Patents

Literature

91 results about "Sodium Thiosulfate Pentahydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

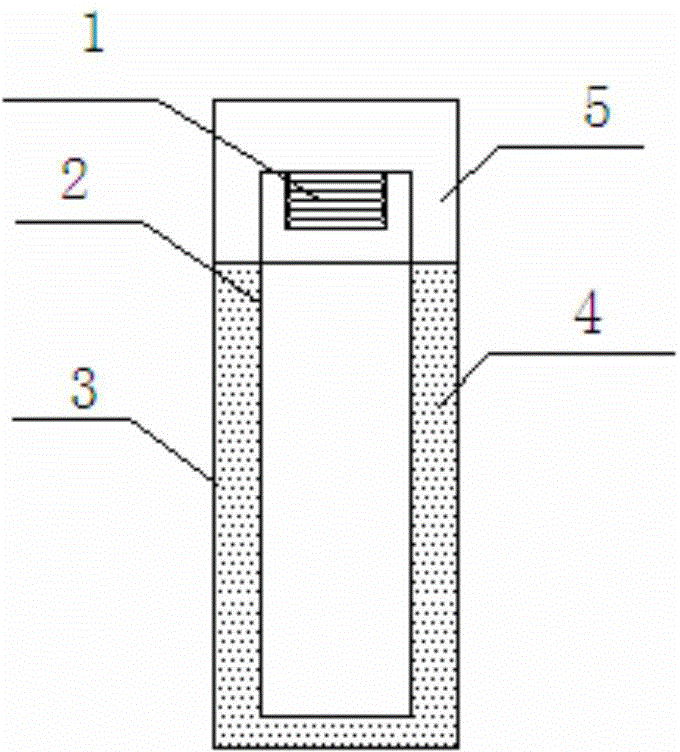

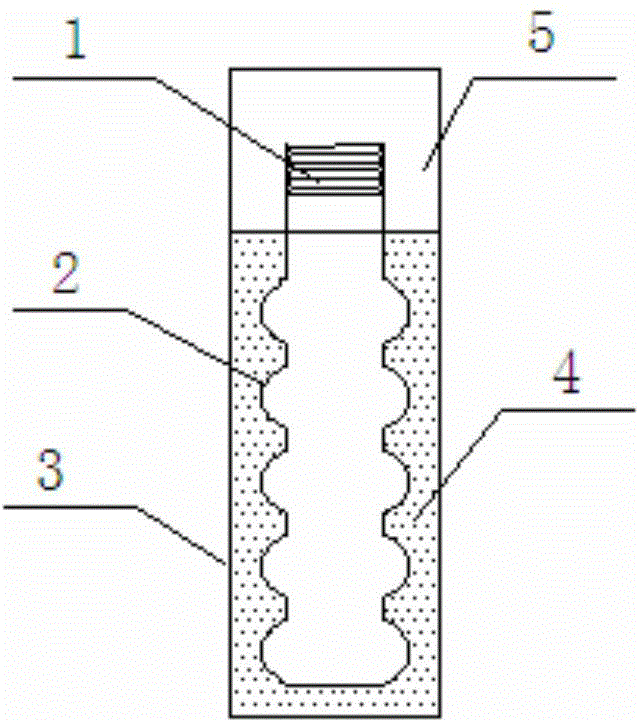

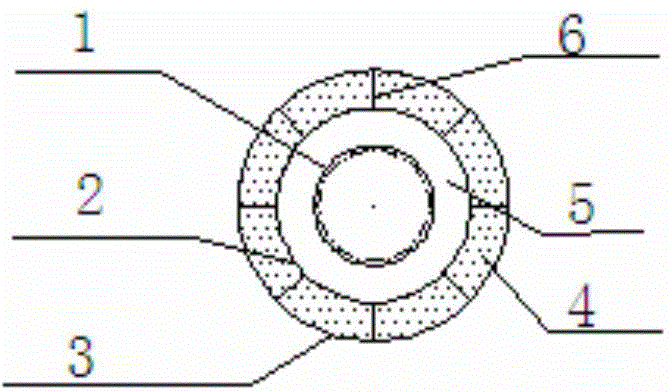

Phase transition temperature adjusting system and phase transition temperature adjusting cup

ActiveCN104887011AHeat absorption and release performance are highly matchedGuaranteed to drink normallyDrinking vesselsCarbon nanotubeSodium Thiosulfate Pentahydrate

