Patents

Literature

2653 results about "Acrylate copolymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acrylates Copolymer is a general term for copolymers of two or more monomers consisting of acrylic acid, methacrylic acid or one of their simple esters.

Stable aqueous surfactant compositions

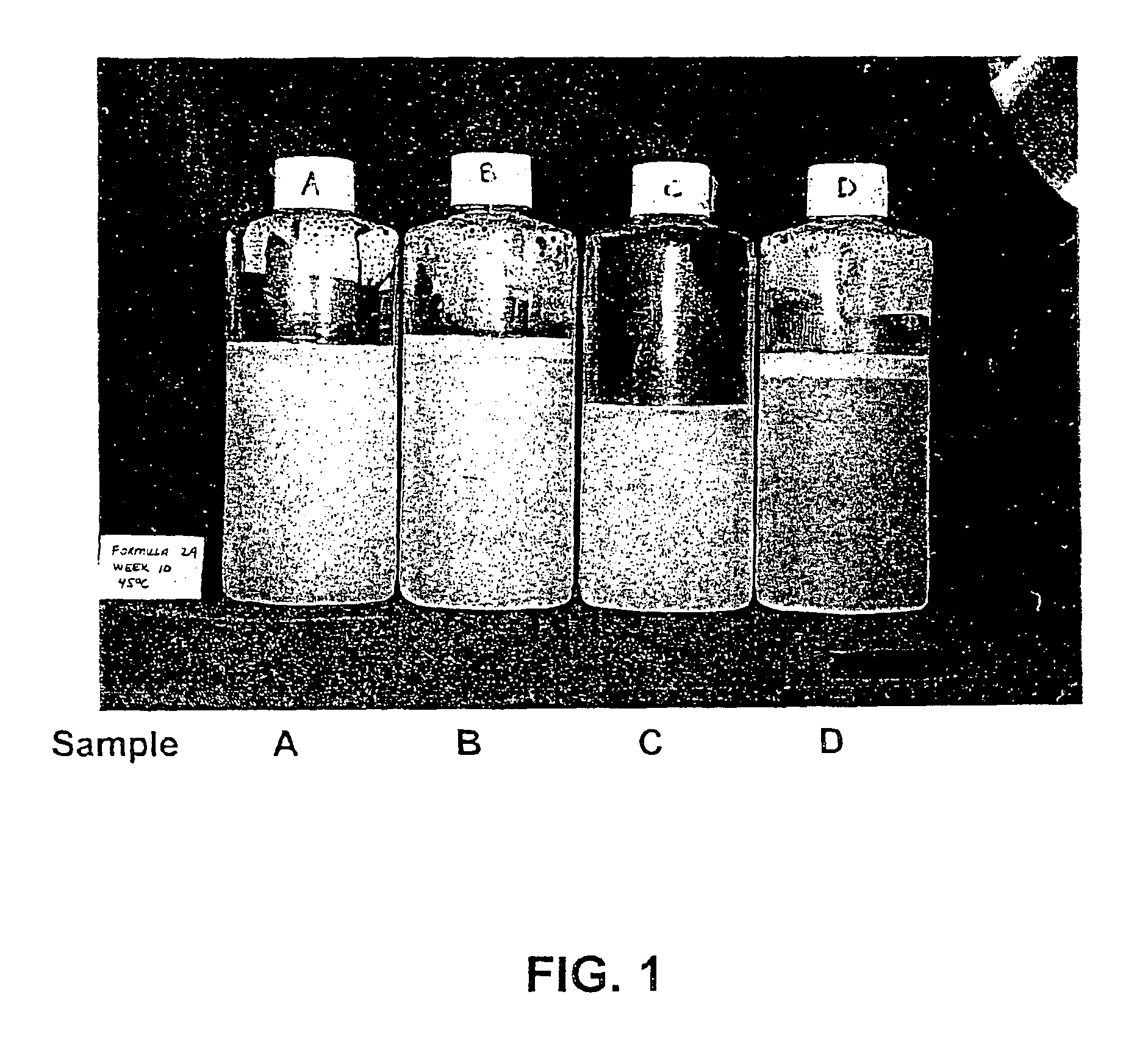

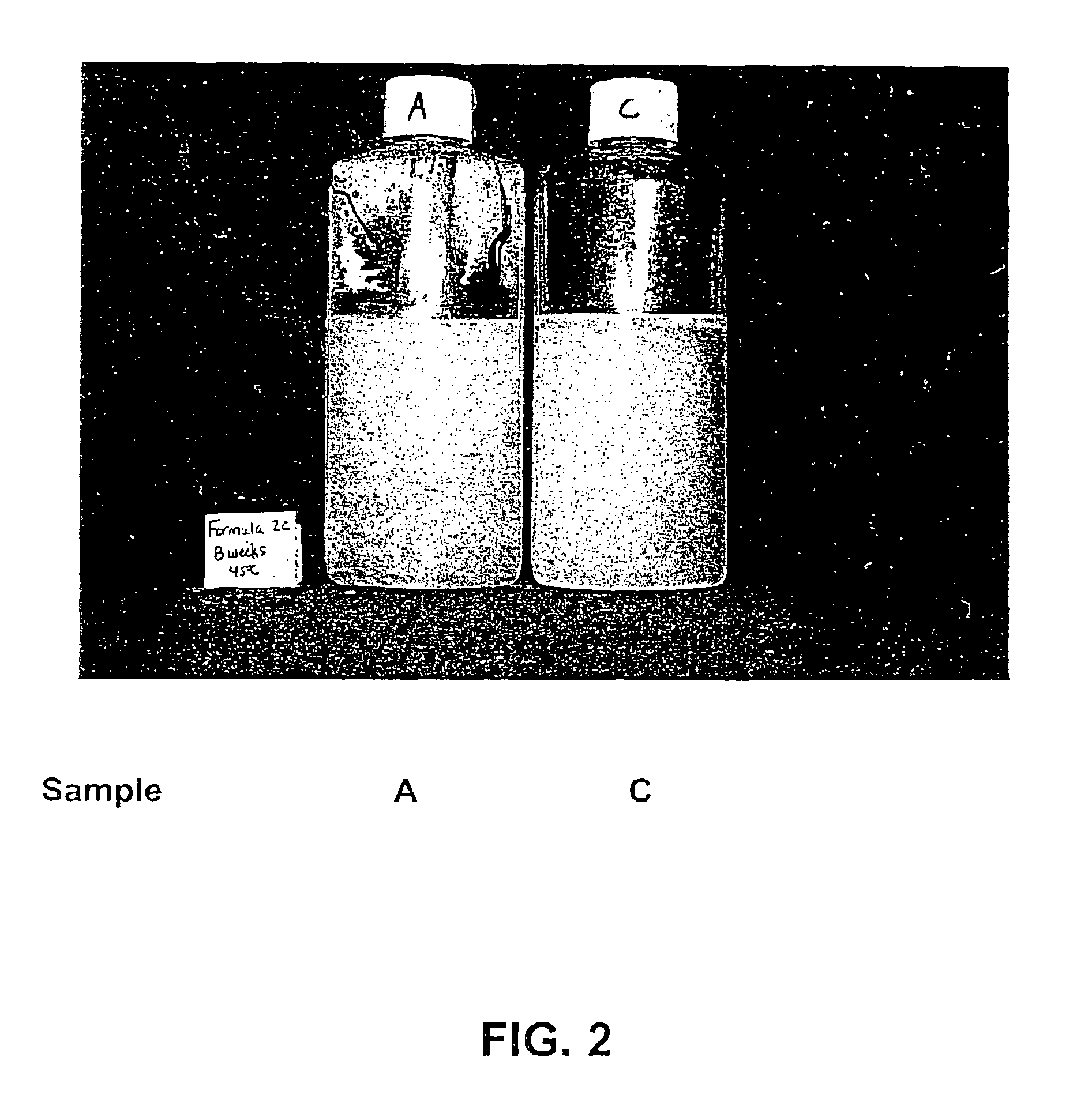

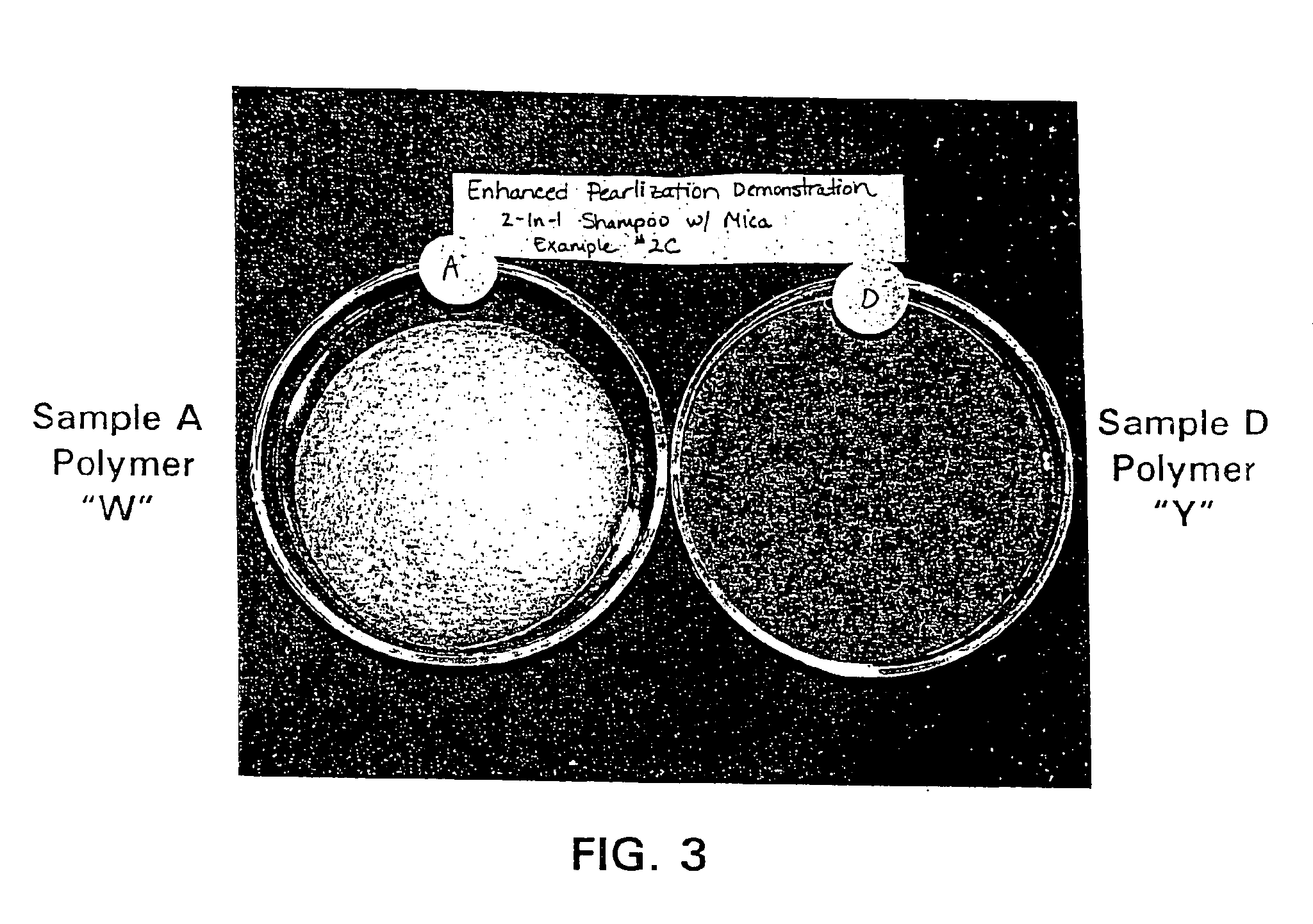

InactiveUS6897253B2Enhanced pearlescent appearanceLow compositionInorganic/elemental detergent compounding agentsBiocideHair dyesAcid substances

A stable, aqueous composition containing a substantially crosslinked alkali-swellable acrylate copolymer rheology modifier, a surfactant, an alkaline material, and various compounds therein, as for example substantially insoluble materials requiring suspension or stabilization, such as a silicone, an oily material, or a pearlescent material. Additionally, this invention also relates to the formation of a rheologically and phase stable cationic hair dye composition. The invention further relates to the incorporation of an acidic material after the addition of an alkaline material to reduce the pH of the composition without negatively impacting the viscosity of the composition.

Owner:LUBRIZOL ADVANCED MATERIALS INC

Self adaptive cement systems

InactiveUS20070137528A1Avoid seizuresInhibit migrationSolid waste managementDrilling compositionSelf-healingChemical products

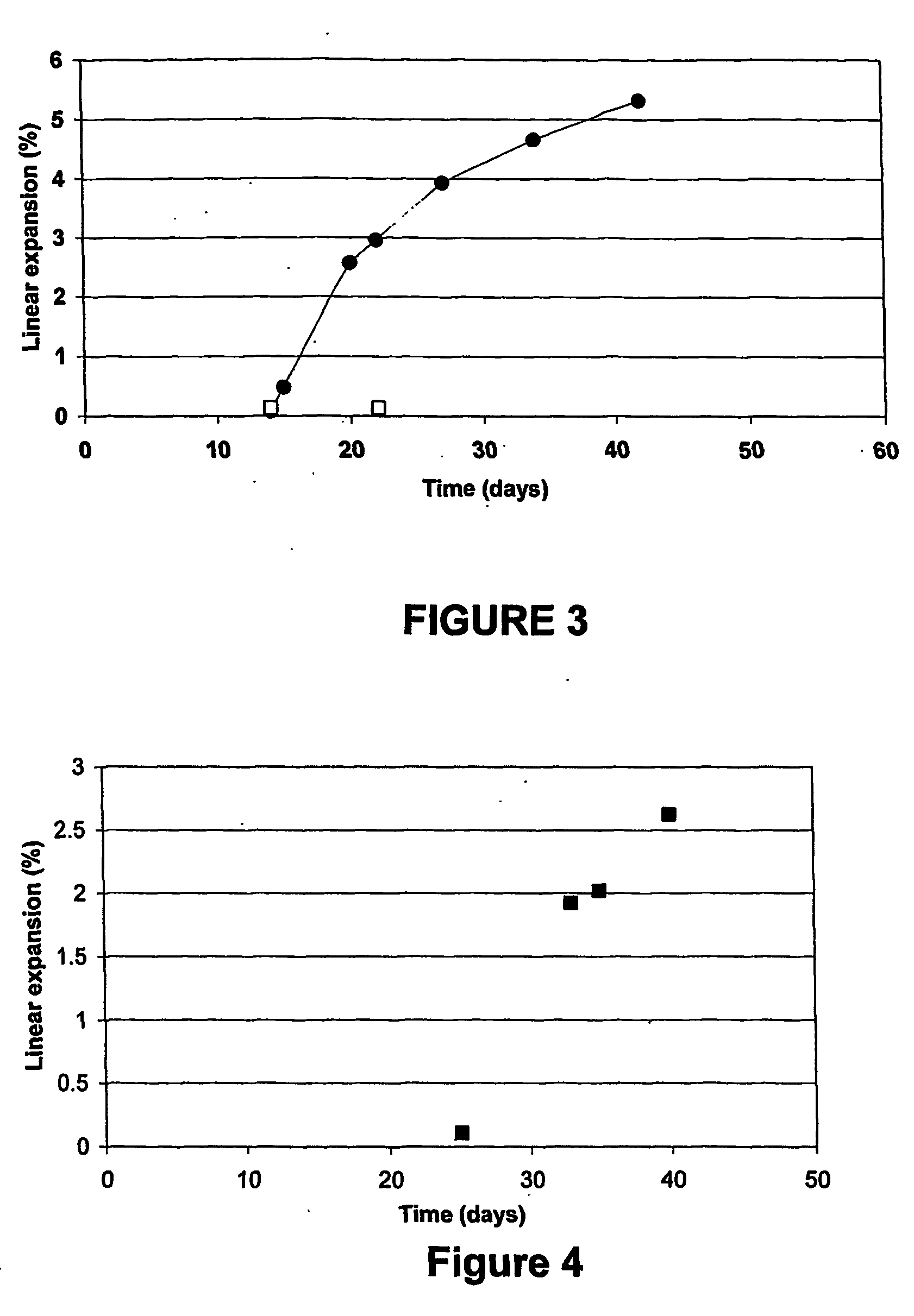

A self-adaptive cement system includes cement, water and at least one additive that reacts or and expands in contact with oil and gas. Several chemical products have been identified including rubber alkylstyrene, polynorbornene, resins such precrosslinked substituted vinyl acrylate copolymers and diatomaceous earth. These additives have the effect of making the cement self-healing in the event of physical failure or damage such as micro-annuli. The self healing property is produced by the contact with subterranean hydrocarbon fluids, the potential repair mechanism is thus activated if and when needed in case of start of loss of zonal isolation. In another embodiment, the expansion is deliberately induced by pumping a hydrocarbon fluid in the vicinity of the set cement.

Owner:SCHLUMBERGER TECH CORP

Curable pressure sensitive adhesive compositions

Owner:3M INNOVATIVE PROPERTIES CO

Electrically Conductive Ink, Electrically Conductive Circuit, and Non-Contact-Type Medium

InactiveUS20080169122A1Improve conductivityWell formedConductive layers on insulating-supportsPrinted circuit aspectsHigh humidityContact type

Owner:TOYO INK SC HOLD CO LTD

Use of a Partially Neutralized, Anionic (Meth)Acrylate Copolymer as a Coating for the Production of a Medicament Releasing Active Substance at Reduced Ph Values

(EN) The invention relates to the use of a partially neutralized, anionic (meth)acrylate copolymer comprising radically polymerized units of 25 to 95 percent by weight of C1 to C4 alkyl esters of acrylic or methacrylic acid and 5 to 75 percent by weight of (meth)acrylate monomers with an anionic group, at least 4 percent of which are neutralized by means of a base, for producing a medicament that is provided with an active substance-containing core and is coated with the partially neutralized, anionic (meth)acrylate copolymer. Said medicament releases at least 30 percent of the active substance contained therein in 30 minutes at a pH at which the active substance is sufficiently soluble and stable and at which the corresponding medicament that is coated with the non-neutralized anionic (meth)acrylate polymer releases less than 10 percent of the active substance contained therein.

