Patents

Literature

77results about How to "Good waterproof and moisture permeability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of waterproof moisture-permeable nanofiber composite membrane

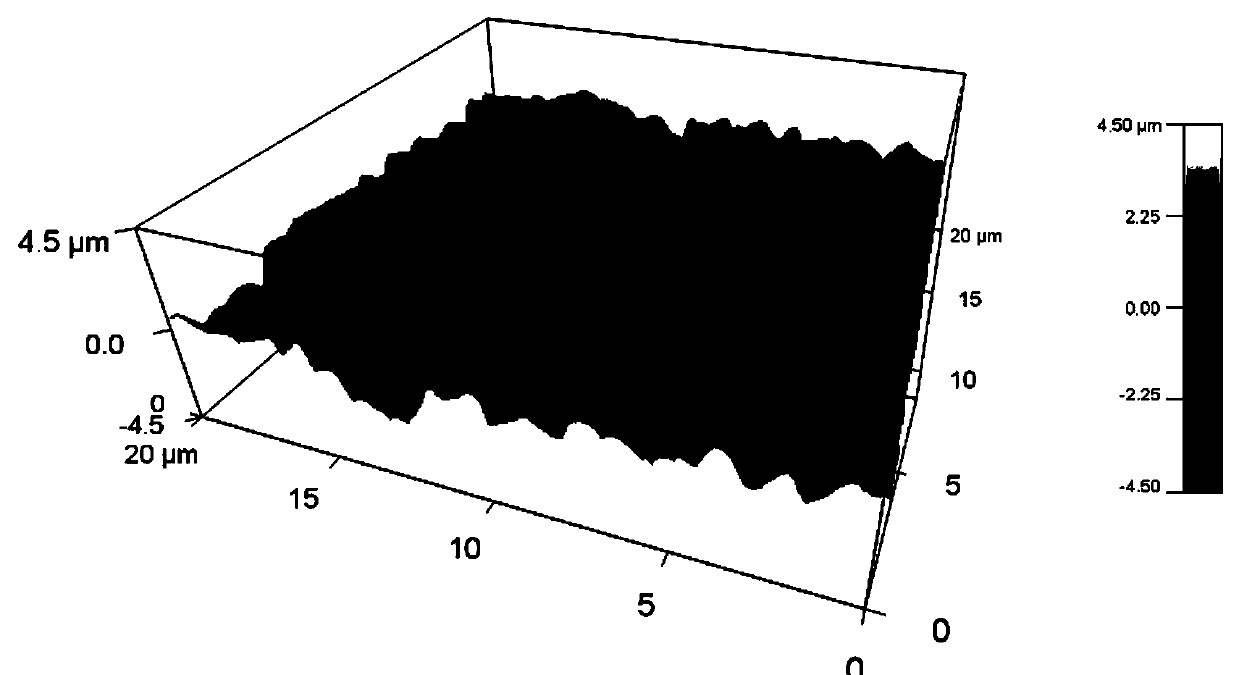

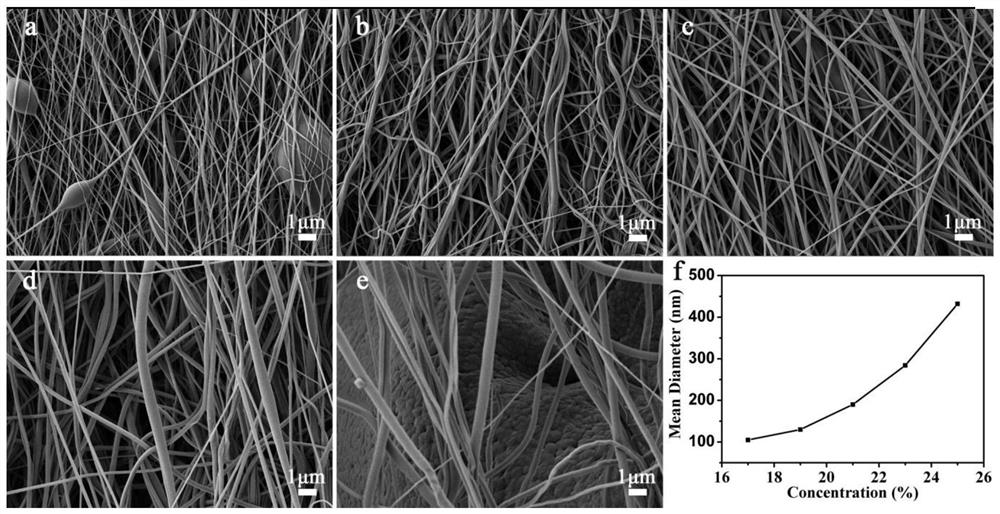

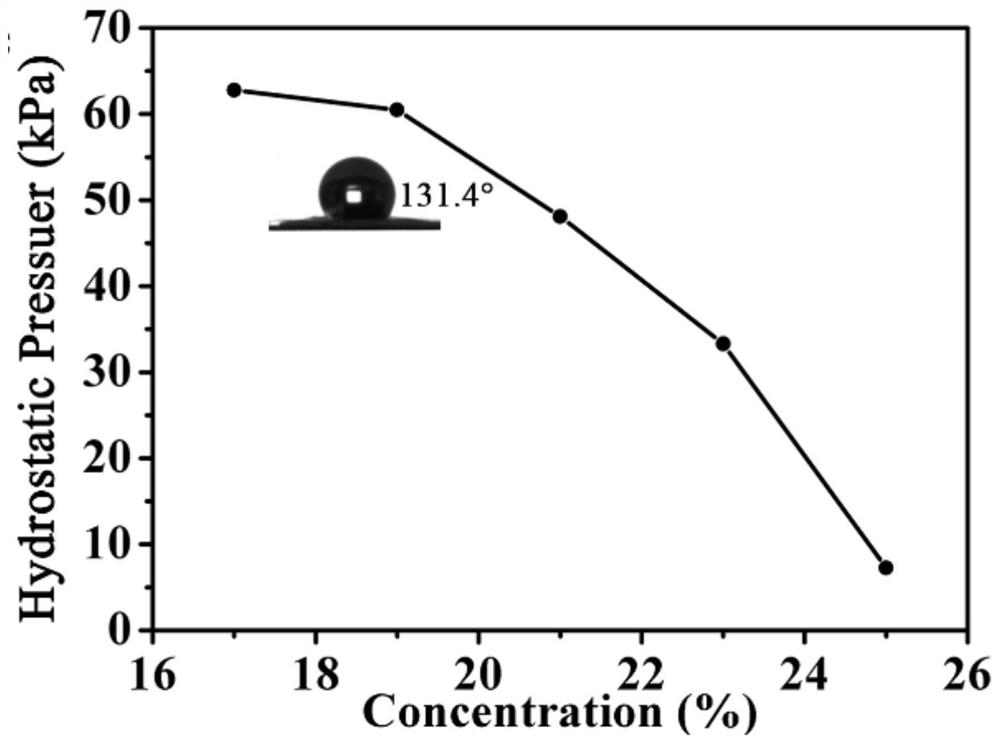

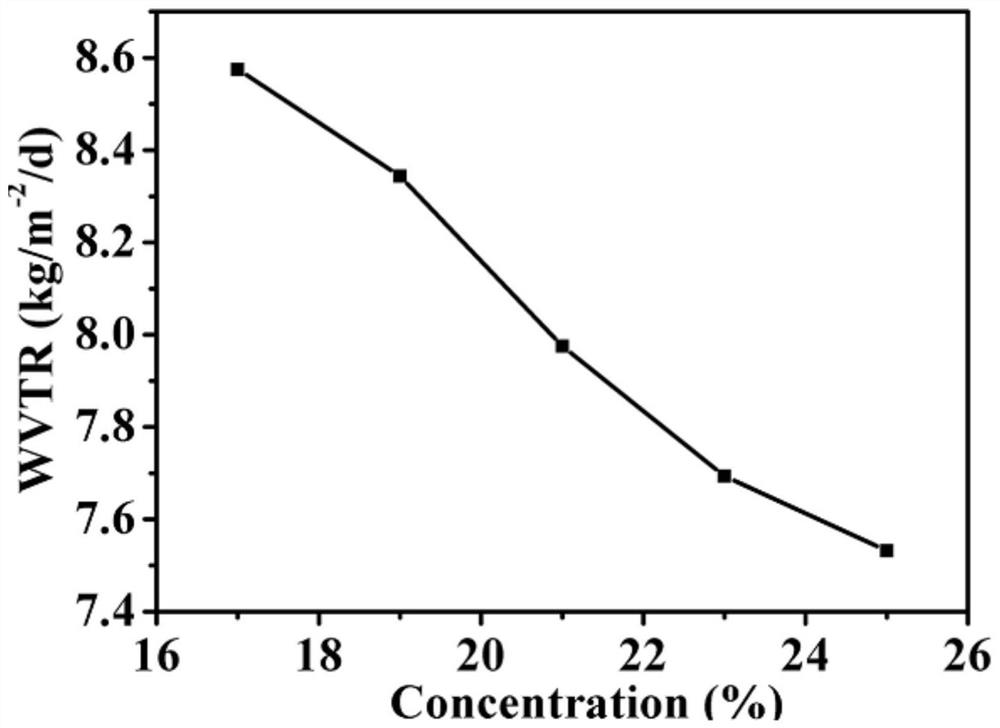

InactiveCN110438659AImprove performanceSmall fiber diameterSilicaElectro-spinningWater vaporLiquid water

The invention relates to a preparation method of a waterproof moisture-permeable nanofiber composite membrane, and belongs to the technical field of textile materials. According to the preparation method, polyacrylonitrile is taken as a main raw material, polyvinylidene fluoride and polyurethane are added, the waterproof and moisture-permeable nanofiber composite membrane is prepared, and the waterproof and moisture-permeable membrane prepared from polyacrylonitrile nanofibers has the characteristics of high porosity, fine fiber diameter and small pore diameter. The waterproof and moisture-permeable effect of the fiber membrane is effectively improved, the hydrophobic microporous membrane is preliminarily obtained by blending polyacrylonitrile, polyvinylidene fluoride and polyurethane through a solution, the waterproof moisture-permeable membrane with a certain welding structure is obtained in combination with heat treatment, penetration of liquid water is effectively prevented, polyurethane is a block polymer, polar groups such as hydrophilic groups which exist on a macromolecular chain segment provide a carrier for water vapor transfer, meanwhile, the polyurethane has a certain hydrophobic property by the hydrophobic group on the chain segment, and by addition of the polyurethane, the nanofiber composite membrane has excellent comprehensive performance.

Owner:欧名龙

Microporous plastic film

ActiveCN104164067AFully biodegradableWill not cause white pollutionMoisture permeabilityPlastic film

The invention relates to a microporous plastic film. According to the invention, an area of surface pores with diameters within a range of 0.2-7mum accounts for 0.5-15% of a total surface area. A water resistance of the film is higher than 800mm, and a moisture permeability of the film is higher than 1000g / m<2>.day. A stiffness of the film is lower than 40mm. The microporous plastic film provided by the invention has complete biodegradability, and does not cause white pollution. The film is green and environment-friendly, and has good waterproof performance and moisture permeability. The film is soft, and provides a comfortable touch. The film has good forming and processing performances, and can be applied in fields such as sanitary materials, clothing, and building. The microporous plastic film has waterproof, moisture-permeating, and air-permeating effects.