Owner:YUTIAN ENERGY CO LTD

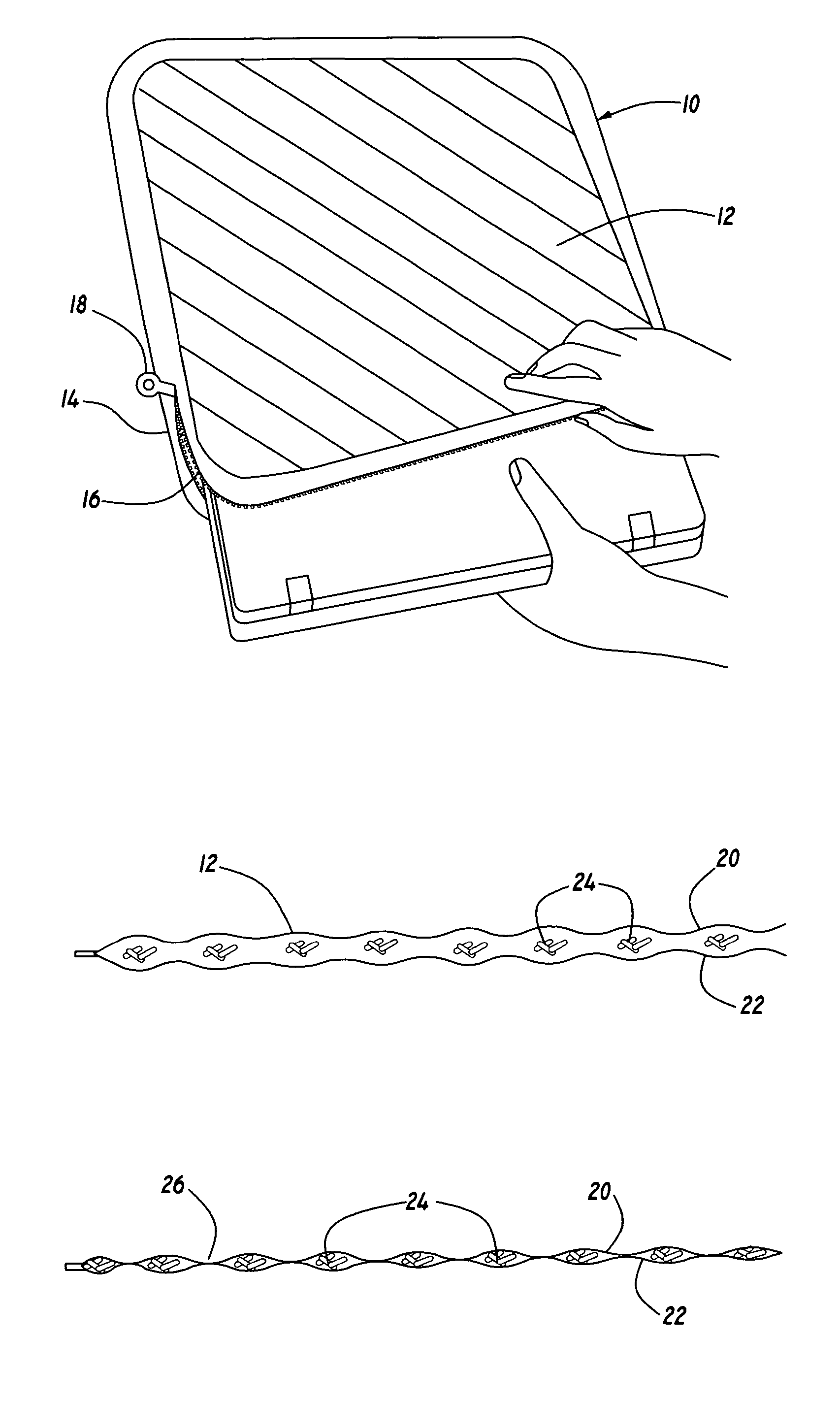

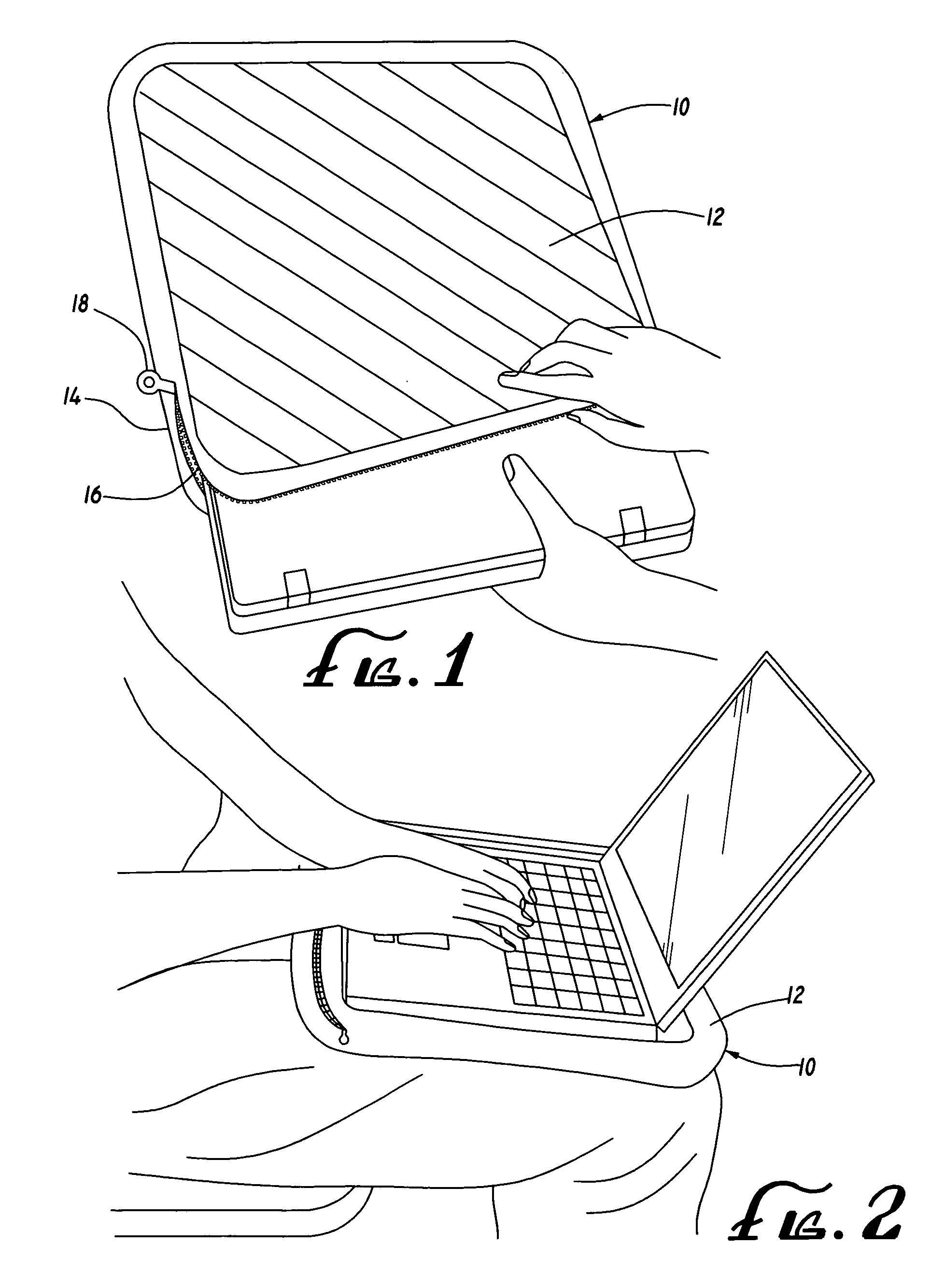

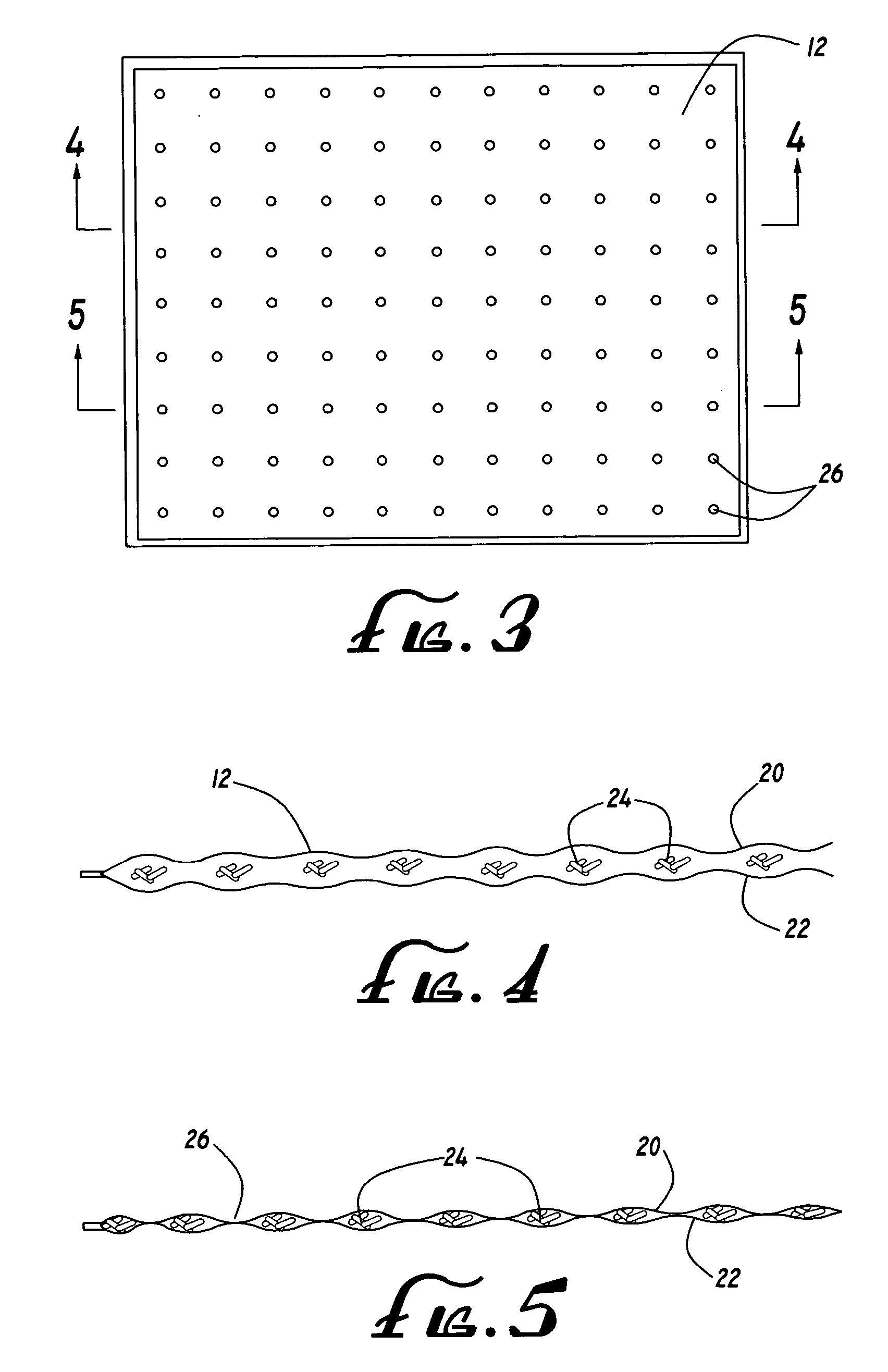

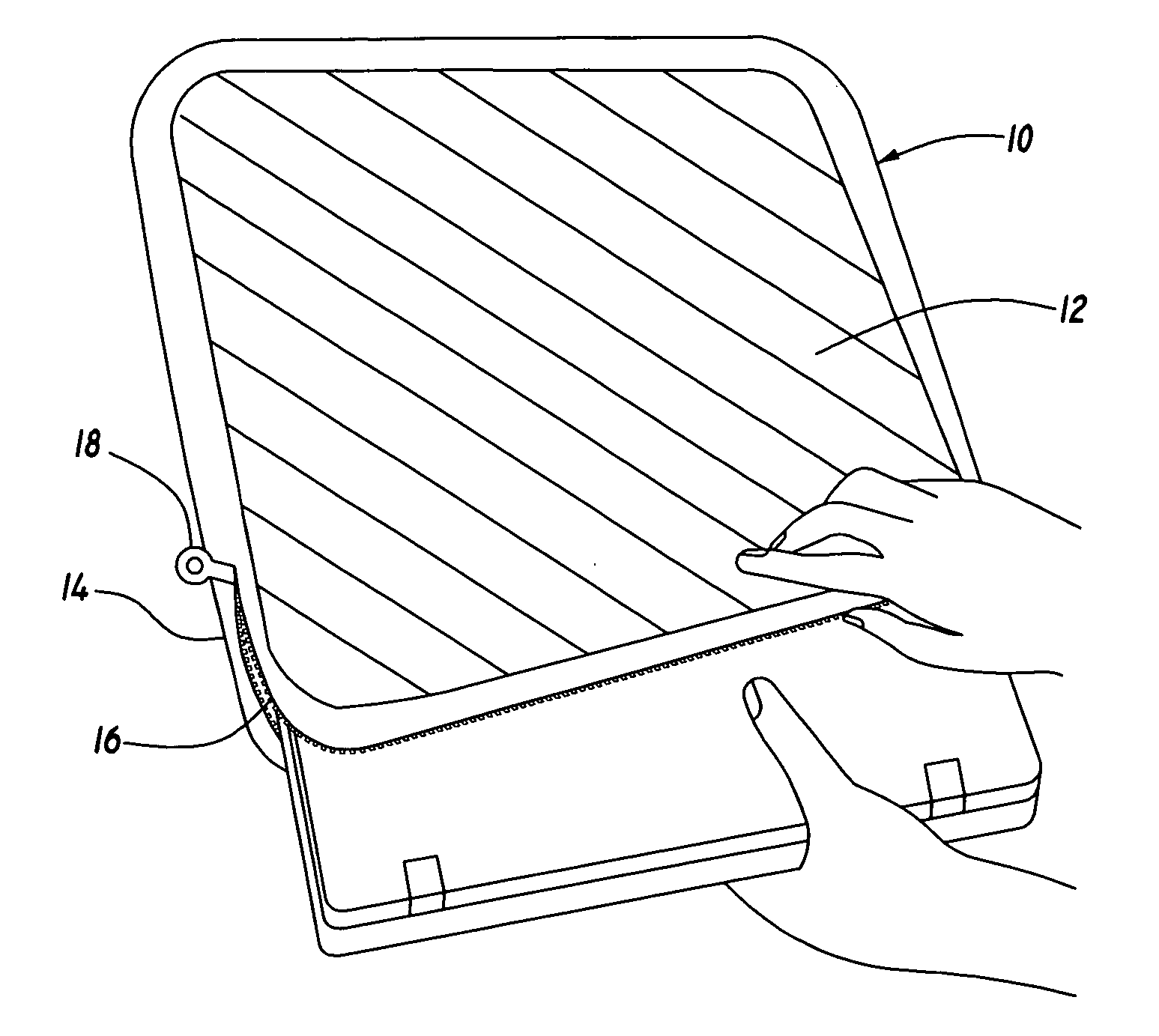

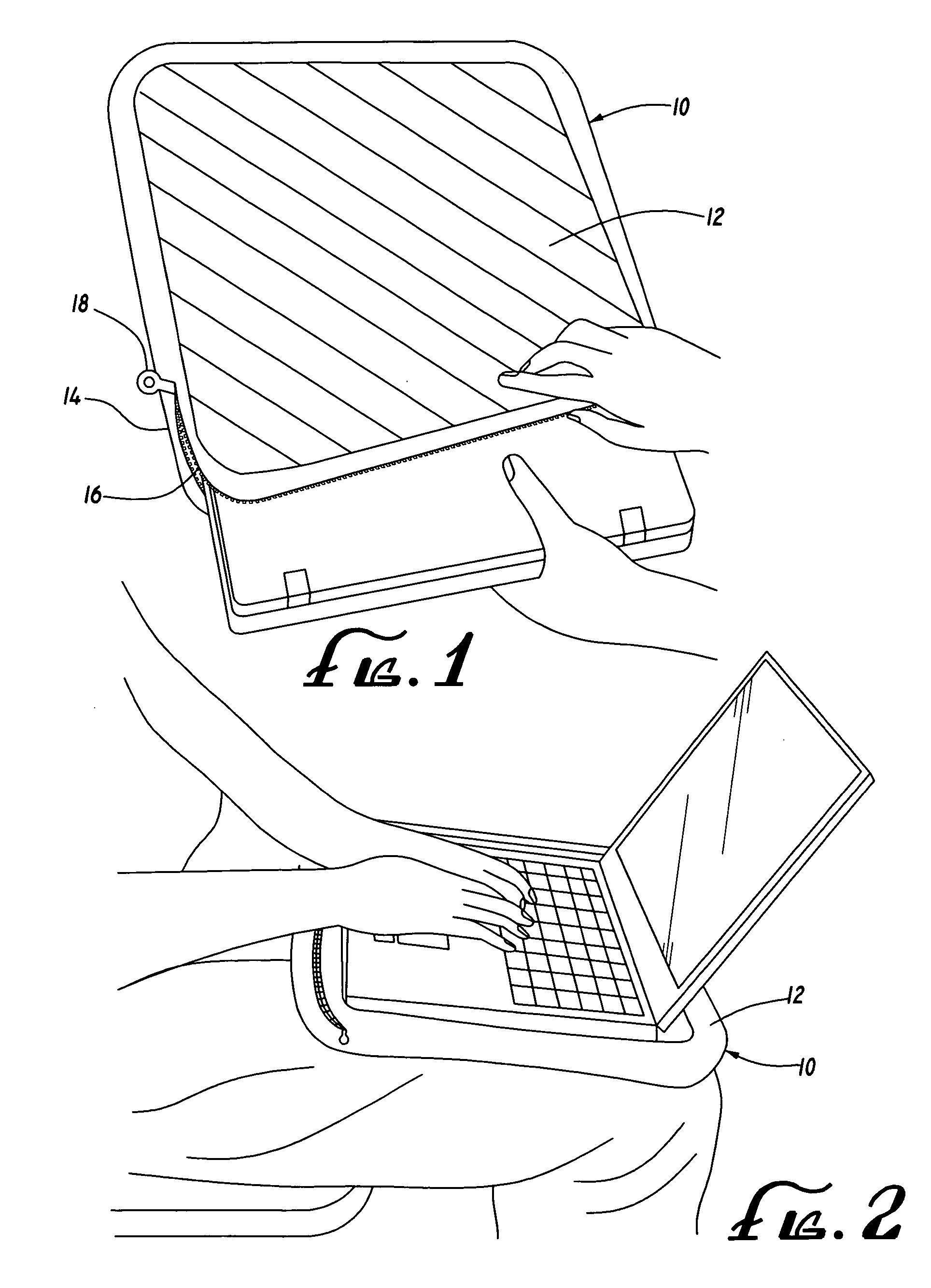

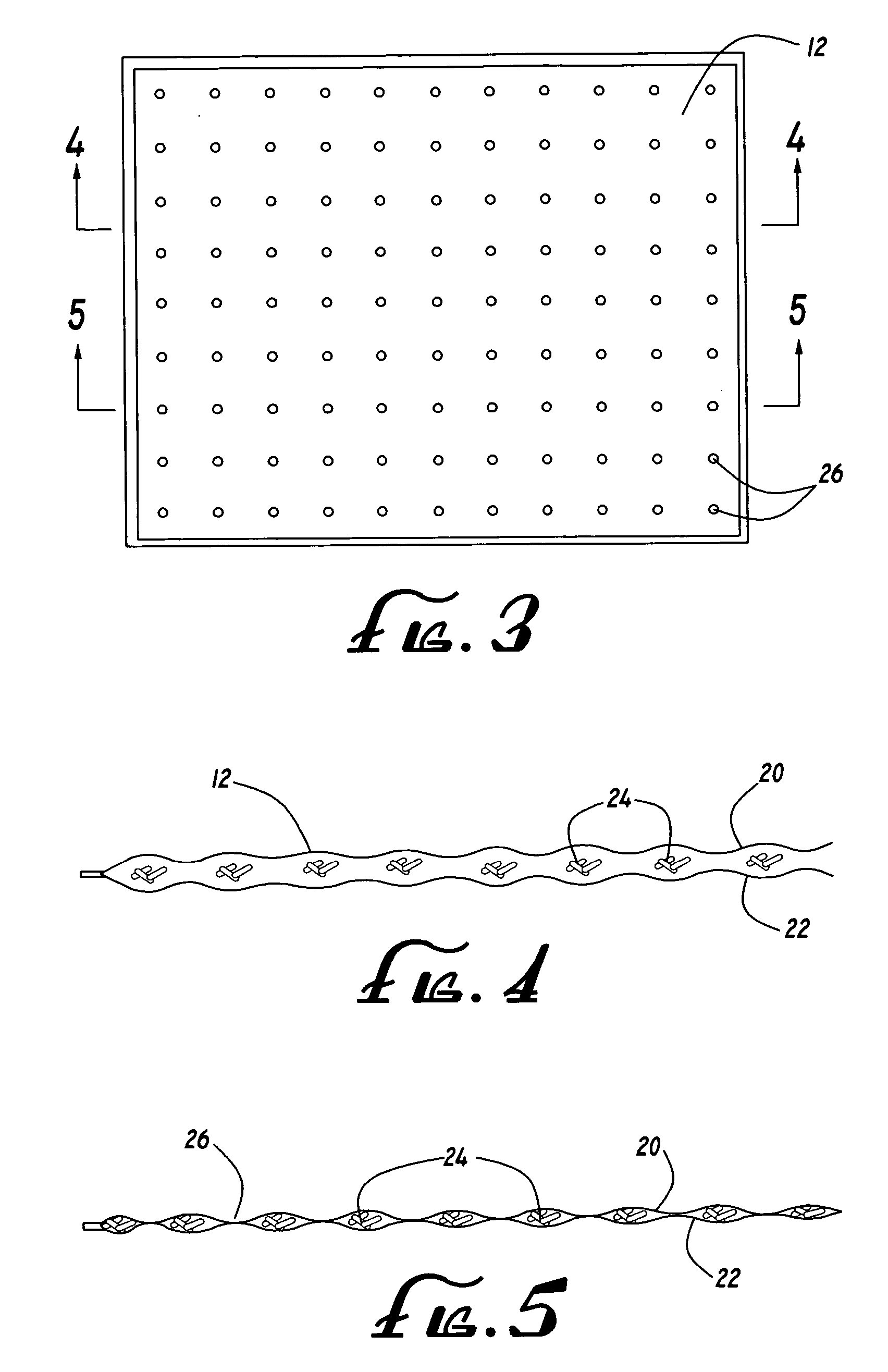

Conductive cooling pad for use with a laptop computer

InactiveUS7324340B2Details for portable computersCooling/ventilation/heating modificationsDisodium phosphateSodium Thiosulfate Pentahydrate

A self contained laptop computer cooling pad that does not require any electrical power to operate and will effectively and efficiently reduce the operating temperature of the computer and reduce the heat being transferred into the user's lap. The cooling pad contains a phase-changing compound such as sodium sulfate decahydrate, sodium carbonate decahydrate, disodium phosphate dodecahydrate or sodium thiosulfate pentahydrate, and may be made of a soft, flexible material that will contain the phase-changing compound and prevent excess shifting within the cooling pad. The cooling pad is placed under the laptop computer when operating the computer to effectively transfer heat away from the computer by conduction and prevent passage onto the user. The cooling pad may be in the form of a sleeve to additionally provide padded storage for the computer when not in use.

