Patents

Literature

288results about How to "Improve adhesion fastness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

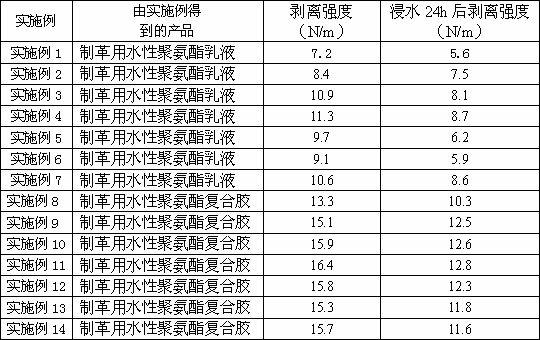

Water-based polyurethane composite adhesive for tanning and preparation method and application of composite adhesive

InactiveCN102618202ATroubleshoot MigrationOvercome the problem that the performance cannot fully meet the requirements of useNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePolyol

The invention discloses water-based polyurethane composite adhesive for tanning and a preparation method and application of the composite adhesive, belongs to the technical field of water-based polyurethane composite adhesive preparation methods, and in particular relates to a method for preparing composite adhesive in the fields of artificial leather and synthetic leather. The method for preparing the water-based polyurethane composite adhesive for tanning is characterized by comprising the following steps of: reacting polyol polymer and isocyanate, adding chain extender, hydrophilic chain extender, cross linker, catalyst and solvent, reacting, cooling and emulsifying, to obtain emulsion; and mixing the emulsion, curing agent, wetting agent, tackifier, adsorbent and thickening agent uniformly, and thus obtaining the hot-melt adhesive for artificial leather adhesive layers. The water-based polyurethane composite adhesive for tanning is used for compounding polyvinyl chloride (PVC) / cloth for artificial leather of luggage and clothes. The prepared water-based polyurethane composite adhesive for tanning has high adhesive fastness and good water and solvent resistance, and can be applied to processes of knife coating, roll coating and the like of binding materials of middle layers of artificial leather and synthetic leather in the fields of textiles, leather processing and the like.

Owner:江阴市诺科生物新材料科技有限公司

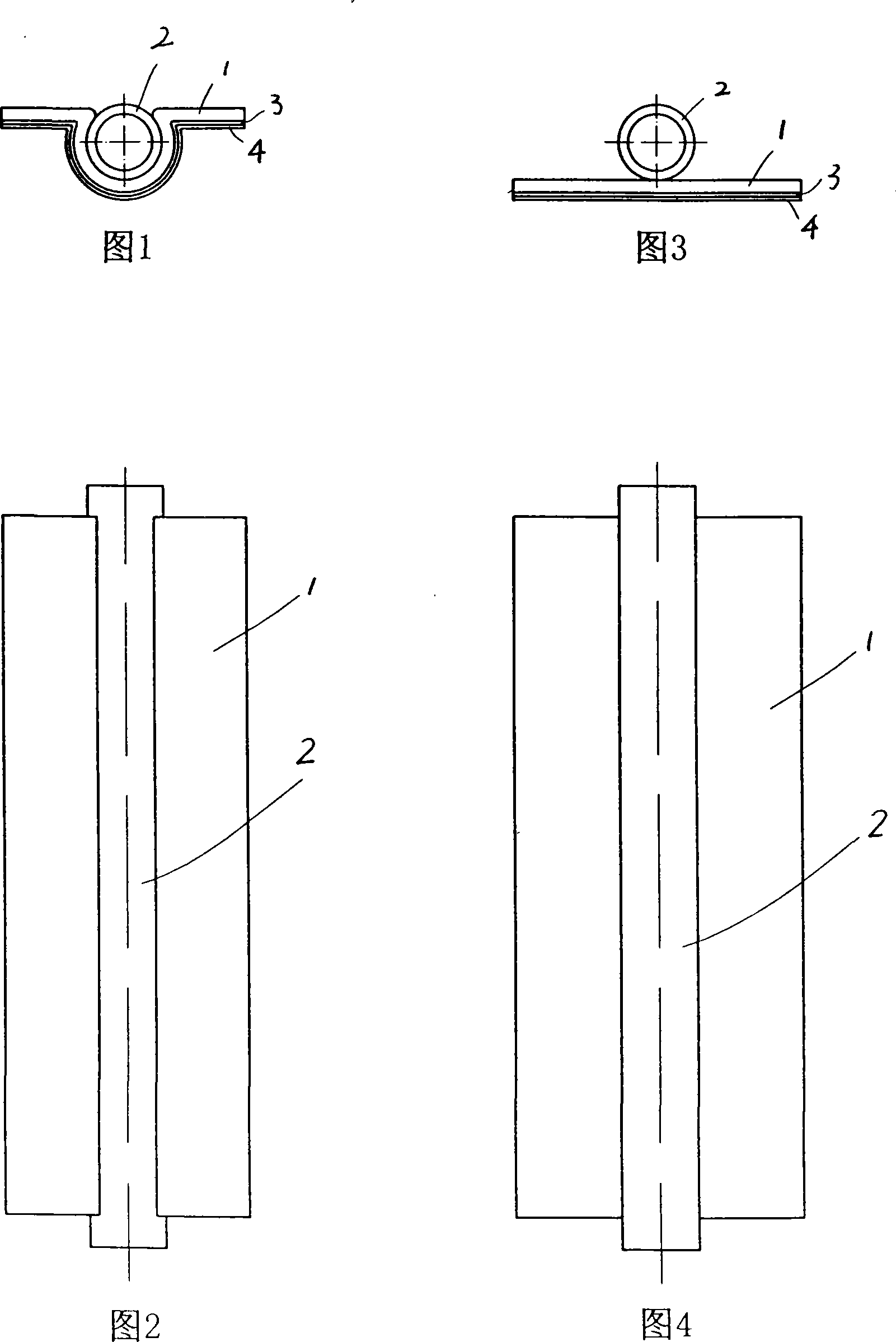

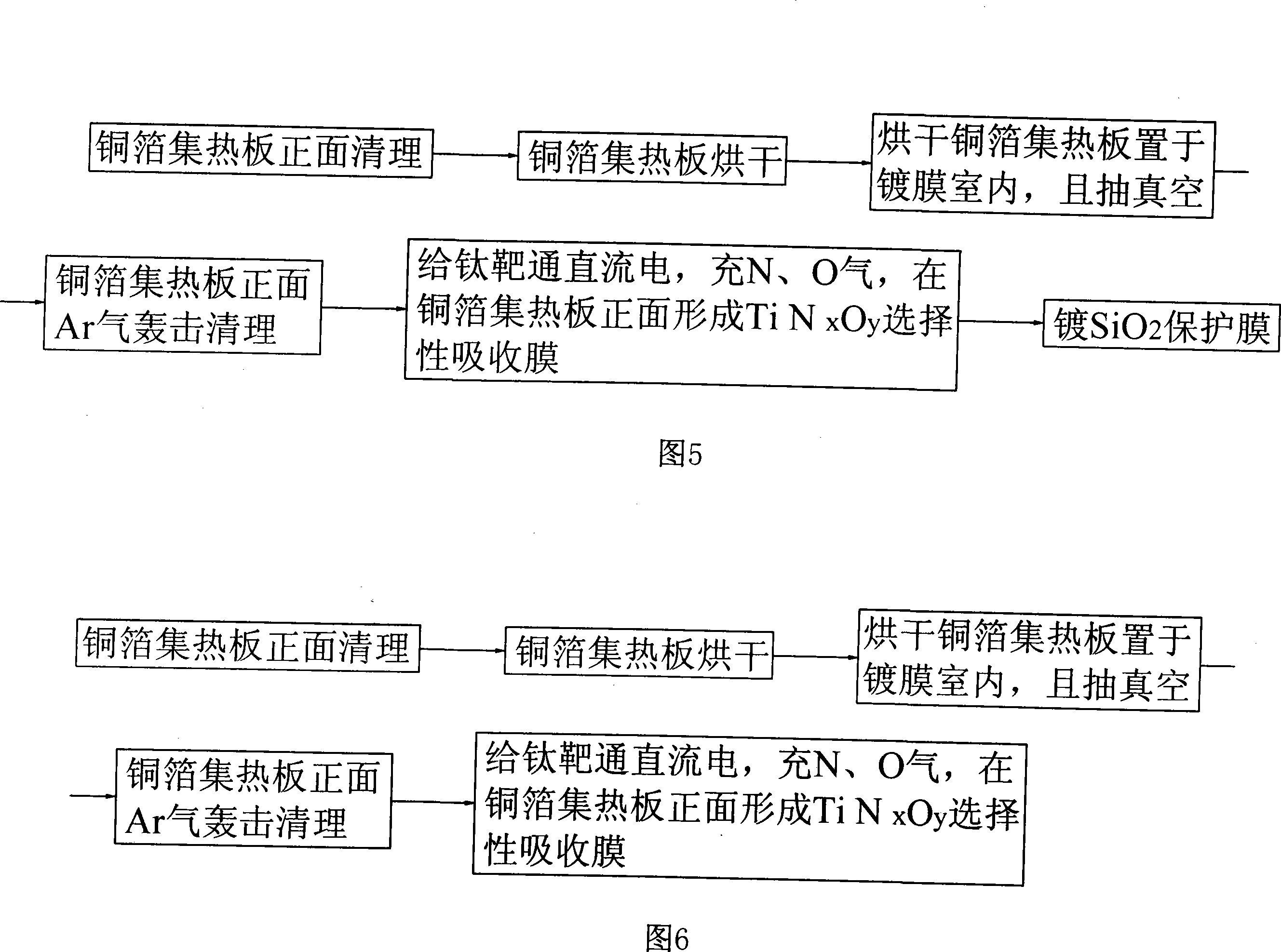

Solar flat-board heat collector plate core and heat collection plate selective absorption membrane plating method

ActiveCN101240944AReasonable structureImprove heat exchange effectSolar heat devicesVacuum evaporation coatingLow emissivityCopper foil

The present invention provides a plate core of solar plate heat collector and a metallic-membrane plating method of collecting plate selectively absorbing film, the plate core is welded by a copper foil heat collecting plate and a copper fluid medium arranged on the reverse of the heat collecting plate, an absorbing film is arranged on the front of the heat collecting plate, the absorbing film TiNxOy is a selective absorbing film. The absorbing film has a reasonable structure, better heat exchanging effect and high absorptivity etc. The metallic-membrane plating method adopts direct double targets vacuum sputter coater, using copper foil as basic material, titanium target as cathode, treating the front of the copper foil heat collecting plate in turns; drying the copper foil heat collecting plate; dried copper foil heat collecting plate is placed in the film coating room being vacuumized; the method adopts Ar bombarding the front of the copper foil heat collecting plate, processing twice cleaning; connecting DC to titanium target, inflating N2, O2 at the same time, TiNxOy selectively absorbing film is formed after reaction. The method has an advanced process, even cladding material, an even plane and high absorptivity and low emissivity, the heat collecting plate and the selectively absorbing film are agglutinated powerfully.

Owner:JIANGSU DOCTORXIA SOLAR ENERGY

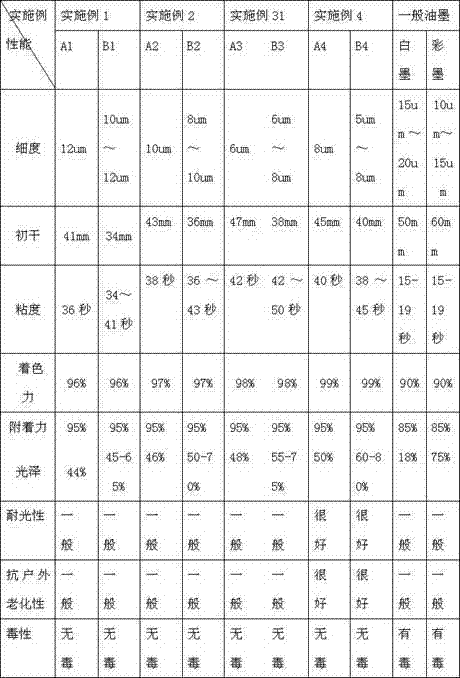

Method for preparing resin for UV photocuring ink

InactiveCN101698698AImprove adhesion fastness and temperature resistanceModerate viscosityInksPrepolymerPhotoinitiator

The embodiment of the invention provides a method for preparing a resin for UV photocuring ink, comprising the following steps of preparing polyester polyol by adding phthalandione, isophthalicacid, sebacylicacid and dineopentyl alcohol into anchoic acid and 1,6-hexanediol after primary lipidation, performing secondary lipidation and polycondensation reaction to obtain the polycondensation product polyester polyol; mixing epoxy resin containing hydroxyl, isocyanate and the obtained polyester polyol for mixed reaction to prepare epoxy modified polyurethane prepolymers; mixing the obtained epoxy modified polyurethane prepolymers with acrylate monomer containing hydroxyl for reaction, adding UV initiator and inhibitor for reaction to prepare epoxy modified urethane acrylate with the molecular weight of 5000-10000 and viscosity of 4000-6000mpa.s, namely the resin for UV photocuring ink. The resin prepared by the method has good performance, and the adhesion and heat resistance of the ink products are improved. The step that the traditional photocuring resin needs to be added with polyfunctional reactive diluent with more toxicity is omitted, thus being more environment-friendly.

