Patents

Literature

9784 results about "Release agent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A release agent (also mold release agent, release coating, or mold release coating) is a chemical used to prevent other materials from bonding to surfaces. It can provide a solution in processes involving mold release, die-cast release, plastic release, adhesive release, and tire and web release.

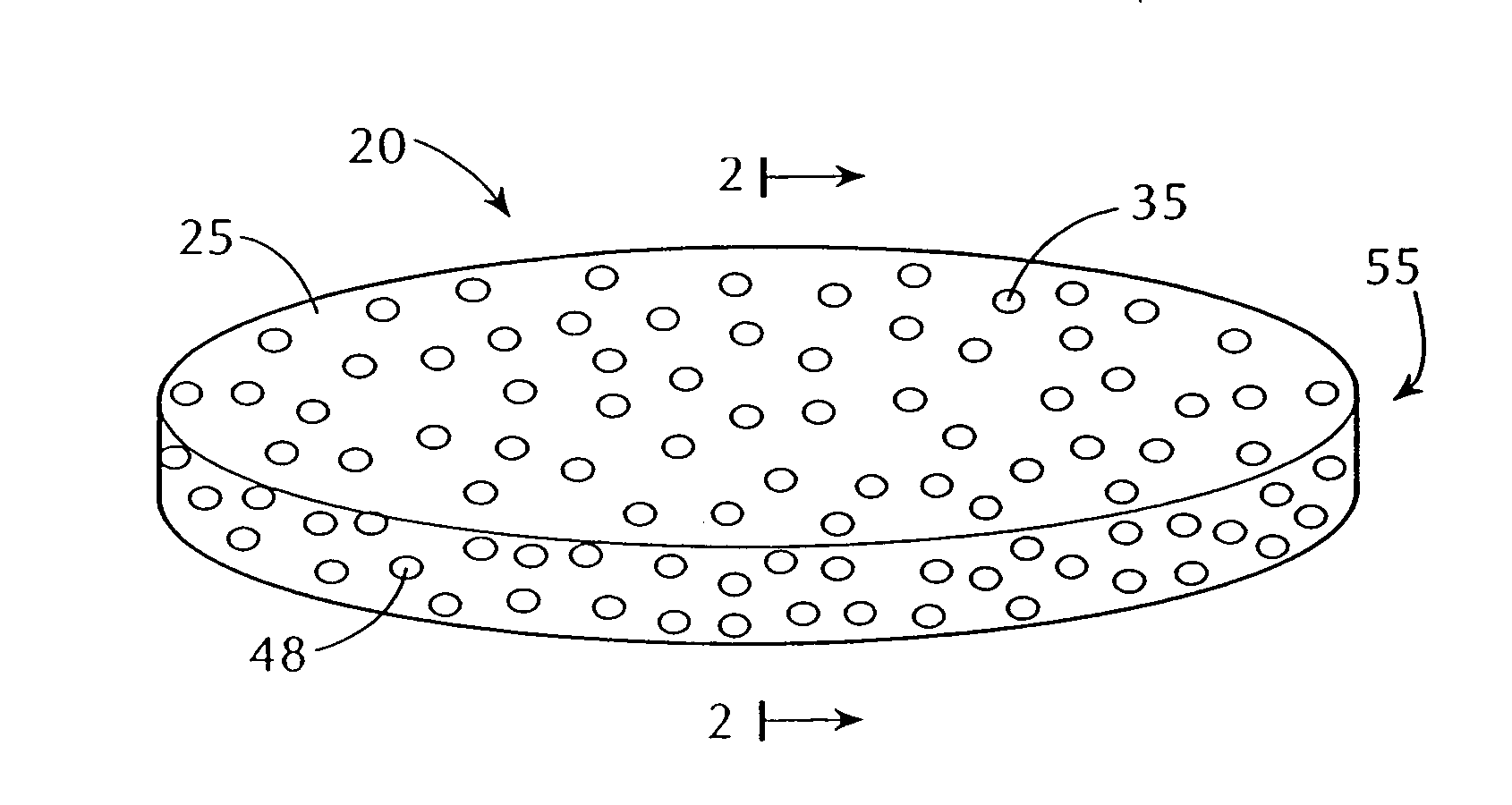

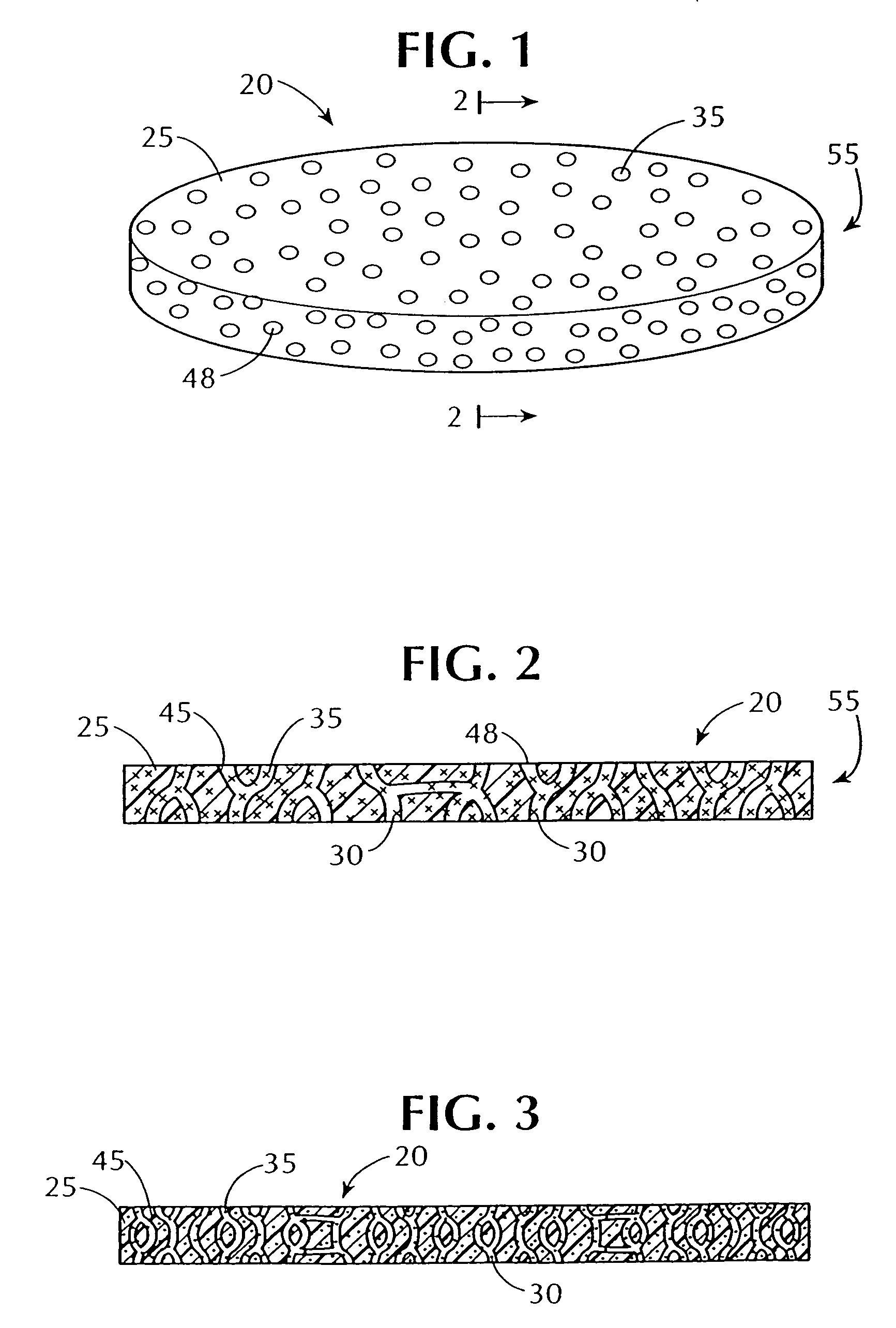

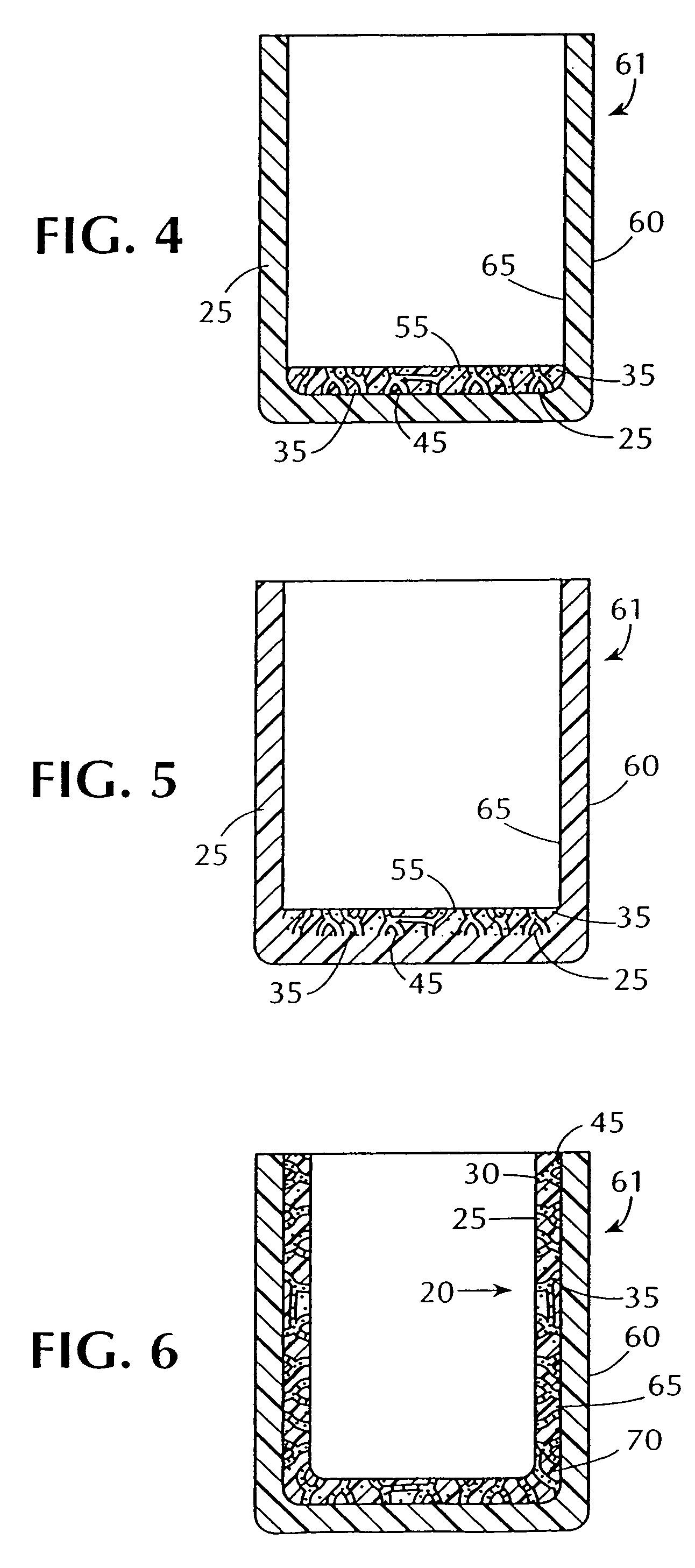

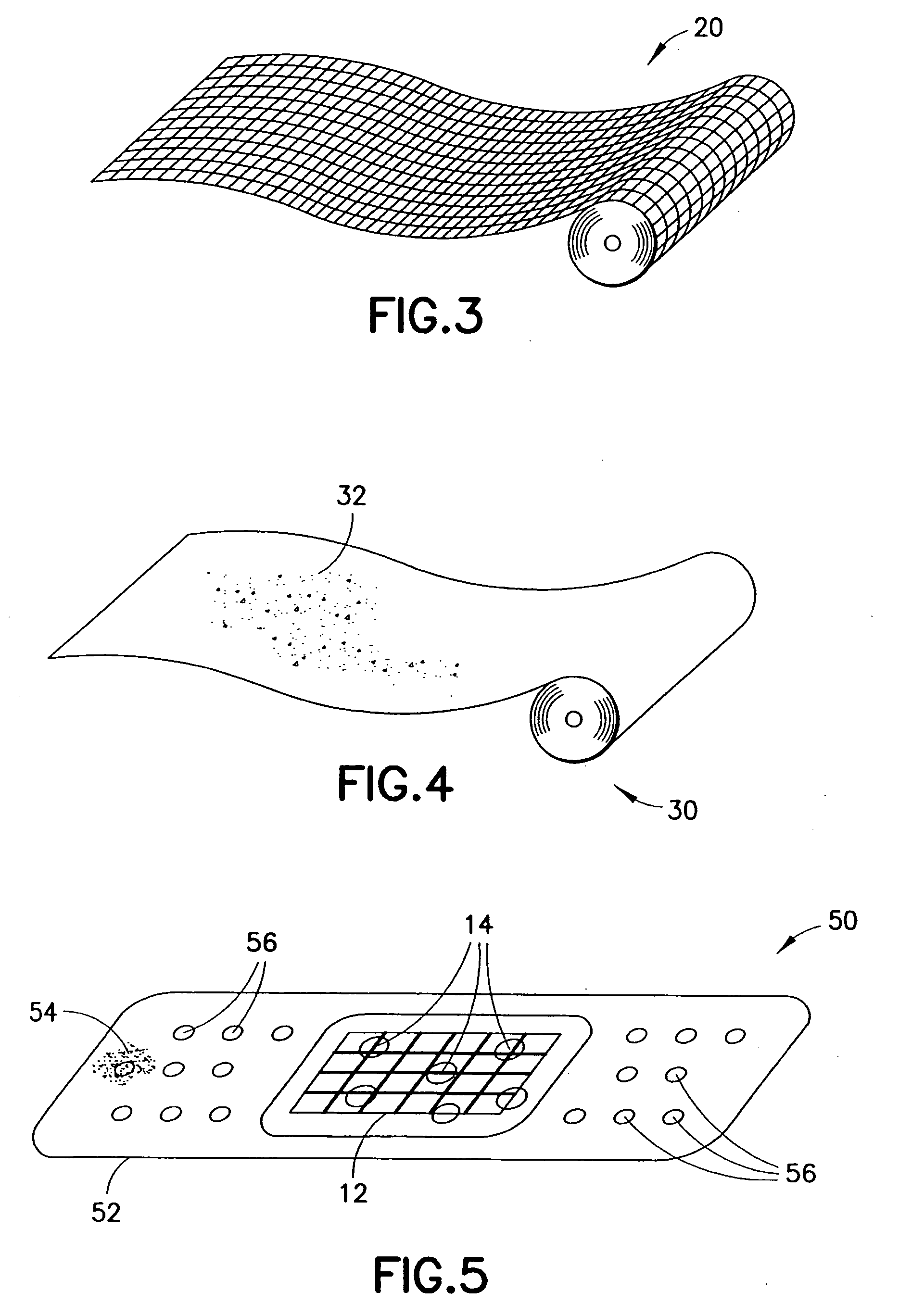

Desiccant entrained polymer

The present invention includes a composition having a co-continuous interconnecting channel morphology. These co-continuous interconnecting channels are predominately occupied with a polymer and particles that control the percolation through the composition. The particles are composed of a material such as an absorbing agent, releasing agent and / or activation agent. The polymer composition may be used to form a desired shaped article such as plug type inserts and liners for closed containers, or it may be formed into a film, sheet, bead or pellet.

Owner:CSP TECH NORTH AMERICA

Cosmetic and Pharmaceutical Masks Based on Ion-Pair Delivery System

InactiveUS20040219124A1Easy to disassembleMaximum absorption and bioavailabilityCosmetic preparationsToilet preparationsCross-linkBiopolymer

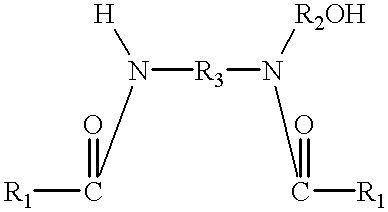

The present invention discloses a novel ion-pair delivery system based mask compositions for face, hair, skin, and body applications. These compositions come off from the site of their application essentially in one piece with the appearance, for example, of a piece of sea-weed or a continuous film. These mask compositions are suitable for a variety of delivery system methods, such as peel-off mask, moisturizing mask, exfoliating mask, prosthetic mask, soaking mask, depilatory mask, rub-off mask, two-phase mask, two-compartment mask, heat-releasing mask, and such. These mask compositions are made from the biopolymer based films that are cross-linked with divalent or trivalent metal cations. During the cross-linking process, such divalent and trivalent metal cations may also act as release agents for other face, hair, skin, and body beneficial compositions in their enhanced bioavailable forms by an ion-pair activation mechanism.

Owner:GUPTA SHYAM K

System and method for healing a wound at a tissue site

Provided herein is a system and method for facilitating removal of a drape from a tissue site. One aspect provides a system comprising a drape, and adhesive layer, and a release agent, where the system is adapted to be coupled to a tissue site and released therefrom upon or after exposure to an external stimulus. Another aspect provides a method for application and removal of a drape using less force than required with a conventional drape.

