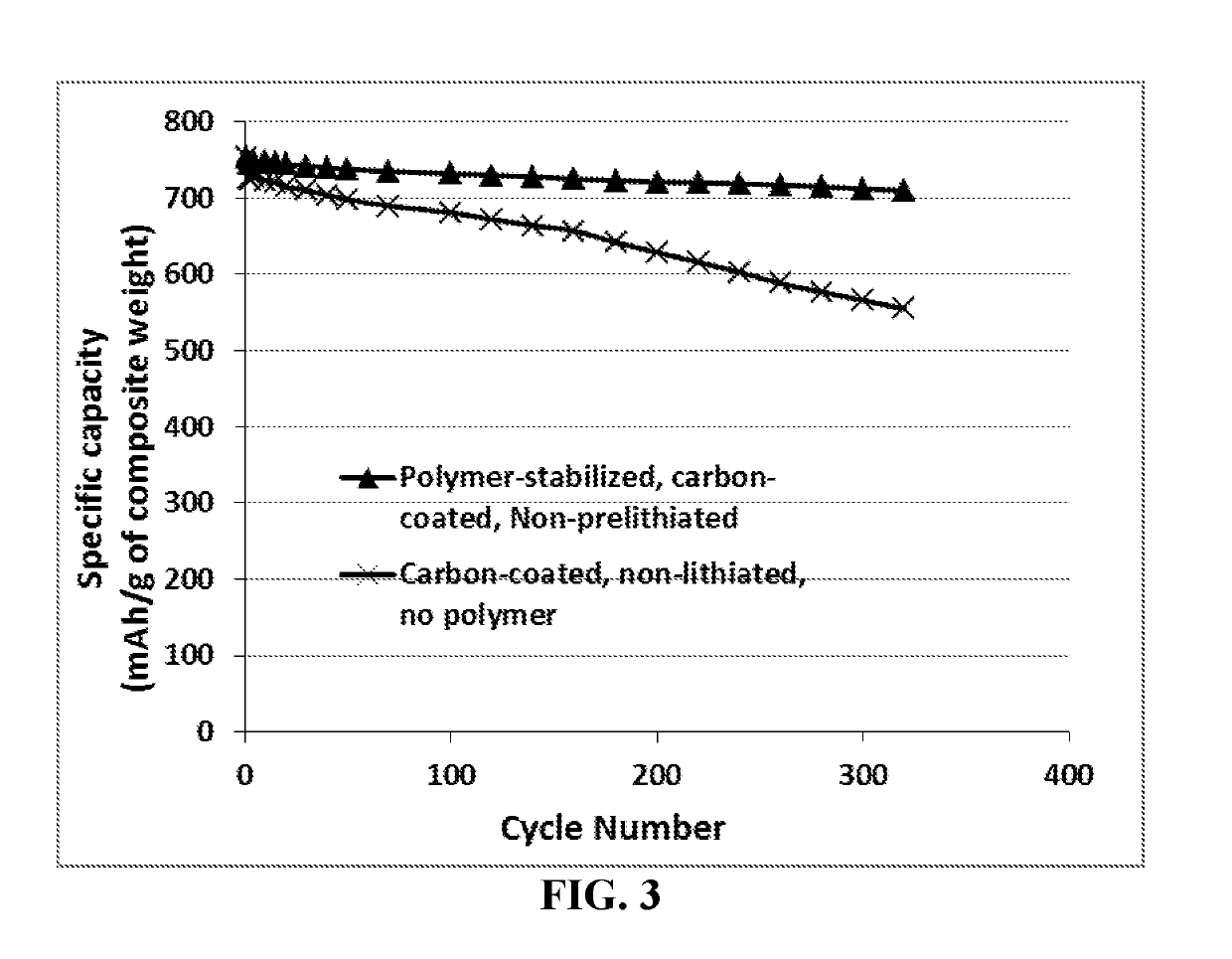

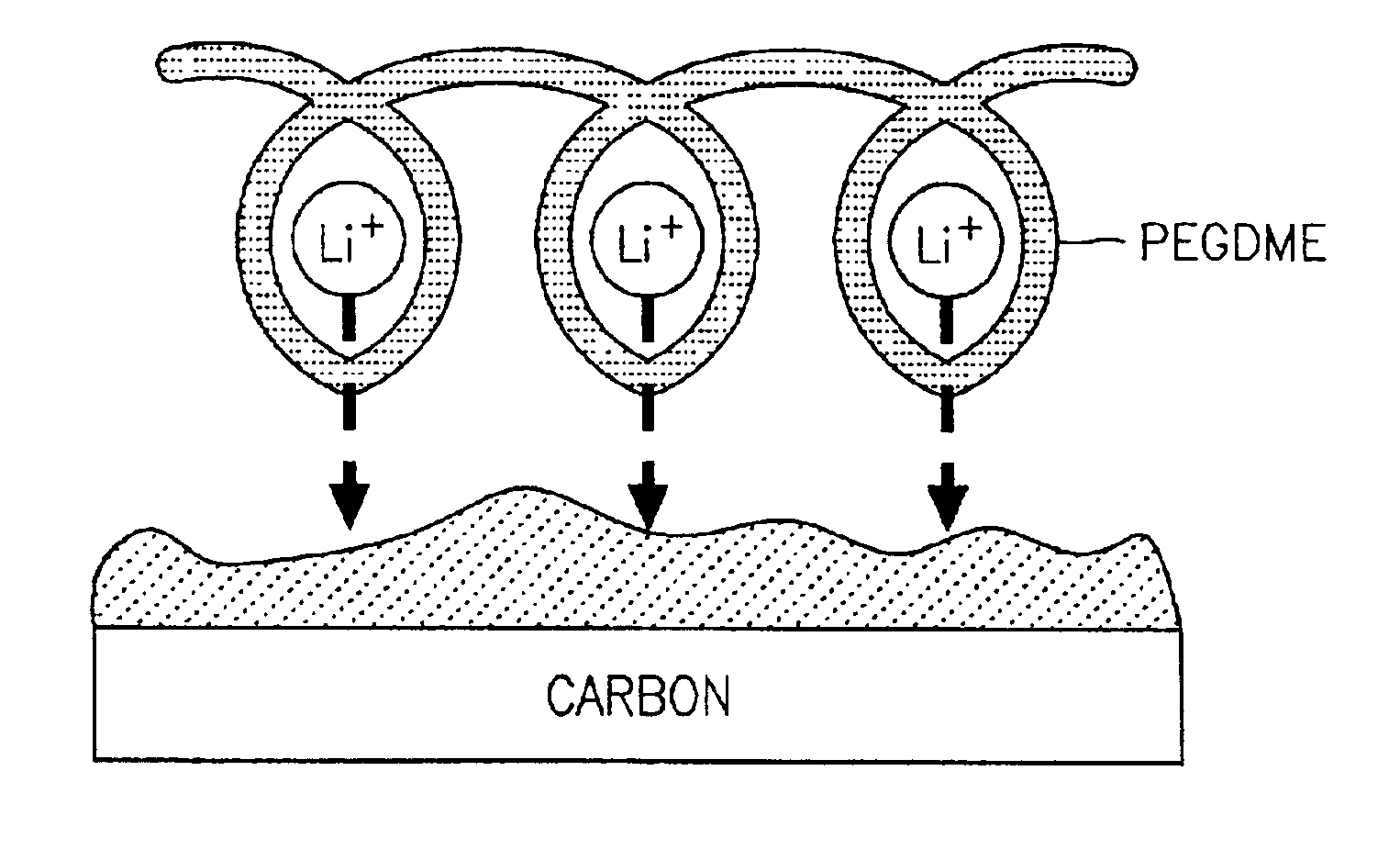

Surface-Stabilized Anode Active Material Particulates for Lithium Batteries and Production Method

ActiveUS20190115617A1High specific capacityLong charge-discharge cycle lifeElectrode manufacturing processesFinal product manufactureParticulatesPoly(ethylene glycol) dimethyl ether

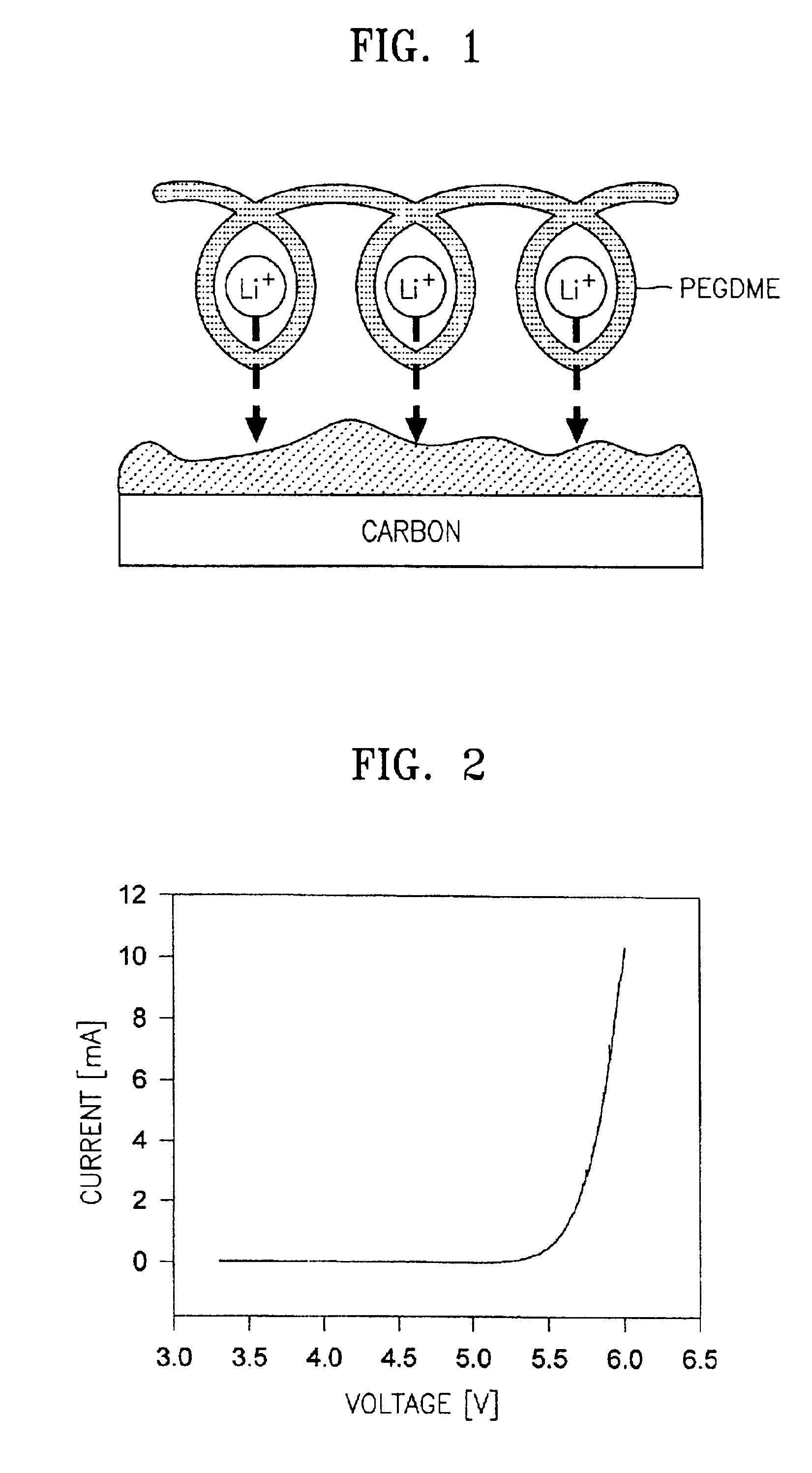

Provided is a surface-stabilized anode active material particulate (for use in a lithium battery), comprising: (a) one or a plurality of prelithiated or un-prelithiated anode active material particles (with or without a coating of carbon, graphene, or ion-conducting polymer); (b) a protecting polymer layer that wraps around, embraces or encapsulates the one or plurality of anode active material particles, wherein the protecting polymer layer has a thickness from 0.5 nm to 5 μm, and a lithium ion conductivity from 10−8 S / cm to 5×10−2 S / cm at room temperature and the protecting polymer layer contains a polymer selected from poly(ethylene oxide) (PEO), polypropylene oxide (PPO), poly(acrylonitrile) (PAN), poly(methyl methacrylate) (PMMA), poly(vinylidene fluoride) (PVdF), poly bis-methoxy ethoxyethoxide-phosphazene, polyvinyl chloride, poly(vinylidene chloride), polydimethylsiloxane, poly(vinylidene fluoride)-hexafluoropropylene (PVDF-HFP), polyethylene glycol (PEG), a PEG derivative, polyethylene glycol methyl ether, polyethylene glycol dimethyl ether, a sulfonated polymer, or a combination thereof.

