Steel-making method and application thereof and continuous casting method

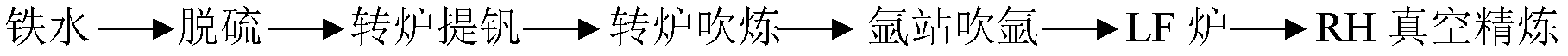

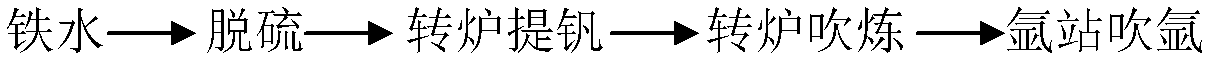

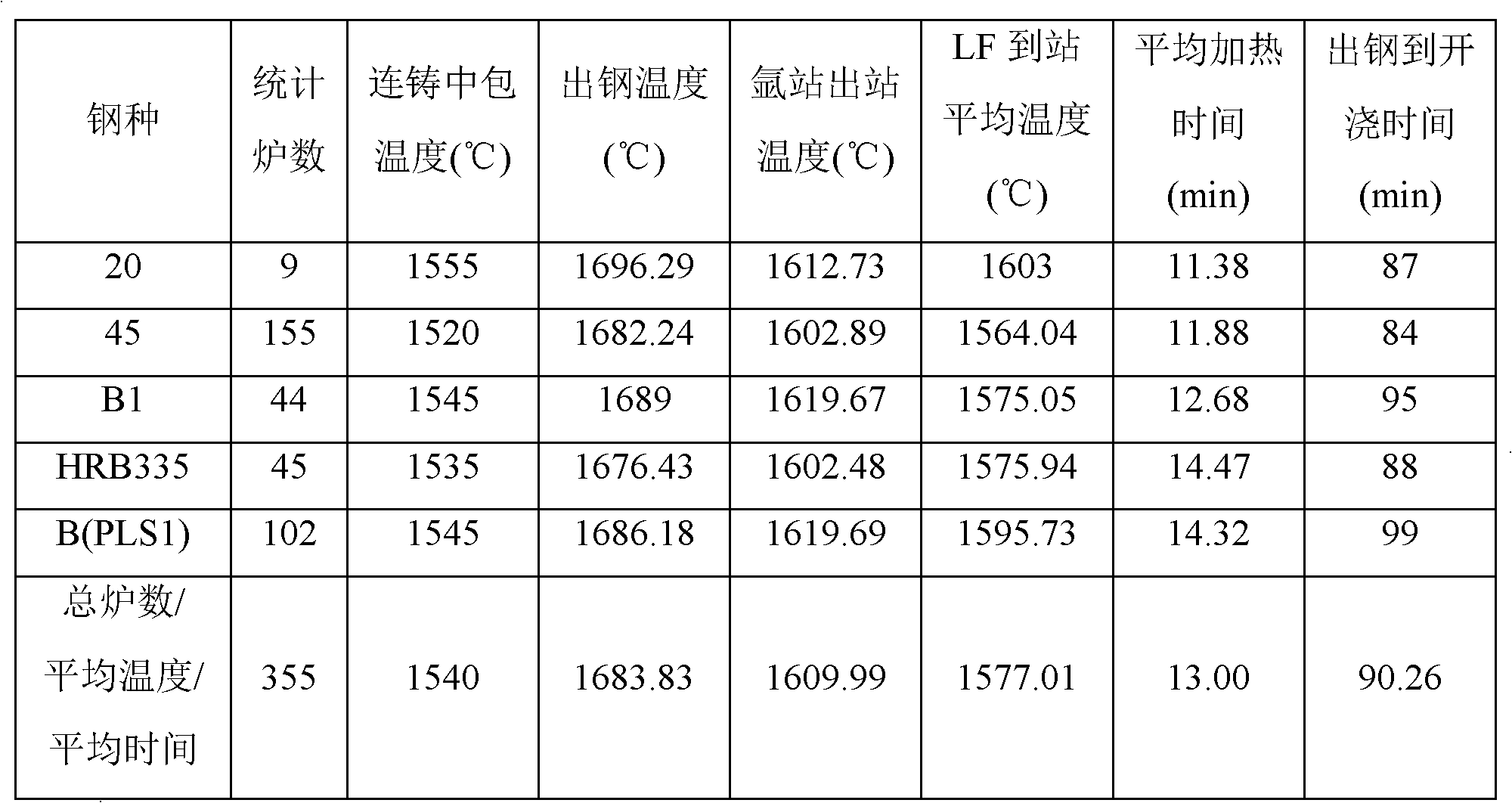

A technology of molten steel and steel types, applied in the field of continuous casting, which can solve the problems of long heating time of LF furnace, increased energy consumption, long time of steelmaking process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation method of the mold powder is well known to those skilled in the art, for example, it can be pre-melted slag or mechanically mixed slag, wherein: CaO can be derived from pre-melted slag, wollastonite, cement clinker and other CaO-containing Material; SiO 2 Can be derived from pre-melted slag, wollastonite, cement clinker, quartz sand, feldspar, etc. containing SiO 2 Material; Al 2 O 3 It can be derived from pre-melted slag, bauxite, cement clinker, white mud, etc. containing Al 2 O 3 Material; Na 2 O can come from pre-melted slag, Na 2 CO 3 Wait for Na 2 O's material; F - Can be derived from pre-melted slag, CaF 2 (Fluorite) etc. containing F - C can be derived from materials containing C such as carbon black, graphite and coke.

[0045] According to the present invention, the surface of the molten steel is condensed into a hard shell through the cooling of the crystallizer, the molten steel with the hard shell is continuously drawn from the outlet of the crys...

Embodiment 1

[0052] The mold powder used in Example 1 contains CaO and SiO 2 , Al 2 O 3 , MgO, MnO, Na 2 O, CaF 2 , C, wherein, based on the total weight of the mold powder, the content of CaO is 18% by weight, SiO 2 The content is 30% by weight, the Al 2 O 3 The content of MnO is 10% by weight, the content of MgO is 1% by weight, the content of MnO is 2% by weight, Na 2 The content of O is 7% by weight, CaF 2 The content of C is 7% by weight, and the content of C is 25% by weight. The basicity of the mold powder is 0.6, the melting point is 980-1020°C, and the viscosity is 0.1-0.2 Pa·S.

Embodiment 2

[0053] The mold powder used in Example 2 contains CaO and SiO 2 , Al 2 O 3 , MgO, MnO, Na 2 O, CaF 2 , C, wherein, based on the total weight of the mold powder, the content of CaO is 22% by weight, and SiO 2 The content is 28% by weight, the Al 2 O 3 The content of MnO is 9% by weight, the content of MgO is 2% by weight, the content of MnO is 4% by weight, Na 2 The content of O is 6% by weight, CaF 2 The content of C is 6% by weight, and the content of C is 23% by weight. The basicity of the mold powder is 0.78, the melting point is 980-1020°C, and the viscosity is 0.1-0.2 Pa·S.

[0054] The tundish covering agent used in the following Examples 1-2 contains CaO, SiO 2 , Al 2 O 3 , MgO and CaF 2 , Based on the total weight of the tundish covering agent, the content of the CaO is 45% by weight, the SiO 2 The content is 6% by weight, the Al 2 O 3 The content of MgO is 37% by weight, the content of MgO is 5% by weight, and the CaF 2 The content is 7% by weight.

[0055] Example 1

[0056...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com