Patents

Literature

998results about How to "Increase mass transfer rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

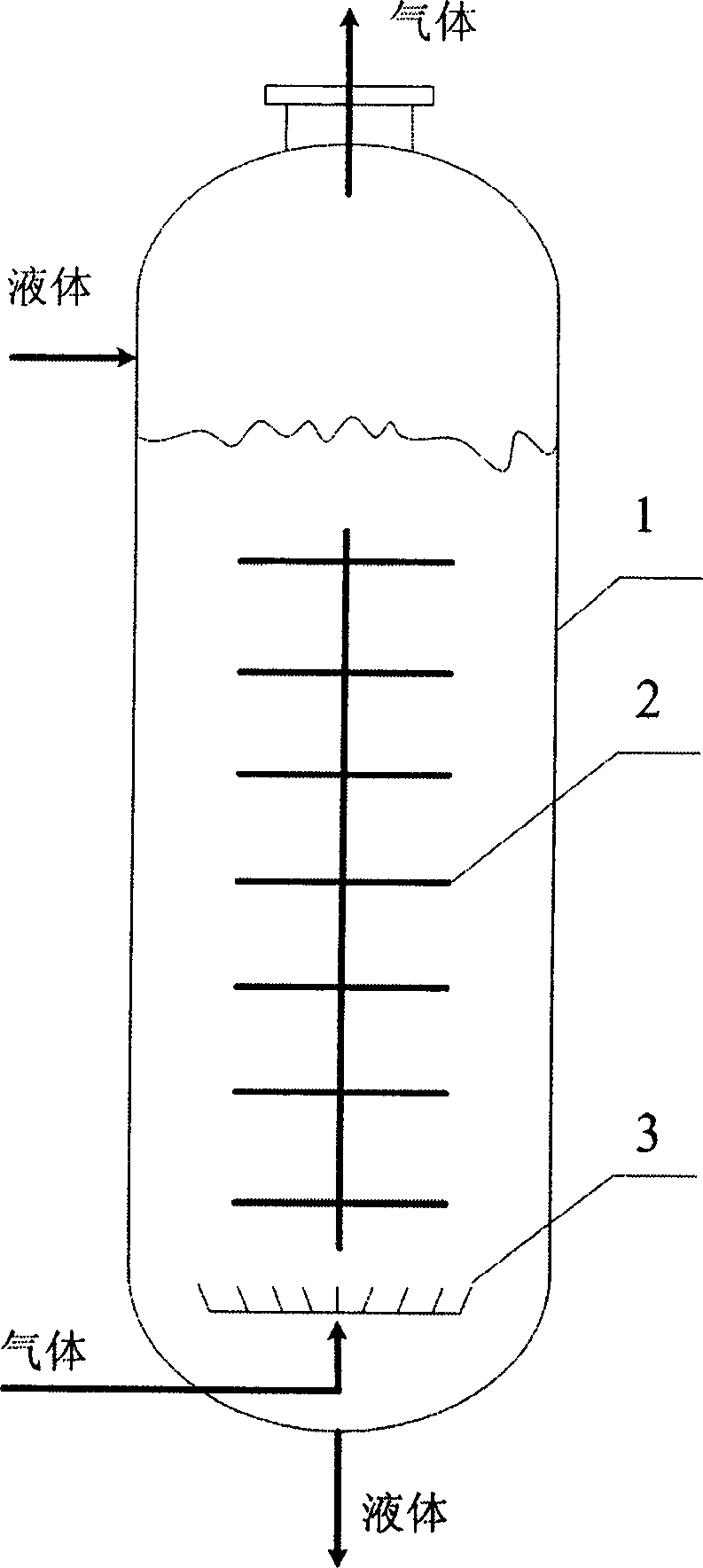

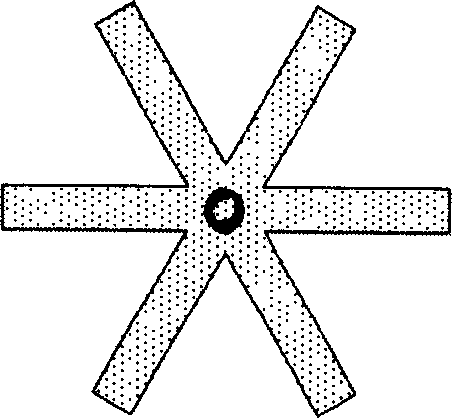

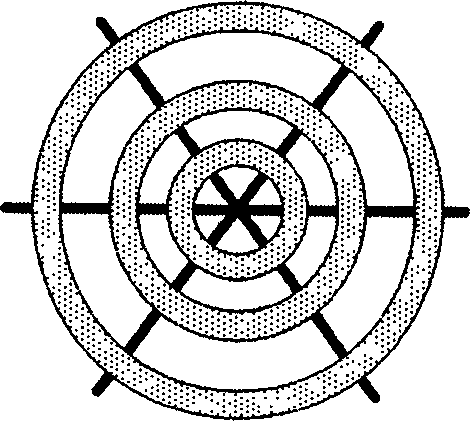

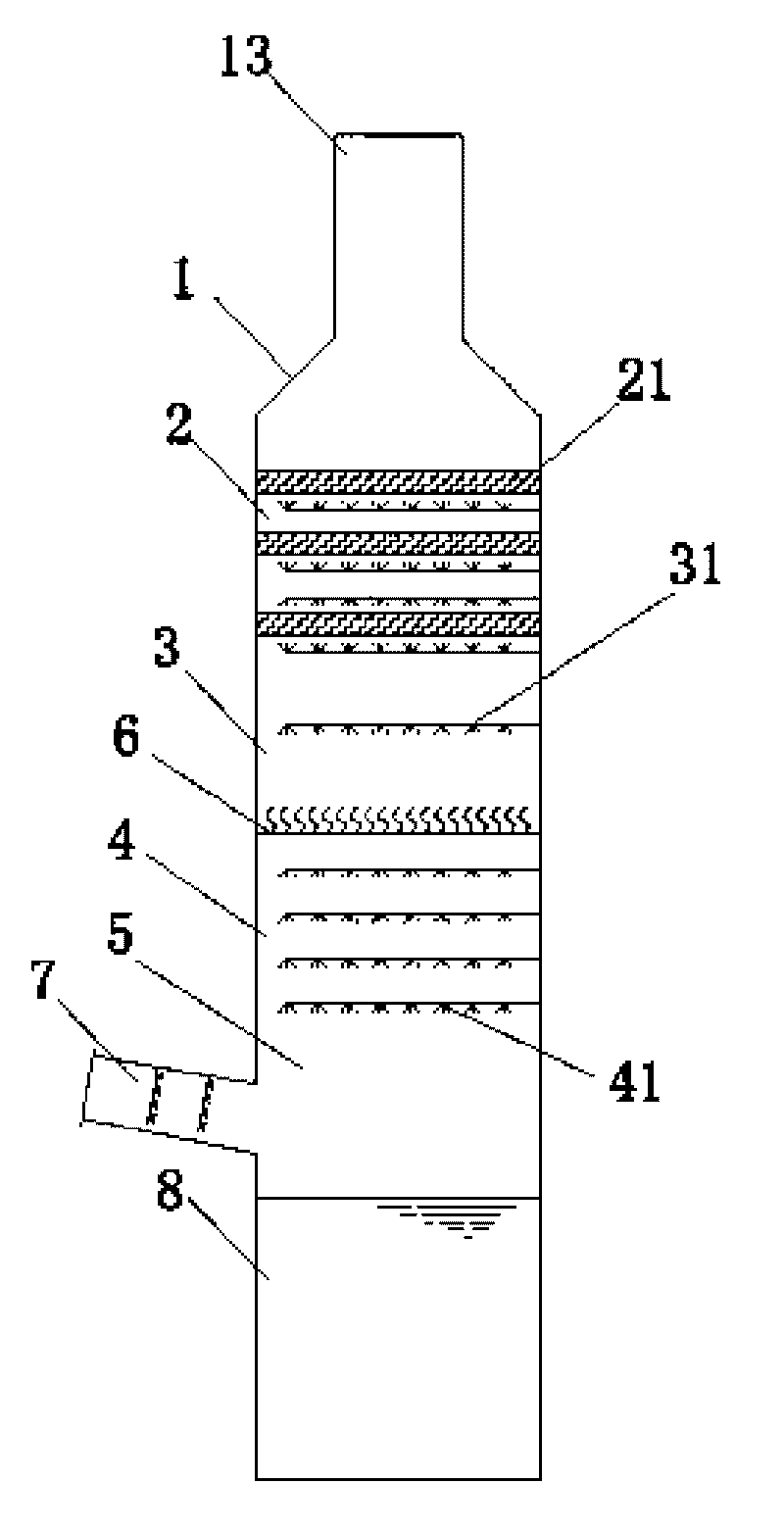

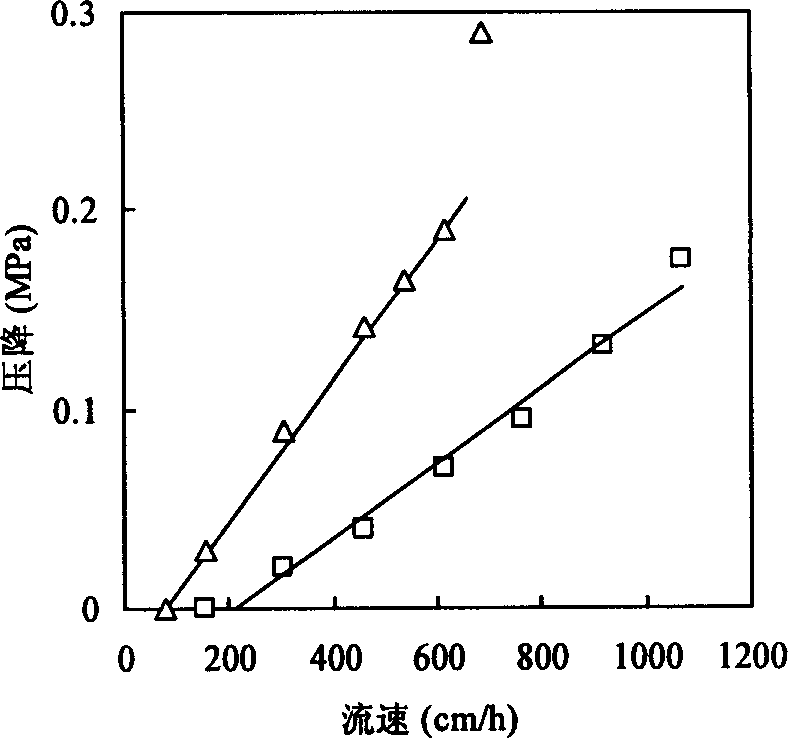

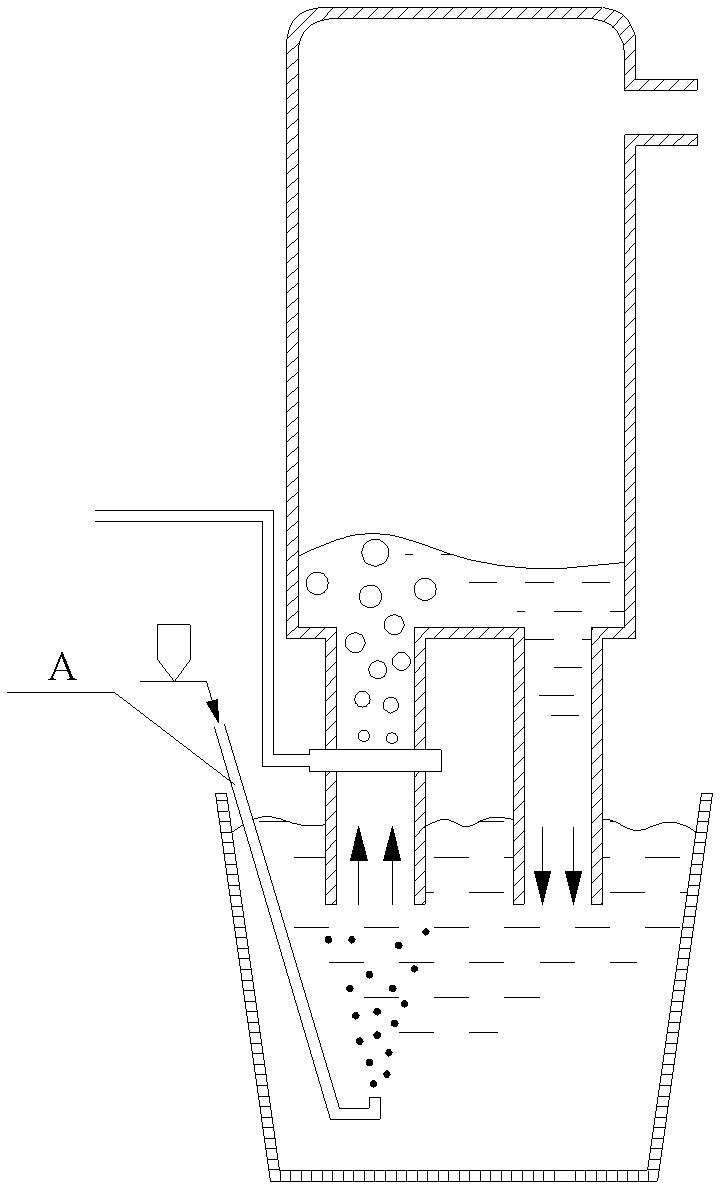

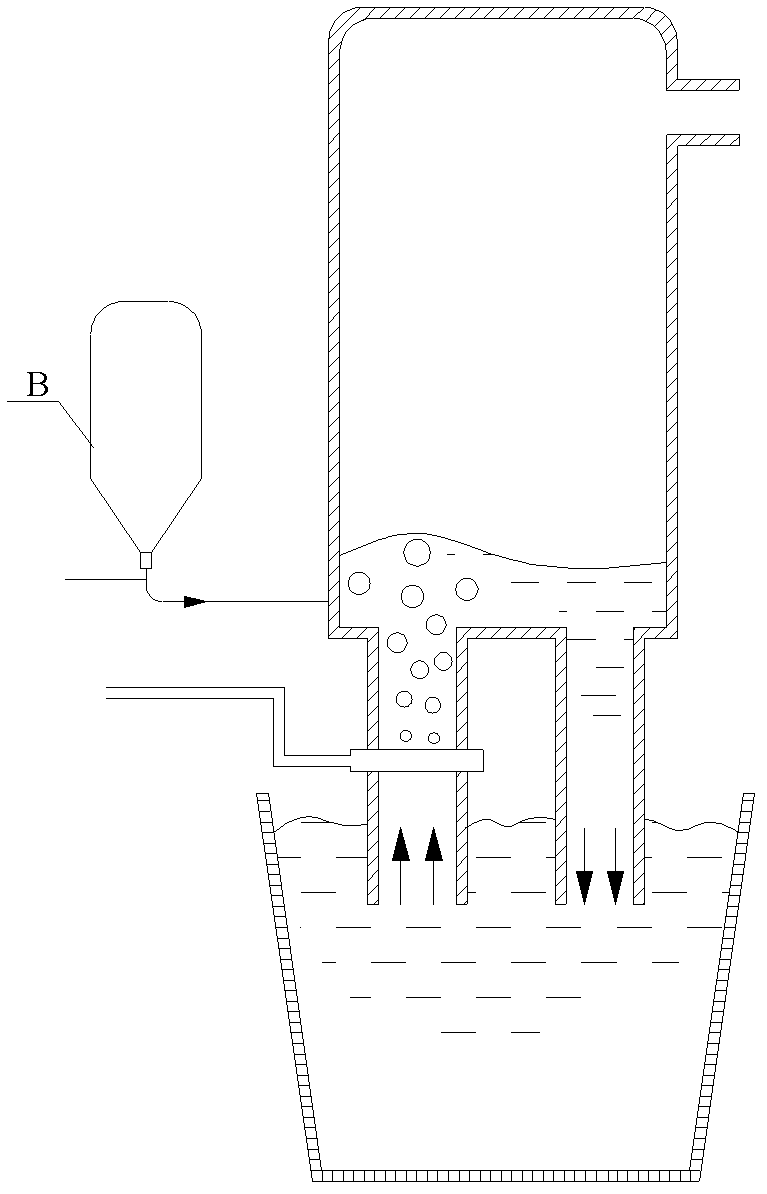

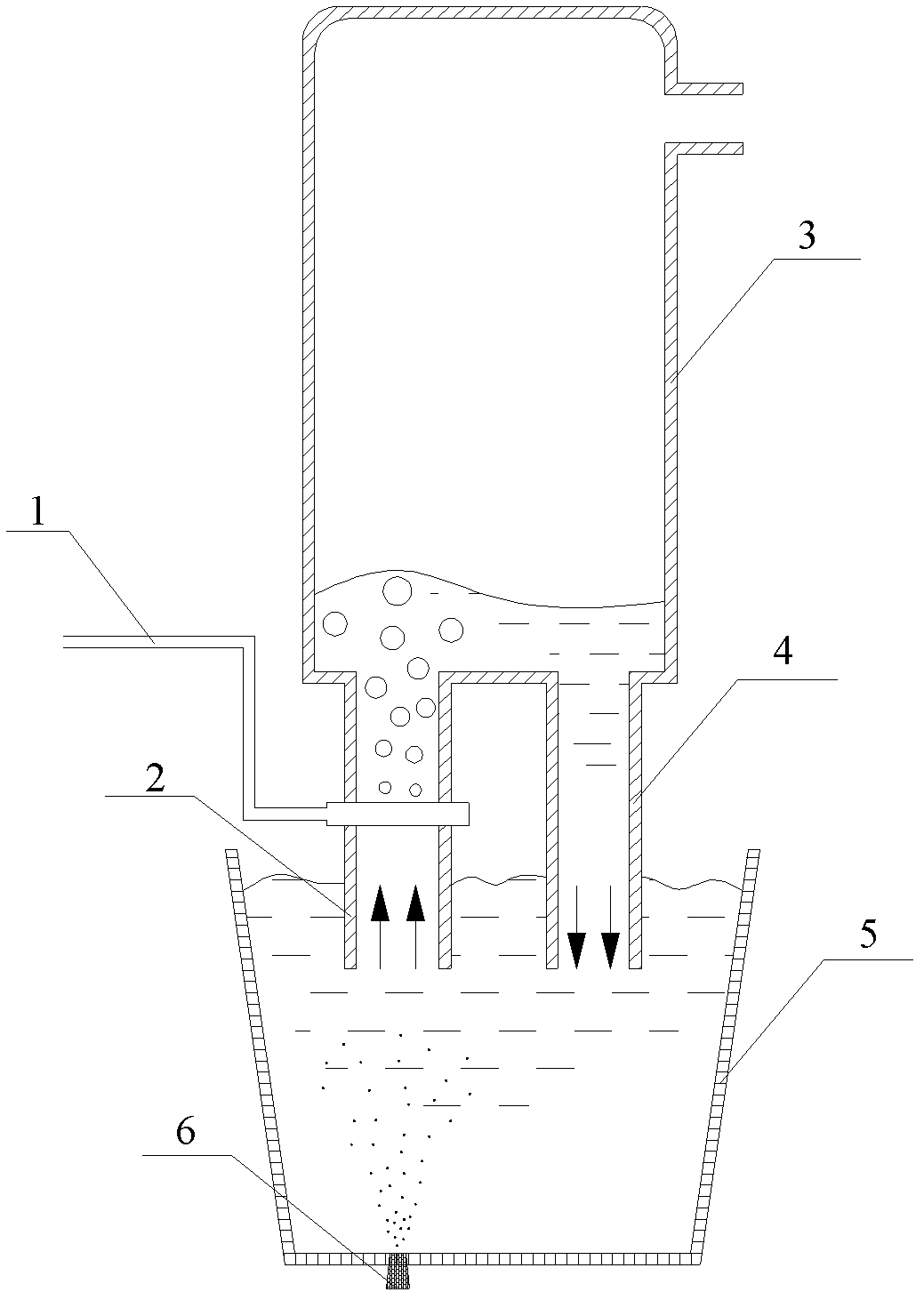

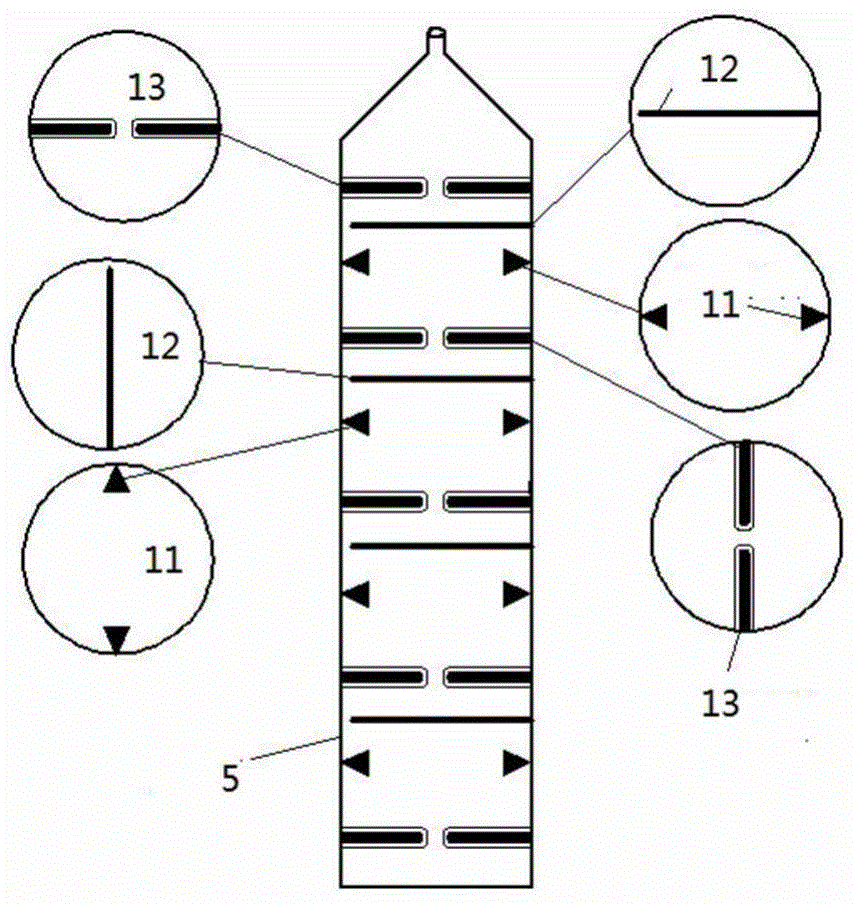

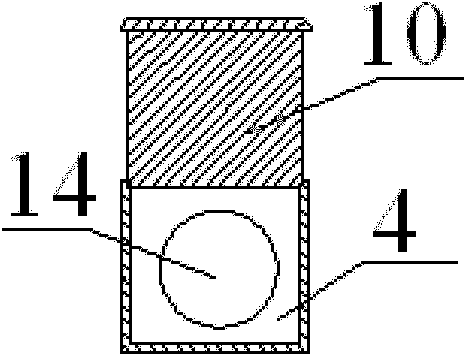

Bubbling tower reactor having damping internal construction member

InactiveCN1785495AIncrease mass transfer rateInhibit flow rateLiquid-gas reaction processesEngineeringTower

A bubbling column reactor with internal damping member features that said internal damping member is coaxially installed in the reaction region above gas distributor for suppressing the flow speed in central region to make the radial speed distribution more uniform and interferring the flow field to promote local turbulence and increase gas-liquid mass transfer speed.