Owner:EVONIK OPERATIONS GMBH

Non-phosphorus compound scale and corrosion inhibitor for treatment of circulating cooling water

ActiveCN1621362AEasy to useIncrease the concentration factorScale removal and water softeningPhosphateTungstate

The composite phosphate-free scale inhibiting corrosion inhibitor for treating circular cooling water consists of scale inhibitor and corrosion inhibitor. The scale inhibitor consists of one or several of PASP, PVA, oxidized starch, polyacrylic acid, acrylic acid / acrylate copolymer and acrylic acid / acrylate copolymer with sulfo radical. The corrosion inhibitor consists of one or several of sodium salt / potassium salt / ammonium salt of organic salt, sodium / potassium / ammonium borate, nitrous organic matter, soluble molybdenate, soluble tungstate, soluble nitrate, soluble nitrite and soluble zinc salt. The composite scale inhibiting corrosion inhibitor has excellent scale inhibiting and corrosion inhibiting performance, is environment friendly, and is especially the treatment of hard circulation water with high calcium and high alkali content.

Owner:BEIJING YANHUA XINGYE TECH DEV +1

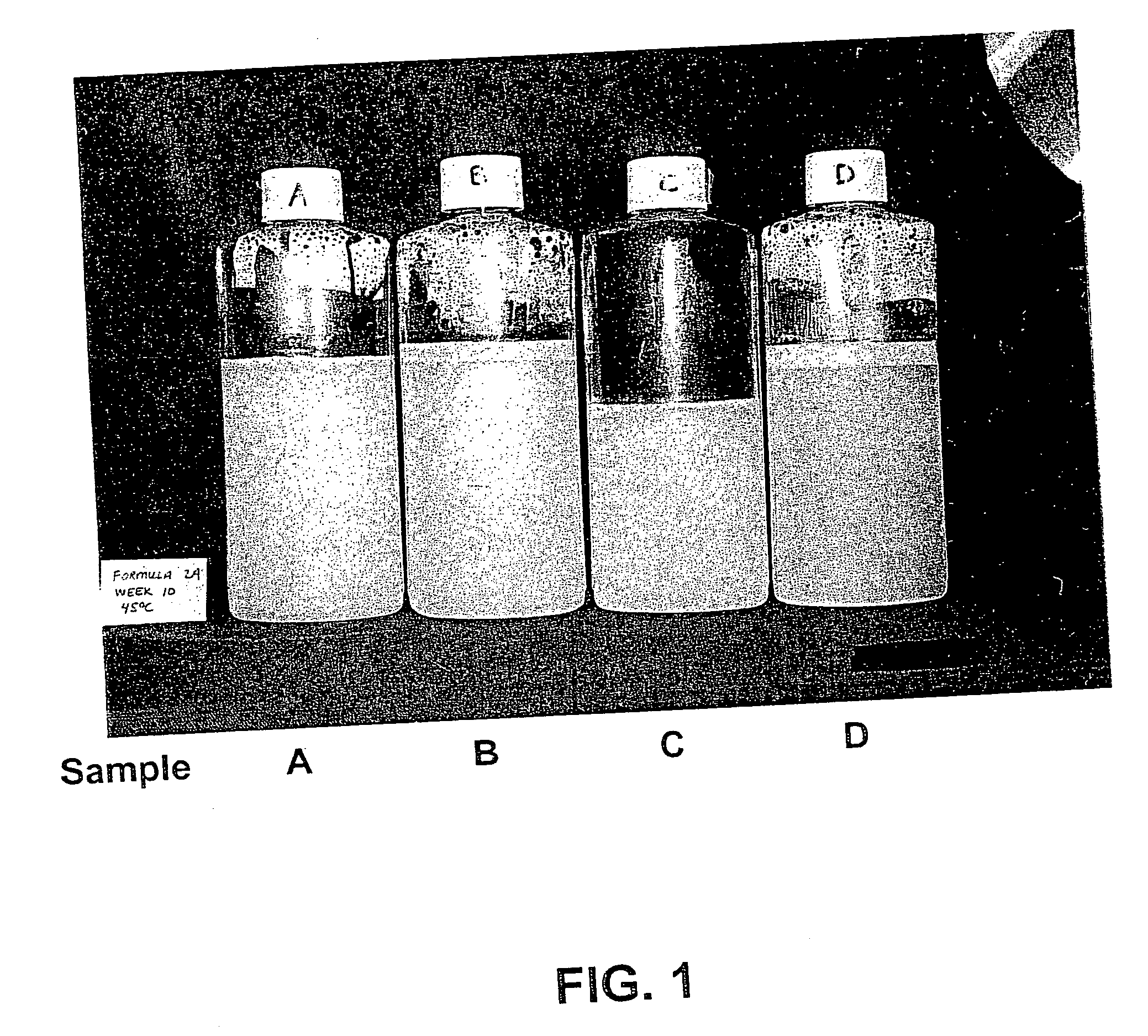

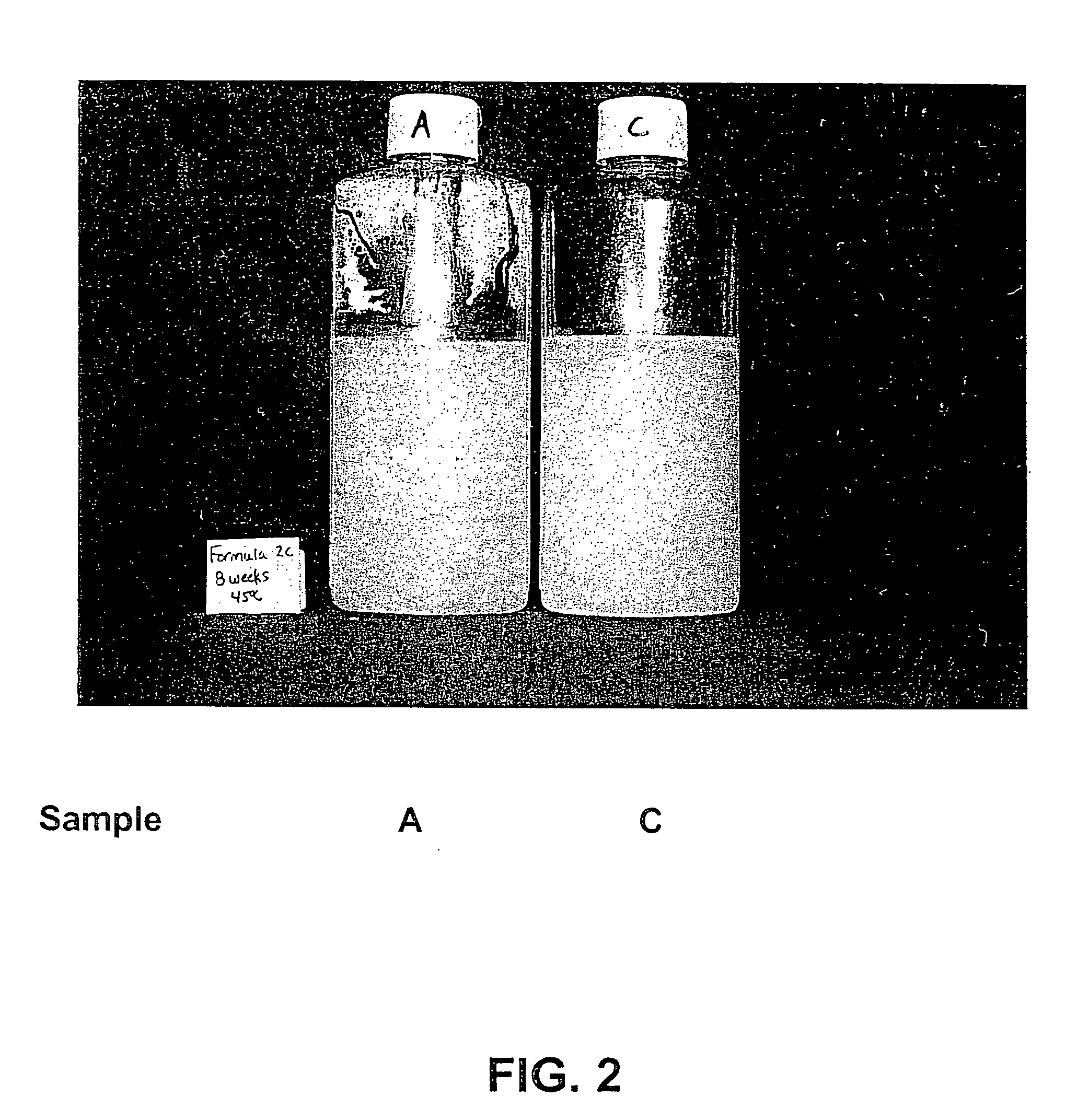

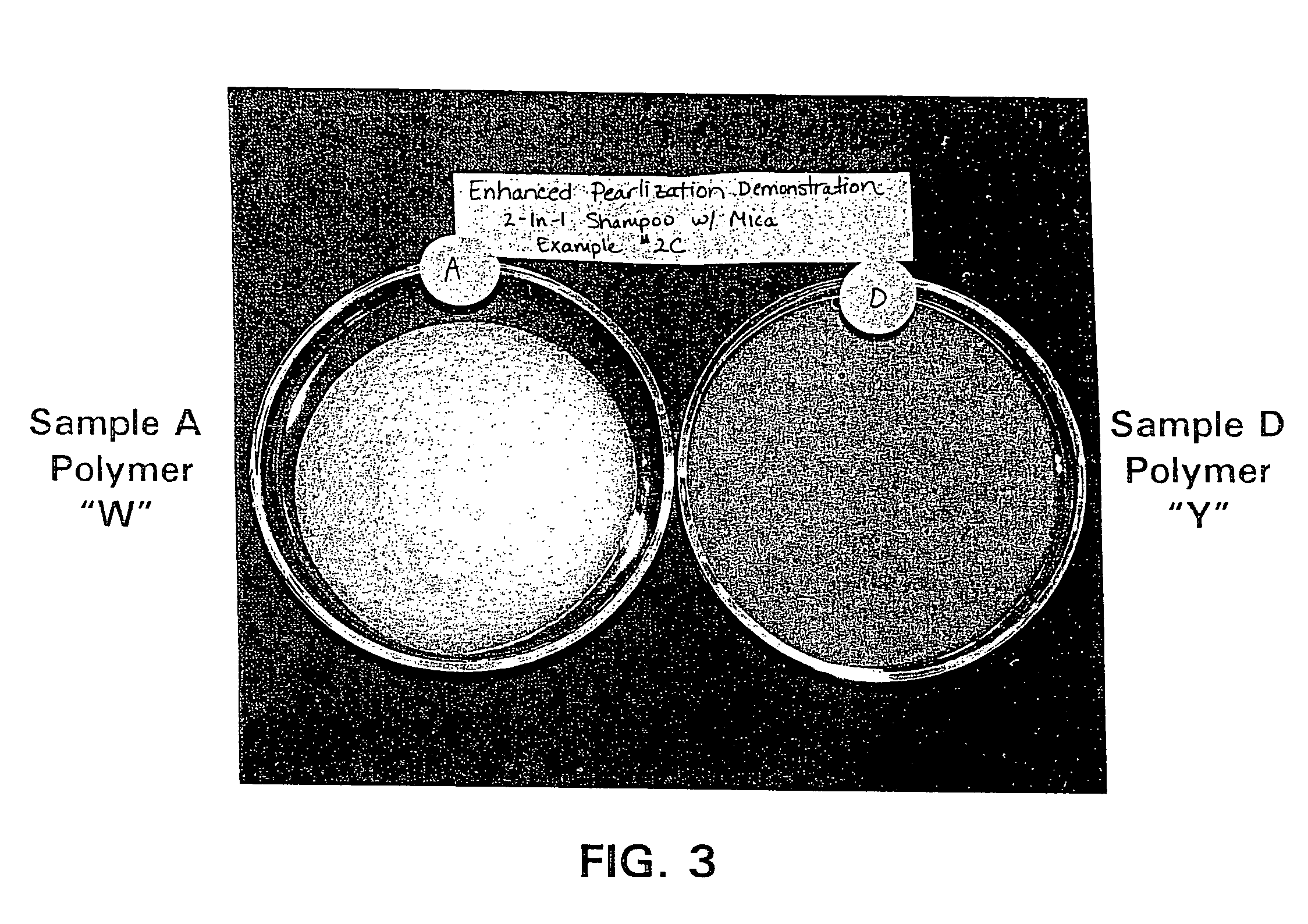

Stable aqueous surfactant compositions

InactiveUS20050158268A1Good lookingLow compositionInorganic/elemental detergent compounding agentsCosmetic preparationsHair dyesAcid substances

A stable, aqueous composition containing a substantially crosslinked alkali-swellable acrylate copolymer rheology modifier, a surfactant, an alkaline material, and various compounds therein, as for example substantially insoluble materials requiring suspension or stabilization, such as a silicone, an oily material, or a pearlescent material. Additionally, this invention also relates to the formation of a rheologically and phase stable cationic hair dye composition. The invention further relates to the incorporation of an acidic material after the addition of an alkaline material to reduce the pH of the composition without negatively impacting the viscosity of the composition.

Owner:LUBRIZOL ADVANCED MATERIALS INC

Injection molding method for neutral and acidic-group containing (meth)acrylate copolymers

InactiveUS20020160042A1Reduce contentOrganic dyesPharmaceutical non-active ingredientsMeth-Additive ingredient

The invention relates to a process for producing mouldings by injection moulding, the steps in the process being A) Melting a mixture made from a) a (meth)acrylate copolymer composed of from 40 to 100% by weight of free-radical-polymerized C1-C4-alkyl esters of acrylic or methacrylic acid and from 0 to 60% by weight of (meth)acrylate monomers having an anionic group in the alkyl radical, where the copolymer comprises b) from 0.1 to 3% by weight of a release agent, and, where appropriate, the mixture may comprise c) from 0 to 50% by weight of a drier, d) from 0 to 30% by weight of a plasticizer, e) from 0 to 100% by weight of additives or auxiliaries, f) from 0 to 100% by weight of an active pharmaceutical ingredient, g) from 0 to 20% by weight of another polymer or copolymer, where the amounts given for components b) to g) are based on the (meth)acrylate copolymer a) and the mixture prior to melting has a content of more than 0.5% by weight of low-boiling constituents with vapour pressure of at least 1.9 bar at 120° C., B) Devolatilizing the mixture in the thermoplastic state at temperatures of at least 120° C., thereby lowering to not more than 0.5% by weight the content of the low-boiling constituents with vapour pressure of at least 1.9 bar at 120° C., C) Injecting the molten and devolatilized mixture into the mould cavity of an injection mould, the temperature of the mould cavity being below the glass transition temperature of the (meth)acrylate copolymer by at least 10° C., cooling the molten mixture, and removing the resultant moulding from the mould.

Owner:PFIZER INC +1

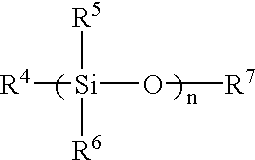

Silyl (METH) acrylate copolymers, processes for preparing the same, antifouling paint compositions containing the silyl (METH) acrylate copolymers, antifouling coating films formed from the antifouling paint compositions, antifouling methods using the antifouling paint compositions, and hulls or underwater structures coated with the antifouling coating films

InactiveUS6458878B1Improve antifouling performanceSuppressed hydrolysis rateAntifouling/underwater paintsPaints with biocidesMeth-Unsaturated monomer

Disclosed is a silyl (meth)acrylate copolymer which comprises 20 to 80% by weight of (a) silyl (meth)acrylate constituent units (I), 0.01 to 40% by weight of (b) acrylic unsaturated monomer constituent units (II) and 5 to 79.9% by weight of Ĉ unsaturated monomer constituent units other than the constituent units (a) and (b). Also disclosed is a process for preparing the silyl (meth)acrylate copolymer, an antifouling paint composition comprising the copolymer, a coating film formed from the paint composition, a hull with the coating film and an antifouling method using the paint composition.

