Waterborne polyurethane emulsion for making waterproof strip and preparation method thereof

A water-based polyurethane and waterproof strip technology, applied in the direction of polyurea/polyurethane adhesives, adhesive types, adhesives, etc., can solve the problems that water-based polyurethane products have few patents and literature reports, and achieve good waterproof and moisture permeability. The effect of soft bonding and high adhesion fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

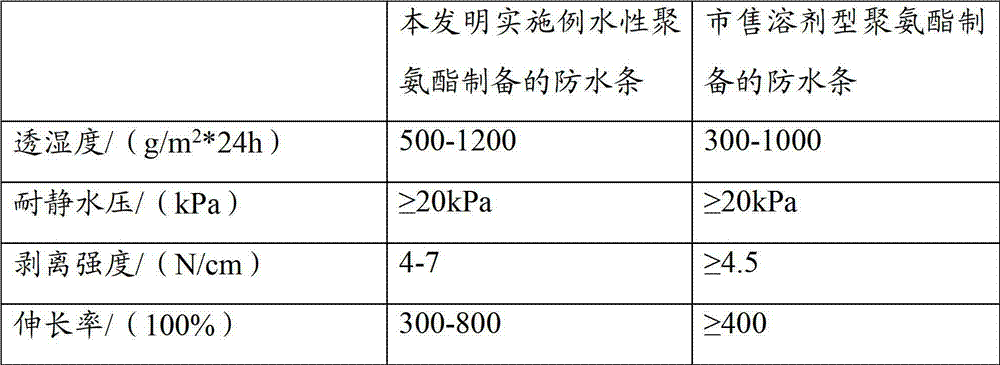

Examples

preparation example Construction

[0043] The above-mentioned preparation method of the water-based polyurethane emulsion for making waterproof strips comprises the following steps:

[0044] The polyol is added to the reactor, at 100-120 ° C, vacuum dehydration 2h, then the temperature is reduced to 70 ° C, add diisocyanate, hydrophilic chain extender, non-hydrophilic chain extender and catalyzer, at 80- React 2-4h at 95 ℃, after NCO content reaches the theoretical value, the temperature of reaction is reduced to 30-40 ℃, add neutralizer to carry out neutralization reaction, after continuous reaction 0.5-1h, be included in deionized water emulsification and dispersion , finally adding a chain extender containing active hydrogen, and stirring and reacting for 0.5-1 h to obtain the water-based polyurethane emulsion for making waterproof strips.

[0045] The catalyst is an organotin catalyst, and the added amount is 0-0.1% of the amount of the water-based polyurethane; the neutralizing agent is triethylamine, and ...

Embodiment 1

[0048] The water-based polyurethane emulsion described in this embodiment for making waterproof strips is composed of water-based polyurethane and water with a mass ratio of 0.76:1;

[0049] The raw material composition of described water-based polyurethane and its weight percentage are as follows:

[0050] (a) 24.1 wt% of diisocyanates (toluene diisocyanate and 1,6-hexamethylene diisocyanate);

[0051] (b) 68.7 wt % of polyols (polyethylene adipate-diethylene glycol and polytetrahydrofuran diol);

[0052] (c) 3.1 wt% non-hydrophilic chain extender (ethylene glycol);

[0053] (d) 4.1 wt% hydrophilic chain extender (dimethylolpropionic acid);

[0054] (e) 0% of chain extenders containing active hydrogen; the sum of the above raw materials is 100%;

[0055] The molar ratio of isocyanate groups to hydroxyl groups in the above raw materials was 1.2.

[0056] The above-mentioned preparation method of the water-based polyurethane emulsion for making waterproof strips comprises t...

Embodiment 2

[0060] The water-based polyurethane emulsion described in this embodiment for making waterproof strips is composed of water-based polyurethane and water with a mass ratio of 0.51:1;

[0061] The raw material composition of described water-based polyurethane and its weight percentage are as follows:

[0062] (a) 22.5 wt % of diisocyanate (isophorone diisocyanate);

[0063] (b) 70.2 wt% polyols (polybutylene adipate diol and polyoxyethylene diol);

[0064] (c) 2.0 wt% of a non-hydrophilic chain extender (1,4-butanediol);

[0065] (d) 3.9 wt% hydrophilic chain extender (dimethylolpropionic acid);

[0066] (e) 1.4% active hydrogen-containing chain extender (ethylenediamine); the sum of the above raw materials is 100%;

[0067] The molar ratio of isocyanate groups to hydroxyl groups in the above raw materials was 1.0.

[0068] The above-mentioned preparation method of the water-based polyurethane emulsion for making waterproof strips comprises the following steps:

[0069] Add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com