Patents

Literature

320 results about "Unit/Kilogram" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The kilogram or kilogramme (symbol: kg) is the base unit of mass in the International System of Units (SI), and is defined as being equal to the mass of the International Prototype of the Kilogram (IPK, also known as "Le Grand K" or "Big K"), a cylinder of platinum-iridium alloy stored by the International Bureau of Weights and Measures at ...

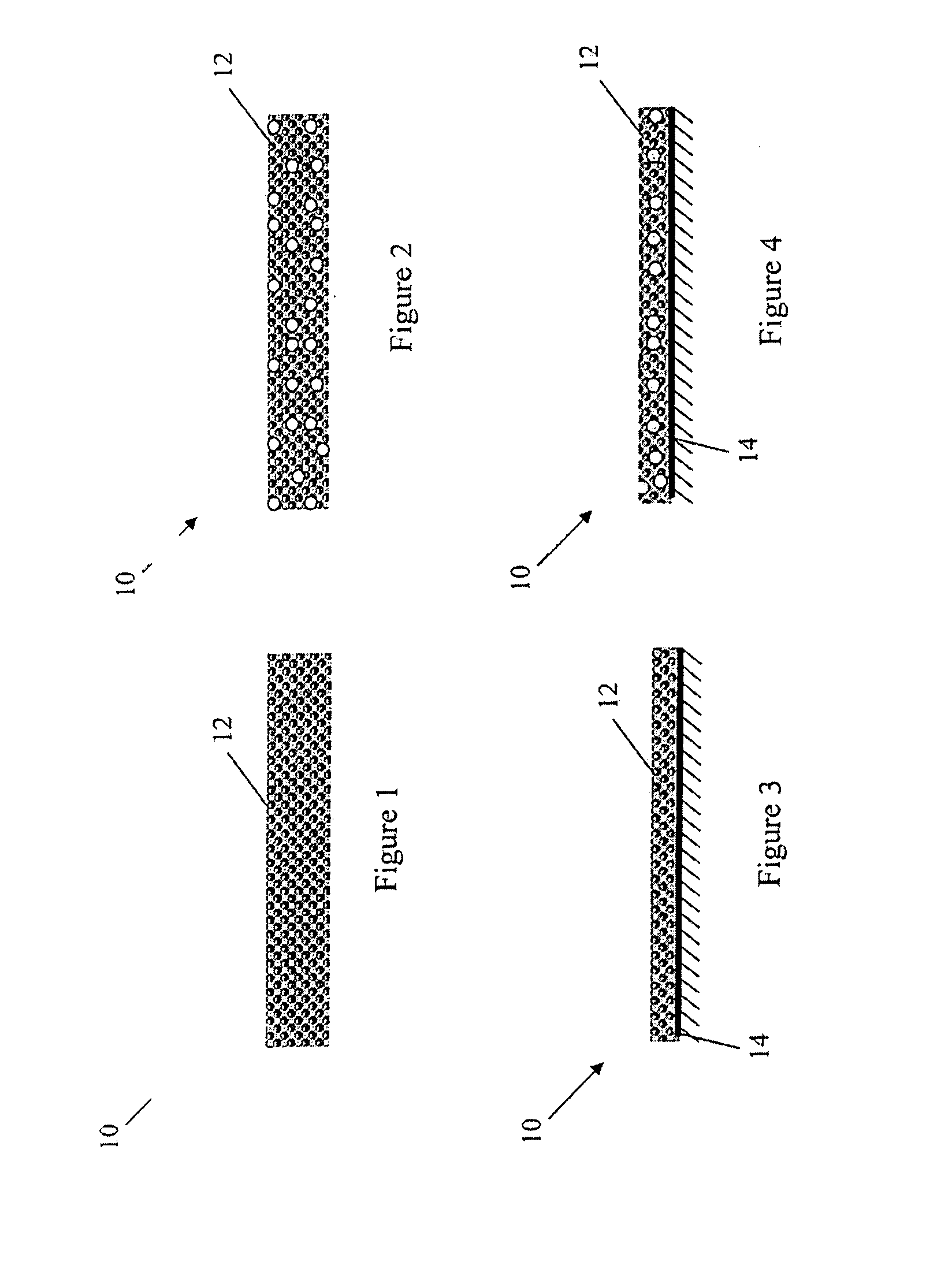

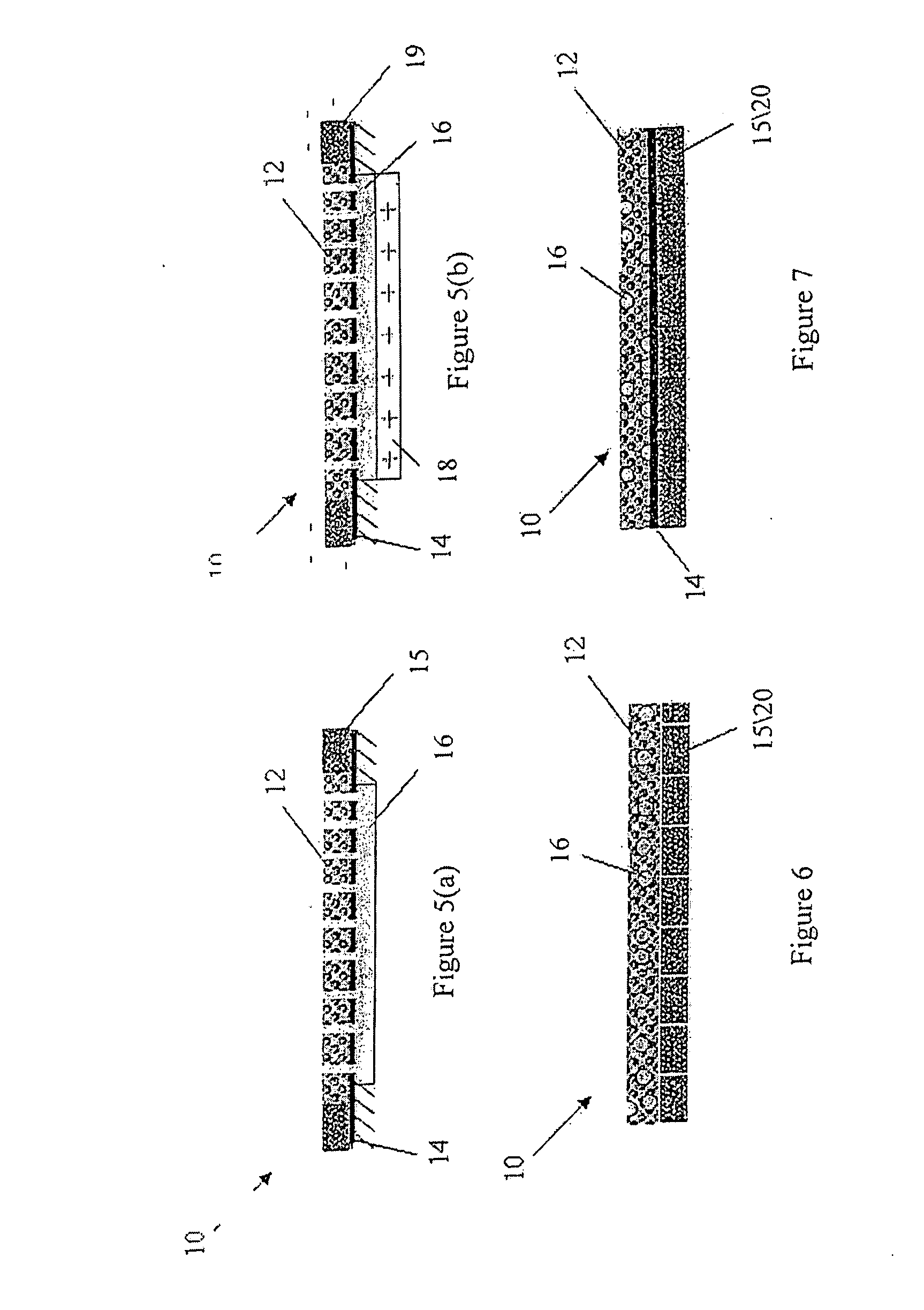

Medical devices and methods of making and using

Owner:INFRAMAT CORPORATION

Lumen - supporting devices and methods of making and using

Disclosed herein are medical devices, particularly lumen-supporting devices, which include a biocompatible nanostructured ceramic material configured to be disposed adjacent to a luminal surface and having an average grain size dimension of about 1 nanometer to about 1000 nanometers, a strain to failure of at least about 1 percent, and a cross-sectional hardness greater than or equal to about 350 kilograms per square millimeter. Also disclosed are methods of making and using the lumen-supporting devices.