Owner:GLOBAL GRAPHENE GRP INC

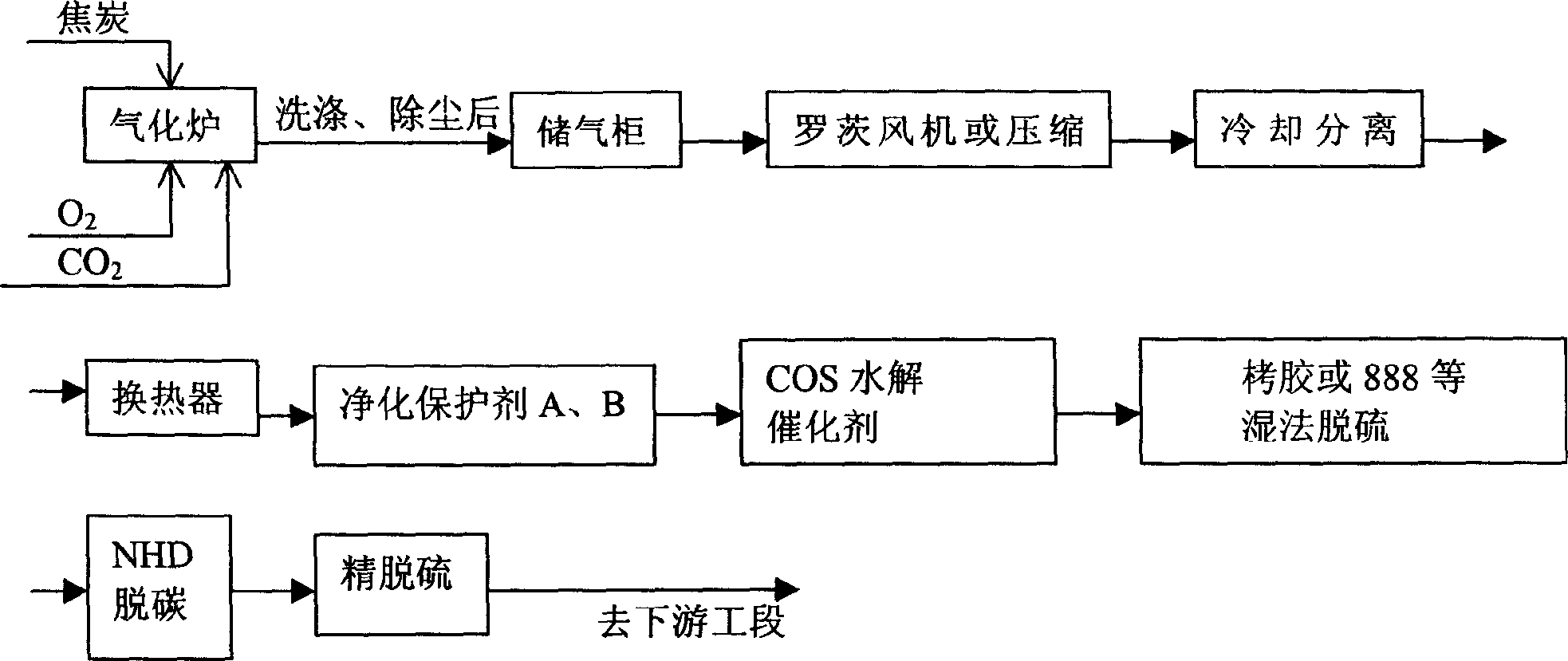

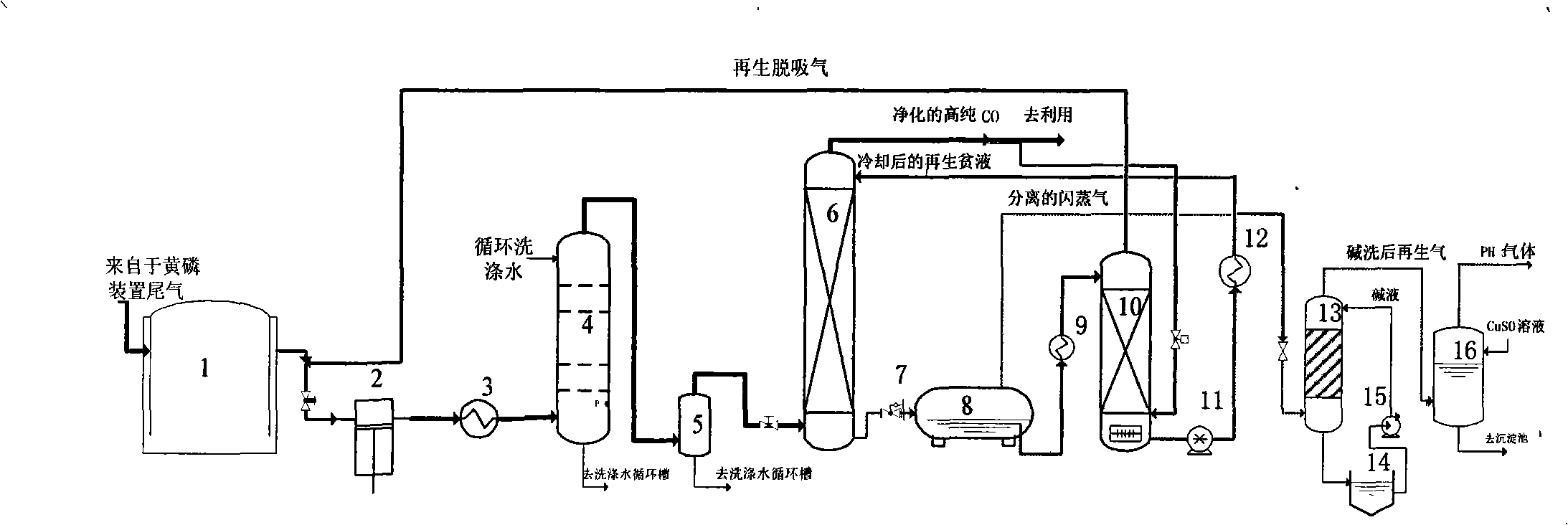

Process for preparing high purity carbon monoxide gas by desulfurization of organic sulfur at low and normal temperature

ActiveCN1844326AAchieve recyclingImprove and protect the ecological environmentCombustible gas purificationPoly(ethylene glycol) dimethyl etherDesorption

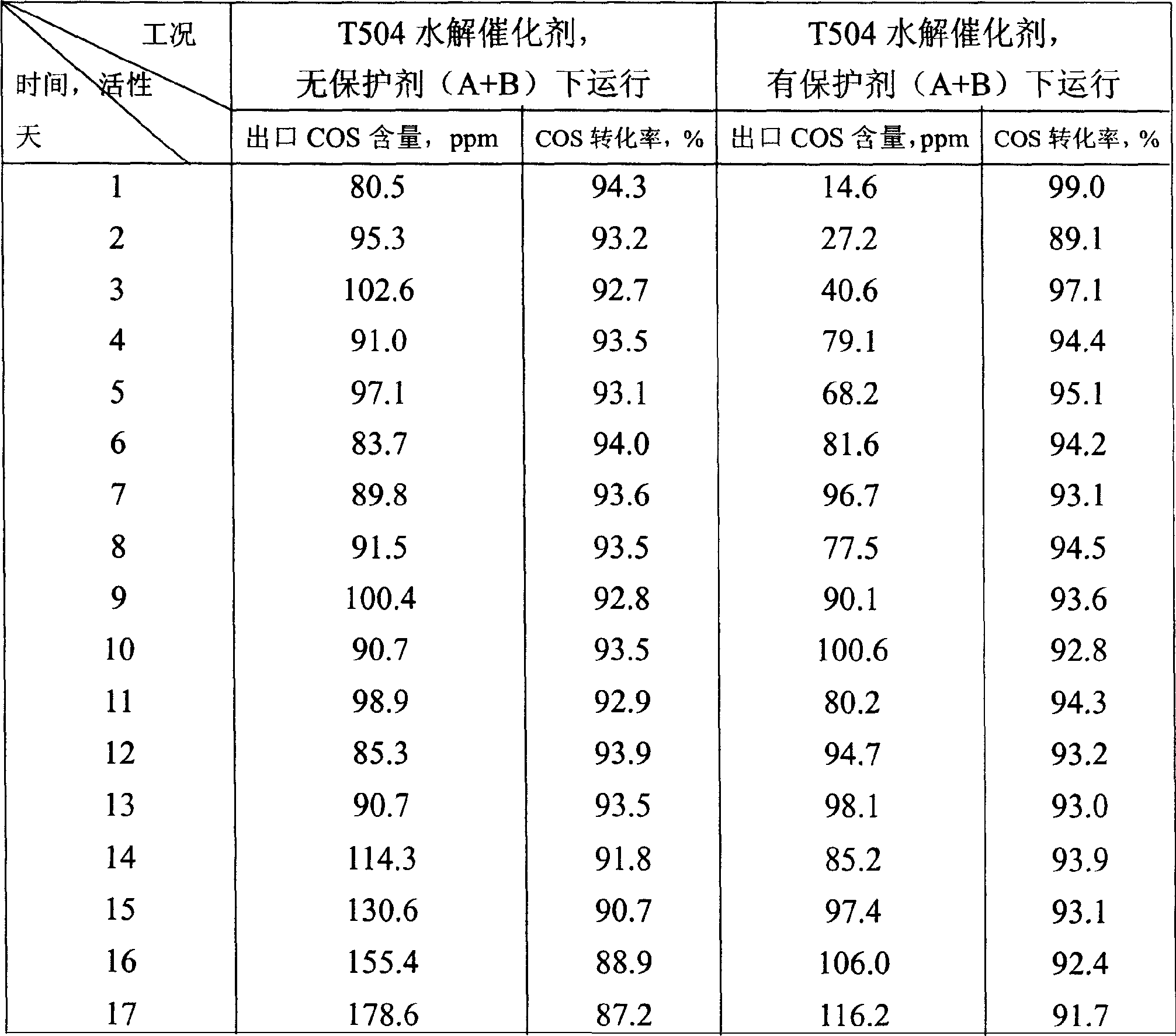

The invention relates to a technology for removing organic sulfur at a low or normal temperature to prepare high-purity carbonic oxide gas. The method consists of gasifying the coke with carbon monoxide or carbon dioxide to prepare the raw gases including 10 % -99 % CO, 0.1 %-90 % CO2, 0.001 %-2 % O2, 50-9000ppm COS, 10-10000ppm H2S, through gas storage holder, after pressurization and pyrogenation, entering purification tower filled with puripreservatives of A and B to remove hazardous materials including nitrogen oxide, hydrogen arsenide, hydrogen phosphide, hydrogen chloride, hydrogen nitrile, oxides of sulfur and sulfureted hydrogen, entering tower for removing organic sulfur filled with sulfur carbonyl hydrolyst, hydrolyzing 85%-95% of sulfur carbonyl for conversion into sulfureted hydrogen, at 20-150 DEG C, with a pressure of 0.1-10 MP, in which the refined raw gases can be used by productions of fine chemical industry including downstream acetate, dimethyl formamide,dimethyl ether, toluene diisocyanate or methyl diphenylene diisocyanate. The technology converts 85 %-95 % of sulfur carbonyl into sulfureted hydrogen, can adopt routine wet desulfurization to replace polyethylene glycol dimethyl ether desulfuration,can carry out cycle utilization of carbon dioxide and sulfur carbonyl of decarburized desorption gases of polyethylene glycol dimethyl ether, and can carry out zero discharge of poison material of sulfur carbonyl, which is good for environmental conservation.

Owner:HAISO TECH +1

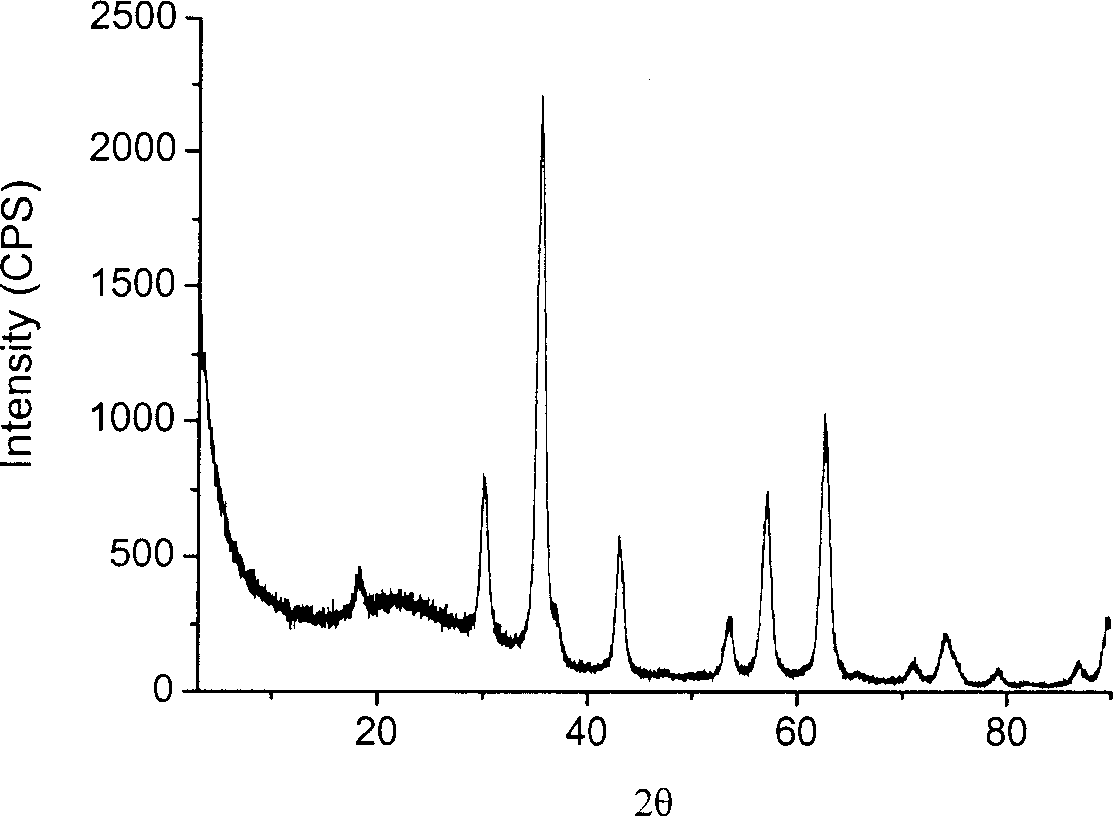

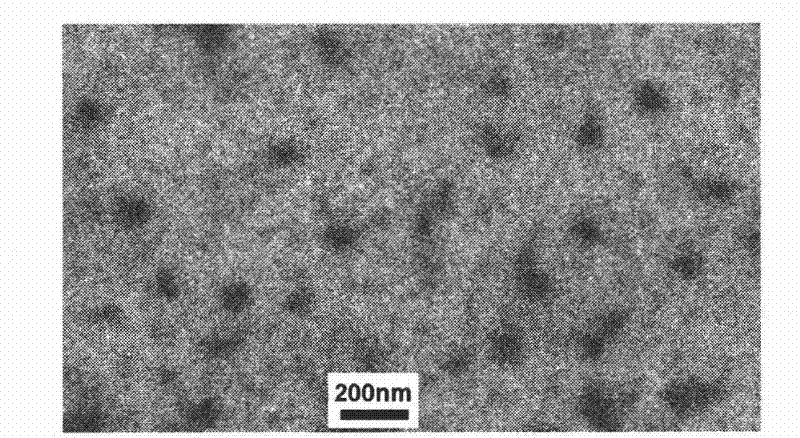

Method for producing water dispersing magnetic nano particle with high-crystallinity

InactiveCN1549283AUniform and controllable particle sizeHigh crystallinityNanostructure manufactureInductances/transformers/magnets manufactureFerric oxalateIron salts