Owner:CHUGOKU MARINE PAINTS

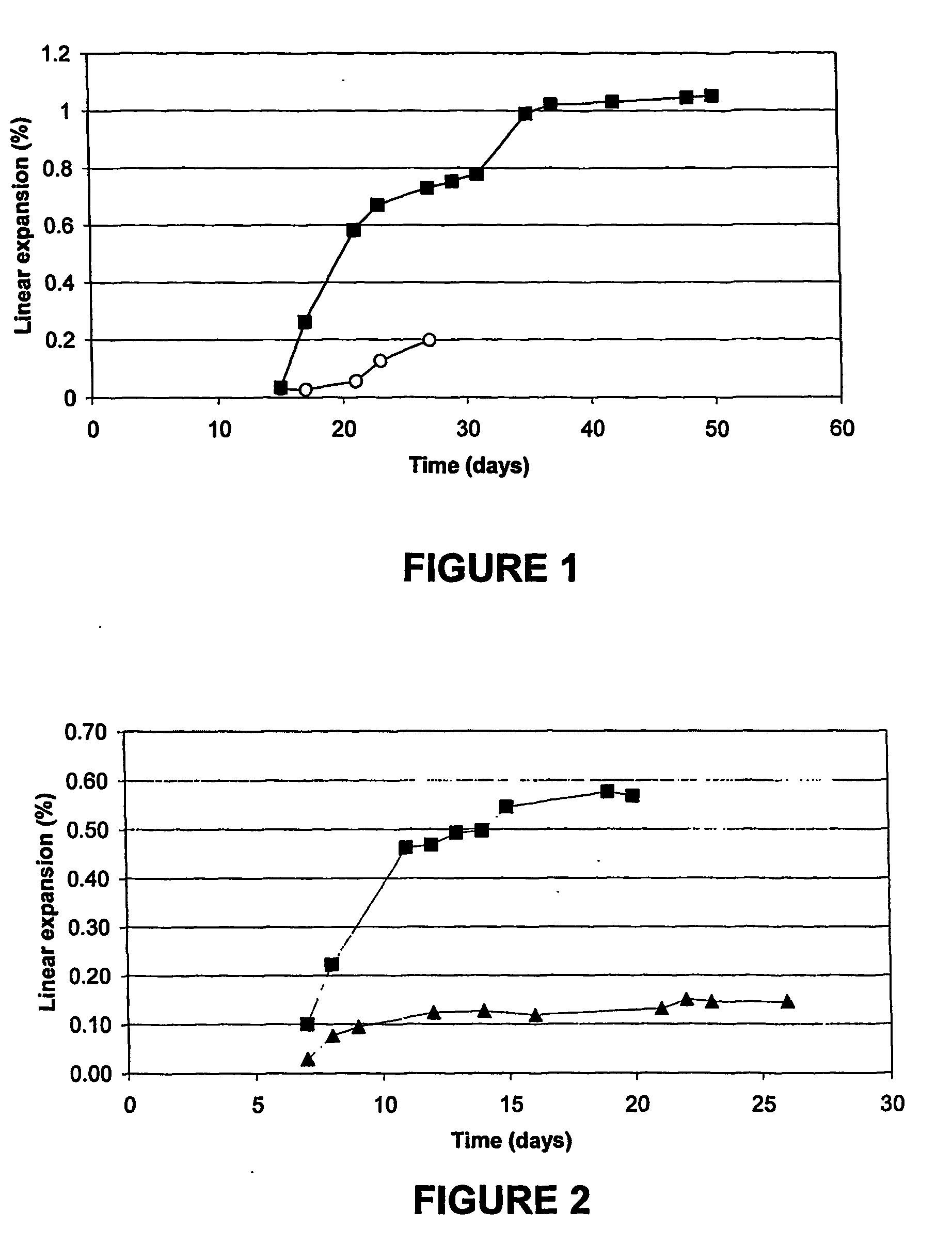

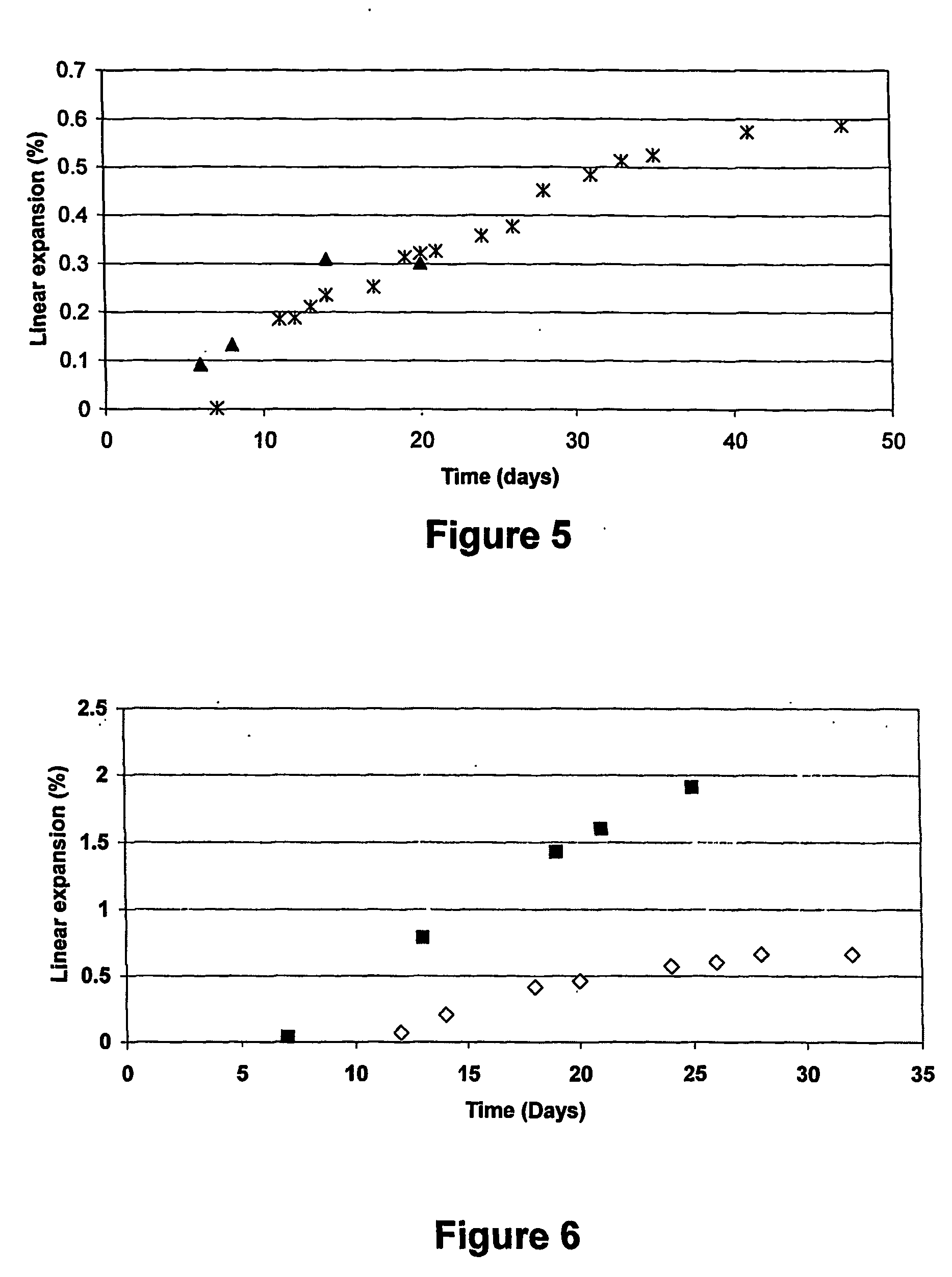

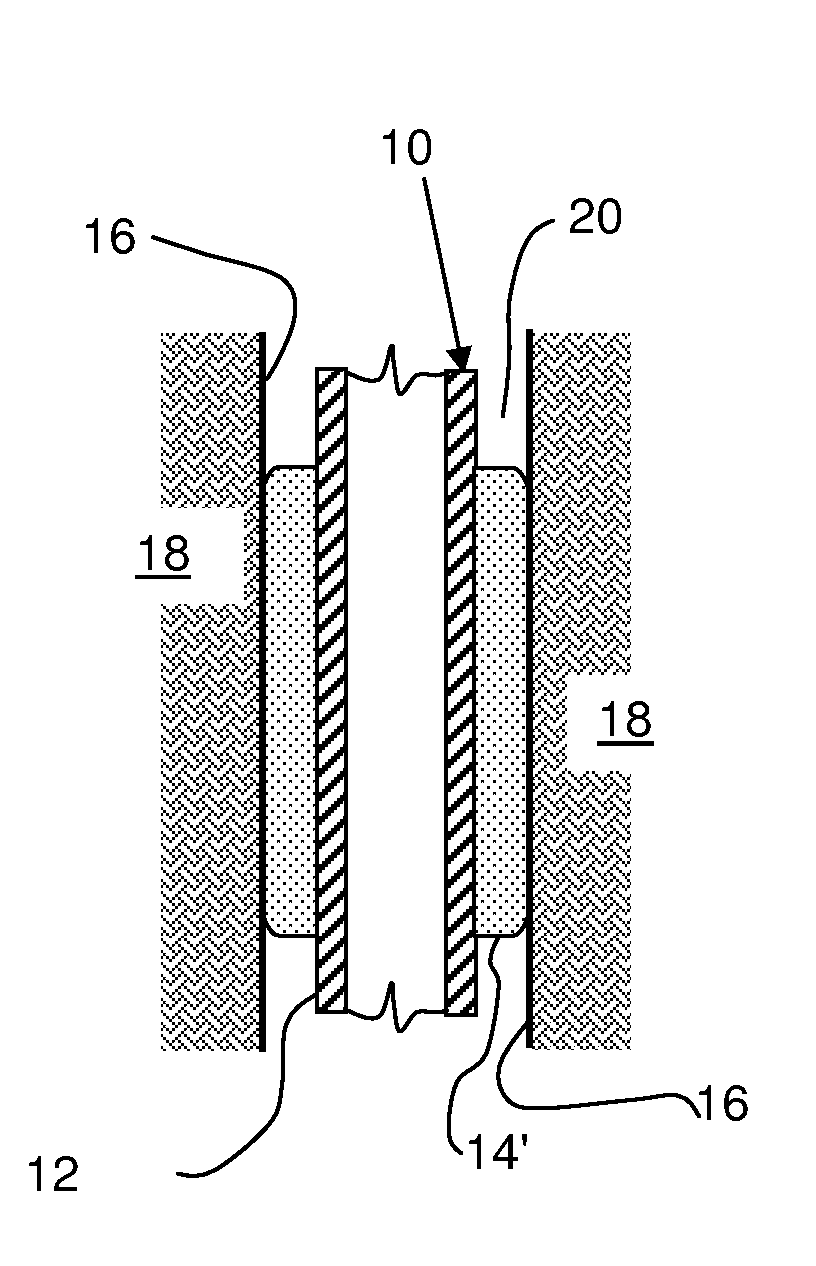

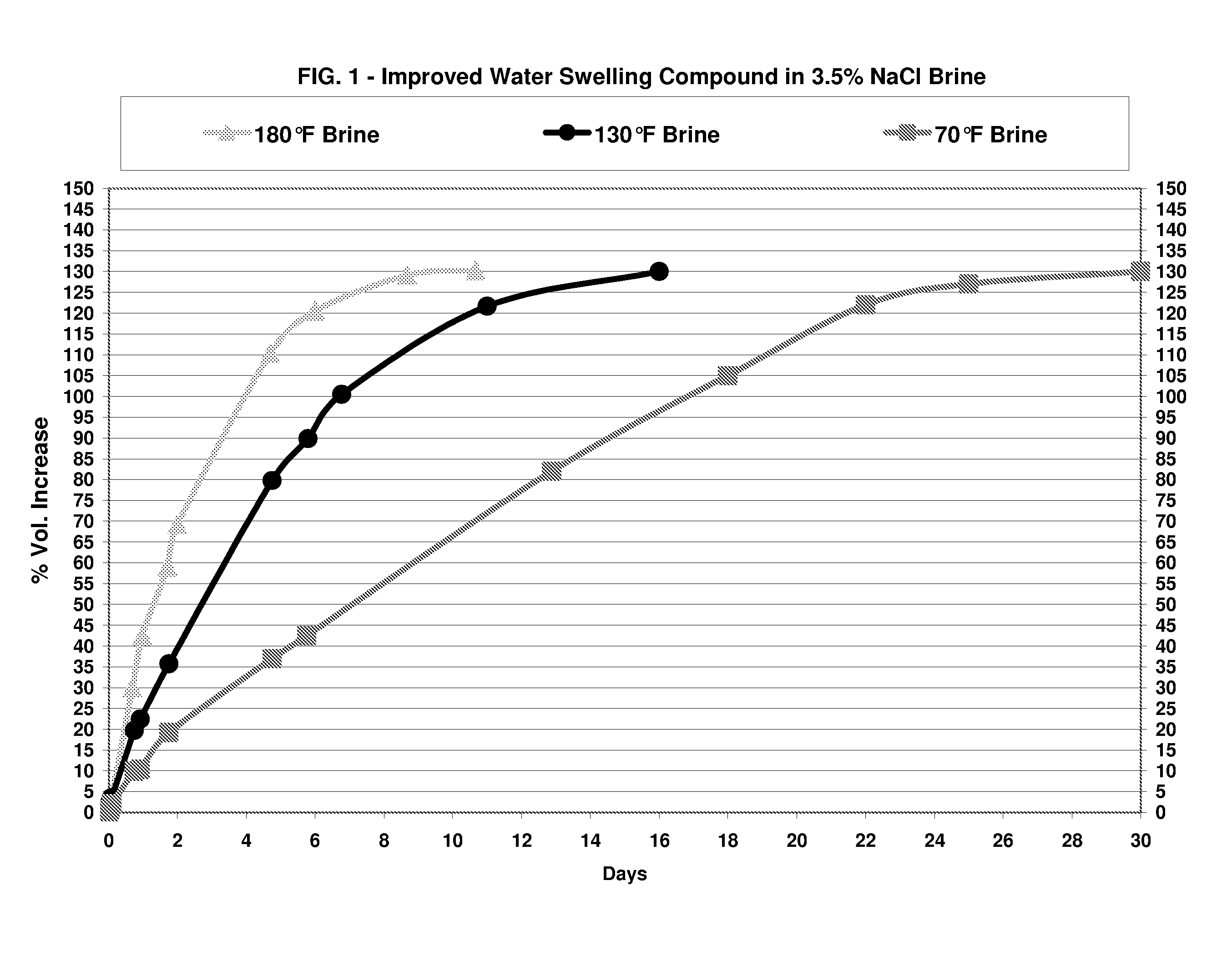

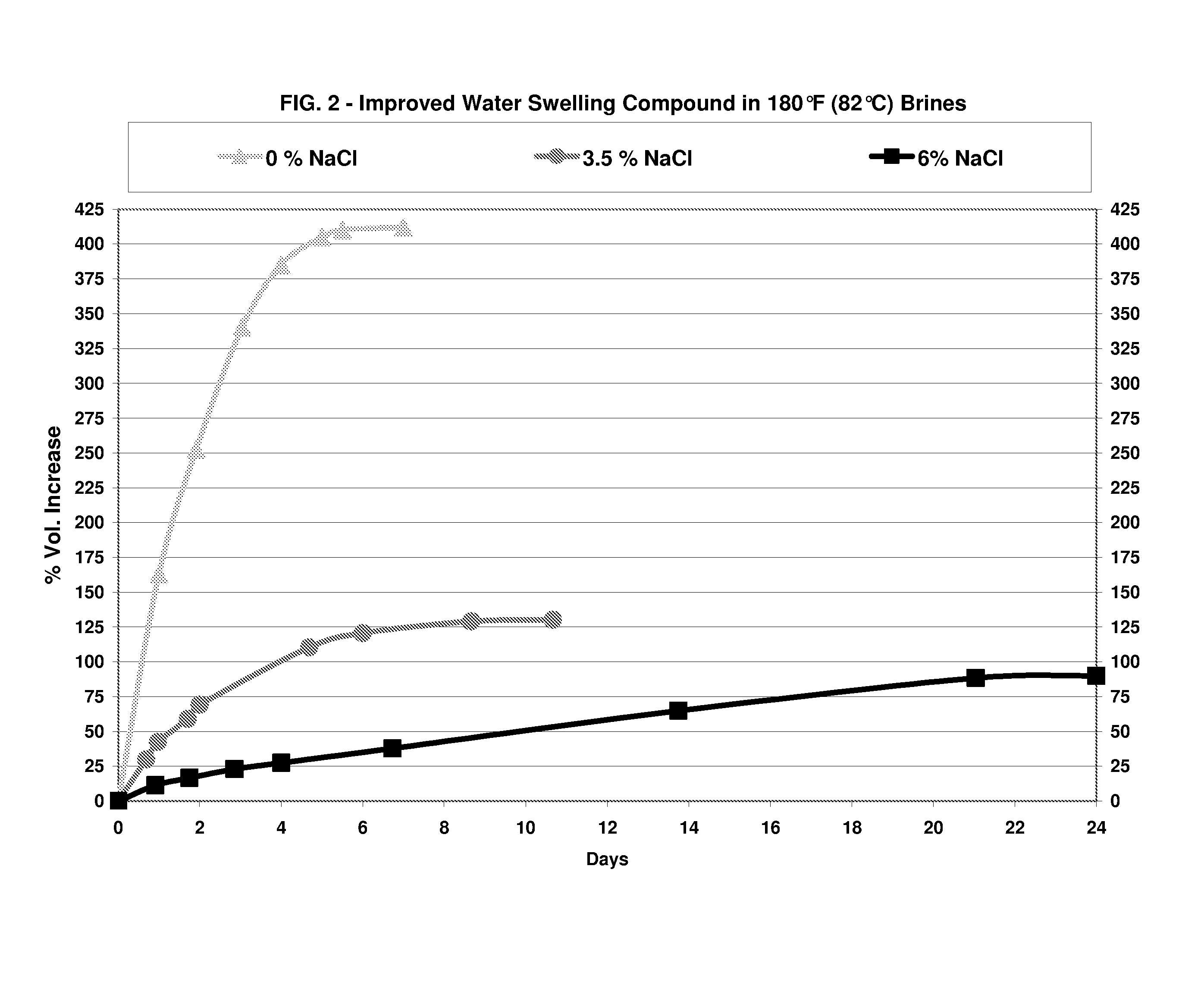

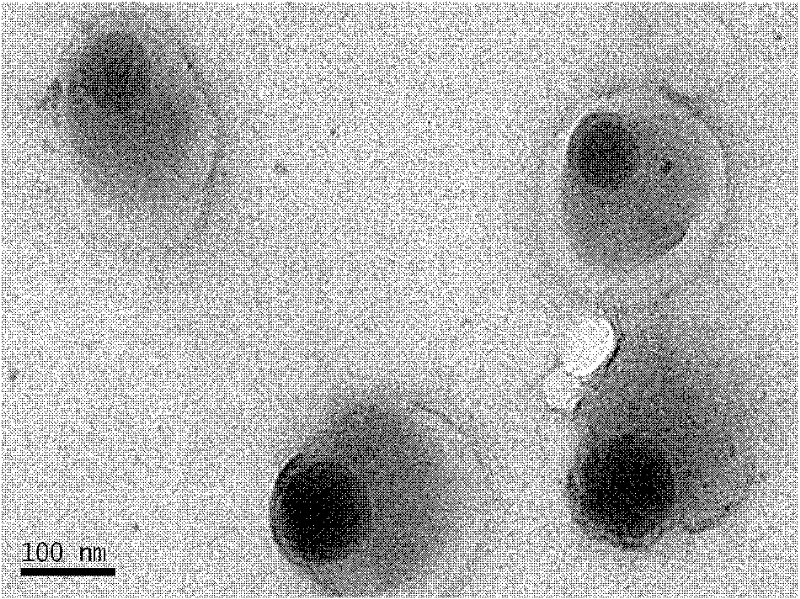

Water Swelling Rubber Compound for Use In Reactive Packers and Other Downhole Tools

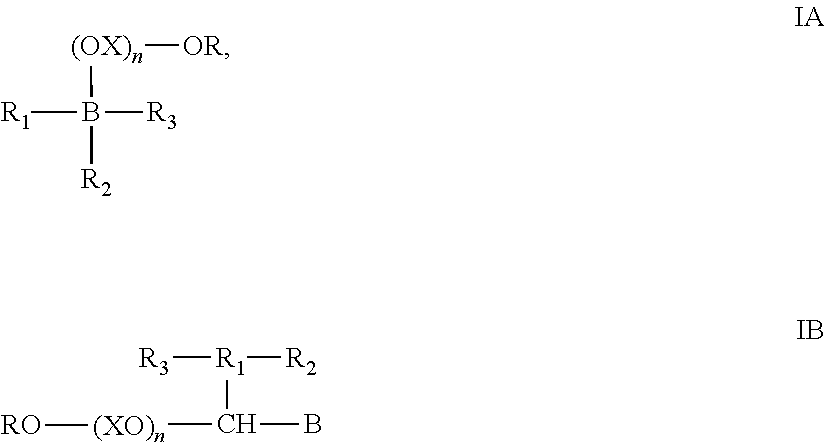

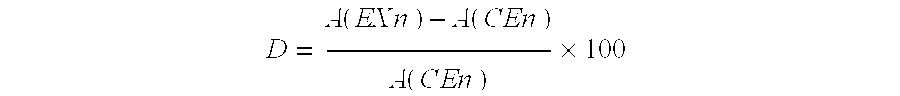

Through the combination of at least two polymer families, and the optimization of other components, a rubber compound has been developed for use in downhole applications that will swell in water-based fluids. A cellulose component, such as carboxy methyl cellulose (CMC), is used together with an acrylate copolymer (AC) that can increase the swelling capacity of an acrylonitrile butadiene rubber (NBR) in water to over 1000%. The amount of swelling achieved depends on physical boundaries and limitations, the salinity of the water, and the temperature.

