Patents

Literature

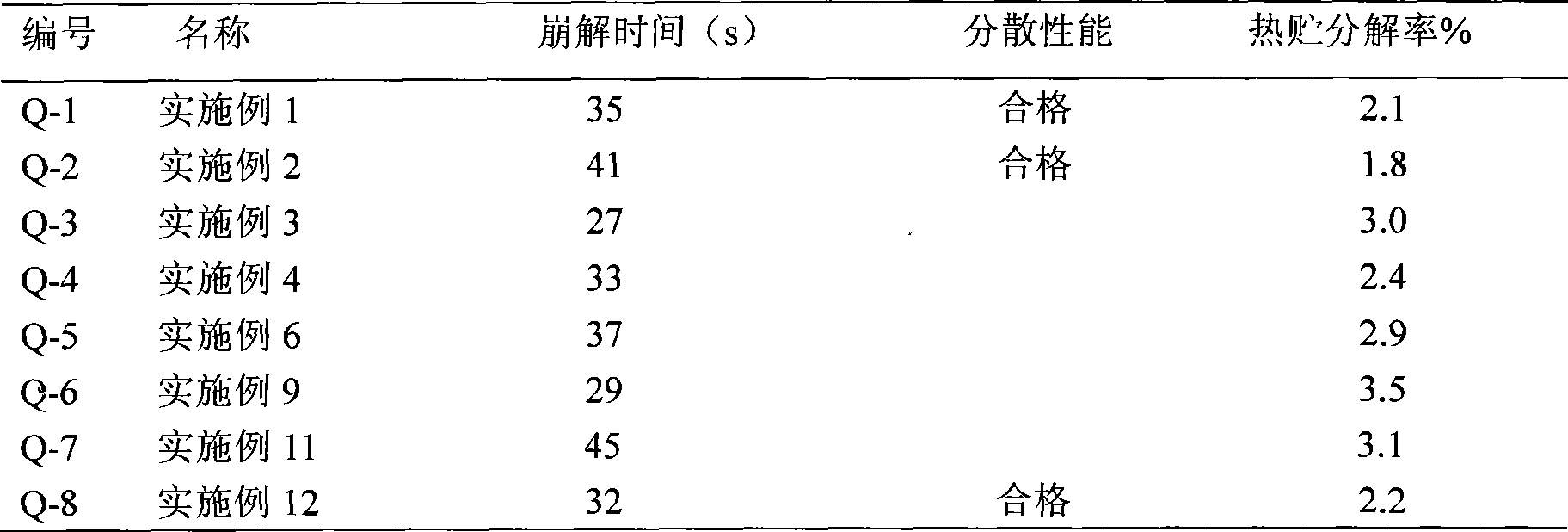

9867 results about "Borax" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Borax, also known as sodium borate, sodium tetraborate, or disodium tetraborate, is an important boron compound, a mineral, and a salt of boric acid. Powdered borax is white, consisting of soft colorless crystals that dissolve in water. A number of closely related minerals or chemical compounds that differ in their crystal water content are referred to as borax, but the word is usually used to refer to the octahydrate. Commercially sold borax is partially dehydrated.

Fertilizer water-dispersion granule and preparation thereof

The invention relates to a fertilizer water dispersible granule and a method for preparing the same. The fertilizer water dispersible granule comprises one or more of plant nutrient substances and at least one surfactant which are processed to prepare the regular or irregular granular water dispersible granule. The fertilizer water dispersible granule consists of the following raw materials in portion by weight: 5 to 95 portions of the plant nutrient substance, 1 to 40 portions of the surfactant and 0 to 94 portions of an assistant. The invention has a preferential proposal: the plant nutrient substance comprises monopotassium phosphate, boric acid or borax, humic acid and salt thereof. The fertilizer water dispersible granule also comprises one or more of growth regulators. In addition, the fertilizer water dispersible granule can also comprise a disintegrating agent, an adhesive, a filler, a colorant and other assistants. The preparation method comprises: the metering, pulverization, even mixing, pelletization and drying of formula materials to obtain the fertilizer water dispersible granule. The fertilizer water dispersible granule has rapid disintegrating and dissolving (dispersing) speed in water, is fully dissolved, does not block a nozzle and a drop irrigation pipeline, is uneasy to absorb moisture, has high content of effective compositions, low packaging, storage, transportation, metering and use cost and high utilization rate of the effective compositions, reduces waste and environmental pollution, is widely applied to economic crop, gardening, lawn and urban greening and has extremely wide market application prospect.

Owner:SHENZHEN LANGTAI BIOTECH

Amino acid compound leaf fertilizer and preparation method thereof

InactiveCN102219610APromote absorptionNutritional diversityFertilizer mixturesMonopotassium phosphateAmino acid