Owner:TORAY ADVANCED MATERIALS RES LAB CHINA

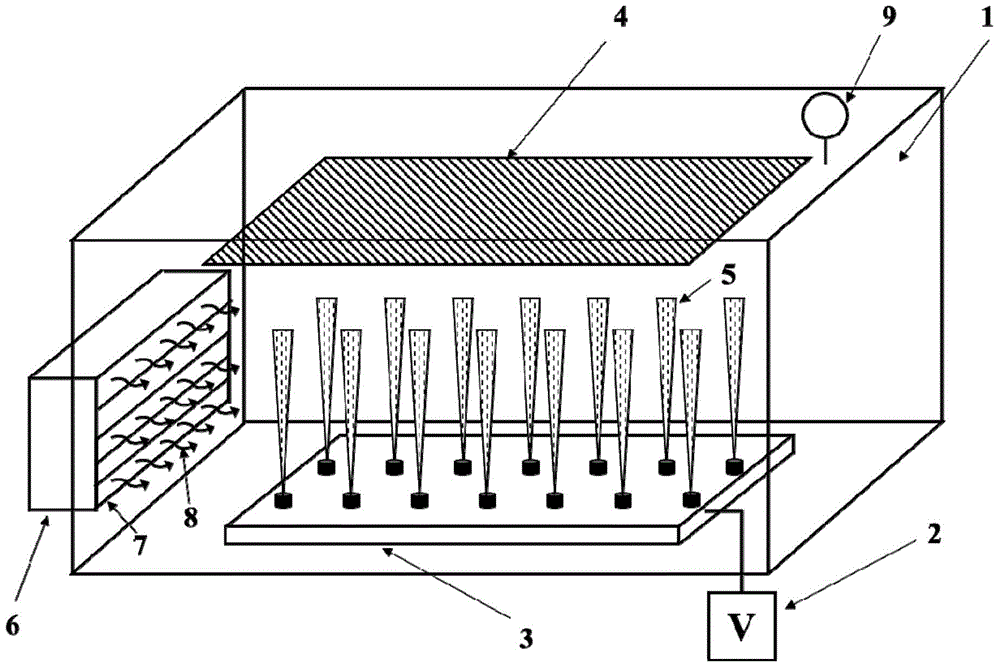

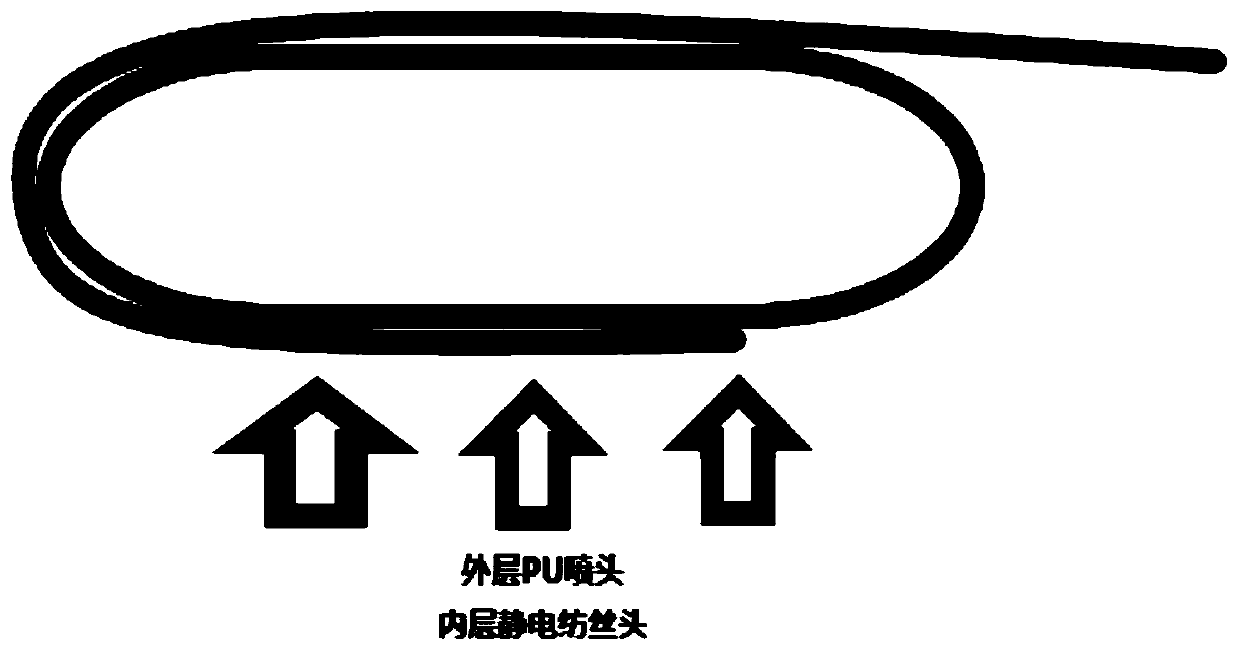

Electrostatic spinning method and device of fiber-based waterproof moisture-permeable film high in moisture-permeable flux

ActiveCN104452109AGood waterproof and moisture permeabilityPorosity is easy to controlNon-woven fabricsPorosityFiber

The invention relates to an electrostatic spinning method and device of a fiber-based waterproof moisture-permeable film high in moisture-permeable flux. The electrostatic spinning method includes that during electrostatic spinning, polymer solution jet flow is injected at a certain included angle with air of a certain temperature and / or lateral air flow of non-solvent steam, and polymer molecules in the jet flow are quickened to be separated and solidified into fibers; water-pressure resistance of the electrostatic spinning film, namely the fiber-based waterproof moisture-permeable film high in moisture-permeable flux is greater than or equal to 100kPa, and the moisture-permeable flux is greater than or equal to 15000g / m<2> / d. The electrostatic spinning device is composed of an electrostatic spinning box, a high-voltage direct-current power supply, an electrostatic spinning hydraulic system, a spinning jet and a receiving base material, and a steam generation and air supply system is mounted on one side of the electrostatic spinning box. The fiber-based waterproof moisture-permeable film produced by the method has the advantages of small bore diameter, controllable adhesion degree and high porosity; the film is high in water-pressure resistance and moisture-permeable flux when used in the waterproof and moisture-permeable areas, and is wide in actual application prospect.

Owner:DONGHUA UNIV

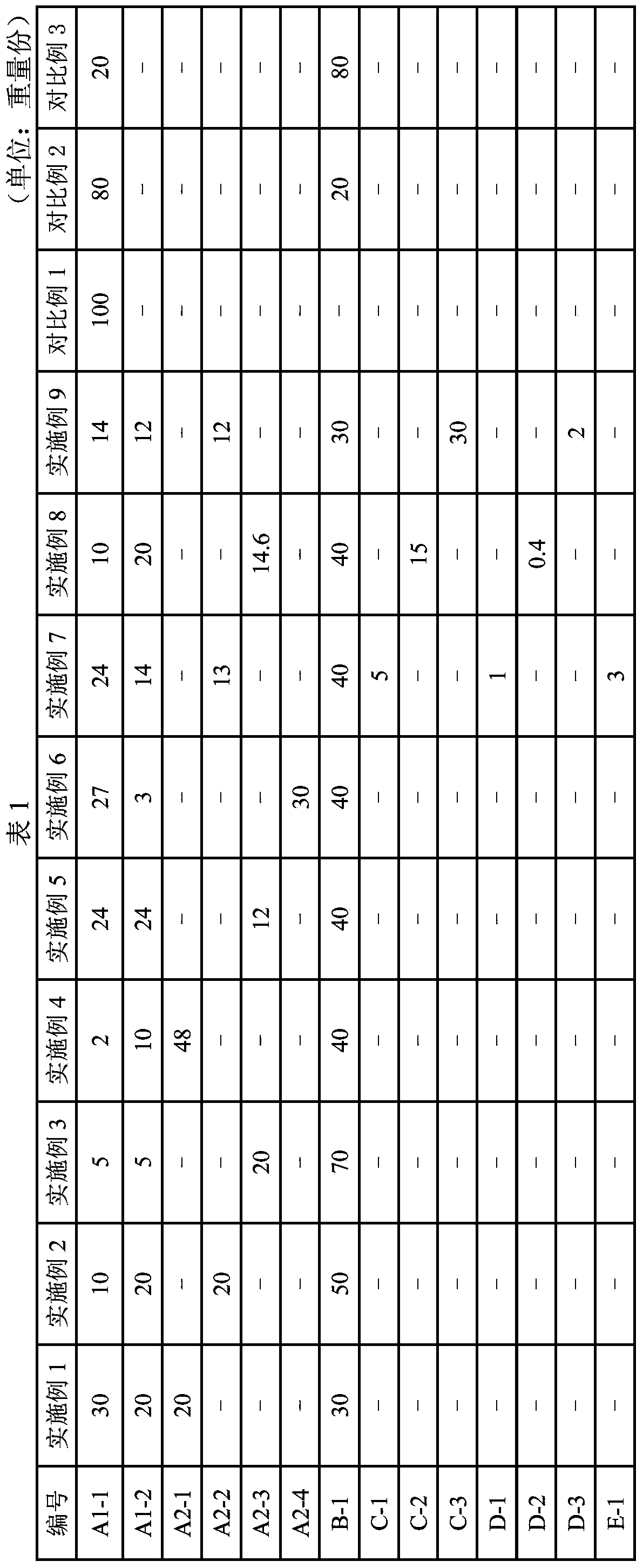

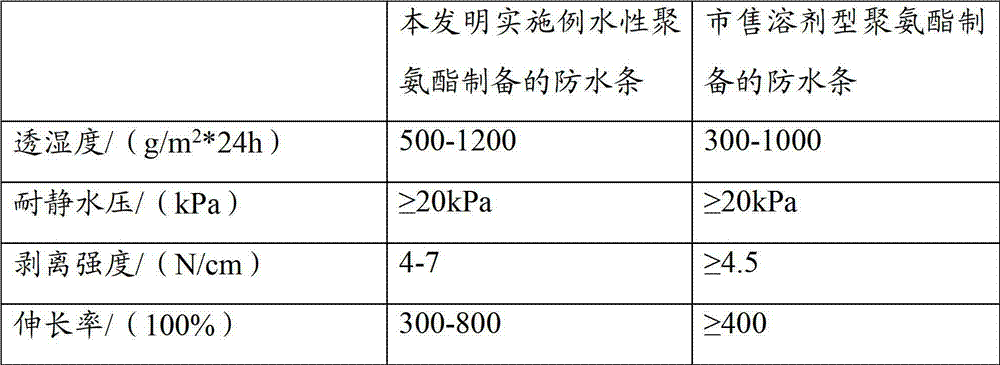

Waterborne polyurethane emulsion for making waterproof strip and preparation method thereof

ActiveCN103030775AImprove performanceImprove adhesion fastnessPolyureas/polyurethane adhesivesEmulsionOrganic solvent

The invention discloses waterborne polyurethane emulsion for making a waterproof strip. The emulsion comprises waterborne polyurethane and water according to the mass ratio of 0.5-0.9 to 1, wherein the waterborne polyurethane comprises the following components in percentage by weight: (a) 8-50% of diisocyanate, (b) 25-80% of polyhydric alcohol, (c) 0-10% of non-hydrophilic chain extender, (d) 0.5-15% of hydrophilic chain extender, and (e) 0-8% of active hydrogen-containing chain extender; the total weight percentage of the components is 100%; and the molar ratio of isocyanate group NCO to hydroxyl group OH in the components of the waterborne polyurethane is 2-5 to 1. The waterborne polyurethane emulsion does not contain or only contains a very small amount of volatile organic solvent, has the solid content of 25-50%, is lower in viscosity and can be used for making the waterproof strip after high-speed film coating and curing; and the waterproof strip has the characteristics of high bonding degree, high strength, soft bonding part, good waterproof and moisture-permeable performance and the like.

Owner:广东宏昌新材料科技有限公司

Waterproof and moisture permeable type thermoplastic polyurethane film and preparation method thereof

InactiveCN104448788AGood waterproof and moisture permeabilityPrevent penetrationToluene diisocyanateWater vapor

The invention discloses a waterproof and moisture permeable type thermoplastic polyurethane film and a preparation method thereof. The waterproof and moisture permeable type thermoplastic polyurethane film is prepared from the following components in percentage by weight: 80-85 percent of thermoplastic polyurethane, 8-10 percent of a slipping agent and 7-10 percent of a Matt agent, wherein the thermoplastic polyurethane is prepared from the following raw materials in parts by weight: 58-63 parts of poly(tetramethylene ether glycol), 30-35 parts of toluene diisocyanate, 5-8 parts of 2-ethoxyethyl acetate and 1-3 parts of dibutyl tin diacetate. By virtue of the mode, the waterproof and moisture permeable type thermoplastic polyurethane film is excellent in waterproof and moisture permeable performance, is capable of preventing permeation of water drops and ensuring free penetration of water vapor and can be used in a bad environment.

