Patents

Literature

452results about How to "Not easy to flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

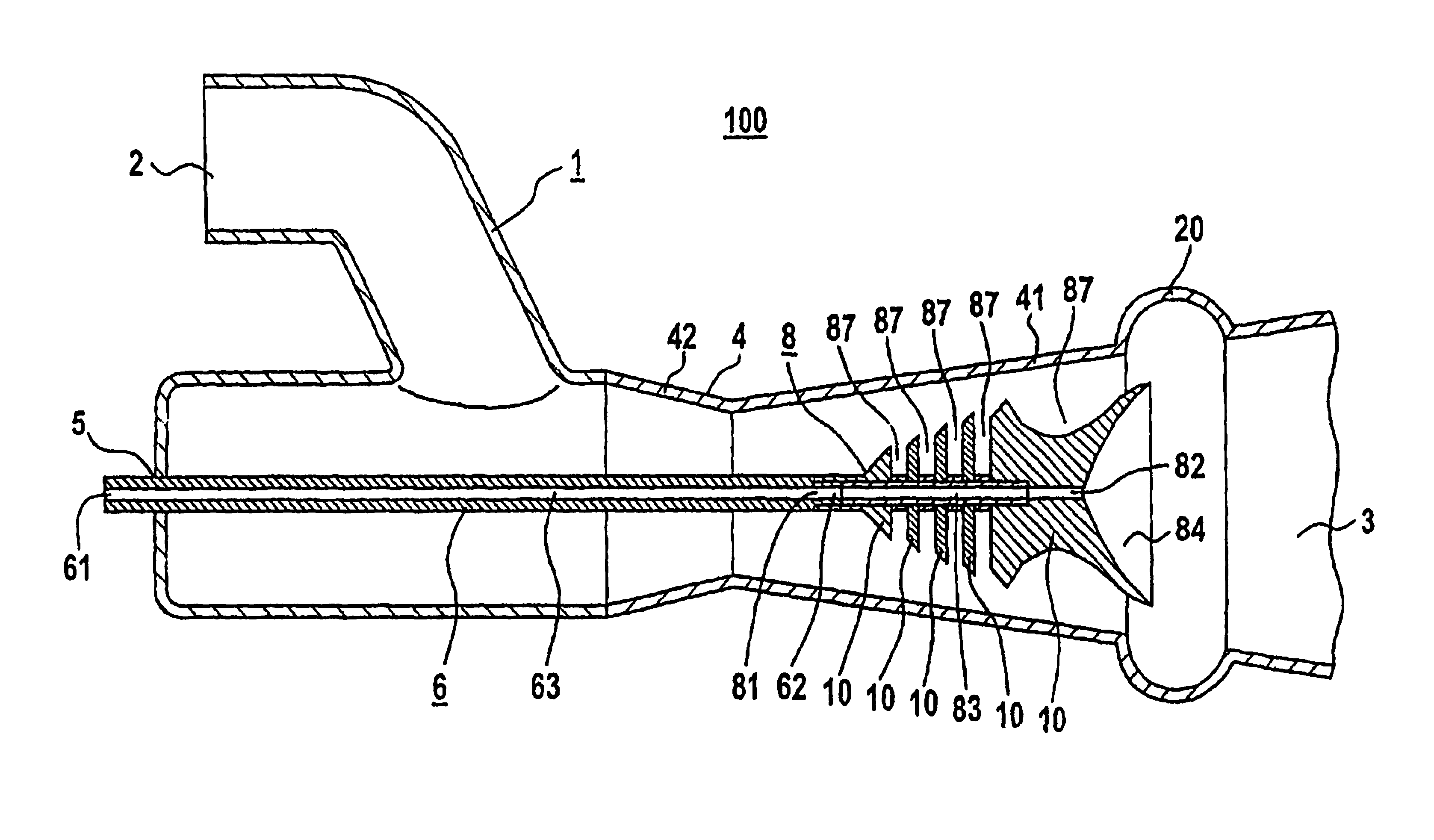

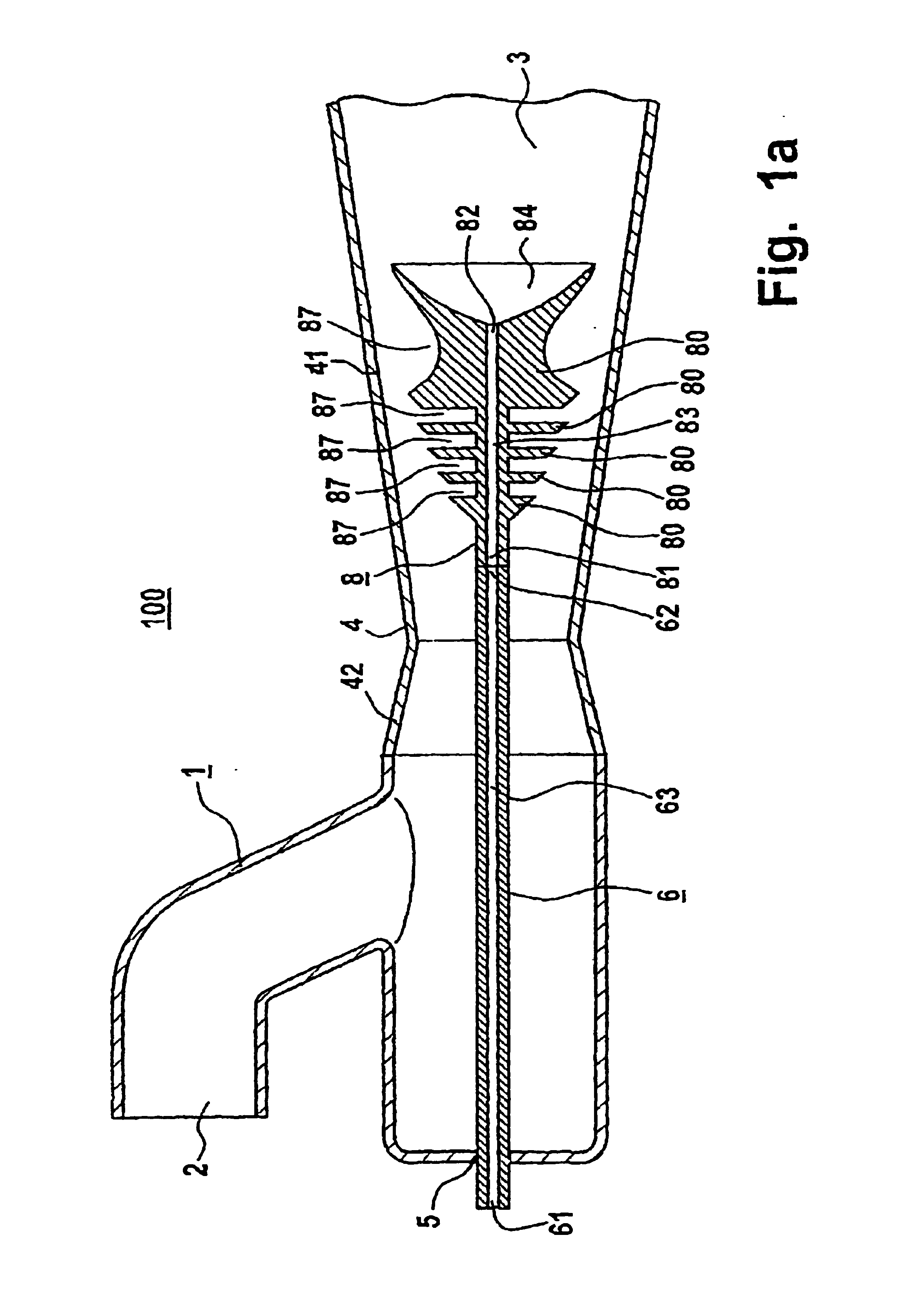

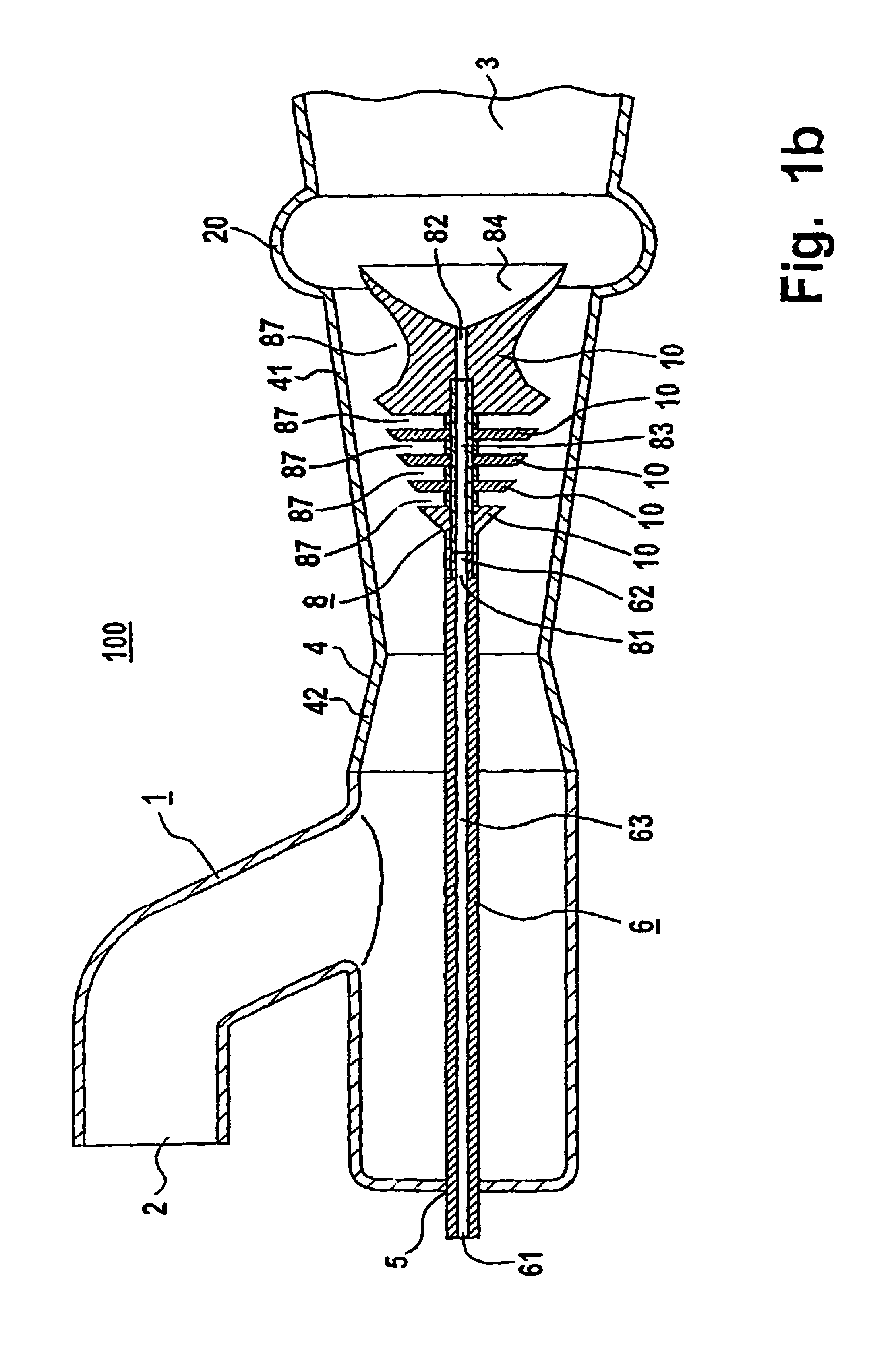

Cavitation mixer

InactiveUS6935770B2Not easy to flowGreat mixing actionFlow mixersTransportation and packagingEngineeringSupercavitation

A device for mixing the components of a mass flow flowing through it, provides a particularly homogeneous mixture with any desired long-term stability, even if components which are generally immiscible or can only be mixed with very great difficulty are being mixed. The device has a body (8), which it is difficult for medium to flow around, arranged in a through-flow chamber (4), this body being arranged at least partially in a part of the through-flow chamber (4) which widens in the direction of flow, so that the cavitation action and mixing action of the supercavitation field generated by the body (8) which it is difficult for medium to flow around is significantly reinforced.

Owner:LOCHER MANFRED LORENZ

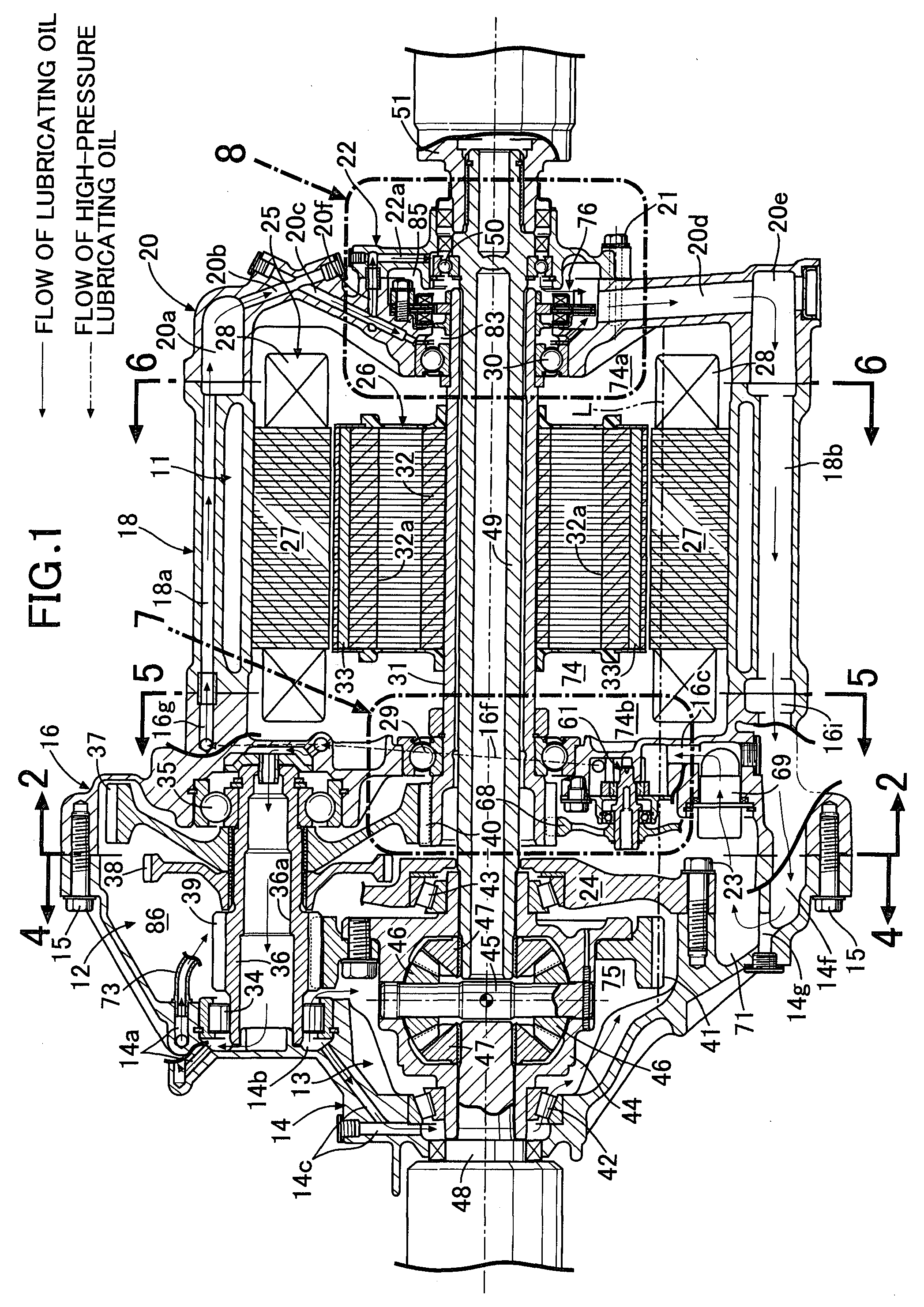

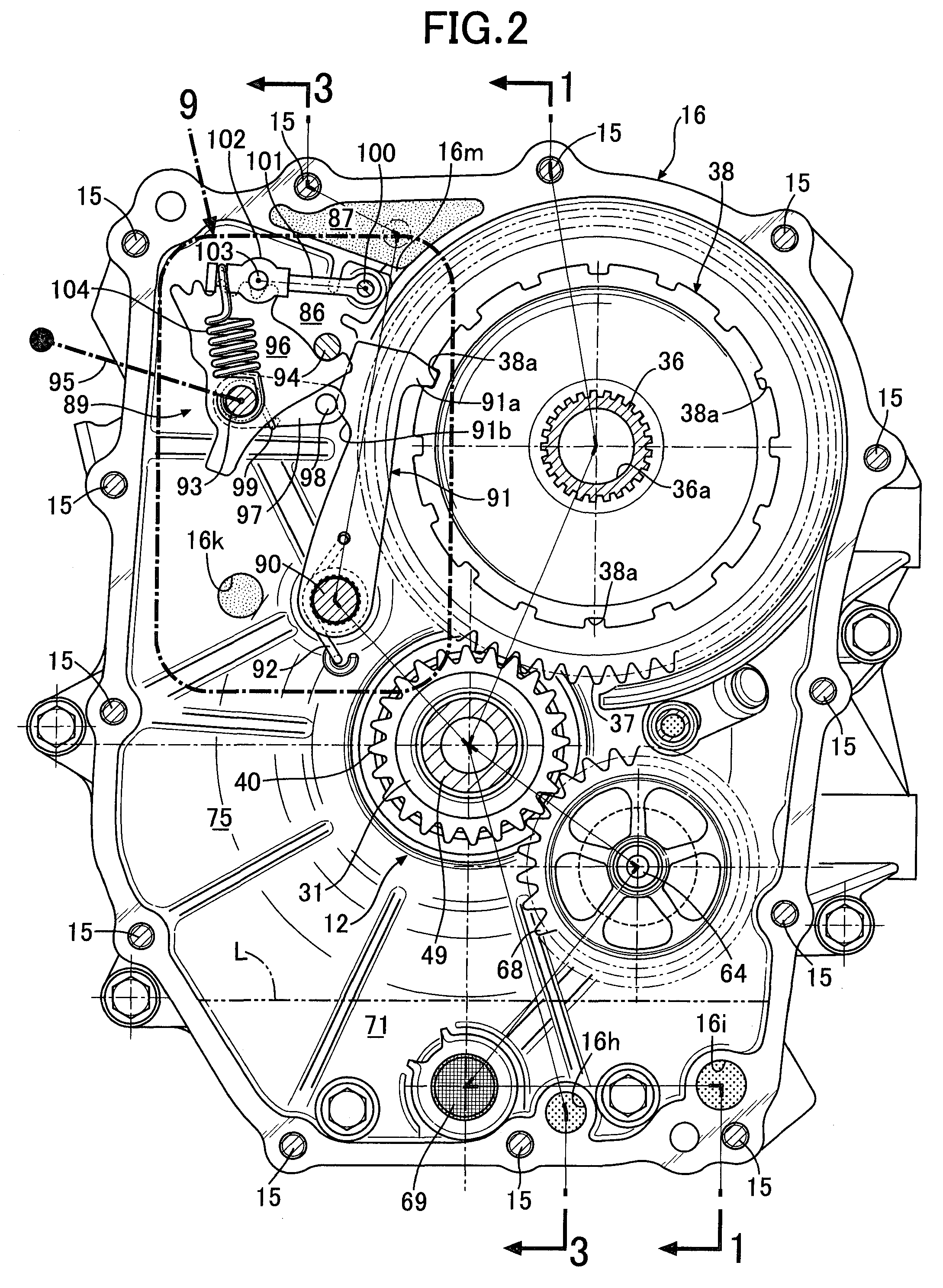

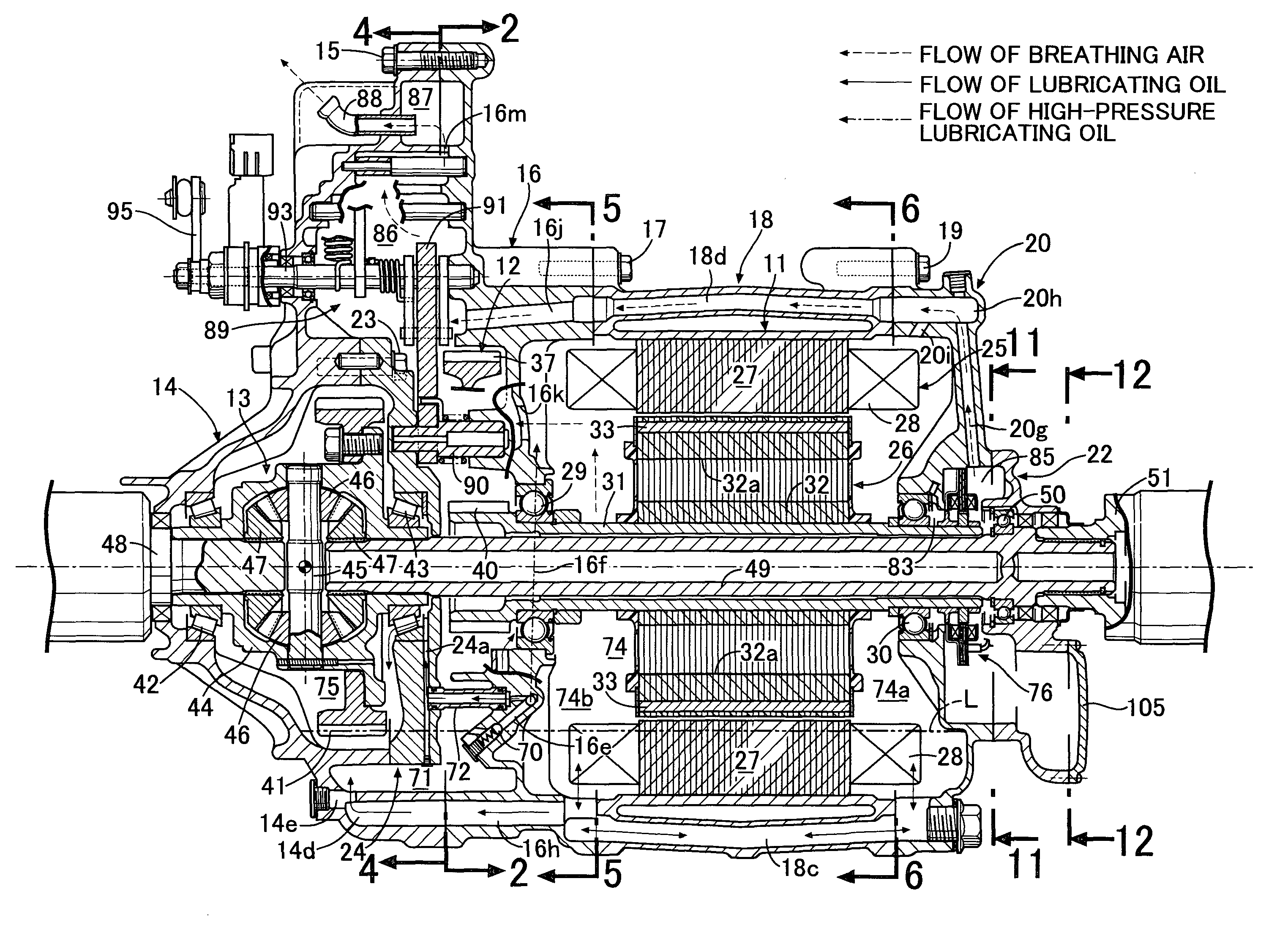

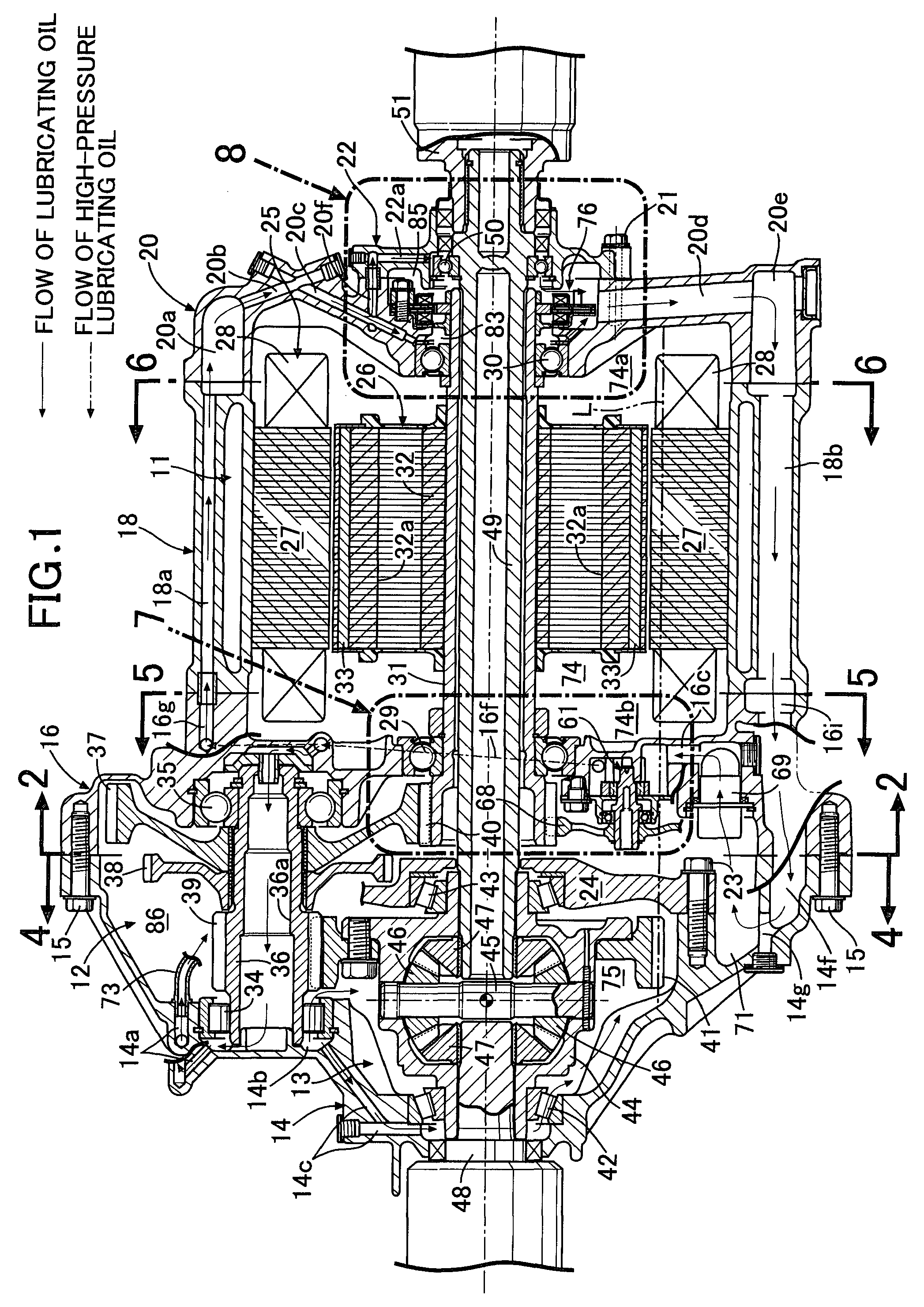

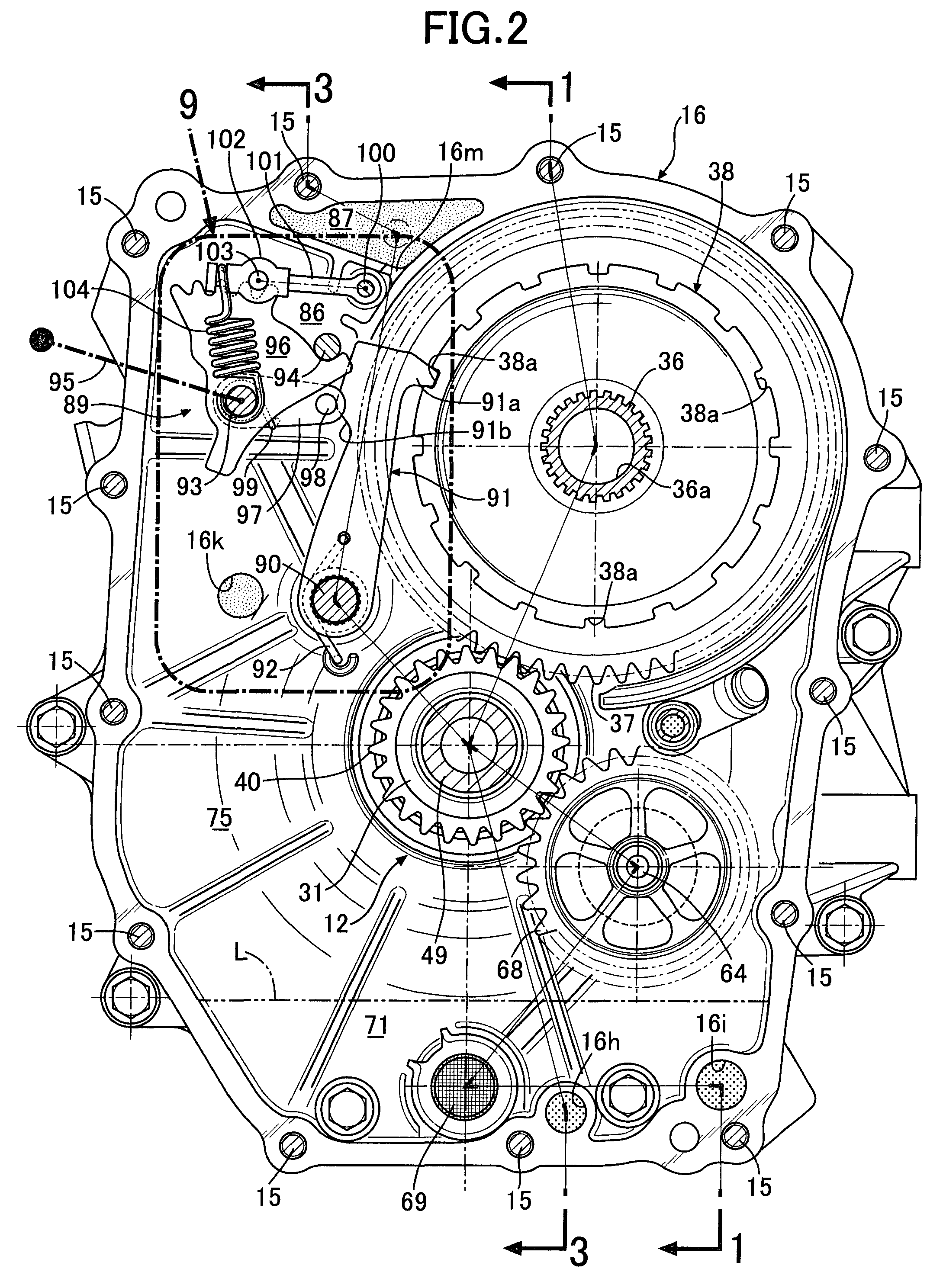

Motor-type power device

ActiveUS20090127954A1Suppress stirring resistance of oilEnsure performanceGearboxesGear lubrication/coolingEngineeringCentrifugal force

Due to a centrifugal force in a vehicle width direction due to turning of an automobile, oil in an electric motor housing chamber housing an electric motor and oil in a transmission housing chamber housing a reduction gear and a differential gear flows to-and-fro via oil communication passages that penetrate a partitioning wall. An opening on the transmission housing chamber side of the oil communication passages is spaced from the partitioning wall. Hence, when oil moves from the transmission housing chamber side to the electric motor housing chamber side, it is possible to prevent the oil quantity on the electric motor housing chamber side from increasing excessively and suppress an increase in resistance to oil stirring by a rotor of the electric motor while retaining a constant oil amount on the transmission housing chamber side to ensure lubricating performance for the reduction gear and the differential gear.