Owner:BEIJING COMENS NEW MATERIALS

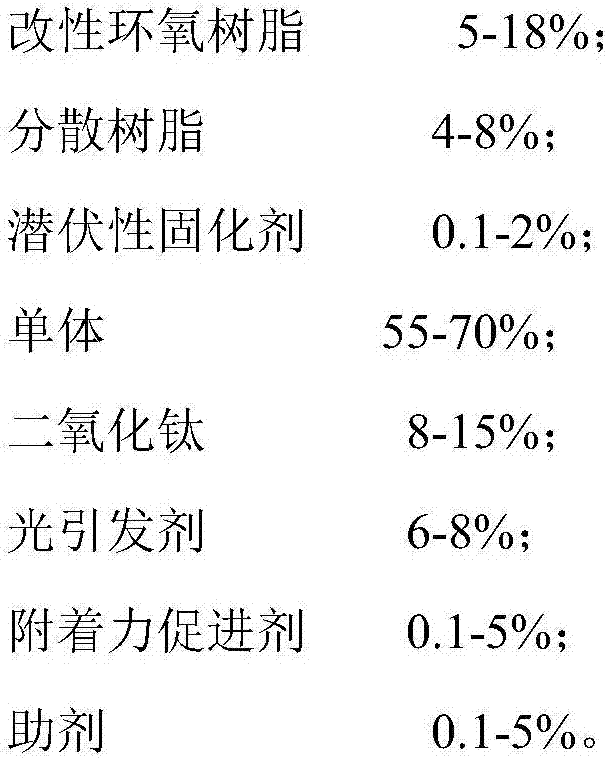

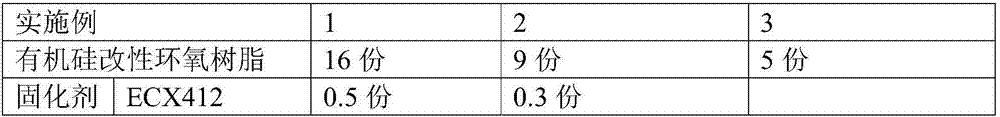

UV-LED ink-jet printing character ink and preparation method thereof

ActiveCN107216715AExtended service lifeSolidification and environmental protectionInksInspection/indentification of circuitsHardnessLength wave

The invention discloses UV-LED ink-jet printing character ink and a preparation method thereof. The ink is prepared from the following raw materials in percent by weight: 5-18% of modified epoxy resin, 4-8% of dispersion resin, 0.1-2% of a latent curing agent, 55-70% of a monomer, 8-15% of titanium dioxide, 6-8% of an initiator, 0.1-5% of an adhesion promoter and 0.1-5% of an assistant. The ink is suitable for UV lamp curing, is especially suitable for UV-LED lamps of which the wavelengths are 365nm and 395nm, and has the characteristics of low viscosity, good adhesive force, high temperature resistance, yellowing resistance and good hardness.

Owner:江门市阪桥电子材料有限公司 +1

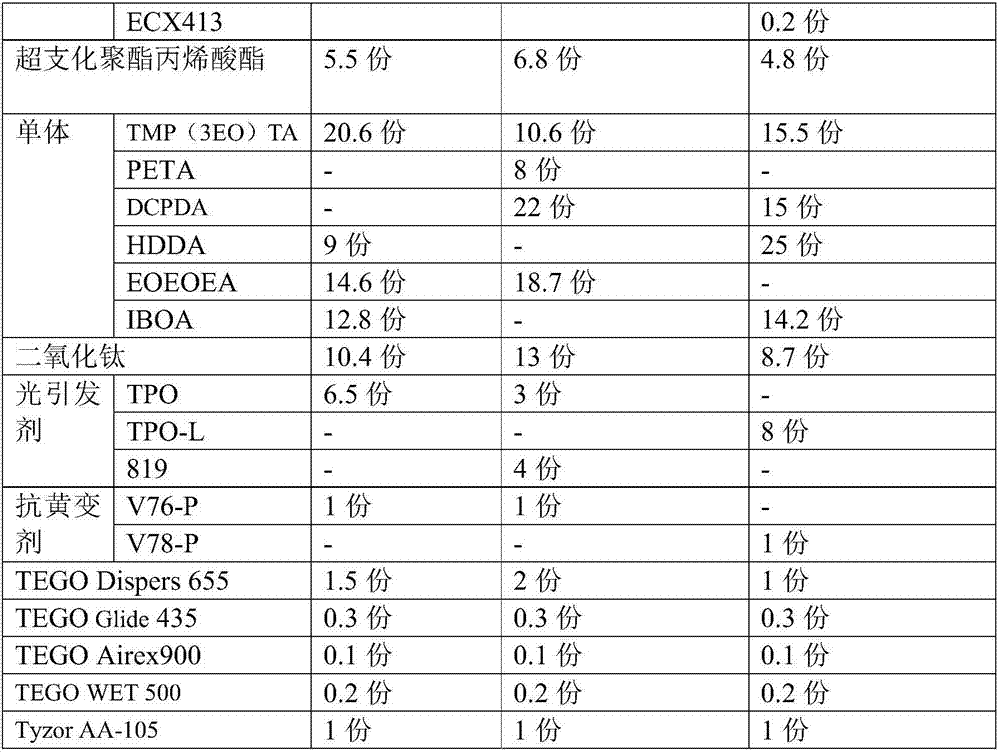

Preparation method of hydrophilic PTFE (polytetrafluoroethylene) composite microporous membrane

ActiveCN104353370AImprove hydrophilicityImprove adsorption stabilitySemi-permeable membranesPolymer scienceOrganic chemistry

The invention relates to a preparation method of a hydrophilic PTFE (polytetrafluoroethylene) composite microporous membrane. The preparation method comprises the following steps: 1, adding inorganic nano particles in the formula of a PTFE raw material, uniformly mixing and stretching to obtain a PTFE composite microporous membrane; 2, adding a polyhydroxy compound and a couping agent to water to prepare a modified water solution, soaking the PTFE composite microporous membrane obtained in the step 1 until the membrane is transparent, then dipping into the modified water solution, taking out and drying; and 3, dipping the dried PTFE composite microporous membrane in a pentanedial solution, and after taking out, washing and drying to obtain the hydrophilic PTFE composite microporous membrane. The preparation method has the advantages that after the PTFE composite microporous membrane is treated by the modifying method, the hydrophilic property of the membrane is remarkably improved; persistence of the hydrophilic property is obviously improved while the hydrophilic property is ensured; the preparation process is easy and feasible, is low in cost and is suitable for industrial production.

Owner:中材科技膜材料(山东)有限公司

Production process of conductive fabric via plasma treatment

InactiveCN1436889AImprove adhesion fastnessIncrease contact areaPhysical treatmentFiberElectromagnetic shielding

The present invention relates to the preparation of conductive fabric and is especially plasma treatment process of conductive fabric with coated conducting metal layer on the surface and thus electrothermal, antistatic, electromagnetic shielding and other functions. The process includes the steps of: defatting and decontaminating substrate materail, electrochemical activating, metallizing and surface treatment as well as characterized low temperature plasma treatment step before the electrochemical activating step to etch the surface of fabric fiber at the conditions of 20-400 W power and 1-100 Pa air pressure and for 40 min. The said etching effect on the surface of fabric raise the fastness of metal layer on the fabric.

Owner:INST OF CHEM CHINESE ACAD OF SCI

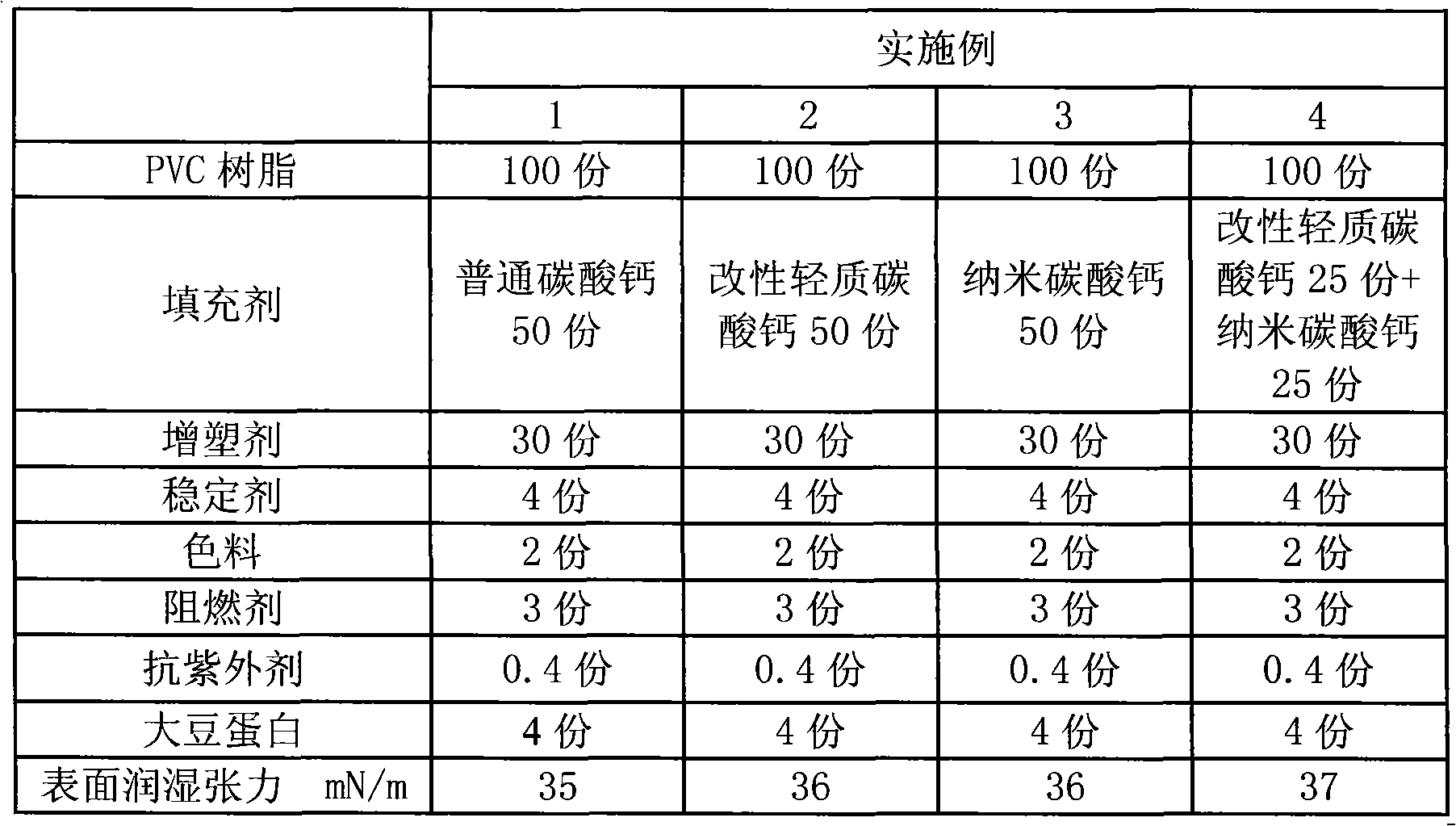

Hot-melt adhesive for bonding layer of artificial leather and preparation method as well as application thereof

InactiveCN102618204AImprove high temperature resistanceGood chemical resistanceNatural rubber adhesivesNon-macromolecular adhesive additivesPolymer scienceAdhesive

The invention relates to a hot-melt adhesive for the bonding layer of artificial leather and a preparation method as well as application thereof. The preparation method comprises the following steps of: firstly reacting low polymer polyalcohol, an expoxy resin and aromatic polyhydroxy special polyether with diisocyanate, then adding a hydrophilic chain extender and a micromolecule polyalcohol chain extender for carrying out chain extension reaction to obtain an intermediate product, neutralizing by using organic amine, emulsifying by using water to generate a polyurethane emulsion, finally removing an organic solvent at a reduced pressure to obtain a waterborne polyurethane emulsion, adding a special organic silicon surface active agent, a FeCl3 aqueous solution, a waterborne curing agent, natural rubber, chloroprene rubber, nitrile butadiene rubber and a thickening agent, and preparing the hot-melt adhesive for the bonding layer of artificial leather. The bonding layer of artificial leather is used for compositing spinning fabrics and PVC (Polyvinyl Chloride) / cloth in the fields of bags, suitcases and clothing. The prepared adhesive has the excellent performances of firm bonding strength, water resistance, acid resistance, alkali resistance and the like and is applied to the artificial leather fields of clothing, bags, suitcases and the like.

Owner:江阴市诺科生物新材料科技有限公司

Environment-friendly, strong acid-resistant, strong base-resistant and steaming-resistant ink and preparation method

The invention relates to environment-friendly, acid-resistant, base-resistant and steaming-resistant ink. The ink comprises a component A, namely ink, and a component B, namely a crosslinking agent, wherein the composition and the weight ratio of the component A and the component B are as follows: the component A comprises 64.5-78.5 parts of aqueous polyurethane emulsion, 8 parts of organic pigment, 3-10 parts of nano-sized aluminum oxide, 8.5-20.5 parts of isopropanol, 0.4 parts of dispersing agent and 0.3 parts of antifoaming agent; and the weight of the component B is 3-5 percent of that of the component A. The preparation method is simple; a single aqueous resin is used as an ink bonding material; the comprehensive performance of the ink, such as water resistance, high temperature resistance and bonding firmness, is improved by adding the nano-sized aluminum oxide for the first time, and the color fixing effect can be achieved; the types of raw materials are reduced; the price is low; and the environment-friendly, strong acid-resistant, strong base-resistant and steaming-resistant ink is applicable to flexible packaging materials which are resistant to steaming sterilization for a long time.