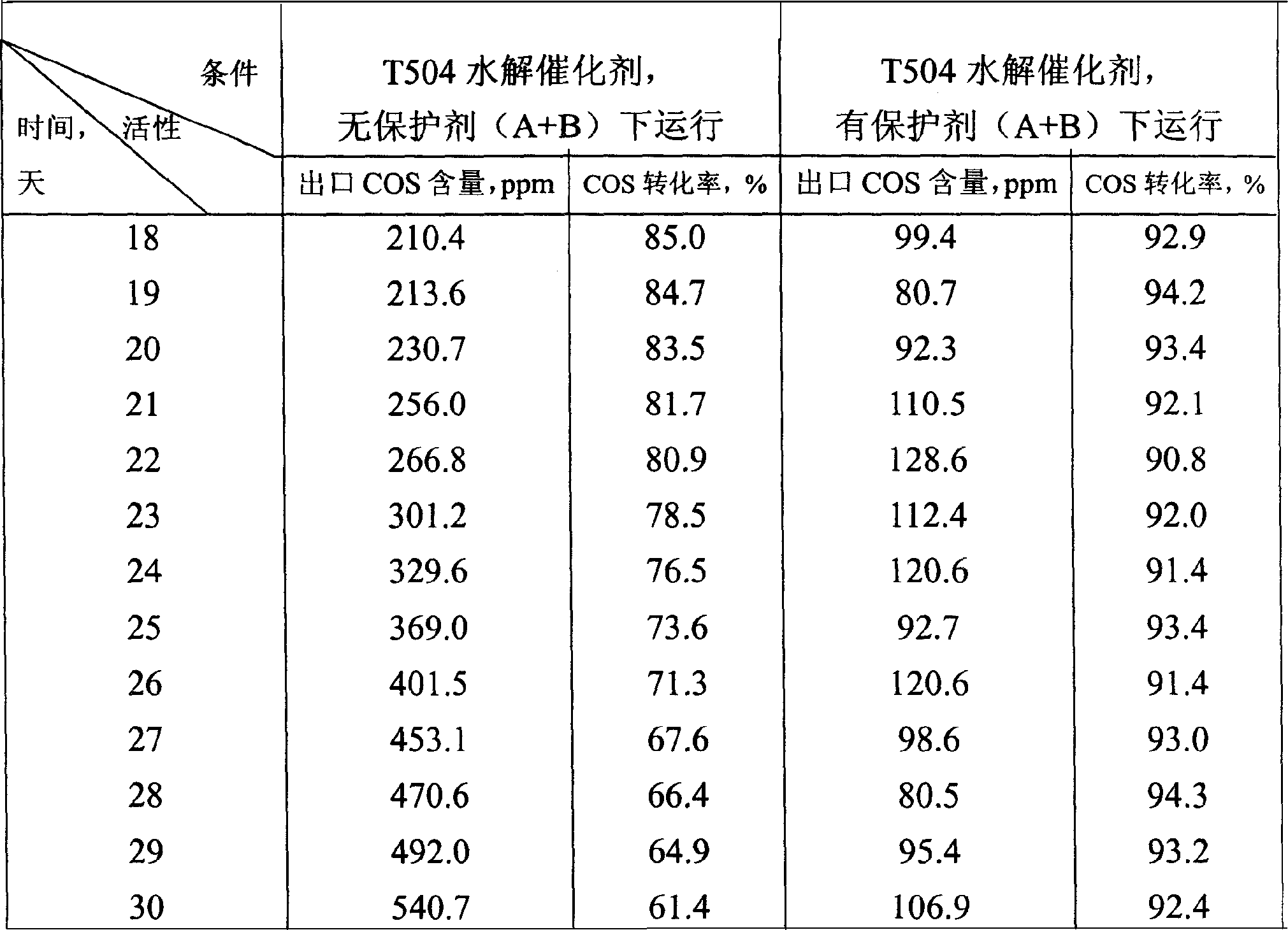

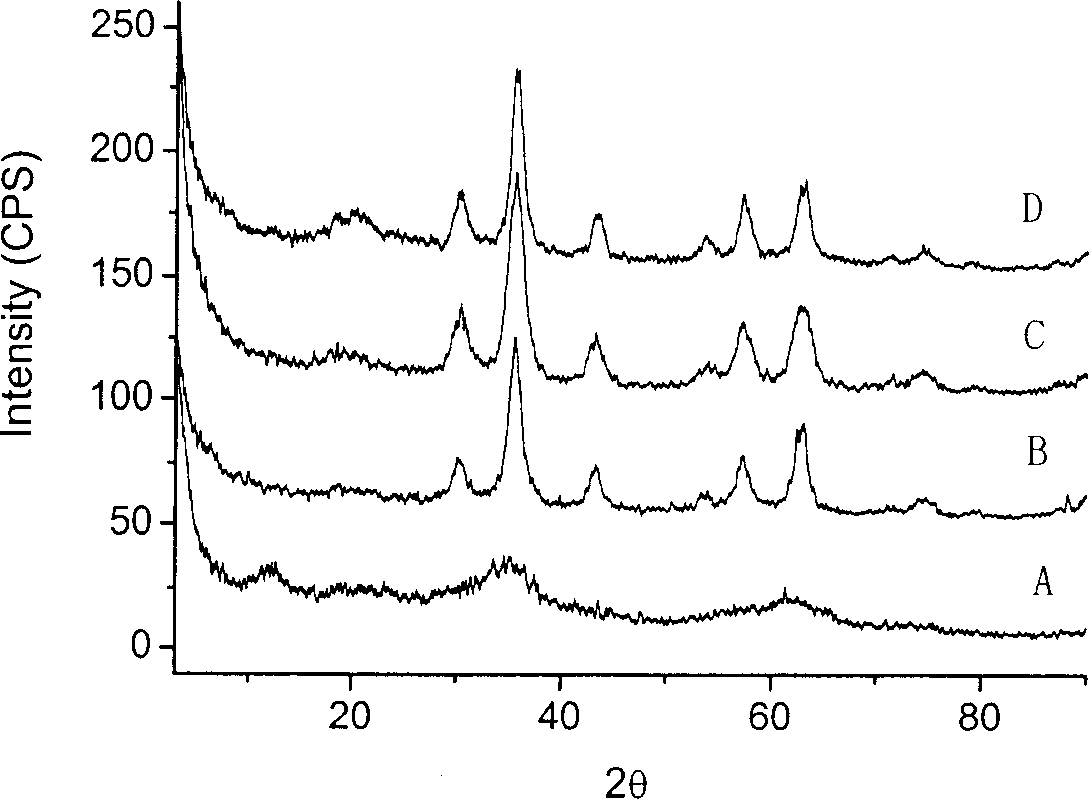

The new method for preparing high crystallinity monodisperse water-soluble magnetic nano microparticles is characterized by that it selects the inorganic iron salts of anhydrous iron trichloride and iron chloride, etc. or metal organic iron compounds (such as iron pentacarbonyl, iron triacetylacetonate, iron biacetylacetonate, complex of cupferron and iron salt, iron octoate and ferric oxalate, etc.) as iron raw material, and utilizes high-temp. decomposition of them in high boiling point polar solvent (for example alpha-pyrrolidone and its derivatives (N-methyl-2-pyrrolidone and N-ethyl-2-pyrrolidone, etc.), N,N-dimethyl-2-imidazolone, hexametapol, gamma-butyrolactone and its derivative and low molecular weight (molecular weight M is less than or equal to 5000) polyglycol and its derivatives) to prepare magnetic nano microparticles. Said invention can adopts different iron raw materials and high boiling point polar solvents so as to obtain different types of magnetic nano microparticles (Fe, Fe2O3 and Fe3O4) with different sizes and crystallinities and different crystal structures.

Owner:苏州欣影生物医药技术有限公司

Synthesis method of fluorocyclotriphosphazene

ActiveCN105732718AHigh yieldImprove catalytic performanceGroup 5/15 element organic compoundsSecondary cellsPoly(ethylene glycol) dimethyl etherOrganic solvent

The invention discloses a synthesis method of fluorocyclotriphosphazene. The synthesis method includes: dissolving chlorocyclotriphosphazene in an organic solvent; adding a fluorinating agent and a catalyst for reaction for 1-20 h to obtain fluorocyclotriphosphazene. The catalyst accounts for 1-20% of total mass of raw materials and is polyethylene glycol, methoxypolyethylene glycol or polyethylene glycol dimethyl ether.Polyethylene glycol, methoxypolyethylene glycol or polyethylene glycol dimethyl ether is used as the catalyst and is nontoxic, low in price and high in catalytic capability; using of polyethylene glycol, methoxypolyethylene glycol or polyethylene glycol dimethyl ether can greatly increase fluorinating reaction speed and lower cost. Polyethylene glycol, methoxypolyethylene glycol or polyethylene glycol dimethyl ether is used, yield of synthetic fluorocyclotriphosphazene is increased, and yield is higher than 92% and is up to 99% maximumly.

Owner:SHANDONG ZESHI NEW MATERIALS TECH CO LTD

Desulfurization and decarburization integrated absorption process for polyglycol dimethyl ether

InactiveCN101492616ALess investmentSimple processCombustible gas purificationPoly(ethylene glycol) dimethyl etherTower

The invention discloses an NHD desulphurization-decarbonization absorption process. The invention is characterized in that the NHD desulphurization and decarbonization are finished in one absorption tower, systemic circulation is low, running equipment is less, and hydrogen sulphide at the outlet of the absorption tower is not more than or equal to 2ppm and CO2 index can be less than or equal to 5% according to follow-up product requirement. The concentration of the hydrogen sulphide in regenerated acid gas is over 70%, and the hydrogen sulphide can be directly used by downstream products. The invention has the advantages of simple process, reasonable energy utilization, convenient operation, low investment and small occupied space, and is suitable for the purification system for producing methanol, synthetic ammonia or other gases.

Owner:YANKUANG LUNAN CHEM FERTILIZER PLANT

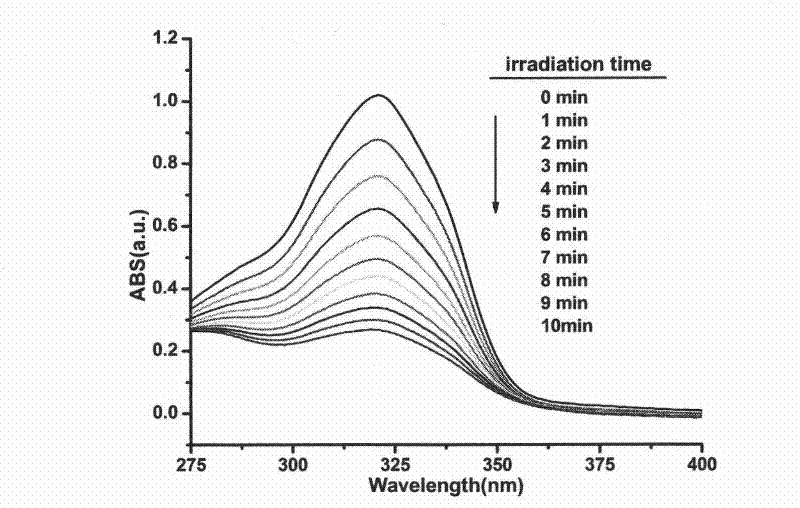

Preparation method of coumarin-modified hyaluronic acid graft micelle emulsifier

InactiveCN102344501AEasy to useImprove hydrophobicityCosmetic preparationsToilet preparationsPoly(ethylene glycol) dimethyl etherUltraviolet

The invention discloses a preparation method of a coumarin-modified hyaluronic acid graft micelle emulsifier. The preparation method comprises the following steps that 1, carboxyl groups in a main chain of hyaluronic acid undergo an esterification reaction with hydroxy groups of 7-hydroxy-4-methylcoumarin in the presence of polyethylene glycol dimethyl ether as a phase transfer agent to produce a graft HA-g-Coumarin; and 2, the graft HA-g-Coumarin can carry out self-assembly to form nanometer micelles, wherein the nanometer micelles are dispersed steadily in an oil-water interface and are separated from the oil-water interface to form a stable emulsification disperse system. The preparation method of the coumarin-modified hyaluronic acid graft micelle emulsifier HA-g-Coumarin has the advantages of simple preparation technology, mild conditions, favorable function of absorbing ultraviolet rays having a certain wavelength, and good application prospects in the field of cosmetic-based sunburn prevention.

Owner:JIANGNAN UNIV

High Efficiency Electroluminescent Devices and Methods for Producing the Same

InactiveUS20110042657A1High-efficiency and bright displaySolid-state devicesSemiconductor/solid-state device manufacturingPoly(ethylene glycol) dimethyl etherElectron injection

Aspects of the disclosure include electroluminescent devices and methods for making the same. The devices include a substrate, a hole-injection electrode layer, an electroluminescent layer, and an electron-injection electrode layer, such as a layer that includes an air-stable, low work function material, which layer is capable of achieving efficient electron injection with reduced current leakage. In certain embodiments, the devices may contain an efficient electron injection layer that includes a composition comprising a polymer, e.g., a polymer that contains polar components (such as a polar functional group), and a metal diketonate. In certain embodiments, the devices may contain an electron injection layer that includes polyethylene glycol dimethyl ether and barium or calcium acetylacetonate. Methods of manufacturing such devices, for instance, employing a solution processing step for the deposition of an electron injection layer, as well as the use of the produced device(s) in electroluminescent displays is also provided herein.