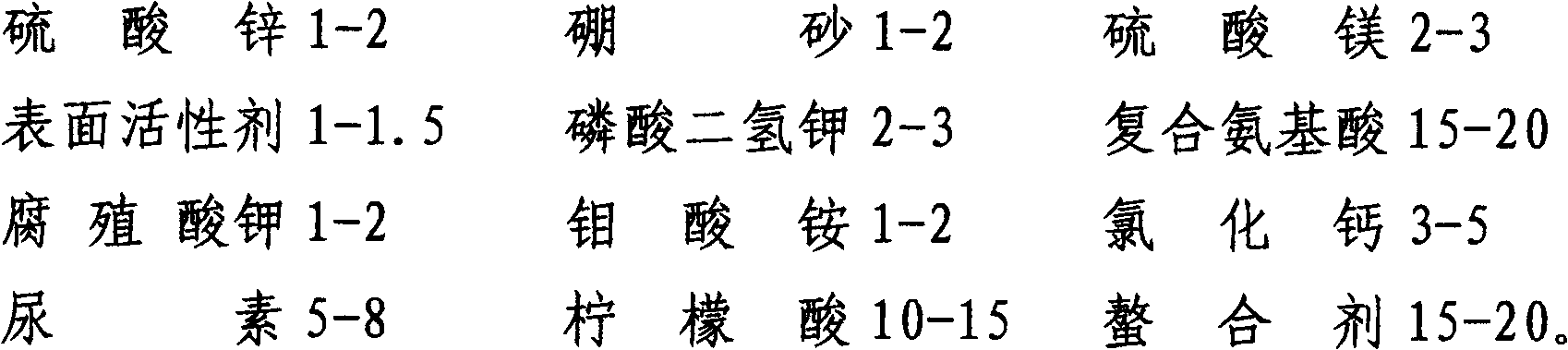

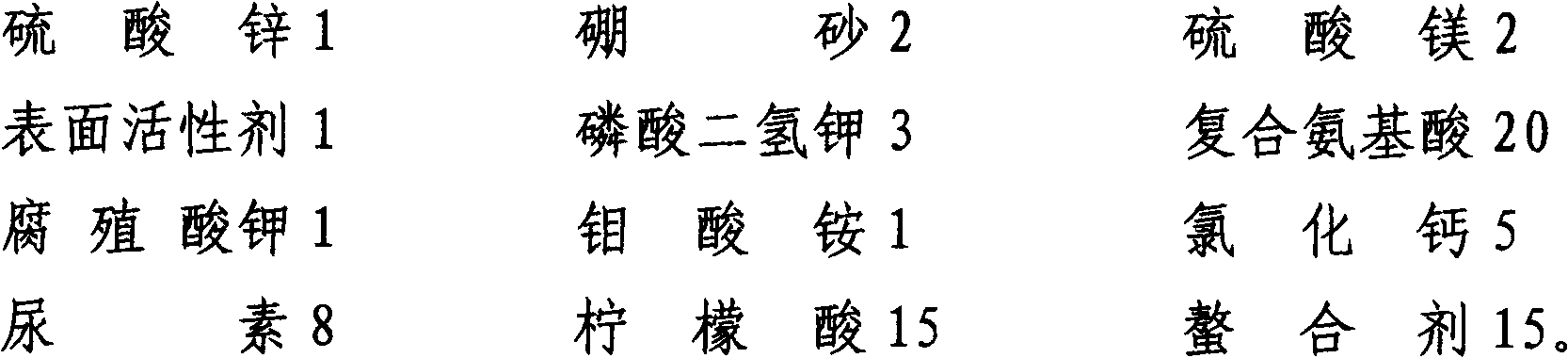

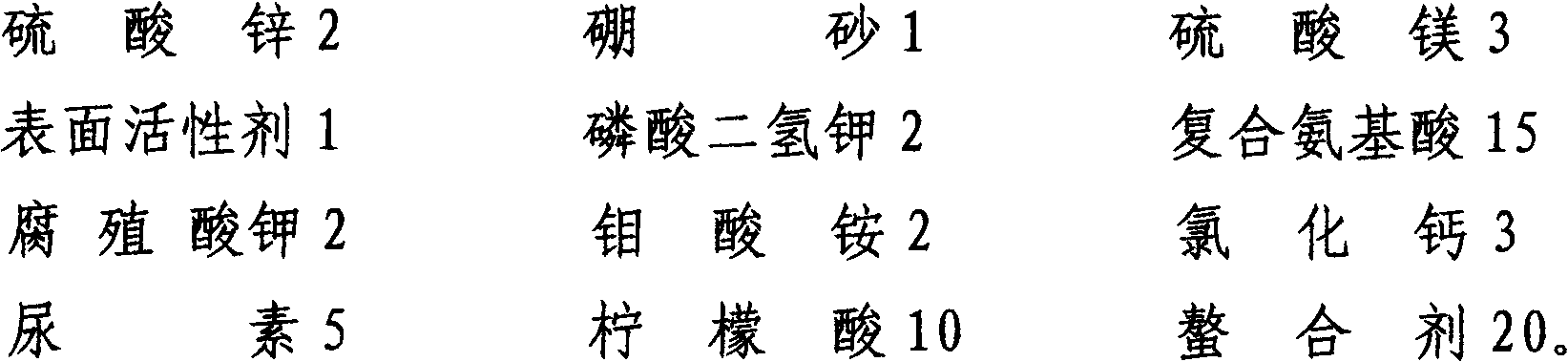

The invention discloses an amino acid compound leaf fertilizer and a preparation method thereof, relating to the technical field of production of agricultural fertilizer. The amino acid compound leaf fertilizer is prepared by the following components according to parts by weight: 1-2 parts of zinc sulphate, 1-2 parts of borax, 2-3 parts of magnesium sulfate, 1-1.5 parts of surfactant, 2-3 parts of monopotassium phosphate, 15-20 parts of compound amino acid, 1-2 parts of potassium humate, 1-2 parts of ammonium molybdate, 3-5 parts of calcium chloride, 5-8 parts of urea, 10-15 parts of citric acid, and 15-20 parts of chelant; the amino acid compound leaf fertilizer has the characteristics of being complete in nutrient, high in utilization rate, good in absorption, fast in effect and the like, and can be widely applied to crops such as tobacco, oranges and tangerines, vegetables, melon and fruits and the like.

Owner:HUNAN ZHONGKE AGRI

Liquid fertilizer with pyroligneous liquor and oxalacetic liquor and production thereof

InactiveCN1778773AMagnesium fertilisersFertilisers by pryogenic processesRare-earth elementPlant regulators

A liquid fertilizer containing wood vinegar liquid or oxalic vinegar liquid and its production are disclosed. The liquid fertilizer consists of urea 1í½20.0%, potassium phosphate 1í½20.0%, potassium nitrate 1í½20.0%, lime nitrate 0.1í½10.0%, magnesium sulfate 0.1í½5.0%, ferrous sulfate 0.1í½5.0%, manganous sulfate 0.1í½5.0%, zinc sulfate 0.1í½5.0%, cupric sulfate 0.1í½5.0%, boron sand or boric acid 0.1í½2.0%, sodium molybdate or ammonium molybdate 0.1í½1.0%, plant hormone or plant regulator, rare earth element or humus acid or pesticide auxiliaries etc. The process is carried out by proportioning and mixing. It can improve bacterium inhibiting and plant growth regulating functions.

Owner:ZHEJIANG JIANZHONG BAMBOO IND

Specialized organic/inorganic composite biological medicine fertilizer for watermelon, and preparation method thereof

The invention provides a specialized organic / inorganic composite biological medicine fertilizer for watermelon, and a preparation method thereof. The weight parts of composition raw materials are as follows: 50-70 parts of sludge produced by sewage treatment, 20-30 parts of tree ash, 30-40 parts of watermelon vines, 20-30 parts of cow manure, 15-20 parts of bagasse, 5-7 parts of fishbone dust, 8-10 parts of oil cakes, 10-15 parts of the tree ash, 10-15 parts of phosphorus slag, 8-10 parts of poultry feather, 8-10 parts of monoammonium phosphate, 10-12 parts of triple superphosphate, 12-15 parts of potassium chloride, 2-4 parts of carboxymethyl chitosan, 20-30 parts of modified bentonite, 10-12 parts of decomposed coal, 2-4 parts of seven leaf clover, 9-11 parts of angled bittersweet, 8-10 parts of capillary artemisia, 5-7 parts of fructus cnidii, 6-8 parts of fructus quisqualis, 3-5 parts of wormwood, 3-5 parts of litsea cubeba, 8-10 parts of daturae flower powder, 3-5 parts of paraffin, 1-1.25 parts of zinc sulfate, 2-3 parts of ferrous sulfate, 0.8-1.2 parts of borax, 10-12 parts of potassium fulvic acid, 3-4 parts of chili oil and 0.2-0.5 part of EM strains. A green organic fertilizer is obtained by mixing a plurality of organic wastes and fermenting the mixture, thereby reducing environment pollutions. The specialized organic / inorganic composite biological medicine fertilizer for the watermelon has the advantages of comprehensive nutrition and enhanced sterilizing effects by mixing the fermented organic materials and inorganic fertilizer and adding medicine juice of the Chinese herbal medicine having insectidical functions. With the application of the fertilizer, watermelon quality can be effectively increased; and the watermelon has green leaves, bright flower, prolonged flowering period and increased output.