Owner:HONDA MOTOR CO LTD

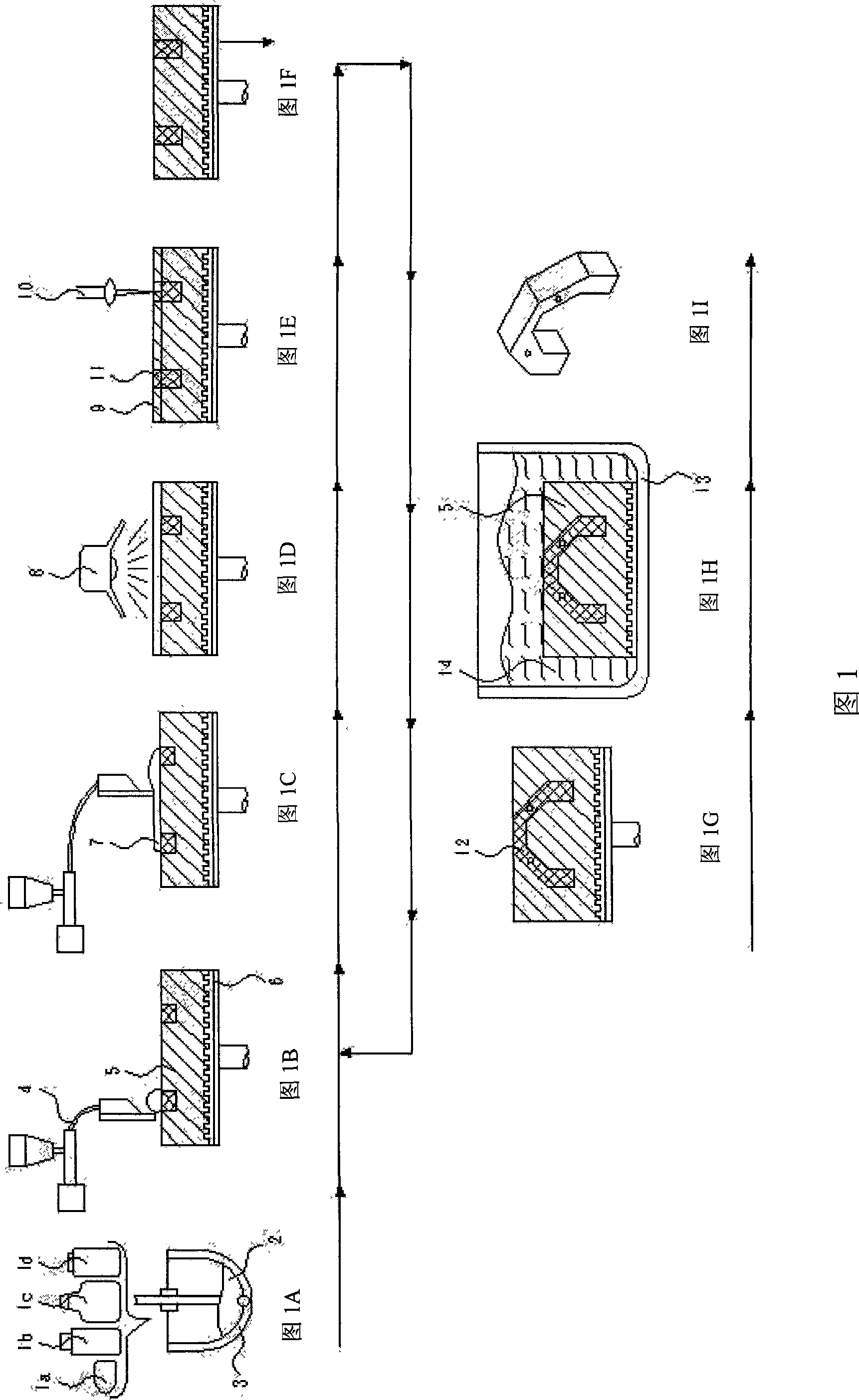

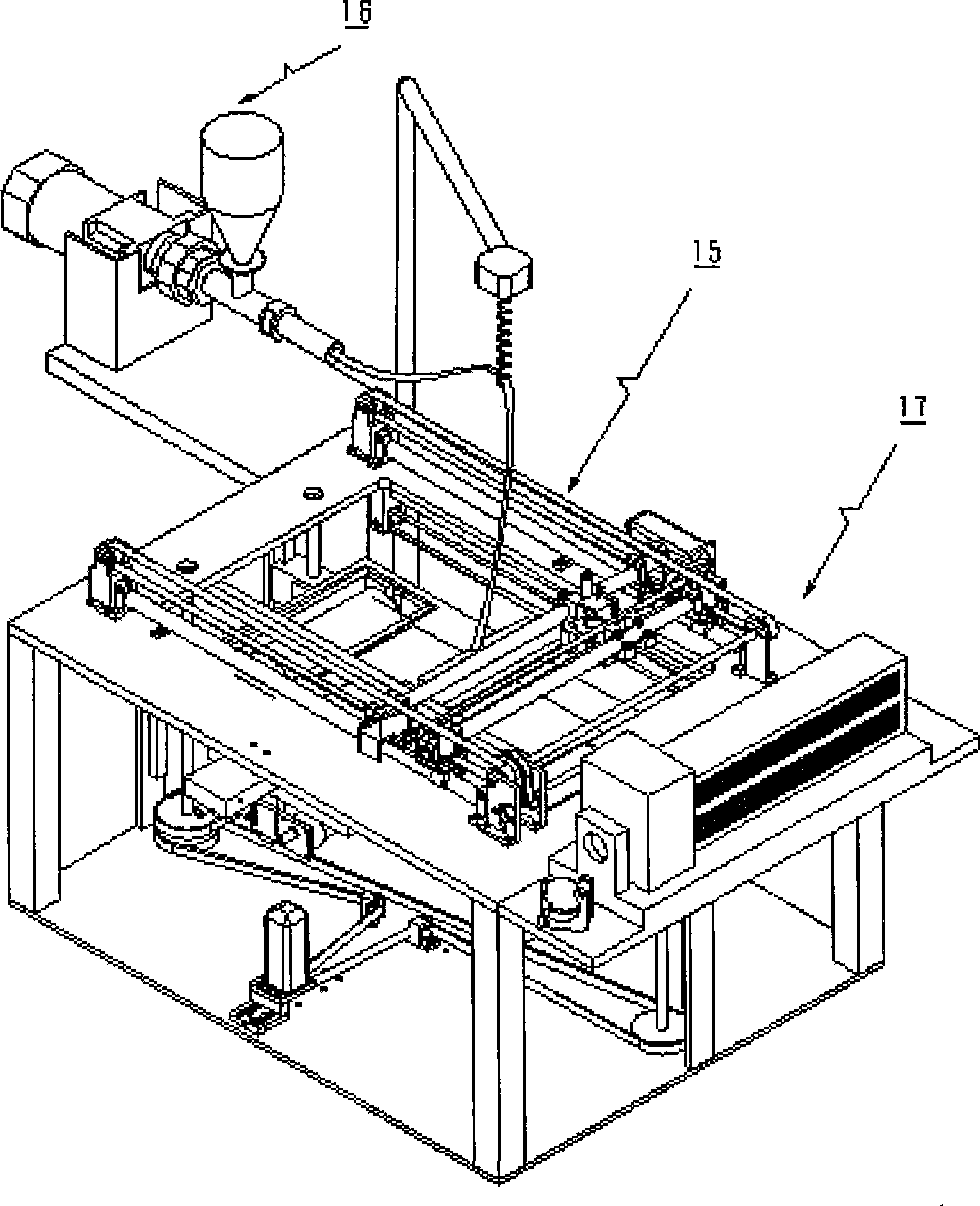

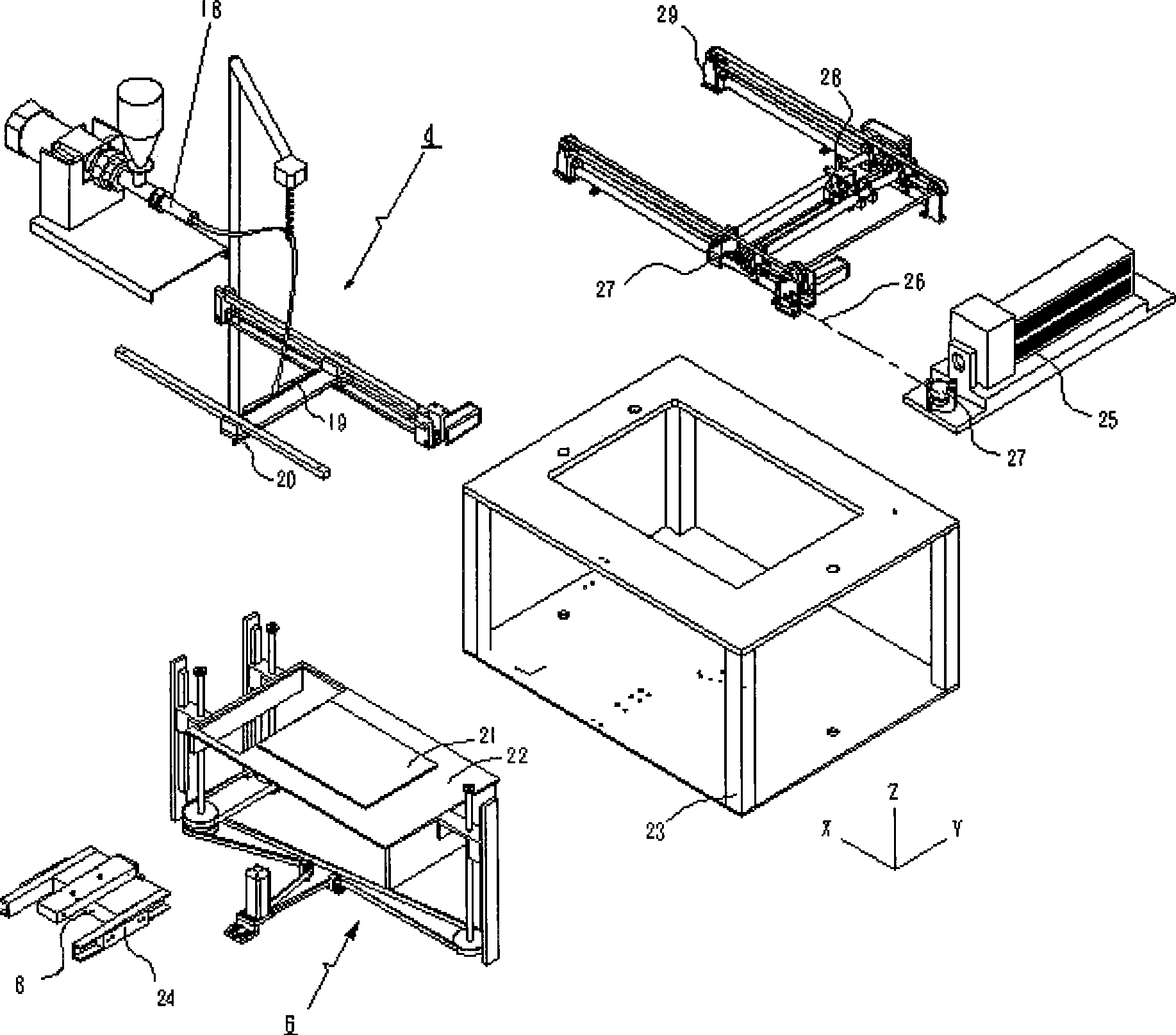

Manufacture method and device of three-dimensional workpiece

InactiveCN101422963AReduce the staircase effectHigh resolutionLiquid surface applicatorsIncreasing energy efficiencySelective laser sinteringAdhesive

The invention provides a method and equipment using organic adhesive mixed solvent and powder to manufacture three-dimensional workpieces. The work principle is as follows: the raw materials are stirred into slurry, which is laid as a green compact thin layer that can disintegrate in disintegrant; the green compact thin layer can form a workpiece thin layer that does not disintegrate in the disintegrant after scanned by an energy beam; in such a cycle, the steps of laying the thin layer and energy beam scanning are repeated, and then the three-dimensional workpiece can be formed; and the disintegant is used for separating the green compact not scanned by the energy beam from the workpiece, thus remaining the needed three-dimensional workpiece. The invention is widely applicable to manufacturing plastic, metallic, ceramic and compound workpieces, can avoid the defects of a selective laser sintering method, can use fine and very thin powder and therefore, can manufacture a finished product which is better than that made in the traditional selective laser sintering method in surface roughness and texture fineness, in addition, through subsequent densified sintering, the metallic and ceramic workpieces can have the strength superior to that in the traditional selective laser sintering method.

Owner:OUKESI INT

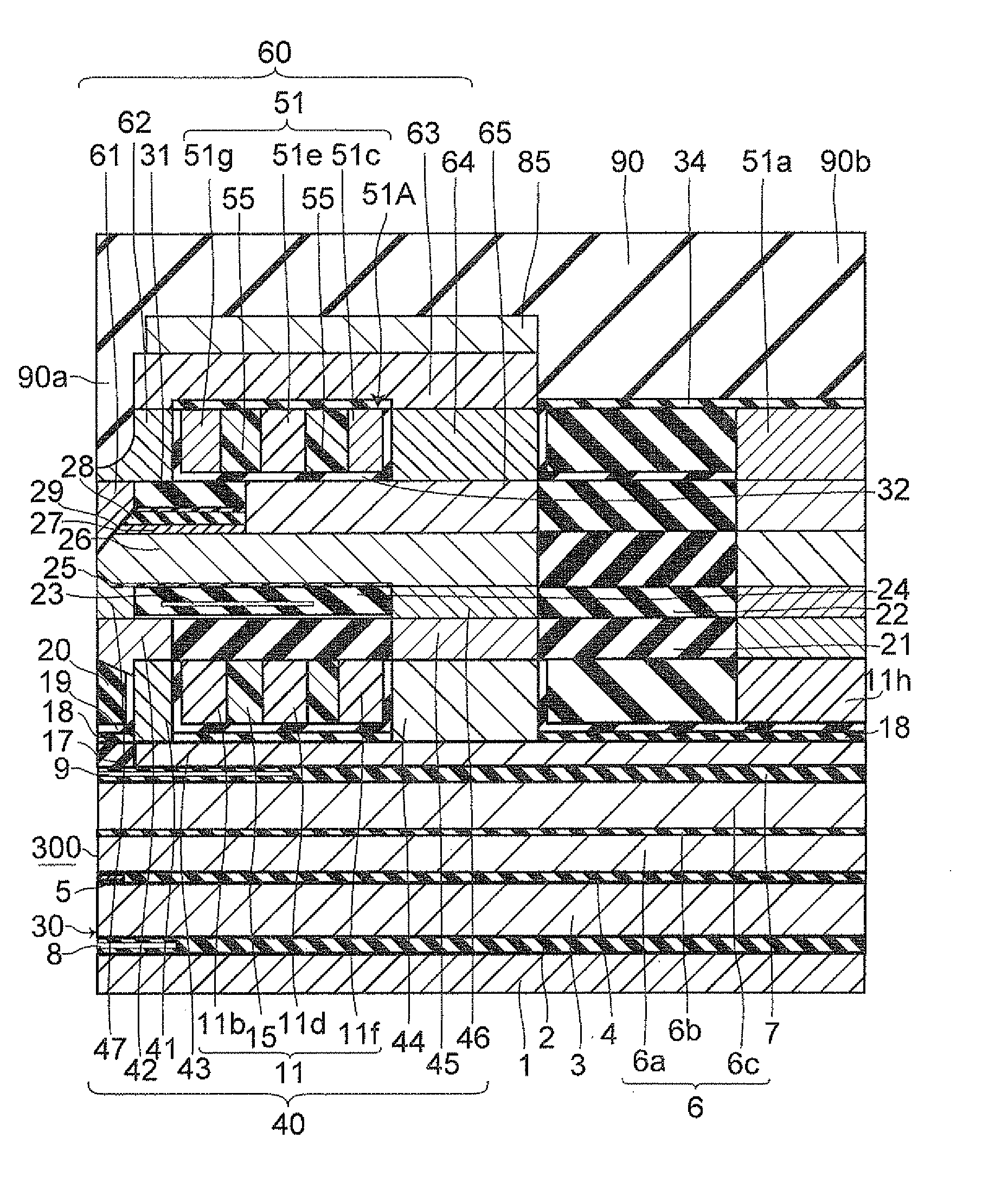

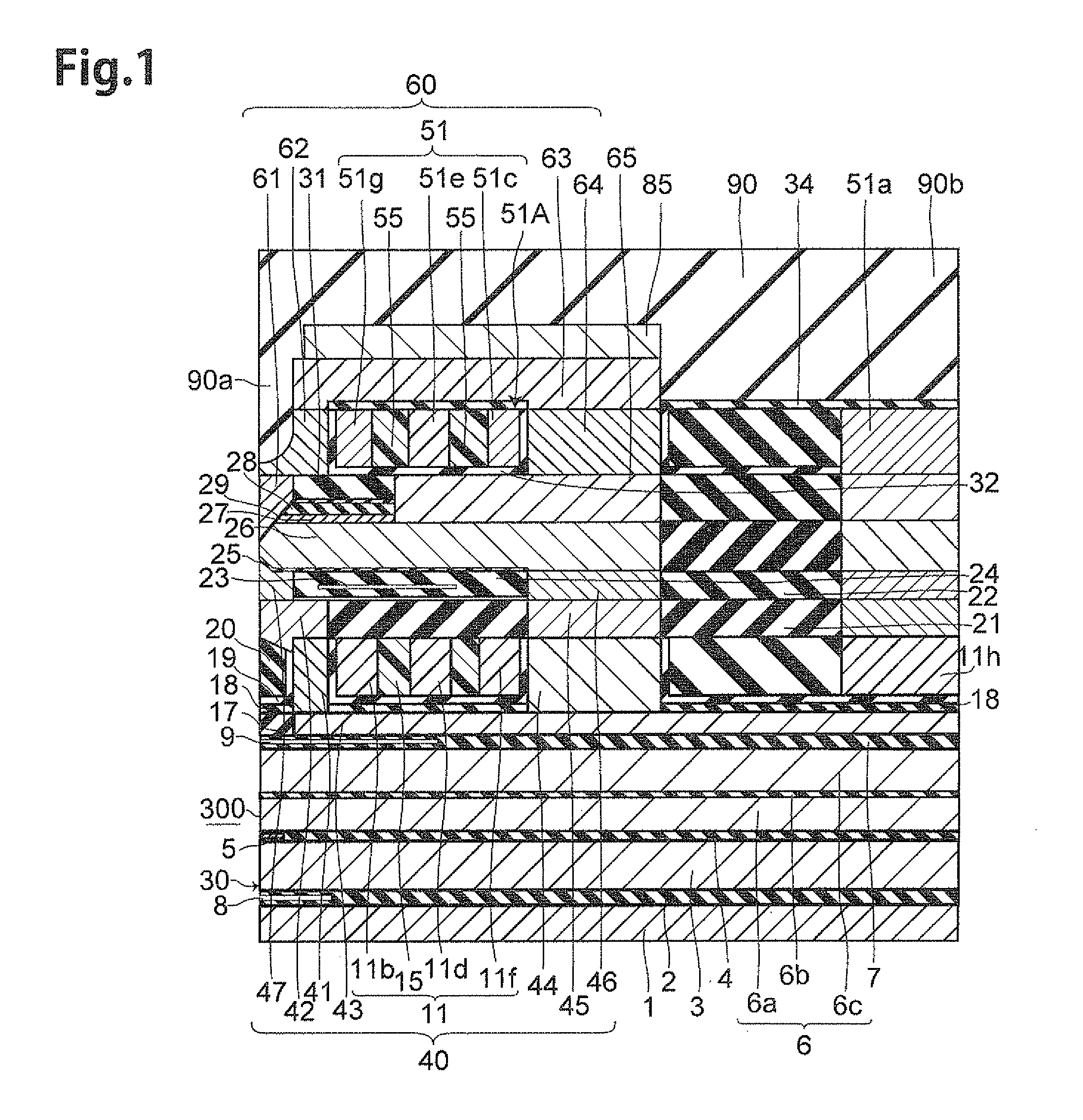

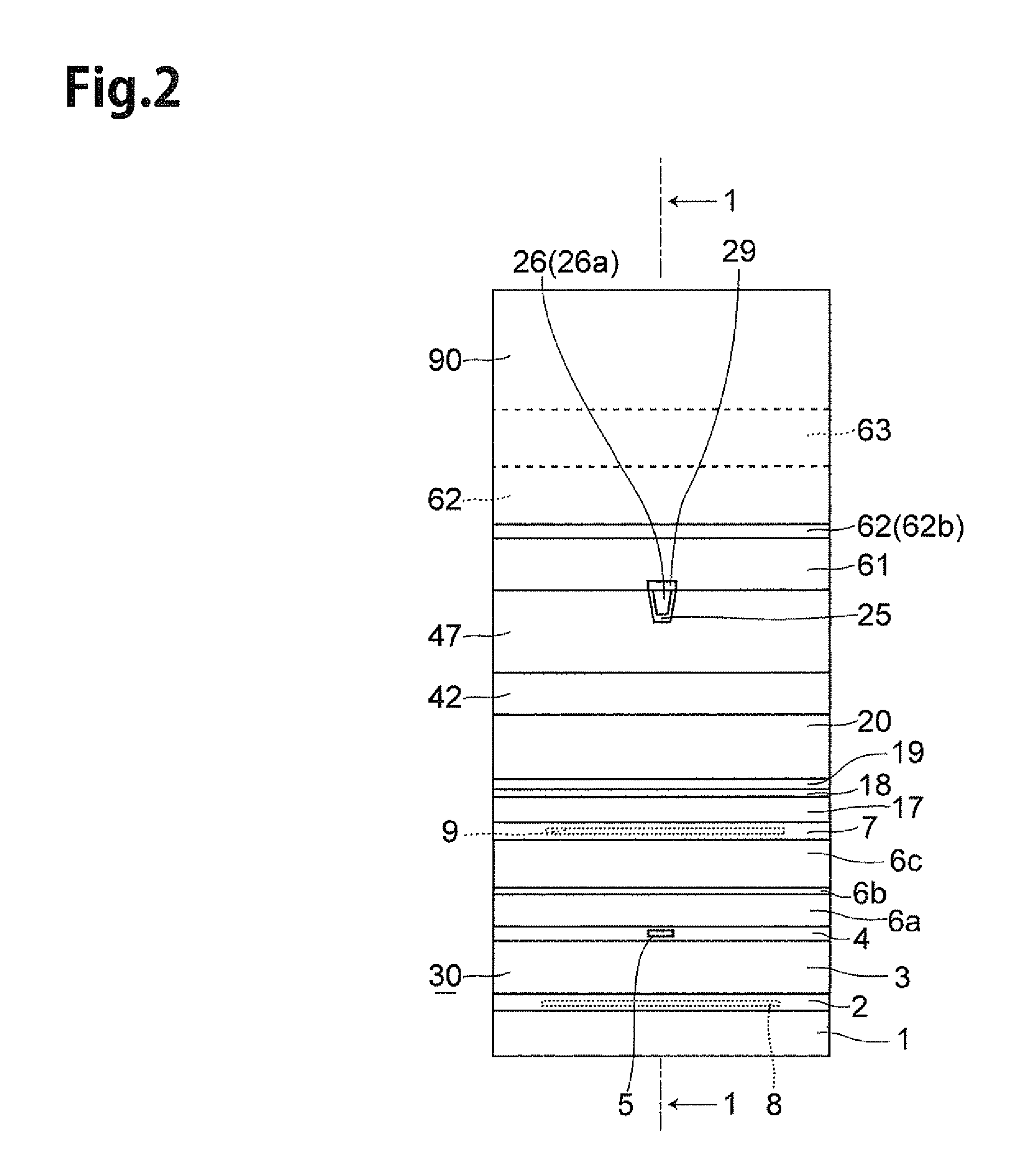

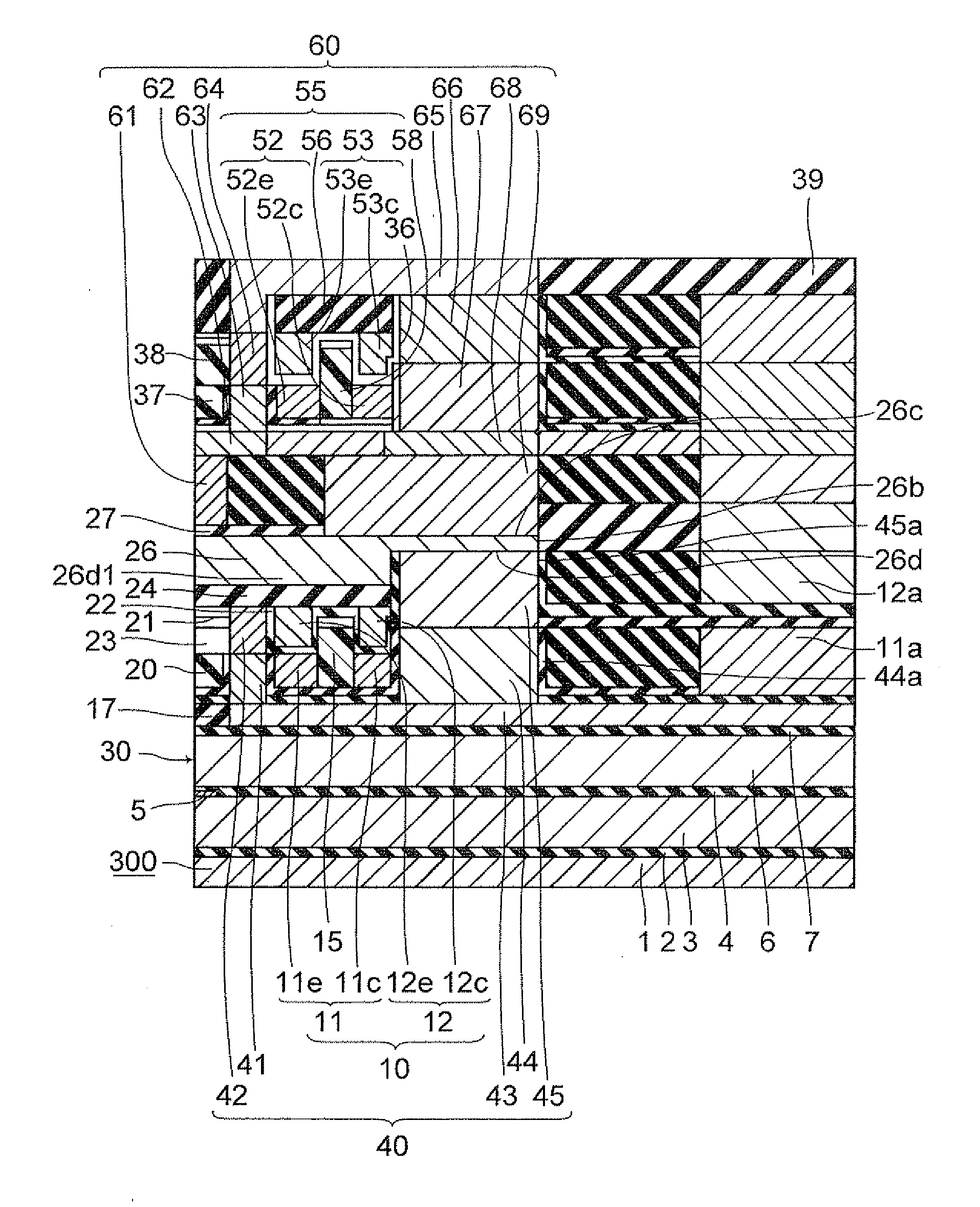

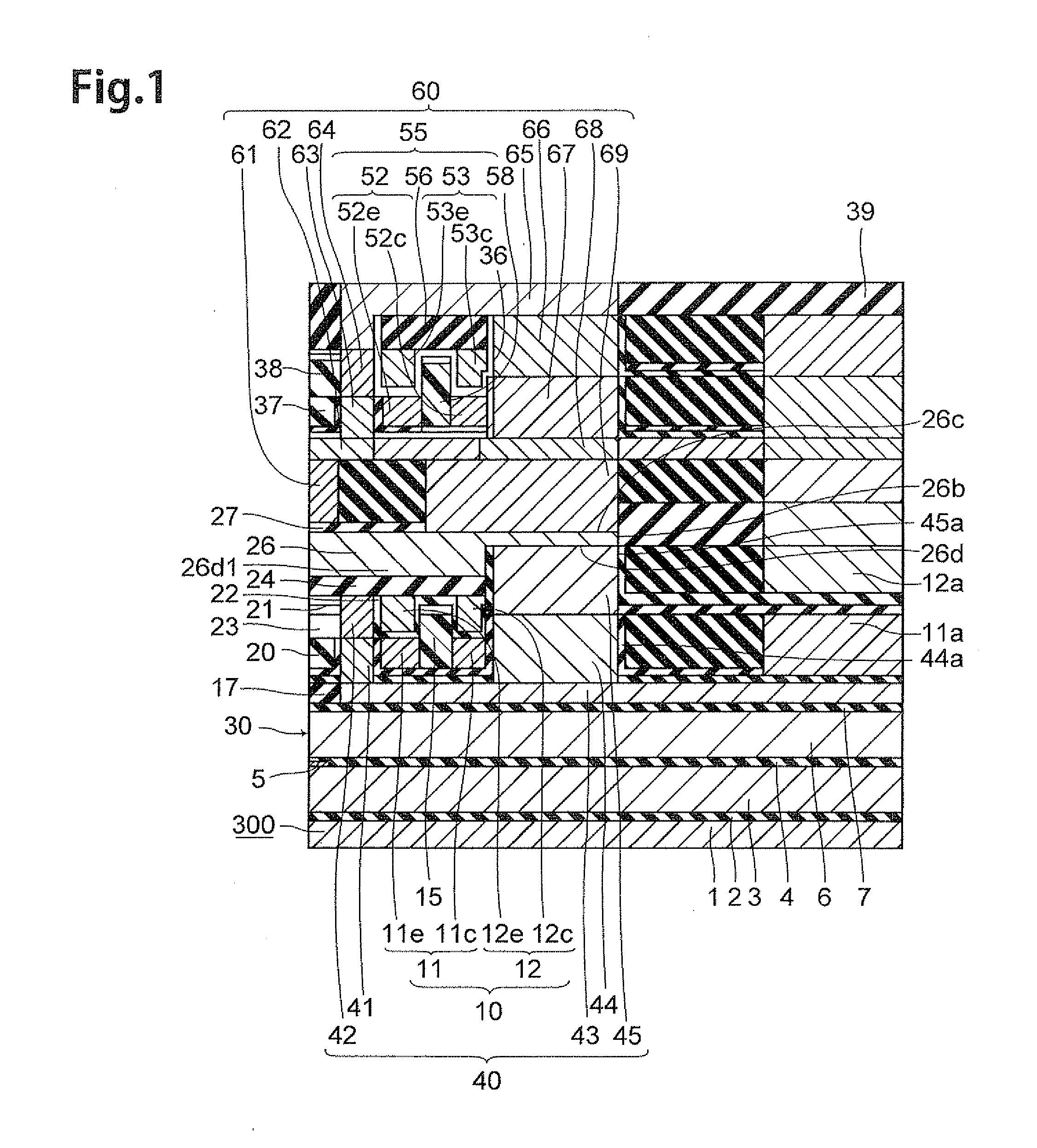

Thin-film magnetic head, method of manufacturing the same, head gimbal assembly, and hard disk drive

ActiveUS8310787B1Lower resistanceSuppress feverHeads using thin filmsRecord information storageHard disc driveMagnetic poles

A thin-film magnetic head is constructed such that a main magnetic pole layer, a write shield layer, a gap layer, and a thin-film coil are laminated on a substrate. The thin-film magnetic head has a shield magnetic layer. The shield magnetic layer is connected to the main magnetic pole layer. The shield magnetic layer has a lower front shield part. A front end angle representing an angle formed between a front end face of the lower front shield part and a lower end face is set at an obtuse angle. The front end face is disposed in the medium-opposing surface. The lower end face is disposed at a position closest to the substrate in the lower front shield part.