Owner:ZHEJIANG UNIV

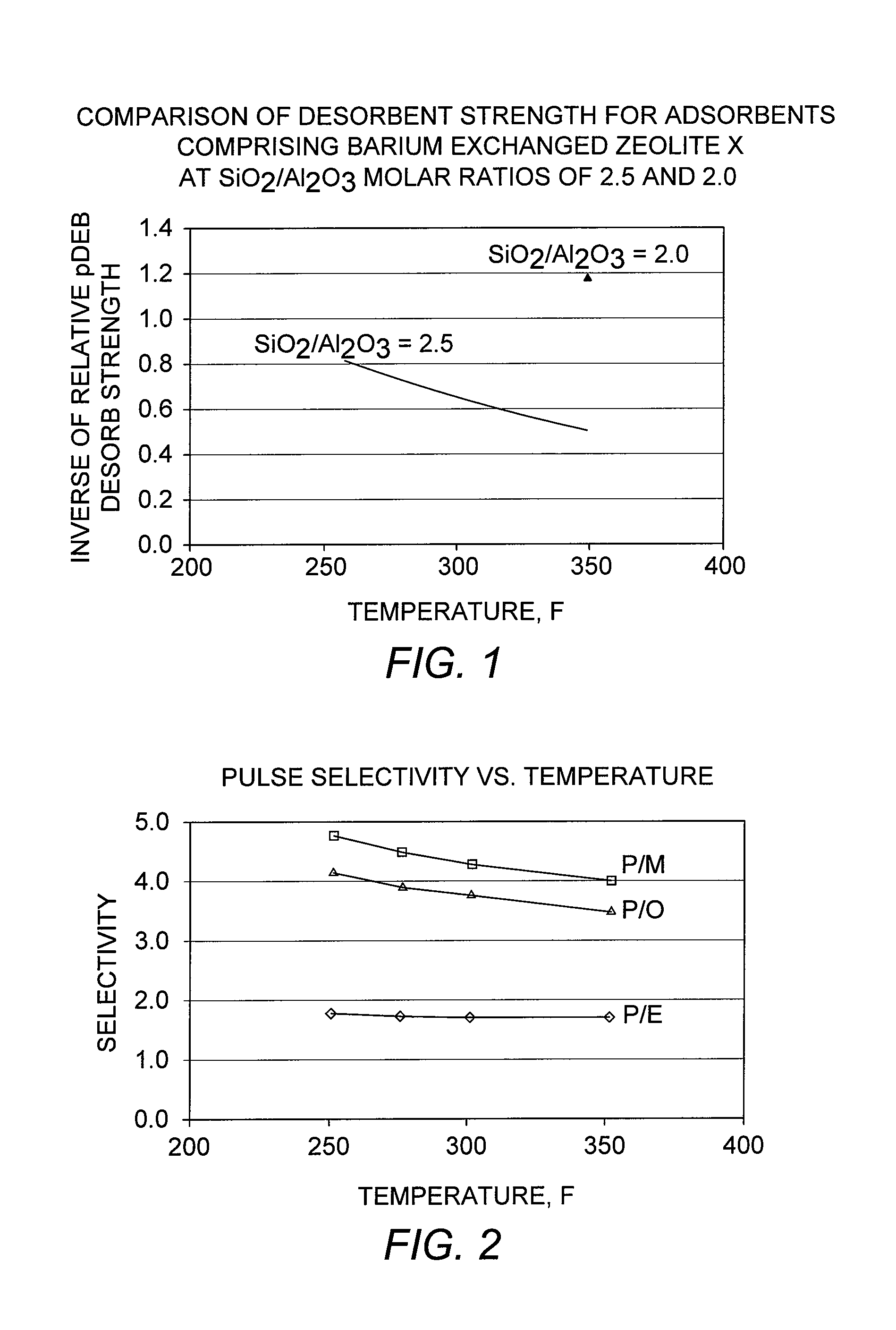

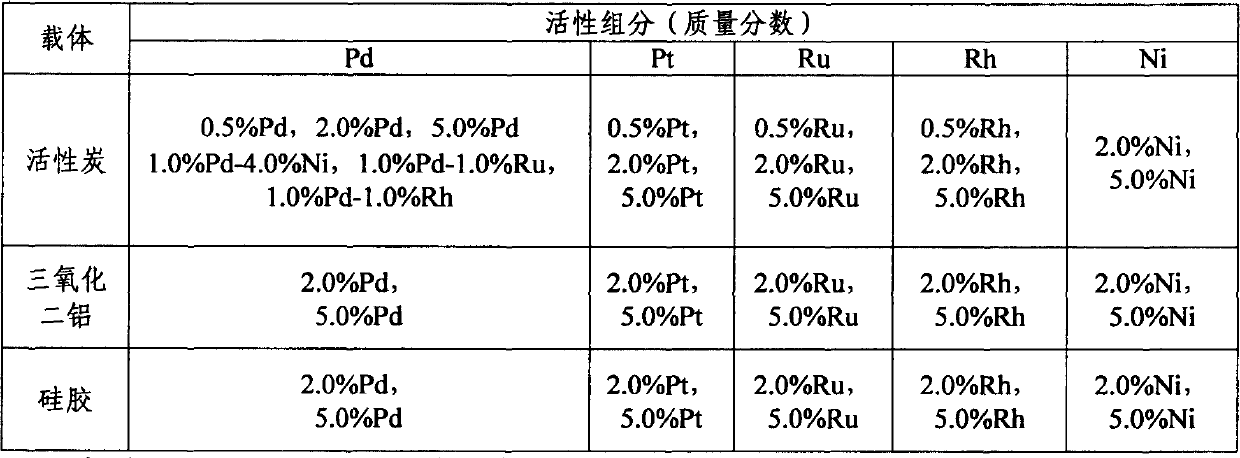

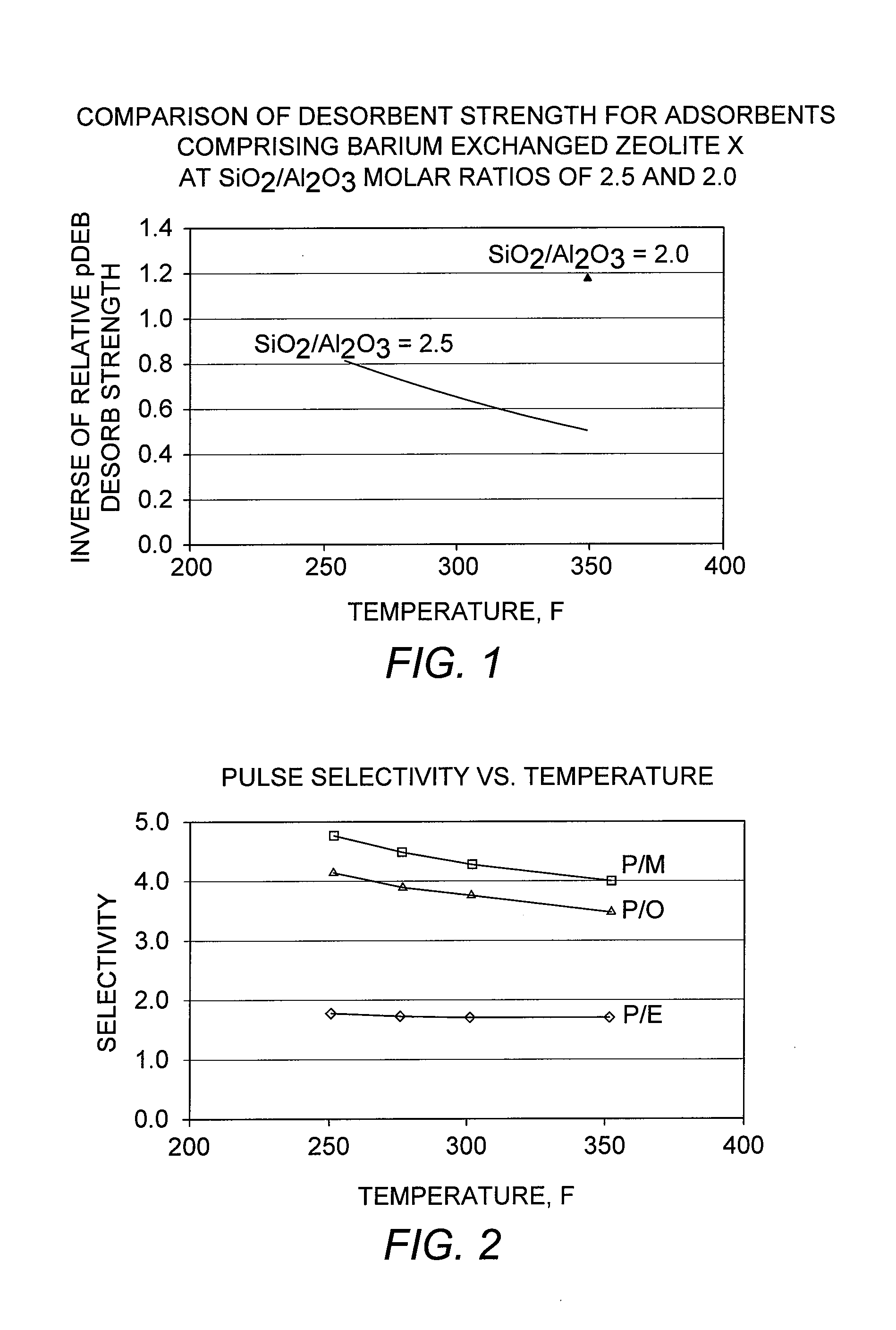

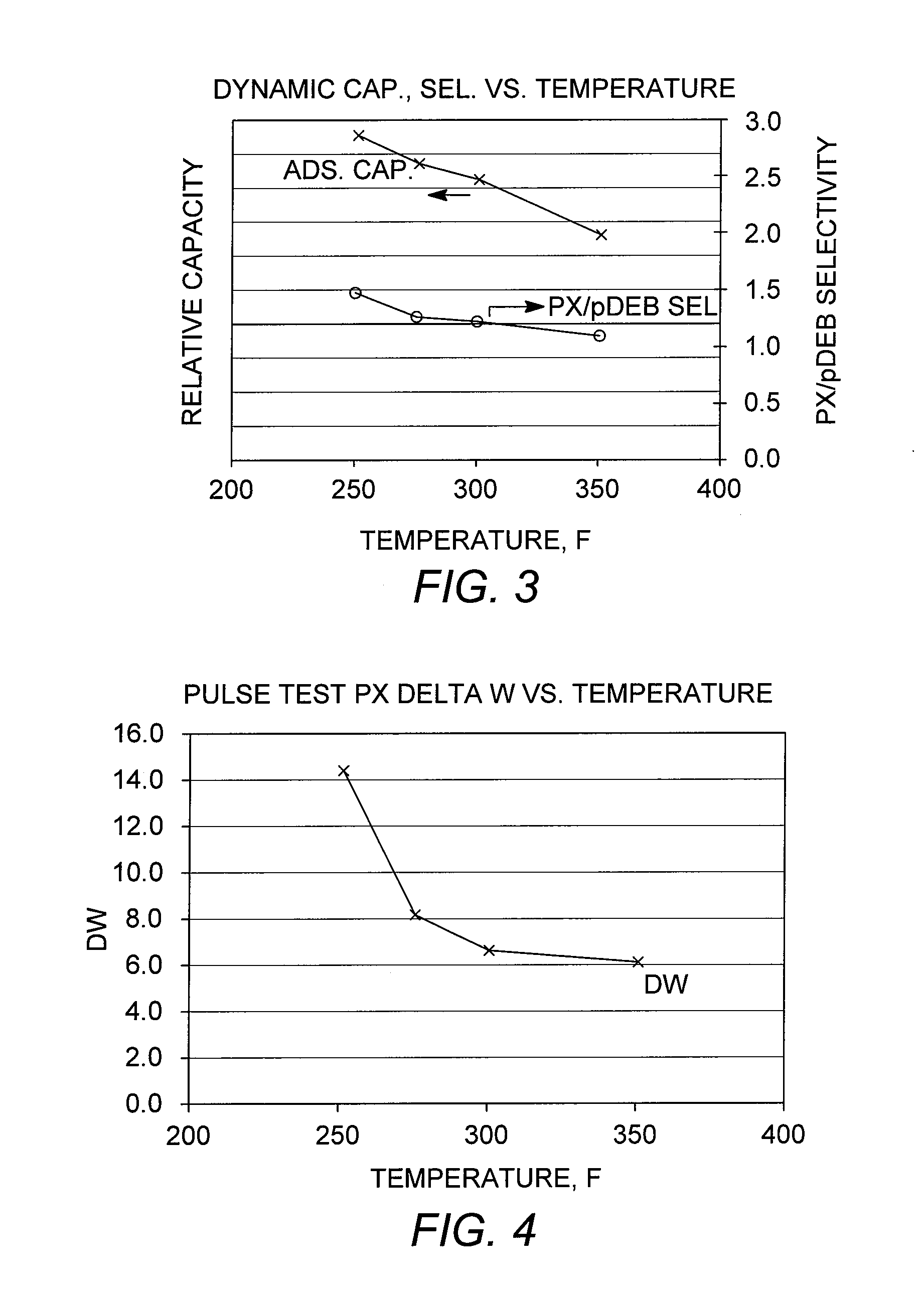

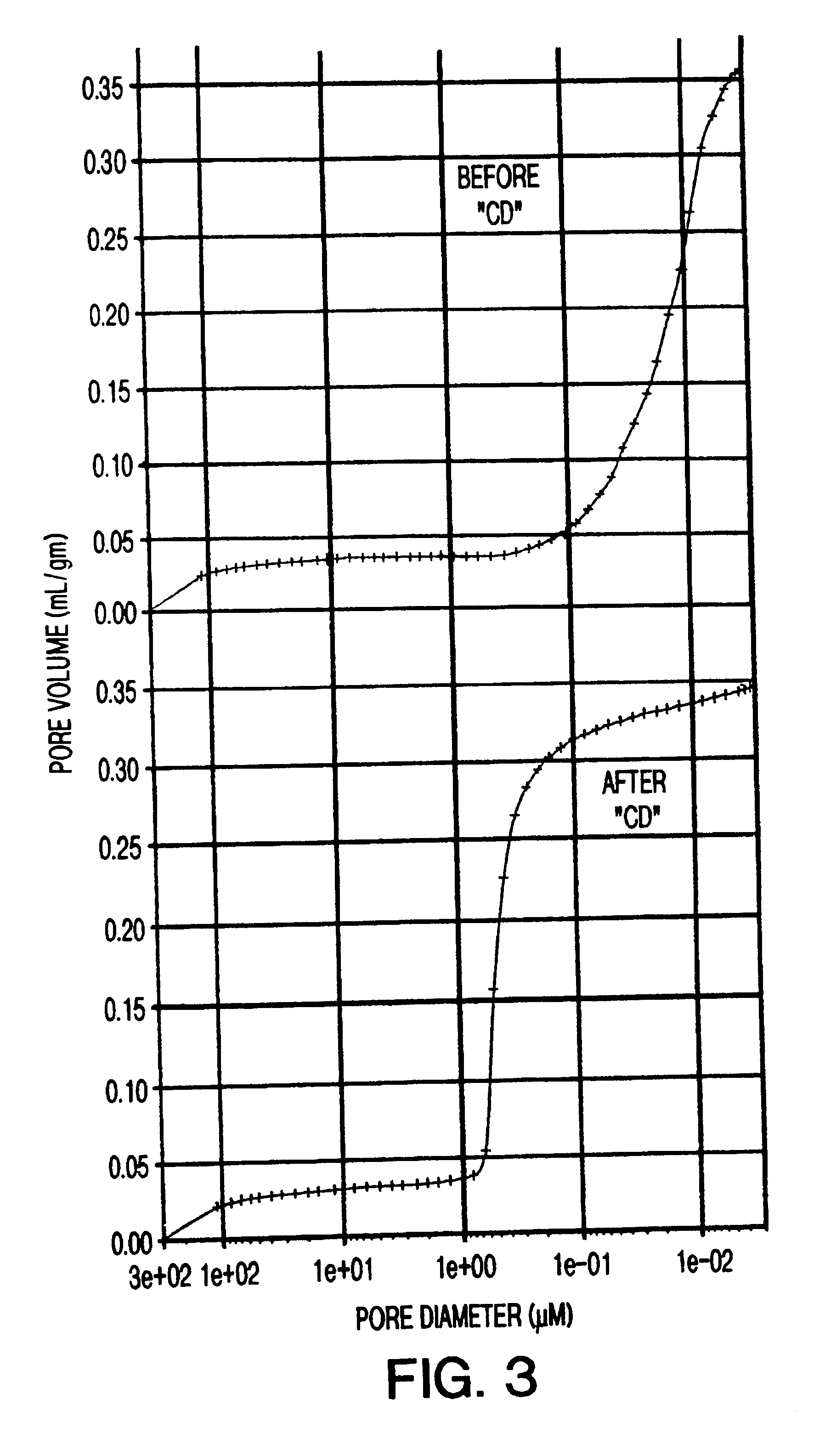

Binderless adsorbents and their use in the adsorptive separation of para-xylene

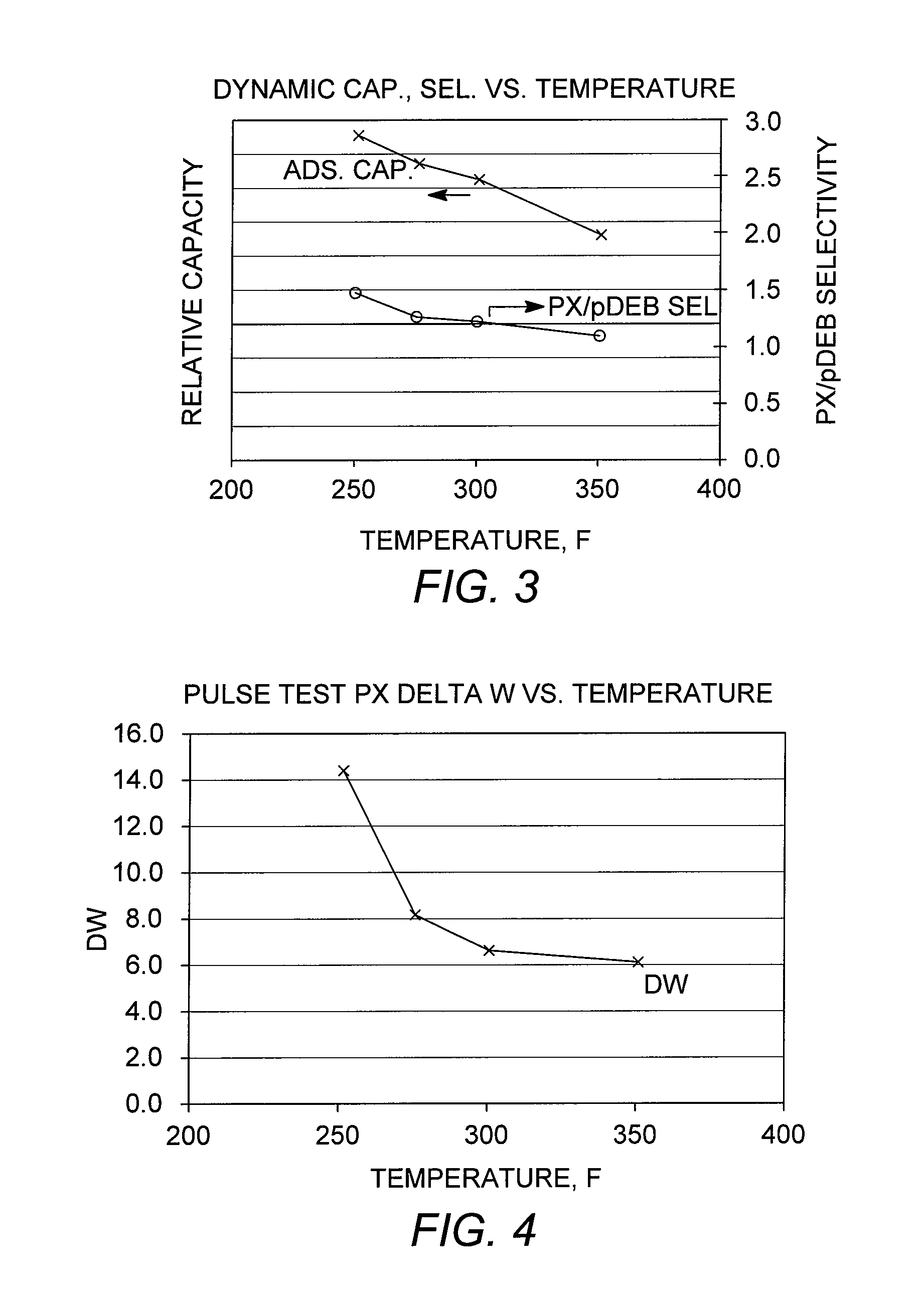

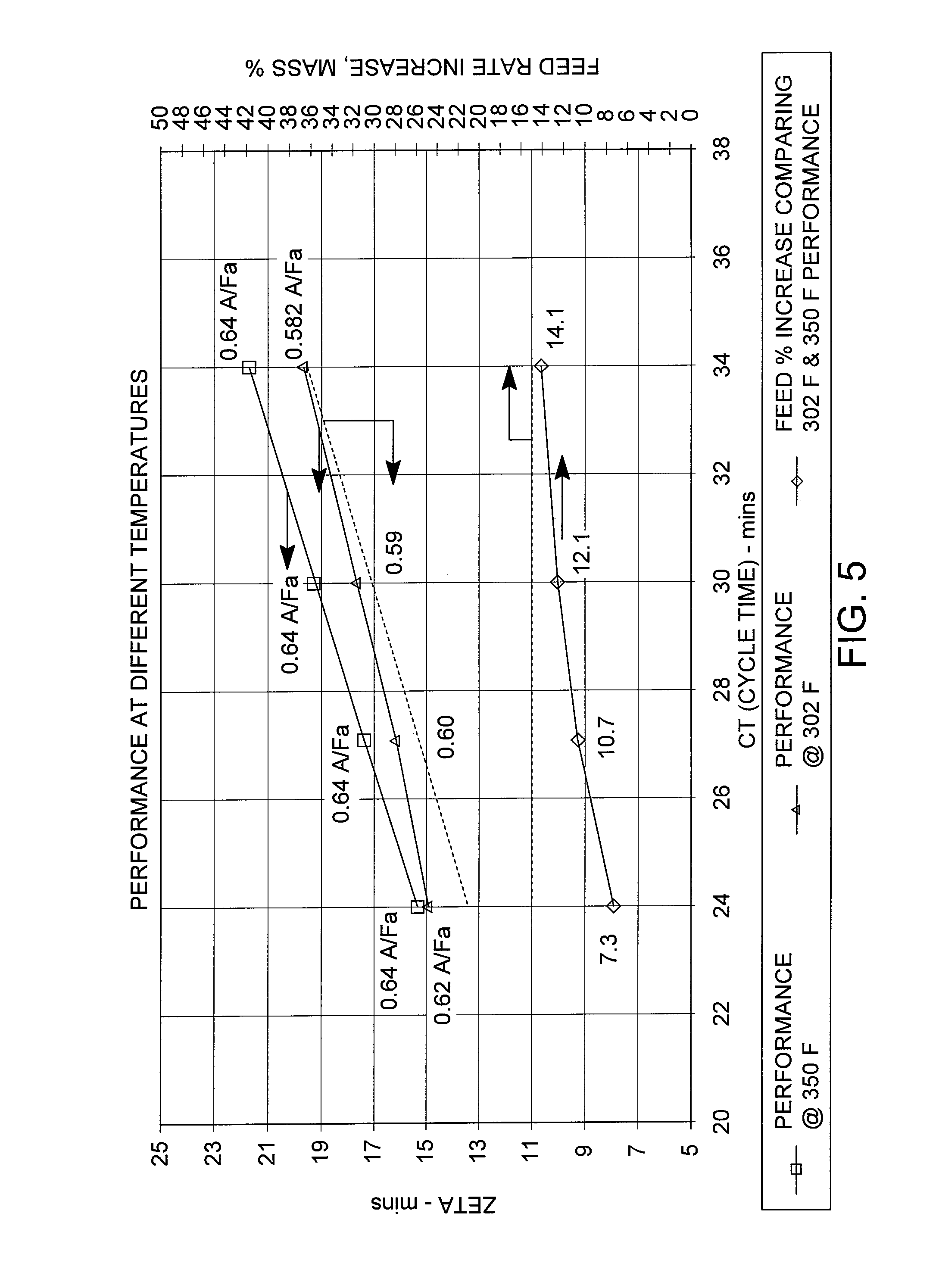

ActiveUS7820869B2Improve performanceIncrease mass transfer rateMaterial nanotechnologyMolecular sieve catalystsProduction rateSorbent

Adsorbents and methods for the adsorptive separation of para-xylene from a mixture containing at least one other C8 aromatic hydrocarbon (e.g., a mixture of ortho-xylene, meta-xylene, para-xylene, and ethylbenzene) are described. Suitable binderless adsorbents (e.g., formulated with the substantial absence of an amorphous material that normally reduces selective pore volume), particularly those with a water content from about 3% to about 5.5% by weight, improve capacity and / or mass transfer. These properties are especially advantageous for improving productivity in low temperature, low cycle time adsorptive separation operations in a simulated moving bed mode.

Owner:UOP LLC

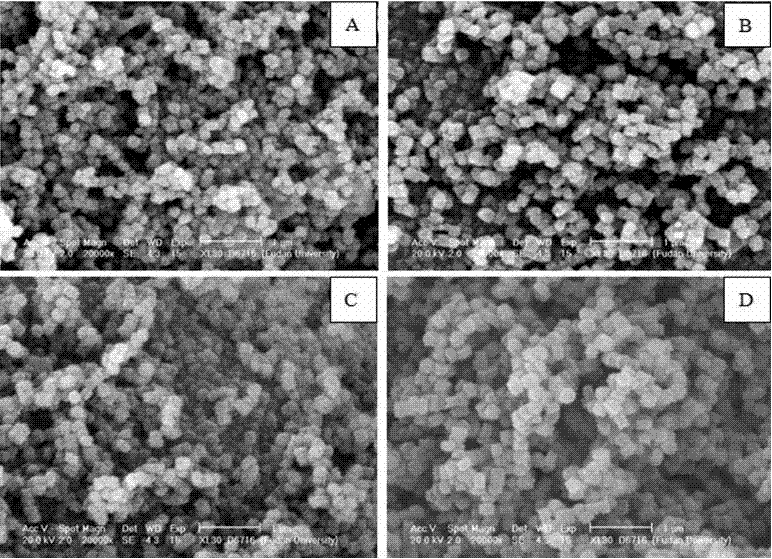

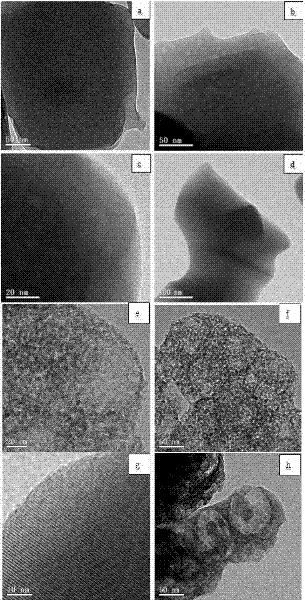

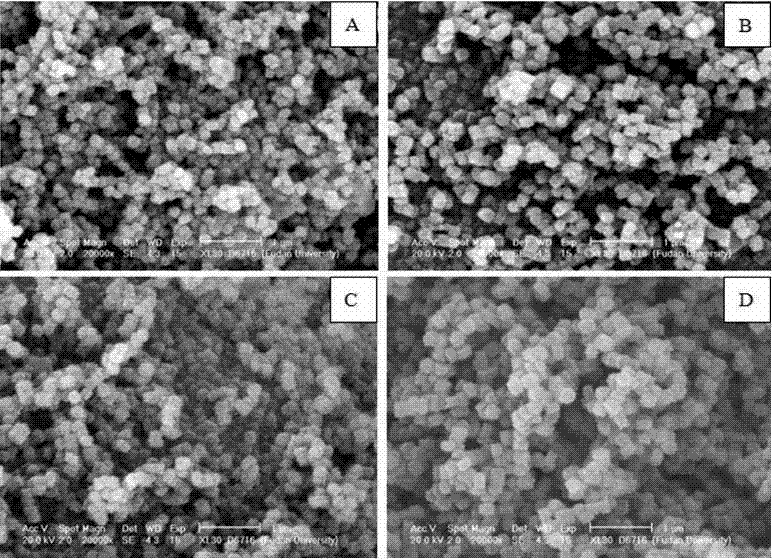

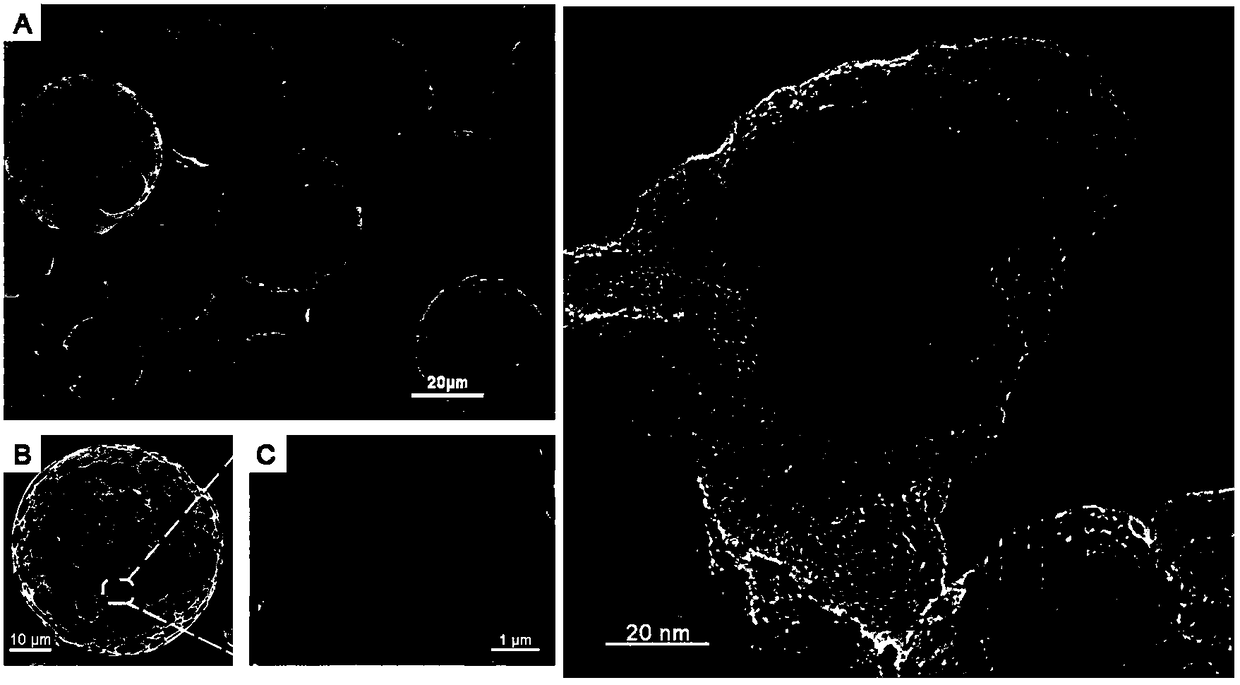

Three-dimensional interconnected hierarchical-structured zeolite molecular sieve material and preparation method thereof

InactiveCN102390843AIncrease mass transfer rateIncrease reaction rateCrystalline aluminosilicate zeolitesActive agentPetrochemical

The invention belongs to the technical field of mesoporous composite materials, and particularly relates to a three-dimensional interconnected hierarchical-structured zeolite molecular sieve material and a preparation method thereof. The method comprises the following steps of: self-assembling anionic and cationic surfactants, serving as primary constitutional units, in solution phase to form a secondary constitutional unit; self-assembling in solution to be compounded into amphipathic block copolymer; then, self-assembling in the solution by taking the amphipathic block copolymer as a template agent and by using a structural guide agent and inorganic silicon to obtain a silicon dioxide / surfactant / template agent composite material; and finally, calcining to remove the surfactant and the template agent to obtain the hierarchical-structured mesoporous zeolite molecular sieve material consisting of interconnected mesopores, micropores and macropores. The material has higher specific surface area and stronger hydrothermal stability, and has a broad application prospect in the aspects of petrochemical industry, heavy oil catalysis cracking, biological separation, adsorption and the like. The material obtained in the invention has the advantages of superior performance, simple synthesis method and readily available raw material and is suitable for industrial production.