Owner:SRI INTERNATIONAL

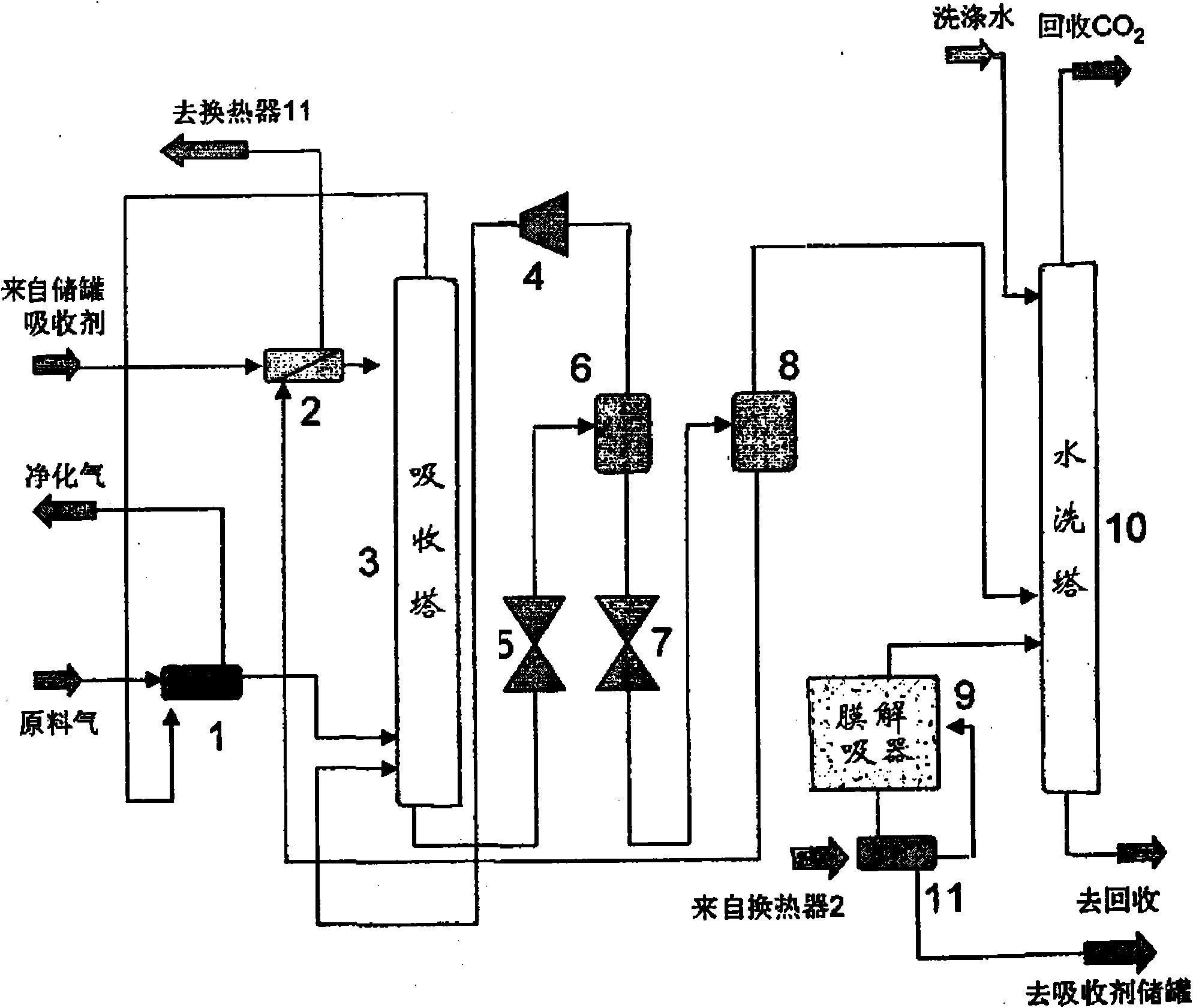

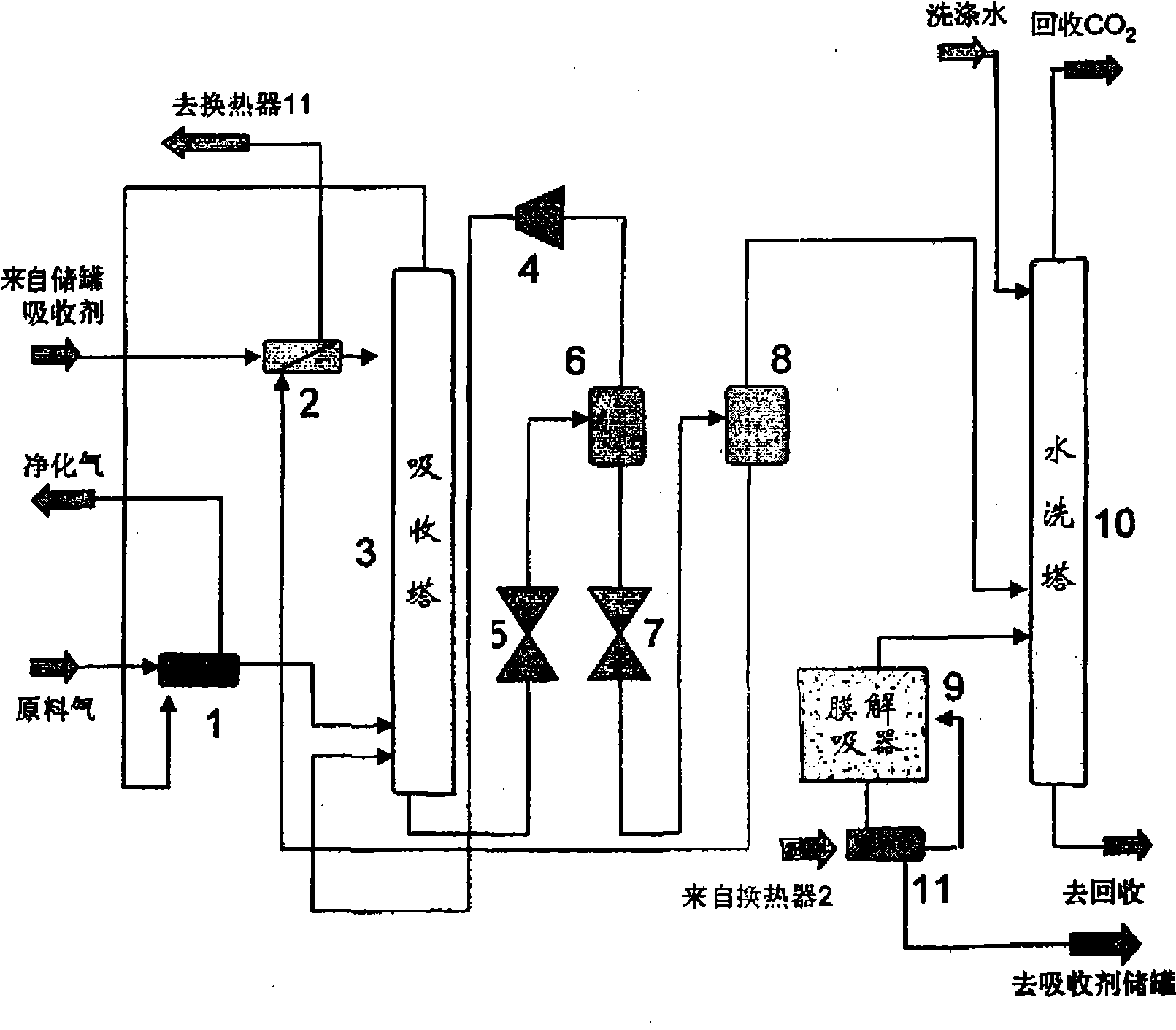

CO2 trapping method combining dimethyl carbonate absorption and membrane desorption

InactiveCN101830462ALow priceReduce energy consumptionProductsCarbon compoundsPoly(ethylene glycol) dimethyl etherDesorption

The invention discloses a CO2 trapping method combining dimethyl carbonate absorption and membrane desorption, belonging to the technical field of chemical engineering. The method comprises the following steps of: decarbonizing feed gas containing CO2 by dimethyl carbonate absorption; then carrying out two-stage throttling expansion and membrane desorption regeneration on CO2-absorbed absorbent rich liquor, and discharging CO2 gas generated by the throttling expansion and the membrane desorption out of the battery limit. Compared with a decarbonizing process of the inventor, which adopts the dimethyl carbonate as the absorbent, the new process of the dimethyl carbonate decarburization and the membrane desorption can reduce the comprehensive energy consumption by 5-20 percent. Compared with the propylene carbonate method maturely applied in industry at present, the energy consumption can be reduced by 30-40 percent; compared with the polyethylene glycol dimethyl ether method, the price of a solvent is lower, and polymerization losses are reduced by 40-60 percent; and compared with the low-temperature methane swabbing process, the operating temperature is milder, and the equipment investment is reduced by 30-40 percent. The CO2 removing efficiency can reach 95 percent or above.

Owner:TSINGHUA UNIV

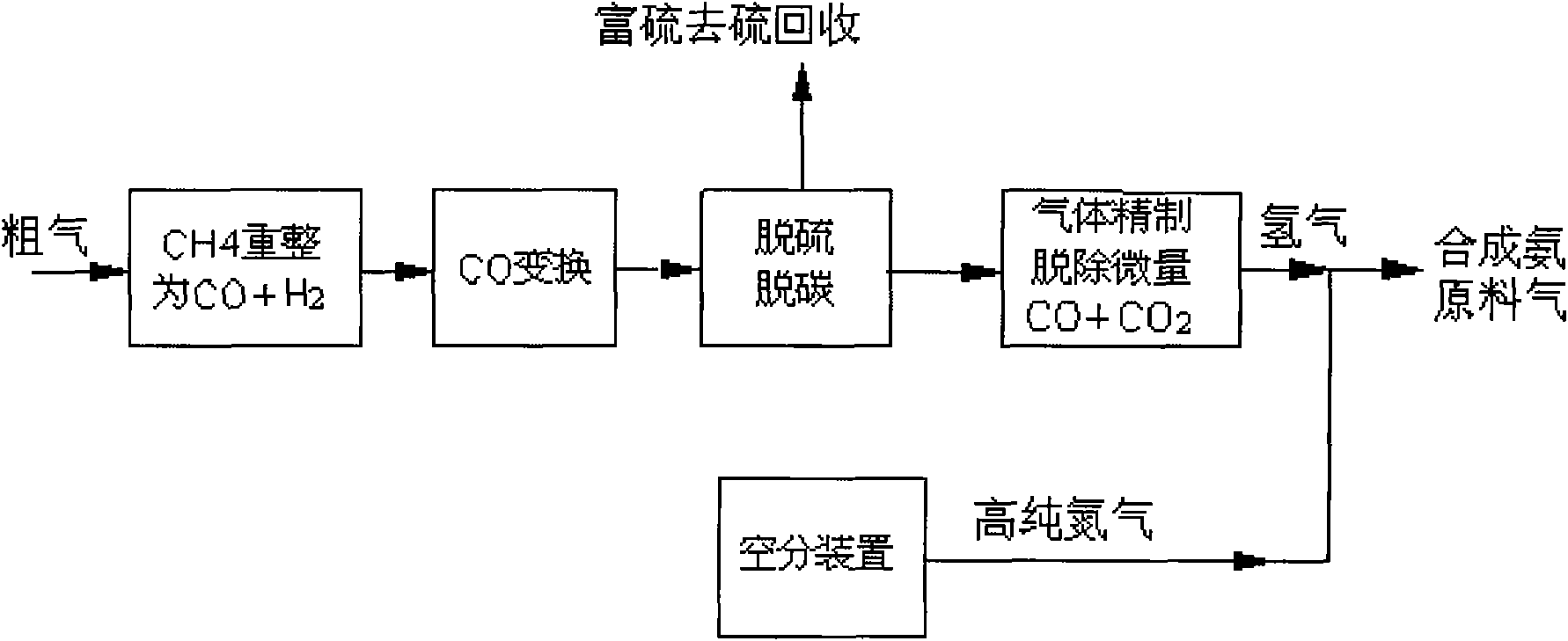

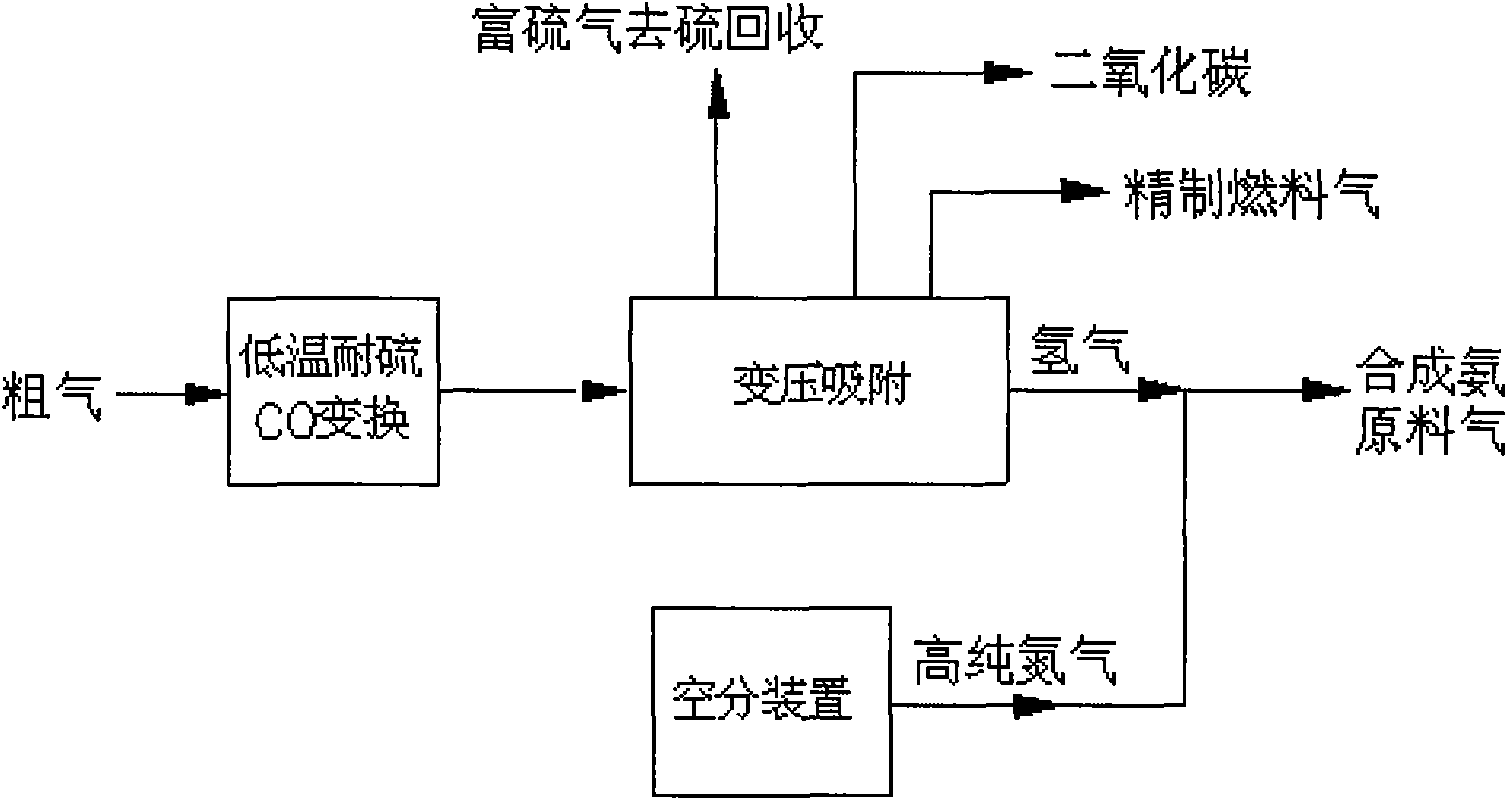

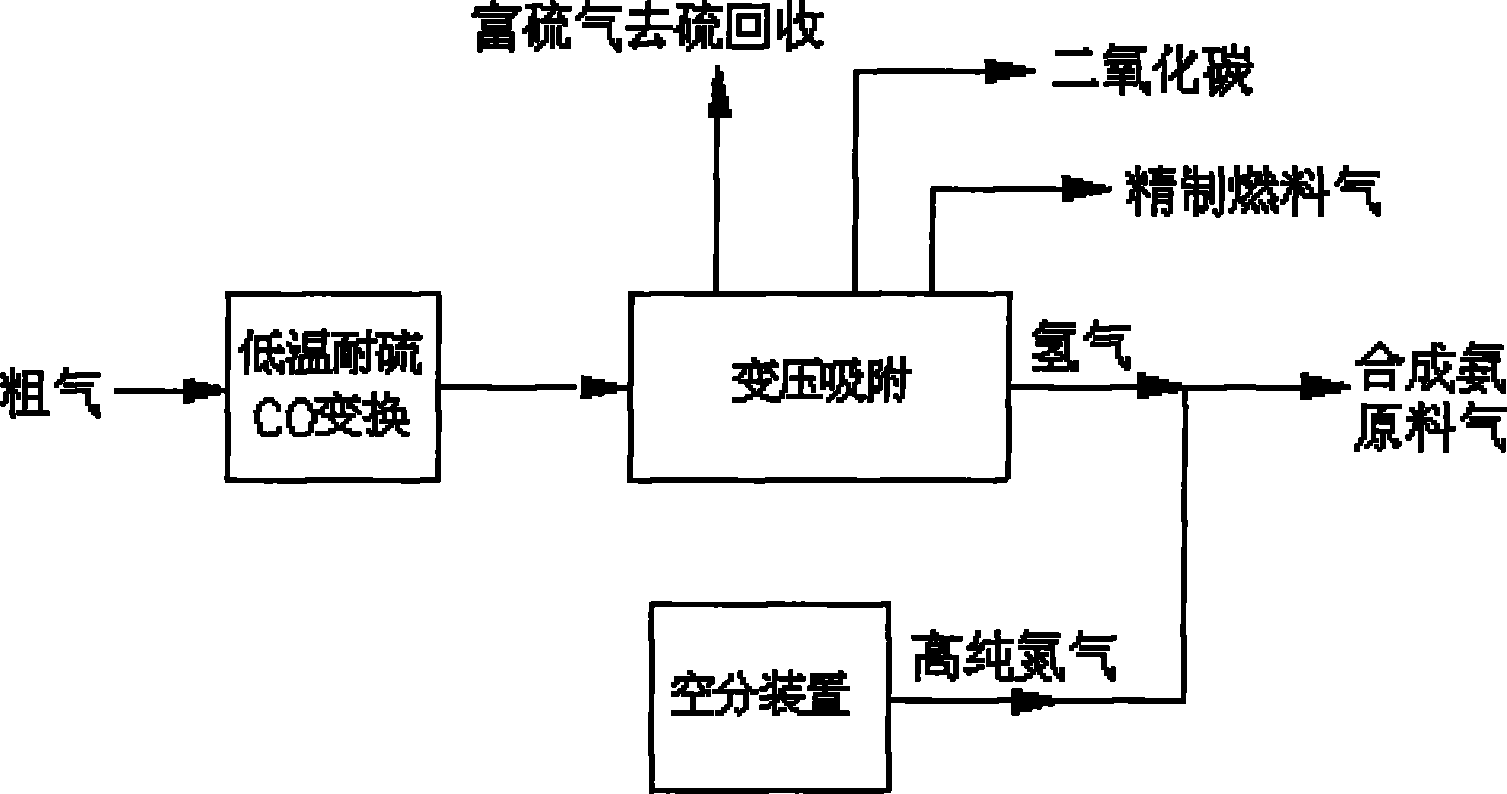

Combined process for preparing power generation co-production synthesis ammonia feed gas by using crude gas containing CH4

InactiveCN102134056ALow running costGood environmental effectHydrogen separation using solid contactCombustible gas catalytic treatmentPoly(ethylene glycol) dimethyl etherMethanation

The invention relates to a combined process for preparing a power generation co-production synthesis ammonia feed gas by using a crude gas containing CH4, comprising the following steps of: firstly enabling the preprocessed crude gas containing CH4 to enter a low-temperature sulfur tolerant shift device to transform CO into hydrogen; then acquiring high-purity hydrogen through a pressure swing adsorption device; preparing the synthesis ammonia feed gas through the acquired high-purity hydrogen and high-purity nitrogen from an air separation device; and using a pressure swing adsorption tail gas as a refined fuel gas. Compared with the prior art, the combined process provided by the invention substitutes for the traditional process comprising a CH4 reforming procedure, a transformation procedure, a desulfuration and decarburization procedure adopting a low-temperature methanol washing method or a polyethylene glycol dimethyl ether method and a methanol-methanation refining procedure, achieves the standard of a synthesis ammonia refining gas by desorbing harmful gas carbon monoxide, carbon dioxide and sulfur impurities through a pressure swing adsorption process, meets the requirements on the synthesis of synthesis ammonia and has the advantages of low operating cost, obvious environmental-friendly effect and high resource utilization ratio.