Owner:JIANGSU HONGYUAN NEW MATERIAL TECH

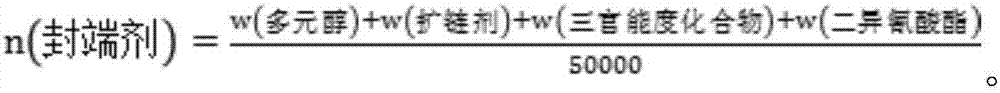

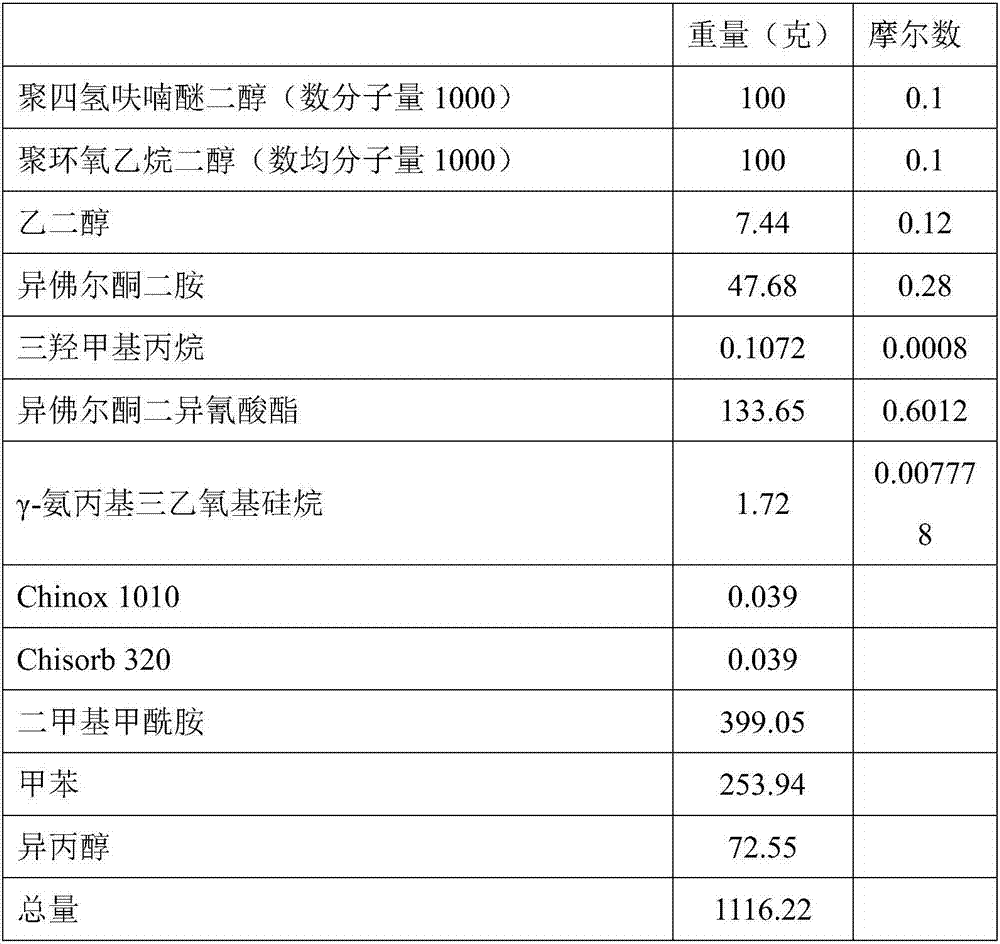

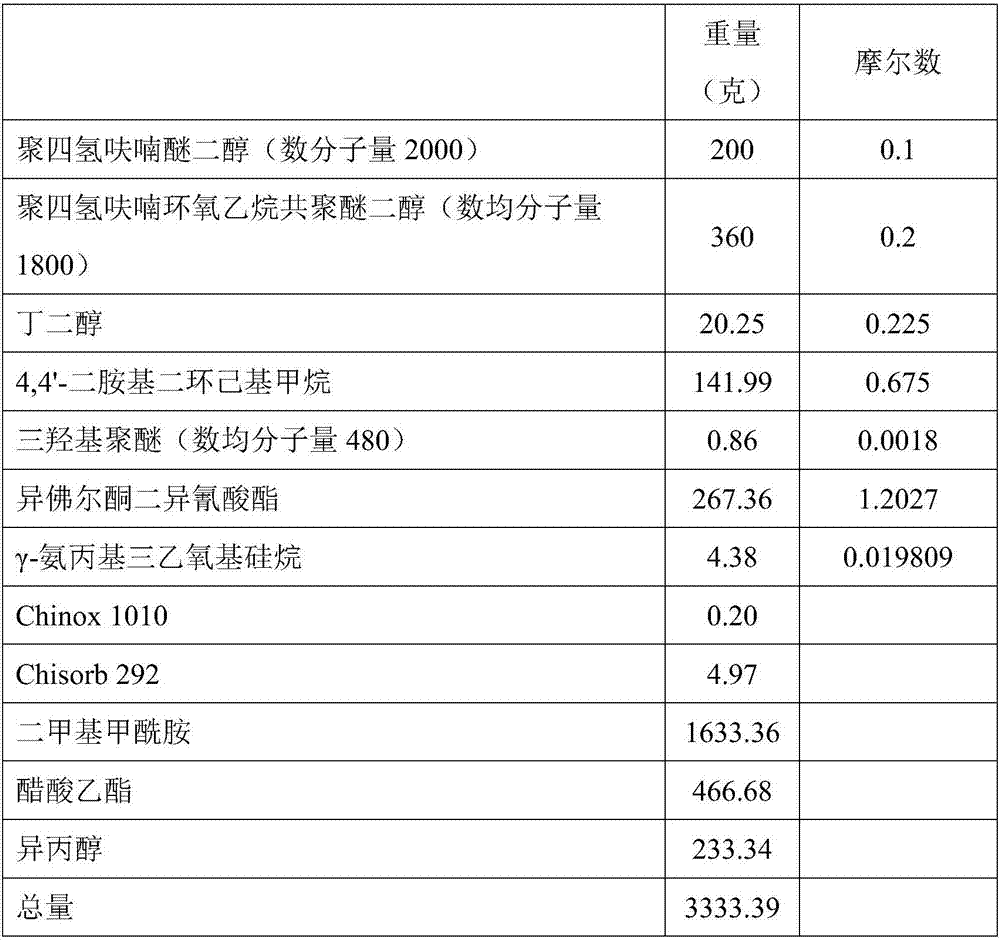

Surface layer polyurethane resin for waterproof and moisture permeable synthetic leather and preparation method of polyurethane resin

ActiveCN107501505AGood waterproof and moisture permeabilityExcellent wear resistancePolyurea/polyurethane coatingsTextiles and paperIsocyanateEpoxide

The invention discloses a surface layer polyurethane resin for waterproof and moisture permeable synthetic leather and a preparation method of the polyurethane resin. The surface layer polyurethane resin for the waterproof and moisture permeable synthetic leather is made from raw materials comprising polyol, chain extenders, a tri-functionality compound, diisocyanate and a sealing agent. The polyol contains polyol A and polyol B in a molar ratio of 1:1-1:3, wherein polyol A is selected from one or more of polytetramethylene ether glycol and polytetrahydrofuran propylene epoxide polyether diols, and the polyol B is selected from one or more of polytetrahydrofuran epoxyethane polyether diols, propylene epoxide epoxyethane polyether diols and polyepoxide glycol; the chain extenders comprise a dihydroxyl chain extender and a diamino chain extender; the tri-functionality compound is a trihydroxy compound; and the blocking agent is a monoamine silane coupling agent. The waterproof and moisture permeable polyurethane synthetic leather disclosed by the invention not only has excellent waterproof property and moisture permeability, but also has excellent wear resistance.

Owner:江苏华峰超纤材料有限公司

Method for forming porous polyurethane membrane

ActiveCN102343224AUniform internal pore sizeHigh porositySemi-permeable membranesPorositySurface layer

The invention relates to a method for forming a porous polyurethane membrane, belonging to the technical field of membrane science and engineering. The method for forming the porous polyurethane membrane, provided by the invention, comprises the steps of: dissolving thermoplastic polyurethane in an organic solvent to prepare a membrane casting solution, immersing the membrane casting solution in an environment constituted by atomized microspheres which is prepared by an atomization device and used for solidification, and slowly performing a solidification forming process of the membrane casting liquor from outside to inside. According to the method, the forms of the microspheres on the surface and in the inner part can be effectively controlled in a forming process of the porous polyurethane membrane, and compact structures on the surface layer of the porous polyurethane membrane can be effectively reduced. The formed porous polyurethane membrane has the characteristics of uniformly distributed microspheres on the surface layer, no compact layer structure, uniform inner pore size, and large porosity. The method is simple to operate and has not pollution to the environment, and thedosage of an atomizing solution for solidification is lower. The prepared porous polyurethane membrane has a favorable waterproof breathability, and can be widely applied to the fields of clothes fabrics, leather, medical treatment and public health, and the like.

Owner:WUHAN YONGSEN BIOTECH

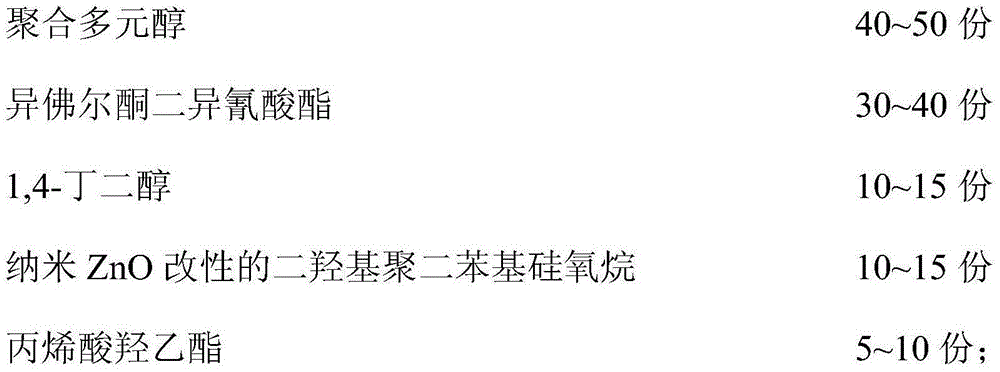

Waterproof breathable antibacterial thermoplastic polyurethane elastomer and preparation method thereof

