Patents

Literature

4375 results about "Feldspar" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Feldspars (KAlSi₃O₈ – NaAlSi₃O₈ – CaAl₂Si₂O₈) are a group of rock-forming tectosilicate minerals that make up about 41% of the Earth's continental crust by weight. Feldspars crystallize from magma as veins in both intrusive and extrusive igneous rocks and are also present in many types of metamorphic rock. Rock formed almost entirely of calcic plagioclase feldspar is known as anorthosite. Feldspars are also found in many types of sedimentary rocks.

Strontium feldspar aluminum titanate for high temperature applications

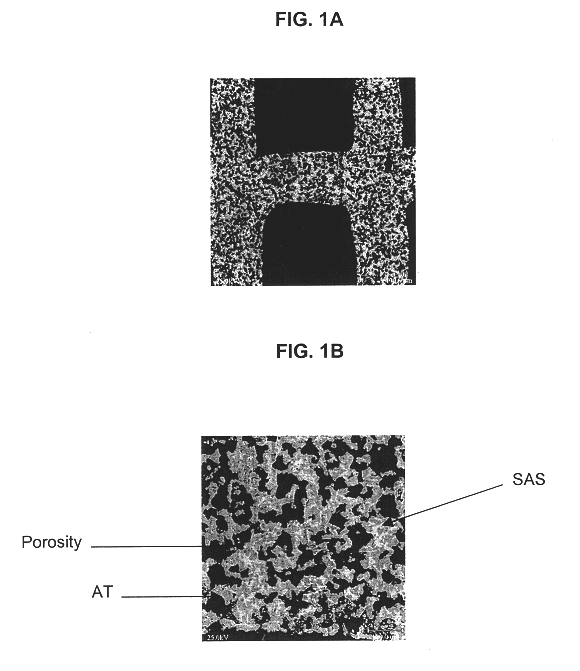

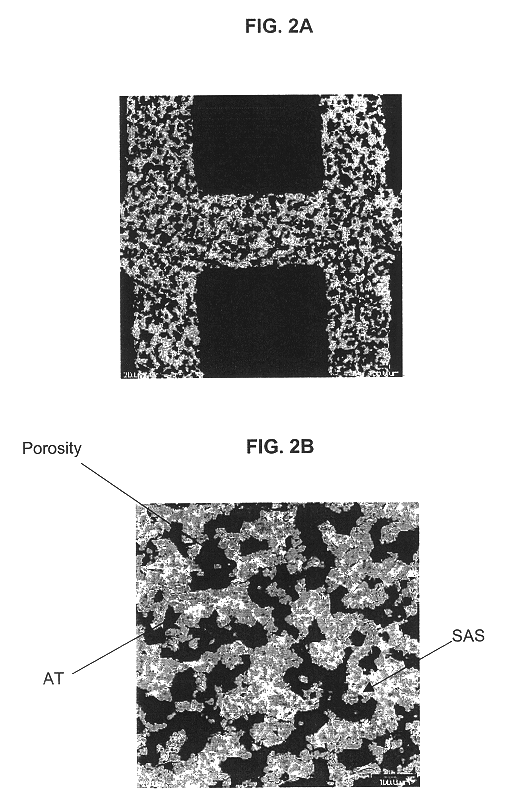

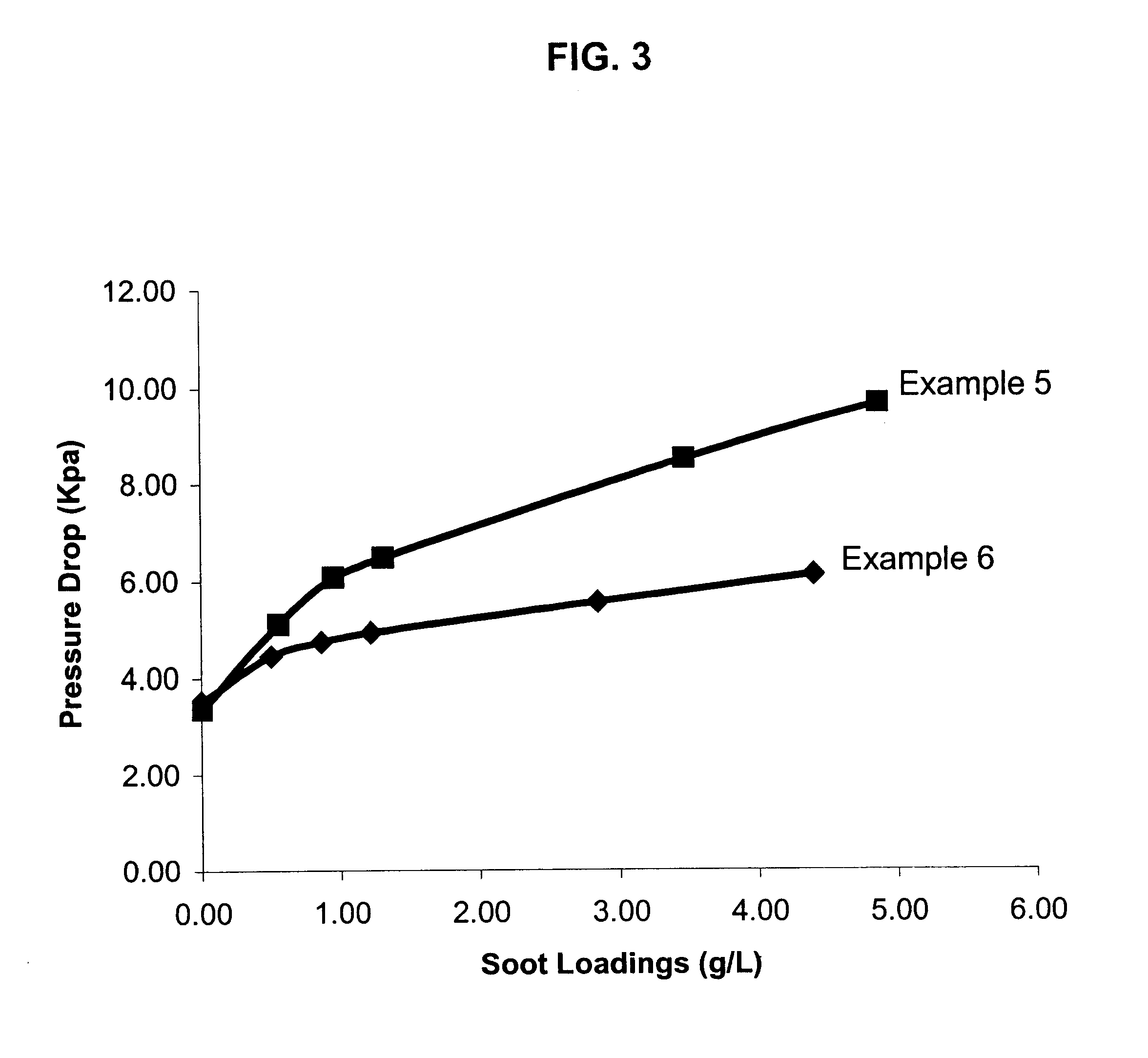

InactiveUS6620751B1Improve stabilityReduce bloatInternal combustion piston enginesDispersed particle filtrationMicrometerRoom temperature

A structure for use in high temperature applications and including a porous ceramic material consisting essentially of about 50-90 percent by weight iron or magnesium stabilized aluminum titanate (AlTiO5) and about 10-50 percent by weight strontium feldspar (SrO.Al2O3.2SiO2), and having a coefficient of thermal expansion over a temperature range from room temperature to 1000° C. of about -10x10-7 / ° C. to +15x10-7 / ° C., a heat capacity at 500° C. greater than 3.2 J / cm3K, a porosity of about 15-50 percent by volume, preferably 40-50 percent by volume, and a median pore size of about 5-50 micrometers, preferably 8-15 micrometers. The structure is especially useful as a diesel exhaust particulate filter.

Owner:CORNING INC

Monolithic honeycomb structure made of porous ceramic and use as a particle filter

InactiveUS6582796B1Prevent the evaporation of the waterEasy curingInternal combustion piston enginesSilencing apparatusSodium BentoniteOxygen

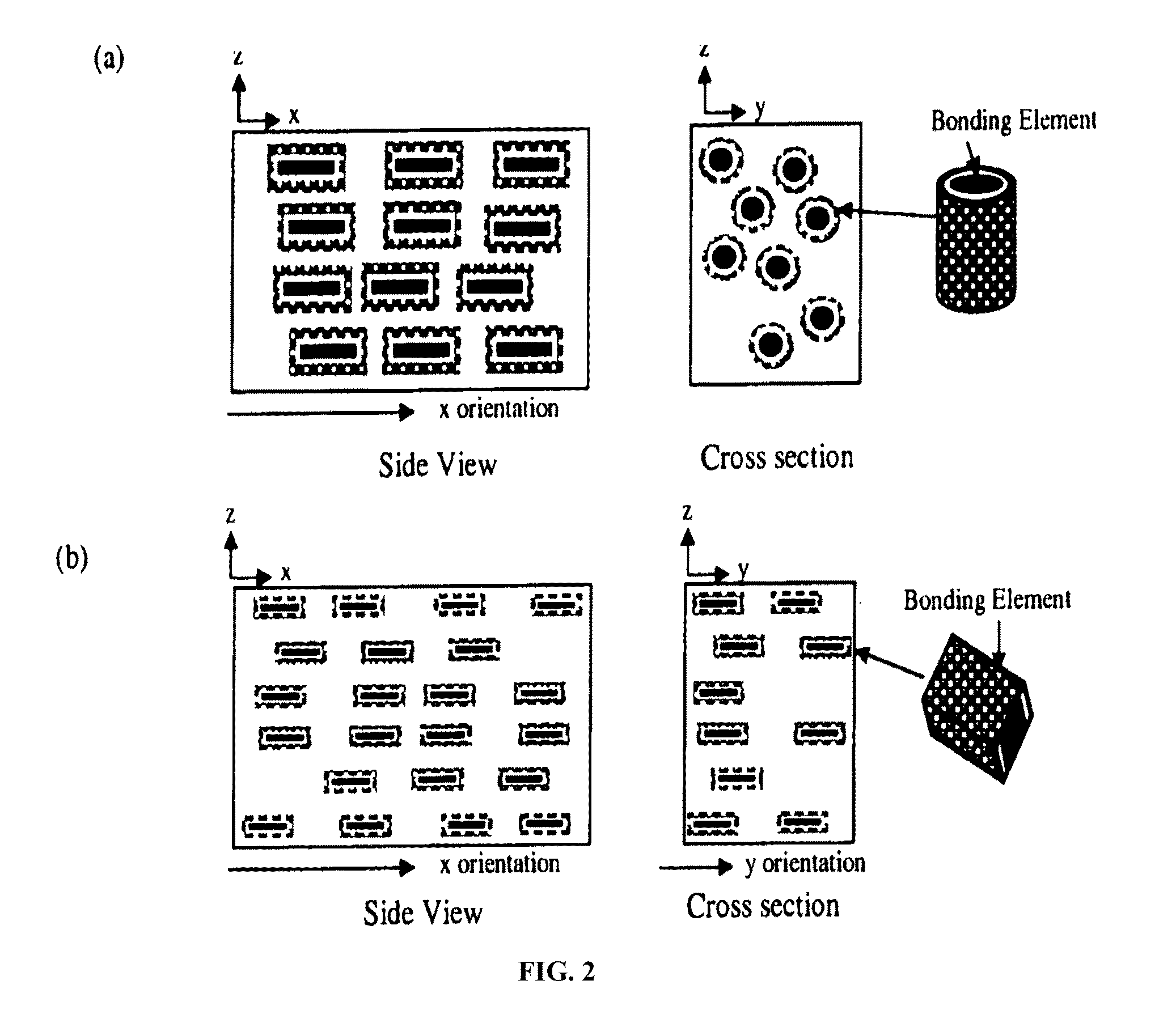

A monolithic honeycomb-type structure useful in particular as a particle filter for exhaust gases from diesel engines has a number of passages that empty into the end faces of said monolith, but are alternately open and sealed. The monolith consists of a porous refractory material that comprises: 70 to 97% by mass of alpha and / or beta crystallographic-type silicon carbide that has at least one particle size and preferably at least two particle sizes, and 3 to 30% by mass of at least one bonding ceramic phase in the form of a micronic powder or particles that are obtained by atomization, comprising at least one simple oxide, for example, B2O3, Al2O3, SiO2, MgO, K2O, Li2O, Na2O, CaO, BaO, TiO, ZrO2 and Fe2O3 and / or at least one mixed oxide, for example, the alkaline aluminosilicates (of Li, Na, or K) or alkaline-earth aluminosilicates (of Mg, Ca, Sr or Ba), clays, bentonite, feldspars or other natural silico-aluminous materials. The production of the monolith comprises a calcination stage under an oxygen-containing atmosphere at a temperature up to 1650° C., but less than 1550° C.