Owner:3M INNOVATIVE PROPERTIES CO

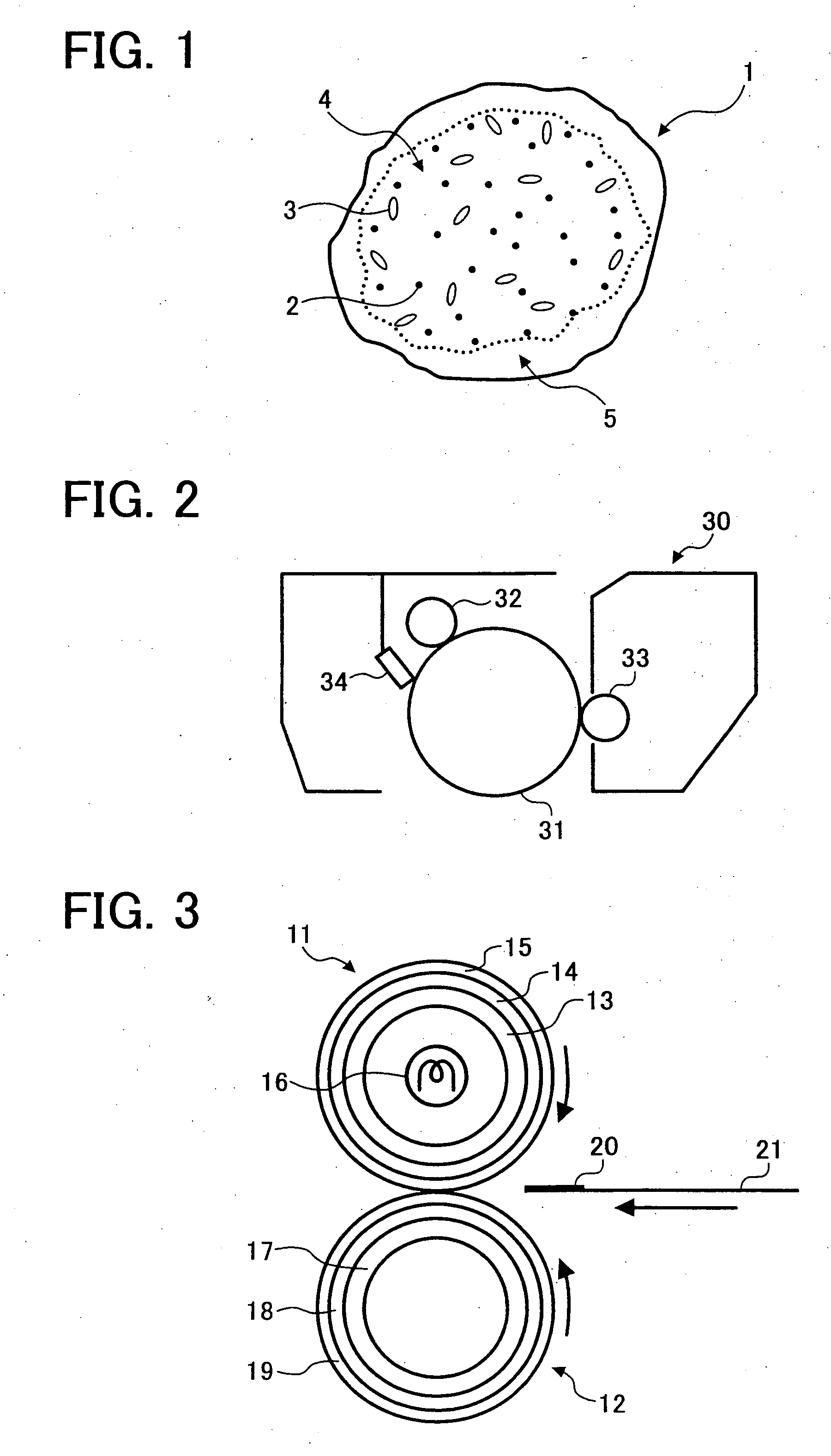

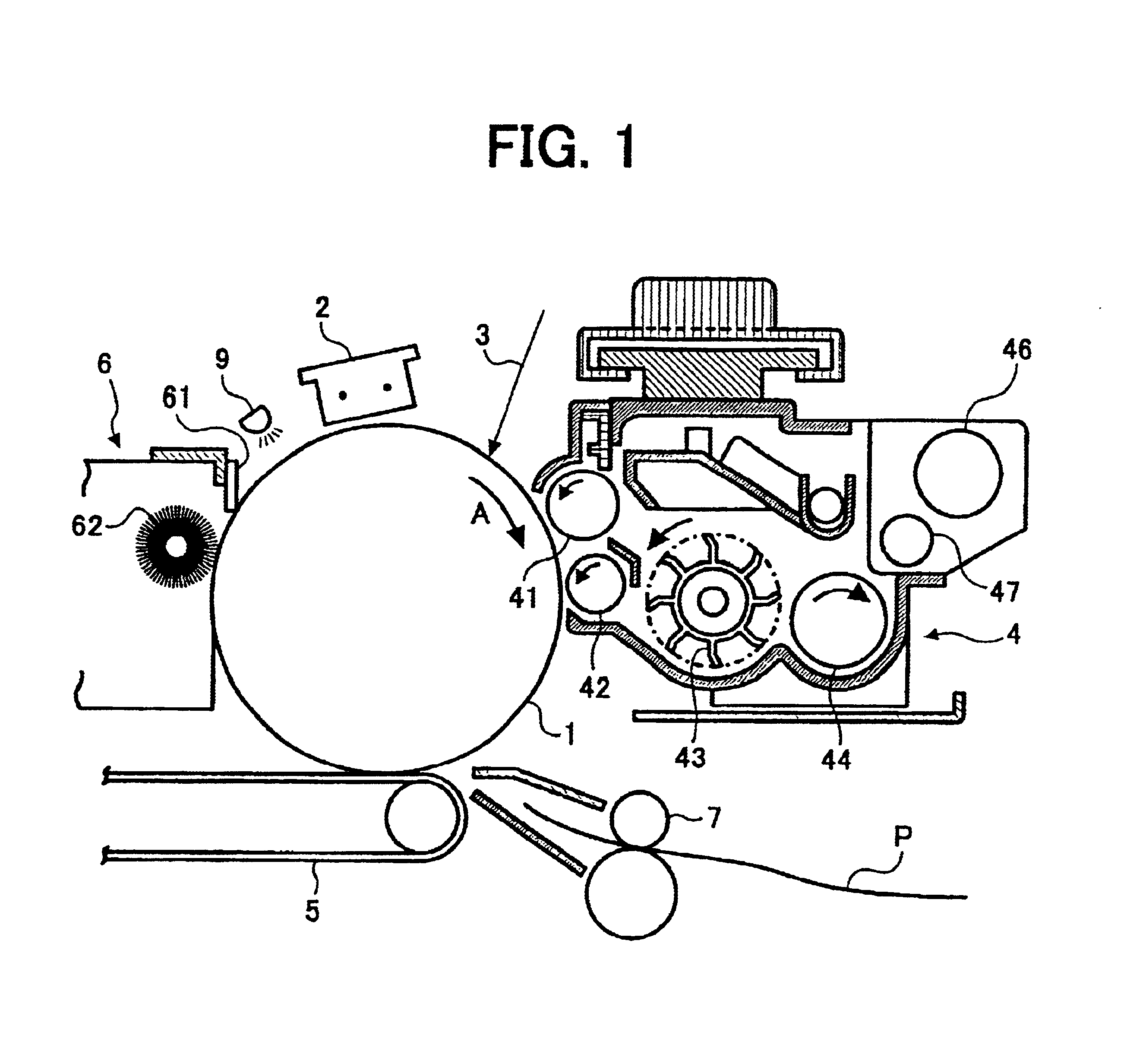

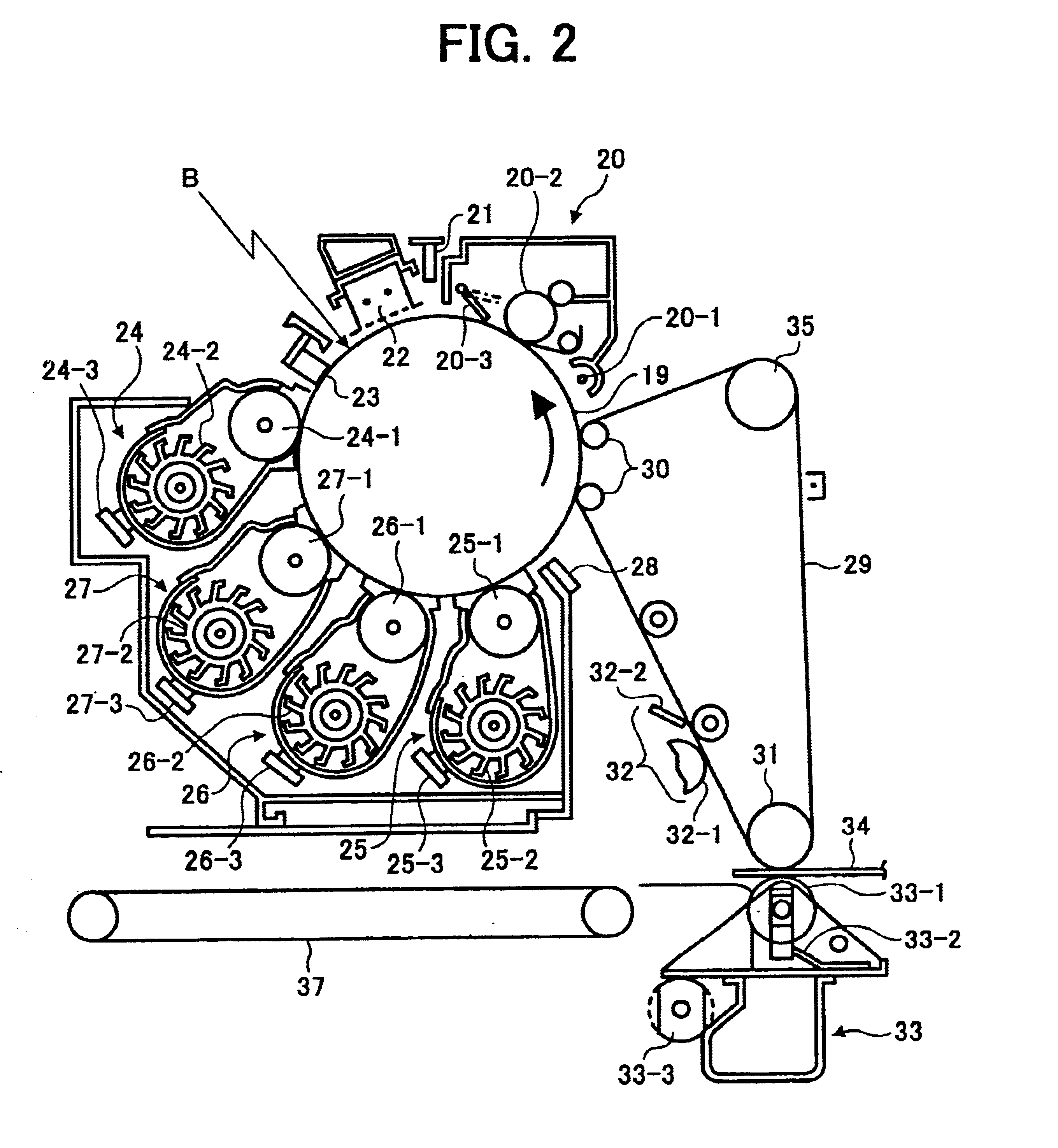

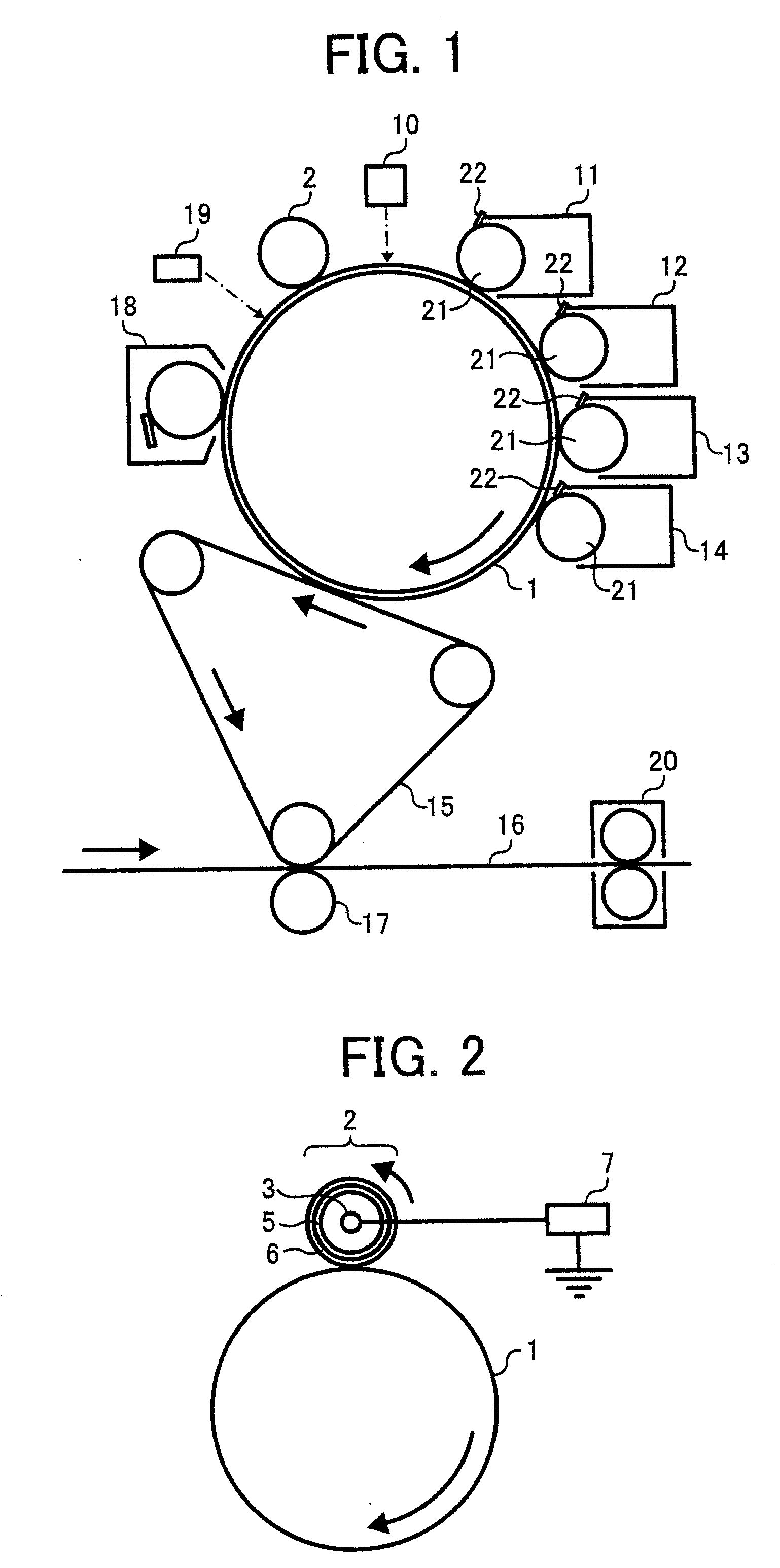

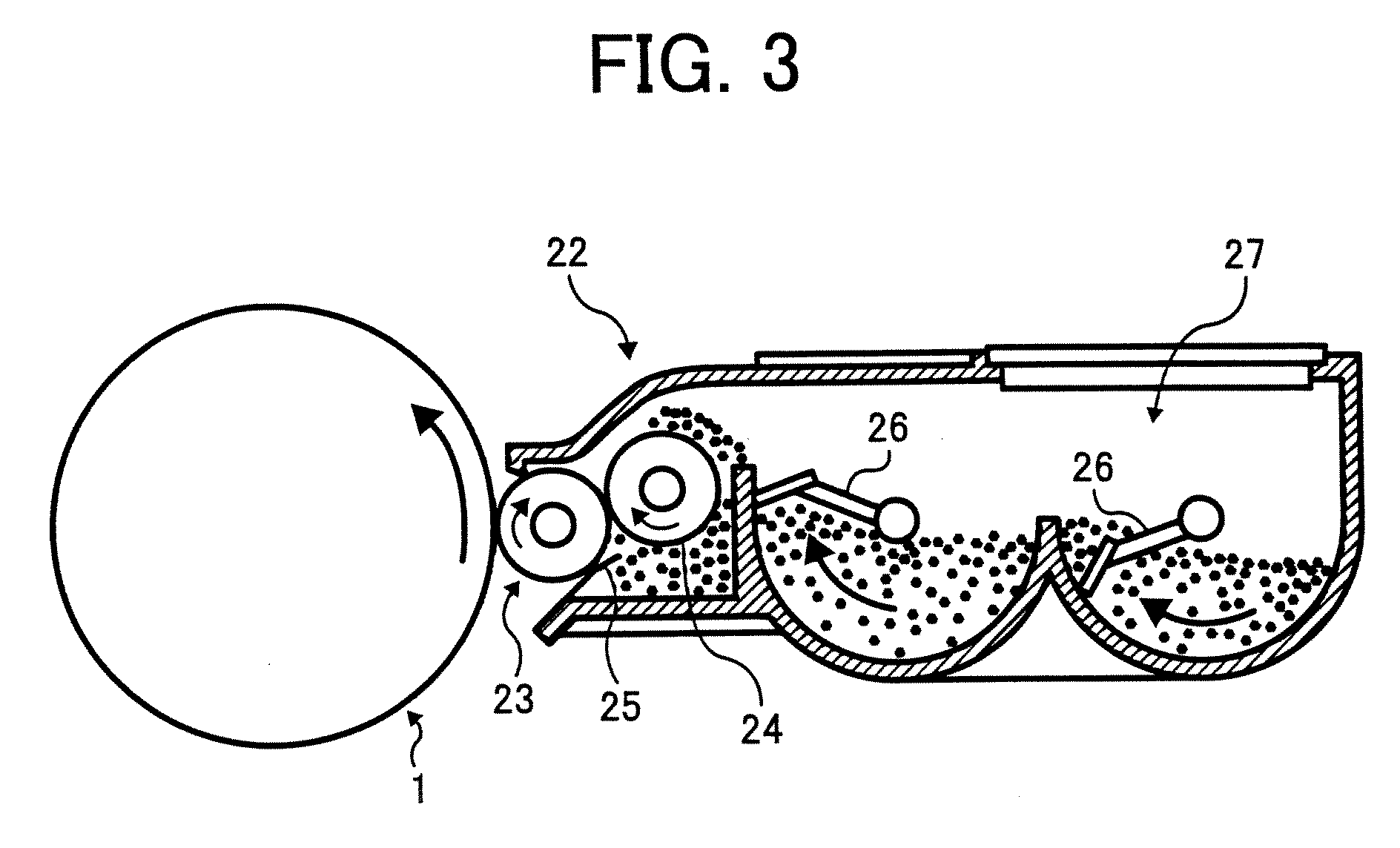

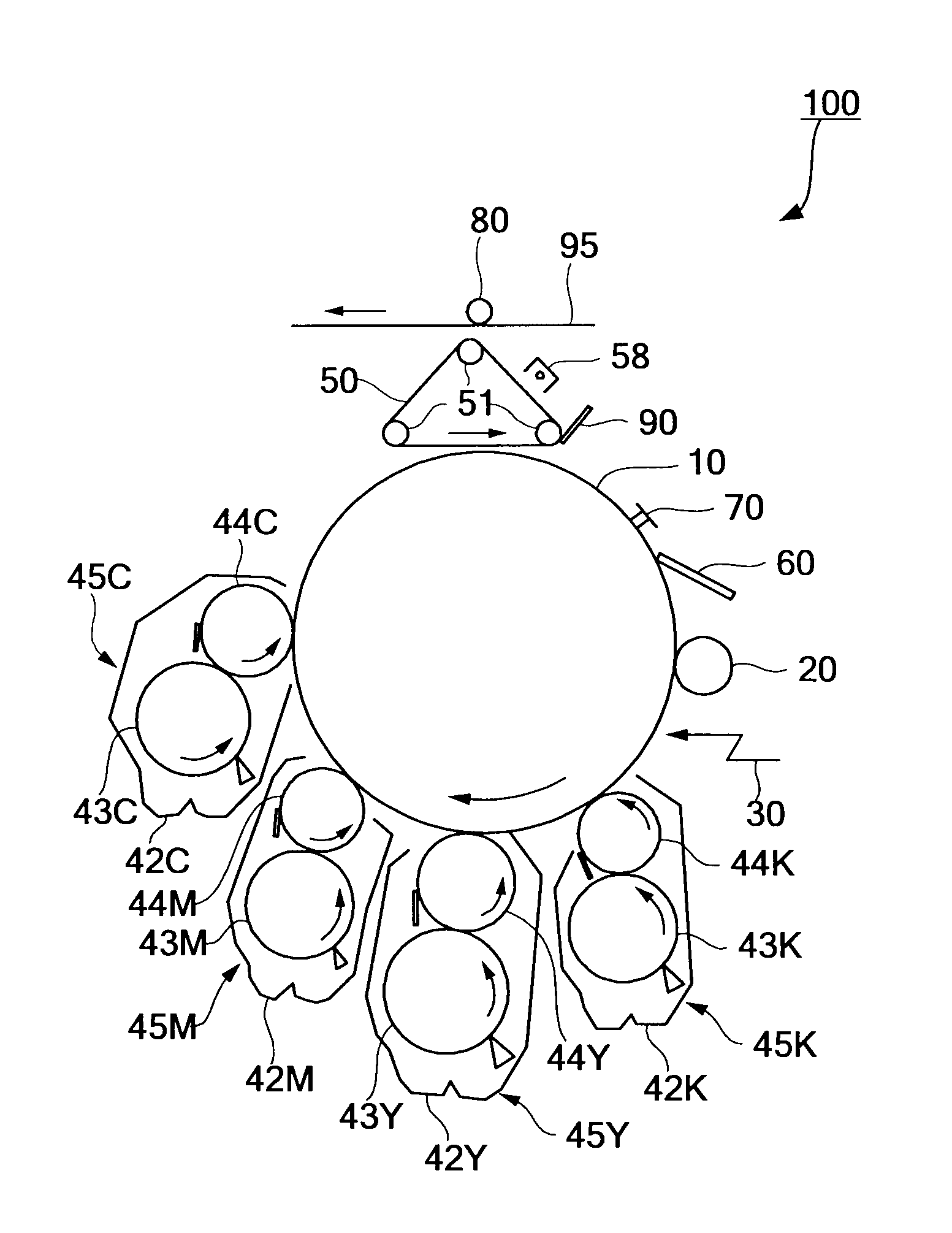

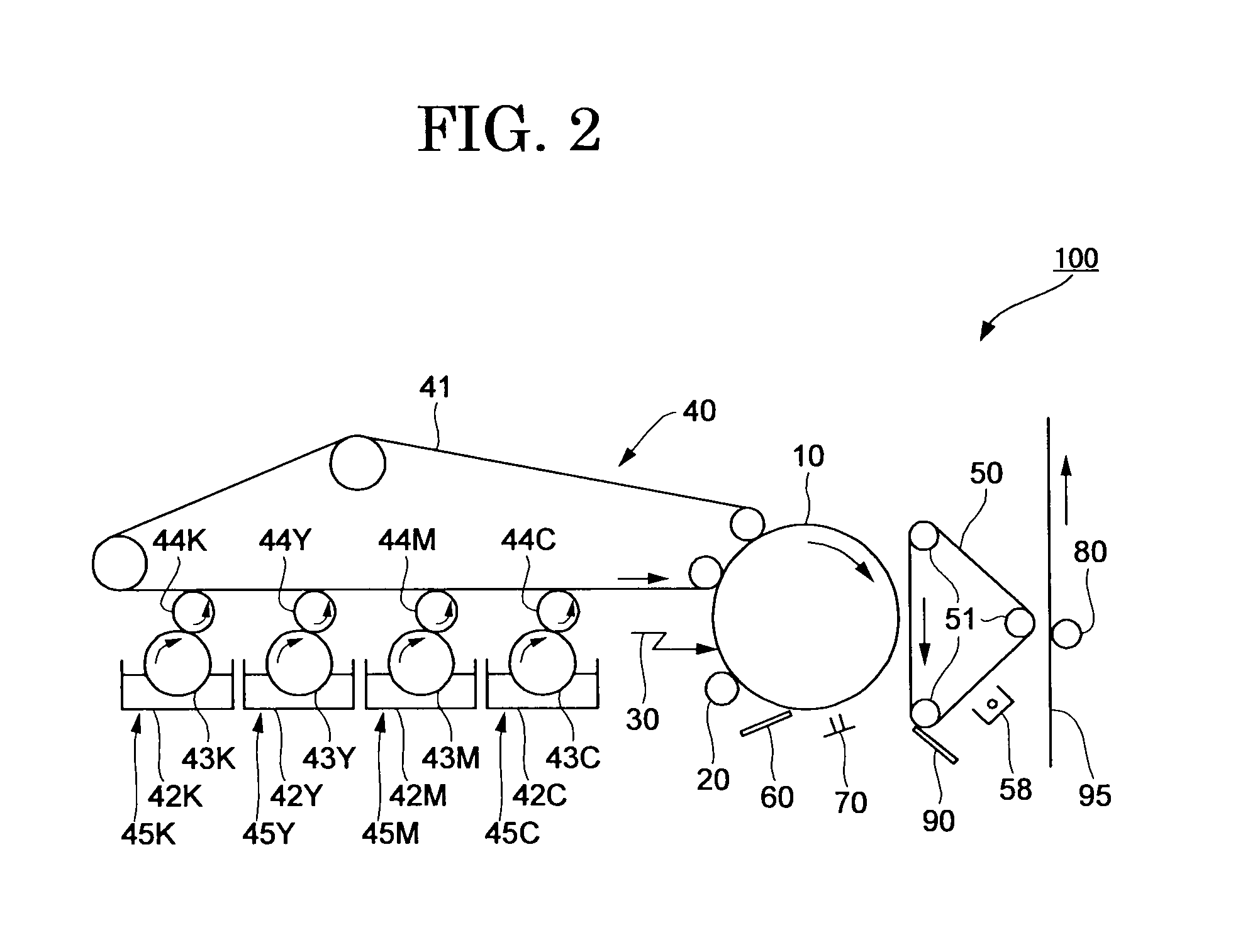

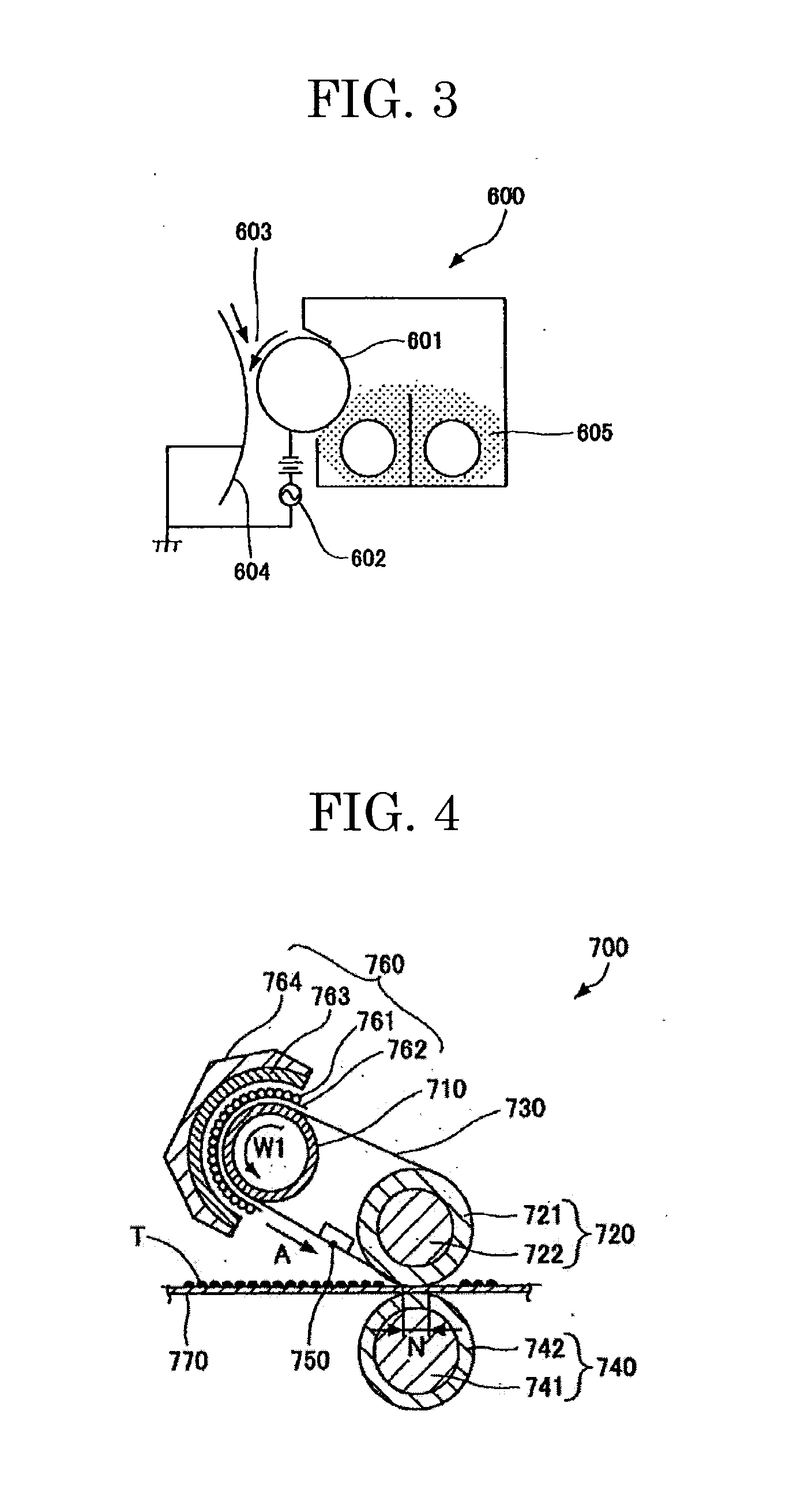

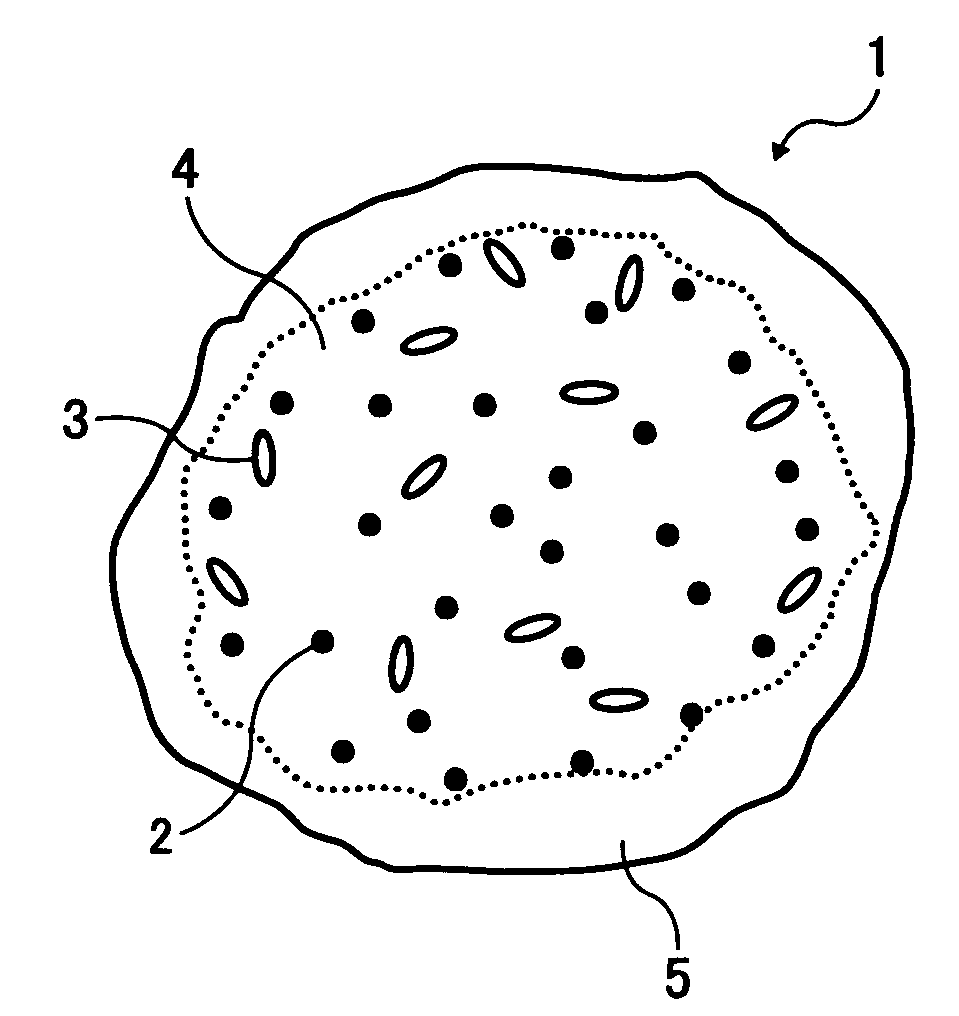

Toner, toner manufacturing method, developer, image forming apparatus, and process cartridge for the image forming apparatus

ActiveUS20060204882A1High quality imagingStable productionElectrographic process apparatusDevelopersPolyesterImage formation

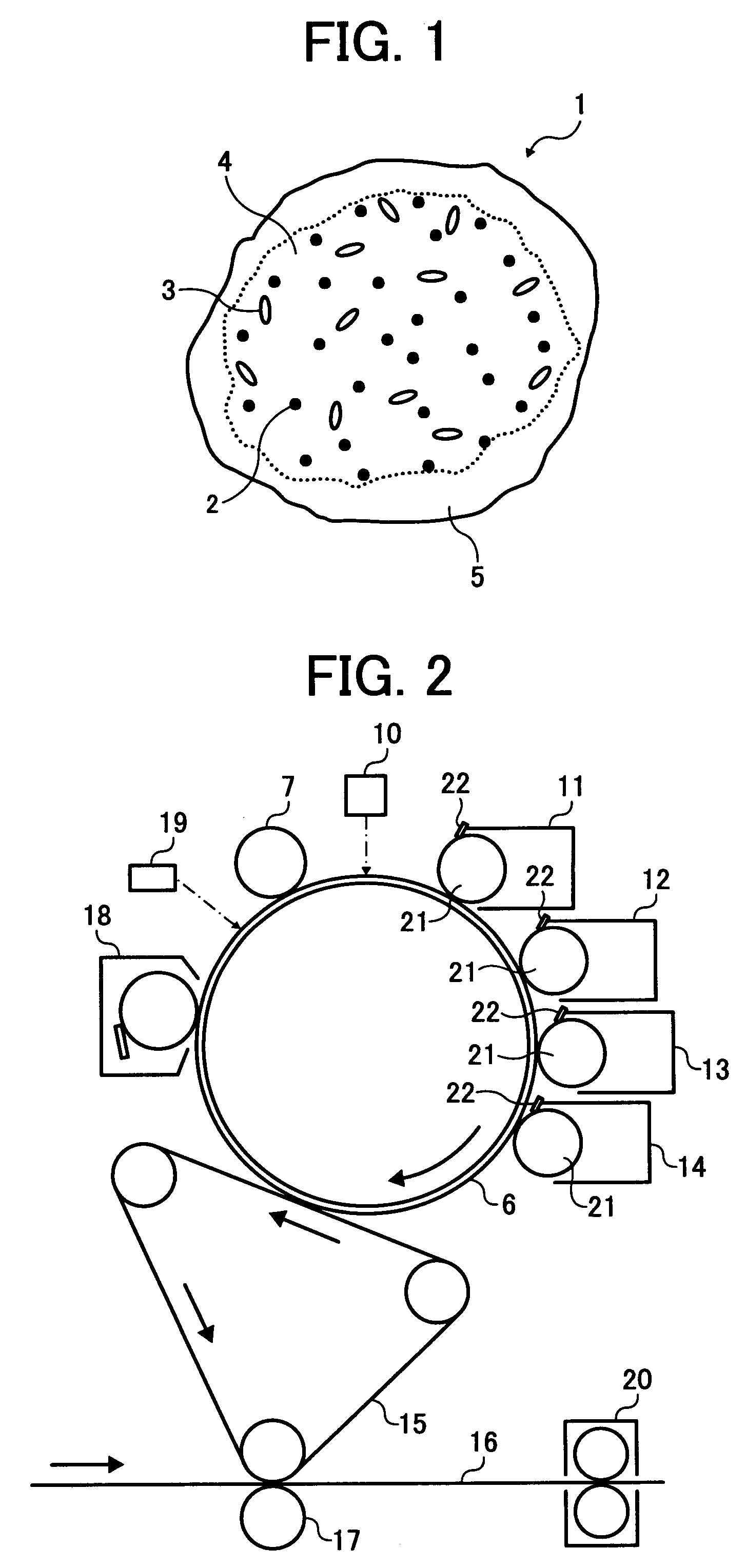

A toner having a core containing a colorant, a release agent and a binder resin (A), and a shell containing a binder resin (B), the shell overlying the core, wherein the binder resin (A) contains a resin having a polyester skeleton, the binder resin (B) contains a vinyl copolymer resin, and a weight ratio of the shell to the core is from 0.05 to 0.5, and wherein the toner has a volume average particle diameter of from 3 to 8 μm; a toner manufacturing method of such the toner can be used in an image forming apparatus and in a process cartridge.