Owner:HEADWAY TECH INC +1

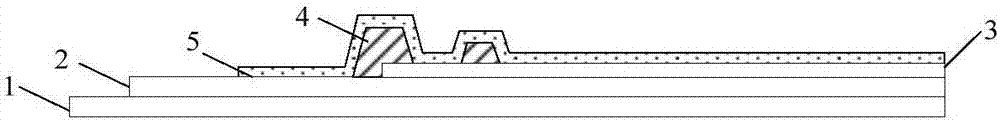

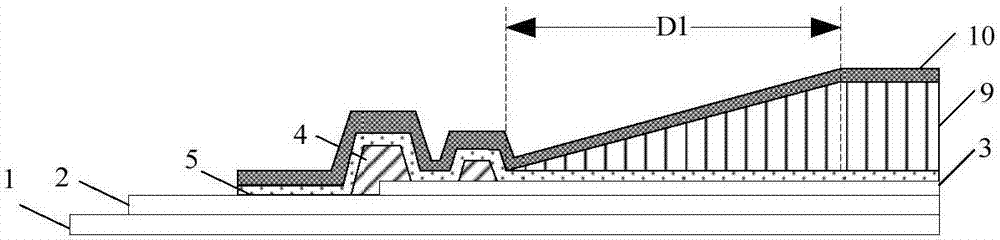

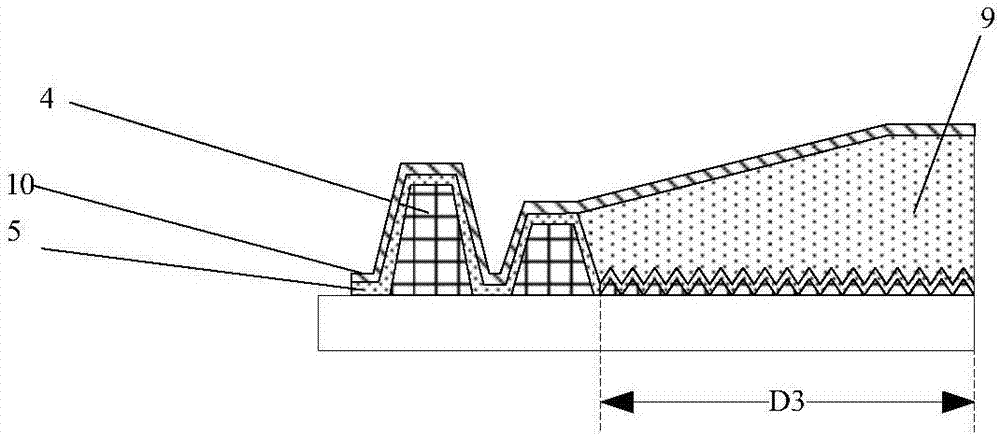

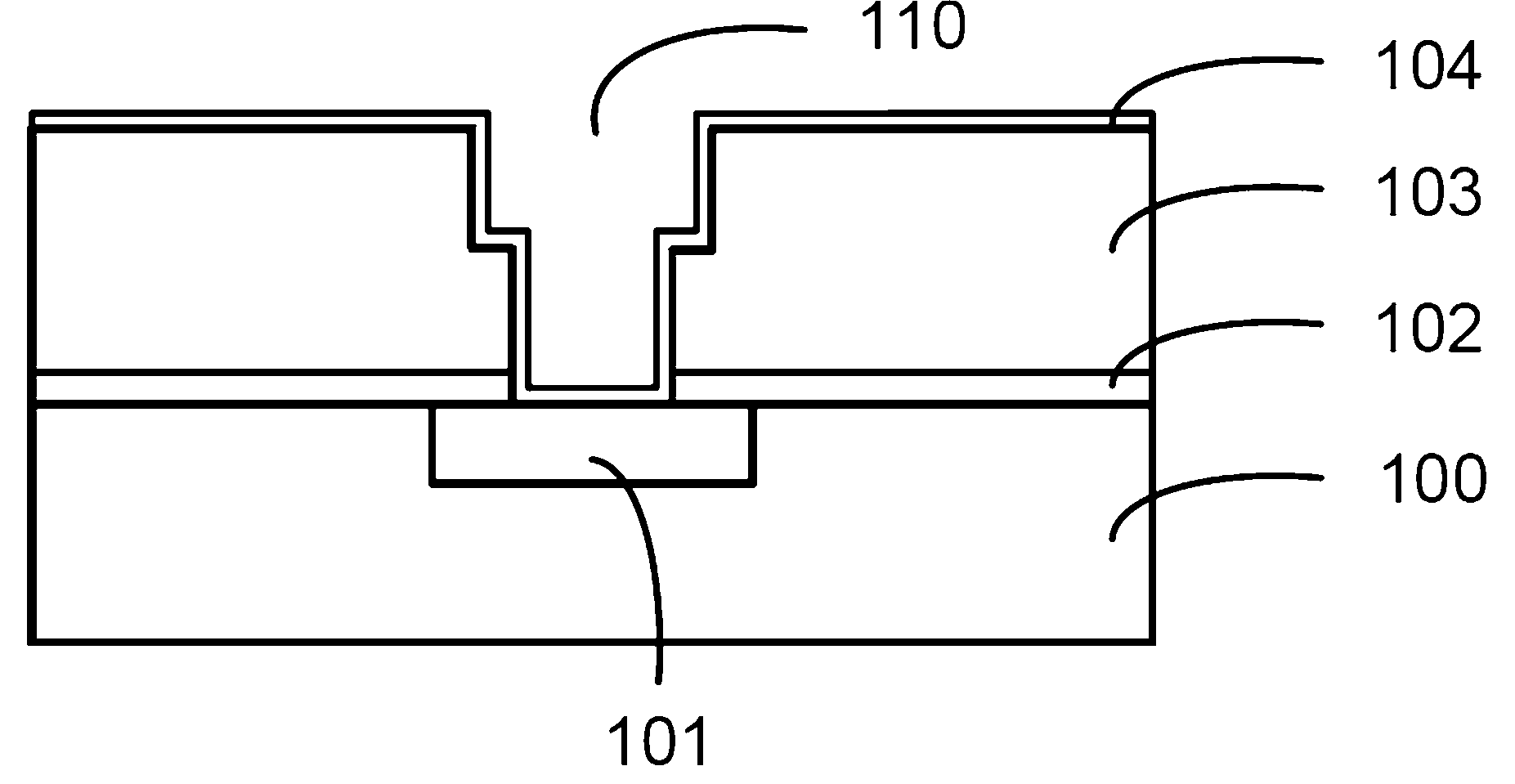

Packaging method and packaging structure of OLED display substrate, and display apparatus

InactiveCN107507931ASpeed up the flowReduce design distanceSolid-state devicesSemiconductor/solid-state device manufacturingEngineering

The invention provides a packaging method and packaging structure of an OLED display substrate, and a display apparatus, and belongs to the technical field of display. For the packaging method of an OLED display substrate, the OLED display substrate includes a display area, a blocking structure at the edge of the OLED display substrate, and a non-display area which is arranged between the display area and the blocking structure. The packaging method of an OLED display substrate includes the step of printing rheological property organic material in the area enclosed by the blocking structure, and before printing the rheological property organic material, the packaging method also includes the step of processing the surface, for contacting the rheological property organic material, of the OLED display substrate to enable the flowing speed of the rheological property organic material in the non-display area to be less than the threshold The packaging method and packaging structure of an OLED display substrate can realize a narrow frame of the display apparatus.

Owner:BOE TECH GRP CO LTD +1

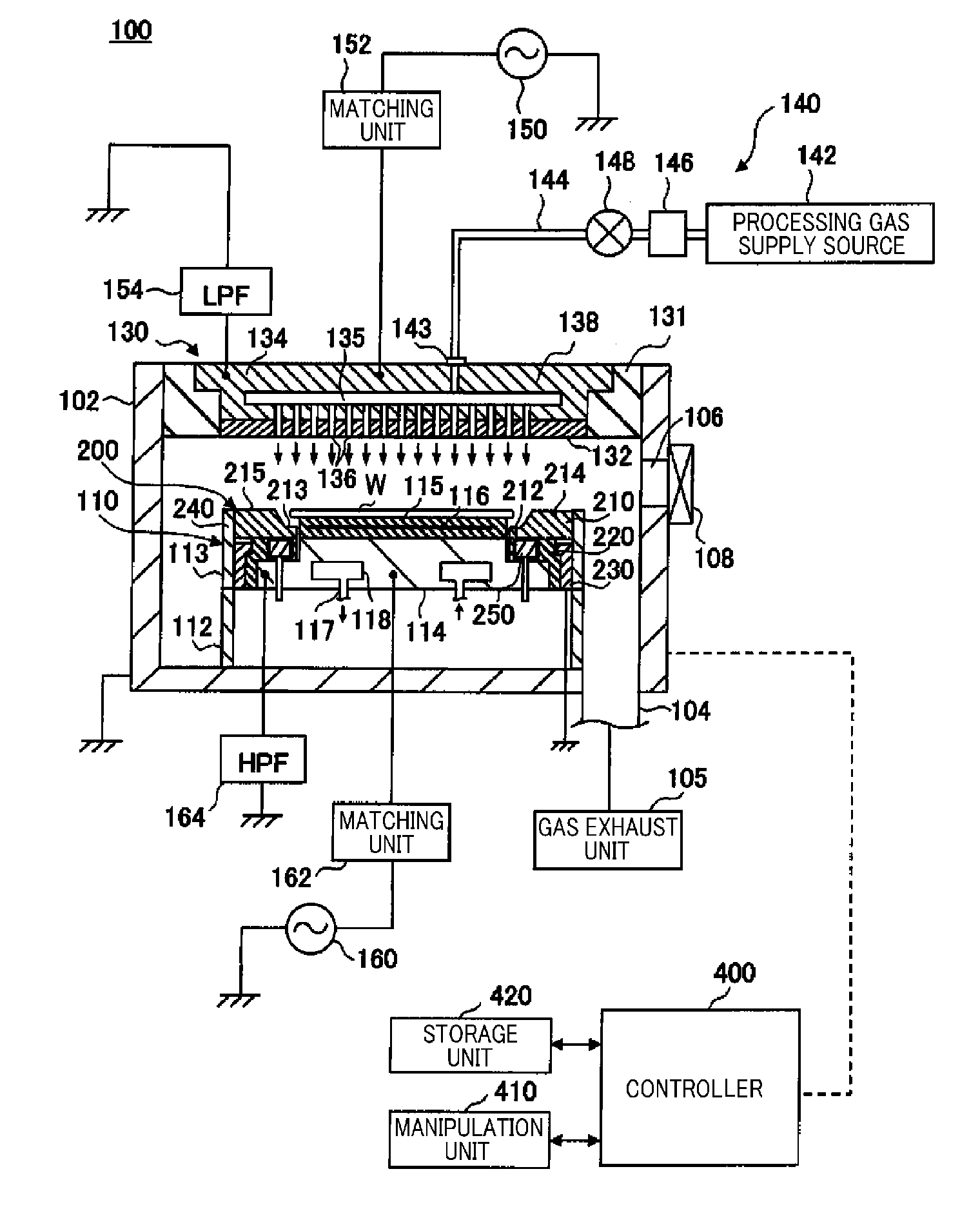

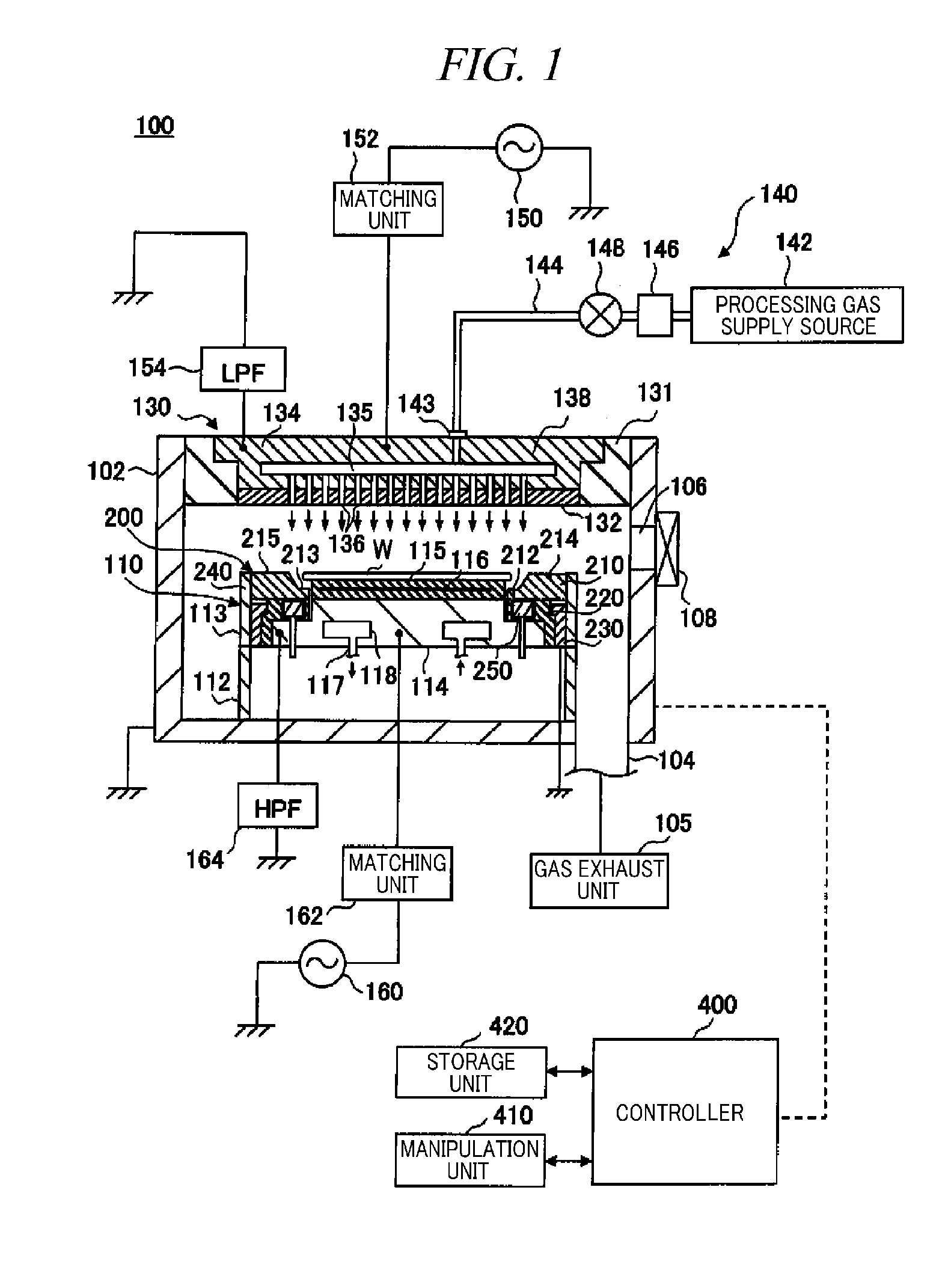

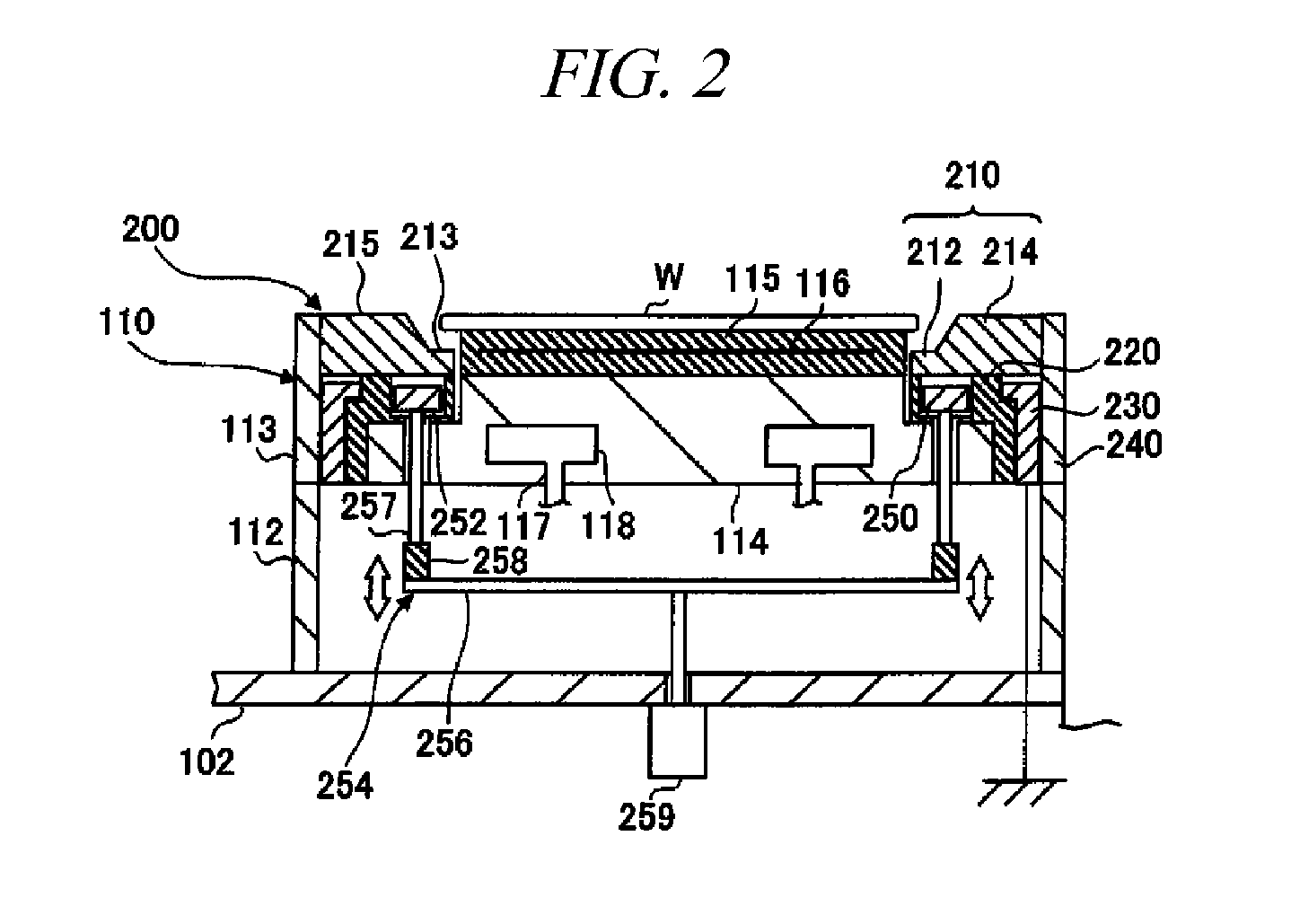

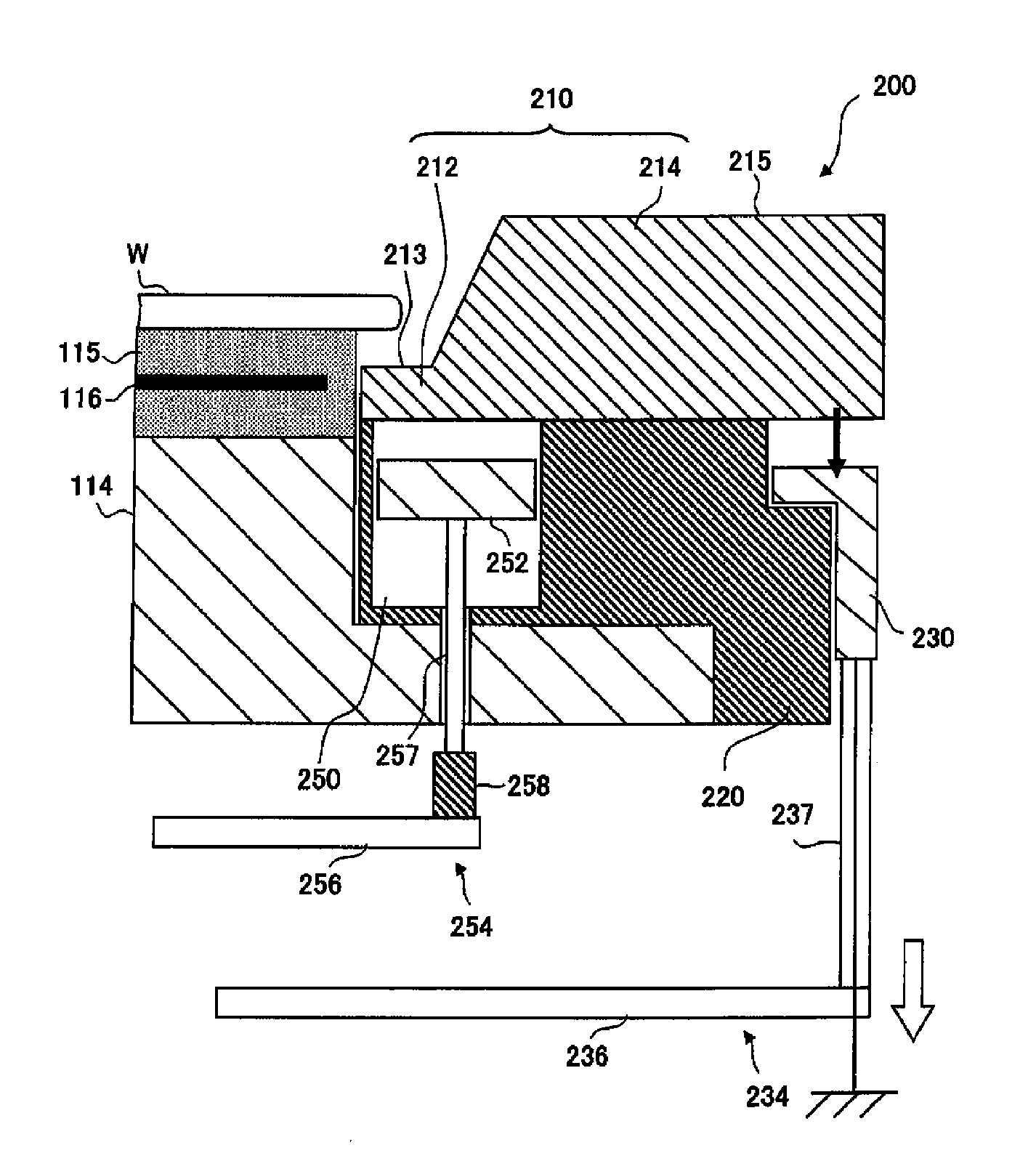

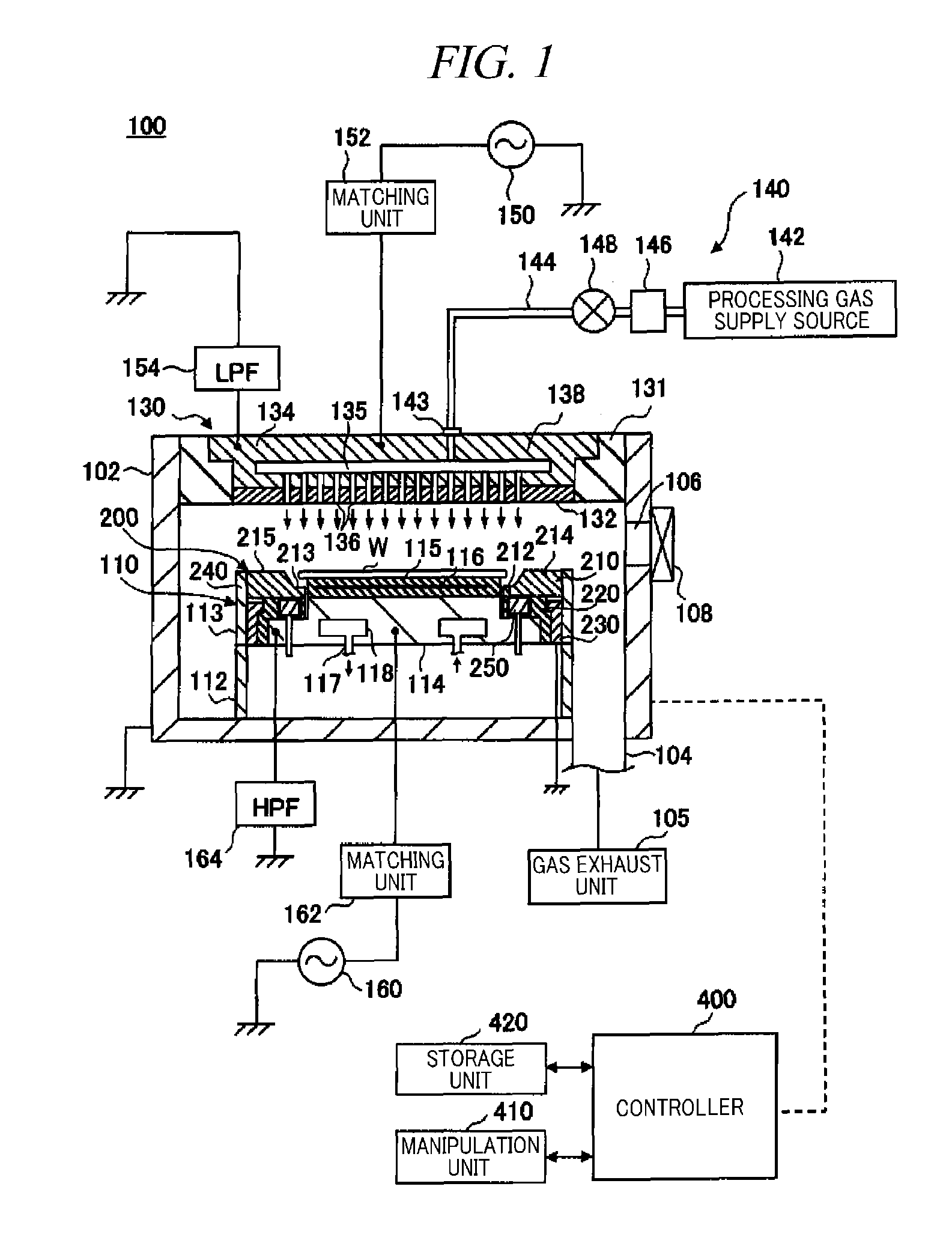

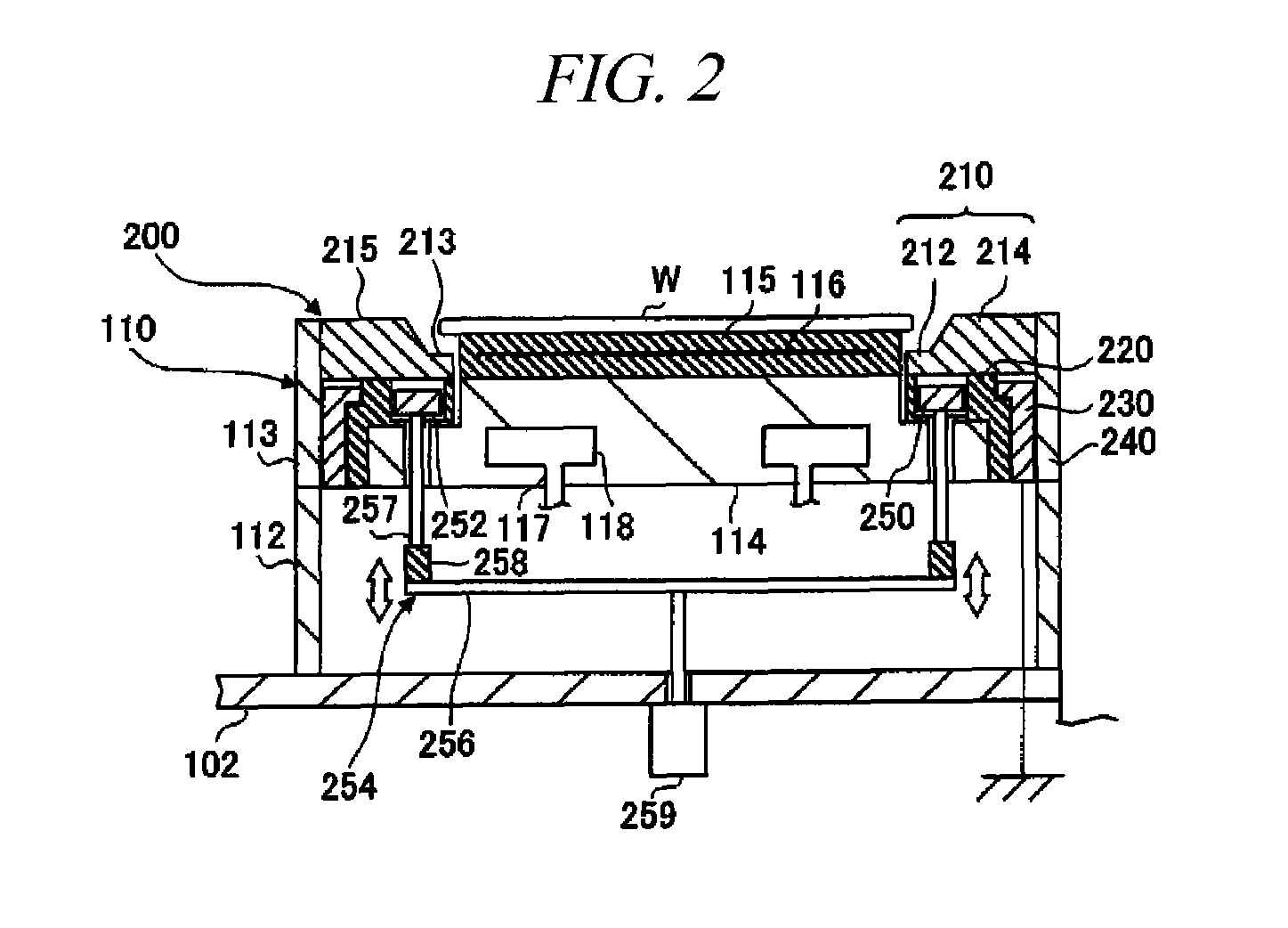

Plasma processing apparatus, plasma processing method and storage medium for storing program for executing the method

ActiveUS20120061351A1Suppress decrease top surface electric potentialSpeed up the flowLiquid surface applicatorsElectric discharge tubesHigh frequency powerEngineering

There is provided a plasma processing apparatus including a susceptor 114, having a substrate mounting portion for mounting thereon a substrate, to which a high frequency power is applied; a focus ring 210, disposed to surround the substrate mounted on the substrate mounting portion, including an outer ring 214 having a top surface higher than a top surface of the substrate and an inner ring 212 extending inwardly from the outer ring so as to allow at least a part of the inner ring to be positioned below a periphery of the substrate, the outer ring and the inner ring being formed as a single member; a dielectric ring 220 positioned between the focus ring and the susceptor; a dielectric constant varying device 250 for varying a dielectric constant of the dielectric ring.