Owner:INST FR DU PETROLE

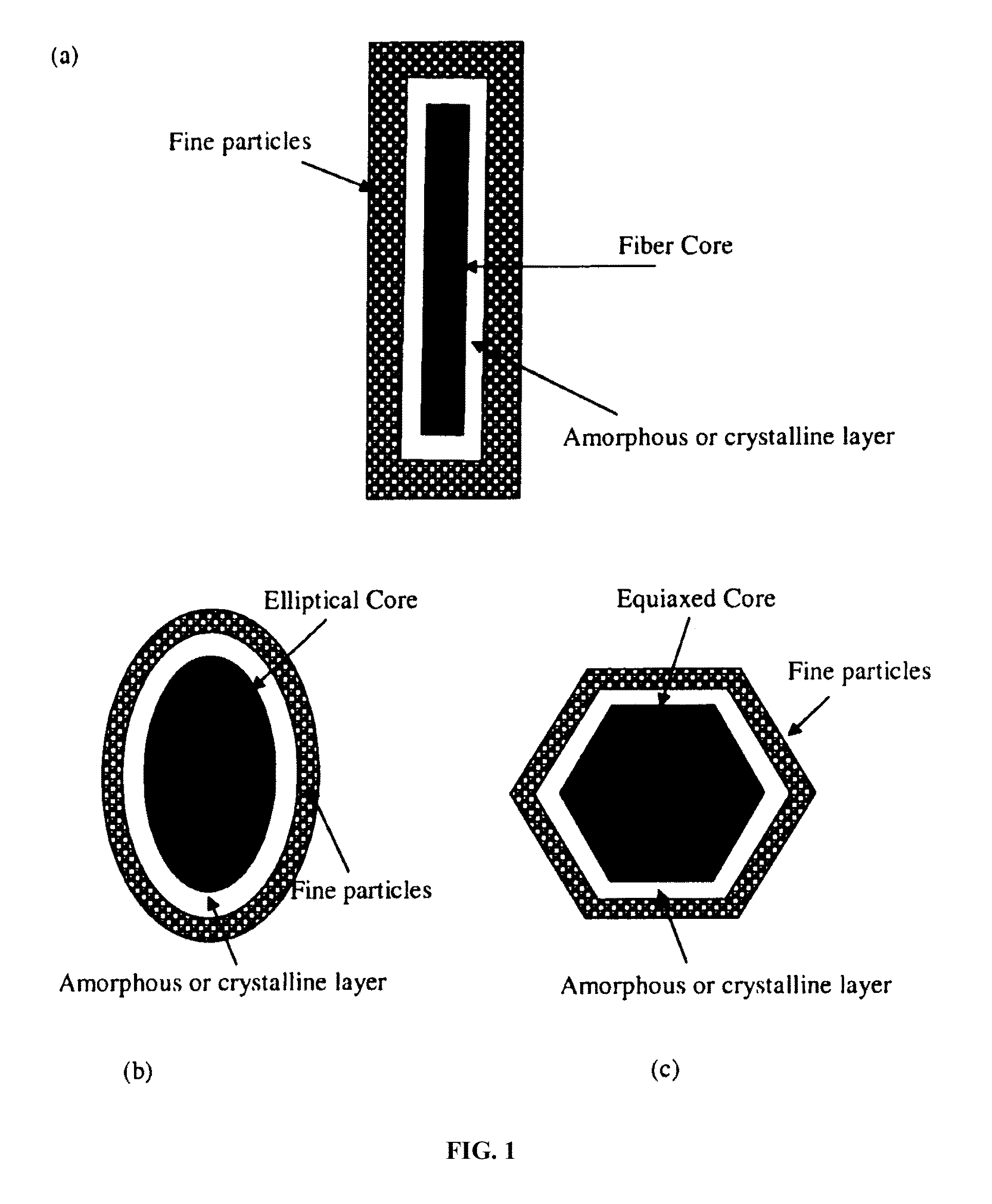

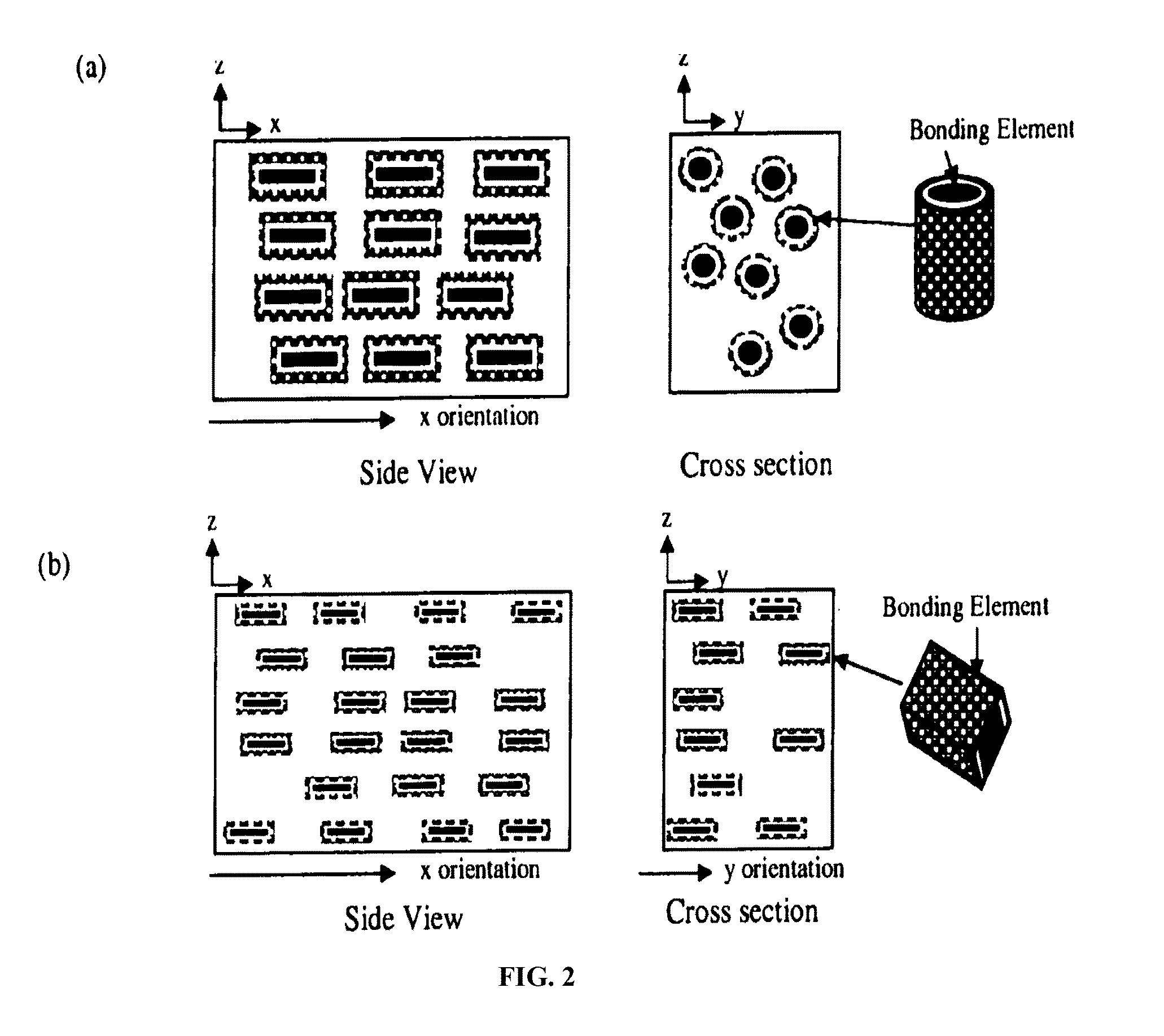

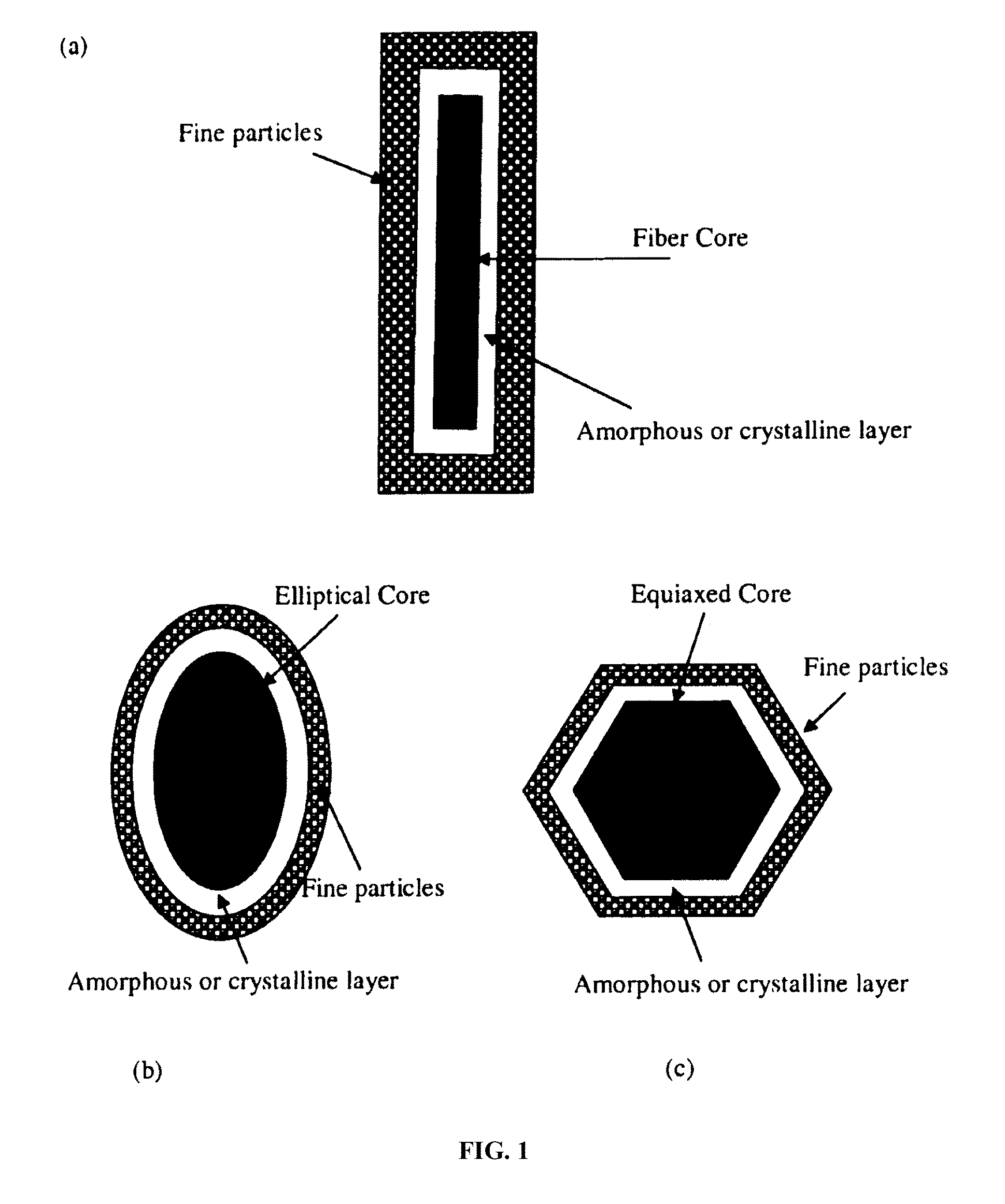

Marble-like composite materials and methods of preparation thereof

InactiveUS20140127450A1Low costIncrease consumptionLayered productsCoatingsCalcium silicateFlexural strength

The invention provides novel marble-like composite materials and methods for preparation thereof. The marble-like composite materials can be readily produced from widely available, low cost raw materials by a process suitable for large-scale production. The precursor materials include calcium silicate and calcium carbonate rich materials, for example, wollastonite and limestone. Various additives can be used to fine-tune the physical appearance and mechanical properties of the composite material, such as pigments (e.g., black iron oxide, cobalt oxide and chromium oxide) and minerals (e.g., quartz, mica and feldspar). These marble-like composite materials exhibit veins, swirls and / or waves unique to marble as well as display compressive strength, flexural strength and water absorption similar to that of marble.

Owner:RIMAN RICHARD E +1

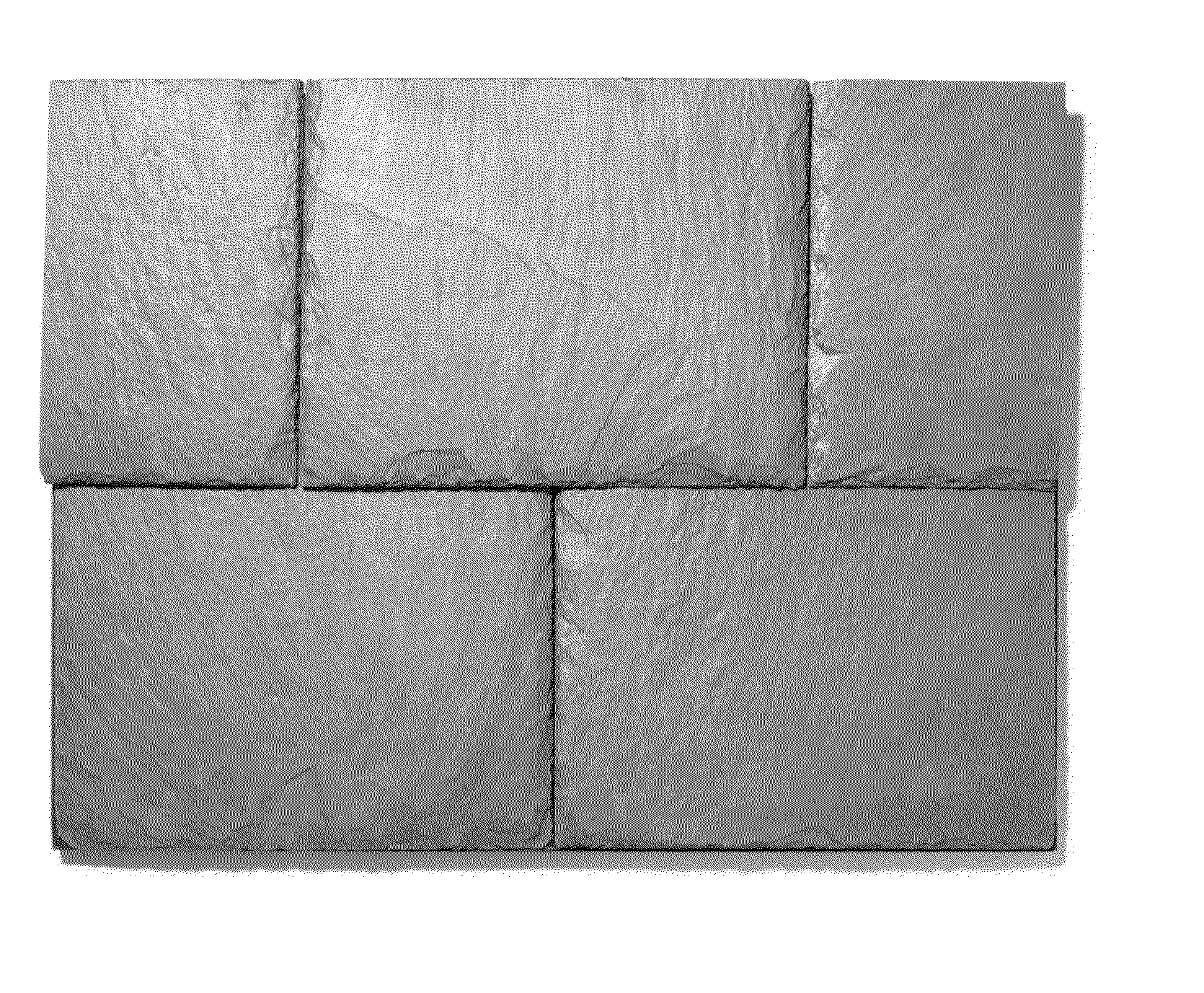

Slate-like composite materials and methods of preparation thereof

InactiveUS20140127458A1Low costIncrease consumptionRoof covering using tiles/slatesRecord information storageCalcium silicateFlexural strength

The invention provides novel slate-like composite materials and methods for preparation thereof. The slate-like composite materials can be readily produced from widely available, low cost precursor materials by a process suitable for large-scale production. The precursor materials include calcium silicate, for example, wollastonite, and particulate filler materials which comprise silicon dioxide-rich materials such as quartz, mica, feldspar, sand and glass. Additives can include calcium carbonate-rich and magnesium carbonate-rich materials. Various additives can be used to fine-tune the physical appearance and mechanical properties of the composite material, such as colorants such as particles of colored materials, such as colored glass, colored sand, and colored quartz particles, and pigments (e.g., black iron oxide, cobalt oxide and chromium oxide). These slate-like composite materials exhibit visual patterns unique to slate as well as display compressive strength, flexural strength and water absorption similar to that of slate.