Owner:BAKER HUGHES INC

Method for injection moulding moulded bodies consisting of (meth) acrylate copolymers

InactiveUS20040104501A1Reduce contentLittle reabsorptionPharmaceutical non-active ingredientsEndocrine system disorderPolymer scienceMeth-

The invention relates to a process for producing mouldings by injection moulding the steps in the process being a) melting and mixing of a (meth)acrylate copolymer composed of from 85 to 98% by weight of C1-C4-alkyl (meth)acrylates capable of free-radical polymerization and from 15 to 2% by weight of (meth)acrylate monomers having a quaternary ammonium group in the alkyl radical, with from 10 to 25% by weight of a plasticizer, and also from 10 to 50% by weight of a dryers [sic] and / or from 0.1 to 3% by weight of a release agent, and, where appropriate, with other conventional pharmaceutical additives or auxiliaries and / or with an active pharmaceutical ingredient, b) devolatilizing the mixture at temperatures of at least 120° C., thus reducing the content of the low-boiling constituents with a vapour pressure of at least 1.9 bar at 120° C. to not more than 0.5% by weight, and c) injecting the devolatilized mixture at a temperature of from 80 to 160° C. into the mould of an injection moulding system and removing the resultant moulding from the mould.

Owner:ROEHM GMBH & CO KG +1

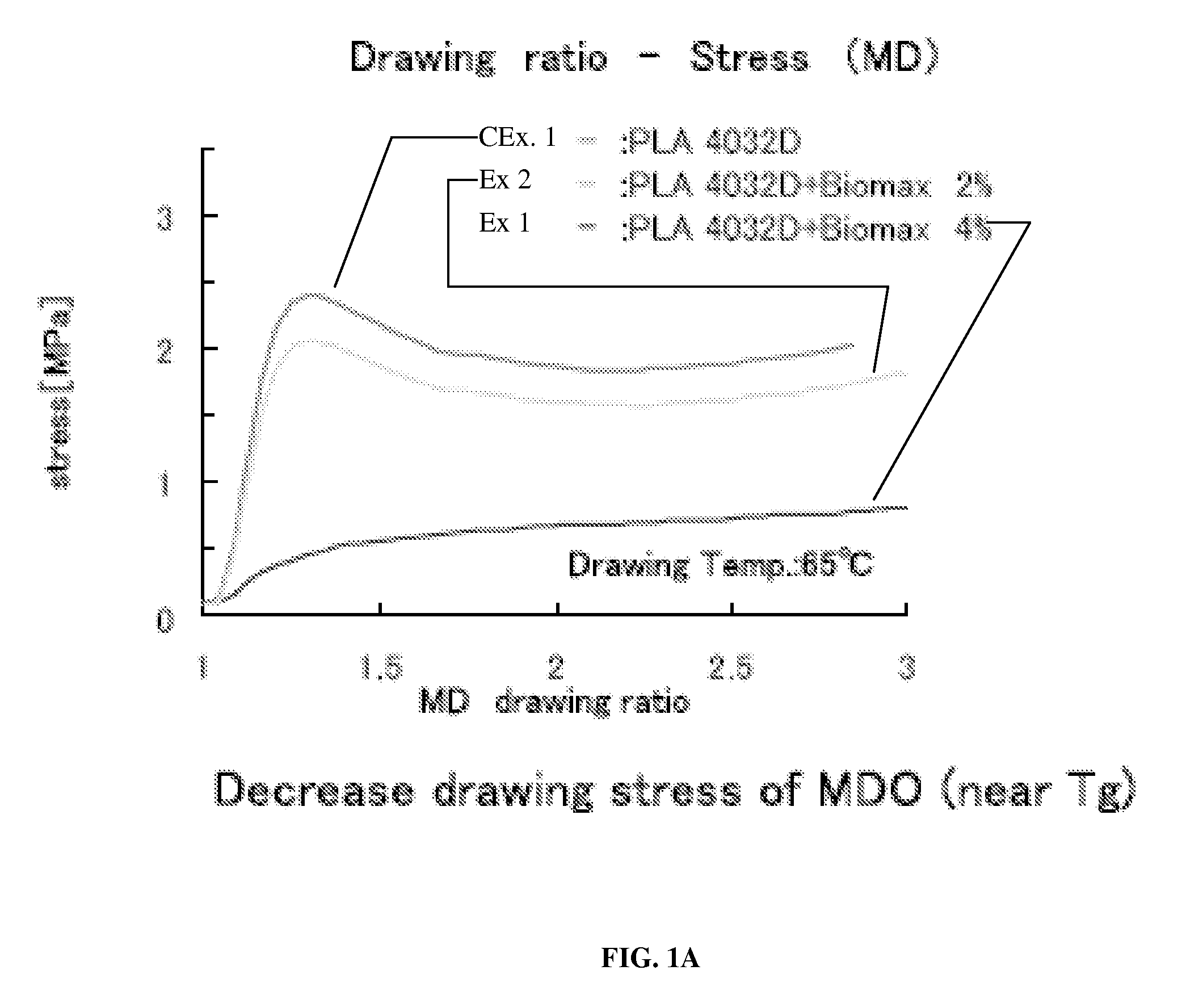

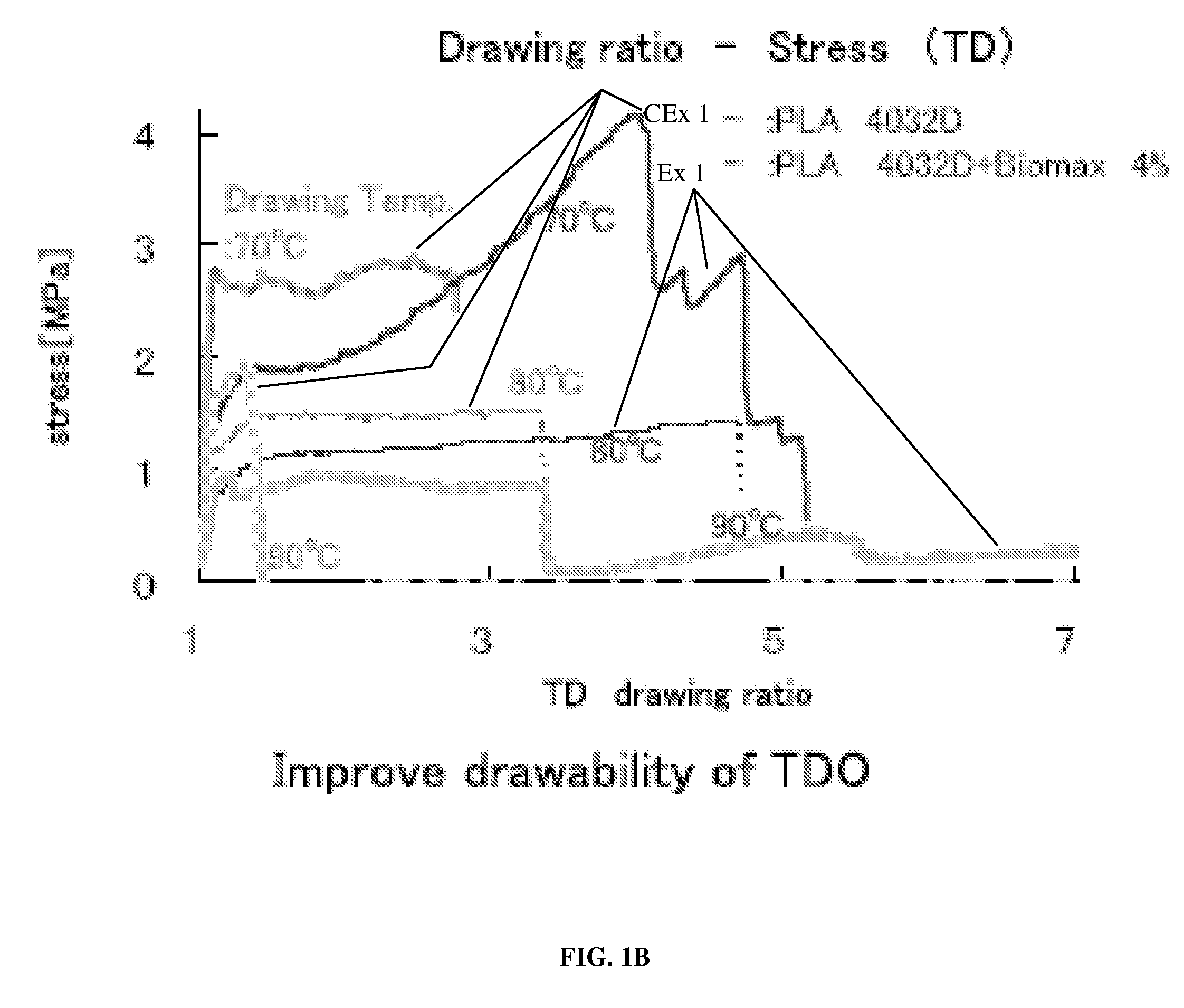

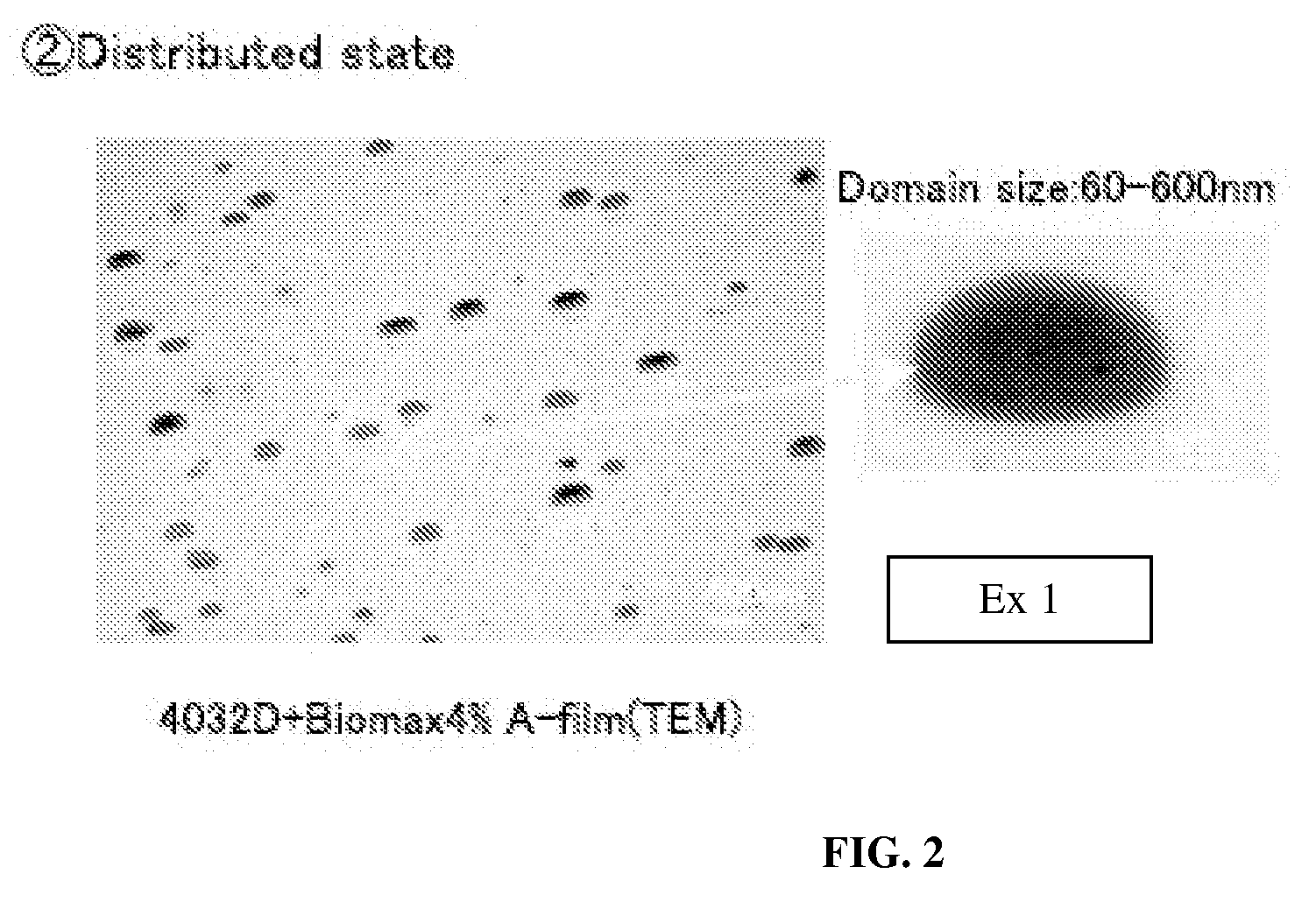

Process to produce biaxially oriented polylactic acid film at high transverse orientation rates

InactiveUS20090148715A1High rate of orientationEasy to stretchSynthetic resin layered productsDomestic articlesTransverse orientationEthylene

A biaxially oriented laminate film including a first amorphous polylactic acid polymer heat sealable resin layer and a second core layer including a blend of crystalline polylactic acid polymer and 2-10 wt % of the core layer of an ethylene-acrylate copolymer. The laminate film, exhibiting the property to be transverse oriented in excess of 6 times its original width, typically 8 to 10 times its original width with excellent operability and relatively low haze, is disclosed. The laminate film may further have additional layers such as a third polylactic acid resin-containing layer disposed on the side of the core layer opposite the heat sealable layer, a metal layer, or combinations thereof.