Owner:INFRAMAT CORPORATION

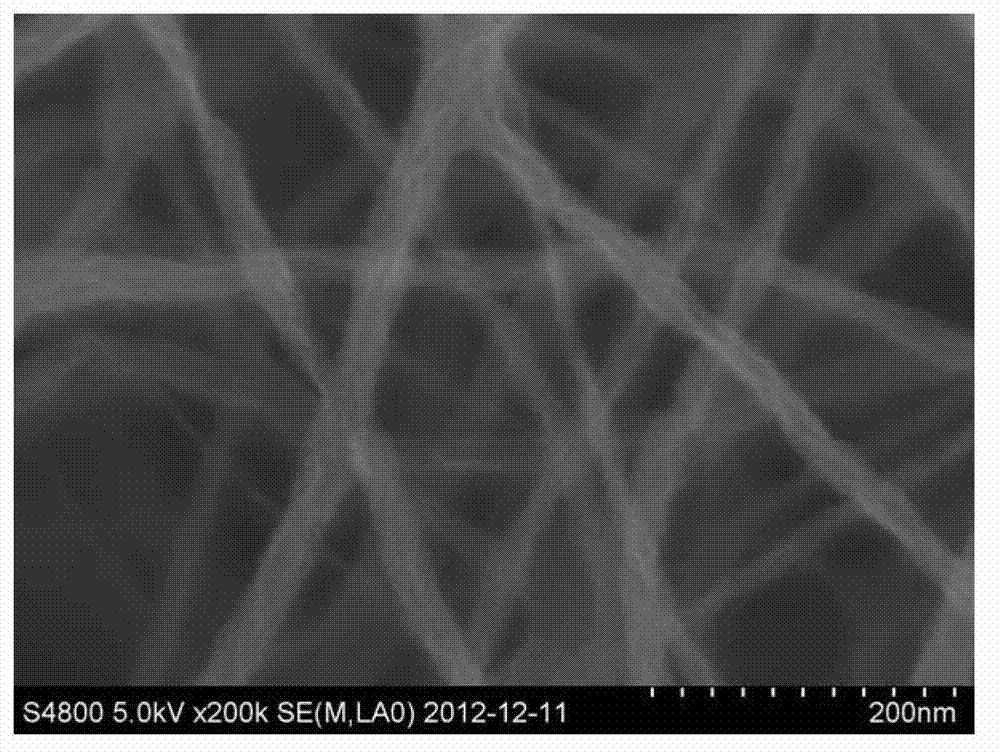

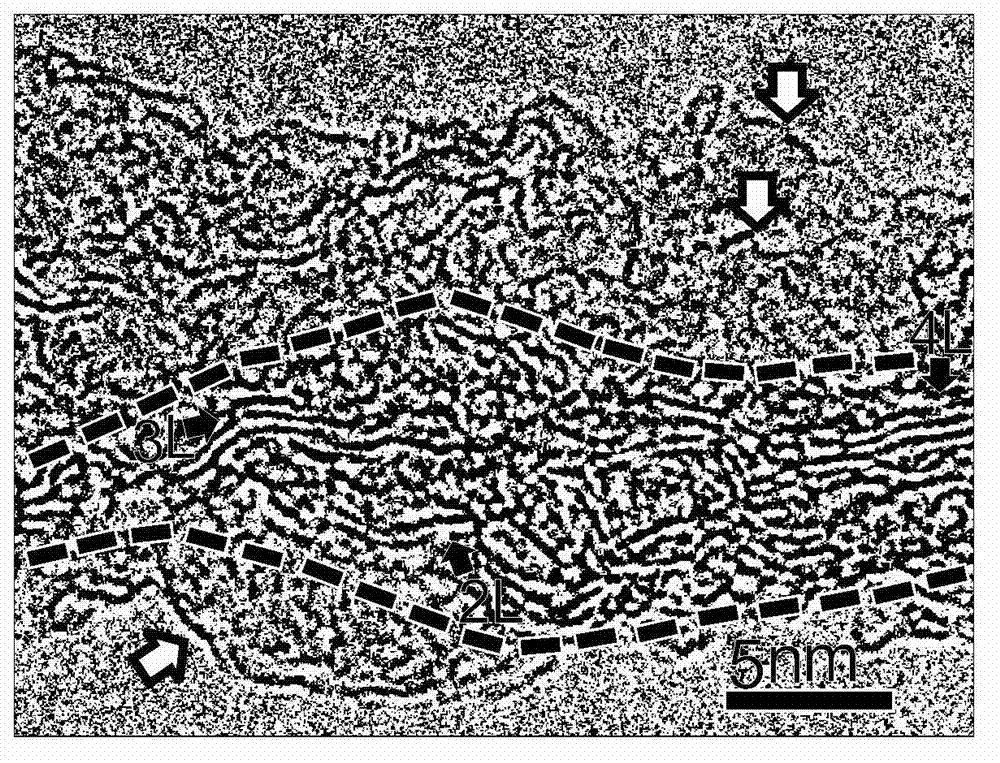

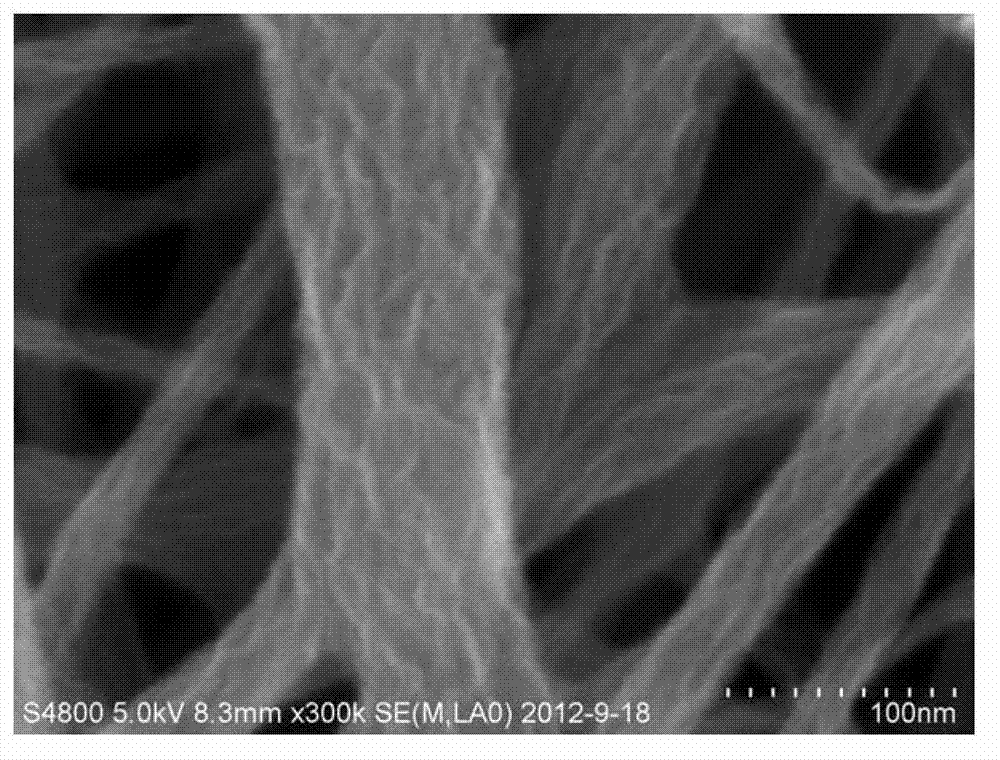

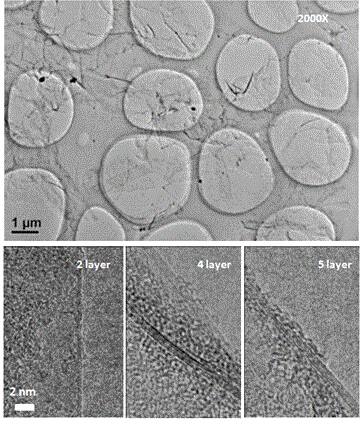

Preparation method of graphene nano-fiber and super-capacitor application thereof

ActiveCN103198931AEasy to fixNo reunionHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceFiber

The invention relates to a preparation method of a graphene nano-fiber and super-capacitor application of the preparation method of the graphene nano-fiber. The preparation method of the graphene nano-fiber includes the following steps: (1) an electrostatic spinning method is utilized to prepare a polymer fiber; (2) the polymer fiber obtained by the method is conducted with stabilizing treatment in appropriate temperature and in an oxygen-bearing atmosphere; (3) the fiber after the stabilizing treatment is conducted with carbonization thermal treatment in an NH3-bearing atmosphere and in appropriate temperature. The surface of the prepared graphene nano-fiber is provided with a graphene sheet which grows along the radial direction, and the thickness of the graphene sheet is 1 to 10 atomic layers. The graphene nano-fiber integrates the advantages of graphene and carbon nanofibers, solves the problems of graphene agglomeration and recrystallization, is high in surface activity and has various application values. The graphene nano-fiber is utilized to serve as a super-capacitor of electrode material preparation. Therefore, compared with the prior art, the preparation method of the graphene nano-fiber and the super-capacitor application of the preparation method of the graphene nano-fiber have good performance. The working voltage reaches 1.8-2.2 volts; the energy density reaches 41.3 watt hour / kilogram; and the specific capacitance in acid can reach 300 F / g.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