Owner:TOKYO ELECTRON LTD

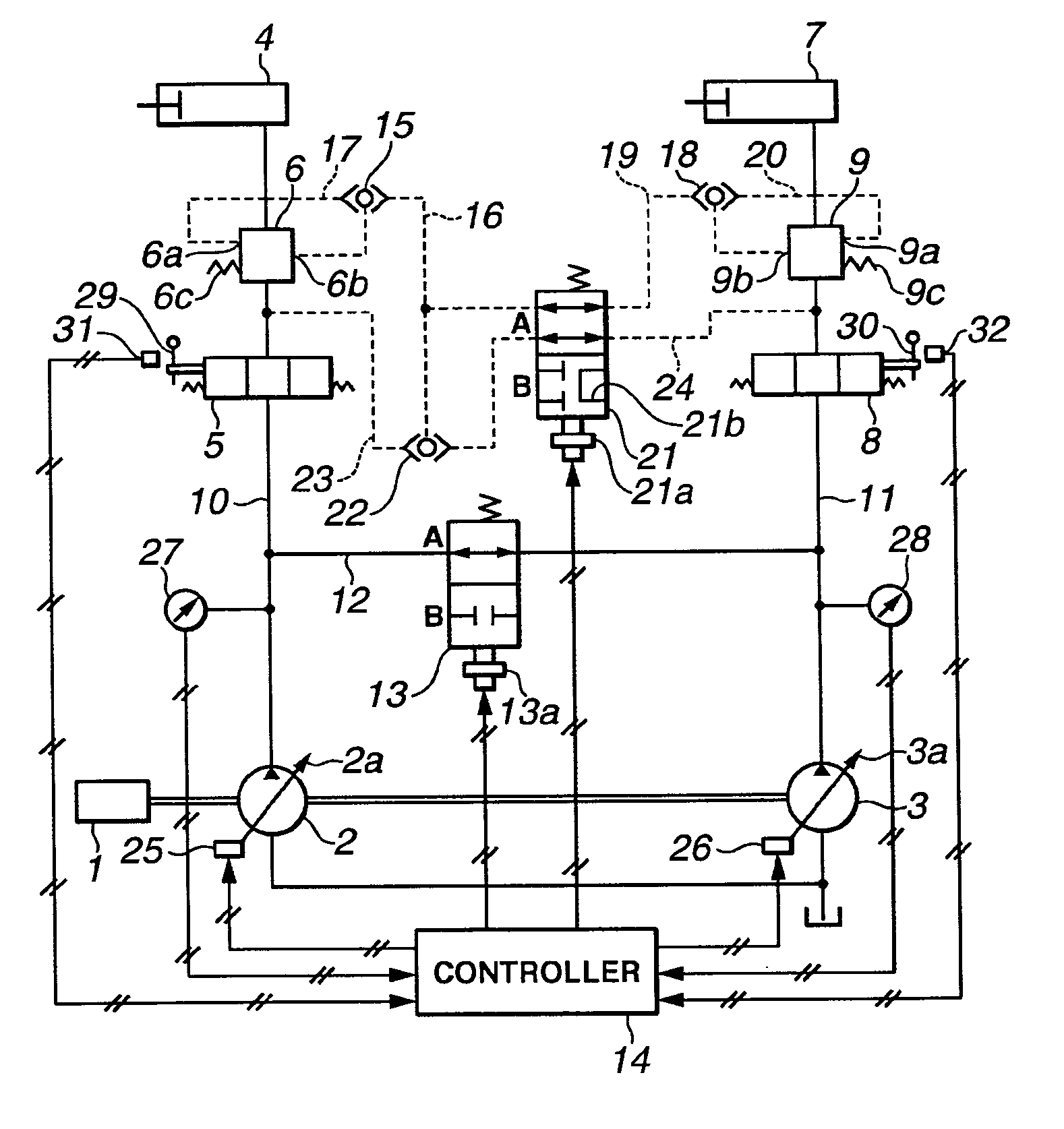

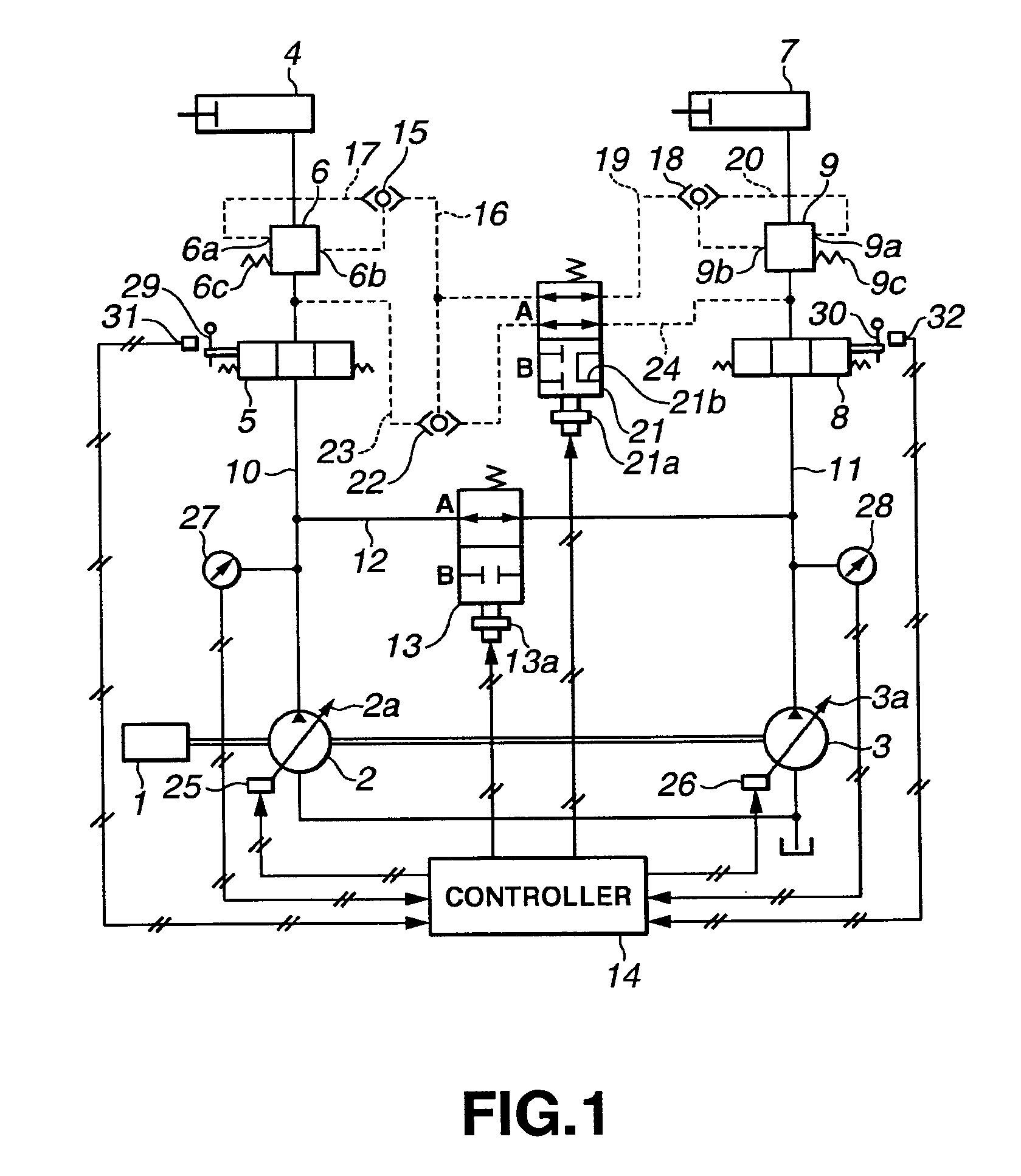

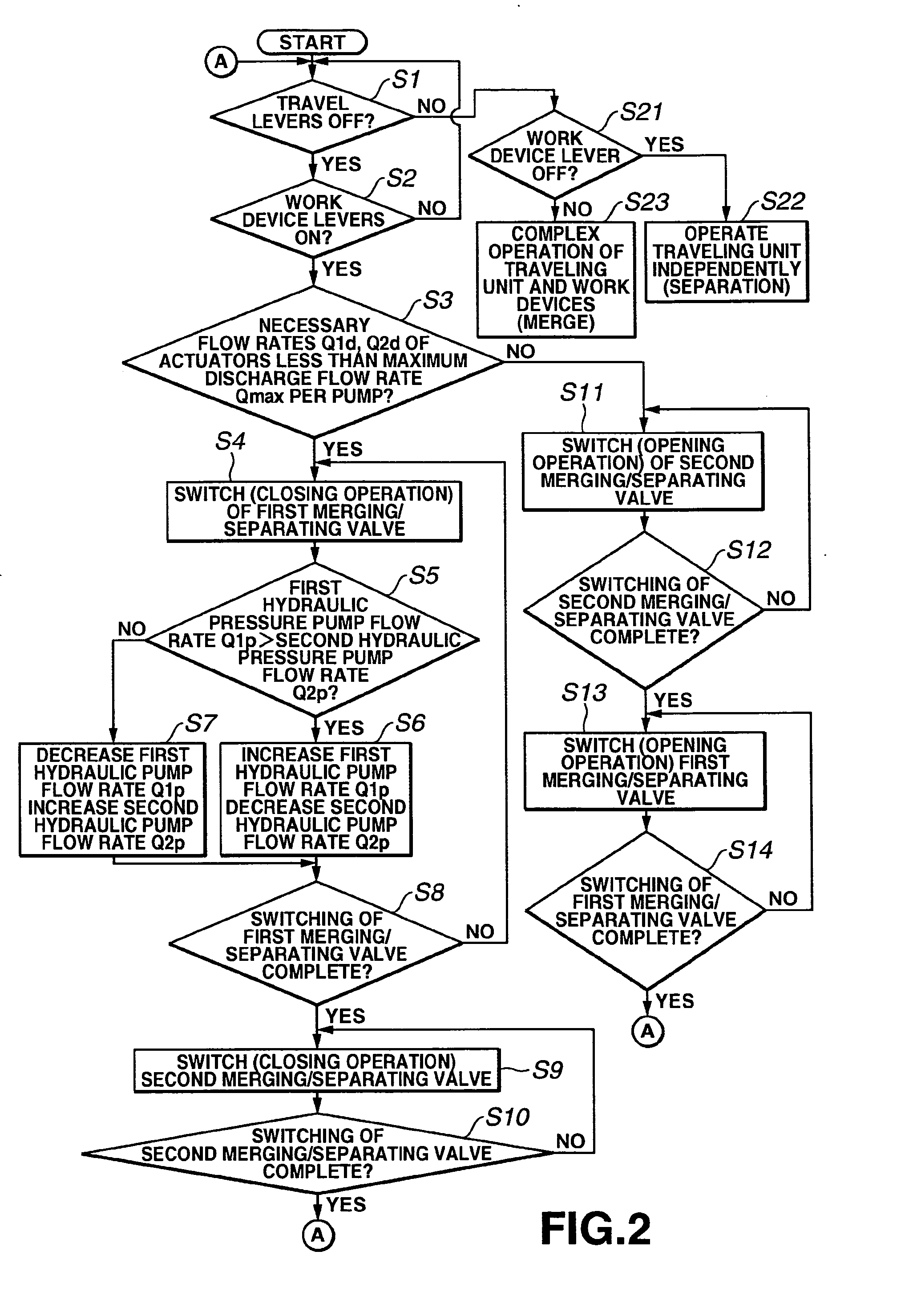

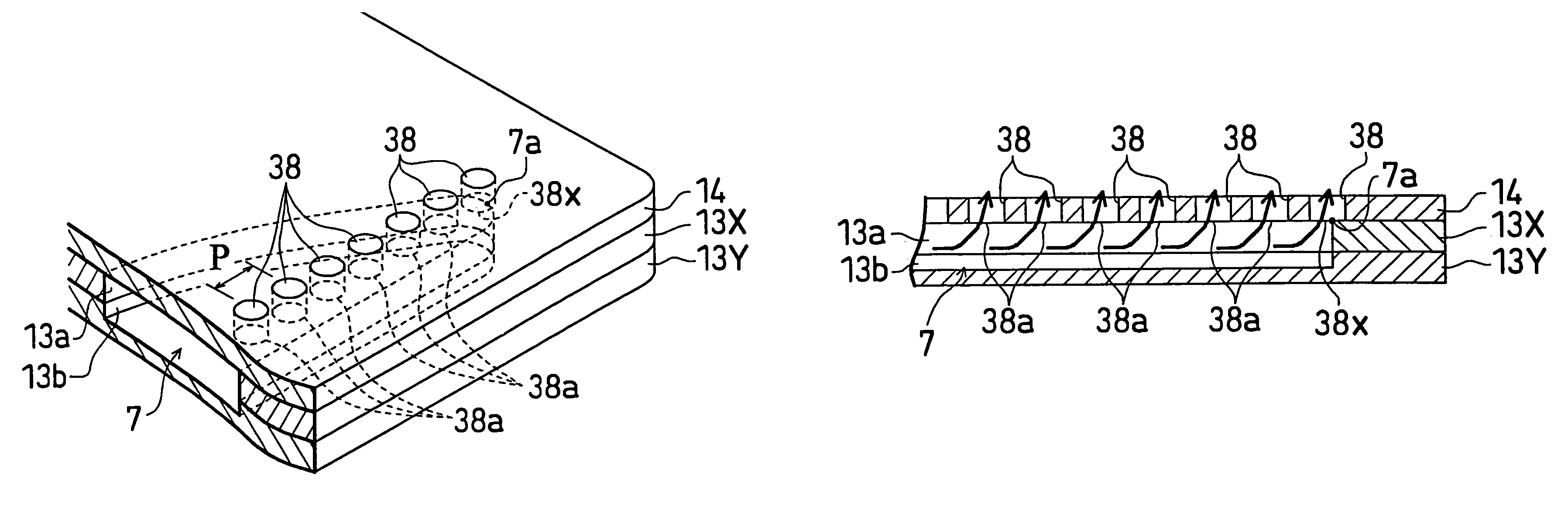

Hydraulic pressure control device of construction machine

ActiveUS20070125078A1Operability is lostReduce work efficiencyFluid couplingsServomotorsHydraulic pumpOperability

A hydraulic pressure control device of a construction machine enabling an increase in operability and working efficiency by suppressing a fluctuation in flow rates occurring before and after the switching of a merging-separating valve, in energy efficiency by accurately determining the switching timing of the merging-separating valve to suppress the pressure energy loss of a pressure compensating valve, and working efficiency in the compound motion of plural hydraulic actuators. When a controller determines that necessary flow rates of first and second hydraulic actuators are less than maximum discharge flow rate of each of first and second variable displacement hydraulic pumps when the first merging-separating valve is in a merging position, the switching of the first merging-separating valve is controlled so that firstly the first merging-separating valve is switched to a separating position and, after the switching is completed, the second merging-separating valve is switched.

Owner:KOMATSU LTD

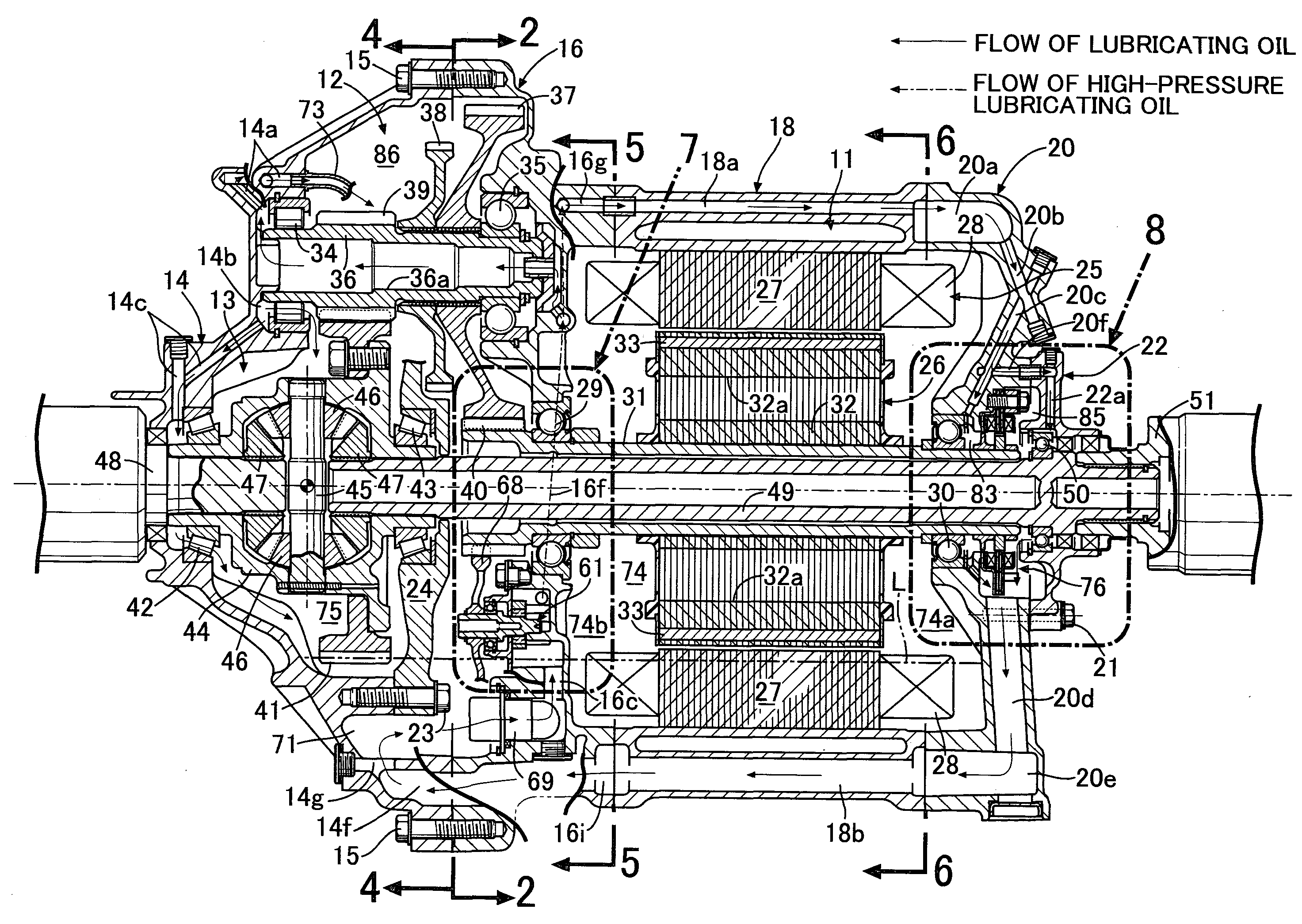

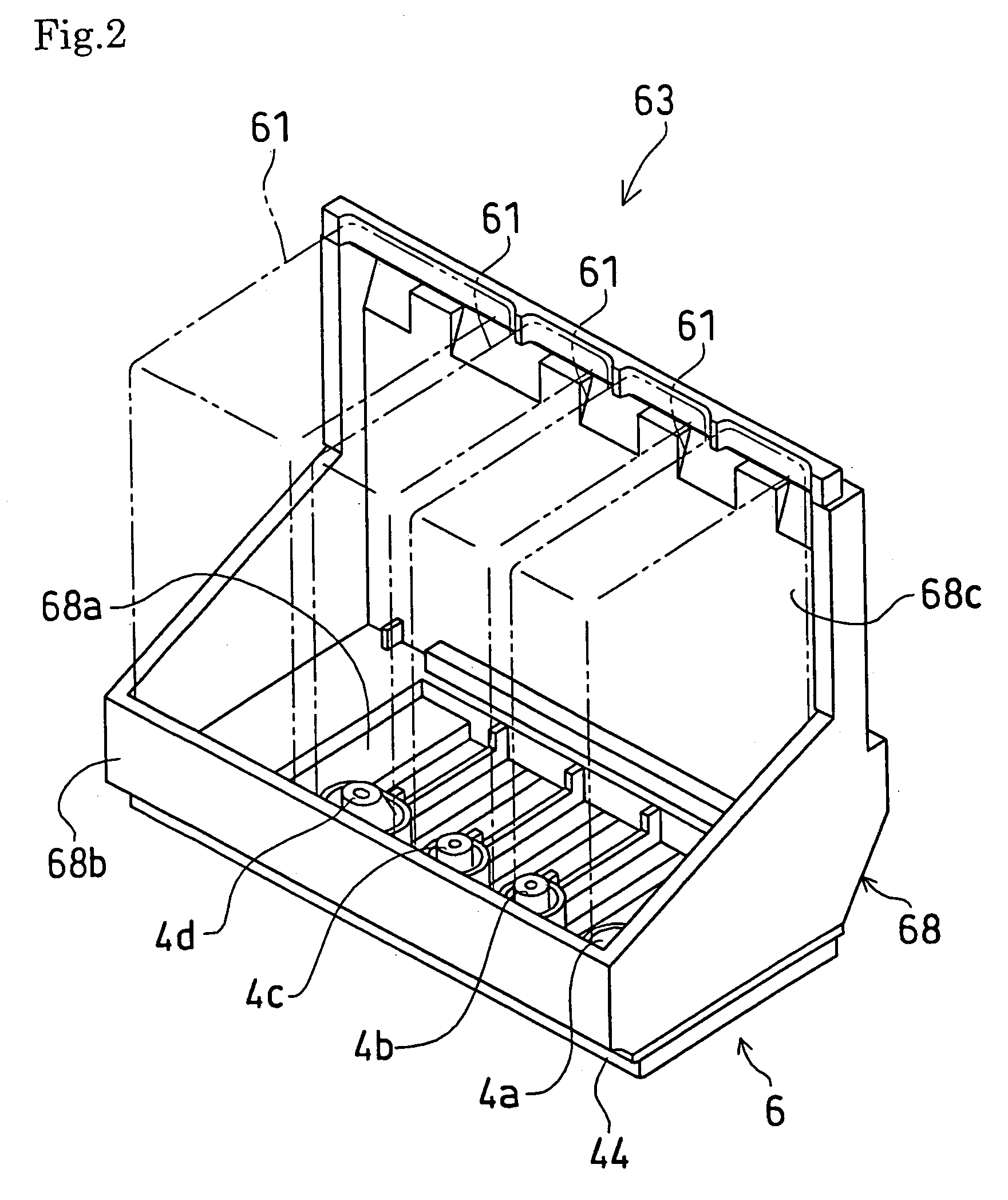

Motor-type power device

ActiveUS7884511B2Suppress stirring resistance of oilReduce oil resistanceGearboxesGear lubrication/coolingCentrifugal forceElectric motor

Due to a centrifugal force in a vehicle width direction due to turning of an automobile, oil in an electric motor housing chamber housing an electric motor and oil in a transmission housing chamber housing a reduction gear and a differential gear flows to-and-fro via oil communication passages that penetrate a partitioning wall. An opening on the transmission housing chamber side of the oil communication passages is spaced from the partitioning wall. Hence, when oil moves from the transmission housing chamber side to the electric motor housing chamber side, it is possible to prevent the oil quantity on the electric motor housing chamber side from increasing excessively and suppress an increase in resistance to oil stirring by a rotor of the electric motor while retaining a constant oil amount on the transmission housing chamber side to ensure lubricating performance for the reduction gear and the differential gear.

Owner:HONDA MOTOR CO LTD

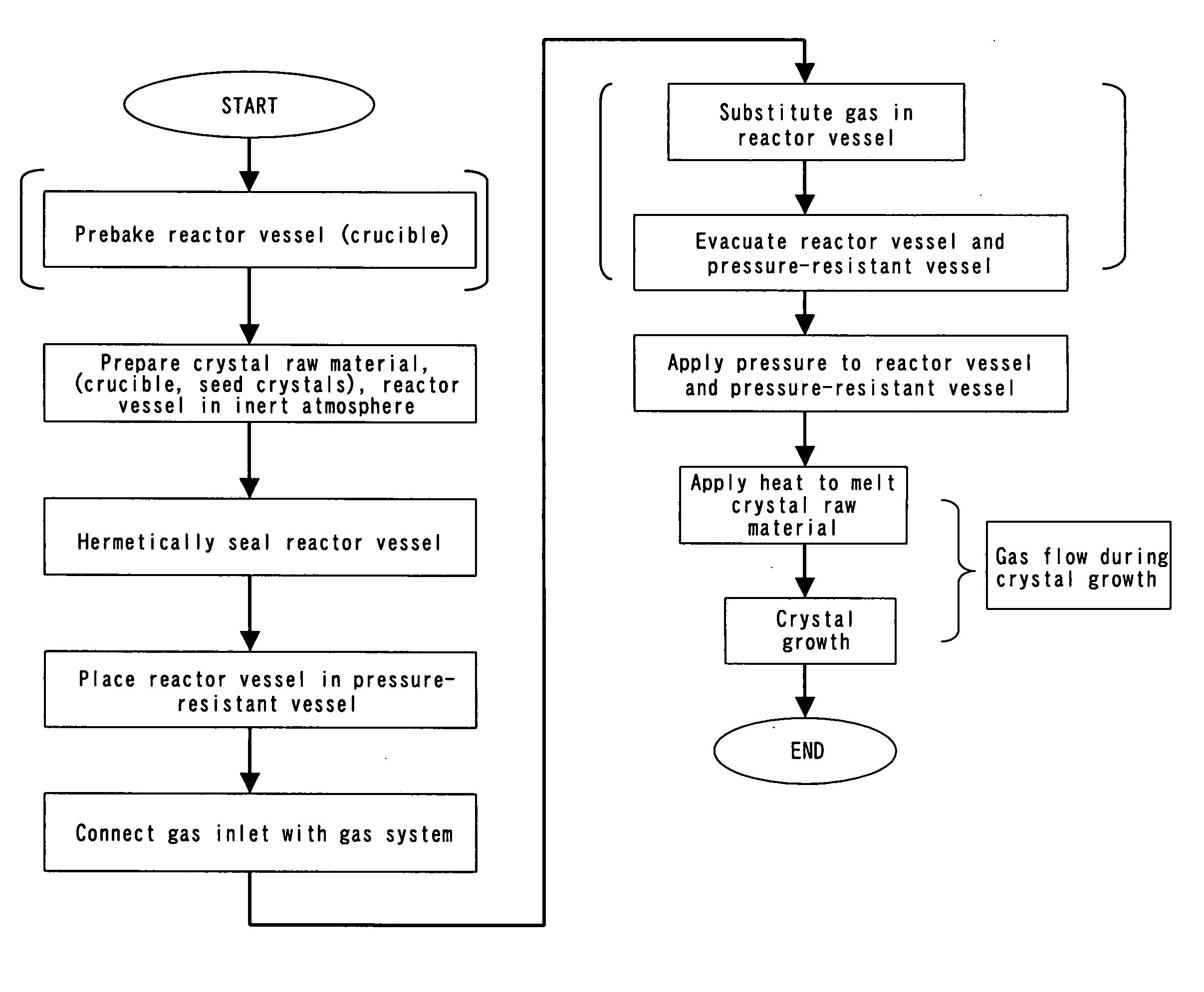

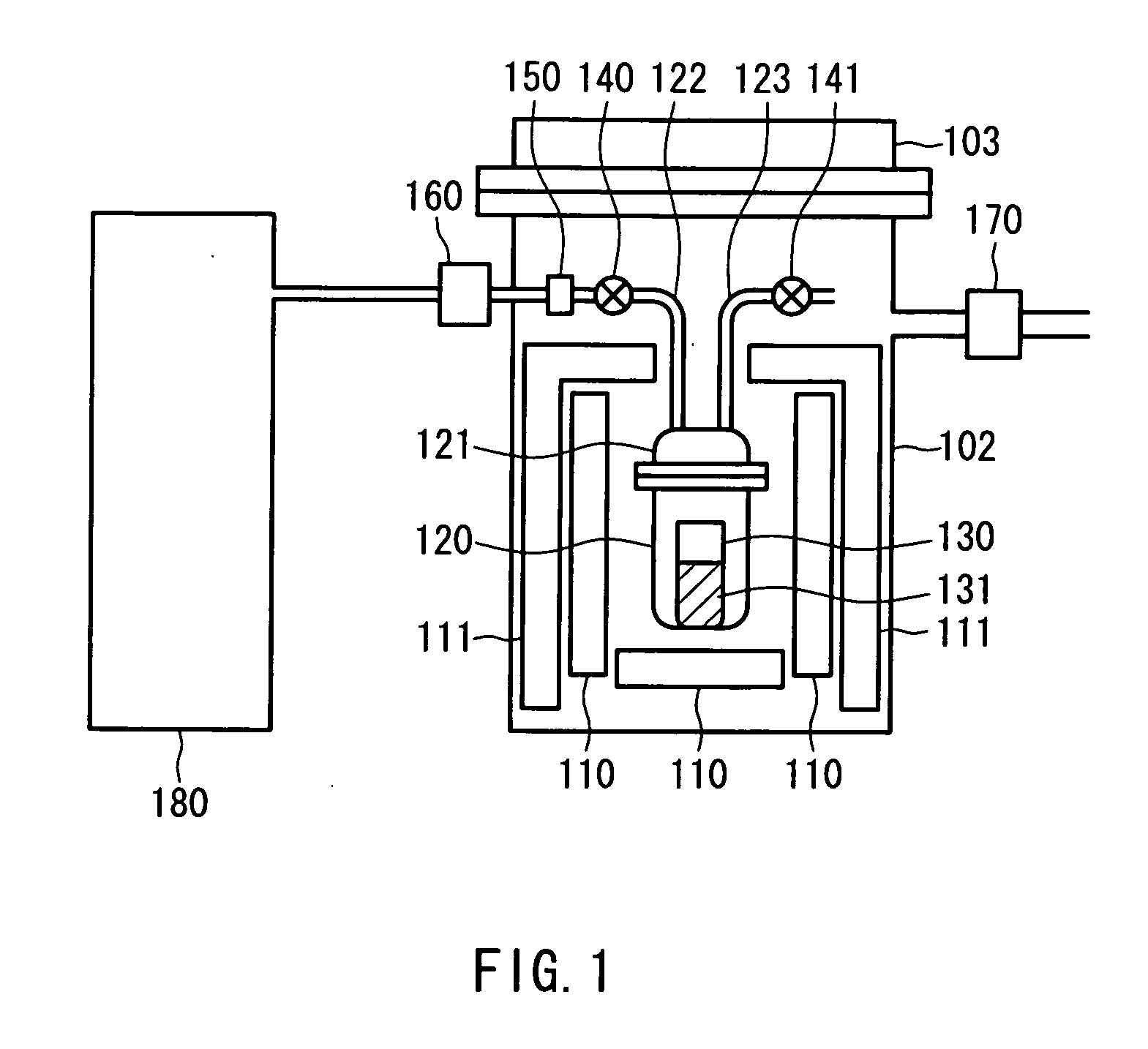

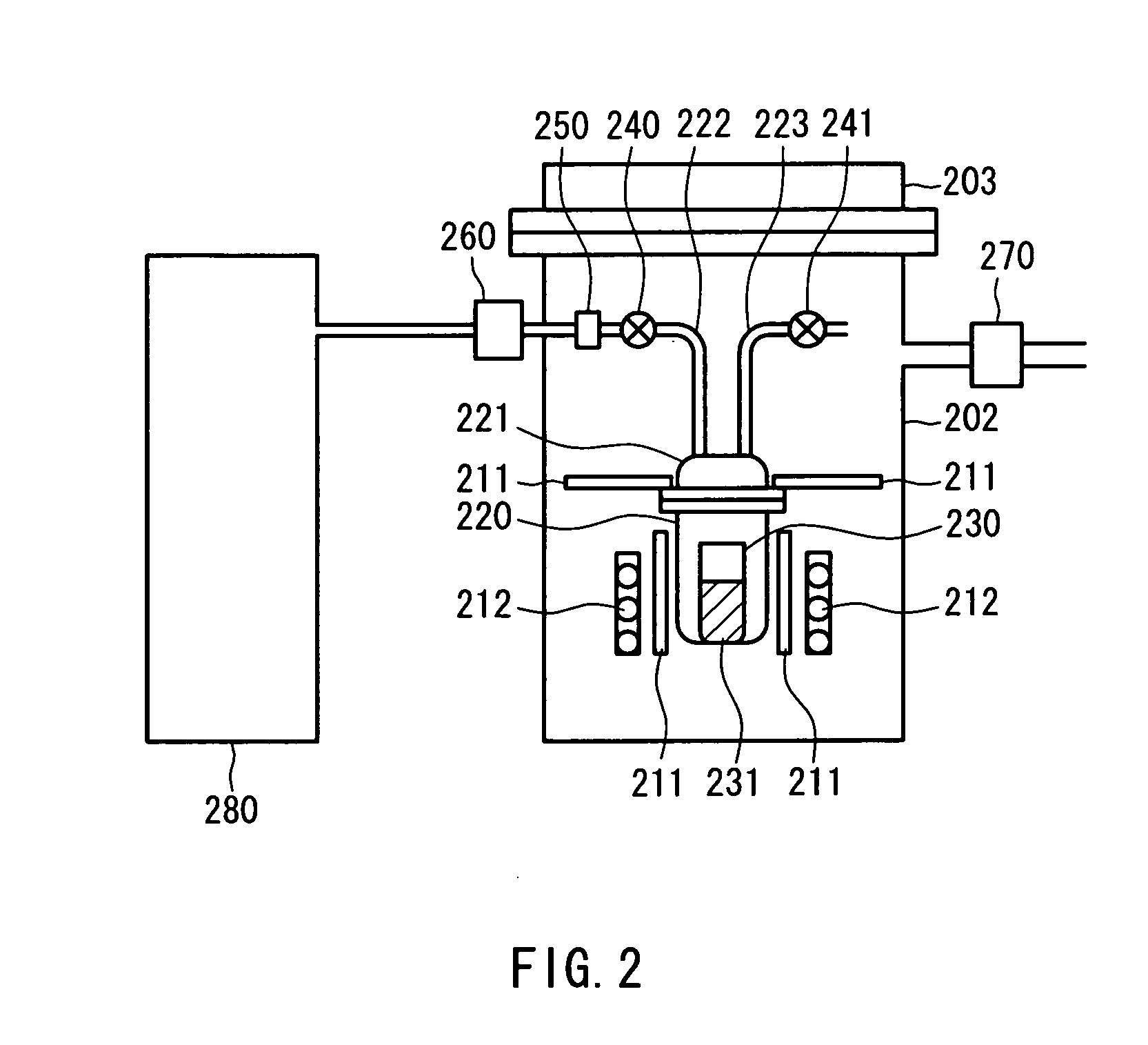

Apparatus for production of crystal of group III element nitride and process for producing crystal of group III element nitride