Owner:TORAY PLASTICS AMERICA

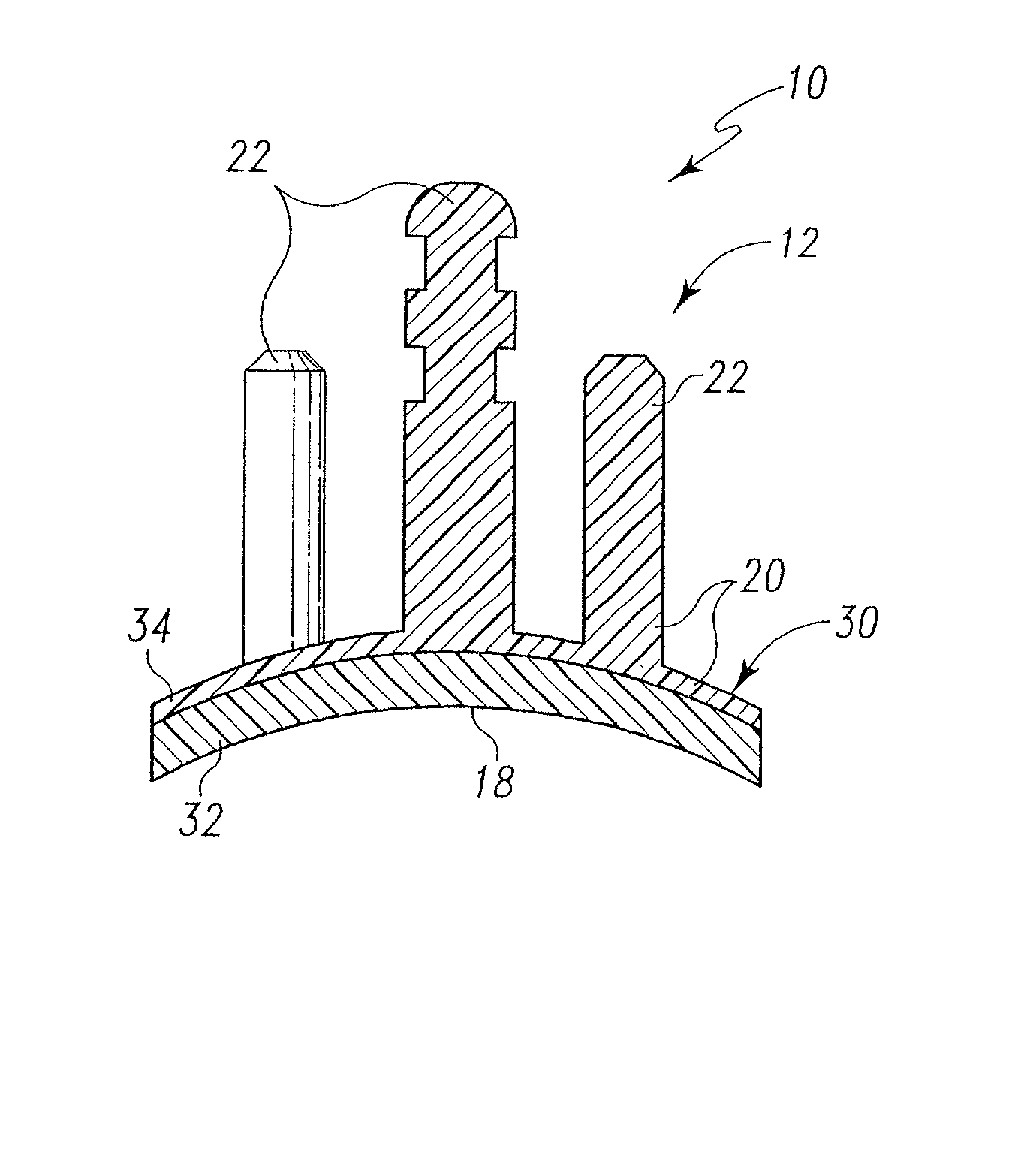

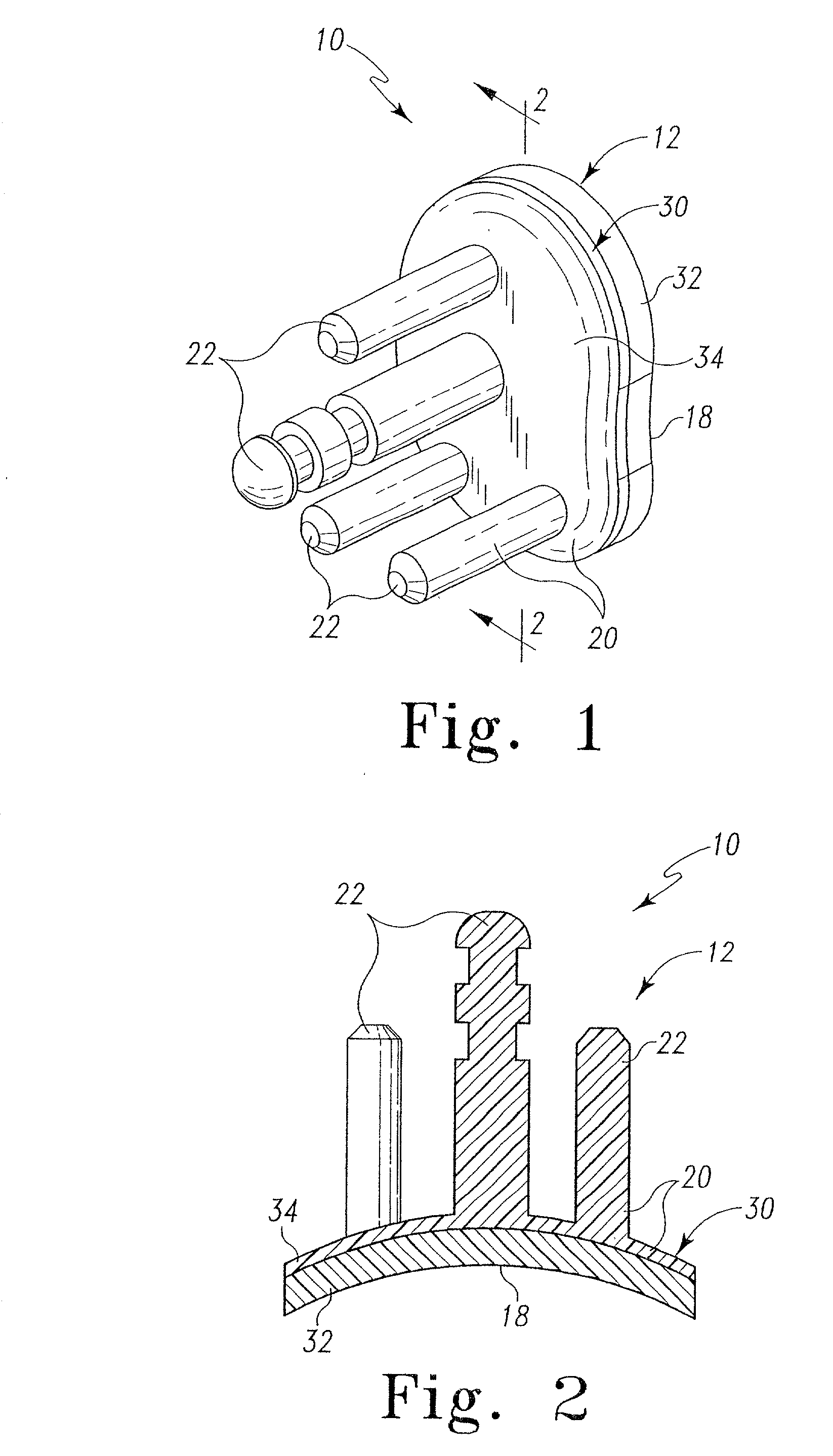

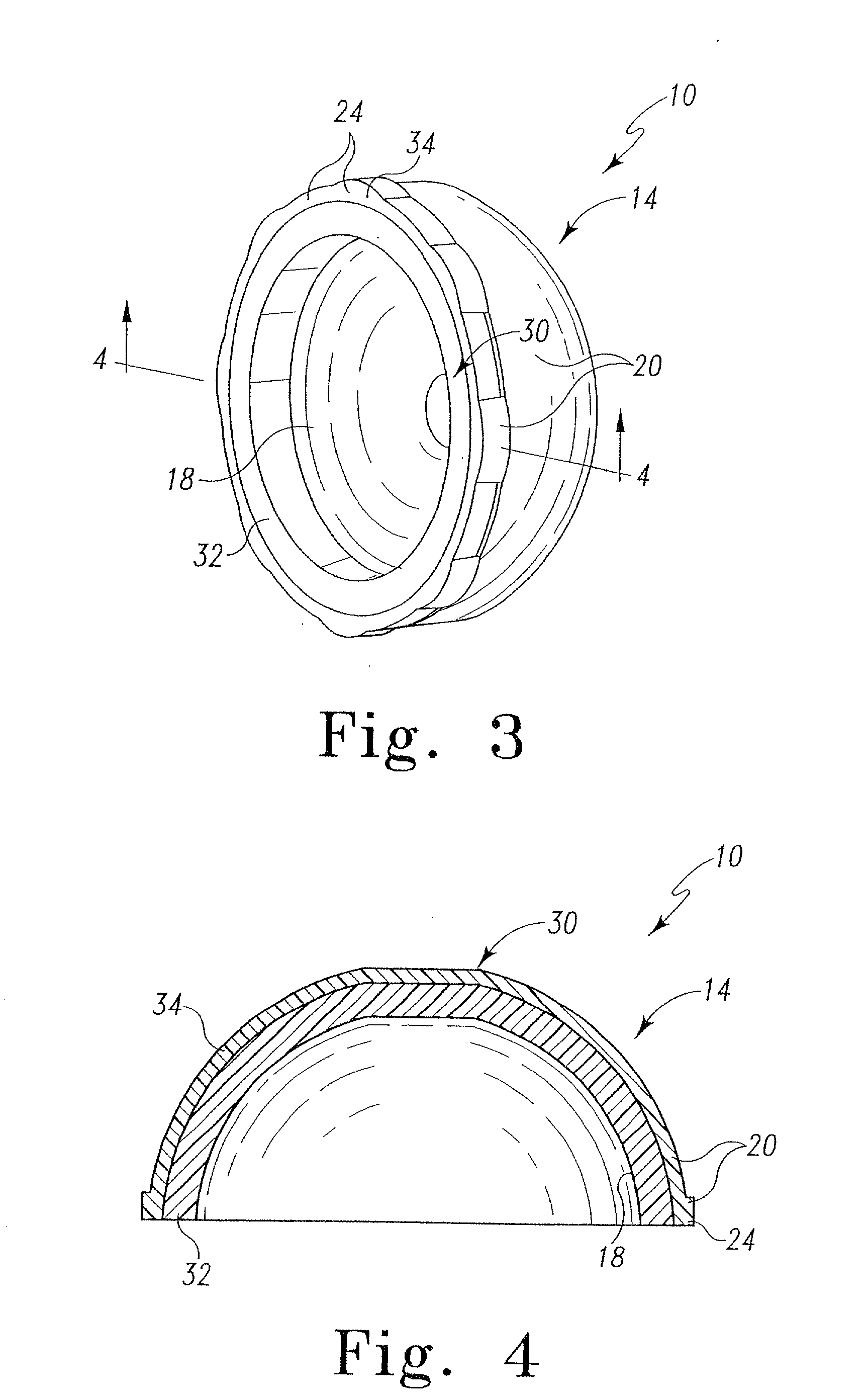

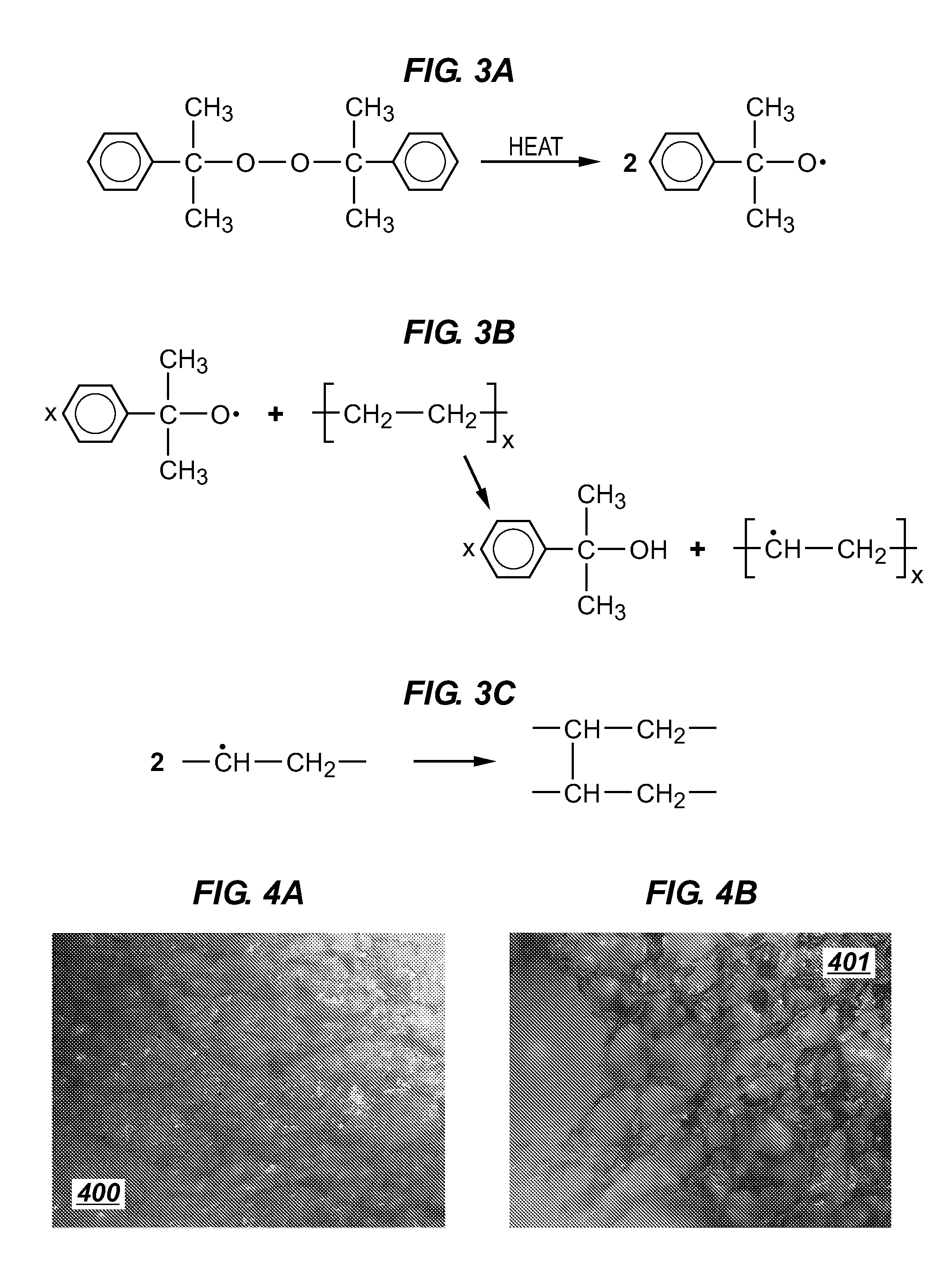

Composite prosthetic bearing constructed of polyethylene and an ethylene-acrylate copolymer and method for making the same

Owner:DEPUY SYNTHES PROD INC

Colorants for keratin fibers

InactiveUS20070006397A1Good conditionHigh viscosityCosmetic preparationsHair cosmeticsFiberCosmetic vehicle

The present patent application relates to an agent for the coloring of keratin fibers based on oxidative dye precursors and / or direct-penetrating dyes, that contains a combination of at least one cationic hydroxyethyl cellulose and at least one acrylate copolymer in a suitable cosmetic carrier as well as a multicomponent-kit for the coloring of keratin fibers.

Owner:THE PROCTER & GAMBLE COMPANY

Foam compositions for selective recovery of oil spills and other applications

InactiveUS20110287929A1Improve oil absorption capacityOther chemical processesSeawater treatmentSaline waterSalt water

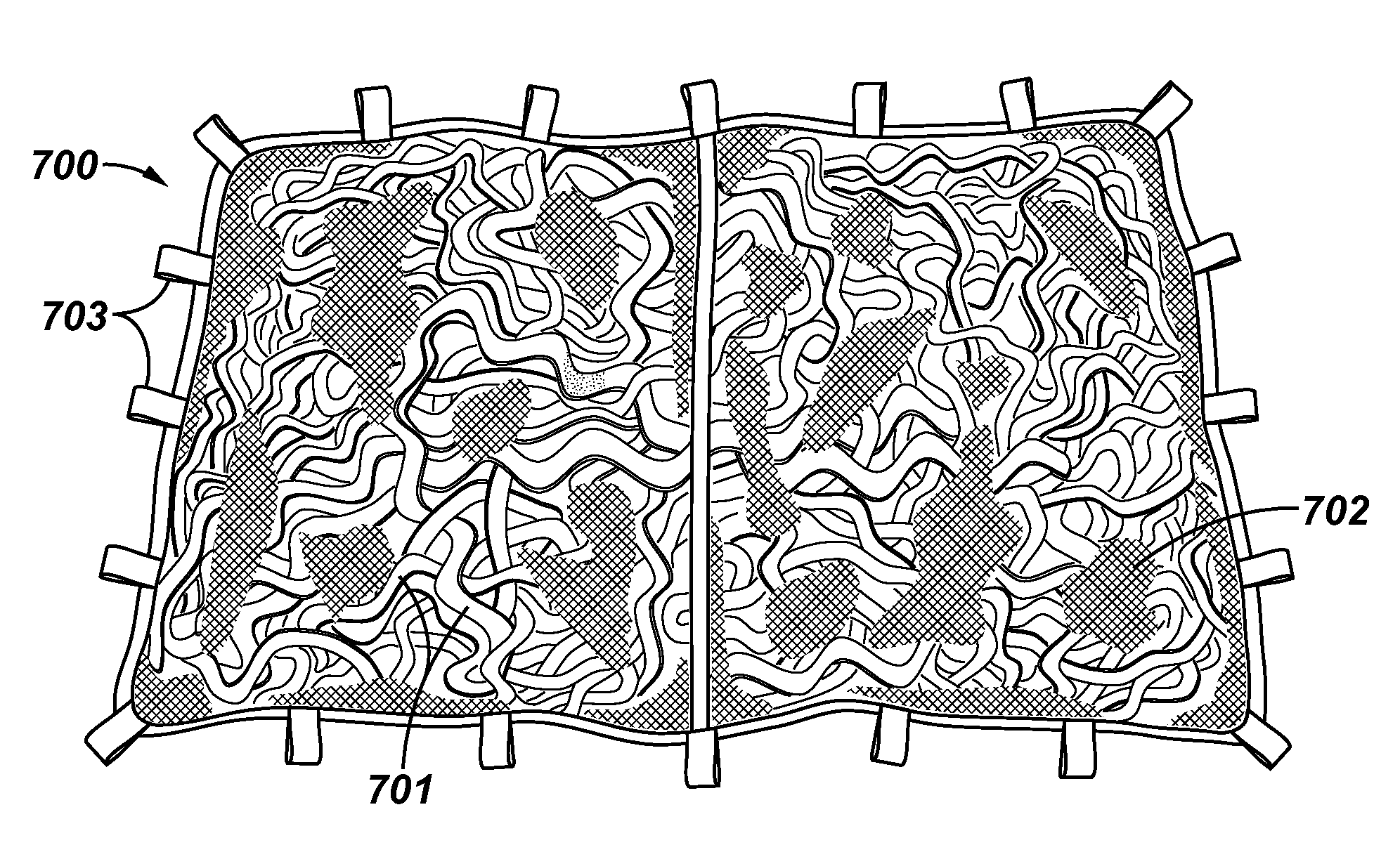

A polymer composition for use in the removal and recovery of oil slicks or spills floating on the surfaces of bodies of water or present on land, such as beaches comprising a foam of a blend of polyethylene and an ethylene-alkyl acrylate copolymer and a process for using such foams in the selective removal of oil from fresh water or salt water and the recovery of the absorbed oils from the foams is disclosed. The polymer composition is also for use in other applications in which absorption of liquids is desired.

Owner:OPFLEX TECH

Molding material containing a matting agent

The invention relates to a moulding composition, comprising a) 50 to 99.9% by weight of a matrix composed of a thermoplastic polymer and b) from 0.1 to 50% by weight of a matting agent in the form of a (meth)acrylate copolymer dispersed in the matrix, characterized in that the matting agent is a (meth)acrylate copolymer which has been prepared from the following monomers, b1) from 50 to 95% by weight of methyl methacrylate b2) from 5 to 50% by weight of C1-C6-alkyl acrylates b3) from 0.01 to less than 0.5% by weight of a crosslinking monomer and / or graft-linking agent having two or more ethylenically unsaturated radicals capable of free-radical polymerization, b4) from 0 to 20% by weight of one or more other, non-crosslinking ethylenically unsaturated monomers capable of free-radical polymerization, where the entirety of the constituents b1) and b2) and, where appropriate, b3) and / or b4) gives 100% by weight, and the glass transition temperature Tmg of the matting agent is at least 20° C.