Owner:ZAMBRZYCKI DAWID +6

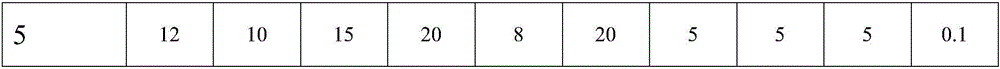

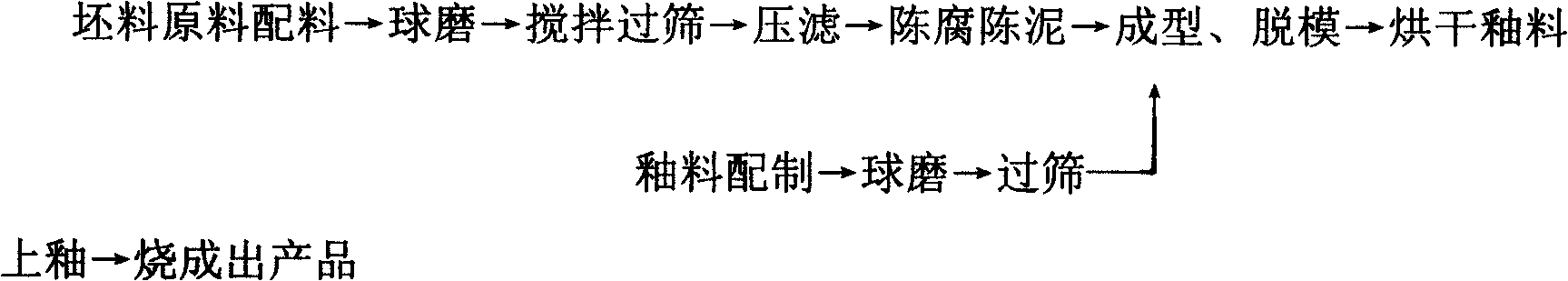

Raw material matting glaze

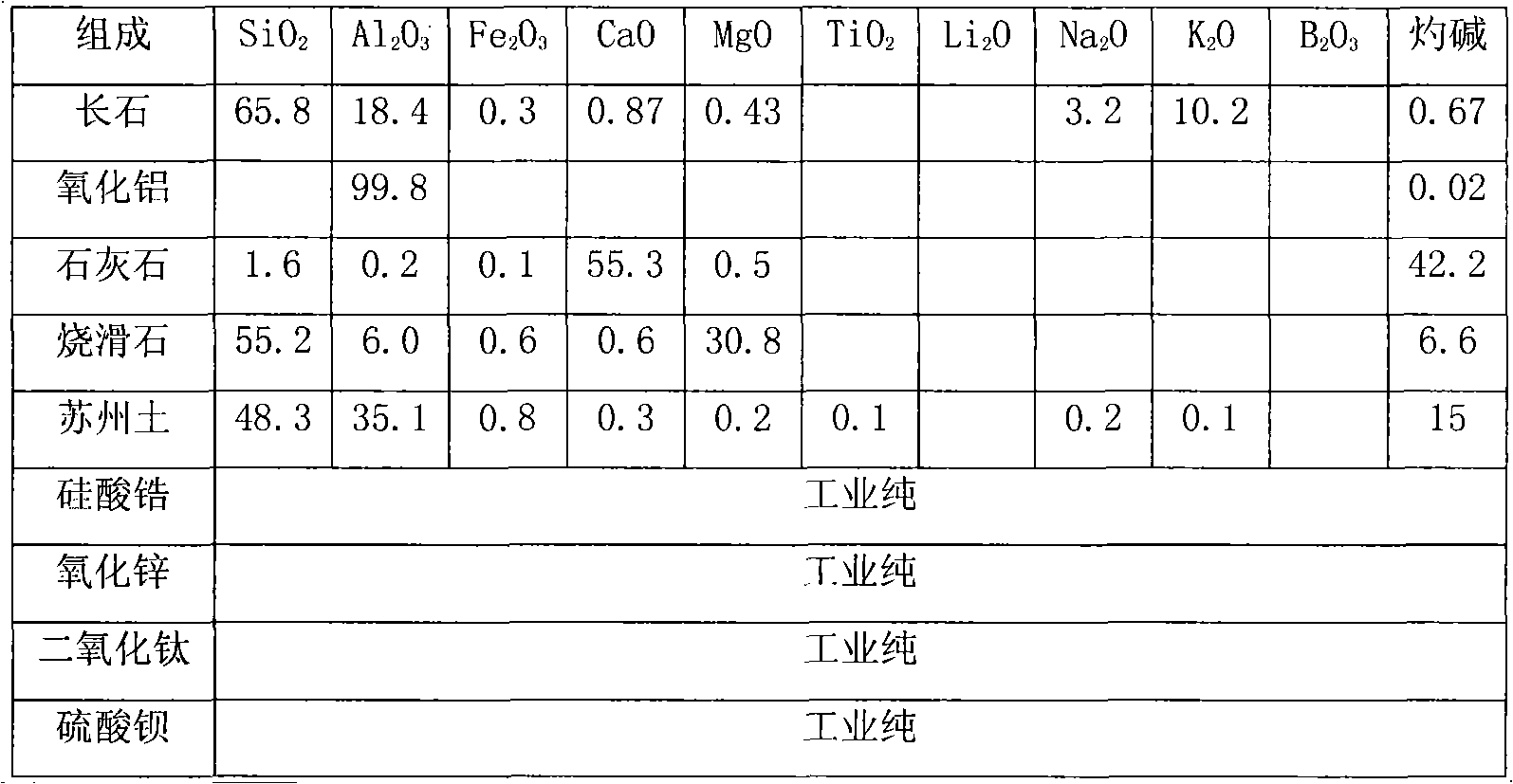

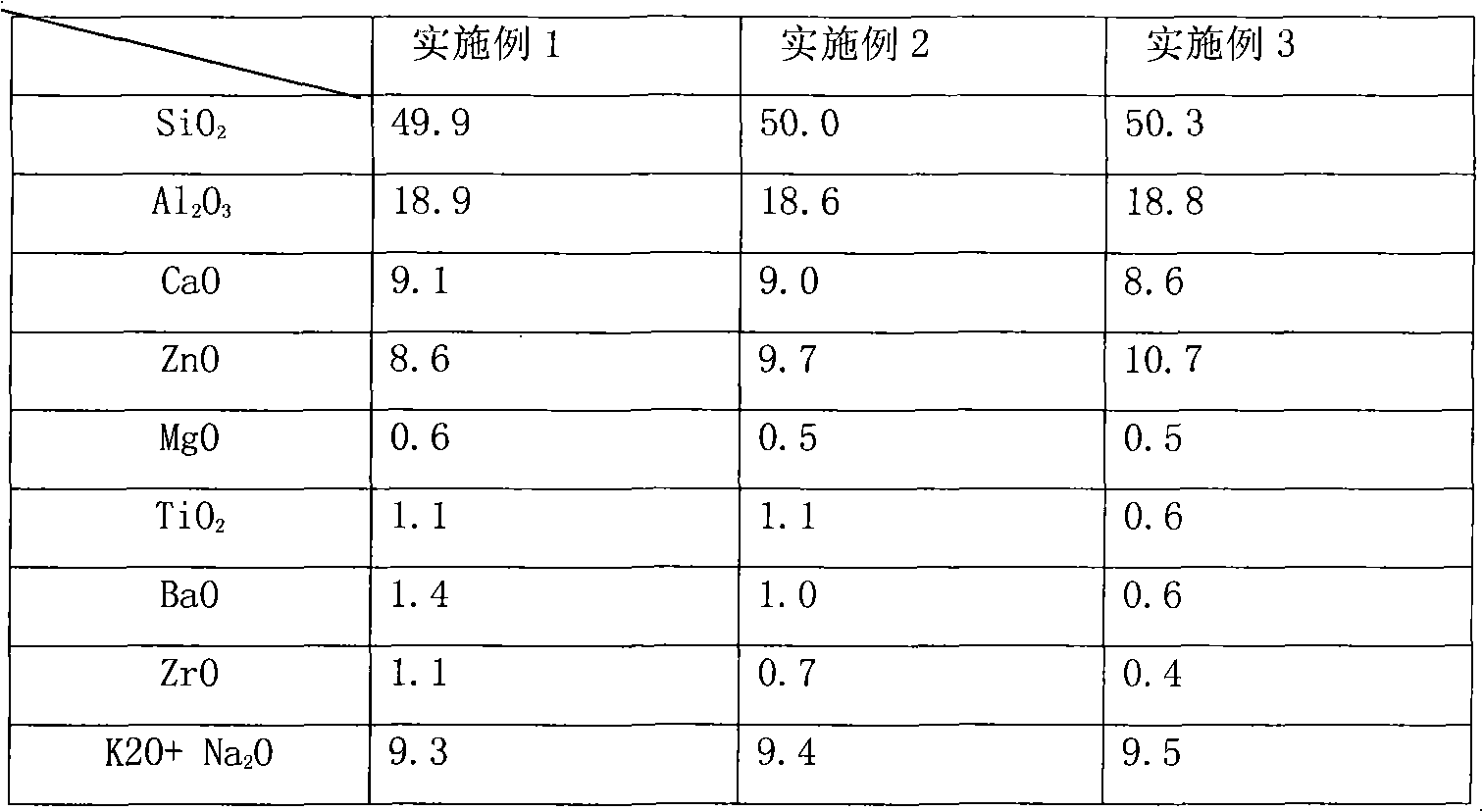

The invention relates to ceramic glaze, in particular to raw material matting glaze used for producing high-quality matting bone china products. The raw material matting glaze comprises the following chemical components in percent by weight: 48-60 percent of SiO2, 12.0-22.0 percent of Al2O3, 5.0-12.0 percent of ZnO, 5-12 percent of CaO, 0.5-2.0 percent of MgO, 0.0-3 percent of BaO, 0.0-3.0 percent of ZrO2, 0.0-2.0 percent of TiO2 and 5.0-15.0 percent of K2O and Na2O. The feldspar of the mineral raw material is mainly introduced. The invention has simple, scientific and reasonable constituent and is the raw material glaze; and the glaze does not need to be made into frits, therefore, energy sources are largely saved; the blank glaze has good adaptability, low firing temperature and wide firing range; the fired finished-product ceramic glaze surface is fine, moist, smooth and soft and does not have strong reflect light; and the glaze surface has strong corrosion resistance, high mechanical strength and good thermal shock stability and is easy to clean, therefore, the glaze is especially suitable for tableware dish-washing machines. The invention thoroughly solves the problems of the gloss and the texture of high-grade bone china.

Owner:张垠

Mineral glass beads for road markings

InactiveCN101857368AHigh reflective brightnessStrong retro-reflective effectSmithsoniteRefractive index

The invention relates to mineral glass beads for road markings, which relates to optical glass beads and solves the problems of low refractive index and poor reflective brightness of the current glass beads for the road markings. The mineral glass beads for the road markings are the optical glass beads, wherein the glass beads are prepared from the following components in part by weight: 40 parts of sandstone, 28 to 32 parts of barite, 1835 to 22.5 parts of diamond, 2.5 parts of datolite, 2 parts of feldspar, 4 parts of mirabilite and 2 parts of smithsonite. The mineral glass beads can be widely used in road markings of airfield runways and high-level roads.

Owner:大庆路通科技有限公司

Method for preparing microcrystalline glass by using blast furnace slag

The invention discloses a method used for the preparation of microcrystalline glass by use of blast furnace slag, wherein blast furnace slag is crushed and sifted out and then is mixed with 0 to 10 wt percent of feldspar and 0 to 5 wt percent of zirconite to make mixed powder material with the weight proportion of blast furnace slag no less than 85 percent; then, the mixed powder material is made into slurry through ball milling mixing and agglomerant is added in after the slurry is dried to complete granulation; and finally, microcrystalline glass is made through direct tabletting crystallizing sintering. The method has the advantages that: (1) ironmaking blast furnace slag is adopted as main material with the addition amount of the blast furnace slag reaching more than 85 percent, which not only saves resources and reduces pollution, but also realizes cycle economy; (2) cheap silicate materials including zirconite and feldspar are adopted as additives; (3) powder tabletting sintering method is adopted to make microcrystalline glass, thereby omitting the complex process of casting moulding after high-temperature fusion of glass or sintering after fusion water quench in the prior glass process and sintering process.

Owner:ZHENGZHOU UNIV +1

Expendable pattern casting (EPC) molding shell paint for casting steel and preparation method thereof

InactiveCN102407275AHigh strengthImprove breathabilityFoundry mouldsFoundry coresFiberPolyvinyl alcohol

The invention relates to an expendable pattern casting (EPC) molding shell paint for casting steel, and the EPC molding shell paint comprises surface a layer fireproof paint and a back layer reinforcing paint, wherein the surface layer fireproof paint comprises the following components in parts by weight: 80-90 parts of high-chromium alundum powder, 10-20 parts of calcined kaolinite, 6-8 parts ofcalcium rectorite powder, 1-3 parts of sodium tripolyphosphate, 3-5 parts of polyvinyl formal solution, 0.3-0.5 part of ethoxylated alkyl sodium sulfate, 0.6-1.0 part of polyether type modified polydimethylsiloxane and 60-75 parts of water; and the back layer reinforcing paint comprises the following components in parts by weight: 75-85 parts of coal gangue sand, 15-25 parts of kaolinite, 3-6 parts of feldspar powder, 8-13 parts of calcium rectorite powder, 8-10 parts of sodium tripolyphosphate, 1.5-2.0 parts of wood fiber and 30-45 parts of water. A molding shell manufactured by the surface layer fireproof paint and the back layer reinforcing paint has the characteristics of high strength and refractoriness, good air permeability and the like.