Owner:RICOH KK

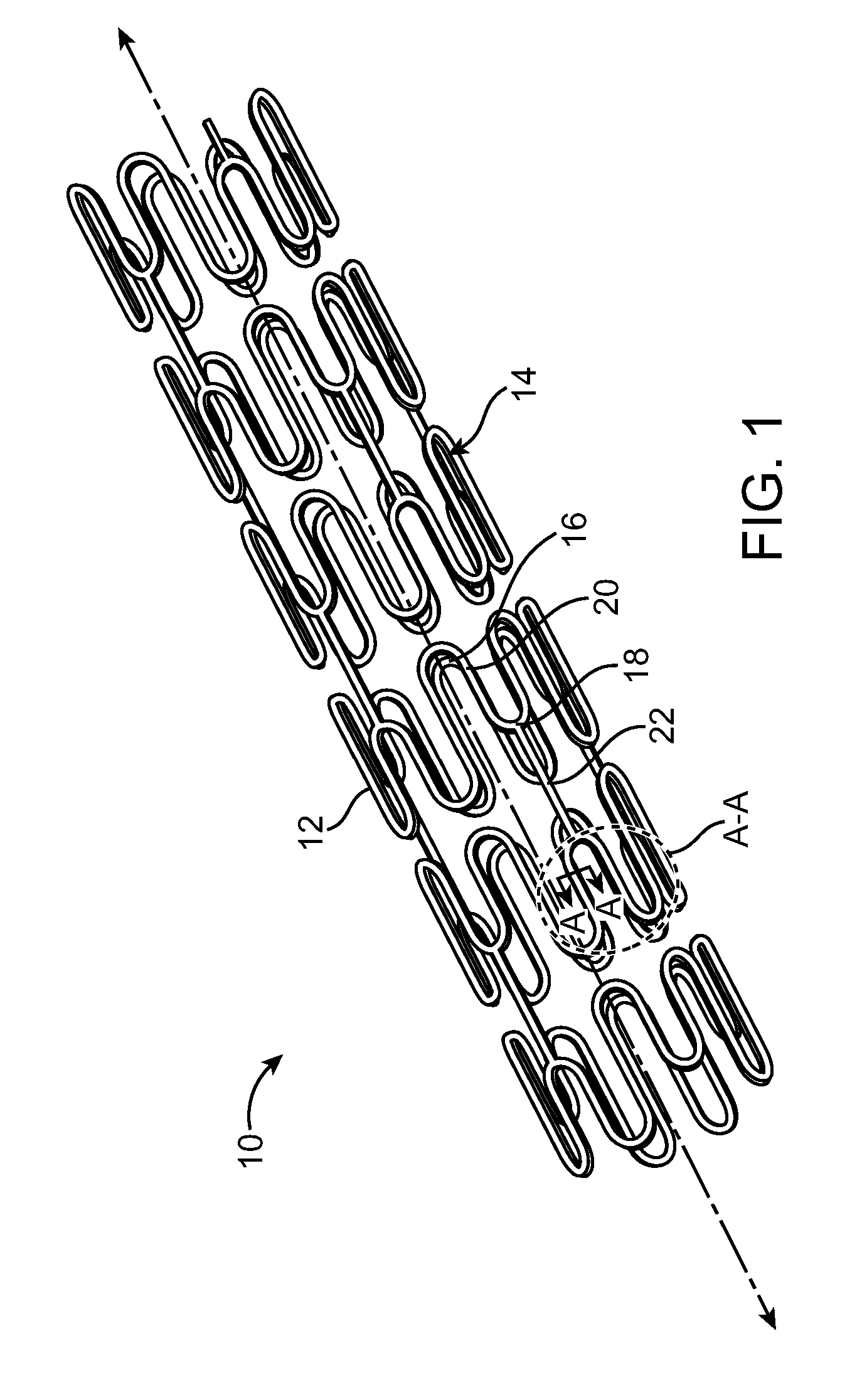

Toner and developer, toner container, process cartridge, image forming method and image forming apparatus

InactiveUS20060210902A1DevelopersElectrographic processes using charge patternImage formationEngineering

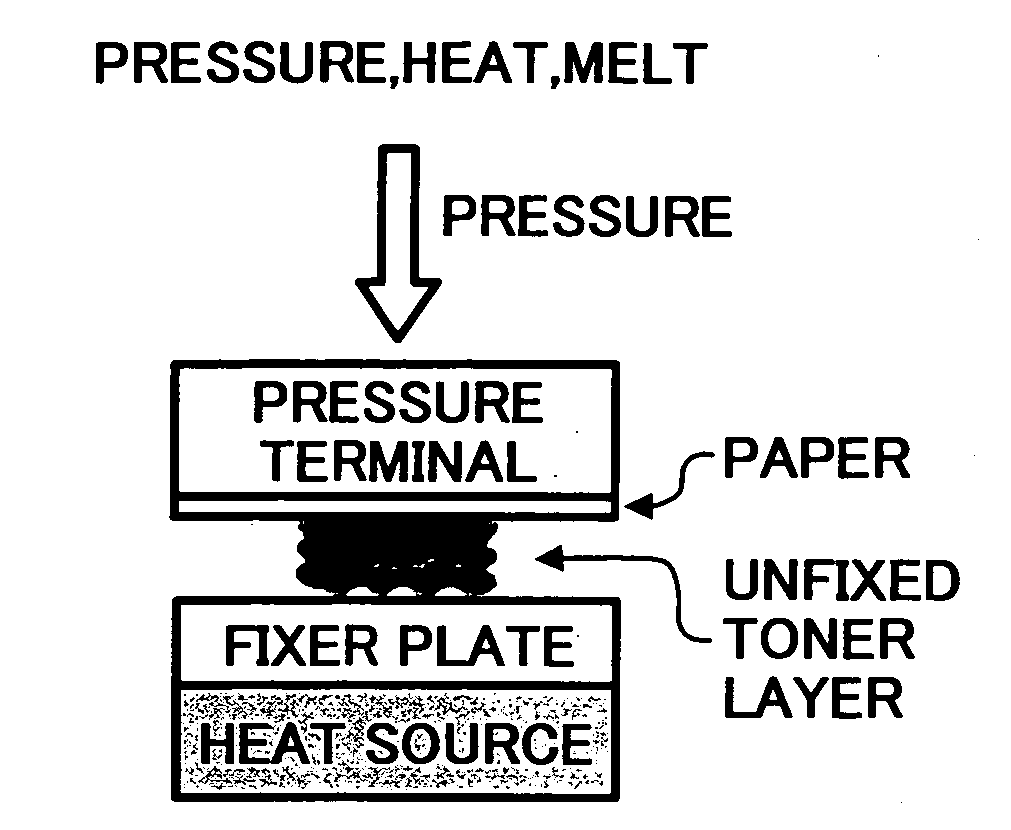

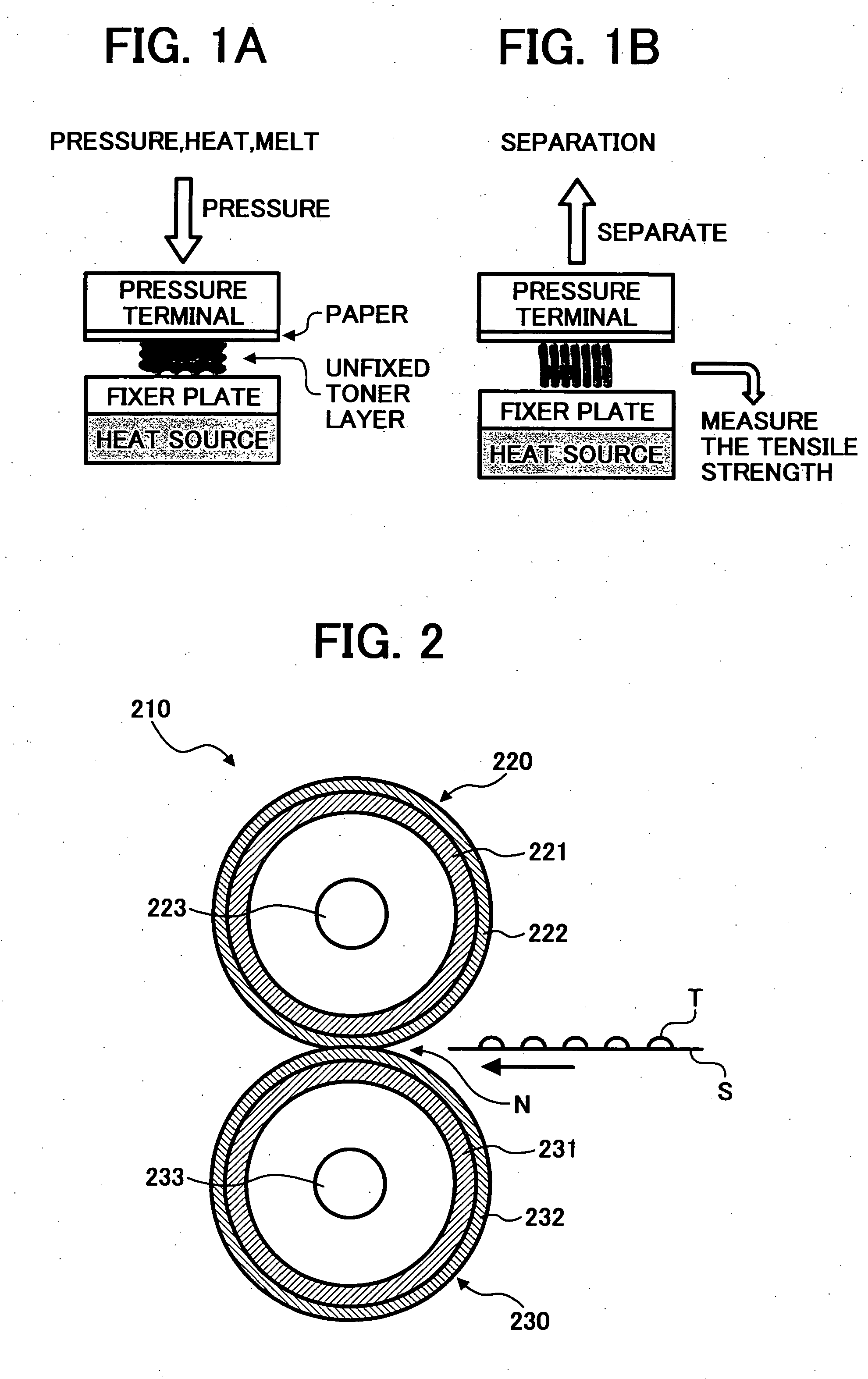

A toner including a binder resin, a colorant and a release agent, and satisfying the following relationships (1) and (2): 1.0≦FT120 / FT160≦1.5 (1) wherein FT120 is a maximum tensile strength (N) when a recording medium having the toner unfixed on is vertically separated from the surface of a substrate having a temperature of 120° C. at a constant speed after pressed thereto at a pressure of 100 kPa, and FT160 is same except that the substrate has a temperature of 160° C.; 1.0≦FP100 / FP200≦1.5 (2) wherein FP100 is a maximum tensile strength (N) when a recording medium having the toner unfixed on is vertically separated from the surface of a substrate having a temperature of 160° C. at a constant speed after pressed thereto at a pressure of 100 kPa, and FP200 is same except that the pressure is 200 kPa.