Owner:XIONG WEI

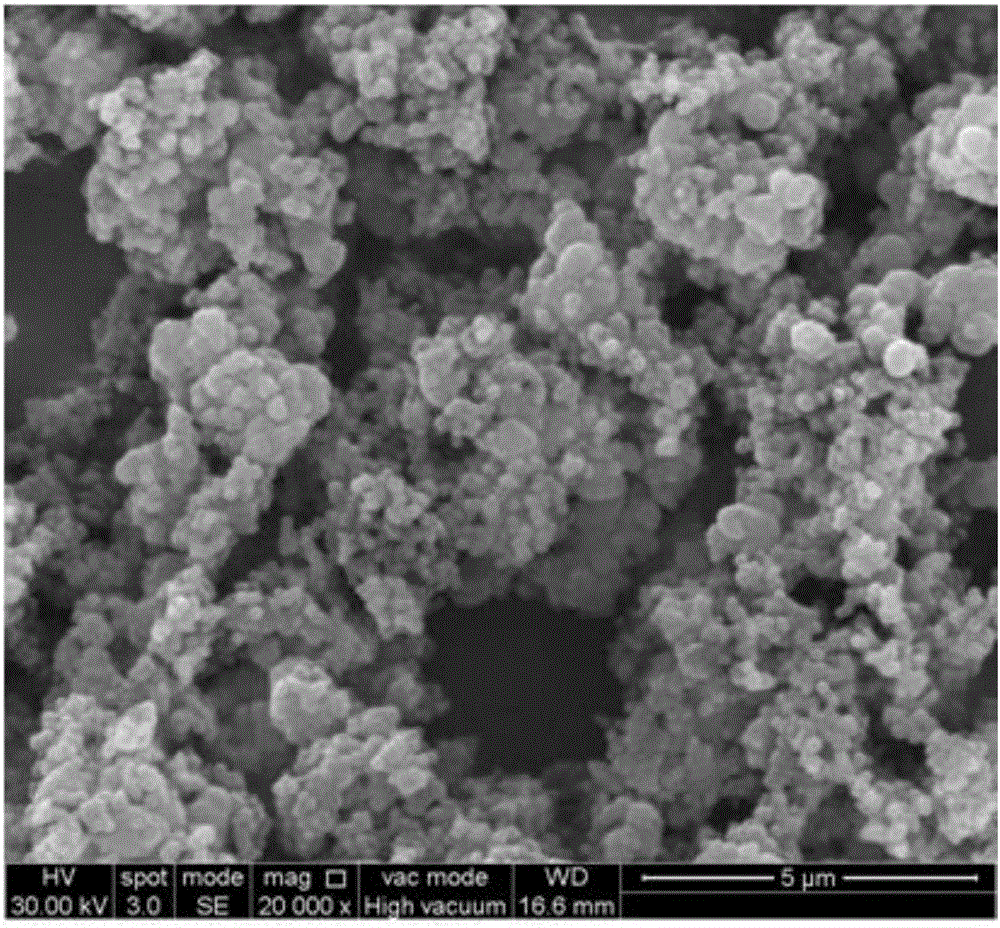

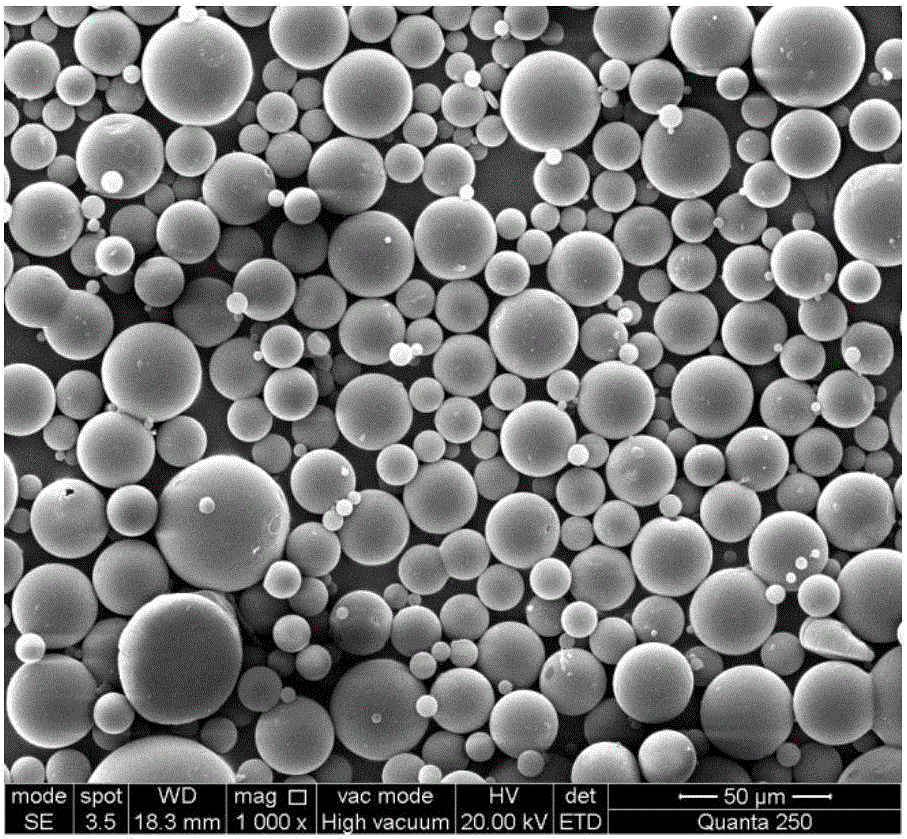

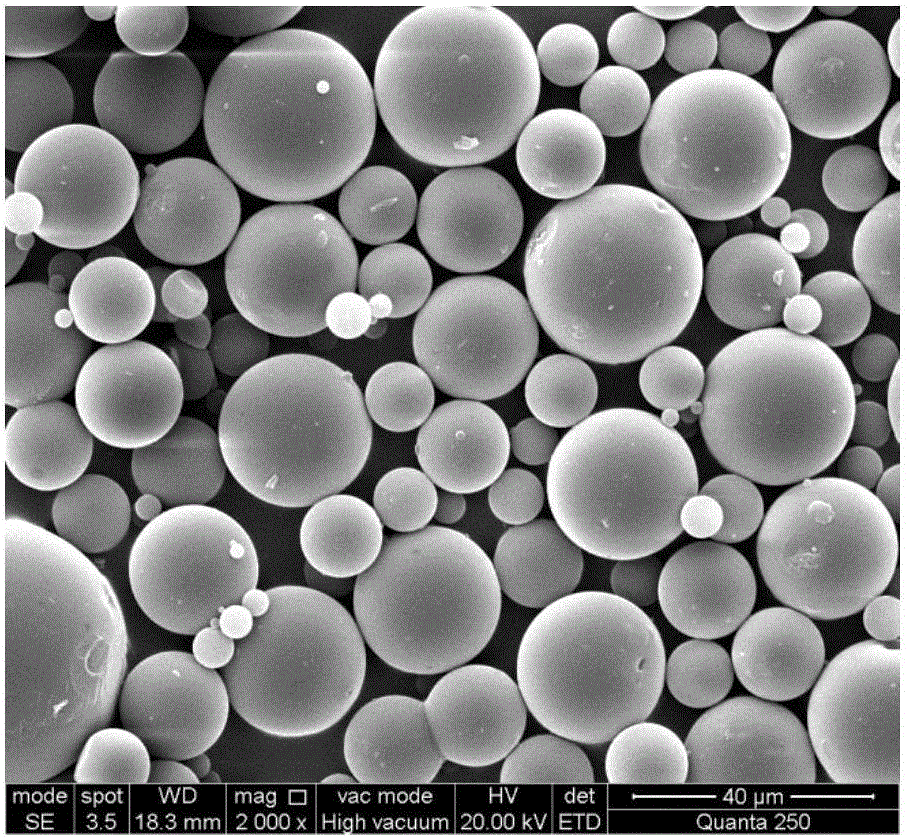

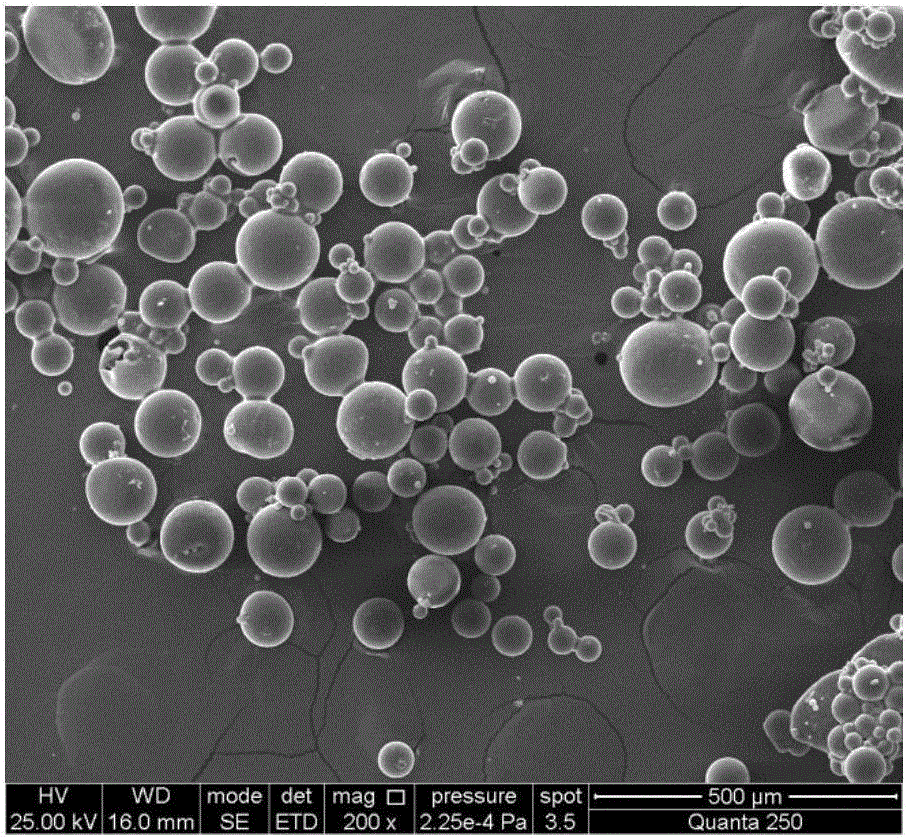

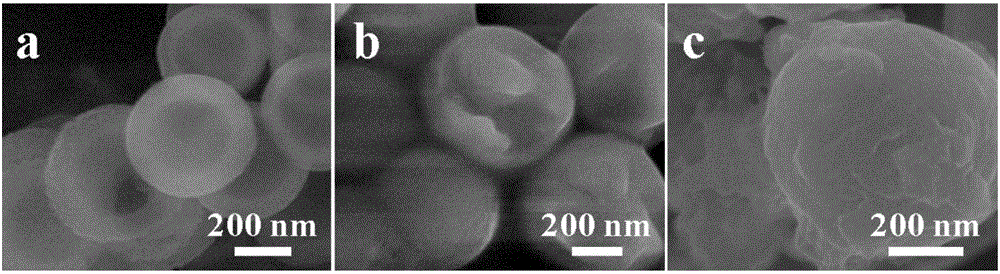

Inorganic hydrated salt phase change energy storage microcapsule and preparation method thereof

InactiveCN106244117AIncrease coverageSimple processHeat-exchange elementsCalcium Chloride HexahydratePotassium fluoride

Belonging to preparation methods of energy storage microcapsule materials, the invention provides an inorganic hydrated salt phase change energy storage microcapsule and a preparation method thereof. The energy storage microcapsule includes an inorganic hydrated salt serving as the core material and an inorganic material serving as the wall material. The core material is one or more of potassium fluoride dehydrate, sodium acetate trihydrate, sodium thiosulfate pentahydrate, calcium chloride hexahydrate, magnesium sulfate heptahydrate, barium hydroxide octahydrate, sodium sulfate decahydrate, sodium sulfate decahydrate, disodium hydrogen phosphate dodecahydrate, ammonium aluminium sulfate dodecahydrate, aluminum potassium sulfate dodecahydrate, and aluminum sulphate ocatadecahydrate. The wall material is one or more of silicon dioxide, calcium carbonate, alumina and titanium dioxide. The core material accounts for 30%-80% of the mass of the microcapsule composite material, and the wall material accounts for 20%-70% of the mass of the microcapsule energy storage material. The prepared phase change energy storage microcapsule material has a phase transition temperature of 25-100DEG C and a diameter of 0.1-50 micrometers. The phase change energy storage microcapsule has the advantages of high encapsulation rate, good sealing performance, large phase change potential heat value, and simple preparation method, and has great industrial application prospect.

Owner:CHINA UNIV OF MINING & TECH

Micronized tanaproget, compositions, and methods of preparing the same

The present invention provides compositions, desirably pharmaceutical compositions, containing micronized tanaproget. The compositions can also contain microcrystalline cellulose, croscarmellose sodium, anhydrous lactose, magnesium stearate, micronized edetate calcium disodium hydrous, and micronized sodium thiosulfate pentahydrate. The compositions are useful in contraception and hormone replacement therapy and in the treatment and / or prevention of uterine myometrial fibroids, benign prostatic hypertrophy, benign and malignant neoplastic disease, dysfunctional bleeding, uterine leiomyomata, endometriosis, polycystic ovary syndrome, and carcinomas and adenocarcinomas of the pituitary, endometrium, kidney, ovary, breast, colon, and prostate and other hormone-dependent tumors, and in the preparation of medicaments useful therefor. Additional uses include stimulation of food intake.

Owner:WYETH LLC

Inorganic hydrous salt phase change microcapsule energy-storage material and preparing method

InactiveCN106221674AAchieve solidificationImprove heat transfer efficiencyHeat-exchange elementsCalcium Chloride HexahydrateSodium Thiosulfate Pentahydrate

The invention relates to a preparing method of an inorganic hydrous salt phase change microcapsule energy-storage material and belongs to preparing methods of energy-storage materials. The energy-storage material comprises a core material and a wall material, wherein the core material is prepared from one or more of calcium chloride hexahydrate, sodium sulfate decahydrate, sodium thiosulfate pentahydrate, disodium hydrogen phosphate dodecahydrate, sodium acetate trihydrate and sodium carbonate decahydrate inorganic hydrous salt, and the wall material is prepared from one or more of polystyrene, polymethyl methacrylate, poly(ethyl acrylate), polyurethane, cellulose acetate butyrate (CAB) and a diphenylmethane diisocyanate polymer, the core material accounts for 30-80% of the microcapsule energy-storage material by mass, and the wall material is prepared from the polymer and accounts for 20-70% of the microcapsule energy-storage material by mass. The phase change point of the obtained phase change microcapsule energy-storage material ranges from 20 DEG C to 90 DEG C, and the particle size ranges from 1 micrometer to 100 micrometers. The phase change microcapsule energy-storage material prepared with the method is high in encapsulation rate, good in sealing performance, large in phase change latent heat value, simple in preparing method and large in industrial application prospect.

Owner:CHINA UNIV OF MINING & TECH

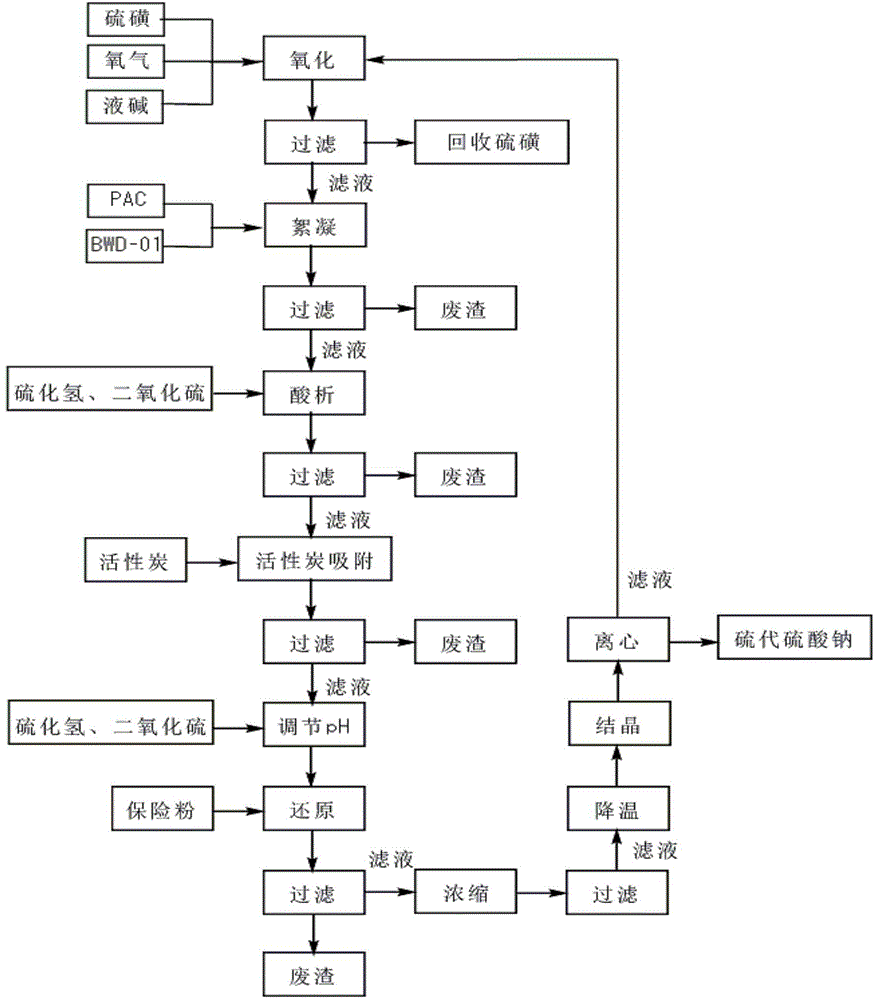

Method for treating disperse blue 56 reducing mother-liquor wastewater

ActiveCN104609618AMake full use of resourcesIncrease added valueThiosulfates/dithionites/polythionitesMultistage water/sewage treatmentFlocculationSulfur

The invention discloses a method for treating disperse blue 56 reducing mother-liquor wastewater. The method is characterized by comprising the following steps: (1) reduction: adding sulfur into disperse blue 56 reducing mother-liquor wastewater, and heating and stirring for reaction; (2) oxidation: pumping oxygen into the reduced wastewater for oxidation, and filtering to obtain a filtrate I and unreacted sulfur; (3) flocculation: adding a flocculant into the filtrate I, stirring for flocculation, and filtering to obtain a filtrate II; (4) reductive decoloration: adding a reductive decolorizer into the pickled filtrate II, and concentrating and separating to obtain a filtrate V and a filter cake I; (5) crystallization: adding a sodium thiosulfate seed crystal into the cooled filtrate V for crystallization, and separating to obtain solid sodium thiosulfate pentahydrate and a centrifugate. The method is concise in technological process, simple to operate, and mild in conditions, can treat wastewater through additional cheap raw materials to produce high-value products, makes the best of resources in wastewater and improves the added value of wastewater treatment.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

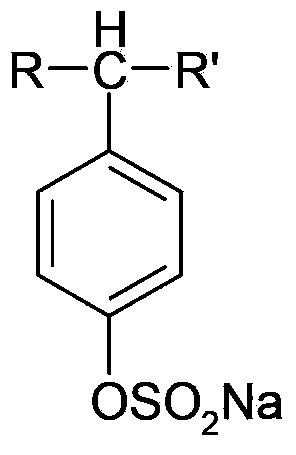

Oil well deep composite blocking profile control agent and application thereof

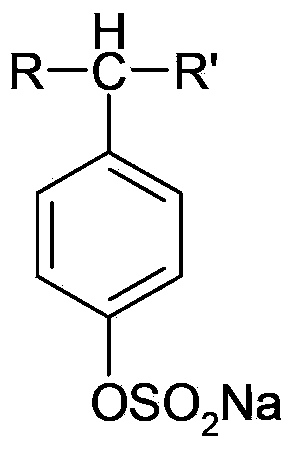

ActiveCN103421475ANot easy to flowPlay a sealing roleDrilling compositionSealing/packingSulfonateSodium Thiosulfate Pentahydrate

The invention relates to an oil well deep composite blocking profile control agent and the application thereof. The composite blocking profile control agent comprises the following components: gel blocking agent solution, particle blocking agent, authigene air source and surface active agent, wherein in the gel blocking agent solution, the weight ratio of the partially hydrolyzed polyacrylamide, the sodium bichromate and the sodium thiosulfate pentahydrate is 1:0.025:0.35, a water solution with the total weight concentration of 0.5-1% is prepared from the partially hydrolyzed polyacrylamide, sodium bichromate and sodium thiosulfate pentahydrate, and hydrochloric acid capable of adjusting the pH of the gel blocking agent solution to 3.5-4.5 is contained; the particle blocking agent comprises phenolic resin and phenolic resin, wherein the weight ratio of the phenolic resin and the phenolic resin is 1:0.06; the authigene air source is CO(NH2) 2; the surface active agent is alkylaryl sulfonate; the weight ratio of the gel blocking agent solution, the particle blocking agent, the authigene air source and the surface active agent is 60:6:2:1. According to the composite blocking profile control agent disclosed by the invention, deep blocking and profile control at the oil layer of an oil well is realized through the Jamin Effect of foam generated in the deep part of stratum and the physical blocking function of a solid phase blocking agent.