Owner:HUBEI UNIV OF TECH

Lightweight ceramisite prepared from coal ashes and gasification slag as well as preparation method and application thereof

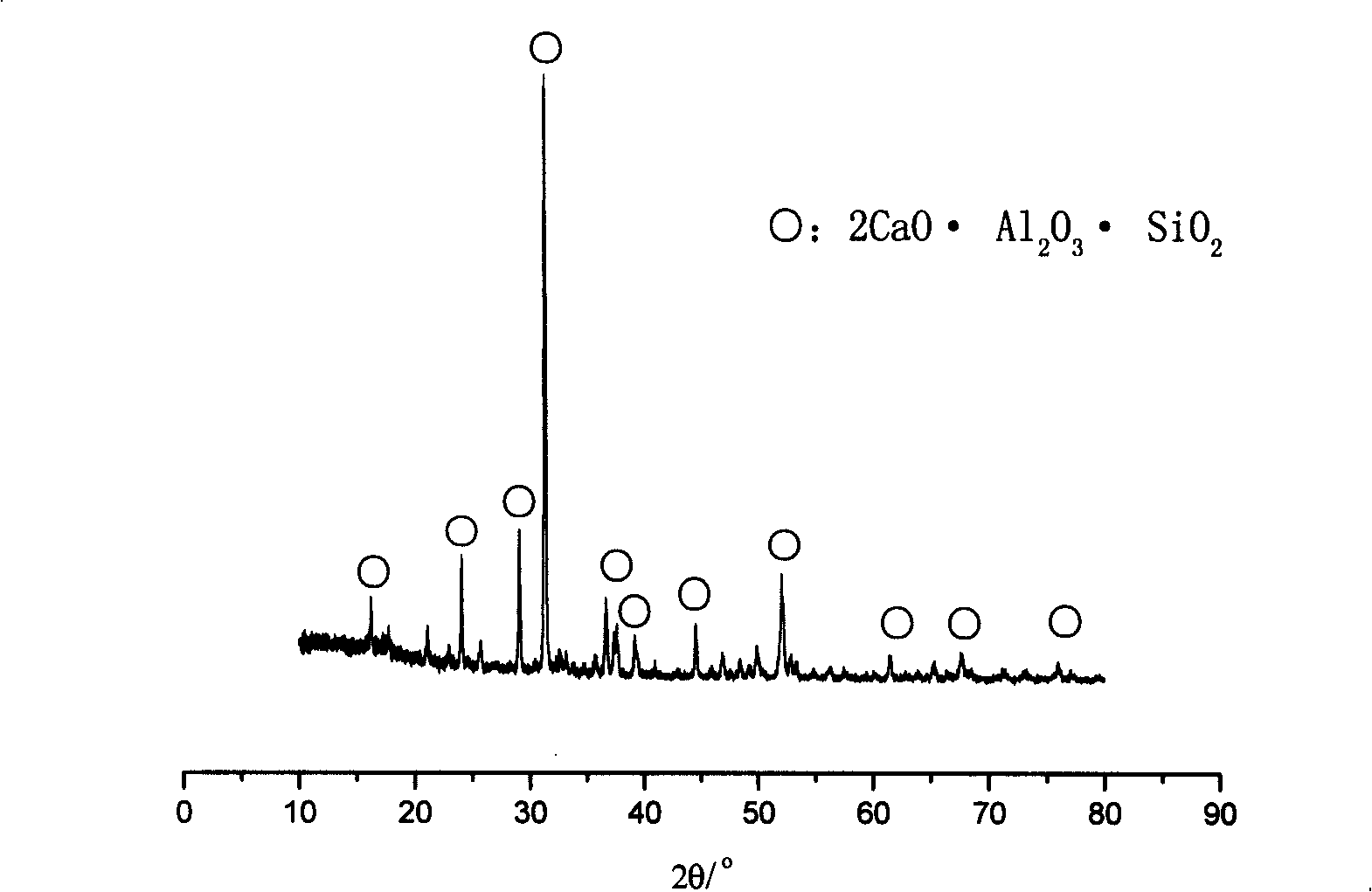

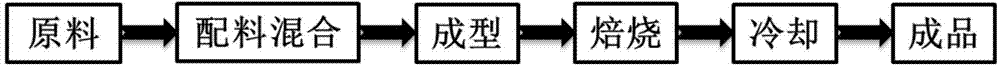

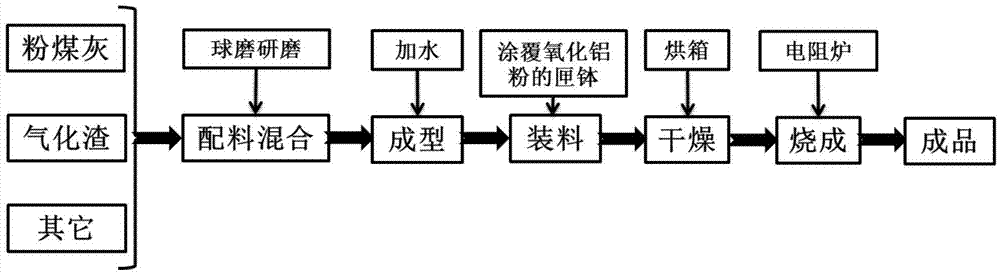

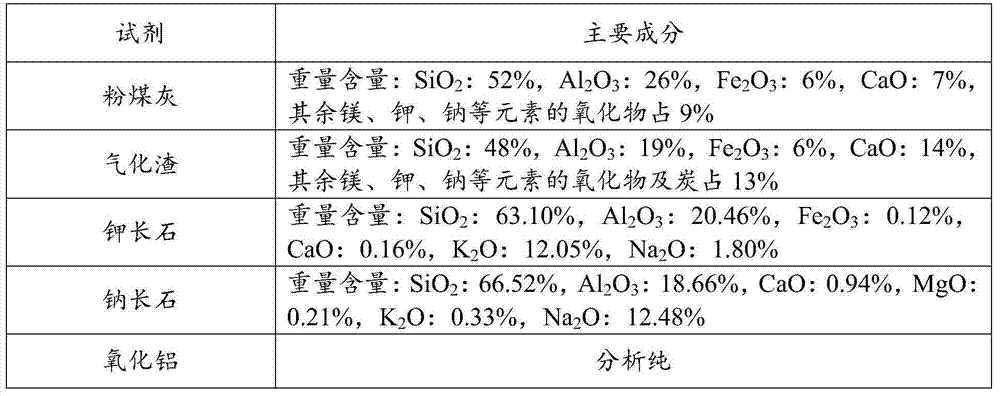

ActiveCN104774023ASignificant environmental benefitsImprove performanceSolid waste disposalCeramicwareSlagExpanded clay aggregate

The invention relates to the technical field of building materials, and in particular relates to lightweight ceramisite prepared from coal ashes and gasification slag as well as a preparation method and an application thereof. The lightweight ceramisite is prepared from the following raw materials with the following components in parts by weight: 100 parts of base materials comprising 40-90 parts of coal ashes, 10-30 parts of gasification slag, 0-20 parts of potassium feldspar and 0-20 parts of albite; and 0-4 parts of additional auxiliaries which are selected from one or two of semicoke or silicon carbide, wherein the coal ashes account for 40-90%, and the gasification slag particles account for 10-30%; and the sintering temperature is 1120-1200 DEG C, the energy consumption is reduced, the raw material distribution is relatively wide and the raw materials are easily available. The lightweight ceramisite has bulk density lower than or equal to 700 kg / m<3>, is smaller in weight, higher in strength, wider in raw material distribution and easier to obtain, and the barrel pressure strength can be higher than 10 MPa.

Owner:北京大学包头创新研究院

Wood-like composite materials and methods of preparation thereof

InactiveUS20140342124A1High compressive strengthLow water absorptionConstruction materialNatural patternsCalcium silicateFlexural strength

The invention provides novel wood-like composite materials and methods for preparation thereof. The wood-like composite materials can be readily produced from widely available, low cost precursor materials by a production process that involves casting in a mold that is suitable for large-scale production. The precursor materials include calcium silicate, for example, wollastonite, and particulate filler materials which comprise silicon dioxide-rich materials such as quartz, mica, feldspar, sand and glass. Additives can include calcium carbonate-rich and magnesium carbonate-rich materials. Various additives can be used to fine-tune the physical appearance and mechanical properties of the composite material, such as colorants such as particles of colored materials, such as, and pigments (e.g., black iron oxide, cobalt oxide and chromium oxide). These wood-like composite materials exhibit visual patterns unique to wood as well as display compressive strength, flexural strength and water absorption superior to that of wood.

Owner:ZAMBRZYCKI DAWID +4

Heat curable thermosetting luminescent resins

InactiveUS6905634B2Improve luminous performanceImprove propertiesLuminescent paintsElectroluminescent light sourcesSodium BentoniteAlkaline earth metal

Luminescent polymers are prepared from thermosetting unsaturated polyesters, suspending fillers and phosphorescent pigments and utilized to make gel coated articles and molded, cast and fiberglass reinforced plastic (FRP) articles. The luminescent polymers show bright and long-lasting photoluminescent afterglow, strong thermostimulation of afterglow by heat and electroluminescent properties. The preferred thermosetting unsaturated polyester resins are prepared by condensing mixtures of ethylenically unsaturated and aromatic dicarboxylic acids and anhydrides with dihydric alcohols and a polymerizable vinylidene monomer. Preferred suspending fillers and thixotropic modifiers include silica, microspheres, glass fibers and other short fibers, nepheline syenite, feldspar, mica, pumice, magnesium sulfate, calcium carbonate, bentonite and the various clays and thixotropic modifiers and mixtures thereof. Preferred phosphorescent pigments include alkaline earth aluminate phosphors, zinc sulfide phosphors and mixtures of these phosphors.