Owner:RICOH KK

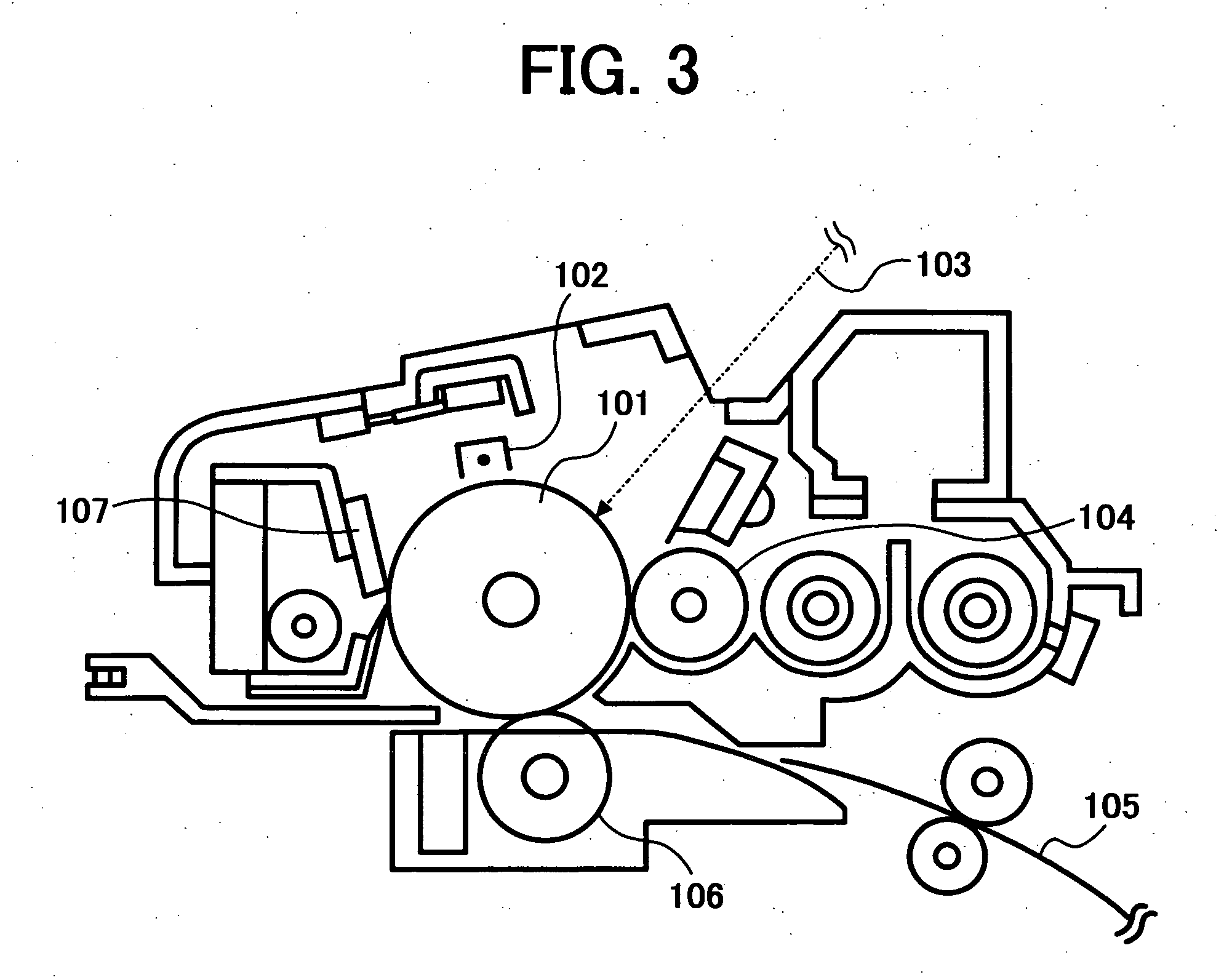

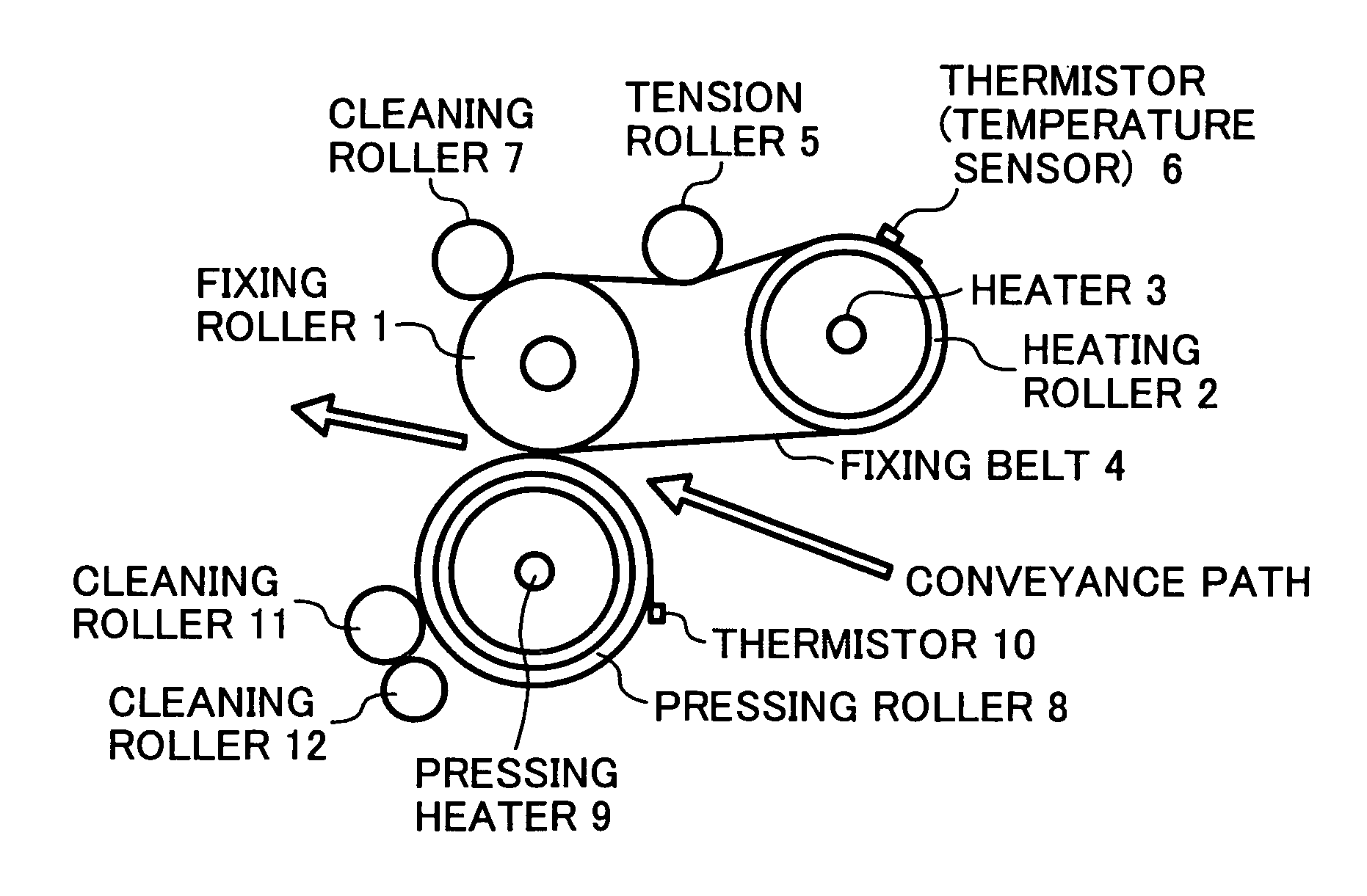

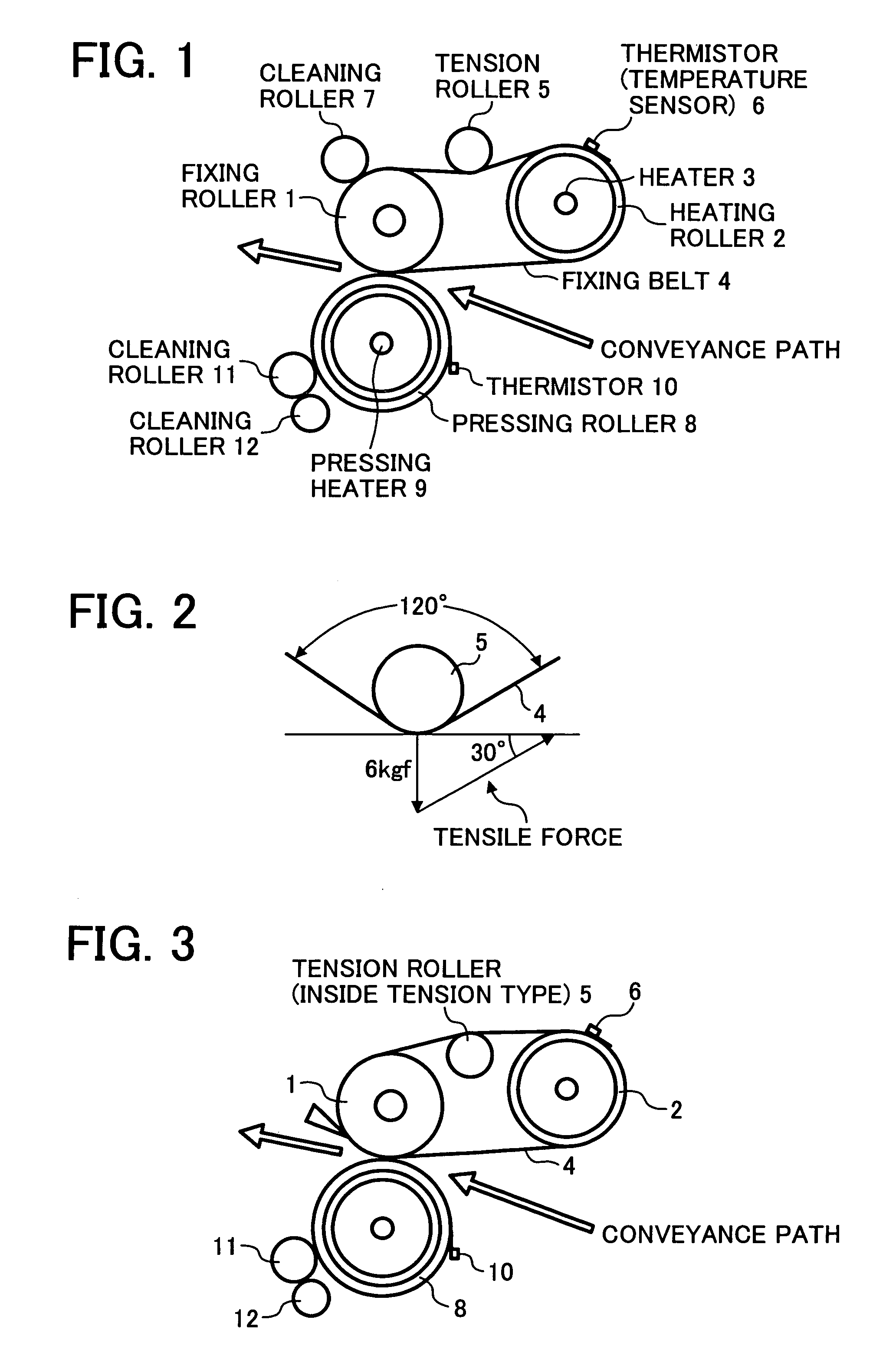

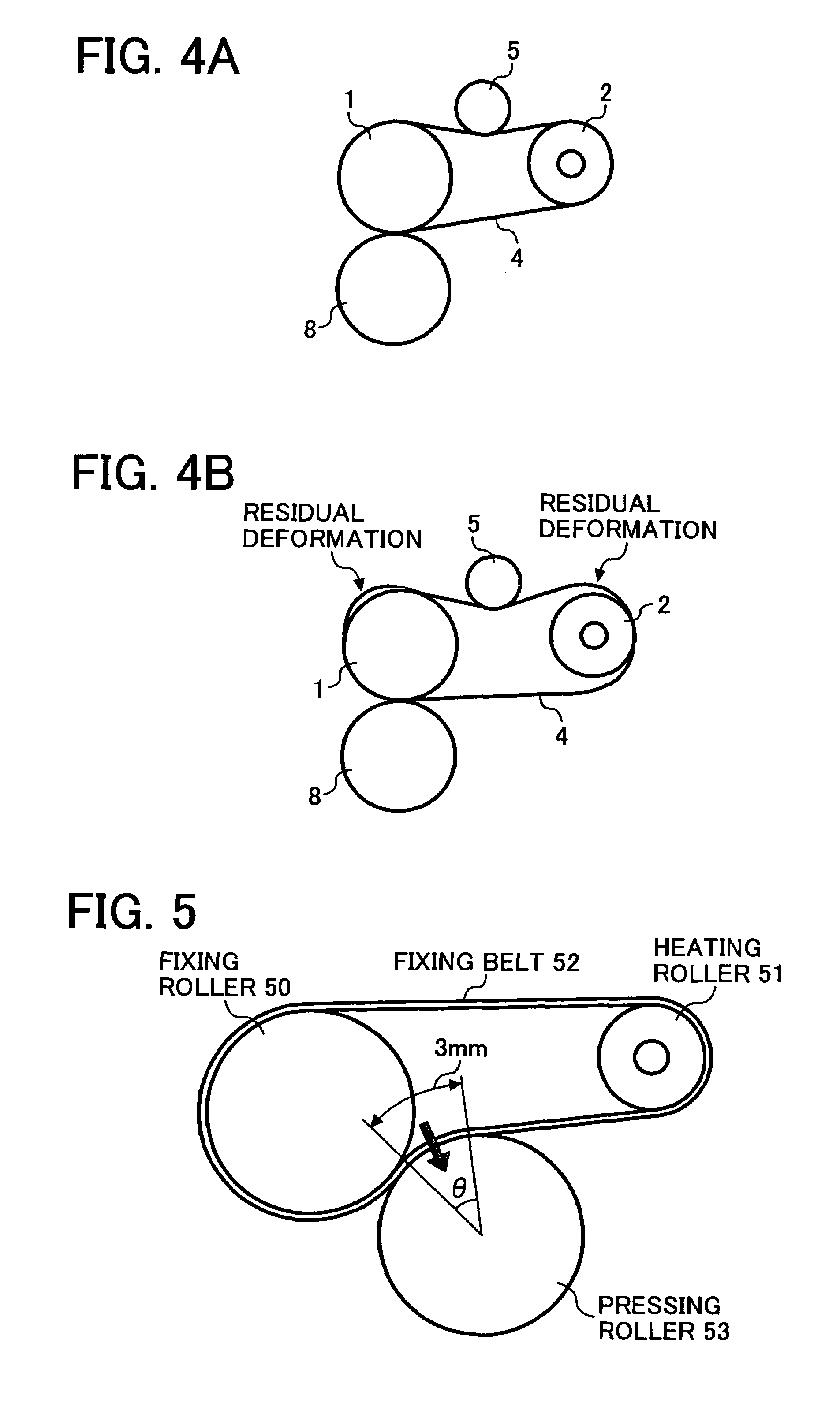

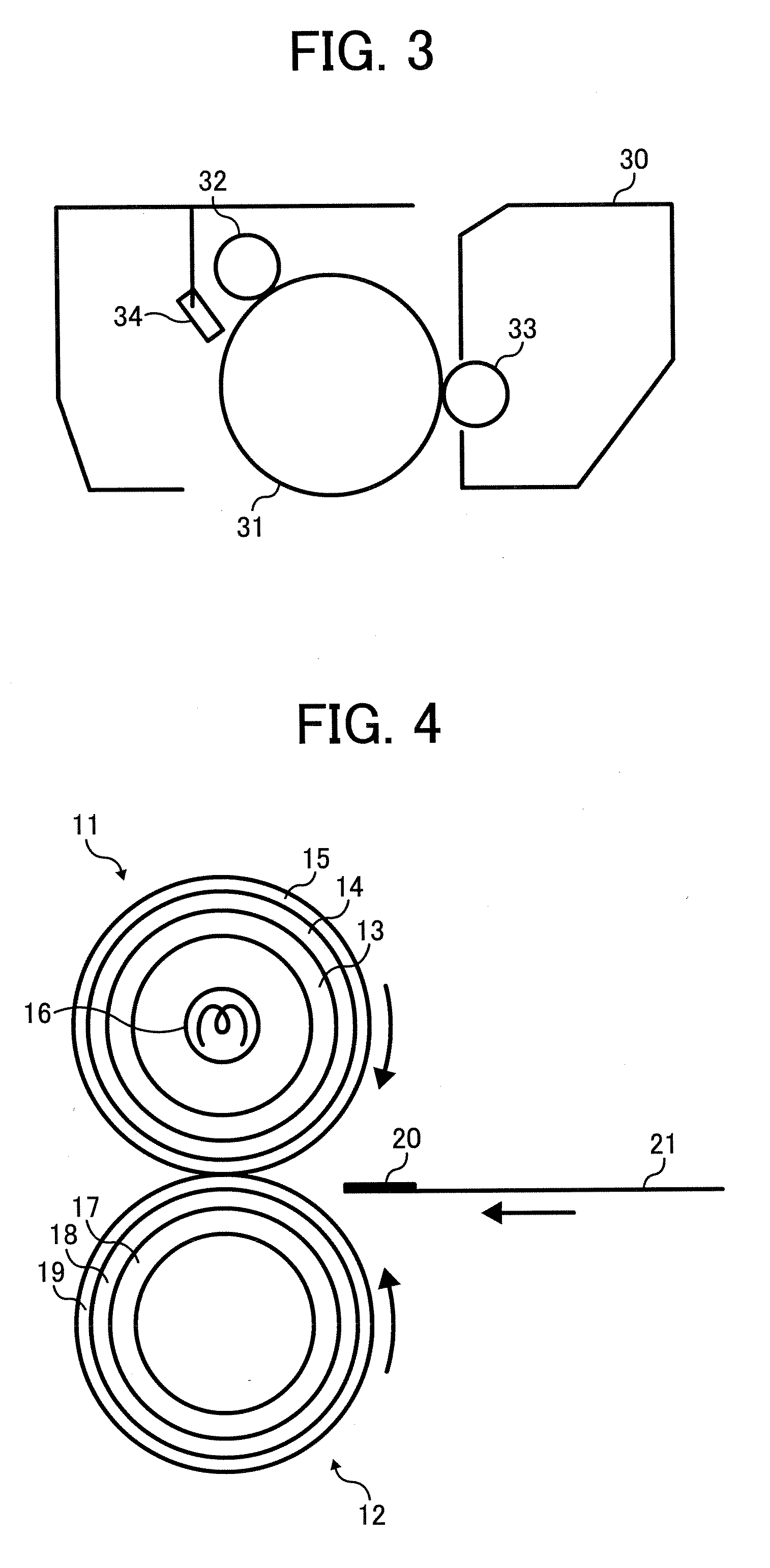

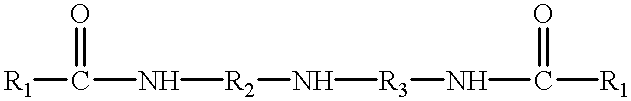

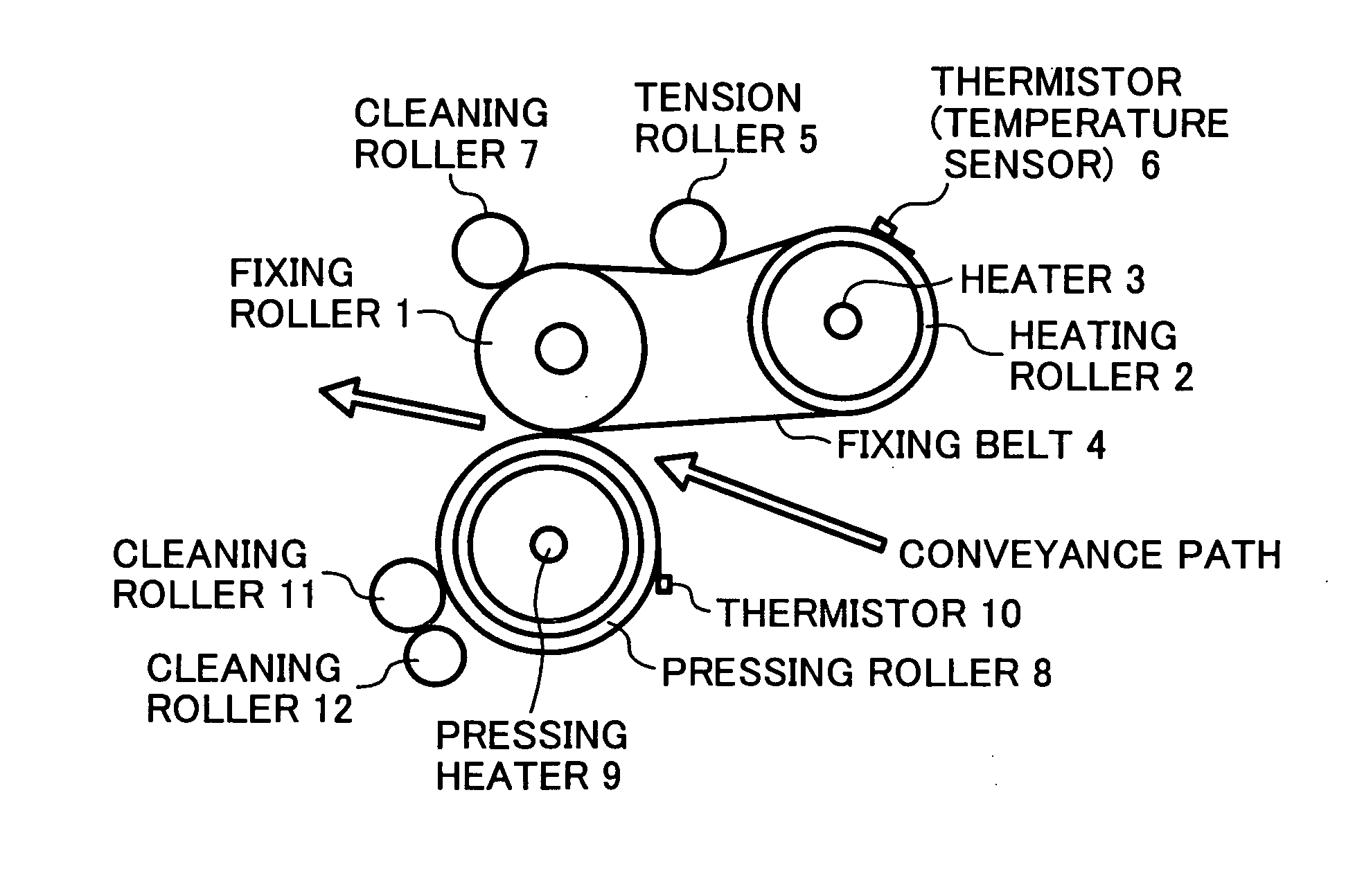

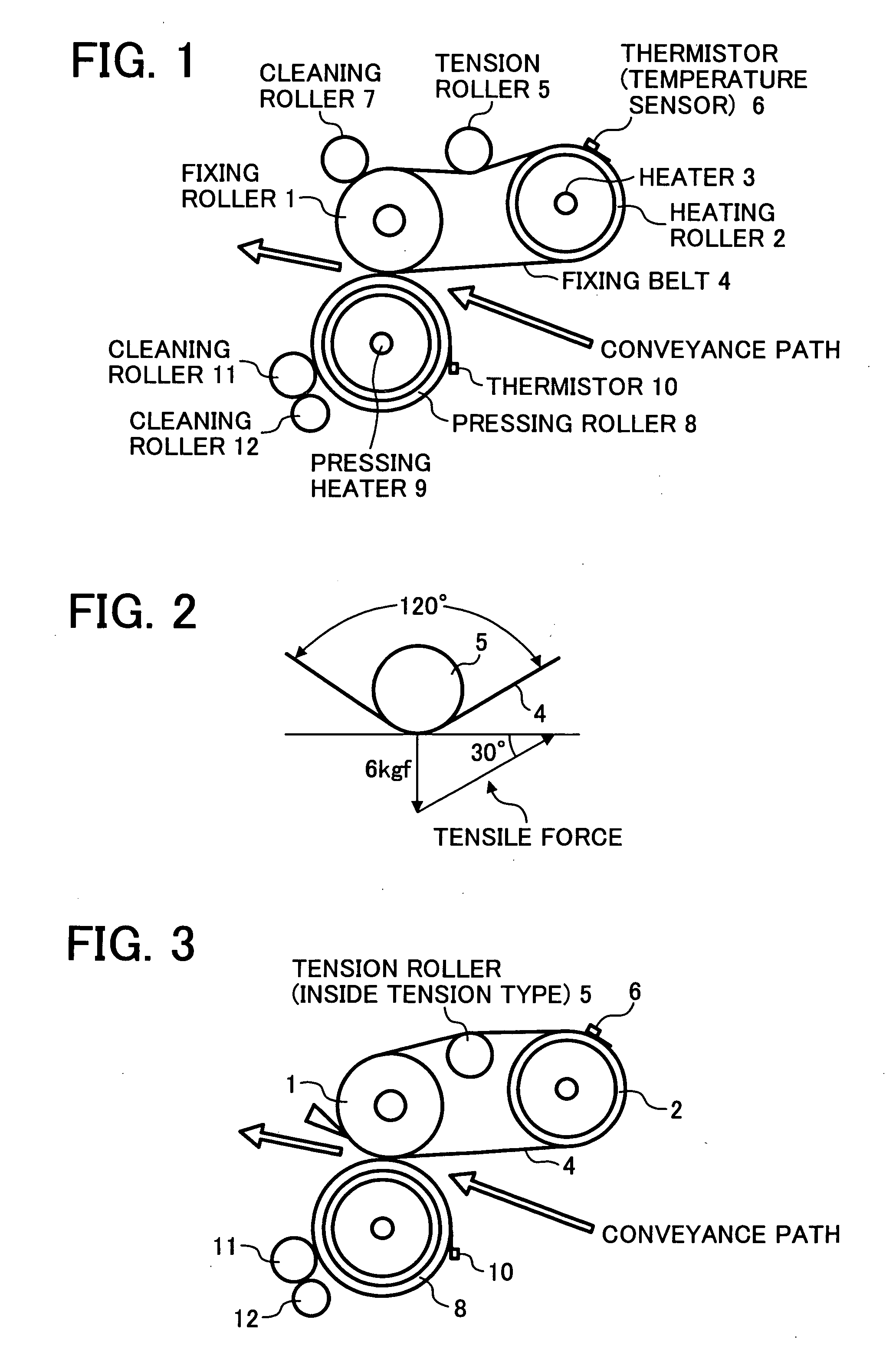

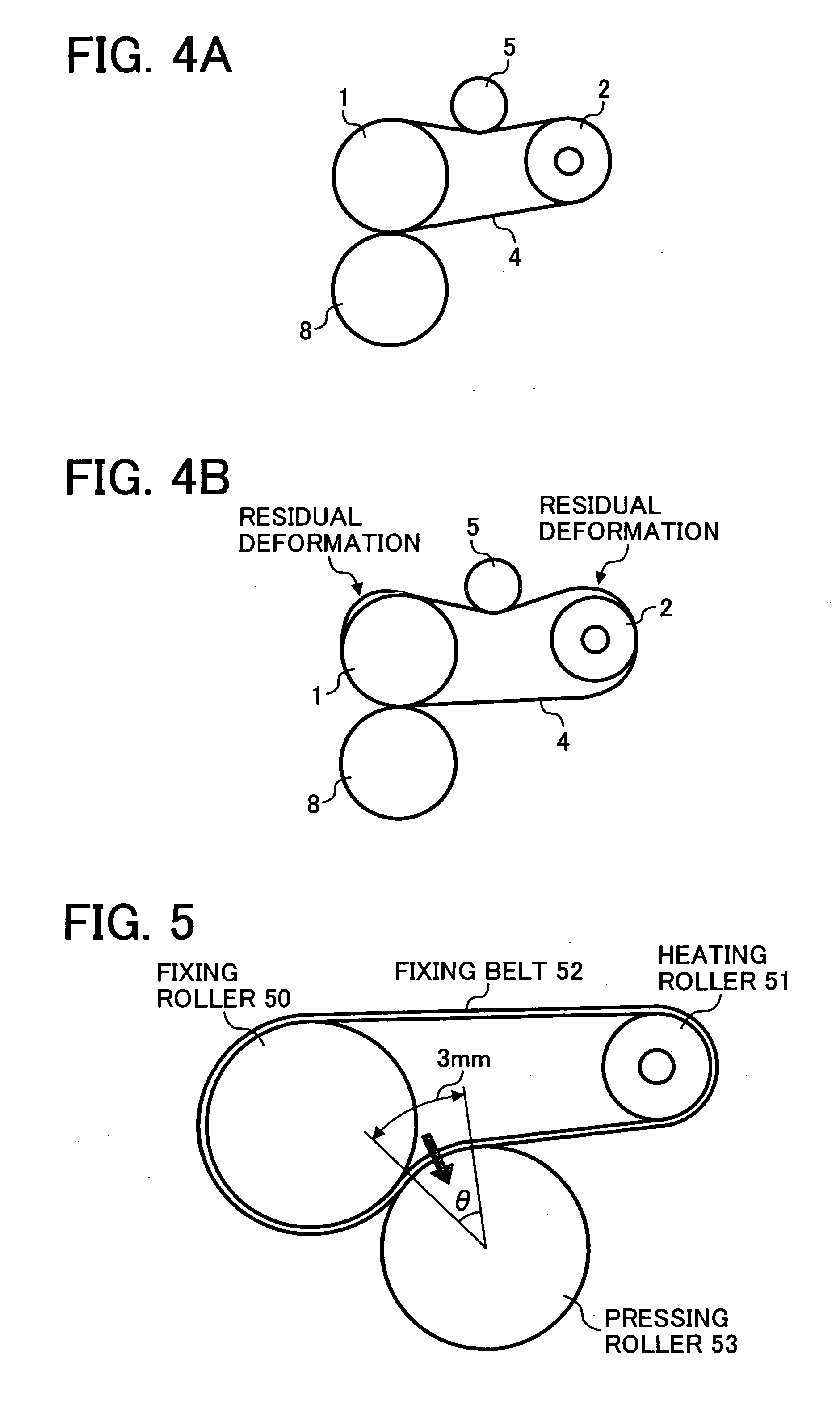

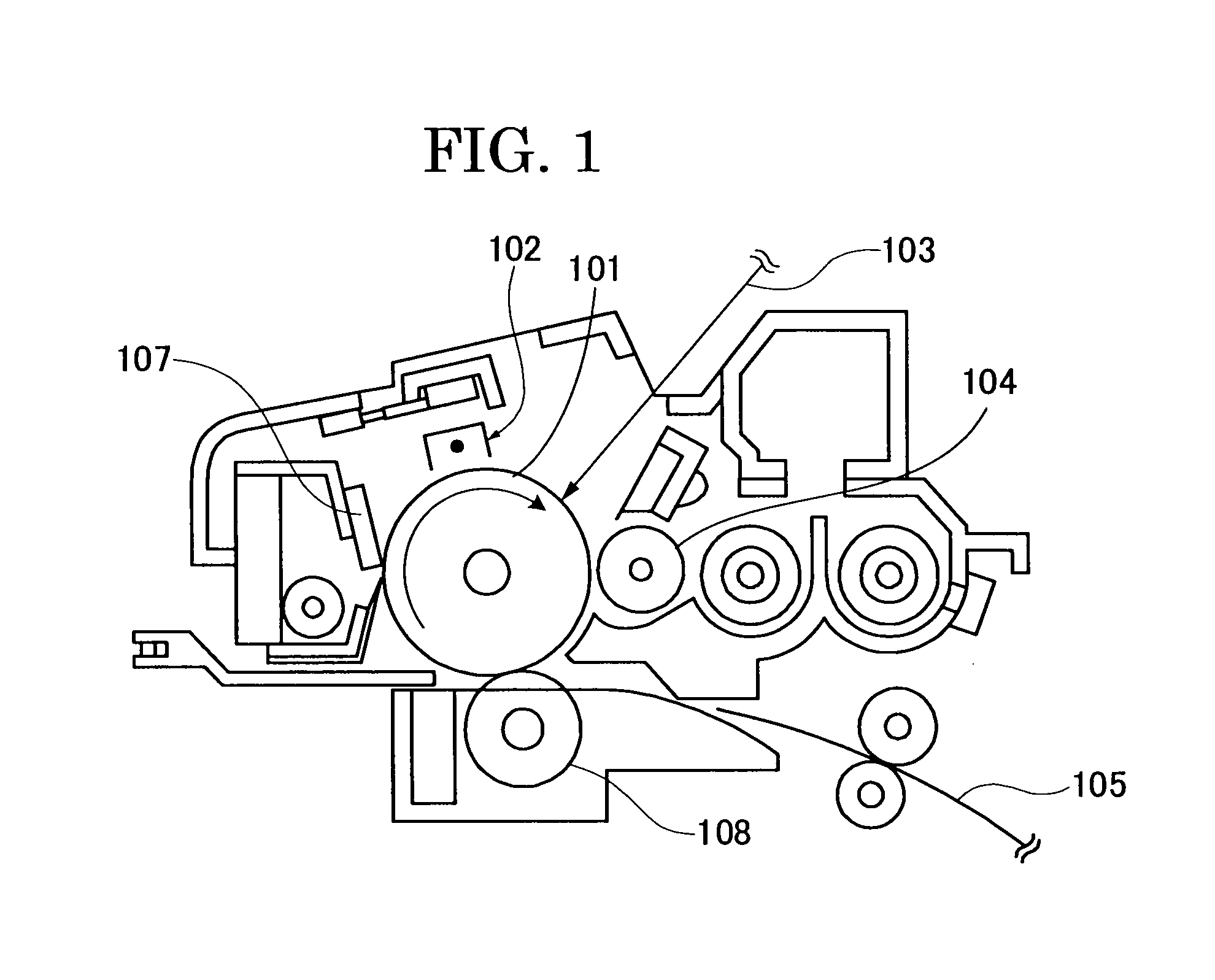

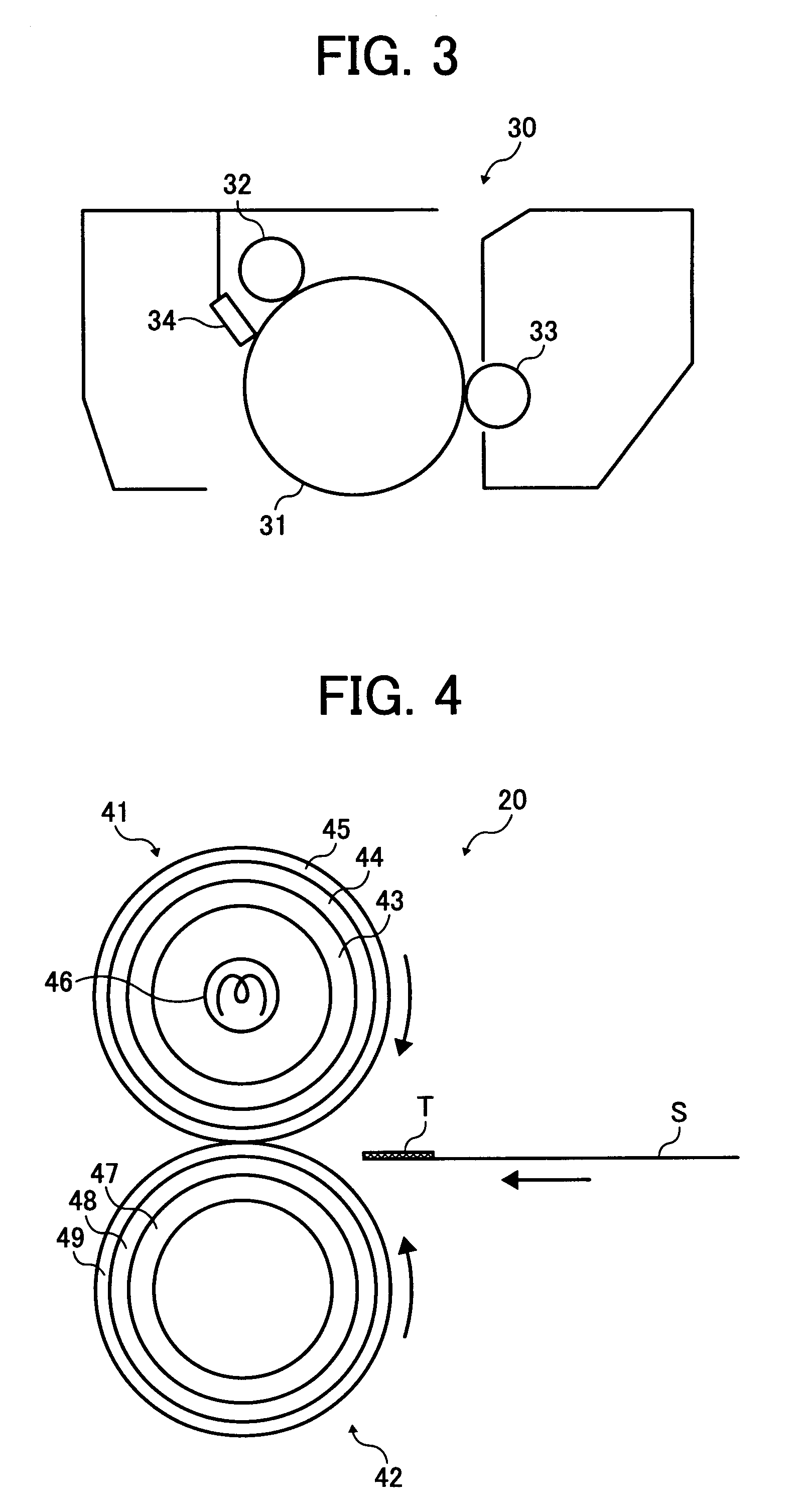

Belt fixing unit with heat-resisting resin base member and image forming toner for use in the fixing unit

A belt fixing unit, an image forming apparatus, and a toner material are disclosed capable of obviating undesirable fixing belt deformation and low image quality. The belt fixing unit includes a fixing roller, a heating roller, a fixing belt, and a pressing roller in contact with the fixing roller to form a fixing nip having the fixing belt intervening there between, the fixing belt including at least a base member formed of a heat-resisting resin having a thickness of 90 μm or smaller and acted upon by a tensile force of 0.49 N / mm or less. The toner is a low-melting point toner formed by subjecting a toner preparatory solution containing at least a prepolymer having a functional group containing a nitrogen atom, a polyester, a colorant and a releasing agent dispersed in an organic solvent to extension and / or crosslinking reactions in an aqueous medium.