InactiveUS20070157876A1Quality improvementImprove controllabilityBy pulling from meltFrom melt solutionsNitrogenManufactured apparatus

A manufacturing apparatus of Group III nitride crystals and a method for manufacturing Group III nitride crystals are provided, by which high quality crystals can be manufactured. For instance, crystals are grown using the apparatus of the present invention as follows. A crystal raw material (131) and gas containing nitrogen are introduced into a reactor vessel (120), to which heat is applied by a heater (110), and crystals are grown in an atmosphere of pressure applied thereto. The gas is introduced from a gas supplying device (180) to the reactor vessel (120) through a gas inlet of the reactor vessel, and then is exhausted to the inside of a pressure-resistant vessel (102) through a gas outlet of the reactor vessel. Since the gas is introduced directly to the reactor vessel (120) without passing through the pressure-resistant vessel (102), the mixture of impurities attached to the pressure-resistant vessel (102) and the like into the site of the crystal growth can be prevented. Further, since the gas flows through the reactor vessel (120), there is no aggregation of an evaporating alkali metal, etc., at the gas inlet or the like, and such an alkali metal does not flow into the gas supplying device (180). As a result, the quality of Group III nitride crystals obtained can be improved.

Owner:MORI YUSUKE +1

Bilayer edible sheet

There is provided an edible sheet obtainable by steps of: producing a base sheet layer by mixing ingredients such as starch with water and drying a mixture with a hot air to produce a base sheet layer; mixing functional ingredients such as flavoring agents with a particular organic solvent; applying a mixture of functional ingredients on the base sheet; and drying the mixture with a air to form a functional ingredient layer on the base sheet layer. The edible sheet of the present invention can solve problems such as occurrence of hardening, hygroscopicity, fragility, discoloration and the like due to coexistence of the functional ingredients such as flavoring agents, acidulants, pharmaceutically active agents and the like with other ingredients.

Owner:SHOWAKAKOU

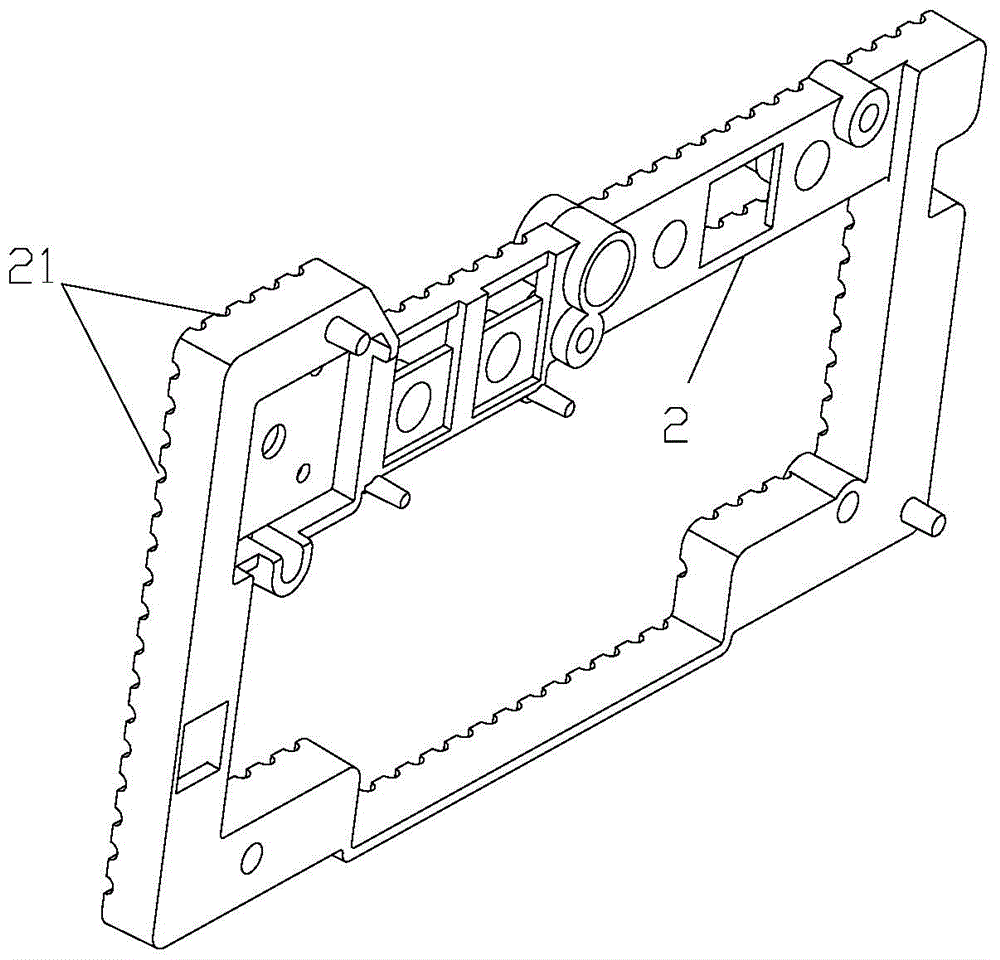

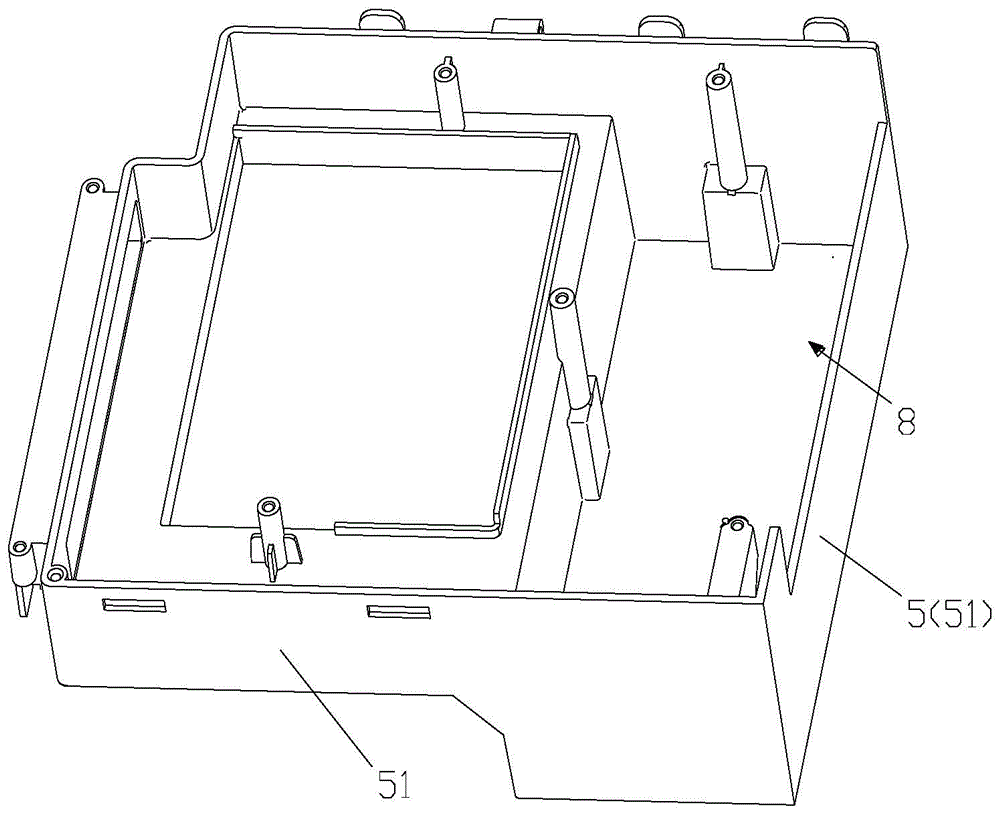

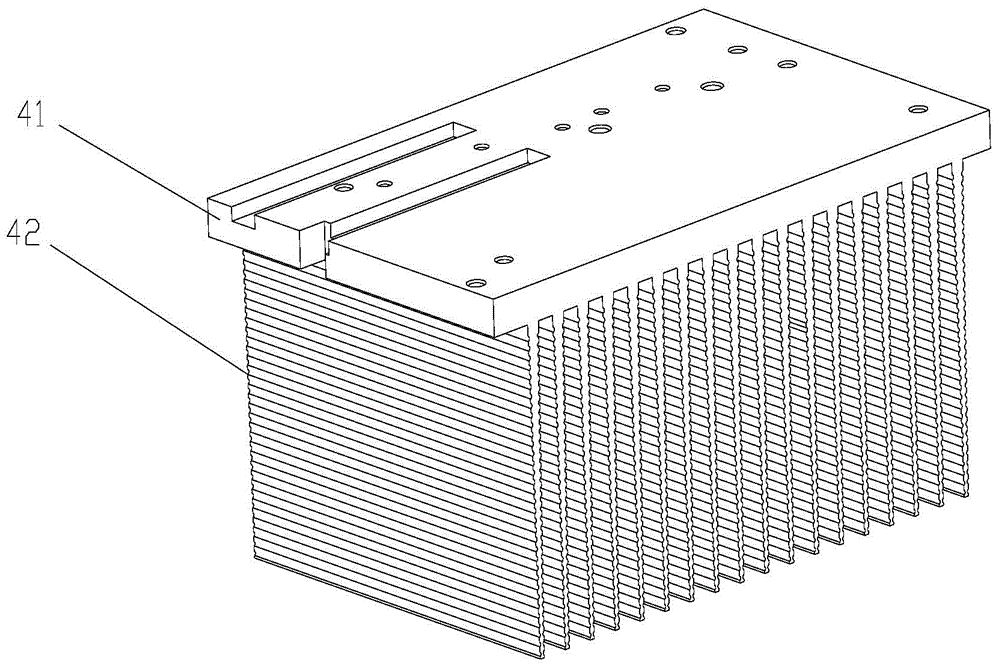

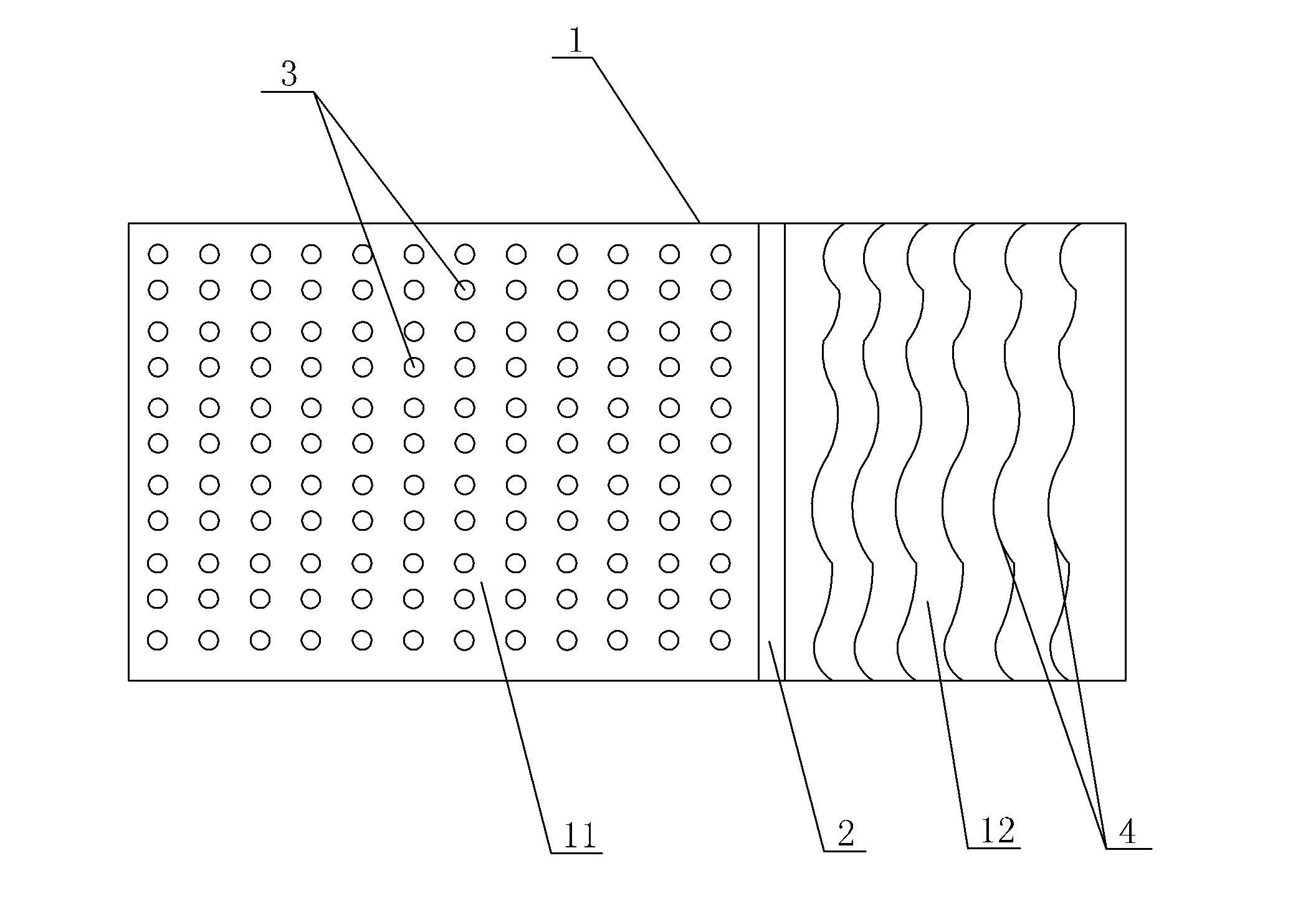

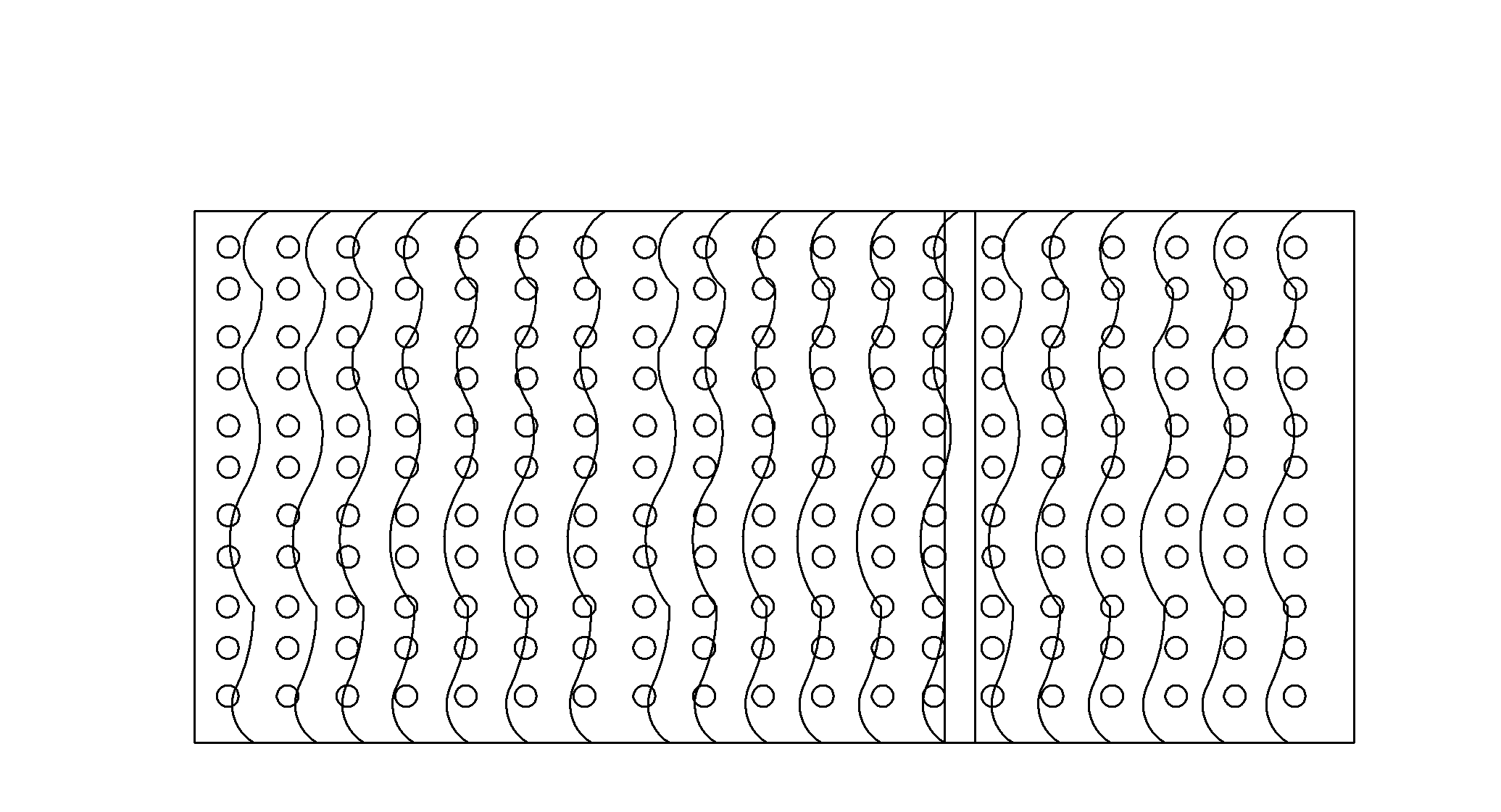

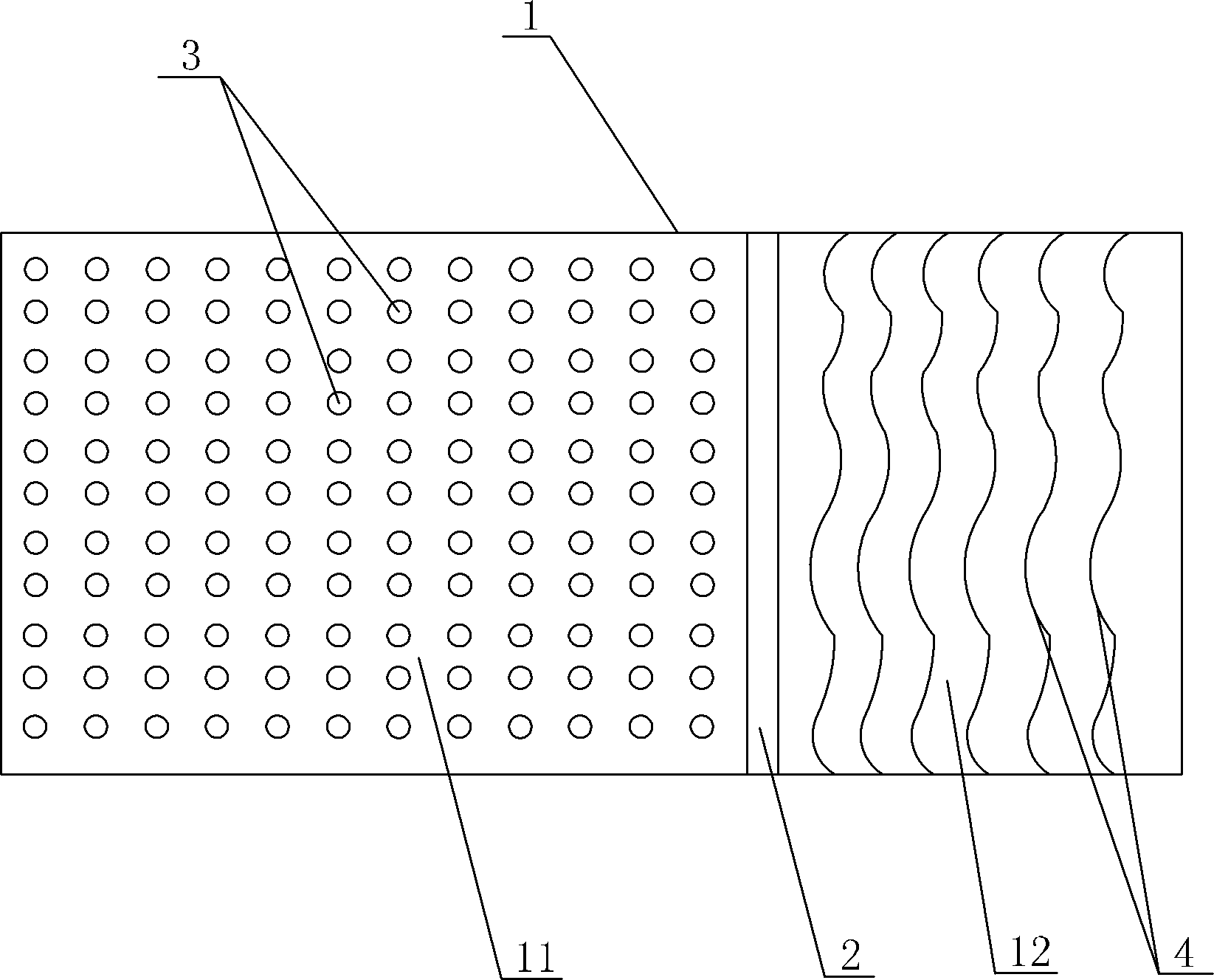

Heat radiation structure of circuit module and outdoor unit of variable-frequency air conditioner

ActiveCN104697077AImprove surface heat dissipationNot easy to gatherLighting and heating apparatusAir conditioning systemsComputer moduleElectric control

The invention discloses a heat radiation structure of a circuit module and an outdoor unit of a variable-frequency air conditioner. The heat radiation structure comprises a circuit board (1), a mounting support (2), electronic devices (3) and a heat radiator (4), wherein the electronic devices penetrate one side of the mounting support to be connected with a circuit board on the other side, and the heat radiator is abutted against the surfaces of the electronic devices; a zigzag structure (21) used for reducing mutual contact area is formed on the contact surface between the circuit board and the mounting support. Furthermore, the heat radiation structure comprises an electric control box (5), various parts are sequentially stacked in the electric control box, the heat radiator extends out of the electric control box, and an air inlet passage (7) facing the heat radiator is formed on the electric control box. The heat radiation structure is mounted in a case (9) via the electric control box and close to an air wheel (12) of the outdoor unit. With the zigzag structure, water accumulation is well prevented; with the mounting structure and the air passage, heat radiation effect of the heat radiator is well improved so as to radiate heat on the surface of the circuit board.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