Owner:BURNELL JONES PETER

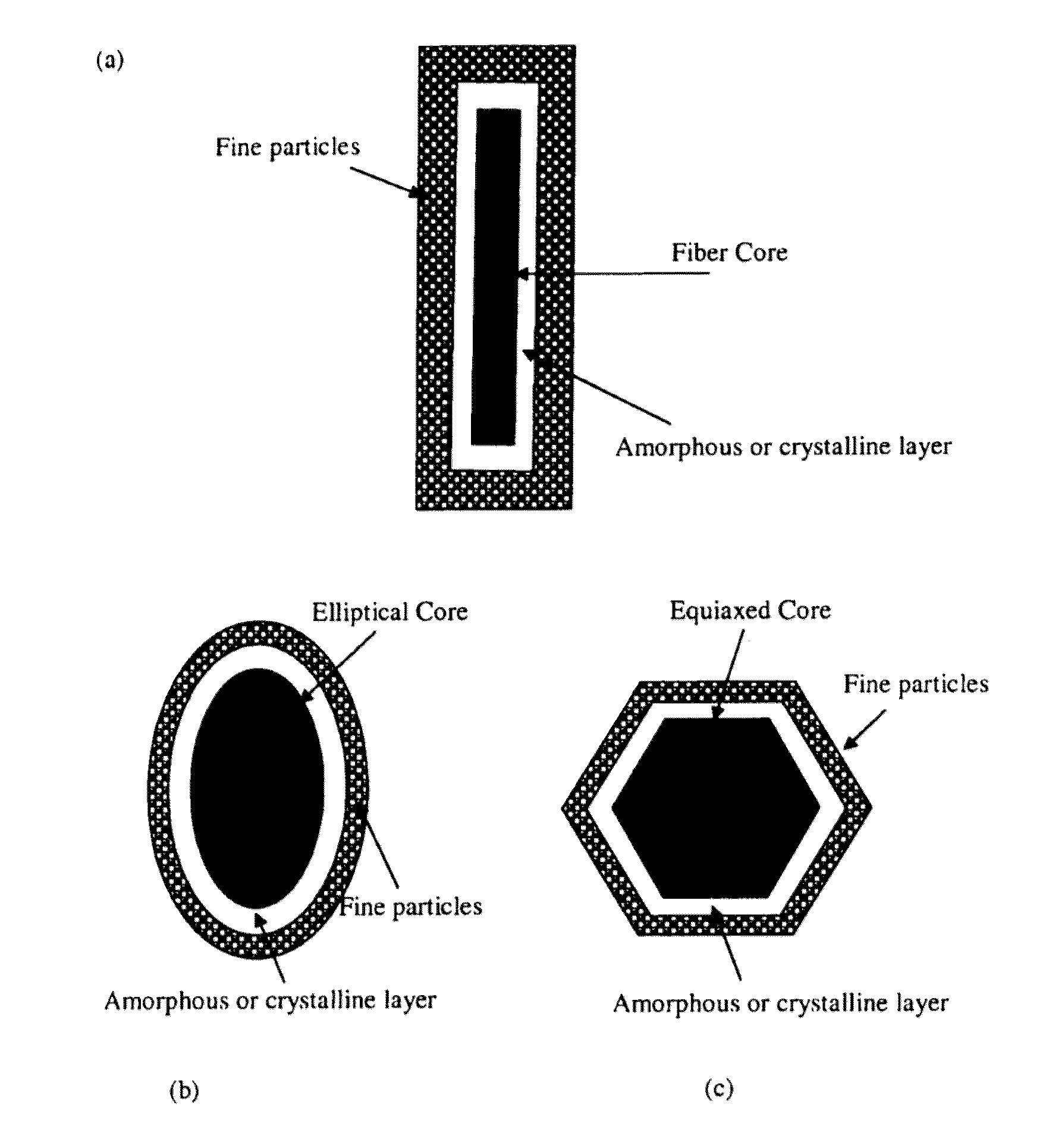

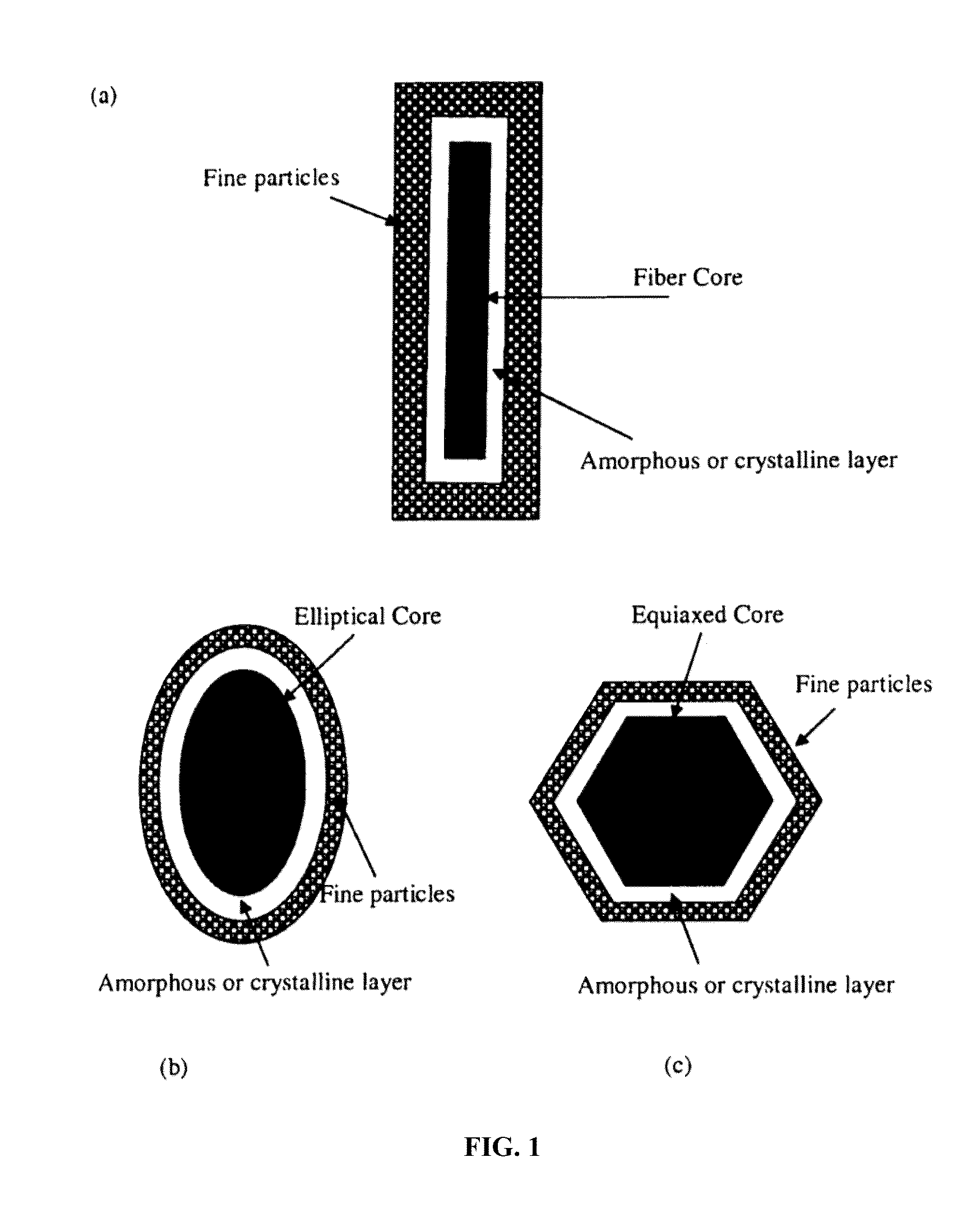

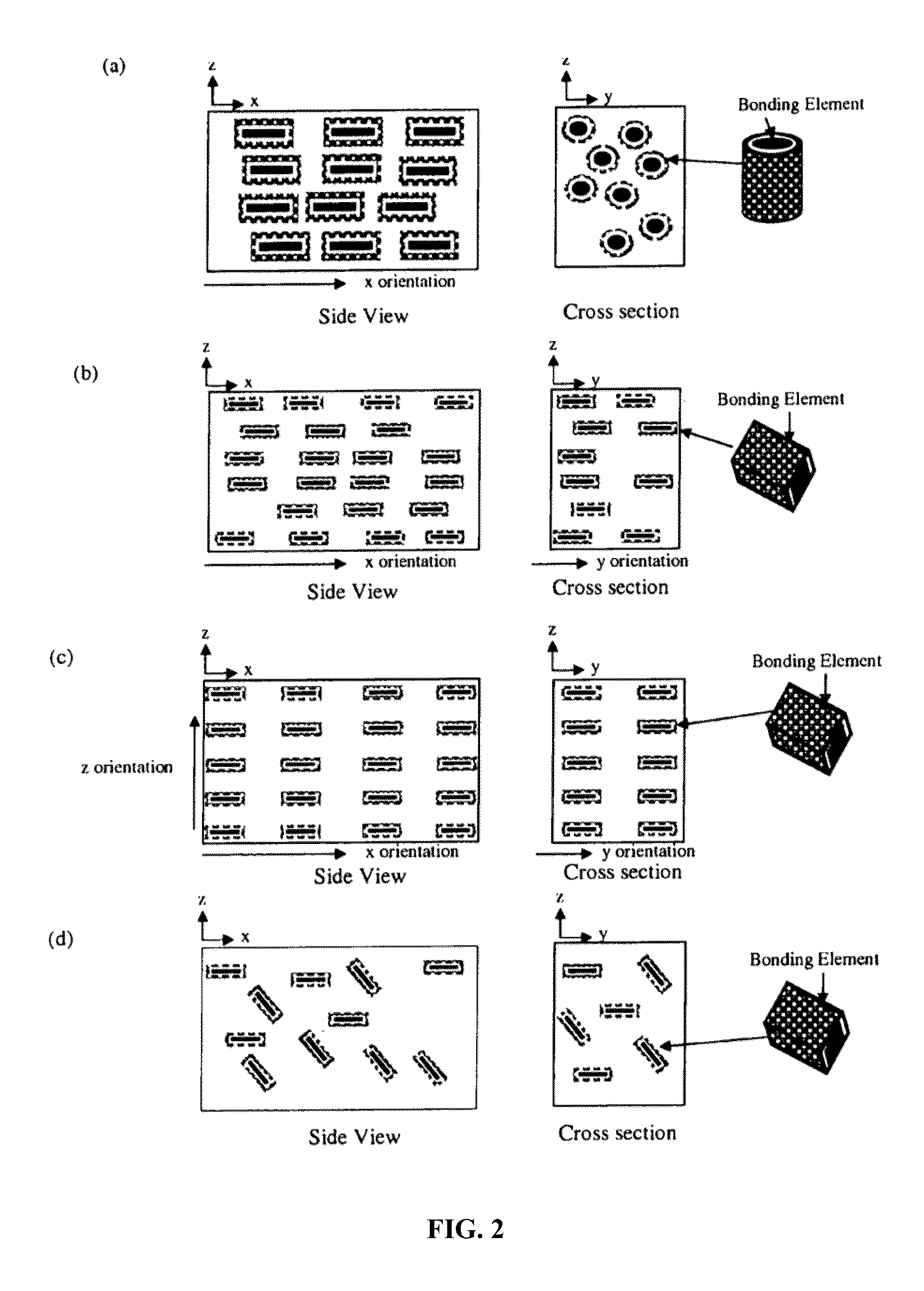

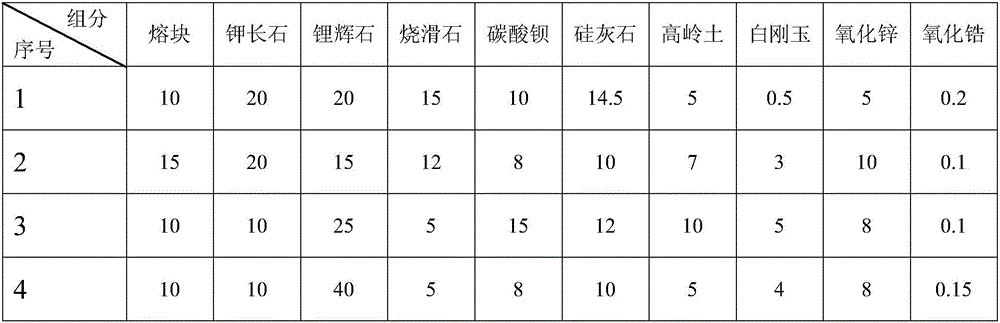

Wear-resistant transparent glaze and method for preparing glazed tile by utilizing same

The invention provides a wear-resistant transparent glaze and a method for preparing a glazed tile by utilizing the same. According to the components of the wear-resistant transparent glaze, spodumene, frit, potash feldspar, calcinedtalc, barium carbonate and zinc oxide are adopted as a fluxing agent, and the Si / Al ratio is adopted by utilizing wollastonite and kaolin. Meanwhile, the wear-resistant performance of the glaze is improved by adopting white corundum and zirconium oxide as a wear-resistant agent. The weight percentage of zirconia relative to the total weight of the raw materials of the wear-resistant transparent glaze is smaller than or equal to 0.2%. The above wear-resistant transparent glaze is applied onto the surface of a green body, and then the green body is polished after being sintered in a furnace to obtain a glazed tile product. Compared with the prior art, the wear-resistant transparent glaze is excellent in wear resistance, and can be used for preparing ceramic tiles with thin glaze layers. The decorative properties and the anti-pollution characteristics of obtained products are greatly improved. Meanwhile, the manufacturing cost of products is lower.

Owner:FOSHAN DONGPENG CERAMIC +3

Method for preparing no-foaming and no-deformation ceramics by utilizing ceramic waste

InactiveCN101671160ARealize green productionEmission reductionSolid waste disposalCeramic materials productionFeldsparMaterials science

The invention discloses a method for preparing no-foaming and no-deformation ceramics by utilizing ceramic waste, comprising the following steps: all raw materials are mixed by weight percentage: 1-99percent of ceramic waste, 0-40 percent of ceramic clay, 0-30 percent of quartz, 0-35 percent of feldspar and 1-50 percent of aluminum oxide or aluminous rich matter; water is added by 50-150 percentof total weight of the raw materials, and 0.5-5 percent of grinding aids and 0.5-5 percent of binders are added to carry out ball-milling, the no-foaming and no-deformation ceramics can be prepared bydrying, formation and sintering. The technology provide by the invention not only solves the problem of the treatment of a great amount of ceramics in ceramic industry, but also solves excessive consumption problem of raw material resource in the ceramic industry, thereby greatly reducing the waste discharge in the ceramic industry and reducing environmental pollution caused by accumulation and land filling of the ceramic waste. The technology has the advantages of high waste utilization rate, simple process and low cost.

Owner:SOUTH CHINA UNIV OF TECH

Light glazed ceramic tile with anion function and low water absorption and production method thereof

The invention discloses a light glazed ceramic tile with anion function and low water absorption and a production method thereof. The formula of the glazed ceramic tile is as follows: fancy glaze containing 0.1-90 portions of stamp powder, 0.0-190 portions of pigments, 100-200 portions of stamp-pad ink and 0.01-15 portions of anion material; a green body containing 10-45 portions of ceramic shraff, 15-20 portions of clay, 10-20 portions of feldspar, 30-50 portions of sandstone, 30-50 portions of water, 0.0-0.3 portion of lignin, and 0.0-1.0 portion of sodium tripolyphosphate; and conventionalcover glaze. The production method comprises the following steps: stirring and screening the fancy glaze materials to obtain the fancy glaze; conducting ball-milling, screening and pelleting after materials of the green body are mixed, and then conducting compression moulding and drying, glazing, embossing, and sintering for 50-55 minutes at the temperature of 1195-1205 DEG C, thus obtaining the product. The ceramic tile has the characteristics of being light, low in water absorption, high in mechanical strength, small in coefficient of thermal conductivity, strong in antifouling capability and the like, can continuously release anions with the number of more than 500 / cm3 in space, and can be widely applied to decoration of building outer walls and home furnishing spaces.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD +2

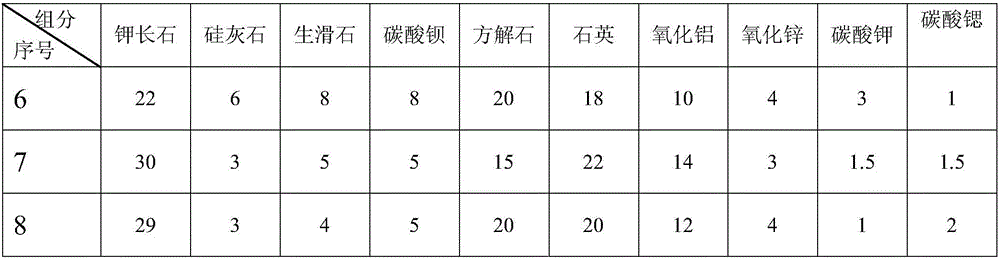

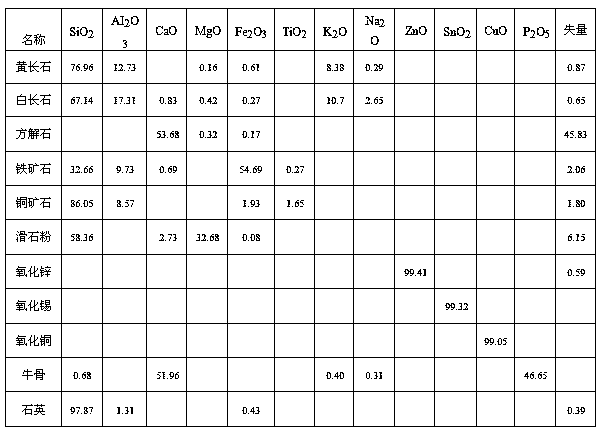

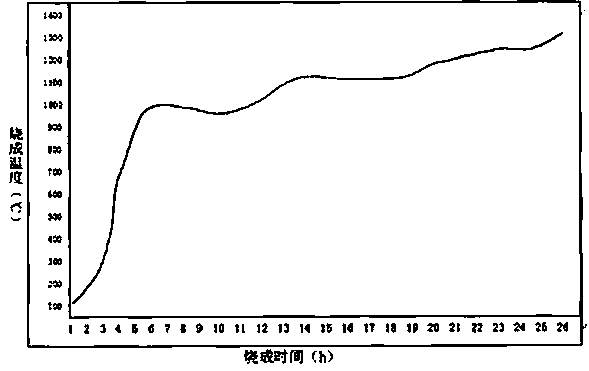

Novel tang-dynasty jun porcelain glaze and manufacturing process thereof

The invention discloses novel tang-dynasty jun porcelain glaze. Yellow feldspar, white feldspar, calcite, quartz, copper ore and iron core are used as glaze raw materials; the yellow feldspar, the white feldspar, the calcite, the quartz, the talcum powder, the copper ore, the zinc oxide, the tin oxide, the copper oxide and ox bone are used as ground coat raw materials; the burnt jun porcelain glaze satisfies the requirement of the tang-dynasty jun porcelain glaze technology, so that the glaze color is natural and variable.