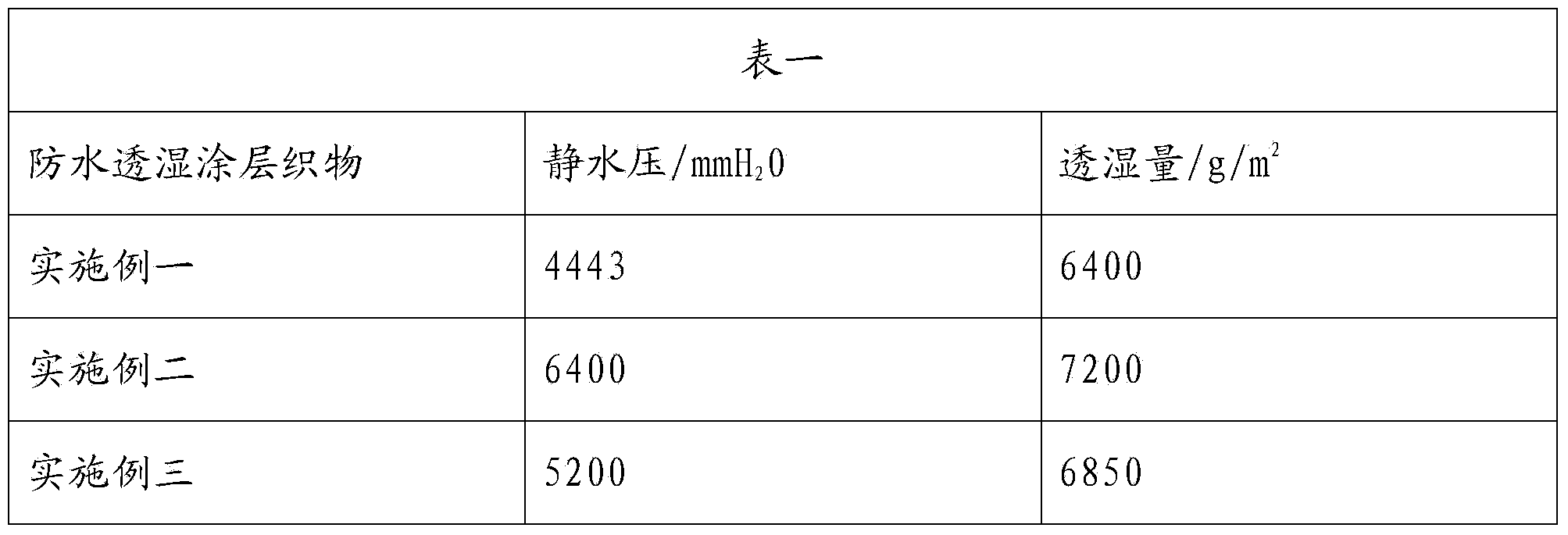

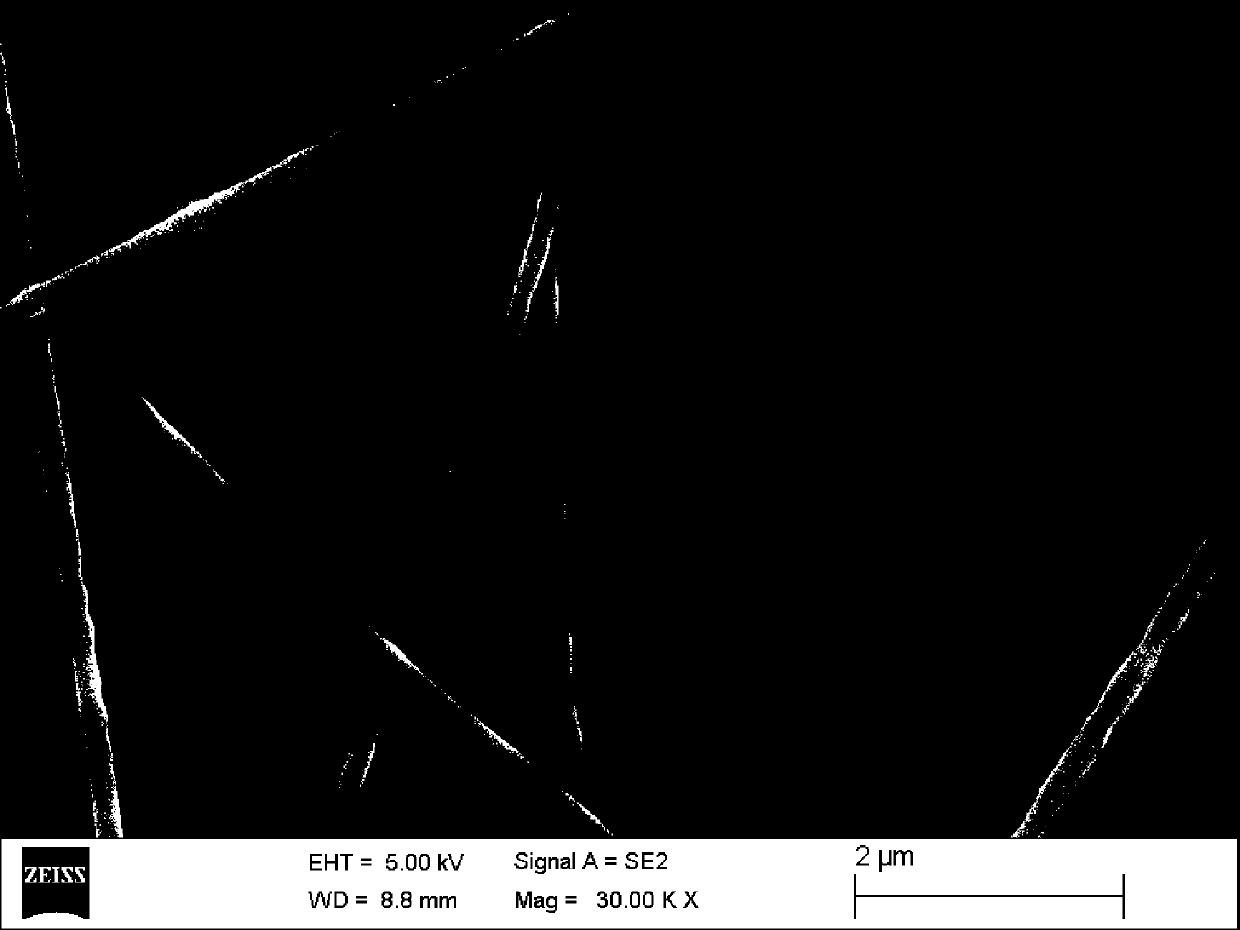

The present invention provides a waterproof breathable antibacterial thermoplastic polyurethane elastomer and a preparation method thereof. The thermoplastic polyurethane elastomer is prepared from the following main components by weight: 40-50 parts of polymeric polyol, 30-40 parts of isophorone isocyanate, 10-15 parts of 1,4-butanediol, 10-15 parts of nano ZnO-modified dihydroxy polydiphenylsiloxane and 5-10 parts of hydroxyethyl acrylate. The present invention uses a mixture of fluorine-containing polyether glycol and adipic acid 1,4-butanediol adipate diol as the polymeric polyol; the synergic effect of the two improves the water and oil repellency of the target product; while dihydroxy polydiphenylsiloxane and hydroxyethyl acrylate supplemented with nano ZnO increase the antibacterial properties of the thermoplastic polyurethane elastomer, and endow the elastomer with good mechanical properties.

Owner:DONGGUAN JIXIN POLYMER SCI & TECH

Anti-creasing, waterproof and moisture-permeable pearly-luster polyurethane synthetic leather

InactiveCN105350343AImprove wear resistanceImprove wrinkle resistanceCoatingsTextiles and paperFiberPolyethylene glycol

The invention relates to anti-creasing, waterproof and moisture-permeable pearly-luster polyurethane synthetic leather. The synthetic leather comprises a base cloth layer, a middle layer and a surface layer, wherein a modifying additive is used in the surface layer for modification and comprises raw materials in parts by weight as follows: 0.5-1 part of tannic acid, 1-2 parts of mica powder, 0.5-1 part of citric acid, 4-8 parts of polyethylene glycol, 4-8 parts of glass fiber, 2-4 parts of sisal fiber, 2-4 parts of sorghum straw, 0.2-0.5 parts of a silane coupling agent KH550, 3-6 parts of triisopropanolamine, 25-50 parts of olive oil and 0.5-3 parts of sodium chloride. The anti-creasing, waterproof and moisture-permeable pearly-luster polyurethane synthetic leather has the advantages that the synthetic leather does not wrinkle and does not have creases after being bent, the camber is good during lasting for shoemaking, the bent part of a shoe is shaped well, the polyurethane synthetic leather has high physical mechanical strength and good durability, and shoe products made of the polyurethane synthetic leather have good anti-creasing performance, do not have creases and are comfortable.

Owner:HANGZHOU FUYANG WEIWEN ENVIRONMENTAL PROTECTION TECH CO LTD

Preparation method of water-based high-performance waterproof and moisture permeable coated fabric

The invention discloses a preparation method of water-based high-performance waterproof and moisture permeable coated fabric. The preparation method comprises the following steps: (1) preparing a prime coat adhesive; (2) preparing a topcoat adhesive; (3) preparing coated fabric. The preparation method is short in production technology process, simple in process, water-based and environment-friendly, and free from pollution, and saves cost and reduces the energy consumption, and a coated finish product has the advantages of excellent waterproof and moisture permeable performance, full hand feeling, high draping property and the like.

Owner:DRAGON CLAN CHINA

Method for preparing windproof moisture-penetrable wool polyester viscose gabardine

ActiveCN101962915AIncrease elasticityStrong tear resistanceWoven fabricsLiquid/gas/vapor textile treatmentPolyesterHigh density

The invention relates to a method for preparing windproof moisture-penetrable wool polyester viscose gabardine, which comprises the following steps of: preparing a high-density twill base fabric from wool polyester viscose blend fibers, performing waterproof finish on the base fabric by using a micro-molecular waterproof agent, and sequentially coating a microporous polyurethane adhesive with the pore diameter of between the diameters of water drop molecules and water molecules on the fabric twice through a microporous wet coating. Therefore, the prepared wool polyester viscose gabardine fabric has the advantages of a wool fabric, a polyester fabric and a viscose fabric, namely soft color and handfeel, stiff and smooth and strong feeling, ultra-high tearing strength and windproof and moisture-penetrable performance, and capability of well meeting the requirement of the market on the windproof moisture-penetrable fabric.

Owner:WUJIANG HENGRUN TEXTILE FACTORY

Production method of non-woven fabric for wound dressing

InactiveCN103877605AKeep clean and hygienicHeal fastFibre treatmentAbsorbent padsWound dressingNonwoven fabric

The present invention discloses a production method of a non-woven fabric for wound dressing. The production method comprises: mixing water, granular water-soluble chitosan and granular calcium alginate at a room temperature, and uniformly stirring to prepare an antibacterial finishing solution, wherein the concentration of the chitosan is 1-3%, and the concentration of the calcium alginate is 0.02-0.05%; placing a non-woven fabric into the blended antibacterial finishing solution, soaking, finishing, dewatering, and drying; and carrying out high temperature shaping on the treated non-woven fabric, and carrying out high temperature compounding on the shaped non-woven fabric and a thermoplastic polyurethane TPU film. According to the present invention, the non-woven fabric is preferably selected, is a non-woven cloth, and has characteristics of softness, air permeability, no fiber tow production, and assurance of fresh and health wound; the finishing solution is adopted to carry out the soaking treatment, such that the original softness of the non-woven fabric can not be damaged, the functions of bacterial killing, bacterial inhibiting, inflammation eliminating and hemostasis are provided for the non-woven fabric, and the wound can be easily and rapidly healed; and the thermoplastic polyurethane TPU film has a good water resistance and moisture permeability performance.

Owner:QINGDAO TONGGUANWANG IND

Fluorinated graphene-containing waterproof and moisture-permeable composite fabric and preparation method thereof

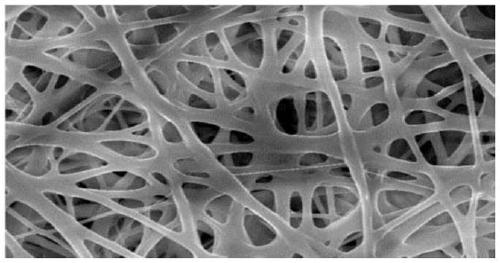

ActiveCN110973743AReduce weightGood water repellencySynthetic resin layered productsLaminationFiberHuman body

The invention belongs to the field of electrostatic spinning functional materials, and relates to a preparation method of a material capable of being applied to the waterproof and moisture permeable field, in particular to a fluorinated graphene-containing waterproof and moisture-permeable composite fabric and a preparation method thereof. The composite fabric has the advantages of super-hydrophobicity, high efficiency, better air and moisture permeability, energy conservation and the like. The average diameter of the fiber is 130 to 150 nm, the nanofiber waterproof and moisture permeable composite film is of a three-dimensional network structure, the hole diameter is small, a curved communication hole structure is formed, breathability is good, external severe weather infringement can beeffectively avoided, rain and snow penetration is prevented, sweat and moisture generated by movement of a human body can be discharged in time, so that the microenvironment of the human body is regulated and controlled, good comfort is provided for the human body, the protection function and the heat and moisture comfort of the garment fabric are unified, and the composite fabric is innovativelyapplied to the fields of medical treatment and public health, building outer walls, aerospace, aquatic product industry and the like.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Waterproof and moisture-permeable polyurethane and preparation method and application thereof

InactiveCN111848911AGood waterproof and moisture permeabilityChange interface statePolyurea/polyurethane coatingsLeather surface finishingPolymer scienceOrganometallic catalysis

The invention provides waterproof and moisture-permeable type polyurethane, which is prepared from the following raw materials in parts by mass: 110 to 150 parts of polyhydric alcohol, 45 to 60 partsof diisocyanate, 10 to 15 parts of fluorine-containing dihydric alcohol, 3 to 8 parts of fluorine-containing monohydric alcohol, 0.1 to 0.3 part of an organic metal catalyst, 7 to 10 parts of a hydrophilic chain extender, 5 to 8 parts of a neutralizer, 3 to 5 parts of a post-chain extender and 500 to 700 parts of water. According to the invention, polyhydric alcohol and diisocyanate are taken as main bodies, fluorine-containing dihydric alcohol is utilized to change the interface state of the material and improve the water resistance and moisture permeability, fluorine-containing monohydric alcohol is utilized to play a waterproof role in chain segments, and under the combined action of auxiliaries such as an organic metal catalyst, a hydrophilic chain extender and the like, the water resistance and moisture permeability are further improved. The embodiment shows that the polyurethane disclosed by the invention has the water pressure resistance of 78-88 KPa, the moisture permeability of 6.8-8.2 kg / m <2> / d and the air permeability of 5.7-6.3 mm / s.

Owner:QI HE LI HOU CHEM CO LTD

Aperture-controllable micro-porous membrane and making method thereof

ActiveCN106867017AGood waterproof and moisture permeabilityStrong and goodPorous membraneMoisture permeability

The invention discloses an aperture-controllable micro-porous membrane and a making method thereof. The micro-porous membrane is a polyurethane resin membrane, the aperture of the micro-porous membrane is 0.5-20 [mu]m, and the content of acid-soluble micro-particles in the membrane is 5.0 wt% or less. The acid-soluble micro-particles are used in coated resin, and are dissolved through acid treatment to obtain the aperture-controllable micro-porous membrane. The method is simple and easy, and the obtained micro-porous membrane has superior water pressure resistance, superior moisture permeability and soft hand feeling, can be used in outdoor sports wear, and has wide application prospect.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

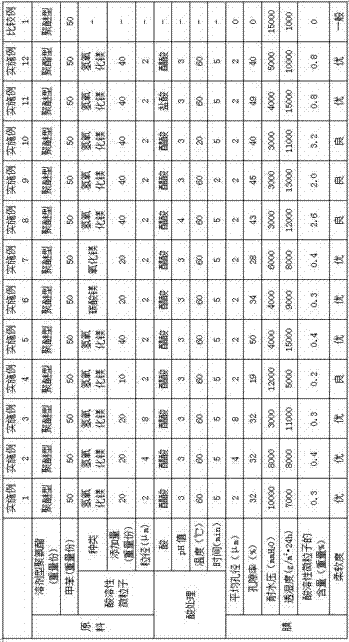

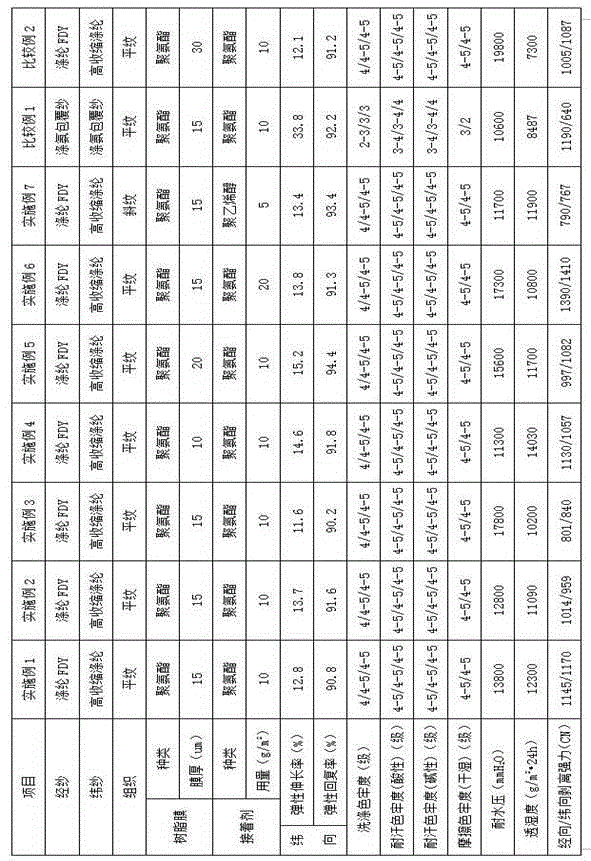

Terylene elastic fabric

InactiveCN105328960AGood waterproof and moisture permeabilityDoes not affect color fastnessSynthetic resin layered productsWoven fabricsYarnMoisture permeability