Owner:PETROCHINA CO LTD

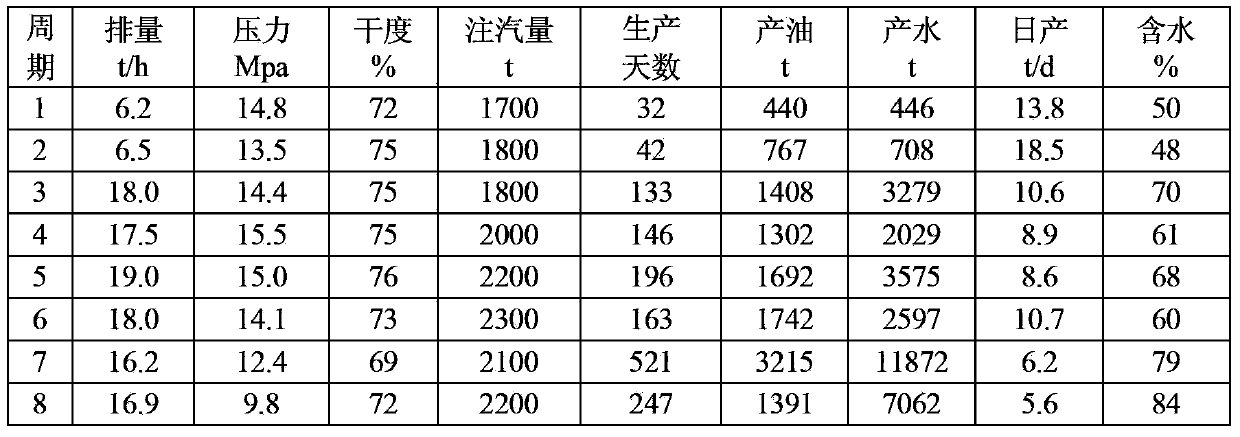

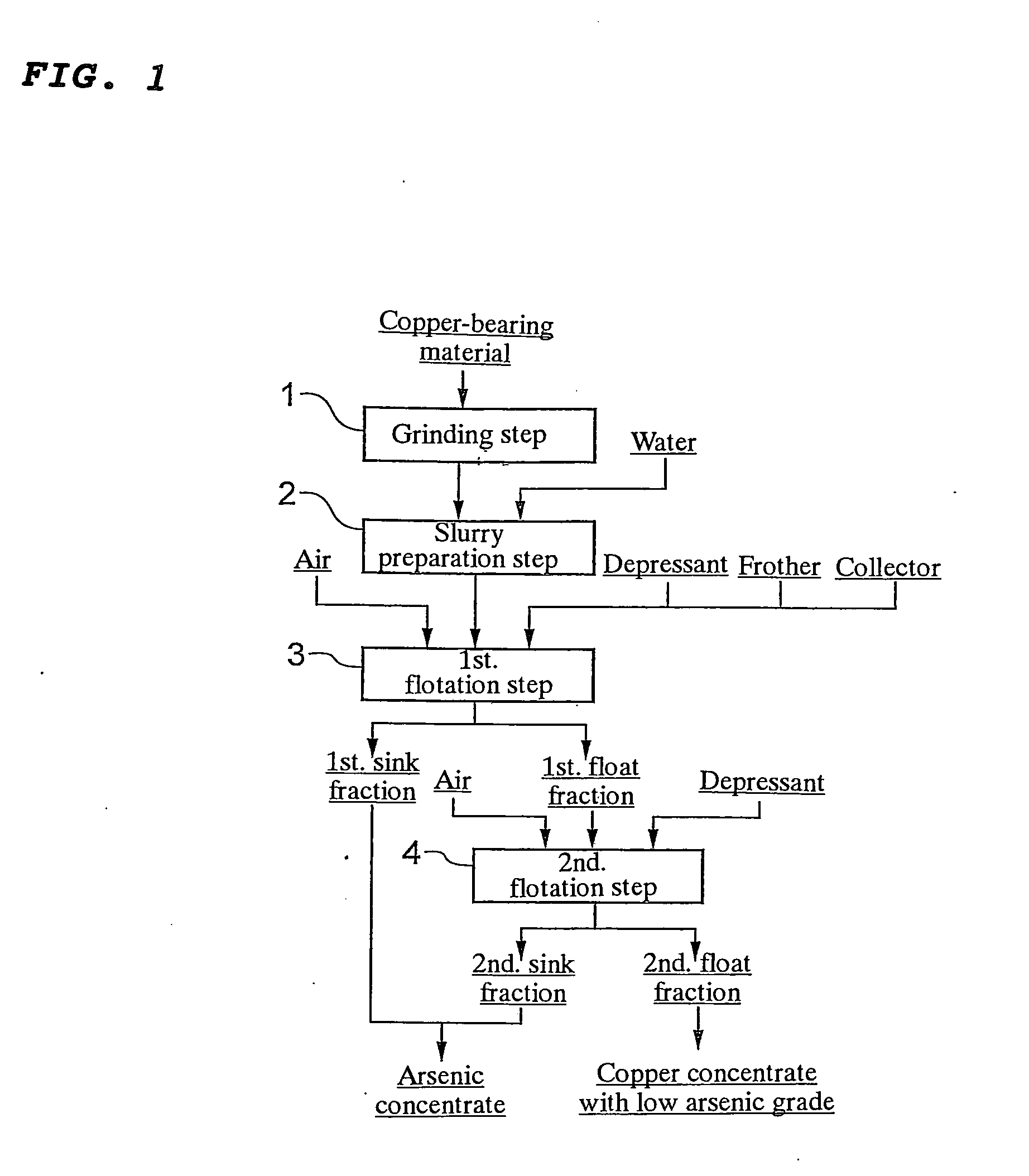

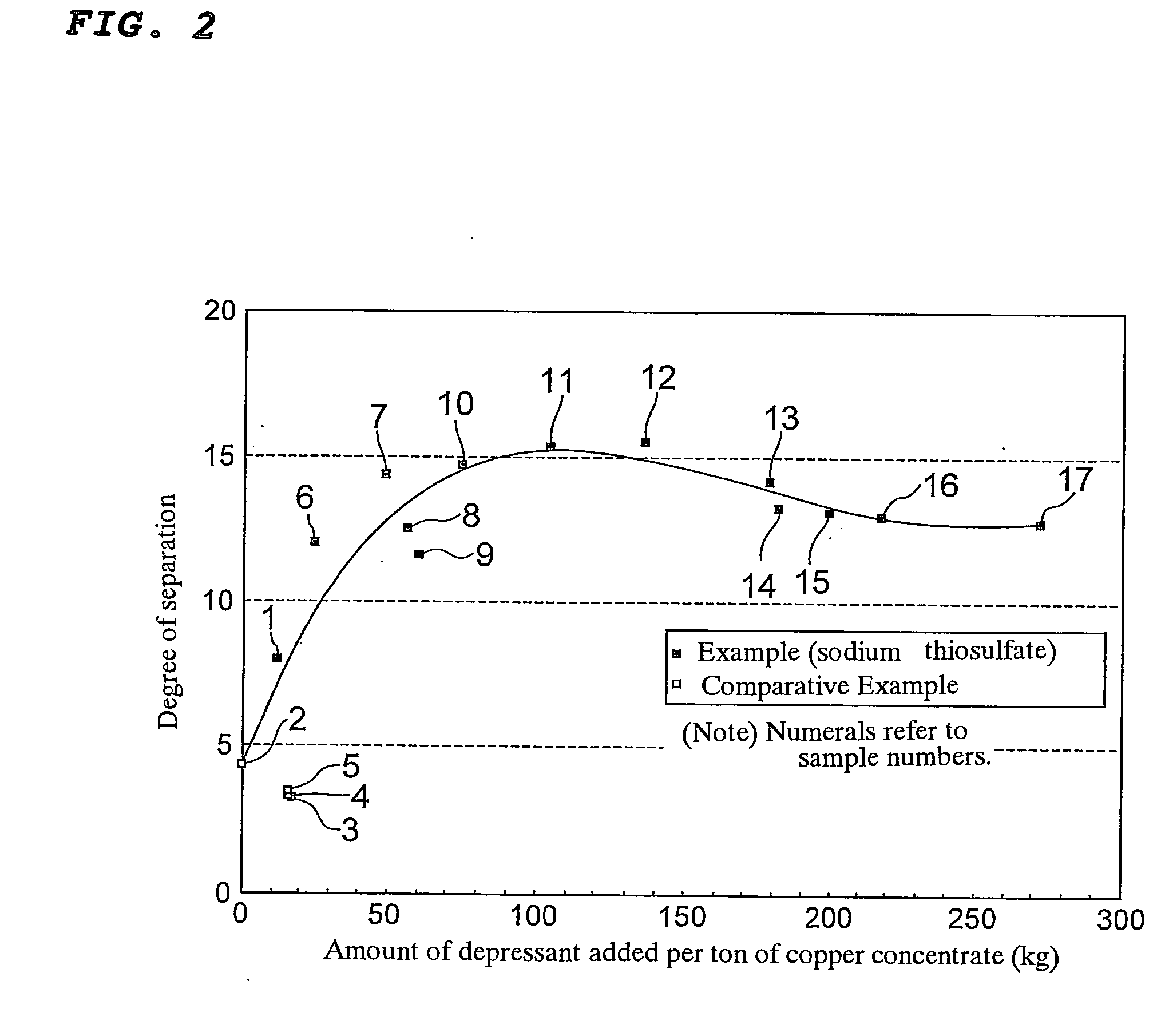

Method for separating arsenic mineral from copper-bearing material with high arsenic grade

ActiveUS20110094942A1Efficiently obtainedReduce adverse effectsFlotationCentrifugesSodium Thiosulfate PentahydrateSlurry

There is provided a method for separating an arsenic mineral from a copper-bearing material containing arsenic, such as a copper ore or a copper concentrate, to obtain a copper concentrate with low arsenic grade.The method for separating an arsenic mineral from a copper-bearing material by flotation includes adding a flotation agent containing a depressant, a frother, and a collector to a slurry composed of a copper-bearing material containing arsenic, and blowing air into the slurry to float a copper concentrate, wherein the depressant is sodium thiosulfate. The sodium thiosulfate is preferably added in an amount of 10 kg or more and 200 kg or less in terms of sodium thiosulfate pentahydrate per ton of copper-bearing material to be subjected to flotation. Further, the oxidation-reduction potential of the slurry to be subjected to flotation, as measured against a silver / silver chloride reference electrode, is preferably −10 mV or more and 50 mV or less.

Owner:SUMITOMO METAL MINING CO LTD

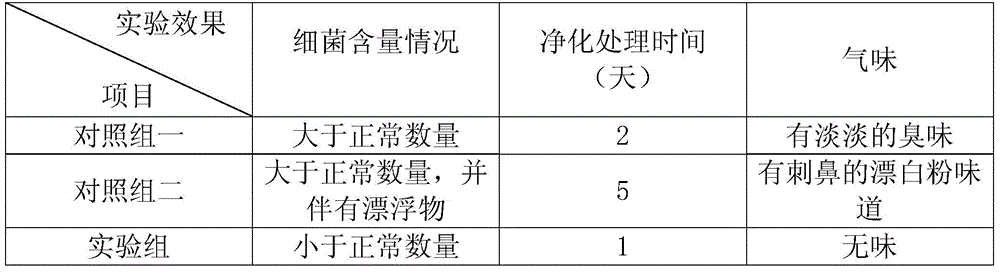

Sewage treatment formula and preparation method thereof

InactiveCN105692925AImprove adsorption capacityQuick killSpecific water treatment objectivesTreatment using complexing/solubilising chemicalsChlorine dioxideSodium Thiosulfate Pentahydrate

The invention discloses a sewage treatment formula and a preparation method thereof. The sewage treatment formula is prepared from, by weight, 55-85 parts of polyacrylamide, 30-54 parts of chlorine dioxide, 35-65 parts of sodium thiosulfate pentahydrate, 40-60 parts of diluted hydrochloric acid, 50-80 parts of aluminium polychlorid, 35-55 parts of inorganic polyphosphates, 20-45 parts of sodium hypochlorite, 100-120 parts of cohesive soil, 80-110 parts of talcum powder, 40-60 parts of activated carbon cellosilk, 45-65 parts of nanometer magnetic powder, 20-40 parts of poval, 10-30 parts of triethylenediamine and 30-60 parts of magnesium silicate. The sewage treatment formula and the preparation method of the sewage treatment formula have the advantages of rapid headwaters purification, sterilization and dirt precipitation.

Owner:张锐

Cooling pad for laptop computer

InactiveUS20060232935A1Details for portable computersCooling/ventilation/heating modificationsDisodium phosphateThermal relief

A self contained laptop computer cooling pad that does not require any electrical power to operate and will effectively and efficiently reduce the operating temperature of the computer and reduce the heat being transferred into the user's lap. The cooling pad contains a phase-changing compound such as sodium sulfate decahydrate, sodium carbonate decahydrate, disodium phosphate dodecahydrate or sodium thiosulfate pentahydrate, and may be made of a soft, flexible material that will contain the phase-changing compound and prevent excess shifting within the cooling pad. The cooling pad is placed under the laptop computer when operating the computer to effectively transfer heat away from the computer by conduction and prevent passage onto the user. The cooling pad may be in the form of a sleeve to additionally provide padded storage for the computer when not in use.

Owner:XIONG WEI

Micronized Tanaproget, Compositions, and Methods of Preparing the Same

InactiveUS20100189789A1Powder deliveryOrganic active ingredientsEccentric hypertrophySodium Thiosulfate Pentahydrate

The present invention provides compositions, desirably pharmaceutical compositions, containing micronized tanaproget. The compositions can also contain microcrystalline cellulose, croscarmellose sodium, anhydrous lactose, magnesium stearate, micronized edetate calcium disodium hydrous, and micronized sodium thiosulfate pentahydrate. The compositions are useful in contraception and hormone replacement therapy and in the treatment and / or prevention of uterine myometrial fibroids, benign prostatic hypertrophy, benign and malignant neoplastic disease, dysfunctional bleeding, uterine leiomyomata, endometriosis, polycystic ovary syndrome, and carcinomas and adenocarcinomas of the pituitary, endometrium, kidney, ovary, breast, colon, and prostate and other hormone-dependent tumors, and in the preparation of medicaments useful therefor. Additional uses include stimulation of food intake.