Owner:ROEHM GMBH & CO KG

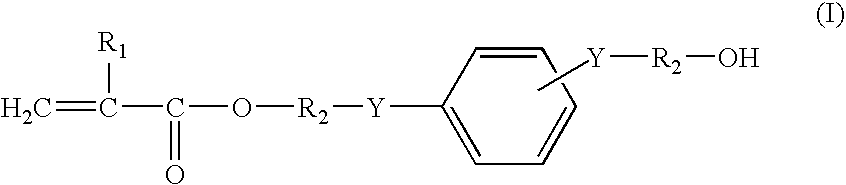

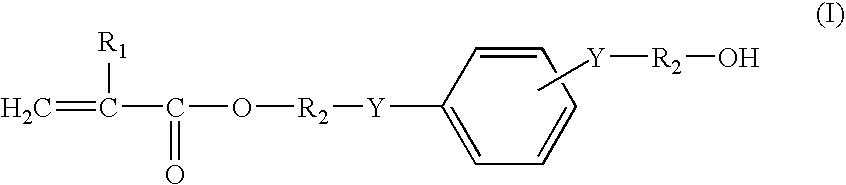

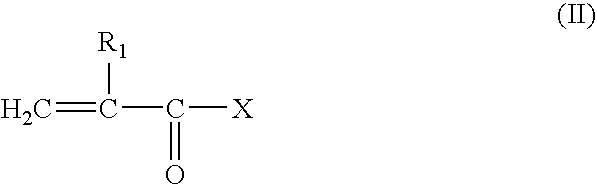

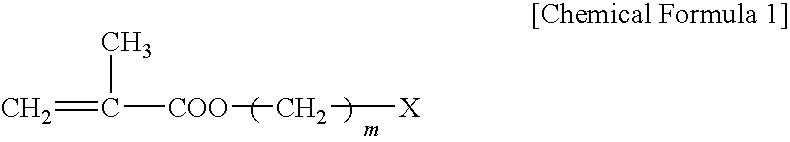

(Meth)Acrylate Compound and Process For the Production Thereof, (Meth)Acrylate Copolymer and Process For the Production of (Meth)Acrylate Copolymer, and Soft Intraocular Lens

ActiveUS20080139769A1High refractive indexAvoid it happening againOrganic compound preparationCarboxylic acid esters preparationMeth-Hydrogen atom

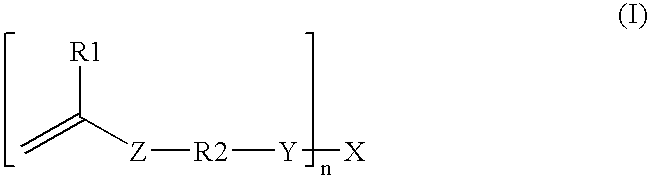

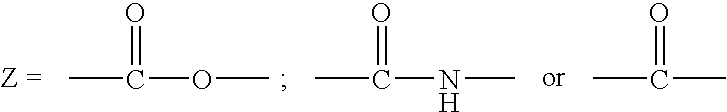

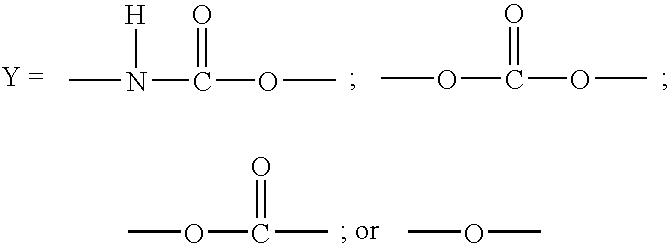

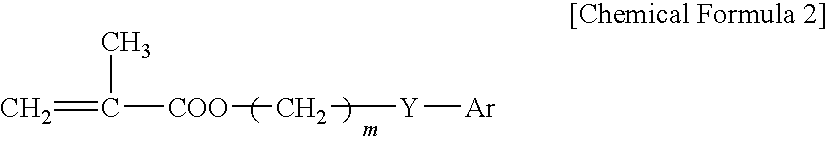

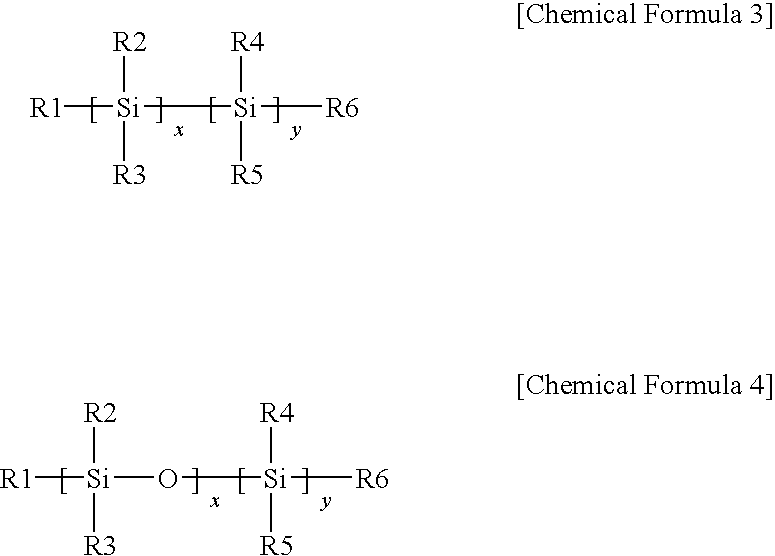

A (meth)acrylate copolymer obtained by copolymerization of a monomer mixture containing a monomer (A) of the general formula (I),wherein R1 is a hydrogen atom or methyl, R2 is a linear or branched alkylene group having 1 to 8 carbon atoms and Y is a single bond or an oxygen atom, a monomer (B) copolymerizable with the monomer (A) and a crosslinking monomer (C).

Owner:HOYA CORP

Barrier coating for thermoplastic films

The present invention generally relates to a barrier coating composition for application to a thermoplastic film comprising (a) a nano-clay additive in an amount from about 1 wt % to 50 wt % of said barrier coating, wherein said nano-clay additive comprises untreated nano-clay platelets; and (b) a base coating in an amount from about 50 wt % to 99 wt % of said barrier coating, wherein said base coating comprises a polymer selected from the group consisting of polyvinylidene chloride (PVdC), poly(vinyl)alcohol (PVOH), ethylene vinyl alcohol (EVOH), acrylate copolymers and mixtures thereof.

Owner:JINDAL FILMS AMERICAS LLC

Compositions with freeze thaw stability

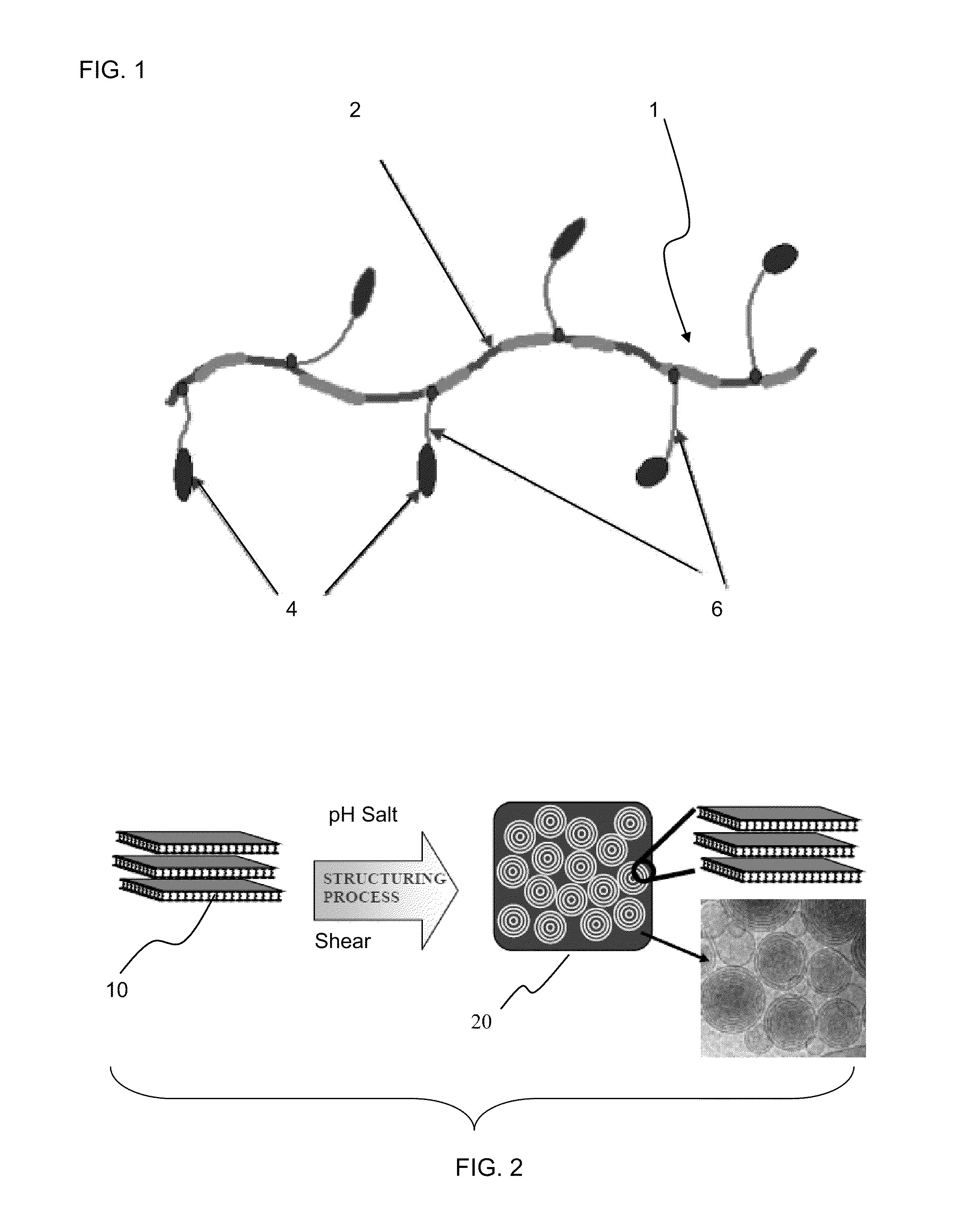

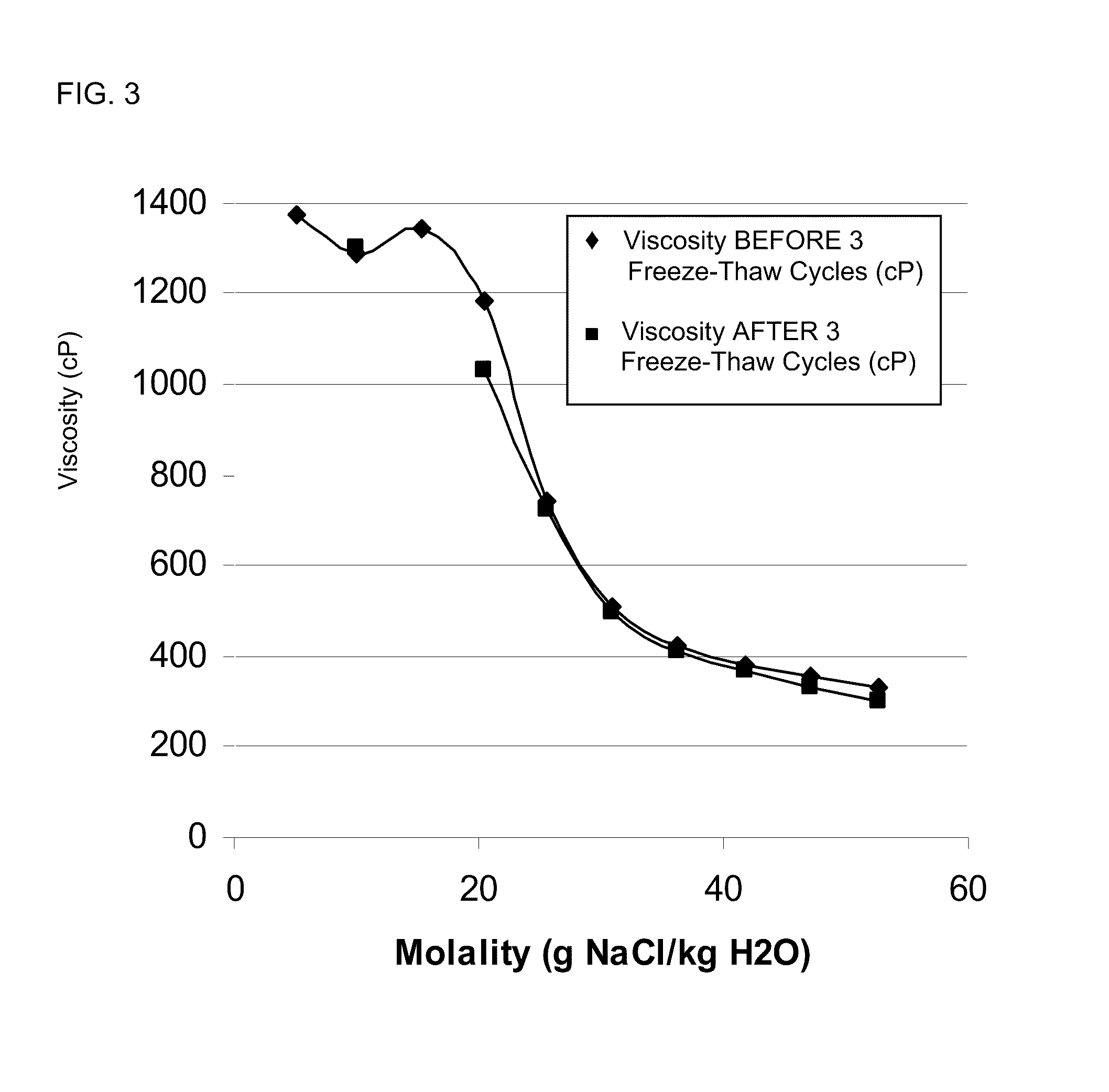

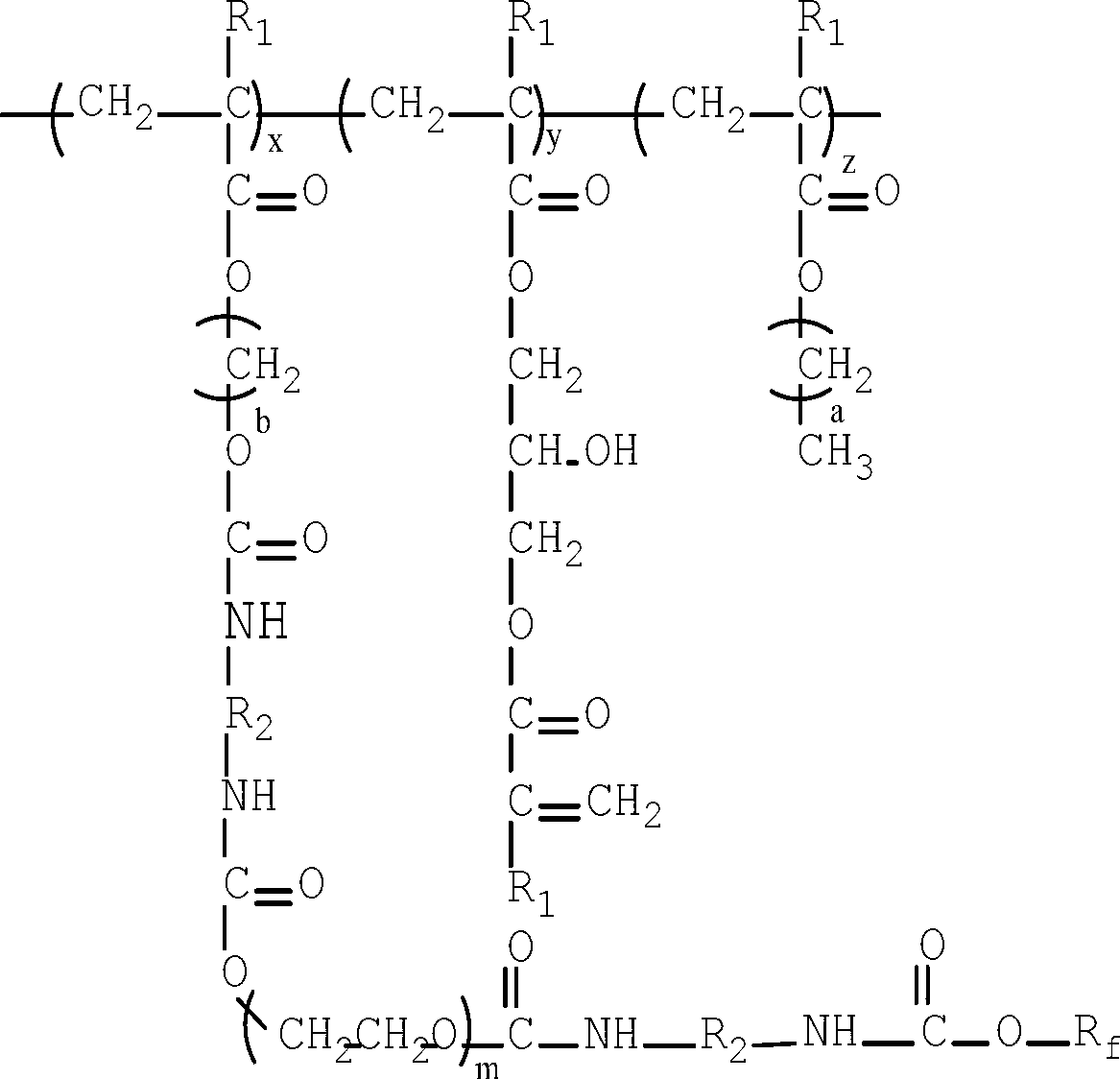

ActiveUS20110223125A1Reduce the amount requiredCosmetic preparationsHair cosmeticsPolymer scienceSide chain

Composition including freeze thaw stability polymer such as a copolymer having a weight average molecular weight of at least about 30,000 grams per mole, a blend of a first polymer and a second polymer, a crosslinked alkali swellable acrylate copolymer, or at least one polymerizable reactive alkoxylated acrylate monomer. The copolymer has one or more first monomeric units and one or more second monomeric units. The one or more first monomeric units each independently including at least one bicycloheptyl-polyether, bicycloheptenyl-polyether or branched (C5-C50)alkyl-polyether group per monomeric unit. The bicycloheptyl-polyether or bicycloheptenyl-polyether group may optionally be substituted on one or more ring carbon atoms by one or two (C1-C6)alkyl groups per carbon atom. The one or more second monomeric units each independently including at least one pendant linear or branched (C5-C50)alkyl-polyether group per monomeric unit. The first and second monomeric units do not both have branched (C5-C50)alkyl-polyether group.