The invention discloses a piece of terylene elastic fabric. The piece of fabric comprises a base cloth and a resin film. The base cloth is a piece of woven fabric formed by terylene fully-drawn yarn as warp yarn and terylene high-shrinkage elastic yarn as filling yarn, wherein the broadwise elastic elongation ratio of the fabric is 10-20%, the broadwise elastic recovery rate is above 90%, the initial stage water-pressure resistance of the fabric is above 10000mmH2O, and the moisture permeability is above 10000g / m<2>.24h. The fabric can be used for producing jackets, wind coats, leisure wears, trousers, etc.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

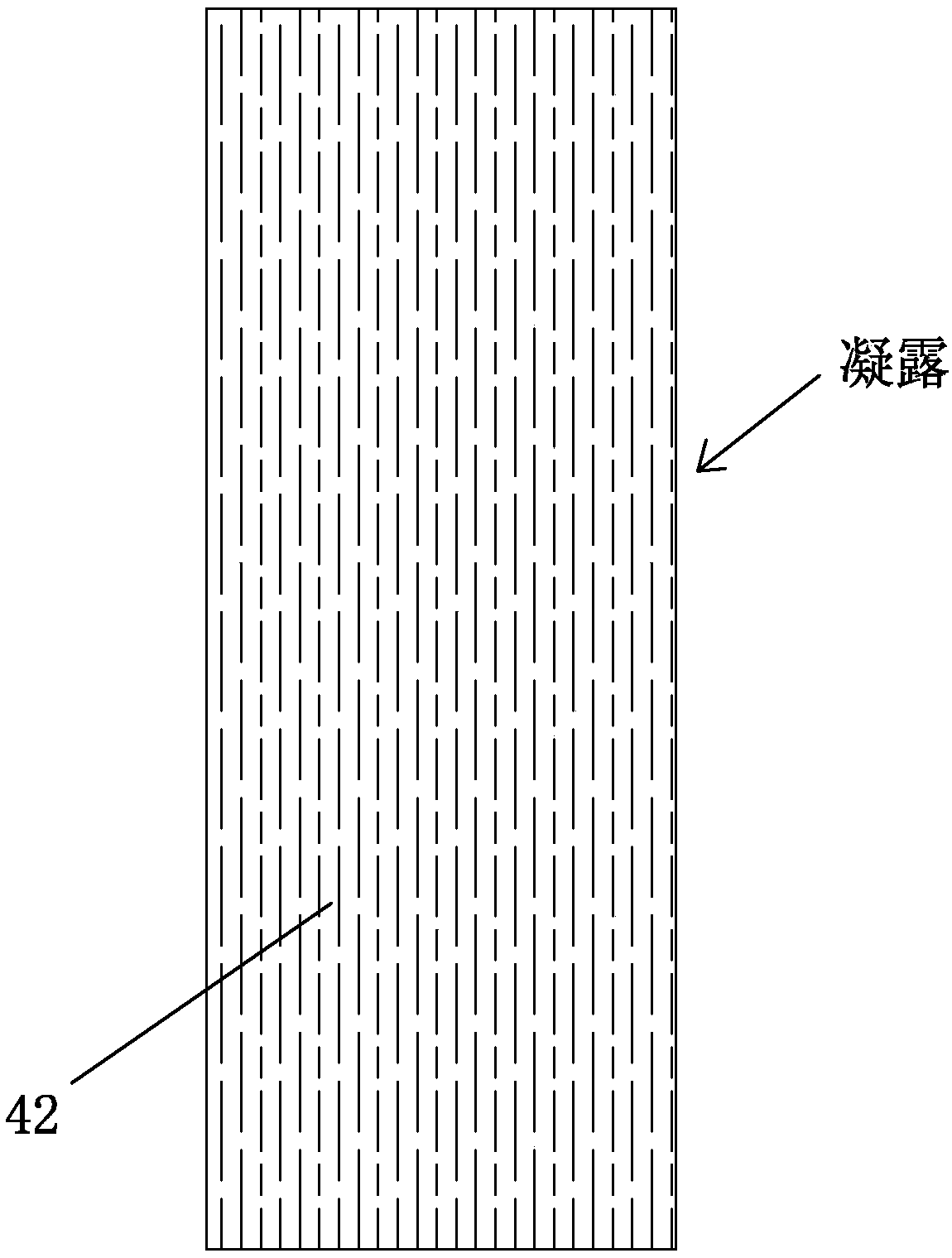

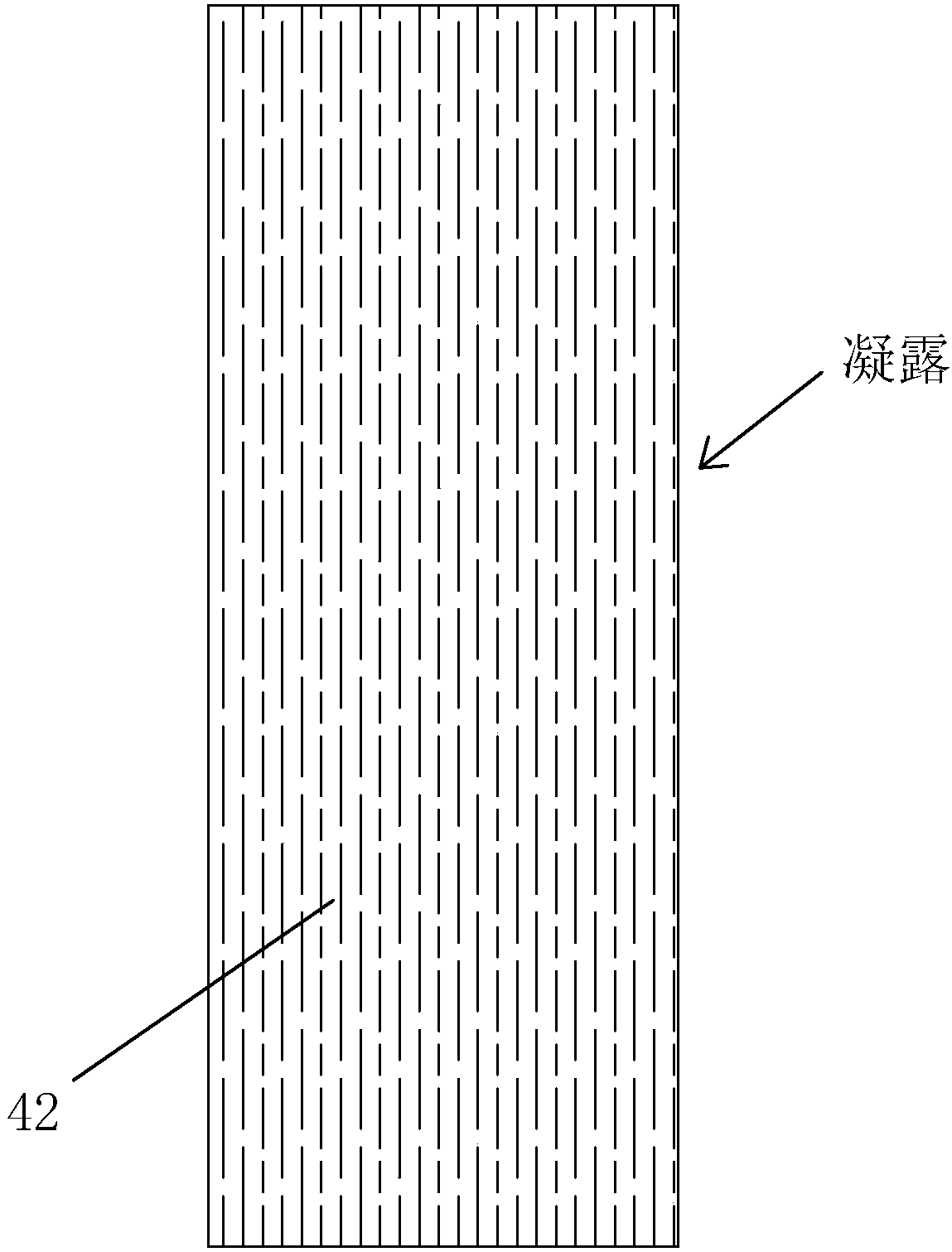

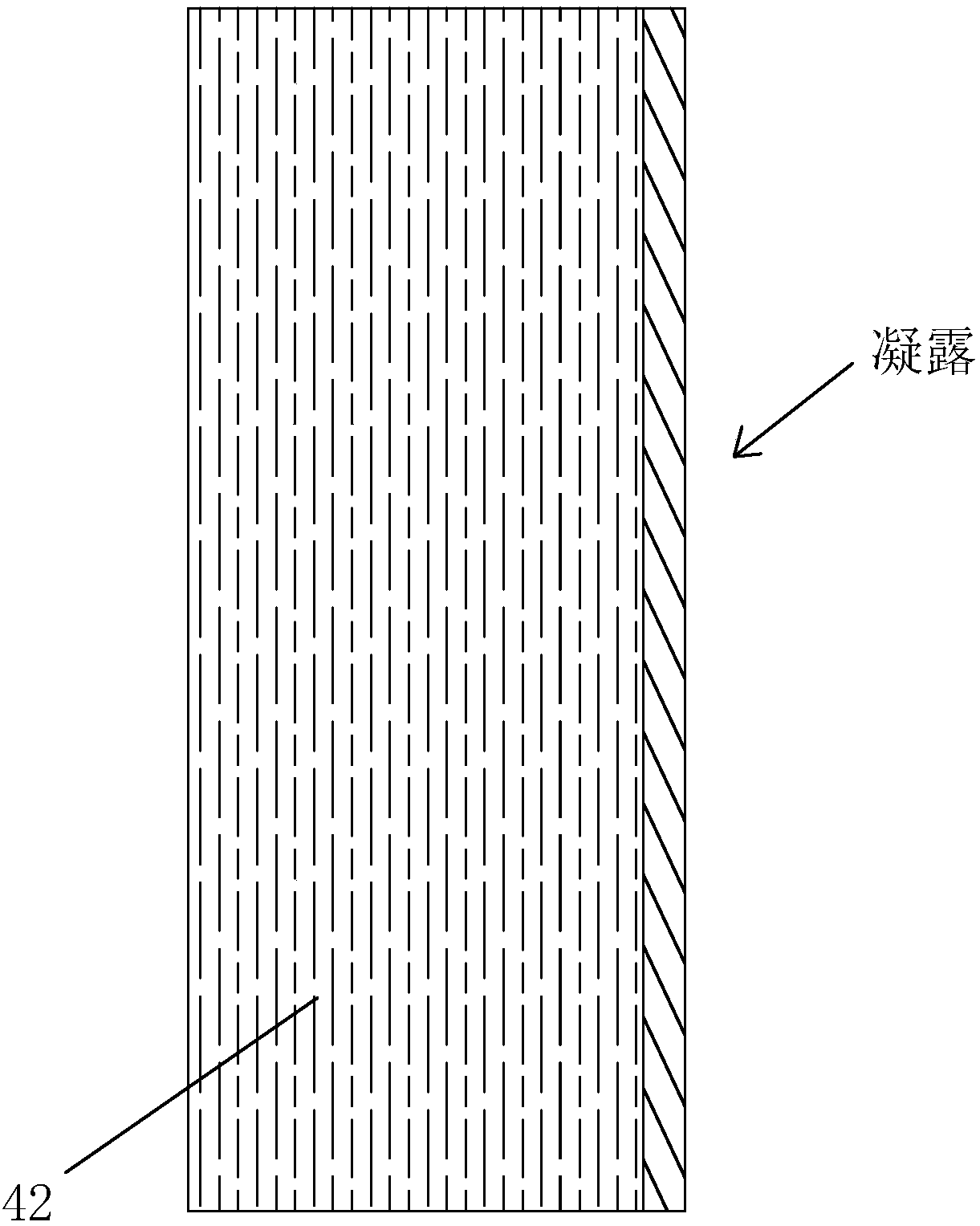

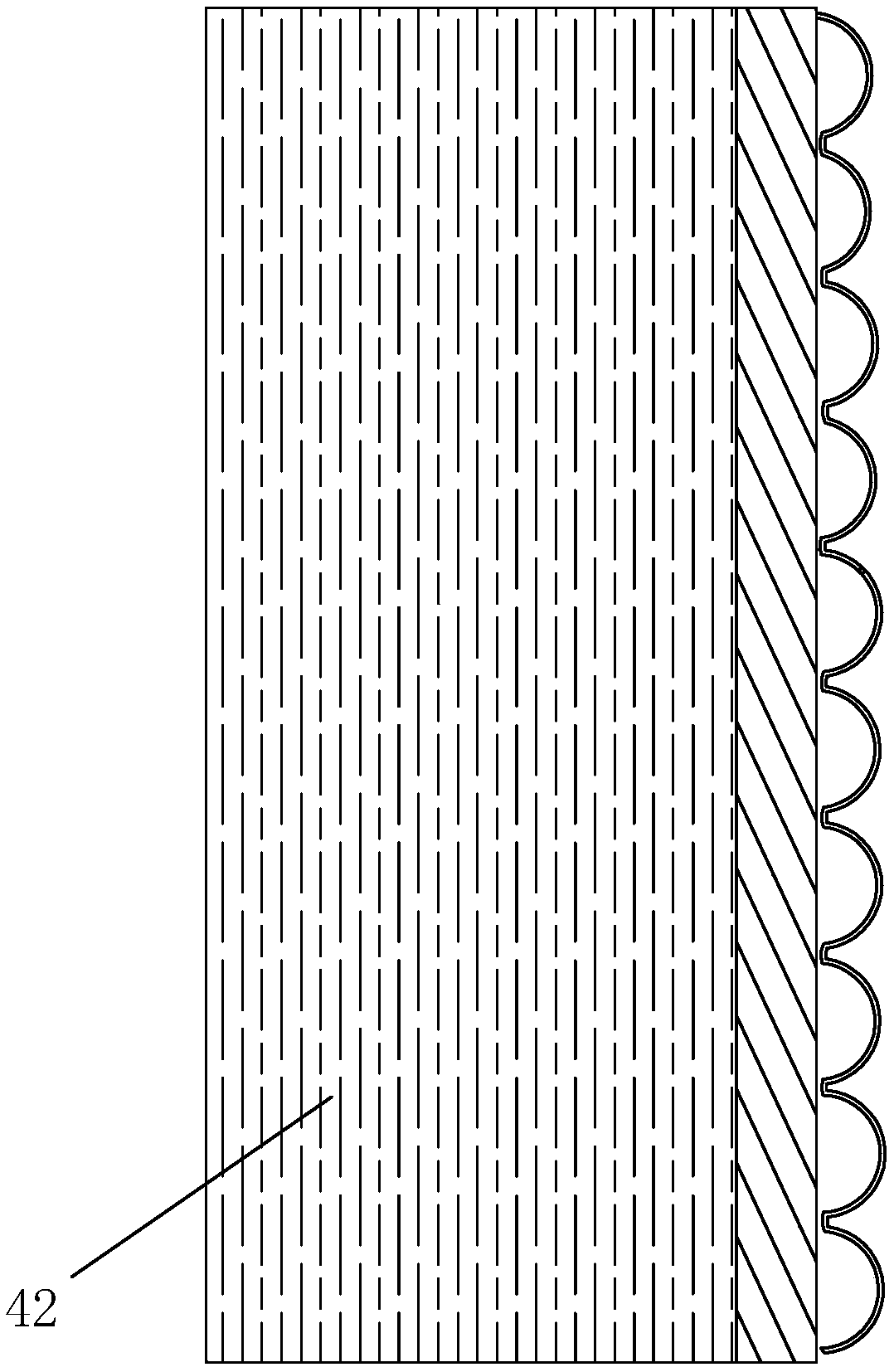

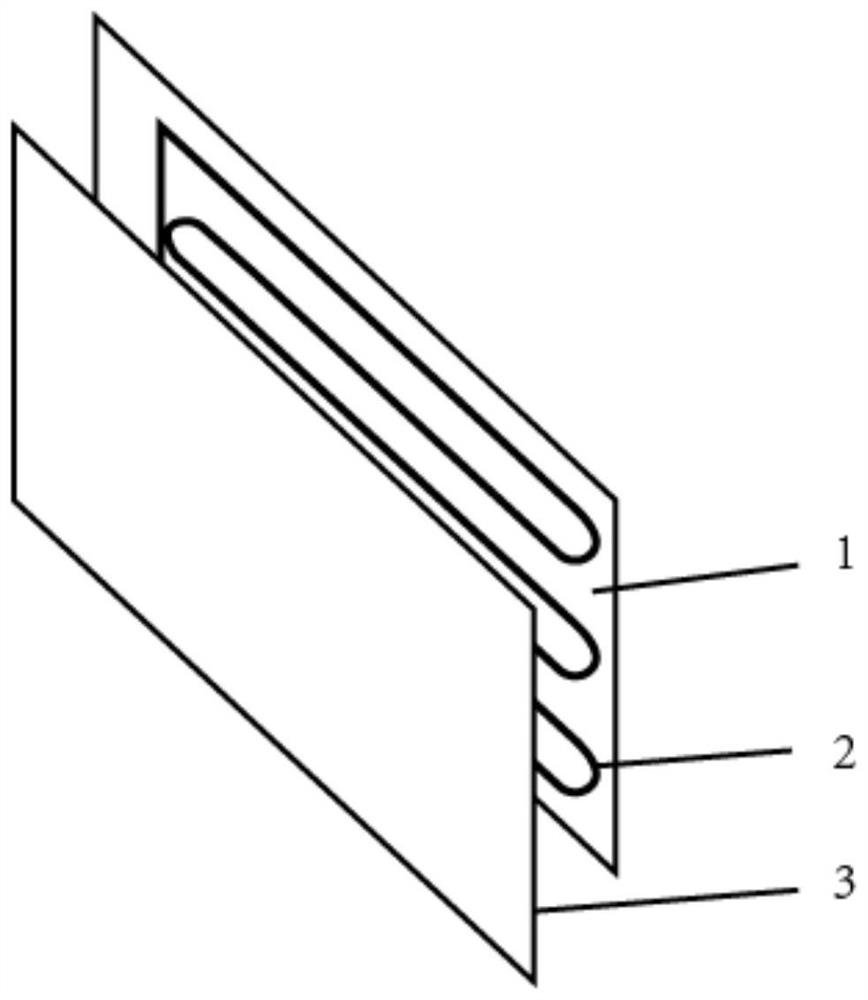

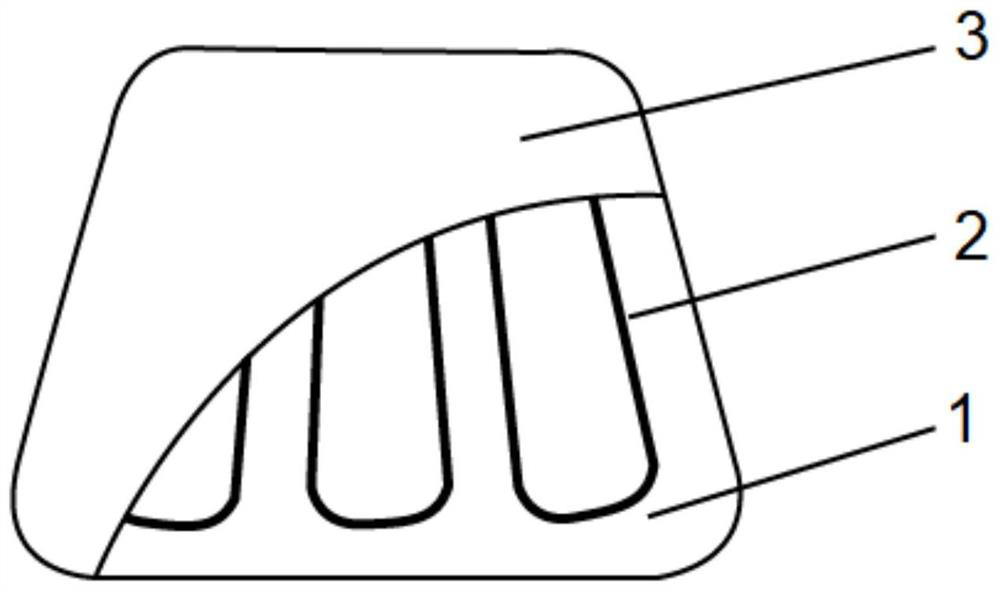

Waterproof and moisture-permeable coiled material with three-dimensional structure, production method and wall structure

ActiveCN109397771APlay a protective effectPrevent rotLamination ancillary operationsSynthetic resin layered productsManufacturing technologyNonwoven fabric

The invention relates to a waterproof and moisture-permeable coiled material with a three-dimensional structure, a production method and a wall structure. The waterproof and moisture-permeable coiledmaterial can be applied to wall construction and the wall structure. The invention further discloses a protective material for the wall construction and the wall structure and a manufacturing technology process and method thereof. The waterproof moisture-permeable coiled material comprises a waterproof and moisture-permeable coiled material body, wherein the waterproof and moisture-permeable coiled material body comprises a first non-woven fabric layer, a waterproof and moisture-permeable functional layer and a second non-woven fabric layer, and elastic protrusions are arranged outside the