Owner:WYETH LLC

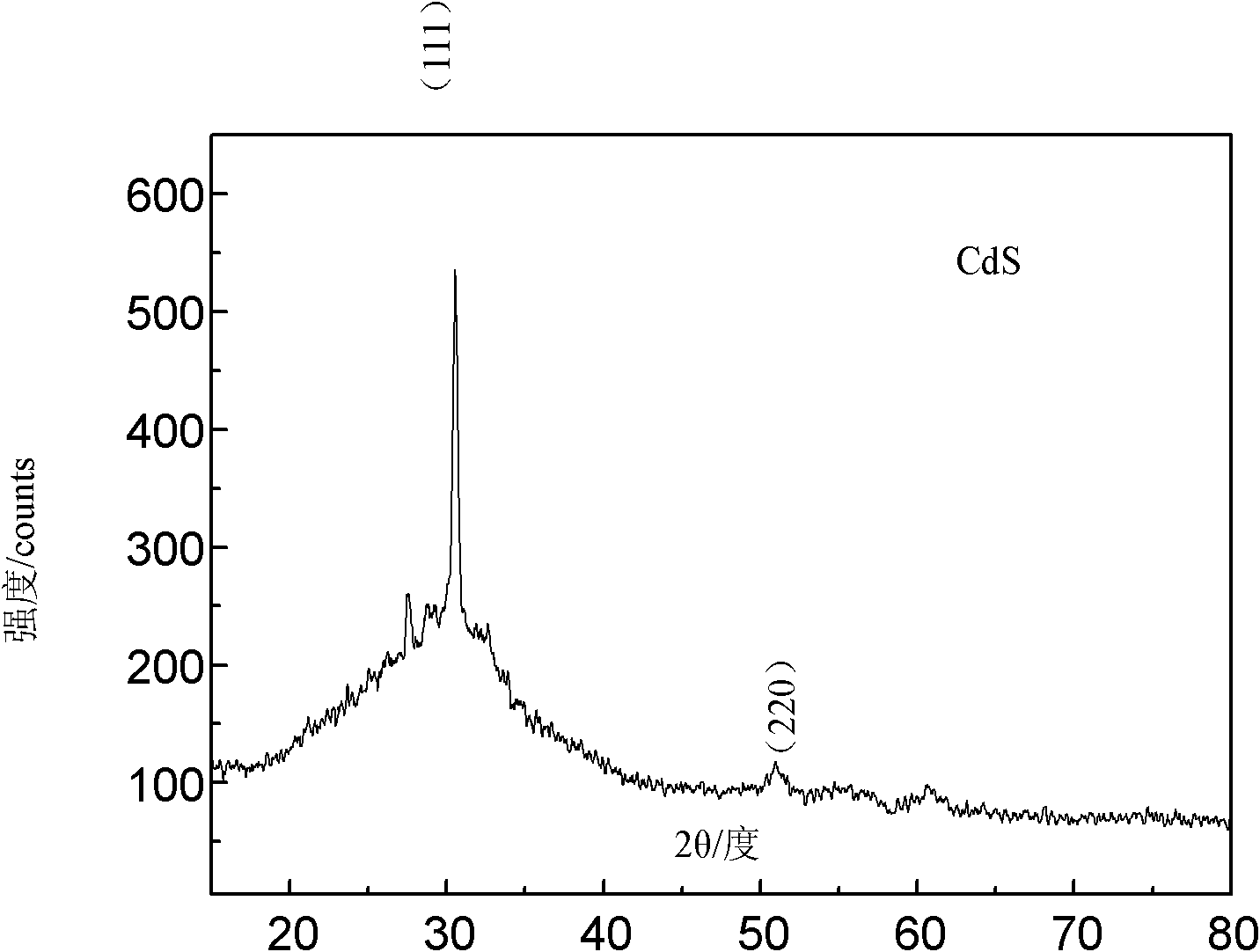

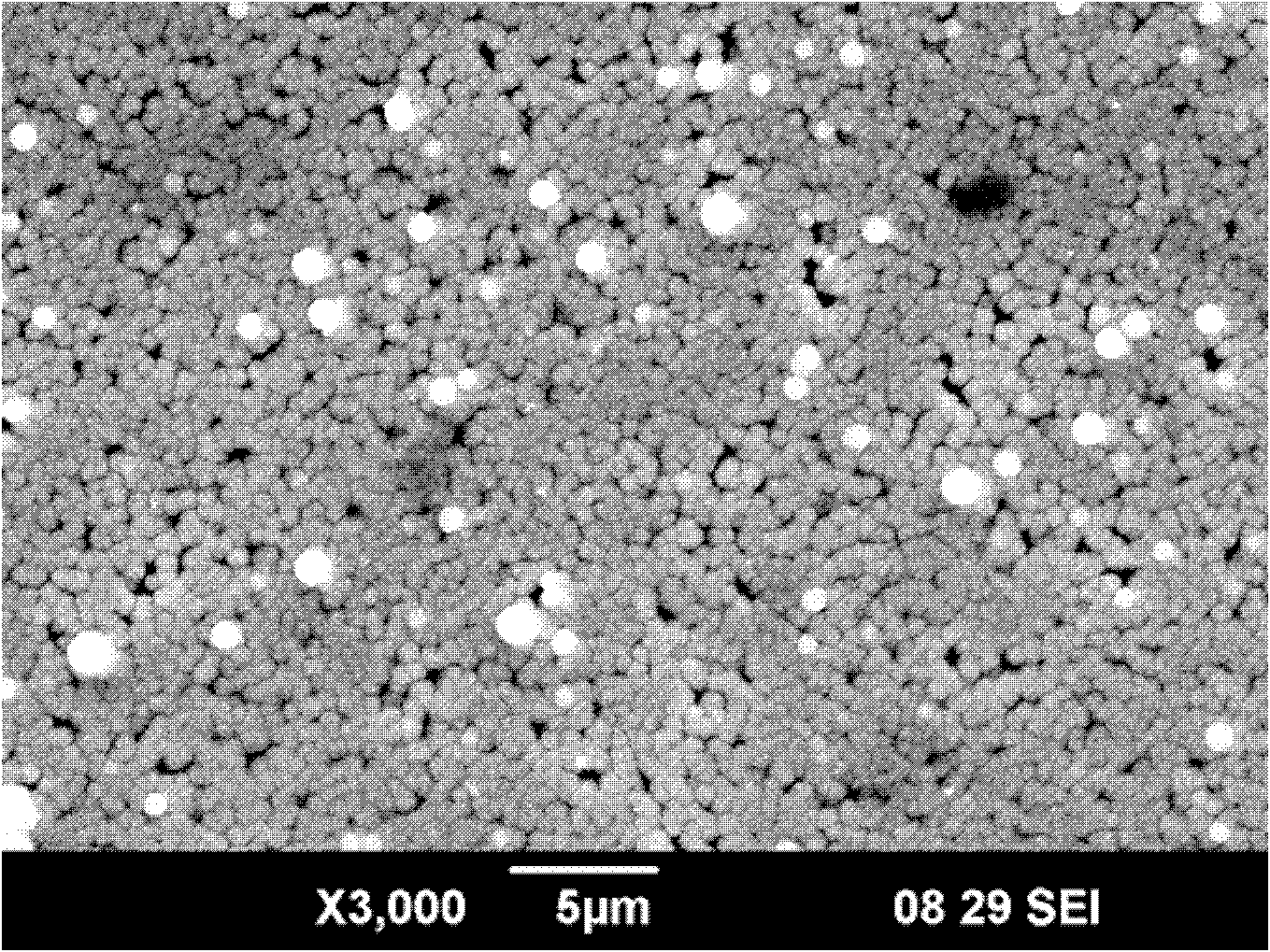

Method for preparing spherical cadmium sulfide (CdS) semiconductor film

InactiveCN101847583ASimple process equipmentHigh purityElectrolytic inorganic material coatingSemiconductor/solid-state device manufacturingProcess equipmentSodium Thiosulfate Pentahydrate

The invention relates to a method for preparing a spherical cadmium sulfide (CdS) semiconductor film, which comprises the following steps of: putting cadmium acetate into a beaker, dripping oleic acid into the beaker, uniformly mixing the cadmium acetate and the oleic acid, and adding distilled water into the mixture to obtain solution A; adding sodium thiosulfate pentahydrate into the solution A and performing ultrasonic dispersion to obtain solution B; adding a film forming aid into the solution B and performing ultrasonic processing to form a uniform sol C; fixing a substrate to a cathode of an electrodeposition device, immersing the substrate in the sol C for electrodeposition to obtain a cadmium sulfide film D, and diluting the solution subjected to electrodeposition by ten times to obtain solution E; and pouring the solution E into a hydrothermal reaction kettle, putting the film D into the hydrothermal reaction kettle, immersing the film D in the solution E, naturally cooling to room temperature after the reaction is finished, taking the film D out, and cleaning and drying the hydrothermal reaction kettle to obtain a CdS photoelectric film on the surface of the substrate. In the method, the reaction is finished in a liquid phase and subsequent crystallization and thermal treatment are avoided; processing equipment is simple; the quality of the film is controlled by controlling the deposition voltage, deposition time, the pH value of a precursor and microwave hydrothermal postprocessing; and the obtained film has high purity and uniformity.

Owner:SHAANXI UNIV OF SCI & TECH

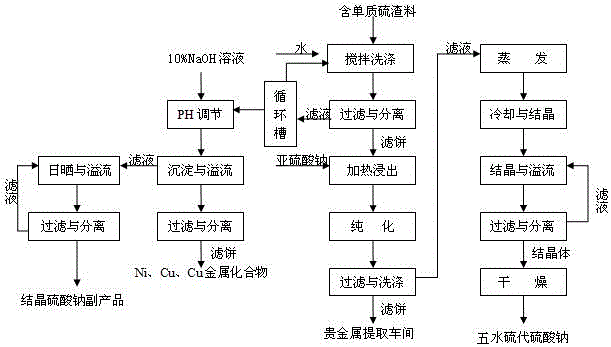

Production method of sodium thiosulfate pentahydrate

InactiveCN106430114AEfficient recyclingIncrease productivityThiosulfates/dithionites/polythionitesNickel oxides/hydroxidesSlagSulfite salt

The invention relates to a production method of sodium thiosulfate pentahydrate. The method is characterized by comprising the following steps: (1) adding water into an elemental sulfur-containing slag material, stirring and washing, filtering and separating to obtain a filter cake A and filtrate A; (2) adding sodium sulfite and water into the filter cake A, wherein the adding amount of the sodium sulfite is 1.1-1.2 times of a theoretical value, and the adding amount of the water is 15-20 times of the mass of the sulfur-containing slag material; carrying out agitation leaching on an obtained mixture under the condition of heating; after that, filtering and washing to obtain a precious metal-containing filter cake B and filtrate B; evaporating the filtrate B, carrying out cooling crystallization and spillover, filtering and separating, and drying to obtain the sodium thiosulfate pentahydrate. After the production method is adopted, valuable elements are effectively recycled, and two products, i.e., the sodium thiosulfate pentahydrate and sodium sulfate are obtained.

Owner:JINCHUAN GROUP LIMITED

Preparation method of adsorbent containing SnO2/Sb2O5, product and application of adsorbent

ActiveCN103861550AImprove adsorption capacityEnhanced interactionOther chemical processesRadioactive decontaminationSorbentUltraviolet

The invention relates to a preparation method of an adsorbent containing SnO2 / Sb2O5. According to the method, SbCl3 with a stable chemical property and low toxicity is taken as a Sb source, sodium thiosulfate pentahydrate, namely SnCl4, is utilized as a Sn source, and a SnO2 / Sb2O5 binary composite oxide is prepared. The preparation method comprises the following steps of oxidizing Sb<3+> as Sb(V) in a non-water system taking alcohol as a solvent by adopting the combination of H2O2 oxidation and ultraviolet irradiation, further carrying out hydrolytic precipitation on Sb(V) and Sb<4+> by utilizing a small amount of water introduced by utilizing H2O2 solution as a reactant, and forming a binary SnO2 / Sb2O5 composite oxide. The method provided by the invention has the advantages that the hydrolyzing speed of Sb<3+> is slow, the generation of the Sb2O3 is effectively controlled, the Sn / Sb2O5 binary composite oxide with the Sb<3+> oxygenation efficiency being 100% is obtained, the adsorbent can remove the radioactive isotope Co ions and a complex thereof and stable isotope Co ions and a complex thereof, and the adsorptive property of the SnO2 / Sb2O5 binary composite oxide and pure Sb2O5 obtained by the introduction of Sb is improved by 200 times.