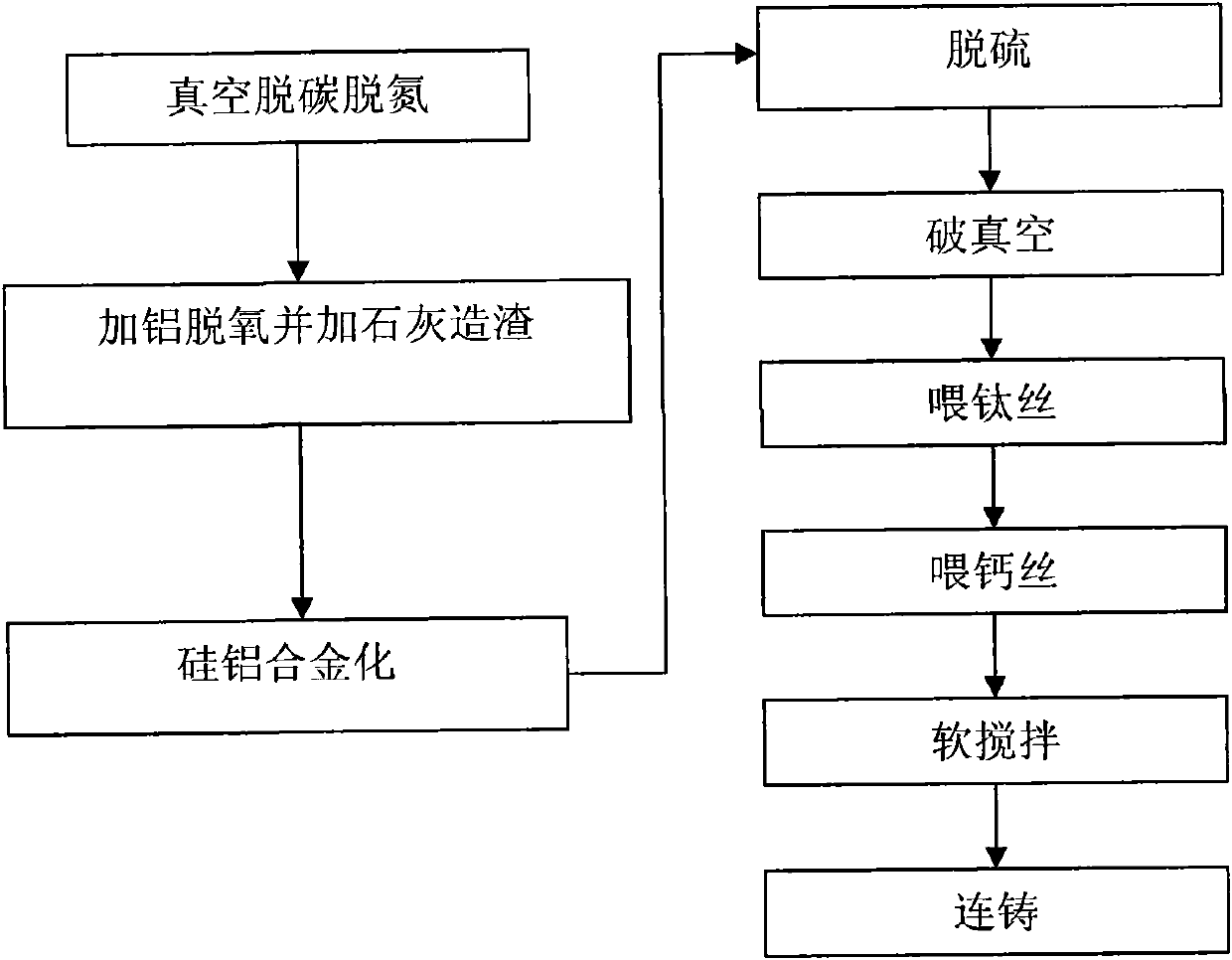

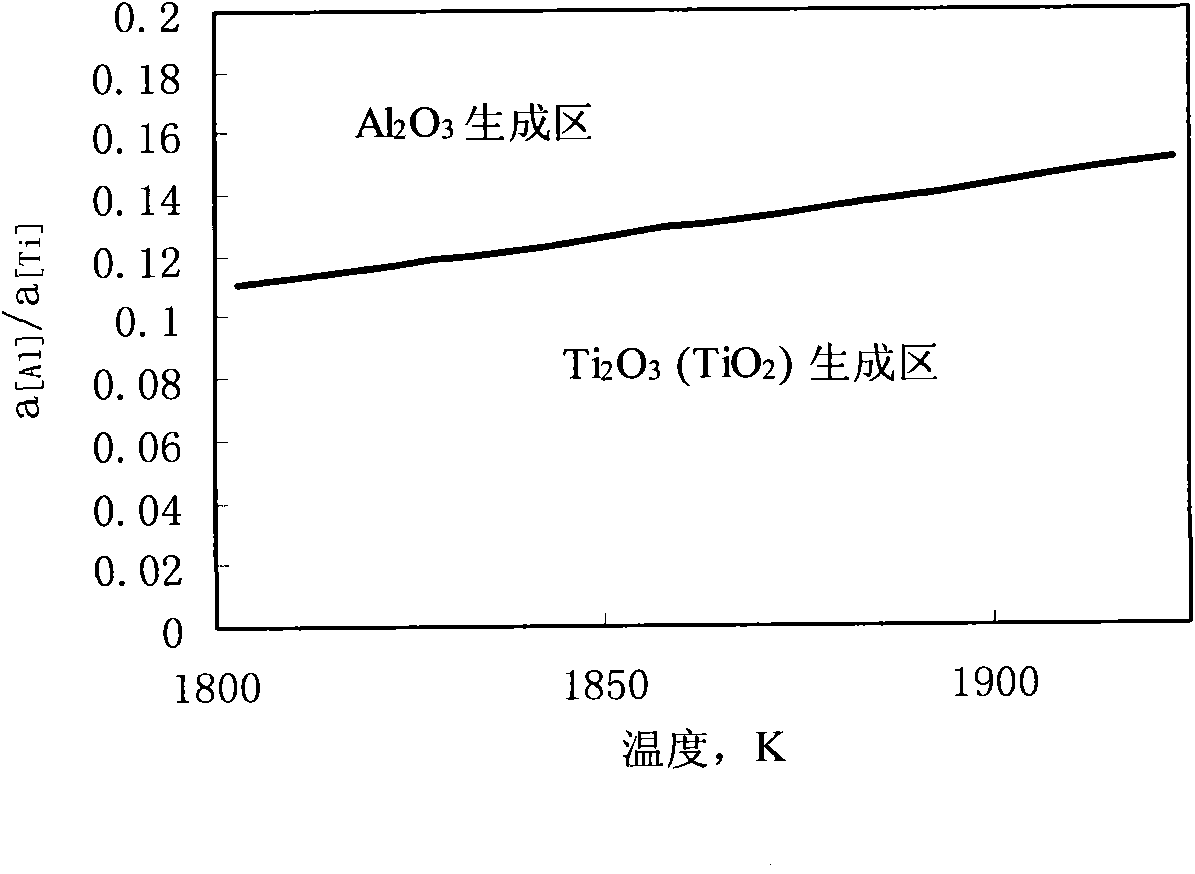

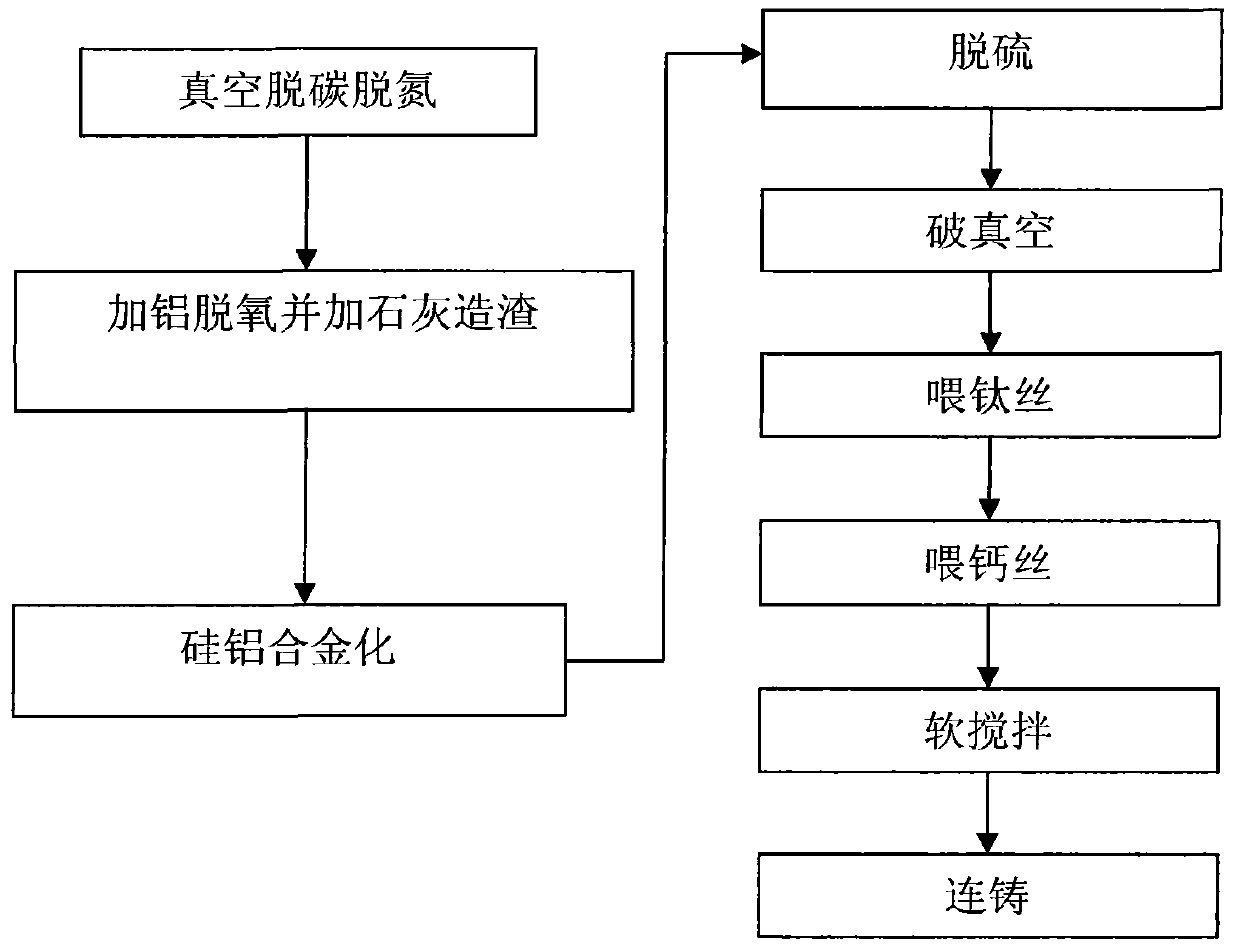

Production method of ultralow-oxygen titanium-containing ferrite stainless steel

The invention discloses a production method of ultralow-oxygen titanium-containing ferrite stainless steel, which comprises the following steps: 1) preparing molten ferrite stainless steel under a vacuum condition in a vacuum oxygen blowing decarburization furnace, wherein the carbon mass percentage content and nitrogen mass percentage content in the molten ferrite stainless steel are both less than 0.01 percent; 2) performing deoxidization, namely adding 6 to 12 kilograms of aluminum block or grains into each ton of steel and adding 10 to 28 kilograms of active lime into each ton of steel; 3) alloying silicon and aluminum, namely adding 2 to 9 kilograms of silicoferrite which contains 70 to 80 percent of silicon into each ton of steel and adding 0 to 1 kilogram of aluminum blocks or grains into each ton of steel, wherein the aluminum content is 0.02 to 0.1 percent; 4) performing desulphurization; (5) breaking vacuum; 6) softly stirring; 7) feeding titanium wires; 8) feeding silicon and calcium wires, wherein the calcium content is 5 to 30ppm; 9) softly stirring; and 10) continuously casting. The method can be used for producing ultralow-oxygen titanium-containing ferrite stainless steel, prevent or inhibit forming magnesia alumina spinel which are harmful impurities in a production process, improve product quality, prevent the water gap of tundish from being blocked in a continuous casting process and guarantee smooth production.

Owner:BAOSHAN IRON & STEEL CO LTD

Building structures containing external vapor permeable foam insulation

InactiveUS20100313507A1High standardAvoid dangerConstruction materialWallsWater vapor permeabilityWater vapor

Attach a thermoplastic polymeric foam to multiple spaced apart structural support members of a structure wherein the foam has a resistance to water vapor permeability (mu) that is less than 50, a thermal conductivity that is less than 40 milliwatts per meter*Kelvin, a compressive strength that is greater than 80 kilopascals, and a density of 48 kilograms per cubic meter or less to provide insulation while also providing water vapor-permeability and structural durability to the structure.

Owner:DOW GLOBAL TECH LLC

Fine feed for rhizomys in rearing period

InactiveCN102960572AImprove bioavailabilityIncrease payAnimal feeding stuffPantothenic acidNicotinic Acids

The invention discloses a fine feed for rhizomys in a rearing period. The fine feed comprises the following raw materials in percentage by weight: 20%-42% of corn, 12%-18% of soybean meal, 30%-50% of rice bran, 10%-23% of bran, 1%-3% of fish meal, 2% of calcium hydrophosphate, 0.5% of stone dust, 1% of common salt and 1% of premix. One kilogram of premix provides 88 million IU (international units) of VA (vitamin A), 60,000 IU of VE (vitamin E), 325 million IU of VD (vitamin D), 310g of VK (vitamin K), 110g of VB (vitamin B), 220g of VB, 65g of VB, 1220g of VB, 50g of pantothenic acid, 10g of nicotinic acid, 800mg of folic acid, 10g of biotin, 30g of Lys (lysine), 60g of Met (methionine), 30g of potassium, sodium, zinc and the like, and 30g of VC (vitamin C); and the main nutritional levels of the obtained fine feed are that the digestible energy is 2.85-3.01 Mcal / kg, and crude protein is 15.52%-18.07%. The fine feed disclosed by the invention can meet the nutritional requirements of the rhizomys sinensis in the rearing period, has a reasonable formula, and can ensure the rapid growth, robust physique, low disease incidence and low mortality rate of the rhizomys.

Owner:JIANGXI ACAD OF FORESTRY

Method for preparing regenerative gel material using waste concrete

The invention discloses a preparation technique of regenerating coagulation material with waste concrete, which features following steps: 1, crush waste concrete and separate the rough material with sand pulp; 2, crush the separated sand pulp into powder of particle size smaller or equal than 10 millimeter and then grind into powder of specify area larger than 300 square meter per kilogram; 3, sinter the grinded powder after blended in blending machine at 400-900 deg.C for 1.5 to 2.5 hours, fast cool down to room temperature with blowing air, blend again in blending machine to get the product. The regenerating coagulation material can be blending material in concrete production.