waterproof and moisture-permeable coiled material body in an arrayed mode. According to the waterproof and moisture-permeable coiled material, the production method and the wall structure, a wall body iswaterproof and moisture-permeable, the ventilation and drainage effects are better, the service life of the wall body is longer, the construction is more convenient, and the labor cost and the material cost are lowered.

Owner:SUZHOU ZIAN METAL PROD

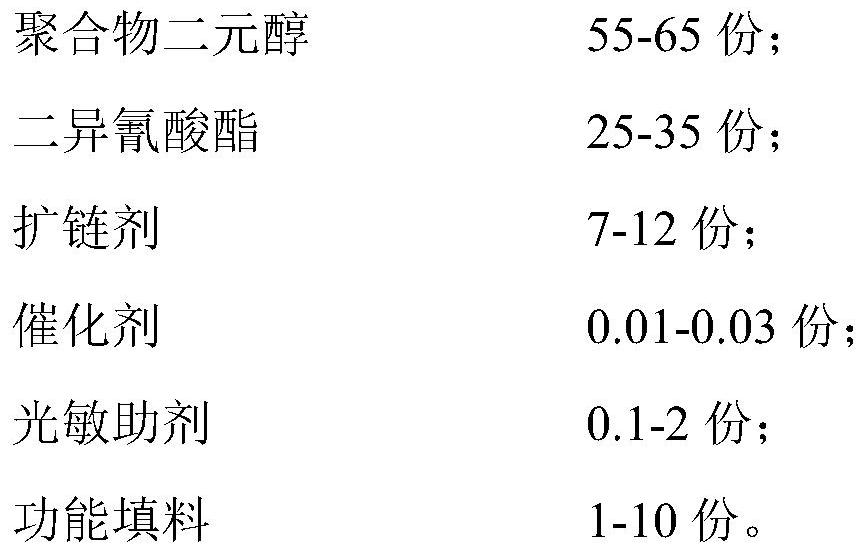

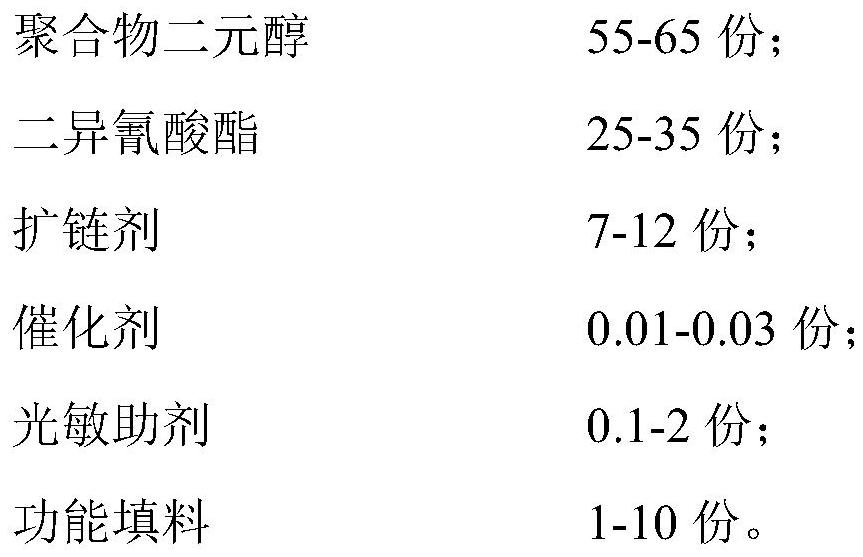

Photochromic thermoplastic polyurethane elastomer material for waterproof and moisture-permeable film, and preparation method thereof

ActiveCN112048053ASatisfy the pursuitWith photosensitive color changing functionPolymer sciencePtru catalyst

The invention belongs to the technical field of thermoplastic polyurethane elastomers, and particularly relates to a photochromic thermoplastic polyurethane elastomer material for a waterproof and moisture-permeable film, and a preparation method thereof. The material is prepared from, by weight, 55-65 parts of polymer diol, 25-35 parts of diisocyanate, 7-12 parts of a chain extender, 0.01-0.03 part of a catalyst, 0.1-2 part of a photosensitive auxiliary agent, and 1-10 parts of a functional filler. The photochromic thermoplastic polyurethane elastomer material for the waterproof and moisture-permeable film has excellent mechanical properties, the waterproof and moisture-permeable rate of the prepared film is greater than 10000 g / m<2> / 24h, the hydrostatic pressure resistance of the prepared film is greater than 10000 mmH2O, the film can be changed from colorless to colored under the irradiation of ultraviolet rays with certain wavelength, and then the film is changed from colored to colorless after being irradiated by visible light. The material can be used as a functional film material in the fields of clothing, shoe material bags and suitcases and the like, and has wide application prospects.