Owner:三维印制(厦门)新材料有限公司

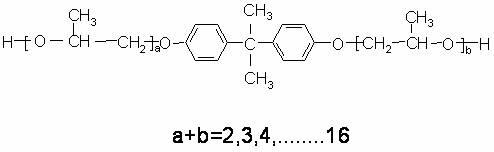

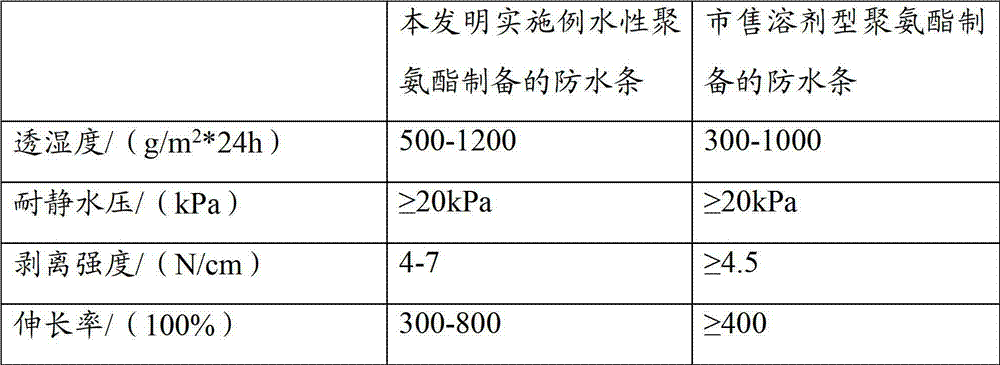

Waterborne polyurethane emulsion for making waterproof strip and preparation method thereof

ActiveCN103030775AImprove performanceImprove adhesion fastnessPolyureas/polyurethane adhesivesEmulsionOrganic solvent

The invention discloses waterborne polyurethane emulsion for making a waterproof strip. The emulsion comprises waterborne polyurethane and water according to the mass ratio of 0.5-0.9 to 1, wherein the waterborne polyurethane comprises the following components in percentage by weight: (a) 8-50% of diisocyanate, (b) 25-80% of polyhydric alcohol, (c) 0-10% of non-hydrophilic chain extender, (d) 0.5-15% of hydrophilic chain extender, and (e) 0-8% of active hydrogen-containing chain extender; the total weight percentage of the components is 100%; and the molar ratio of isocyanate group NCO to hydroxyl group OH in the components of the waterborne polyurethane is 2-5 to 1. The waterborne polyurethane emulsion does not contain or only contains a very small amount of volatile organic solvent, has the solid content of 25-50%, is lower in viscosity and can be used for making the waterproof strip after high-speed film coating and curing; and the waterproof strip has the characteristics of high bonding degree, high strength, soft bonding part, good waterproof and moisture-permeable performance and the like.

Owner:广东宏昌新材料科技有限公司

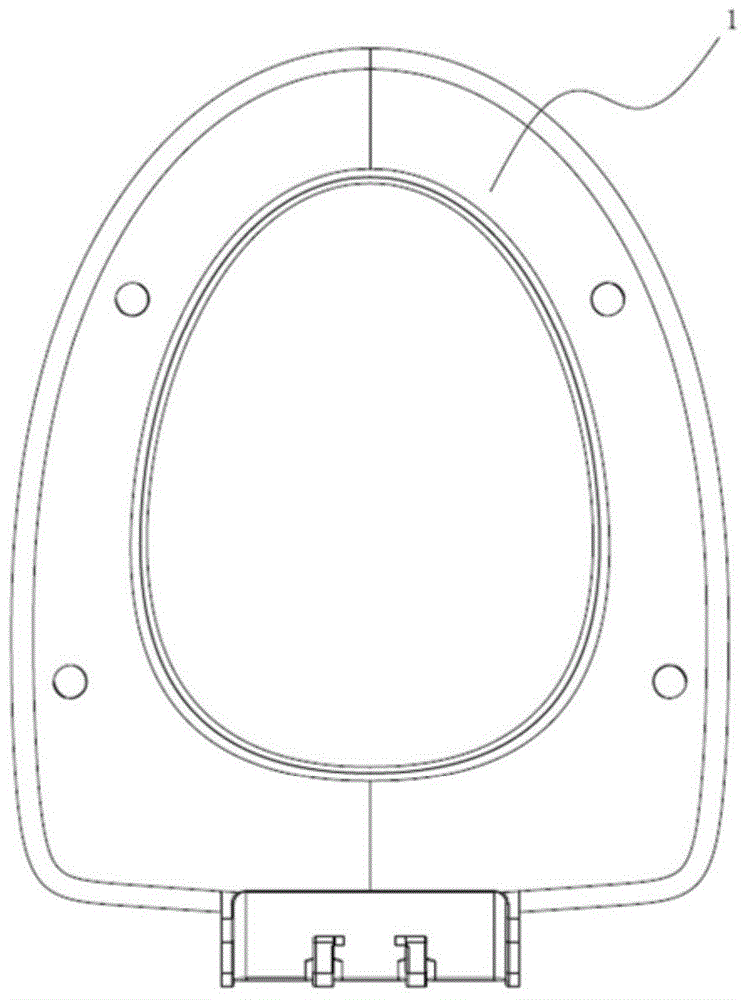

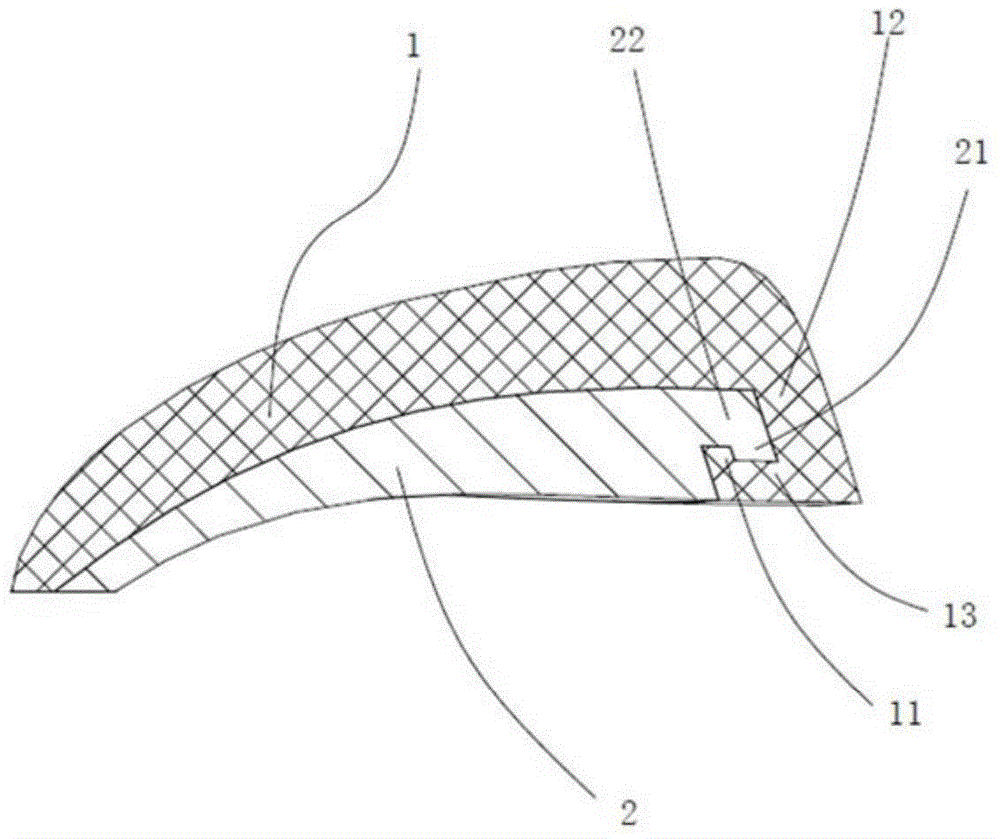

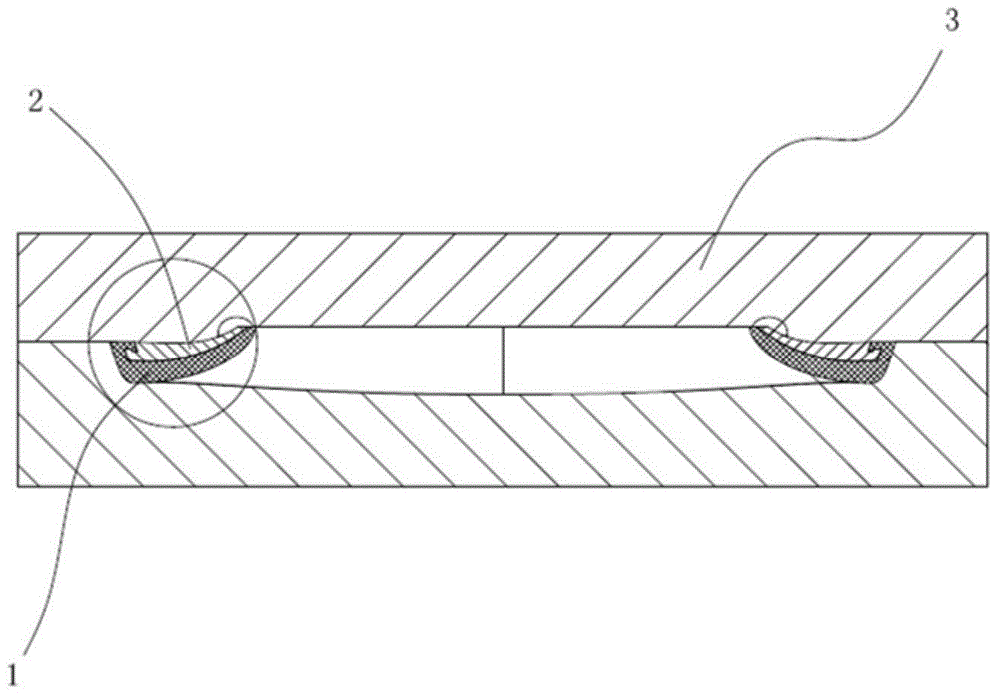

Compound type polyurethane toilet seat and preparation technology thereof

ActiveCN104545656AReduce usage costsReduce processing costsBathroom coversDomestic articlesAbrasive blastingEngineering

The invention discloses a compound type polyurethane toilet seat, including a surface coating layer, a positioning structure and a seat cushion support, wherein the surface coating layer of made of polyurethane and seamlessly wraps the outer surface of the seat cushion support by the positioning structure. The preparation technology includes the steps of: 1, spraying mold release agents and intramode paint in a mold cavity; 2, cleaning the surface of the seat cushion support; 3, polishing or abrasive blasting; 4, thermally processing seat cushion support; 5, spraying the mold release agent in the mold cavity, and installing the seat cushion support in the mold cavity; 6, injecting polyurethane material into the mold cavity, and shaking the mold; 7, foaming the polyurethane material; 8, after the polyurethane is cured in the mold, opening the mold to take out the product, and thereby completing the whole preparation technology of the product. The compound type polyurethane toilet seat achieves the one-time composite molding of the polyurethane toilet seat, optimizes the processing technology, saving the use cost, increases the bonding intensity of the product, and improves the use quality of the product.

Owner:FINEHOPE POLYUREHTHANE PROD

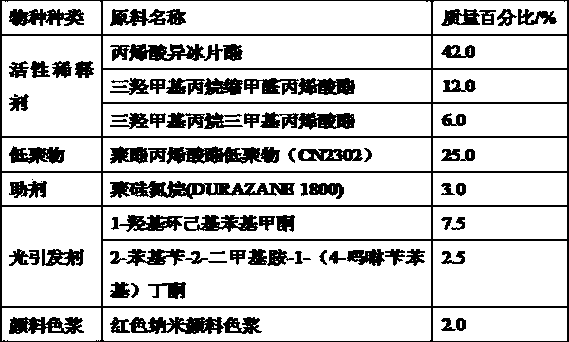

Boiling-resistant UV (Ultraviolet) curing jet-ink for non-absorbent substrate and preparation method of jet-ink

The invention discloses boiling-resistant UV (Ultraviolet) curing jet-ink for a non-absorbent substrate and a preparation method of the jet-ink. The UV curing jet-ink consists of the following components in percentage by weight: 60-75 percent of reactive diluent, 15-25 percent of polyester acrylate oligomer, 2-6 percent of nanometer pigment paste, 0.5-3 percent of polysilazane and 5-10 percent of photoinitiator. The UV curing jet-ink is uniformly dispersed, and the adhesion force of the jet-ink can reach 100 percent and the hardness is larger than 3H after the non-absorbent substrate is cured; the jet-ink is not cracked after baking at 200 DEG C for 1 hour, and the performances are not remarkably weakened after the jet-ink is soaked in cold water or boiled in water at 80 DEG C for 1 hour. The boiling-resistant UV curing jet-ink is suitable for multiple non-absorbent substrates, has excellent water resistance, simple in process and environment-friendly, and the substrate does not need to be pretreated.