Owner:合肥科友生物科技有限公司

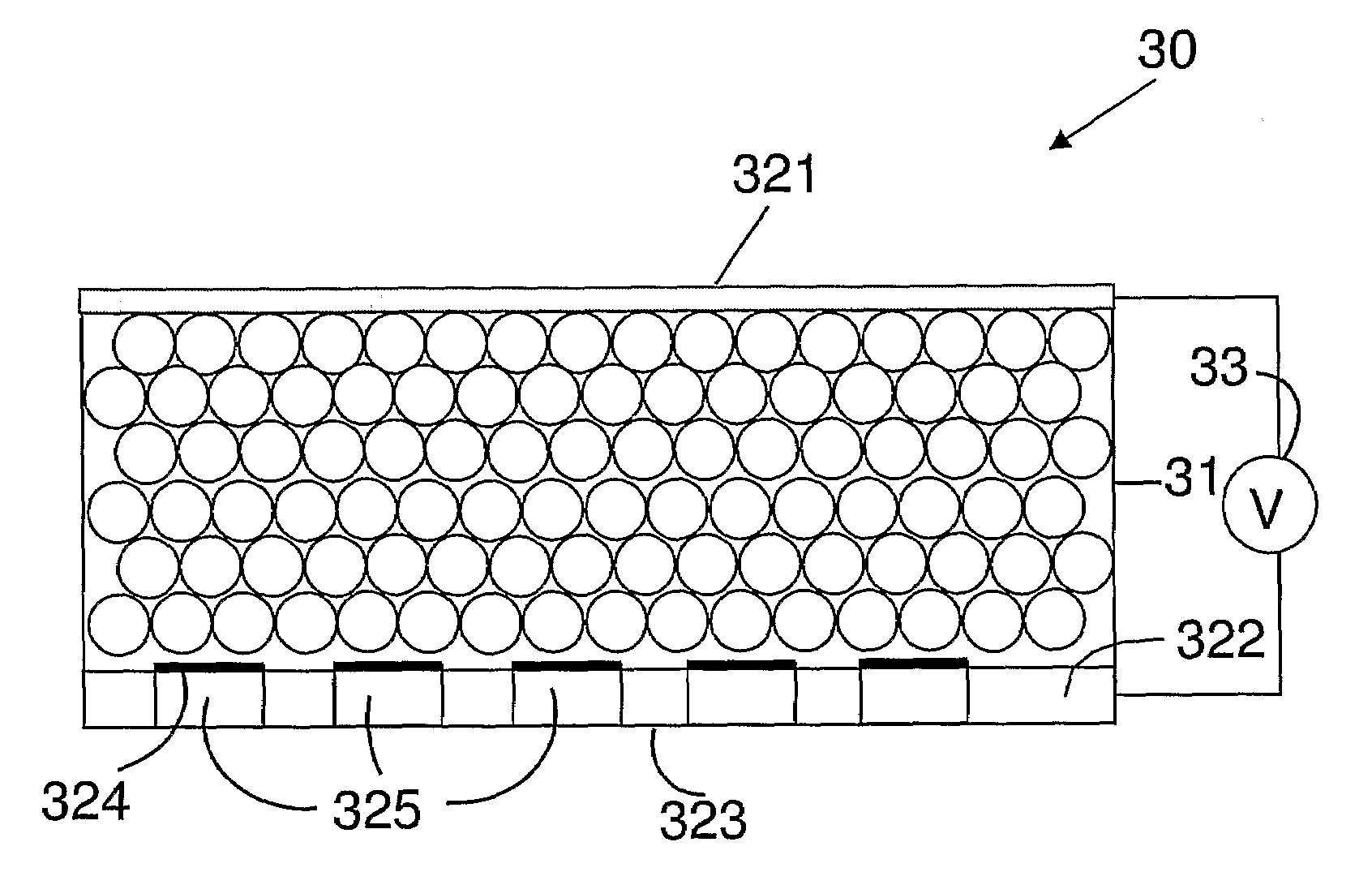

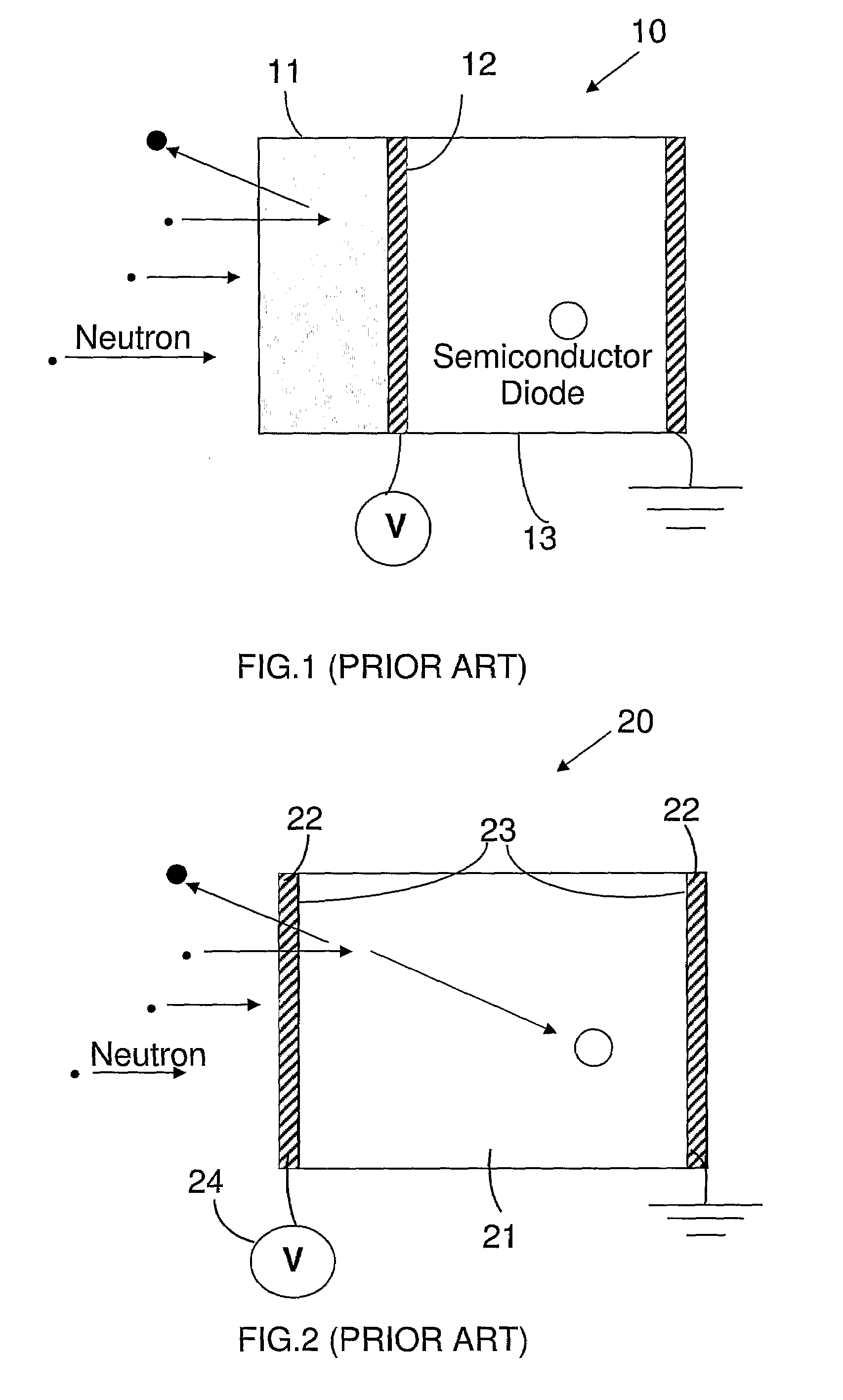

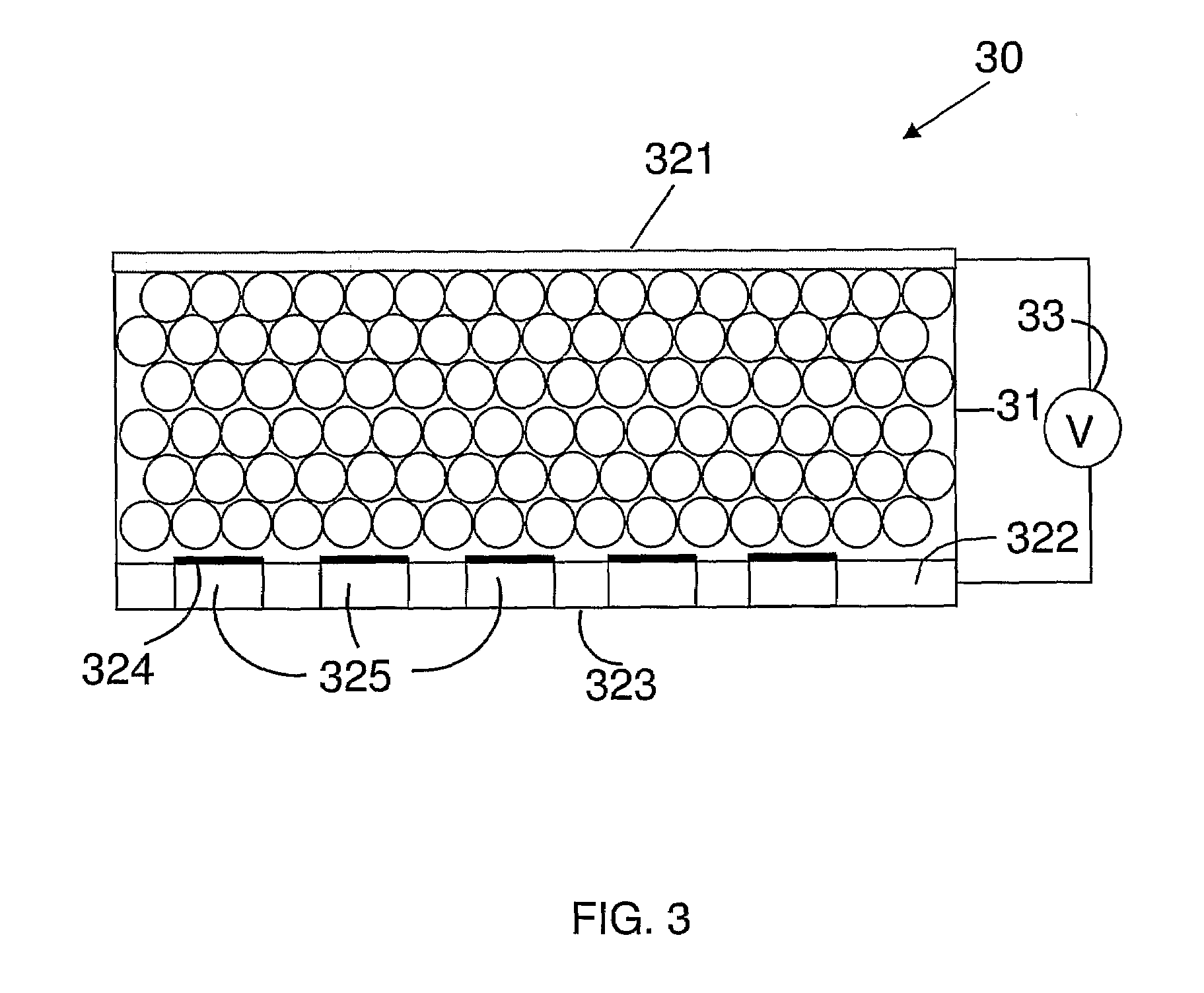

Solid-state neutron and alpha particles detector and methods for manufacturing and use thereof

InactiveUS20090302226A1Optimize detection resultsMeasurement with semiconductor devicesSolid-state devicesParticulatesSemiconductor materials

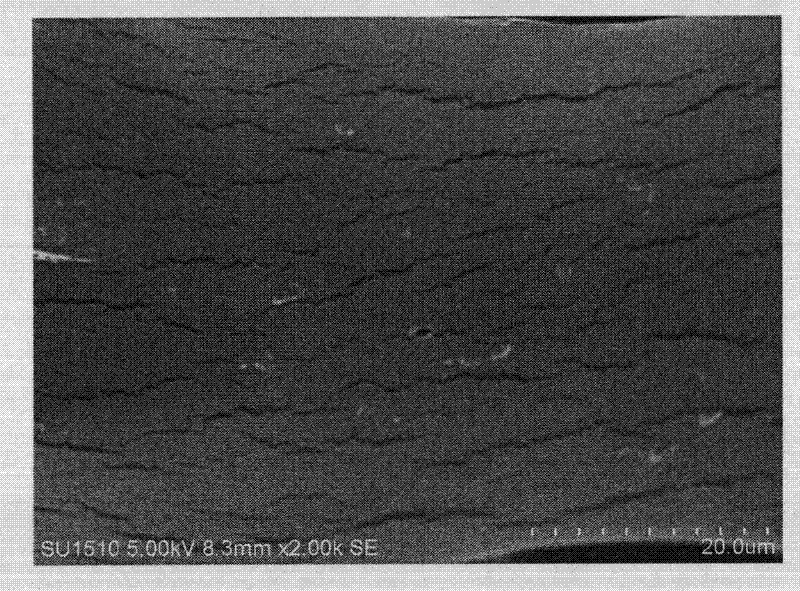

A solid-state detector for detection of neutron and alpha particles detector and methods for manufacturing and use thereof are described. The detector has an active region formed of a polycrystalline semiconductor compound comprising a particulate semiconductor material sensitive to neutron and alpha particles radiation imbedded in a binder. The particulate semiconductor material contains at least one element sensitive to neutron and alpha particles radiation, selected from a group including 10Boron, 6Lithium, 113Cadmium, 157Gadolinium and 199Mercury. The semiconductor compound is sandwiched between an electrode assembly configured to detect the neutron and alpha particles interacting with the bulk of the active region. The binder can be either an organic polymer binder or inorganic binder. The organic polymer binder comprises at least one polymer that can be selected from the group comprising polystyrene, polypropylene, Humiseal™ and Nylon-6. The inorganic binder can be selected from B2O3, PbO / B2O3 / , Bi2O3 / PbO, Borax glass, Bismuth Borate glass and Boron Oxide based glass.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD

Bio-organic fertilizer special for improving saline-alkali lands and preparation method thereof

The invention relates to a bio-organic fertilizer special for improving saline-alkali lands and a preparation method thereof. The bio-organic fertilizer is prepared from the following raw materials by weight: 5-20% of bean pulp, 64-70% of vinegar dregs, 10-25% of humic acid, 5-7% of calcium magnesium phosphate, 0.1-0.3% of zinc sulfate, 0.1-0.2% of borax and 0.05-0.1% of compound microbial strains. The preparation method of the bio-organic fertilizer comprises the steps of compound microorganism selecting, activating, primary expanding, secondary expanding and expanding by tabling, material mixing, fermenting, turning, finished product preparing, low-temperature drying, detecting and measuring and packaging. The organic matters and the humus in the bio-organic fertilizer can adsorb the free ions fixed in the soil of the saline-alkali lands, reduce the solution concentration of the soil and neutralize the alkali in the soil of the saline-alkali lands, thus alleviating or eliminating the saline-alkali harms, and simultaneously release the potassium ions and increase the contents of the organic phosphorus and the inorganic phosphorus, thus improving the effectiveness of the fertilizer.

Owner:山西晨雨晋中肥业有限公司

Phase transition temperature adjusting system and phase transition temperature adjusting cup

ActiveCN104887011AHeat absorption and release performance are highly matchedGuaranteed to drink normallyDrinking vesselsCarbon nanotubeSodium Thiosulfate Pentahydrate

Owner:YUTIAN ENERGY CO LTD

Preparation method and application method of grape special fertilizer

ActiveCN101693639AIncrease productionImprove qualityClimate change adaptationAlkali orthophosphate fertiliserSodium BentoniteAdditive ingredient

The invention relates to preparation method and application method of a grape special fertilizer, wherein the preparation method comprises the following steps: preparing an I-type fertilizer by taking the following ingredients in parts by weight: 30-40 parts of urea, 20-30 parts ammonium phosphate, 15-30 parts of potassium sulphate, 1-3 parts of humic acid, 1-3 parts of excrement, 1-5 parts of synergist, 0.1-1.0 part of ferrous sulphate, 0.1-0.8 part of zinc sulfate, 0.1-0.6 part of manganese sulphate, 0.1-0.6 part of borax, 0.1-0.4 part of copper sulfate, 3-7 parts of plaster and 3-13 parts of bentonite; preparing an II-type fertilizer by taking the following ingredients in parts by weight: 7-15 parts of urea, 25-35 parts ammonium phosphate, 35-45 parts of potassium sulphate, 1-3 parts of humic acid, 1-5 parts of excrement, 2-5 parts of synergist, 0.1-1.0 part of ferrous sulphate, 0.1-0.8 part of zinc sulfate, 0.1-0.6 part of manganese sulphate, 0.1-0.6 part of borax, 0.1-0.4 part of copper sulfate, 3-7 parts of plaster and 3-13 parts of bentonite; and blending, spraying, pelleting and drying at lower temperature to obtain the product. The application method of the fertilizer comprises the following steps: taking an organic fertilizer and the II-type fertilizer as a base fertilizer; applying the I-type fertilizer before blossom, applying the II-type fertilizer in the young fruit development period, and meanwhile, respectively spraying monopotassium phosphate and rare earth mixed liquid once on the leaf surfaces; and spraying calcium nitrate or calcium acetate to enhance the storage resistance property before picking.

Owner:新疆满疆红农资化肥科技有限公司

High-antiwear cutting fluid

InactiveCN104277900AImprove anti-wear performanceLow costLubricant compositionLanthanum fluoridePolyethylene glycol

The invention discloses a high-antiwear cutting fluid, which comprises the following raw materials in parts by weight: 10-25 parts of soybean oil, 5-15 parts of rapeseed oil, 8-25 parts of 2-ethylhexyl oleate, 15-30 parts of fatty alcohol-polyoxyethylene ether, 3-8 parts of disodium sulphonatoacetate, 1-5 parts of copper / silica composite nano materials, 5-12 parts of citric acid-modified lanthanum fluoride nanoparticles, 20-40 parts of an imidazoline-ammonium salt corrosion inhibitor, 3-15 parts of glycerin, 2-15 parts of triethanolamine, 2-6 parts of borax, 0.5-1.5 parts of benzotriazole, 8-20 parts of polyethylene glycol and 30-50 parts of water. The high-antiwear cutting fluid is excellent in antiwear, cooling, lubrication, cleaning and antirust functions, and is low in cost and strong in stability.

Owner:CHAOHU GUANGFENG METAL PROD

Protein-based wood adhesive and preparation method thereof

InactiveCN102719217ANo health damageAvoid decompositionNon-macromolecular adhesive additivesProtein adhesivesPolyvinyl alcoholAdhesive

The invention discloses a protein-based wood adhesive which is characterized by being made of the following raw materials in part by weight: 100 parts of water, 5 to 50 parts of protein-containing raw materials, 10 to 14 parts of polyamide epichiorobydrin (PAE), 5 to 15 parts of modifier, 1 to 15 parts of acidity regulator, 0 to 15 parts of stabilizer, 0 to 10 parts of humectant, 0 to 10 parts of anti-freeze, 0.1 to 10 parts of preservatives, 0 to 10 parts of mold inhibitor, 0 to 10 parts of enzyme inhibitor, and 0 to 10 parts of filling. The protein-containing raw materials contain over 10% of coarse protein, and the modifier is one of or a mixture of several of polyacrylamide, polyvinyl alcohol, polyvinyl acetate, borax, ammonium thiosulfate, carbamide and isocyanate. The invention also discloses a preparation method of the protein-based wood adhesive. The invention adopts common chemical materials and adopts a break-through normal-temperature material-mixing technique, which uses water as solvent. The adhesive has the advantages of high stickiness, evenness and convenience in adhesive application and stable product quality.

Owner:马晓平

Method for preparing organic sustained release fertilizer synergist

InactiveCN101591208AHigh calorific valueIncrease temperatureAgriculture gas emission reductionFertilizer mixturesMonosodium glutamateSodium Bentonite

The invention provides a method for preparing an organic sustained release fertilizer synergist. The synergist comprises the following components in portion by weight: 25 to 60 portions of organic component, 3 to 15 portions of synergistic component, 10 to 13 portions (solid) and 3.5 to 9 portions (liquid) of sustained release component, 0.5 to 5 portions of trace elements, 18 to 30 portions of inorganic nutrient, and 2 to 7 portions of additive. The synergist is prepared by the method of weighing, mixing, spray granulation and low-temperature drying, wherein the organic component contains 2 to 5 portions of humic acid, 25 to 45 portions of mature garbage or barnyard manure, and 2 to 5 portions of residue of monosodium glutamate and sugar; the synergistic component contains 1 to 3 portions of zeolite, 1 to 5 portions of fly ash, and 2 to 5 portions of synergistic agent; the sustained release component contains 10 to 13 portions of bentonite, 0.02 to 0.1 portion of nitrification inhibitor, and 4 to 8 portions of urease inhibitor (liquid); the trace elements contain 0.1 to 1 portion of zinc sulfate, 0.1 to 1 portion of manganese sulfate, 0.1 to 1 portion of borax, 0.1 to 1 portion of copper sulfate, and 0.1 to 1 portion of ferrous sulfate; the inorganic nutrient contains 6 to 9 portions of urea, 7 to 9 portions of ammonium phosphate, and 5 to 7 portions of potassium sulfate; and the additive contains 2 to 7 portions of plaster. The synergist is suitable for the planting of field crops and forest fruits.

Owner:新疆满疆红农资化肥科技有限公司

Plant nutrient liquid fertilizer

InactiveCN102701861AImprove stress resistanceSolve the problem of lack of nutrientsFertilizer mixturesSucrosePhosphate

The invention relates to a plant nutrient liquid fertilizer. In order to solve the problem of over fertilization, the plant nutrient liquid fertilizer is prepared from the following raw materials in proportion by weight: aqua brassin 12-36, gibberellin 1-4, indoleacetic acid 30-80, abscisic acid 10-20, naphthaleneacetic acid 50-90, salicylic acid 80-180, vitamin C 1-3, cane sugar 40-100, chitin 20-80, 0.05-0.2 percent triacontanol 400-1,000, hydrolyzed protein 2-5, potassium dihydrogen phosphate 300-400, thiourea 40-120, cobalt chloride 5-12, borax 50-100, sodium silicate 30-55, urea 300-500, ammonium molybdate 50-80, copper sulfate 30-65, zinc sulfate 120-200, magnesium sulfate 100-150, calcium chloride 50-120, manganese sulfate 40-80 and water in the amount of 3-8 times the total amount of all the raw materials or water in the amount capable of dissolving all the raw materials, wherein the water is de-ionized water or micro cluster water; and the preparation method is that all the materials are prepared into aqueous solution. The plant nutrient liquid fertilizer has the advantages of favorably solving the problems of over fertilization and shortage of nutrient elements in soil, obviously improving the plant adverse resistance, improving the photosynthesis and the accumulation efficiency of nutritive materials and improving the yield and the quality.