Owner:RHODIA OPERATIONS SAS

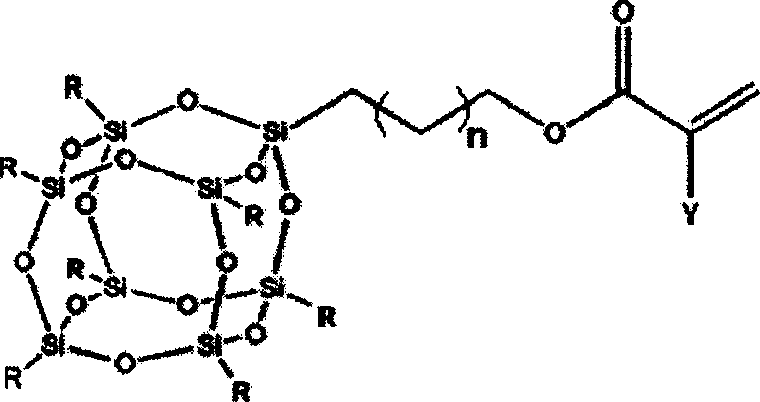

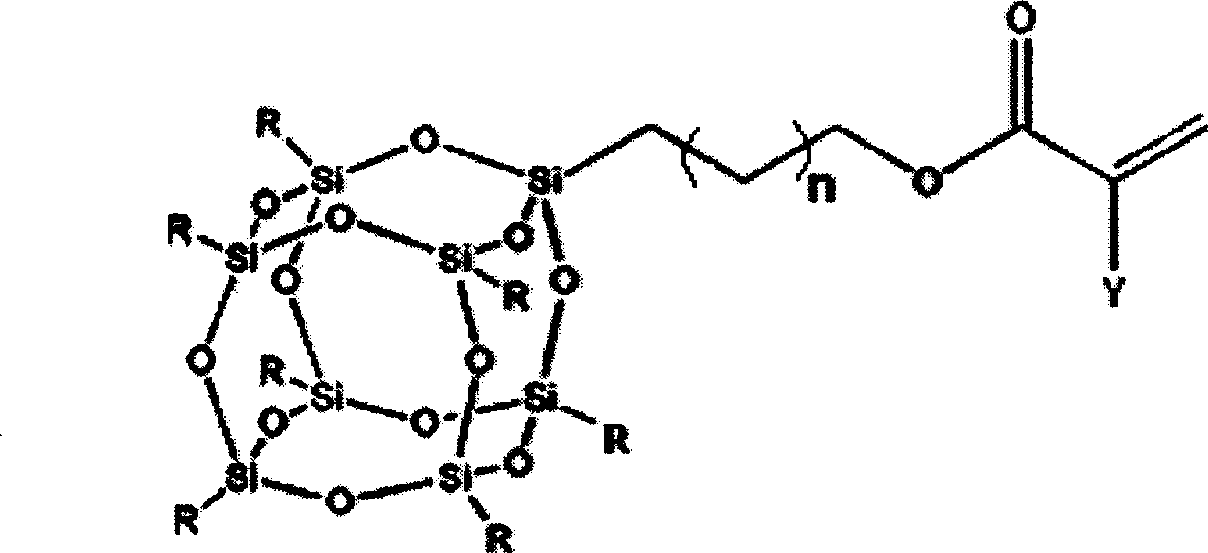

Coating material containing POSS acrylate copolymer and preparing method

The invention relates to a manufacturing method for coat material containing POSS acrylate copolymer. It takes free radical copolymerized to acr monomer and other acr monomer, and uses as modifier adding into the base compounding of UV coat, after taking UV solidification the coat material of high rigidity would be gained. The constituent includes 40-55% light-cured resin, 5-20% active modifier, 20-45% spike, 1-10% photoinitiator, 2-10% anti-foam additive. The rigidity of coat could reach to 6H, and the shrinkage ratio could reach 2%.

Owner:XIAMEN UNIV

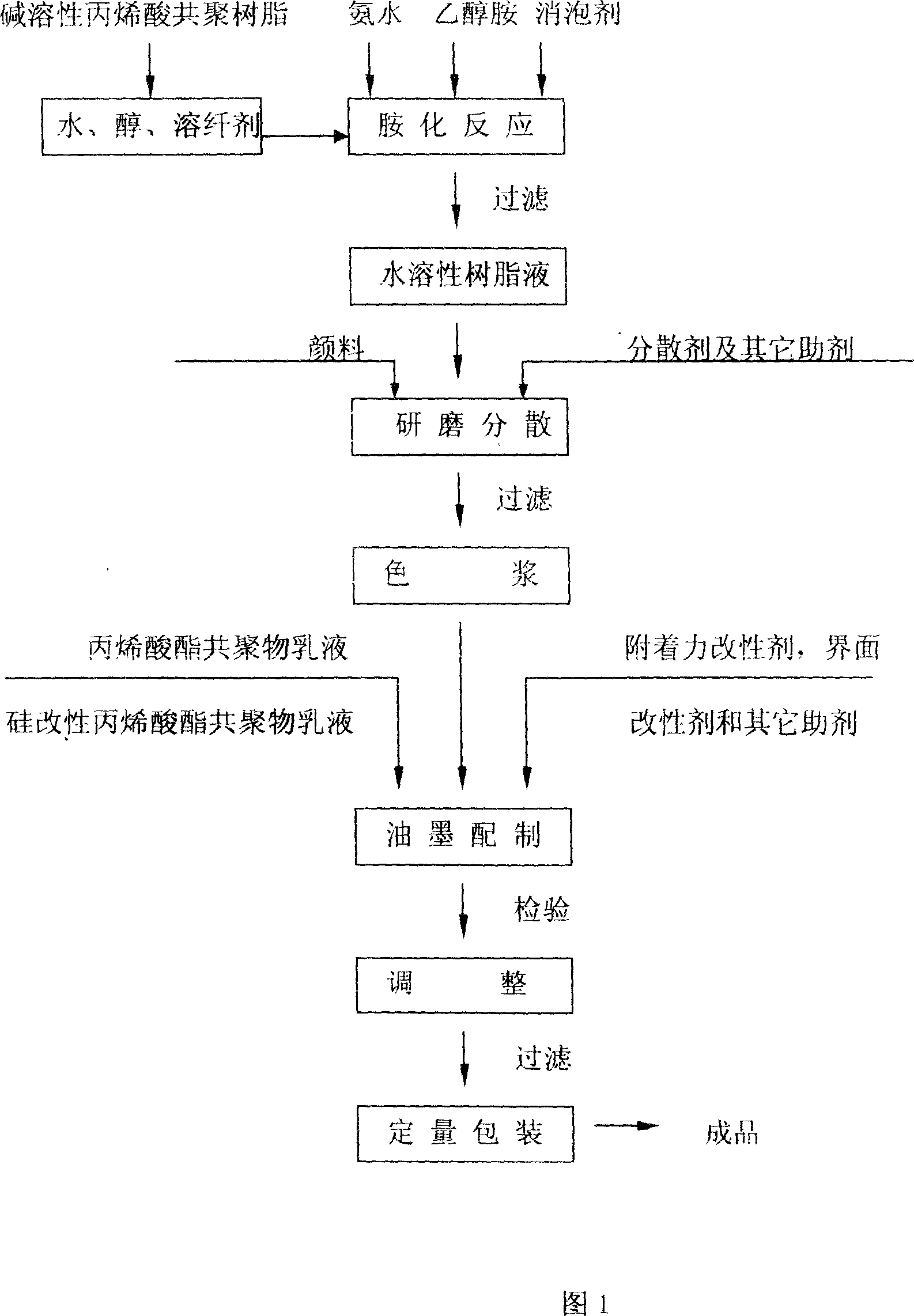

Plastic-film water intaglio printing ink

InactiveCN101029194AImprove adhesion fastnessImprove stabilityInksOther printing apparatusEmulsionDispersed media

A water plastic-film intaglio printing ink consists of alkali soluble acrylic copolymer, low-Tg value acrylate copolymer emulsion, high-Tg value acrylate copolymer emulsion, silicon modified acrylate copolymer emulsion as grinding dispersing medium and filming medium. Adhesion modifier, interface modifier and other various accessories are added into ink and the ink can be produced proportionally for red ink, yellow ink, blue ink, black ink and other-color inks. It has bright color, better saturation degree, alkali-resistance and dispersion.

Owner:BEIJINGYINGKEFAN CHEM PRODS

Photoprotective compositions with glycol and styrene/acrylate copolymer

InactiveUS20090202459A1Improve performanceCosmetic preparationsToilet preparationsLength waveOrganic chemistry

A photoprotective composition includes one or more photoactive agents (such as a UV filter compound), one or more optimizing agents, and a copolymer booster. Such a composition provides an unexpected synergistic combination of the one or more optimizing agents and the copolymer booster for increasing at least one of SPF, UVA / UVB ratio, critical wavelength, photostability of UVA absorber and PFA, and any combinations thereof, of the composition.

Owner:EVEREADY BATTERY CO INC

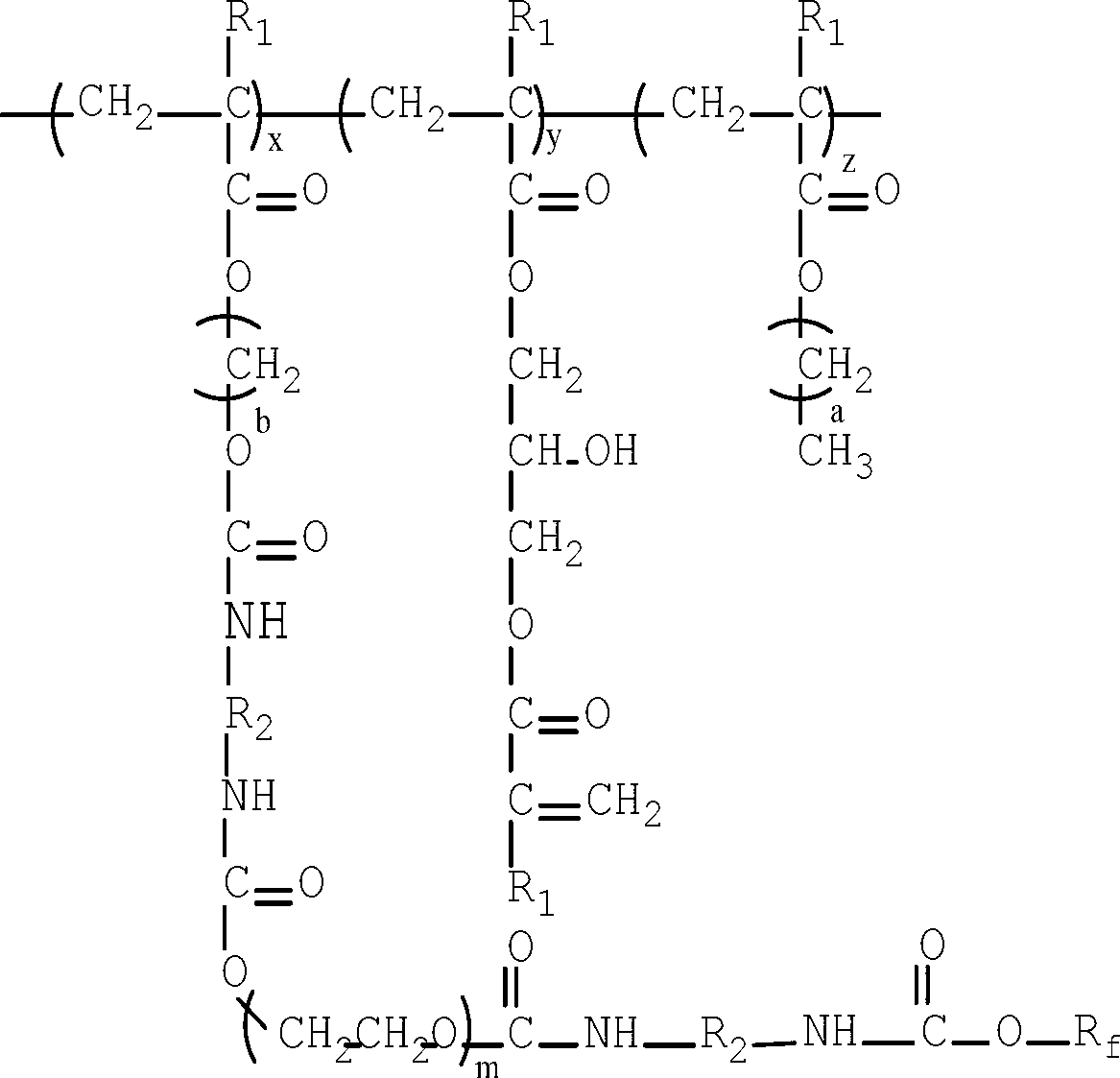

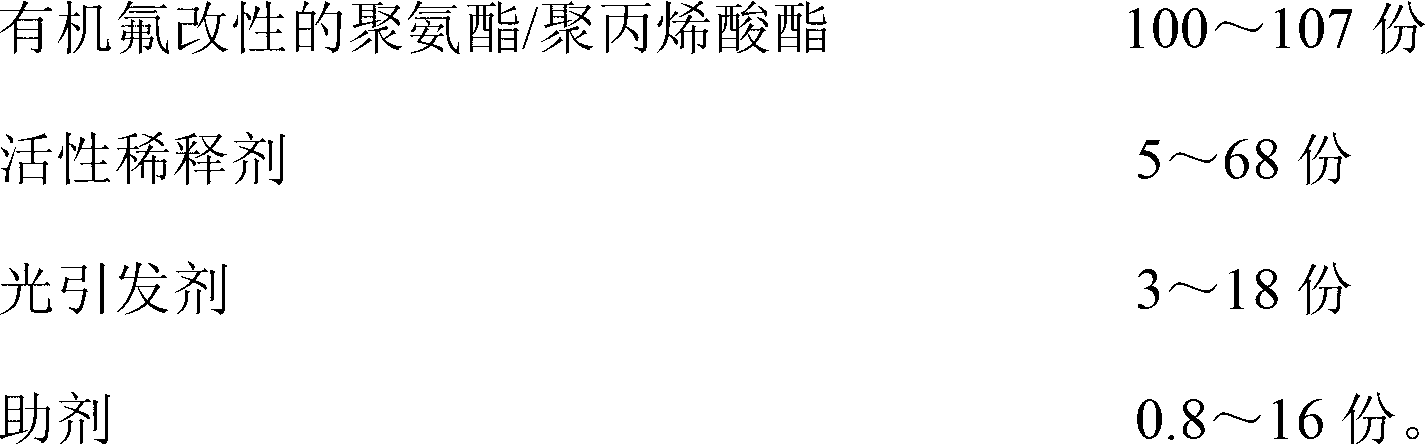

Polyurethane/polyacrylate copolymer modified by organic fluoride and ultraviolet curing coating prepared by polyurethane/polyacrylate copolymer

The invention belongs to the field of coatings, and particularly relates to a polyurethane / polyacrylate copolymer modified by organic fluoride and an ultraviolet curing coating prepared by the polyurethane / polyacrylate copolymer. A method for preparing the polyurethane / polyacrylate copolymer modified by organic fluoride comprises the following steps: 1), preparing a polyurethane prepolymer modified by organic fluoride; 2), preparing a (methyl) acrylate prepolymer; and 3), preparing the polyurethane / polyacrylate copolymer modified by organic fluoride. A method for preparing an ultraviolet curing agent by taking the polyurethane / polyacrylate copolymer modified by organic fluoride as a raw material comprises the steps that taking 100-107 parts of polyurethane / polyacrylate, 50-68 parts of an reactive diluent, 13-18 parts of a photoinitiator and 8-16 parts of an auxiliary; stirring fully for 5-15 minutes until all the materials are mixed uniformly; and obtaining the polyurethane / polyacrylate copolymer modified by organic fluoride and the ultraviolet curing coating prepared by the polyurethane / polyacrylate copolymer.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

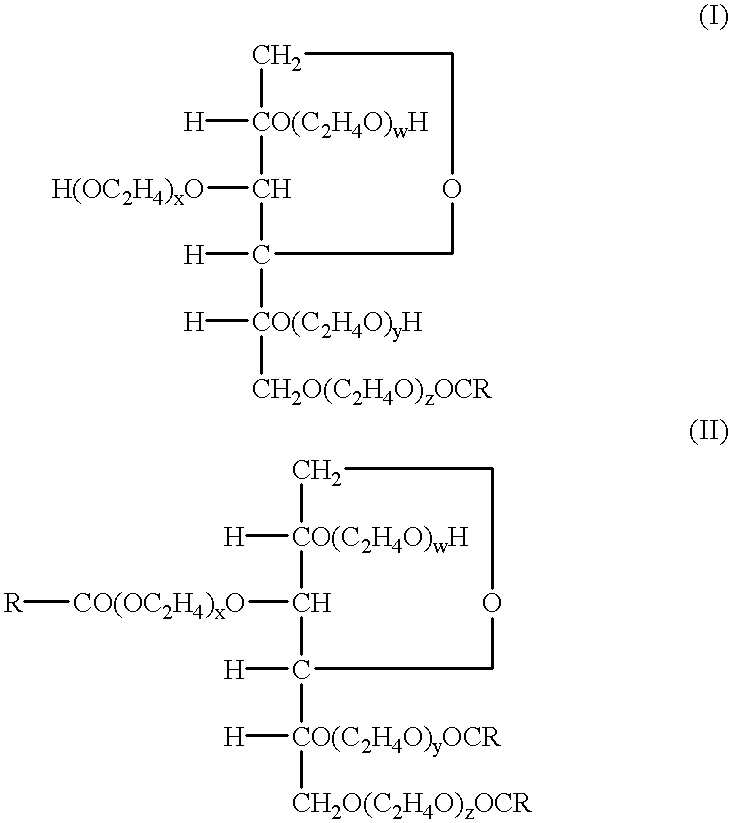

Hydrocolloid adhesive mass useful for medical purposes

The present invention relates to a novel hydrocolloid adhesive mass useful for medical purposes, characterized in that said hydrocolloid adhesive mass comprises:a) 0.2 to 5 parts by weight of an ethoxylated sorbitan fatty acid ester;b) 20 to 50 parts by weight of a hydrocolloid;c) 32 to 120 to parts by weight of an adhesive matrix made up of one or more polymers selected from poly(styrene / olefin / styrene) block copolymers, low-molecular polyisobutylenes and high-molecular polyisobutylenes, and one or more compounds selected from sticky resins, or tackifying resins, plasticizers, polybutenes, antioxidants, ethylene / vinyl acetate copolymers, butyl rubbers and ethylene / propylene block copolymers; andd) 0 to 15 parts by weight of an acrylate copolymer with a glass transition temperature below -20° C. It further relates to the use of this hydrocolloid adhesive mass for the production of dressings, especially for the treatment of superficial, deep, chronic or acute dermo-epidermal lesions, exudative wounds and bums.

Owner:LABORATOIRE URGO

Blends of ethylene copolymers with high-frequency weldability

InactiveUS20060160952A1Use welding processingWoven fabricsEmulsion paintsMeth-Ethylenevinylacetate copolymer

Disclosed are high frequency-active blends comprising (a) copolymers of ethylene and maleic anhydride or its functional equivalents and (b) ethylene copolymers with polar comonomers such as ethylene / vinyl acetate copolymers, ethylene / alkyl (meth)acrylate copolymers and ethylene / (meth)acrylate / carbon monoxide terpolymers; and films, powders, multilayer structures, and articles prepared therefrom.