Owner:FUDAN UNIV

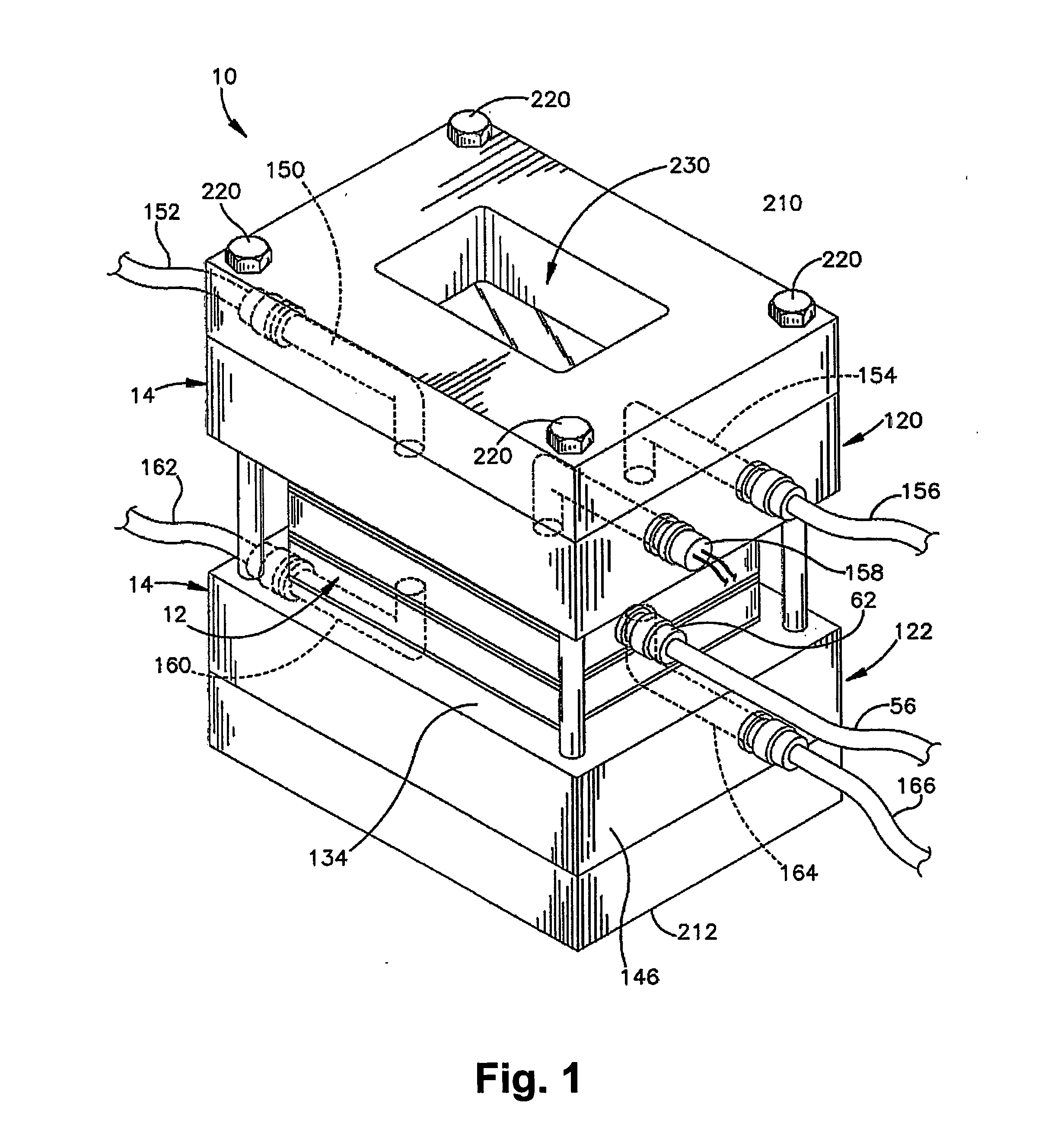

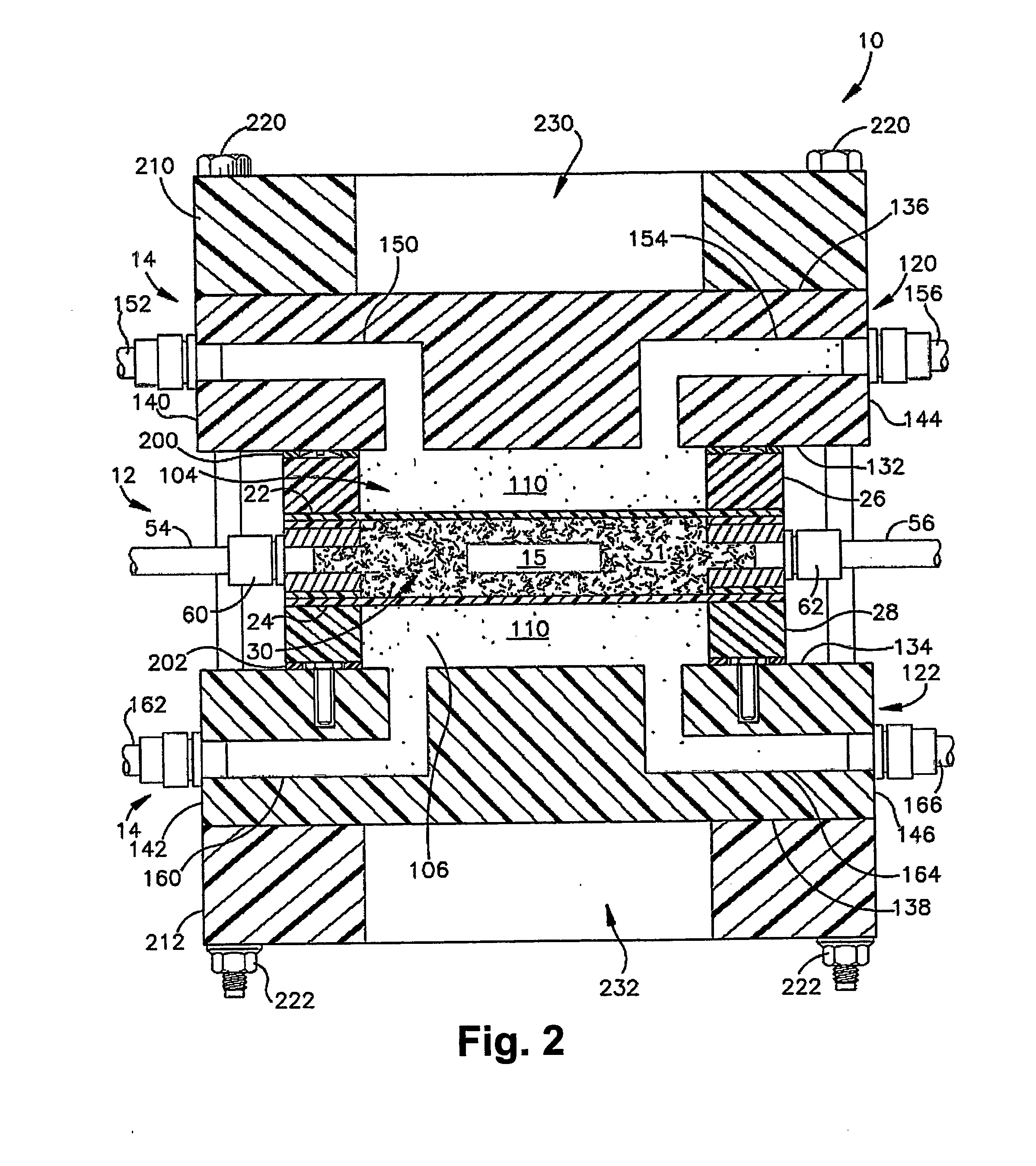

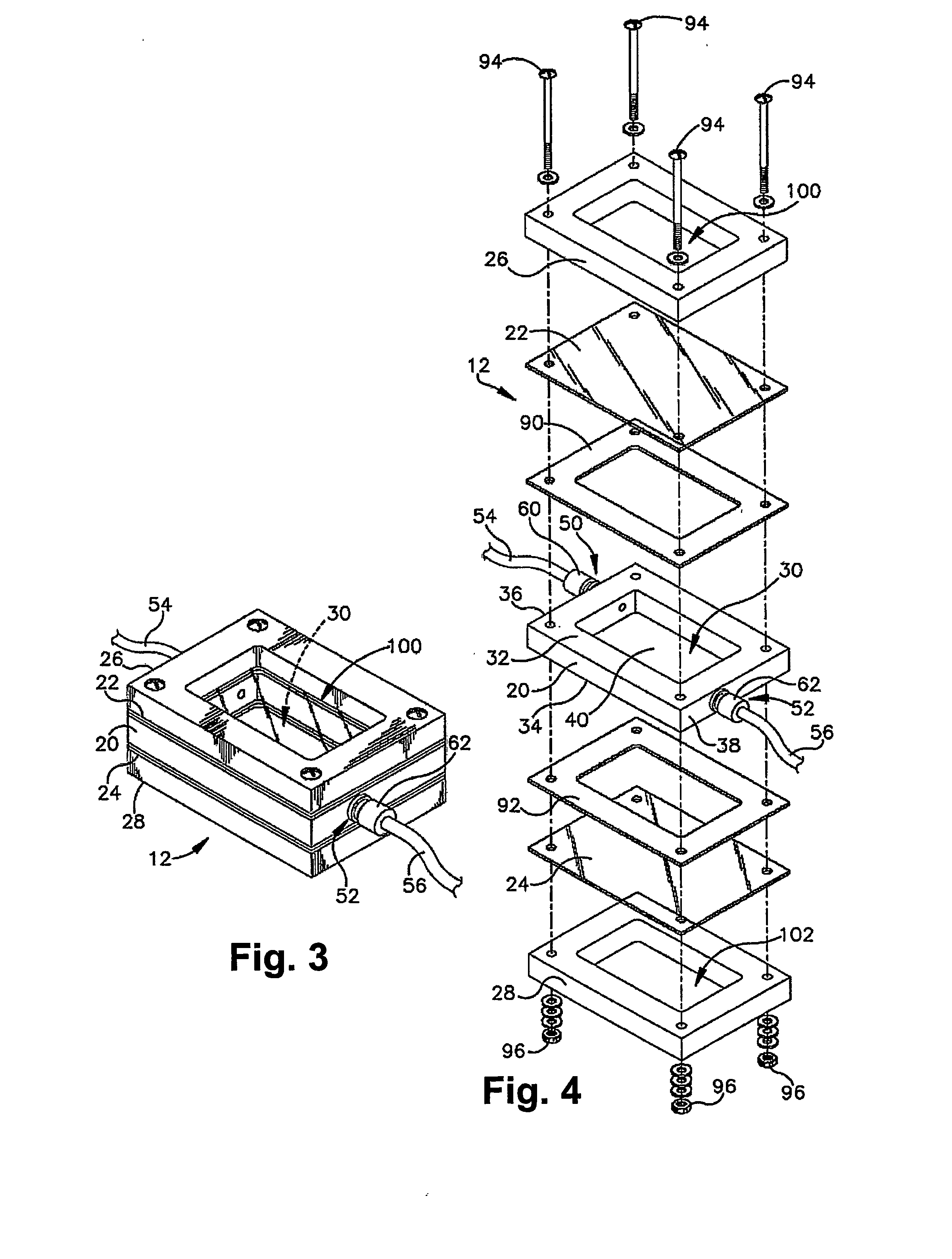

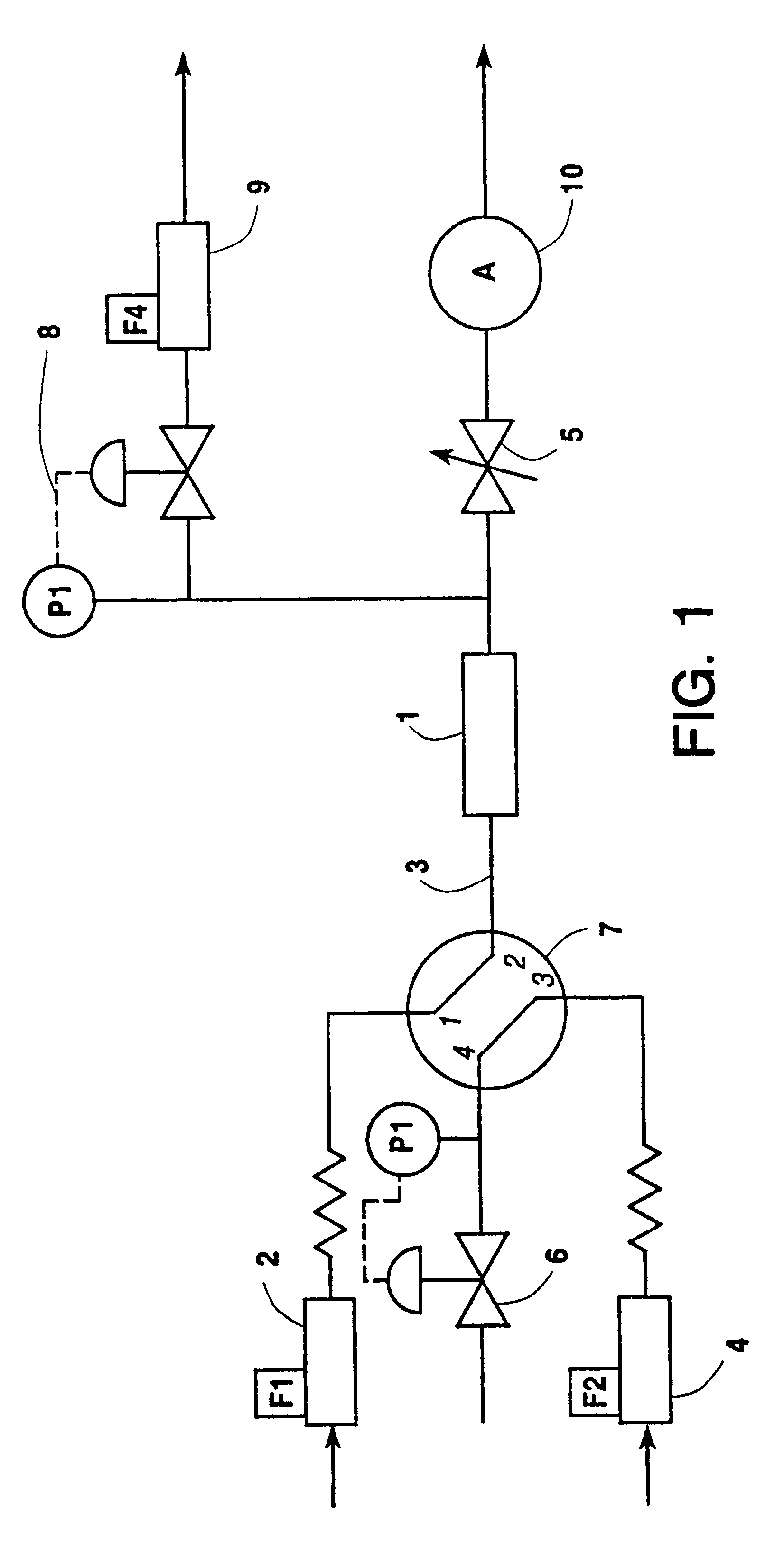

Apparatus and method for tissue engineering

InactiveUS20070042490A1Increase mass transfer rateStable extracellular environmentBioreactor/fermenter combinationsBiological substance pretreatmentsTissue engineeringCulture mediums

A bioreactor system includes a housing and a hydrostatic loading module. The housing includes a chamber with an inlet port and an outlet port. The inlet and outlet ports allowing the chamber to be continuously perfused with a culture medium while chamber is hydrostatically loaded.

Owner:CASE WESTERN RESERVE UNIV

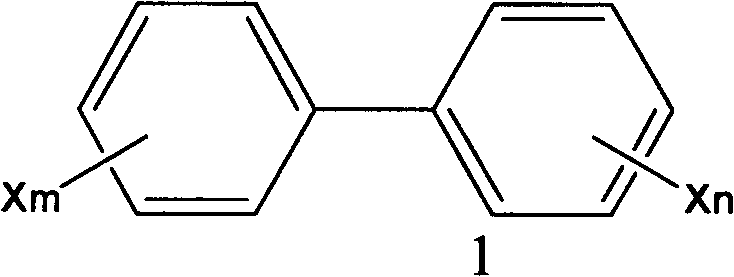

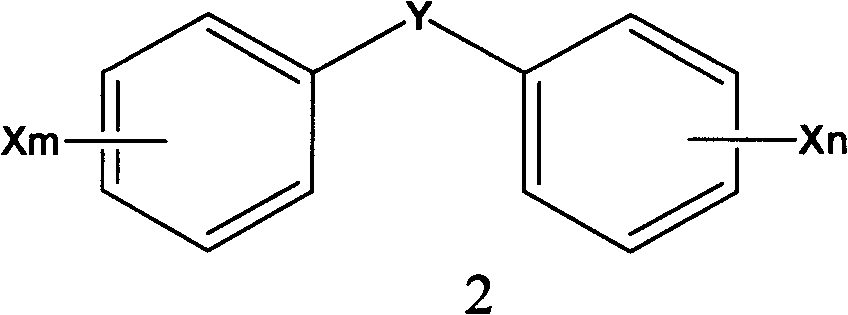

Method for high-efficiency degradation of persistent organic chloridized pollutant

ActiveCN102512783ARapid and efficient hydrodehalogenationIncrease contact areaOrganic compound preparationHydrocarbon from halogen organic compoundsHalogenActive component

The invention relates to a degrading method for an organic chloridized pollutant, in particular to a hydrogenized dehalogenating method for the high-efficiency degradation of a persistent organic halogenated pollutant. Particularly, a reaction system of the method is an organic-water two-phase solvent system and is used for the hydrogenized dechlorination of a persistent organic chloridized pollutant at normal temperature and normal pressure, transition metal is adopted as a catalyst, and this class of catalyst comprises active components and a vector. The active component is one or more in Pd, Rh, Ru, Pt, Ni, Fe, Co and Ir. The active components account for 0.5 to 5.0 percent of the mass fraction of the catalyst. The reaction pressure is the normal pressure, and the reaction temperature is controlled at 30 to 55 DEG C. According to the method, the preparation is simple, and special equipment is not needed. The dehalogenating reaction condition is mild, the operation is easy to control, the use quantity of the catalyst is little, and the removing rate of halogen is high.

Owner:YANTAI INST OF COASTAL ZONE RES CHINESE ACAD OF SCI

Binderless adsprbents and their use in the adsorptive separation of para-xylene

ActiveUS20090326309A1High adsorbent capacity/mass transfer propertyIncreased para-xylene productivityMaterial nanotechnologyMolecular sieve catalystsSorbentSimulated moving bed

Adsorbents and methods for the adsorptive separation of para-xylene from a mixture containing at least one other C8 aromatic hydrocarbon (e.g., a mixture of ortho-xylene, meta-xylene, para-xylene, and ethylbenzene) are described. Suitable binderless adsorbents (e.g., formulated with the substantial absence of an amorphous material that normally reduces selective pore volume), particularly those with a water content from about 3% to about 5.5% by weight, improve capacity and / or mass transfer. These properties are especially advantageous for improving productivity in low temperature, low cycle time adsorptive separation operations in a simulated moving bed mode.

Owner:UOP LLC

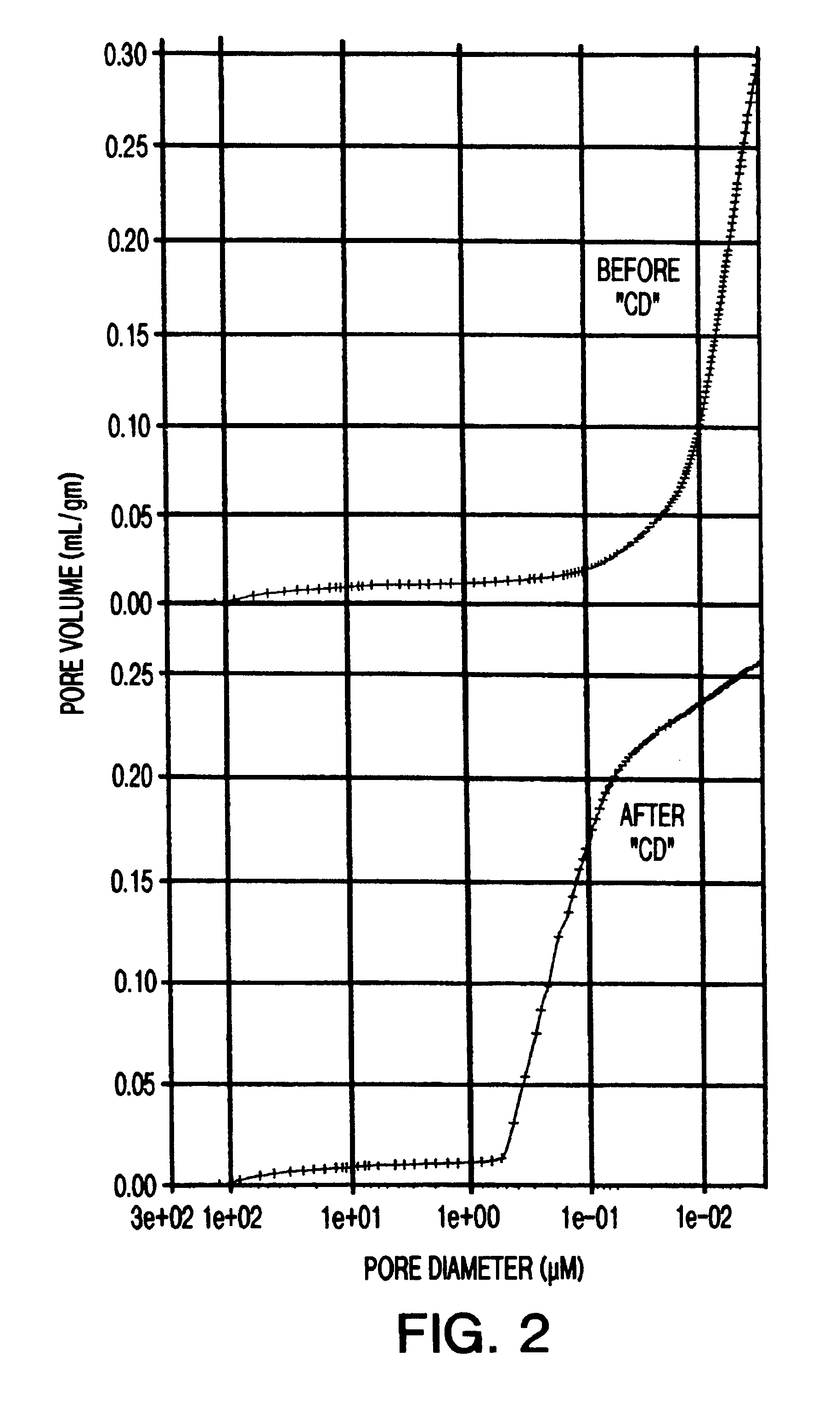

Advanced adsorbent for PSA

InactiveUS6425940B1Increase mass transfer rateMass transfer speedGas treatmentMolecular sieve catalystsSorbentOrganic chemistry

The invention relates to adsorbent materials having comparatively high intrinsic adsorption rates. Methods are disclosed whereby such rates can be achieved. In preferred embodiments, the adsorbent is a LiX zeolite material.

Owner:PRAXAIR TECH INC

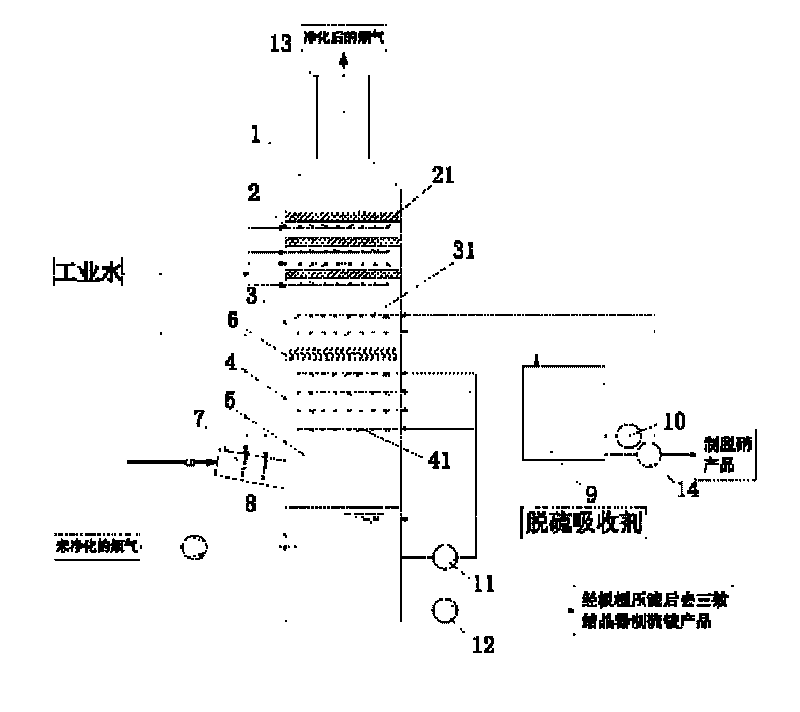

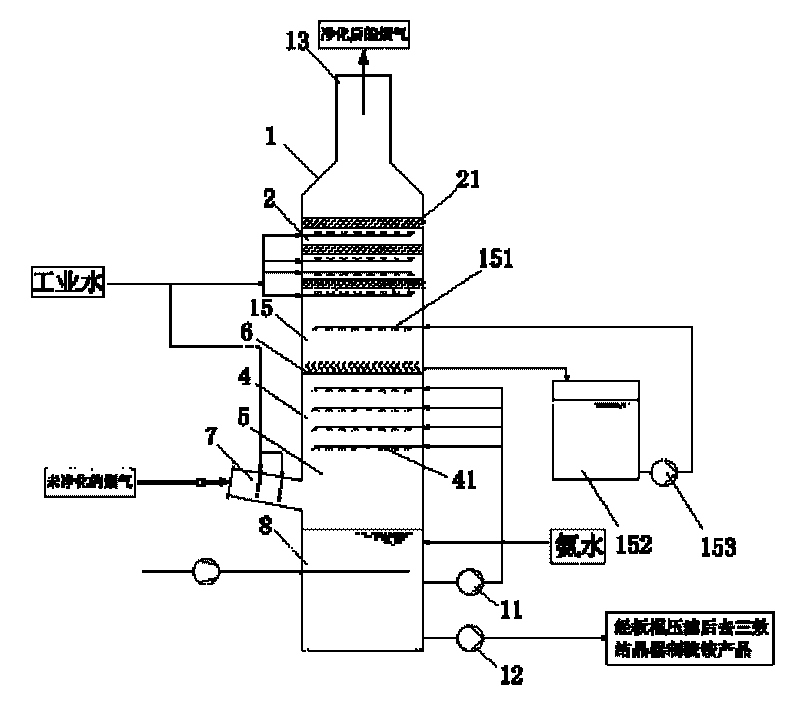

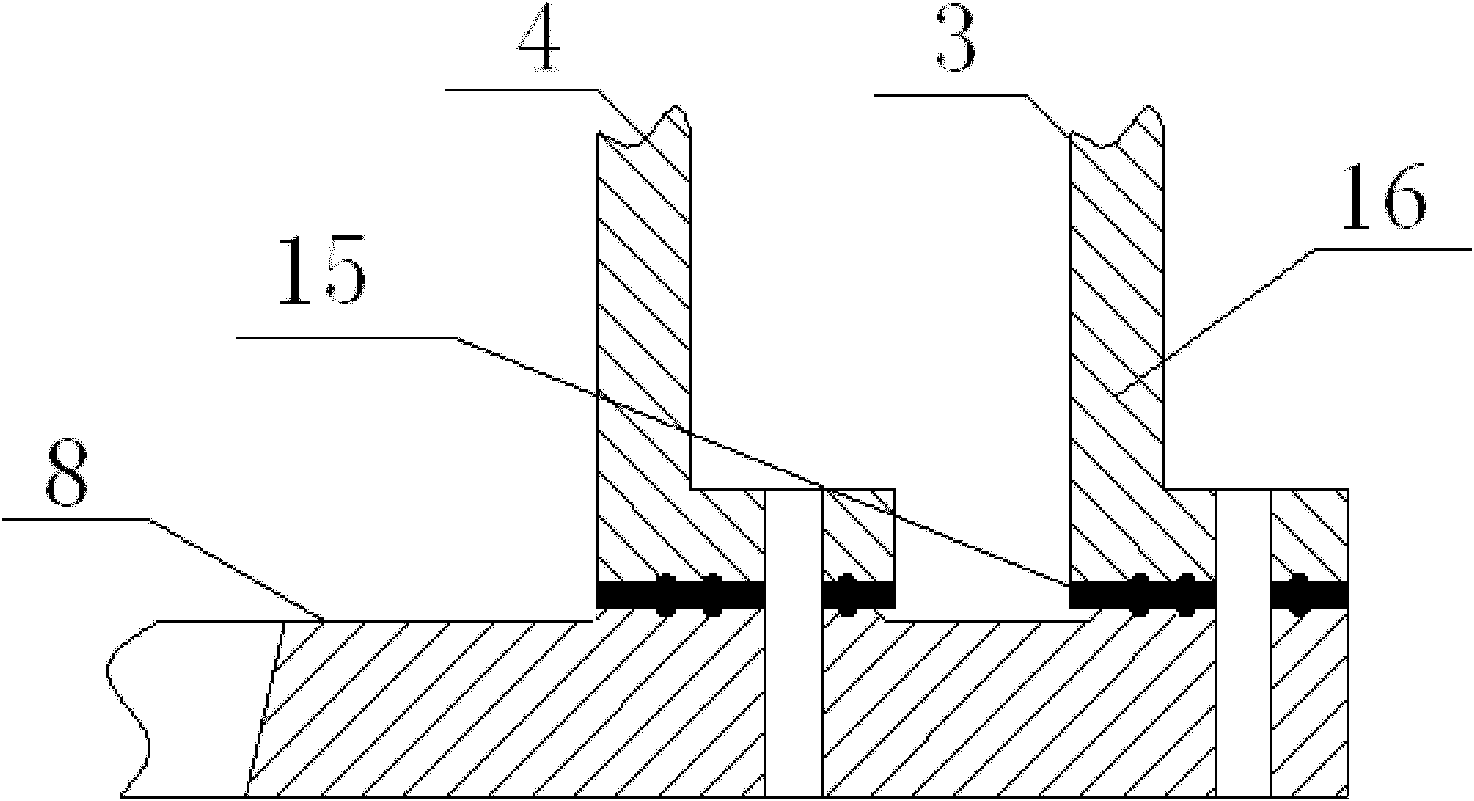

Treatment technique for pollutants in sinter fume and spraying and absorbing tower thereof

InactiveCN101708420AEasy to handleQuality improvementLighting and heating apparatusDispersed particle separationMulti pollutantEngineering

The invention discloses a treatment technique for pollutants in sinter fume and a spraying and absorbing tower thereof. After cooling and dedusting, the sinter fume is led into the spraying and absorbing tower, moves upwards to pass through at least two spraying and absorbing sections partitioned from up down in the spraying and absorbing tower, each spraying and absorbing section sprays and absorbs more than one pollutant in the sinter fume and the spraying and absorbing solution does not fall into the absorbing section of next layer, after passing through all the spraying and absorbing sections, the fume is demisted and exhausted from the top of the spraying and absorbing tower. The spraying and absorbing tower comprises a tower body, the tower body is partitioned into a demisting section, more than two spraying and absorbing sections and a fume inlet section from up down and a seriflux pool on the bottom of the tower body, and the adjacent spraying and absorbing sections are partitioned by a tower board assembly. The invention has the advantages that the loss of system resistance is small, the structure is simpler and more compact, the operation is convenient, the absorption effect is good, the treatment capacity is high and the like, and the invention can treat various pollutants in sinter fume.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