Owner:JIA COUNTY RENSHI CERAMIC IND CO LTD

Core glaze for matte sand streak enamel glaze and production method thereof

The invention discloses a core glaze for a matte sand streak enamel glaze, belonging to the technical field of enamel glazes. The core glaze comprises, by weight, 20 to 35% of quartz sand, 20 to 30% of magnesium oxide, 18 to 28% of soda ash, 8 to 15% of potash feldspar, 2 to 5% of borax, 1 to 2% of fluorite, 1 to 3% of calcium carbonate, 2 to 5% of trisodium phosphate and 0.02 to 0.1% of cobalt oxide. Through cooperative usage of the core glaze with commercially available bright glazes, colorants and the like, matte sand streak glaze products of different colors and different texture can be conveniently and rapidly at a low temperature in a small scale.

Owner:娄底湘信新材料科技有限公司

Formulation for medicinal neutral boron silicate glass

The present invention is one kind of neutral borosilicate glass for medicine production. The neutral borosilicate glass has recipe comprising quartz sand 168-178 Kg, feldspar powder 14.7-18.7 Kg, borax pentahydrate 49-51 Kg, sodium carbonate 8-12 Kg, barium carbonate 8.6-9.4 Kg, sodium nitrate 0.4-0.6 Kg, calcite 1-2 Kg, fluorite 0-4 Kg, potassium carbonate 8.5-9.5 Kg, salt 0.8-1.6 Kg, cerium oxide 0.5-0.9 Kg and cullet 120 Kg. It has high chemical stability, high hydrolysis stability, few alkali metal volatilizations, simple production process and low cost.

Owner:东营力诺玻璃制品有限责任公司

Technique for separating mineral from weak magnetic separation iron tail sand

InactiveCN101219412AProduction process specificationLow costElectrostatic separationFlotationApatiteNon magnetic

The invention relates to a method used for separating minerals from weak magnetic iron tails, which is divided into six stages: primary sorting of strong magnetic minerals, separation of strong magnetic minerals, separation of weak magnetic minerals, separation of non-magnetic minerals, treatment of ore pulp water during the ore dressing process and treatment of finish tail sand. According to the magnetic susceptibility differences, specific gravitydifferences and floating differeces between minerals, magnetite, vanadium titano-magnetite, mixed ore of apatite and xenotime and hematite feldspar concentrate can be separated from the weak magnetic iron by using techniques of crude separation with a strong magnetic separator, refine separation with a weak magnetic separator, gravity separation, floatation, electric separation, etc. The method has advantages of standard production technique, low cost for industrialized production, great variety of separated minerals, stable quality and high separating efficiency, thereby having significant social and economic benefits.

Owner:冯云善

Colorful ceramic and preparation method thereof

The invention provides colored ceramics and a preparation method thereof. Ceramic mud for the colored ceramics at least comprises the following compositions in weight percentage: 20 to 35 percent of kaoline, 60 to 70 percent of at least two of pottery stones, lithium pottery stones, feldspar and quartz, 0.2 to 6 percent of coloring matter, and 1 to 5 percent of nanometer quartz. The method for preparing the colored ceramics comprises the following: a step of pulp injection molding, in which part of colored mud cake or colored mud strip is mixed with liquefacient with 0.3 to 0.8 percent of total amount for pulping, and the mud which is screened from a screen of between 80 and 120 meshes is injected into a mold to produce a hollow or solid briquette; and a step of glazing and maturing, in which the briquette which is manufactured by pulp injection molding or plastic molding is cemented and dried according to creativities, and are directly applied with clear glaze, and the glazed briquette body is placed in an oxydizing flame roller kiln or an electrical kiln for 1 to 4 hours at a temperature of between 1,150 and 1,200 DEG C for maturing. The method can not only reduce clinkering cost, but also improve the moisture retention, bonding performance and corrosion resistance of strong ceramic mud, and further show energy conservation and environmental protection.

Owner:JINGDEZHEN HAHANI CERAMIC CULTURE DEV

Flux-cored wire for austenitic stainless steel welding

ActiveCN102451961AReduce carbon contentImprove oxidation capacityArc welding apparatusWelding/cutting media/materialsManganeseRutile

The invention discloses a flux-cored wire for austenitic stainless steel welding. The flux-cored wire consists of a flux core and an external steel belt; the external steel belt is an austenitic stainless steel belt of which the carbon content is less than 0.025 percent; the carbon content of the flux core is not greater than 0.04 percent and carbon accounts for 18.0 to 24.0 percent based on the total weight of the flux-cored wire; the flux core comprises the following components in percentage by weight: 18.5 to 25.0 percent of metal chromium powder, 8.0 to 10.0 percent of metal nickel powder, 2.0 to 5.0 percent of electrolytic manganese metal, 1.0 to 3.0 percent of aluminum magnesium alloy, 28.0 to 35.0 percent of rutile, 3.0 to 5.0 percent of quartz, 2.0 to 5.0 percent of zircon sand, 2.0 to 5.0 percent of feldspar, 1.0 to 2.0 percent of cryolite, 2.0 to 5.0 percent of arc stabilizer and the balance of iron powder; and the arc stabilizer consists of K2O, Na2O and TiO2 in a weight ratio of (6.0-8.0):(8.0-10.0):(68.0-70.0), and the water content is not greater than 400 ppm.

Owner:CHINA JINGYE ENG TECH CO LTD +1

Ru agate glaze and processing method and application thereof

The invention discloses a Ru agate glaze, which contains the following components by weight parts: 6 to 26 parts of agate, 40 to 65 parts of feldspar, 10 to 23 parts of calcite, 13 to 28 parts of black limestone, 3 to 8 parts of limonite, 2 to 4 parts of talcum and 5 to 10 parts of chestnut ash. The invention also discloses a processing method for the Ru agate glaze and the application of the Ru agate glaze on Ru porcelains, and also discloses a Ru porcelain. The basic tones of the glaze of the Ru porcelain fired with the Ru agate glaze are green and blue, and therefore the glaze can present the deep colors of azure, cyan and bluish white as well as the bright, transparent colors of pea green, light green and light greenish blue; the texture of the porcelain body is fine and dense, the porcelainizing degree is high, the water absorption does not exceed 1.2 percent, and the sound is silvery when the product is knocked; the thermostability is good, and defects, such as through cracks and leakage, do not exist.

Owner:郭秀贞

Heat resisting red porcelain chinaware

The invention discloses a heat-resistant purple sand ceramic tool. The manufacture material includes stock and glaze; wherein, the stock is formed by the following components according to weight percentage: 1 to 15 percent of purple sand soil, 25 to 38 percent of triphane, 5 to 30 percent of bauxite clay, 5 to 30 percent of kaolin, 2 to 6 percent of talc, 5 to 20 percent of alum clay, 5 to 20 percent of grog and 5 to 25 percent of attaclay; the glaze is formed by the following components according to weight percentage: 20 to 35 percent of paste, 10 to 25 percent of petalite, 15 to 25 percent of grog, 8 to 15 percent of clinker, 12 to 25 percent of yellow earth, 6 to 9 percent of iron red, 0 to 0.15 percent of trimeric sodium phosphate and 1 to 2 percent of water glass. The adoption of triphane in the material of ceramics can largely enhance the heat-resistant capability, and the ceramics can be heated by electricity or fire and even the firing without water causes no crack. The heat-resistant purple sand ceramics can be adopted either as tableware or as drinking vessel.

Owner:熊禄生

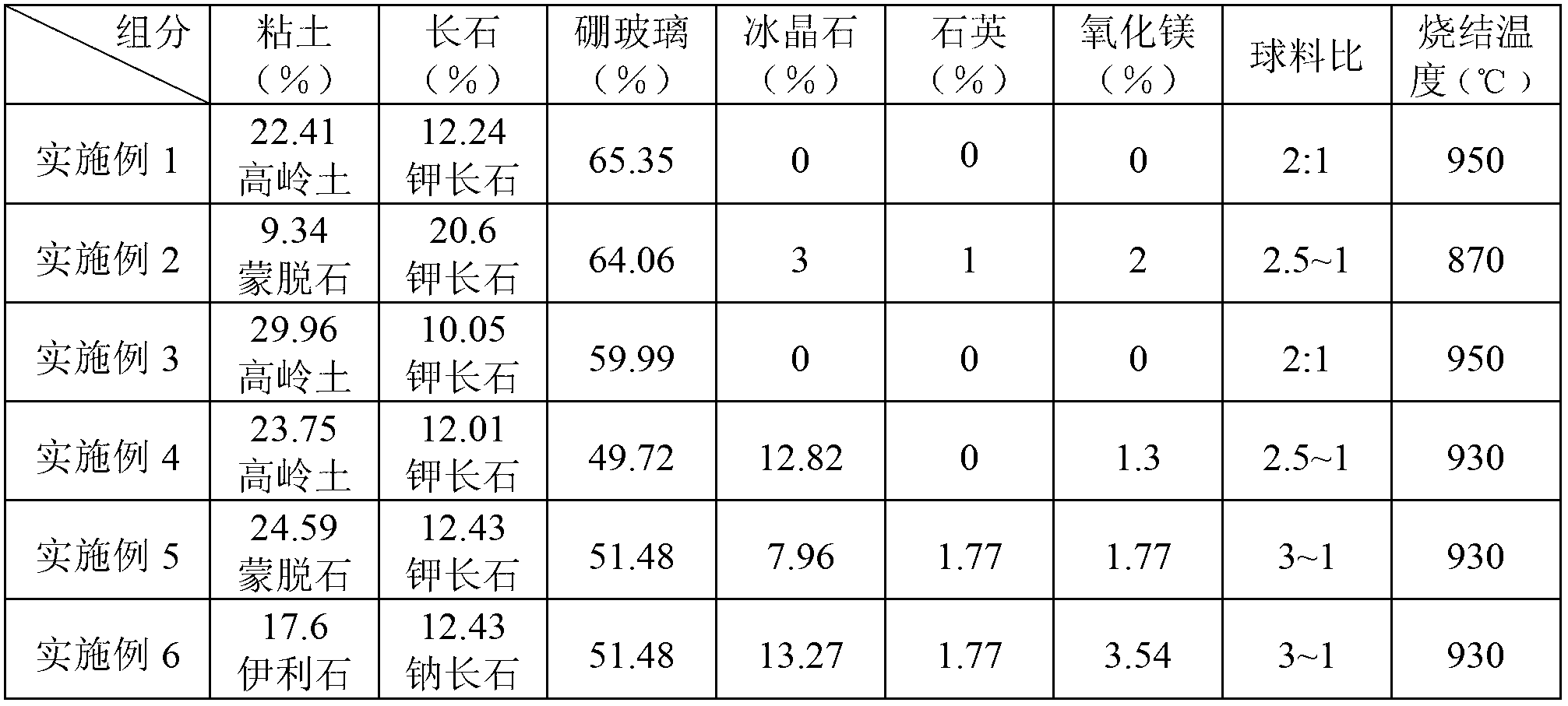

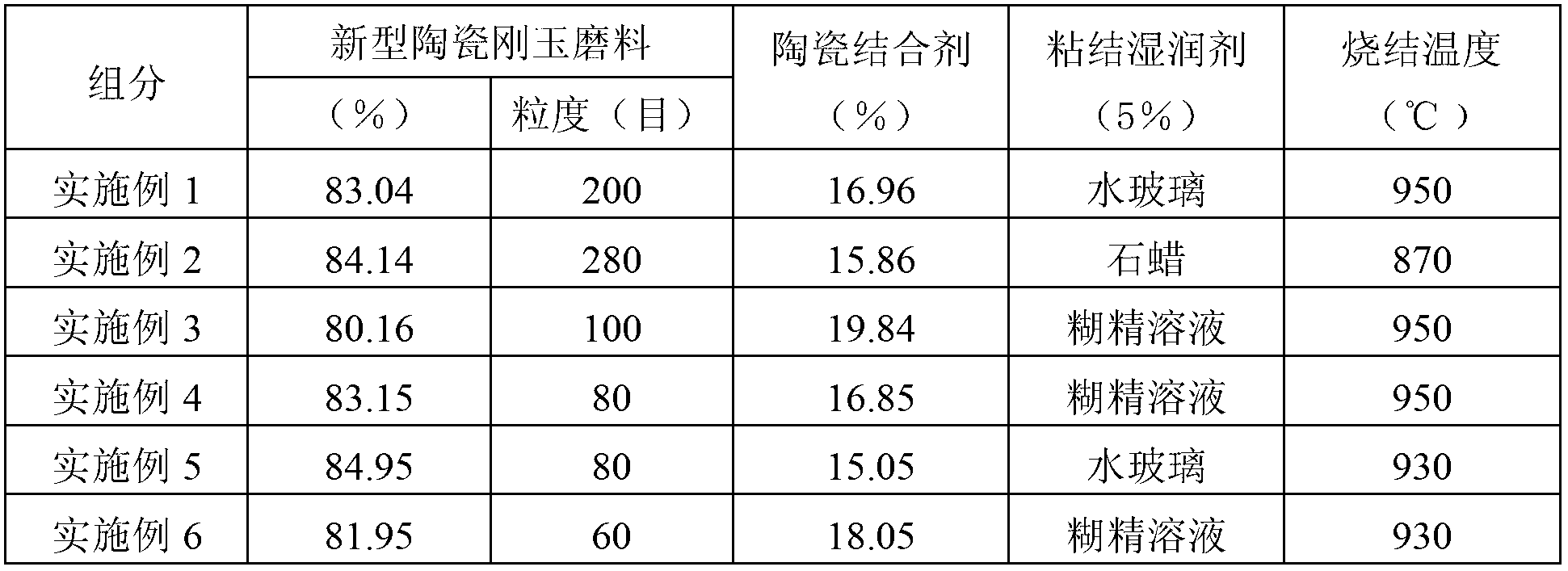

Novel ceramic corundum grinding tool of low-temperature and high-strength ceramic bonding agent and preparation method thereof

InactiveCN102699825ASharp abrasiveStrong cutting forceAbrasion apparatusGrinding devicesGrinding wheelBorosilicate glass

The invention discloses a novel ceramic corundum grinding tool of a low-temperature and high-strength ceramic bonding agent. The grinding tool consists of the following components in percentage by mass: 15 to 20 percent of ceramic bonding agent, 80 to 85 percent of novel ceramic corundum grinding material and 5 percent of bonding wetting agent, wherein the bonding agent consists of the following components in percentage by mass: 10 to 30 percent of clay, 10 to 30 percent of feldspar, 45 to 70 percent of borosilicate glass, 0 to 15 percent of kryocide, 0 to 5 percent of quartz and 0 to 5 percent of magnesium oxide. The novel ceramic corundum grinding tool can be sintered at the sintering temperature of 850 to 980 DEG C, and by the grinding tool, a grinding wheel can be safely used at the rotation speed of 80 to 100m / s. The single-travel feeding amount of the grinding tool can be over 0.3mm, the metal removing rate is over 3 times that of an ordinary corundum grinding wheel, the grinding interval time is 3 to 5 times that of the ordinary corundum grinding wheel, the service life is 5 to 10 times that of the ordinary corundum grinding tool, and the novel ceramic corundum grinding tool is superior to a super-hard grinding tool and the ordinary grinding tool in performance and price.