Owner:SHANGHAI HUANQIU ENG

Hydrogen sulfide leakage emergency removing dry powder, and preparation method thereof

InactiveCN103949140AGood dispersionConvenient secondary processingDispersed particle separationSulfolanePoly(ethylene glycol) dimethyl ether

The invention relates to a hydrogen sulfide leakage emergency removing dry powder, and a preparation method thereof. The hydrogen sulfide leakage emergency removing dry powder is mainly used for solving problems of existing technology that environmental pollution is caused, and removing efficiency is low. The hydrogen sulfide leakage emergency removing dry powder mainly comprises, by mass, 65 to 99% of a removing agent, 0.5 to 15% of a moisture-proof agent, and 0.5 to 20% of an additive; the additive is at least one selected from polyethylene glycol dimetyl ether, N-methylpyrrolidinone, propylene carbonate, tributyl phosphate, N-methylcaprolactam, methyl alcohol, alkyl alkylol amine, sulfolane, bentonite, carboxymethyl cellulose, and sodium carboxymethylcellulose. The hydrogen sulfide leakage emergency removing dry powder is capable of solving the above problems preferably, and can be used for hydrogen sulfide leakage emergency removing.

Owner:CHINA PETROLEUM & CHEM CORP +1

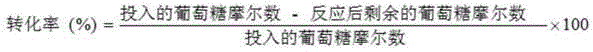

Method of synthesizing 5-hydroxymethyl furfural

InactiveCN104829560AHigh yieldReduce volatilityOrganic chemistryPoly(ethylene glycol) dimethyl etherDouble phase

A method of synthesizing 5-hydroxymethyl (5-HMF) furfural includes a step of adding an alcohol ether substance into an ionic liquid reaction system to achieve high-effective synthesis of the 5-HMF, wherein the alcohol ether substance includes following compounds, which are soluble, partial soluble or non-soluble with the ionic liquid: ethyl glycol dimethyl ether, propylene glycol dimethyl ether, polyethylene glycol dimethyl ether, polyethylene glycol, polypropylene glycol dimethyl ether, propylene glycol and polypropylene glycol, to form a homogeneous phase or double phase system with the ionic liquid. In the reaction system, a small-molecular additive can be selectively added and the 5-HMF is synthesized with a substance containing glucose or fructose as raw materials, wherein the substance may be: cellulose, oligomerization cellulose, semi-cellulose, starch, glucose and fructose. For example, adding the ethyl glycol dimethyl ether to a [BMIM]Cl / CrCl3.6H2O catalytic system with addition of less amount of ethanol additive, a glucose raw material being 80 wt% on the basis of the mass of the ionic liquid is high-effectively converted into 5-HMF, wherein the yield of the reaction is 1.85 times than that of a reaction without the ethyl glycol dimethyl ether and the ethanol additive. The method can be used for high-effectively synthesizing the 5-HMF from a lignocelluloses derivative.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

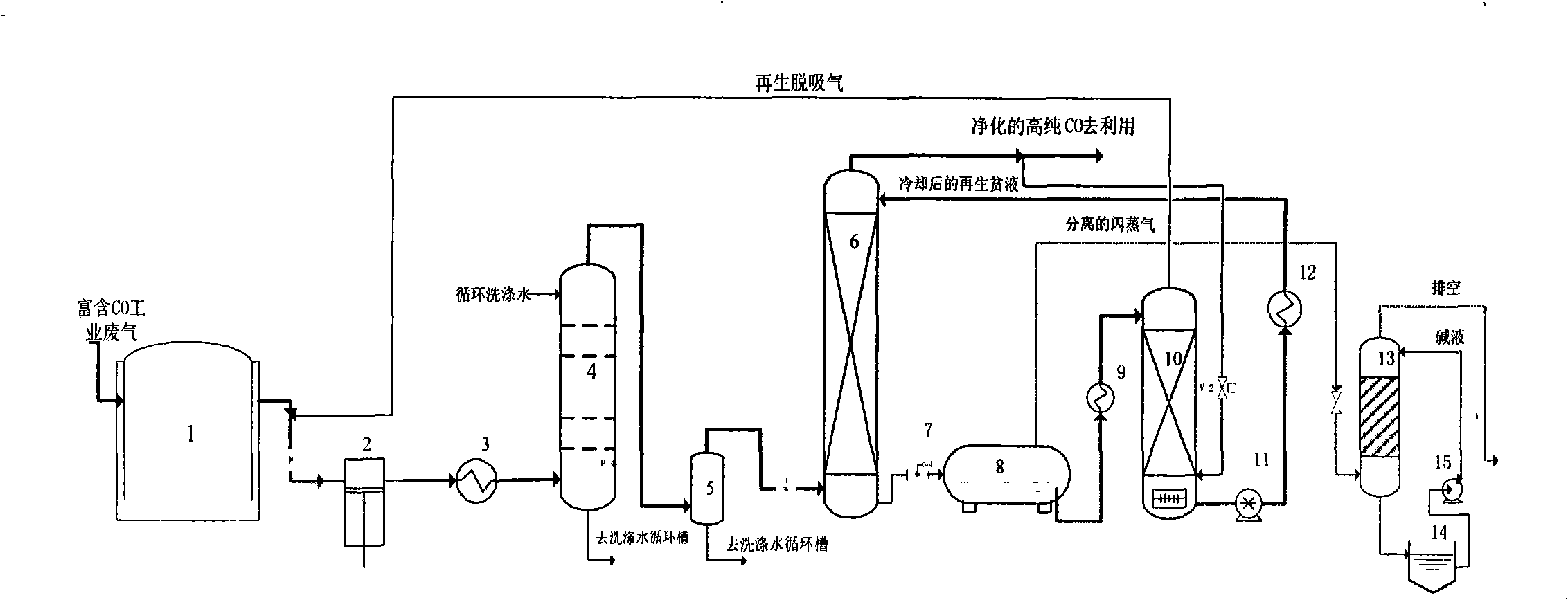

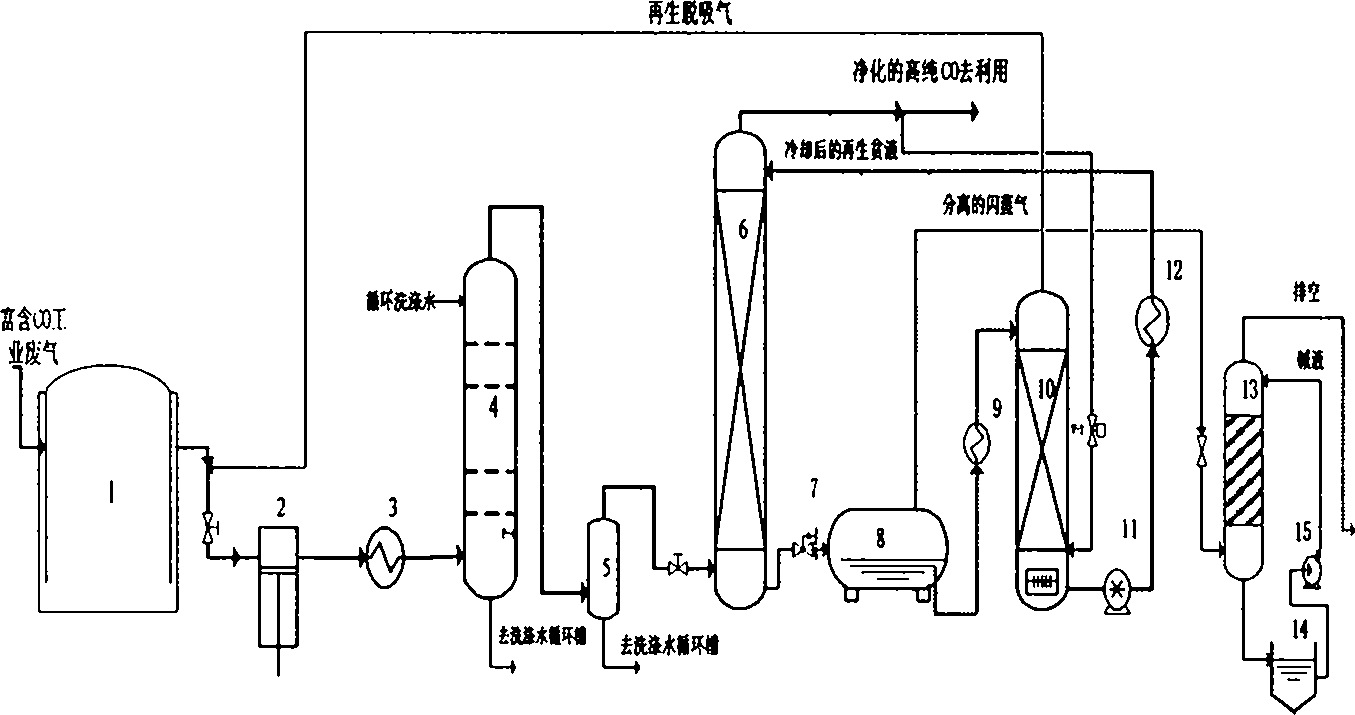

Purification method of industrial tail gas rich in carbon monoxide

InactiveCN101856589AImprove solubilityThe purpose of purification and recyclingDispersed particle separationHigh concentrationChemical industry

The invention relates to a method taking composite solvents, such as dimethyl ether of polyethlene glycol and the like, as an absorbent to purify industrial tail gas rich in CO, which belongs to the technical field of the clean production of chemical industry. In the method, the counterflow physical absorption of the impurity components of H2S, PH3, HCN, HF, AsH3 and the like in the tail gas is carried out in an absorption tower by utilizing the composite solvents of the method under the conditions of low temperature or normal temperature and 0.1 to 3.5 MPa (gage pressure) after the industrial tail gas rich in the CO is washed by water and dewatered, and the removal rate of the main impurity components reaches more than 99 percent. Absorption liquid which flows out from the bottom of the absorption tower and is rich in the impurity components is throttled, decompressed and heated by a flash evaporator to escape most of the impurity components, the absorption liquid enters a regenerating tower after being reheated and is in counterflow contact with part of refluent purified gas, and impurities are further desorbed. The absorption liquid after being desorbed by the regenerating tower is delivered to the absorption tower for recycle, and the desorption gas of the regenerating tower is delivered back to an inlet of a purification system. The high-concentration foreign gas escaping from the flash evaporator is utilized after alkali washing or copper sulfate liquid washing.

Owner:毕亚凡 +1

Polymeric gel electrolyte and lithium battery employing the same

InactiveUS6949318B2Improve ionic conductivityIncrease rangeNon-metal conductorsFinal product manufactureMethacrylatePoly(ethylene glycol) dimethyl ether