Owner:WUHAN UNIV OF TECH

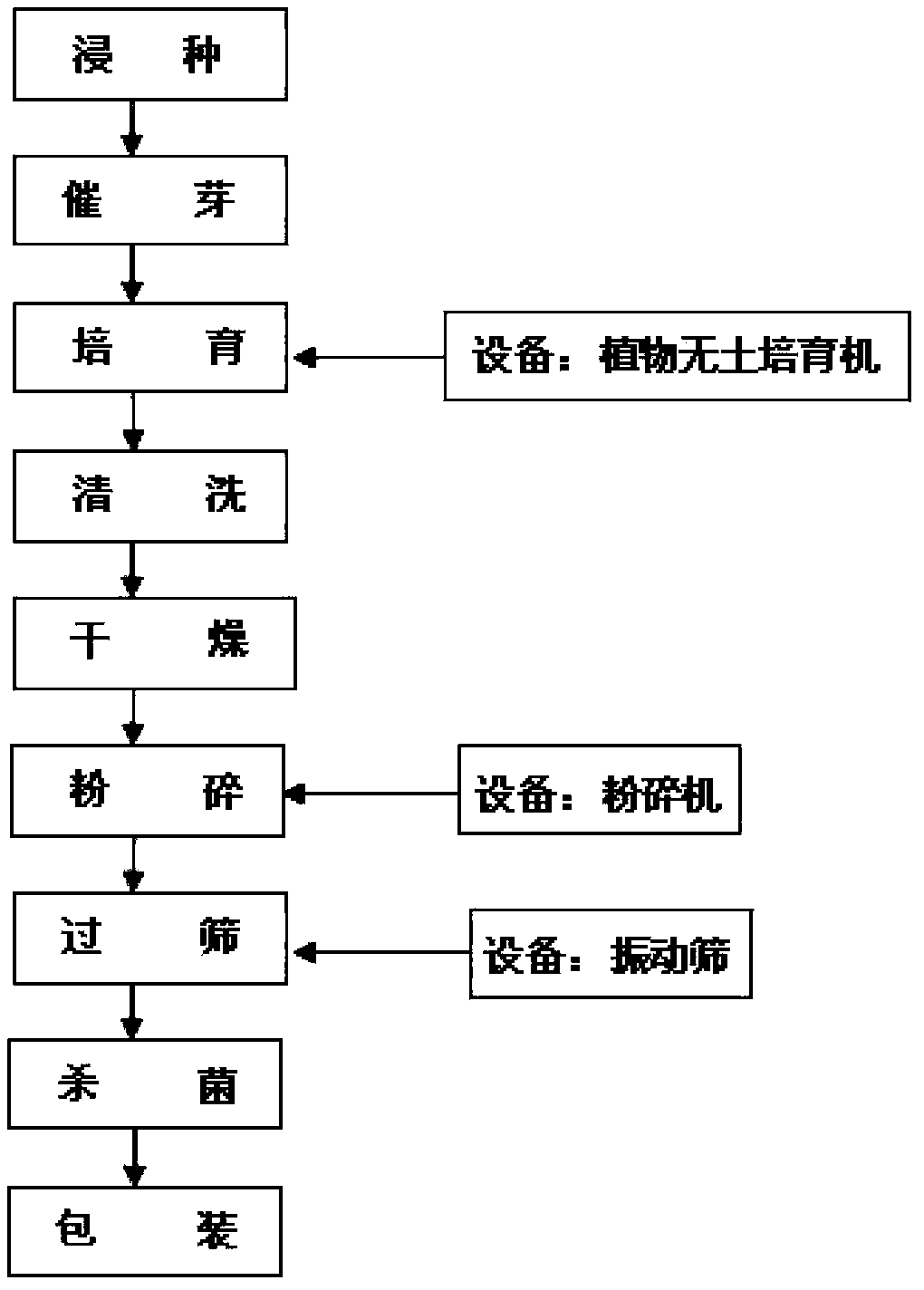

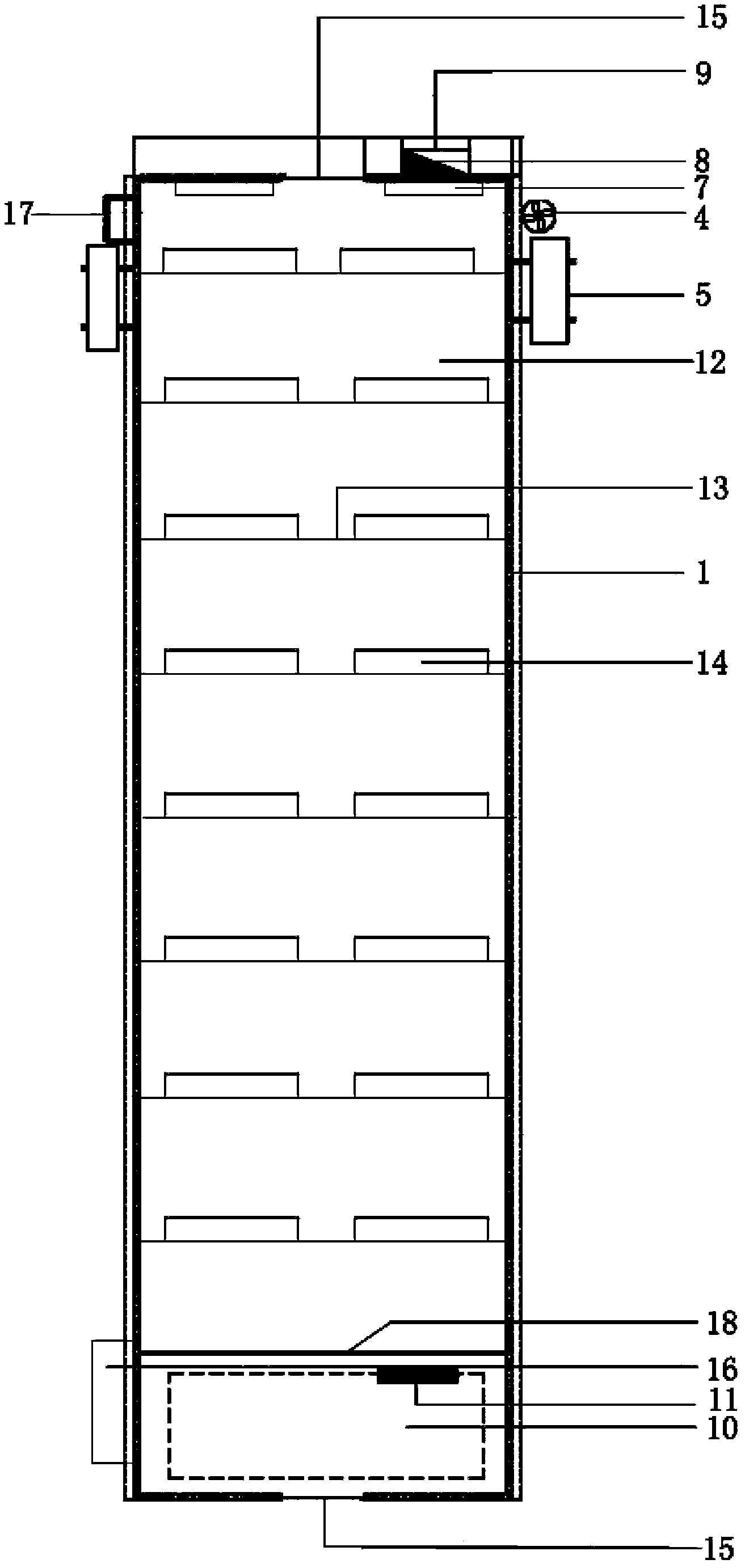

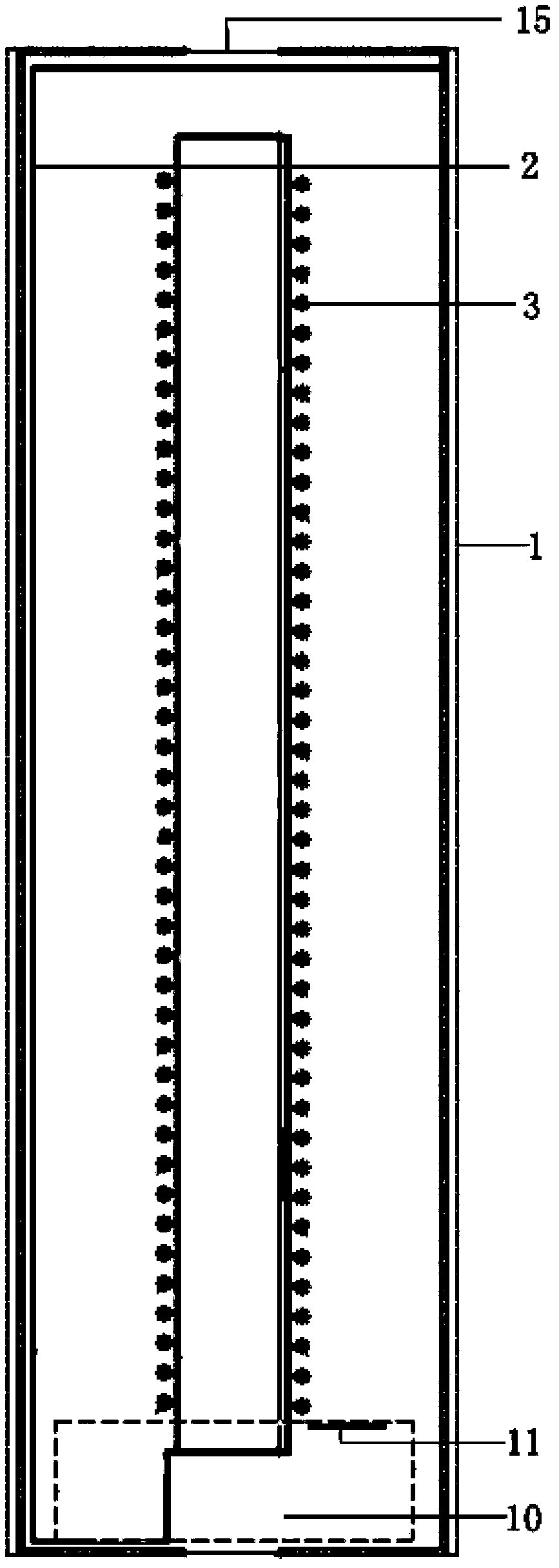

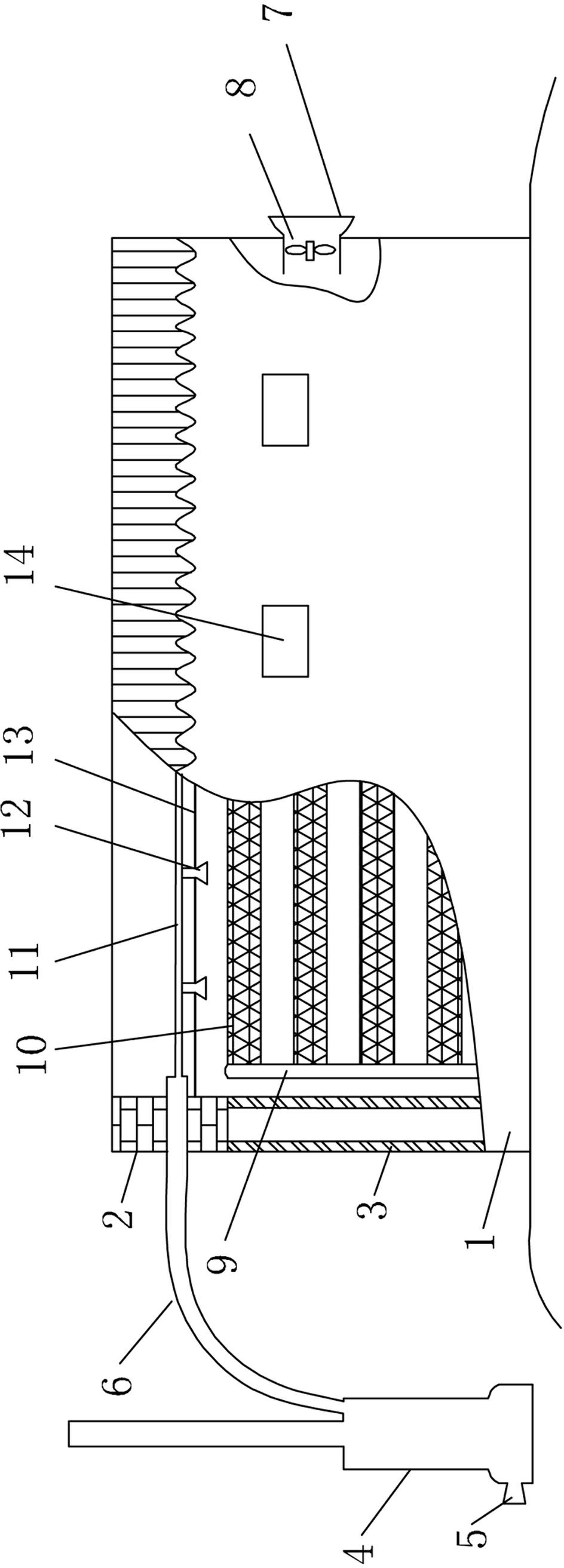

Processing technology of selenium enriched malt powder and soilless cultivation machine for plant

InactiveCN103504216AIncrease selenium contentAgriculture gas emission reductionCultivating equipmentsControl systemUltraviolet

The invention discloses a processing technology of a selenium enriched malt powder and a soilless cultivation machine for plants, aims to provide an easily controlled processing technology of a selenium enriched malt powder with high selenium content, and a soilless cultivation machine for plants. The process comprises the following steps: soaking, germination, cultivation, cleaning, drying, crushing, sieving, sterilizing and packaging. The soilless cultivation machine for plants comprises a casing main frame (1), a water circulation system, a ventilation system, fluorescent lamps (6), a middle control system (8), a water tank (10), cultivation rooms (12), cultivation racks (13), cultivation discs (14), heat preservation doors (15), a ladder (17), ultraviolet lamps (7) and a converter (16). The invention can greatly increase the selenium content of the produced malt powder to the highest content of 800 mg of selenium in per kilogram of wheat malt powder, and the content is far higher than the highest content of 50 mg of selenium in per kg of wheat malt powder in the prior art.

Owner:张常松

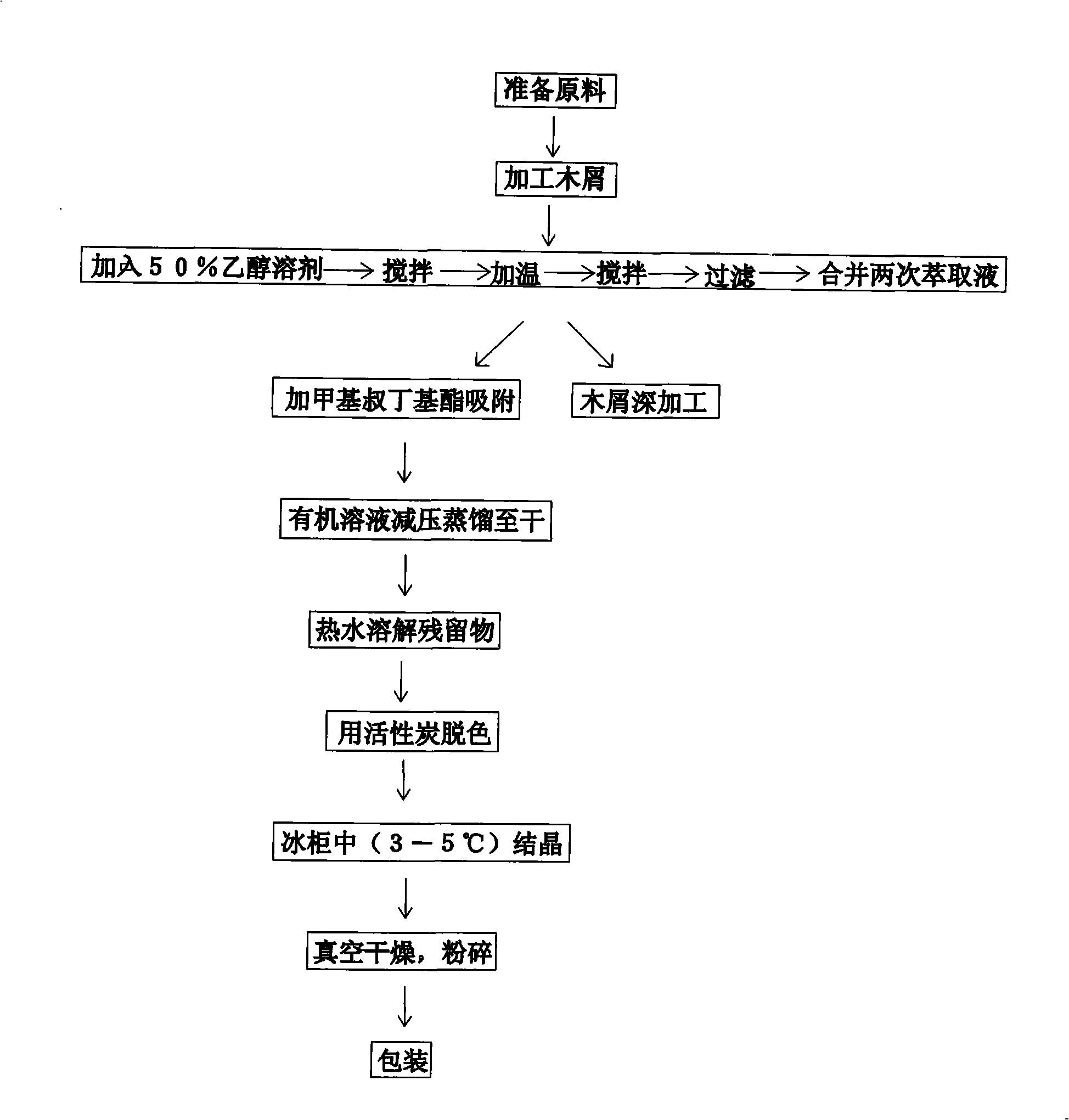

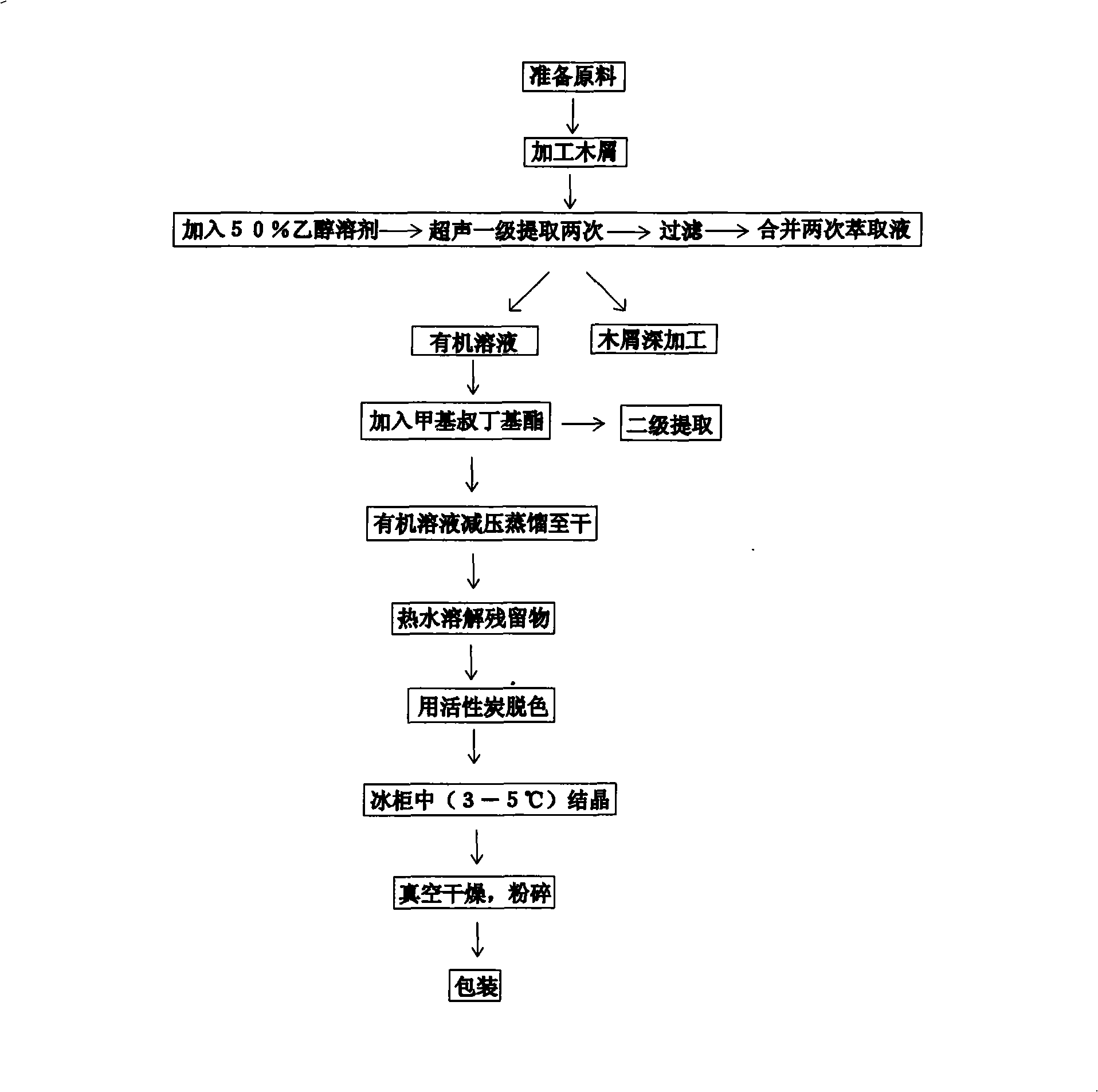

Method for extracting dihydroquercetin form larch

InactiveCN101333203AFree radical scavengingLesion hindranceOrganic chemistryConiferophyta medical ingredientsLarchUnit/Kilogram

Disclosed is a method for extracting dihydro quercetin from larch. The invention is an improved production method. Due to different production materials and extraction processes, the dihydro quercetin products in U.S. and European markets are very expensive, at a price of 200-1000 euros per gram. Such a high market price economically limits the wide range of practicability of dihydro quercetin products. During the pretreatment of raw materials, 50 kilograms of larch wood chips and 500-800 liters of 50% ethanol solution are added into a reactor to get fully stirred and mixed; then the mixture is extracted and filtered for the second extraction; the filtrates are combined and adsorbed; the organic solvents are collected and dried by a vacuum evaporator through organic phase vacuum distillation; according to a weight proportion of 10:1, the residues are dissolved with hot water, decolorized with activated carbon and then crystallized at a temperature of 3-5 DEG C to precipitate the dihydro quercetin product which is then crushed after vacuum drying to finished product. The invention is used to extract dihydro quercetin from larch.