Owner:SHANDONG INOV POLYURETHANE

Making technology of functional textile fabric

InactiveCN102926192AGood waterproof and moisture permeabilityImprove surface roughnessFibre typesPolymer scienceWater vapor permeability

The invention relates to a processing technology of a functional fabric, and concretely relates to a making technology of a functional textile fabric. Ultrafine fibers are adopted as a raw material, crepe weaves are selected, high-contraction filaments are added to the crepe weaves to improve the surface roughness, and simultaneously a low-surface-energy substance is grafted to the surfaces of the fibers, so indexes comprising the water repellency grade, the oil repellency grade, the contact angle and the like of the fabric are greatly increased, and the water vapor permeability, the air permeability, the drapability and the creasing property of the fabric are obviously improved, thereby the fabric obtained through using the technology has high waterproof and moisture-permeable performances.

Owner:张天国

Acrylates waterborne coating gum and production method thereof

InactiveCN102797155AGood waterproof and moisture permeabilityIncrease profitFibre treatmentTextile printerMethacrylate

The invention provides an acrylates waterborne coating gum, belonging to the technical field of textile printing and dyeing agents. The acrylates waterborne coating gum mainly comprises the following components by mass percent: 5-10% of ethyl methacrylate, 10-20% of polyacrylic ammonia ester, 1-3% of acrylamide, 5-15% of methacrylic acid dimethyl ammonia ethyl ester, 5-10% of acetone, 1-2% of a conditioning agent and the balance of a diluent. The acrylates waterborne coating gum is good in waterproof property and moisture permeability, soft, wear resistant and low temperature resistant; and a compact firm film can be formed on the surface of the textile, so that the adhesive property is high; and the utilization rate of the raw materials is high, and the cost is relatively low.

Owner:苏州市华元化工有限公司

Waterproof and moisture permeable cloth with three-dimensional structure, production method and wall structure

InactiveCN108360695AGood waterproof and moisture permeabilityGood microelasticityLamination ancillary operationsSynthetic resin layered productsManufacturing technologyEngineering

The invention relates to a waterproof and moisture permeable cloth with a three-dimensional structure, a production method and a wall structure. The waterproof and moisture permeable cloth, the production method and the wall structure can be applied to wall construction and wall buildings, meanwhile, a protection material of wall construction and the wall structure and a manufacturing technology process and method of the protection material are included. The waterproof and moisture permeable cloth with the three-dimensional structure comprises a waterproof and moisture permeable cloth body, the waterproof and moisture permeable cloth body comprises a first non-woven cloth layer, a waterproof and moisture permeable functional layer and a second non-woven cloth layer, and elastic bulges arearranged outside the waterproof and moisture permeable cloth in an array mode; and construction is more convenient, and the labor cost and material cost are reduced.

Owner:SUZHOU ZIAN METAL PROD

Preparation method of waterproof, moisture-permeable and temperature-adjustable intelligent nanofiber membrane

InactiveCN112160072ASimple preparation processGood waterproof and moisture permeabilityFilament/thread formingNon-woven fabricsFiberPolymer science

The invention discloses a preparation method of a waterproof, moisture-permeable and temperature-adjustable intelligent nanofiber membrane. The preparation method comprises the following steps of taking a mixture of polyvinylidene fluoride (PVDF) doped with carbon nanotubes (CNTs) and polyvinyl butyral (PVB) as a shell layer, taking n-octadecane as a core layer, and preparing the waterproof, moisture-permeable and temperature-adjustable intelligent nanofiber membrane with a skin-core structure through a coaxial electrostatic spinning method. According to the preparation method, the nano intelligent fiber is non-toxic, excellent in waterproof and moisture permeable performance, moderate in latent heat of phase change, high in mechanical strength and simple in technological process, and hasa wide application prospect.

Owner:ZHEJIANG SCI-TECH UNIV

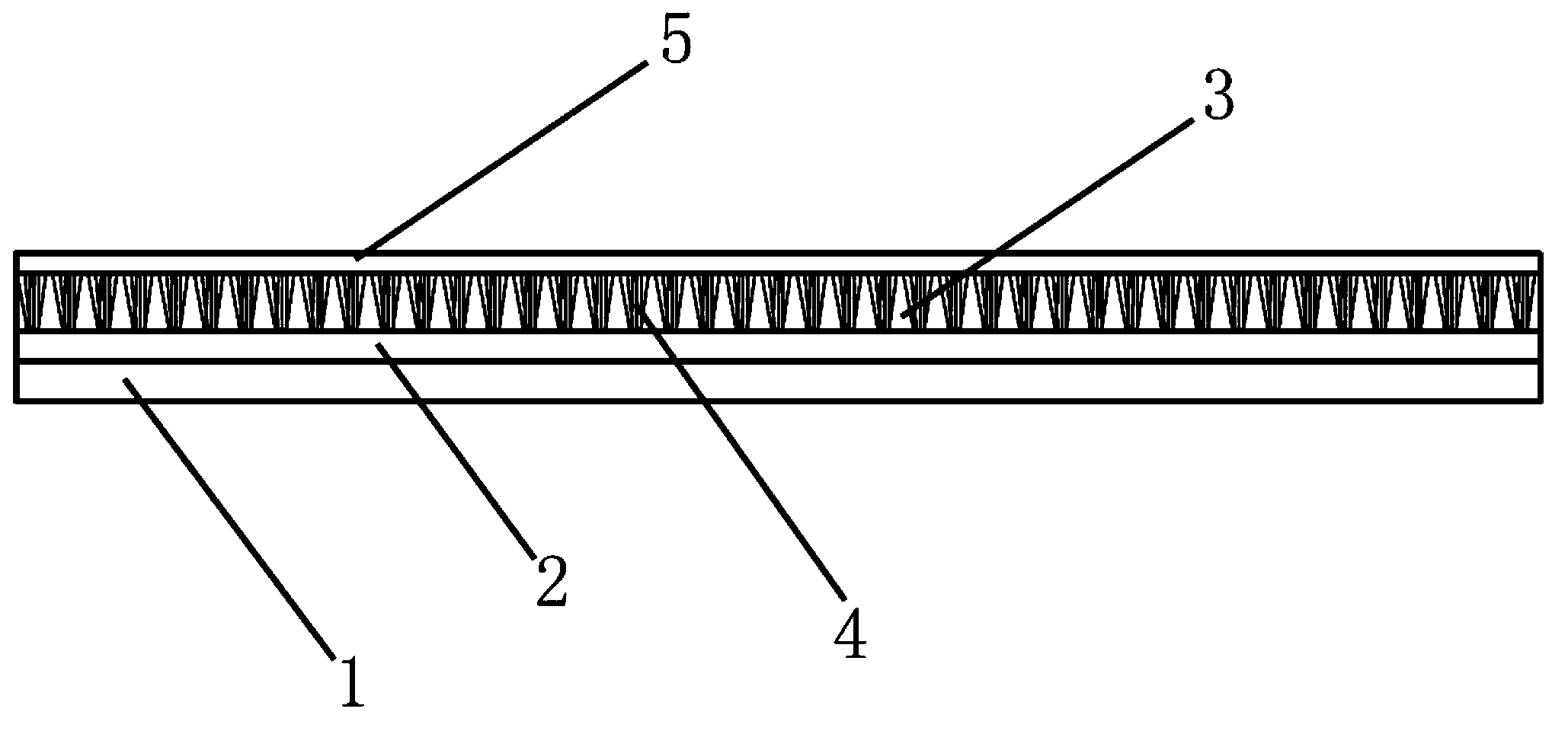

Graphene polymerized nano energy heating sheet and preparation method thereof

PendingCN111918425AReasonable structural designHigh heating efficiencyHeating element materialsHuman healthPolymer chemistry

The invention relates to a graphene polymerization nanometer energy heating sheet and a preparation method thereof. The graphene polymerization nanometer energy heating sheet comprises a fiber composite fabric 1, a heating filament and a fiber composite fabric 2 from inside to outside, wherein the heating filament is embroidered on the fiber composite fabric 1 in a circuitous winding shape througha computer embroidery mode, the first fiber composite fabric is tightly connected with the second fiber composite fabric in a gluing mode, and the heating wire is clamped between the first fiber composite fabric and the second fiber composite fabric. According to the graphene polymerization nanometer energy heating sheet and the preparation method thereof, the structure design is reasonable, theheating effect is good, the heat conduction speed is high, the temperature rise is rapid, the electricity is not conducted, the service life is long, water, electric shock and fire are prevented, thesafety is high, far infrared waves and negative oxygen ions are released, radiation is avoided, human health is facilitated, the preparation method is simple, the flexibility is high, and the application prospect is good.

Owner:元然(苏州)新能源科技有限公司

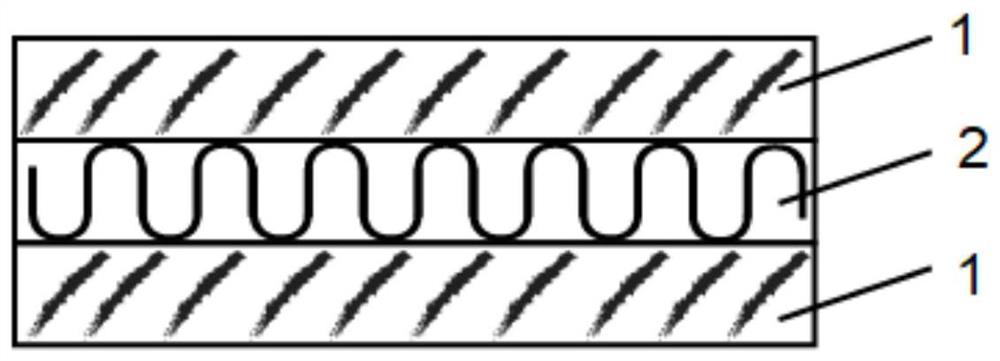

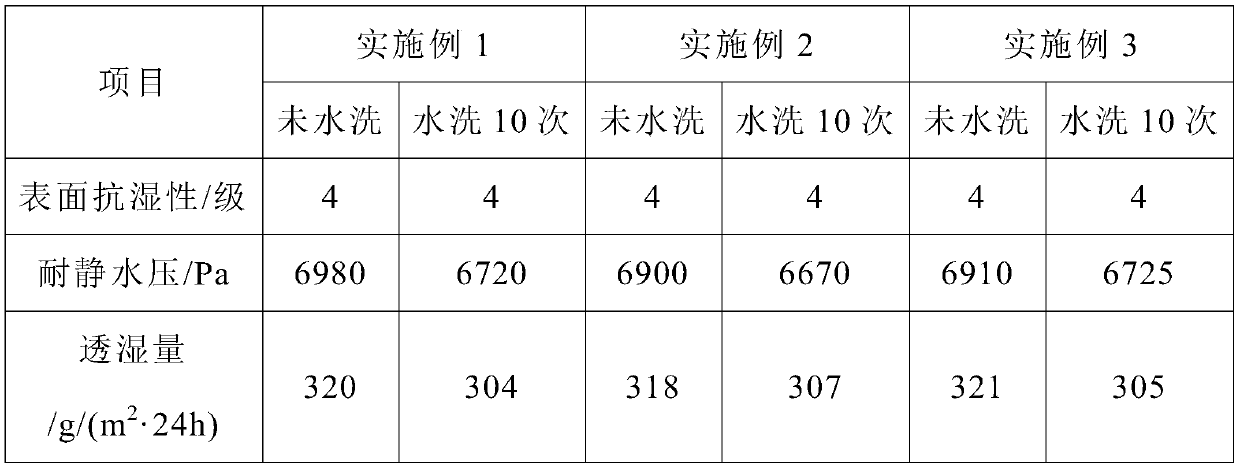

Washable waterproof moisture-permeable foam adhesive laminated fabric and preparation method thereof

ActiveCN111516311AImprove wrinkle resistanceGood quality and stabilityLamination ancillary operationsNon-macromolecular adhesive additivesFoaming agentAdhesive

The invention discloses a washable waterproof moisture-permeable foam adhesive laminated fabric and a preparation method thereof. The laminated fabric comprises a modified fabric, a foam adhesive anda waterproof film from bottom to top, the modified fabric is prepared from a cotton fabric, sodium hydroxide, oxalic acid, a first modifier and a second modifier; wherein the foam glue is obtained byfoaming a foaming agent; the waterproof membrane is prepared from a pretreatment membrane, polydimethylsiloxane and cyclohexane; the pretreatment film comprises a first waterproof layer and a second waterproof layer from bottom to top. The invention discloses a washable waterproof moisture-permeable foam adhesive laminated fabric and a preparation method thereof. The preparation method is simple in process operation and reasonable in component proportion, the waterproof film with hydrophobic, waterproof and moisture-permeable performance is attached to the surface of the modified fabric through a foam glue attaching method, and the prepared attached fabric has excellent waterproof and moisture-permeable performance, high hydrophobic performance, excellent washing resistance and high practicability.