Owner:RICOH KK

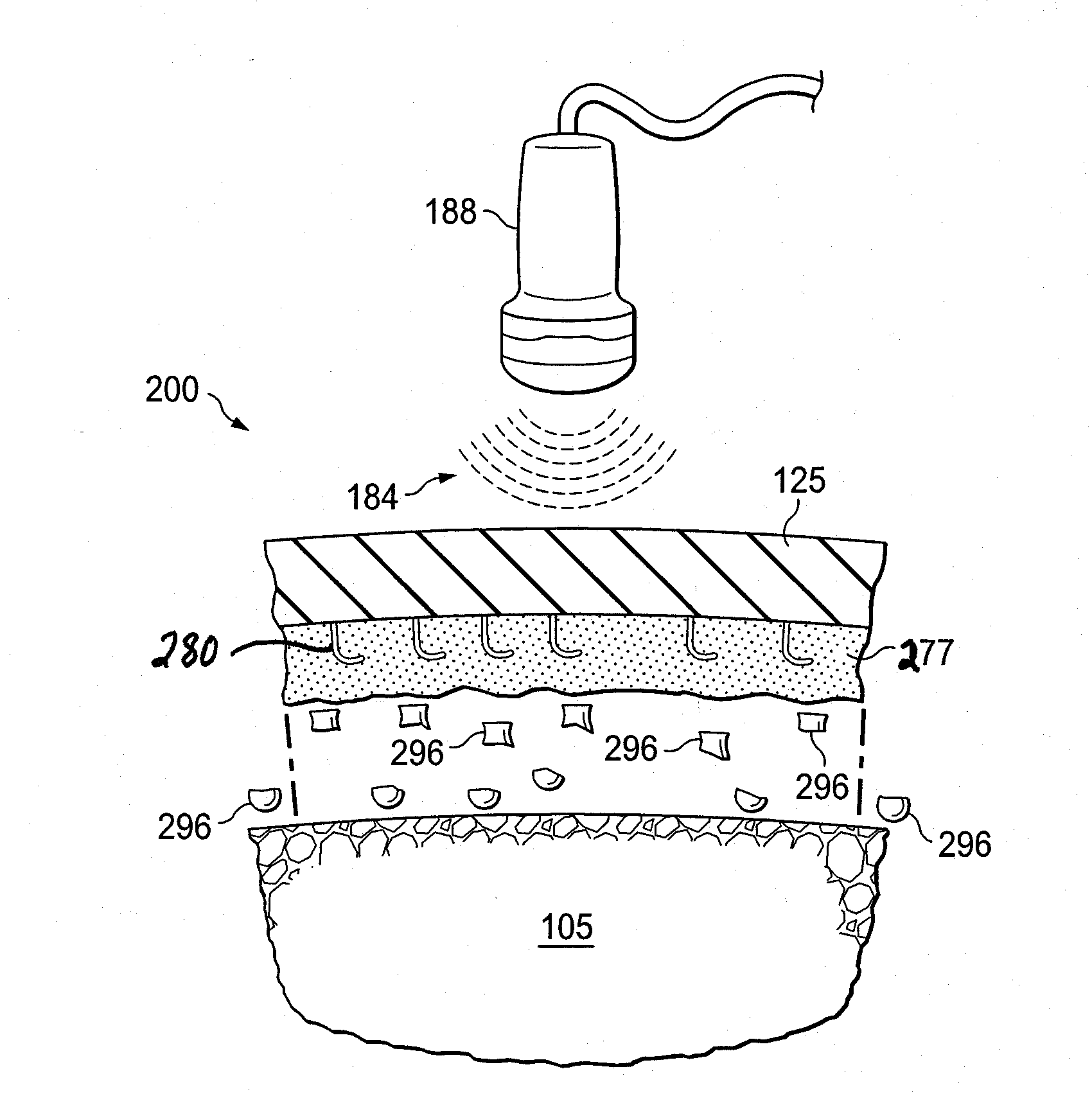

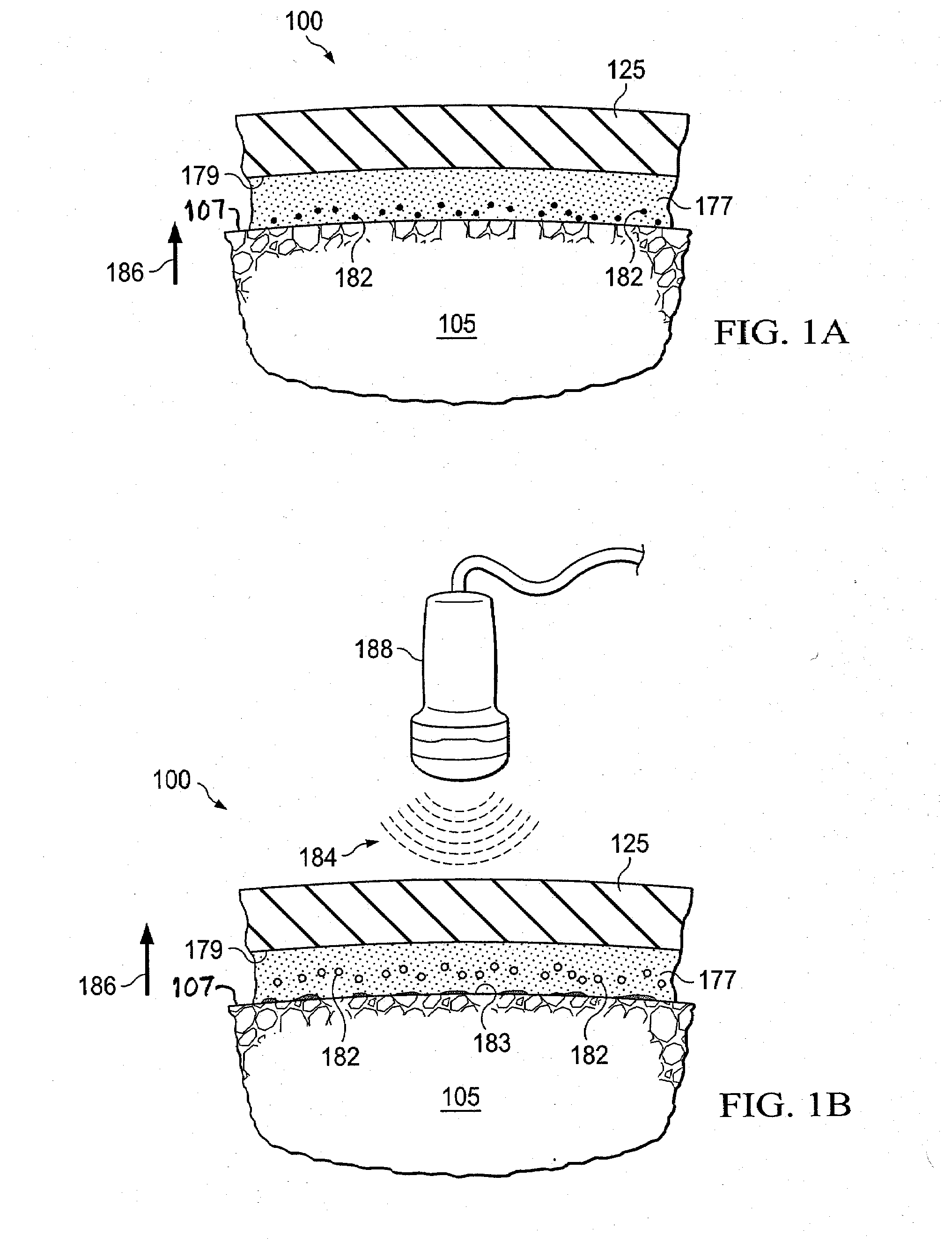

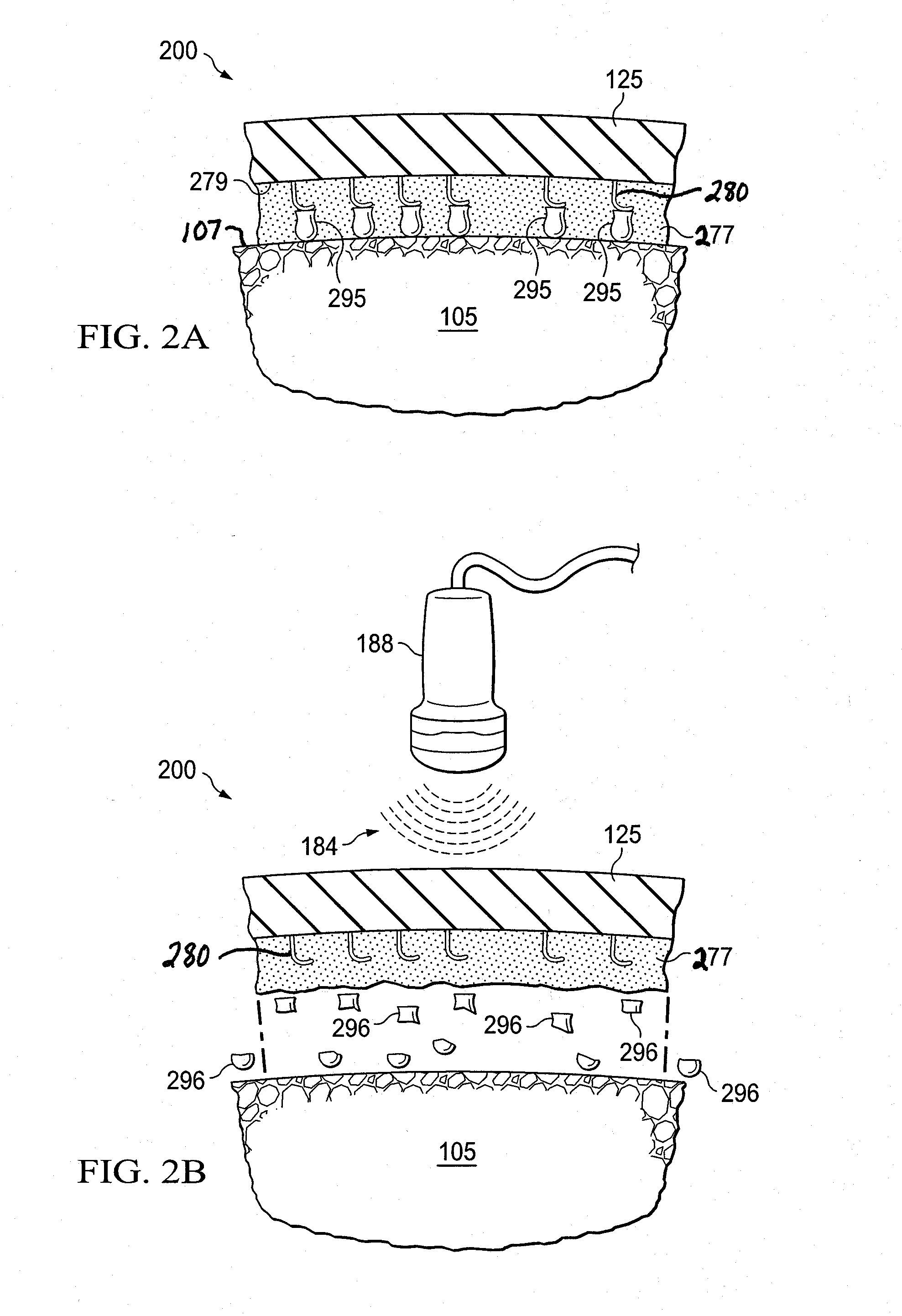

Ultrasonic assisted deposition of anti-stick films on metal oxides

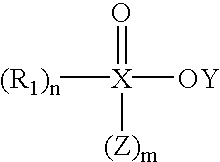

InactiveUS20020130441A1Inhibit entry and adhesionLiquid surface applicatorsOptical articlesUltrasonic assistedCasting mold

A method and apparatus for ultrasonic assisted deposition of a release agent onto a workpiece is disclosed. The release agent can be any fluorinated or non-fluorinated phosphorous-containing organic acid. The workpiece can be any workpiece desired to be coated with the release agent, such as a surface needing an anti-stick coating required in a plastic casting or injection mold. Metal oxide workpiece surfaces strongly bond to fluorinated phosphorus-containing organic acids. In particular, the present invention can deposit anti-stick coatings onto smooth or porous surfaces, such as anodized aluminum and its alloys, using ultrasonic assisted deposition

Owner:KORRY ELECTRONICS

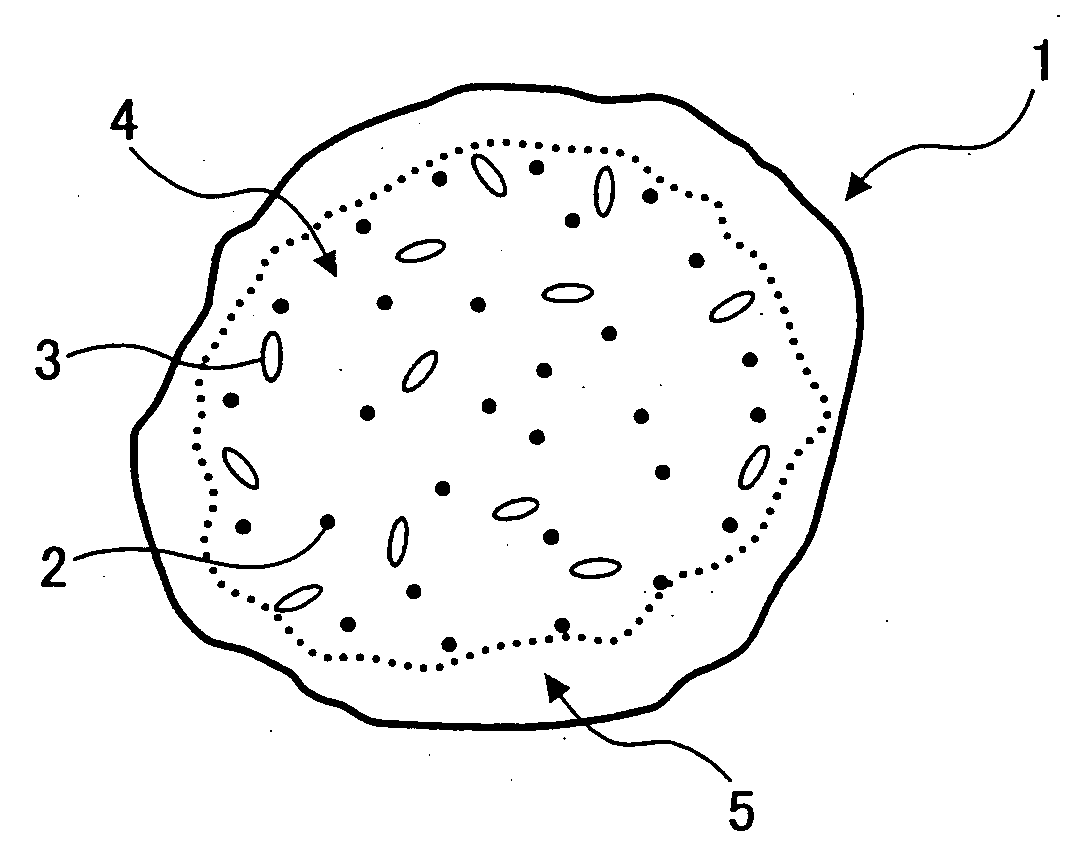

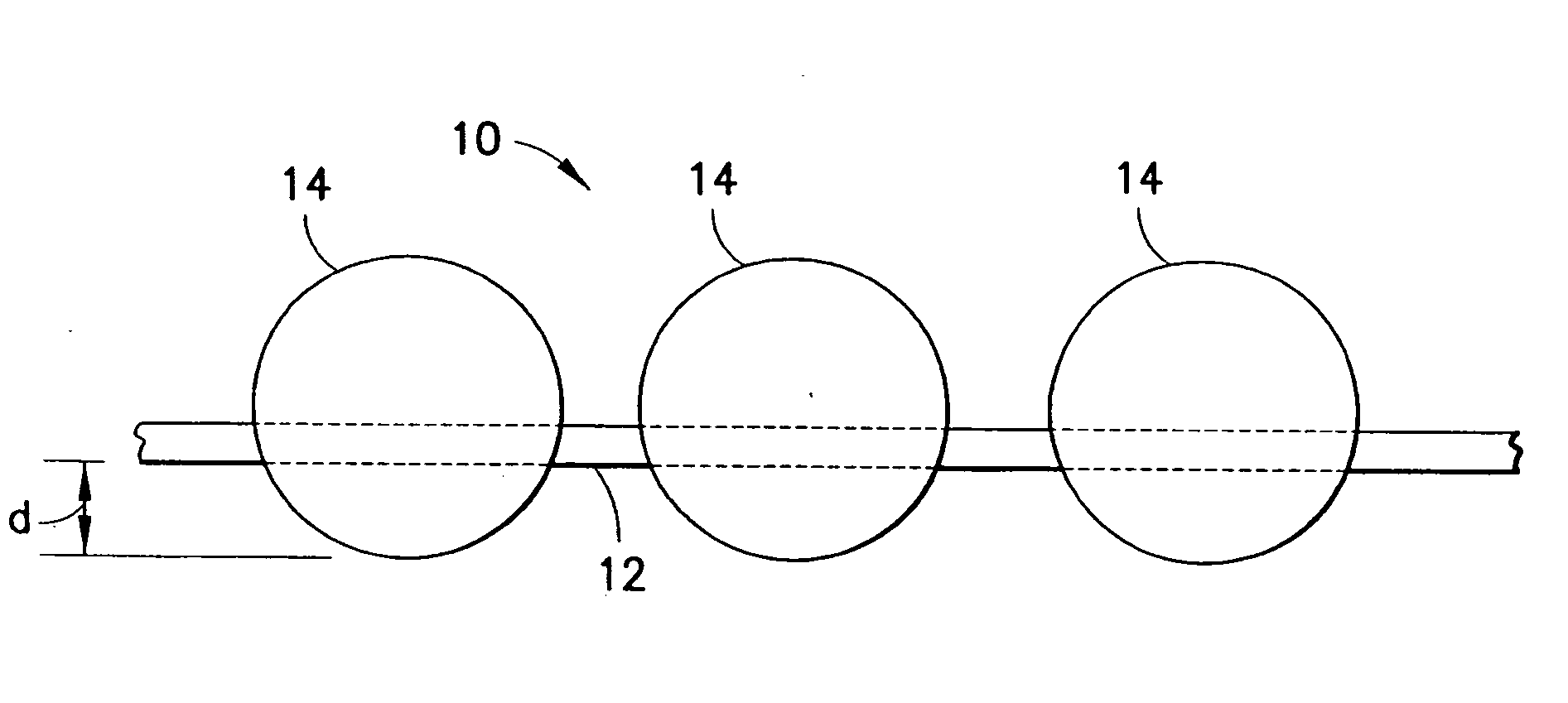

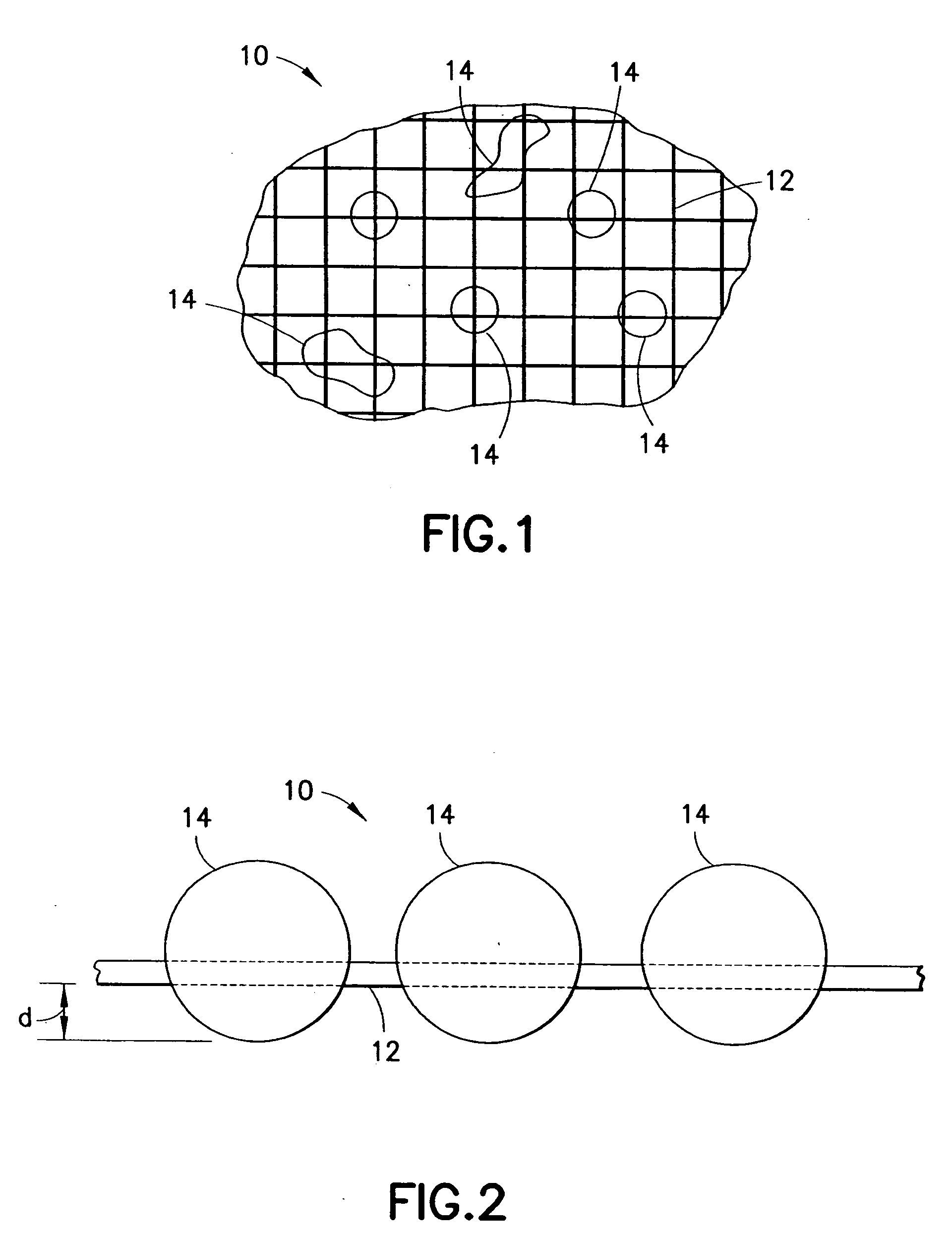

Toner and method of preparing the toner

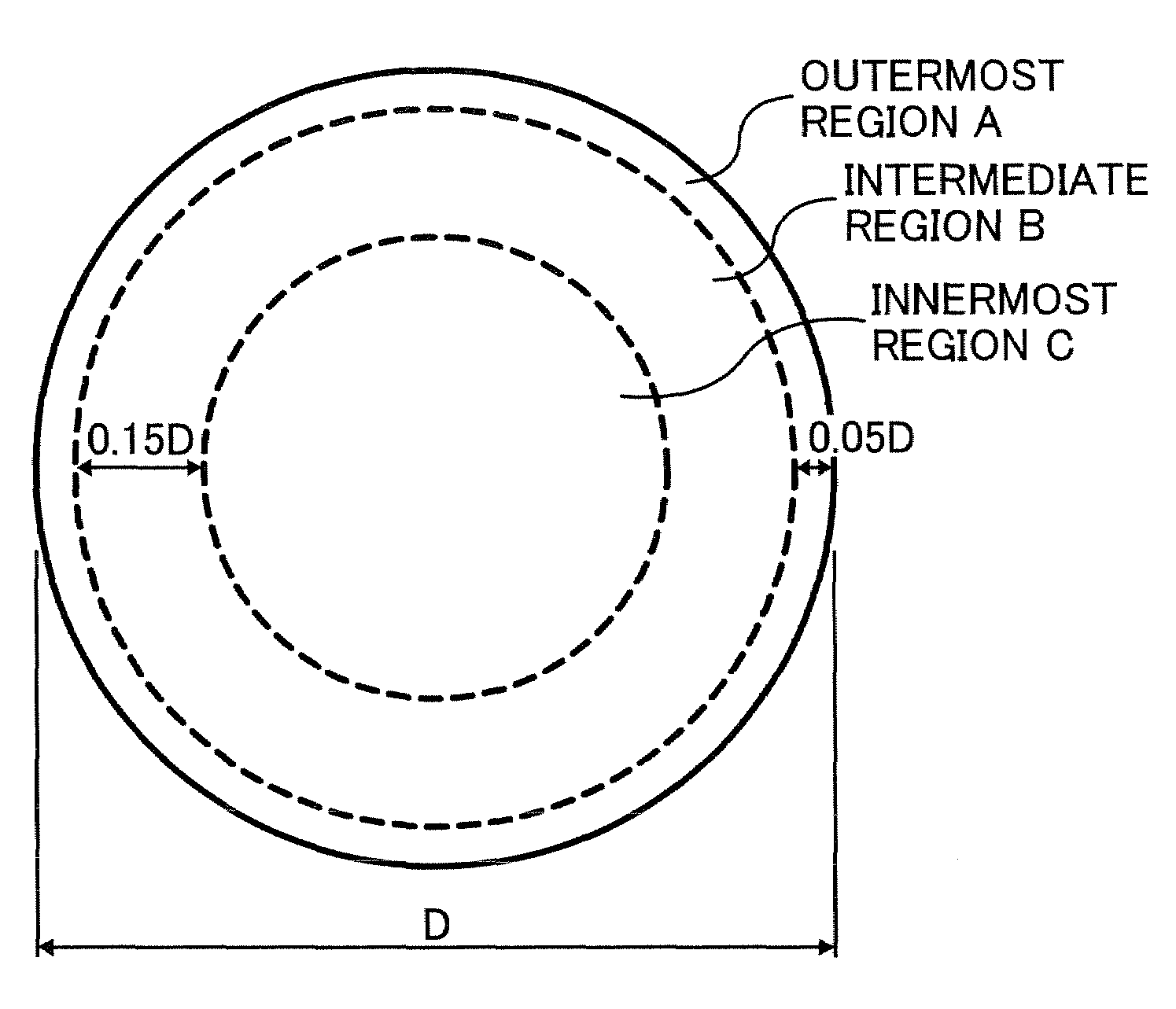

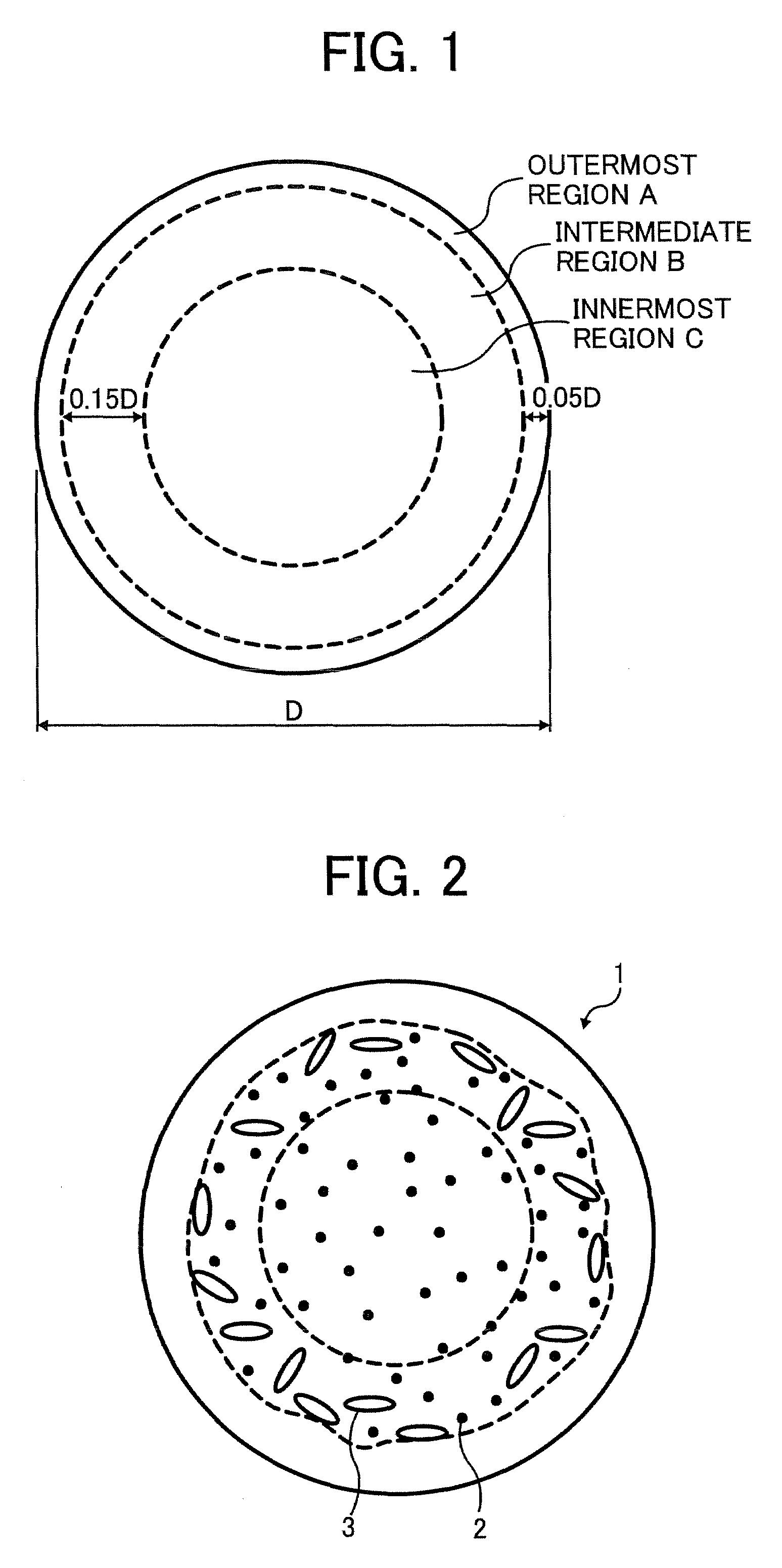

A toner is provided including a binder resin, a colorant, and a release agent, which has a volume average particle diameter (Dv) of from 3 to 9 μm, and wherein the binder resin and the release agent form a sea-island structure in which the island formed of the release agent is dispersed in the sea formed of the binder resin in a cross-sectional image of the toner obtained by a transmission electron microscope (TEM), and the following relationships are satisfied: IB>IA and IB>IC, wherein each of IA, IB, and IC represents an area ratio (%) of the island in an outermost region (A) of the cross-sectional image of the toner, an intermediate region (B) thereof located under the outermost region (A), and an innermost region (C) thereof located under the intermediate region (B); and a method of preparing the toner.