Owner:TSINGHUA UNIV

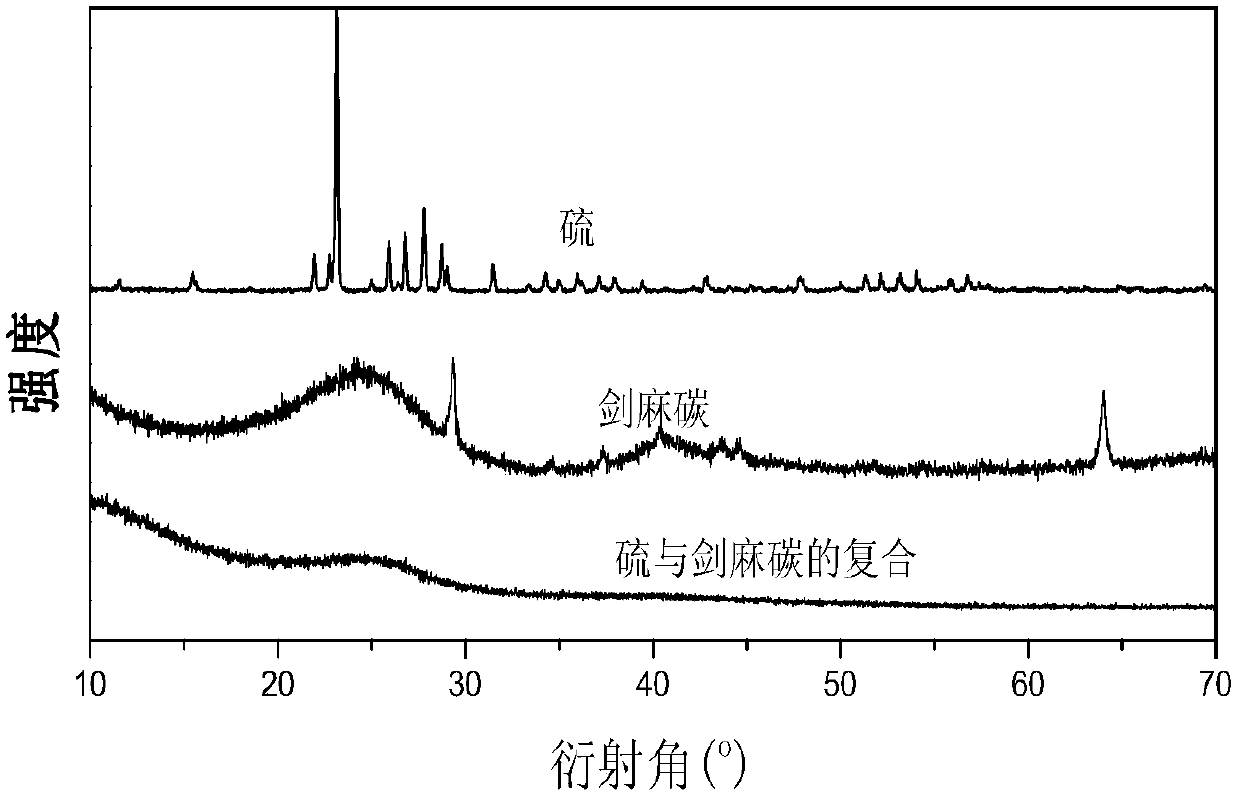

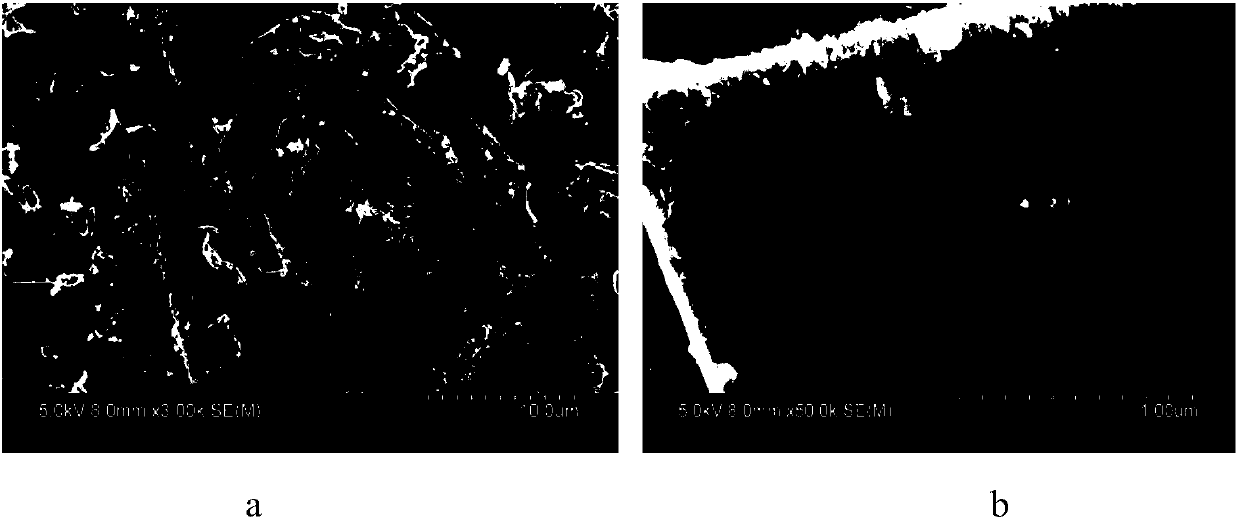

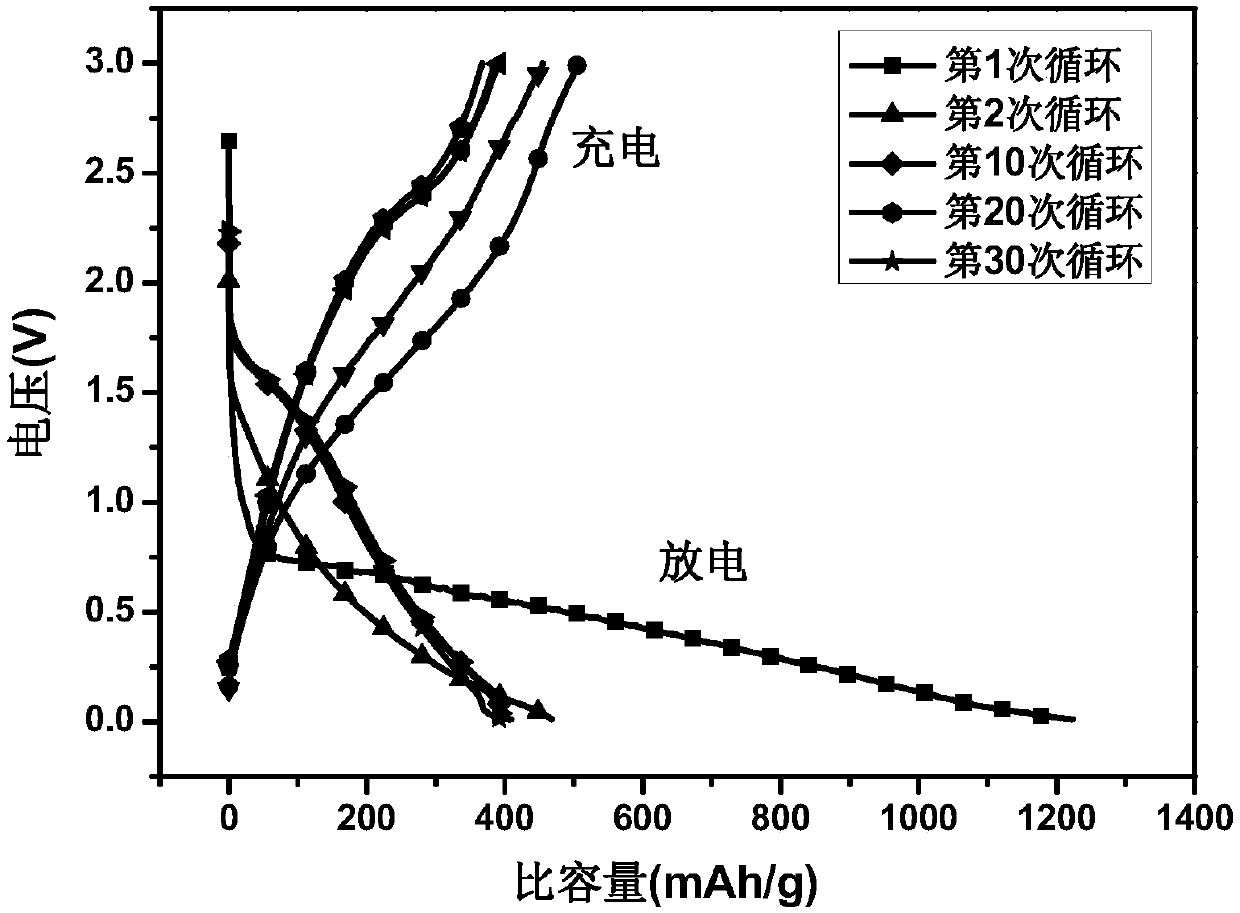

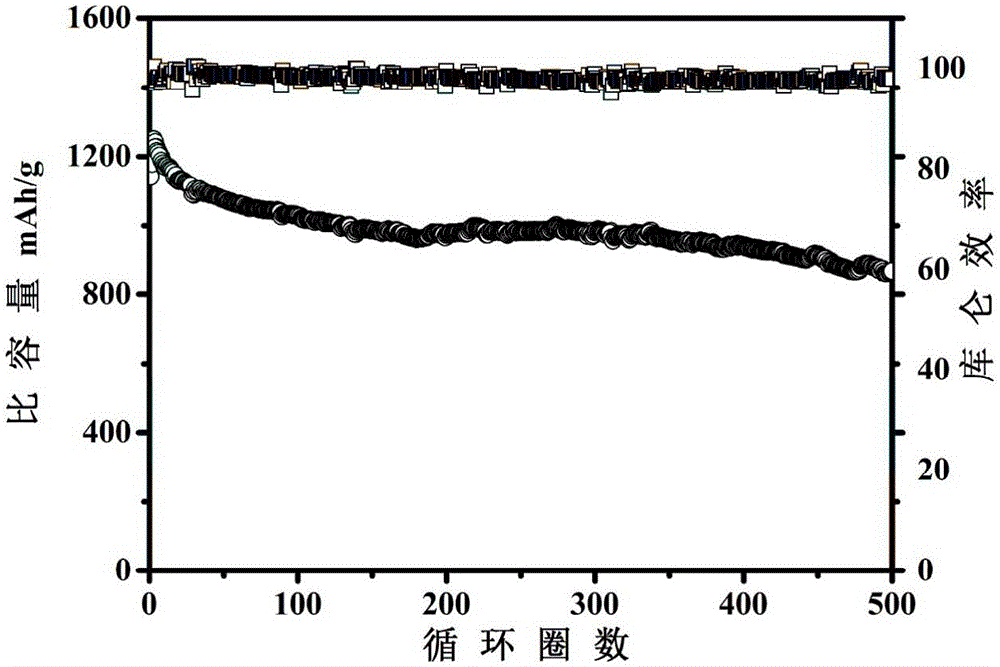

Preparation method of sulfur/sisal fiber charcoal lithium ion battery composite negative electrode material

InactiveCN107732177ARich sourcesEasy to degradeCell electrodesReaction temperatureSodium Thiosulfate Pentahydrate

The invention discloses a preparation method of a sulfur / sisal fiber charcoal lithium ion battery composite negative electrode material. The method comprises the following steps: (1) deionized water is used for respectively preparing acid and sodium thiosulfate pentahydrate into an acid solution and a sodium thiosulfate solution whose concentrates are 1-2mol / L; (2) sisal fiber is cut into small segments of 2-3 centimetres, sisal and the two solutions in the step (1) are mixed, then ultrasonic concussion is carried out for 25-35 minutes, a hydrothermal reaction is carried out for 12-16 hours, reaction temperature is 120-200 DEG C, washing with water is carried out till the solution is neutral, and drying is carried out; (3) calcination is carried out in an inert gas atmosphere whose gas flow is 20-100ml / min for 0.5-2 hours, heating rate of calcination is 1-10 DEG C / min, natural cooling is carried out to room temperature, and the sulfur / sisal fiber charcoal lithium ion battery compositenegative electrode material is obtained. The method has the advantages of low raw material cost, green and environmental protection, and simple preparation technology; and a new approach is provided for preparation of the lithium ion battery negative electrode material.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

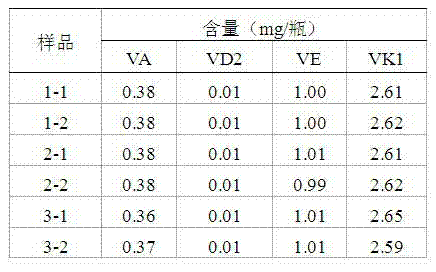

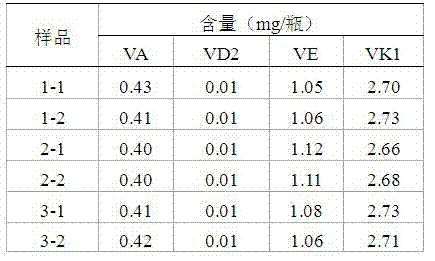

Compound vitamin submicron emulsion lyophilized powder for injection and preparation method of compound vitamin submicron emulsion lyophilized powder

InactiveCN102552293AEasy to useNo side effectsPowder deliveryHydroxy compound active ingredientsSodium bicarbonatePhospholipin

The invention provides compound vitamin submicron emulsion lyophilized powder for injection; the oil phase of the prepared submicron emulsion is soybean oil for injection only; the emulsifying agent is soybean phospholipids for injection, which are safely degraded and have no toxic or side effects, so the emulsifying agent has great safety advantage. The compound vitamin submicron emulsion lyophilized powder comprises compound vitamin, emulsifying agent, oil, sodium oleate, sodium bicarbonate, sodium thiosulfate pentahydrate, cryoprotectant and injection water; each 100 ml of lyophilized powder comprises 0.01 mg-2.0 g of compound vitamin, 0.5-3.0 g of oil, 0.5-4.0 g of emulsifying agent, 0.05-0.3 g of sodium oleate, 2-10 g of sodium bicarbonate, 0.1-0.5 g of sodium thiosulfate pentahydrate, cryoprotectant and injection water. According to the invention, a plurality of vitamins with different dissolubility are held in a preparation, so that compound vitamin injection, which can carry medicine successfully, is safe to take and has no toxic, is prepared.

Owner:SHENYANG PHARMA UNIVERSITY

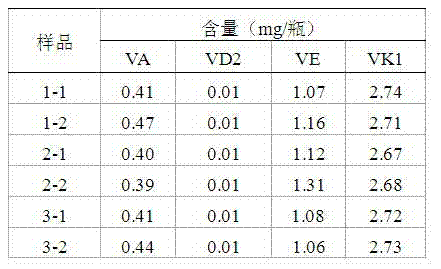

Preparation method of sodium n-propyl thiosulfate

The invention discloses a preparation method of sodium n-propyl thiosulfate. The preparation method of sodium n-propyl thiosulfate comprises the following steps: adding sodium thiosulfate pentahydrate in a high-speed shearing reactor, and dissolving sodium thiosulfate pentahydrate with equivalent distilled water, wherein the rotation speed of the high-speed shearing reactor is 6000-10000 r / min; and then adding polyethylene glycol 400 and n-propyl bromide, and reacting through heating and refluxing. The preparation method has the beneficial effects that a sodium thiosulfate aqueous solution reacts with n-propyl bromide, wherein the former is the aqueous solution, and the latter is an organic phase, so the sodium thiosulfate aqueous solution is immiscible with the organic phase; and polyethylene glycol 400 is a phase transfer catalyst so that the two phases which are immiscible originally are miscible in a certain degree, thereby effectively promoting the reaction to conduct, reducing the amount of polyethylene glycol 400, saving cost and shortening reaction time.

Owner:江苏兄弟维生素有限公司

A method for preparing a lithium-sulfur battery positive electrode material

InactiveCN108039457AImprove discharge capacityImprove cycle stabilityCell electrodesLi-accumulatorsFiltrationHexamethylenetetramine

A method for preparing a lithium-sulfur battery positive electrode material is disclosed. The method includes 1) adding resorcinol, furfural and hexamethylenetetramine in order into a solvent and mixing the mixture; 2) subjecting the solution obtained in the step 1) to sealed thermal treatment to obtain gel; 3) subjecting the obtained gel to thermal treatment to obtain xerogel; 4) crushing the xerogel obtained in the step 3), feeding nitrogen, and performing thermal treatment to obtain nitrogen doped carbon aerogel; 5) adding hydrochloric acid, sodium thiosulfate pentahydrate, a dispersing agent and the carbon aerogel obtained in the step 4) into distilled water in order and stirring the mixture; 6) subjecting the suspension obtained in the step 5) to ultrasonic treatment for 20 min; 7) subjecting the solution obtained in the step 6) to suction filtration to obtain black powder; and 8) subjecting the black powder obtained in the step 7) to thermal treatment at 155 DEG C for 24 h to obtain the nitrogen doped carbon aerogel adsorbed material as the lithium-sulfur battery positive electrode material. The method is simple, high in cost performance ratio, good in reproducibility and suitable for commercial production.