Owner:魏玉芳

Functional bioorganic and semi-organic fertilizers and preparation method thereof

ActiveCN101891544AIncrease enzyme activityIncrease profitFertilizer mixturesEcological environmentLivestock manure

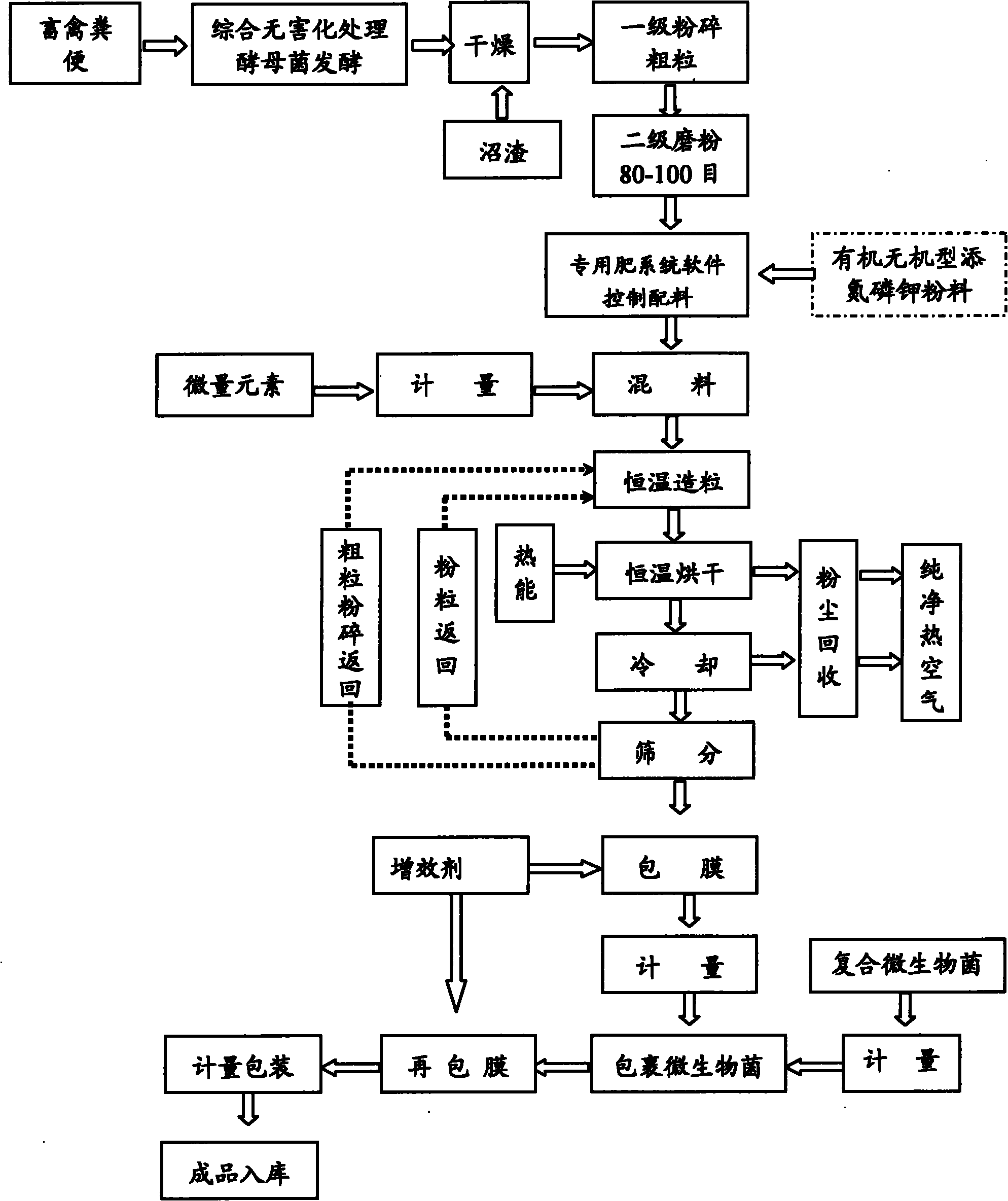

The invention discloses a functional bioorganic fertilizer and a semi-organic fertilizer and a preparation method thereof. The method comprises the following steps of: adding microzyme into livestock manure to perform anaerobic and aerobic fermentation; deodorizing, drying and crushing (after biogas slurry of residues after fermentation in a methane tank is separated, the biogas dregs are dried and crushed); adding a certain amount of humic acid, amino acid, borax, ammonium molybdate and zinc sulfate, or also adding nitrogen, phosphor and kalium inorganic nutrients; automatically blending materials by using a computer according to a proportion; after uniformly stirring, granulating by using a granulator, and drying, cooling and screening the grains; and coating a synergist and nitrogen-fixing, phosphorous-dissolving and potassium-releasing composite bacteria on qualified grains to prepare the functional bioorganic and semi-organic fertilizers. The product has the functions of preserving moisture and fertility, resisting drought, coldness, plant diseases and insect pests and the like, improves the soil structure, promoting the proliferation of beneficial microorganisms in soil, jointly participating substance circulation of a soil ecosystem and the like, has quick response and long effect, is mainly used as a base fertilizer for crops to save time and manpower, can realize waste recycling, protects ecological environment, integrates land utilization, land nourishment and land protection, and ensures constant soil productivity.

Owner:杨泉胜

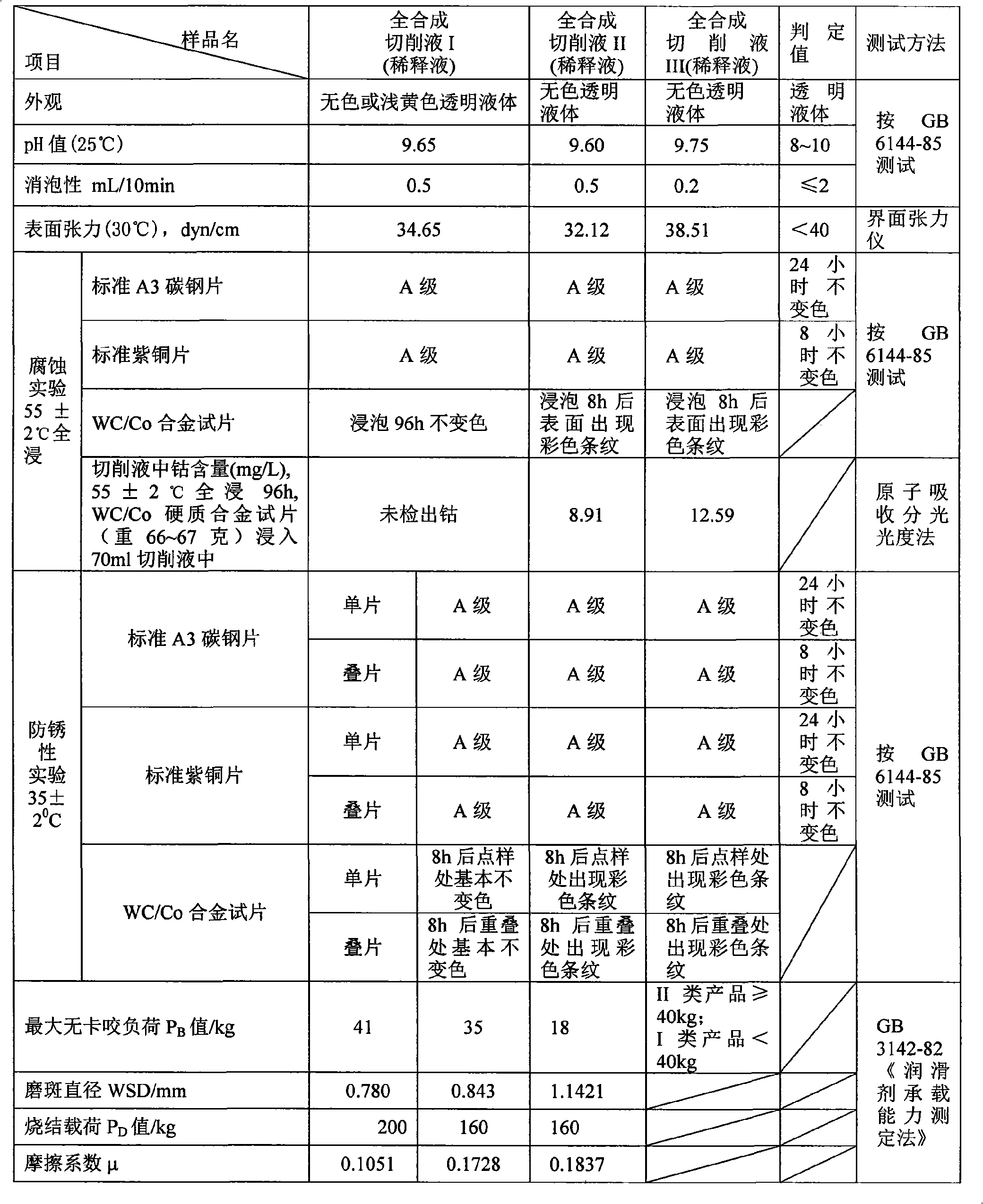

Fully synthetic cutting fluid

InactiveCN101560430ASolve the problem of protocobaltAvoid leachingLubricant compositionActive agentPolyethylene glycol