Owner:黑龙江花旗科技发展有限公司 +2

Chinese medicinal herb pre-mixture for preventing swine high fever

InactiveCN101167808AEnhance immune functionQuality improvementAmphibian material medical ingredientsAnthropod material medical ingredientsWeight gainingLicorice roots

The invention discloses a Chinese herbal medicine premixed agent for curing swine high fever, which takes raw materials of traditional Chinese medicine such as astragalus root, codonopsis pilosula, honeysuckle flower, weeping forsythia, radix isatidis, folium isatidis, echinacea purpurea root, cicada shell, secretio bufonis, borneo camphor, vitamin C, enzymatic probiotics (licorice root, and medicated leaven), and garlicin, and the medicine is made into fine powder (200 orders) and is evenly mixed, 0.5 kilogram of the premixed agent is added to 100 kilograms of fodder ( basic daily grains) when in use. After the fodder is eaten by a pig, digestion and absorption of a pig can be advanced, appetite can be simulated, and growing speed can be increased, and daily weight gain reaches 1.81%, and the consumption of the fodder is reduced by 14%. The invention can play a role of health care, improve immune function and disease-resistant capacity of a pig, prevent and cure swine high fever reduce morbidity by 95%, and reduce death rate by 98%. And the invention has the advantages of extensive raw material source, low cost, and safety and innocuity, and does not generate drug resistance, which is an ideal Chinese herbal medicine premix substitution, and meat does not contain residual medicine.

Owner:赵代良

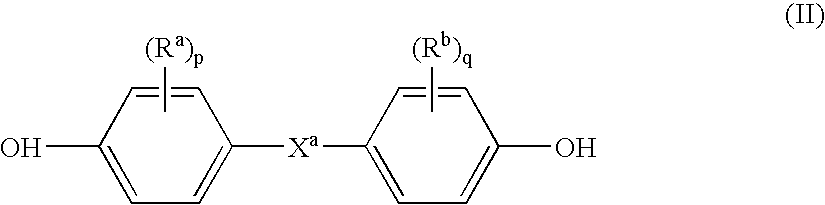

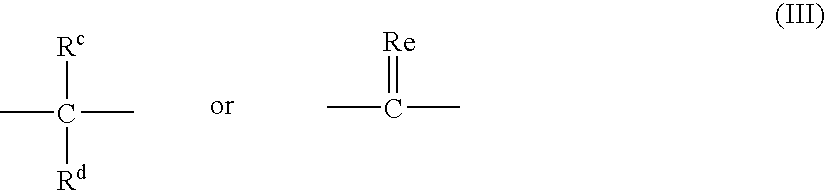

Polycarbonate composition and method of making thereof

InactiveUS20050209434A1Ceramic shaping apparatusChemical/physical/physico-chemical processesPhosphatePolystyrene

A polycarbonate composition comprises chloride, sulfate, phosphate or a combination of two or more of the foregoing ionic species in an amount of zero to about 100 parts per billion based on the total weight of the composition; and phenol, carbonic diester, aromatic dihydroxy compound or combination of two or more of the foregoing organic compounds in an amount of zero to about 500 parts per million by weight based on the total weight of the composition; wherein the polycarbonate has a weight average molecular weight of about 40,000 to about 90,000 dalton as determined by gel permeation chromatography using polystyrene standards and a melt volume rate of about 1 to about 35 cm3 / 10 minutes when measured at about 300° C. with a force of about 1.2 kilograms.

Owner:SABIC INNOVATIVE PLASTICS IP BV

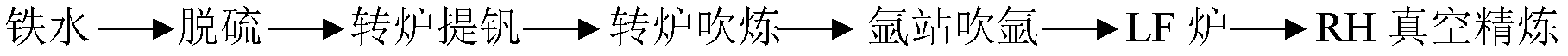

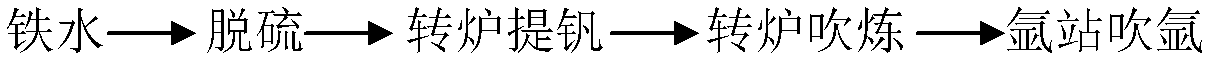

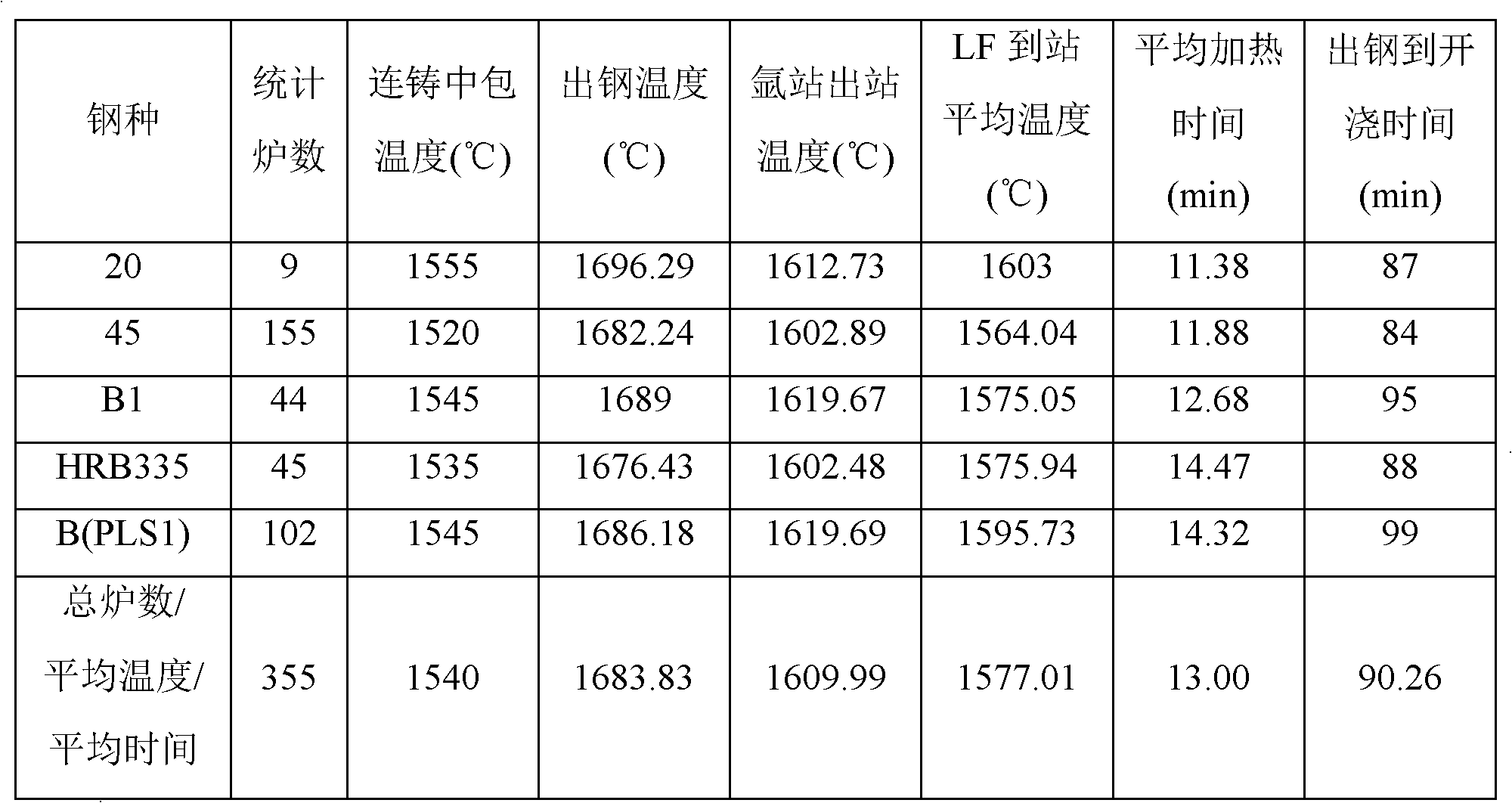

Steel-making method and application thereof and continuous casting method

InactiveCN103160634AShort processing timeReduce temperature dropManufacturing convertersSlagAdditive ingredient

The invention discloses a steel-making method and an application thereof and a continuous casting method, wherein the method comprising the following steps: firstly, a converter can be used for an primary making and then molten steel obtained from the primary making can be tapped in a steel ladle; secondly, in a steel tapping process, before steel is alloyed, the molten steel can be in recarburization and in selective deoxidization so as to regard total weight of the molten steel as a basic standard and activated oxygen contents of the molten steel is less than or equal to 100 parts per million (ppm); a slag foaming agent can be added to absorb impurities in the molten steel and gas evolution of the slag foaming agent is larger and equal to 90 liters per kilogram; thirdly, after the steel tapping argon can be blew into the molten steel of the steel ladle so that the molten steel can be in thermoregulation process; an selective feeding aluminum and a selective feeding carbon can be carried out according to ingredients of the molten steel so as to regard the total weight of the molten steel as the basic standard and the activated oxygen contents of the molten steel is less than and equal to the 50 ppm and carbon content of the molten steel can be adjusted as a middle limitation of ingredient demands of steel types. According to steel-making method and the application and the continuous casting method, the steel-making method which is provided can be used for accurately controlling the ingredients of the molten steel and regulating rhythms of making steel. The steel-making method is short in process time, small in temperature fall degree and low in energy consumption.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

Method for production of organic fertilizer by utilizing pig manure

InactiveCN103964942AAccelerated ripeningIncrease humification factorBio-organic fraction processingOrganic fertiliser preparationOxygenOrganic content

The invention discloses a method for production of an organic fertilizer by utilizing pig manure. The method comprises the following steps: A, pretreatment of raw material: the pig manure is used as raw material, the carbon-nitrogen ratio is adjusted to 28, the moisture content of the raw material is reduced to 60 percent, and EM strains are added; B, compost fermentation: compost fermentation is performed by adopting an aerobiotic windrow type composting technology; C, postprocessing of compost products: the moisture is reduced to be below 30 percent, particles can pass through a sieve with 60 mesh, and microelements or functional microorganisms are add for adjustment; D, packaging and storing of finished products. The organic fertilizer produced with the method is excellent in product quality, and is in strict conformance with the national standards and industrial standards of the commercial organic fertilizer: the organic content is not less than 45 percent, the total nutrient content is not less than 5 percent, the moisture content is not greater than 30 percent, and the pH value is 5.5-8.5; the death rate of ova of roundworms is not less than 98 percent, and the number of manure coli-group is not greater than 50 unit / g; in the produced organic fertilizer, in per kilogram of dry matters, the heavy metal content standards of the product are as follows: As is not greater than 30, Hg is not greater than 5, Pb is not greater than 100, Cd is not greater than 3 and Cr is not greater than 300.