Owner:RICOH KK

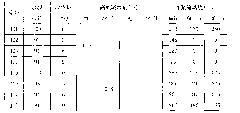

Hemostatic agents and devices for the delivery thereof

InactiveUS20070276308A1Minimize injuryEliminate feverNon-adhesive dressingsPlastersMedicineHemostatic Agent

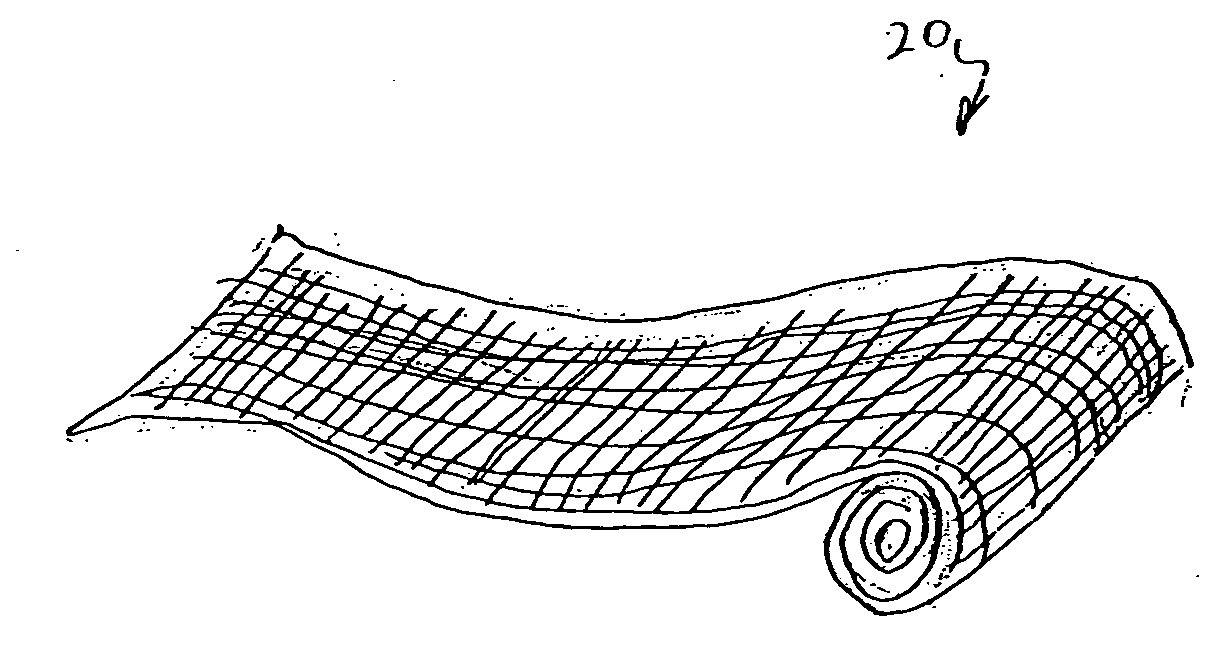

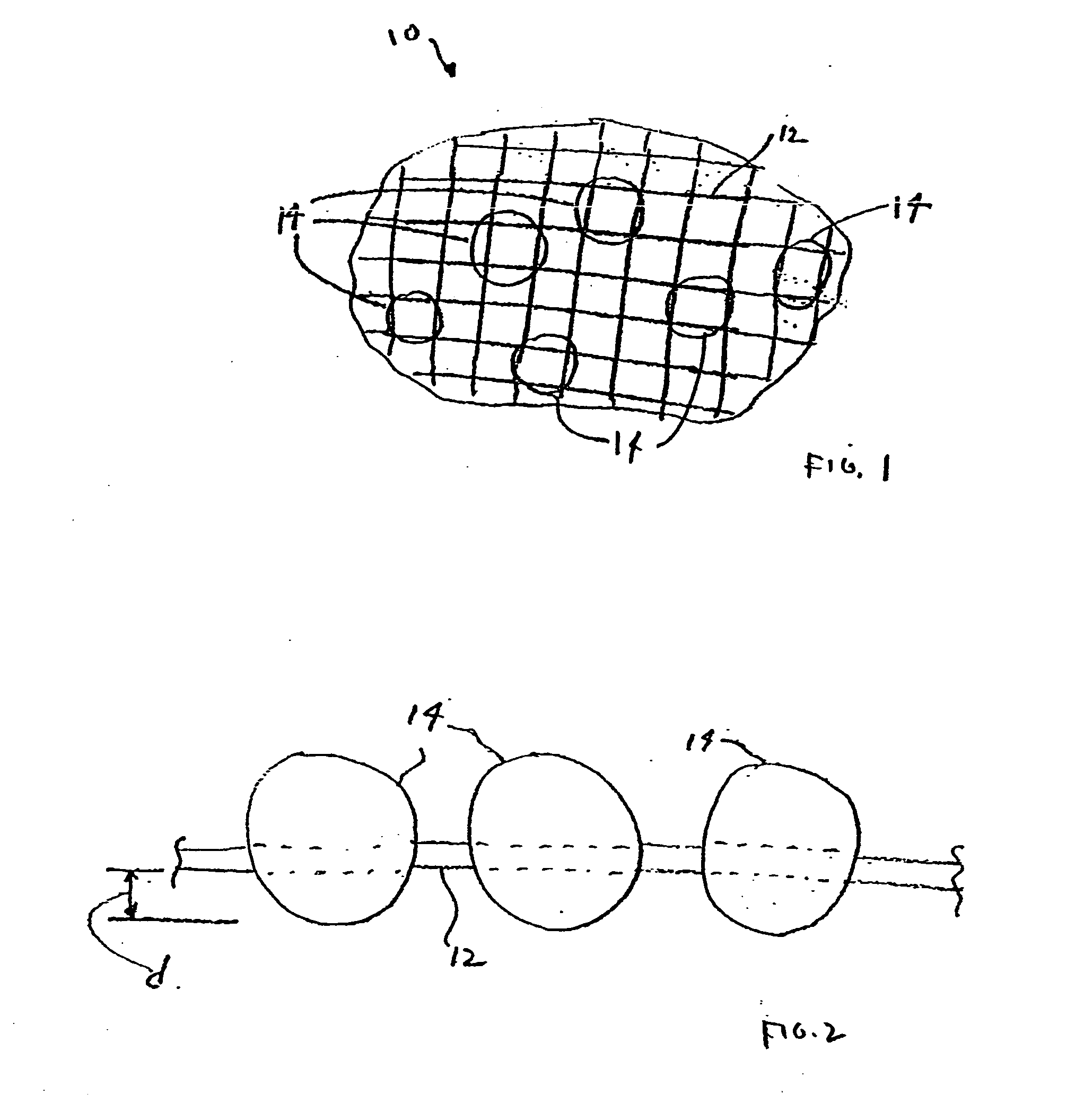

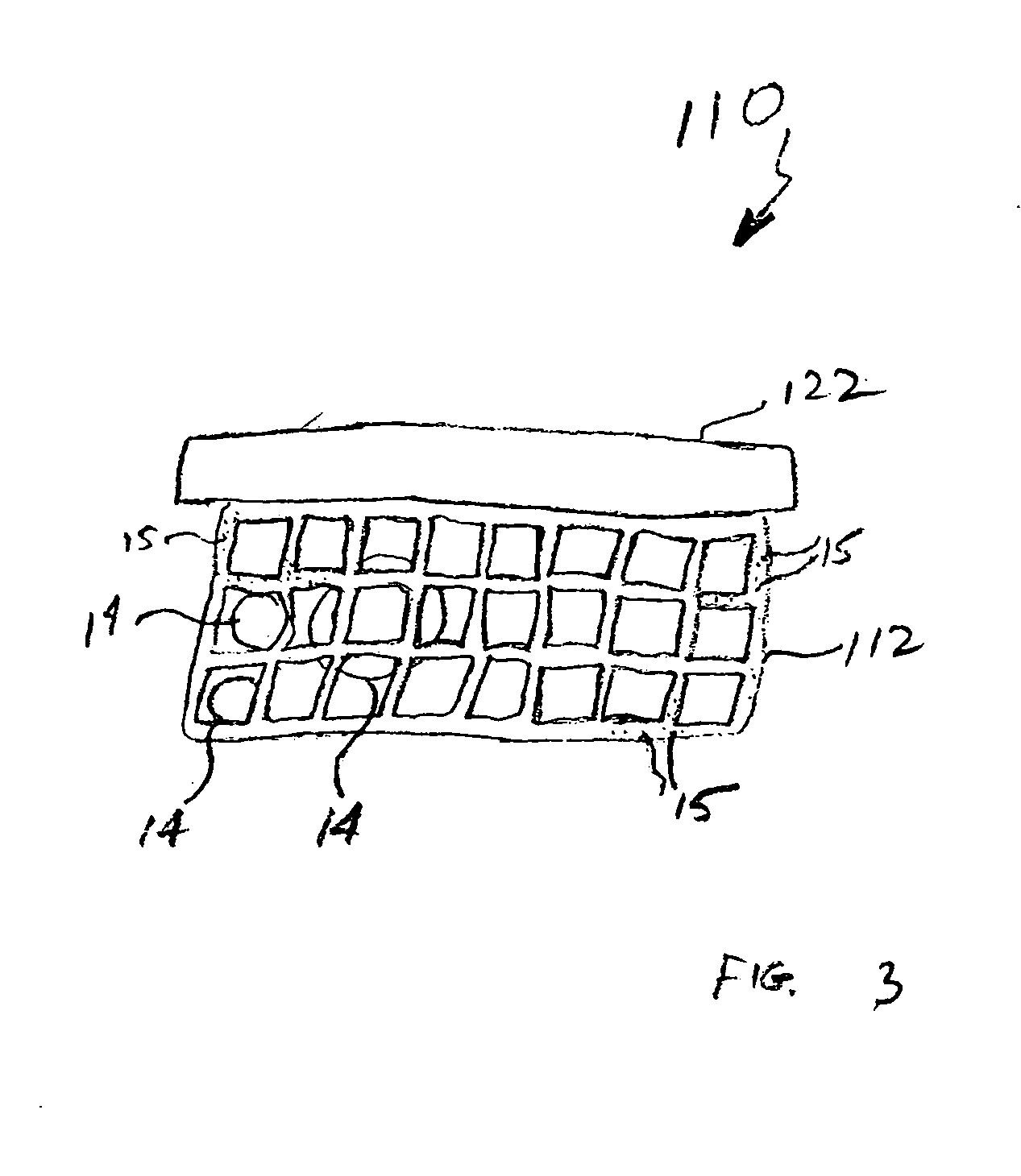

A hemostatic agent comprises diatomaceous earth in particle form. Devices for promoting hemostasis comprise diatomaceous earth in particle form and a receptacle for retaining the particles therein. The receptacle is defined by a mesh having openings therein. A hemostatic sponge comprises a substrate, diatomaceous earth disposed on the substrate, and a release agent disposed on the substrate. A hemostatic sponge may also comprise a film into which diatomaceous earth is incorporated, or it may comprise a substrate, diatomaceous earth disposed on the substrate, and a film disposed over the diatomaceous earth. A hemostatic sponge may also comprise a first substrate, diatomaceous earth disposed on the first substrate, and a second substrate disposed on the diatomaceous earth. When treating a bleeding wound using any of the foregoing devices, application of the device causes the diatomaceous earth to come into contact with blood to cause a clotting effect.

Owner:TELEFLEX LIFE SCI LTD

Surfactant compositions with enhanced soil release properties containing a cationic gemini surfactant

InactiveUS6358914B1Improve decontamination abilityImproves suspending/stabilizing propertyCationic surface-active compoundsOrganic detergent compounding agentsSURFACTANT BLENDCopolymer

Compositions are disclosed comprising a conventional surfactant, a cationic or amphoteric gemini surfactant and a polymeric soil release agent. The conventional surfactant comprises a hydrophilic group and a hydrophobic group. The gemini surfactant comprises two surfactant moieties attached to each other by a spacer moiety. Each surfactant moiety having at least one hydrophilic group and at least one hydrophobic group. Novel trimeric and tetrameric cationic gemini surfactants are also disclosed along with their use in combination with soil release polymer compositions that exhibit superior cleaning efficacies when incorporated in laundry and other cleaning detergent systems. Novel surfactant / soil release polymer compositions are also disclosed employing known cationic gemini surfactants. The polymeric soil release agent can be any conventional polymeric soil release agent, but preferably comprising PET-POET copolymer. The compositions are useful as surfactant additive packages, detergents and fabric softeners.

Owner:RHODIA OPERATIONS SAS

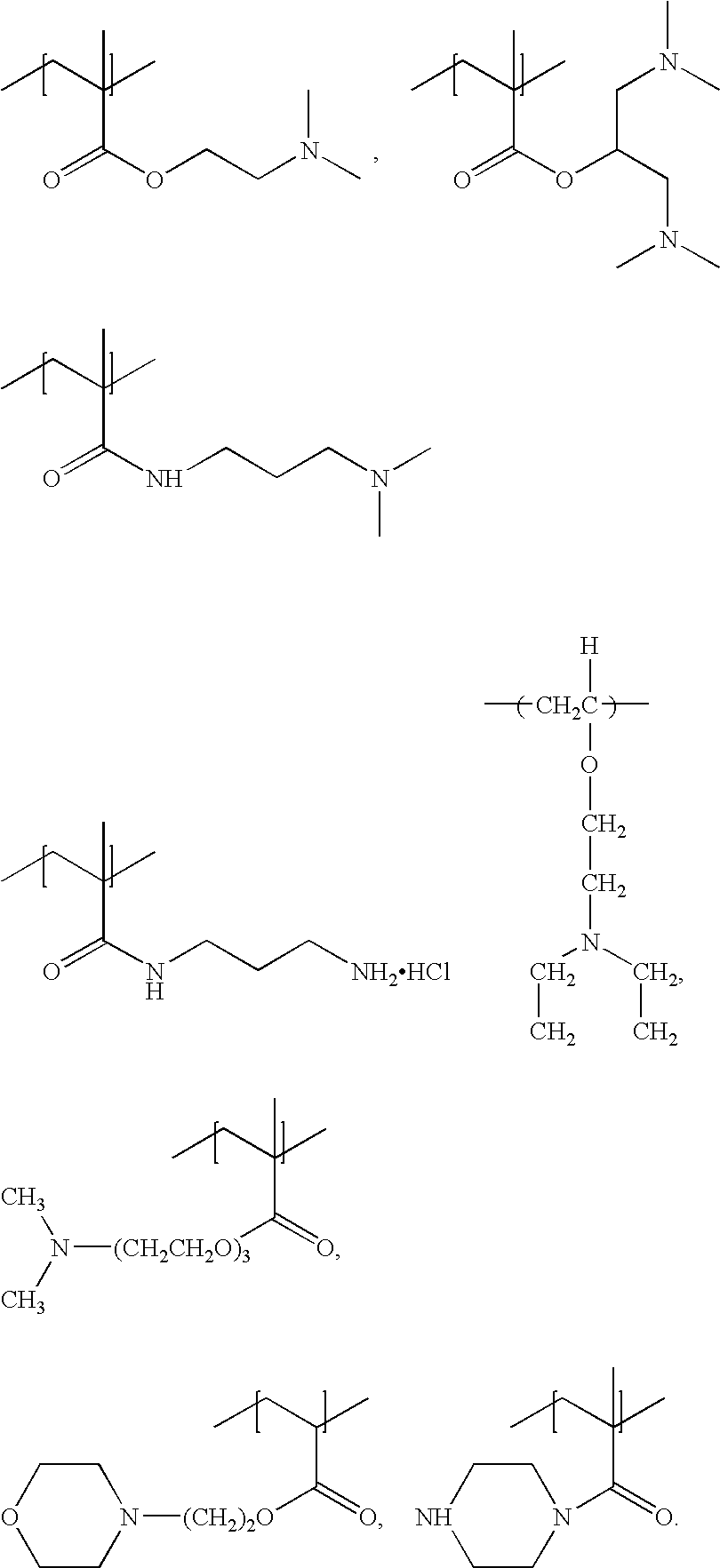

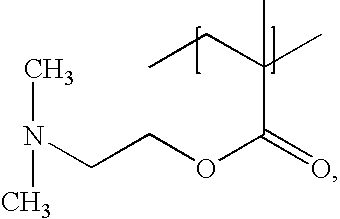

Block polymers, compositions and methods of use for foams, laundry detergents, shower rinses and coagulants

InactiveUS6864314B1Extended suds suds durationExtended suds volume sudsCosmetic preparationsNon-fibrous pulp additionShaving creamSurface cleaning

The present invention relates to a block polymeric material. Typically the block polymer comprises units capable of having an average cationic charge density of about 15 or less, preferably 5 or less, more preferably from about 0.05 to about 5, even more preferably from about 0.05 to about 2.77, even more preferably from about 0.1 to about 2.75, most preferably from about 0.75 to about 2.25 units per 100 daltons molecular weight at a pH of from about 4 to about 12. The polymeric material is a suds enhancer and a suds volume extender for personal care products such as soaps and shampoos. The compositions have increased effectiveness for preventing re-deposition of grease during hand and body washing. The polymers are also effective as a soil release agent in fabric cleaning compositions. The polymeric material is also effective in oil well treating foam, fire-fighting foam, hard surface cleaning foam, shaving cream, post-foaming shaving gel, dephiliatories and as a coagulant / retention aid for titanium dioxide in paper making.

Owner:SOLVAY USA

Injection molding method for neutral and acidic-group containing (meth)acrylate copolymers

InactiveUS20020160042A1Reduce contentOrganic dyesPharmaceutical non-active ingredientsMeth-Additive ingredient

The invention relates to a process for producing mouldings by injection moulding, the steps in the process being A) Melting a mixture made from a) a (meth)acrylate copolymer composed of from 40 to 100% by weight of free-radical-polymerized C1-C4-alkyl esters of acrylic or methacrylic acid and from 0 to 60% by weight of (meth)acrylate monomers having an anionic group in the alkyl radical, where the copolymer comprises b) from 0.1 to 3% by weight of a release agent, and, where appropriate, the mixture may comprise c) from 0 to 50% by weight of a drier, d) from 0 to 30% by weight of a plasticizer, e) from 0 to 100% by weight of additives or auxiliaries, f) from 0 to 100% by weight of an active pharmaceutical ingredient, g) from 0 to 20% by weight of another polymer or copolymer, where the amounts given for components b) to g) are based on the (meth)acrylate copolymer a) and the mixture prior to melting has a content of more than 0.5% by weight of low-boiling constituents with vapour pressure of at least 1.9 bar at 120° C., B) Devolatilizing the mixture in the thermoplastic state at temperatures of at least 120° C., thereby lowering to not more than 0.5% by weight the content of the low-boiling constituents with vapour pressure of at least 1.9 bar at 120° C., C) Injecting the molten and devolatilized mixture into the mould cavity of an injection mould, the temperature of the mould cavity being below the glass transition temperature of the (meth)acrylate copolymer by at least 10° C., cooling the molten mixture, and removing the resultant moulding from the mould.

Owner:PFIZER INC +1

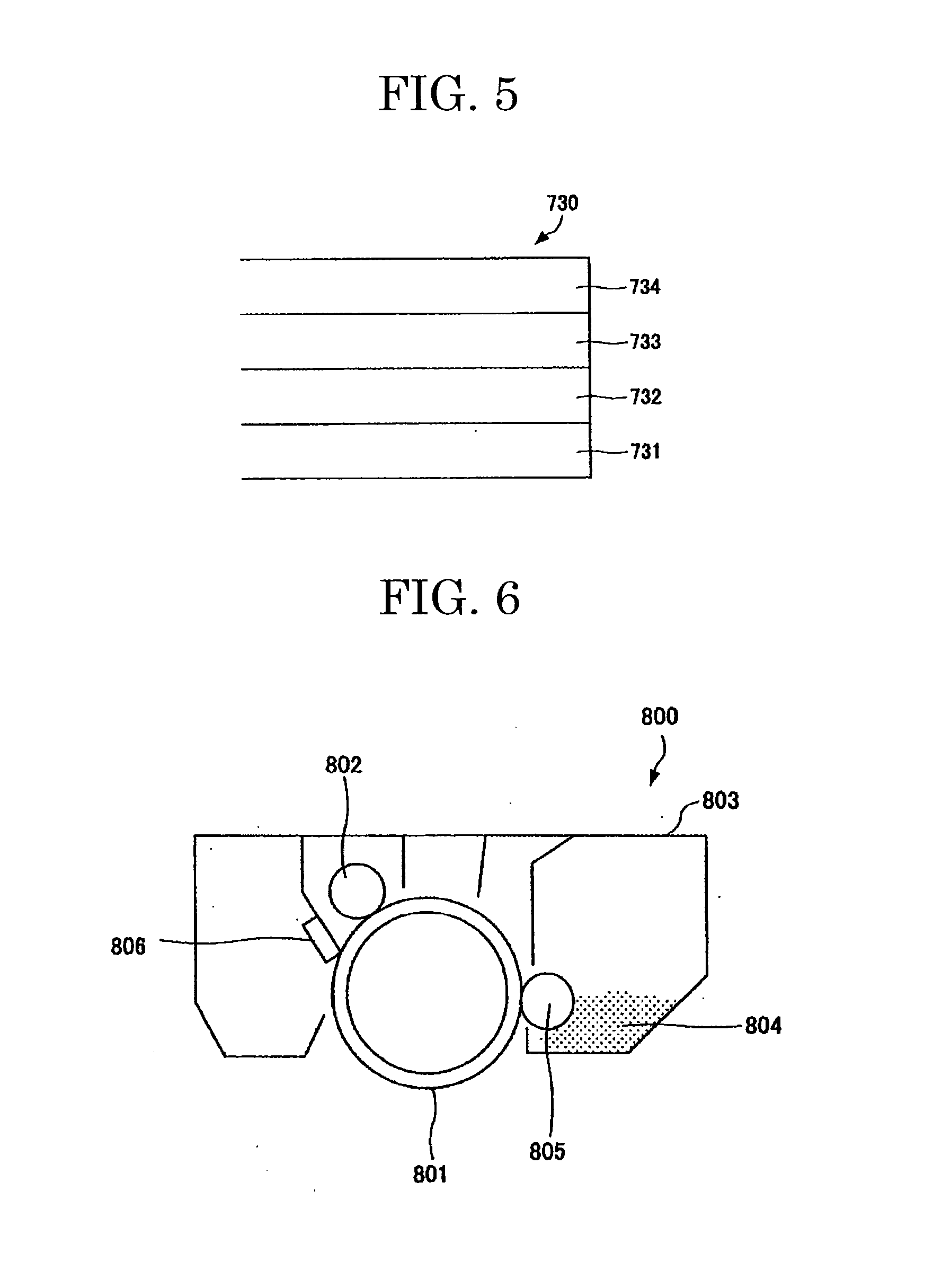

Belt fixing unit and image forming toner for use in the fixing unit

ActiveUS20050163543A1Reduce eliminateElectrographic process apparatusDevelopersPolyesterOrganic solvent

A belt fixing unit, an image forming apparatus, and a toner material are disclosed capable of obviating undesirable fixing belt deformation and low image quality. The belt fixing unit includes a fixing roller, a heating roller, a fixing belt, and a pressing roller in contact with the fixing roller to form a fixing nip having the fixing belt intervening there between, the fixing belt including at least a base member formed of a heat-resisting resin having a thickness of 90 μm or smaller and acted upon by a tensile force of 0.49 N / mm or less. The toner is a low-melting point toner formed by subjecting a toner preparatory solution containing at least a prepolymer having a functional group containing a nitrogen atom, a polyester, a colorant and a releasing agent dispersed in an organic solvent to extension and / or crosslinking reactions in an aqueous medium.

Owner:RICOH KK

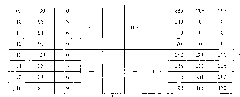

Clay-based hemostatic agents and devices for the delivery thereof

ActiveUS20070275073A1Minimize injuryEliminate feverAntibacterial agentsPowder deliveryBandageMaterials science

A device for promoting the clotting of blood comprises a clay material in particle form and a receptacle for containing the clay material. At least a portion of the receptacle is defined by a mesh. Another device comprises a gauze substrate and a clay material disposed on the gauze substrate. Another device is a bandage comprising a substrate, a mesh mounted on the substrate, and particles of a clay material retained in the mesh. A hemostatic sponge comprises a substrate, a hemostatic material disposed on a first surface of the substrate, and a release agent disposed on a second surface of the substrate. The release agent is disposed on the wound-contacting surface of the substrate. When treating a bleeding wound, application of the hemostatic sponge causes at least a portion of the hemostatic material to come into contact with blood through the release agent and through the substrate.

Owner:TELEFLEX LIFE SCI LTD

Controlled/slow release polycarboxylate water reducing agent for inhabiting aggregate mud content influence and preparation method thereof

InactiveCN101798197ARich microporous structureLarge specific surface areaCarboxylic acidWater reducer

The invention relates to a controlled / slow release polycarboxylate water reducing agent for inhabiting the aggregate mud content influence, which is characterized in that the controlled / slow release polycarboxylate water reducing agent comprises the following ingredients by weight parts: 75 to 95 parts of polycarboxylate water reducing agents, 2 to 5 parts of retarders and 5 to 25 parts of slow release agents. Because natural zeolite powder has the characteristics of microporous structure, large specific surface area and strong surface absorption capability, the natural zeolite powder can be used as the slow release agents. The invention utilizes the natural zeolite powder as the slow release agents, and the surface of the natural zeolite powder can absorb a large number of polycarboxylate water reducing agents and a small number of retarders after the natural zeolite powder is mixed with the polycarboxylate water reducing agents and the retarder. Clay can preferentially absorb the natural zeolite powder with strong surface absorption capability when the natural zeolite powder is doped into concrete to be stirred with gelled materials, aggregates and water, and the excessive absorption of the polycarboxylate water reducing agent by the clay is avoided, so the absorption of the polycarboxylate water reducing agents on cement grains and the dispersing effect taking are ensured.

