Phase transition temperature adjusting system and phase transition temperature adjusting cup

A technology of temperature regulation system and temperature regulation cup, which is applied in the direction of drinking water vessels, etc., can solve the problems of low temperature control accuracy, many limiting factors in the use process, complex system, etc., and achieve simple structure, easy operation, and little external environment influence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

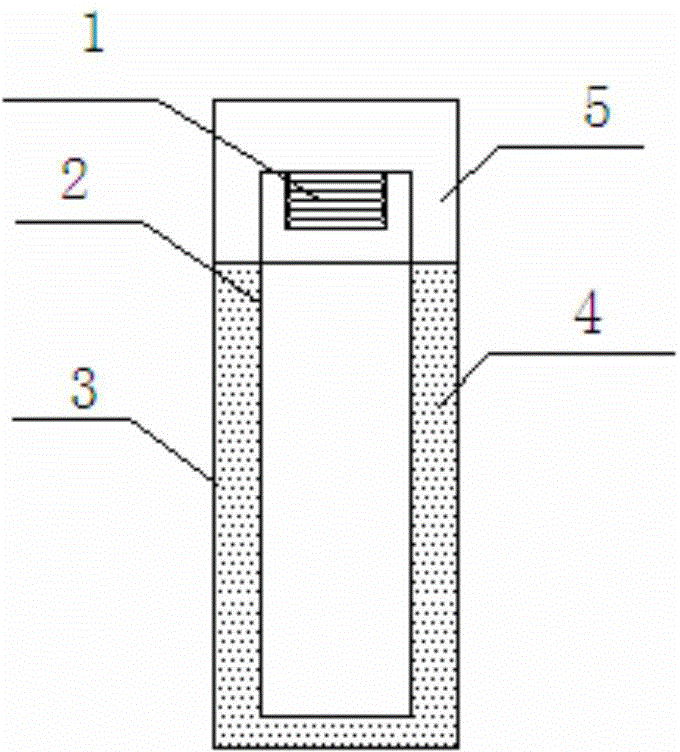

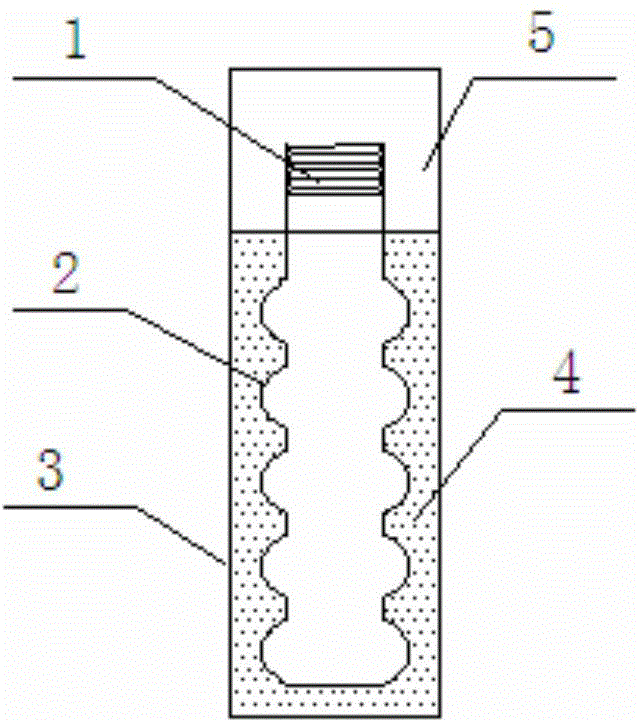

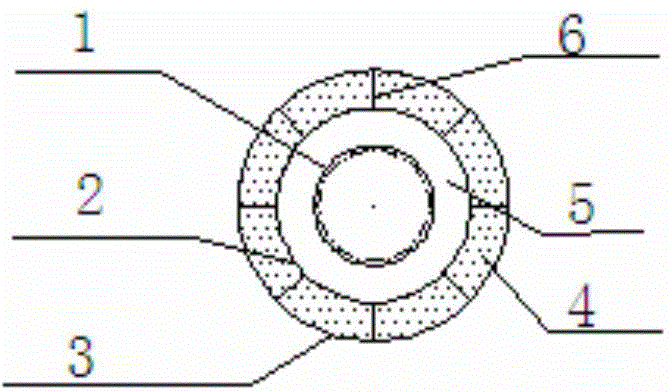

[0026] A phase-change temperature-regulating cup comprises a cup body shell, an inner cup shell, and a top cover, and a composite phase-change material is filled between the cup inner shell and the outer shell. The inner shell of the cup is selected from the inner shell of the corrugated structure. The ratio of the volume of the inner shell of the cup to the volume between the inner and outer shells is 1:1.15.

[0027] The composite phase change material includes a basic phase change material, a nucleating agent, a thermally conductive filler, and a thickening agent. The mass percentage of the basic phase change material is 75%, the addition amount of the nucleating agent is 5%, the addition amount of the thermally conductive filler is 20%, and the addition amount of the thickener is 0%. The basic phase change material is sodium sulfate decahydrate. The nucleating agent is borax. The thermally conductive filler is selected from two mixtures of graphite and carbon fiber, and...

Embodiment 2

[0029] A phase-change temperature-regulating cup comprises a cup body shell, an inner cup shell, and a top cover, and a composite phase-change material is filled between the cup inner shell and the outer shell. The inner shell of the cup adopts the inner shell of the tube outer fin structure. The ratio of the volume of the inner shell of the cup to the volume between the inner and outer shells is 1:1.1.

[0030] The composite phase change material includes a basic phase change material, a nucleating agent, a thermally conductive filler, and a thickening agent. The mass percentage of the basic phase change material is 95%, the addition amount of the nucleating agent is 0.5%, the addition amount of the thermally conductive filler is 3%, and the addition amount of the thickener is 1.5%. The basic phase change material is sodium carbonate decahydrate. Two kinds of nucleating agents are selected: strontium hydroxide octahydrate and strontium chloride hexahydrate, and the ratio is...

Embodiment 3

[0032] A phase-change temperature-regulating cup comprises a cup body shell, an inner cup shell, and a top cover, and a composite phase-change material is filled between the cup inner shell and the outer shell. The inner shell of the cup adopts the inner shell of the tube outer fin structure. The ratio of the volume of the inner shell of the cup to the volume between the inner and outer shells is 1:1.

[0033] The composite phase change material includes a basic phase change material, a nucleating agent, a thermally conductive filler, and a thickening agent. The mass percentage of the basic phase change material is 80%, the addition amount of the nucleating agent is 3%, the addition amount of the thermally conductive filler is 15%, and the addition amount of the thickener is 2%. The basic phase change material is selected from two mixtures of sodium acetate trihydrate and sodium thiosulfate pentahydrate in a ratio of 1:4. The nucleating agent is selected anhydrous disodium h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com