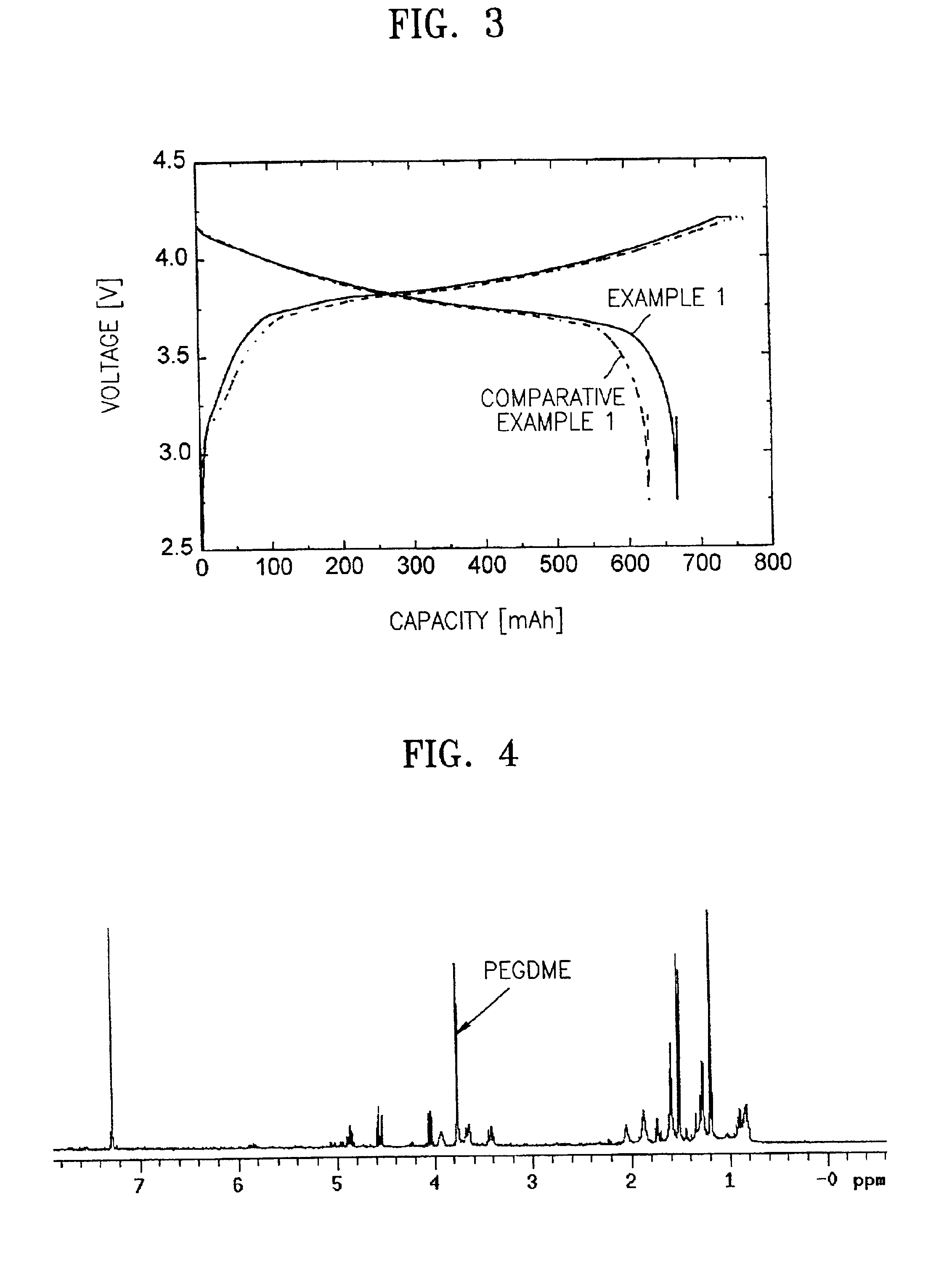

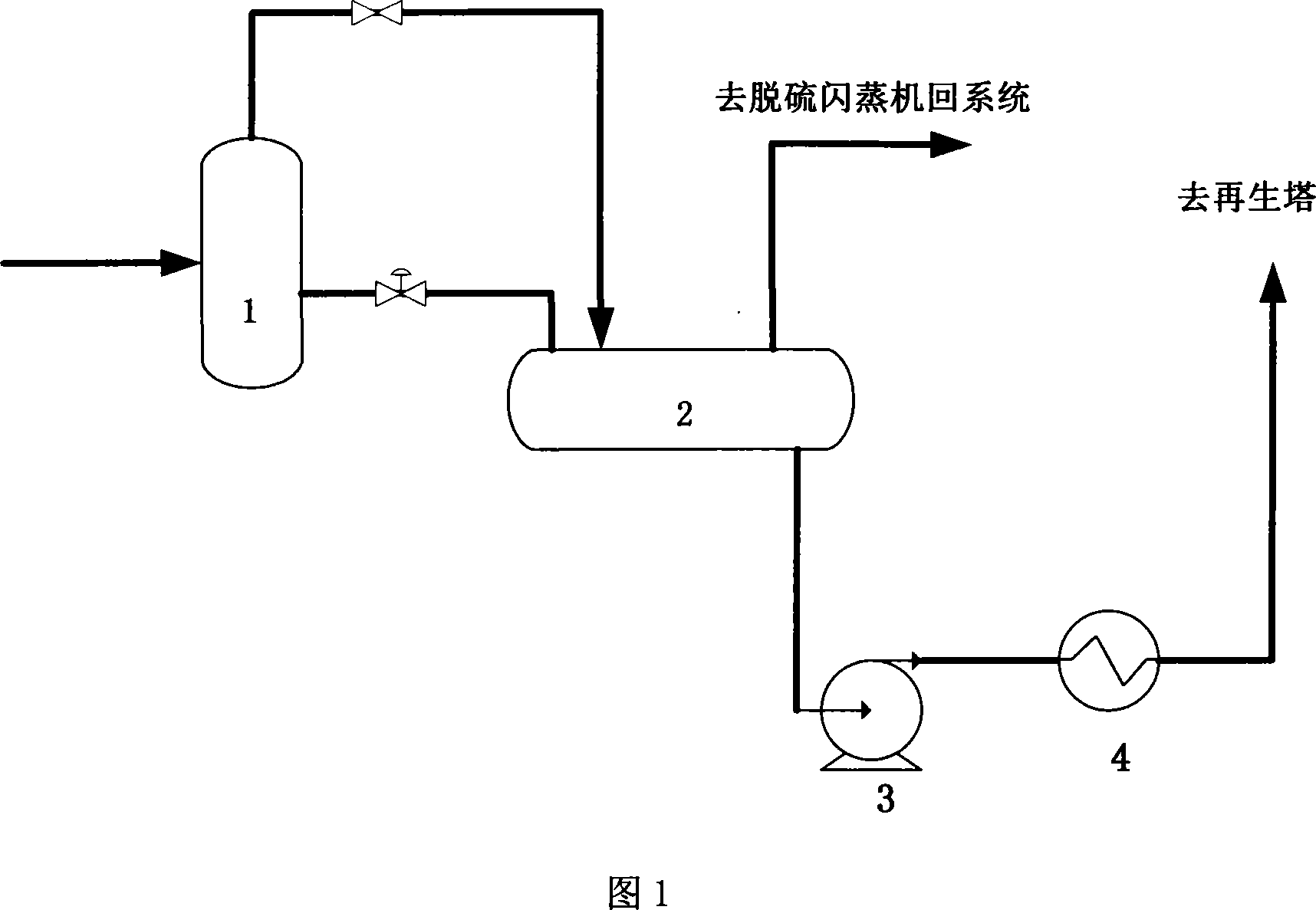

A polymeric gel electrolyte and a lithium battery employing the same are disclosed. The polymeric gel electrolyte includes a first ionic conductive polymer having a weight-average molecular weight of greater than or equal to 5,000 and smaller than 100,000, a second ionic conductive polymer having a weight-average molecular weight of 100,000 to 5,000,000, and an electrolytic solution that includes a lithium salt and an organic solvent. The first ionic conductive polymer preferably is at least one polymer selected from polyethyleneglycol dimethylether, polyethyleneglycol diethylether, polyethyleneglycol dimethacrylate, polyethyleneglycol diacrylate, polypropyleneglycol dimethacrylate, polypropyleneglycol diacrylate, and mixtures and combinations thereof, and the second ionic conductive polymer preferably is at least one polymer selected from polyvinylidenefluoride, polyvinylidenefluoride-hexafluoropropylene copolymer, polyurethane, polyethylene oxide, polyacrylonitrile, polymethylmethacrylate, polyacrylamide, polyacetate, and mixtures and combinations thereof.

Owner:SAMSUNG SDI CO LTD

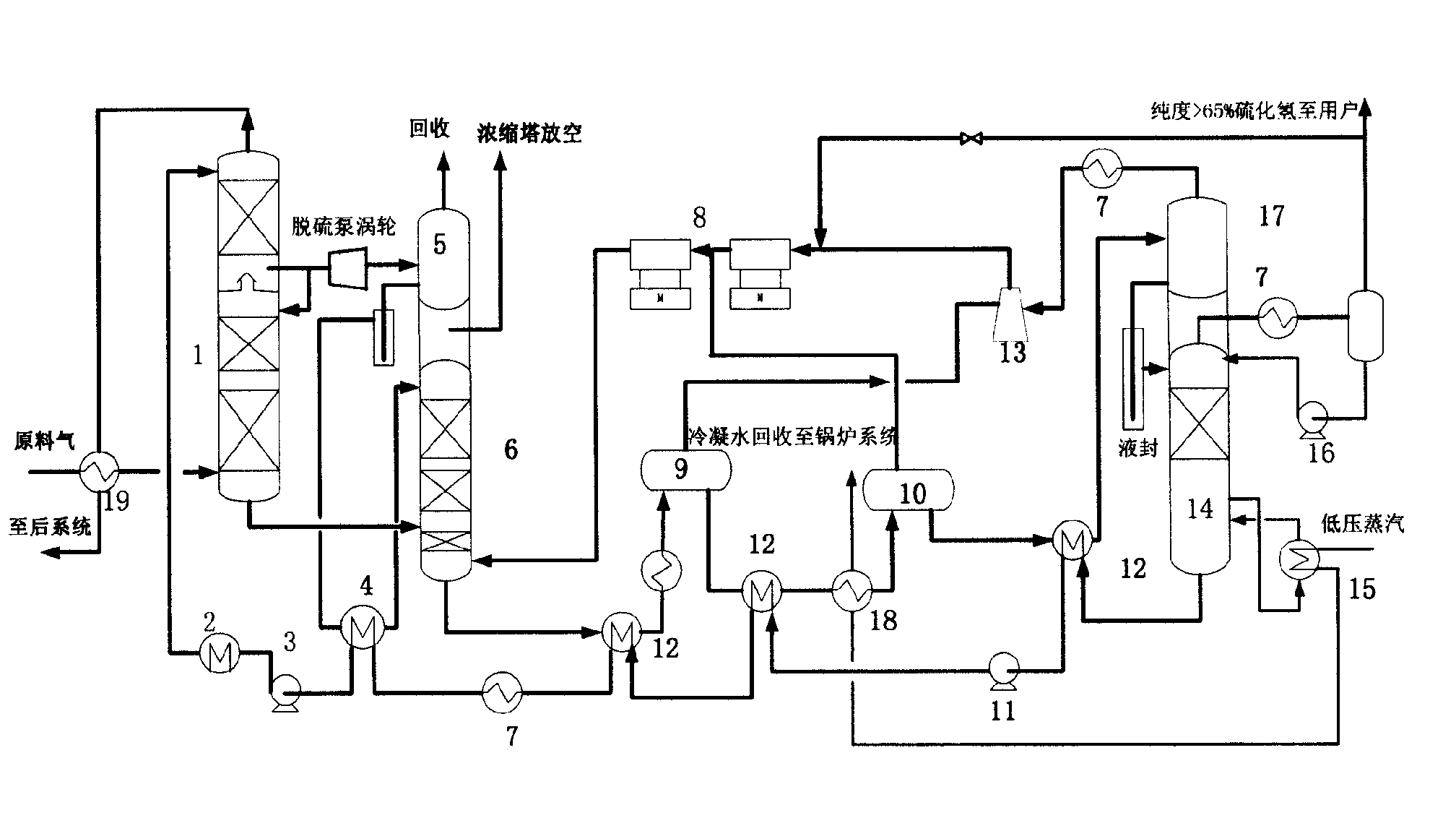

Polyethyleneglycol dimethyl ether desulfurizing system optimization extracting and concentrating technology

InactiveCN101077467AIncrease temperatureEfficient use ofHydrogen sulfidesDispersed particle separationPoly(ethylene glycol) dimethyl etherGas phase

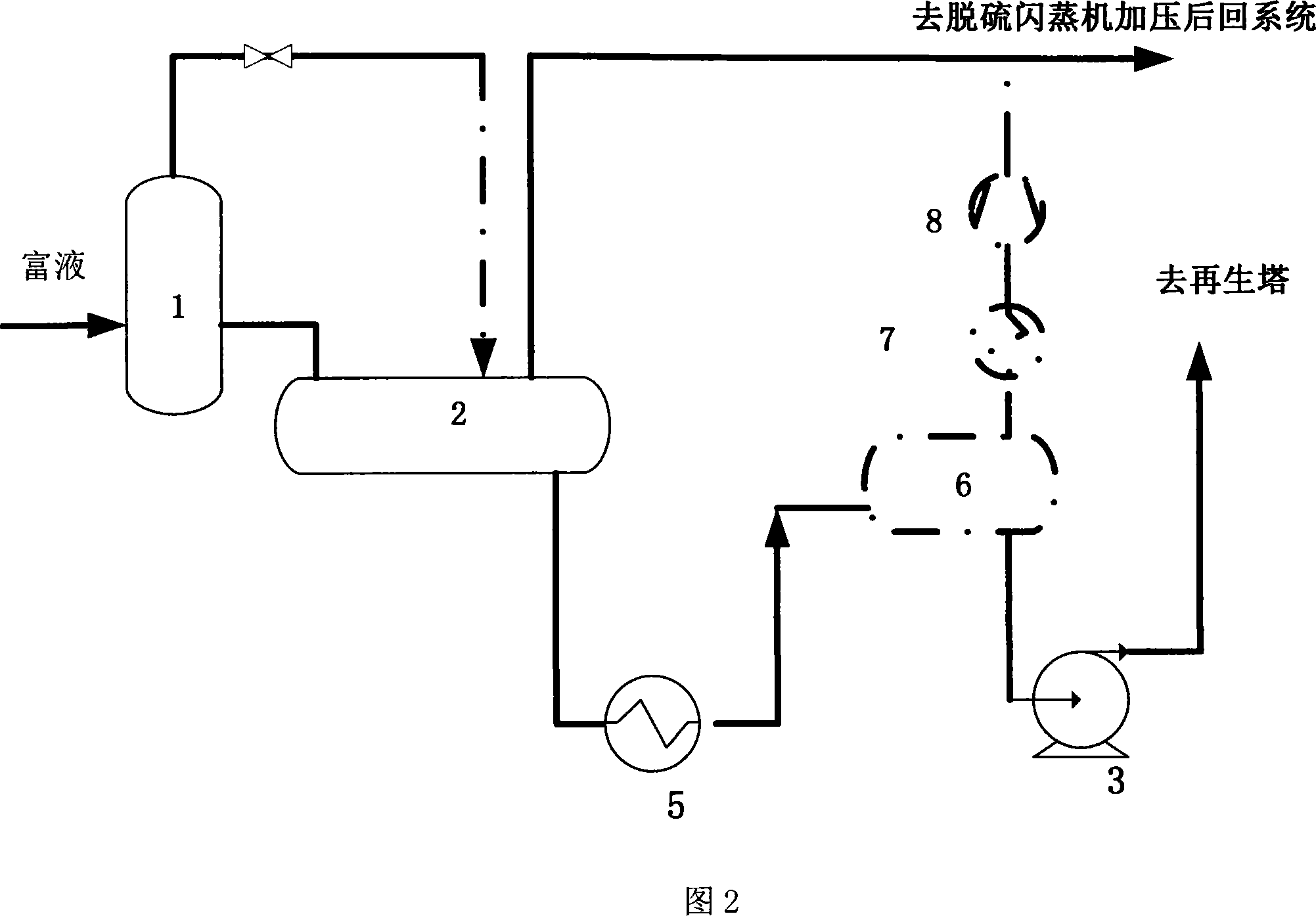

The present invention discloses optimized concentration process of NHD desulfurization system, and has the advantages of environment friendship, high S recovering rate, reuse of recovered material, etc. The optimized concentration process includes: 1. feeding the rich NHD solution with absorbed hydrogen sulfide to the flash tank I; 2. connecting the flash tank I to the flashed gas pipeline in the gas phase outlet side of the flash tank II; 3. heating the rich solution from the flash tank II to 90-130 deg.c in a heat exchanger and high temperature decompression regenerating the rich solution in a low pressure flash tank at pressure lower than 30 KPa; 4. water cooling and separating flash gas from the low pressure flash tank, pressurizing to 50-150 KPa, mixing with flash gas from the flash tank II, pressurizing the gas mixture in desulfurizing flash machine, and returning to the concentrating tower system; and 5. regenerating the rich solution from the low pressure flash tank in a regenerating tower.