The invention discloses a fully synthetic cutting fluid which comprises anion active agent, non-ionic surface active agent, polyethylene glycol, borax, bactericide, foam suppressor, pH regulator, water and additive; wherein, the additive is prepared by the following method: the surface active agents are dissolved by acetone, the mixed solution is added with toluene and heated up to 50-60 DEG C, and the reaction system is dripped with acrylate monomer as well as azodiisobutyronitrile (AIBN) or ammonium persulfate (APS) evocating agent; after that, the temperature is preserved for 3-5h, the reaction stops, and organic solvent is removed, so that the additive is obtained. Compared with the existing fully synthetic cutting fluid, the fully synthetic cutting fluid of the invention can completely inhibit leaching of cobalt element in hard alloy containing cobalt when metal is processed, well solves the problem of separating the cobalt in the existing fully synthetic cutting fluid, and is environment-friendly and efficient.

Owner:CENT SOUTH UNIV

Liquid agent multielement fertilizer and its production method

InactiveCN1410395AChange physiologyPromote absorptionOrganic fertilisersFertilizer mixturesManganesePlant cell

A multi-element liquid fertilizer contains active components, additive and water. Its active components includes 13 components, such as potassium sulfate, borax, copper sulfate, manganese sulfate, zinc sulfate, etc.. The additives include 9 components, such as disodium hydrogen phosphate, nitric acid, useful bacteria, useful enzyme, etc.. It can improve the activity of plant cells, change physiological mechanism of plant, increase yield, and make plant robust.

Owner:孙国庆 +1

Preparation method of water-soluble chitosan/polyvinyl alcohol composite films

InactiveCN102504296AGood antibacterial effectGood biocompatibilityFlexible coversWrappersComposite filmBiocompatibility Testing

The invention discloses a preparation method of water-soluble chitosan / polyvinyl alcohol composite films capable of being used as biological package materials. Water-soluble chitosan and polyvinyl alcohol are respectively dissolved in deionized water, the solution is subjected to mixing casting for forming films, then, the films are soaked into one kind of solution or several kinds of mixed solution from glutaraldehyde solution, borax solution, epichlorohydrin, glyoxal and sodium tripolyphosphate to be subjected to crosslinking for 40 to 60 minutes, peeling and natural drying or baking are carried out, and the water-soluble chitosan / polyvinyl alcohol composite films are obtained. The composite films have good antibacterial activity, biocompatibility and biodegradability, in addition, special gas blocking performance and excellent mechanical performance are realized, and the composite films have the advantages of chitosan and the polyvinyl alcohol. In addition, the production cost is low, the preparation process is simple, the production efficiency is high, and the environment is friendly.

Owner:常州绿之源高分子材料有限公司

Environment-protecting synergistic agent for fuel coal

InactiveCN101440328AIncreased flammable contentIncreased space gapSolid fuelsFuel additivesSodium bicarbonateFurnace temperature

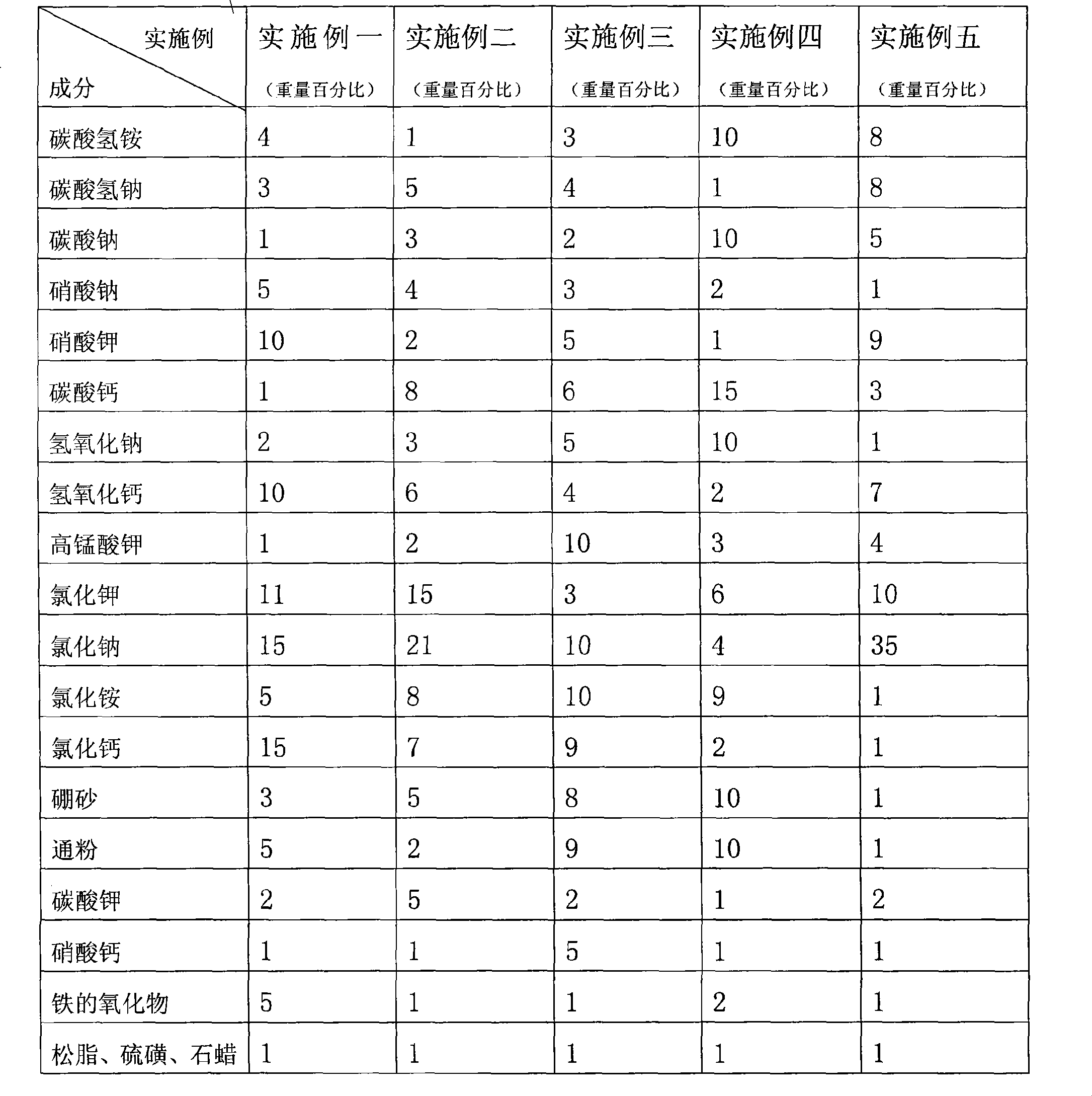

The invention discloses a bunker coal environment-friendly synergist, which comprises the following components by weight percent: 1 to 10 percent of ammonium bicarbonate, 1 to 8 percent of sodium bicarbonate, 1 to 10 percent of sodium carbonate, 1 to 5 percent of sodium nitrate, 1 to 10 percent of potassium nitrate, 1 to 15 percent of calcium carbonate, 1 to 10 percent of sodium hydroxide, 2 to 10 percent of calcium hydroxide, 1 to 10 percent of potassium permanganate, 3 to 15 percent of potassium chloride, 10 to 35 percent of sodium chloride, 1 to 10 percent of ammonium chloride, 1 to 15 percent of calcium chloride, 1 to 10 percent of borax, 1 to 10 percent of macaroni, 1 to 5 percent of potassium carbonate, 1 to 5 percent of calcium nitrate, 1 to 5 percent of iron oxide, and the balance being micro turpentine, sulfur and paraffin wax. The bunker coal environment-friendly synergist makes flame of combustion be more rampant and denser, the furnace temperature rise to a higher level, the hearth be brighter and cleaner and tail gas be cleaner.

Owner:李政 +1

Core glaze for matte sand streak enamel glaze and production method thereof

The invention discloses a core glaze for a matte sand streak enamel glaze, belonging to the technical field of enamel glazes. The core glaze comprises, by weight, 20 to 35% of quartz sand, 20 to 30% of magnesium oxide, 18 to 28% of soda ash, 8 to 15% of potash feldspar, 2 to 5% of borax, 1 to 2% of fluorite, 1 to 3% of calcium carbonate, 2 to 5% of trisodium phosphate and 0.02 to 0.1% of cobalt oxide. Through cooperative usage of the core glaze with commercially available bright glazes, colorants and the like, matte sand streak glaze products of different colors and different texture can be conveniently and rapidly at a low temperature in a small scale.