Owner:XIAN UNIV OF TECH

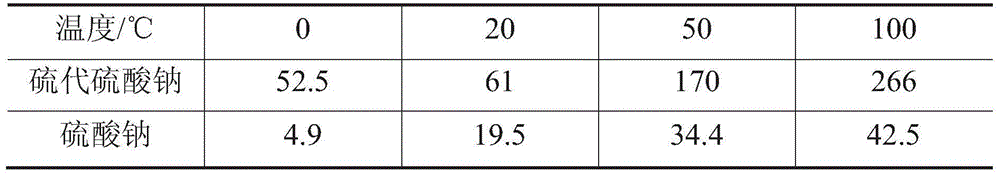

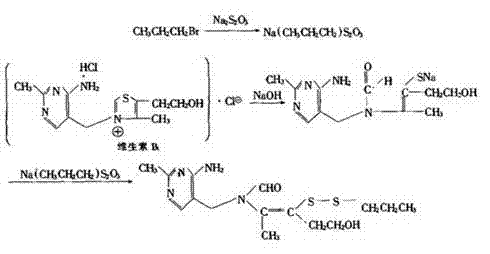

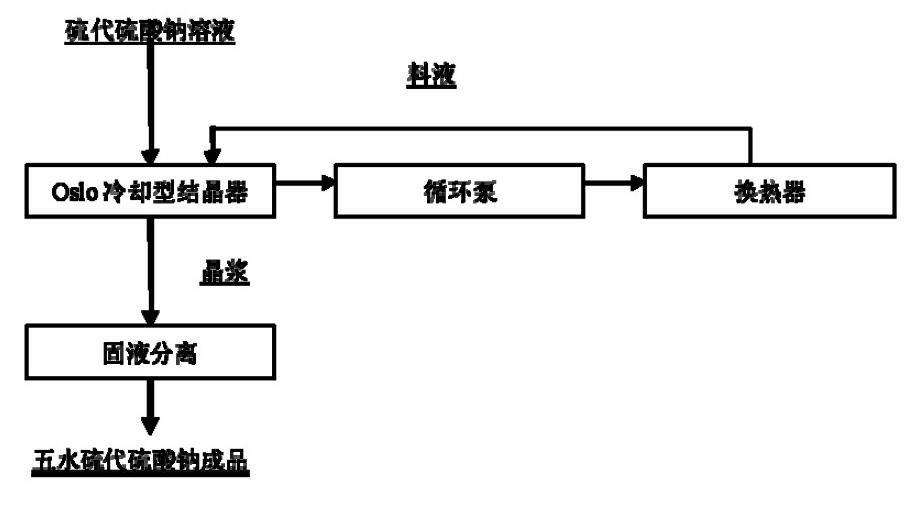

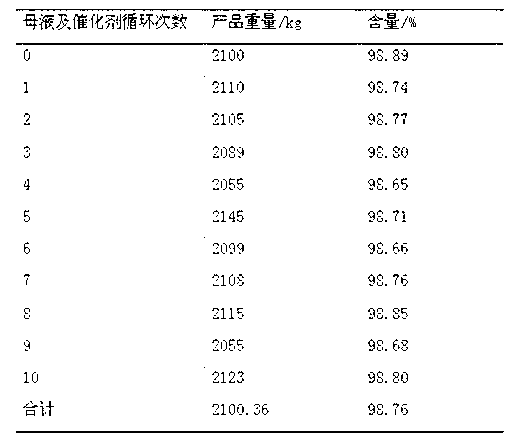

Method for crystallizing sodium thiosulfate pentahydrate

InactiveCN102145879AStable operating parametersImprove product qualityThiosulfates/dithionites/polythionitesAutomatic controlRetention time

The invention discloses a method for crystallizing sodium thiosulfate pentahydrate, which particularly comprises the following steps of: continuously feeding sodium thiosulfate solution with the concentration of less than 51Be' into an Oslo cooling crystallizer and continuously feeding the obtained solution into a heat exchanger through a circulating pump for the cooling and temperature reduction; and when the temperature is reduced to a saturation temperature, adding seed crystals in one step, and continuously discharging crystal mush and carrying out solid and liquid separation, wherein the crystallization temperature is in the range of 30 to 38 DEG C and the crystallization retention time is in the range of 15 to 20 hours. In the invention, the Oslo cooling crystallizer capable of maintaining stable growth of the crystals and realizing circulation of clear liquid is used so as to provide an excellent condition for the growth of the crystals; on the basis of continuous operation, large and uniform crystals can be grown, the purity of the product reaches over 99 percent, and the granularity of the product is over 3mm; compared with a discontinuous crystallizer, the production capacity of the Oslo cooling crystallizer capable of continuously operating in unit effective volume is improved by over 30 percent; operation parameters in the continuous crystallizing process are stable; the products have stable quality and no differences among batches; and automatic control can be realized.

Owner:CITIC JINZHOU METAL +1

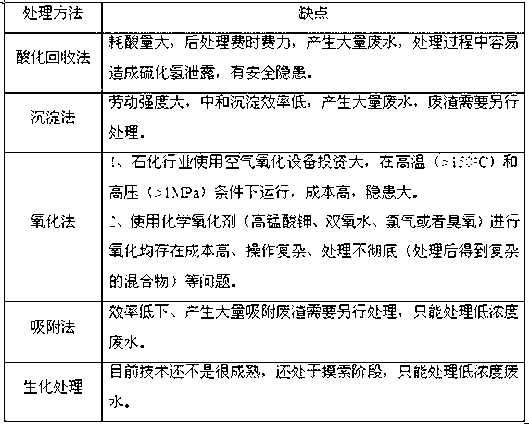

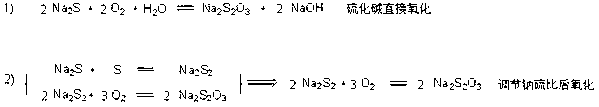

Method for treating sodium sulfide waste water

ActiveCN102992469AReduce production and operation costsLow costThiosulfates/dithionites/polythionitesWater/sewage treatment by oxidationSodium Thiosulfate PentahydrateEconomic benefits

The invention relates to a method for treating sodium sulfide waste water, which comprises the following steps: mixing the sodium sulfide waste water, industrial waste sulphur and a catalyst; then introducing air for oxidation reaction; after the oxidation reaction is completed, filtering, and carrying out concentration, temperature reduction and crystallization on the filter liquor, and filtering again to obtain a sodium thiosulfate crystal and crystallizing mother liquor; and drying the sodium thiosulfate crystal to obtain sodium thiosulfate pentahydrate. The method disclosed by the invention reduces the production and operation cost by carrying out the oxidation reaction at lower temperature and pressure, thereby greatly enhancing the safety of the reaction process; the method greatly reduces the cost by using the air as an oxidation source, obtains a single product with the content of more than 98.5% after reaction, has the advantages of certain economic benefit, perpetual recycling of circulating mother liquor, zero discharge of waste liquor and is a green process.

Owner:SHANDONG HUIHAI PHARMA & CHEM

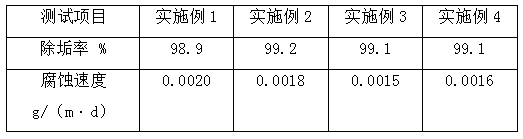

Heat supply boiler and pipeline descaling agent

InactiveCN108300605AGood descaling effectStable structureInorganic/elemental detergent compounding agentsCationic surface-active compoundsEthylenediamineSodium metasilicate

The invention belongs to the technical field of chemical descaling treatment and in particular relates to a heat supply boiler and pipeline descaling agent which comprises the following components: anorganic acid, diethylenetriaminepenta(methylenephosphonic) acid sodium, sodium thiosulfate pentahydrate, dodecyl dimethyl benzyl ammonium chloride, an adhesive, a non-ionic surfactant, a corrosion inhibitor, an anti-rusting agent, a bactericide and a chelating agent, wherein the organic acid is weak acidity; the rusting agent is triethanolamine; the bactericide is isothiazolinone; the adhesive comprises water-soluble rubber powder, sodium metasilicate and carboxymethyl cellulose sodium; the corrosion inhibitor is a mixture of hexamethylenetetramine and sodium dodecyl benzene sulfonate; the chelating agent is ethylenediamine tetraacetic acid disodium salt or sodium pyrophosphate. The descaling agent is good in descaling effect and free of oxidation or corrosion upon a furnace, and in addition has a sterilization effect and is very safe and healthy, and equipment shutdown is not needed in the use process.

Owner:HEBEI JIASHICHENG ENERGY TECH CO LTD

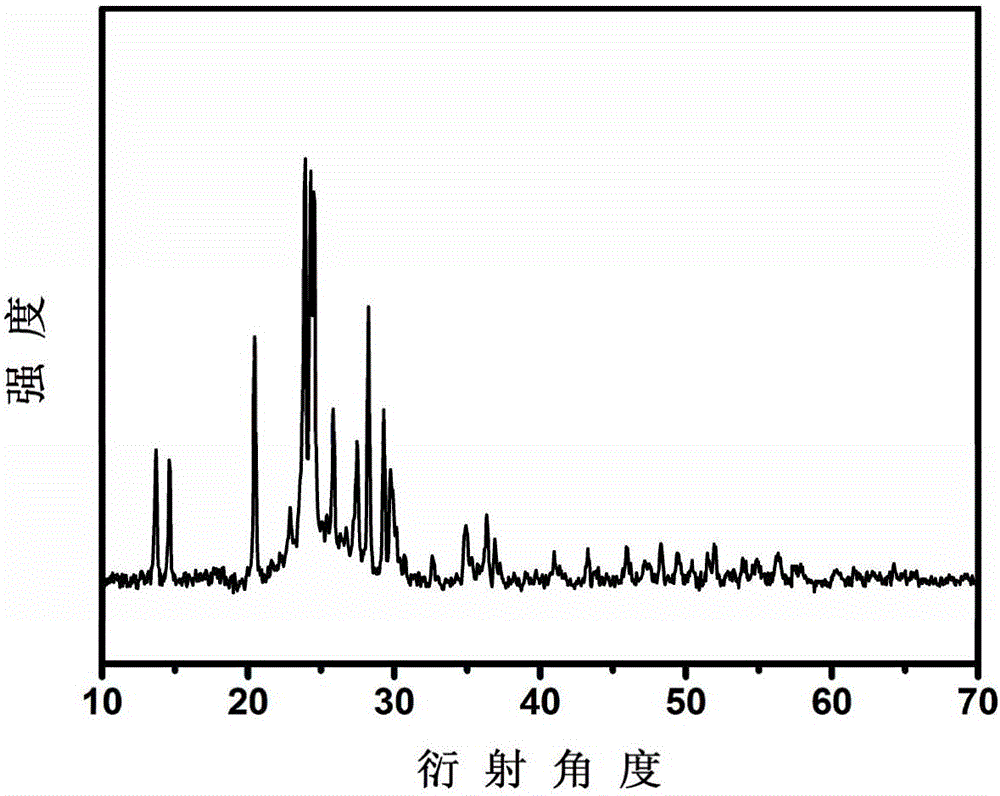

Preparation method for conducting polymer/sulfur compound anode material with sandwich structure

InactiveCN106356513ASimple lifeHigh specific capacityCell electrodesSecondary cellsHigh rateConductive polymer

The invention relates to a preparation method for a conducting polymer / sulfur compound anode material with a sandwich structure. The method comprises the following steps: 1) preparing a polyaniline hollow ball by taking phosphoric acid, phenylamine, hydrogen peroxide and ferric chloride as raw materials according to a hydrothermal method; 2) preparing a polyaniline / sulfur sandwich compound material precursor by taking the polyaniline hollow ball, sodium thiosulfate pentahydrate, polyvinylpyrrolidone and hydrochloric acid as raw materials according to a normal temperature liquid phase compounding method; 3) synthesizing a polyaniline / sulfur sandwich compound anode material by taking the precursor, aniline, hydrochloric acid and ammonium persulfate as raw materials. The preparation method provided by the invention is simple in process, environment-friendly and suitable for industrial production. The prepared sandwich structure compound anode material applied to a lithium sulfur battery has the advantages of high specific capacity, excellent cycle performance, high rate capability, and the like.

Owner:WUHAN UNIV OF TECH

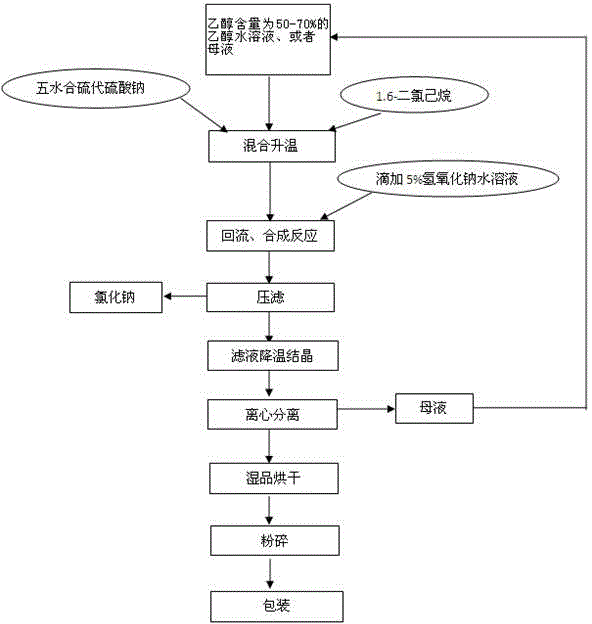

Preparation method of dihydrate hexamethylene-1,6-disodium dithiosulfate

ActiveCN103819377AEasy to separateHigh reaction yieldOrganic chemistryChemical industryAqueous sodium hydroxide

The invention relates to a preparation method of dihydrate hexamethylene-1,6-disodium dithiosulfate. The preparation method comprises the following steps: firstly, adding ethanol water with the ethanol content of 50-70% or recycled mother liquor into a reaction kettle, then adding sodium thiosulfate pentahydrate and 1,6-dichlorohexane, stirring and warming to prepare a sodium hydroxide water solution, when the sodium hydroxide water solution is not dripped any longer, continuously stirring in a backflow manner, reducing the temperature to be below 40 DEG C while stirring at a low speed, discharging and centrifugally separating, drying, oiling, smashing and packaging to obtain an anti-reversion agent finished product. The preparation method has the benefits that the product prepared through the technology has the purity reaching 99% and the yield of more than 95%, and is simple and convenient to separate and high in reaction yield; mother liquor in the production process can be repeatedly used; the preparation method is green and environment-friendly, does not need to process emissions, and is suitable for the current green and environment-friendly chemical industry production requirement.