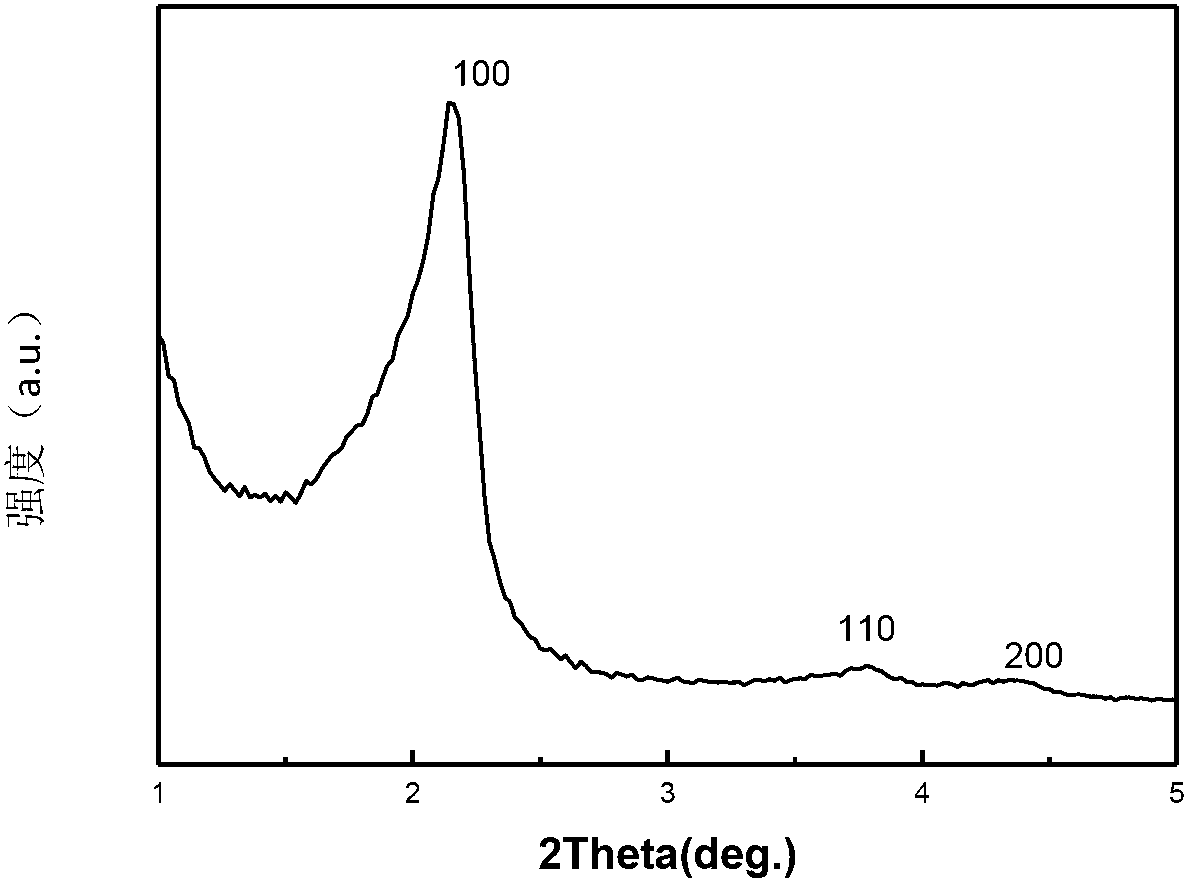

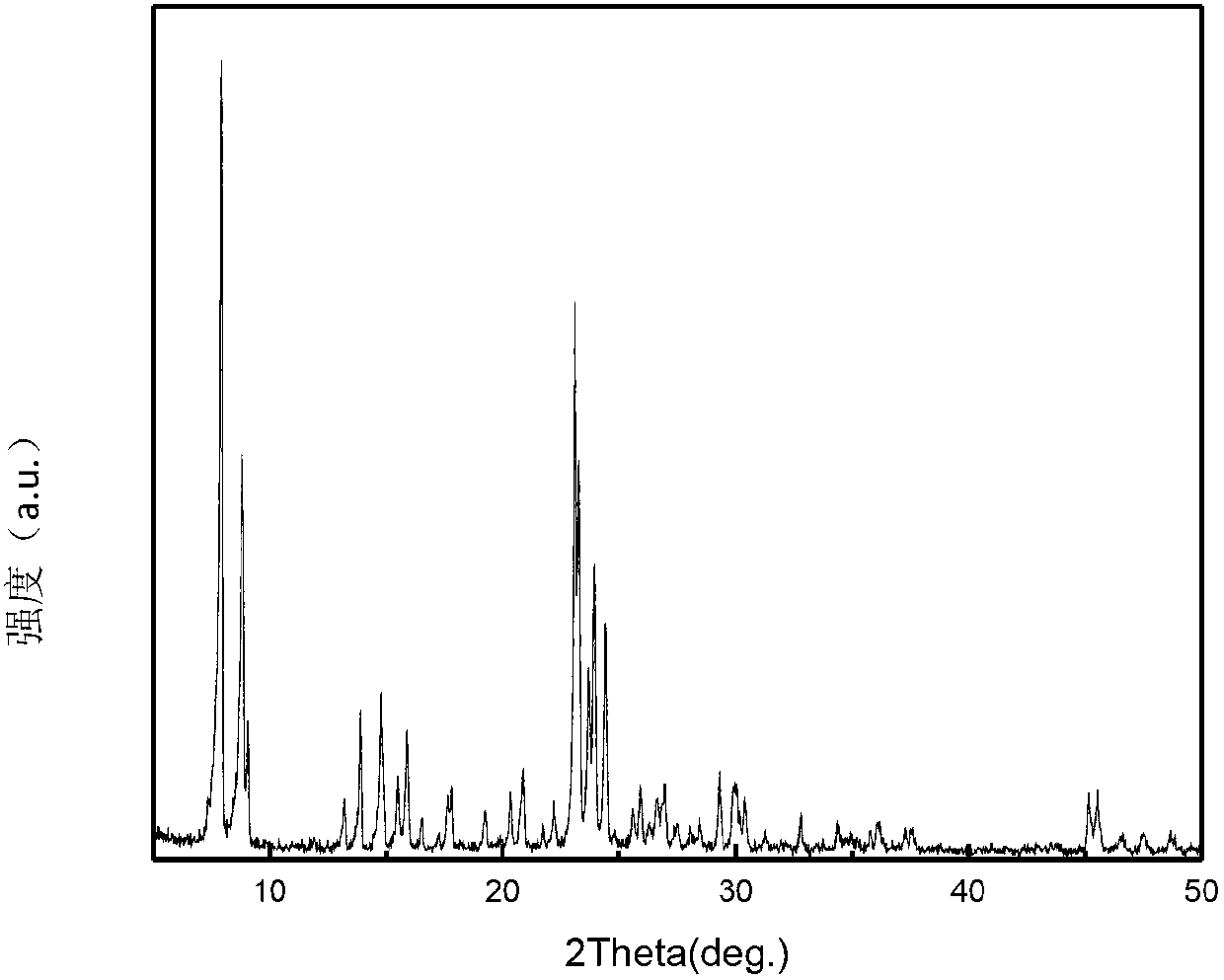

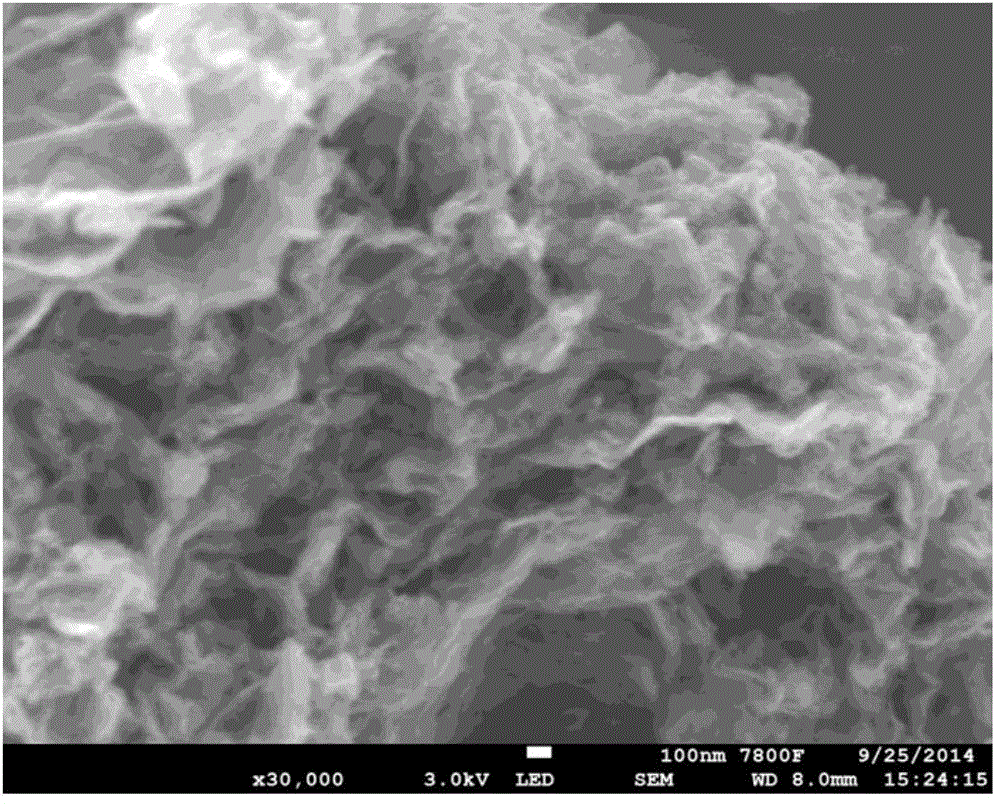

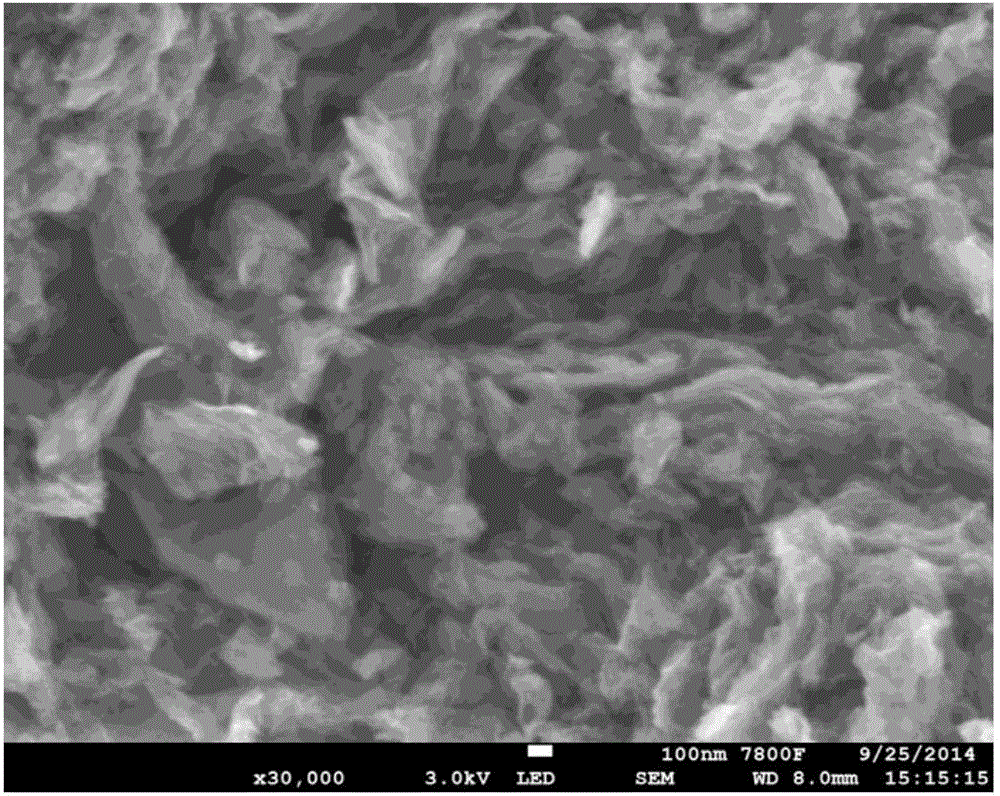

Ordered mesopore ZSM-5 molecular sieve and preparation method thereof

InactiveCN103101930AImprove performanceRemarkable resultsPentasil aluminosilicate zeolitePore diameterPetrochemical

The invention discloses a preparation method of an ordered mesopore ZSM-5 molecular sieve. The preparation method comprises the following steps of: firstly preparing an ordered mesopore silicon oxide molecular sieve serving as a silicon source through an organic template method; and then transforming the ordered mesopore silicon oxide molecular sieve into the ordered mesopore ZSM-5 molecular sieve in situ by adopting a hydrothermal method. The ordered mesopore ZSM-5 molecular sieve disclosed by the invention is provided with ordered micropores with pore diameter being 0.2-2 nanometers and ordered mesopores with pore diameter being 2-50 nanometers and has wide application prospect in the fields of petrochemical industry, petroleum processing, coal chemical industry, and the like.

Owner:SHANGHAI NORMAL UNIVERSITY

Non-noble metal catalyst for oxygen reduction, and preparation and application of catalyst

ActiveCN105749947AIncreased oxygen reduction activityHigh activityPhysical/chemical process catalystsCell electrodesReduction ActivityFreeze-drying

Disclosed is a non-noble metal catalyst for oxygen reduction. The catalyst comprises a flake-like graphene carrier; a nitrogen-doped carbon skeleton arranged between neighbor flake layers of the flake-like graphene carrier; the graphene flake layers are separated by the nitrogen-doped carbon skeleton; and nanometer particles are adhered to the flake layers of graphene. The nanometer particles are one or more than two of carbon-coated non-noble metal particles, carbon-coated non-noble metal carbide particles, and carbon-coated non-noble metal nitride particles. A preparation method of the non-noble metal catalyst for oxygen reduction comprises: adding graphite oxide and non-noble metal precursor salt into water; performing mixing and standing; adding nitrogen-containing micro-molecules, a Nafion solution, and an oxidizing agent; performing uniform mixing; allowing the obtained solution to be evaporated; performing freeze-drying; and performing temperature programming thermal treatment and other after-treatment to obtain the non-noble metal catalyst for oxygen reduction. The catalyst has advantages of high oxygen reduction activity, good mass transfer performance, and low price.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Granular anti-hardening acid-base dual-purpose ternary micro-electrolysis filler and preparation method thereof

ActiveCN102583659AReduce consumptionWith strengthWater/sewage treatmentElectrolysisChemical oxygen demand

The invention relates to a granular anti-hardening acid-base dual-purpose ternary micro-electrolysis filler and a preparation method thereof. The grain size of the filler ranges from 1mm to 5mm, and iron powder, aluminium powder and graphite powder are mixed in a mass ratio of (2-6):(2-6):1 to perform granulation and then are sintered by being isolated from air, thus obtaining the filler. The micro-electrolysis filler is applicable to micro electronic treatment on acid sewage or base sewage. According to the invention, the efficiency of micro electrolysis on the sewage is high, a filling areais not easy to harden, and the period of back flushing is long. When the ternary micro-electrolysis filler is used for treating the sewage, CODcr (chemical oxygen demand) of the sewage can be reducedefficiently in a short time, and the biochemistry of the sewage can be improved. According to the invention, the raw materials are easy to obtain, the preparation process is simple, the problem of filler hardening of the conventional micro-electrolysis technology is solved, and the filler is applicable to treatment on the base sewage.

Owner:SHANDONG UNIV

Macropore high-capacity agarose gel media preparing method

InactiveCN1472002AIncrease mass transfer rateLarge adsorption capacityIon-exchange process apparatusComponent separationMicrosphereMicroparticle

A process for preparing high-capacity microreticular agarose gel medium includes such steps as dispersing the granular calcium carbonate as hole-forming agent in the aqueous solution of agarose to obtain suspension, adding it to salad oil, adding emulsifier Span80, emulsifying while stirring, quick cooling for sphericizing, adding epoxy chloropropane, cross linking, reducing with sodium borohydride, and using diluted hydrochloric acid to remove granular calcium carbonate.

Owner:TIANJIN UNIV

Preparation method for 3D Ni-Co bimetallic hydroxide hollow microsphere and application in super capacitor

InactiveCN103680993ASolve the problem that the specific surface is greatly reducedLarge capacityHybrid capacitor electrodesHybrid/EDL manufactureMass transfer resistanceMicrosphere

The invention belongs to the field of chemistry, and provides a preparation method for a 3D Ni-Co bimetallic hydroxide hollow microsphere and application in a super capacitor. The preparation method comprises the following steps: 1) a SiO2 microsphere is synthesized; 2) a AlOOH sol is prepared; 3) the SiO2 microsphere is added into the AlOOH sol so that a SiO2@ AlOOH microsphere is obtained; 4) the SiO2@ AlOOH microsphere, a alkali source and de-ionized water are mixed, and a nickel and cobalt salt precursor is added so that the 3D Ni-Co bimetallic hydroxide hollow microsphere is prepared; and 5) an electrode sheet is prepared. Compared with methods in the prior art, the obtained 3D Ni-Co bimetallic hydroxide hollow microsphere provides a larger specific surface, smaller mass transfer resistance and more excellent structural stability. Besides, the synthesized 3D Ni-Co bimetallic hydroxide hollow microsphere is applied to electrode material of the super capacitor so that the 3D Ni-Co bimetallic hydroxide hollow microsphere is much better than existing precious metal oxide on aspects of cost and performance.

Owner:JIANGNAN UNIV

RH vacuum refining bottom blowing powder injection device

ActiveCN102560009ASolve easy blockageImprove product qualityCharge manipulationMetallurgyWater circulation

The invention relates to an RH vacuum refining bottom blowing powder injection device. The device comprises a driving gas system, a vacuum chamber, a steel ladle and a bottom blowing powder injection member, wherein the vacuum chamber is formed above the steel ladle; the driving gas system comprises a driving gas channel and an air compressor connected with the driving gas channel; an ascending pipe and a descending pipe are arranged at the bottom of the vacuum chamber and stretch into molten steel; the driving gas channel is communicated with the ascending pipe; the bottom blowing powder injection member comprises a powder injection element and a gas storage chamber; a steel sleeve is sleeved outside the powder injection element; the gas storage chamber is fixed below the powder injection element; a powder gas flow conveying pipe at the port of the gas storage chamber is connected with a powder injection system; a gap is formed on the powder injection element; one or two bottom blowing powder injection members are arranged at the bottom of the steel ladle; the distance between the bottom blowing powder injection member and the center of the bottom of the steel ladle is 0 to 0.9 time the radius of the bottom of the steel ladle; and the powder injection element penetrates through the bottom of the steel ladle. The device enhances a stirring effect and improves the quality of steel by combining vacuum refining, molten steel circular flow and bottom blowing powder injection refining.

Owner:NORTHEASTERN UNIV

Method for preparing iron modified SBA-15 mesoporous molecular sieve

InactiveCN101837988AIncrease surface areaIncrease mass transfer rateCrystalline aluminosilicate zeolitesMolecular sieveRoom temperature

The invention relates to a method for preparing an iron modified SBA-15 mesoporous molecular sieve, which comprises the following steps of: 1) adding nonionic surfactant and ferric nitrate nonahydrate into solution prepared from hydrochloric acid and deionized water in a volume ratio of 1 to 10 with pH of about 1, and stirring the solution at the room temperature till the solution is clear and transparent; 2) adding tetraethoxysilane into the mixed solution obtained in the step 1), placing the mixed solution into an ultrasonic pool, acting ultrasonic wave on the mixed solution for 2 hours, adjusting the pH of the mixed solution to between 3 and 4, transferring the mixed solution to a reaction kettle, and hydro-thermally crystallizing the mixed solution for 24 hours at the temperature of 100 DEG C to form the iron modified SBA-15 mesoporous molecular sieve; and 3) filtering the reaction solution obtained in the step 2), repeatedly washing a filtered substance by using water and drying the filtered substance, and calcining the filtered substance for 6 hours at the temperature of 550 DEG C to obtain the SBA-15 mesoporous molecular sieve of which iron ions are high dispersed inside and outside a skeleton. The method reduces the reactive ageing time to 2 hours from 20 hours, does not need to use a mineralizing agent NH4F, greatly shortens the reaction period, and reduces the reaction cost.

Owner:CHONGQING UNIV OF TECH

Sludge treatment method and application thereof

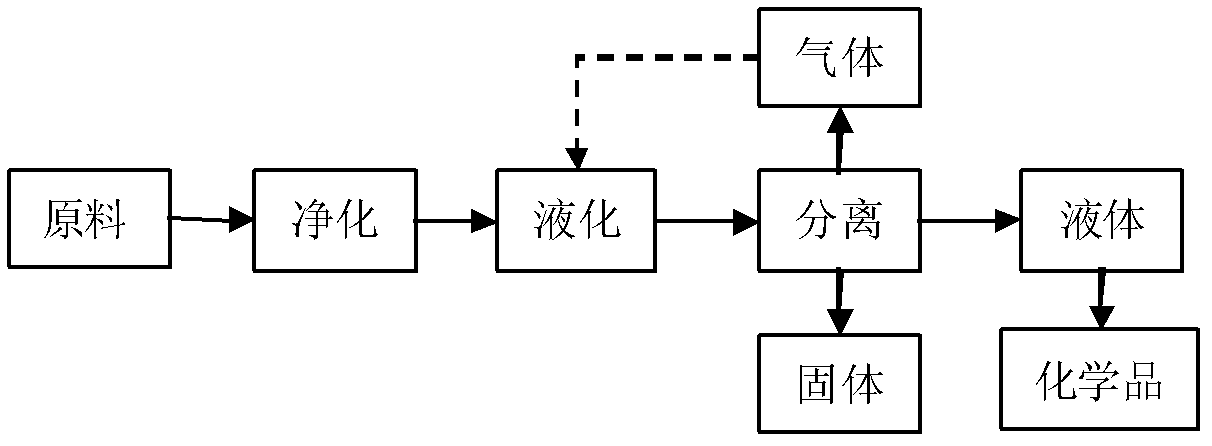

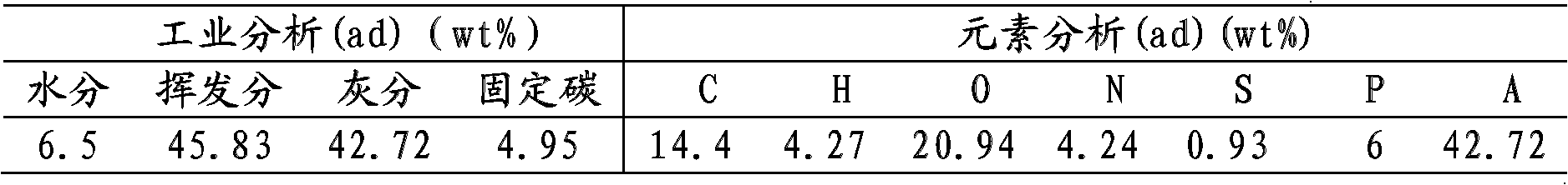

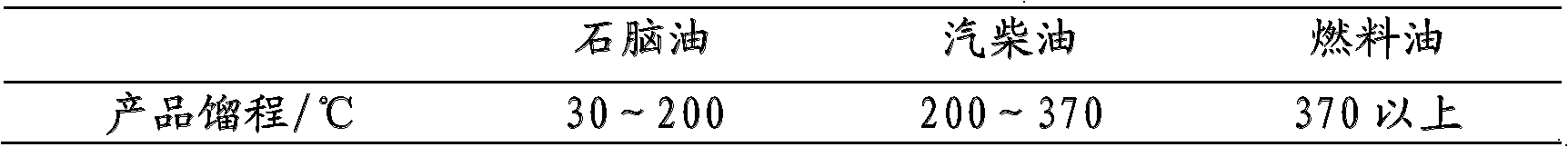

ActiveCN102557366ARealize resource utilizationImprove mass transfer and heat transfer rateSludge treatment by pyrolysisLiquid hydrocarbon mixture productionChemistryLiquefaction

The invention relates to a sludge treatment method for preparing oil products by liquefying sludge. The method comprises the step of performing liquefaction on the sludge in the subcritical or supercritical state of water to obtain the oil products. In addition, the invention also relates to application of the sludge treatment method to sludge treatment.