Owner:MUYUAN FOODS CO LTD

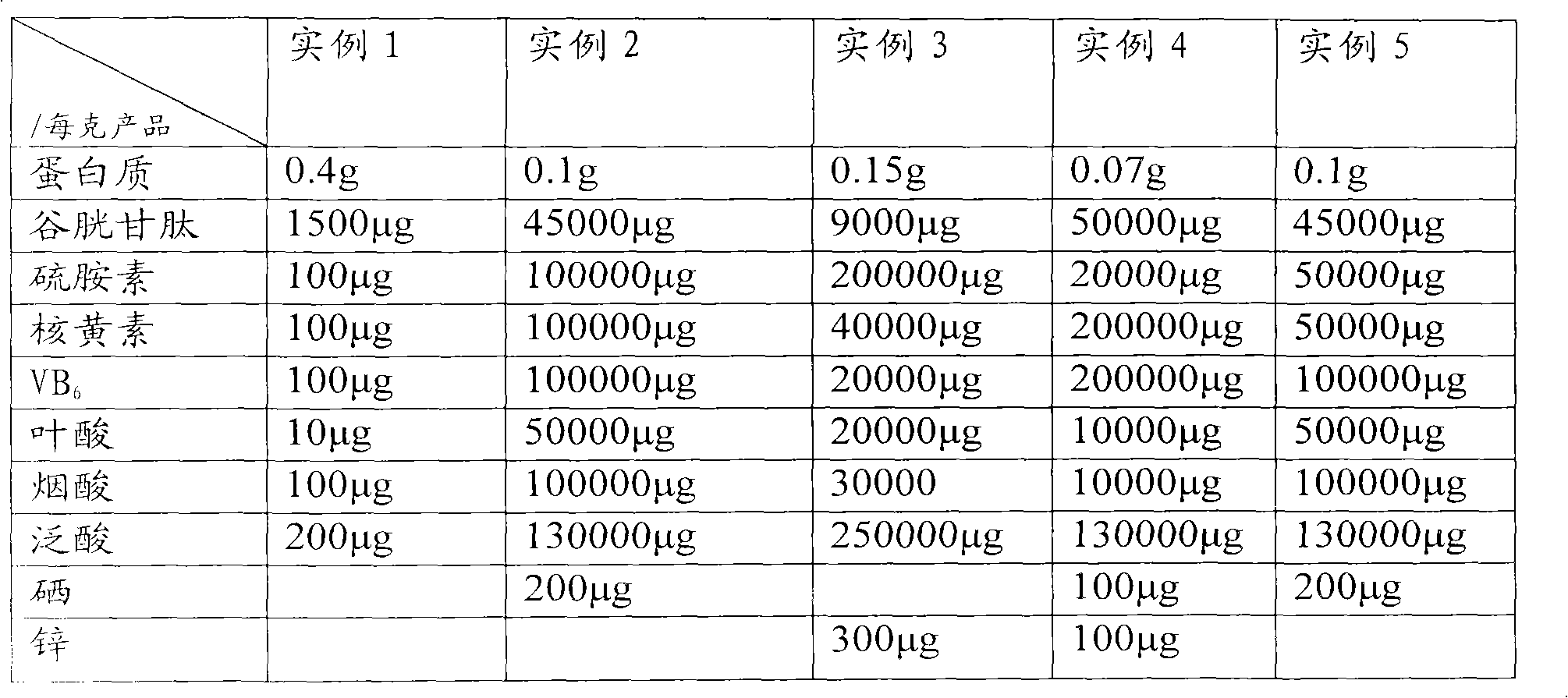

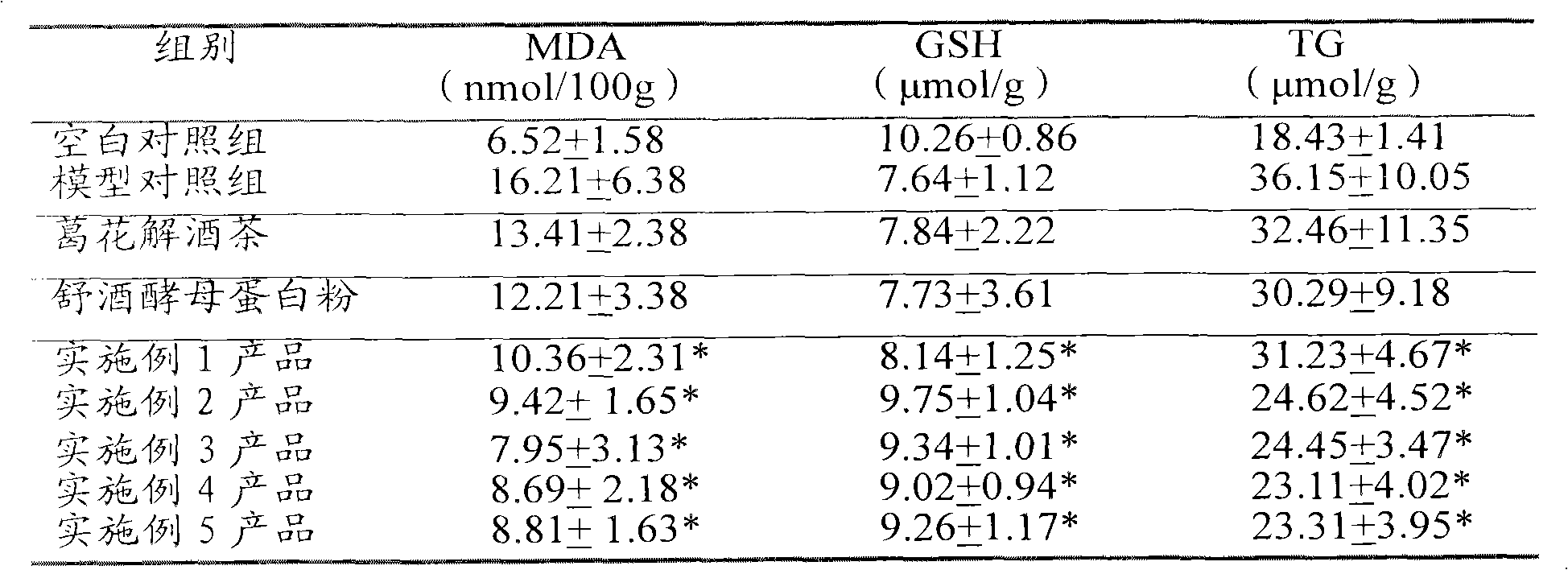

Liver-protecting and alcoholism-relieving product using Saccharomyces cerevisiae as main material

The invention provides a liver-protecting and alcoholism-relieving product using Saccharomyces cerevisiae, which contains over 42 percent of proteins, more than 500 milligrams of total B vitamins per kilogram and more than 800 milligrams of glutathione per kilo gram, as main materials. The invention also provides a method for producing the liver-protecting and alcoholism-relieving product.

Owner:ANGEL NUTRITECH CO LTD

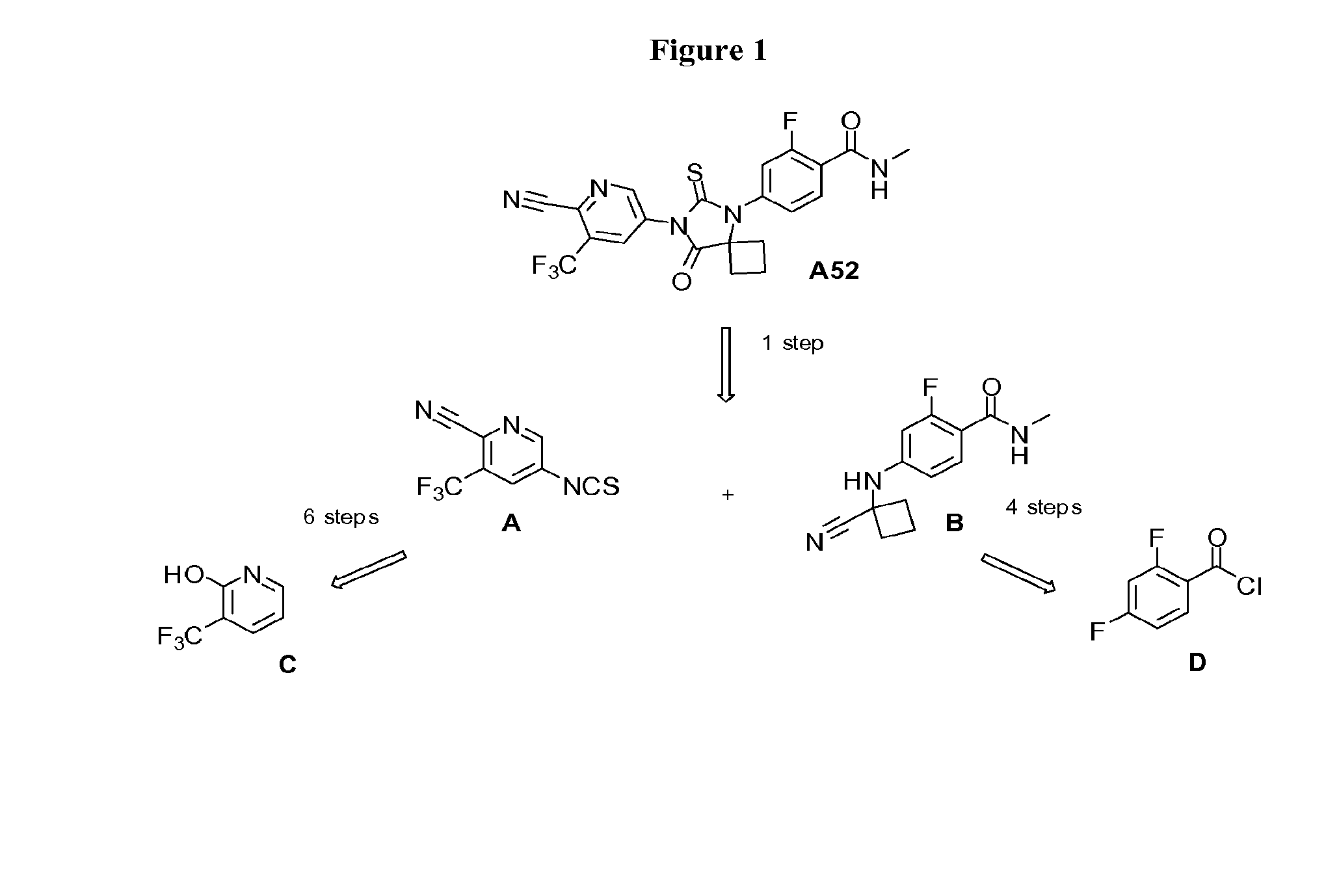

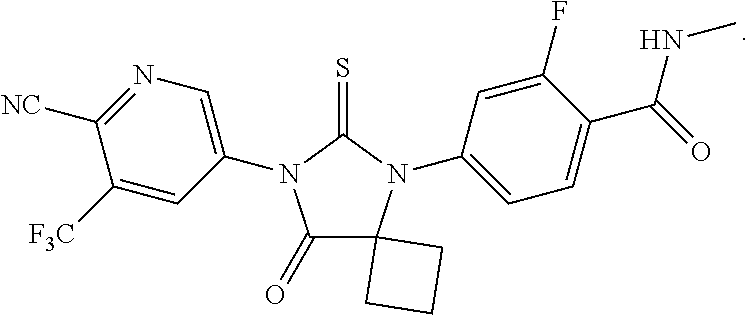

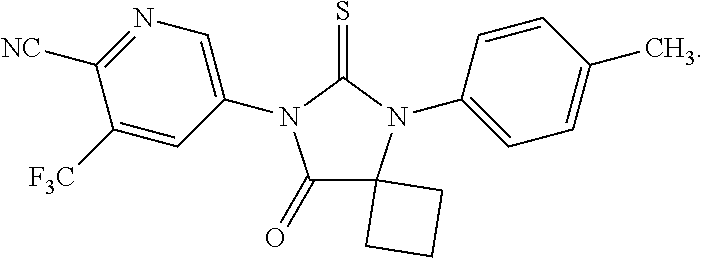

Synthesis of thiohydantoins

ActiveUS20130225821A1Efficient routingCarboxylic acid nitrile preparationOrganic compound preparationProstate cancerCombinatorial chemistry

A novel synthesis of the anti-androgen, A52, which has been found to be useful in the treatment of prostate cancer, is provided. A52 as well as structurally related analogs may be prepared via the inventive route. This new synthetic scheme may be used to prepare kilogram scale quantities of pure A52.

Owner:SLOAN KETTERING INST FOR CANCER RES

Preparation method for special pigment for aqueous printing ink

The invention relates to a preparation method for special pigment for aqueous printing ink. The method comprises the following steps of: (1), preparing diazotization liquid by a diazotization process for later use; (2), preparing coupling fluid; and (3), coupling, namely a, adding the diazotization liquid into the coupling fluid at the flow speed of 25 minutes, and controlling the pH value to be 10 and the temperature to be below 15 DEG C; b, continuing stirring for one hour and adding rosin fluid; c, reacting for 60 minutes and then adding 60 kilograms of 95 percent anhydrous calcium chloride; and d, raising the temperature to 85 DEG C after one hour, adding 40 kilograms of strontium nitrate dissolved with water with the temperature of 70 DEG C, raising the temperature to 90 DEG C, regulating the pH value to be 6 to 6.5 by using aluminum sulphate fluid, adding 7 kilograms of dissolved rosin amine, stirring for 60 minutes, and filtrating, rinsing, drying and crushing. The method has the advantages of use of aqueous solvent, simple process and low cost. Furthermore, the environmentally-friendly aqueous printing ink has low mammalian toxicity, no pollution, good flocculability, and good stability in an aqueous medium.