Owner:YANKUANG LUNAN CHEM FERTILIZER PLANT

Hydrophilic polyurethane pressure-sensitive adhesive for skins, and preparation method thereof

ActiveCN104491922AGood initial adhesionStrong holding powerSurgical adhesivesAbsorbent padsFiberPoly(ethylene glycol) dimethyl ether

The invention provides a hydrophilic polyurethane pressure-sensitive adhesive for skins, and a preparation method thereof. The pressure-sensitive adhesive comprises polyurethane, sweetgum resin, alginate, gelatin, fibrous proteins, plant polysaccharides, methacryloylethyl sulfobetaine, triethyl citrate and polyethylene glycol dimethyl ether. The preparation method comprises the following steps: weighing all the above components according to weight parts; mixing polyurethane with sweetgum resin, alginate and gelatin in an open mill, adding the fiber proteins, the plant polysaccharides, methacryloylethyl sulfobetaine, triethyl citrate and polyethylene glycol dimethyl ether, continuously mixing for uniform dispersion, and carrying out hot pressing by using a plate vulcanizing machine to form the pressure-sensitive adhesive with desired thickness. Compared with pressure-sensitive adhesives in the prior art, the acrylic medical pressure-sensitive adhesive prepared in the invention has the advantages of good initial tack, low peel strength, no sensitization, no residue and very strong permanent adhesion.

Owner:WEIXIN INDAL & TRADE GUANGZHOU

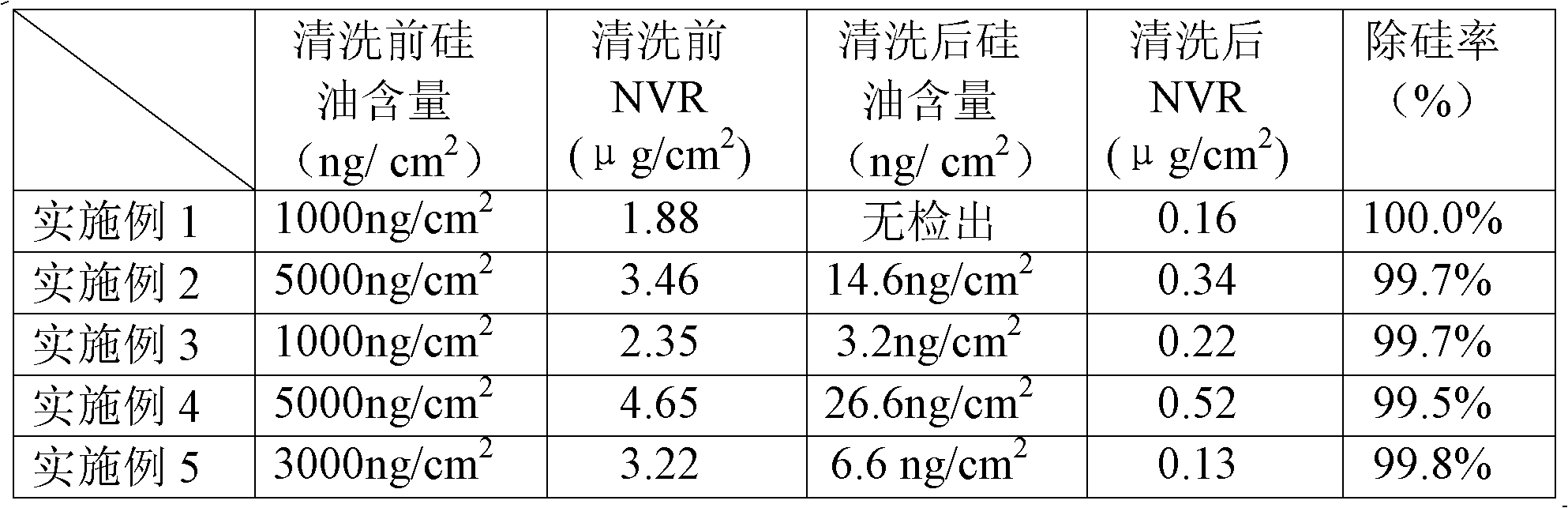

Silicone oil removing water base detergent

ActiveCN102358873AEasily biodegradableEfficient removalOrganic detergent compounding agentsSurface-active detergent compositionsWater basedPoly(ethylene glycol) dimethyl ether

The invention discloses a silicone oil removing water base detergent, comprising a mixed liquor of water and polyoxyethylene octylphenol ether, sorbide ester, glycol monoether and polyethylene glycol dimethyl ether, wherein the polyoxyethylene octylphenol ether accounts for 0.01-0.5wt% of the mixed liquor, and the sorbide ester accounts for 0.005-0.1wt% of the mixed liquor, and the glycol monoether accounts for 0.1-1.0wt% of the mixed liquor, and the polyethylene glycol dimethyl ether accounts for 0.01-0.5wt% of the mixed liquor. Aiming at problems that dust free chamber consumptions have standard exceeded silicone oil content and are not easily cleaned, and exisiting silicone oil removing detergent is not suitable for processing of dust free chamber consumptions, the invention provides a water base detergent, which is suitable for cleaning dust free chamber consumptions, and has simple formula, low costs, good silicone oil removing effect and good biodegradability.

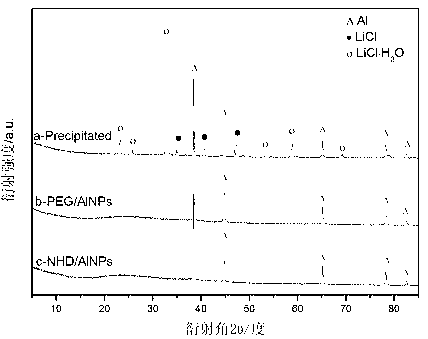

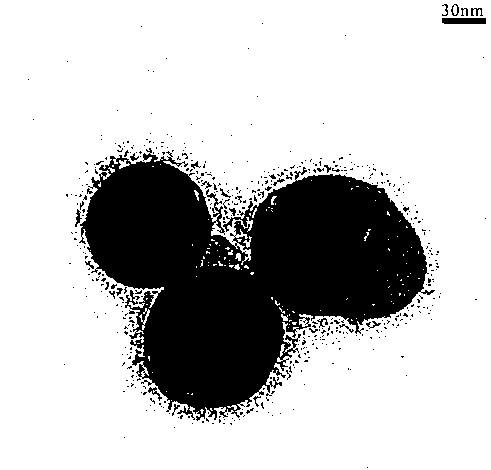

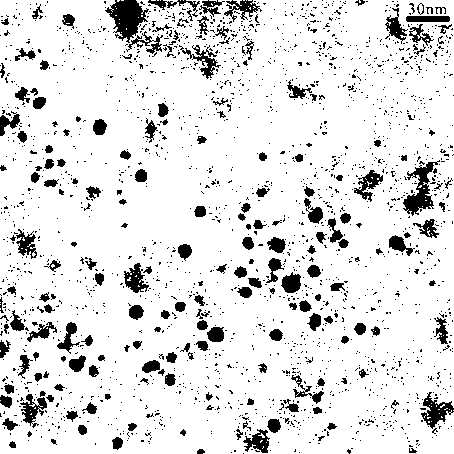

Method for preparing aluminum nanoparticles coated with dispersion stabilizers by liquid-phase chemical reduction method

InactiveCN103056388AAvoid reunionProvides antioxidant protectionNanotechnologyDispersityAluminium chloride

The invention discloses a method for preparing aluminum nanoparticles coated with dispersion stabilizers by a liquid-phase chemical reduction method. The method is characterized by including: purifying commercially available mesitylene; dispersing aluminum chloride in the mesitylene; and in the presence of nitrogen, adding polyethylene glycol or polyethylene glycol dimethyl ether serving as the dispersion stabilizer and lithium aluminum hydride in the mesitylene dispersed with the aluminum chloride according to the mass ratio of 1-2.5:0.5-1:0.5-1 among the aluminum chloride, the lithium aluminum hydride and the dispersion stabilizer, stirring for reacting 12-24 hours at the temperature of 164-166 DEG C, cooling, performing centrifugal separation, abandoning supernatant liquid, removing residual mesitylene solvents, washing by low-temperature methyl alcohol, performing ultrasonic washing and centrifugal separation, abandoning supernatant liquid and performing vacuum drying for lower materials so that the aluminum nanoparticles coated with the dispersion stabilizers are obtained. The prepared aluminum nanoparticles coated with the dispersion stabilizers are uniform in size and good in dispersity, have certain activity and are applicable to the fields of rocket propellants, explosives and powders, solar back plates and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

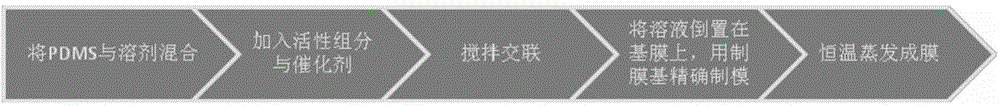

Membrane for desorbing CO2 from solution containing CO2 and preparation method of membrane

ActiveCN104607073AReduce lossesReduce desorption energy consumptionCarbon compoundsDistillationPoly(ethylene glycol) dimethyl etherMethyl carbonate

The invention belongs to the technical field of separation, and discloses a membrane for desorbing CO2 from a solution containing CO2 and a preparation method of the membrane. The membrane for desorbing CO2 from the solution containing CO2 comprises a base membrane and a polydimethylsiloxane membrane with an active group, wherein the active group is an ester group or an amino group; the thickness of the polydimethylsiloxane membrane is 10-70 microns. The preparation method comprises the following steps: mixing the polydimethylsiloxane and an active crosslinking agent, coating the mixture on the base membrane, and crosslinking and curing at a certain temperature to form the membrane. According to the membrane for desorbing CO2 from the solution containing CO2, the solution absorbing CO2 is one of methanol, acetone, polyethylene glycol dimethyl ether, propylene carbonate, dimethyl carbonate, diethyl carbonate and butyl succinate; the permeation flux of the membrane is up to 0.2-1.1 kg / (h*m2), and the enrichment factor is up to 23-50.

Owner:TSINGHUA UNIV

Method for synthesizing dihydric alcohol single vinyl ether and double vinyl ether

ActiveCN102173982AHigh catalytic activityEther preparation by compound additionVinyl etherPoly(ethylene glycol) dimethyl ether

The invention relates to a method for synthesizing dihydric alcohol single vinyl ether and double vinyl ether. The method comprises the following steps of: preparing alcohol potassium solution from mixed liquid consisting of dihydric alcohol, potassium hydroxide and polyethylene glycol dimethyl ether; adding zinc oxide, triphenylphosphine or a mixture of the zinc oxide and the triphenylphosphine into the prepared alcohol potassium solution to prepare a reaction mixture; heating the reaction mixed liquid to 80 to 200 DEG C; introducing ethyne to react; after the reaction is finished, distilling the product under reduced pressure of below 2 kPa; and collecting fractions with the kettle temperature of below 180 DEG C to obtain a crude product of the dihydric alcohol single vinyl ether and double vinyl ether. The method has the advantages of preparing vinyl ether by reacting under normal pressure and low reaction temperature and improving catalytic activity.

Owner:NANJING FORESTRY UNIV +1

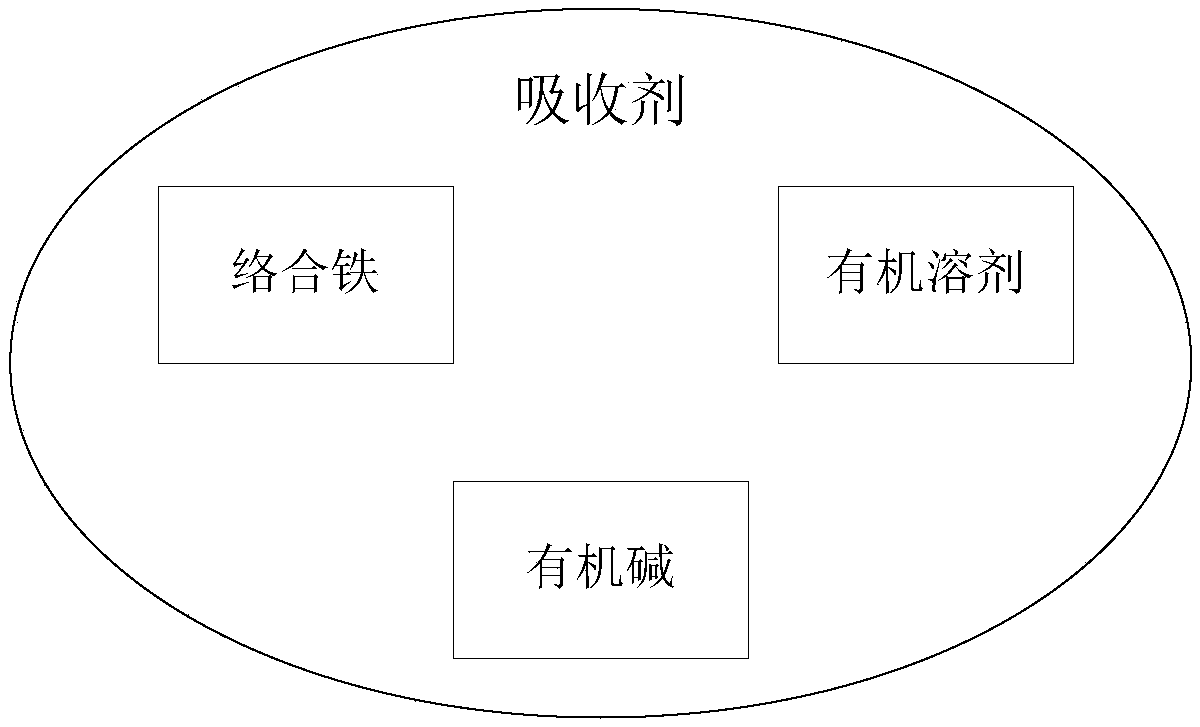

Desulfurizing and decarbonizing absorbent

InactiveCN109432990AAvoid degradationLow costProductsGas treatmentEthylenediaminePoly(ethylene glycol) dimethyl ether

The invention discloses a desulfurizing and decarbonizing absorbent which comprises complex iron, an organic solvent and organic alkali, wherein the mass content of the iron is 0.3-10 g / L, and the mass content of the organic alkali is 0-100 g / L; the complex ion comprises 1-butyl-3-methylimidazole EDTA-Fe, EDTA-Fe and EDTA ferric sodium salt, the organic solvent comprises dimethyl sulfoxide, polyethylene glycol dimethyl ether, or a mixture of dimethyl sulfoxide and polyethylene glycol dimethyl ether; the organic alkali can be dissolved into the organic solvent and specifically comprises 1-butyl-3-methylimidazole. According to the absorbent, the degradation of a complexing agent is avoided by adopting nonaqueous solution of the complex ion, and the cost of liquid phase catalytic oxidation islowered. Additionally, absorption liquid can be used for physically absorbing carbon dioxide while oxidation absorption of hydrogen sulfide, so that the cost of equipment for absorption is lowered.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