Owner:TIANJIN UNIV

Foamed ceramic material and preparation method thereof

The invention discloses a foamed ceramic material and a preparation method thereof. The method for preparing the foamed ceramic material comprises the step of: crushing, forming, firing and swelling an ingredient composed of tailings, feldspar, a foaming agent, a foaming regulator and a fluxing agent, wherein the tailings are at least one of iron ore tailings with 60 weight percent of silicon oxide, quartz tailings, kyanite tailings and bauxite tailings. According to the method for preparing the foamed ceramic material, the foamed ceramic material can be prepared by the tailings, so that the high added values of the tailings are utilized. In addition, the prepared foamed ceramic material has the advantages of excellent performances like small density, high strength, low water absorption rate, low heat conduction rate, no combustion, long service life and the like.

Owner:NEW METALLURGY HI TECH GRP

Glass fiber blanket and producing method thereof

ActiveCN103103695AImprove adhesionGood peeling effectGlass making apparatusNon-woven fabricsGlass fiberFlat glass

The invention discloses a glass fiber blanket and a producing method thereof. The method comprises the steps of mixing the following components , by mass, 35-40 parts of silica flour, 5-12 parts of feldspar, 9-14 parts of borax, 1-3.5 parts of calcite, 6-8 parts of dolomite, 11-14 parts of soda ash, and 15-25 parts of sheet glass to form a mixture; melting the mixture to obtain glass metal; placing the glass metal in a centrifugal machine for spinning treatment to obtain glass fiber and spraying water and binders onto the surface of the glass fiber in a vaporific mode at the same time; placing the glass fiber coated with the binders in a cotton collecting machine to enable the glass fiber to evenly fall onto the cotton collecting machine under the action of a negative-pressure fan to form a glass cotton layer; and conveying the glass cotton layer well laid to a curing oven through a conveyer to be cured to obtain the glass fiber blanket.

Owner:CHENGDU HANJIANG NEW BUILDING MATERIAL

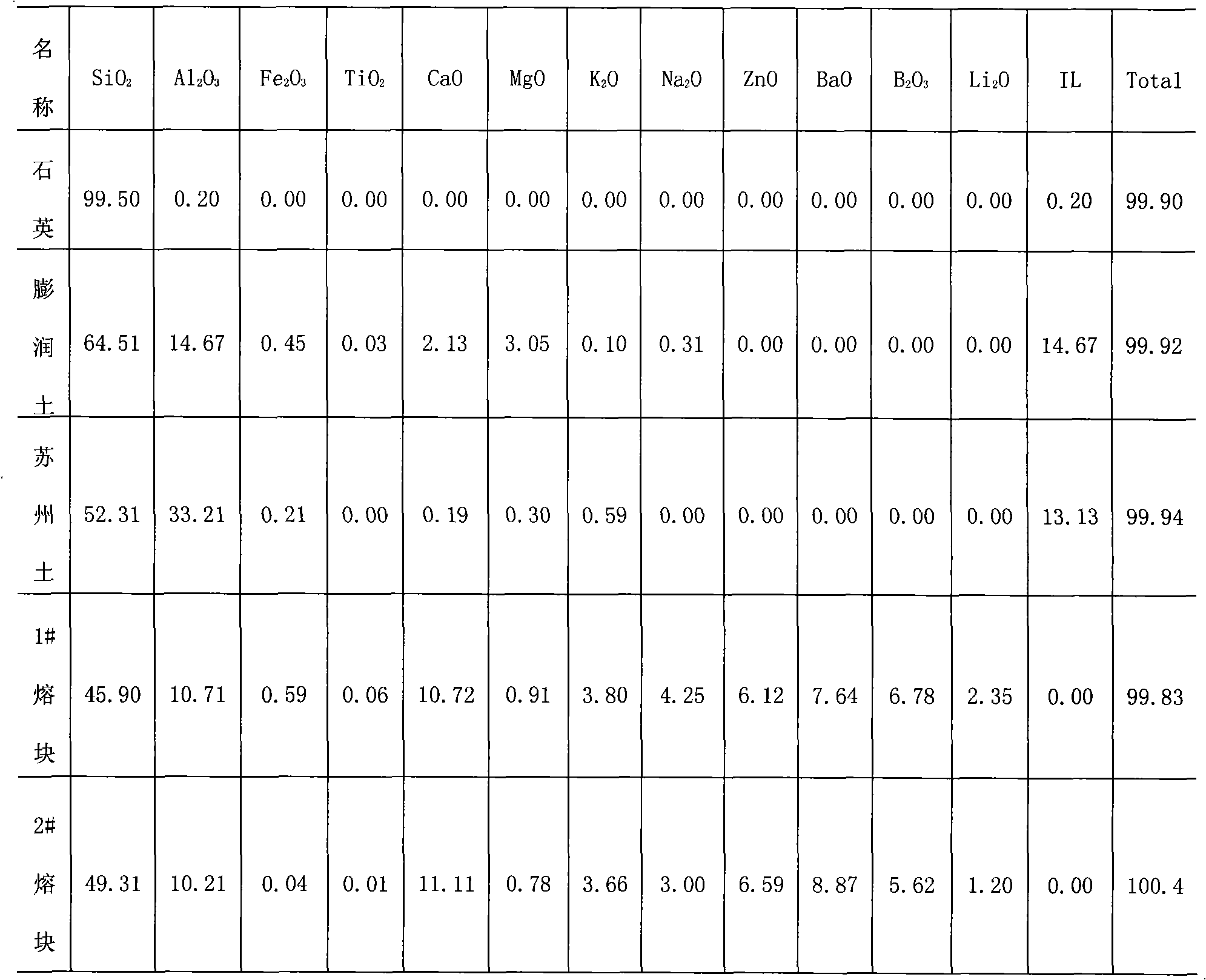

Bone porcelain with high resistance of heat shocks and production method thereof

InactiveCN101289307AReduce contentSmall coefficient of thermal expansionClaywaresHigh resistanceSodium Bentonite

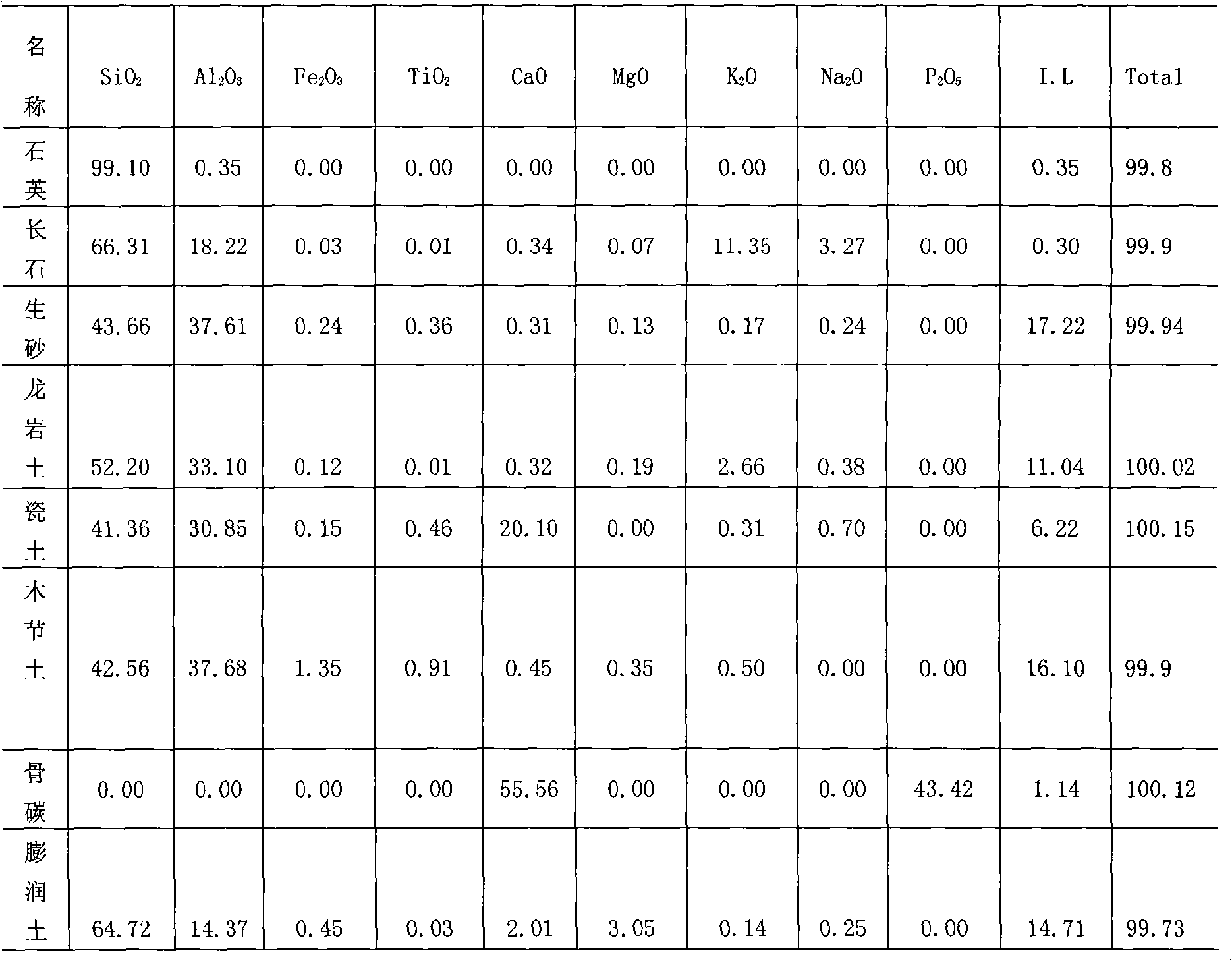

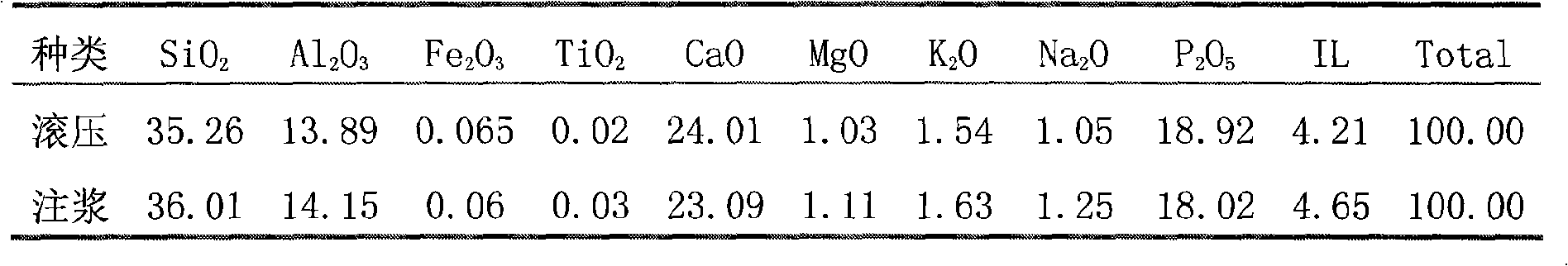

The invention relates to a bone china with high resistance to heat shocks and a manufacture method thereof. The raw material components of the bone china stock and the weight percentages are: 9 to 12 of quartz, 7 to 10 of feldspar, 11 to 14 of greensand, 4 to 7 of Longyan clay, 5 to 8 of china clay, 4 to 7 of kibushi clay, 42 to 46 of bone coal and 7 to 10 of bentonite; the raw material components and the weight percentages of glaze material are: 5 to 8 of the quartz, 2 to 5 of the bentonite, 3 to 6 of Suzhou clay, 50 to 53 of model one fused block and 34 to 37 of model two fused block; the bone china has the resistance to heat shocks that no crack occurs during the heat change in the water with the temperature of 200 to 20 DEG C for once. The manufacture steps are as follows: preparing stock paste, preparing glaze paste, roller forming, grouting and forming, biscuit firing, glazing, glaze firing and decorating firing. The enamel layer of the invention has the advantages of large elasticity, good toughness and mechanical property. The raw material ingredients have no lead and zero radioactivity, which are green. The manufacture method is scientific and reasonable, and the product has the resistance to heat shocks that no crack occurs during the heat change in the water with the temperature of 200 to 20 DEG C at one time.