Owner:东莞市听雨轩服装有限公司

Colorfast carpet

The invention belongs to the field of textile, and particularly relates to a piece of colorfast carpet, which comprises a base cloth layer, a bonding agent layer and a carpet surface layer, wherein the carpet surface layer is fixedly arranged on the base cloth layer through the bonding agent layer. The colorfast carpet is characterized in that the carpet surface layer is formed by nanometer fiber cotton strands, and a PTFE (polytetrafluoroethylene) microporous film layer covers the upper part of the carpet surface layer. The colorfast carpet provided by the invention has the advantages that the structure is simple, and the practicability is high.

Owner:天津立秋工艺品有限公司

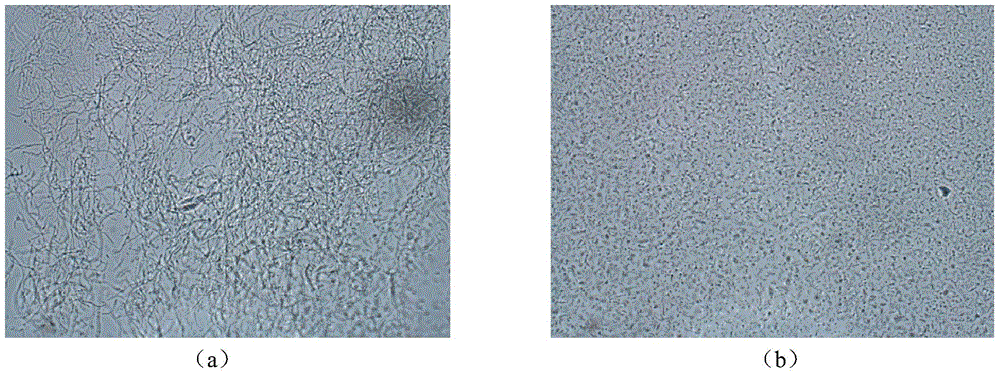

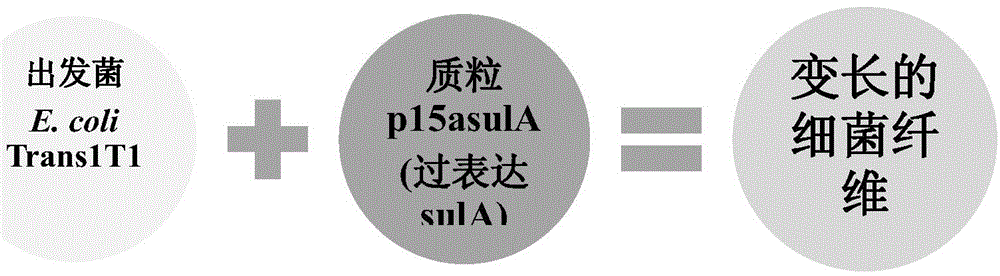

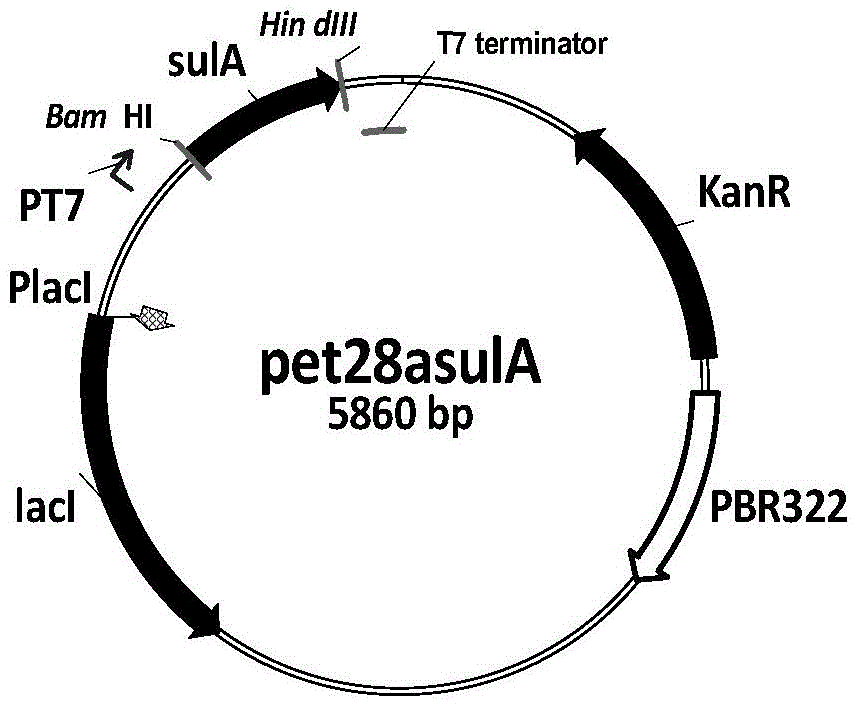

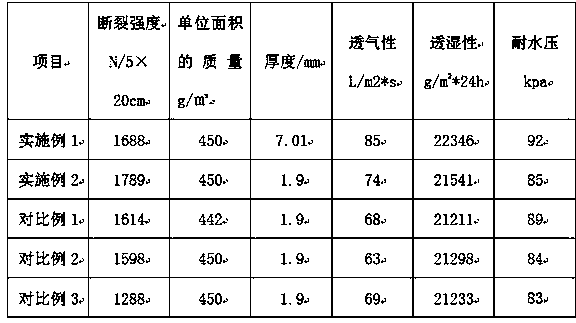

Bacterial fiber material made from bacterial cells, and applications thereof

ActiveCN105463625AShorten the production cycleReduce labor costsBacteriaFibre chemical featuresPerspirationMoisture permeation

The present invention relates to the field of materials, particularly to bacterial fibers obtained by changing bacterial form, further to recombinant bacterial cells producing bacterial fibers through genetic molecule operation. The present invention further relates to a method for spinning by using the bacterial fibers, and the obtained textile. According to the present invention, compared with the existing natural fibers, the bacterial fibers of the present invention have advantages of short production cycle, low labor cost and low production cost; compared with the artificial fibers, the bacterial fibers of the present invention have advantages of environmental protection, degradability and the like of the natural fibers; and the bacterial fibers adopted as the textile material have advantages of gloss, softness, ultra-high density, light weight, good water resistance and good moisture permeation, good perspiration wicking action, good warm keeping property, good wear resistance, high cleaning ability, high stain removing ability and the like, and are ultra-fine fibers.

Owner:TSINGHUA UNIV

Waterproof, oil resistant, and moisture permeable garment fabric

InactiveCN108951133ALower glass transition temperatureGood moisture permeabilityArtificial filaments from viscoseLiquid repellent fibresPolyesterCellulose fiber

The invention discloses a waterproof, oil resistant, and moisture permeable garment fabric, which is prepared from following raw materials: ultrafine polyester fibers, mulberry bark fibers, polyvinylidene chloride fibers, chitin, graphene regenerated cellulose fibers, and a waterproof and oil resistant agent. The prepared garment fabric can resist water and oil, the performance / cost ratio is high,the price is cheap, and moreover, the garment fabric can resist static electricity, water, and oil, is moisture permeable, is resistant to oil contamination and water stains, and has stable chemicalproperties and long service time.

Owner:HEFEI SHENGDA GARMENT ACCESSORIES CO LTD

Thermoplastic polyurethane film and preparing method thereof

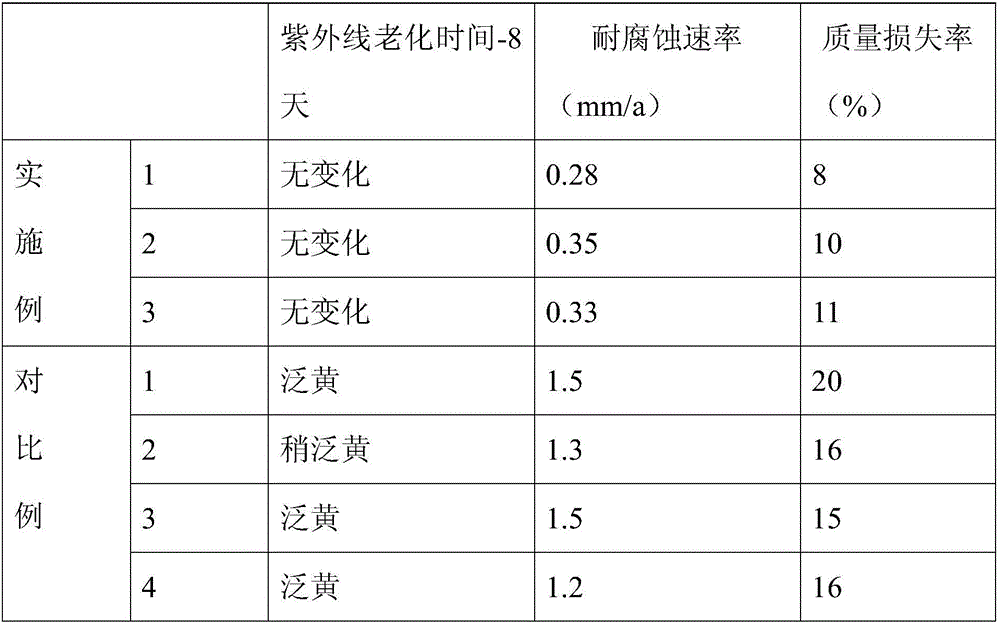

InactiveCN105924944AGood waterproof and moisture permeabilityAccelerated corrosionIsocyanateChemistry

The invention discloses a thermoplastic polyurethane film and a preparing method thereof. The thermoplastic polyurethane film is prepared from, by weight, 80-85 parts of thermoplastic polyurethane, 8-10 parts of slipping agent and 7-10 parts of matt agent. Thermoplastic polyurethane is prepared from 40-50 parts of polytetramethylene ether glycol, 25-30 parts of composite diisocyanate, 5-8 parts of ethylene glycol monoethyl ether acetate, 1-3 parts of dibutyltin diacetate and 5-8 parts of styrene-acrylonitrile-glycidyl methacrylate. By adding composite diisocyanate, regulating the ratio of components in composite diisocyanate, utilizing the synergistic effect of the two components and adding styrene-acrylonitrile-glycidyl methacrylate, the thermoplastic polyurethane film with high corrosion resistance and weather resistance is prepared.

Owner:WUXI JIABANG ELECTRIC POWER PIPE FACTORY

Waterproof and moisture-permeable film and preparation and application thereof

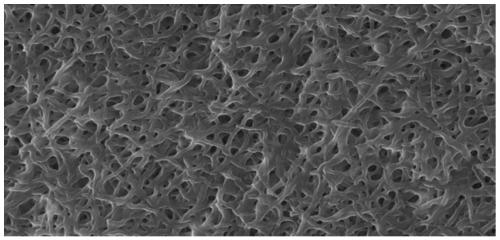

ActiveCN111531994AGood waterproof and moisture permeabilitySolve the problem of low productivitySynthetic resin layered productsLaminationPolymer scienceSpinning

The invention relates to a waterproof and moisture-permeable film and preparation and application thereof. The moisture-permeable film is prepared by the steps that in PU moisture-permeable pulp, polyoxyethylene (PEO) is drawn into superfine fibers through an electrostatic spinning technology and the superfine fibers are implanted therein, water-soluble PEO is dissolved out through water washing after film forming and attaching, microporous channels are formed in the film, and the microporous waterproof and moisture-permeable effects are achieved. Compared with a PU film, the moisture permeability of the novel waterproof and moisture-permeable film is improved by 30%-80%, the strength is improved by 100%-150% compared with an electrostatic spinning film, and the attaching performance and the subsequent processability are better.

Owner:湖州因爱伟大卫生用品有限公司

Method for forming porous polyurethane membrane

ActiveCN102343224BUniform internal pore sizeHigh porositySemi-permeable membranesPorositySurface layer

Owner:WUHAN YONGSEN BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com