Owner:NANCHANG UNIV

Toner and image forming apparatus using the toner

InactiveUS6846604B2Good reproducibilityHigh color reproductionElectrographic process apparatusDevelopersCharge controlEngineering

A toner composition including toner particles including mother toner particles, which include a binder resin, a colorant and a release agent, and a charge controlling agent which is located on a surface of the mother toner particles and fixed thereon, wherein the toner particles have a spherical degree of from 0.960 to 1.000 and a specific surface area of from 0.70 to 2.5 m2 / g. The toner composition optionally includes an external additive which is present on the surface of the toner particles.

Owner:RICOH KK

Extruded gluten based pet chew bodies

InactiveUS20050214349A1Facilitate easeEasy to storeAnimal feeding stuffAccessory food factorsFiberAdditive ingredient

A method of forming solid gluten-based pet chew is provided wherein a gluten mixture is heated to a maximum temperature of up to about 80° C. to create a substantially homogeneous and flowable mixture under extrusion processing conditions. The formulation includes from about 40-90% by weight of grain protein, from about 10-40% by weight plasticizer, and at least about 0.01 by weight of a reducing agent such as sodium bisulfite for cleaving disulfide bonds present in the grain protein. Dental health agents including an acidulent and a chelator are added to promote good dental health. Optional ingredients such as fillers, fiber, lubricant / mold release agents and colorants can also be used. The formulations can be processed in extrusion or injection molding equipment.

Owner:DERMAPET

Method of molding plastic semiconductor packages

InactiveUS6309916B1Good package releaseImprove adhesionSemiconductor/solid-state device detailsConfectioneryShell moldingSemiconductor package

In the manufacture of semiconductor packages having molded plastic bodies, the plating of all of the surfaces of the molding tool that comes into contact with the molten resin during molding with a nodular thin dense chromium ("NTDC") coating prevents the surfaces from adhering to the package body and ensures good package release, without formation of cracks or craters in the package body. This, in turn, permits the amount of both release agents and adhesion promoters used in the molding compound to be substantially reduced, or eliminated altogether, thereby resulting in a package body having improved strength and adhesion with the components of the package, and hence, an improved resistance of the package body to the propagation of cracks and its subsequent penetration by moisture.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

Method for preparing polylactic acid foam material

The invention relates to a preparation method for an expanded material of polylactic acid; the polylactic acid, a tackifying modifier, a chemical inhibitor, a vesicant, a foaming accessory ingredient, a abscess stabilizer and a parting agent are mixed under high temperature according to a certain proportion to obtain a basic mixture; then the basic mixture is arranged in a die to carry out moulding foaming on a vulcanizing machine with a certain temperature and a certain pressure to manufacture the foaming material of polylactic acid. The foaming material of polylactic acid manufactured by the method of the invention has excellent performances of being biodegradable, controllable density, easy processing as well as good barrier property, has similar foaming shaping performance and shock-absorbing capacity with polystyrene, can replace the foaming material of polystyrene, can be used as the materials for heat isolating, sound isolating and shock absorption and has broad application in the fields of cushion packaging, transportation, electric apparatus, refrigeration, agriculture and forestry and gardening.

Owner:SHANGHAI JIAO TONG UNIV

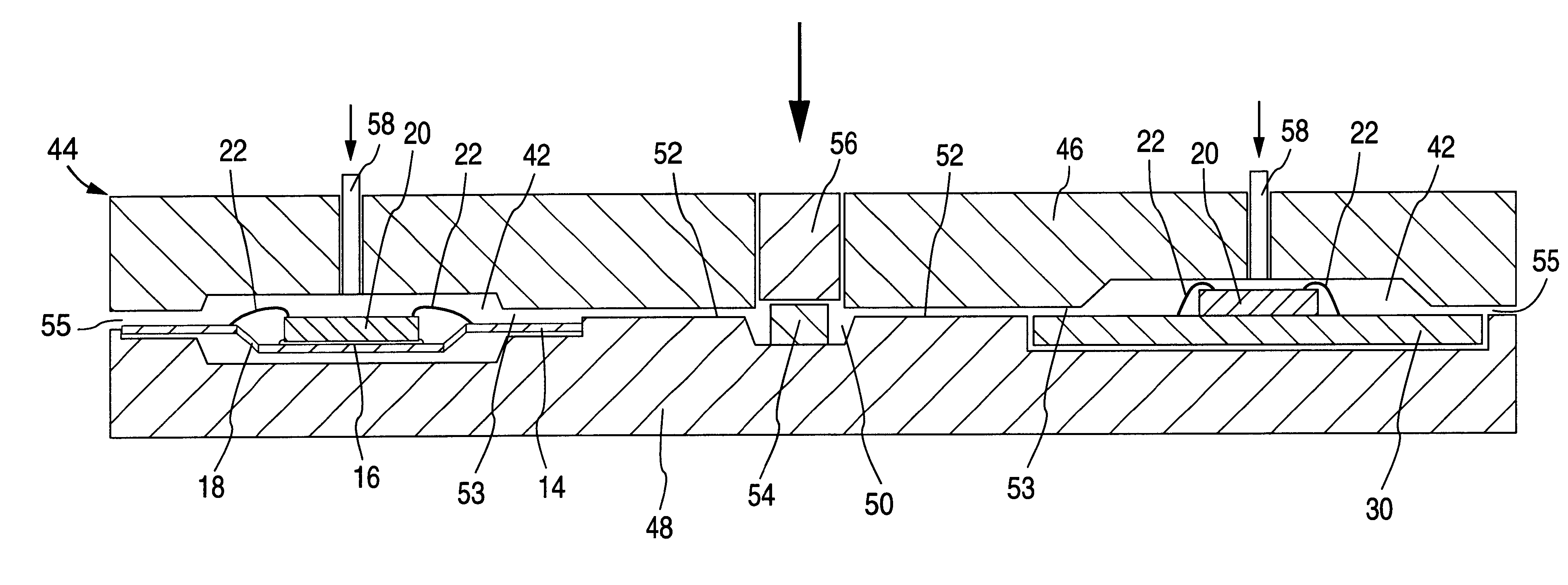

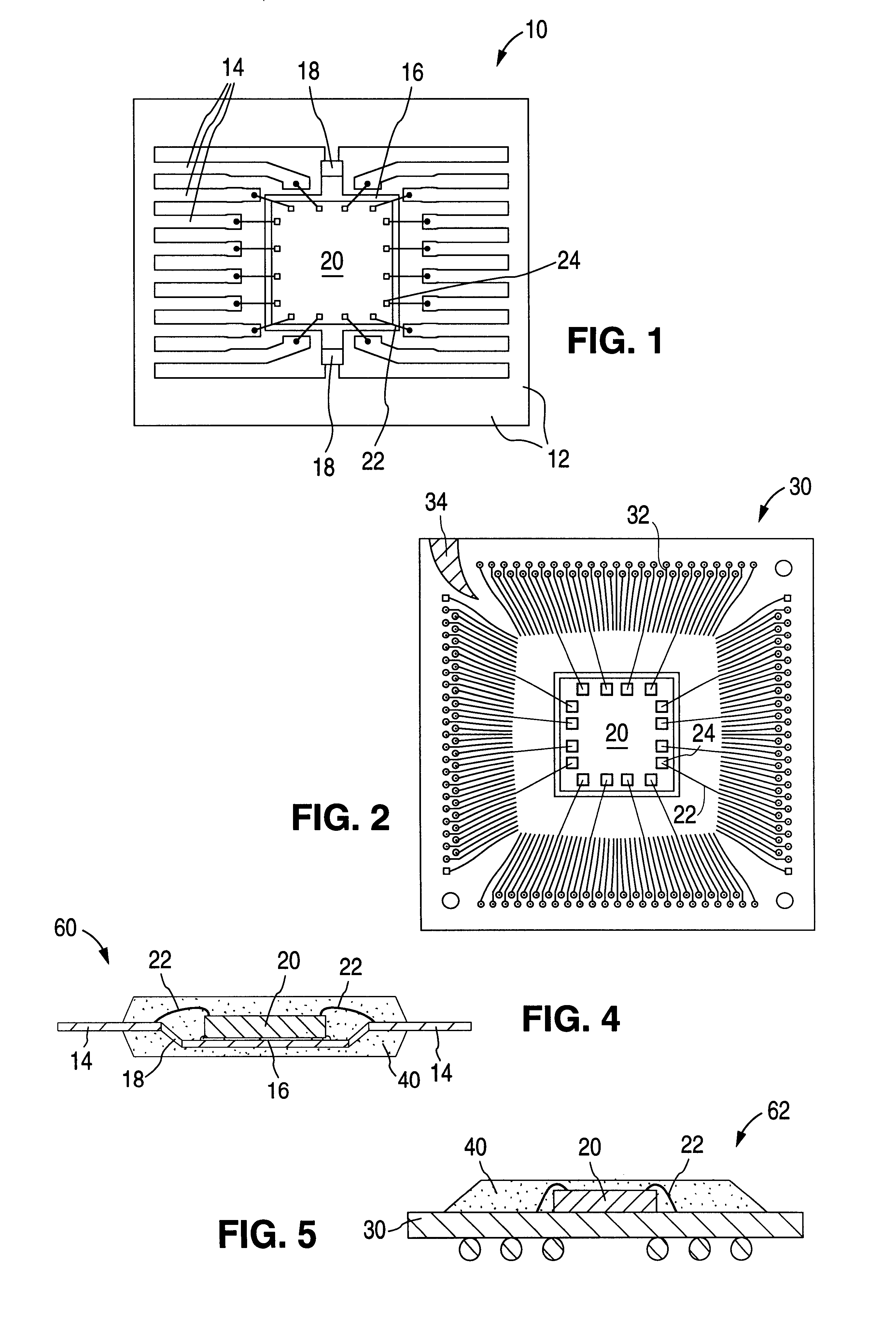

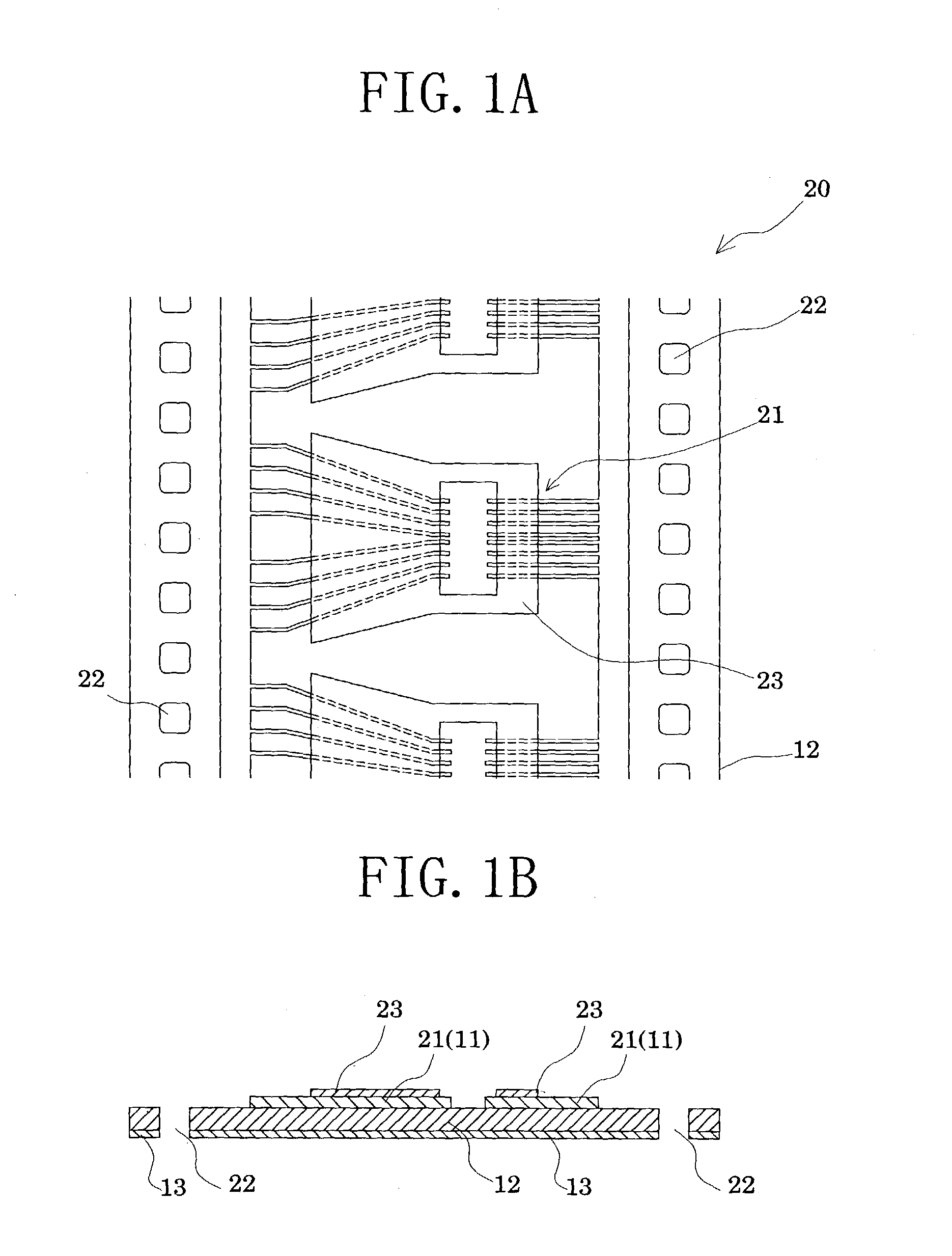

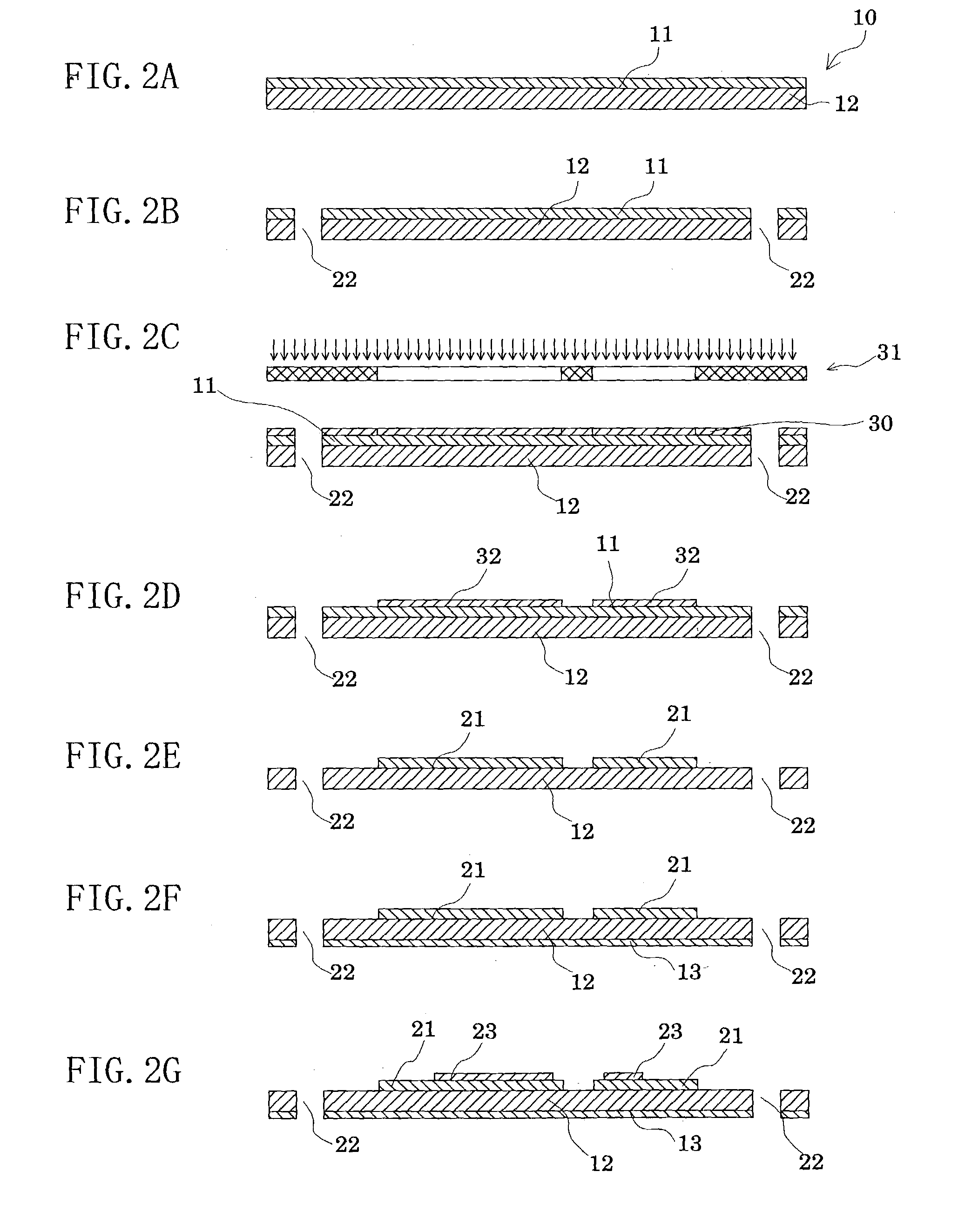

COF flexible printed wiring board and method of producing the wiring board

InactiveUS7173322B2Improve reliabilityIncrease productivityPrinted circuit assemblingDomestic cooling apparatusSilane compoundsElectrical conductor

The present invention provides a COF flexible printed wiring board whose insulating layer is not melt-adhered to a heating tool, to thereby enhance reliability and productivity of a semiconductor chip mounting line, and also provides a method of producing the COF flexible printed wiring board. The COF flexible printed wiring board contains an insulating layer, a wiring pattern, on which a semiconductor chip being mounted, formed of a conductor layer provided on at least one side of the insulating layer and a releasing layer, wherein the releasing layer is formed from a releasing agent containing at least one species selected from a silane compound and silica sol and is provided on a surface of the insulating layer, which is opposite to the mounting side of the semiconductor chip.

Owner:MITSUI MINING & SMELTING CO LTD

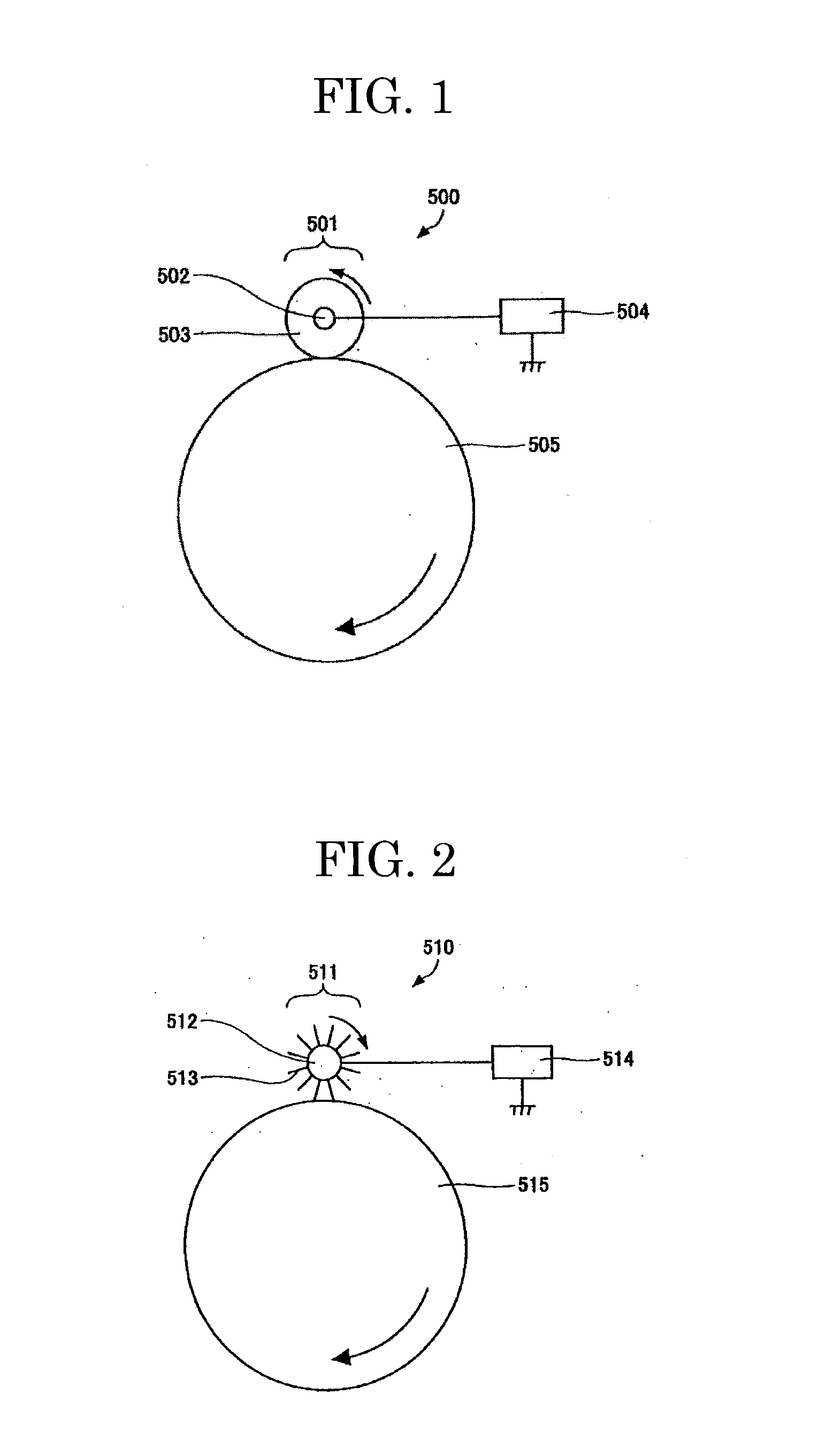

Toner, and image forming method and apparatus and process cartridge using the toner

A toner including toner particles including a binder resin, a colorant and a release agent, and an external additive including a first particulate inorganic material having a formula of MgxSiyOx+2y where each of x and y is an integer, and a number average secondary particle diameter of from 0.02 μm to 2 μm, wherein the first atomic ratio (Mg / Si) s in a surface portion of the first particulate inorganic material is not greater than (preferably less than) the second atomic ratio (Mg / Si)e in the entire first particulate inorganic material. Alternatively, a toner including toner particles including a binder resin and a colorant, and an external additive which includes a particulate inorganic material having a formula of MgxSiyOx+2y where each of x and y is an integer and which has a surface treated with a fatty acid.

Owner:RICOH KK

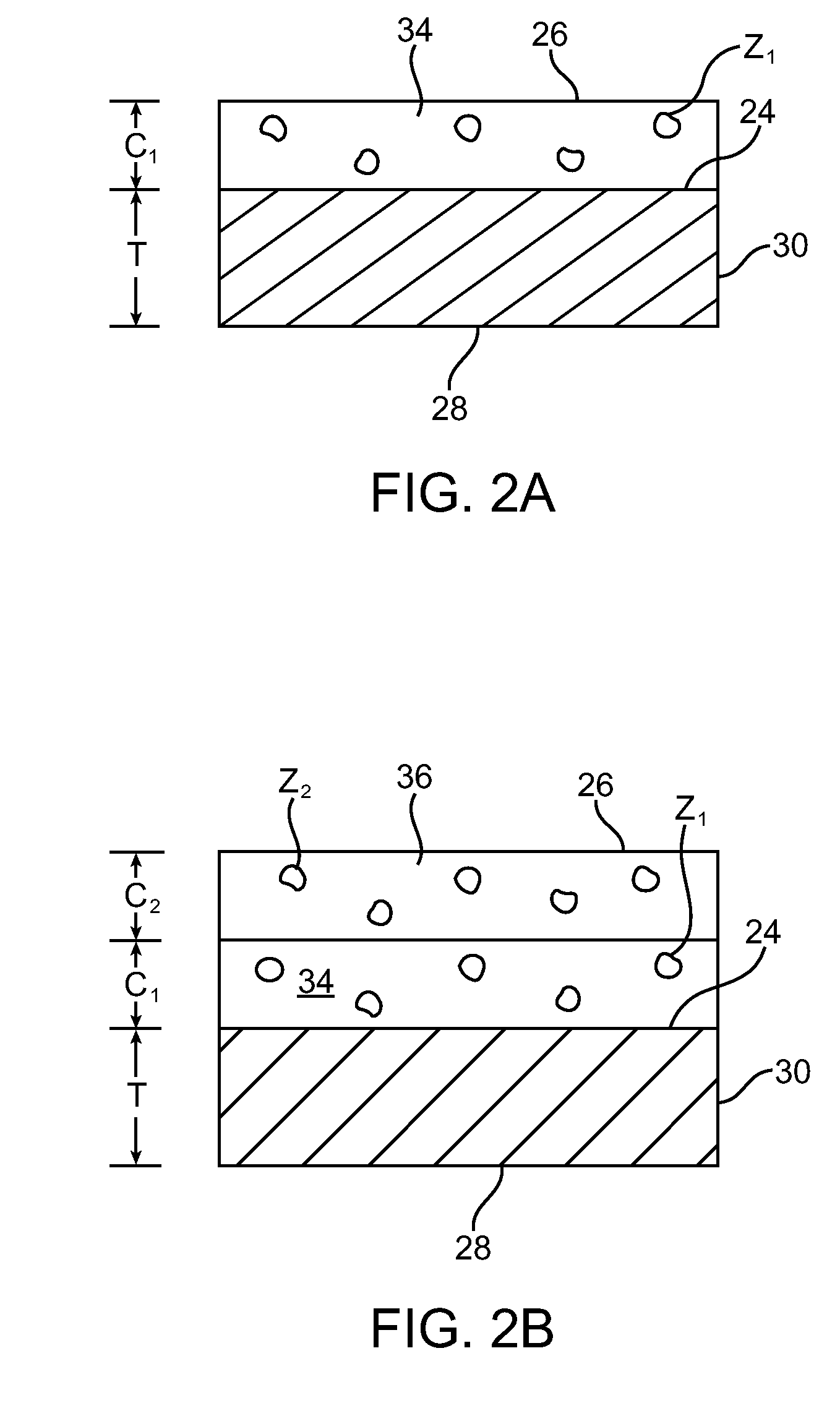

Medical Device Having Coating With Zeolite Drug Reservoirs

A medical device having a drug-eluting coating that includes a pharmaceutical compound or, more generally, a therapeutic material housed within pores of a zeolite carrier. The zeolite carrier has an open porous structure with reservoirs for holding the therapeutic material. The therapeutic material loaded zeolites may be suspended or dispersed within a bioerodible polymer matrix to provide controlled delivery of the therapeutic material. Zeolite drug carriers may have enhanced or optimally engineered pore sizes for a particular therapeutic material and release profile. Along with a therapeutic material, reservoirs of a zeolite drug delivery system may include a release agent. The release agent may be used to entrap the therapeutic material until such time as a triggering condition is met that prompts the release agent to activate and thereby release the therapeutic material from the zeolite reservoir.