Owner:娄底湘信新材料科技有限公司

Formulation for medicinal neutral boron silicate glass

The present invention is one kind of neutral borosilicate glass for medicine production. The neutral borosilicate glass has recipe comprising quartz sand 168-178 Kg, feldspar powder 14.7-18.7 Kg, borax pentahydrate 49-51 Kg, sodium carbonate 8-12 Kg, barium carbonate 8.6-9.4 Kg, sodium nitrate 0.4-0.6 Kg, calcite 1-2 Kg, fluorite 0-4 Kg, potassium carbonate 8.5-9.5 Kg, salt 0.8-1.6 Kg, cerium oxide 0.5-0.9 Kg and cullet 120 Kg. It has high chemical stability, high hydrolysis stability, few alkali metal volatilizations, simple production process and low cost.

Owner:东营力诺玻璃制品有限责任公司

Multiple-effect type water-based synthesized cutting solution and preparation thereof

InactiveCN101323813AExtended service lifeImprove extreme pressure and anti-wearLubricant compositionWater basedCleansing Agents

The invention relates to a multi-effect water-based composite cutting / grinding fluid which consists of water-soluble oil, cleaning agent, extreme pressure antiwear agent, antirust, antibacterial agent, complexant, solubilizer and anstatic agent. The water-soluble oil is the mixture of aminoethyl alcohol and triethanolamine oleate, the cleaning agent is anionic surfactant or nonionic surfactant, the extreme pressure antiwear agent is one or two of additives A, B, C, D, E and F, the antirust is benzotriazole and sodium benzoate, the antibacterial agent is boric acid and borax, the complexant is EDTA and the solubilizer is urea. The cutting / grinding fluid with various improved performances is non-toxic and tasteless, is an environment-friendly product and has no harm to human body and the skin of users; the operating cycle is normally more than 6 months.

Owner:大连弘瑞化工有限公司

High-quality strawberry planting dedicated slow-release compound fertilizer

InactiveCN104030800AImprove the phenomenon of single fixationGood release effectFertilizer mixturesMicrobial agentGluconates

The invention relates to the compound fertilizer field, and particularly relates to a high-quality strawberry planting dedicated slow-release compound fertilizer. The fertilizer is prepared from the following raw materials in parts by weight: 10-15 parts of a 1250-2000 mesh diatomite, 4-5 parts of borax, 2-3 parts of ammonium molybdate heptahydrate, 10-12 parts of sodium humate, 20-25 parts of urea, 18-22 parts of potassium nitrate, 25-28 parts of organic compost, 2-4 parts of fish meal, 1-3 parts of sesame leaves, 8-10 parts of alfalfa meal, 15-18 parts of corn distiller grains, 2-4 parts of brine, 8-10 parts of an erythromycin fungi residue, 1-2 parts of an EM microbial agent, 4-6 parts of a fern root residue, 1-3 parts of nano silver, 1-2 parts of a semen ginkgo powder, 4-6 parts of 1,6-hexanediol diacrylate, 10-12 parts of an acrylic resin dispersion liquid, 1-2 parts of isocyanate, 1-2 parts of calcium stearoyl lactate, 2-4 parts of zinc gluconate, 6-8 parts of table vinegar, and 4-5 parts of an auxiliary agent. The compound fertilizer has multiple nutrients, is low in production cost and good in slow-release effect, allows double coating to be formed on the nutrients by utilizing diatomite and a coating agent in the process, also contains various trace elements, has no toxicity and no pollution, and is excellent in quality of planted strawberry and obvious in yield and income increasing effects.

Owner:ANHUI SUNSON CHEM

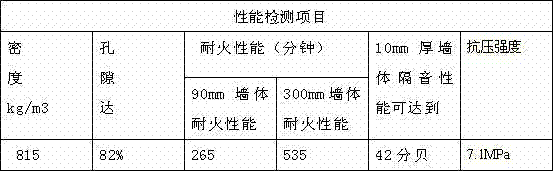

Acetylene sludge aerated concrete block and preparation method thereof

ActiveCN102875070ALow bulk densityGood heat insulationSolid waste managementCeramicwareSODIUM METAPHOSPHATEParaffin wax

The invention provides an acetylene sludge aerated concrete block, which is prepared by processing the following raw materials in part by weight: 20-30 parts of acetylene sludge, 25-30 parts of coal ash, 5-10 parts of cement, 4-6 parts of modified attapulgite, 5-10 parts of water treatment sludge, 5-10 parts of soda residue, 5-10 parts of light calcium powder, 10-15 parts of lime, triethanolamine, 4-5 parts of gypse, 0.02-0.08 part of aluminium powder, oxidized paraffin wax soap, 0.01-0.02 part of calcium bicarbonate, 2-3 parts of chelky slag, 1-2 parts of lignocellulose, 0.3-0.5 part of water glass, 0.03-0.05 part of borax, 1-2 parts of sodium hexametaphosphate, 1-2 parts of hydroxy propyl methyl cellulose sodium and 1-2 parts of superfine polyvinyl alcohol, wherein the weight of the triethanolamine is 0.1-0.3 percent of that of the lime, and the weight of the oxidized paraffin wax soap is 3-5 percent of that of the aluminium powder. According to the invention, the acetylene sludge is added into the raw materials of the aerated concrete block, and meanwhile other conventional additives and modified nano additives are added; the aerated concrete block is prepared by adopting a proper technology and is low in cost and good in performance; the circulating economy effect of changing waste into valuable is realized; the pollution is reduced; and the prepared aerated concrete block has the characteristics of light volume weight, high thermal insulation performance, good sound absorption effect and high strength and can be used for non-bearing or bearing wall bodies.

Owner:广东合盛建筑工程有限公司

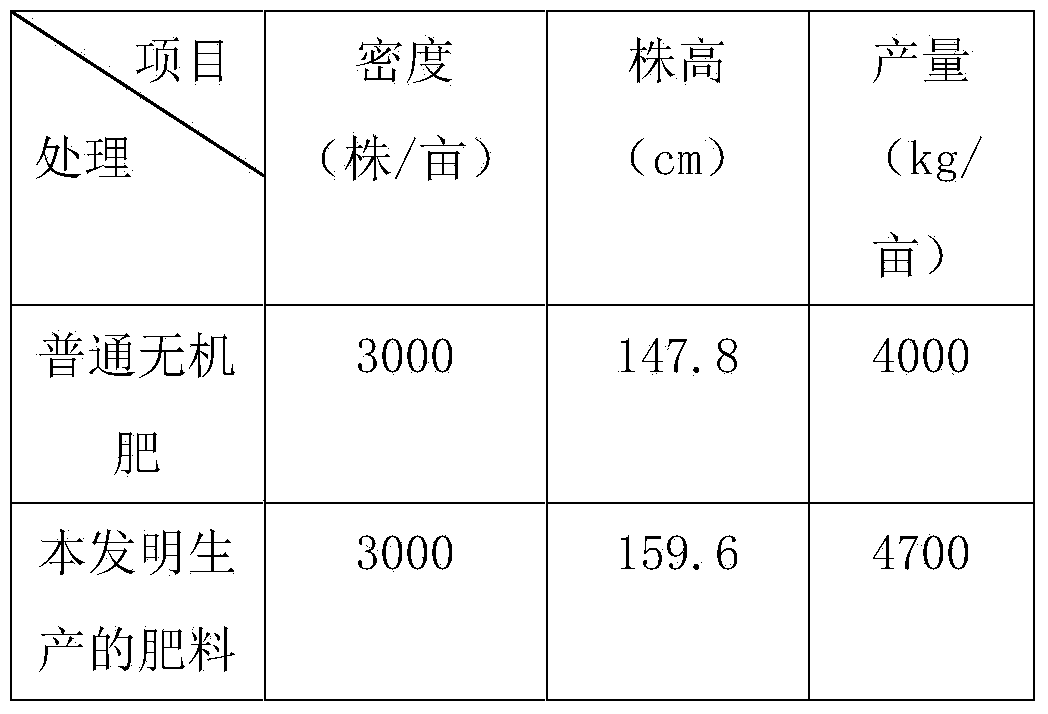

Method for producing organic fertilizer by utilizing poultry and livestock excrement

InactiveCN103524247AIncrease productionEffective absorptionFertilizer mixturesSodium BentoniteAnimal feces

The invention discloses a method for producing an organic fertilizer by utilizing poultry and livestock excrement. The organic fertilizer is prepared from the following raw materials in parts by weight: 200-250 parts of dried poultry and livestock excrement, 1-2 parts of EM (effective microorganism) inoculant, 250-350 parts of straw, 50-60 parts of expanded perlite, 50-60 parts of expanded vermiculite, 35-45 parts of diatomaceous earth, 50-65 parts of bentonite, 10-15 parts of borax, 15-25 parts of magnesium sulfate, 10-13 parts of zinc sulfate, 9-15 parts of copper sulfate, 35-50 parts of gypsum, 15-20 parts of sodium humate, 60-80 parts of monopotassium phosphate, 100-150 parts of beer waste residue, and 10-13 parts of soil conditioner. According to the method, a jade component is contained in the soil conditioner, and contains massive trace elements beneficial to human bodies; the fertilizer contains an adsorption component which can effectively adsorb and immobilize toxic heavy metal elements in the soil, so that the heavy metal elements can be prevented from being absorbed by crops. The method is simple, and is low in production cost; the fertilizer does not contain harmful bacteria, and is rich in beneficial biological bacteria.