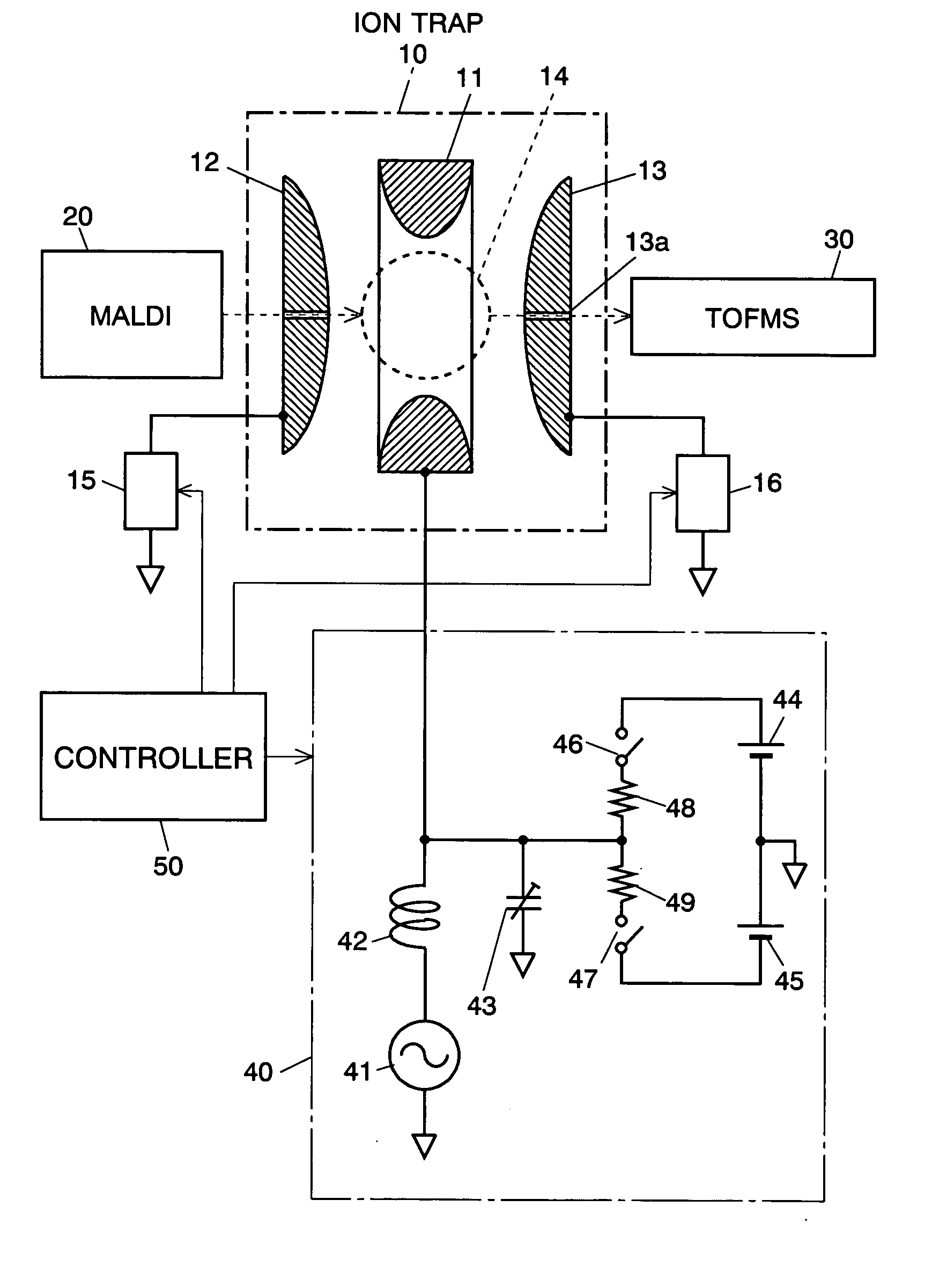

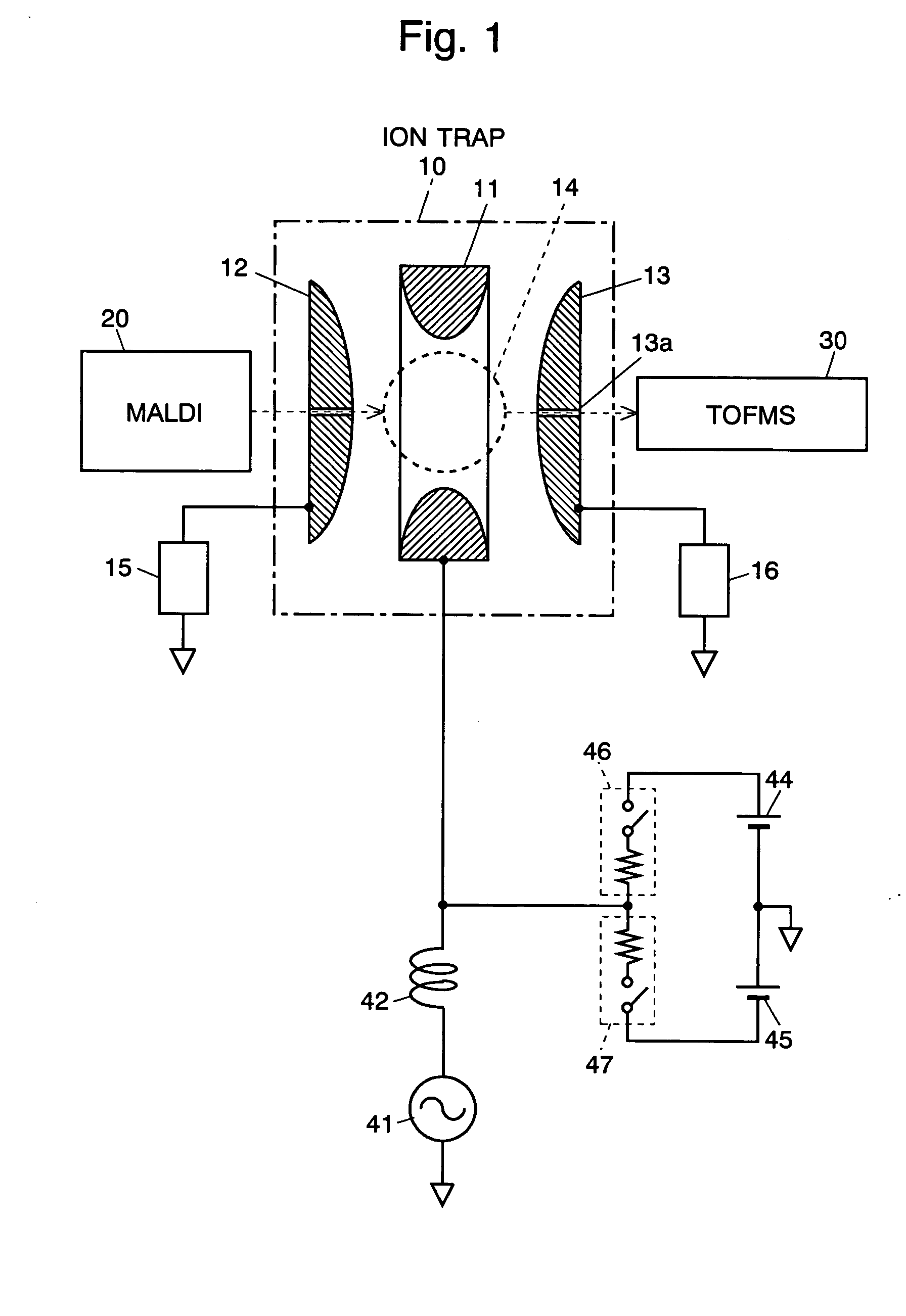

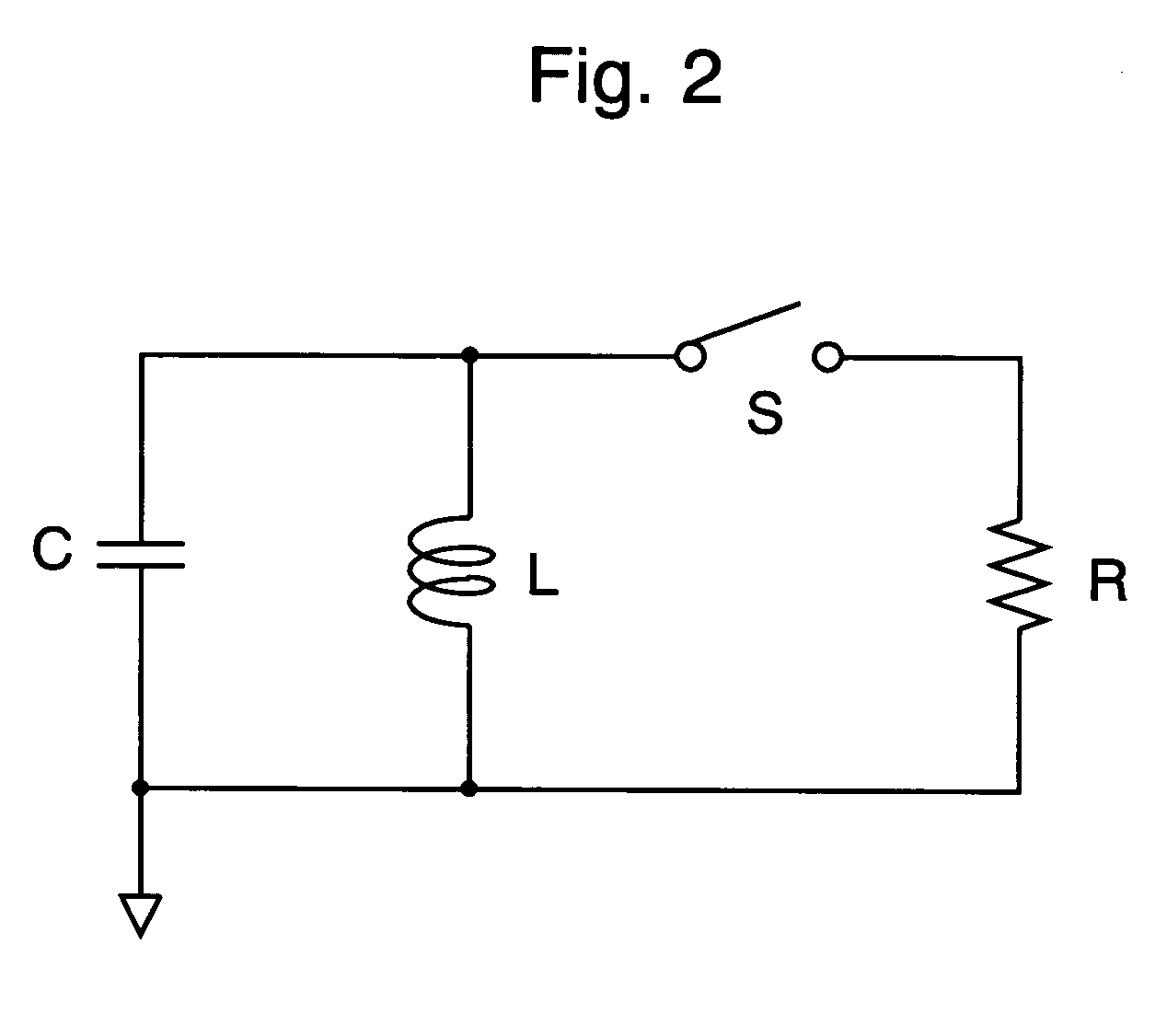

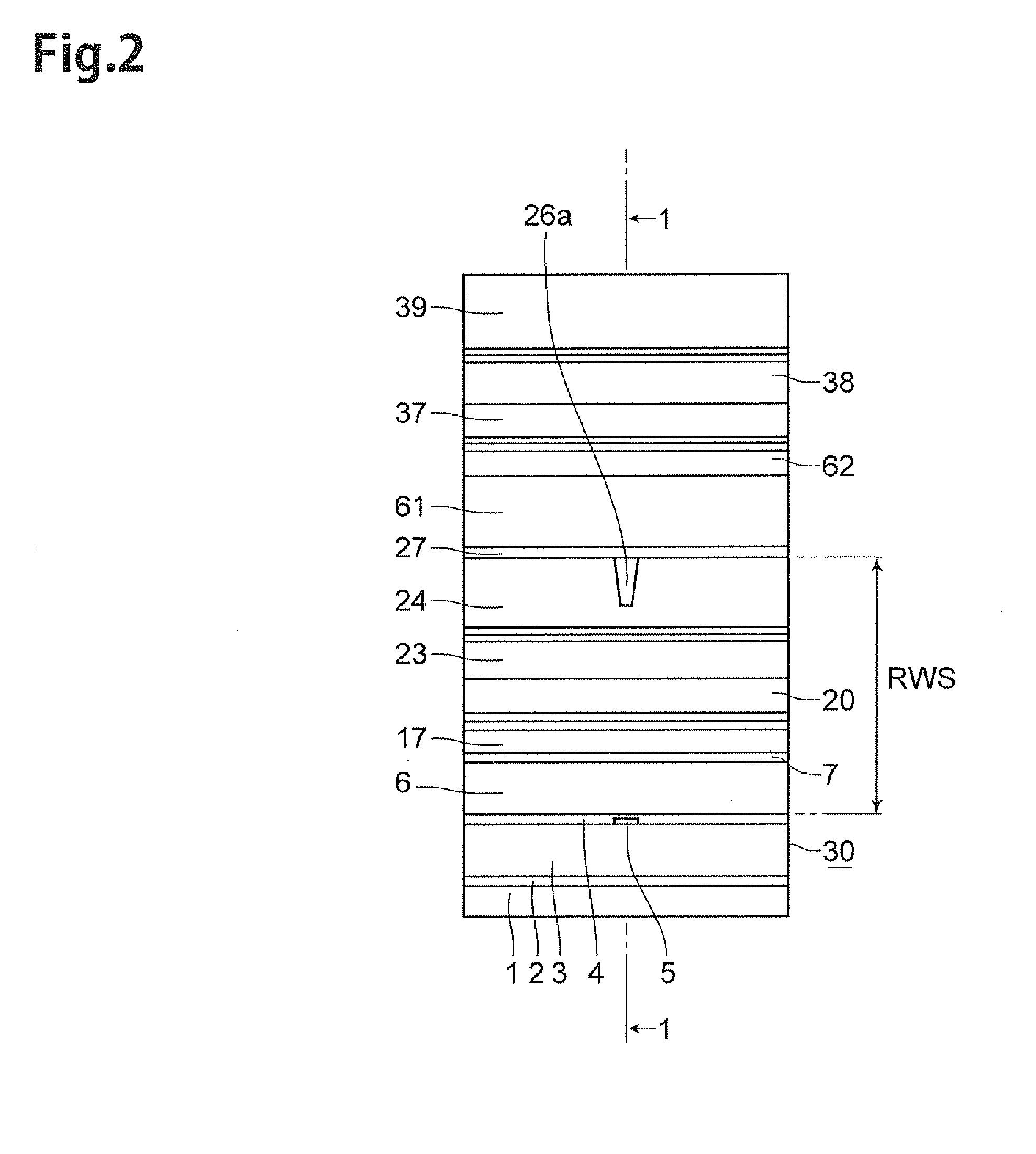

Ion storage device

InactiveUS20050127291A1Reduce the total massNot easy to flowSpectrometer circuit arrangementsStability-of-path spectrometersCapacitanceLc resonant circuit

In the ion storage device 10 according to the present invention, an LC resonant circuit 40 for generating an RF voltage for trapping ions is connected to at least one of the electrodes 11, 12 and 13 surrounding the ion storing space 14. The LC resonant circuit 40 includes switching devices 46, 47 and resistances 48, 49 for stopping the RF voltage when the ions stored in the ion storing space 14 are ejected. The inductance L, the capacitance C and the resistance R of the LC resonant circuit are set to substantially satisfy the critical damping condition, which means that R=X / 2 where X=ω0L=(ω0C)−1. According to this configuration, the RF voltage damps fast when the RF voltage is stopped by the switching devices 46, 47, and the deterioration of the mass resolution of the mass analyzer or the peak shift in the mass spectrum is prevented.

Owner:SHIMADZU CORP

Plasma processing apparatus, plasma processing method and storage medium for storing program for executing the method

ActiveUS9076636B2Suppress decrease top surface electric potentialSpeed up the flowLiquid surface applicatorsElectric discharge tubesHigh frequency powerEngineering

There is provided a plasma processing apparatus including a susceptor 114, having a substrate mounting portion for mounting thereon a substrate, to which a high frequency power is applied; a focus ring 210, disposed to surround the substrate mounted on the substrate mounting portion, including an outer ring 214 having a top surface higher than a top surface of the substrate and an inner ring 212 extending inwardly from the outer ring so as to allow at least a part of the inner ring to be positioned below a periphery of the substrate, the outer ring and the inner ring being formed as a single member; a dielectric ring 220 positioned between the focus ring and the susceptor; a dielectric constant varying device 250 for varying a dielectric constant of the dielectric ring.

Owner:TOKYO ELECTRON LTD

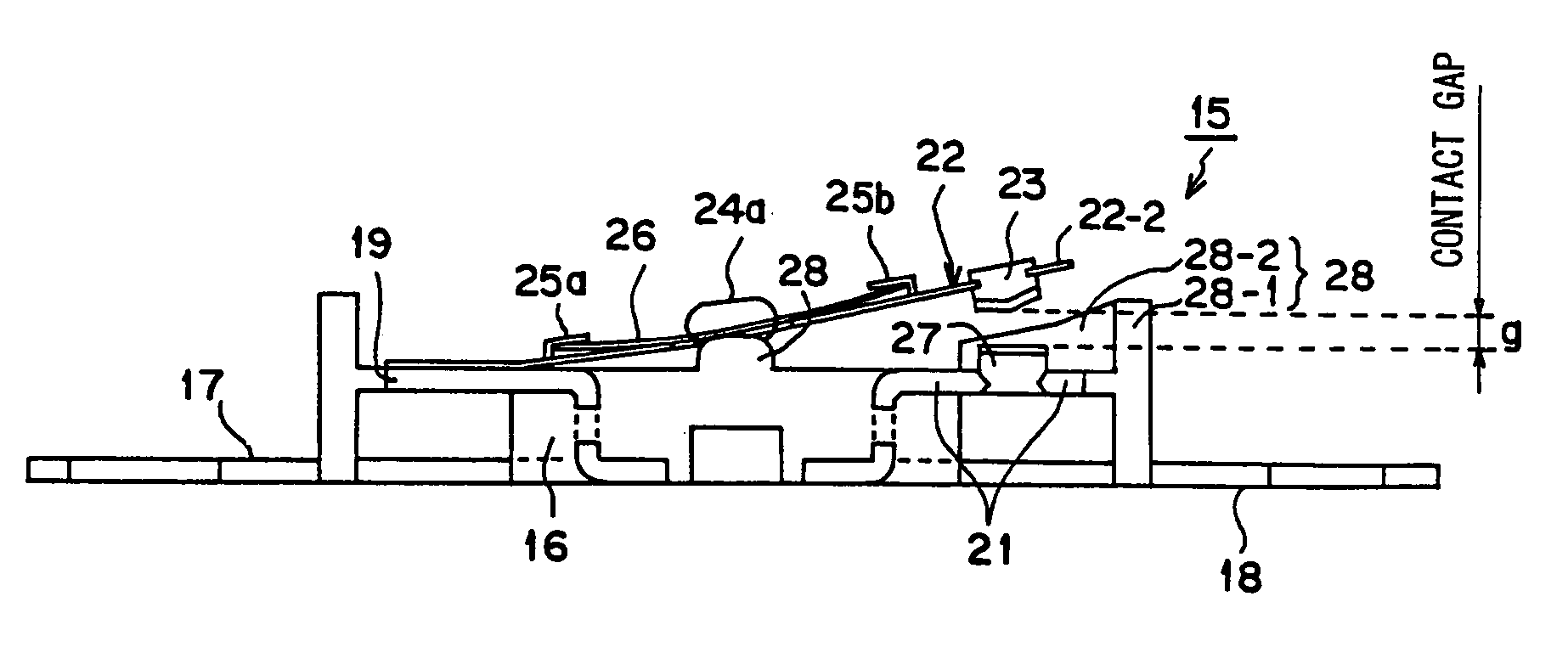

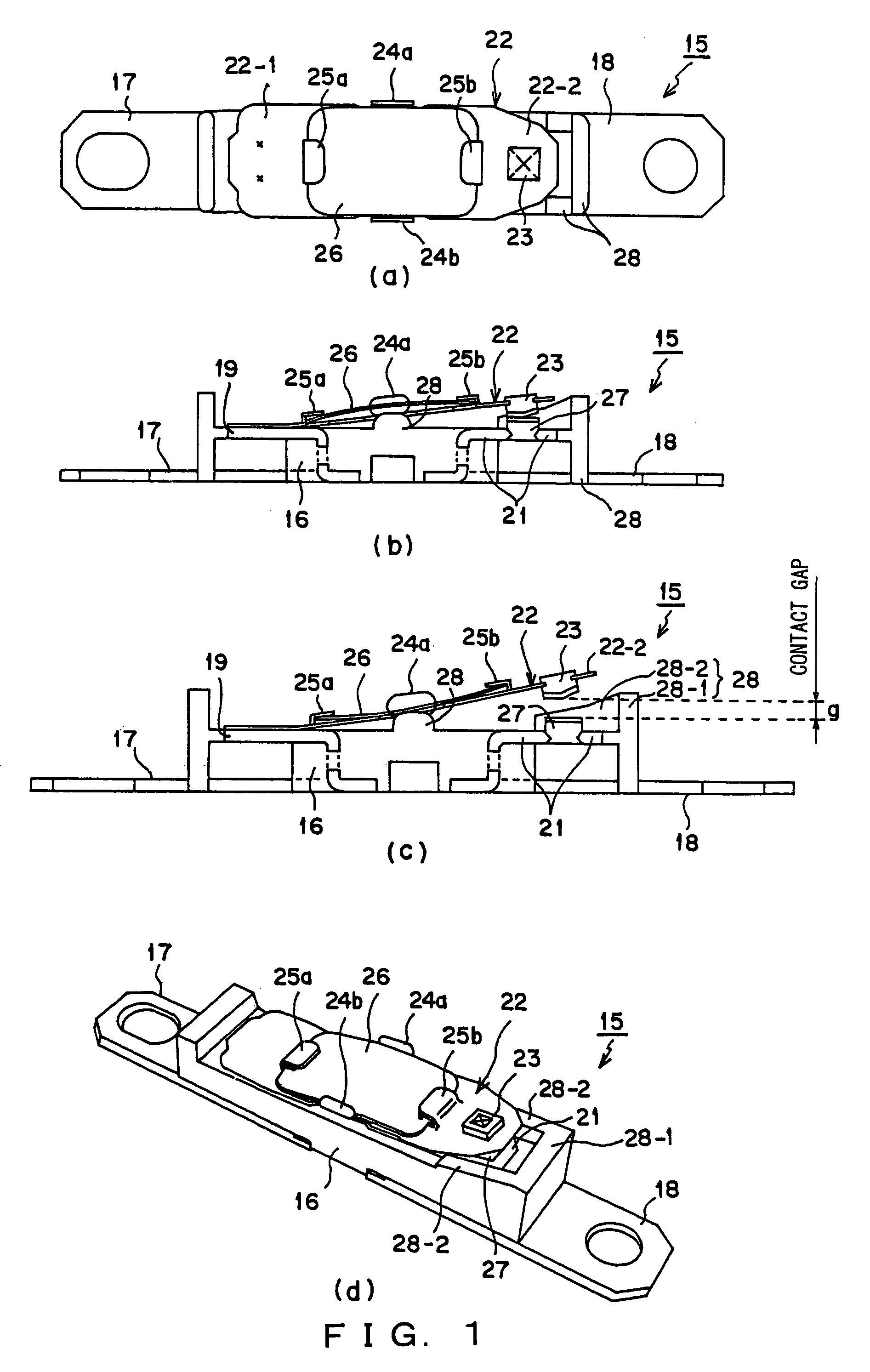

Thermal protector

InactiveUS7026907B2Increase freedomImprove reliabilityElectrothermal relaysHair dryingEngineeringMechanical engineering

Owner:UCHIYA THERMOSTAT

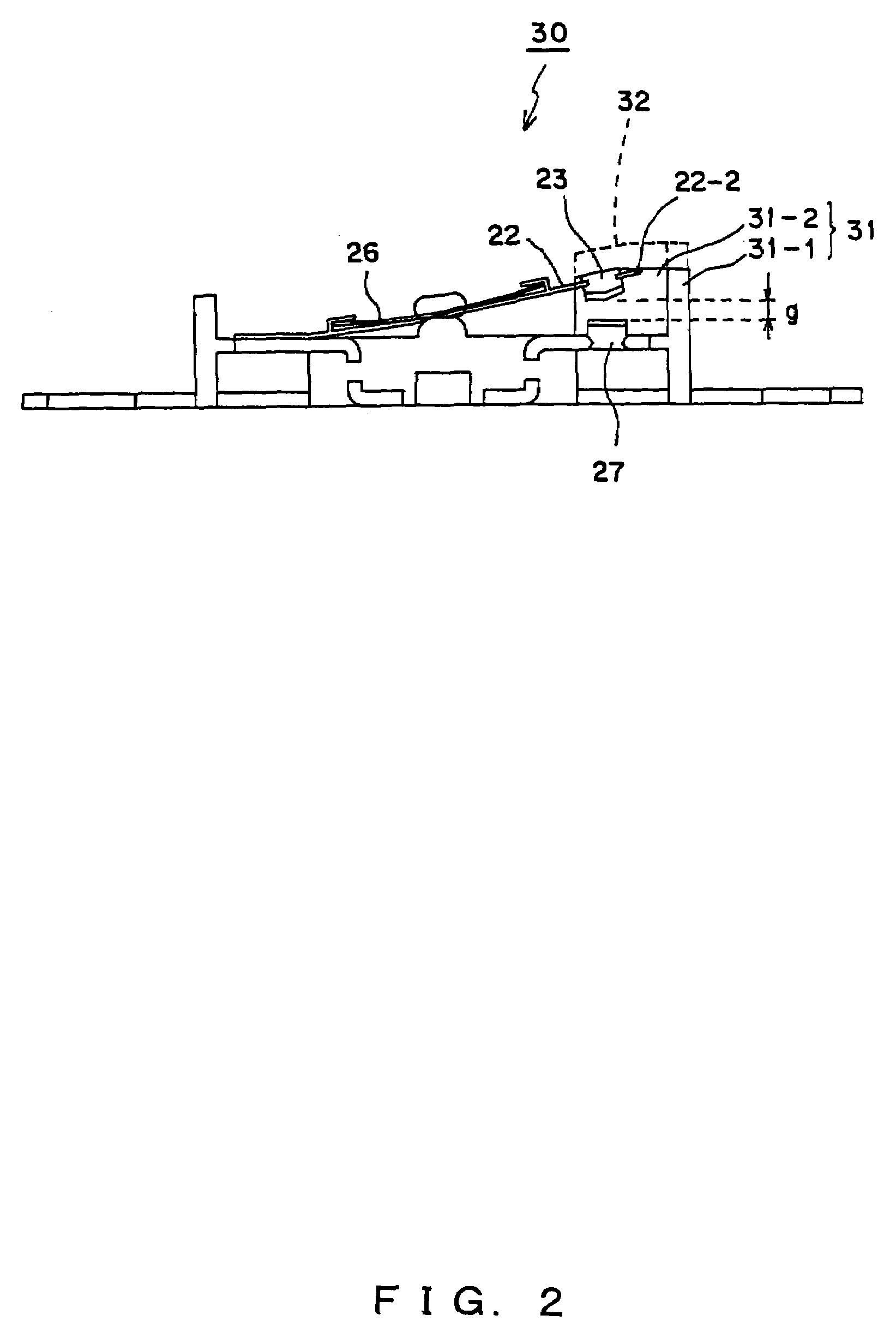

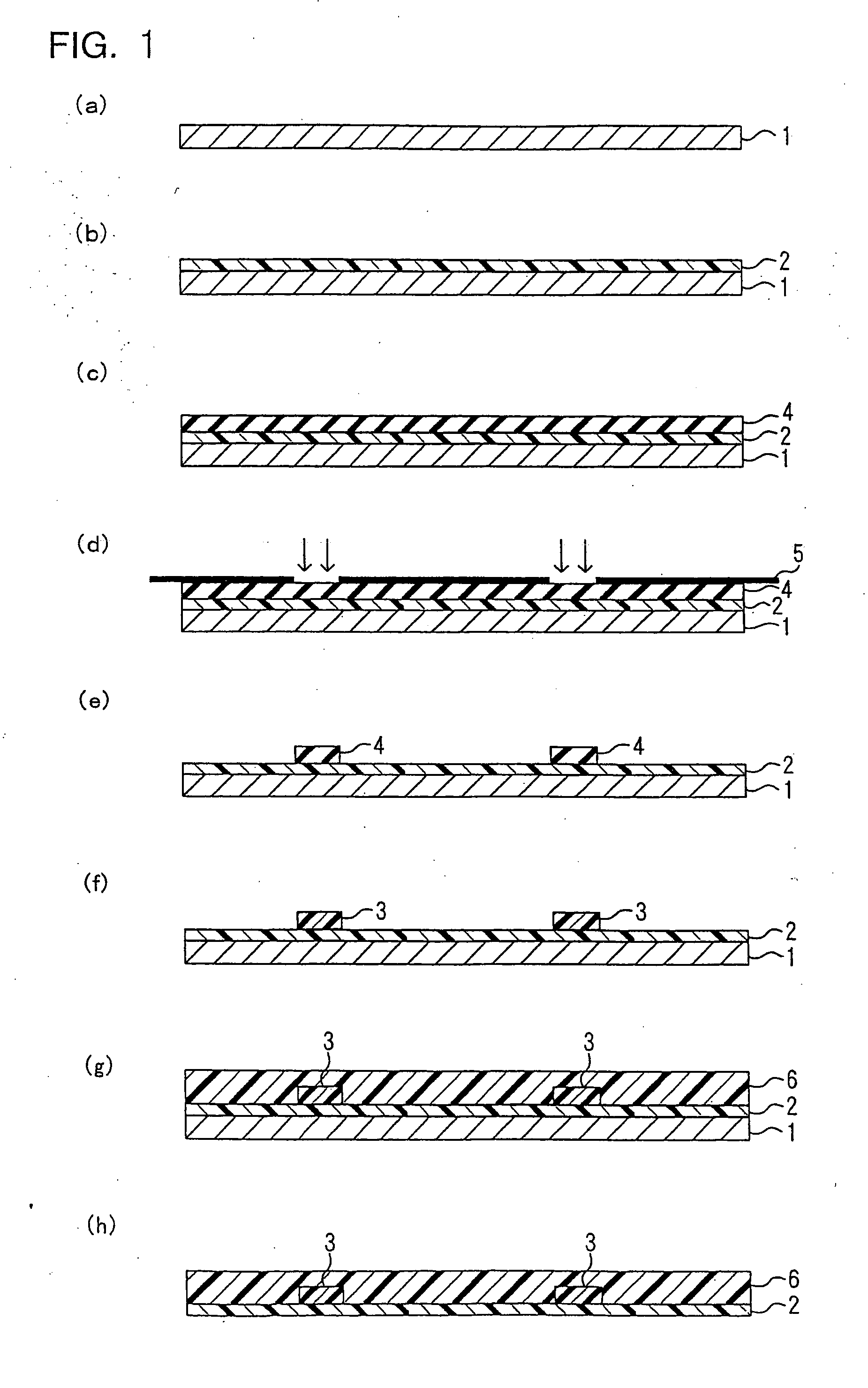

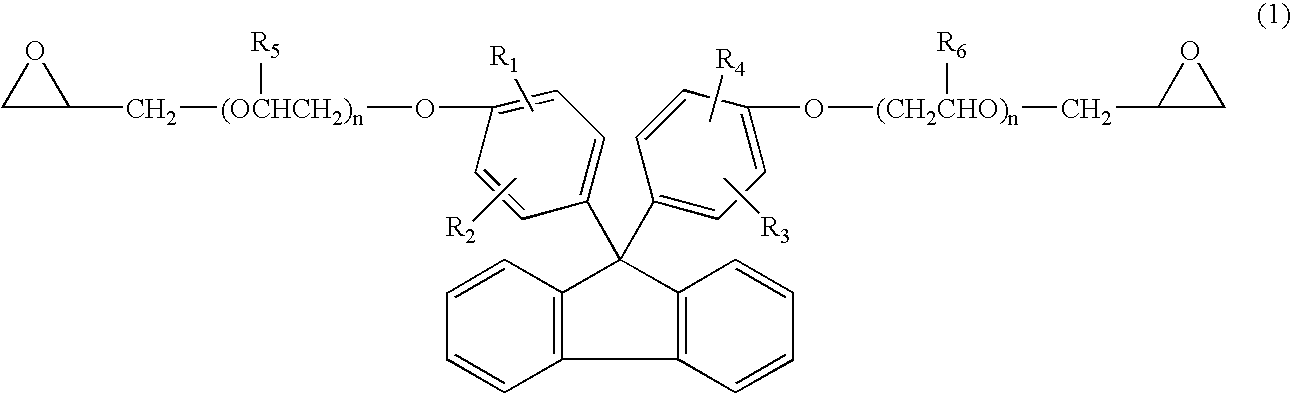

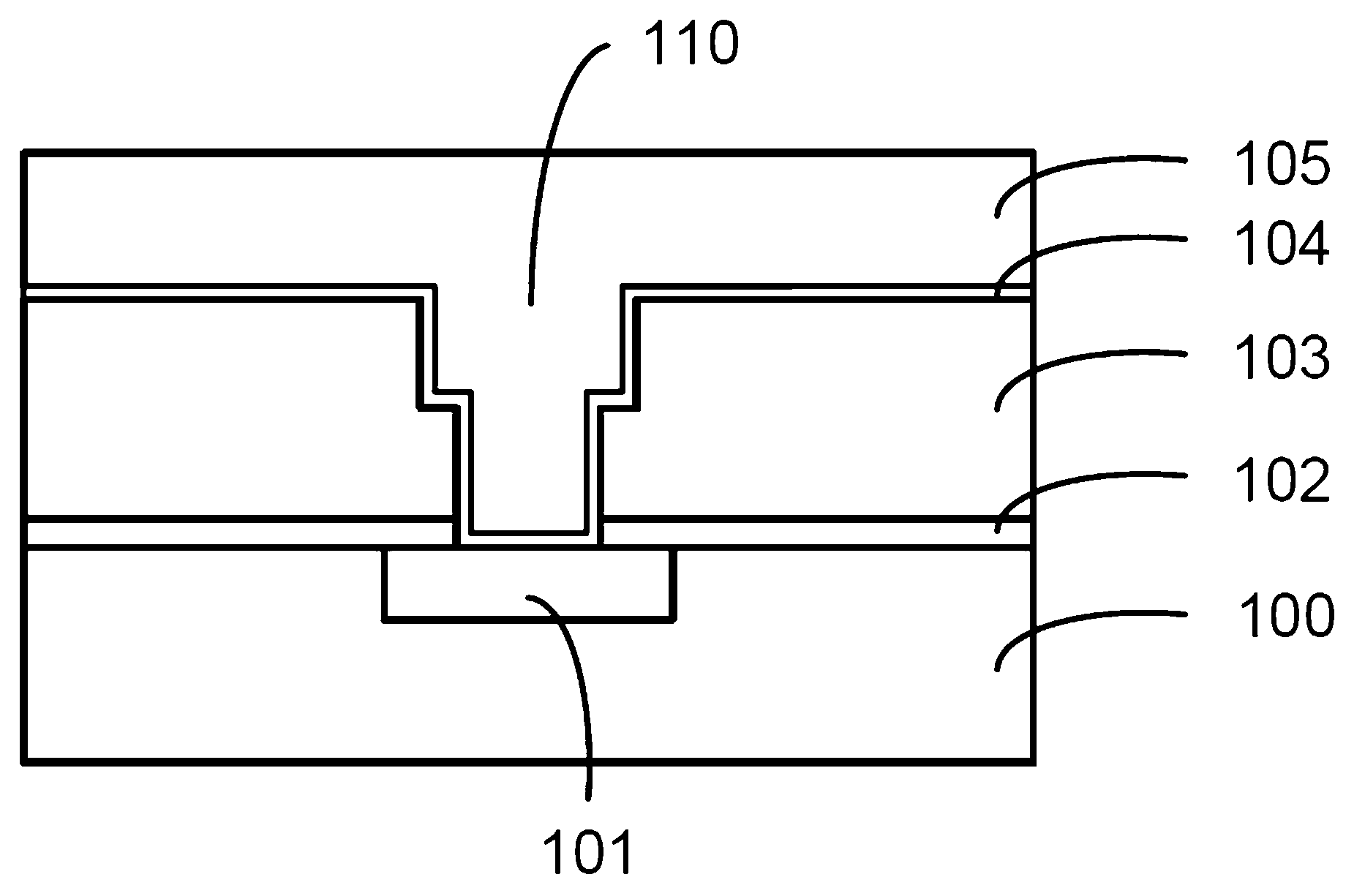

Optical waveguide and production method thereof

InactiveUS20050201714A1Increase productivityIncrease productionOptical articlesOptical waveguide light guidePhotoacid generatorWaveguide

A production method of an optical waveguide that can provide increased production efficiency and can also provide improved workability and production stability and provide an optical waveguide produced by the production method of the optical waveguide. A varnish comprising photopolymerizable resion composition comprising a fluorene derivative and a photoacid generator is coated over an under clad layer 2 and then is dried, to form a resin layer 4 having substantial no surface tack. Sequentially, the resin layer 4 is exposed to light in the state of being contacted with a photo mask 5 by a contact exposure method and then is developed, to form the resin layer 4 into a pattern. Thereafter, the resin layer 4 is cured to form a core layer 3 and then an over clad layer 6 is formed on the under clad layer 2 in such a manner as to cover the core layer 3, to thereby produce an optical waveguide. This method can allow the forming of the resin layer 4 having no surface tack, and as such can allow the use of the contact exposure to expose the resin layer to light. Hence, the number of processes and time-consuming and complicated works involved in the interposition of the spacer can be reduced, thus providing increased production efficiency.