Owner:WUJIANG TUNCUN PIGMENT PLANT

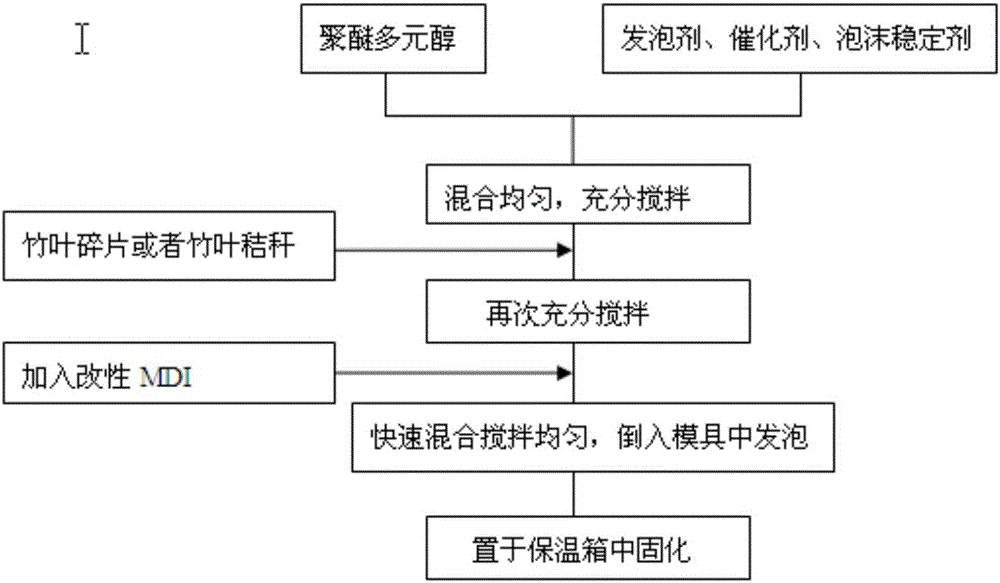

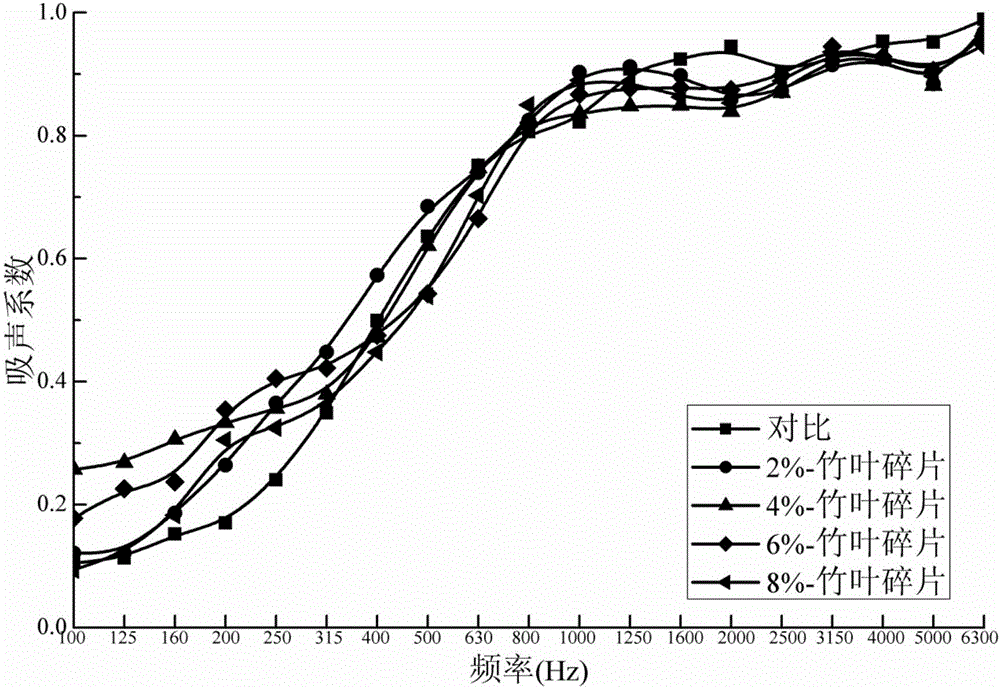

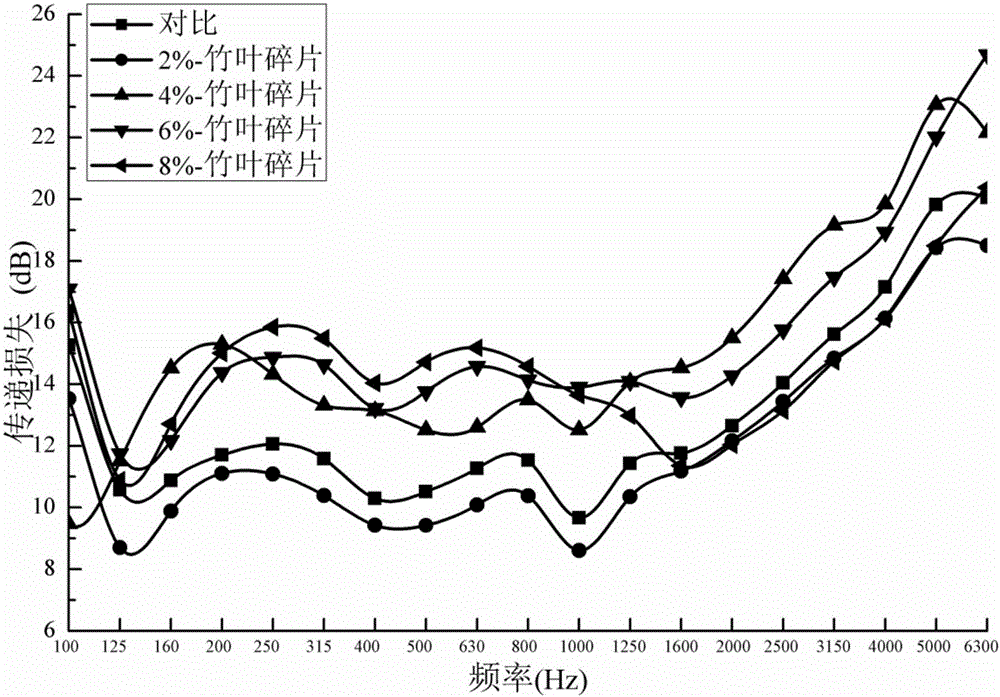

Polyurethane composite acoustic packaging material and preparing method thereof

InactiveCN105693978AHigh average sound absorption coefficientImprove sound insulationFoaming agentGram

The invention discloses a polyurethane composite acoustic packaging material and a preparing method thereof to solve the problem of the prior art that the low-frequency sound absorption performance of a sound absorption material is poor. The polyurethane composite acoustic packaging material comprises, by mass, 60 parts of polyether polyol 330 N, 40 parts of polyether polyol 3630, 35 parts of isocyanate modified MDI, 3 parts of foaming agent deionized water, 3 parts of foaming agent triethanolamine, 5 parts of foaming agent dichlorofluoroethane (HCFC-14lb), 0.04 part of catalyst A1, 1 part of catalyst A33, 0.9 part of foam stabilizer silicone oil, and 2-8 parts of 1-2 mm bamboo leaf chip, or 2-8 parts of 2-3 mm bamboo leaf chip or 2-8 parts of 3-4 mm bamboo leaf straw, wherein one mass part is a mass unit, namely gram or kilogram. The invention further discloses a preparing method of the polyurethane composite acoustic packaging material.

Owner:JILIN UNIV

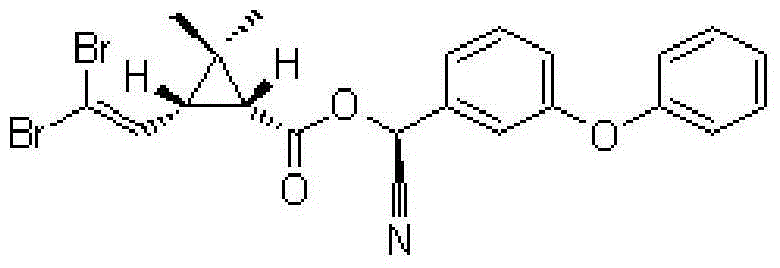

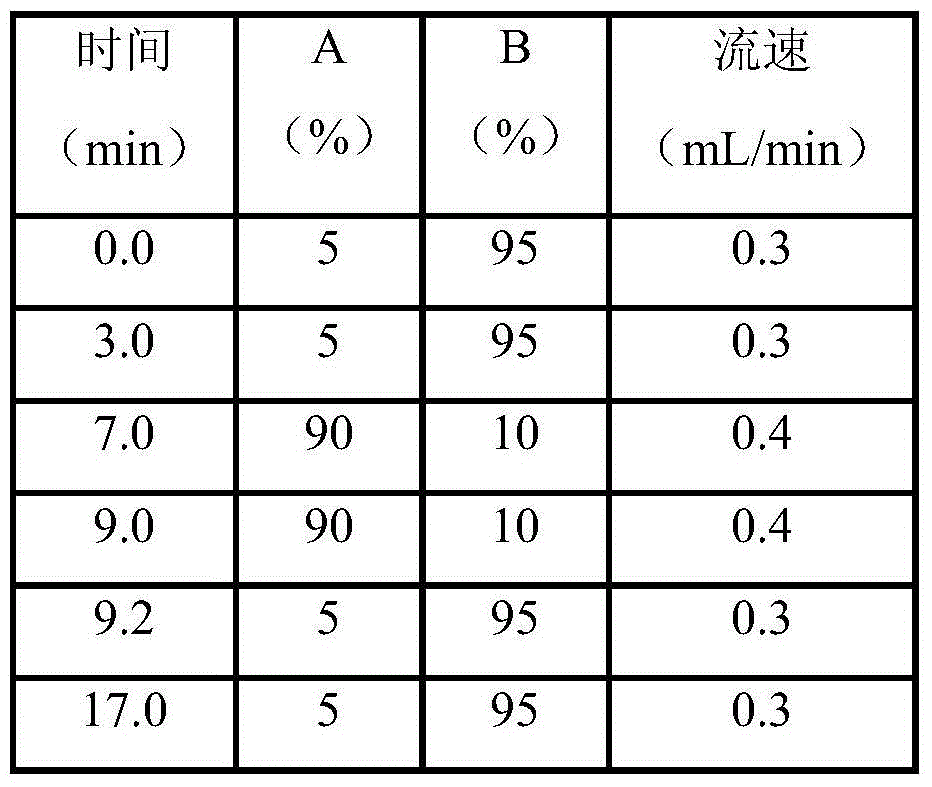

Method for testing group of biomarkers

ActiveCN104458988AAvoid interferenceSimple and fast operationComponent separationMatrix solutionRelative standard deviation

The invention discloses a method for testing a group of biomarkers. The method comprises the following steps: (1) extraction and purification; (2) preparation of standard working solutions, wherein blank samples are processed with the method shown in the step (1), and biomarker series concentration standard working solutions of at least three concentrations are prepared with matrix solutions of the blank samples within the range of 2-100 micrograms per liter; (3) liquid chromatogram-tandem mass spectrometry (LC-MS / MS) determination. A dispersive solid-phase extraction technique is used for the method, a sample pre-processing method capable of avoiding interference of matrixes in the samples easily, conveniently, quickly and effectively is developed, the pre-processing method is combined with the high performance liquid chromatography-tandem mass spectrometry (HPLC-MS / MS) and is used for qualitative confirmation and quantitative detection of content of the biomarkers in animal tissue and urine, the recovery rate of the method ranges from 4.2% to 106.2%, the average relative standard deviation (RSD) ranges from 6.4% to 13.0%, the limit of detection is 20.0 microgram per kilogram, the limit of quantitation is 50.0 microgram per kilogram, and the method has the advantages of being easy and convenient to operate, quick, accurate, high in sensitivity and good in repeatability.

Owner:INSPECTION & QUARANTINE TECH CENT SHANDONG ENTRY EXIT INSPECTION & QUARANTINE BUREAU

Building outer wall fire-proof heat-insulating material and preparation method thereof

The invention relates to a building outer wall fire-proof heat-insulating material and a preparation method thereof. The building outer wall fire-proof heat-insulating material is characterized by comprising a low-heat conduction fire-proof gelling material and a polystyrene foaming granule; per-cube weight ratio of low-heat conduction fire-proof gelling material to polystyrene foaming granule is (180-230):(6-10), wherein the low-heat conduction fire-proof gelling material contained in per-cube heat-insulating material comprises the following raw materials by weight: 50-90 kilograms of water glass, 50-75 kilograms of slag, 25-35 kilograms of coal ash, 25-35 kilograms of steel slag, 0.1-0.5 kilogram of fibers, 1.0-3.0 kilograms of redispersible latex powder, 1.0-3.5 kilograms of foam stabilizers, 2-10 kilograms of foaming agents and 2-10 kilograms of water. The building outer wall fire-proof heat-insulating material disclosed by the invention has the advantages of excellent fire-proof capacity, lower heat conductivity coefficient and higher strength.

Owner:广西启利新材料科技股份有限公司

Polyimide film and production process thereof

The invention relates to a polyimide film and a production process thereof. The polyimide film is mainly formed by the polymerization of material A 4,4'-bis(4-aminophenoxy)diphenylether and material B biphenyl tetracarboxylic acid dianhydride, wherein the ratio of the number of imide groups to the molecular weight of chain links is 2 / 678. The production process comprises the following steps: weighing the material A and the material b according to a weight ratio of 1.3:(0.99-1.0), and using N,N'-dimethyl acetamide as a solvent; throwing the material A into the solvent, stirring until the material A is dissolved, throwing the material B into the solvent in multiple times at a time interval of 20-50 minutes, and stirring, wherein the temperature is limited to 20-70 DEG C, and the weight of the solvent is 3-9 times of the total weight of the material A and the material B; and stopping throwing the material B when the resin viscosity reaches the reaction end point (4.0-7.0*10<5> centipoises) at 30 DEG C, continuing to stir for 4-6 hours to obtain a polyamic acid resin solution, casting into a film, and carrying out imidization; and regulating the viscosity when the material B remains 0.3-0.5 kilogram, wherein 0.03-0.1 kilogram of the material B is thrown each time, and the throwing amount is gradually reduced. The imide group content of the film is greatly reduced, and the alkali resistance and the moisture resistance of the film are greatly improved.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

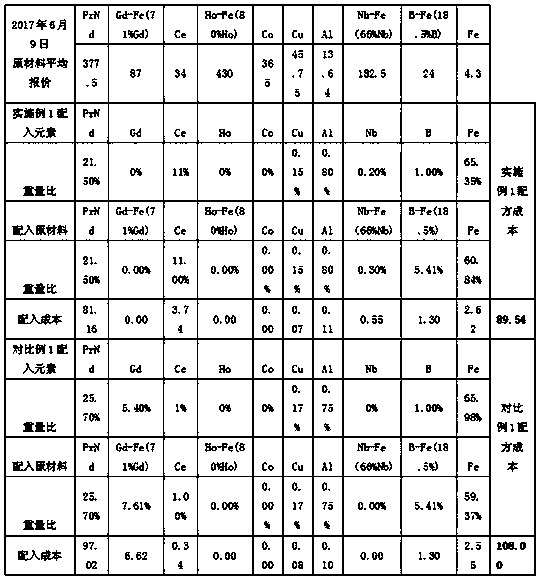

Low-cost N35 NdFeB magnet with high cerium content and sintering method thereof

InactiveCN107610858ALow costReduce consumptionInorganic material magnetismInductances/transformers/magnets manufactureNiobiumCerium

A low-cost N35 NdFeB magnet with high cerium content and a sintering method thereof belong to the technical field of powder metallurgy. The low-cost N35 NdFeB magnet is prepared from the following rawmaterials based on percent by weight according to a sintering process, 12-27% of praseodymium neodymium (Pr-Nd), 7-15% of cerium (Ce), 0-0.5% of niobium (Nb), 0-1% of aluminum (Al), 0-1% of copper (Cu), 0.9-1.1% of boron (B), 0-1.2% of cobalt (Co), 0-0.5% of zirconium (Zr) and 0-3% of gadolinium (Gd) with the balance being iron (Fe). In the scheme, a part of praseodymium neodymium (Pr-Nd) is substituted by cerium (Ce), the magnetic performance index reaches national standard of N35 mark sintering NdFeB, and the material cost can be reduced by 15-25 yuan during production of each kilogram of the corresponding mark magnet.

Owner:DONGYANG ZHONGYUAN MAGNETIC MATERIAL

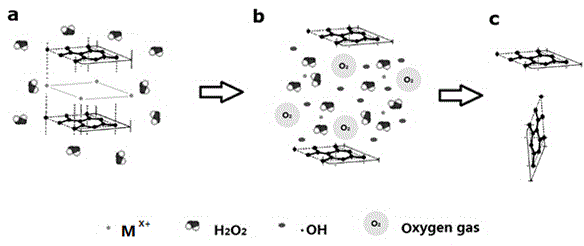

Graphene preparation method

The invention discloses a graphene preparation method comprising the following steps: a, graphite intercalation compound powder is added into a composite inflation fluid, and an inflation reaction is carried out under a temperature of 0-100 DEG C, such that inflated wormlike graphene aggregate suspension liquid is obtained; b, the wormlike graphene aggregate suspension liquid is subjected to a filtration treatment; c, the wormlike graphene aggregate is sequentially washed with a metal ion complexing agent and water, such that a wormlike graphene aggregate wet material with a pH value of 6-8 is obtained; d, the washed wormlike graphene aggregate wet material is added into water; an ultrasonic wave vibration treatment is carried out for 0.5-20h, such that stripping is realized and graphene is dispersed in water; and a graphene solution is obtained; and e, the water in the graphene solution is removed, such that graphene powder is obtained. With the method provided by the invention, hundreds of kilograms of a high-quality graphene product can be produced in one batch.