Owner:清远市美佳乐环保新材股份有限公司

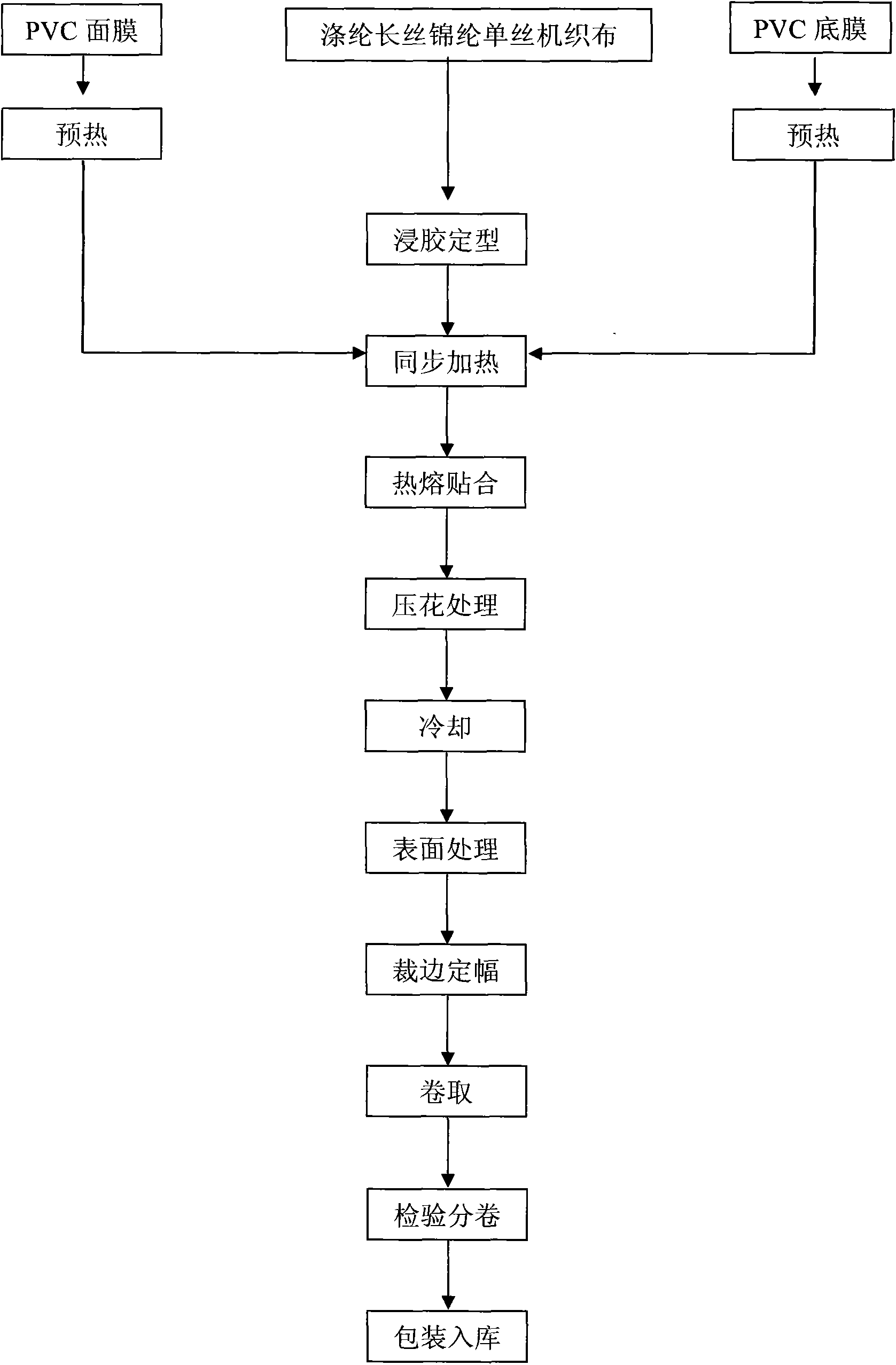

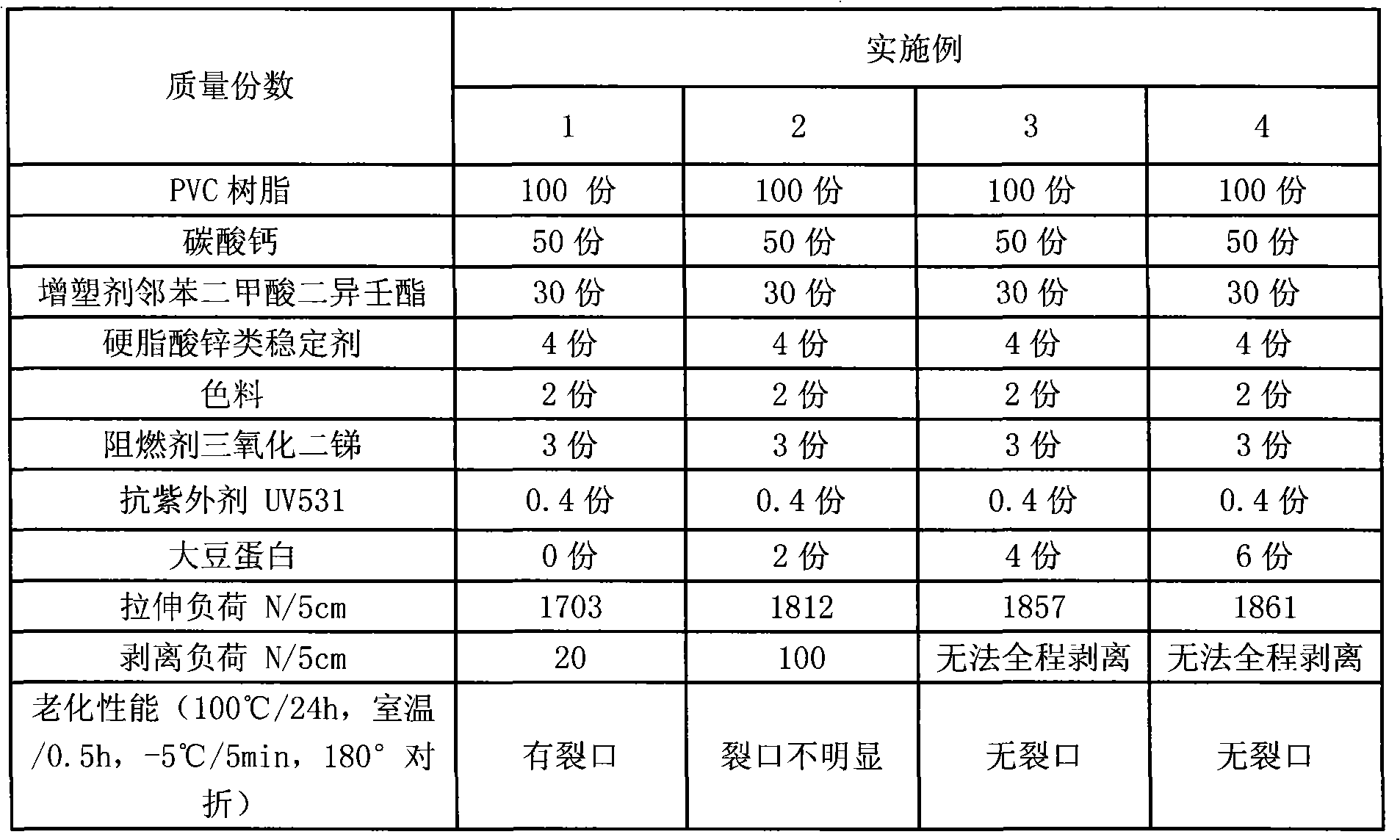

Non-curling flexible composite material

ActiveCN101581042AStress reliefImprove adhesion fastnessLamination ancillary operationsSynthetic resin layered productsPolyesterPolymer science

The invention relates to a non-curling flexible composite material, which is prepared by the following method: (1) high tenacity polyester filament is adopted as warp, nylon monofilament is adopted as weft, woven fabrics manufactured by a plain weaving process of a Sulzer gripper loom are adopted as framework materials; and (2) after the framework materials in the step (1) are processed by gum dipping and pre-setting, a double-sided PVC film is adopted for hot melting and jointing, and after cooling and surface treatment, the non-curling flexible composite material is prepared. The flexible composite material prepared by the invention has excellent non-curling performance, and simultaneously has the characteristics of high ink absorption, high strength, aging resistance and the like.

Owner:浙江华生科技股份有限公司

Corrugated board adhesive glue and preparation method therefor

InactiveCN103421446AReduce forceLow gelatinization temperatureNon-macromolecular adhesive additivesStarch adhesivesPolyvinyl alcoholAdhesive glue

The invention provides a corrugated board adhesive glue. The adhesive glue comprises the following raw materials, by weight, 400-600 parts of water, 80-120 parts of corn starch, 4-6 parts of polyvinyl alcohol, 0.8-1.2 parts of sodium borate and 8-12 parts of sodium hydroxide solution. The adhesive glue is advantaged by simple process, simple operation, low-cost raw materials, low-temperature technology requirement and firm adhesion.

Owner:天津市大港巨龙造纸厂

Polytetrafluoroethylene membrane filter material and preparation method thereof

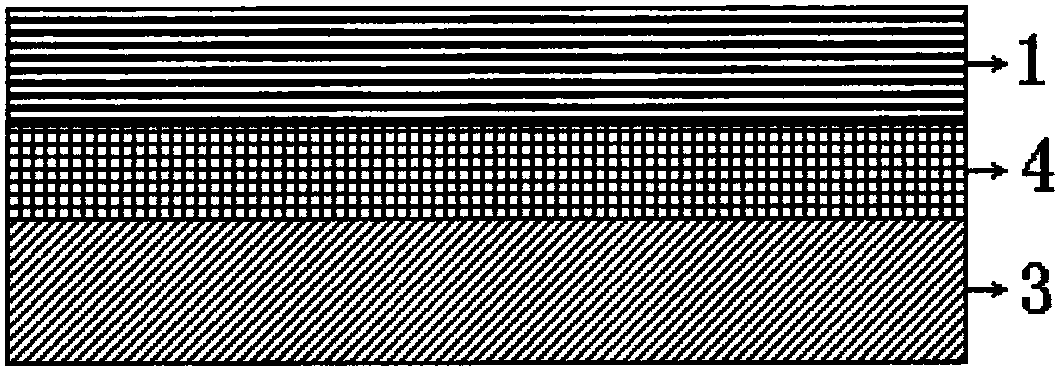

PendingCN108057279AImprove adhesion fastnessEfficient filtering effectSynthetic resin layered productsLaminationFiberAdhesive

The invention discloses a polytetrafluoroethylene membrane filter material and a preparation method thereof. The polytetrafluoroethylene membrane filter material comprises a PTFE micro-porous membrane, a fluoropolymer bonding layer and a punched felt bottom layer which are sequentially compounded. The preparation method comprises the following steps: coating the surface of the punched felt with afluoropolymer to make the upper fiber surface of the punched felt wrapped with a layer of a low surface energy adhesive, cladding a hot roll with the PTFE micro-porous membrane to preheat the PTFE micro-porous membrane, allowing the PTFE micro-porous membrane to enter a rolling mill rolling seam, and carrying out hot rolling on the PTFE micro-porous membrane and the fiber punched felt, wherein thePTFE micro-porous membrane is fully heated before being compounded in order to improve the adherence fastness of the PTFE micro-porous membrane and the punched felt and improve the membrane production rate. A unique gluing and hot bonding technology is adopted to make the surface of a punched filter material coated with the PTFE micro-porous membrane in order to obtain the membrane filter material with a high PTFE membrane adherence fastness and achieve high-efficiency, low-resistance and long-life filtering effects.