Owner:安徽环绿建设工程有限公司

Water soluble fertilizer containing high-concentration humic acid and preparation method thereof

ActiveCN103408373AImprove buffering effectReduce heavy metal contentFertilizer mixturesDipotassium hydrogen phosphateHigh concentration

The invention provides a water soluble fertilizer containing high-concentration humic acid. The water soluble fertilizer comprises, by weight, 15-25 parts of a water soluble humic acid salt, 18-25 parts of urea, 9-15 parts of dipotassium hydrogen phosphate, 8-13 parts of potassium acetate, 0.5-2 parts of borax, 0.1-10 parts of polyglutamic acid, 1-5 parts of rhamnolipid, 5-10 parts of a hydroxymethyl cellulose aqueous solution and 30-40 parts of water. The water soluble fertilizer has humic acid content greater than or equal to 150g / L. The invention also provides a preparation method of the water soluble fertilizer containing high-concentration humic acid. The preparation method comprises the following steps of 1, carrying out heating stirring of the water soluble humic acid salt and water to obtain a humic acid salt solution, 2, adding dipotassium hydrogen phosphate, potassium acetate, borax, polyglutamic acid, rhamnolipid and urea into the humic acid salt solution, and carrying out heating stirring to obtain a mixed solution, and 3, carrying out emulsification of the hydroxymethyl cellulose aqueous solution and the mixed solution to obtain the water soluble fertilizer containing high-concentration humic acid. The water soluble fertilizer has obvious fertilizer efficiency, is environmentally friendly, stable and uniform and has a wide application range.

Owner:陕西鼎天济农腐殖酸制品有限公司

Cultivating material for edible fungus and its production technology

InactiveCN100999428AHas disinfection and antibacterial effectReduce financial burdenSuperphosphatesUrea compound fertilisersPhosphoric acidBio engineering

This invention involves a mushroom cultivation material and production process, it belongs to the field of bio-engineering technology. This mushroom cultivation material contains Chinese crud drug residue 30 ~ 40 share, cotton shells 50 ~ 60 share, urea 1 ~ 2 share, wheat bran 5 ~ 7 share, potassium sulfate 0.5 to 1.5 share, calcium superphosphate 0.5 to 1.2 share, zinc sulfate, magnesium sulfate, borax, ferrous sulfate together for 0.4~1 share, calcined lime 0.5 to1.3 share. Because of using materials containing substances such as Chinese crud drug residue, the produced mushroom cultivation material of this invention has antibacterial effect. Through the implementation of the invention reached so no longer waste residue cause environmental pollution, reduce the factory heavy economic burden caused by the sewage problem.

Owner:王贤

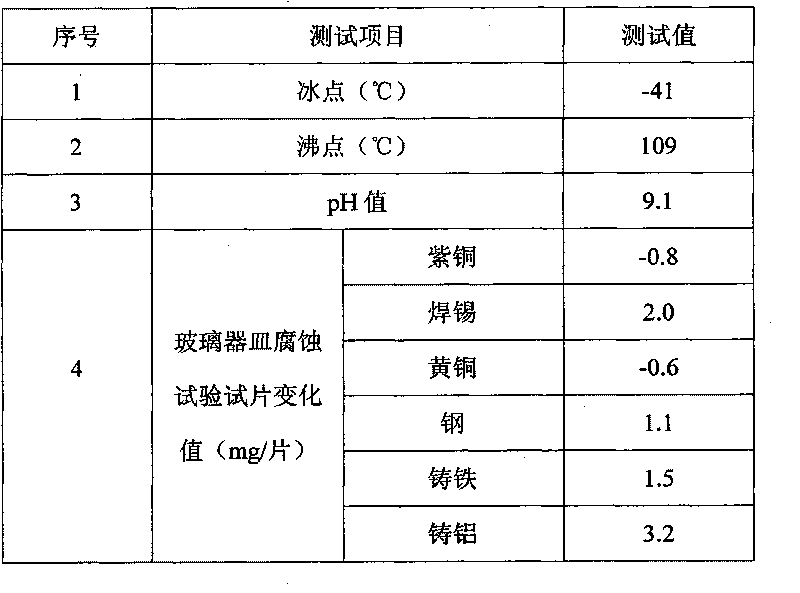

Engine antifreezing solution

ActiveCN101691484AAvoid the disadvantages of instabilityWith boiling suppressionHeat-exchange elementsCooperative interactionSebacic acid

The invention relates to an engine antifreezing solution which is prepared by mixing the following components to react: glycol, sodium molybdate, sodium hydroxide, isooctanoic acid, sebacic acid, sodium benzoate, benzotriazole, sodium 2-mercaptobenzothiazole, dye and deionized water. The invention adopts a new formula which uses organic matter as main component and inorganic matter as auxiliary component to reach the aim of controlled release on the basis of conventional inorganic and all-organic engine antifreezing solution technologies, wherein the organic acid uses the combination of monoacid and binary acid. The invention does not contain sodium borate and silicate so as to avoid the defect that precipitate is easy to generate due to the existence of sodium borate and silicate in glycol series antifreezing solution and the antifreezing solution is unstable; and the engine antifreezing solution of the invention does not contain amine, nitrate, phosphate and other substances which are harmful to the environment and human body. The researched antifreezing solution has good performances of stability, freeze-proofing, boil-proofing, corrosion-proofing and scale prevention through the cooperative interaction of components so as to perform multi-level anticorrosion protection for the cooling system of the vehicle.

Owner:SHAANXI DADI IND CO LTD OF CHINA NAT NUCLEAR

Bio-fertilizer

InactiveCN101125774AHigh sweetnessNice colorClimate change adaptationExcrement fertilisersNematodePhosphate

The invention discloses a bio fertilizer that takes nitrogen, phosphorus and potassium as carriers and evericin mixture as desinsection component. The bio fertilizer comprises evericin mixture, ammonium sulphate, monoammonium phosphate, lemery, borax, zinc sulfate, green copperas, calcium powder, rootage agent, brown sugar, chicken manure, pepper powder, peanut cake or castor cake. The invention is suitable for various vegetables and melon and fruit crops; after application, the fruits of the crops grow right, the crops can ripe early and the flower is good-looking; the invention decreases the application of agricultural chemical, improves the output and melon and fruit saccharinity, saves cost about 20-30 percent; besides, the invention can effectively inhibit the increase of root nematode have special effect on white fly, the invention has the advantages of fertilizing effect as well as agricultural chemical effect, thus having very good practicality value.

Owner:刘国英

Dry farm cultivating agent

The dry-land planting agent refers to a kind of droughtresistance crop's nutrient specific to the growth of the plants. The invention is composed of the following components: AU absorber with super strength, carbamide, potassium dihydrogen phosphate, ammonium dibasic phosphate, calcium nitrate, bitter salt, ammonium molybdate, zinc sulfate, manganese sulfate, boracic acid or borax, ferrous sulphate, fulvic acid potassium, disodium edta, fatty alcohol polyethenoxy ether, 6- benzyl aminopurine, melissyl alcohol, potassium naphthylacetic acid, indolebutyric acid, gibberellin, santobrite, potassium sorbate, ketotriazole, penta azole alcohol., thiram, carbendazim, acid brilliant scarlet, humic acid, bluestone, potassium permanganate, potassium chloride, polyethylene glycol, bentonite or water. The invention is featured by sopping, molding moisture, molding fertilizer, withering resistance, disinsection, sterilization, strengthening the effects of the pesticide, accelerating the burgeon of the plants, increasing roots, innocuity, no pollution and low cost.

Owner:王亚玲

Special fertilizer for oil tea

InactiveCN102816015APromote growthImprove disease resistanceBio-organic fraction processingOrganic fertiliser preparationPaulowniaCamellia oleifera

The invention discloses a special fertilizer for oil tea. The fertilizer is prepared from the following components according to a certain weight ratio: an oil tea cake, peanut bran, sawdust of paulownia, bone meal, Chinese herbal medicine residue, humic acid, a nitrogen-phosphorus-potassium fertilizer, a biological bacterial preparation, a biological insecticide, zinc sulfate, magnesium sulfate, sodium molybdate and borax. According to the invention, long-term demands of oil tea for nutrients can be completely satisfied when the special fertilizers for the oil tea with different proportions of N, P and K are applied in different growth stages of the oil tea, and the special fertilizer provided by the invention has the advantages of a reasonable formula, balanced nutrition, safety, no pollution and capacity of promoting better growth of the oil tea, enhancing soil environment and improving quality and oil output of the oil tea.

Owner:安徽金农生态农业科技发展有限公司

Water soluble abrasive composition containing borax pentahydrate

InactiveUS6037316ASuitable for processingFine granularityInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsHard-surface cleanerWater soluble

The invention provides an improved surface safe, aqueous, liquid hard surface cleaner which contains a nonionic surfactant, or combination of nonionic and anionic surfactants, a water soluble abrasive, namely, borax pentahydrate, in an amount which takes at least a portion of the abrasive out of solution, and water.

Owner:THE CLOROX CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com