Owner:NITTO DENKO CORP

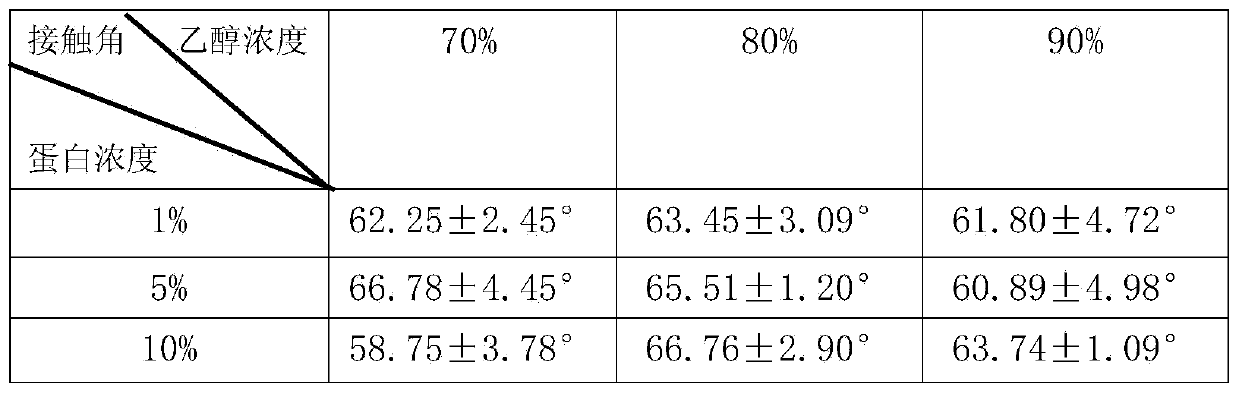

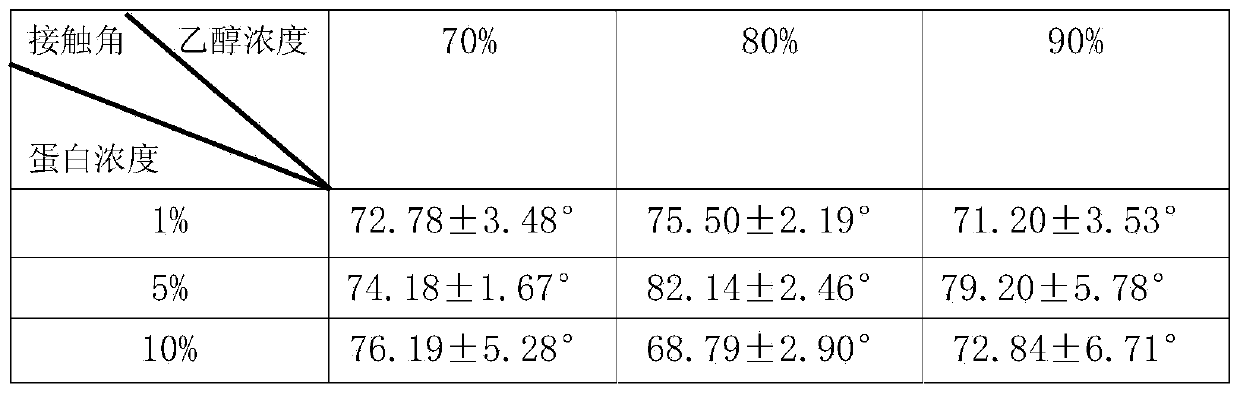

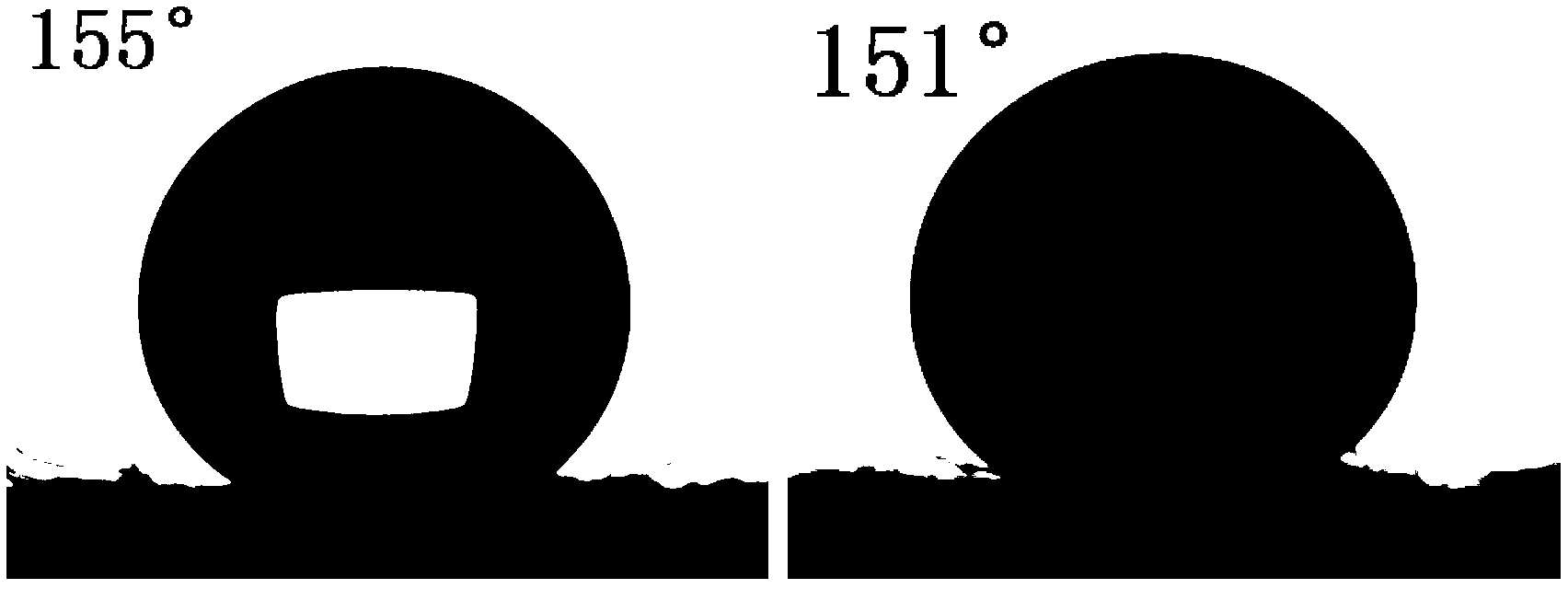

Preparation method of highly hydrophobic edible membrane

ActiveCN104210162ANaturally non-toxic and biocompatibleNon-toxic and biocompatibleFlexible coversWrappersWater activityAcetic acid solution

The invention relates to a preparation method of a highly hydrophobic edible membrane. The method comprises the following steps: adding degreased chitosan into an aqueous acetic acid solution, fully hydrating to obtain an aqueous chitosan acetic acid solution, evenly dispensing the aqueous chitosan acetic acid solution to a glass plate, and drying; preparing an ethanol aqueous solution containing 50%-95% by mass of ethanol, and adding prolamine to obtain a prolamine solution; evenly dispensing the prolamine solution to the treated glass plate, dropwise washing the glass plate with pure water, and drying; preparing an ethanol aqueous solution containing 70%-90% by mass of the ethanol, adding prolamine to obtain a prolamine solution; and evenly dispensing to the treated glass plate, and drying. The edible membrane material can be used for overcoming the defect that the polysaccharide or protein membrane material is poor in waterproof property, and the time of water drops staying on the surface of the membrane during transportation can be shortened, so that the content of water penetrating through a packaging membrane can be reduced, the water activity of food can be guaranteed, and the growth of microorganisms can be inhibited.

Owner:SOUTH CHINA UNIV OF TECH

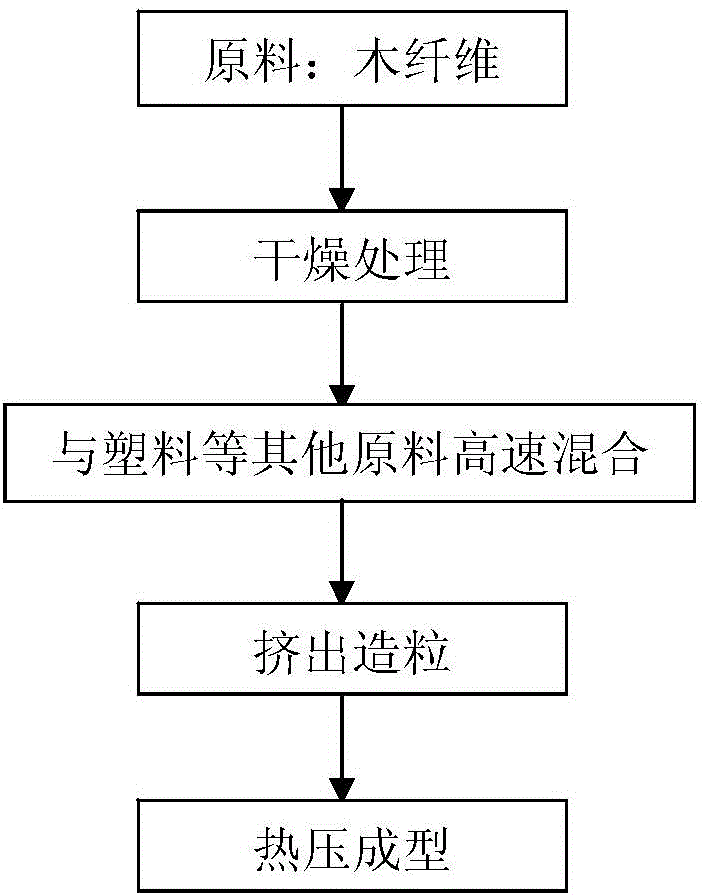

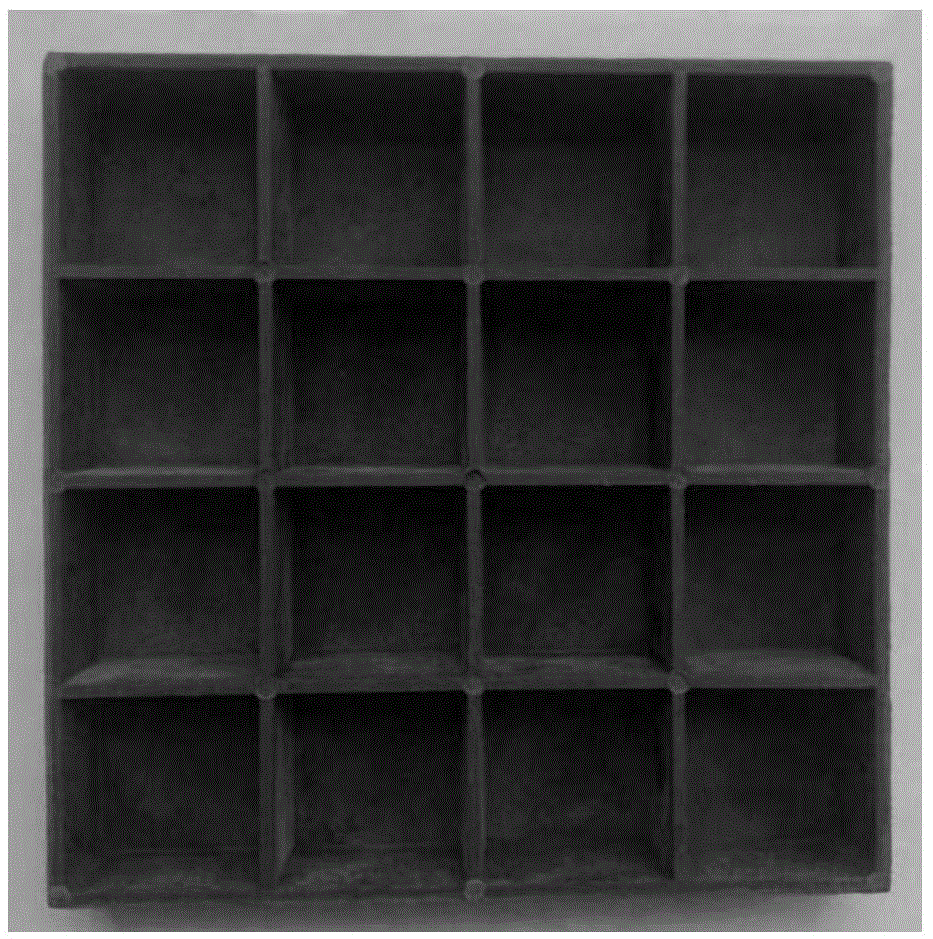

Wood-plastic composite and preparation method for special-shape molded member thereof

The invention provides a wood-plastic composite. The wood plastic composite comprises a biomass material and a plastic; the biomass material is wooden fiber with a length of 0.1 to 4.0 nm and a length-diameter ratio of 1: 1 to 400: 1; and in virtue of the characteristic of the large length-diameter ratio and low possibility of flowing of the wooden fiber, filling effect and reinforcing effect are exerted on the wood plastic composite, so the mechanical properties of the wood plastic composite are substantially improved and in particular, resistance to impact and creep and other performance of the wood plastic composite are improved, which enables the application scope of the wood plastic composite to be broadened. When a molding process is employed for preparation of the molded member of the wood plastic composite, the thickness and mechanical properties of the molded member can be improved and preparation of the special-shape molded member can be realized; and the advantages of low cost and good market application prospect are obtained.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

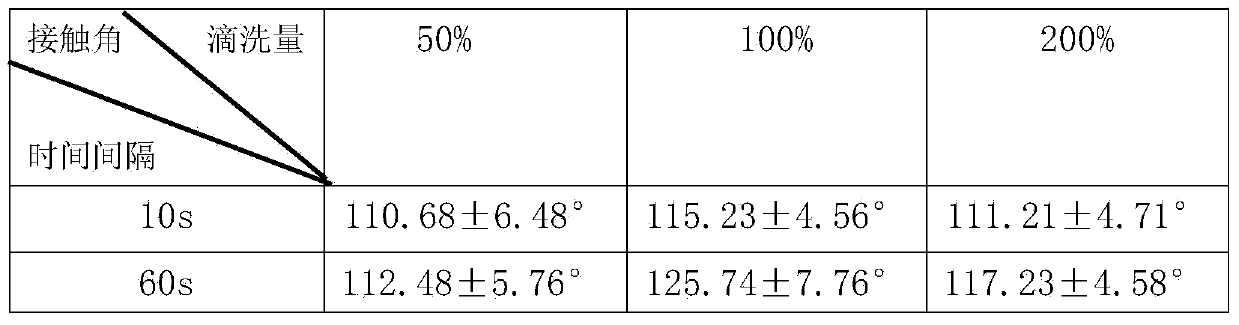

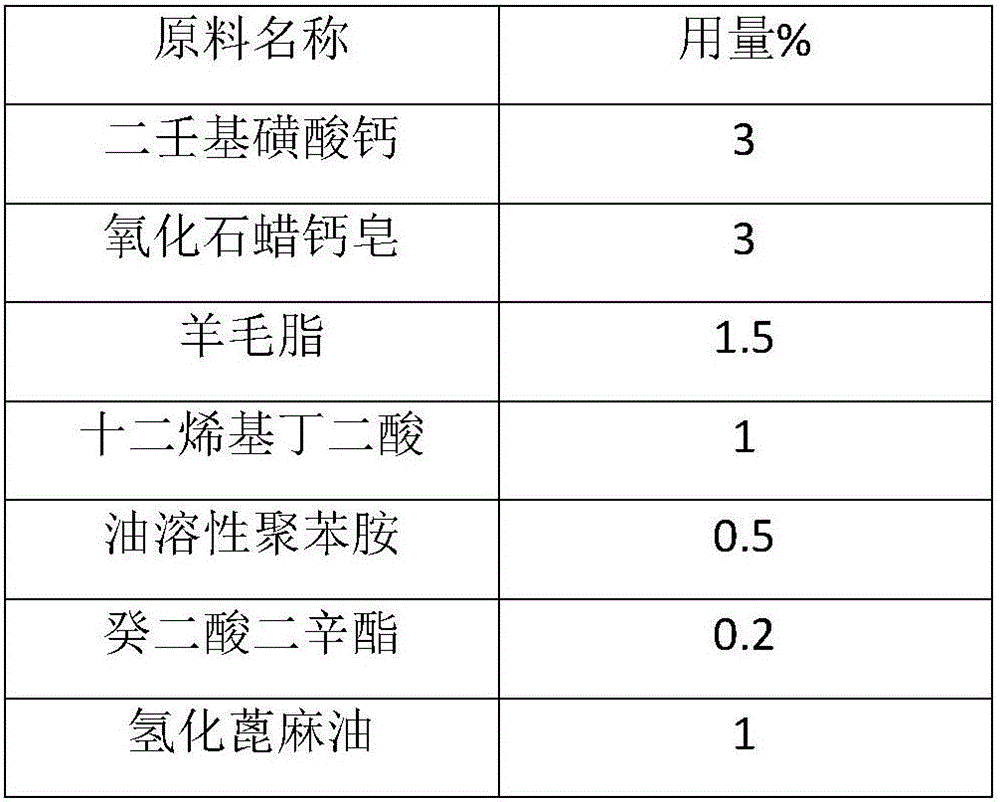

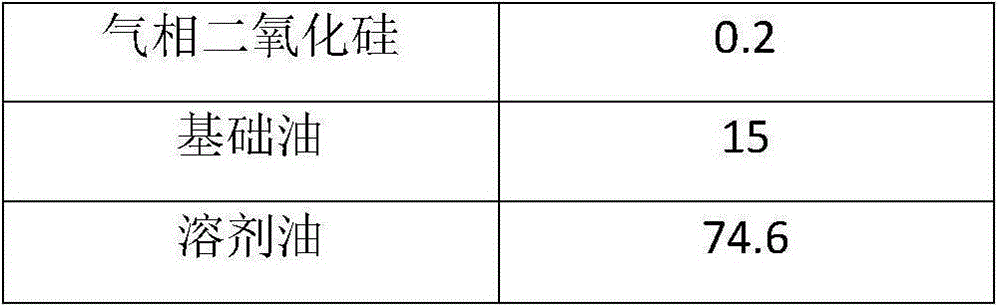

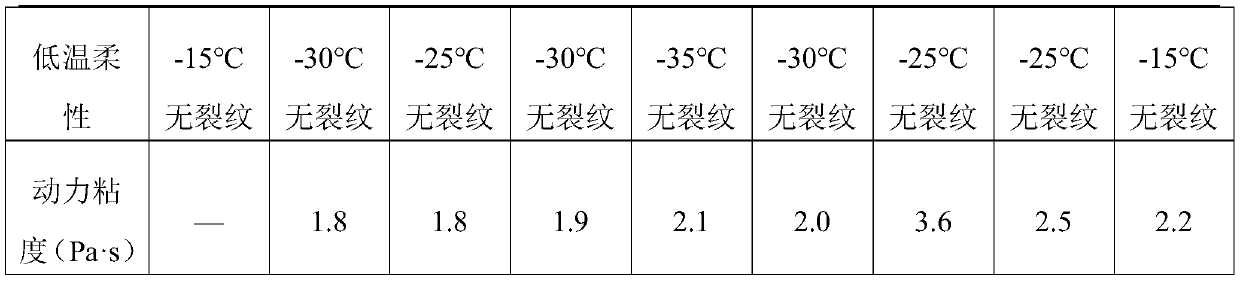

Solvent type thixotropic anti-rust oil and preparation method thereof

InactiveCN106221880ALess overall consumptionImprove thixotropyLubricant compositionFilm-forming agentSolvent

The invention relates to anti-rust oil for steel corrosion protection and a preparation method of anti-rust oil, in particular to solvent type thixotropic anti-rust oil and a preparation method thereof and belongs to the field of metal protection. The solvent type thixotropic anti-rust oil is prepared from components including, by weight, 5-30% of an anti-rust agent, 0.1-5% of a thixotropic agent, 0.1-5% of a film-forming agent, 0.1-3% of a coalescing agent, 5-20% of the base oil and the balance of dearomatization solvent oil. The thixotropic agent is combined with oil-soluble polyaniline, so that good salt fog resistance of the anti-rust oil is achieved, and time for salt fog can reach more than 400 hours.

Owner:NANJING KERUN NEW MATERIAL TECH

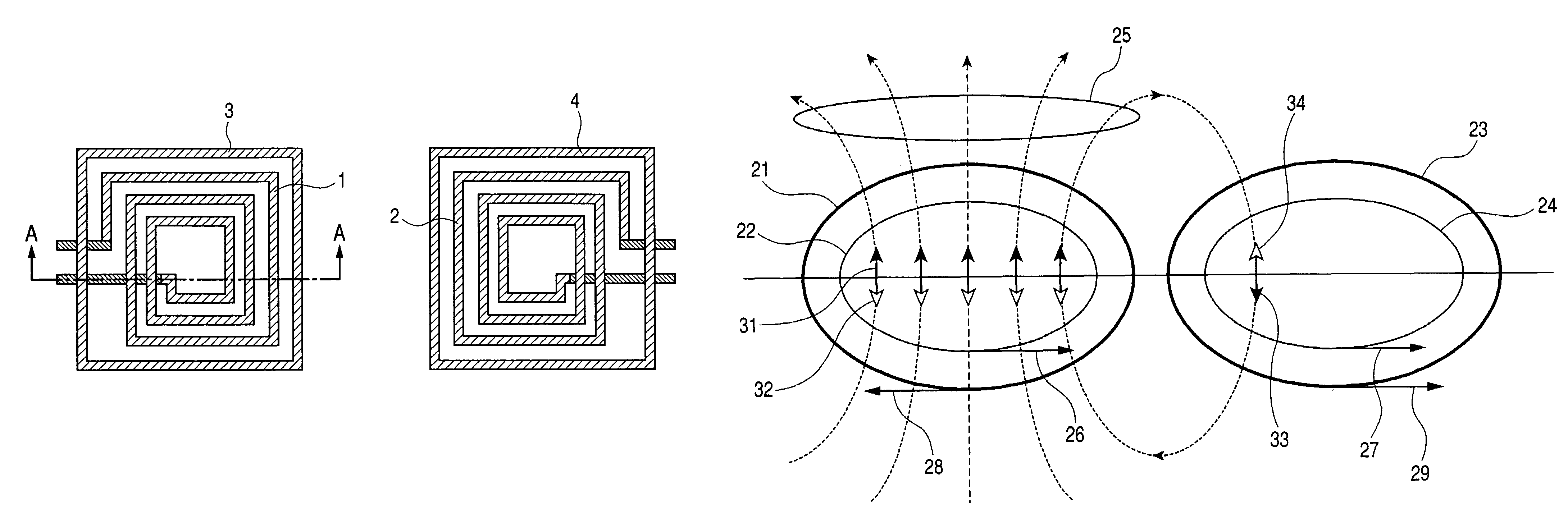

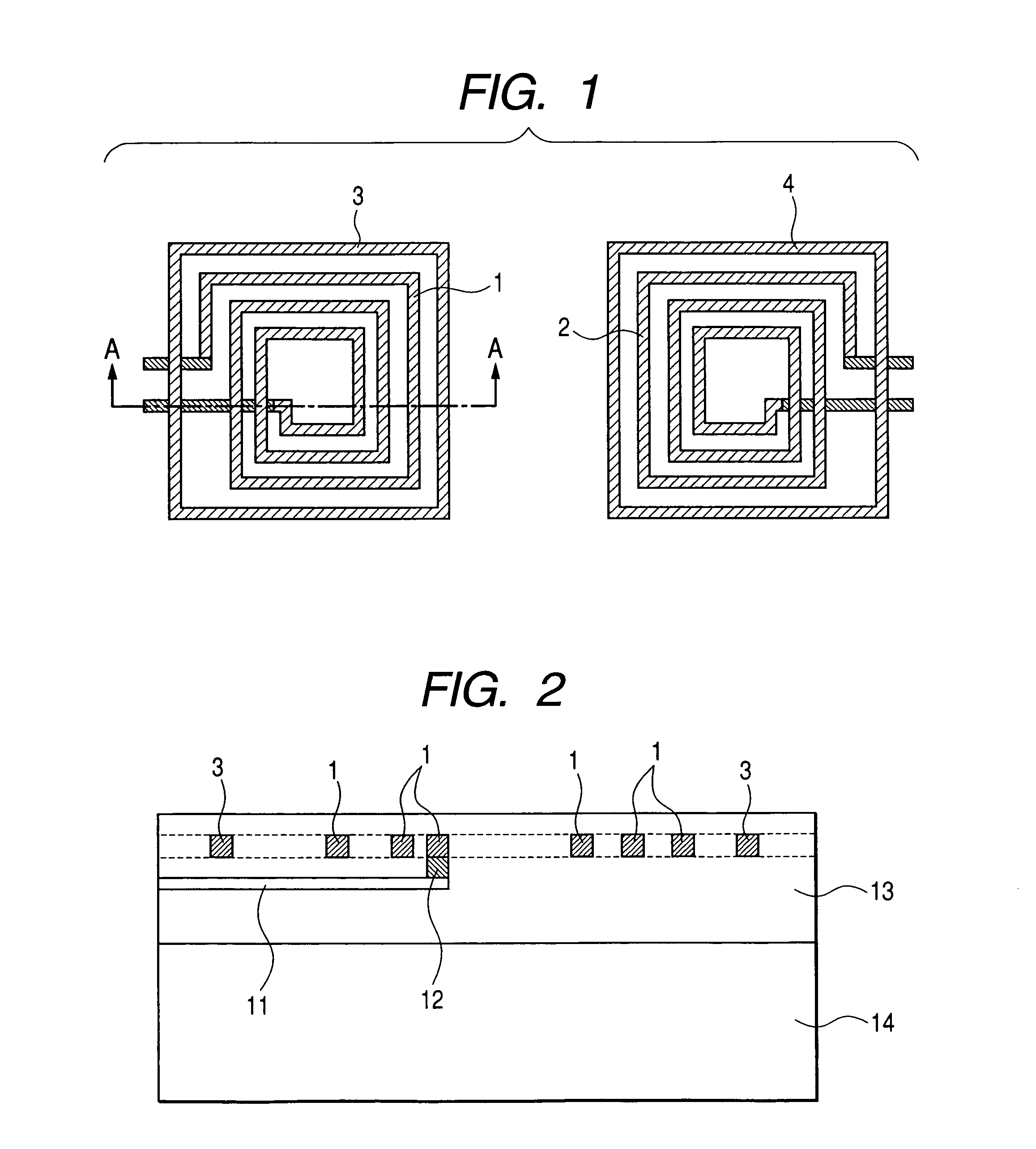

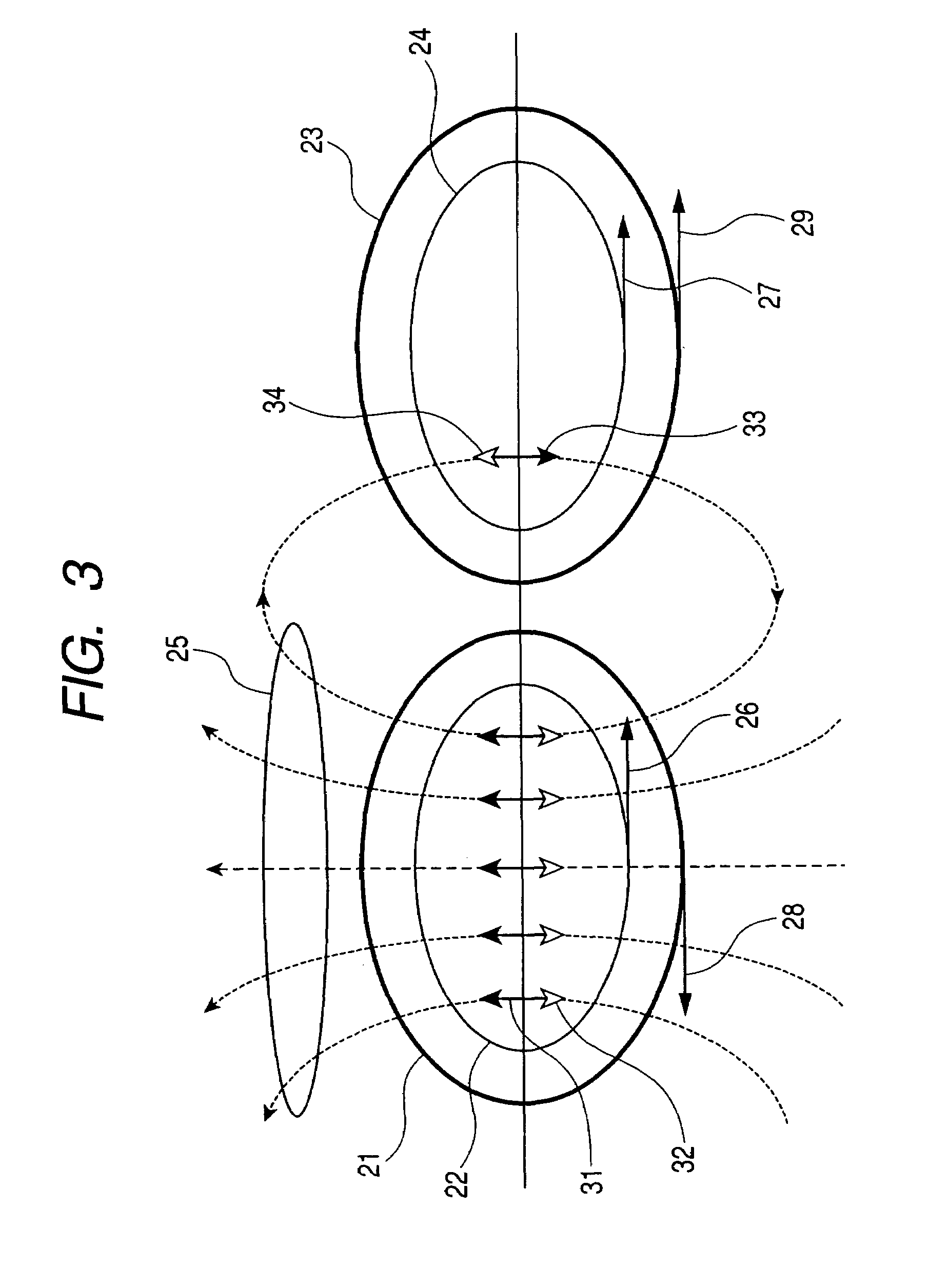

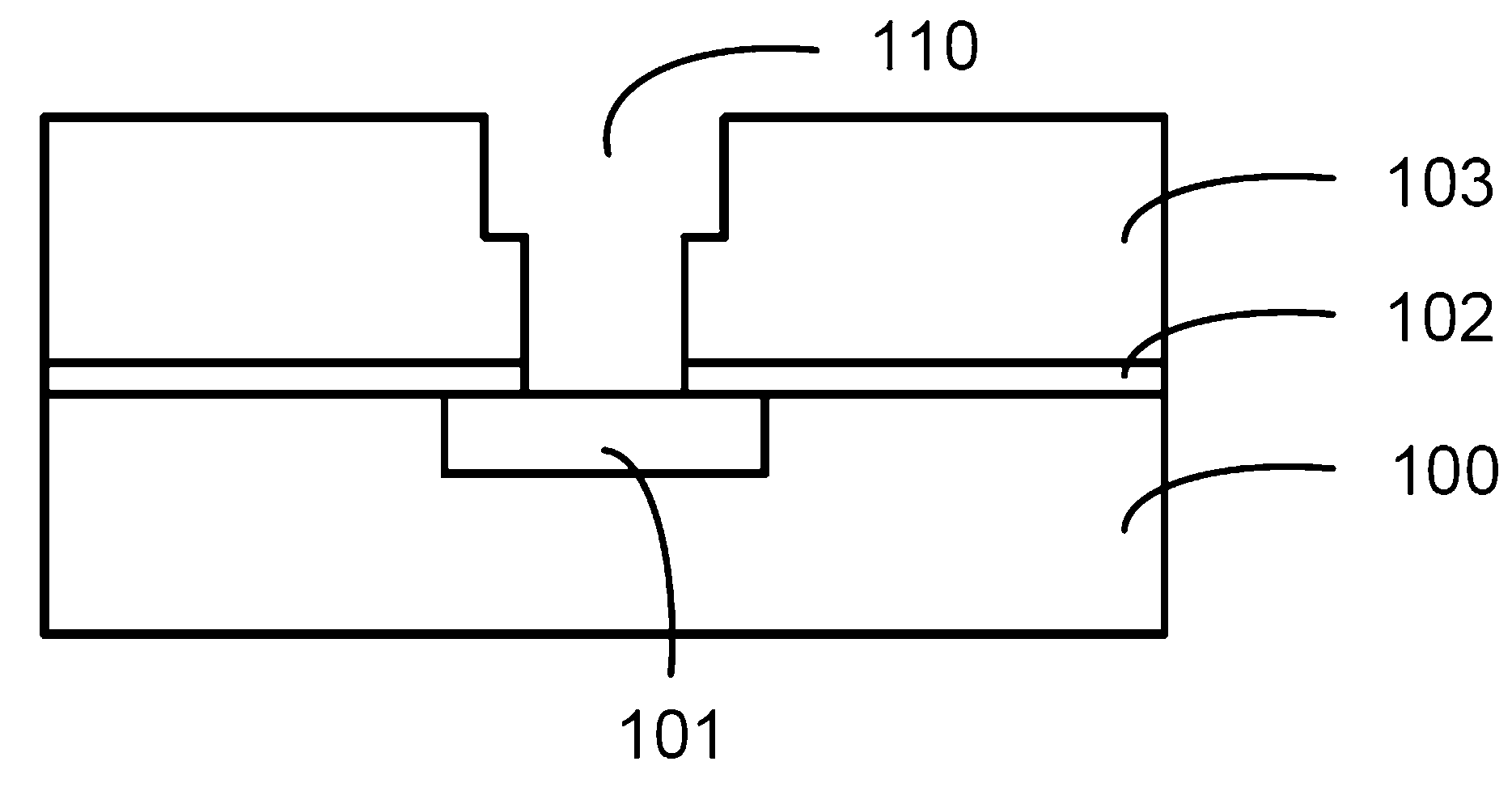

Semiconductor devices with inductors

ActiveUS7642618B2InhibitionReduce distractionsSemiconductor/solid-state device detailsTransformers/inductances coils/windings/connectionsCarrier signalClosed loop