Owner:ZHEJIANG YANPAI FILTRATION TECH

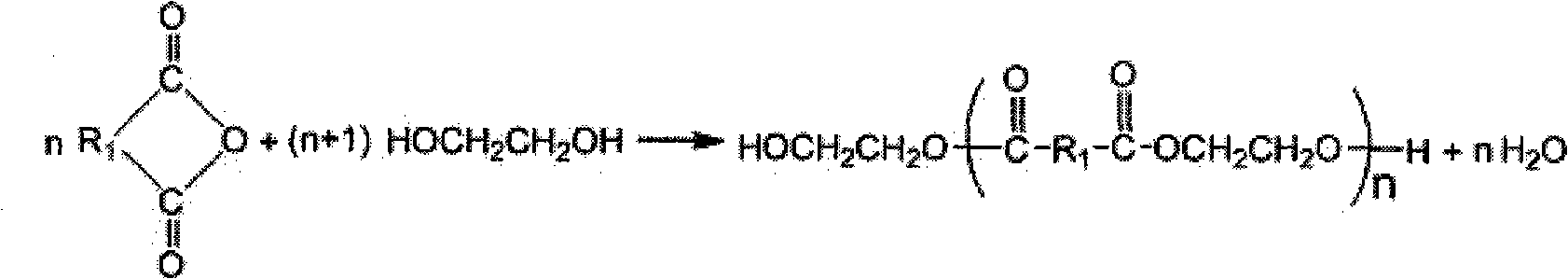

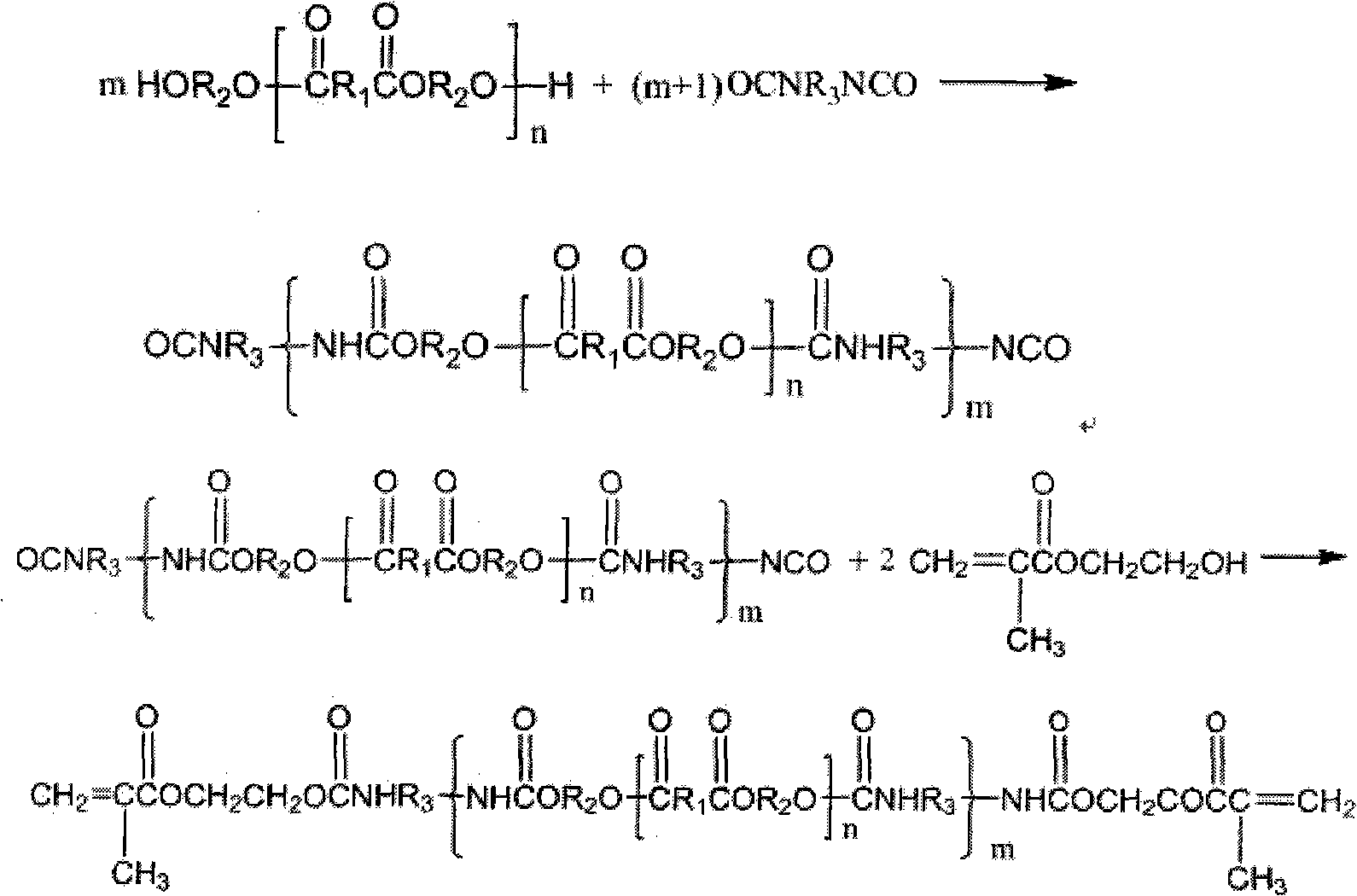

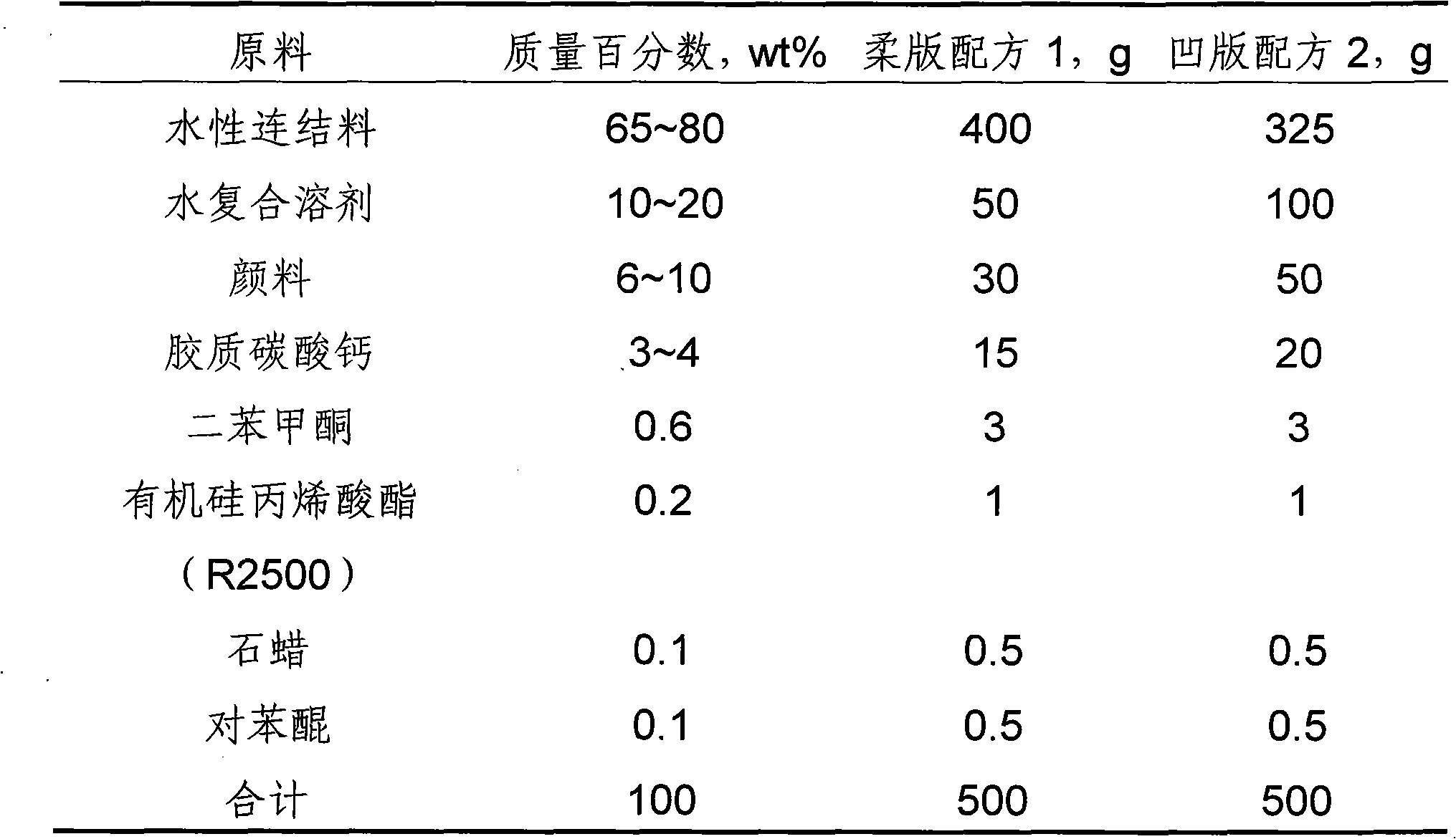

Preparation method of water-based UV ink (ultraviolet) of unsaturated polyester polyurethane segmented copolymer

The invention relates to a preparation method of water-based UV ink (ultraviolet) of unsaturated polyester polyurethane segmented copolymer. The preparation method includes the steps as follows; dihydric alcohol, maleic anhydride and phthalic anhydride are adopted to generate unsaturated polyester oligomer of hydroxyl end group by progressive polycondensation; after progressive addition polymerization with reactive diluent as the solvent, the unsaturated oligomer, polyethylene glycol ether and diisocyanate are subjected to chain extension with water functional monomer to generate unsaturatedpolyester polyurethane segmented prepolymer solution of isocyanate end group and with hydrophilic function; and after the prepolymer is end-sealed with methacrylic acid-beta hydroxyethyl, monoethanolamine is taken as neutralizer that is dispersed in water while stirred to obtain water-based joining material of unsaturated polyester polyurethane segmented prepolymer. The water-based joining material and the pigment filler, the photosensitizer and the assistant are formulated to prepare water-based UV ink of unsaturated polyester polyurethane segmented prepolymer.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Water-based ultraviolet-curing printing ink and preparation method thereof

The invention discloses a water-based ultraviolet-curing printing ink and a preparation method thereof. The printing ink comprises the following raw materials by weight: 20-30 parts of epoxy acrylic resin, 10-15 parts of polyurethane acrylic resin, 5-10 parts of polyester acrylic resin, 4-6 parts of diphenyl ketone, 2-4 parts of 2,2-diethoxyacetophenone, 10-15 parts of pigments, 2-3 parts of isopropanolamine, 8-12 parts of pentaerythritol triacrylate, 15-20 parts of diacrylic acid-1,6-hexylene glycol ester, 3-5 parts of propylene glycol ethyl ether, 1-2 parts of a fluorocarbon surfactant FC-4430, 0.5-1 part of a defoamer BYK-019, 3-5 parts of a compound filler and 20-25 parts of de-ionized water. The water-based printing ink is excellent in performance, can be instantly cured after being irradiated by ultraviolet rays, is free from evaporation of a petroleum solvent, cannot pollute the environmental and is safe to use; the printing ink can be still kept stable in performance and cannot be mildewed after being stored in the printing process and even an ink fountain for a long term; a printed product is good in color stability and high in brightness, and an ink layer is higher in friction resistance, chemical resistance and adhesiveness; the printing ink has a wide application prospect.

Owner:青岛米品品服装有限公司

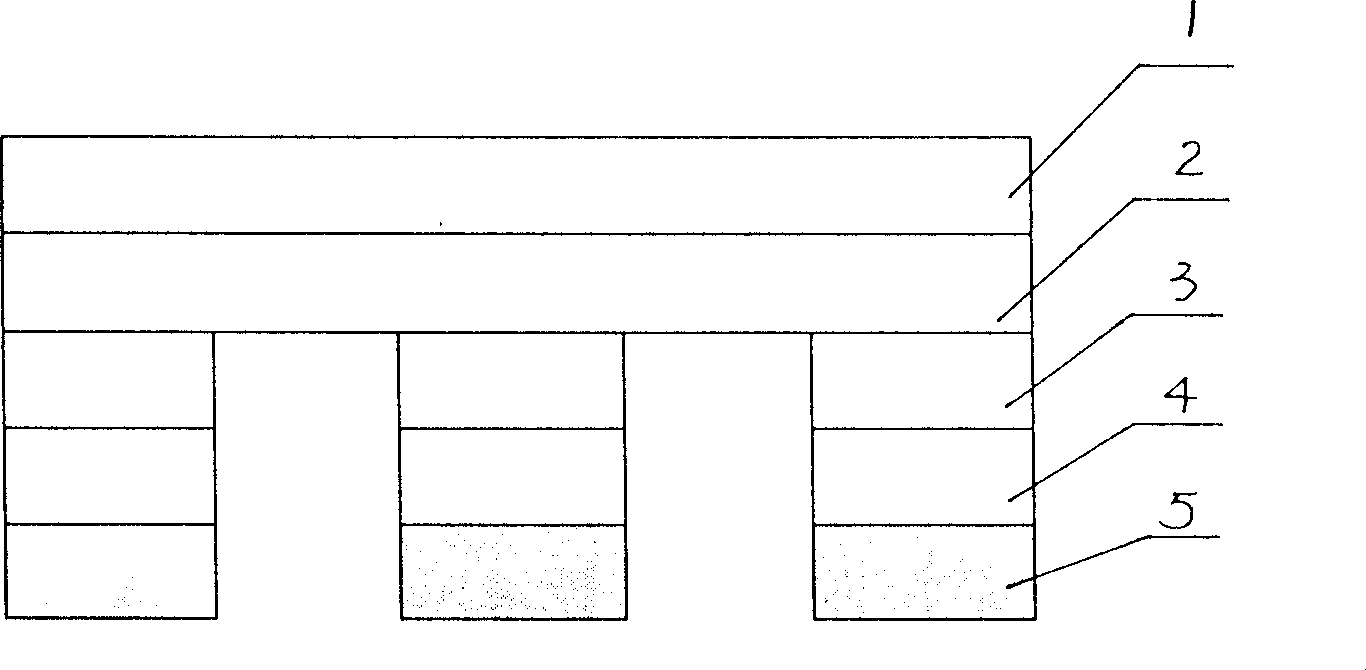

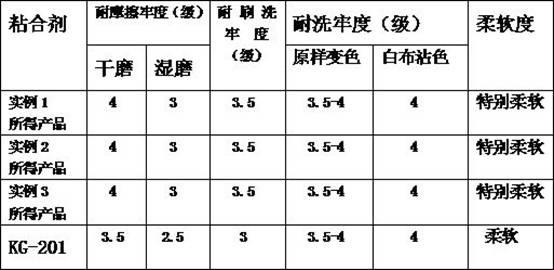

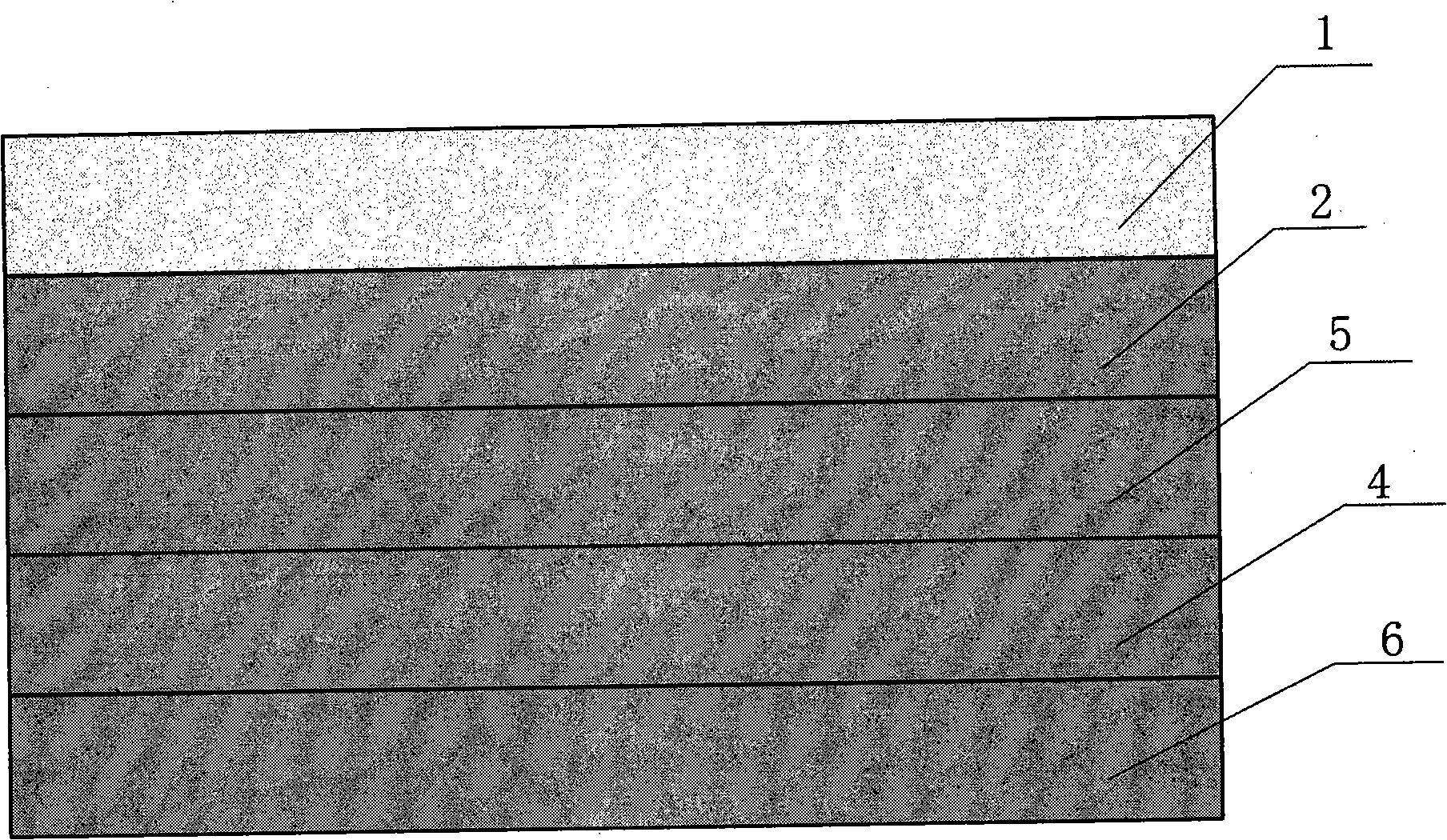

Printing and transfer printing film, fabricating method, and method for forming pattern on object of carrying printed pattern