Owner:MEDTRONIC VASCULAR INC

Toner, as well as image forming apparatus and image forming method using the same

ActiveUS20080280218A1Good storage stabilityLow temperature-fixing propertyDevelopersElectrographic process apparatusCarboxylic acidPropanediol

To provide a toner produced by emulsifying or dispersing in an aqueous medium particles containing at least polyester resin particles and by aggregating the polyester resin particles, wherein the polyester resin particles contain a polyester resin, the polyester resin is produced by condensation polymerization of an alcohol component containing 65 mol % or more 1,2-propanediol in a dihydroxy alcohol component and a carboxylic acid component containing purified rosin, and the softening point of the polyester resin is 80° C. or more and less than 120° C., and wherein the toner comprises a colorant and a releasing agent.

Owner:RICOH KK

Toner and image forming method

ActiveUS20130157193A1Good storage stabilityExcellent low temperature fixabilityDevelopersElectrographic processes using charge patternPolyester resinPolymer chemistry

A toner containing colorant, releasing agent, and binder resin containing crystalline polyester resin, and non-crystalline polyester resin containing urethane bond, urea bond, or both, the non-crystalline polyester resin containing first and second non-crystalline polyester resins, both containing urethane bond, or urea bond, or both, wherein monomers constituting the first non-crystalline polyester resin contains isocyanate monomer for forming the urethane bond, the urea bond, or the both, in an amount of 0.5 mol % or greater to total amount of the monomers, monomers constituting the second non-crystalline polyester resin contain isocyanate monomer for forming the urethane bond, the urea bond, or the both, in an amount of 0.5 mol % or greater to total amount of the monomers, the first non-crystalline polyester resin has Tg of −60° C. or higher but lower than 10° C., and the second non-crystalline polyester resin has Tg of 30° C. or higher but lower than 70° C.

Owner:RICOH KK

Skin cleansing composition for removing ink

InactiveUS6265363B1Easy to cleanEfficient removalInorganic/elemental detergent compounding agentsCosmetic preparationsAlcoholStain

A skin cleansing composition suitable for removing ink and other stains from the hands and arms of a user includes an effective amount of a low molecular weight alcohol having from one to twelve carbon atoms and an effective amount of a peroxide releasing agent, e.g., a percarbonate salt, preferably sodium percarbonate, such that together, the alcohol and percarbonate salt provide a synergistic reaction that effectively removes ink from the skin of the user. Other additives such as fillers, abrasives, and detergents may be employed to provide further cleansing action.

Owner:GOJO IND INC

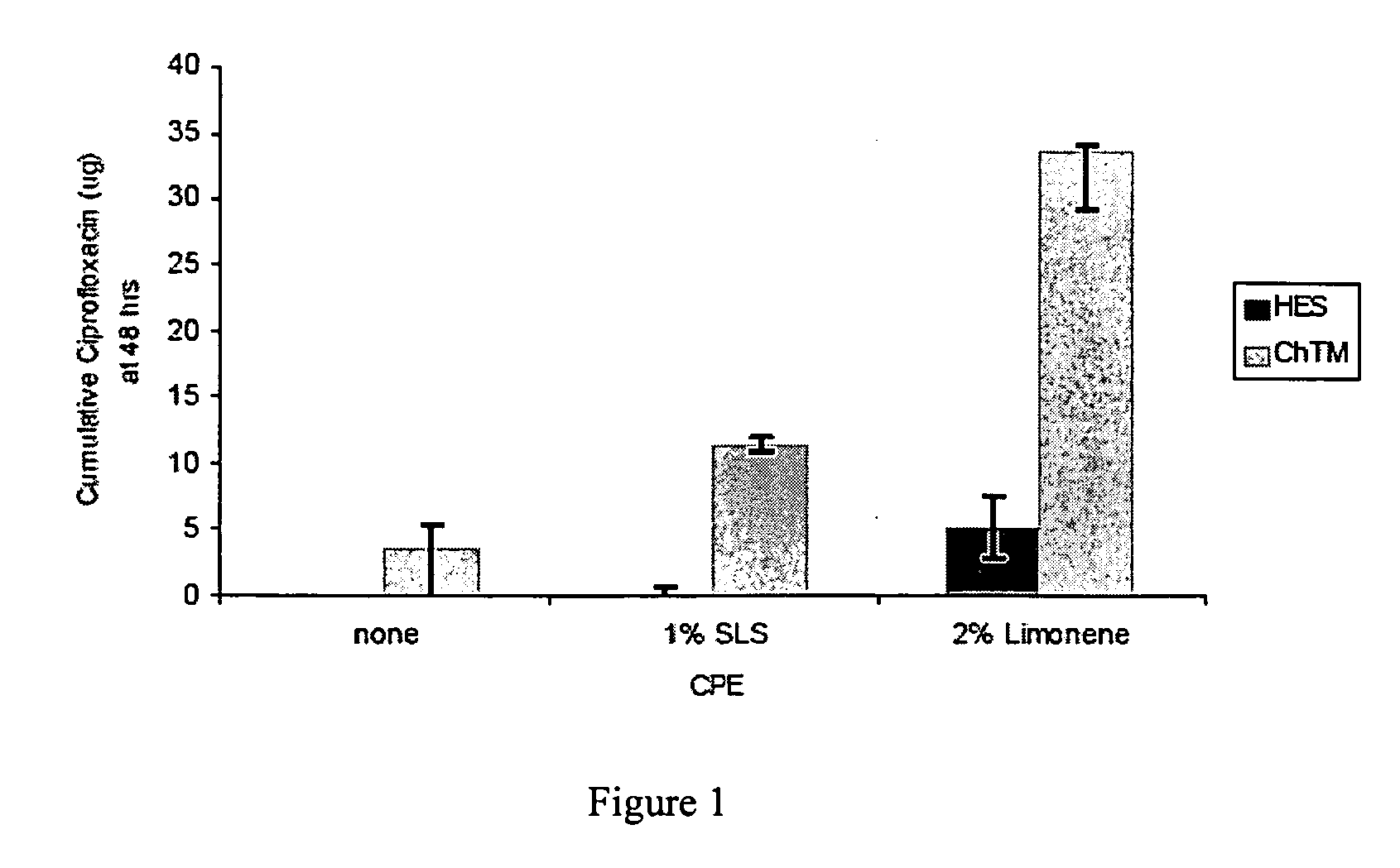

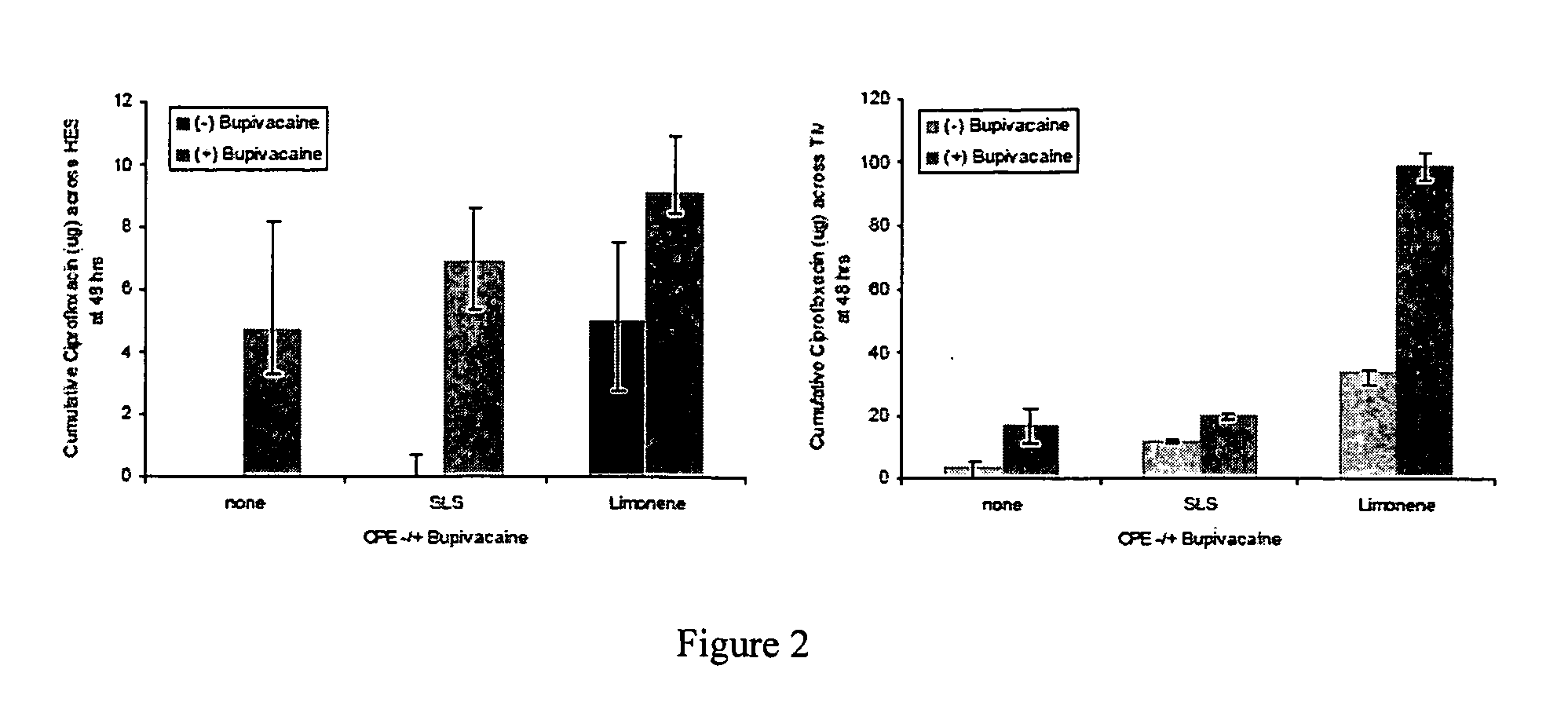

Tympanic membrane permeating ear drops and uses thereof

ActiveUS20110166060A1Maximizes exposure and concentrationImprove throughputBiocideSenses disorderMedicineAntibiotic Y

The present invention provides compositions and methods for noninvasive delivery of therapeutic agents across an intact tympanic membrane. For example, the compositions include a penetration enhancer which increases the flux of a therapeutic agent (e.g., antibiotic) across the tympanic membrane. Such compositions are particularly useful in the treatment of otitis media. Additionally, the composition may include a sustained release agents that, in some embodiments form sustained release reservoirs, in situ, once administered to a patient.

Owner:MASSACHUSETTS INST OF TECH +1

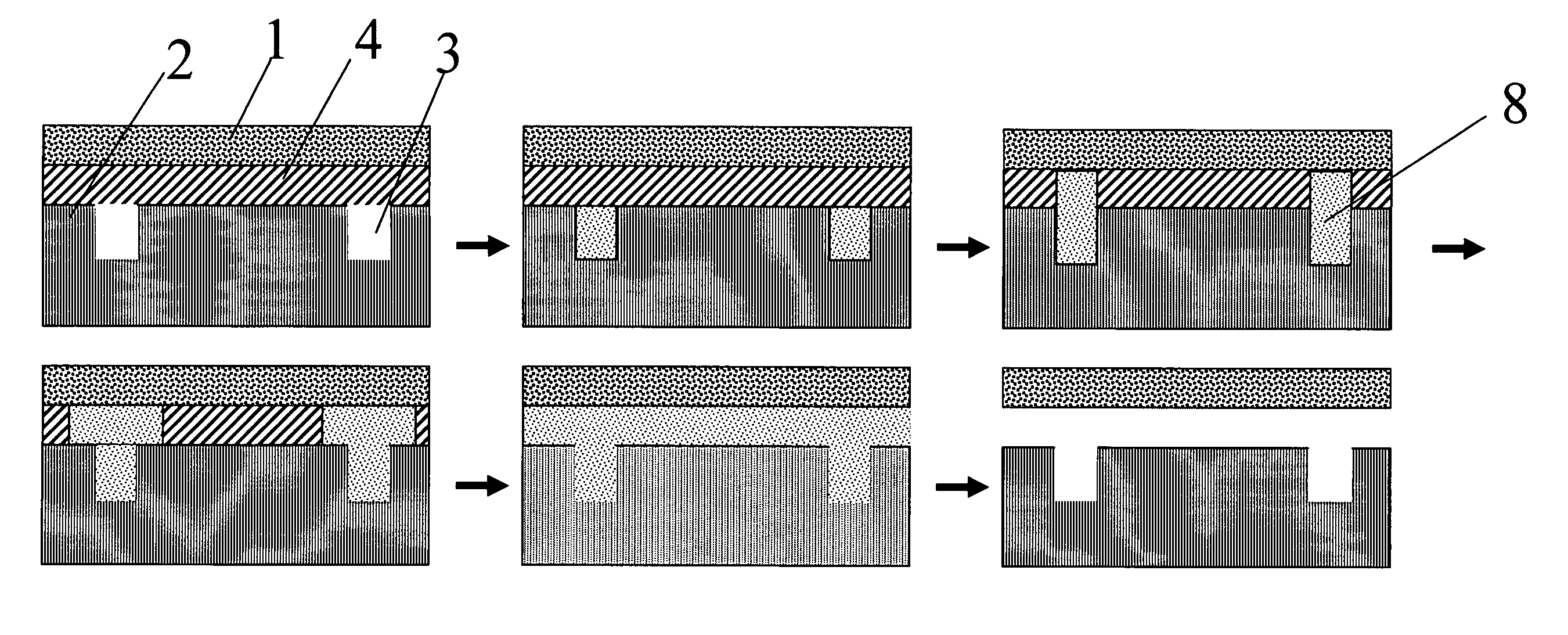

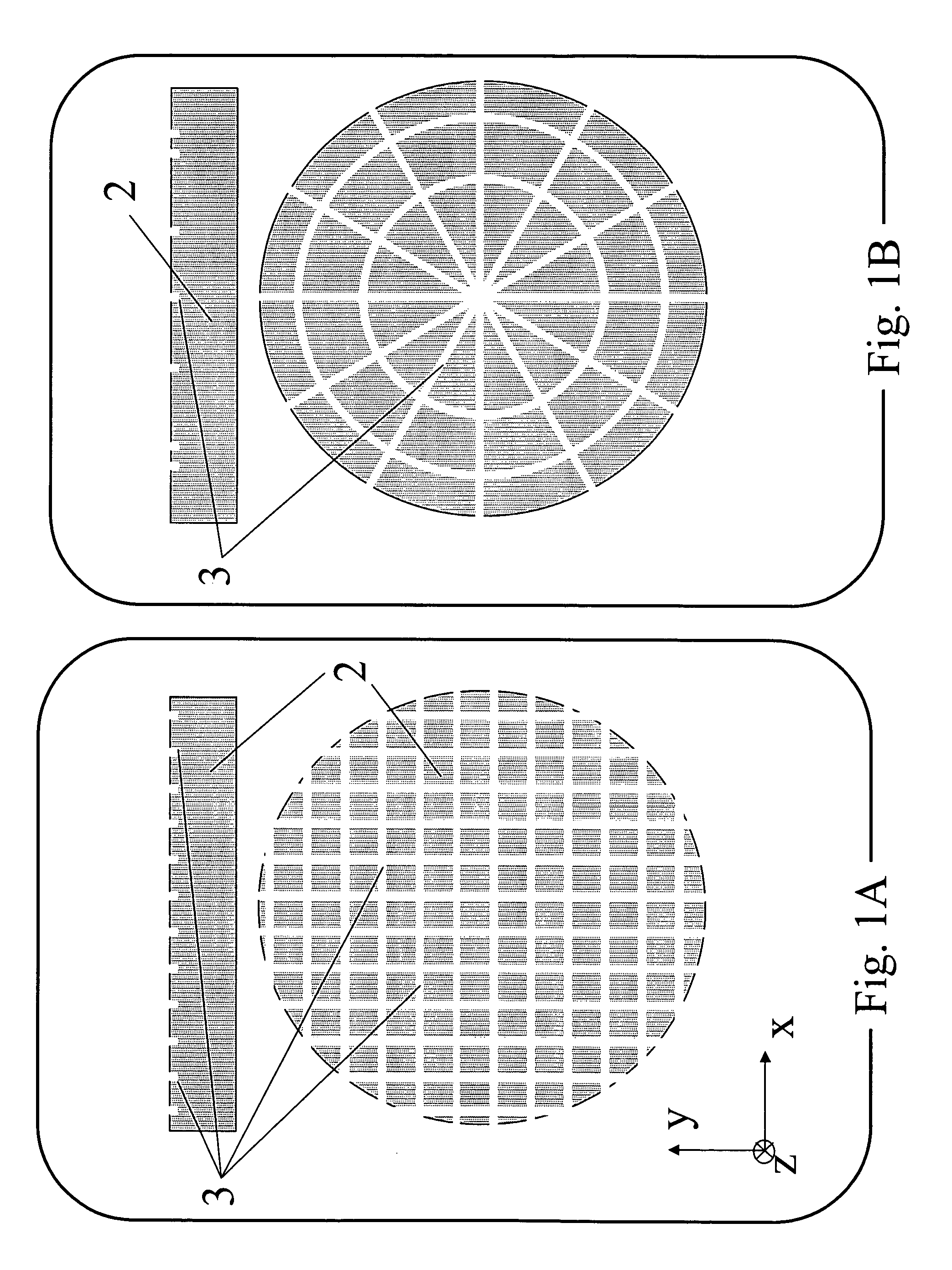

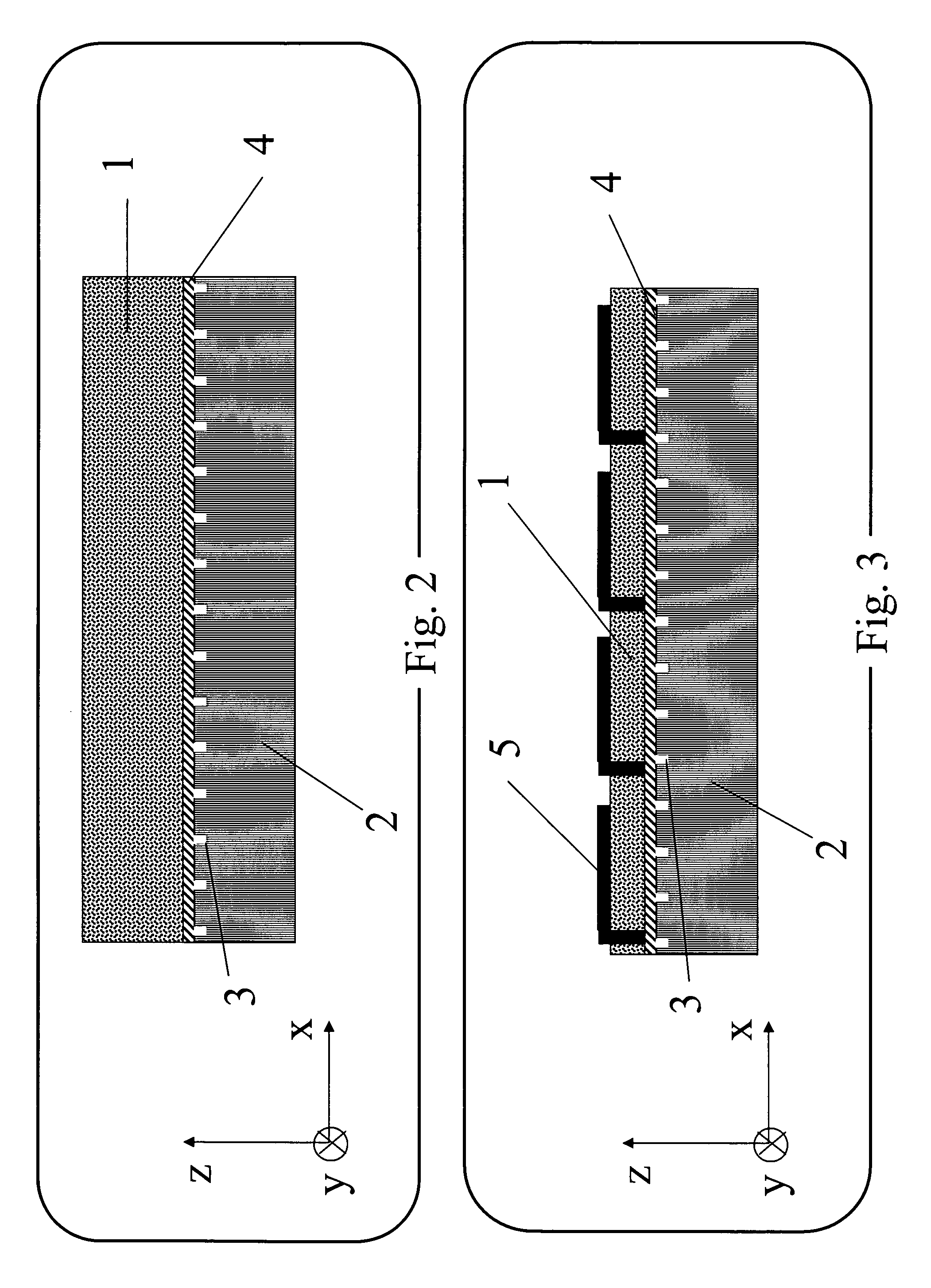

Method for the manufacture of electronic devices on substrates and devices related thereto

Methods for manufacturing electronic devices and devices produced by those methods are disclosed. One such method includes releasably bonding a first surface of a device substrate to a face of a first carrier substrate using a first bonding agent to produce a first composite substrate, where the face of the first carrier substrate includes a pattern of trenches. The method also includes processing the device substrate to manufacture an electronic device on a second surface of the device substrate. The method further includes releasing the device substrate from the first carrier substrate by a releasing agent.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW) +1

Toner and developer

ActiveUS20120052434A1Excellent low temperature fixabilityHigh temperature offset resistanceDevelopersWaxAcrylic resin

A toner containing: a non-crystalline polyester resin; a crystalline polyester resin; a releasing agent; a graft-modified polymer; and a colorant, wherein the graft-modified polymer is a polymer having a glass transition temperature of higher than 40° C. but lower than 80° C., and obtained by grafting an acrylic resin onto at least one of a hydrocarbon wax and a crystalline polyester resin, and wherein a SP value of the non-crystalline polyester resin is defined as SP1, a SP value of the crystalline polyester resin is defined as SP2, a SP value of the releasing agent is defined as SP3, and a SP value of the graft-modified polymer is defined as SP4, and SP1, SP2, SP3 and SP4 satisfy relations represented by Formulas (1) to (3):SP1>SP4>SP2>SP3 Formula (1),0.1<SP1−SP4<1.0 Formula (2), and0.1<SP4−SP2<1.0 Formula (3).

Owner:RICOH KK

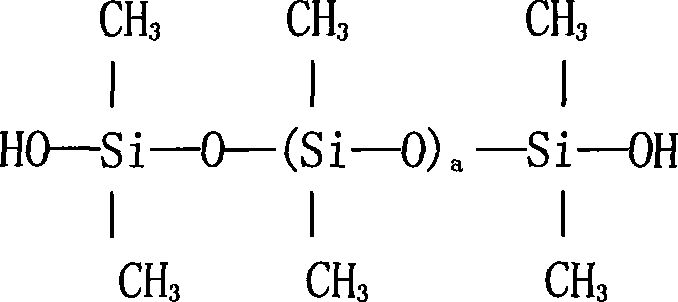

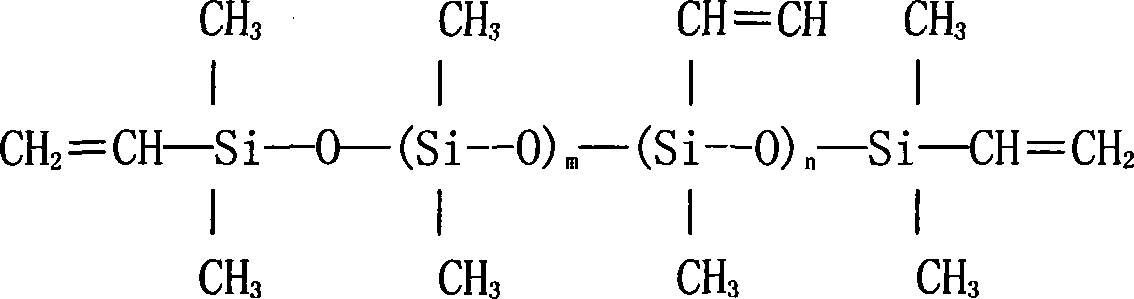

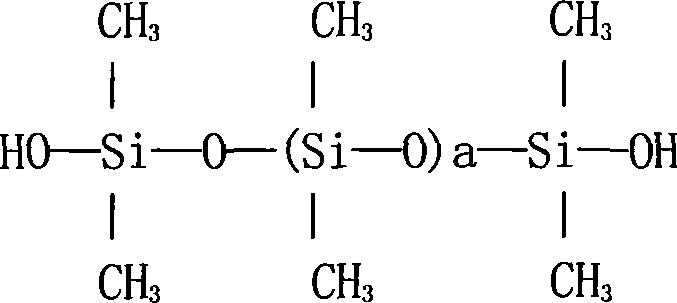

Highly ripping-resistant high temperature sulfidation silicon rubber and method for making same

The invention relates to a high anti-tearing and high temperature vulcanized silicon rubber, which is made through mixing and vulcanization of peroxide vulcanization agent and a combination which uses methylvinyl silicone rubber as base adhesive. The combination, according to weight proportion, comprises 100 of methylvinyl silicone rubber with low vinyl content, 1 to 30 of hydroxyl silicone oil, 0.1 to 3 of inner mold release agent, 15 to 80 of reinforcement agent, 1 to 10 of methylvinyl silicone rubber with high vinyl content and 1 to 10 of hydrogen-containing silicone oil; wherein, the vinyl molar content of the low vinyl-content methyvinyl silicone rubber is 0.01 percent to 0.15 percent; the vinyl molar content of the high vinyl-content methylvinyl silicone rubber is 1 percent to 10 percent. The invention has the advantages that the high vinyl-content methylvinyl silicon rubber is added into the methylvinyl silicone rubber, leading unsymmetrical concentration-crosslinking or one place multiple crosslinking to be formed during sulfuration period and the silicone rubber to generate so large resistance at the place that the rubber is difficult to be torn. In addition, the broken and tensile strength of vulcanized silicon rubber products is up to 8.5 MPa, and the tear strength is up to 45 N / mm.

Owner:SHANGHAI HUITIAN NEW CHEMICAL MATERIALS CO LTD

Toner for developing electrostatic image, and developer, toner container, image forming apparatus and process cartridge using the toner

A toner including a core including at least a colorant, a release agent and a first binder resin; and a shell located overlying the core and including at least a second binder resin, wherein the first binder resin includes a polyester resin including a unit obtained from a diol selected from the group consisting of aliphatic diols and alicyclic diols, and the second binder resin includes a vinyl copolymer, and wherein a weight ratio (S / C) of the shell (S) to the core (C) is from 0.05 to 0.5 and the toner has a volume average particle diameter of from 3 to 8 μm.

Owner:RICOH KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com