Owner:四川烯材科技有限公司

Cast-in-situ colored permeable ecological concrete and road surface construction process thereof

The invention relates to concrete, in particular to cast-in-situ colored permeable ecological concrete and a road surface construction process thereof. Each cubic meter of concrete is prepared from the following raw materials by weight: 200 to 350 kilograms of cement, 80 to 150 kilograms of water, 1,200 to 1,550 kilograms of coarse aggregates, 180 to 280 kilograms of fine aggregates, 4.5 to 5.5 liters of ZS series concrete admixture and 10 to 18 kilograms of pigment. The ecological concrete can be mixed by utilizing a mixing plant; and after being conveyed to a construction site by a commercial concrete mixer and added with the admixture, the ecological concrete can be subjected to the pouring constructing of road surfaces directly without vibrating and are only needed to be plastered by a metal trowel, so the construction efficiency is improved greatly. The ecological concrete is used for road surface engineering, uses a small amount of the cement, has high strength and water permeability, and can be widely applied to light traffic road surfaces such as side pavements, parks, neighborhoods and the like.

Owner:SHENZHEN WEIHAI BUILDING MATERIAL

Method for extracting dihydroquercetin form larch

InactiveCN101333204AFree radical scavengingInhibition of lesionsOrganic chemistryConiferophyta medical ingredientsLarchUnit/Kilogram

Disclosed is a preparation method for extracting dihydro quercetin from larch. The invention is an improved production method. Due to different production materials and extraction processes, the dihydro quercetin products in U.S. and European markets are very expensive, at a price of 200-1000 euros per gram. Such a high market price economically limits the wide range of practicability of dihydro quercetin products. During the pretreatment of raw materials, 50 kilograms of larch wood chips and 500-800 liters of 50% ethanol solution are added into an extractor to get fully stirred and mixed; then the mixture is extracted and filtered for the second extraction; the filtrates are combined and adsorbed; the organic solvents are collected and dried by a vacuum evaporator through organic phase vacuum distillation; according to a weight proportion of 10:1, the residues are dissolved with hot water, decolorized with activated carbon and then crystallized at a temperature of 3-5 DEG C to precipitate the dihydro quercetin product which is then crushed after vacuum drying to finished product. The invention is used to extract dihydro quercetin from larch.

Owner:黑龙江花旗科技发展有限公司 +2

Spotted deer feed additive

InactiveCN101912054AIncrease profitFast growthAnimal feeding stuffAccessory food factorsCysteamineFeed additive

The invention provides a spotted deer feed additive. The additive for basic feed comprises the following components by mass: 100 to 300 grams of complex enzyme, 250 to 2,000 grams of amino acid-trace element chelate, 35 to 55 grams of cysteamine, 500 to 800 grams of sodium chloride, 180 to 1,500 grams of vitamins, 1 to 2 kilograms of fish bone meal, 200 to 450 grams of astragalus root, 50 to 300 grams of sodium selenite-vitamin E premix, 20 to 60 grams of rock flour, 10 to 30 grams of zeolite powder, 10 to 20 grams of honey and 15 to 25 grams of carotene. The spotted deer feed additive is specially used in artificial raising and propagating of spotted deer. The additive has green, environmentally-friendly and pollution-free effects and effects of effectively balancing and coordinating with various nutrients in the feed and improving growth speed, feed utilization rate and productive performance. In the invention, expensive apparatuses are not used, the operation is simple, the use is convenient, the raw materials are readily available and the cost is low.

Owner:HEILONGJIANG ACAD OF SCI INST OF NATURAL RESOURCES

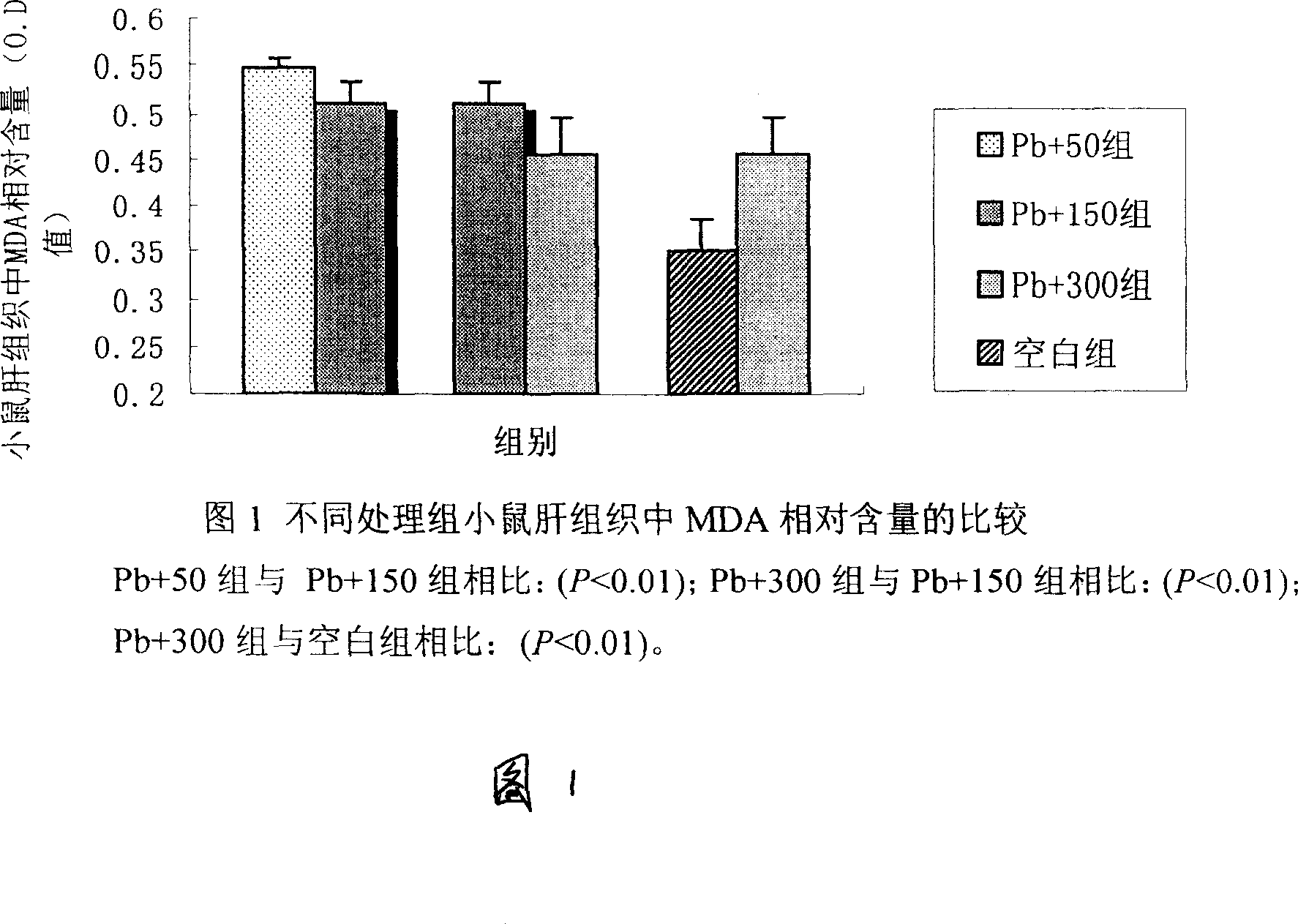

Use of extract of bracken flavone as medicament for lead expelling and lead poisioning alleviation

InactiveCN101011432AEnhance pharmacological effectsLittle side effectsAntinoxious agentsPteridophyta/filicophyta medical ingredientsMedicineBracken

The invention relates to a method for using bracken chromocor extractive to prepare the drug used to discharge lead and release the lead poison, wherein, each day and each kilogram can use 30-180mg drug, to obtain significant lead discharge effect. And each day and each kilogram can use 50-300mg bracken chromocor to obtain significant lead poison release effect. The inventive drug will not discharge needed element of human body, while the bracken chromocor extractive contains the needed elements as iron and zinc of people.

Owner:WEST ANHUI UNIV

Method for preparing titanium alloy hip joint for surgery implantation

The invention discloses a method for preparing a titanium alloy hip joint for surgery implantation. The method comprises the following steps of: selecting 25 to 30 mass percent of Nb, 5 to 5.5 mass percent of Zr, 2 to 3 mass percent of Ta and the balance of titanium sponge; pressing the materials into an electrode-block welding electrode and smelting, wherein the smelting speed at the first time is 5 kilograms per minute, and the smelting speed at the second time and the third time is 8 kilograms per minute; the smelting temperature at each time is 1,850 to 3,300 DEG C, an arc striking current is 4 to 5 kilo-amperes, and a smelting current is 6 to 18 kilo-amperes; cooling for 2.5 to 4.5 hours; cogging and heating to 700 to 850 DEG C, and performing rotary swaging and deformation; annealing and heating at the temperature of 700 to 850 DEG C; keeping the temperature for 60 to 120 minutes and taking out from the furnace; cooling at room temperature, and straightening and polishing a bar material; and machining the ground bar so as to obtain the titanium alloy hip joint. The prepared hip joint is free from toxic elements and host response, approximates to a natural bone and has high bone conduction.

Owner:宝鸡市三立有色金属有限责任公司

Pollution-free specially-raised kilogram-level chicken house and raising method

InactiveCN102524105AMeet the needs of different growth and development stagesScientific and reasonable settingBird housingsHigh densityEngineering

A pollution-free specially-raised kilogram-level chicken house and a raising method belong to the field of raising technology. The chicken house is characterized in that a fan is used for longitudinal ventilation, an air outlet is disposed on the exterior wall of one end of the chicken house, a wet curtain is used for cooling the chicken house, a wet curtain layer is disposed in the middle of the exterior wall of the other longitudinal end of the chicken house, an air heater is disposed outside the chicken house, an air supply pipe is connected with the air heater and an indoor air supply branch pipe, the indoor air supply branch pipe is connected with a plurality of hot air outlet, and a plurality of rows of composite cages are disposed inside the chicken house and supported by a support. The raising method is characterized in that high-density multilayer group caging is adopted, the good method is used for good varieties, green pollution-free fodder materials and additives are used, and the raising process is specified. The raising method includes: fodder matching, seed selection, racking, separate caging, and inspection for sale; and obtaining pollution-free specially-raised kilogram-level chicken. The chicken house is scientific and reasonable in arrangement, the fodder is delicate, green and environment-friendly, chicken groups raised in the chicken cage grow and develop orderly and healthily, disease occurrence is low, growth speed is high, fodder utilization rate is high, and raising benefits are guaranteed.

Owner:德州市陵城区世海养殖专业合作社

Novel process for producing rubber vulcanization accelerator DM

The invention discloses a novel process for producing a rubber vulcanization accelerator DM and relates to a chemical assistant production method. The novel process is characterized by comprising the following steps of: adding 400 to 600 kilograms of accelerator M into a reactor; fully beating for 0.8 to 1.2 hours; adding 5 to 10 kilograms of copper acetate serving as a catalyst with beating; dropping 10 to 20 percent of hydrogen peroxide at a speed of 80 to 150L / hour; and discharging, spin drying and oven drying at the end of the reaction. Moreover, the end of the reaction is assayed by 1 percent of cobalt oleate by the steps of: putting a small amount of materials into a test tube with 50 milliliters of acetone and dropping the cobalt oleate, wherein if the solution does not go green, the reaction ends. The novel process has the following remarkable advantages that: the DM is directly oxidized by the hydrogen peroxide; the method is simple and easy to operate; the whole production process is clean, environmentally-friendly and suitable for industrial mass production; and the utilization of the process is favorable for the healthy development of rubber assistant industry.

Owner:河南省开仑化工有限责任公司

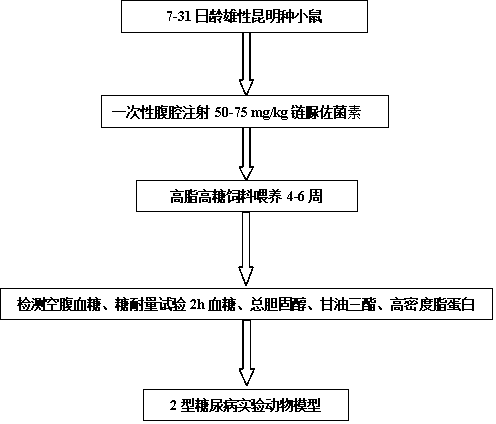

Construction method for mouse type 2 diabetes mellitus (T2DM) animal experiment model

ActiveCN104257671ASmall doseHigh molding rateOrganic active ingredientsAnimal husbandryIntraperitoneal routeHigh fat

The invention patent relates to the technical field of animal experiment model construction, in particular to a construction method for a mouse type 2 diabetes mellitus (T2DM) animal experiment model. The method includes the following steps: male Kunmin mice at the age of 7 to 31 days are selected; 50 to 75 mg / Kg (milligrams per kilogram) of streptozotocin is taken by the mice through intraperitoneal injection at a time; after the mice are continuously fed with high-fat high-glucose feed for 4 to 6 weeks upon free eating, the mice of which fasting blood-glucose is above 7.0 millimoles per liter, blood glucose in a 2-hour oral glucose tolerance test is above 11.1 millimoles per liter, cholesterol is above 5.7 millimoles per liter, triglyceride is above 1.7 millimoles per liter, and high-density lipoprotein is below 1.0 millimole per liter at the same time are defined as T2DM animal experiment models. The model can simulate the T2DM characteristics of humans, and adopts multiple testing indicators to accurately define T2DM; due to the light weights of the underage animals, the streptozotocin dosage is small, so that the experiment cost is reduced.

Owner:QINGHAI NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com