InactiveCN1915681AIncrease elasticityImprove adhesion fastnessDecorative surface effectsThermographyEngineeringHot melt

A printable transfer film for generating pattern on fabric or leather is composed of film as carrier, parting layer, thermo-fusible adhesive layer, and printable layer. Its preparing process and a method for generating pattern on the object are also disclosed.

Owner:泰州悦然纸尚装饰材料有限公司

Method for preparing environmental friendly aquosity polyurethane inarching fluorine contained fabric finish agent

InactiveCN101130594AEliminate harmful substancesImprove adhesion fastnessFibre treatmentPrepolymerEmulsion

The invention relates to a making method of fluorine-containing fabric finishing agent with friendly environment type of water-based polyurethane grafting for water resistance dressing fabric mainly, which is characterized by the following: reacting diisocyanate and diatomic alcohol compound to form prepolymer with -NCO end-group; capping with hydroxyl allyl propionate after reacting hydrophilic monomer and glycol with fluorine and 1, 4 butanediol to extend chain; adding deionized water to stir after adjusting pH to neutral with amine to produce PUA pre-emulsion; grafting copolymerization with fluorine-containing acrylate to be the finishing agent. The invention improves high adhesive strength with bonded fabric with mellow hand and waterproof ventilating moisture permeating, which is an ideal fabric finishing material without unwanted volatile solvent during process of roller coating and dip-coating and curing, fits the environment-protecting technical requirement of fabric with the waterproof ventilating moisture permeating absolutely.

Owner:江阴市诺科科技有限公司

Method for preparing resin for latently-curable polyurethane ink

ActiveCN101781453AGuaranteed storage lifeImprove adhesion fastnessInksPolymer scienceOrganic solvent

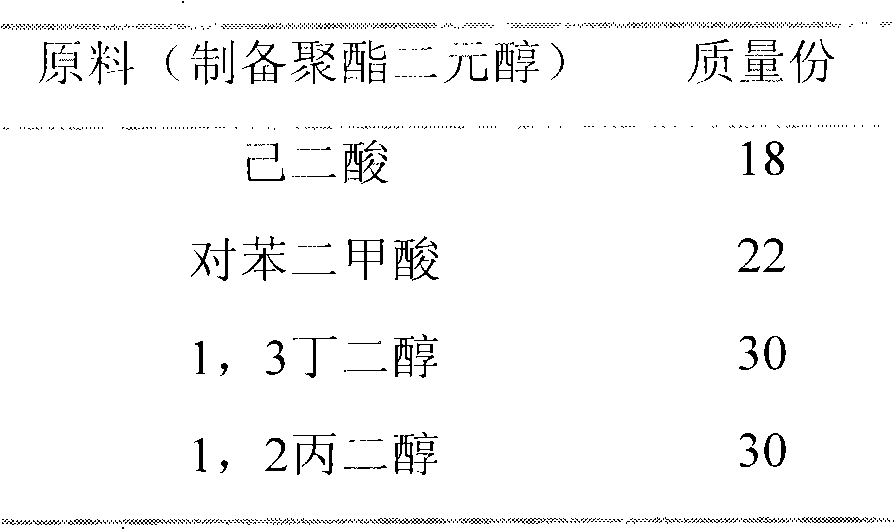

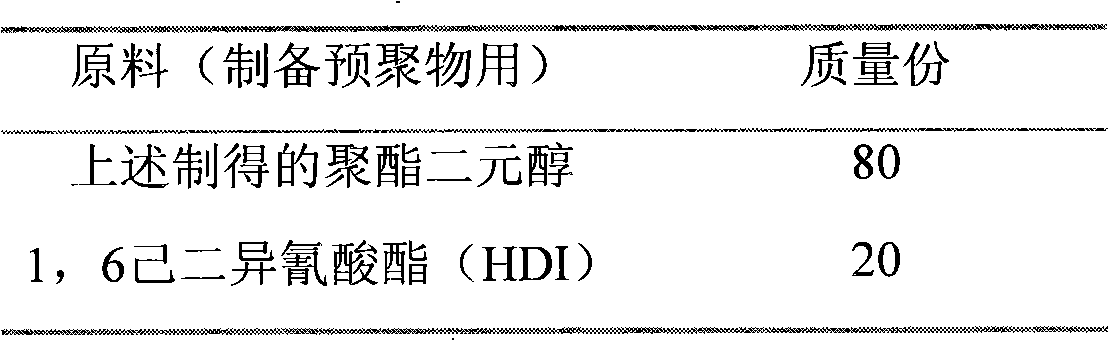

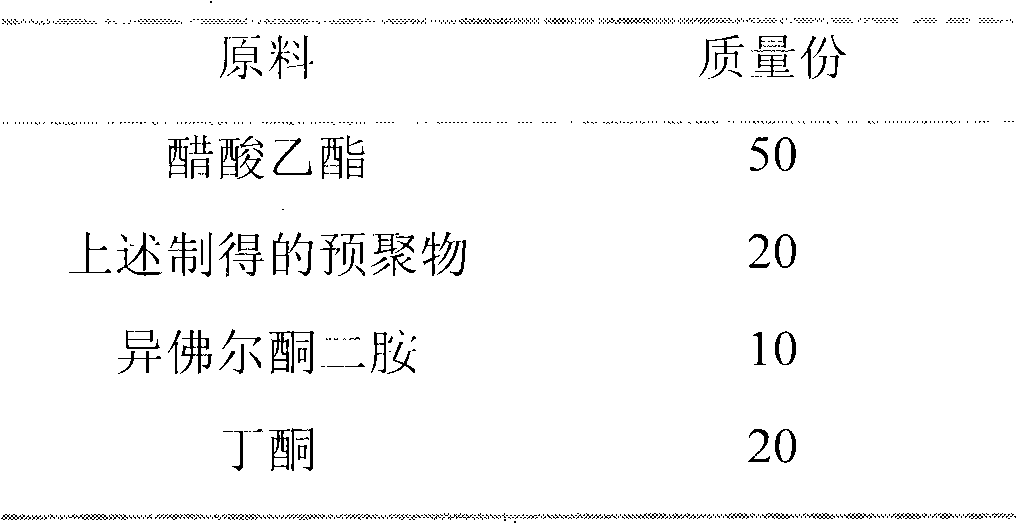

The invention discloses a method for preparing resin for latently-curable polyurethane ink. The method for preparing the resin comprises the following steps of: preparing polyesterglycol: adding adipic acid, terephthalic acid, 1,3-butanediol and 1,2-propylene glycol into a polyester synthesis kettle, heating the mixture to 200 to 240 DEG C to perform esterification for 5 to 6 hours and generatinglow vacuum, high vacuum and long vacuum in the polyester synthesis kettle to obtain the polyesterglycol by polycondensation; preparing prepolymers: performing a reaction of the prepared polyesterglycol and diisocyanate to obtain a product, of which the isocyanic acid group content is 3 to 4 percent and which is the prepolymer; preparing the resin A: adding an organic solvent into the prepared prepolymer, uniformly stirring, adding the mixture into a polyamine chain extender and an organic solvent to perform an reaction for 2 to 3 hours at the temperature of between 70 and 80 DEG C to obtain the resin A; and mixing: mixing the prepared resin A and the latent-curing agent, stirring the mixture for 0.5 to 1 hour to obtain the resin for the latently-curable polyurethane ink. The resin has theadvantages of good ink-preparing performance and high temperature resistance.

Owner:BEIJING COMENS NEW MATERIALS

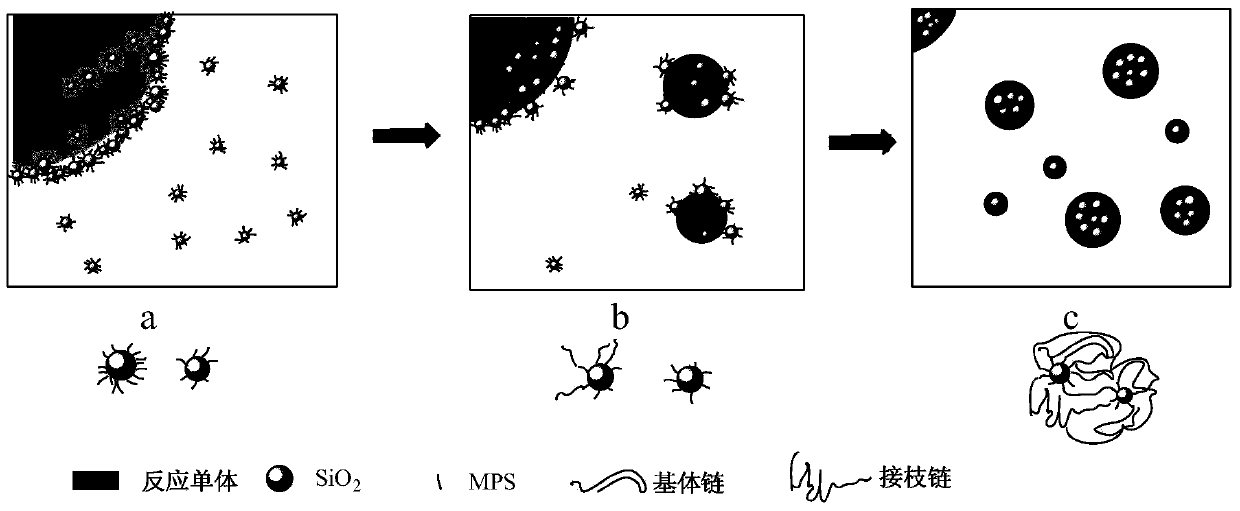

Preparation method of pomegranate-shaped organic-inorganic nano-composite microspheres

The invention discloses a preparation method of pomegranate-shaped organic-inorganic nano-composite microspheres, which comprises the following steps: mixing an aqueous dispersion solution of silicon dioxide modified by proper amount of double-bond silane coupling agent in a coupling method with a phenylpropyl monomer, anionic emulsifier, non-anionic emulsifier and water, and stirring simply, so that a milky emulsified liquid is obtained; adding initiator to perform emulsion polymerization in the presence of silicon dioxide, so that the pomegranate-shaped organic-inorganic nano-composite microspheres with multiple silicon dioxide particles wrapped in phenylpropyl emulsion particles are obtained finally and are stably dispersed in the emulsified liquid. The preparation method has the advantages that the sources of the raw materials are extensive, the raw materials are easy to obtain, the preparation process is simple, and moreover, in the prepared pomegranate-shaped organic-inorganic nano-composite microspheres, the wrapping rate of silicon dioxide is high, the structure is neat and the placement stability is good. The adhesion property and the film forming performance of the composite microsphere particles are adjustable, the adhesive force and the transparency of the corresponding glue film are good, and the organic-inorganic nano-composite microspheres can be applied to the fields of coating, textile, rubber, plastics, biology, medicine and the like.

Owner:杭州华利实业集团有限公司

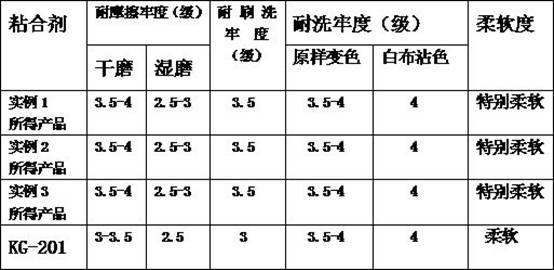

Pigment printing imitated reactive printing adhesive and preparation method thereof

ActiveCN102619103AGood flexibilityImprove adhesion fastnessEster polymer adhesivesDyeing processIsooctyl acrylateTextile printer

The invention relates to pigment printing imitated reactive printing adhesive and a preparation method thereof. The pigment printing imitated reactive printing adhesive is polymer emulsion prepared from fatty alcohol-polyoxyethylene ether (peregal O-25), sodium dodecyl benzene sulfonate, butyl acrylate, dimethyl aminopropyl methacrylamide, glycidyl methacrylate, iso-octyl acrylate, methyl methacrylate, acrylic acid, ammonium persulphate, sodium hydrogensulfite and deionized water through polymerization by using seeded emulsion. The pigment printing imitated reactive printing adhesive product has obvious advantages in indexes such as softness, rub fastness and fastness to washing, and quality of the pigment printing imitated reactive printing product can be obviously improved.