Owner:ENN ENVIROTECH CO LTD

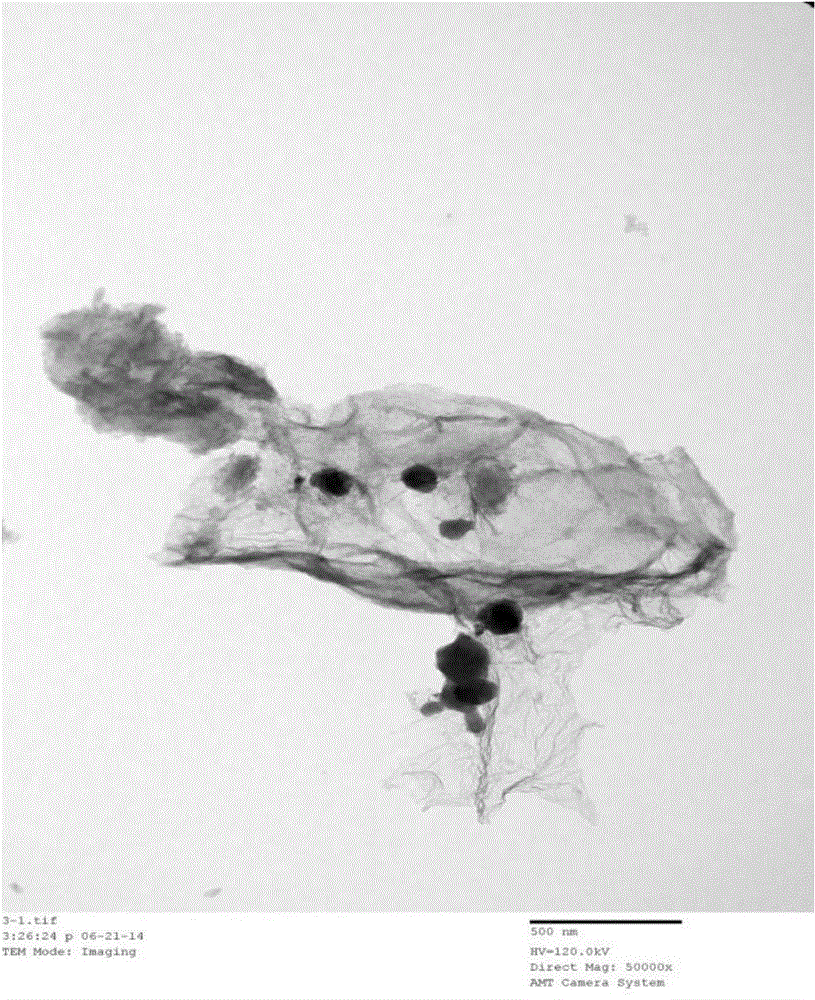

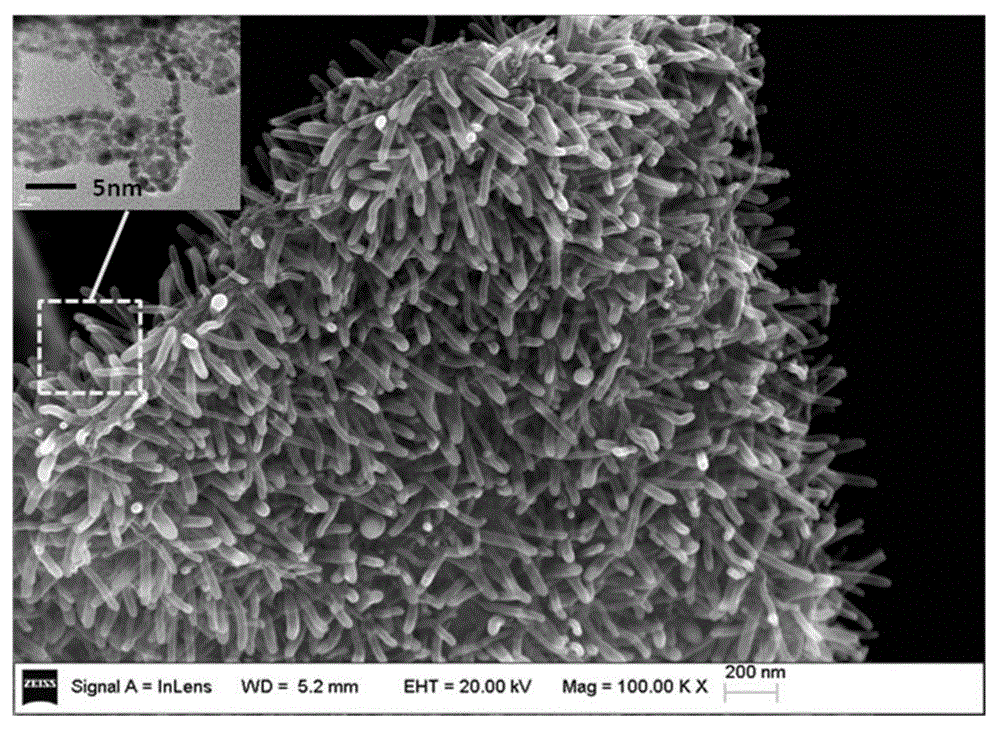

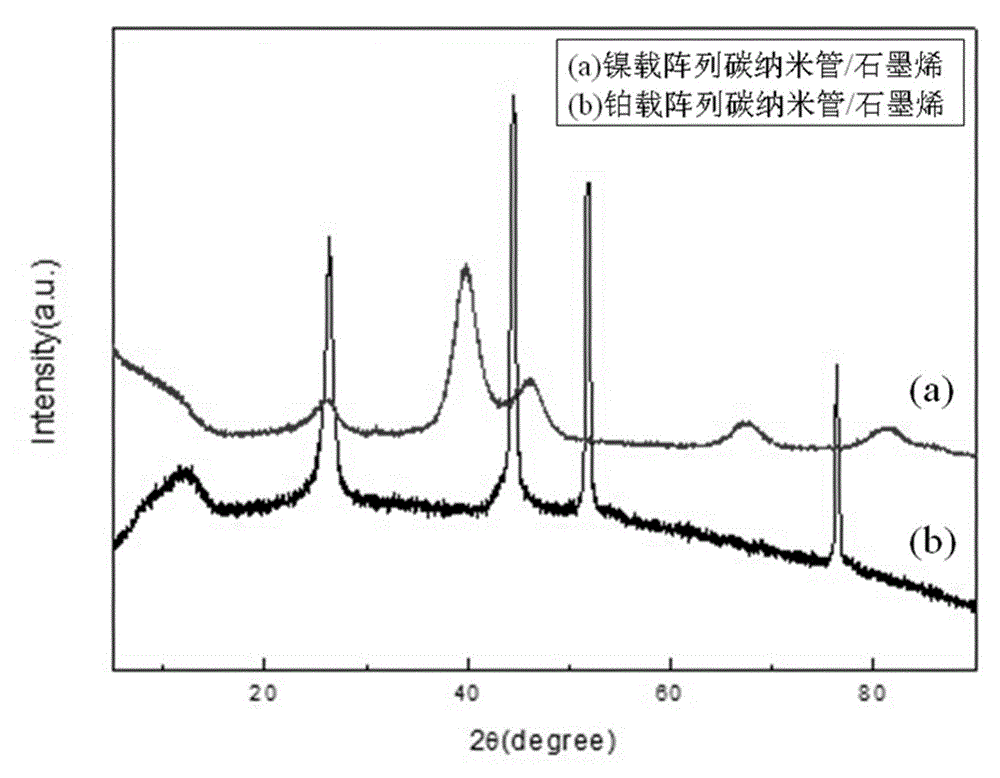

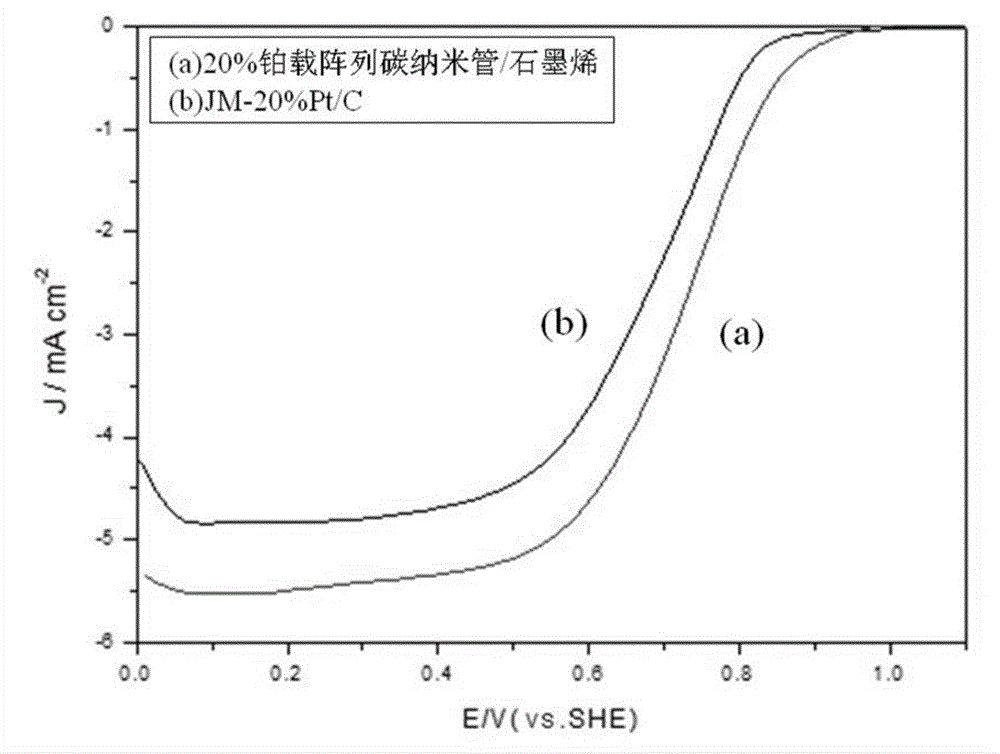

Array carbon nano-tube/graphene platinum-supported catalyst for fuel cell and preparation method of array carbon nano-tube/graphene platinum-supported catalyst

ActiveCN104466204AImprove transmission efficiencyIncrease profitMaterial nanotechnologyCell electrodesGas phaseReaction rate

The invention provides an array carbon nano-tube / graphene platinum-supported catalyst for a fuel cell and a preparation method of the array carbon nano-tube / graphene platinum-supported catalyst, belonging to the field of electrochemistry. The catalyst comprises the following components in percentage by mass: 60-80% of array carbon nano-tube / graphene and 20-40% of platinum. The array carbon nano-tubes / graphene is used as a catalyst support, and the platinum serving as a metal component is loaded on the support. The preparation method comprises the steps of firstly, preparing a nickel / cobalt-supported graphene composite; then, growing an upright ordered carbon nano-tube on the graphene through chemical vapor deposition; and finally, reducing platinum on the support, namely the graphene-array carbon nano-tube. The support has a special structure, and the upright ordered carbon nano-tube grows on the graphene, so that the relatively large specific surface area is obtained, the utilization ratio of platinum can be increased, a smooth ion and electron channel is also provided for electro-catalytic reaction, the electro-catalytic reaction rate can be favorably increased, and finally, the catalytic efficiency of the catalyst and the utilization ratio of precious metal can be favorably increased.

Owner:BEIJING UNIV OF CHEM TECH

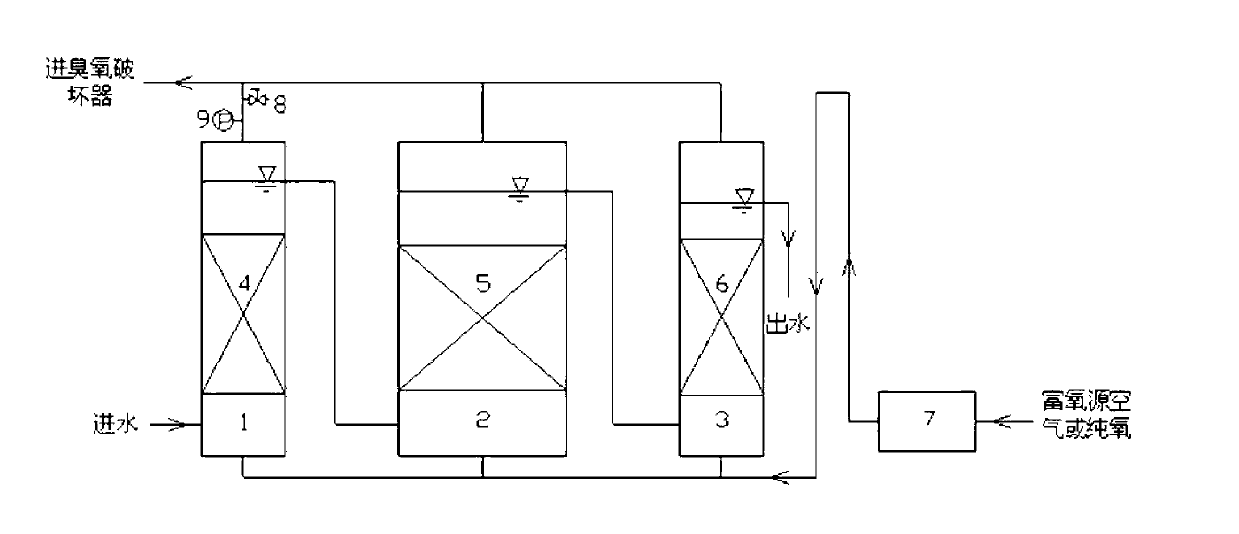

Process method for performing advanced treatment on petrochemical wastewater through catalytic ozonation

ActiveCN103274514AIncrease mass transfer rateIncrease the dissolved concentrationWater/sewage treatment by oxidationPorosityCatalytic oxidation

The invention discloses a process method for performing advanced treatment on petrochemical wastewater through catalytic ozonation. The method is characterized by comprising the following steps of: allowing petrochemical wastewater to sequentially flow through a pre-oxidation tower, a catalytic oxidation tower I and a catalytic oxidation tower II, and respectively filling high-porosity inert filler, activated aluminum oxide-based catalyst and granular active carbon in three towers, wherein the pre-oxidation tower operates under pressure. The ozone is prepared by an oxygen-enriched source or oxygen source ozone generator, and tail gas in the tower is collected and treated in a unified mode.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +2

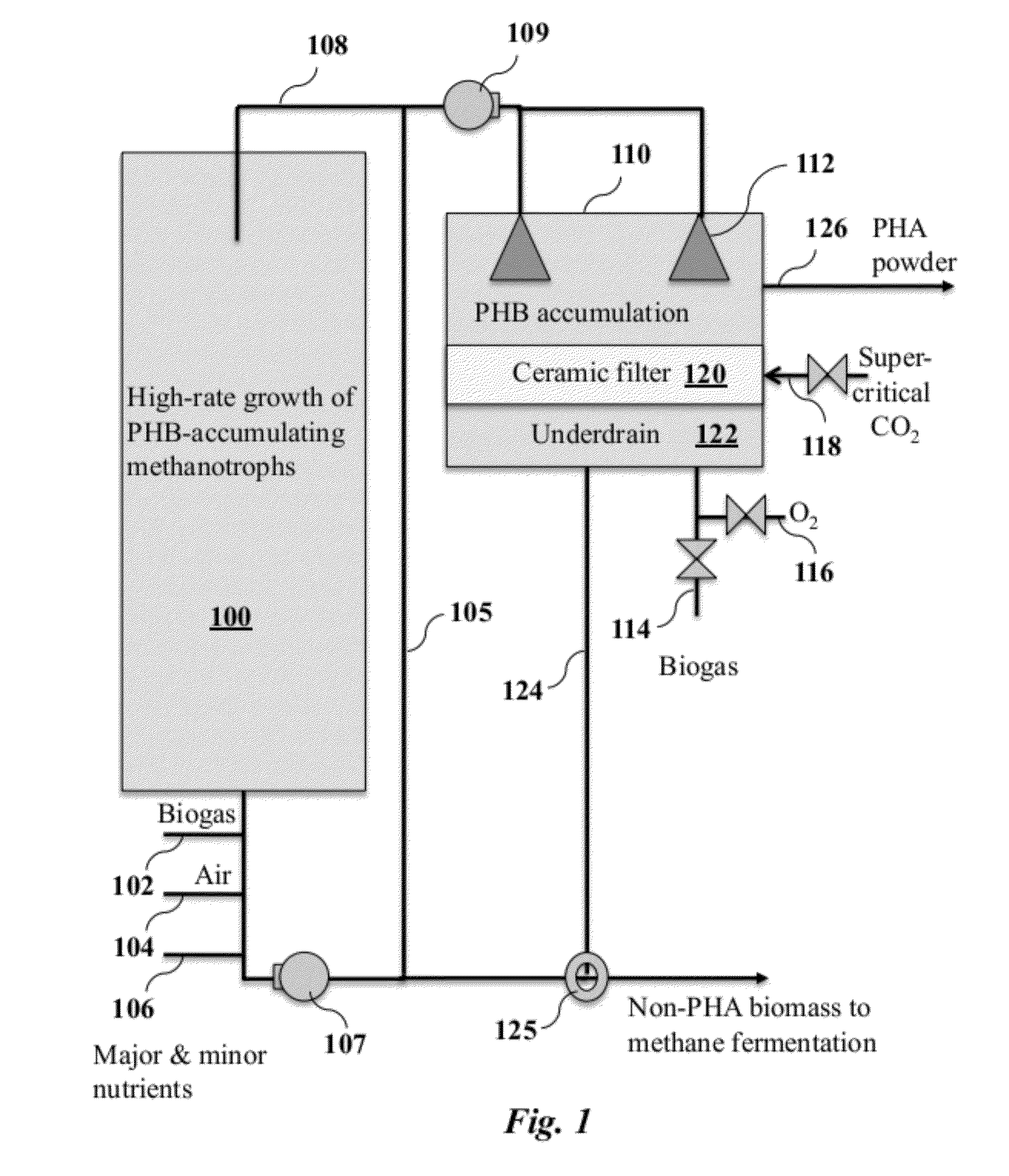

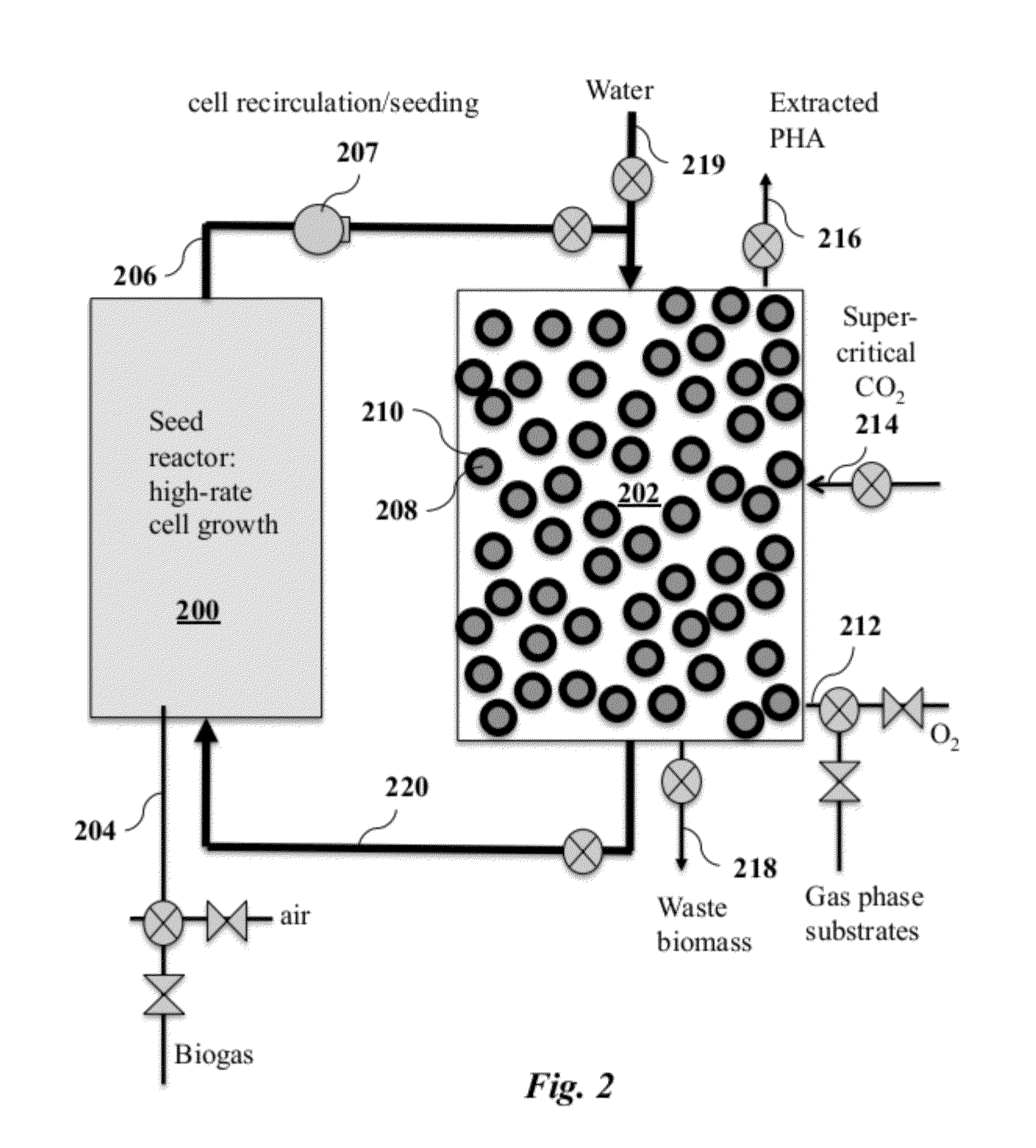

High Solids Fermentation for Synthesis of Polyhydroxyalkanoates From Gas Substrates

InactiveUS20120028321A1Simple and economic techniqueLow cost productionFermentationMicroorganismGas phase

Production of polyhydroxyalkanoates (PHAs) is performed by delivering substrates such as methane in gas phase during a high solids fermentation. Microorganisms are grown under balanced conditions, then gas phase substrates are delivered under unbalanced conditions to produce PHA granules inside the cells. The cells containing these granules are lysed and the bioplastic powder recovered. The balanced phase growth may occur in submerged liquid cultures or attached as biofilms to a surface.