Owner:HEZE JIACHENG CHEM CO LTD

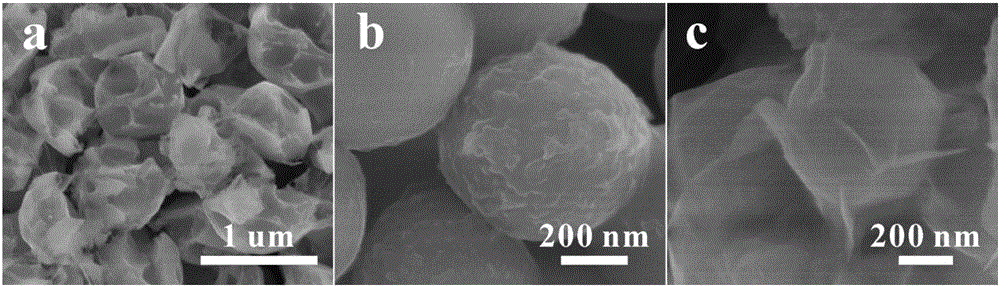

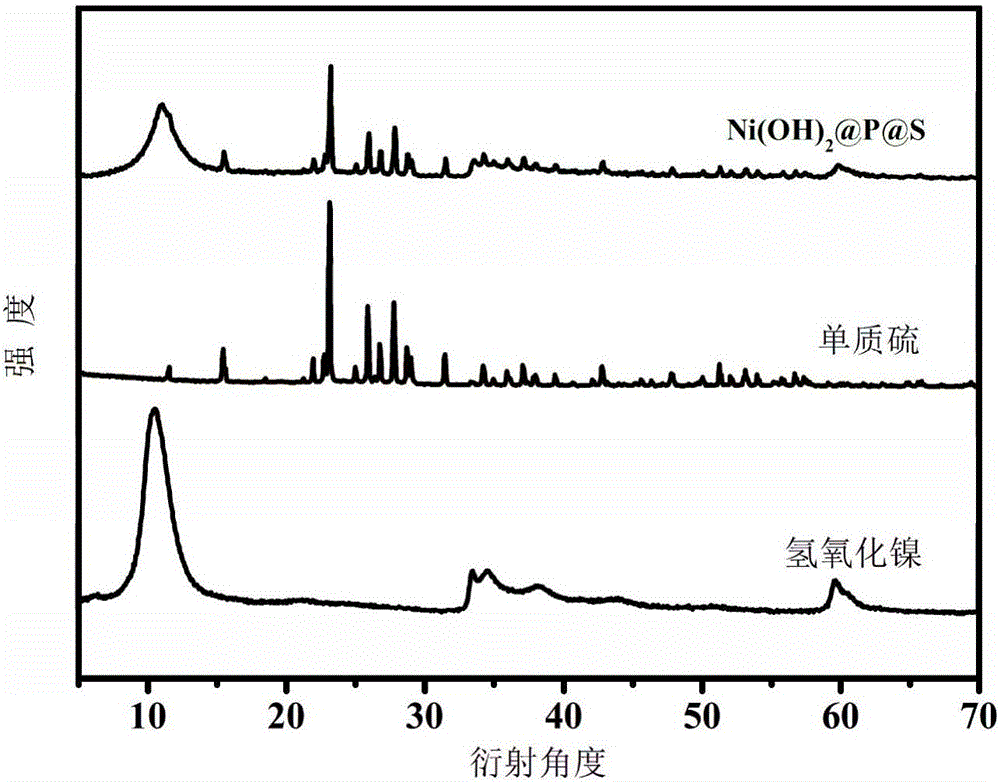

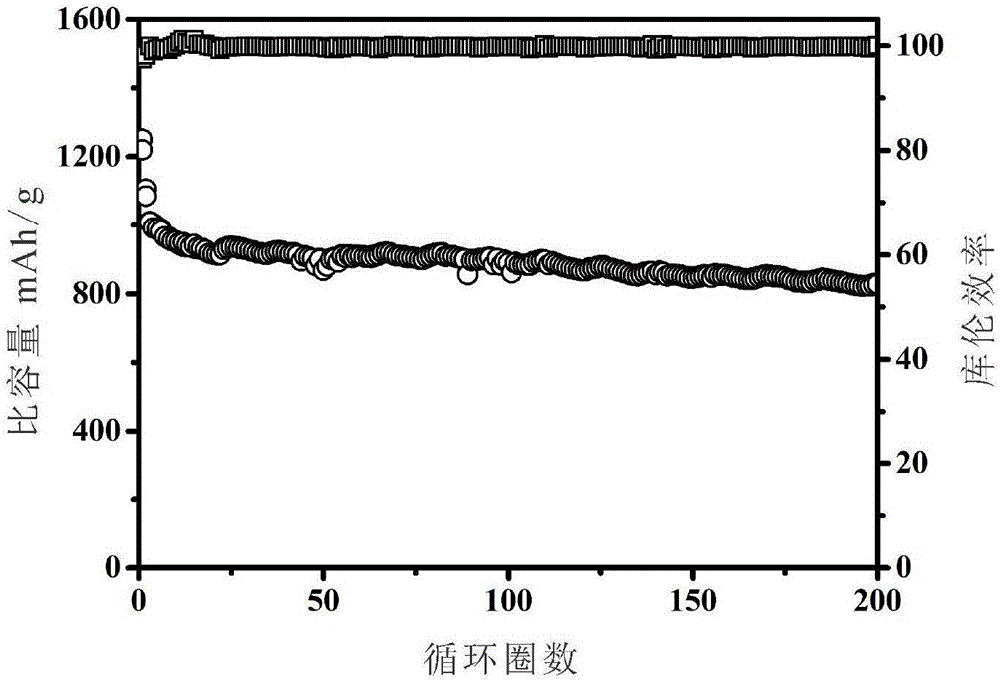

Preparation method of metallic oxide/conducting polymer dually-modified sulfur composite anode material

InactiveCN106450203ASolution to short lifeHigh specific capacityCell electrodesConductive polymerSodium Thiosulfate Pentahydrate

The invention relates to a preparation method of a metallic oxide / conducting polymer dually-modified sulfur composite anode material. First, sodium thiosulfate pentahydrate and polyvinylpyrrolidone are adopted for synthesizing hollow nano-sulfur particles, and through the structure, the utilization rate of sulfur is increased, and expansion and shrinkage stress generated in the lithiation process can be released inwards; second, the outer layer of hollow nano-sulfur is wrapped with polyaniline, high-temperature sulfidizing is utilized for generating strong chemical bonds between polyaniline and sulfur, and polyaniline is promoted to have a physical barrier and a chemical acting force at the same time to jointly inhibit loss of polysulfide compounds, and the stability of battery circulation is improved; last, good electrochemical performance of nickel metal hydroxide is utilized for conducting external modification, the wettability of the composite material and the transmission efficiency of ions and electrons are improved, and the electrochemical performance of a lithium-sulfur battery is further improved. The lithium-sulfur battery prepared through the method has the advantages of being high in energy density, good in circulating performance, good in rate capability and the like.

Owner:WUHAN UNIV OF TECH

Antifouling and wear-resisting textile material and preparation method thereof

InactiveCN107326473AImprove wear resistanceAlso has anti-fouling propertiesConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsBeta-Hydroxybutyric acidBenzoyl peroxide

The invention discloses an antifouling and wear-resisting textile material and a preparation method thereof. The antifouling and wear-resisting textile material is prepared from the following raw materials in parts by weight: 10 to 25 parts of acrylonitrile fibers, 12 to 25 parts of carboxymethyl cellulose, 2 to 10 parts of nano-microcrystalline cellulose, 10 to 20 parts of bamboo charcoal fibers, 11 to 28 parts of diglycidyl ether, 3 to 5 parts of lauryl alcohol, 1 to 3 parts of bis-(phenyldimethyl siloxane)methylsilanol, 4 to 6 parts of beta-hydroxybutyrate, 1 to 3 parts of sodium thiosulfate pentahydrate, 8 to 14 parts of terephthaloyl chloride, 3 to 7 parts of fluorosilane, 1 to 4 parts of methyl L-pyroglutamate, 2 to 3 parts of benzoyl peroxide butyl acetate, 3 to 5 parts of 2,2'-(ethylenedioxy)dianiline, 1 to 2 parts of zinc diricinoleate, 1 to 2 parts of barium metaborate, 2 to 5 parts of an adhesive, 2 to 5 parts of a dispersant and 1 to 4 parts of a thermal stabilizer. The antifouling and wear-resisting textile material prepared by the preparation method has good wear-resisting performance and also has an antifouling property. Meanwhile, the invention further discloses the preparation method of the antifouling and wear-resisting textile material.

Owner:SUZHOU COMFORT TEXTILE NEW MATERIALS TECH CO LTD

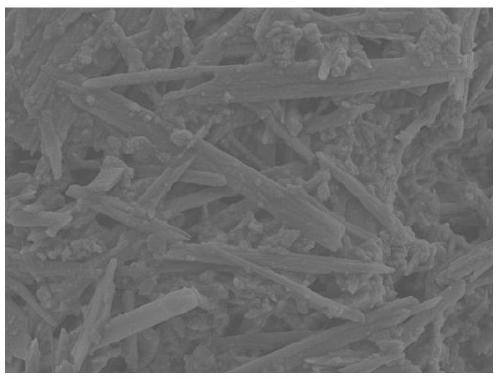

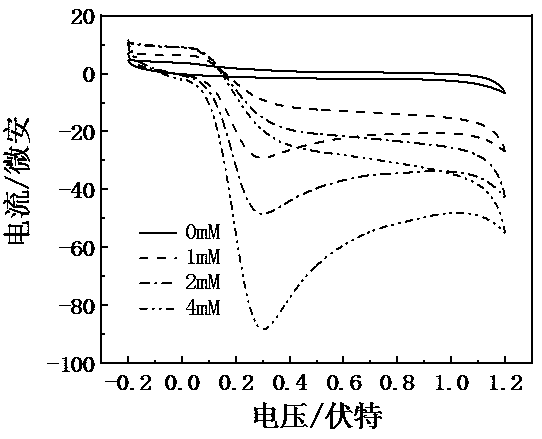

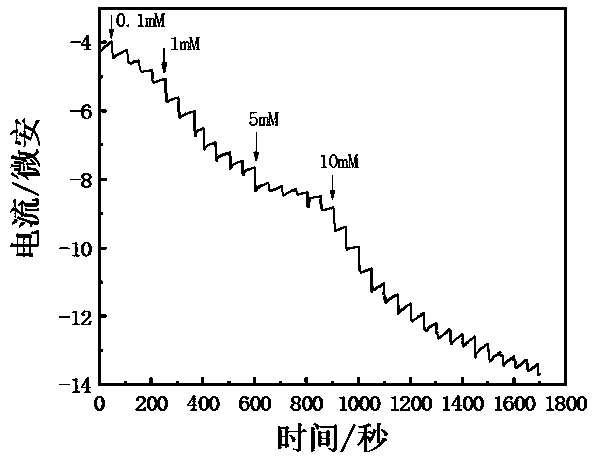

Preparation method and application of rod-like nickel disulfide-molybdenum disulfide nano-composite

ActiveCN111422929AImprove performanceEasy to synthesizeMolybdenum sulfidesMaterial electrochemical variablesHydration reactionThio-

The invention relates to a preparation method and application of a rod-like nickel disulfide-molybdenum disulfide nano composite. The preparation method comprises the following steps: dispersing nickel nitrate hexahydrate and sodium thiosulfate pentahydrate in deionized water, adding hexadecyl trimethyl ammonium bromide, stirring, adding ethylenediamine, uniformly stirring, transferring into a high-pressure reaction kettle for reaction, centrifugally separating, cleaning with ethanol and deionized water, drying, calcining in a tubular furnace to obtain nickel disulfide, weighing ammonium tetrathiomolybdate and nickel disulfide, adding ammonium tetrathiomolybdate and nickel disulfide into an N,N-dimethylformamide solution, adding hydrazine hydrate, carrying out ultrasonic treatment, transferring the mixed solution into a high-pressure reaction kettle for reaction, centrifugally separating, cleaning with ethanol and deionized water, drying to obtain a rod-like nickel disulfide-molybdenumdisulfide nano-composite, dispersing the composite into a mixed solution of water, ethanol and perfluorosulfonic acid, dropwise coating on the surface of a clean glassy carbon electrode and naturallyair-drying to form a three-electrode system together with a platinum wire and a saturated calomel electrode, wherein the clean glassy carbon electrode is used as a working electrode.

Owner:YANGZHOU UNIV

Bamboo product color processing agent and processing method thereof

InactiveCN107662262ASolve monotonous colorsColorfulWood treatment detailsReed/straw treatmentSucroseAdditive ingredient

The invention discloses a bamboo product color processing agent and a processing method thereof. The processing agent is prepared from an ingredient A and an ingredient B, wherein the ingredient A isprepared from sodium pyrophosphate, sodium thiosulfate pentahydrate, potassium ferric sulfate dodecahydrate, white alum, ammonium chromic sulfate, sodium imide and olive oil; the ingredient B is prepared from one or several kinds of materials from an alginate water solution, a dextrin water solution and a sucrose water solution. The processing agent has color adjusting and dying substances; when being used, the processing agent can synchronously complete the color adjusting and the dyeing; more colors can be obtained; the problems of single color of bamboo products in the prior art are solved;the market requirements can be met; the processing cost can be reduced; higher economic benefits are obtained. The processing method combines the color adjusting and the dyeing into one step. The bamboo product color processing method has the advantages that the process is simple; the cost is low; the operation is simple and convenient, and the like.

Owner:重庆瑞海竹艺有限公司

Method for preparing superfine alumina-chromic oxide or alumina and chromic oxide by using aluminium-chromium mud

InactiveCN101805830ASolve the problem of resource recyclingChromium trioxideProcess efficiency improvementAluminium hydroxideSodium Thiosulfate Pentahydrate

The invention relates to a method for preparing superfine alumina-chromic oxide or alumina and chromic oxide by using aluminium-chromium mud which is a chromium ore industrial solid waste, belonging to the technical field of preparation processes of inorganic nonmetallic materials and waste solid recycling and regeneration. The method comprises the following steps of: taking the solid waste aluminium-chromium mud as raw material, washing, sieving, adding hydrochloric acid for dissolving, filtering to remove solid impurities, adding ammonia and polyethylene glycol in the filtrate to generate precipitation, filtering, and drying the precipitation to obtain a solid mixture of superfine aluminium hydroxide and chromium hydroxide. Superfine alumina-chromic oxide can be prepared by baking the solid mixture at the temperature of 250-300 DEG C after thermal decomposition. Superfine alumina can be prepared by adding hydrogen peroxide in the solid mixture, filtering, separating the precipitation and solution, drying the precipitation and baking at the temperature of 140-150 DEG C. Superfine chromic oxide can be finally obtained by adding proper amount of hydrochloric acid, sodium thiosulfate pentahydrate and polyethylene glycol in the solution, adjusting the pH of the solution to 1-1.5, adjusting the pH of the solution to 7-8 when the color of the solution is similarly green in the reaction process to enable chromium hydroxide to spontaneously deposit, and baking the obtained chromium hydroxide precipitation at the temperature of 200-300 DEG C.

Owner:SHANGHAI UNIV

Flocculant and preparation method thereof

InactiveCN106745621AImprove coagulation efficiencyGood effectWaste water treatment from textile industryWater/sewage treatment by flocculation/precipitationAluminateChlorine dioxide

The invention discloses a flocculant and preparation method thereof. The flocculant is prepared from the following formula components in parts by mass: 6 to 8 parts of polyvinylpyrrolidone, 2 to 6 parts of aluminium polychlorid, 1 to 2 parts of sodium carbonate, 7 to 9 parts of natural organic acid, 5 to 7 parts of sodium thiosulfate pentahydrate, 6 to 10 parts of polyacrylamide, 6 to 7 parts of calcium aluminate, 3 to 7 parts of chlorine dioxide, 4 to 6 parts of aluminum ammonium sulfate, 6 to 10 parts of sodium hypochlorite, 5 to 9 parts of sodium carbonate, 6 to 8 parts of calcium disodium versenate and 1 to 3 parts of lubricant. The flocculant provided by the invention has the advantages that the flocculating efficiency is high, the effect is good, the flocculant is specially suitable for dyeing wastewater treatment, the decolorization rate is over 90 percent, and the removal rate of CODcr is more than 78 percent.

Owner:钦州市钦南区科学技术情报研究所

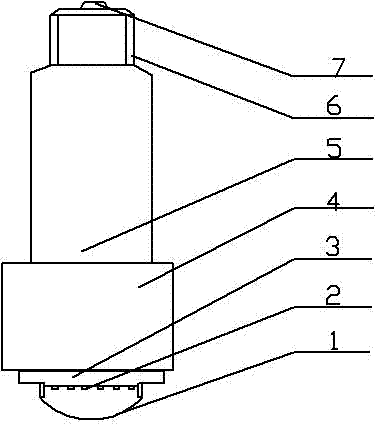

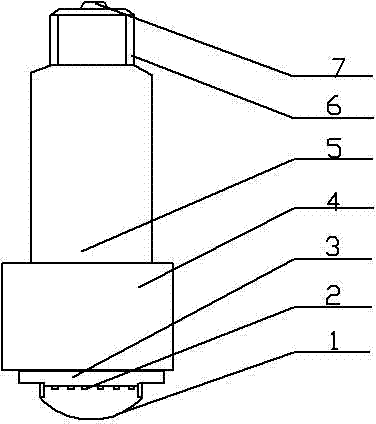

Radiating structure of heat accumulating light emitting diode (LED) lamp

InactiveCN102401364AEasy to useNo noisePoint-like light sourceLighting heating/cooling arrangementsSodium Thiosulfate PentahydrateEngineering

The invention discloses a radiating structure of a heat accumulating light emitting diode (LED) lamp. The radiating structure comprises a lampshade, an LED chip, a radiating pedestal, a heat accumulating box, a lamp body, a screw mouth and a lamp electrode tip, wherein the LED chip is tightly attached to the radiating pedestal; the lamp body is fixedly connected with the radiating pedestal by the heat accumulating box; a control circuit is arranged in the lamp body; and the control circuit is connected with the LED chip by using a lead. The heat accumulating box is sealed, a heat accumulating material is put into the heat accumulating box, and the heat accumulating material is sodium thiosulfate pentahydrate, the melting point of which is about 50 DEG C. The radiating structure has the advantages that: a fan for radiating is not used, and a moving component is not installed; the LED lamp is reliable in use and energy-saving, and has no noise; heat generated when the LED chip works is absorbed by using melting latent heat of the heat accumulating material, so that the temperature of the LED chip is controlled, and the LED chip is effectively prevented from being impacted by heat; and the radiating structure is easy to make and install and convenient to produce.

Owner:林勇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com