Owner:LIAONING FIXED STAR FINE CHEM

Metal wire drawing-imitating decoration film

InactiveCN104416993AImprove adhesion fastnessEasy to useSynthetic resin layered productsSpecial ornamental structuresPrinting inkSteel plates

The invention provides a metal wire drawing-imitating decoration film which comprises a PET base film, a primer layer, a metal wire drawing-imitating pattern layer, and a printing ink layer; the primer layer is printed on the surface of the PET base film; the metal wire drawing-imitating pattern layer is printed on the surface of the primer layer; and the printing ink layer is printed on the surface of the metal wire drawing-imitating pattern layer. The decoration film of the invention is few in production procedures, low in manufacturing cost, and distinct in the metal wire drawing-imitating pattern, has different glossiness effects such as matt, common, highlight, and the like, has high combining strength with various sheet materials, has good aging resistance and long service life, is widely used in surface decoration of color steel plates, integrated furred ceilings, bureau doors, cabinets, and industrial products, and has very good anti-rust, protective, decorative, and beatifying effect on decorated color plates.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Printed circuit board and manufacturing method thereof

InactiveCN103763854AIncrease the number of layers of conductive linesReduce thicknessPrinted circuit detailsConductive pattern formationMiniaturizationConductive materials

The invention discloses a printed circuit board and a manufacturing method of the printed circuit board. The printed circuit board comprises a substrate and is characterized in that at least one surface of the substrate is provided with two or more layers of conductive circuits which are overlaid vertically and arranged in a cross mode, an insulation material layer is arranged between every two vertically adjacent layers of conductive circuits, and the conductive circuits are isolated through the insulation material layers. According to the printed circuit board, conductive ink is adopted as conductive material for manufacturing the conductive circuits, and the multiple layers of conductive circuits arranged on the substrate in an overlaid mode are isolated through the insulation material layers, so that the layer number of the conductive circuits of the printed circuit board is increased, a laminated insulation hard board is not needed, the thickness of the printed circuit board is greatly reduced, and the printed circuit board is more adaptive to miniaturization electronic devices.