Owner:CRIDDLE CRAIG S +3

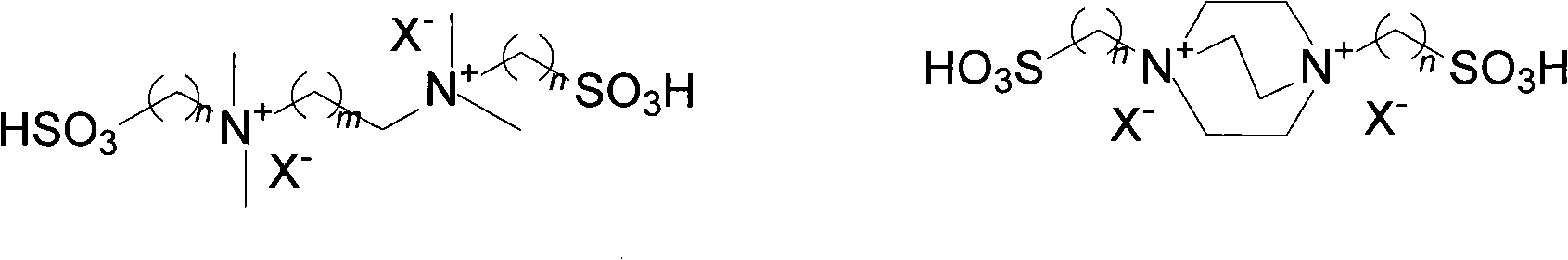

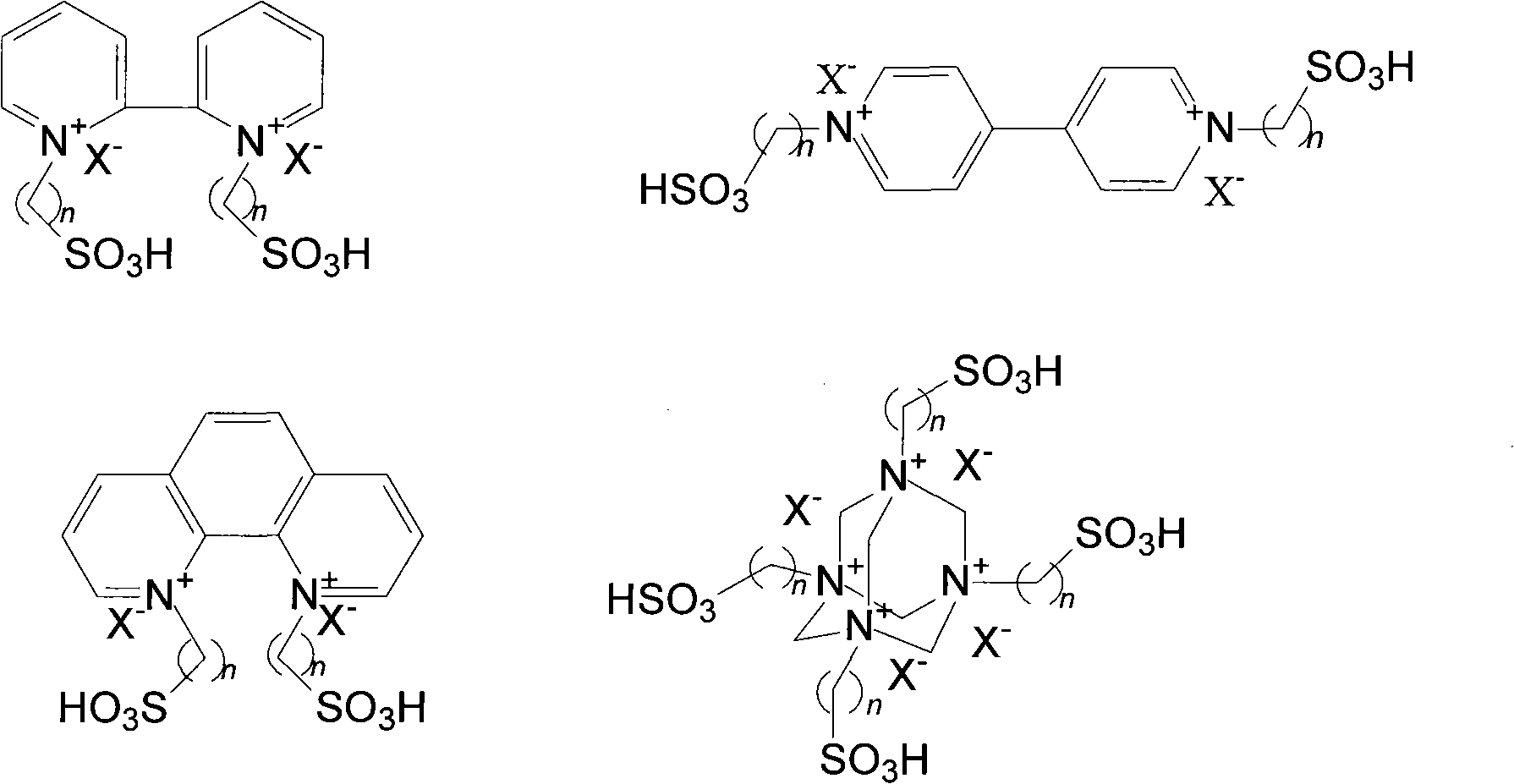

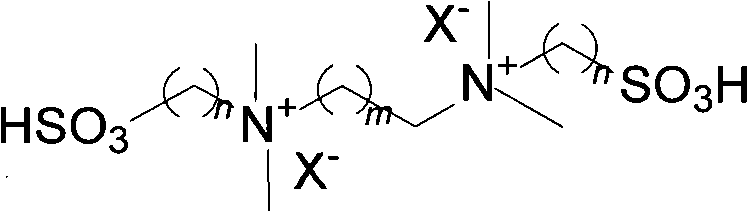

Biodiesel catalyst and method for preparing biodiesel by using same

InactiveCN101927182ACatalytic activity doubledWell mixedFatty acid chemical modificationOrganic compound preparationBiodieselAlcohol

The invention relates to a method for synthesizing biodiesel based on multi-sulfoacid functional ion liquid. The method is characterized by synthesizing the biodiesel through esterification reaction by using fatty acid and alcohol as standard reactants and selecting the multi-sulfoacid functional ion liquid as a catalyst. The method has the advantages of low corrosivity, high catalyst activity, clean reaction process and simple and convenient post-treatment; and the catalyst has the characteristics of high-density reactive site of liquid acid, non-volatility of solid acid and easy separation property and reusability, and waste oils contain a large amount of fatty acid, so the method of the invention can be taken as an important method for industrial use of the waste oils.

Owner:BEIJING FORESTRY UNIVERSITY

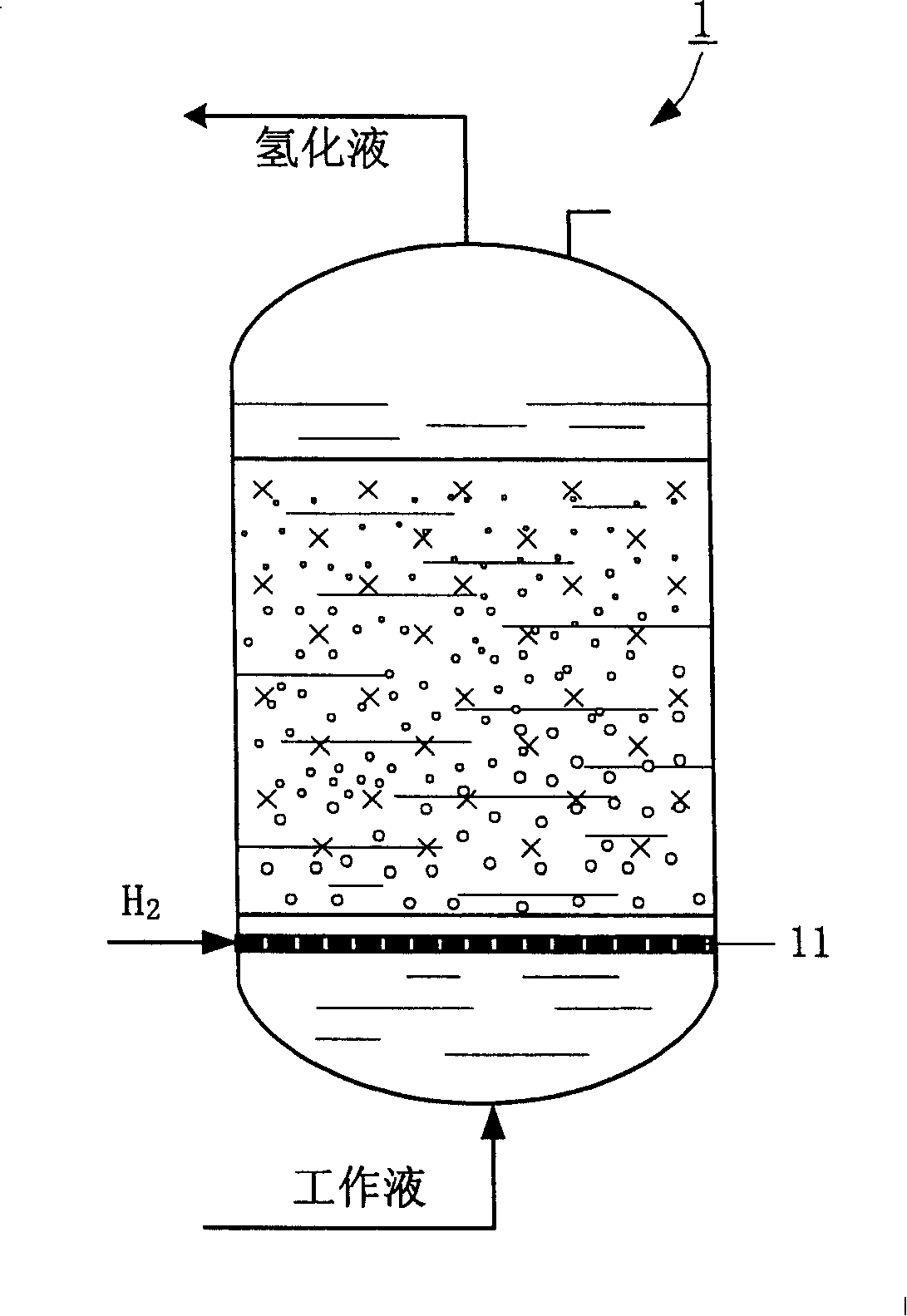

Method for producing hydrogen peroxide by anthraquinone process

InactiveCN101229915AIncrease production capacityEvenly distributedPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesWorking fluidHydrogenation reaction

The invention provides a process for producing hydrogen peroxide by using an anthraquinone method. The process includes the following steps: hydrogen is added in the anthraquinone to generate anthrahydroquinone which is oxidized to generate the anthraquinone and the hydrogen peroxide. The reaction in which the hydrogen is added in the anthraquinone to generate anthrahydroquinone means that working fluid with the anthraquinone and the hydrogen are led in a fixed bed reactor which is filled with catalyst with the hydrogen so that hydrogenation is generated between the working fluid with the anthraquinone and the hydrogen to generate the anthrahydroquinone under the effect of the catalyst; the obtained hydrogenated working fluid with the anthrahydroquinone is conducted out of an oxidation device, wherein, when the working fluid with the anthrahydroquinone and the hydrogen are conducted in the fixed bed reactor, the working fluid is continuous phase, in which the hydrogen is distributed in the form of bubbles; when the working fluid with the anthrahydroquinone and the hydrogen are conducted in the fixed bed reactor, a feeding inlet is made not higher than a discharging outlet where the hydrogenated liquid is discharged out of the fixed bed reactor. By using the method, utilization efficiency of the catalyst as well as the production capability of the reactor is promoted and bed resistance is reduced.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Universal preparation method and application of active site-electrode structure integrated air electrode

InactiveCN108365230AIncrease mass transfer rateFast electron transferCell electrodesActivation methodMicrosphere

The invention relates to a universal preparation method for an active site-electrode structure integrated air electrode. The universal preparation method is characterized in that various polymer microspheres having open internally-communicating hierarchical-pore structures are conjugated with active sites like noble metal groups, transition metal groups, and hetero atom-doped carbon groups in virtue of different treatment methods; the different treatment methods may be one or more selected from the group consisting of a carbon tetrachloride cross-linking method, a concentrated-sulfuric-acid sulfonation method, a carbon dioxide gas activation method, a dopamine coating method, an ammonia gas activation method, a polyaniline coating method, an in-situ precious-metal loading method, an in-situ transition metallide growth method and an in-situ heteroatom doping method. The universal method described in the invention can flexibly conjugate open internally-communicating hierarchical-pore electrode structures containing super-macro pores, macro pores, meso pores and micropores with a plurality of different highly-active catalytic sites by using appropriate methods, so the catalytic performance of the air electrode and the overall performance of a fuel cell and a metal-air battery are improved.

Owner:UNIVERSITY OF CHINESE ACADEMY OF SCIENCES

Method for simultaneous desulfurization-denitrification-demercuration based on combination of free radical pre-oxidation and wet absorption

ActiveCN104801178AAchieve integrated removalIncrease mass transfer rateDispersed particle separationAir quality improvementSulfate radicalsDecomposition

The invention relates to a system for simultaneous desulfurization-denitrification-demercuration based on a combination of free radical pre-oxidation and wet absorption. The system adopts the structure that ultraviolet light and a catalyst are combined to decompose a peroxide; during decomposition, strong oxidative hydroxy or sulfate radical free radical are generated for oxidative removal of SO2, NOx and Hg0 in an impact bed; part of flue gas from an emission source and part of catalyst particles are mixed and sprayed into the impact bed through high-speed nozzles, and the other part of flue gas and catalyst particle are mixed and sprayed into the impact bed through the high-speed nozzles which are coaxially arranged in an opposite manner; meanwhile, a peroxide solution is sprayed into the impact bed through sprayers, so that such three gas steams are subjected to impact and mixing in the impact bed. The system has the advantages that the ultraviolet light and the catalyst are combined to decompose the peroxide, strong oxidative hydroxy or sulfate radical free radical are generated for oxidation of SO2, NOx and Hg0, so that gas-sate divalent mercury, nitrogen dioxide, sulfur trioxide, sulfuric acid and nitric acid are generated, and then SO2, NOx and Hg0 are removed in a wet desulfurization system at the tail part. Therefore, the system provided by the invention can be used for transforming the conventional coal burning boiler to achieve sulfur-nitrogen-mercury integrated removal, and has a broad market application prospect.

Owner:苏州弗兰特环保科技有限公司

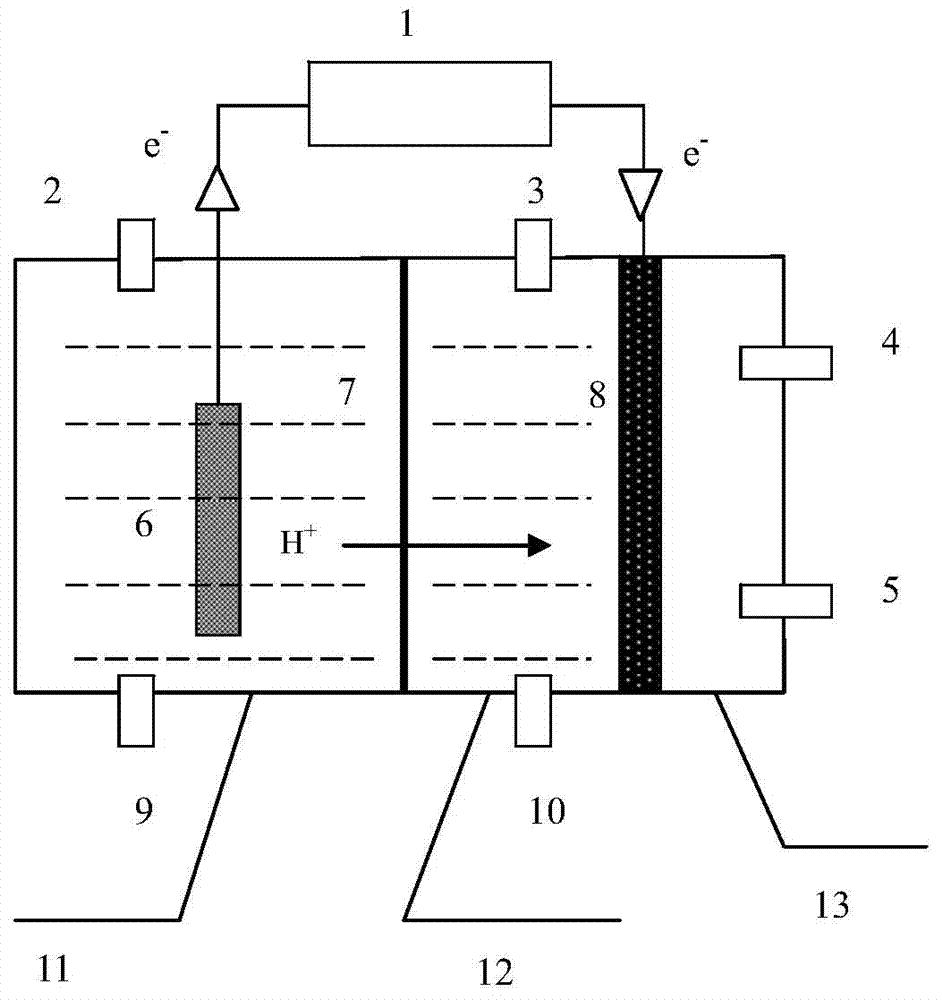

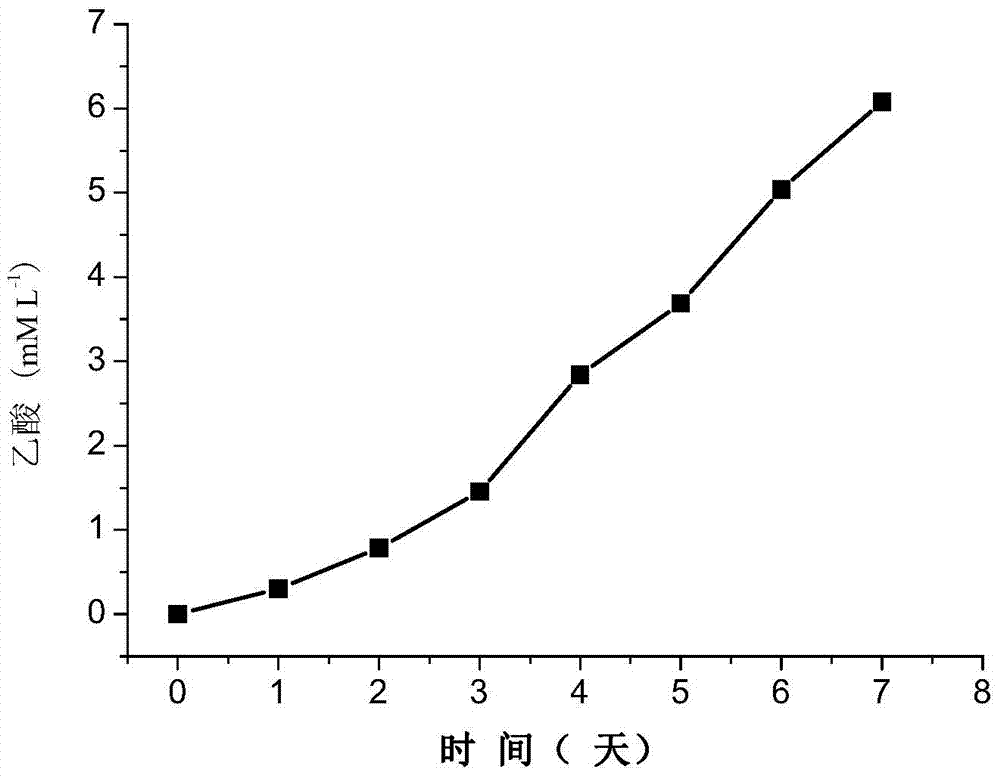

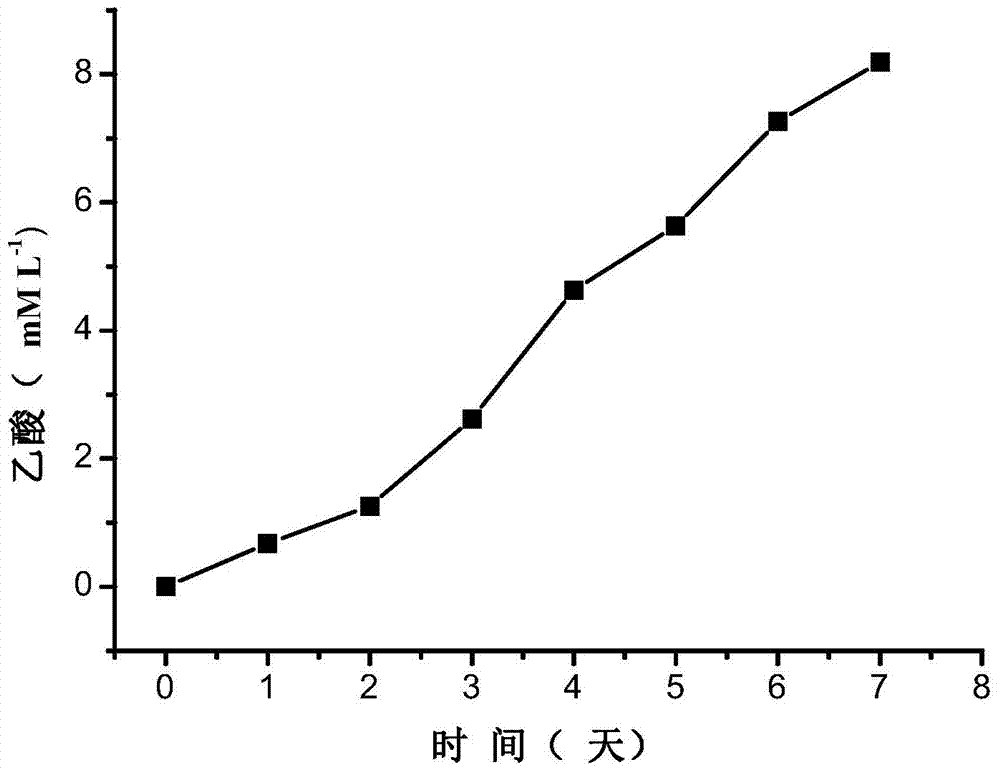

Apparatus and method for producing acetic acid by reducing carbon dioxide through microbial-electrochemical system

ActiveCN104328046ALow costIncrease mass transfer rateProductsElectrolysis componentsElectrochemical responseAcetic acid

The invention provides an apparatus and a method for producing acetic acid by reducing carbon dioxide through a microbial-electrochemical system. The apparatus includes an anode chamber and a cathode chamber, wherein the anode chamber and the cathode chamber separated by a separator. An anode is arranged inside the anode chamber and a cathode is arranged inside the cathode chamber. The anode and the cathode are connected in series outside the anode chamber and the cathode chamber through a power supply to form a loop. The cathode divides the cathode chamber into a cathode liquid chamber and a cathode gas chamber and is a gas diffusion electrode. The invention also discloses a method for producing acetic acid by reducing carbon dioxide through the apparatus. In the invention, the cathode is in the structure of a gas diffusion electrode so that a mass transfer rate and a catalytic rate of carbon dioxide in an electrochemical reaction. An acetic acid generating rate is higher. The apparatus and the method have an important application prospect in fixation and conversion of carbon dioxide.