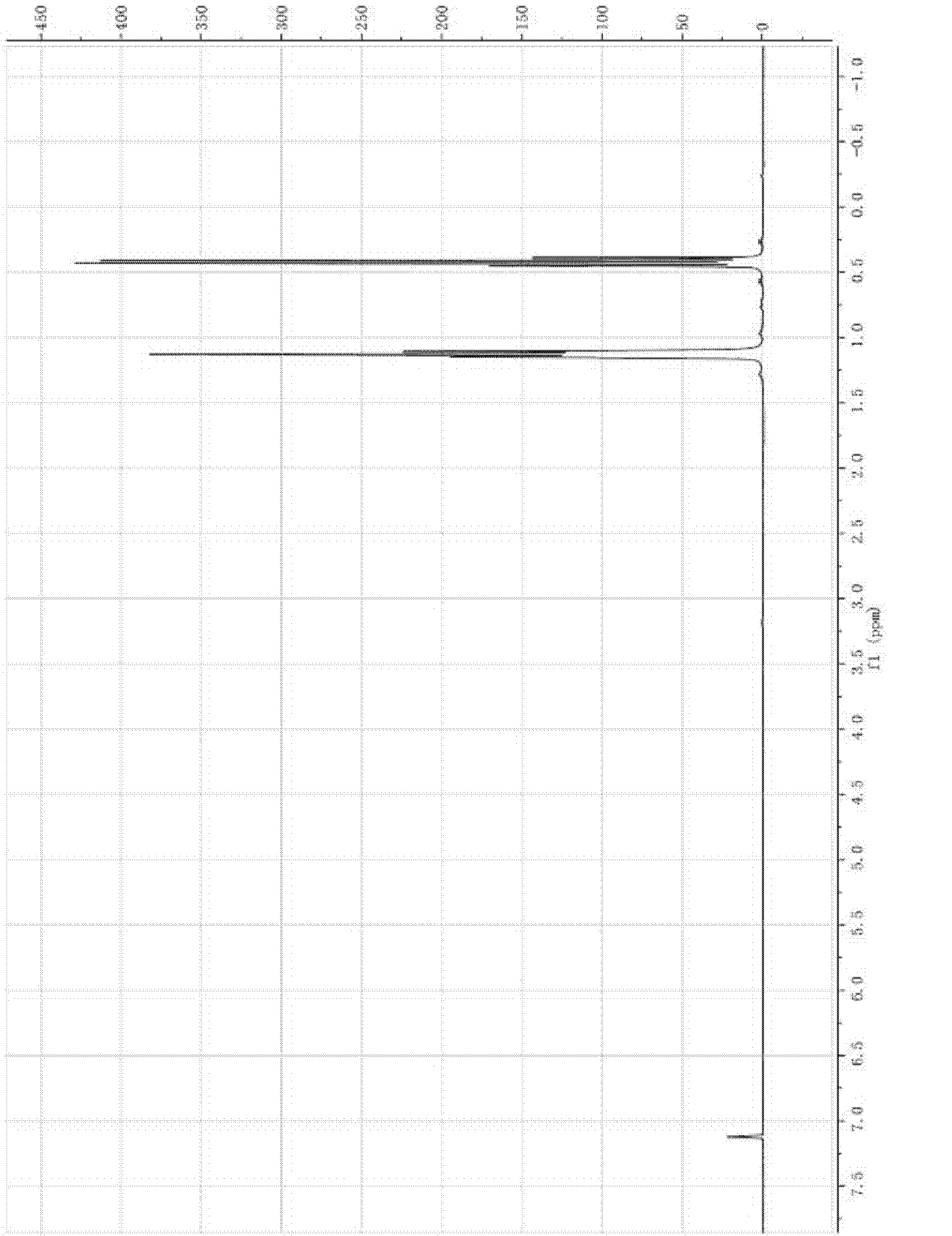

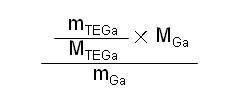

Method for one-step process preparation of high-purity triethyl gallium

ActiveCN102503968AAdequate responseLow costGroup 3/13 element organic compoundsChemical recyclingPoly(ethylene glycol) dimethyl etherMg alloys

The invention belongs to the field of preparation of compounds containing group III elements in a periodic table and relates to a method for one-step process preparation of high-purity triethyl gallium. The method comprises the following steps: taking polyethylene glycol dimethyl ether as a solvent under the protection of an inert gas, taking a gallium magnesium alloy and metal magnesium as raw materials, adding halogenated ethane into a reaction system under stirring, and controlling the reaction speed by controlling dropping rate; and removing low-boiling point substances by distillation after the reaction is completed, and then performing decomplexation on a complex of the polyethylene glycol dimethyl ether solvent and the triethyl gallium to get the triethyl gallium. The process disclosed by the invention is simple to operate, stable in reaction conditions, convenient to control and safer. Compared with a traditional industrial method, raw materials are cheaper, the reaction yield is high and the safety is stronger. The raw materials which are not reacted can be recycled and the production cost is greatly reduced. The raw materials do not contain natural substances, the reaction process is high in safety coefficient, and the method is particularly suitable for industrial production.

Owner:苏州普耀光电材料有限公司

Method for extracting and removing nitrogen from fuel oil by use of polyethylene glycol and modified compounds thereof

ActiveCN107937013AEfficient removalStable physical propertiesHydrocarbon oils refiningHydrocarbon oils treatmentPoly(ethylene glycol) dimethyl etherPolyethylene glycol

The invention relates to a method for extracting and removing nitrogen from fuel oil by use of polyethylene glycol and modified compounds thereof. According to the method, polyethylene glycol, polyethylene glycol dicarboxylate, polyethylene glycol monomethyl ether and polyethylene glycol dimethyl ether are adopted as extraction agents; the active hydroxyl / carboxyl or O atoms included in the extraction agents are subjected to hydrogen-bond interaction with N atoms or N-H groups of organic nitride so as to efficiently remove the organic nitride from the fuel oil. The adopted extraction agents only contain such elements as C, H and O; new pollutants (organic sulfur, nitrogen and the like) are not introduced in the nitrogen removal process, meeting the requirements of green industry; moreover,the extraction agents are insoluble in the fuel oil, the physical property is stable that the extraction agents can be recycled; the nitrogen removal conditions are mild, high-temperature and high-pressure environment is not needed, the operation is easy, the required equipment is not complicated, and the cost is relatively low.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

High-selectivity decarbonization absorbent adopting physical method

ActiveCN104096453APromote absorptionIncrease mass transfer rateProductsReagentsPoly(ethylene glycol) dimethyl etherCo2 absorption

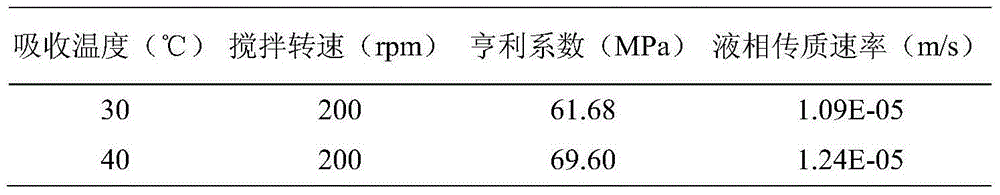

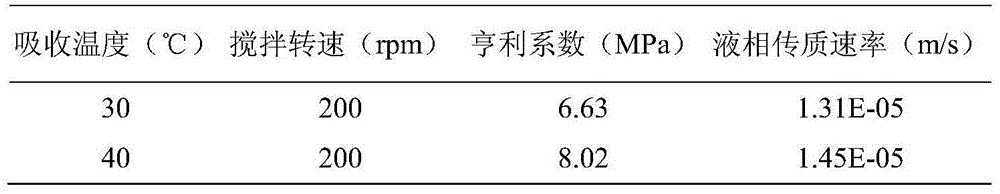

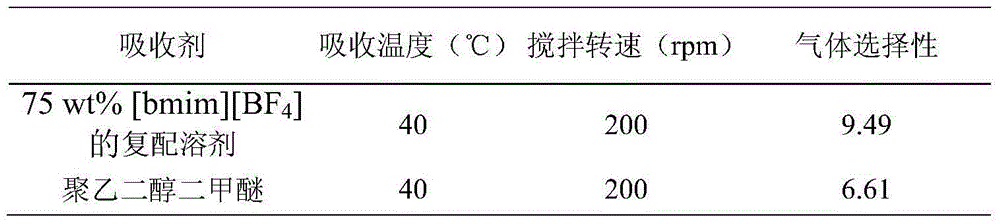

The invention belongs to the technical field of gas separation and purification, and relates to a high-selectivity decarbonization absorbent adopting a physical method. According to the absorbent, an ionic liquid and a polyethylene glycol dimethyl ether compound solvent are taken as absorbents, wherein the ionic liquid not only has higher carbon dioxide absorbing capacity, but also can remarkably improve the selectivity for separating methane and carbon dioxide, and polyethylene glycol dimethyl ether can further improve the carbon dioxide absorbing capacity and simultaneously increases the carbon dioxide mass transfer rate; the compound solvent is contacted with treated gas, and the purpose of gas purification is achieved; and the concentration of the ionic liquid in the compound absorbent is 10%-90% at the weight percent. According to the technical scheme, the absorbent has high selectivity in separation of methane and carbon dioxide, and the mass transfer rate and the absorbing capacity are high; and the absorbent can be widely used for separating and purifying carbon dioxide in process gases such as natural gas, shale gas, coal bed gas, biogas and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for extracting nitrogen from fuel oil by using polyethylene glycol and its modified compounds

ActiveCN107937013BEfficient removalStable physical propertiesHydrocarbon oils refiningHydrocarbon oils treatmentNitrogen removalPoly(ethylene glycol) dimethyl ether

Owner:WUHAN INSTITUTE OF TECHNOLOGY

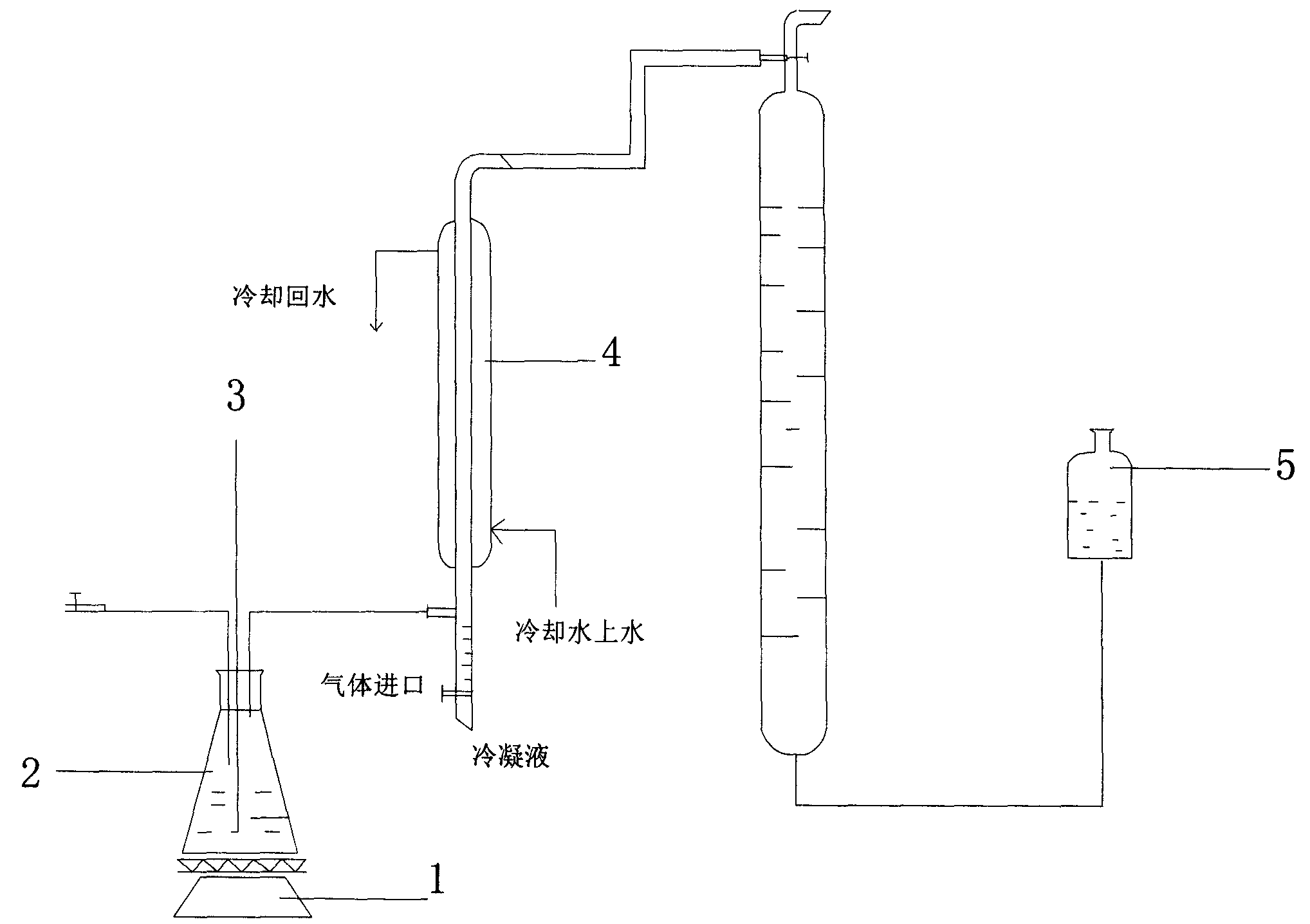

Method for measuring content of acid gas in polyethylene glycol dimethyl ether absorption solution

InactiveCN101551308AQualitatively judge componentsGuaranteed uptimeMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationSteam condensationPoly(ethylene glycol) dimethyl ether

The invention discloses a method for measuring the content of acid gas in polyethylene glycol dimethyl ether absorption solution. The method comprises the following steps of: heating the polyethylene glycol dimethyl ether absorption solution which is led out from a production system, cooling a great deal of mixture of water steam and flash steam which is generated due to heating after entering a color shape condenser, condensing the steam, recycling the dried gas through a gas-collecting bottle, later demarcating the volume amount thereof, and implementing chromatographic analysis and quantitative analysis of H2S to the dried gas for simultaneously measuring the substance compositions such as COS and the like which are difficult to be titrated out in the solution. By the analysis, the absorption condition and saturation of the solution in the production system are determined.

Owner:YANKUANG LUNAN CHEM FERTILIZER PLANT

Method for utilizing modified polyethylene glycol to remove thiophene sulfur in gasoline

InactiveCN108034445ANo pollutionMild operating conditionsHydrocarbon oils refiningHydrocarbon oils treatment productsPoly(ethylene glycol) dimethyl etherSulfur

The invention relates to a method for utilizing modified polyethylene glycol to remove thiophene sulfur in gasoline. According to the method, a polyethylene glycol monomethyl ether or polyethylene glycol dimethyl ether extracting agent with the average molecular weight as 150 to 600 is mixed and extracted with high thiophene sulfur fuel oil according to a mass ratio of 0.1 to 3; thus, most sulfurin the fuel oil can be removed, and a mass distribution coefficient is 1.8 or more. The extracting agent has the advantages of stable physical property, insolubility to the fuel oil, no oil pollutionand no self loss; after recycling and regenerating, extracting and desulfurizing capacity of the extracting agent fundamentally keeps unchanged; the whole desulfurizing technology has the advantages of moderate conditions, no high-temperature and high-pressure conditions, simpleness in operation and no requirement for complex and expensive equipment; furthermore, the extracting agent can be recycled repeatedly, so that desulfurizing cost is low; the extracting agent is suitable for desulfurizing treatment of the high thiophene sulfur fuel oil.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com