Semiconductor devices are provided with high performance high-frequency circuits in which interference caused by inductors is reduced. In a semiconductor device including a modulator circuit to modulate a carrier wave by a base band signal to output an RF signal and a demodulator circuit to demodulate the RF signal by use of the carrier wave to gain the base band signal and a local oscillator to generate the carrier wave, inductors respectively having a closed loop wire are adopted. Interference caused by mutual inductance is reduced by the closed loop wire. For example, where inductors are adopted in the modulator circuit, a closed loop wire is disposed around the outer periphery of the inductors.

Owner:RENESAS ELECTRONICS CORP

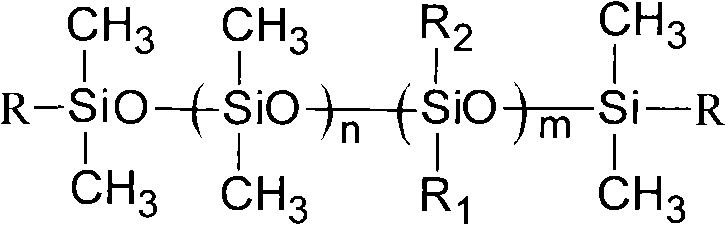

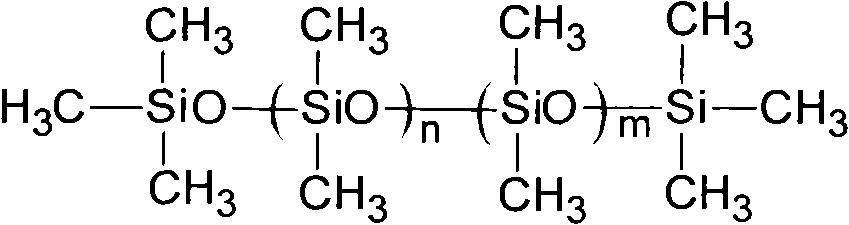

Silicone oil electric force compound grease and preparation method thereof

InactiveCN102024505AImprove high temperature resistanceImprove low temperature resistanceNon-conductive material with dispersed conductive materialCable/conductor manufactureSilicone oilMetal powder

The invention discloses electric force compound grease and a preparation method thereof. The silicone oil electric force compound grease mainly comprises silicon oil, white carbon black and conductive metal powder, wherein the white carbon black is subject to surface treatment with a lipophilic processing agent. The silicone oil electric force compound grease comprises the following components in parts by weight: 100 parts of silicon oil, 20-33 parts of precipitated silica subject to the surface treatment with the lipophilic processing agent, 65-90 parts of conductive metal powder, 0-2 parts of stabilizing agent and 0-2 parts of anti-oxygen agent, or the silicone oil electric force compound grease is also composed of the following components in parts by weight: 100 parts of silicon oil, 10-15 parts of fumed silica subject to the surface treatment with the lipophilic processing agent, 65-90 parts of conductive metal powder, 0-2 parts of stabilizing agent and 0-2 parts of anti-oxygen agent. The silicone oil electric force compound grease disclosed by the invention has the advantages of high dropping point temperature, good attachment property, stable rationalizing property, long service life and good economic property.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV +2

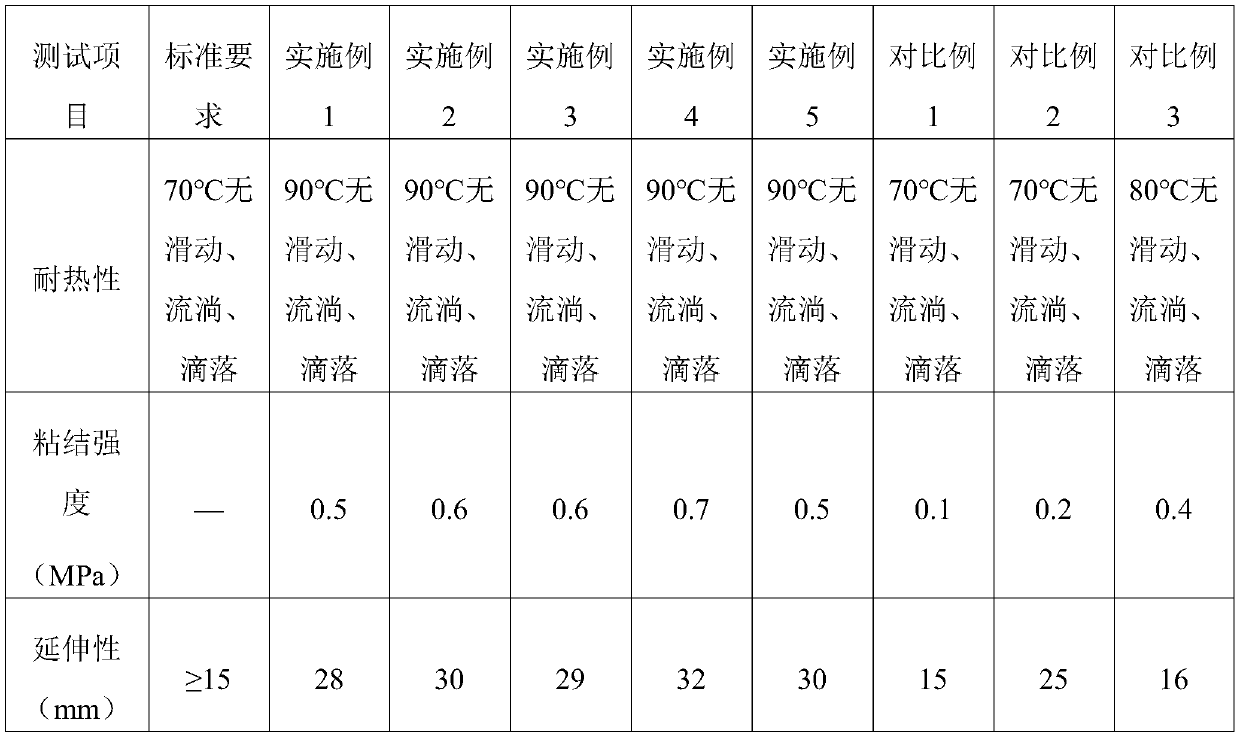

Novel high-temperature-resistant non-curing waterproof coating and preparation method thereof

InactiveCN110016291AImprove high temperature resistanceImprove adhesionFireproof paintsOther rubber coatingsPolymer sciencePolyamide

The invention belongs to the technical field of building materials, and provides a novel high-temperature-resistant non-curing waterproof coating. The coating is composed of the following components in percentage by weight: 25-35% of asphalt, 15-30% of rubber oil, 10-20% of waste tire rubber powder, 5-10% of styrene-butadiene rubber, 1-3% of styrene-butadiene-styrene (SBS), 4-10% of tackifying resin, 10-20% of fly ash, 2-5% of a high-temperature modifier and 2-5% of a viscosity reducer, wherein the high-temperature modifier is a BL modifier or polyamide wax. The preparation method is carried out by adopting a three-section-type feeding method and comprises the following steps: adding asphalt and rubber oil, carrying out heating to 150 DEG C, then adding the SBS, the styrene-butadiene rubber, the tackifying resin and the viscosity reducer, carrying out heating to 180 DEG C, then adding the fly ash and a high-temperature modifier, mixing the components at 180 DEG C to form a uniform liquid, and carrying out cooling and discharging to obtain the novel high-temperature-resistant non-curing waterproof coating. The invention solves the problem that a non-curing rubber asphalt waterproofcoating is poor in heat resistance.

Owner:河南驼峰防水科技有限公司

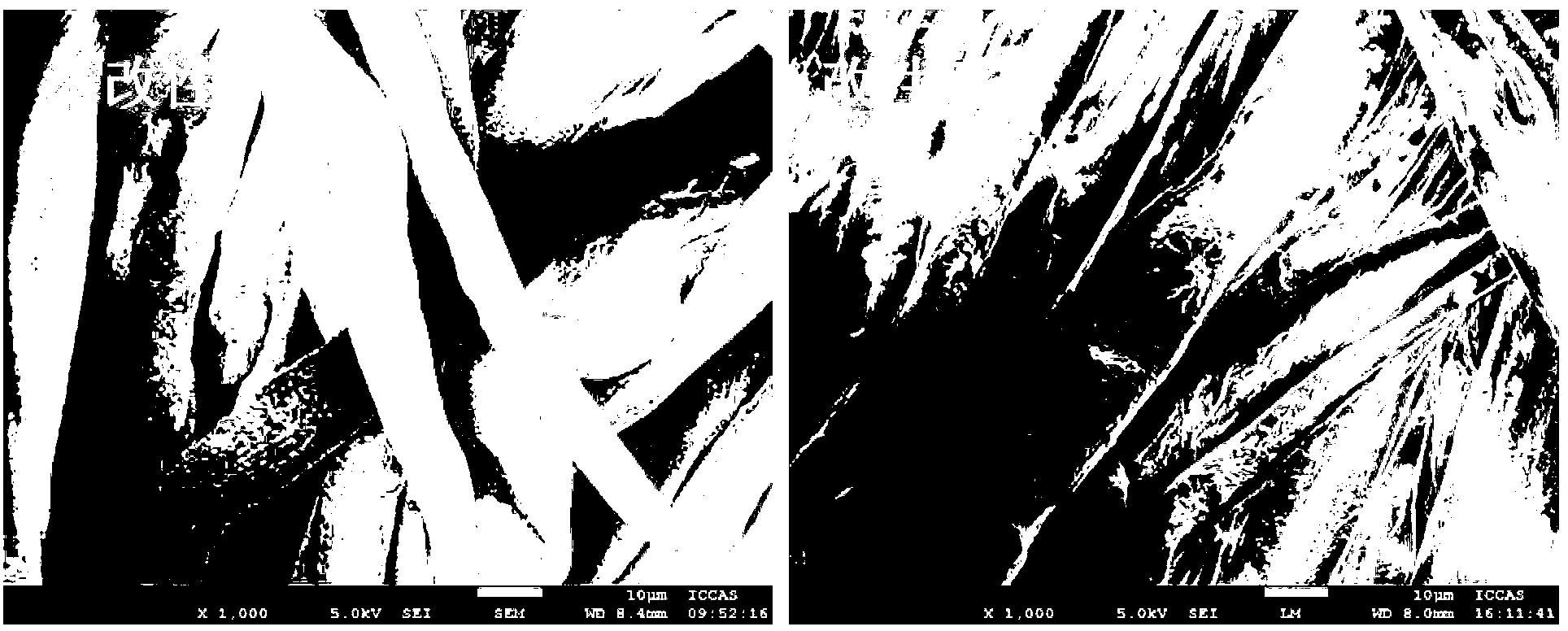

Super-hydrophobic textile and preparation method thereof

The invention discloses a super-hydrophobic textile and a preparation method thereof. The preparation method comprises the following steps of dissolving wax into an organic solvent to obtain a solution; dipping the textile into the solution, and taking out the textile from the solution, and drying the textile to obtain the super-hydrophobic textile. Any textile with a mesh structure is subjected to super-hydrophobic (blood) modification by a direct immersion method. A convex liquid level is formed by the blood at the interface of the bleeding position because of super-hydrophobic (blood) property; certain additional pressure is generated, so that the blood does not easily flow outside. Therefore, the preparation method can be used for preparing a hemostatic material or an impermeable blood material.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Method for preparing black plaster

InactiveCN101274059AEasy to pasteNot easy to flowHeavy metal active ingredientsAerosol deliveryViscous liquidMedicine

The invention discloses a preparation method of black plaster, solving the problem that the existing black plaster is over done or under done. The preparation method comprises the steps of: immersing required traditional Chinese medicine combination in sesame oil of three times of amount for seven days and seven nights, frying with medium fire under temperature ranging from 220 to 230DEG C, filtering drug oil when the colors of the medicinal materials are dark brown on surface and dark yellow at inner, boiling the obtained drug oil under temperature ranging from 300 to 320 DEG C, dripping the drug oil into bead, removing fire when the surplus of the drug oil is 80 percent of sesame oil amount, adding yellow lead ( the amount of the yellow lead to be added is 0.47 times of the amount of the drug oil), continuing boiling the drug oil until that the small oil grain which is obtained by dripping the viscous liquid drug oil into water can not stick to hand so as to obtain the black plaster which is proper done. Since the added amount of the sesame oil and yellow lead as well as the boiling temperature are strictly controlled, the black plaster of the invention can be properly prepared; when in use, the black plaster is not only easy to plaster but also difficult to flow and has convenient use.

Owner:梁进

Cold-accumulation type refrigerant and cold-accumulation type cold compress bag

InactiveCN102660232AIncrease heat of solutionFormation does not affectHeat-exchange elementsTherapeutic coolingPotassium nitrateCommon cold

The invention discloses a cold-accumulation type refrigerant and a cold-accumulation type cold compress bag. The refrigerant comprises the following components in percentage by weight: 30-40% of urea, 6-12% of ammonium chloride, 6-12% of potassium nitrate, 2-5% of guar and 35-45% of water. The cold compress bag comprises an outer bag, wherein solid materials comprising the refrigerant and water are arranged in the outer bag, and a sealing strip is arranged in the outer bag to separate the solid materials from the water. The refrigerant disclosed by the invention comprises three refrigerants, the solution heat of the cold compress bag is increased by various refrigerants, and the cold compress effect is better. Because the macromolecule edible-grade guar gum is added in refrigerant particles, the cold compress time of the cold-accumulation type cold compress bag disclosed by the invention is 2-3 times longer than the traditional common cold-accumulation type cold compress bag, so that the whole system is in a colloid shape and is unlikely to flow, and the use comfort level of a patient is improved. The solid materials and the water are separated by the sealing strip, and the cold compress bag is convenient to use; and in the transportation process, the solid materials and the water can be effectively separated and cannot be mixed, which is convenient for transporting the cold compress bag.

Owner:湖州新驰医药科技有限公司

Manufacturing method of copper interconnection structure

ActiveCN102881633APrevent proliferationImprove reliabilitySemiconductor/solid-state device manufacturingManganeseInterconnection

The invention discloses a manufacturing method of a copper interconnection structure, which comprises the steps as follows: a) providing a semiconductor substrate, forming an oxygen-containing dielectric layer on the upper surface of the semiconductor substrate, and forming a groove for forming the copper interconnection structure in the oxygen-containing dielectric layer, b) forming a tantalum metal layer on the oxygen-containing layer and in the groove, c) forming a copper-manganese seed crystal layer on the tantalum metal layer, and d) forming the copper interconnection structure on the copper-manganese seed crystal layer in the groove and performing an annealing process. According to the manufacturing method, the tantalum metal layer is formed between the oxygen-containing dielectric layer and the copper-manganese seed crystal layer, the annealing process is performed to form a thinner anti-diffusion barrier layer by reactions of oxygen in the oxygen-containing dielectric layer and manganese in the copper-manganese seed crystal layer with the tantalum metal layer, cooper is effectively prevented from diffusing to the oxygen-containing dielectric layer, and the electric resistance of the copper interconnection structure is not affected.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Ink-jet head with ink blockage prevention device

InactiveUS6979078B2Easy dischargeAvoid it happening againPrintingEngineeringElectrical and Electronics engineering

Owner:BROTHER KOGYO KK

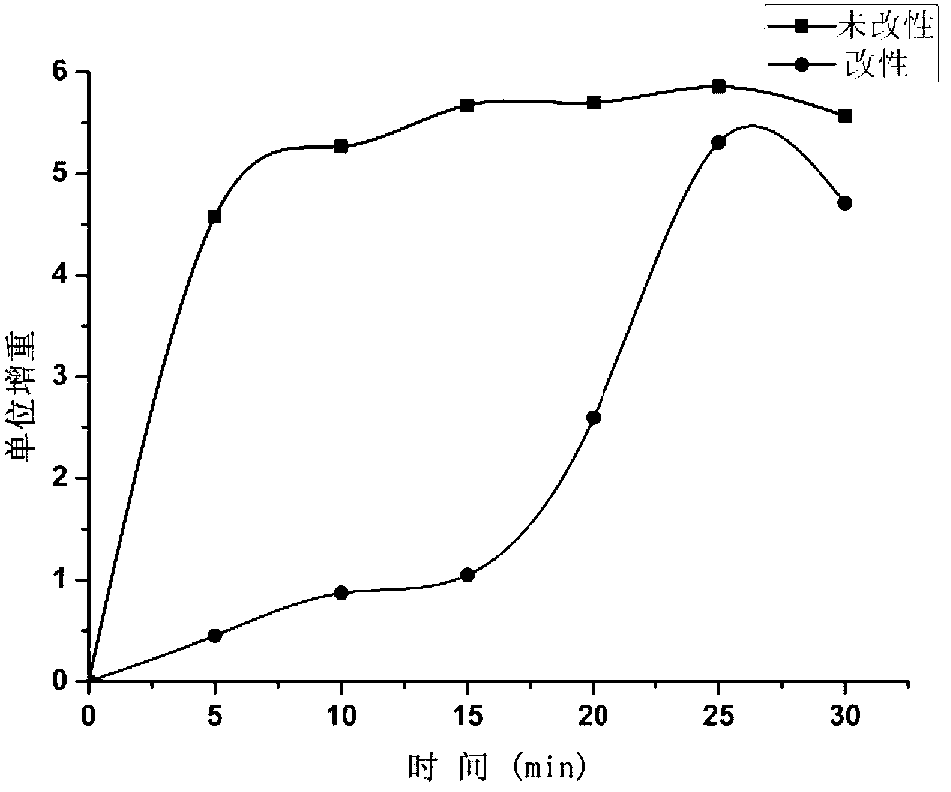

Slow-release water supply type fertilizer and application thereof

InactiveCN102826914AReduce rheologySimple manufacturing methodFertilizer mixturesEngineeringMoisture

The invention relates to fertilizers, and in particular relates to a slow-release water supply type fertilizer and an application thereof. The slow-release water supply type fertilizer comprises the following components: water and fertilizer together accounting for 94-99.5 percent in total, a thickening agent accounting for 0.50-5.00 percent in total, and a slow release agent accounting for 0.00-1.00 percent. Moisture and fertilizer nutrients contained in the slow-release water supply type fertilizer provided by the invention are slowly released to the root of a plant through biodegradation effects, so that soil is capable of providing the moisture and the nutrients to the plant for a long period of time.

Owner:覃柏立 +1

Thin-film magnetic head, method of manufacturing the same, head gimbal assembly, and hard disk drive

ActiveUS20120170154A1Lower resistanceIncreasing magnetic path lengthConstruction of head windingsElectrical connection between head and armHard disc driveMagnetic poles

Owner:HEADWAY TECH INC +1

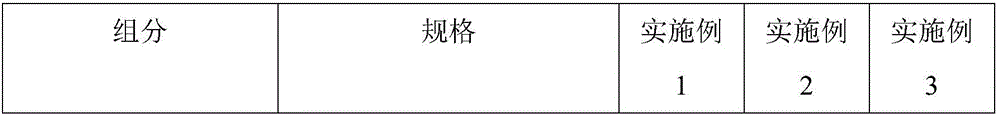

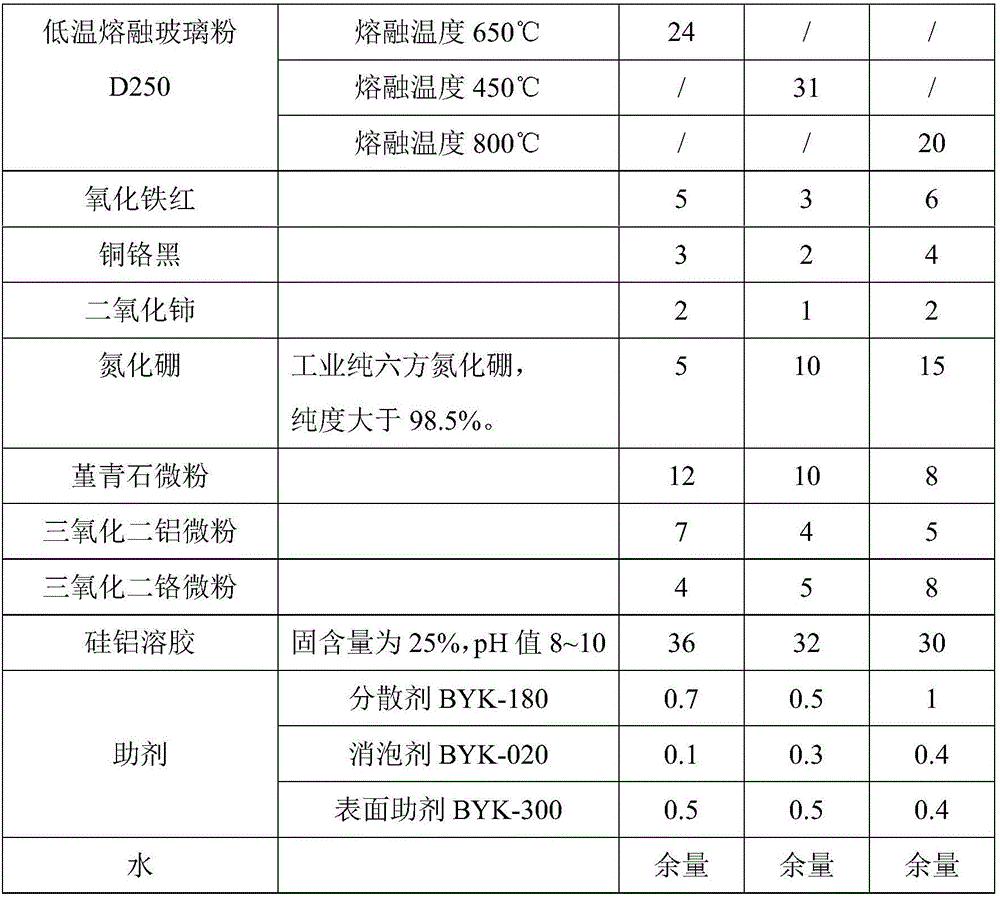

Low-temperature sintering high-heat conduction ceramic paint suitable for metal base material and preparation method and application thereof

The invention discloses a low-temperature sintering high-heat conduction ceramic paint suitable for metal base material and a preparation method and an application thereof. The paint comprises the following raw materials: low-temperature molten glass powder, iron oxide red, copper-chrome black, cerium dioxide, boron nitride, iolite micro powder, alumina micro powder, chromium sesquioxide micro powder, 20-50% of silicon aluminium sol, 0.5-3% of an auxiliary agent, and the balance of water. The method comprises the following steps: a metal matrix is processed, then the surface of the metal matrix is uniformly coated with a paint and dried in shade; and the coated metal matrix is heated at the temperature of 650-900 DEG C to form the low-temperature sintering high-heat conduction ceramic paint. The paint has the advantages of easy acquisition of the raw materials and low cost, is tightly combined with the metal matrix, has effective high temperature oxidation resistance, acid corrosion resistance and abrasion resisting effects of a heating furnace flue heat exchanger on a metal heat exchanger, ceramic coating surface is smooth and clean, slag buildup of the heat exchanger is effectively reduced, the service life of the metal heat exchanger is prolonged, and the heat exchange efficiency effect is increased.

Owner:武汉钢铁有限公司

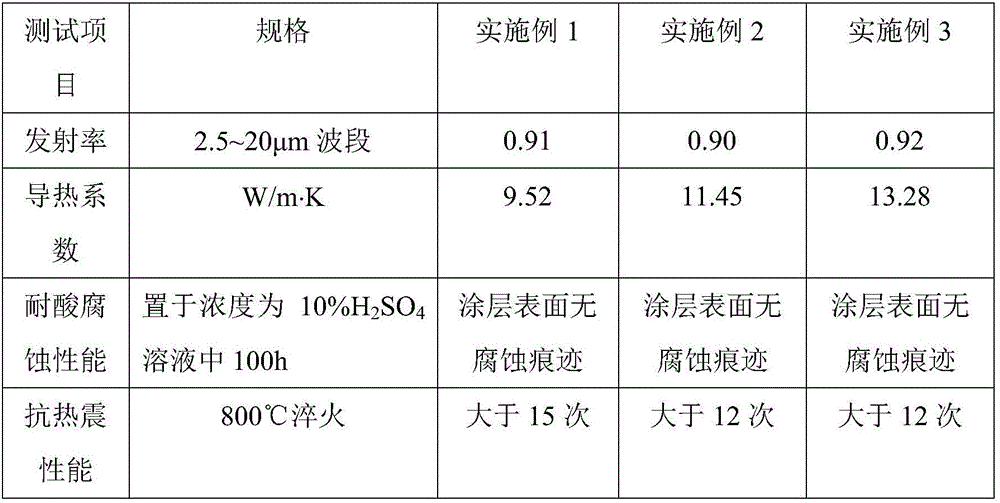

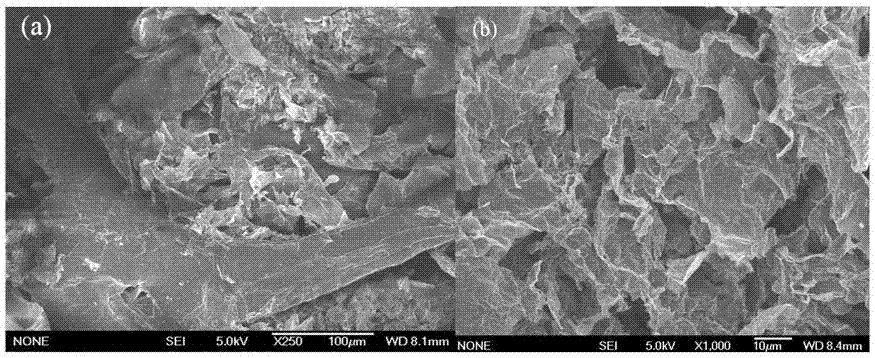

Reduced graphene oxide-polyurethane dual-sponge adsorption film, preparation method therefor and application of reduced graphene oxide-polyurethane dual-sponge adsorption film

ActiveCN106861657AImprove adsorption capacityNot easy to flowOther chemical processesWater contaminantsFreeze-dryingLarge size

The invention discloses a reduced graphene oxide-polyurethane dual-sponge adsorption film, a preparation method therefor and an application of the reduced graphene oxide-polyurethane dual-sponge adsorption film. The reduced graphene oxide-polyurethane dual-sponge adsorption film comprises reduced graphene oxide sponge and a polyurethane hot-pressed sponge film, wherein the reduced graphene oxide sponge is uniformly filled in pores of the polyurethane hot-pressed sponge film and is physically bonded with the polyurethane hot-pressed sponge film. The preparation method comprises the following steps: (1) preparing a graphene oxide-polyurethane sponge dispersion solution; (2) carrying out freeze drying; and (3) carrying out hot-pressing film forming. The reduced graphene oxide-polyurethane dual-sponge adsorption film has the advantages that the adsorption performance is good, the efficiency of removing contaminants from water is high, large-size preparation can be achieved, the adsorption film is easy to recover and can be repeatedly used, and the like; and the preparation method is simple in process and low in cost and advantageously achieves industrial production.

Owner:HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com