Owner:NANJING UNIV OF TECH

Method for preparing high-purity bulleyaconitine A

The invention discloses a method for preparing high-purity bulleyaconitine A. The method comprises the following steps of: soaking a fresh radix aconiti agrestis root in acid aqueous solution, performing homogenate extraction and cavitation mixing solid-liquid extraction, collecting and concentrating the filtrate, and respectively performing gradient elution to obtain a crude bulleyaconitine A product through ion exchange resin column chromatography and macroporous adsorption resin column chromatography; and uniformly mixing crude bulleyaconitine A product and ethanol aqueous solution, dissolving in a water bath, cooling the filtrate to room temperature, standing and crystallizing at the temperature of 4 DEG C, repeatedly washing the crystal by using the ethanol aqueous solution, and obtaining a final product. According to the method, crushing and extracting are finished in one step through a homogenization method, and the method has the advantages of zero dust and simple flow. By adoption of a negative-pressure cavitation extraction technology, the mass transfer rate is improved, heating is not required, and the production period is shortened; and moreover, the reagents used in the whole process are ethanol and water, the organic solvent amount is greatly reduced, the production cost can be reduced, the environmental pollution is reduced, and the method has good application prospect.

Owner:INST OF MEDICINAL PLANTS YUNNAN ACAD OF AGRI SCI

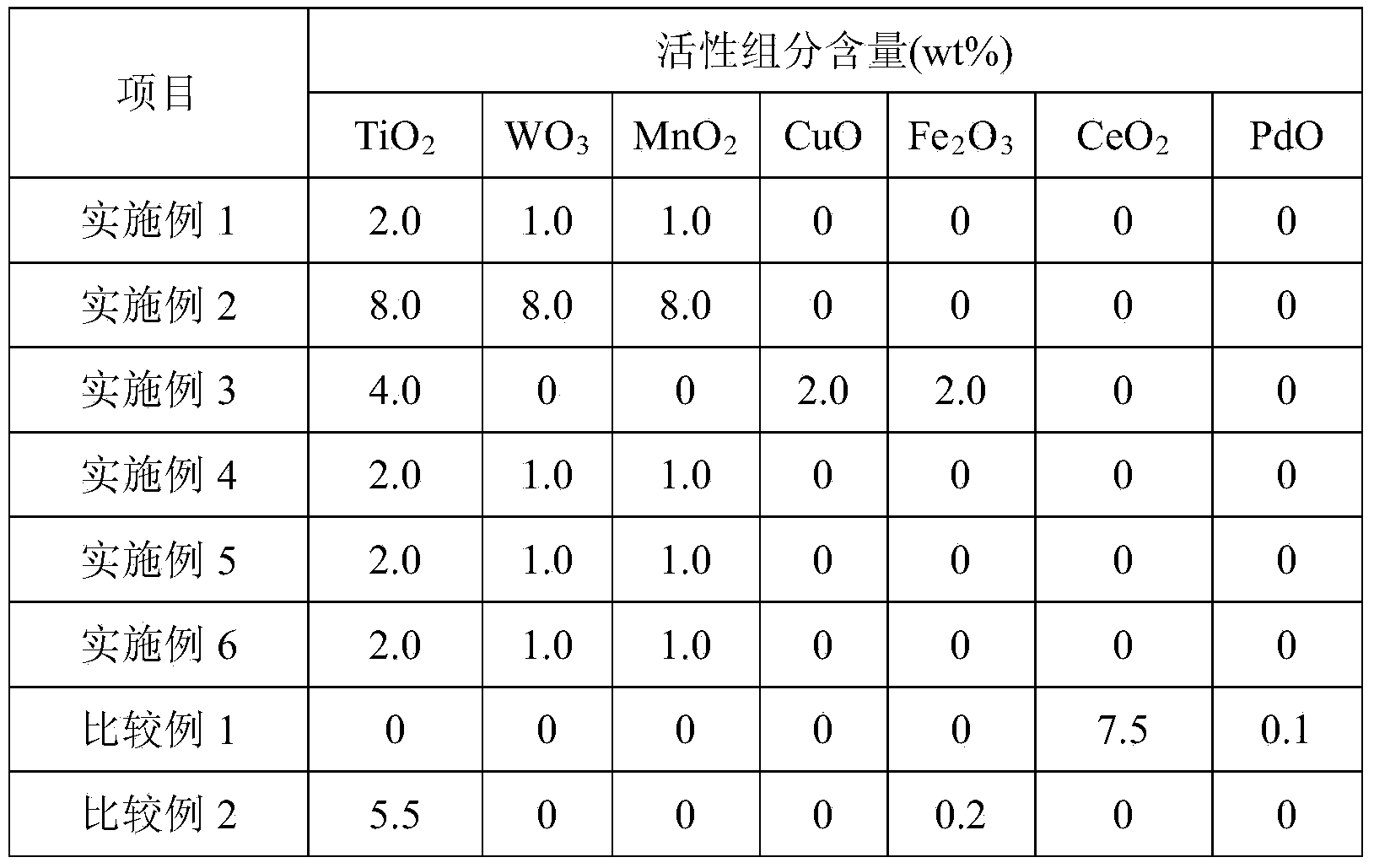

Preparation method for photocatalyst used for treating volatile organic compounds

ActiveCN103521218ASimple preparation stepsLow costDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsIonCoating

The invention provides a preparation method for a photocatalyst used for treating volatile organic compounds. The preparation method is characterized in that titanium dioxide is used as a main active component, a transition metal is added as an auxiliary agent, and a normal temperature spraying process is employed to load titanium dioxide on a metal or ceramic honeycomb carrier. The preparation method comprises the following concrete steps: A) dissolving titanyl sulfate in deionized water, adjusting a pH value to 7 to 10 by using a 5 to 25% ammonia-water solution, subjecting an obtained white precipitate to centrifugation and washing, mixing and beating the precipitate and deionized water and adjusting the pH value to 7 to 10 by using H2O2 and HCl with stirring so as to obtain a titanium sol; B) adding a surfactant into the titanium sol, adding micro metal oxide powder with stirring, adding a binder and carrying out high-speed shearing and uniform stirring so as to prepare a stable coating solution; and C) uniformly spraying the coating solution on the carrier and drying and roasting the carrier so as to obtain a finished catalyst product. The catalyst prepared by using the method has the characteristics of high volatile organic compound removal efficiency, a long life, easy loading and unloading, a low price, etc.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

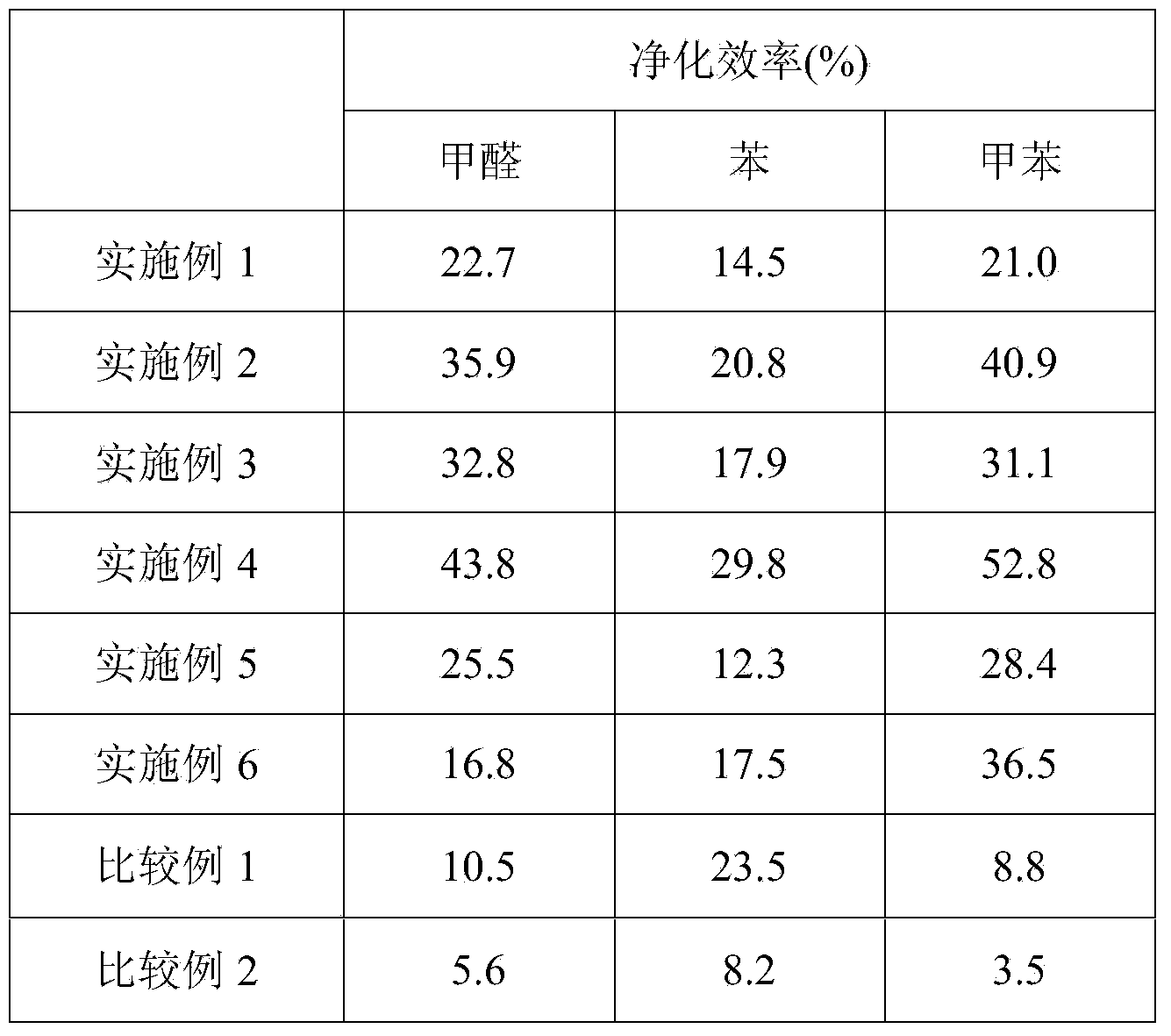

Method for extracting dihydroquercetin form larch

InactiveCN101333203AFree radical scavengingLesion hindranceOrganic chemistryConiferophyta medical ingredientsLarchUnit/Kilogram

Disclosed is a method for extracting dihydro quercetin from larch. The invention is an improved production method. Due to different production materials and extraction processes, the dihydro quercetin products in U.S. and European markets are very expensive, at a price of 200-1000 euros per gram. Such a high market price economically limits the wide range of practicability of dihydro quercetin products. During the pretreatment of raw materials, 50 kilograms of larch wood chips and 500-800 liters of 50% ethanol solution are added into a reactor to get fully stirred and mixed; then the mixture is extracted and filtered for the second extraction; the filtrates are combined and adsorbed; the organic solvents are collected and dried by a vacuum evaporator through organic phase vacuum distillation; according to a weight proportion of 10:1, the residues are dissolved with hot water, decolorized with activated carbon and then crystallized at a temperature of 3-5 DEG C to precipitate the dihydro quercetin product which is then crushed after vacuum drying to finished product. The invention is used to extract dihydro quercetin from larch.

Owner:黑龙江花旗科技发展有限公司 +2

Preparation method of 3D coralline graphene/NiCo2O4 composite material and application of same in super capacitor

InactiveCN104576075AGood dispersionLarger than surfaceHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceMass transfer resistance

The invention belongs to the chemistry field, and provides a preparation method of a 3D coralline graphene / NiCo2O4 composite material and the application of the 3D coralline graphene / NiCo2O4 composite material in a super capacitor. The preparation method comprises the steps that (1) GO is synthesized; (2) Ni-Co salt and an alkali source are added into suspension liquid of the GO, and microwave heating is carried out to assist in preparing a GO / Ni-Co layered double metal hydroxide composite material; (3) high-temperature calcination is carried out on the prepared GO / Ni-Co layered double metal hydroxide composite material to manufacture the 3D coralline graphene / NiCo2O4 composite material; (4) an electrode plate is manufactured, the simulation super capacitor is assembled, and the performance of the simulation super capacitor is evaluated. Compared with the prior art, the 3D coralline graphene / NiCo2O4 composite material prepared through the preparation method is more excellent in electrical conductivity, larger in specific area, smaller in mass transfer resistance and longer in cycle life. Furthermore, when applied to the electrode material of the super capacitor, the synthetic 3D coralline graphene / NiCo2O4 composite material is much superior than existing precious metal oxide in cost and performance.

Owner:江苏江大环保科技开发有限公司

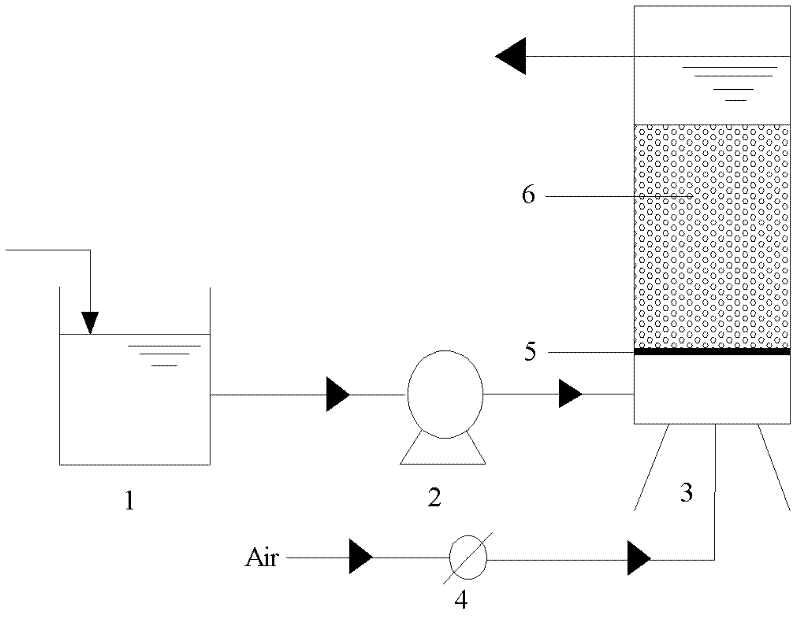

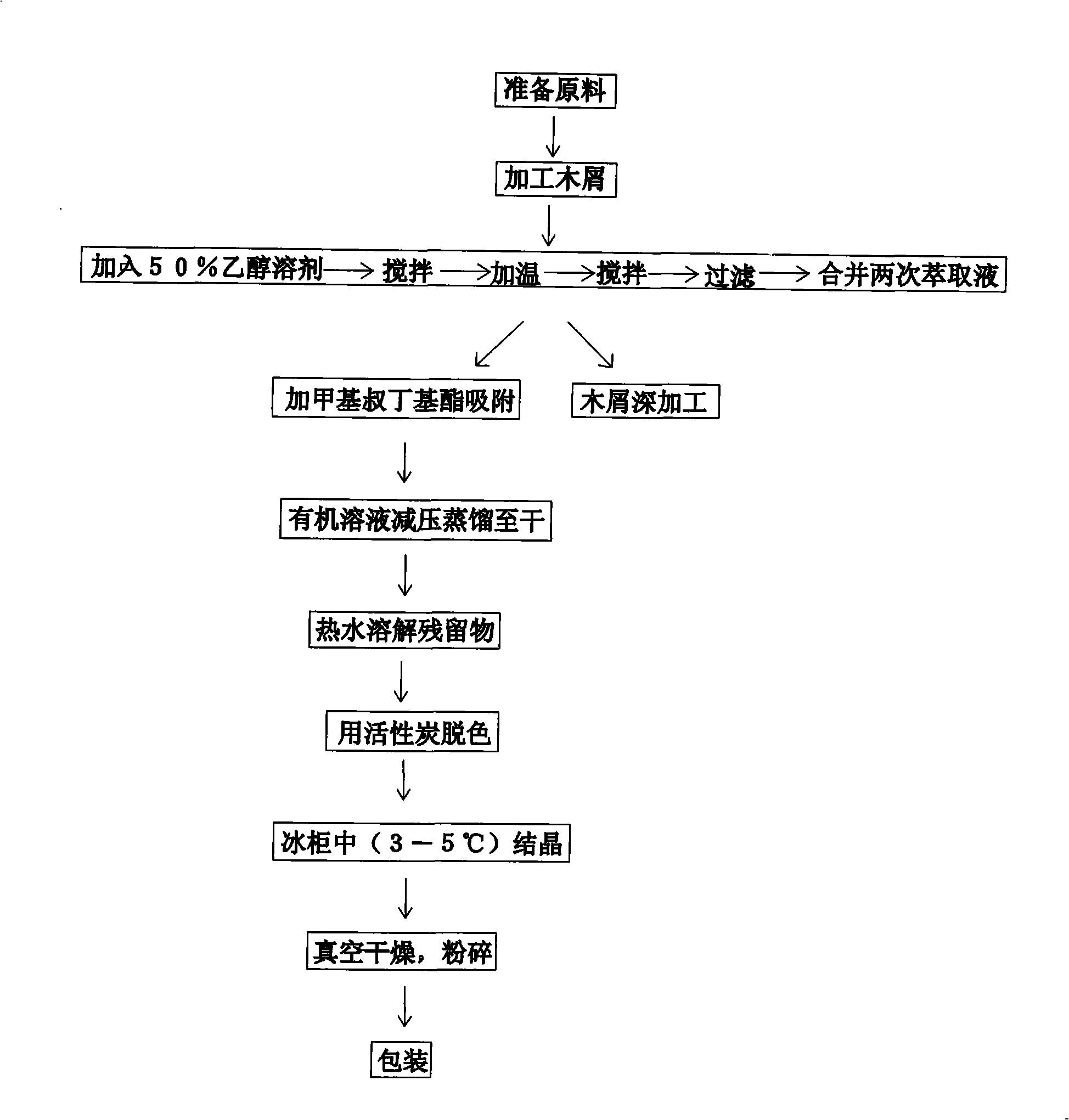

Membrane type photobioreactor for enhancing microalgae culturing

InactiveCN101985595AEasy to fixIncrease mass transfer rateBioreactor/fermenter combinationsBiological substance pretreatmentsPhotobioreactorEngineering

The invention discloses a membrane type photobioreactor for enhancing microalgae culturing. The membrane type photobioreactor comprises an external light source, a bottom plate, an inner sleeve and an outer sleeve, wherein the inner sleeve and the outer sleeve are vertically arranged on the bottom plate; the outer sleeve is positioned on the outer side of the inner sleeve and surrounds the inner sleeve; the top end of the outer sleeve is horizontally provided with a transparent top cover plate, the top of the outer sleeve is provided with a plurality of air outlets and the bottom of the outersleeve is provided with a discharge port; the bottom of the inner sleeve is provided with a plurality of exchange holes; the bottom plate is provided with an air inlet which is surrounded by the inner sleeve; the air outlets are positioned above the top end of the inner sleeve; the bottom plate is vertically provided with a membrane component which is positioned inside the inner sleeve; and the bottom edge of the membrane component is hermetically fixed with the bottom plate and surrounds the air inlet. The membrane type photobioreactor for enhancing microalgae culturing has the advantages ofsimple structure, simplicity and convenience in operation, stable performance, larger specific surface area and light transmission efficiency; and by using the membrane component, the gas is uniformly distributed, and the photobioreactor can be independently used or connected with a track pool for amplified culturing of the microalgae.

Owner:ZHEJIANG UNIV

Nano-stage ceramic metal additive for lubricating oil and preparation thereof

The invention relates to a nanoscale ceramic metal additive for lubricating oil (grease) and preparation, which is a composite fluid comprising kubonit, molybdenum and copper powder. The powder is a nanoscale globular solid particulate which is formed by covalent bond structure of kubinit and molybdenum and coordinate bond of copper. The kubinit is globular framework, molybdenum is coated around the globular kubinit framework, and the copper is combined with the crystal defecting portion of the globular framework in the shape of point and sheet. The proportion of kubinit, molybdenum and copper in the powder is 7-8.5:1-1.5:0.5-1.

Owner:张启峰 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com