Owner:SHANGHAI MEADVILLE ELECTRONICS

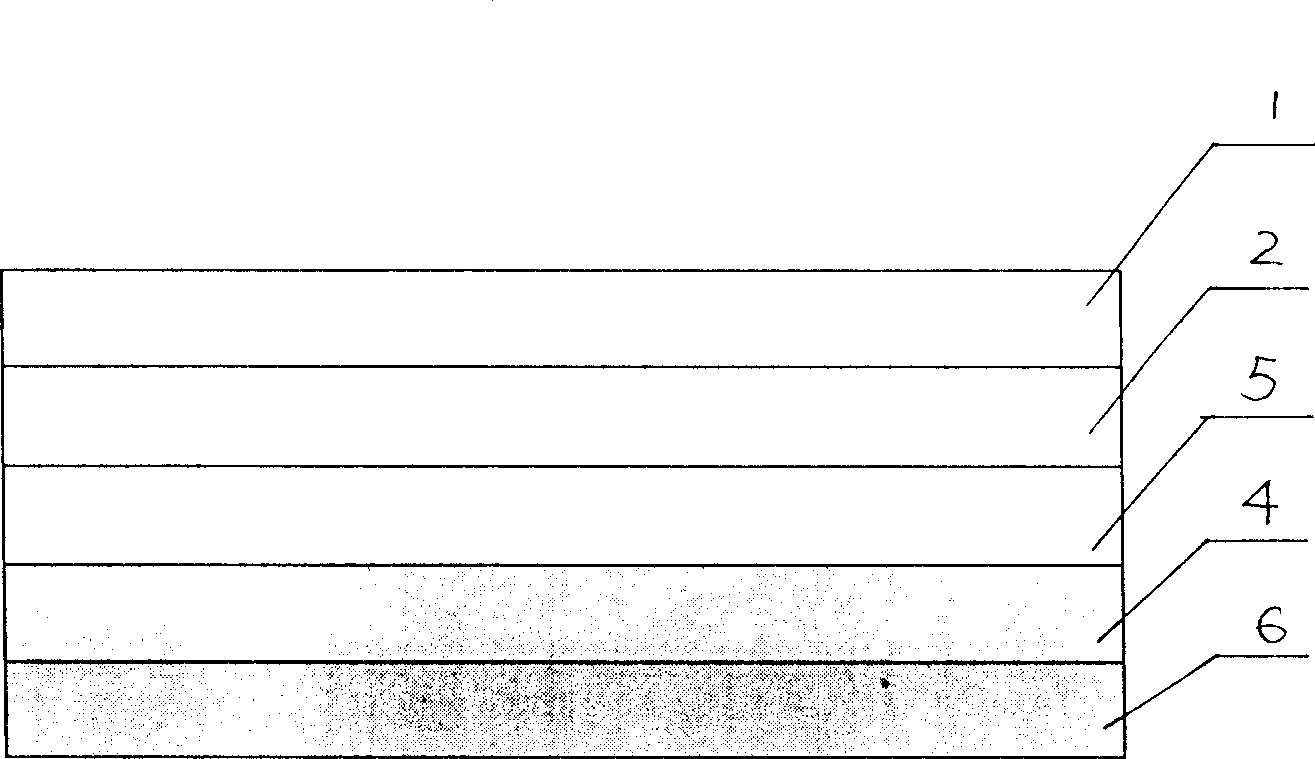

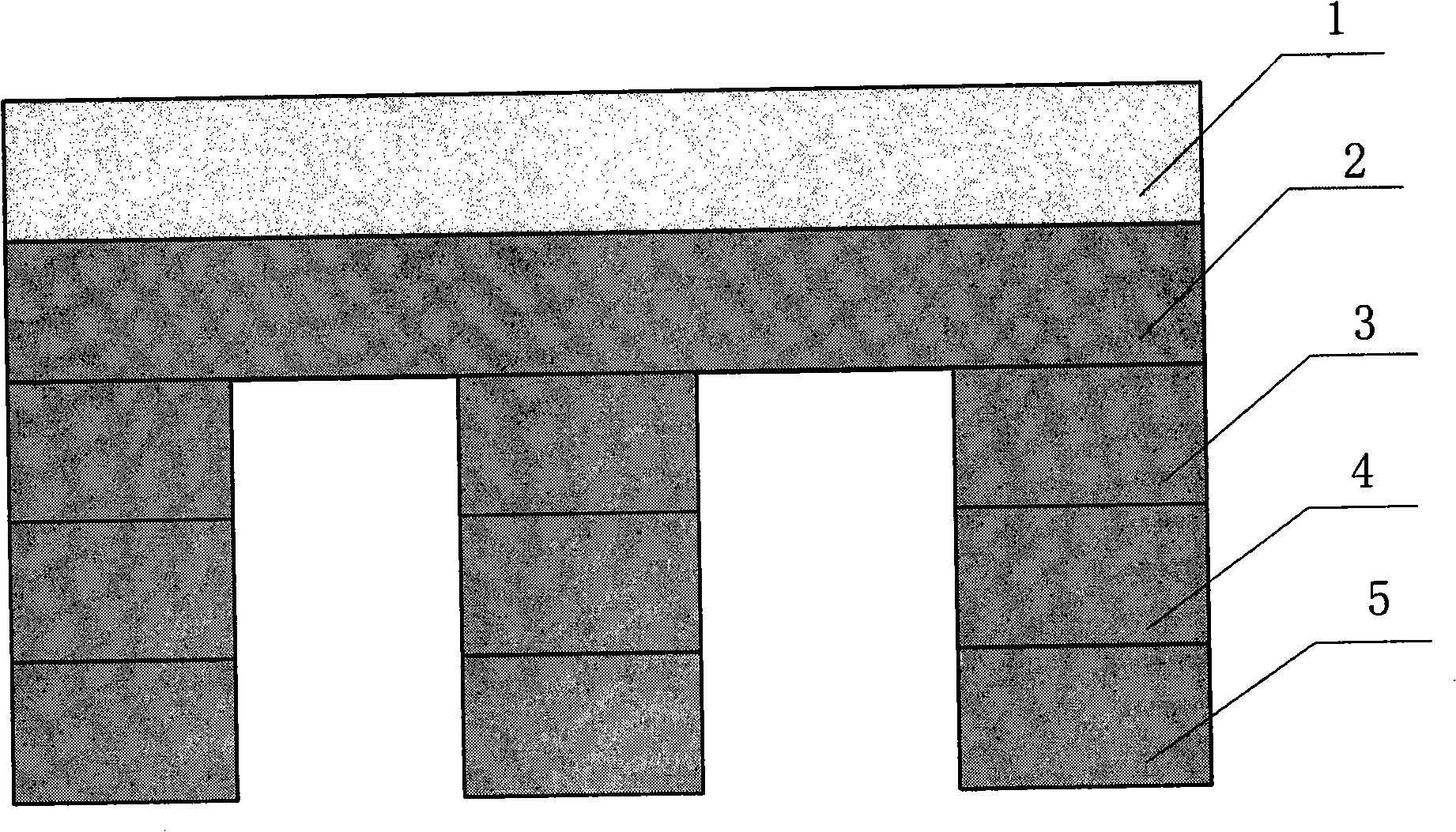

Transfer printing film capable of printing

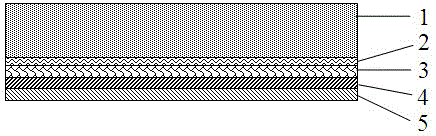

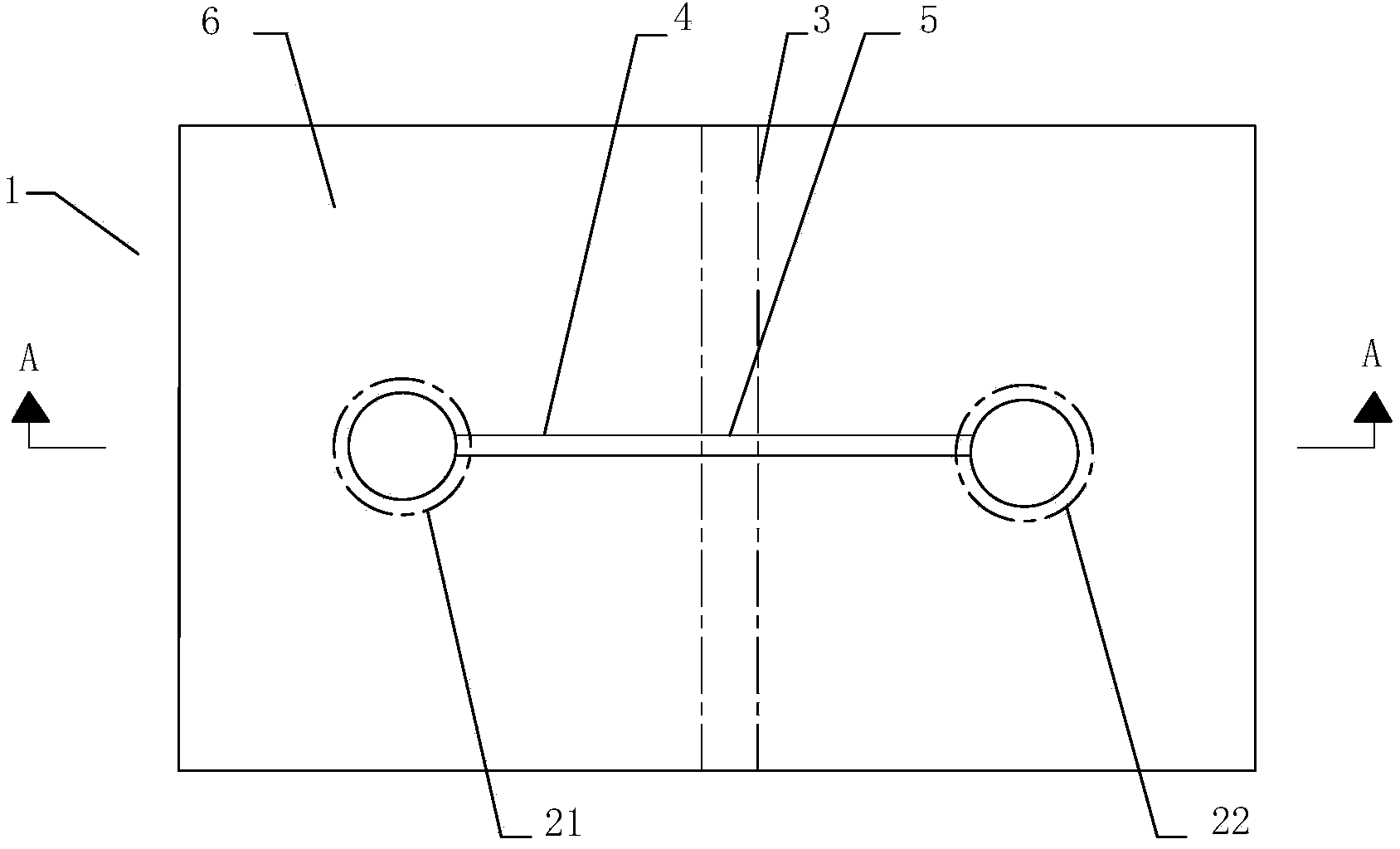

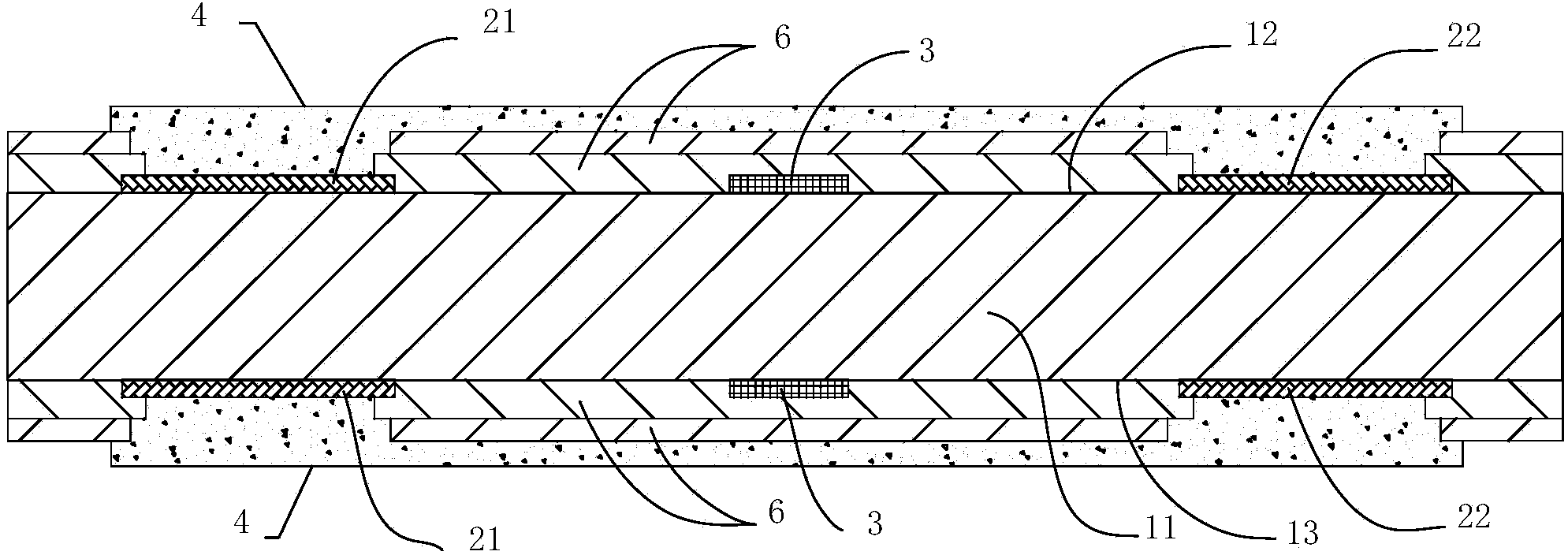

InactiveCN101327699AIncrease elasticityImprove adhesion fastnessLayered productsDecorative surface effectsEngineeringHot melt

The invention discloses a printable transfer film which comprises a transfer carrier film (1), a release layer (2) and a thermal welding layer (5). The printable transfer film also comprises a printable layer (6). The transfer carrier film (1) is totally covered with the release layer (2) which is totally covered with the thermal welding layer (5). The thermal welding layer (5) is totally covered with the printable layer (6). A background layer (4) is clipped between the printable layer (6) and the thermal welding layer (5) and is characterized in that the printable layer (6) and the background layer (4) can be integrated into one through changing the resin polarity of the background layer (4) and adding printable auxiliary agent.

Owner:王兆进

Method for preparing fluorine-containing waterproof and oil-proof agent through emulsifier-free emulsion polymerization

ActiveCN103570860AOvercome the defect of easy migrationImprove stabilityFibre treatmentFiberOrganic solvent

The invention discloses a method for preparing fluorine-containing waterproof and oil-proof agent through emulsifier-free emulsion polymerization. The fluorine-containing polyacrylate fabric waterproof and oil-proof agent is prepared by taking thiocarbonate active end group-containing fluorine-containing amphiphilic block copolymer as an emulsifier. Compared with a micromolecular emulsifier, the fluorine-containing polyacrylate emulsifier-free emulsion prepared by adopting the amphiphilic block copolymers not only has high stability and high solid content, but also has excellent waterproof and oil-proof properties. Meanwhile, an organic solvent is not used in the method, so that the harm of the organic solvent on human health and environments can be avoided. In addition, a crosslinked monomer is selected to improve the washability, and enables the polymer to have reactive hydroxyl group which can be crosslinked with a reaction group on fiber or be self-crosslinked, so that the adhesion degree of a finishing agent on the fiber can be enhanced, and the washability can be improved.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing polyurethane linking agent used for environment-friendly ink

InactiveCN101168633AMeet environmental requirementsReduction and Elimination of Hazardous SubstancesInksPolyesterPolyol

The invention relates to a preparation method of environmentally friendly printing ink polyurethane coupling agent. The invention is characterized in that vulcabond and polyester polyol are used to generate performed polymer with -NCO end group, then dimethylolpropionic acid and 1,4-butanediol are used to operate the chain extension reaction, finally, spasmolytol is used to adjust the pH value toneutrality, ethanol is added into the spasmolytol to be agitated, and then the printing ink polyurethane coupling agent is attained. The agglutination fastness of the coupling agent is strong, and thebinding strength of the printing ink and printing backing material can be obviously promoted. The invention has the advantages that no harmful solvent exists in the processing process. The inventionfully accords with the environmentally friendly technical requirements of chemical engineering accessory ingredient.

Owner:江阴市诺科生物新材料科技有限公司

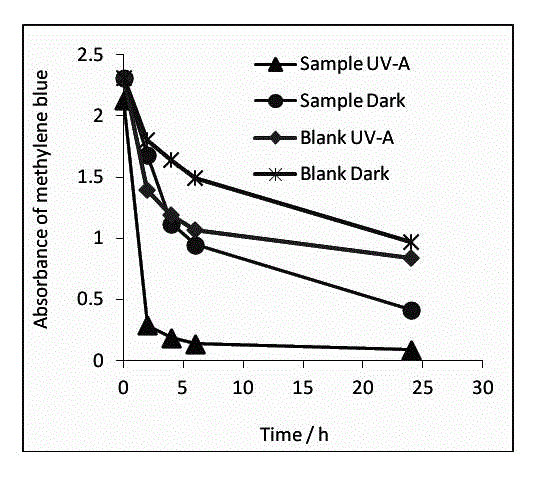

Preparation method of high-adsorption supported photocatalyst

InactiveCN104475173AImprove smoothnessDry evenlyWater/sewage treatment by irradiationMolecular sieve catalystsFilm-forming agentUltrasonic dispersion

The invention discloses a preparation method of a high-adsorption supported photocatalyst. The method comprises the following steps: 1, respectively weighing a photocatalyst raw material, a curing agent, a film forming agent and a dispersant, adding the raw material, the curing agent, the film forming agent and the dispersant into a film forming assistant, mixing and dissolving, and carrying out ultrasonic dispersion to obtain a photocatalysis powder suspension liquid; 2, immersing a supporting carrier in the photocatalysis powder suspension liquid, carrying out ultrasonic dispersion, and standing; 3, carrying out film forming drying on the supporting carrier obtained in step 2 at 80-120DEG C; and 4, sintering the film forming dried supporting carrier at 200-800DEG C for 2-8h, and naturally cooling the supporting carrier to obtain the high-adsorption supported photocatalyst. The high-adsorption supported photocatalyst prepared in the invention has the advantages of uniform dispersion, good photocatalytic activity, extremely good adhesiveness and super strong adsorption effect.

Owner:姚 燕燕

Preparation method of environment-friendly type aqueous polyurethane hot sol for clothing artificial leather

InactiveCN101157841AImprove adhesion fastnessHigh strengthPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsPolymer scienceAlcohol

The invention relates to an environment-friendly preparation method of waterborne polyurethane thermosol used for artificial leather of cloth. The thermosol made in the preparation method is mainly used for bonding of synthesized artificial leather in fabric and clothing production. Diisocyanate and binary alcohols compound can be mixed to make prepolymer, the terminal group of which is minus NCO, and then dihydromethyl propionic acid and 1, 4-butanediol are added to do chain extending reaction. In the end after amine being used for adjusting the pH value to neutrality, deionized water is added and stirred. Then the environment-friendly waterborne polyurethane thermosol used for the artificial leather of cloth is obtained. The waterborne polyurethane thermosol made in the method has high adhesion strength and can stand strong intensity. The bonding fabric is soft and has good water resistance and waterproof performance.

Owner:华明扬

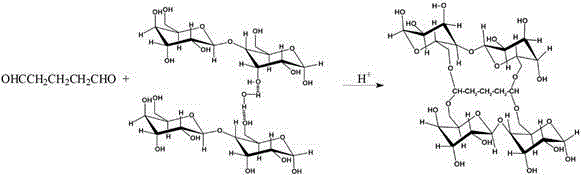

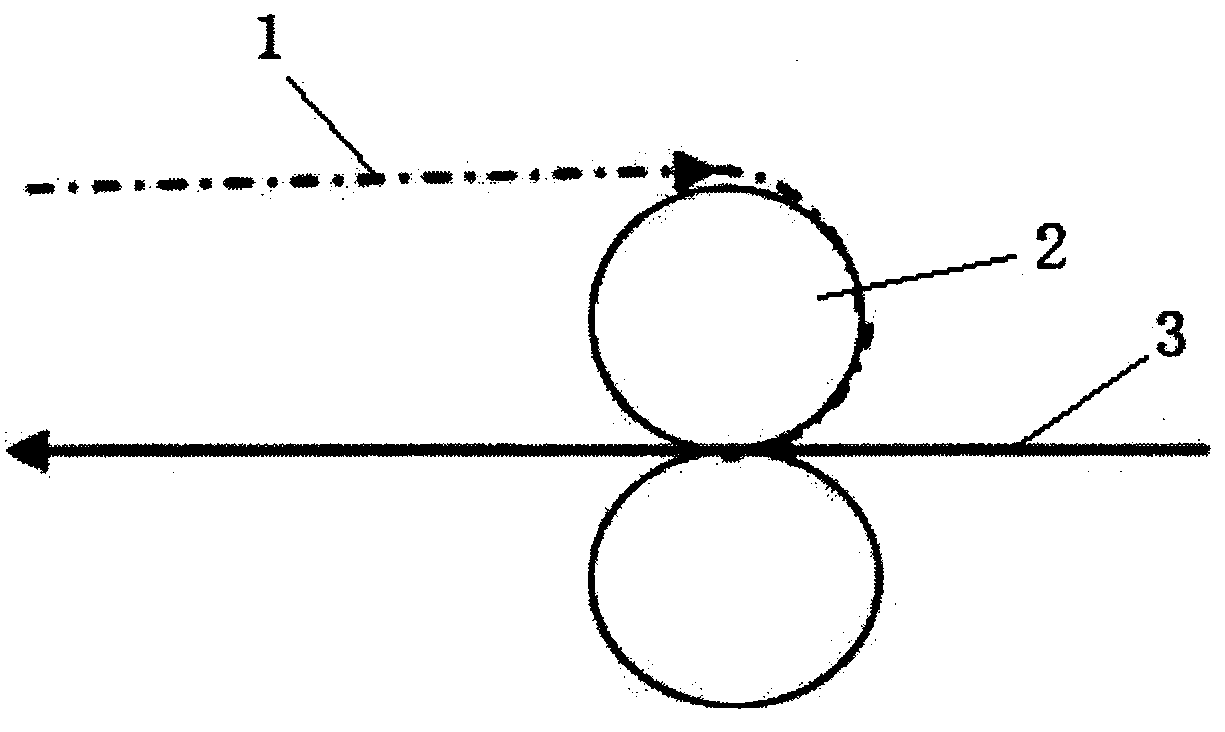

Method for printing words on surface of cable with fluoroplastic sheath

ActiveCN101804722AHigh fastnessImprove adhesion fastnessRotary pressesPrinting press partsHigh concentrationWater cooling

The invention provides a method for printing words on the surface of a cable with a fluoroplastic sheath, which comprises the following steps: performing water-cooling sizing after extruding the fluoroplastic sheath of the cable; performing surface drying; and printing words on the surface of the fluoroplastic sheath by adopting a type wheel. During water-cooling sizing, a heating device is adopted to maintain the water temperature about 130 DEG C under the pressure of 0.2MPa; after the surface of the fluoroplastic sheath is dried, the surface thereof is treated; a plasma flamethrower ionizes the air to generate a high-concentration plasma source, and plasmas are sprayed through compressed air to treat the surface of the fluoroplastic sheath, so that the surface is roughened; the arc type wheel is used to print words on the surface of the fluoroplastic sheath; and another plasma flamethrower dries the printed words. The method for printing the words on the surface of the cable with the fluoroplastic sheath can obviously improve the adhesion firmness of the printed words, so that the printed words have good scuff resistance and are difficult to erase, and the cable is convenient to lay and use.

Owner:JIANGSU HENGTONG POWER CABLE +2

Gravure alcohol ester plastic in-print environment-friendly ink

The invention discloses a gravure alcohol ester plastic in-print environment-friendly ink. A white ink includes polyurethane resin, ternary vinyl chloride-acetate copolymer, aldehyde-ketone resin, phenolic resin, a dispersing agent, a defoaming agent, a leveling agent, an antistatic agent, an adhesion promoter, a whitening agent, a wax powder, titanium dioxide and a diluent. A color ink includes polyurethane resin, ternary vinyl chloride-acetate copolymer, aldehyde-ketone resin, phenolic resin, a dispersing agent, a defoaming agent, a leveling agent, an antistatic agent, an adhesion promoter, a pigment and a diluent. The ink provided by the invention solves the problem that an existing printing ink cannot completely remove benzophenone residual and has good product performance.

Owner:CHENGDU PRESSTER NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com