Owner:PERFORMANCE MATERIALS NA INC

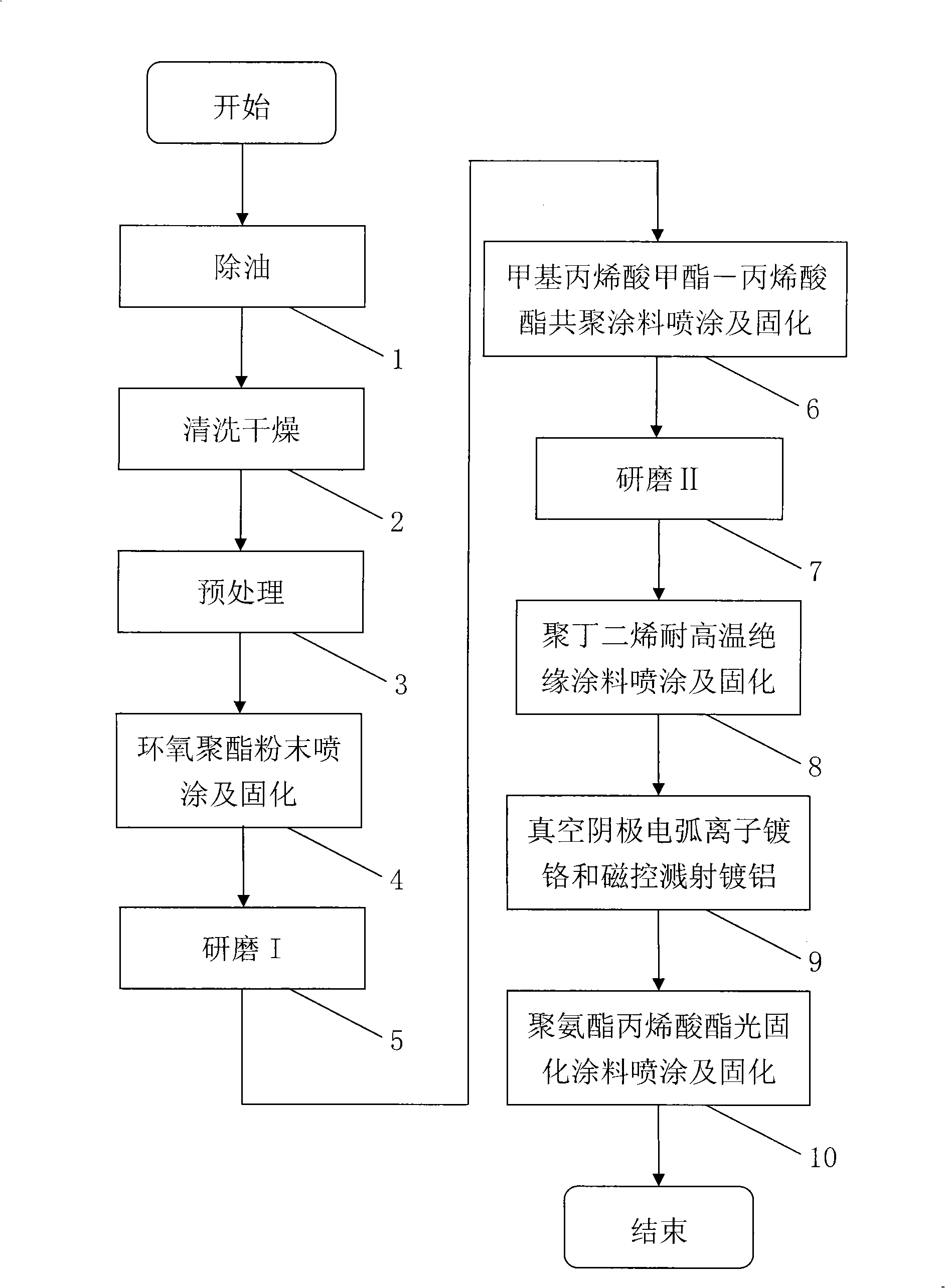

Film coating process for aluminium alloy wheel hub

InactiveCN101343740AReduce pollutionReduce energy consumptionVacuum evaporation coatingSputtering coatingPolyesterFilm coating

The invention discloses an aluminum alloy wheel hub coating technology. The aluminum alloy wheel hub coating technology comprises the procedures of oil removing, cleaning and drying, pre-treating, epoxy polyester powder spraying and solidifying, grinding I, methyl methacrylate-acrylate copolymer paint spraying and solidifying, grinding II, polybutadiene high temperature resistant insulating coating spraying and solidifying, vacuum cathode arc ion chromium plating and magnetism control sputtering aluminum plating, and polyurethane methacrylate light solidifying paint spraying and solidifying in sequence. The aluminum alloy wheel hub coating technology adopts dry electric plating to replace the traditional wet electric plating, the plating layer surface quality and the physical and chemical properties are approximately equivalent to the wet electric plated aluminum alloy wheel hub, the chromium consumption is reduced to about one fifth of the wet electric plating, the water consumption is reduced to about one seventh of the wet electric plating, precious nickel and copper are not utilized, the poisonous metal substance such as hexavalent chromium is not contained, the pollution to the environment is reduced, the energy, water and precious metal consumption is remarkably reduced, the technological flow is simplified, the production efficiency is enhanced, the heavy polishing working sequence is omitted, the working condition is remarkably improved, and the cost is reduced.

Owner:HUZHOU JINTAI PLATING IND

Multifunctional concrete structure endurance protective agent, preparation and application method thereof

The invention discloses a multifunctional concrete structure endurance protective agent as well as the preparation and application method thereof. The protective agent provided by the invention contains the following ingredients of: an organic / inorganic composite fluorosilicone-acrylate copolymer, lithium silicate, sodium silicate, lithium molybdate, sodium tetraborate, sal glauberi, 1,2-aminoazophenylene, nanometer titanium dioxide, anhydrous ethanol and water. The protective agent can penetrate inside concrete, wherein a densification ingredient can minimize internal holes and cracks to raise the compactness of concrete, and a rust-resistant ingredient can penetrate into concrete and be adsorbed on the surface of steel bar so as to passivate and protect the steel bar; the low-surface energy silicon fluoride ingredient can be solidified to form a cured film on the surface of concrete so as to endow the protective agent with the hydrophobic performance; a nanometer ingredient can endow the cured film layer with properties of resisting ultraviolet and ageing and improving the organic polymer performance as well as the self-cleaning performance. In addition, hydroxy generated from the hydrolysis of siloxane group can perform a condensation reaction with hydroxy on the surface of concrete to produce chemical bond, so as to raise the anchoring strength between the film and concrete and improve the interface combination. The protective agent provided by the invention can be widely applied in various concrete structure engineering protections to raise the service life of concrete.

Owner:CENT SOUTH UNIV +1

Branched (Meth)acrylate Copolymer with High Refractive Index and Method for Preparing the Same

Disclosed herein is a branched (meth)acrylate copolymer prepared by polymerizing a monomer mixture comprising (A) about 20 to about 99.999% by weight of a (meth)acrylate monomer having a refractive index higher than methyl methacrylate; (B) about 0 to about 79.999% by weight of a mono-functional unsaturated monomer; and (C) about 0.001 to about 10% by weight of a crosslinking monomer. The copolymer has a refractive index of about 1.495 to about 1.590.

Owner:LOTTE ADVANCED MATERIALS CO LTD

Adhesives with improved rivet properties and laminates using the same

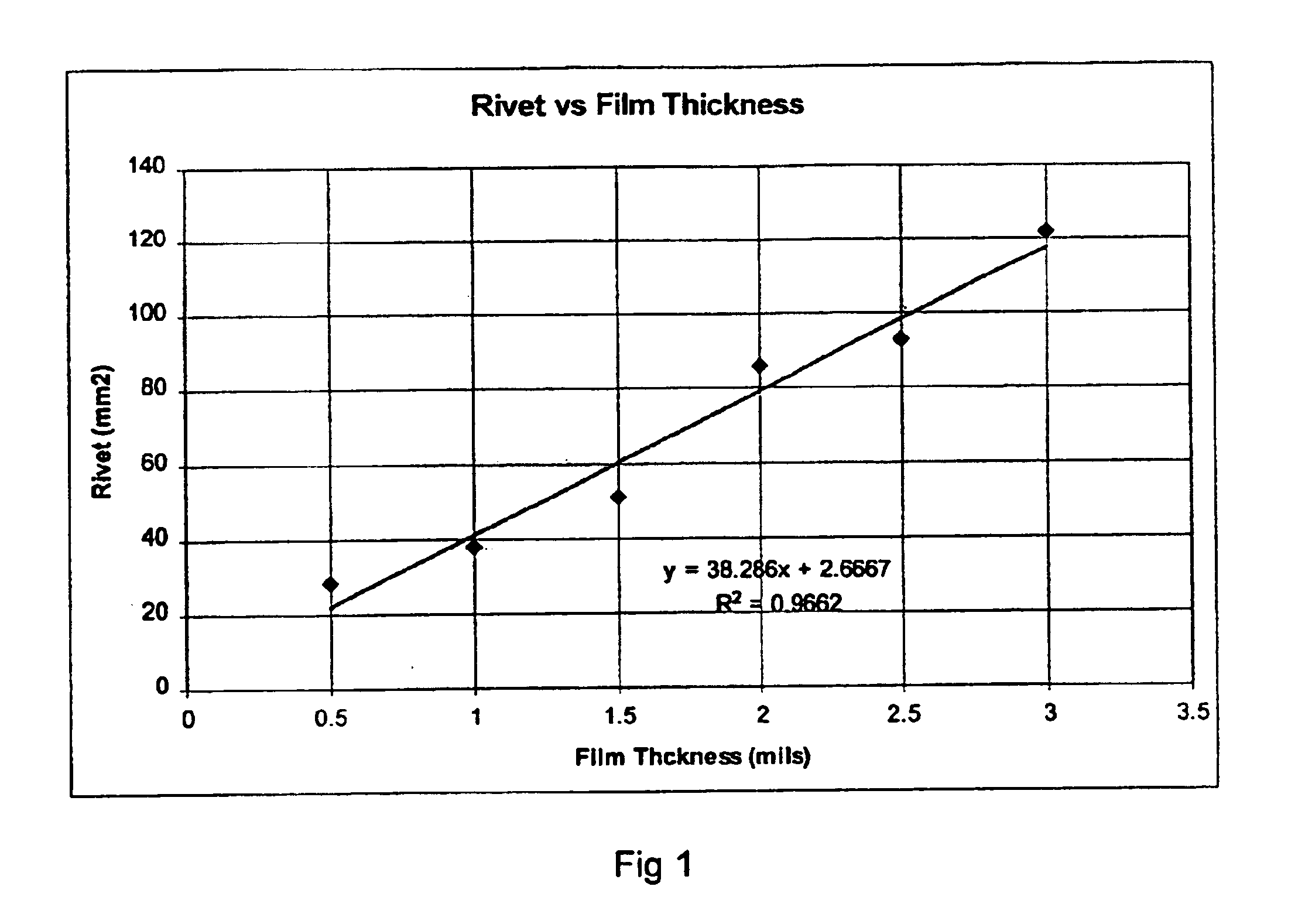

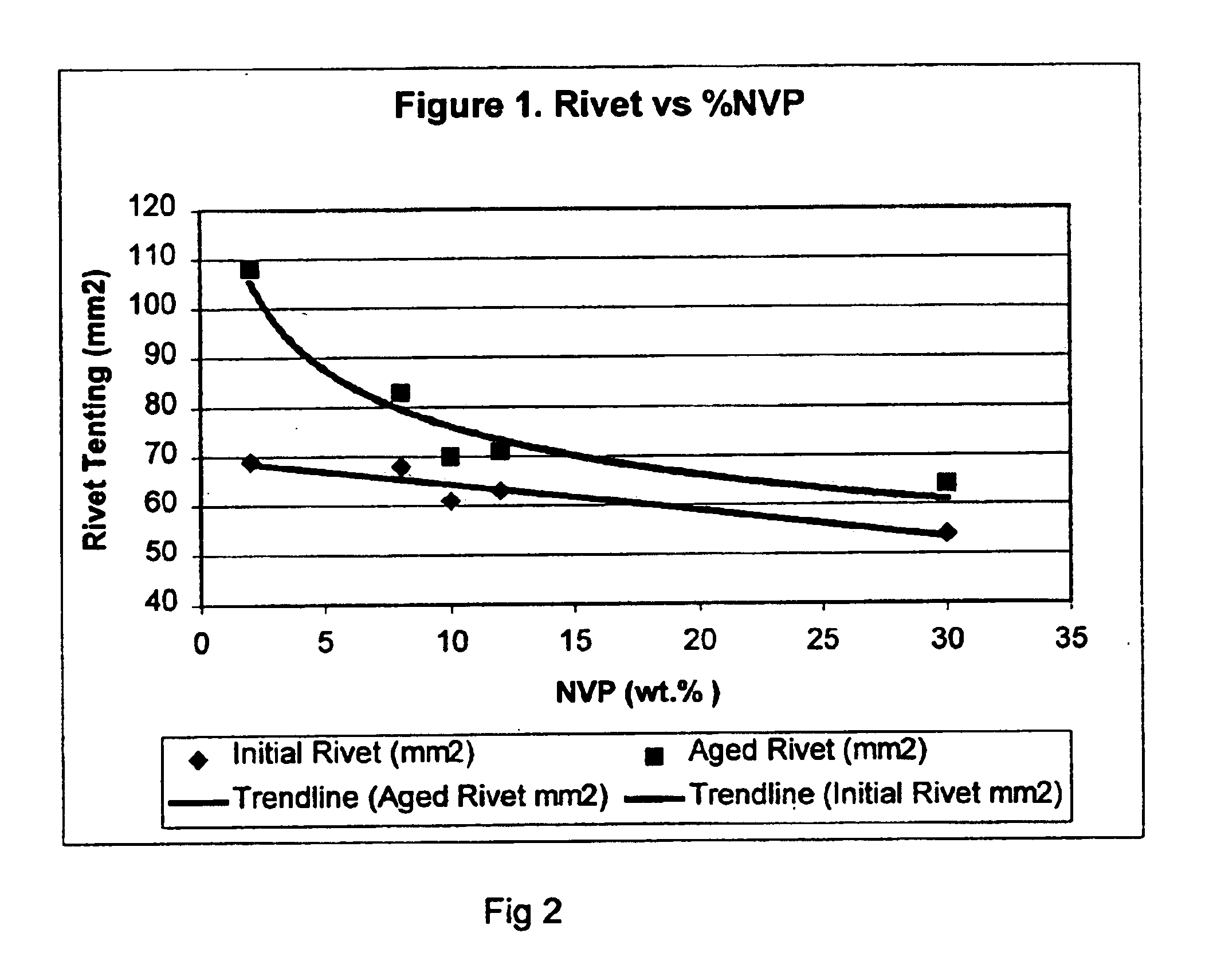

InactiveUS6844391B1Improve performanceOutstanding removal characteristicLiquid surface applicatorsChemical liquid solidificationMethacrylateCohesive strength

Acrylate copolymer pressure-sensitive adhesive constructions are described which provide excellent retention of rivet properties. Tenting around rivets is minimized even after undergoing thermal aging while in contact with additive rich films like PVC. This is achieved by the inclusion of a synergistic amount of an N-vinyl lactam monomer and acid monomer with the bulk of the monomers being an alkyl acrylate save and / or methacrylate esters. A concomitant increase in cohesive strength is also achieved which affords good removal characteristics. The use of appropriate adhesive blends is further disclosed which allows retention of these features while also improving cold temperature properties.

Owner:AVERY DENNISON CORP

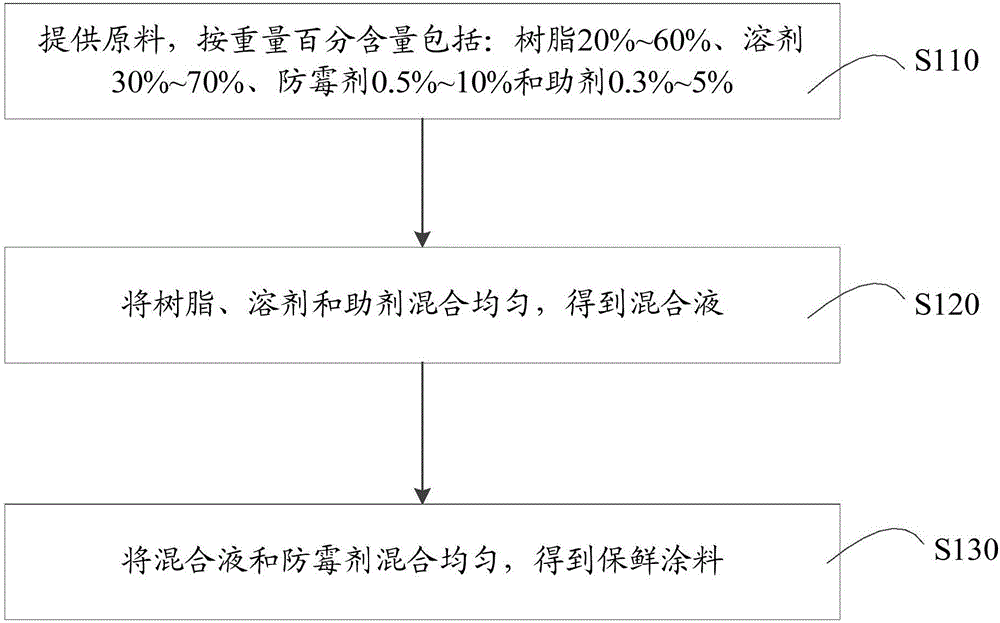

Mildewproof preservative film and preparation method thereof

InactiveCN106634129AIncrease contactNo porosityAntifouling/underwater paintsPaints with biocidesCarvacryl acetateSolvent

The invention discloses a mildewproof preservative film and a preparation method thereof. The mildewproof preservative film comprises a base layer and a mildewproof preservative coating arranged on the base layer, wherein the mildewproof preservative coating is prepared from a mildewproof preservative paint. The mildewproof preservative paint comprises the following components in percentage by weight: 20-60% of resin, 30-70% of solvent, 0.5-10% of mildew preventive and 0.3-5% of aid. The resin is composed of at least one of polyurethane, an acrylate copolymer, polyvinyl alcohol, polyvinylidene chloride, modified polyvinylidene chloride, an ethylene-vinyl acetate copolymer, a polyvinyl acetate copolymer and a vinyl acetate-butyl ester copolymer; and the solvent is composed of at least one of water and ethanol. The mildewproof preservative coating of the mildewproof preservative film has the advantages of compact surface and no void; and by adding the mildew preventive, the mildewproof preservative coating has the favorable effects of keeping the moisture constant and preventing mildewing. The mildewproof preservative film is especially suitable for preserving fruits, bread, tobacco and other foods which have shorter storage period, can easily mildew in a short time and need to be eaten in time.

Owner:CHANGDE JINRUN NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com