Owner:唐山隆达骨质瓷有限公司

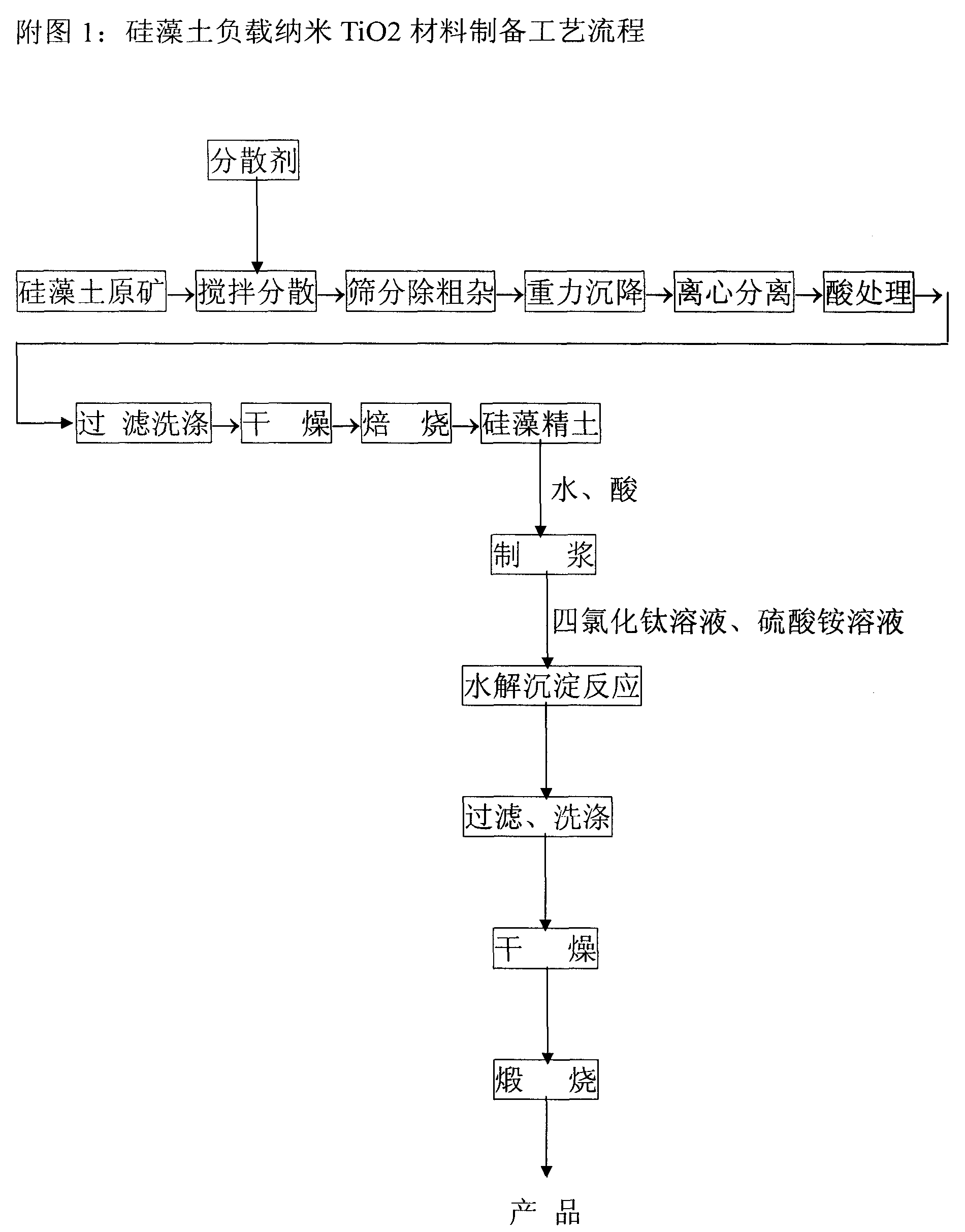

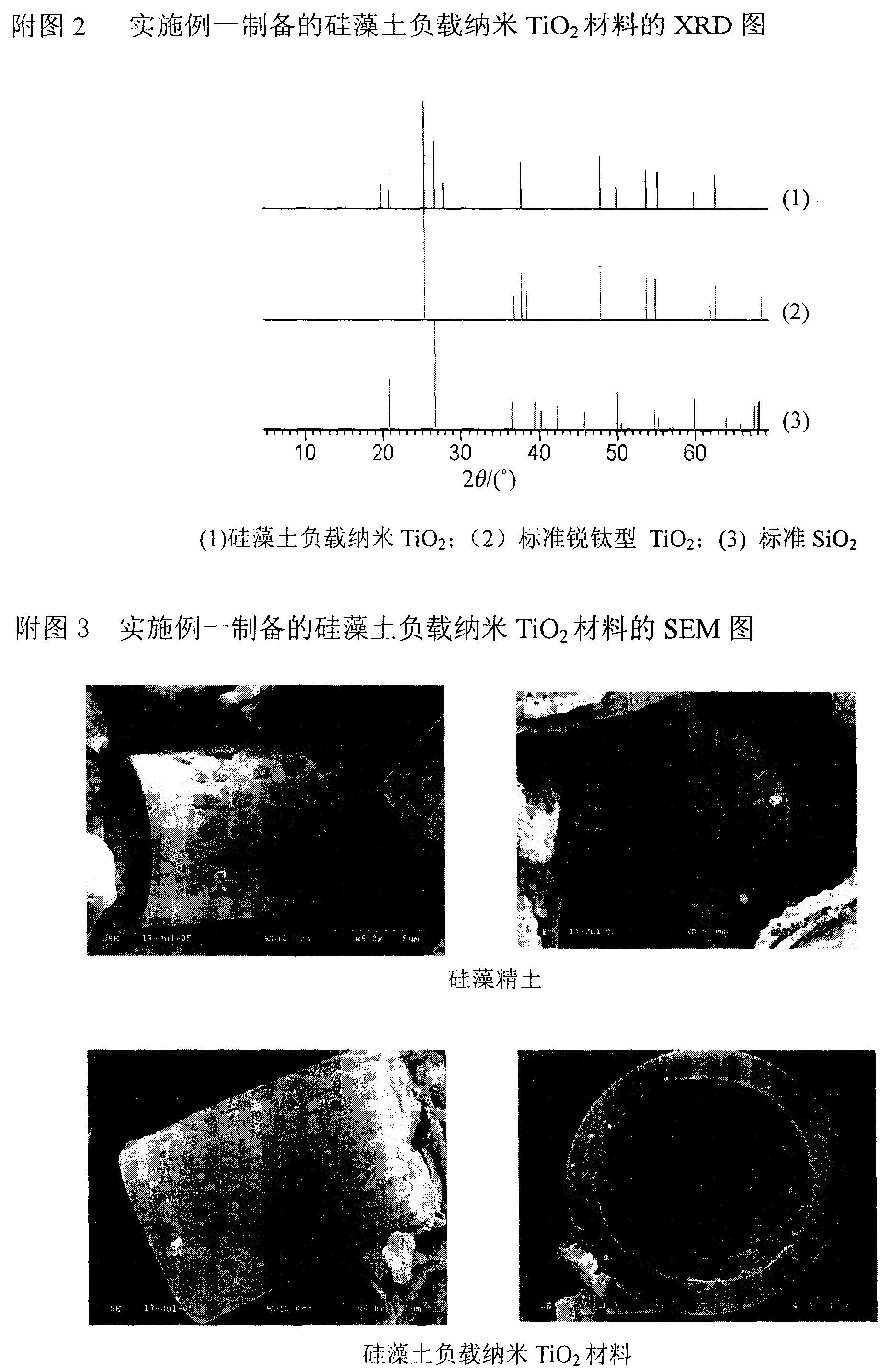

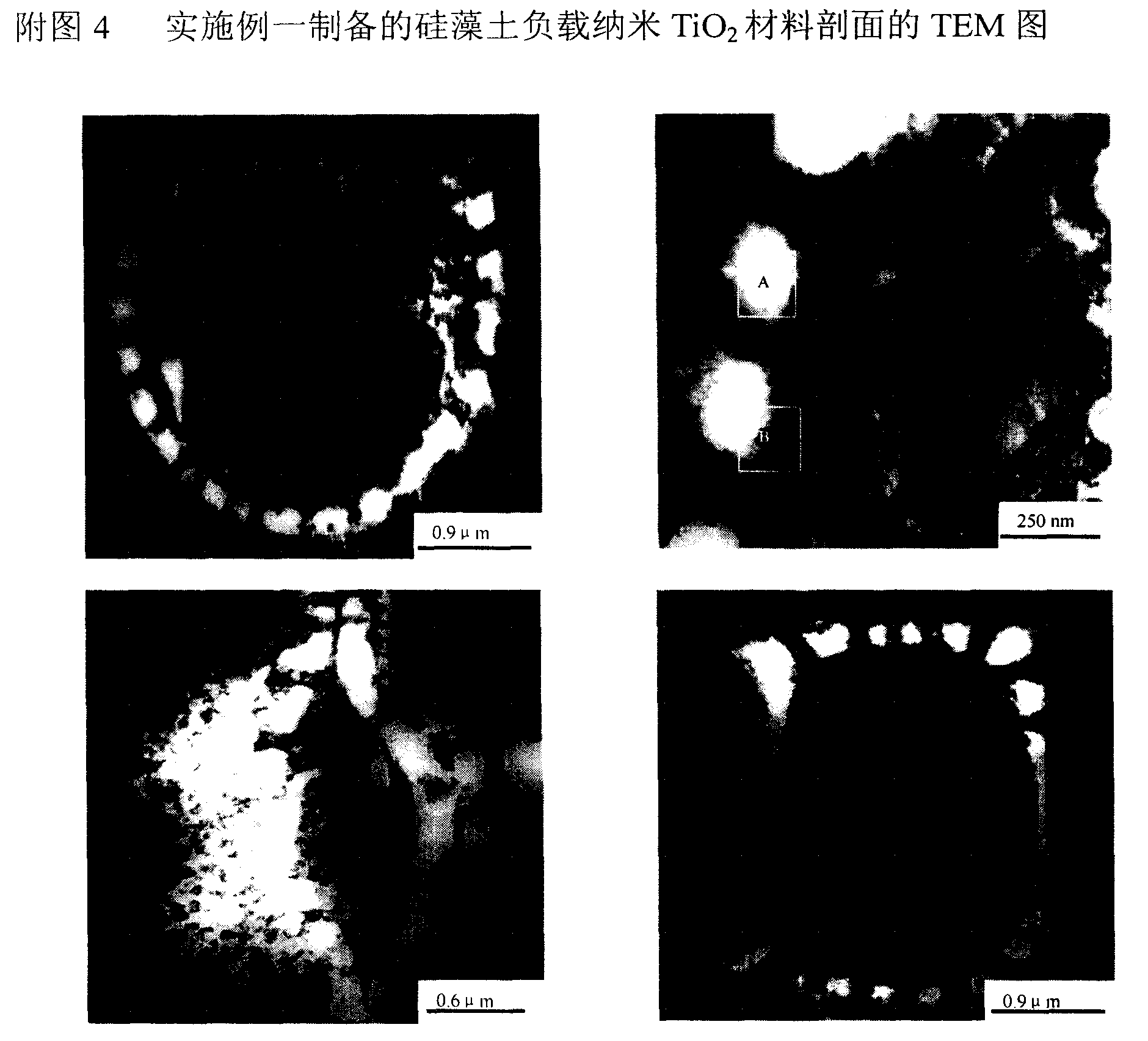

Method for producing tripolite loading nano-TIO2 material capable of being used for water and air purification

InactiveCN101195086AReduce manufacturing costGood photocatalytic effectPhysical/chemical process catalystsForeign matterDecomposition

The invention relates to a process for preparing diatom earth loading nanometer Ti2O material for purifying water and air, which belongs to the field of material process and environmental treatment. Diatom earth raw ore is filled with water and is churned and scattered, is screened, is sunken by gravity, and is eccentrically sunken, sulfuric acid is adopted to dissolve clay-type foreign matters which are left in pore passages after ores which mutually grow with diatom earth like quartz, feldspar, mica, and clay and the like and organic matters which are mixed such as grass roots and barks and the like are removed, and diatom fine soil is attained. Further, diatom fine soil is filtered, dried, and baked, and diatom fine soil after baked is filled with water, and is churned, and is filled with acid to regulate the PH value, and is filled TiCl4 solution, and is filled with ammonia sulfate solution to proceed hydrolytic decomposition deposition reaction, and product yield after the reaction is filtered, washed, dried, and baked to attain the nanometer Ti2O material.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +1

Production method of superfine glass wool product

The invention discloses a production method of a superfine glass wool product. The production method comprises the following steps of: recovering shattered glass, cleaning and crushing; preparing raw materials including feldspar, dolomite, sodium carbonate and borax, and testing and analyzing the components of the raw materials; calculating the use levels of the raw materials according to the required proportion of the compound in a batch mixture, and weighting and mixing the raw materials and the shattered glass to prepare the batch mixture; founding the batch mixture to obtain uniform, purified and transparent molten glass; preparing a binder; fiberizing the molten glass to obtain glass wool, and spraying the binder into the glass wool; solidifying and sizing and the glass wool; and carrying out aftertreatment on the glass wool product. In the invention, the water soluble resin binder is used so that the produced glass wool product has good elasticity and is uniform. Since the recovered waste glass is adopted as the main raw material, the recycle of resource is realized, the environment is protected, and the cost is saved. In addition, the production method of the superfine glass wool product has simple operation.

Owner:许立江

Method for producing photo catalytic self-cleaning enamel

InactiveCN101067207ASimple processReduce manufacturing costPhysical/chemical process catalystsQuenchingChemical stability

The process of preparing photocatalytic self-cleaning enamel includes the following steps: 1. preparing enamel clinker with enamel material quartz, feldspar, borax, etc, through mixing, smelting in a crucible, water quenching and stoving; 2. mixing enamel clinker with clay, dielectric and deionized water, grinding, sieving and stoving to form the enamel; 3. derusting and degreasing steel plate or iron casting, stoving, coating the enamel, stoving and firing to form enameled plate; and 4. soaking the enameled plate in titania colloid solution, vertically drawing, stoving and sintering to form enameled plate with titania film. The process is simple and low in cost, and the prepared self-cleaning enamel material has excellent photocatalytic performance and high chemical stability.

Owner:DONGHUA UNIV

460MPa-level flux-cored wire for ocean engineering and application thereof

ActiveCN105269174AStable mechanical propertiesImprove crack resistanceArc welding apparatusWelding/cutting media/materialsCrack resistanceWeld seam

The invention provides a 460MPa-level flux-cored wire for ocean engineering. The 460MPa-level flux-cored wire comprises a carbon steel sheath and a flux core, wherein the carbon steel sheath accounts for 84-87% of the total mass of the flux core; the flux core accounts for 13-16% of the total mass of the flux-cored wire; the flux-cored wire consists of the following components in percentage by mass: 30-42% of rutile, 1-2% of sodium fluoride, 3-6% of feldspar, 3-5% of ferrotitanium, 1-3% of silicon iron, 0.5-1% of rear earth, 3-5% of magnesium powder, 5-10% of electrolytic manganese, 1-2% of aluminum powder, 7-9% of nickel powder, 4-7% of ferroboron, 0.2-0.5% of graphite, 3-6% of silicon-manganese alloy, 0.5-1% of zircon sand and the balance of Fe and inevitable impurities. By virtue of control in aspects of chemical components, diffusible hydrogen, low-temperature stability and the like, the 460MPa-level flux-cored wire meets the requirements of crack resistance and low-temperature impact resistance, is good in all-position welding process, attractive in welding seam and excellent in mechanical property, has seawater corrosion resistance; and content of diffusible hydrogen of deposited metal reaches ultralow hydrogen level.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com